Patents

Literature

22989 results about "Sieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A mesh strainer, also known as sift, commonly known as sieve, is a device for separating wanted elements from unwanted material or for characterizing the particle size distribution of a sample, typically using a woven screen such as a mesh or net or metal. The word "sift" derives from "sieve". In cooking, a sifter is used to separate and break up clumps in dry ingredients such as flour, as well as to aerate and combine them. A strainer is a form of sieve used to separate solids from liquid.

Method for providing a grinding surface on glass implements used in personal care

ActiveUS8790749B2Increase variabilityEasy to manufacturePretreated surfacesManicure/pedicurePersonal careFlat glass

Manufacturing method of grinding surface on glass cosmetics, in particular the nail and skin file, from flat glass of FLOAT type, is carried out by marking at least one abrasive surface on one or two sides of a glass pane or intermediate product. This surface is then coated with fusing glue, powdered with clean quartz sand with grain size between 1 and 500 μm using a sieve, and the surplus sand is knocked-down. The intermediate product with fixed sand is inserted into the fusing furnace where it is baked at the temperature of up to 900° C. The abrasive surface may be roughened by sand blasting before the fusing glue application; the intermediate product coated with fusing glue can be decorated with glass fritte.

Owner:HACEK OVER SKUTCHANOVA ZUZANA

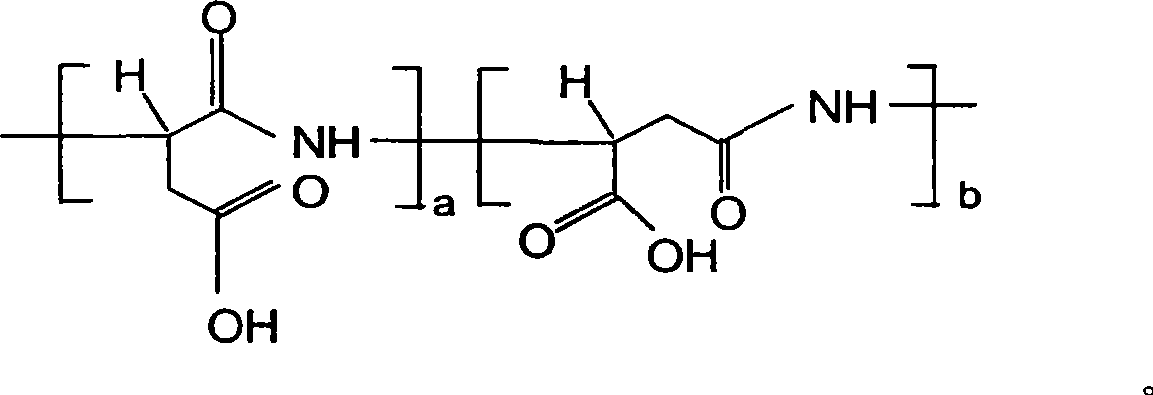

Superabsorbent polymers having anti-caking characteristics

InactiveUS6124391ALittle and no caking problemEliminate the problemPigmenting treatmentAbsorbent padsPolymer scienceSuperabsorbent polymer

A particulate material composition of superabsorbent polymer particles, wherein less than about 60% by weight of the superabsorbent polymer particles will pass through a U.S. Standard 50 mesh sieve. The composition has anti-caking properties and also reduced dusting. The composition can be produced by mixing the superabsorbent polymer particles with an inorganic powder, such as clay.

Owner:EVONIK DEGUSSA GMBH

Microfluidic systems for size based removal of red blood cells and platelets from blood

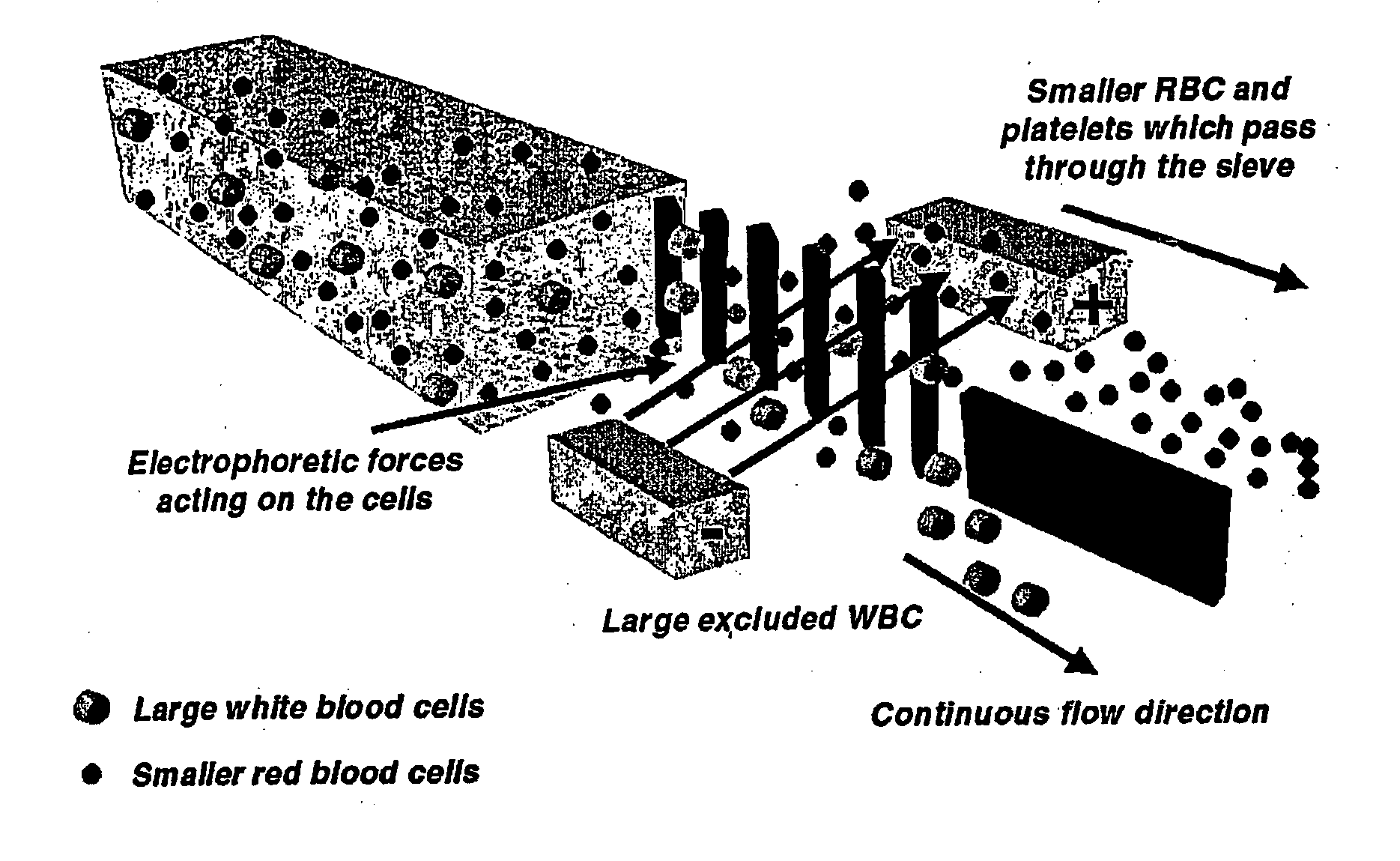

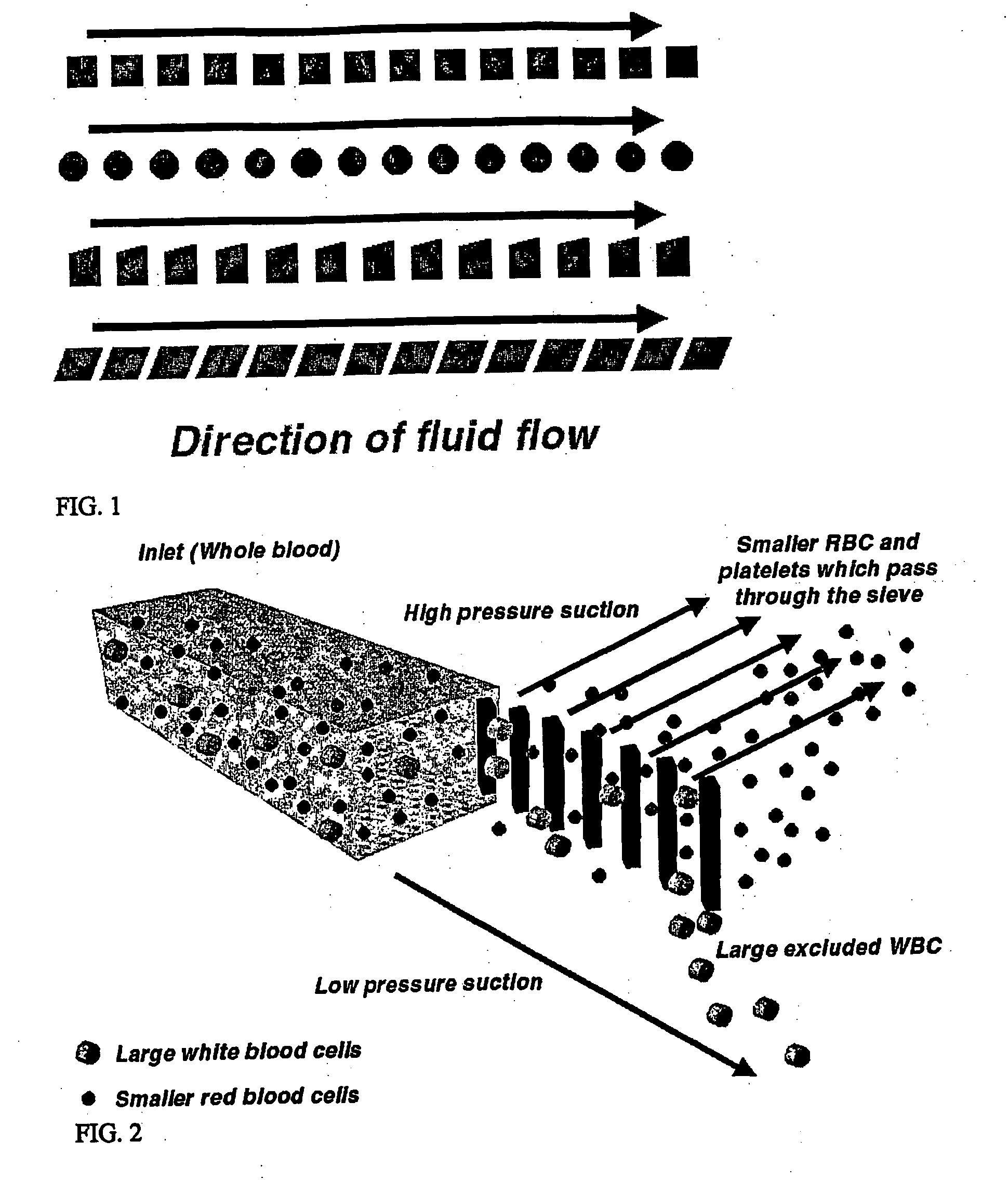

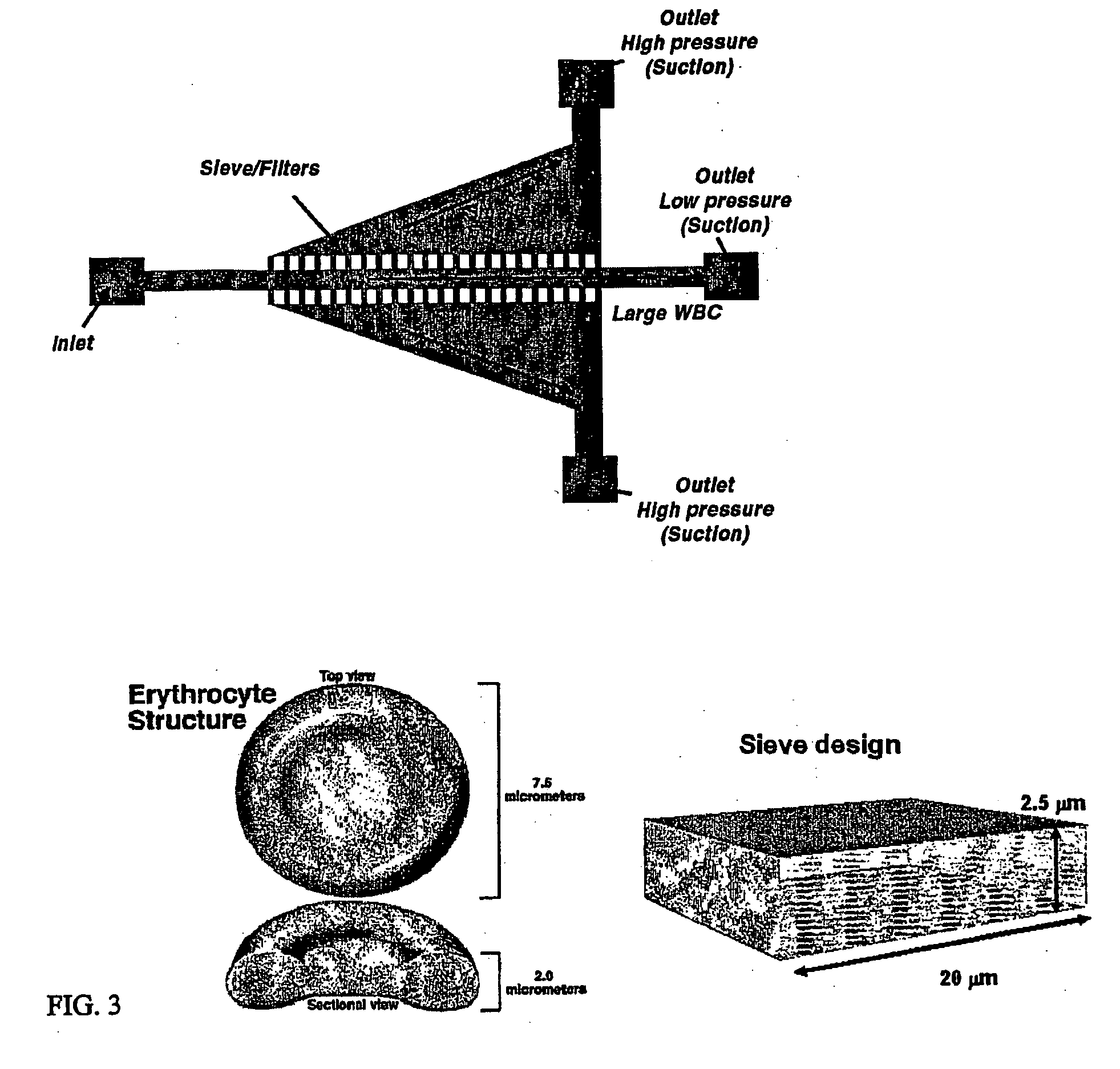

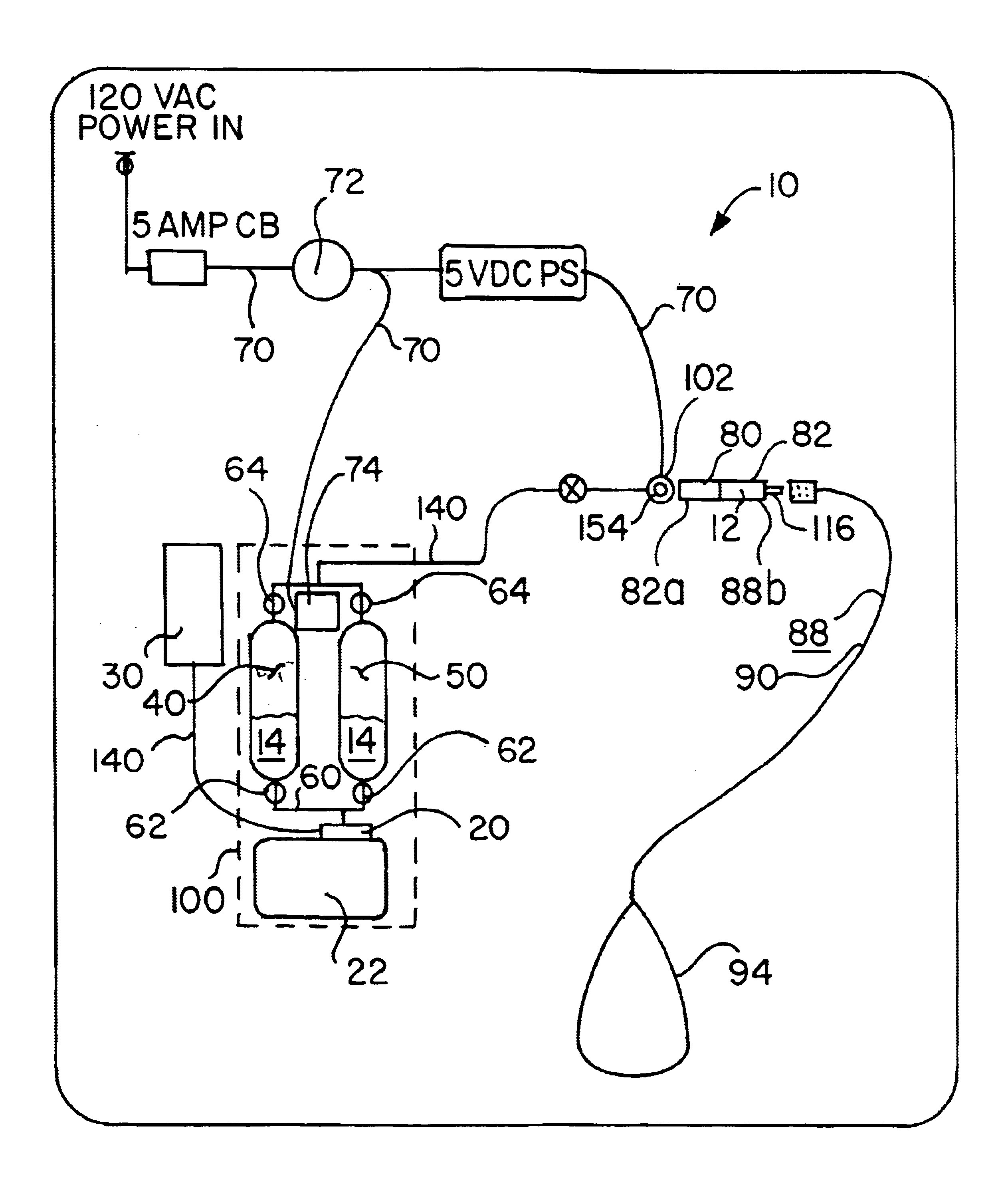

The invention features devices and methods for enriching a sample in one or more desired particles. An exemplary use of these devices and methods is for the enrichment of cells, e.g., white blood cells in a blood sample. In general, the methods of the invention employ a device that contains at least one sieve through which particles of a given size, shape, or deformability can pass. Devices of the invention have at least two outlets, and the sieve is placed such that a continuous flow of fluid can pass through the device without passing through the sieve. The devices also include a force generator for directing selected particles through the sieve. Such force generators employ, for example, diffusion, electrophoresis, dielectrophoresis, centrifugal force, or pressure-driven flow.

Owner:THE GENERAL HOSPITAL CORP

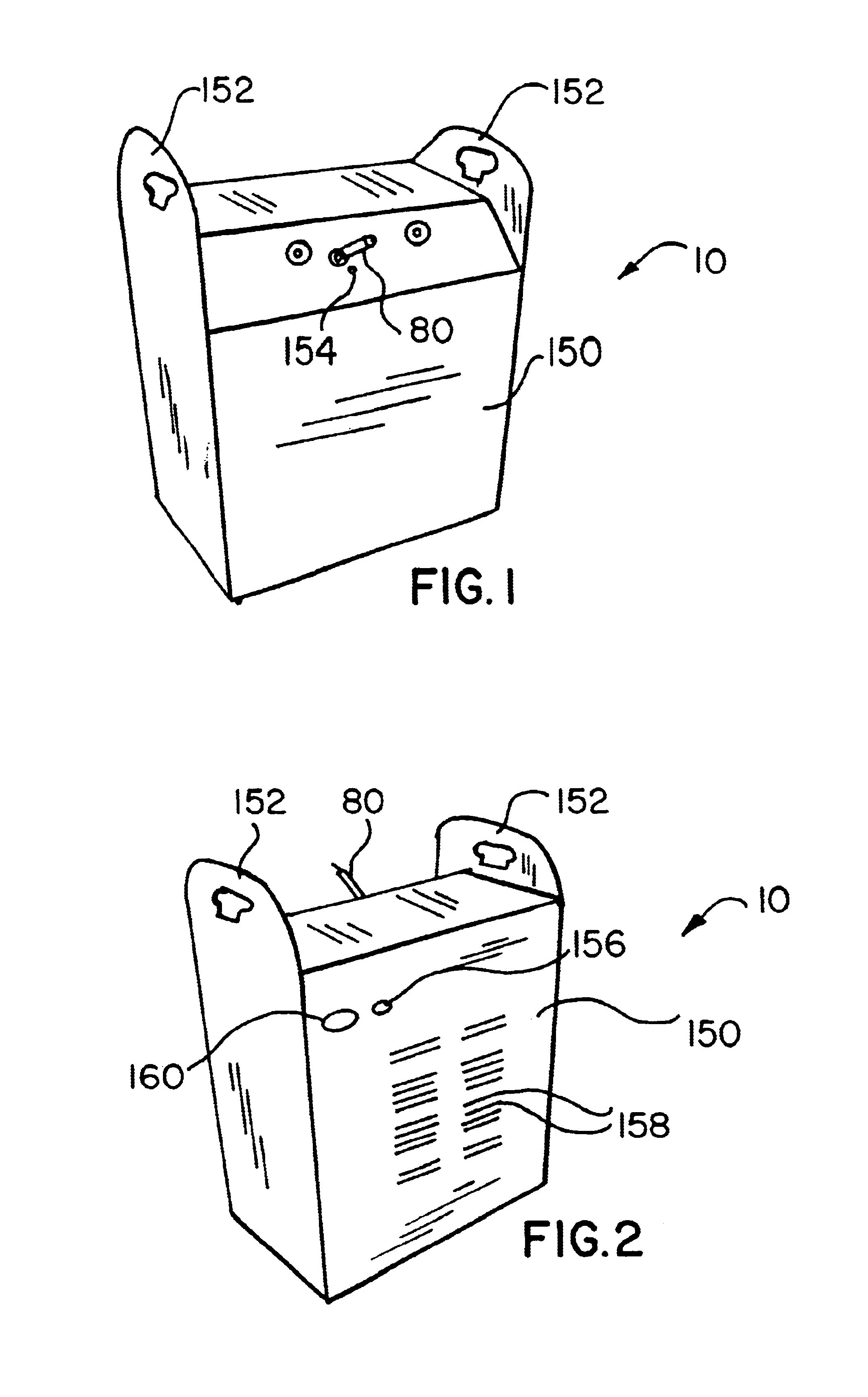

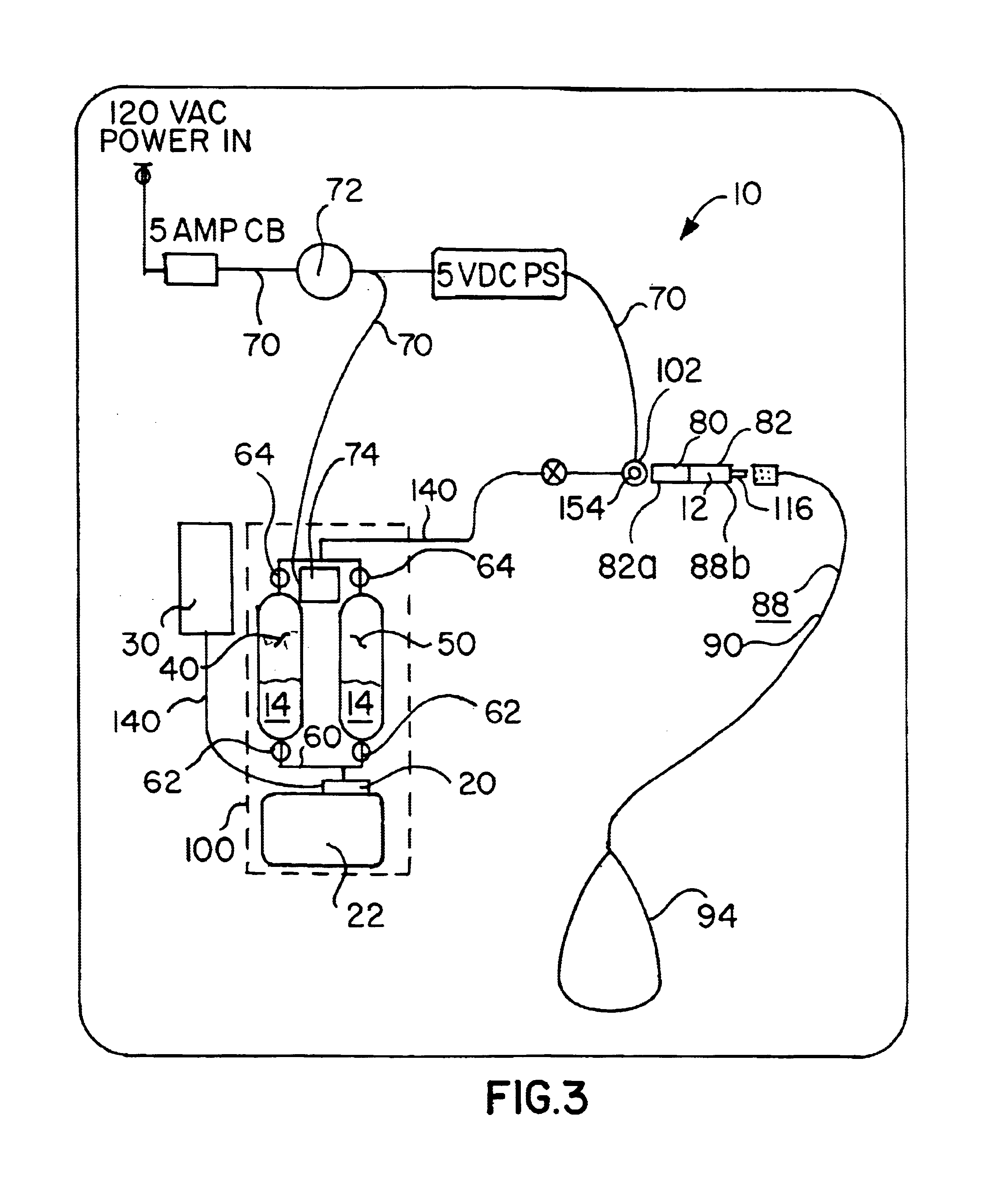

Oxygen concentrating aroma mixing breathable air delivery apparatus and method

InactiveUS6866041B2Operating means/releasing devices for valvesOther heat production devicesAtmospheric airAir compressor

An apparatus for concentrating the oxygen content of and injecting aroma into a stream of air and delivering the stream of air to the nostrils of a person includes an air intake filter in fluid communication with the air compressor for drawing a stream of air out of the surrounding atmosphere; a sieve bed in fluid communication with the air intake means, each sieve bed containing a quantity of nitrogen absorption material and having sieve bed input and output valve mechanism; so that the sieve bed extracts nitrogen from the air stream so that the proportion of oxygen exiting the sieve bed is elevated, and as the input valve mechanism closes, the sieve bed output valve mechanism opens and vents absorbed nitrogen from the sieve bed to the atmosphere; an aroma chamber containing aroma releasing material in fluid communication with the output valve mechanism.

Owner:EVOLUTION

Magnetic biological carrier and preparation method thereof

InactiveCN102225806APromote recoveryRealize dynamic regenerationSustainable biological treatmentBiological water/sewage treatmentResource utilizationEngineering

The invention discloses a magnetic biological carrier and a preparation method thereof. The raw materials of the magnetic biological carrier comprise aggregate, iron oxide, a binder and a reducing agent. The preparation method of the magnetic biological carrier comprises the following steps of: mixing the aggregate, iron oxide and the reducing agent, crushing, screening with a 60-mesh sieve to obtain a mixed material, adding water which is 30-60% of the mixed material by weight to the binder, stirring for dissolving the binder to obtain a binder solution, then mixing the binder solution with the mixed material, uniformly stirring, granulating and shaping to obtain 2-10 mm granules, drying the granules till the water content of the granules is less than 10%, and calcining at the temperature of 350-1100 DEG C for 0.2-10 hours to obtain the magnetic biological carrier. The magnetic biological carrier provided by the invention can be applied to the deep treatment of secondary treatment water of domestic sewage, meets the requirements of landscape water replenishing and circulating cooling water treatment, and can be used for realizing the deep treatment and resource utilization of industrial wastewater.

Owner:HEFEI UNIV OF TECH

Portable oxygen concentrator

Owner:KONINK PHILIPS ELECTRONICS NV +1

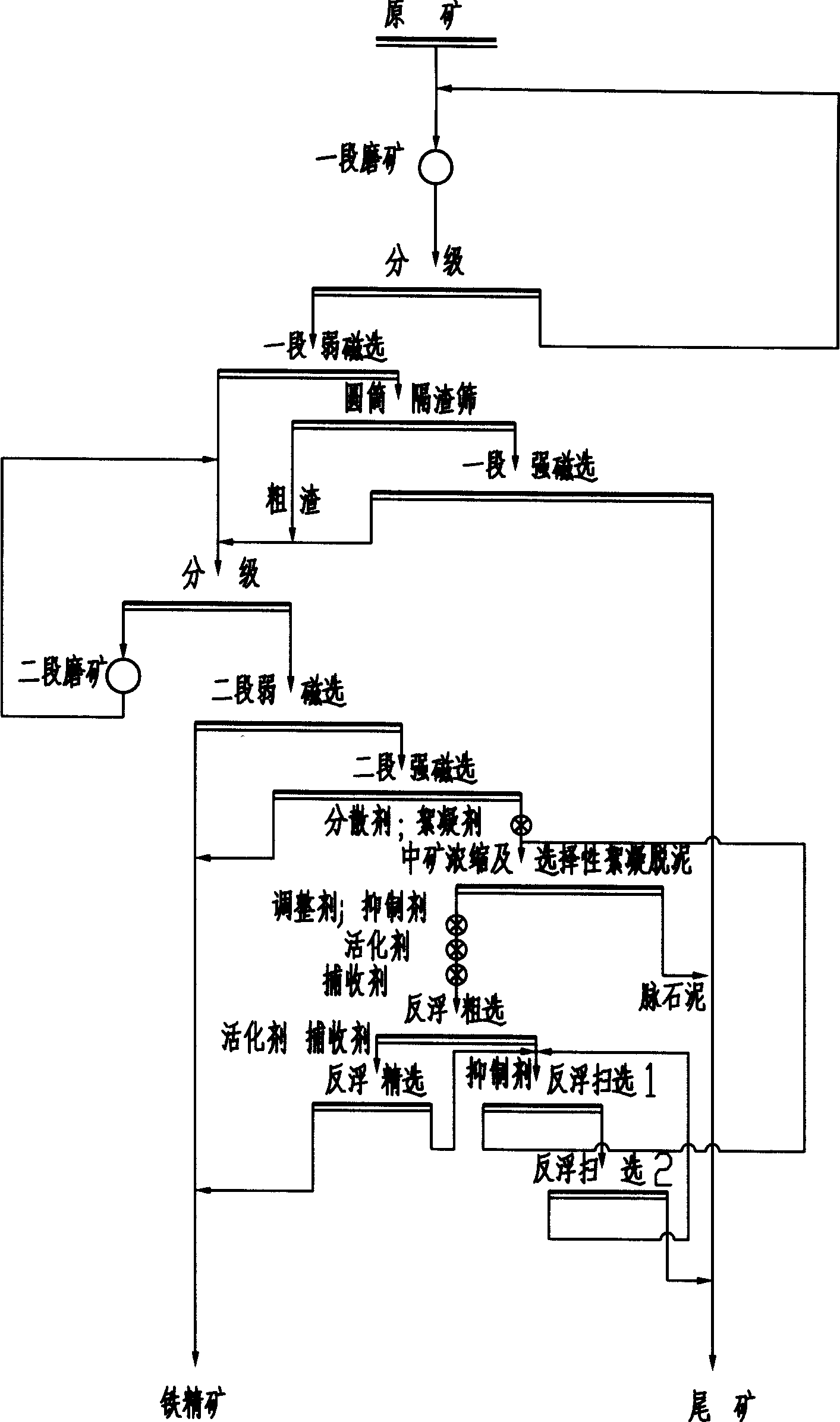

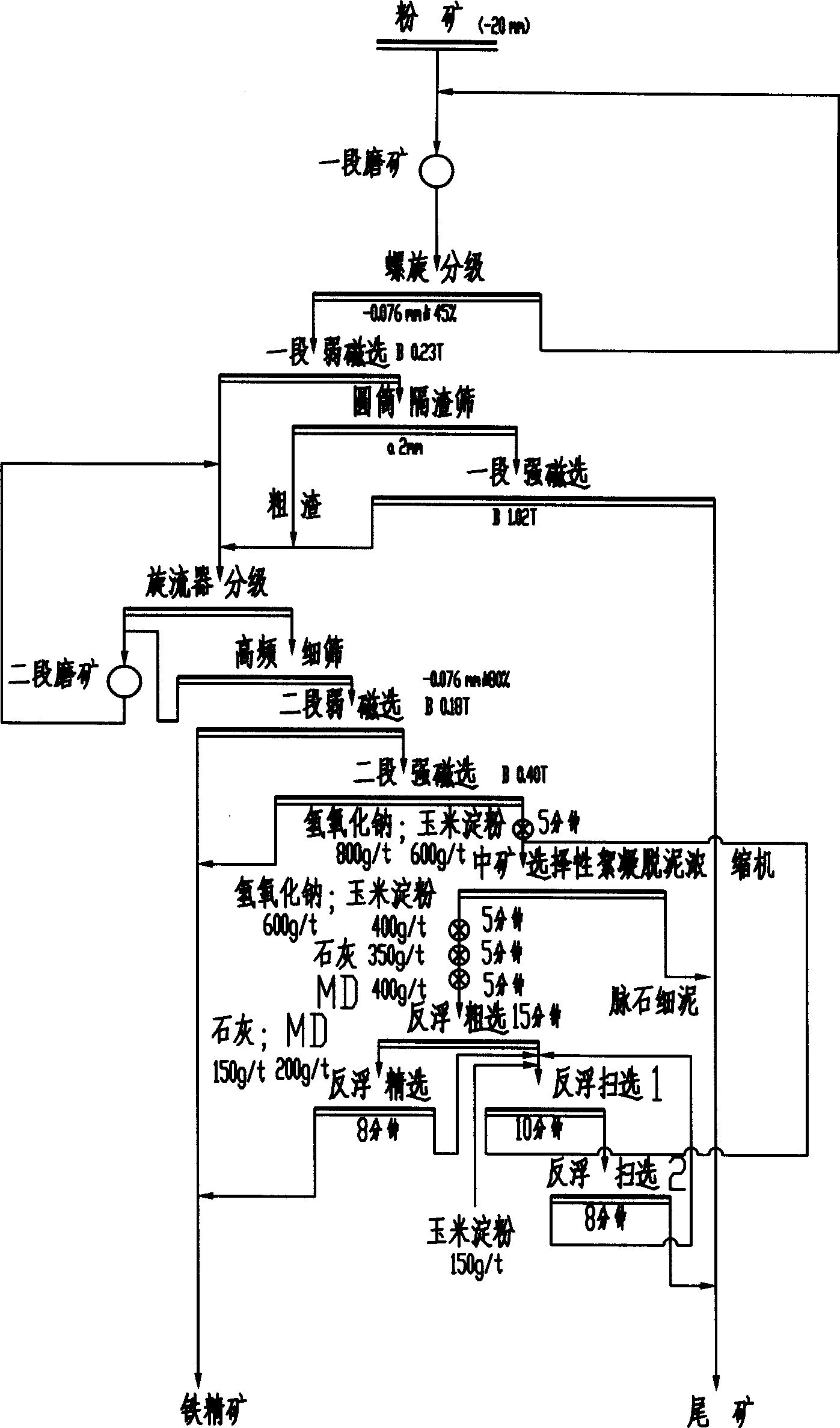

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method and device for separating magnesium and lithium and enriching lithium from salt lake brine

ActiveCN102382984AGood choiceImprove stabilityProcess efficiency improvementSupporting electrolyteIon-exchange membranes

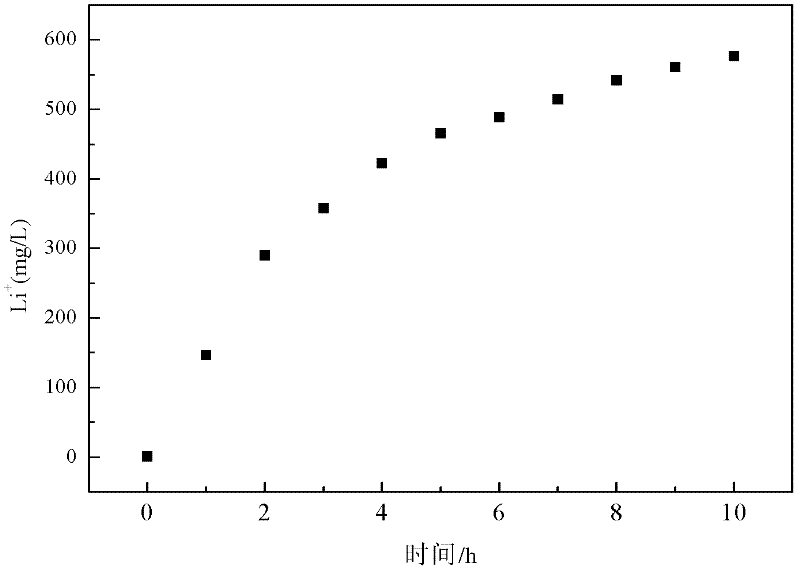

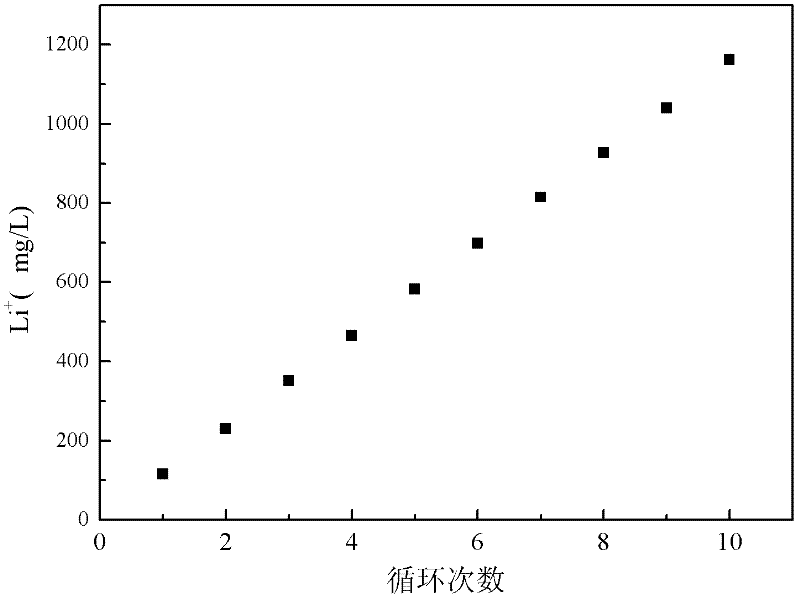

The invention relates to a method and a device for separating magnesium and lithium and enriching the lithium from salt lake brine. The method comprises the following steps of: separating an electrodialyzing device into two areas by using an anion exchange membrane, namely a lithium salt chamber and a brine chamber, filling the salt lake brine in the brine chamber, and filling a supporting electrolyte solution which does not contain Mg<2+> in the lithium salt chamber; placing a conducting matrix coated by an ionic sieve in the brine chamber as a cathode; placing the conducting matrix coated by a lithium-embedded ionic sieve in the lithium salt chamber as an anode; under the driving of an external electric potential, embedding Li <1+> in the brine in the brine chamber into the ionic sieve to form the lithium-embedded ionic sieve, and recovering the lithium-embedded ionic sieve into the ionic sieve after the lithium-embedded ionic sieve in the lithium salt chamber releases the Li <1+> into a conducting solution; and discharging a liquid in the brine chamber after the lithium is embedded, adding the salt lake brine again, alternatively placing electrodes in the two chambers, and repeating and circulating operations. Through the method and the device for separating magnesium and lithium and enriching lithium in the salt lake brine, the separation of the lithium and other ions is effectively realized, and a lithium-enriched solution is synchronously obtained. The method has a short flow and low production cost, is simple to operate, can be operated continuously, and is easy to industrially apply.

Owner:CENT SOUTH UNIV

Pre-selection method of low-ore grade magnetic iron ore

InactiveCN101502819ASolve the costSolve the problem of large tailingsSievingScreeningSeparation technologyMagnetite

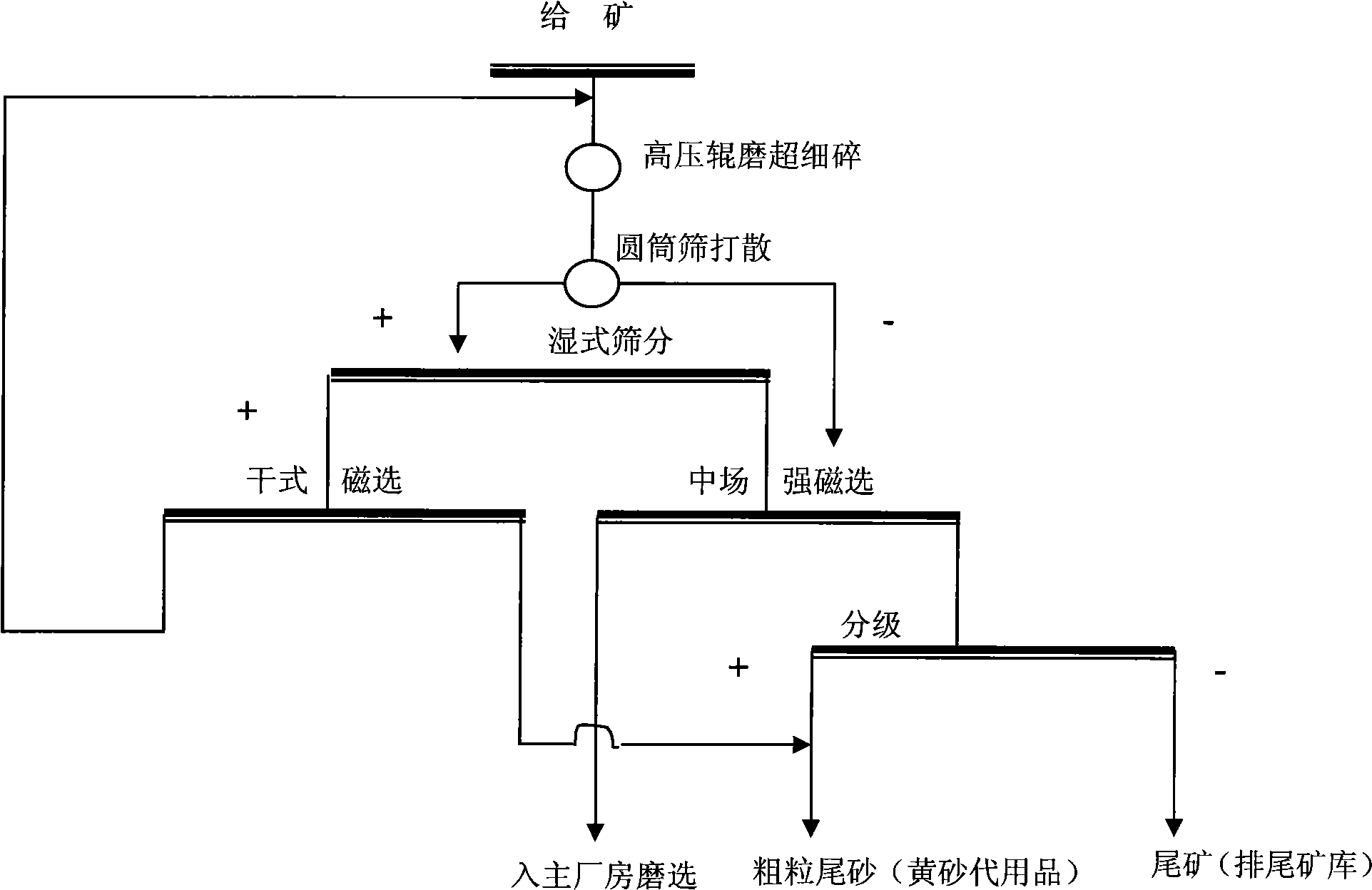

The invention discloses a preselecting method of low-grade magnetic iron ore, comprising the steps of crushing the raw ore of the magnetic iron ore by coarse crushing, intermediate crushing and fine crushing operations, conveying to subject to ultra-fine crushing operation, and then crushing by a high-pressure roller mill, scattering the crushed product by a wet cylindrical sieve, conveying the ore on the cylindrical sieve to the vibrating sieve by a belt to perform wet gradation, conveying the ore on the vibrating sieve to a dry magnetic separator by the belt to discard the waste, returning the ore concentrate of the dry magnetic separator to the high-pressure roller mill to crush the ore concentrate again, perform magnetic separation and discarding tailings of the ore concentrate below the vibrating sieve and the ore concentrate below the cylindrical sieve in a wet coarse grain intermediate-field intensity magnetic separator, and selecting the coarse ore concentrate of the intermediate-field intensity magnetic separator by a grinding separation technology. The invention has the advantages that the invention selects quantities of qualified mine tailings by wet magnetic separation before grinding ore, reduces ore grinding work, reduces ore grinding energy consumption and has high system processing capacity; the invention can be widely used in magnetic ore dressing plant, and in particular suitable for treatment of preselecting low-grade magnetic iron ore with the iron grade lower than or equal to 22%.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Integral supported carbon molecular sieve catalyst, preparing method and applications thereof

InactiveCN101224432AReduce the number of growthSave raw materialsMolecular sieve catalystsEther preparation by compound dehydrationGas phaseCarbon nanotube

A catalyst for an integrated supported carbon modular sieve comprises an integrated beehive cordierite, a carbon-nano tube and an HZSM-5 modular sieve, wherein the carbon-nano tube takes 7-20 proportions, HZSM-5 takes 10-30 proportions, and cordierite tales 60-80 proportions. The preparation method is that: carbon-nano tube is produced in situ on the integrated beehive cordierite by using chemical vapor deposition firstly, and the carbon-nano tube is taken as carrier, then the ZSM-5 modular sieve is developed on the carrier by using a secondary growth method. The catalyst for an integrated supported carbon-modular sieve can be used for the gas-phase synthesis of dimethyl ether DME by the dehydration of methanol.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Process for isomerization dewaxing of hydrocarbon streams

InactiveUS20030168379A1Yield maximizationReduce pointsMolecular sieve catalystsHydrocarbon by hydrogenationMolecular sieveIsomerization

A process for isomerization dewaxing of a hydrocarbon feed which includes contacting the hydrocarbon feed with a large pore size, small crystal size, crystalline molecular sieve and an intermediate pore size, small crystal size, crystalline molecular sieve to produce a dewaxed product with a reduced pour point and a reduced cloud point. In a preferred embodiment, the feed is contacted with the molecular sieves sequentially, first with the large pore sieve followed by the intermediate pore sieve.

Owner:EXXON RES & ENG CO

Biochar mixing type protected horticultural vegetable field soil heavy metal passivant and preparation method thereof

InactiveCN102807872ASimple processNo pollution in the processAgriculture tools and machinesOrganic fertilisersSoil heavy metalsBiochar

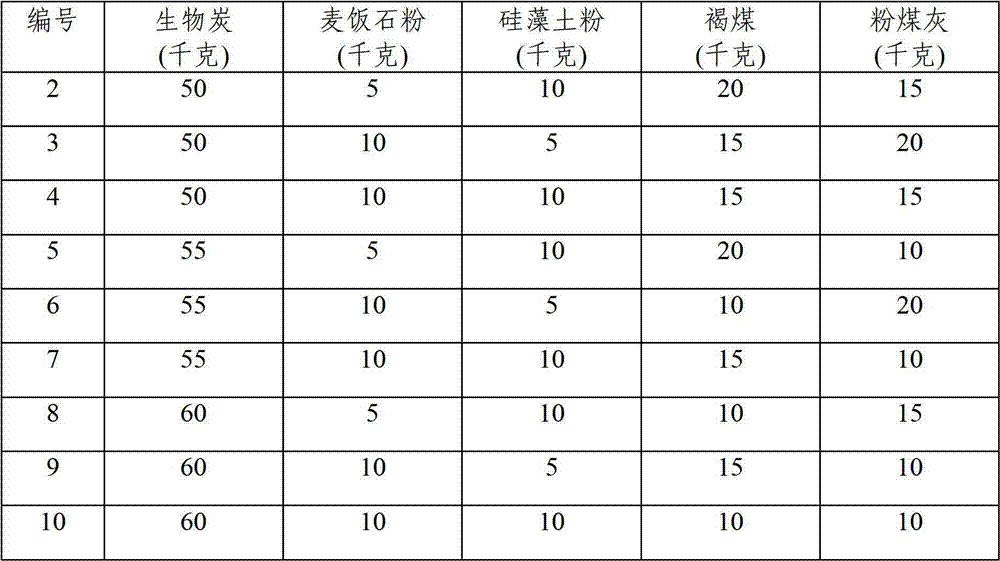

The invention relates to a soil improvement technology and an environment protection technology and particularly discloses a biochar mixing type protected horticultural vegetable field soil heavy metal passivant and a preparation method thereof. The soil heavy metal passivant comprises the following components in percentage by weight: 50 to 60 percent of biochar, 5 to 10 percent of medical stone powder, 5 to 10 percent of diatomite powder, 10 to 20 percent of lignite and 10 to 20 percent of coal ash. The preparation method for the soil heavy metal passivant comprises the following steps of: mixing the medical stone powder which is screened by an 80-mesh sieve, the diatomite powder which is screened by an 80-mesh sieve, the lignite, and the coal ash which is screened by an 80-mesh sieve, uniformly stirring, mixing with biochar which is screened by a 20-mesh sieve, fully stirring, and mixing uniformly to prepare the soil heavy metal passivant. The soil heavy metal passivant is easy to prepare; and the effects of passivating the protected horticultural vegetable field soil heavy metal, and reducing the content of recyclable heavy metal of plant in soil can be achieved under the synergistic effects of all components.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Dewaxing catalyst containing compound molecule sieve and preparation method thereof

ActiveCN1803998AHigh activityHigh selectivityMolecular sieve catalystsPetroleum wax recoveryMolecular sieveSilicon

The dewaxing catalyst contains composite molecular sieves by weight ratio as 80-99:1-20; wherein, one has one-dimensional hollow structure, and another has macropore structure and non-framework silicon of 1-20wt% taken the oxide and based on the molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline sulfur reduction in fluid catalytic cracking

InactiveUS6852214B1Reduce sulfur contentLow sulfurCatalytic crackingMolecular sieve catalystsOxidation stateGasoline

The sulfur content of liquid cracking products, especially the cracked gasoline, of the catalytic cracking process is reduced by the use of a sulfur reduction additive comprising a porous molecular sieve which contains a metal in an oxidation state above zero within the interior of the pore structure of the sieve. The molecular sieve is normally a large pore size zeolite such as USY or zeolite beta or an intermediate pore size zeolite such as ZSM-5. The metal is normally a metal of Period 4 of the Periodic Table, preferably zinc or vanadium. The sulfur reduction catalyst may be used in the form of a separate particle additive or as a component of an integrated cracking / sulfur reduction catalyst.

Owner:MOBIL OIL CORP +1

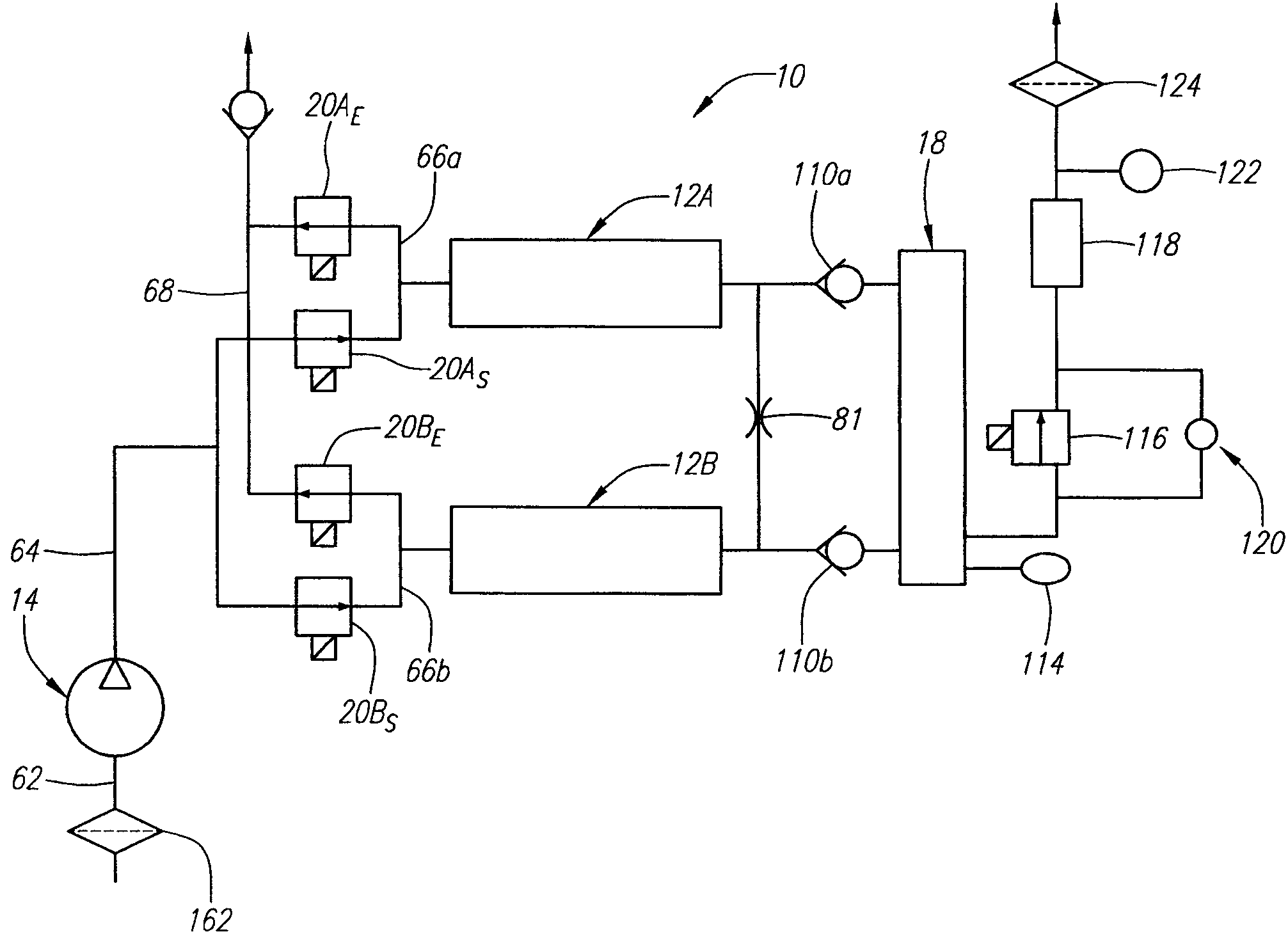

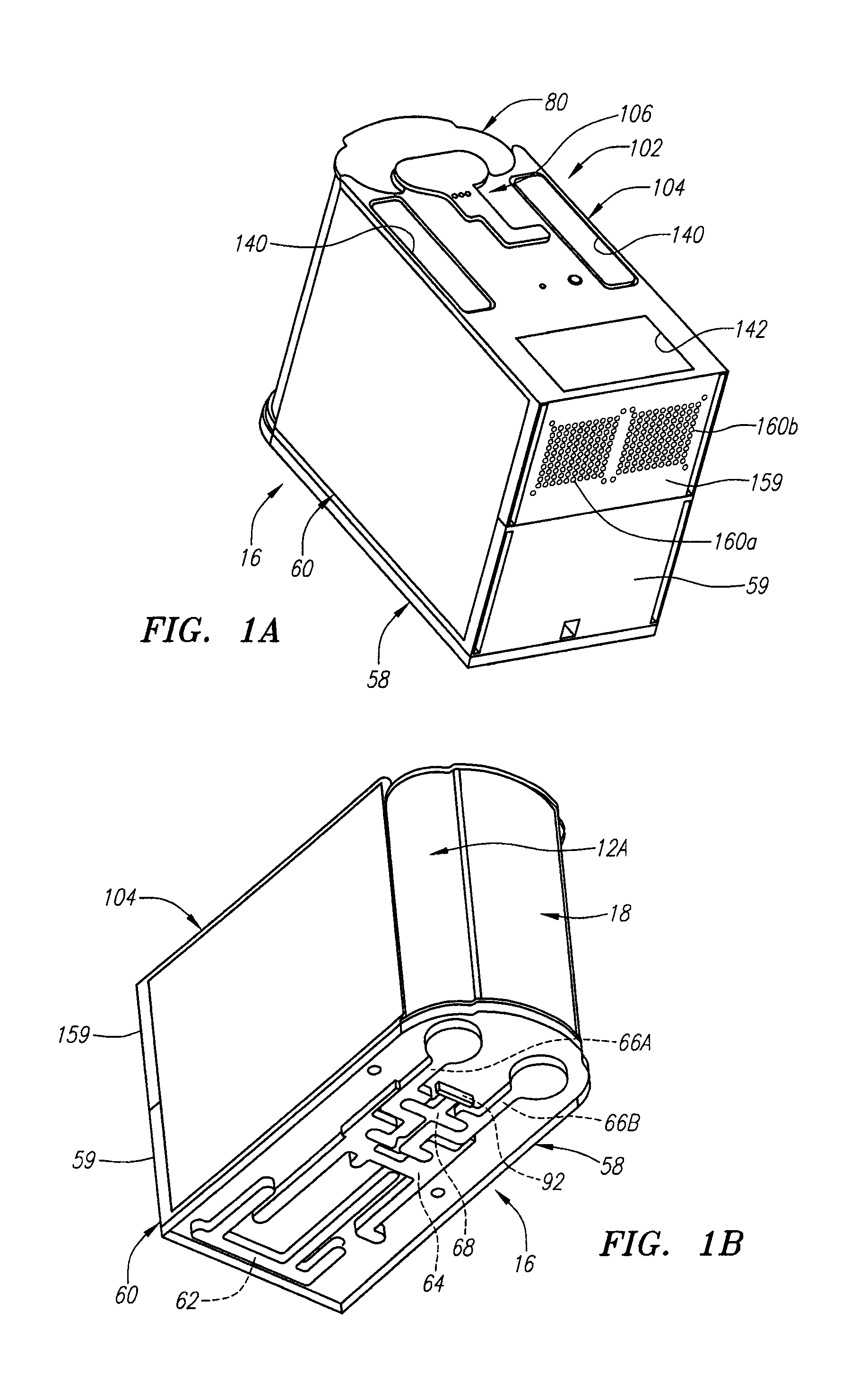

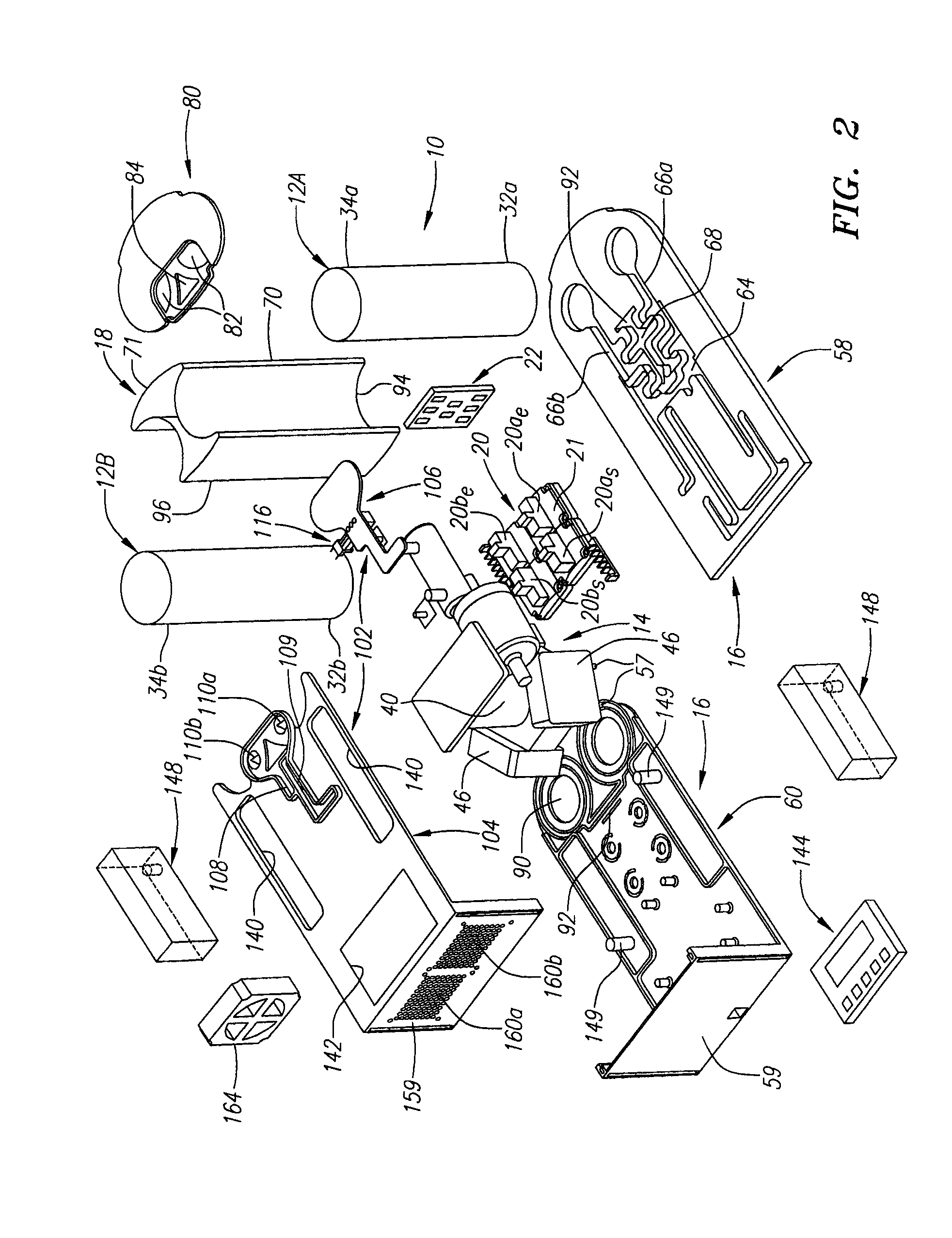

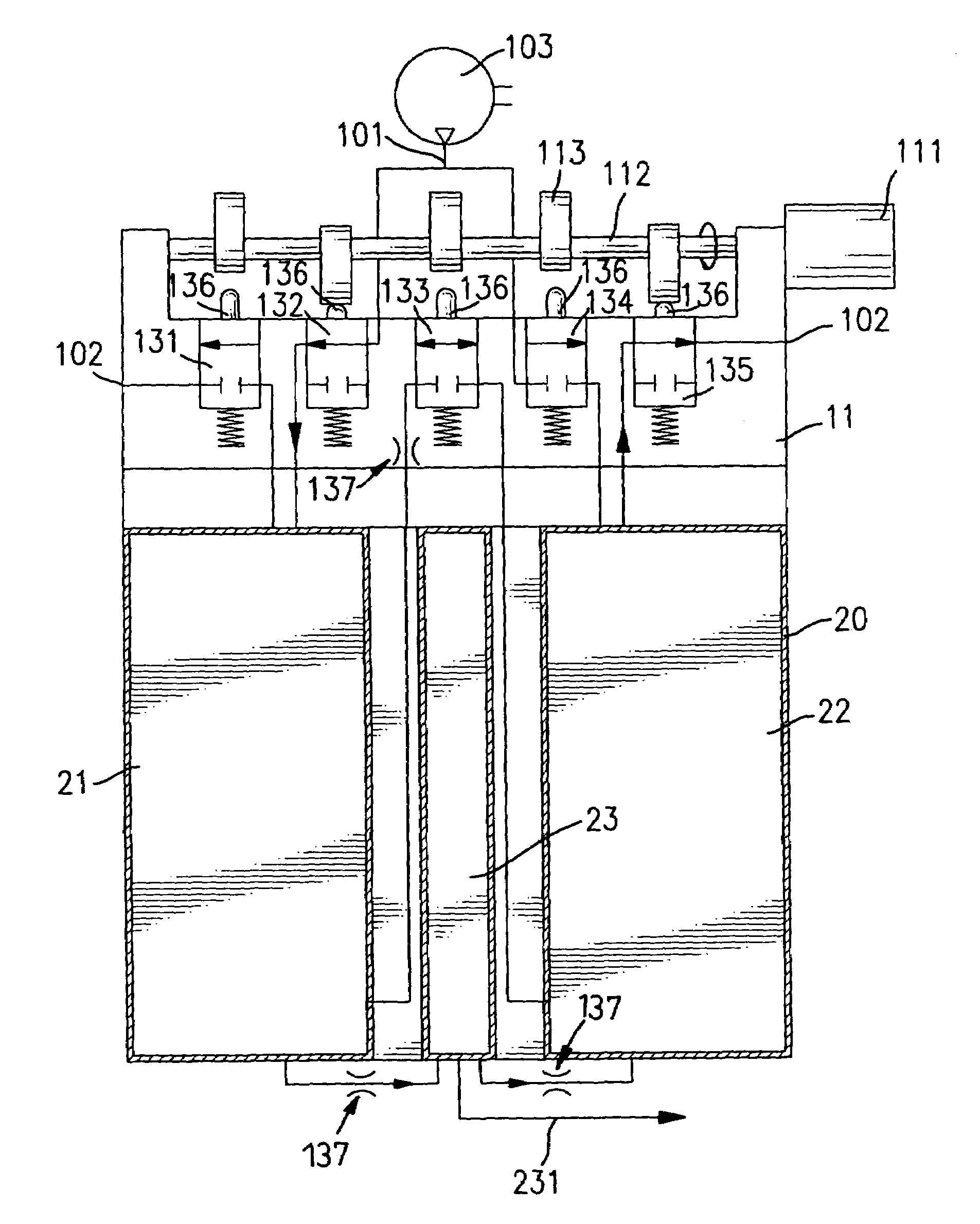

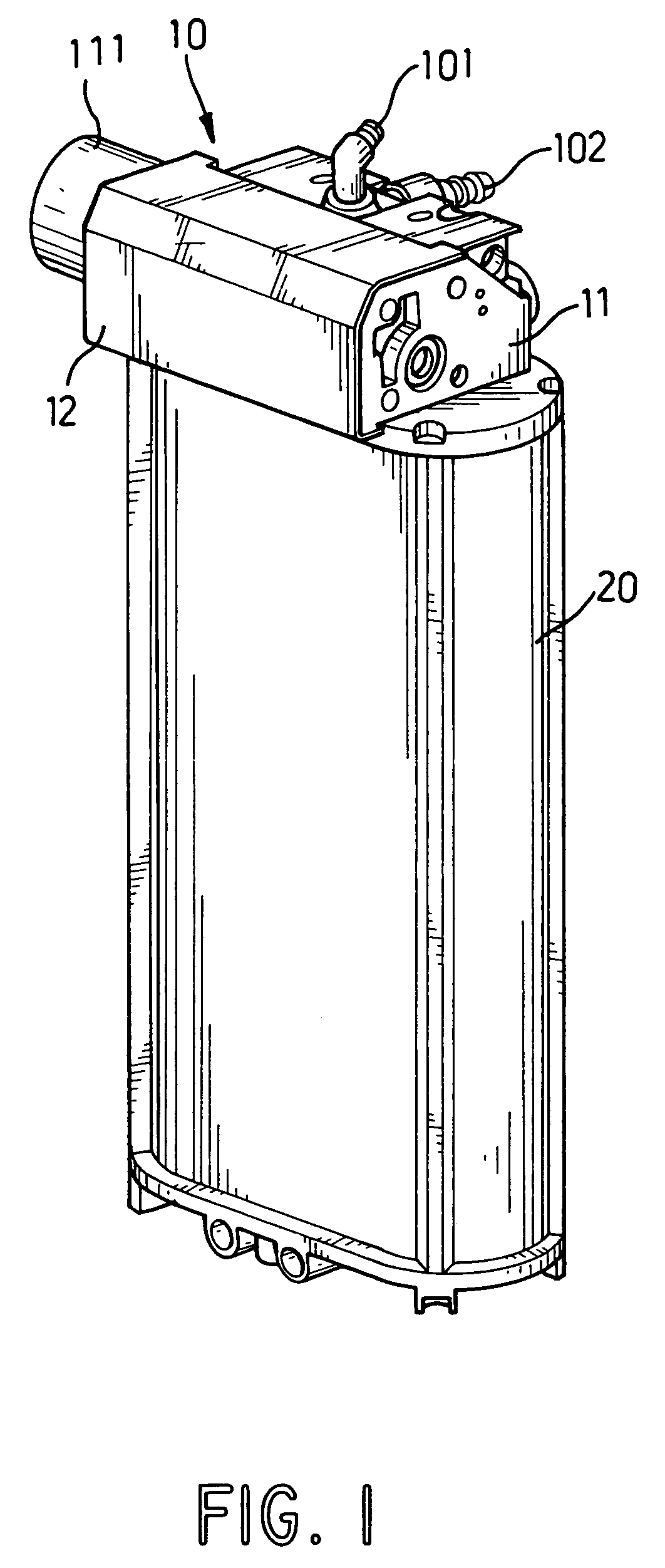

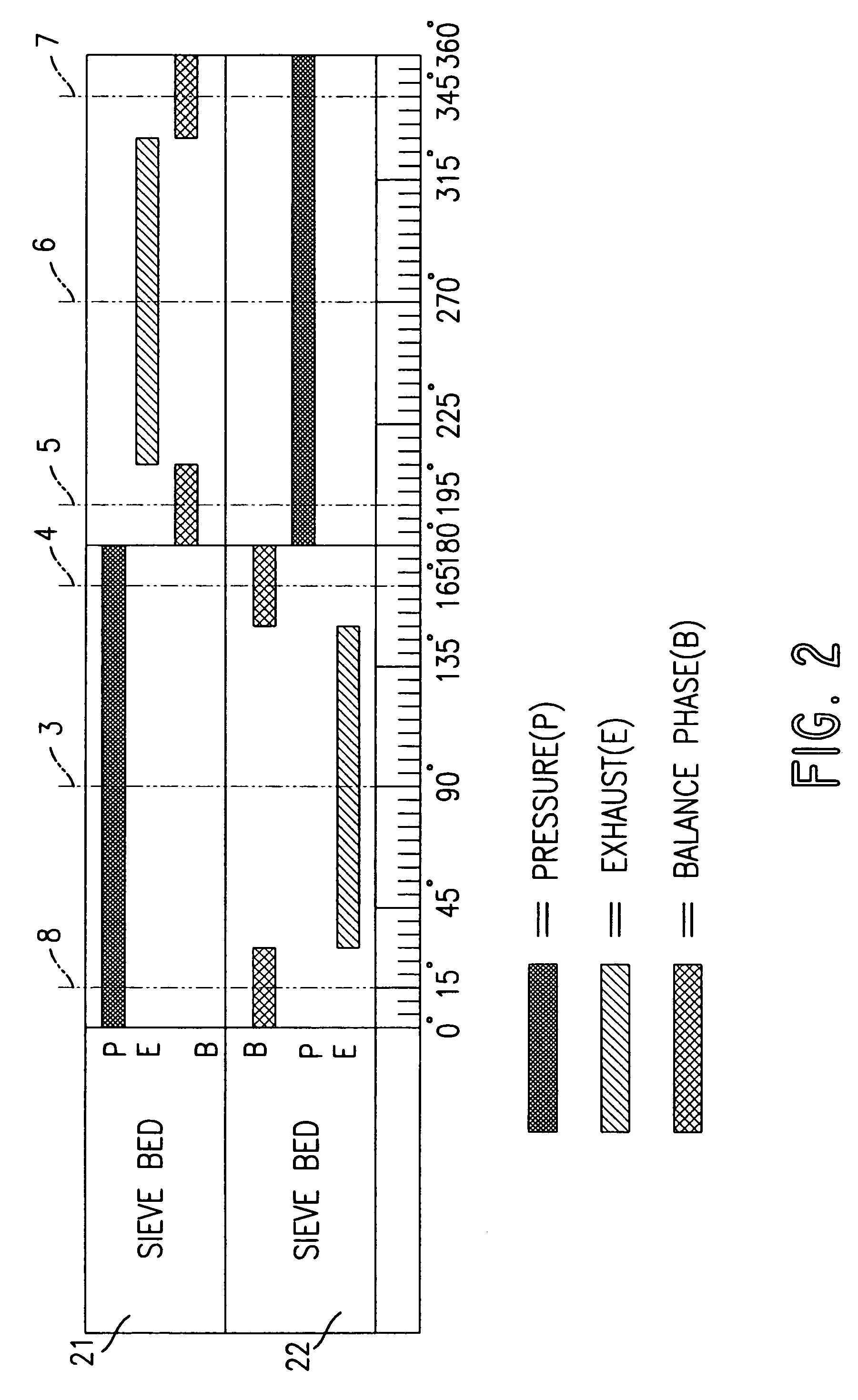

Rapid cycle pressure swing adsorption oxygen concentration method and mechanical valve for the same

InactiveUS7637989B2Efficiently concentrate oxygenRapid cycle pressure swingGas treatmentBreathing filtersMolecular sieveEnrichment methods

A rapid cycle pressure swing adsorption oxygen concentration method uses a mechanical valve that has at least one cam-actuated flow control valve to switch flow of fluid, such as compressed air coming into a sieve tank that is fitted with molecular sieve materials. The cam-actuated flow control valve is repeatedly actuated by the rotating cams to become open or closed to complete a cycle that precisely controls the flow direction, pressure conditions and pressurized timing in the sieve tank whereby performance and efficiency of producing rapidly oxygen is high.

Owner:MERITS HEALTH PRODS

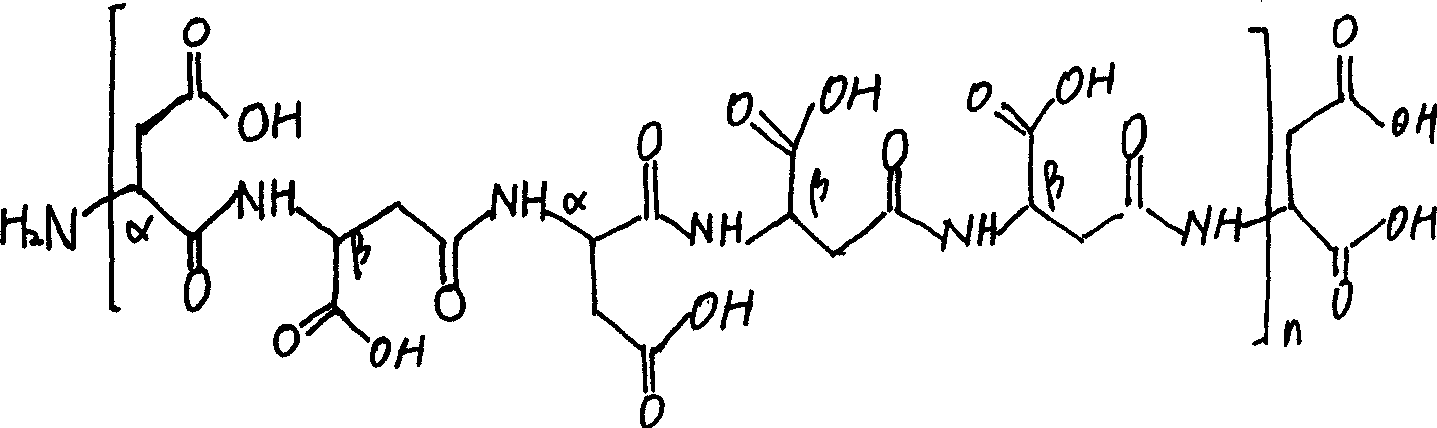

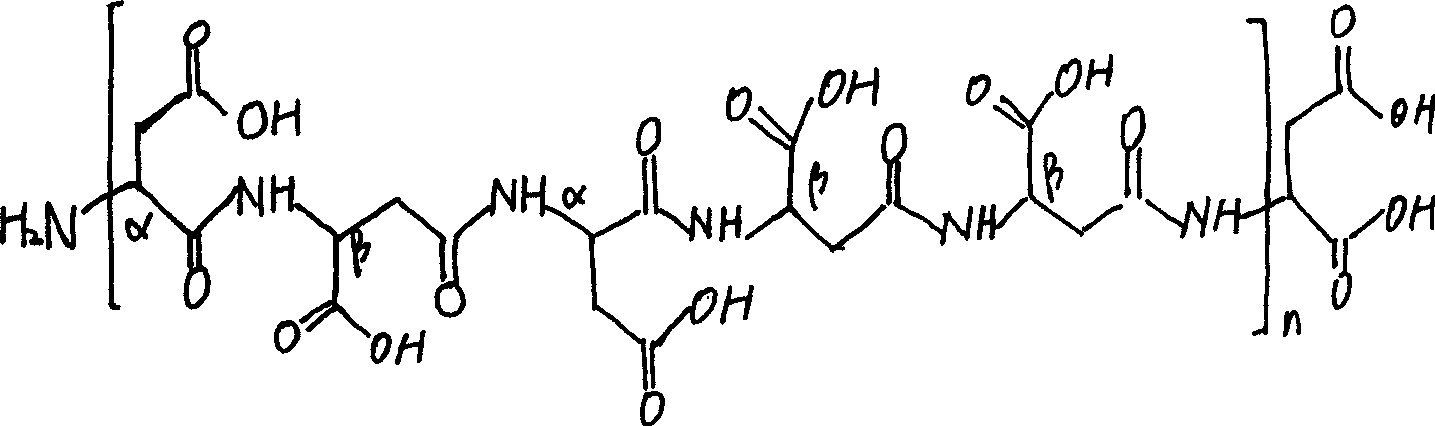

Nitrogen fertilizer compound synergist and preparation method

ActiveCN101450880AImprove the absorption and utilization effectIncrease profitAgriculture gas emission reductionFertilizer mixturesTrace element compositionNitrification inhibitors

The invention relates to nitrogen element fertilizer, in particular to a nitrogen element fertilizer composite synergist and a preparation method thereof. The composite synergist consists of a biochemical inhibitor, a synergist, a nitrogen element stabilizer, a carrier and microelements, the weight portion ratio of the materials is 1:0.01-1: 0.01-0.5: 0.5-1: 0-0.05, wherein the biochemical inhibitor can be a nitrification inhibitor and a urease inhibitor, the synergist can be poly-aspartic acid, and the nitrogen element stabilizer can be hydrolyzed amino acid, humic acid, alginic acid or alginic acid water soluble salt. The preparation method comprises the following steps: crushing the raw materials, screening the raw materials with a sieve of 30 to 100 meshes, and stirring and mixing the raw materials according to the proportion. The nitrogen element fertilizer composite synergist is suitable for growing long acting nitrogenous fertilizer taking urea or ammonium nitrogen fertilizer as raw materials and can be applied to various soils together with urea or ammonium nitrogen fertilizer so as to effectively prolong the fertilizer efficiency period of the urea or the ammonium nitrogen fertilizer. The fertilizer efficiency period can reach 100 to 120 days. The nitrogen element fertilizer composite synergist has remarkable resistance to diseases, drought and lodging, effectively improves the capability of soil to reserve nutrients, and has good effects for off-season crops.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

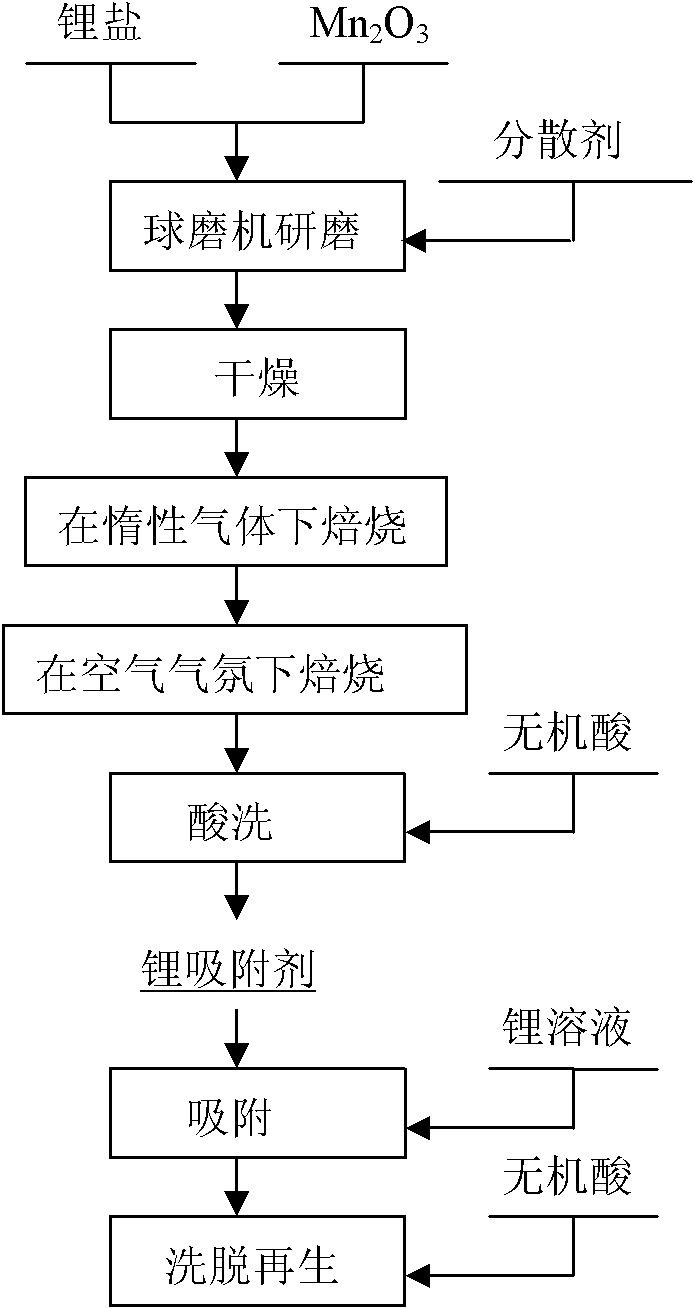

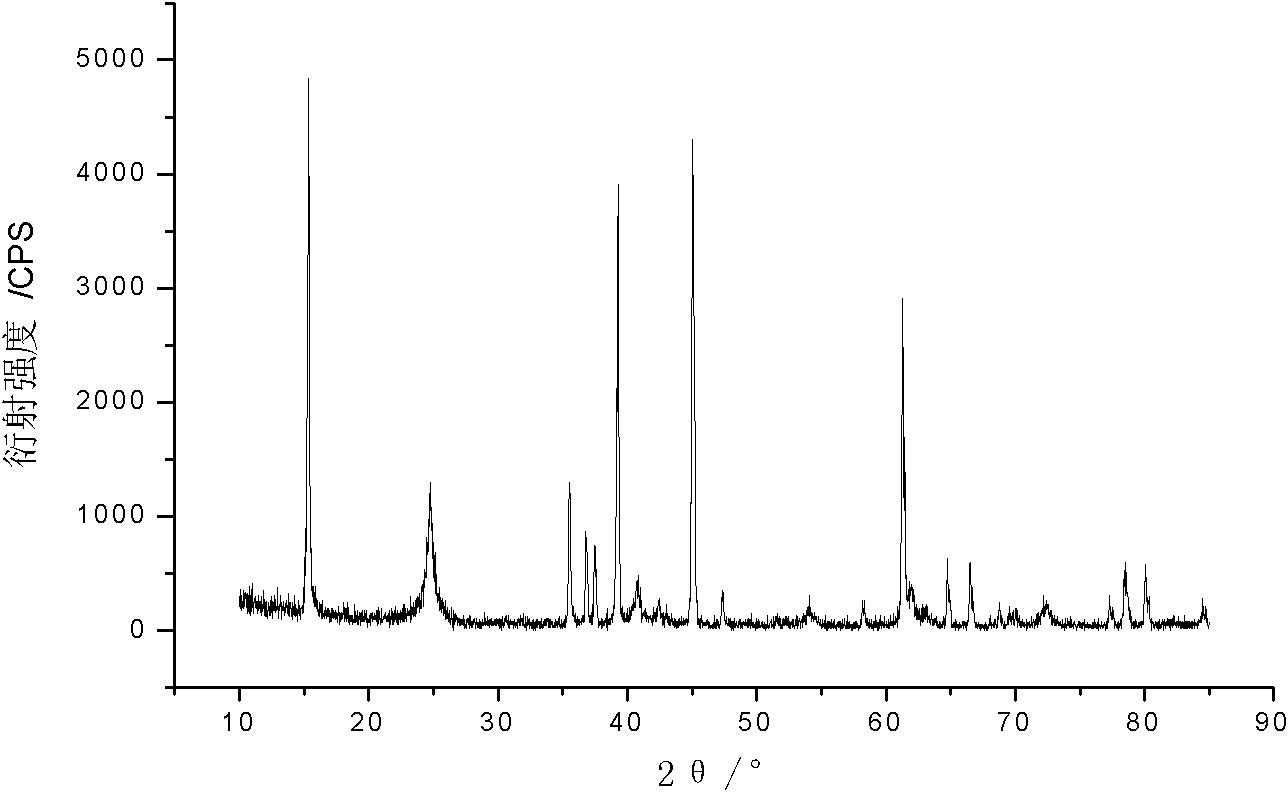

Manganese series lithium ion sieve adsorbent and preparation method of precursor thereof

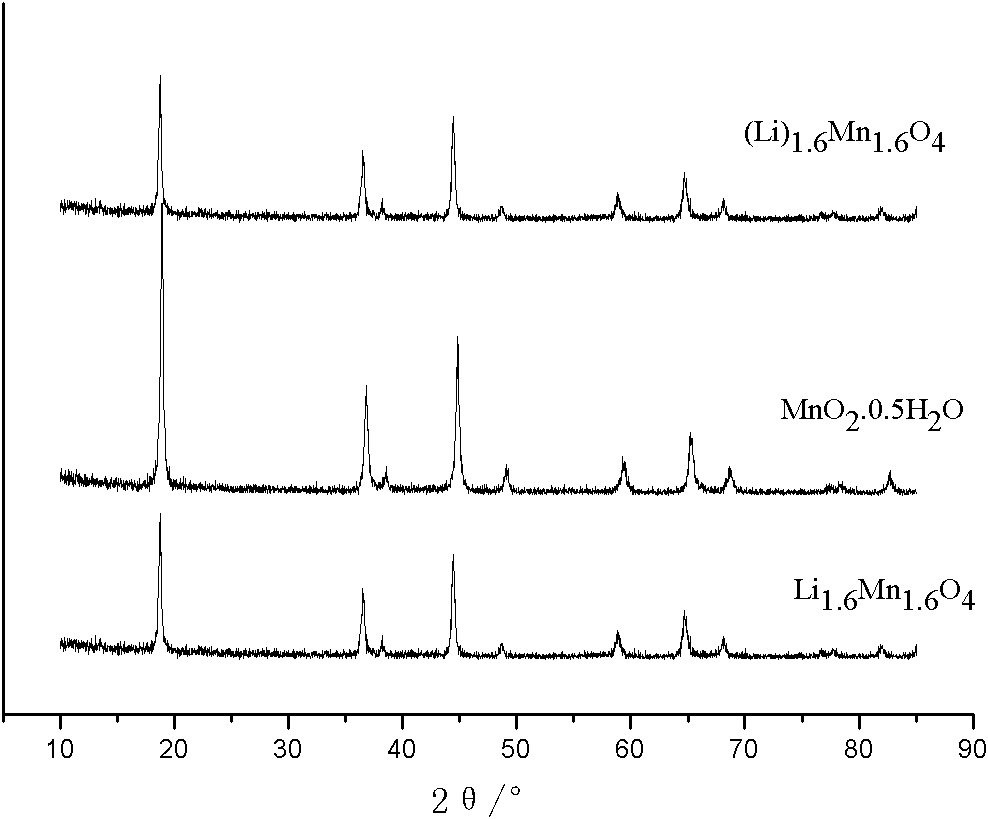

ActiveCN101961634ALow priceThe ratio is easy to controlOther chemical processesManganese oxides/hydroxidesSorbentManganese

The invention discloses a method for preparing a manganese series lithium ion sieve adsorbent, and relates to a method for preparing an inorganic adsorbent for adsorbing lithium from liquid lithium resources such as brine of salt lake, seawater and the like. In the method, a cubic crystal ion sieve precursor Li1.6Mn1.6O4 is prepared from Mn2O3 and LiOH or Li2CO3 serving as raw materials by using two sections of solid-phase reactions, wherein the precursor also can be used as an anode material of a lithium ion battery. The precursor is acidized to obtain a lithium ion sieve adsorbent MnO2.0.5H2O (or expressed as H1.6Mn1.6O4), and the ion sieve is the lithium adsorbent which has high selectivity on lithium. The method has the advantages of simple and readily available raw materials, simple process, high adsorption capacity of the ion sieve, low cost, high purity of products and is easy to realize industrial production.

Owner:CENT SOUTH UNIV +1

Beneficiation method for removing long quarry impurities by adopting strong magnetic flotation

InactiveCN101898168AIncrease production capacityImprove grinding efficiencyFlotationMagnetic separationEngineeringBall mill

The invention relates to a beneficiation method for removing long quarry impurities by adopting strong magnetic flotation, comprising the steps of crushing, grinding, sieving, desliming, strong magnetically floating, floating, concentrating and dewatering. The concrete beneficiation method comprises the following steps of: breaking and grinding ore in a ball mill; grading ground minerals by a spiral grader and a hydraulic hydrocyclone twice; combining with the ball mill into a closed cycle; respectively mounting high-frequency linear vibration sieves in overflows graded twice; respectively removing impurities over 3 mm and 1 mm, such as mica, grass-roots bark, and the like; removing most of muddy substances from minerals through desliming equipment after the impurities are removed; removing mechanical iron, weakly magnetic iron ore, tourmaline and partial mica in a strong magnetic flotation machine; floating the minerals passing through the strong magnetic flotation machine again to remove residual iron minerals, mica and black minerals; and finally, concentrating and dewatering the minerals to form a product.

Owner:衡阳县湘雁矿业有限公司

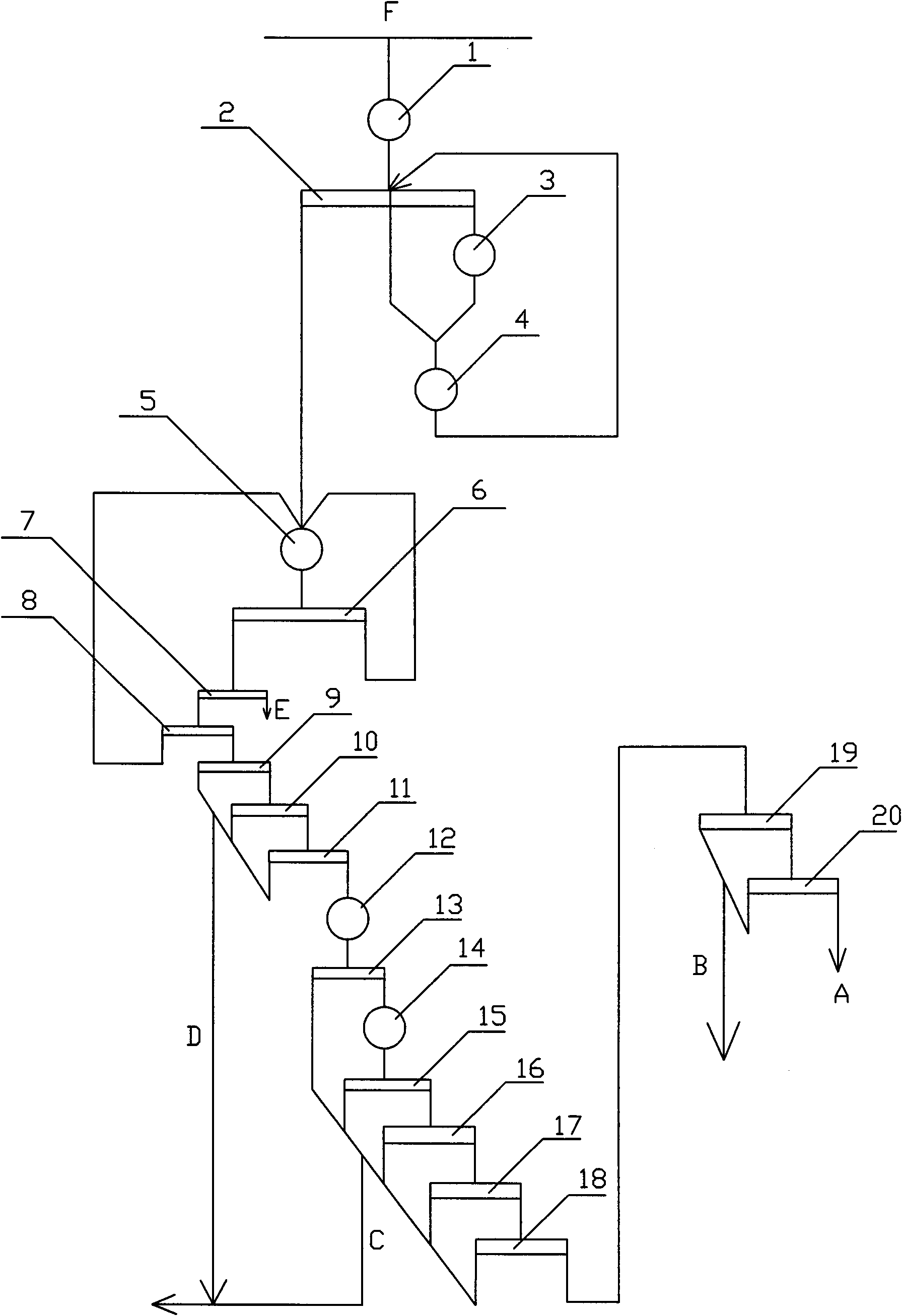

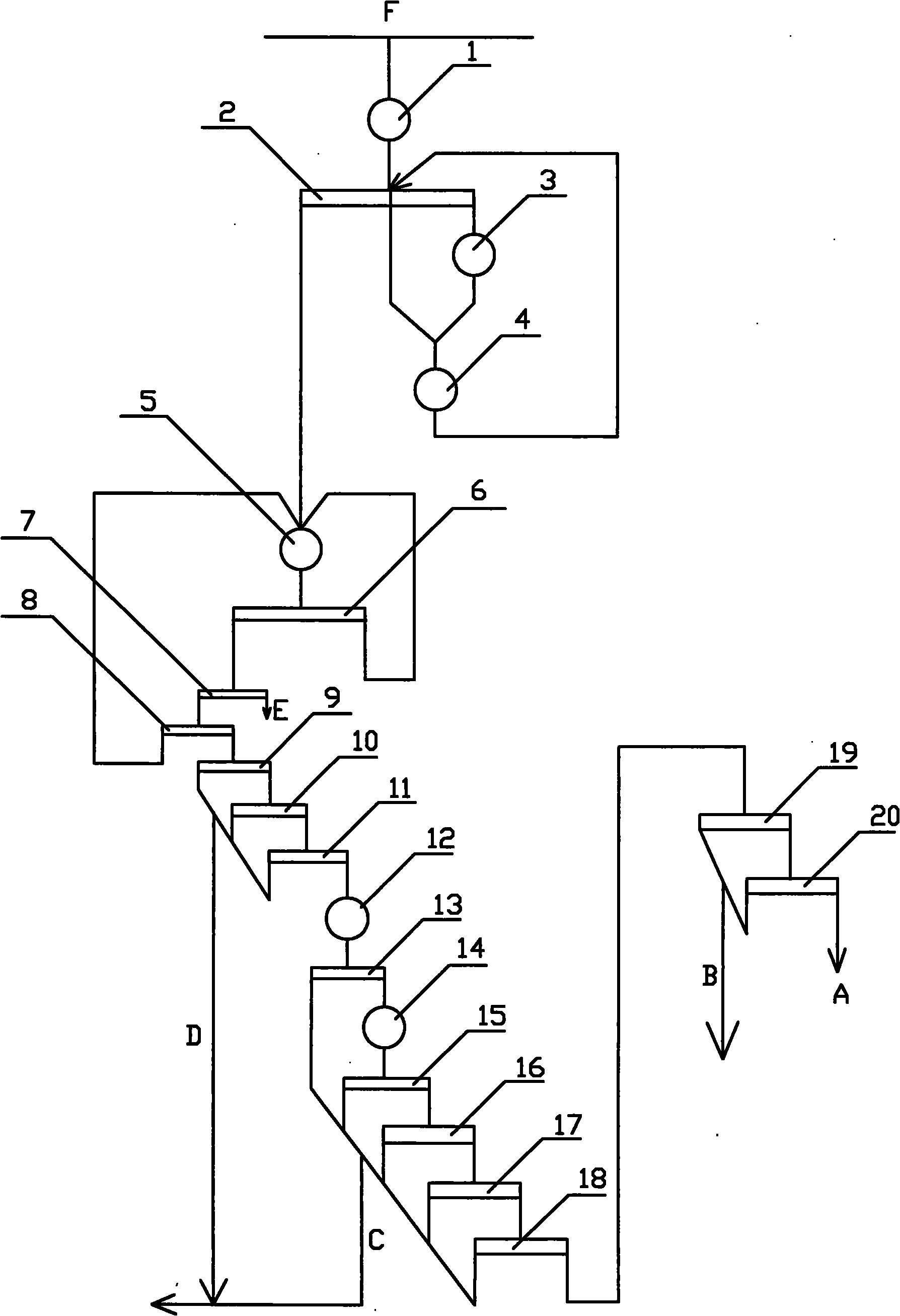

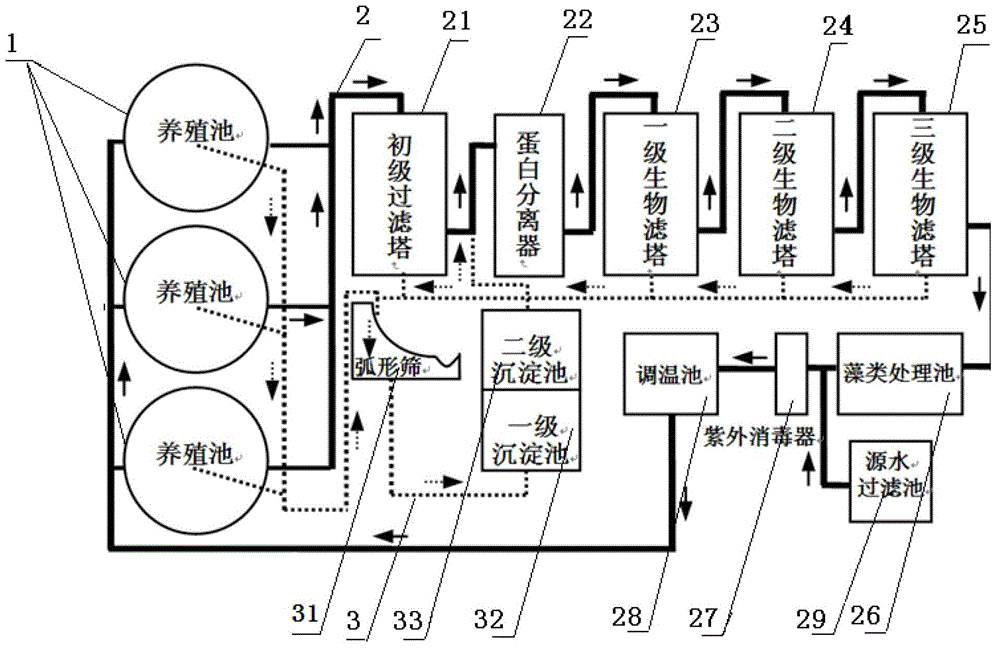

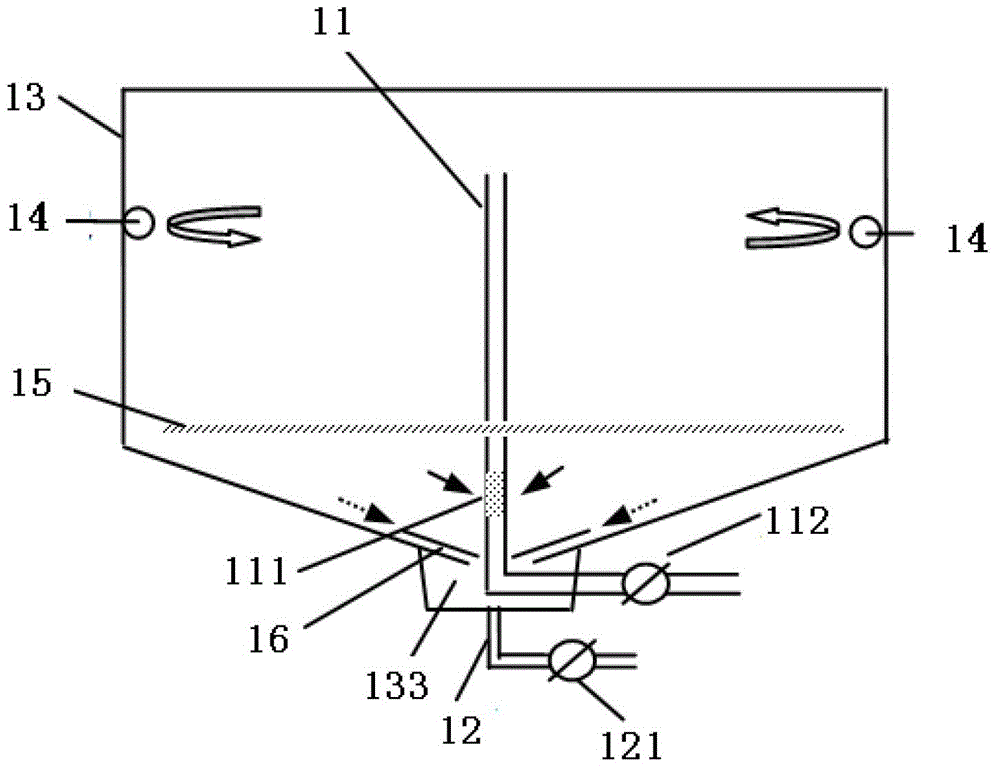

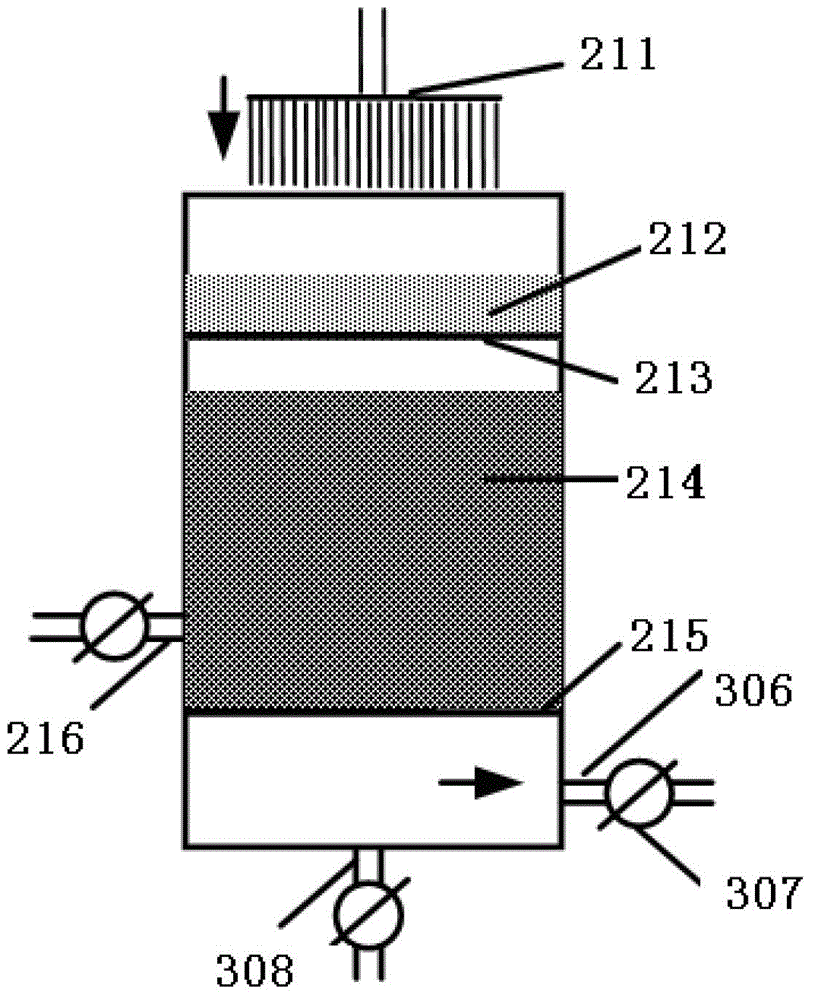

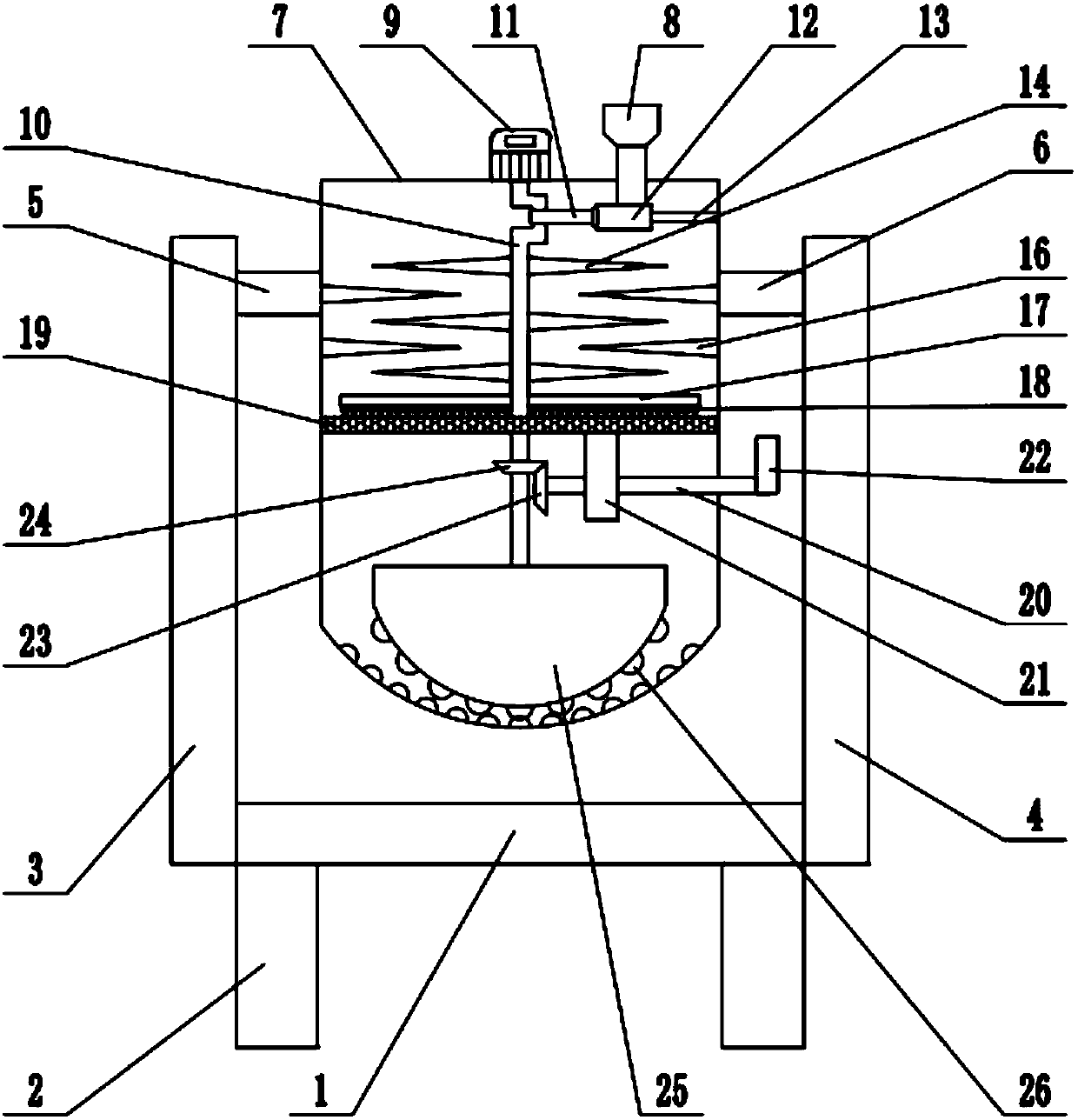

Ecological seawater rare fish factorization circulating water aquaculture system

InactiveCN102742536AReduce flow rateEfficient retentionPisciculture and aquariaResource utilizationBiological filter

The invention discloses an ecological seawater rare fish factorization circulating water aquaculture system which comprises an aquaculture pond, a primary filter tower, an albumen segregator, a primary biological filter tower, a secondary biological filter tower, a tertiary biological filter tower, an algae treating pond, a source water filter pond, a UV (Ultraviolet) sterilizer, a temperature adjusting pond, an arc-shaped sieve, a primary sedimentation pond and a secondary sedimentation pond. A bidirectional drainage system is adopted by the aquaculture pond, the water containing less smaller particles at the lower part of the pond and the water containing more larger particles at the bottom of the pond are respectively drained and then input into different processing units for recycle. Molluscs, sea cucumbers and algae are drawn into aquaculture waste, wastewater disposal and resource utilization by the circulating water aquaculture system, so that the circulating water aquaculture system has an obvious ecological characteristic. The ecological seawater rare fish factorization circulating water aquaculture system has the advantages of high treatment efficiency of aquaculture wastewater and rubbish, simpler equipment, low energy consumption, high backwash efficiency, resource utilization of aquaculture wastewater and rubbish, less circulation supplement water, high treatment efficiency of inorganic nutrient salt in the water and high economic additional value.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

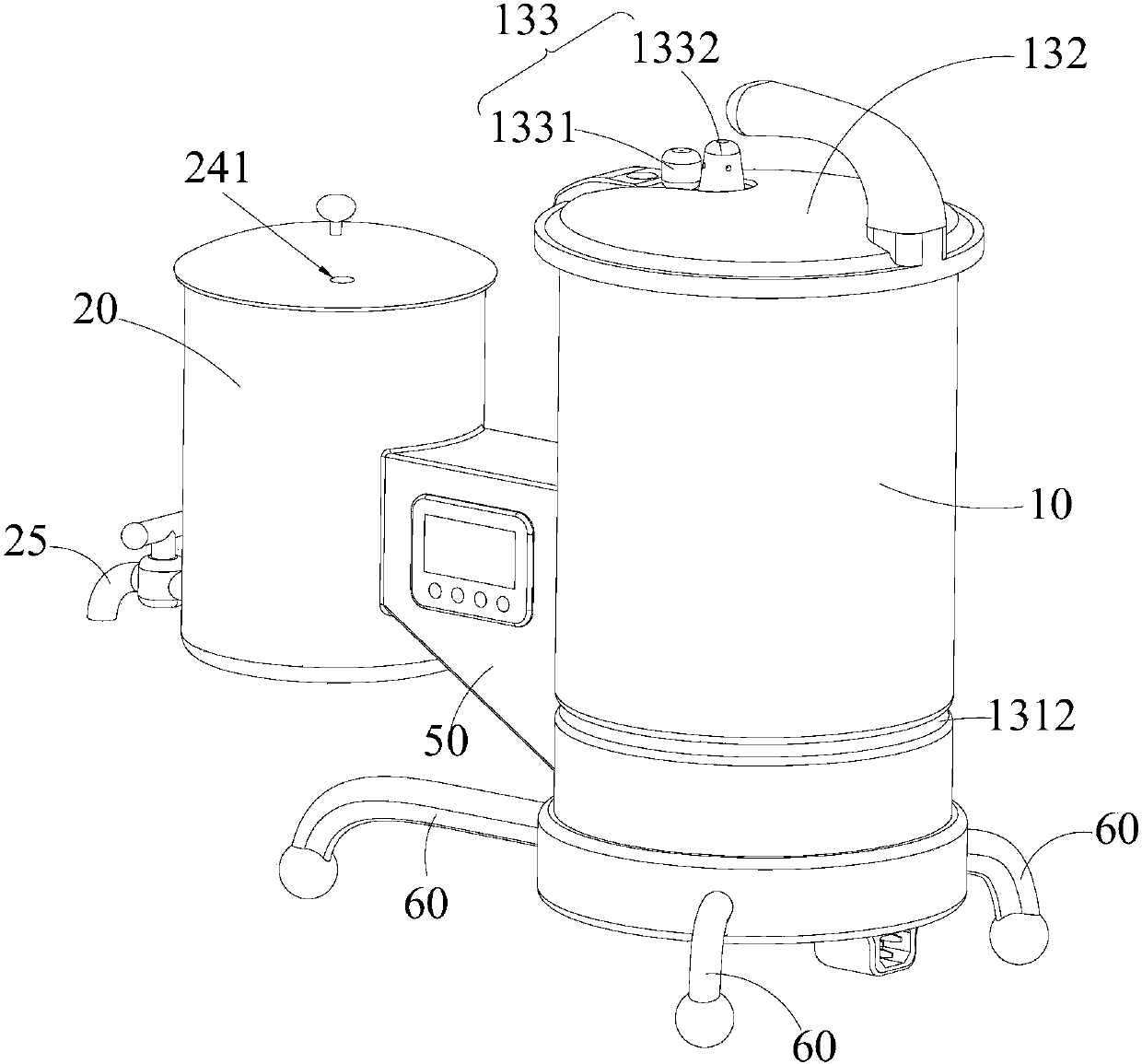

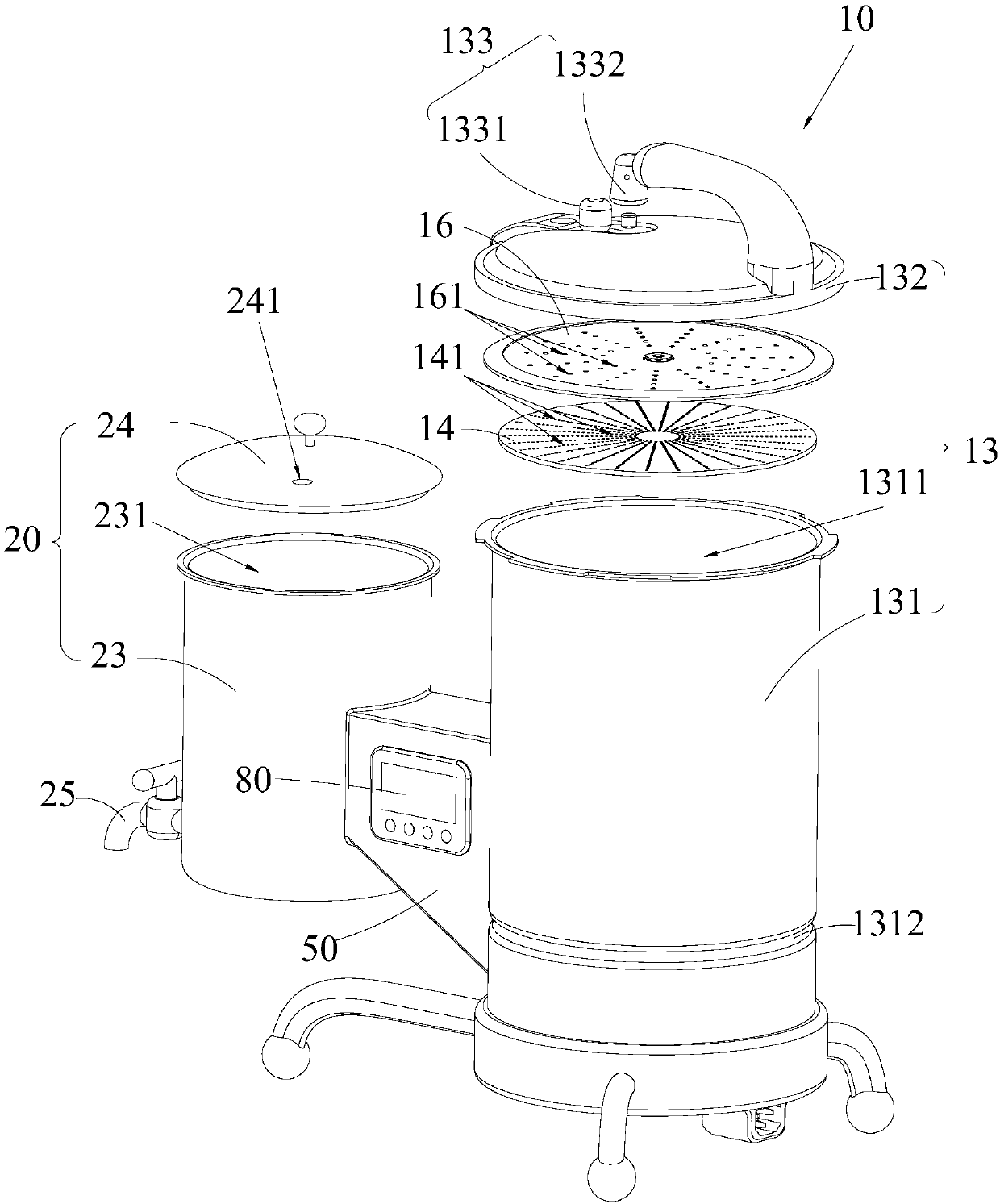

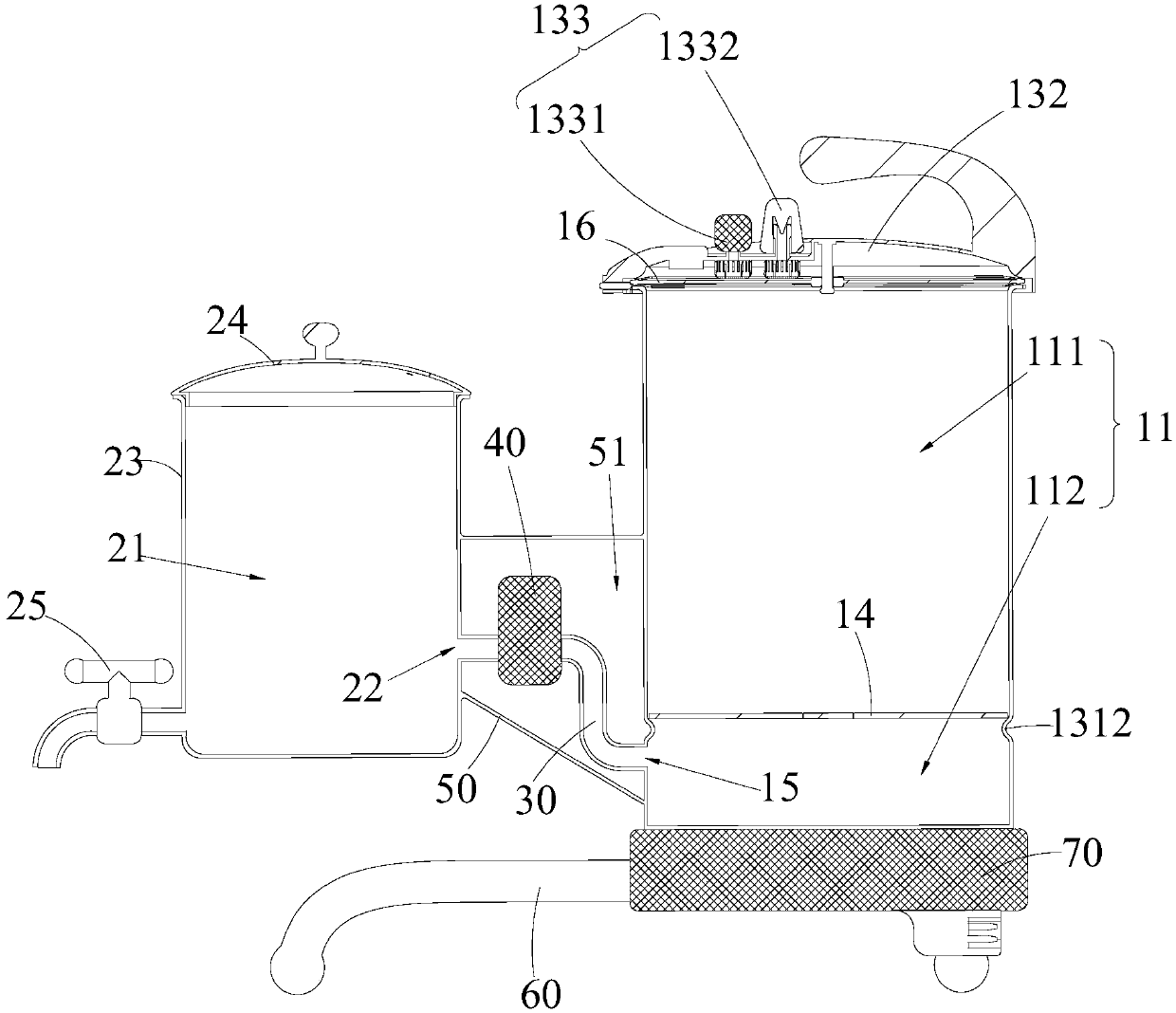

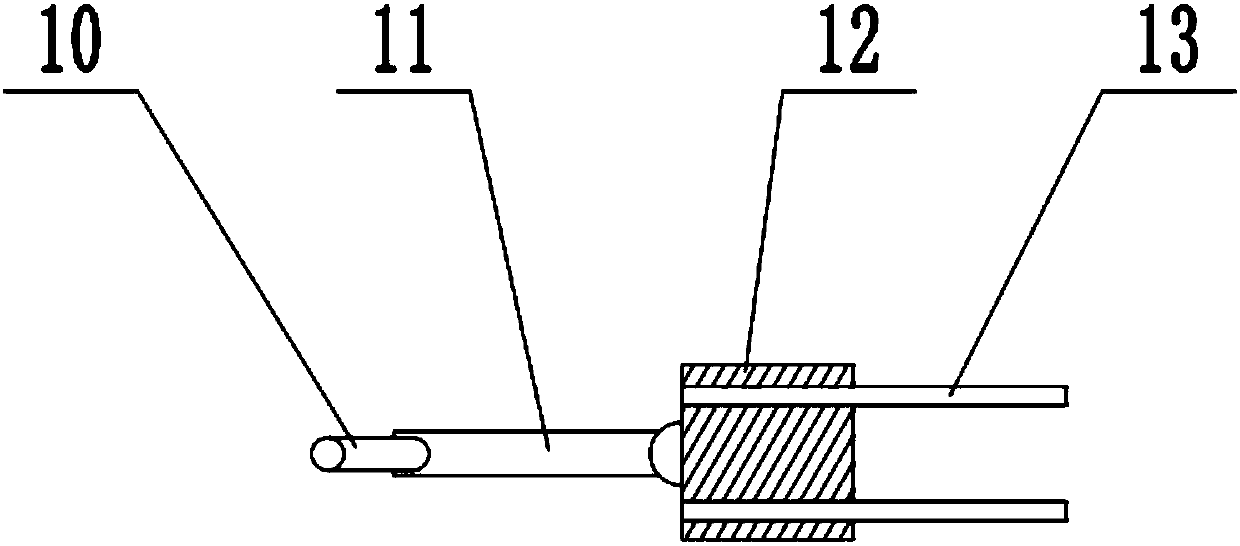

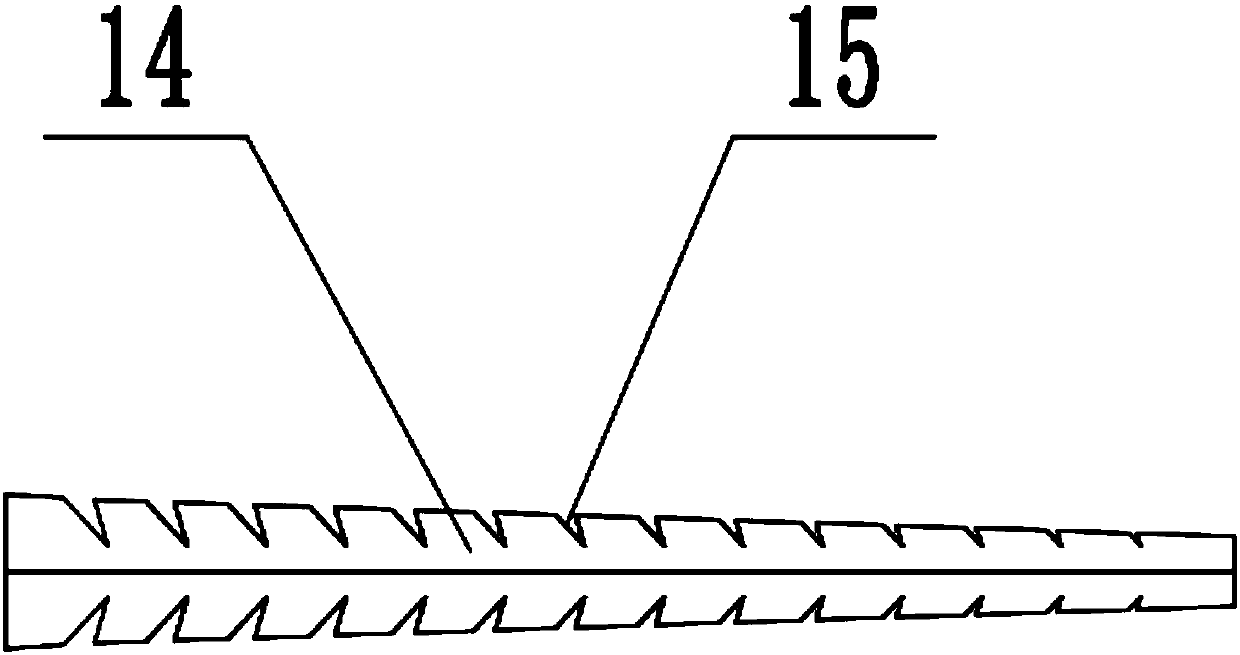

Cooking device

The invention is applicable to the technical field of kitchen appliances and provides a cooking device. The cooking device comprises a pressure cooker with a cooking space and a soup pot with a soup containing space, and the pressure cooker comprises a pot body assembly with the cooking space, and a sieve plate which is suspended in the pot body assembly and used for supporting food; the sieve plate divides the cooking space into an upper containing cavity above the sieve plate and a lower containing cavity below the sieve plate; the sieve plate is provided with screen meshes for allowing water to leak from the upper containing cavity to the lower containing cavity and keeping food in the upper containing cavity. The cooking device further comprises a drainage pipe and a controllable watervalve, the upper containing cavity and the lower containing cavity are used for being communicated with the soup containing space, and the controllable water valve is arranged on the drainage pipe. After the cooking device cooks the food, people only need to turn on the controllable water valve to separate the food from the water, then the controllable water valve is turned off for steaming, subsequent work can be conducted without manually taking out the food, the process is simple, and the efficiency is high.

Owner:杜禹

Process for producing particulate, water-soluble cellulose derivatives using a superheated gas mixture containing steam

The present invention relates to a new, particularly economical process for preparing particulate water-soluble cellulose derivatives. The process involves forming a feed composition of swollen and / or dissolved cellulose derivative, and water. The feed composition is contacted with a superheated gas mixture, in a sieve-free high rotational speed gas jet impact mill, and the cellulose derivative of the feed composition is converted into a solid state form of finely particulate particles. The superheated gas mixture, with which the feed composition is contacted, is selected from: (i) a superheated gaseous mixture of steam and an inert gas; and (ii) a superheated gas mixture of steam and air. The superheated gas mixture has a steam content of 40 wt. % to 99 wt. %, based on the total weight of the superheated gas mixture.

Owner:DOW GLOBAL TECH LLC

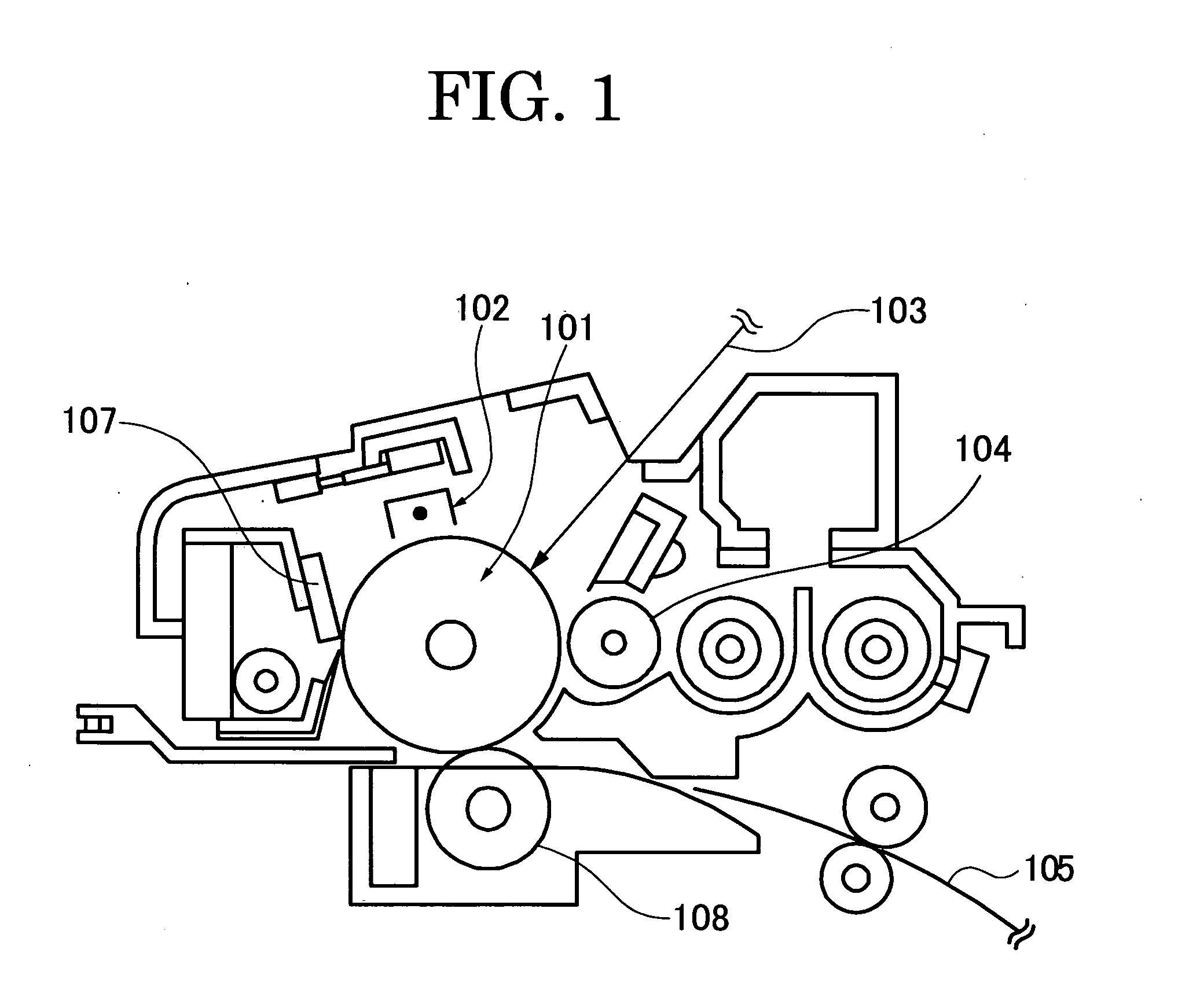

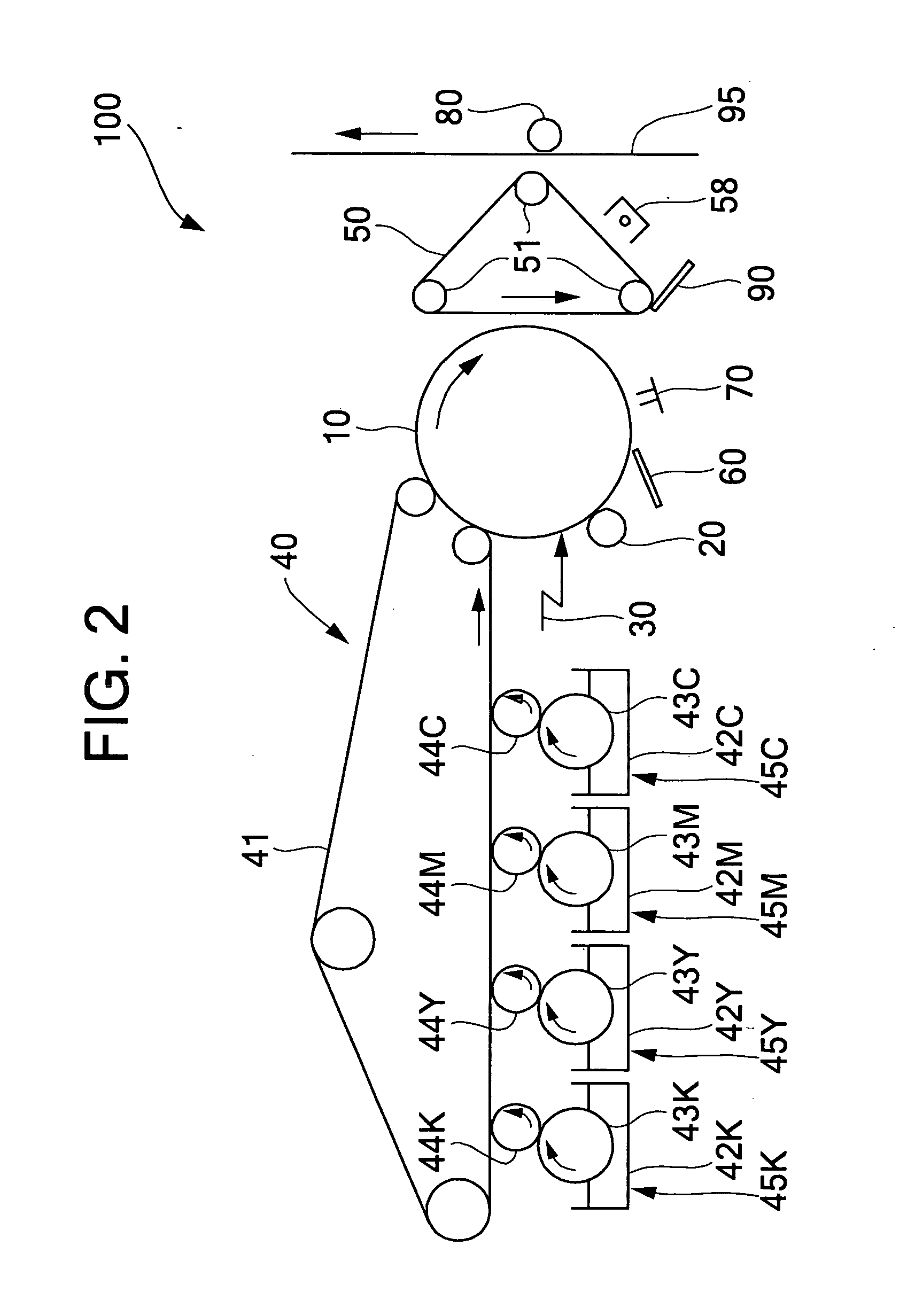

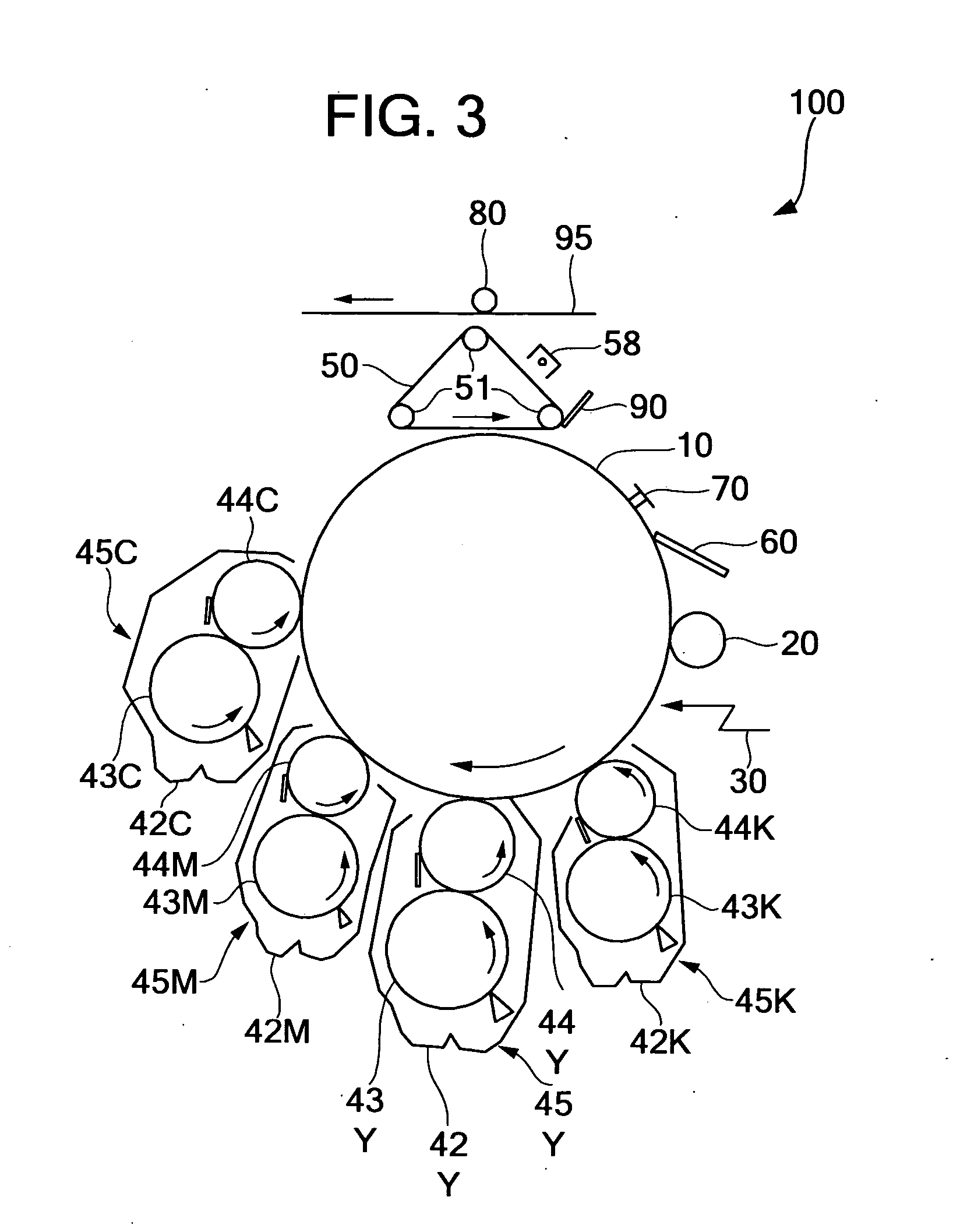

Toner, developer, toner container, process cartridge, image forming apparatus, and image forming method using the same

ActiveUS20060063081A1Good transferabilityFavorable cleaning abilityElectrographic process apparatusDevelopersElectrical conductorSuction force

It is an object of the present invention to provide a toner that can sustain favorable transferability and cleaning ability for prolonged periods; prevent photoconductor filming; exhibit no variation in image nonuniformity or external additive immersion induced by developer agitation at the time of use; excels in stability with flowability and charge stability over prolonged periods. Therefore, provided is the toner of which the quantity of aggregate of residual external additives found on the sieve of 635-mesh and 452 cm2 of mesh area, after 0.2 g of the toner on the sieve is blasted with air at a blow pressure of 0.2 MPa from 160 mm above the sieve while being air-suctioned at a suction force of 5 mmHg, and then air-suctioned at a suction force of 20 mmHg, is 4,500 or less and 5 or more.

Owner:RICOH KK

Swing type coffee bean crushing and grinding equipment

The invention discloses swing type coffee bean crushing and grinding equipment. The equipment comprises a base, supporting feet, a left fixing frame, a right fixing frame and a crushing tank; the leftfixing frame is fixedly connected at the left end of the base; the right fixing frame is fixedly connected at the right end of the base; the crushing tank is arranged between the left fixing frame and the right fixing frame; a motor is fixedly connected on the upper surface of the crushing tank; a crankshaft is arranged inside the crushing tank; a sliding block is arranged below a feeding port; the right end of a connecting rod is hinged to the side wall of the sliding block; a plurality of main crushing blades are distributed on the crankshaft; a plurality of auxiliary crushing blades are fixedly connected on the inner walls of the left side and the right side of the crushing tank; a fixing rod is arranged below the main crushing blades; a sieve plate is arranged below the fixing rod; and a grinding hammer head is fixedly connected at the lower end of the crankshaft. Coffee beans are intermittently placed into the crushing tank, so that the coffee beans are crushed more thoroughly, and the crushing efficiency is improved; the coffee beans are crushed through cooperation of the main crushing blades with the auxiliary crushing blades; and the sieve plate is vibrated up and down, sothat the crushed coffee beans fall to the bottom of the crushing tank favorably.

Owner:张先吉

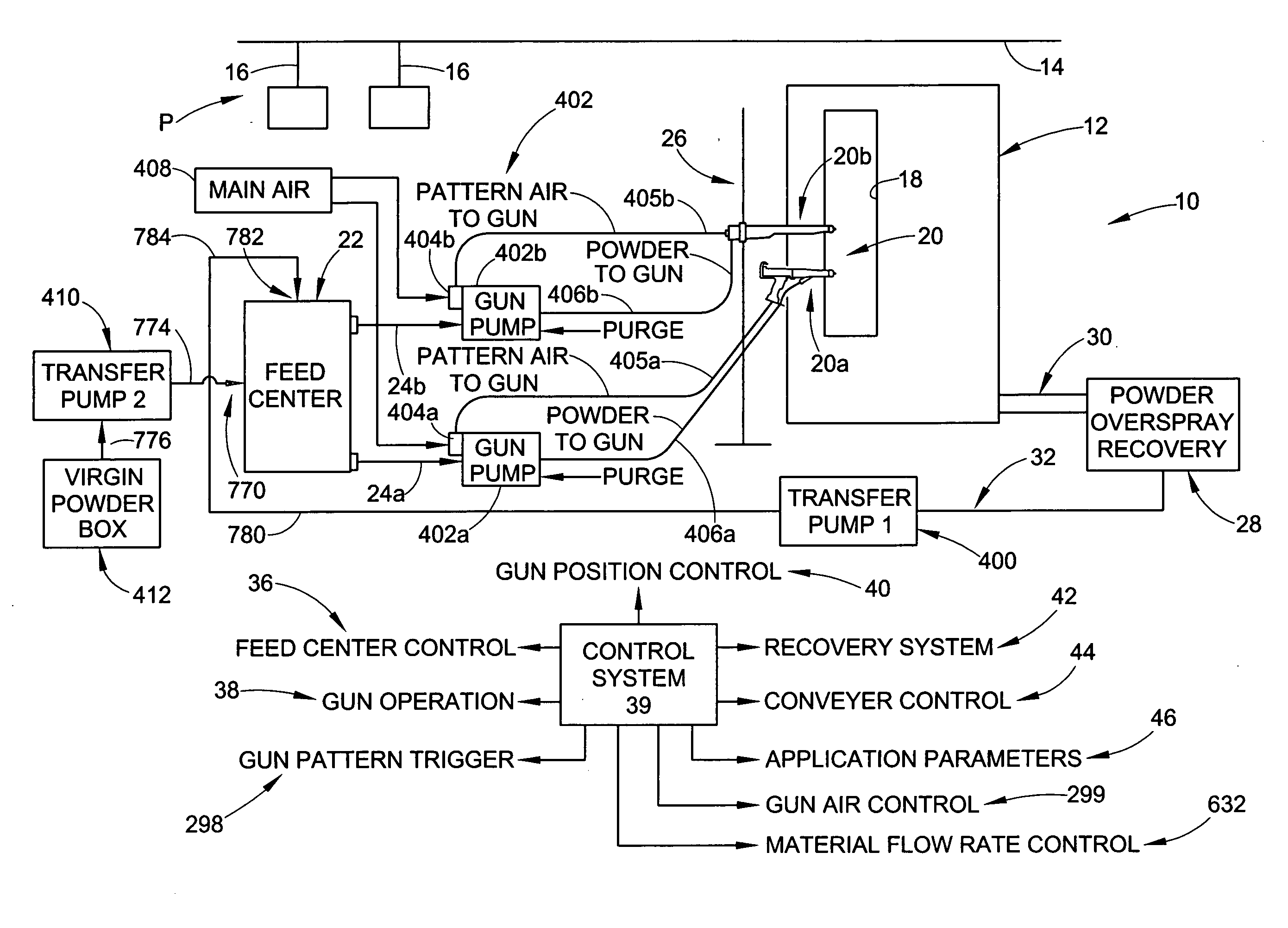

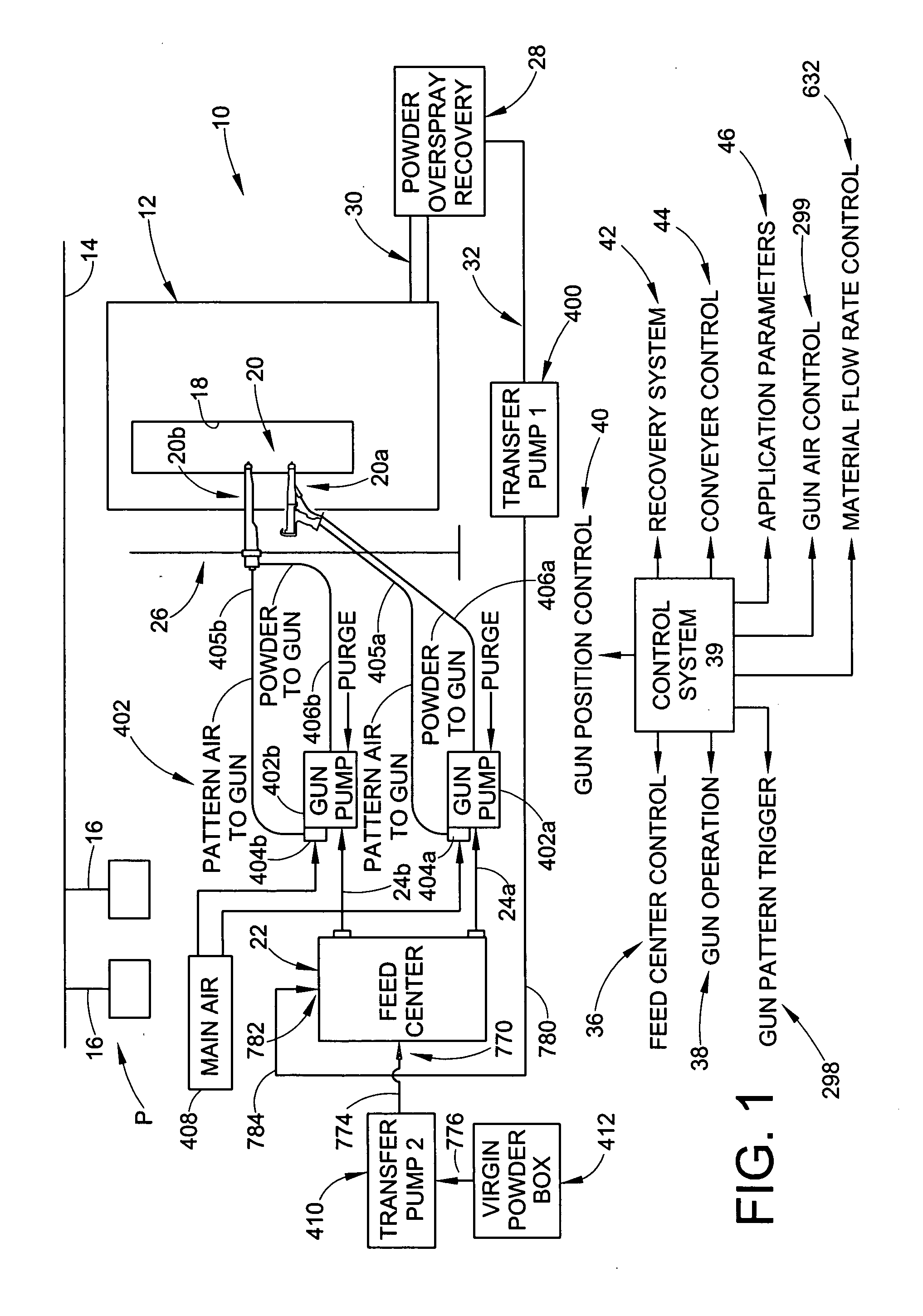

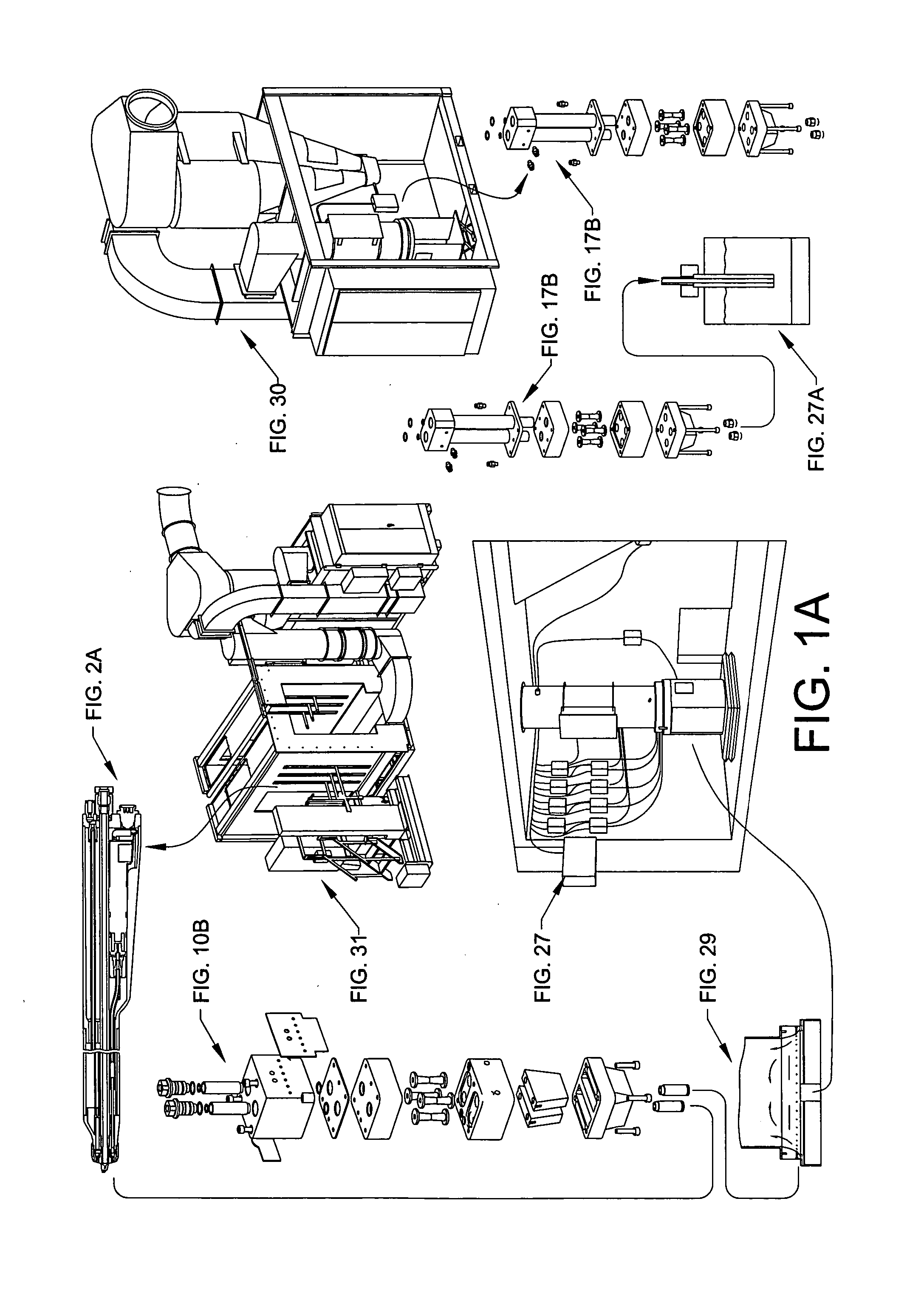

Improved particulate material application system

InactiveUS20050126476A1Good cleanabilityShorten color change timeLiquid surface applicatorsLiquid spraying apparatusSiphonAmbient pressure

A material supply for a material application system such as a powder coating application system includes a feed hopper in the form of a duct. The duct is connectable to negative pressure during a color change process and is disconnected from the negative pressure during a spray application process. The negative pressure can be provided from a powder overspray recovery system such as an after filter blower. Dampers are provided to control air flow through the hopper duct and to allow the duct to be at ambient pressure during a supply mode of operation. The hopper duct also includes a suction interface for pumps, in the form of a siphon ring, as well as a fluidizing function. A removable sieve is provided with an optional vibration feature. Powder may be added to the duct via an access door or transfer pumps for new powder and / or reclaimed powder overspray.

Owner:NORDSON CORP

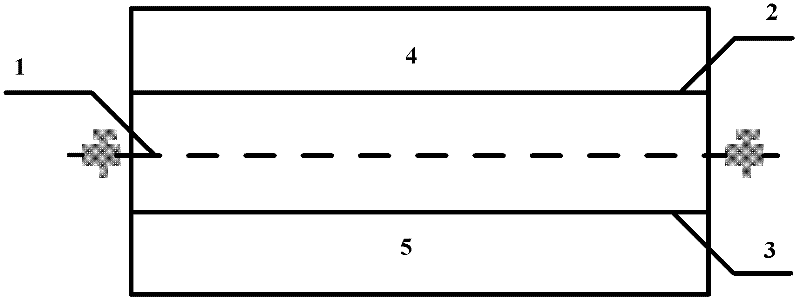

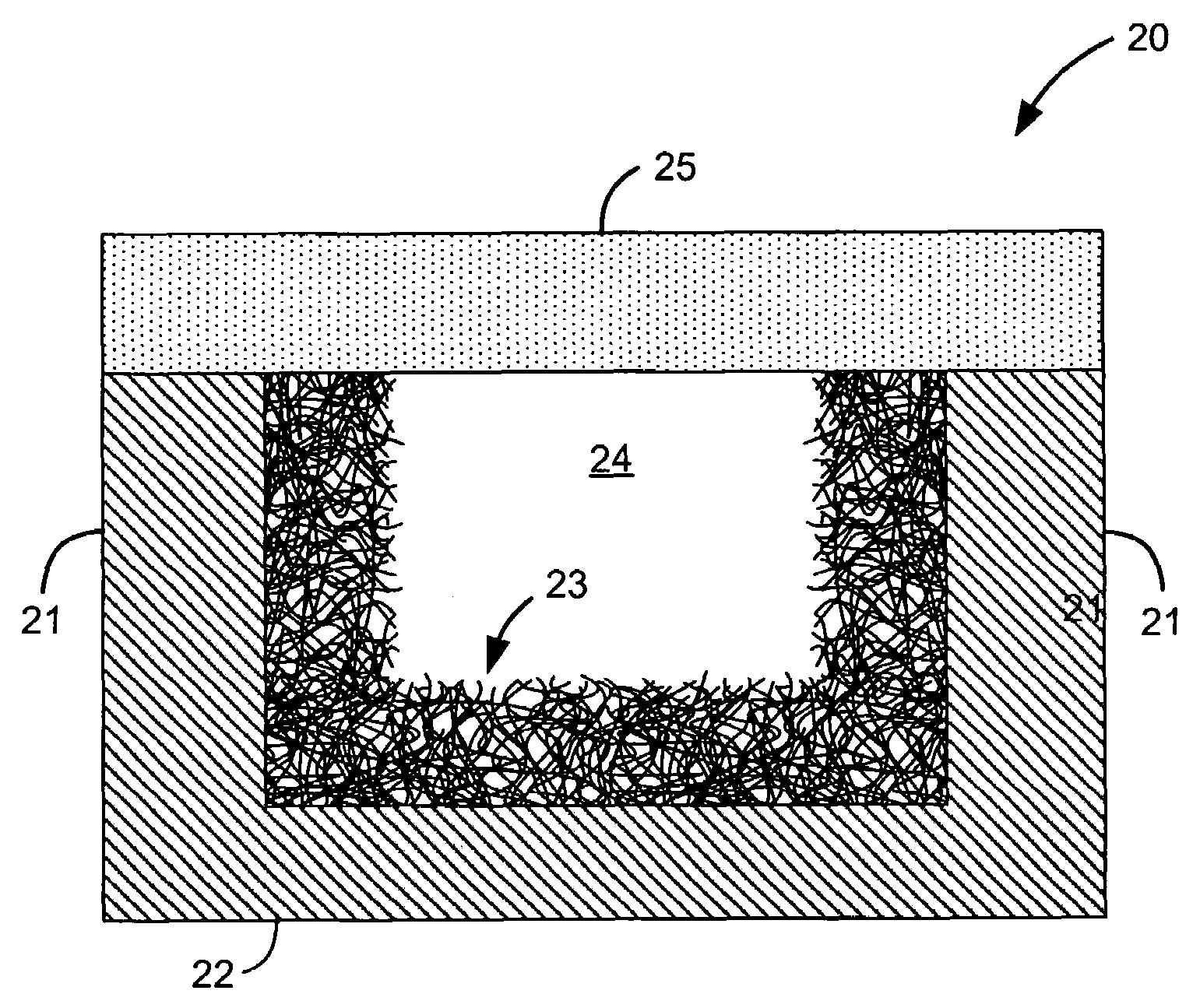

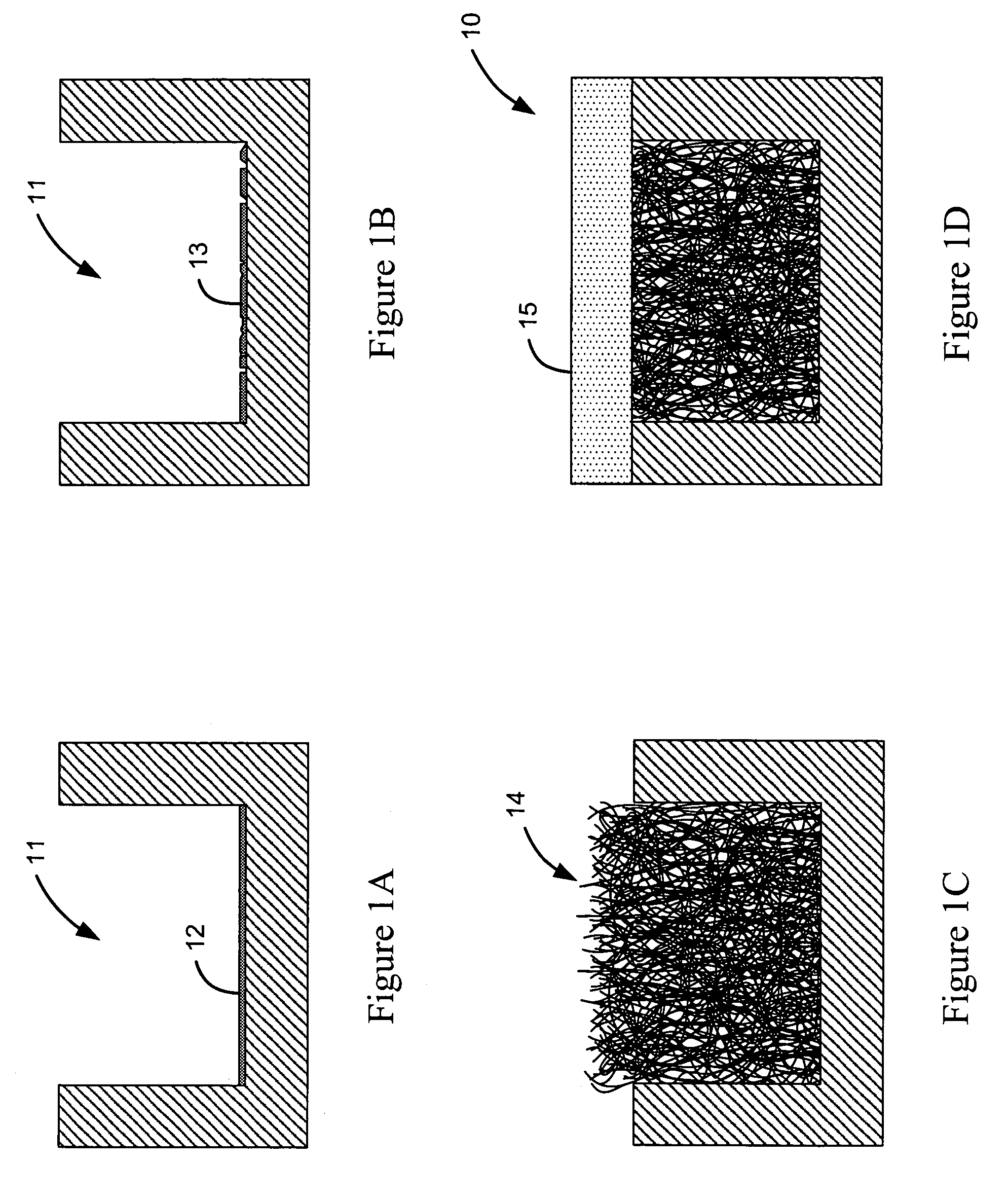

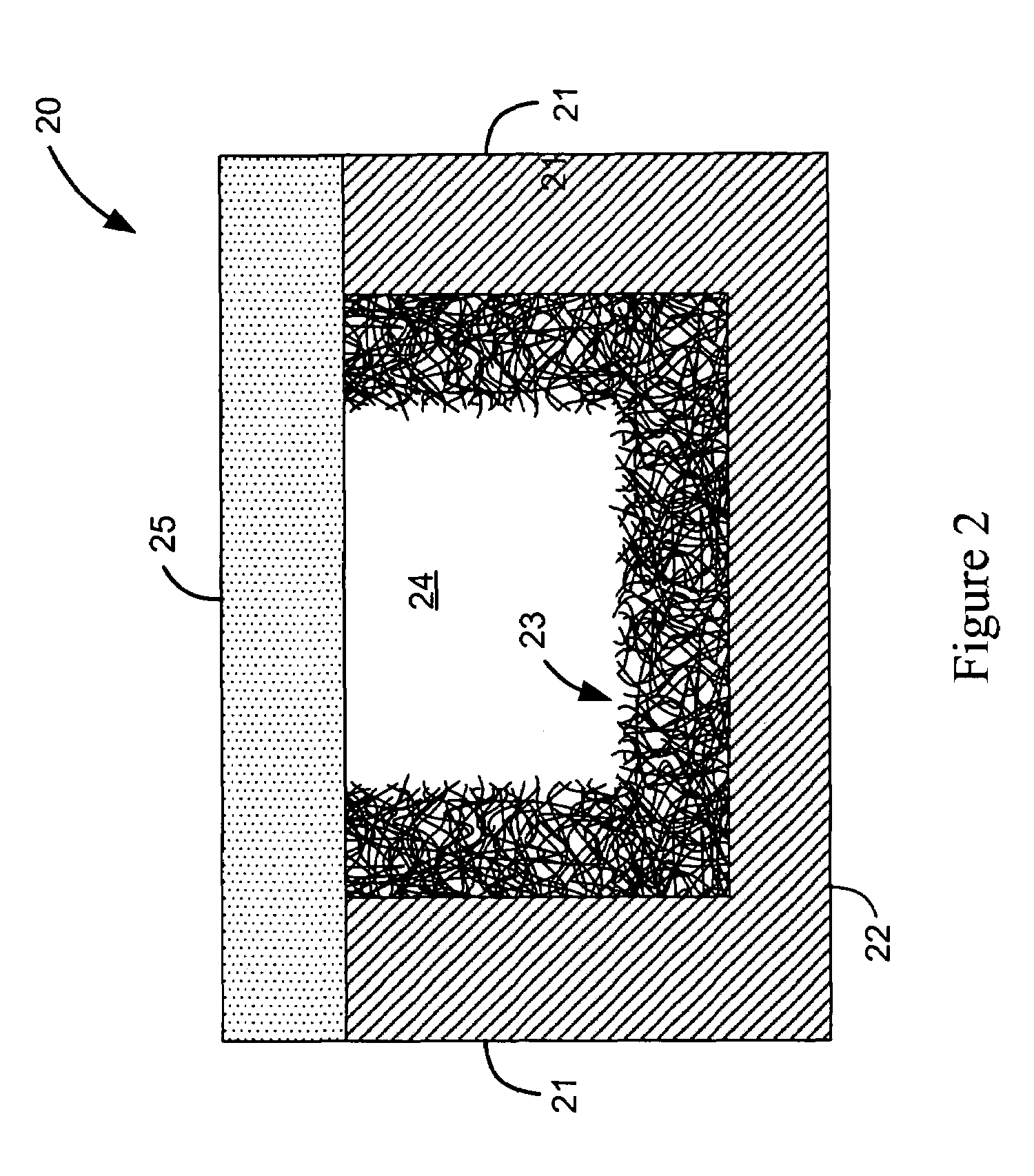

Microfluidic sieve using intertwined, free-standing carbon nanotube mesh as active medium

InactiveUS7290667B1Material nanotechnologySemi-permeable membranesCarbon nanotubeMicrofluidic channel

A microfluidic sieve having a substrate with a microfluidic channel, and a carbon nanotube mesh. The carbon nanotube mesh is formed from a plurality of intertwined free-standing carbon nanotubes which are fixedly attached within the channel for separating, concentrating, and / or filtering molecules flowed through the channel. In one embodiment, the microfluidic sieve is fabricated by providing a substrate having a microfluidic channel, and growing the intertwined free-standing carbon nanotubes from within the channel to produce the carbon nanotube mesh attached within the channel.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

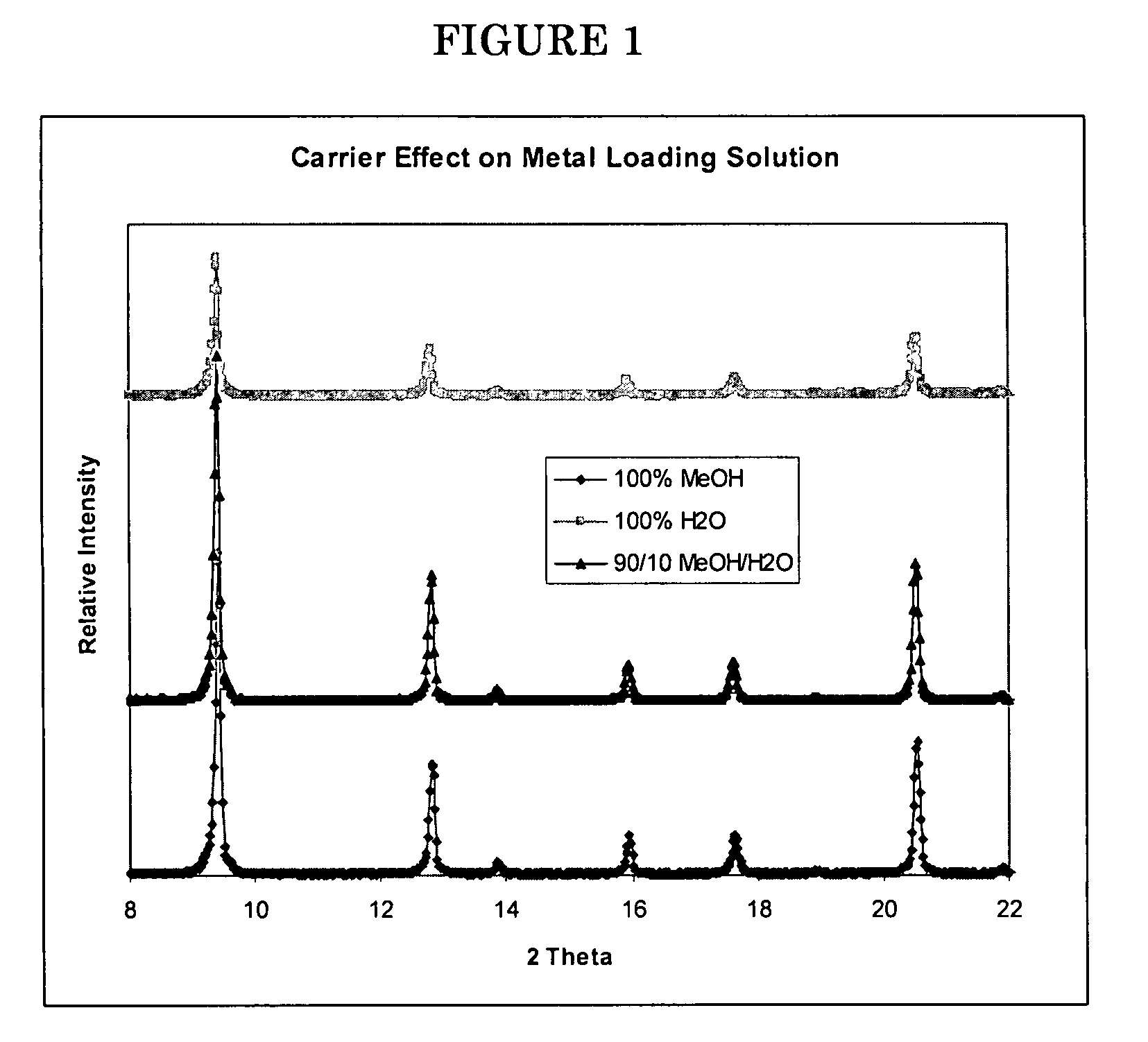

Metal loading of molecular sieves using organic carriers with limited water content

The present invention relates to processes for preparing modified molecular sieves, as well as catalytic processes utilizing same. More particularly, the present invention relates to processes for preparing metal-containing molecular sieve coatings, and preferably metal oxide-coated molecular sieves. The present invention also includes the catalytic sieves made according to these processes.

Owner:EXXONMOBIL CHEM PAT INC

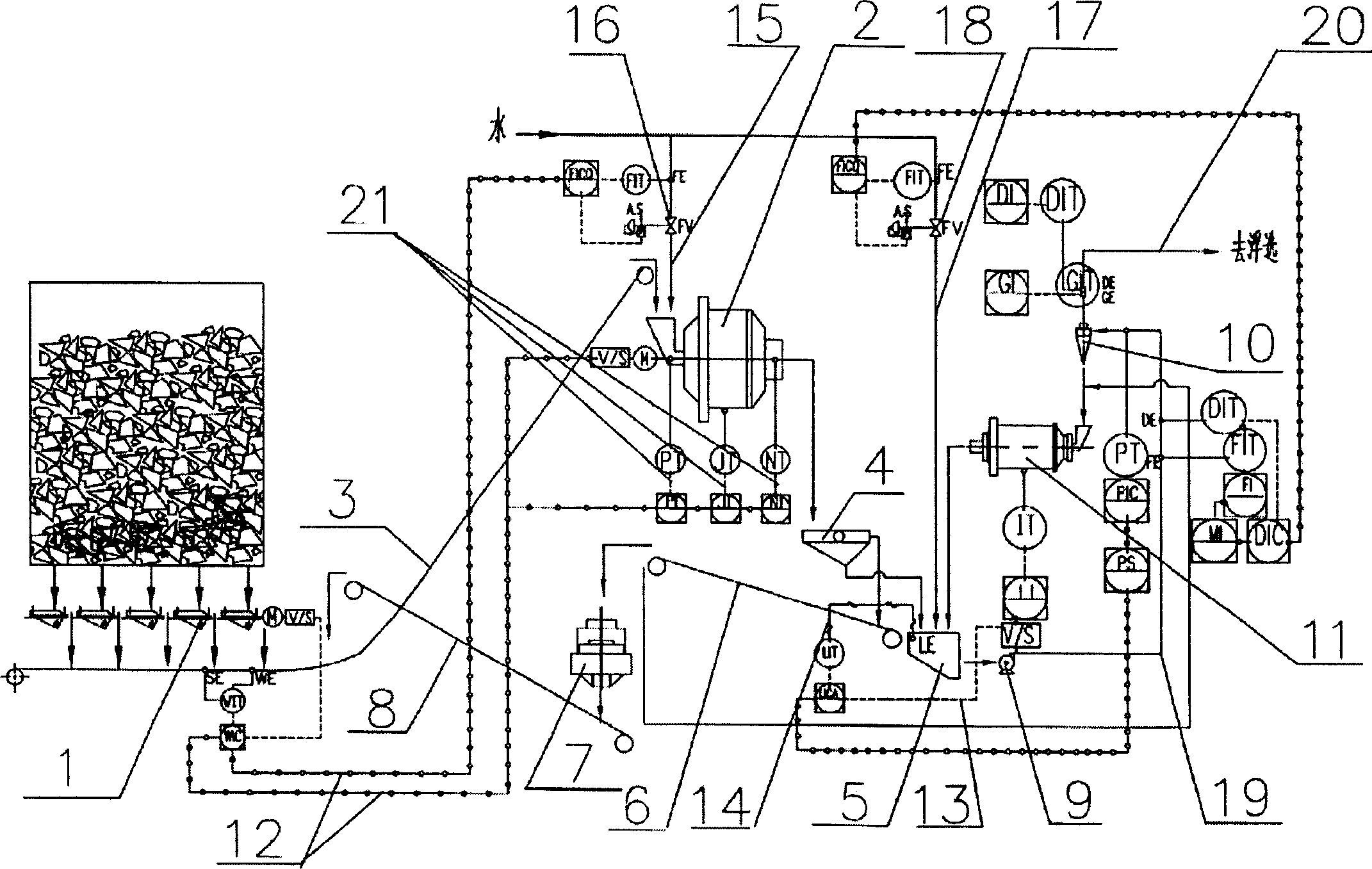

Semi-automill ball-milling type ore grinding system and its control system

A semi-automatic grinder-ball grinder system for grinding ore is composed of a vibration feeder, a semi-automatic grinder with variable-speed driver and load monitor, a vibration sieve, a crusher, a sludge pump, cyclone unit with concentration, flow and granularity detections, and a ball grinder with variable-speed driver. Its control method is also disclosed.

Owner:CHINA ENFI ENGINEERING CORPORATION

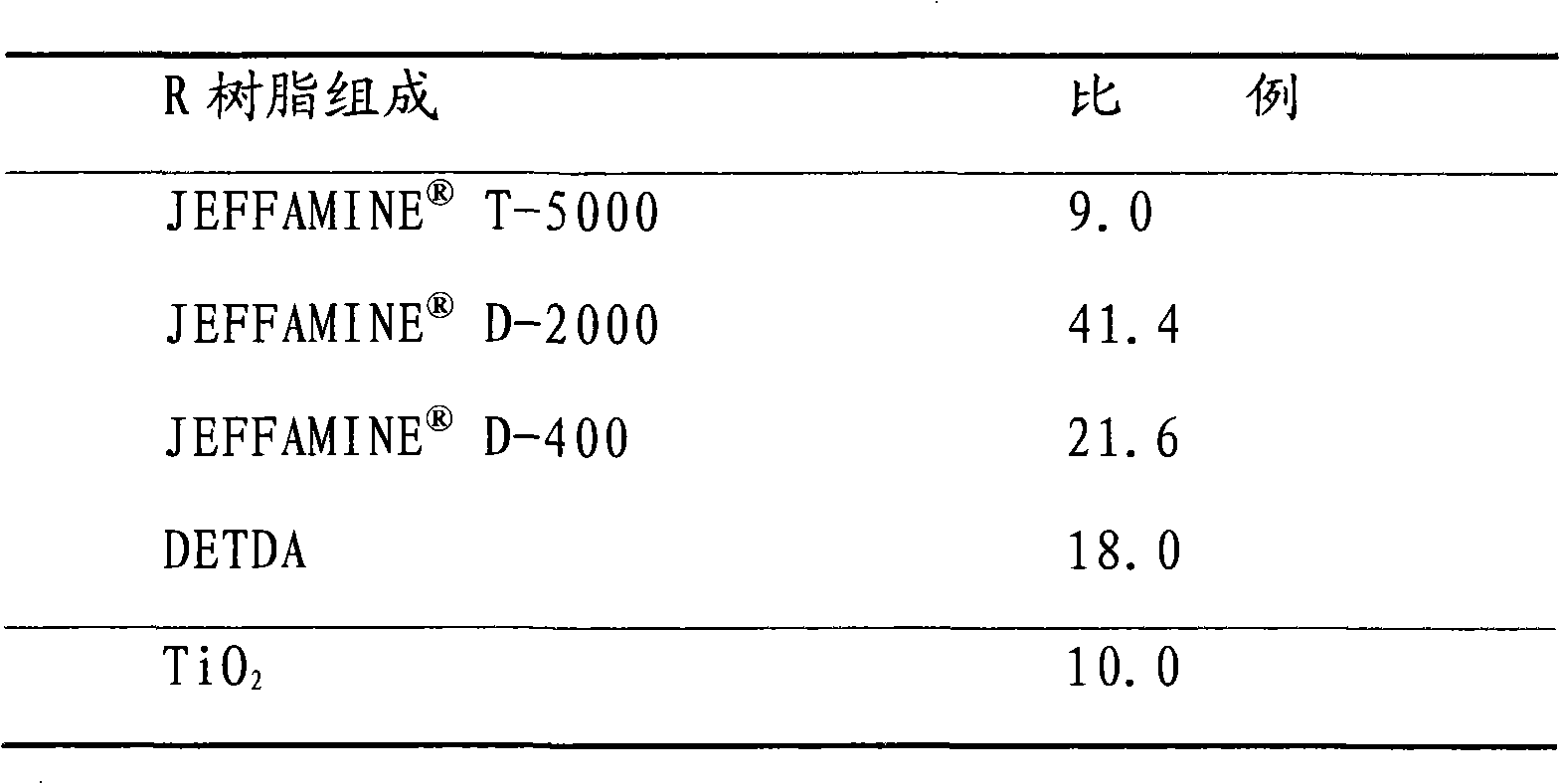

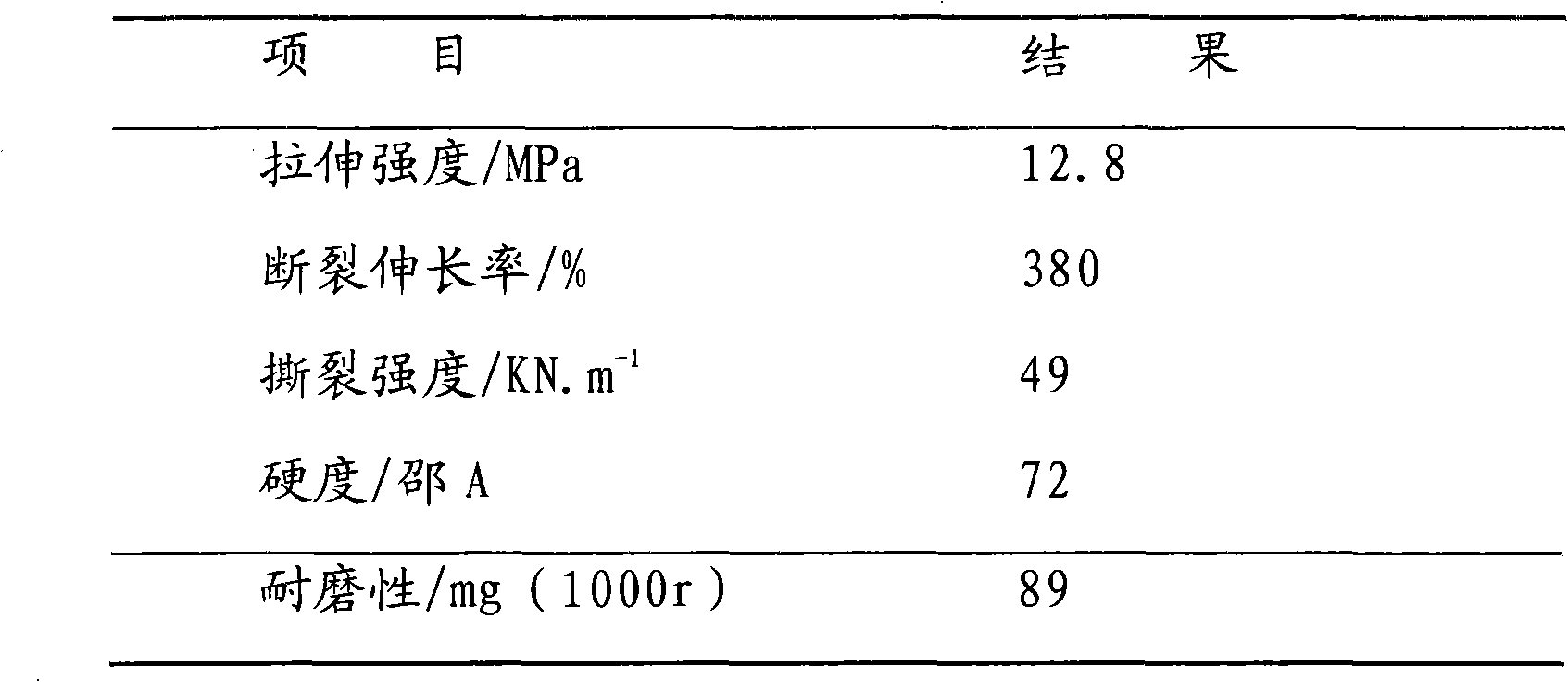

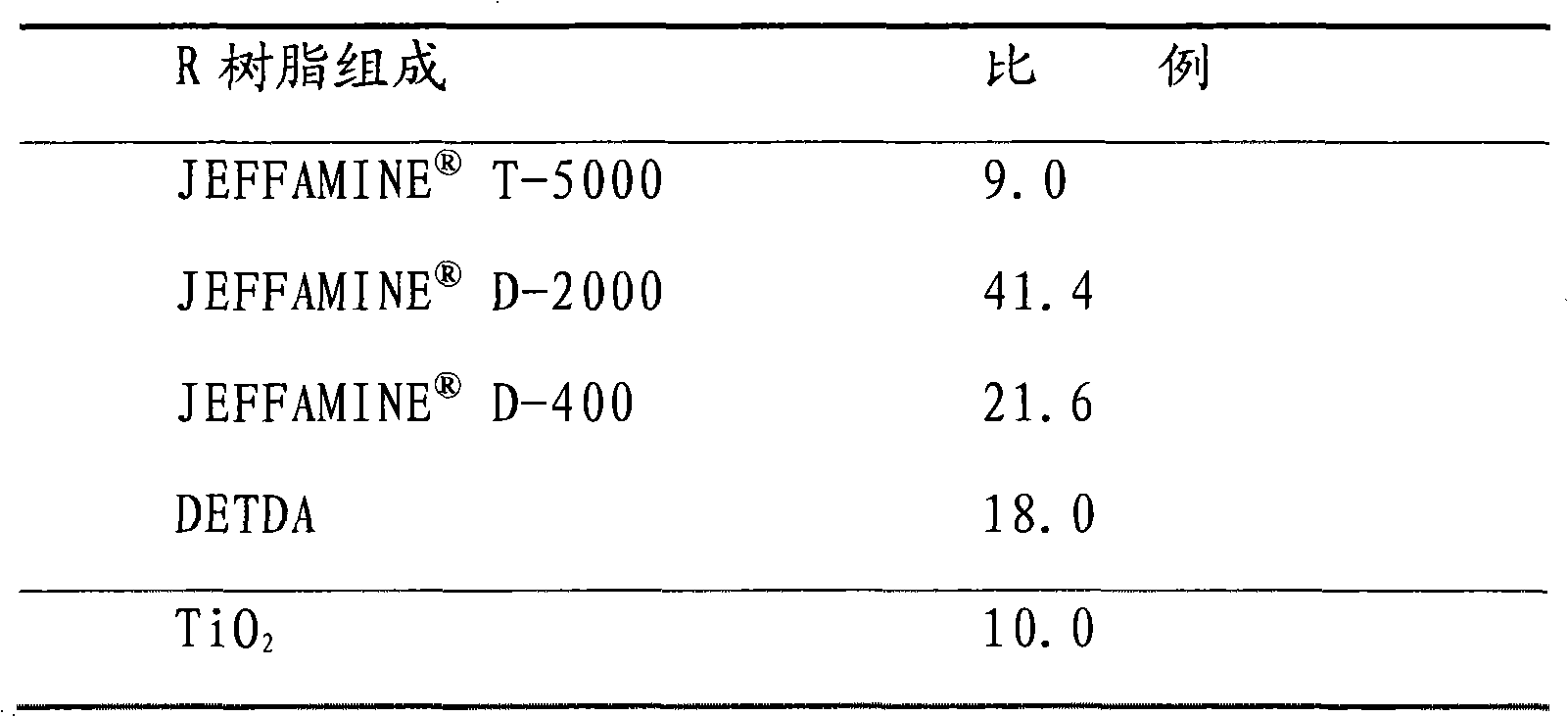

Spray polyurea elastomer for mine, preparation and construction method thereof

InactiveCN101302393ANot affected by ambient temperatureNot affected by ambient humidityLiquid surface applicatorsPolyurea/polyurethane coatingsElastomerPolyol

The invention provides a spraying polyurea elastomer applied to a mine, a method for making the same and a construction method. The spraying polyurea elastomer can solve the problem of poor wearing resistance in the prior art. The invention comprises the following technical proposals that: the spraying polyurea elastomer applied to the mine comprises two compositions A and R, wherein, the composition A is a semi-prepolymer synthesized by 45 to 65 portions of polyisocyanate and 35 to 55 portions of polyether polyol; the composition R comprises 55 to 80 portions of amine terminated polyether, 15 to 33 portions of chain extender and 5 to 25 portions of antiwear filler; and the compositions A and R are matched for use according to an isocyanate index of between 0.9 and 1.2. The spraying polyurea elastomer has good physical performance, high wearing resistance, good oil resistance, hydrolization resistance, bacteria resistance and aging resistance and good construction performance and can be used in a vibration sieve equipment lining, a flotation equipment lining, etc. of the mine and other application places which have high requirement on wearing resistance.

Owner:青岛佳联化工新材料有限公司

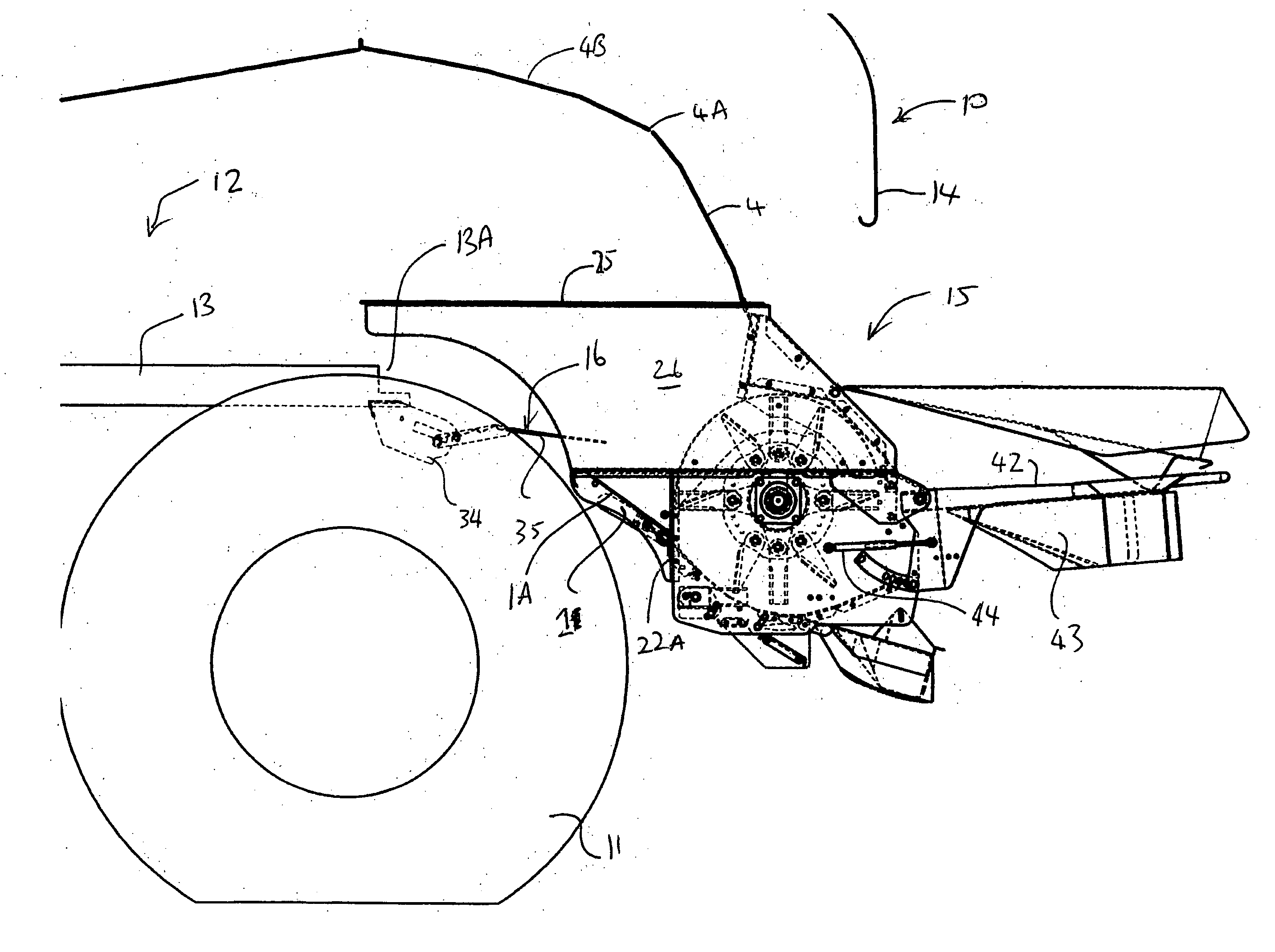

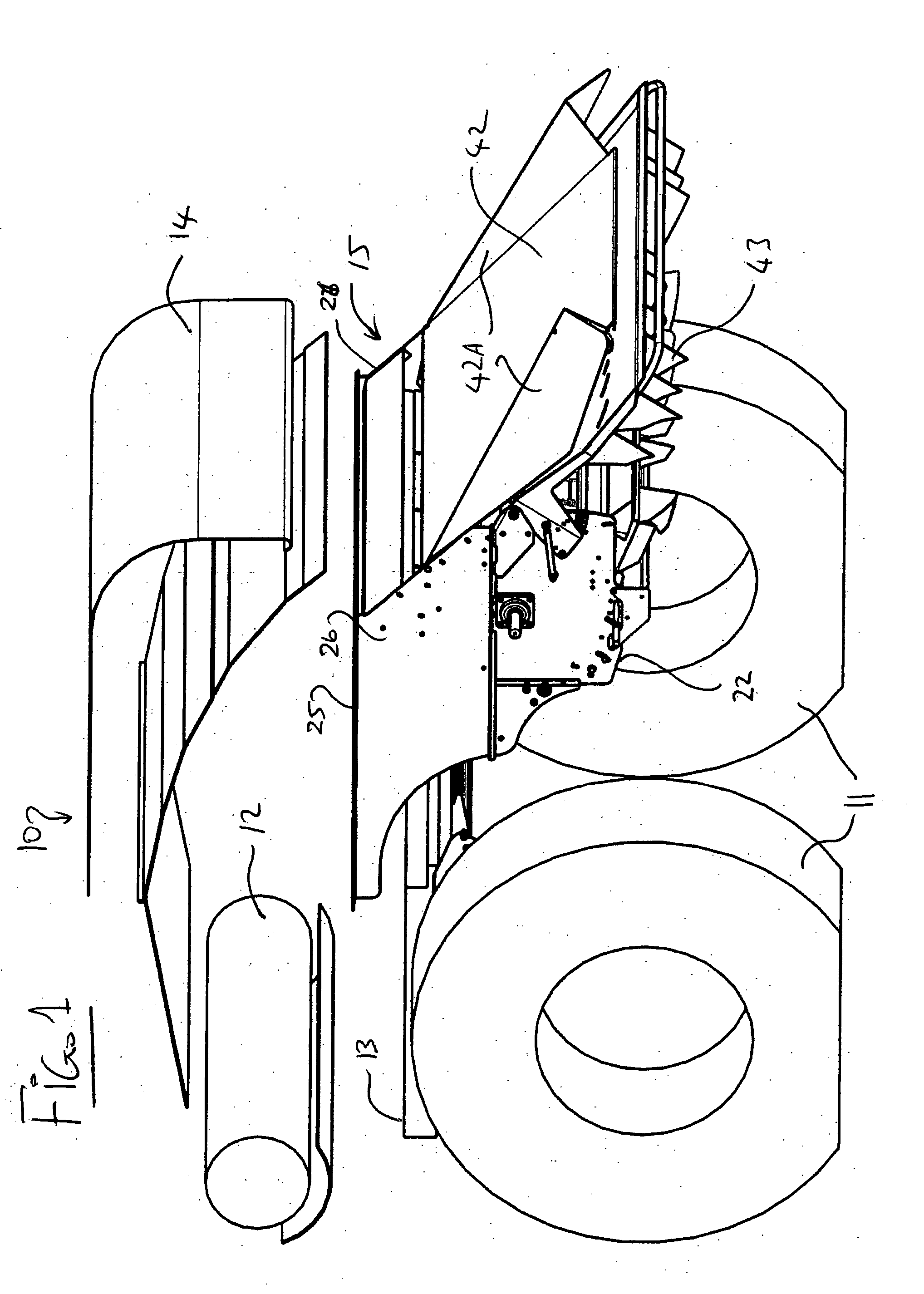

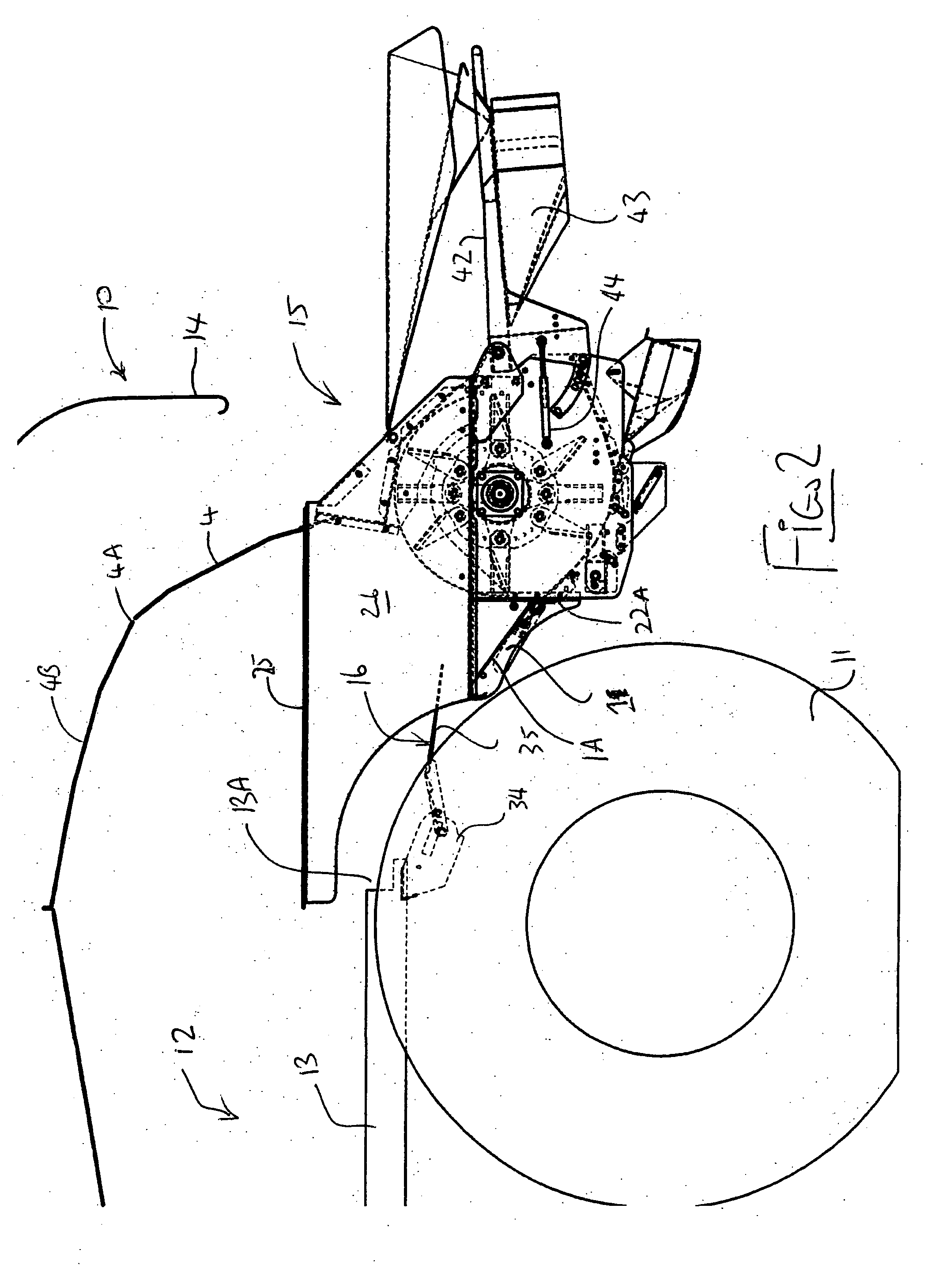

Combine harvester with ready adjustment of discharge positions of straw and chaff

A combine harvester has a straw chopper attached to a rear hood behind the rear edge of the sieve assembly with a chaff guide system to bypass the chaff in front of the chopper and a straw guide system to bypass the straw above the chopper and over the tailboard. The chopper has a housing with a feed opening into which straw and / or chaff can be fed depending upon the positions of the chaff guide system and the straw guide system. A chopping assembly mounted in the housing discharges through a discharge opening through onto the tailboard having a plurality of guide fins for spreading. The housing bottom wall has a pivotal adjustment portion to allow chaff entering the feed opening and engaging the chopping assembly to discharge from the housing at a discharge position different from the discharge opening for spreading onto a supplementary spreading device.

Owner:REDEKOP CHAFF SYST

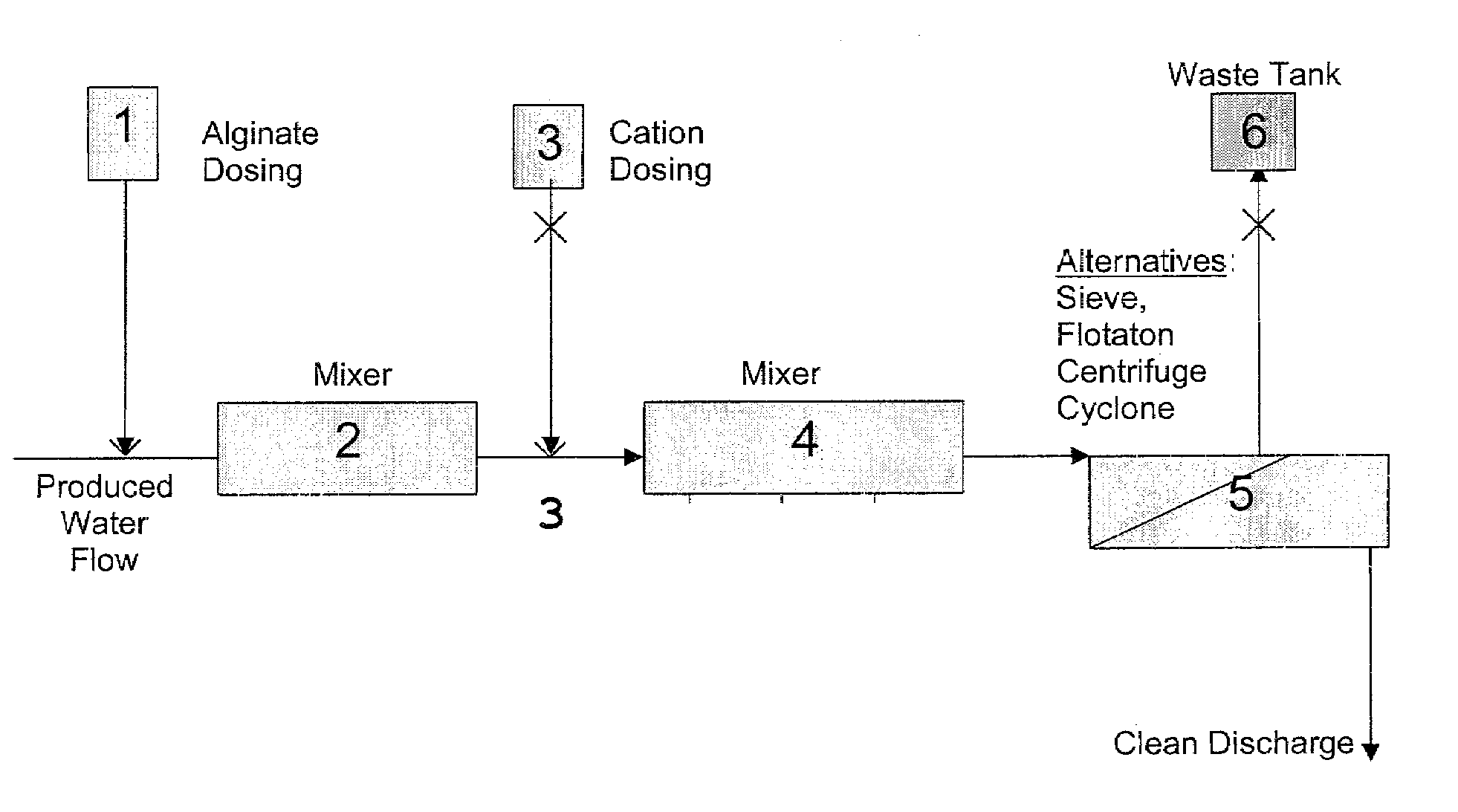

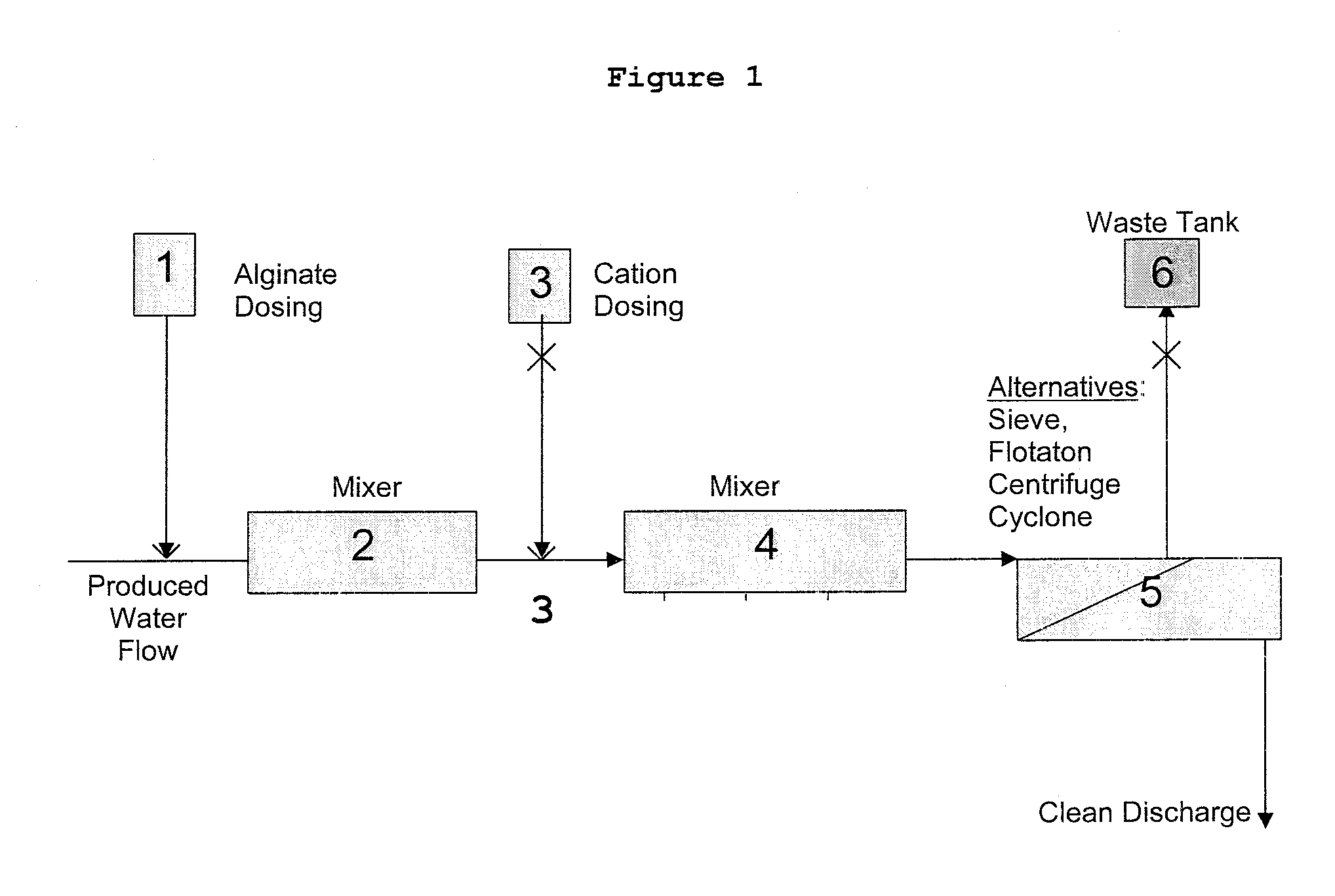

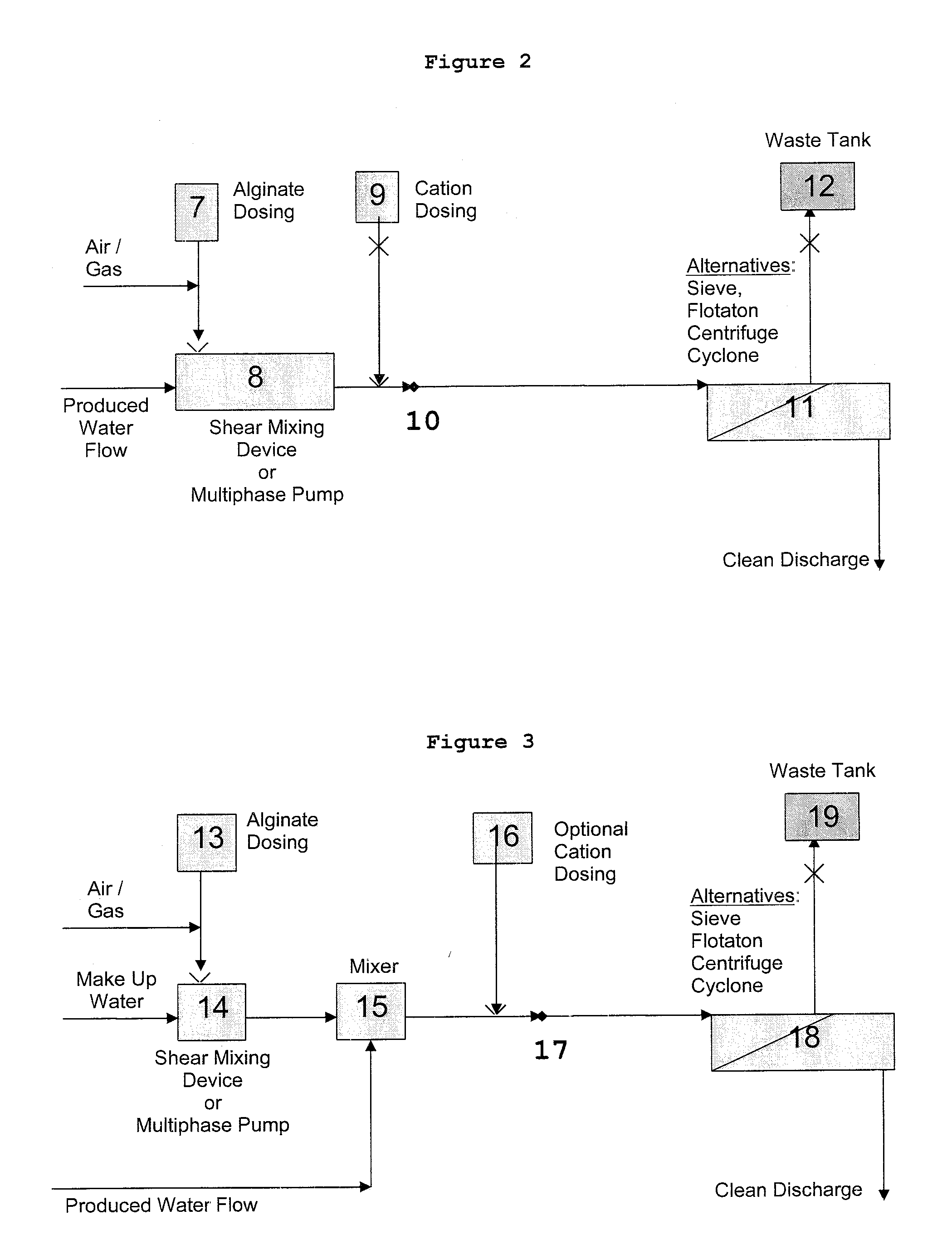

Method for removal of materials from a liquid stream

ActiveUS20070235391A1Avoid premature gellingHigh puritySolid sorbent liquid separationWater/sewage treatment by ion-exchangeCycloneMicroparticle

A method for removal of dissolved materials and / or particles from a liquid stream comprising flocculation by vigorously mixing polysaccharides or hydrocolloids into the liquid stream and subsequent gelation of the polysaccharides or hydrocolloids with cations capable of gelling same. Large, strong gelled agglomerates of pollutant and polysaccharide or hydrocolloid are formed with the help of suitable cations. The gelled agglomerates are well suited to separation from a liquid stream by flotation, in a sieve, in a centrifuge, in a cyclone or via other conventional separation processes. Also described is a method for mixing of un-dissolved polysaccharide or hydrocolloid with a polluted aqueous stream by shearing the polysaccharide or hydrocolloid into the aqueous stream to improve logistics and provide economic savings in treatment of large volumes of water. Also described is the use of dilute solutions of polysaccharides for treatment of a variety of effluent streams. An application of the invention is provided for removal of hydrocarbons within the oil industry, but also for other kinds of oil-containing water and also water with organic or particulate pollution.

Owner:SORBWATER TECH AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com