Patents

Literature

803results about "High gradient magnetic separators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

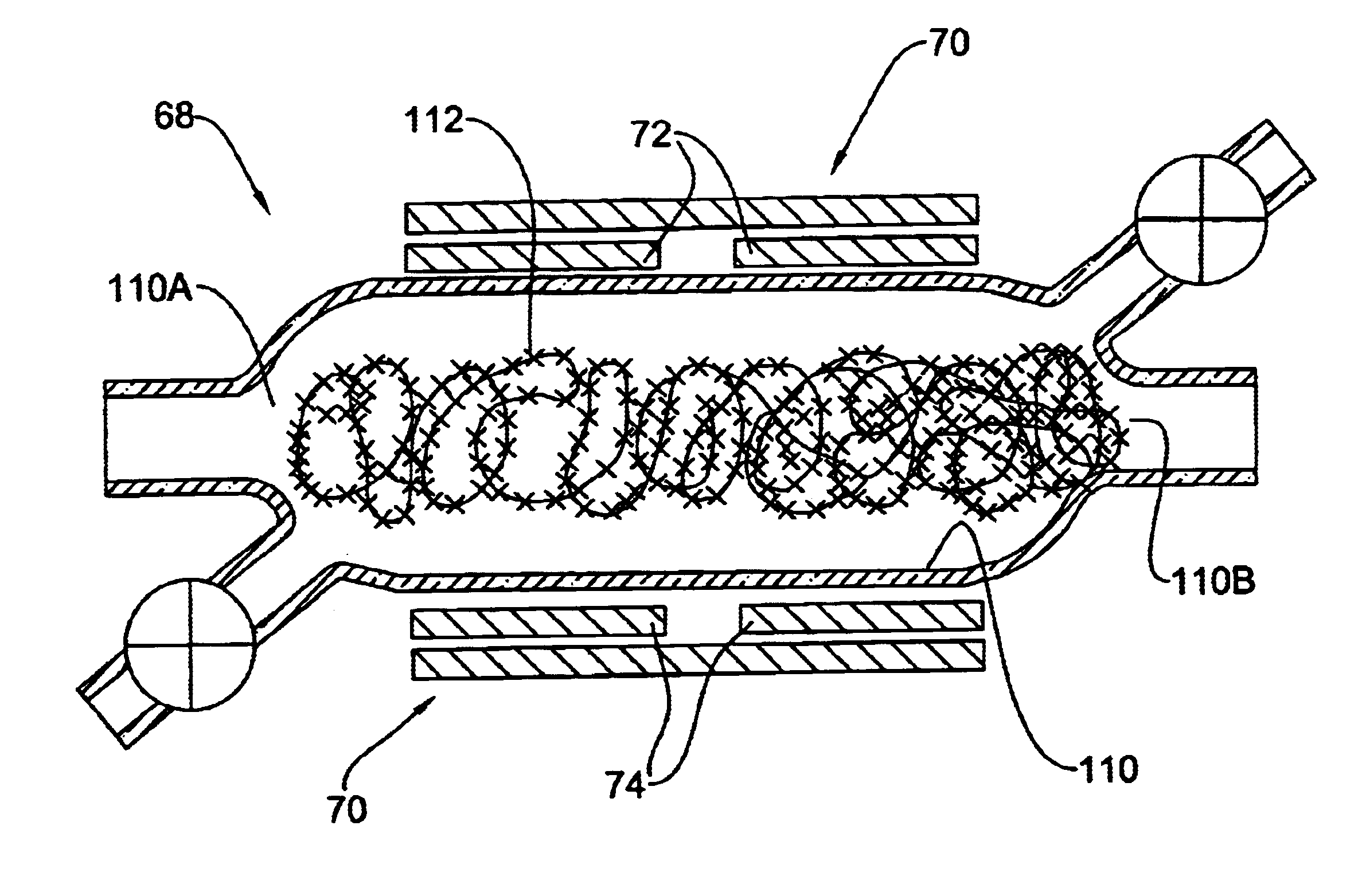

System for correction of a biological fluid

A system is presented for correction of a patient's biological fluid, such as his blood, lymph or spinal fluid, containing various low-, medium- and high-molecular toxins. The system comprises an extracorporeal flow line in the form of a flexible tube interconnected between outlet and inlet means attached to appropriate location(s) on a patient's body. A small amount of the biological fluid, i.e., substantially not exceeding 100 ml, substantially continuously flows through the tube, and is mixed with magneto-conductive particles capable of adsorbing the various toxins. An obtained mixture of the biological fluid with the particles passes through a magnetic field region, and substantially all of the magneto-conductive particles are retained therein. Particle-free biological fluid is then returned into the patient's body through the inlet means.

Owner:IDIALIZA

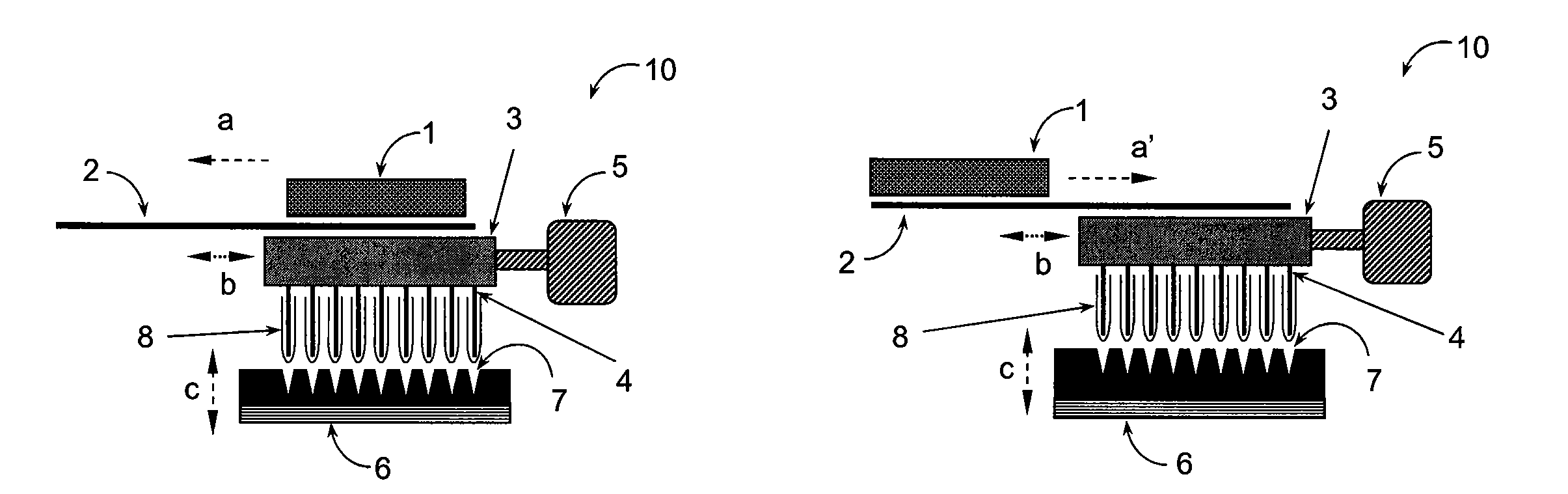

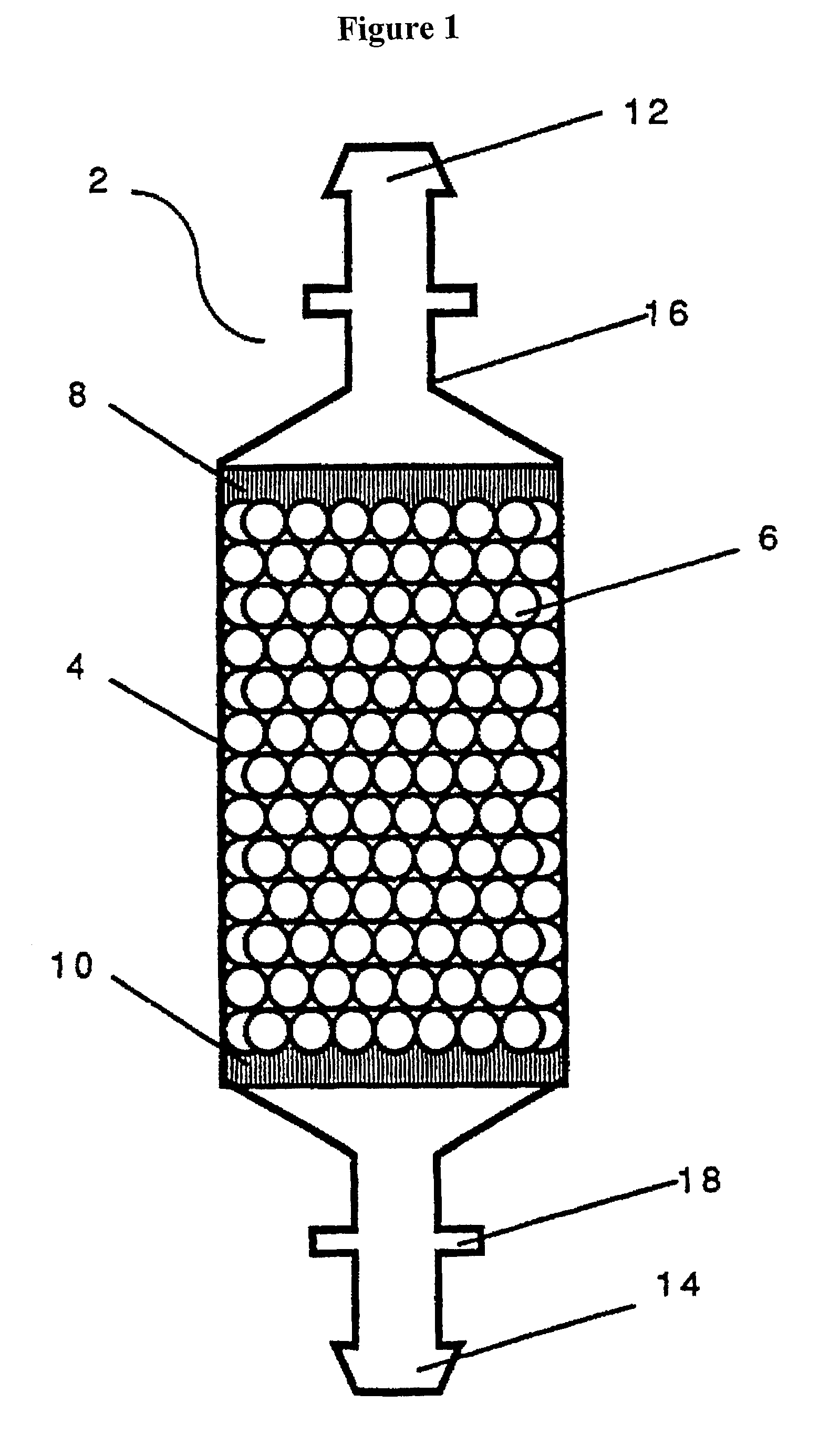

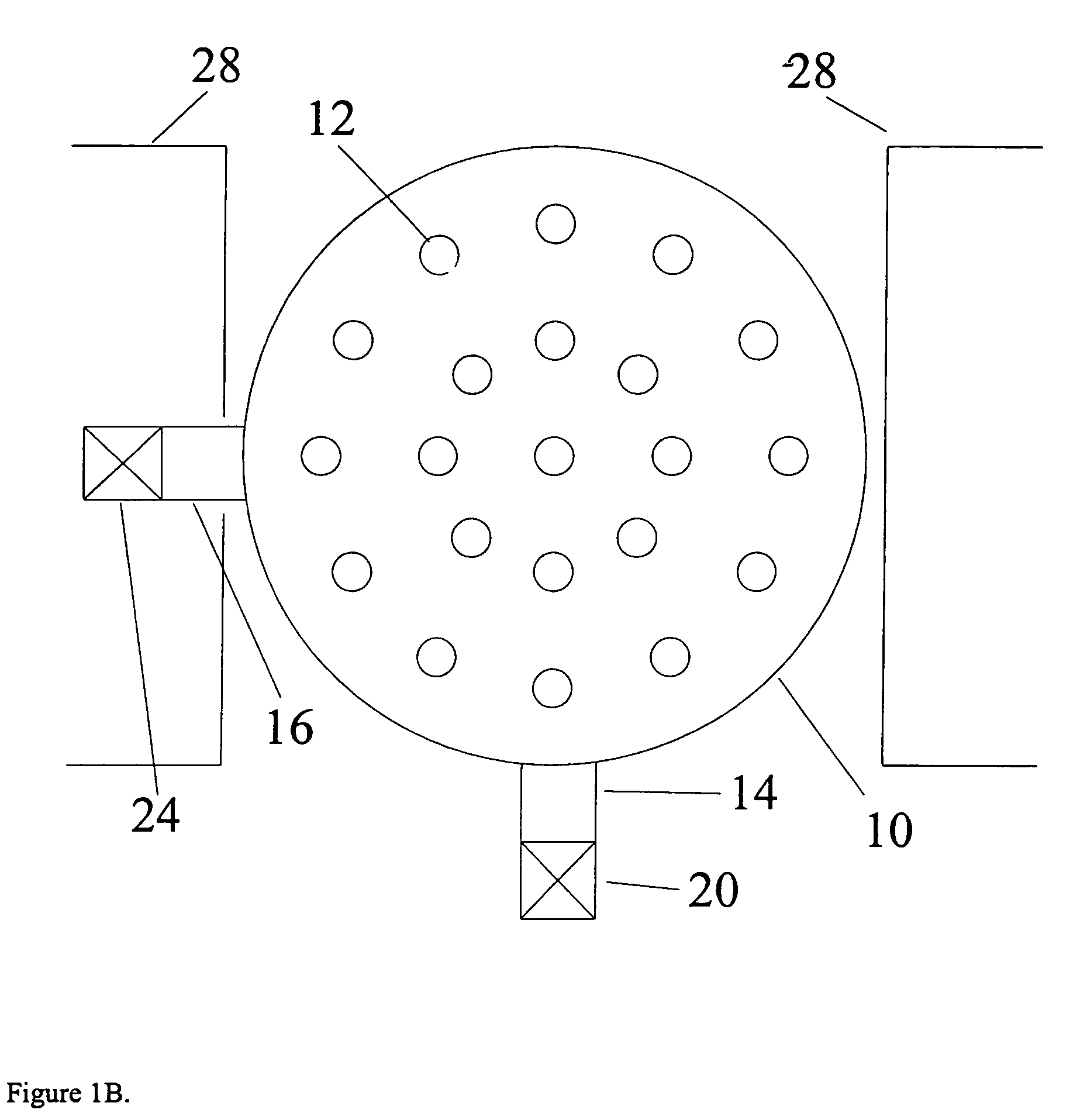

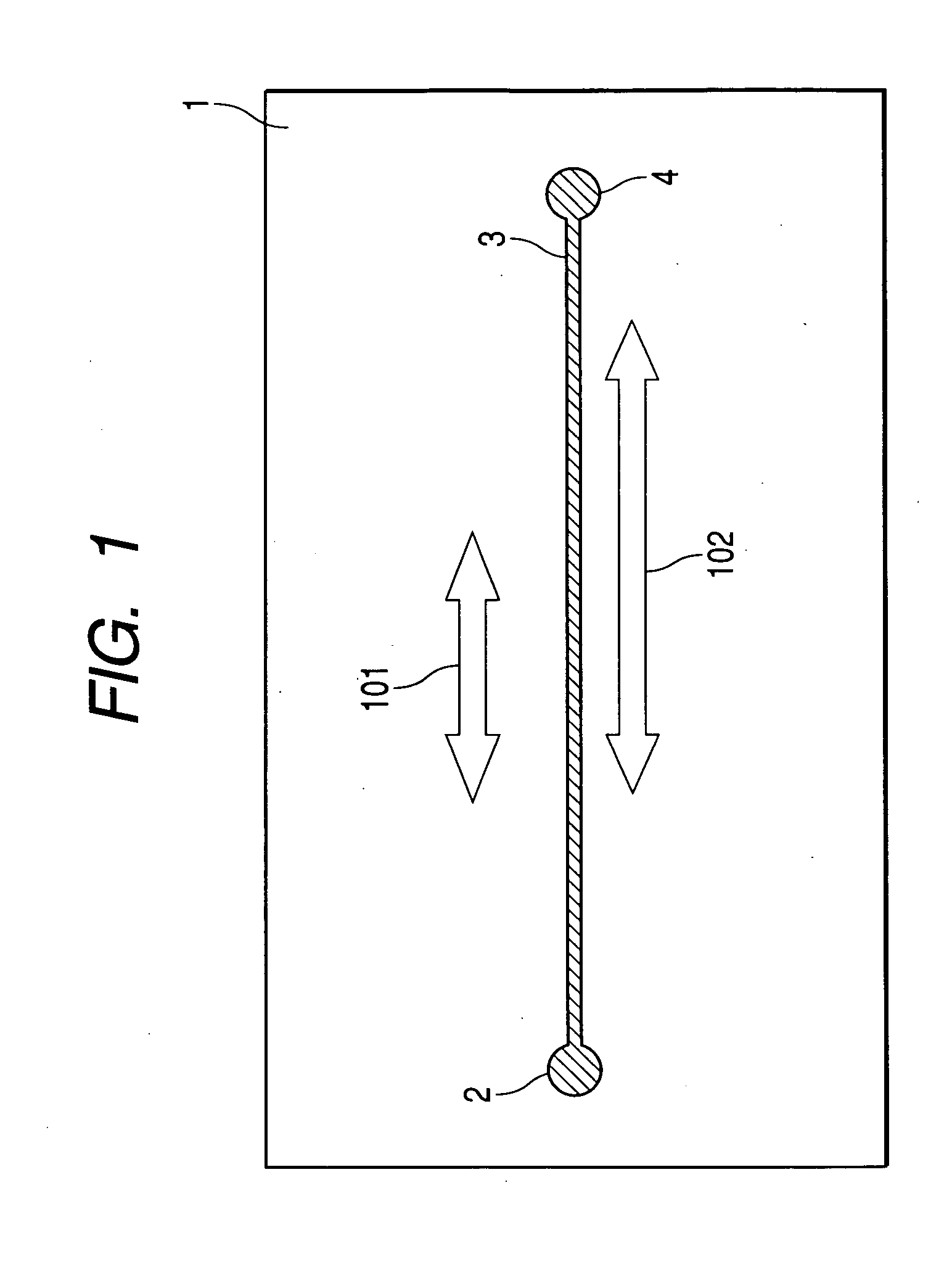

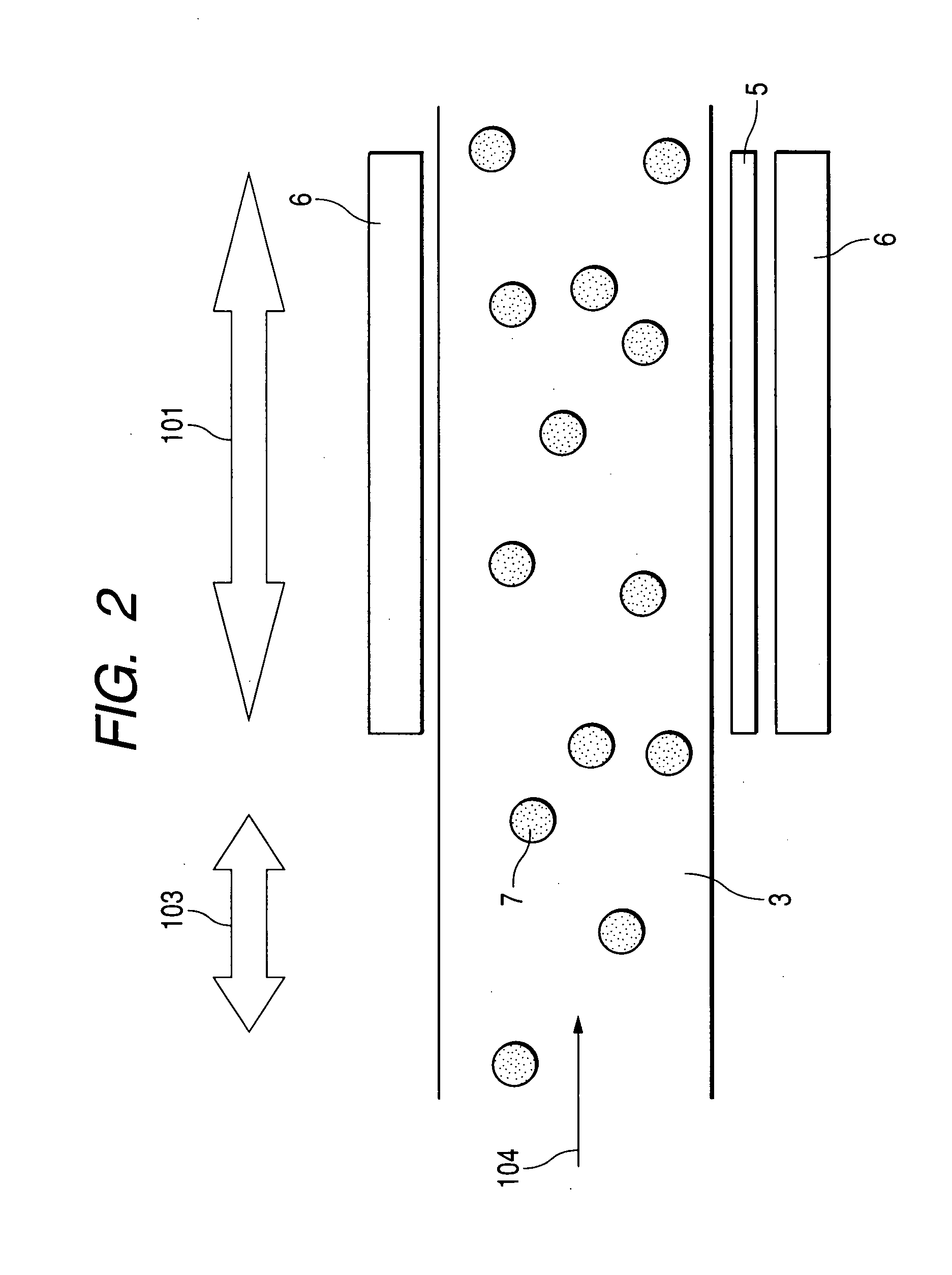

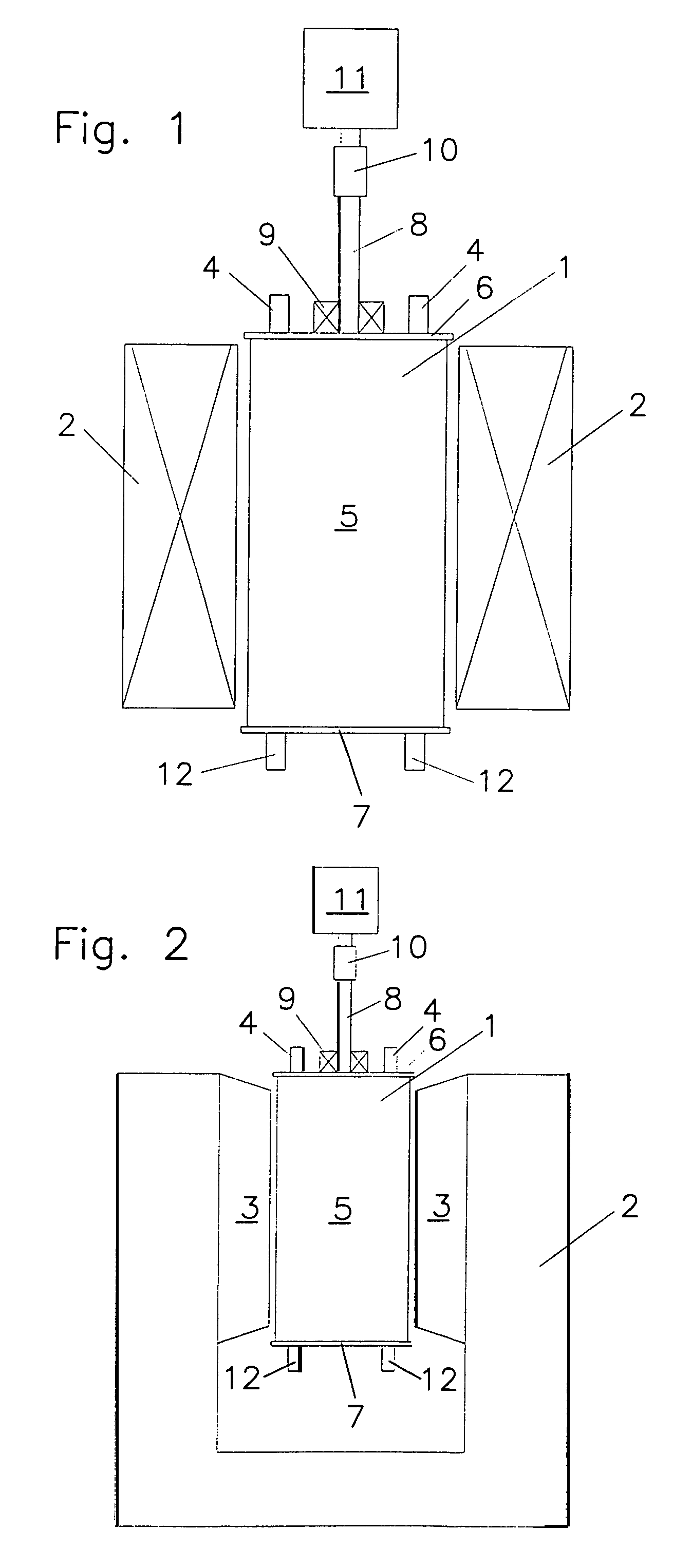

Device and Method for Separating Magnetic or Magnetizable Particles form a Liquid

ActiveUS20080308500A1Small elution volumeIncrease concentrationElectrostatic separationHigh gradient magnetic separatorsEngineeringMagnet

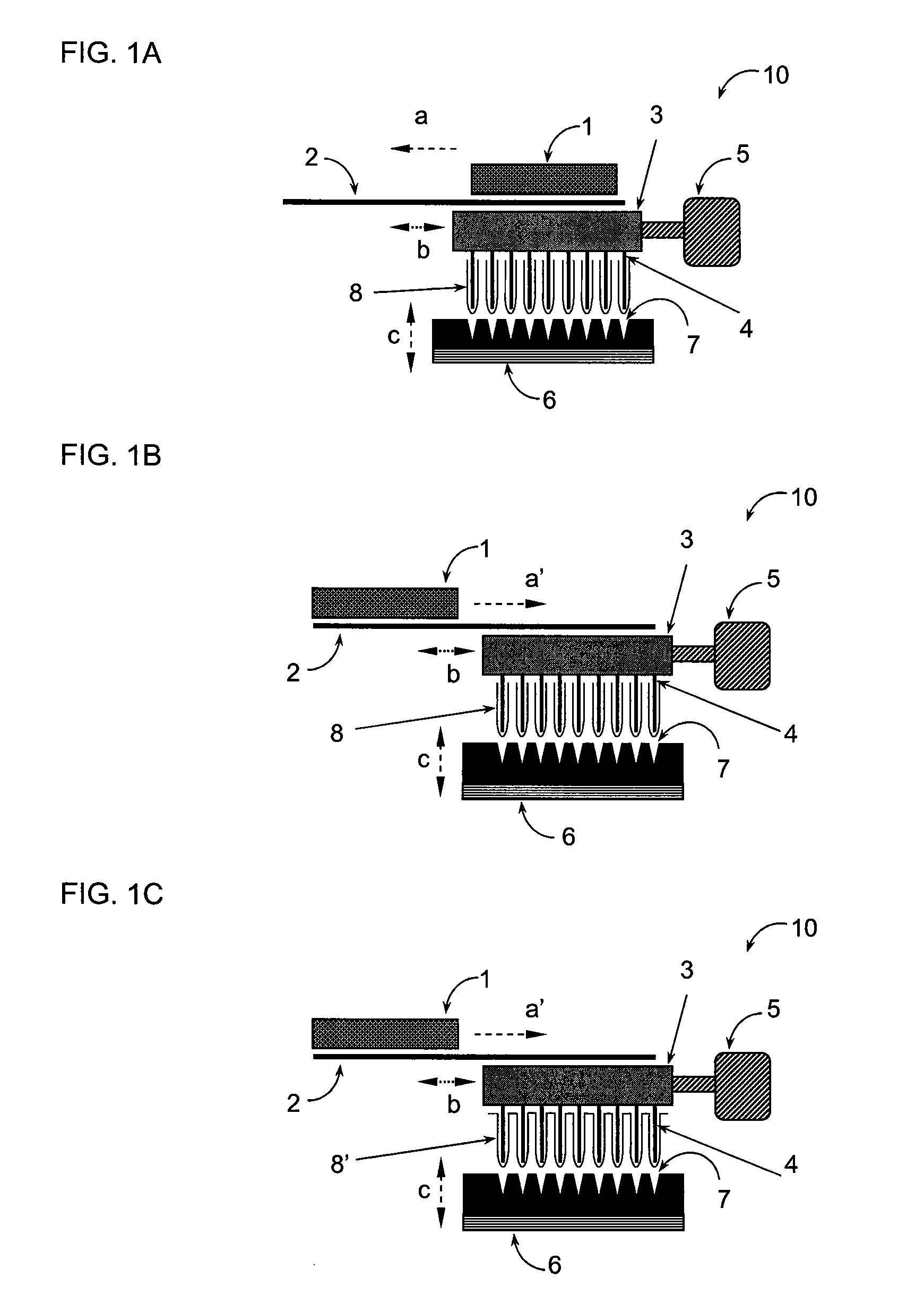

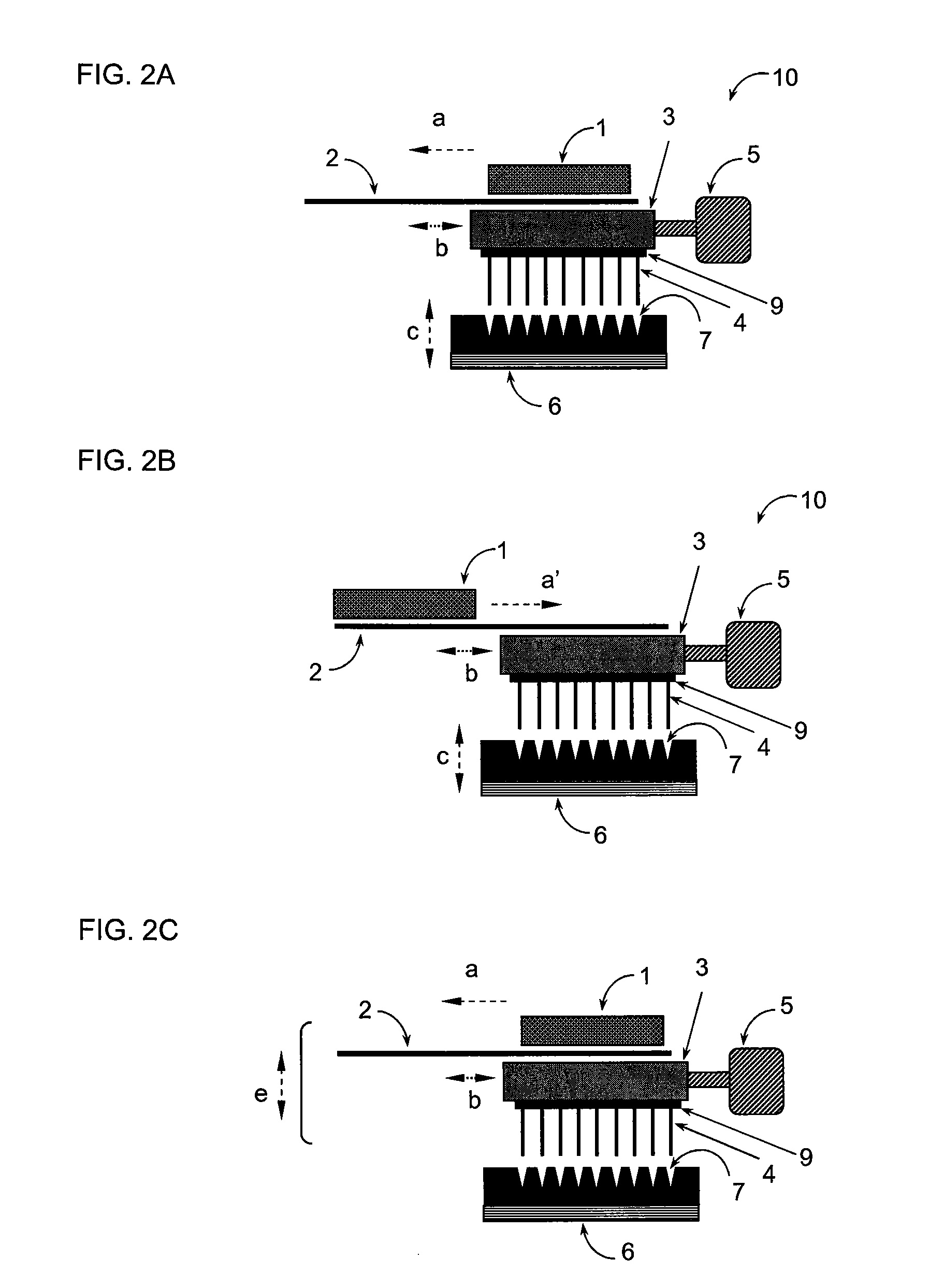

A device (10) is provided for separating magnetic or magnetizable particles from a liquid by using a magnetic field. The device includes a head piece (3) with one or more magnetizable bars (4) which is / are permanently or detachably connected with the head piece (3), as well as one or more permanent magnets (1) whose relative position with respect to the head piece can be changed by a predeterminable movement of the magnet(s) or / and by a predeterminable movement of the head piece.

Owner:CHEMAGEN BIOPOLYMER TECH AKTIENGES

Apparatus and methods for magnetic separation

InactiveUS7056657B2Easy to separateHigh gradientMicrobiological testing/measurementHigh gradient magnetic separatorsSprayerMagnetic poles

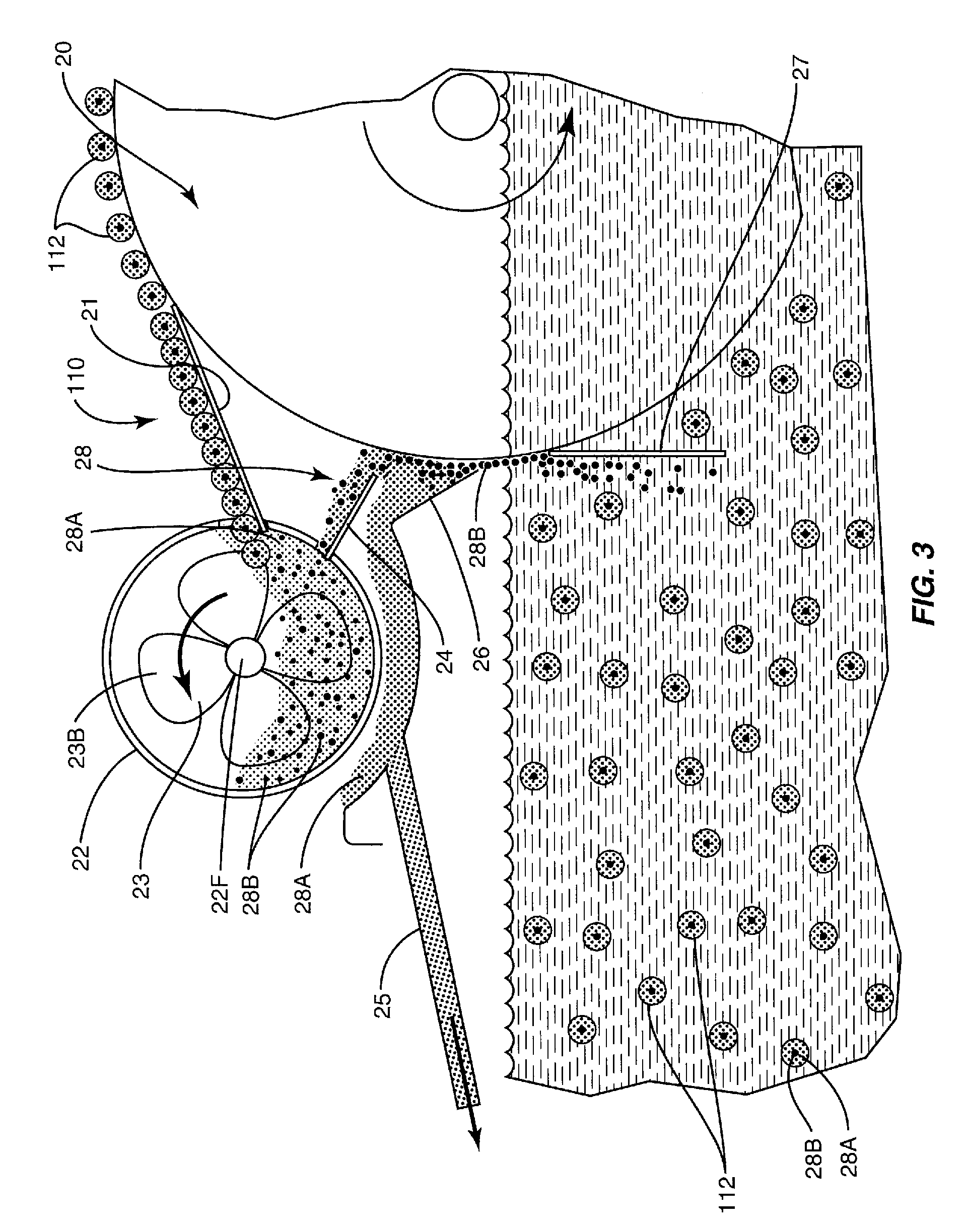

Separation apparatus and method for separating magnetic and / or magnetically-labeled particles from a test medium.Test medium within a reaction chamber is caused to flow past a collecting surface, and a high-gradient magnetic field is applied to the surface to capture magnetically responsive particles in the test medium. The particles are deflected toward the collection surface by baffles, a spinner, or a sprayer, or are funneled past the surface by a plunger operable to be displaced into close proximity to the surface to provide a narrow flow path for the particle-laden test medium. The particles normally suspended in the medium are separated out of suspension by adhesion to the collection surface. The particles may be resuspended by removal of the surface from the high-gradient field, or removal of the high-gradient field from the surface. The collection surface is a thin-walled non-magnetic material having a plurality of magnetic pole faces positioned therearound.

Owner:MENARINI SILICON BIOSYSTEMS SPA

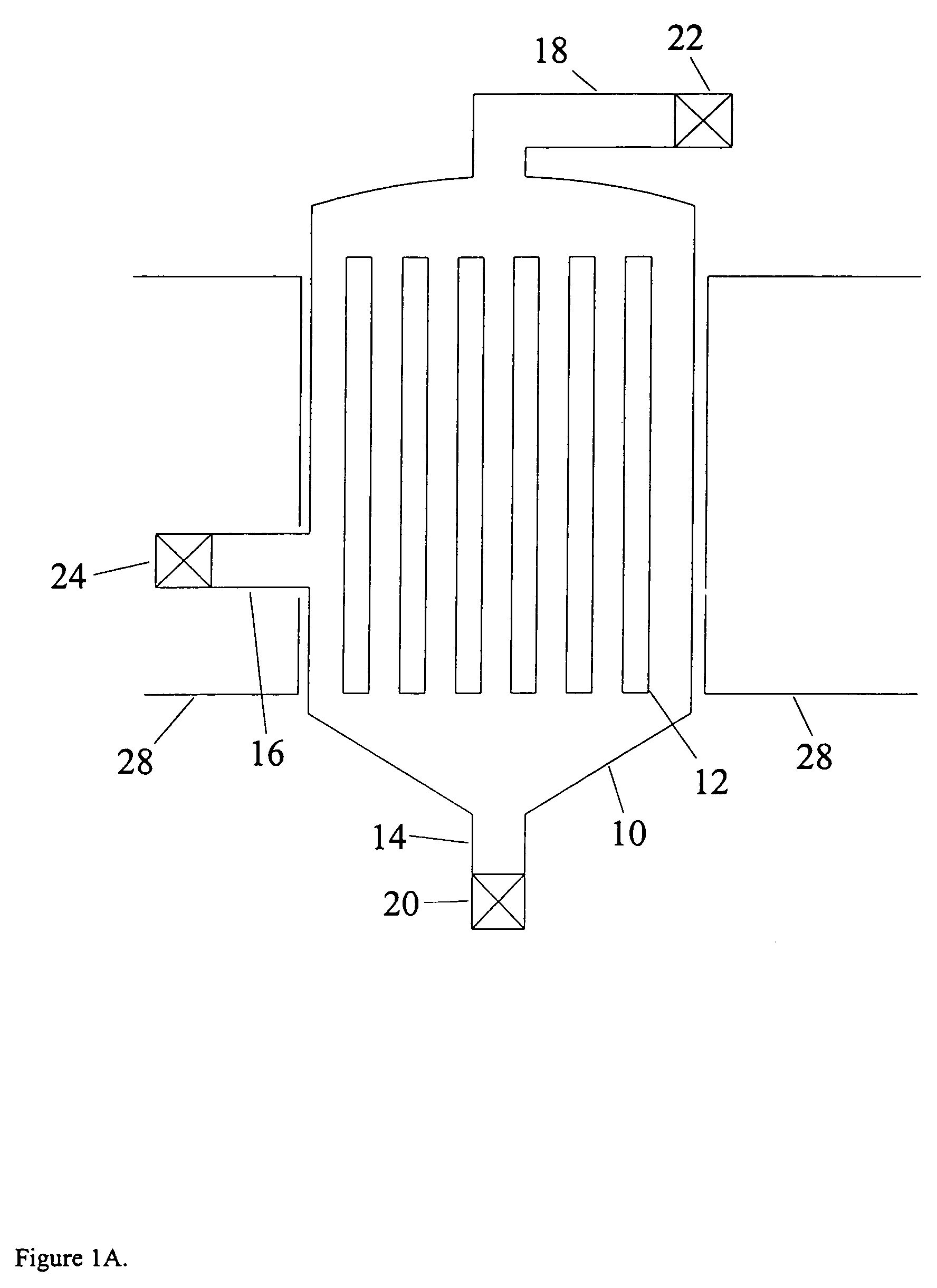

Continuous magnetic seperator and process

InactiveUS20050035030A1High gradient magnetic separatorsFiltration separationMagnetic separatorSlurry

A continuous magnetic separator and process for separating a slurry comprising magnetic particles into a clarified stream and a thickened stream. The separator has a container with a slurry inlet, an overflow outlet for the discharge of the clarified slurry stream, and an underflow outlet for the discharge of a thickened slurry stream. Magnetic particles in the slurry are attracted to, and slide down, magnetic rods within the container. The slurry is thus separated into magnetic concentrate and clarified slurry. Flow control means can be used to control the ratio of the rate of magnetic concentrate to the rate of clarified slurry. Feed control means can be used to control the rate of slurry feed to the slurry inlet.

Owner:RES USA LLC

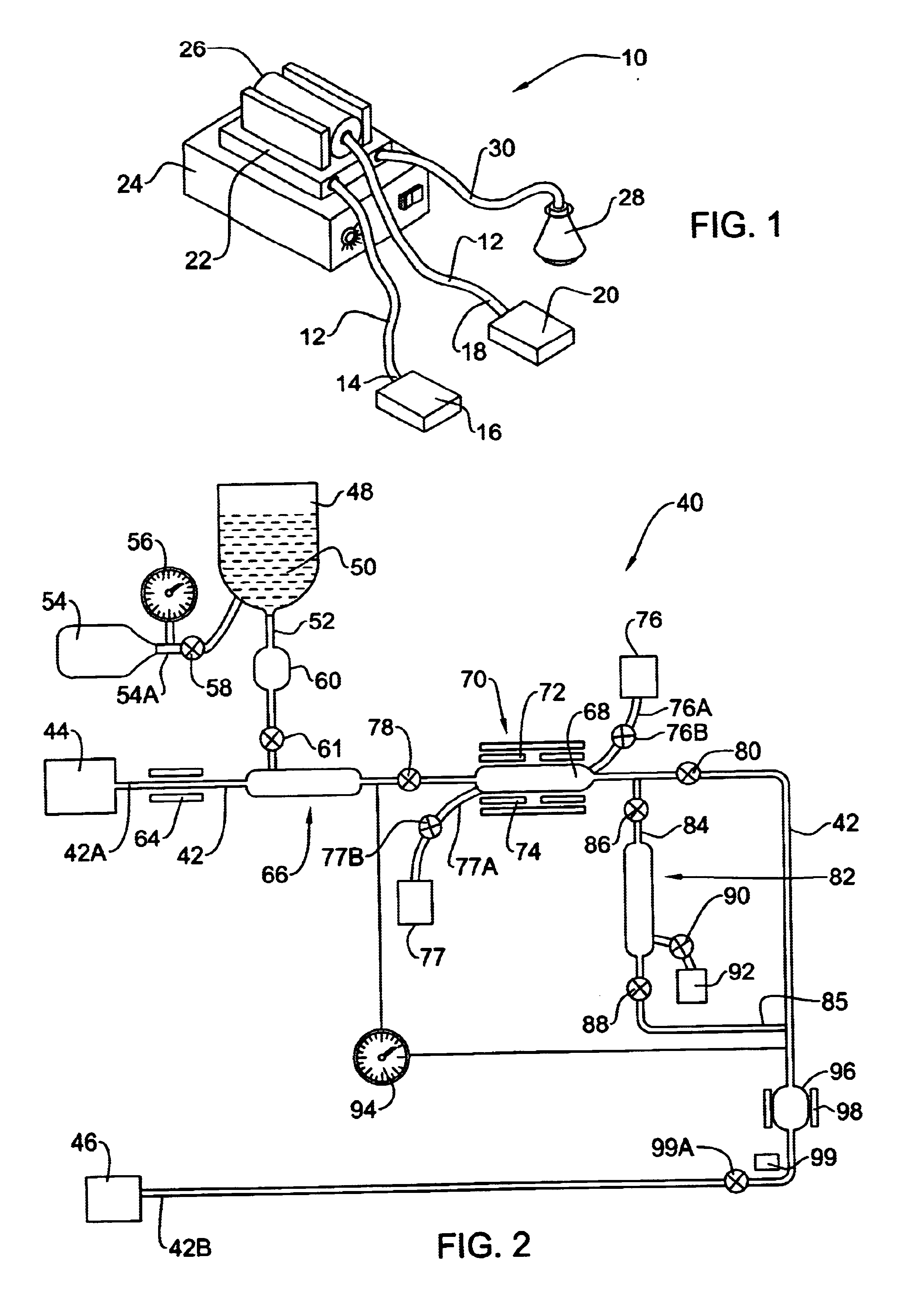

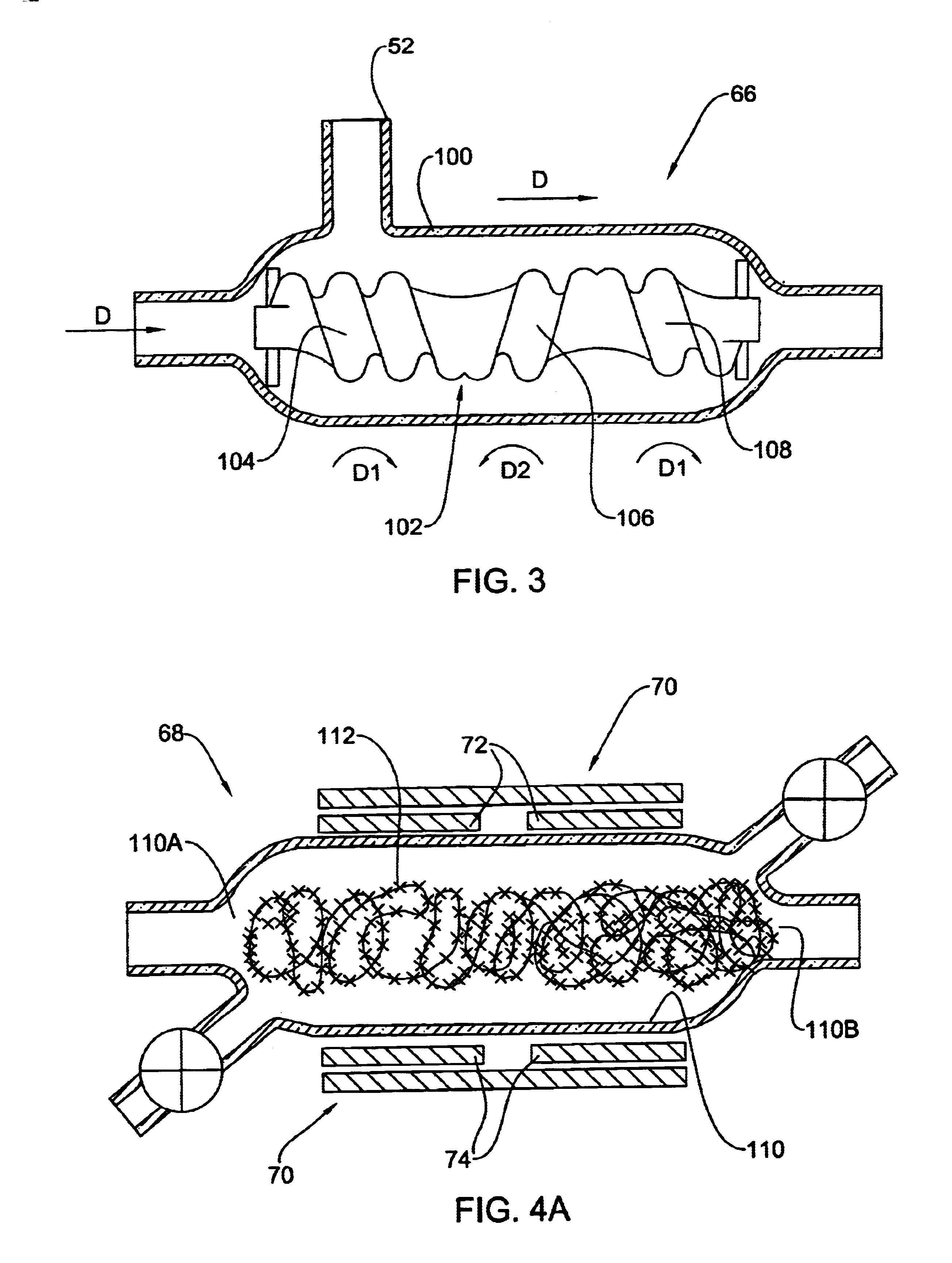

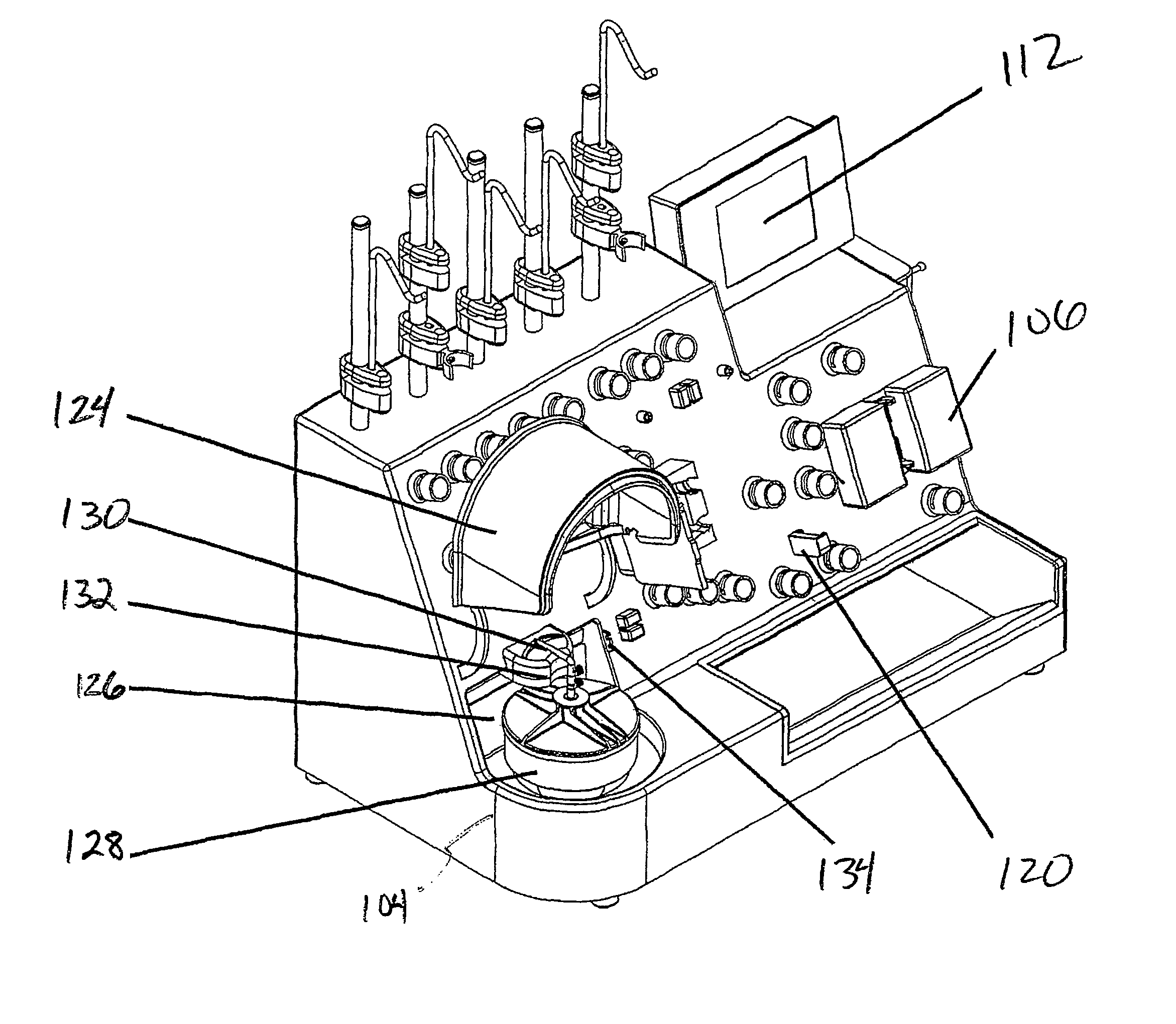

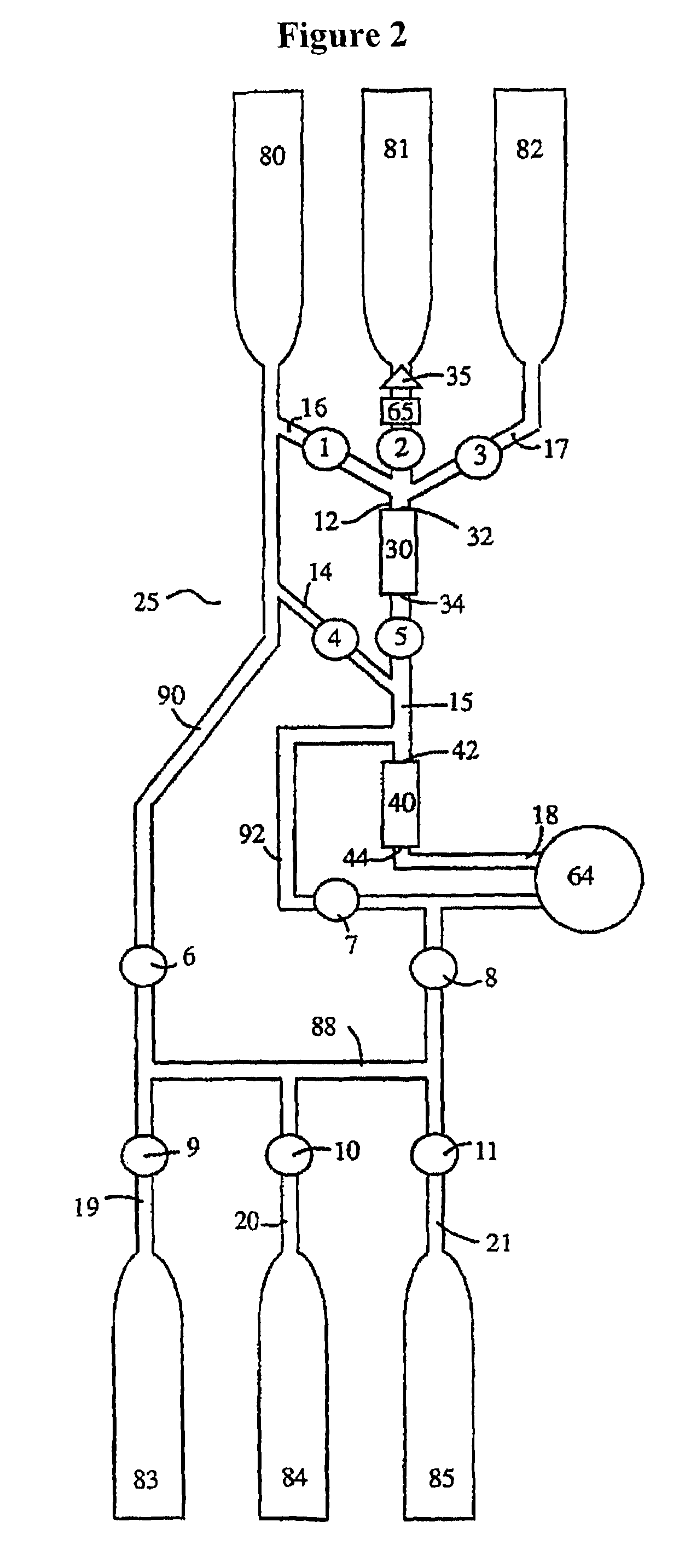

Sample processing system and methods

ActiveUS8727132B2High magnetic separationImprove efficiencyOther blood circulation devicesElectrostatic separationEngineeringCentrifugal force

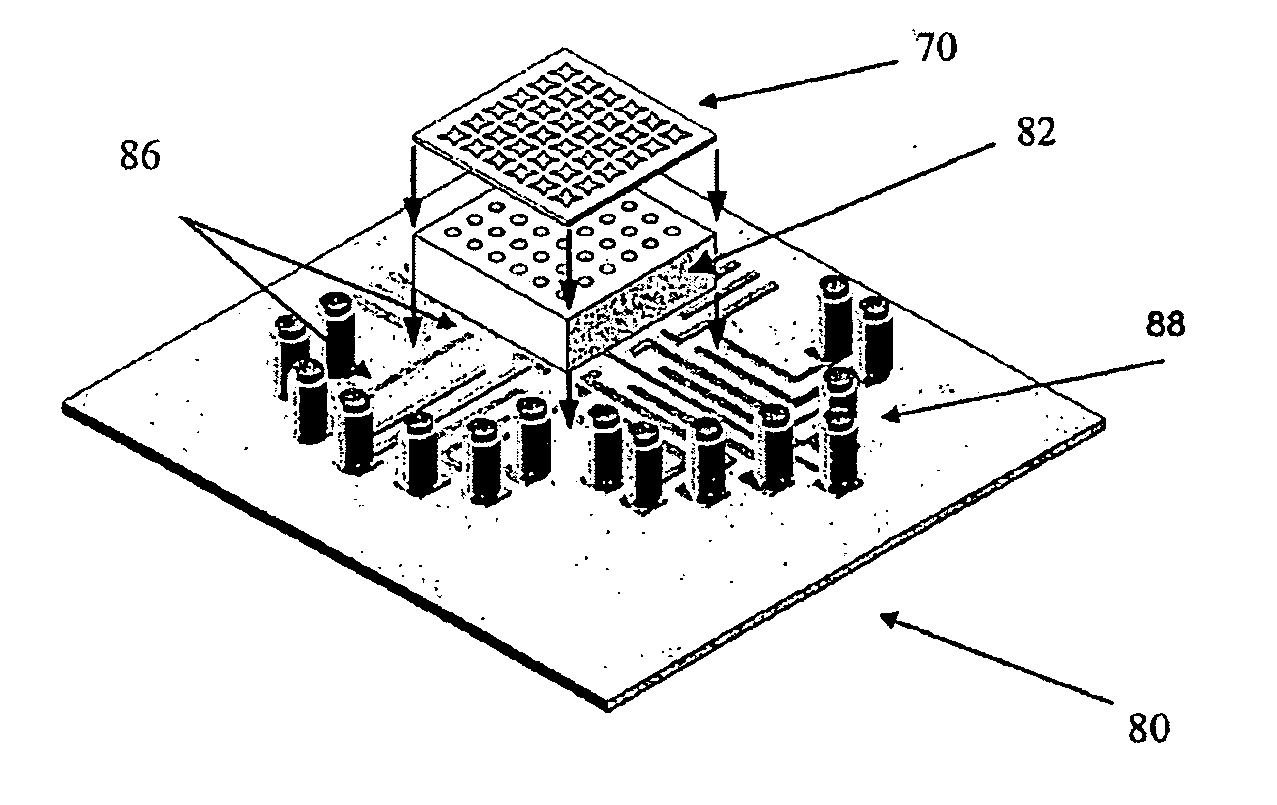

The invention relates to a system, comprising: a) a sample processing unit, comprising an input port and an output port coupled to a rotating container having at least one sample chamber, the sample processing unit configured provide a first processing step to a sample or to rotate the container so as to apply a centrifugal force to a sample deposited in the chamber and separate at least a first component and a second component of the deposited sample; and b) a sample separation unit coupled to the output port of the sample processing unit, the cell separation unit comprising separation column holder (42), a pump (64) and a plurality of valves (1-11) configured to at least partially control fluid flow through a fluid circuitry and a separation column (40) positioned in the holder, the separation column configured to separate labeled and unlabeled components of sample flowed through the column.

Owner:MILTENYI BIOTEC B V & CO KG

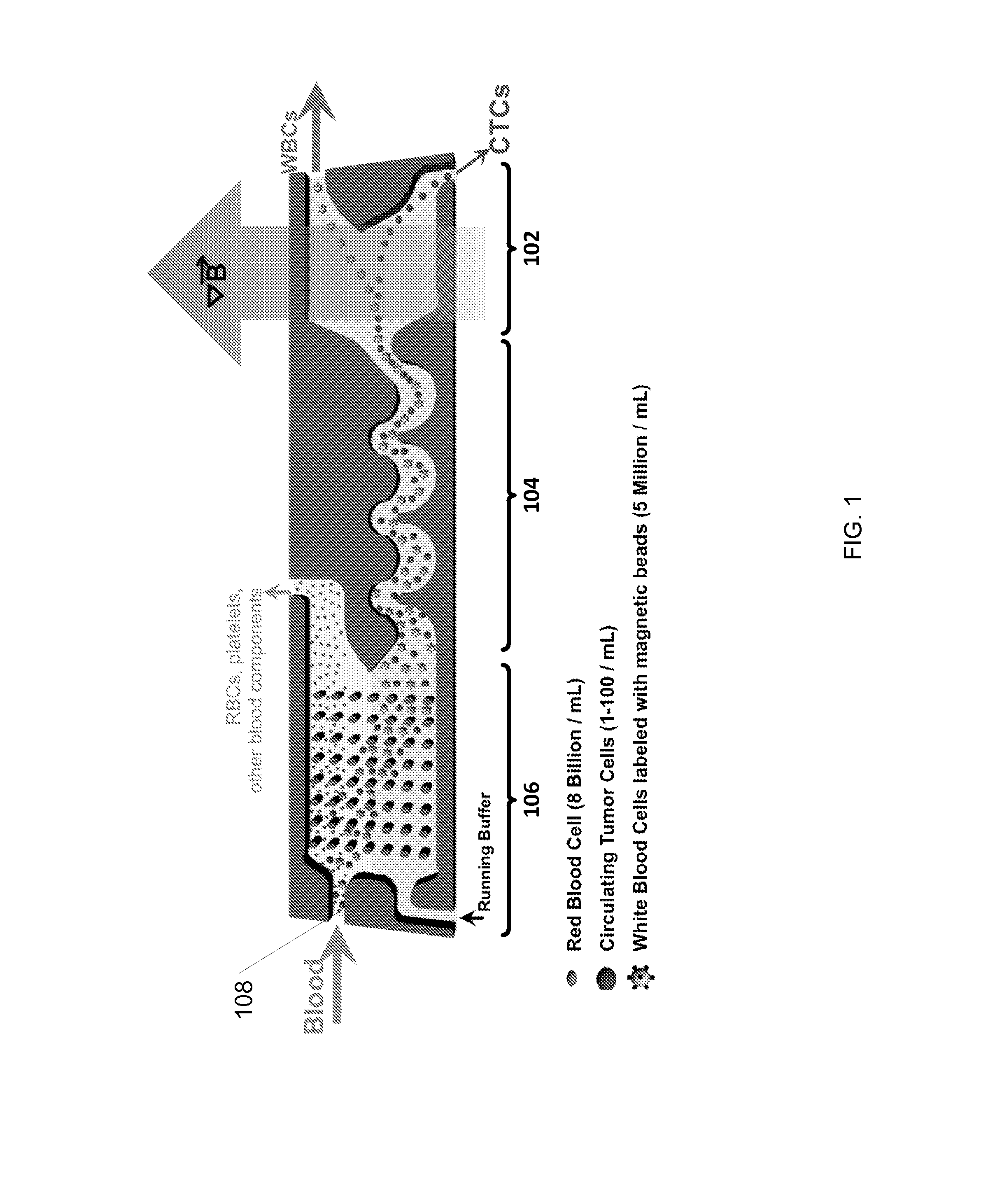

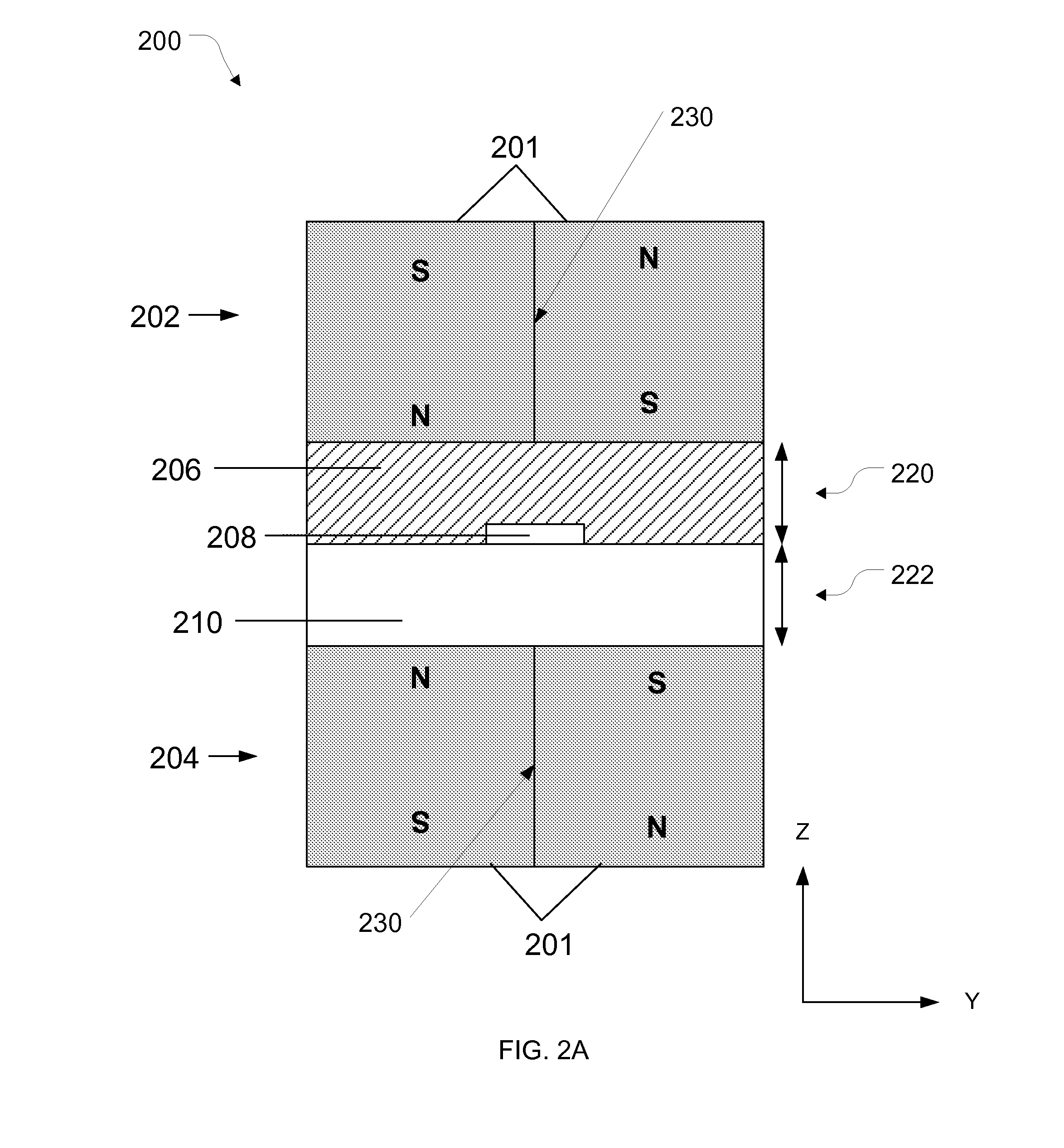

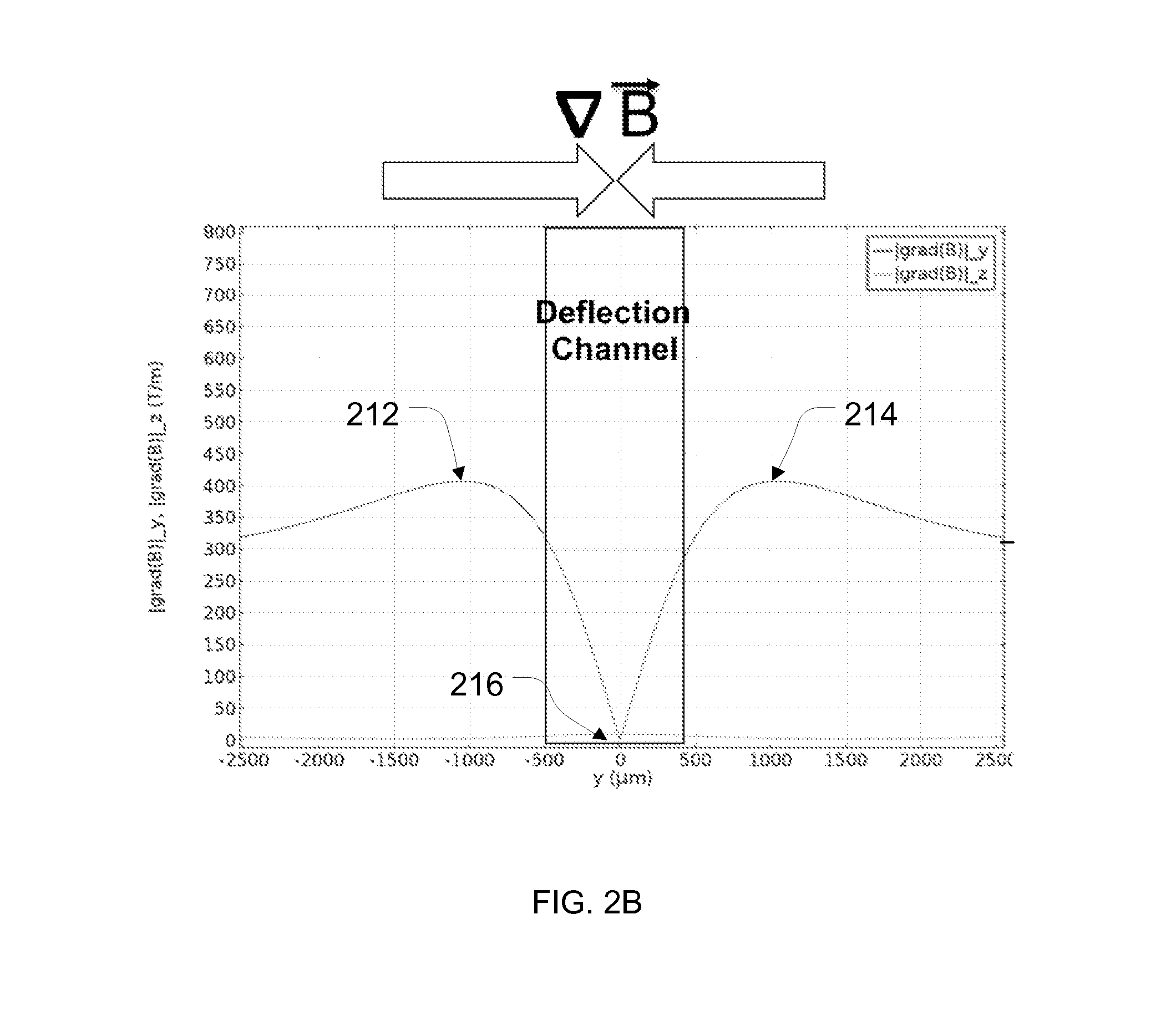

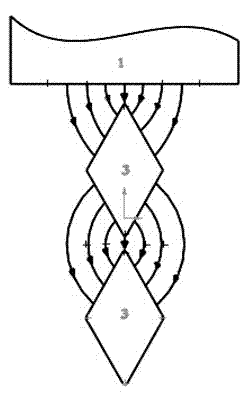

Microfluidic sorting using high gradient magnetic fields

ActiveUS20160244714A1Inhibit aggregationReduce and eliminate formation of plaqueBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic polesMicrofluidic channel

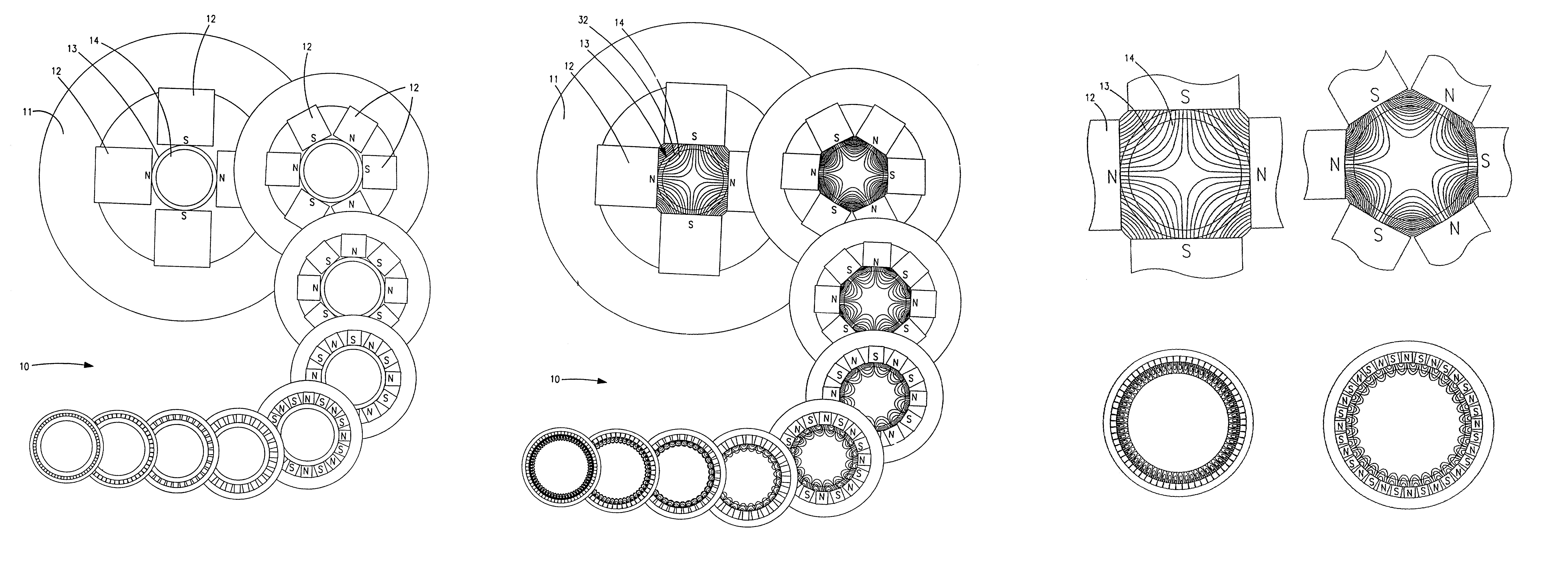

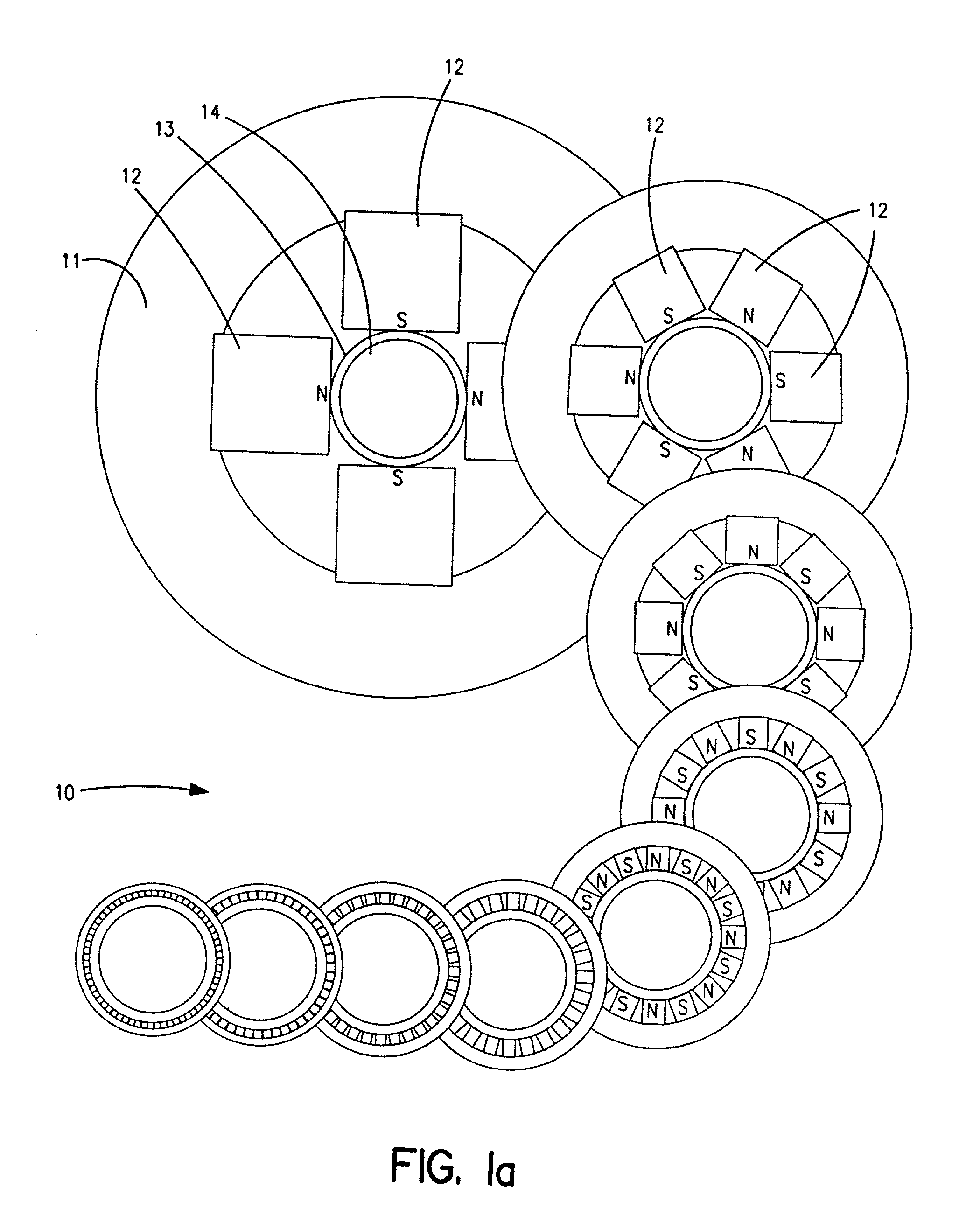

Microfluidic devices are described that include a microfluidic channel, a first array of one or more magnets above the microfluidic channel, each magnet in the first array having a magnetic pole orientation opposite to a magnetic pole orientation of an adjacent magnet in the first array, and a second array of one or more magnets beneath the microfluidic channel, each magnet in the second array having a magnetic pole orientation opposite to a magnetic pole orientation of an adjacent magnet in the second array. The first array is aligned with respect to the second array such that magnetic fields emitted by the first array and second array generate a magnetic flux gradient profile extending through the channel. An absolute value of the profile includes a first maximum and a second maximum that bound a local minimum. The local minimum is located within the microfluidic channel or less than 5 mm away from a wall of the microfluidic channel. Methods of using the new devices are also described.

Owner:THE GENERAL HOSPITAL CORP

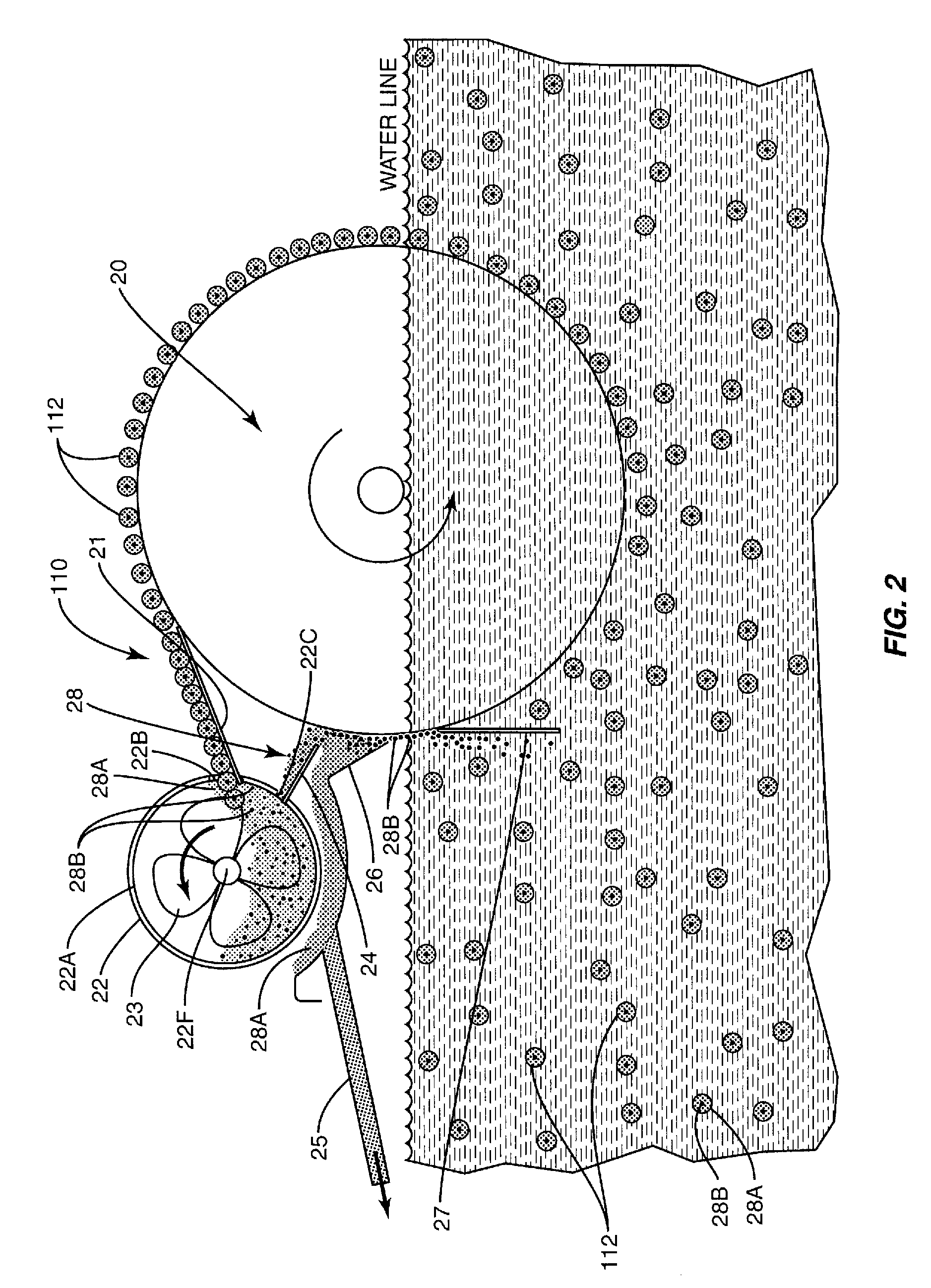

Device for Removing Magnetic Floc from a Magnetic Collector in a Water Treatment System

InactiveUS20080073280A1Water treatment compoundsHigh gradient magnetic separatorsMagnetic tension forceWater treatment system

A water treatment system that utilizes magnetic seeding and magnetic separation to treat water. A magnetic collector is provided for collecting magnetic floc from the water being treated. A floc removal device in the form of a scraper is magnetically held adjacent to or in contact with the magnetic collector for scraping magnetic floc from the magnetic collector. Also disclosed is a disk type magnetic collector that includes a plurality of spaced apart magnetic disks supported on a shaft. A plurality of hook shaped floc removal devices are supported on the shaft with each hook shaped floc removal device being disposed between two magnetic disks or at least adjacent one magnetic disk. The hook type removal devices are spaced so as to engage an adjacent surface of a rotating magnetic disk. As the disk type magnetic collector is rotated, the hook type removal devices engage magnetic floc collected on the surfaces of the magnetic disks and scrape the magnetic floc from the disks.

Owner:CORT STEVEN L

Magnetic bead-based arrays

InactiveUS20080187472A1Easy to separateEasy to replaceSequential/parallel process reactionsFlow mixersFluorescenceMagnetic bead

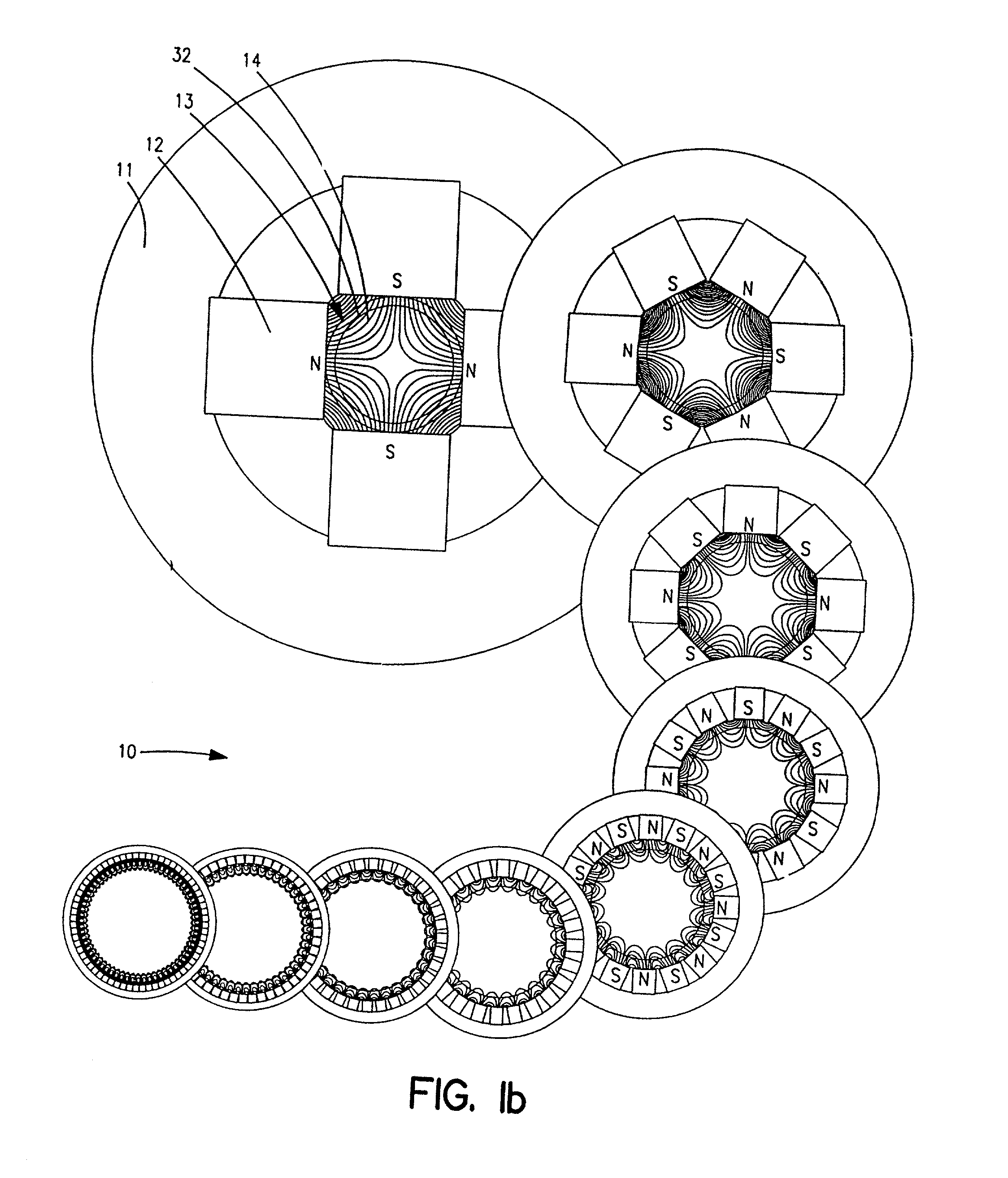

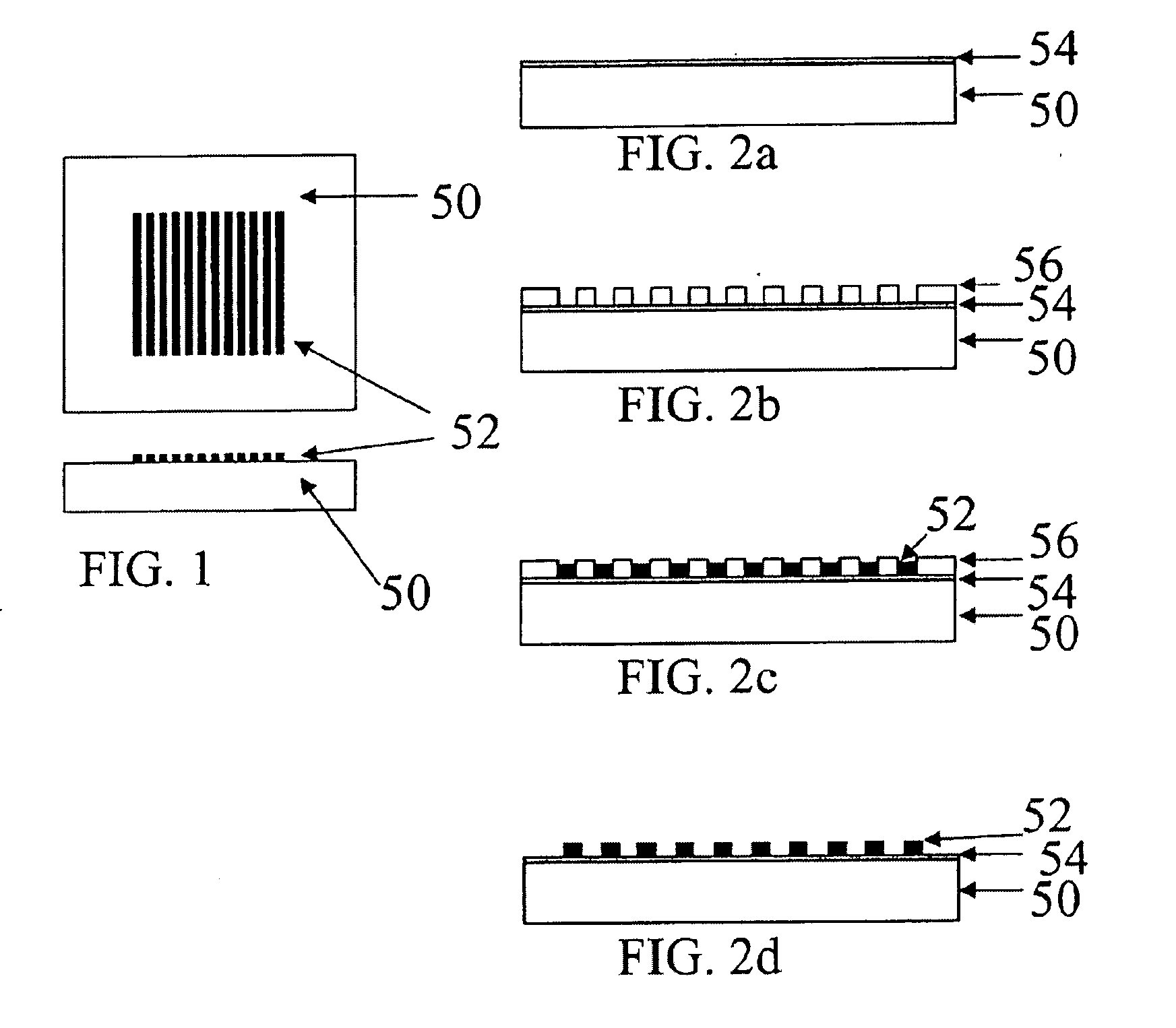

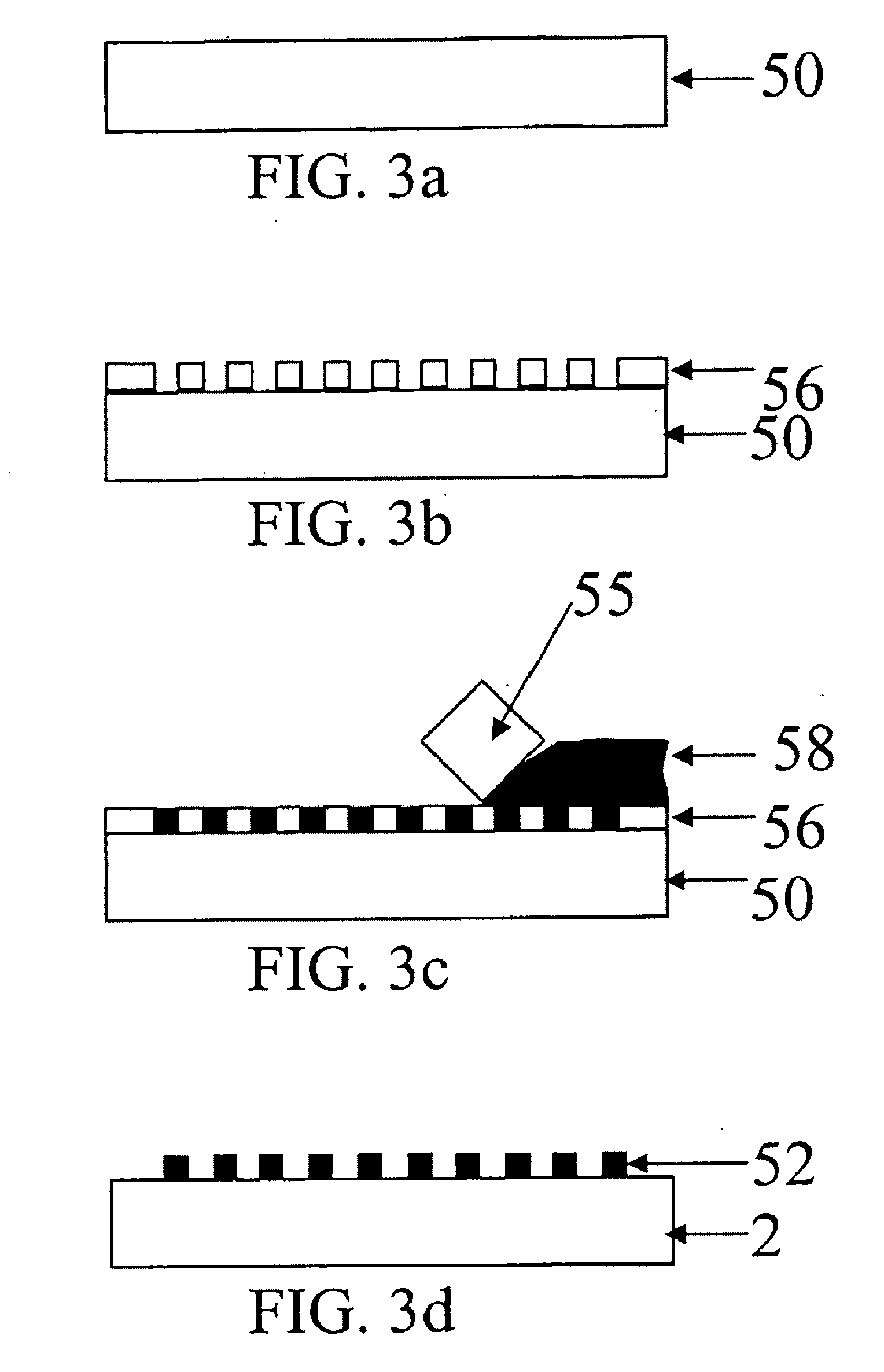

The present invention relates to magnetic particle separators using micromachined magnetic arrays and more particularly, to magnetic particle separators or manipulators using controlled magnetization on micromachined magnetic arrays for the separation of cells and other biological materials. The present invention also pertains to using such devices for the separation and analysis of biological materials for immunoassays, DNA sequencing, protein analysis, and biochemical detection applications. The present invention can also be viewed as a novel method for fabricating fully integrated permanent magnet components within any microelectromechanical system (“MEMS”) structures. The present invention also provides a magnetic particle separation and manipulation system for rapid separation and accurate manipulation of magnetic particles in two-dimensional electromagnetic arrays, which utilize high throughput biological analyses. A disposable cartridge can be produced in low cost using a low cost substrate such as plastic or other polymer, glass, or metal. Magnetic flux is generated by conventional or micromachined electromagnets a platform system consisting of magnetic flux sources, magnetic flux guidance, and a microprocessor control interface. By controlling direction of electric currents into inductors on the platform system, arbitrary magnetic poles can be generated on Permalloy structures of the cartridge to separate and manipulate magnetic particles. The magnetic particle separator and manipulator in the present invention can be easily combined with automated detection systems such as a fluorescent monitoring system.

Owner:AHN CHONG H +2

Beneficiation of rare earth elements bearing ancylite

ActiveUS20170028410A1Small sizeHigh gradient magnetic separatorsFlotationStrontium carbonateRare-earth element

Disclosed herein are methods and systems for recovery of ancylite, a rare earth mineral comprising strontium carbonate, from rare earth ore. In many embodiments, the disclosed methods and systems provide for recovery of greater than 50% of the ancylite from an ancylite containing ore. In many embodiments, the ore is subjected to flotation in the presence of an acid, for example a hydroxamic acid, such as octanohydroxamic acid. The ore may also be subjected to magnetic separation, for example wet high intensity magnetic separation.

Owner:COLORADO SCHOOL OF MINES

Method for separating oolitic hematite

InactiveCN101693222AReduce lossesEconomic beneficiation costHigh gradient magnetic separatorsFlotationSulfateReverse flotation

The invention discloses a method for separating oolitic hematite, and the process of the method comprises discarding tailings of ores by intense magnetic separation through stage grinding and stage separation, and de-phosphorizing and increasing iron to the intense magnetic concentrated by reverse flotation. The intense magnetic separation is functioned of concentrating iron minerals and desliming, thereby preventing smile from influencing flotation. The highly-effective regulator is made from sodium carbonate, sodium silicate and sodium hydroxide, the collecting agent is a composite medicine made from hydroximic acid and alkyl sulfate, and the method for separating oolitic hematite is a key technology for the reverse flotation to further upgrade the concentrate of iron ore. The invention has the advantages of simple technological process, low energy consumption, low cost and good product index, and solves the defects in prior art.

Owner:GUIZHOU UNIV

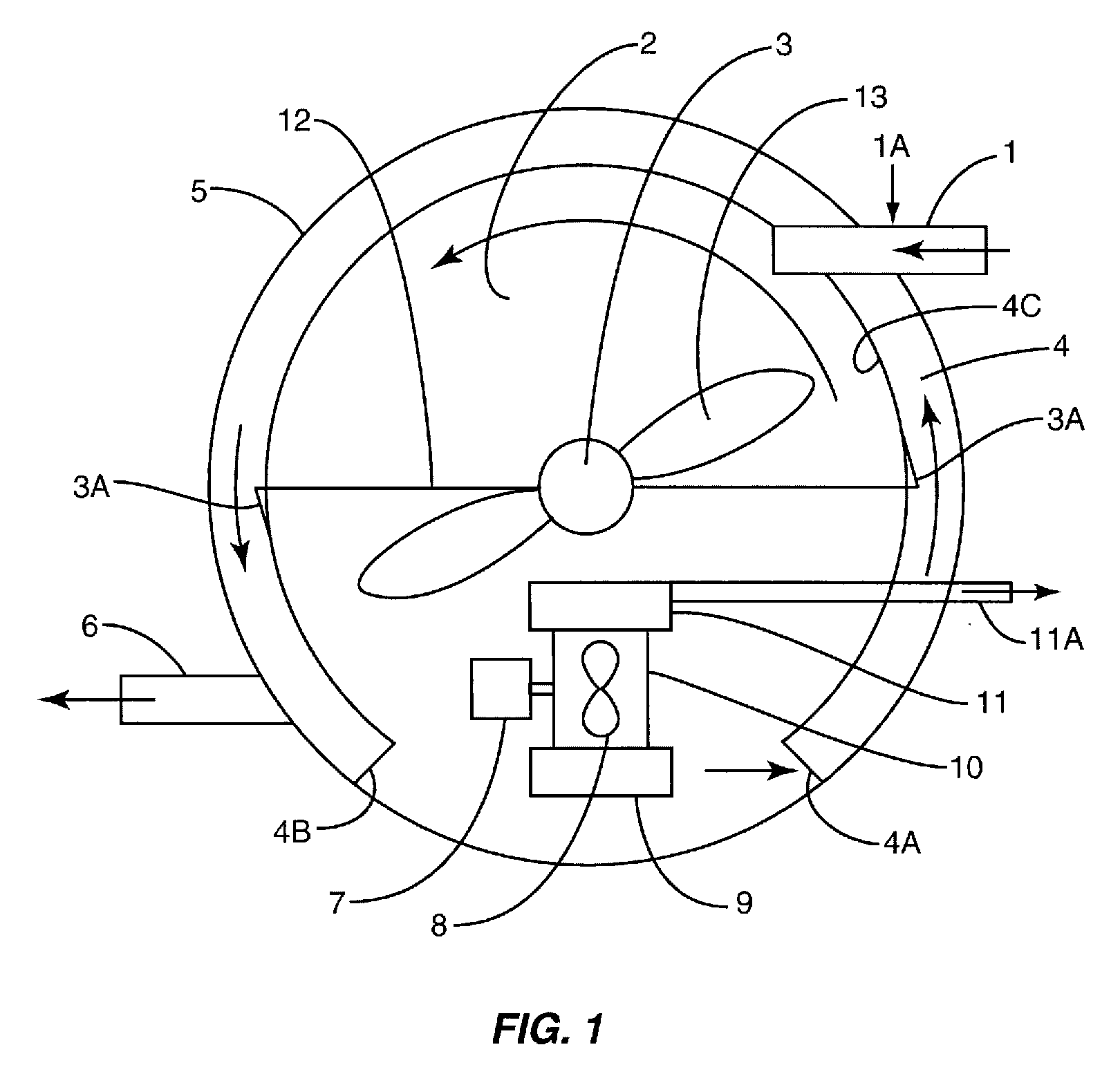

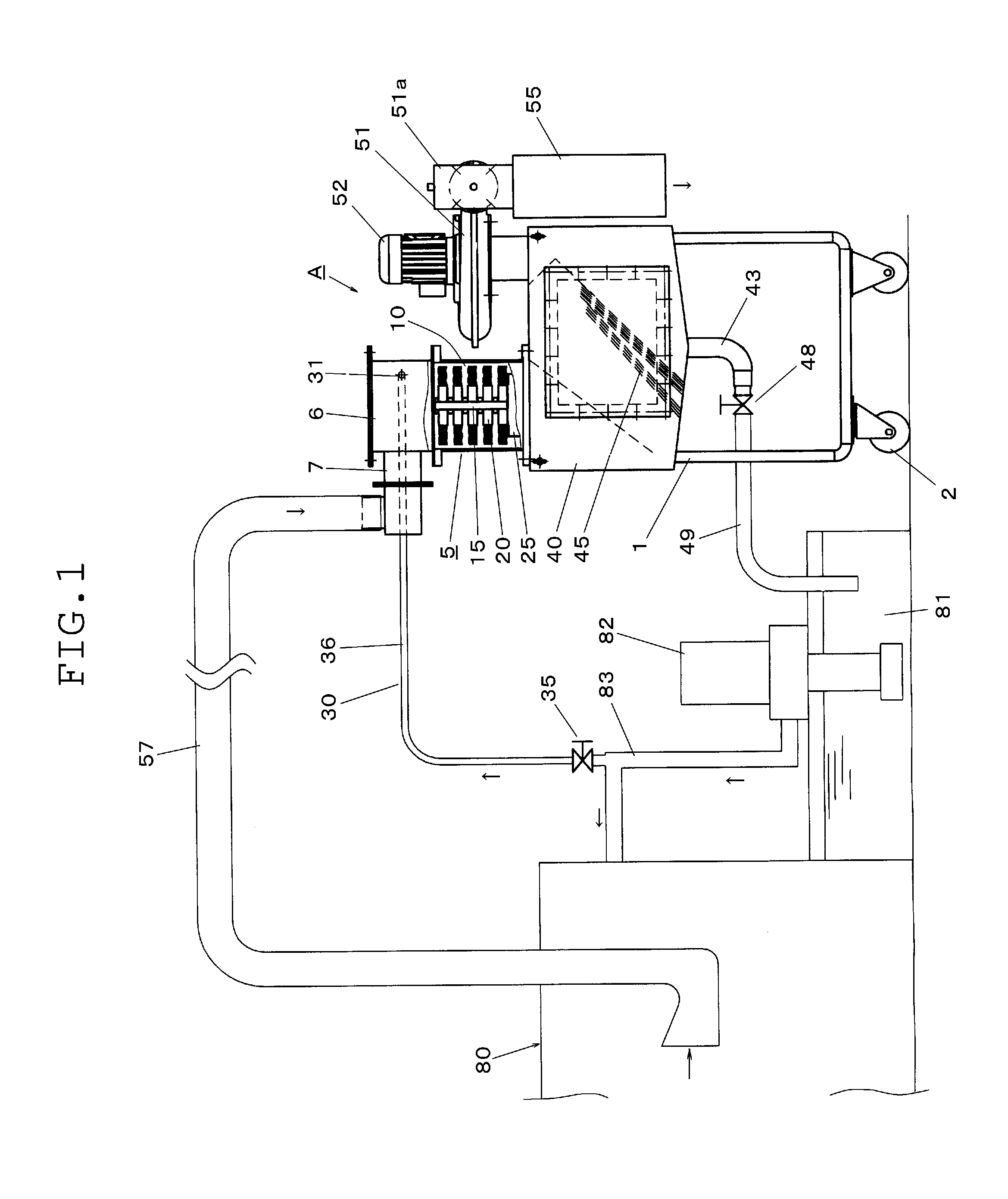

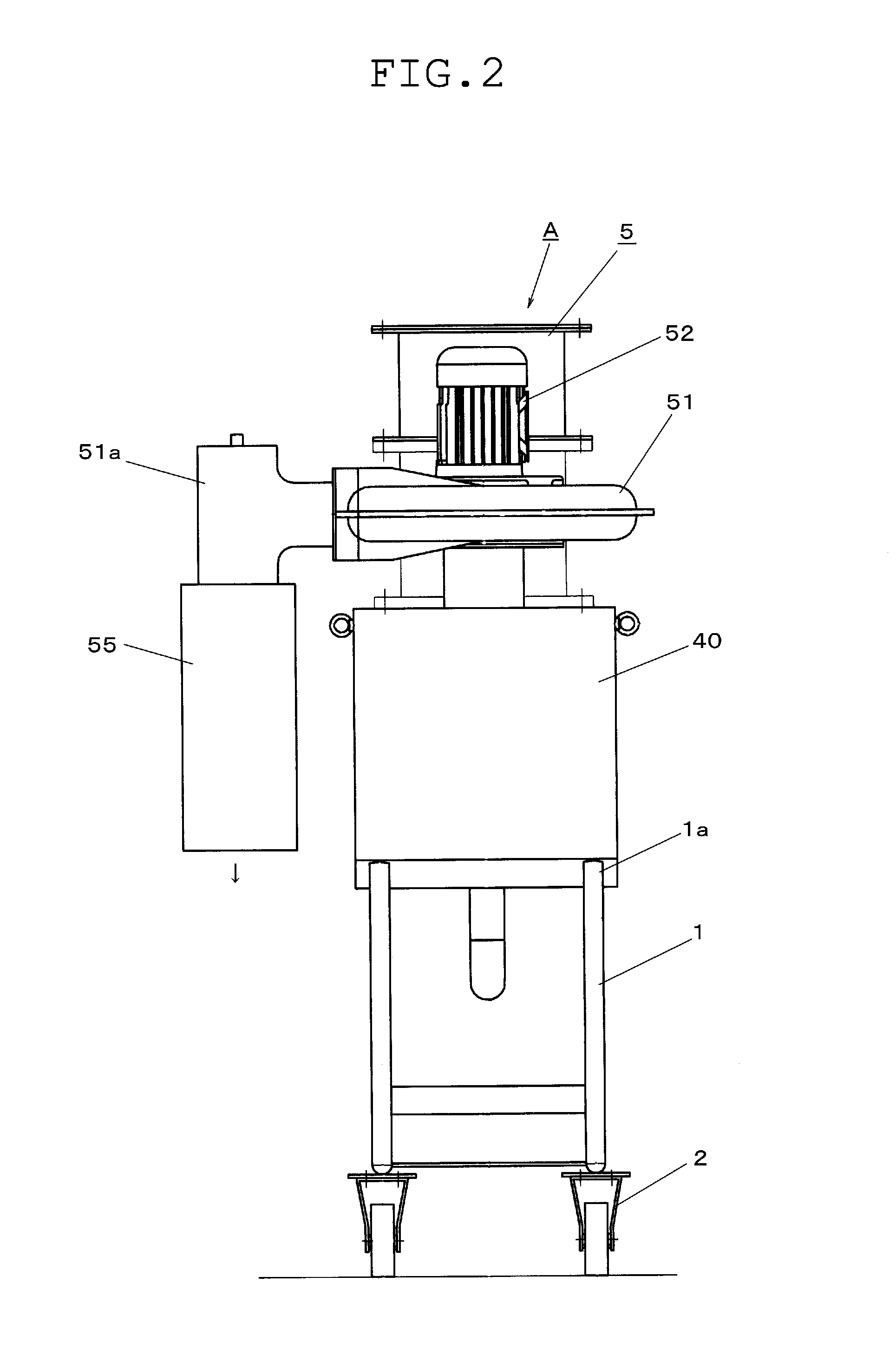

Mist/Dust Collector

ActiveUS20140305304A1Reduce manufacturing costSuitable for collectionCombination devicesHigh gradient magnetic separatorsImpellerCoolant flow

A mist / dust collector includes a tank body, a recovery tank having a demister member, a spraying unit spraying water or coolant fluid from a nozzle, an impeller mounted on a main shaft located in the tank body, so as to be rotatable by air flow, a disc rotary brush and a shaking-off member mounted on the shaft. A suction unit is actuated to draw air containing mist and dust into the tank body interior maintained in a negative pressure state. The impeller is rotated by collision of water or coolant fluid at a predetermined pressure, and the rotary brush and the shaking-off member are rotated simultaneously with the impeller, so that mist and dust are separated from air by a centrifugal action of the rotary brush and the shaking-off member. Mist and dust remaining in the air flowing into the recovery tank are collected by the demister member.

Owner:ANLET CO LTD

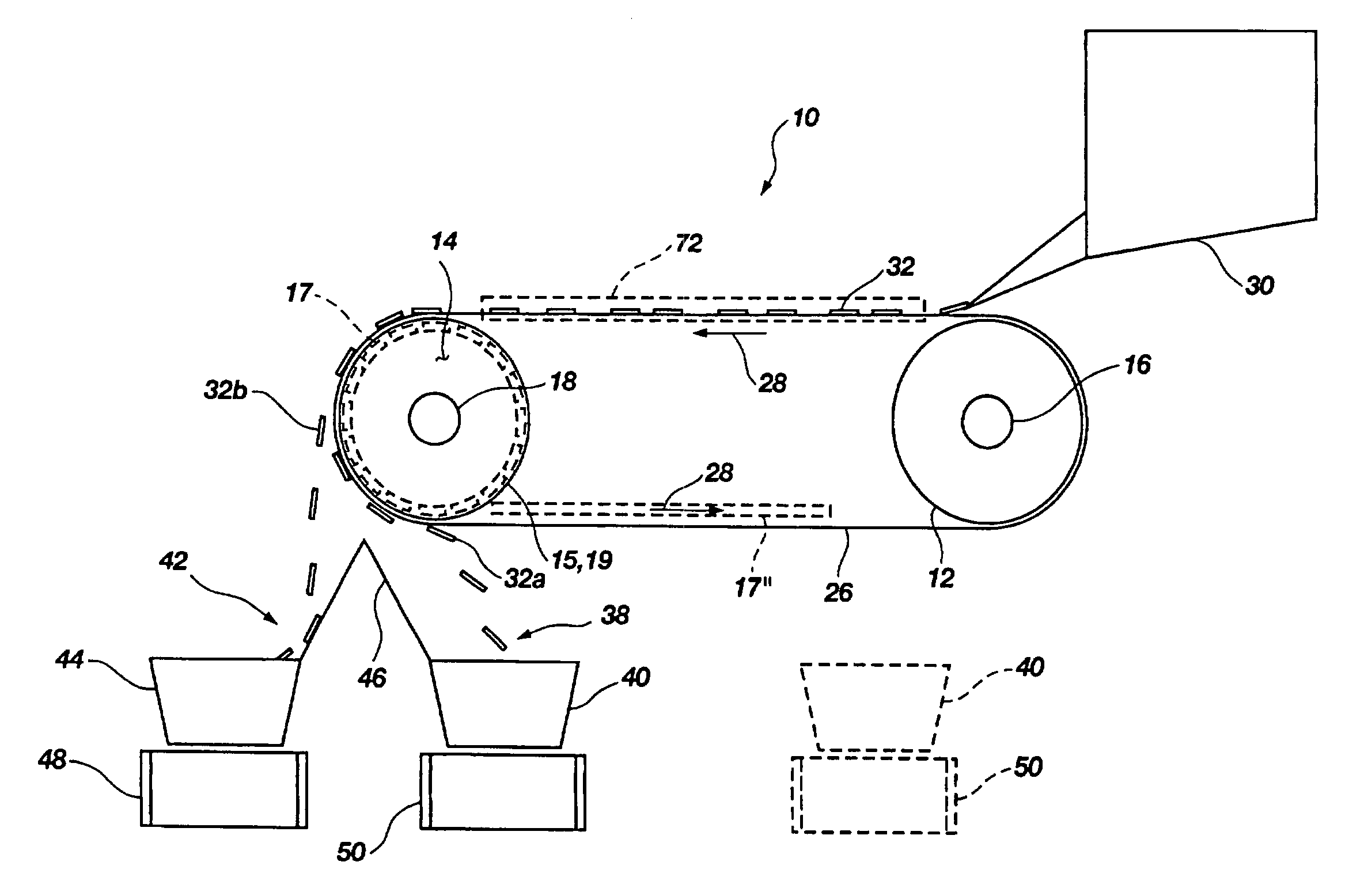

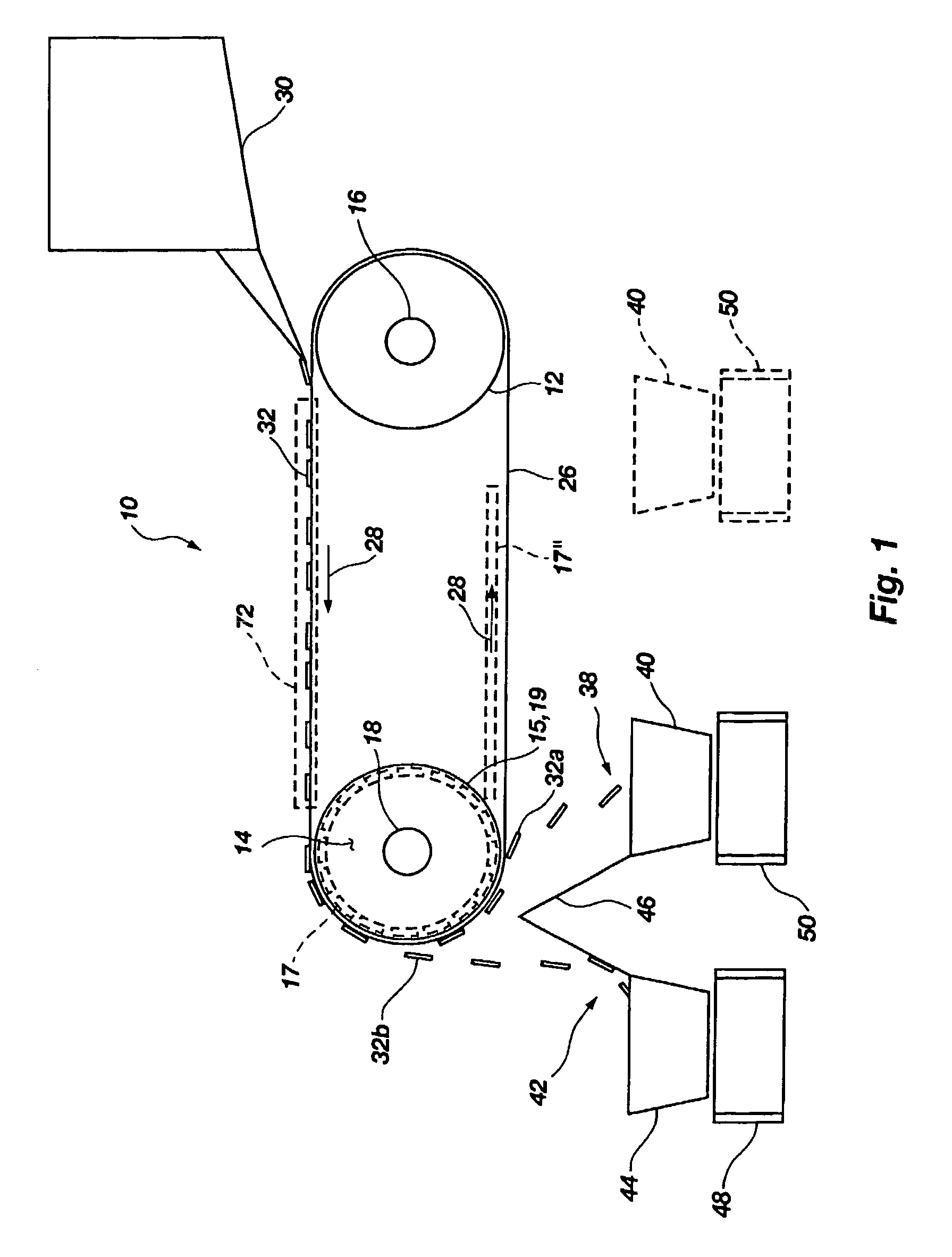

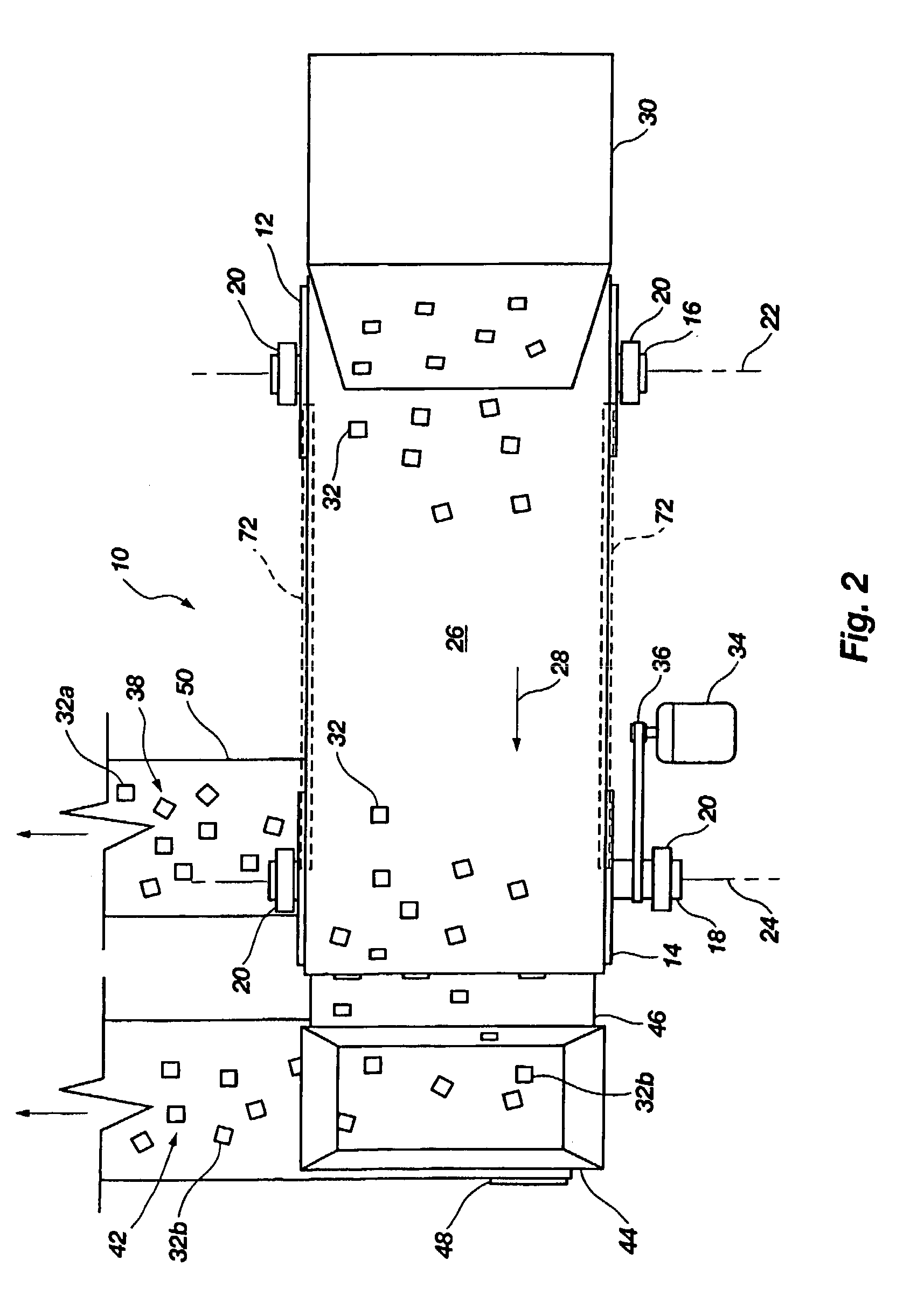

Apparatus for magnetically separating integrated circuit devices

InactiveUS7210581B2Damage impairImpair operationHigh gradient magnetic separatorsElectrical componentsMetallic materialsIc devices

A method and apparatus of separating integrated circuit (IC) devices according to magnetic properties of the devices is disclosed. A plurality of IC devices are subjected to a magnetic field. The IC devices containing only nonferrous material are not responsive to the magnetic field and are thus gathered to a first collection site. The IC devices containing ferrous material adhere to a moving surface proximate the magnetic field and are transported to a second collection site. The sorted devices are then transported to separate locations for further processing. The apparatus used for separating the IC devices may include a conveyor having a magnetic drum and an antistatic belt which travels about the magnetic drum. The conveyor allows nonferrous IC devices to fall off the edge of the magnetic drum into the first collection site while transporting the ferrous IC devices to another location for collection.

Owner:MICRON TECH INC

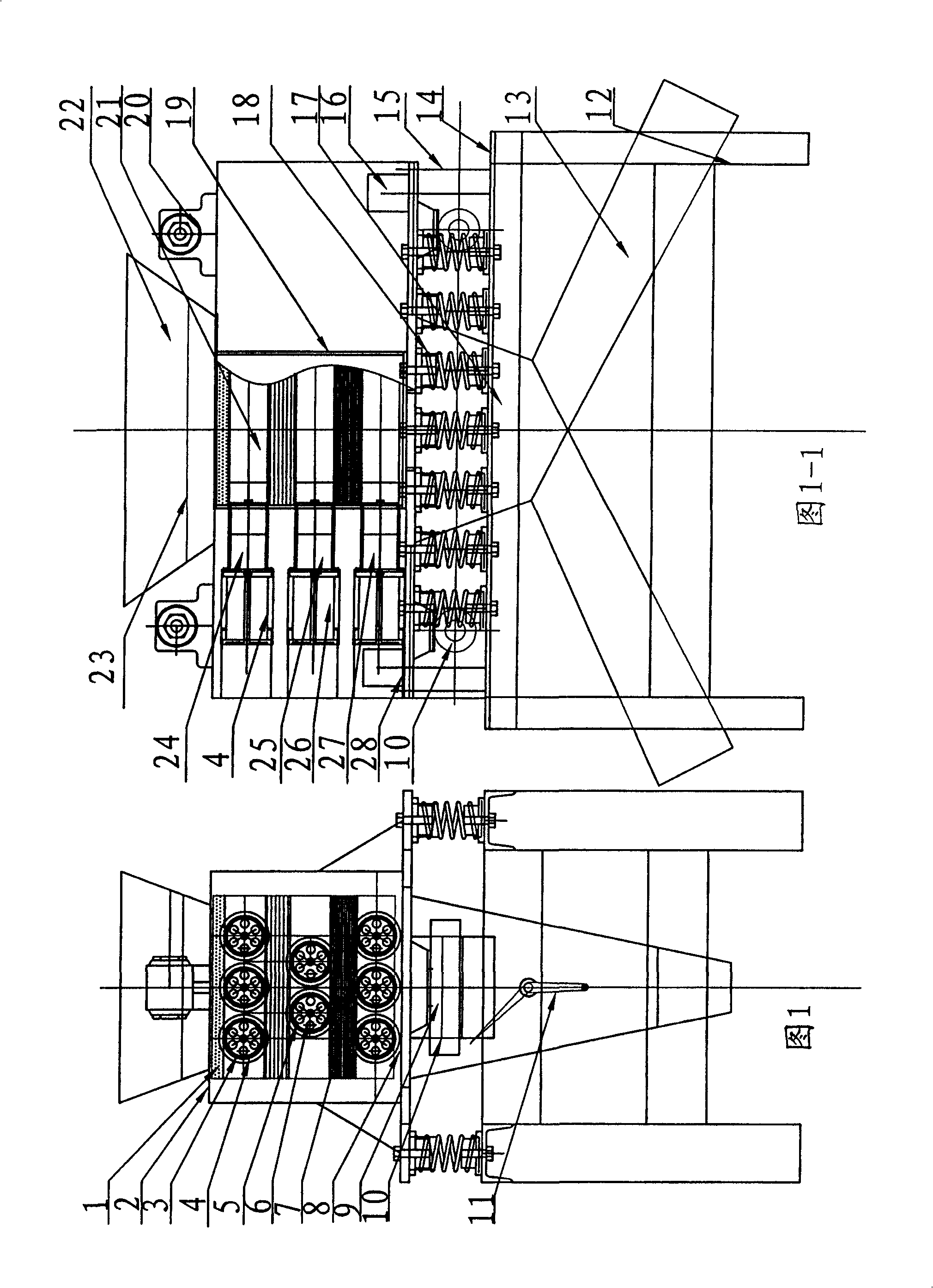

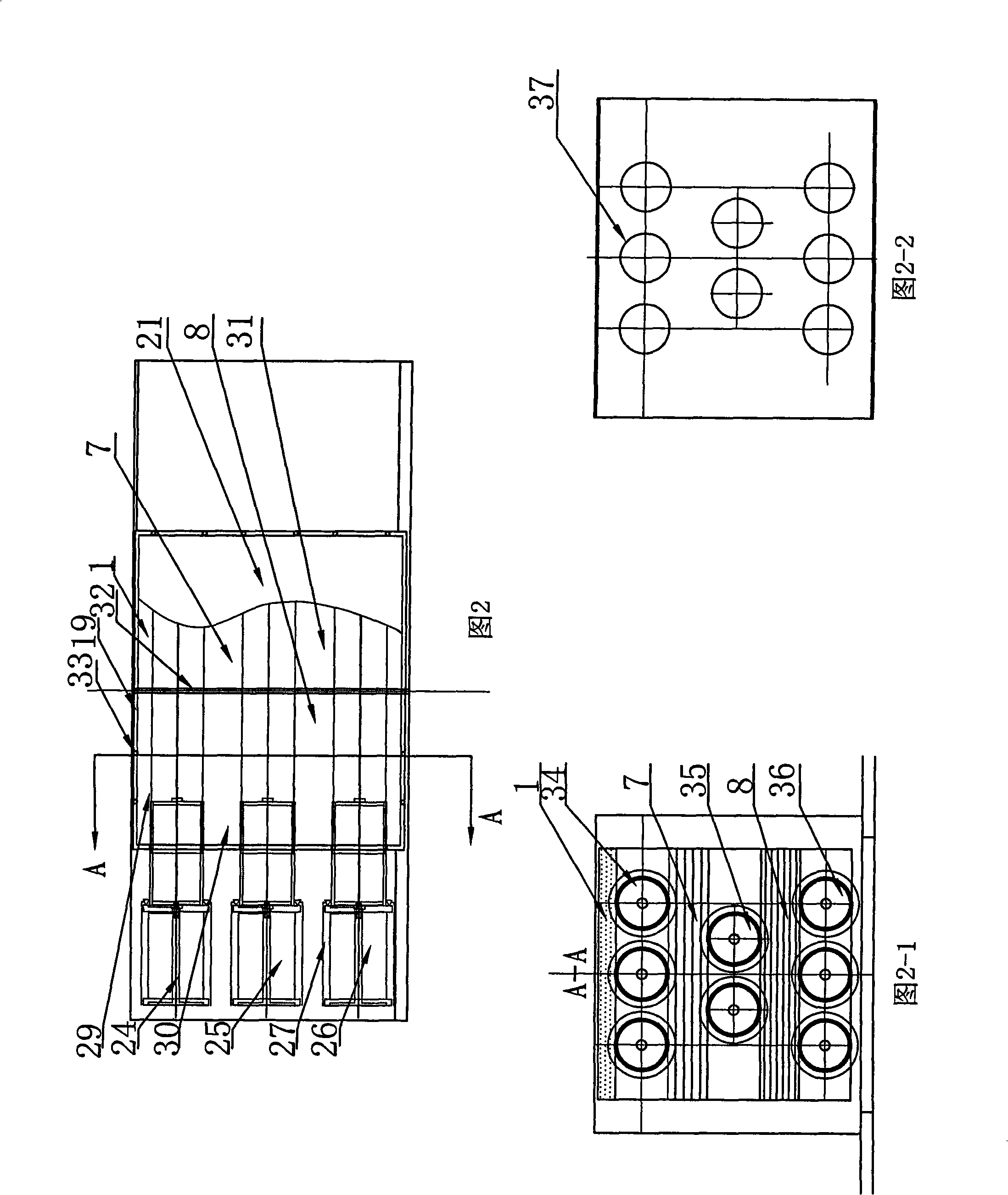

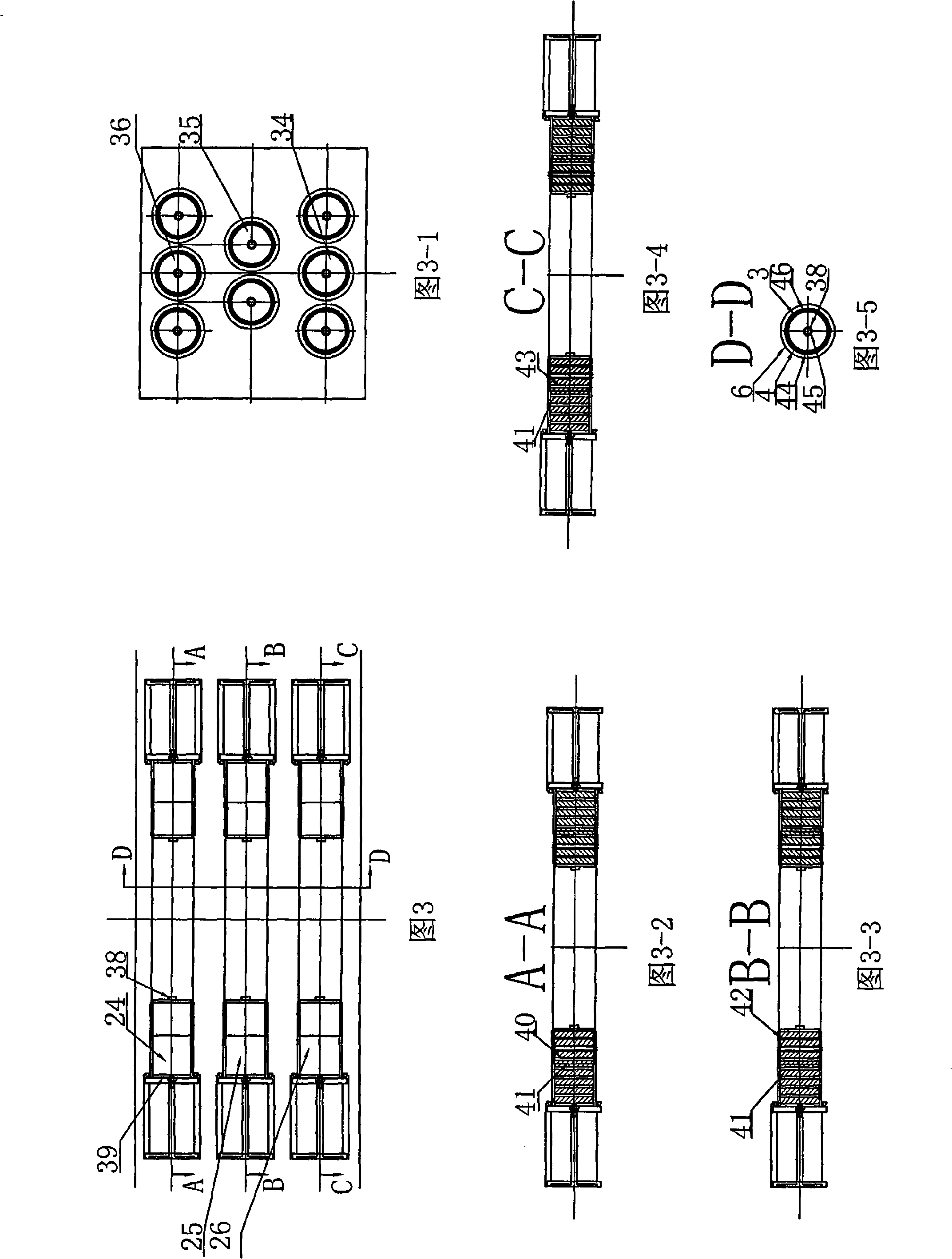

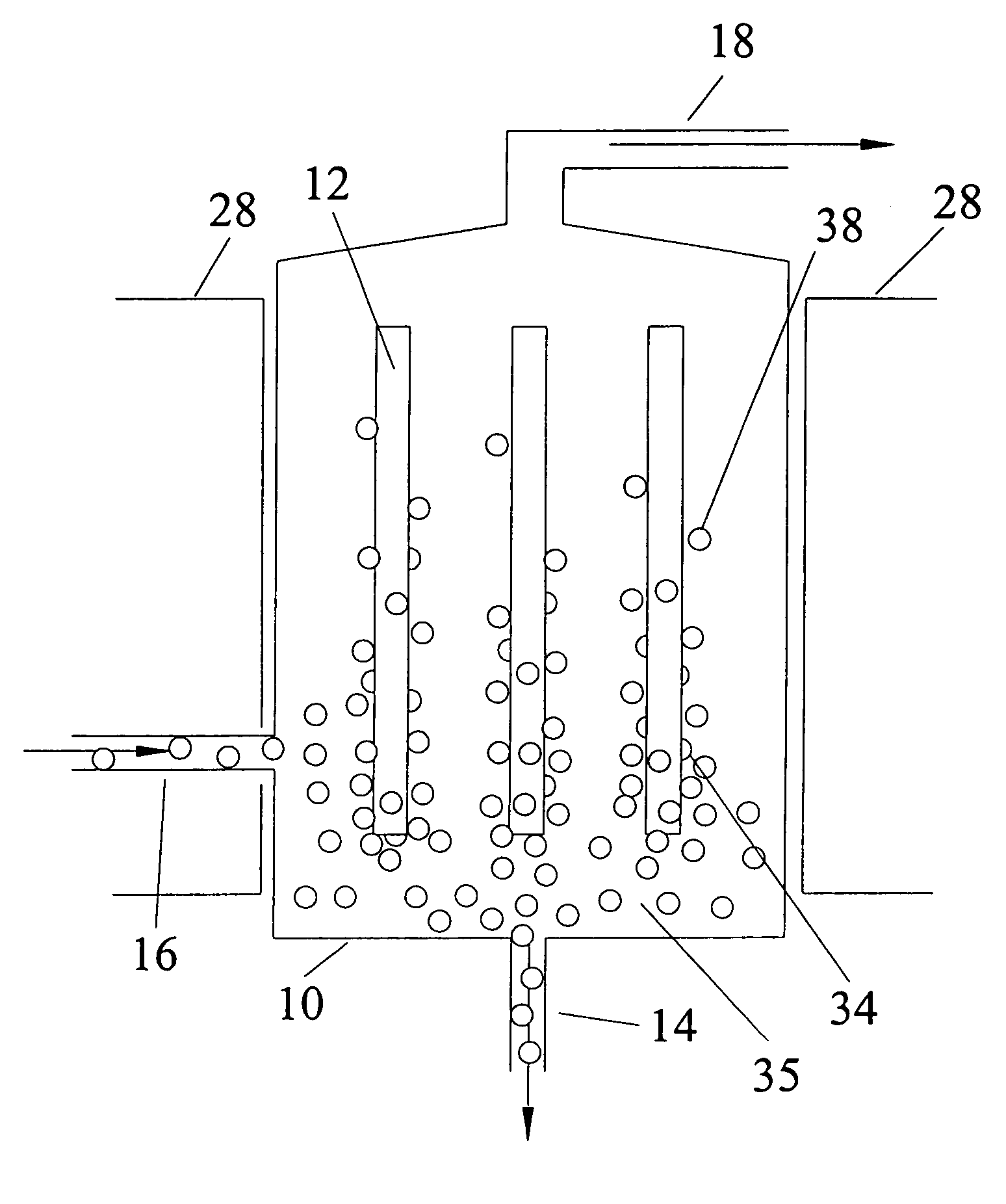

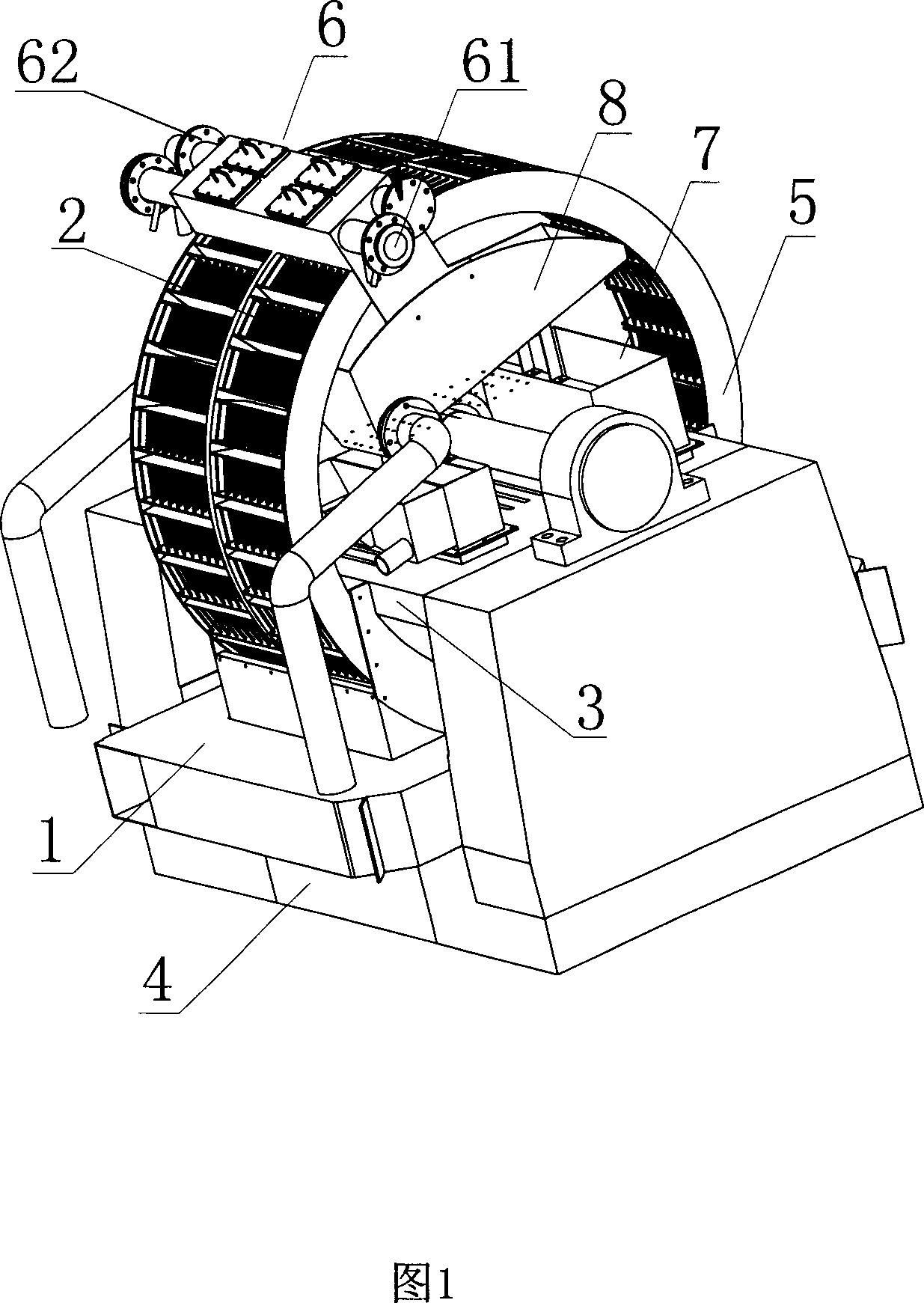

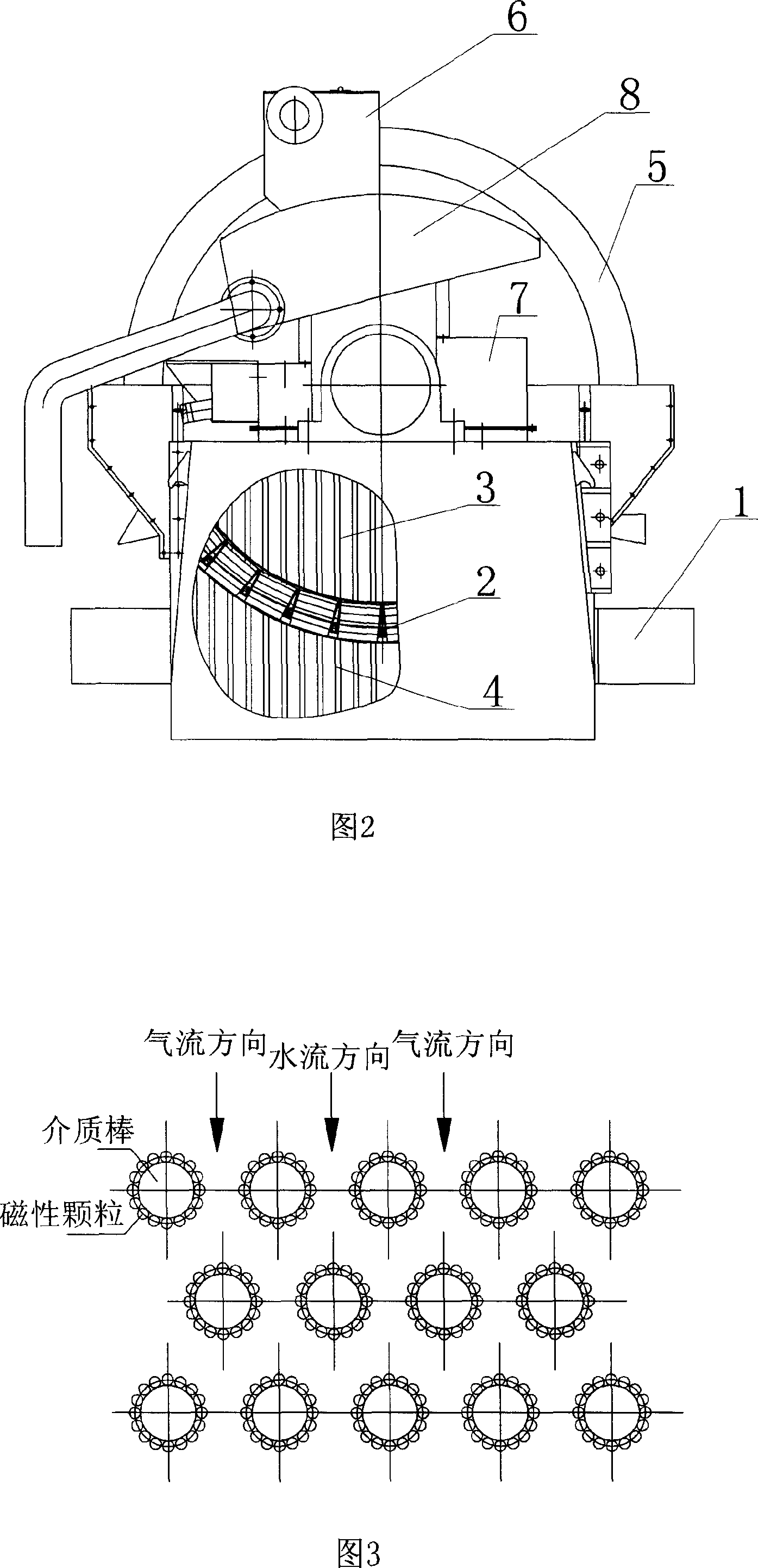

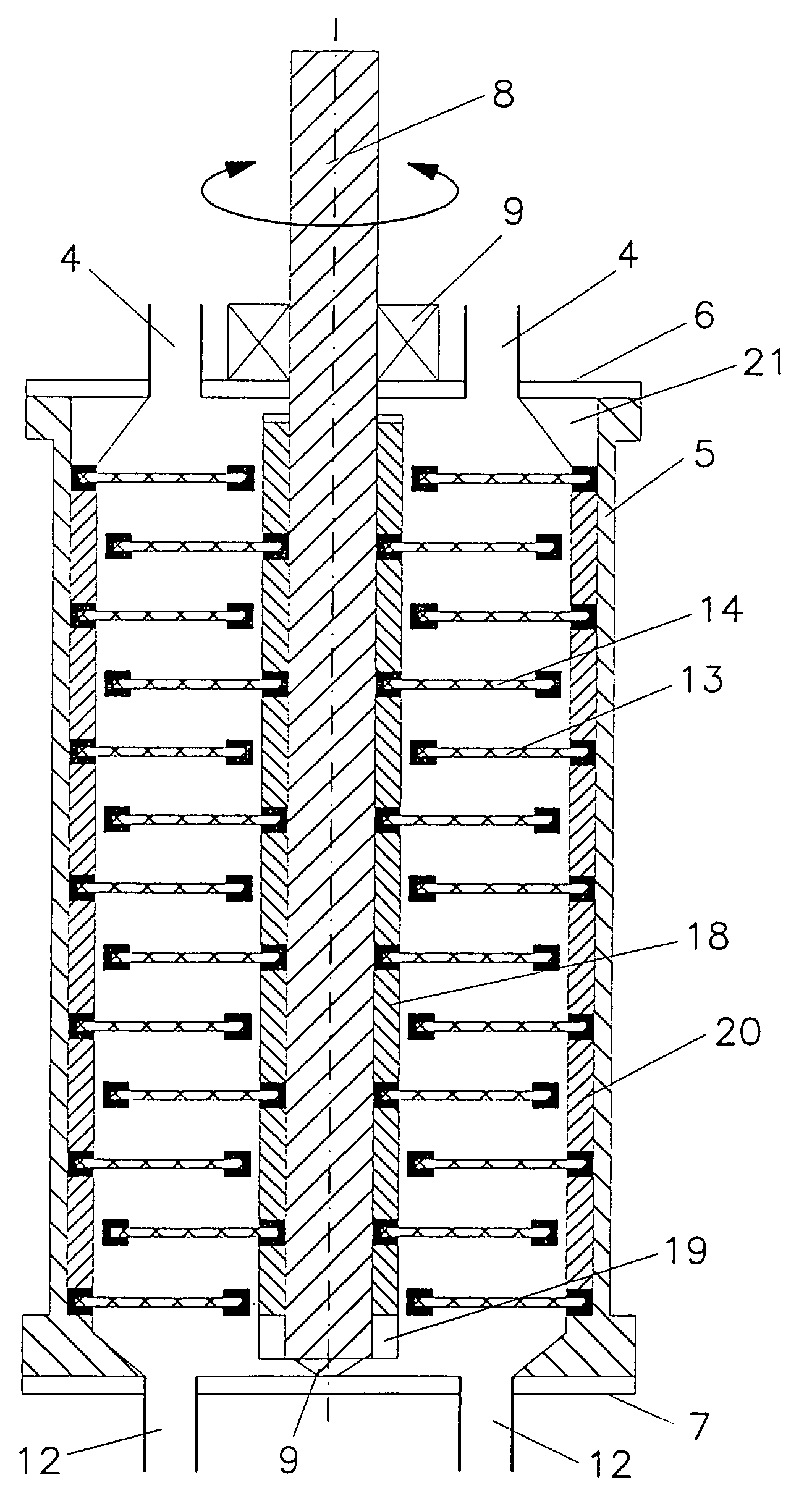

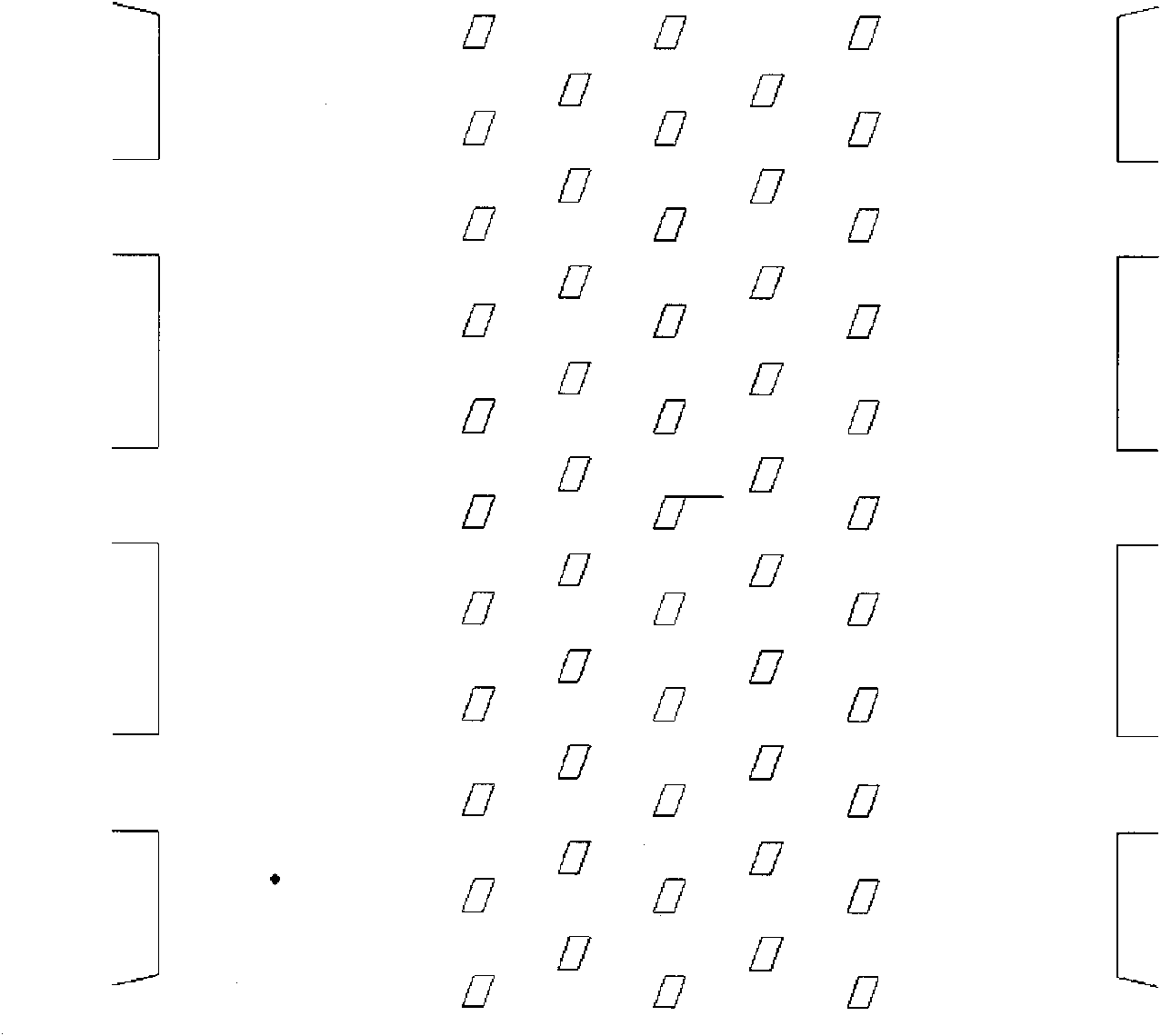

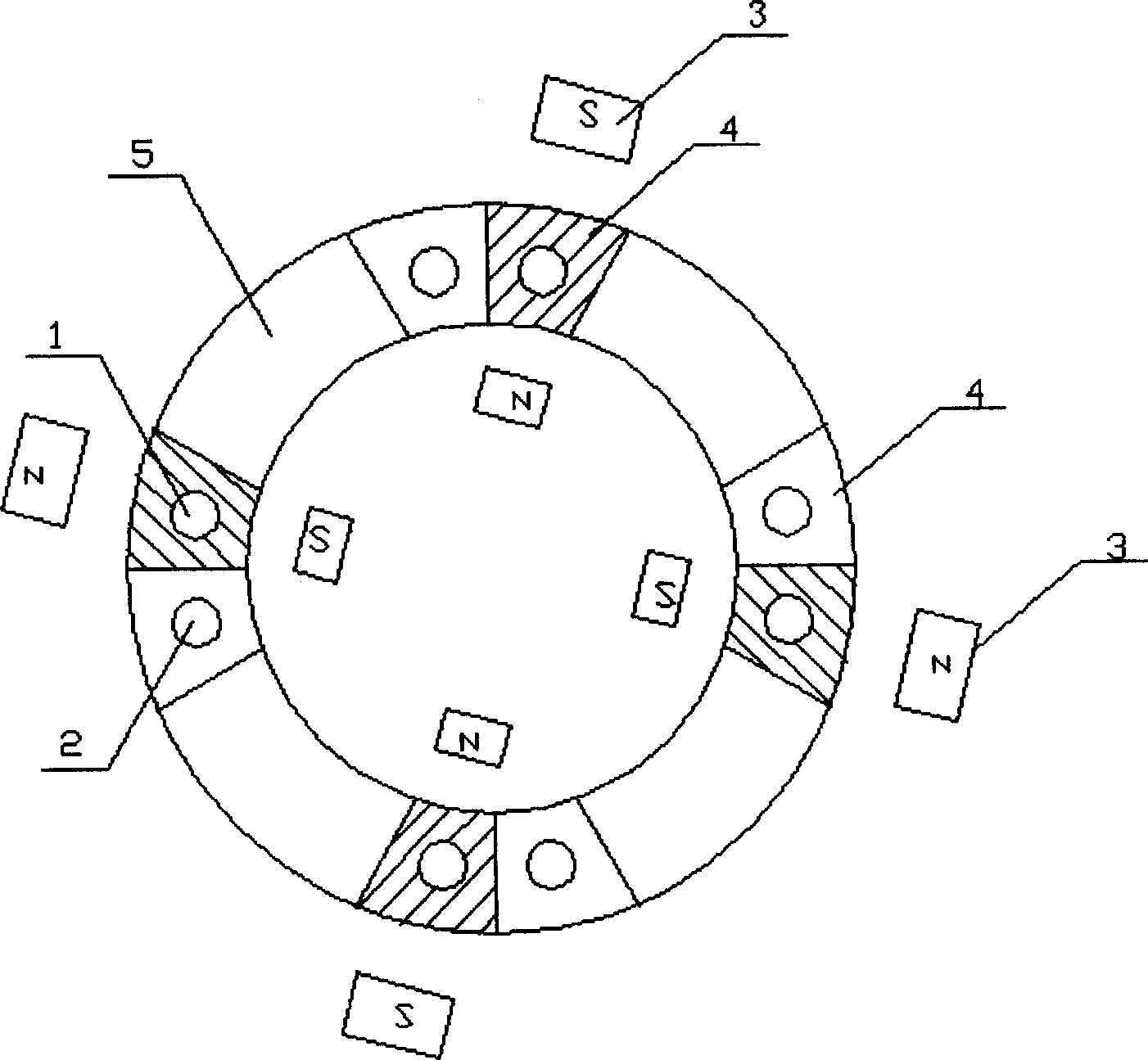

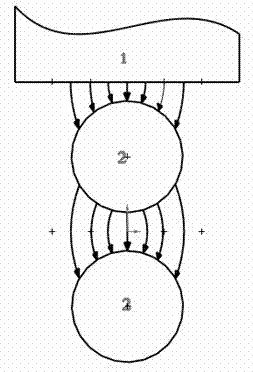

Split type multi-roller multi-component high-gradient vibration magnetic separator in permanent magnetism

InactiveCN101402069AHigh mechanical strengthEasy to replaceHigh gradient magnetic separatorsMagnetic separatorEngineering

The invention relates to a permanent magnetic midsplit type multi-roller multivariate high gradient vibration magnetic selector, which comprises a stander (12), a magnetic selection box body arranged above the stander (12) through a vibration reduction spring set (18), a plurality of permanent magnetic rollers arranged inside the magnetic selection box body, a feed hopper (22) positioned on the top of the magnetic selection box body and a feed discharging passage (17) positioned on the bottom of the magnetic selection box body. The vibration magnetic selector is characterized in that the permanent magnetic rollers are made from magnetic materials with different magnetic strengths; according to a two-dimensional matrix form, the plurality of the permanent magnetic rollers are arranged to construct a multivariate sorting magnetic field; the permanent magnetic rollers made from the magnetic material of the same type are positioned on the same plane; according to the magnetic strengths, the permanent magnetic rollers with different magnetisms are in deltaic alternate arrangement sequentially from top to bottom along the flowing direction of the materials; magnetic concentrating medium grooves with the same specification are arranged between the adjacent permanent magnetic roller layers in different layers and above the upper layer of the permanent magnetic roller layers; and the inside of each groove is provided with magnetic concentrating media with different types.

Owner:HENAN POLYTECHNIC UNIV

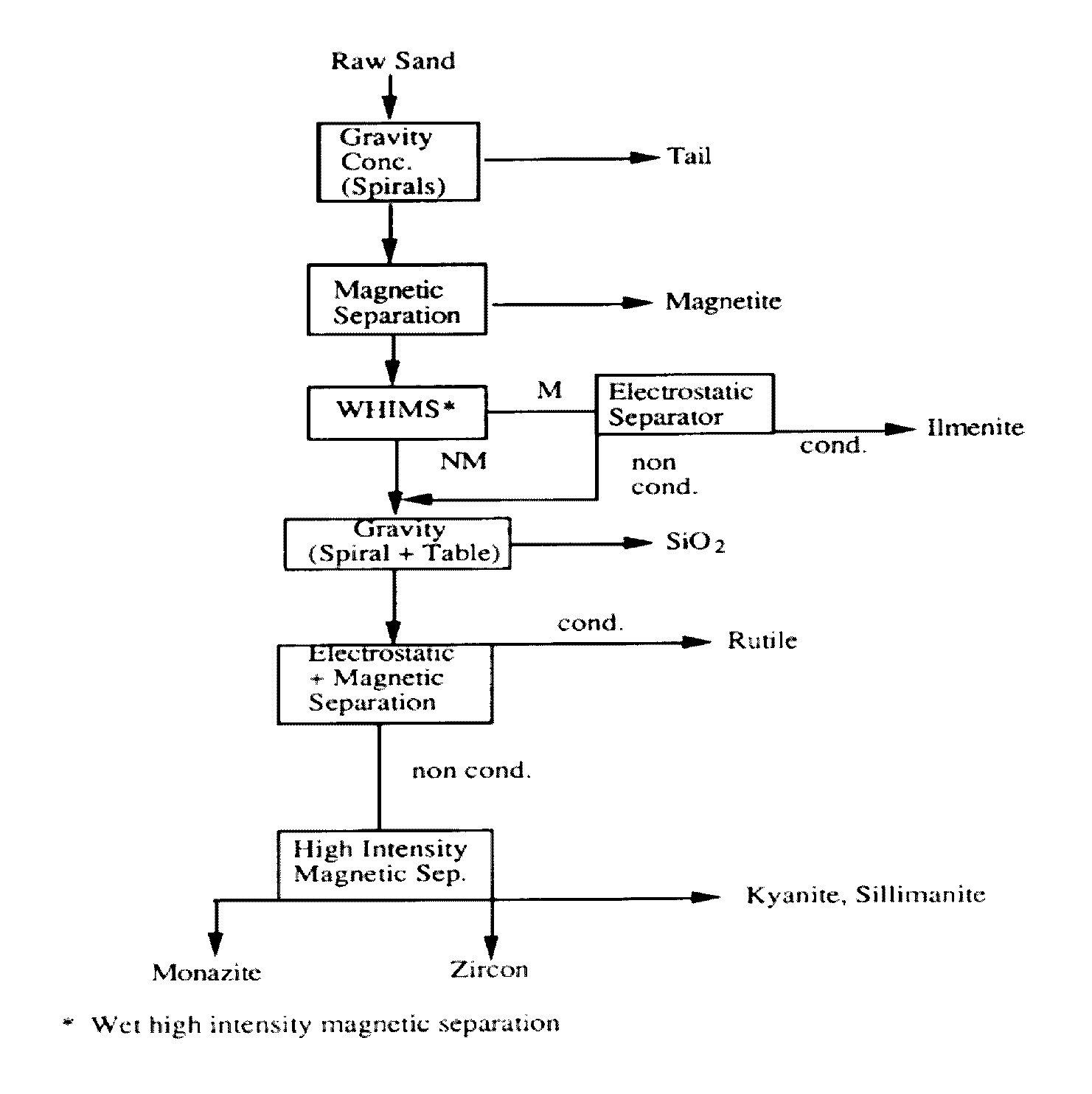

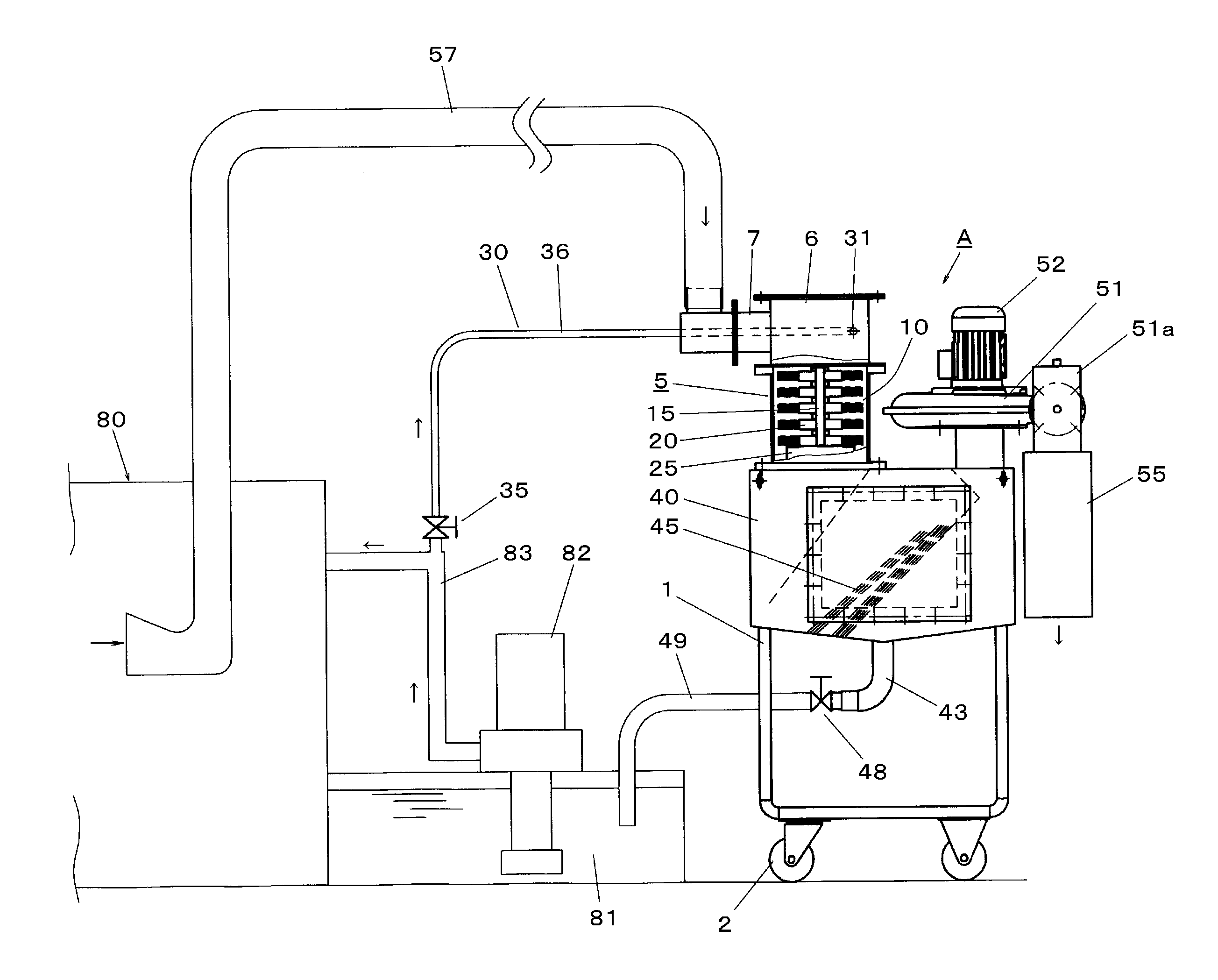

Multiple product separation method of sea beach placer

InactiveCN102614978AStrong magnetismImprove qualityHigh gradient magnetic separatorsWet separationMagnetic mediaEngineering

The invention discloses a multiple product separation method of a sea beach placer, which comprises the following steps: firstly, the roughing integrated concentrate is obtained through the spiral chute re-separation, then, the sectional fine separation of a SLon magnetic separator is adopted for replacing the electronic separation, the sectional section of magnetic separation and fine separation is adopted, meanwhile, high-pulsation fluid force fields and medium width magnetic media are assisted in the magnetic separation process for twice fine separation to separate high-quality titanium concentrate, and the titanium-containing grade TiO2 is greater than or equal to 47 percent; and tailings after ilmenite fine separation are subjected to twice fine separation of high-intensity and large-width magnetic media to respectively separate out monazite, and the final tailings are zircon sand, so the goal of effectively separating the ilmenite, the monazite and the zircon sand is reached. The sectional fine separation of the SLon magnetic separator is adopted for replacing the electronic separation, the problems in the electronic separation flow process are solved, and the separation method has the advantages that the ilmenite, the monazite and the zircon sand can be effectively separated, the production flow process is simple, the field operation implementation is easy, the environment pollution is avoided, and the production cost is low.

Owner:赣州金环磁选科技装备股份有限公司

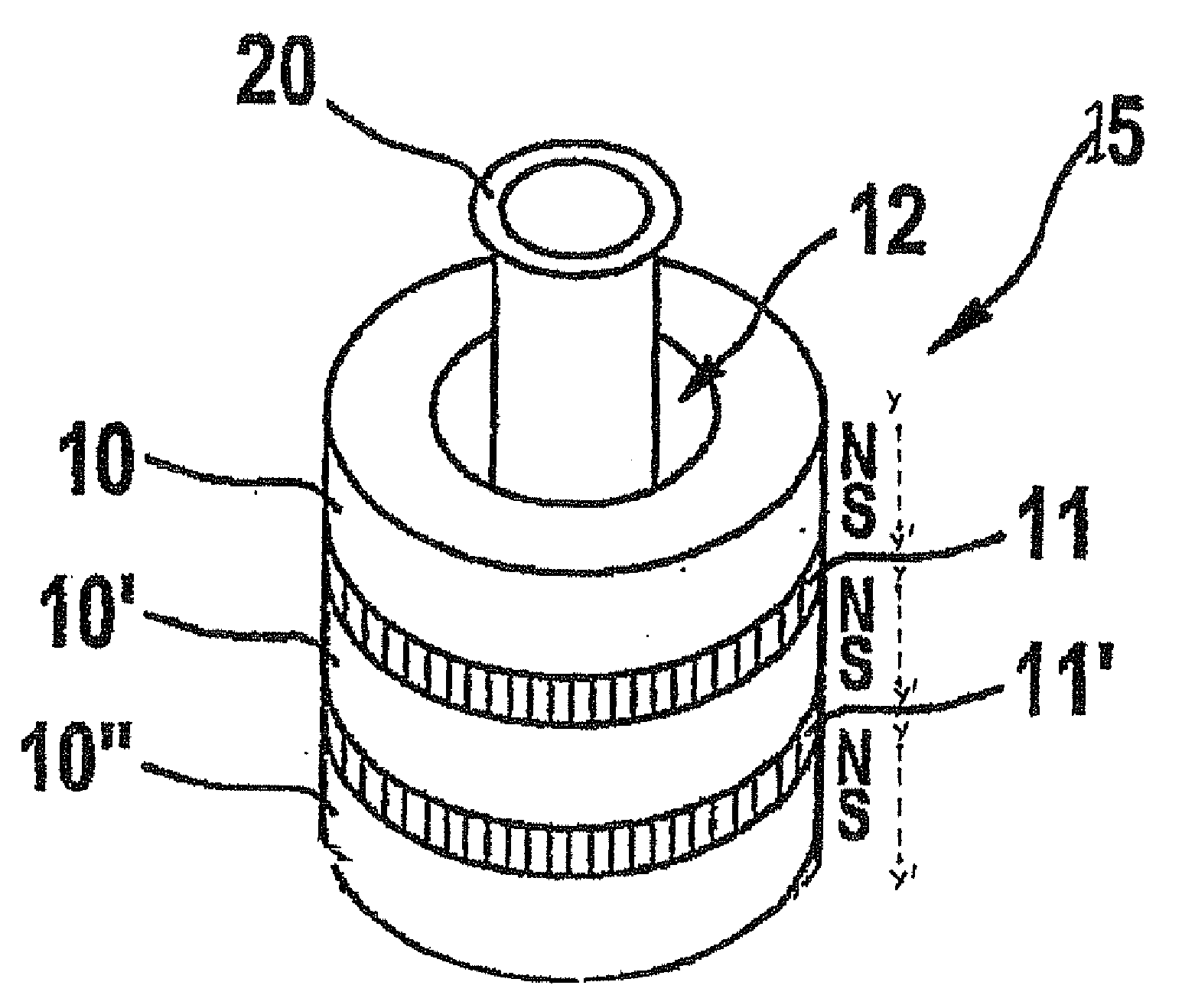

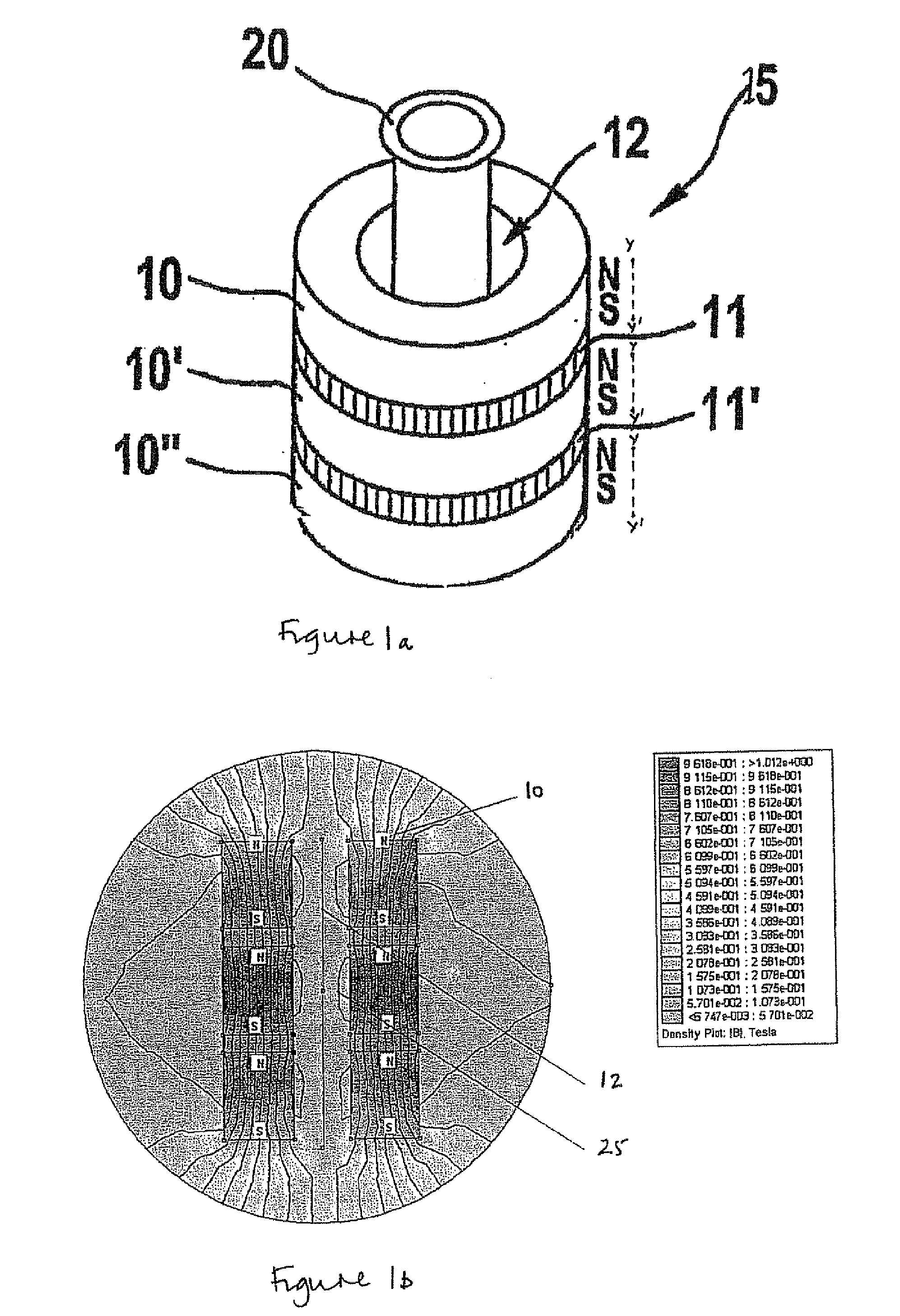

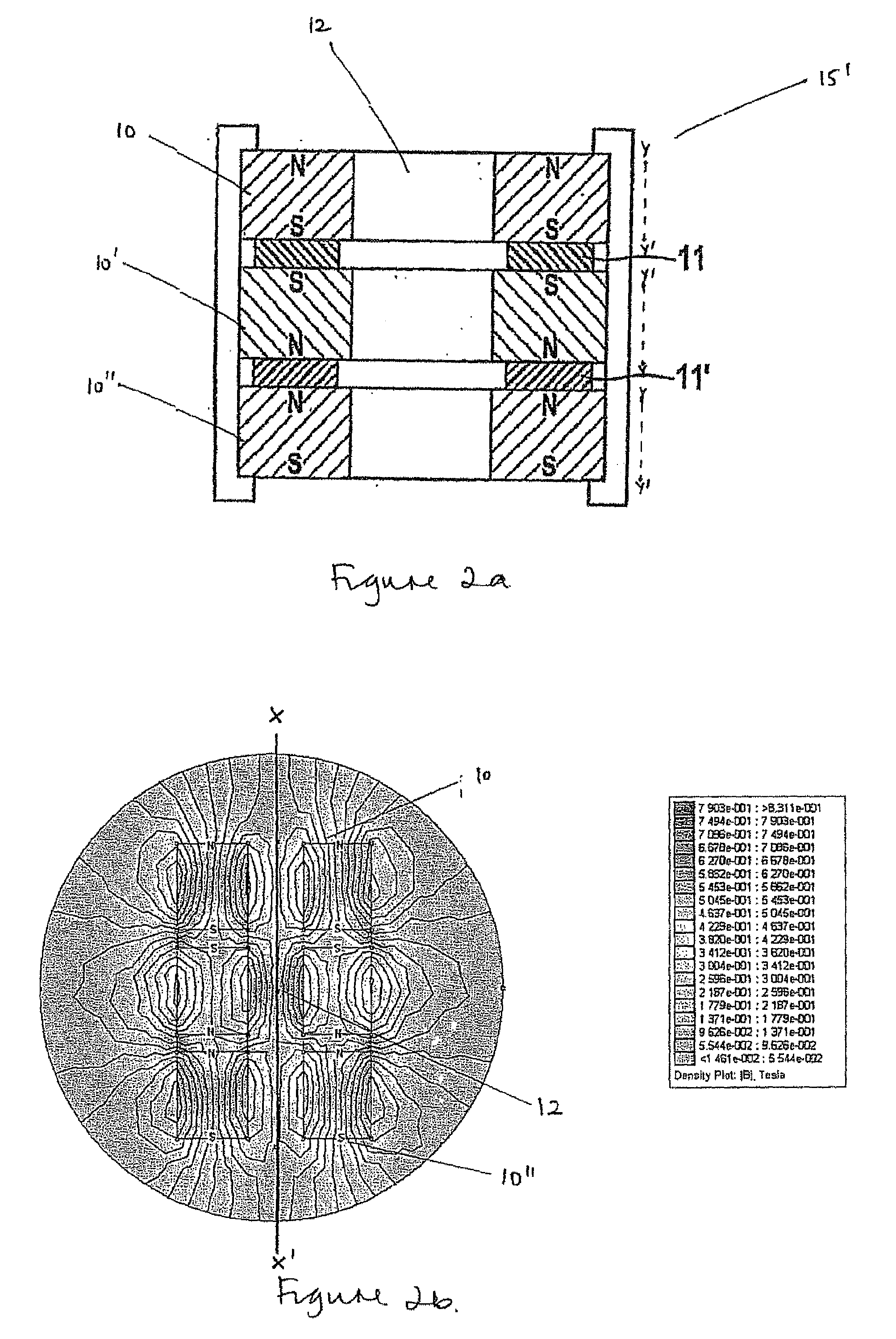

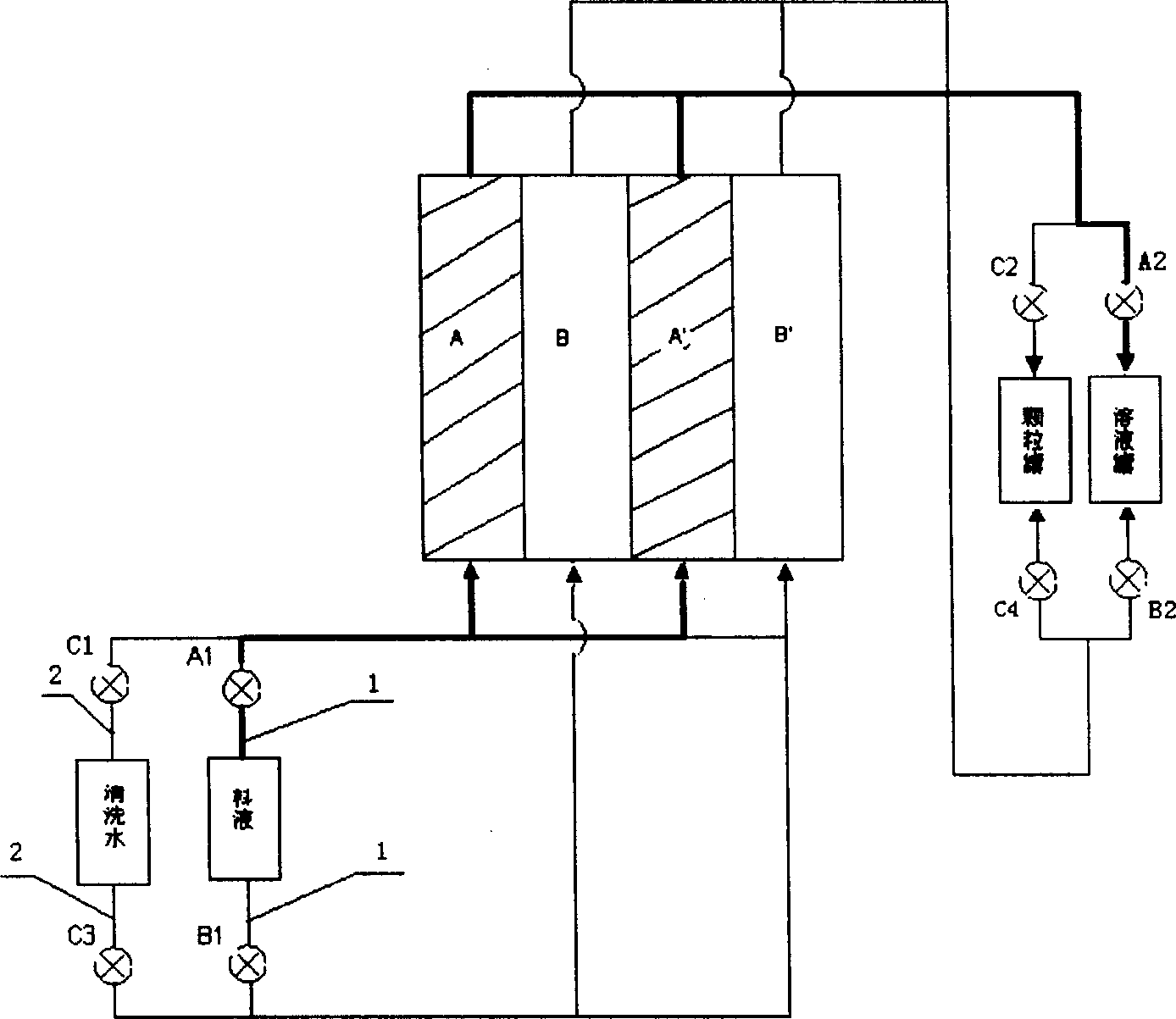

Magnetising portion for a magnetic separation device

ActiveUS20100264090A1Electrostatic separationHigh gradient magnetic separatorsNon magneticMagnetic separation

The present disclosure relates to a magnetising portion for providing a high-gradient magnetic field in a magnetic separation device. The magnetising portion comprises at least one magnetic assembly. The at least one magnetic assembly comprises: a plurality of magnets whereby each magnet has a north pole, south pole and a magnet axis extending between the north and south poles, and the plurality of magnets are arranged one above the other in a direction at least substantially perpendicular to the axis of each magnet in such a manner that the north and south poles of adjacent magnets are arranged alternately and a space is provide between adjacent magnets; and at least one non-magnetic spacing means arranged in the space between adjacent magnets. The present disclosure also relates to magnetic separation devices comprising at least one of the said magnetising portions and to a method of isolating magnetically labelled particles using the magnetic separation devices.

Owner:LIFE TECH AS

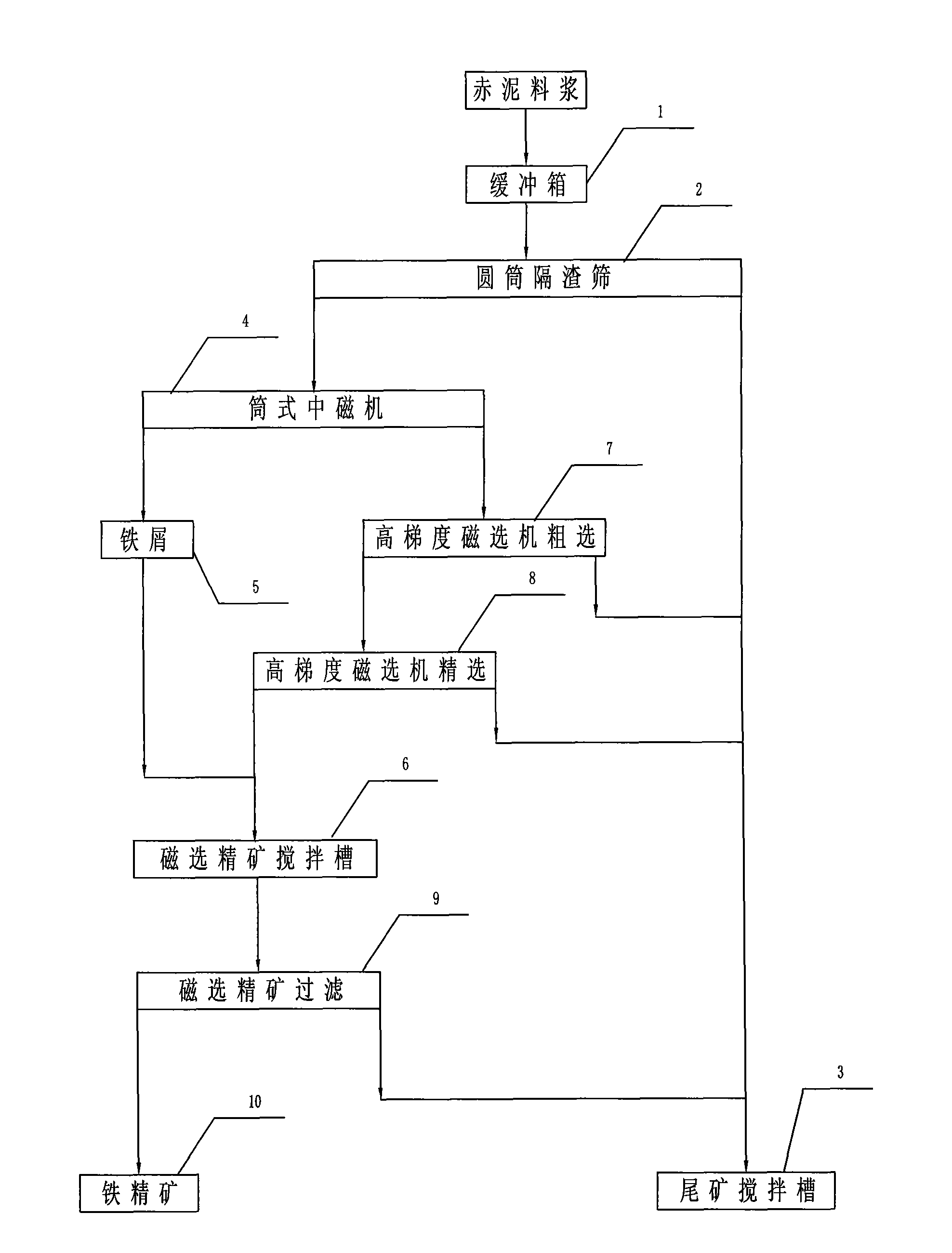

Method for recovering iron concentrates from alumina red mud

The invention provides a method for recovering iron concentrates from alumina red mud, adopting the following technical scheme: a medium-intensity magnetic separator is adopted to recover the stronglymagnetic iron concentrates after red mud tailings are subjected to slag separation, then the obtained tailings are subjected to open rough separating and refined separating by a high gradient magnetic separator to recover weakly magnetic iron concentrates, combining the strongly magnetic iron concentrates and the weakly magnetic iron concentrates and carrying out dehydrating to obtain the iron concentrates. An slon vertical ring pulsating high gradient magnetic separator is selected to replace the traditional high gradient magnetic separator, and the medium-intensity magnetic separator is adopted to recover the strongly magnetic iron concentrates before. The method provided by the invention can be used for efficiently recovering the iron concentrates from the alumina red mud, and the obtained iron concentrates have high grades and good recovery rate; therefore, the method increases the utilization ratio of the alumina red mud, reduces the environmental pollution and is suitable for large-scale application.

Owner:山西华兴铝业有限公司

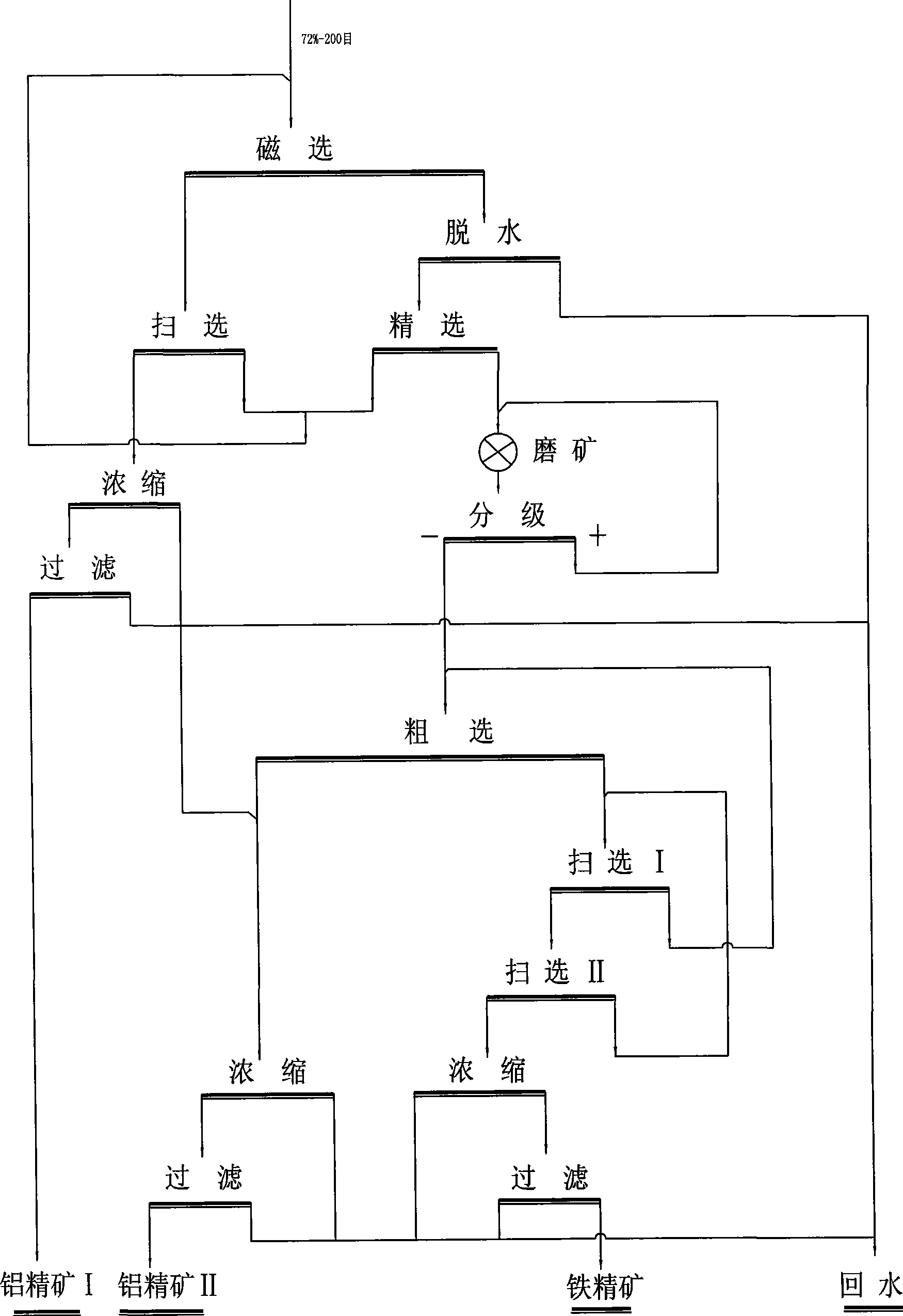

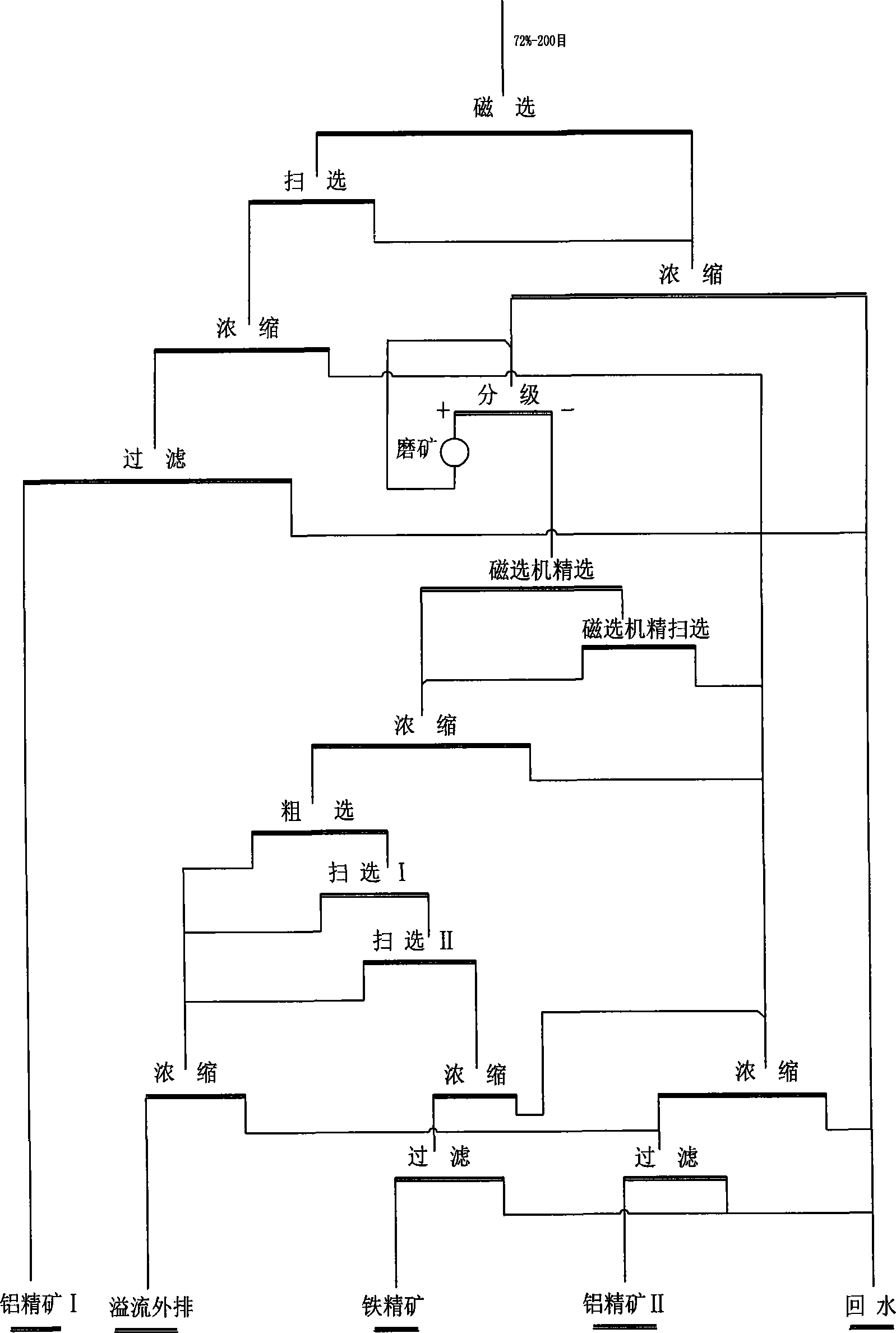

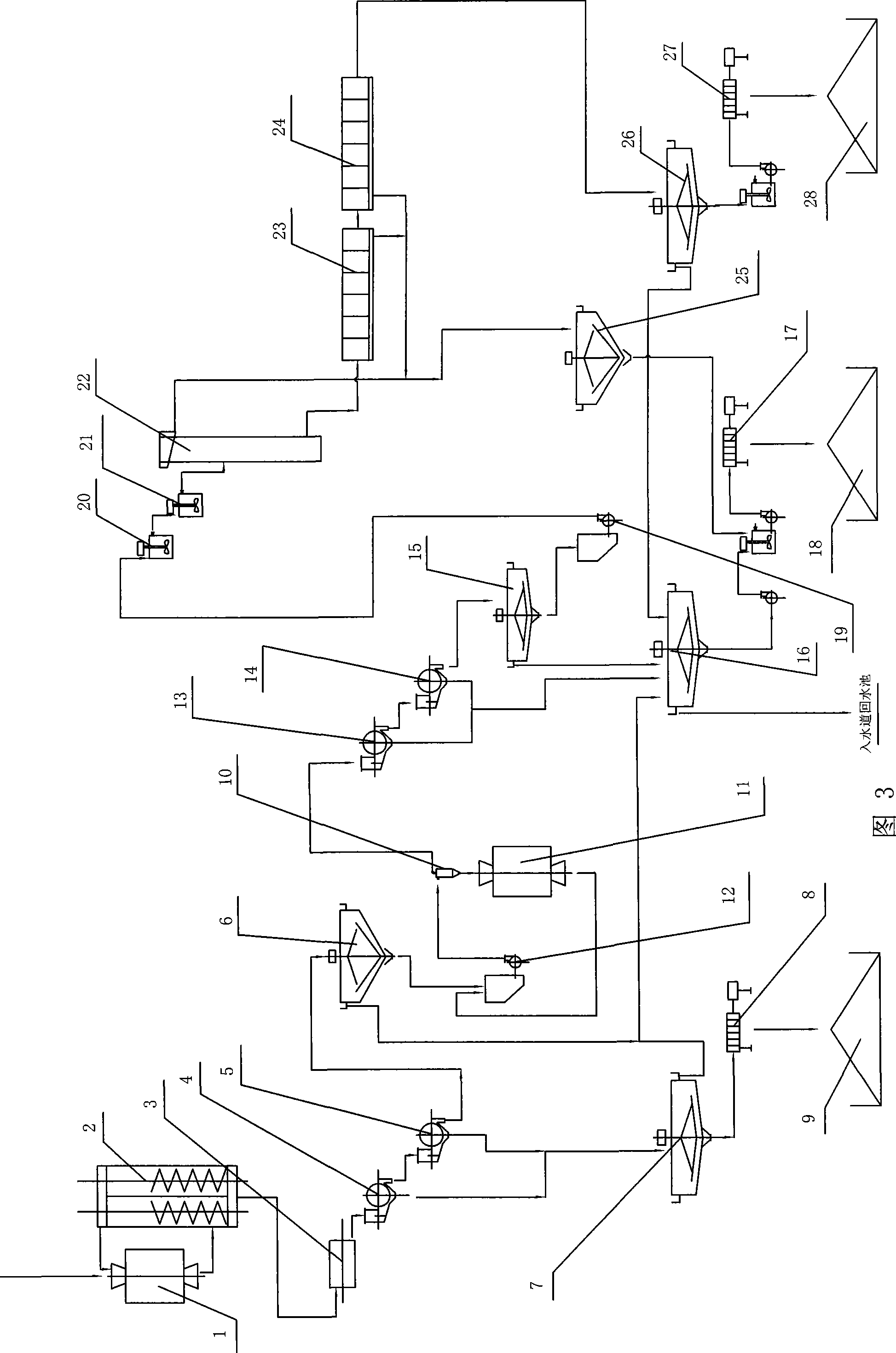

High iron bauxite dressing method

ActiveCN101417260AQuality improvementLower iron contentHigh gradient magnetic separatorsFlotationProduction rateReverse flotation

The invention provides a beneficiation method for high iron bauxite. The invention adopts strengthening magnetic separating-anionic reverse flotation flow, stage grinding and stage magnetic separating. Under the condition of ensuring the magnetic separating iron concentrate recovery rate, strengthening magnetic separating has the priority to obtain higher quality aluminum concentrate one and high grade iron rough concentrate, thus improving the selection grade of the reverse flotation and opening circuit fully in the reverse flotation process, a reverse flotation rougher flotation device adopts a flotation column with large charge and fine even bubbles, thus obtaining iron concentrate with higher quality. In addition, the beneficiation method optimizes and reduces the production rate of material entering reverse flotation operation, and achieving the purposes of energy saving and consumption reducing.

Owner:中铝国际南方工程有限公司

Refining process for lepidolite in tantalum-niobium ore waste rocks

ActiveCN105251606ASolve the way outHigh Lithium Oxide ContentHigh gradient magnetic separatorsFlotationNiobiumIron removal

The invention relates to a refining process for lepidolite in tantalum-niobium ore waste rocks. A combined method with magnetic separation, high gradient magnetic separation, dense medium separation and flotation is adopted. The flotation adopts the process of rough flotation, dual fine flotations and sweeping. The process for refining the lepidolite from the granite-type tantalum-niobium ore waste rocks is provided. The tantalum-niobium ore waste rocks are crushed, screened, ground and subjected to high-frequency screening, spiral grading, permanent magnet magnetic separation for iron removal, high gradient magnetic separation, dense medium separation and flotation, so that lepidolite concentrates are obtained. By means of the method, the lepidolite concentrates are separated from the tantalum-niobium ore waste rocks. The lepidolite concentrates contain at least 4.5% of Li2O, at least 8.0% of K2O and Na2O and at most 0.10% of TiO2 and Fe2O3, the recovery rate of the lepidolite concentrates is larger than 80%, the qualities of the lepidolite concentrates meet the requirement of national standards, and the recovery rate of the lepidolite concentrates exceeds the industry level.

Owner:江西金辉再生资源股份有限公司

Continuous magnetic separator and process

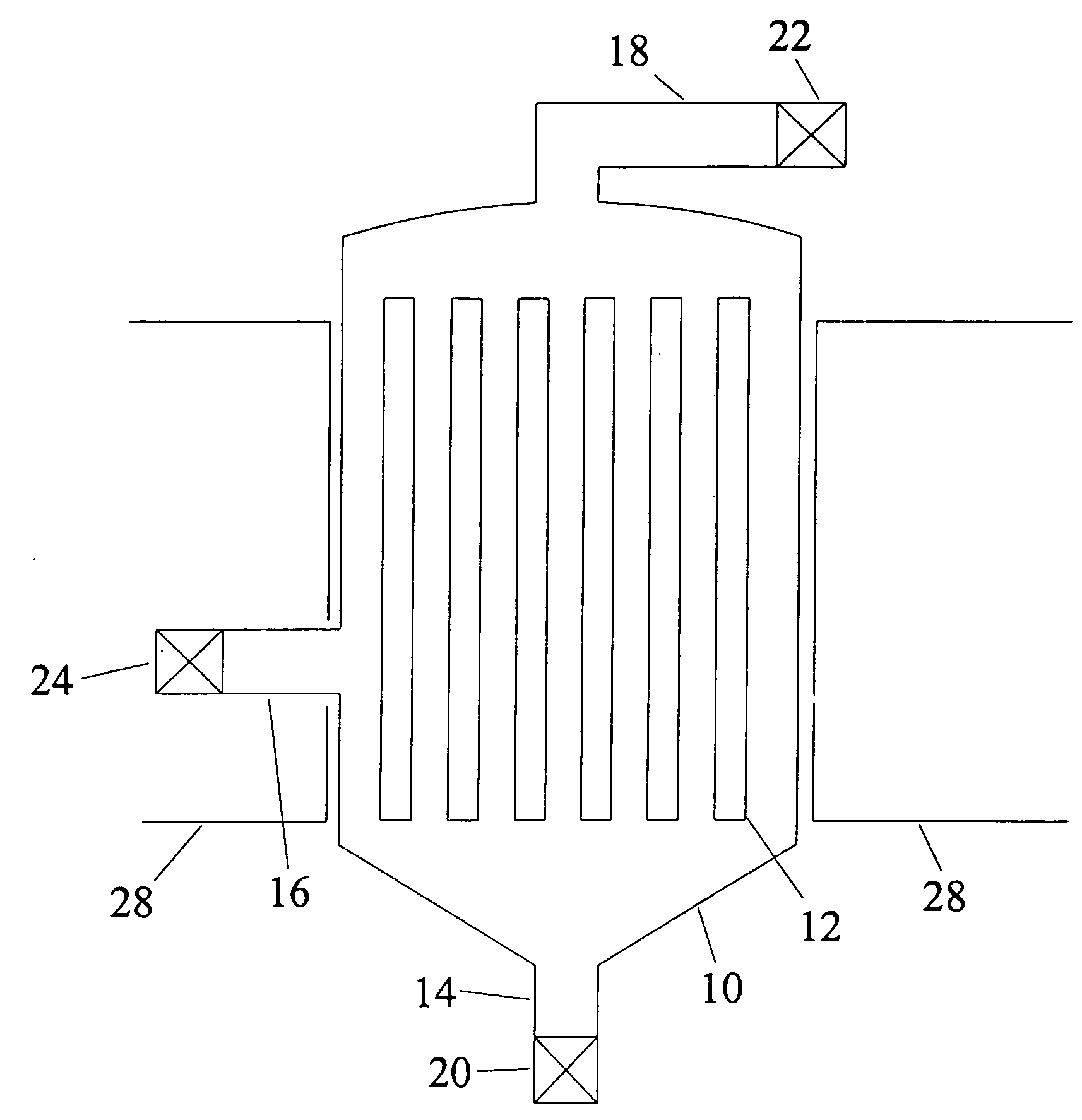

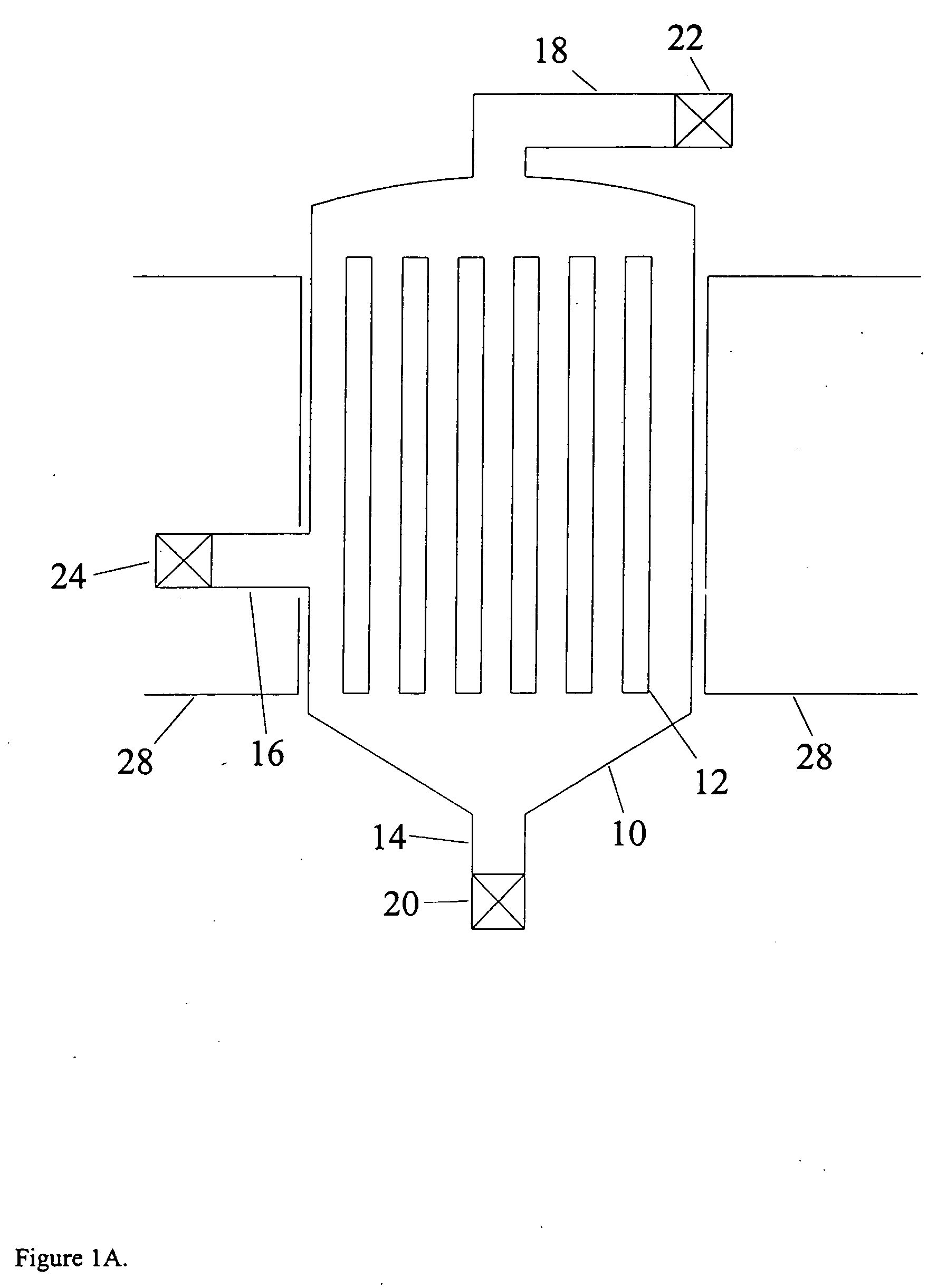

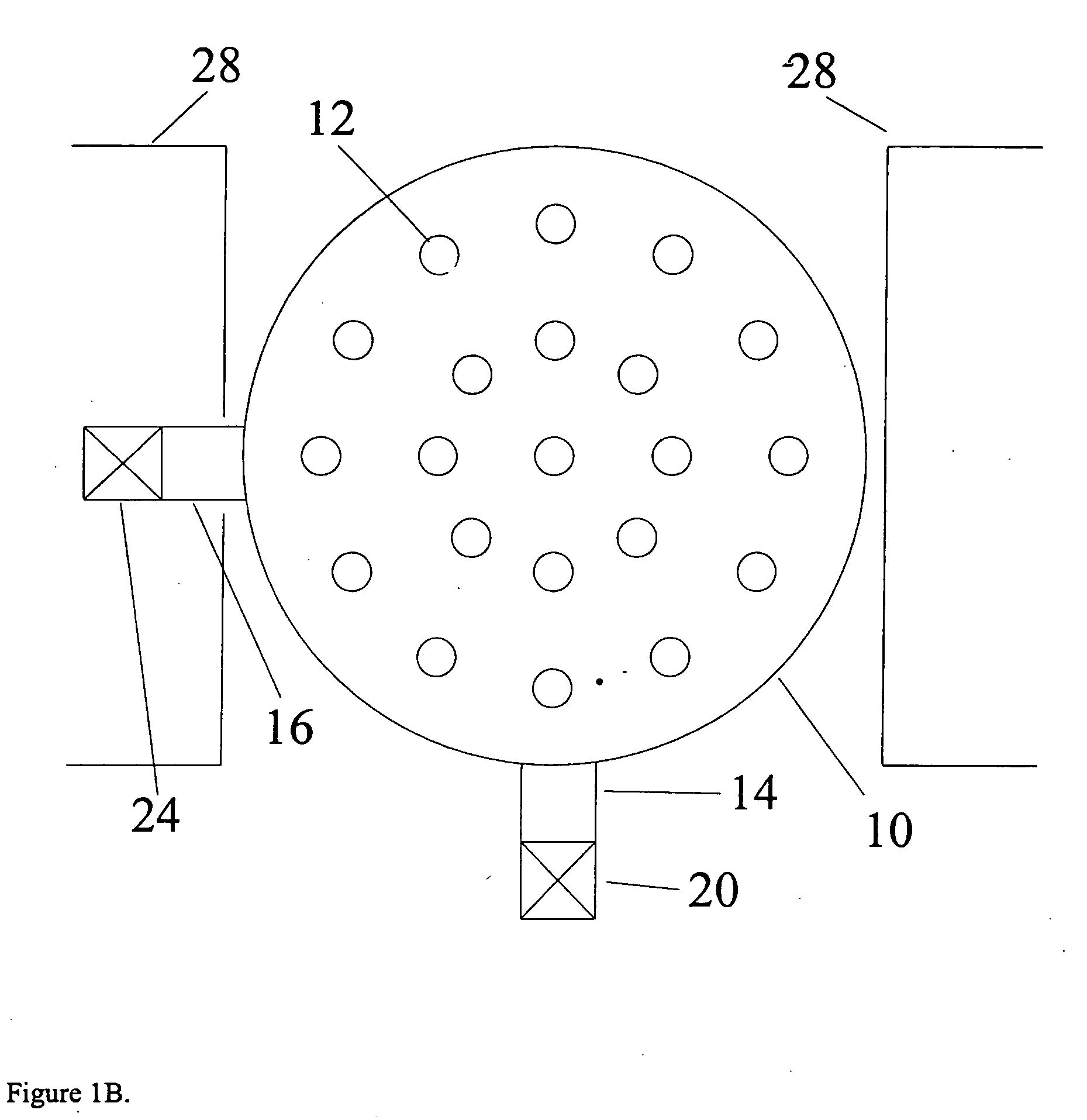

InactiveUS7360657B2High gradient magnetic separatorsFiltration separationMagnetic separatorEngineering

A continuous magnetic separator and process for separating a slurry comprising magnetic particles into a clarified stream and a thickened stream. The separator has a container with a slurry inlet, an overflow outlet for the discharge of the clarified slurry stream, and an underflow outlet for the discharge of a thickened slurry stream. Magnetic particles in the slurry are attracted to, and slide down, magnetic rods within the container. The slurry is thus separated into magnetic concentrate and clarified slurry. Flow control means can be used to control the ratio of the rate of magnetic concentrate to the rate of clarified slurry. Feed control means can be used to control the rate of slurry feed to the slurry inlet.

Owner:RES USA LLC

Method and apparatus for capturing target substance

InactiveUS20050287577A1Increase surface areaReduced Diffusion LengthBioreactor/fermenter combinationsBiological substance pretreatmentsAnalytical chemistryParticle aggregation

Owner:CANON KK

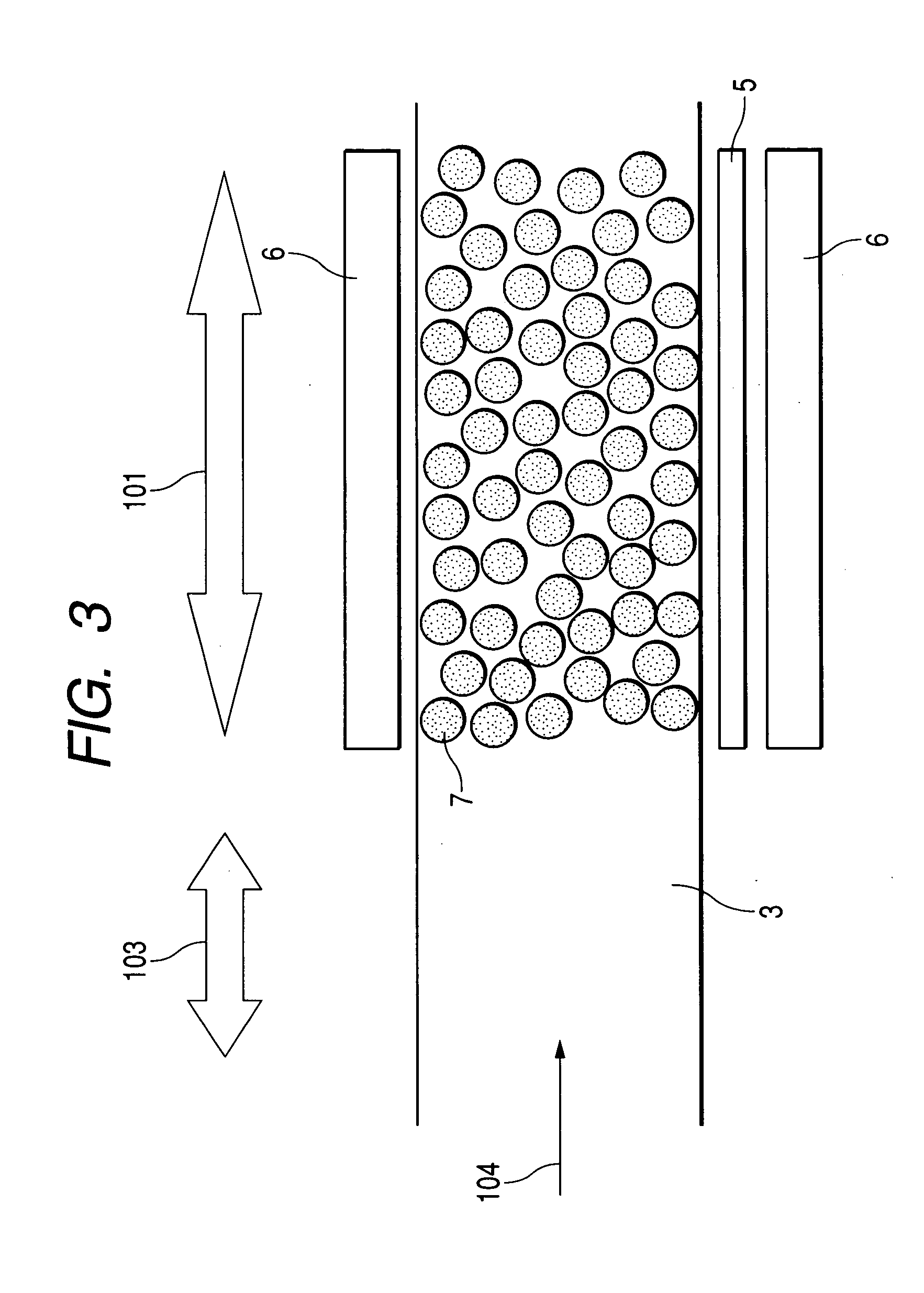

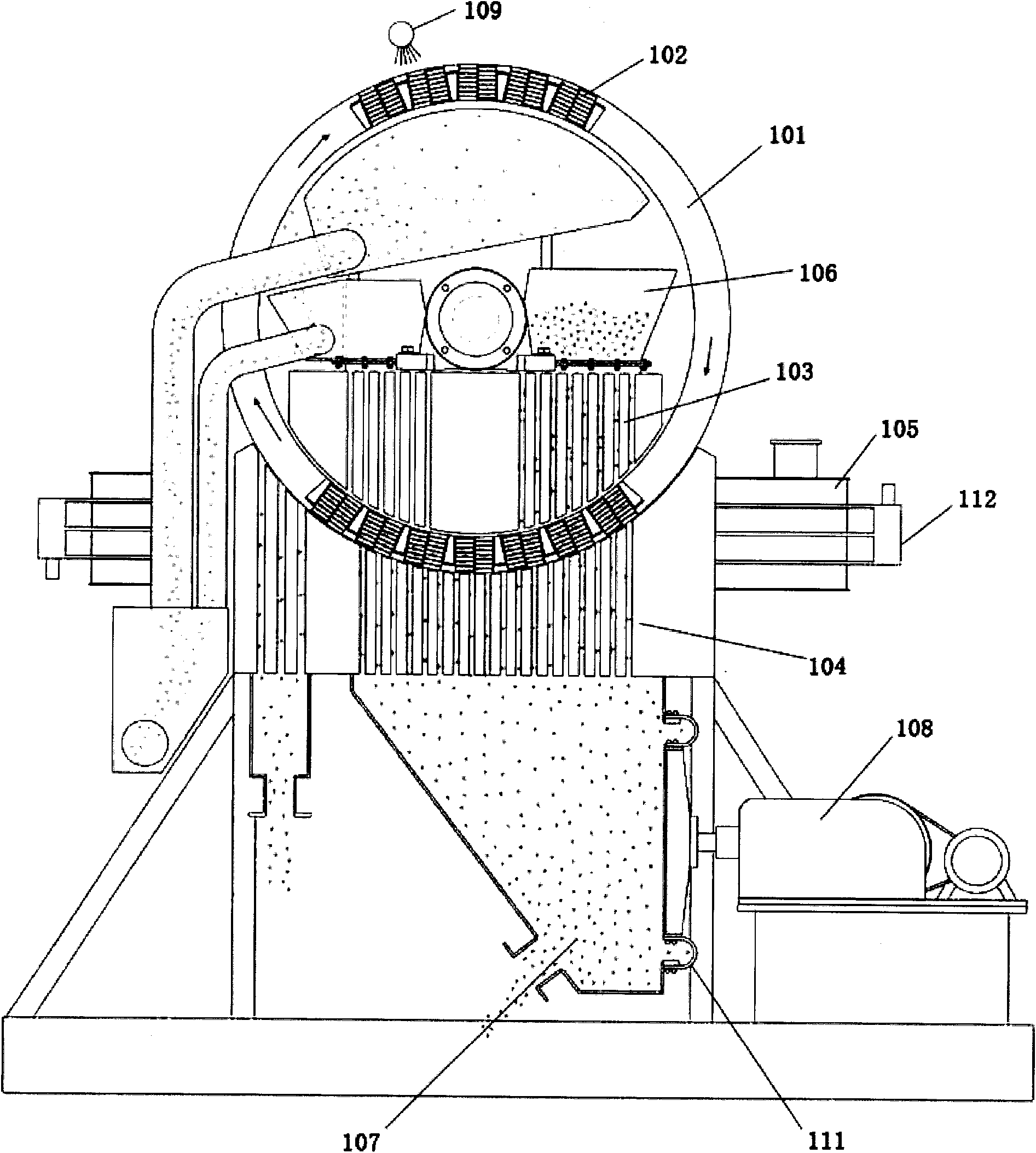

High-gradient magnetic separator

InactiveCN1994578AIncrease pulp concentrationEfficient removalHigh gradient magnetic separatorsDischarge efficiencyWater resources

The invention relates to a high-gradient magnetic selector, which comprises selecting ring, driver, mineral feeder, fine mineral discharger, and fine mineral collector, wherein the selecting ring comprises rotation ring, accumulation medium stack, upper magnetic pole, lower magnetic pole and active coil; the discharger comprises parallel hydraulic discharger and wind discharger at the outer side of rotation ring, while they are relative to the fine mineral collector at the inner side of rotation ring. The invention combines water washing and wind washing to effectively remove the magnetic particles on the magnetic collecting mediums, to improve the mineral discharge efficiency. The invention can save water resource and improve the mineral slurry density.

Owner:广东省资源综合利用研究所

Device and method for separating magnetic or magnetizable particles from a liquid

ActiveUS7776221B2Avoid cross contaminationAnalysis using chemical indicatorsElectrostatic separationEngineeringMagnet

A device is provided to separate magnetic or magnetizable particles from a liquid by using a magnetic field. The device includes two limbs made of a soft-magnetic material. An air gap is provided between be two poles of the limbs. The air gap can receive one or more liquid containers. A head piece is arranged in a fixed or detachable manner on one of the two poles. One or more magnetizable bars are disposed in a fixed or movable manner on the head piece, in the vertical direction. One or more permanent magnets are arranged in a movable manner on at least one point of the device, such that a magnetic field can be produced between the two poles and the magnetic field can be activated or deactivated by moving the magnet(s). The region of the device where the movable magnet(s) are arranged is at least partially surrounded by a material that screens the magnetic field.

Owner:CHEMAGEN BIOPOLYMER TECH AKTIENGES

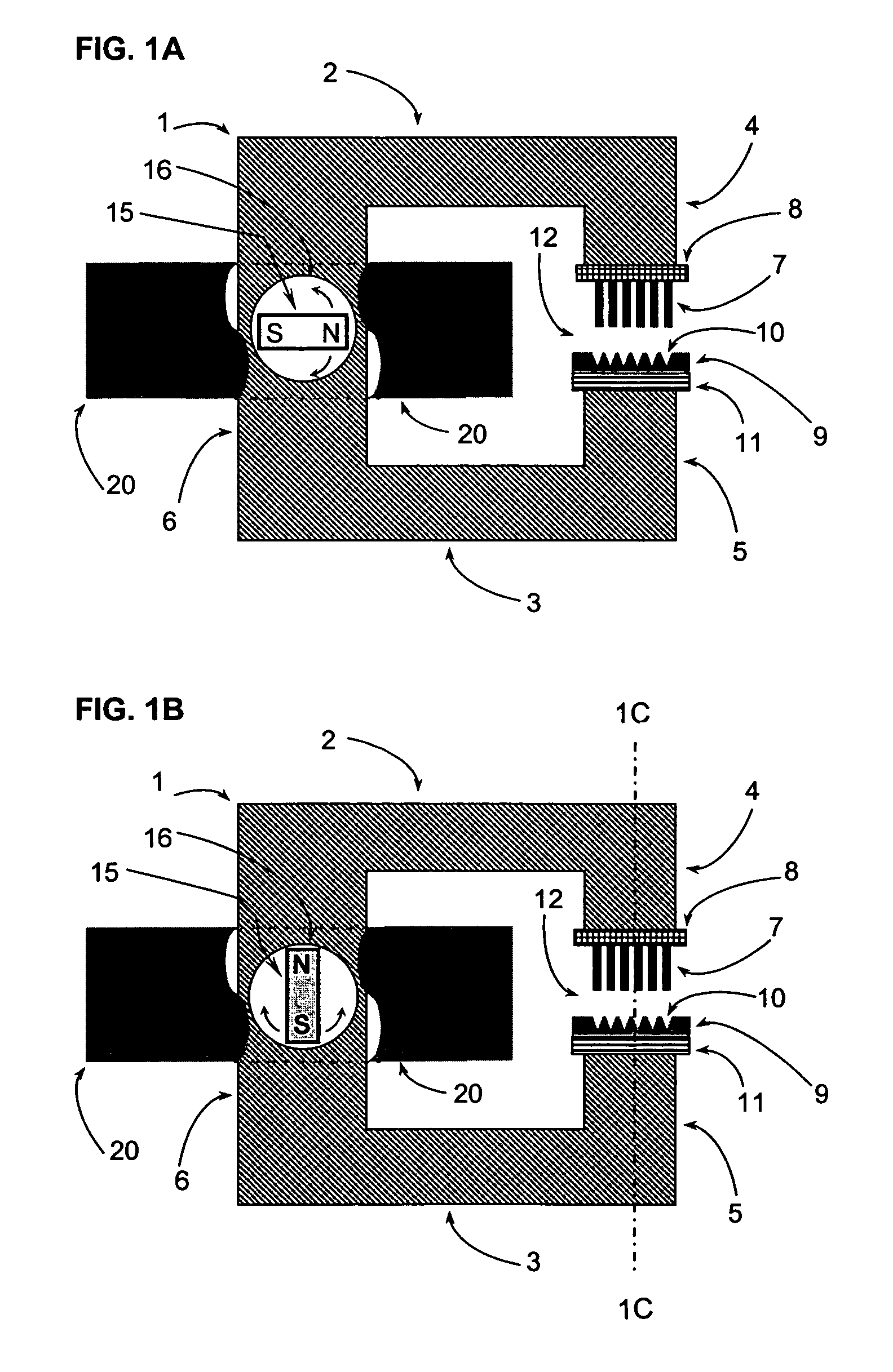

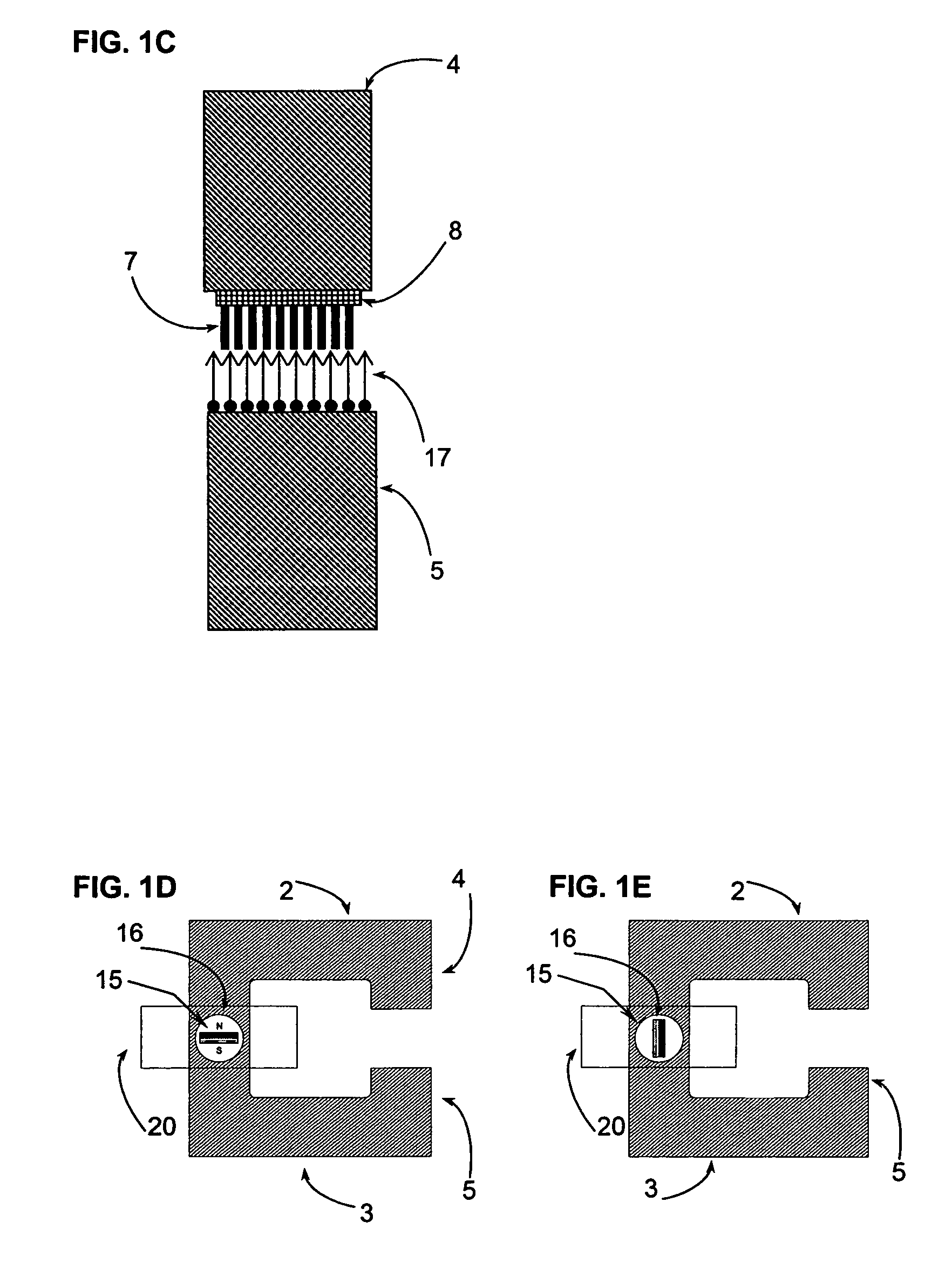

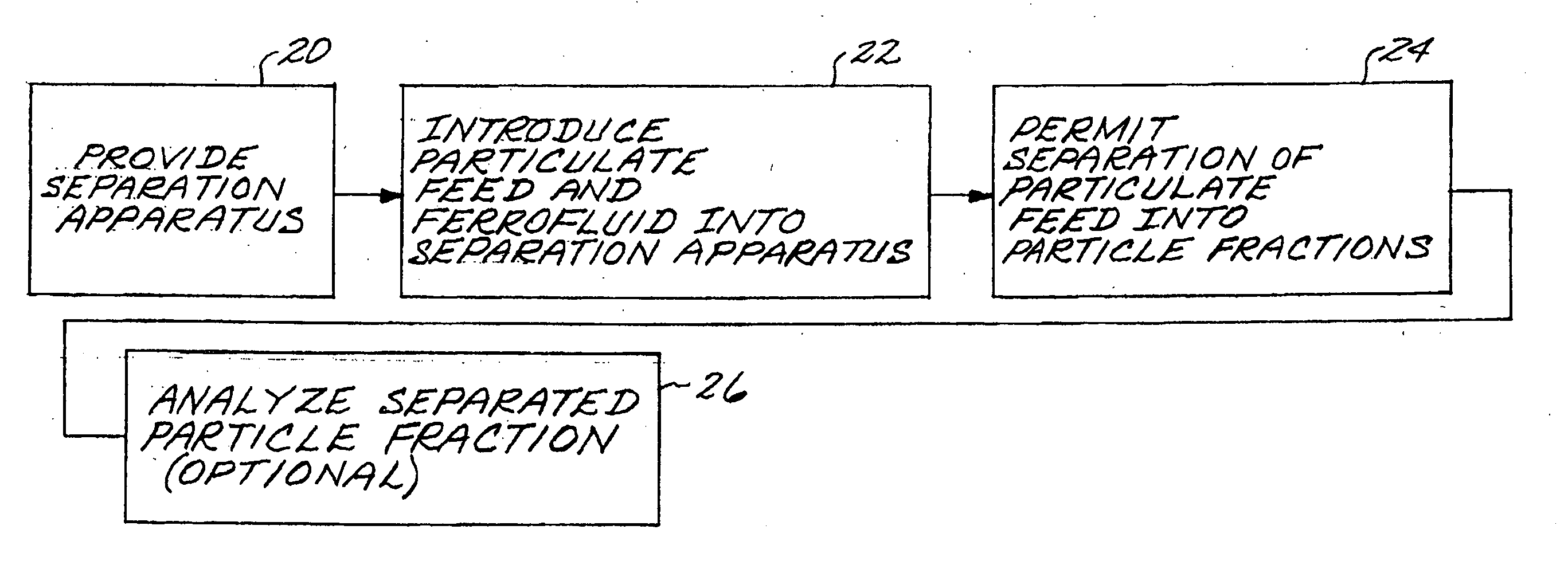

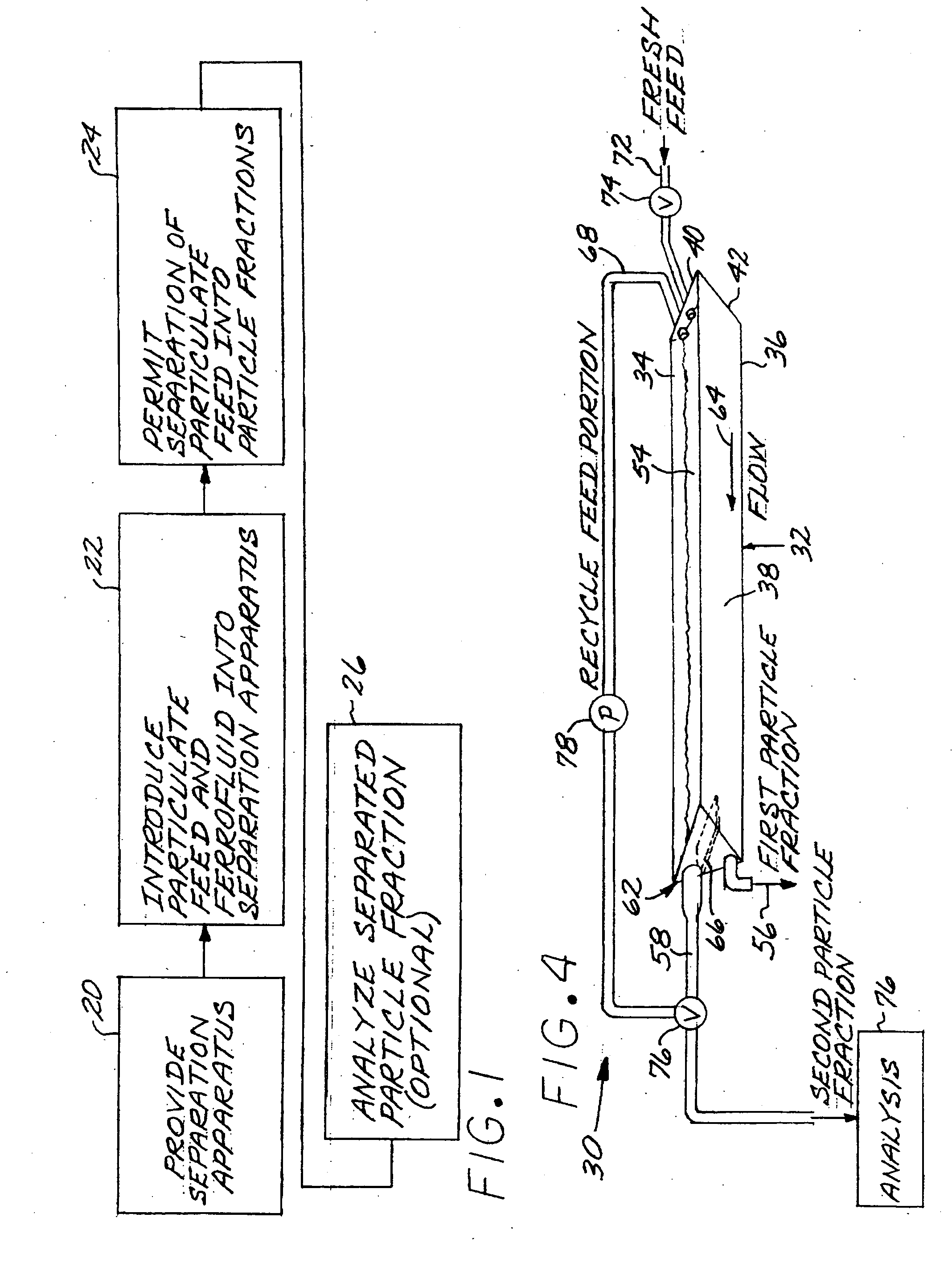

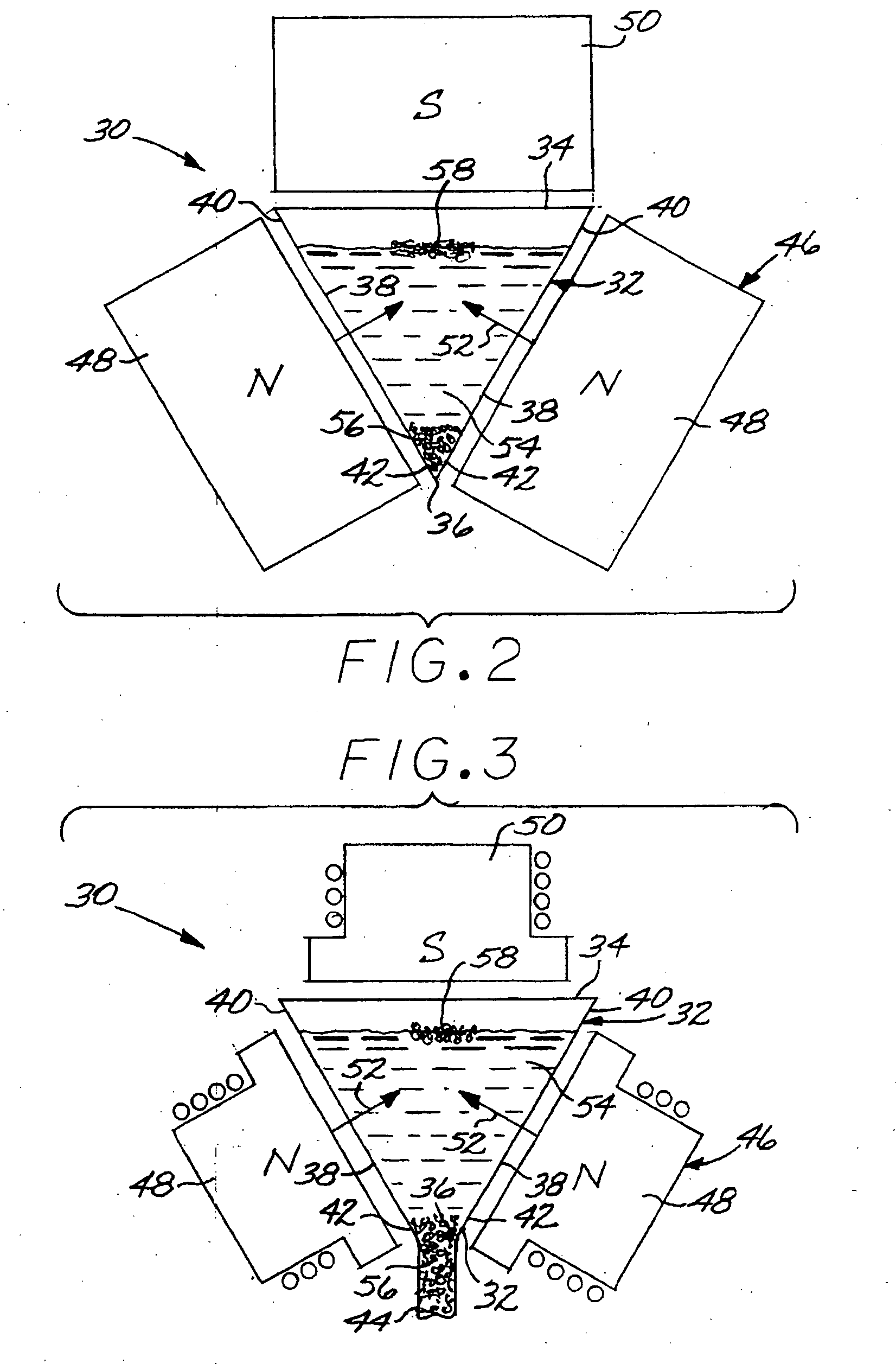

Method for magnetic/ferrofluid separation of particle fractions

InactiveUS20050178701A1Easy to collectEasy to cleanElectrostatic separationHigh gradient magnetic separatorsParticulatesChemical physics

A particulate feed comprising a first particle type and a second particle type is separated by providing a separation apparatus having a separation vessel having a top and a bottom, and wherein the separation vessel includes inwardly sloping side walls. A magnet structure has a first pole positioned exterior of and adjacent to each of the side walls of the separation vessel, and a second pole positioned above the separation vessel. A mixture of the particulate feed and a ferrofluid is introduced into the separation vessel, and the particulate feed is separated into a first particle fraction comprising a majority of the first particle type, which sinks in the separation vessel, and a second particle fraction comprising a majority of the second particle type which floats in the separation vessel.

Owner:GENERAL ELECTRIC CO

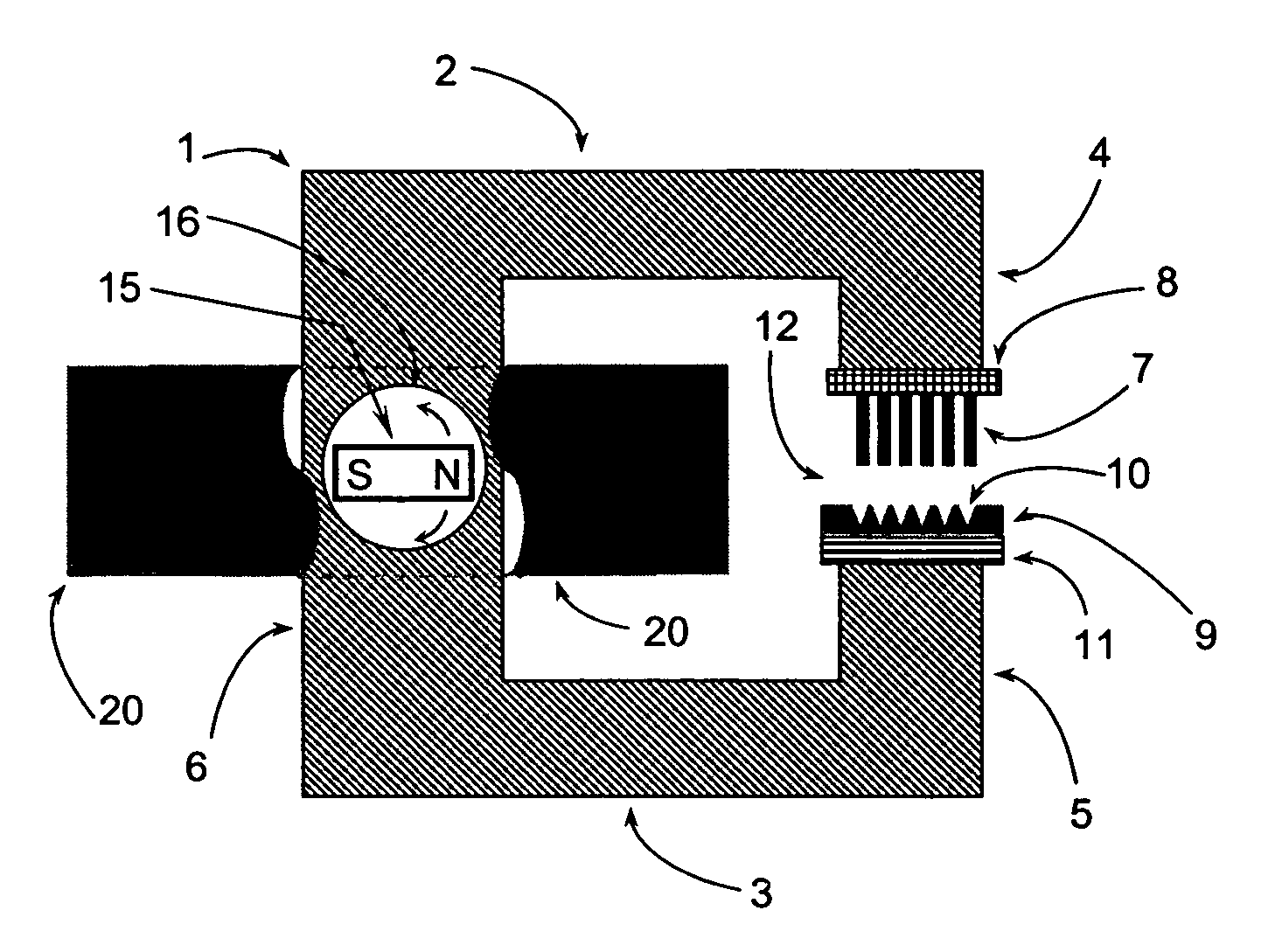

High gradient magnetic separator

ActiveUS7506765B2Facilitated releaseHigh gradient magnetic separatorsWater/sewage treatment by magnetic/electric fieldsMagnetic separatorAtomic physics

In a high-gradient magnetic separator for the selective separation of magnetic particles from a suspension which is conducted through a matrix of plate-like separation structures of a magnetic material which are disposed in a magnetic field and through which the suspension is conducted, alternate plates of the separation structures are movable relative to the other plates which are stationary and are all mounted on a carrier by which they can be moved relative to the stationary plates at least during cleaning of the plates for the removal of magnetic particles collected on the plates.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

Vertical-ring magnetic separator for deferrization of pulverized coal ash

InactiveCN101786041AGood removal effectImprove the effective removal rateHigh gradient magnetic separatorsSheet steelMagnetic poles

The invention discloses a vertical-ring magnetic separator for de-ironing of pulverized coal ash. The vertical-ring magnetic separator comprises a rotating ring, an induction medium, an upper iron yoke, a lower iron yoke, an exciting coil, a feeding opening, a tailing bucket and a water washing device, wherein the induction medium is arranged in the rotating ring. The exciting coil is arranged at the periphery of the upper iron yoke and the lower iron yoke, so as to lead the upper iron yoke and the lower iron yoke to become a pair of magnetic poles for generating a magnetic field in the vertical direction. The upper iron yoke and the lower iron yoke are respectively arranged at the inner and outer sides below the rotating ring. The induction medium is layers of steel plate meshes, each steel plate mesh is woven by wire peduncles, and ridge-shaped sharp corners are arranged at the edges of the wire peduncles. The upper iron yoke is connected with the feeding opening, the lower iron yoke is connected with the tailing bucket for discharging, and the water washing device is arranged above the rotating ring. By adopting the vertical-ring magnetic separator in the invention, the de-ironing effect is improved by 20%, and the effective de-ironing rate is increased to 80% from 60%; moreover, the pressure for de-ironing of solution in the subsequent process is relieved, the production cost is reduced, and the production efficiency is increased.

Owner:CHINA SHENHUA ENERGY CO LTD +1

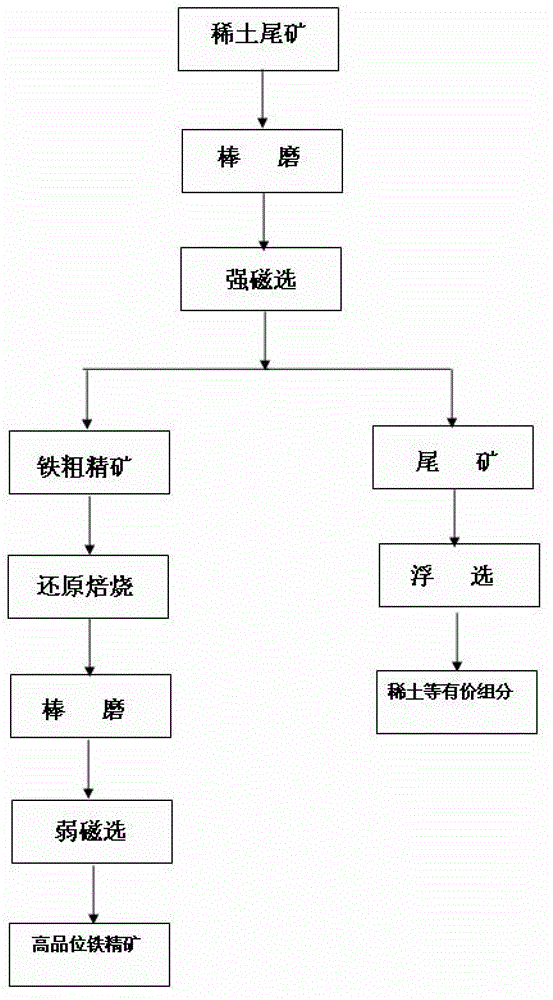

Method for recovering iron from rare-earth tailings and producing high-grade fine iron powder

InactiveCN102876882ALow priceWide variety of sourcesHigh gradient magnetic separatorsIron powderNiobium

The invention discloses a method for recovering iron from rare-earth tailings and producing high-grade fine iron powder. Iron minerals are efficiently recovered from rare-earth tailings and high-grade fine iron powder is produced by a strongly magnetic pre-enrichment-iron rough concentrate reduction roasting-low-intensity magnetic separation method. The method is characterized by comprising the following steps of: performing rod milling of the rare-earth tailings, pre-enriching by a high-gradient high-intensity magnetic separator, recovering valuable ingredients such as rare earth and niobium from obtained tailings of high-intensity magnetic separation by methods such as a flotation method, and uniformly mixing an obtained iron rough concentrate and a carbon-containing reducing agent in a certain proportion for reduction roasting; and performing rod milling of a roasted product, and thus obtaining an iron rough concentrate with the grade of more than 90 percent and the recovery rate of more than 90 percent by a low-intensity magnetic separation method. According to the method, the iron minerals in the rare-earth tailings are pre-enriched by the high-gradient high-intensity magnetic separator, so that the tailings of high-intensity magnetic separation are further recycled; and the coupling relation between a deep reduction-low-intensity magnetic separation iron recovery process method and the recovery of other valuable components is determined.

Owner:UNIV OF SCI & TECH BEIJING

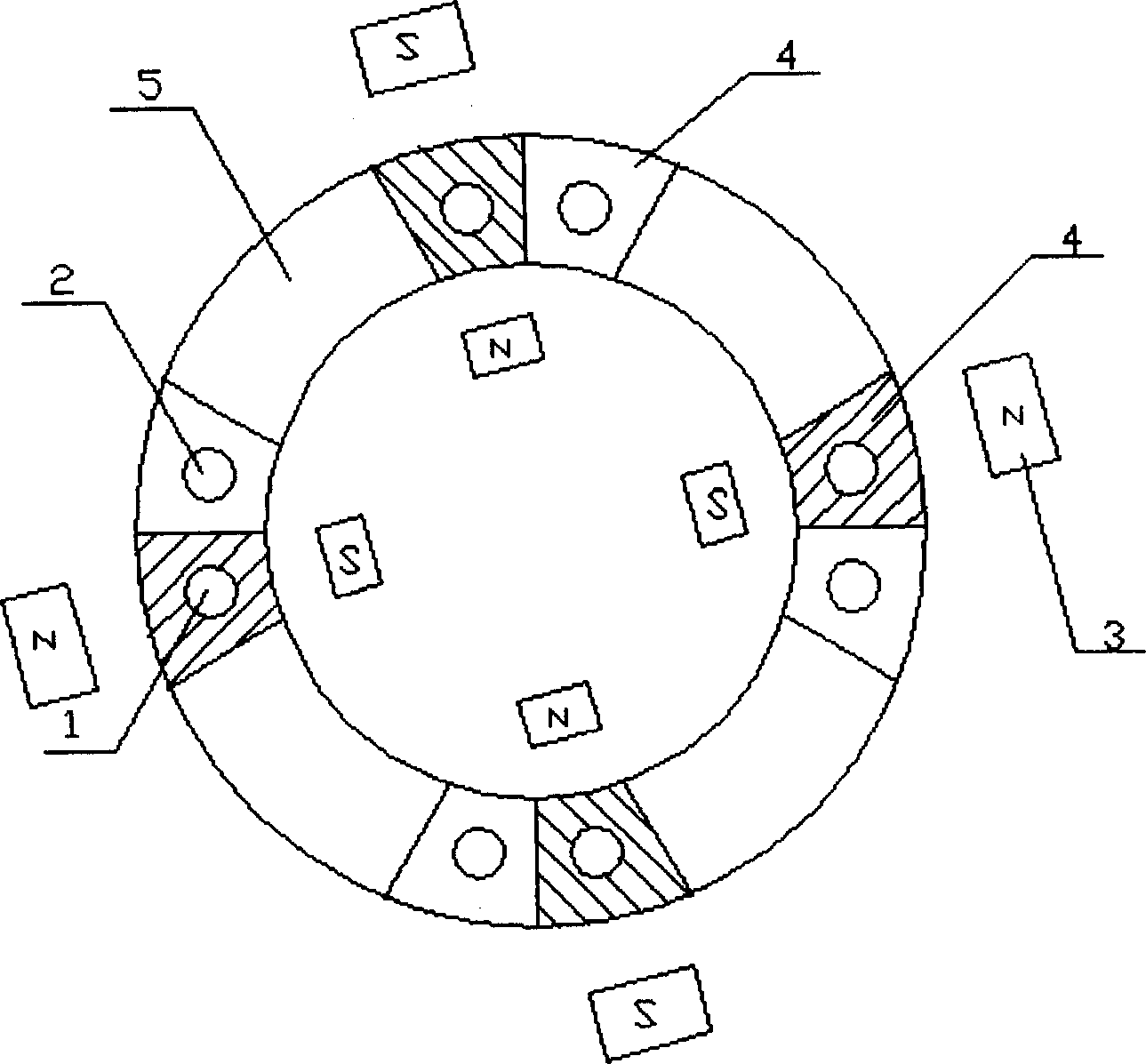

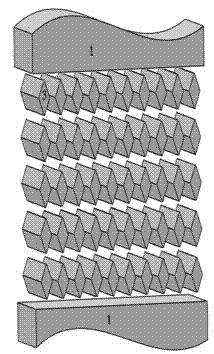

Continuous high gradient magnetic separator

InactiveCN1442234AIncrease the magnetic field strengthHigh gradientHigh gradient magnetic separatorsMagnetic mediaMagnetic separator

A high-gradient continuous magnetic separator for weakly magnetic small particles, has a separation ring composed of multiple separation chambers containing steel fibres and magnetic medium, and at least 4 pairs of C-shaped permanent magnets surrounding said separation ring. The said separation chamber has feed tube and washing water tube. Its advantages are simple structure and easy operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

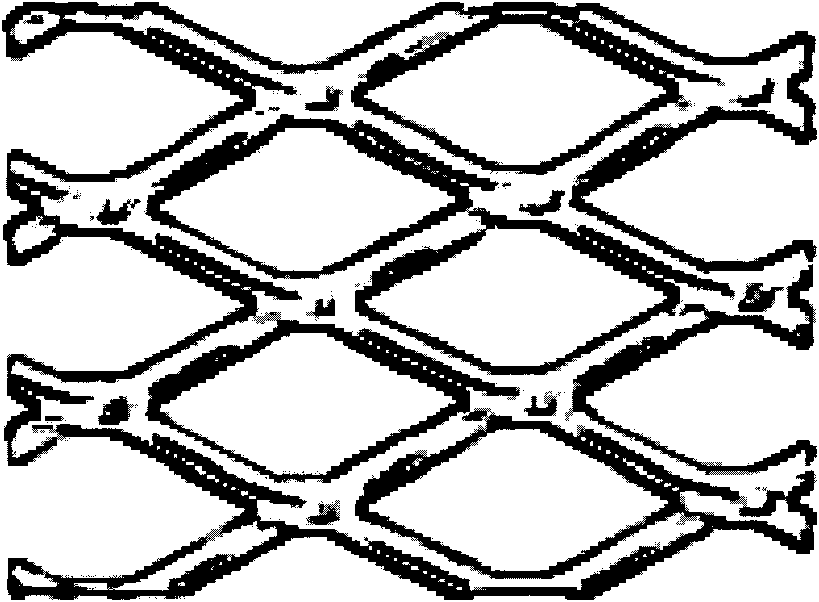

High-gradient magnetic flux converging medium for high intensity magnetic separator

InactiveCN102335638AHigh recovery rateRaise the magnetic field gradientHigh gradient magnetic separatorsMagnetic field gradientLower limit

The invention discloses a novel high-gradient magnetic flux converging medium for a high intensity magnetic separator. The high-gradient magnetic flux converging medium comprises non-magnetic conducting metal plates and a magnetic conducting medium rod, wherein a cross section of the magnetic conducting medium rod has a shape of equilateral rhombus; the rhombic magnetic conducting medium rod is fixed between the two non-magnetic conducting metal plates, thereby forming a separating medium box; the two non-magnetic conducting metal plates are embedded into a separating space of the magnetic separator in a parallel mode and are in suitable size; and two long-end vertex angles (acute angles) of the equilateral rhombic magnetic conducting medium rod are subjected to chamfering treatment. The high-gradient magnetic flux converging medium provided by the invention has the advantages that a gradient of a magnetic field in a magnetic path is high, magnetic resistance is small and energy consumption is saved; the high-gradient magnetic flux converging medium has the advantages of being free from 'magnetic short circuit' phenomenon and being difficult to block during an ore grain recycling process; and the high-gradient magnetic flux converging medium is specially suitable for recycling fine weak-magnetic ore grains and an effective grain level recycling lower limit can reach 5 microns.

Owner:KUNMING UNIV OF SCI & TECH

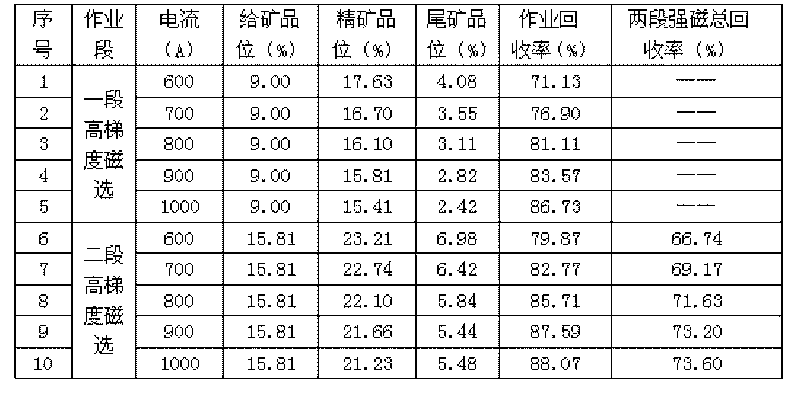

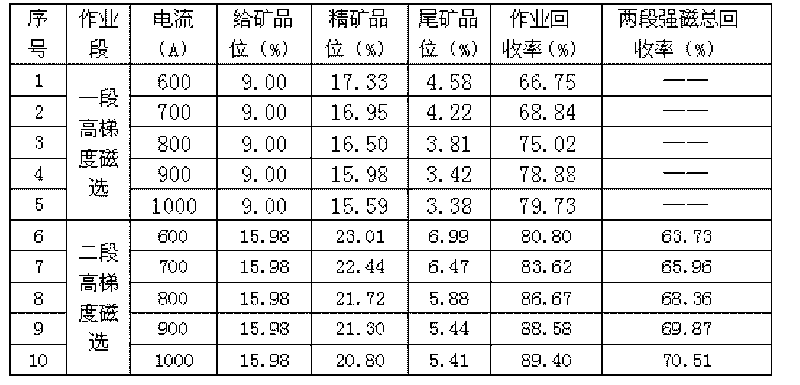

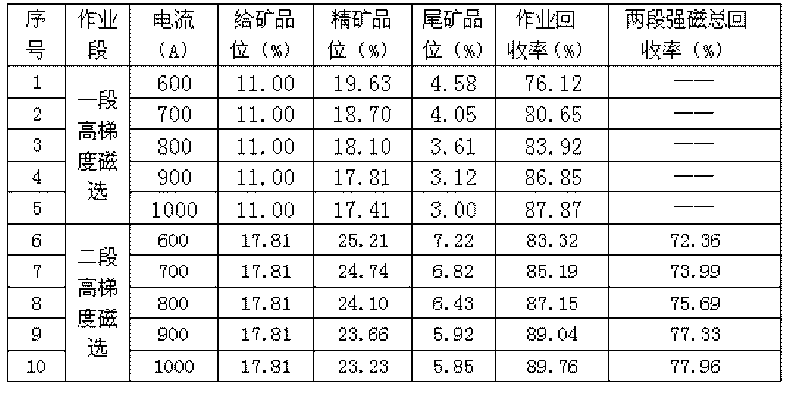

Process for recycling ilmenite through two stages of magnetic separation

ActiveCN101722103AImprove qualityHigh recovery rateHigh gradient magnetic separatorsIlmeniteTitanium

The invention relates to the field of ilmenite separation, in particular to a process for recycling ilmenite from a raw ore through magnetic separation. The technical problem to be solved is to provide an ilmenite recycling process with high recovery rate. The technical scheme for solving the technical problem is to provide the process for recycling the ilmenite through two stages of high-gradient magnetic separation. The process comprises the following steps: performing primary high-gradient magnetic separation on the raw ores after a preparation operation to obtain a primary high-gradient magnetic concentrate; and performing secondary high-gradient magnetic separation on the primary high-gradient magnetic concentrate after the preparation operation to obtain a secondary high-gradient magnetic concentrate. The process can be applied in the field of the ilmenite separation, improves the recovery rate of titanium and reduces production cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

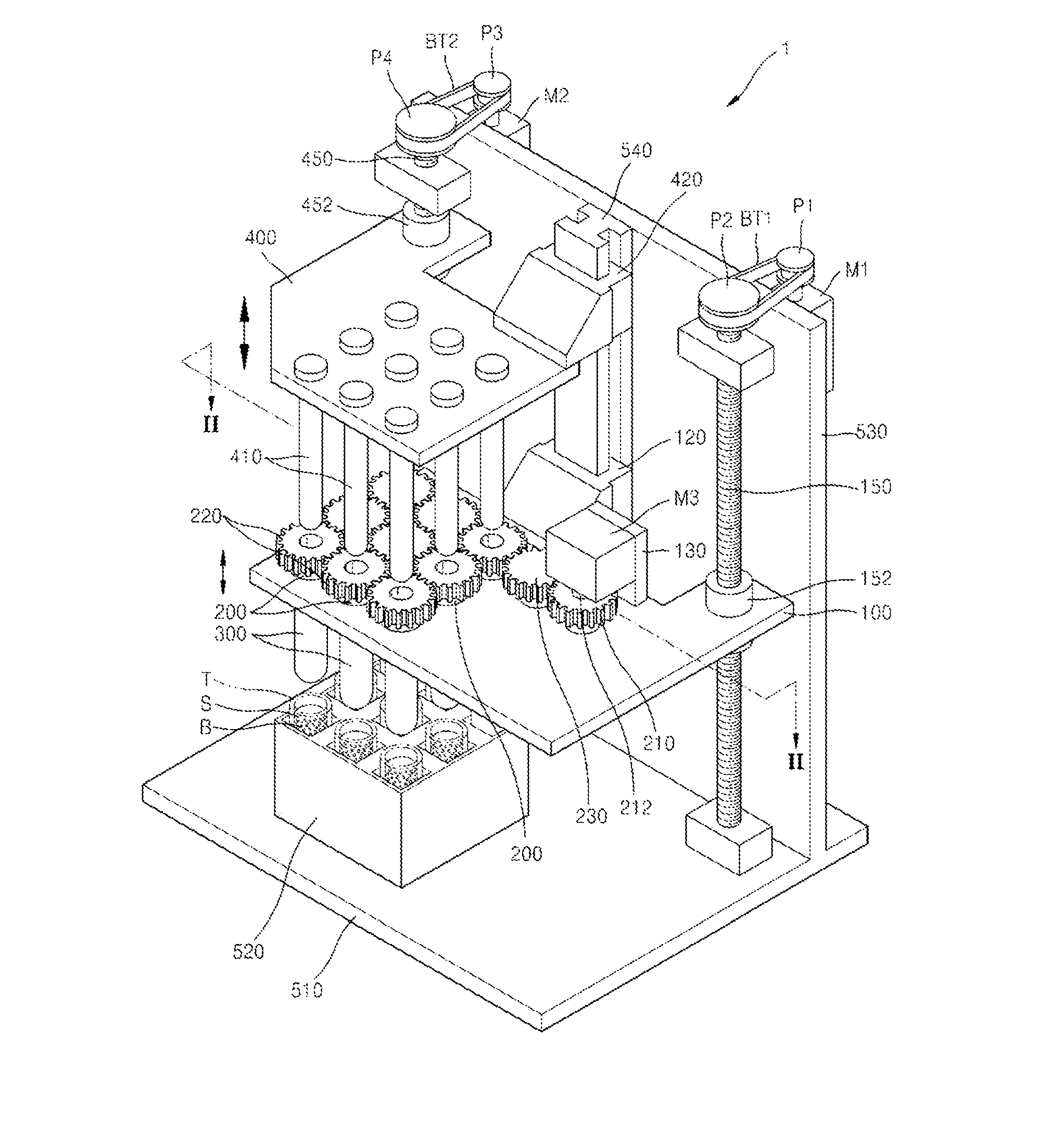

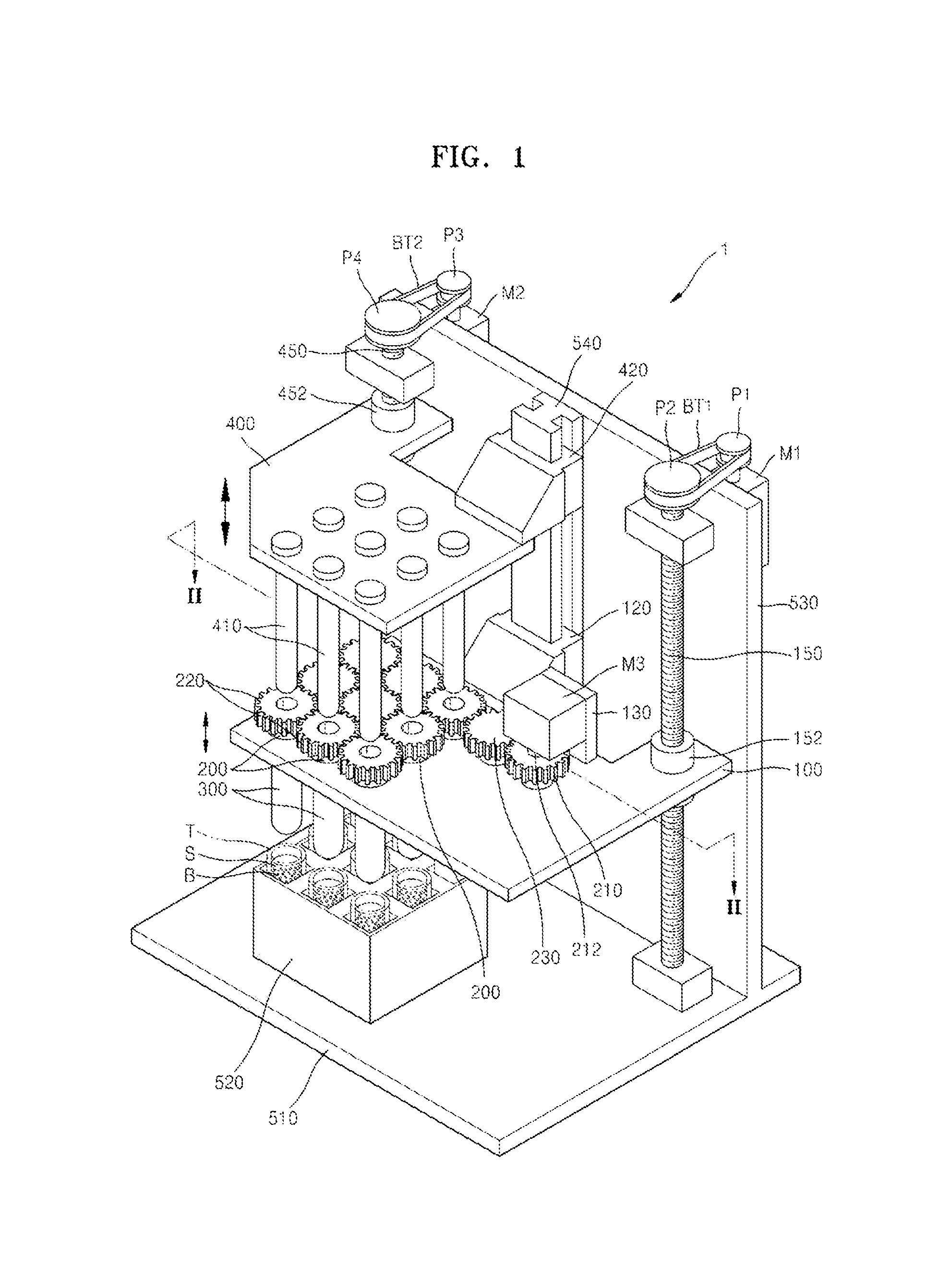

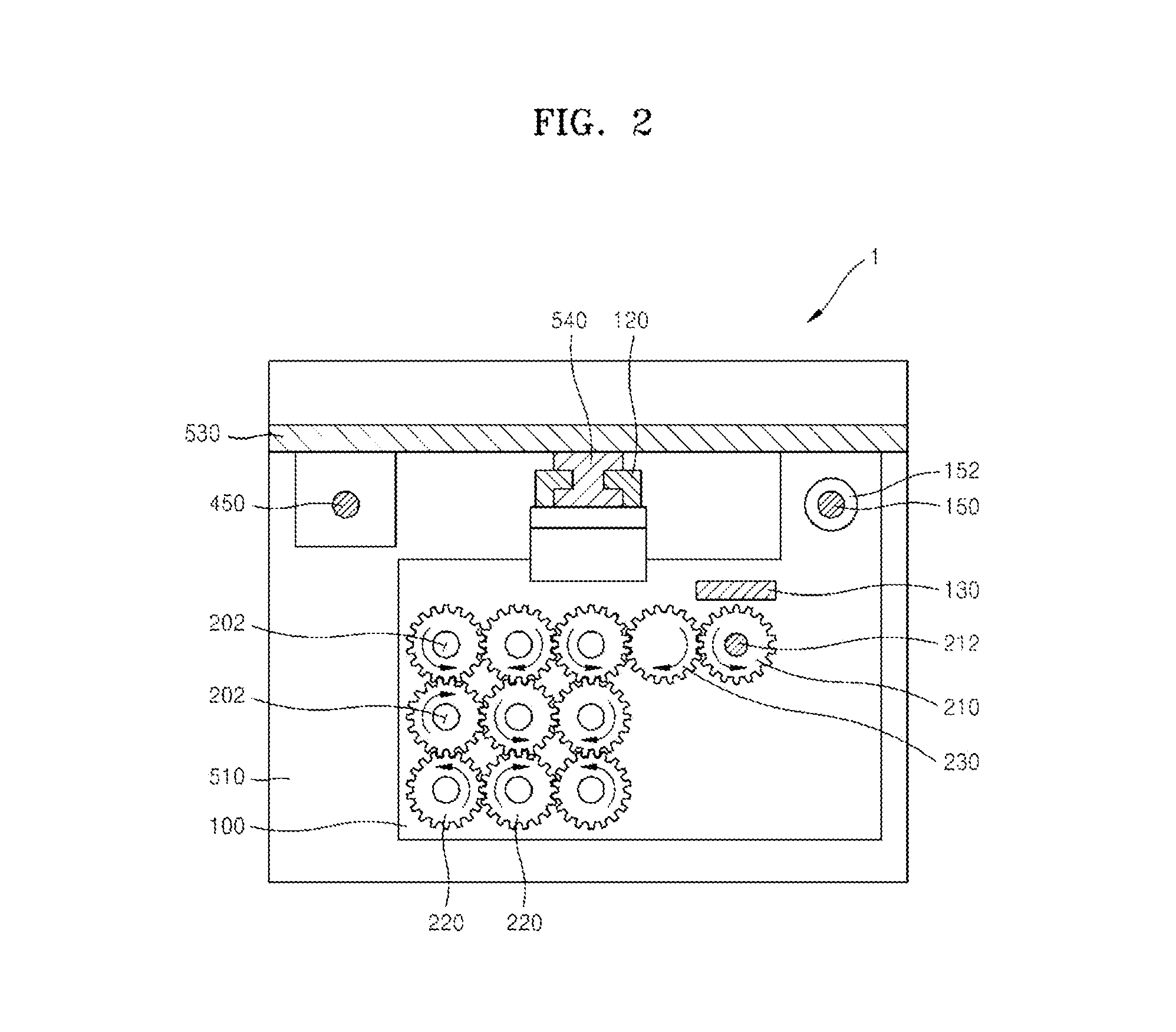

Stirring apparatus

InactiveUS20130126436A1Rotating receptacle mixersShaking/oscillating/vibrating mixersMagnetic tension forceMagnetic bead

Owner:SAMSUNG TECHWIN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com