Cigarette unpunching/punching missing detection device, laser punching machine and detection method

A technology of laser punching machine and detection device, which is applied in the fields of tobacco, paper cigarette manufacturing, application, etc., and can solve the problems of unperforated laser punching machine, data inaccuracy, missing punching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

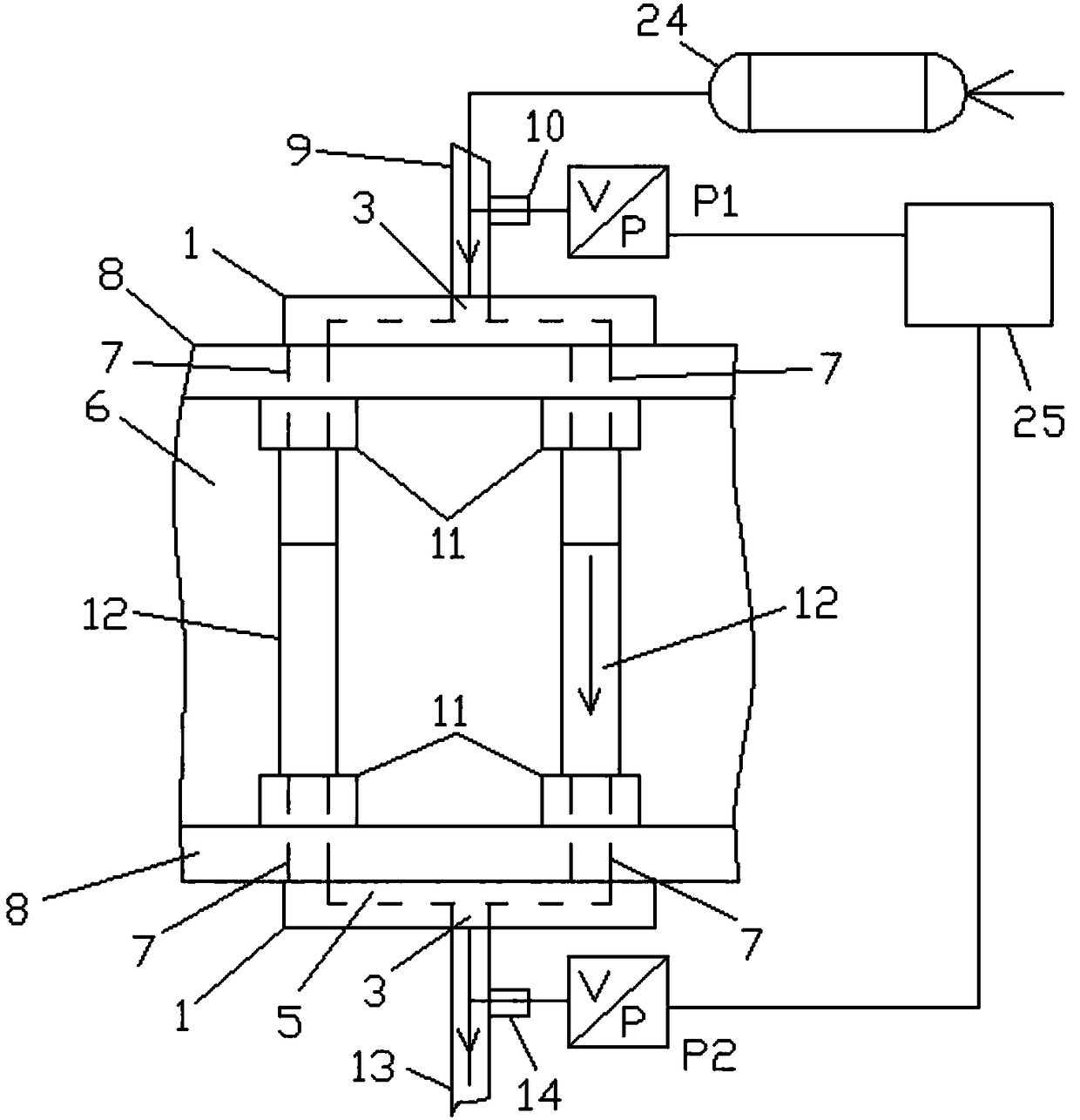

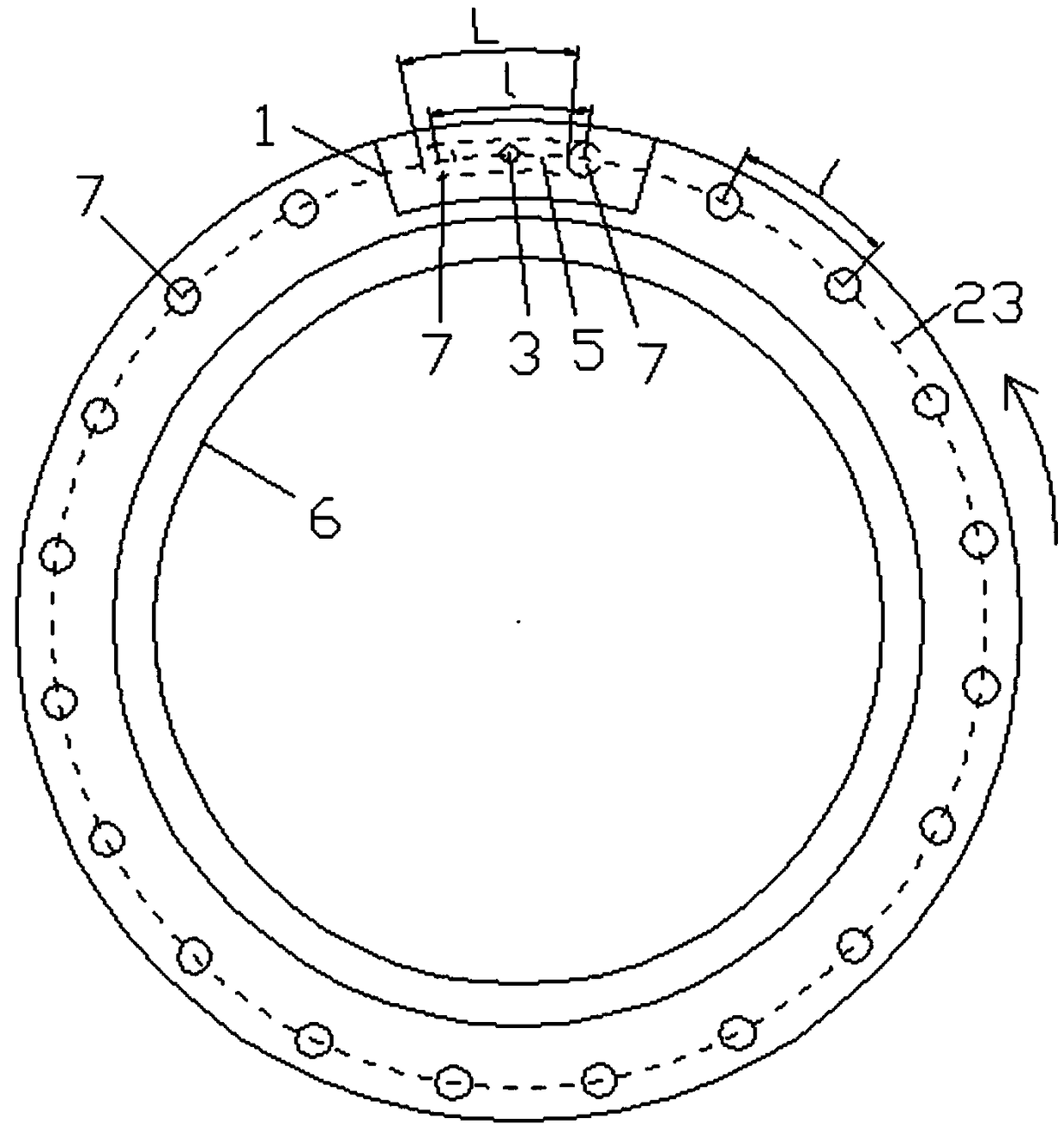

[0025] Depend on Figure 1-Figure 3 The shown cigarette non-perforated / leakage perforated detection device includes two fixed blocks 1 arranged at intervals on the left and right, a first pressure sensor 10, a second pressure sensor 14, an air storage tank 24 and a control system 25, and the two fixed blocks 1 The detection drums 6 are arranged outside the two axial sides of the detection drums 6 respectively, that is, between the two fixed blocks 1 .

[0026] The detection drum 6 is the detection drum 6 of the cigarette making machine. The detection drum 6 is arranged horizontally on the left and right. The central axis of the detection drum 6 extends horizontally from left to right. The detection drum 6 can rotate around its central axis. Flanges 8 are provided at both ends of the axial direction, and the two flanges 8 of the detection drum 6 are axially spaced left and right. Annular protrusions are arranged at both ends of the axial direction, and several ventilation hole...

Embodiment 2

[0034] Depend on Figure 4 Shown is an online laser punching machine, which is provided with the cigarette non-punching / missing punching detection device 22 described in Embodiment 1.

[0035] The online laser punching machine is provided with an electric control system, and the electric control system is a PLC control system. When the cigarette is not perforated / leaked perforation detection device 22 includes a control system, the electric control system of the online laser punching machine 16 is connected with the cigarette. The control system of the non-perforated / missed perforation detection device 22 is connected by communication, and the electronic control system of the online laser punching machine 16 and the control system of the non-perforated / missed perforation detection device 22 of cigarettes can be connected through 485 bus connection.

[0036] Of course, the present invention is not limited to the above-mentioned form. When the unperforated / missing perforation d...

Embodiment 3

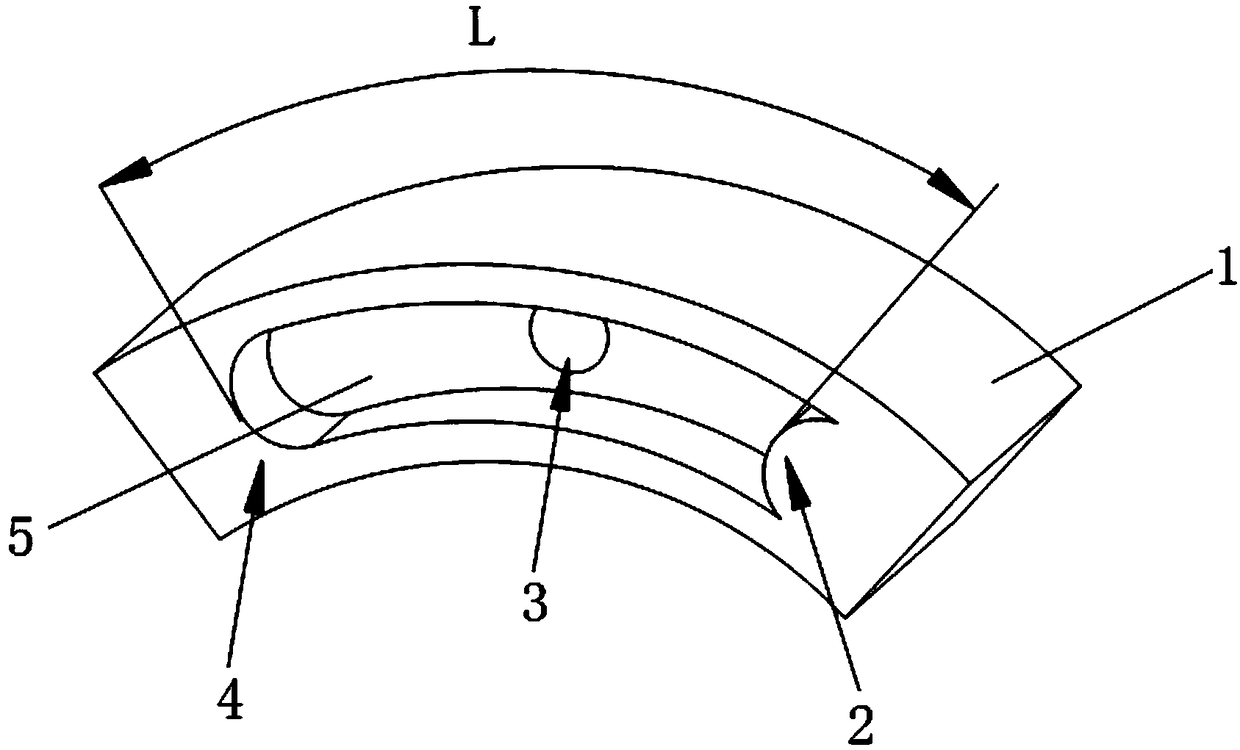

[0043] A method for detecting unperforated / missing perforations of cigarettes, first setting a detection device with unperforated cigarettes 12 described in Embodiment 1, and setting the cigarettes 12 after laser perforation on the two flanges 8, laser perforation processing refers to the filter tip of cigarette 12 is carried out laser perforation (laser perforation is the prior art, so not described in detail), cigarette 12 parallel detection drum 6 central axis, cigarette The two ends of 12 correspond to the two ventilation holes 7 of the two flanges 8 respectively, that is, one end 4 of the cigarette 12 is directly opposite to a ventilation hole 7 on one of the flanges 8 , and the other end 2 is directly opposite to a ventilation hole 7 on the other flange 8 . The air holes 7 are facing each other. Preferably, each air hole 7 is provided with a rubber nozzle 11 connected to it in the axial direction. The rubber nozzle 11 is fixedly connected with the corresponding flange 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com