Patents

Literature

1789 results about "Circular surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics and, in particular, differential geometry a circular surface is the image of a map ƒ : I × S¹ → R³, where I ⊂ R is an open interval and S¹ is the unit circle, defined by f(t,θ):=γ(t)+r(t)𝐮(t)cosθ+r(t)𝐯(t)sinθ, where γ, u, v : I → R³ and r : I → R>0, when R>0 := { x ∈ R : x > 0 }. Moreover, it is usually assumed that u · u = v · v = 1 and u · v = 0, where dot denotes the canonical scalar product on R³, i.e. u and v are unit length and mutually perpendicular.

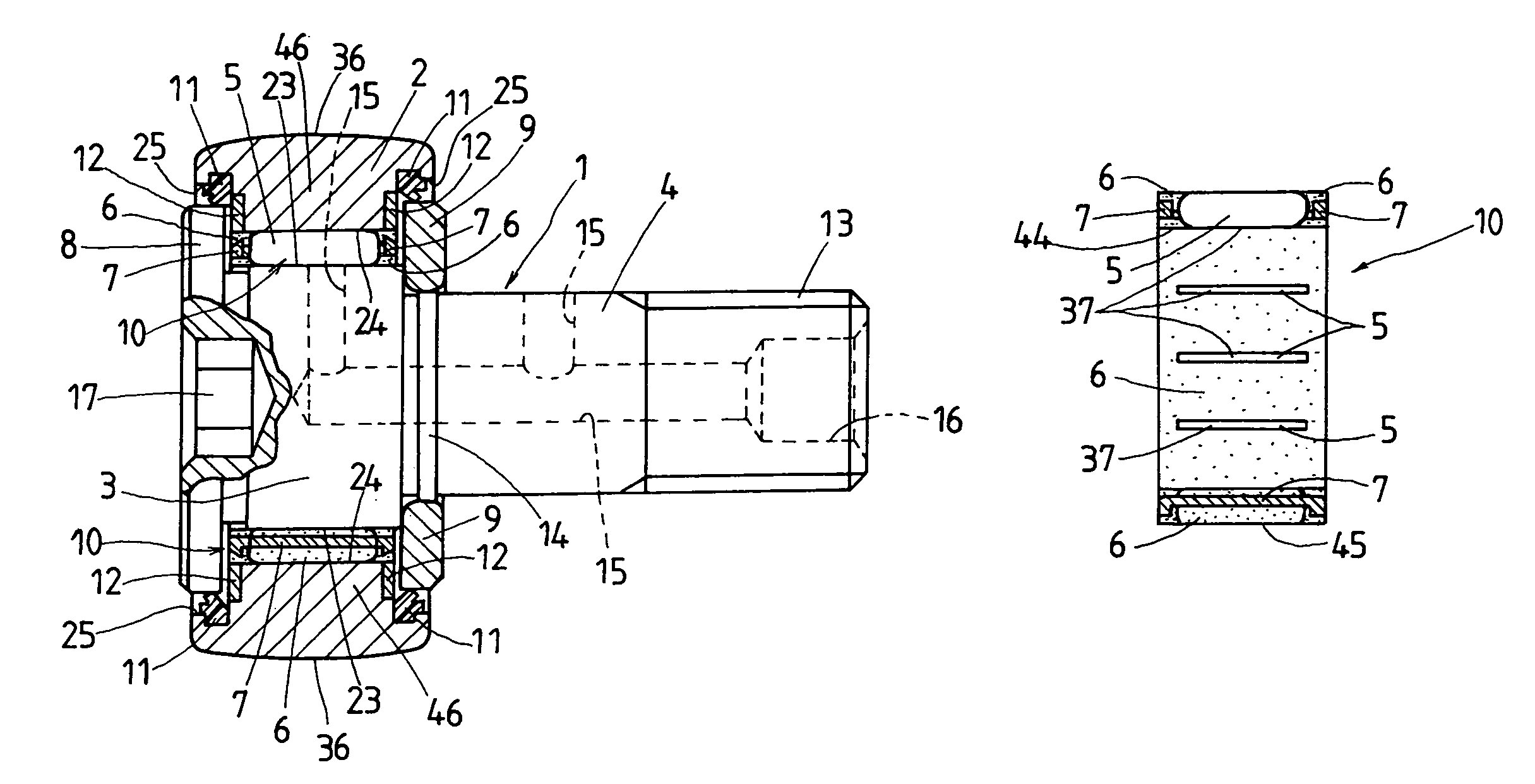

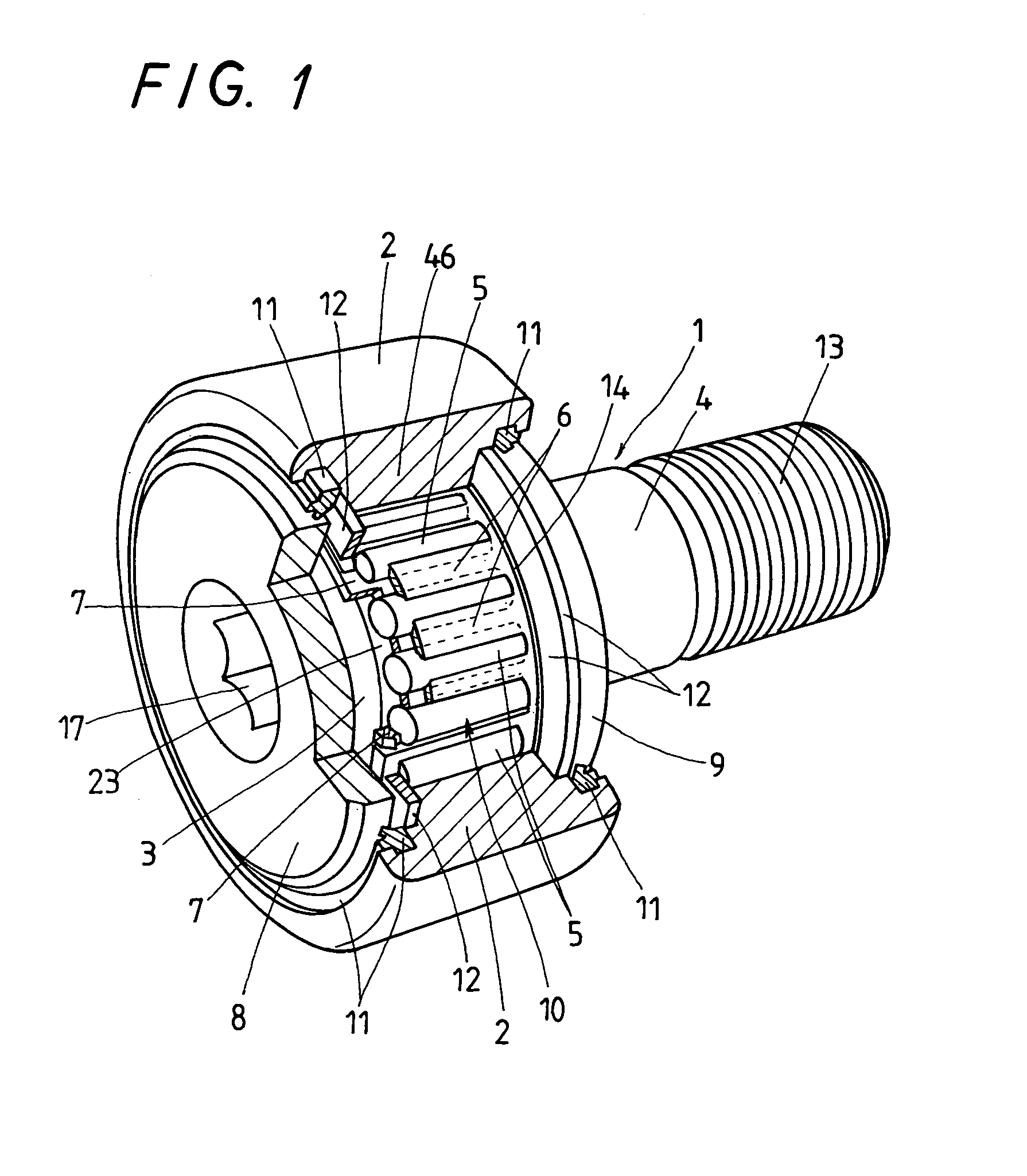

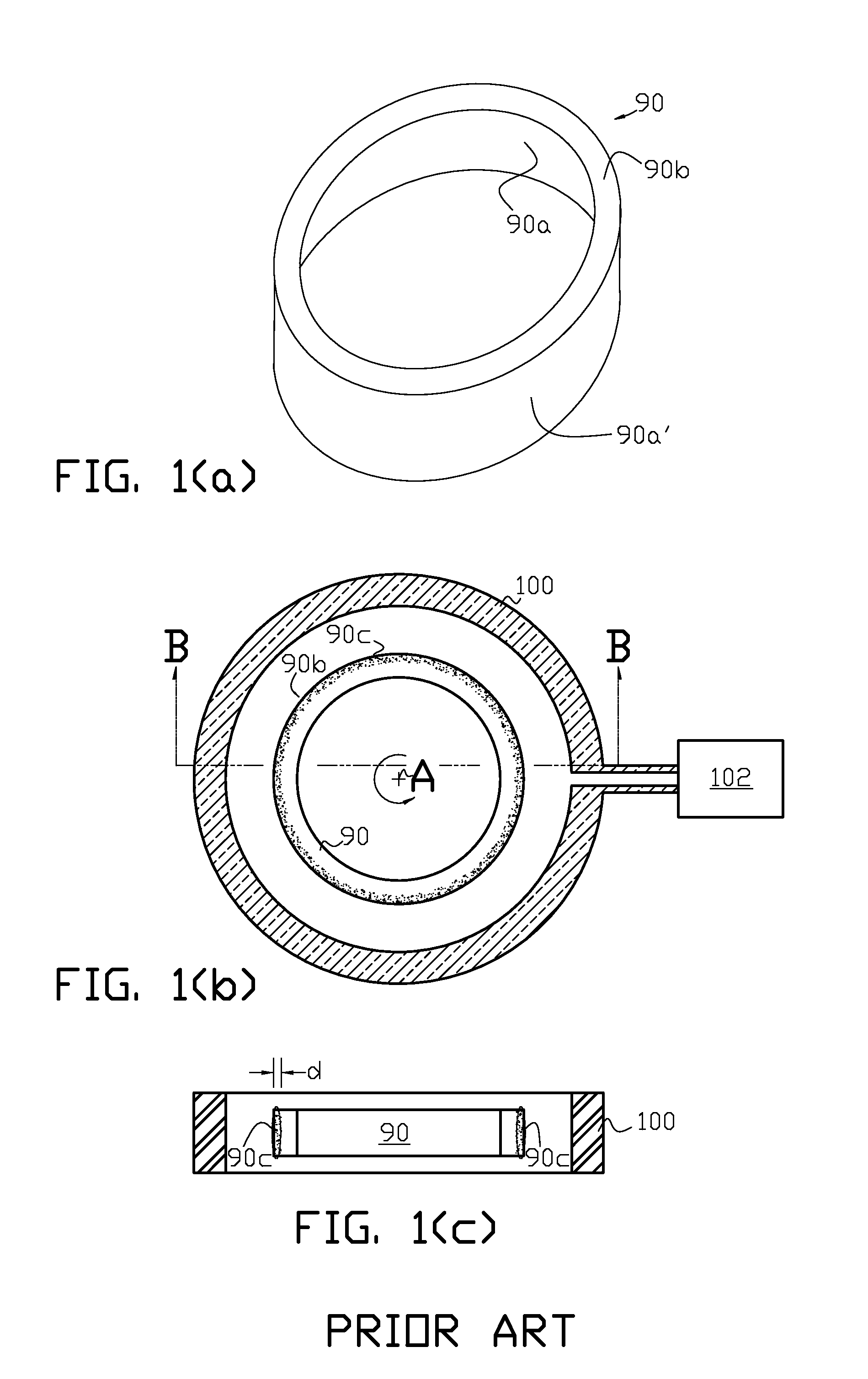

Rolling-contact bearing containing solid lubricant therein

ActiveUS7234873B2Improve air tightnessSmooth movementBearing componentsNeedle bearingsRolling-element bearingEngineering

A cage, rollers and solid lubricant are all formed integrally into a complete unitary molding with using difference in thermal expansion in a mold. Assembling the complete unitary molding into the race in the rolling-contact bearing is made easier. The complete unitary molding is made such that the rollers remain exposed partially at their rolling surfaces above the inside circular surface of the complete unitary molding while the solid lubricant on the outside circular surface of the complete unitary molding is squeezed out from between the rolling surfaces of the rollers and the inside circular surface of the outside mold upon molding operation, thereby getting the rolling surfaces of the rollers exposed partially. The mold is composed of an outside mold, an inside mold and an intermediate mold, which is made of a substance larger in thermal expansion than other substance for the outside and inside molds.

Owner:NIPPON THOMPSON

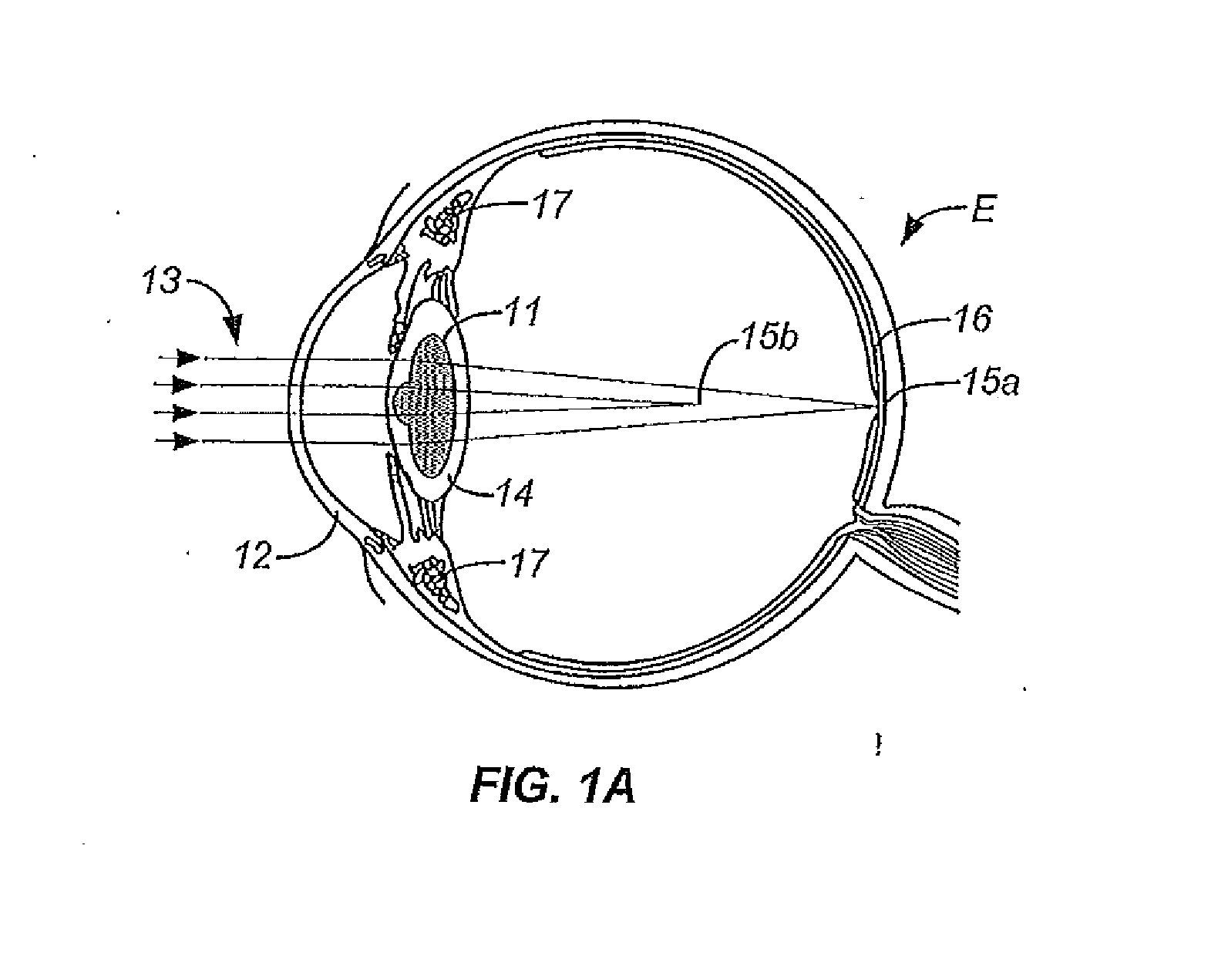

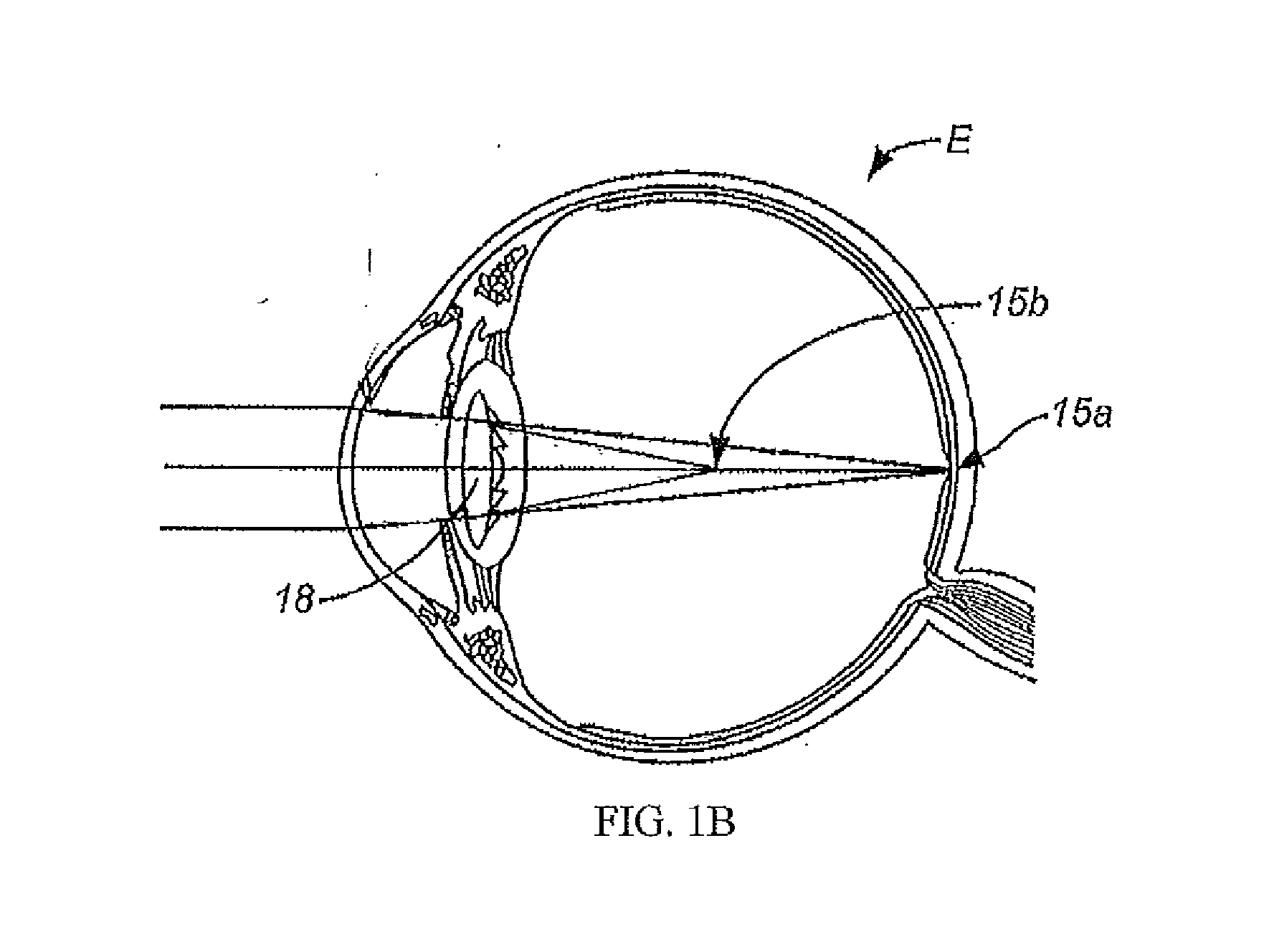

Single microstructure lens, systems and methods

ActiveUS20110149236A1Increase depth of focusSuppresses the distinct bifocalitySpectales/gogglesComputer-aided planning/modellingImaging qualityCircular surface

Systems and methods for providing enhanced image quality across a wide and extended range of foci encompass vision treatment techniques and ophthalmic lenses such as contact lenses and intraocular lenses (IOLs). Exemplary IOL optics can include a circular surface structure which acts as a diffractive or phase shifting profile. In some cases, a single ring IOL includes an anterior face and a posterior face, where a profile can be imposed on the anterior or posterior surface or face. The profile can have an inner portion such as a microstructure or central echelette, and an outer portion. Between the inner portion and the outer portion, there may be a transition zone that connects the inner and outer portions.

Owner:AMO GRONINGEN

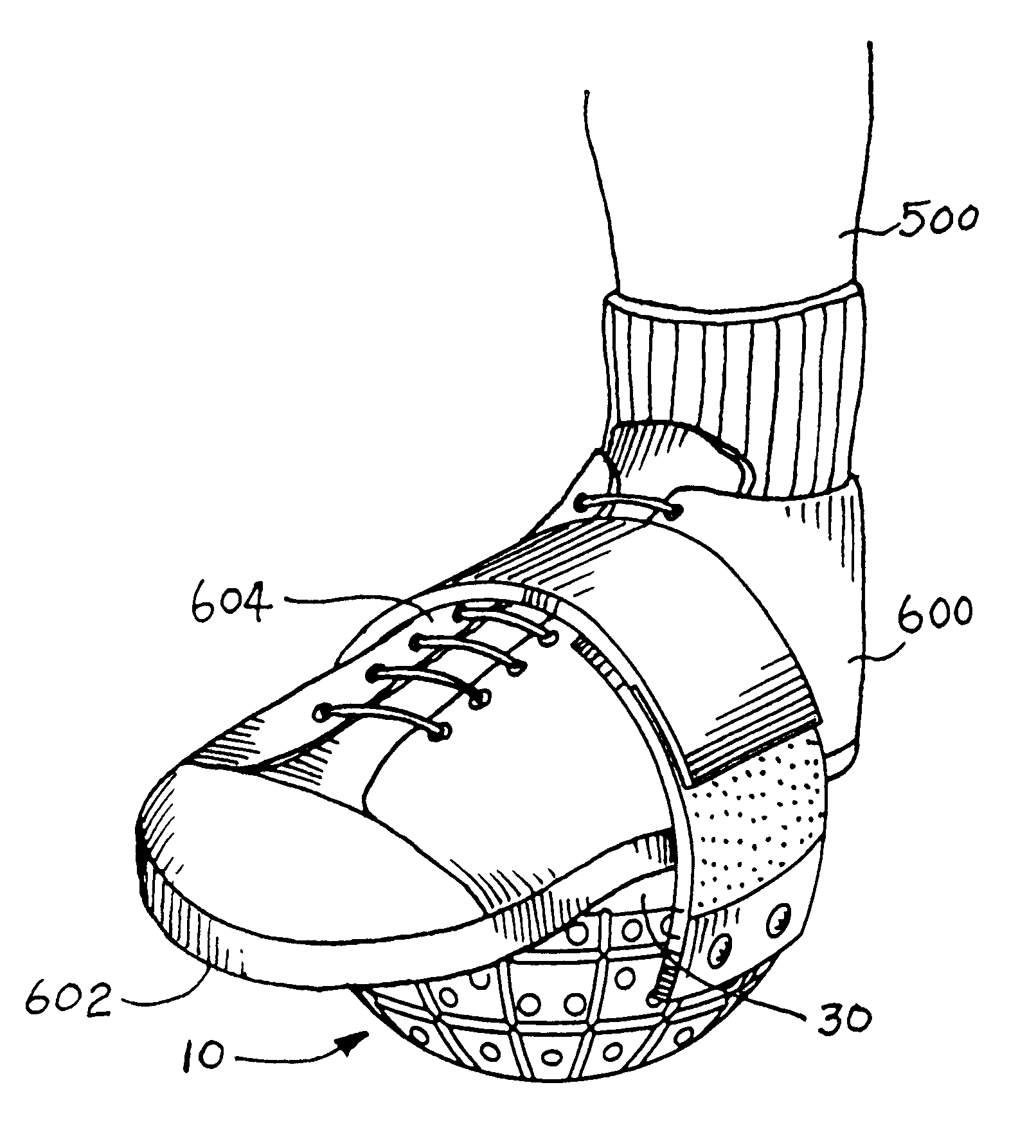

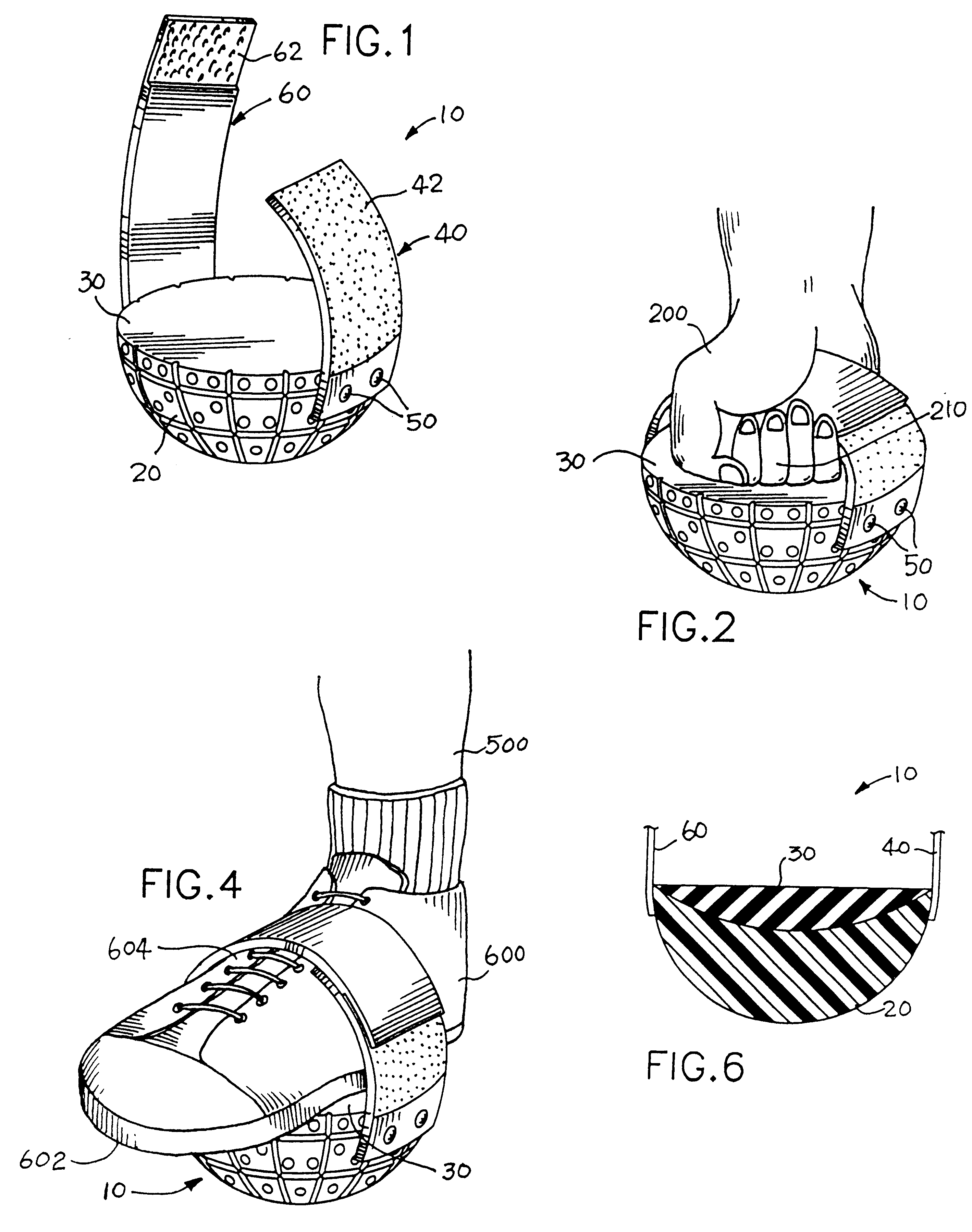

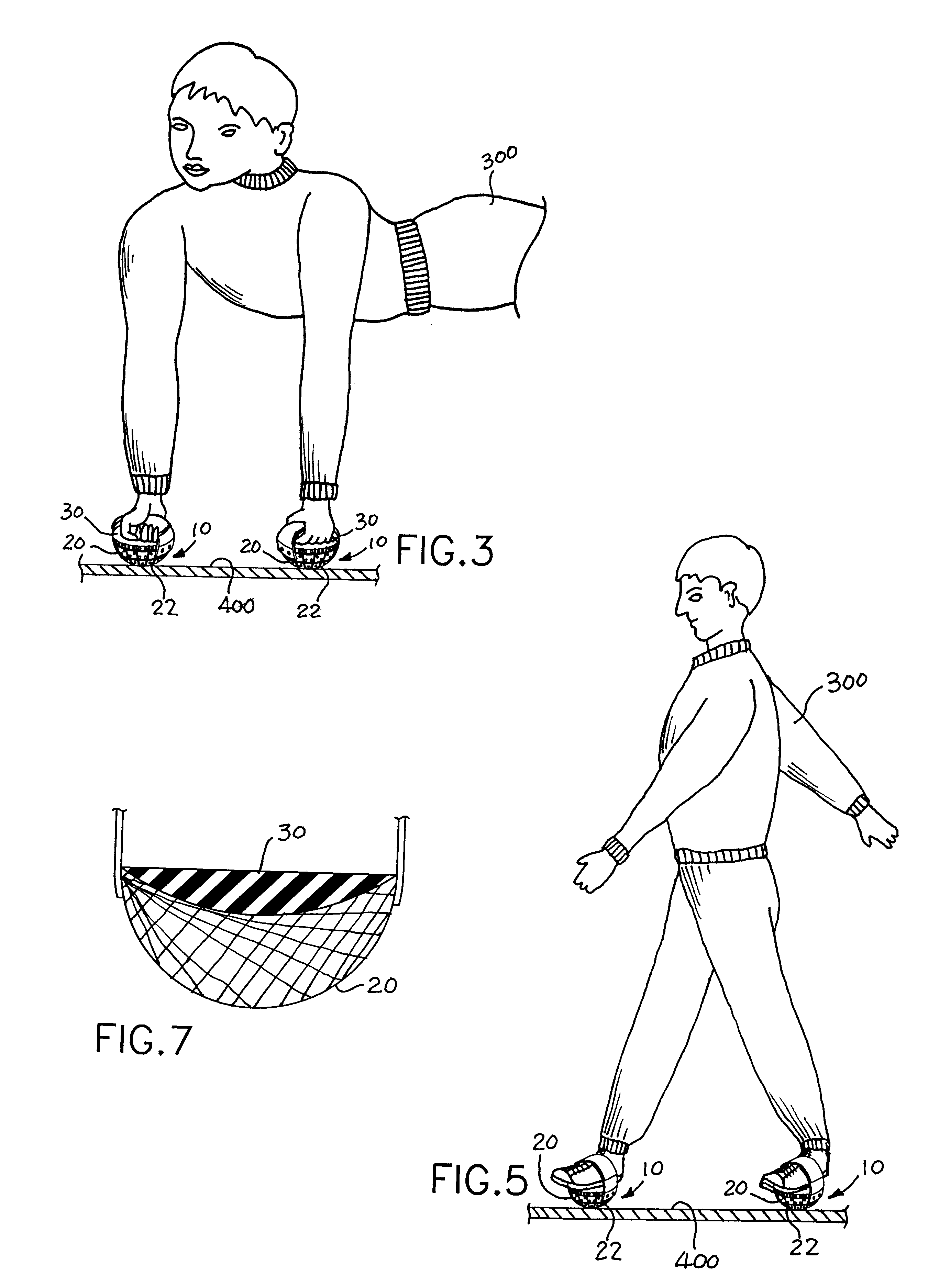

Flexible hemispherical exercise

InactiveUS6551225B1Excessive activationIncrease the number ofStiltsMovement coordination devicesEngineeringLigament structure

A balancing exercise device for an individual, having a flexible hemisphere having a flat circular surface and a hemispherical side surface and being made out of flexible resilient material which will compress when placed under pressure and pair of attachment straps respectively affixed on oppositely disposed sides of the hemispherical side surface and which are connected by connecting members respectively located on each attachment strap so that a body part is held against said flat circular surface when the attachment straps are connected. When each hemispherical side surface is respectively placed against an immovable object and each respective body part is respectively pressed against the flat circular surface of the flexible hemisphere to which it is attached, constant variations of movement in any and all directions of the hemisphere surface puts different stretch on the tendons, muscles, ligaments and joints and thereby stimulates increased numbers of proprioceptors and nerve cells of the body parts and further thereby creates more activation of the muscles and causes the body parts to be exercised completely and evenly.

Owner:ROMERO RON RICHARD

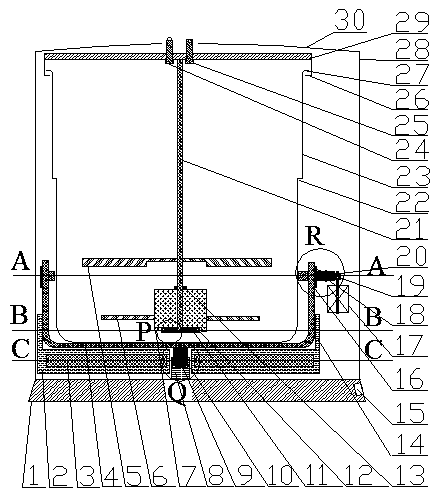

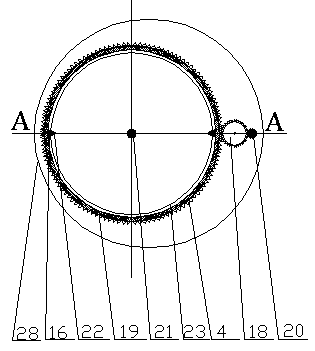

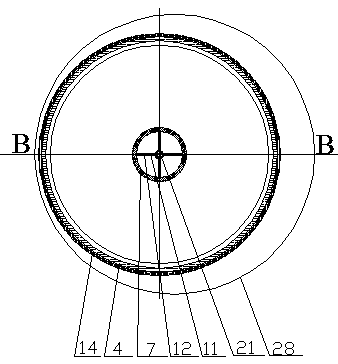

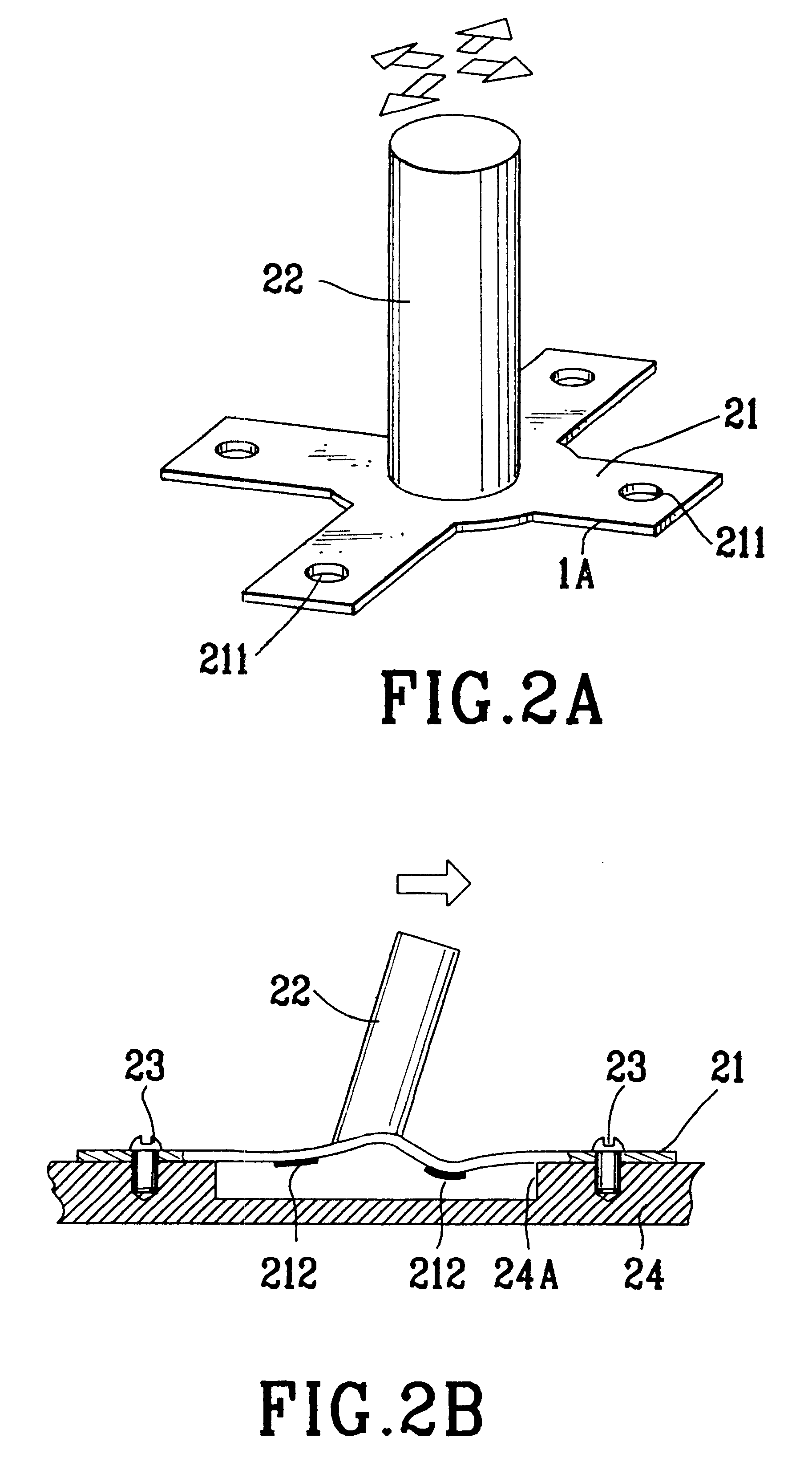

Electric pressure cooker with stirring function

InactiveCN105496184AFlexible rotationImprove stirring performanceCooking vesselsGear wheelCircular surface

An electric pressure cooker with a stirring function comprises a base, a heating plate, a rotary support, a liner and a motor and is characterized in that a rotary support side cylinder is arranged around the rotary support, an external gear ring is fixedly installed on the outer circular surface of the rotary support side cylinder and is meshed with a reduction gear, and the reduction gear is meshed with an output wheel of the motor; the liner is clamped in the rotary support, a long rod is fixedly installed in the middle of the lower side face of a pot cover on an upper opening of the liner, a cross-shaped frame is fixedly installed at the lowermost end of the long rod, each of four fulcrum bars of the cross-shaped frame is sleeved with a sleeve, a heavy square is supported by the sleeves, the long rod is sleeved with a center hole of the heavy square so that the heavy square can rotate around the rod, and a round sink table is arranged on the lower side face of the heavy square; the diameter of a cylinder is D, and D<=2(L+S); an included angle alpha is formed between a lower stirring blade on each of the four sides of the heavy square and the bottom plane of the liner, and alpha is between 15 degrees and 60 degrees; four upper stirring blades are fixedly and symmetrically installed on the portion, above the heavy square, of the long rod, an included angle beta is formed between each upper stirring blade and the bottom plane of the liner, and beta is between -60 degrees and -15 degrees.

Owner:魏伯卿

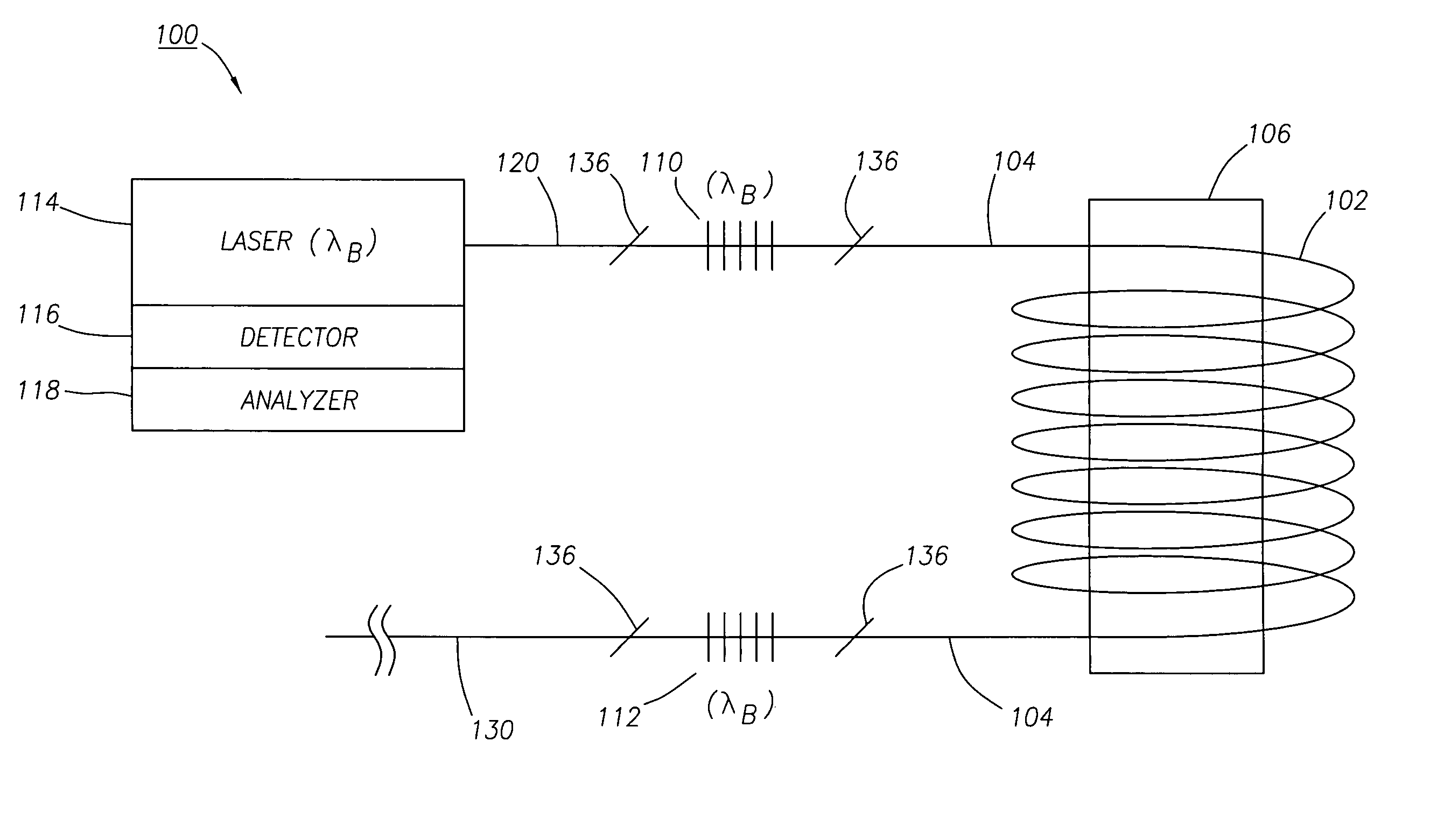

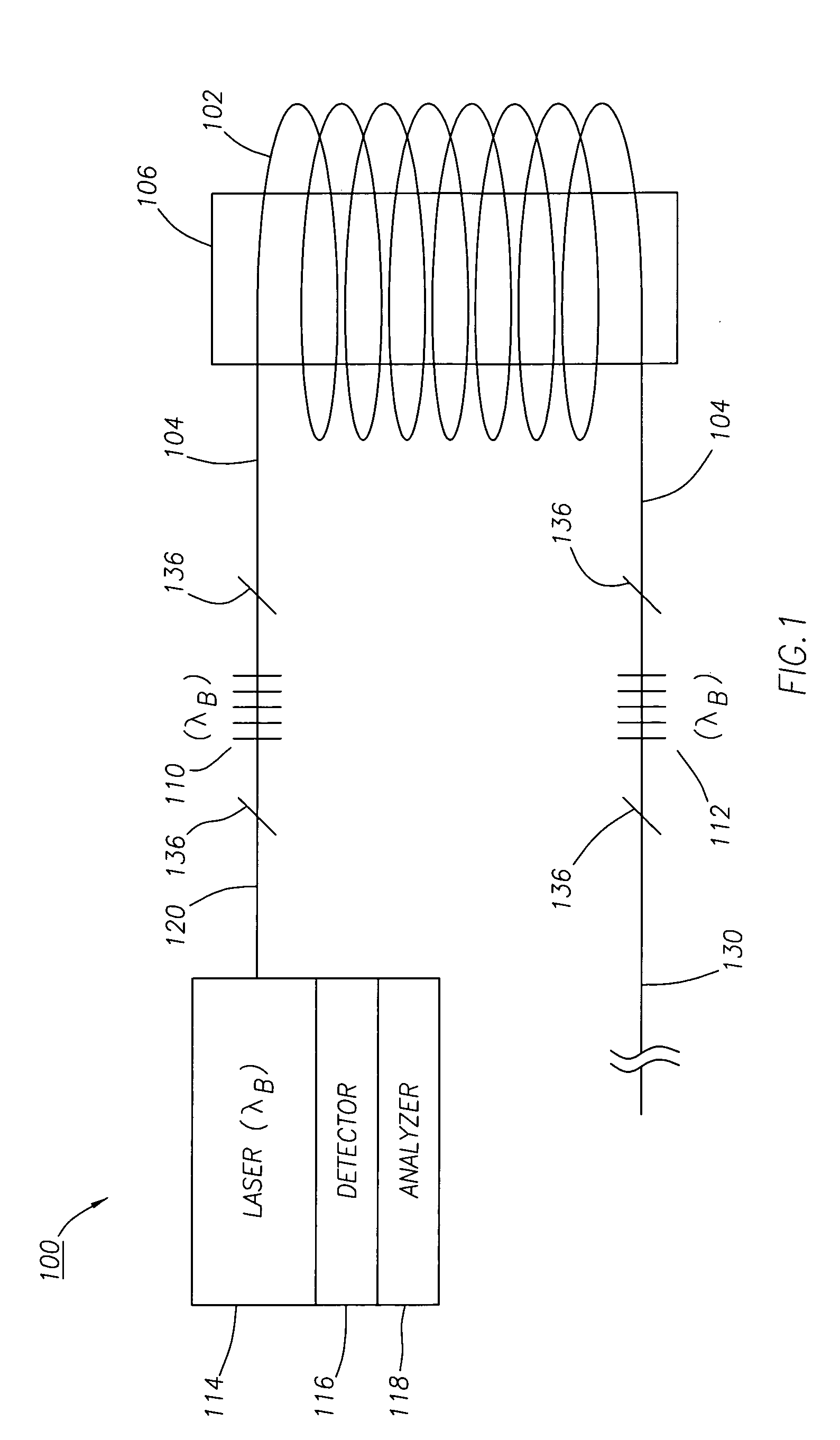

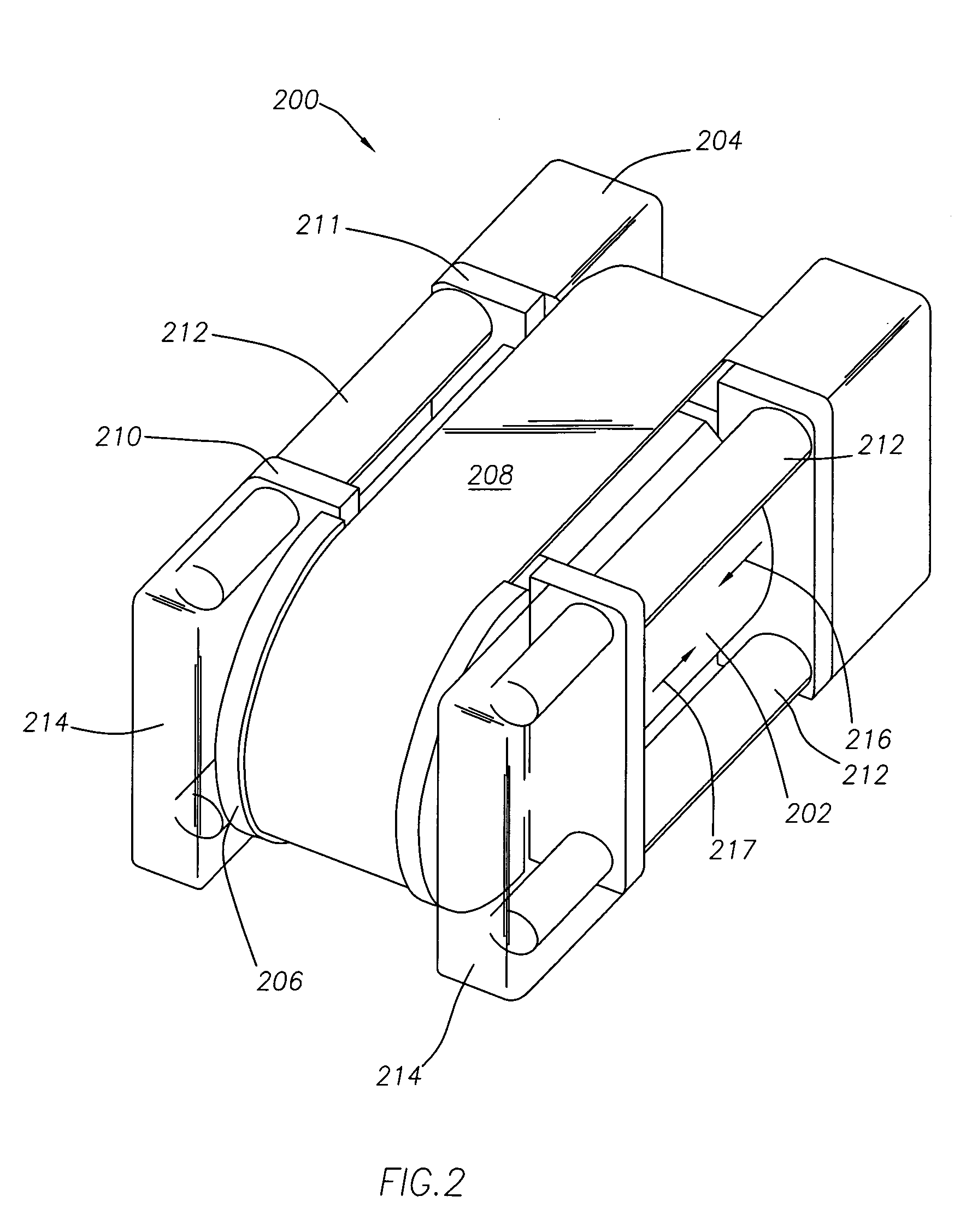

Highly sensitive accelerometer

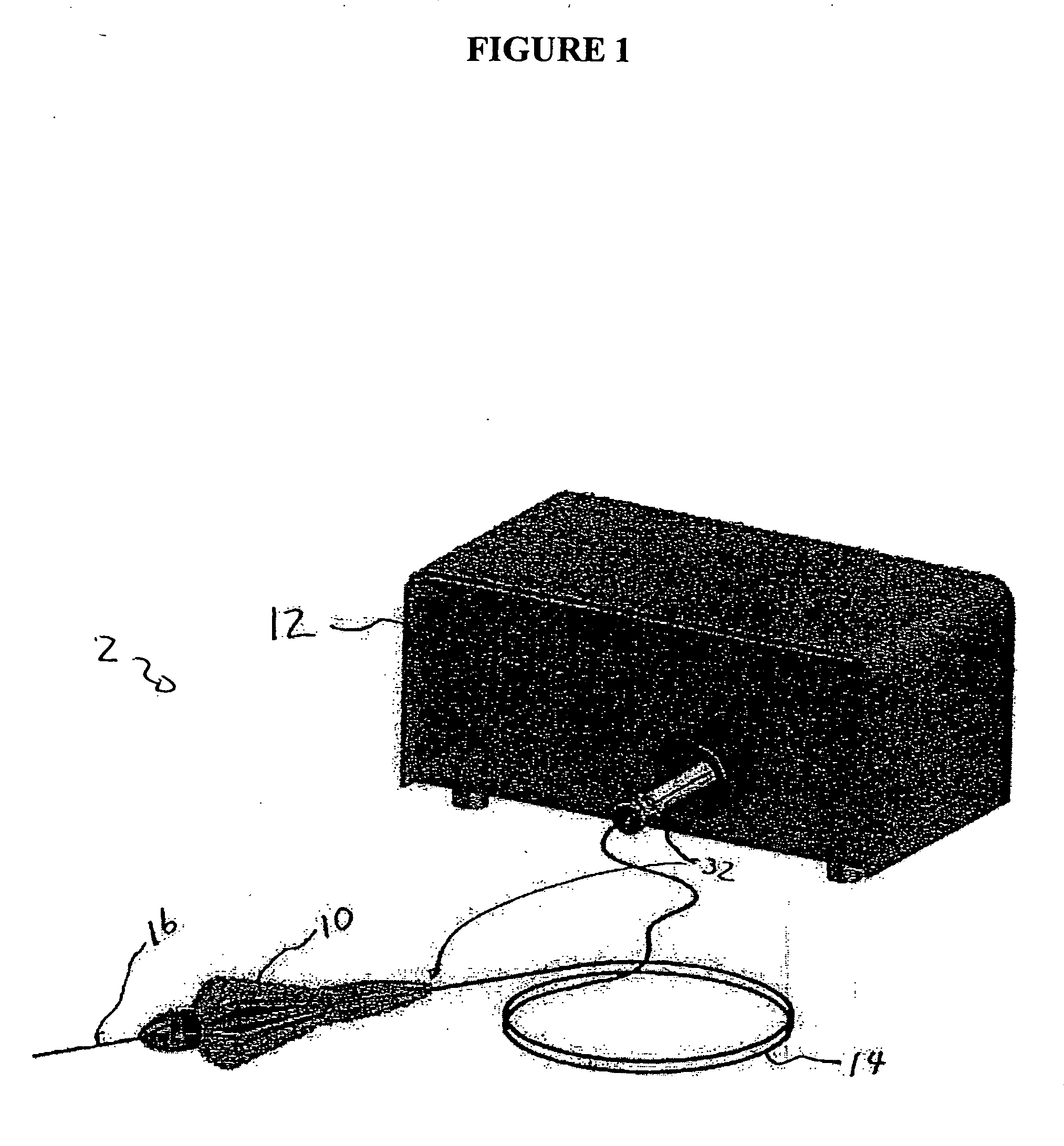

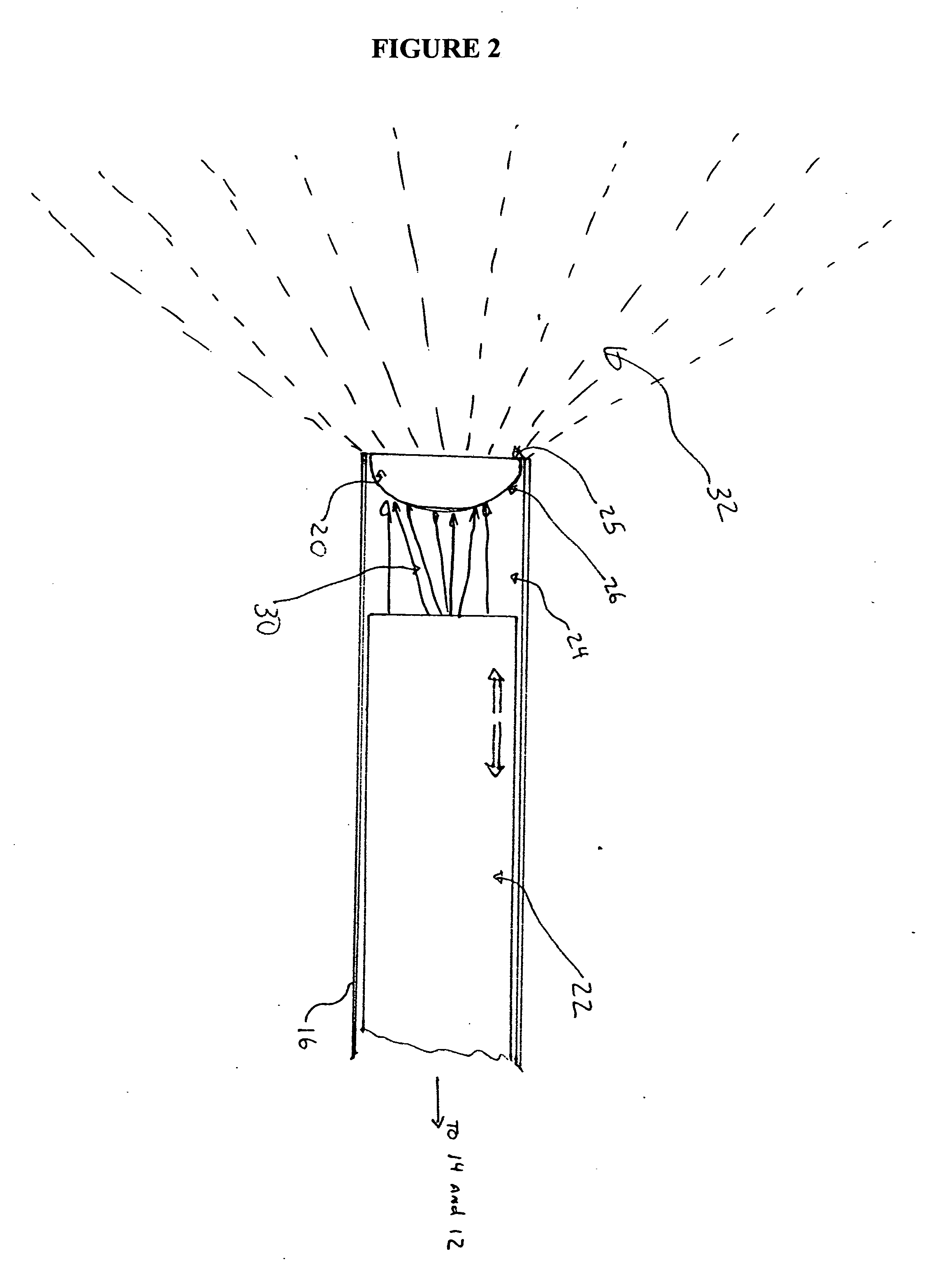

InactiveUS20050097955A1Reduce manufacturing costAcceleration measurement using interia forcesMaterial analysis by optical meansOcean bottomAccelerometer

Accelerometers for determining acceleration and methods of fabricating an accelerometer are disclosed. In one embodiment, the accelerometer includes a frame, a mass movably suspended on the frame, a fixed element having a rounded surface that does not move with respect to the frame, a movable element having a rounded surface that moves with the mass, and a sensing coil of optical waveguide wrapped around the rounded surfaces to detect movement of the mass in response to acceleration based on interferometric sensing of a change in length of the sensing coil. A method of fabricating the accelerometer includes suspending the mass in the frame and wrapping the optical waveguide around the rounded surfaces. Sensitivity and low fabrication cost of the accelerometers enables their use for integration within an ocean bottom seismic cable. Further, the accelerometer may be an in-line or a cross-line accelerometer depending on the arrangement within the frame.

Owner:WEATHERFORD TECH HLDG LLC

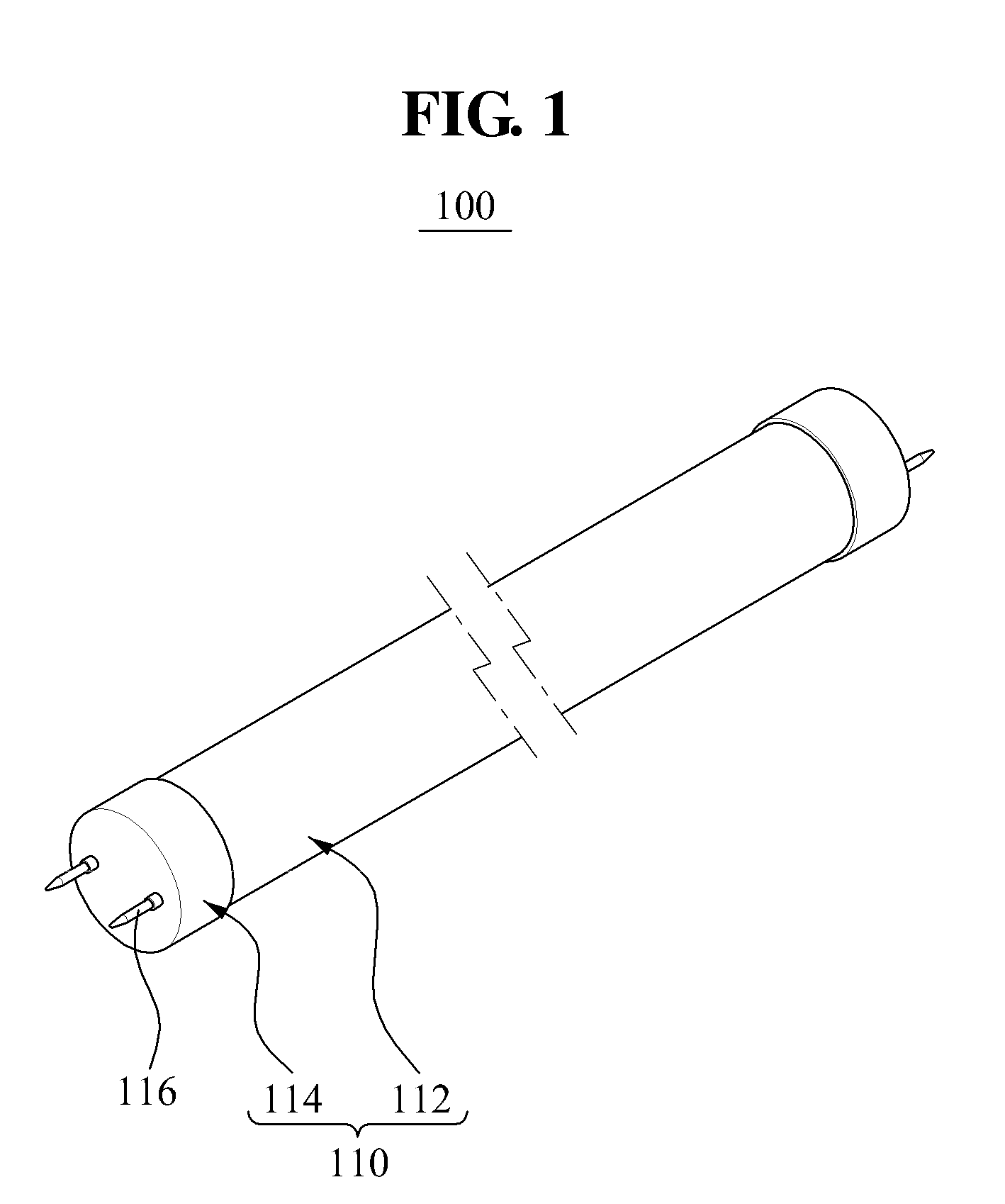

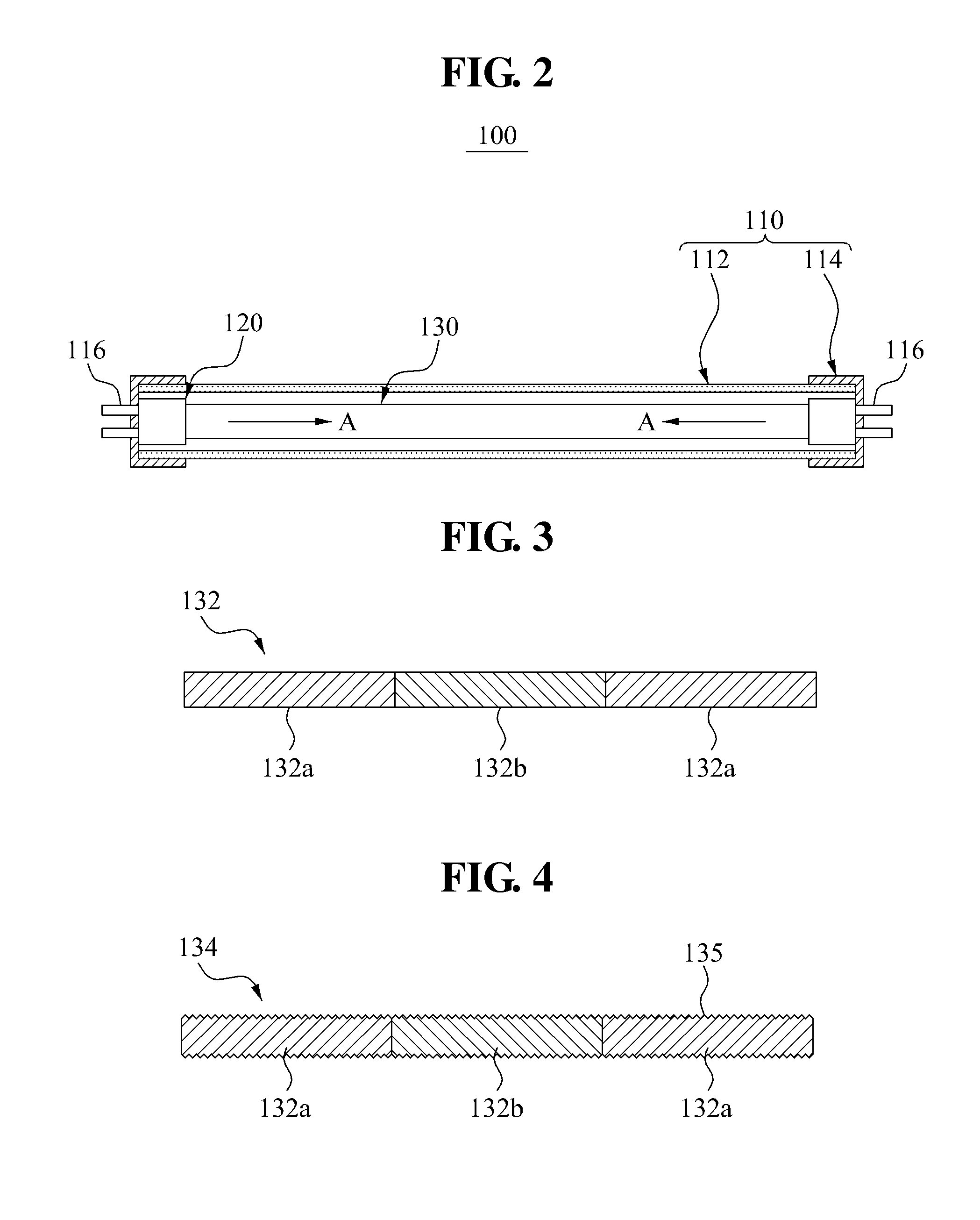

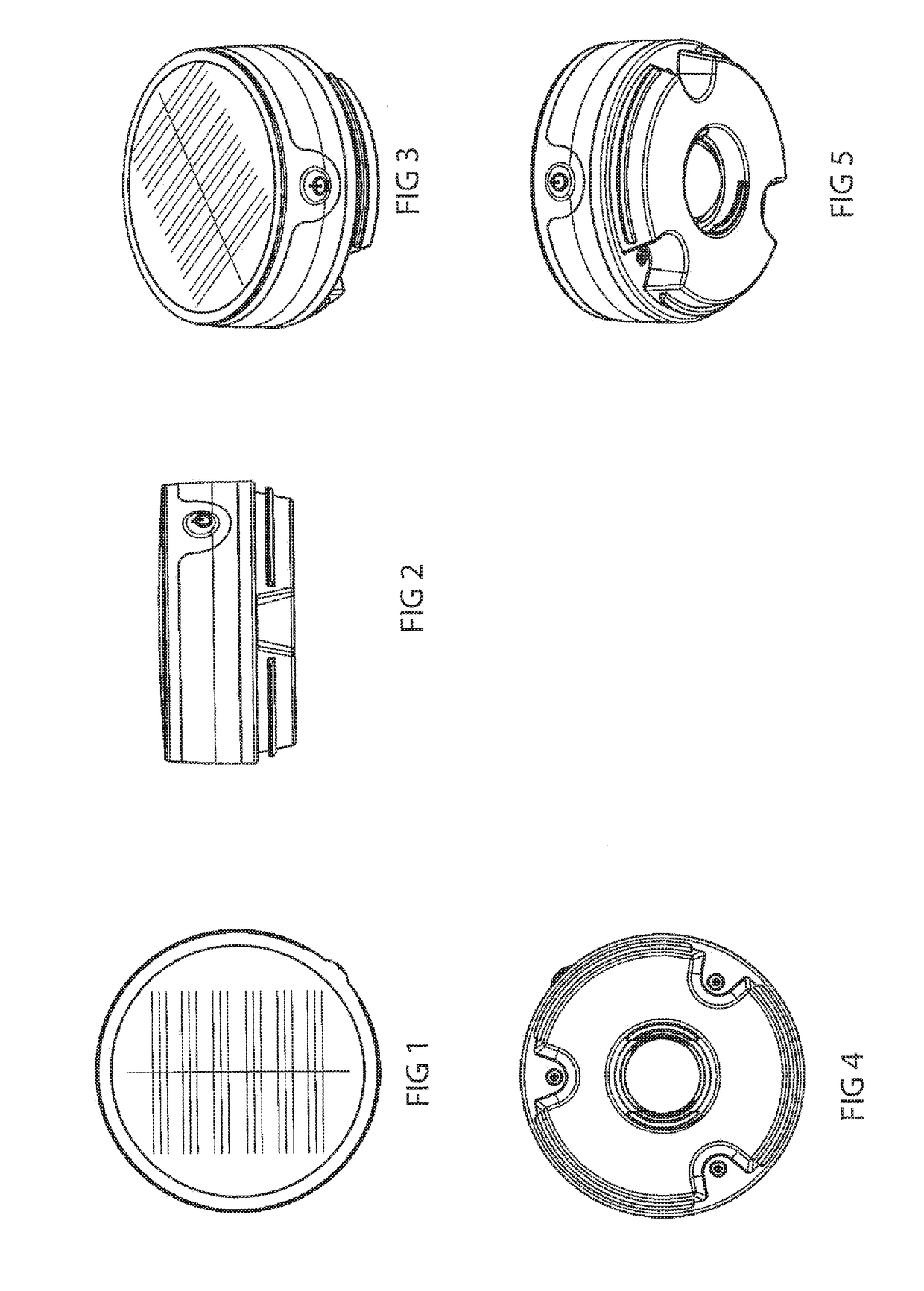

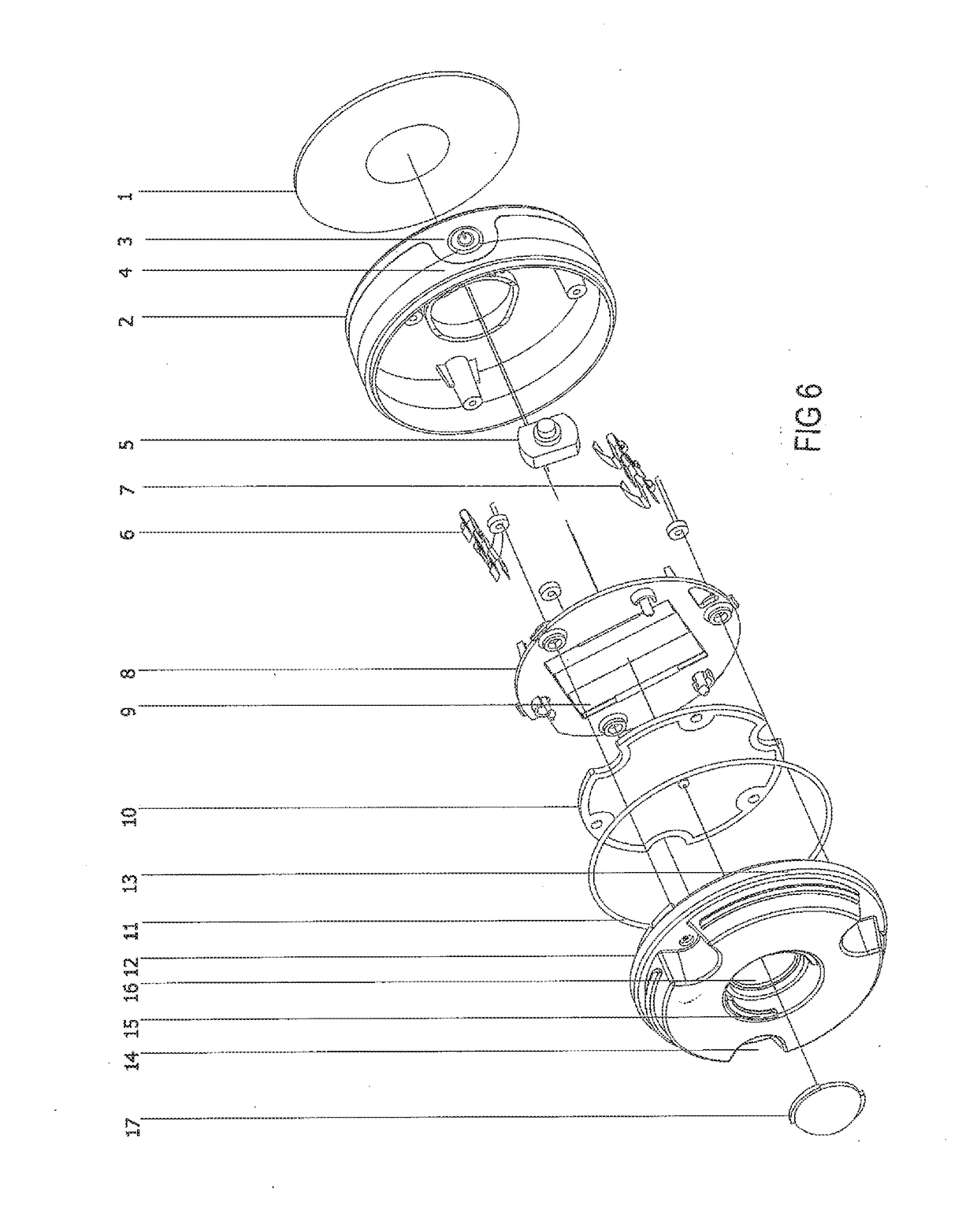

Lighting device

InactiveUS20130170245A1Well representedImprove light uniformityMechanical apparatusFibre light guidesLight guideStraight tube

Owner:SAMSUNG ELECTRONICS CO LTD

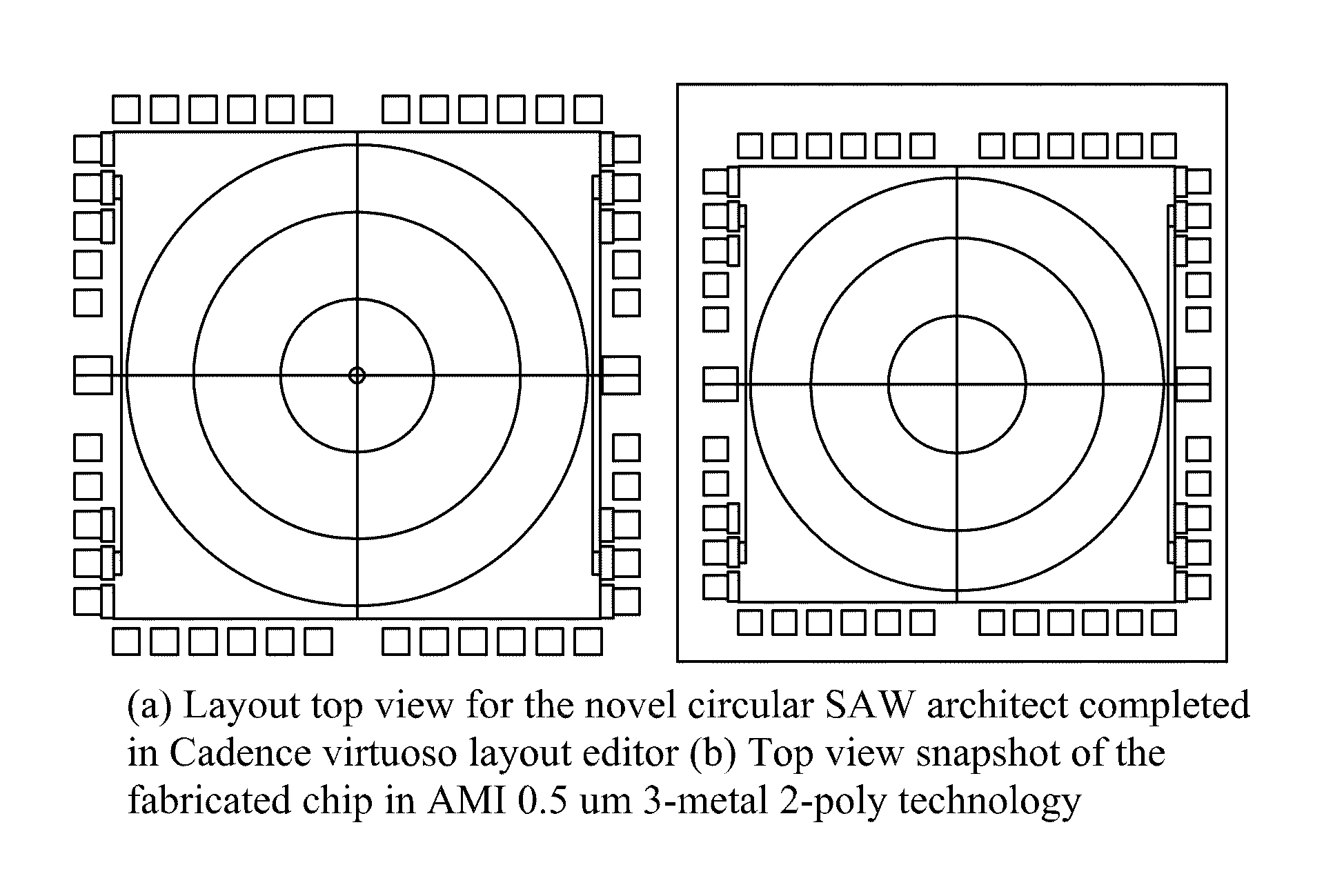

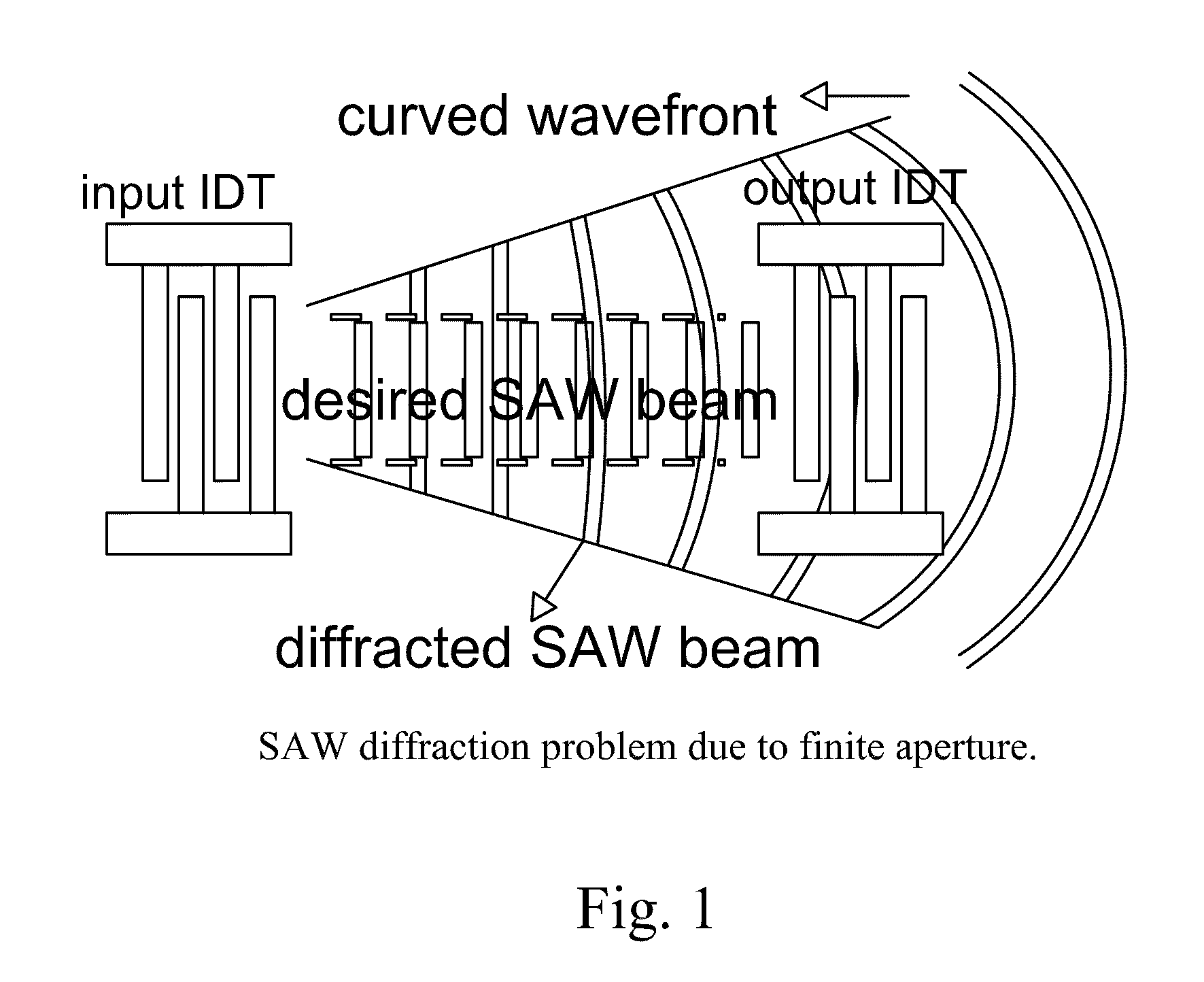

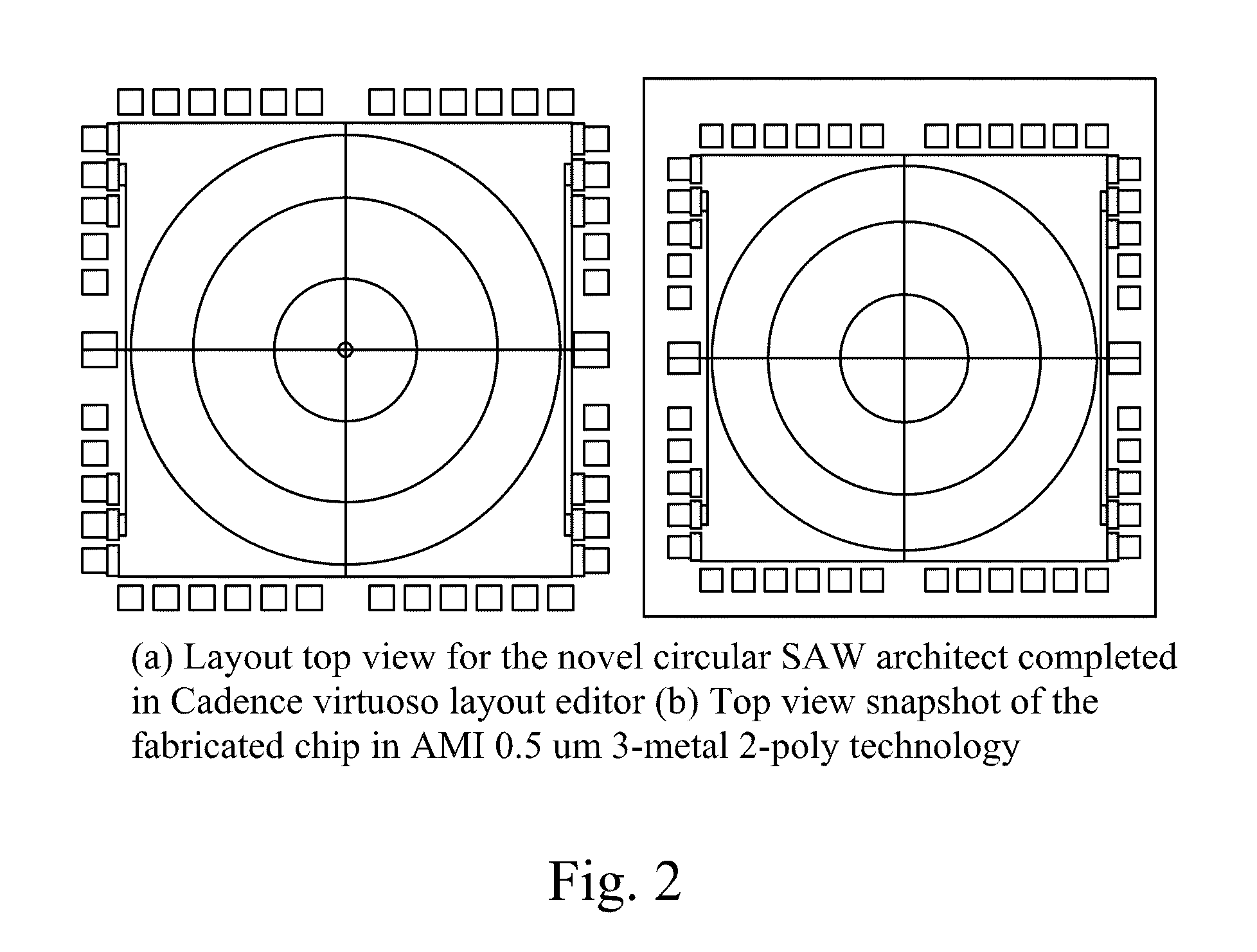

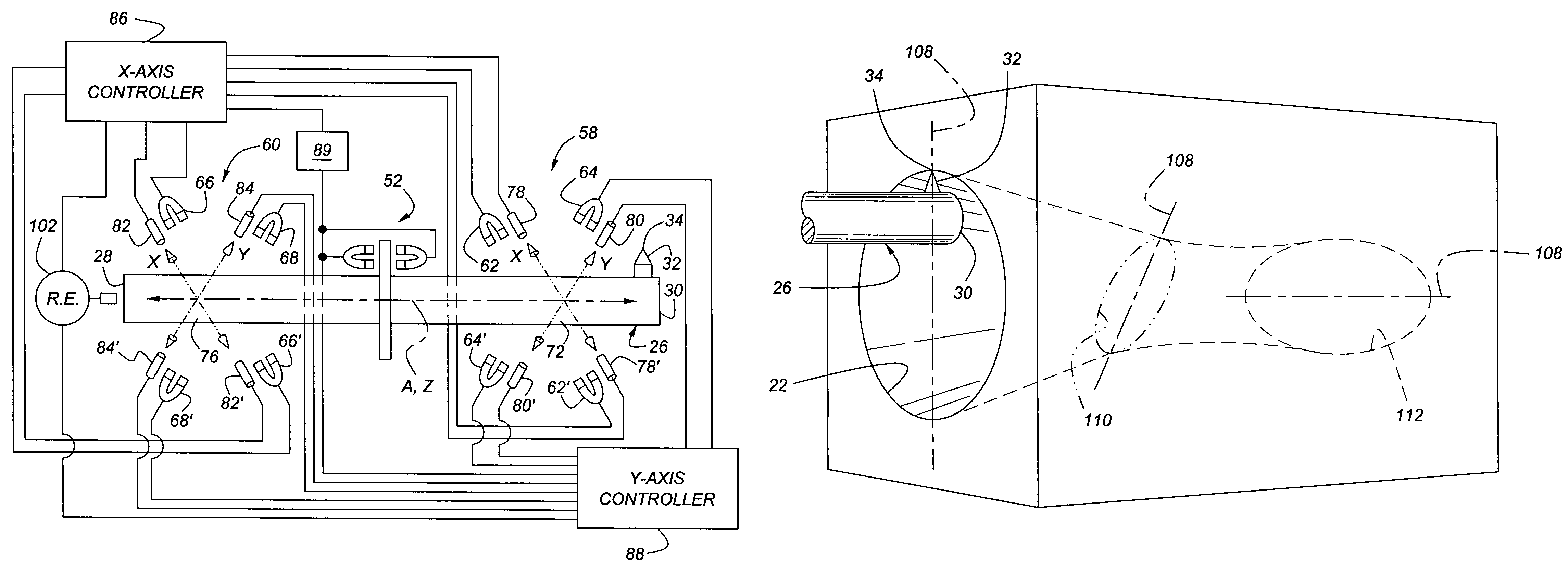

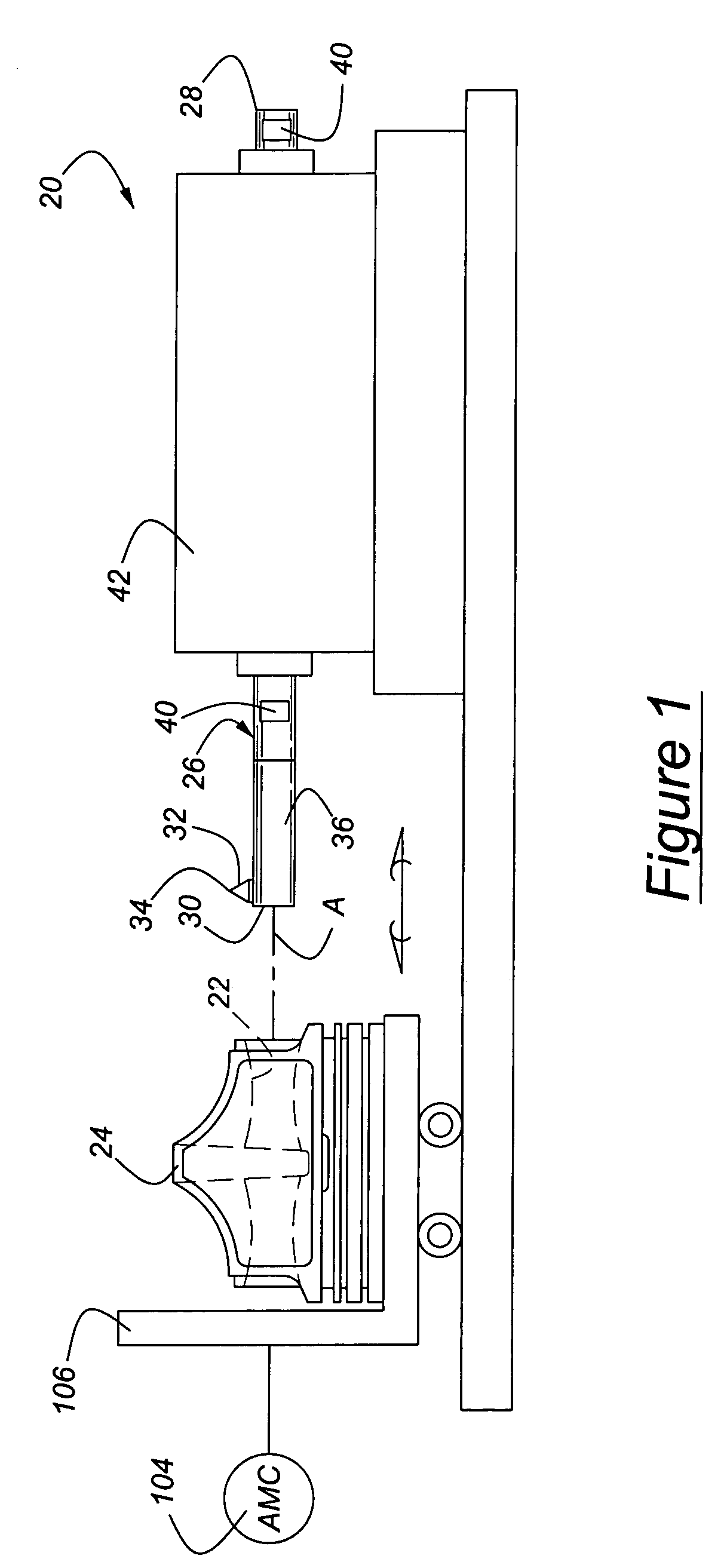

Circular surface acoustic wave (SAW) devices, processes for making them, and methods of use

InactiveUS8018010B2Material analysis using sonic/ultrasonic/infrasonic wavesImpedence networksCMOSTemperature control

The design, fabrication, post-processing and characterization of a novel circular design SAW (Surface Acoustic Wave) based bio / chemical sensor in CMOS technology is introduced. The sensors are designed in AMI 1.5 μm 2 metal, 2 poly process. A unique maskless post processing sequence is designed and completed. The three post-processing steps are fully compatible with any CMOS technology. This allows any signal control / processing circuitry to be easily integrated on the same chip. ZnO is used as the piezoelectric material for the SAW generation. A thorough characterization and patterning optimization of the sputtered ZnO was carried out. The major novelties that are introduced in the SAW delay line features are: The embedded heater elements for temperature control, compensation and acoustic absorbers that are designed to eliminate edge reflections and minimize triple transit interference. Both of these attributes are designed by using the CMOS layers without disturbing the SAW performance.

Owner:GEORGE WASHINGTON UNIVERSITY

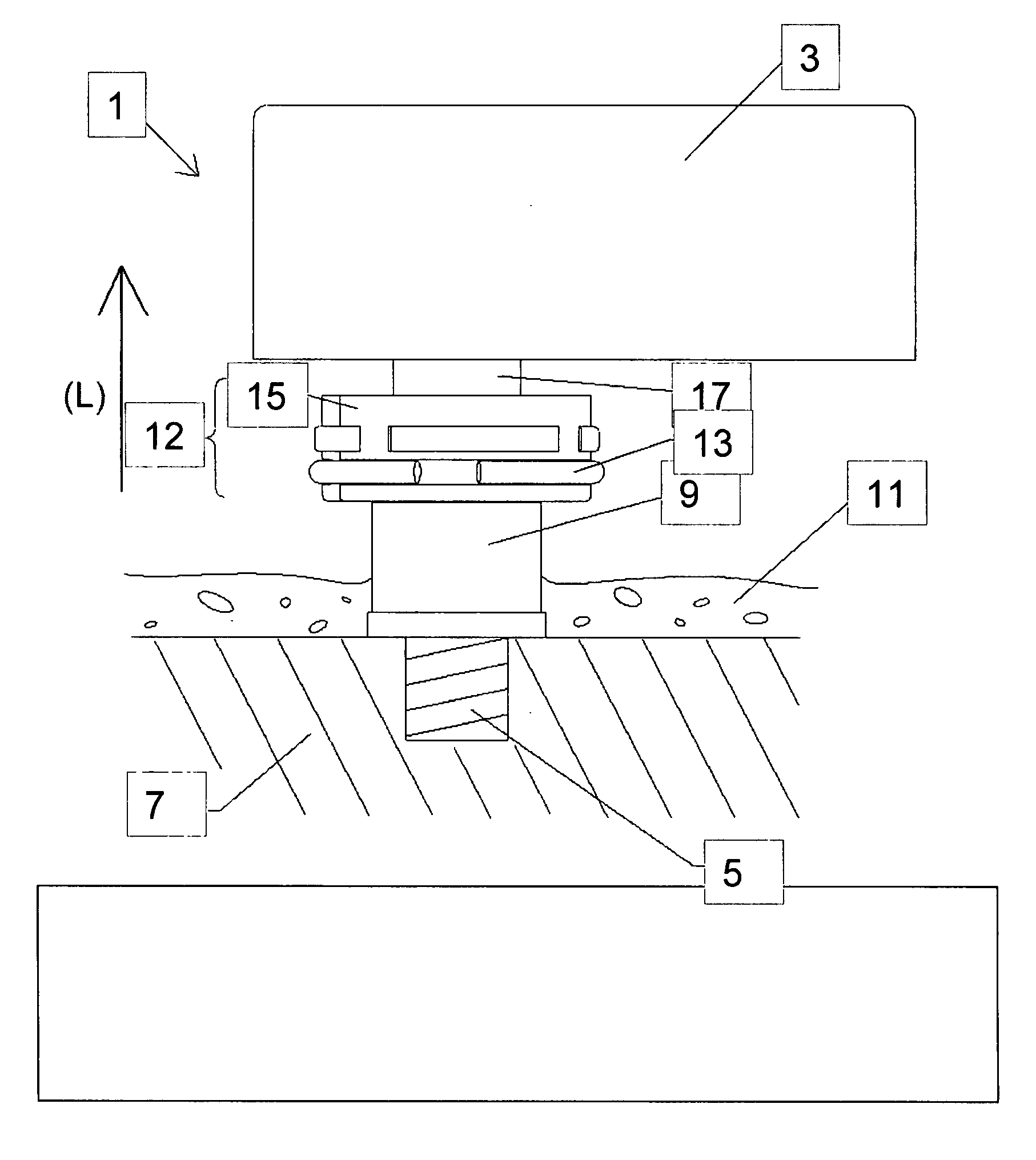

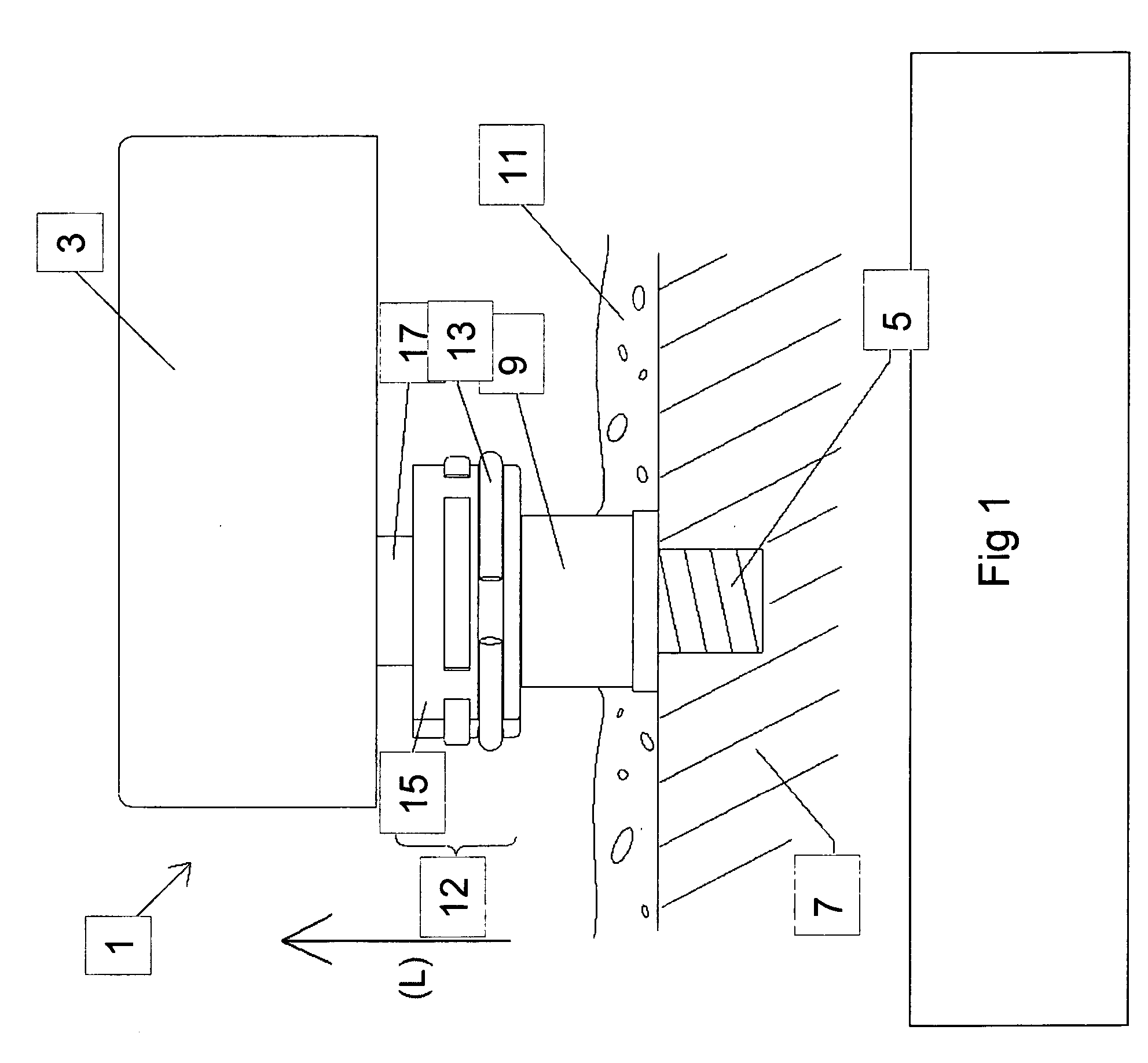

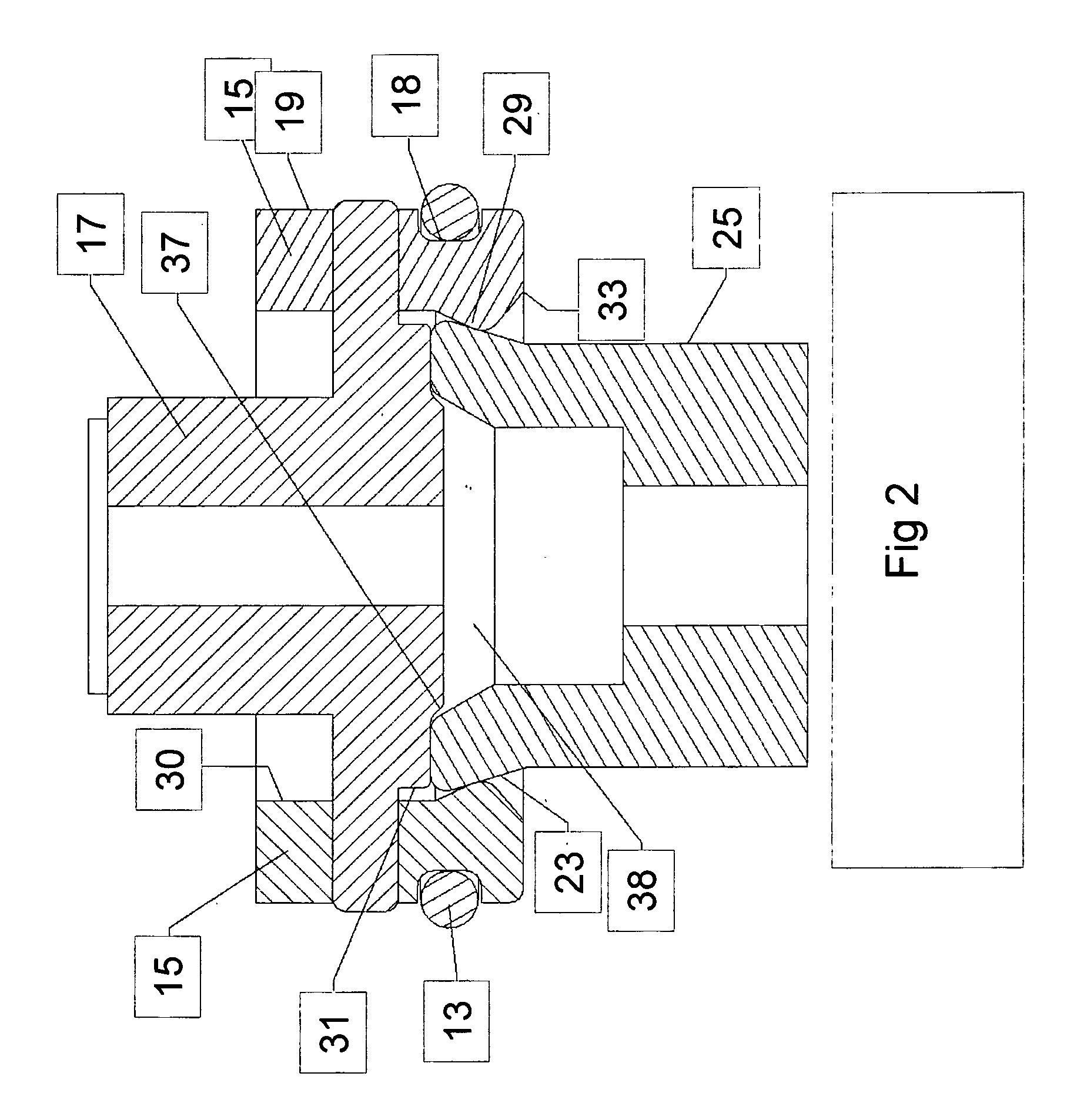

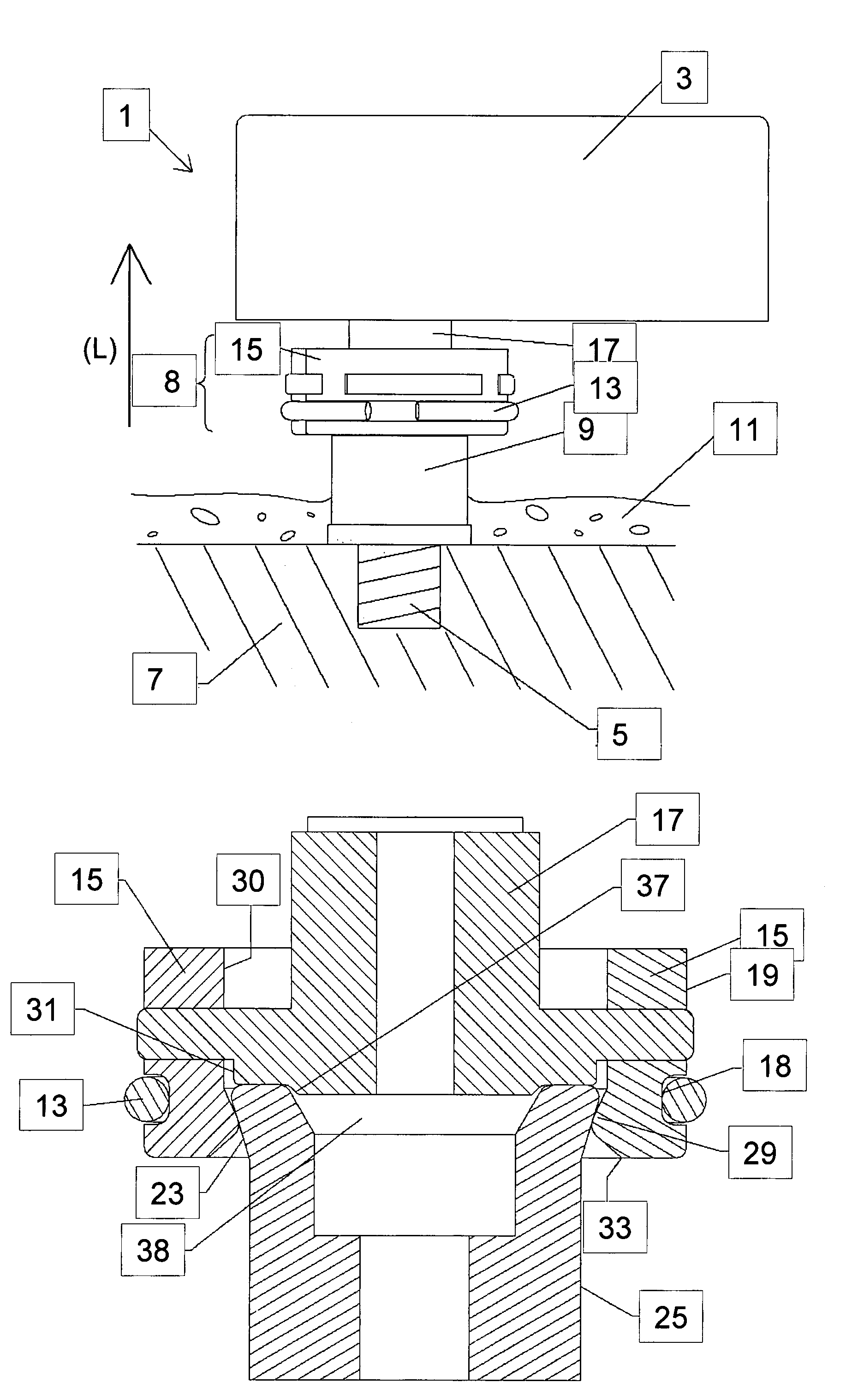

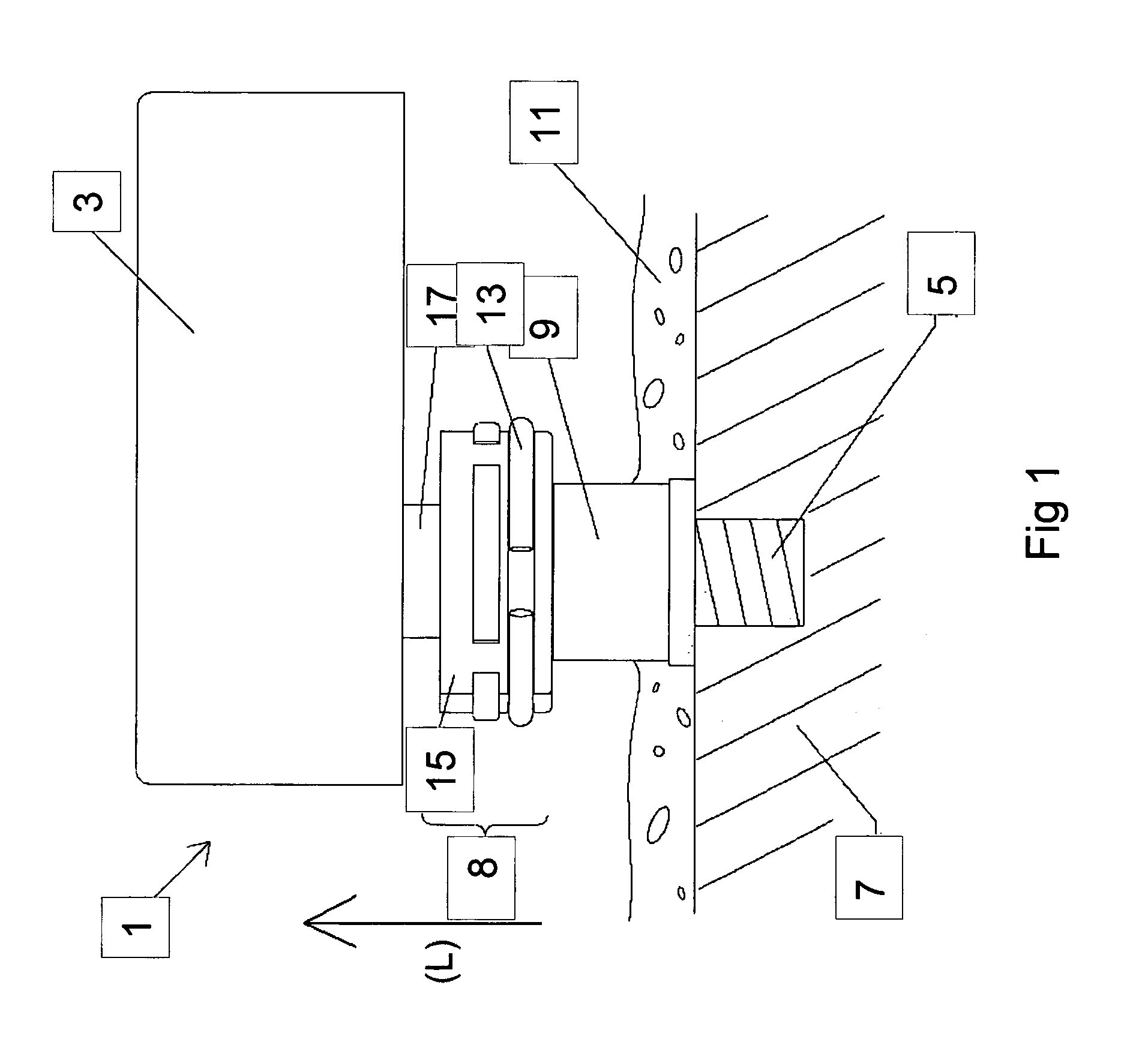

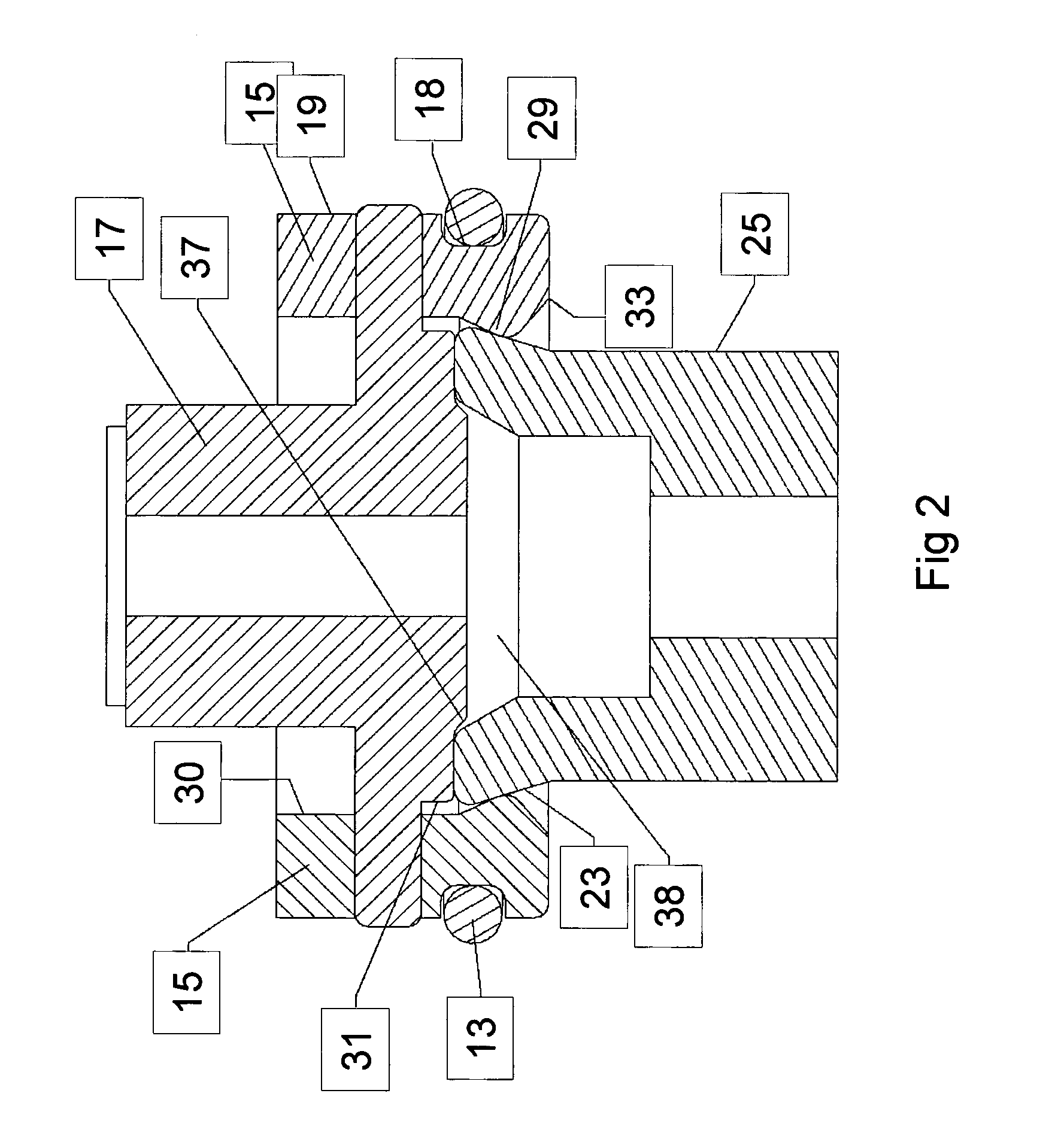

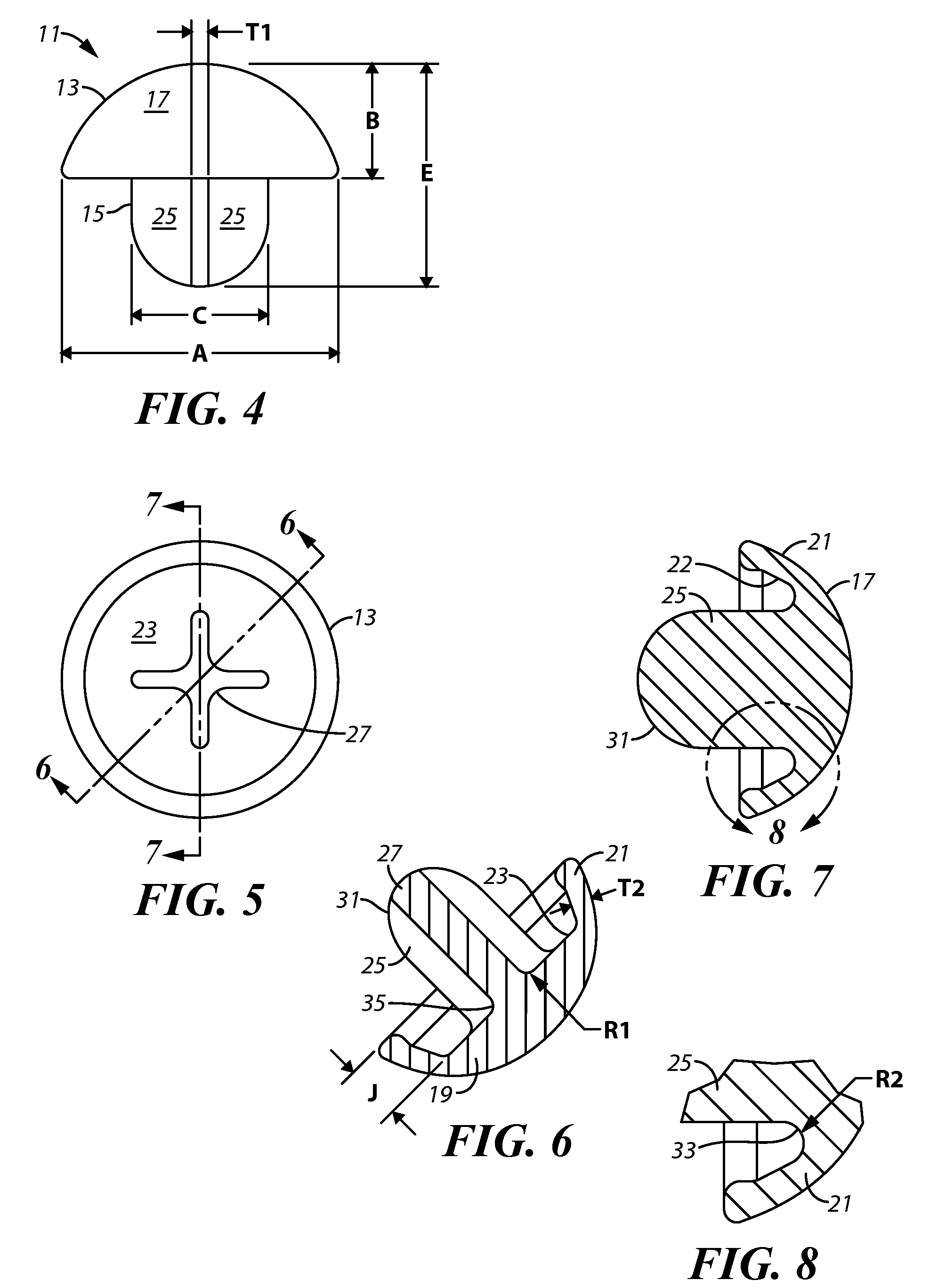

Connector system

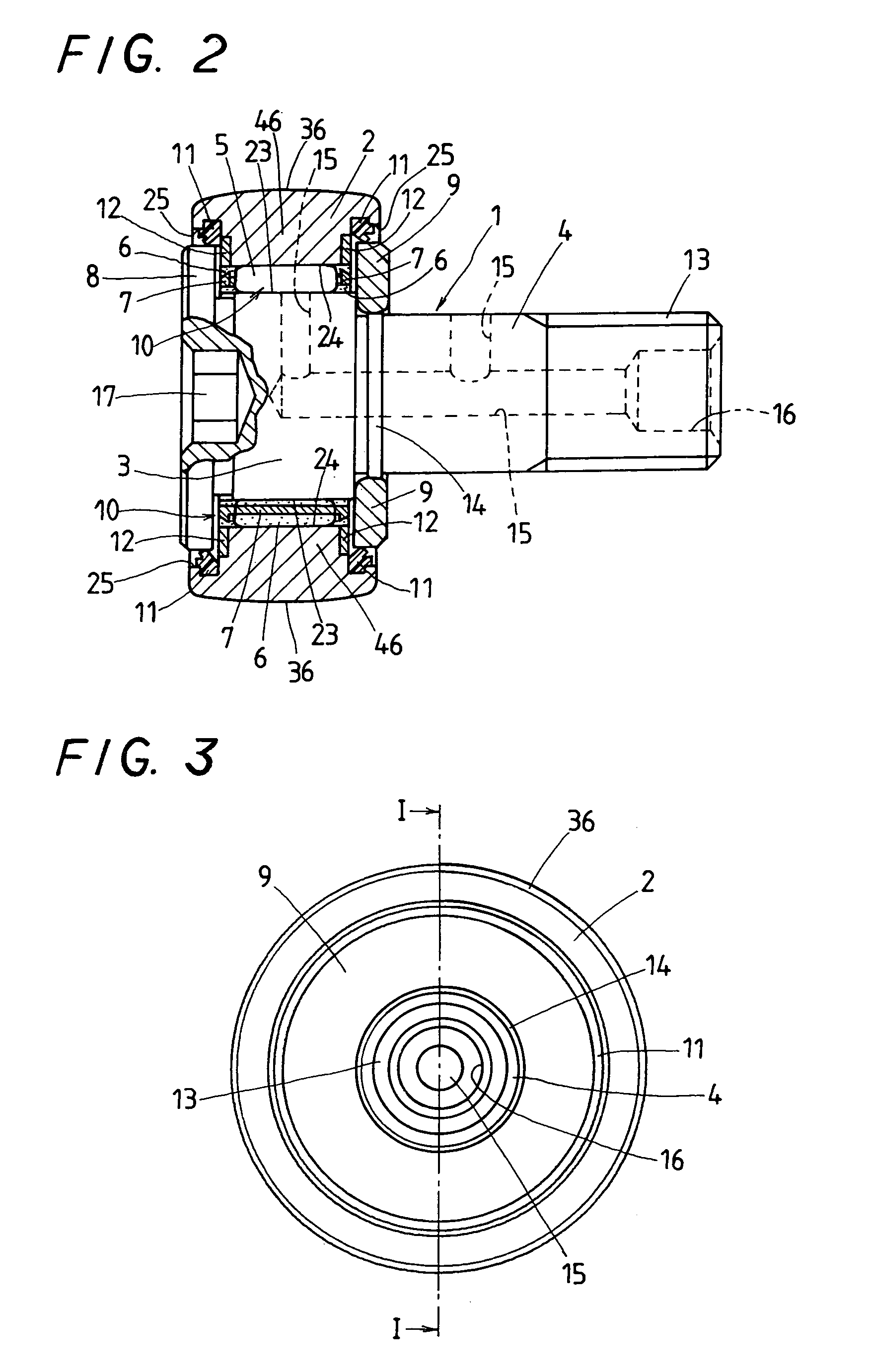

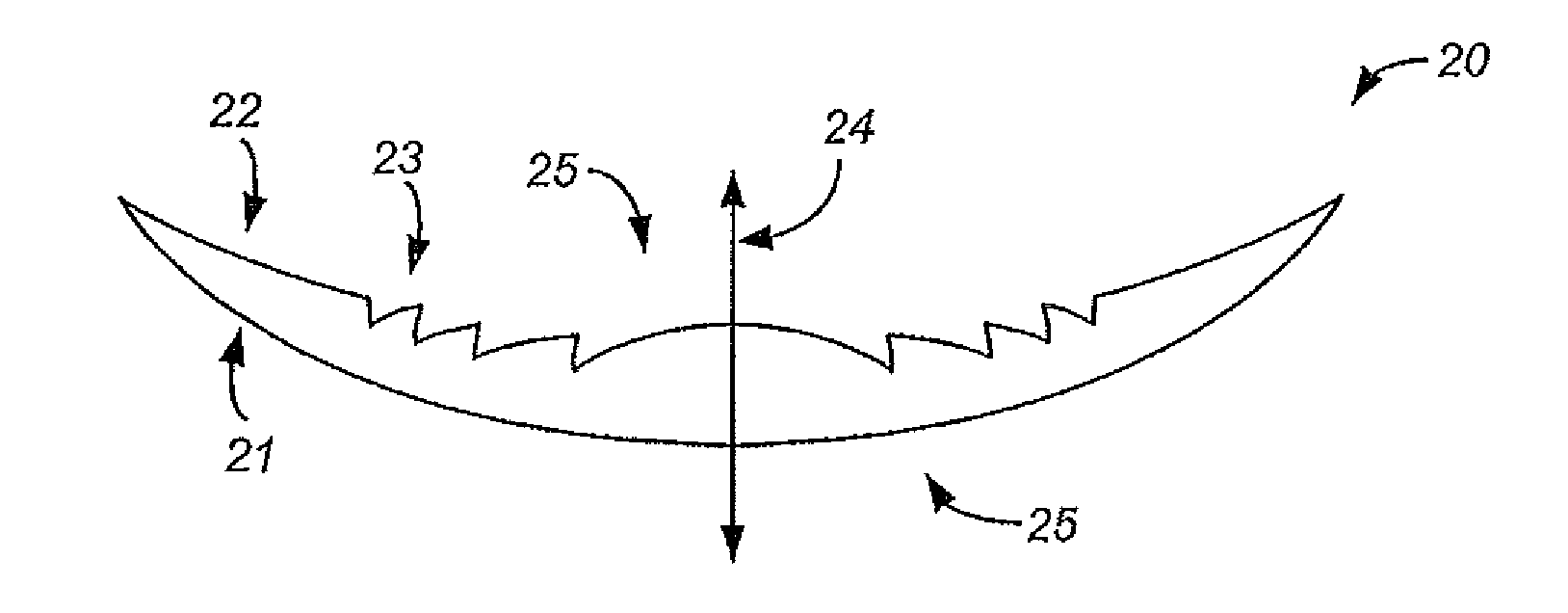

ActiveUS20050248158A1Easy to removeEasy to replaceFlanged jointsBone conduction transducer hearing devicesCouplingEngineering

A connector system for interconnecting a hearing aid (3) with a fixture (5) anchored in a bone segment (7). An abutment (9) has a contact surface (21) with is a substantially circular surface. A connector plate (17) with a substantially circular connector contact surface (20) is in contact with the abutment contact surface (21) when the hearing aid (3) is connected to the abutment (9). The abutment (9) has a wide abutment coupling area and a narrow portion. The abutment coupling area is enclosable by coupling shoes (15). The coupling shoes (15) exert a pressure against the abutment coupling area disposed on a mantle surface (25) of the abutment. The coupling shoes are movable in a radial direction relative to the connector plate (17). The coupling area has an increasing diameter in a lateral direction (L). A coupling area (29) of the coupling shoes has an increasing diameter in the lateral direction (L) to exert a pressure on the abutment (9) against a connector contact surface when the coupling shoes (15) are pressed in the radial direction against the abutment (9).

Owner:OTICON MEDICAL

Connector system

ActiveUS7021676B2Easy to removeEasy to replaceFlanged jointsBone conduction transducer hearing devicesCouplingHearing aid

A connector system for interconnecting a hearing aid (3) with a fixture (5) anchored in a bone segment (7). An abutment (9) has a contact surface (21) with is a substantially circular surface. A connector plate (17) with a substantially circular connector contact surface (20) is in contact with the abutment contact surface (21) when the hearing aid (3) is connected to the abutment (9). The abutment (9) has a wide abutment coupling area and a narrow portion. The abutment coupling area is enclosable by coupling shoes (15). The coupling shoes (15) exert a pressure against the abutment coupling area disposed on a mantle surface (25) of the abutment. The coupling shoes are movable in a radial direction relative to the connector plate (17). The coupling area has an increasing diameter in a lateral direction (L). A coupling area (29) of the coupling shoes has an increasing diameter in the lateral direction (L) to exert a pressure on the abutment (9) against a connector contact surface when the coupling shoes (15) are pressed in the radial direction against the abutment (9).

Owner:OTICON MEDICAL

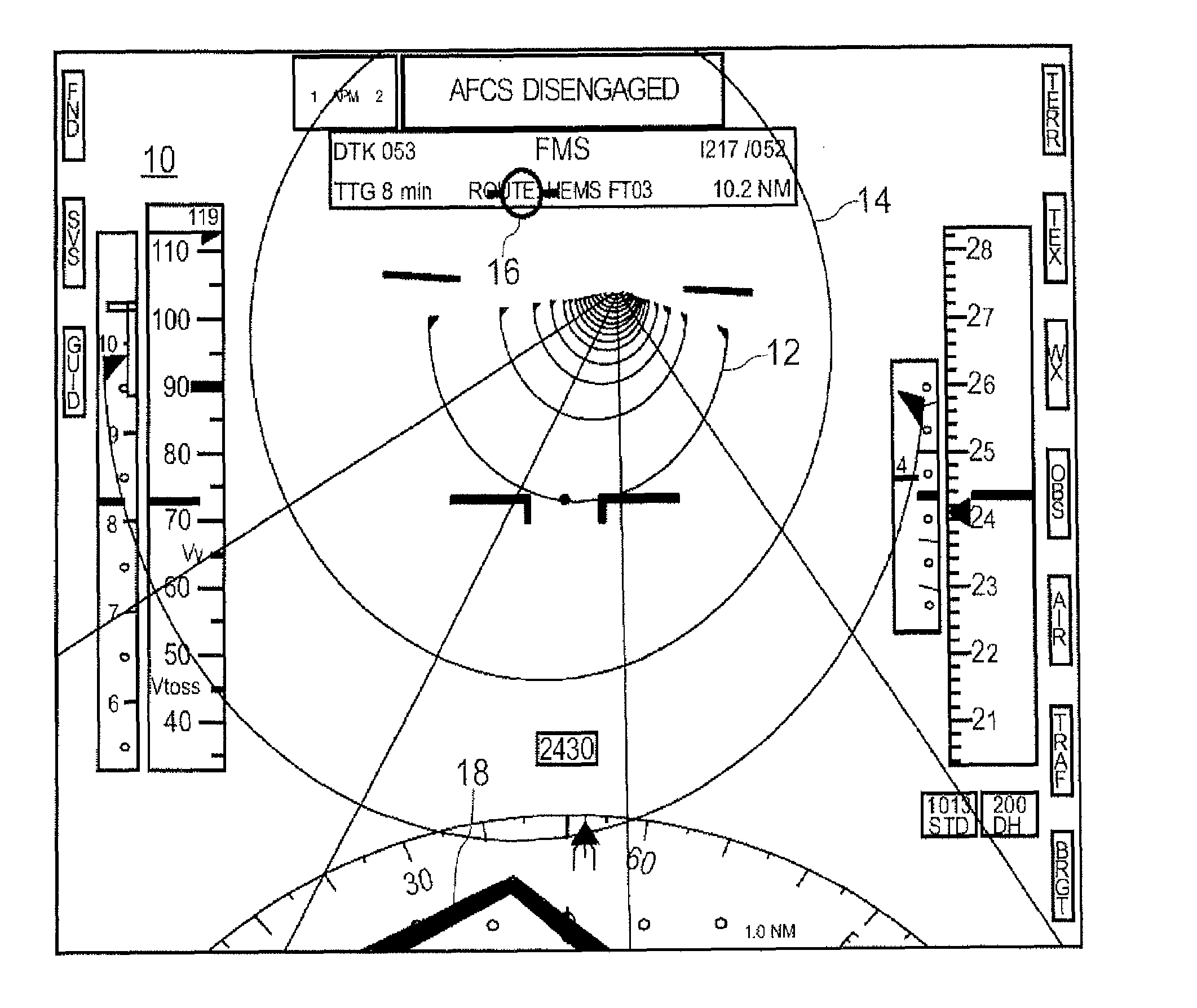

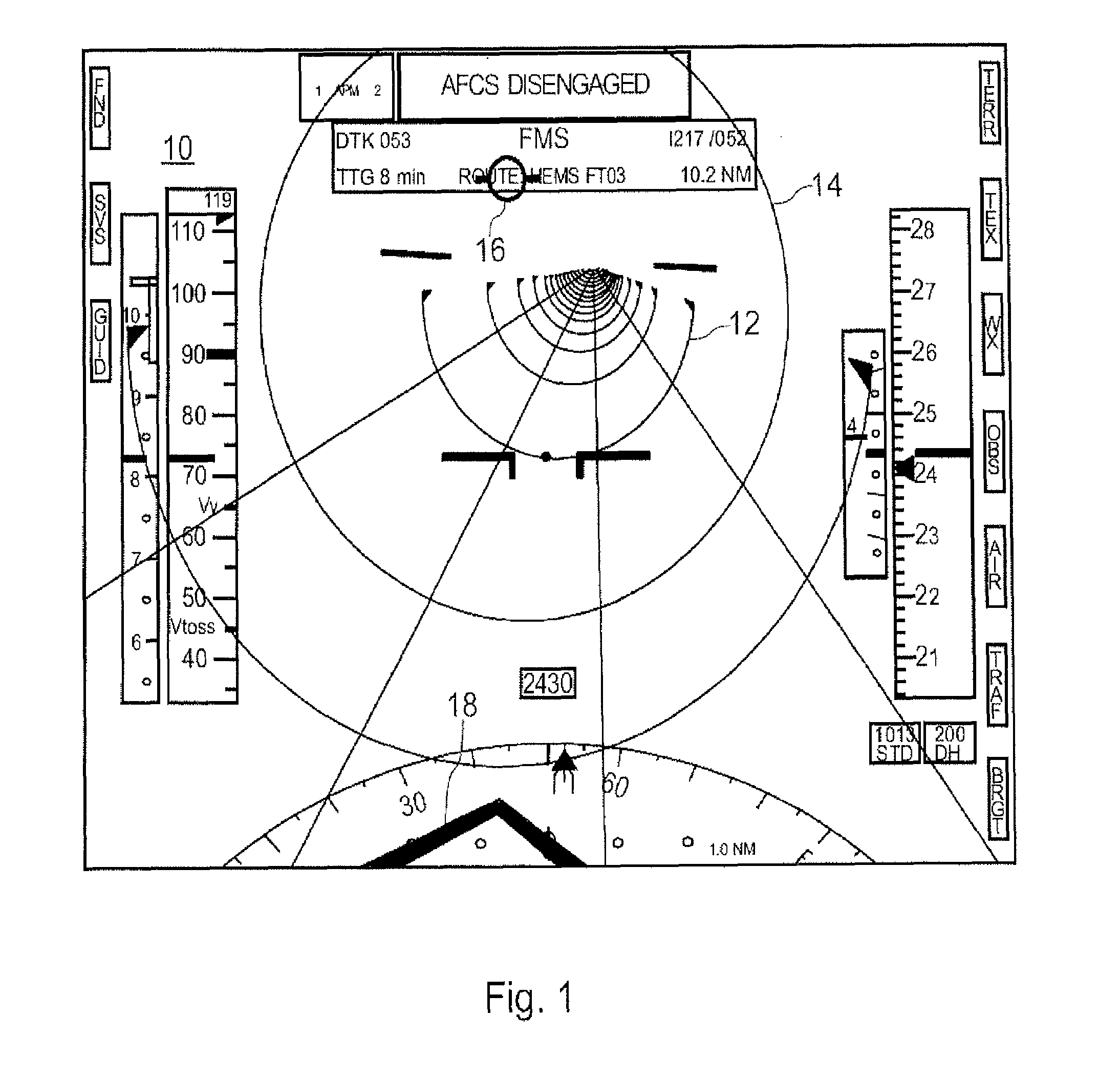

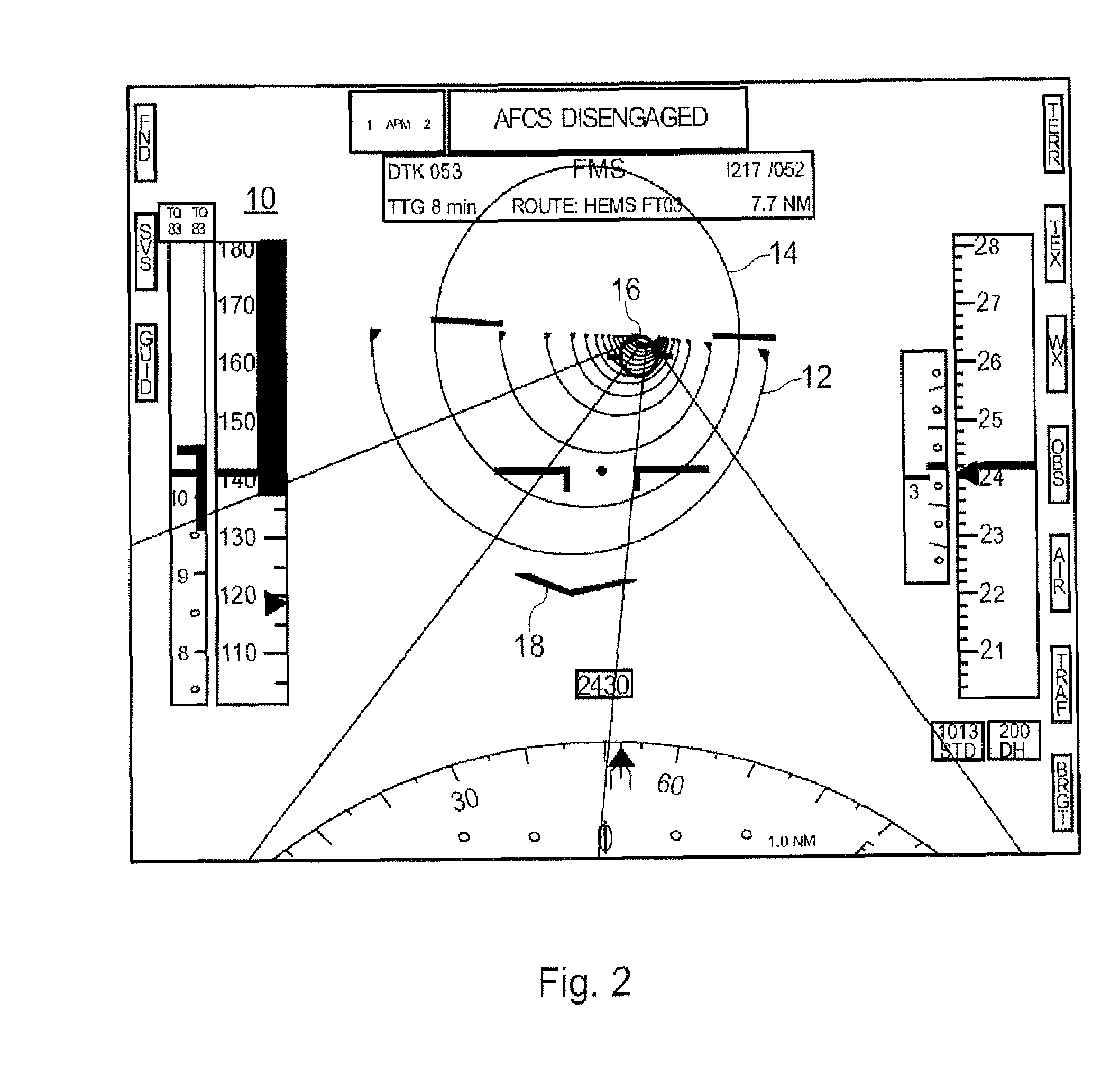

Flight guidance and navigation display for a helicopter

ActiveUS20090281684A1Reduce workloadEasy to explainAnalogue computers for trafficNavigation instrumentsDisplay deviceCircular surface

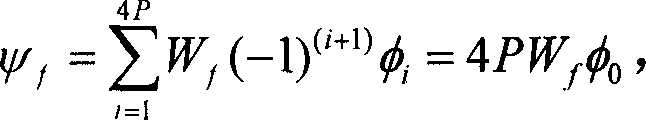

A flight guidance and navigation display (10) for a helicopter, includes a three-dimensional, semicircular flight guidance and navigation tunnel (12) to display a planned flight path of the helicopter; a circular surface (14), which is integrated in the flight guidance and navigation tunnel (12), which circular surface (14) includes a diameter that corresponds to that of the flight guidance and navigation tunnel (12), for displaying a longitudinal position within the flight guidance and navigation tunnel (12); a flight path prediction icon (16) for displaying a position of the helicopter relative to the flight guidance and navigation tunnel (12); and a command signal (18) that relates to the air speed, wherein via the command signal (18) a deviation from a reference speed that has been predetermined by flight planning is displayed.

Owner:AIRBUS HELICOPTERS DEUT GMBH

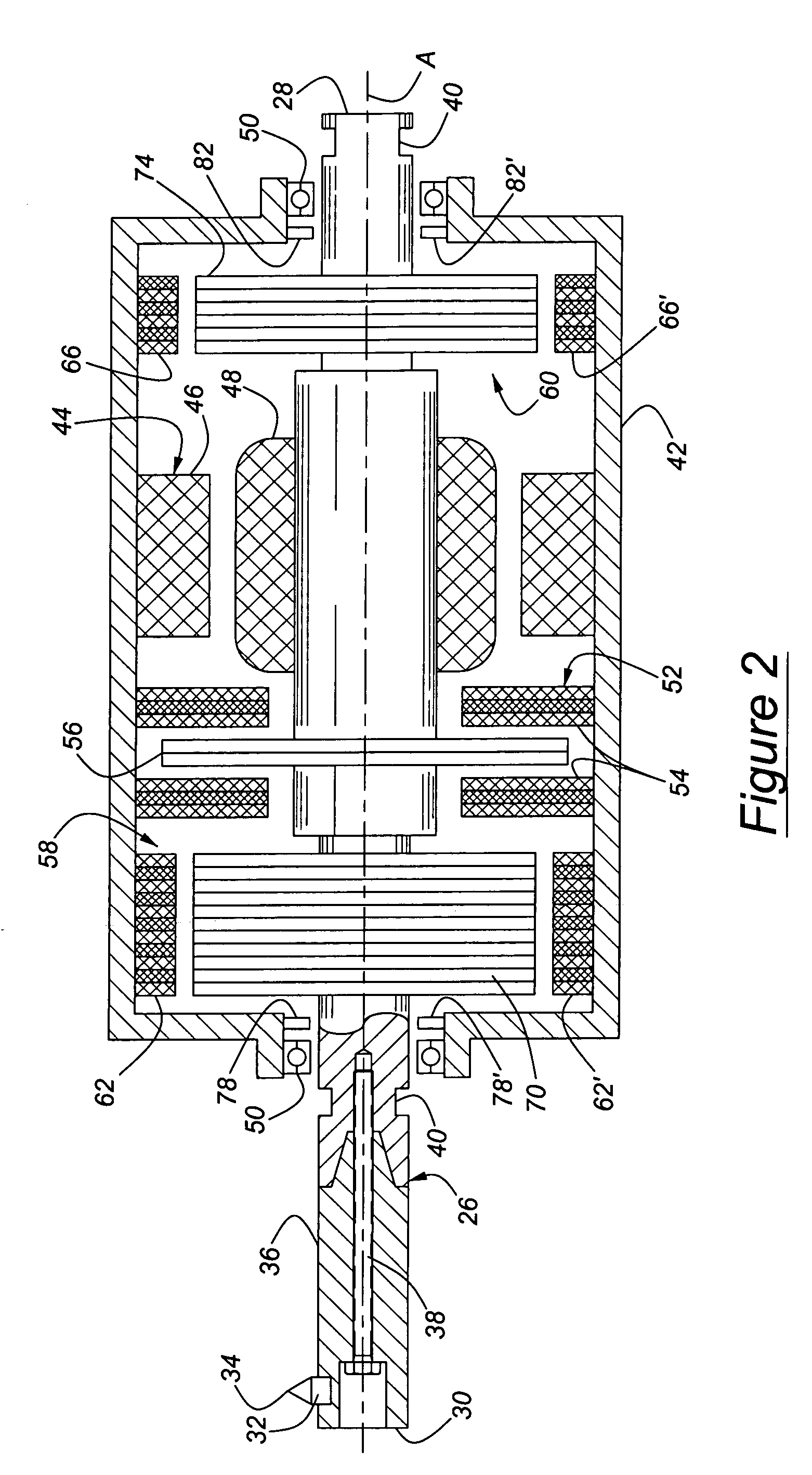

Magnetically levitated high-speed spindle for shaping irregular surfaces

InactiveUS7264430B2High precisionIncrease speedThread cutting toolsTurning machine accessoriesMagnetic bearingEngineering

Owner:FEDERAL MOGUL WORLD WIDE

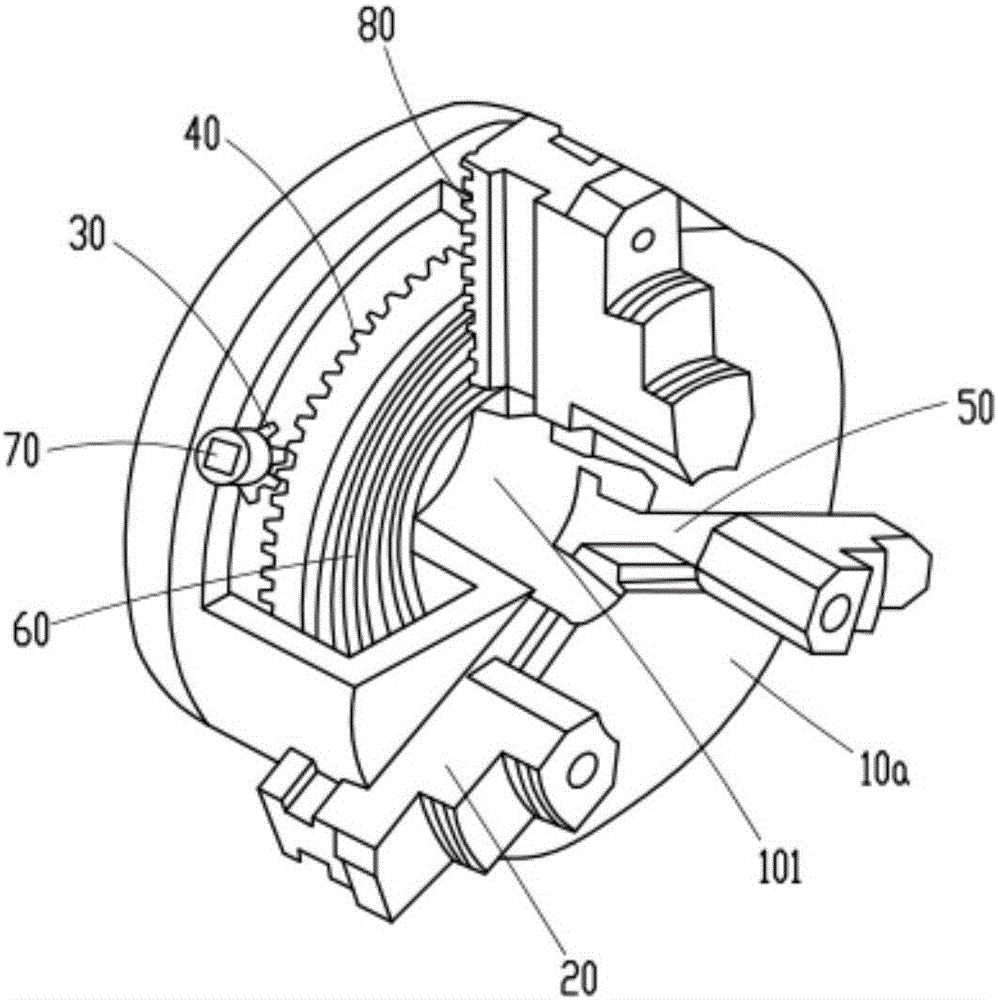

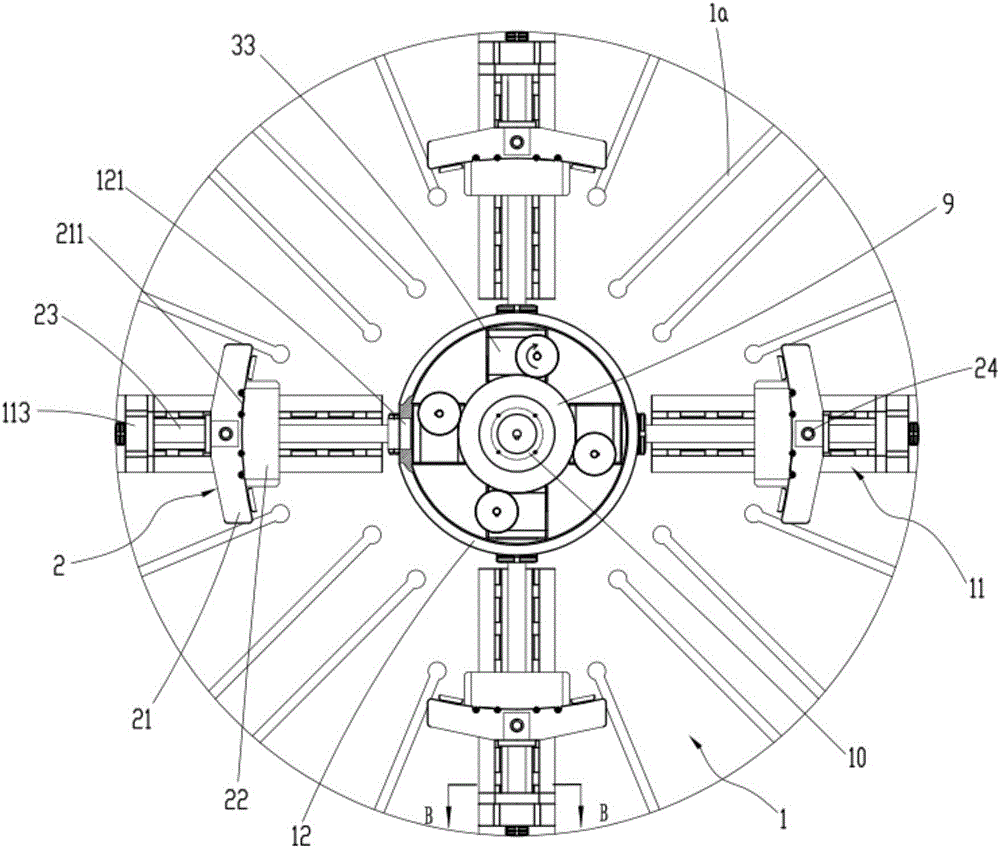

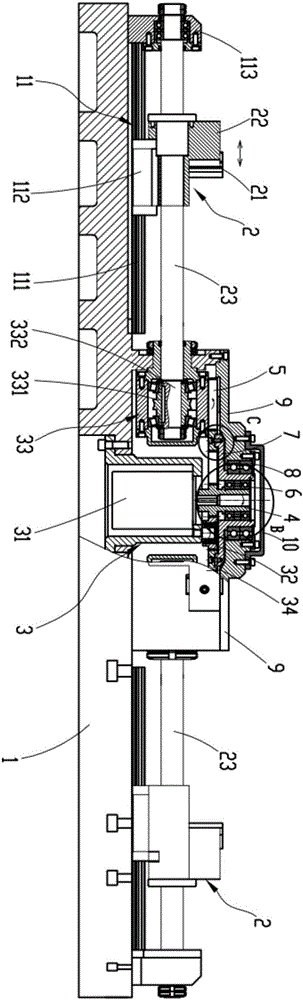

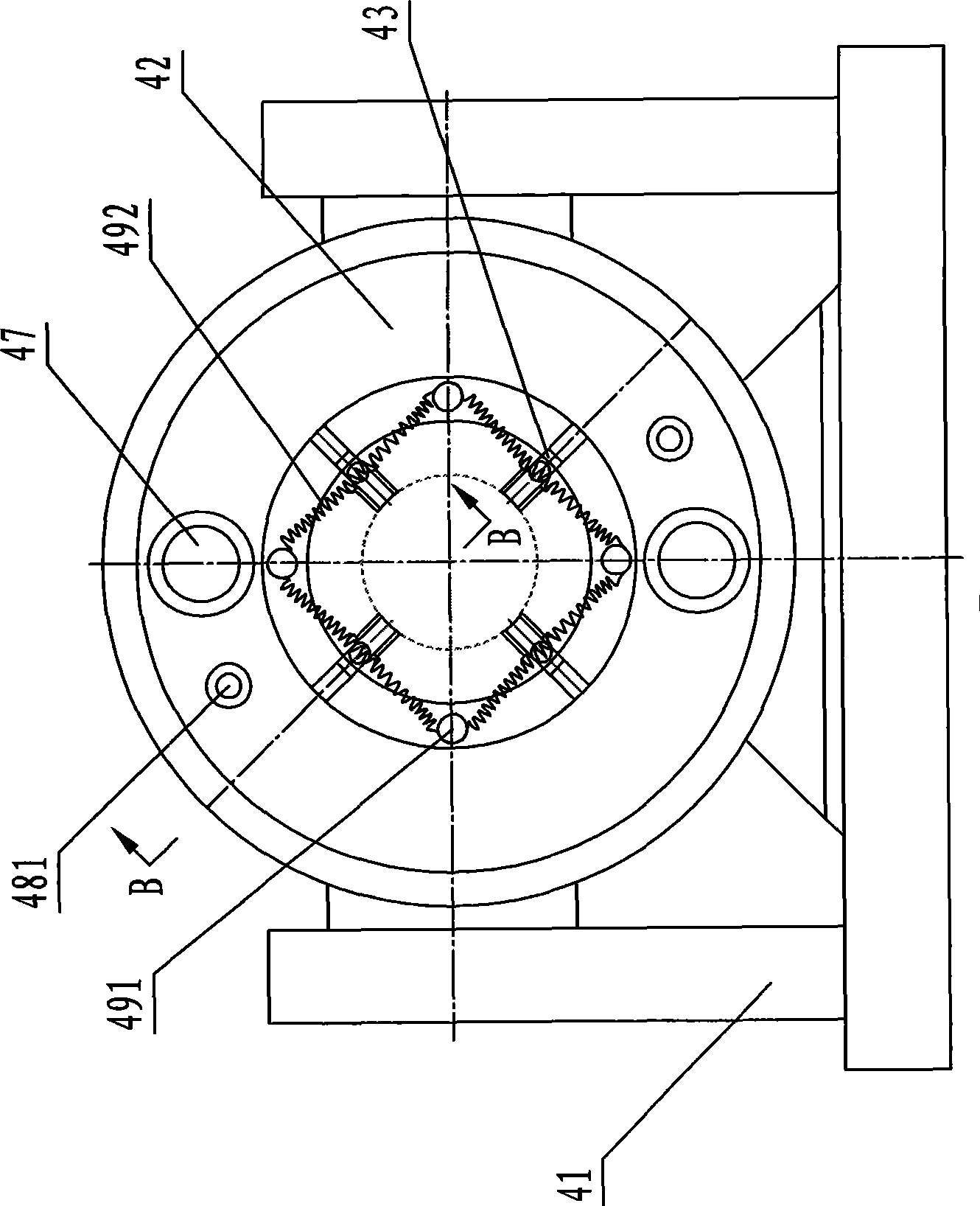

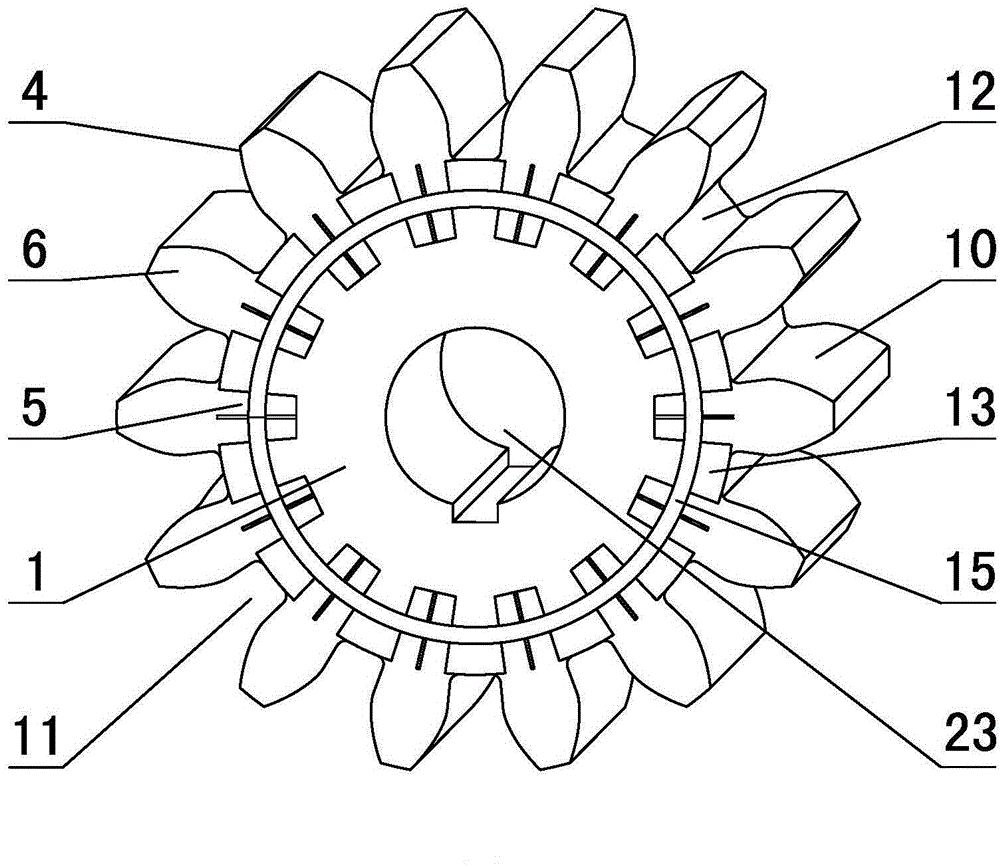

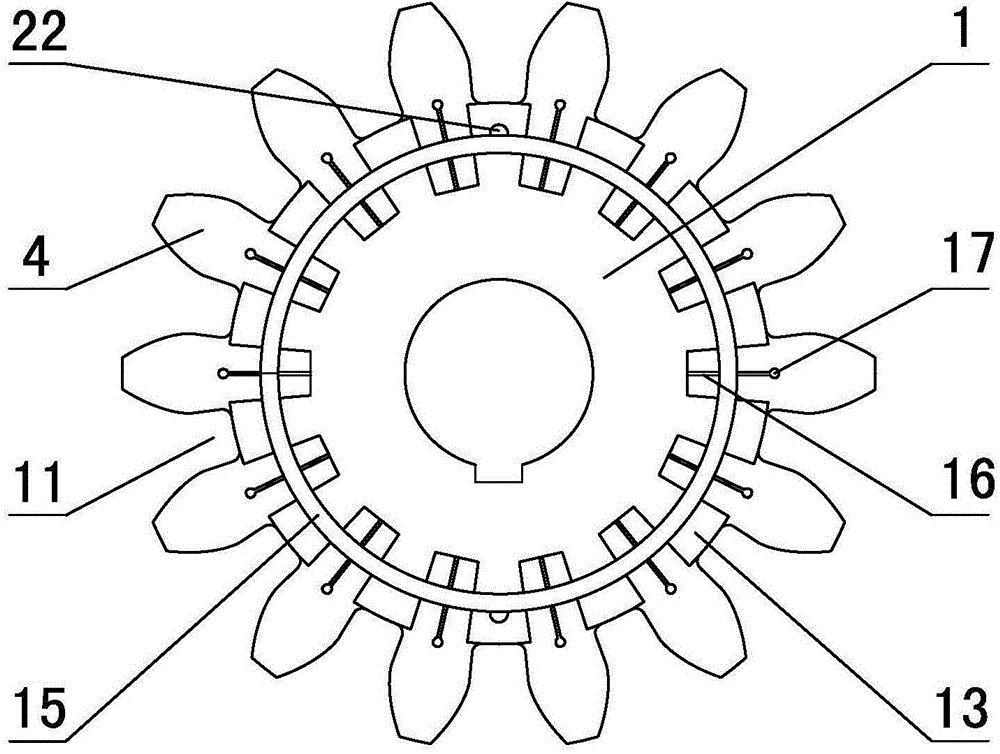

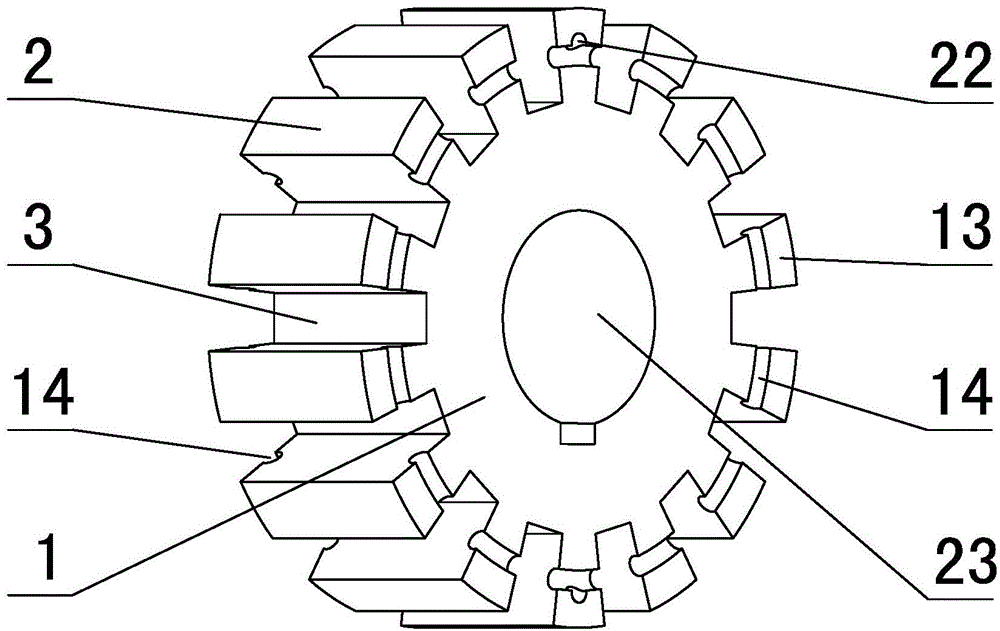

Precise self-centering chuck suitable for super-large workpieces

The invention relates to a precise self-centering chuck suitable for super-large workpieces. The precise self-centering chuck suitable for the super-large workpieces comprises a chuck body and a plurality of jack catch mechanisms arranged on the chuck body in a sliding mode. A jack catch driving mechanism is further arranged on the chuck body and comprises a numerical control moment motor, a plurality of transition gears, a plurality of double-enveloping speed reducers and a first gear. The inner circular surface and the outer circular surface of the first gear are provided with inner teeth and outer teeth correspondingly. The numerical control moment motor is provided with motor teeth. The multiple transition gears are all engaged with the motor teeth and the inner teeth of the first gear. The outer teeth of the first gear are engaged with second gears of the multiple double-enveloping speed reducers. The double-enveloping speed reducers drive the jack catch mechanisms to reciprocate to clamp or release the annular workpieces to be machined. The numerical control moment motor is used for sequentially driving the multiple transition gears and the double-enveloping speed reducers to rotate in a matched mode, so that the multiple jack catch mechanisms move inwards or outwards synchronously. The super-large annular workpieces are subjected to automatic centering clamping or releasing, and the clamping positioning accuracy is high.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD

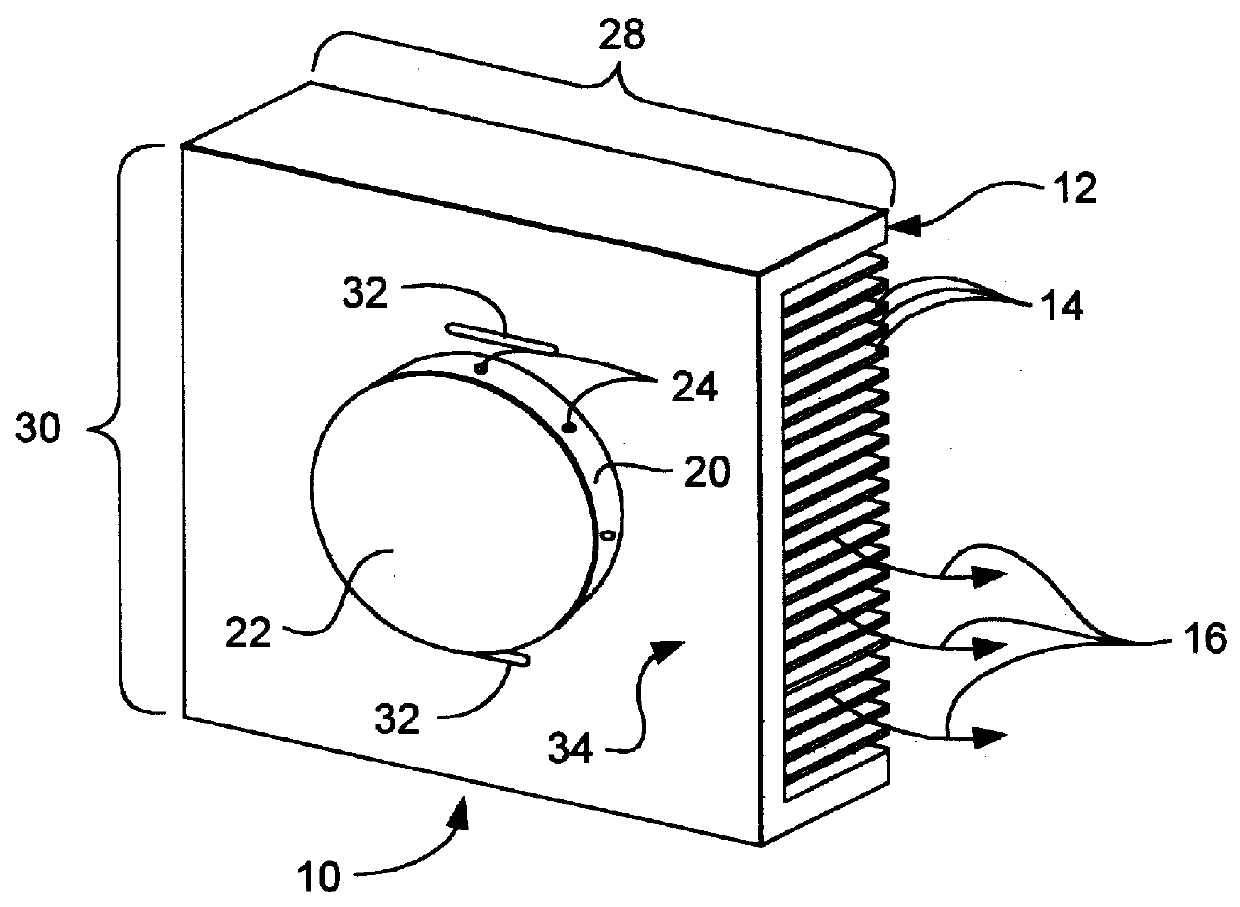

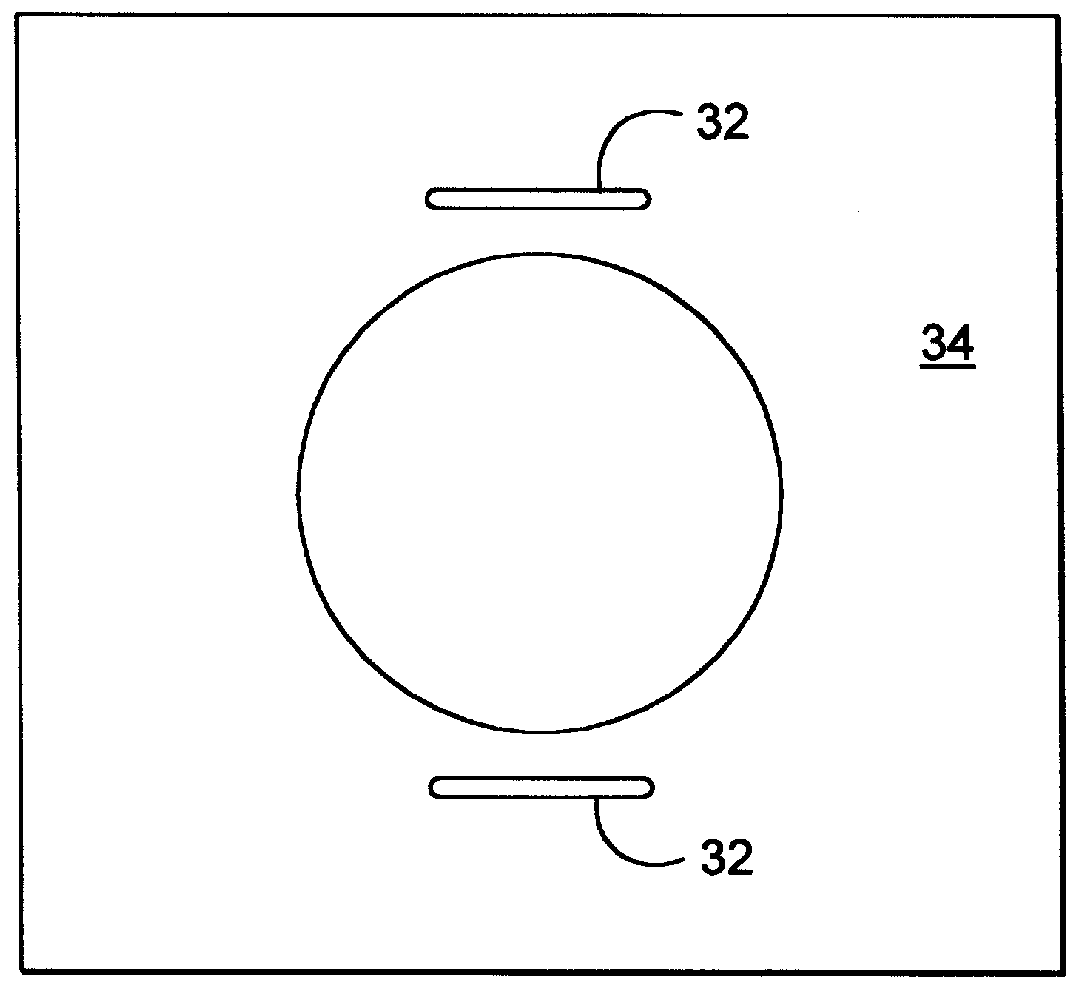

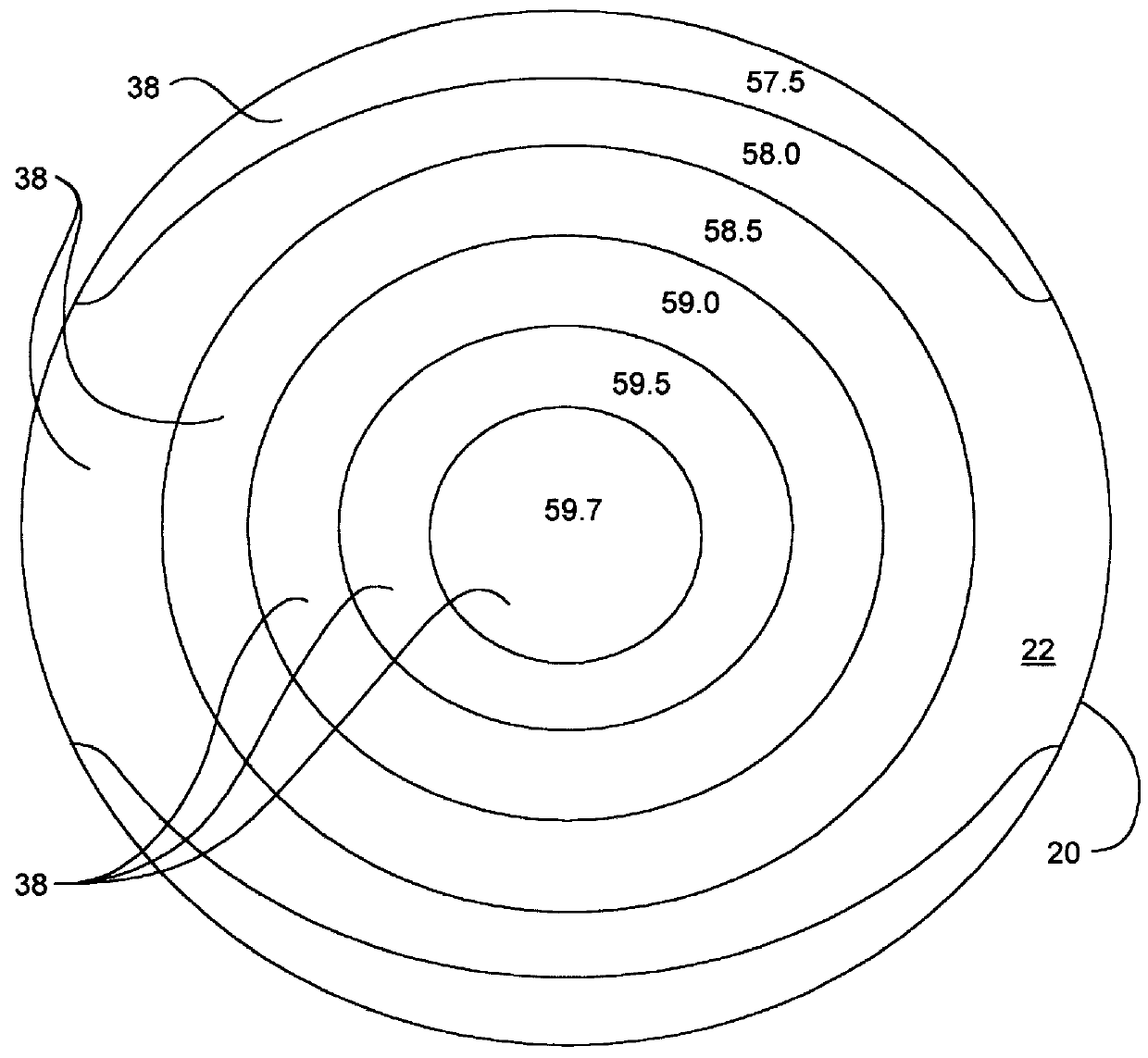

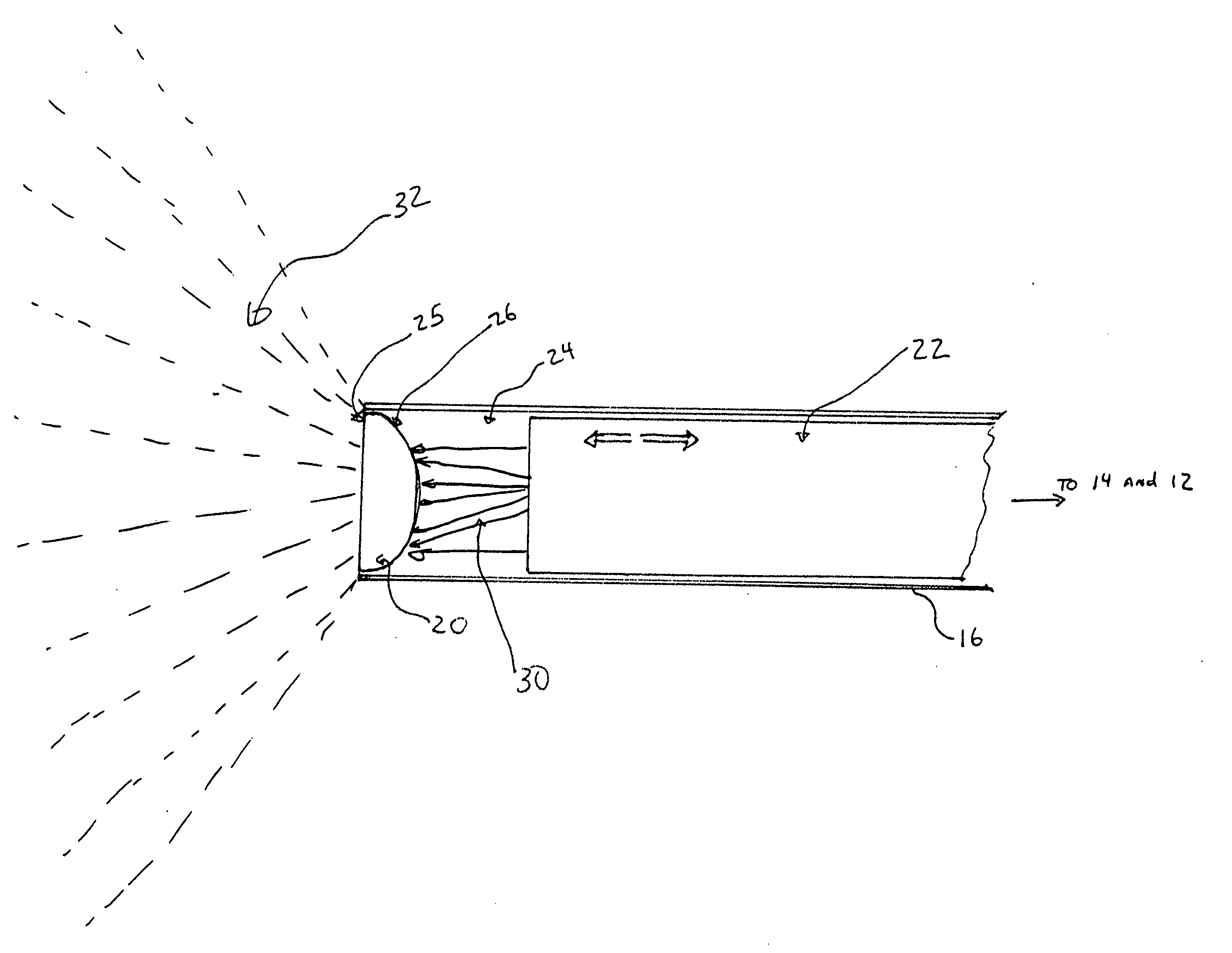

Wafer level burn-in and test thermal chuck and method

InactiveUS6140616ASmall sizeReduce conductivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingHeat flowEngineering

A thermal chuck or heat sink (10) has a lower surface (12) covered with fins (14) parallel to air flow (16), to increase the surface area and promote heat transfer. A pair of slots (32) near pedestal (20) (along the fins) effectively lowers the conductivity of the metal in the direction across the fins. Heat flowing through this region of lowered conductivity experiences a greater temperature drop. This raises the temperature at the adjacent parts of the top surface, and (for properly sized slots) results in circular isotherms. The circular isotherms are turned into a nearly isothermal surface by a precisely dimensioned groove (36) parallel to the top surface (22), extending around the circumference of the pedestal (20). Heat flowing into the outer regions of the circular surface (22) is forced to travel radially inward, thus raising the edge temperature (which would naturally be lower than the center). For properly sized slots (32) and groove (36), it is possible to achieve a nearly constant temperature top surface (22).

Owner:AEHR TEST SYSTS

Surgical wide-angle illuminator

A variable-intensity, wide-angle illuminator is disclosed, one embodiment comprising: a light source for providing a light beam; an optical cable, optically coupled to the light source for receiving and transmitting the light beam; a handpiece, operably coupled to the optical cable to receive the light beam; an optical fiber, operably coupled to the handpiece, wherein the optical fiber is optically coupled to the optical cable to receive and transmit the light beam; an optical element, optically coupled to a distal end of the optical fiber, for receiving the light beam and scattering the light beam to illuminate a surgical field, wherein the optical element comprises a hemispherically shaped sapphire; and a cannula, operably coupled to the handpiece, for housing and directing the optical fiber and the optical element. The optical element can be a small-gauge, diffusive sapphire element having a polished circular surface co-incident with the distal end of the cannula and a light refracting hemispherical surface facing the optical fiber. For example, the optical element can be a 19, 20 or 25 gauge optical element. Further, the cannula and the handpiece can be fabricated from biocompatible materials. The optical cable can comprise a first optical connector operably coupled to the light source and a second optical connector operably coupled to the handpiece (to optically couple the optical cable to the optical fiber housed within the handpiece and cannula).

Owner:ALCON INC

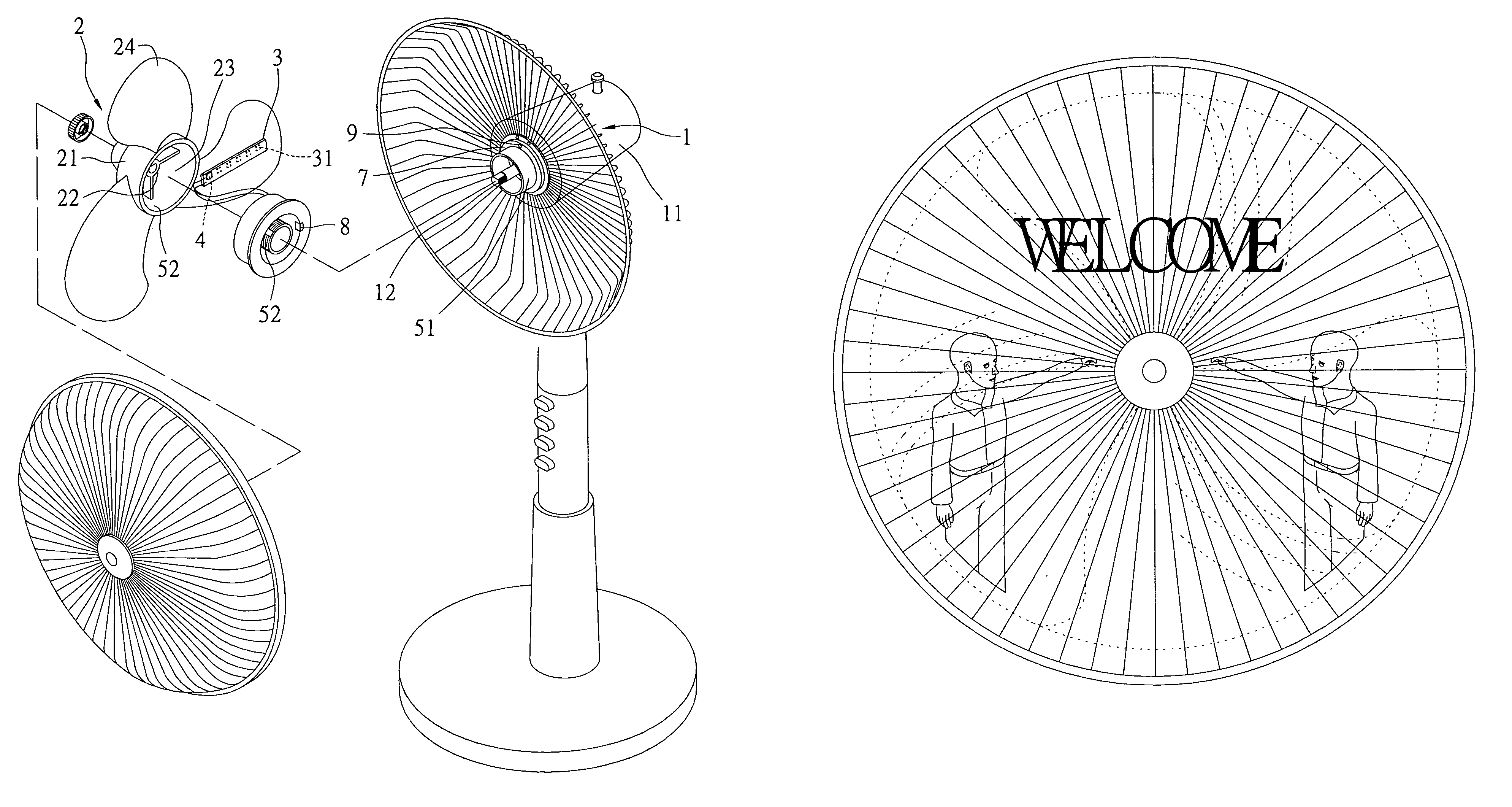

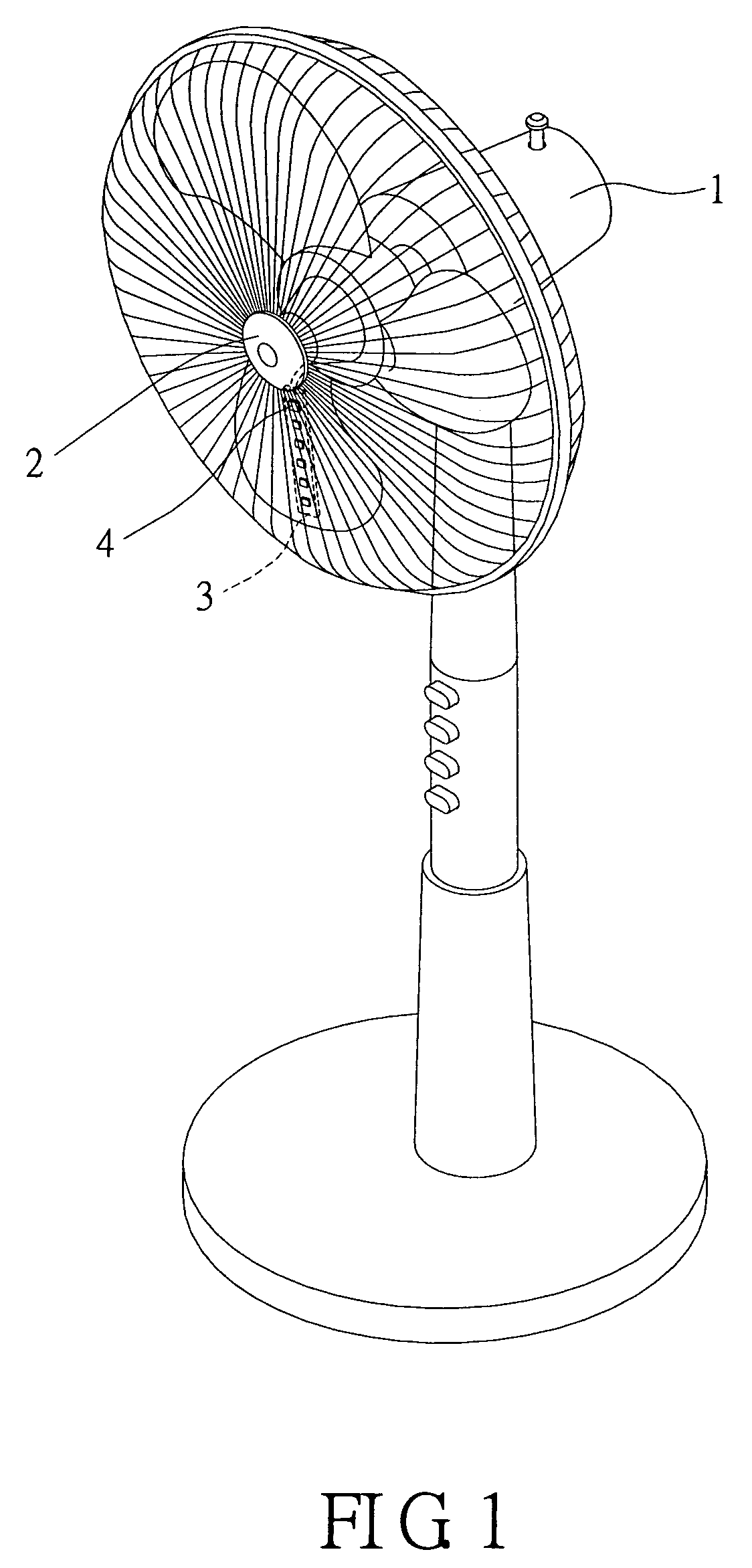

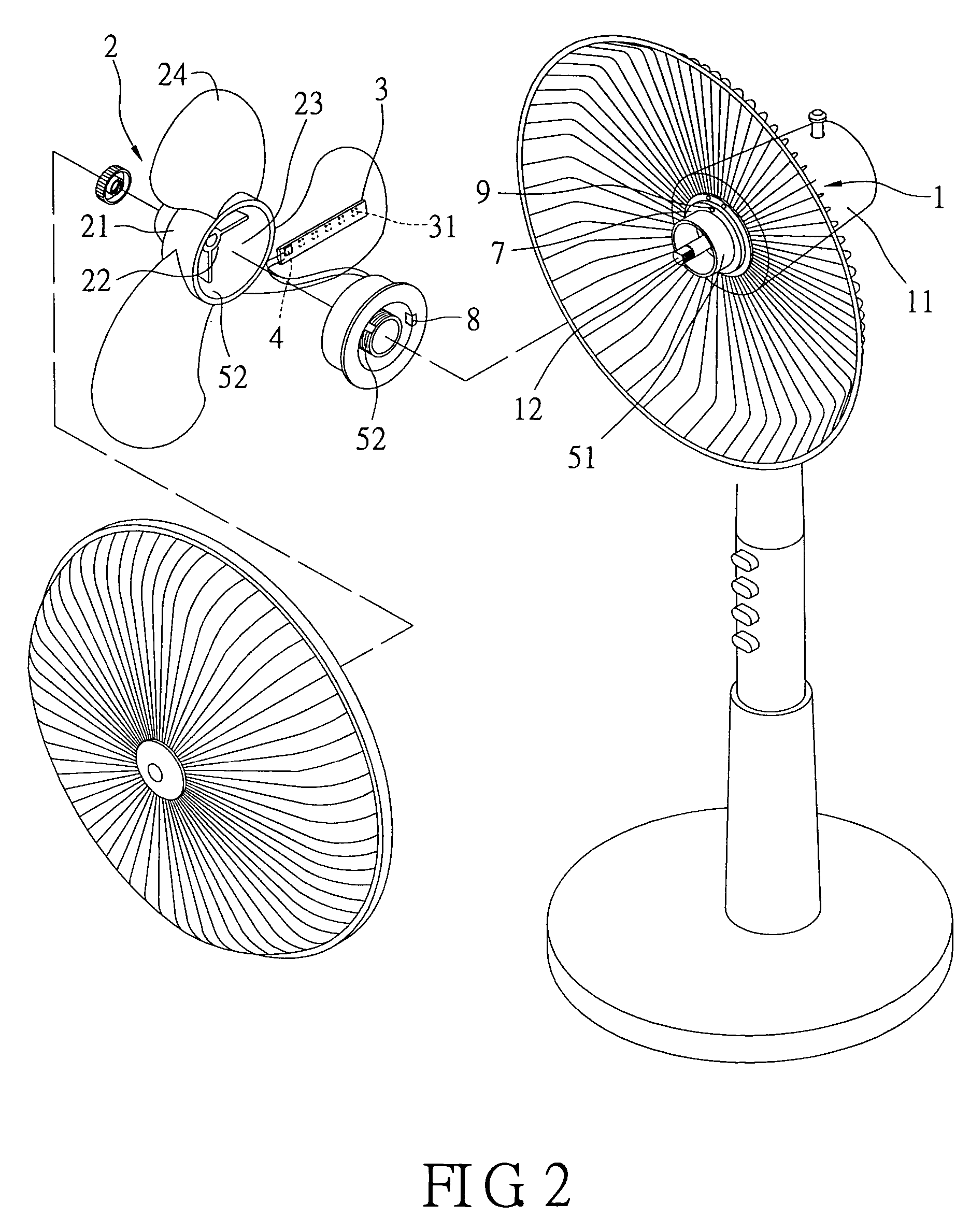

Automatic power generation light-image fan device

An automatic power-generation light-image fan device is described. It has a fan motor, a vane set, a circuit board, a programmable chip, an automatic power-generation component, a rectifier filter circuit, a magnetic sensor and a positioning magnet. In this device, the circuit board is mounted on the vanes of the vane set and also has plural light-emitting elements, which are respectively connected to I / O terminals of the programmable chip, and an accommodating room is mounted on an inner surface of the vane set, in which an inner circular surface of the accommodating room is circularly mounted by an inductance coil whose ends are connected to an input terminal of the rectifier filter circuit. Thereby, the light-emitting elements mounted on the fan can be controlled to generate various different twinkling light-image variations and an effect of persistence of vision when the fan motor is rotating.

Owner:FANG YI FENG

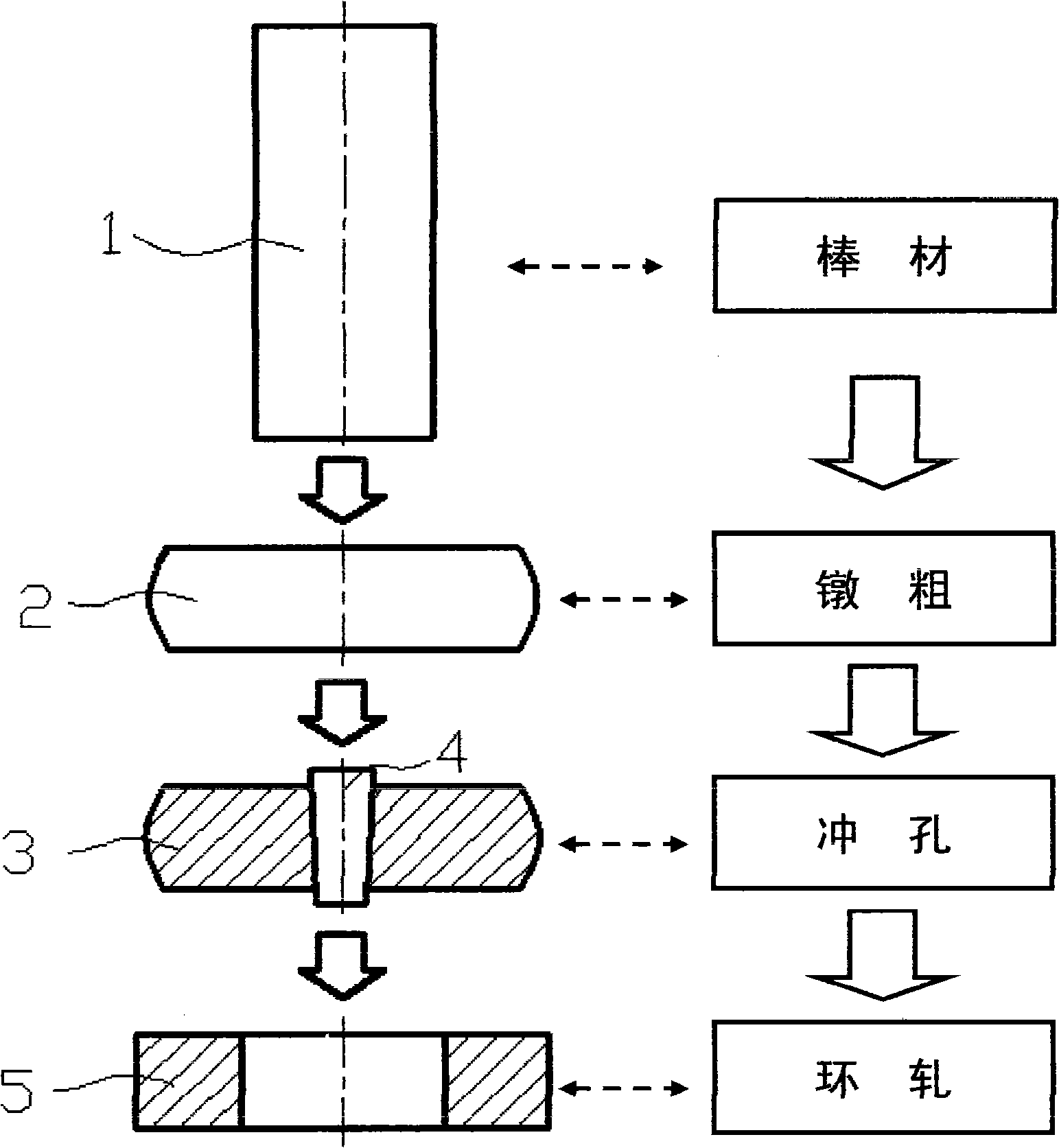

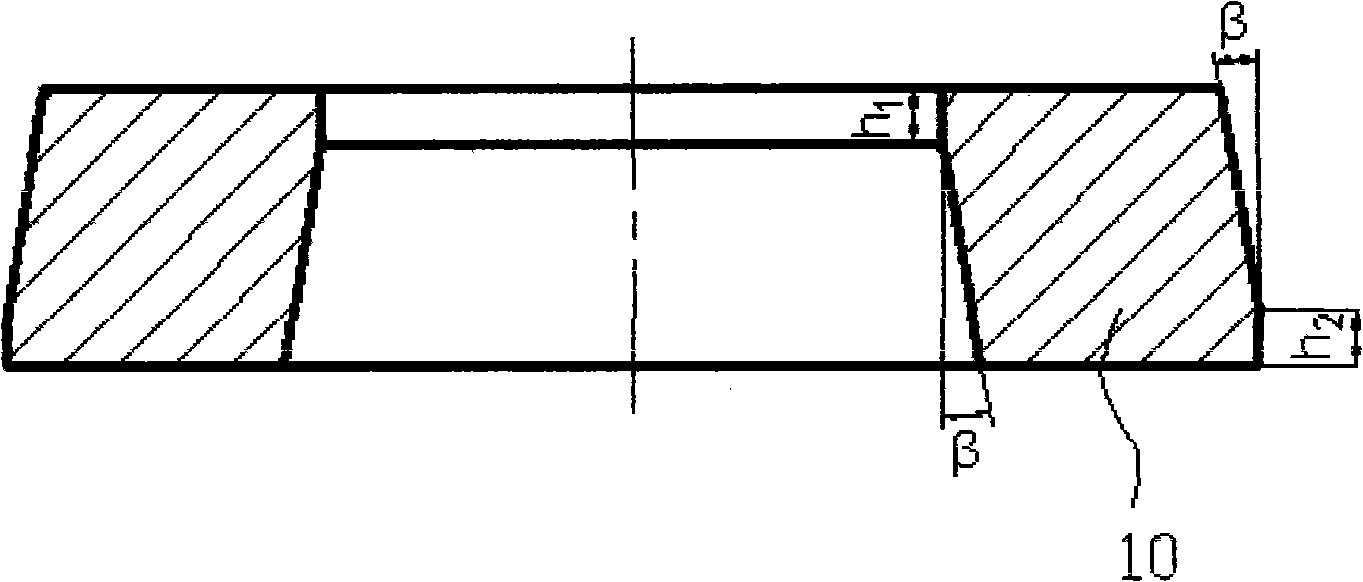

Method for rolling and shaping stainless steel conical ring

The invention discloses a rolling and shaping method for a stainless steel conical ring forging in order to obtain the alloy conical ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 75 to 80 percent so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 15 to 20 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 30 to 35 percent and the ring blank is processed into a pre-rolling blank with pitch; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a conical ring forging after being rolled and deformed by 60 to 70 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the conical ring forging of a ground gas turbine. The method can be adopted to obtain the concial ring forging that is arranged in a flow line along the outline of a part and the circular surface of the forging is a complex curve.

Owner:GUIZHOU AVIATION TECHN DEV

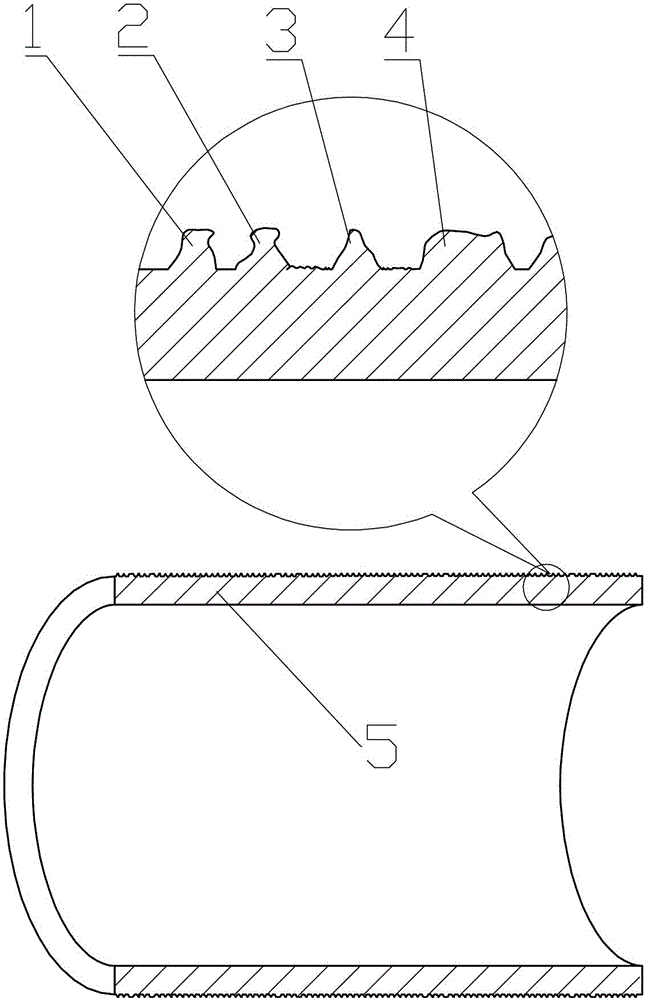

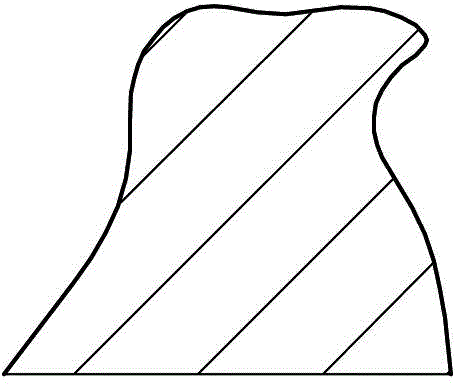

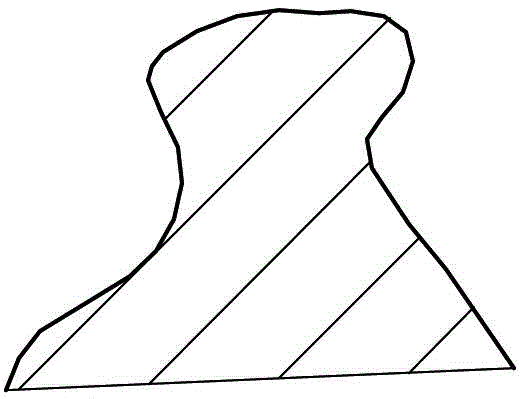

Light-weight engine cylinder sleeve of passenger vehicle and production method of light-weight engine cylinder sleeve

ActiveCN104595050AImprove wear resistanceImprove the anti-friction performance and prolong the service life of the cylinder linerCylinder headsFoundry mouldsCombustion chamberBlack spot

The invention belongs to a light-weight engine cylinder sleeve of a passenger vehicle and a production method of the light-weight engine cylinder sleeve. Black spots are distributed on the outer circular surface of the cylinder sleeve, wherein the shapes of the black spots comprise a dumbbell shape, a positive frustum shape, a worm shape and an olecranon shape; the black spots in the four shapes are randomly distributed on the outer circular surface of the cylinder sleeve; the black spots are 0.25-1.1mm in height. The black points of the cylinder sleeve are only 0.25-1.1mm; the blank cooling speed in the centrifugal casting process of the cylinder sleeve is obviously reduced, thereby obviously improving a metallographic structure, improving the friction resistance of the cylinder sleeve and prolonging the service life of the cylinder sleeve; meanwhile, the black spots are small in height fluctuation, so that the roundness fluctuation in the process of casting an aluminum cylinder body is remarkable reduced; the possibility that engine oil sneaks into a combustion chamber is reduced; the tail gas emission of the combustion chamber is reduced; by the low-height black spots and the excellent metallographic structure, the wall thickness of the cylinder sleeve is reduced by 1mm; the cylinder center distance of the engine cylinder sleeve is reduced by over 2mm.

Owner:ZYNP GRP +1

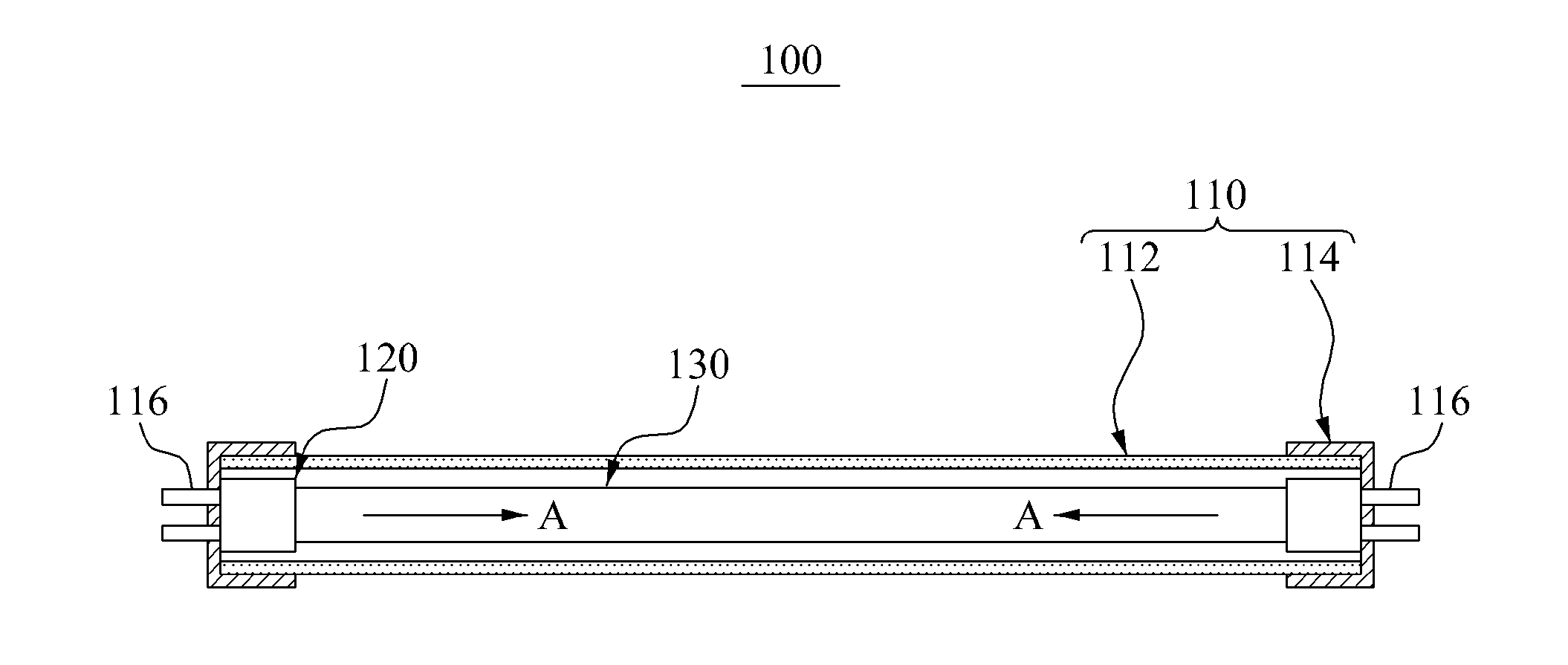

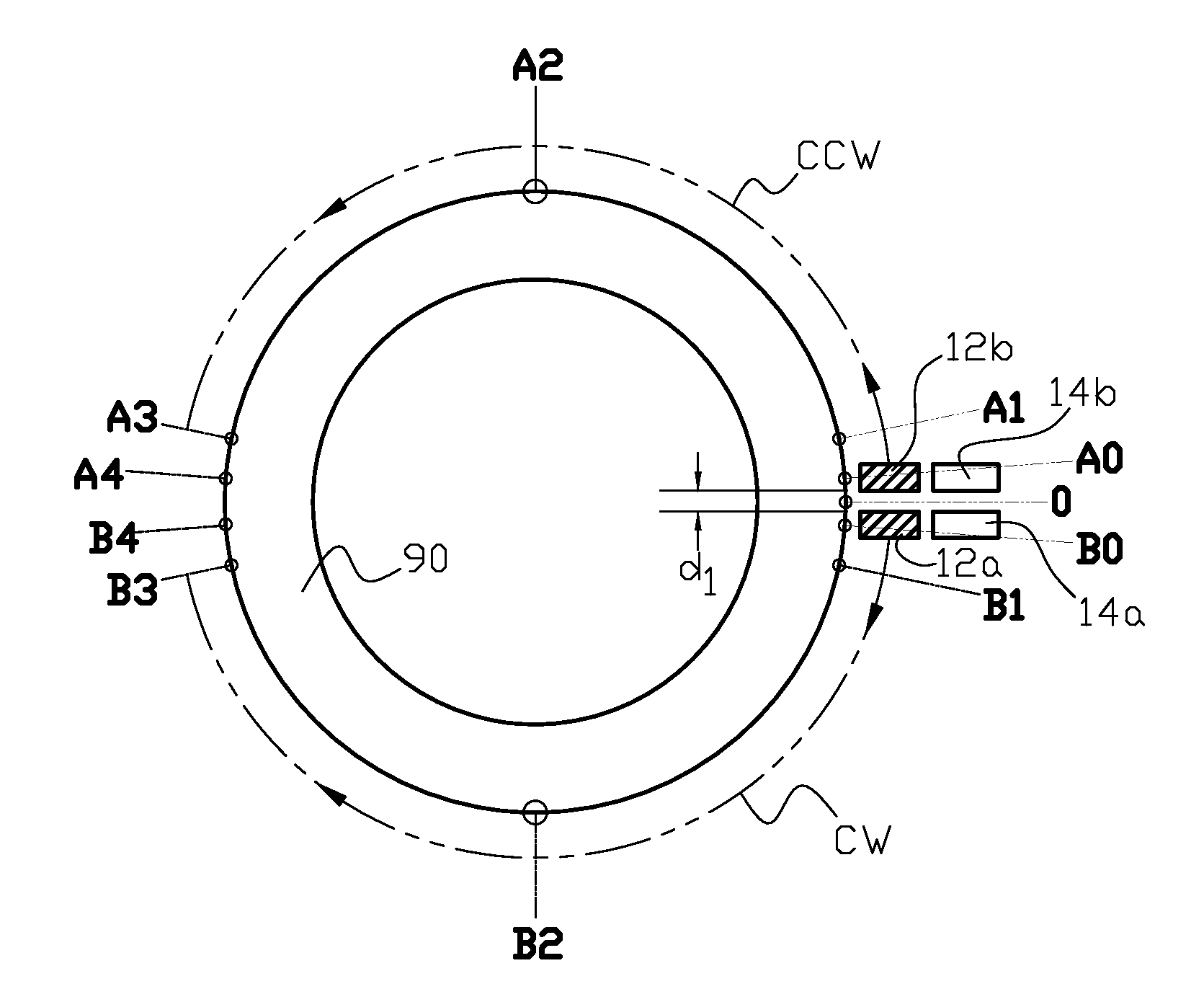

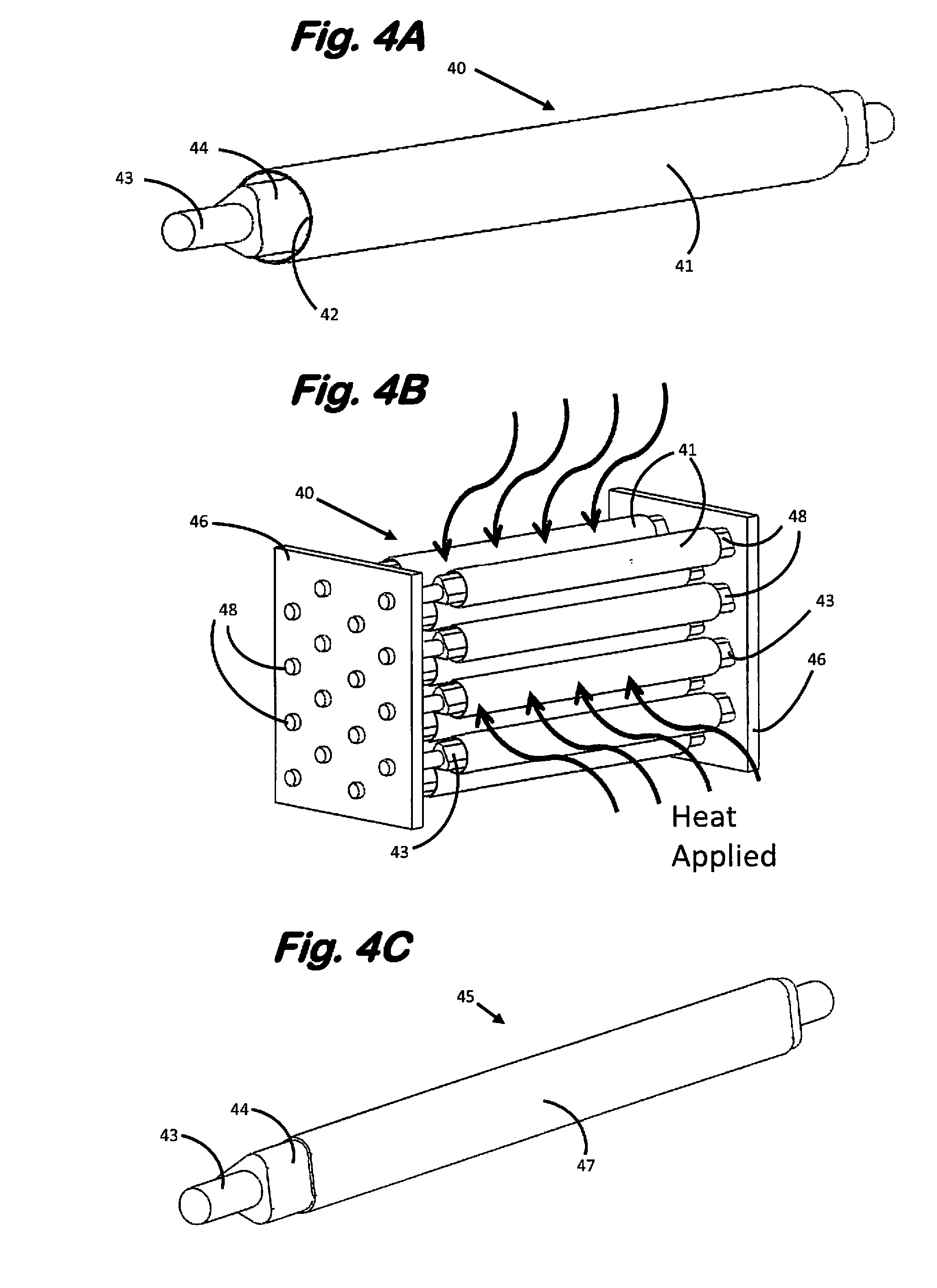

Induction heat treatment of an annular workpiece

ActiveUS20110248023A1Enhance metallurgical uniformityCoil arrangementsIncreasing energy efficiencyInductorCircular surface

Apparatus and method are provided for inductively heat treating a circular surface of annular workpieces where at least one inductor pair is used to perform a scan induction heat treatment of the circular surface. Controlled movement of the inductors and application of quenchant is provided particularly at the initial and final heat treatment locations on the circular surface to enhance metallurgical uniformity of the annular workpiece at these locations. In combination with controlled movement of the inductors, a simultaneous power-frequency control scheme can be applied to the inductors during the heat treatment process.

Owner:INDUCTOHEAT INC

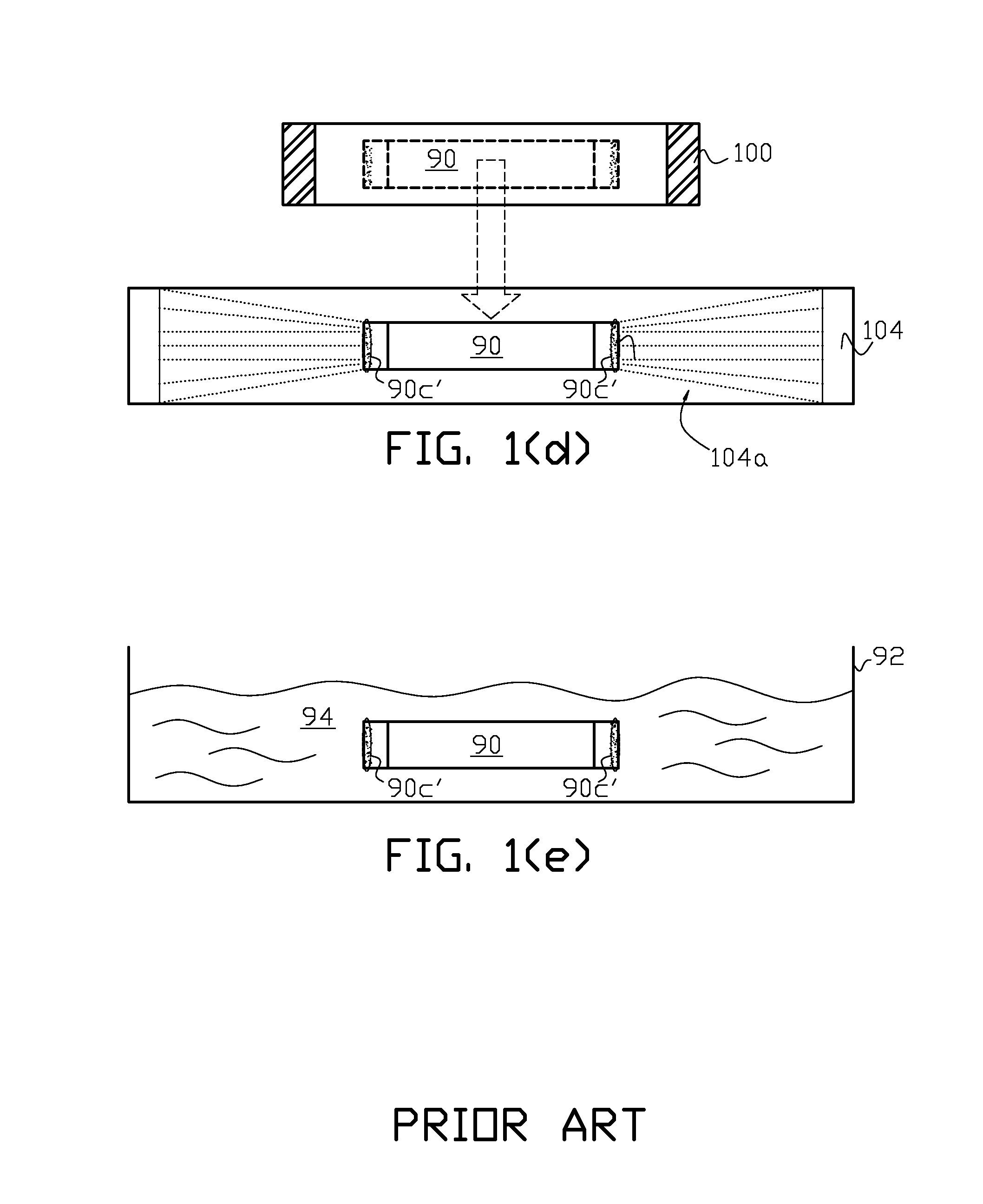

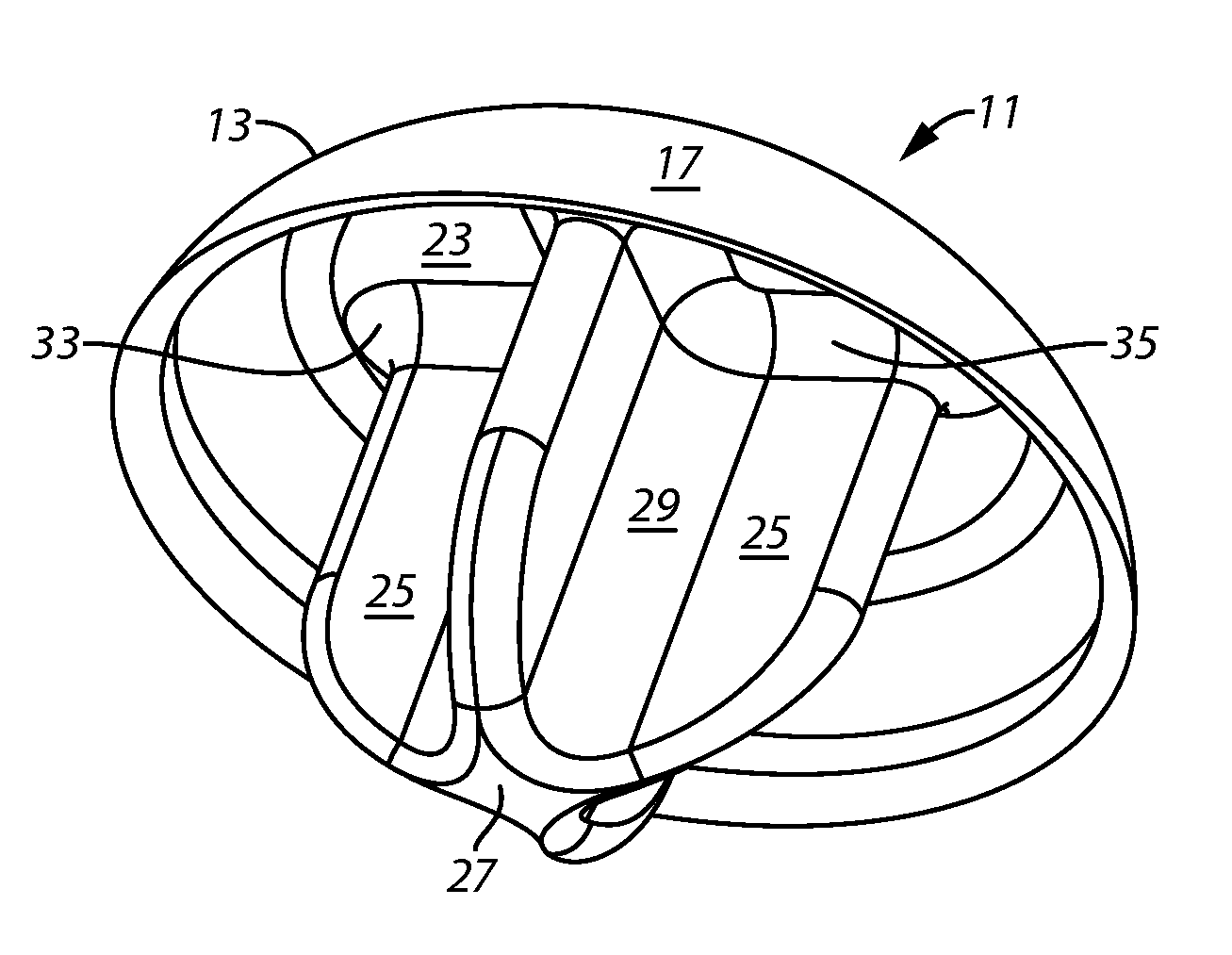

Humeral head resurfacing implant

A humeral head resurfacing implant (11) that has a modulus of elasticity close to that of human cortical bone as a result of its design from an integral substrate of isotropic graphite covered completely with a reinforcing layer of dense isotropic pyrolytic carbon. A carefully engineered cruciform stem (15) extends from the axial center of a flat distal circular surface (23) of a spherical cap portion (19) of the implant head located within the confines of a surrounding skirt portion (21).

Owner:ASCENSION ORTHOPEDICS

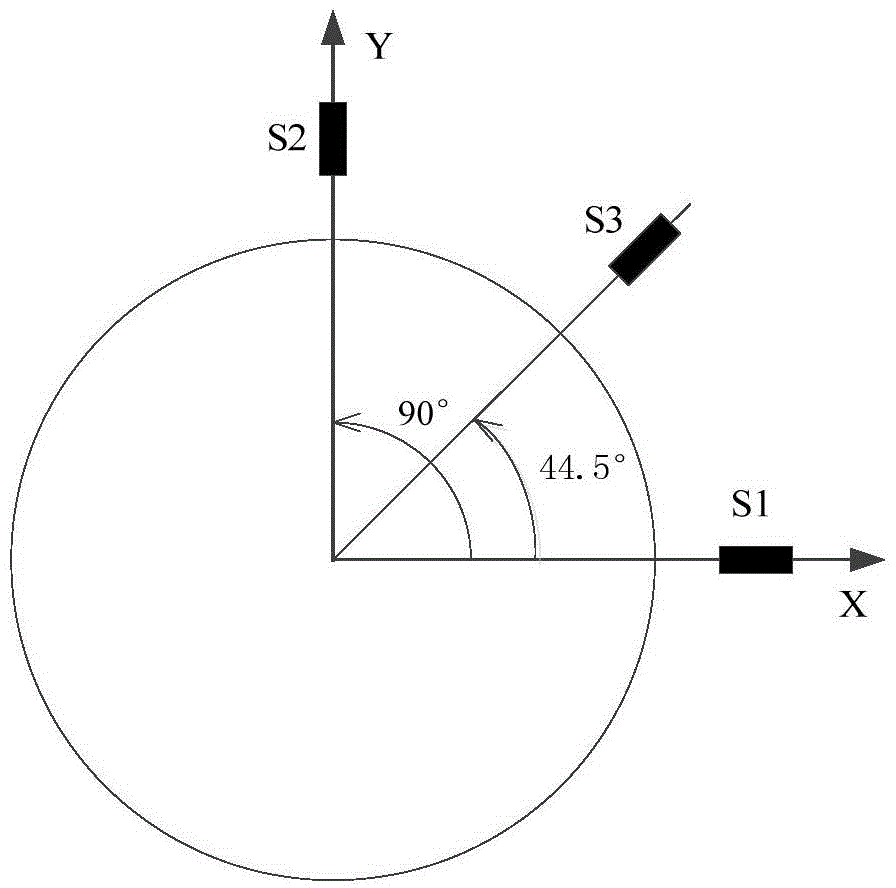

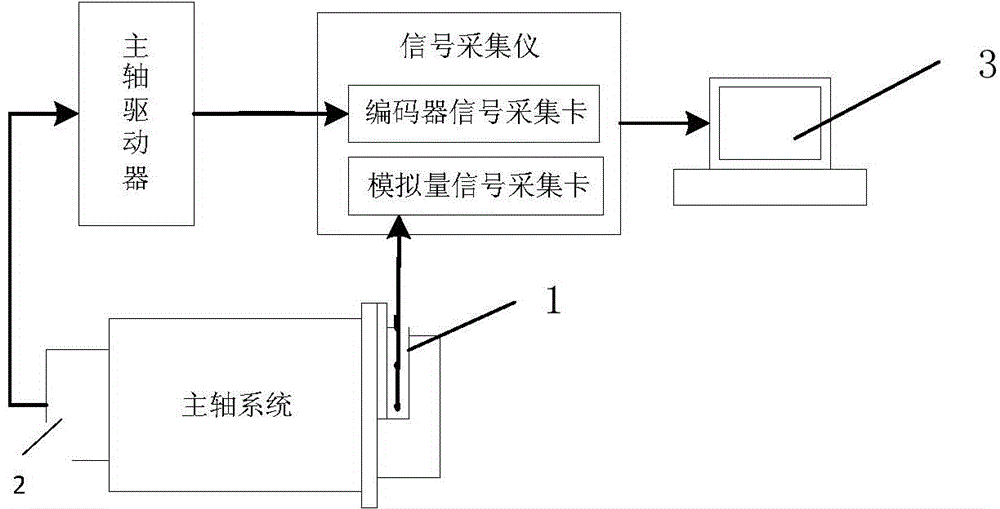

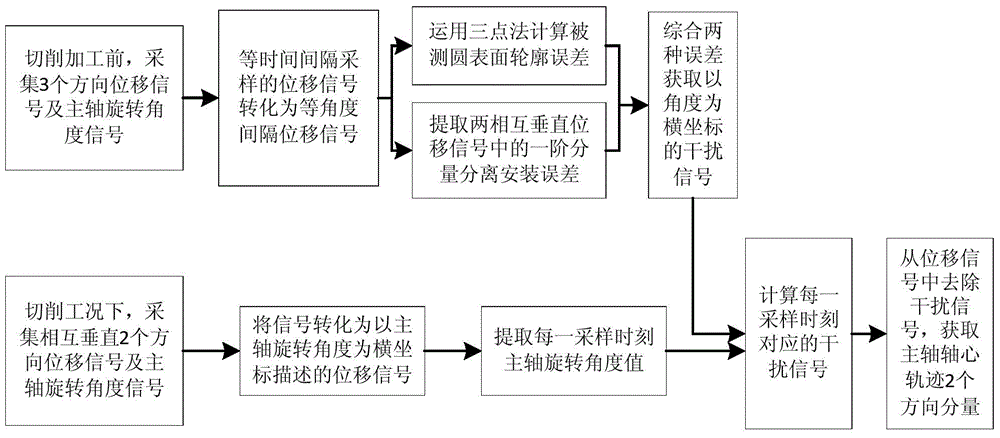

On-line measurement method for axis orbit of main shaft under cutting condition of numerical control lathe

ActiveCN104400560AMeet the requirements of rapid separationEliminate measurement effectsMeasurement/indication equipmentsEngineeringVertical displacement

The invention relates to an on-line measurement method for an axis orbit of a main shaft under cutting condition of a numerical control lathe. The on-line measurement method comprises the following steps of arranging three displacement sensors on a to-be-measured circular surface along the circumferential direction of the main shaft, collecting displacement signals and main shaft rotary angle signals before cutting, converting into rotary angle interval sampling signals, adopting a three-point method to separate the contour error of the to-be-measured circular surface, extracting the displacement signals of the two vertical displacement sensors, and calculating the installation eccentric error; according to the contour error and the installation eccentric error, obtaining an interference signal guided by the to-be-measured circular surface; under the cutting condition, adopting an interpolation method to calculate the interference signal corresponding to the main shaft rotary angle signal, removing the interference signal from the displacement signal under the cutting condition, and obtaining the axis orbit of the main shaft. The method has the advantages that the influence on the separation calculation by the speed fluctuation of the main shaft is avoided, the requirements of separation accuracy and rotary error quick separation are met, and the on-line quick separation of the rotary error is realized.

Owner:XI AN JIAOTONG UNIV

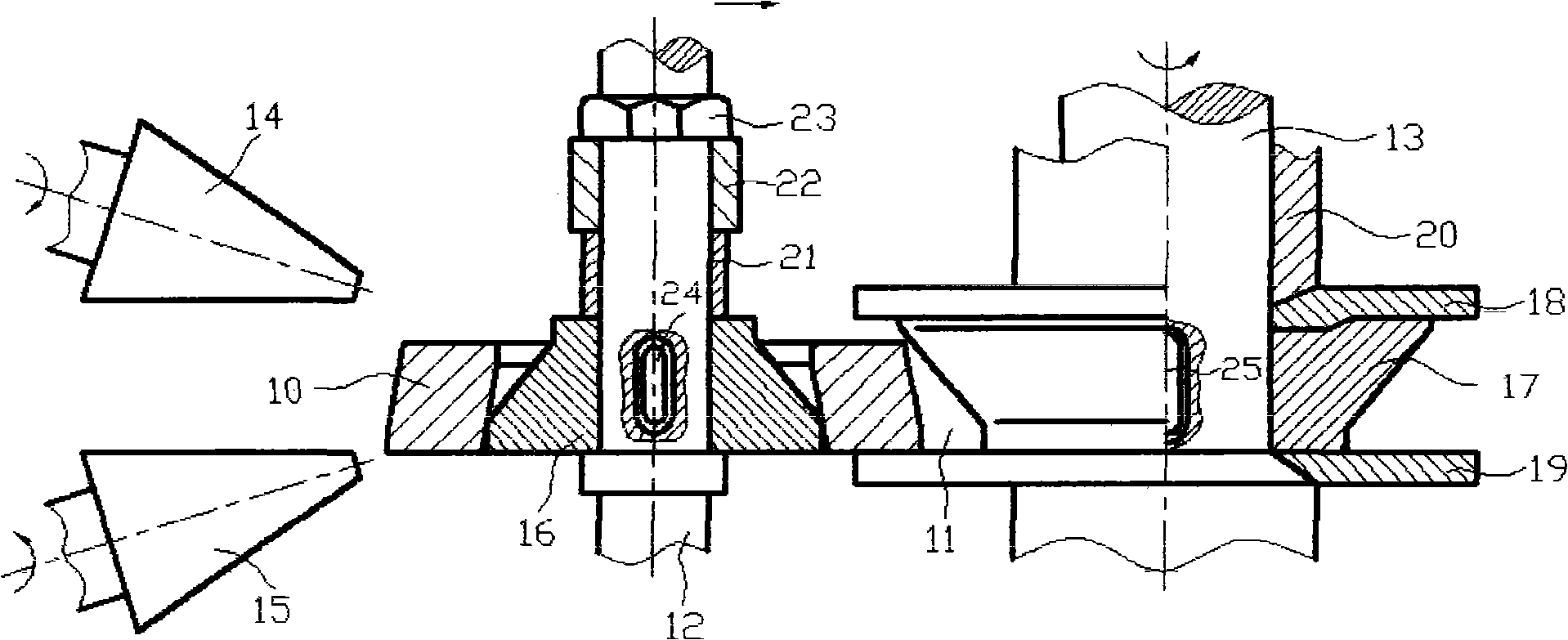

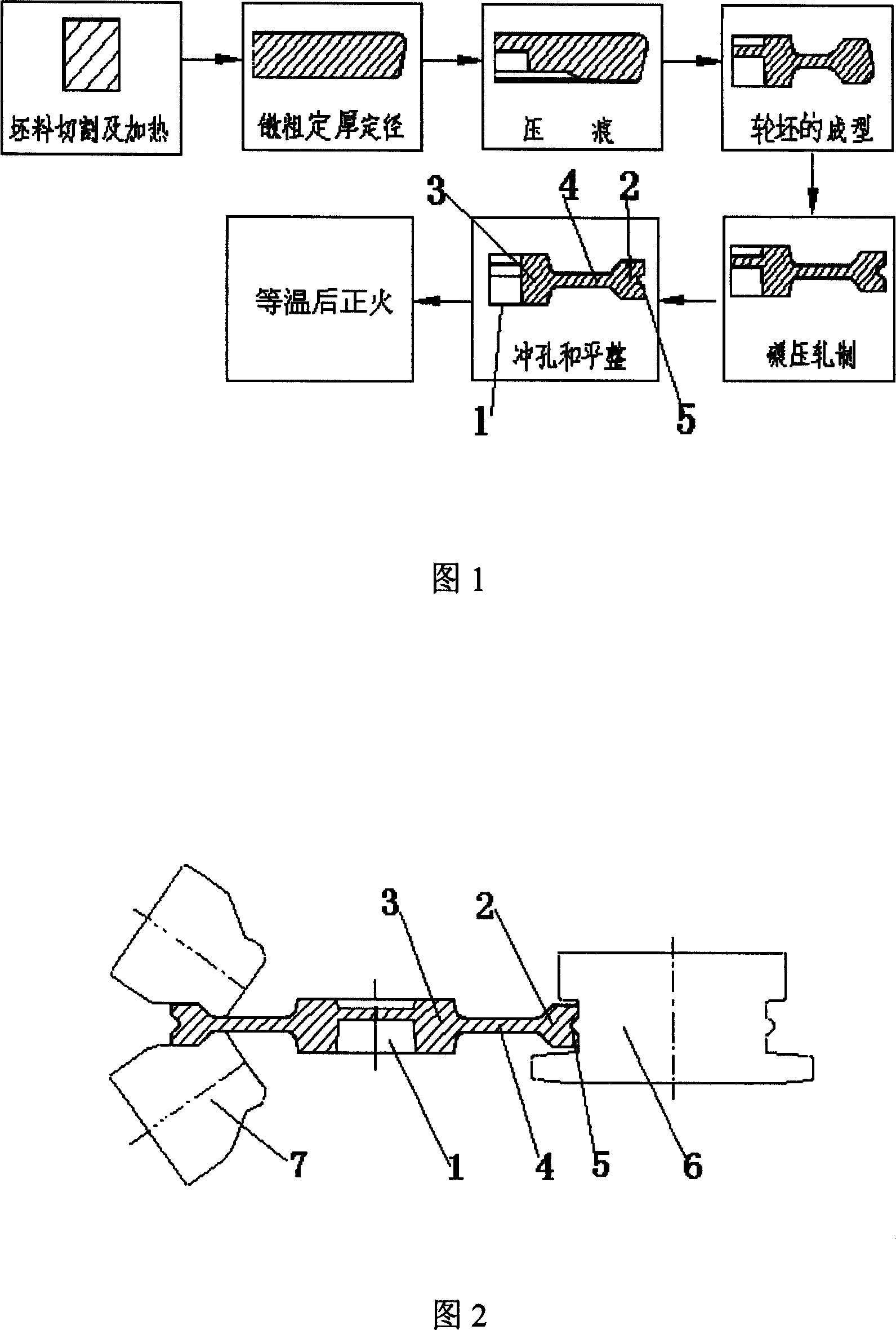

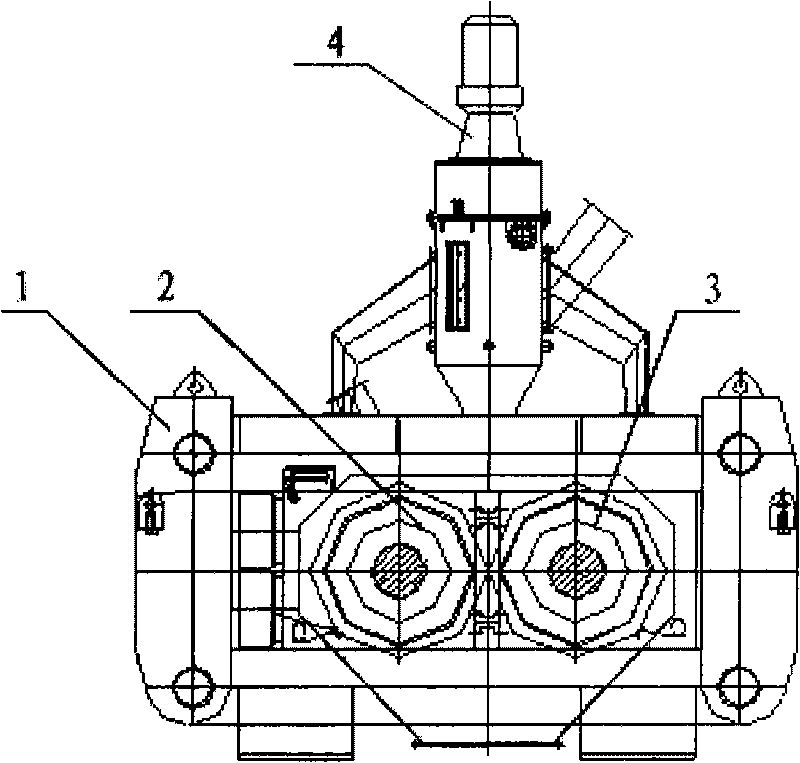

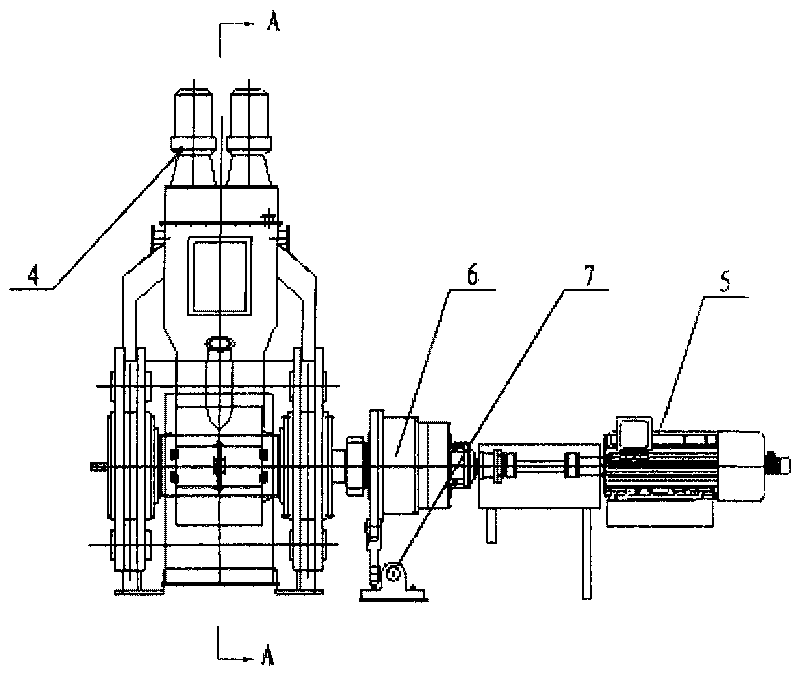

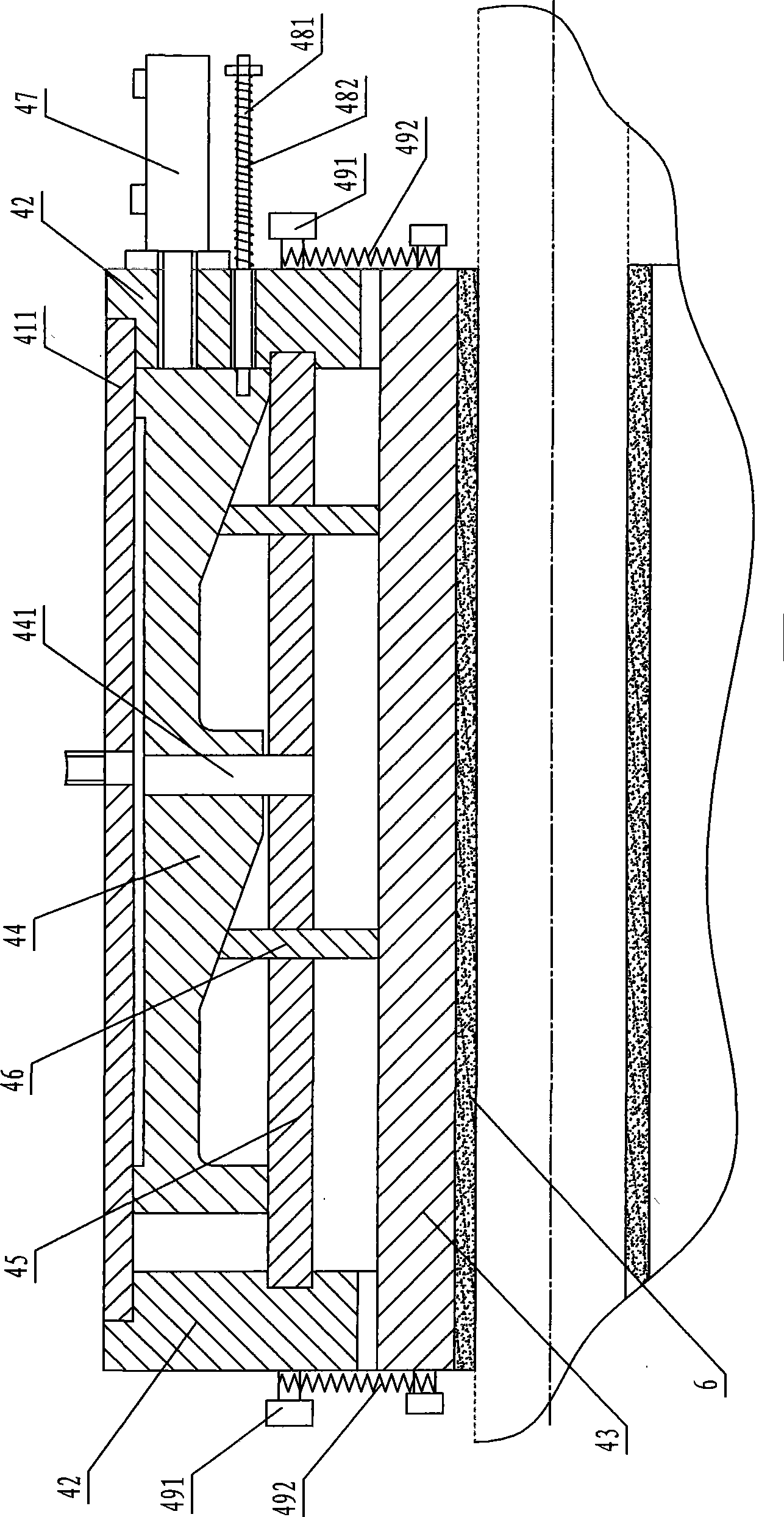

Forging and rolling technology and hot rolling and forging apparatus for making large pulley

ActiveCN101020287AHigh mechanical strengthImprove wear resistancePortable liftingFurnace typesHigh wear resistanceUltimate tensile strength

The present invention discloses forging and rolling technology for large pulley. The forging and rolling process includes hot forging and upsetting steel blank to the required thickness and diameter, die forging to form the hub and spokes, and hot rolling to form the inner circular surface, end surfaces, outer circular surface and slot in circumference of the rim. The present invention also provides the corresponding hot rolling apparatus. The present invention can obtain pulley with high strength, high wear resistance, small internal stress, less deformation and other advantages.

Owner:MAANSHAN IRON & STEEL CO LTD

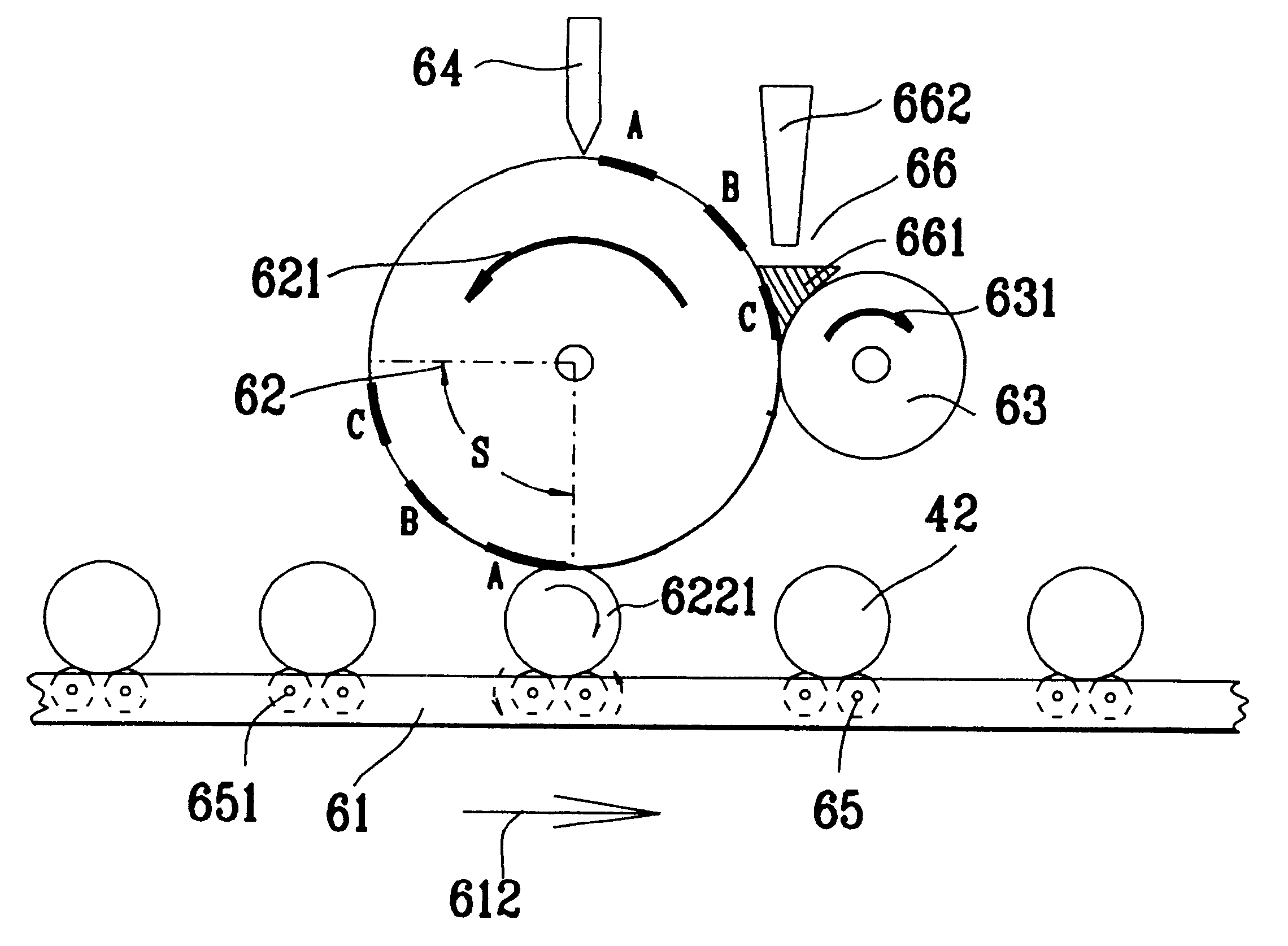

Pulverized coal molding method without binding agent and double-roller molding machine suitable for method

InactiveCN101722669AMeet shipping requirementsMeet industrial application requirementsShaping pressWater contentCircular surface

The invention provides a pulverized coal molding method without binding agent, which comprises the following steps of: 1. screening pulverized coal with the granularity of not more than 6mm by a screening device, carrying out drying dehydration processing on the pulverized coal and controlling the water content to be 2-15 percent; 2. forcibly compressing and feeding the pulverized coal obtained in the step 1 into a seam between double rollers of a double-roller molding machine by a feeding machine; and 3. running the double-roller molding machine, continuously rotating the double rollers of which at least one roller circular surface is distributed with pits and compacting and molding molded coal by the pits. The invention also provides the double-roller molding machine which is suitable for the method. The invention solves the problem of pulverized coal molding without binding agent of weak caking coal and non-caking coal, such as low-order bituminous coal, middle and old aged lignite, and the like.

Owner:CHNA ENERGY INVESTMENT CORP LTD +4

Portable Solar Light That Can Be Secured To Functional Accessories That Can Be Illuminated

The invention relates to a solar light, which is a base component suitable for multiple uses with functional accessories that can be illuminated, formed by: an upper casing (4) having a flat external surface with a peripheral rim that admits a central circular surface that corresponds to the solar panel disc where the photovoltaic cells (1) are attached, said peripheral rim or rubber band (2) projecting towards the lower end of the upper casing (4) in a convex curved lower peripheral protrusion (3) intended to receive the button of the activation / deactivation switch (5) of the light; an intermediate part or panel (8) that houses the battery holder or the batteries (9) together with the snap contacts (6, 7) of the batteries, a printed circuit board and the light-generating means (10) and an O-ring seal (11); and a lower translucent casing (12) formed by an inverted truncated cone-shaped body having a central cylindrical perforation (16) on the flat lower face thereof, said perforation having a threaded interior (15) and having the convex flat lens (17) secured to the base edge thereof, and on the inverted truncated cone-shaped layer of which lower translucent casing (12) a horizontal peripheral rib is provided at mid-height forming the peripheral thread (13) that is interrupted by three vertical slots or recesses (14) having a semi-circular cross-section, and being disposed at equal distance to one another, and wherein the lower translucent casing (12) includes the lateral and central means for securing the light to the functional accessories that can be illuminated.

Owner:SULILAB SPA

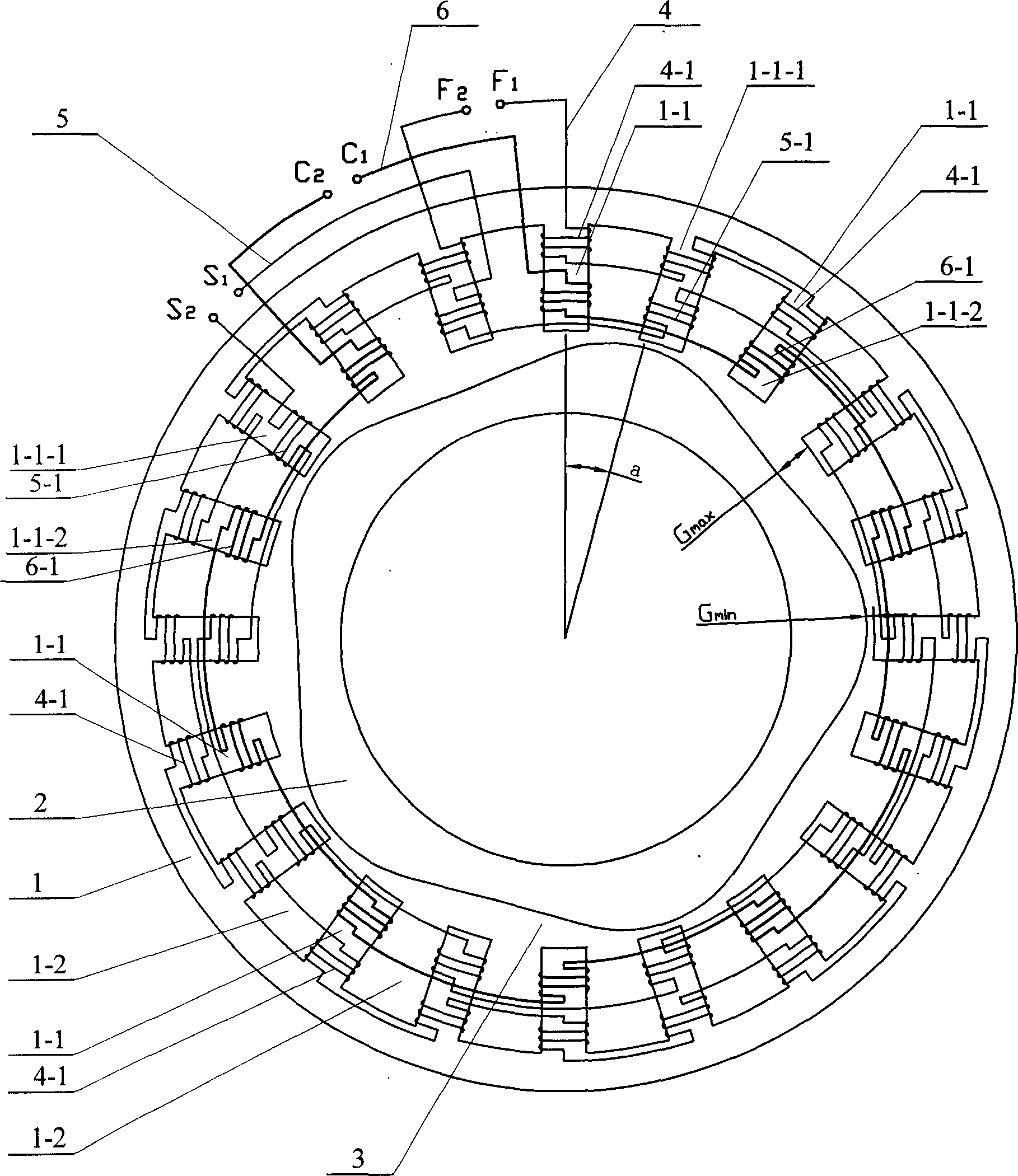

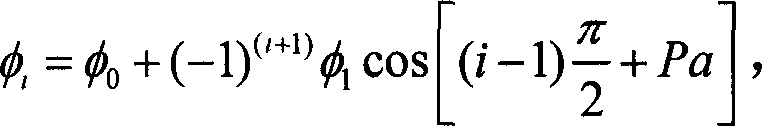

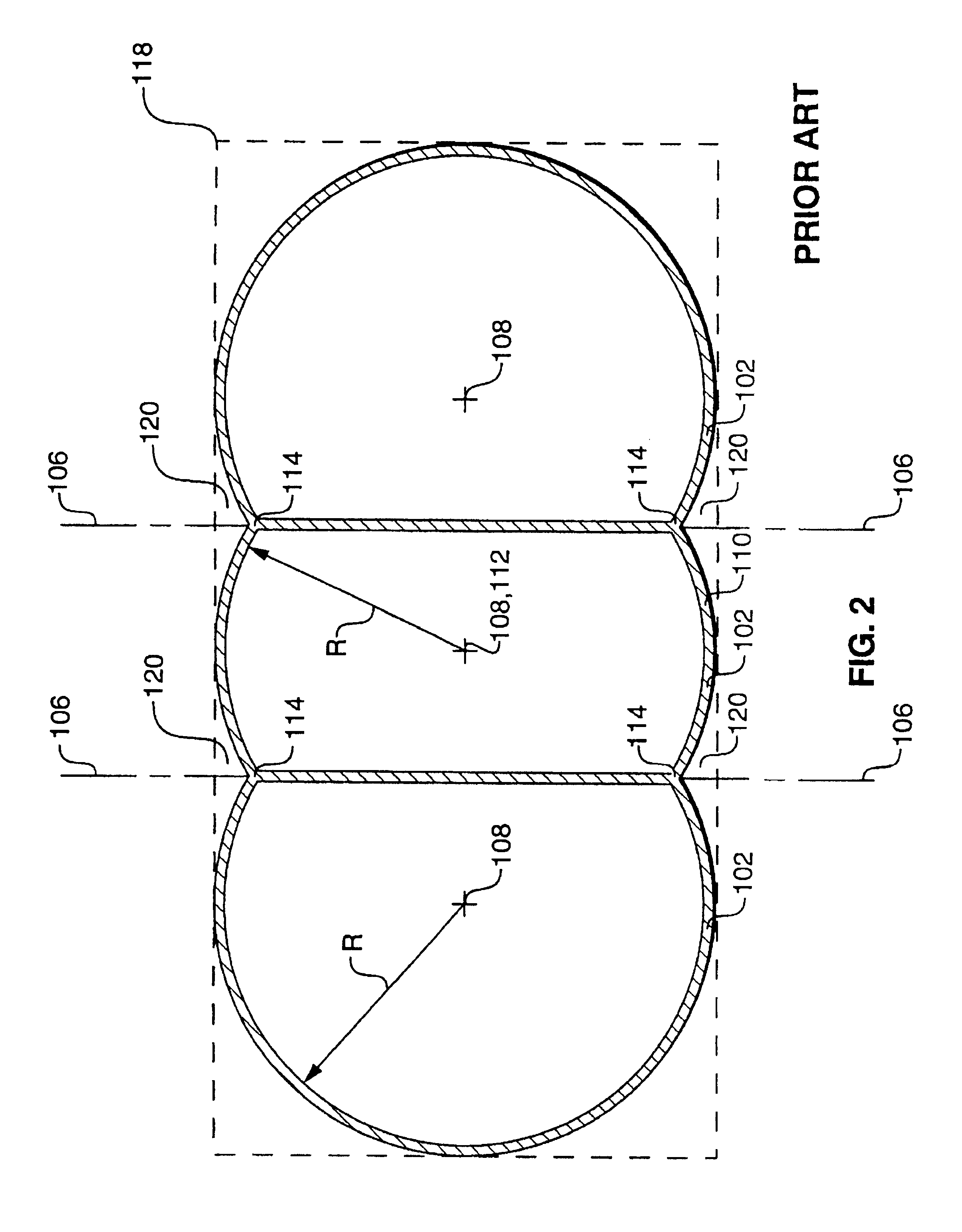

Magnetoresistance brushless multi-polar rotation transformer

The invention relates to a reluctance brushless multipolar rotational transformer. And the external circular surface of a rotor is uniformly provided with P wave crests and P wave throughs, where these wave crests and wave throughs are smoothly interlinked to compose the wavy external circular surface of the rotor, and excitation, sine and cosine windings are positive phase-to-negative phase connected in series. As a constant voltage alternating current passes through the excitation winding, the sine and cosine windings output voltages whose electromotive force amplitudes make p sine and cosine variations with the rotation angle of the rotor. And the invention has characters of simple structure, convenient to make, and especially applied to the rotor position sensor of a brushless DC motor.

Owner:HARBIN INST OF TECH

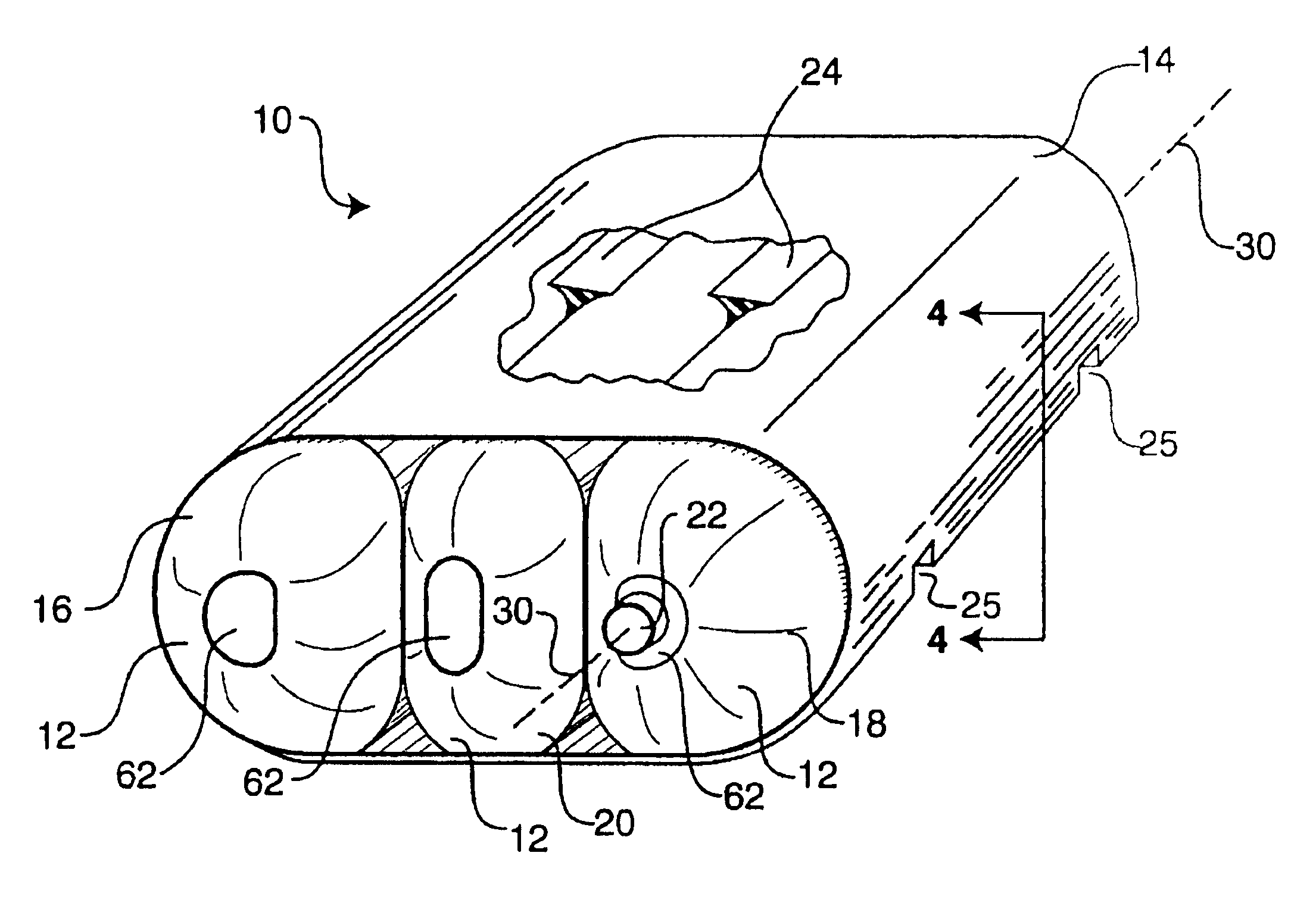

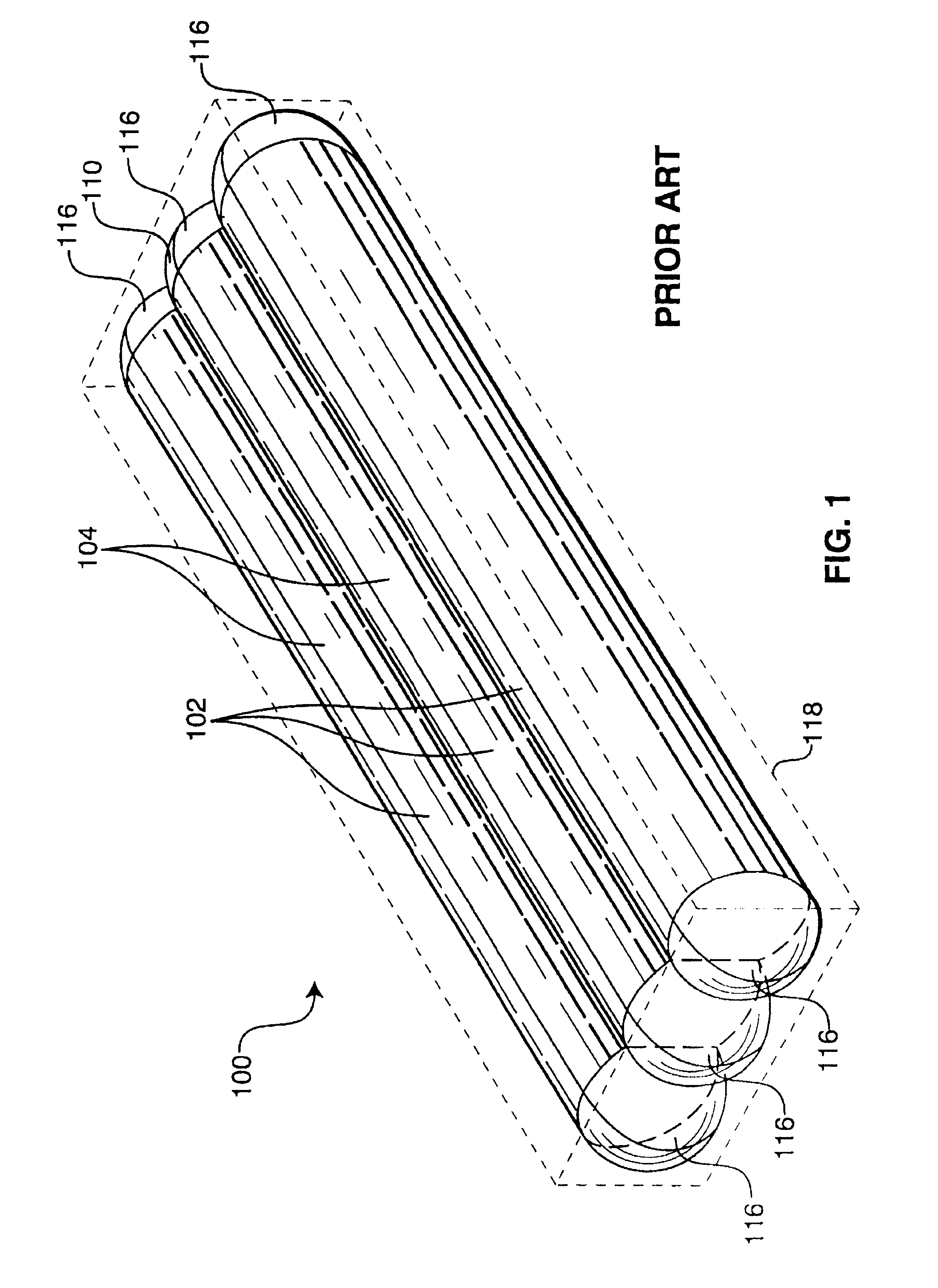

Composite conformable pressure vessel

InactiveUSRE41142E1Trend downIncrease pressureGas handling applicationsLarge containersLine tubingCompressed natural gas

A pressure vessel for holding a pressurized fluid such as compressed natural gas (“CNG”) includes two end cells and zero or more interior cells. The cell geometry ensures that the cells meet one another at tangential circular surfaces, thereby reducing the tendency of adjacent cells to peel apart. A web secured about the cells includes two sheets that are tangent to the cells. Unused volumes between the cells and the web contain wedges of foam or rubber. A valve provides fluid communication between the interior of the pressure vessel and a pressurized fluid line. The filled weight of one pressure vessel does not exceed the filled weight of a conventional gasoline tank that occupies substantially the same space as the pressure vessel. The pressure vessel may be configured with exterior recesses for engaging conventional gasoline tank straps.

Owner:NORTHROP GRUMMAN SYST CORP

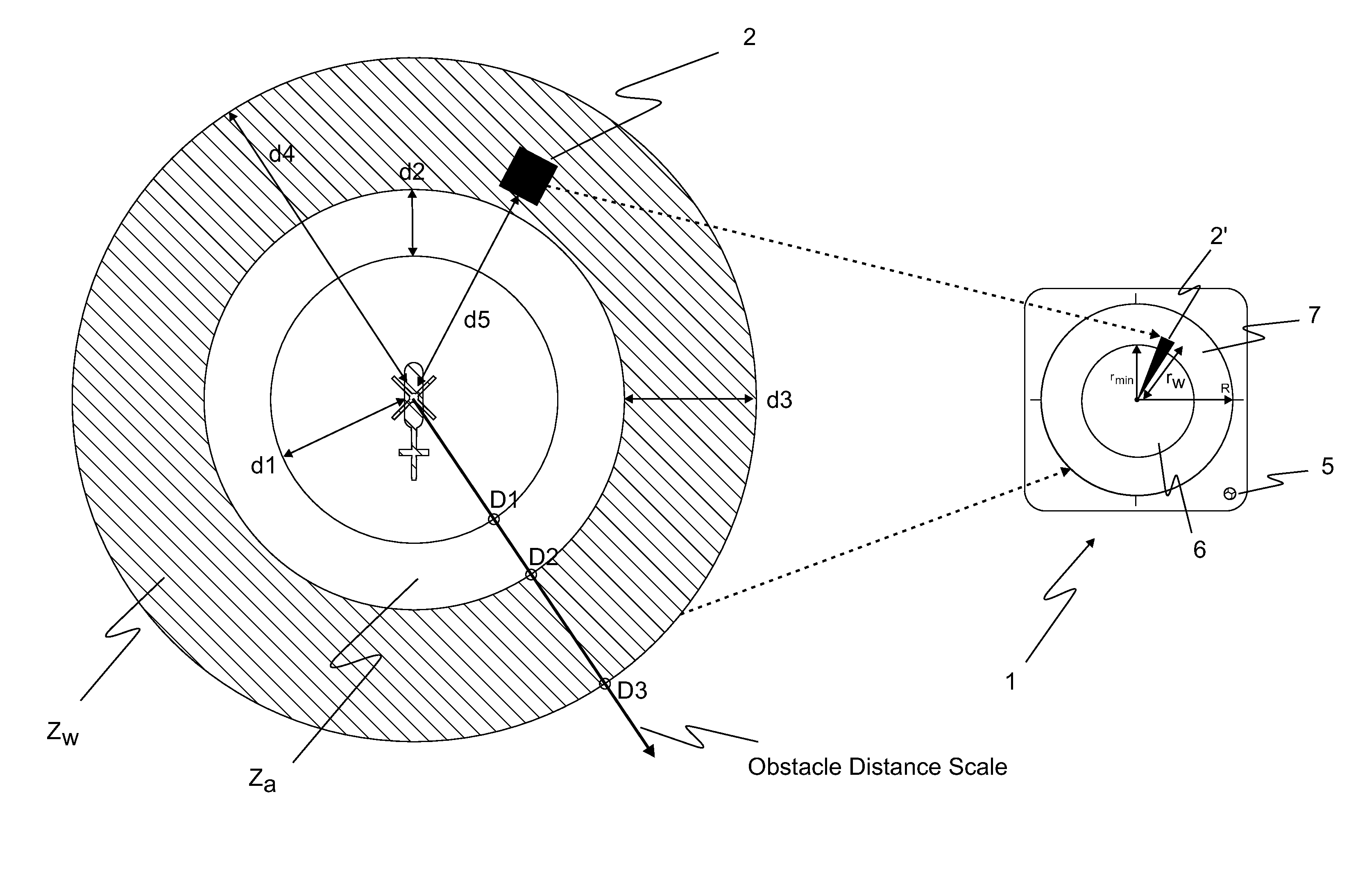

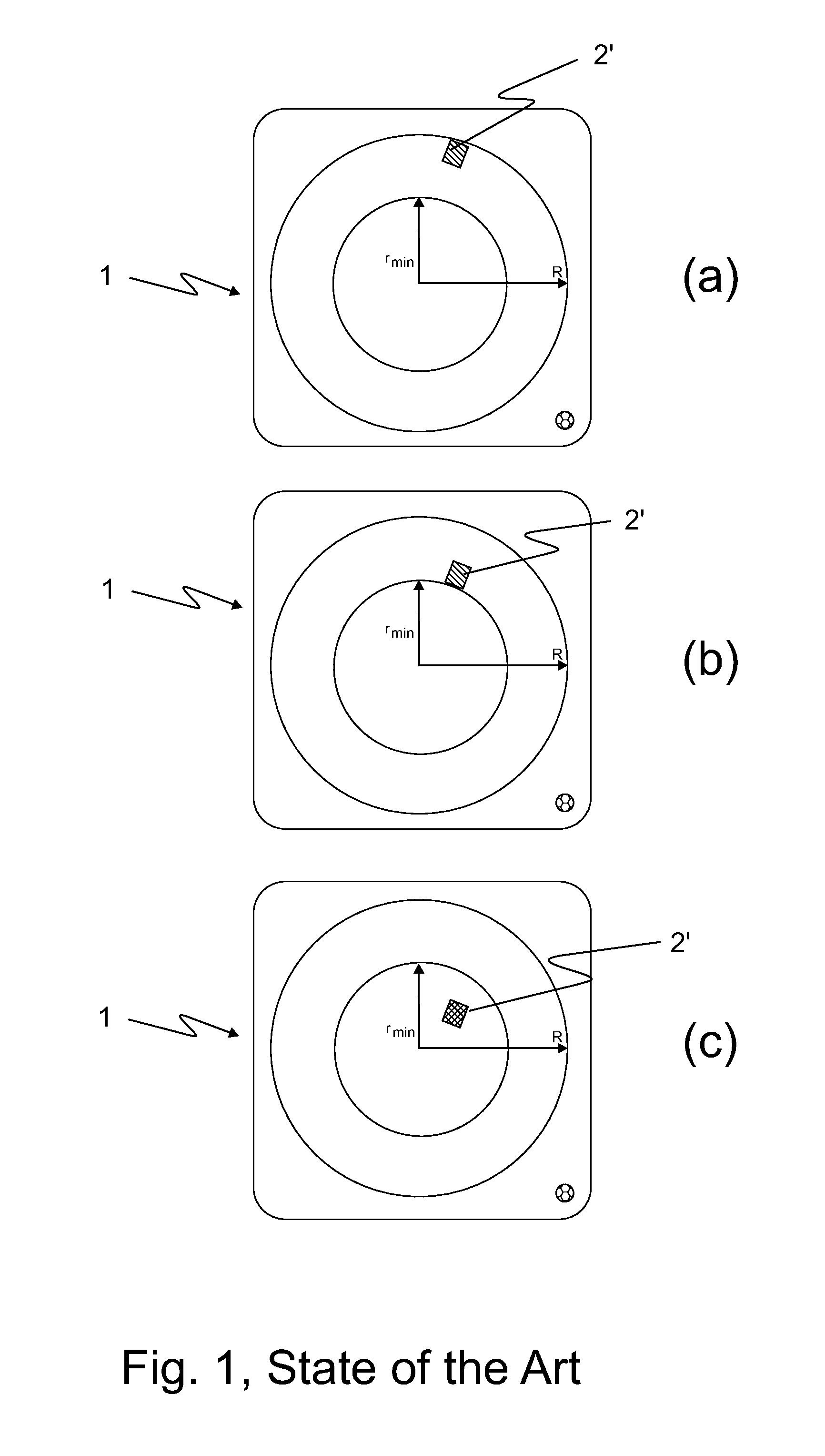

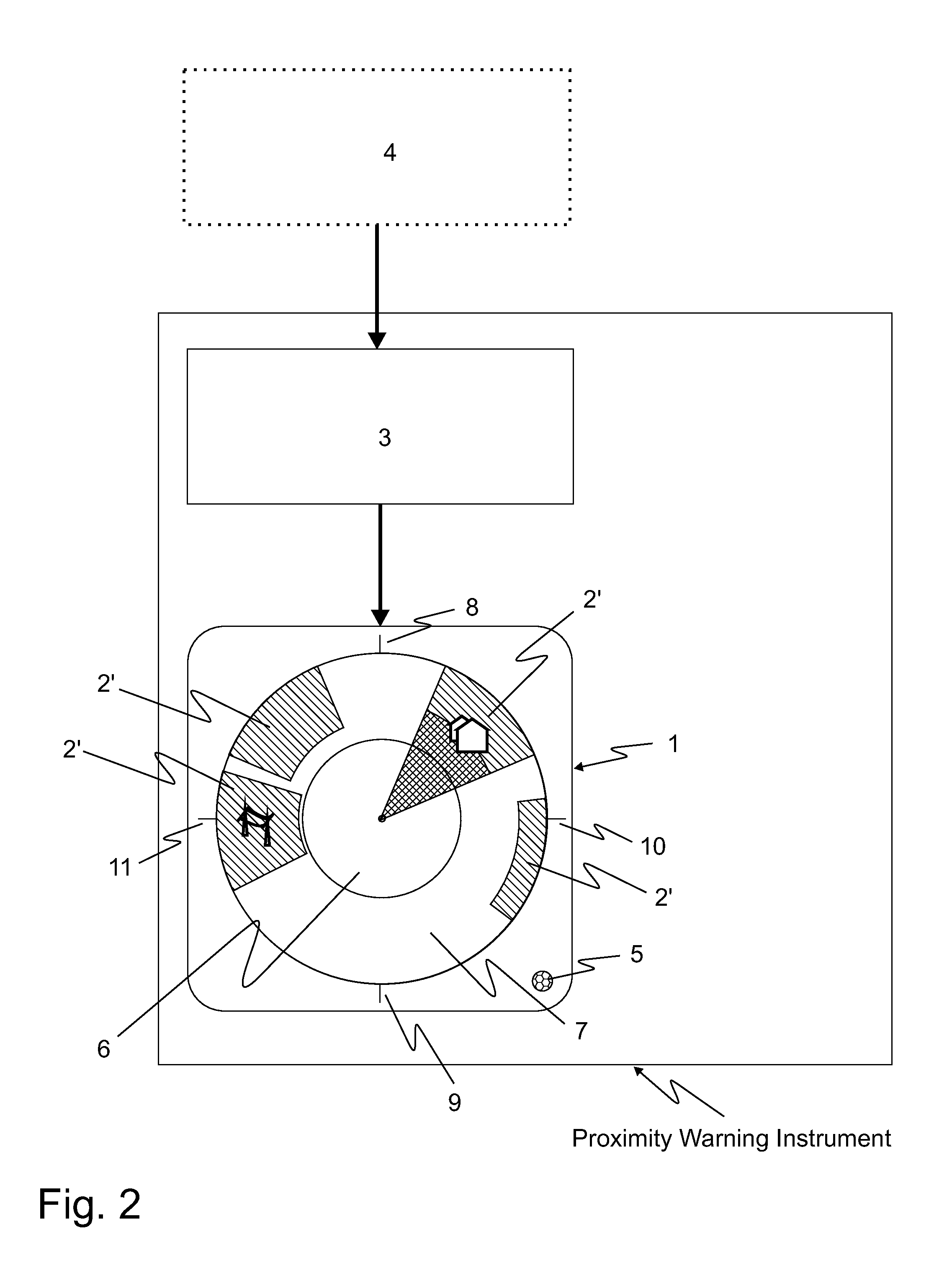

Obstacle information system of a helicopter

ActiveUS20130332062A1Increase display areaAnti-collision systemsNavigation instrumentsInformation processorCircular surface

An obstacle information system and method for a helicopter with a warning information processor (3) and a display unit (1) for any obstacle (2) within a predetermined minimum distance d4. Said warning information processor (3) is fed with information related to detected distance d5 and direction of said at least one obstacle (2) detected by an obstacle sensor system (4) to compute and prepare the information for presentation on the display unit (1). Said display unit (1) comprises at least an indication area with a central circular surface (6) and a concentric ring-shaped area (7) around the circular surface (6). Said circular surface (6) is used exclusively for alerts. The ring-shaped area (7) is used for both. Warnings and alerts and the repartition in the indication area of circular surface (6) and ring-shaped area (7) are dependent on the detected distance d5 of said at least one obstacle (2).

Owner:AIRBUS HELICOPTERS DEUT GMBH

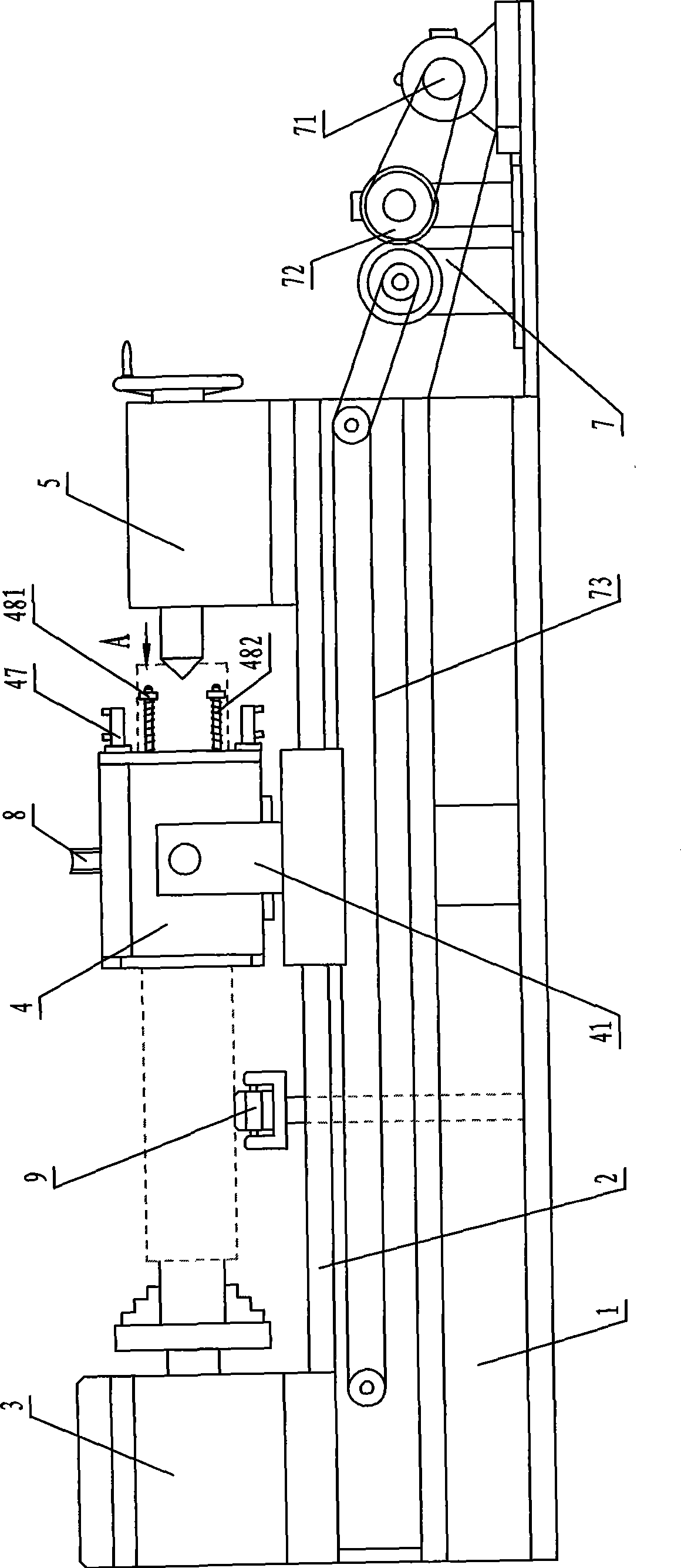

Equipment for grinding surface of long shaft workpiece

InactiveCN101462244AGuaranteed grinding accuracySolve the problem that the processing quality cannot meet the design requirementsGrinding carriagesRevolution surface grinding machinesCircular surfaceLong axis

The invention discloses a device for grinding the surface of a long-shaft type workpiece, which comprises a guide rail arranged on a lathe bed, wherein the guide rail is provided with a grinding head sleeved on the workpiece annularly; the grinding head is equivalently provided with at least two grinding strips annularly; the grinding head is also provided with a structure to drive all the grinding strips to perform radial motions so as to enclasp or break away from the workpiece; and the grinding head is driven to perform axial reciprocating movement on the guide rail by a driving device, and achieves the processing of grinding the outer circular surface of the workpiece through the rotary motion of the workpiece and the axial reciprocating movement of the grinding head. The grinding head of the device is sleeved on the workpiece annularly and performs axial reciprocating movement along the guide rail simultaneously so as to ensure the straightness of the motion and the grinding precision of the workpiece surface in the grinding process, and solve the difficult problem that the processing quality cannot reach the design requirement in the process of the one-step grinding of the long-shaft kind workpiece, thus the workpiece roundness, the cylindricity and the surface roughness can achieve the designed specified value, and the product quality and the working efficiency are improved.

Owner:CHANGZHOU TENT HYDRAULIC MACHINERY

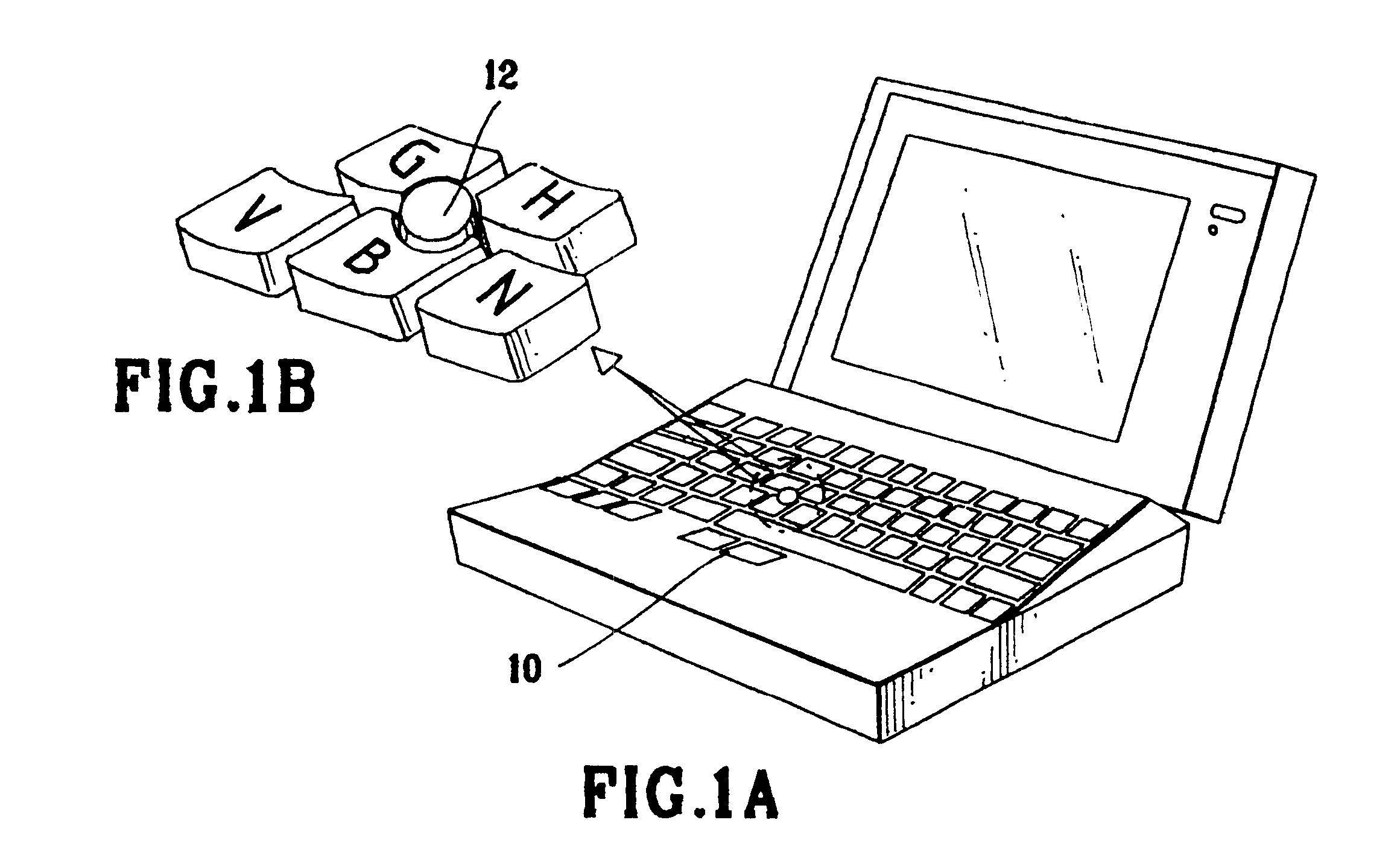

Pointing stick device and the manufacturing method thereof

InactiveUS6570556B1Manual control with multiple controlled membersMechanical apparatusDisplay deviceEngineering

A pointing stick used to control the cursor's movement on a display device is provided. The pointing stick includes a substrate and a stick. The stick has one end connected to the substrate and a portion of the stick is in form of cylinder. A plurality of sensors are disposed over the circular surface of the cylinder of the stick.

Owner:BENQ CORP

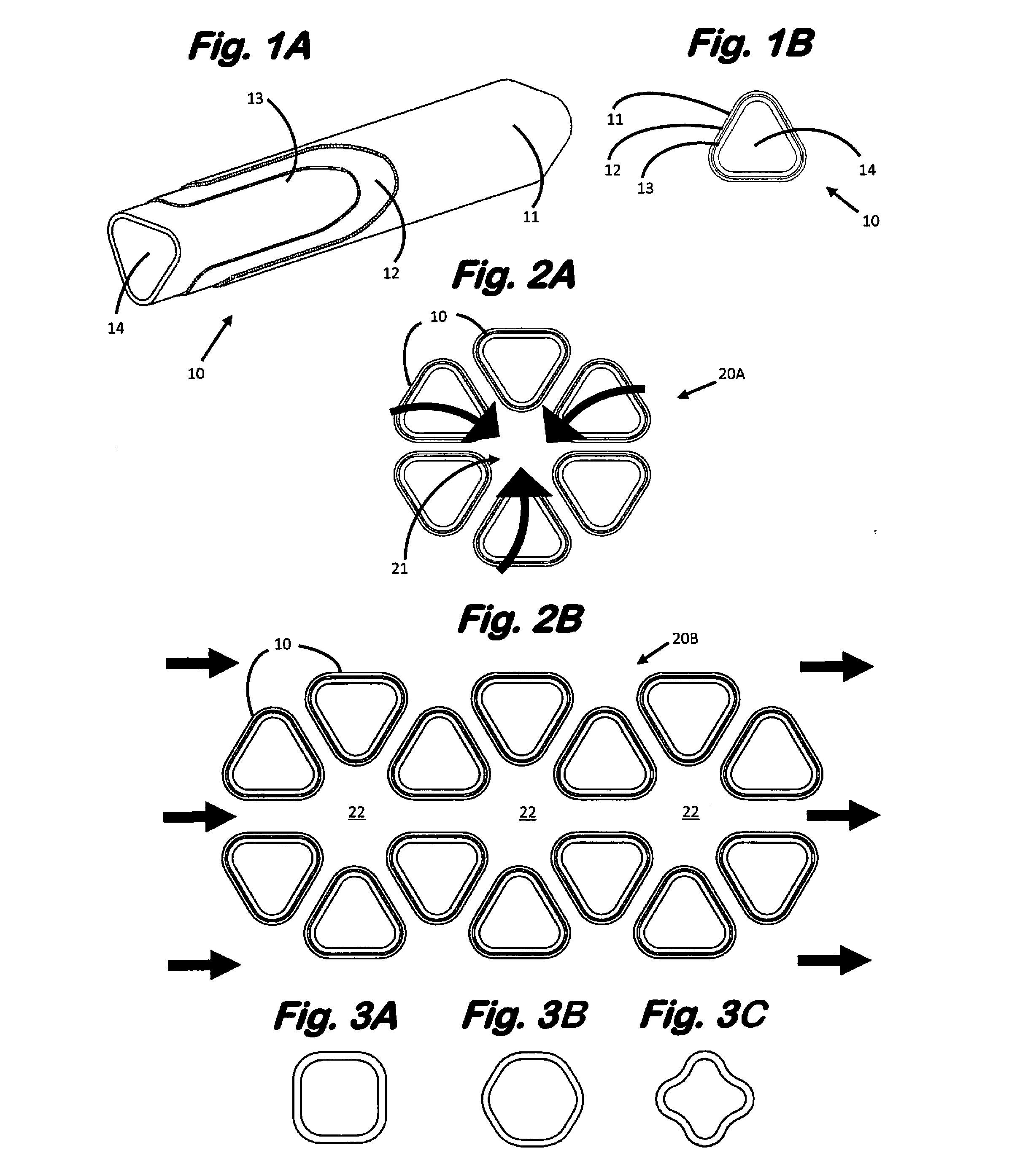

Process for producing tubular ceramic structures of non-circular cross section

ActiveUS20130059223A1Small sizeEasy to disassembleMolten spray coatingElectrode manufacturing processesFuel cellsMetallurgy

Tubular ceramic structures of non-circular cross section, e.g., anode components of tubular fuel cells of non-circular cross section, are manufactured by applying ceramic-forming composition to the external non-circular surface of the heat shrinkable polymeric tubular mandrel component of a rotating mandrel-spindle assembly, removing the spindle from said assembly after a predetermined thickness of tubular ceramic structure of non-circular cross section has been built up on the mandrel and thereafter heat shrinking the mandrel to cause the mandrel to separate from the tubular ceramic structure of non-circular cross section.

Owner:WATT FUEL CELL CORP

Detachable vibration reduction gear

ActiveCN104565288ASolve the accuracy problemSolve the vibrationPortable liftingGearing elementsGear wheelEngineering

The invention discloses a detachable vibration reduction gear, which comprises a basic wheel, wherein the diameter of the basic wheel is not greater than the diameter of a tooth root circle of the gear with a specified basic modulus; axial through slots with the number being the same as the number of gear teeth are formed in the basic wheel; detachable wheel teeth are respectively embedded in the through slots, and comprise tenon bodies inserted in the through slots and tooth heads integrally connected with the tenon bodies; end parts, close to the tenon bodies, of the tooth heads extend to two sides to form tooth head bumps; the lower surfaces of the tooth head bumps are arc faces adapting to the external circular surface of the basic wheel; the upper surfaces of the tooth head bumps are in smooth connection with the tooth profile curved surfaces of the detachable wheel teeth to form part of slot bottom faces of gear tooth slots; wheel tooth fixing slots are formed in gear wheel surfaces; circular ring shaped fixing bars are embedded in the fixing slots; vibration reduction slots are also formed in the tenon bodies of the detachable wheel teeth. The detachable vibration reduction gear provided by the invention not only is simple in structure and convenient for replacing the wheel teeth so as to reduce economic loss, but also can realize the universalization of a gear main body structure and has higher practical value.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com