Patents

Literature

2132 results about "Iron removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

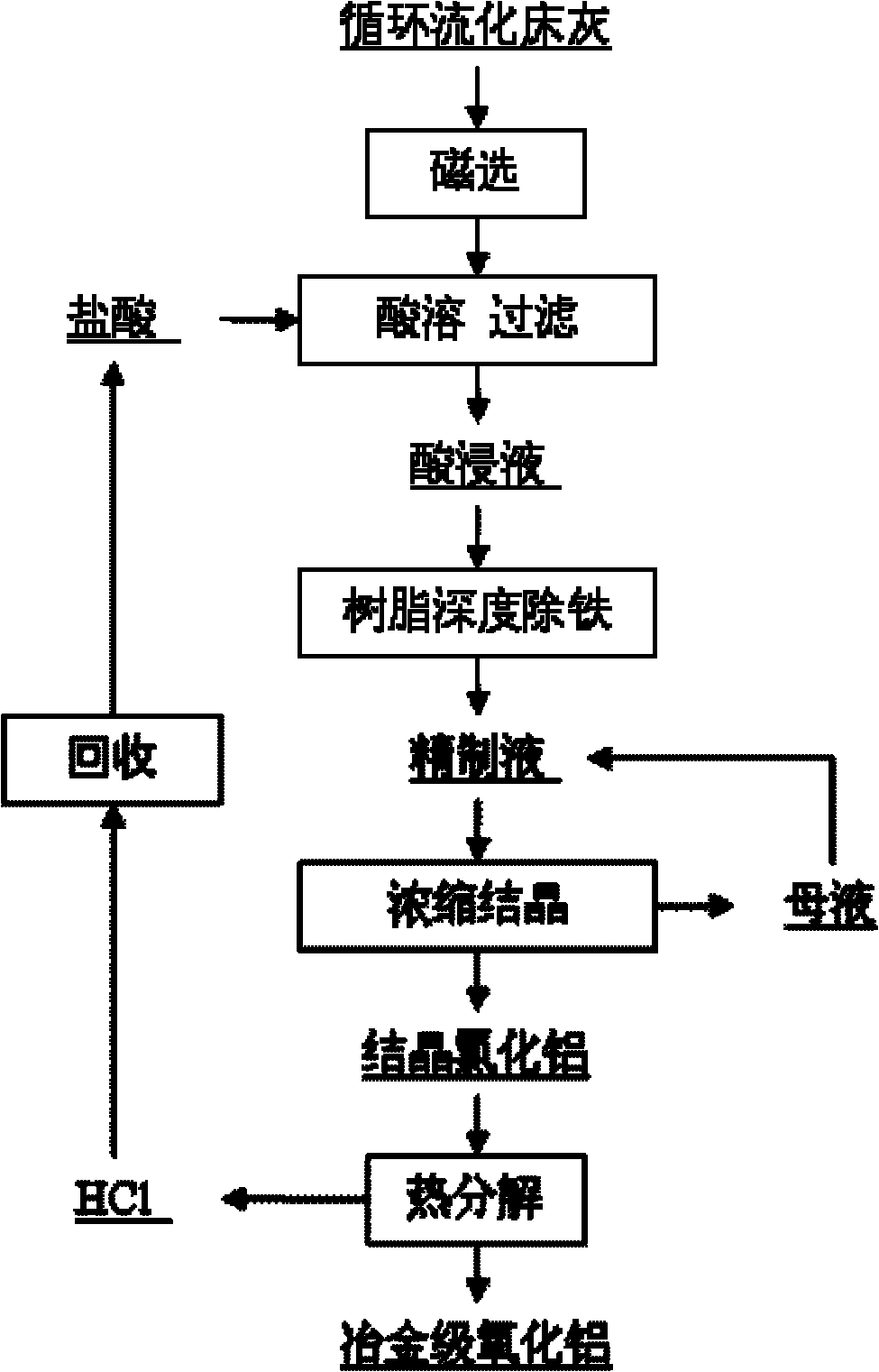

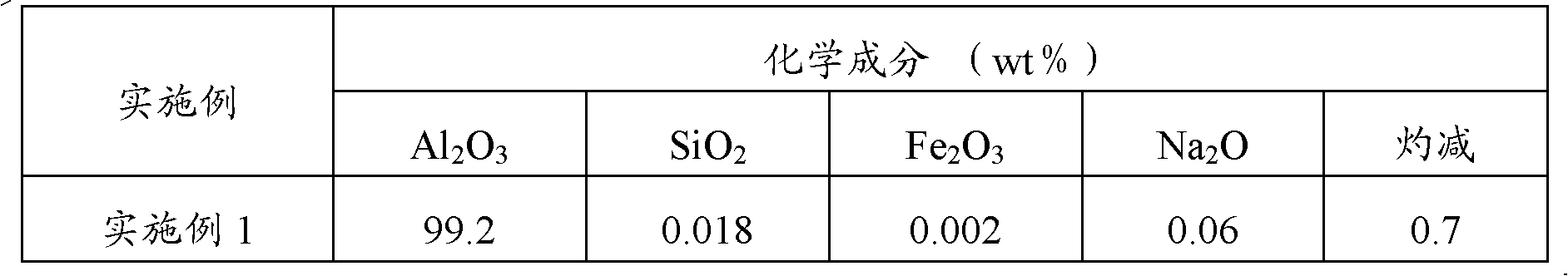

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

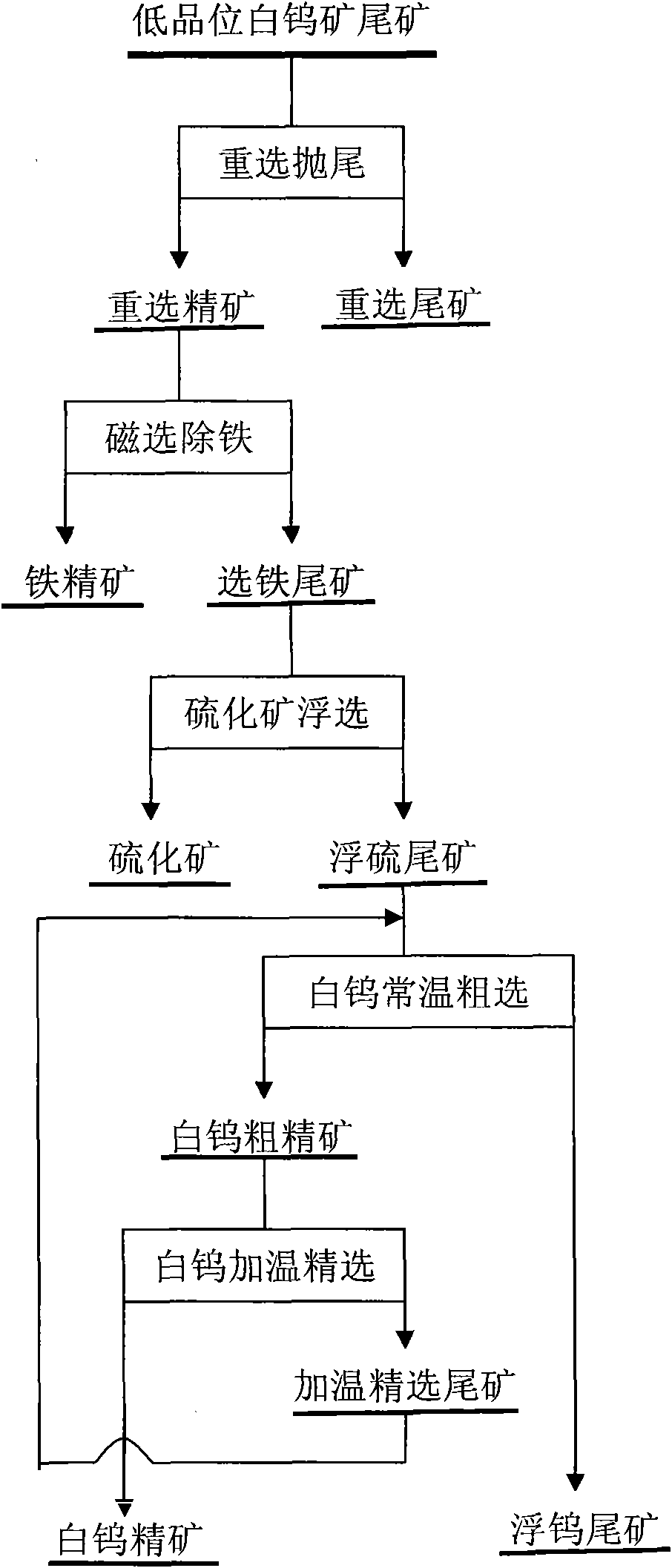

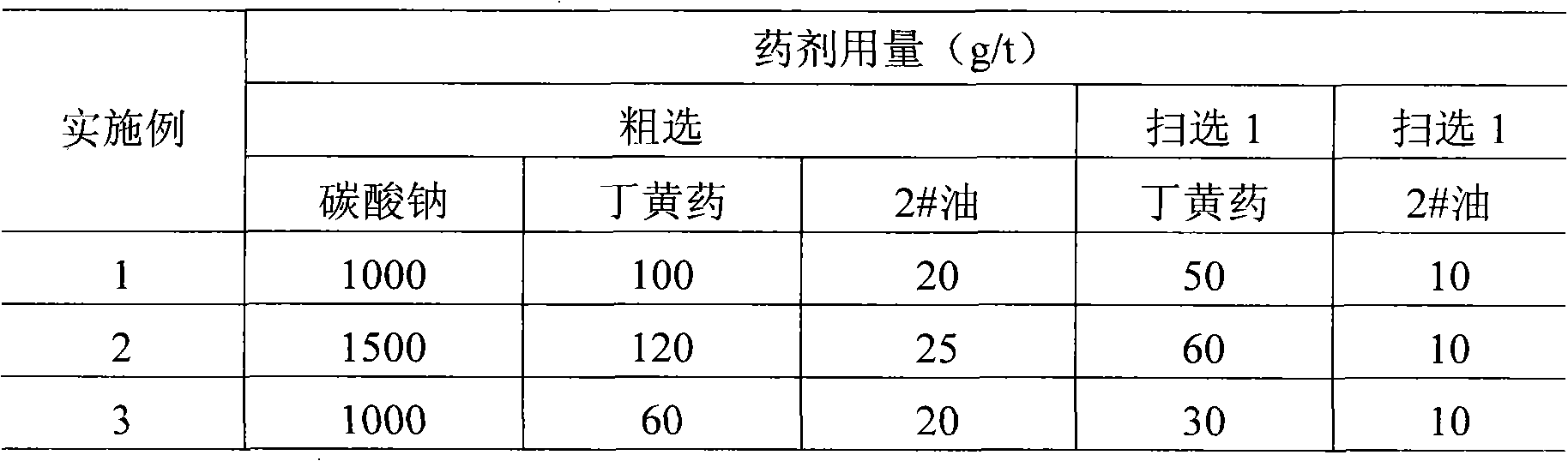

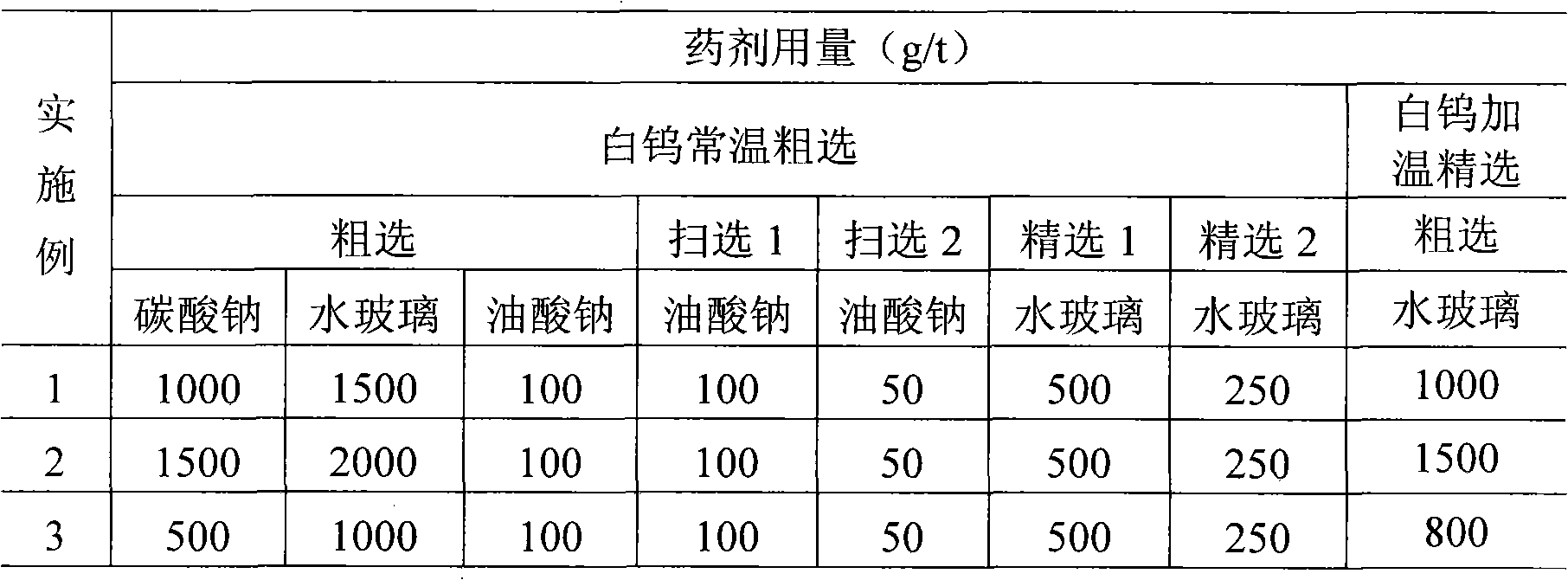

Ore dressing method of low-grade scheelite

InactiveCN101869876AImprove sorting indexImprove the quality of selectionFlotationIron removalLower grade

The invention relates to an ore dressing method of a low-grade scheelite, which is characterized by comprising the following steps: 1. tailing discard by gravity concentration; 2. iron removal by magnetic separation; 3. sulfide ore flotation; 4. normal-temperature rougher flotation of scheelite; and 5. heating concentration of the scheelite. The invention provides a lower-cost ore dressing method for dressing scheelite concentrates from the tailings of the low-grade scheelite. The invention has the characteristics that the comprehensive recovery cost is saved, the beneficiation feed grade of the scheelite is improved, the flotation feed ore quantity is reduced, the dosage of a flotation reagent is reduced, the used ore dressing reagent is more friendly to the environment, and secondary pollution can not be caused. The method of the invention is applicable for low-grade scheelite resources with 0.03 to 0.15 percent of WO3.

Owner:广东省资源综合利用研究所

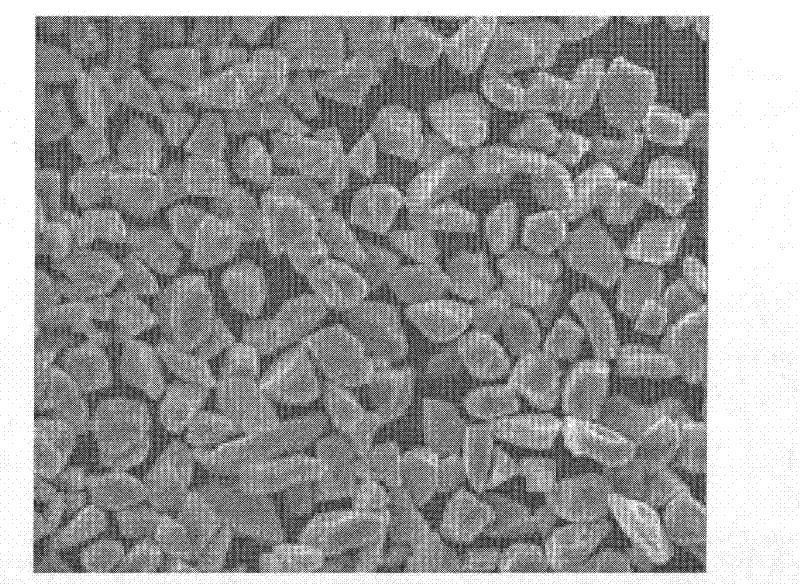

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

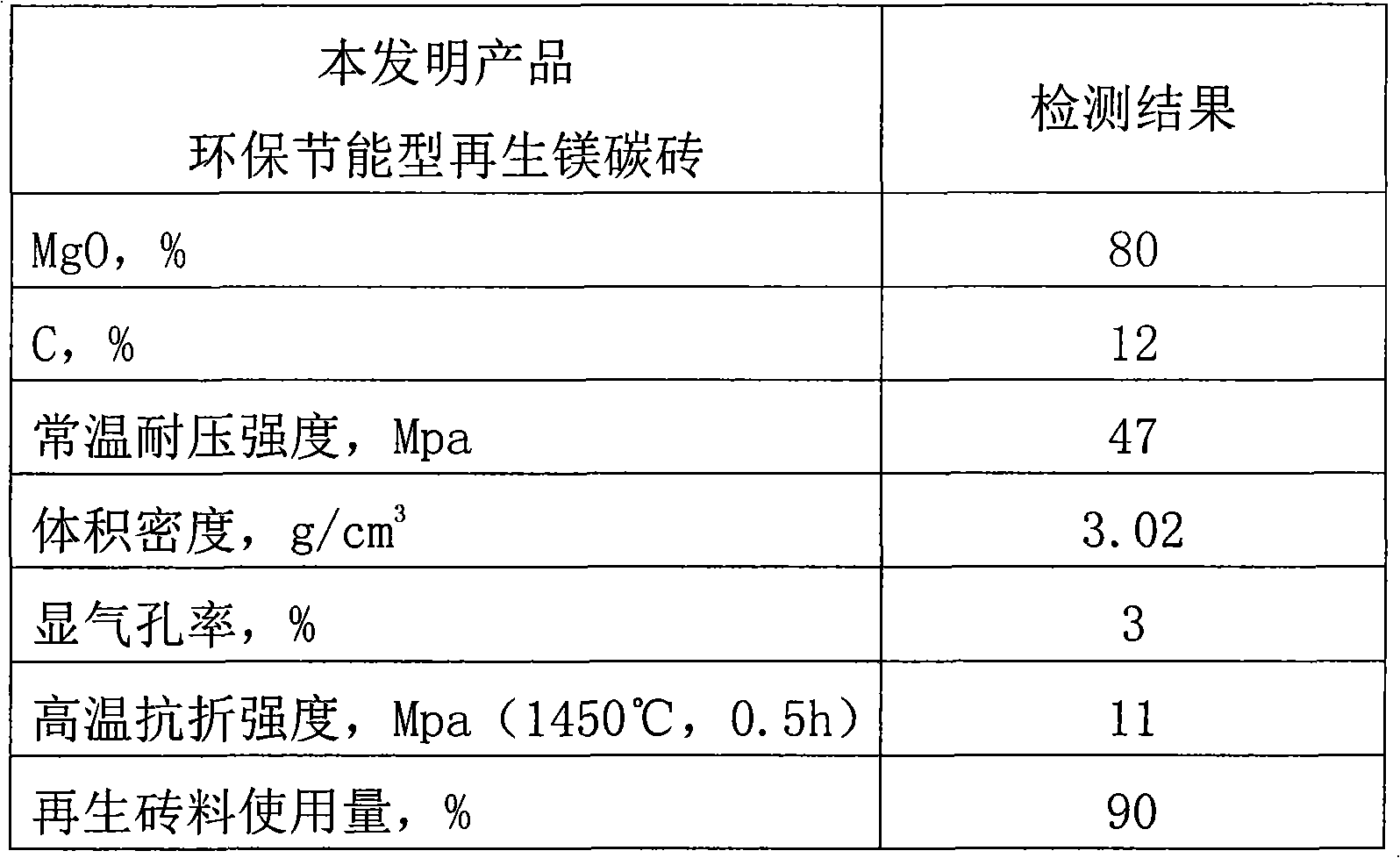

Production method of environment-friendly and energy-saving type regenerative magnesia-carbon brick

InactiveCN101851103AImprove recycling ratesSolve the problem of unstable performanceSolid waste managementBrickResonance

The invention discloses a production method of an environment-friendly and energy-saving type regenerative magnesia-carbon brick, comprising the following production steps: (1) sorting and crushing waste magnesia-carbon bricks; (2) powdering with weak acid aqueous solution; (3) carrying out high-temperature drying to dehydrate and electromagentic resonance to homogenize; (4) carrying out crushing, particle shaping, iron removing and screening; (5) mixing materials: mixing regenerative aggregates, fine powder and newly-added and electrically-fused magnesite aggregates, and fine powder; and (6)forming. The mixed material is added with a bonding agent, is treated by high-speed constant-temperature mixing, hydraulic forming and electric heating drying and obtains a regenerative magnesia-carbon brick product. The production method solves the problem that the product in the prior art has unstable performance, can retain usable components such as electrically-fused magnesite, crystalline flake graphite and the like in the raw material furthest, has high recovery and utilization rate and is energy-saving and environment-friendly.

Owner:吴钦合

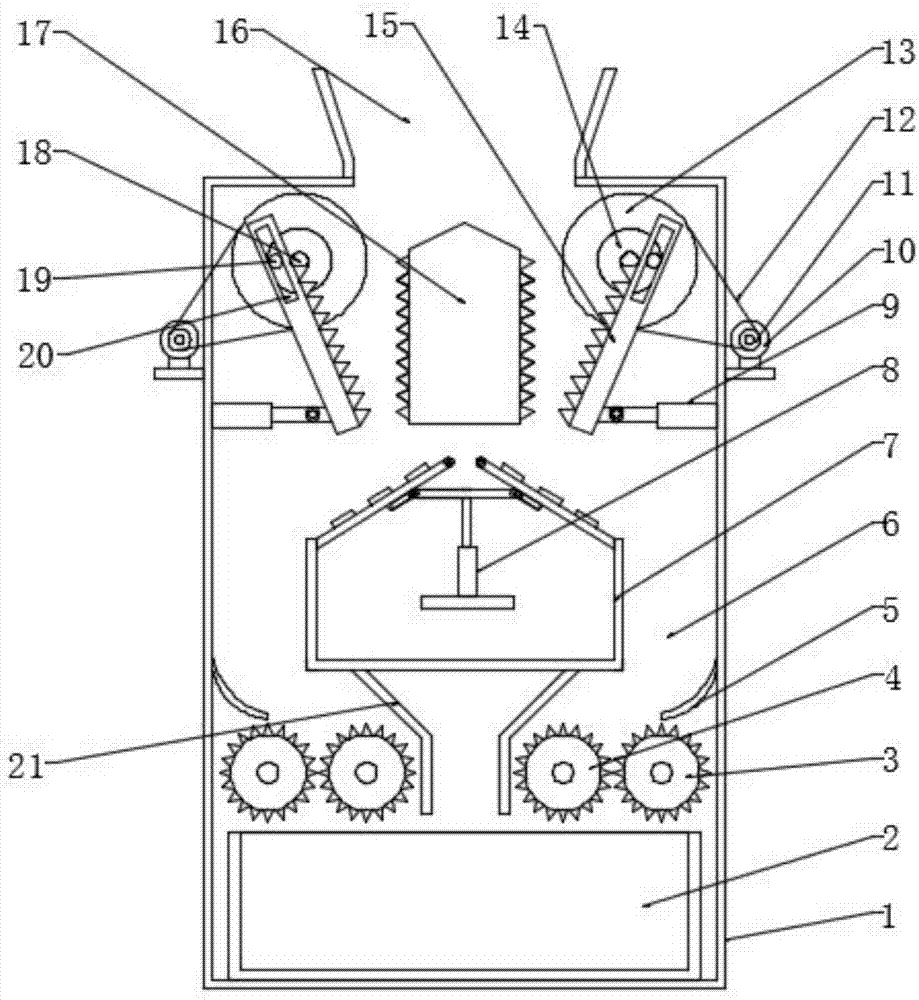

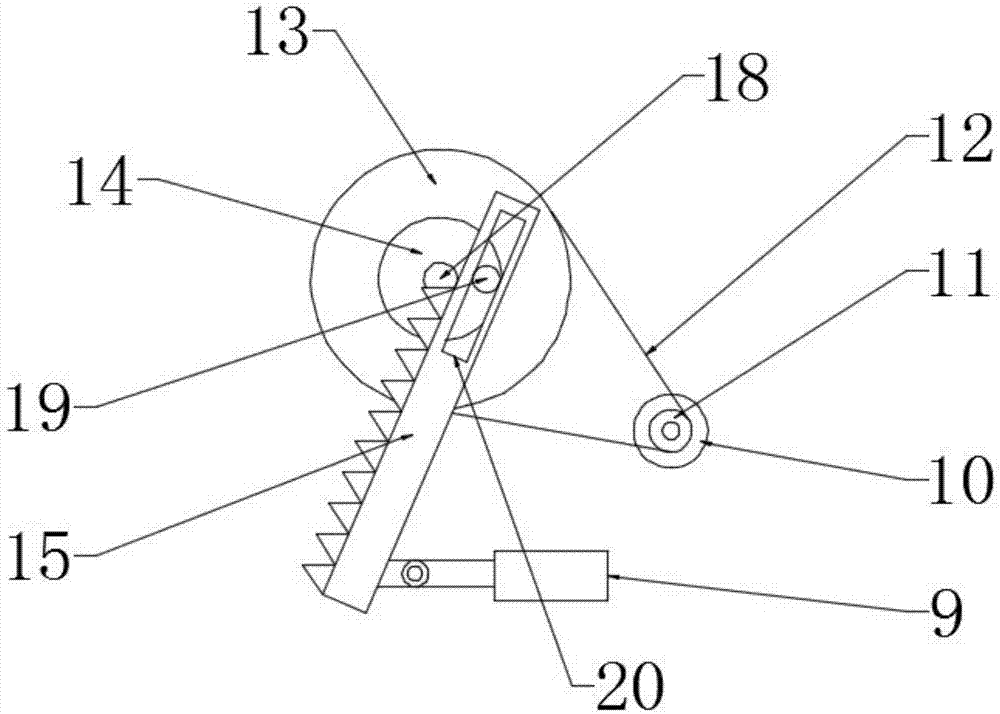

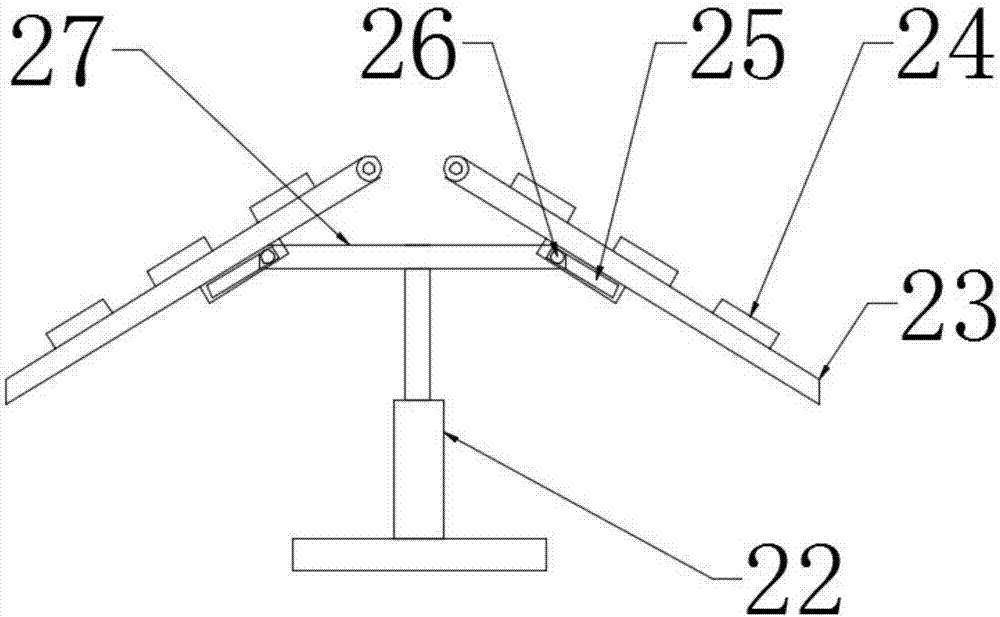

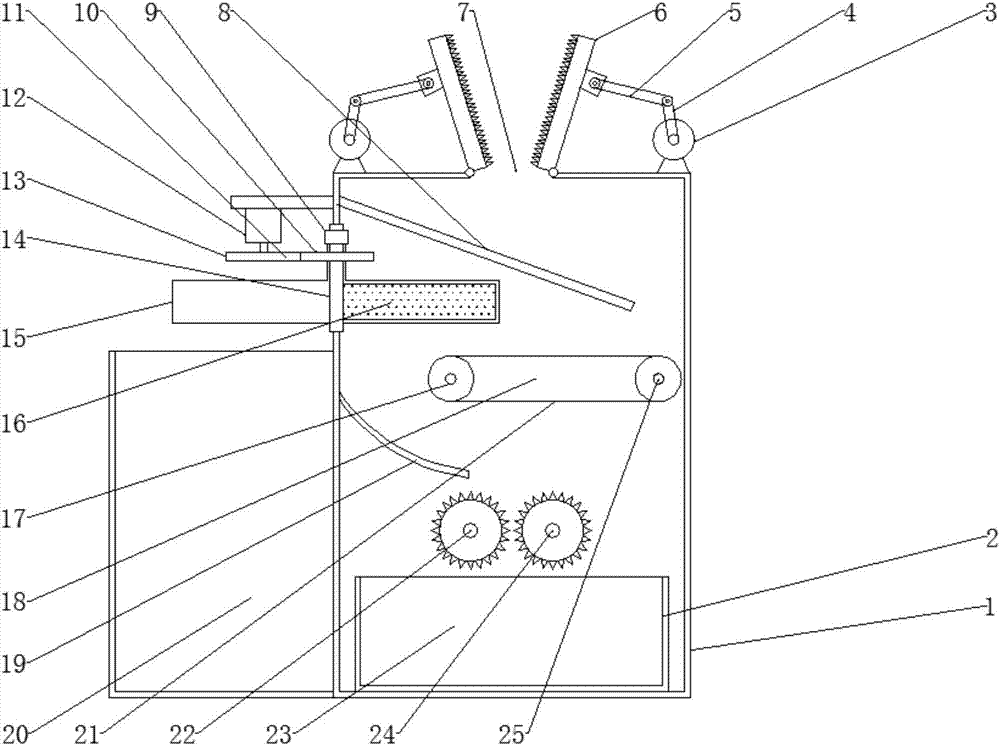

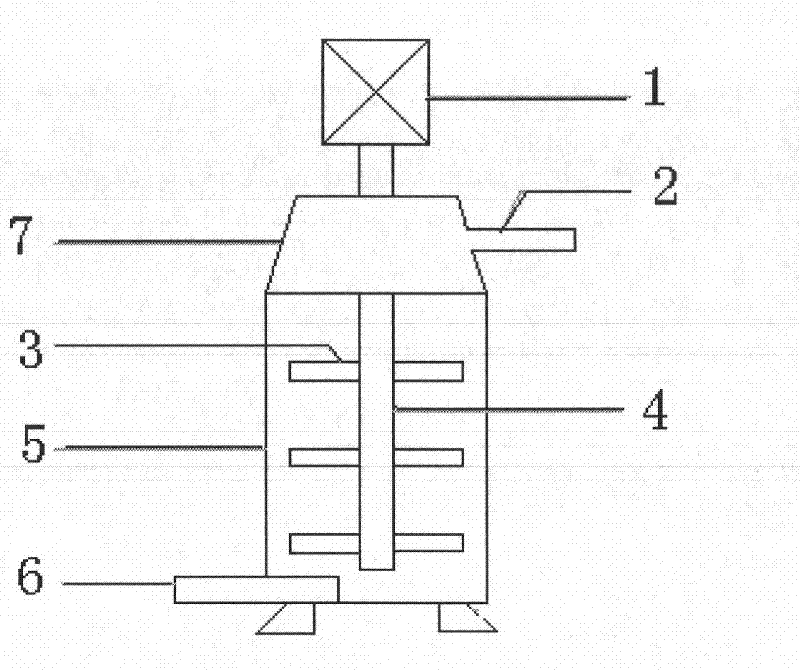

Efficient crushing device for construction waste recovery

InactiveCN107350004AAdjustable sizeGood for subsequent crushingMagnetic separationGrain treatmentsHydraulic cylinderIron removal

The invention discloses an efficient crushing device for construction waste recovery. The efficient crushing device comprises a box body, and a preliminary breaking mechanism is fixedly arranged at the upper part of the inner chamber of the box body. The preliminary breaking mechanism comprises a fixed breaking plate, a movable breaking plate, a disc, a hydraulic cylinder and a motor. An iron removal mechanism is arranged under the preliminary breaking mechanism, and a first crushing roller and a second crushing roller are arranged under the iron removal mechanism. In the falling process of massive construction wastes, the preliminary breaking mechanism breaks the massive construction wastes step by step, so that metal in the wastes is exposed. Moreover, follow-up crushing is facilitated, and the crushing efficiency is improved. The size of broken particles of construction wastes can be adjusted, and the breaking degree can be adjusted. The construction wastes are subjected to second level of crushing through the first crushing roller and the second crushing roller, and the construction wastes are crushed more thoroughly. The crushing effect is good, and the crushing efficiency is high. The metal, such as steel bars in the construction wastes can be removed through the iron removal mechanism and are collected. The efficient crushing device has the advantages of simple structure and convenience in operation.

Owner:广西综改咨询服务有限公司

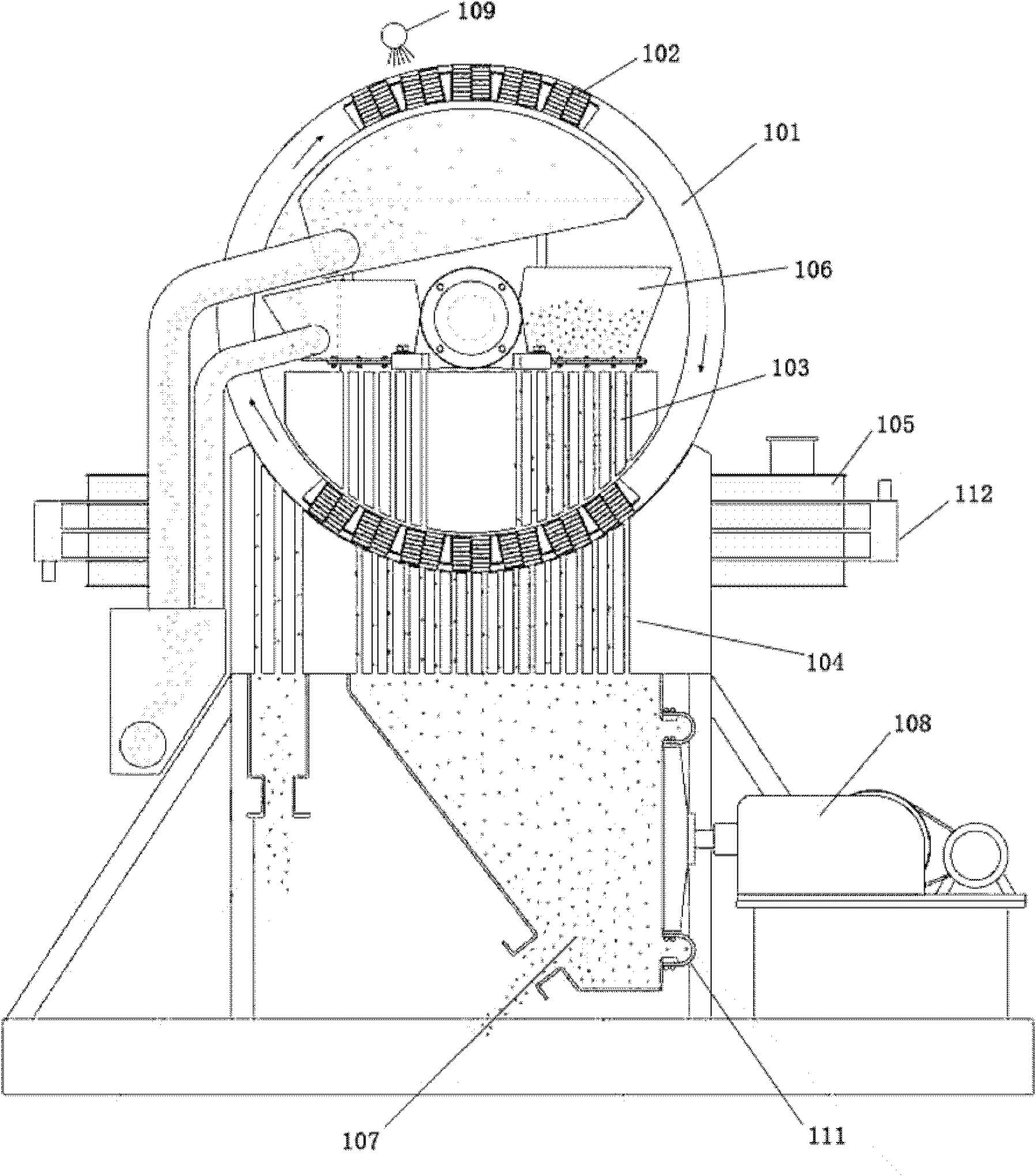

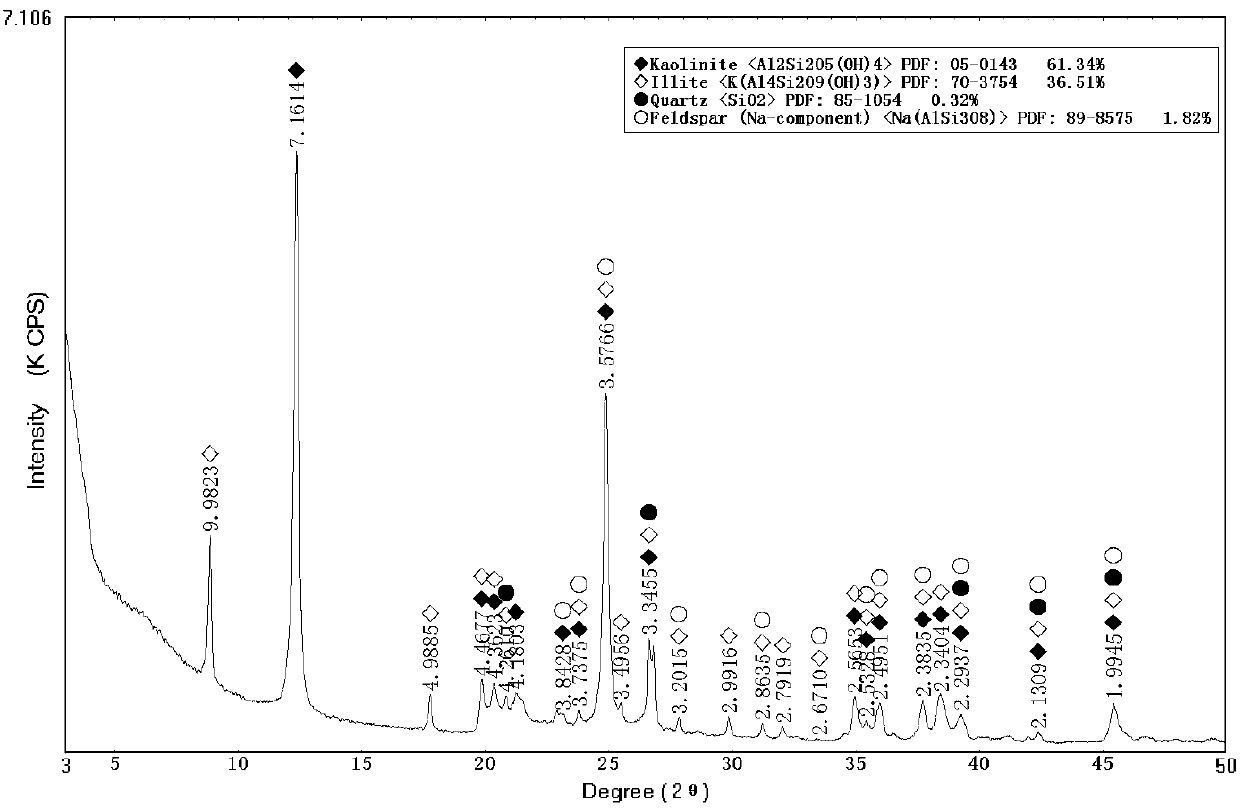

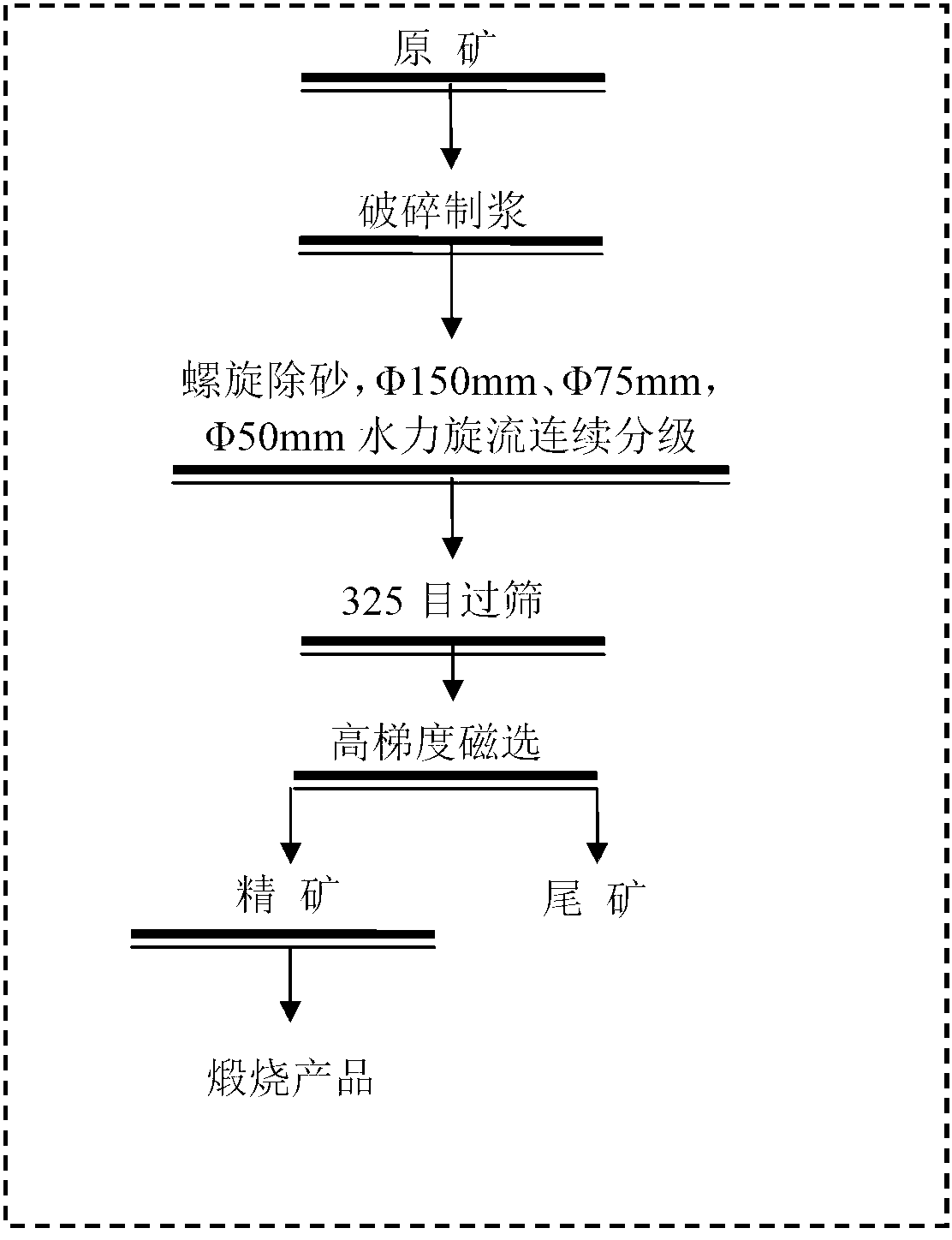

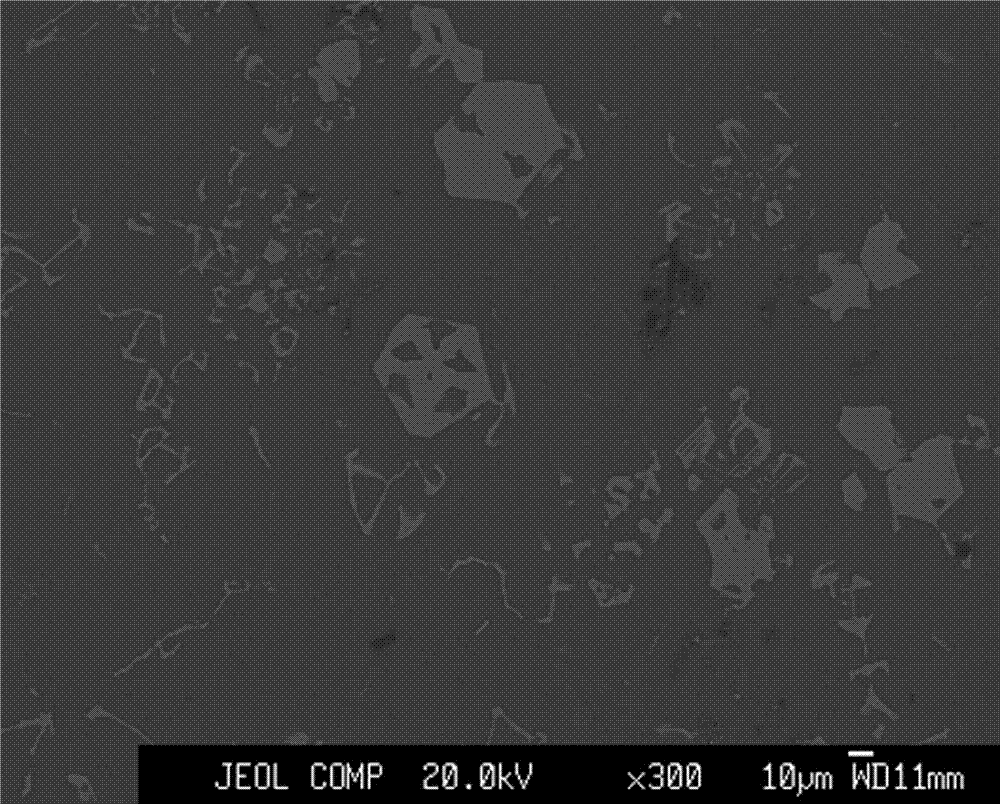

Technique for efficiently removing iron from kaolin

The invention relates to a technique for efficiently removing iron from kaolin by magnetic separation, which is characterized by comprising the following steps: (1) purifying kaolin raw ore to obtain a magnetic separation raw material; (2) adding water to the magnetic separation raw material obtained in the step (1) to prepare a mixed slurry with the solid content of 10-20 wt%, adding sodium hexametaphosphate accounting for 0.2-0.6 wt% of the magnetic separation raw material, slurrying, stirring for 20 minutes, and passing through a 325-mesh wet sieve; (3) carrying out high-gradient magnetic separation on the undersize slurry of the 325-mesh sieve in the step (2): while controlling the magnetic field intensity of the high-gradient magnetic separator at 1.0-1.8T and the slurry flow rate at 0.8-1.8cm / s, the slurry is subjected to magnetic separation by the high-gradient magnetic separator to obtain a concentrate slurry; (4) adding alum accounting for 1-6 wt% of the concentrate slurry into the concentrate slurry obtained in the step (3), flocculating, carrying out pressure filtration, drying, and packaging to obtain a magnetic concentrate; and (5) calcining the magnetic concentrate obtained in the step (4) to obtain the calcined kaolin. The technique has the advantages of high iron removal efficiency and obvious whitening effect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

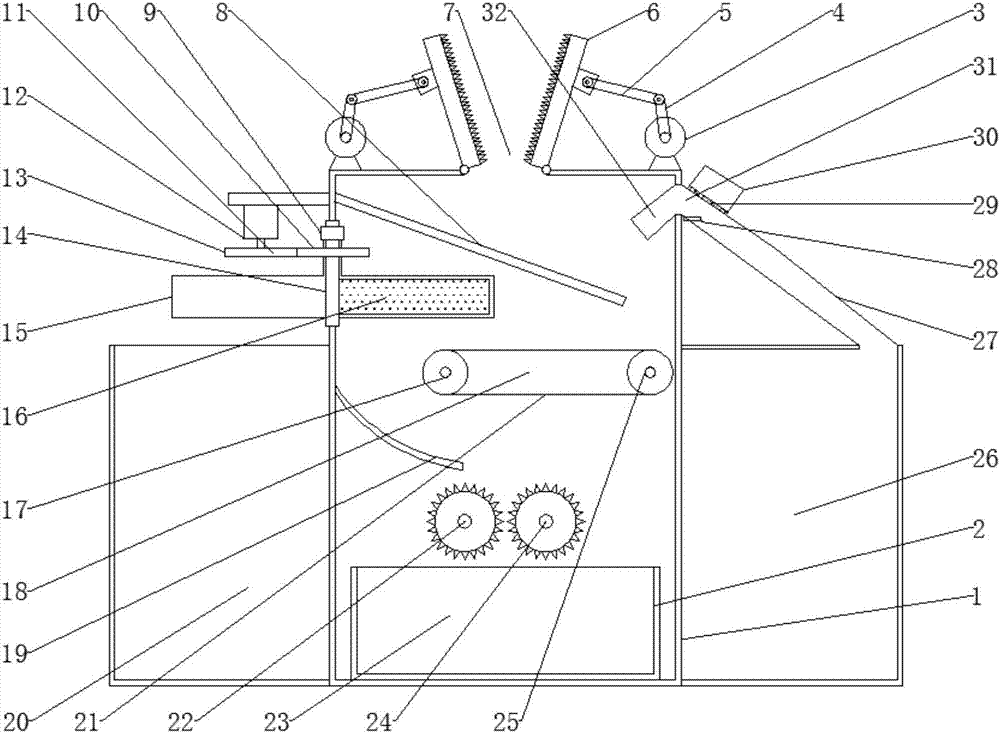

High-efficiency crushing device for construction waste recovery

InactiveCN106944182AEasy to reproduceAvoid affecting service lifeGas current separationMagnetic separationIron removalArchitectural engineering

The invention discloses a high-efficiency crushing device for recycling construction waste, which includes a machine body, a first motor, a first connecting rod, a second connecting rod and a movable jaw plate are symmetrically arranged on the top of the body, and the first motor is driven to connect the first connecting rod. The other end of the first connecting rod is hinged with the second connecting rod, and the other end of the second connecting rod is hinged with a movable jaw plate. The bottom of the movable jaw plate is connected to the top of the body through a hinge. An inclined plate is fixed in the lower part of the body, a conveying device is arranged under the inclined plate, an iron removal device is arranged above the conveying device, an arc-shaped plate is fixed under the left end of the conveying device, and a secondary crushing device is arranged under the right end of the arc-shaped plate. The invention is provided with a first motor, a first connecting rod, a second connecting rod and a movable jaw plate, which can pre-shred the construction waste, and is provided with an iron removal device to remove metals such as steel bars and steel bars in the construction waste to avoid Damage the device and affect the service life of the device.

Owner:合肥红蔻健康管理有限公司

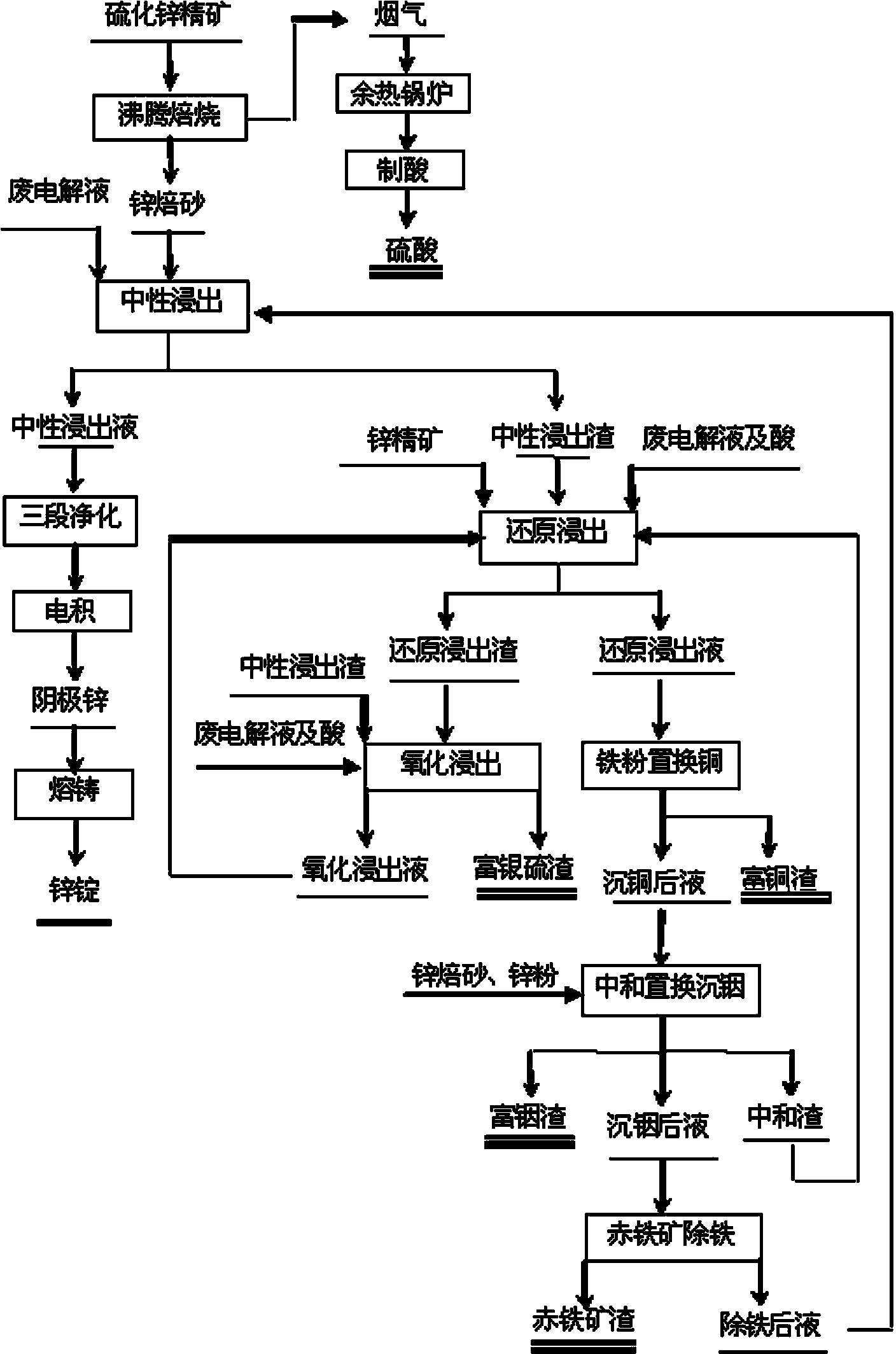

Method for individually processing high-iron zinc sulfide concentrate

ActiveCN103409622AThe process is highly targetedHigh enrichment ratioProcess efficiency improvementIndiumHydrometallurgy

The invention belongs to the technical field of hydrometallurgy, and particularly relates to a method for individually processing high-iron zinc sulfide concentrate. The method comprises a step of subjecting the high-iron zinc sulfide concentrate to calcination in a fluidized bed combustion boiler to obtain zinc calcine; a step of subjecting the zinc calcine to neutral leaching to produce neutral leaching solution and neutral leaching residue; a step of, after the neutral leaching residue and the high-iron zinc sulfide concentrate are mixed, successively performing reduction leaching and oxidation leaching, and circulating oxidation leaching solution to the reduction leaching to produce reduction leaching solution and silver-rich sulfur residue; a step of replacing the reduction leaching solution by using iron powder to precipitate copper and to produce copper-rich slag and solution after copper precipitation; a step of subjecting the solution after copper precipitation to pre-neutralization by using the zinc calcine, and then replacing by using zinc powder to precipitate indium and to produce indium-rich slag and solution after indium precipitation; and a step of bubbling oxygen into the solution after indium precipitation, heating and removing iron to obtain iron removal solution and hematite slag. The hematite slag can be utilized as a raw material for ironmaking. The method has strong pertinence, short technological process and high metal recovery yield, and the method is clean, efficient, energy-saving and environmental friendly. Separation and comprehensive utilization of zinc, indium, copper and iron are achieved.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

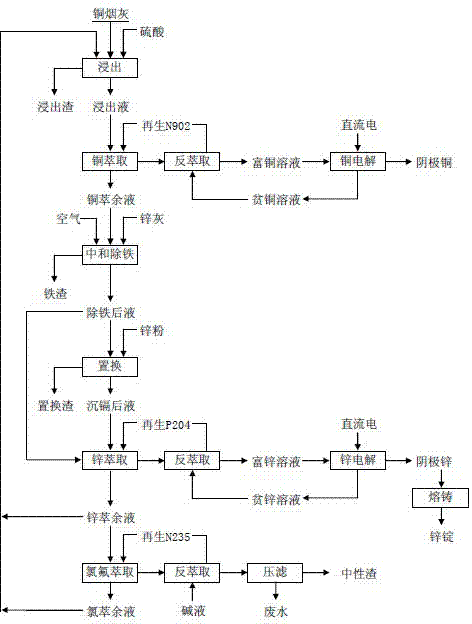

Technology for recovering production of electrolytic copper and zinc from smelting ash

ActiveCN102851693AWide adaptabilityFlexiblePhotography auxillary processesProcess efficiency improvementElectrolysisCopper oxide

The invention discloses a technology for recovering production of electrolytic copper and zinc from smelting ash. The technology comprises a step of smelting ash leaching, a step of copper extraction and purification through copper electrodeposition, a step of iron removal through neutralization, a step of cadmium removal, and a step of zinc extraction and purification through zinc electrodeposition. The method is characterized in that chemical components in the smelting ash are analyzed, and the smelting ash is leached by a sulfuric acid solution leaching agent; the leachate obtained after the above leaching reaction undergoes a separation operation of copper extraction and purification through the copper electrodeposition; the resultant copper extraction liquor is neutralized by high-zinc dust which is a neutralizer to remove iron; cadmium is displaced and deposited by zinc powder having a mass same with cadmium after the iron removal through the neutralization; and the zinc extraction is carried out through the zinc electrodeposition by casting zinc ingot products. The technology has a wide adaptability, adopts two steps to complete the exchange reaction of zinc oxide and copper oxide in the raw material with an acid, and adopts the high-zinc dust as the neutralizer, so the massive zinc loss caused by entrainment of routine neutralizers comprising calcium oxide and sodium hydroxide is avoided. A zinc extraction liquor obtained in the above step is purified by N235, so economy and effectiveness are realized.

Owner:江西自立环保科技有限公司

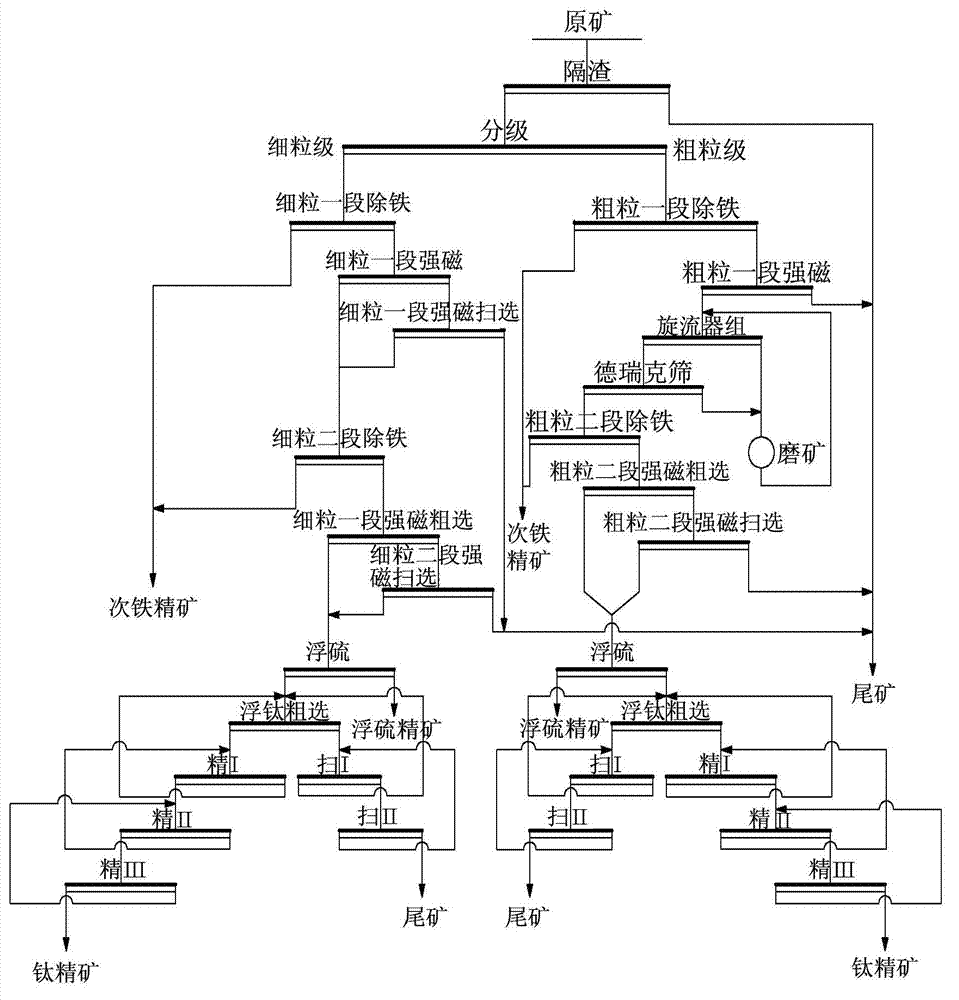

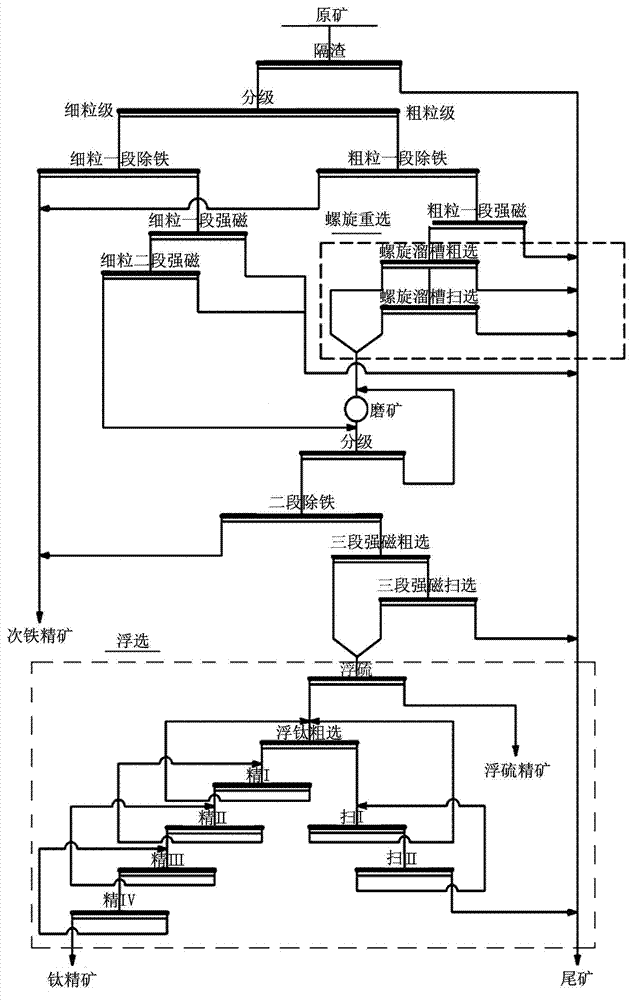

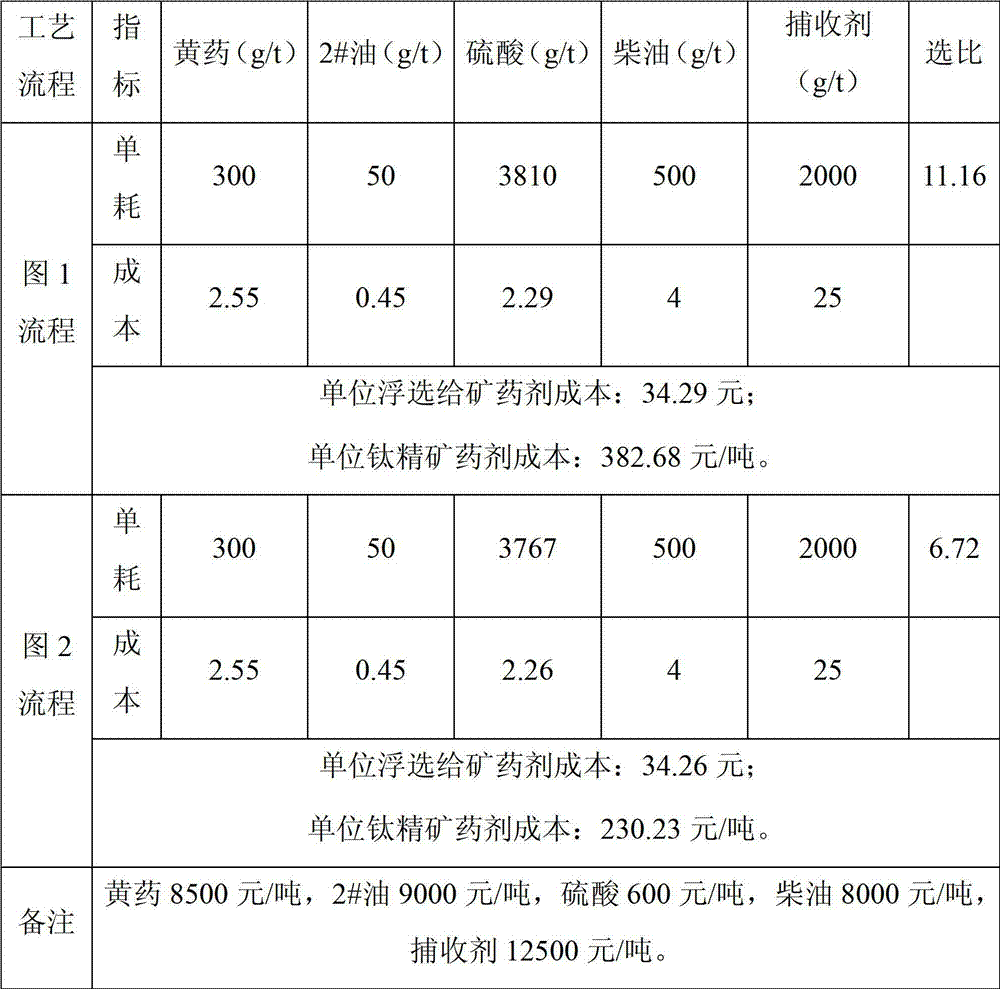

Beneficiation method of low-grade ilmenite

ActiveCN103041912AQuality assuranceHigh recovery rateWet separationMaterials scienceMagnetic separation

The invention provides a beneficiation method of low-grade ilmenite. The beneficiation method includes the following steps: screening and grading raw ore to obtain coarse grain materials and fine grain materials, subjecting the coarse grain materials and fine grain materials to first-stage iron removal respectively to obtain coarse grain iron tailings, fine grain iron tailings and inferior iron ore concentrates, subjecting the coarse grain iron tailings with iron removed to first-stage high intensity magnetic separation to obtain high intensity concentrates and tailings, subjecting the high intensity concentrates to spiral gravity to obtain gravity concentrates and subjecting the gravity concentrates to ore grinding, subjecting the fine grain iron tailings with iron removed to first-stage high intensity magnetic separation and second-stage high intensity magnetic separation sequentially to obtain high intensity magnetic concentrates and mixing the high intensity magnetic concentrates with the gravity concentrates with ore ground to be graded, and subjecting the unqualified graded mixed concentrates to ore grinding and subjecting the qualified mixed concentrates to second-stage iron removal, three-stage high intensity magnetic separation and flotation sequentially to obtain the final ilmenite concentrates. The beneficiation method of ilmenite is applicable to low-grade ilmenite. According to the beneficiation method, the quality of the ilmenite concentrates can be ensured while the recovery of the ilmenite concentrates can be improved, thereby great economic benefit can be obtained.

Owner:PANGANG GRP MINING

Production technology of high

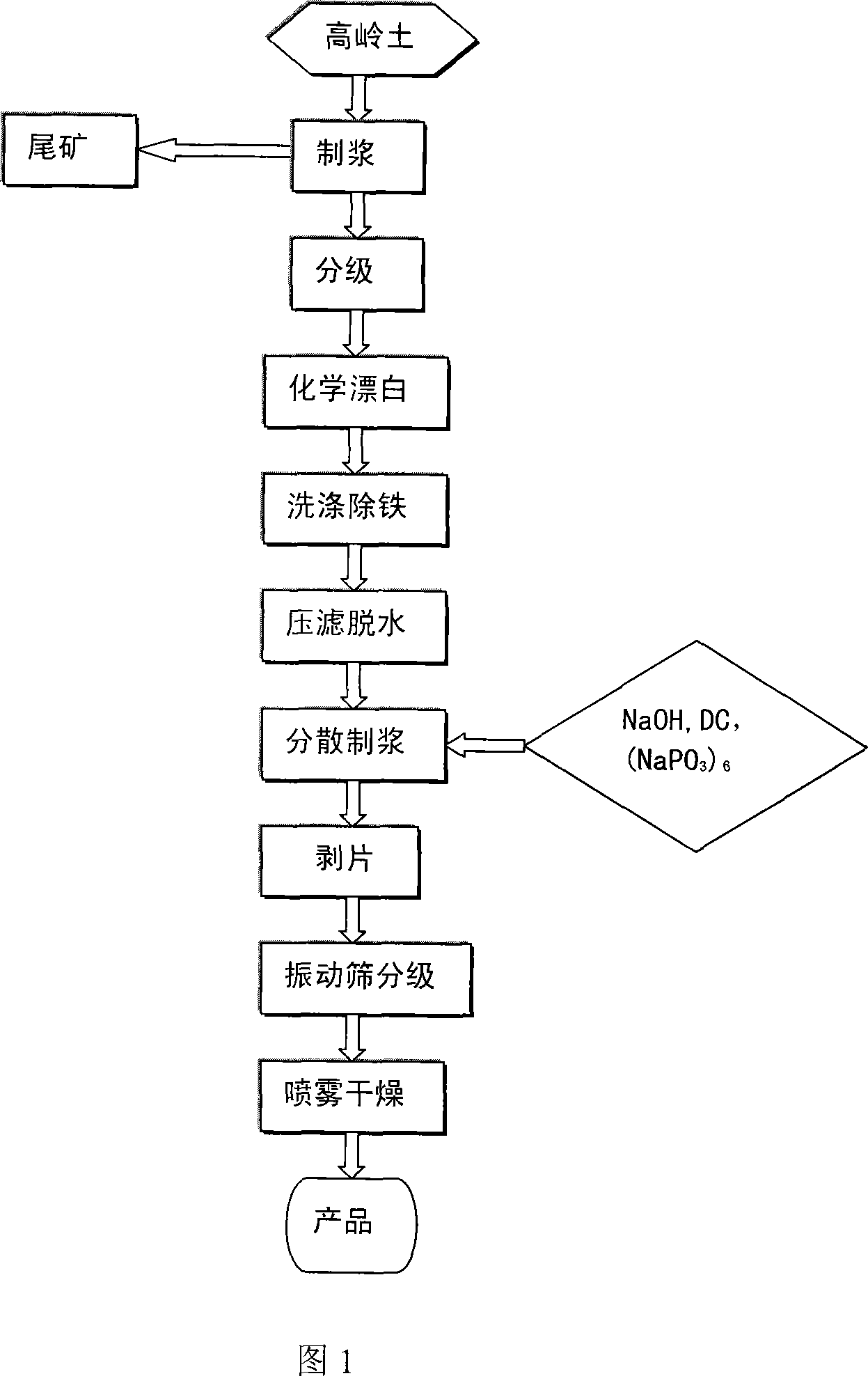

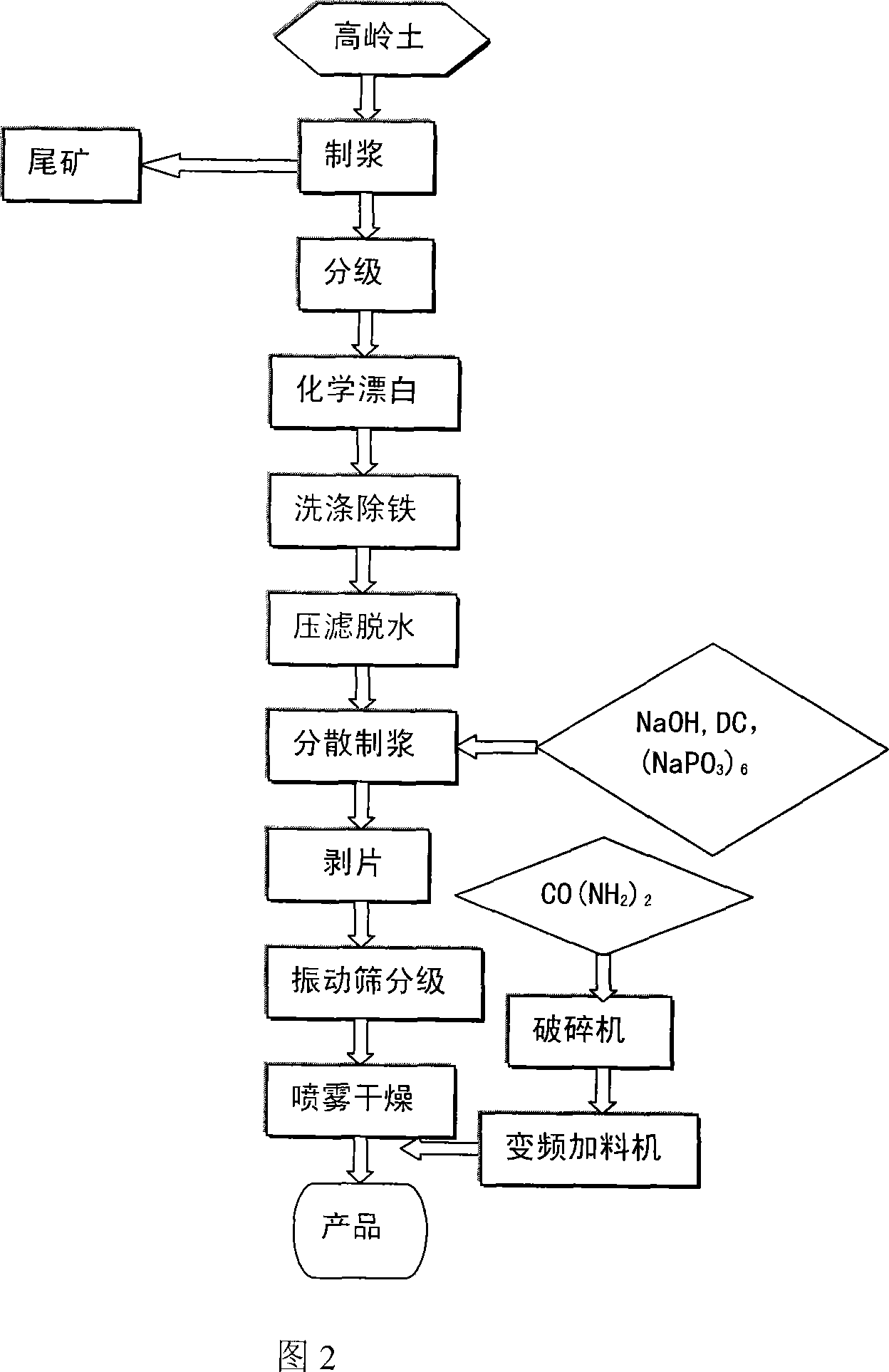

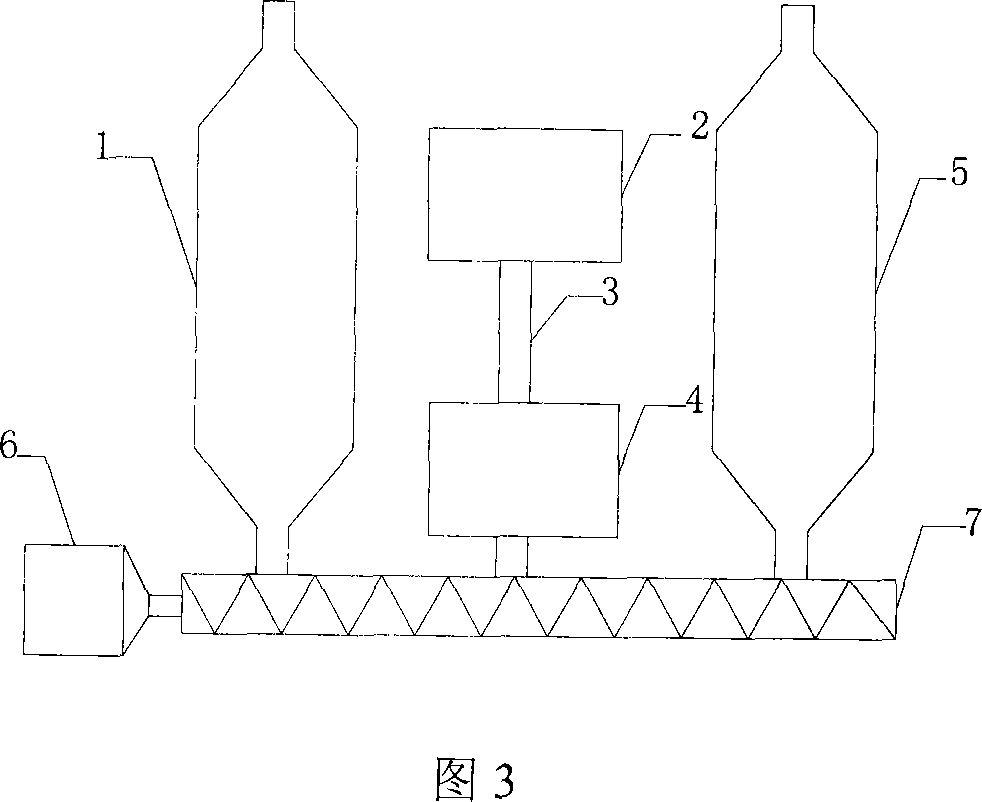

InactiveCN101117004AImprove performancePerformance impactClay processing apparatusThermal insulationKaolin clay

The present invention relates to a manufacturing technique of kaolin with high viscosity and concentration. A manufacturing technique of kaolin with high viscosity and concentration is characterized by comprising following procedures: 1) manufacturing kaolin slurry J with kaolin extracted by hydraulic machinery method undergoing pulping, classification, chemical bleaching, iron removal by washing, dehydrating through pressure filters, dispersed pulping, exfoliation, vibration screen classification ; 2) spray drying and intercalation which is accomplished by a) firstly, improving product lines of a spray drying equipment, that is, adding a thermal insulation layer to a packing auger, a lift pot and a storage hopper of the spray drying equipment, and then arranging a variable frequency feeding machine communicated with a urea crusher through pipelines on the packing auger of the bottom of a spray drying mouth of the spray drying equipment; b) spray drying to achieve kaolin powder; c) intercalating intercalation agent urea with the kaolin powder through the variable frequency feeding machine with parameter of a fresh feed pump between 2 HZ and 8 HZ and with additional of mass of the intercalation agent urea between 2 percent and 10 percent of the mass of the kaolin powder; thereby getting final kaolin products with viscosity and concentration between 72 percent and 73.7 percent. The manufacturing technique can produce kaolin with high viscosity and concentration.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

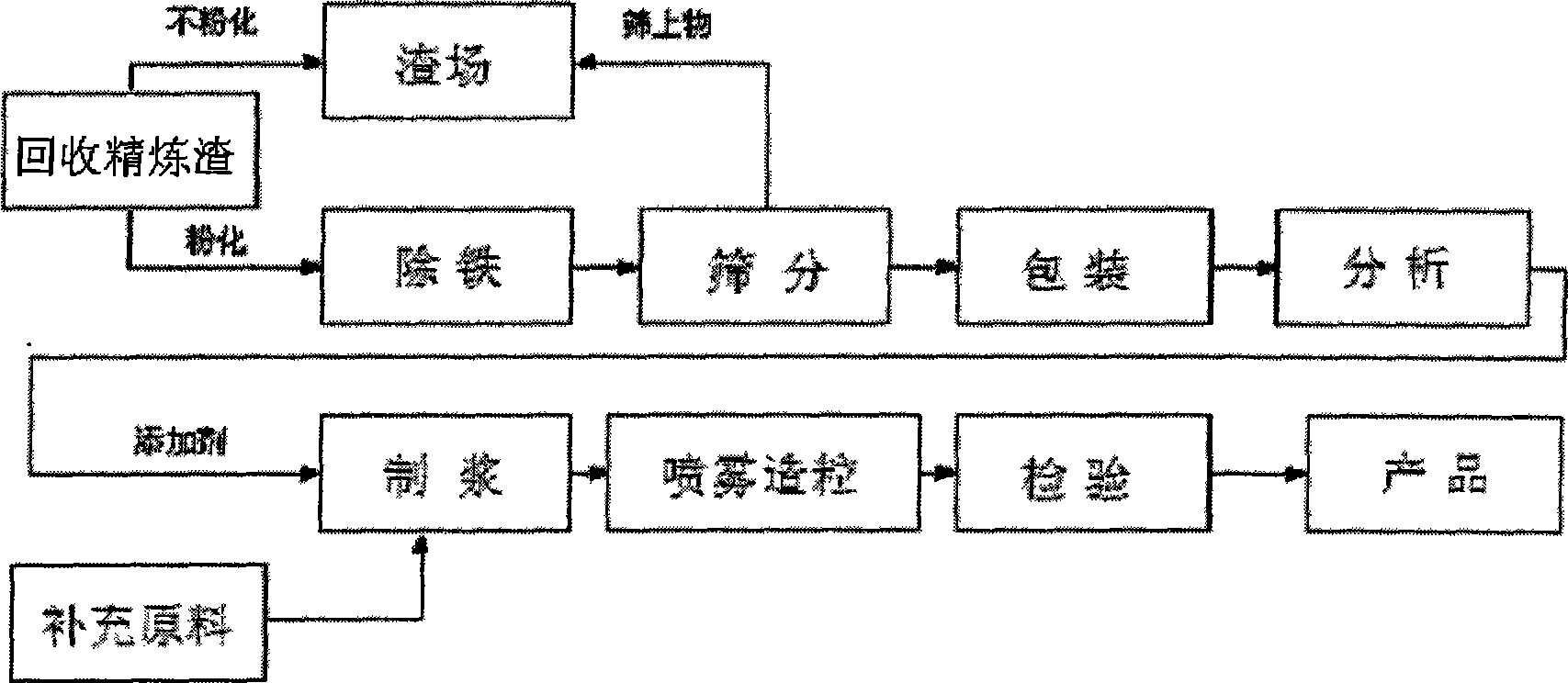

Method for preparing protecting residue from recovery refining slag

The invention relates to a method for preparing protecting slag from recovered refining slag remained in a ladle after continuous casting, which is characterized in that the recovered refining slag is natural cooled down, pulverized, subjected to iron removal and passes a 80-mesh screen; undersize is picked up and subjected to component analysis; according to the target component of the prepared protecting slag, if corresponding amount of natural mineral or fine powder of manually synthesized material containing the lacked components needs to be added, butane radical sodium xanthate and balling bonding agent in the general adding amount are added to prepare pulp with the solid content of between 50 and 70 weight percent, and the pulp is sprayed at the tower top at a hot air temperature of between 550 and 650 DEG C to prepare hollow micro balls. The invention has two characteristics: 1. the method has the simple recycling process, and the materials used to prepared the protecting slag are calculated and added only by the principle of adding what lacks and adding how much lacks, so that the component requirement on the protecting slag preparation is met; and 2. due to high added value of the product, the value of the recovered refining slag can be fully utilized.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

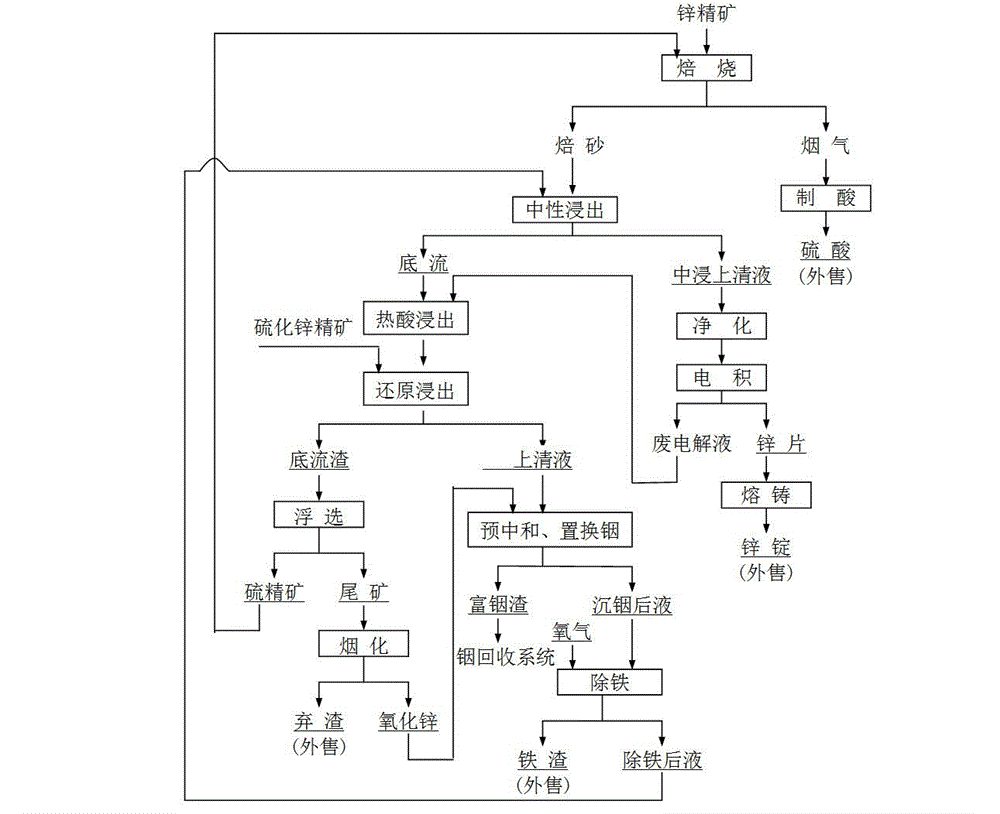

Zinc hydrometallurgy production process

InactiveCN102876888AReduce lossesHigh recovery rateProcess efficiency improvementCement factoryIndium

The invention relates to a zinc hydrometallurgy production process. According to the zinc hydrometallurgy production process provided by the invention, reduction leached supernate is subjected to preneutralization, then zinc dust is added for replacing indium, after the indium is separately removed, oxygen with the concentration being not lower than 98 percent is filled into liquid obtained after the indium is deposited, controlling the temperature in the range of 160 to 200 DEG C and controlling the pressure in the range of 1,000 to 2,000kPa, so that iron precipitates in the liquid obtained after the indium is deposited enter slags. The iron removed liquid obtained by the zinc hydrometallurgy production process has the iron content being lower than 1.2g / l, the iron removed liquid can be directly returned to be subjected to neutral leaching, and the system has stable production working conditions and is beneficial to stable production; in the iron slags obtained by the zinc hydrometallurgy production process, the zinc content is lower than 1 percent, the zinc loss is low and the zinc recovery rate is high; the iron slags can be directly sold to a cement plant and an iron and steel plant to be used as the raw materials without being stacked in a slag field, so that the zinc hydrometallurgy production process is beneficial to environmental-protection and the comprehensive utilization of resources and mineral resources are saved.

Owner:广西华锡集团股份有限公司 +1

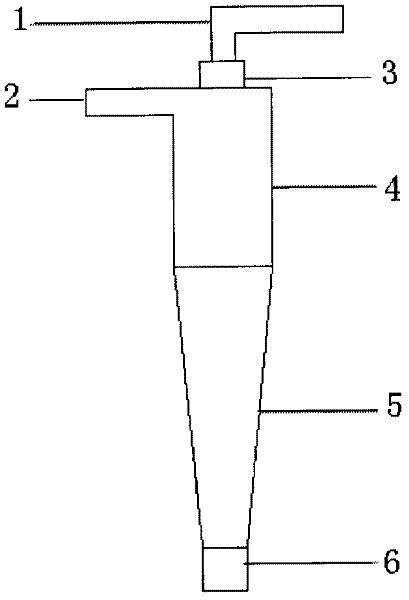

Technology for breaking, sorting and recycling household garbage incineration slag

ActiveCN103769287AImprove cleanlinessReduce frictional heatSolid waste disposalGrain treatmentsSlagFiltration

The invention relates to a technology for breaking, sorting and recycling household garbage incineration slag. The technology comprises the following steps: by utilizing gravitational potential energy and using water as a medium and circulating flow, vertically arranging an iron removal device, a hopper, a breaker, a magnetic separator, a jigger, screening equipment, a slag finished product collection tank, a sedimentation tank and the like which are equipment for treating the household garbage incineration slag in every link from high to low; injecting water and the garbage incineration slag into the breaker so as to form a material flow, obtaining slag materials with fine particles, light mass and optimized components through the breaker, the jigger and the screening equipment under the action of material gravity flow, filtering through the collection tank and the sedimentation tank and directly transporting the dried fine-grained slag finished product to a finished product warehouse finally; and reblending clear water obtained after sedimentation and filtration and the garbage incineration slag raw material so as to be recycled. The technology has the advantages that the exertion of gravitational potential energy is facilitated in a material treatment process, and the friction heat energy of the materials and the equipment is reduced; and the dust fog pollution in the treatment process is reduced, and environments are protected.

Owner:TONGXIANG TONGDE WALL BUILDING MATERIALS +2

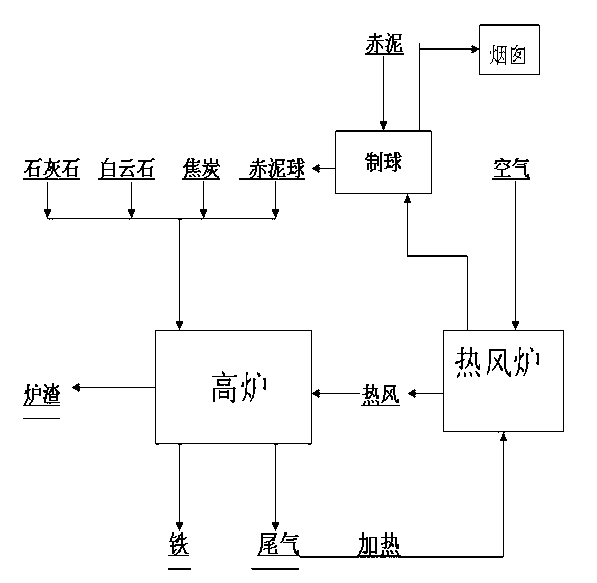

Method for recycling iron from waste red mud in alumina production

InactiveCN103074456AHigh recovery rateGood quality pig ironBlast furnace detailsProcess efficiency improvementRed mudSlag

The invention relates to a method for recycling iron from waste red mud in alumina production. The method is characterized in that waste red mud in alumina production is dried, the moisture content after drying ranges from 1% to 10%, the particle size of the smashed red mud is less than or equal to 0.15mm, and the red mud is manufactured into pellets of 15mm to 50mm under the pressure ranging from 10kN to 70kN. Heat produced by blast furnace gas burning is used to dry the red mud pellets to be with a moisture content less than or equal to 1%, then the dried red mud pallets, coke, limestone and dolomite are mixed according to the proportion and added into a blast furnace to be smelted directly, finally the mixture is separated through iron slag to obtain metallic iron and slag, iron can directly serve as a steel-making material, and the slag can be recycled for subsequent comprehensive utilization. According to the method, industrial waste serves as a main material, environmental pollution is reduced, and the waste can be recycled; and the method has the advantages that the quality of the recycled iron is good, the iron recovery rate is high and can achieve more than 98%, the technological process is simple, the production is easily achieved, and tailings after iron removal are easily processed.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

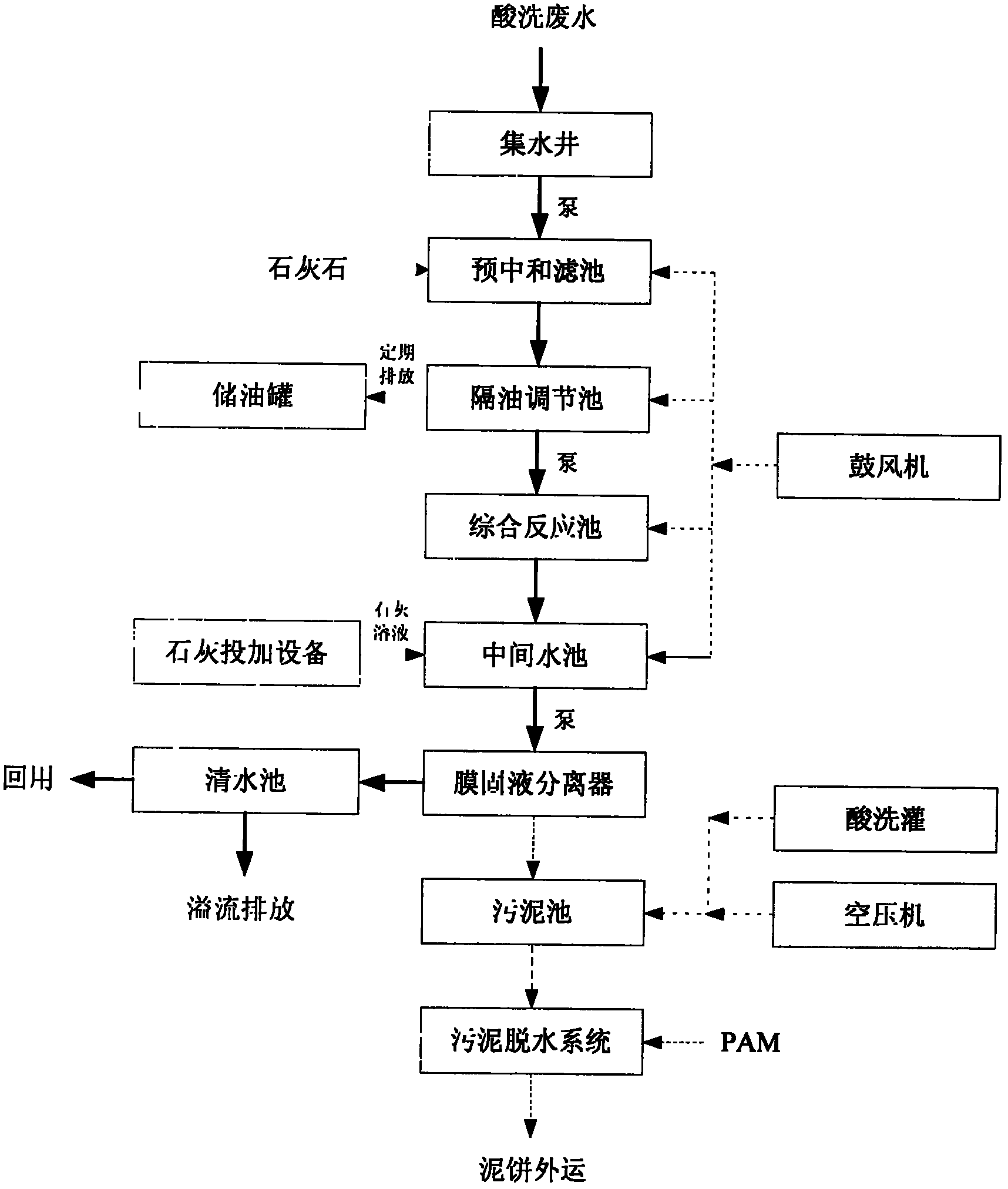

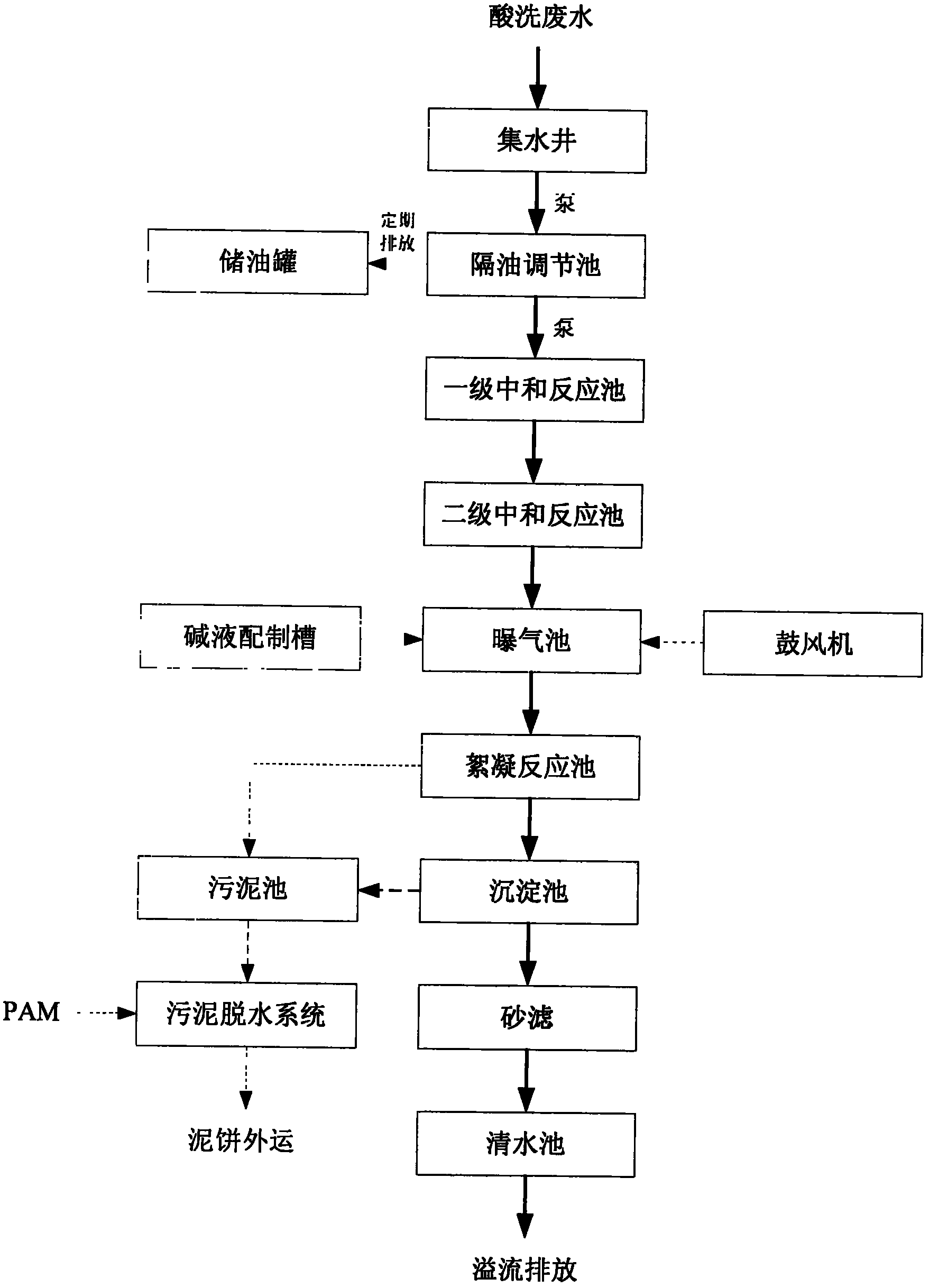

Method for treating acid-washing wastewater and metallic ions in iron and steel industry

InactiveCN102107963ALow running costGuaranteed uptimeWater contaminantsMultistage water/sewage treatmentFerric hydroxideZinc hydroxide

The invention provides a method for treating acid-washing wastewater and metallic ions in iron and steel industry, which comprises steps as follows: acid-washing wastewater naturally flows into a water collecting well and enters a preneutralization filter chamber under the elevation action of a pump, the preneutralization filter chamber is provided with 10-200mm limestone which is in a graded distribution mode, and after the acid-washing wastewater is preneutralized by the limestone, the pH value of the effluent water is controlled at 5-6, wherein the method provided by the invention greatly lowers the chemical expenses and operating cost as compared with the conventional method of directly adding an alkali solution; the acid-washing wastewater, which is subjected to initial pH value regulation, naturally flows into an oil separation regulating chamber, so that iron ions in the wastewater react with the alkali solution to form a precipitation mixture of ferric hydroxide, zinc hydroxide and the like; and the wastewater is elevated into a membrane solid-liquid separator to complete solid-liquid separation, so that the wastewater can be discharged after reaching the standard. The invention thoroughly solves the problems that the precipitate can not easily settle, the iron can not be easily removed, and the iron ions are dissolved out. The invention has the advantages of simple technique, high economy, low requirements for technical levels of workers, and high controllability, is reliable to operate, and has wide market prospects.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Method for harmlessly treating aluminum ash

ActiveCN106629774AMalleableImprove operational safetySilicaAluminium oxide/hydroxide preparationHazardous substanceAluminium hydroxide

The invention discloses a method for harmlessly treating aluminum ash. The method comprises the following steps: (1) performing ball milling on aluminum ash to be treated in a ball mill to flattening metal aluminum in the aluminum ash into flat aluminum, and performing sieving to separate the flat aluminum from the aluminum ash to obtain first aluminum ash; (2) placing the first aluminum ash in a first container provided with an air vent, adding a first part of water into the first container, performing stirring to conduct reaction on aluminum nitride in the first aluminum ash and the water to generate ammonia and aluminum hydroxide, and discharging the ammonia through the air vent, to obtain a material left in the first container after the ammonia is discharged to be recorded as a first material; (3) performing iron removal operation on the first material, to obtain the first material subjected to iron removal to be recorded as a second material; (4) performing centrifugal dehydration operation on the second material, and then performing drying to obtain an oxide-containing mixture. According to the method, harmful substances and flammable and explosive substances in the aluminum ash are safely removed to implement harmless treatment and reclamation of the aluminum ash without heating.

Owner:佛山市吉力达铝材科技有限公司

Raw material proportion of bice glaze and firing method thereof

The invention relates to a mixture ratio of raw materials of a grey blue glaze. The grey blue glaze comprises the following compositions by weight percentage: 30 to 35 percent of quartz, 32 to 38 percent of feldspar, 8 to 11 percent of talcum, 2 to 5 percent of clay, 6 to 9 percent of limestone, 3 to 5 percent of aluminum oxide, 7 to 9 percent of zirconium silicate, 0.01 to 0.05 percent of manganese oxide, 0.1 to 0.4 percent of ferric oxide, 0.01 to 0.05 percent of chromic oxide, 0 to 0.3 percent of cobalt oxide, 0 to 1 percent of dispersant and 0 to 1 percent of carboxymethyl cellulose sodium. The grey blue glaze is prepared by steps of drying, grinding, screening, iron removal, aging, glaze spraying and firing according to the mixture ratio of the grey blue glaze. The mixture ratio of raw materials of the grey blue glaze and the method for firing the grey blue glaze can improve the appearance quality of ceramic pieces and the performance of glaze layers and can meet requirements for batch production and ensure high qualification rate of products and good economic benefits due to the adoption of the prior equipment in the firing process.

Owner:CHINA XD ELECTRIC CO LTD +1

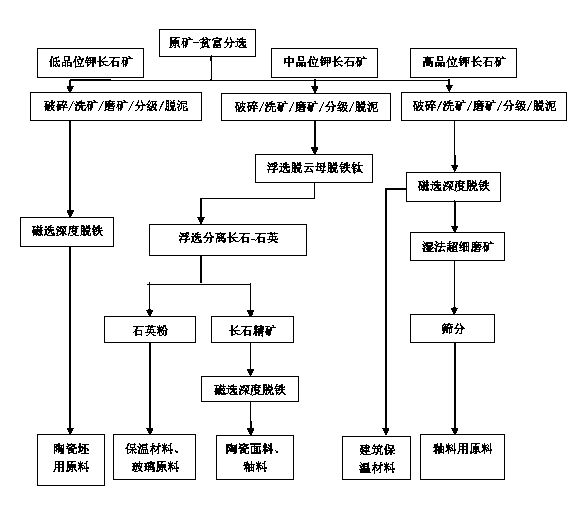

Mineral processing technology by utilizing grade difference of potassium feldspar

The invention relates to a mineral processing technology by utilizing the grade difference of potassium feldspar. The mineral processing technology comprises the following steps that (1), potassium feldspar raw ore is mined and sorted in a separated mode according to the three classes of low-grade potassium feldspar ore, medium-grade potassium feldspar ore and high-grade potassium feldspar ore; (2), the mineral processing processes of crushing, washing, grinding for grading, desliming, and magnetic separation for deep iron removal are carried out on the low-grade potassium feldspar ore; (3), the mineral processing processes of crushing, washing, grinding for grading, desliming, flotation for mica removal and iron removal, flotation for separating feldspar from quartz, and magnetic separation for deep iron removal are carried out on the medium-grade potassium feldspar ore; (4), the mineral processing processes of crushing, washing, grinding for grading, desliming, magnetic separation for deep iron removal, wet superfine grinding and screening are carried out on the high-grade potassium feldspar ore. The different mineral processing technical schemes are adopted for the potassium feldspar ore of different grades, and the purposes of being free of environmental pollution, simplifying the production processes and efficiently developing and utilizing resources are achieved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

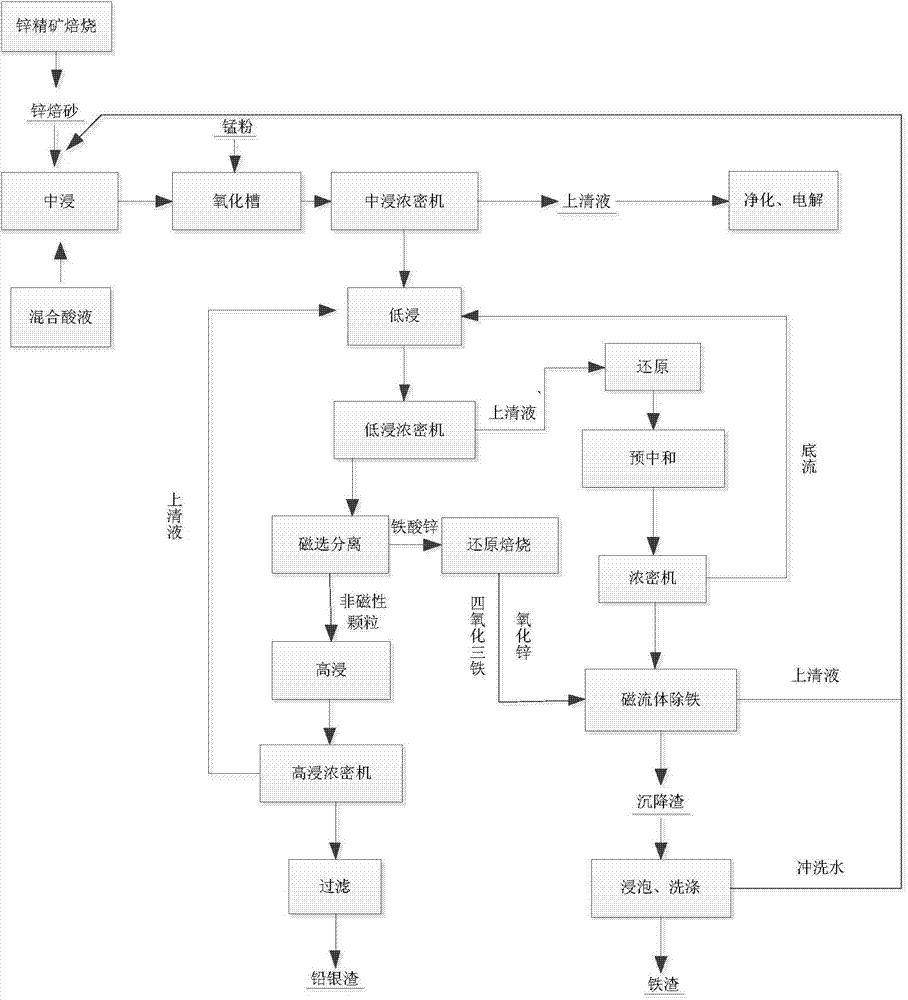

Zinc smelting technology

ActiveCN103540765AImprove leaching rateHigh recovery rateProcess efficiency improvementMagnetic separationNon magneticCalcination

The invention discloses a zinc smelting technology. The zinc smelting technology comprises the following step that high-iron sphalerite concentrate is subjected to calcination, neutral leaching and low-acid leaching; zinc ferrite is separated from the low-grade leaching residues by a magnetic separator and the non-magnetic leaching residues are further treated by high-acid leaching; and the zinc ferrite is decomposed into ferroferric oxide and zinc oxide by reduction roasting, and the ferroferric oxide and the zinc oxide are used respectively as a magnetic seed and a neutralizer used in a leachate magnetofluid iron-removal technology. Through combination of a wet method and a fire method, a zinc leaching rate and a lead and silver recovery rate are improved, and the calcinations of the zinc ferrite are used in the magnetofluid iron-removal technology so that an iron-removal technology cost is effectively reduced and iron residues are pure, have high iron content and are conducive to iron residue comprehensive utilization. The zinc smelting technology can efficiently prepare high-quality zinc leachate, utilize agents having wide sources and a low cost, prepare a very-low iron-content zinc leachate, greatly improve the efficiency of the zinc wet method smelting technology, basically prevent a valuable metal loss and promote resource comprehensive utilization.

Owner:CHANGSHA HASKY ENVIRONMENTAL PROTECTION TECH DEV CO LTD

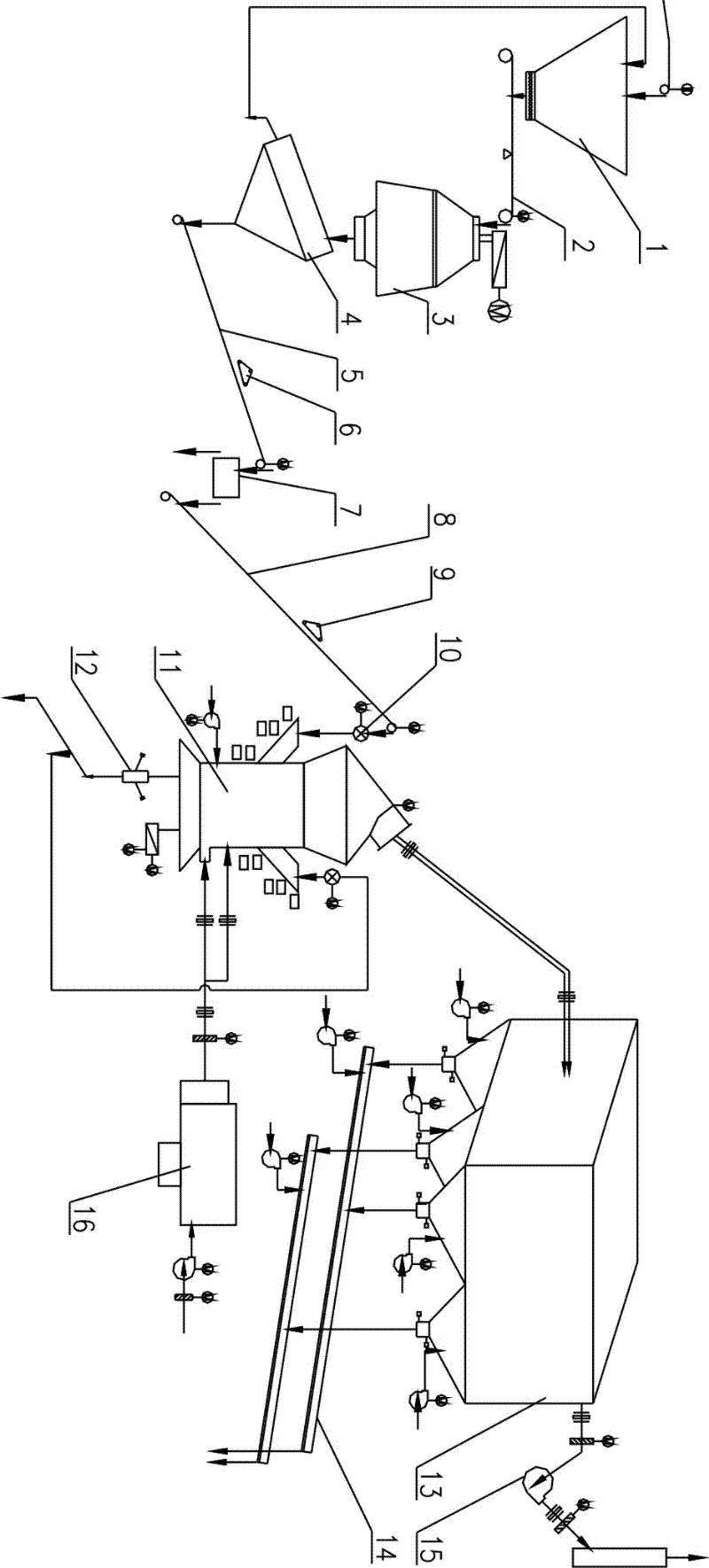

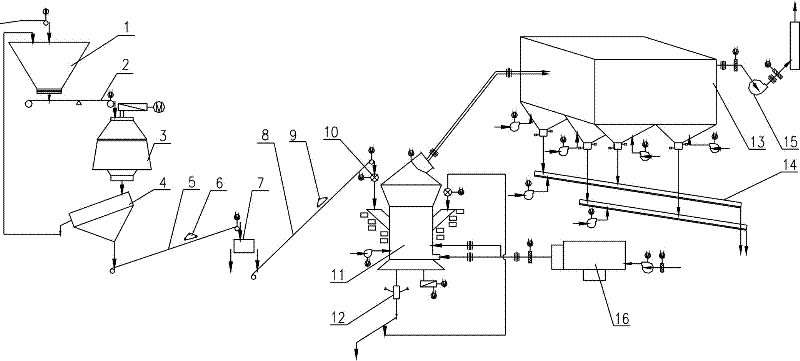

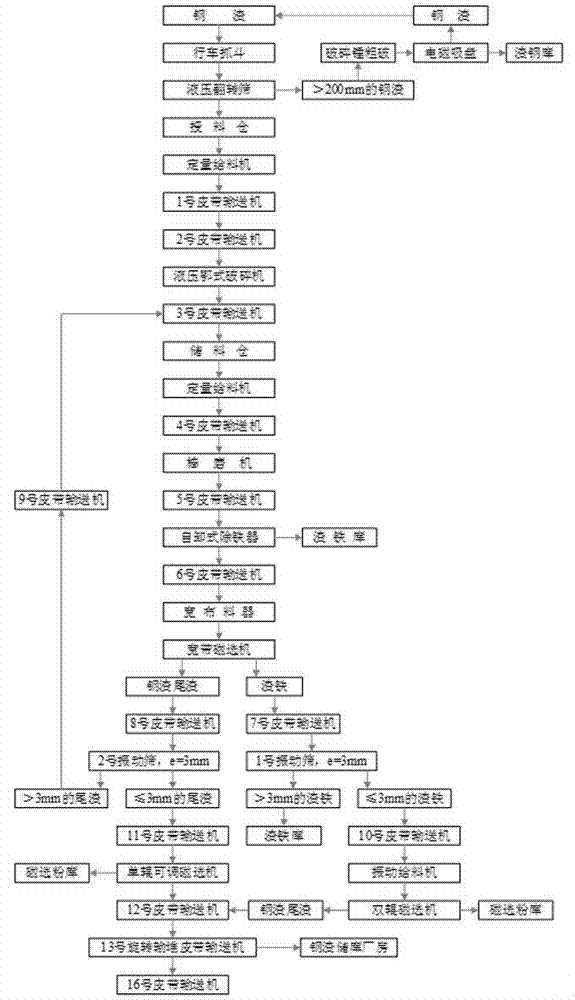

Steel slag grinding production technology and system

The invention discloses a steel slag grinding production technology and system. In the production technology, steel slag of which the moisture is less than or equal to 5% and the granularity is less than 80mm is sent into a column grinder to be grinded to obtain fine powder which contains more than 90% of powder of which the granularity is less than 5mm; the fine powder is screened by a vibrating screen; the screened steel slag fine powder is sent into a strong magnetic separation machine by a belt conveyor to remove iron to ensure that the iron content in the steel slag fine powder is below 2%; and the steel slag fine powder subjected to iron removal is sent into a slag vertical mill to be dried and grinded to obtain a steel slag product of which the specific surface area is 4200-4500cm<2> / g. The production system mainly comprises a charging cabin, a column grinder, a vibrating screen, a belt conveyor, a strong magnetic separation machine and a slag vertical mill. The steel slag grinding production system has the advantages of big yield, high grinding efficiency, low use cost and operation cost and obvious power saving effect, and the economic benefit is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

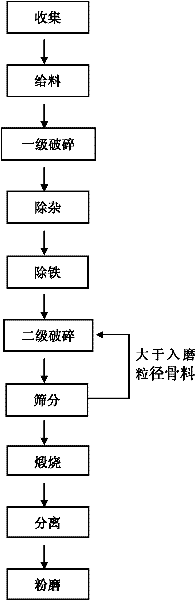

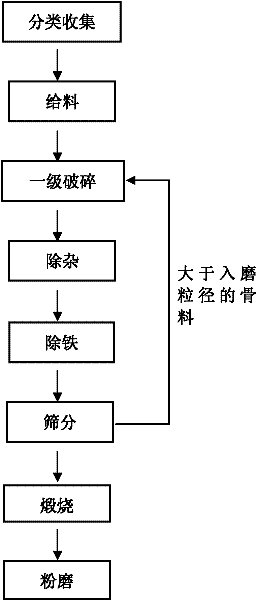

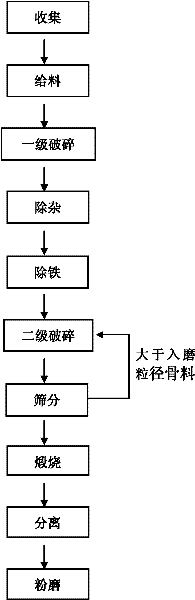

Method for recycling waste clay

InactiveCN102218435AGive full play to the role of materialImprove grindabilityConstruction waste recoverySolid waste disposalLitterIron removal

The invention provides a method for recycling waste clay, which comprises the following steps of: removing impurities from construction waste materials through treatment processes such as crushing, impurity removal, iron removal, sieving and the like, and preparing the materials into a recycled aggregate meeting the requirement of grinding equipment on particle size; burning up combustibles in the recycled aggregate through a calcining process to reduce ignition loss and water content; separating a concrete component from a clay brick component in the recycled aggregate; and grinding the clay brick component to obtain regenerated powder. By the method, waste clay brick resources can be fully utilized by a simple process; moreover, the regenerated clay powder obtained in the production has good performance, wide application range and high added value.

Owner:上海德滨环保科技有限公司

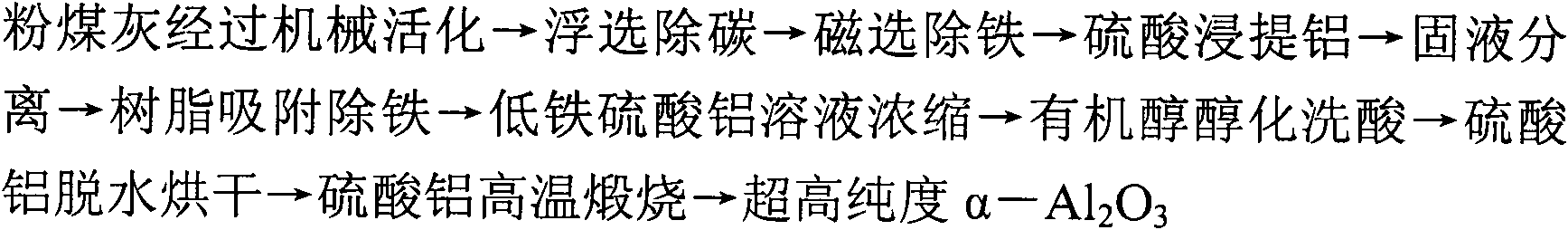

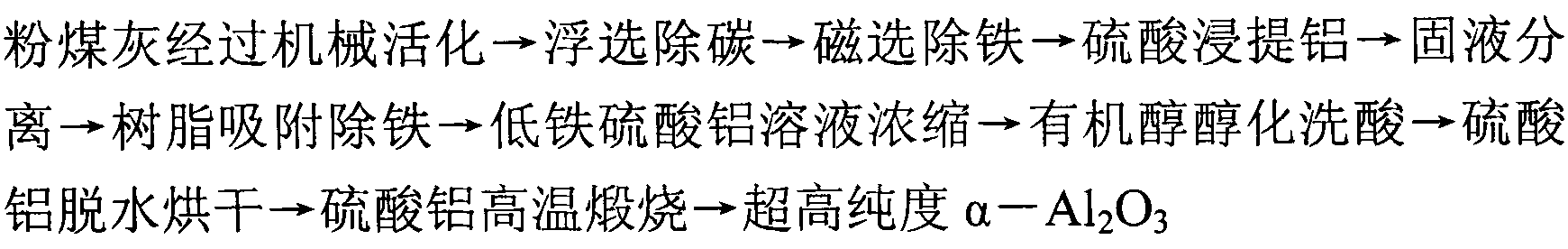

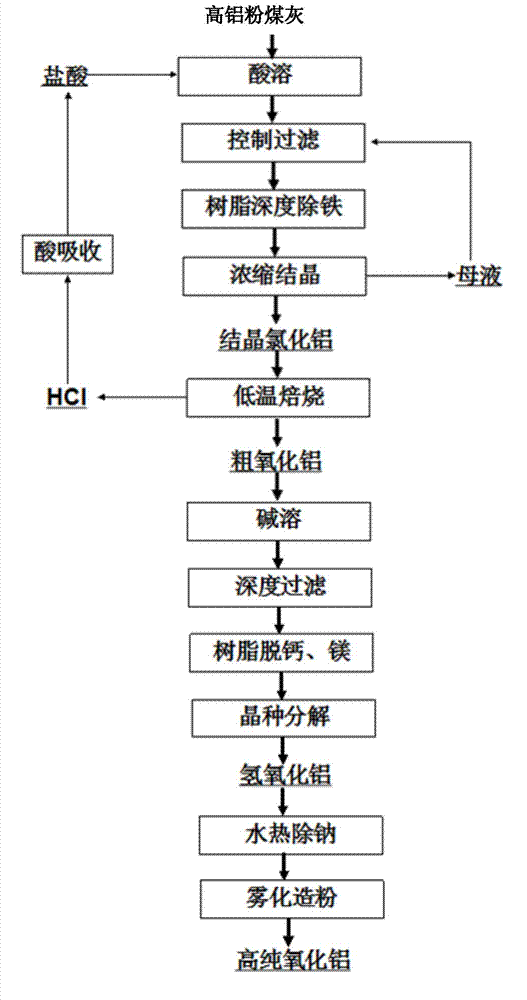

Process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina

InactiveCN102101686AReduce energy consumptionEasy to operatePigmenting treatmentSolid waste disposalAcid washingBiological activation

The invention discloses a process method for ultra-high purity alumina preparation by utilizing coal ash and comprehensive utilization of ultra-high purity alumina. In the process method, mechanical activation, flotation decarbonization, magnetic separation iron removal sulfuric acid aluminum lixiviation, solid-liquid separation, resin absorption iron removal, low-iron aluminum sulfate concentration, organic alcohol alcoholization acid washing, aluminum sulfate dehydration drying and aluminum sulfate high-temperature calcination are carried out on the coal ash so as to obtain ultra-high purity alpha-Al2O3, wherein the content of the Fe2O3 in the ultra-high purity alpha-Al2O3 is less than 2 ppm. By using the process method, the complicated purification problem that intermediate aluminum sulfate in the process of coal ash reclamation is necessarily subjected to a called Bayer circulation process is avoided, thereby simplifying the process flow, reducing the energy consumption, reducing the resource consumption and solving the technical problem of over-large secondary residue quantity accumulation. The process method has the advantages that the extraction efficiency is high, and the circulation recovery of organic alcohol and sulfuric acid and comprehensive utilization of byproducts such as resin and the like are achieved. In the invention, the process is simple, the process flow is short, the production process is easy to control, the content of the impurity in the product is low, and the quality of the product is stable.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

Refining process for lepidolite in tantalum-niobium ore waste rocks

ActiveCN105251606ASolve the way outHigh Lithium Oxide ContentHigh gradient magnetic separatorsFlotationNiobiumIron removal

The invention relates to a refining process for lepidolite in tantalum-niobium ore waste rocks. A combined method with magnetic separation, high gradient magnetic separation, dense medium separation and flotation is adopted. The flotation adopts the process of rough flotation, dual fine flotations and sweeping. The process for refining the lepidolite from the granite-type tantalum-niobium ore waste rocks is provided. The tantalum-niobium ore waste rocks are crushed, screened, ground and subjected to high-frequency screening, spiral grading, permanent magnet magnetic separation for iron removal, high gradient magnetic separation, dense medium separation and flotation, so that lepidolite concentrates are obtained. By means of the method, the lepidolite concentrates are separated from the tantalum-niobium ore waste rocks. The lepidolite concentrates contain at least 4.5% of Li2O, at least 8.0% of K2O and Na2O and at most 0.10% of TiO2 and Fe2O3, the recovery rate of the lepidolite concentrates is larger than 80%, the qualities of the lepidolite concentrates meet the requirement of national standards, and the recovery rate of the lepidolite concentrates exceeds the industry level.

Owner:江西金辉再生资源股份有限公司

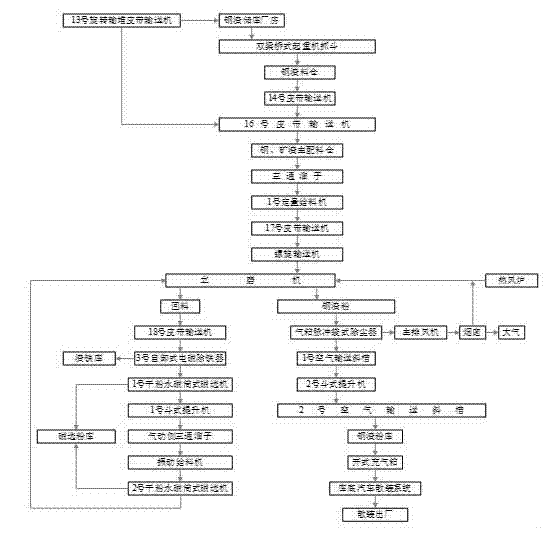

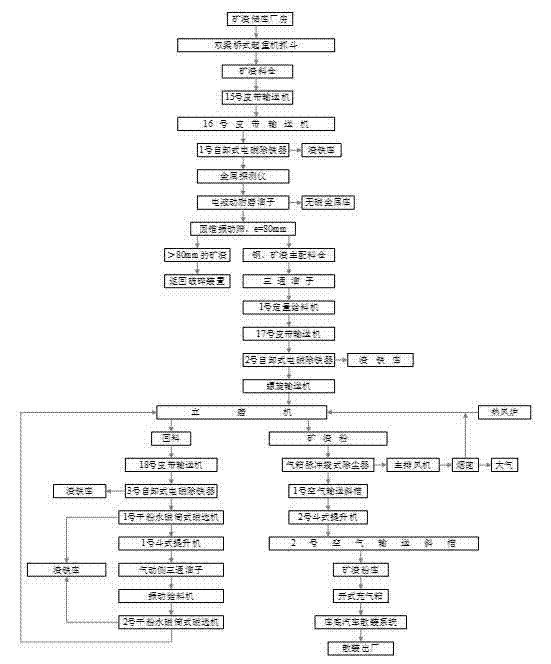

Production method for grinding steel-iron slag powder, mineral slag powder and steel slag powder by using vertical mill

ActiveCN104291714AImprove uniformitySimplify production stepsManufacturing cost reductionIron powder

The invention relates to a production method for grinding steel-iron slag powder, mineral slag powder and steel slag powder by using a vertical mill. The innovation points comprise that the same vertical mill is employed for independently grinding steel-iron slag powder, mineral slag powder and steel slag powder, steel slag tailings obtained in the steel-slag processing and metal recovery processing step and mineral slag obtained in the mineral-slag metal-removal pretreatment step are sent into the vertical mill according to the ratio of 2-4:8-6, and then a step of using the vertical mill to grind steel and iron slag powder and a step of performing magnetic separation on a recycled material of the vertical-mill ground steel and iron slag powder to remove iron and performing closed cycling are executed, so that the technology of using the vertical mill to grind steel and iron slag powder is realized. The method helps to simplify conventional production steps of steel and iron slag powder, improve the uniformity of the steel and iron slag powder and reduce production energy consumption and cost. The production method is capable of realizing sharing of most of equipment while realizing recovery and reutilization of resource by using the same vertical mill to respectively grind steel and iron slag powder, mineral powder and steel slag powder, so that the utilization rate of equipment and resource are substantially improved, and the manufacturing cost is reduced.

Owner:JIANGSU RONGDA NEW MATERIAL

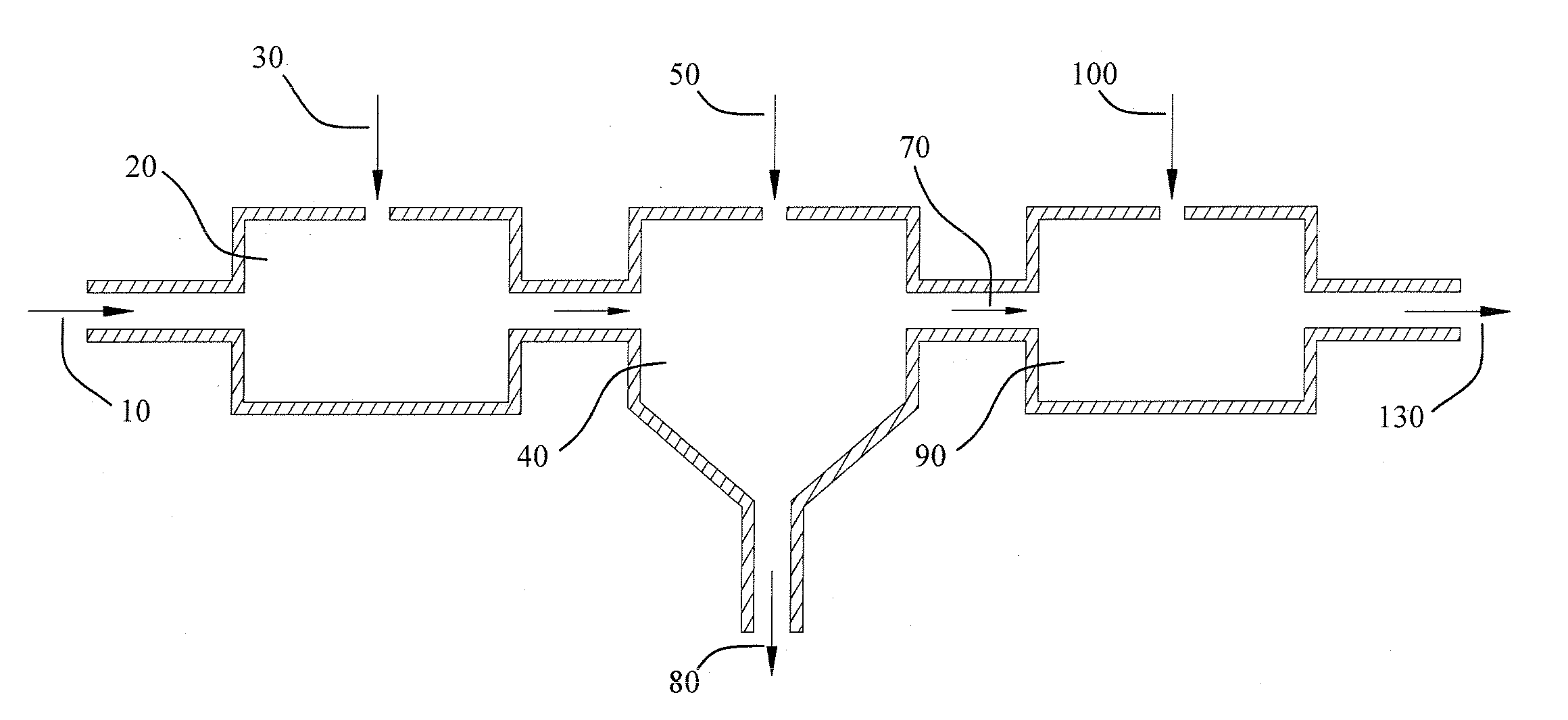

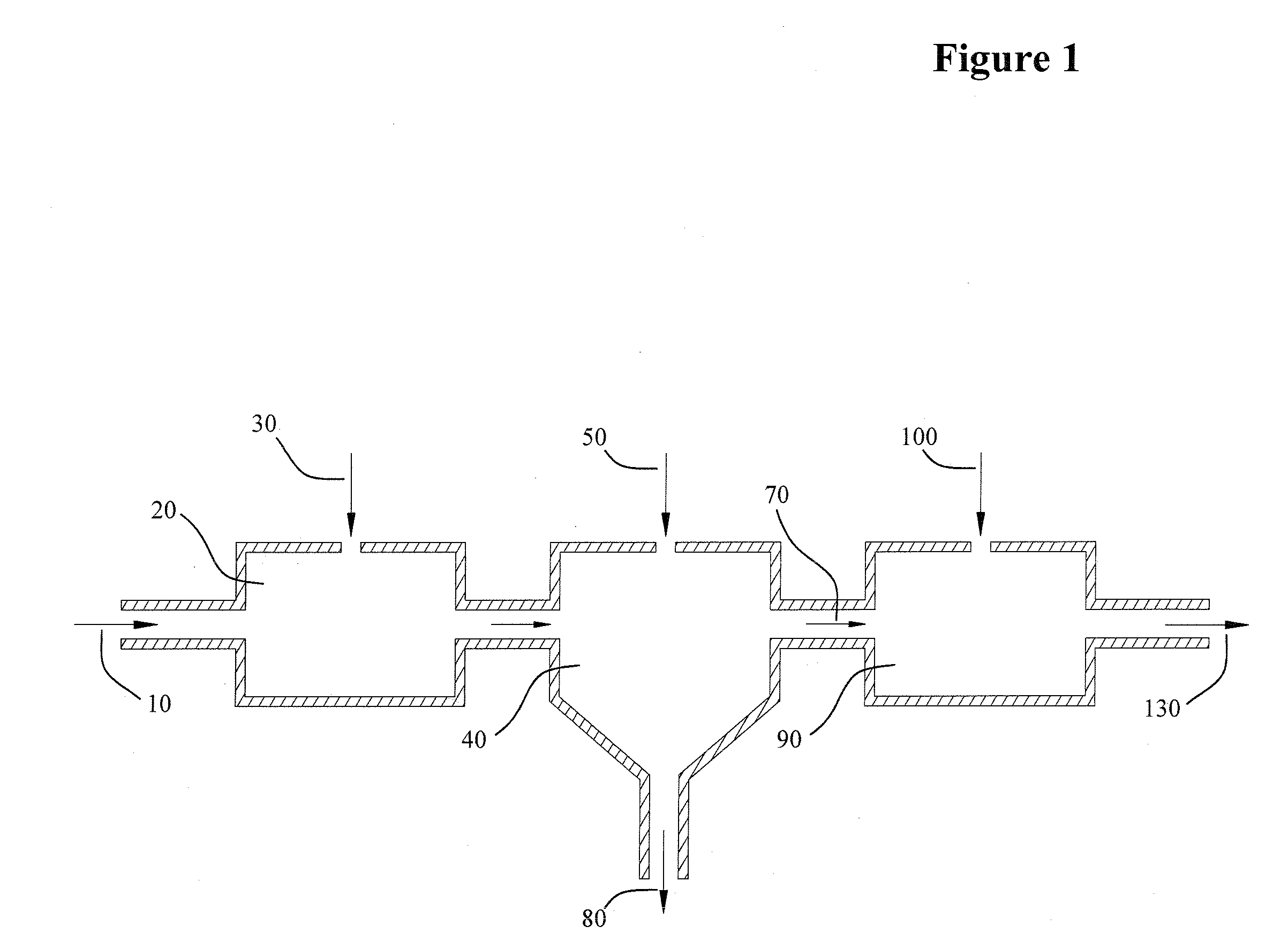

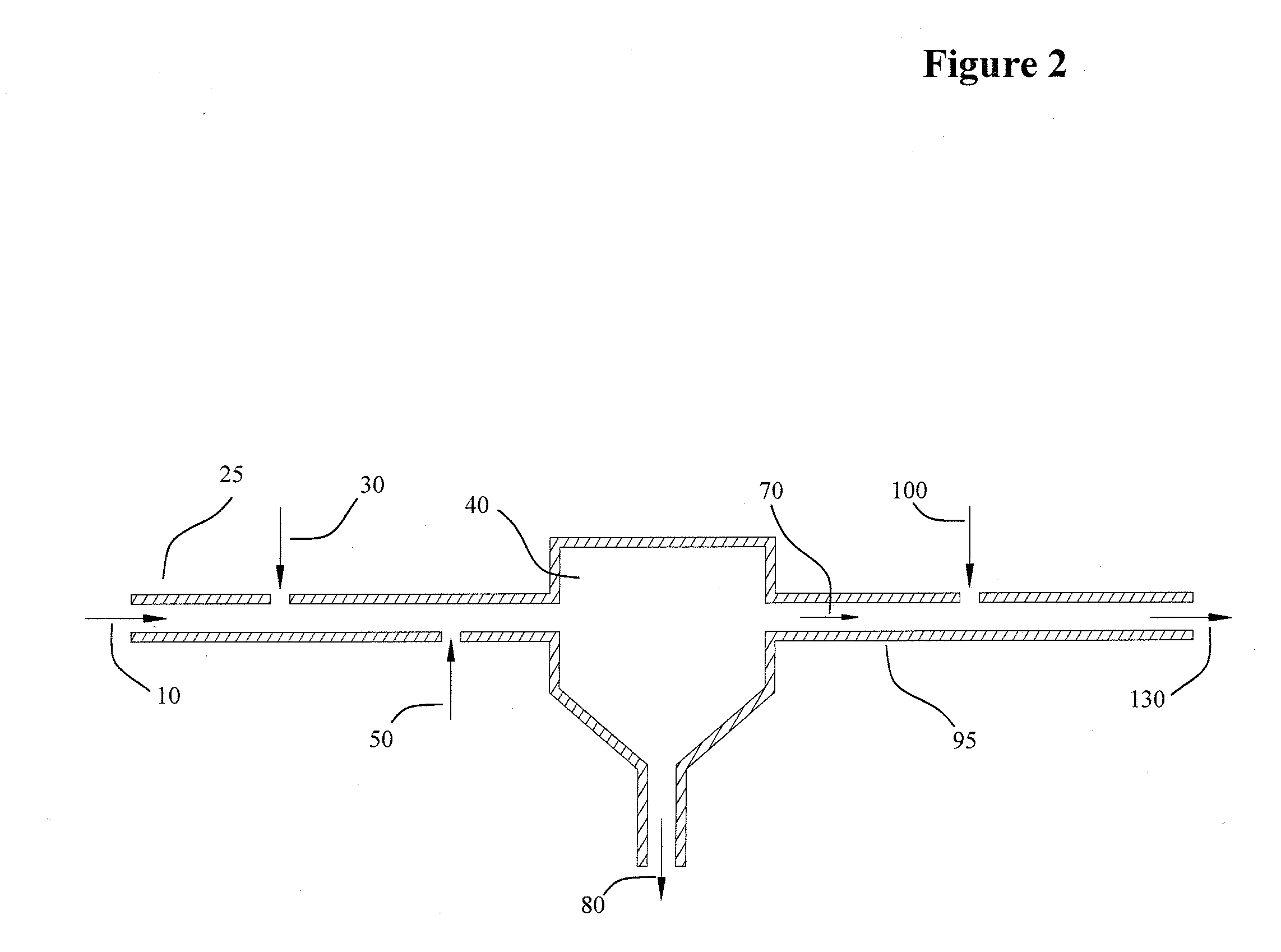

Aqueous iron removal process and apparatus

InactiveUS20110180470A1Minimal iron contentOther chemical processesWater contaminantsIron removalPhosphoric acid

A process and associated apparatus to reduce both ferrous (Fe++) iron and ferric (Fe+++) iron from an aqueous solution. A pH swing process is described in which a phosphoric acid solution is first added and then a base chemical is added. The combination results in generation and precipitation of iron phosphate. The method and apparatus affords flocculent enhanced settling and removal of the iron precipitates and process suitable buffering of the resulting reduced iron aqueous solution.

Owner:LAYNE CHRISTENSEN COMPANY

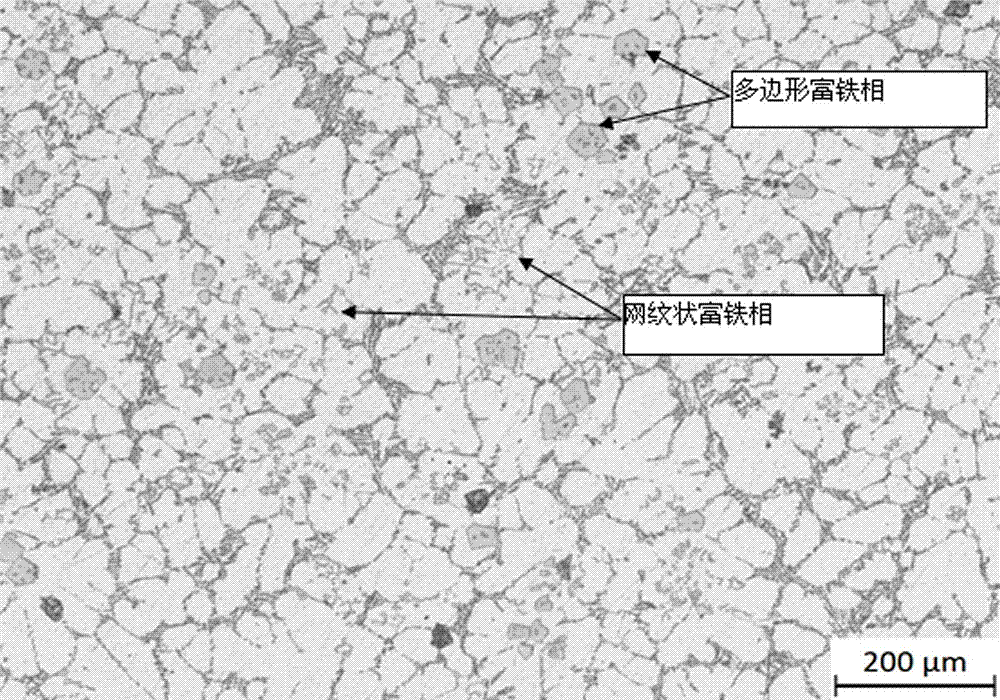

Deironing method for secondary aluminum

The invention relates to a deironing method for secondary aluminum. The deironing method is characterized by comprising the following steps of (1) preheating 50-70% Al-B intermediate alloy and 30-50% Al-Mn intermediate alloy for 30-60 minutes at 150-250 DEG C, wherein the intermediate alloys account for 0.5-2% of mass of aluminum-silicon secondary aluminum; (2) maintaining the temperature for 10-30 minutes after heating the aluminum-silicon secondary aluminum to 400 DEG C; and raising the temperature to 700 DEG C; (3) after the aluminum-silicon secondary aluminum is melted, adding the intermediate alloys, slowly stirring, and standing for 0.5-4 hours after the intermediate alloys are melted; (4) dusting casting, fixing a mold on a vibration platform, and casting and cooling under the condition of mechanical vibration, wherein the frequency of the vibration platform is 10-40 Hz and the amplitude of the vibration platform is 5-10 cm. The deironing method is used for removing iron, refining grains and improving the shape of an iron-rich phase, can reduce the iron content of the secondary aluminum and improve the extension strength and rate of the secondary aluminum and is suitable for the aluminum-silicon secondary aluminum.

Owner:GUANGDONG INST OF NEW MATERIALS

A kind of production method of silicon wafer cutting blade material

The invention relates to a production method of a silicon wafer cutting blade material. The production method of the silicon wafer cutting blade material uses high-purity green silicon carbide as the raw material and comprises the following steps: performing jaw crushing, screening, performing automatic circulation type wet ball milling and hydraulic cyclone classification, performing automatic overflow carbon removal, performing magnetic separation to automatically remove iron, performing alkali washing, cleaning, performing overflow classification under automatic control of a programmable logic controller (PLC), centrifuging to dewater, drying, mixing, performing fine screening and the like. The silicon carbide blade material prepared by the method has equiareal shape, sharp edges and high cutting capability; the blade material particles have large specific surface area and clean appearance and high suitability to cutting fluid such as polyethylene glycol; the product ground by automatic circulation type wet ball milling and cyclone classification has more equiareal shapes, good grain shape and high yield, and overgrinding can be avoided; and automatic magnetic separation is adopted to perform acid-free iron removal, thus the method has high efficiency, environmental friendliness and high degree of automation and is suitable for large-scale production. The product ground by the method has high particle size concentration degree and good grain shape, and better cutting effect can be realized.

Owner:JIANGSU TAYAL PHOTOVOLTAIC AUXILIARY MATERIAL

Method for preparing high-purity aluminum oxide from fly ash

ActiveCN103693665AEfficient removalMeet the requirements of high-purity aluminaAluminium oxide/hydroxide preparationChemical industrySeed crystal

The invention belongs to the field of chemical industry and relates to a method for preparing chemical-grade high-purity aluminum oxide from fly ash. The method comprises the steps of dissolving with acid, carrying out controlled filtering, carrying out deep iron removal, concentrating for crystallizing, roasting at low temperature, dissolving with alkali, carrying out deep filtering, removing calcium and magnesium with resin, decomposing seed crystals, carrying out hydrothermal synthesis to remove sodium, atomizing to produce powder, and the like. The method disclosed by the invention has the advantages that the energy consumption is low, the raw materials are reused, the loss is little, the production cost is low, the technical conditions of a process are broad, the industrialization is easy to realize, and the like.

Owner:CHINA SHENHUA ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com