Patents

Literature

60results about How to "Constant cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

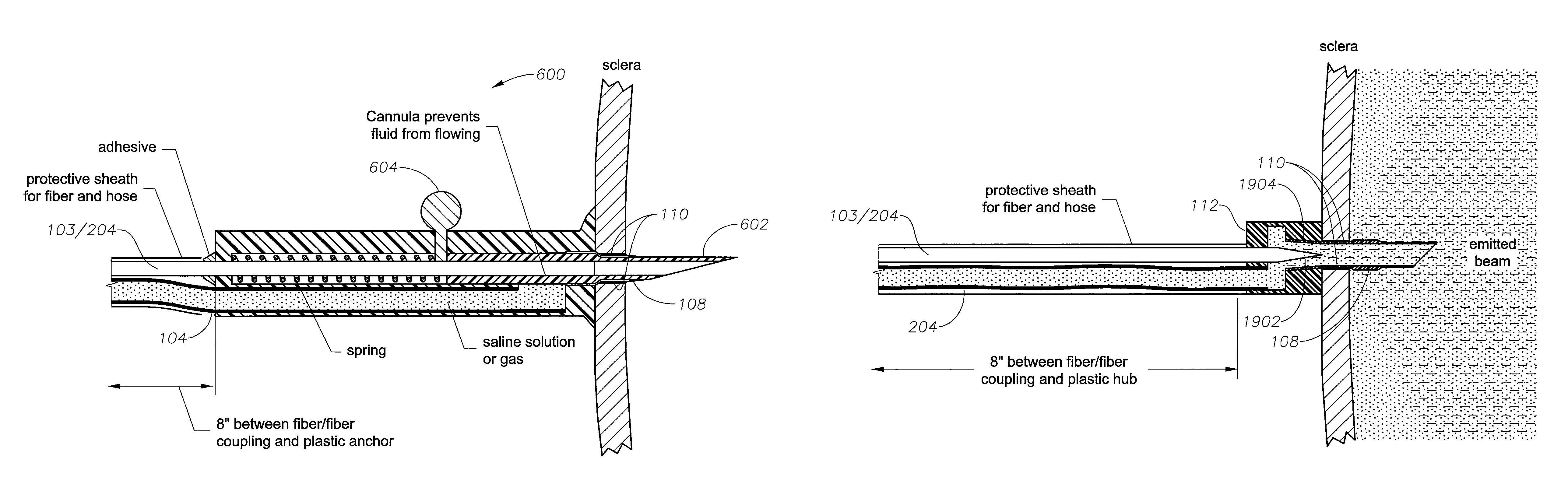

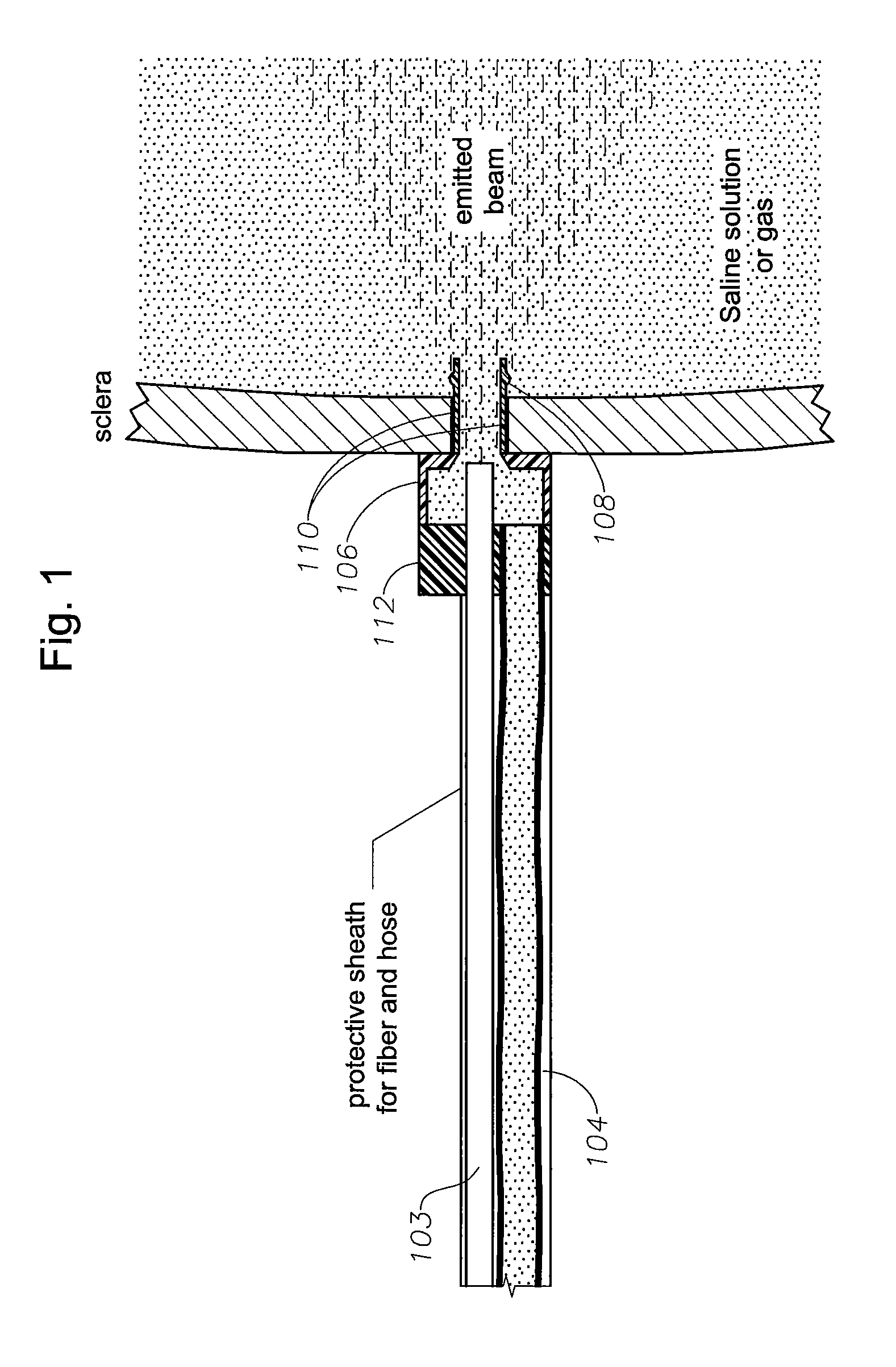

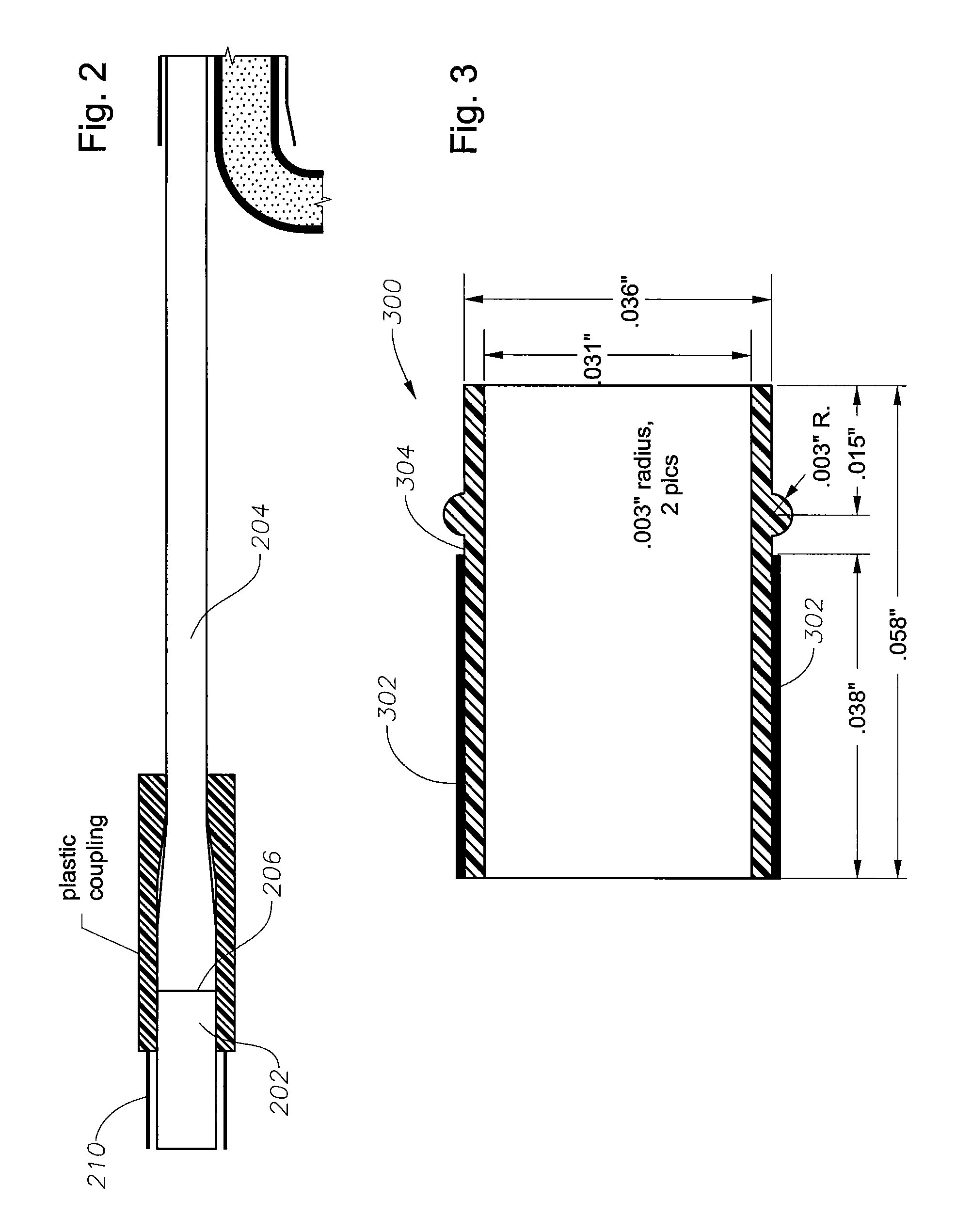

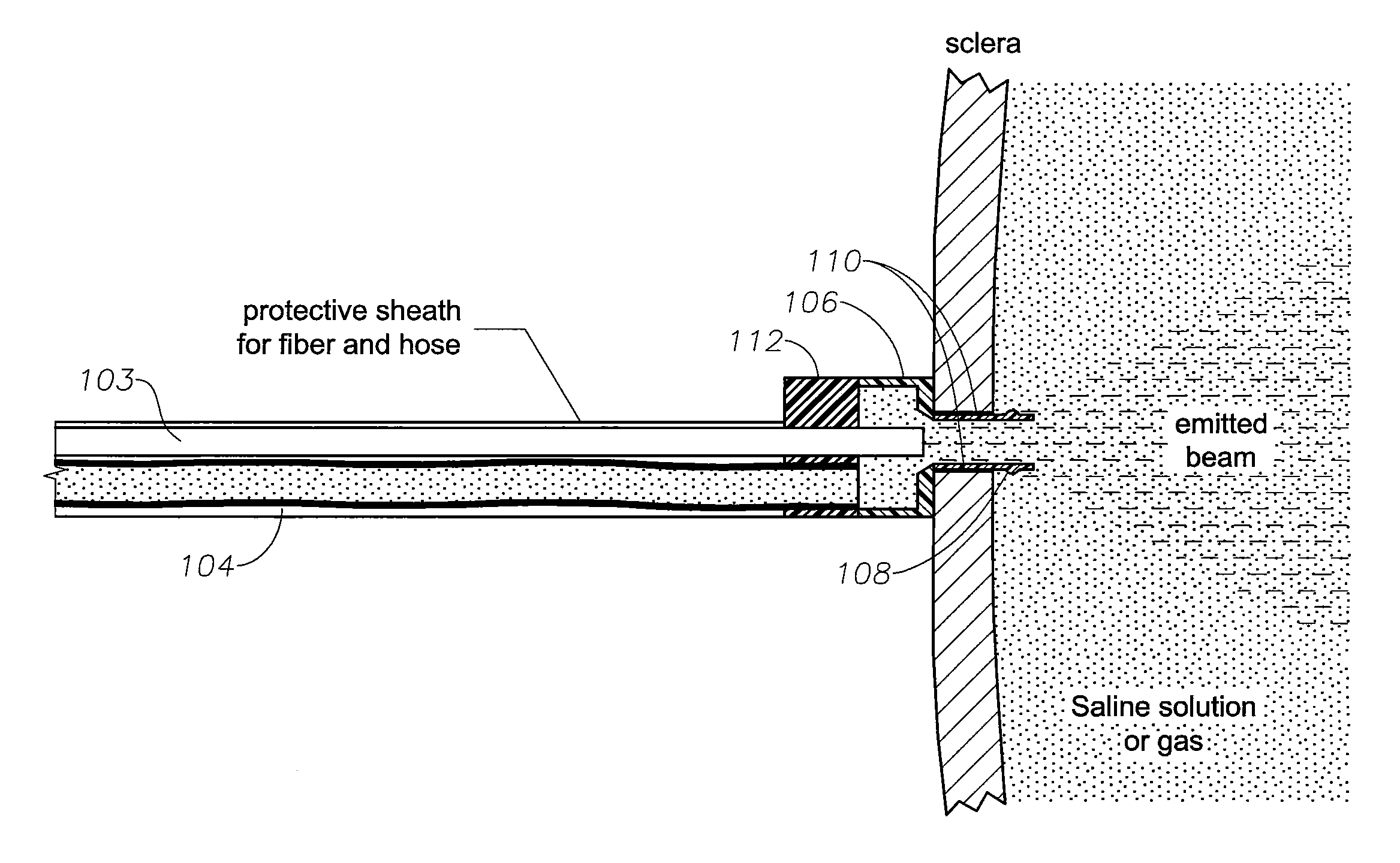

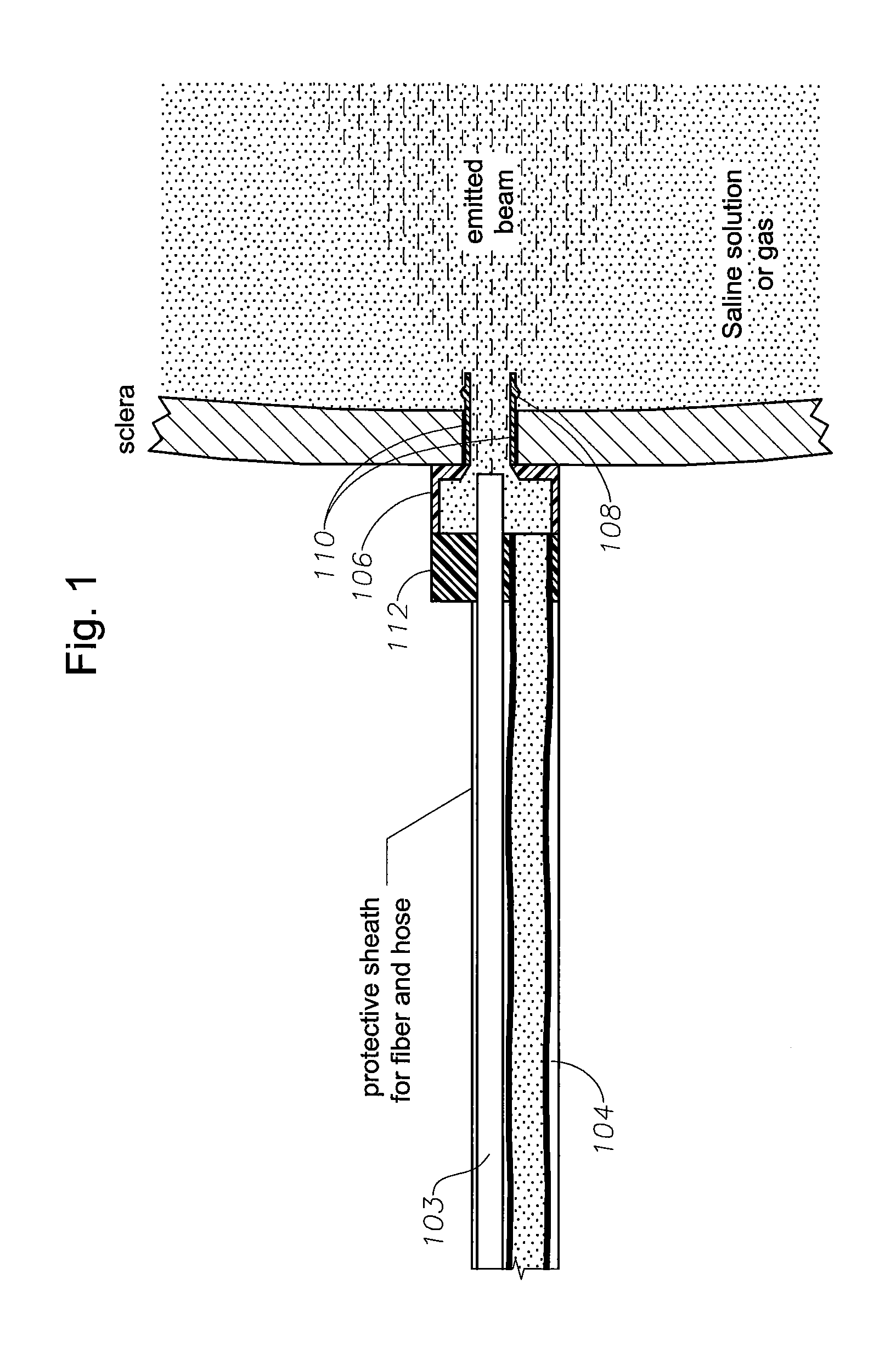

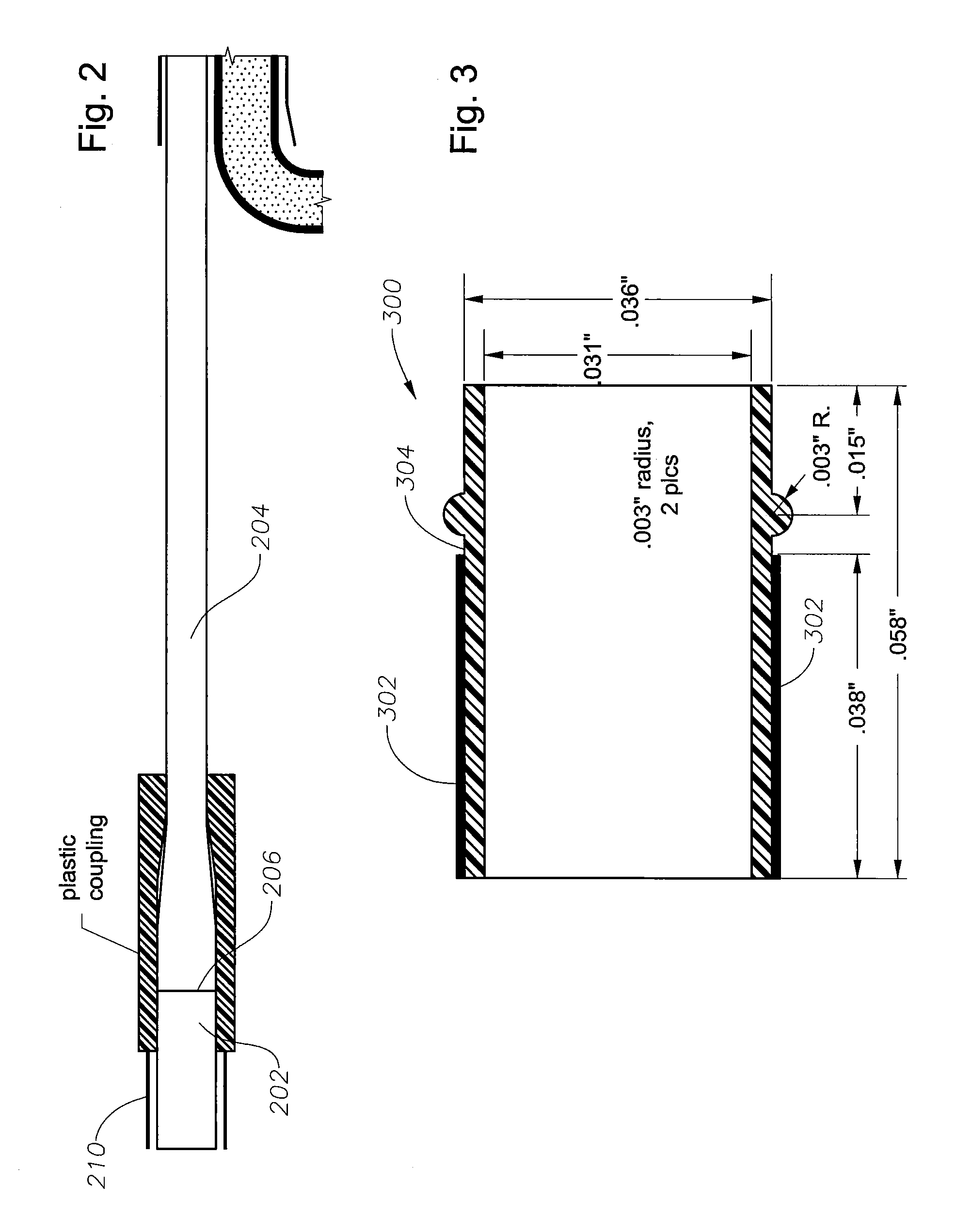

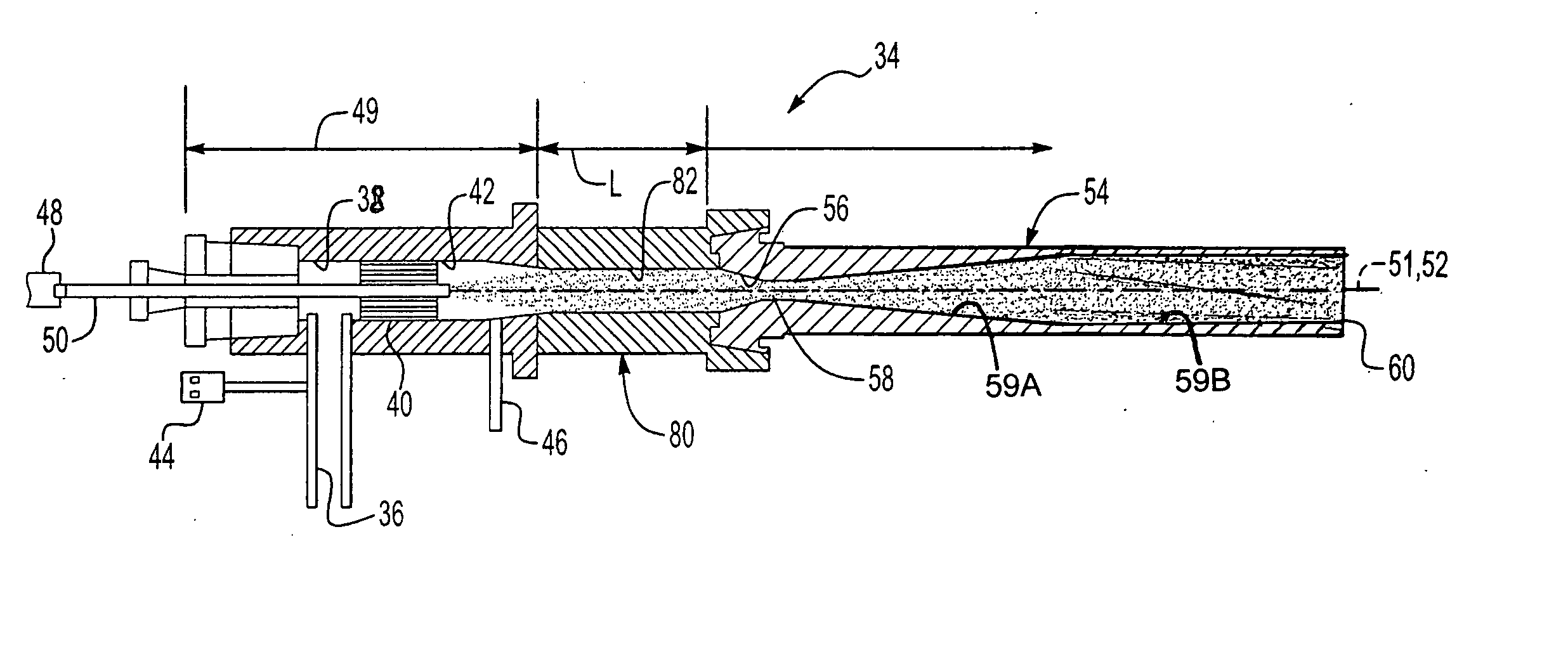

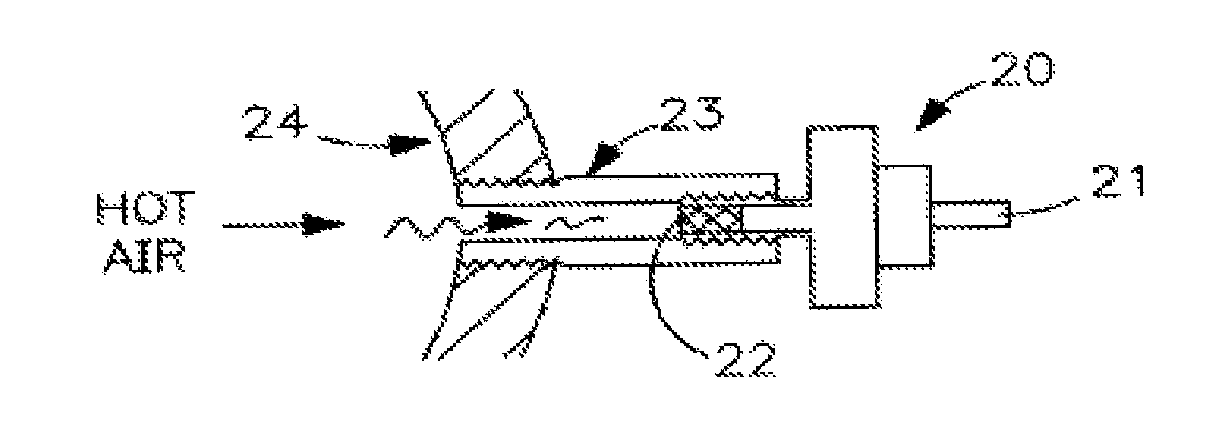

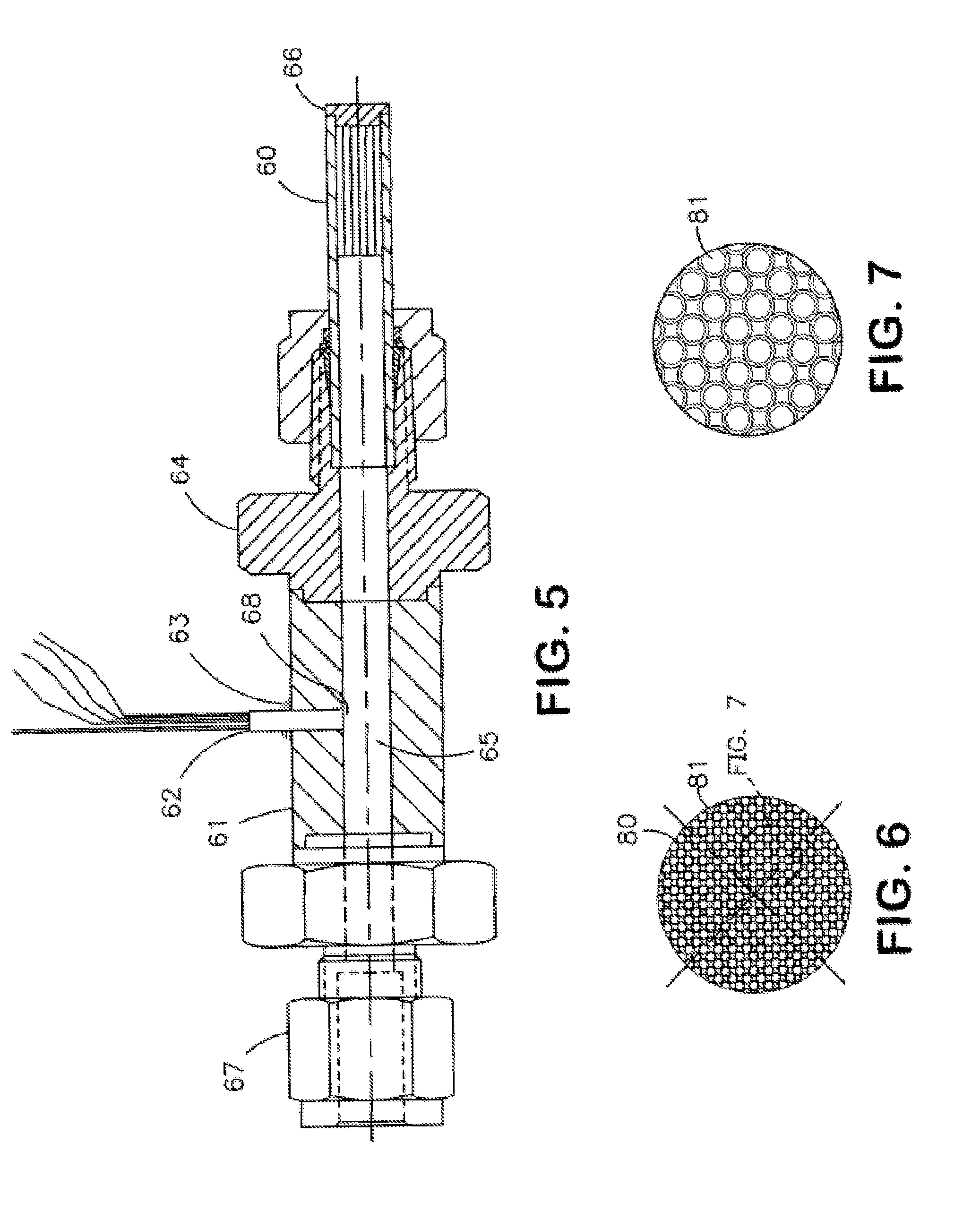

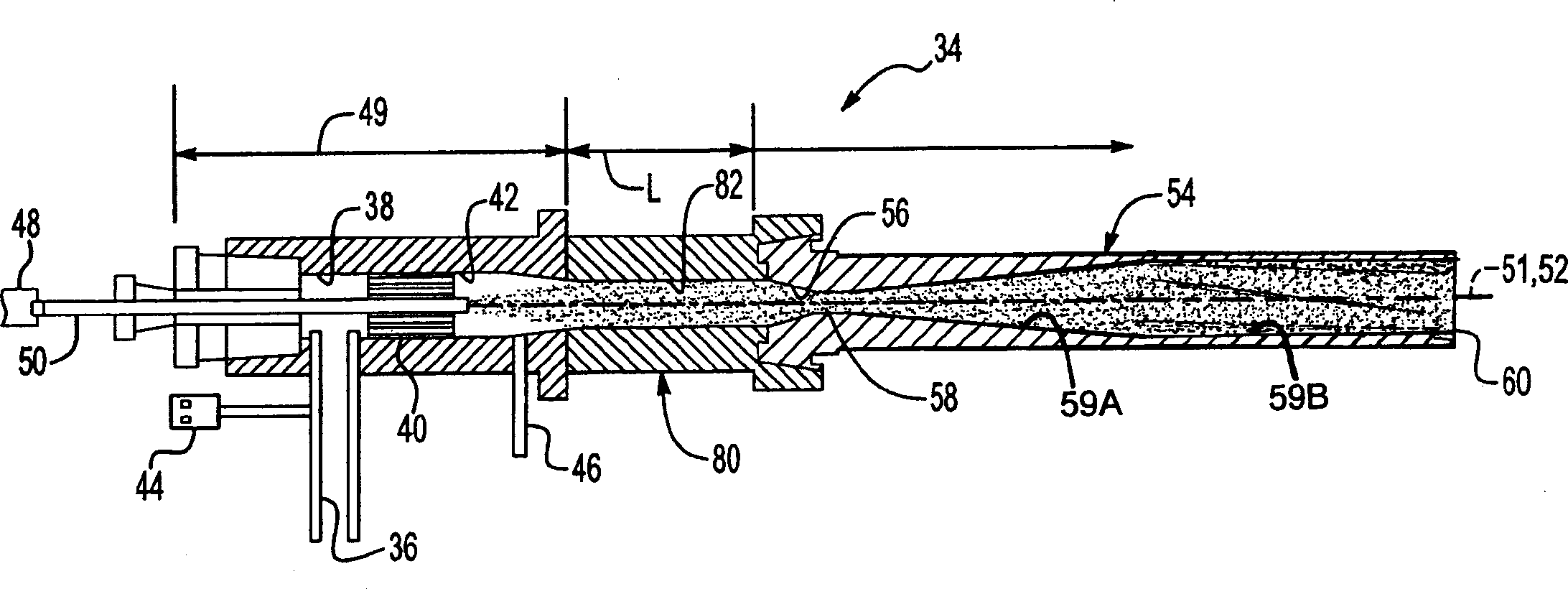

Illuminated infusion cannula

ActiveUS7783346B2Increase flow rateHigh light transmittanceElectrotherapyEye surgeryFiberTransmittance

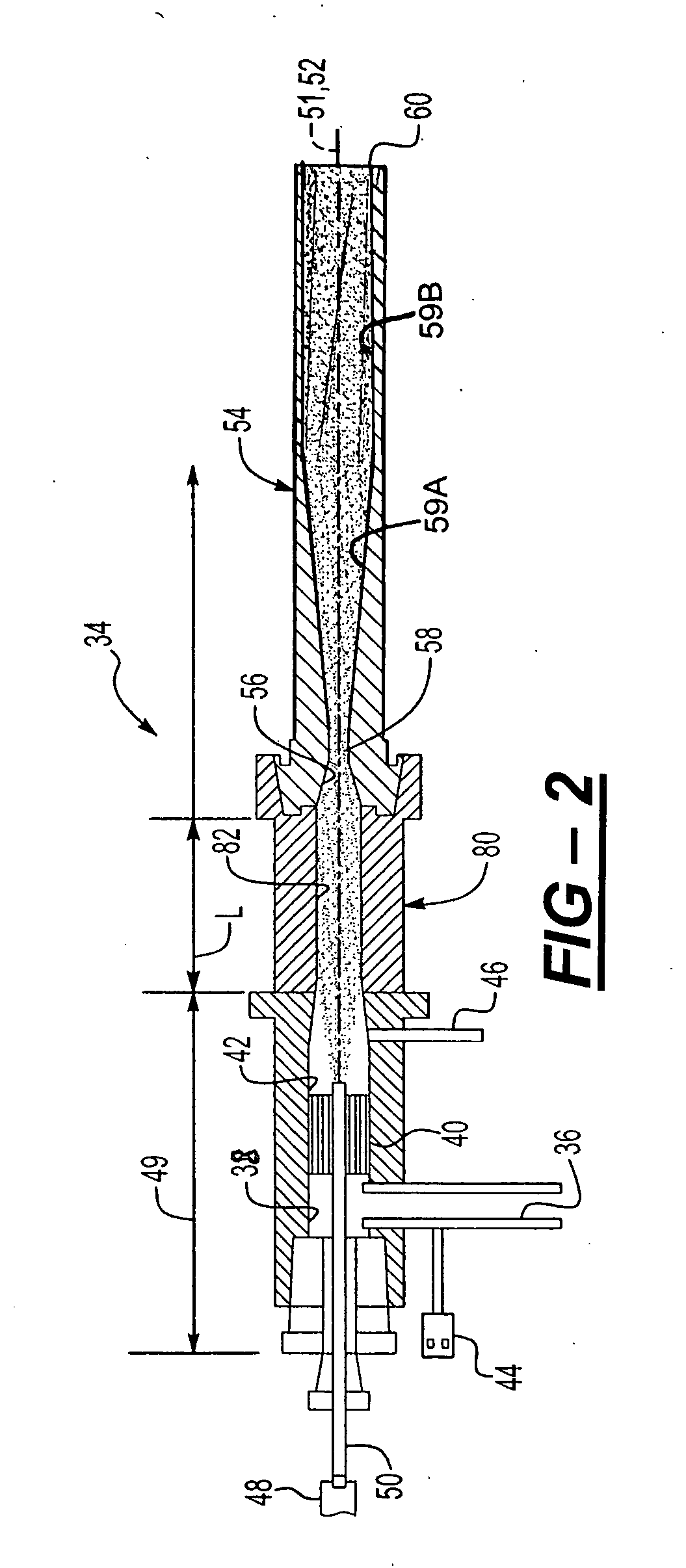

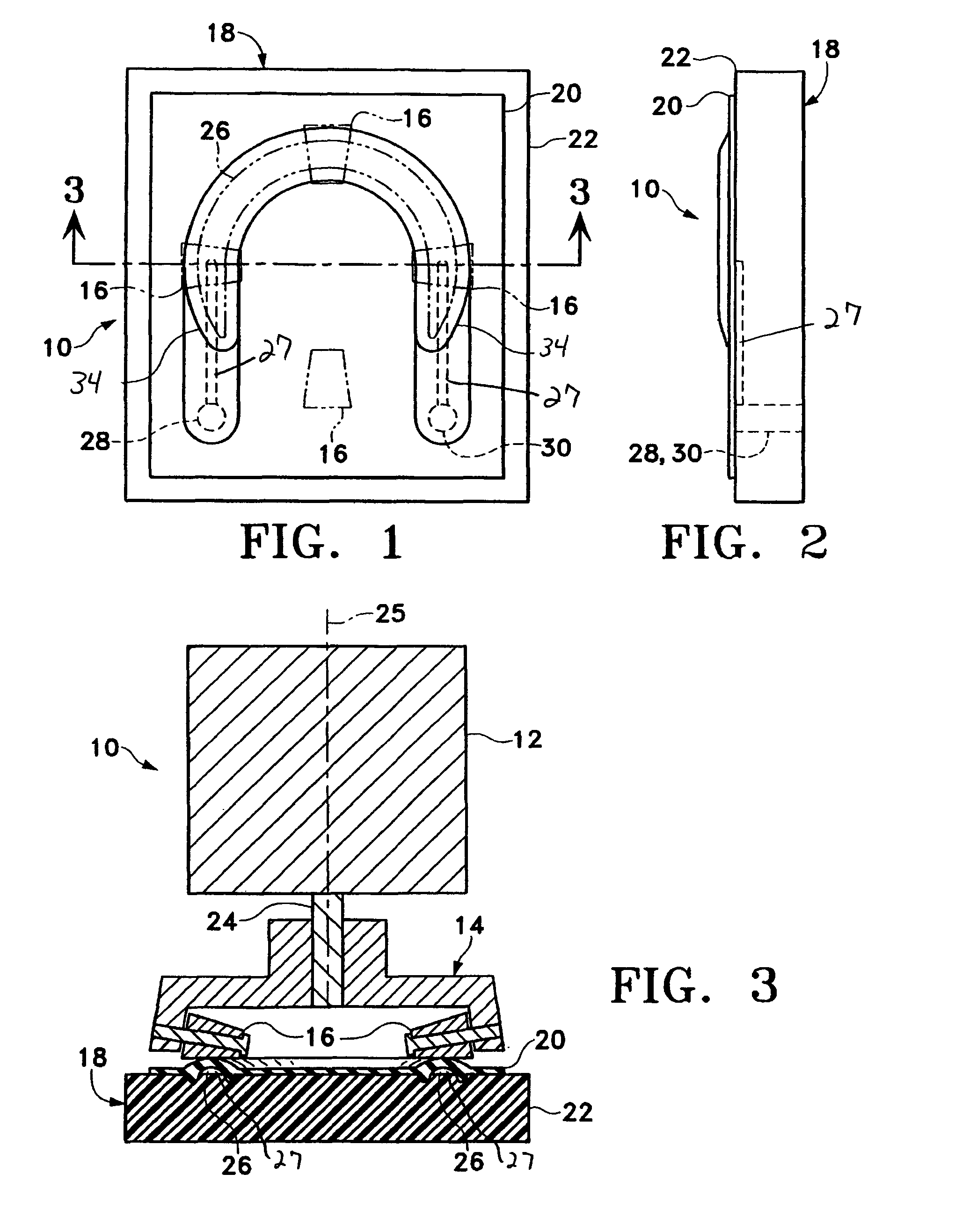

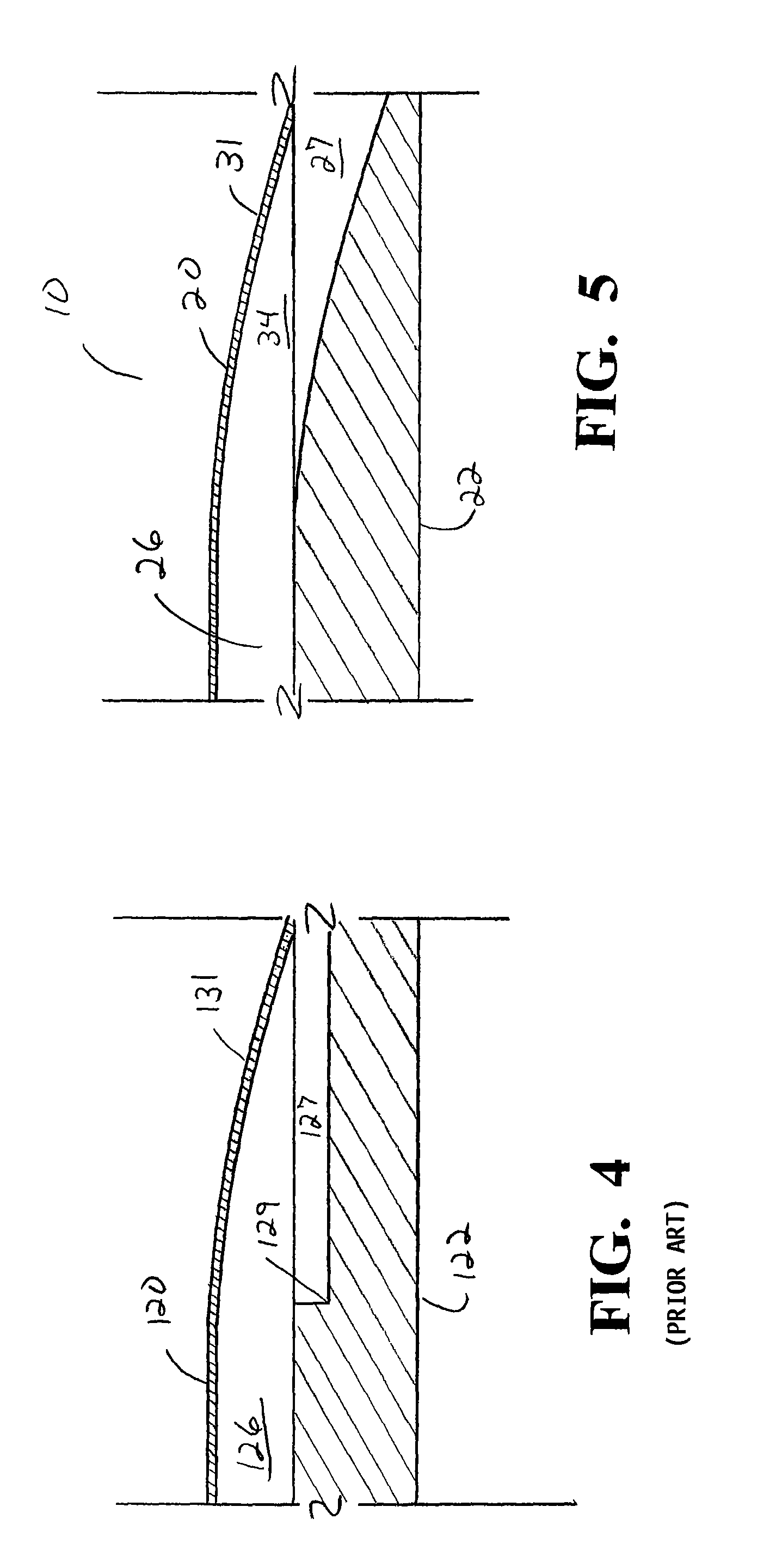

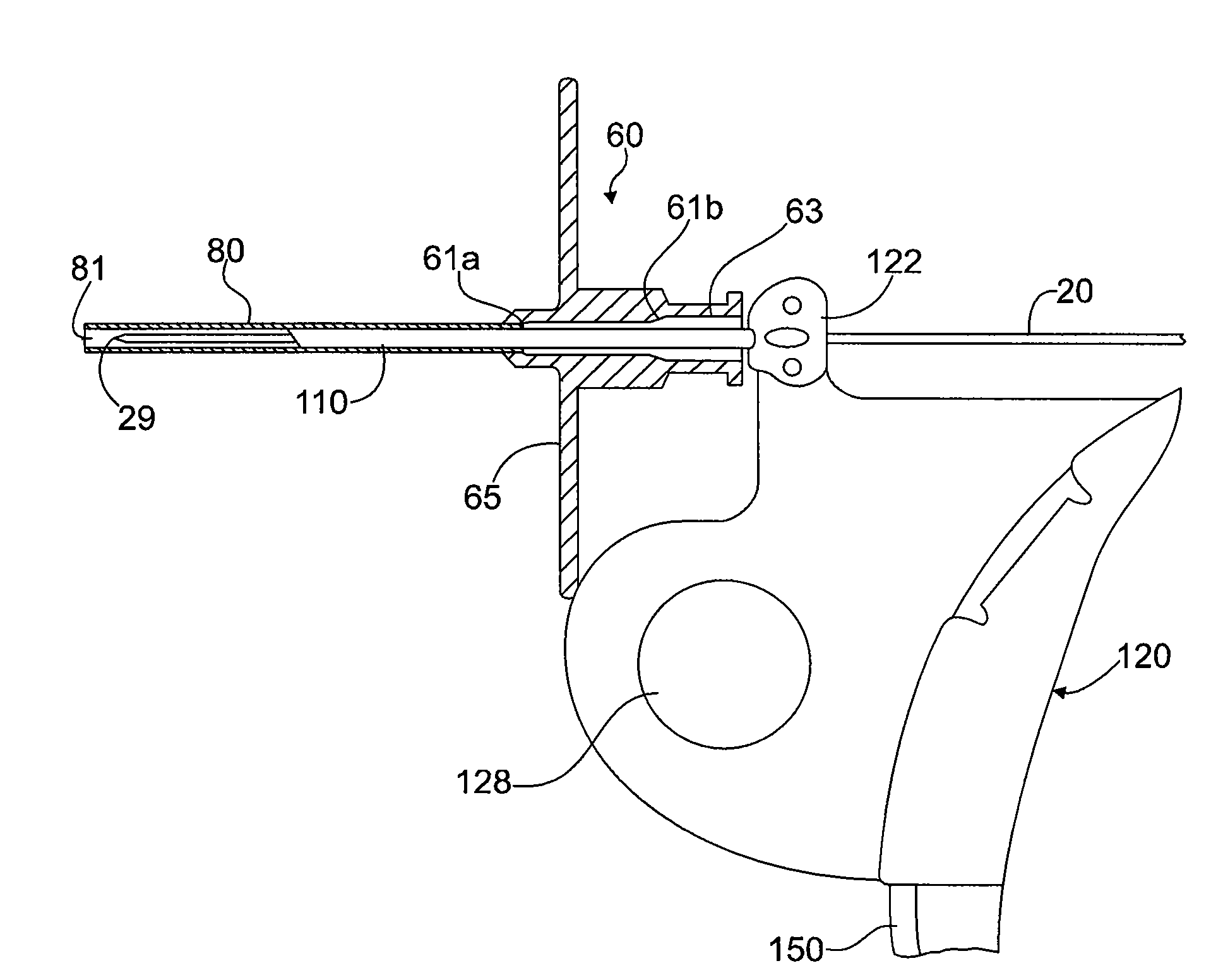

A transparent illuminated infusion cannula is provided for illuminating an area during eye surgery. An optical fiber may be spaced a certain distance away from the cannula such that fluid flow around the distal end of the fiber and into the transparent cannula may occur with a much higher flow rate than what had previously been possible. The fiber cannula airspace may be optimized so that the cross-sectional area of the fluid conduit remains substantially constant in order to achieve a best compromise between high light transmittance and high fluid flow rate.

Owner:ALCON INC

Illuminated infusion cannula

ActiveUS20070179430A1Increase flow rateHigh light transmittanceElectrotherapyEye surgeryFiberTransmittance

A transparent illuminated infusion cannula is provided for illuminating an area during eye surgery. An optical fiber may be spaced a certain distance away from the cannula such that fluid flow around the distal end of the fiber and into the transparent cannula may occur with a much higher flow rate than what had previously been possible. The fiber cannula airspace may be optimized so that the cross-sectional area of the fluid conduit remains substantially constant in order to achieve a best compromise between high light transmittance and high fluid flow rate.

Owner:ALCON INC

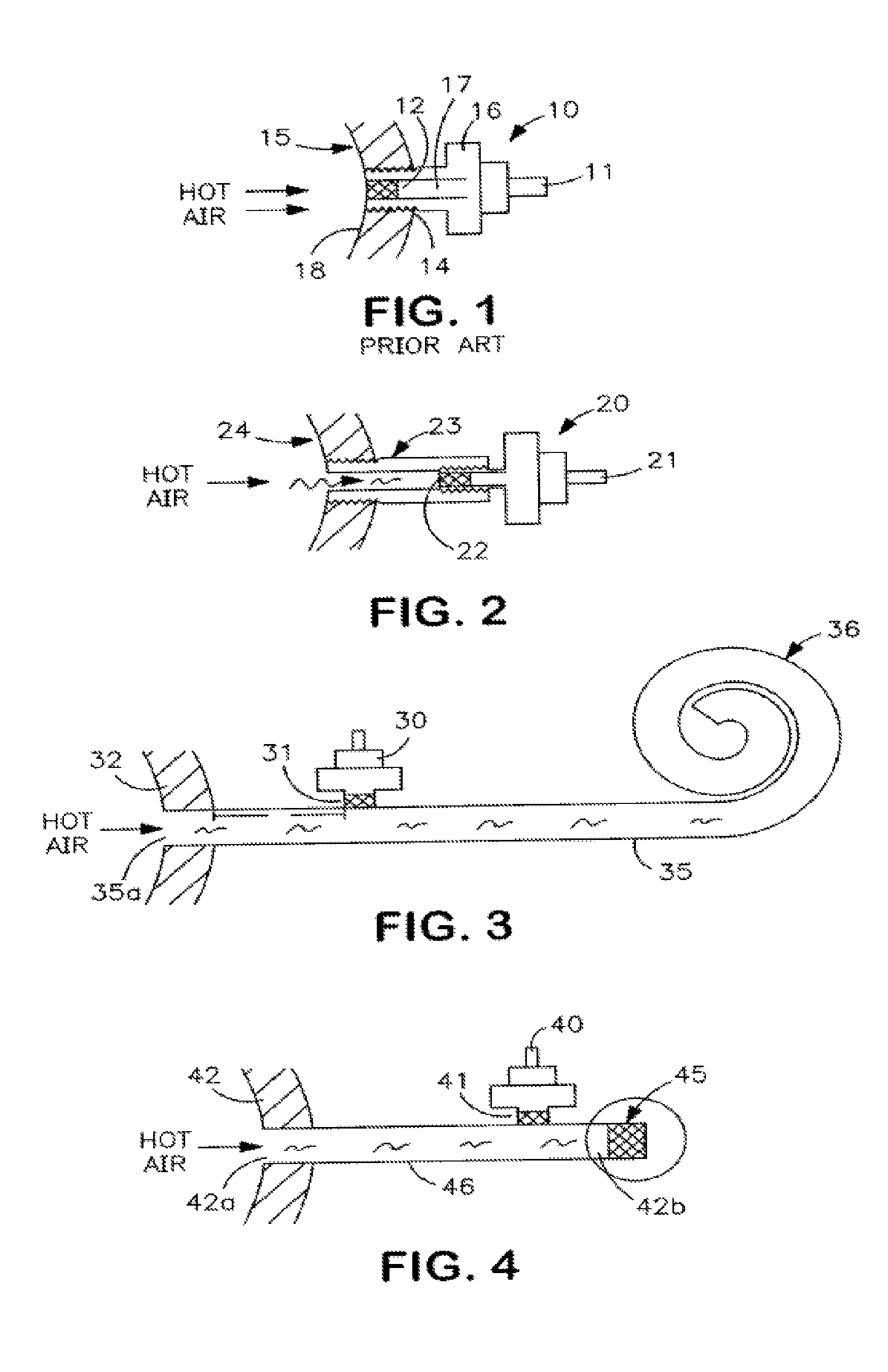

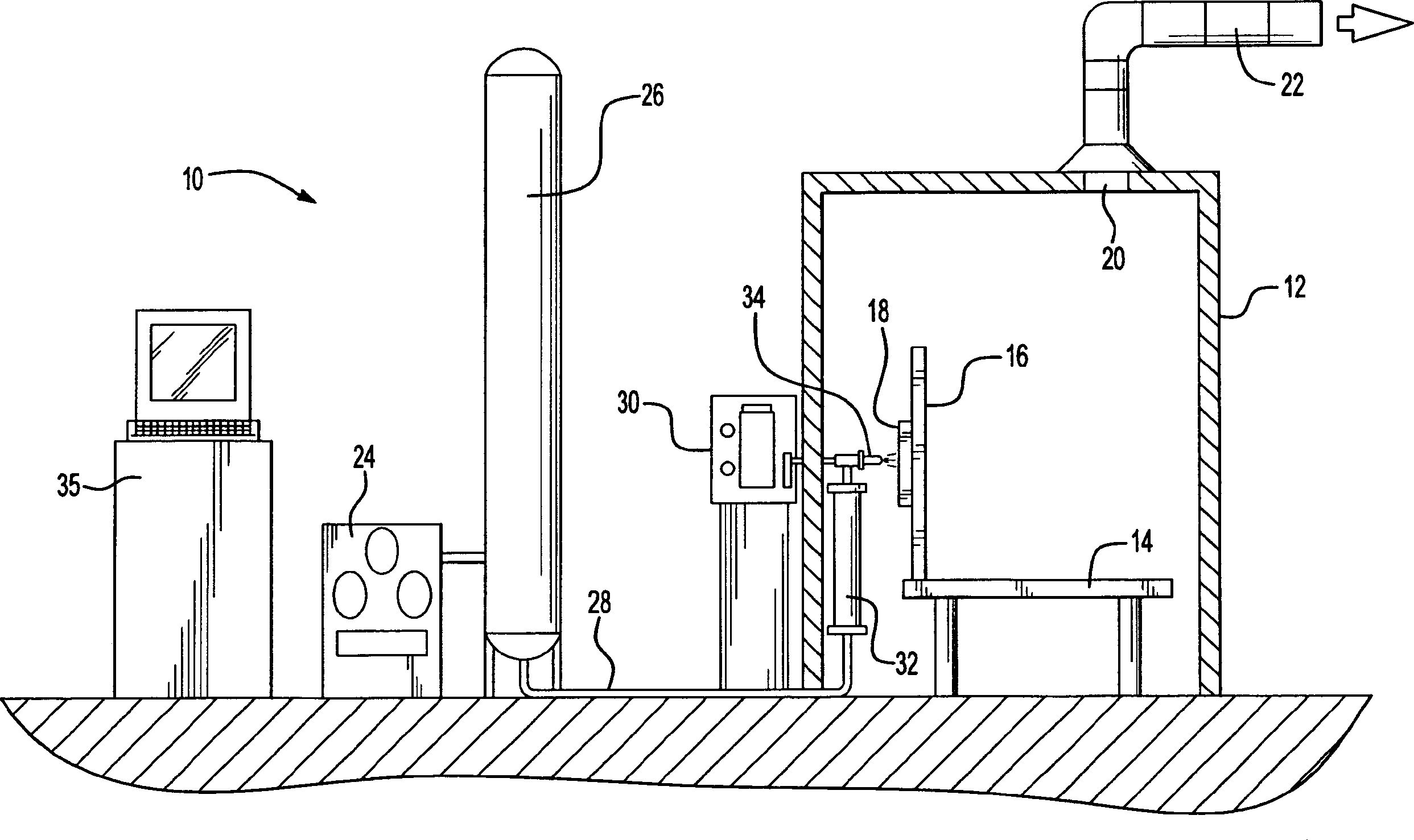

Continuous in-line manufacturing process for high speed coating deposition via a kinetic spray process

InactiveUS20060040048A1Constant cross-sectional areaMolten spray coatingPretreated surfacesSpray coatingEngineering

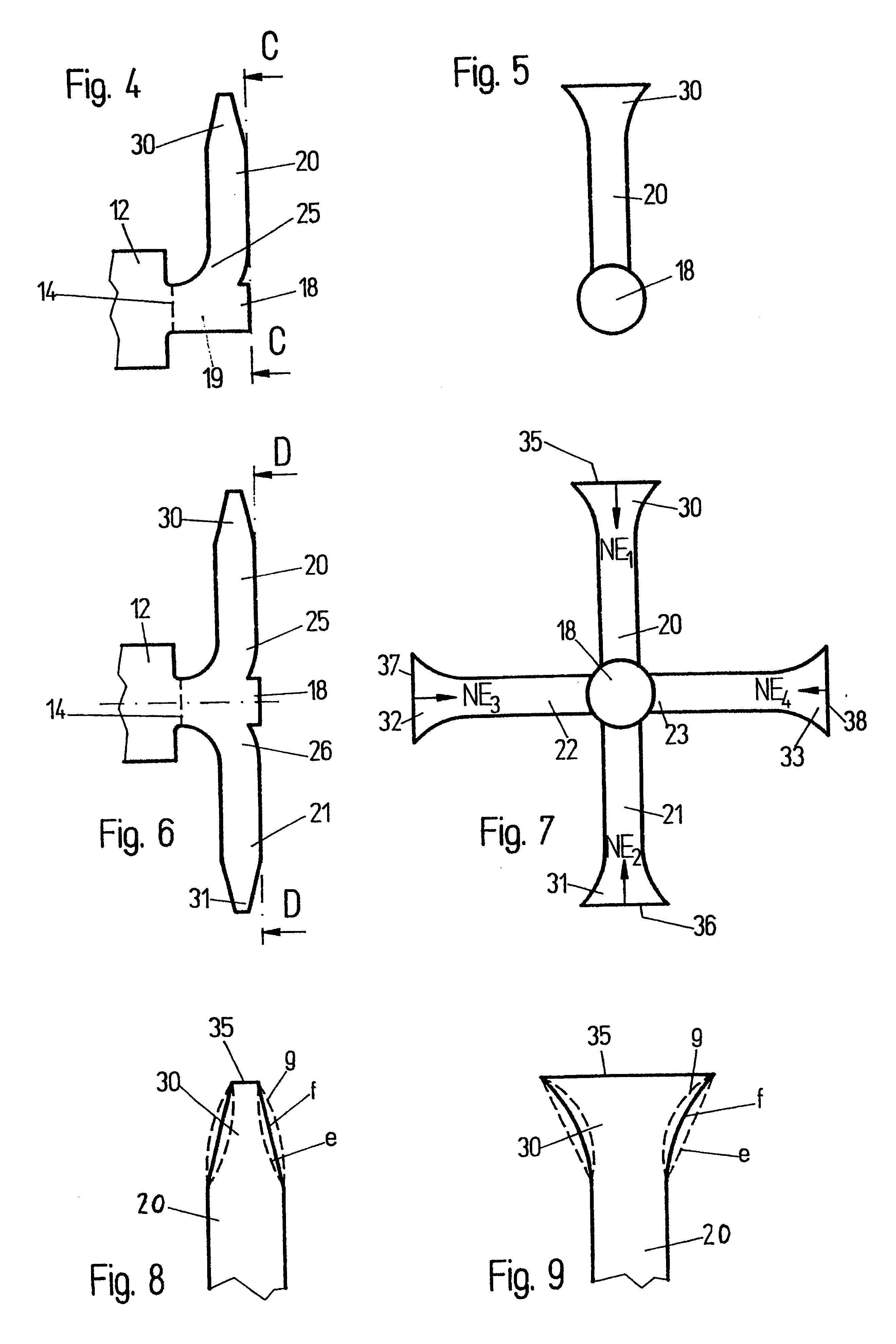

An improved kinetic spray system and a method for using the same in a high speed manufacturing environment are disclosed. The improved kinetic spray nozzle system comprises: a gas / powder exchange chamber connected to a first end of a powder / gas conditioning chamber having a length along a longitudinal axis of equal to or greater than 20 millimeters; a converging diverging supersonic nozzle, the supersonic nozzle having a converging section separated from a diverging section by a throat, the diverging section comprising a first portion and a second portion, with the first portion having a cross-sectional area that increases along a length of the first portion and with the second portion having a substantially constant cross-sectional area along a length of the second portion; and the converging section connected to a second end of the powder / gas conditioning chamber opposite the first end. The method includes: use of the disclosed nozzle system with the addition of hard particles that permit maximum enhancement of particle temperature while not permitting clogging of the nozzle; use of controlled particle feed rates to match the desired very high traverse speeds; and use of pre-heating of the substrate to clean it an to enhance particle bonding. With the disclosed nozzle system coupled with the disclosed methods one can apply kinetic spray coatings at traverse speeds of over 200 centimeters per second with a deposition efficiency of over 80 percent.

Owner:F W GARTNER THERMAL SPRAYING

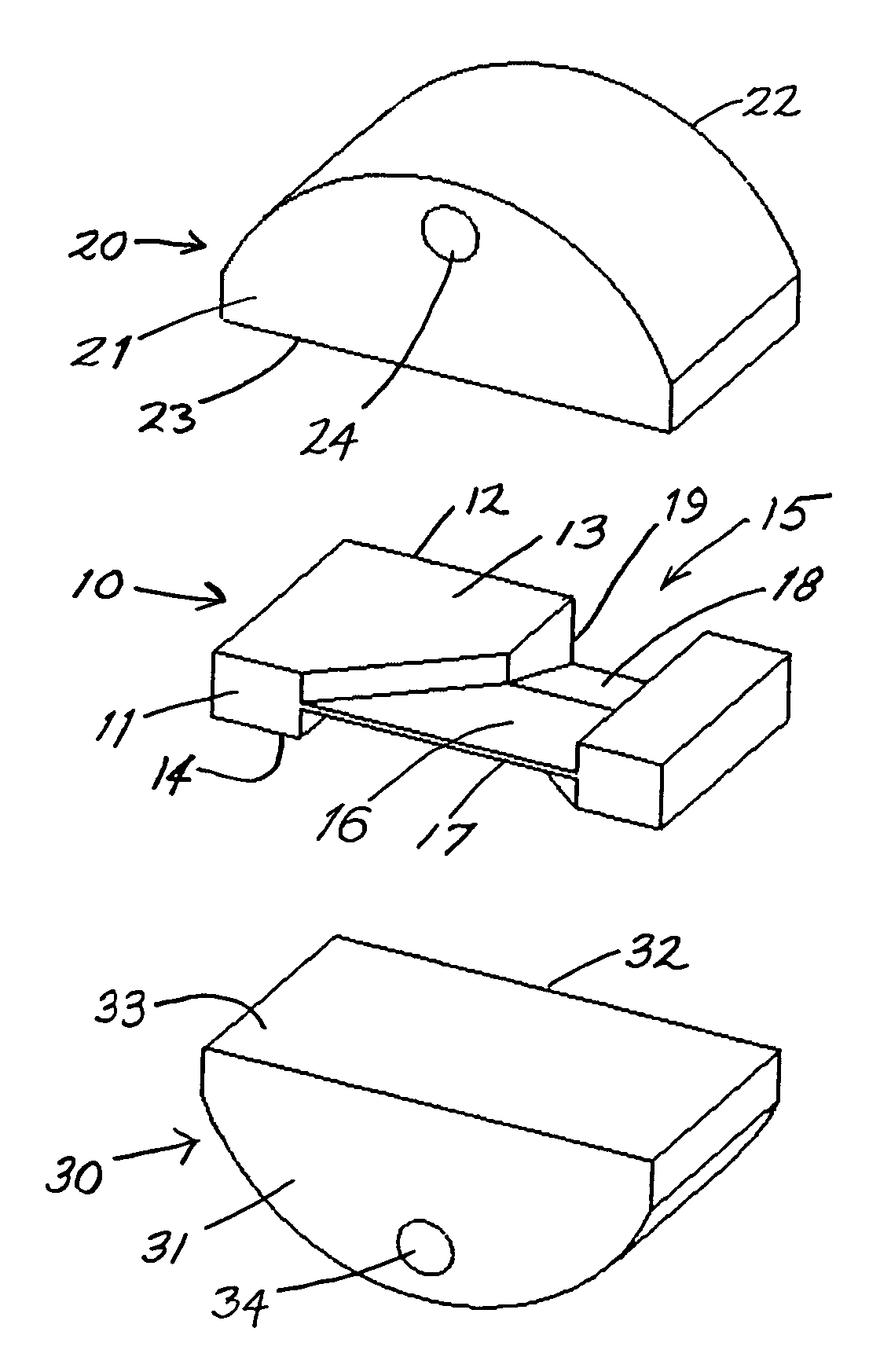

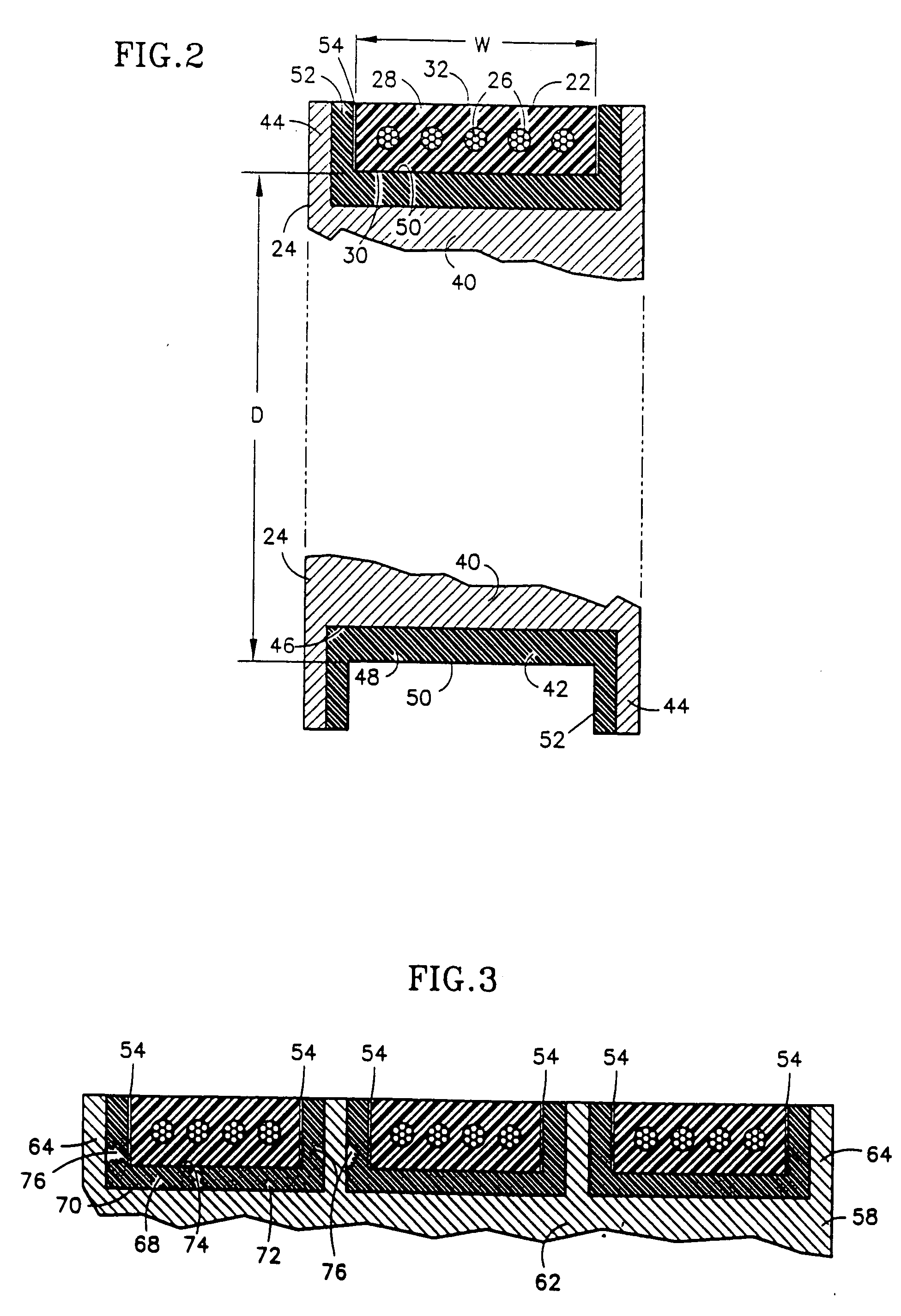

Layer multiplying apparatus

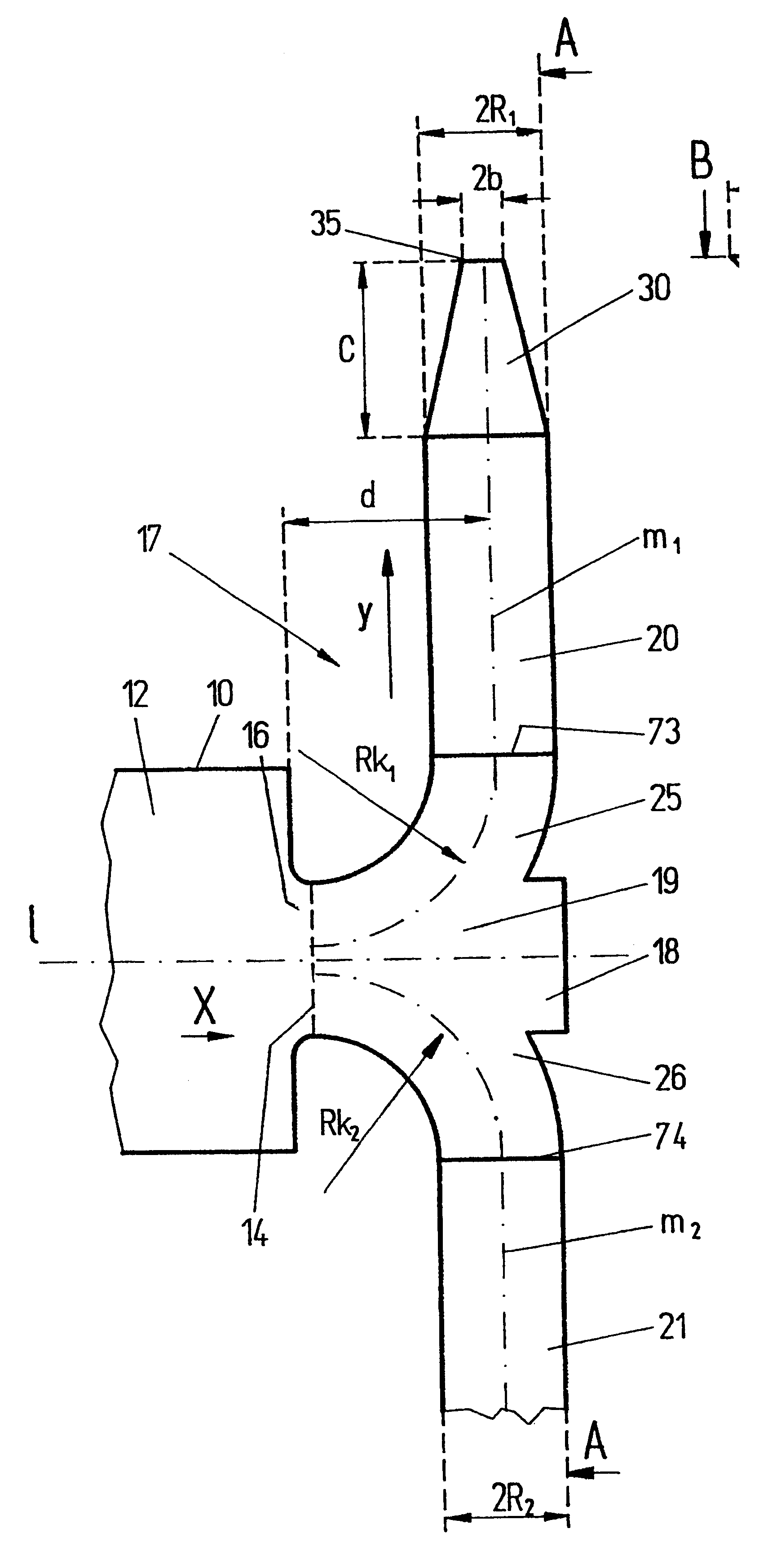

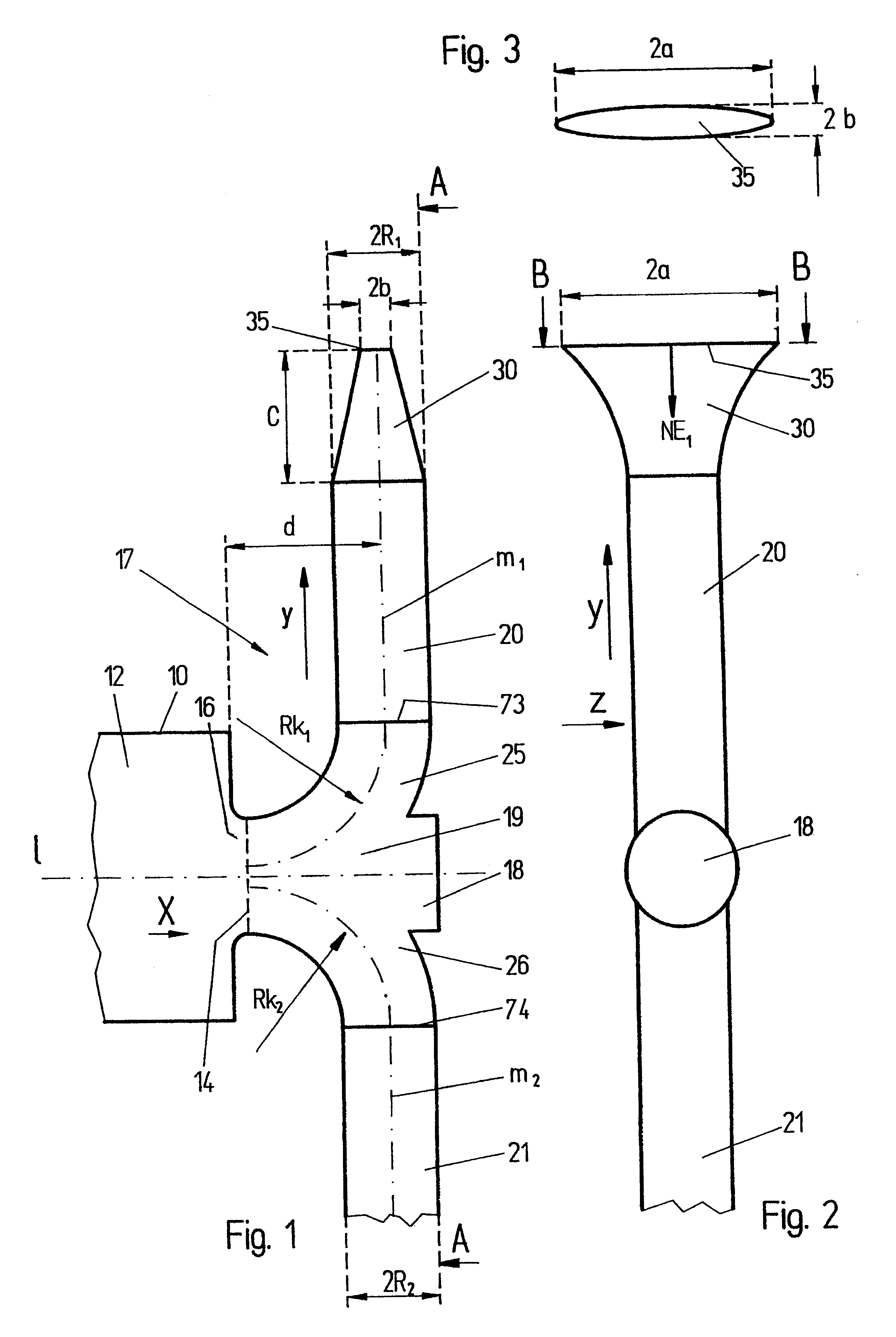

InactiveUS20100239700A1Reduce shear stressComplex to manufactureConfectionerySweetmeatsEngineeringMechanical engineering

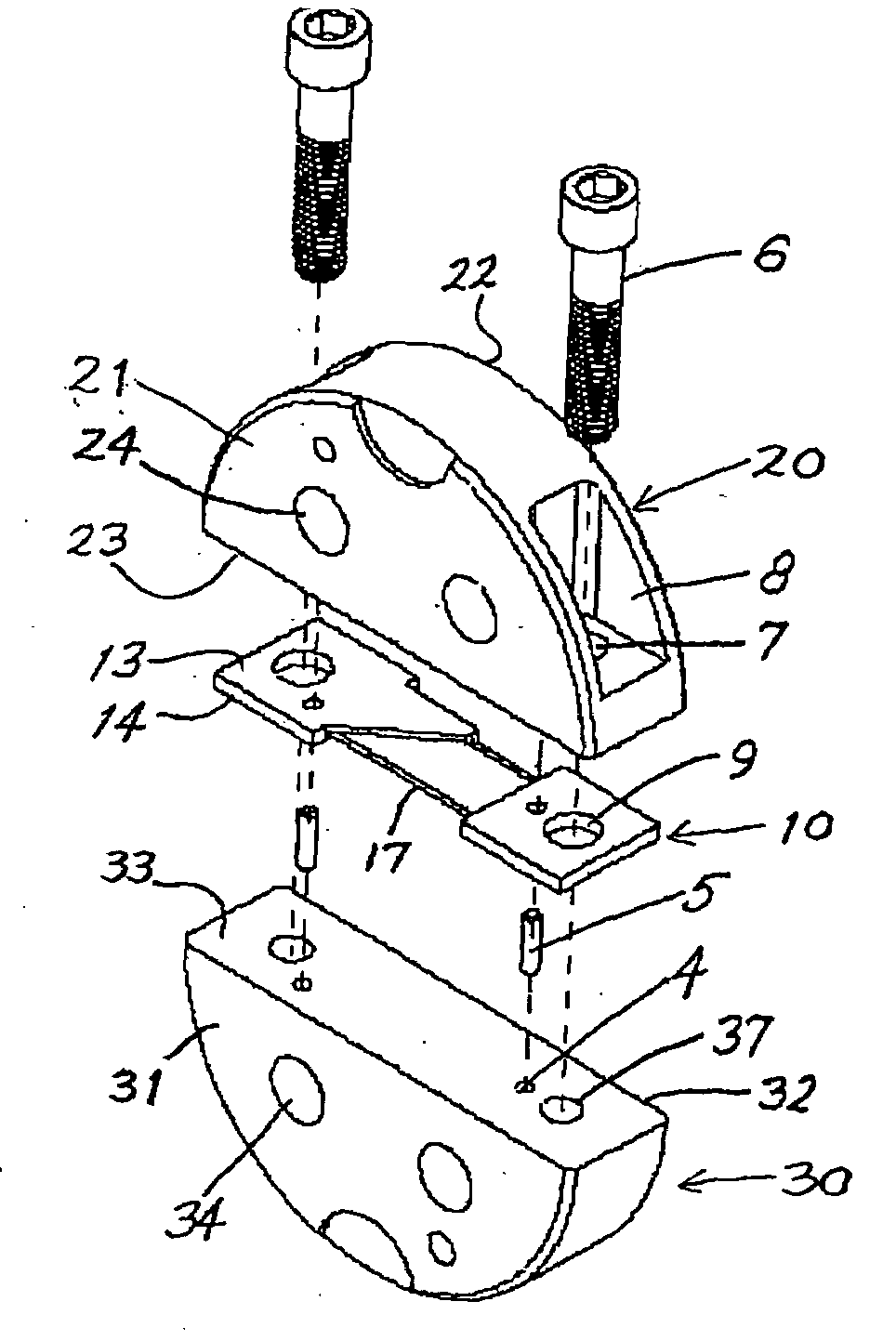

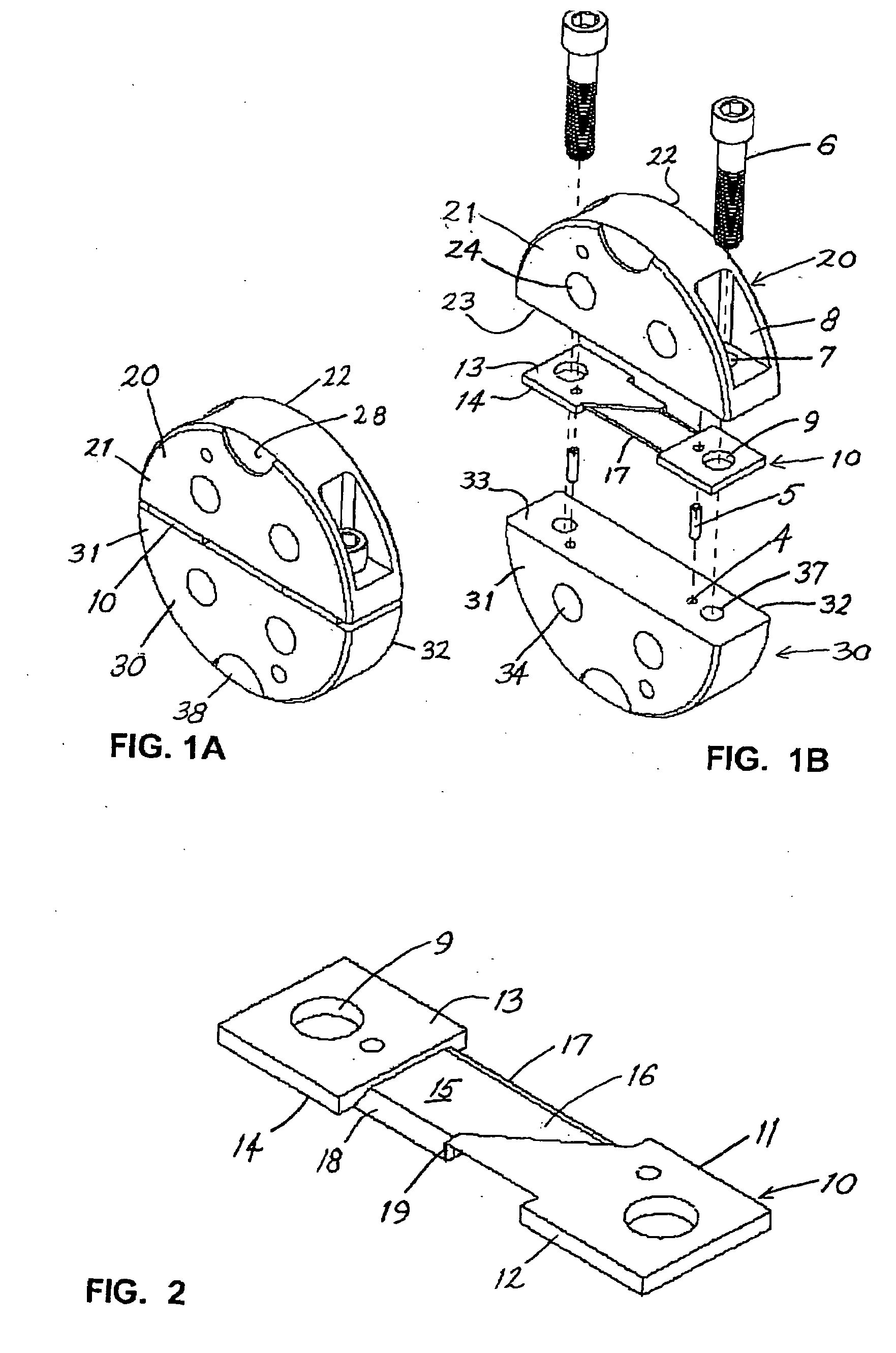

Apparatus for multiplying layers in a composite polymer stream includes an intermediate section having open conduits sandwiched between housing sections that close the conduits. The conduits have respective first stages separated by a first blade extending to a first face, and respective second stages separated by a second blade extending to a second face. The first stages separate the stream into sub-streams and compress and shift the sub-streams in a first dimension, whereas the second stages shift the sub-streams in a second dimension. In order to maintain a constant cross-sectional area of the sub-streams, the housing sections may be provided with complementary open channels. The apparatus can be used to multiply layers which are side-by-side or one-over-another by changing orientation in the direction of flow.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

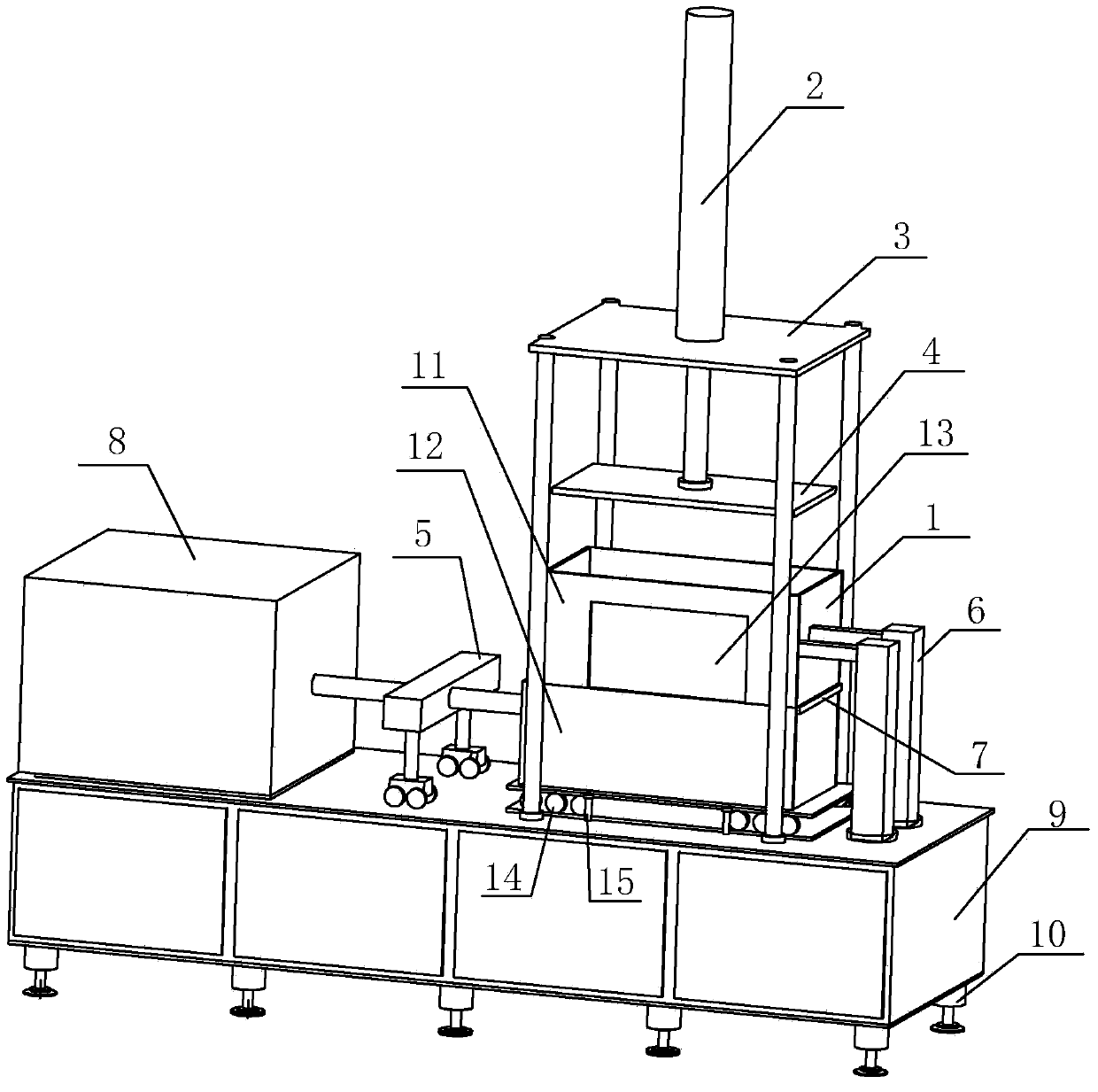

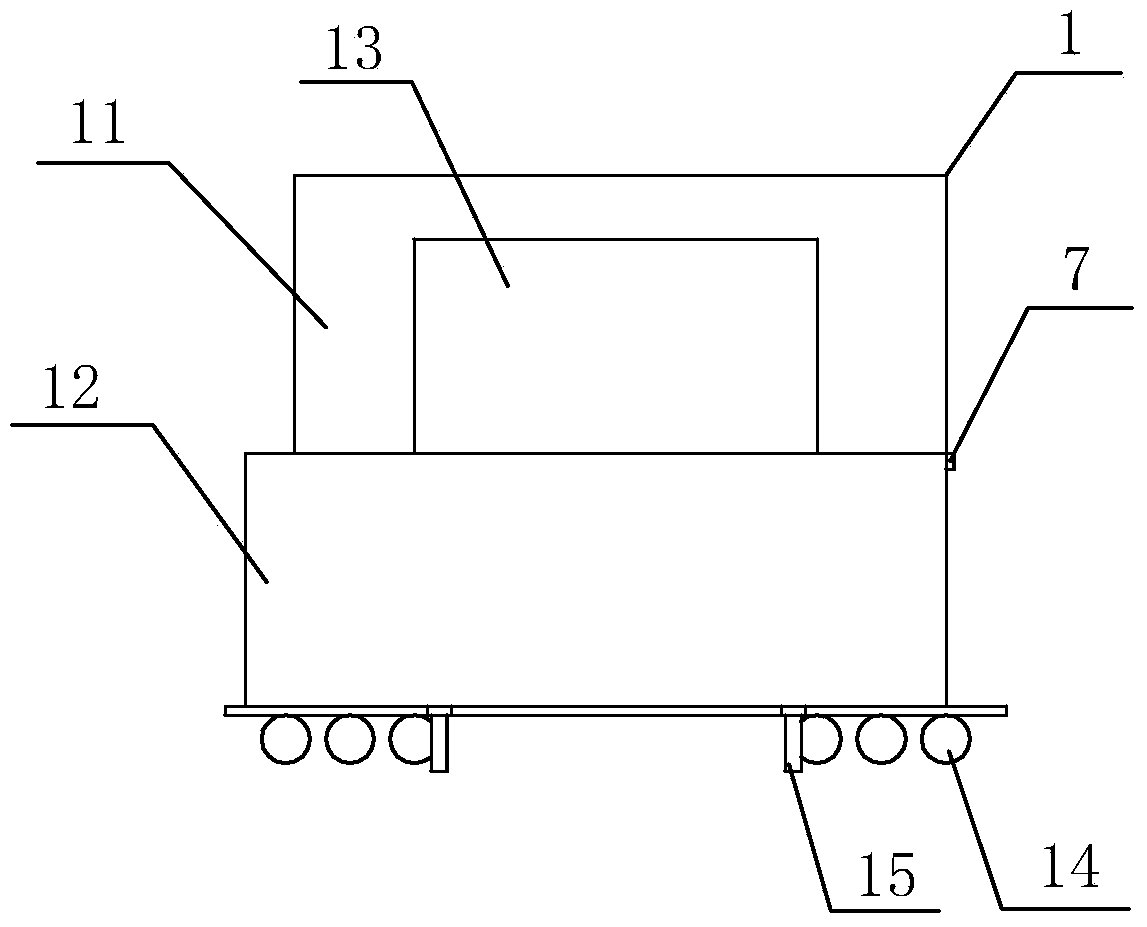

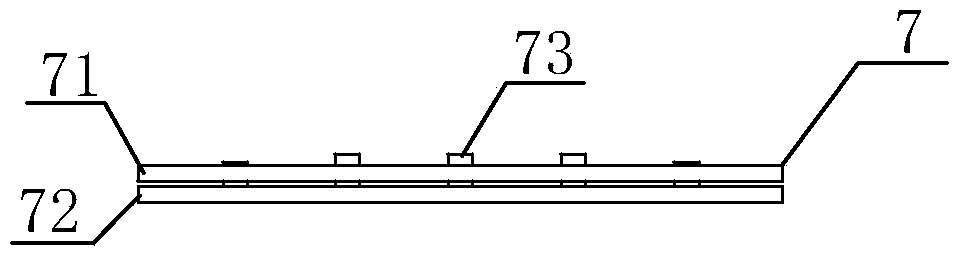

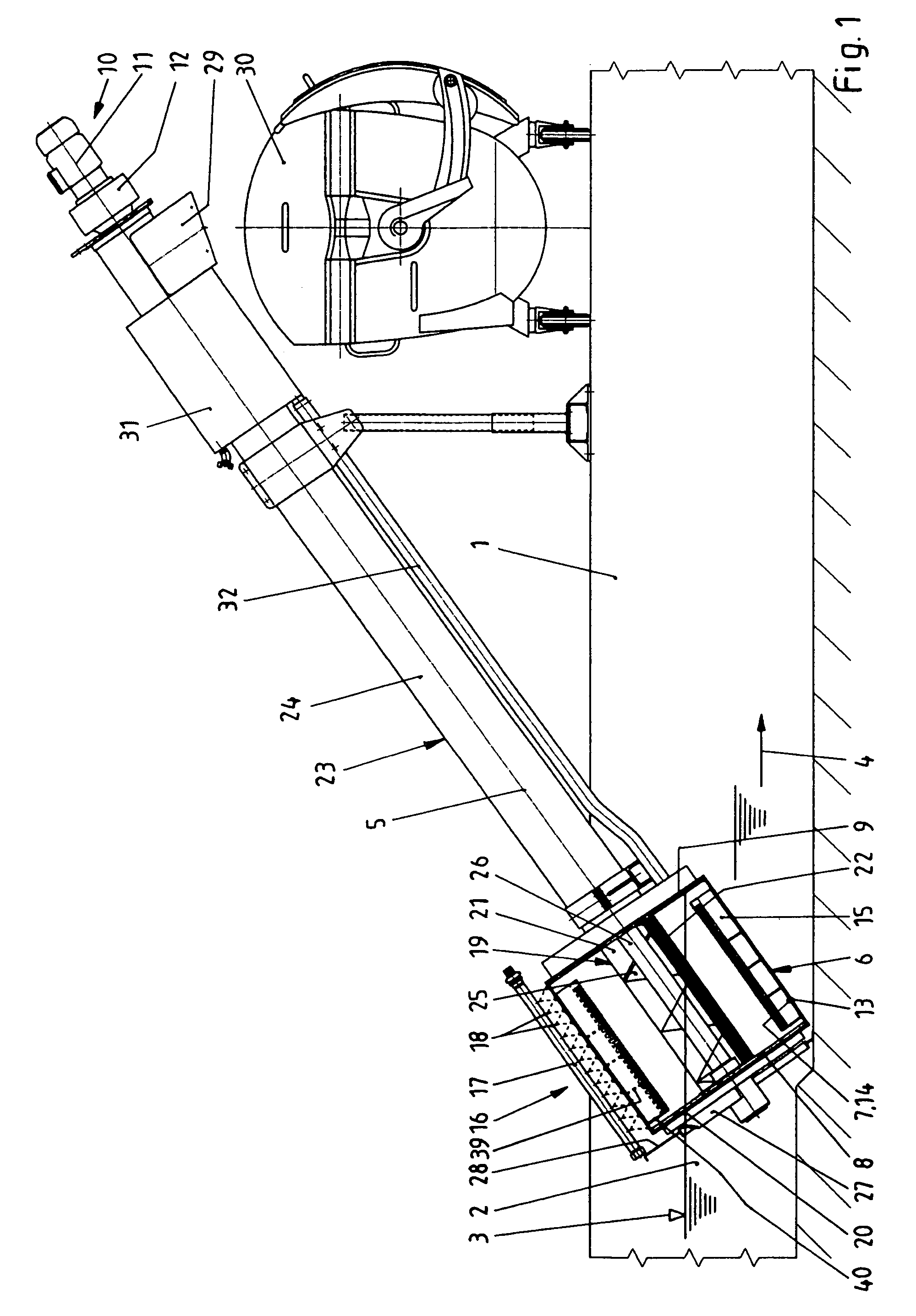

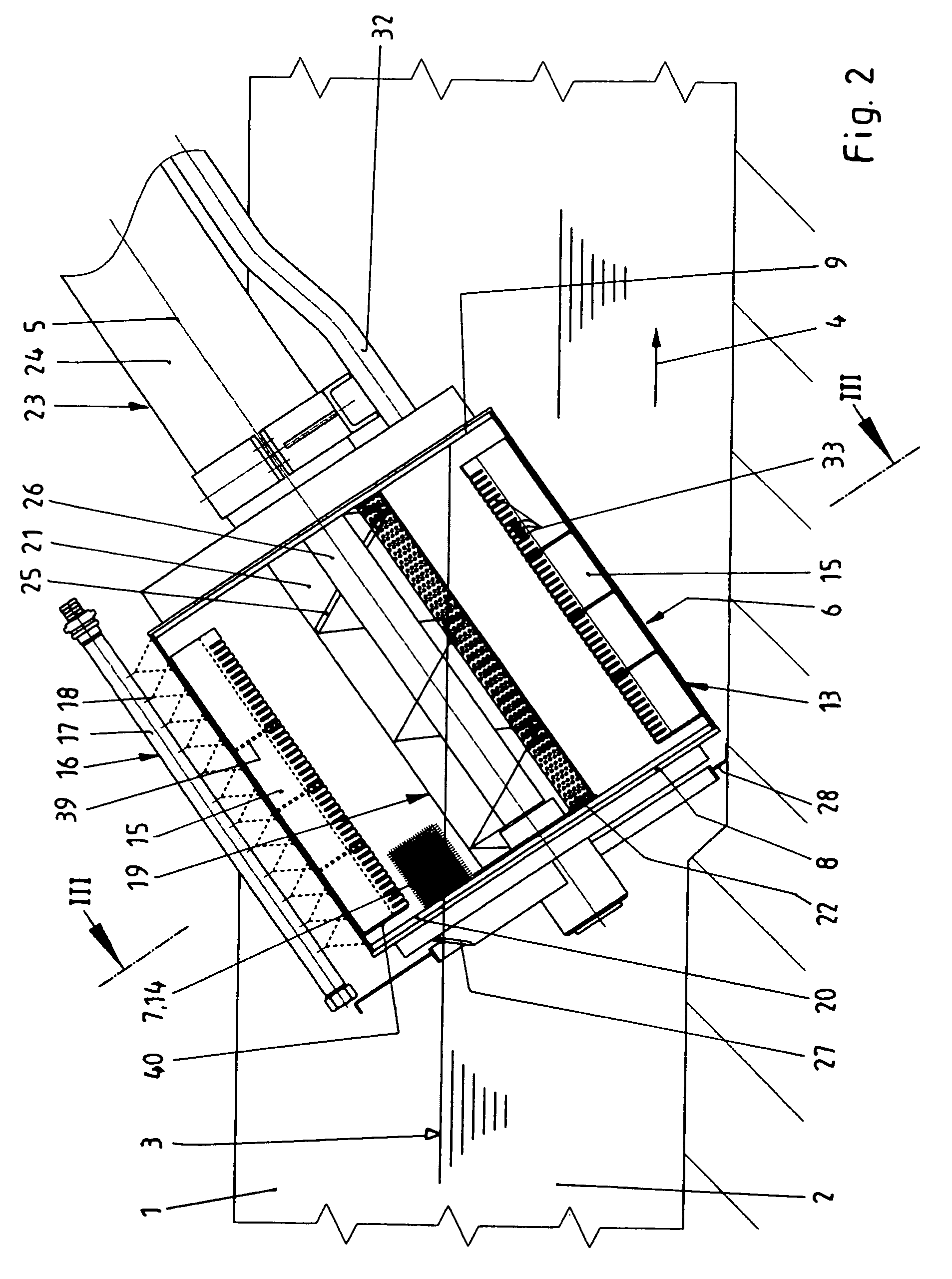

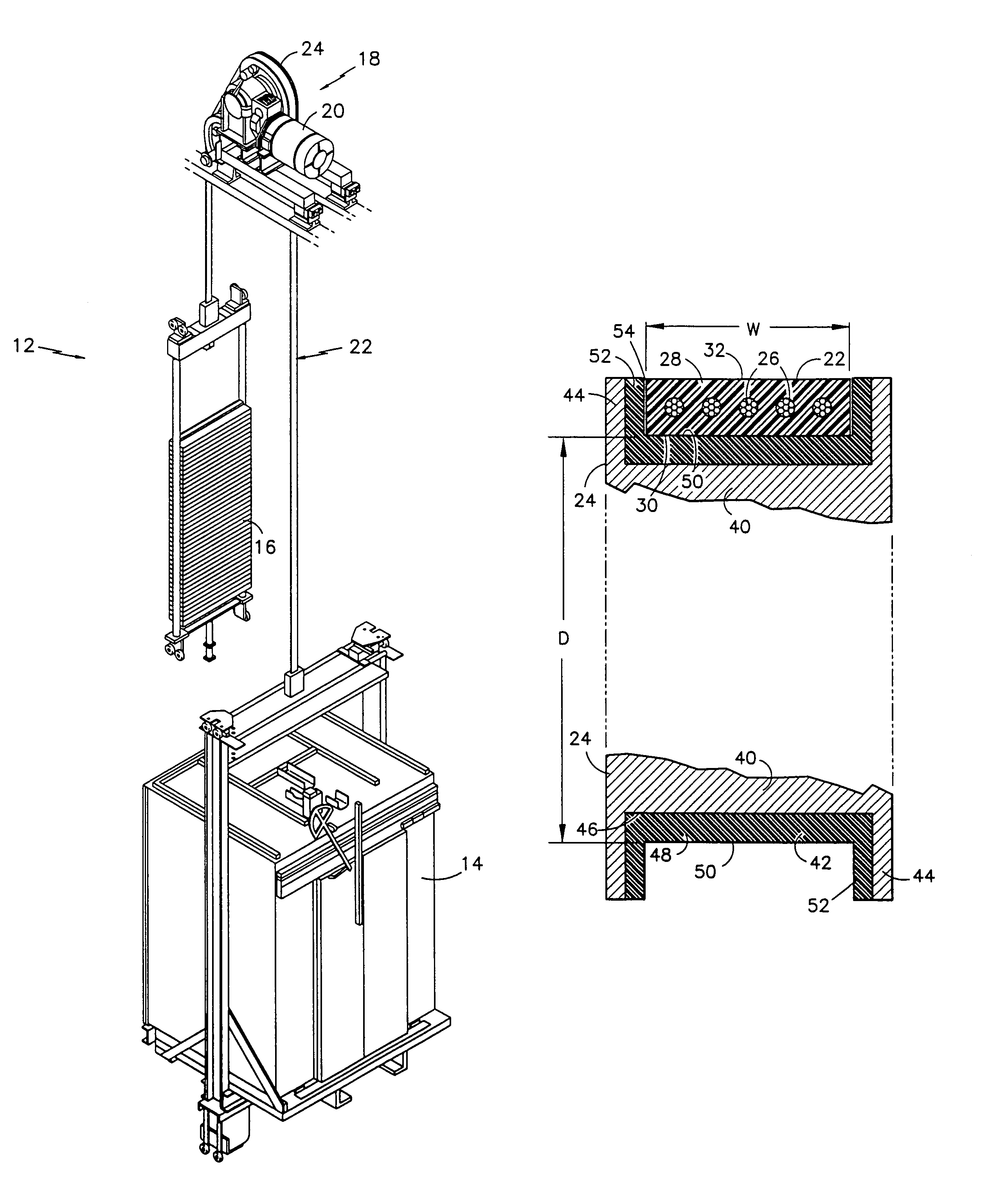

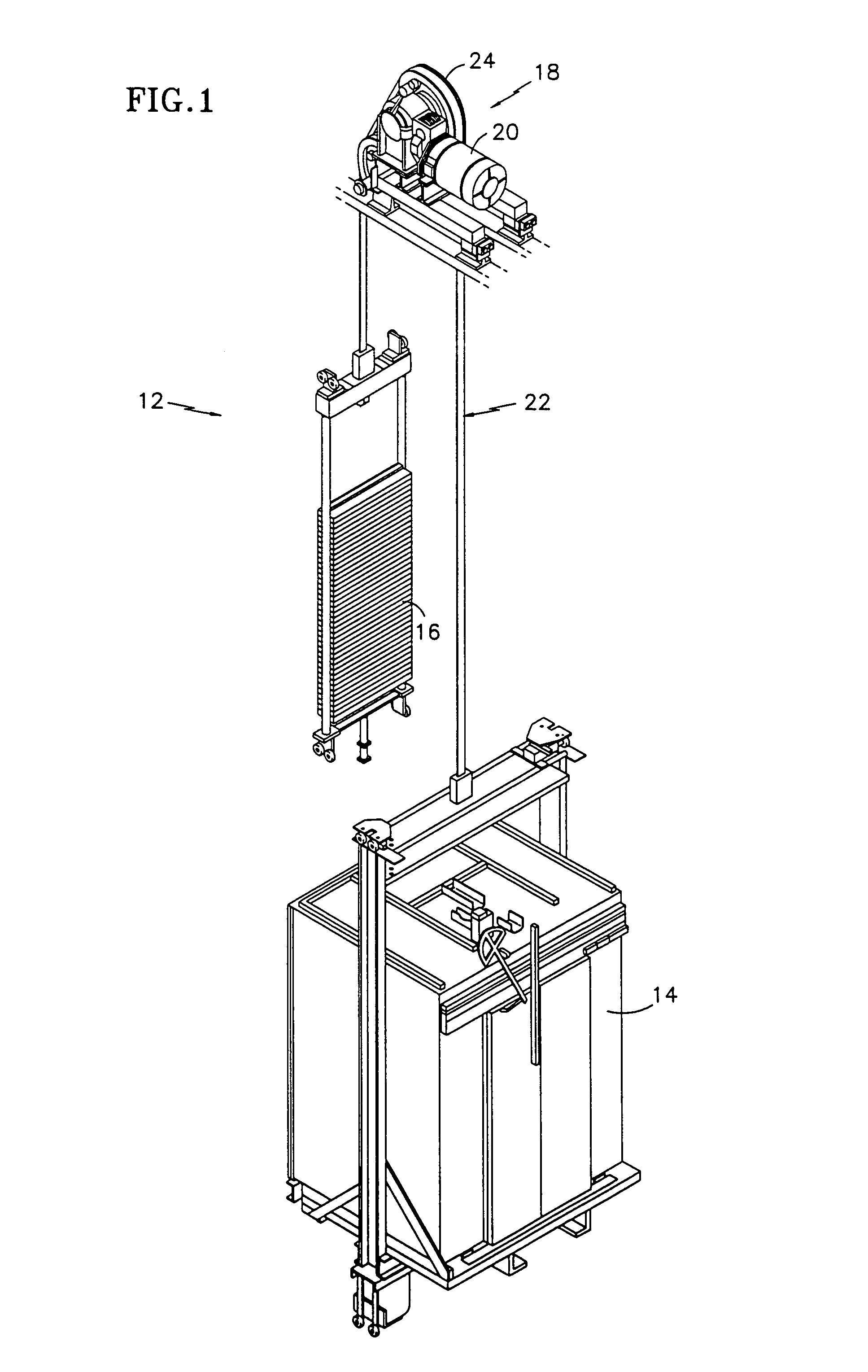

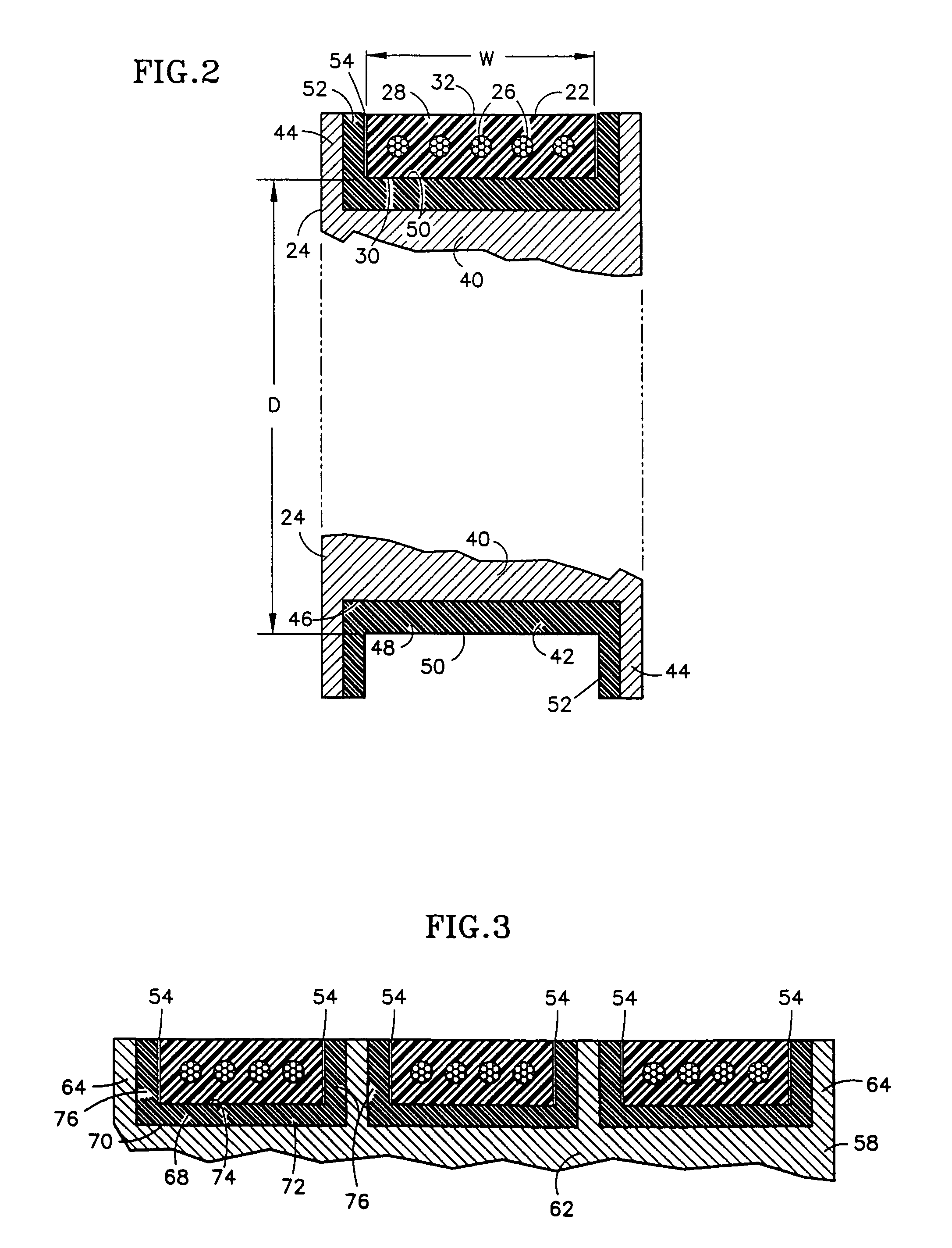

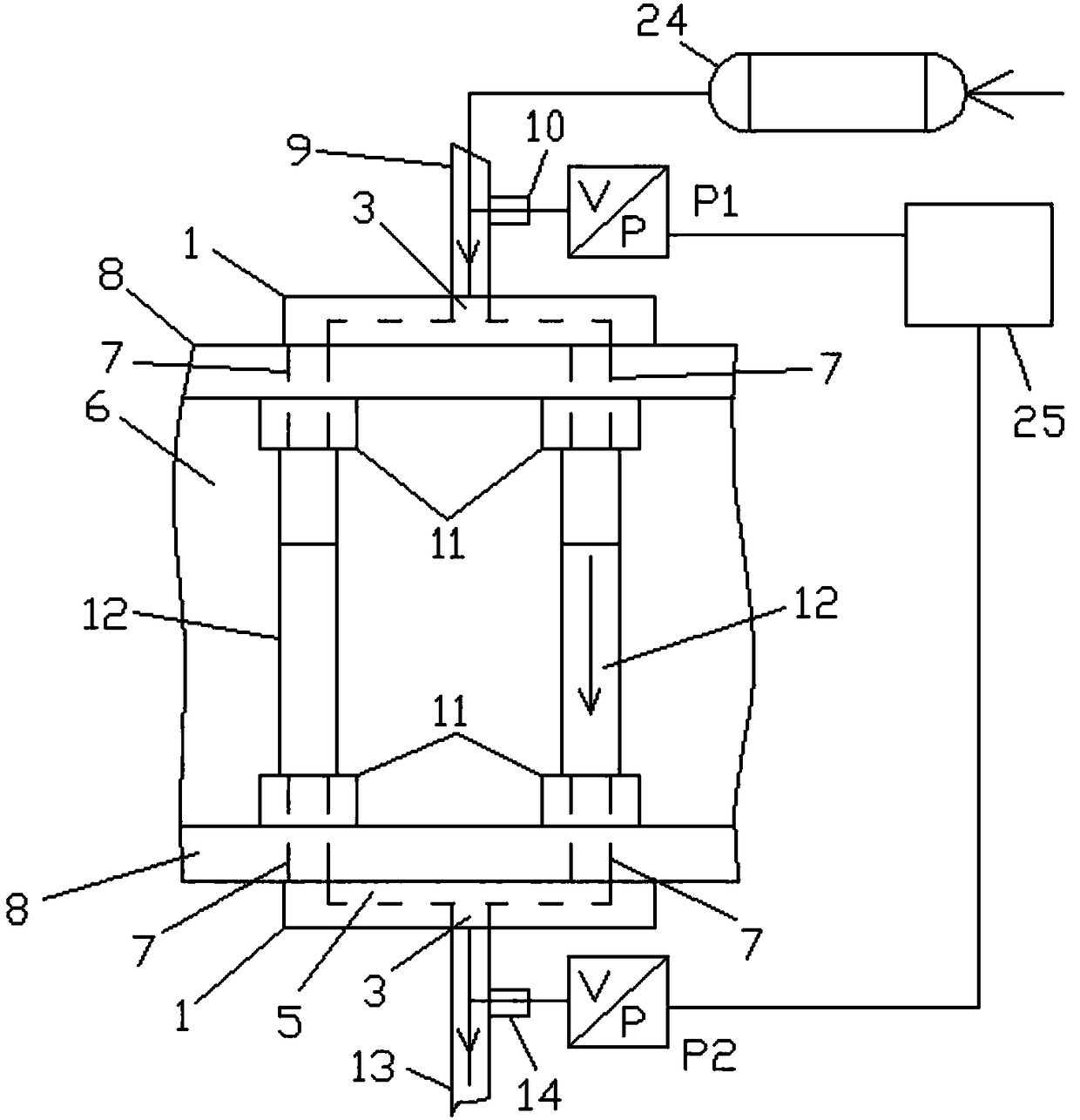

Direct shear test data acquisition instrument for big visual model of reinforced earth

ActiveCN104198301AImprove reliabilityNot easy to embedMaterial strength using steady shearing forcesDigital videoData acquisition

The invention relates to a direct shear test data acquisition instrument for a big visual model of reinforced earth. The direct shear test data acquisition instrument comprises a vertical loading system, a horizontal loading system and a shear box, wherein the shear box comprises an upper shear box and a lower shear box which are both filled with packing; the horizontal loading system comprises a push-pull electromotor and a sliding balanced pushing rod, and a displacement sensor and a pressure sensor are mounted on the push-pull electromotor; one end of the sliding balanced pushing rod is connected with the push-pull electromotor, and the other end of the sliding balanced pushing rod is connected with the lower shear box; a counterforce device is mounted on one side, far away from the sliding balanced pushing rod, of the lower shear box and connected with the upper shear box; transparent tempered glass is arranged on one side wall of the upper shear box in the shear direction, and a digital video camera is mounted in front of the tempered glass; a geotechnical material spring clip is mounted at one end of the lower shear box. The direct shear test data acquisition instrument is convenient to use, small in test error, precise test data and convenient to widely promote and use.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

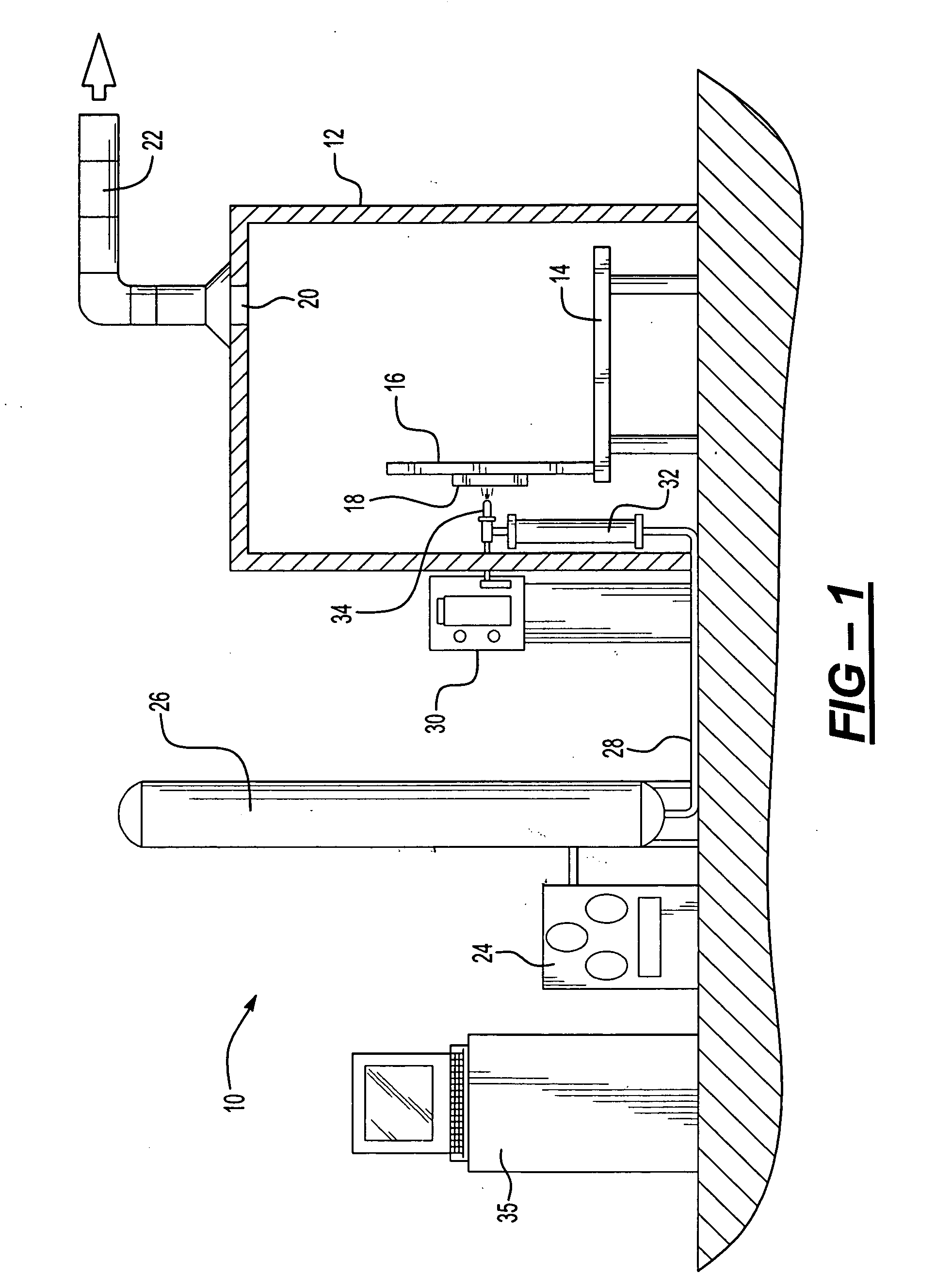

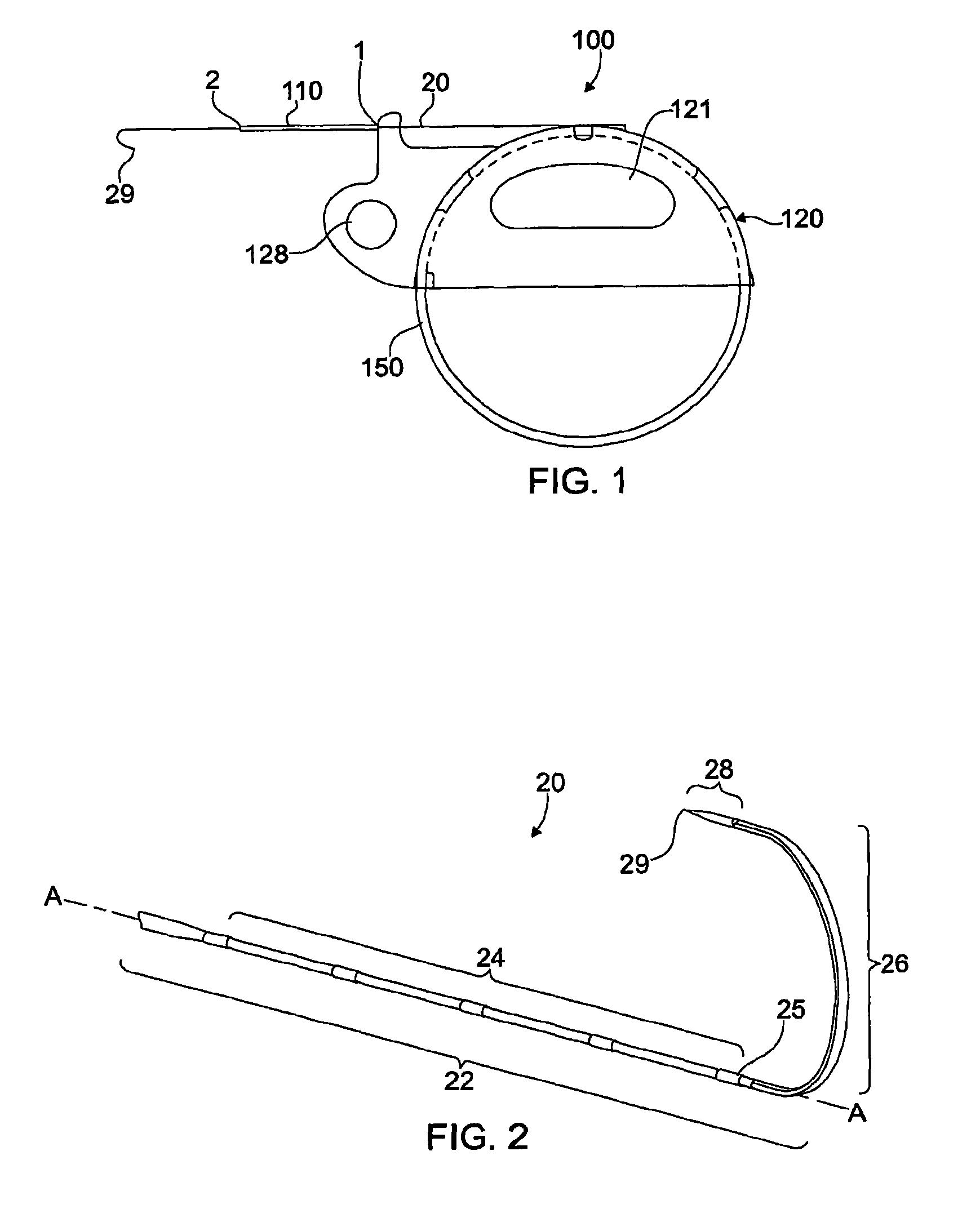

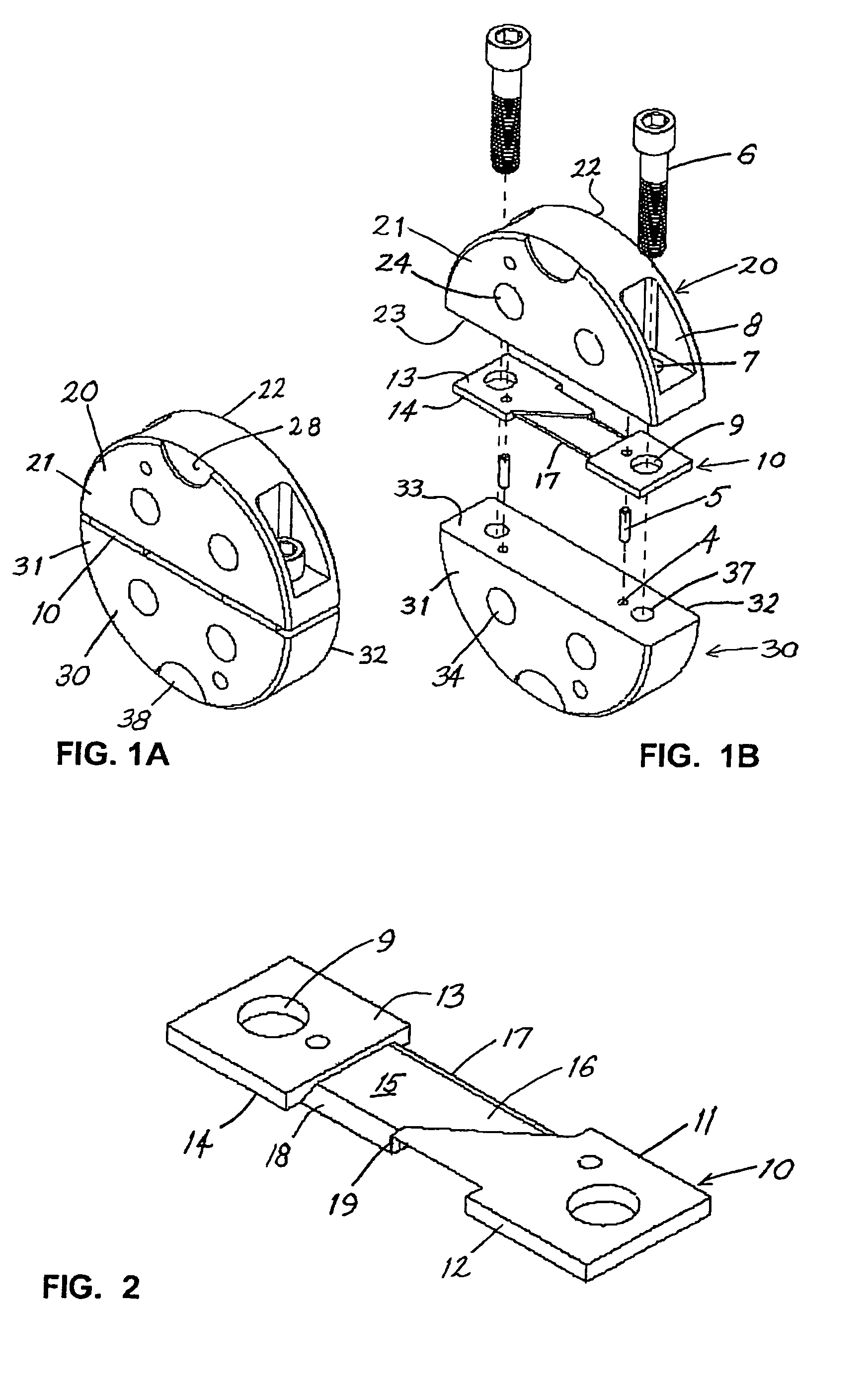

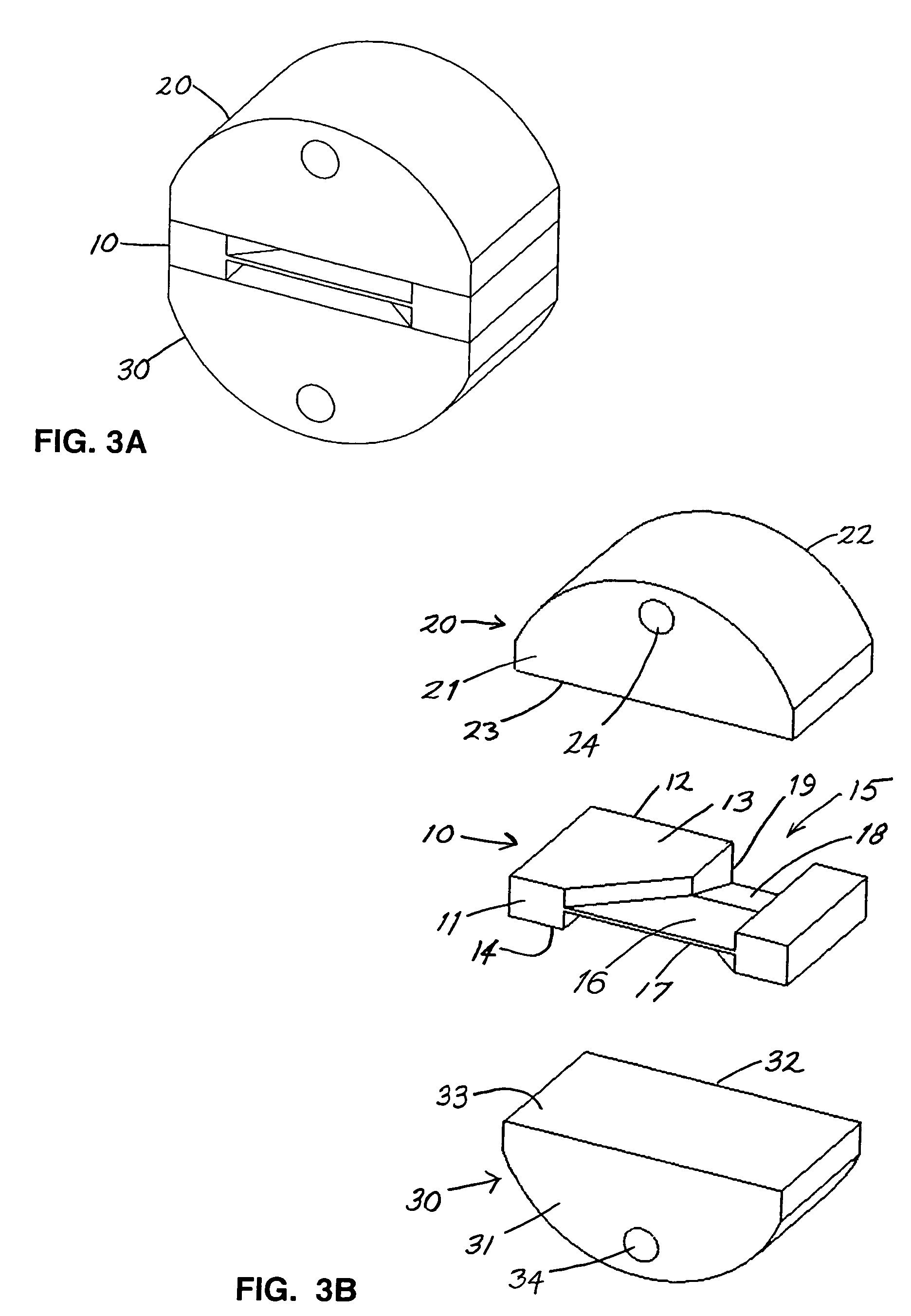

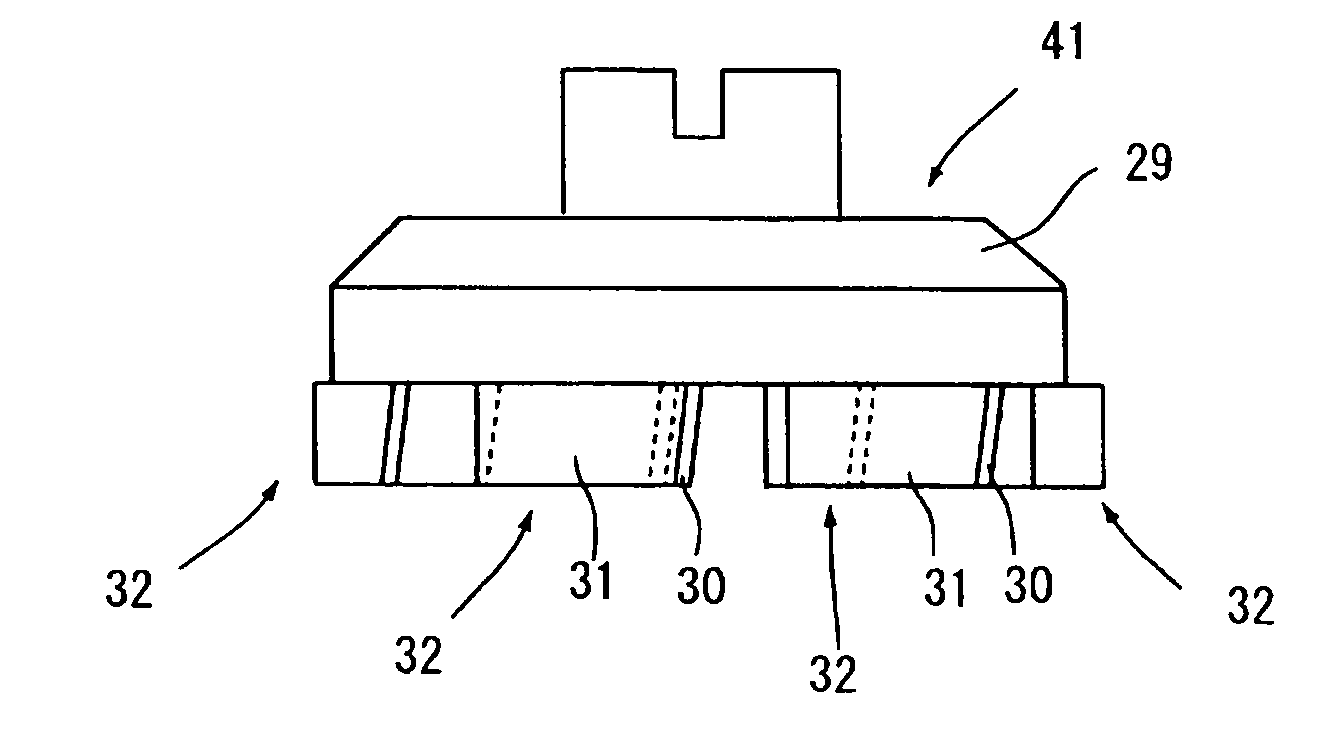

Surgical cassette

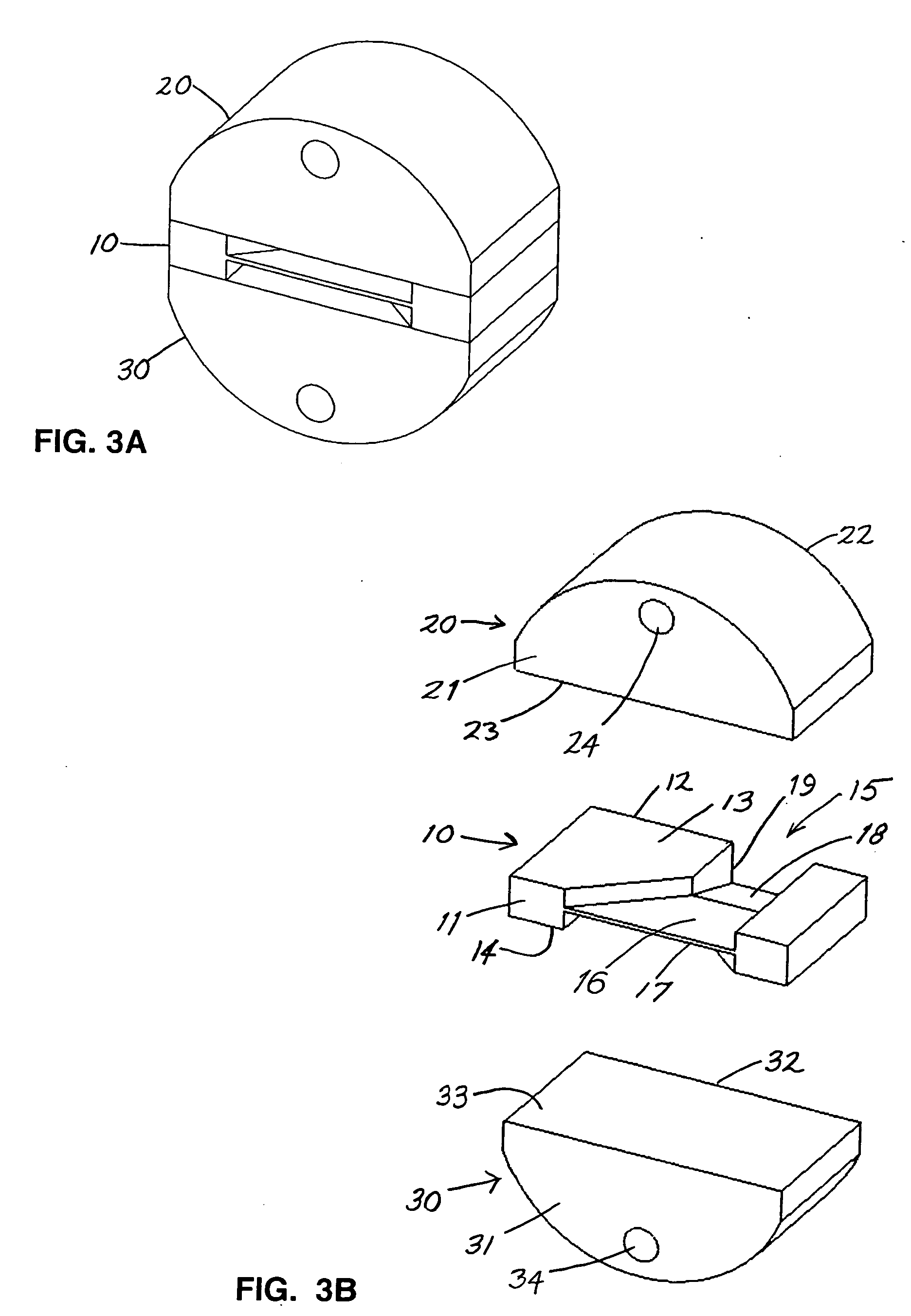

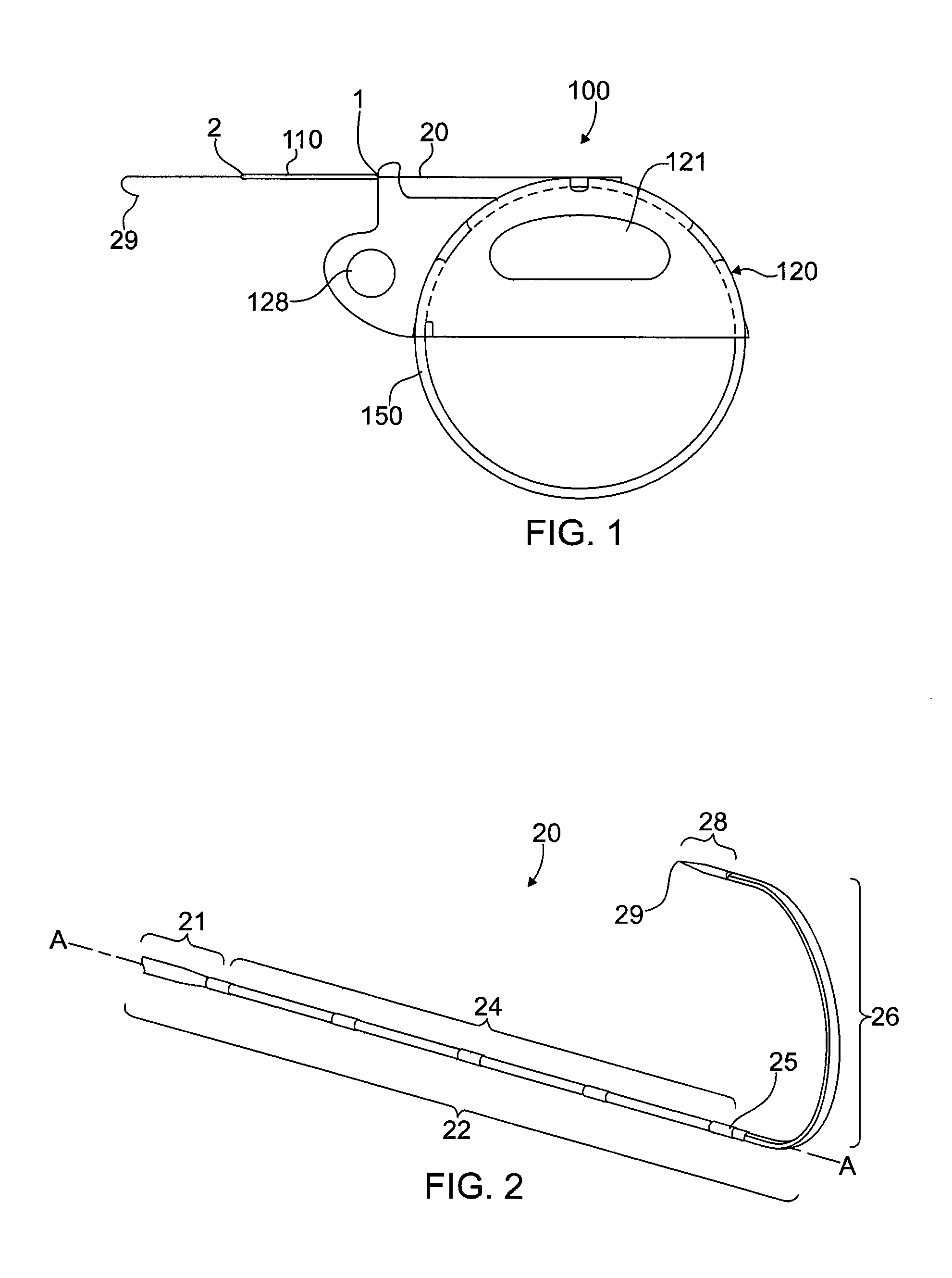

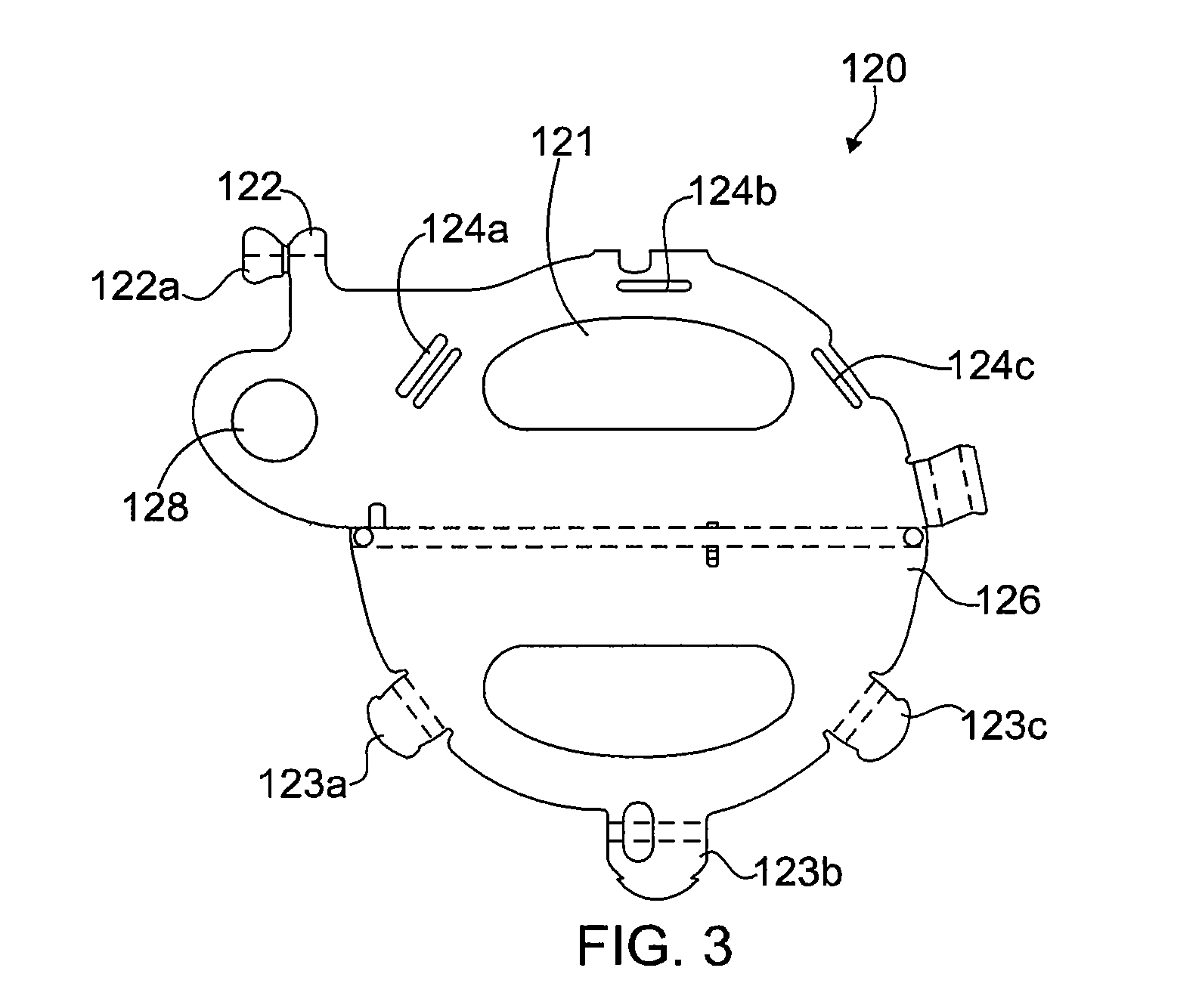

ActiveUS7775780B2Constant cross-sectionConstant cross-sectional areaAnaesthesiaFlexible member pumpsPeristaltic pumpElastomer

A cassette having an elastomeric sheet that is bonded or mechanically attached to a rigid substrate. A flow channel is molded into the rigid substrate that corresponds to a flow channel molded into the elastomeric sheet. The cassette is used in combination with a peristaltic pump having pump head rollers that are mounted radially from the axis of rotation of the pump motor so as to compress the elastomeric flow channels against the rigid substrate during operation. The flow channels molded into the rigid substrate have smooth, fluid lines free from sharp edges and abrupt direction changes and correspond with the fluid channels molded into the elastomeric sheet so as to provide a transition region with a relatively constant cross-section over its entire length that approximates the cross-sectional area of the flow channels molded into the rigid substrate and the fluid channel molded into the elastomeric sheet so that the entire fluid path is of relatively constant cross-sectional area.

Owner:ALCON INC

Casting system for thixoforms

Diecasting machine for production of mouldings from thixotropic metal billets, containing a sprue system which connects a cylindrical casting chamber cavity with a moulding cavity, where the sprue system has a cylindrical sprue cavity immediately adjacent to the casting chamber cavity and contains at least one sprue, and all sprues lead laterally away from the generated surface of the sprue cavity and each sprue has a concentric center line and at its end facing towards the moulding cavity has an inlet opening for introduction of the thixotropic metal alloy into the moulding cavity, and the sprue system is connected to the casting chamber cavity by a passage opening perpendicular in relation to a concentric longitudinal axis of the cylindrical casting chamber cavity, wherein each sprue has a circular or elliptical cross section with a substantially constant cross sectional area over its entire length.

Owner:ALCAN TECH & MANAGEMENT LTD

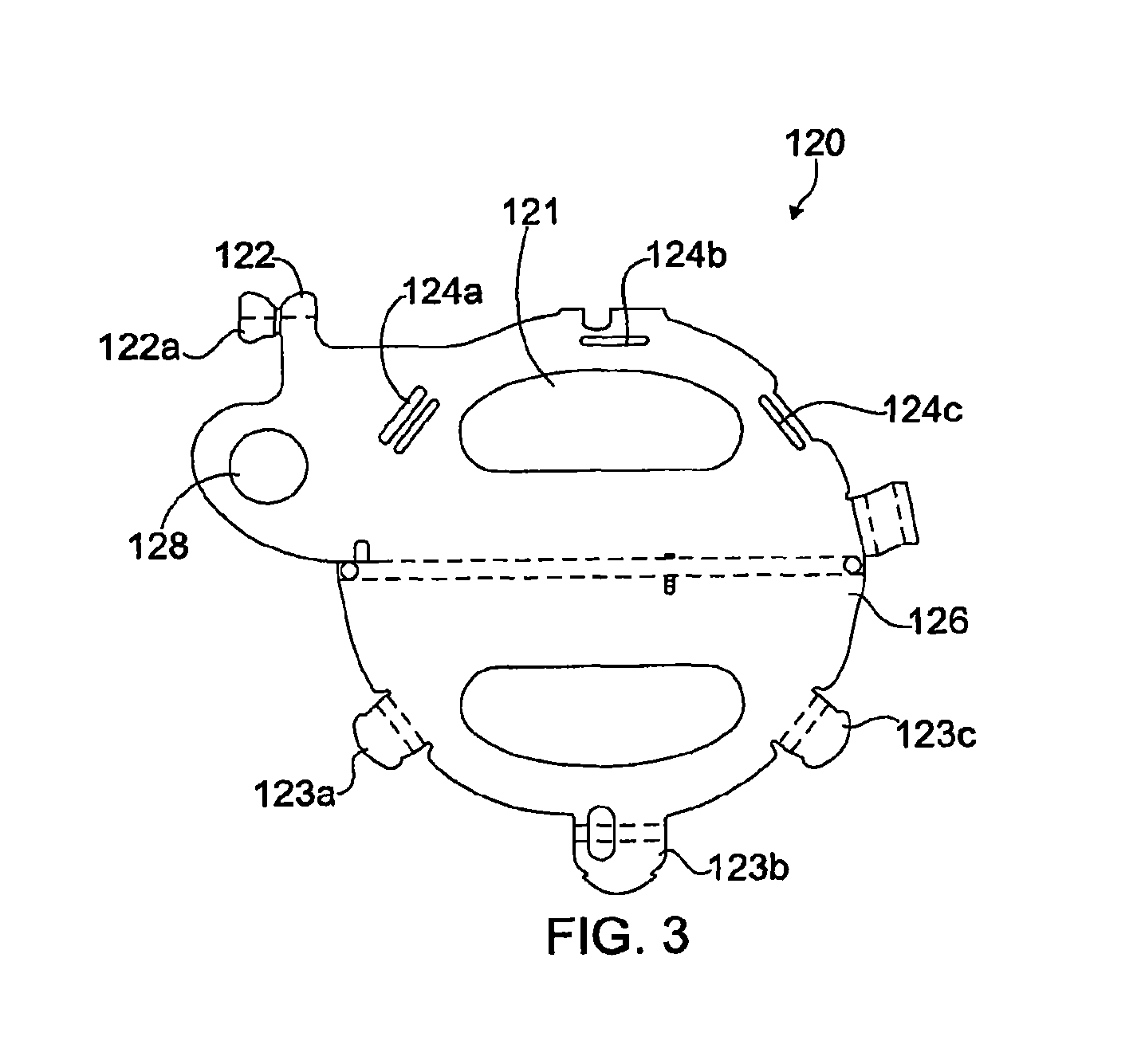

Apparatus, system, and method of shielding the sharp tip of a transseptal guidewire

ActiveUS20090182281A1Avoid contactAvoid damageGuide needlesInfusion syringesSyringe needleGeneral surgery

Apparatus, system, and methods for introducing a sharp tip of a transseptal guidewire through a hub of a transseptal needle and into a lumen of a transseptal needle are provided. The apparatus includes a holder that contains the transseptal guidewire and a shield coupled to the holder. The shield has a wall defining a lumen that accommodates the sharp tip of the transseptal guidewire. The cross-sectional shape of the wall is substantially constant along at least a portion of its length and sized to fit within the lumen of the transseptal needle, thereby inhibiting contact between the sharp tip of the transseptal guidewire and the hub of the transseptal needle when the wall of the shield is positioned to extend into the lumen of the transseptal needle. The lumen of the shield has a substantially constant cross-sectional area along at least a portion of its length and an outer surface of the wall of the shield is cylindrical along the same length.

Owner:BOSTON SCI MEDICAL DEVICE LTD

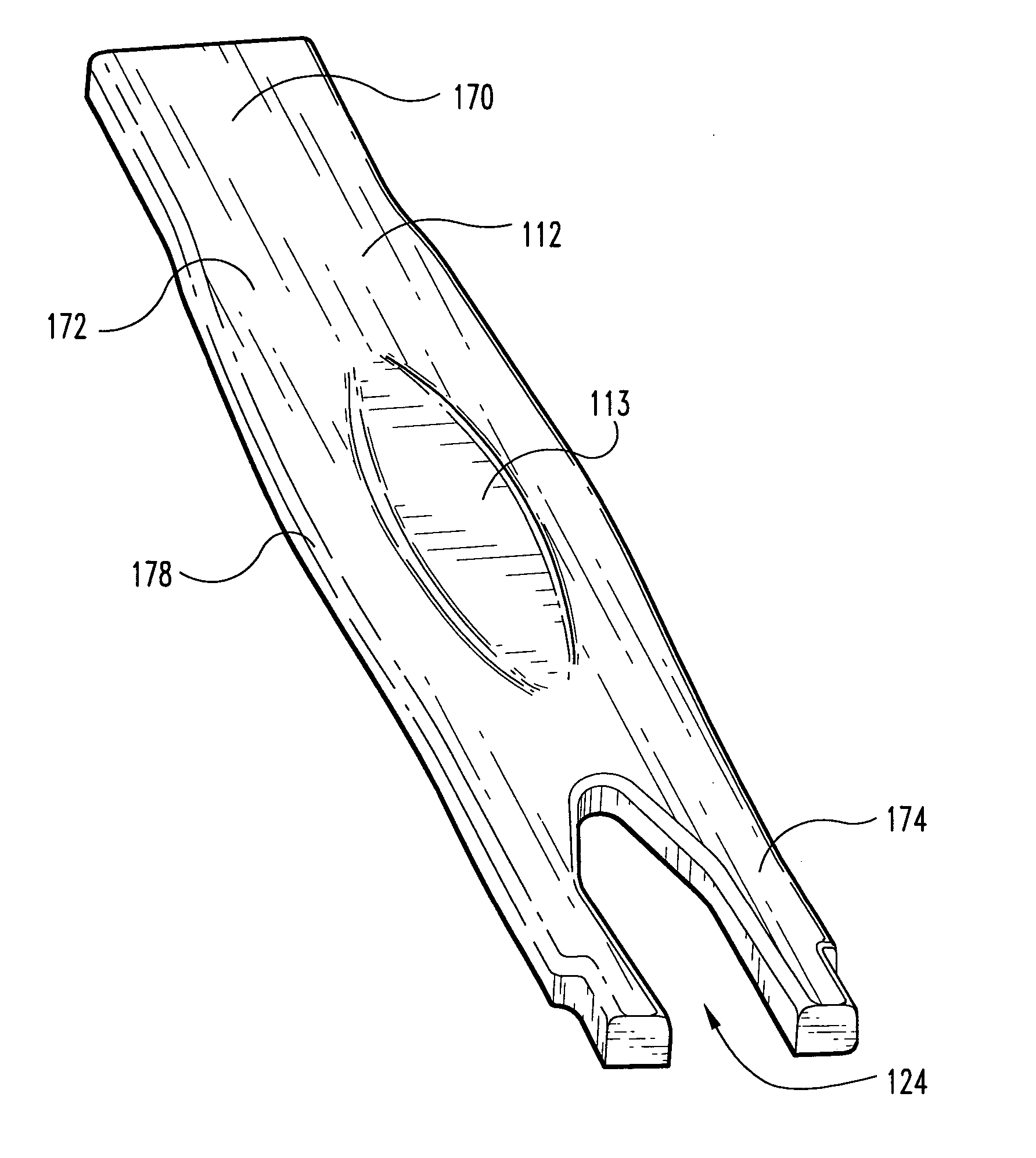

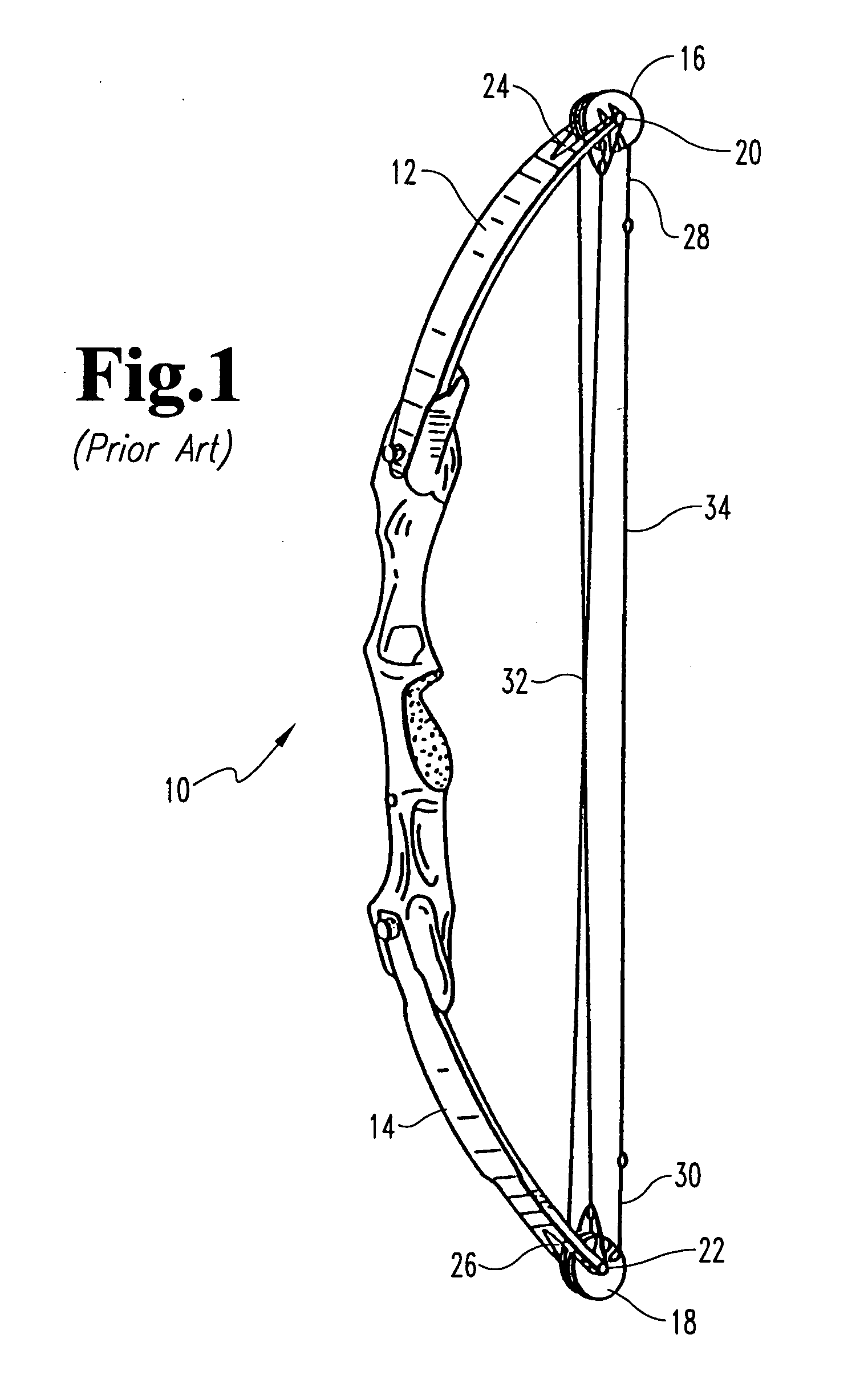

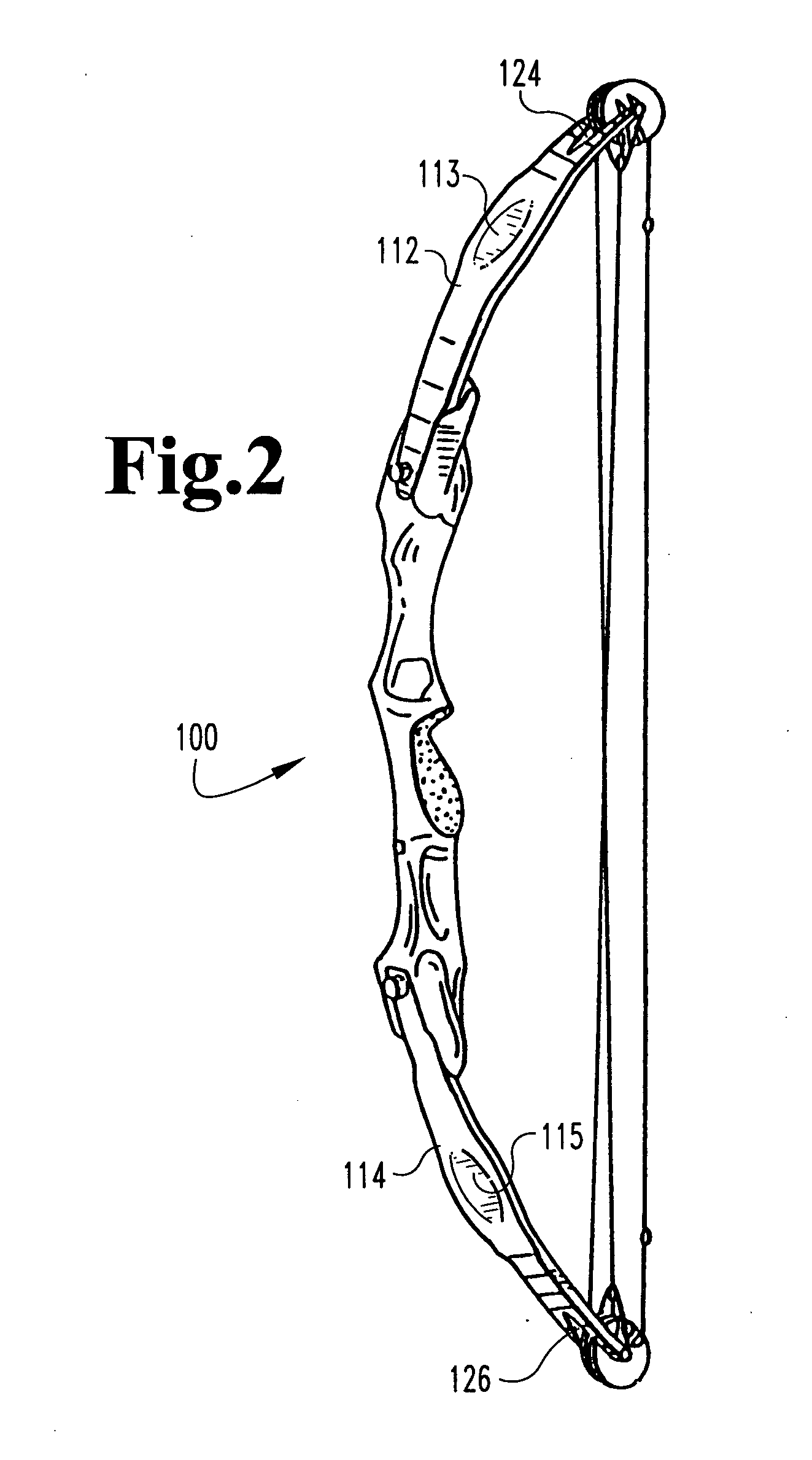

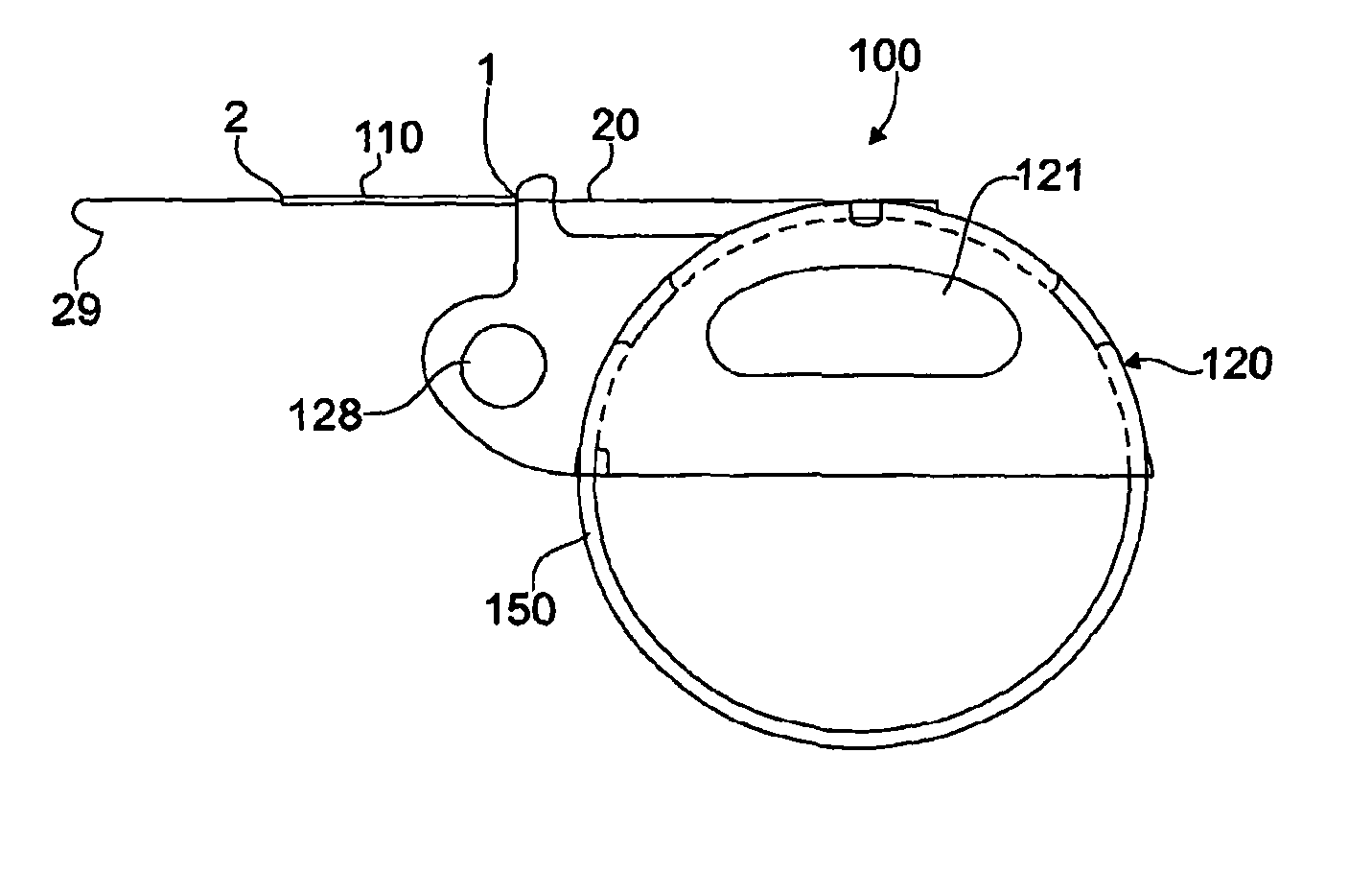

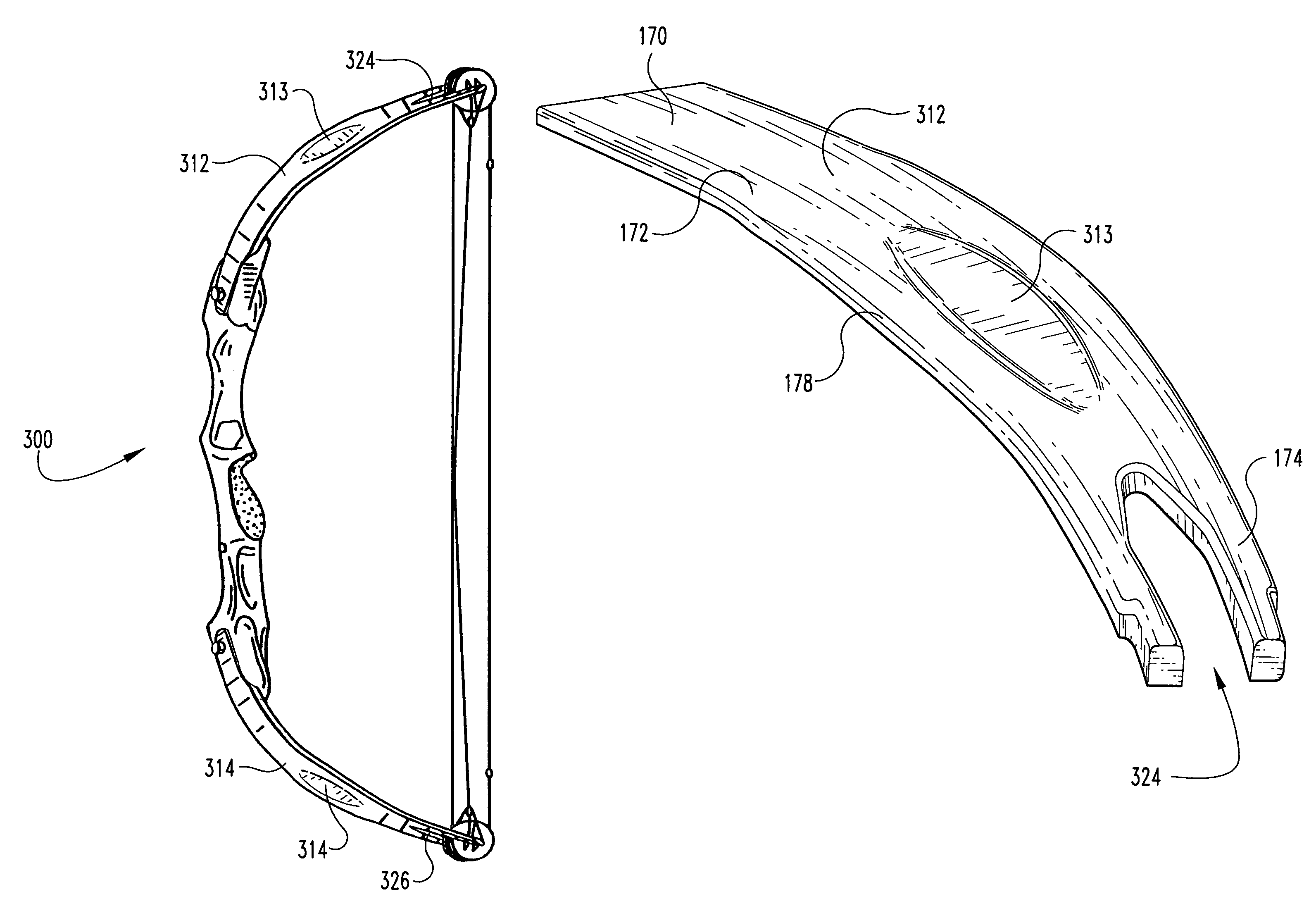

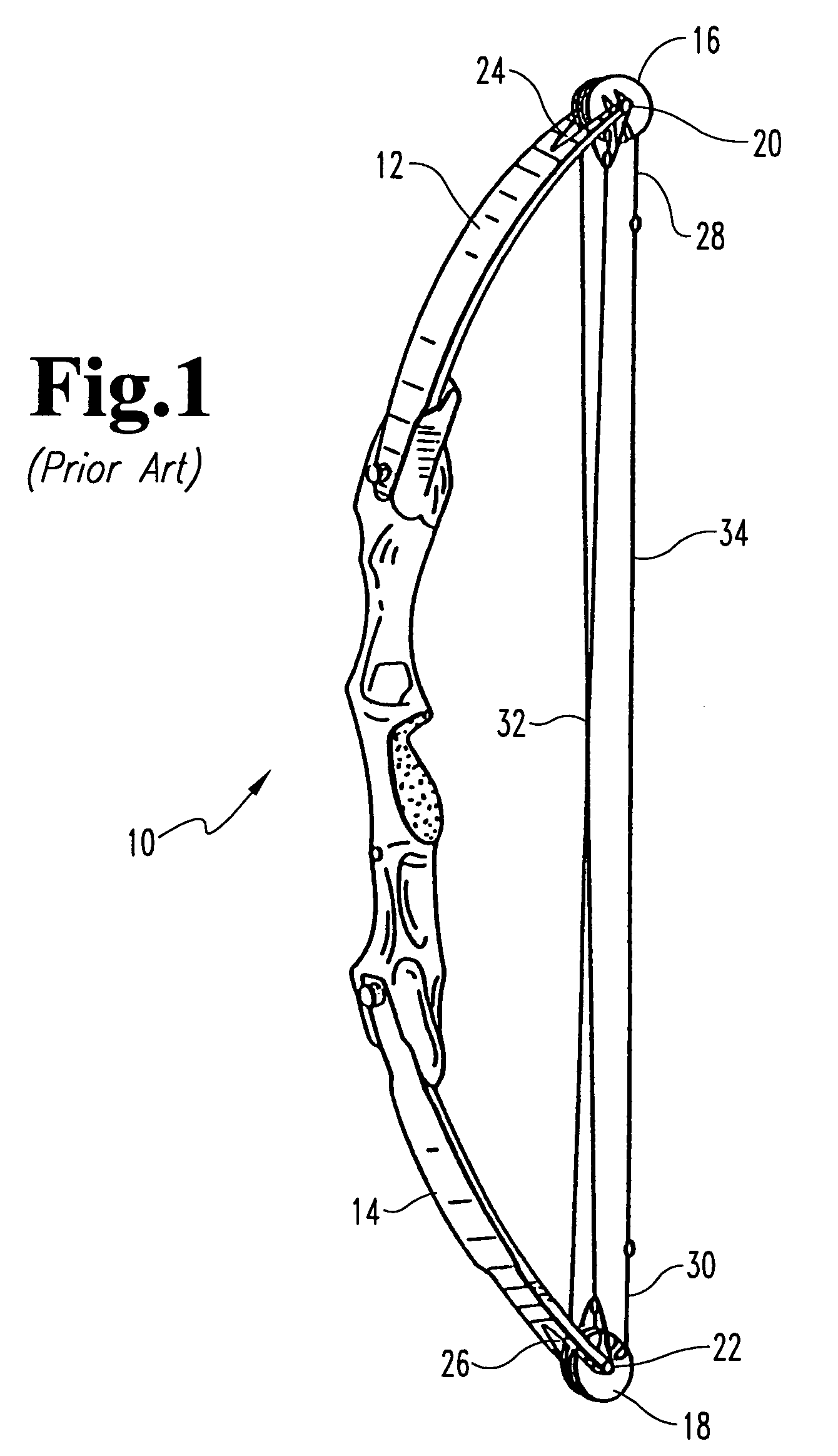

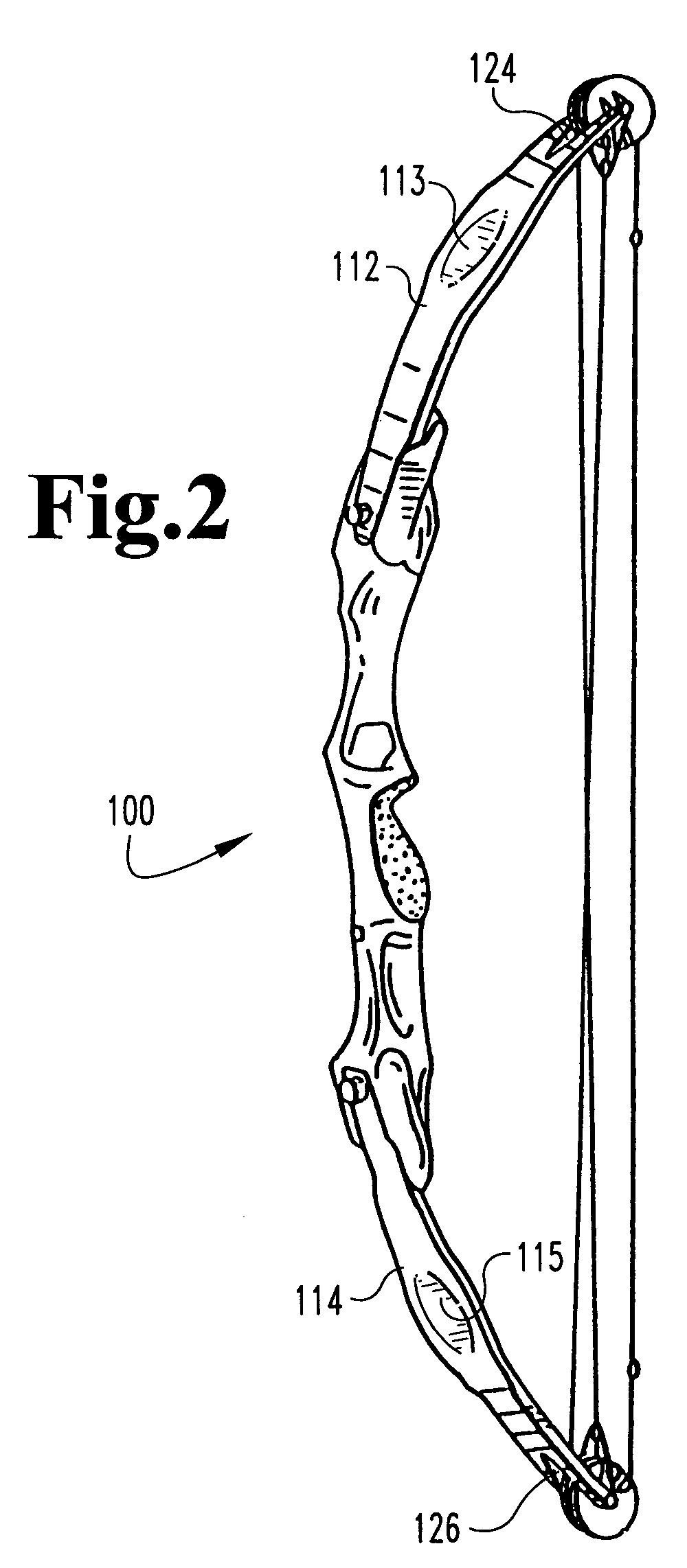

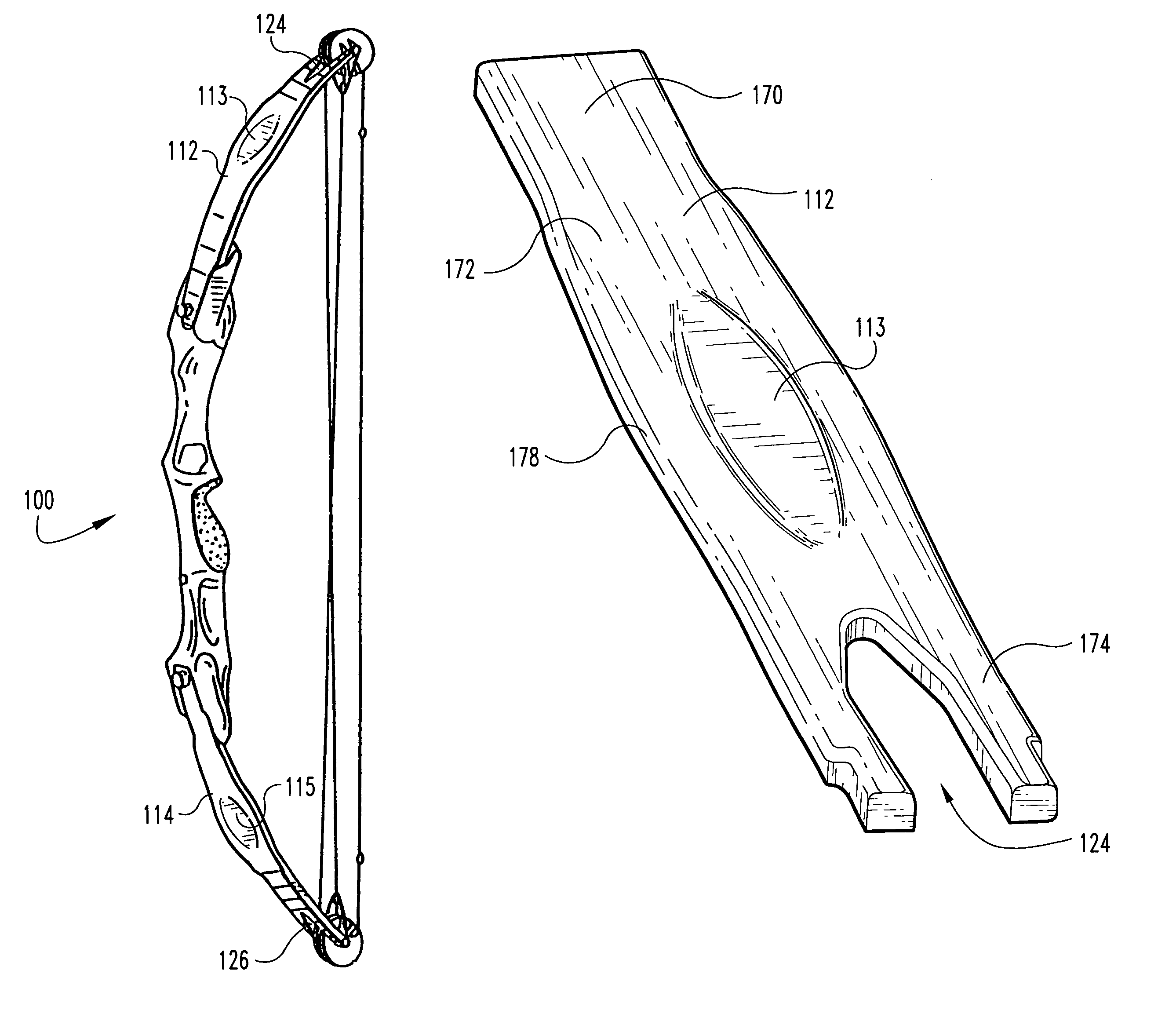

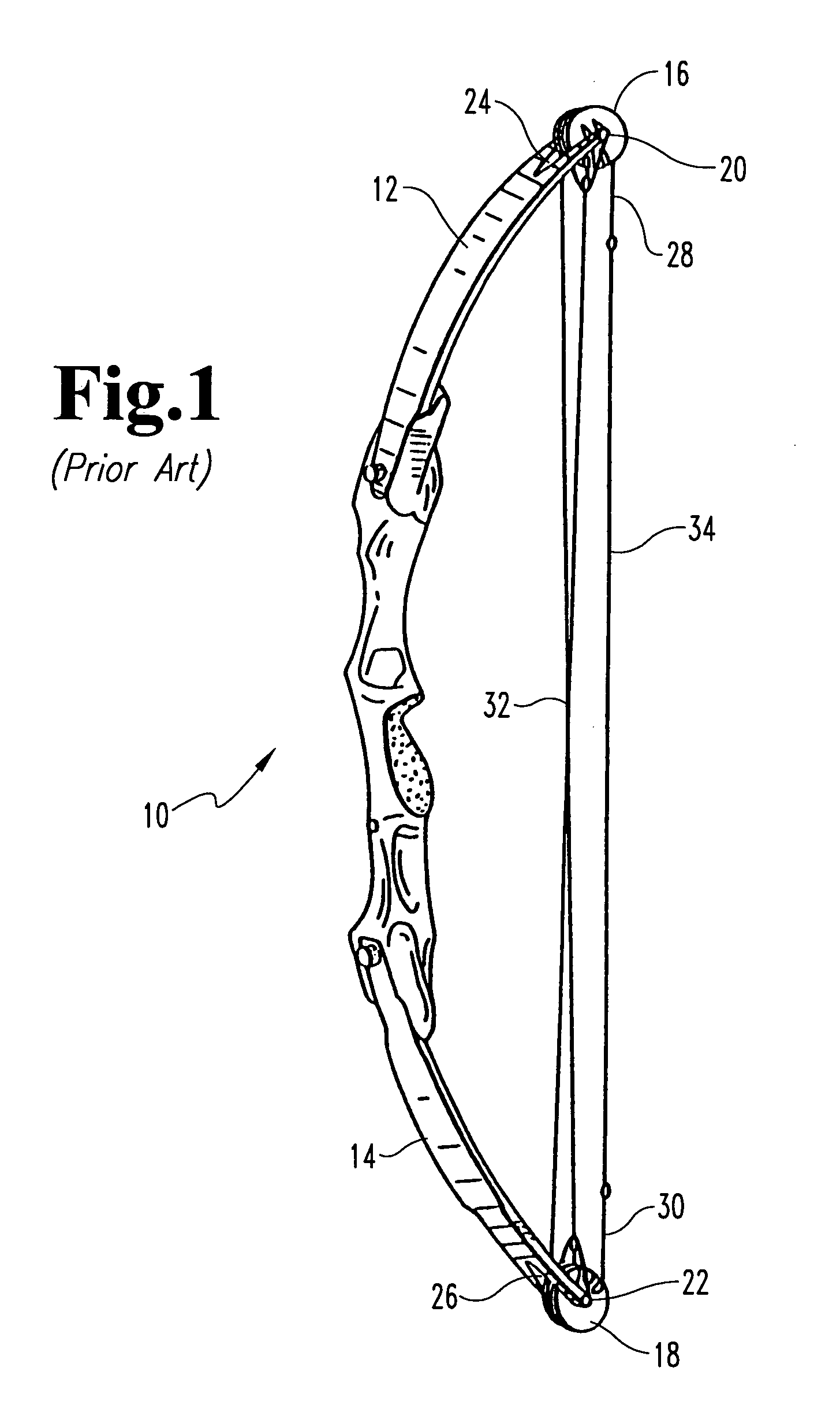

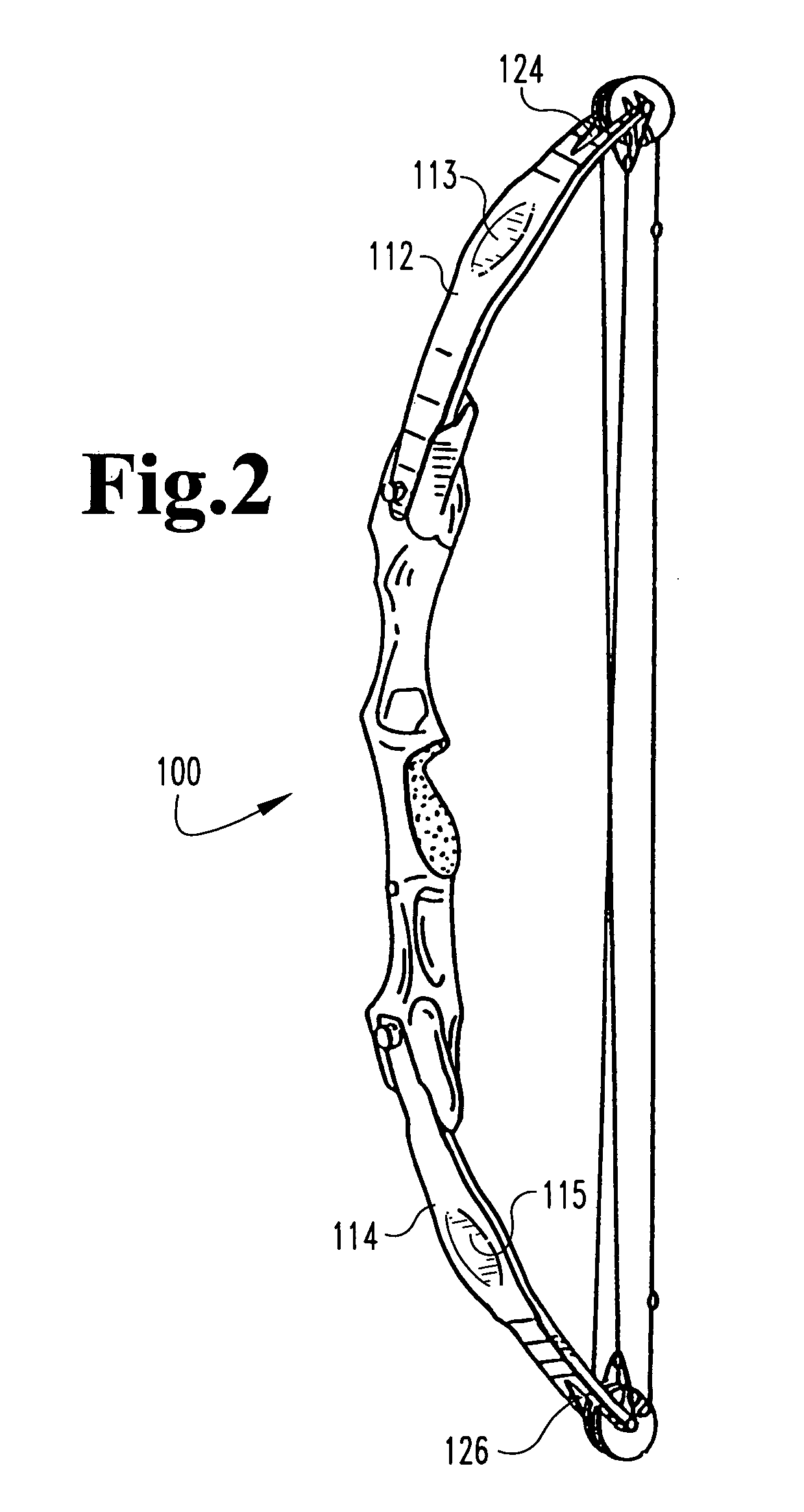

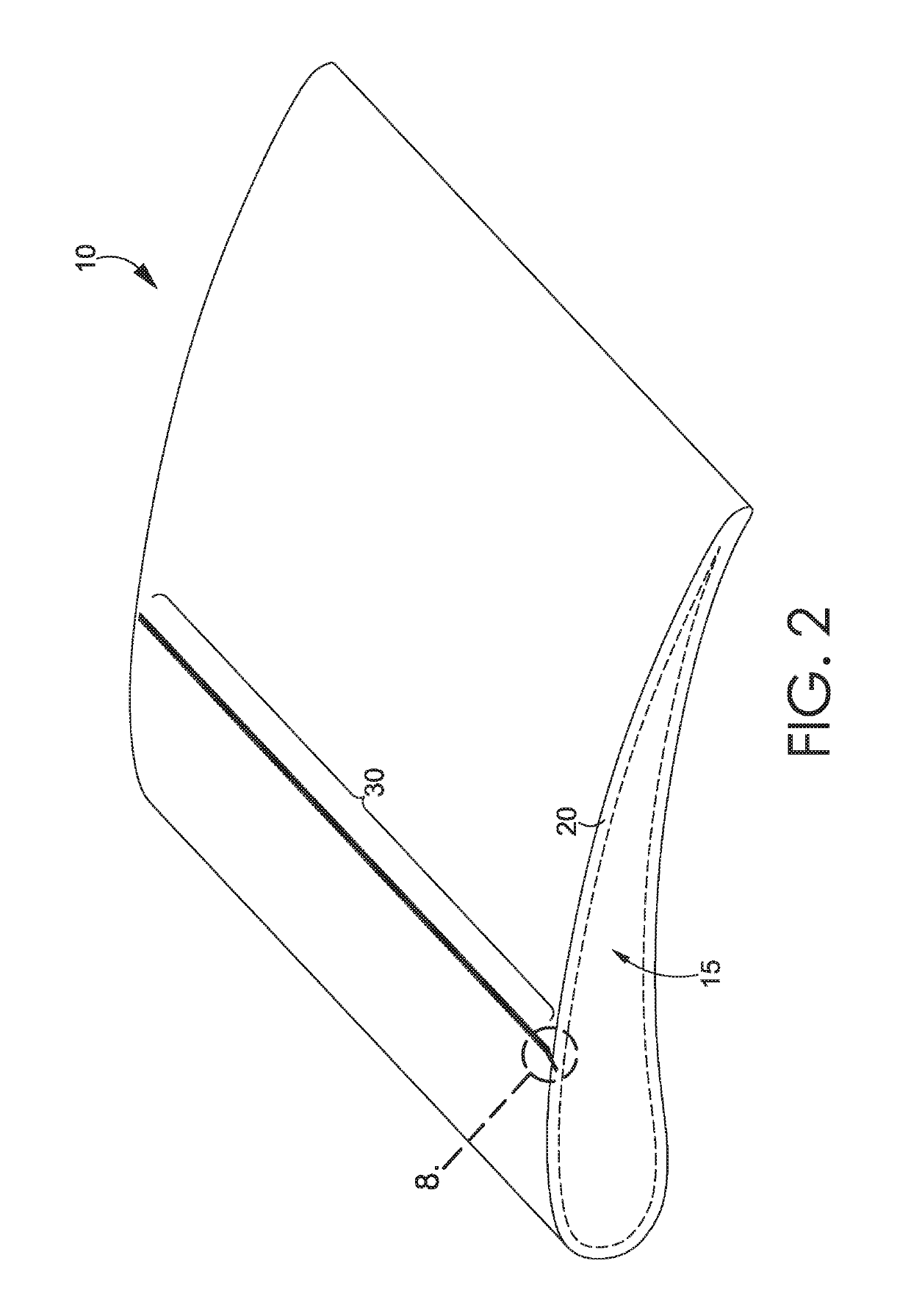

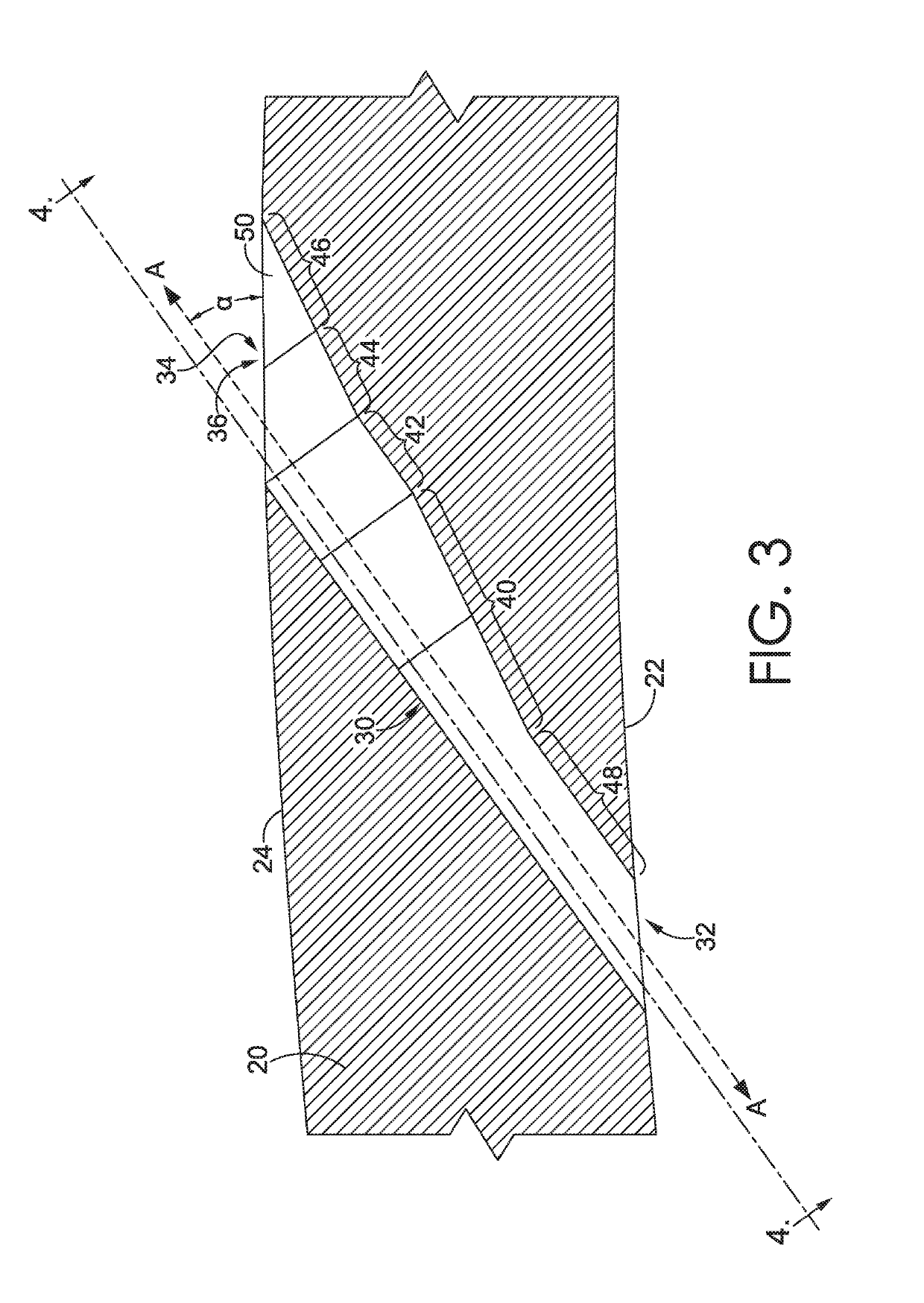

Method for manufacturing ribbed archery bow limb portions and the ribbed archery bow limb portions produced thereby

ActiveUS20050139200A1Constant cross-sectional areaMaintaining cross sectional areaBows/crossbowsPresent methodEngineering

Typically a limb for an archery bow has a butt section or end attachable to a bow riser, a middle or hinge section and an opposing tip section or end. In a preferred embodiment, the present method and limb includes a rib section formed in the middle or hinge portion of the limb. This allows a narrowed front-profile to be presented in the hinge section, while maintaining the total cross-sectional area. In one preferred method, at least one half of a mold is formed to define a rib section in the hinge section of the limb. Preferably the rib section runs longitudinally along the length of the hinge section, and may include a tapered profile along the edges and ends of the rib. In another preferred embodiment, the limb, including a rib section, is curved prior to assembly into an archery bow.

Owner:BEAR ARCHERY

Apparatus, system, and method of shielding the sharp tip of a transseptal guidewire

ActiveUS7963947B2Avoid damageConstant cross-sectional areaInfusion syringesSurgical needlesSyringe needleGeneral surgery

Apparatus, system, and methods for introducing a sharp tip of a transseptal guidewire through a hub of a transseptal needle and into a lumen of a transseptal needle are provided. The apparatus includes a holder that contains the transseptal guidewire and a shield coupled to the holder. The shield has a wall defining a lumen that accommodates the sharp tip of the transseptal guidewire. The cross-sectional shape of the wall is substantially constant along at least a portion of its length and sized to fit within the lumen of the transseptal needle, thereby inhibiting contact between the sharp tip of the transseptal guidewire and the hub of the transseptal needle when the wall of the shield is positioned to extend into the lumen of the transseptal needle. The lumen of the shield has a substantially constant cross-sectional area along at least a portion of its length and an outer surface of the wall of the shield is cylindrical along the same length.

Owner:BOSTON SCI MEDICAL DEVICE LTD

Pressure transducer employing a micro-filter and emulating an infinite tube pressure transducer

InactiveUS7975552B2Reduce the total massSmall sizeFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsTransducerAcoustic wave

Owner:KULITE SEMICON PRODS

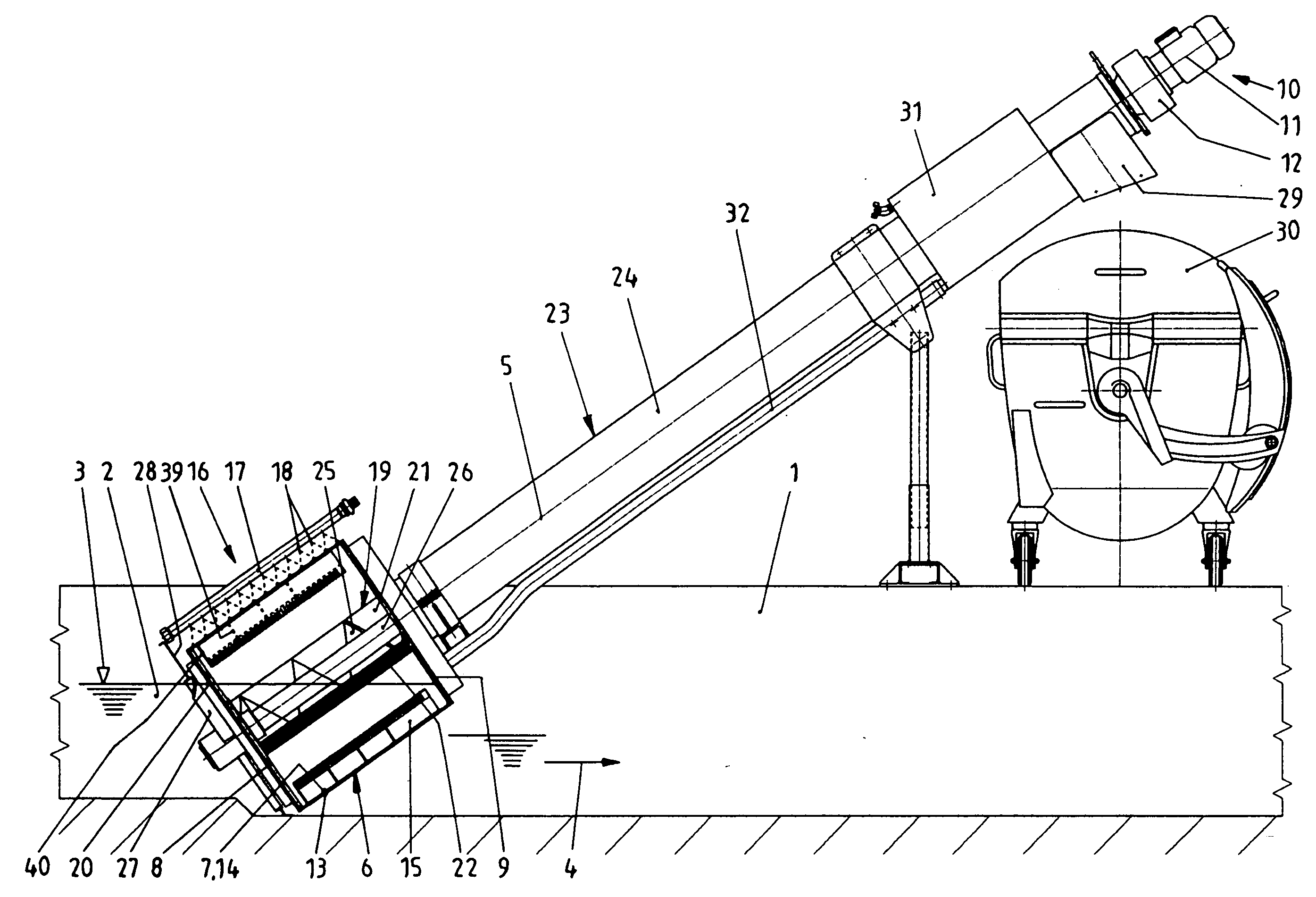

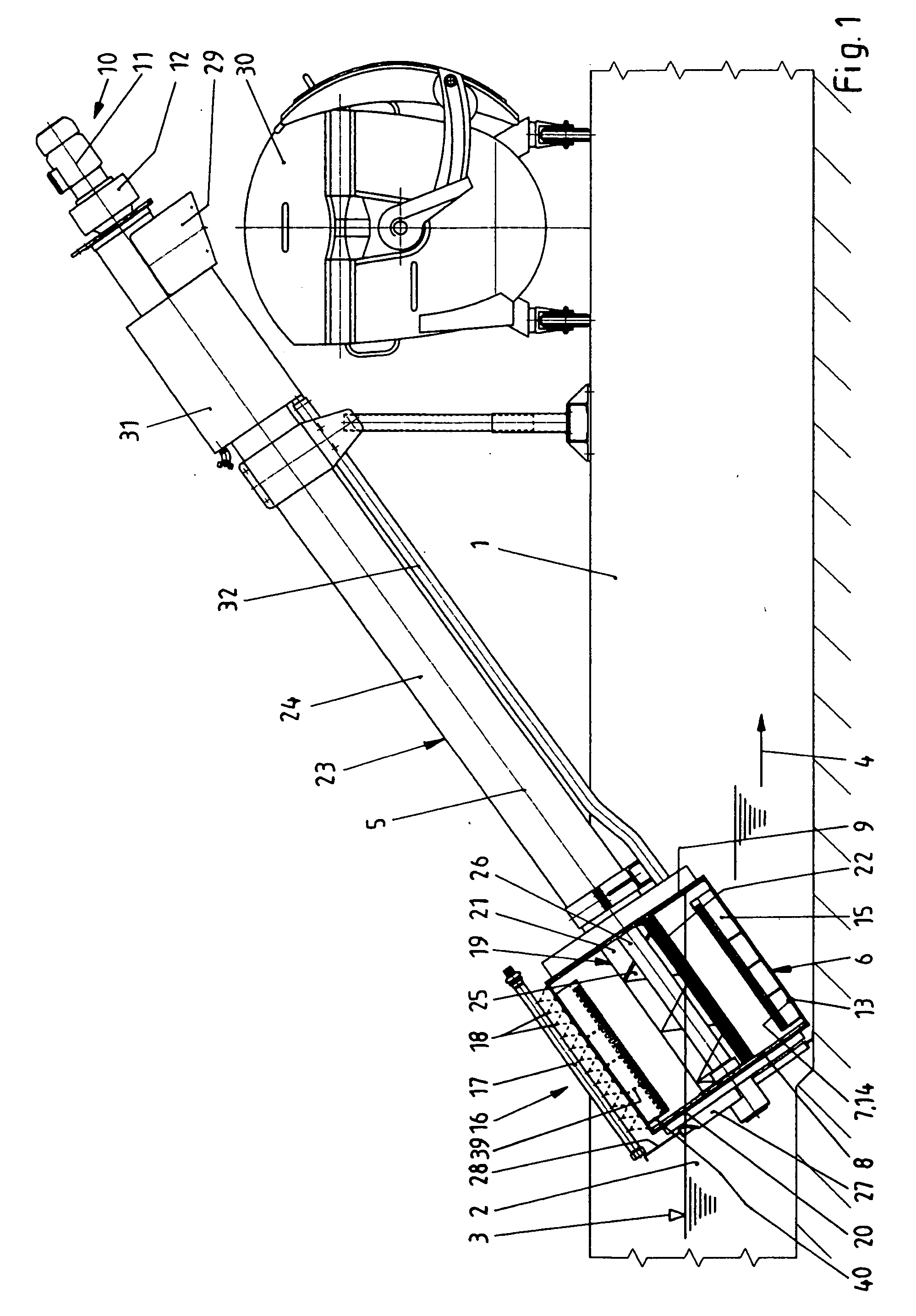

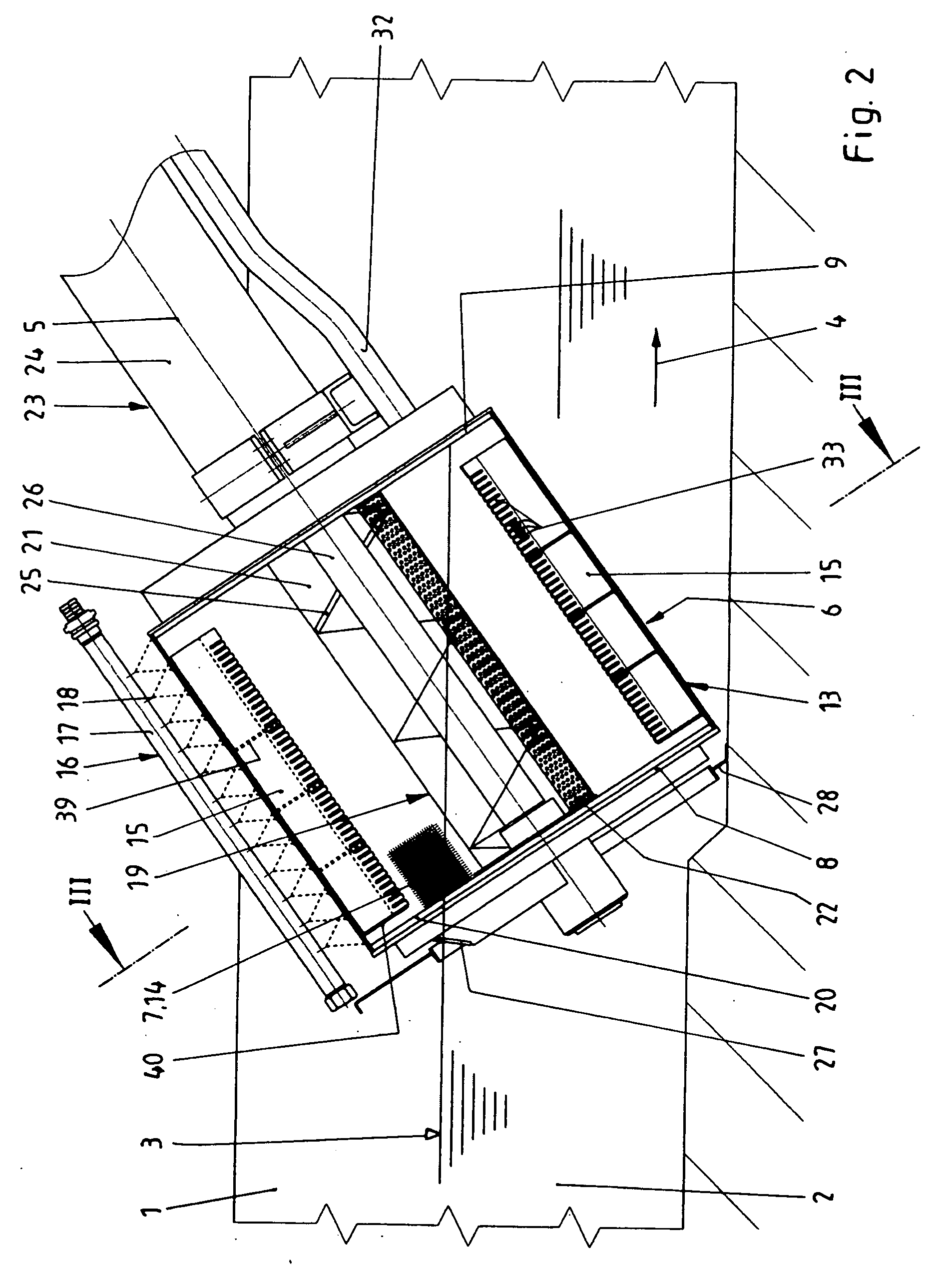

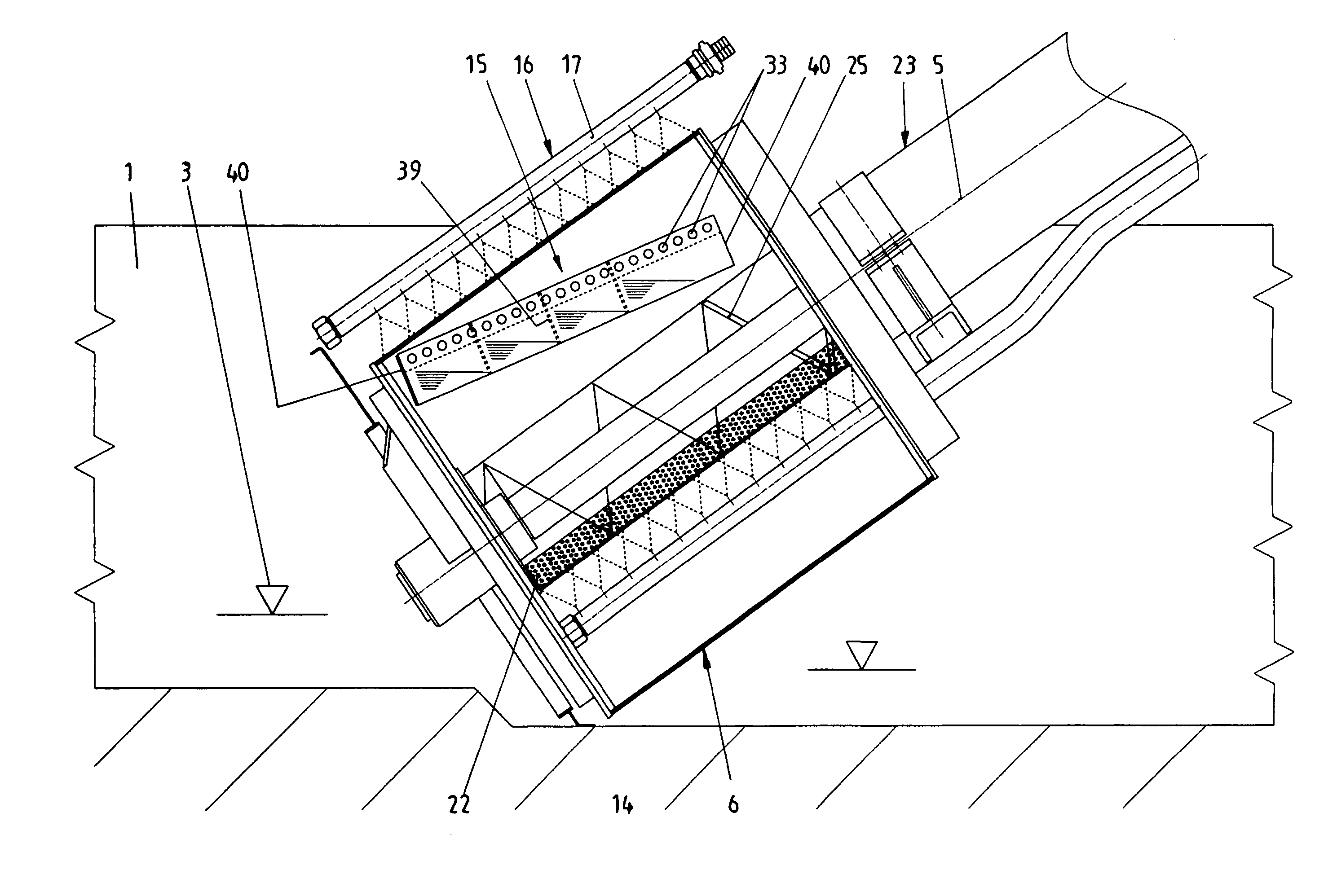

Apparatus for removing material from a liquid flowing through a channel

InactiveUS20050247610A1Economically manufacturedConstantFatty/oily/floating substances removal devicesSewerage structuresScrew conveyorSieve

An apparatus for removing material from a liquid flowing through a channel includes a sieve grate, a screw conveyor and a detaching device. The sieve grate has an inflow side, an inner side and an outer side. The sieve grate is designed to be cylindrical and to be rotatably driven. The sieve grate is arranged at an inclined orientation to be partially submerged in the liquid. The sieve grate at the inflow side includes an open face. The sieve grate at the inner side includes a plurality of guide plates. The sieve grate includes a shaping carrier element. The sieve grate includes a mesh fabric, the mesh fabric being designed and arranged to form a separation surface for the material. The screw conveyor includes a housing. The screw conveyor includes a driven conveying screw. The screw conveyor is coaxially arranged with respect to the sieve grate. The screw conveyor in the region of the sieve grate includes a feeding hopper for the material, the feeding hopper having a bottom side and including a majority of openings located in the region of the bottom side. The detaching device is arranged at the outer side of the sieve grate and above the feeding hopper in a stationary way. The detaching device is designed and arranged to detach material which adheres to the separation surface from inside of the sieve grate.

Owner:HANS HUBER MASCHEN & ANLAGENBAU

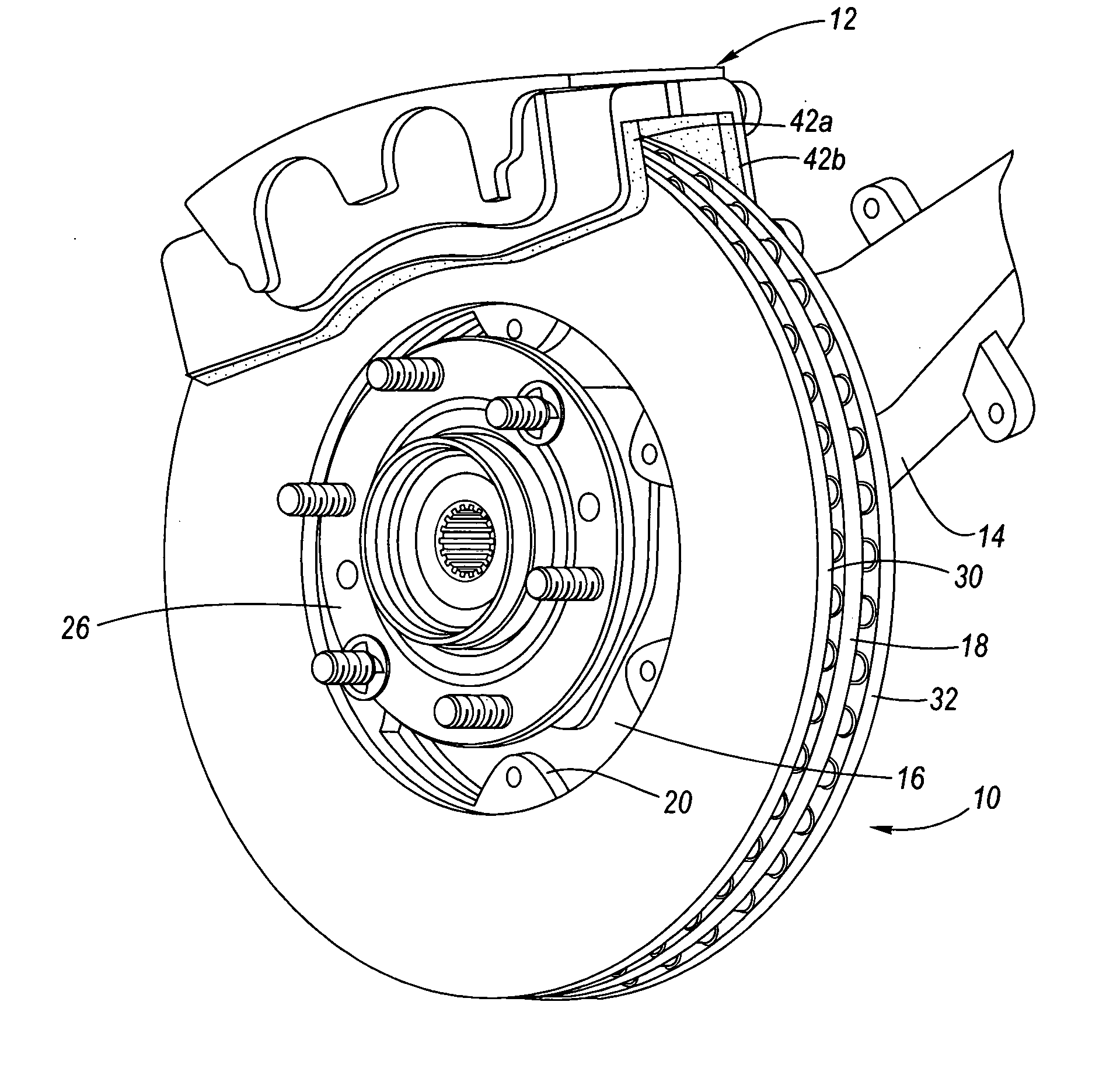

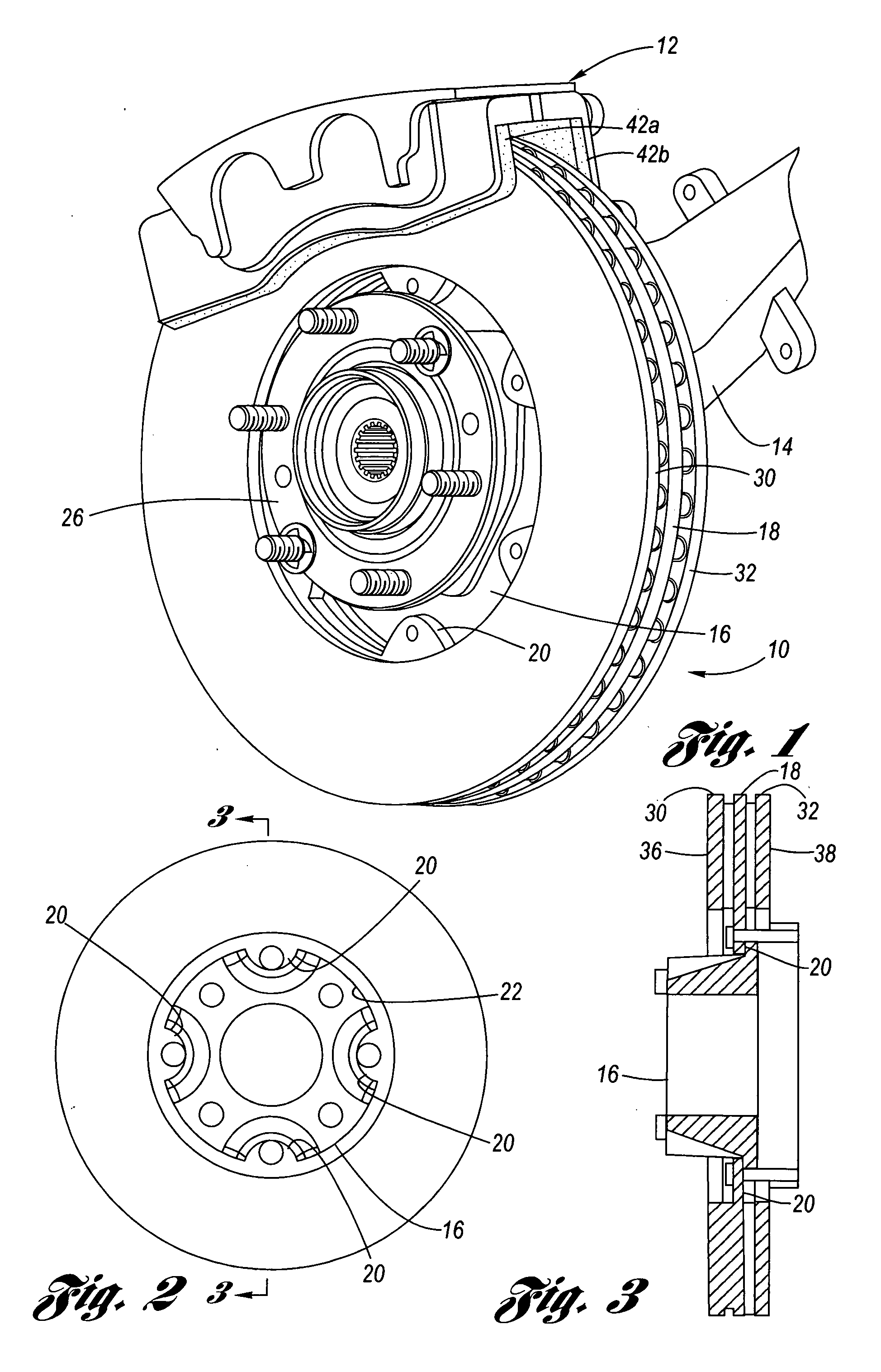

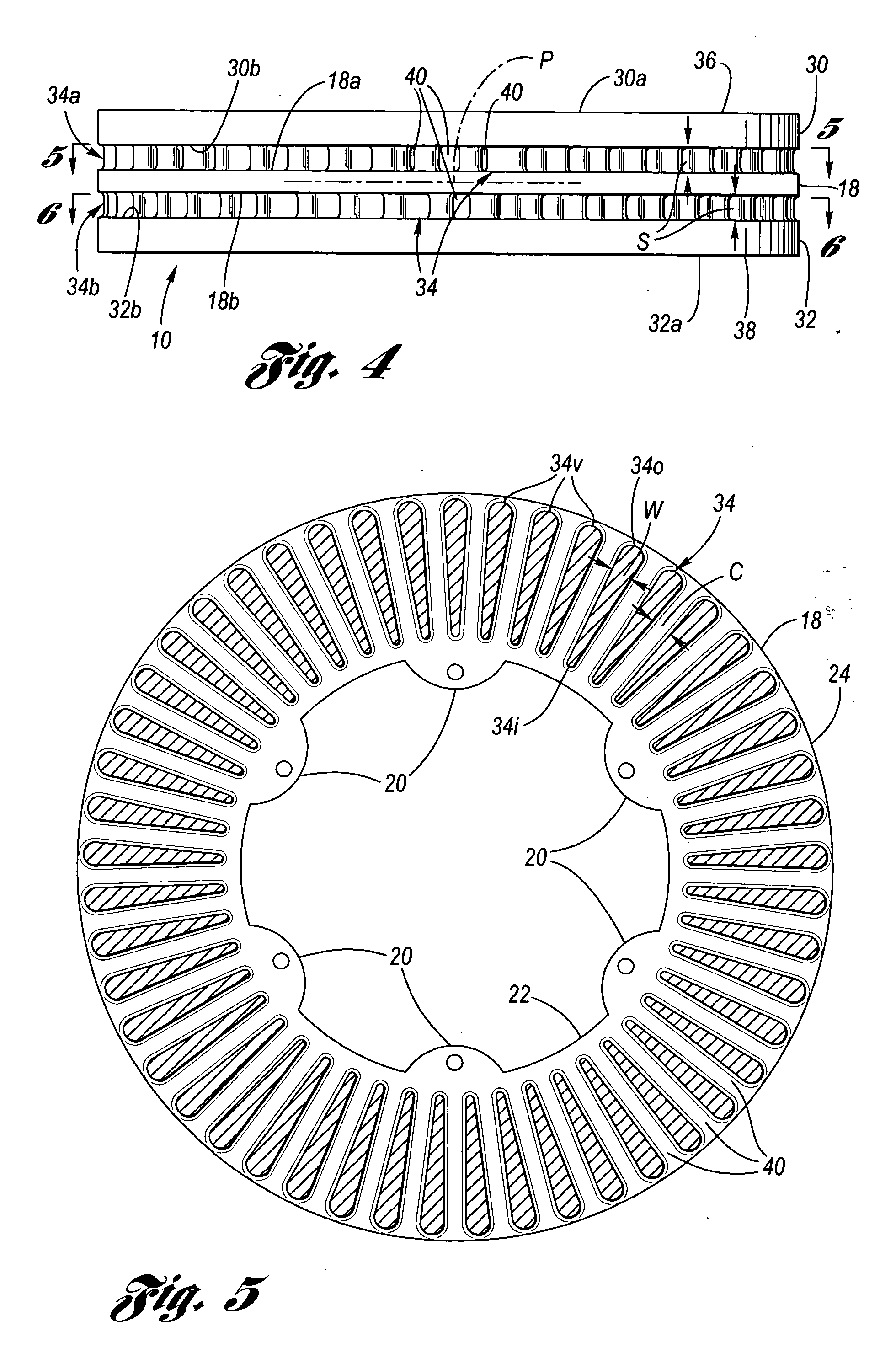

Hatless brake rotor

InactiveUS20050263358A1Reduce brake noiseReduce pulsationBraking element arrangementsNoise/vibration controlAir cycleAir movement

A hatless rotor for an automotive disk brake system, wherein the following improvements are realized over known disk brake systems: reduced braking noise, improved air cooling, decoupling of wheel to rotor cross-talk, reduced brake pulsation, reduced mass, reduced rotor cheeks temperature during braking, and better air movement access for improved cooling of the rotor cheeks. The hatless rotor includes a first rotor cheek, a second rotor cheek and a central disk, wherein the first and second rotor cheeks are spaced from, and mutually interconnected to, the central disk by first and second sets of vanes, staggered relative to each other, and configured to provide optimal air circulation. The central rotor disk is connected directly to the motor vehicle axle hub via a suitable rotor hub connected thereto.

Owner:GENERAL MOTORS COMPANY

Apparatus for removing material from a liquid flowing through a channel

InactiveUS7160443B2Easy to produceConstant cross-sectional areaFatty/oily/floating substances removal devicesSewerage structuresEngineeringScrew conveyor

An apparatus for removing material from a liquid flowing through a channel includes a sieve grate, a screw conveyor and a detaching device. The sieve grate has an inflow side, an inner side and an outer side. The sieve grate is designed to be cylindrical and to be rotatably driven. The sieve grate is arranged at an inclined orientation to be partially submerged in the liquid. The sieve grate at the inflow side includes an open face. The sieve grate at the inner side includes a plurality of guide plates. The sieve grate includes a shaping carrier element. The sieve grate includes a mesh fabric, the mesh fabric being designed and arranged to form a separation surface for the material. The screw conveyor includes a housing. The screw conveyor includes a driven conveying screw. The screw conveyor is coaxially arranged with respect to the sieve grate. The screw conveyor in the region of the sieve grate includes a feeding hopper for the material, the feeding hopper having a bottom side and including a majority of openings located in the region of the bottom side. The detaching device is arranged at the outer side of the sieve grate and above the feeding hopper in a stationary way. The detaching device is designed and arranged to detach material which adheres to the separation surface from inside of the sieve grate.

Owner:HANS HUBER MASCHEN & ANLAGENBAU

Method for manufacturing ribbed archery bow limb portions and the ribbed archery bow limb portions produced thereby

InactiveUS7311096B2Constant cross-sectional areaMaintaining cross sectional areaBows/crossbowsPresent methodEngineering

Typically a limb for an archery bow has a butt section or end attachable to a bow riser, a middle or hinge section and an opposing tip section or end. In a preferred embodiment, the present method and limb includes a rib section formed in the middle or hinge portion of the limb. This allows a narrowed front-profile to be presented in the hinge section, while maintaining the total cross-sectional area. In one preferred method, at least one half of a mold is formed to define a rib section in the hinge section of the limb. Preferably the rib section runs longitudinally along the length of the hinge section, and may include a tapered profile along the edges and ends of the rib. In another preferred embodiment, the limb, including a rib section, is curved prior to assembly into an archery bow.

Owner:BEAR ARCHERY

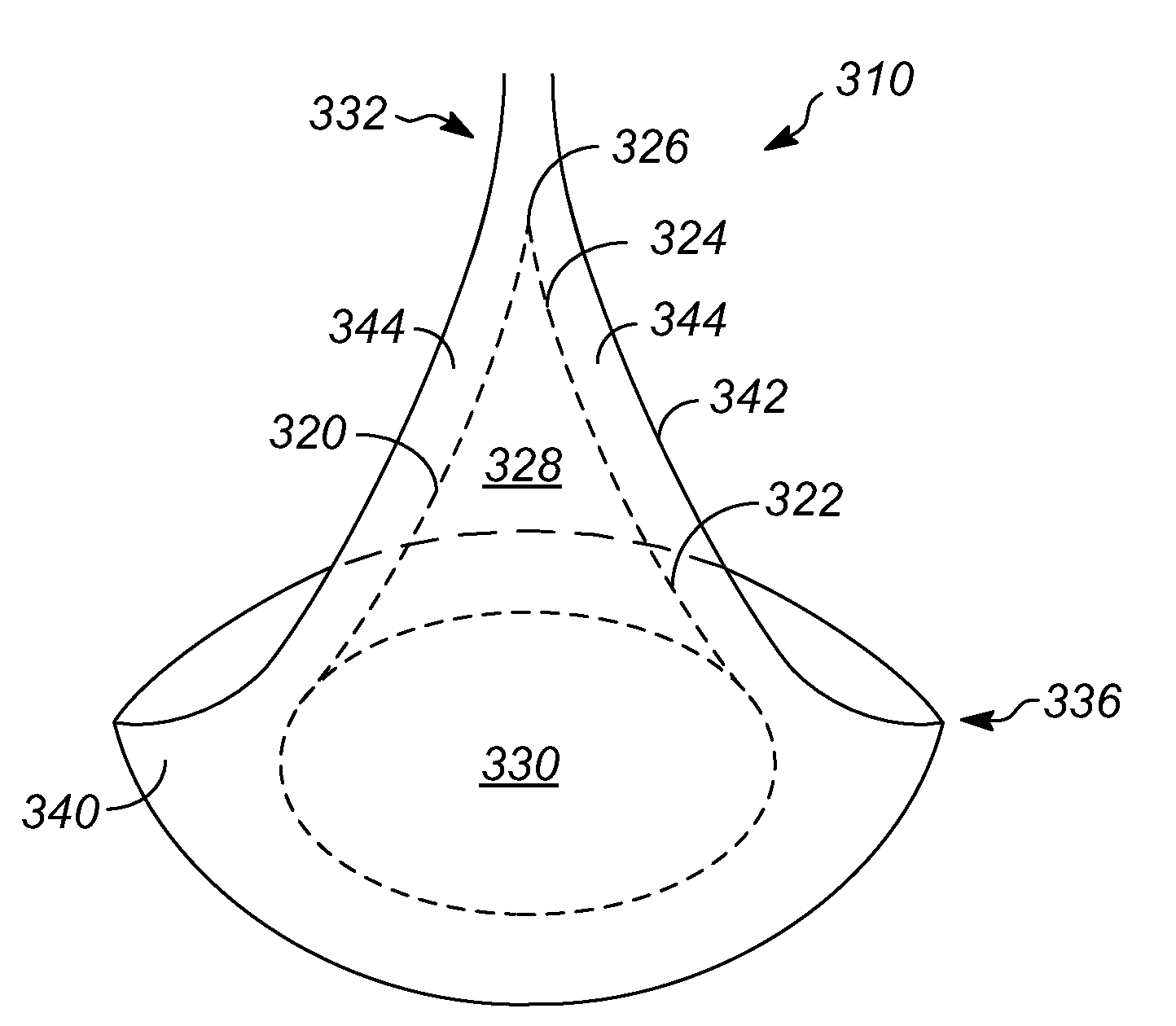

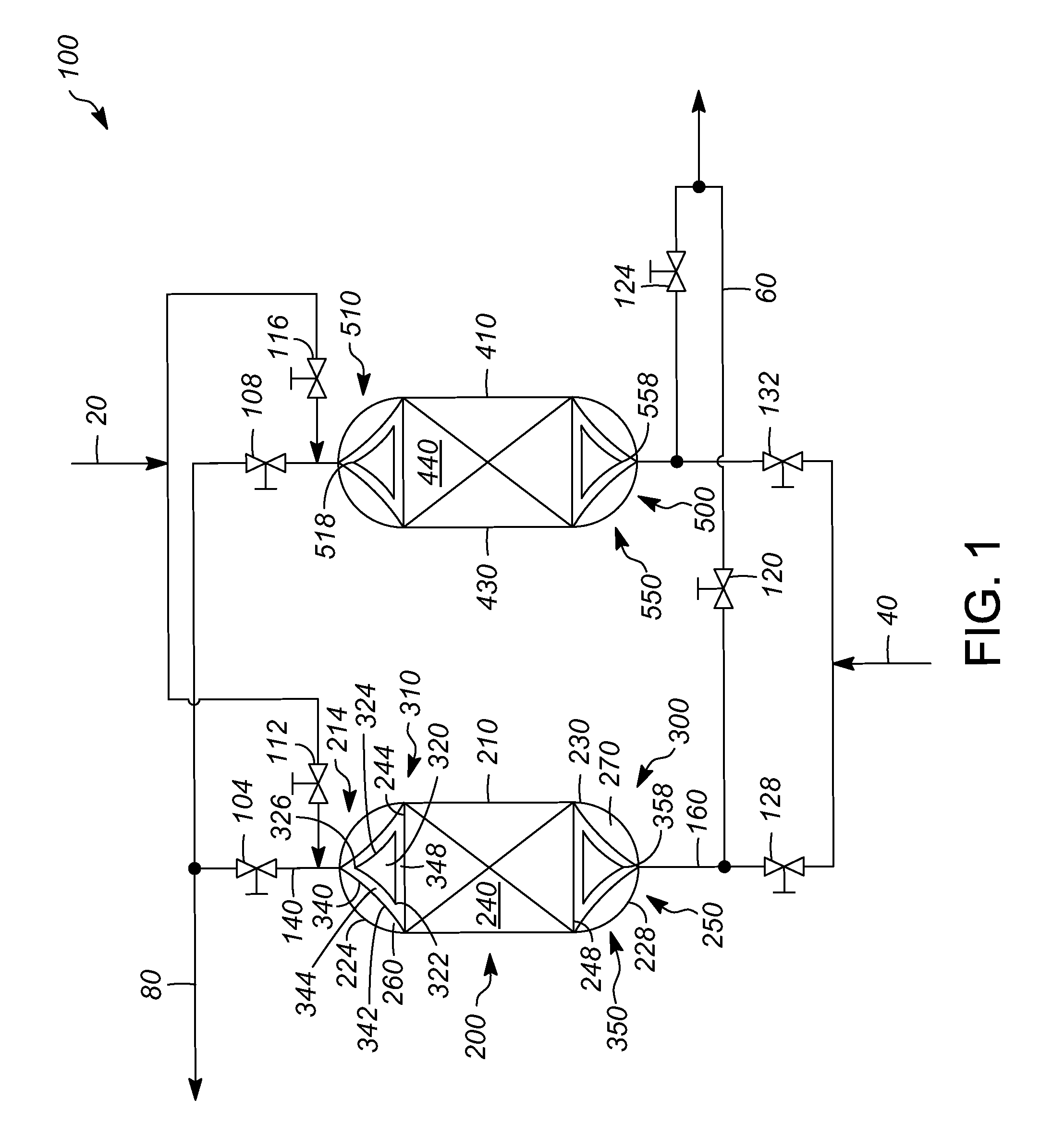

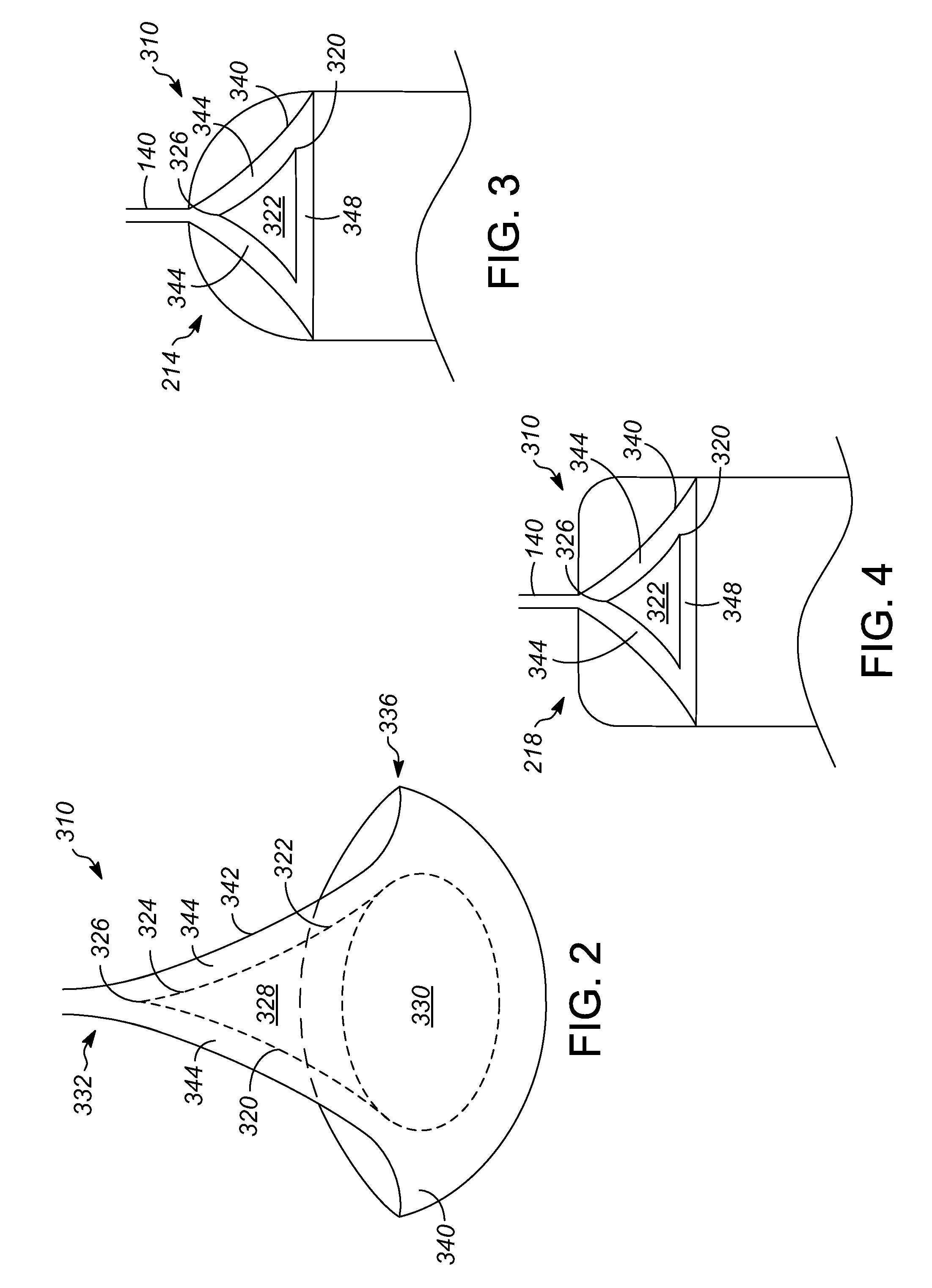

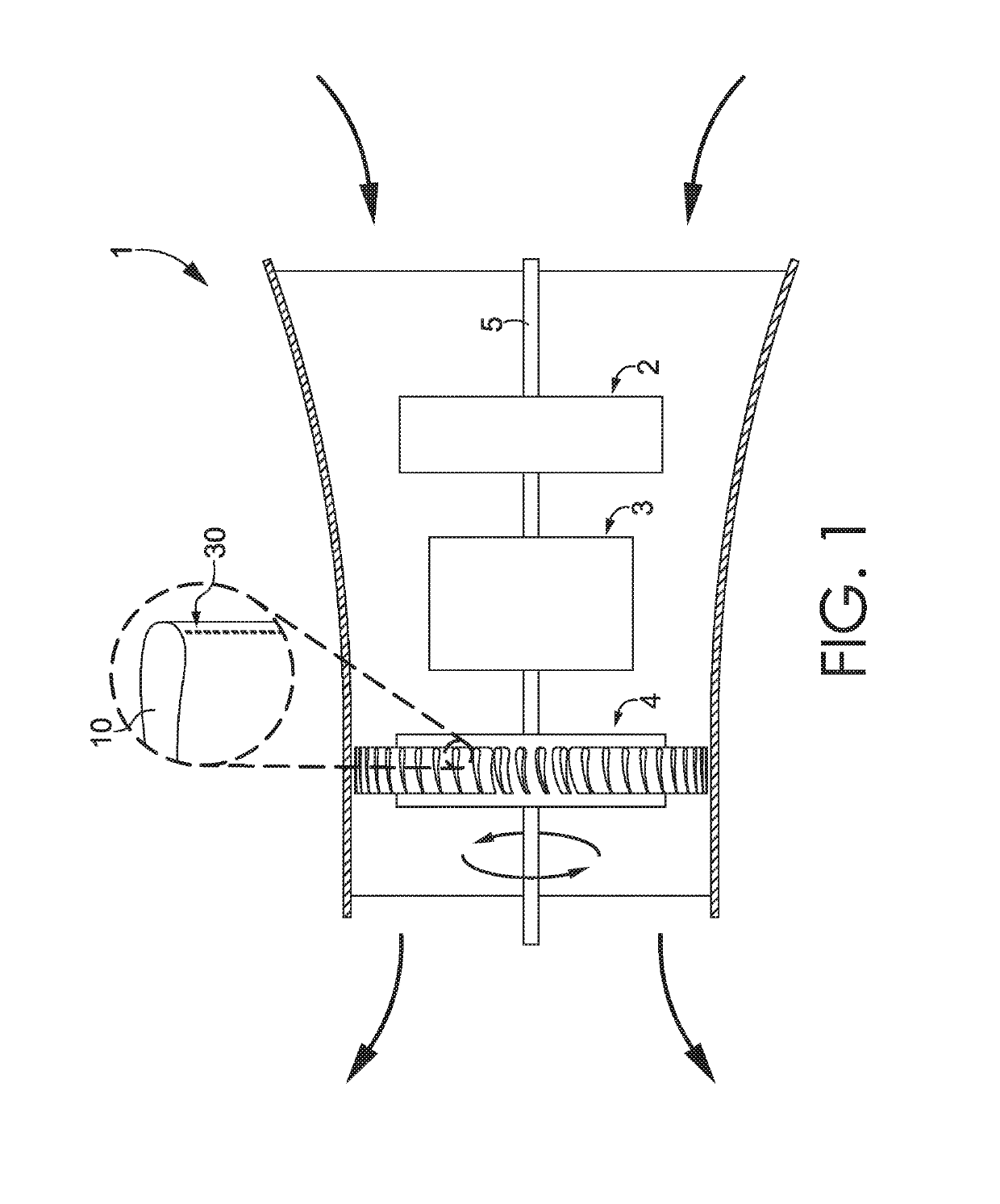

Vessel, system, and process for minimizing unequal flow distribution

InactiveUS20100326275A1Constant cross-sectional areaInexpensive and easily installableGas treatmentHydrogen separation using solid contactEngineeringPressure swing adsorption

One exemplary embodiment can be a pressure swing adsorber vessel. The pressure swing adsorber vessel can include one or more walls. Generally, the one or more walls contain an adsorbent bed having a first side and a second side and at least one spacer forming a cusp. Usually, the one or more walls and the adsorbent bed define at least one void volume adjacent to the adsorbent bed, and the cusp of the at least one spacer may be positioned in the at least one void volume. The cusp can be positioned opposing an incoming feed stream or a desorbent stream.

Owner:UOP LLC

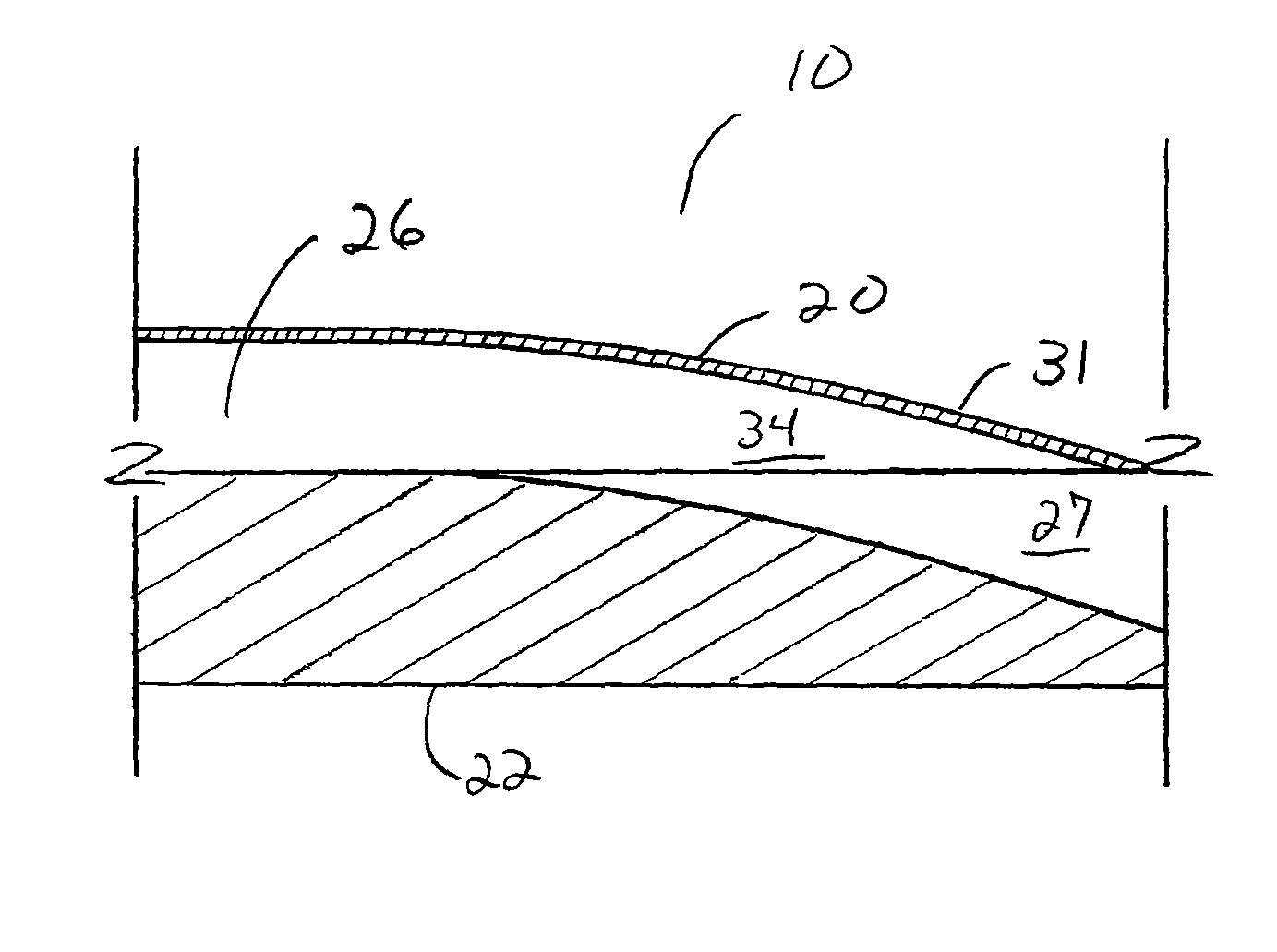

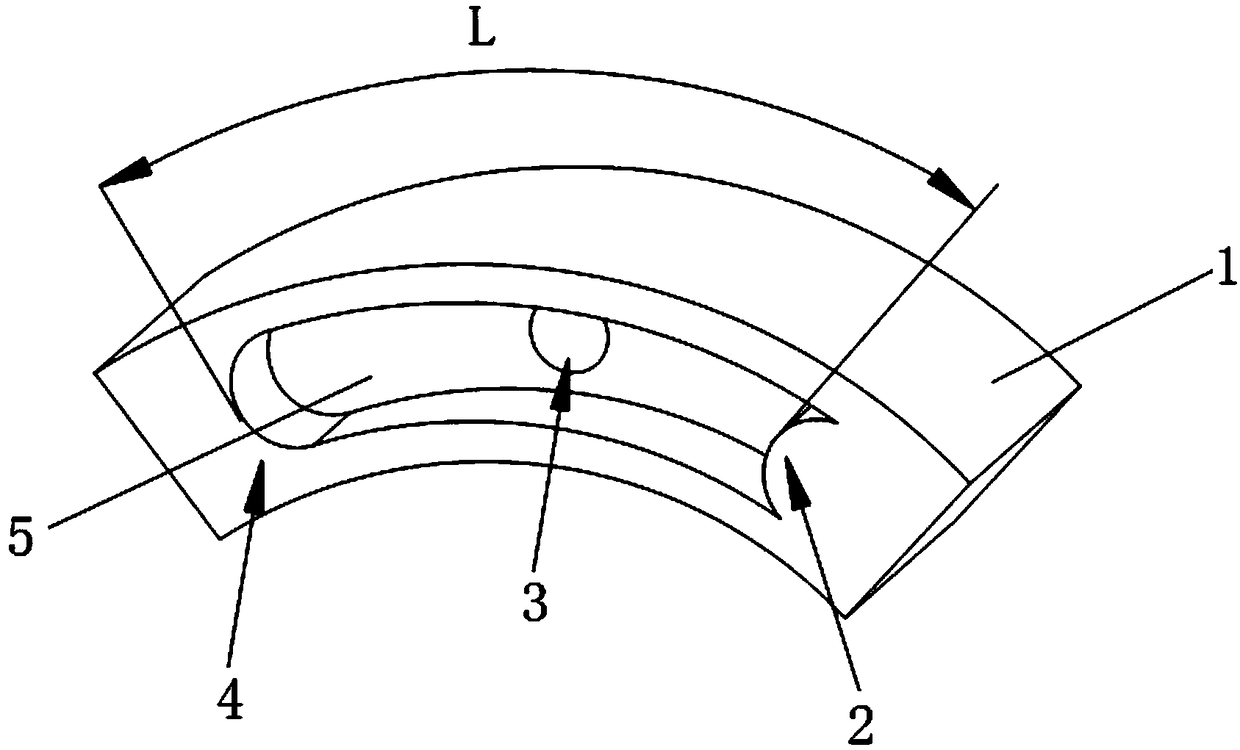

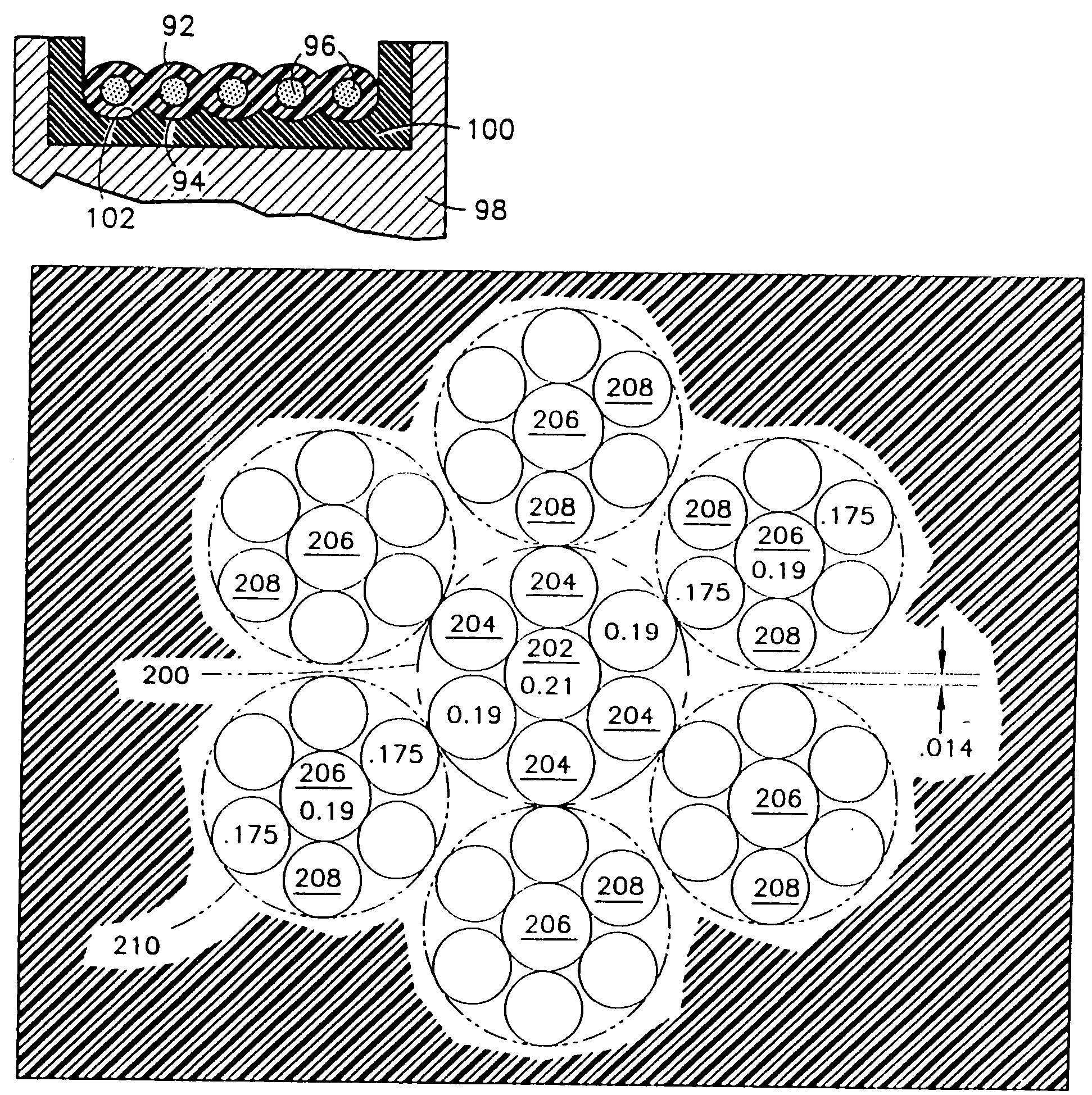

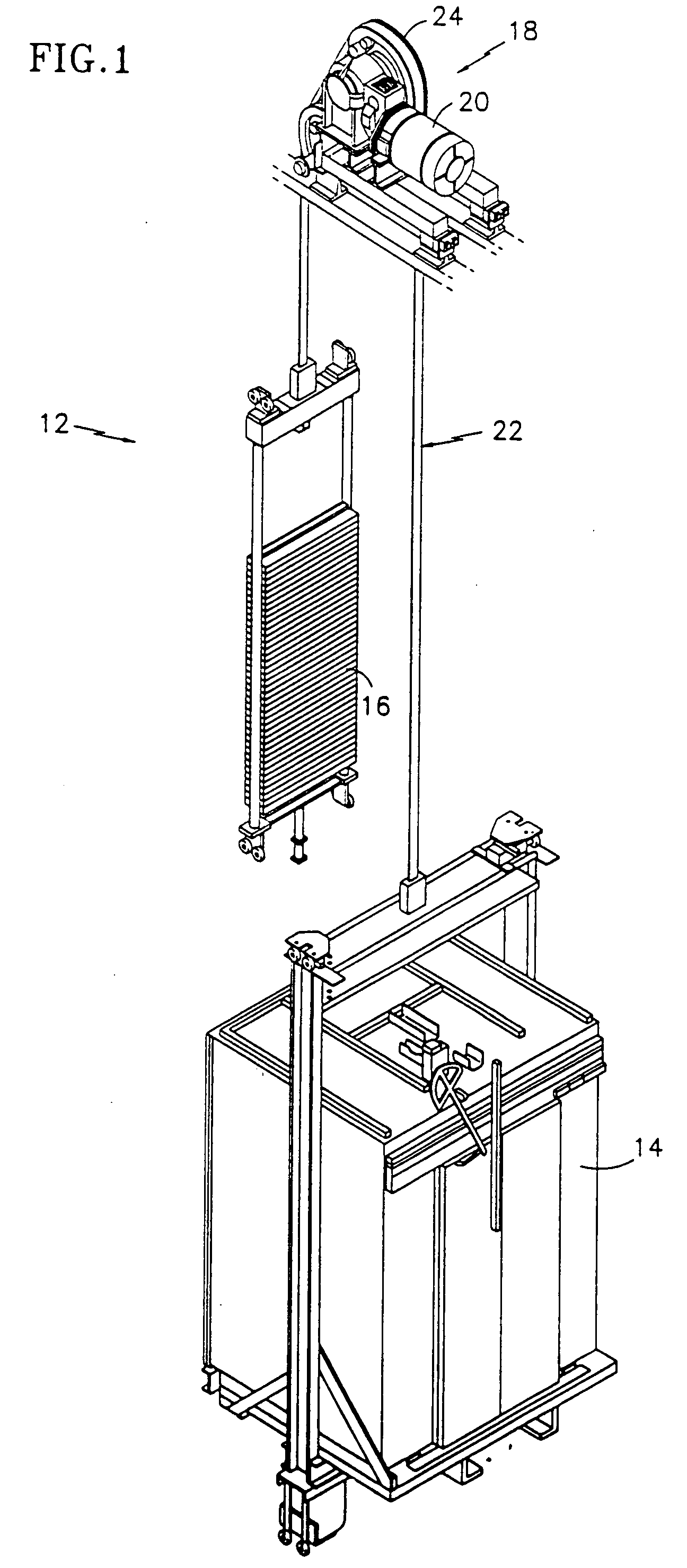

Tension member for an elevator

InactiveUS9352935B2Minimizing diameter DMaximum rope pressure is reducedElevatorsBuilding liftsTension memberLoad carrying

A tension member for an elevator system has an aspect ratio of greater than one, where aspect ratio is defined as the ratio of tension member width w to thickness t (w / t). The increase in aspect ratio results in a reduction in the maximum rope pressure and an increased flexibility as compared to conventional elevator ropes. As a result, smaller sheaves may be used with this type of tension member. In a particular embodiment, the tension member includes a plurality of individual load carrying cords encased within a common layer of coating. The coating layer separates the individual cords and defines an engagement surface for engaging a traction sheave.

Owner:OTIS ELEVATOR CO

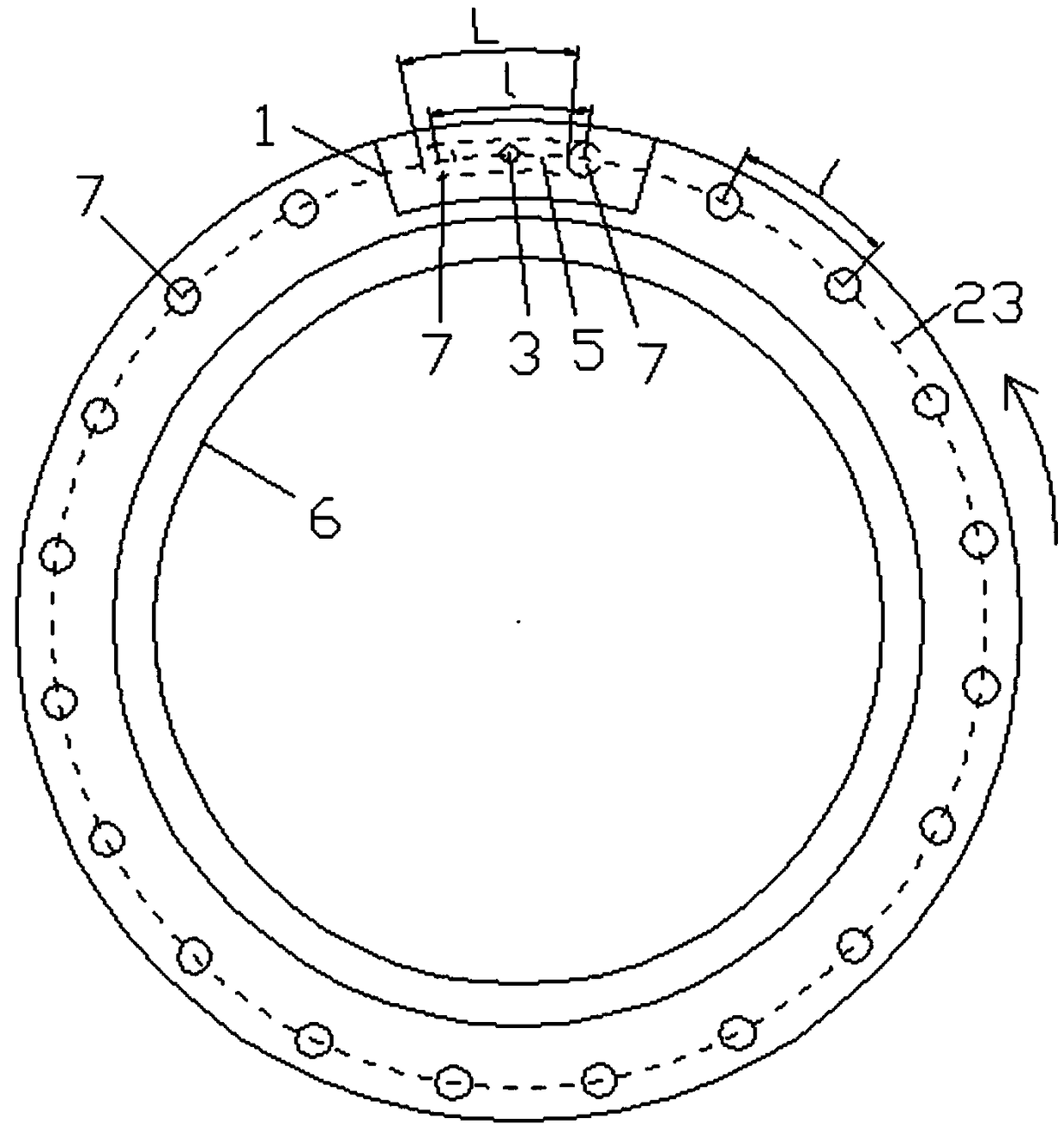

Cigarette unpunching/punching missing detection device, laser punching machine and detection method

The invention discloses a cigarette unpunching / punching missing detection device, a laser punching machine and a cigarette unpunching / punching missing detection method, and belongs to the technical field of cigarette equipment. The cigarette unpunching / punching missing detection device comprises two fixing blocks and a detection drum arranged between the two fixing blocks; the detection drum is adetection drum of a cigarette making machine; flanges are arranged at the two ends of the axial direction of the detection drum; a plurality of vent holes are circumferentially formed in the flanges at intervals; gas guiding grooves and gas holes communicated with the gas guiding grooves are formed in the fixing blocks; the gas guiding grooves are arc-shaped grooves with convex arcs at one ends and concave arcs at the other ends; the lengths of the gas guiding grooves are equal to integral multiples of the distance between adjacent vent holes in the circumferential direction of the detection drum. A cigarette unpunching / punching missing detection method is achieved by the cigarette unpunching / punching missing detection device. The invention discloses the cigarette unpunching / punching missing detection device, the laser punching machine and the cigarette unpunching / punching missing detection method.

Owner:江苏瑞驰机电科技有限公司

Method for manufacturing ribbed archery bow limb portions and the ribbed archery bow limb portions produced thereby

ActiveUS6932071B2Constant cross-sectional areaMaintaining cross sectional areaSpring gunsBows/crossbowsPresent methodEngineering

Typically a limb for an archery bow has a butt section or end attachable to a bow riser, a middle or hinge section and an opposing tip section or end. In a preferred embodiment, the present method and limb includes a rib section formed in the middle or hinge portion of the limb. This allows a narrowed front-profile to be presented in the hinge section, while maintaining the total cross-sectional area. In one preferred method, at least one half of a mold is formed to define a rib section in the hinge section of the limb. Preferably the rib section runs longitudinally along the length of the hinge section, and may include a tapered profile along the edges and ends of the rib.

Owner:BEAR ARCHERY

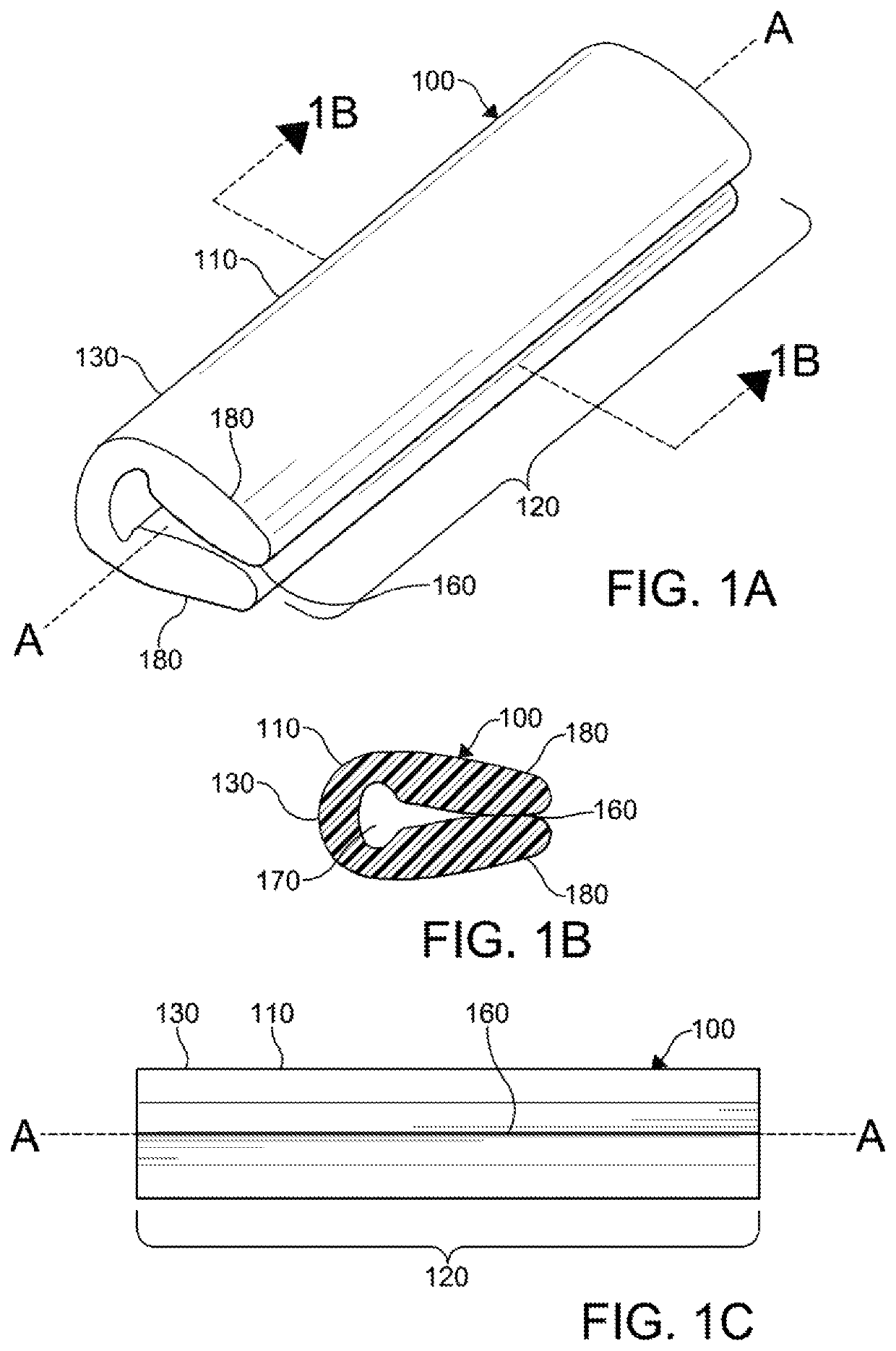

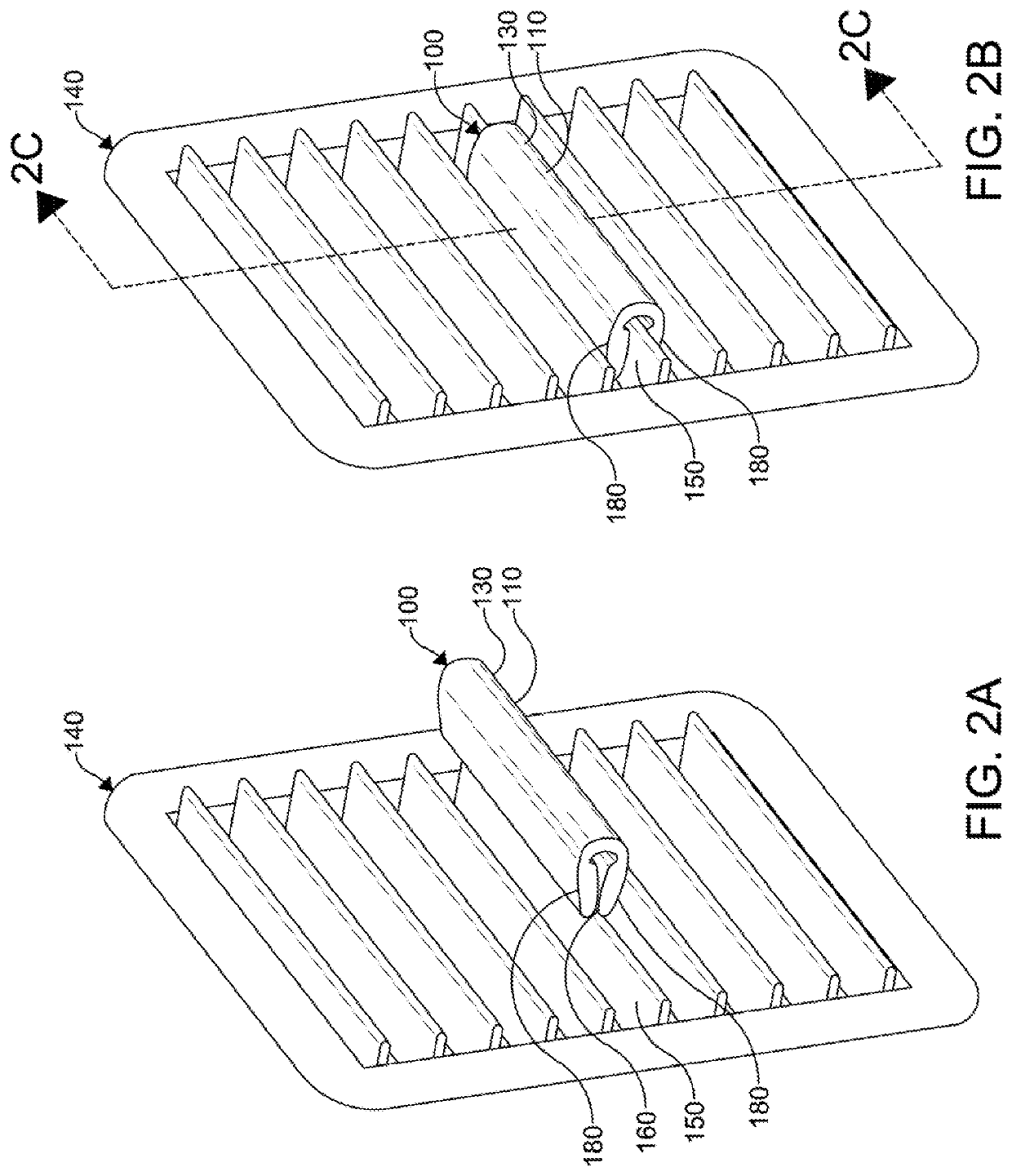

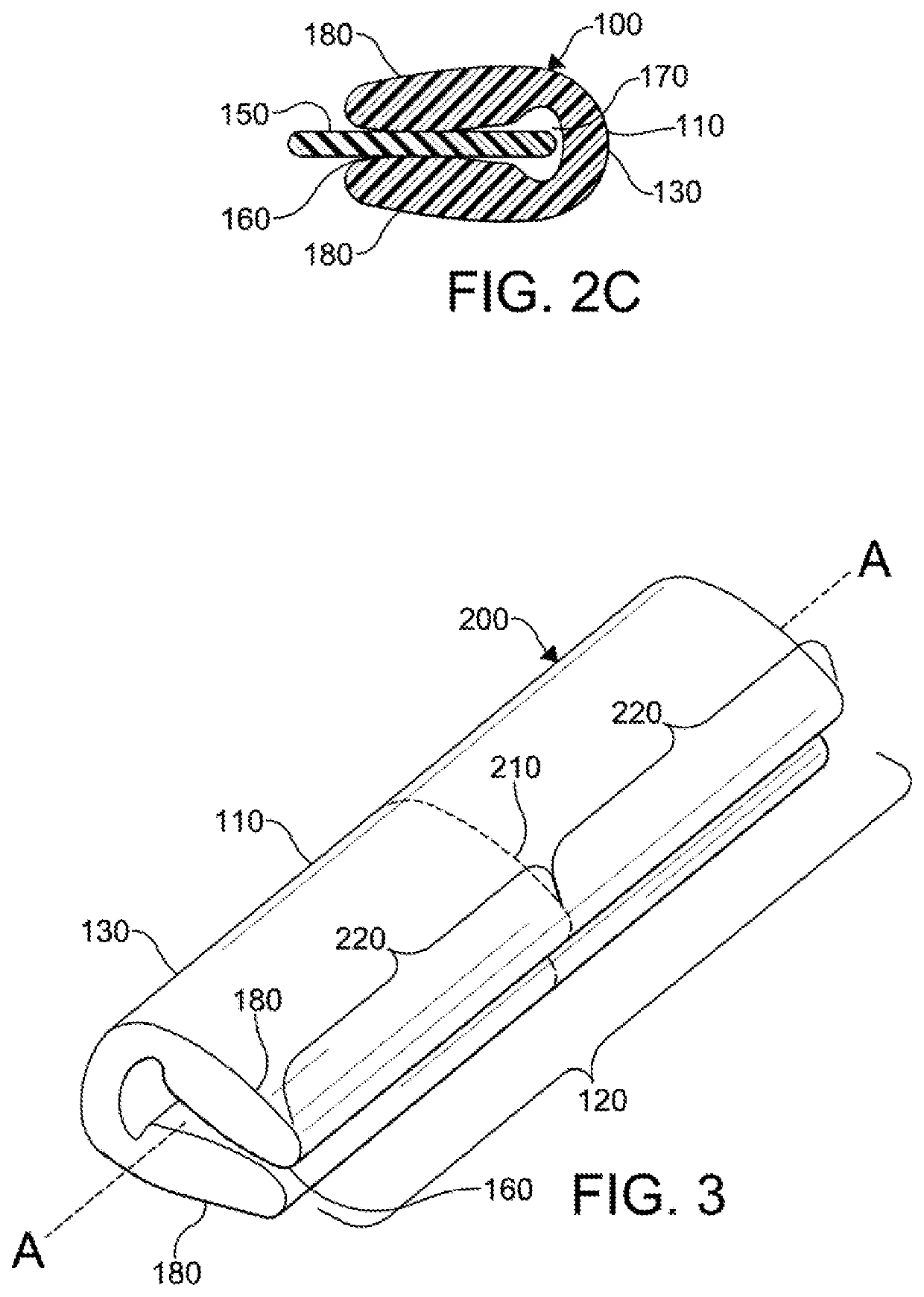

Solid state fragrancing

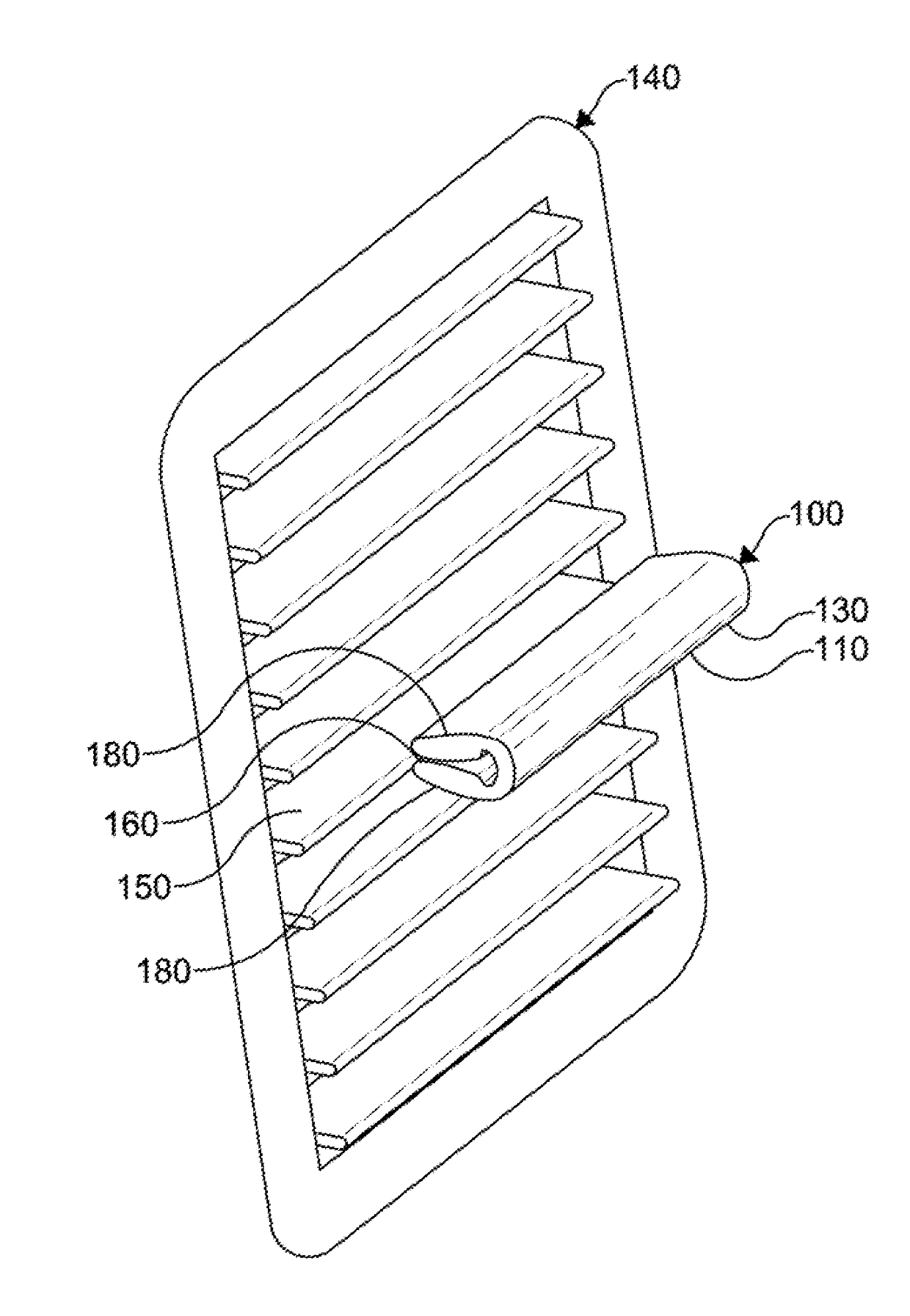

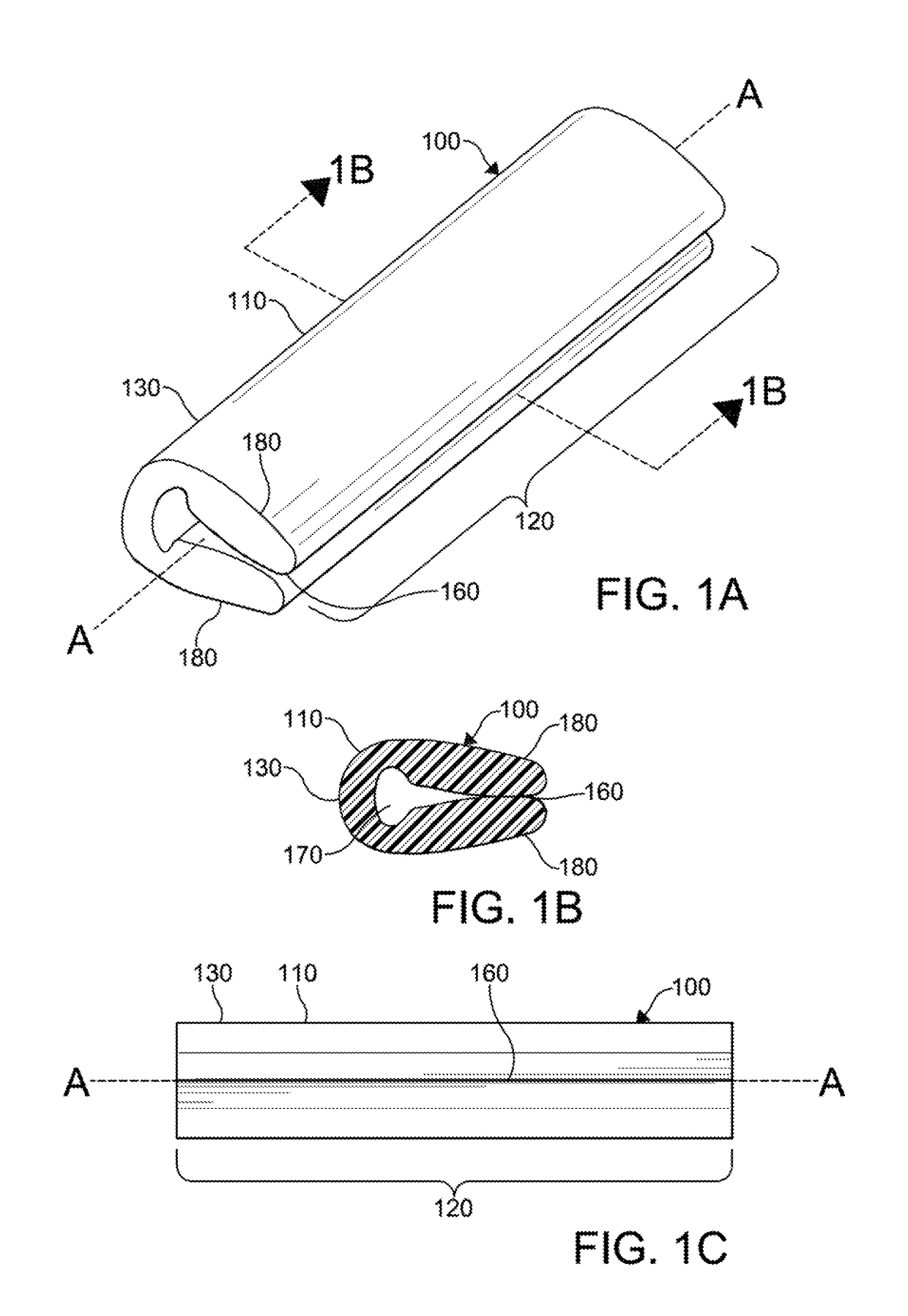

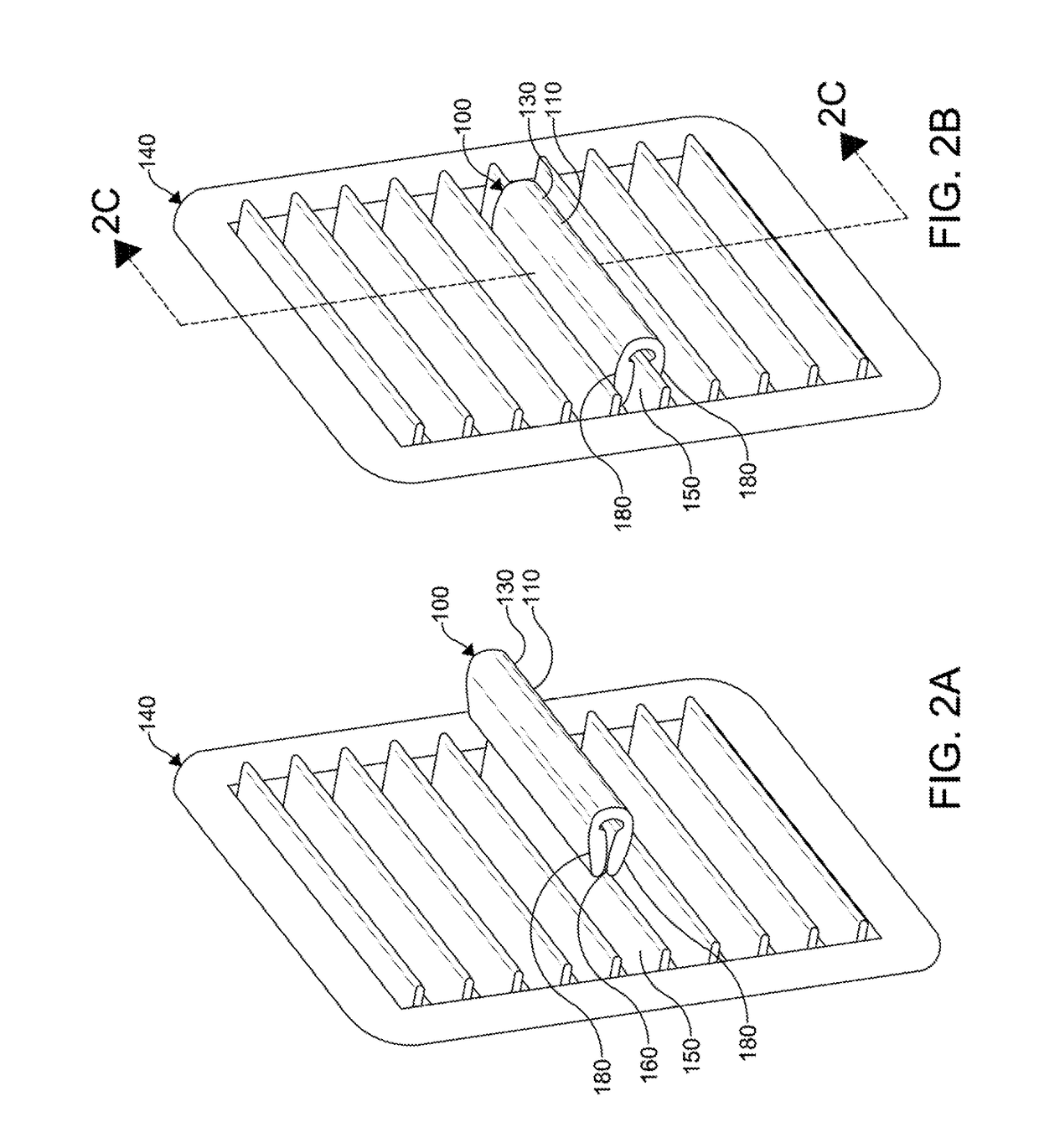

ActiveUS10493177B2Easy to manufactureMinimizes any negative effectCosmetic preparationsAir-treating devicesEngineeringLong lasting

Fragrance control is provided by articles of manufacture including various solid state fragrancing objects, methods of using such objects, and systems that employ one or more such objects. The fragrancing object can be easy to manufacture, long lasting, provide fragrance that is consistently released over time, provide an indication to the user that the object needs to be replaced, and can hold a desired ratio of fragrance. The solid state fragrancing object can be coupled to an air vent to inconspicuously provide fragrance to a user in an environment, such as the interior of a vehicle.

Owner:IMPACT PRODS +1

Airfoil cooling passageways for generating improved protective film

ActiveUS10280763B2Improve coverage and uniformityImproved cooling holeEngine manufactureEngine fuctionsGas turbinesCooling channel

An airfoil for a gas turbine engine, the airfoil comprising a wall having a first surface, a second surface, and a passageway extending through the wall from a first opening in the first surface to a second opening in the second surface, the passageway having one or more sections between the first opening and the second opening, the one or more sections in fluid communication with each other, the plurality of sections comprising a first diffuser section providing a first change in cross-sectional area within the passageway, a second diffuser section providing a second change in cross-sectional area within the passageway, a flow conditioning section, and an edge section having two surfaces set opposite each other across the passageway, the two surfaces extending along the passageway substantially in parallel to one another, the edge section being located adjacent to the second opening.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Layer multiplying apparatus

InactiveUS8215940B2Reduce shear stressIncrease shear stressConfectionerySweetmeatsEngineeringMechanical engineering

Apparatus for multiplying layers in a composite polymer stream includes an intermediate section having open conduits sandwiched between housing sections that close the conduits. The conduits have respective first stages separated by a first blade extending to a first face, and respective second stages separated by a second blade extending to a second face. The first stages separate the stream into sub-streams and compress and shift the sub-streams in a first dimension, whereas the second stages shift the sub-streams in a second dimension. In order to maintain a constant cross-sectional area of the sub-streams, the housing sections may be provided with complementary open channels. The apparatus can be used to multiply layers which are side-by-side or one-over-another by changing orientation in the direction of flow.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Continuous in-line manufacturing process for high speed coating deposition via kinetic spray process

InactiveCN1781610AIncrease the cross-sectional areaConstant cross-sectional areaPretreated surfacesLiquid spraying apparatusUltrasonic nozzleEngineering

An improved power injection system and its method of use in a high speed manufacturing environment. The powered nozzle system comprises: a gas / powder exchange chamber connected to a first end of a regulating chamber having a length along a longitudinal axis equal to or greater than 20 mm; a convergent ultrasonic nozzle having a converging portion separated from a diverging portion by a throat, the diverging portion comprising a first portion of increasing cross-sectional area along its length and a second portion of substantially constant cross-sectional area along its length; and a converging portion connected to a second end of the adjustment cavity opposite said first end. The method includes: using a nozzle system with the addition of hard particles that allow for maximum particle temperature without clogging the nozzle; using controlled particle feed rates to accommodate very high traverse speeds; and preheating the substrate for cleaning substrate thereby enhancing particle binding properties. In conjunction with the disclosed nozzle systems and methods, kinetic spraying can be performed at traverse speeds in excess of 200 cm / s and deposition efficiencies in excess of 80%.

Owner:DELPHI TECH INC

Solid state fragrancing

ActiveUS20180193511A1Easy to manufactureMinimizes any negative effectAir-treating devicesGaseous substancesFlavorEngineering

Fragrance control is provided by articles of manufacture including various solid state fragrancing objects, methods of using such objects, and systems that employ one or more such objects. The fragrancing object can be easy to manufacture, long lasting, provide fragrance that is consistently released over time, provide an indication to the user that the object needs to be replaced, and can hold a desired ratio of fragrance. The solid state fragrancing object can be coupled to an air vent to inconspicuously provide fragrance to a user in an environment, such as the interior of a vehicle.

Owner:IMPACT PRODS +1

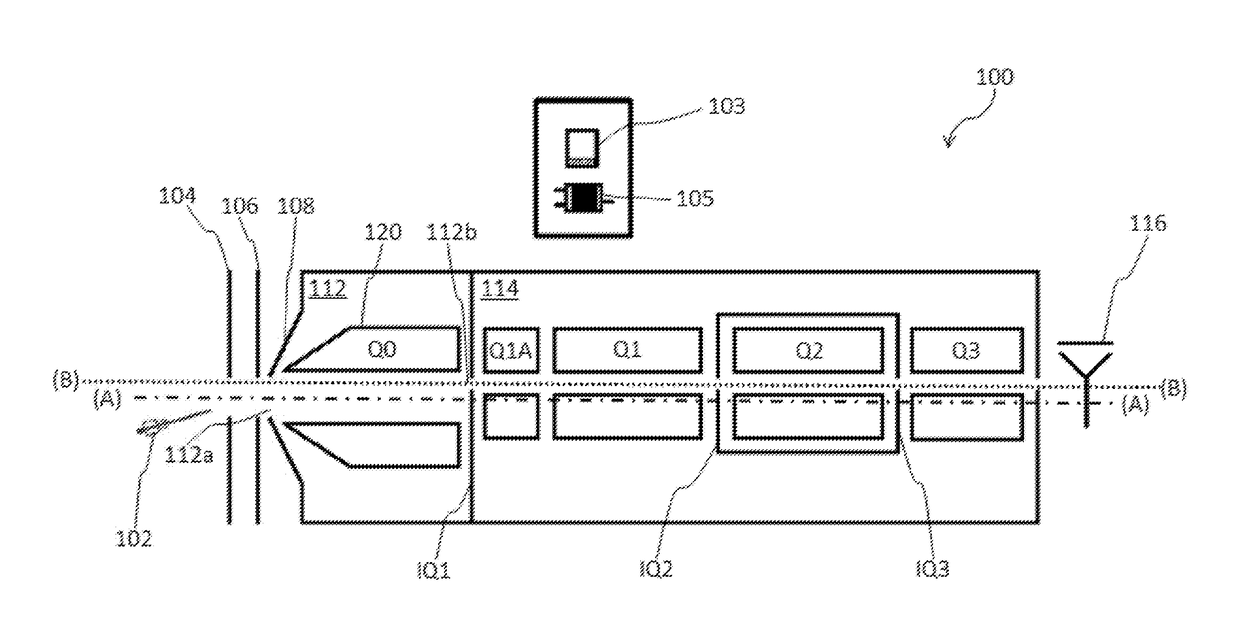

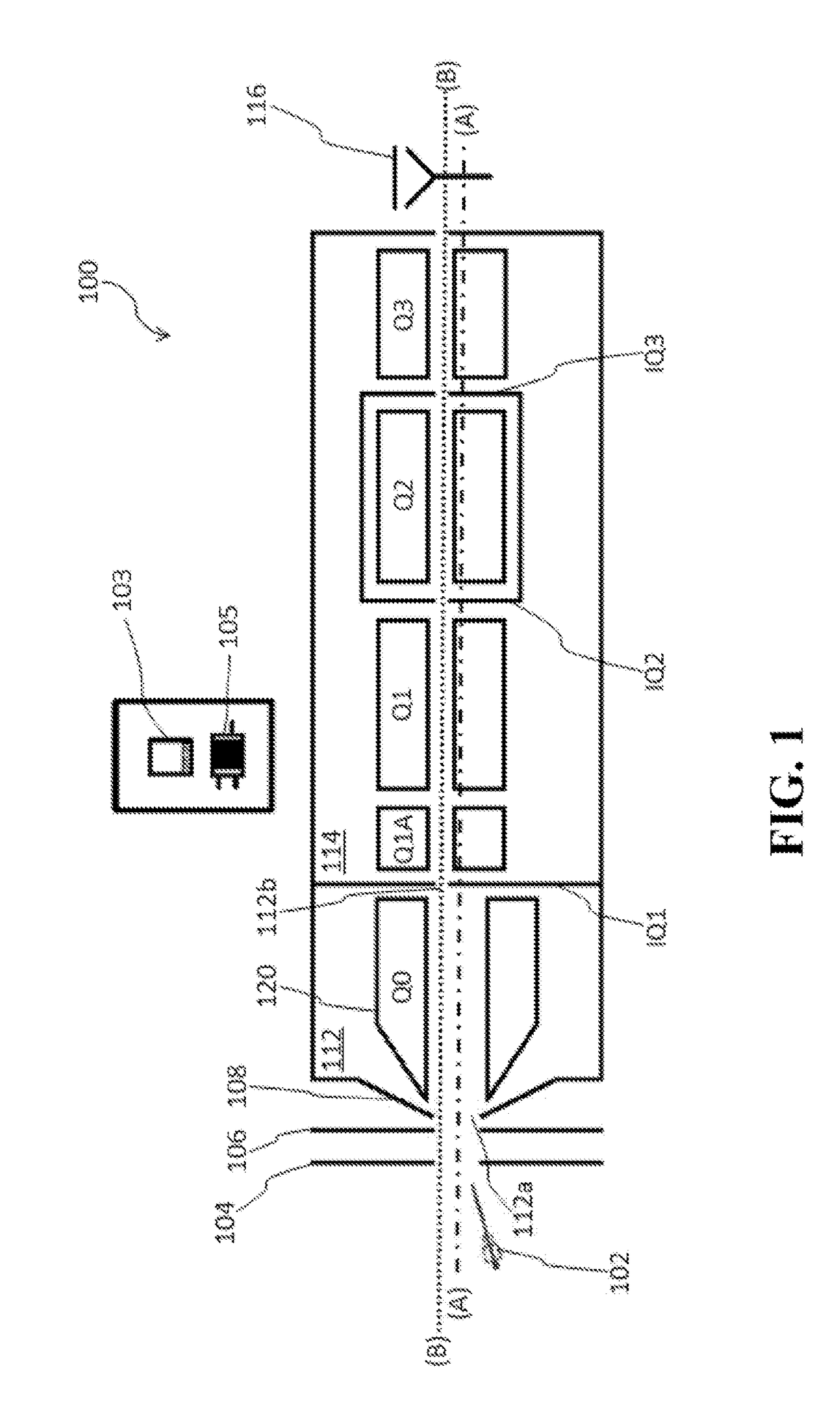

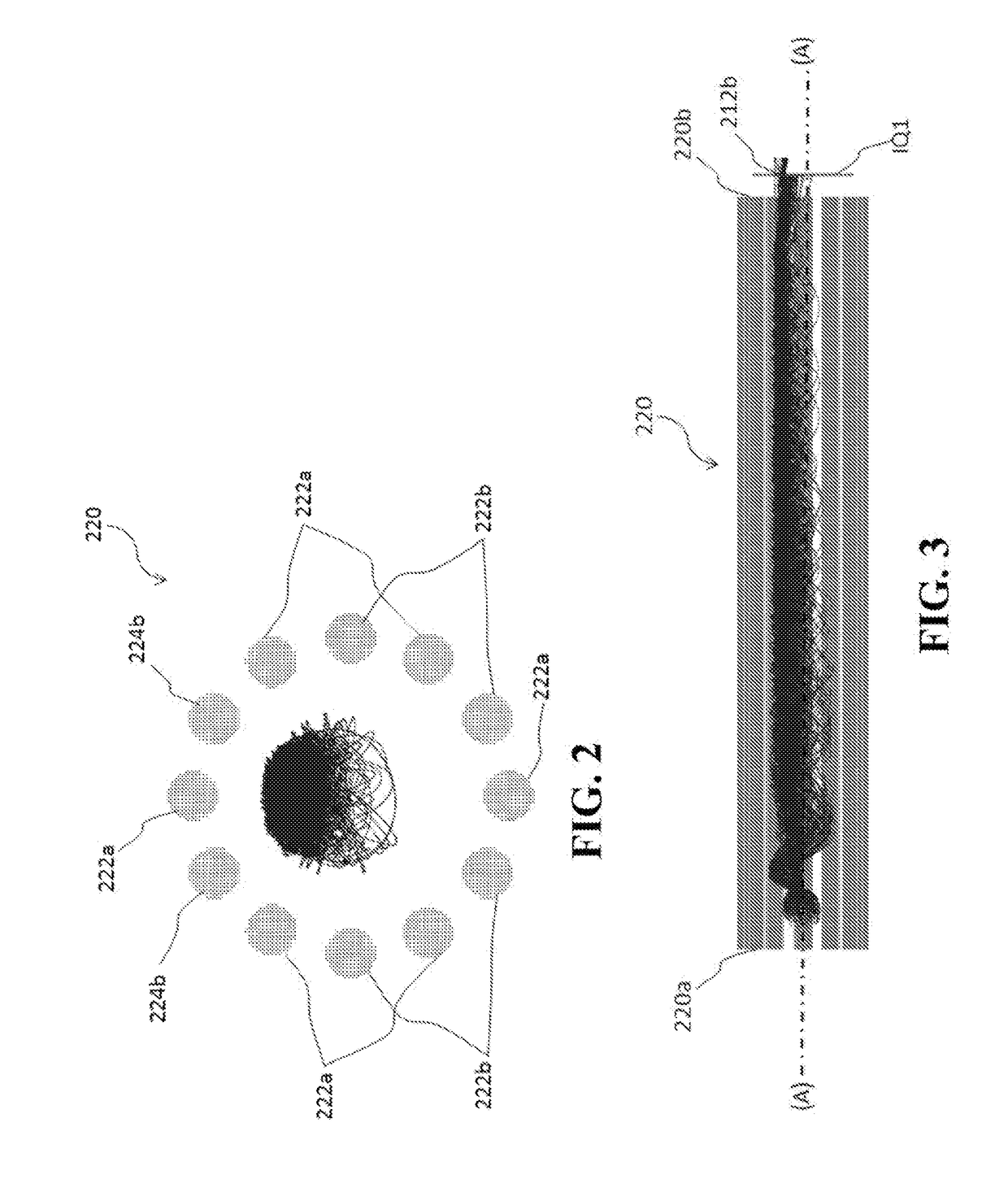

Multipole Ion Guide

ActiveUS20180122627A1Improve throughputImprove robustnessElectron/ion optical arrangementsDowntimeSolvation

Systems and methods described herein utilize an ion guide for use in mass spectrometer systems, which ion guide can receive ions from an ion source for transmission to downstream mass analyzers, while preventing debris (e.g., unsolvated droplets, neutral molecules, heavy charged clusters) from being transmitted into a high-vacuum chamber of the mass spectrometer system. In various aspects, systems and methods in accordance with the present teachings can increase throughput, improve the robustness of the system, and / or decrease the downtime typically required to disassemble / clean sensitive components within the high-vacuum portions of the mass spectrometer system.

Owner:DH TECH DEVMENT PTE

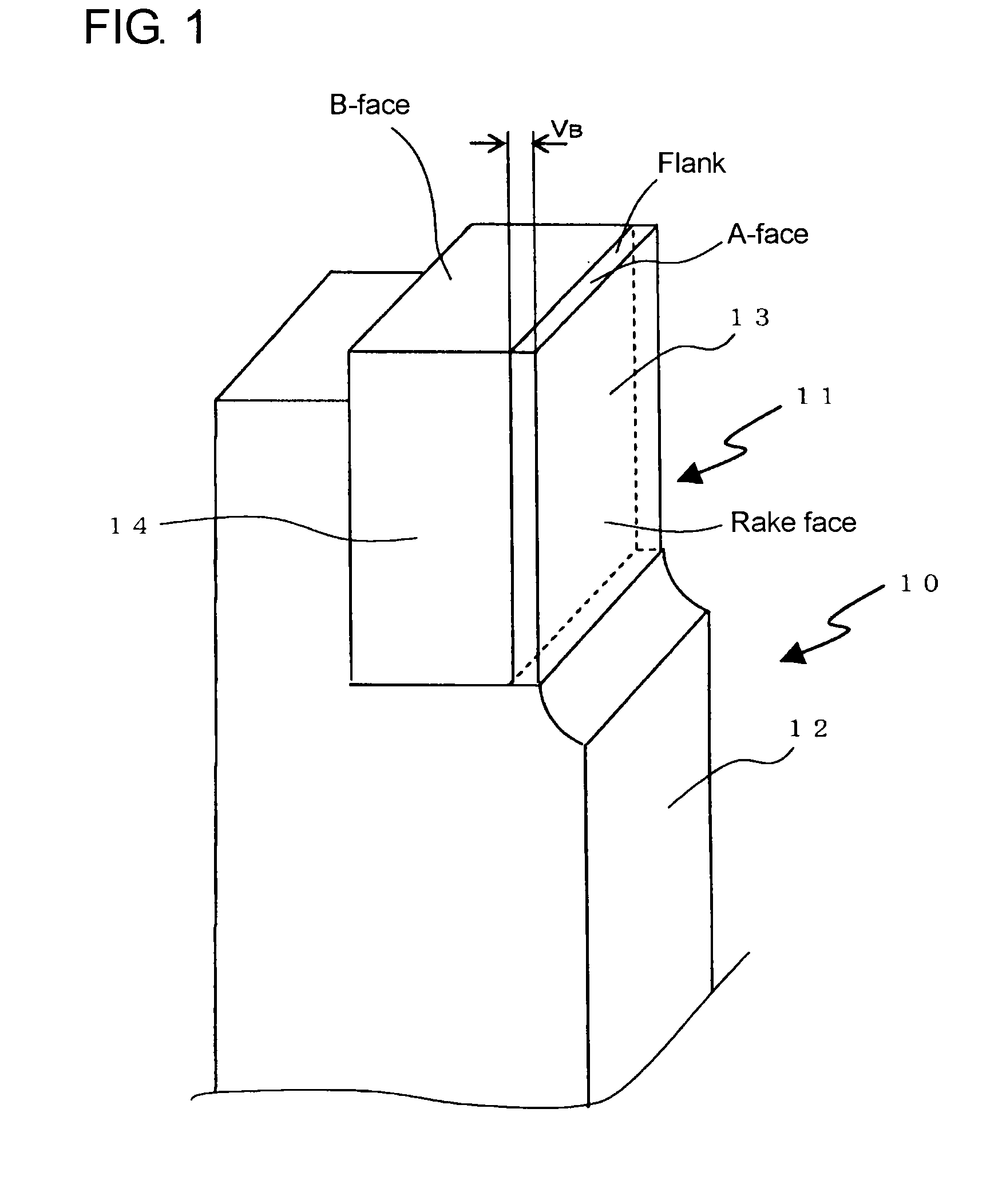

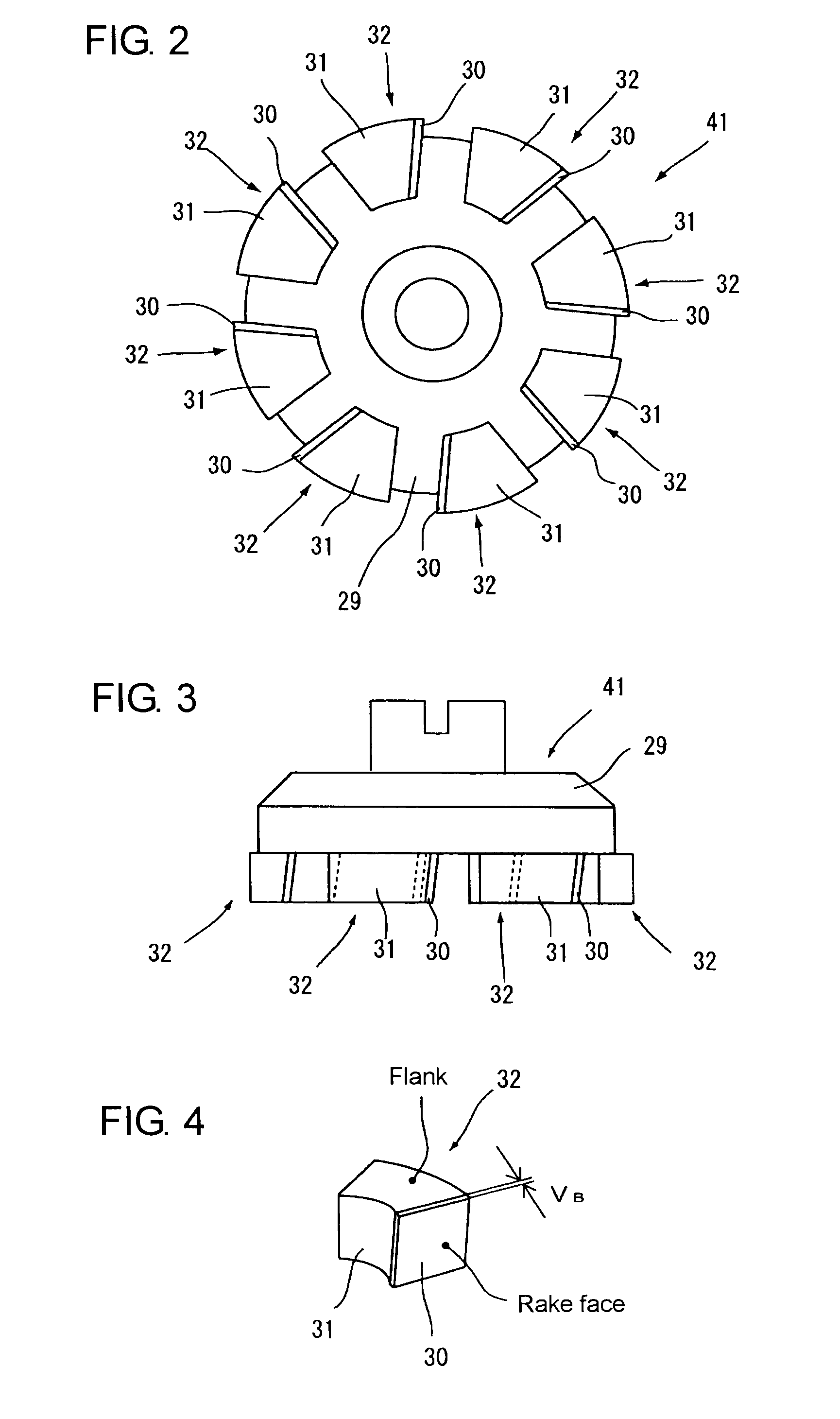

Cutting tool, method of forming cutting tool, and method of manufacturing cutting tool

InactiveUS20100202840A1Constant cross-sectional areaImprove cutting lifeTool workpiece connectionMilling cuttersHardnessMechanical engineering

A cutting tip including a cutting edge portion made of a high-hardness material to take a thin-plate shape; and a support portion made of a material which is more worn in contact with a workpiece than the cutting edge portion not to exert a machining action on the workpiece even in contact with the workpiece, and securing and supporting the cutting edge portion on a reverse side of a rake face of the cutting edge portion. Thus, the width of flank wear is prevented from increasing and chipping of the cutting edge is prevented, so that the life of the cutting tip can be extended.

Owner:JTEKT CORP

Tension member for an elevator

InactiveUS20090107776A1Minimize diameterCheapElevatorsOther workshop equipmentTension memberLoad carrying

A tension member for an elevator system has an aspect ratio of greater than one, where aspect ratio is defined as the ratio of tension member width w to thickness t (w / t). The increase in aspect ratio results in a reduction in the maximum rope pressure and an increased flexibility as compared to conventional elevator ropes. As a result, smaller sheaves may be used with this type of tension member. In a particular embodiment, the tension member includes a plurality of individual load carrying cords encased within a common layer of coating. The coating layer separates the individual cords and defines an engagement surface for engaging a traction sheave.

Owner:BARANDA PEDRO S +2

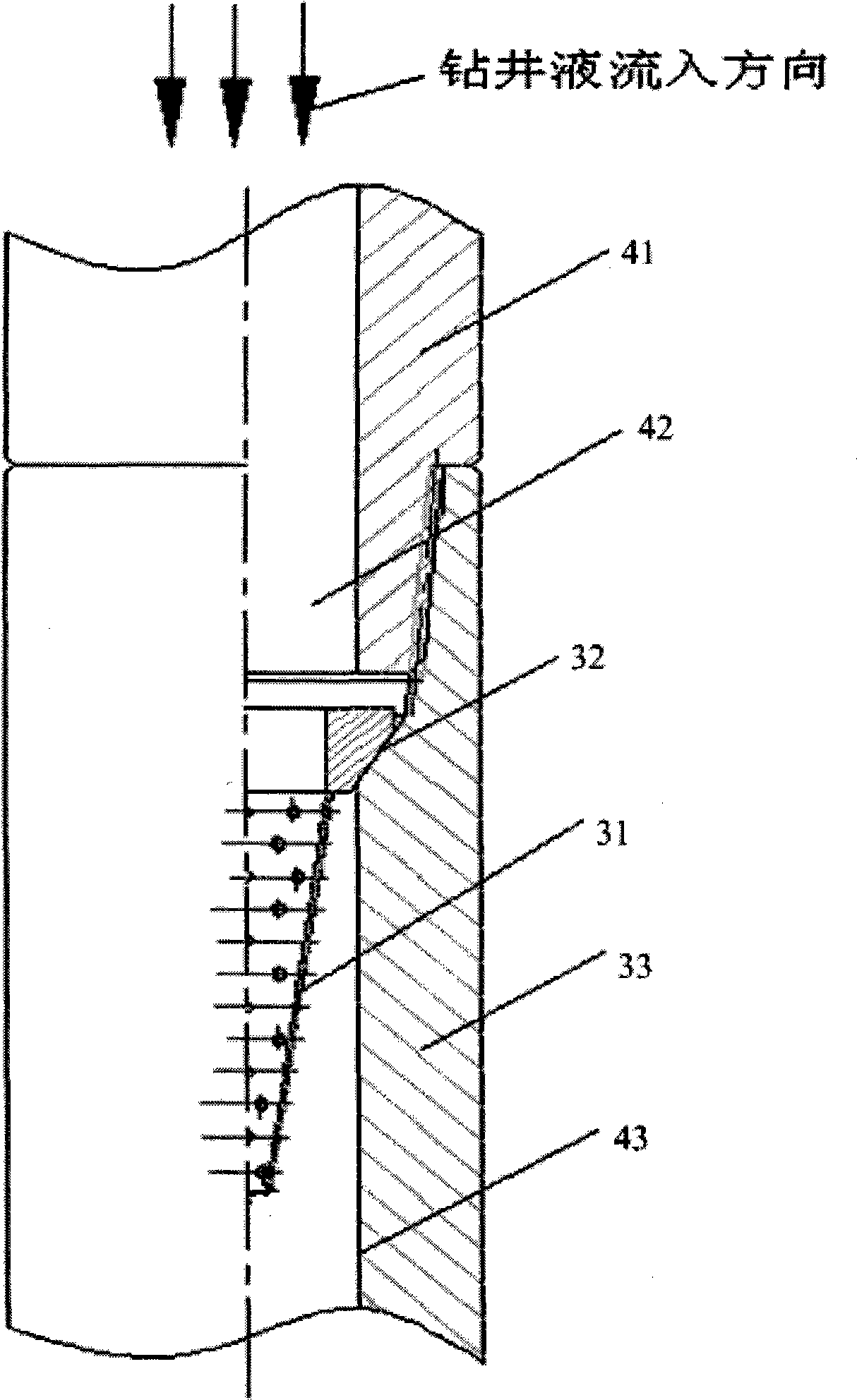

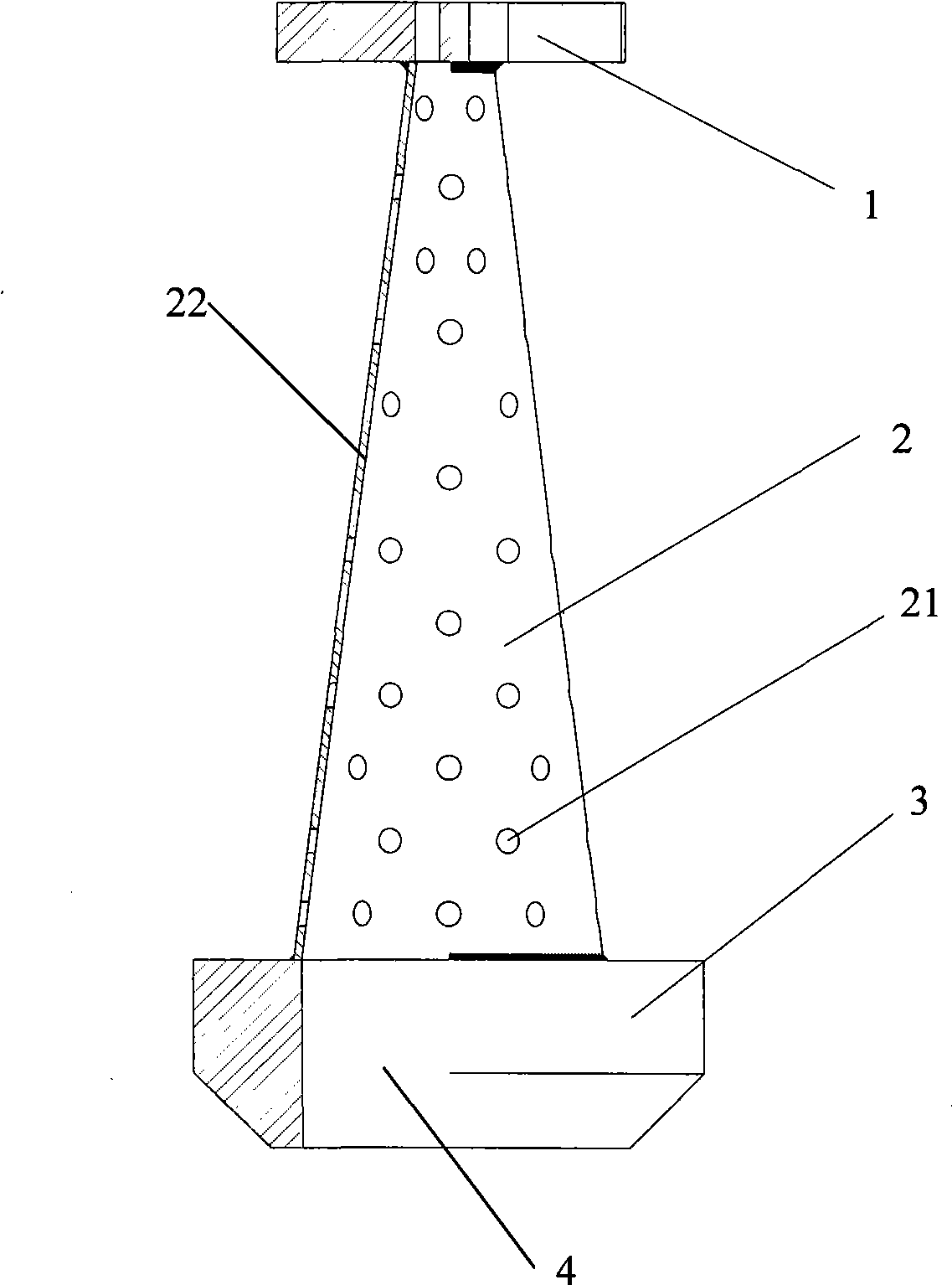

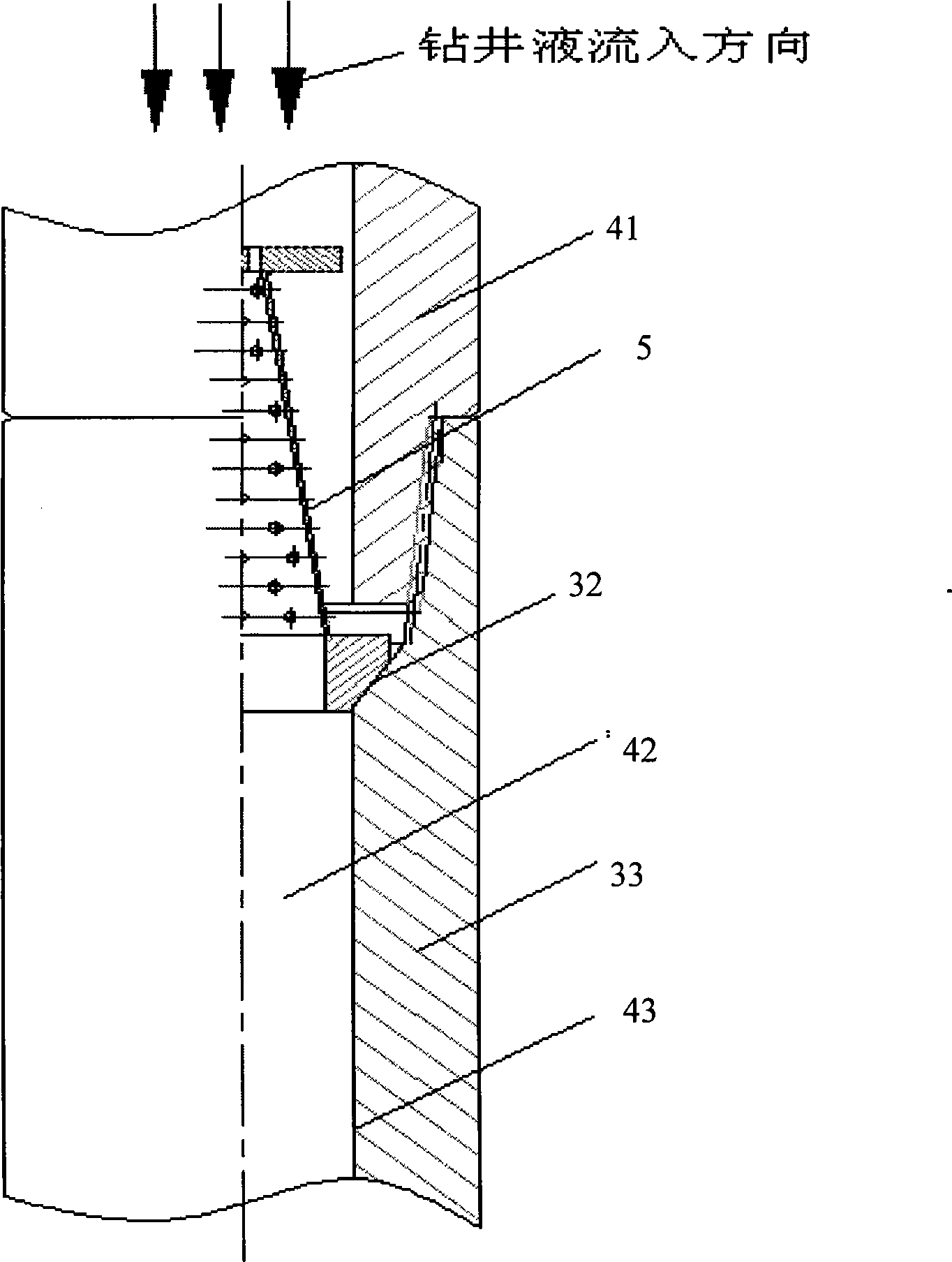

Drilling tool filter screen for realizing protection of internal wall of drilling tool

InactiveCN101530692AReduce accidentsGuaranteed filtering effectEarth drilling toolsDrill bitsWell drillingPetroleum

The invention relates to a drilling tool filter screen for realizing protection of the internal wall of a drilling tool. The drilling tool filter screen is arranged at the upper part of a small end of the internal thread of the drilling tool and an opening thereof faces downward; the drilling tool filter screen adopts a mode that drilling fluid flows into an inner cavity of the filter screen by filter holes on the filter screen from the outer part of the filter screen to filter impurities. The drilling tool filter screen for protecting the internal wall of the drilling tool guarantees that the impurities in the drilling fluid are filtered, simultaneously can protect the internal wall of the drilling tool effectively, reduce drilling tool accidents caused by washing out and abrasion of the drilling fluid to the internal wall of the drilling tool, prolong the service life of the drilling tool and can be widely applied to fields of drilling operation of petroleum gas.

Owner:张继川

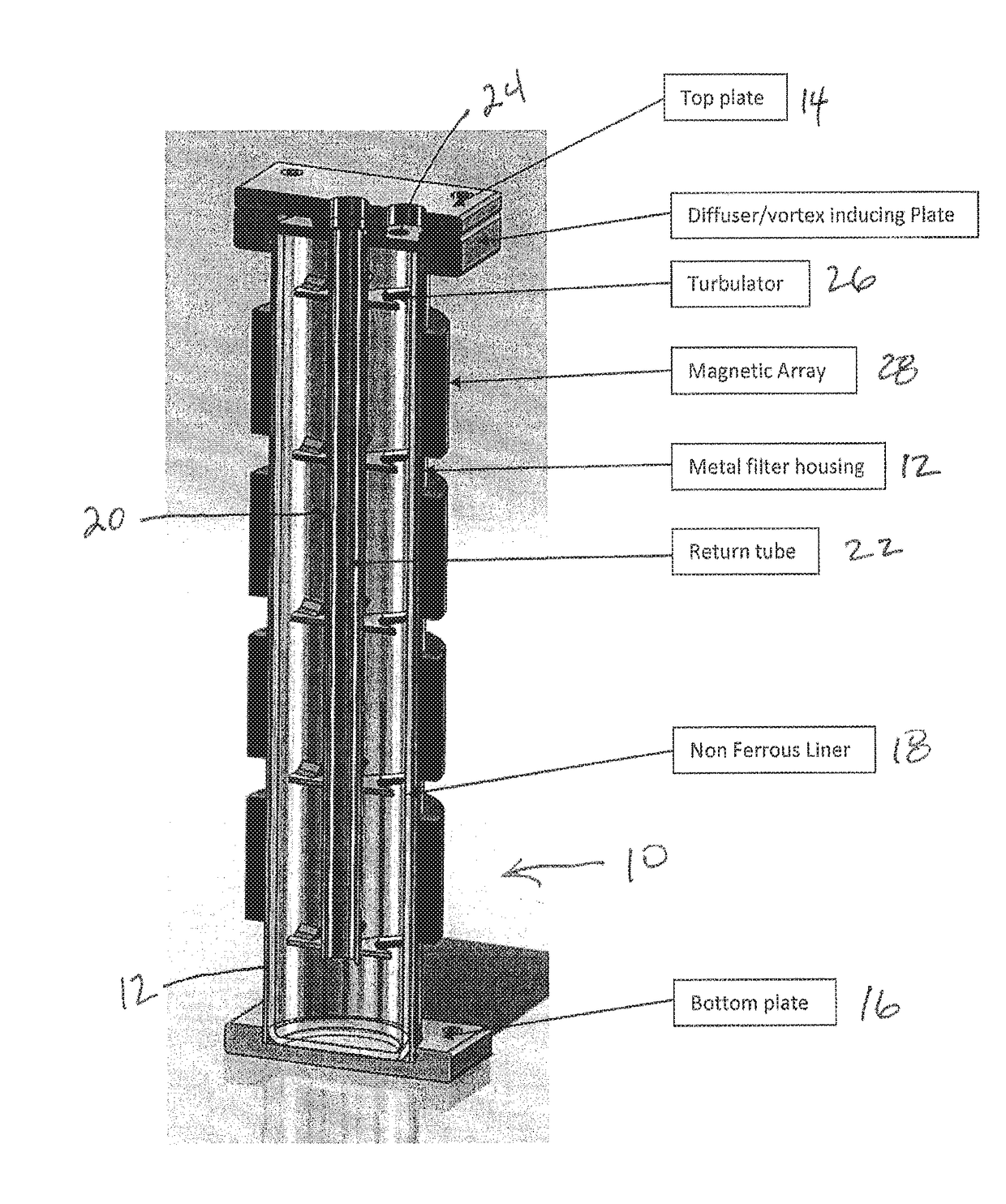

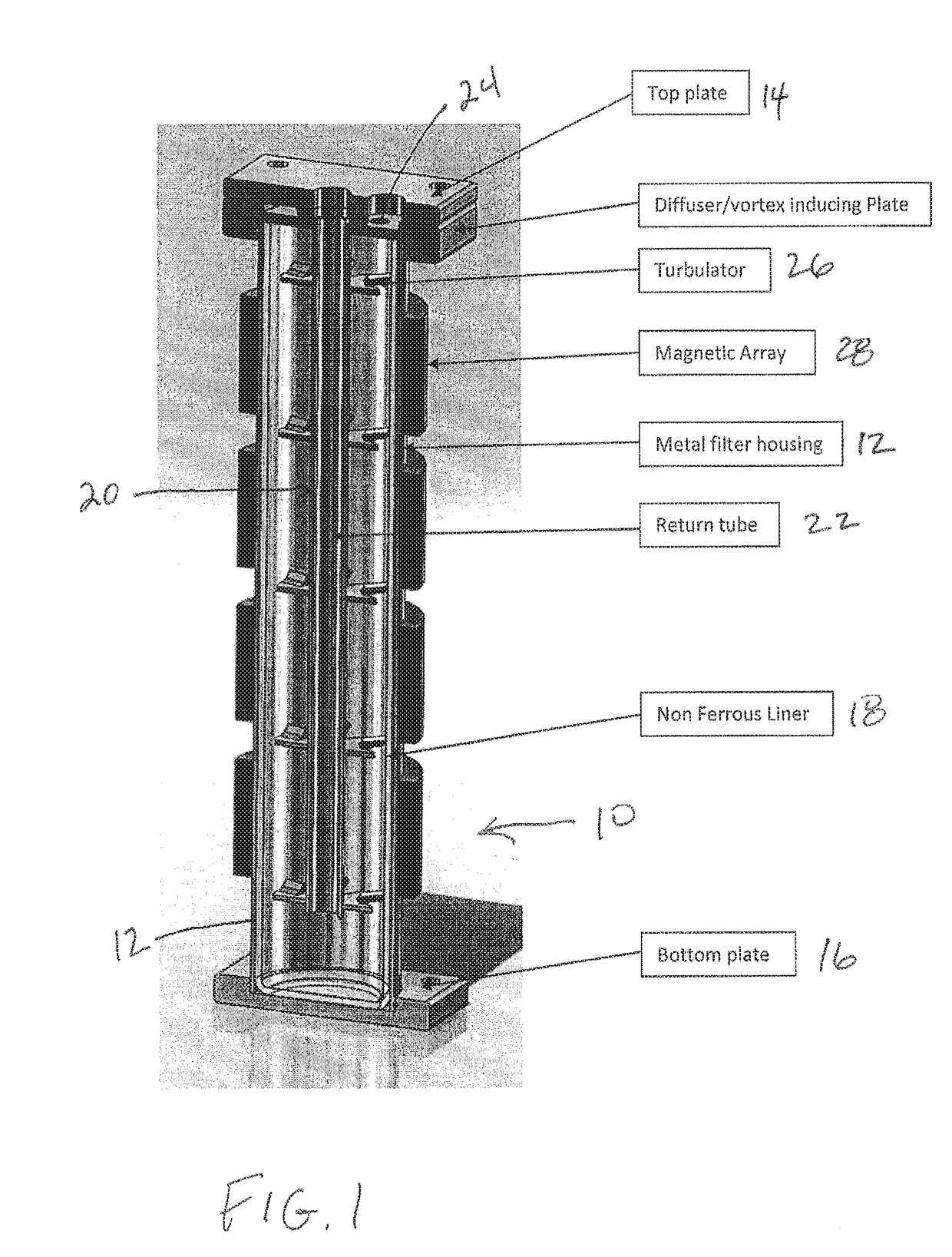

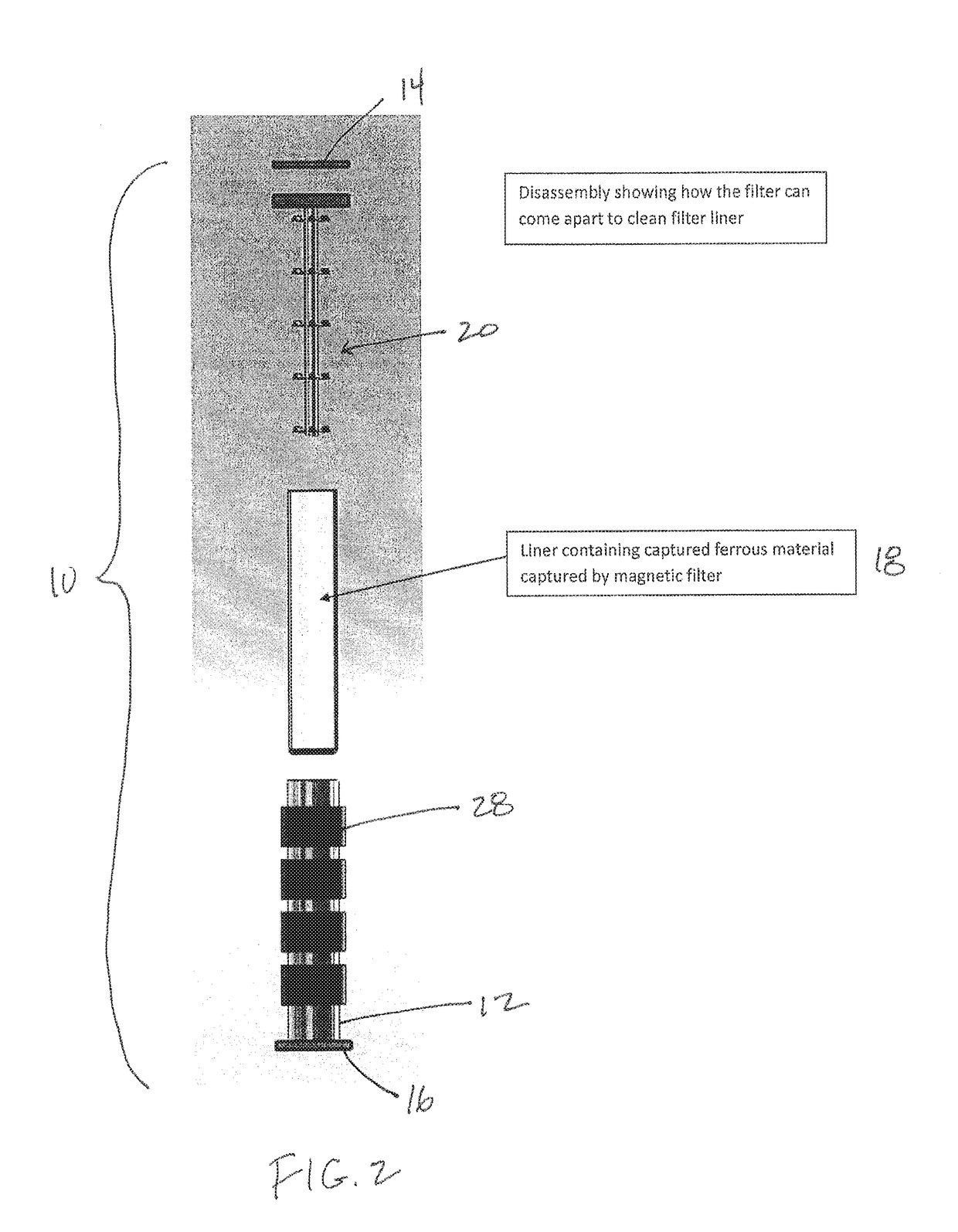

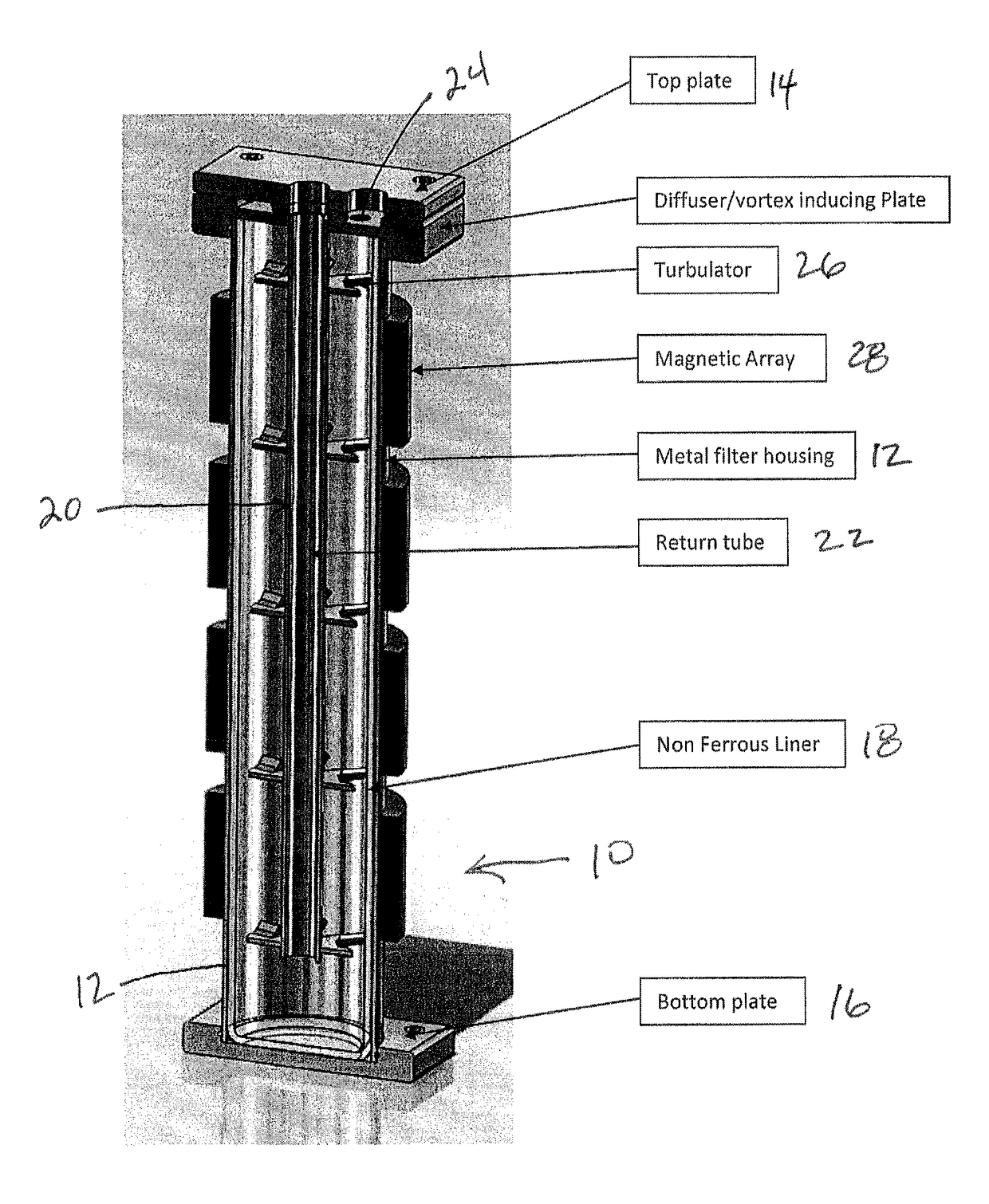

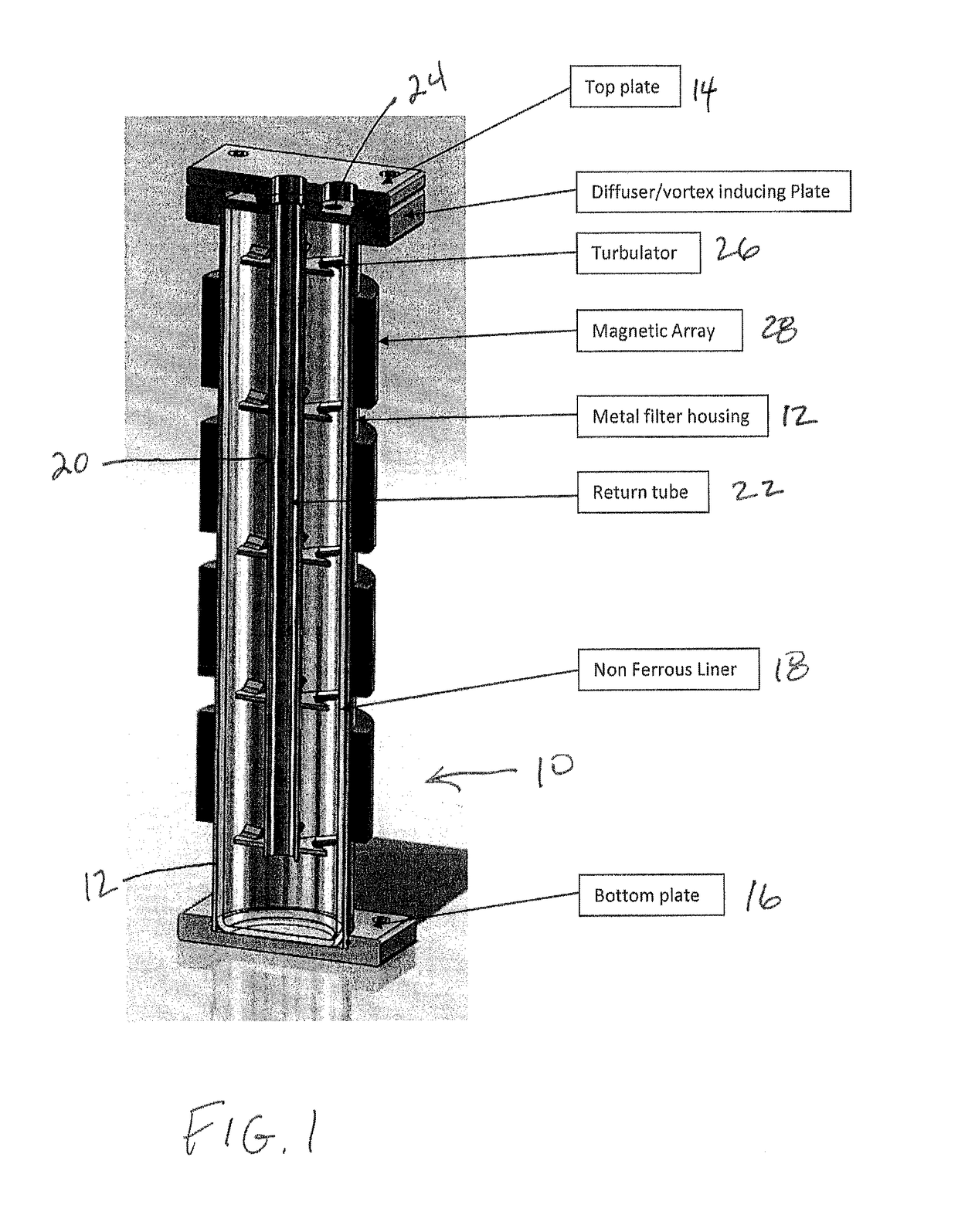

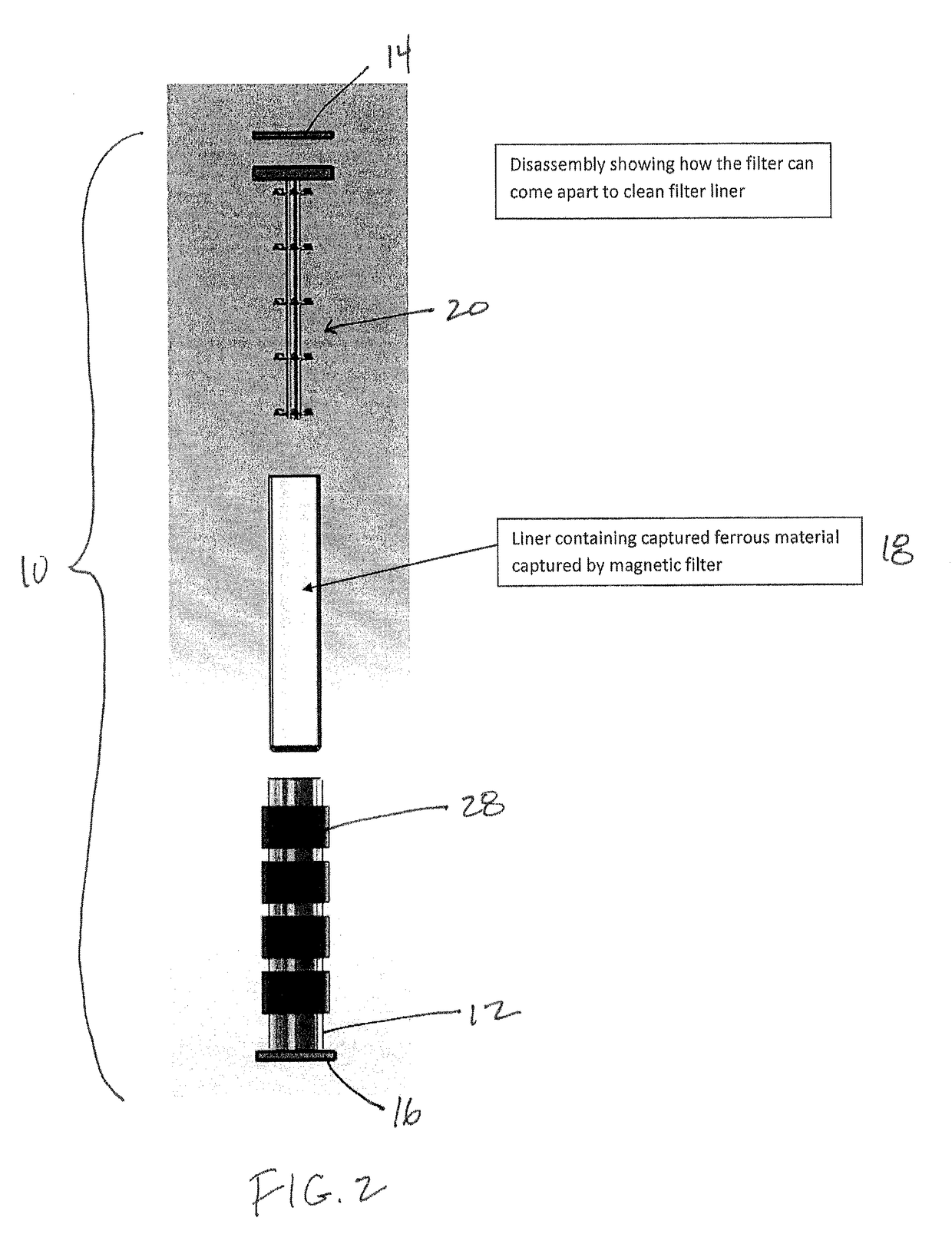

Filter Element With Magnetic Array

InactiveUS20180141054A1Effective trapping characteristicEasy maintenanceElectrostatic separation housingHigh gradient magnetic separatorsBiomedical engineeringFilter element

A filter for removing ferrous particles from a fluid. The filter has an outer filter housing and a non-ferrous liner inside the housing. A plurality of magnets are longitudinally extended at intervals outside the liner. An insert inside the liner imparting a directional flow to the fluid inside the filter whereby ferrous particles in the fluid are trapped by the magnets and held against the non-ferrous line.

Owner:FLEENOR MFG INC

Filter Element With Magnetic Array

InactiveUS20170312757A1Effective trapping characteristicEasy maintenanceElectrostatic separationHigh gradient magnetic separatorsNonferrous metalBiomedical engineering

A filter for removing ferrous particles from a fluid. The filter has an outer filter housing and a non-ferrous liner inside the housing. A plurality of magnets are longitudinally extended at intervals outside the liner. An insert inside the liner imparting a directional flow to the fluid inside the filter whereby ferrous particles in the fluid are trapped by the magnets and held against the non-ferrous line.

Owner:FLEENOR MFG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com