Patents

Literature

249 results about "Siderite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Siderite is a mineral composed of iron(II) carbonate (FeCO₃). It takes its name from the Greek word σίδηρος sideros, “iron”. It is a valuable iron mineral, since it is 48% iron and contains no sulfur or phosphorus. Zinc, magnesium and manganese commonly substitute for the iron resulting in the siderite-smithsonite, siderite-magnesite and siderite-rhodochrosite solid solution series.

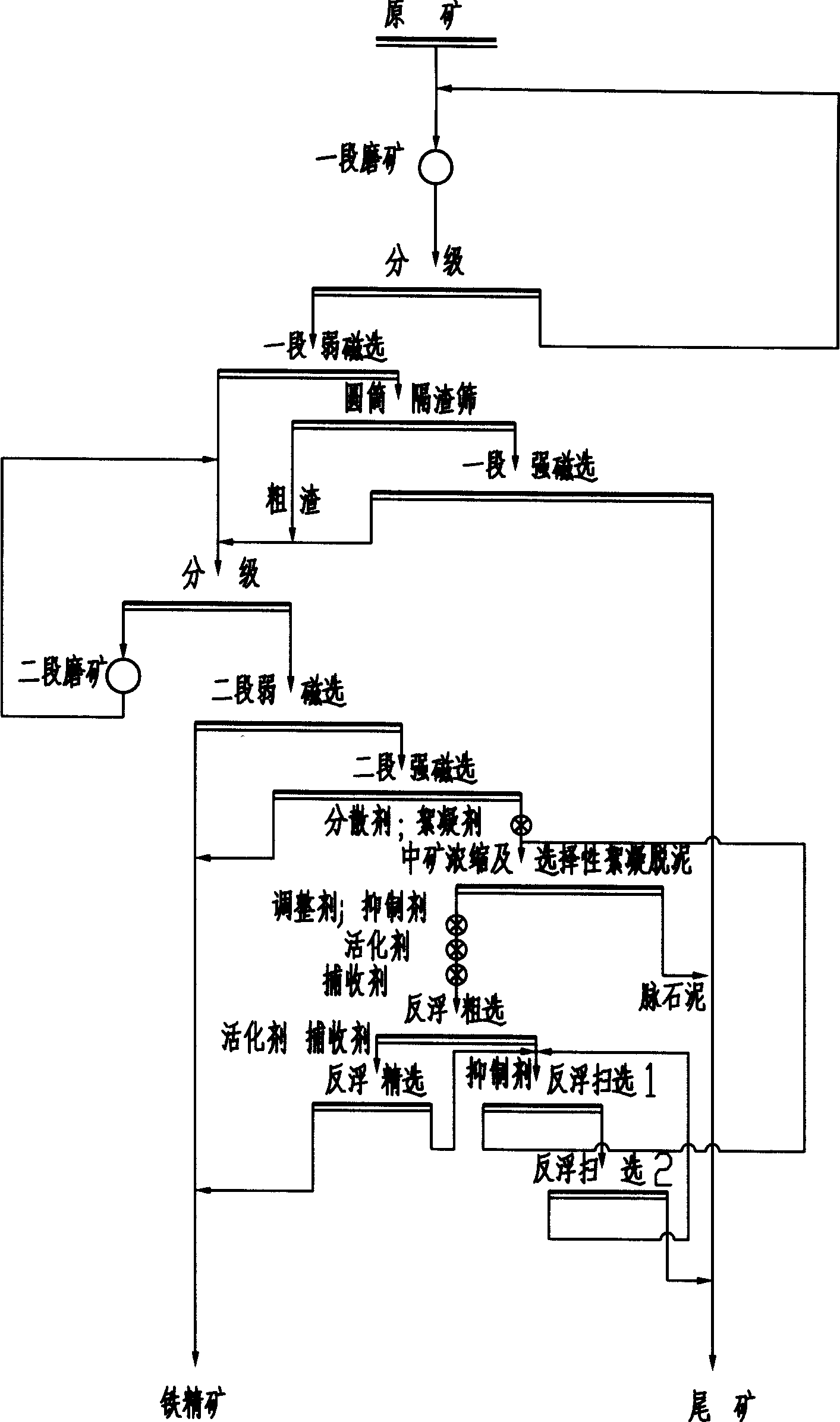

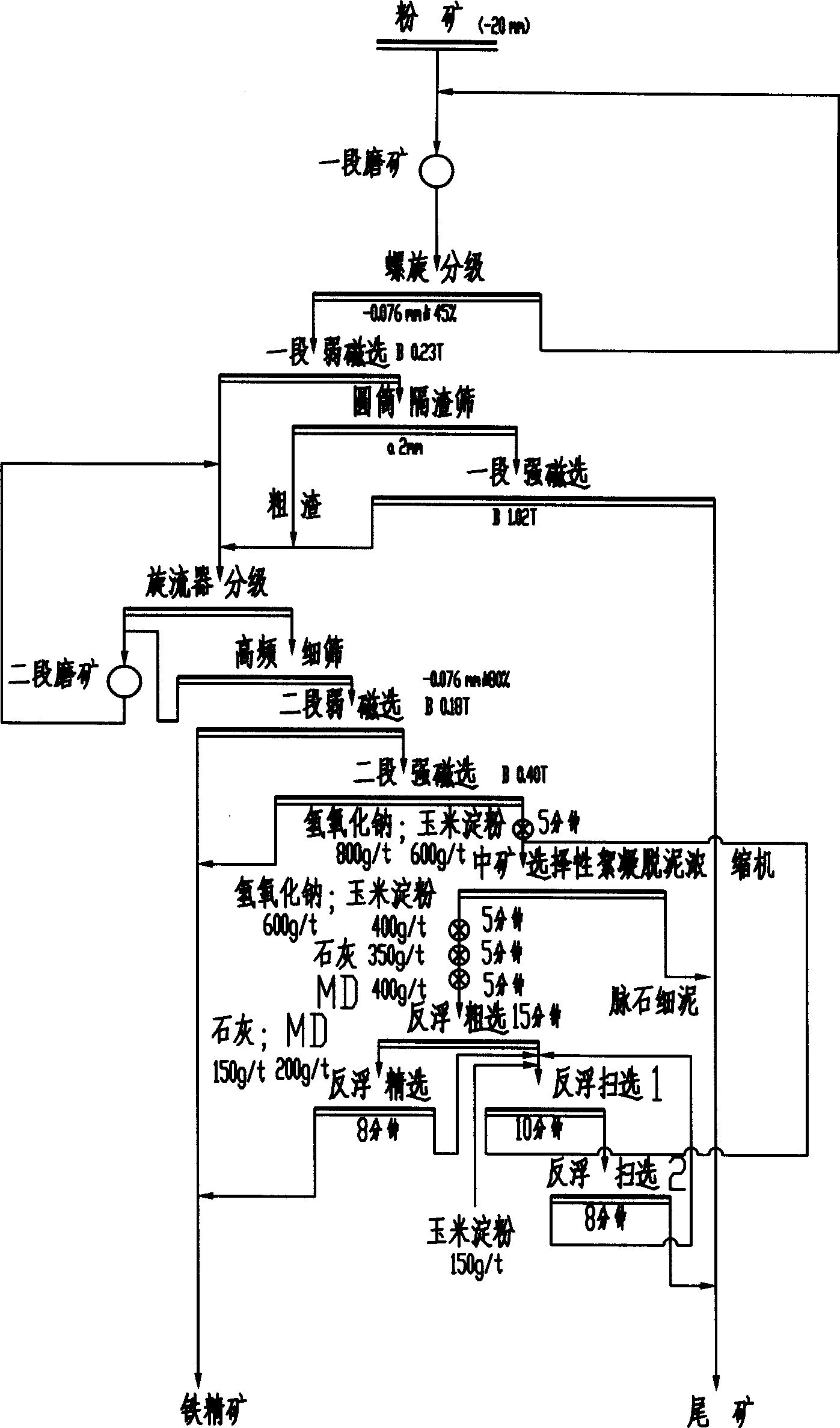

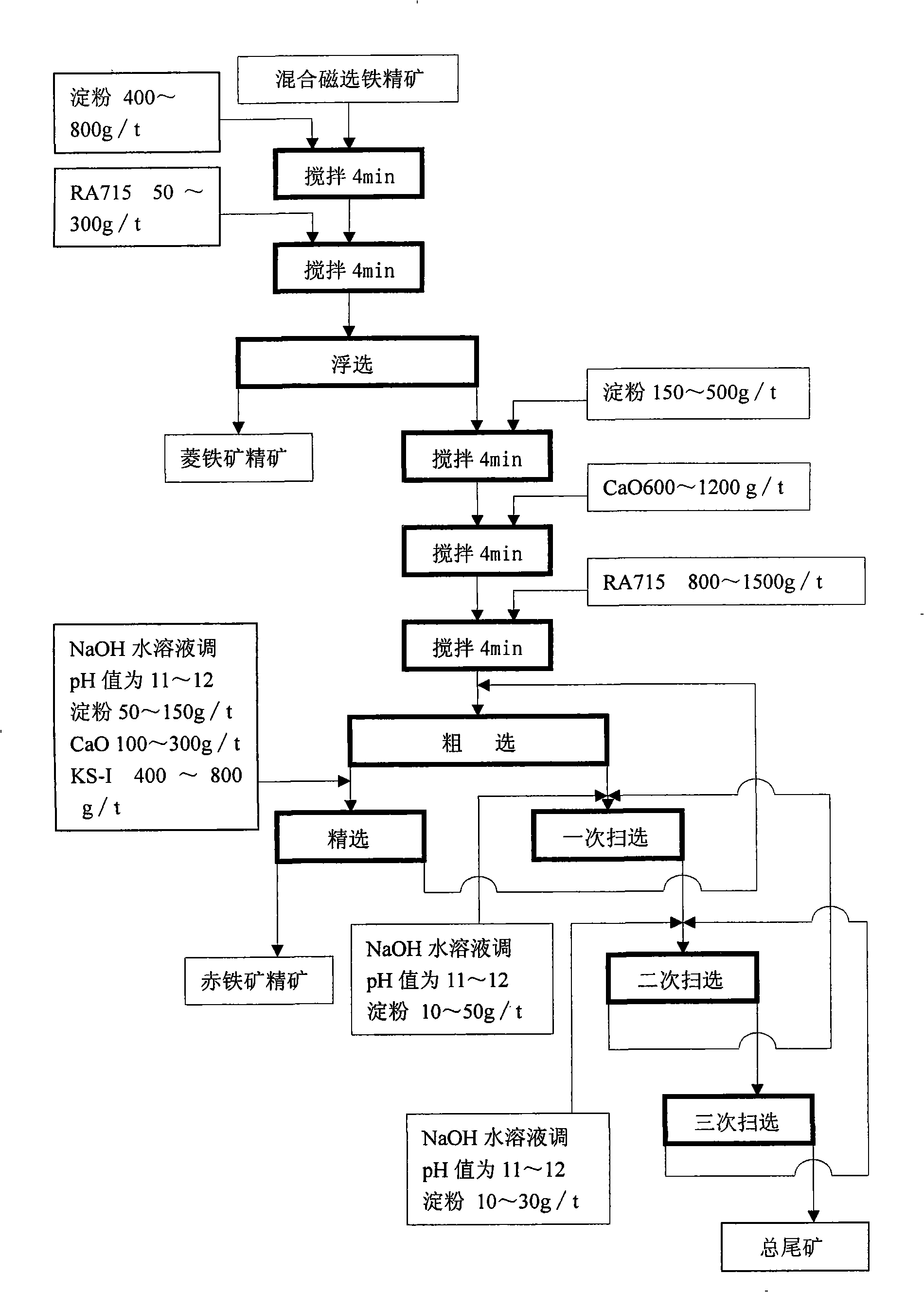

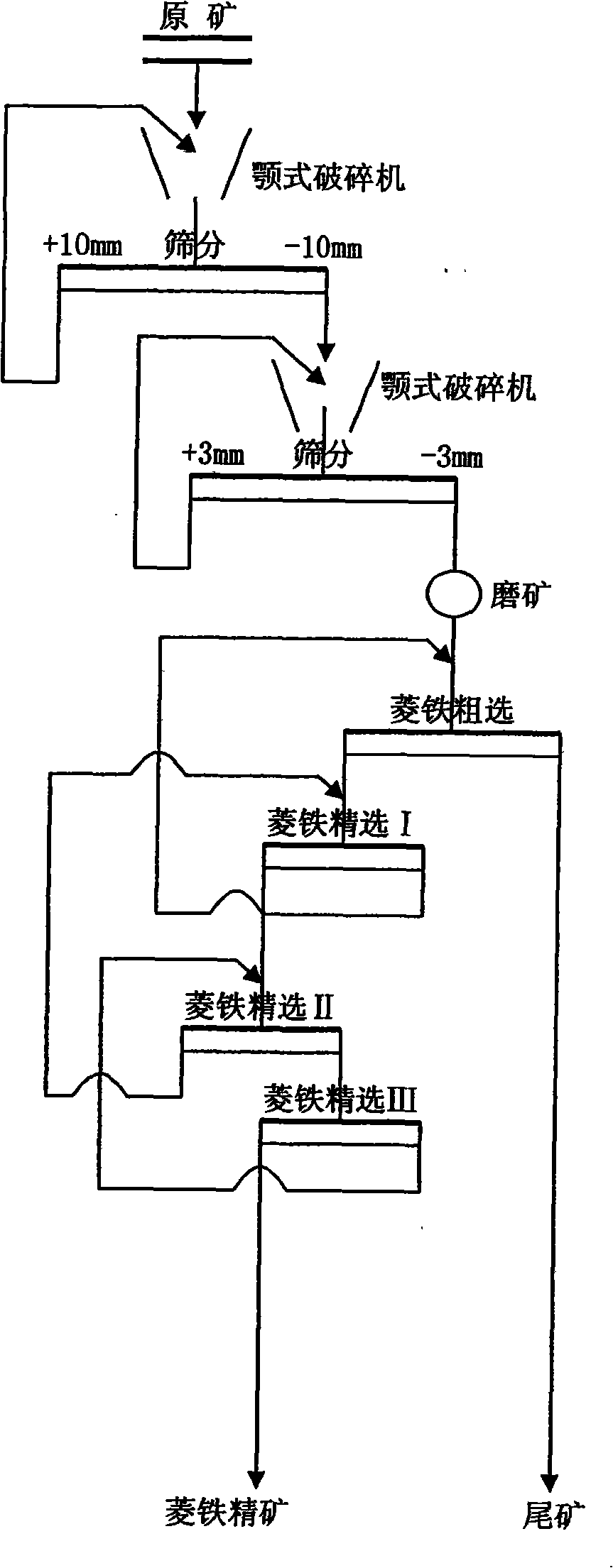

Beneficiation method for recycling specularite

InactiveCN101428248AReduce consumptionReduce the number of equipmentDifferential sedimentationFlotationIronstoneSlag

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

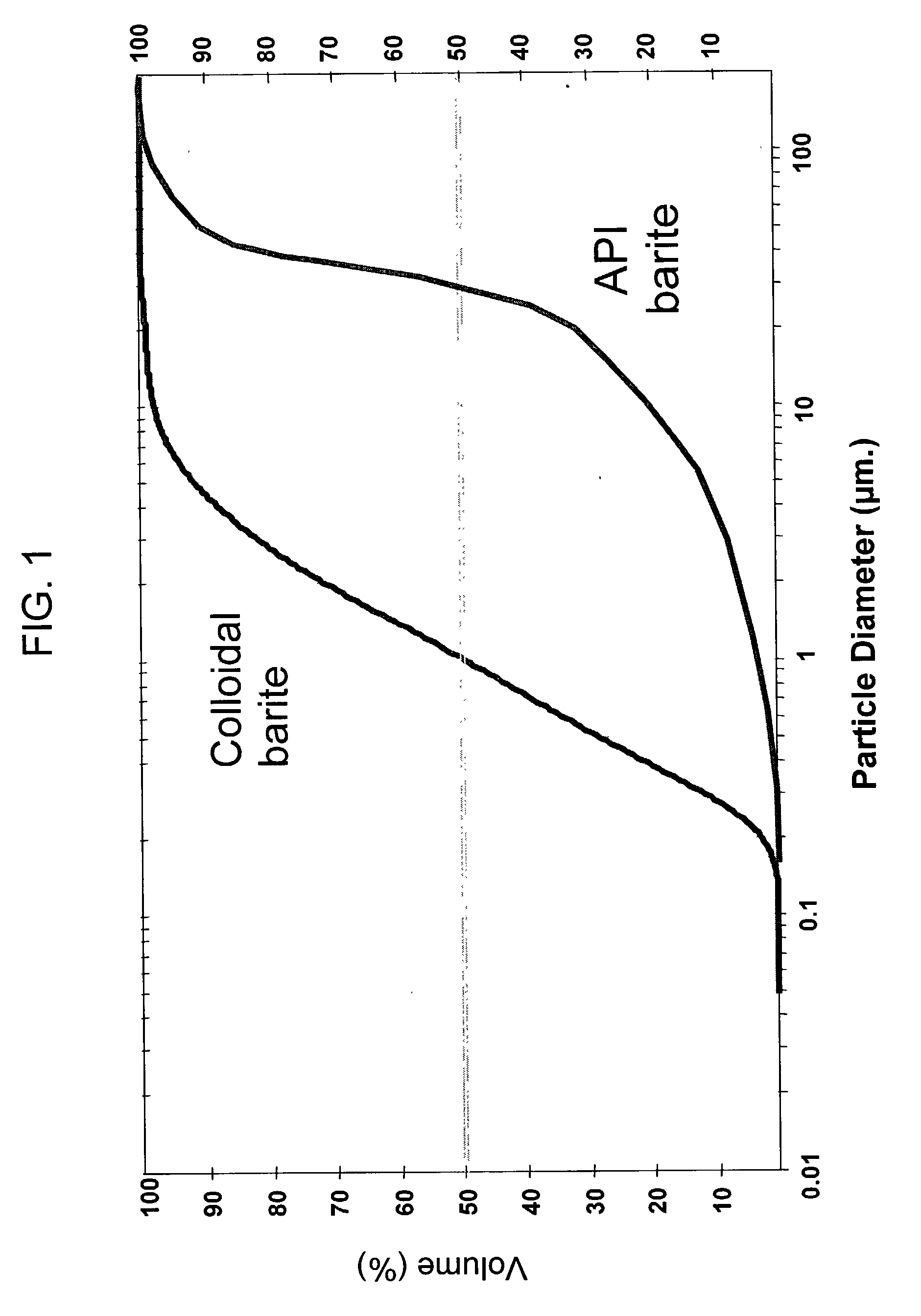

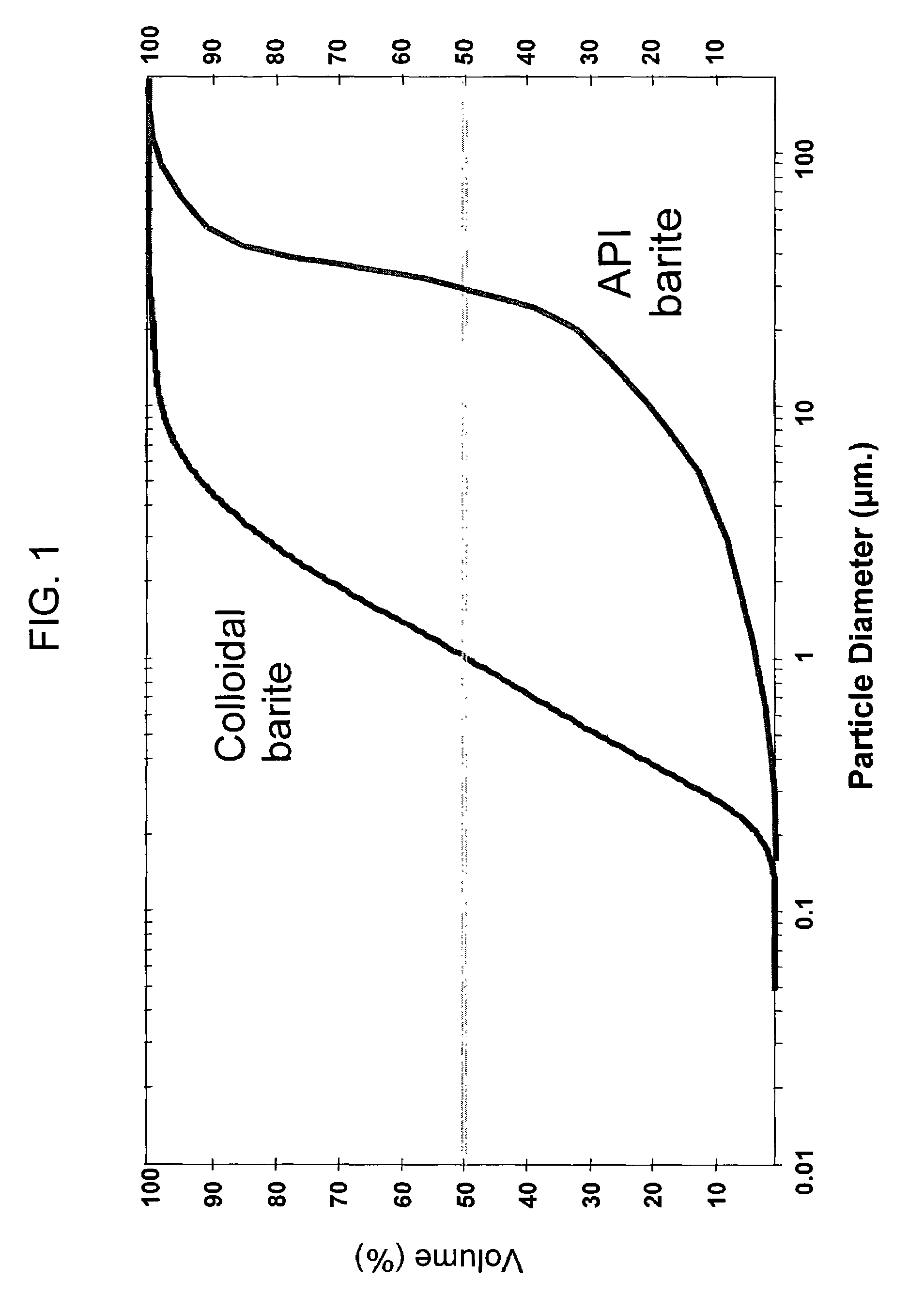

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20060188651A1Liquid surface applicatorsOther chemical processesVolumetric Mass DensitySolid particle

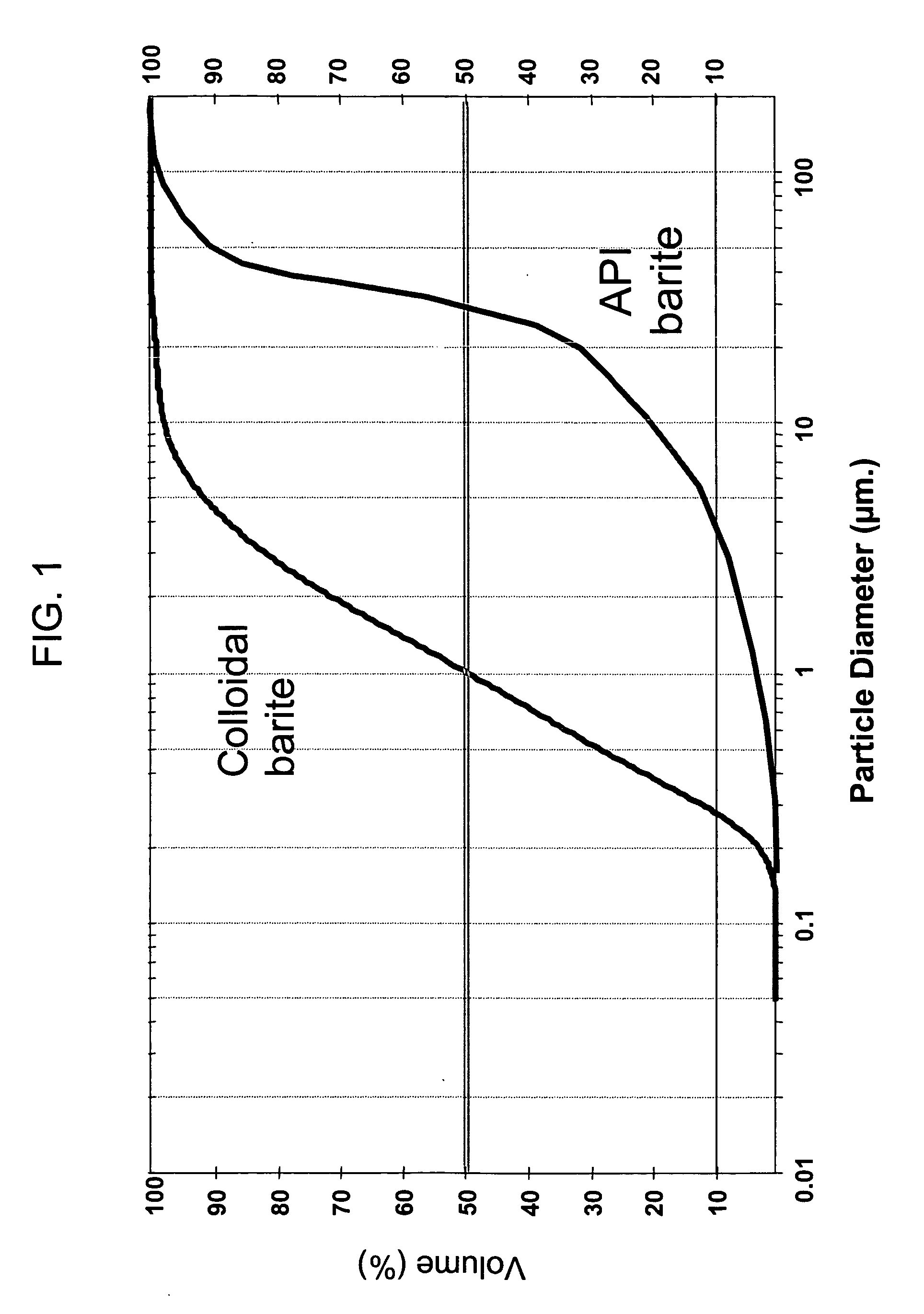

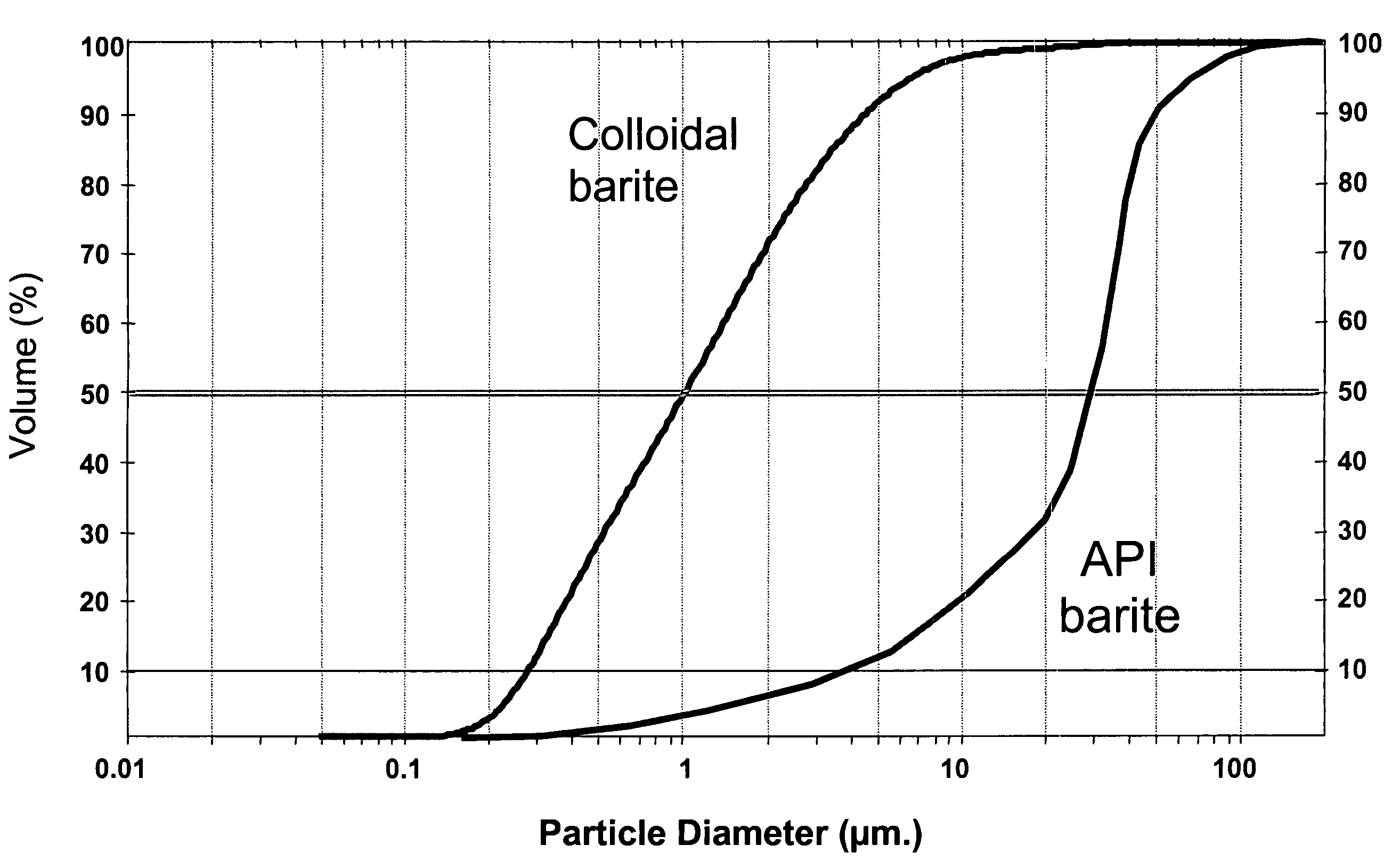

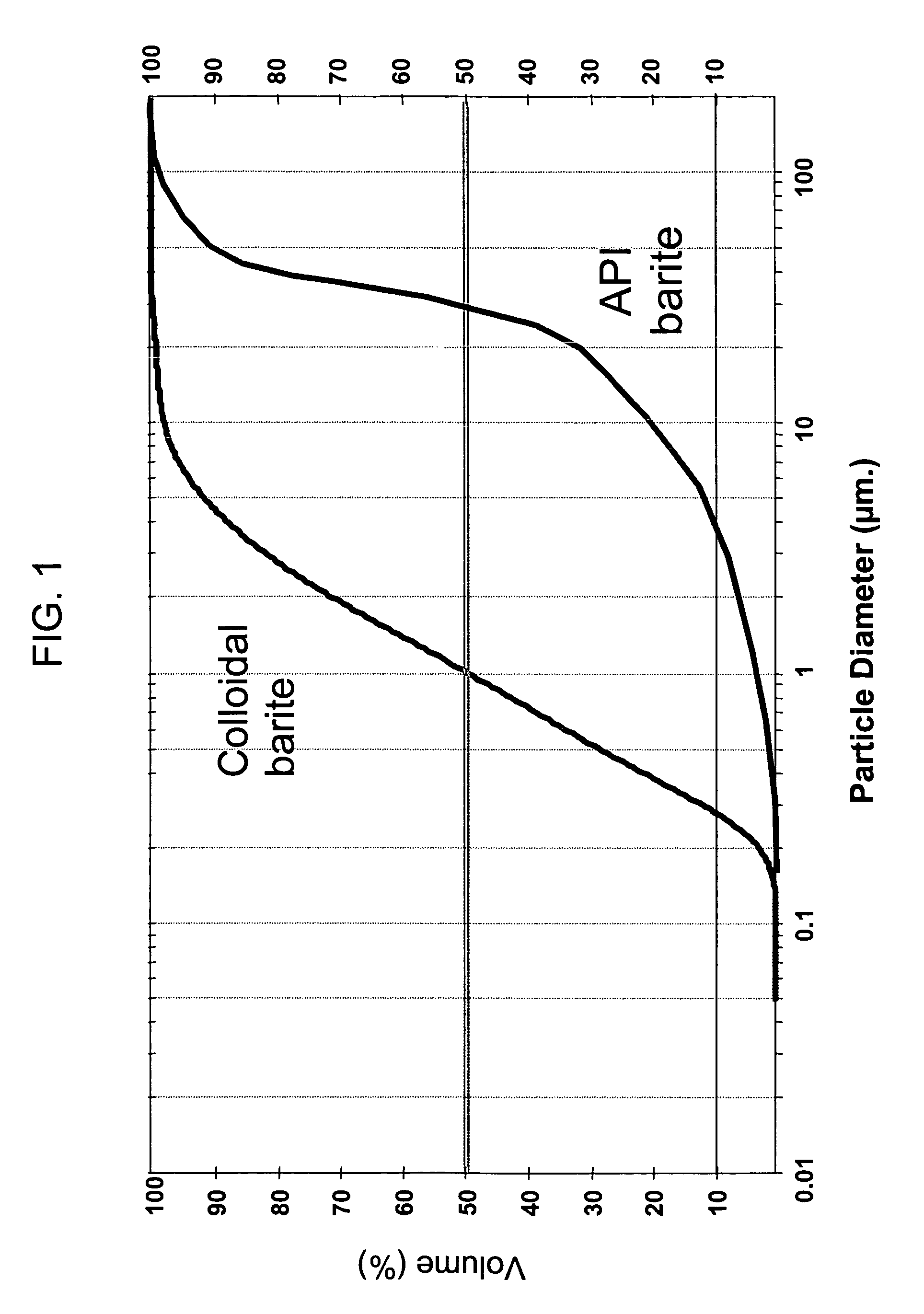

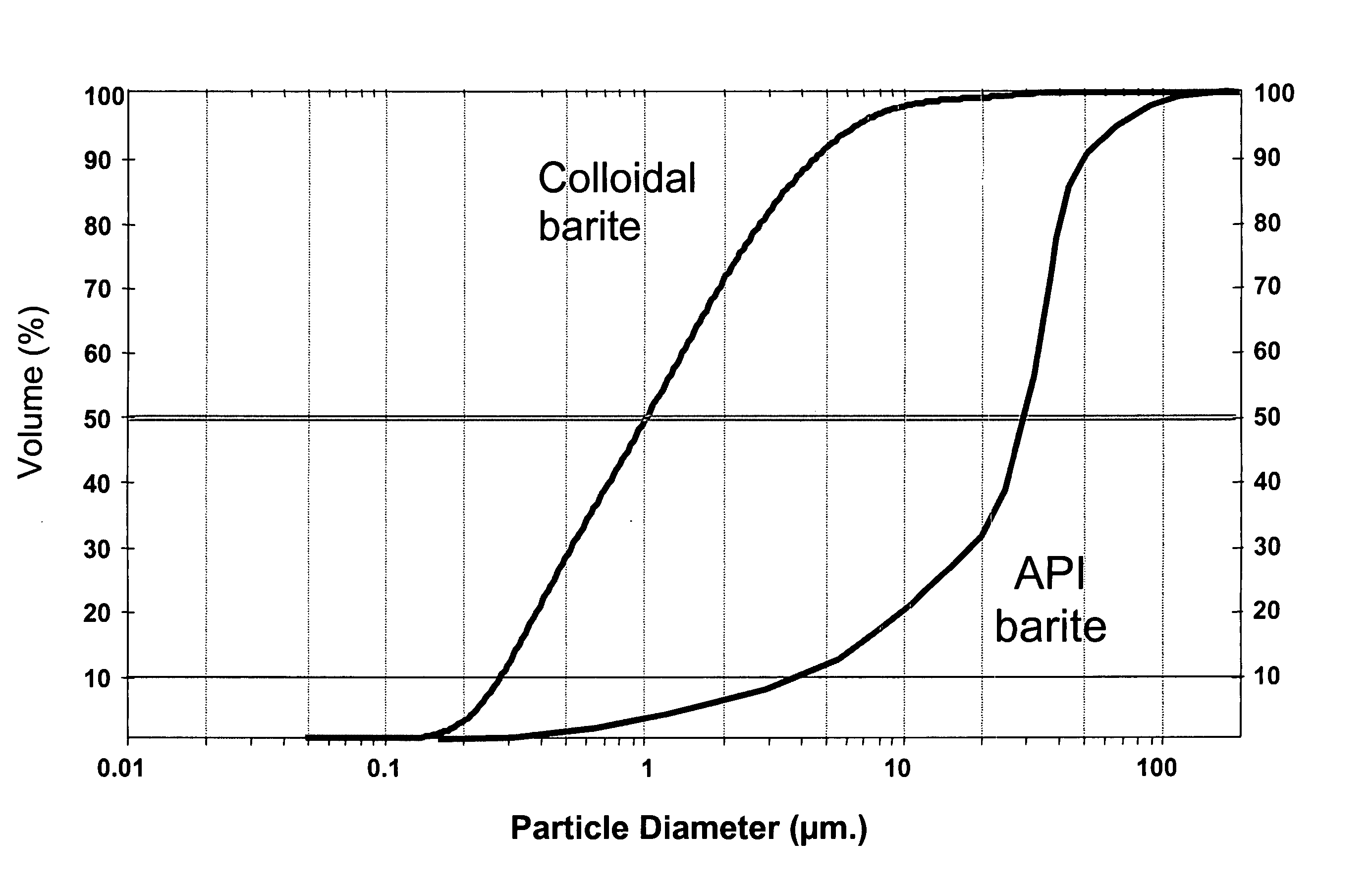

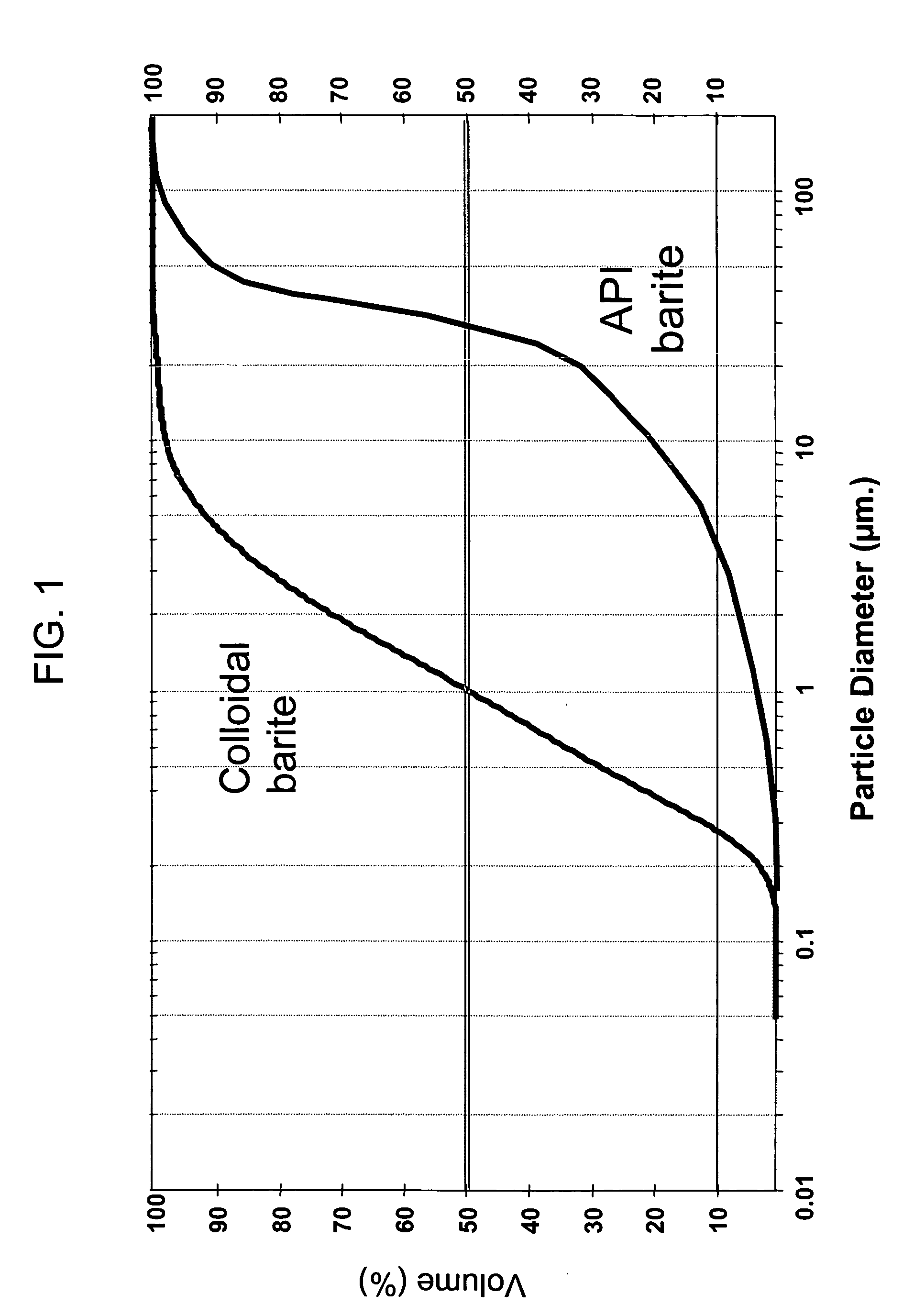

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

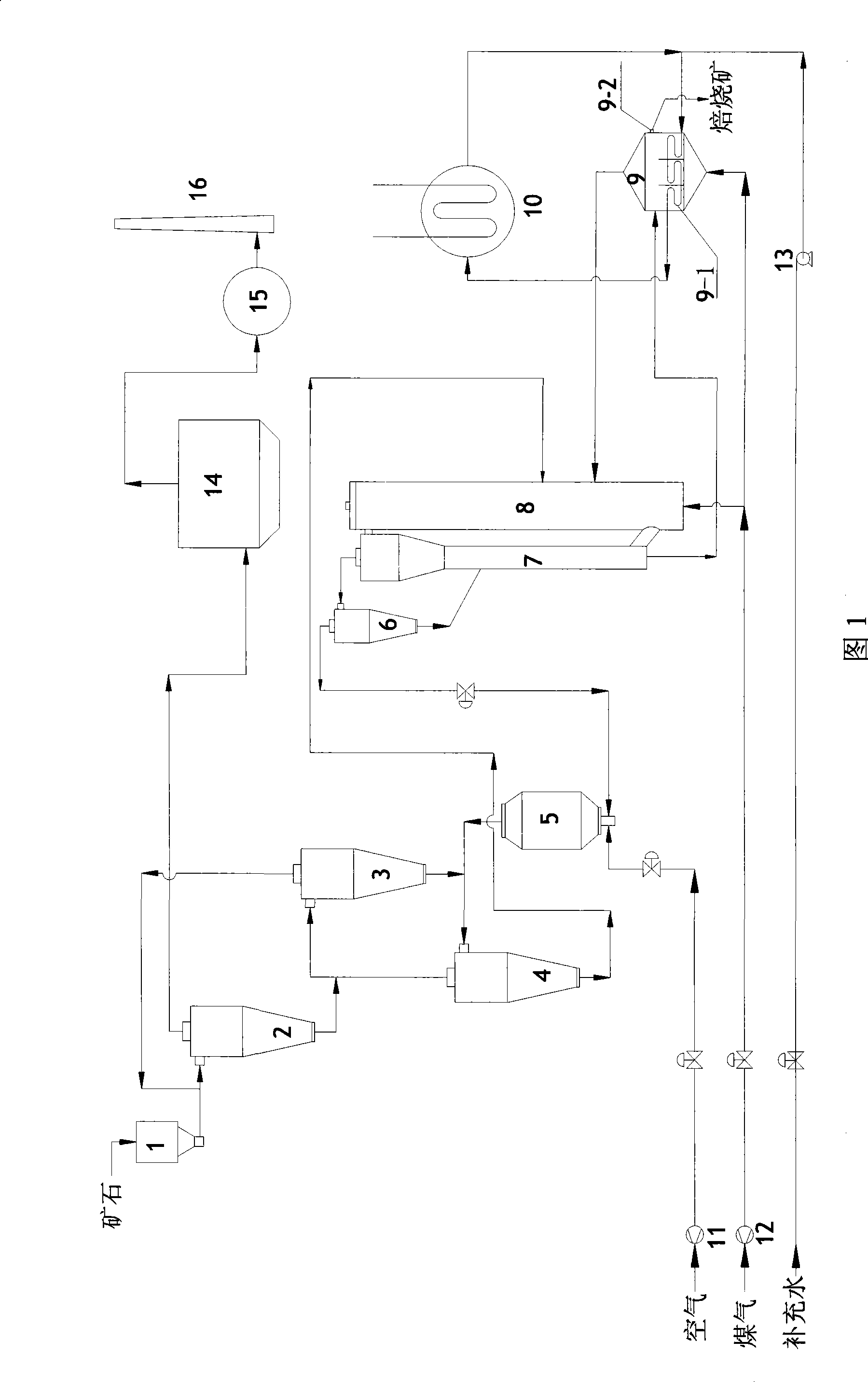

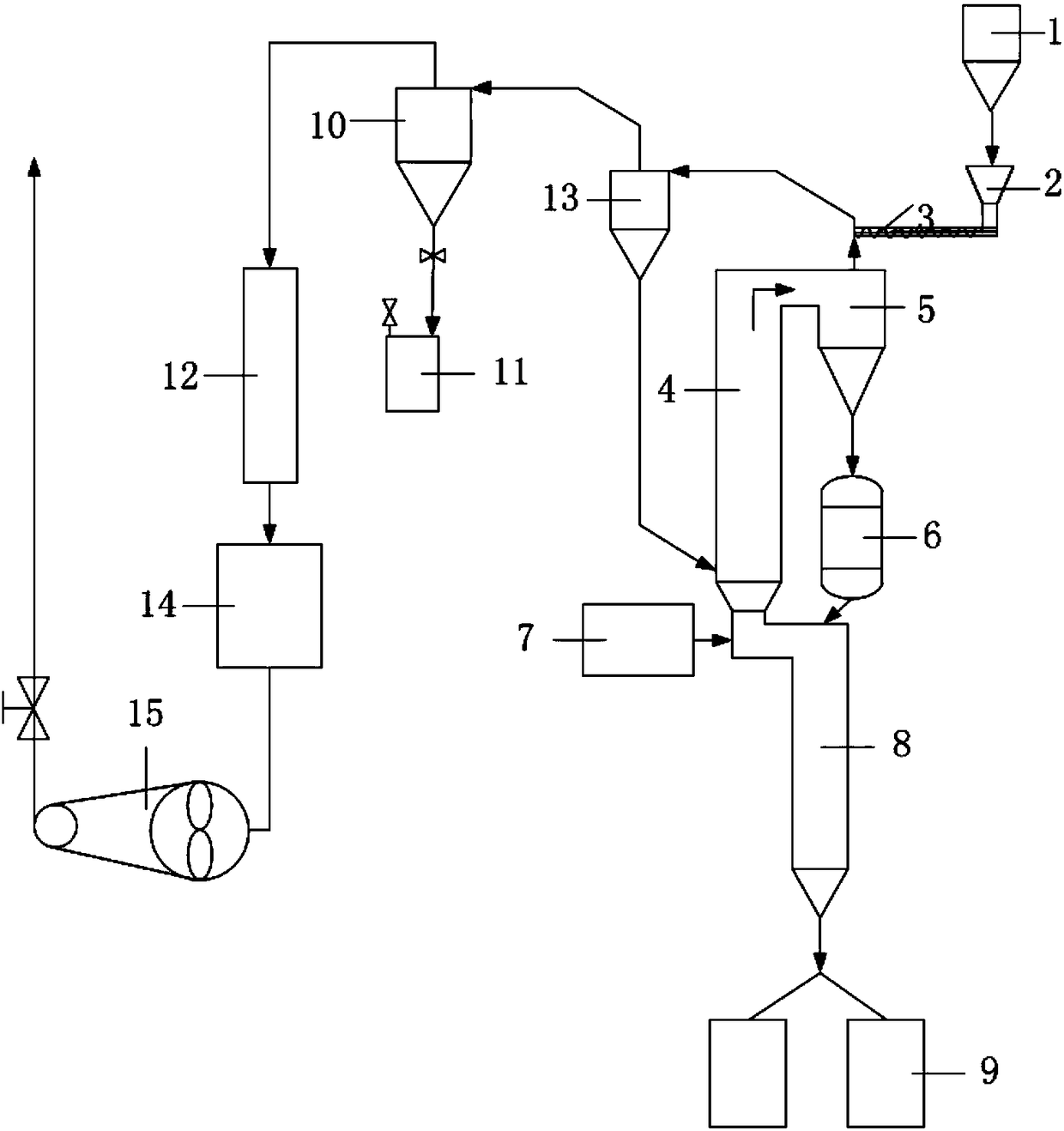

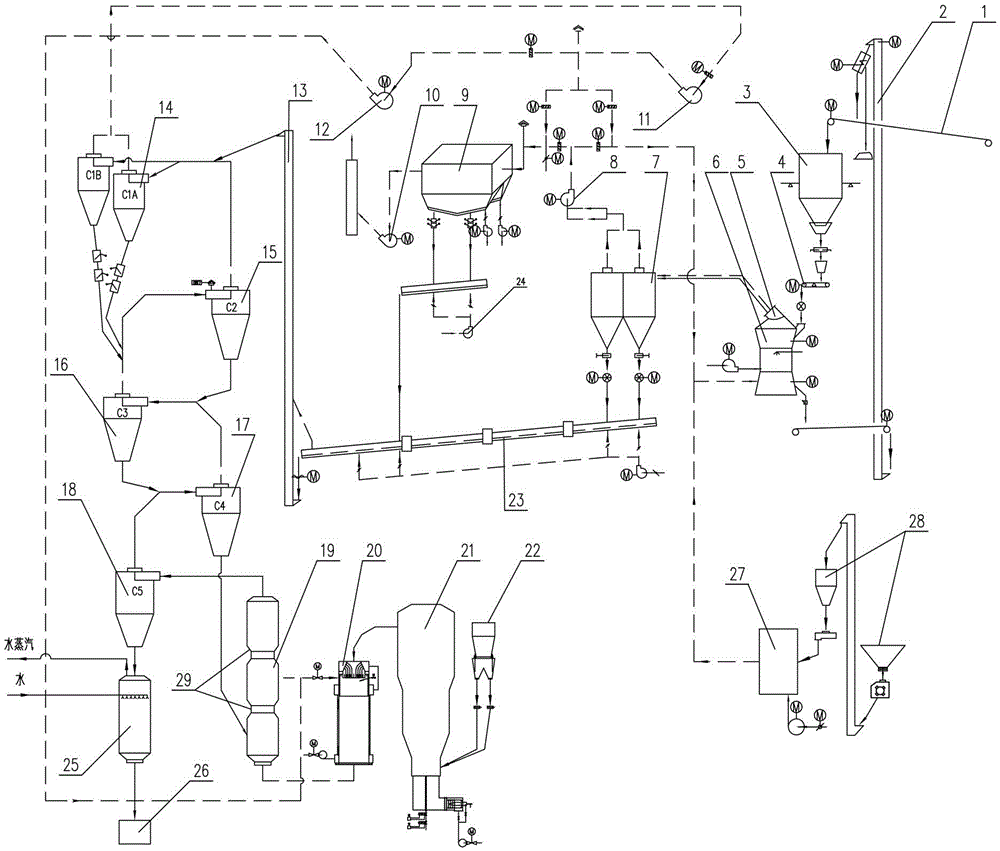

Magnetization roasting technique system for refractory iron ore powder and roasting technology

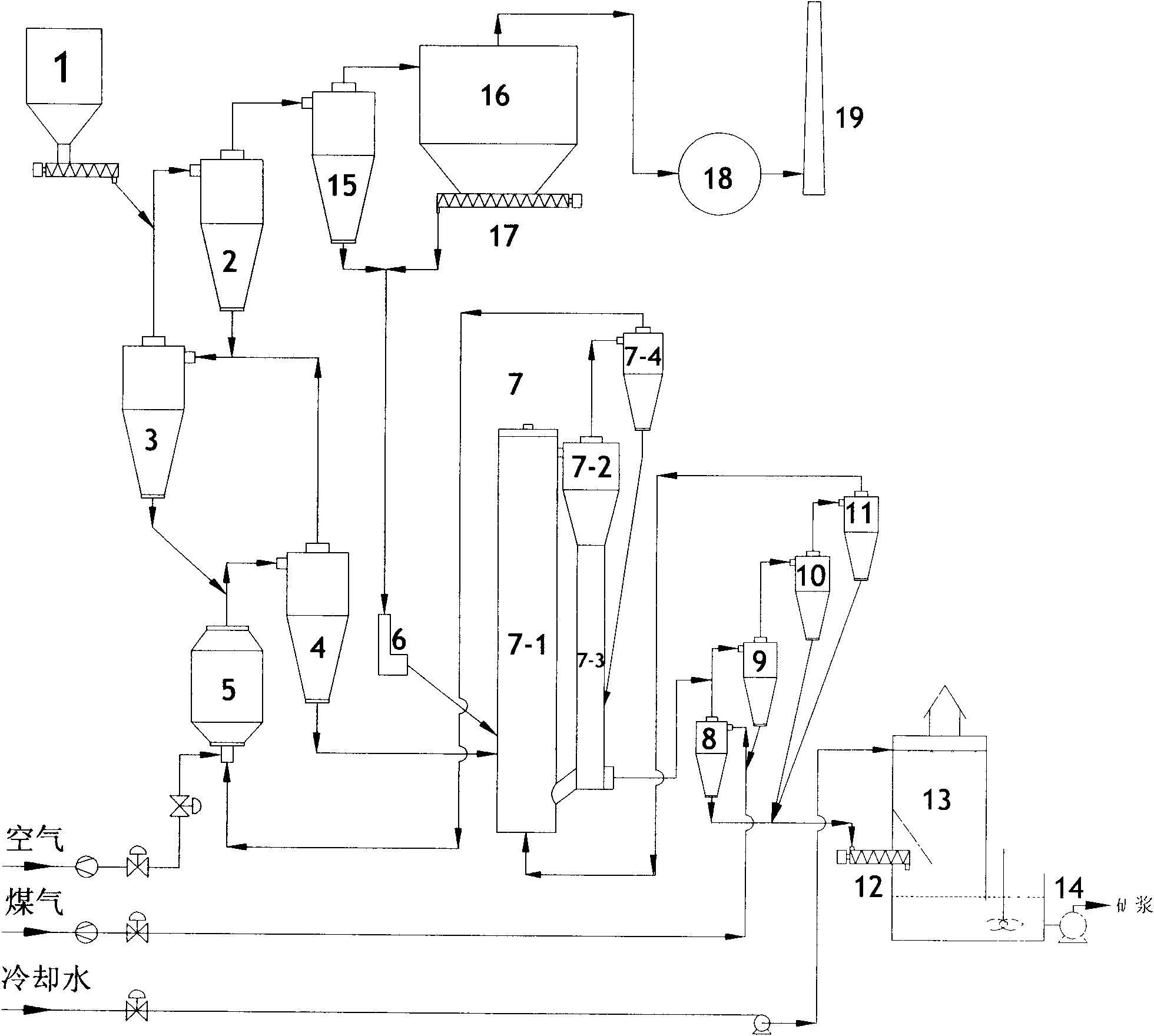

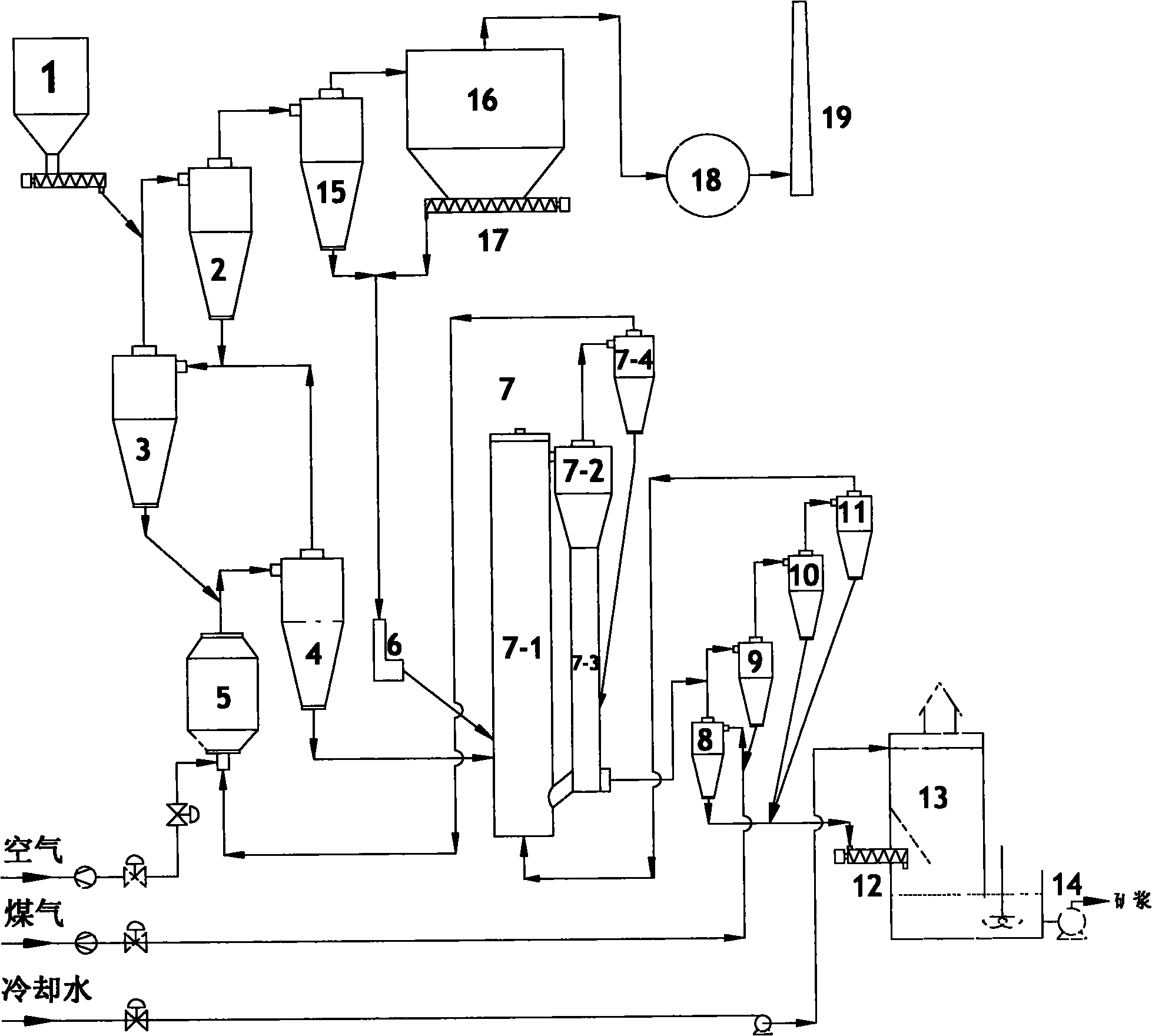

The invention belongs to the fields of chemical engineering and metallurgy and in particular relates to a process system which adopts a circulating fluid bed to carry out magnetization roasting on limonite, siderite, sedimentary hematite and other refractory iron ore powder bodies. The process system adopts a high-efficiency low-resistance reactor of the circulating fluid bed to carry out the magnetizing roasting to the iron ore powder body; firstly, roasted tail gas in a combustion chamber releases latent heat of unreacted reducing gas through combustion; secondly, the roasted tail gas exchanges heat with the cold iron ore powder body through a multilevel cyclone preheater to reclaim heat; and finally a fluidizing cooler is adopted to reclaim sensible heat of high-temperature roasting ore. The process system has the advantages of high magnetizing roasting efficiency and full heat reclaiming and utilization in the roasting process and the like, can reduce energy consumption of the refractory iron ore powder body in the process of magnetizing roasting and improve the economical efficiency of the refractory iron ore in the process of magnetizing roasting.

Owner:深圳市中科九台资源利用科技产业股份有限公司

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20050101493A1Photosensitive materialsScale removal and water softeningVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

Siderite-based nitrogen and phosphorus removal material and application method thereof

ActiveCN103801254AWith strengthHigh porosityOther chemical processesTreatment with aerobic and anaerobic processesPorosityPhosphate

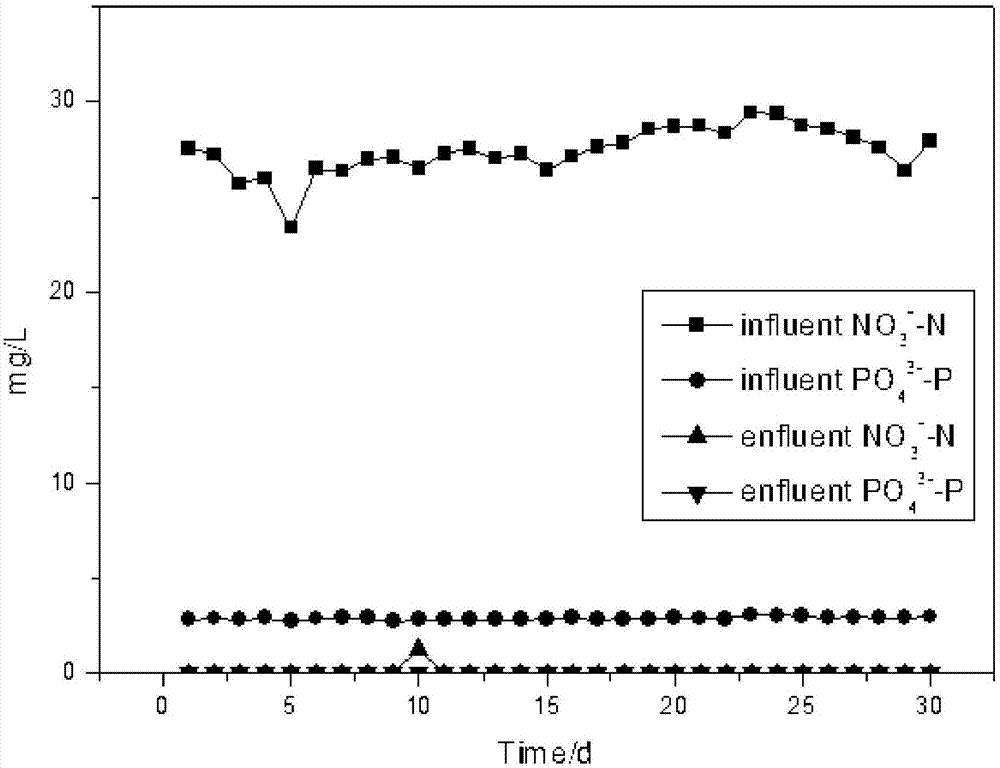

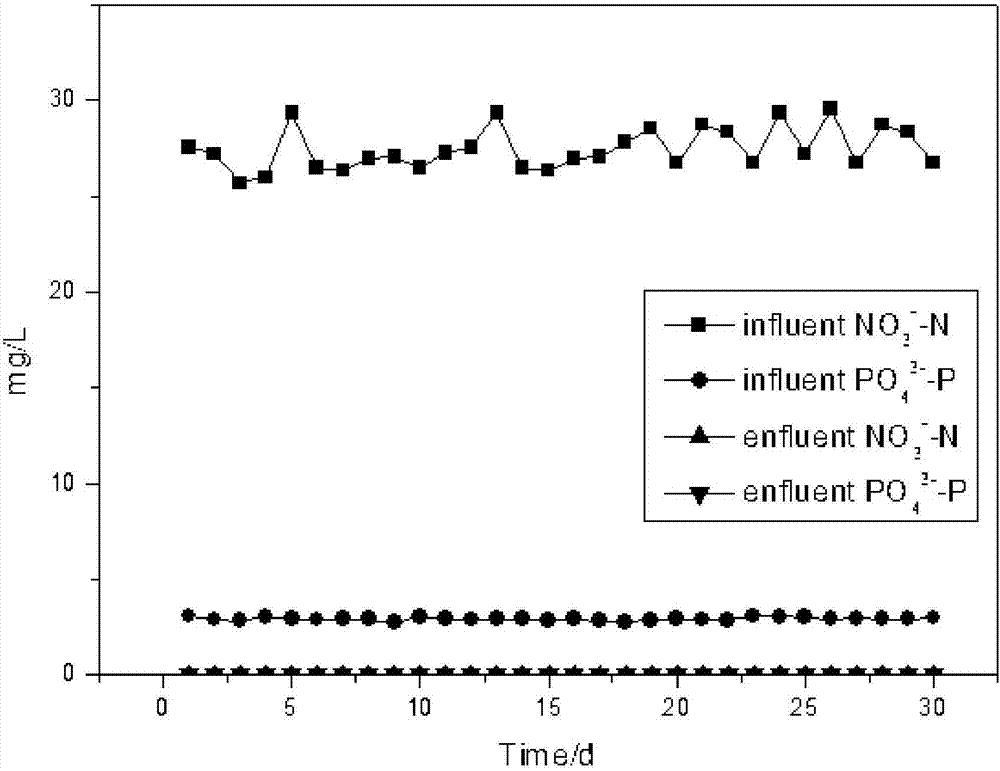

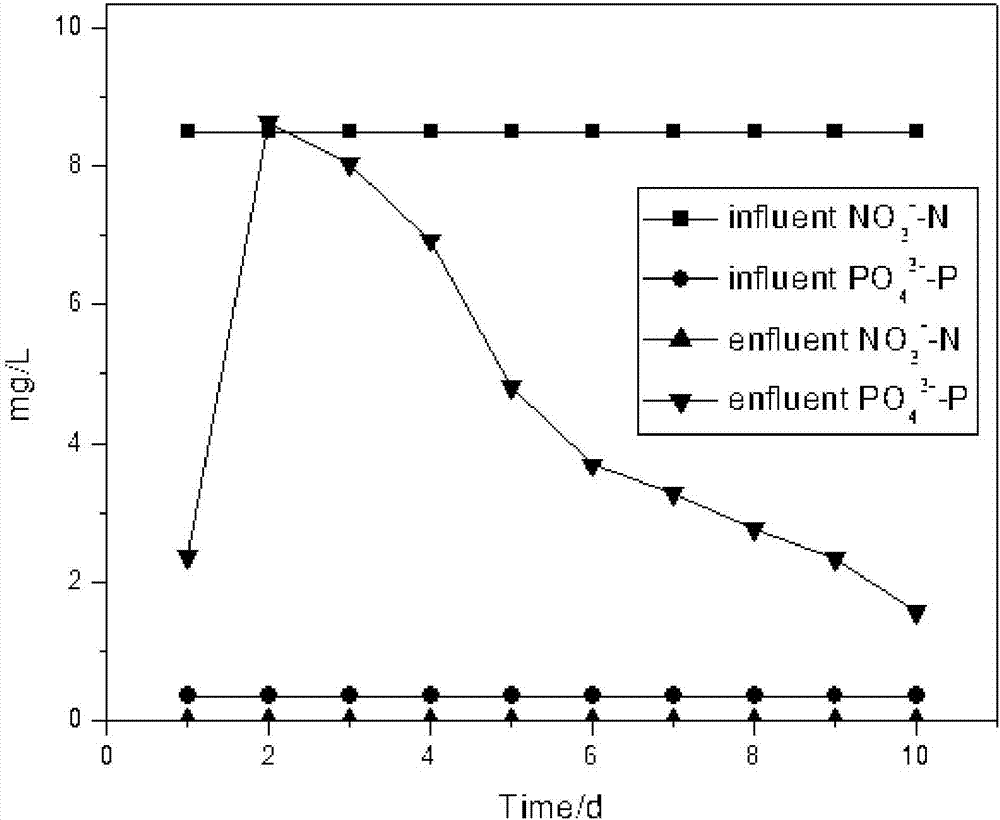

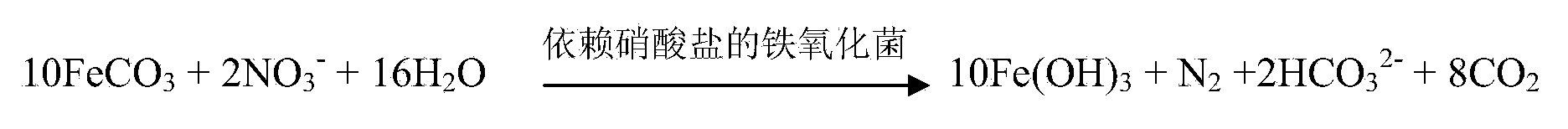

The invention discloses a preparation method and applications of a siderite-based nitrogen and phosphorus removal material. The preparation method is implemented through steps of crushing siderite ores, enabling the obtained ores to pass through a 40-mesh sieve, and adding a foaming agent into siderite ore powder in an appropriate proportion of the siderite ore powder, a binder and a pore-foaming agent or in an appropriate proportion of the siderite ore powder and a binder so as to obtain a porous granular material taking the siderite ore powder as a main body; and the porous granular material has the characteristics of high particle strength, high porosity, large specific surface area, large microbial load, and the like. The material is a microbial carrier, an anaerobic microorganism electron donor and a phosphorus removal adsorbent. The material is fed in a fixed bed to treat wastewater by way of filtering, and vaccinates nitrate-depended iron-oxidizing-bacteria-based anaerobic strain liquid, and under anaerobic conditions, microorganisms reduce nitrates into nitrogen by taking ferrous irons in siderite as electron donors, and the adsorption effect on phosphorus is enhanced. The material is mainly used for synchronously removing nitrate nitrogen and phosphates in wastewater.

Owner:HEFEI UNIV OF TECH

Magnetic roasting system and process for powder of refractory iron ore

The invention belongs to the fields of chemical industry and metallurgy and in particular relates to a magnetic roasting system and process for powder of a refractory iron ore such as limonite, siderite, deposited hematite and the like by using a circulating fluidized bed. The powder of the iron ore is magnetically roasted by using a circulating fluidized bed reactor; the latent heat of unreacted reductive gas in roasting tail gas is released through combustion in a combustion chamber firstly, and then, heat is recovered through the heat exchange between a multistage cyclone preheater and the powder of a cold iron ore; and the sensible heat of the powder of a high-temperature roasted iron ore is recovered in a way that cold coal gas and the powder of the high-temperature roasted iron exchange heat in a cyclone cooler. The magnetic roasting system and process have the advantages of high magnetic roasting efficiency, high heat utilization efficiency in the roasting process and the like and can be used for reducing the energy consumption in the magnetic roasting process of the powder of the refractory iron ore and improving the economical efficiency in the magnetic roasting process of the powder of the refractory iron ore.

Owner:深圳市中科九台资源利用科技产业股份有限公司

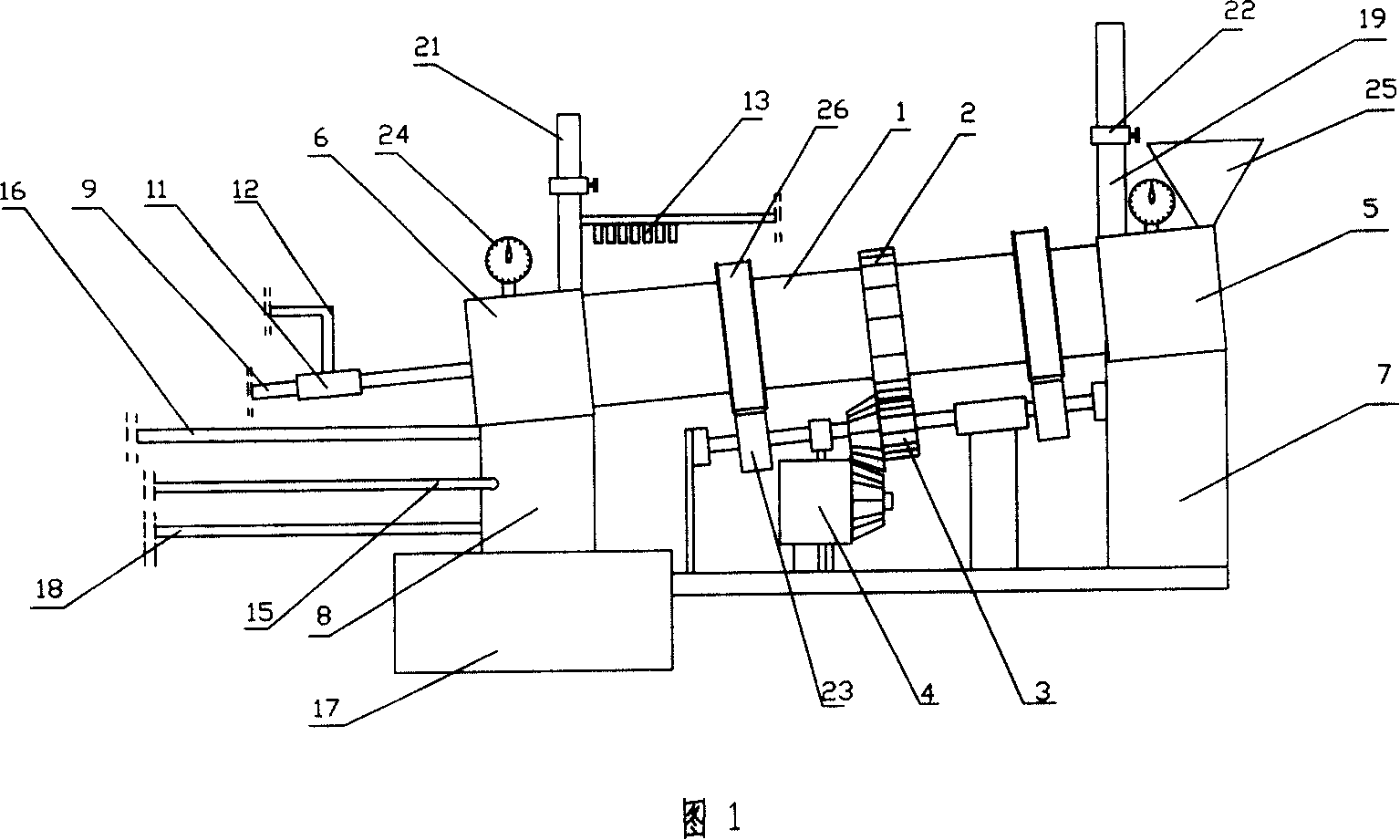

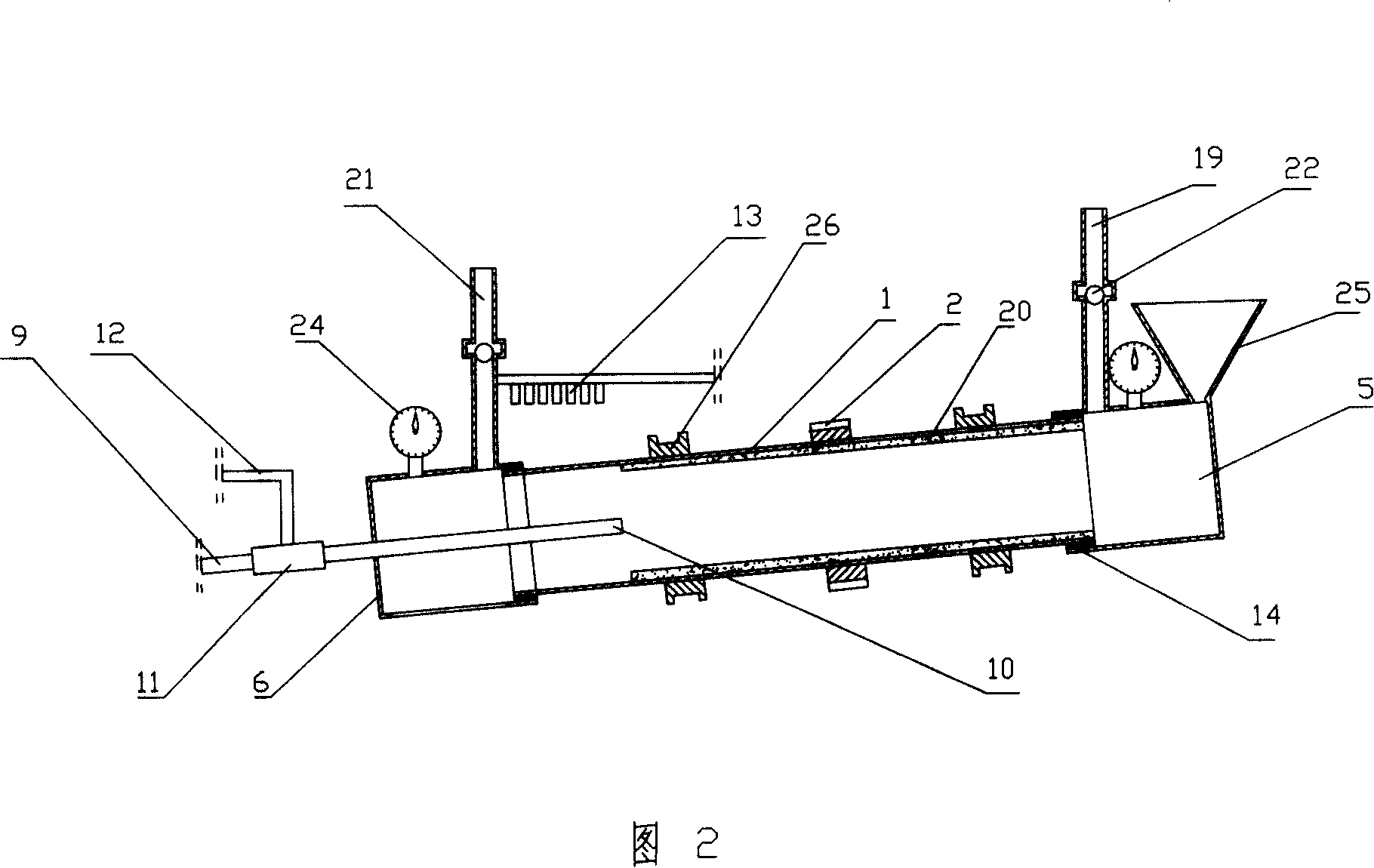

Method for producing iron concentrate by brown hematite and siderite and reduction roaster

The present invention discloses a method for adopting the limonite and the siderite to produce iron powder and a reduction roaster. The material adopts the limonite and the siderite or the specularite, the hematite, and the sulphuric acid slag, the inclined rotary reduction roaster is used, the pressure of the furnace chamber is 250 to 350 Pa, under the deoxidizing atmosphere, the inert solid is rotated and moved to 650 to 900 DEG C from the low temperature, and is cooled and magnetized, and lastly become the iron powder through the dressing by magnetic separation. The present invention is adopted to produce the iron powder, the resources is rich and the production cost is low, and through the utilization of the powder metallurgy art, the iron content of the iron powder is controlled and the activation energy of the iron powder is reduced, and the chemical reaction ability is increased, thereby the output of iron powder is high, the quality is good, the iron powder is loose and porous, the specific surface is big, the apparent density is large, the manufacture cost of pellets sinter and steel smelting can be reduced greatly, and the iron powder can use directly to produce iron oxide red as well as H and N synthetic iron catalyst, or produce ultrapure iron powder.

Owner:郭元杰

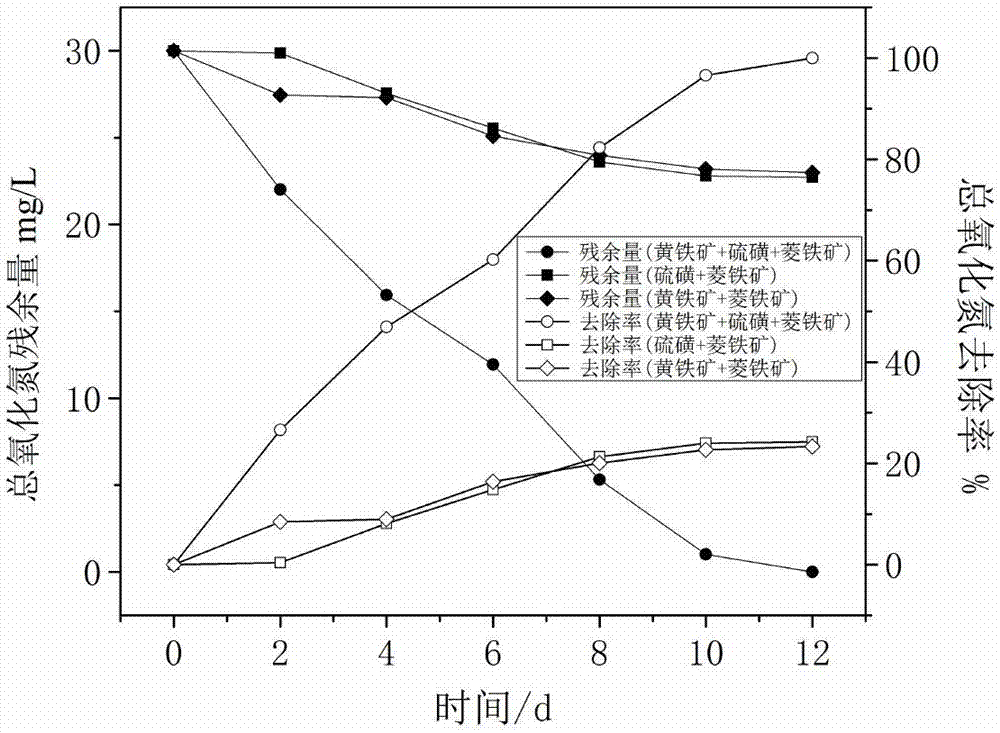

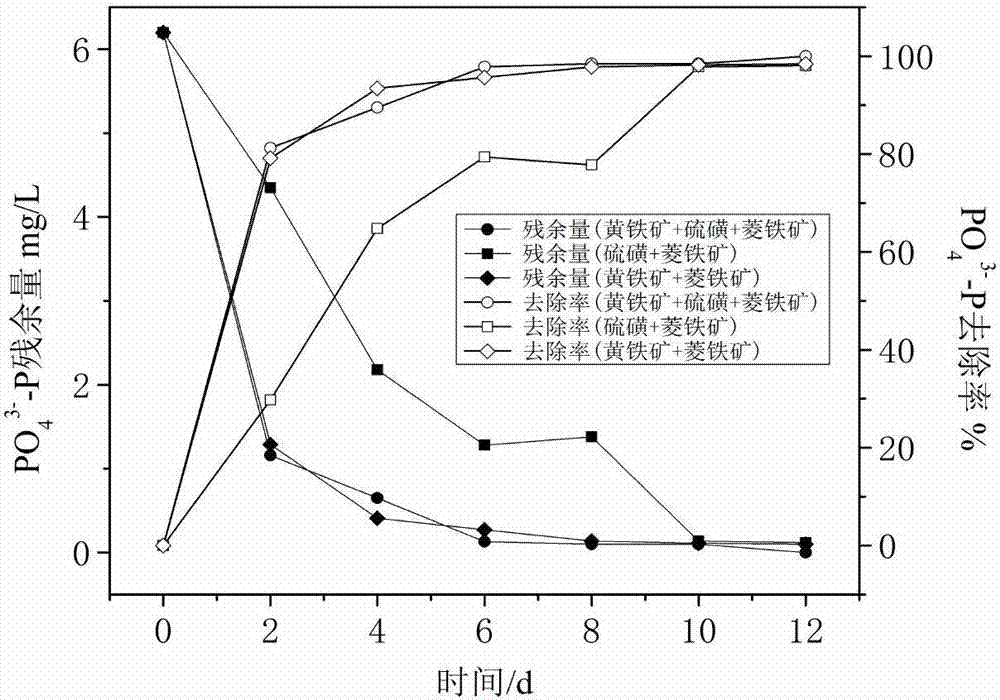

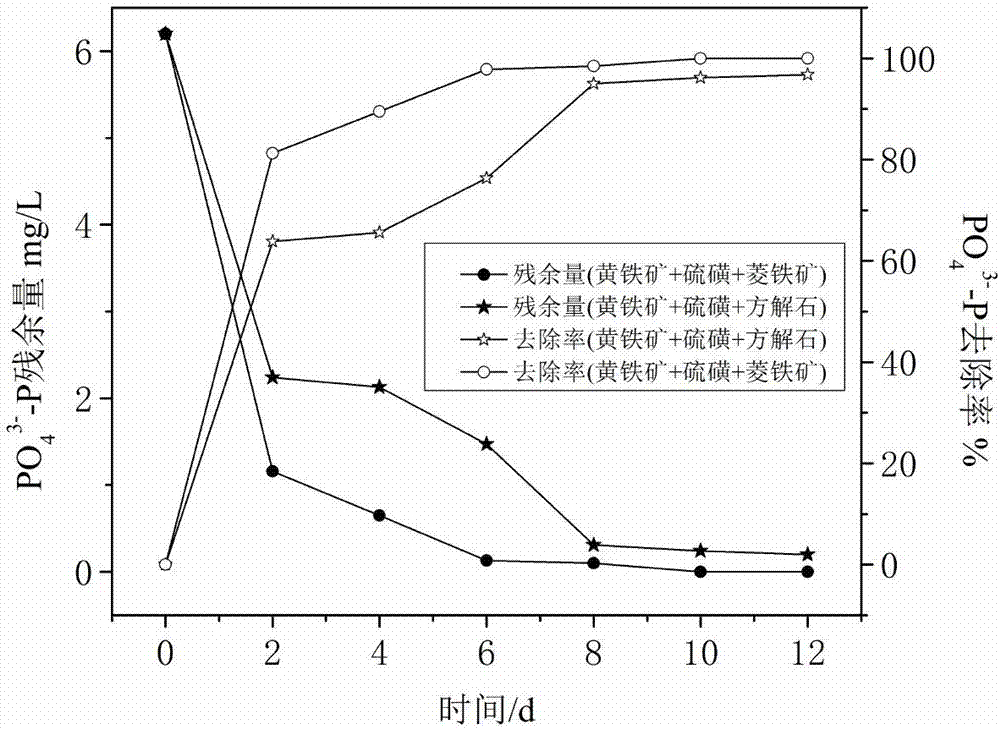

Sewage treatment method for simultaneously removing phosphor and nitrogen in process of reinforcing autotrophic denitrification of sulfur

ActiveCN107176702AOptimizationImprove denitrification effectWater treatment compoundsWater contaminantsPhosphate ionSiderite

The invention discloses a sewage treatment method for simultaneously removing phosphor and nitrogen in a process of reinforcing autotrophic denitrification of sulfur and belongs to the technical field of sewage treatment. According to the method, pyrite, sulfur and siderite are adopted for strengthening a denitrification process of the wastewater and the effect of simultaneously removing phosphor and nitrogen is promoted. According to the method, pyrite and sulfur are used as sulfur sources and siderite is used as a carob source in a reaction system. The synergistic effect of the pyrite and sulfur can strengthen the utilization of the thalli for the siderite, so that the denitrification capacity can be reinforced. The ferric and ferrous ions, which are released by pyrite and siderite, and phosphate radical ions can form the ferric phosphate sediment, so that the dephosphorization capacity is reinforced. The method has an excellent effect, is low in cost and is suitable for engineering application.

Owner:NANJING UNIV

Stepped-flotation separation method for iron ore containing carbonas

InactiveCN101274302ANo difficulty returningImprove flotation environmentFlotationMagnetic separationIronstoneHigh intensity

The invention discloses a flotation and separation method of carbonate-bearing iron ore which has fractional steps and is characterized in that the carbonate-bearing iron ore is milled by a ball milling method and pre-separated by adopting low-intensity magnetic separation and high-intensity magnetic separation, and iron ore concentrate that is obtained from the mixed magnetic separation is separated by the flotation technique with fractional steps, which comprises the following steps: in the first step, siderite concentrate is selected under neutral condition by adopting the direct flotation technique; in the second step, the hematite concentrate is selected under strong basicity condition by adopting the reverse flotation technique. The flotation and separation method of the carbonate-bearing iron ore of the invention has smooth process running, the siderite selection in the first step improves flotation environment, and the hematite selection in the second step can finally obtain the hematite concentrate with the iron grade of over 66 percent and the recovery rate of over 62 percent. The flotation and separation method of the carbonate-bearing iron ore of the invention provides an exploiting method of the domestic potential iron ore resources with low iron grade and has important significance to the economical and reasonable exploiting of the carbonate-bearing iron ore.

Owner:ANSTEEL GRP MINING CO LTD +1

Process for producing iron finished ore powder utilizing low grade siderite

InactiveCN1995411AImprove the quality of beneficiationReduce manufacturing costMagnetic separationFlue gasLower grade

The invention discloses a manufacturing technique of iron concentrate powder from low-grade siderite, which comprises the following steps: adopting low-grade siderite as raw material; breaking; sieving; obtaining the sintered ore with grain size at 10-40mm; adopting flue gas as fuel; proceeding magnetic sintering; transmitting FeCO3 in the siderite into Fe3O4; cooling the material below 300 deg. c due to isolating air; quenching; balling the sintered ore; proceeding magnetic sieve, stripping magnet-stripping and magnetic sieve with magnetic strength at 800-1000 oerst; obtaining the product.

Owner:周云富

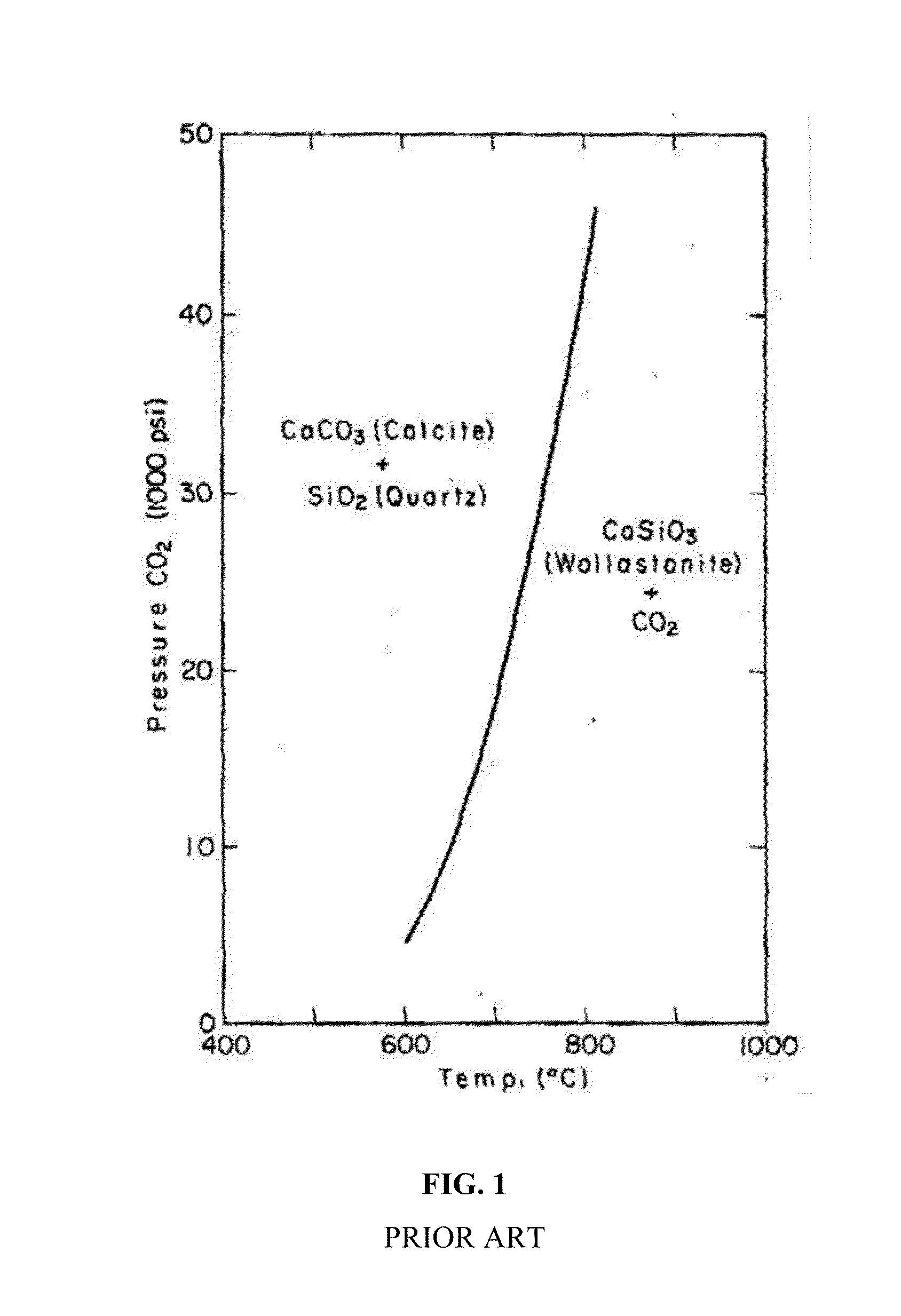

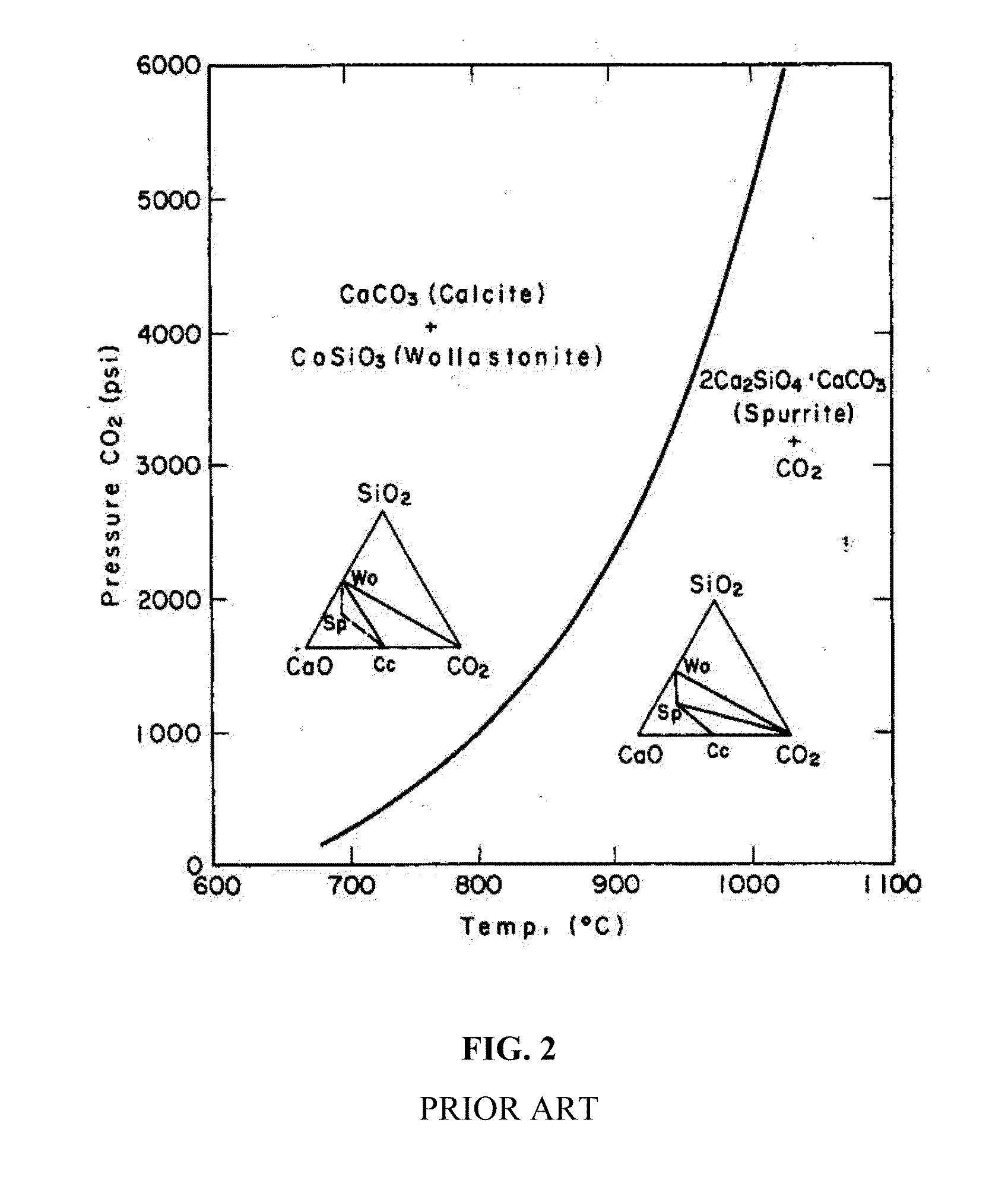

Anticorrosive coatings, processes and uses thereof

InactiveUS20160168720A1Desirable carbon footprintWide applicationSynthetic resin layered productsSolid state diffusion coatingSideriteCarbonation

The invention provides novel methods for anticorrosive protection of iron or steel surfaces, such as on embedded iron or steel reinforcement components in composite materials and on steel surfaces of piles and vessels. The unique siderite coating formed during a carbonation curing possesses excellent anticorrosive properties and is suitable for improving the overall service life of coated objects.

Owner:SOLIDIA TECH

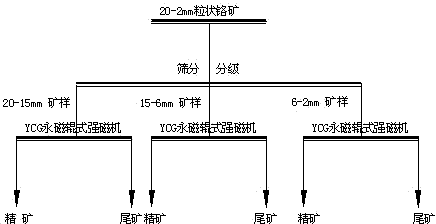

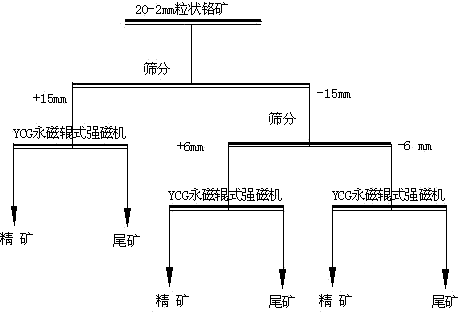

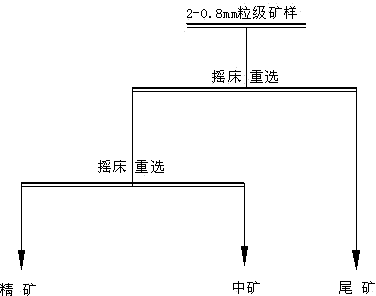

Novel beneficiation technology of high-grade ferrochrome ore

The invention discloses a novel beneficiation technology of high-grade ferrochrome ore. The novel beneficiation technology includes the following technological processes that ferrochrome ore is broken and is screened and classified into the ore of +20 mm fraction and the ore of -20 mm fraction. The ore of the +20 mm fraction receives manual back picking or hotching, large waste ore is thrown, and block concentrate is obtained. The narrow grade of the -20 mm fraction is screened and classified into four fractions, namely the 20-15 mm fraction, the 15-6 mm fraction, the 6-2 mm fraction and the 2-0 mm fraction. For the 20-15 mm fraction, the 15-6 mm fraction and the 6-2 mm fraction, a permanent magnet roller type intensity magnetic separator is used for performing dry intense magnetic separation. The 2-0 mm fraction is further screened and classified into the 2-0.8 mm fraction and the 0.8-0 mm fraction. For the 2-0.8 fraction, a shaker is selected again to obtain shaker gravity concentrate, and for the 0.8-0 mm fraction, a spiral chute and the shaker are used and a united procedure is selected again to obtain the thin-particle gravity concentrate. The novel beneficiation technology can be used for obtaining the concentrate and removing tailings in advance and has the advantage of being lower in energy consumption compared with other technologies. The technology can be used for grading chrome ore and can also be used for grading other weak magnetic iron minerals such as manganese ore, goethite, siderite and limonite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

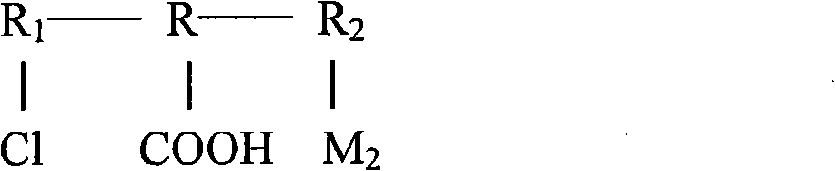

Additive for increasing the density of an oil-based fluid and fluid comprising such additive

A wellbore fluid having an oleaginous phase and an additive for increasing the density of the wellbore fluid. The additive comprises solid colloidal particles coated with a dispersant coated onto the colloidal particle during the comminution process of forming the particles. Exemplary starting materials for the colloidal particles include commonly known weighting agents including barite, calcium carbonate, dolomite, ilmenite, hematite or other iron ores, olivine, siderite, and strontium sulfate as well as mixture and combinations of these and other similar weighting materials. The dispersant in one illustrative embodiment, is selected from carboxylic acids of molecular weight of at least 150 Daltons. Alternatively, the dispersant coating may be made of compounds including oleic acid, polybasic fatty acids, alkylbenzene sulfonic acids, alkane sulfonic acids, linear alpha-olefin sulfonic acid or the alkaline earth metal salts of any of the above acids, and phospholipids as well as mixtures and combinations of these compounds. In another illustrative embodiment the dispersant is a polyacrylate ester. The illustrative polymeric dispersant should have an average molecular weight from about 10,000 Daltons to about 200,000 Daltons.

Owner:MI

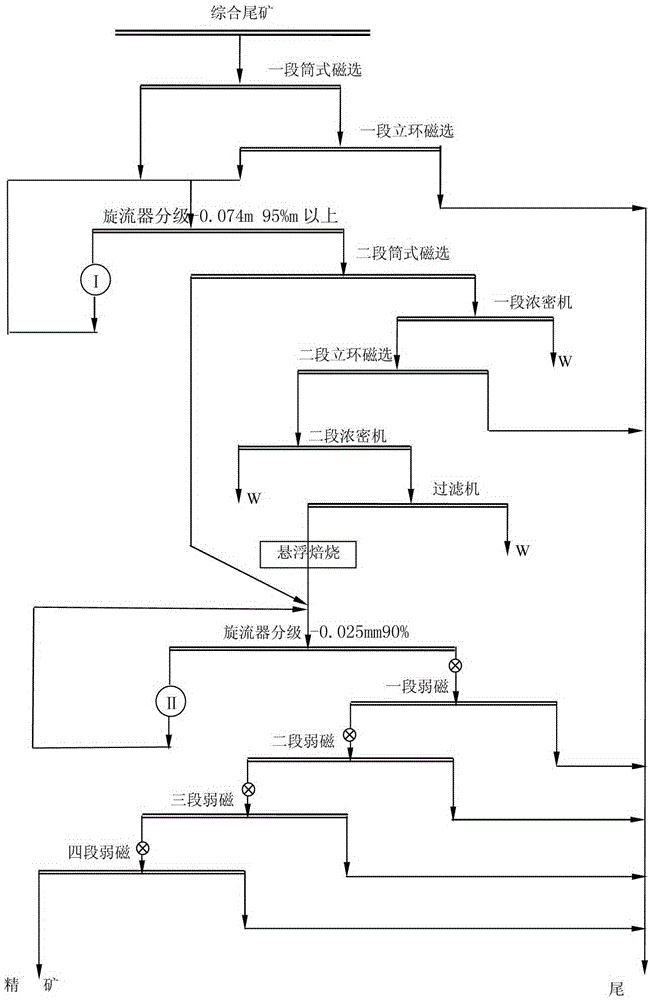

Tailing recovery process adopting preconcentration-roasting-regrinding and magnetic separation method

ActiveCN105233976AEfficient recyclingReduce the processing volume of subsequent grinding and sorting operationsMagnetic separationProcess efficiency improvementMagnetic separatorReducing atmosphere

The invention relates to a tailing recovery process adopting a preconcentration-roasting-regrinding and magnetic separation method. The tailing recovery process is characterized by comprising the following steps: concentrate extraction and tailing discarding are carried out by virtue of a preconcentration process which sequentially comprises first-section drum magnetic separation, first-section vertical ring magnetic separation, ore grinding, second-section drum magnetic separation and second-section vertical ring magnetic separation, so that a rough concentrate grade is increased, and a subsequent operation treatment amount is reduced; suspension roasting is adopted, so that a rotational-flow suspension state of rough concentrate materials in a suspension magnetization roasting furnace under the conditions of a high temperature of 500 DEG C and a reducing atmosphere can be ensured, and micro-and fine-grained hematite, siderite and limonite in the rough concentrate materials are converted to magnetic iron minerals; and meanwhile, multi-section continuous fine separation is carried out by virtue of a regrinding and fourth-section low-intensity magnetic separation machine, thus the good indexes of a concentrate grade of more than 65% and a metal recovery rate of 48-55% are obtained.

Owner:ANSTEEL GRP MINING CO LTD

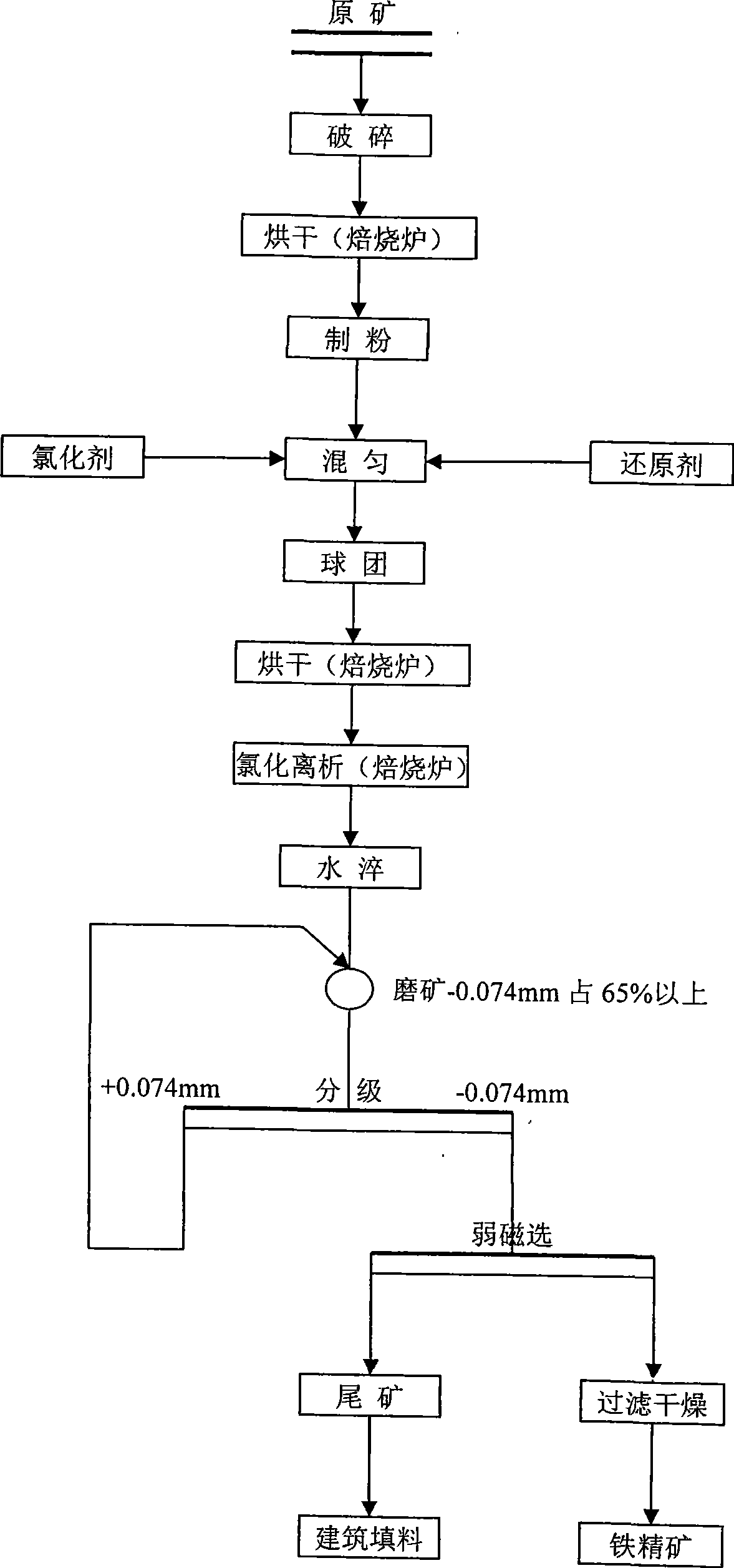

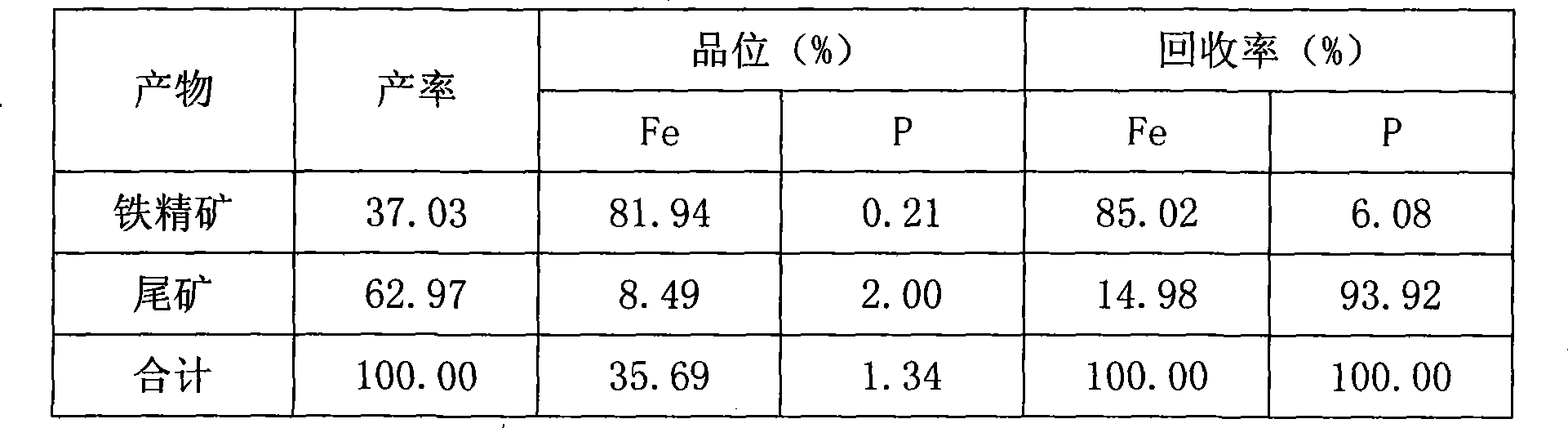

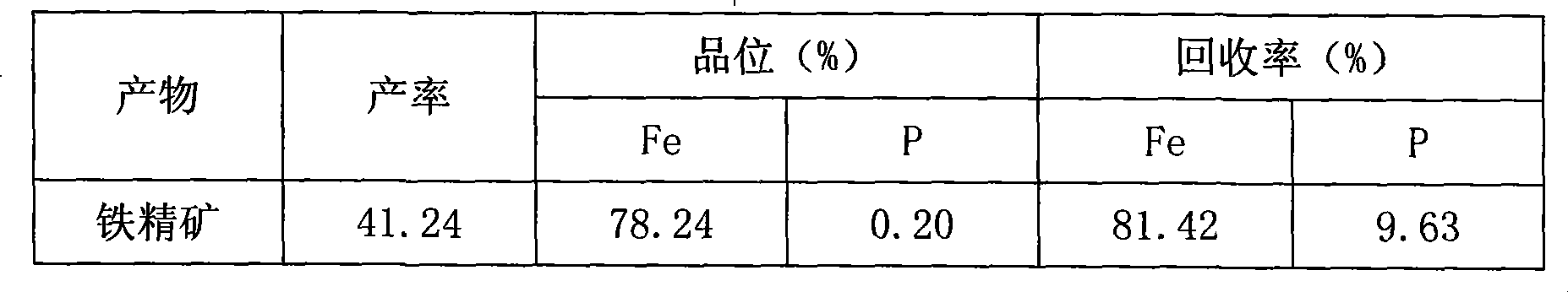

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288AReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

The invention relates to a chloridizing segregation-low-intensity magnetic separation method for reducing phosphorus of a high phosphorus iron ore. A chloridizing segregation-low intensity magnetic separation process is adopted to realize iron increase and phosphorous reduction in the method. A chlorinating agent and a reducing agent coke are added to the high phosphorus iron ore and mixed evenly, then chloridizing segregation roasting is carried out in a roasting furnace; the roasted product is water quenched and ball milled, and then separated by a low-intensity magnetic field magnetic separator, thus being capable of obtaining an iron ore concentrate with the iron grade more than 80%, the iron recovery rate more than 85% and the phosphorous content less than 0.20%. The iron ore concentrate powder can be taken as a raw material for smelting pig iron after being pelletized. Additionally, with regard to high phosphorus iron ores which contain sulfur or contain sulfur and arsenic at the same time, such as hematite, hematite-limonite ore, oolitic hematite-limonite ore, hematite, siderite and the like, the product iron ore concentrate with the sulfur content less than 0.20% and the arsenic content less than 0.04% can also be obtained.

Owner:昆明晶石矿冶有限公司

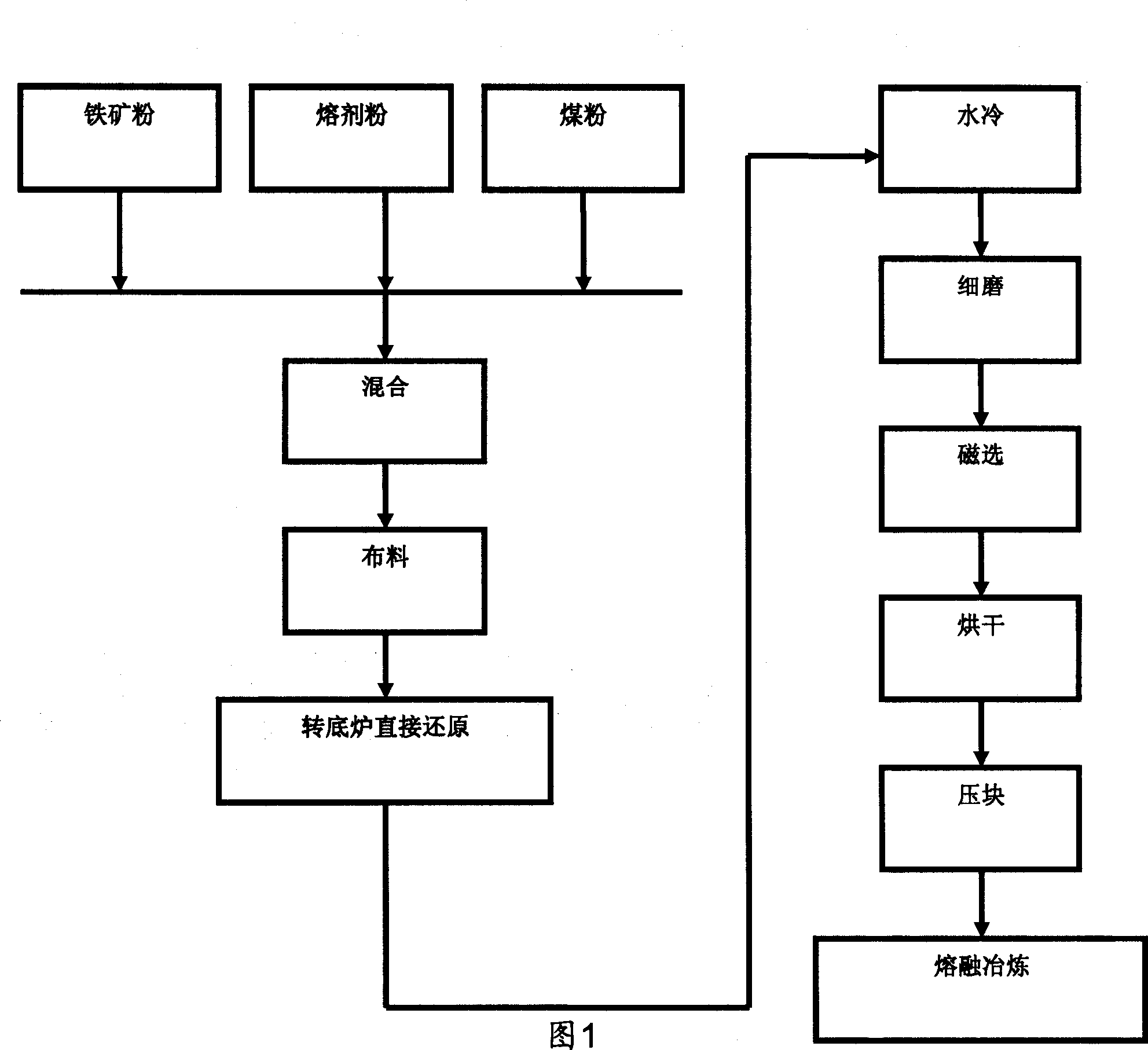

Ore coal, melting ironmaking method after direct reduction-flotation-agglomeration

The invention discloses a method for carrying out direct reduction, sorting, agglomeration, smelting and ironmaking on ore and coal. Firstly, certain amount of the ore, the coal and a solvent are mixed, are placed in a rotary hearth furnace and are heated to the temperature of between 1,100 and 1,350 DEG C, are kept at the temperature for 15 to 40 minutes and are directly reduced to obtain a reduced iron material with metallizing rate of between 80 and 92 percent; the reduced iron material at high temperature of between 800 and 1,100 DEG C is directly transported into water, is cooled and is subjected to fine grinding and sorting; and the iron material after the fine grinding and sorting is subjected to drying and agglomeration by high-temperature oxygen-lost exhaust gas and finally is transported into a submerged arc furnace or other smelting equipment for carrying out slag-iron separation and molten iron production. The method has a simple process, short flow and high efficiency, needs no coke and is suitable for low-grade ore and non-blast furnace ore which is difficult to be used by the prior blast furnaces, such as oolitic hematite, ultrafine particle hematite, limonite, siderite and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS7449431B2Photosensitive materialsScale removal and water softeningVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the comminution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these-and other similar solids.

Owner:MI

Additive for increasing the density of a fluid for casing annulus pressure control

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:M1 LIMITED

Siderite/sulfur biofilter tank and method for simultaneous removal of nitrogen and phosphorus in water by using same

ActiveCN107512771AThe effect of nitrogen and phosphorus removal is remarkableWidely distributedWater contaminantsWater/sewage treatmentElectron donorNitrifying bacteria

The invention discloses a siderite / sulfur biofilter tank and a method for simultaneous removal of nitrate nitrogen and phosphorus in water by using the same, and belongs to the field of sewage deep treatment. The method comprises the following steps: (1) preparation and construction of a biofilter tank packing; (2) startup of the biofilter tank; and (3) operation of the biofilter tank. In the method, sulfur autotrophic denitrifying bacteria take sulfur as electron donors, nitrate in water is reduced into nitrogen gas, and nitrate nitrogen in the water is removed; siderite provides an inorganic carbon source for supporting performing of autotrophic denitrifying reaction and simultaneously releases iron ions for chemical removal of phosphorus, so that the simultaneous denitrification and phosphorus removal of the filter tank is realized. The biofilter tank has the advantages of simple structure, convenient start-up, stable operation, high efficiency of denitrification and phosphorus removal, and is suitable for deep treatment of sewage.

Owner:NANJING UNIV +1

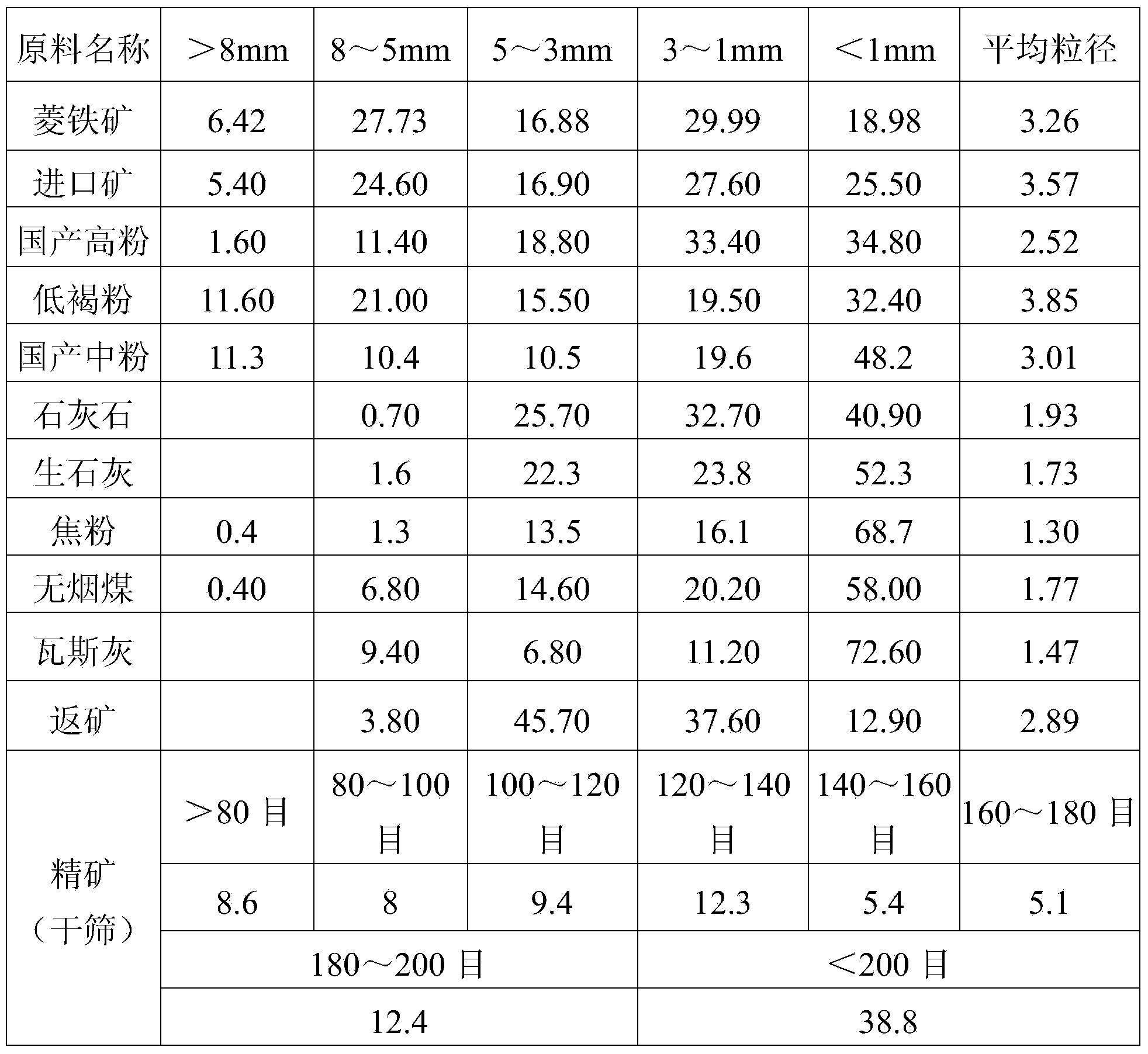

Method for sintering vanadium/titanium magnetite concentrate and siderite

The invention discloses a method for sintering a vanadium / titanium magnetite concentrate and siderite, which comprises the steps as follows: crude fuel materials are prepared, and comprises siderite, iron ore, a flux and fuel materials; crude ore of the siderite is processed, the content of one kind of siderite with a particle grade greater than 8 mm is less than 10 wt% of the total siderite, and the content of another kind of siderite with a particle grade less than 1 mm is less than 20 wt% of the total siderite, so that the siderite is obtained, and the iron ore comprises the vanadium / titanium magnetite concentrate and other kind of iron ore; the crude fuel materials are mixed, on the basis of the total weight of the crude fuel materials, the weight percent of the siderite is 1wt%-10wt%, the weight percentage of the vanadium / titanium magnetite concentrate is 50wt%-60wt%, in addition, the weight percentage of the iron ore is 10wt% to 30wt%; mixing, material distribution, ignition and sintering are performed. According to the method for sintering the vanadium / titanium magnetite concentrate and the siderite, low-quality siderite and low-quality vanadium / titanium magnetite concentrate are used and sintered, as a result, the resource shortage can be remitted, the raw material cost is lowered, and the level of main technical indexes is kept.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

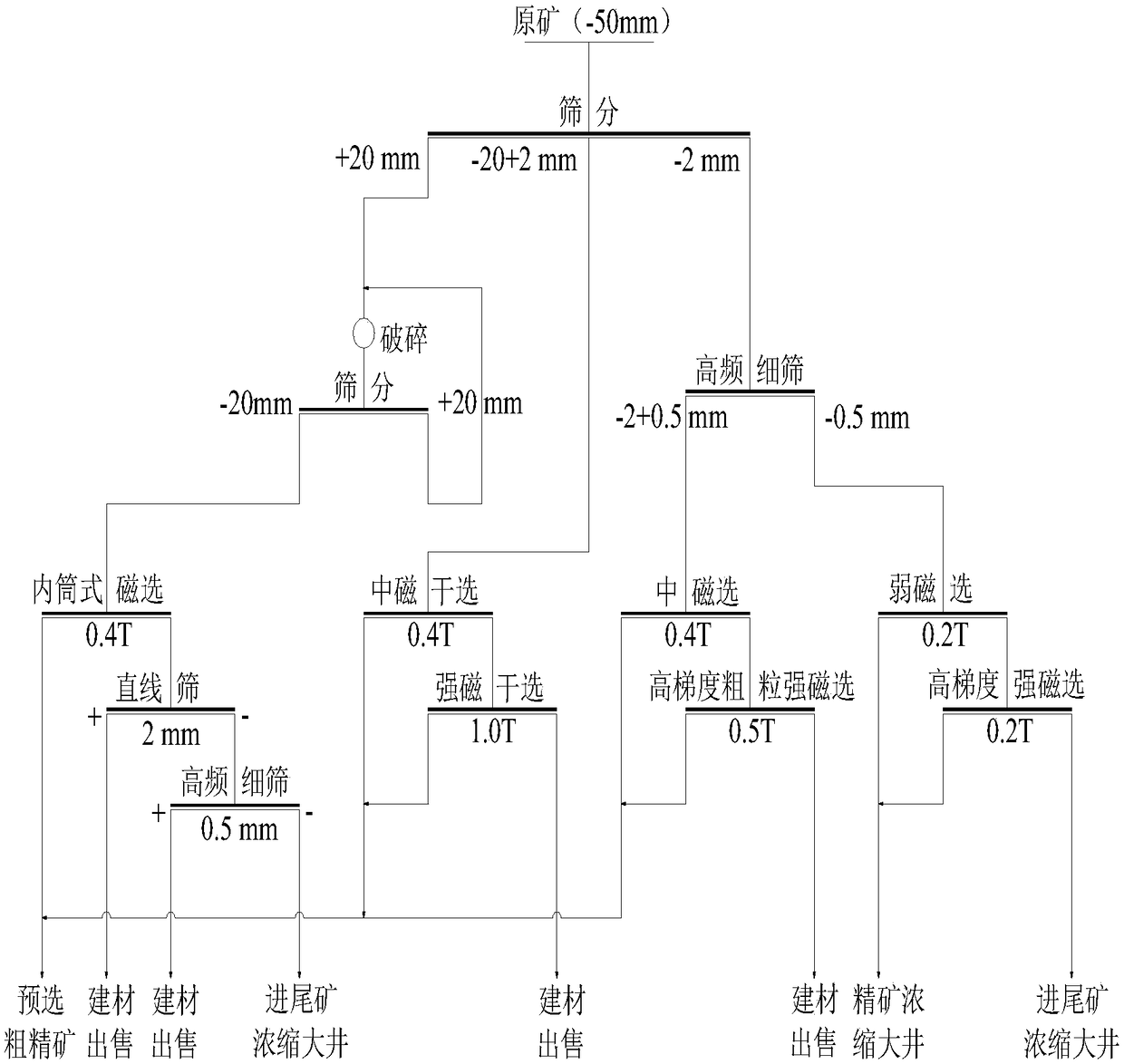

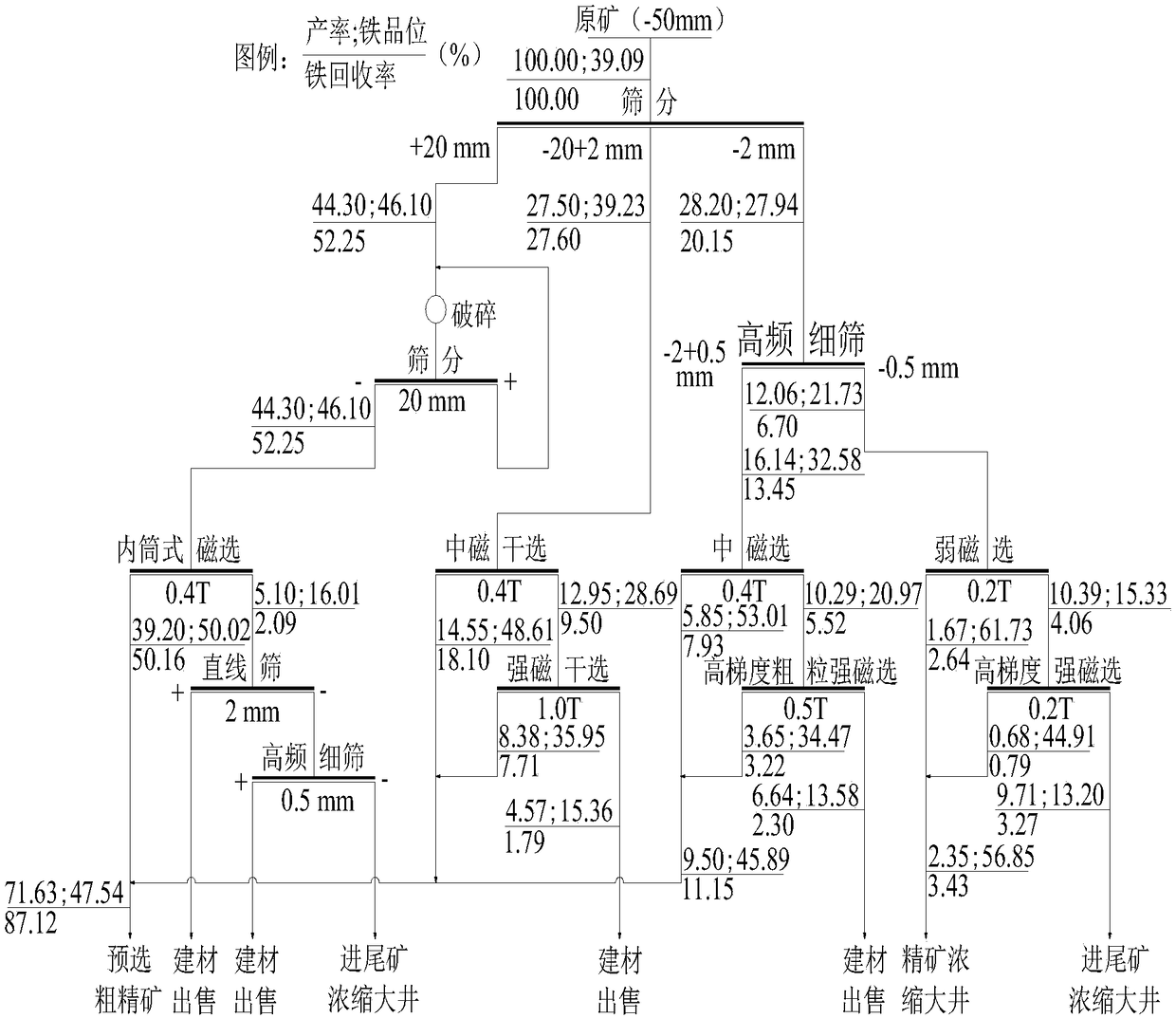

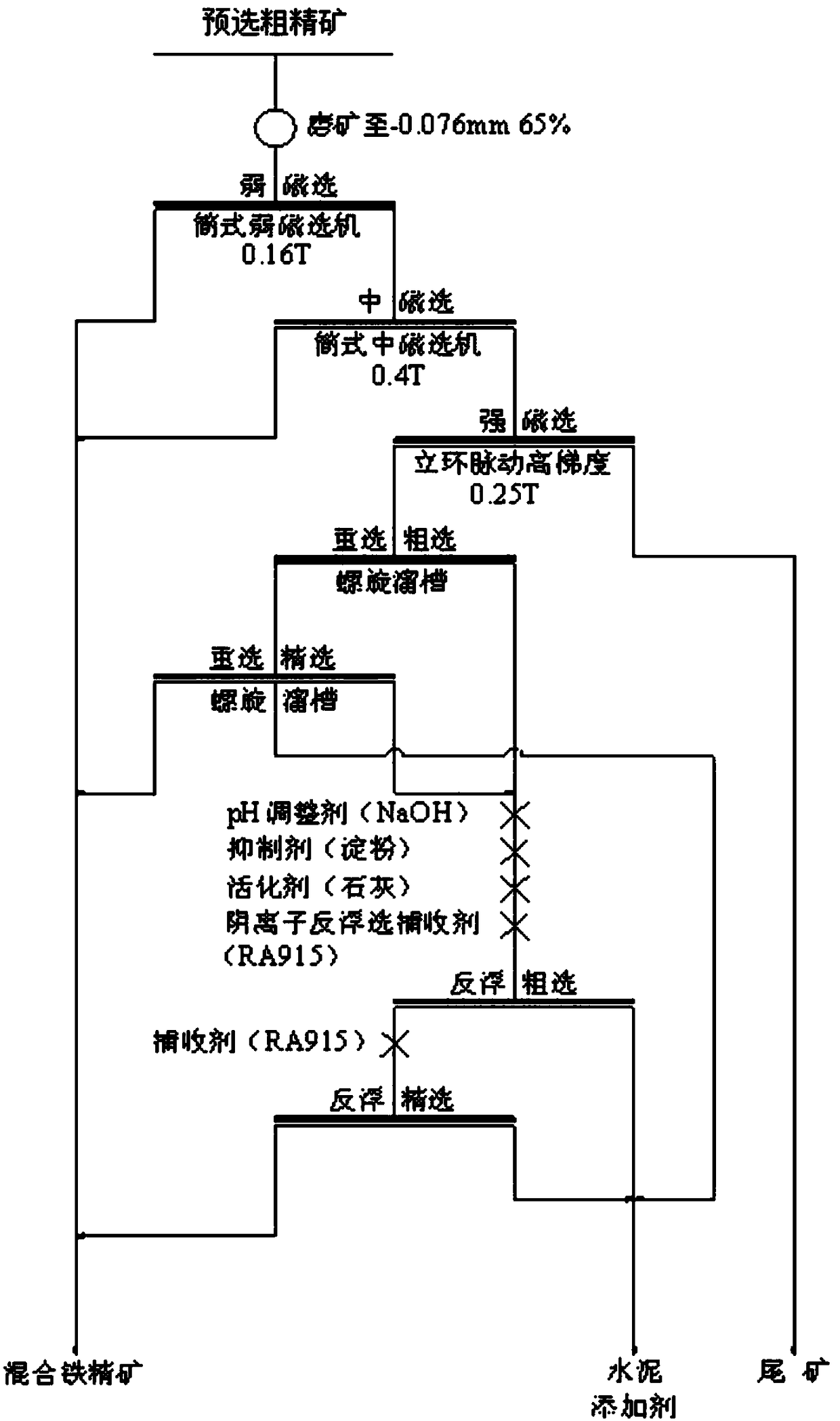

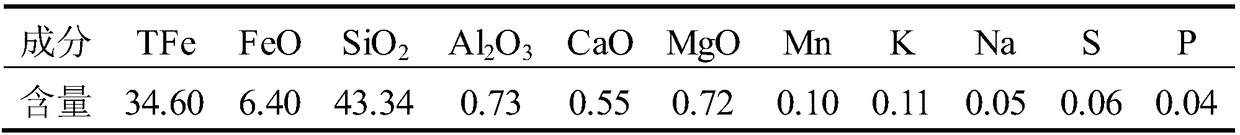

Novel grading prescreening precise separation method for mixed iron ore including magnetic iron ore, hematite and siderite

The invention discloses a novel grading prescreening precise separation method for mixed iron ore including magnetic iron ore, hematite and siderite. Intermediate smashed products with the particle size being -50 mm are subjected to grading prescreening at first, prescreened rough concentrate, prescreened fine-particle iron ore concentrate and building material products with different particle grades are obtained; the prescreened rough concentrate is subjected to ore grinding and grading closed loop operation after being precisely smashed, low intensity magnetic separation concentration (C1),intermediate intensity magnetic separation concentration (C2), gravity concentrate (3) and reverse flotation iron ore concentrate (C4) are obtained, and a cement additive product is obtained. The novel grading prescreening precise separation method has the advantages that the adaptability is high, the energy saving effect is good, economic benefits are large, the separation precision and the resource comprehensive utilization rate are high, and the discharging amount of tailings is small, the method is especially suitable for screening of the mixed iron ore including the magnetic iron ore, thehematite and the siderite, wherein the TFe grade is 35.0%-42.0%, the hematite / limonite difficult to screen accounts for 19-25% of the total amount of the mixed iron ore, and the siderite accounts for17-23% of the total amount of the mixed iron ore.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

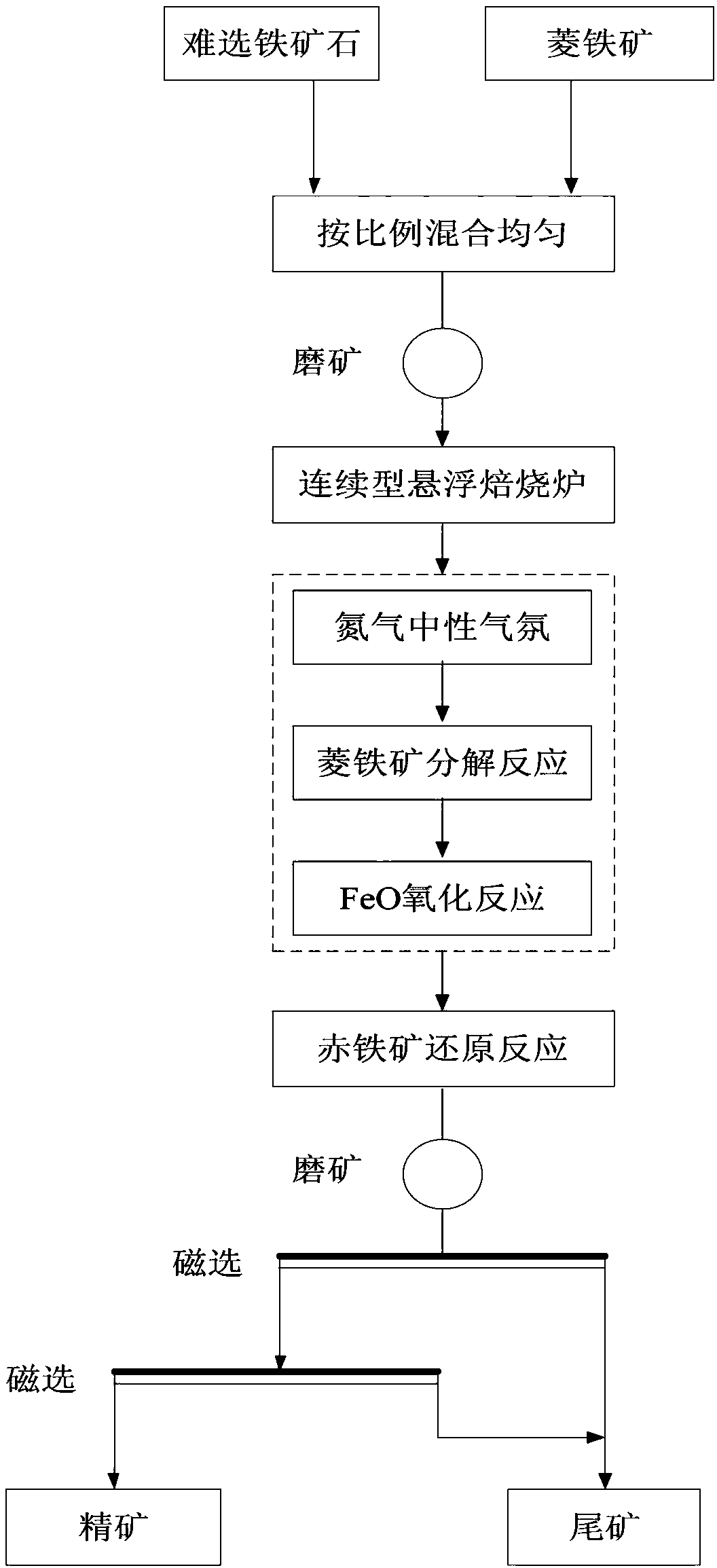

Method for producing iron ore concentrate through suspension magnetizing roasting with siderite as reducing agent

The invention provides a method for producing iron ore concentrate through suspension magnetizing roasting with siderite as a reducing agent, and belongs to the technical field of mineral processing.A continuous type suspension roaster is adopted for suspension roasting at the temperature ranging from 500 DEG C-600 DEG C for 60 s to 100 s after preheating is carried out, CO decomposed from the siderite is used for restoring materials, two-stage magnetic separating is then adopted, and the high-grade iron ore concentrate is obtained. By means of the method, the CO decomposed from the sideritein ore is sufficiently used for restoring feebly magnetic iron mineral such as hematite and limonite into magnetite, carbon emission and environmental pollution which are caused by use of a coal reducing agent are eliminated, and a new way is developed for cleaning and efficient using of iron ore difficult to separate.

Owner:NORTHEASTERN UNIV

In-situ remediation method for nitrate pollutions in groundwater

ActiveCN104129850AReduce solubilityDoes not change the compositionTreatment with anaerobic digestion processesContaminated groundwater/leachate treatmentParticulatesAnaerobic microorganisms

The invention discloses an in-situ remediation method for nitrate pollutions in groundwater, which is characterized by comprising the steps of crushing low-grade siderite ores, and screening the obtained object so as to obtain particles with a particle size of 0.1-1 mm; excavating a groove in an aquifer perpendicular to the flow direction of groundwater, and filling the siderite particles into the groove so as to build an underground permeable wall; and injecting nitrate-dependent iron oxidizing bacteria liquid for oxidizing siderites and reducing nitrates in the presence of iron oxidizing bacteria of anaerobic microorganism depended nitrates. New iron oxides also have a function of absorbing other pollutants in purified water.

Owner:HEFEI UNIV OF TECH

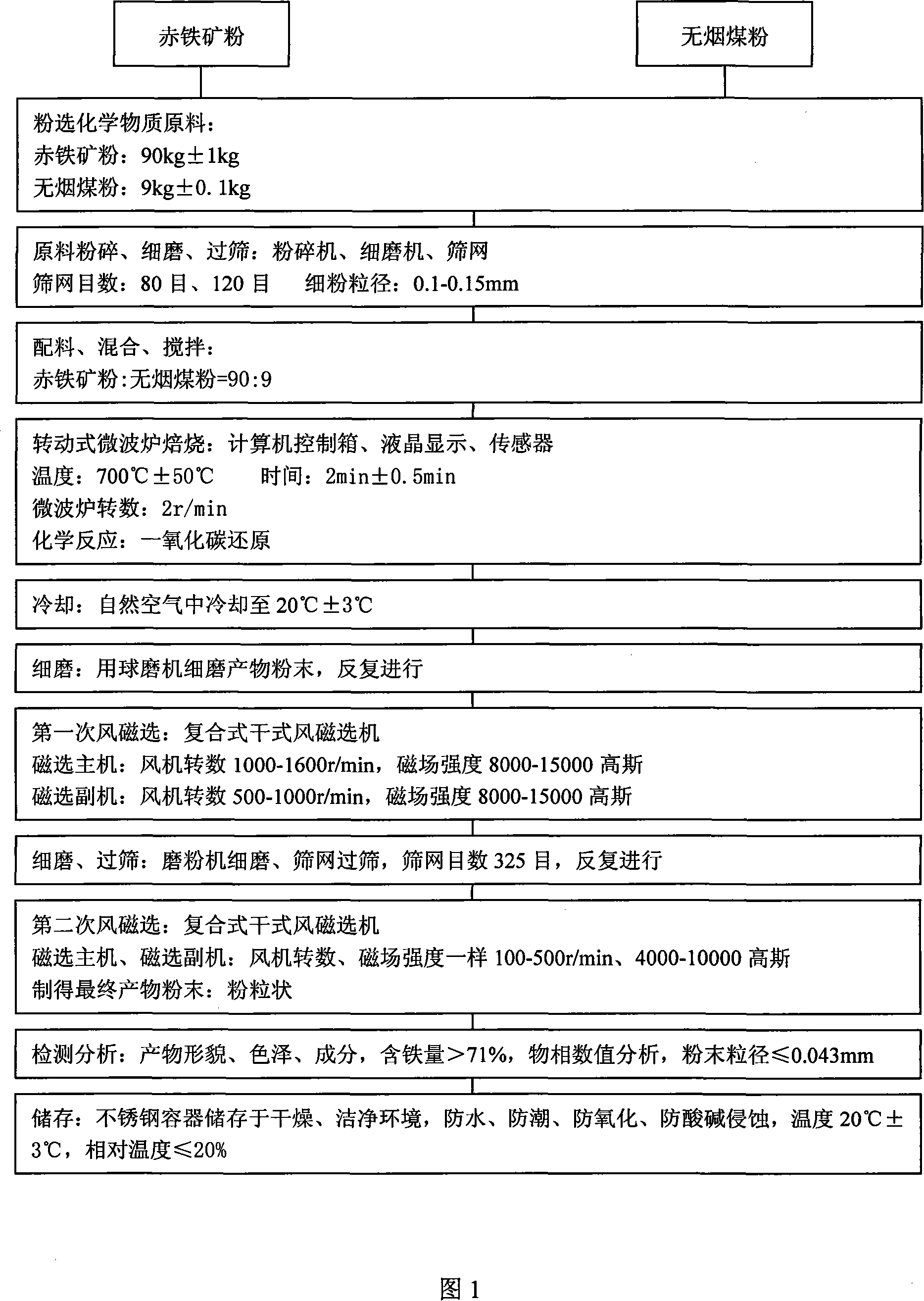

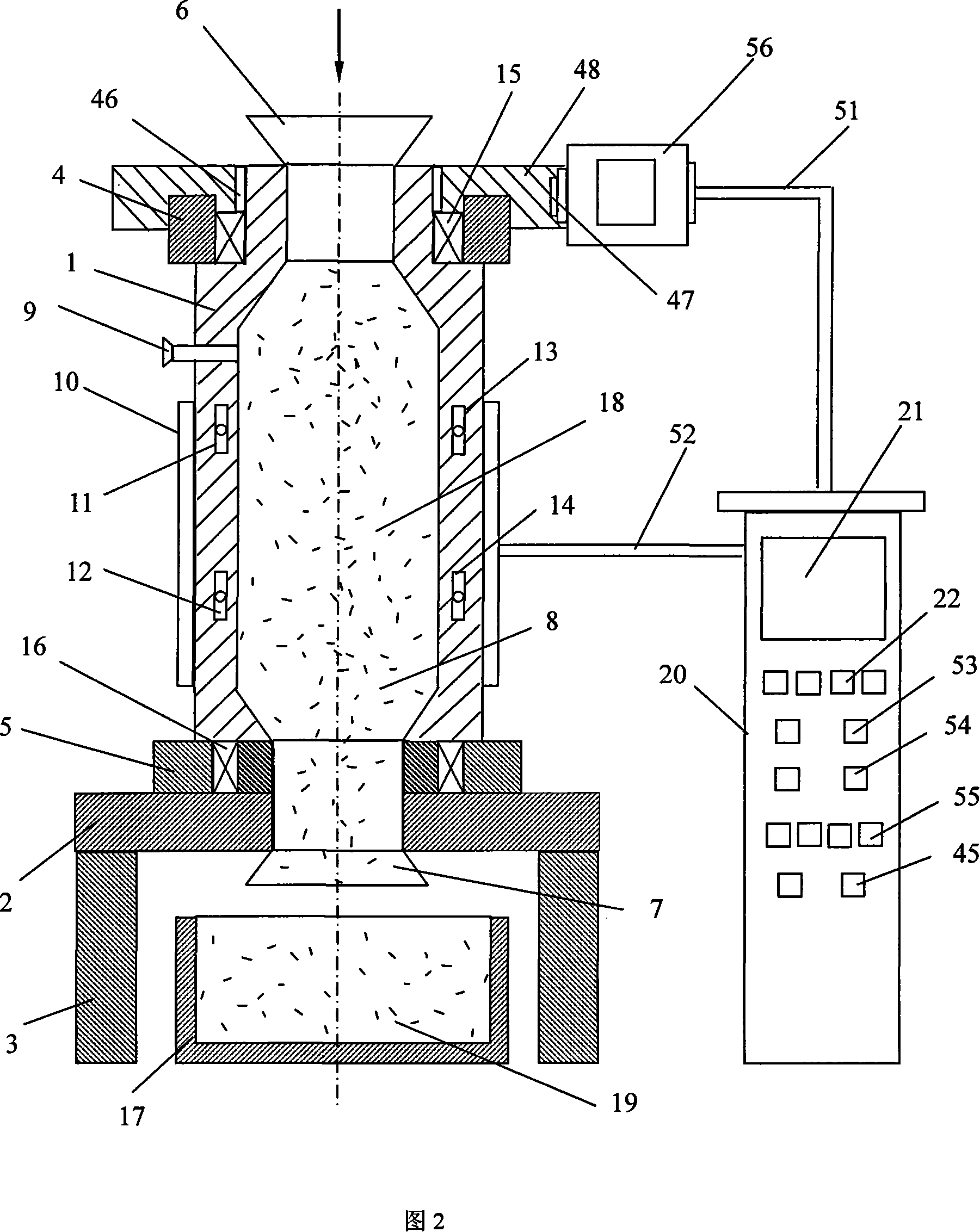

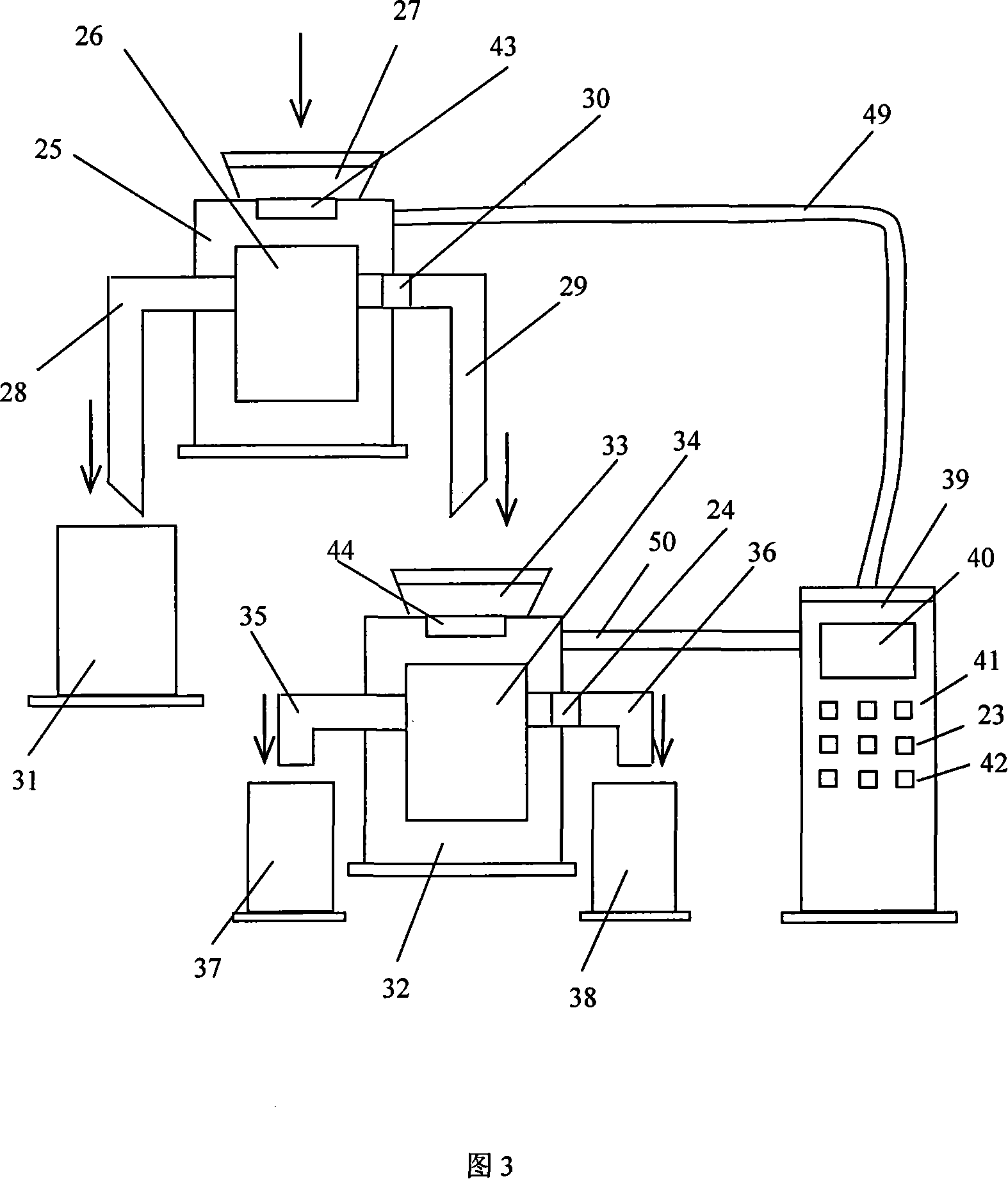

Microwave roasting dry type wind magnetic selection method for hematite powder

The invention relates to a method of microwave roasting dry wind magnetic separation of hematite powder, which is a technology of rotary microwave oven roasting, dry wind magnetic separation and mineral processing and purification adopted to solve the deficiencies of wet mineral separation. The collected hematite powder, along with anthracite powder and under the condition of water-free, is crushed, finely ground, sieved, mixed, stirred, carbon reduced and roasted in a microwave oven at 700DEG C, and finally powder is obtained; afterwards, with the processes of cooling, fine grinding and magnetic separation, the hematite powder with high iron content and high purity is obtained. The method of roasting and wind magnetic separation does not require water washing and filtration, which is characterized by water saving and environmental protection. The method is in particular suitable for mineral dressing of the mining area without water source featuring short process flow, wherein microwave oven roasting, computer-controlled combined type dry wind magnetic separator, liquid crystal display, and sensor for displaying temperature information are clean beneficiation technologies. The method can bring 93-95 percentage yield rate and manufacture the powder with 71 percent iron content. The method can also be used for beneficiation of limonite and siderite.

Owner:TAIYUAN UNIV OF TECH

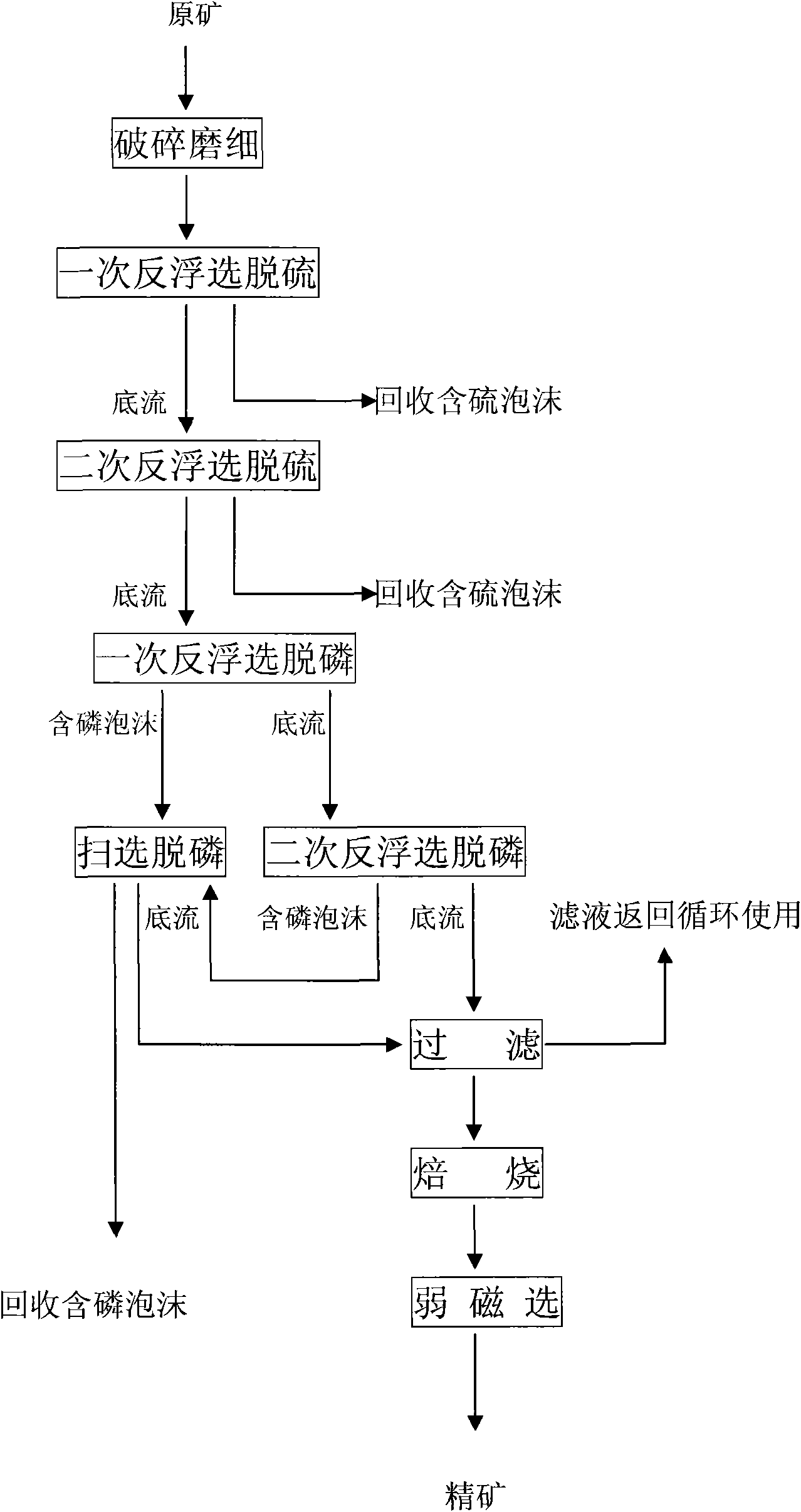

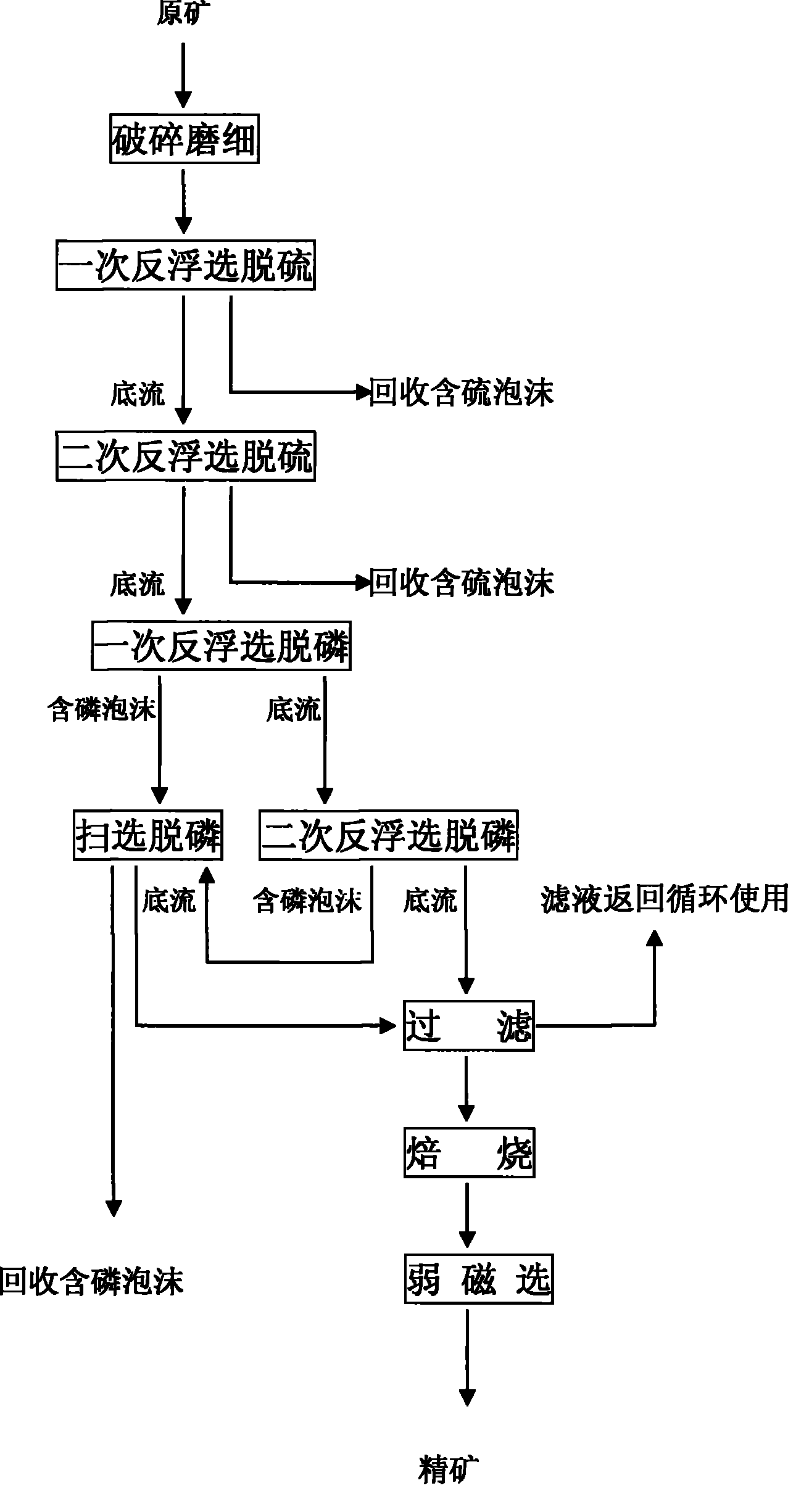

Comprehensive processing method of high phosphorus-sulfur siderite

InactiveCN101862701ASolve the contradiction between supply and demandHigh sorting qualityFlotationWet separationSideriteSulfur containing

The invention provides a comprehensive processing method of high phosphorus-sulfur siderite, which is characterized in that high-quality iron ore concentrate with grade of iron reaching more than 60 percent and recycling rate of iron reaching more than 70 percent is obtained through ore grinding, reverse-floatation desulphurization, reverse-floatation dephosphorization, scavenging dephosphorization, reduction roasting and ore grinding and low-intensity magnetic separation; moreover, the iron ore concentrate contains less than 0.08 percent phosphorous, less than 0.30 percent sulfur and less than 8 percent silicone, so the high phosphorus-sulfur siderite resource is reasonably utilized, and the problem of the contradiction of the supply and the demand of the iron ore resource can be thoroughly solved. The method is free from discharging any waste, the floated filter liquid is completely returned to be recycled in the process procedures, the floated sulfur-contained and phosphorous-contained foam is processed after being recycled to become valuables; therefore, the process is simple and convenient, the production cost is low, and the selection quality is high.

Owner:KUNMING IRON & STEEL HLDG CO LTD

Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

The invention relates to the production techniques of iron ore concentrate of refractory ore, in particular to a preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore. The method comprises the following steps that firstly, the crushed iron ore is ground into fine ore; then the fine ore is subjected to low-temperature roasting, and during the low-temperature roasting, the fine ore is made to be in a roasting system to be preheated and roasted; the roasted ore enters a cooling system to be cooled; and then the cooled roasted ore is subjected to size mixing and sent to a magnetic separation system to be separated, and high-grade iron ore concentrate is obtained through separation. According to the method, the process is simple, the temperature and air flow are distributed uniformly, control is easy, the automation degree is high, the number of operation components of equipment is small, refractory siderite and limonite can be treated, the magnetizing roast efficiency of the refractory iron ore is high, heat is substantially recycled during roasting, the roasted ore is stable in quality and high in magnetic separation efficiency, and the technical indexes that the grade of the iron ore concentrate is larger than 60%, and the iron recycling rate is larger than 85% can be achieved.

Owner:湖北华方装备有限公司

Composition of base fluid and polymeric dispersing agent-absorbed polymer-coated colloidal particles

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:M1 LIMITED

Singleness siderite full flotation mineral separation method

InactiveCN101264465AEfficient separationStrong physicochemical adsorptionFlotationIronstoneChemical adsorption

The invention relates to a single siderite all-flotation mineral separation method, belonging to the technical field of iron ore separation of mineral processing engineering, which adopts all-flotation technological process to process the single siderite ore with small amount of hematite-limonite, magnetic pyrite, pyrite and other ores. The processing method comprises the following steps: (1) the material is crushed below 3mm, mixed evenly and ground with liquid-solid weight ratio 1:2 and 75% to 95% of particle size of 0.074 mm, and (2) one roughing and triple cleaning are processed and the siderite concentrate ore with grade TFe larger than or equal to 38% and 75 to 86% of the iron recovery is acquired. The single siderite all-flotation mineral separation method has the advantages of adopting the siderite collecting agent for collecting, enabling the strong physico-chemical adsorption between the siderite surface and the collecting agent surface, and realizing the effective separation of the siderite and other ores.

Owner:KUNMING UNIV OF SCI & TECH +1

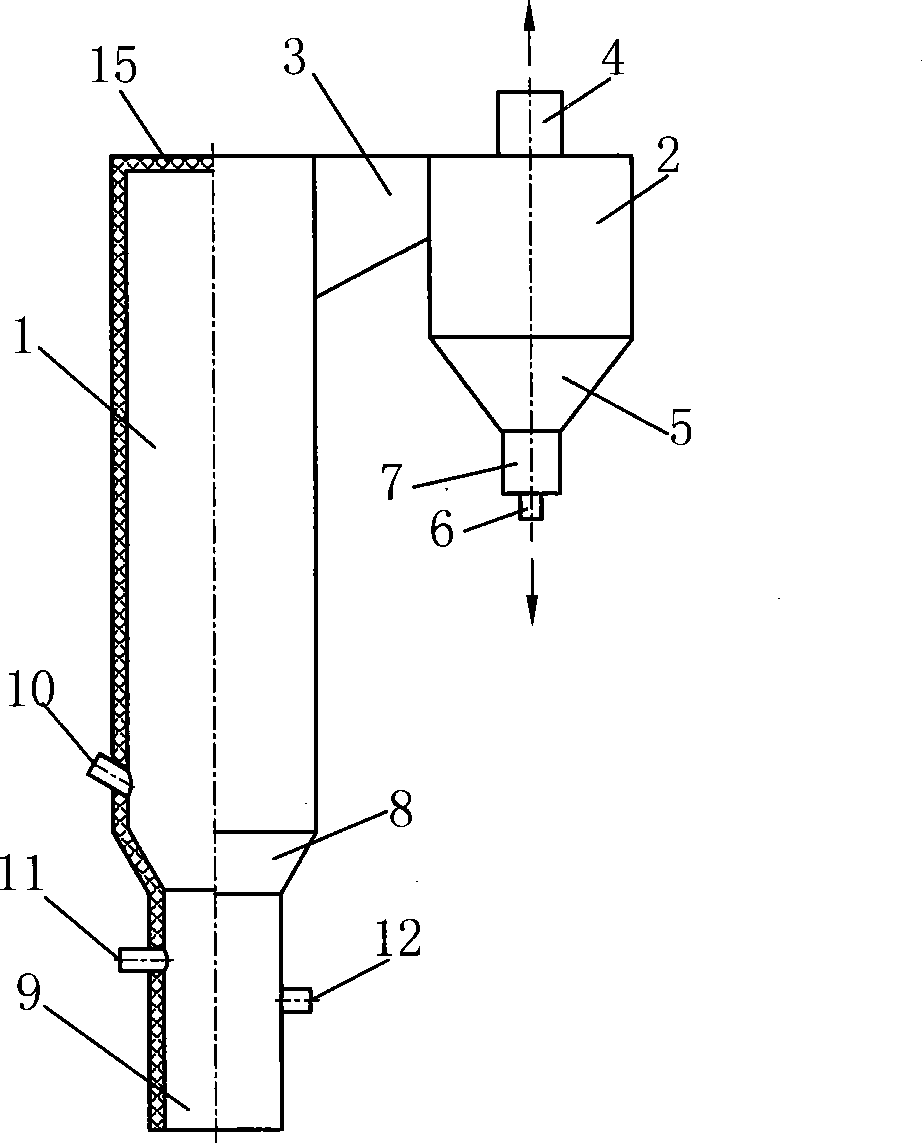

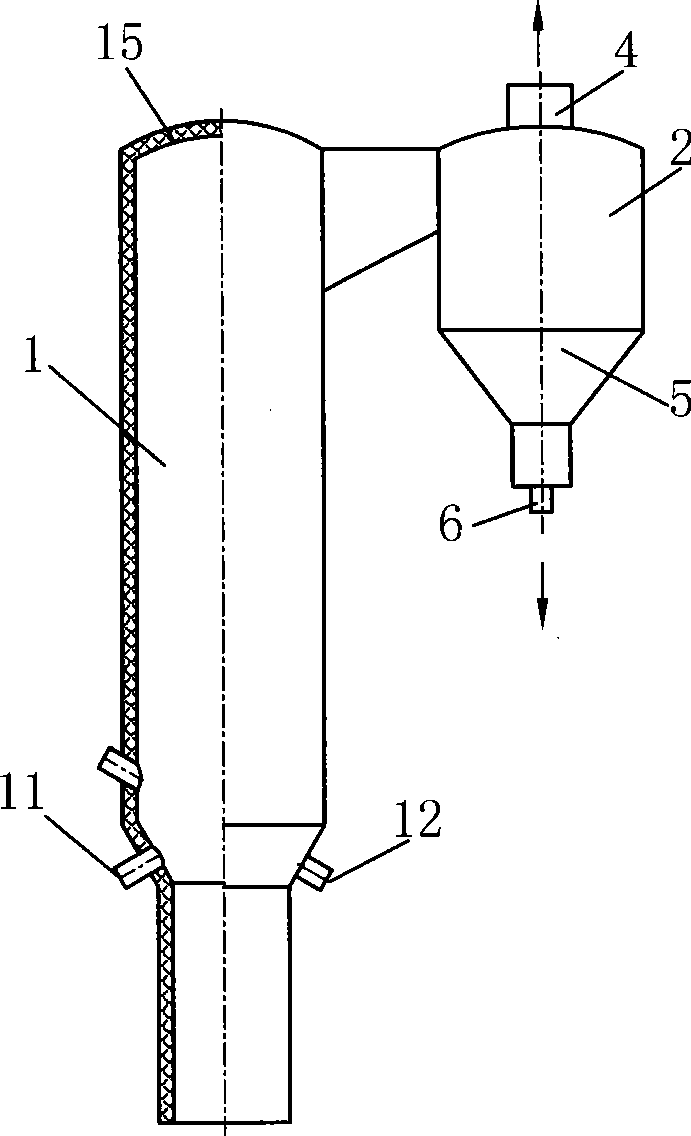

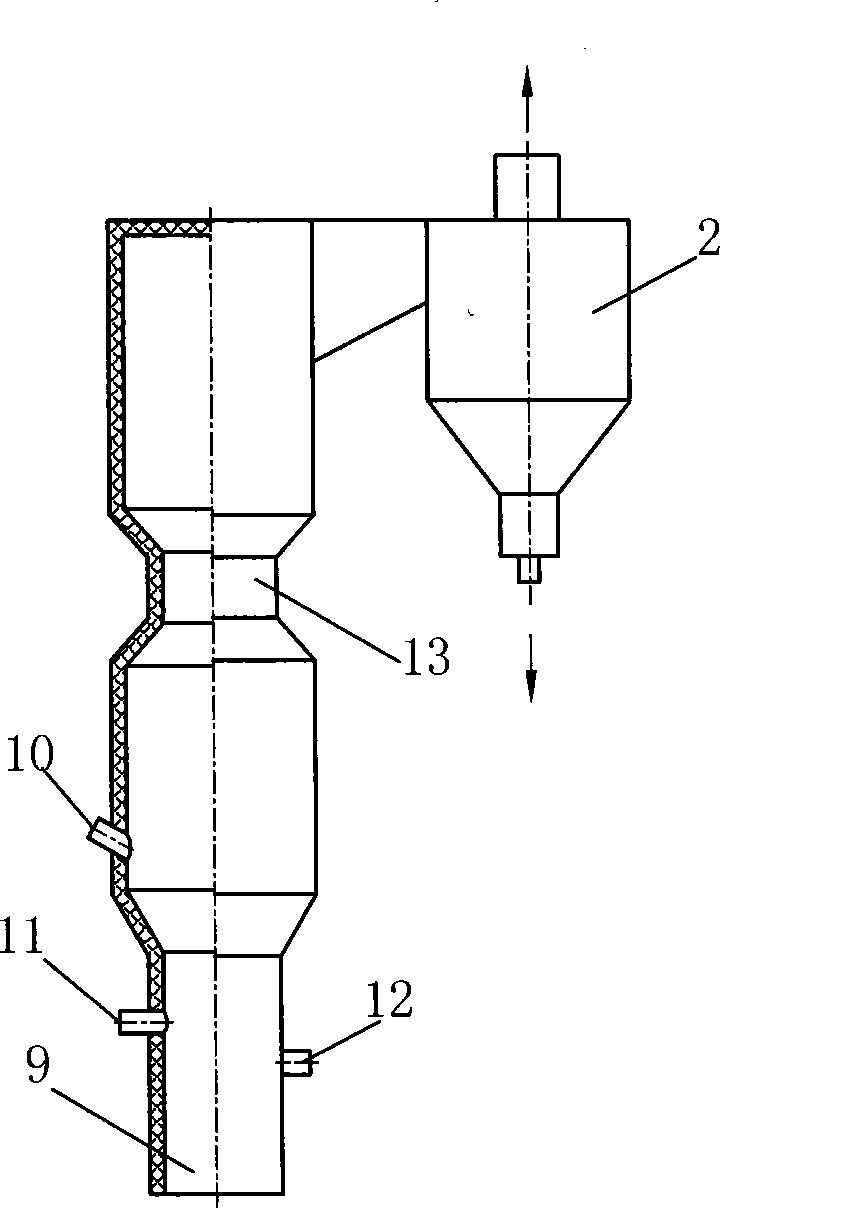

Suspending magnetization roasting furnace

InactiveCN101392989AIncrease magnetic susceptibilityFluidised-bed furnacesMagnetic susceptibilityRed mud

The invention provides a suspension magnetizing roasting furnace, which consists of a furnace body and a cyclone separator, wherein an upper part discharge port of the furnace body is fixedly connected with a feeding port of the cyclone separator; a top cover of the cyclone separator is fixedly provided with an exhaust pipe, the lower end of a conical platform body of the cyclone separator is fixedly connected with a material discharge pipe, the lower end of the furnace body is vertically provided with a conical platform body and a vertical guide pipe which are fixedly connected with each other into a whole; and the furnace wall of the lower part of the cylindrical furnace body is provided with the feeding port, a heat supply port of an auxiliary combustor and a heat supply port of a heat supply roaster respectively. The furnace has the advantages: 1. the furnace is widely applied to the magnetized roasting of various refractory minerals such as iron-bearing mineral, siderite, complex multi-phase iron ore and the like and wastes such as ore tailings, slag, red mud and the like; 2. powdery materials are suspended in air flow for quick heat transfer and deep reducing reaction, and the magnetic susceptibility of the obtained roasted product is high, and better than that of the prior equipment; and 3. the equipment is easy for mass production, and the throughput of one furnace can reach 2 million tons per year, which is few times higher than that of other known equipment.

Owner:SHENYANG XINBO IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com