Patents

Literature

606 results about "Comminution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comminution is the reduction of solid materials from one average particle size to a smaller average particle size, by crushing, grinding, cutting, vibrating, or other processes. In geology, it occurs naturally during faulting in the upper part of the Earth's crust. In industry, it is an important unit operation in mineral processing, ceramics, electronics, and other fields, accomplished with many types of mill. In dentistry, it is the result of mastication of food. In general medicine, it is one of the most traumatic forms of bone fracture.

Acicular calcite and aragonite calcium carbonate

InactiveUS6071336AIncrease costIncrease production costCalcium/strontium/barium carbonatesPigmenting treatmentToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

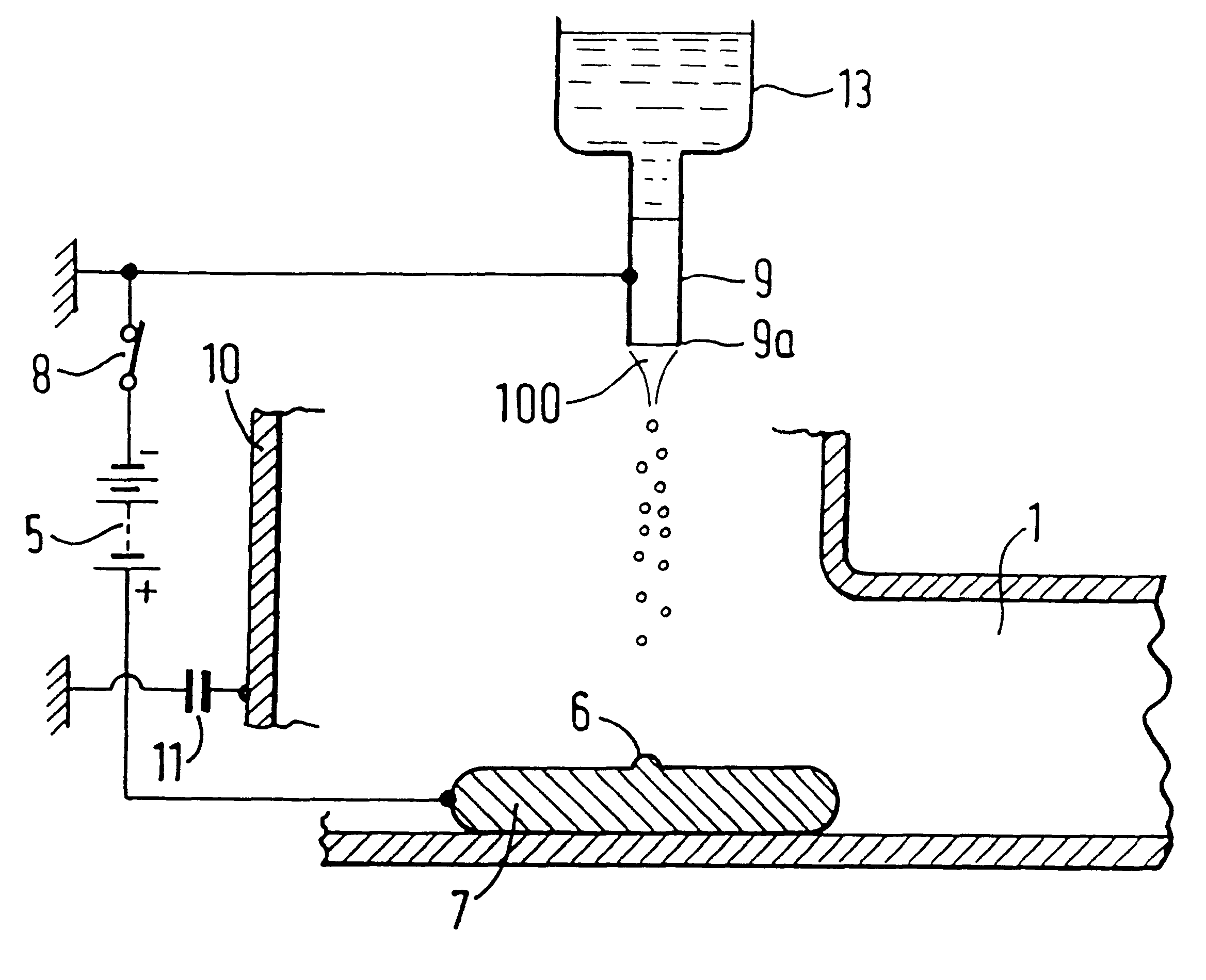

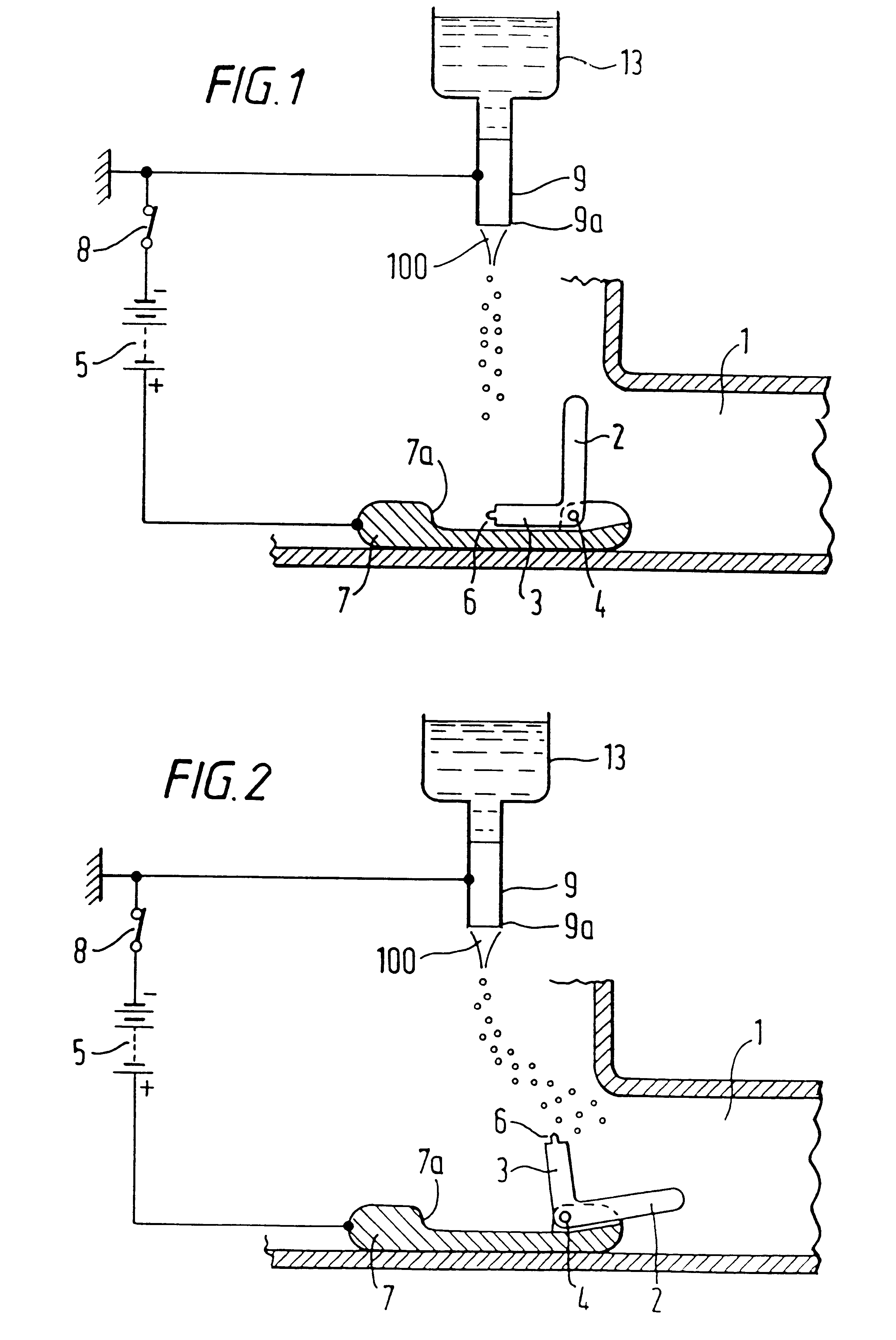

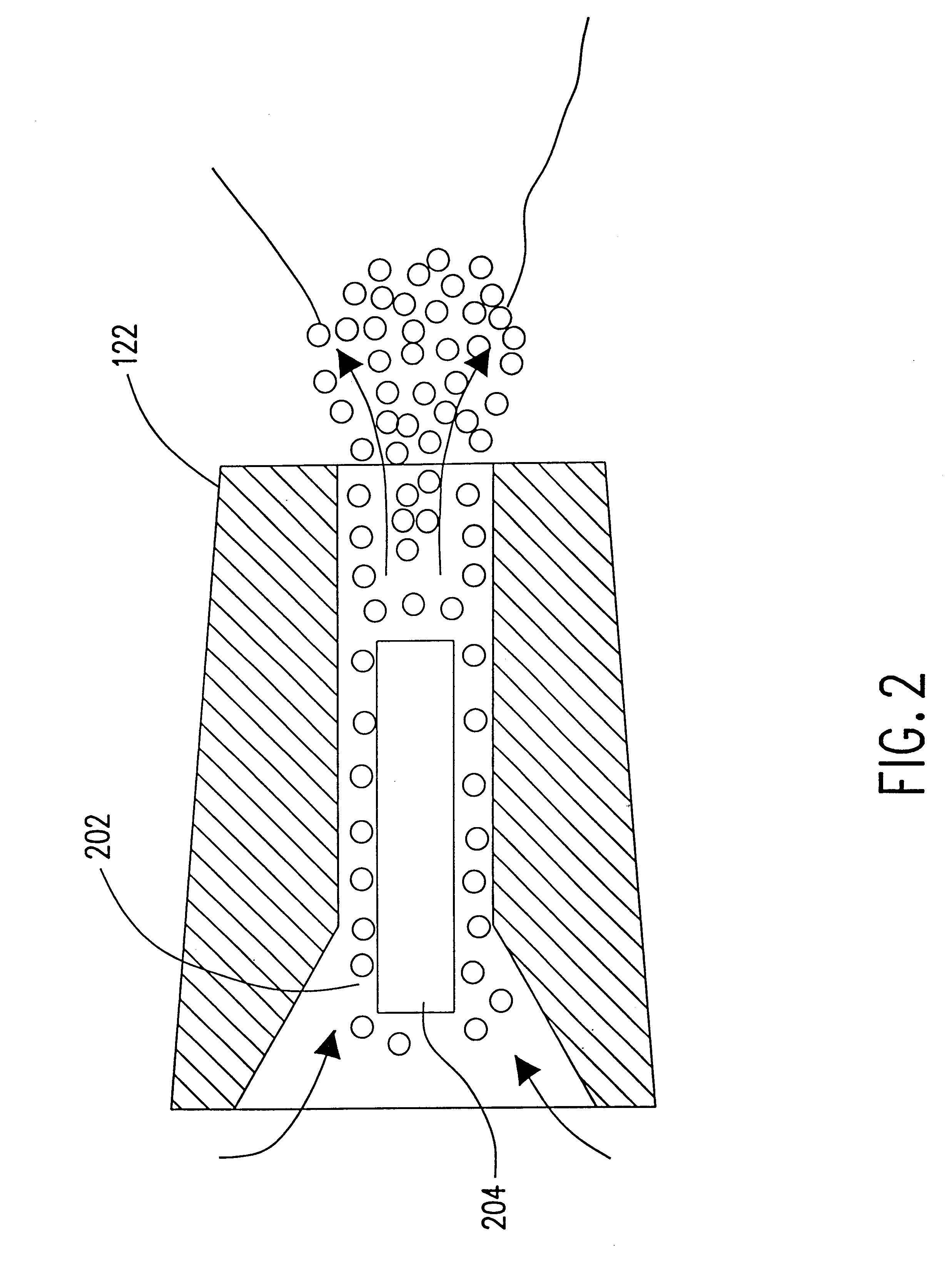

Dispensing device

An inhaler for enabling inhaled administration, has a housing having an outlet duct defining a passageway through which air can be drawn by inhalation on the part of a user. The housing contains a capillary nozzle; a container for containing a quantity of liquid to be supplied to the capillary nozzle; and an electric field controller for applying a voltage to the liquid prior to issue from the container via the capillary nozzle to expose the liquid to an electric field to cause comminution of the liquid emerging from the capillary nozzle to product a spray of electrically charged droplets such that upon inhalation by the user, electrically charged droplets for the deposition in the user's airways.

Owner:BATTELLE MEMORIAL INST

Device for comminuting dry ice granules, and dry ice dispensing arrangement having such a device

The invention relates to a device for comminuting dry ice granules, comprising a housing having a flow channel for dry ice granules which can be applied, by means of compressed gas, to a surface to be cleaned, and also comprising a first comminution member for comminuting the dry ice granules which are to be dispensed. In order to provide a device of this kind with which different degrees of comminution of dry ice granules can be achieved in a simple manner, it is proposed according to the invention that the device has at least one second comminution member which can be disposed in the housing in a position in which a total degree of comminution, which is greater than the individual degree of comminution which can be achieved solely by the first comminution member, can be achieved in combination with the first comminution member. A dry ice dispensing arrangement for dispensing a mixture of compressed gas and dry ice granules is also proposed, having a device of the above kind.

Owner:ALFRED KARCHER GMBH & CO KG

Method of creating ultra-fine particles of materials using a high-pressure mill

Owner:CORNERSTONE TECH

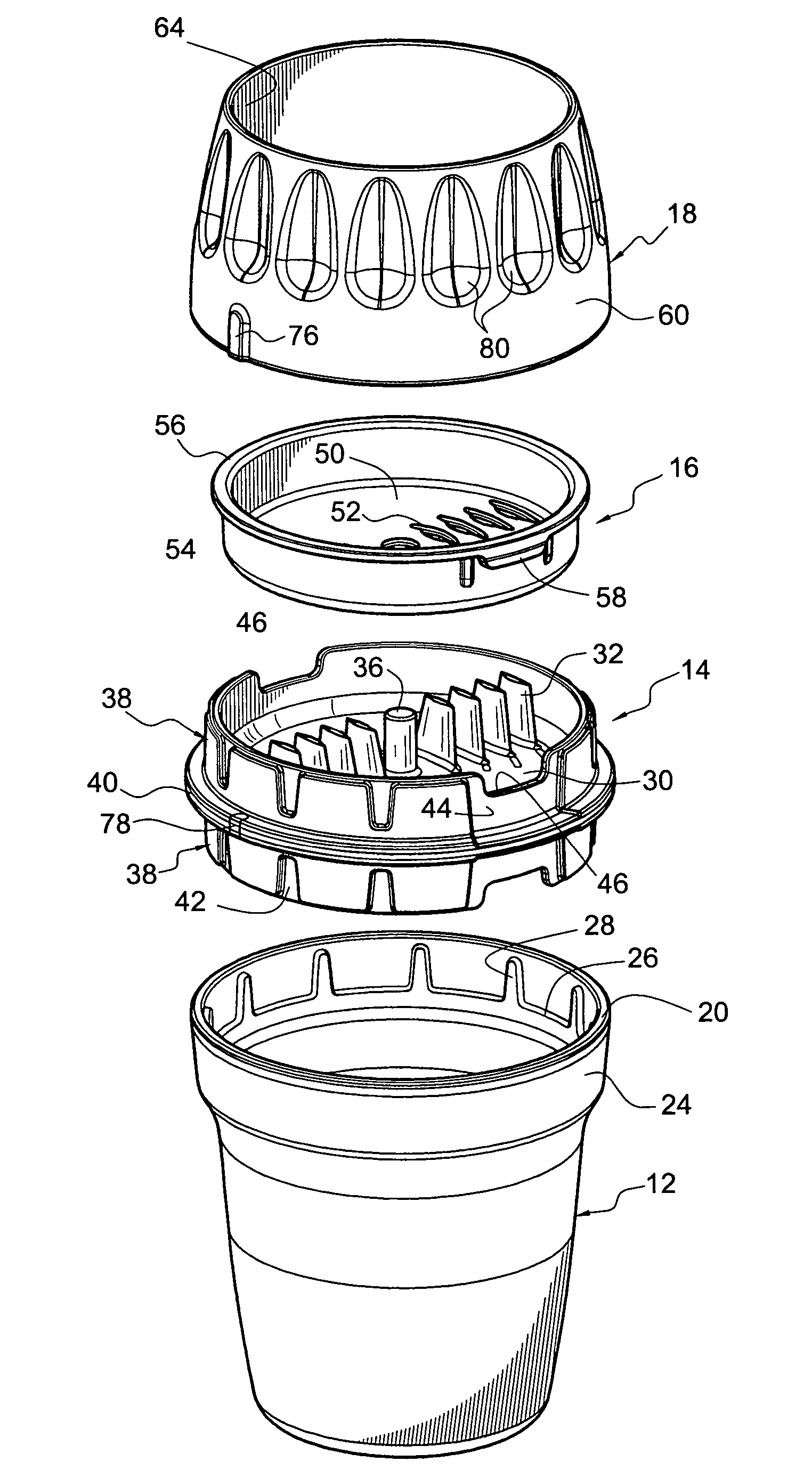

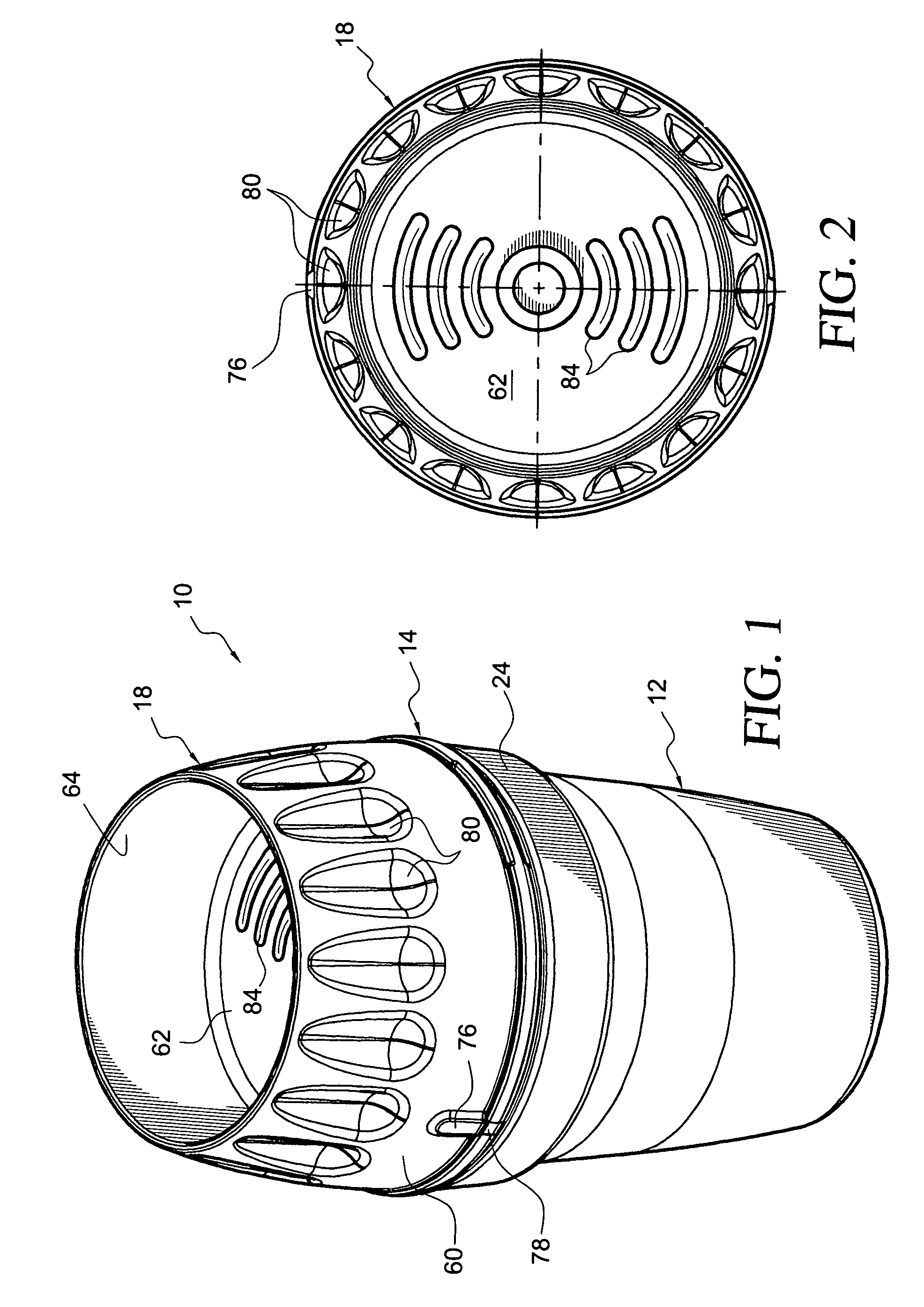

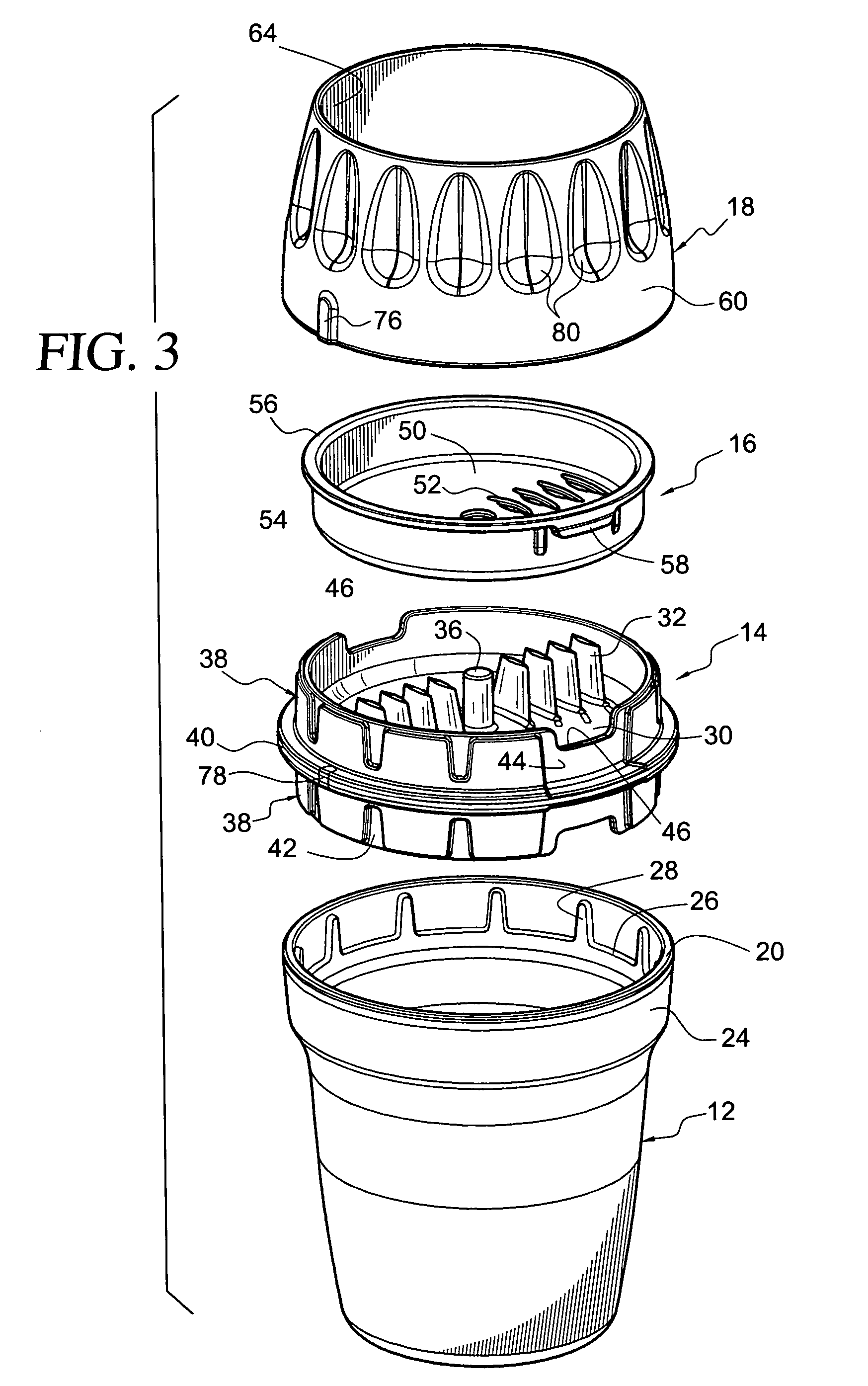

Processing tool for foodstuffs

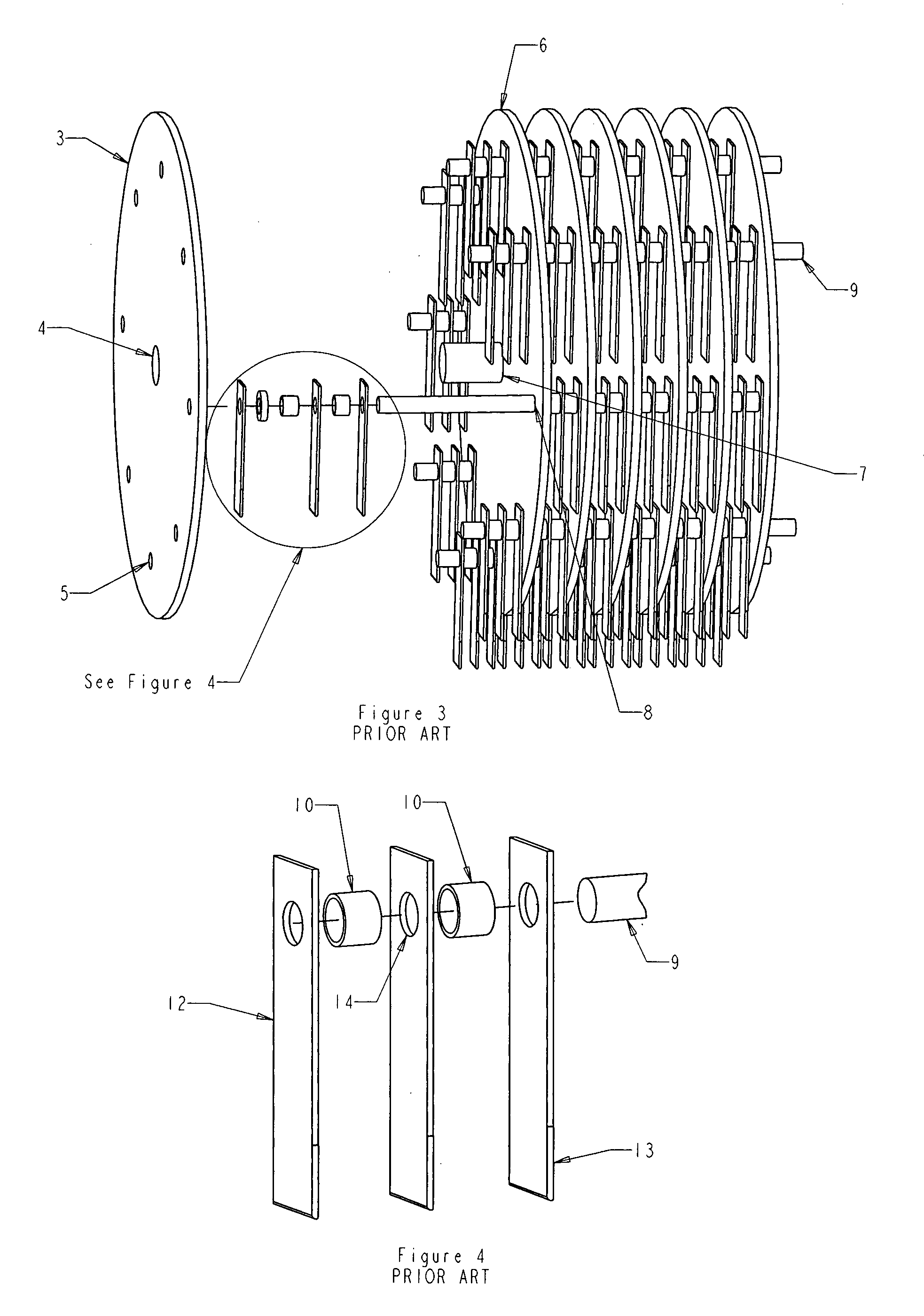

A processing tool for garlic and like edibles including a container mounted comminuting unit having-upper-and lower sets of spaced linearly aligned blades selectively presented in an upwardly directed operating position upon an inverting of the unit, the blades of each set having a comminuting profile differing from that of the blades of the other set and are selectively engaged by a set of spaced pusher teeth aligned along a sinusoidal path and mounted on an overlying cap for, upon rotation of the cap relative to the comminuting unit, moving an edible through the comminuting blades for the desired comminution thereof, the cap including a separate chamber for preparation of the edible before the comminuting process.

Owner:DART IND INC

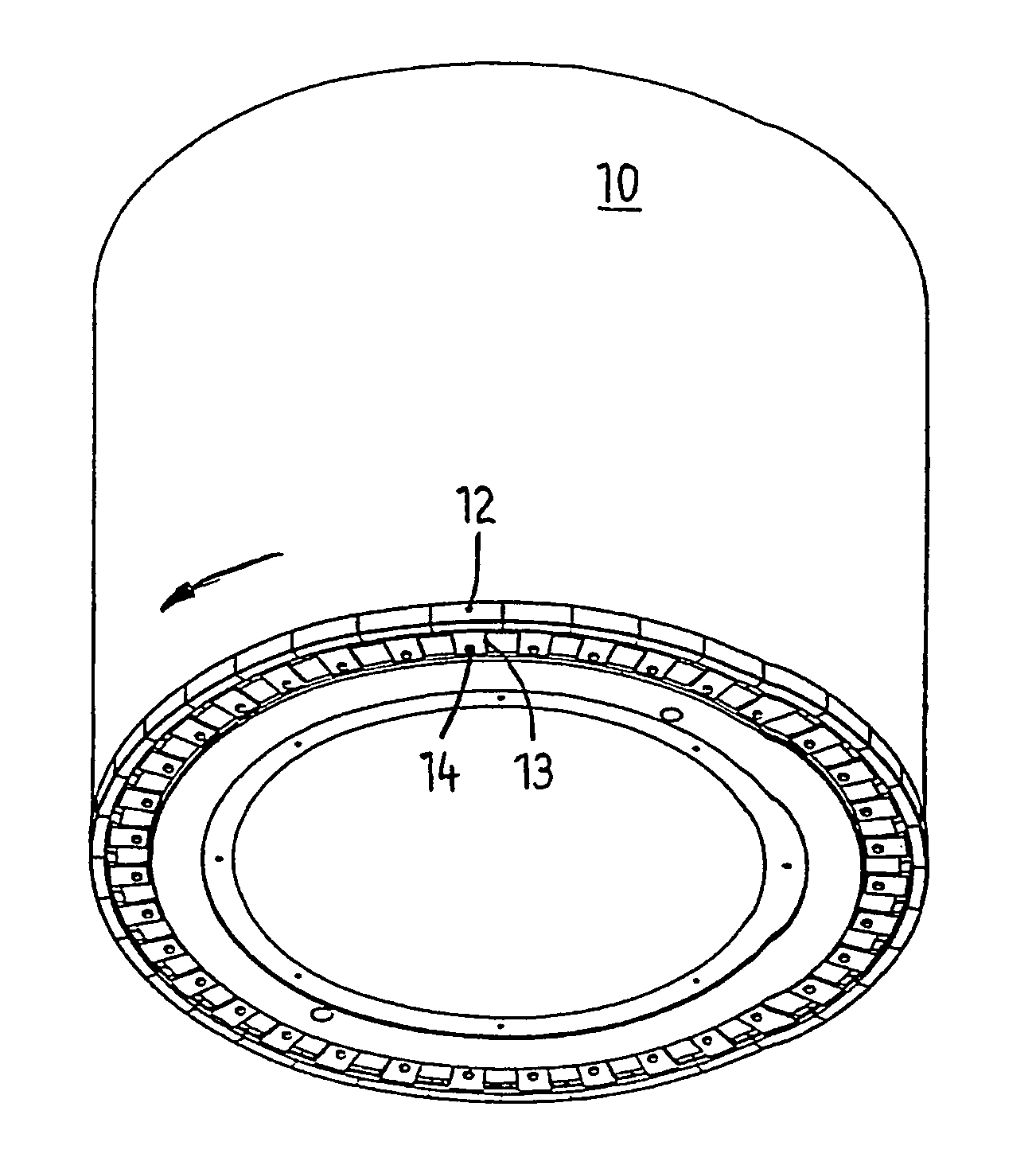

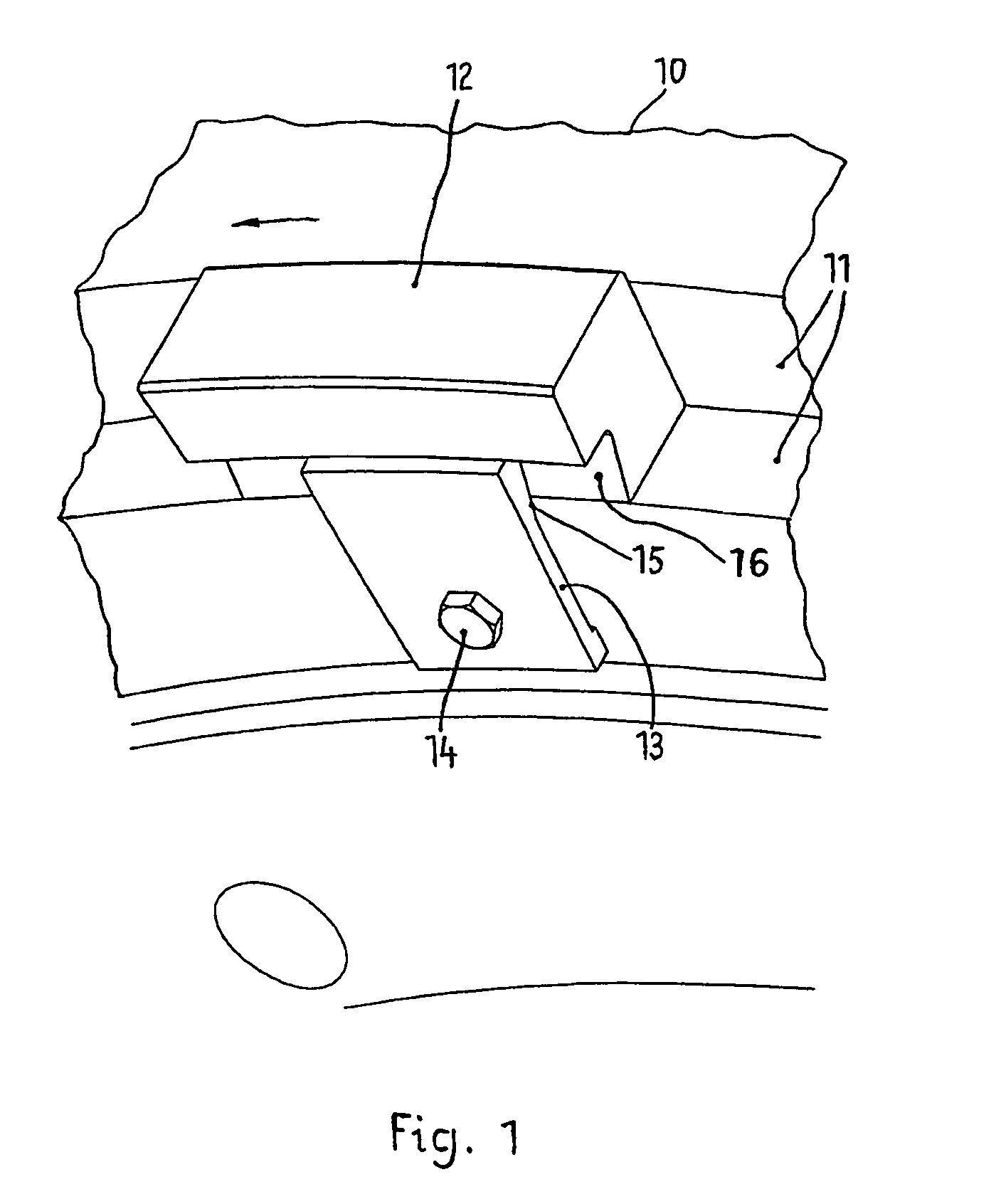

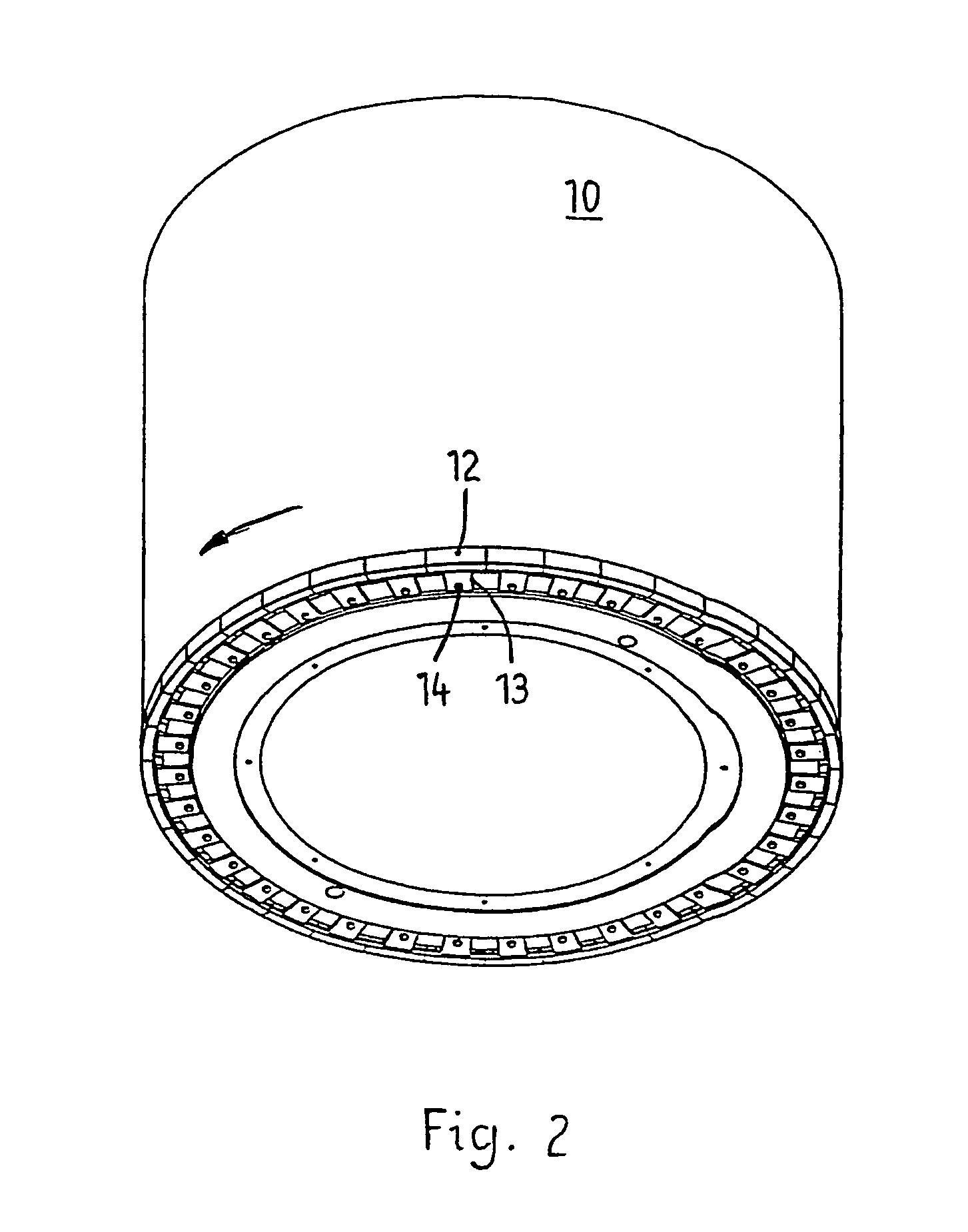

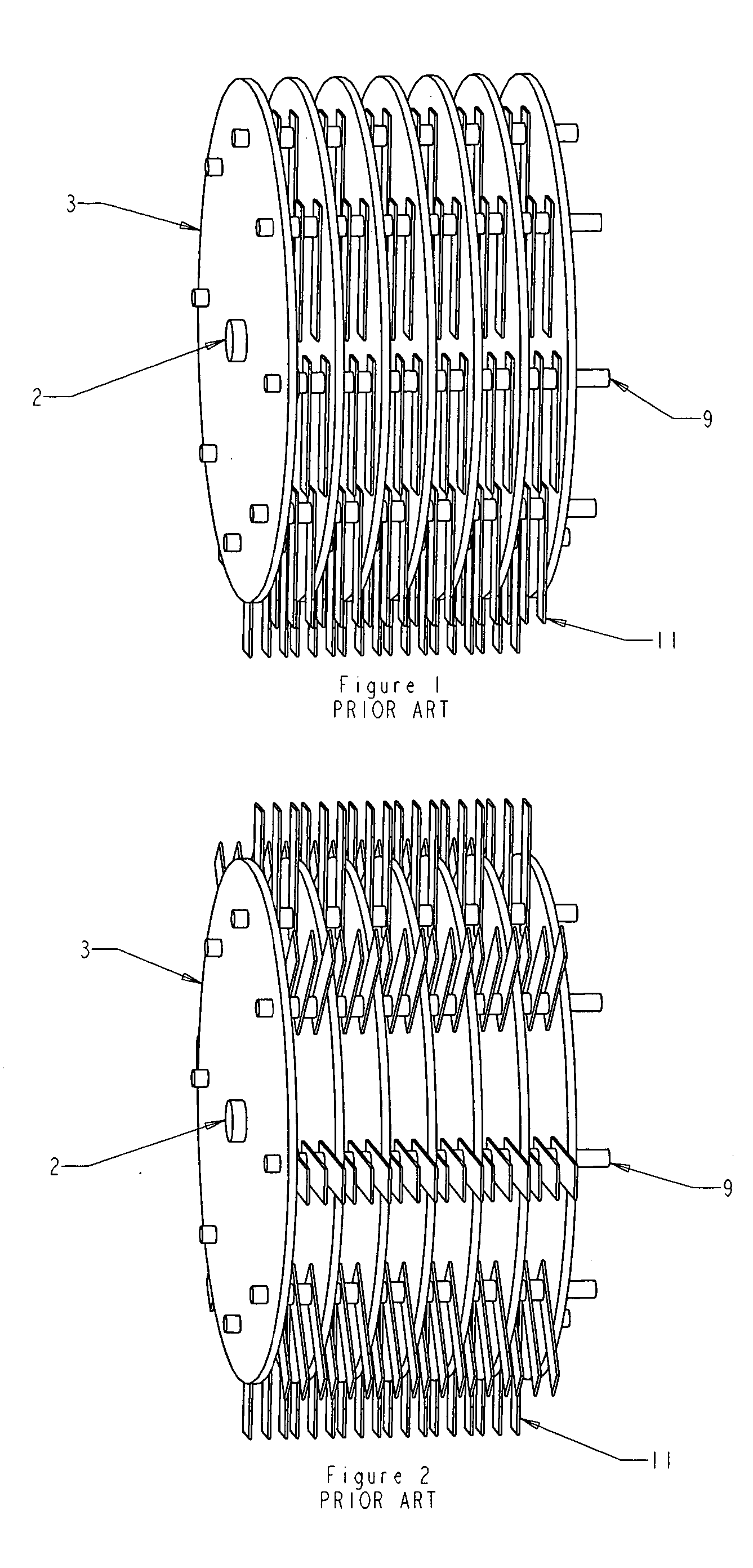

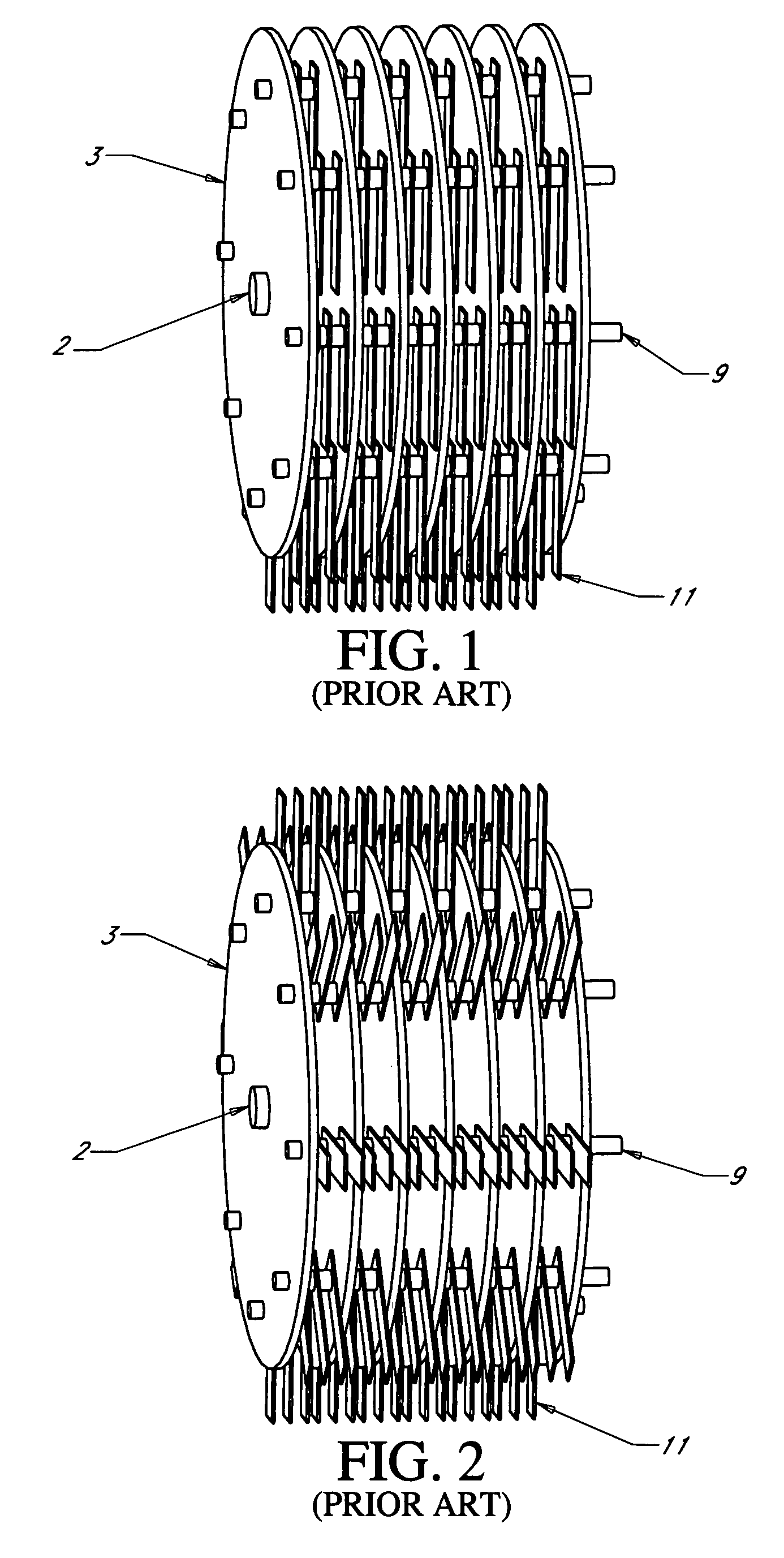

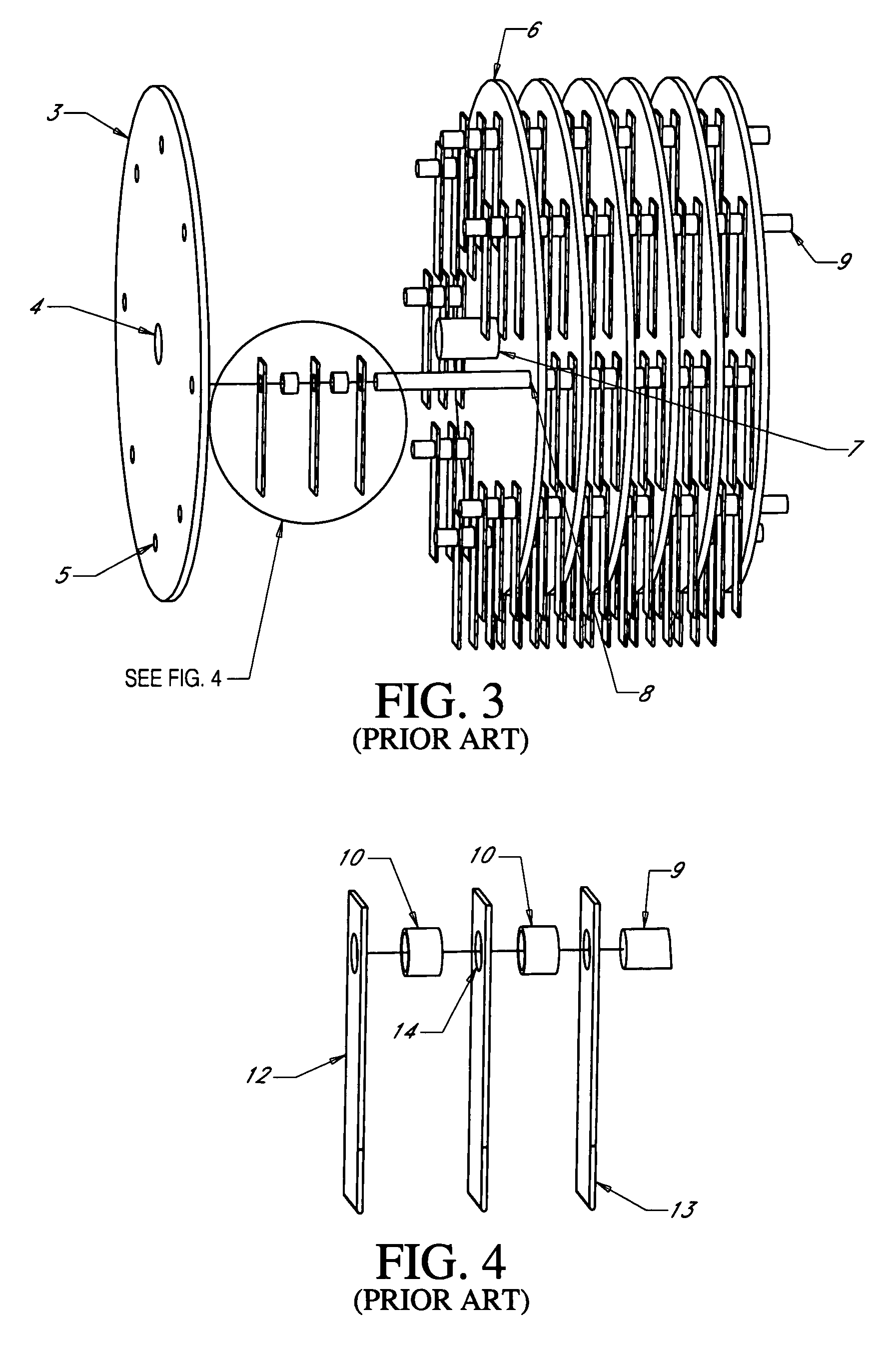

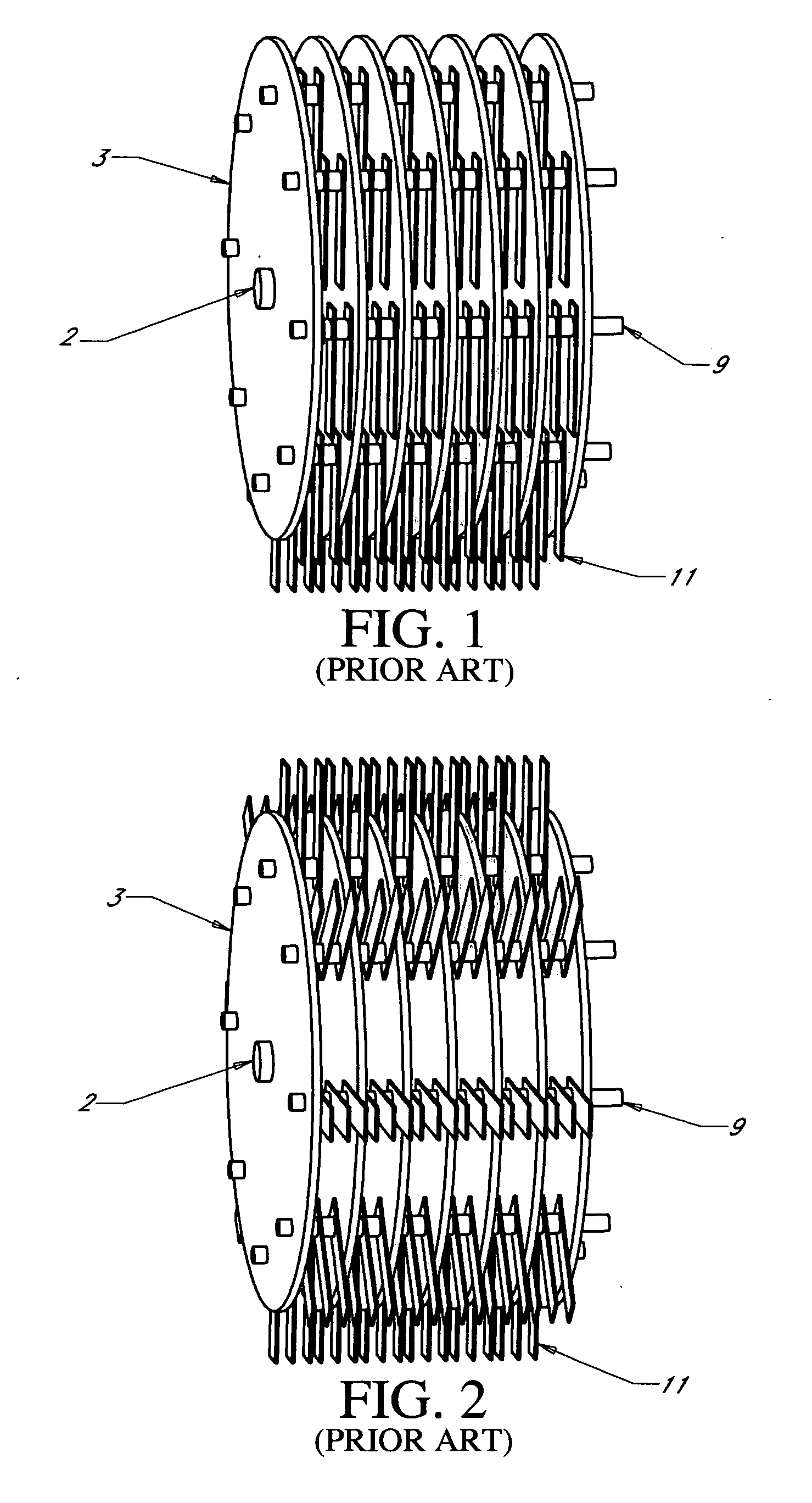

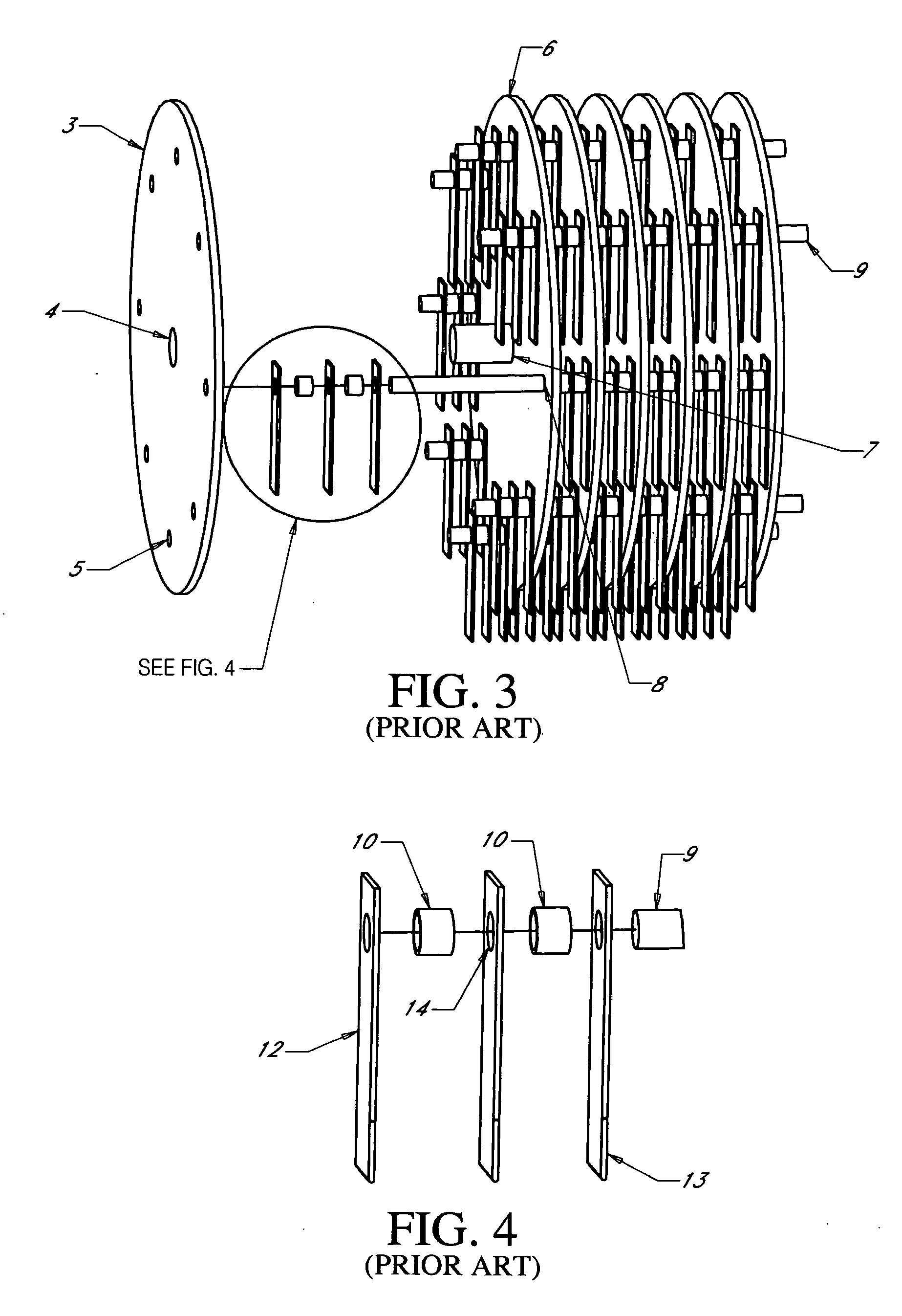

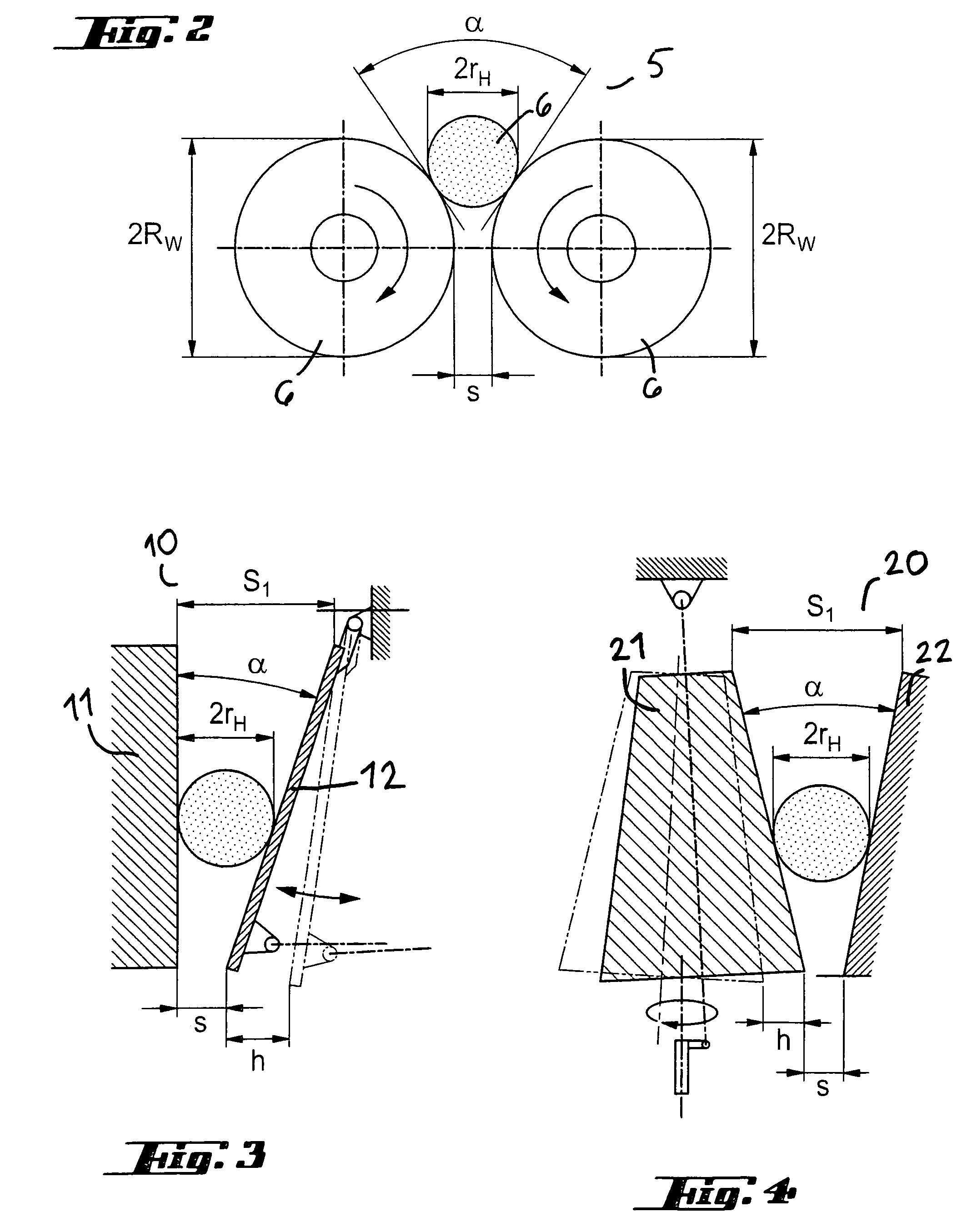

Grinding roller for the pressure comminution of granular material

The aim of the invention is to provide grinding rolls in particular for high-pressure roller mills or rolling presses for pressure grinding a granular material not only with a wear-resistant coating but also with a face armour plating in the area of the roller annular edge, which has a long service life due to the high wear resistance thereof and whose production and repair are, in general, relatively simple and inexpensive. For this purpose, the inventive face armour plating consists of a plurality of prefabricated hard bodies which are circularly arranged side by side in such a way that the circular face edge of the roller is formed, said hard bodies are disposed on said circular shoulder of a roll shell such that said hard bodies are placed axially and radially against said circular shoulder of the roll shell and are movably assembled with the roll shell.

Owner:KHD HUMBOLDT WEDAG GMBH

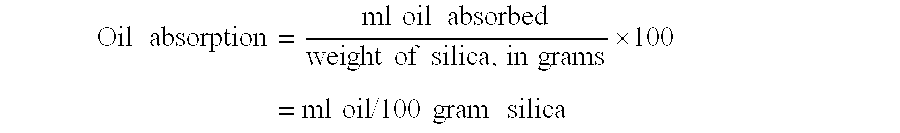

Method for making particulate compositions and products thereof

InactiveUS20070001037A1Easy to produceImprove uniformityCosmetic preparationsOther chemical processesParticulatesSilicon dioxide

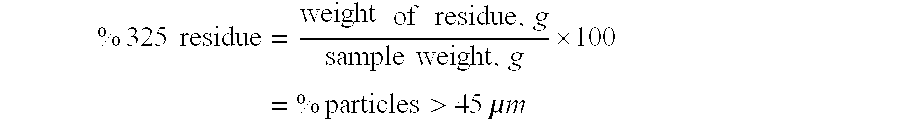

A method of making abrasive compositions, and more particularly, it relates to a method of making precipitated silica abrasive compositions having excellent cleaning performance and lower abrasiveness with post-reactor sizing of the abrasive particles being performed directly via wet comminution and centrifugation, optionally followed by hydraulic chamber press filtering combined with vacuum dewatering and de-agglomeration is provided. By targeting a specific particle size range, it has been determined that higher pellicle film cleaning levels may be achieved without also increasing the dentin abrasion properties of the silica products themselves. As a result, dentifrices including such classified abrasive silica products, exhibiting particularly desirable cleaning benefits, can be provided for improved tooth polishing, whitening, and the like, without deleteriously affecting the hard tooth surfaces. Also encompassed within this invention also are products of this selective process scheme and dentifrices containing such particularly manufactured and classified silica products.

Owner:J M HUBER CORP

Acicular calcite and aragonite calcium carbonate

InactiveUS6022517AReduce conductivityIncrease production costCalcium/strontium/barium carbonatesAmmonium nitratesToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

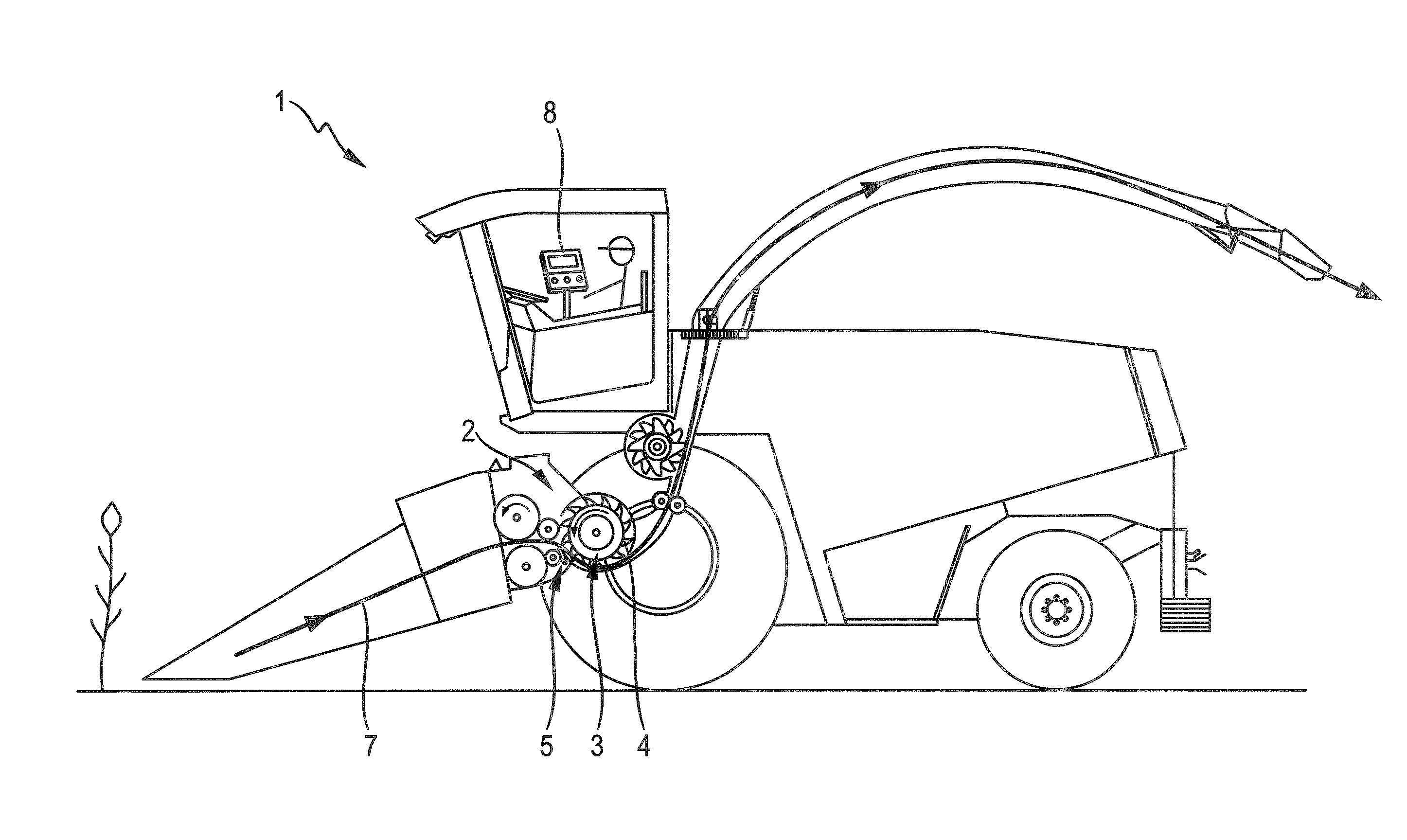

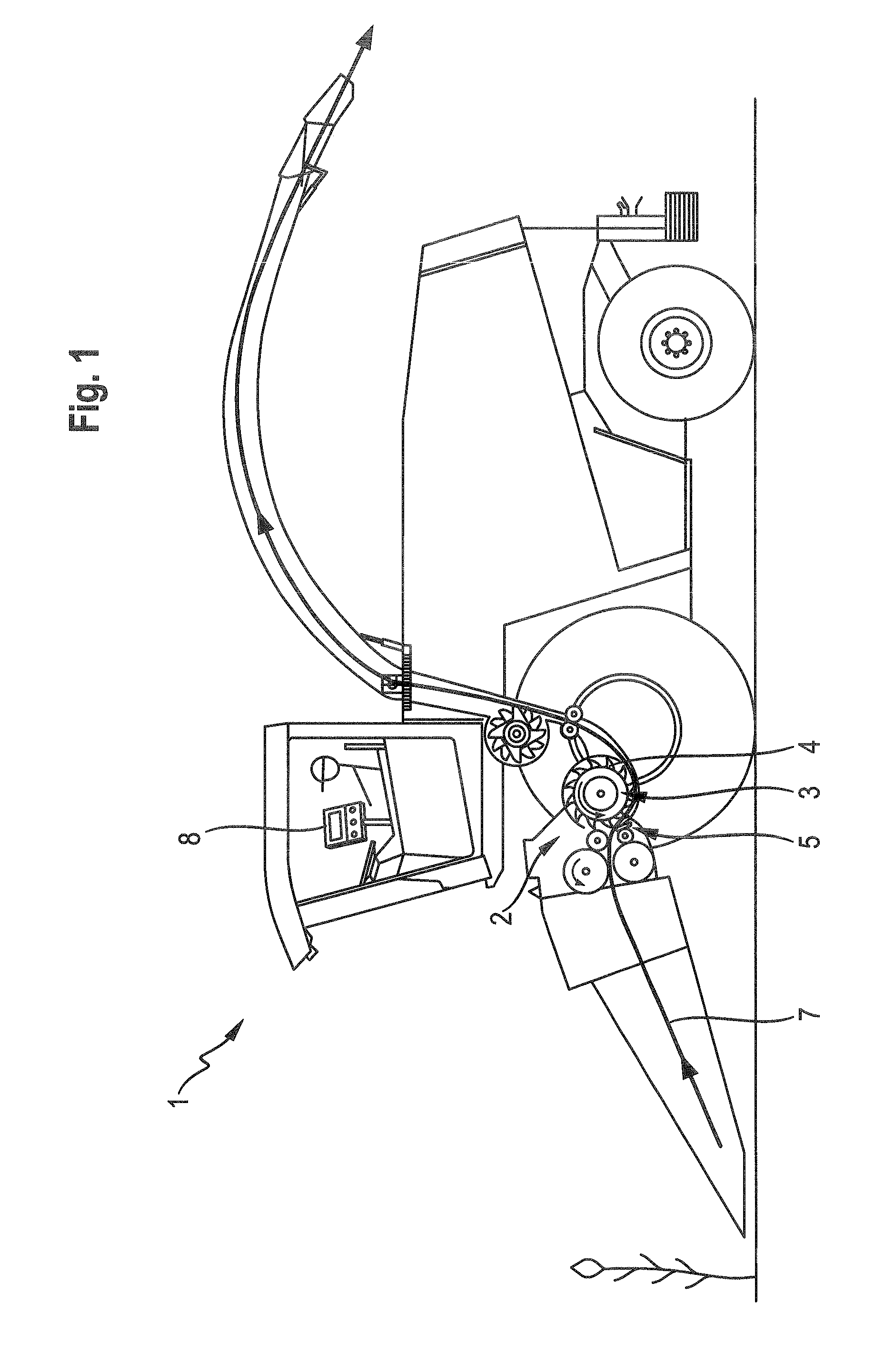

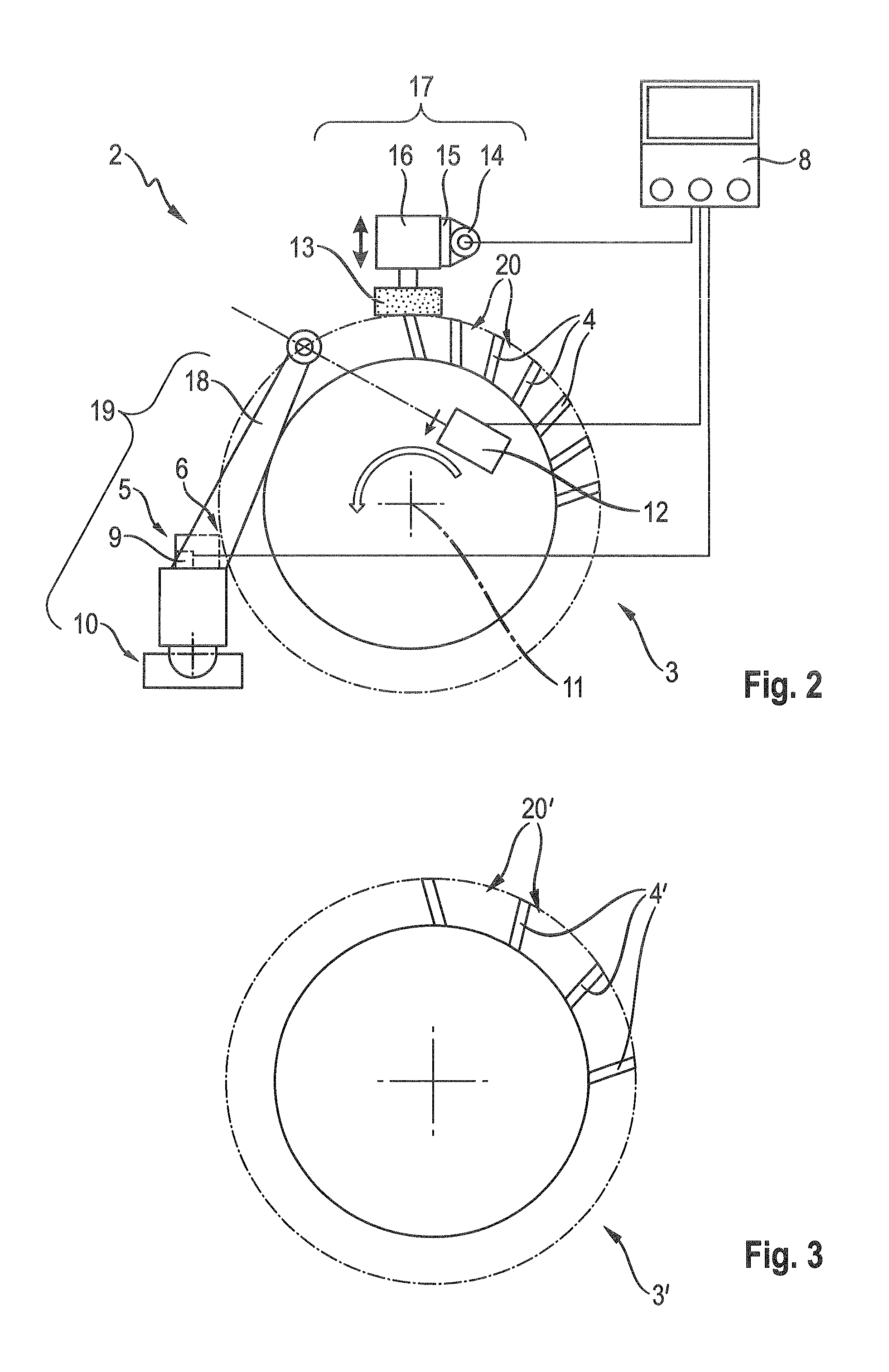

Agricultural harvesting machine

An agricultural harvesting machine embodying a forage harvester includes a comminution assembly with a drum equipped with a plurality of knives. The drum is set into rotation opposite a stationary shear bar in order to comminute crop fed in a region of a cutting gap formed by knives and the shear bar during the harvesting operation. A device controls a rotational speed (n) of the drum at least during a maintenance procedure of the comminution assembly, depending on a property of the drum.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

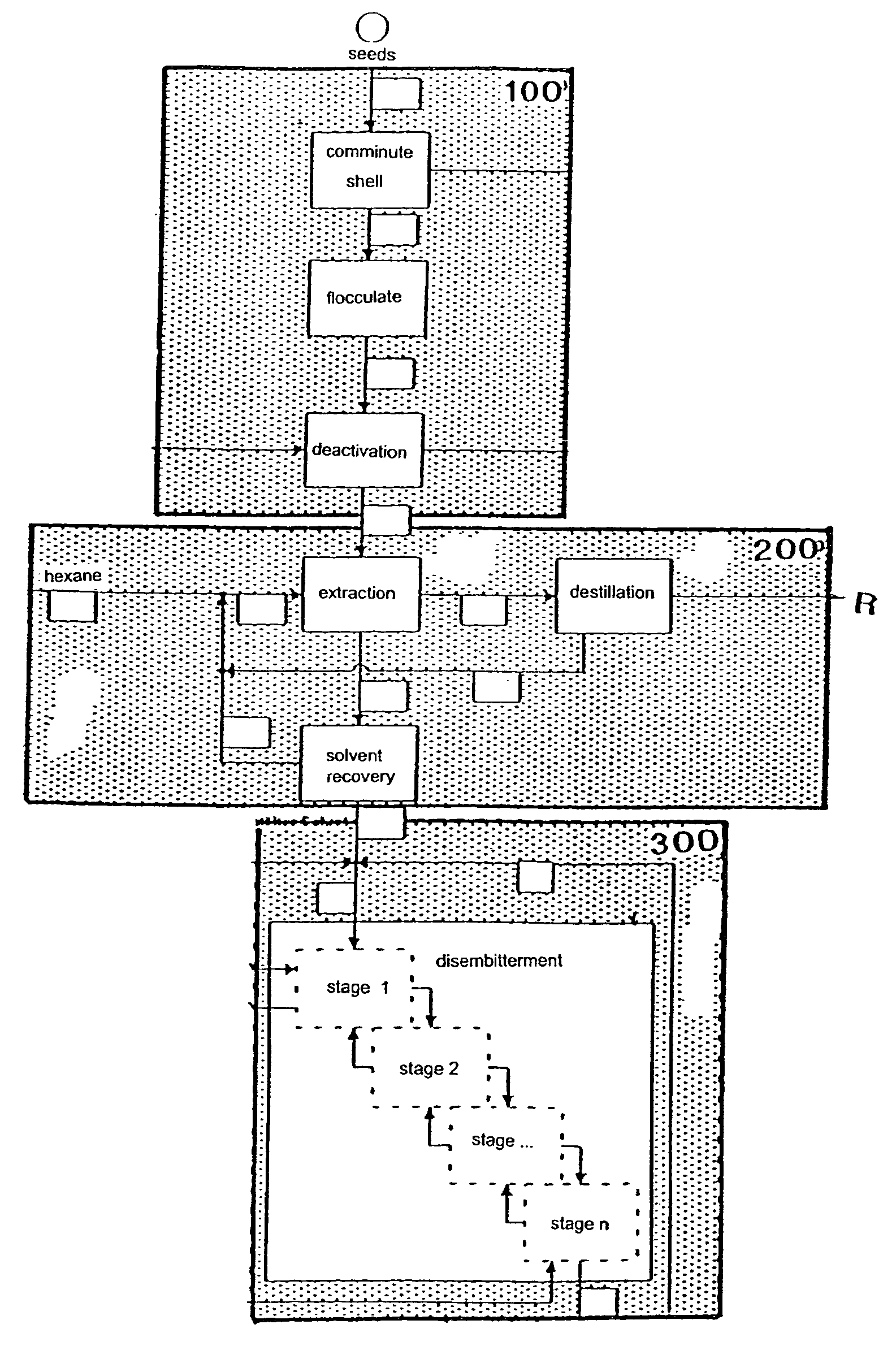

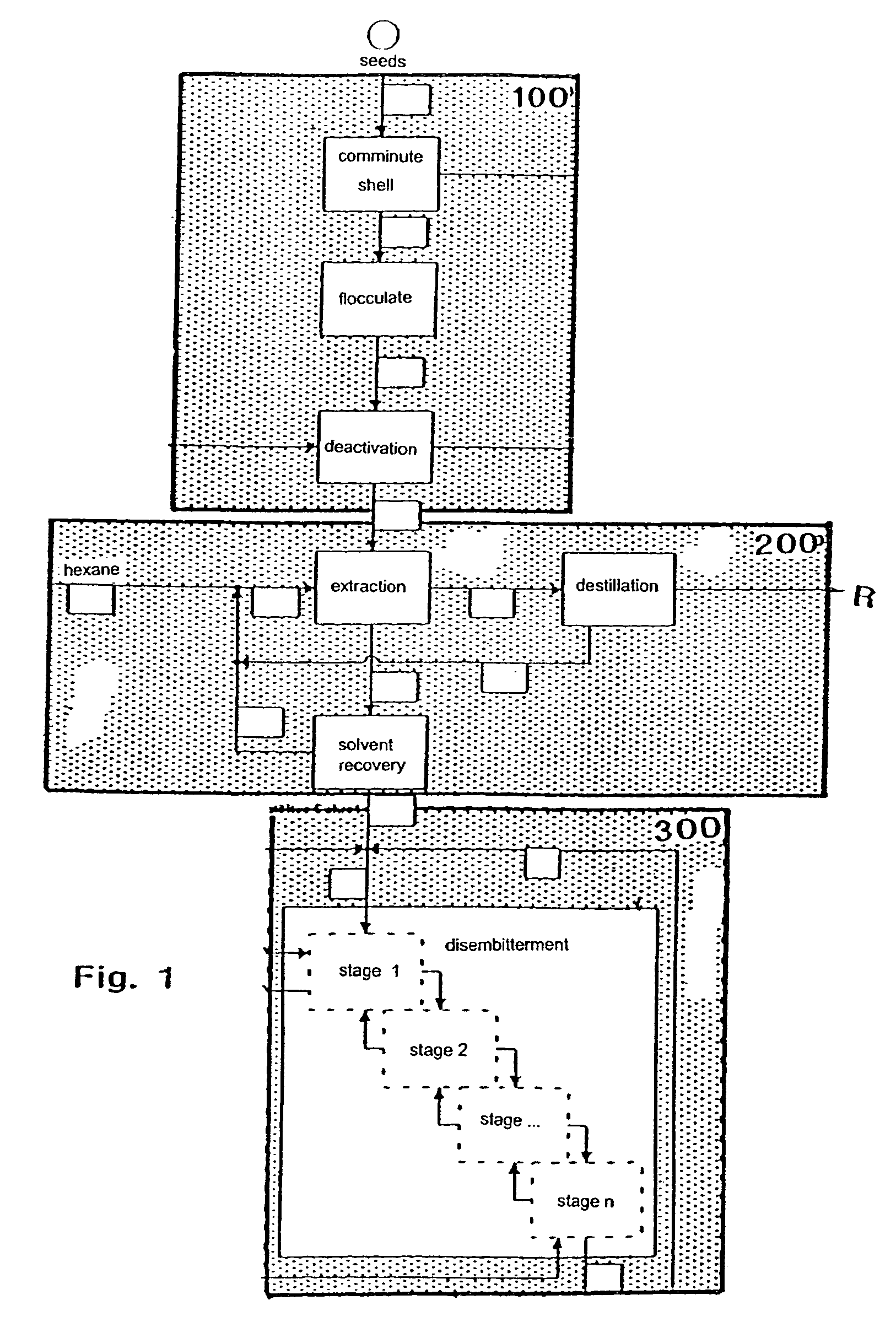

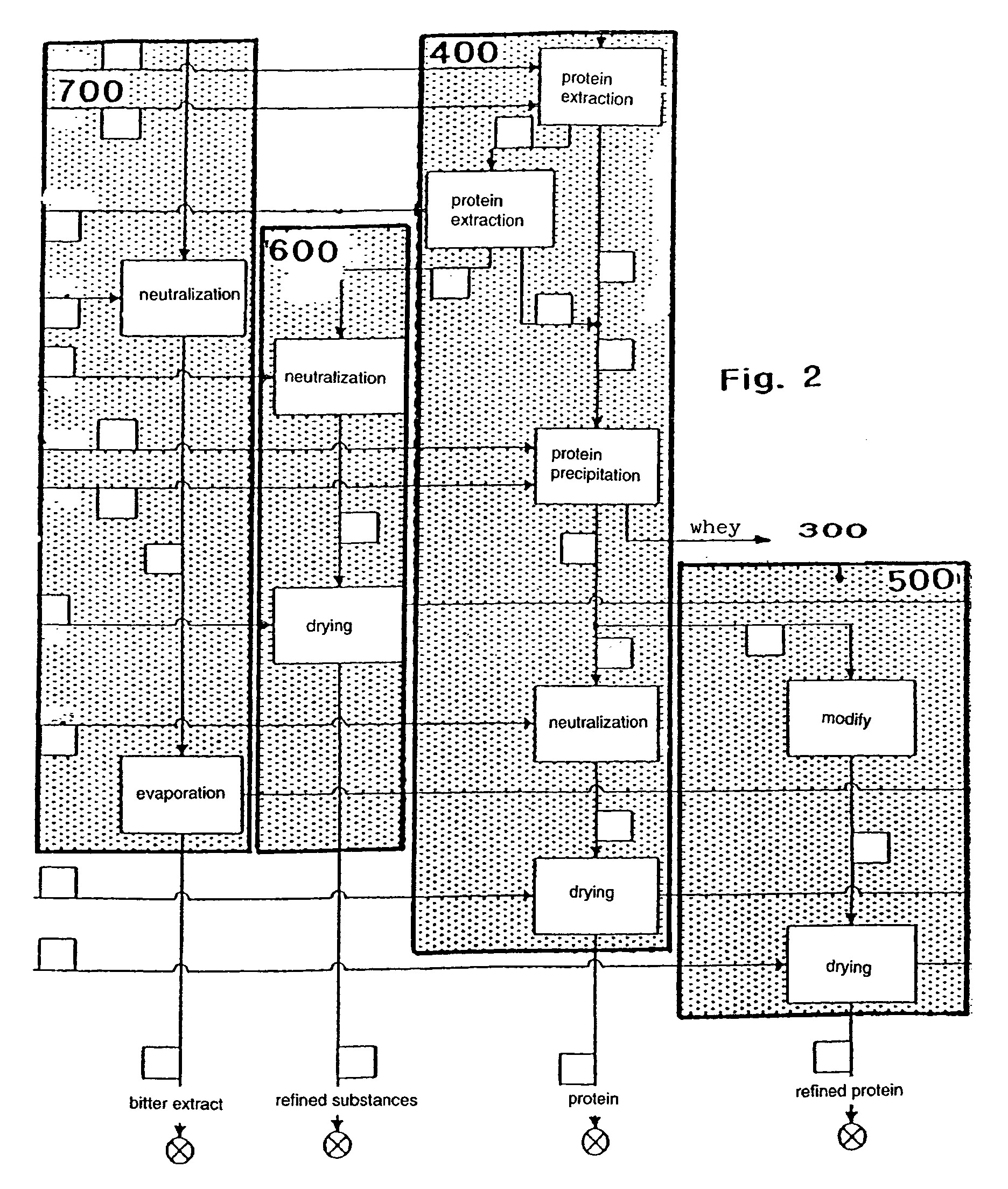

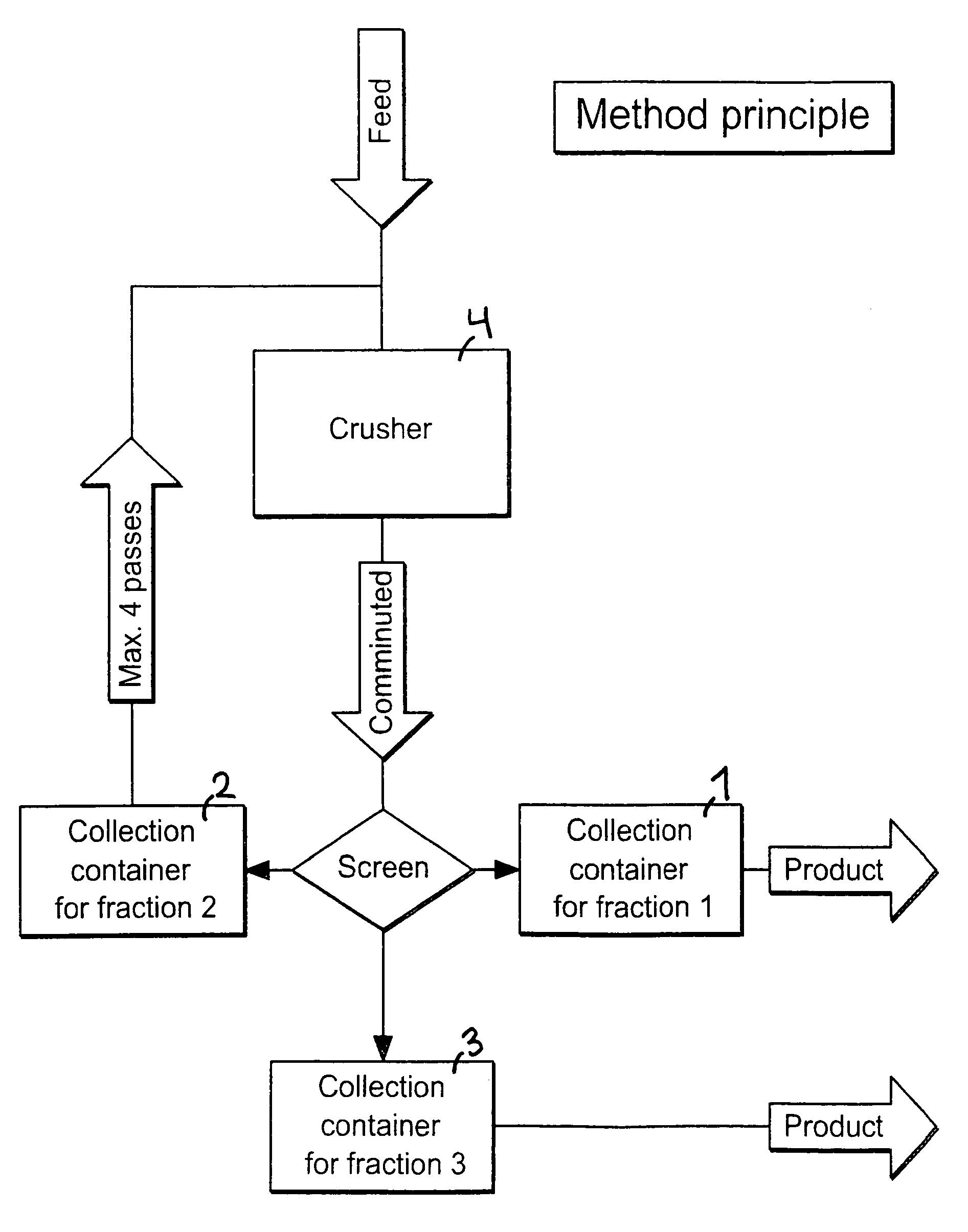

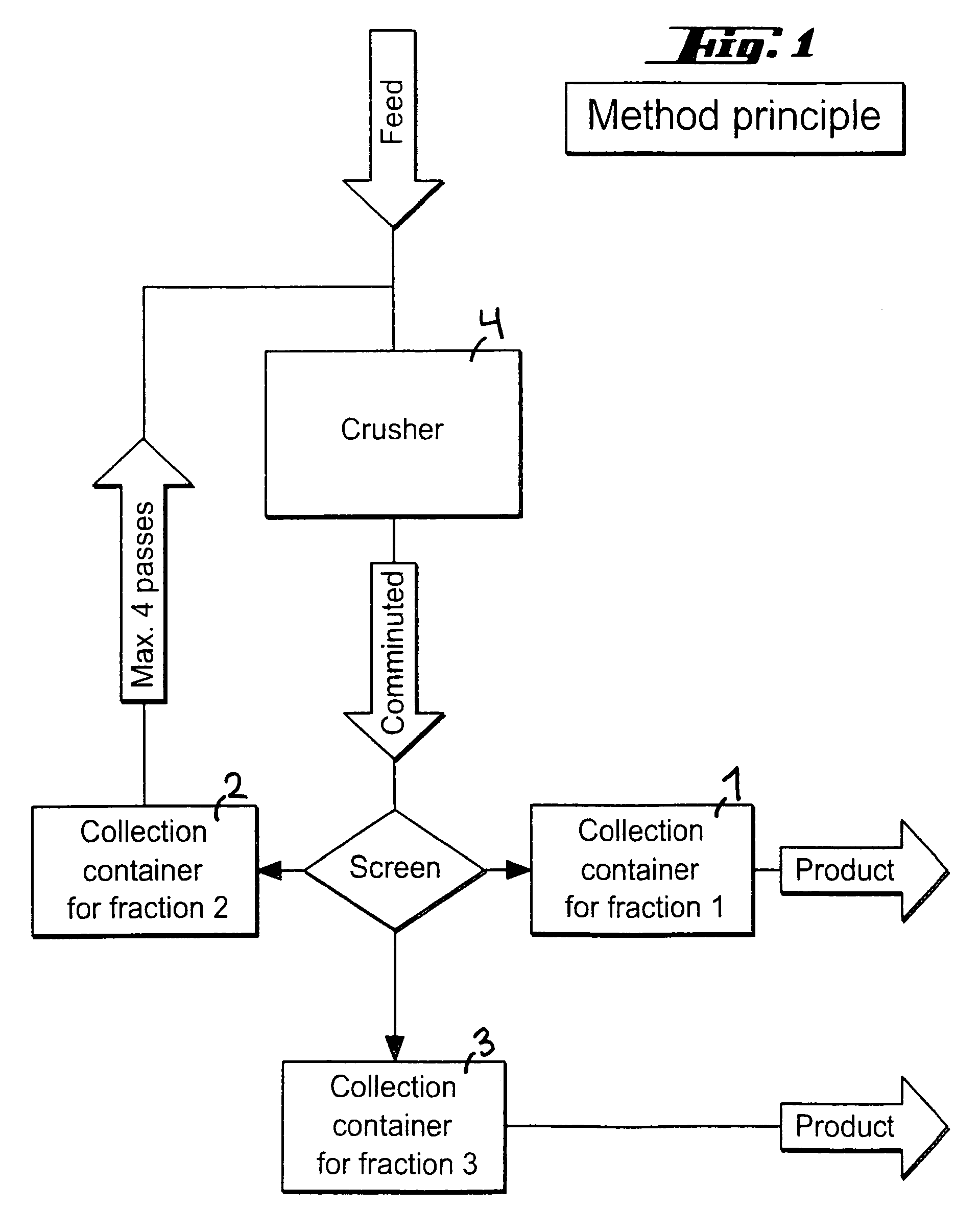

Method for treating and processing lupine seeds containing alkaloid, oil and protein

InactiveUS7074449B1Water being largely excludedAvoid heatProtein composition from vegetable seedsFood preparationFractionationPlanting seed

A method of treating and processing alkaloid, oil and protein-containing lupine seeds for the extraction of products from the lupine seeds by means of targeted fractionation is described, whereby the comminuted lupine seed is de-oiled by introducing a solvent and the residue is depleted of substances soluble in the acid range, preferably of alkaloids, by adding acids. The invention is characterized by the provisions that the lupine seeds are comminuted and / or shaped to form discoid flakes in such a way that after pre-crushing of the shelled or non-shelled seed containing the plant seeds the comminution of the plant seeds is carried out by means of a cooled flocculating roller, and the seed is heated by indirect supply of heat, largely with exclusion of water, and that after de-oiling the depletion of the flakes of substances soluble in the acid range, preferably of alkaloids, is performed by aqueous extraction, with a refined product of reduced alkaloid level and an aqueous extract being obtained.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

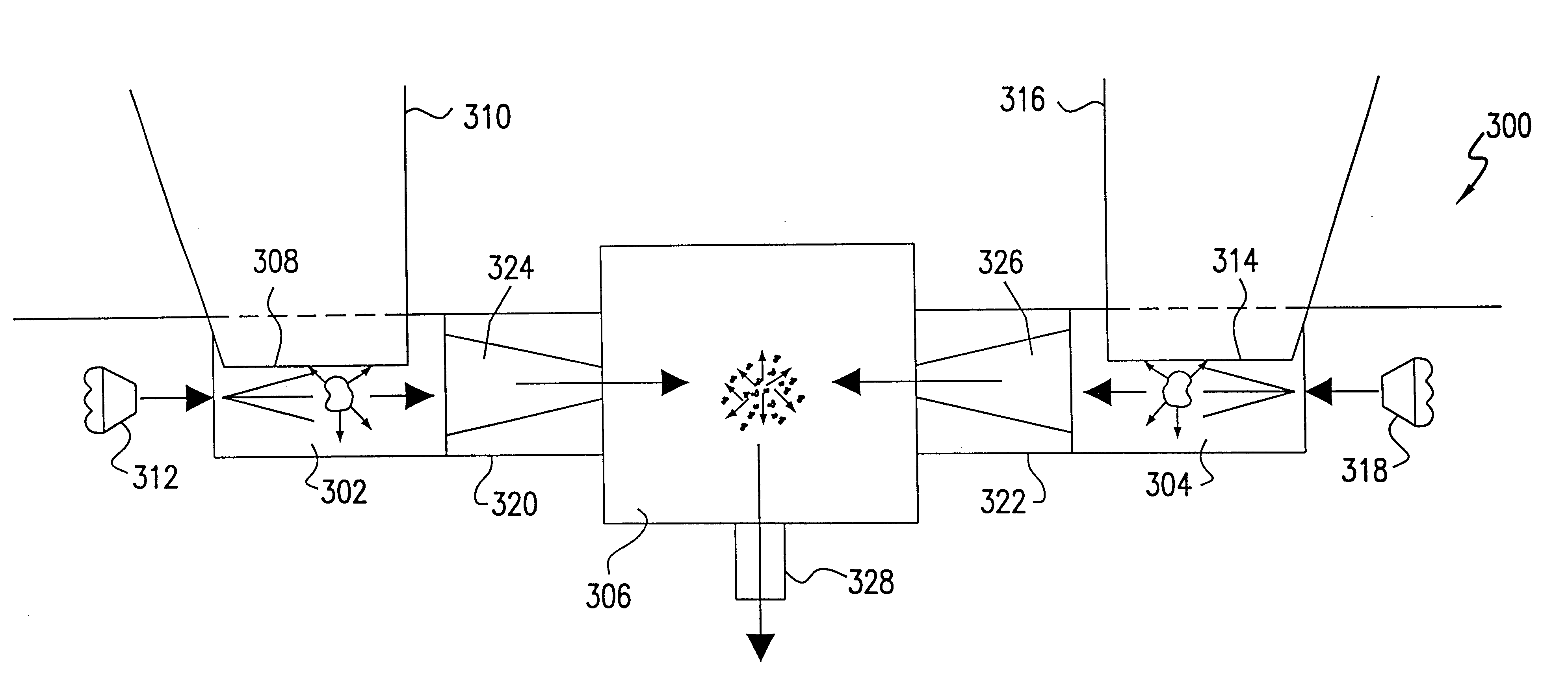

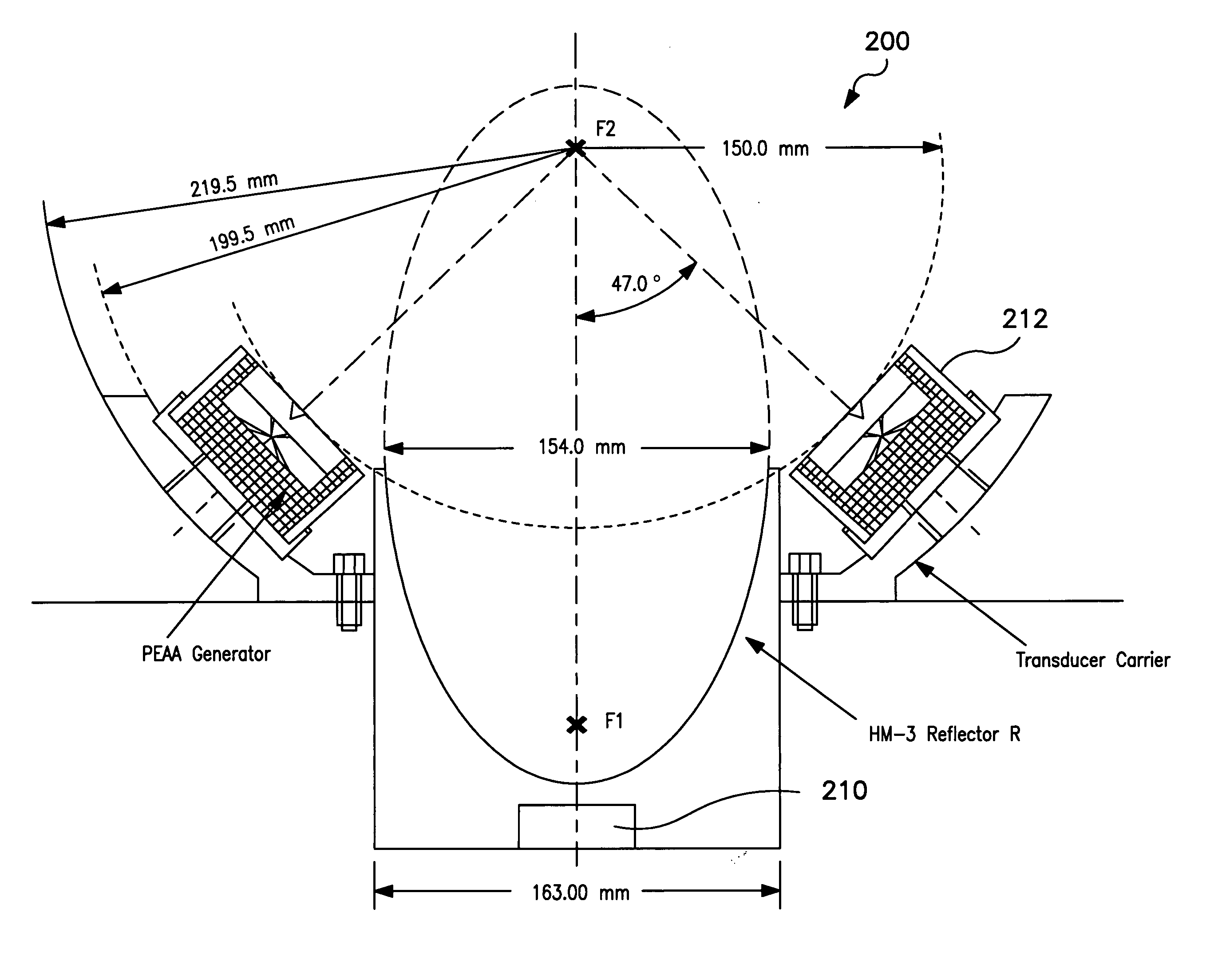

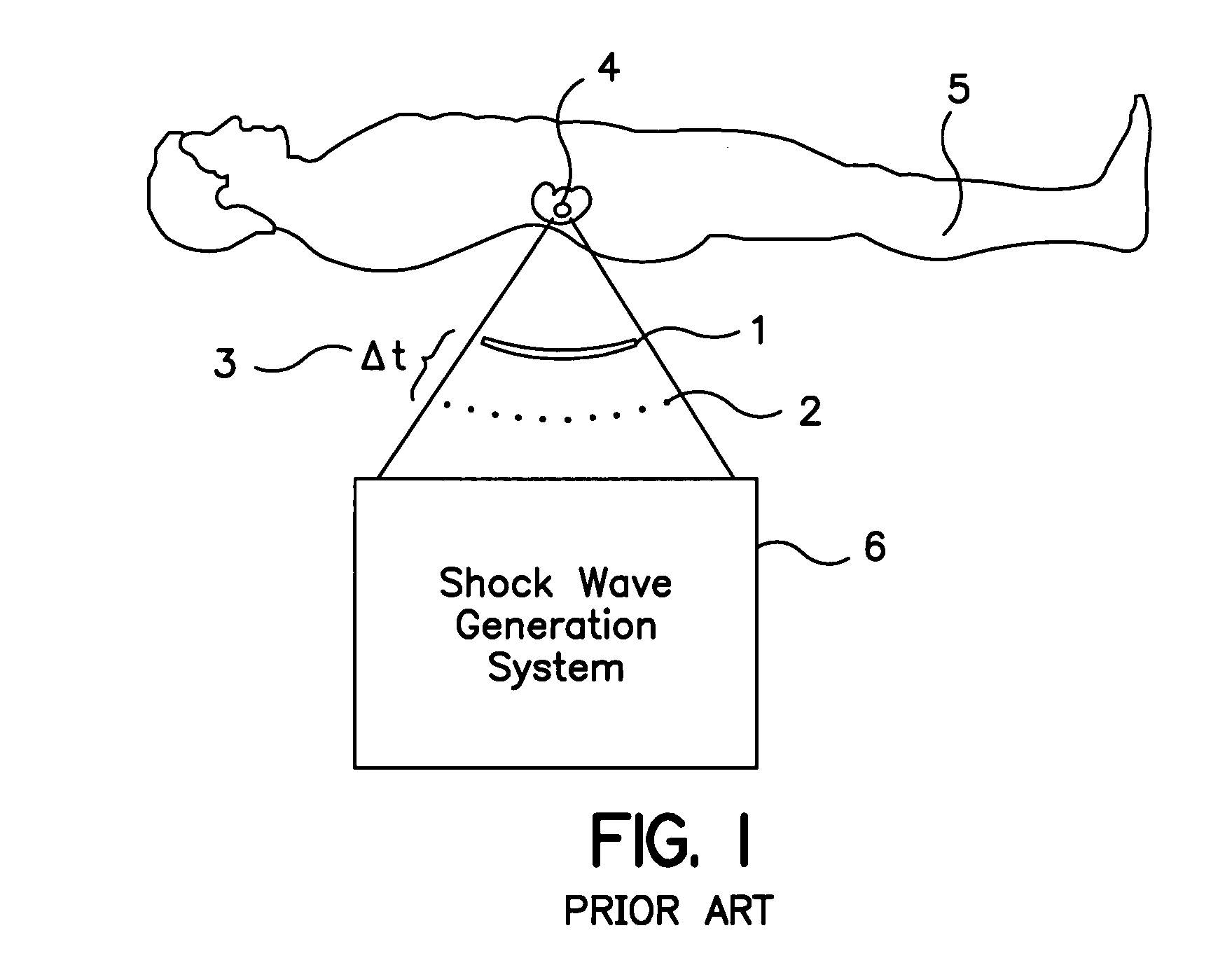

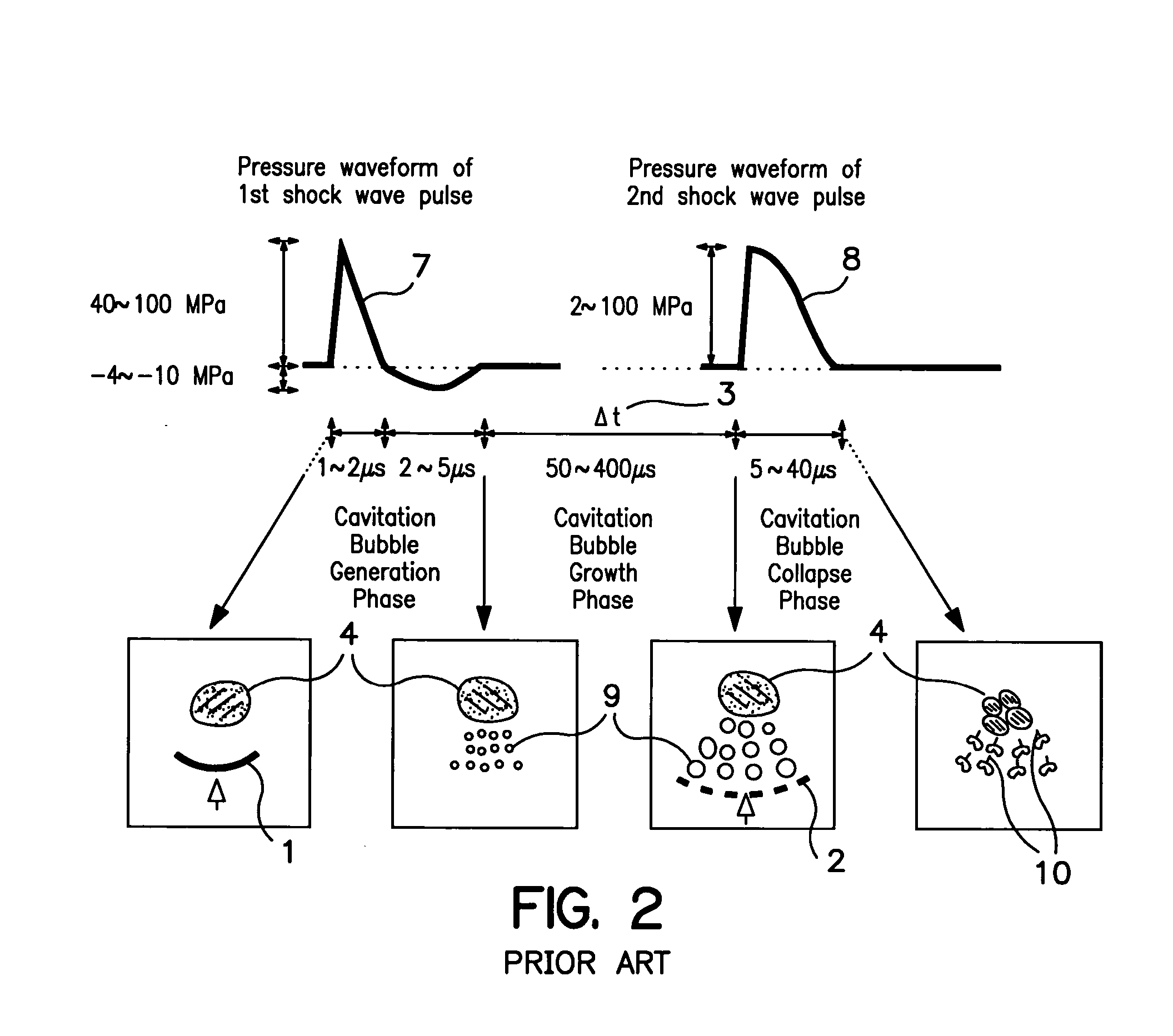

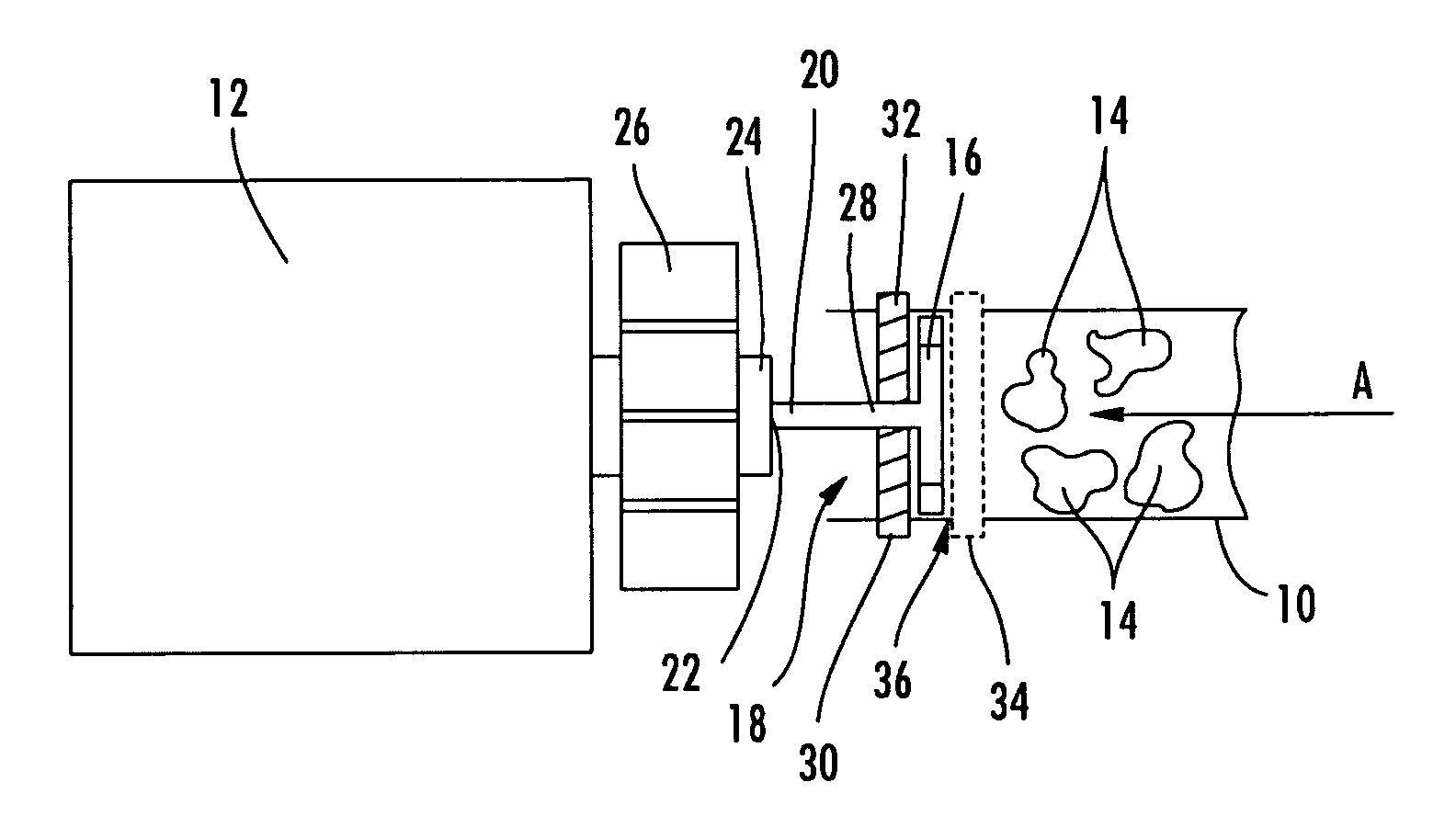

Apparatus for improved shock-wave lithotripsy (SWL) using a piezoelectric annular array (PEAA) shock-wave generator in combination with a primary shock wave source

InactiveUS20050038361A1Improve sharding efficiencyReduce tissue damageSurgeryChiropractic devicesElectricityTime delays

The invention relates to an improved apparatus for the comminution of concretions in vivo by controlled, concentrated cavitation energy using two shock wave pulses with a specified time delay and pressure relationship, with the first shock wave pulse being used to induce a transient cavitation bubble cluster near the target concretion, and the second shock wave pulse to control and force the collapse of the cavitation bubble cluster towards the target concretion with concentrated energy disposition while avoiding injury to surrounding tissue. The invention contemplates the use of an improved combined electrohydraulic or electromagnetic and a piezoelectric annular array shock wave generator to produce improved stone comminution with reduced tissue injury in vivo.

Owner:DUKE UNIV

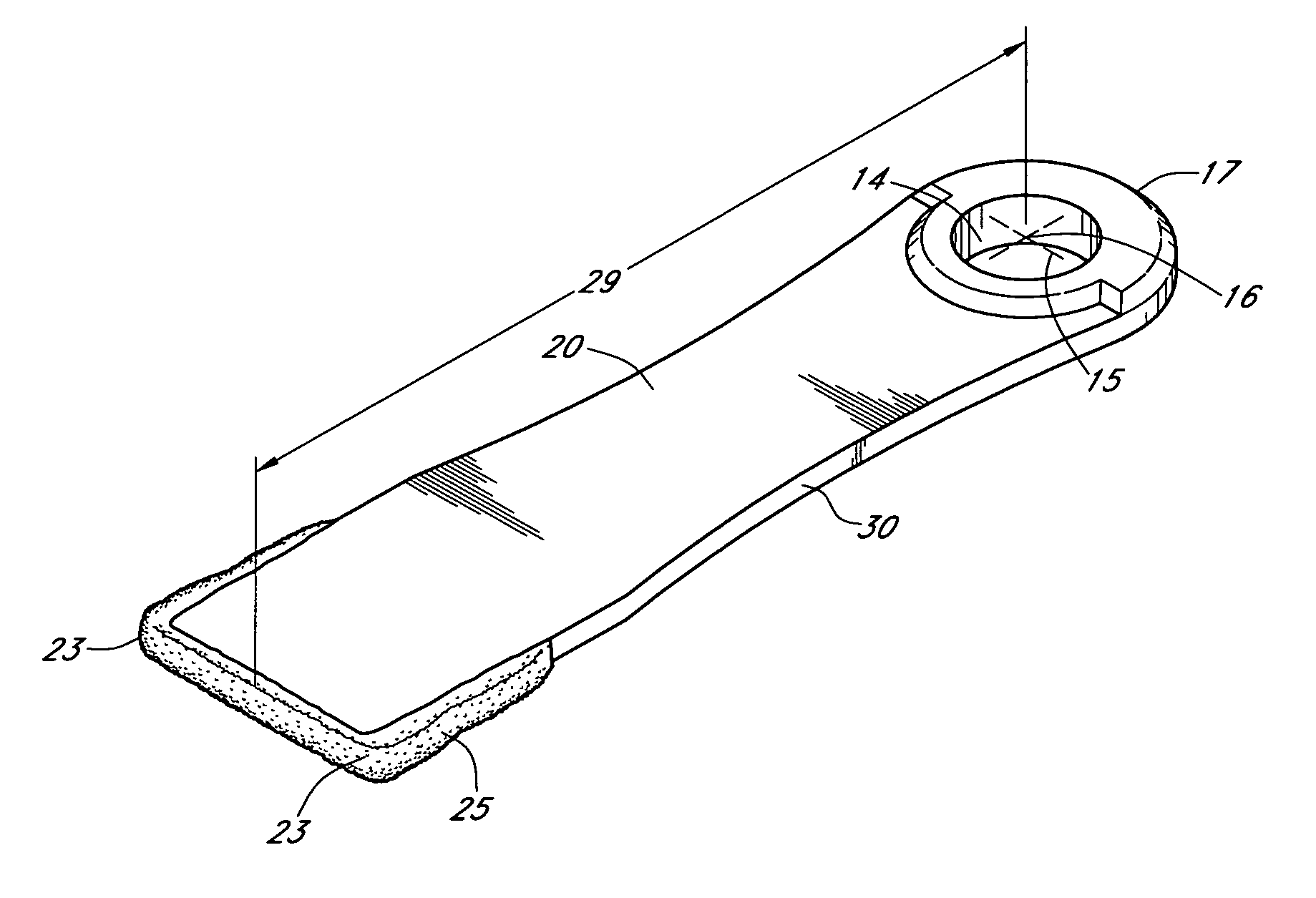

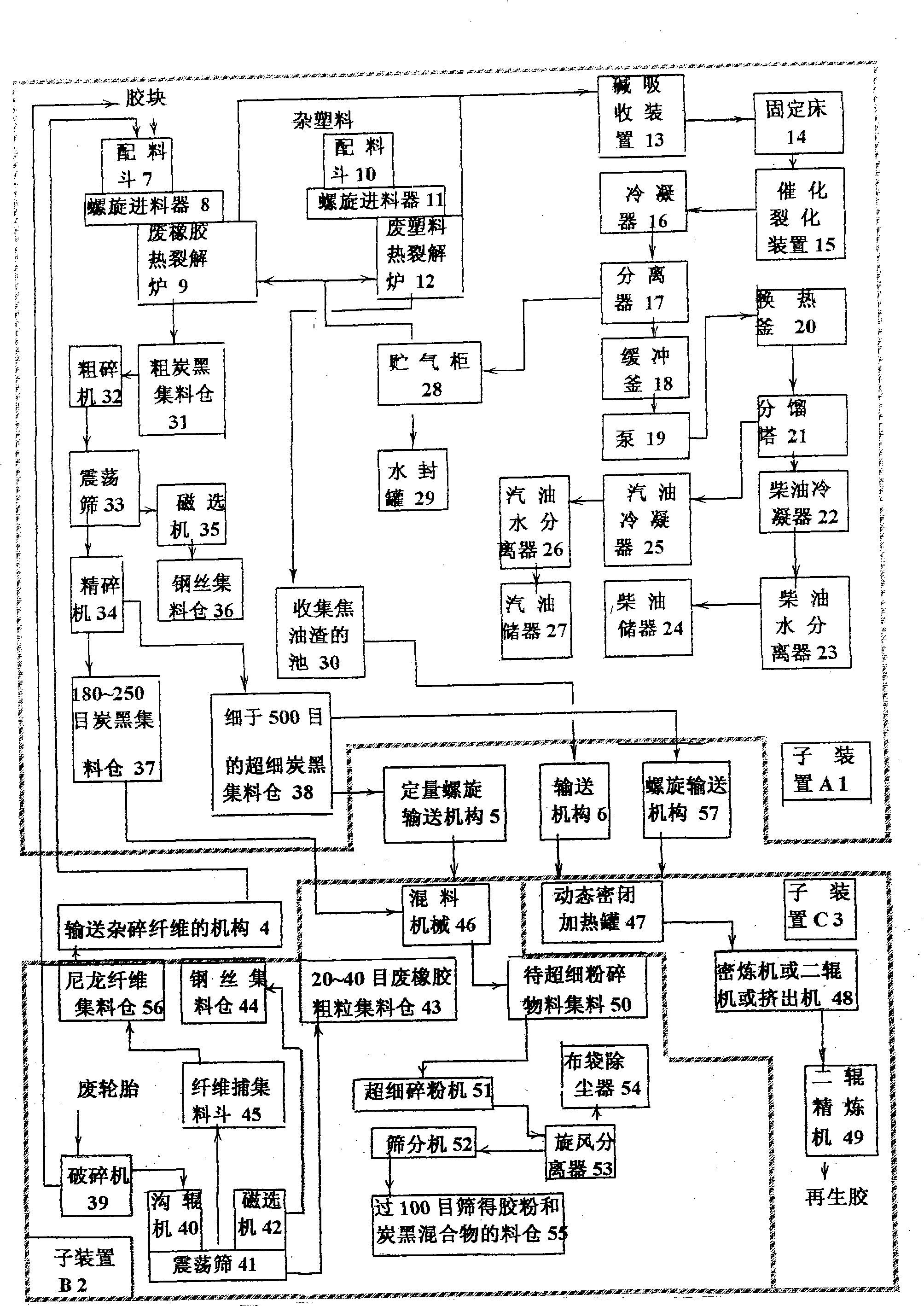

Forged hammermill hammer

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The design as disclosed and claimed is forged increasing the strength of the hammer. The shape of hammer as disclosed and claimed uses this improved strength to reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design incorporates comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

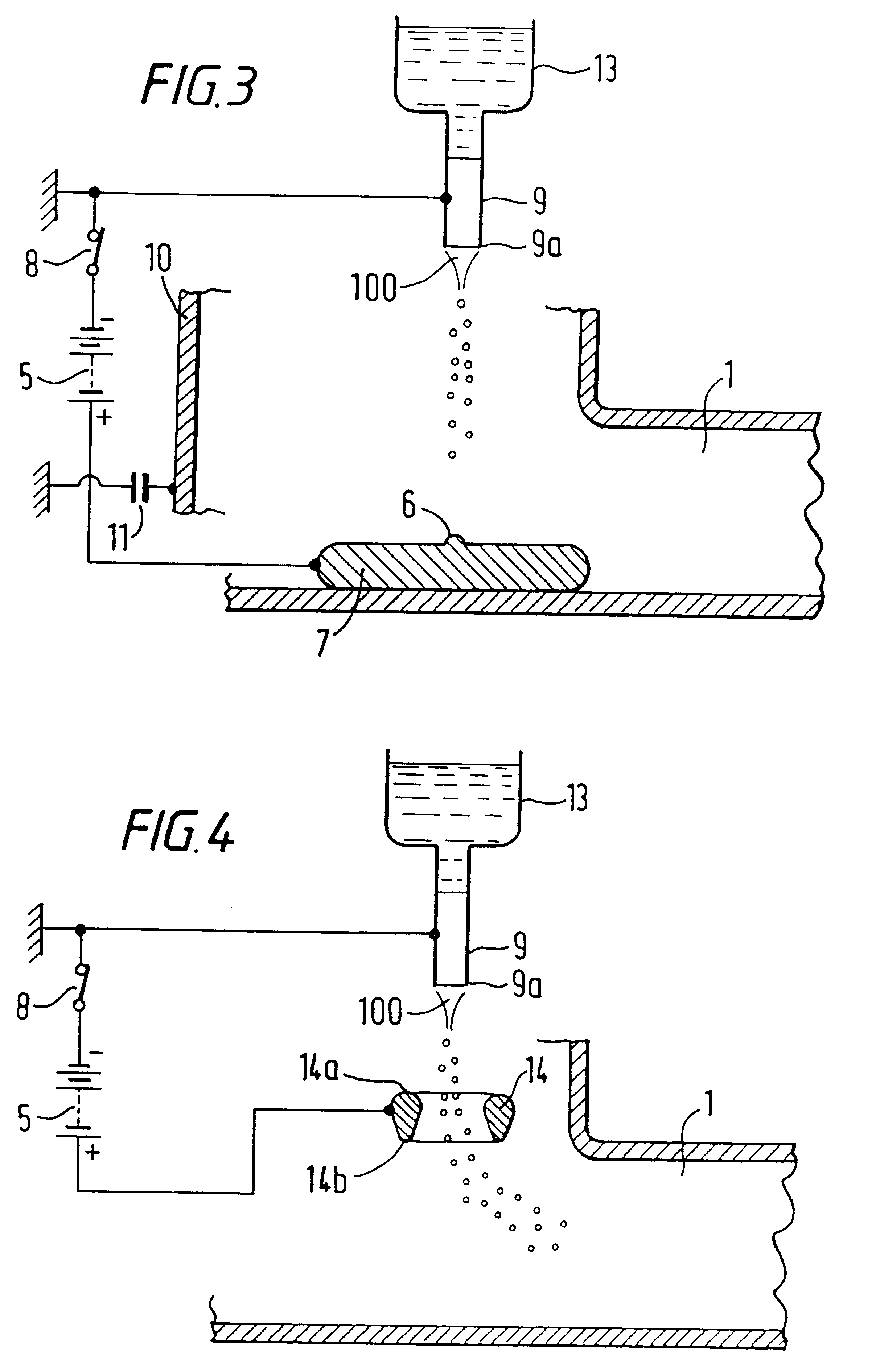

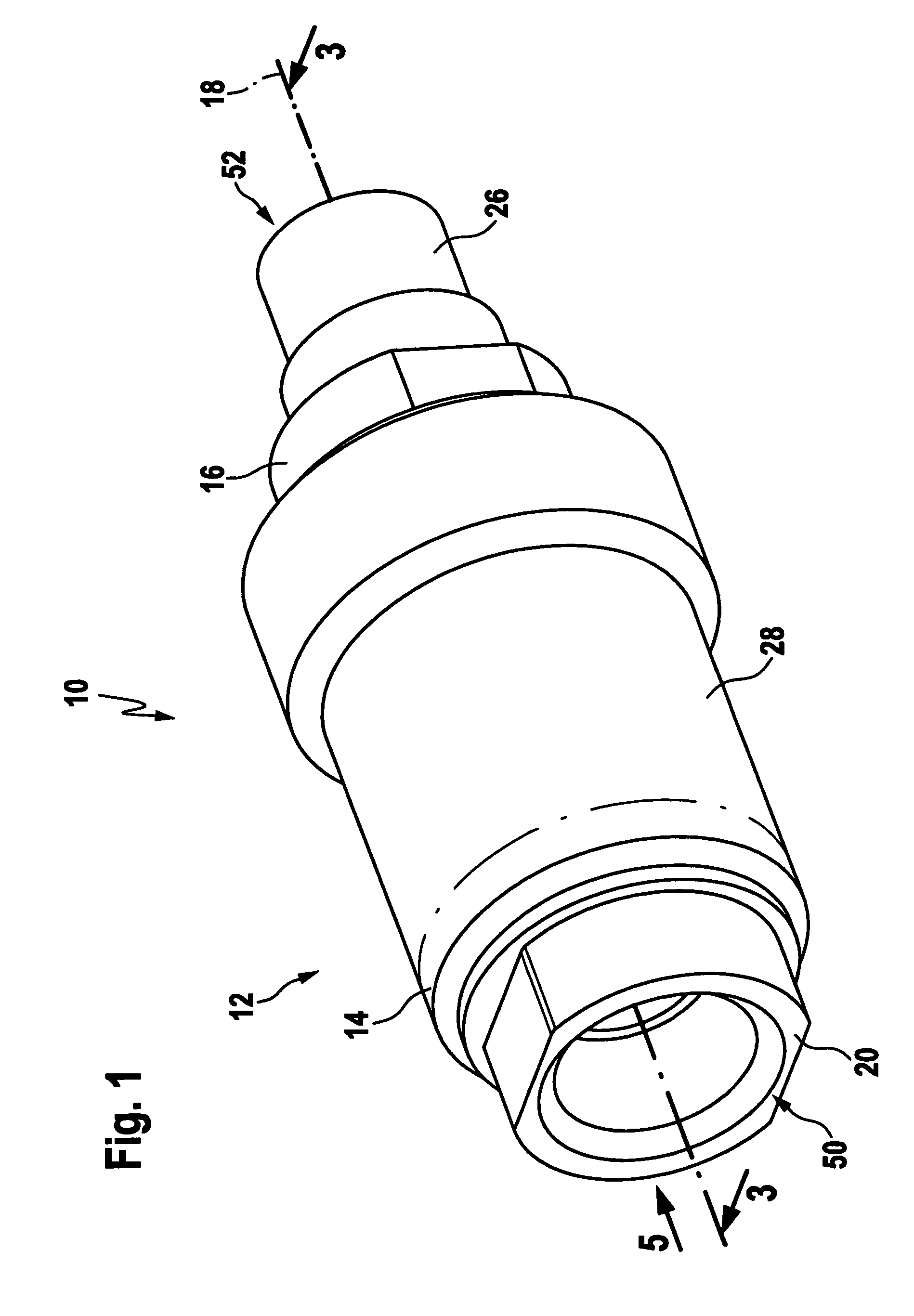

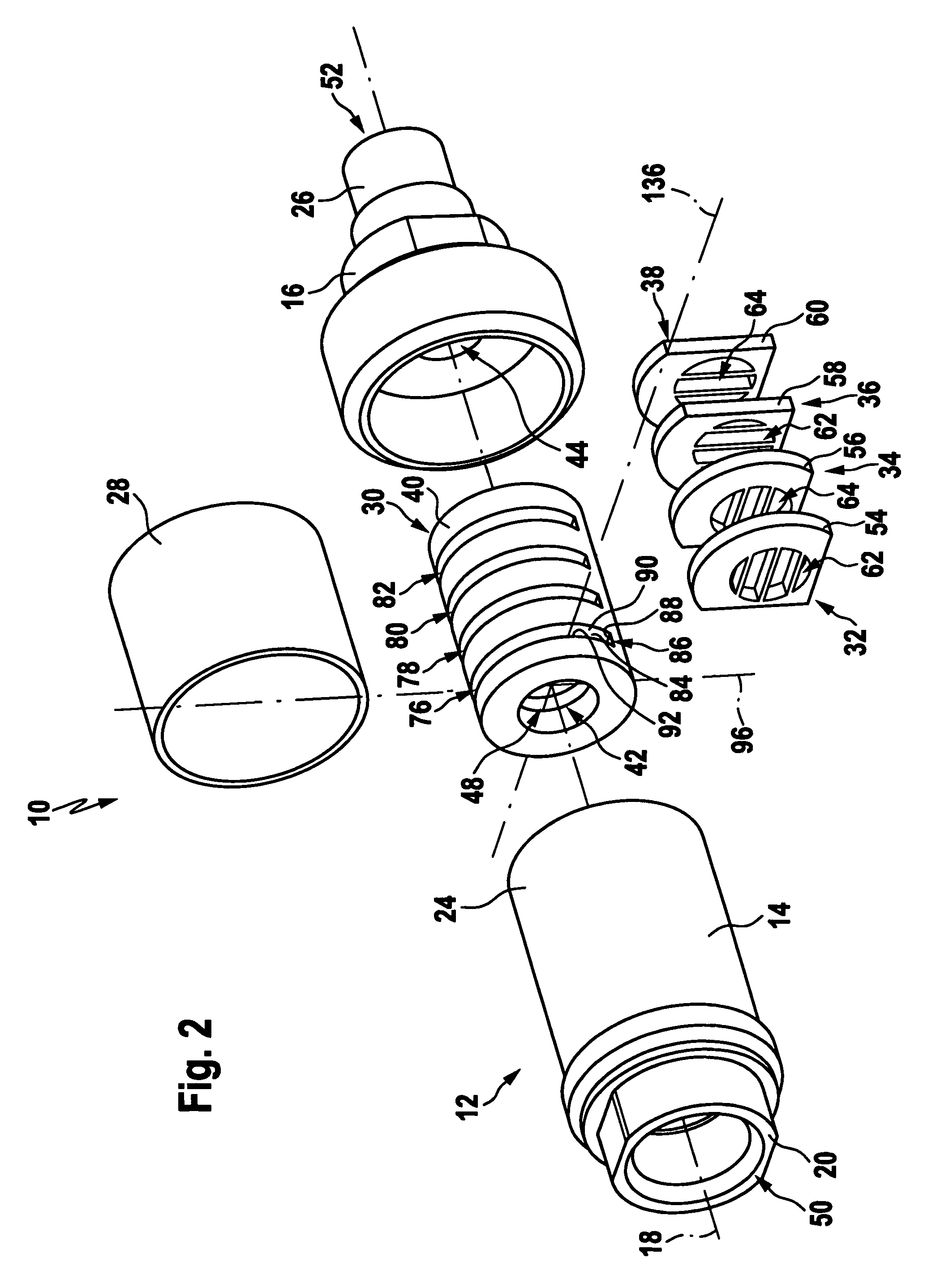

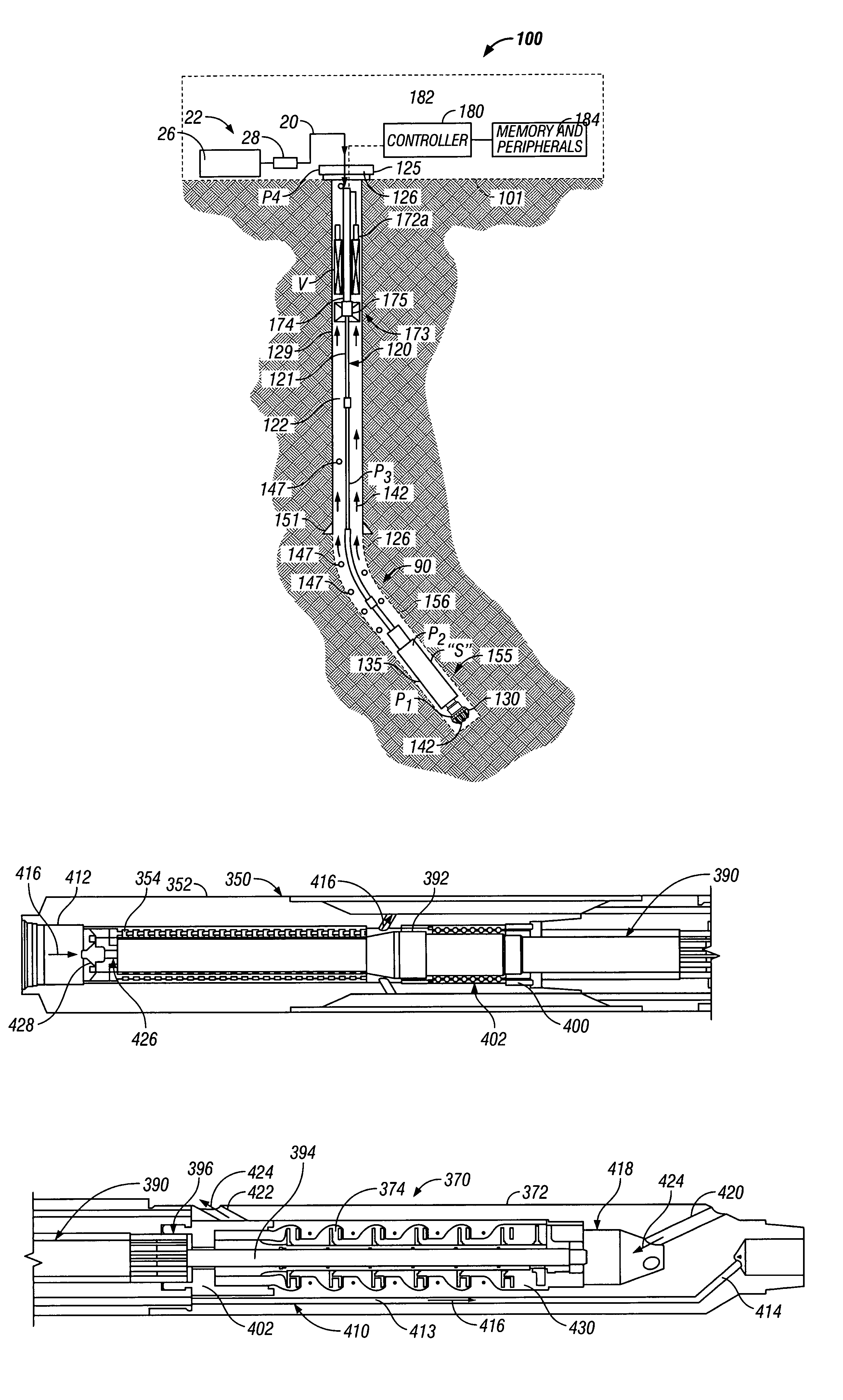

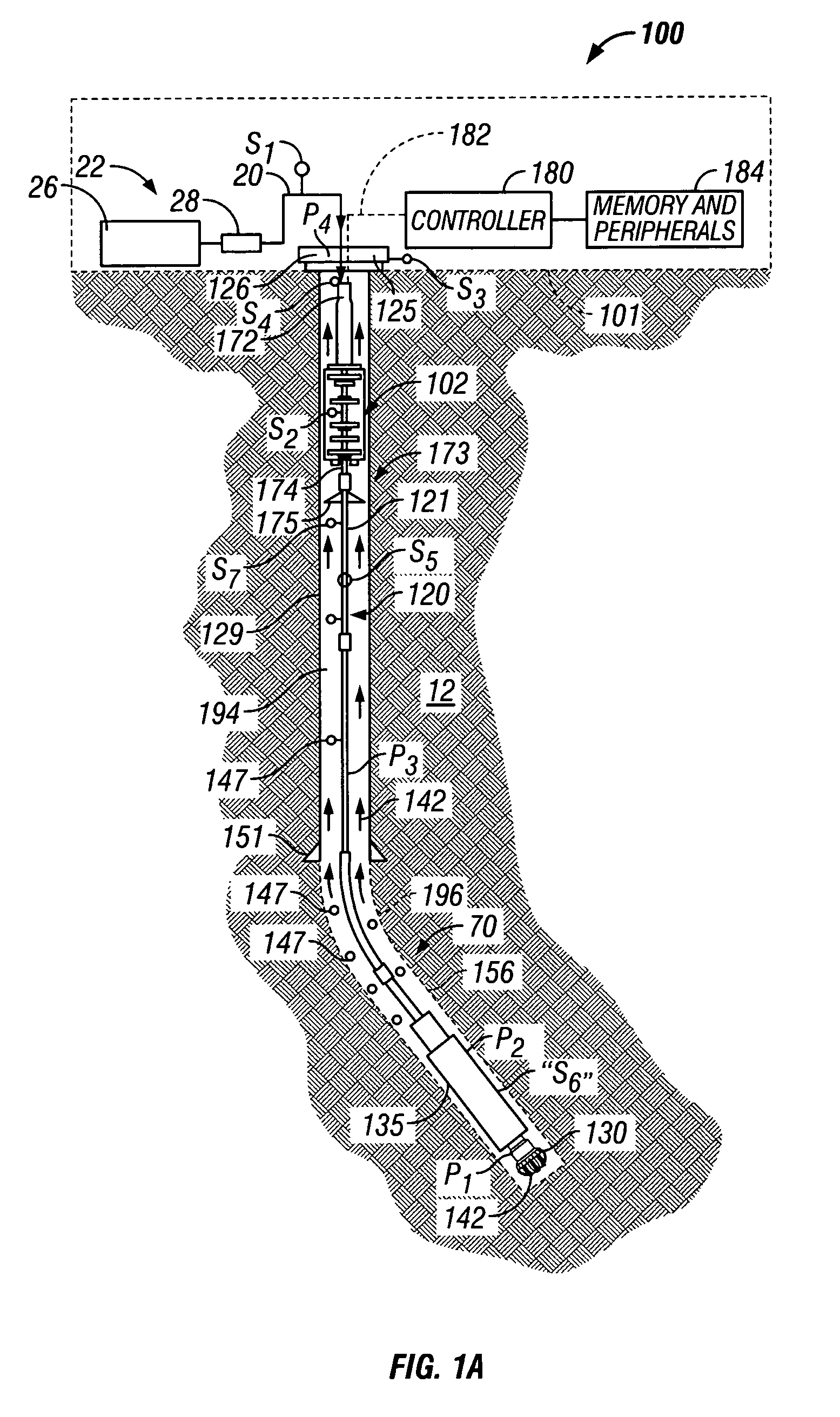

Modular design for downhole ECD-management devices and related methods

InactiveUS7096975B2Improve drilling efficiencyExtend system lifeDrilling rodsConstructionsEngineeringPressure difference

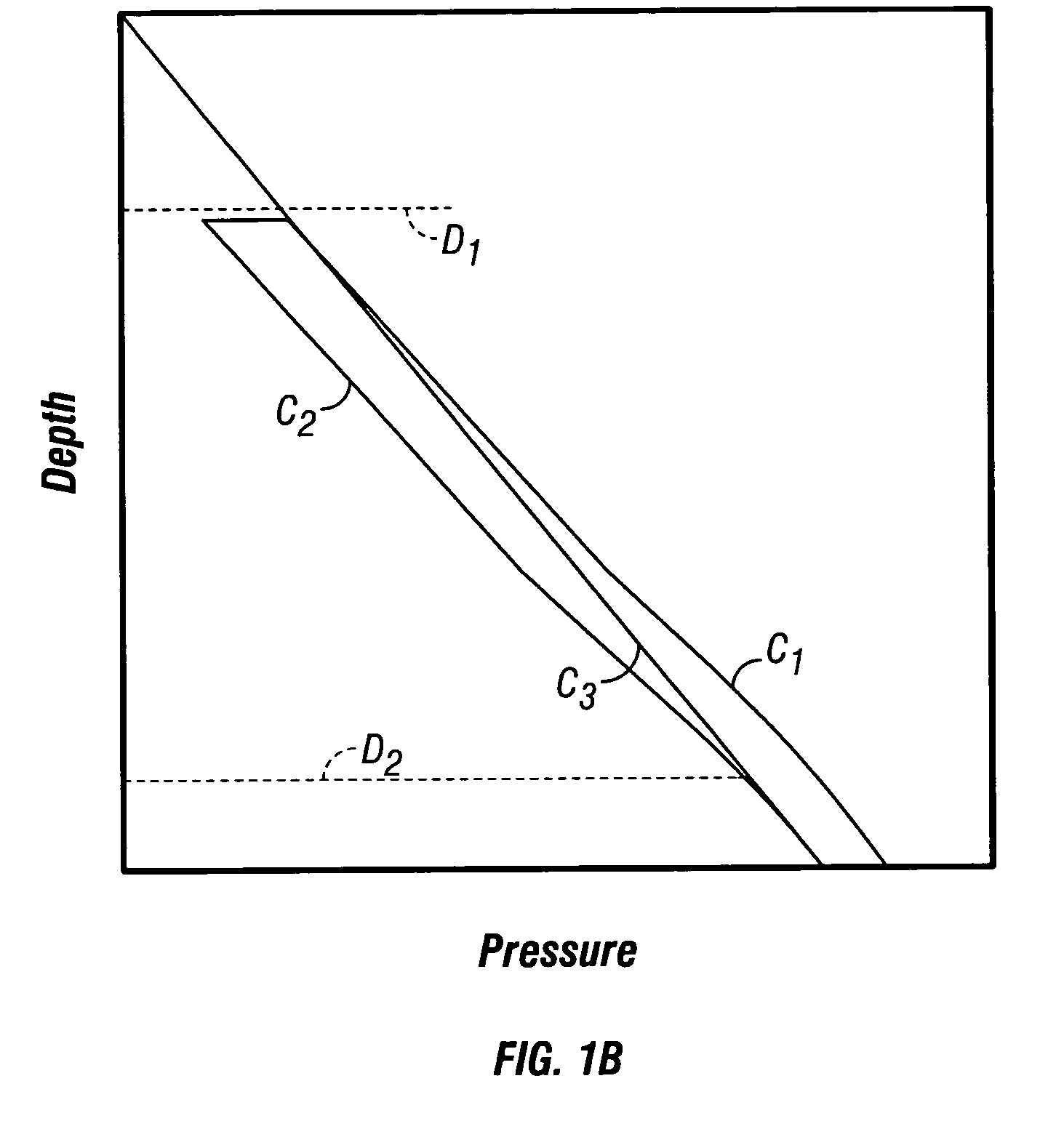

One or more components of a wellbore drilling assembly utilize a modular construction to facilitate assembly, disassembly, repair and / or maintenance of a wellbore drilling assembly and / or to extend the overall operating capabilities of the drilling assembly. In one embodiment, a modular construction is used for an APD Device, a motor driving the modular APD Device, a comminution device, and an annular seal. Individual modules can be configure have different operating set points, operating parameters and characteristics (e.g., rotational speeds, flow rates, pressure differentials, etc.) and / or different responses to given environmental factors or conditions (e.g., pressure, temperature, wellbore fluid chemistry, etc.). In one embodiment, the high-pressure seals used in conjunction with the APD Device and / or motor is a hydrodynamic seal that provides a selected leak or flow rates. Optionally, the seal is modular to provide different degrees of leak rates and / or different functional characteristics.

Owner:BAKER HUGHES INC

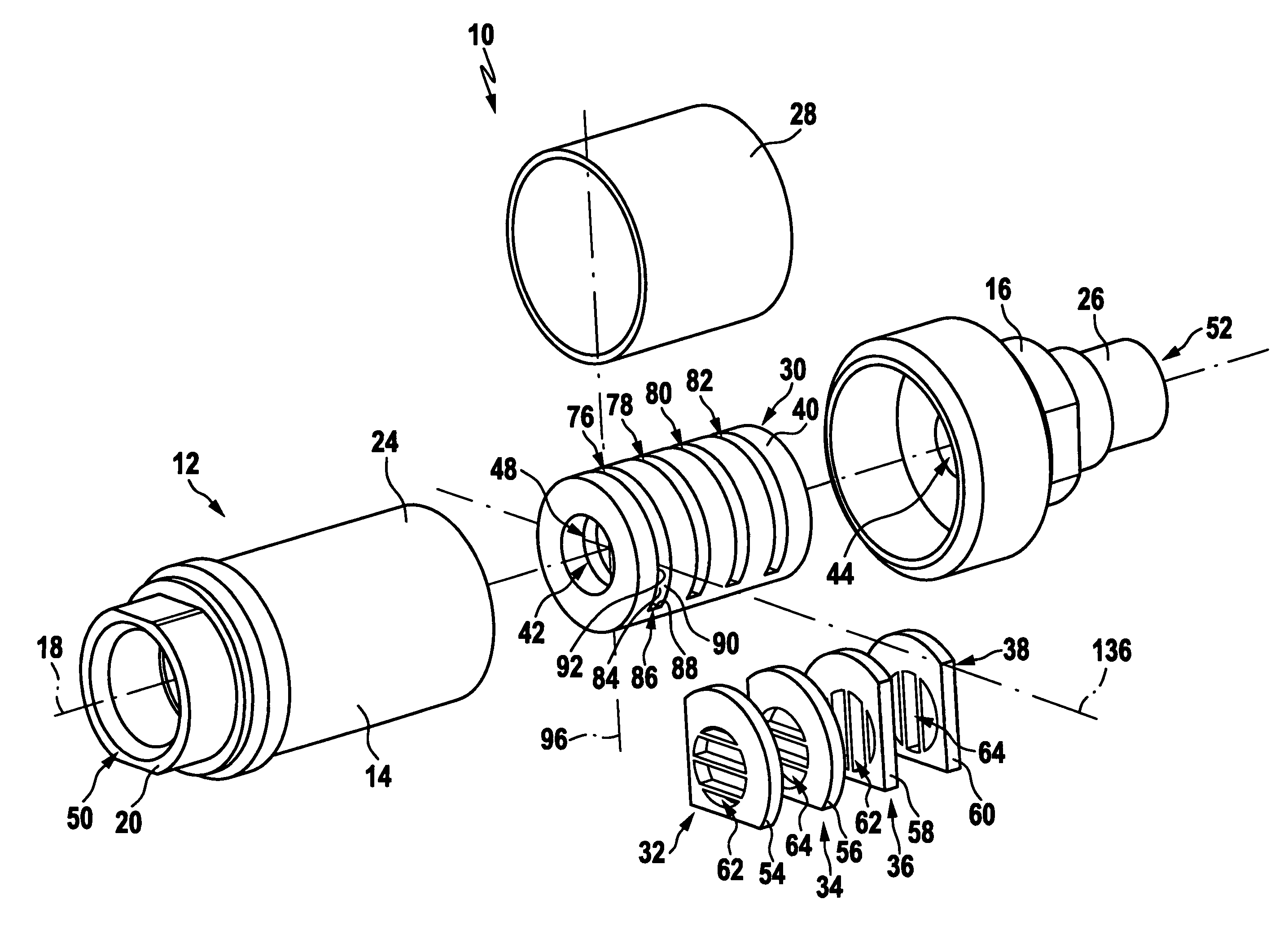

Comminution device and method for comminuting residue in a dishwasher

ActiveUS7497222B2Reduce manufacturing costEasy to crushTableware washing/rinsing machine detailsElectrostatic cleaningEngineeringComminution

A dishwashing machine including a comminution device and a method for comminuting residue in the dishwasher. The comminution device at minimal manufacturing costs, makes it possible to easily comminute the coarse contaminants or residue accumulating during the rinse cycle in the dishwashing machine, flush it out of the dishwasher and at the same time reduce the danger of clogging the sieve(s) placed in the dishwasher. The comminution device preferably is actuated by the lye pump of the dishwashing machine. In this manner the comminution device is actuated easily and efficiently, which both enables cost-effective manufacture of the dishwashing machine, and improves its operating safety and ease of maintenance. In the process the rinse residue can first collect during the rinse cycle in uncomminuted form on the floor of the rinsing container and only then be comminuted when the washing liquid is pumped out and flushed out of the dishwashing machine.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Biological utilization method of waste tobacco stems

InactiveCN103283681AOvercoming palatabilityOvercome absorbencyFood processingAnimal feeding stuffFermentationPollution

The invention provides a biological utilization method of waste tobacco stems. In the biological utilization method, the waste tobacco stems produced in the tobacco threshing and redrying process are used as a main raw material for preparing insect feed by a comminution or fermentation method, and the insect feed is mixed with conventional feed for breeding yellow mealworms, barley insects, dark mealworms, woodlouses, crickets, earthworms and other economic insects. The biological utilization method comprises the main steps: preparing tobacco stem feed; mixing the feed; breeding the insects; and utilizing the insects. Polypides of the produced insects are applicable to the breeding industry, and fecula is applicable to organic agricultural tobacco production. Through the food-taking process of the insects and the very strong decomposing and digesting capability of the insects, the waste tobacco stems are biologically transformed into of insect polypides with multiple purposes and products thereof and are organically connected with the livestock and poultry breeding industry and other industrial chains, so that the waste tobacco stem biomasses can be sustainably recycled, with high efficiency, no pollution and no discharge and good economic, environmental and social benefits are produced.

Owner:朱大恒

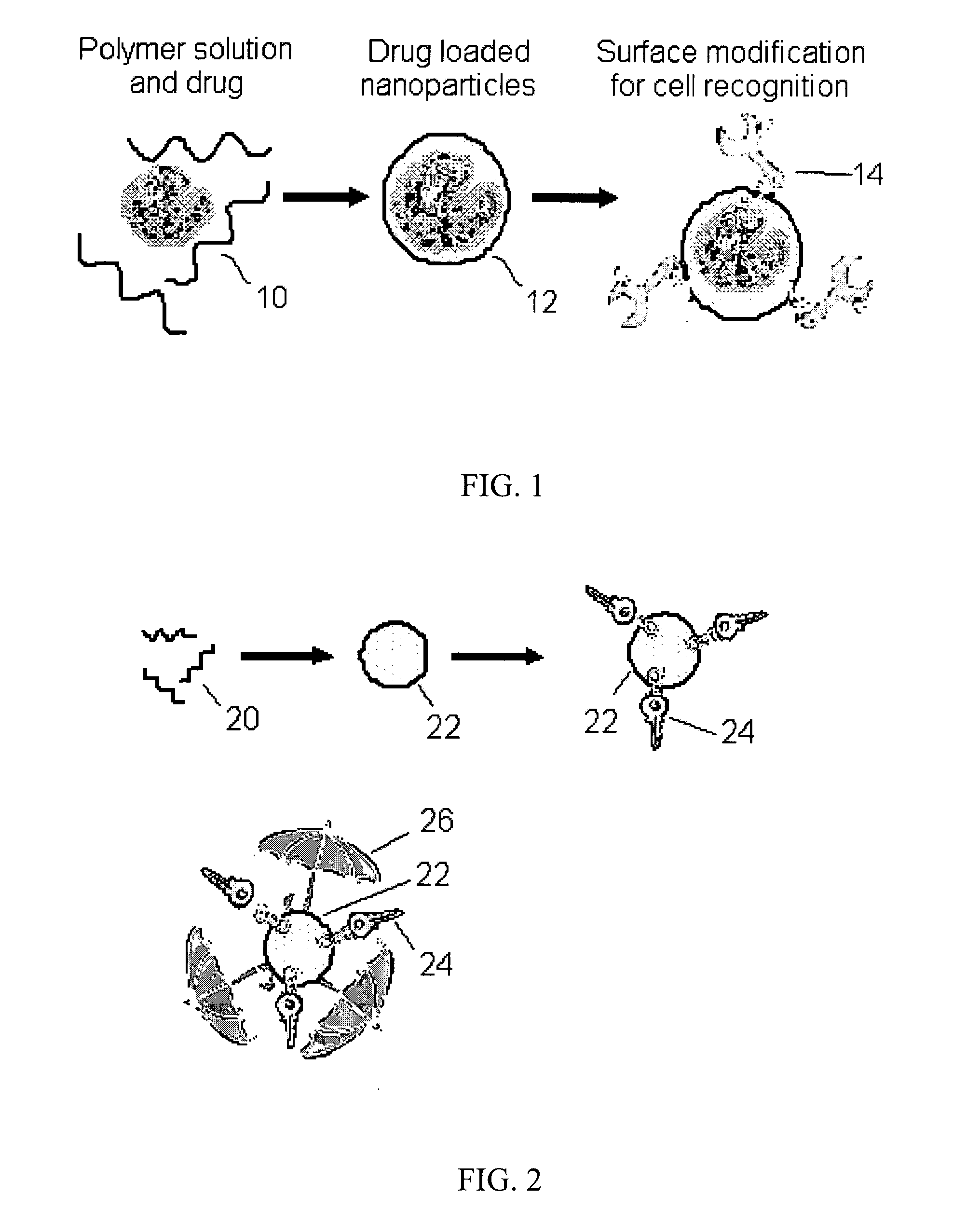

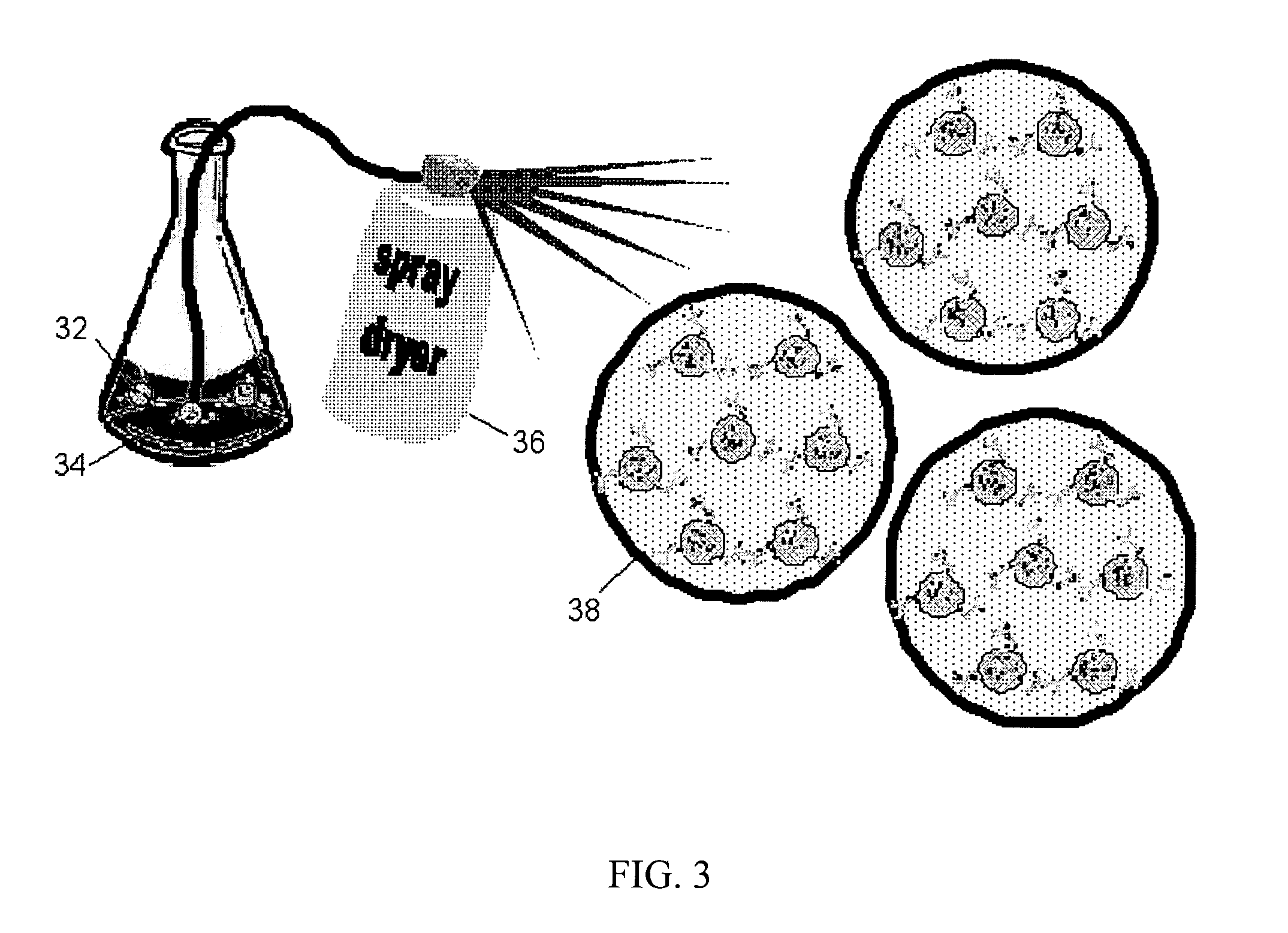

Formulation of powder containing nanoparticles for aerosol delivery to the lungs

Respirable particles carrying active principles or diagnostics in nanoparticle form are created by mixing the nanoparticles with liquid carrier, then forming the resultant mixture into respirable particles. Spray-drying, freeze spray drying and drying followed by comminution may be used to create the respirable particles, which may be delivered to the lung via a dry powder inhaler. In one example, lactose was used as the excipient and spray-dried with two different types of nanoparticle: gelatin and poly butylcyanoacrylate nanoparticles. The incorporation of nanoparticles did not affect the respirable fraction of the carrier powders.

Owner:FINLAY WARREN HUGH +2

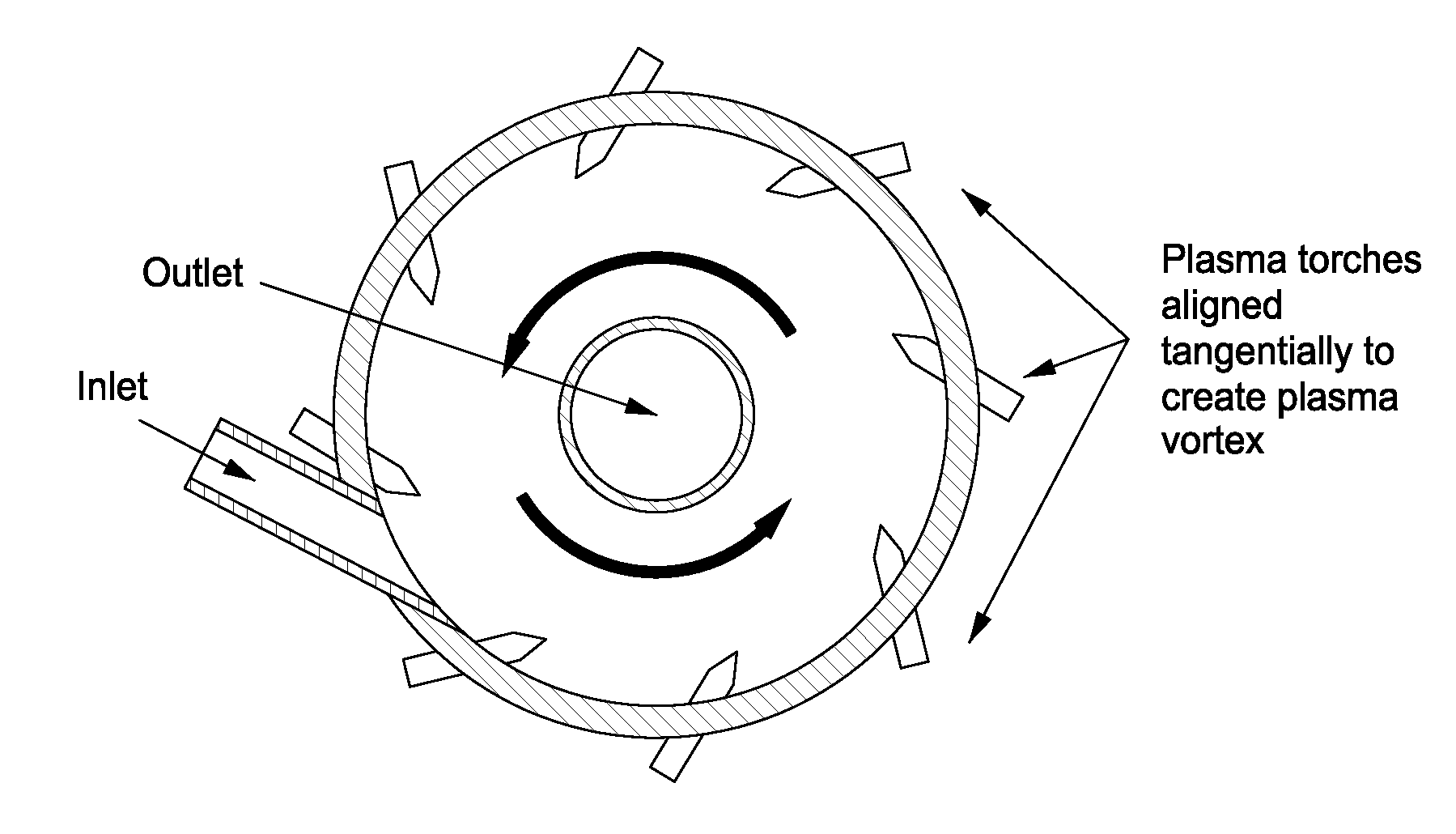

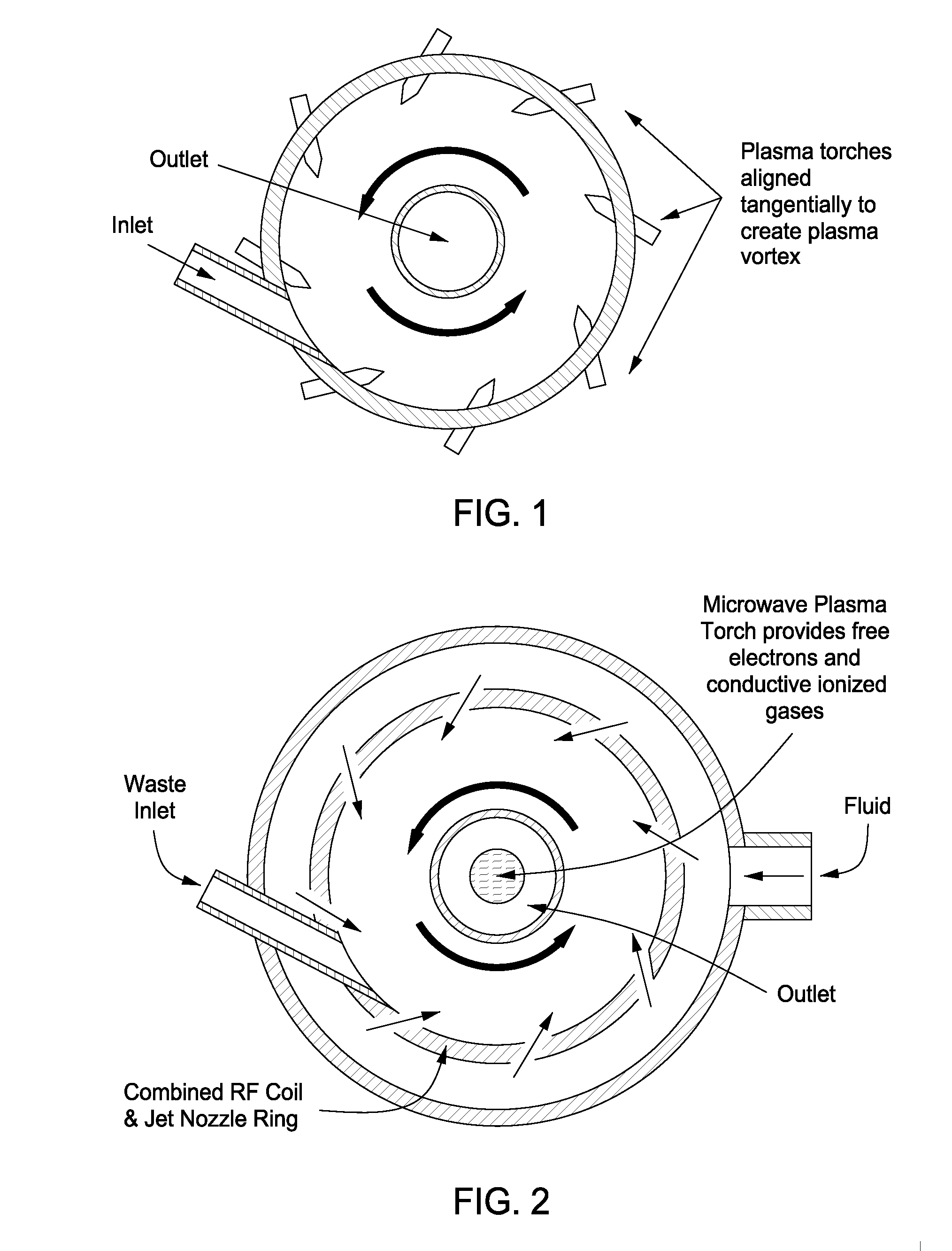

Method for treating a substance with wave energy from plasma and an electrical arc

InactiveUS20120024718A1From normal temperature solutionsLiquid separation by electricitySingle processAngular momentum

An apparatus for synergistically combining a plasma with a comminution means such as a fluid kinetic energy mill (jet mill), preferably in a single reactor and / or in a single process step is provided by the present invention. Within the apparatus of the invention potential energy is converted into kinetic energy and subsequently into angular momentum by means of wave energy, for comminuting, reacting and separation of feed materials. Methods of use of the apparatus in the practice of various processes are also provided by the present invention.

Owner:FORET PLASMA LABS

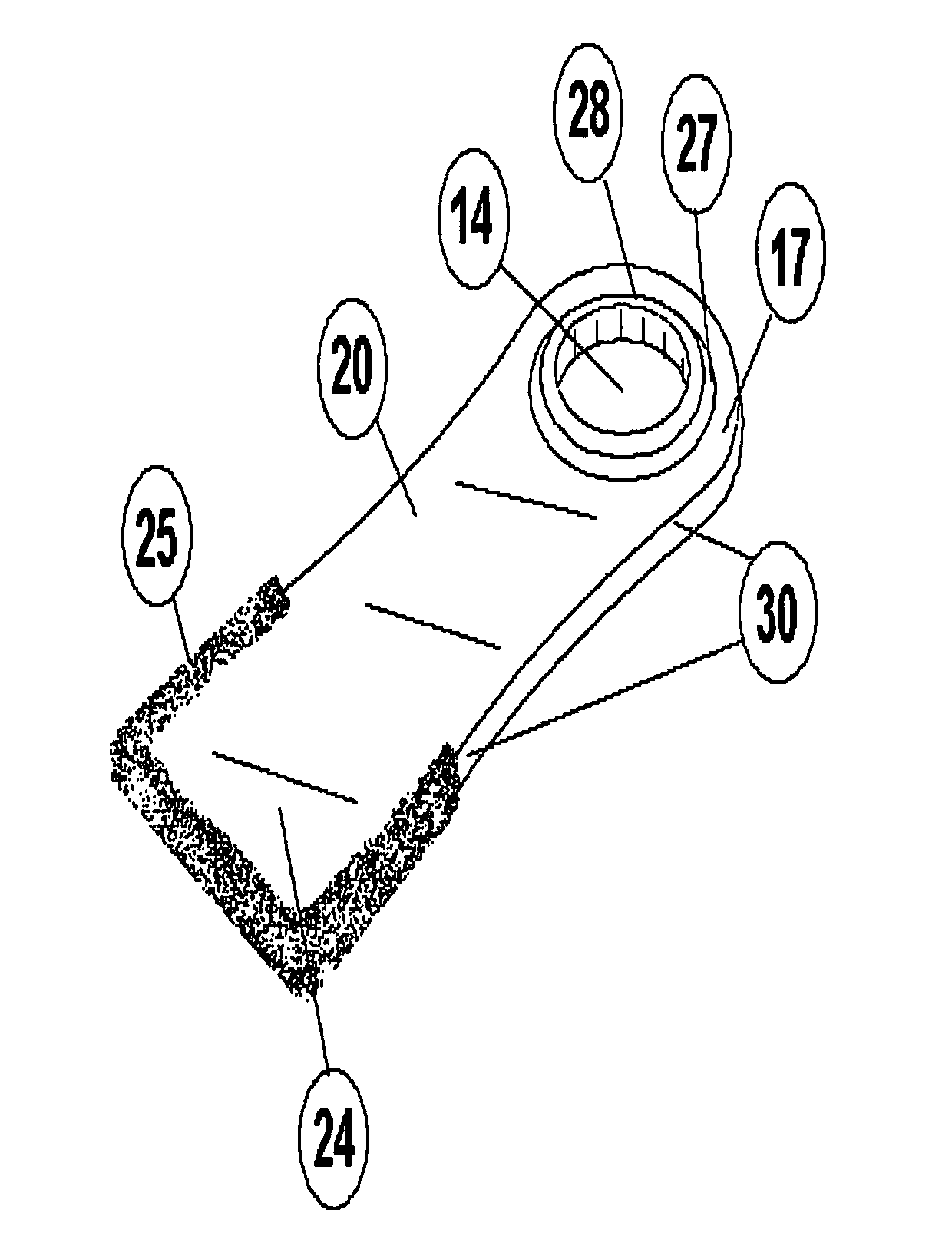

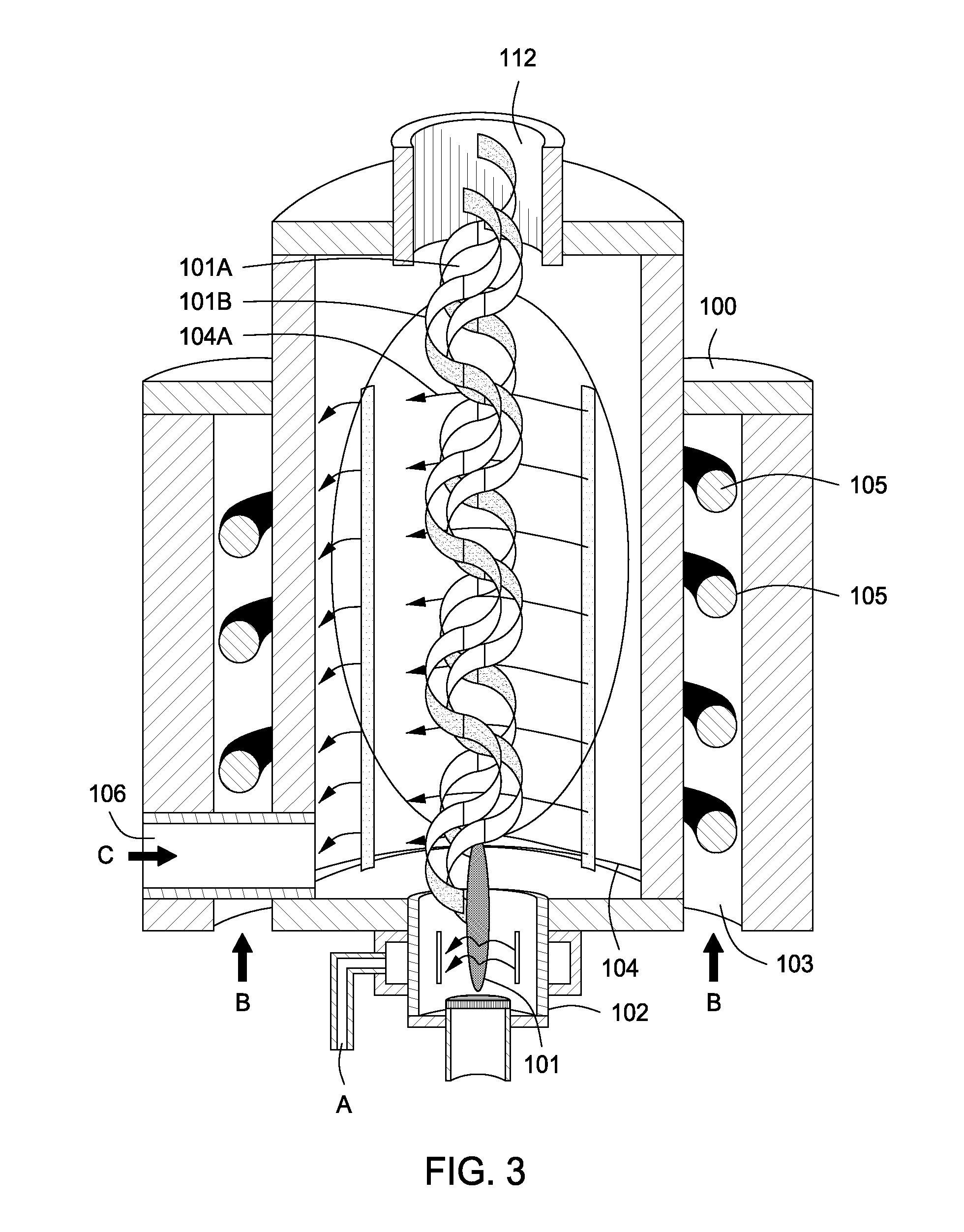

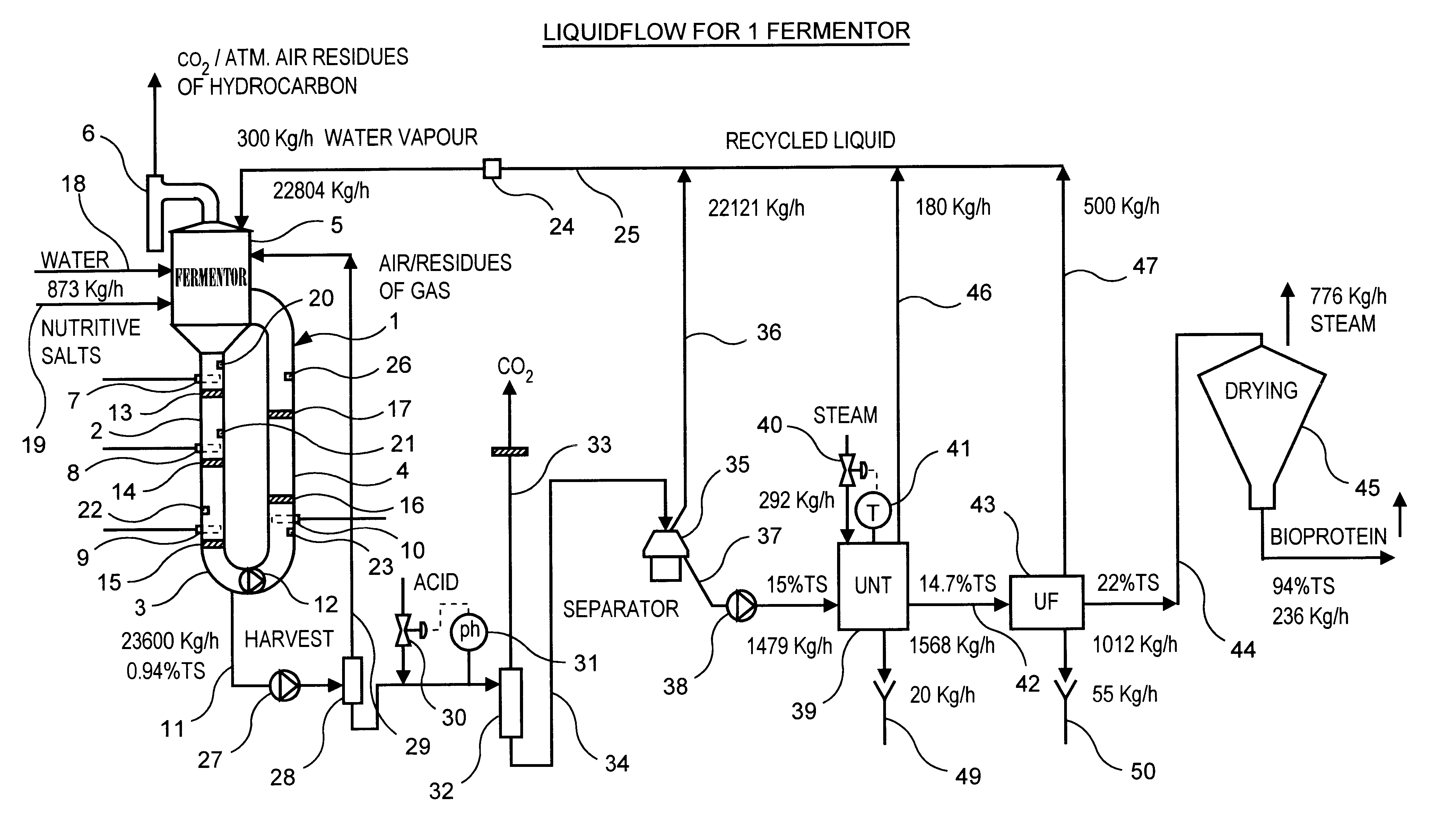

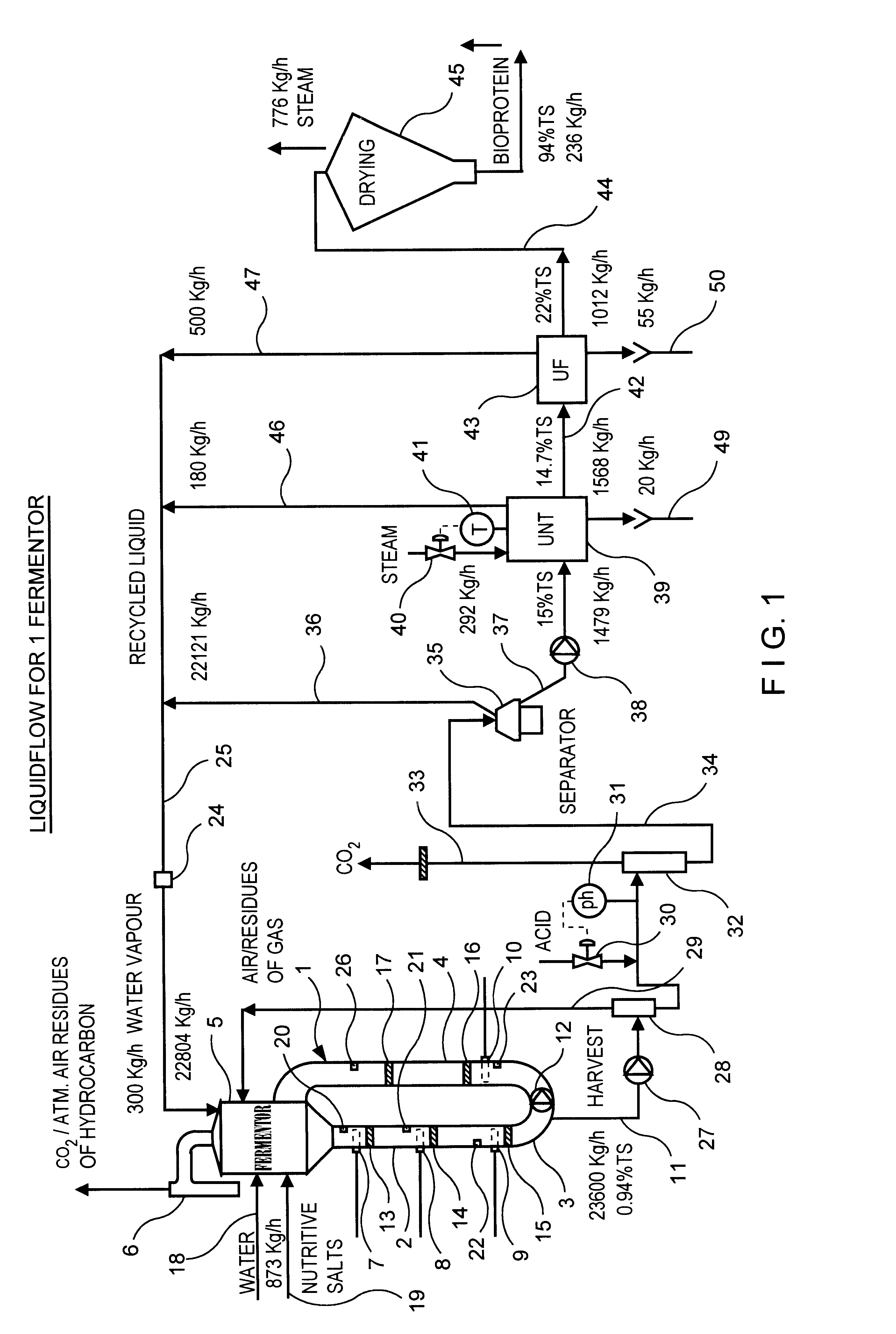

U-shape and/or nozzle u-loop fermentor and method of carrying out a fermentation process

InactiveUS6492135B1Bioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

A U-shape and / or nozzle-U-loop fermentor has a U-part consisting of an essentially vertical downstream part (2), an essentially vertical upstream part (4), a U-shape bend part (3) which connects the lower ends of the downstream and upstream parts, an inline pump (12) placed in the U-part for circulation of fermentation liquid in the fermentor, a top part (5) which is placed above the upper end of the downstream part, gas supply members (7, 8, 9, 10) which are provided in the U-part with appending static-mechanical mixing members (13, 14, 15, 16, 17) for the comminution of the gases introduced into the fermentation liquid, and supply numbers for water and nutrient salts (18) and (19), respectively, and in connection with the supply members (7, 8, 9, 10, 18, 19) or in by-pass arrangements in connection therewith one (or more) ion sensor(s) or analyser(s) (20, 21, 22, 23) for sensing the concentration of at least one of the ion species phosphate, ammonium, nitrate and hydrogen ion, oxygen sensor(s) for sensing the oxygen concentration, and at least one thermo phial for sensing the temperature, said sensor(s), analyser(s) and phial(s) delivering signals to a data processing system (PC), wherein the signals received are processed and the dosage of feed gases, water, minerals and pH adjustment means via the supply members (7, 8, 9, 10, 18, 19) are calculated and optimised from pre-programmed amounts relative to the results measured.

Owner:UNIBIO AS

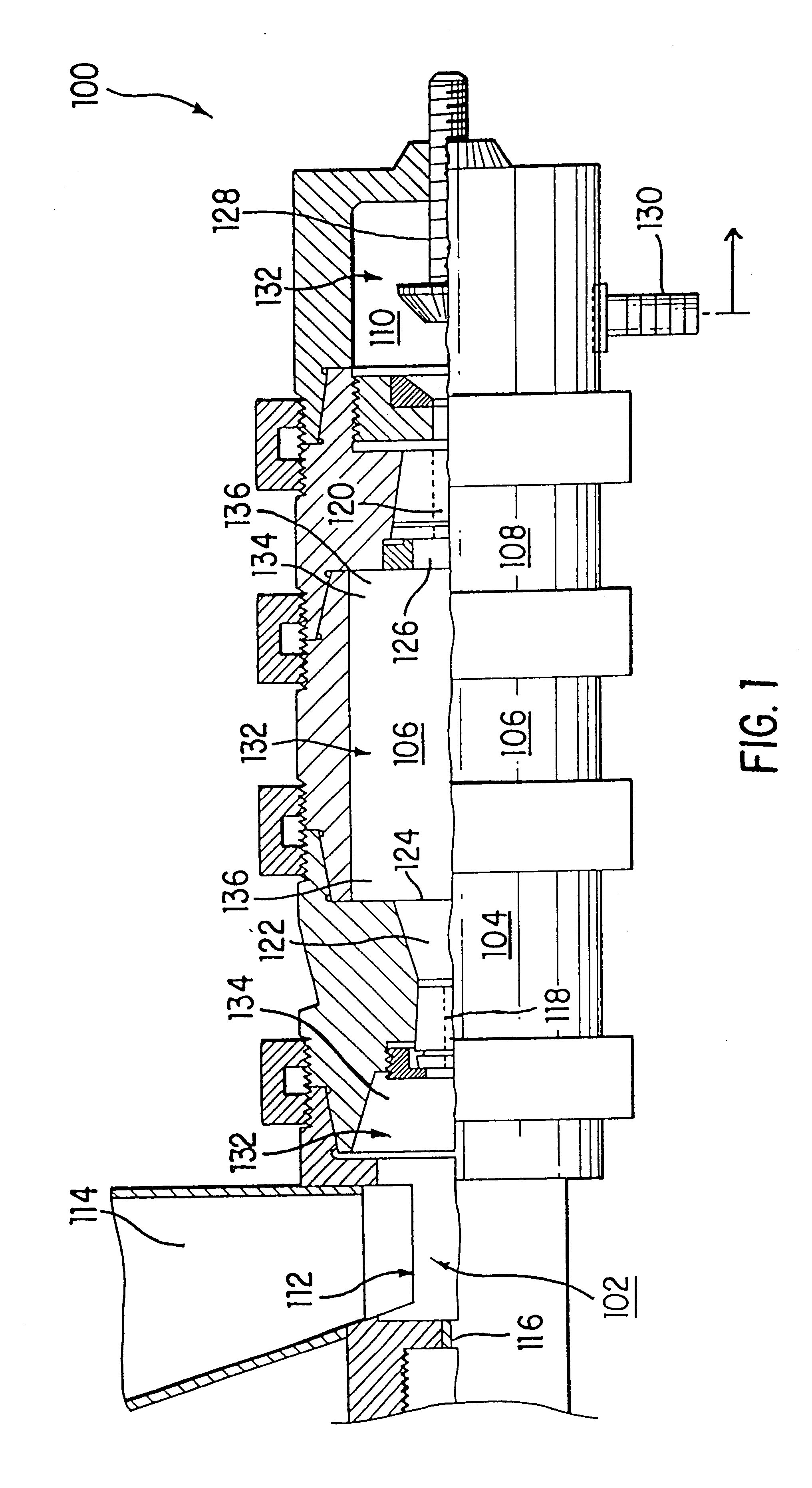

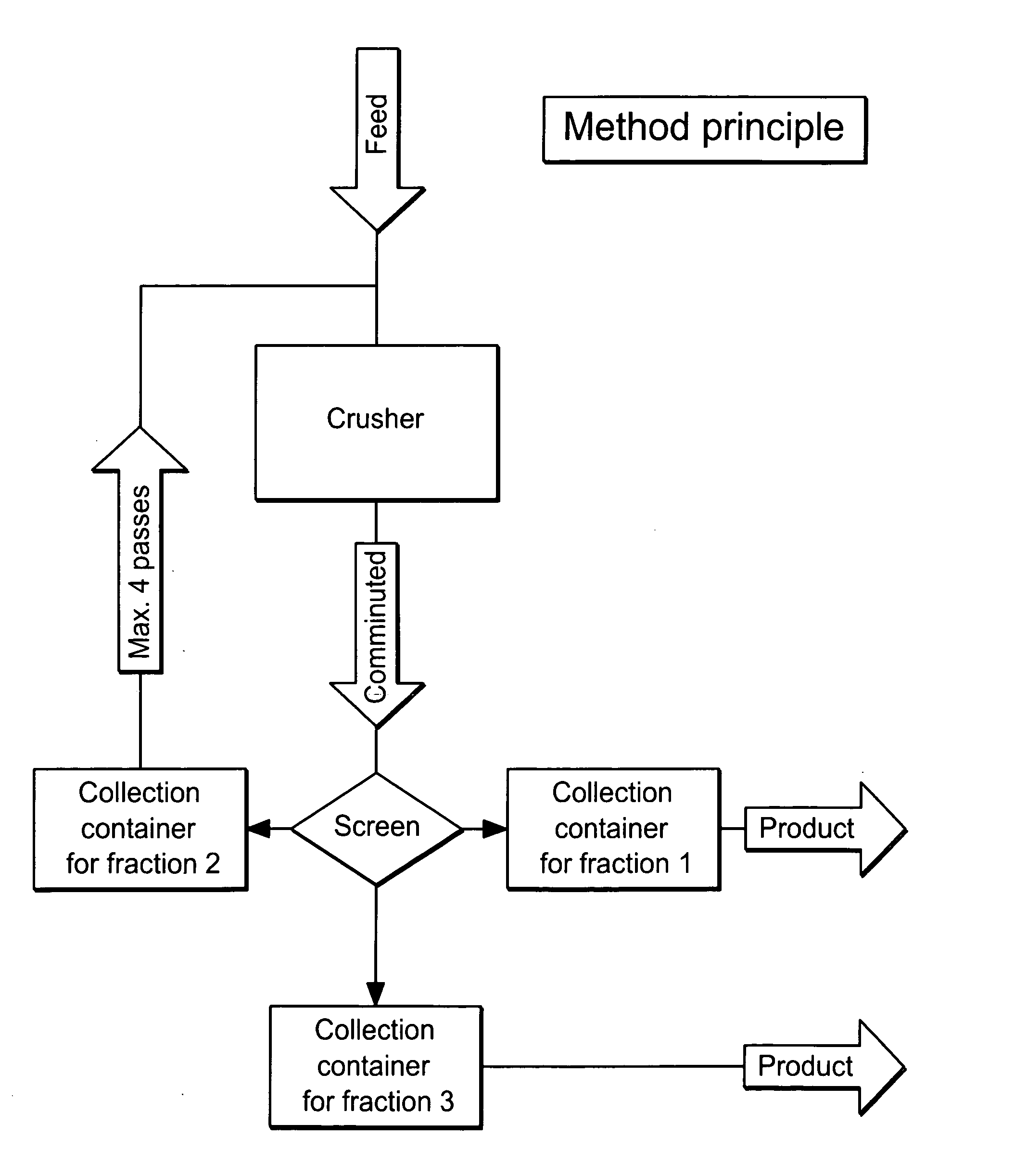

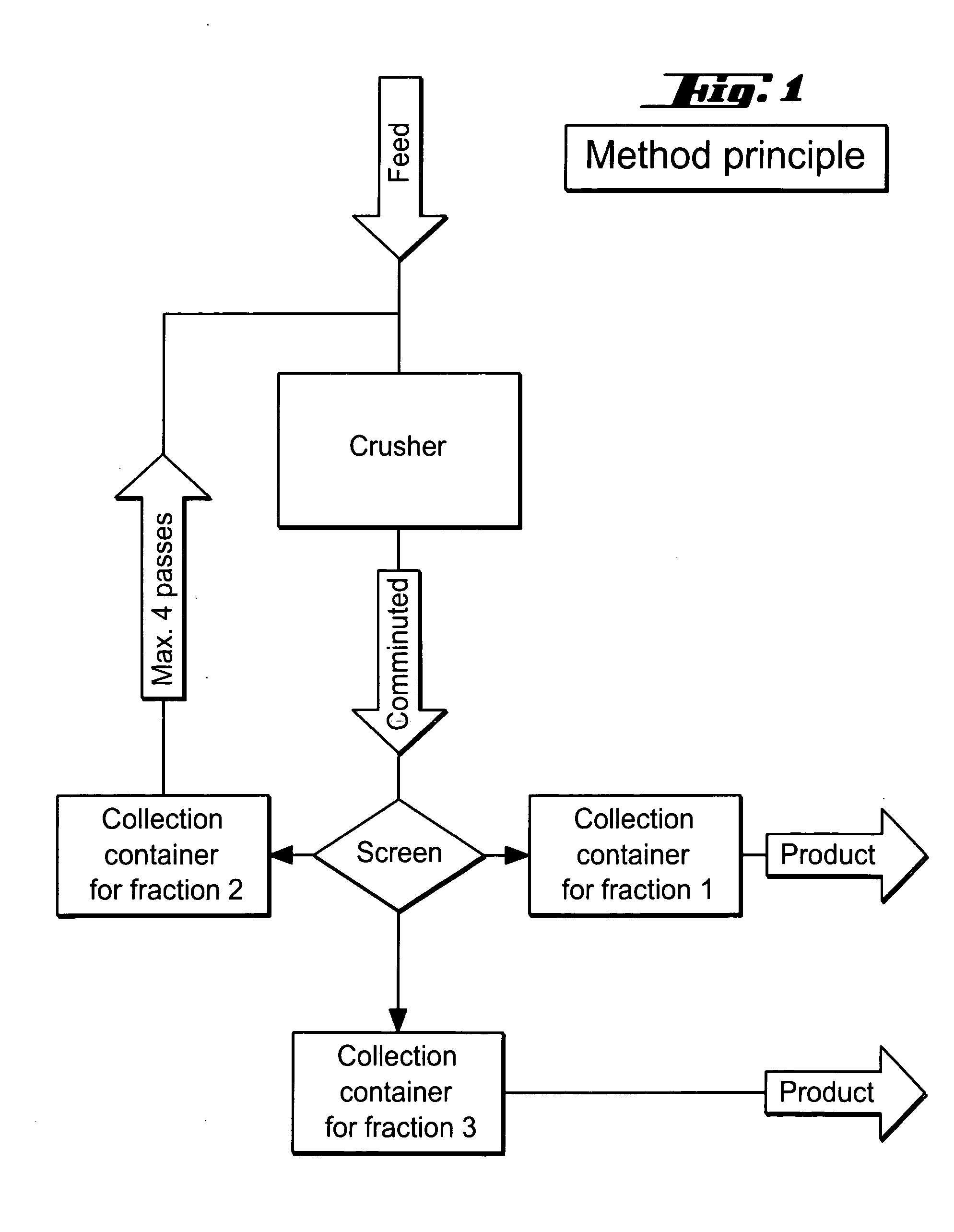

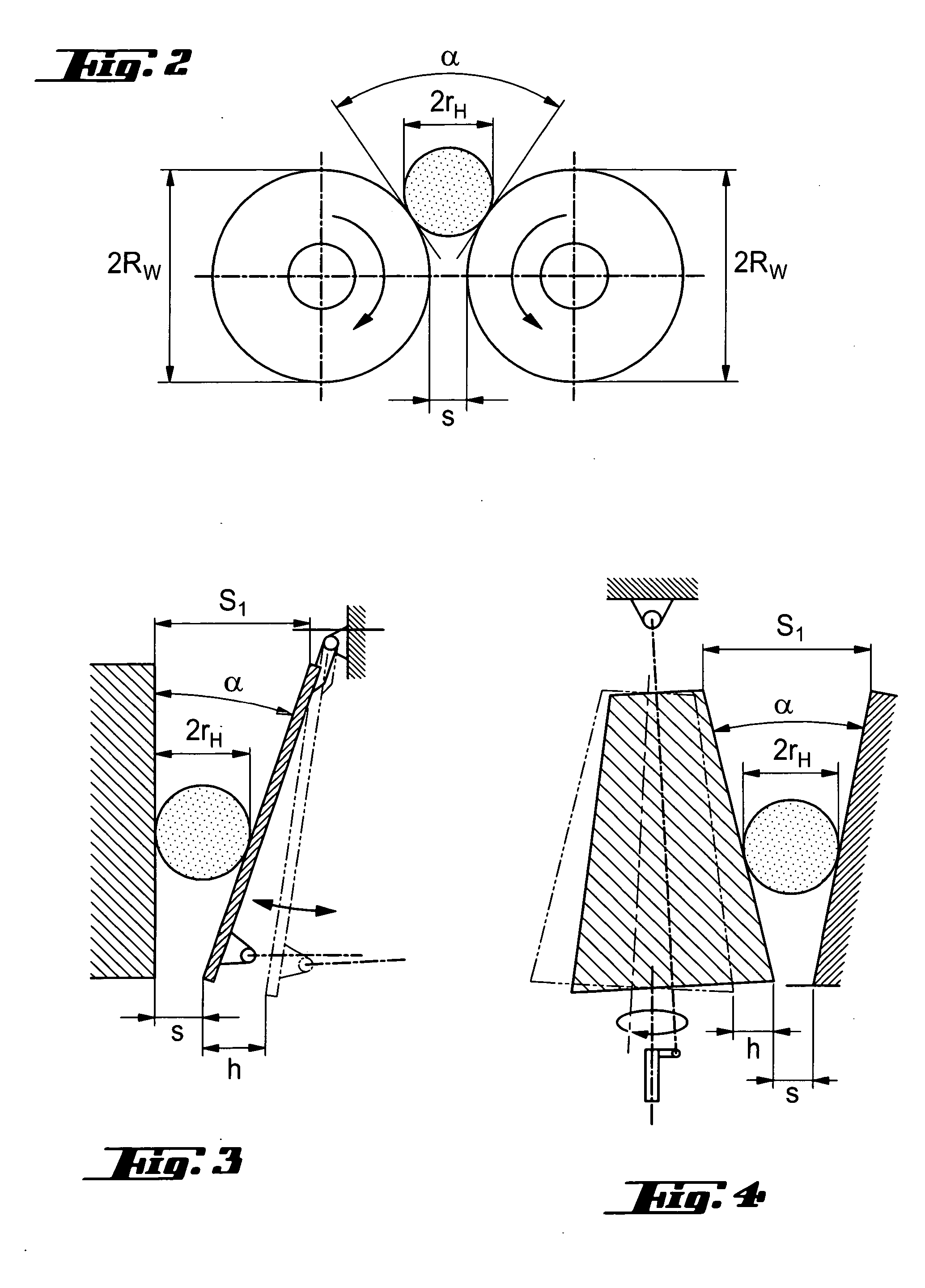

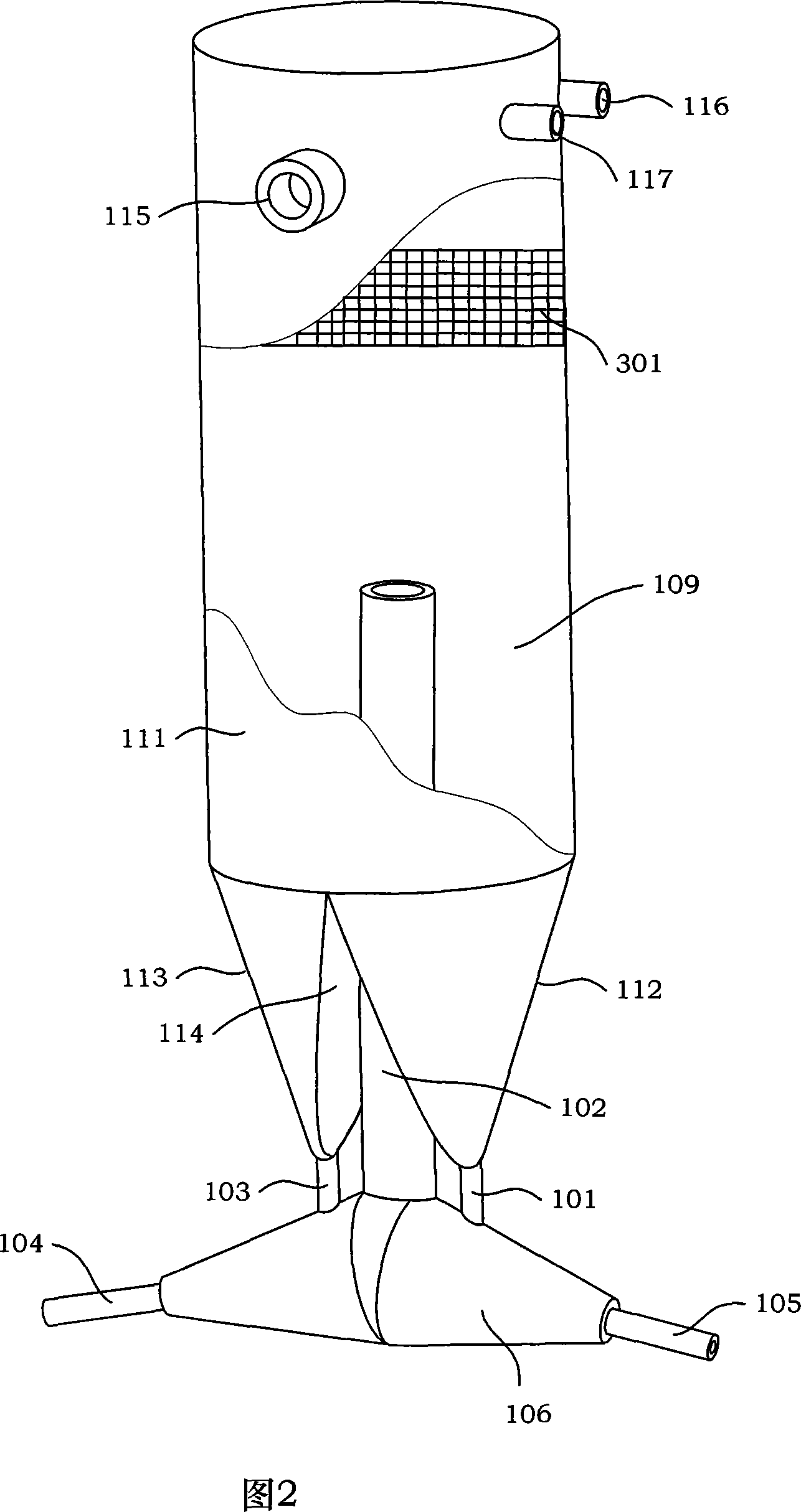

Apparatus and method for the low-contamination, automatic crushing of silicon fragments

ActiveUS20060088970A1Improve productivitySiliconSemiconductor/solid-state device manufacturingWear resistantCrusher

Owner:WACKER CHEM GMBH

Hammermill hammer

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The design as disclosed and claimed may be forged to increase the strength of the hammer. A rod hole shoulder surrounding a portion of the rod hole adjacent the neck may be reduced in the radial dimension. The shape of the hammer body may be varied, as disclosed and claimed, to further improve hammer strength, or reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted.

Owner:GENESIS III

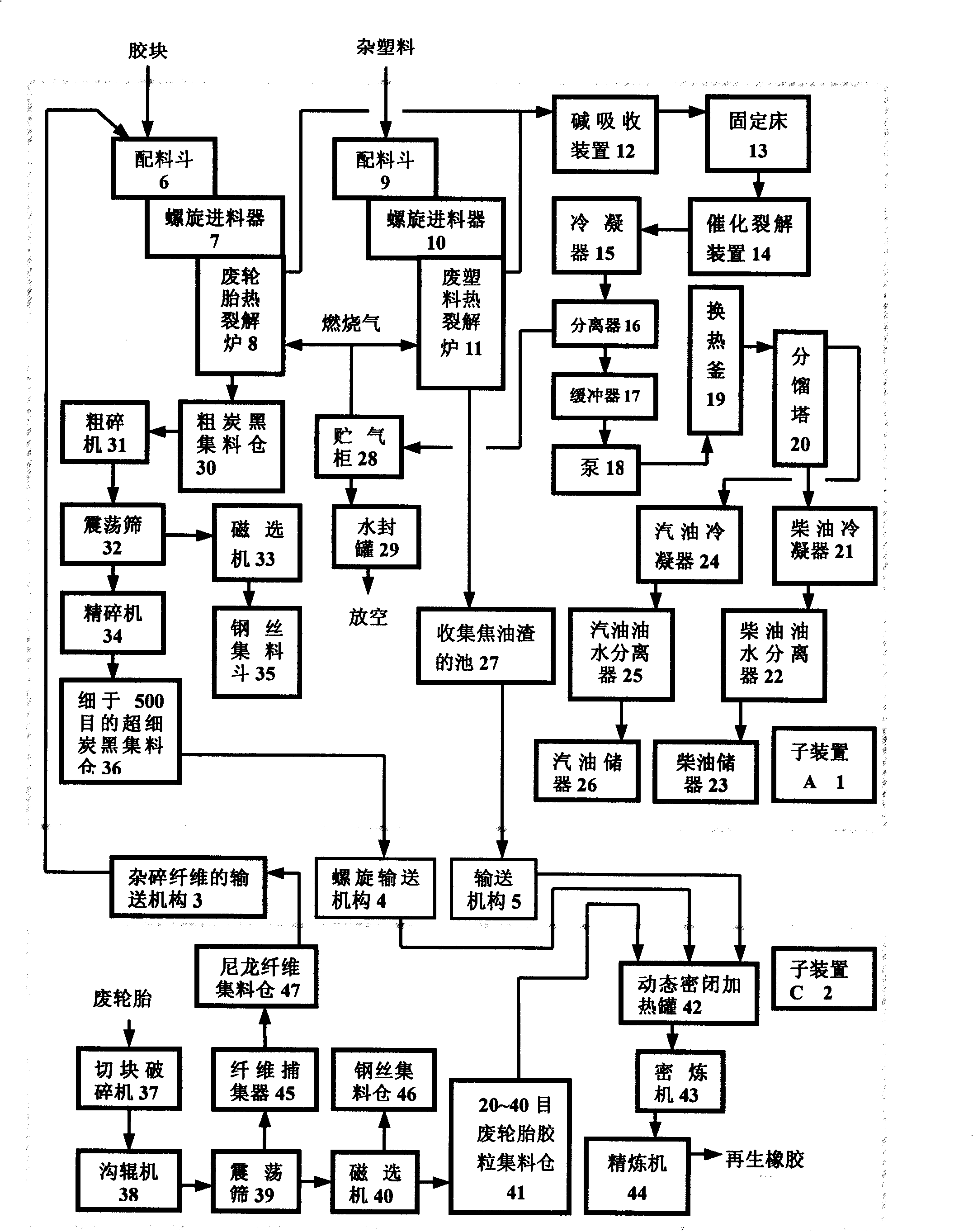

Method and apparatus for combination regeneration, or coproduction with hydrocarbon black of waste and old macromolecule material

ActiveCN101402745AReduce wasteExcellent energy qualityPlastic recyclingLiquid hydrocarbon mixture productionFiberRubber material

The invention discloses a method of combination and regeneration of waste high molecular materials or co-production of the waste high molecular materials and carbon black, and a device thereof, relating to two technologies of existing thermal cracking and non-thermal cracking of the waste high molecular materials and improvement and combination among various technological branches and also relating to the regeneration process of the waste high molecular materials and the combination of the regeneration process of the waste high molecular materials and the production process of general carbon black and an integration device used in the embodiment thereof; and comminution at normal temperature or the combination of the comminution at normal temperature and various branches of renovated rubber technology and an integration device adopted by the embodiment thereof are also included. The method also provides a treatment proposal for applying mixed fiber to recycling and products thereof, which are characterized in that the mixed fiber and plasticized rubber materials or / and oil materials are matched by the weight percentage of 100:5 to 100:100 to obtain a mixture taking the shape of a felt or a rubber felt or a treated felt. The proposal of the integration device also provides a combination device with fractional efficiency higher than that of the existing fractional process for the granularity of rubber powder only by means of a power screen.

Owner:上海橡源驰晨环保科技发展有限公司

Hammermill hammer

ActiveUS20070023554A1Excellent hardness propertiesIncrease torqueGrain treatmentsEngineeringHardness

An improved free swinging hammer mill hammer design is disclosed and described for comminution of materials such as grain and refuse. The hammer design of the present art is adaptable to most hammer mill or grinders having free swinging systems. The improved hammermill hammer may incorporate multiple comminution edges for increased comminution efficiencies. The improved hammermill hammer may incorporate multiple comminution edges for having increased hardness for longer operational run times. The design as disclosed and claimed may be forged to increase the strength of the hammer. The shape of the hammer body may be varied, as disclosed and claimed, to improve the hammer strength reduce or maintain the weight of the hammer while increasing the amount of force delivered to the material to be comminuted. The improved design may also incorporate comminution edges having increased hardness for longer operational run times.

Owner:GENESIS III

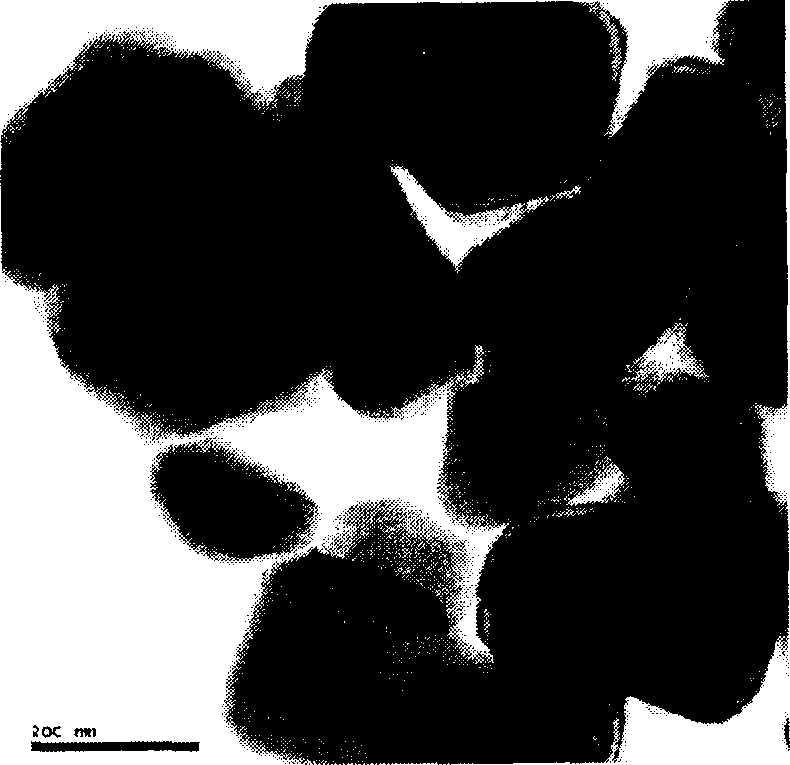

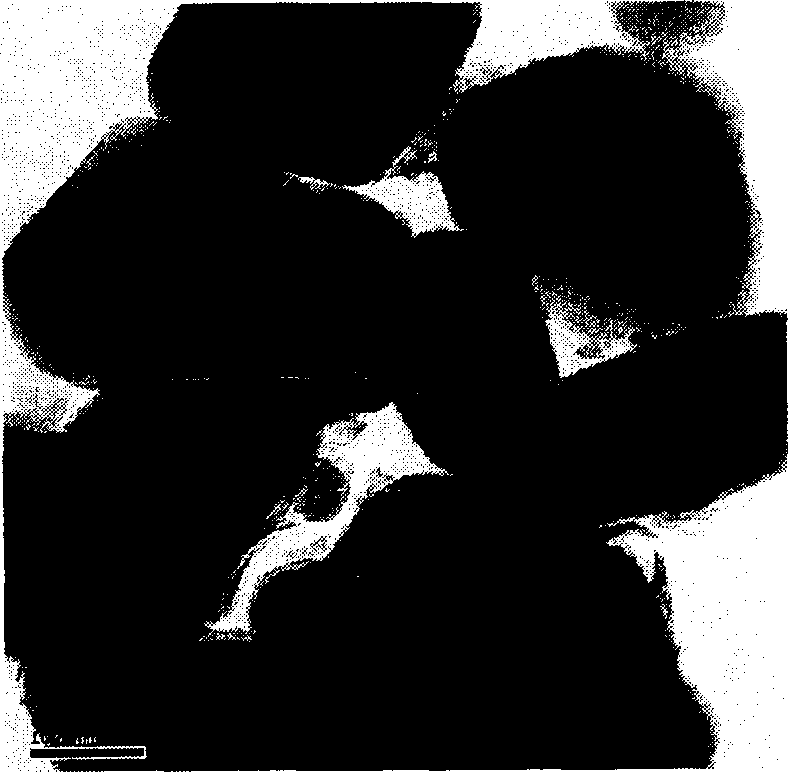

Polycrystalline silicon

Polycrystalline silicon in the form of chunks packed in plastic bags containing a mass of at least 5 kg, including chunks of size from 20 to 200 mm, wherein any fines fraction in the plastic bag is less than 900 ppmw, preferably less than 300 ppmw, more preferably less than 10 ppmw. The polycrystalline silicon, after comminution of a silicon rod obtained by CVD (Siemens process), is sorted and classified, optionally dedusted and then metered and packed. Metering and packing units include elements for removing fines or small particles during metering and during packing. The packing unit includes an energy absorber or a reservoir vessel which enables sliding or slipping of the silicon chunks into the plastic bag. Gas flow generated within the plastic bag after the bag has been filled transports the dust or small particles out of the bag, and these are sucked out with a suction device.

Owner:WACKER CHEM GMBH

Process for preparing titanium dioxide with dispersion sensitive property and high weatherability

InactiveCN1844263AGuaranteed decentralizationGood weather resistancePigment treatment with non-polymer organic compoundsSODIUM SILICATE SOLNSodium hydroxide

The invention relates to a method for preparation of titanic anhydride which is easy to disperse and is of high weatherability. The method consists of selecting 0.1 %-0.5 % hexametaphosphate, 0.1 %-0.3 % isopropanolamine or triethanolamine as disperser, dispersing the titanic anhydride paste and adjusting the PH value of the sodium-hydroxide solution to 10-11, adding silicate of soda solution and dilute sulphuric acid to cover silica dioxide at 91-95 DEG C, in which the added quantity of the soda solution is 1 %-6 % of the silica dioxide, then adjusting the PH value to 6.5-8.5, adding aluminum sulfate solution and sodium-hydroxide solution, in which the added quantity of the aluminum sulfate is 2 %-3.5 % of the aluminum oxide,maturing for 10 min to cover the aluminum oxide, rinshing and drying, then adding some organosilicon additive, performing comminution by gas stream to obtain the said titanic anhydride which is easy to disperse and is of high weatherability. The advantages of this invention lie in that it can effectively guarantee the dispersion of the paste before mat-forming treatment, can carry out the coating of the inorganic mat-forming treatment in single grain surface of titanic anhydride, and can reach the attempt of improving the weatherability and the dispersibility of titanic anhydride.

Owner:江苏镇钛化工有限公司

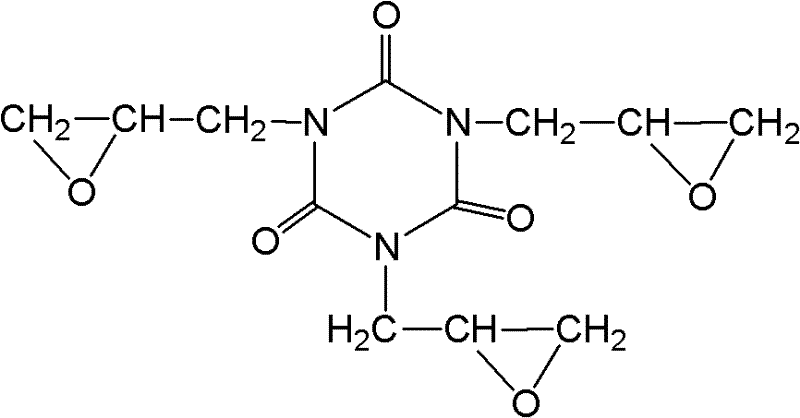

Powdery paint for aluminum profile and preparation method thereof

ActiveCN102516855AStrong adhesionSimple recipePowdery paintsPolyester coatingsComminutionOrganic matter

The invention discloses a powdery paint for aluminum profile and a preparation method thereof. The powdery paint is composed of carboxyl-terminated saturated polyester resin, triglycidyl isocyanurate (TGIC), titanium dioxide, precipitated barium sulfate, a brightener, a leveling agent and benzoin. The preparation method contains the following steps of: batch mixing, melt extrusion, crushing and ultrafine comminution. The powdery paint for aluminum profile has low curing temperature. By the adoption of the powdery paint, volatilization amount of residual TCIC low molecular organic matter is reduced. The powdery paint is beneficial to environmental protection and the health of human body. In addition, the appearance of the film is more flattening and fine.

Owner:广东华江粉末科技有限公司

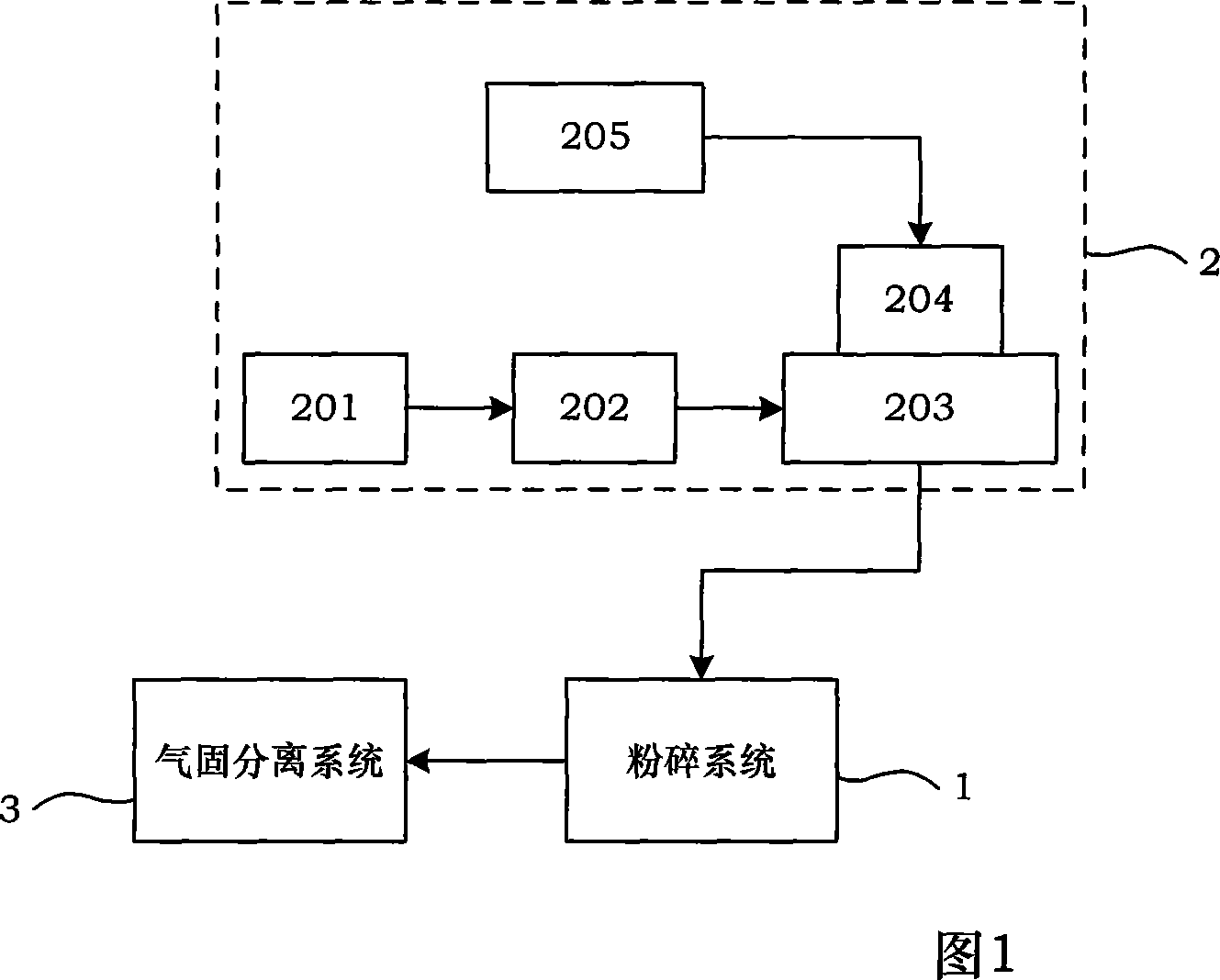

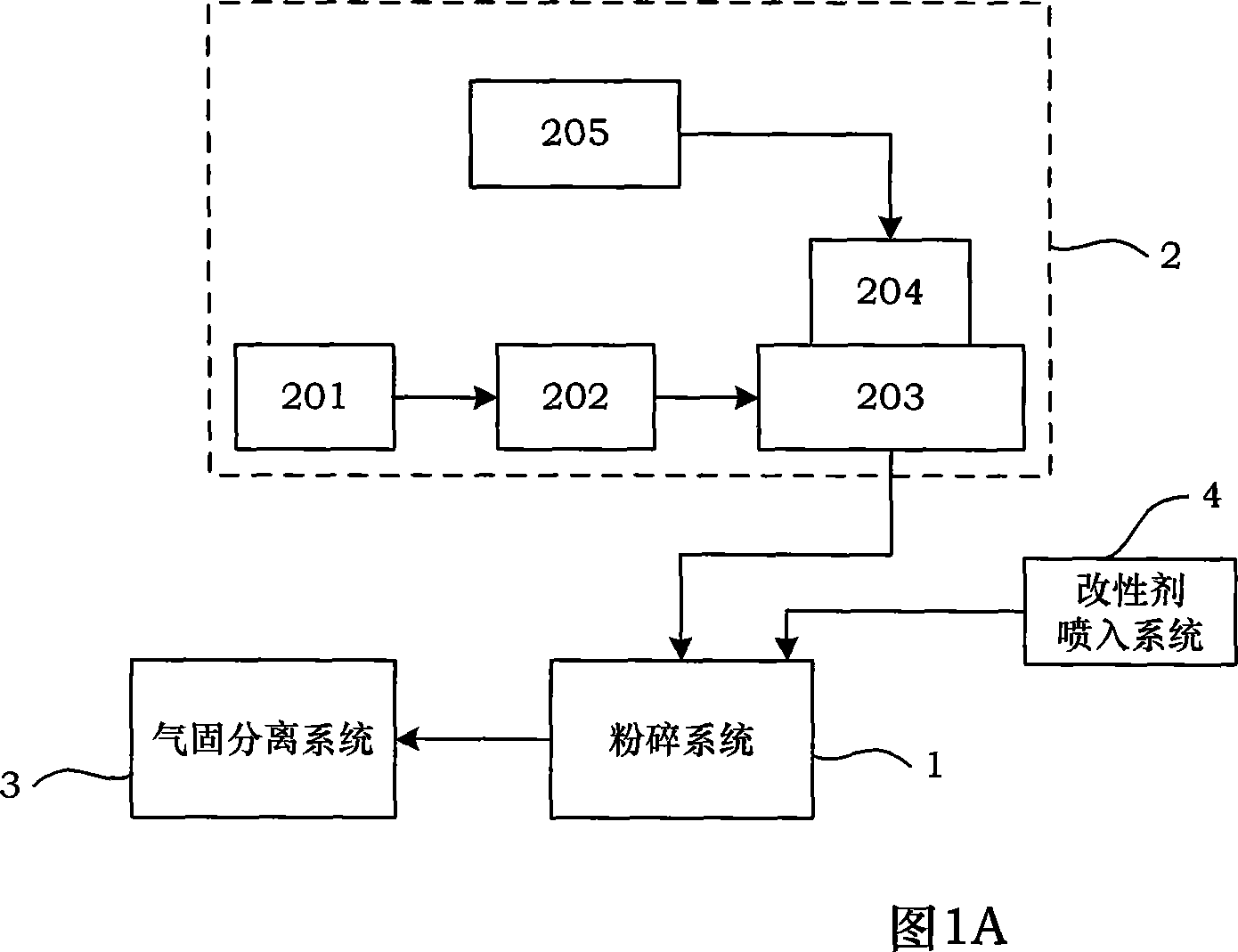

Technique and equipment for preparing Nano granules in high purity by using method of comminution by gas stream

InactiveCN101049580AEasy accessGood for collision smashingDispersed particle filtrationGrain treatmentsNanoparticleEngineering

An apparatus for preparing high-purity nanoparticles by airflow pulverizing method is composed of an air source system, a pulverizing system consisting of left and right reflux pipes and flow-up pipe to form a circulating loop of material, and air-solid separating system. Its process features that the raw material is carried by two supersonic jets for mutual and cyclic collision to obtain nanoparticles.

Owner:BEIHANG UNIV

Apparatus and method for the low-contamination, automatic crushing of silicon fragments

ActiveUS7549600B2Suitable for productionImprove productivitySiliconFine working devicesWear resistantComminution

Owner:WACKER CHEM GMBH

Black coarse grain composite drink and production method thereof

The invention discloses a black coarse grain composite drink with black rice, black sesame, black beans and black peanuts as the main raw materials and a production method thereof. The four kinds of black coarse grains are compounded. During preparation, the method of roasting is adopted for increasing the aroma and removing the beany flavor and the colloid compounding technology, colloid milling, high-pressure homogenization and other ultrafine comminution technology are adopted to fully break and levigate the material granules, so that the functional factors contained in the granules completely enter into the drink. The prepared black coarse grain composite protein drink further has nutritional value because of being rich in melanin substances, proteins, linoleic acid and trace elements. Meanwhile, the drink has natural color and exquisite mouthfeel, is fragrant, sweet, smooth, stable and free of precipitates and lamination, has long shelf life, can be suitable for various consumer population in all seasons and can be used as the thirst-quenching drink for replenishing moisture and the nutritional drink at breakfast.

Owner:SICHUAN BLUE RAY MAYSUN DRINK & FOOD

Additive for increasing the density of an oil-based fluid and fluid comprising such additive

A wellbore fluid having an oleaginous phase and an additive for increasing the density of the wellbore fluid. The additive comprises solid colloidal particles coated with a dispersant during the comminution process of forming the particles. Exemplary starting materials for the colloidal particles include commonly known weighting agents as well as mixture and combinations thereof. The dispersant in one embodiment, is selected from carboxylic acids of molecular weight of at least 150 Daltons. Alternatively, the dispersant coating may be made of compounds including oleic acid, polybasic fatty acids, alkylbenzene sulfonic acids, alkane sulfonic acids, linear alpha-olefin sulfonic acid or the alkaline earth metal salts of any of the above acids, and phospholipids as well as mixtures and combinations of these compounds. In another embodiment the dispersant is a polyacrylate ester having an average molecular weight from about 10,000 Daltons to about 200,000 Daltons.

Owner:MI

Additive for increasing the density of an oil-based fluid and fluid comprising such additive

A wellbore fluid having an oleaginous phase and an additive for increasing the density of the wellbore fluid. The additive comprises solid colloidal particles coated with a dispersant coated onto the colloidal particle during the comminution process of forming the particles. Exemplary starting materials for the colloidal particles include commonly known weighting agents including barite, calcium carbonate, dolomite, ilmenite, hematite or other iron ores, olivine, siderite, and strontium sulfate as well as mixture and combinations of these and other similar weighting materials. The dispersant in one illustrative embodiment, is selected from carboxylic acids of molecular weight of at least 150 Daltons. Alternatively, the dispersant coating may be made of compounds including oleic acid, polybasic fatty acids, alkylbenzene sulfonic acids, alkane sulfonic acids, linear alpha-olefin sulfonic acid or the alkaline earth metal salts of any of the above acids, and phospholipids as well as mixtures and combinations of these compounds. In another illustrative embodiment the dispersant is a polyacrylate ester. The illustrative polymeric dispersant should have an average molecular weight from about 10,000 Daltons to about 200,000 Daltons.

Owner:MI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com