Patents

Literature

526 results about "Circular face" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

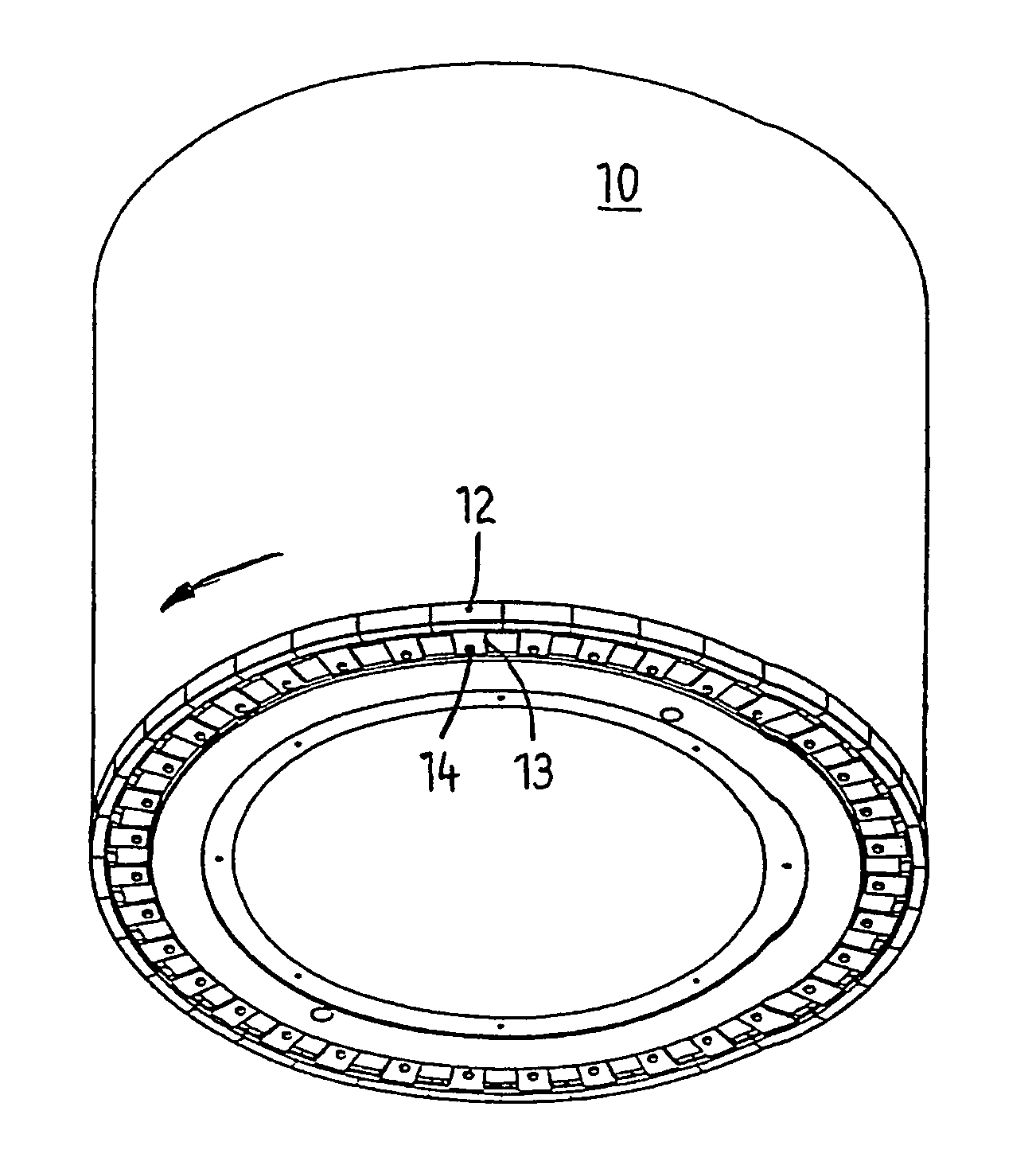

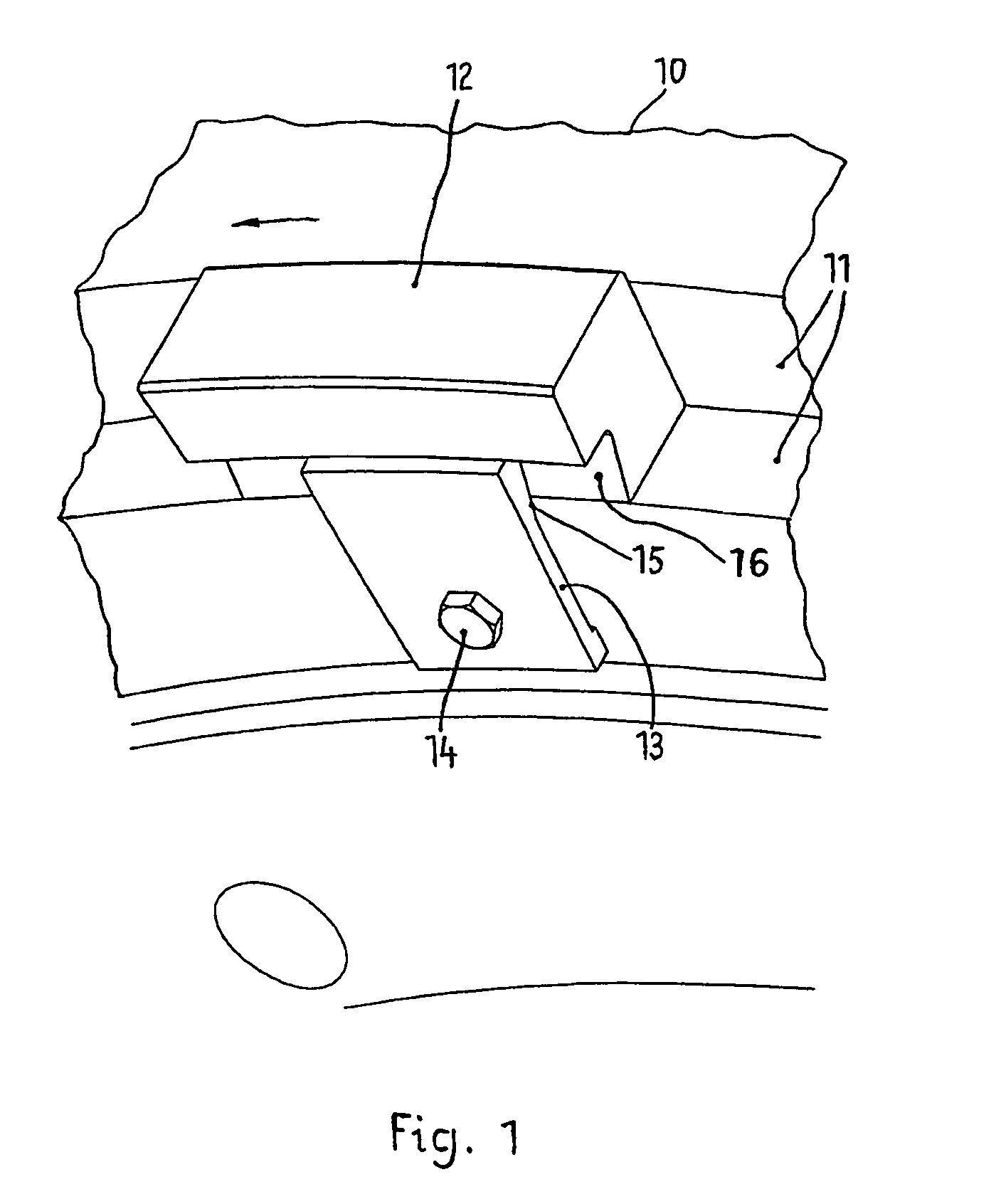

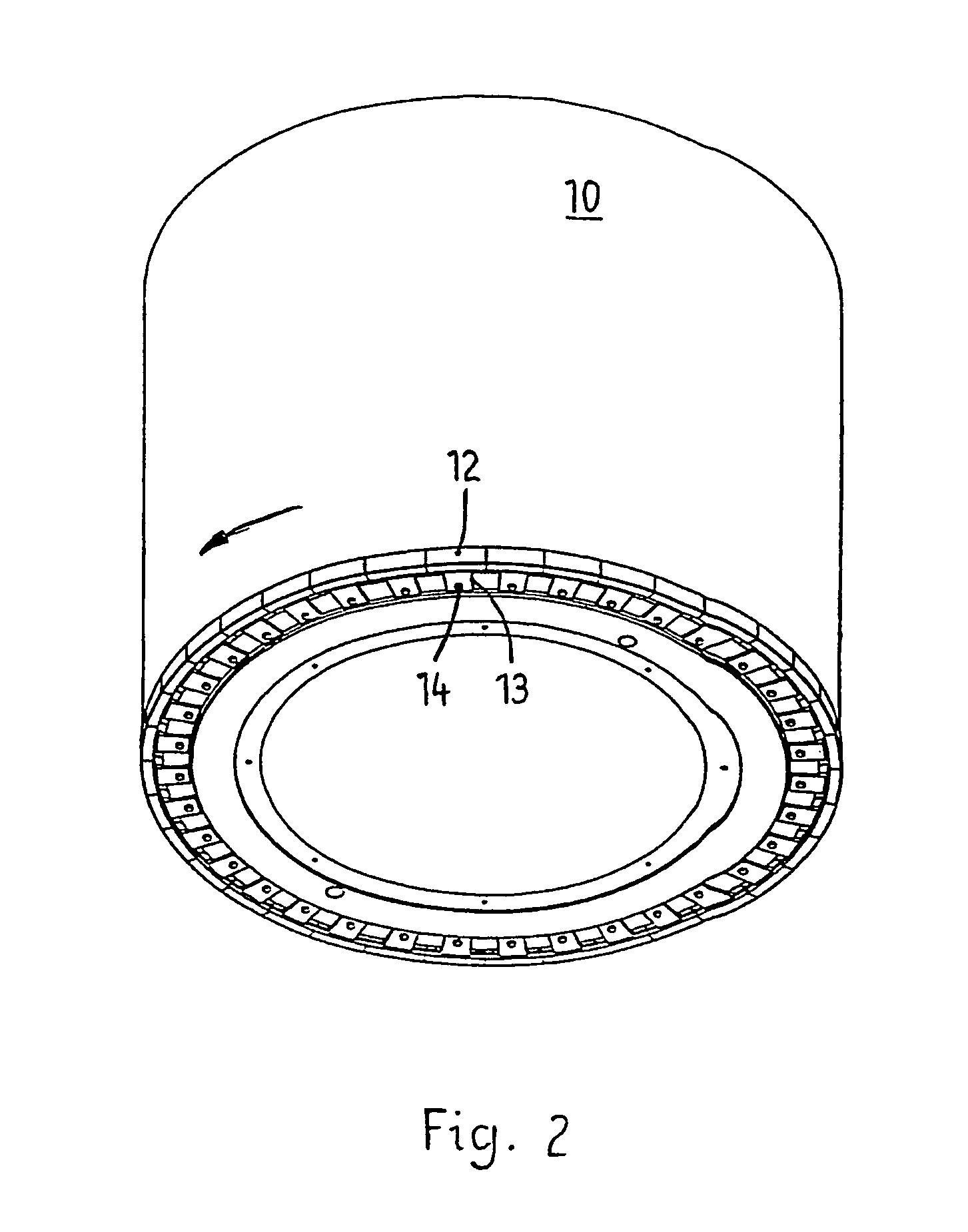

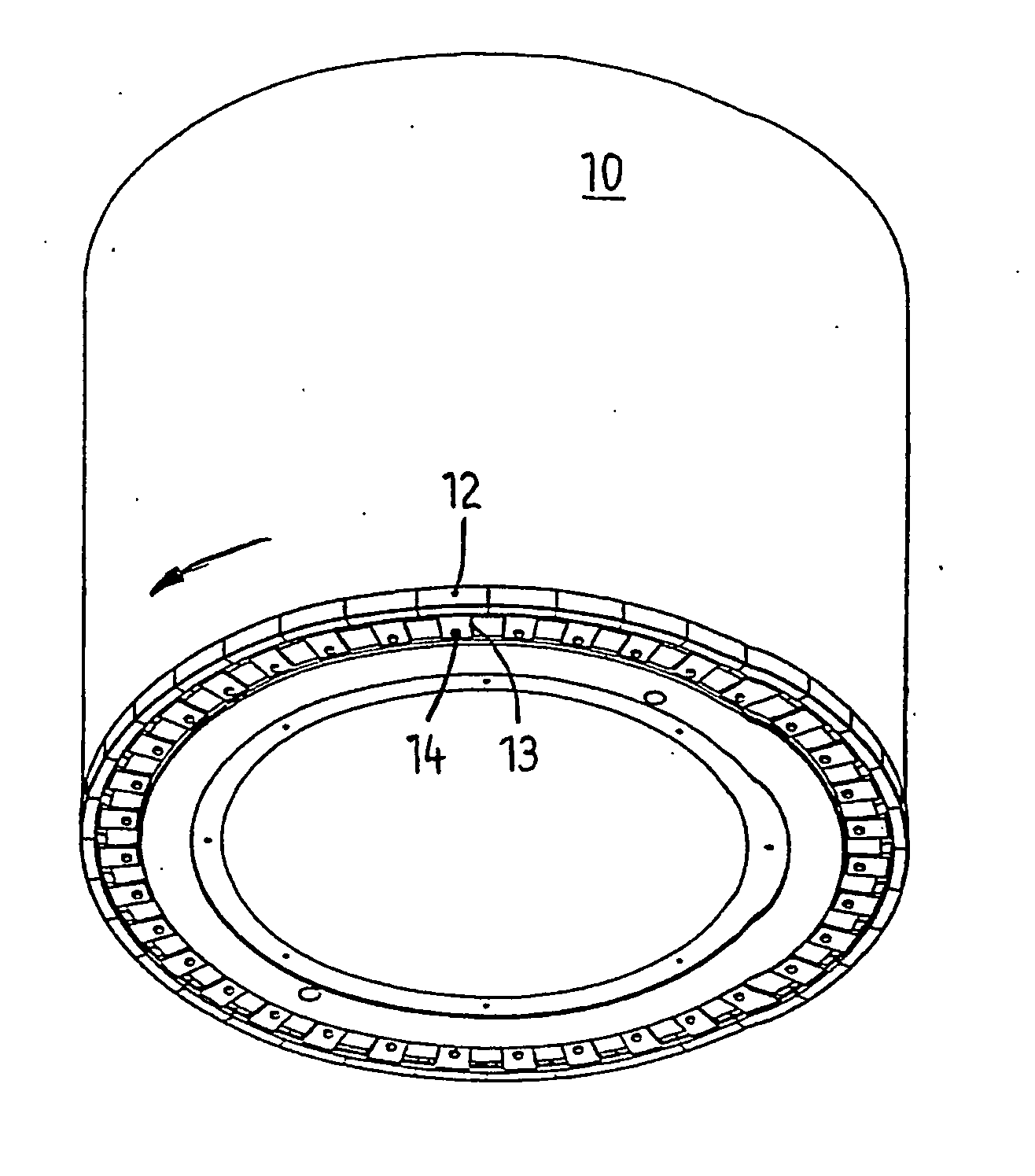

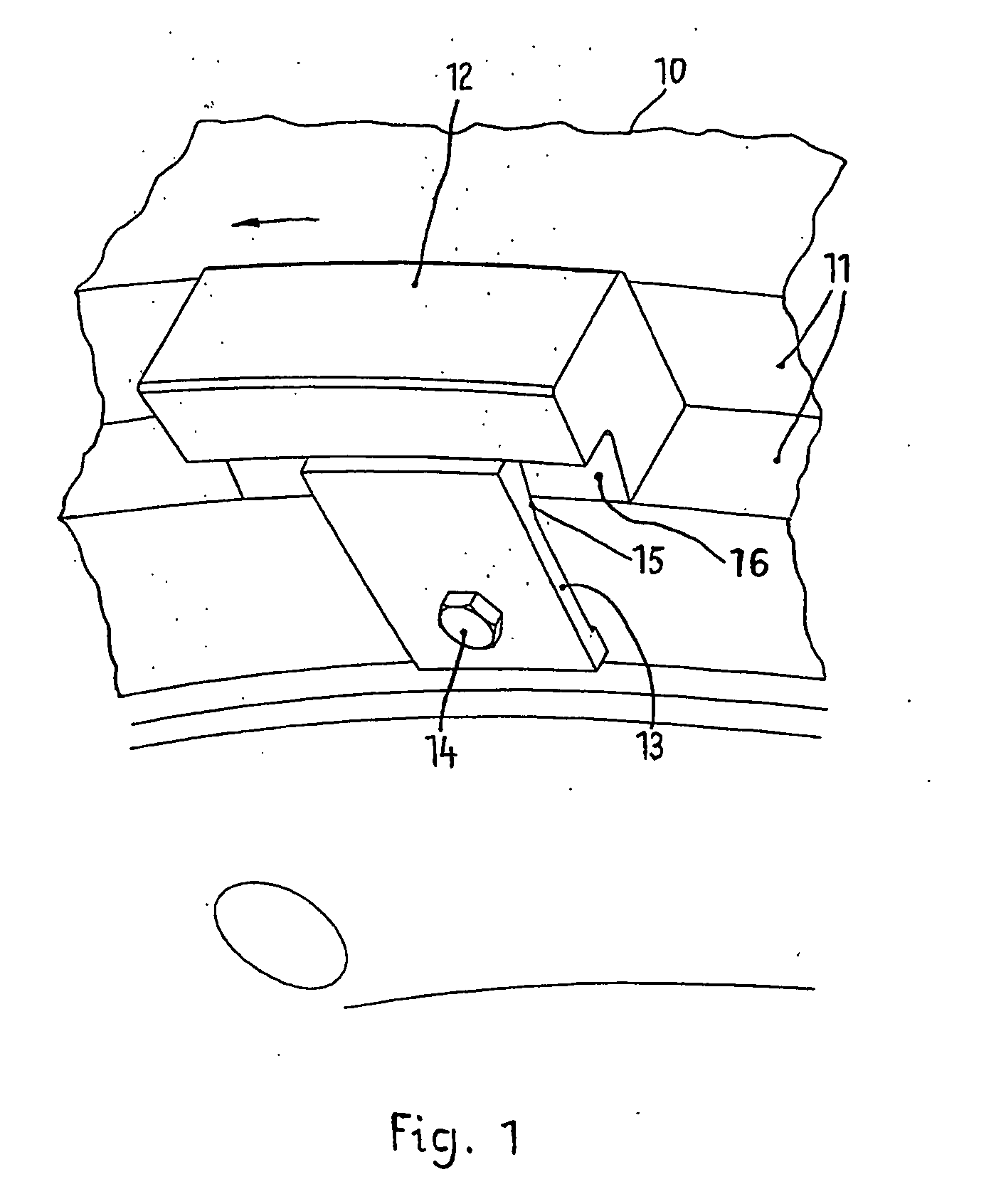

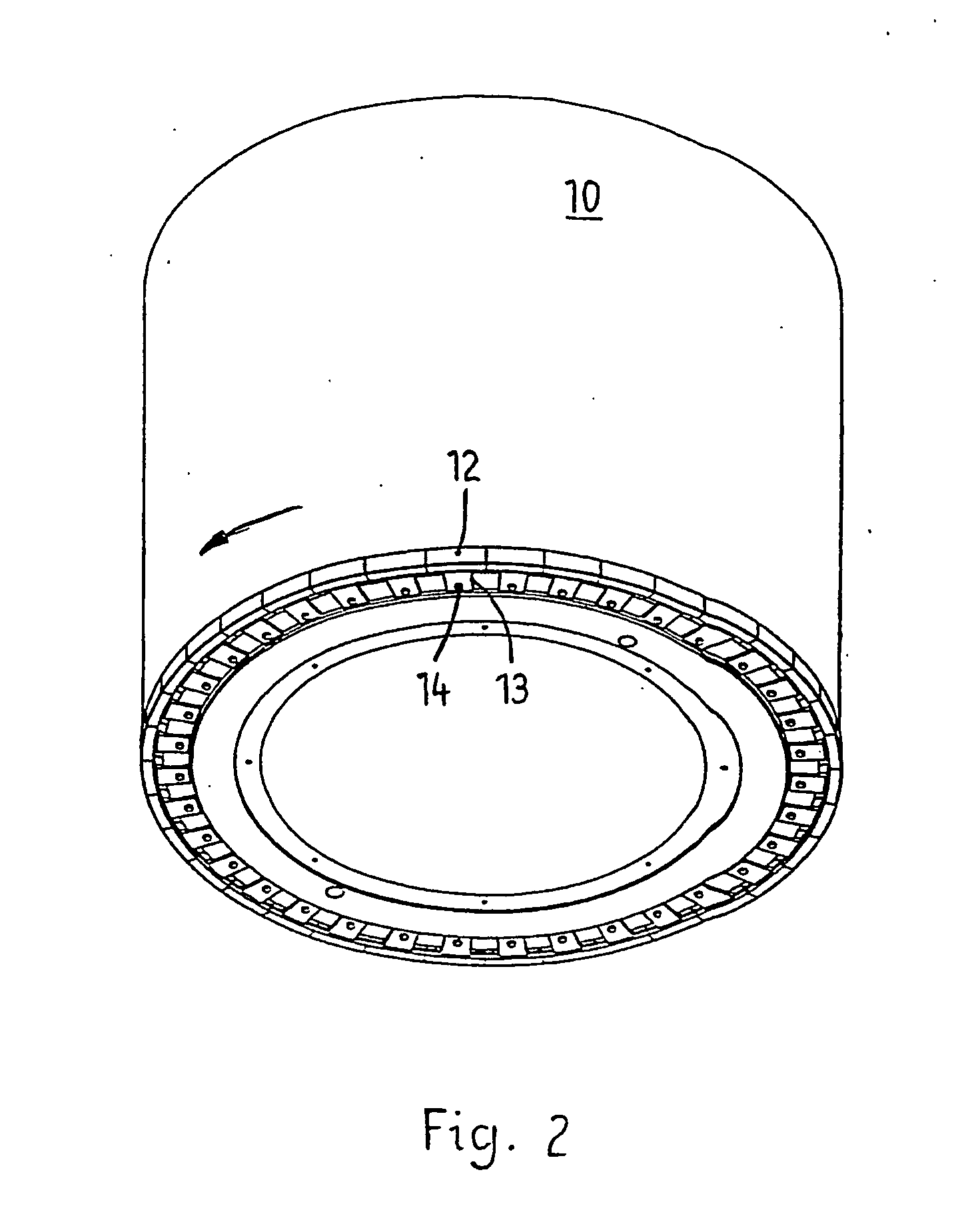

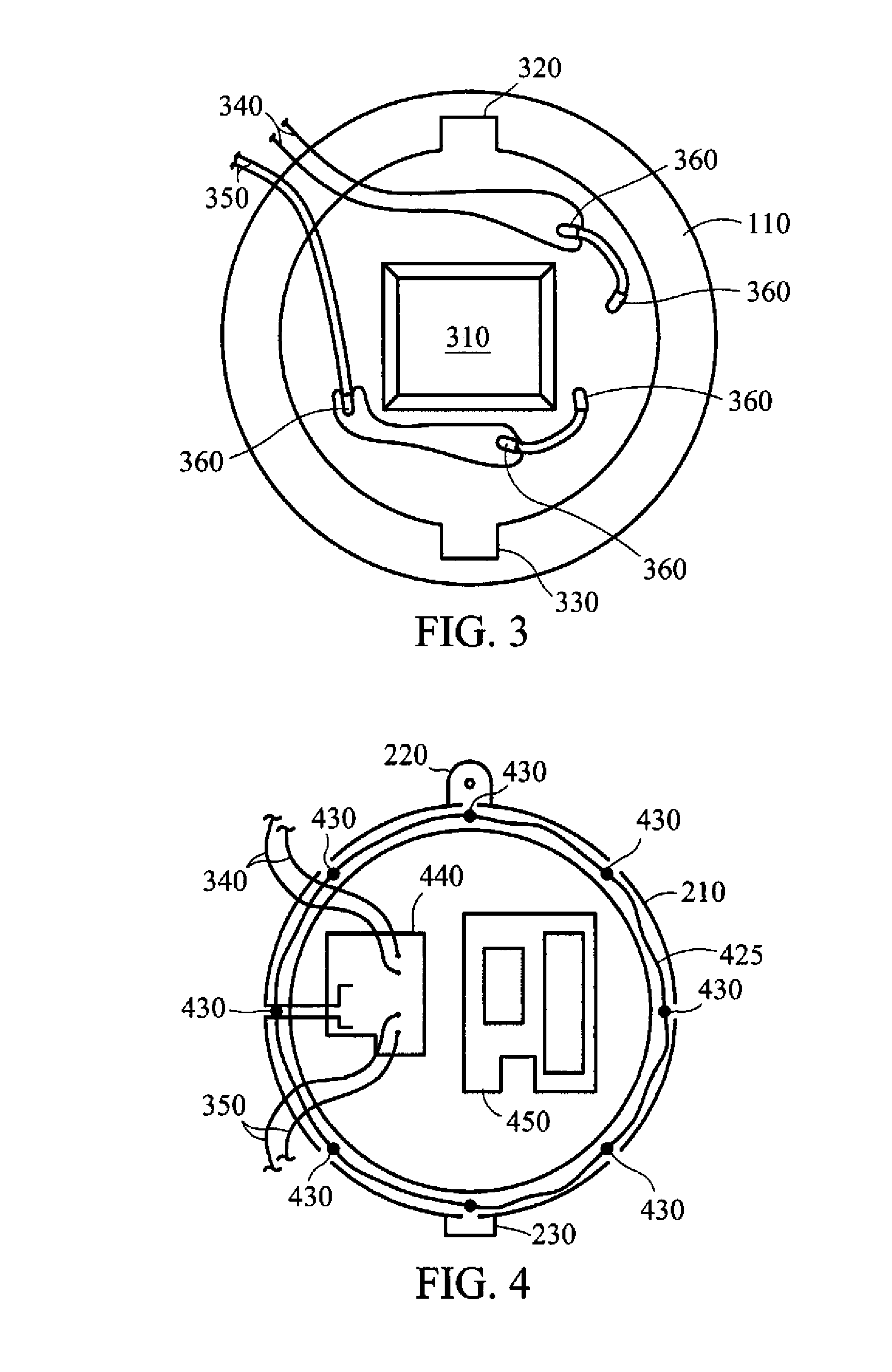

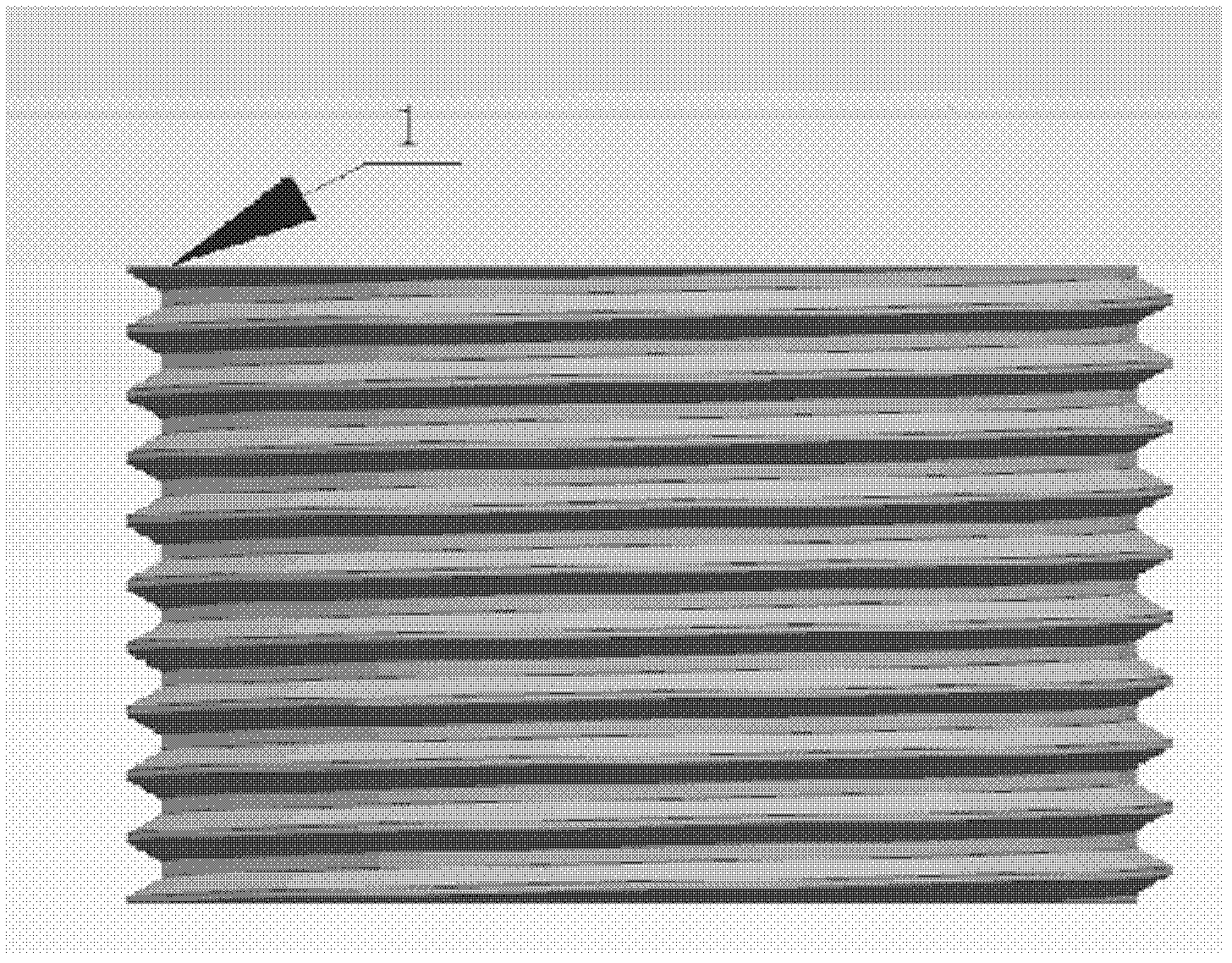

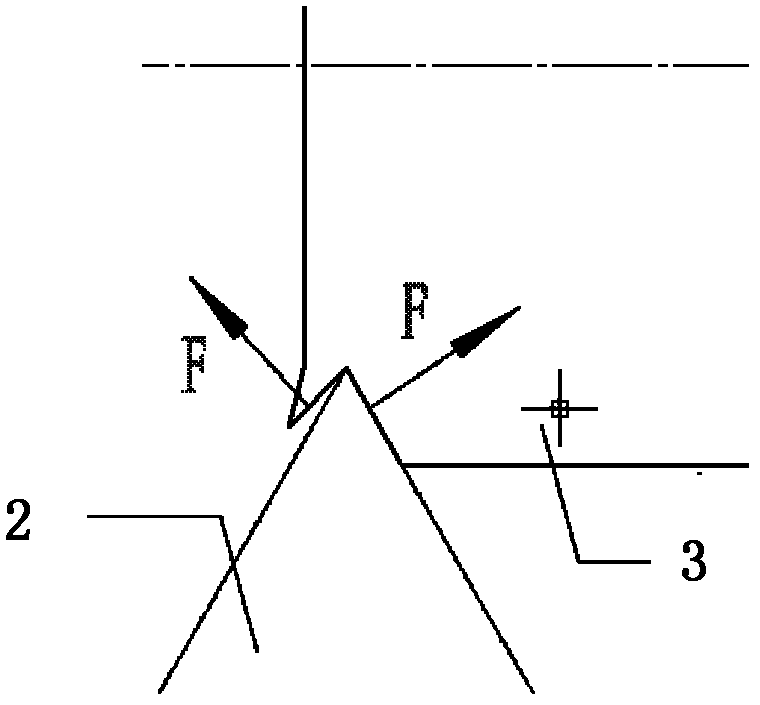

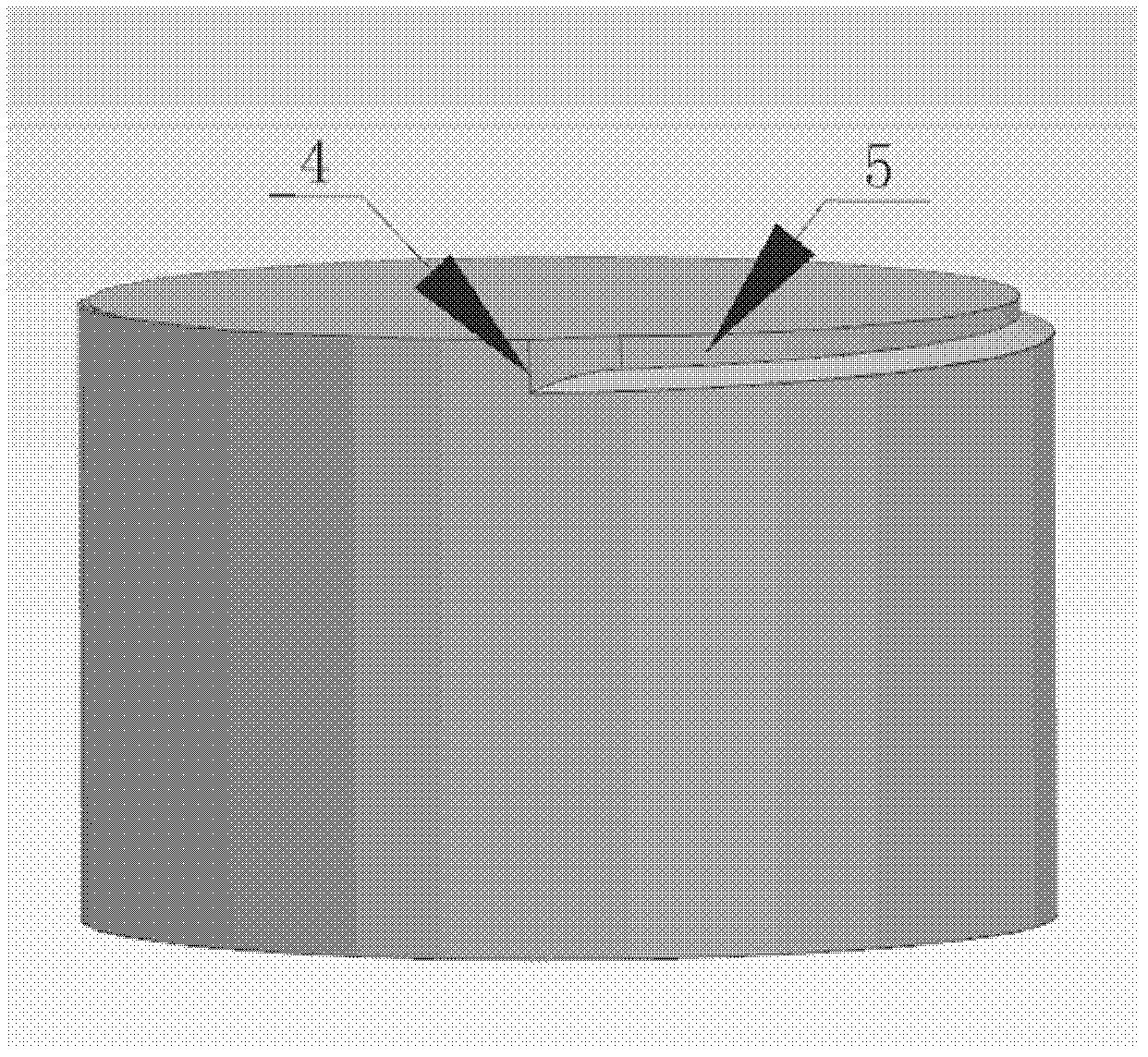

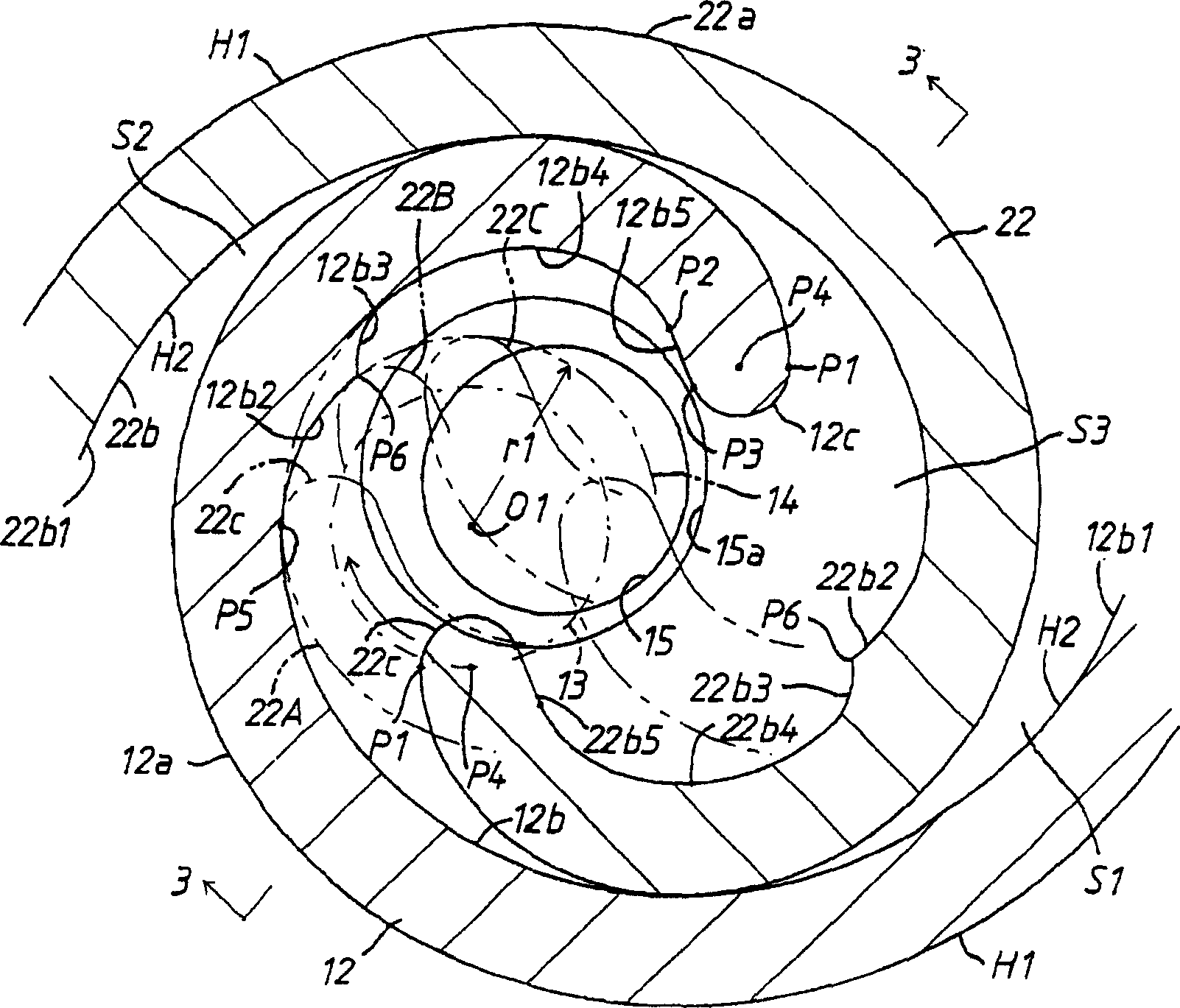

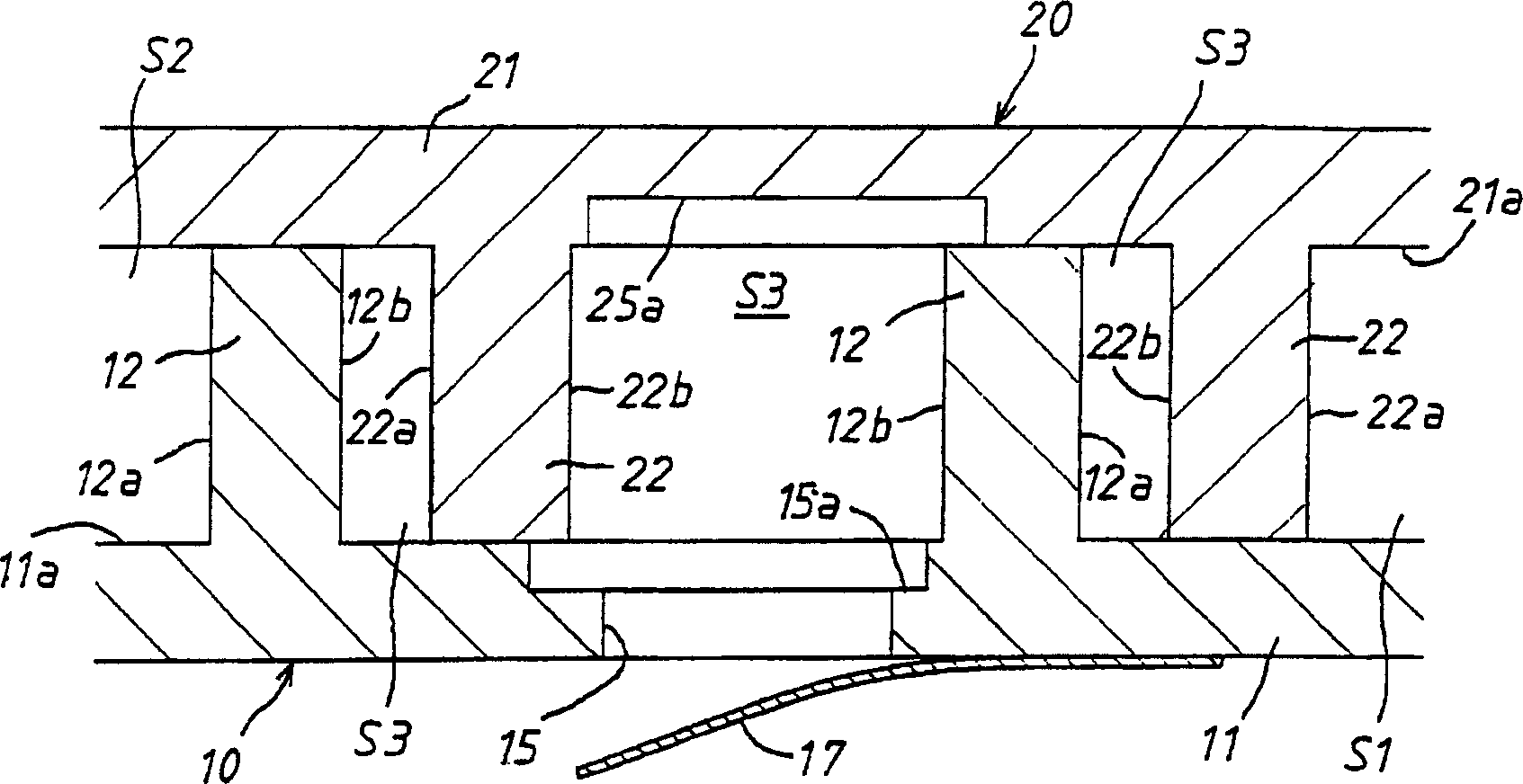

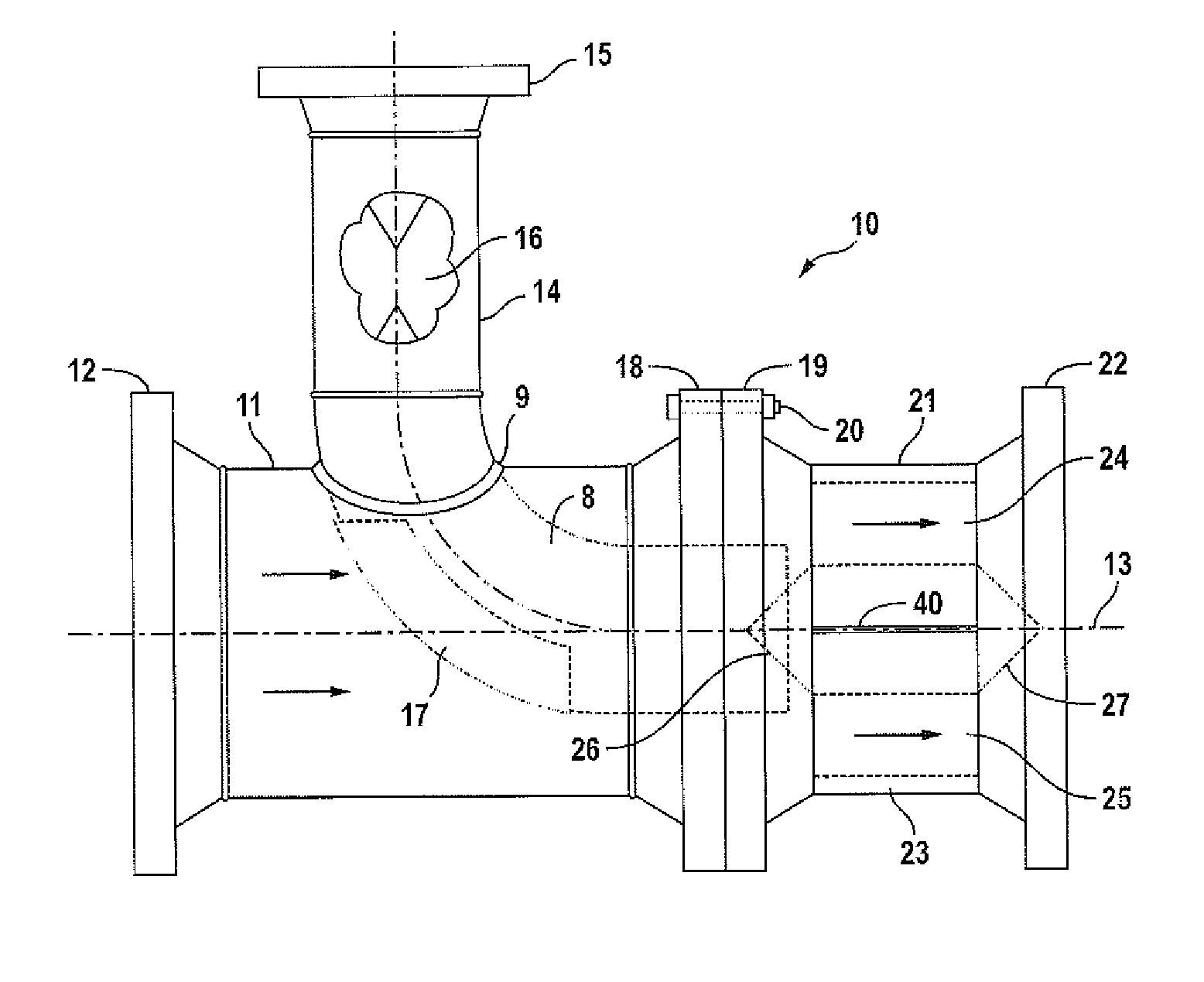

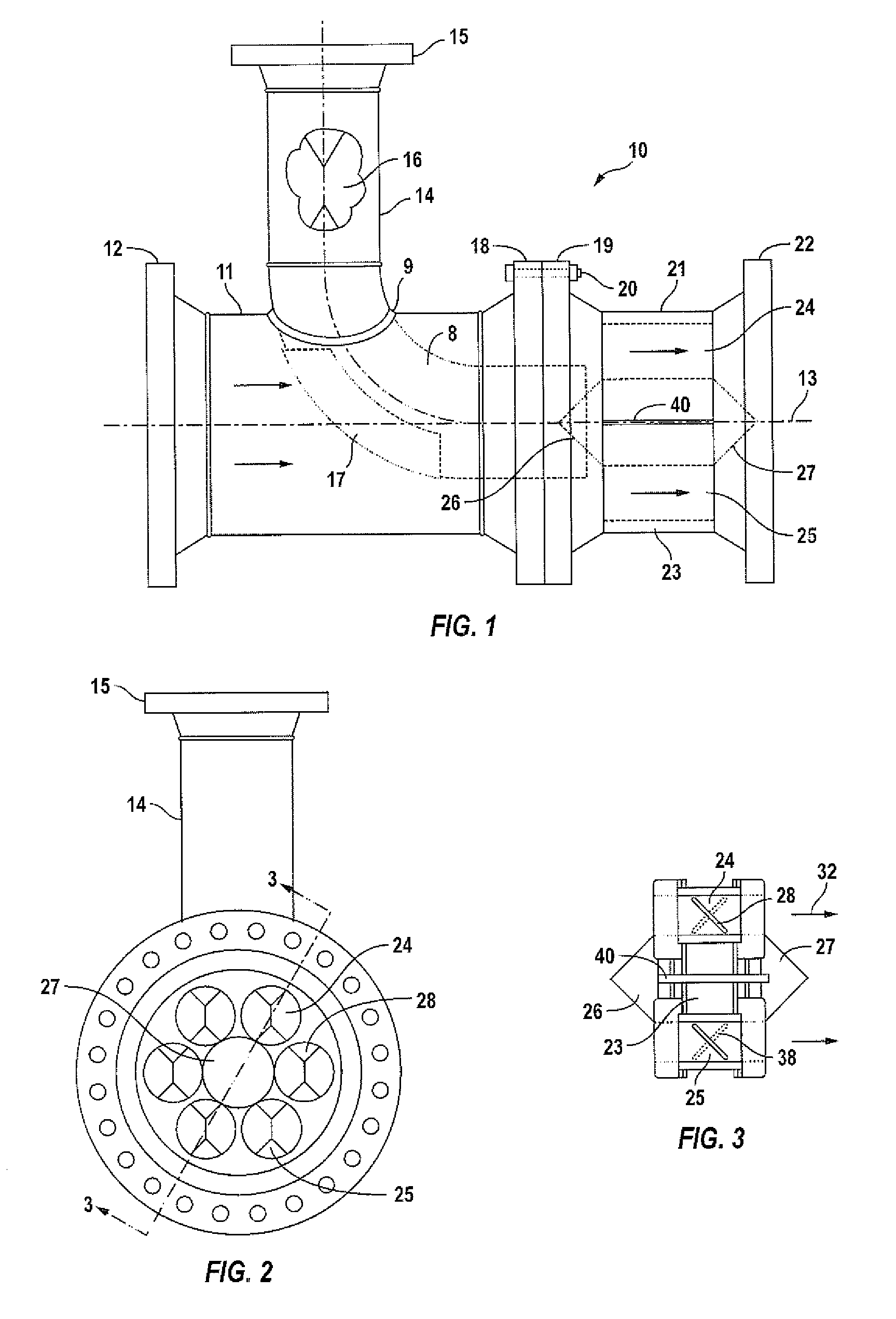

Grinding roller for the pressure comminution of granular material

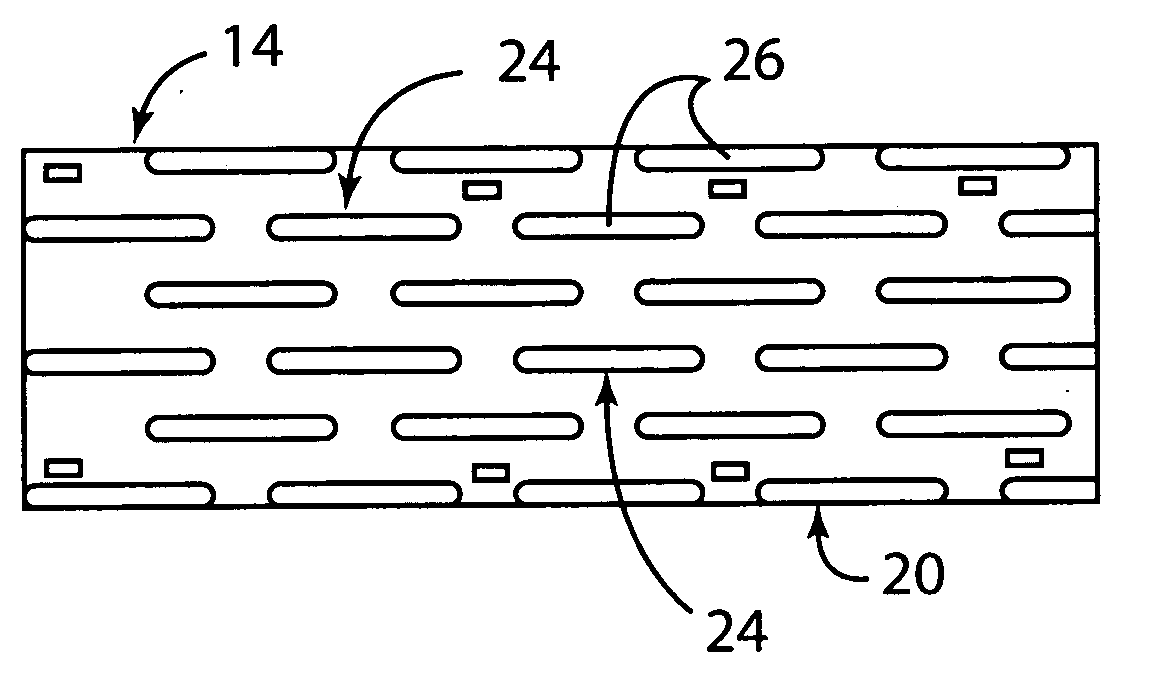

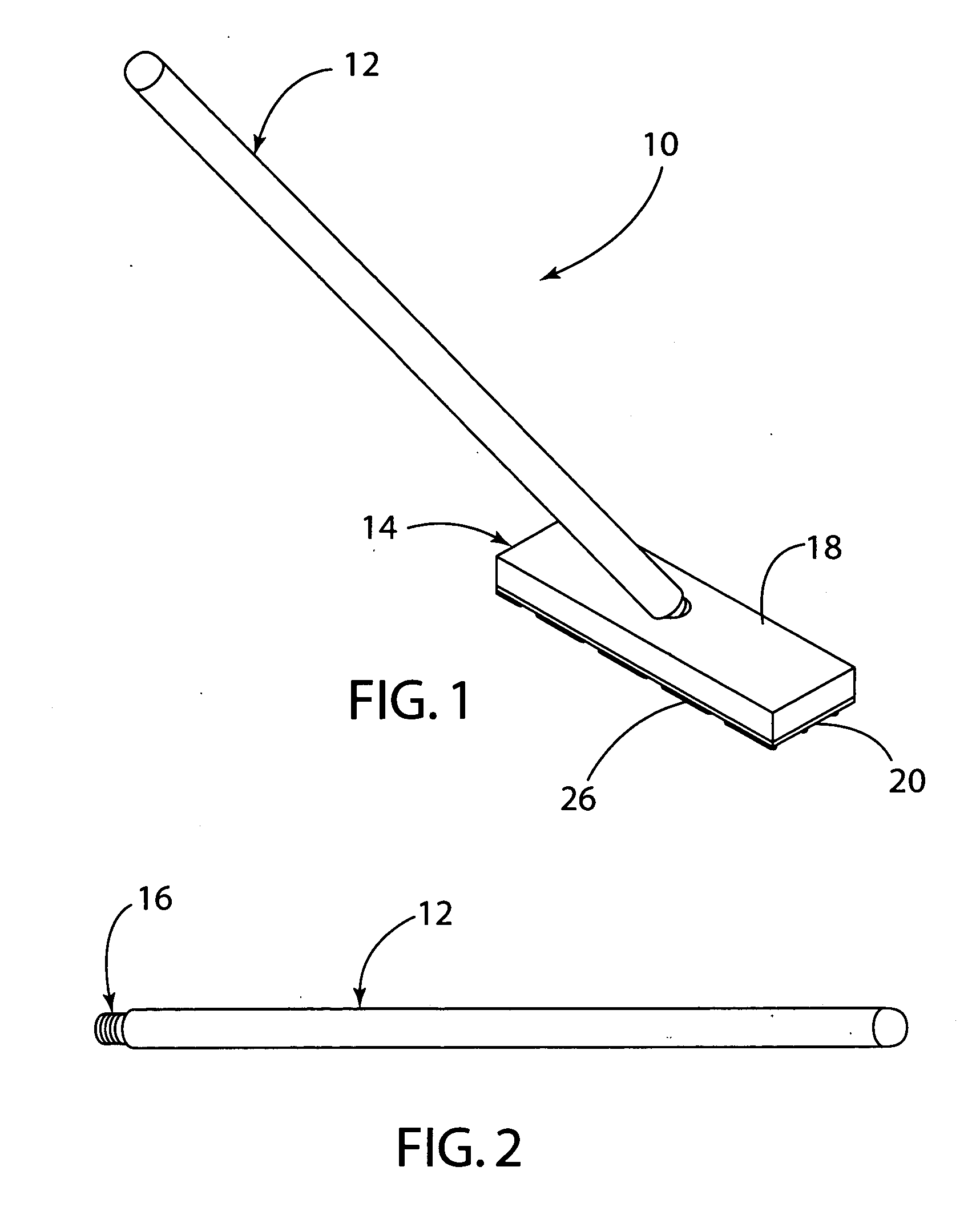

The aim of the invention is to provide grinding rolls in particular for high-pressure roller mills or rolling presses for pressure grinding a granular material not only with a wear-resistant coating but also with a face armour plating in the area of the roller annular edge, which has a long service life due to the high wear resistance thereof and whose production and repair are, in general, relatively simple and inexpensive. For this purpose, the inventive face armour plating consists of a plurality of prefabricated hard bodies which are circularly arranged side by side in such a way that the circular face edge of the roller is formed, said hard bodies are disposed on said circular shoulder of a roll shell such that said hard bodies are placed axially and radially against said circular shoulder of the roll shell and are movably assembled with the roll shell.

Owner:KHD HUMBOLDT WEDAG GMBH

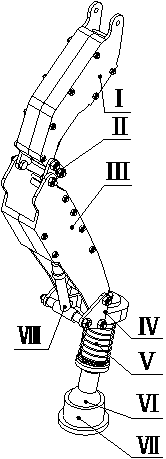

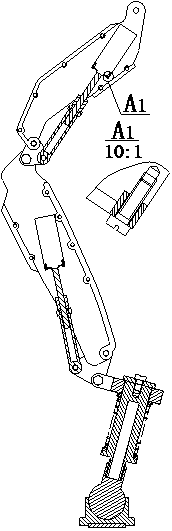

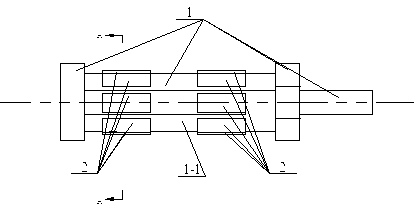

Leg structure of quadruped bionic robot

The invention relates to a leg structure of a quadruped bionic robot. The leg structure comprises a shoulder blade, a shoulder joint, a femur (thign-bone), a knee joint, a tibia (shin bone), a passive ankle joint, a sole and a driving module. The shoulder joint of the leg structure of the quadruped bionic robot is connected with the shoulder blade and the femur, the knee joint is connected with the femur and the tibia, and the passive ankle joint is connected with the tibia and the sole. The joints are driven by ball screws, and accordingly the leg structure has the advantages of high driving efficiency and precision and the like; as the friction force of rolling friction is low, heat generated by friction is reduced and energy consumption is decreased. As the shoulder blade and the femur are of hollow casing structures, the weight is reduced and the energy consumption is further reduced. Since the femur is of elastic buffering and spring energy-storage structure, energy consumption can be further decreased and impact to ground can be buffered. Since the tail ankle joint is provided with a ball hinge coupling and the sole is in the shape of a circular face, the bionic robot can fall to the ground more stably.

Owner:SHANGHAI UNIV

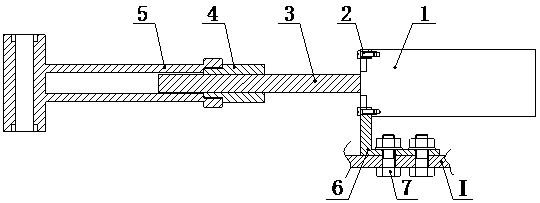

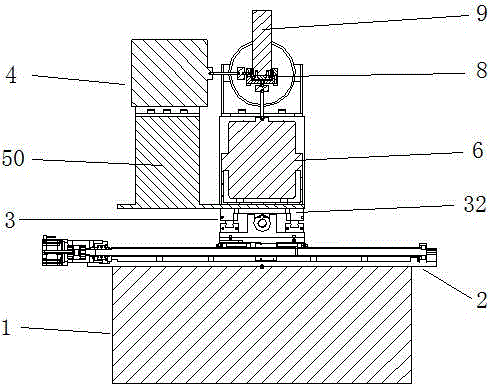

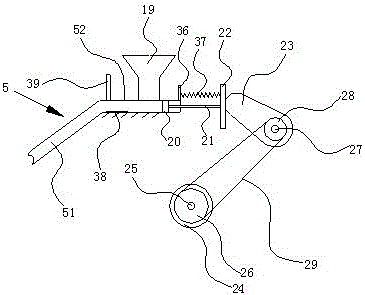

Numerical control supersonic machining apparatus for general lathe

InactiveCN101503755AReduce labor intensitySolve the problem that complex surfaces such as arcs cannot be processedAuxillary equipmentMechanical vibrations separationNumerical controlPatch panel

The invention provides a digital control ultrasonic processing device for a common lathe. The device comprises a pedestal, an intermediate guide rail, an upper support plate and a rotary tool rest, wherein the bottom surface of the pedestal is provided with a dovetail groove; the intermediate guide rail is arranged on the pedestal through a vertical guide rail; the upper support plate is arranged on the intermediate guide rail through a horizontal guide rail; an intermediate shaft is arranged inside the upper support plate; the rotary tool rest is arranged on the intermediate shaft; a patch panel and an electric brush panel are arranged between the rotary tool rest and the upper support plate; an electric brush is connected between the patch panel and the electric brush panel; a lead screw feeding mechanism is arranged on the intermediate guide rail and the upper support plate; a tool rest automatic tool change mechanism is arranged between the upper support plate and the rotary tool rest; a lathe tool, a round amplitude transformer and an external circular amplitude transformer are arranged on the rotary tool rest; and a processing tool bit is arranged on the two amplitude transformers and connected with an energy converter respectively. The digital control ultrasonic processing device for the common lathe has high efficiency and high processing precision and can complete turning, ultrasonic processing of the external circular face and ultrasonic processing of the crown face by clamping for one time.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

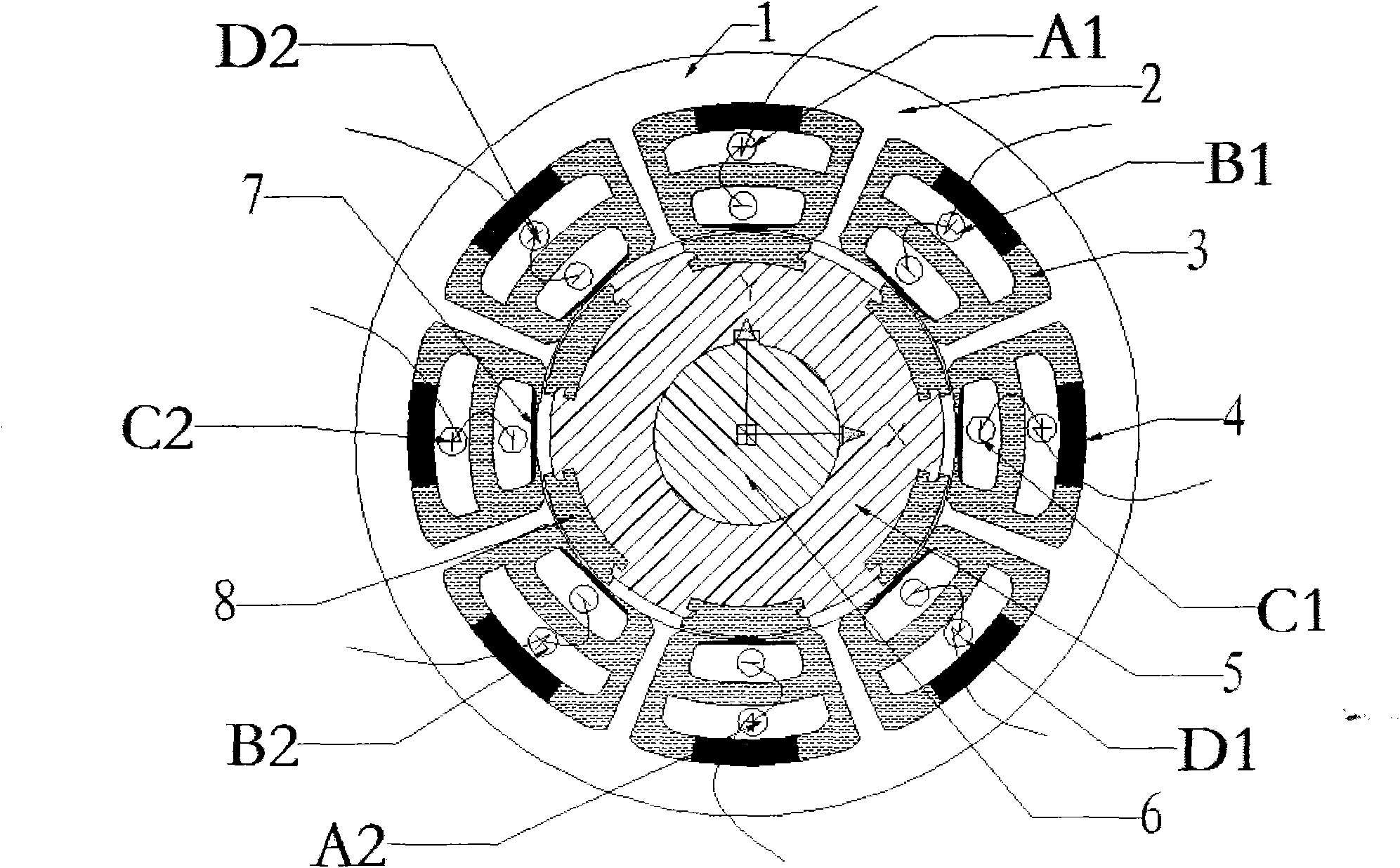

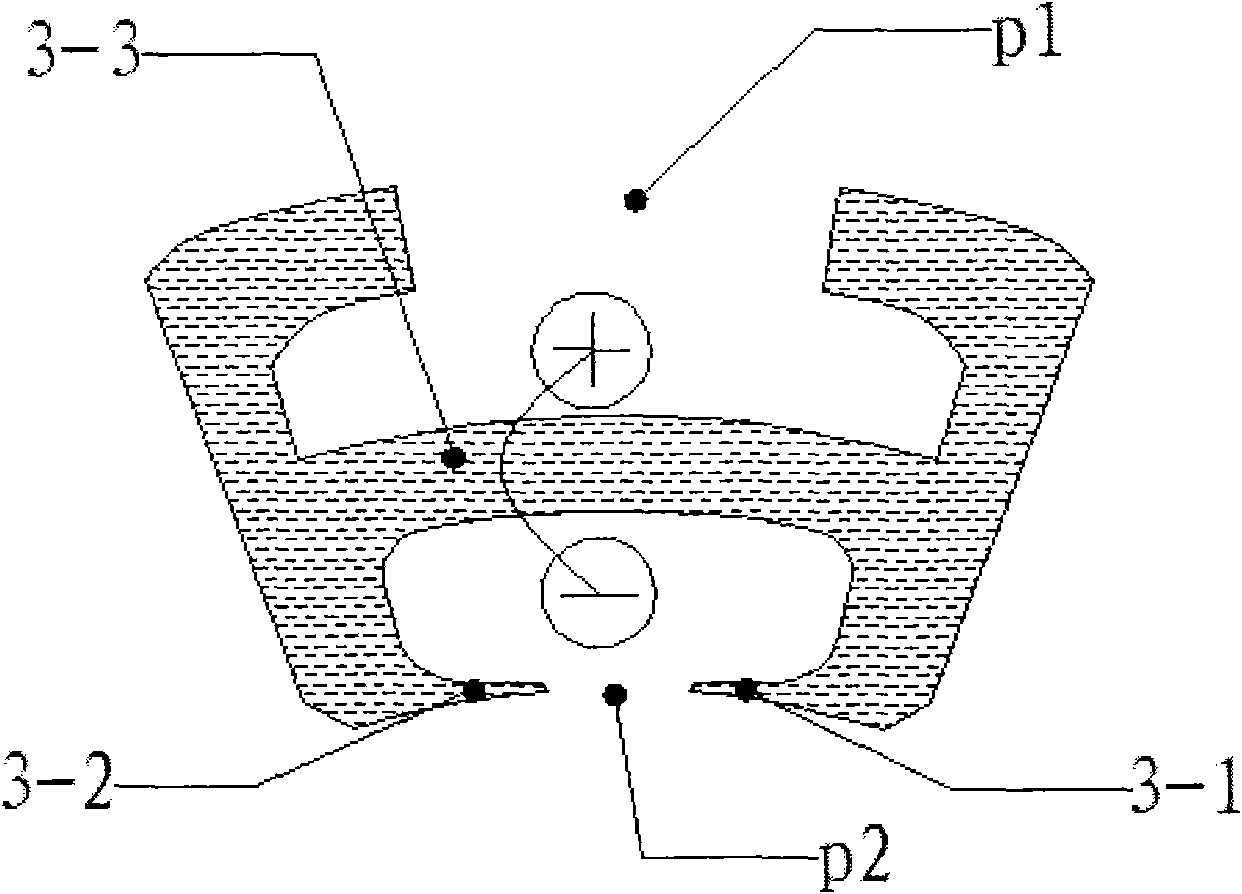

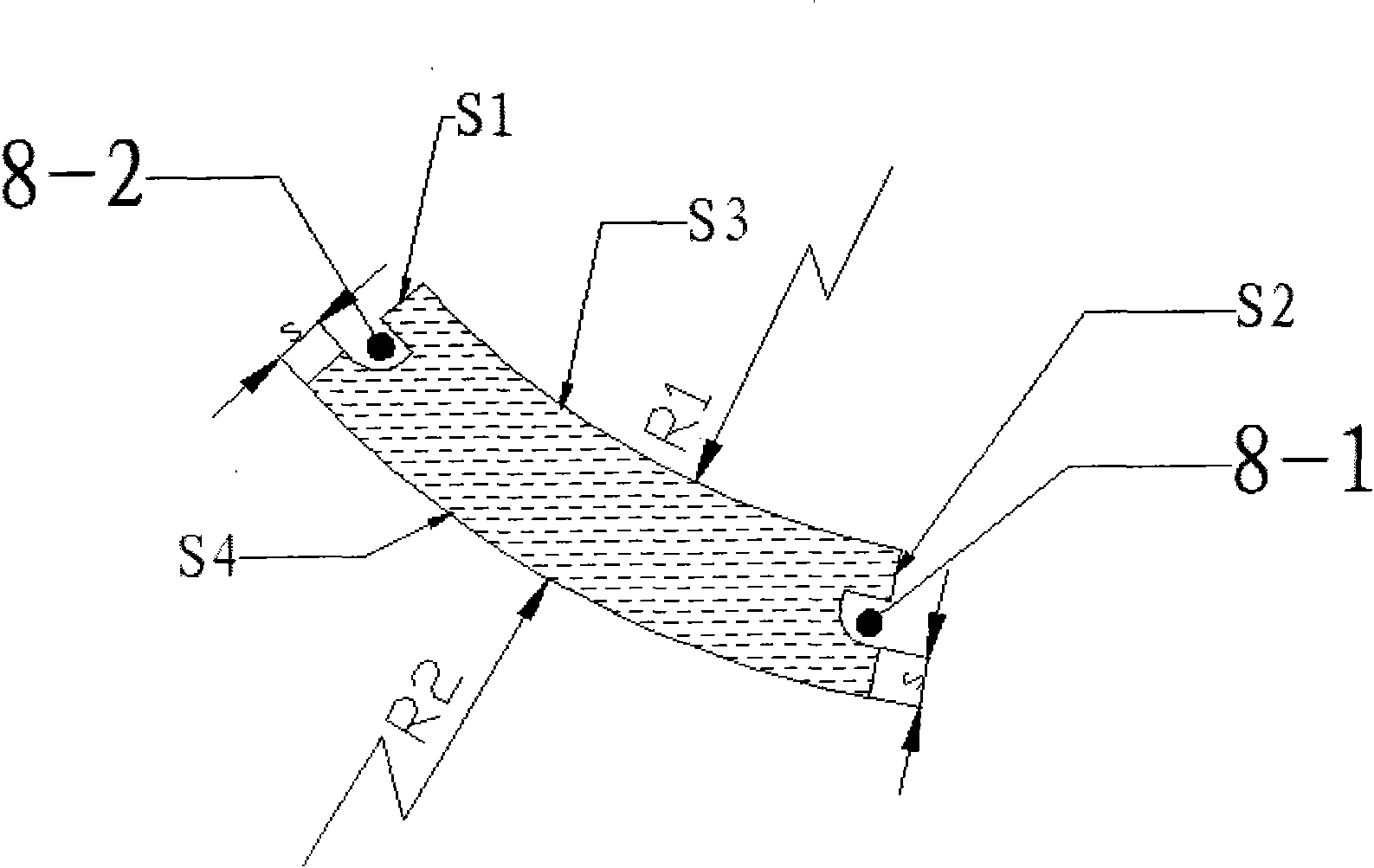

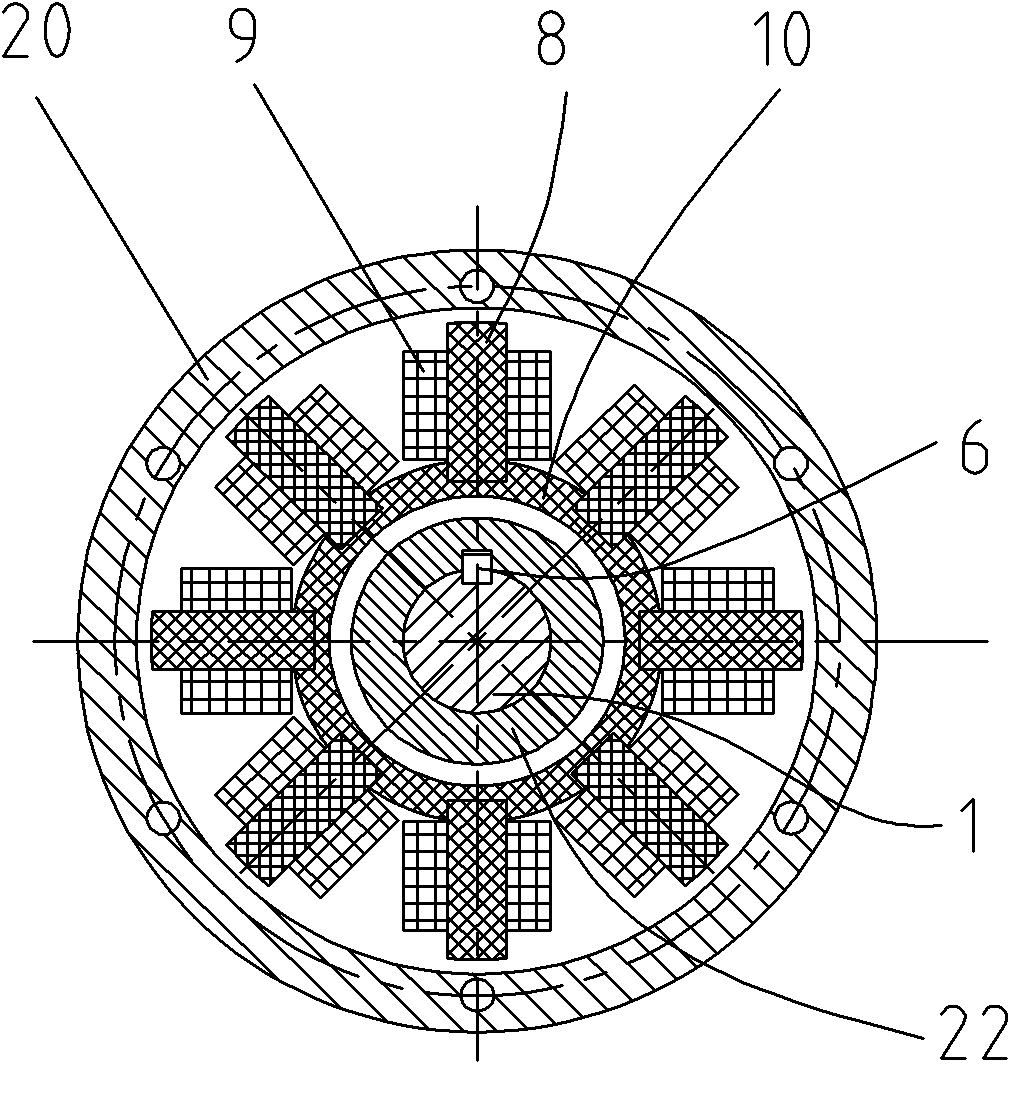

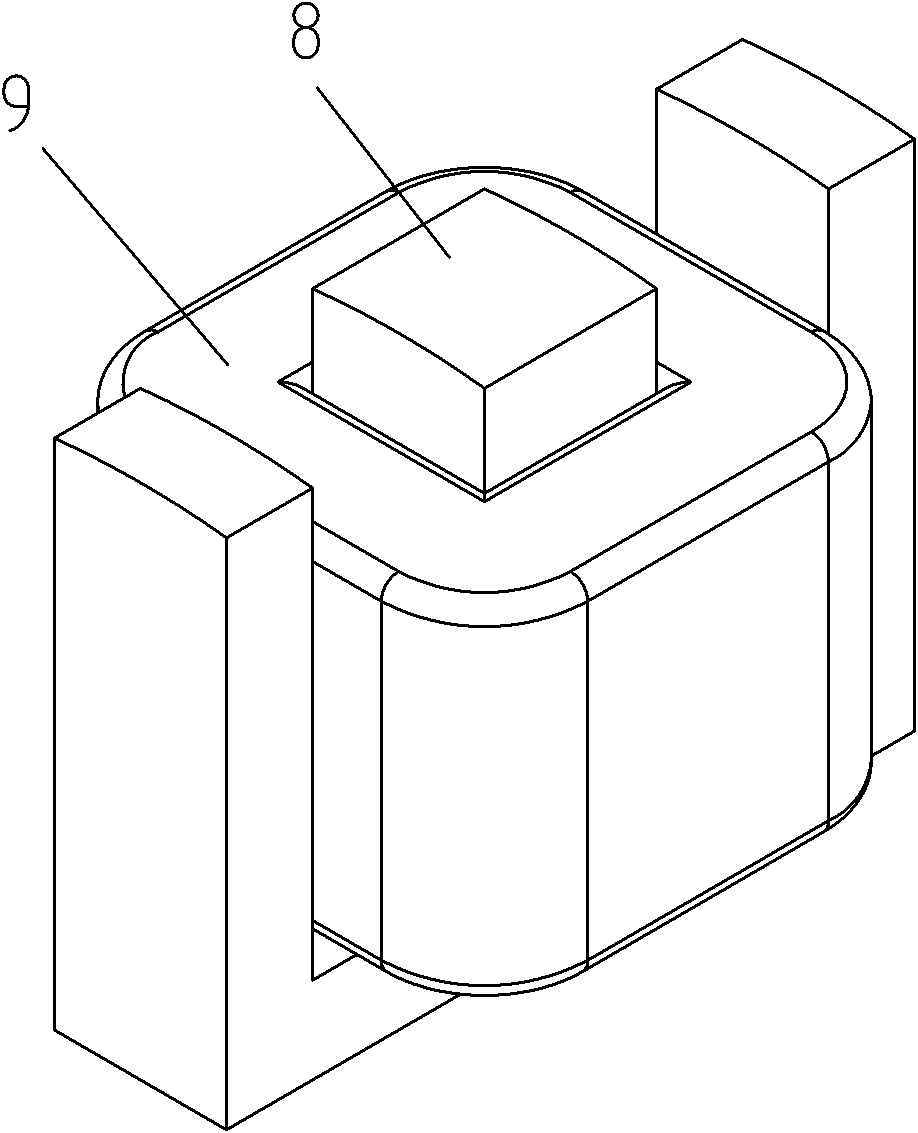

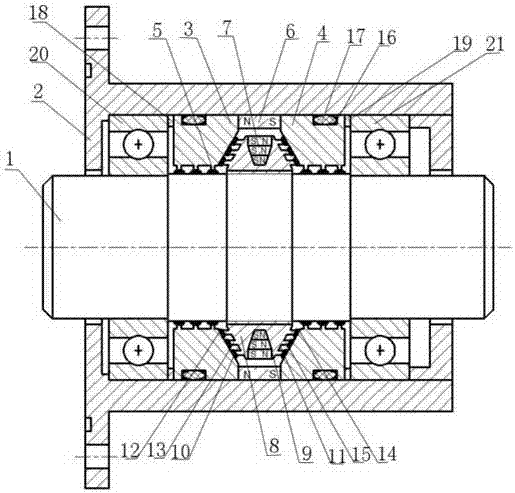

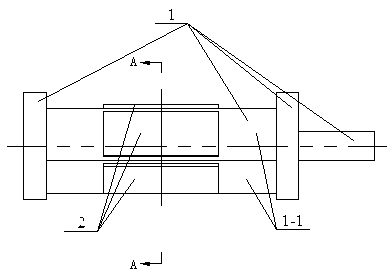

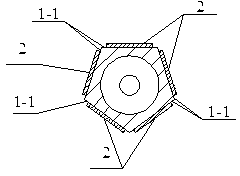

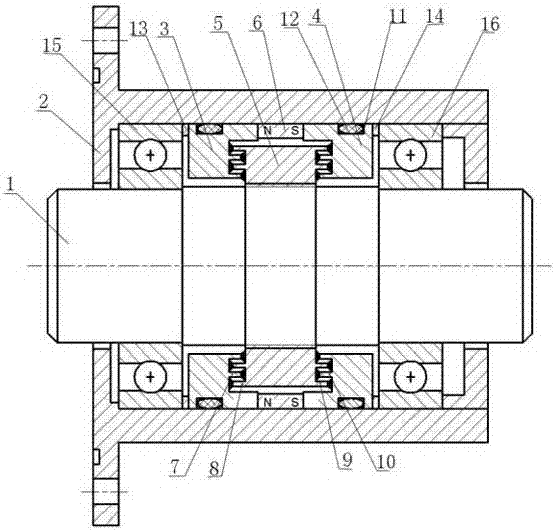

Mixed excitation short-magnetic-circuit variable-reluctance motor

InactiveCN102315746AEasy to installFlexibleMagnetic circuit rotating partsMagnetic circuit stationary partsNoise levelElectrical polarity

The invention discloses a mixed excitation short-magnetic-circuit variable-reluctance motor 1 as well as a stator structure and a rotor structure thereof. An inner circular face t of a base part 2 of the mixed excitation short-magnetic-circuit variable-reluctance motor is provided with modules 2-1 which protrude inwards in a preset interval angle; the stator part comprises a plurality of H-shaped stator sections 3 and first permanent magnets 4 (1) arranged at all the H-shaped stator sections p1, and the polarities of the permanent magnets of the stator sections are opposite; an exciting winding coil is embedded into two stator slots of each H-shaped stator section 3; and the rotor part comprises a rotor body 5 and a plurality of annular body rotor sections 8 arranged on the rotor body and / or second permanent magnets 4 (2), wherein the second permanent magnets are arranged on the s3 surfaces of the annular body rotor sections, and open grooves 8-1 and 8-2 are arranged on the lateral surfaces of the annular body rotor sections. According to the invention, the rotating force of the variable-reluctance motor can be increased, the energy density is improved, the torque ripple and the vibration and noise level are reduced, the performance is stable, and the size is smaller under the requirement of same output torque.

Owner:SOUTH CHINA UNIV OF TECH

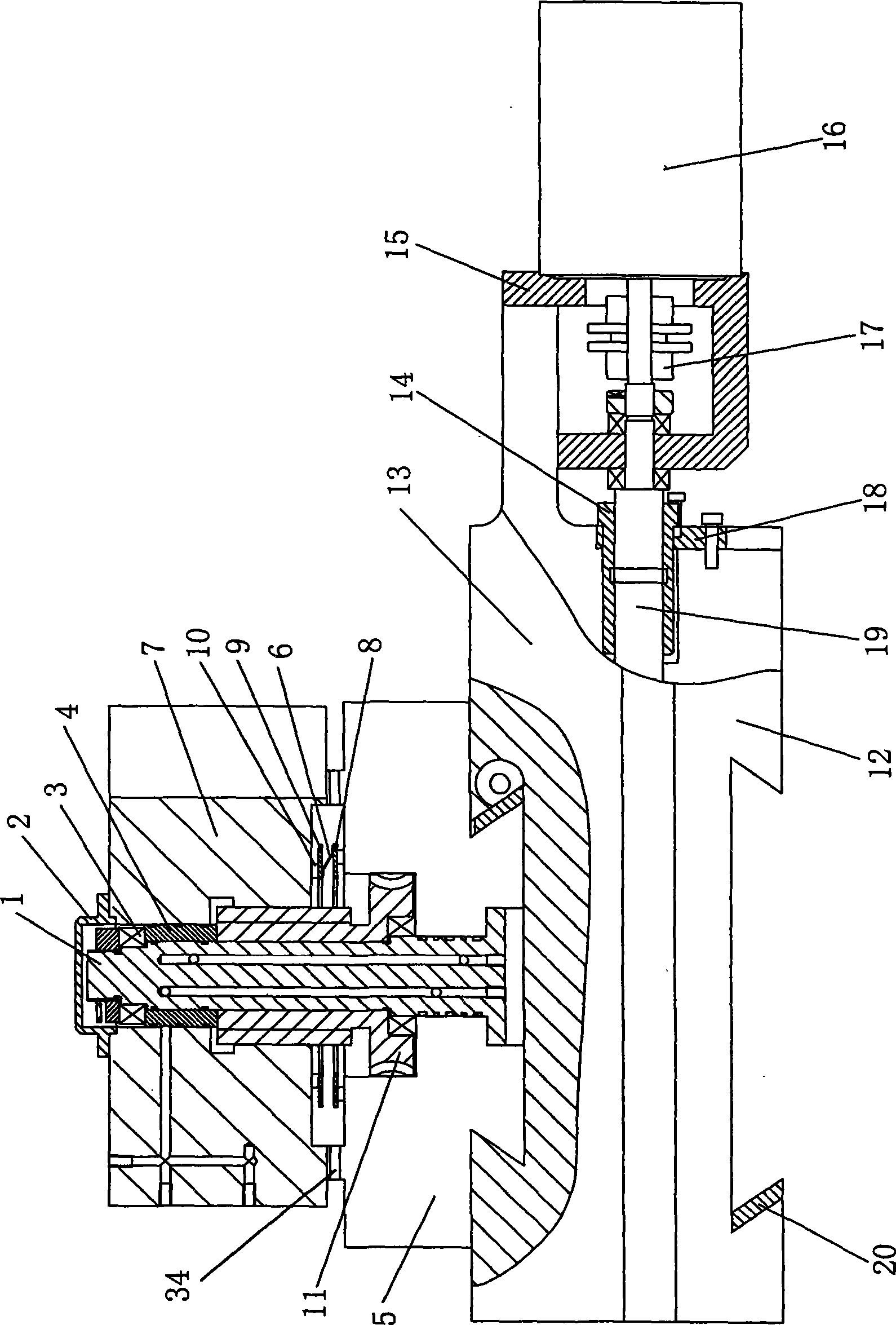

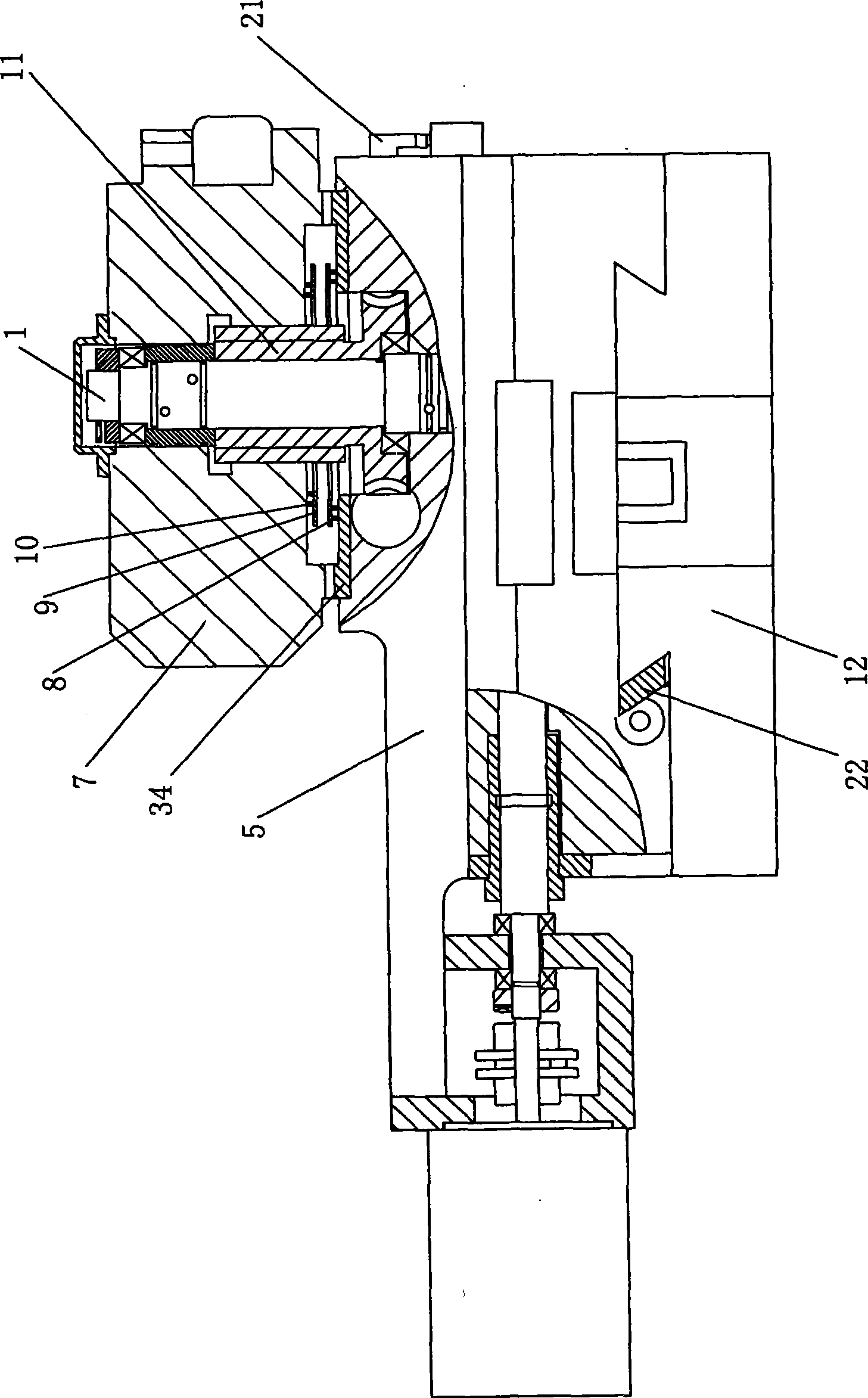

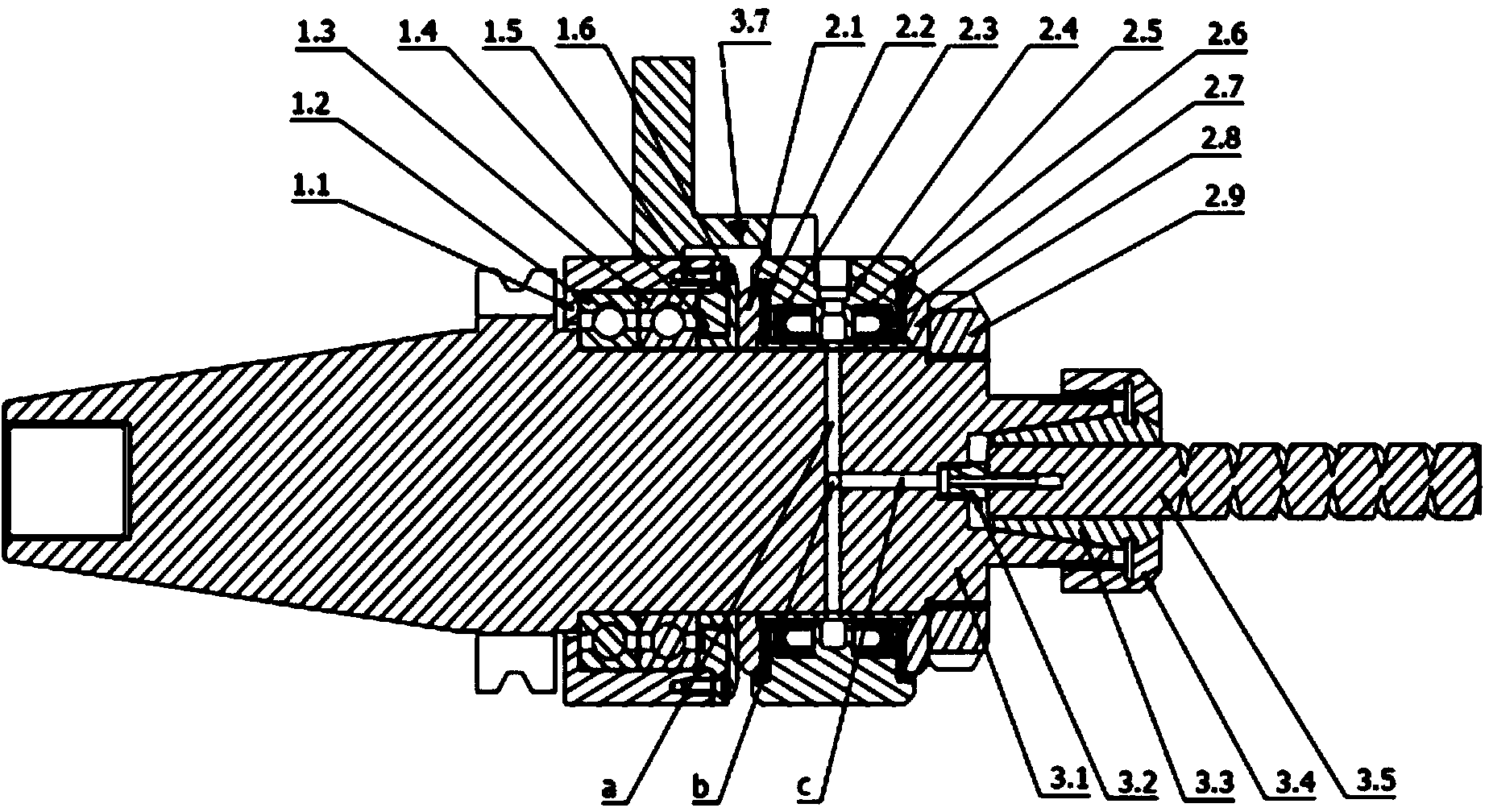

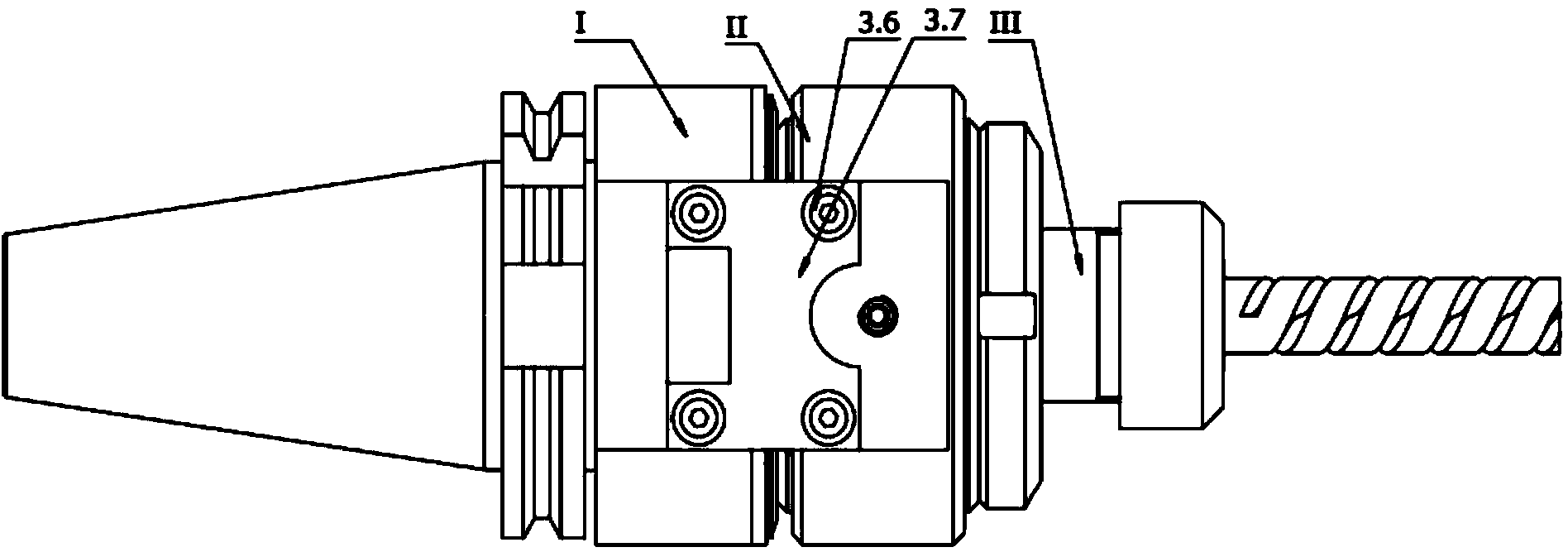

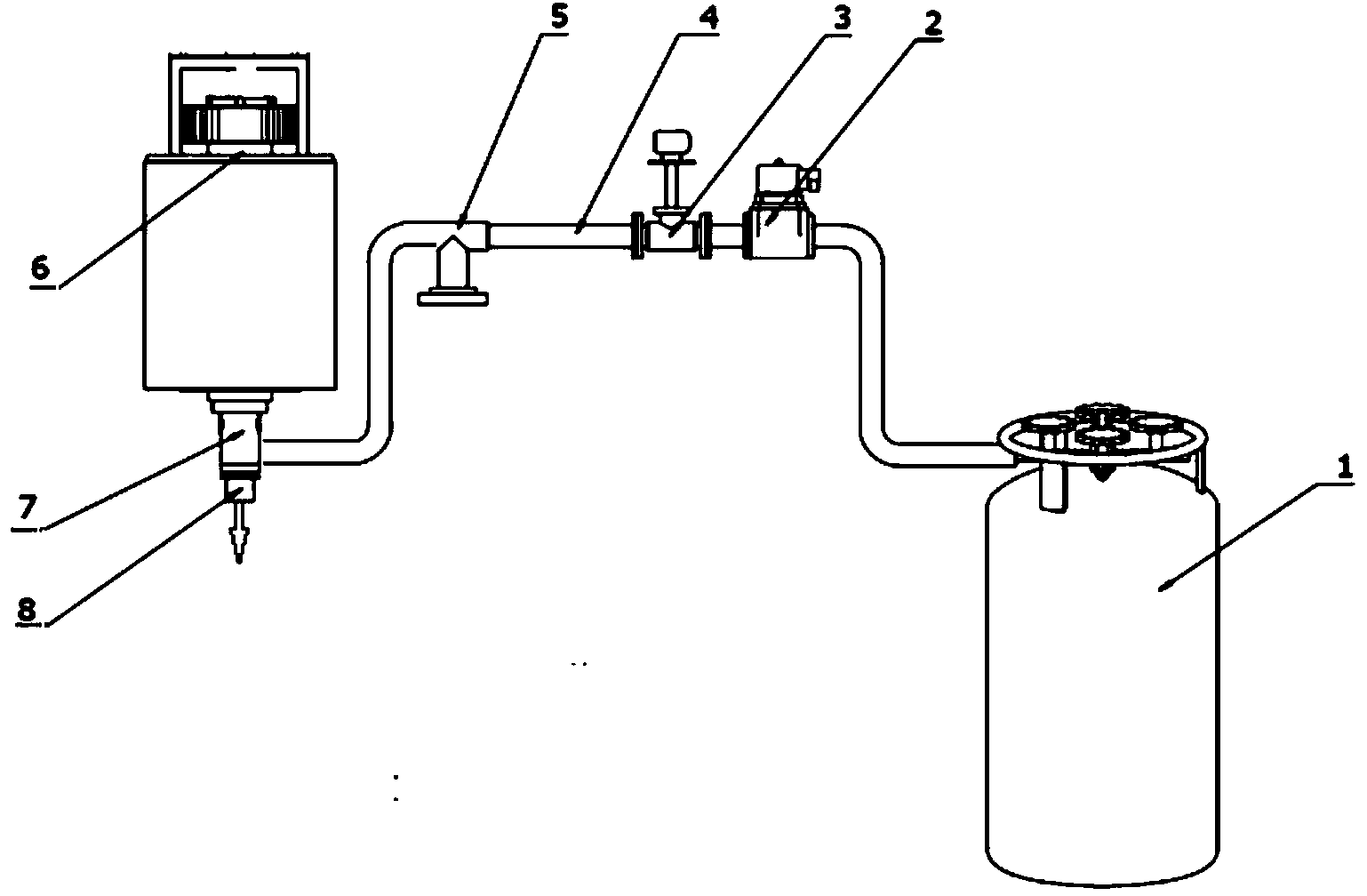

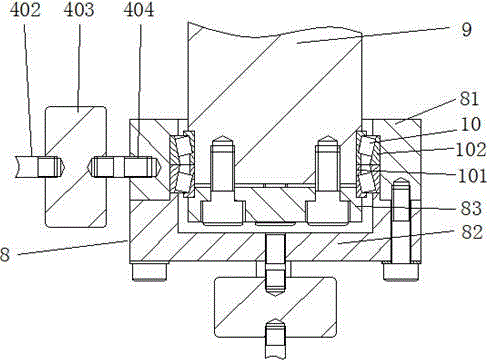

Liquid nitrogen inner spraying type cutter handle device

ActiveCN104015079ASolve the problem of inconvenient delivery of liquid nitrogenSolve the problem of realizing internal spray liquid nitrogen cutting fluidMachine tool componentsPositioning apparatusNumerical controlEngineering

The invention provides a liquid nitrogen inner spraying type cutter handle device, belongs to the design field of machine tools, and relates to a machine tool cutter handle device which achieves the purpose of cold low-temperature cutting through the fact that liquid nitrogen flows in an inner cavity of a cutter handle to a fine hole near a cutting edge of a hollow cutter rod to be sprayed out. The liquid nitrogen inner spraying type cutter handle device is composed of a left cutter handle peripheral assembly, a right cutter handle peripheral assembly and a cutter handle assembly. The left cutter handle peripheral assembly and the right cutter handle peripheral assembly are sequentially arranged on the outer circular face of the cutter handle and are locked by end nuts. In the liquid nitrogen inner spraying type cutter handle device, the surfaces of parts in contact with the liquid nitrogen are subjected to heat insulation material modified treatment, and the heat transferring capacity of the parts is lowered. The liquid nitrogen inner spraying type cutter handle device solves the problem that liquid nitrogen conveying is inconvenient for a workpiece with a complex structure in an existing outer spraying type liquid nitrogen cutting liquid device. The defect that the liquid nitrogen is low in utilization rate is overcome, the purpose that a common built-in type cutting liquid system achieves inner spraying of liquid nitrogen cutting liquid is achieved, the machining precision of difficult-to-machine materials machined by a machine tool is guaranteed, and the machining range of a numerical control machine tool is widened.

Owner:DALIAN UNIV OF TECH

Pipeline inner wall cleaning device

InactiveCN107470280AAvoid entanglementImprove cleaning efficiencyHollow article cleaningWater sourceWater channel

The invention discloses a pipeline inner wall cleaning device, which relates to the field of pipeline cleaning, and comprises a front traveling mechanism, a telescopic mechanism and a rear traveling mechanism which are sequentially connected from front to back; ; The diverging ends of the front traveling mechanism and the rear traveling mechanism are provided with a cleaning mechanism; the cleaning mechanism is provided with a high-pressure nozzle connected to an external water source, and the outlet of the high-pressure nozzle faces the inner wall of the pipeline. The cleaning mechanism includes a first motor fixedly connected to the front end of the front traveling mechanism or the rear end of the rear traveling mechanism, a disc fixedly connected to the output shaft of the first motor, and a high-pressure nozzle detachably connected to the outer surface of the disc; A water channel is provided with one end communicating with the high-pressure nozzle and the other end communicating with the external water source. The present invention realizes the effect of using the high-pressure water jet to strip and clean the dirt on the inner surface of the pipeline by arranging the traveling mechanism and the high-pressure nozzle.

Owner:成都兆丰斯诺科技有限公司

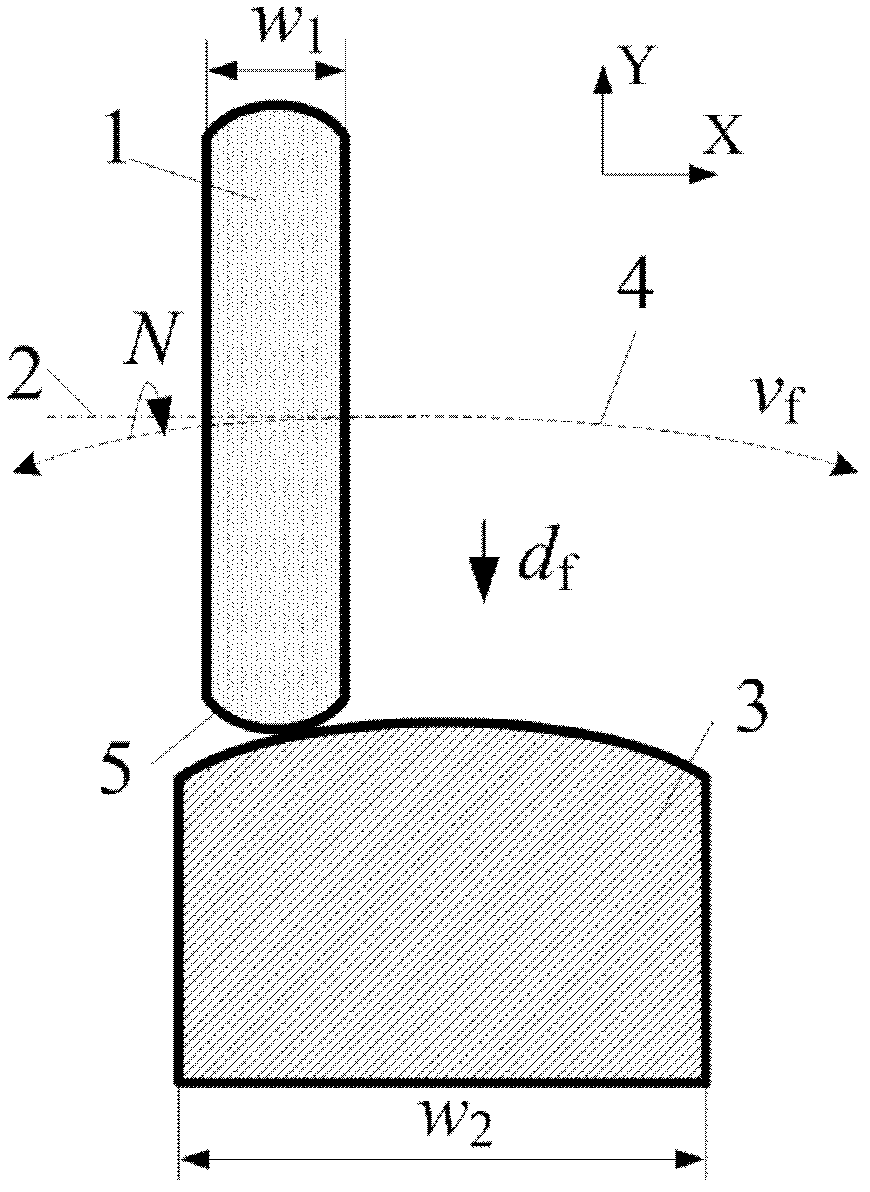

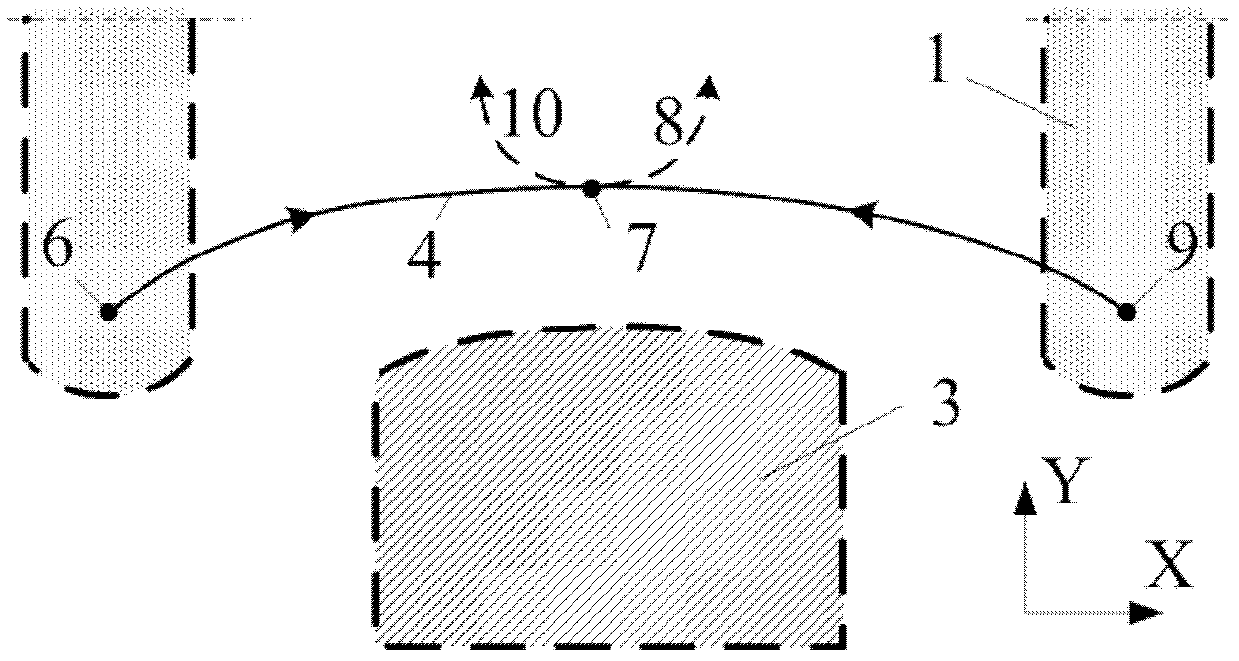

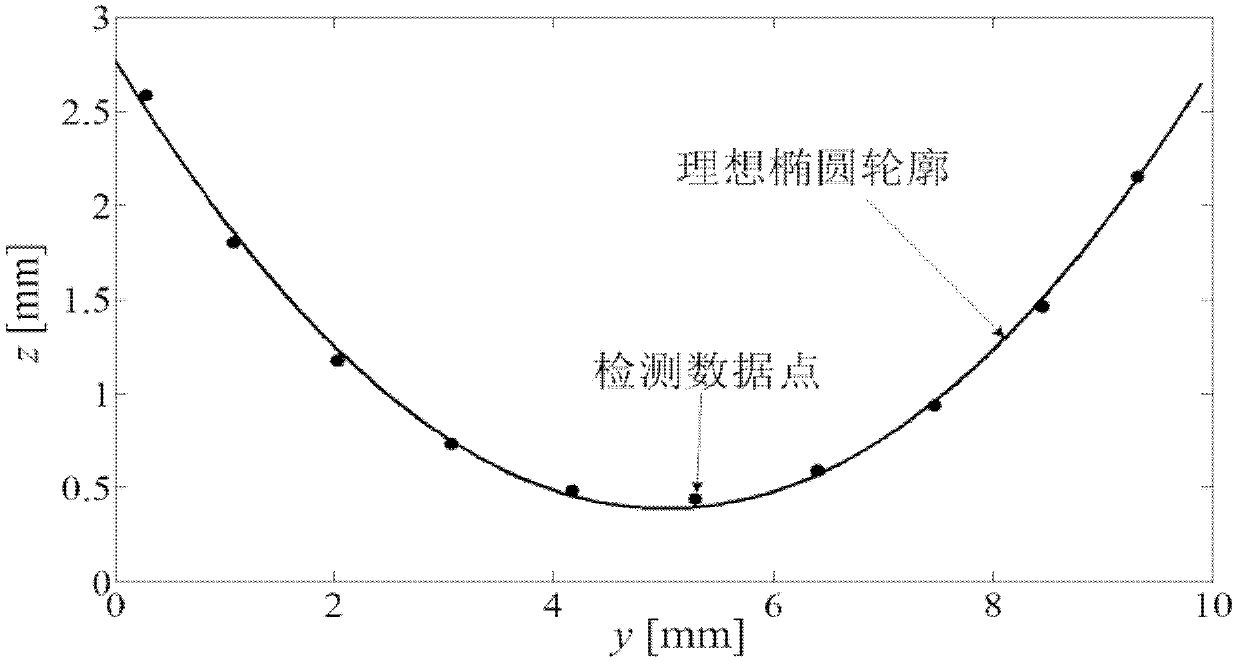

Diamond grinding wheel of elliptical working face and mutual wear forming and trimming method thereof

ActiveCN102350666AEasy to trimTrimming is effectiveAbrasion apparatusAbrasive surface conditioning devicesCarbide siliconStructural engineering

The invention discloses a diamond grinding wheel of an elliptical working face and a mutual wear forming and trimming method thereof. The profile of an axial section of a working face of the diamond grinding wheel is an elliptical arc profile; an end face of the diamond grinding wheel is an elliptical face; in the method, a diamond grinding wheel tool travels from left to right to a top point of an elliptical arc at a first starting point outside one side of a silicon carbide grinding stone along an elliptical arc traveling path, is then lifted along a first circular arc tangential to the top point and with a radius of more than 2mm, next travels from right to left to the top point of the elliptical arc from a second starting point outside the other side of the grinding stone along the elliptical arc traveling path and is lifted along a second circular arc tangential to the top point and with a radius of more than 2 mm. Compared with the conventional circular face diamond grinding wheel, the elliptical face diamond grinding wheel has the advantages that: a flatter grinding wheel elliptical working face and a workpiece curved surface can be used for complexing to grind, the number of effective grinding particles is increased, and the surface quality and the shape accuracy of curved surface grinding are improved.

Owner:SOUTH CHINA UNIV OF TECH

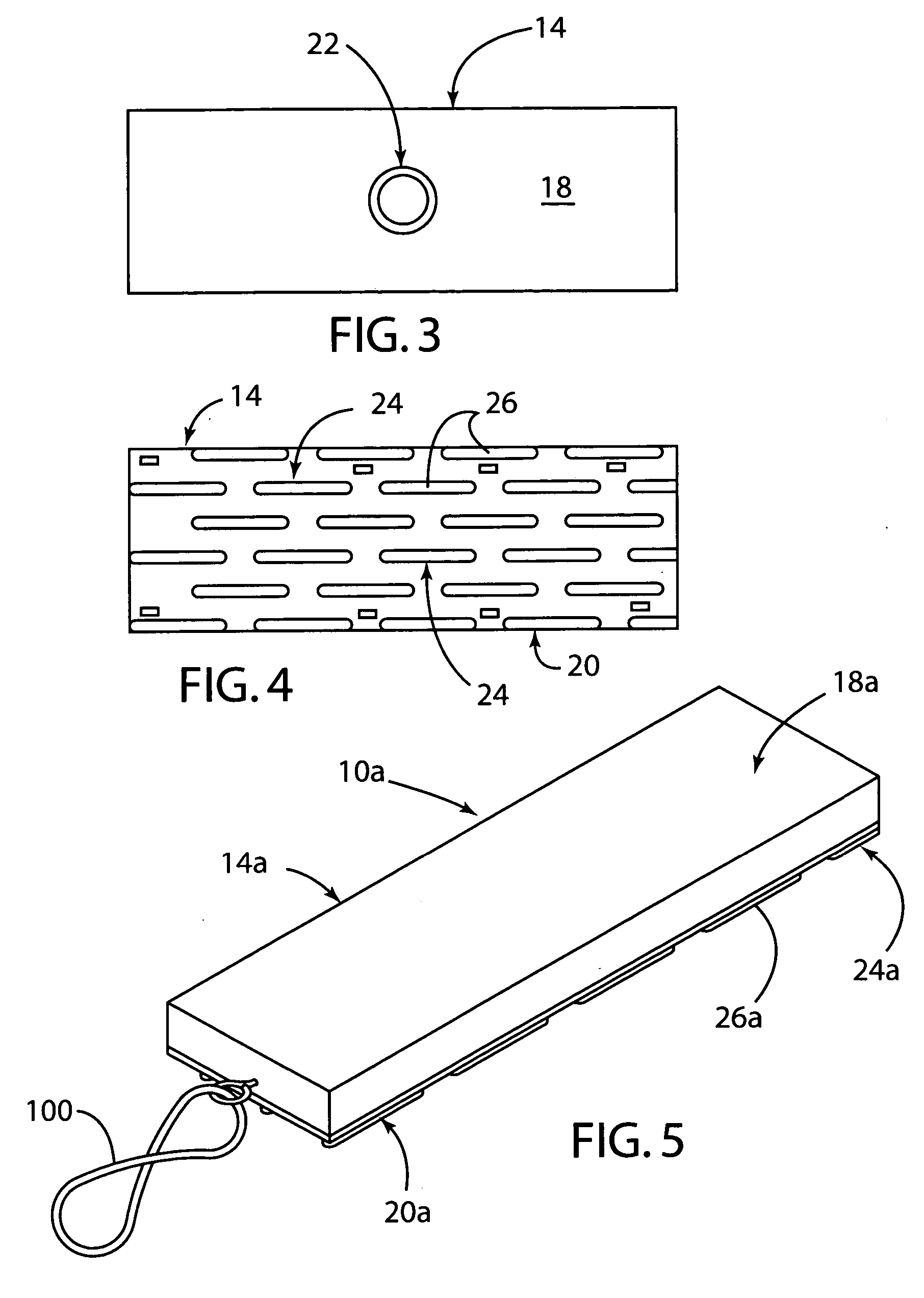

Carpet brush for hair removal

ActiveUS20060200926A1Easy to disassembleLiquid surface applicatorsCarpet cleanersHair removalEngineering

A fabric brush comprising a brush head having a top portion and a bottom portion. The bottom portion of the brush head has a plurality of projections extending downwardly therefrom. The plurality of projections comprise at least one row of aligned projections having a non-circular face extending opposite to the top portion of the brush head.

Owner:BISSELL INC

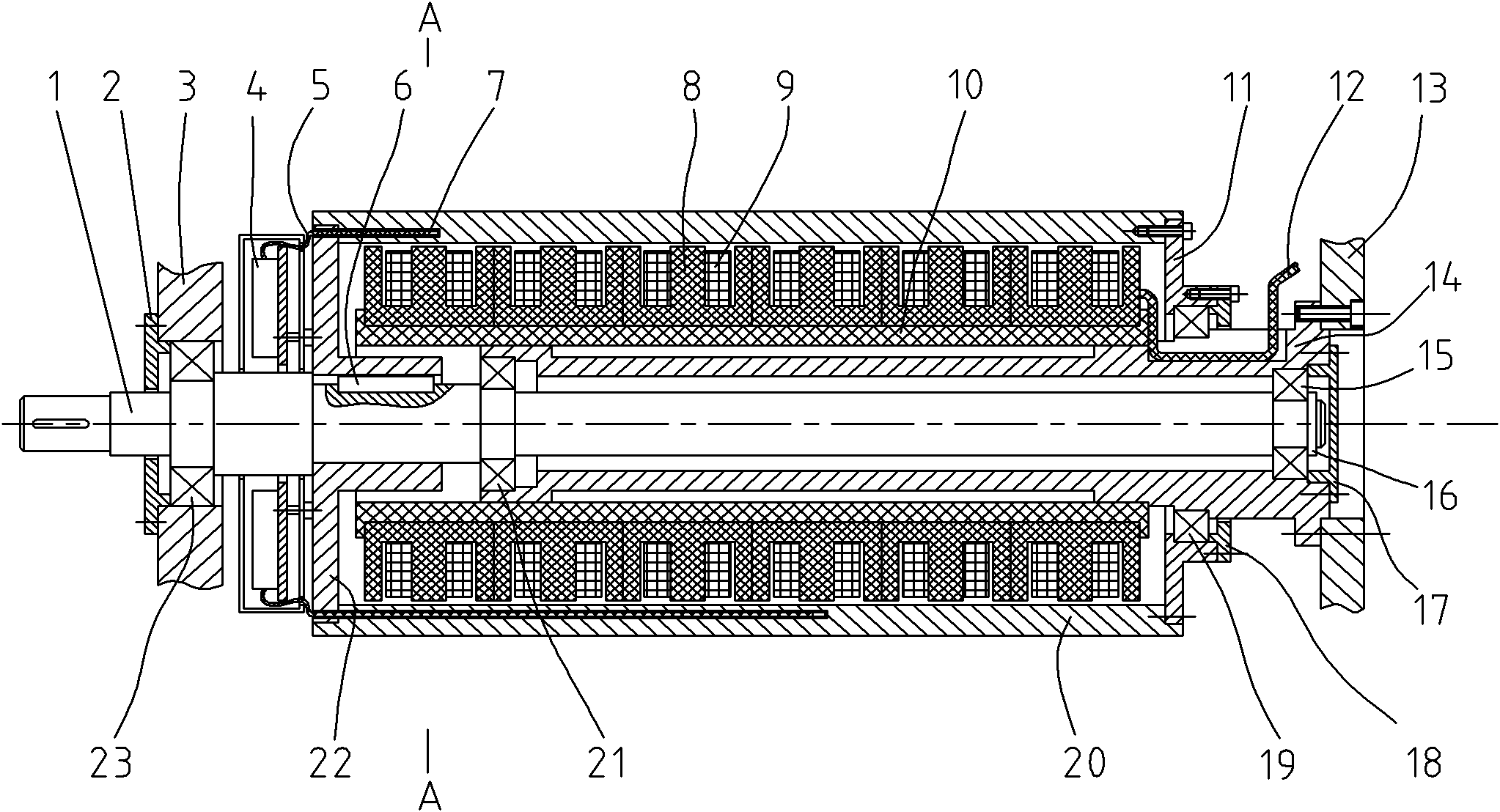

Electromagnetic induction heating press-roller

InactiveCN102137523AImprove induction heating efficiencyAvoid overall overheatingInduction heating apparatusMachine partsExcitation current

The invention discloses an electromagnetic induction heating press-roller, which has an integral double-end supporting structure and comprises a rotating device and a fixing device, wherein the rotating device consists of an action roller and a rotating shaft which are connected; the rotating shaft inputs a rotating torque to drive the action roller to rotate; the fixing device consists of a fixed shaft, a sleeve arranged on the outer side of the fixed shaft, magnetizers and excitation coils; through the magnetizers and excitation coils segmentedly installed outside the sleeve, a magnetic airgap is formed between the outside end face of the fixed magnetizer and the inner circular face of the rotating action roller; the alternating magnetic field forms a circuit through the magnetizer, the air gap and the action roller metal; the magnetic field in the action roller forms an eddy current so as to uniformly heat the working face of the rotating action roller. Since a structure of axially segmented magnetizers and excitation coils is adopted, a magnetic circuit is formed on the working face metal of the heating roller only to avoid the magnetic circuit penetration of the non-heating working part and reduce the excitation current, and simultaneously prevent the machine parts from overheating; besides, the induction heating efficiency can be improved so as to control the axial temperature gratitude of the heating roller continently.

Owner:WUHAN UNIV OF TECH

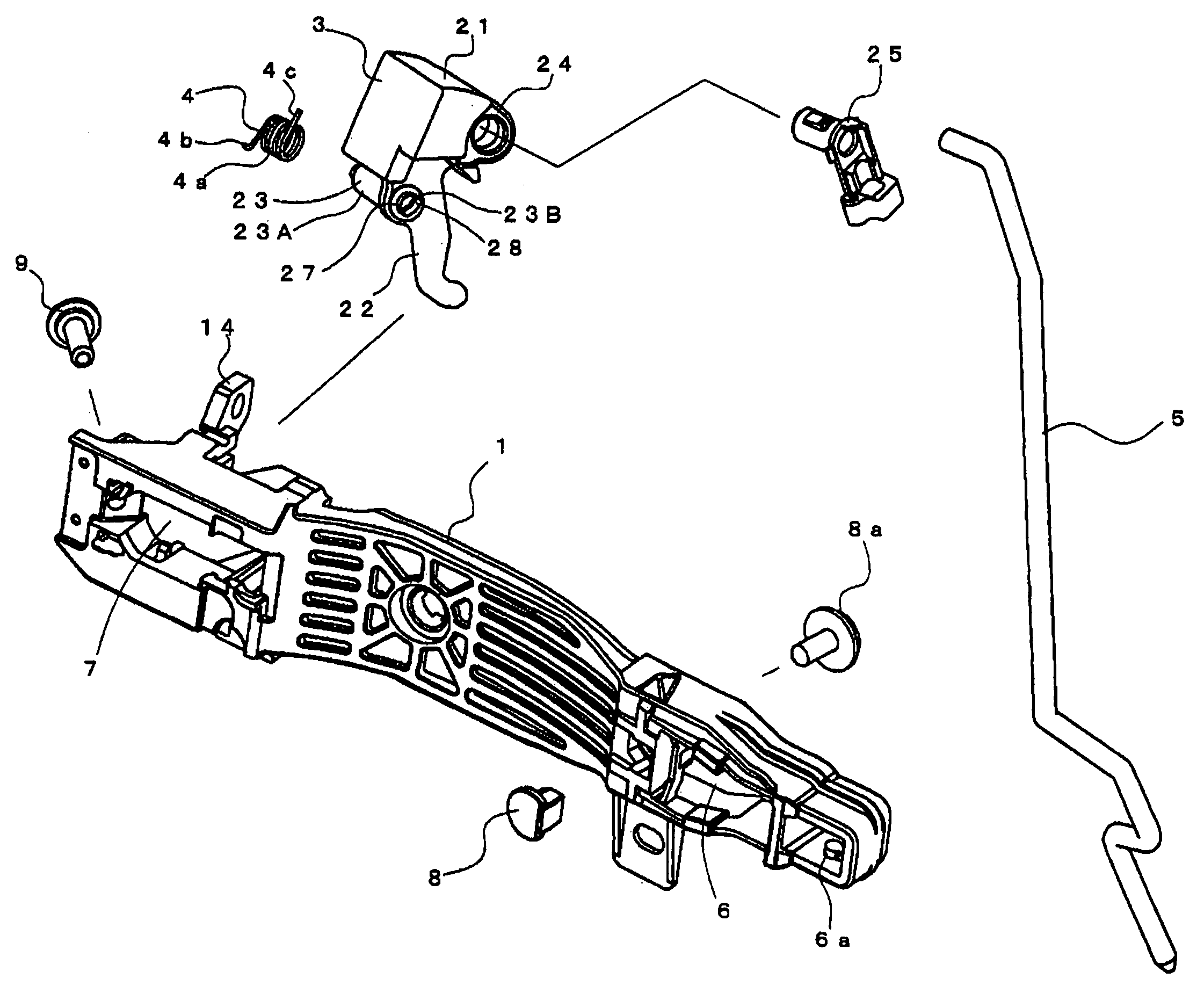

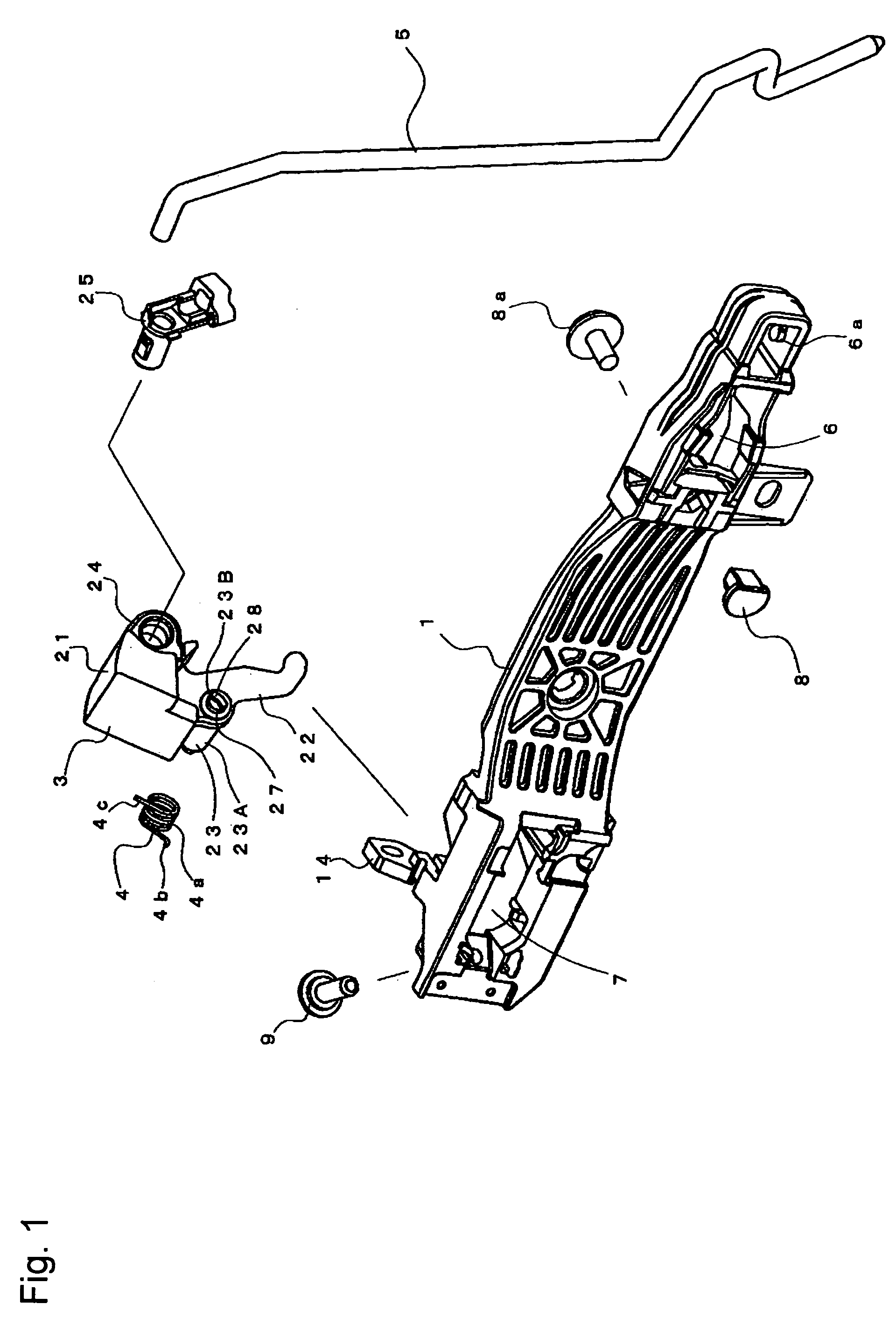

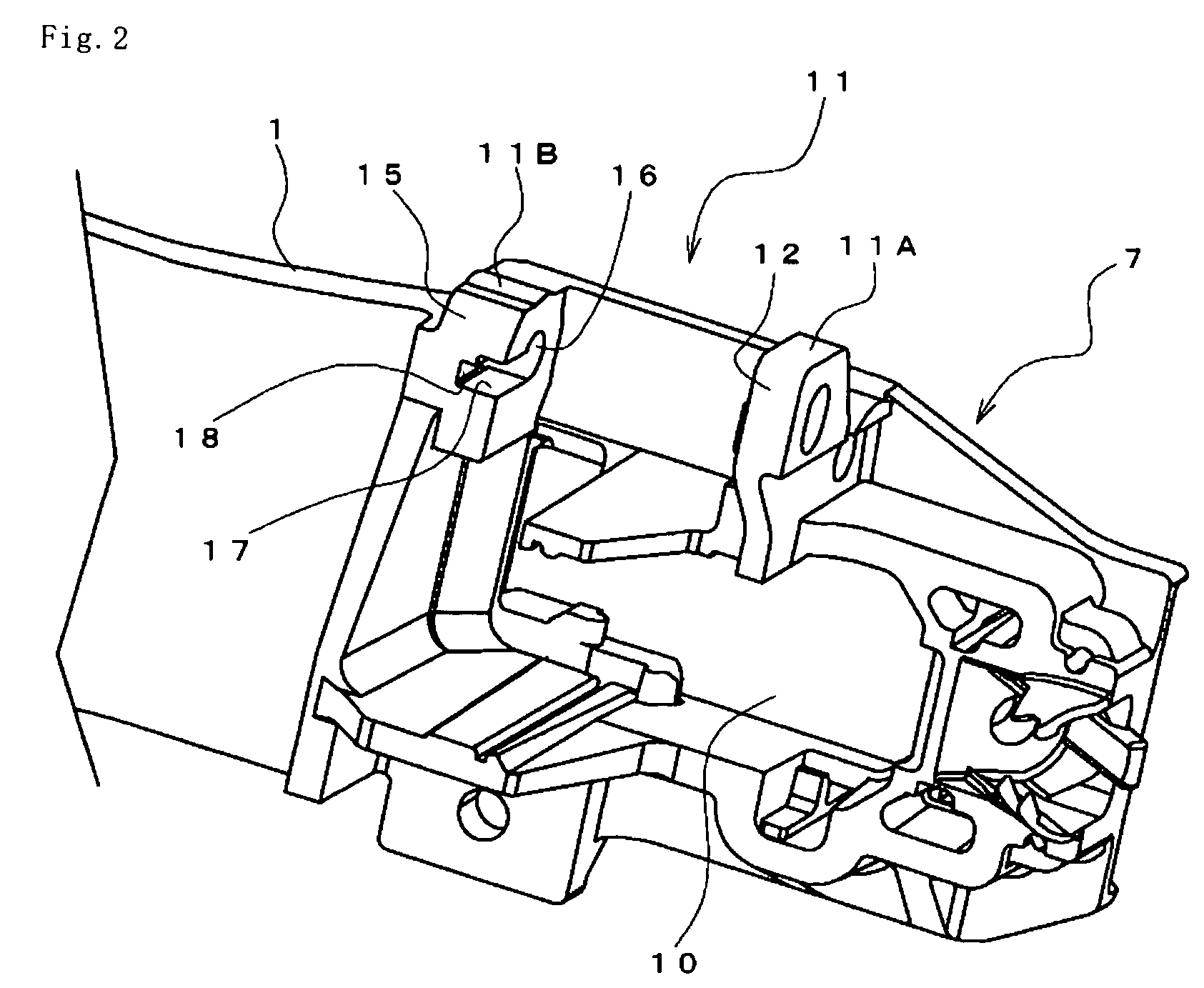

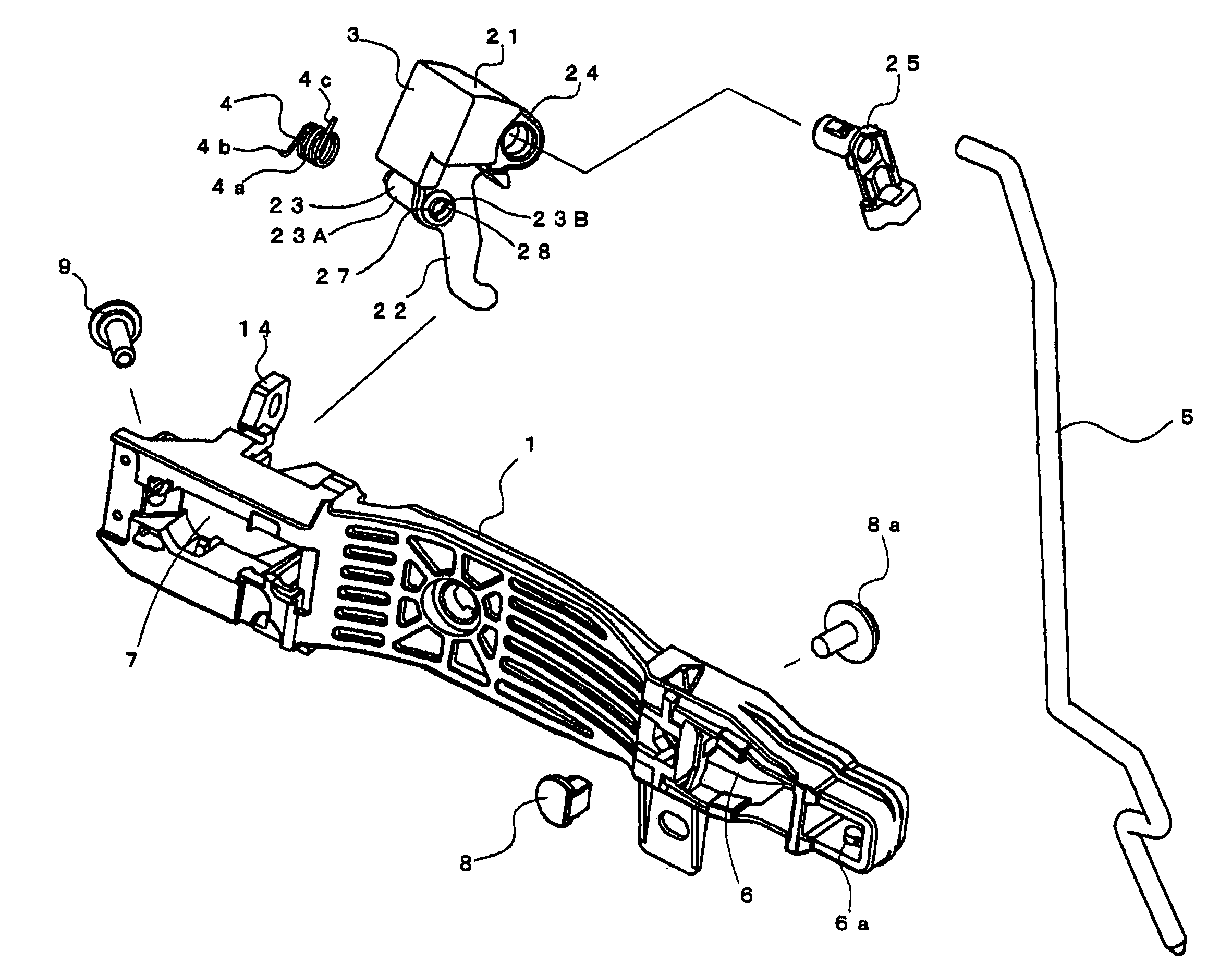

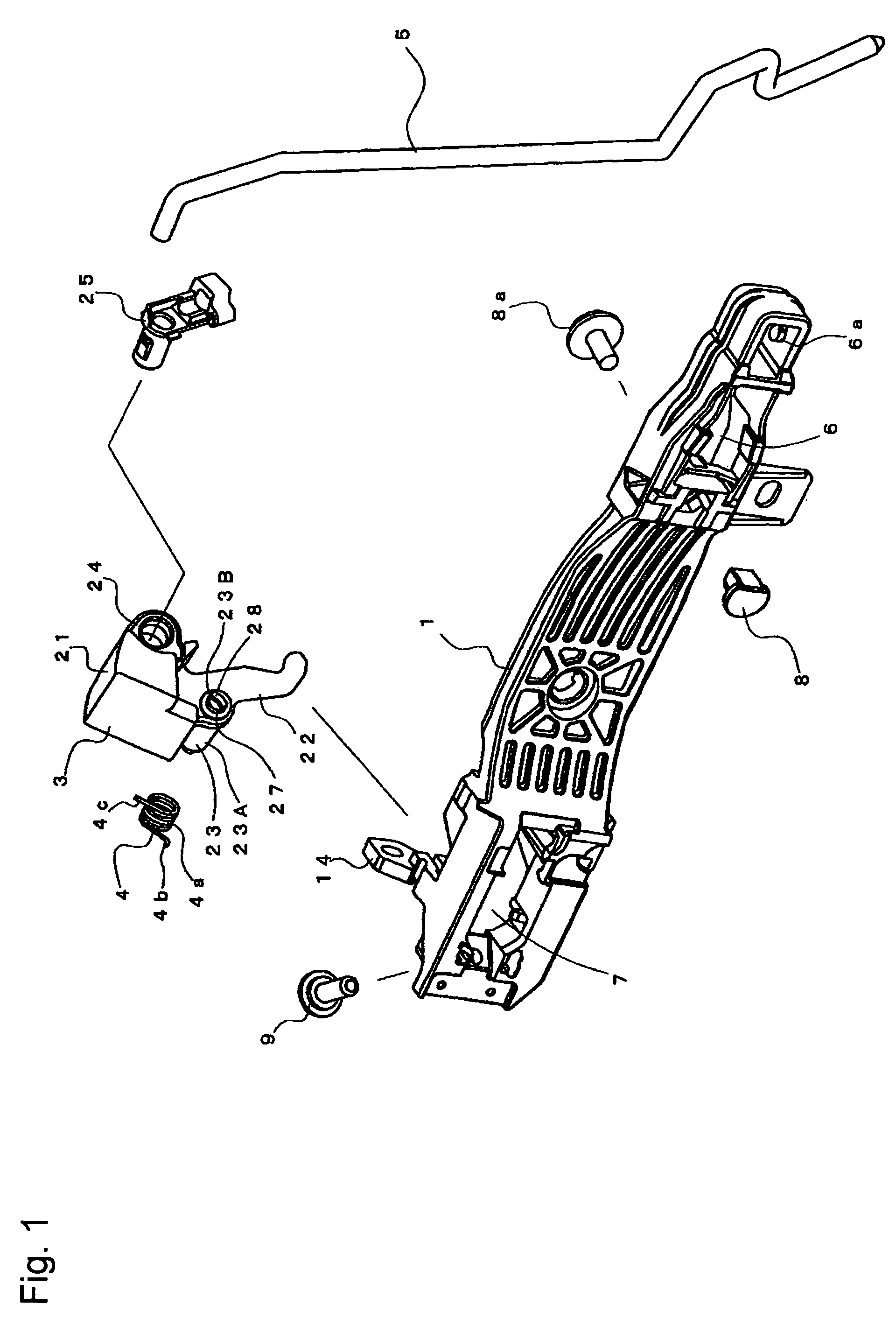

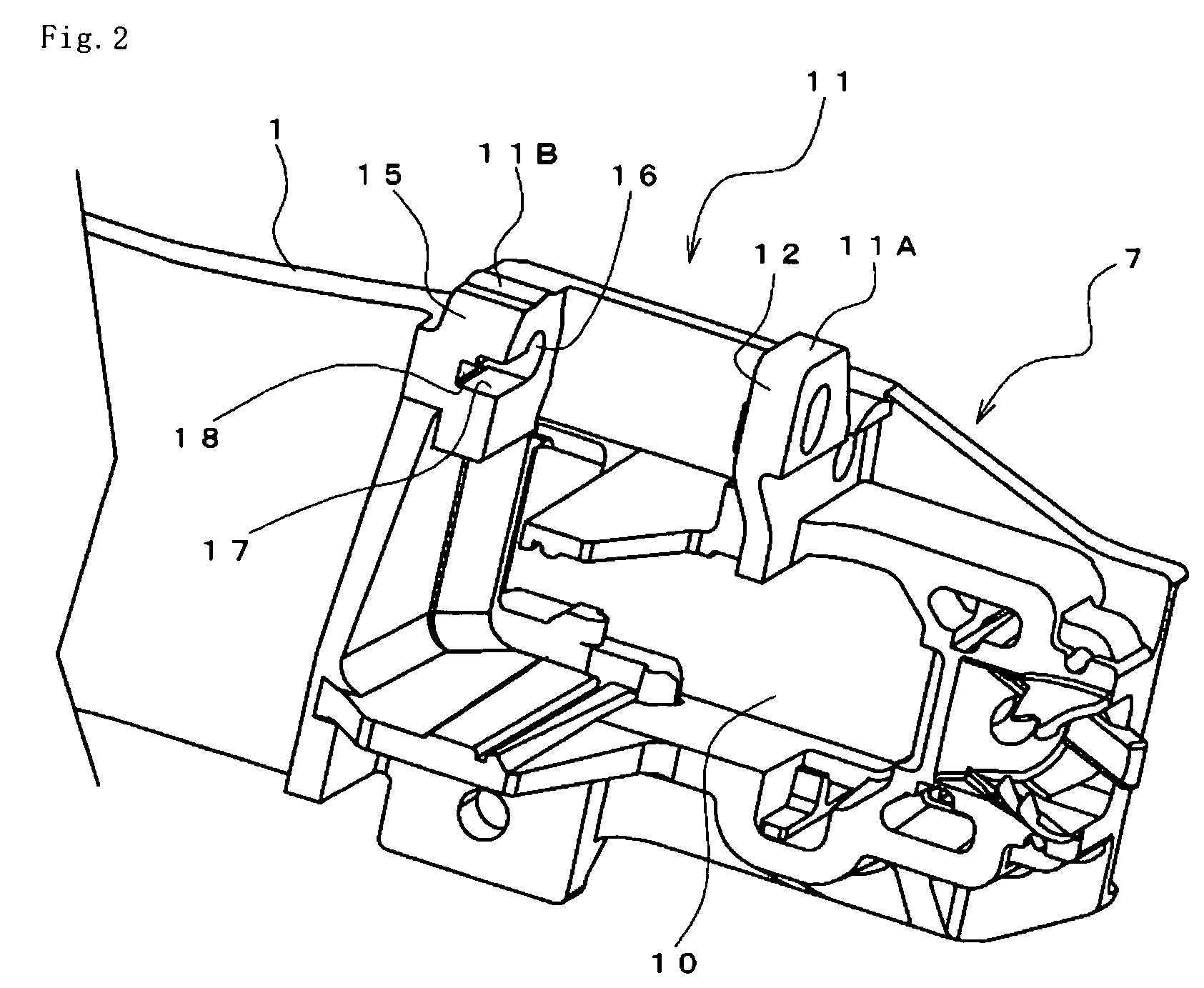

Vehicle door handle apparatus

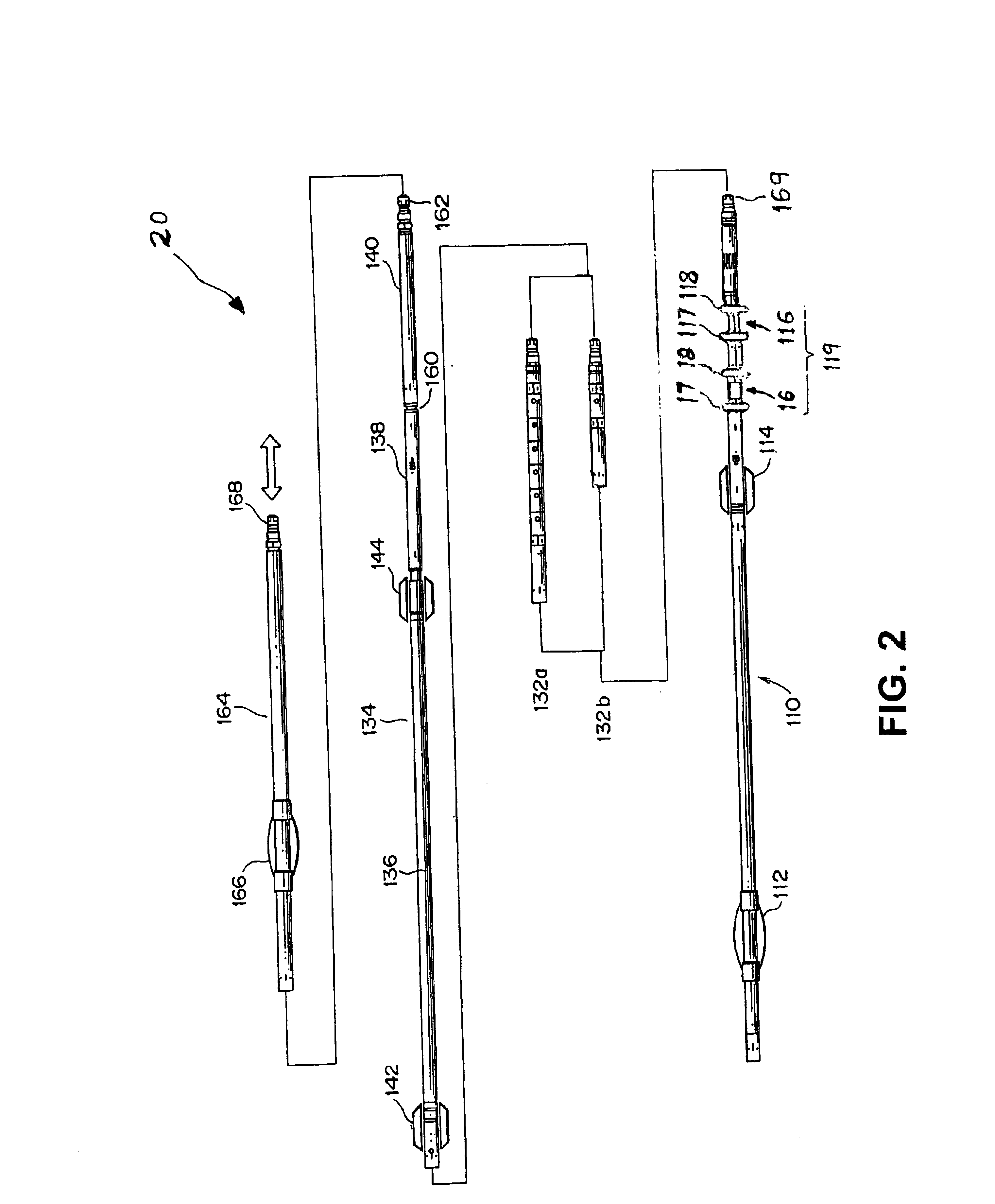

ActiveUS20080277948A1Prevent fallingThe process is simple and convenientTravelling carriersWing handlesEngineeringCircular face

To provide a supporting structure of a rotating section which offers not only facilitated mounting but also resistance to dropout. There are provided a handle base 1 for rotatably supporting one end side of a handle grip 2, and a lever 3 which has a shaft section 23 rotatably supported by a bearing section 11 of the handle base 1 and which is rotated upon pulling of the handle grip 2. The lever 3 includes a first shaft tip section 27 projecting from the shaft section 23 to a shaft tip side and having a part cut away so as to form a circular face, and a second shaft tip section 28 projecting from the first shaft tip section 27 to a shaft tip side and having a width smaller than that of the first shaft tip section 27. The handle base 1 includes a bearing hole 16 for rotatably supporting the first shaft tip section 27 and the second shaft tip section 28 of the lever 3, a first guide rail 17 for guiding the first shaft tip section 27 to the bearing hole 16, and a second guide rail 18 narrower than the first shaft tip section 27 for guiding the second shaft tip section 28 to the bearing hole 16.

Owner:U SHIN LTD

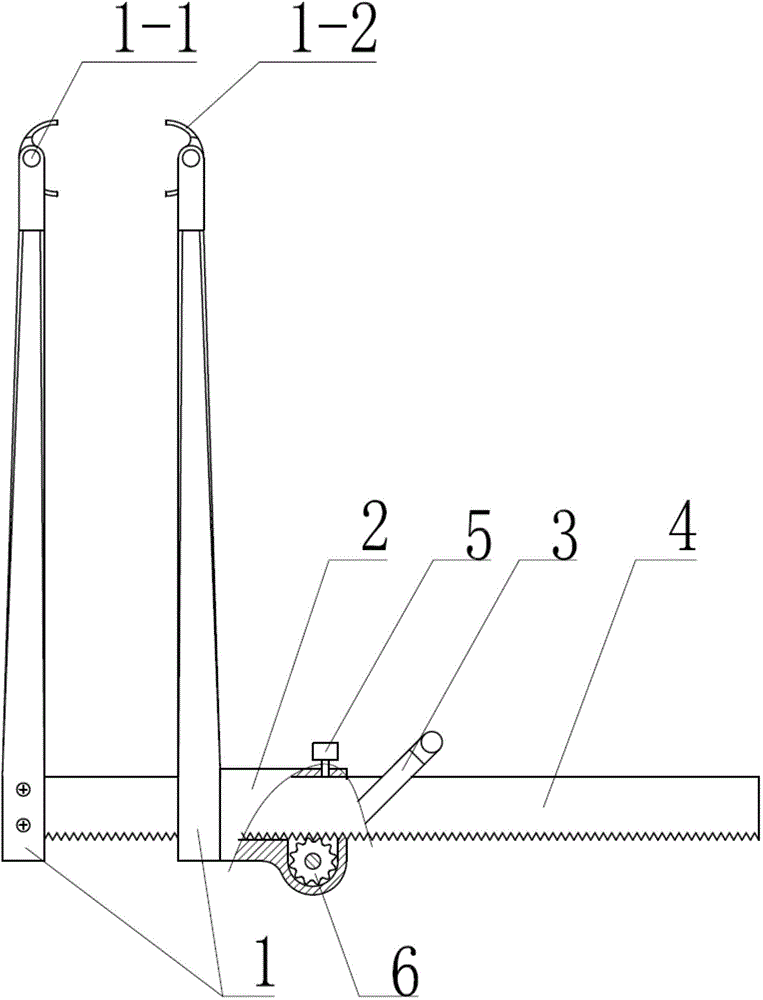

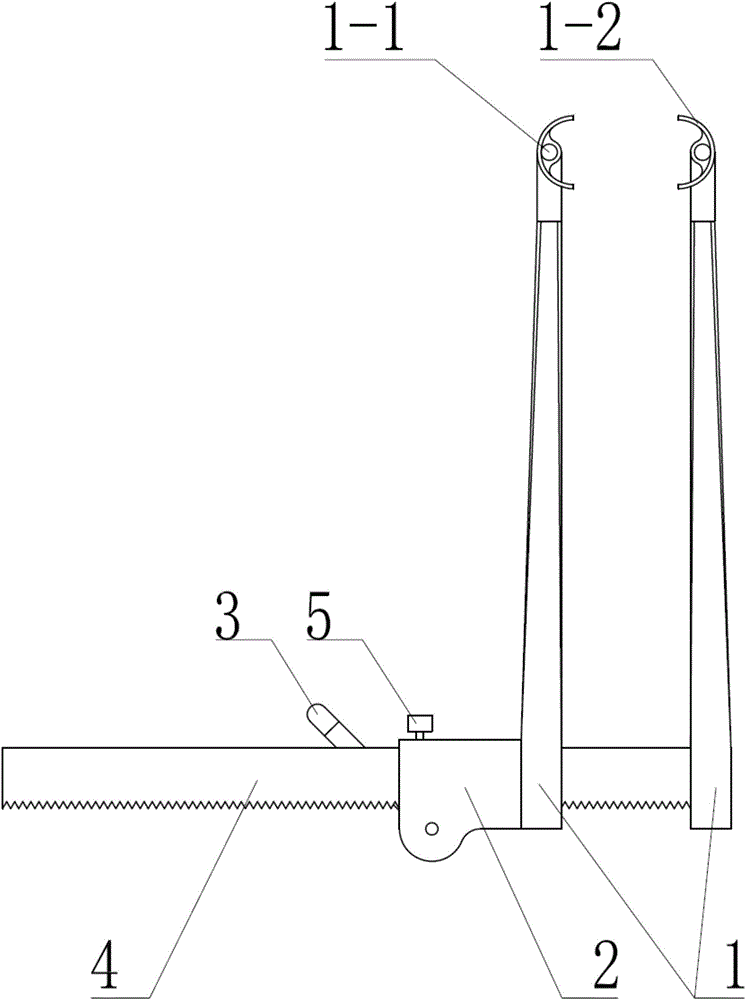

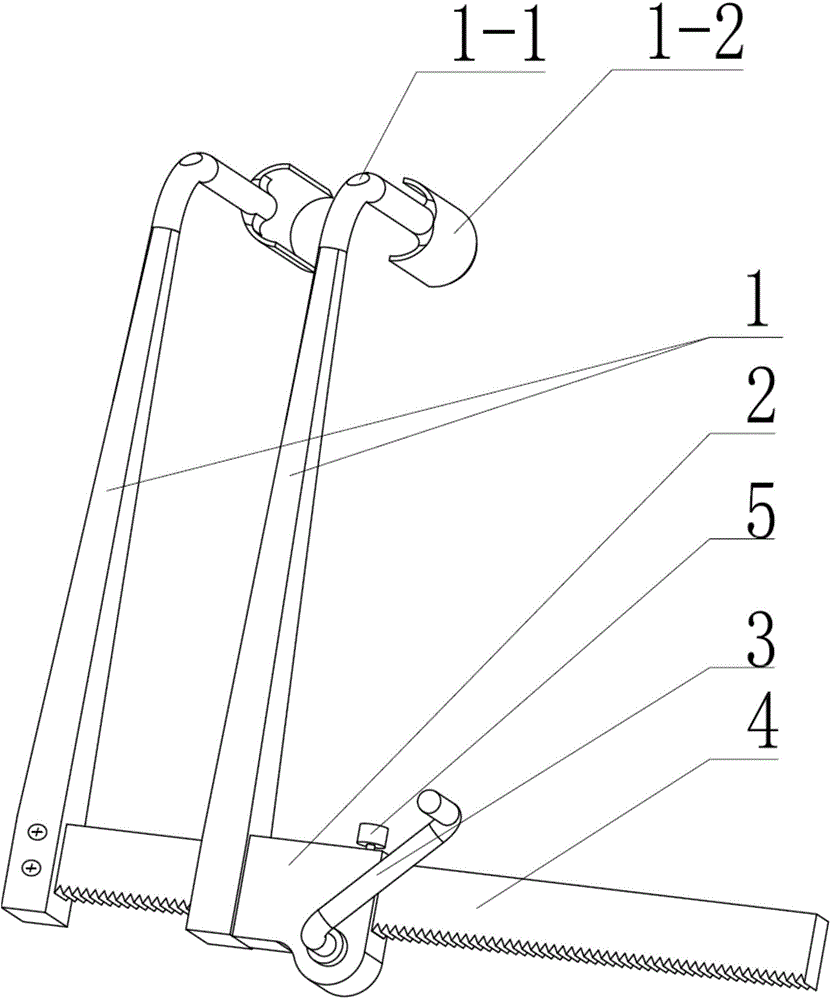

Cervical vertebra anterior distraction device suitable for minimally invasive surgery

The invention relates to a cervical vertebra anterior distraction device suitable for minimally invasive surgery. The cervical vertebra anterior distraction device suitable for minimally invasive surgery comprises two tubular pin seats which are connected through a parallel guiding device. The parallel guiding device is a gear and track transmission mechanism which is composed of a gear, a rack, a guiding sleeve and a handle which are meshed. One of the two tubular pin seats is fixed to the rack, and the other tubular pin seat is fixed to a guiding sleeve. Each tubular pin seat is provided with a round needle hole penetrating through a needle connected with the vertebra to be distracted, wherein the lower end of the tubular pin seat is provided with a circular arc baffle, the radius of the circular arc of the inner circular face of the circular arc baffle is larger than that of the round needle hole, and the inner circular face of the circular arc baffle and the inner surface of the round needle hole are in projection tangency in the plane perpendicular to the axis of the round needle hole. The openings of the circular arc baffles at the lower ends of the two tubular pin seats are opposite.

Owner:陈远明

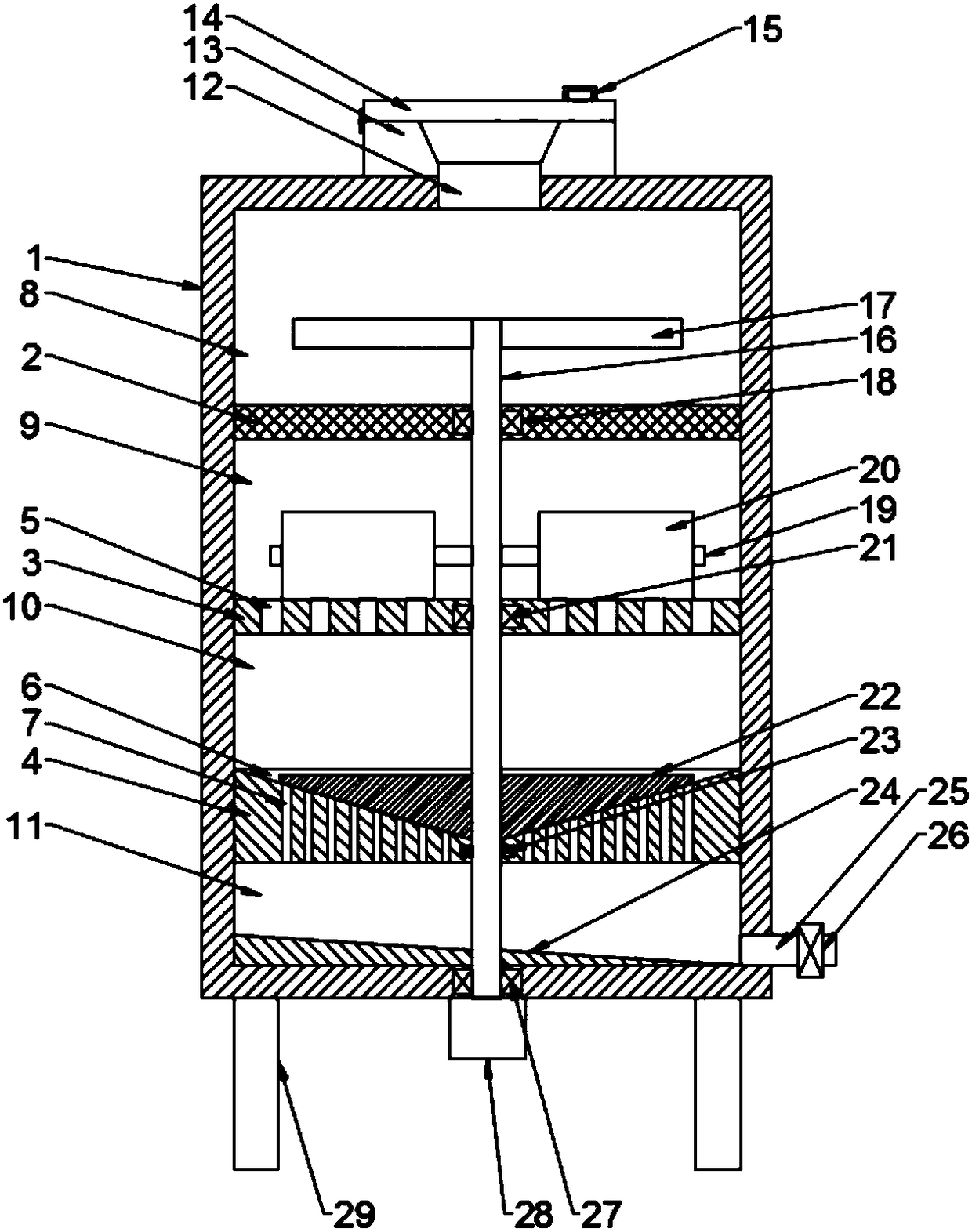

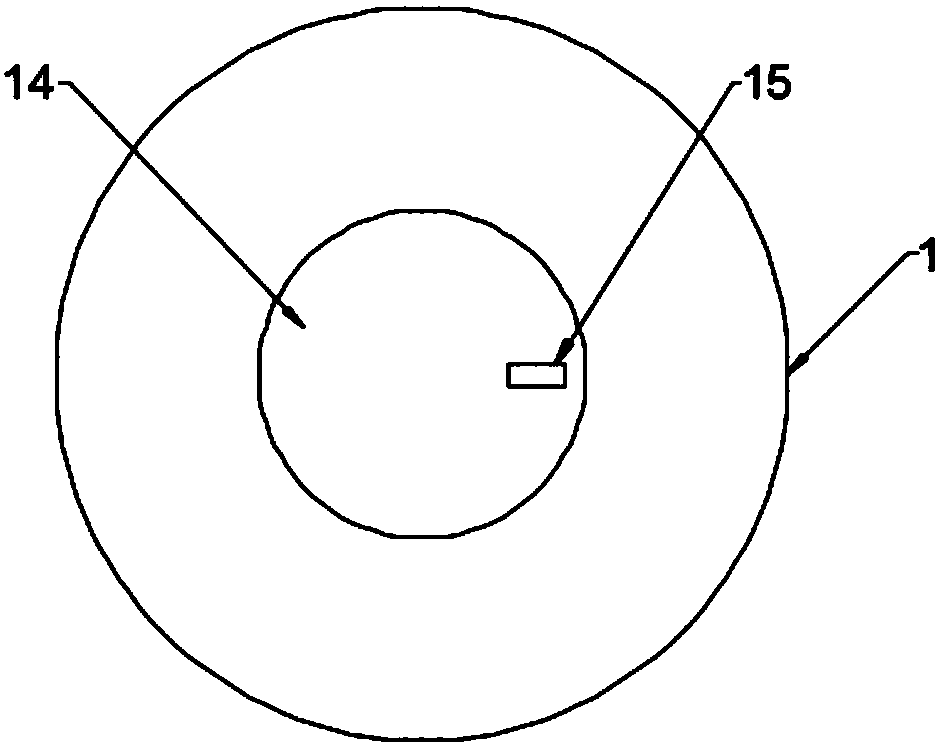

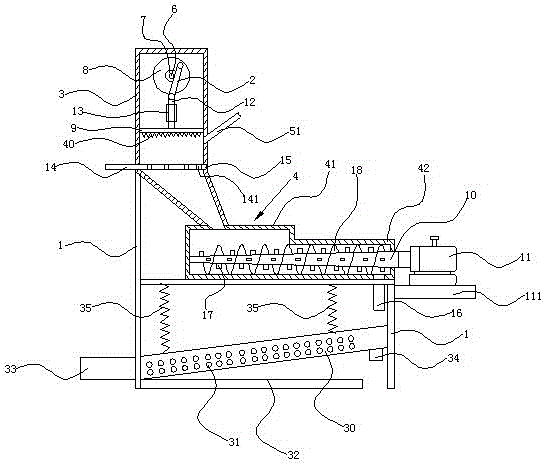

Multi-stage step-by-step-type crushing device for ceramic waste

InactiveCN108160213AAchieve homogenizationImprove crushing qualityCocoaGrain treatmentsMotor shaftCircular face

The invention discloses a multi-stage step-by-step-type crushing device for ceramic waste. The multi-stage step-by-step-type crushing device comprises a box body, an isolating net, a first partition plate and a second partition plate are sequentially arranged in an inner cavity of the box body from top to bottom, a grinding cavity is formed in the top end of the second partition plate, and the inner cavity of the box body is partitioned into a crushing cavity, a pulverizing cavity and a grinding cavity from top to bottom through the isolating net, the first partition plate and the second partition plate. A motor is arranged at the bottom end of the box body, a motor shaft of the motor is fixedly connected with a rotating shaft, a charging hole is formed in the top wall of the crushing cavity, and a plurality of crushing rods are arranged at the top end of the outer circular face of the rotary shaft in a circularly arrayed mode. A plurality of pulverizing rollers are arranged in the pulverizing cavity in a circularly arrayed mode, a grinding disc is arranged in the grinding cavity, and a plurality of supporting legs are evenly arranged at the edge of the bottom end face of the box body. According to the multi-stage step-by-step-type crushing device for the ceramic waste, by forming the crushing cavity, the pulverizing cavity and the grinding cavity and by utilizing the crushingrods, the pulverizing rollers and the grinding disc, multi-time and level-division crushing is conducted, through layer-by-layer crushing and grinding, homogenization of ceramic fragments is achieved,the crushing quality is greatly improved, and the subsequent production requirement is met accordingly.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

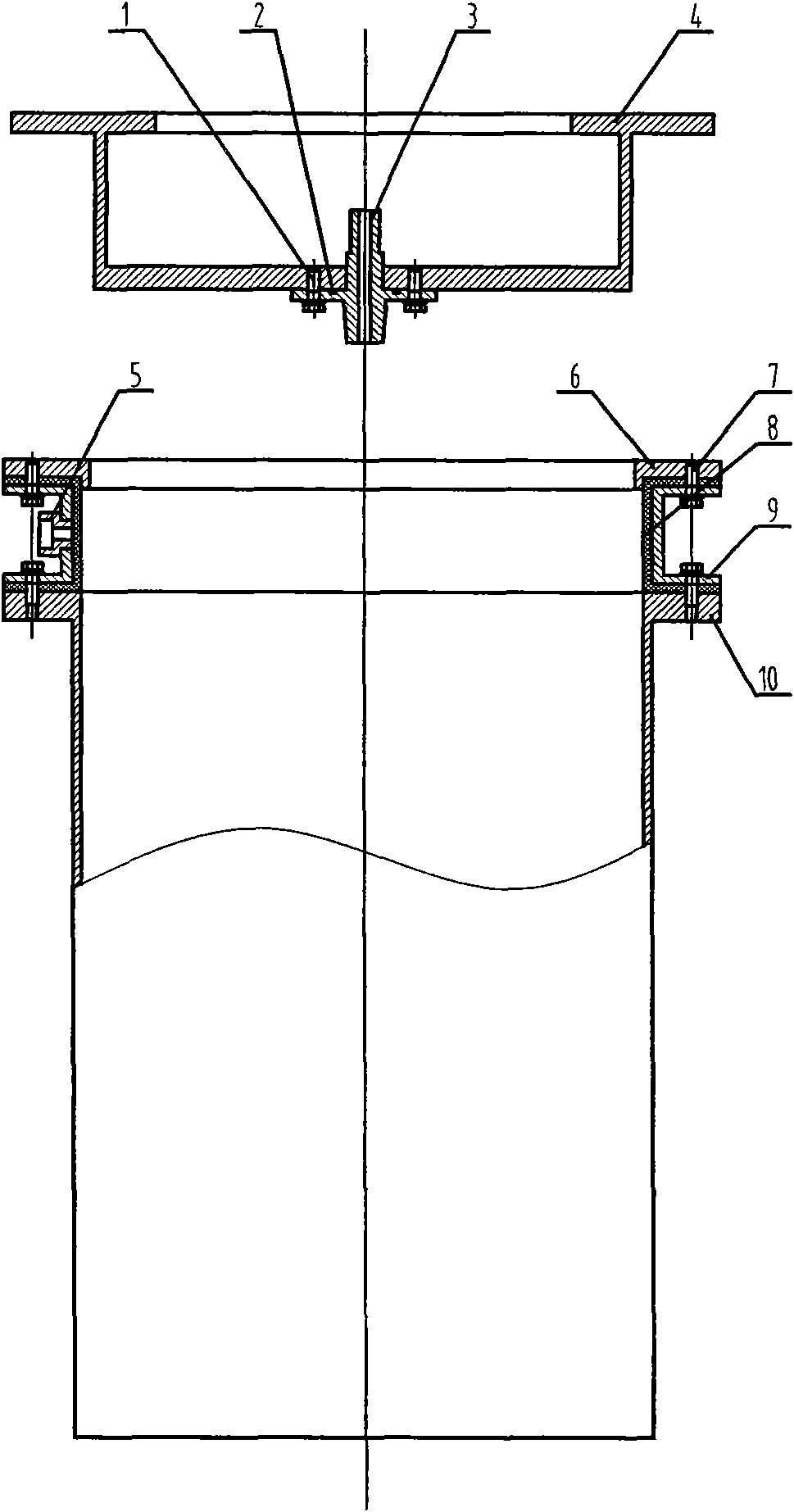

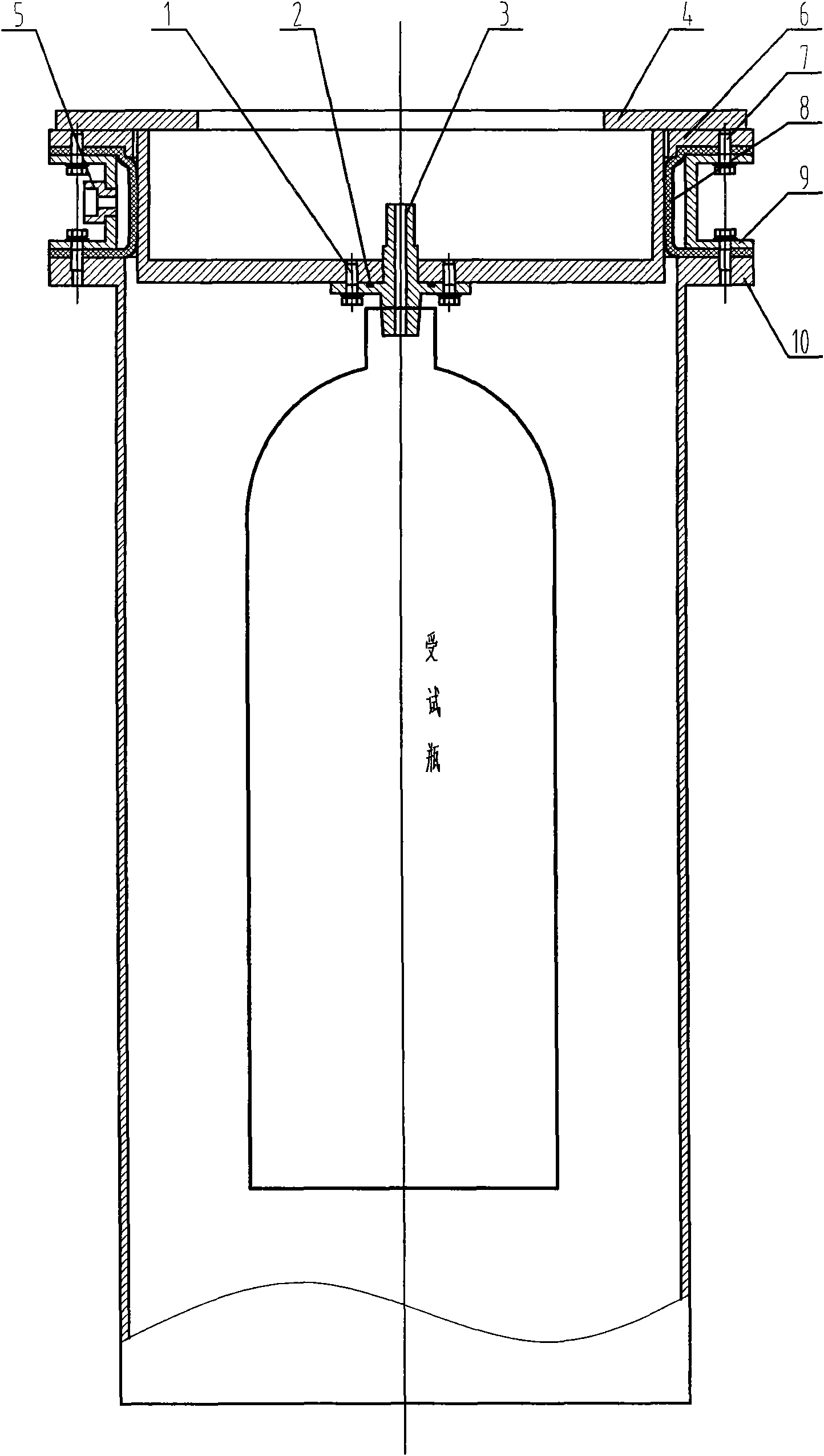

Water jacket and air bag type sealing device for hydraulic test of air bottle outside measuring method

InactiveCN101581643AQuick sealImprove sealingMaterial strength using tensile/compressive forcesGas cylinderEngineering

The invention relates to a water jacket and air bag type sealing device for hydraulic test of an air bottle outside measuring method, in particular to a test container for forming seal between a water jacket and a water jacket cover. The sealing device mainly comprises a pressure test joint, the water jacket cover, a pneumatic joint, a flange, a rubber air bag, a connecting flange and the water jacket, wherein the pressure test joint is fixedly connected with the water jacket cover through a connecting bolt and an O-shaped ring which seals the connecting part; the pneumatic joint is fixedly connected to an outer circular face of the connecting flange; the rubber air bag and the connecting flange are placed between the flange and the water jacket and fixed through the connecting bolts; and the connecting faces of the connecting flange, the flange and the water jacket are sealed through an upper end face and a lower end face of the rubber air bag. The sealing device has a simple, compact and reasonable structure, has simple and convenient operation, is quick, effective and reliable to form a water jacket seal, can ensure smooth hydraulic test of the air bottle outside measuring method, and greatly improves the production efficiency.

Owner:无锡昌华机电制造有限公司

Trapezoid pole shoe sleeve type magnetic fluid seal device

ActiveCN108006233AIncrease magnetic fluxOvercome the problem of being unable to achieve high sealing performance requirements in special working conditions such as high speed and heavy loadEngine sealsCircular faceMagnet

The invention relates to a trapezoid pole shoe sleeve type magnetic fluid seal device comprising a shaft, a shell, a left pole shoe ring, a right pole shoe ring, an upper permanent magnet ring, a lower permanent magnet ring and a trapezoid sleeve. The inner circular face of the left pole shoe ring and the inner circular face of the right pole shoe ring are provided with pole teeth III. The upper permanent magnet ring is arranged on the inner wall of the shell. The trapezoid sleeve is arranged on the shaft in a sleeving manner. The outer circular face of the trapezoid sleeve corresponds to theupper permanent magnet ring. A gap exists between the outer circular face of the trapezoid sleeve and the inner circular face of the upper permanent magnet ring. A groove I is formed in the outer circular face of the trapezoid sleeve. The lower permanent magnet ring is arranged in the groove I. The left end face of the trapezoid sleeve is an inclined annular face I. The right end face of the trapezoid sleeve is an inclined annular face II. The inclined annular face I is provided with pole teeth I. The inclined annular face II is provided with pole teeth II. The trapezoid pole shoe sleeve typemagnetic fluid seal device aims to solve the difficult problem that an existing seal device is poor in pressure resistance.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Grinding Roller for the Pressure Communication of Granular Material

ActiveUS20070215733A1Easy to useImprove wear resistanceCocoaGrain treatmentsWear resistantEngineering

The aim of the invention is to provide grinding rolls in particular for high-pressure roller mills or rolling presses for pressure grinding a granular material not only with a wear-resistant coating but also with a face armour plating in the area of the roller annular edge, which has a long service life due to the high wear resistance thereof and whose production and repair are, in general, relatively simple and inexpensive. For this purpose, the inventive face armour plating consists of a plurality of prefabricated hard bodies which are circularly arranged side by side in such a way that the circular face edge of the roller is formed, said hard bodies are disposed on said circular shoulder of a roll shell such that said hard bodies are placed axially and radially against said circular shoulder of the roll shell and are movably assembled with the roll shell.

Owner:KHD HUMBOLDT WEDAG GMBH

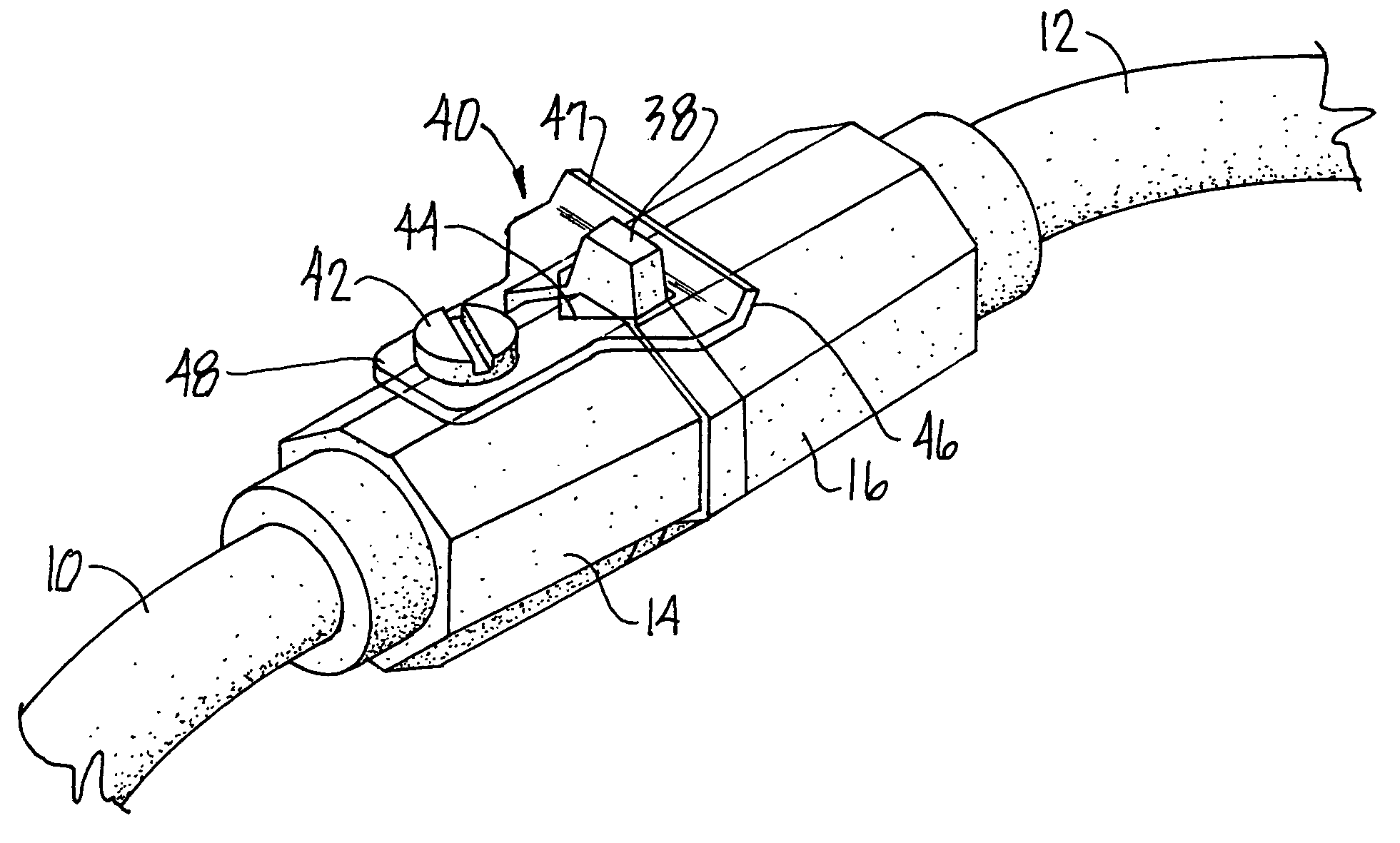

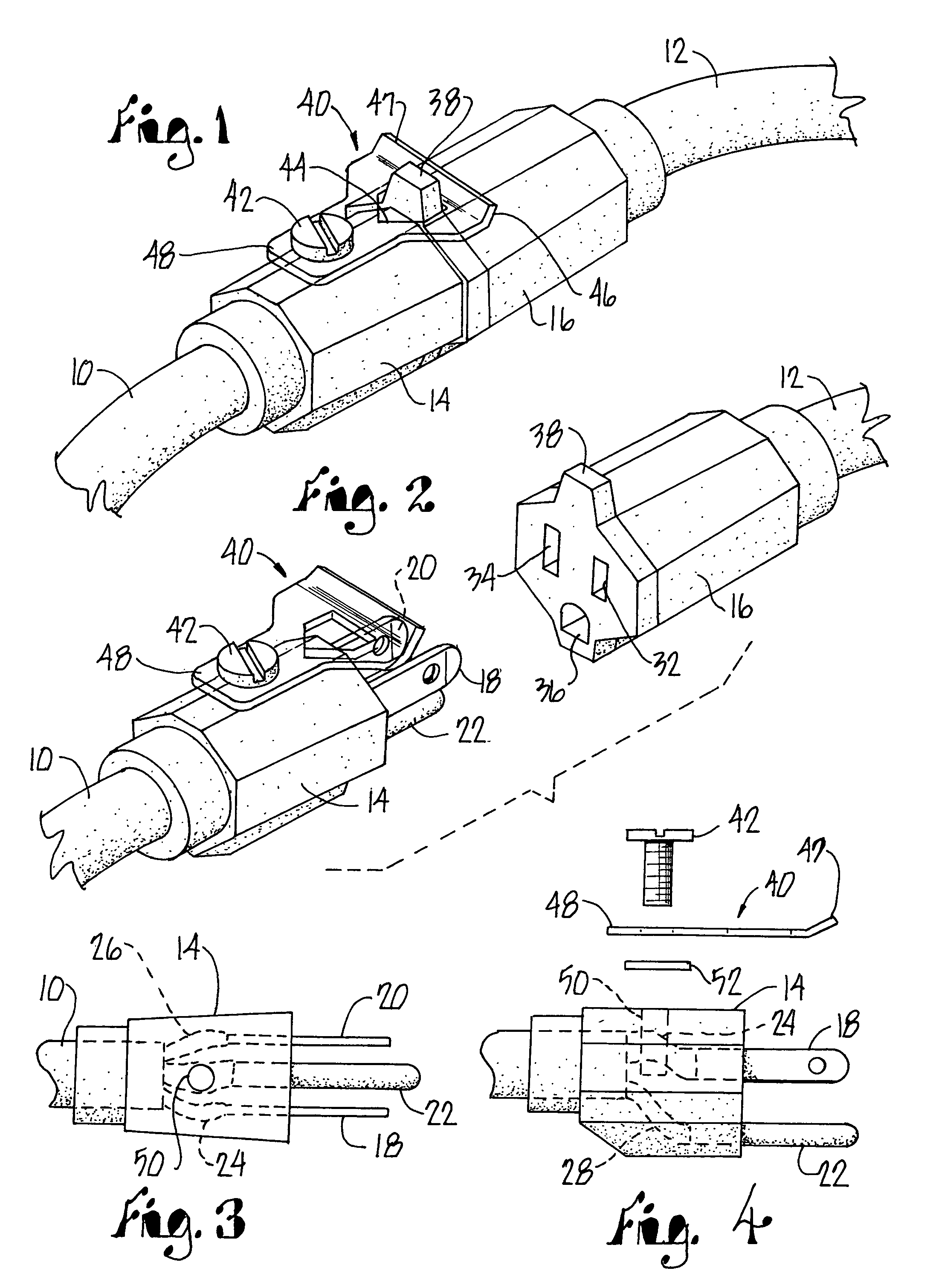

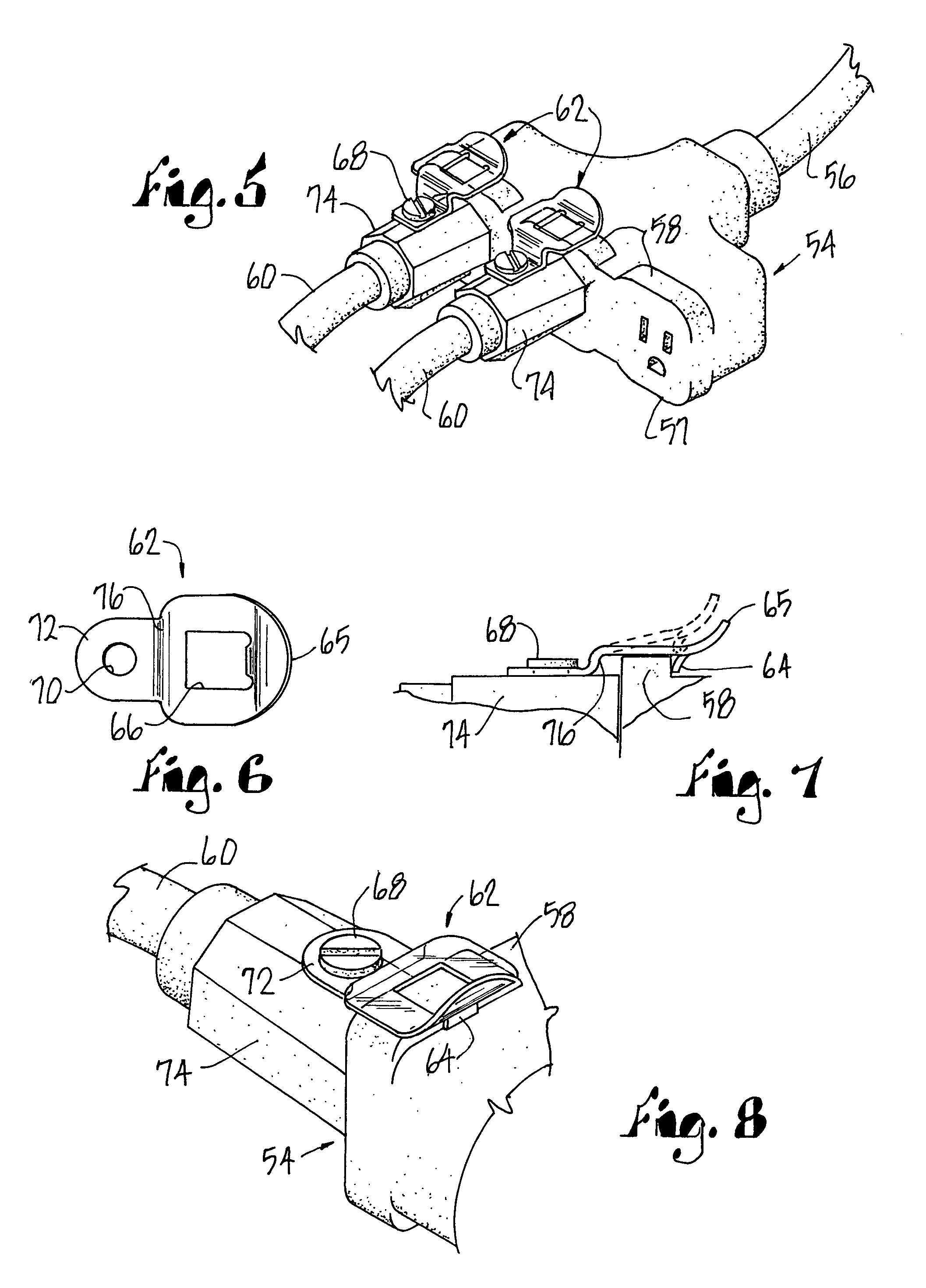

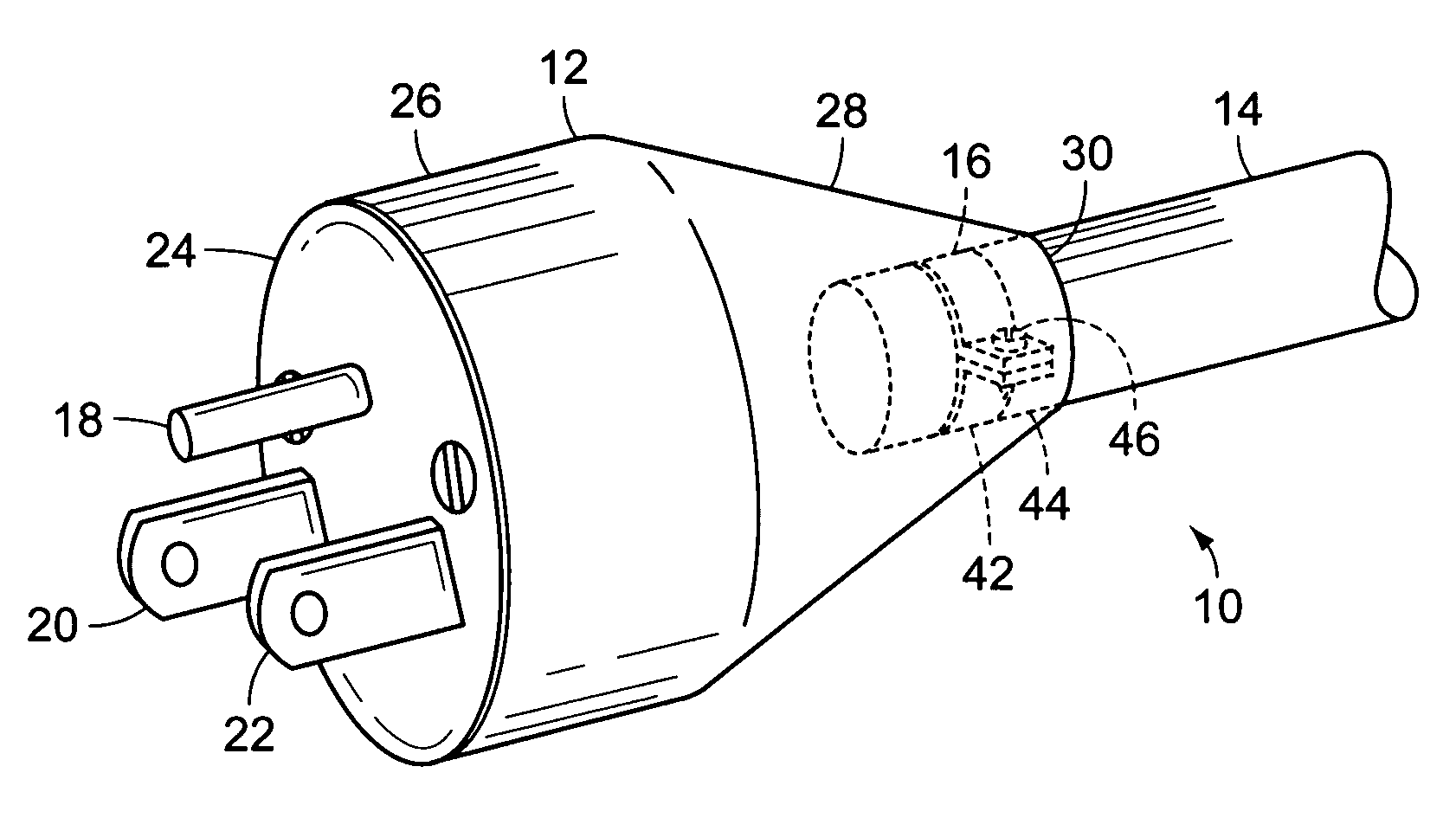

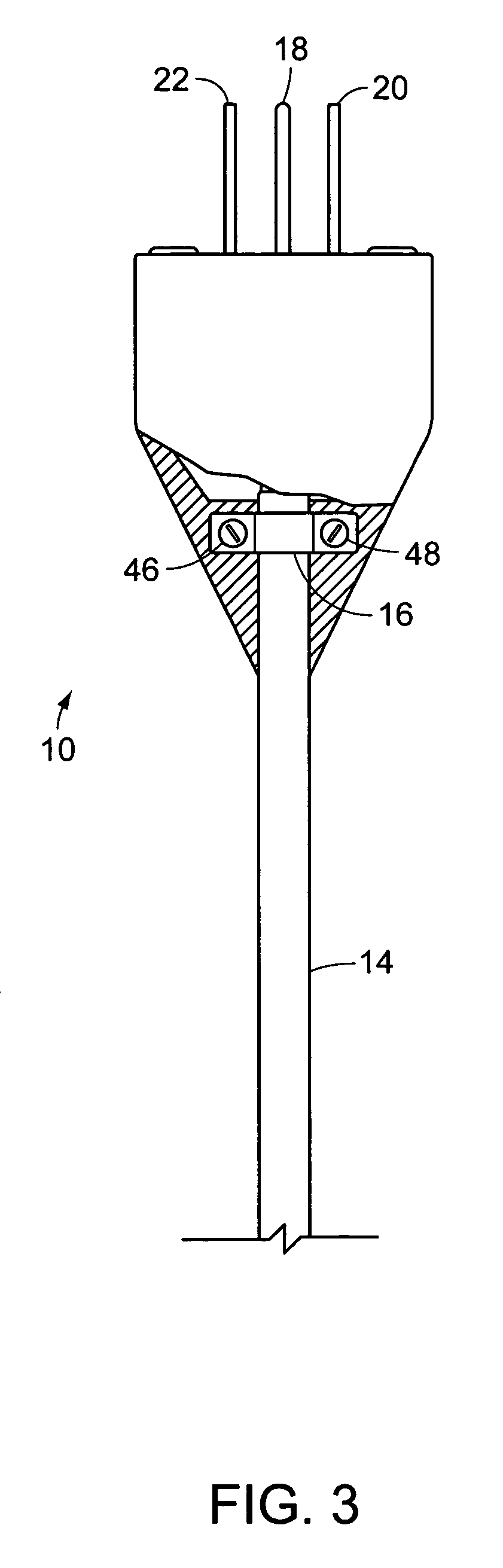

Electrical cord locking connector

InactiveUS7744400B2Tight spacingAvoid separationEngagement/disengagement of coupling partsTwo pole connectionsMating plugEngineering

An electrical cord locking connector joins electrical cords in series and presents a streamlined profile that minimizes interference in restricted spaces through which the cords must be fed to service a job site. The connector joins the ends of successive cords utilizing the outwardly projecting shoulder provided on the female socket of one cord in cooperation with a latch member on the male end of the connecting cord to lock the two cords together. A cord provided with a female end terminating in a replacement cord cap is provided with a socket presenting a generally circular face and an outwardly projecting shoulder at the face for engaging a releasable latch member of a mating plug, thereby preventing separation of the plug and socket under force until the latch member is disengaged.

Owner:R C DESIGN & ENG

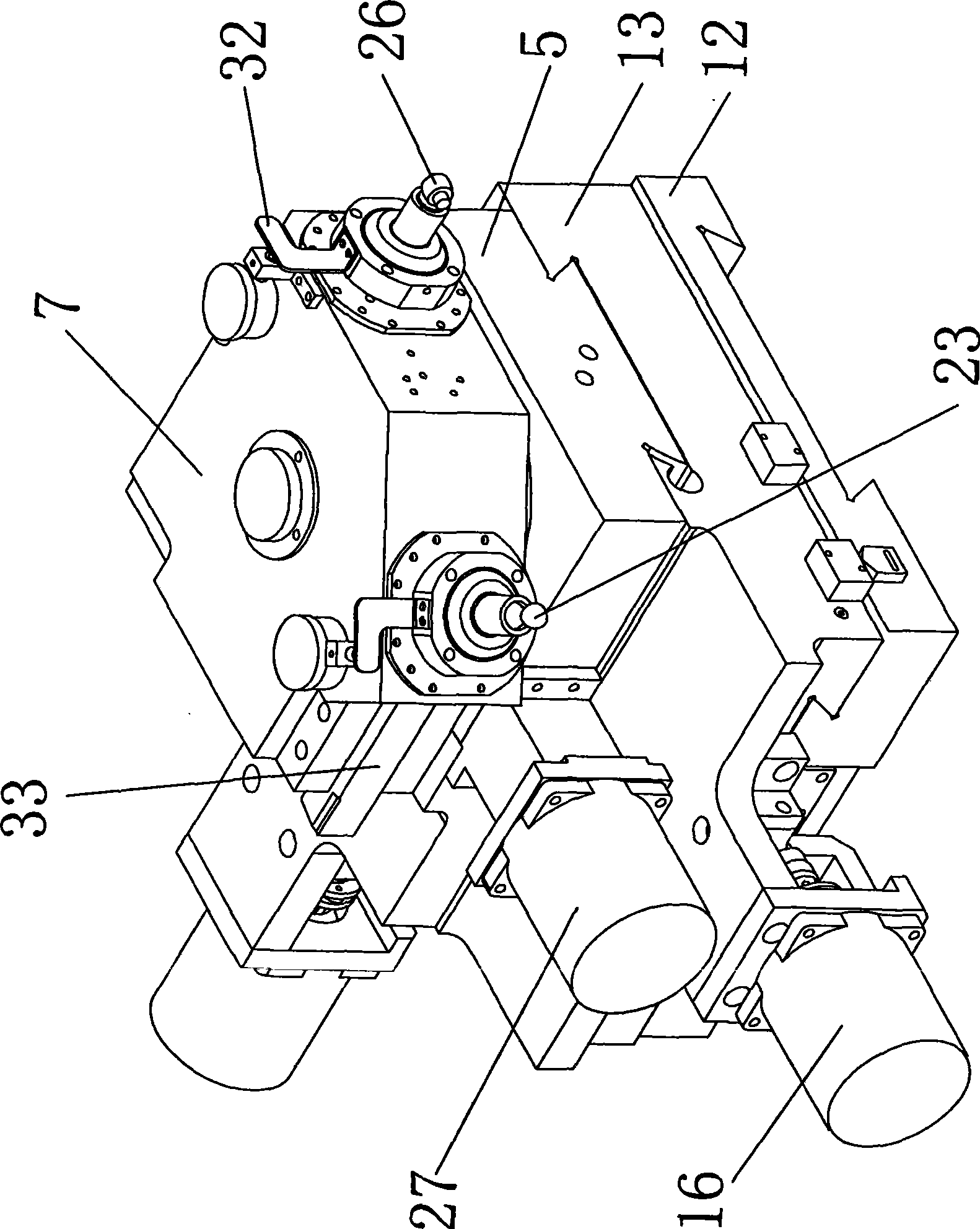

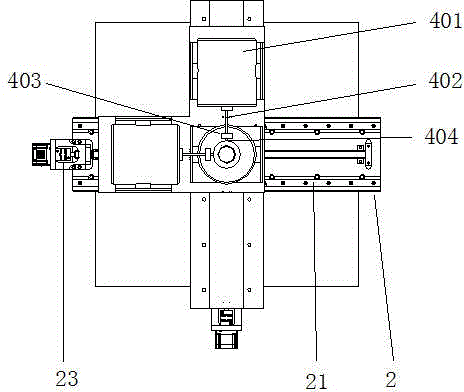

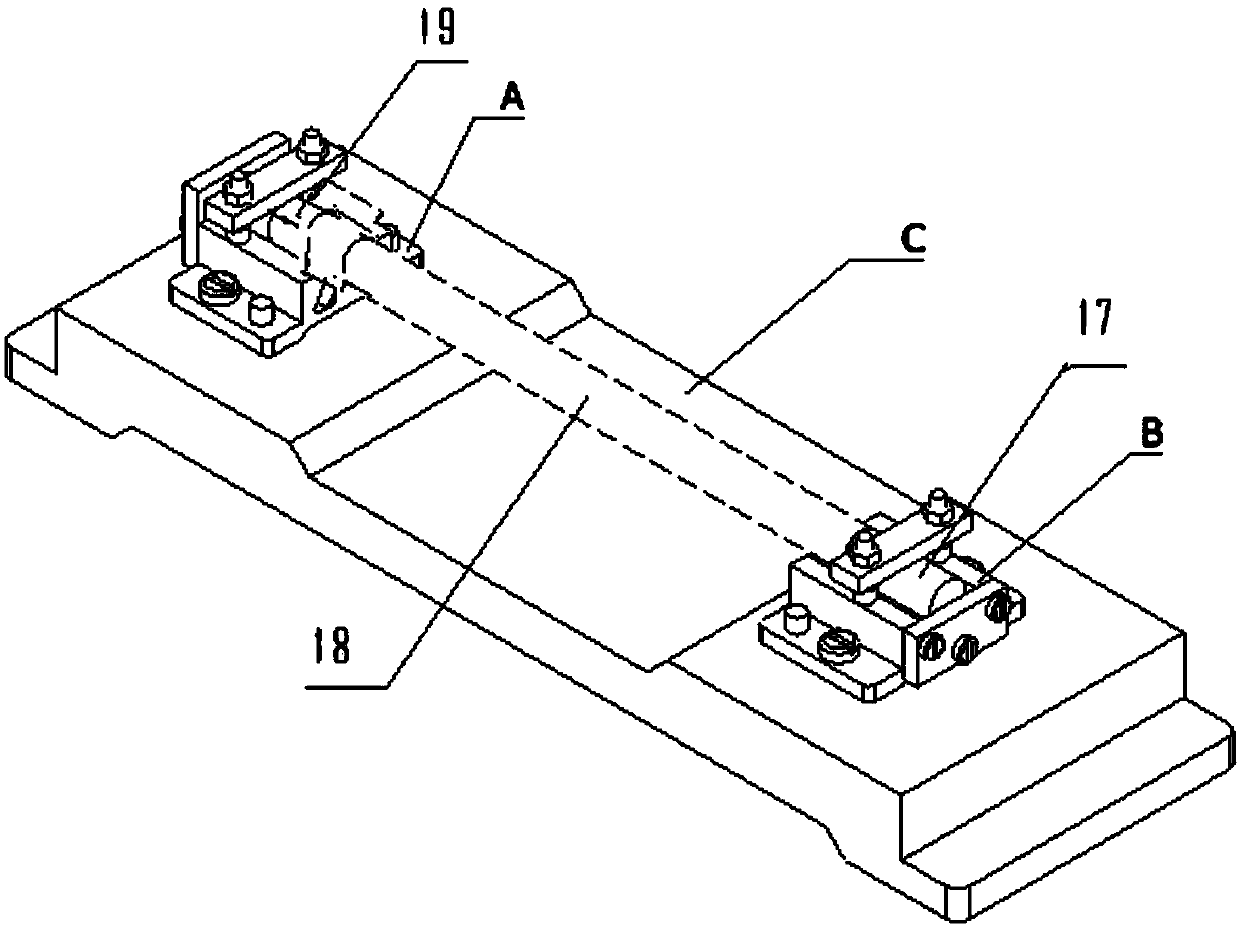

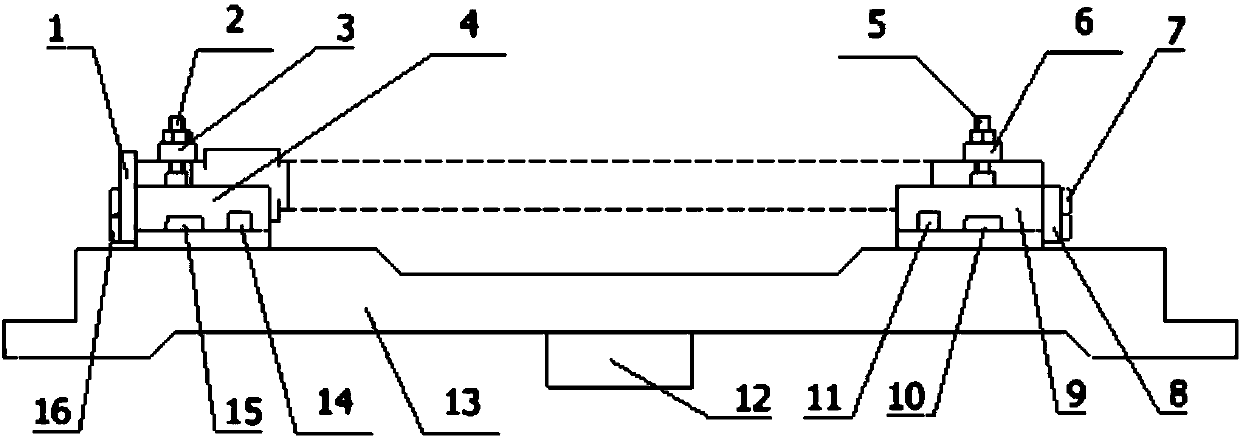

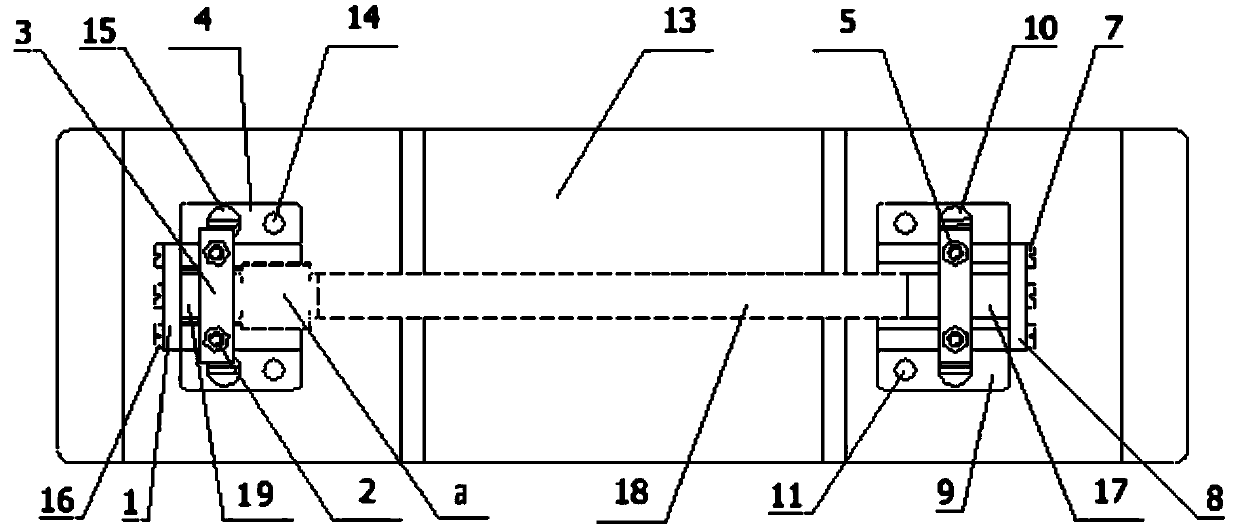

Machine tool three-dimensional dynamic cutting force follow-up analog loading device

ActiveCN104568485AReduce stress deformationImprove machining accuracyStructural/machines measurementStructural engineeringCutting force

The invention discloses a machine tool three-dimensional dynamic cutting force follow-up analog loading device. The machine tool three-dimensional dynamic cutting force follow-up analog loading device comprises a machine tool working table, a main shaft core rod, a Y-axis sliding pair, an X-axis sliding pair, a bearing system, an L-shaped base plate, a force loading system and a follow-up loading control circuit. The Y-axis sliding pair is fixedly connected with the machine tool working table, the X-axis sliding pair is installed on a sliding block of the Y-axis sliding pair, and the L-shaped base plate is fixedly connected with the X-axis sliding pair. The lower end of the main shaft core rod is connected with the bearing system to bear cutting force analog loading. A Z-axis force loading device is installed at a corner part of the L-shaped base plate, and an output shaft of the Z-axis force loading device is connected with a bearing end cover through a tension and pressure sensor. A Y-axis force loading device and an X-axis force loading device are installed at the two ends of the L-shaped base plate respectively, and output shafts of the Y-axis force loading device and the X-axis force loading device are connected with an outer circular face of a bearing outer base through the tension and pressure sensor. By means of the device, machining errors of a machine tool during cutting machining can be measured, and an analysis platform is provided for measurement and analysis of deformation errors, caused by cutting force, of the machine tool.

Owner:江苏中智自动化股份有限公司

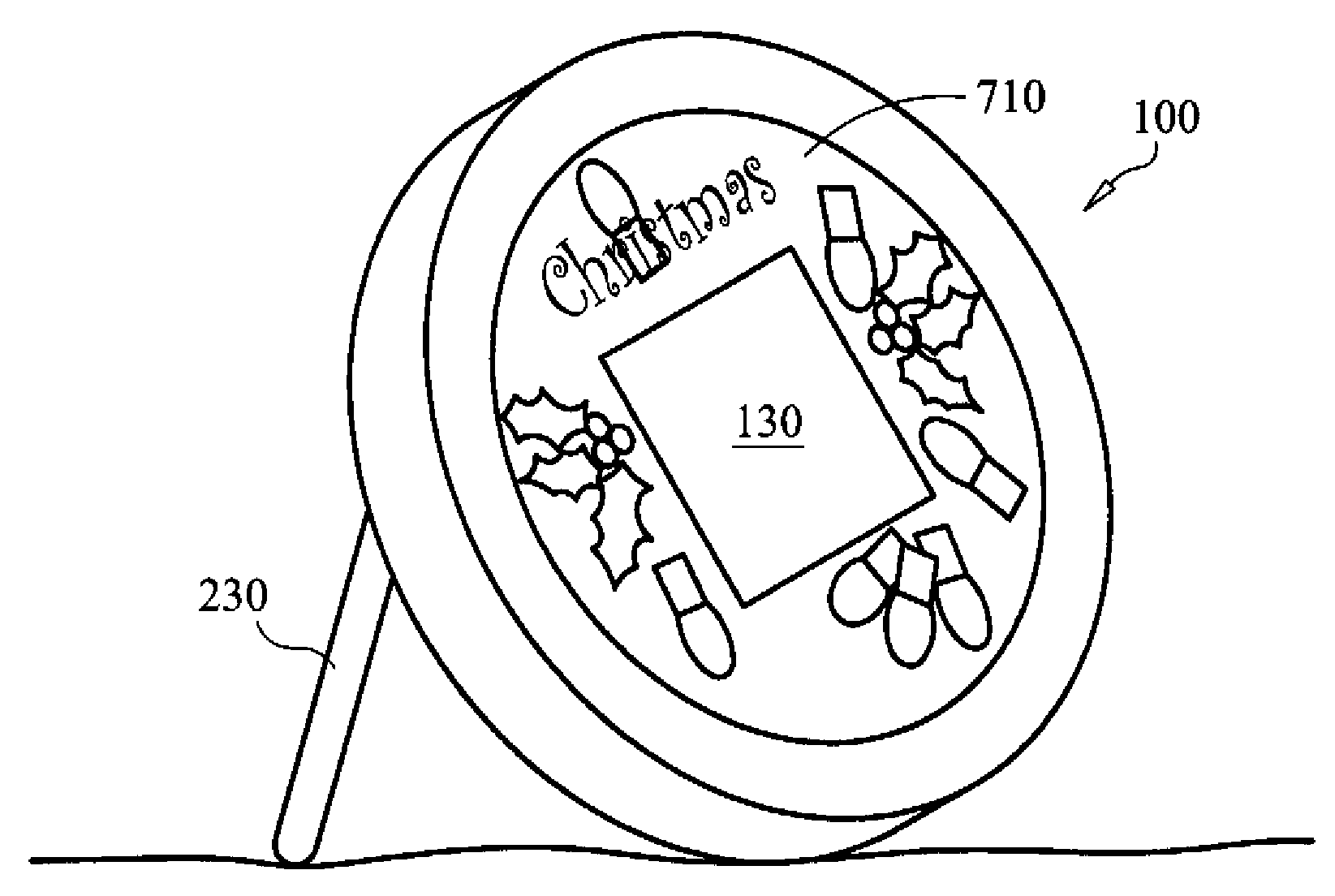

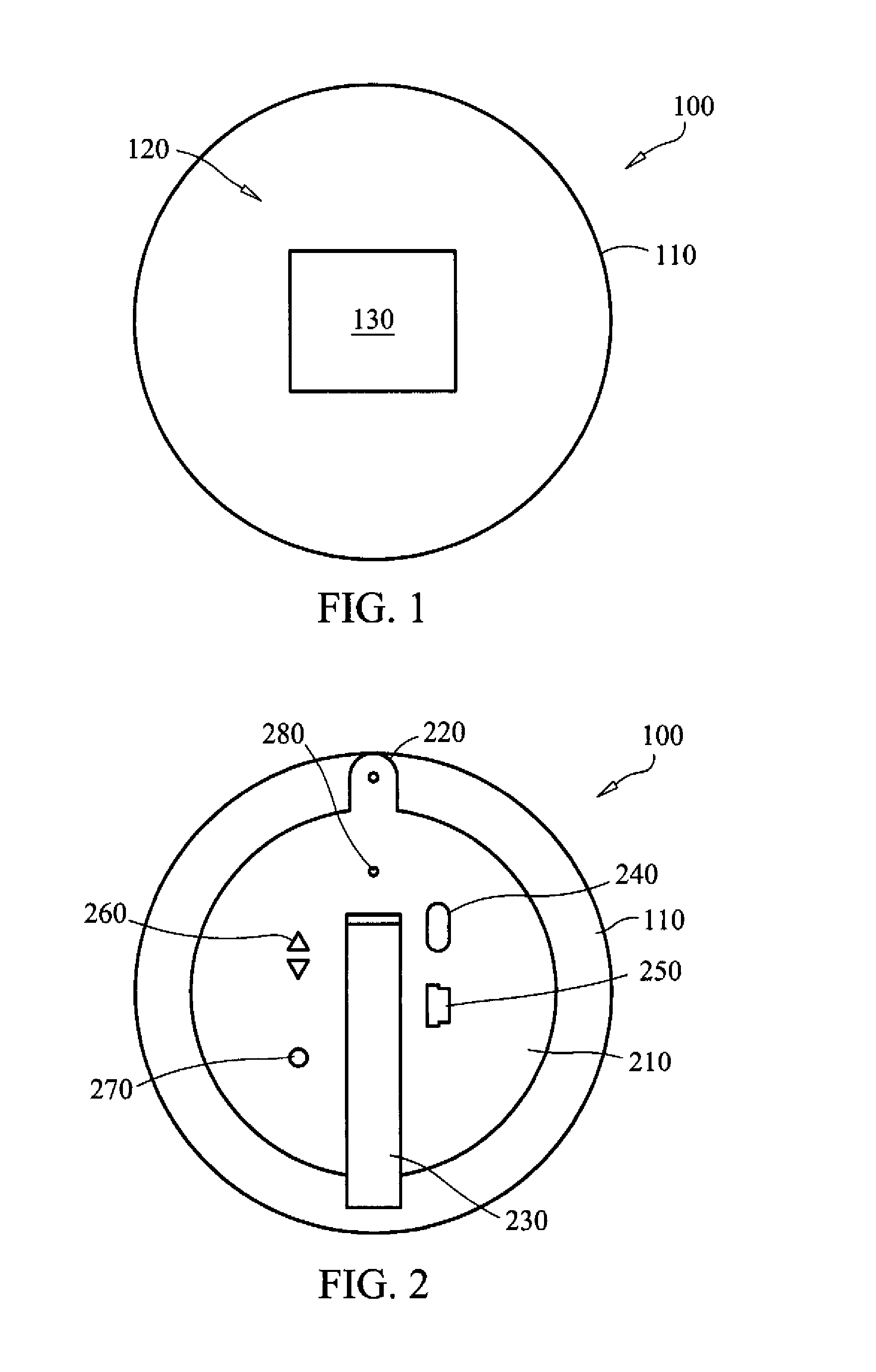

Digital picture display ornament with LEDs

InactiveUS7581849B2Improve the display effectEasy to adaptLighting support devicesPicture framesGraphicsEngineering

Owner:MOCK JASON

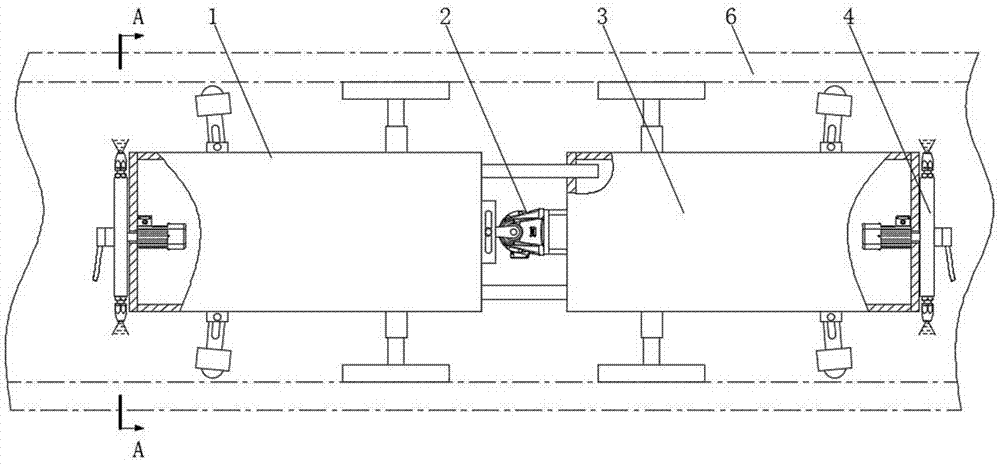

Special clamp for thin and long cylindrical thin wall assembly

InactiveCN104191280AAvoid damageSave time for manual measurement and positioningPositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:DALIAN UNIV OF TECH

Method for avoiding pointy edges at head and tail of thread in thread processing

InactiveCN102489790AAvoid it happening againImprove efficiencyThread cutting machinesEngineeringScrew thread

A method for avoiding pointy edges at the head and the tail of a thread in thread processing belongs to the technical filed of numeral control processing, which can improve surface quality and processing efficiency of a workpiece and effectively avoid the pointy edges at the head and the tail of the thread in the thread processing. The method comprises the following steps of 1 turning a spiral cylinder slot, increasing strength of a starting thread profile, cutting and removing one-second turn to three-fourth turn of the spiral cylinder slot from the internal circular face or the external circular face of the workpiece before the thread is processed on the workpiece, and removing original pointy edges in advance; and 2 processing the thread and feeding a cutter along the spiral cylinder slot. The coordinate of the starting point of the thread is consistent to that of a cutter track line of cut and removed spiral cylinder slot processed at last in the step 1.

Owner:SHENYANG LIMING AERO PARTS MFG

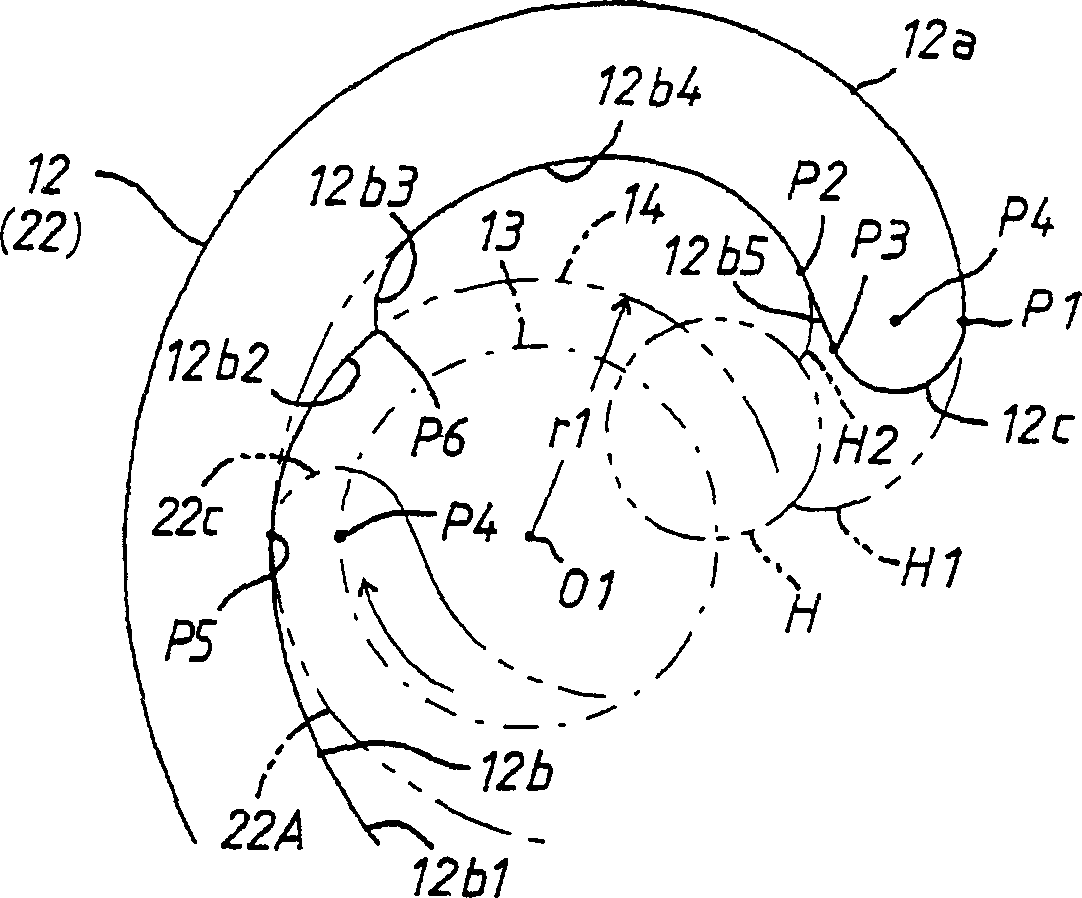

Vortex compressor

ActiveCN1727680AIncrease connection areaReduce power lossRotary piston pumpsRotary piston liquid enginesEngineeringCircular face

The aim of the invention is to improve the compression ratio of a scroll compressor and decrease a power loss due to supercompression. A fixed scroll and a moving scroll on which spiral laps are erected on the inner surfaces of end plates and, respectively, are combined together and compression chambers moved to the central side as a volume is decreased are formed between the two laps. An inner peripheral surface of one lap consists of a first part composed of a part of an inner spiral surface slidably contacting with an outer peripheral surface of the other lap; a recessed circular arc-shaped second part continuously connected to the first part and slidably contacting with a small circular face at the tip on the central side of the other lap; a fourth part positioned further on the outside in a radial direction than the extension face of the second part and connected to a small circular arc face; and a third part discontinuously connected to the second part and rapidly outwardly separated from the extension face of the second part and connected to the fourth part.

Owner:AISIN SEIKI KK +1

Low-frictional-characteristic air cylinder with piezoelectrically actuated cylinder barrel vertically vibrating

InactiveCN103195770AReduce coefficient of frictionSimple structureFluid-pressure actuatorsFrictional coefficientCircular face

The invention discloses a low-frictional-characteristic air cylinder with a piezoelectrically actuated cylinder barrel vertically vibrating, and belongs to the technical field of pneumatics, particularly the technical field for lowering a frictional coefficient of an air cylinder. In order to realize reduction of the frictional coefficient of the air cylinder conveniently, quickly and flexibly, a plurality of planes are arranged around the periphery of an outer circular face of a cylinder barrel of an air cylinder assembly, at least two planes are arranged on a same circle, one or more piezoelectric extension pieces are arranged on each of the planes, the numbers of the piezoelectric extension pieces are identical on each of the planes, one plane of each piezoelectric extension piece is enabled to be connected with the plane, when a plurality of piezoelectric extension pieces are arranged on each of the planes, all the piezoelectric extension pieces arranged on the plane are arranged along the axial direction of the cylinder barrel of the air cylinder assembly, and extension direction of the piezoelectric extension pieces is parallel to an axis of the cylinder barrel of the air cylinder assembly. By the low-frictional-characteristic air cylinder with the piezoelectrically actuated cylinder barrel vertically vibrating, when the piezoelectric extension pieces input a driving signal, the frictional coefficient of a piston and the cylinder barrel can be lowered.

Owner:HARBIN INST OF TECH

Durable steam injector device

Owner:SMITH ROBERT S

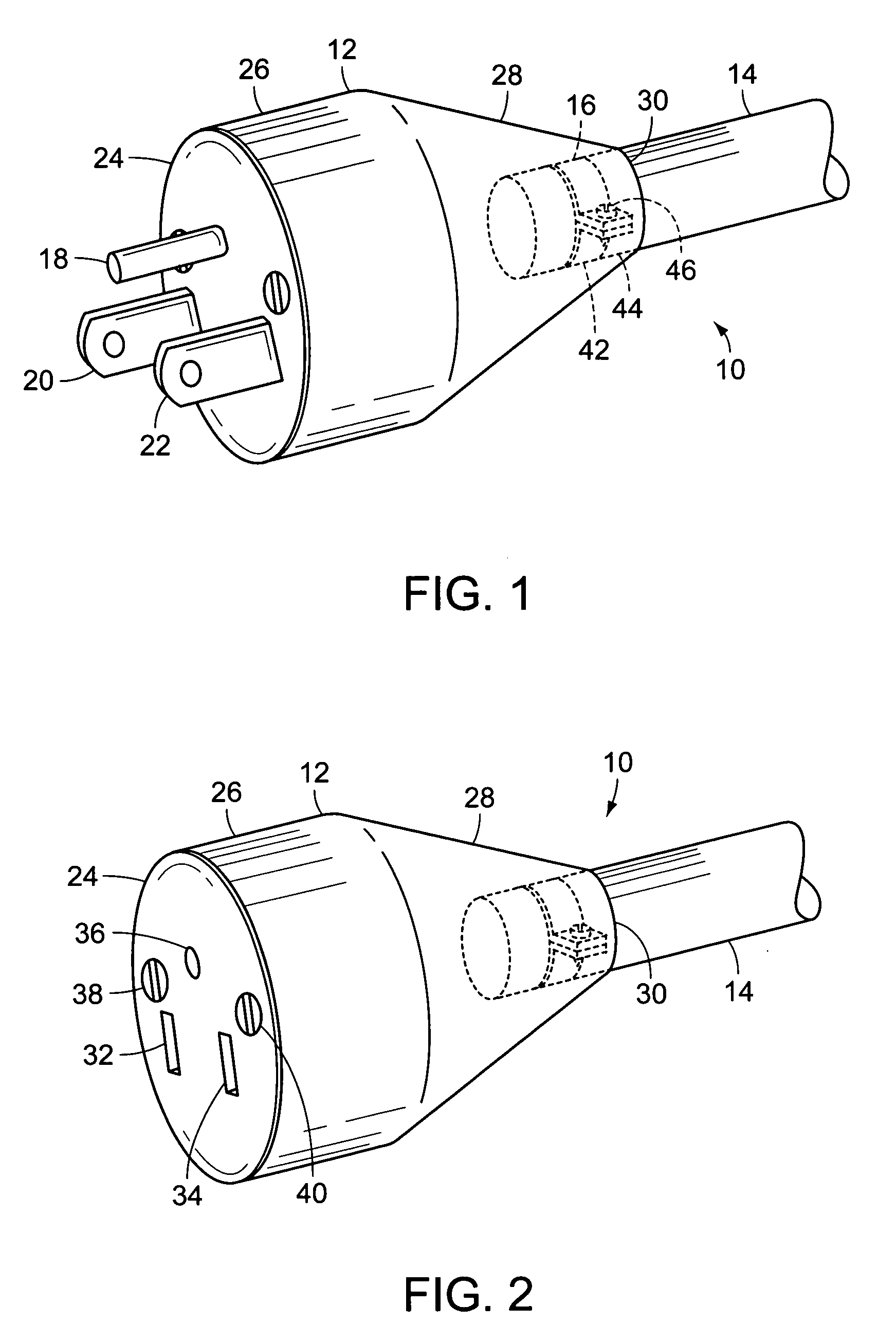

Electrical extension cord

InactiveUS6933447B1Relieving strain on wire connectionElectrically conductive connectionsEngineeringPerpendicular direction

An electrical extension cord that has a male or female adapter, a cylindrical wire casing and a connecting clamp. The adapter has a circular face, a cylindrical upper portion and a conical lower portion. If a male adapter is employed, two to four prongs protrude from the face in a perpendicular direction. If a female adapter is employed, two to four openings are embedded in the face. The prongs and openings are in electrical communication with a power supply. The width of the upper portion is equal to the diameter of the face. In contrast, the lower portion narrows continuously to a minimum diameter that is preferably slightly less than the outer diameter of the casing. The clamp consists of a top plate and a bottom plate that are fastened together by bolts.

Owner:MARC ROBERT

Soybean smashing device with feeding device

The invention discloses a soybean smashing device with a feeding device. The soybean smashing device comprises a supporting frame, a first connecting rod, a first smashing box, a second smashing box, a feeding pipe, a first rotary shaft, a first motor, a rotary wheel, a smashing plate, a smashing shaft and a second motor. The head end of the first connecting rod is eccentrically mounted on the rotary wheel, and a push rod is hinged to the tail end of the first connecting rod. The tail end of the push rod is connected with the smashing plate. A guide sleeve is mounted on the inner wall of the first smashing box. A drawable plate is transversely mounted at the position, below the feeding pipe, of the first smashing box in an inserted manner. A mounting groove allowing the head end of the plate to be mounted therein in an inserted manner is formed in the inner wall of the first smashing box. A discharging pipe is mounted at the bottom of the right side of the second smashing box. A plurality of cutters are mounted on the peripheral wall of the smashing shaft. A spiral screw piece is further mounted on the peripheral wall of the smashing shaft. The smashing shaft is in a circular truncated cone shape, and the diameter of the transverse circular face of the right end of the smashing shaft is larger than that of the transverse circular face of the left end of the smashing shaft. The soybean smashing device can fully smash soybeans, and the soybean smashing effect can be improved remarkably.

Owner:BEIJING LUOKE MACHINERY

Vehicle door handle apparatus

ActiveUS8128137B2Easy to installResistance to dropoutWing handlesVehicle locksEngineeringCircular face

To provide a supporting structure of a rotating section which offers not only facilitated mounting but also resistance to dropout. There are provided a handle base 1 for rotatably supporting one end side of a handle grip 2, and a lever 3 which has a shaft section 23 rotatably supported by a bearing section 11 of the handle base 1 and which is rotated upon pulling of the handle grip 2. The lever 3 includes a first shaft tip section 27 projecting from the shaft section 23 to a shaft tip side and having a part cut away so as to form a circular face, and a second shaft tip section 28 projecting from the first shaft tip section 27 to a shaft tip side and having a width smaller than that of the first shaft tip section 27. The handle base 1 includes a bearing hole 16 for rotatably supporting the first shaft tip section 27 and the second shaft tip section 28 of the lever 3, a first guide rail 17 for guiding the first shaft tip section 27 to the bearing hole 16, and a second guide rail 18 narrower than the first shaft tip section 27 for guiding the second shaft tip section 28 to the bearing hole 16.

Owner:U SHIN LTD

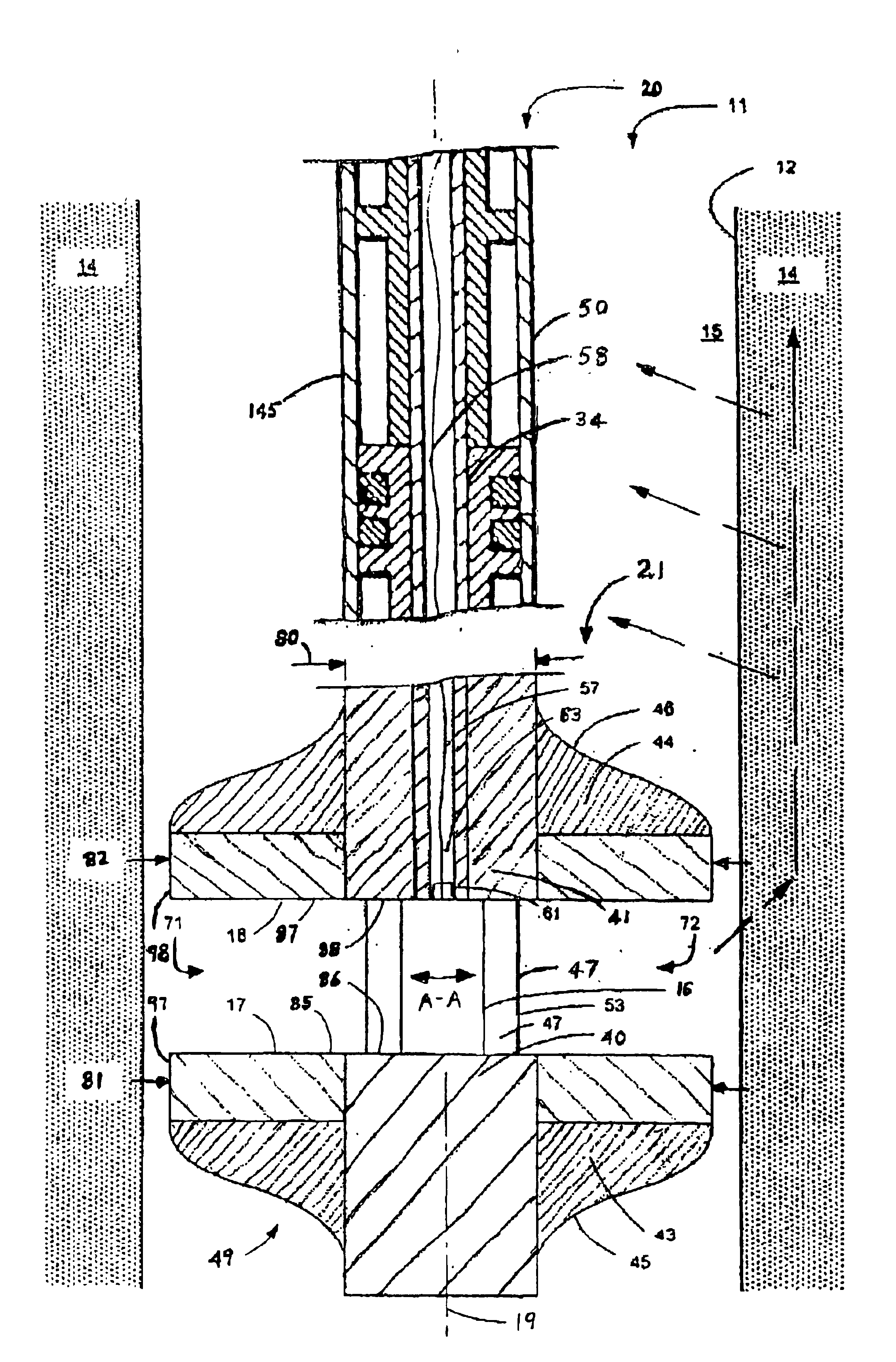

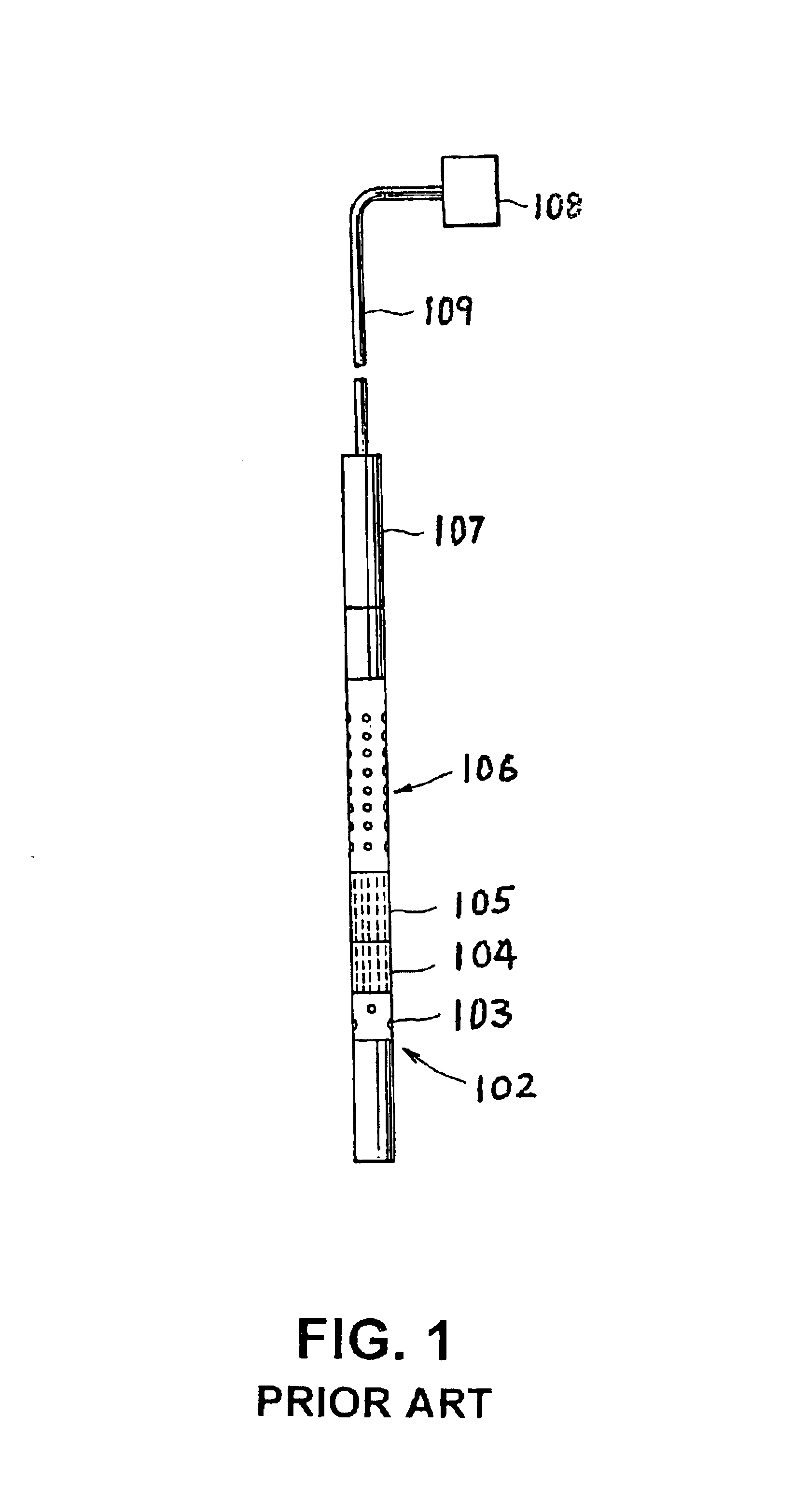

Oil well acoustic logging tool with baffles forming an acoustic waveguide

InactiveUS6868036B2Improve signal-to-noise ratioSeismic energy generationTransmissionAcoustic waveWaveguide

An acoustic logging tool includes external baffle assemblies forming a waveguide structure at the acoustic source. The logging tool is designed for acoustic logging of earth formation surrounding a borehole. The external baffle assemblies form a waveguide structure that is designed to increase signal to noise ratio in an acoustic logging tool using dipole or other acoustic waves. In a preferred embodiment, the acoustic logging tool includes an elongated transmitter module, and a receiver sonde having a linear array of acoustic receivers. The transmitter module includes first and second cylindrical masses spaced apart along the axis by first and second spacers. The first cylindrical mass defines a first circular facing surface and a first cylindrical outer surface. The second cylindrical mass defines a second circular facing surface and a second cylindrical outer surface. A multi-pole acoustic source is fixedly mounted between the first and second circular facing surfaces, and located on the transmitter module axis between the first and second spacers. A first annular baffle assembly surrounding the first cylindrical outer surface has a first annular facing surface co-planar with the first circular facing surface. A second annular baffle assembly surrounding the second cylindrical outer surface has a second annular facing surface co-planar with the second circular facing surface. The annular baffle assemblies form an acoustic waveguide.

Owner:SCHLUMBERGER TECH CORP

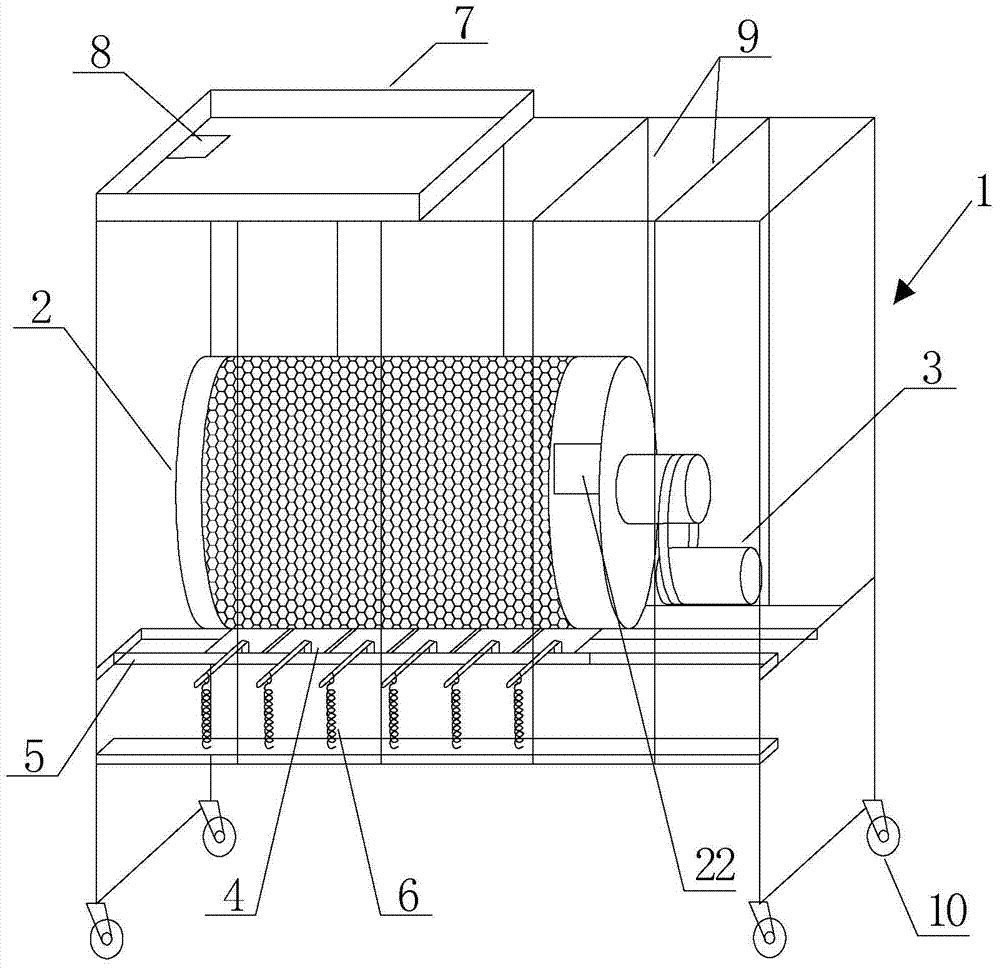

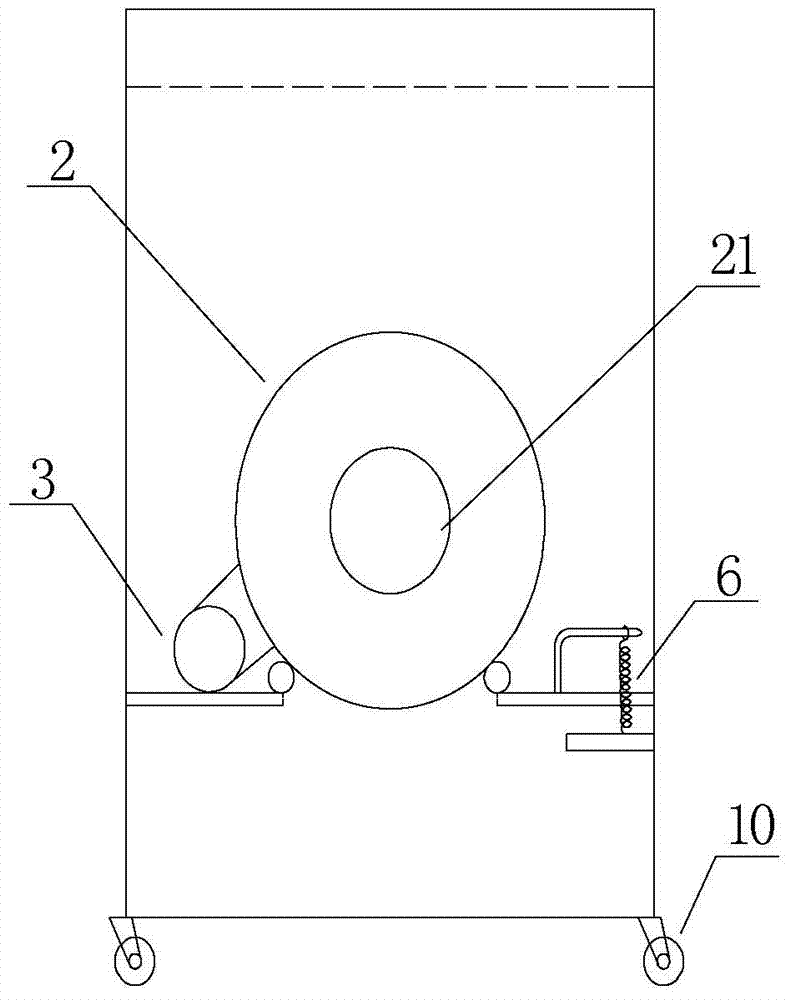

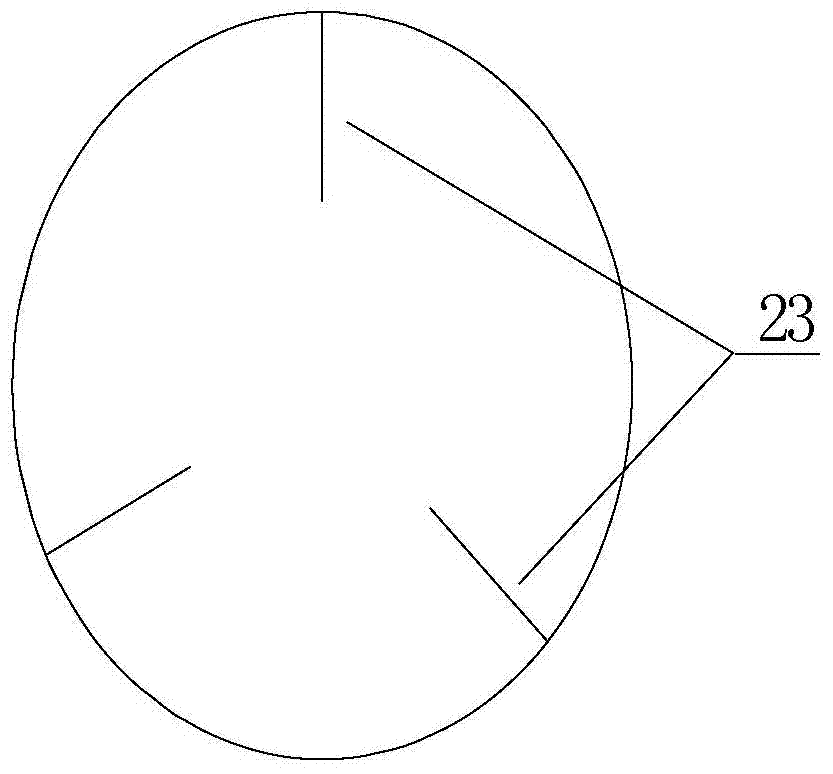

Hot pepper shank removing machine

InactiveCN103689761ATo achieve the effect of picking the handleThe effect of picking the handle is increasedFood treatmentHot peppersEngineering

The invention discloses a hot pepper shank removing machine. The hot pepper shank removing machine comprises a machine frame, wherein a roller and a motor which is used for driving the roller to rotate are arranged in the machine frame, the roller is a meshed roller, a charging opening is formed in a circular face of one end of the roller, a discharging opening is formed in the side face of the other end of the roller, a row of knife blades which are used for removing shanks are arranged at the outer side of the bottom end of the roller along the tangential direction of the roller, the knife edge of one end of each knife blade is in contact with the roller, and the other ends of the knife blades are arranged on a cross rod of the machine frame and are connected with the machine frame through tension springs. Hot peppers are put in the roller from the charging opening and rotate along with the roller, hot pepper shanks can be cut through the cooperation of the knife blades arranged on the machine frame after the hot pepper shanks extend out of meshes of the roller, and then, the shank removing effect can be achieved; the knife edge of one end of each knife blade is in contact with the roller, and the tension springs connected with the machine frame are further arranged at the other ends of the knife blades, so that the knife blades can be upwardly inclined by certain angles along with the rotating roller, and then, the shank cutting effect is improved.

Owner:CHONGQING DAQIAN AGRI DEV

Low-frictional-characteristic air cylinder with piezoelectrically actuated cylinder barrel deviously vibrating

InactiveCN103195772AReduce coefficient of frictionSimple structureFluid-pressure actuatorsFrictional coefficientEngineering

Owner:HARBIN INST OF TECH

Radial sleeve type labyrinth type magnetic fluid sealing device

InactiveCN107956883AReduce lossesIncrease magnetic fluxEngine sealsEngineeringMechanical engineering

The invention relates to a radial sleeve type labyrinth type magnetic fluid sealing device. The radial sleeve type labyrinth type magnetic fluid sealing device comprises a shaft, a shell, a left poleshoe ring, a right pole shoe ring, a sleeve and a permanent magnet ring. The left pole shoe ring and the right pole shoe ring are arranged in the shell in a spaced mode; the shaft is sleeved with thesleeve located between the left pole shoe ring and the right pole shoe ring; the permanent magnet ring is arranged in the shell and located between the left pole shoe ring and the right pole shoe ring; a gap is reserved between the outer circular face of the sleeve and the inner circle face of the permanent magnet ring; pole teeth I are arranged on the right end face of the left pole shoe ring atintervals; pole teeth II are arranged on the left end face of the sleeve at intervals, and pole teeth III are arranged on the right end face of the sleeve at intervals; and pole teeth IV are arrangedon the left end face of the right pole shoe ring at intervals. The radial sleeve type labyrinth type magnetic fluid sealing device is used for solving the problem of low pressure-resistant performanceof an existing sealing device, and the sealing technology is successfully applied to the fields such as the high-speed and heavy-load field.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com