Light-weight engine cylinder sleeve of passenger vehicle and production method of light-weight engine cylinder sleeve

An engine cylinder, lightweight technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problem of reducing the matching performance of wear-resistant piston rings of cylinder liner, deterioration of graphite structure and metallographic structure, fluctuation of exhaust emissions, etc. problems, to achieve the effect of reducing weight, excellent metallographic structure, and reducing roundness fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

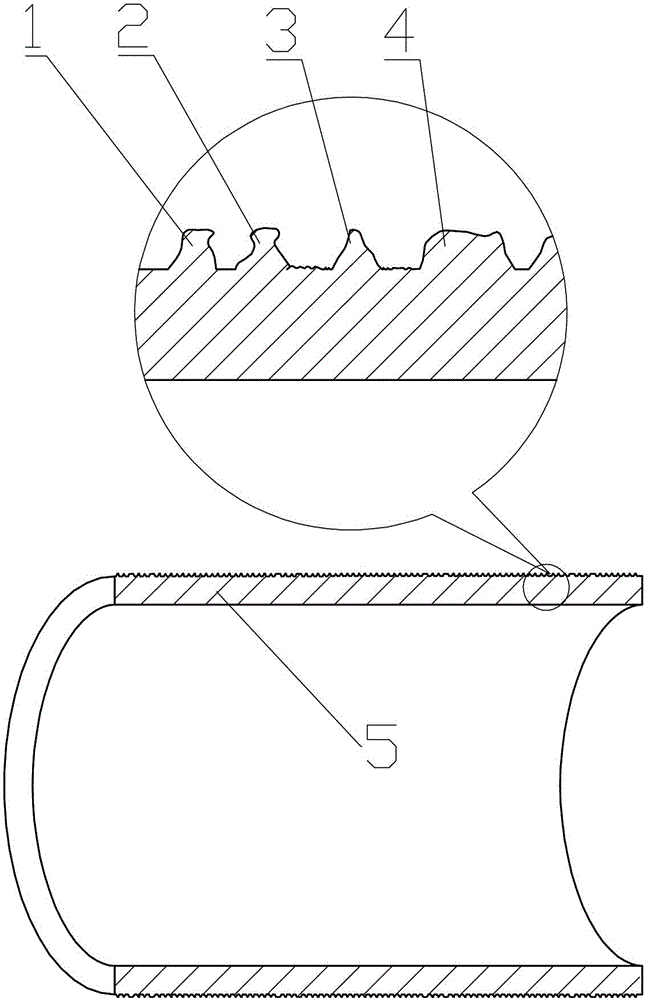

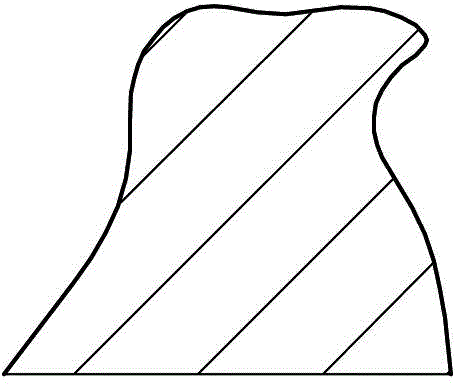

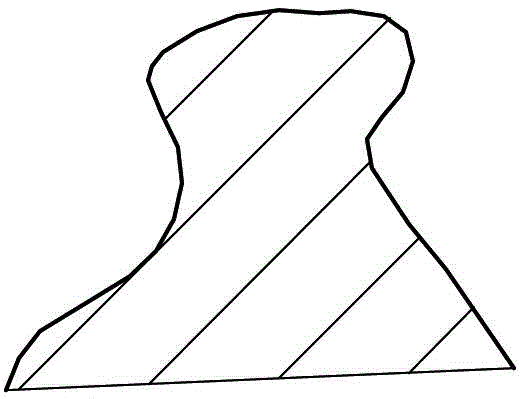

[0021] like figure 1 As shown in -6, a lightweight engine cylinder liner for a passenger car, the cylinder liner 5 has pits distributed on the outer surface of the cylinder liner 5, and the pits include dumbbell-shaped pits 2, upright cone-shaped pits 3, and worm-shaped pits 4 1. There are four types of olecranon-shaped pits. The four shapes of pits are randomly distributed on the outer surface of the cylinder liner, and the height of the pits is 0.25 mm.

[0022] The top of the pit is an irregular arc surface, and the area of a single pit section at a height of 0.2mm from the base surface of the root of the pit is 0.05mm 2 ~0.12mm 2 ;The distance between the edges of two adjacent pits is 0.5mm~2mm; the distance between the edges of two pits refers to the distance between the points on the edge of the two pits on the section at a height of 0.2mm from the base surface of the root of the pits. The minimum value of the distance between two pits, the edge distance between two ...

Embodiment 2

[0027] The difference between the passenger car lightweight engine cylinder liner of embodiment 2 and embodiment 1 is that the height of the pits is 0.5 mm, and the top of the pits is an irregular arc surface, which is higher than the base surface of the root of the pits. The area of a single pit section at 0.2mm is 0.2mm 2 ~0.3mm 2 , the area of the cross-section of the pitting point at a height of 3 / 5 times the height of the root of the pitting point is 0.05mm 2 ~0.7mm 2 ; The distance between the edges of two adjacent pits is 1 mm to 3 mm.

[0028]The preparation method of the lightweight engine cylinder liner for a passenger car comprises the following steps: ① Melting the following ingredients in the following weight percentages into molten iron at 1480°C and releasing them from the furnace: C 2.8%, S 0.03%, Si 1.8%, P 0.1 %, Mn 0.5%, Cr 0.1%, Cu 0.1%, and the balance is iron; ② Preparation of coating solution: in parts by weight, take 10 parts of diatomite, 2.5 pa...

Embodiment 3

[0031] The difference between the passenger car lightweight engine cylinder liner of embodiment 3 and embodiment 1 is that the height of the pits is 1.1 mm, and the top of the pits is an irregular arc surface, which is higher than the base surface of the root of the pits. The area of a single pit section at 0.2mm is 0.8mm 2 ~7mm 2 , the area of the cross-section of the pitting point at 3 / 5 times the height of the root of the pitting point is 0.7mm 2 ~5mm 2 ; The distance between the edges of two adjacent pits is 1.5mm to 5.0mm.

[0032] The difference between embodiment 3 and embodiment 1 is that the preparation method of the lightweight engine cylinder liner for passenger cars includes the following steps: ① Melting each component in the following weight percentages into molten iron at 1550°C and then releasing it from the furnace: C 3.8%, S 0.06%, Si 2.9%, P 0.7%, Mn 0.9%, Cr 0.4%, Cu 0.7%, and the balance is iron; ② Preparation of coating solution: by weight, take 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com