Beneficiation method for recycling specularite

A beneficiation method and mirror iron ore technology are applied in selective deposition methods, chemical instruments and methods, flotation and other directions, which can solve the problems of poor magnetic separation effect, high beneficiation cost, easy deposition, etc. Significant energy saving and consumption reduction, the effect of reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further describe the present invention, the mineral processing method of a specularite reclaiming specularite in Anhui is described in more detail below in conjunction with the accompanying drawings and embodiments.

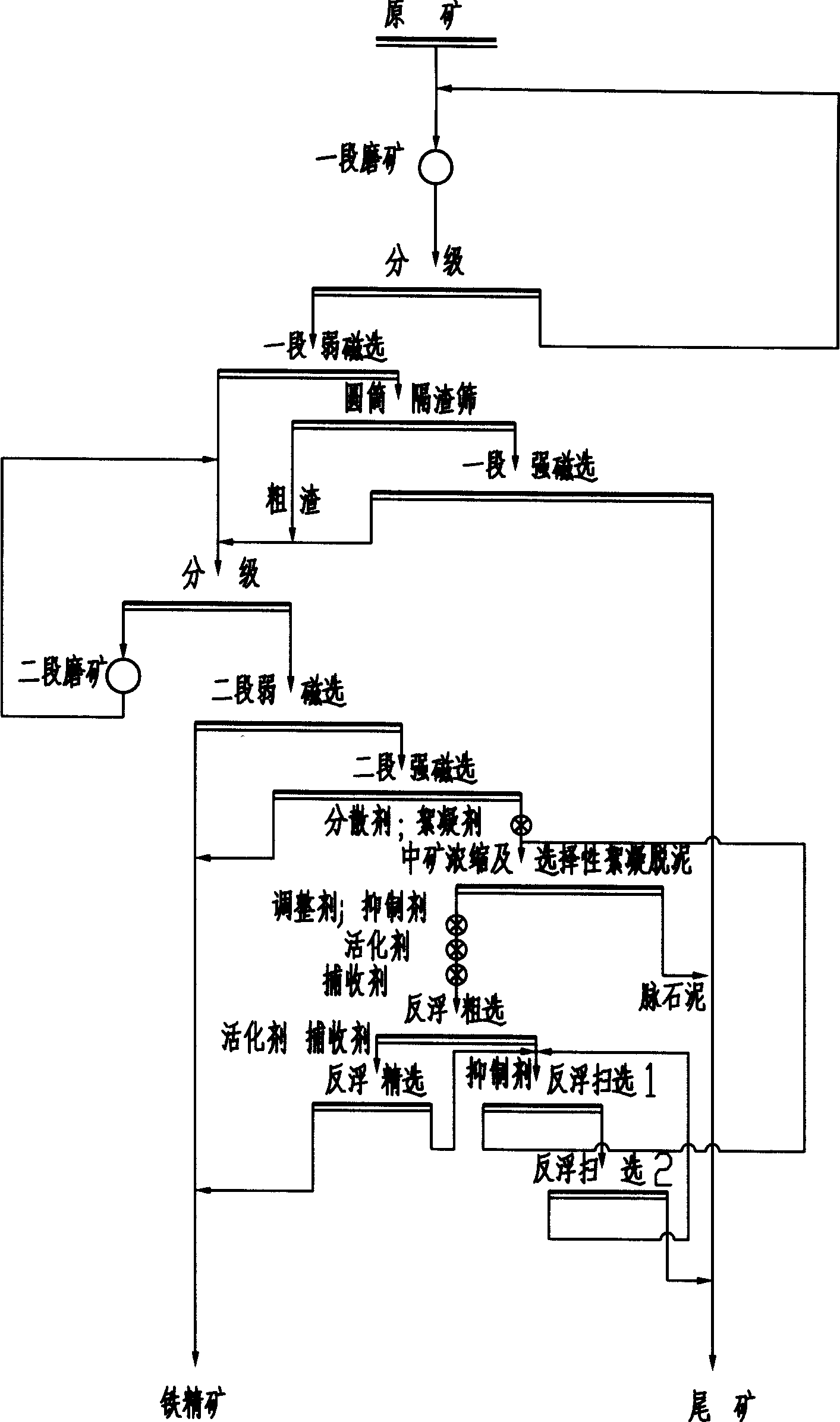

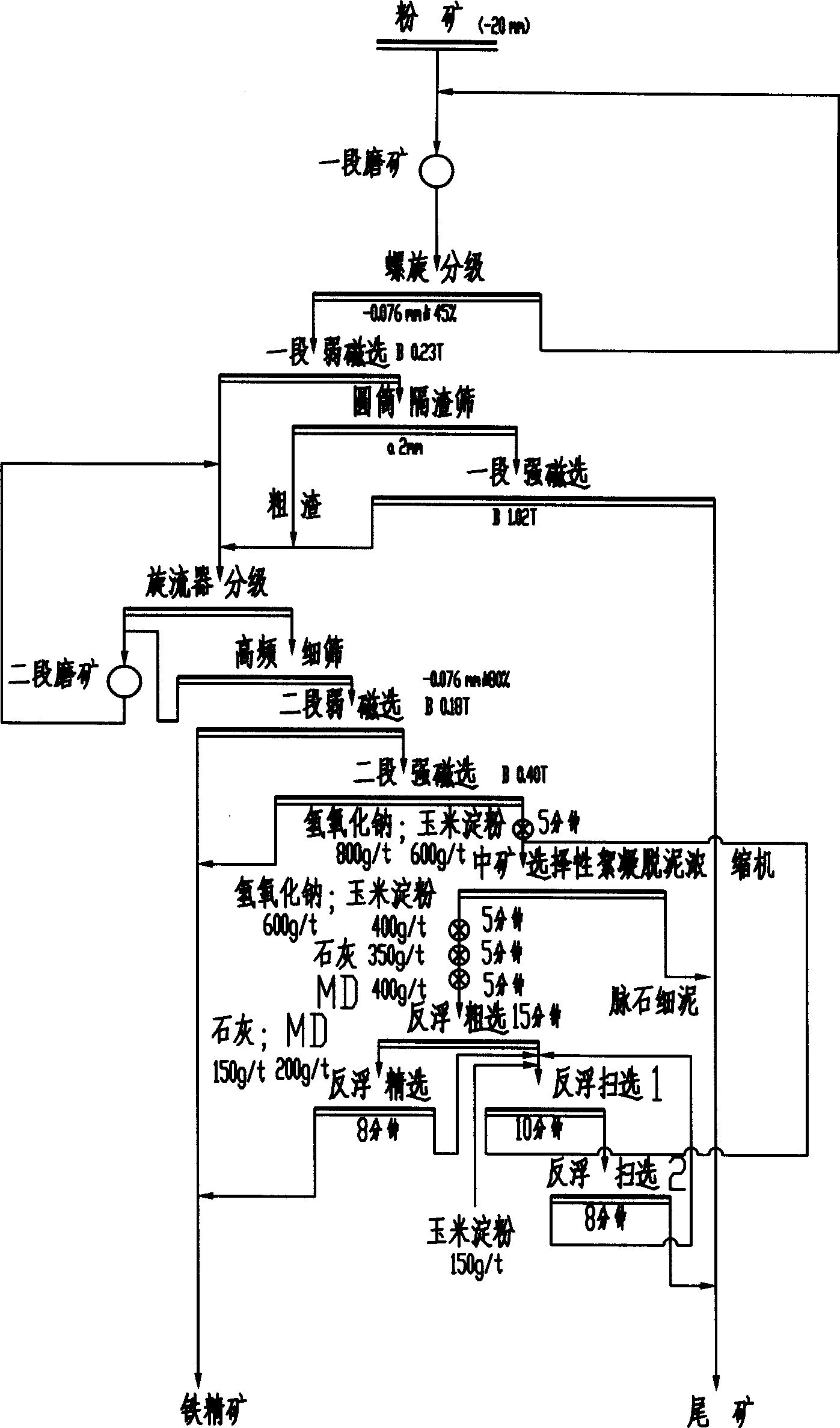

[0033] Depend on figure 1 , figure 2 Find out that a kind of mineral processing method of reclaiming specularite of the present invention comprises following technique, step:

[0034] (1) One stage of grinding - classification - one stage of weak magnetic separation - one stage of strong magnetic separation to throw tailings.

[0035] After the specularite ore is crushed to -20mm, it is fed into a ball mill for a first-stage grinding. The ore discharged from the ball mill is classified by a spiral classifier, and the sand returned from the spiral classifier is returned to the first-stage grinding. 0.076mm (accounting for 45%)) are separated by one stage of weak magnetic separation and one stage of strong magnetic separation, and the qualifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

| Magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com