Low-frictional-characteristic air cylinder with piezoelectrically actuated cylinder barrel vertically vibrating

A longitudinal vibration, low friction technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of oil pollution, increase in volume, etc., and achieve the effects of easy processing, wide application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

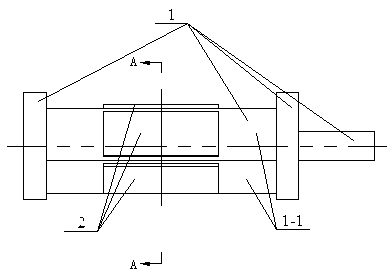

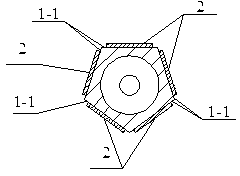

[0010] Specific implementation mode one: see figure 1 , figure 2 To illustrate, this specific embodiment is composed of a cylinder assembly 1 and a plurality of piezoelectric stretchable sheets 2;

[0011] On the outer circular surface of the cylinder barrel of the cylinder assembly 1, a plurality of planes 1-1 are arranged around the circumferential direction, and the number of planes 1-1 on the same circumference is ≥ 2, and each plane 1-1 is provided with One or more piezoelectric stretchable sheets 2, and the number of piezoelectric stretchable sheets 2 on each plane 1-1 is equal, and one plane of each piezoelectric stretchable sheet 2 is connected to the plane 1-1, When a plurality of piezoelectric stretch sheets 2 are arranged on each plane 1-1, all piezoelectric stretch sheets 2 on this surface are arranged along the axial direction of the cylinder barrel of the cylinder assembly 1; the piezoelectric stretch sheets 2 The expansion and contraction direction of the c...

specific Embodiment approach 2

[0016] Specific implementation mode two: see figure 1 , figure 2 To illustrate, the difference between this specific embodiment and specific embodiment 1 is that when multiple piezoelectric stretch sheets 2 are arranged on each plane 1-1, all piezoelectric stretch sheets 2 on this plane are aligned along the cylinder. The axial directions of the cylinder barrels of the assembly 1 are uniformly arranged. Other compositions and connections are the same as in the first embodiment.

[0017] Working principle: It drives the piezoelectric expansion plate 2 to make the cylinder of the cylinder assembly 1 in a state of high-frequency longitudinal vibration, and uses the anti-friction effect produced by the high-frequency longitudinal vibration of the cylinder to reduce the friction between the piston and the cylinder coefficient, so that the cylinder has low friction characteristics.

[0018] Give all piezoelectric stretchable sheets 2 a sinusoidal alternating current that is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com