Production technology of high

A production process, kaolin technology, applied in clay processing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve problems such as low viscosity concentration, and achieve stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

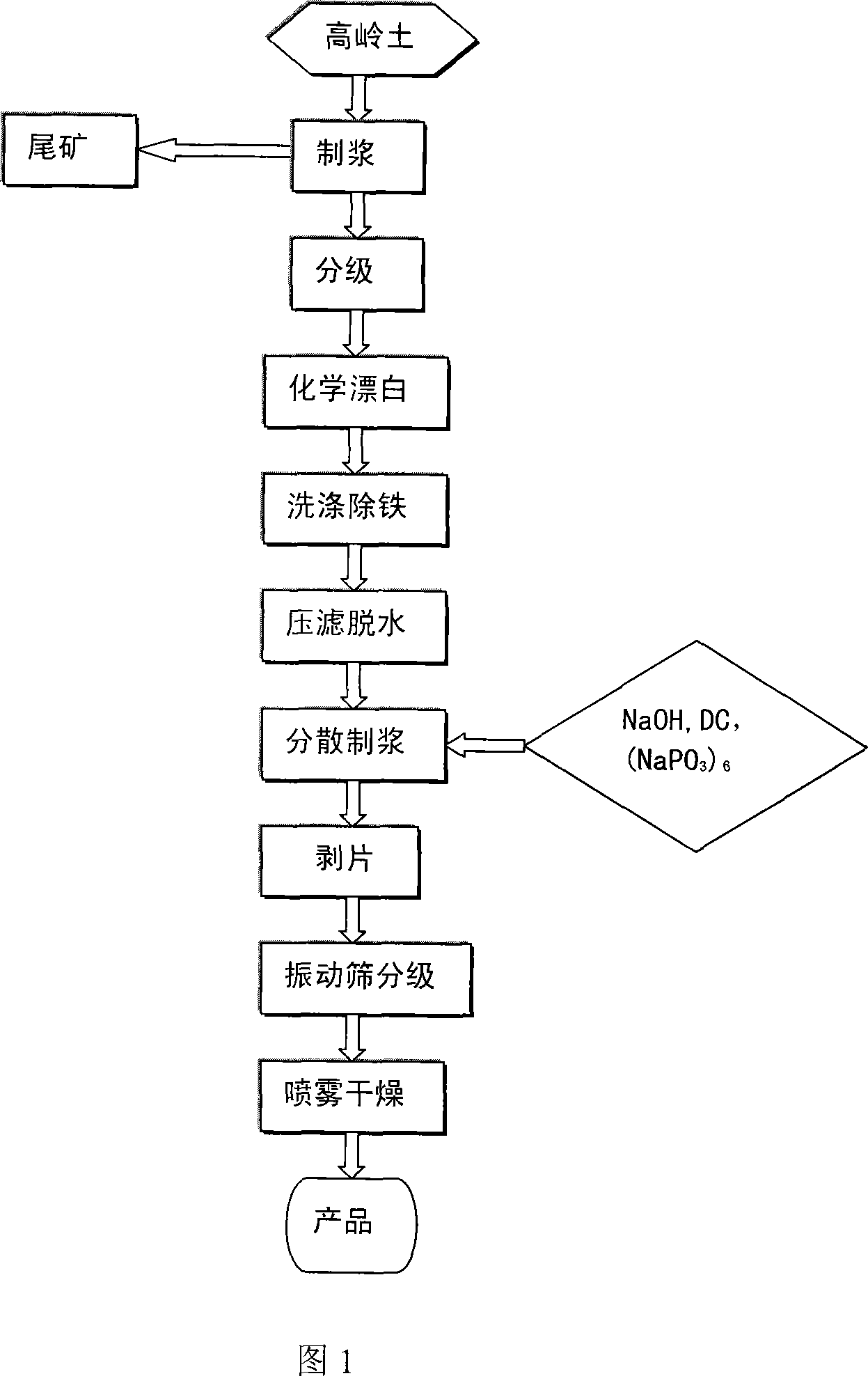

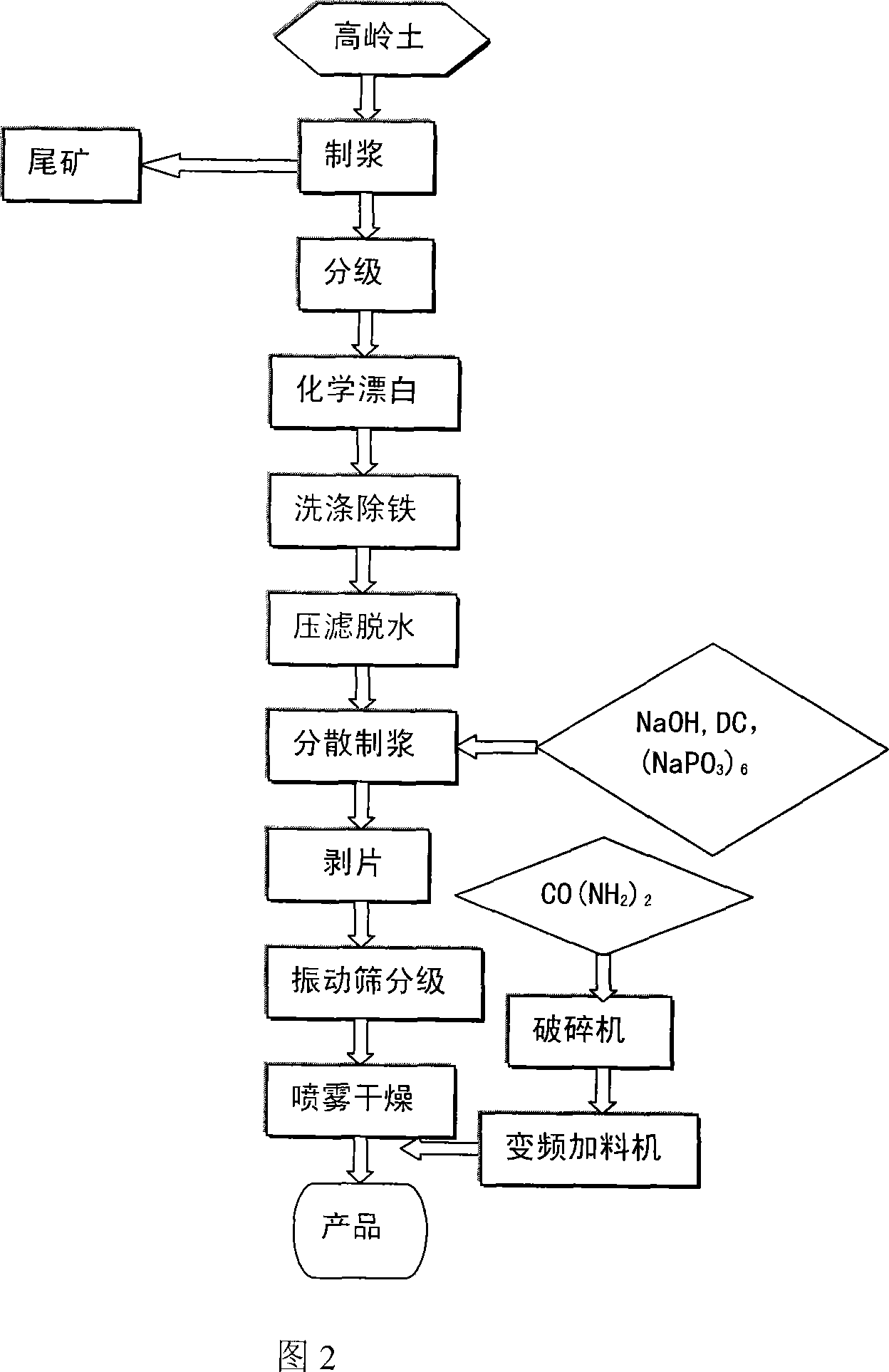

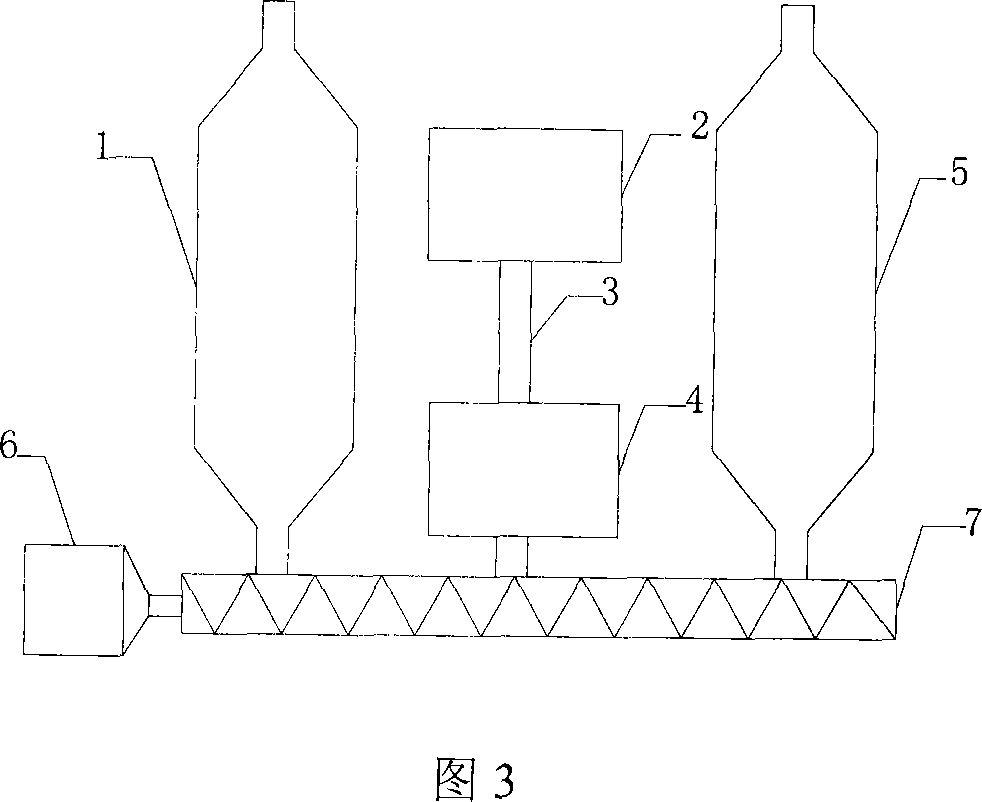

[0042] As shown in Fig. 2 and Fig. 3, a kind of production technique of high viscosity concentration kaolin, it comprises the steps:

[0043] 1) Kaolin ore is mined by hydromechanical method, and kaolin ore slurry J is obtained through pulping, grading, chemical bleaching, washing to remove iron, dehydration by pressure filtration, dispersion pulping, peeling, and vibrating sieve classification;

[0044] The specific steps are:

[0045] a) Pulping (using hydromechanical method to mine kaolin ore and making kaolin slurry): adopting hydromechanical method to mine kaolin ore at the mine, the mass concentration of the collected ore slurry is 6%, and the ore slurry is transported to the Spiral classifier and three-stage hydrocyclone are used to classify and remove sand to obtain kaolin slurry A, which is input into the slurry storage tank; dispersant sodium hexametaphosphate and sodium silicate are added to kaolin slurry A for pulping to obtain kaolin Ore slurry B, the addition am...

Embodiment 2

[0063] A kind of production technology of high viscosity concentration kaolin, it comprises the steps:

[0064] 1) Kaolin ore is mined by hydromechanical method, and kaolin ore slurry J is obtained through pulping, grading, chemical bleaching, washing to remove iron, dehydration by pressure filtration, dispersion pulping, peeling, and vibrating sieve classification;

[0065] The specific steps are:

[0066] a) Pulping (use hydromechanical method to mine kaolin ore and make kaolin slurry): use hydromechanical method to mine kaolin ore at the mine, and the mass concentration of the collected slurry is 8%, and the ore slurry is sent to the Spiral classifier and three-stage hydrocyclone are used to classify and remove sand to obtain kaolin slurry A, which is input into the slurry storage tank; dispersant sodium hexametaphosphate and sodium silicate are added to kaolin slurry A for pulping to obtain kaolin Ore slurry B, the addition amount is to add 1.5 kilograms of sodium hexamet...

Embodiment 3

[0084] A kind of production technology of high viscosity concentration kaolin, it comprises the steps:

[0085] 1) Kaolin ore is mined by hydromechanical method, and kaolin ore slurry J is obtained through pulping, grading, chemical bleaching, washing to remove iron, dehydration by pressure filtration, dispersion pulping, peeling, and vibrating sieve classification;

[0086] The specific steps are:

[0087] a) Pulping (using hydromechanical method to mine kaolin ore and making kaolin slurry): adopting hydromechanical method to mine kaolin ore at the mine, the mass concentration of the collected ore slurry is 9%, and the ore slurry is transported to the Spiral classifier and three-stage hydrocyclone are used to classify and remove sand to obtain kaolin slurry A, which is input into the slurry storage tank; dispersant sodium hexametaphosphate and sodium silicate are added to kaolin slurry A for pulping to obtain kaolin Ore slurry B, the addition is to add 1.1 kilograms of sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com