Patents

Literature

31125results about "Polyurea/polyurethane coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

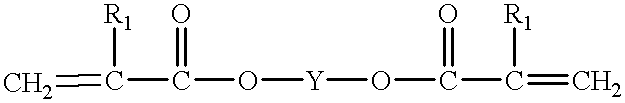

Radiation-curable coating compounds

InactiveUS6605669B2Inhibition of polymerizationNo surface defectsPolyurea/polyurethane coatingsPrinting after-treatmentMeth-Functional monomer

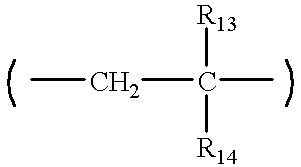

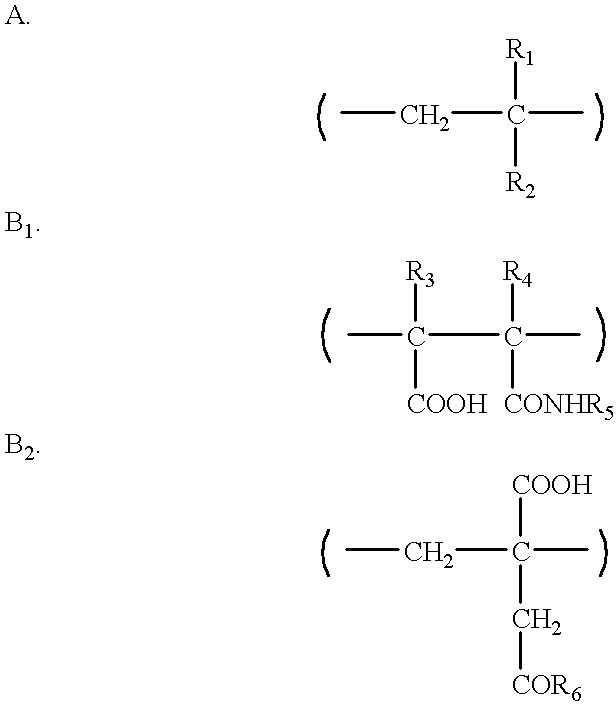

Coating compounds curable by means of high-energy radiation, comprising as binderA) at least one (meth)acrylic copolymer containing olefinic double bonds capable of free-radical polymerization and hydroxyl groups with a C=C equivalent weight from 100 to 10,000 and an OH-value from 20 to 250 mg KOH / g, which is prepared from monomers comprising:A1) at least one olefinically unsaturated, epoxy-functional monomer capable of free-radical polymerization,A2) at least one olefinically unsaturated, carboxy-functional monomer capable of free-radical polymerization andA3) at least one further olefinically unsaturated monomer capable of free-radical polymerization which is different from A1) and A2), andB) at least one component with free isocyanate groups and process for multilayer coating using the coating compounds.

Owner:AXALTA COATING SYST IP CO LLC

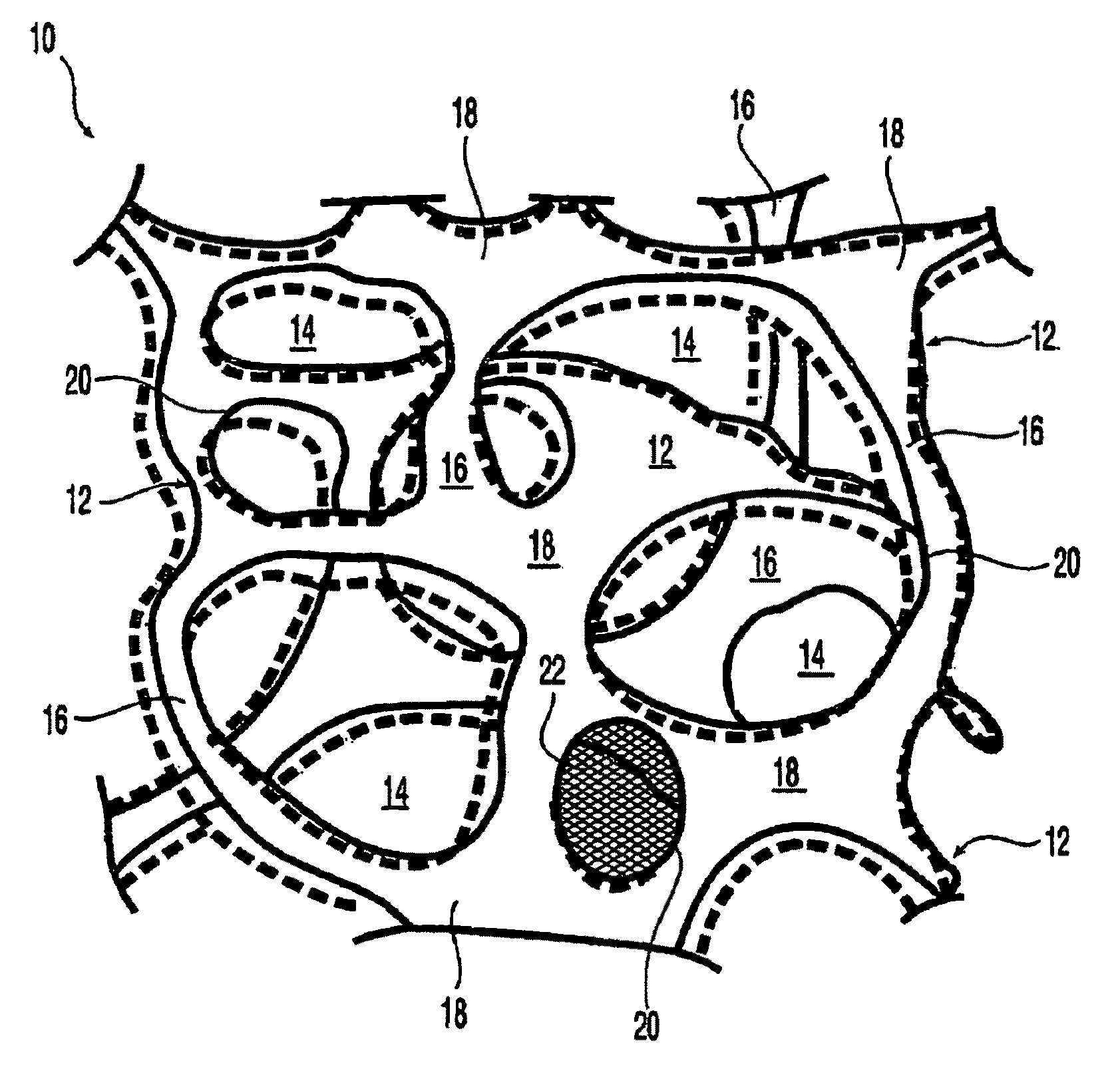

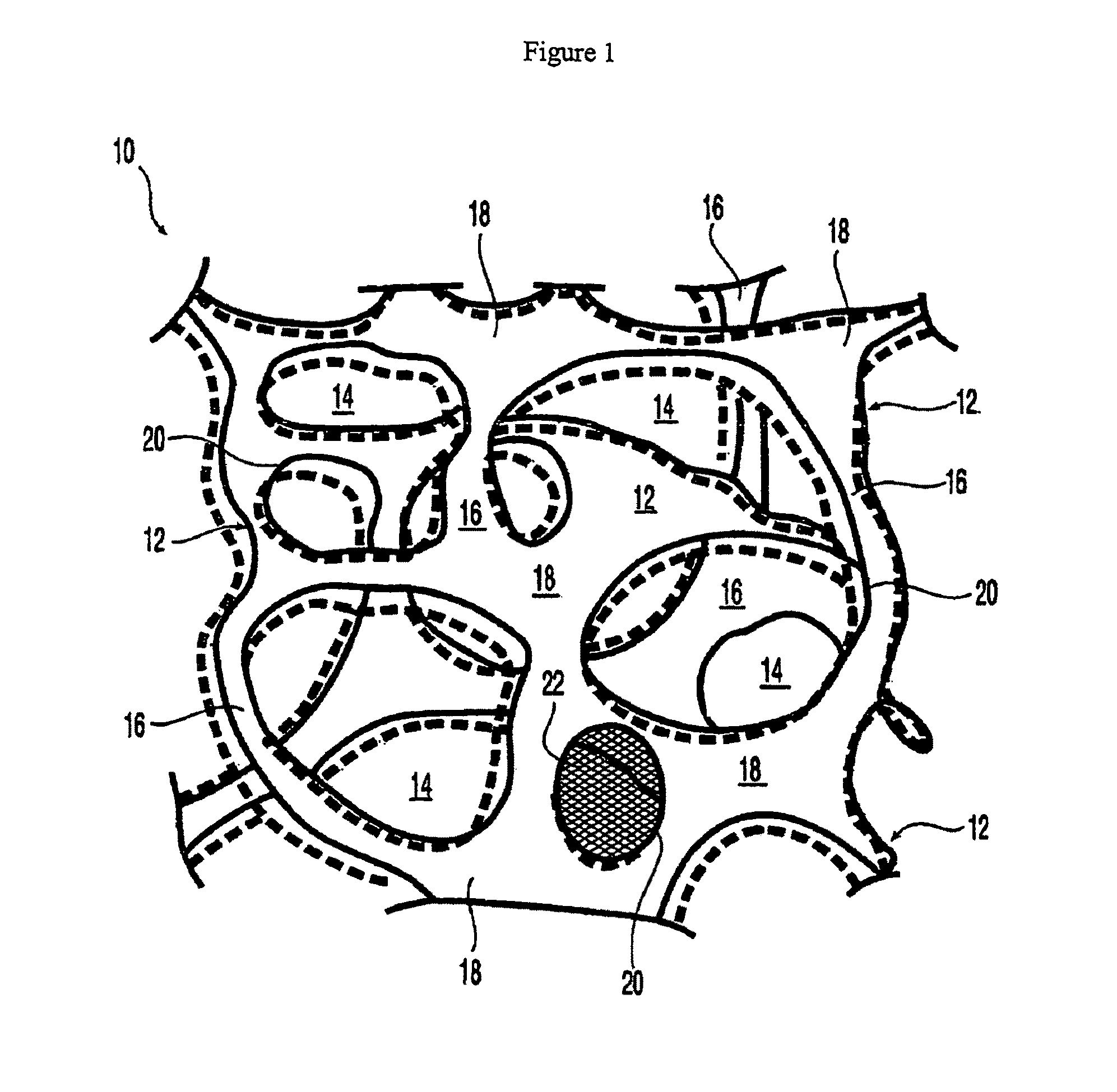

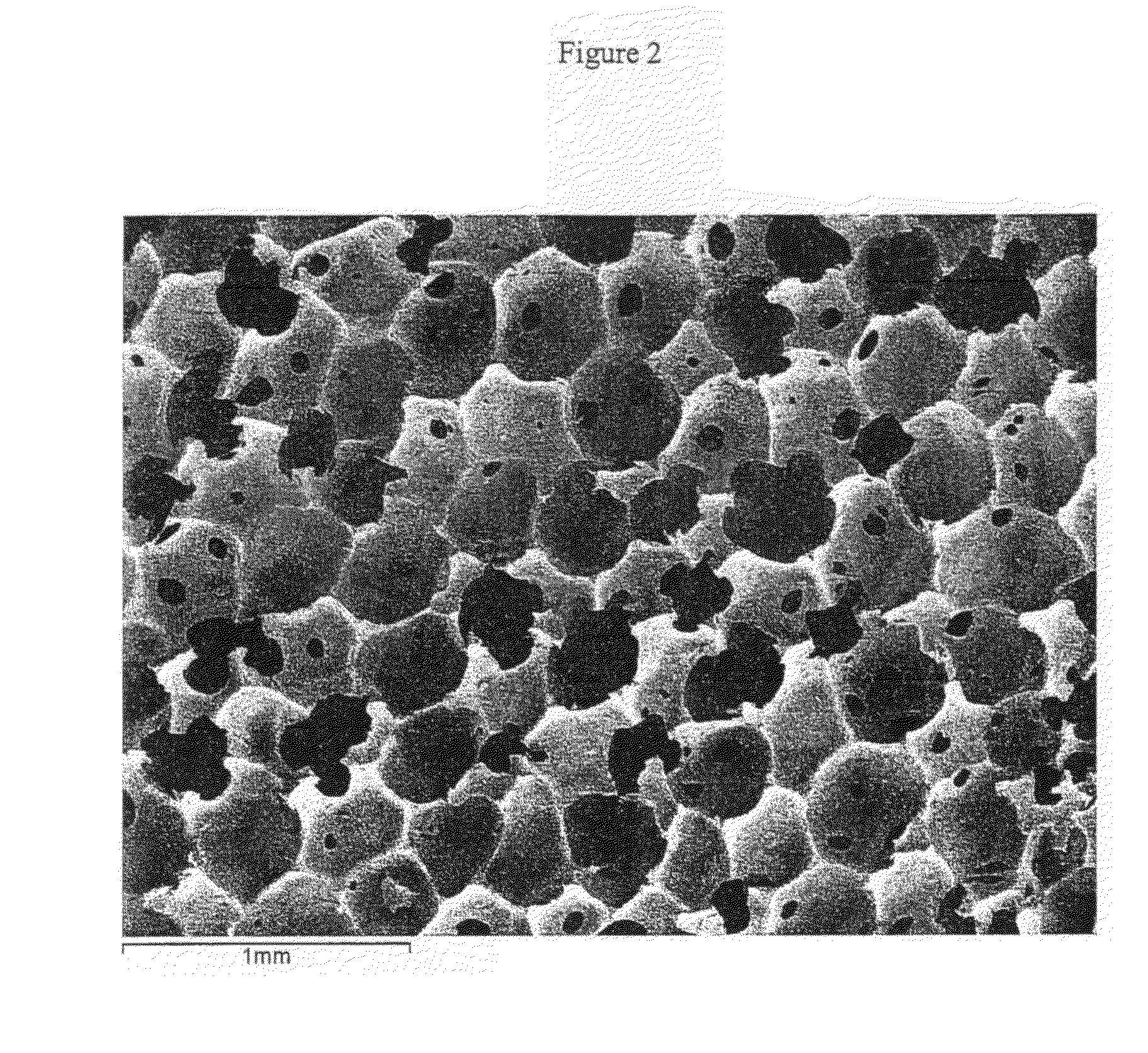

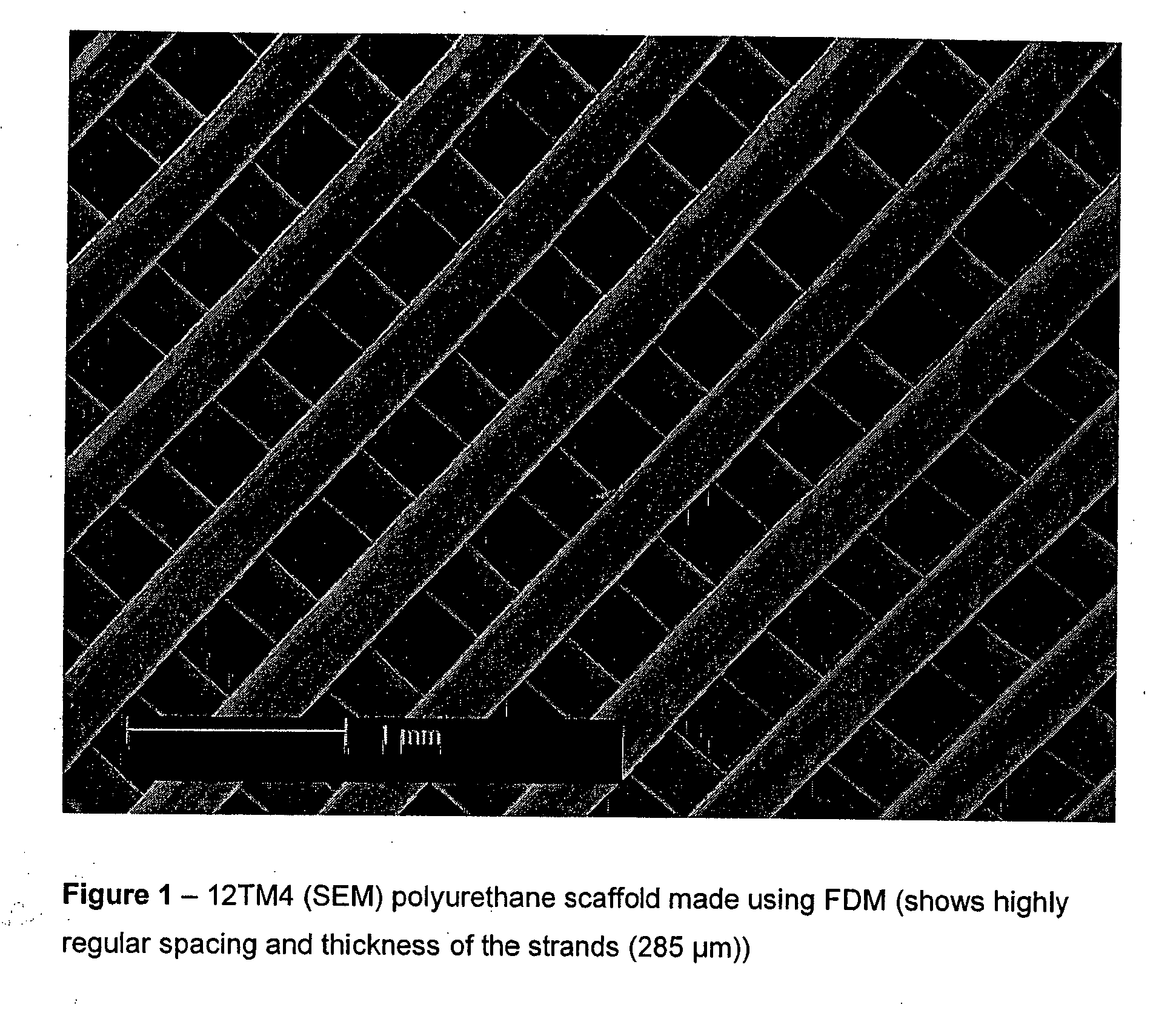

At least partially resorbable reticulated elastomeric matrix elements and methods of making same

ActiveUS8801801B2Small volumeIncrease in sizePolyurea/polyurethane coatingsProsthesisElastomerBiomedical engineering

The present disclosure relates to reticulated elastomeric matrices, and more particularly to at least partially degradable elastomeric elements that are compressible and exhibit resilience in their recovery and that can be employed in diverse applications including, without limitation, biological implantation, especially in humans.

Owner:DSM IP ASSETS BV

Coating composition for multiple hydrophilic applications

InactiveUS20030203991A1Tough and durable and printable surfaceImprove wettabilityOther chemical processesSynthetic resin layered productsColloidWear resistance

A coating composition is disclosed which comprises an aqueous polymeric matrix, a hydrophilic polymer, a colloidal metal oxide and a crosslinker. The coating composition when applied on medical devices is hydrophilic, shows improved lubricity, abrasion resistance and substrate adhesion on metallic or plastic substrates. The coating also shows improved water sheeting thus providing the coated substrates with anti-fog properties. The coating absorbs aqueous dye or stain solutions making the substrate suitable for printing.

Owner:HYDROMER INC

Coating composition for multiple hydrophilic applications

InactiveUS7008979B2Improve adhesionImprove the lubrication effectSurgerySynthetic resin layered productsColloidWear resistance

Owner:HYDROMER INC

Aqueous dispersions of polymer-enclosed particles, related coating compositions and coated substrates

ActiveUS20060251896A1Nanostructure manufactureSynthetic resin layered productsNanoparticleMaterials science

Disclosed are aqueous dispersions of polymer-enclosed particles, such as nanoparticles. Also disclosed are methods for making an aqueous dispersion of polymer-enclosed particles, polymerizable polymers useful in such a method, powder coating compositions formed from such an aqueous dispersion, substrates at least partially coated with such a composition, and reflective surfaces comprising a non-hiding coating layer deposited from such a composition.

Owner:PPG IND OHIO INC

Breathable polyurethanes, blends, and articles

InactiveUS6897281B2Improve breathabilityImprove moisture vapor transmission rateSynthetic resin layered productsPolyurea/polyurethane coatingsGramSide chain

A breathable polyurethane having an upright moisture vapor transmission rate (MVTR) of more than about 500 gms / m2 / 24 hr comprises:(a) poly(alkylene oxide) side-chain units in an amount comprising about 12 wt. % to about 80 wt. % of said polyurethane, wherein (i) alkylene oxide groups in said poly(alkylene oxide) side-chain units have from 2 to 10 carbon atoms and are unsubstituted, substituted, or both unsubstituted and substituted, (ii) at least about 50 wt. % of said alkylene oxide groups are ethylene oxide, and (iii) said amount of said side-chain units is (i) at least about 30 wt. % when the molecular weight of said side-chain units is less than about 600 grams / mole, (ii) at least about 15 wt. % when the molecular weight of said side-chain units is from about 600 to about 1,000 grams / mole, and at least about 12 wt. % when the molecular weight of said side-chain units is more than about 1,000 grams / mole, and(b) poly(ethylene oxide) main-chain units in an amount comprising less than about 25 wt. % of said polyurethane.Coatings and films for textiles and other articles and applications using such polyurethanes have excellent breathability, i.e., high moisture vapor transmission rates (MVTR).

Owner:LUBRIZOL ADVANCED MATERIALS INC

Multi-component coatings that include polyurea coating layers

ActiveUS20060046068A1Synthetic resin layered productsPolyurea/polyurethane coatingsPolymer sciencePolymer chemistry

A polyurea composition, a multi-component composite coating and articles formed therefrom, and methods of forming the same are disclosed. The coating composition is formed from a reaction mixture comprising an isocyanate-functional component and an amine-functional component. The ratio of equivalents of isocyanate groups to equivalents of amine groups is greater than 1 while the volume mixing ratio of the isocyanate-functional component to the amine-functional component is capable of being applied to a substrate at 1:1.

Owner:PPG IND OHIO INC

Nontoxic antifouling paint for oceanographic ship and facilities and method for preparing paint

ActiveCN101967316AInhibit Adhesive CorrosionTo achieve non-toxicRubber derivative coatingsAntifouling/underwater paintsNon toxicityBiofouling

The invention discloses a nontoxic antifouling paint for an oceanographic ship and facilities and a method for preparing the paint. The paint consists of the following components in percentage by weight: 15 to 55 percent of base material, 0.01 to 10 percent of antifouling agent, 10 to 30 percent of filler, 0.3 to 25 percent of pigment, 2 to 8 percent of auxiliary agent and 3 to 55 percent of solvent, wherein the antifouling agent is silver grains with average grain diameter of between 1 and 200nm. The paint does not contain toxic agents, such as dichloro-diphenyl-trichloroethane, organic tin,cuprous oxide and the like, at all while effectively suppressing corrosion of marine biological attachments, meets the related regulations of international maritime organization and future development trend of the antifouling paint, realizes non-toxicity and environmental friendliness of the marine antifouling technology, and can be widely applied to the facilities and the fields, such as ships, floating piers, marine oil platforms, submarine cables, cooling pipes of power plant near the sea, sea water culture net cage and the like.

Owner:CHINA LUCKY FILM CORP +1

Conformal coatings comprising carbon nanotubes

InactiveUS7118693B2Material nanotechnologyMagnetic/electric field screeningModified carbonElectromagnetic interference

Owner:EIKOS

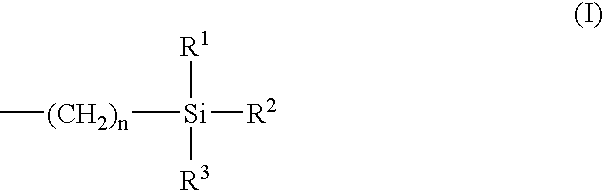

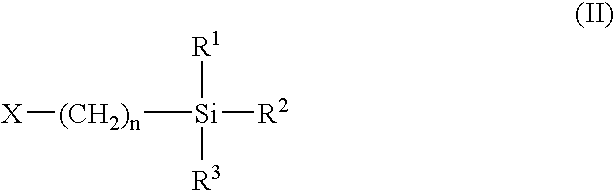

Silane copolymer coatings

InactiveUS6908681B2Maintain good propertiesImprove adhesionMale contraceptivesSurgerySilanesMedical device

Owner:CR BARD INC

Antimicrobial compositions containing colloids of oligodynamic metals

InactiveUS7179849B2Reduced settlingReduce agglomerationOrganic active ingredientsPretreated surfacesSolubilityCatheter

Owner:CR BARD INC

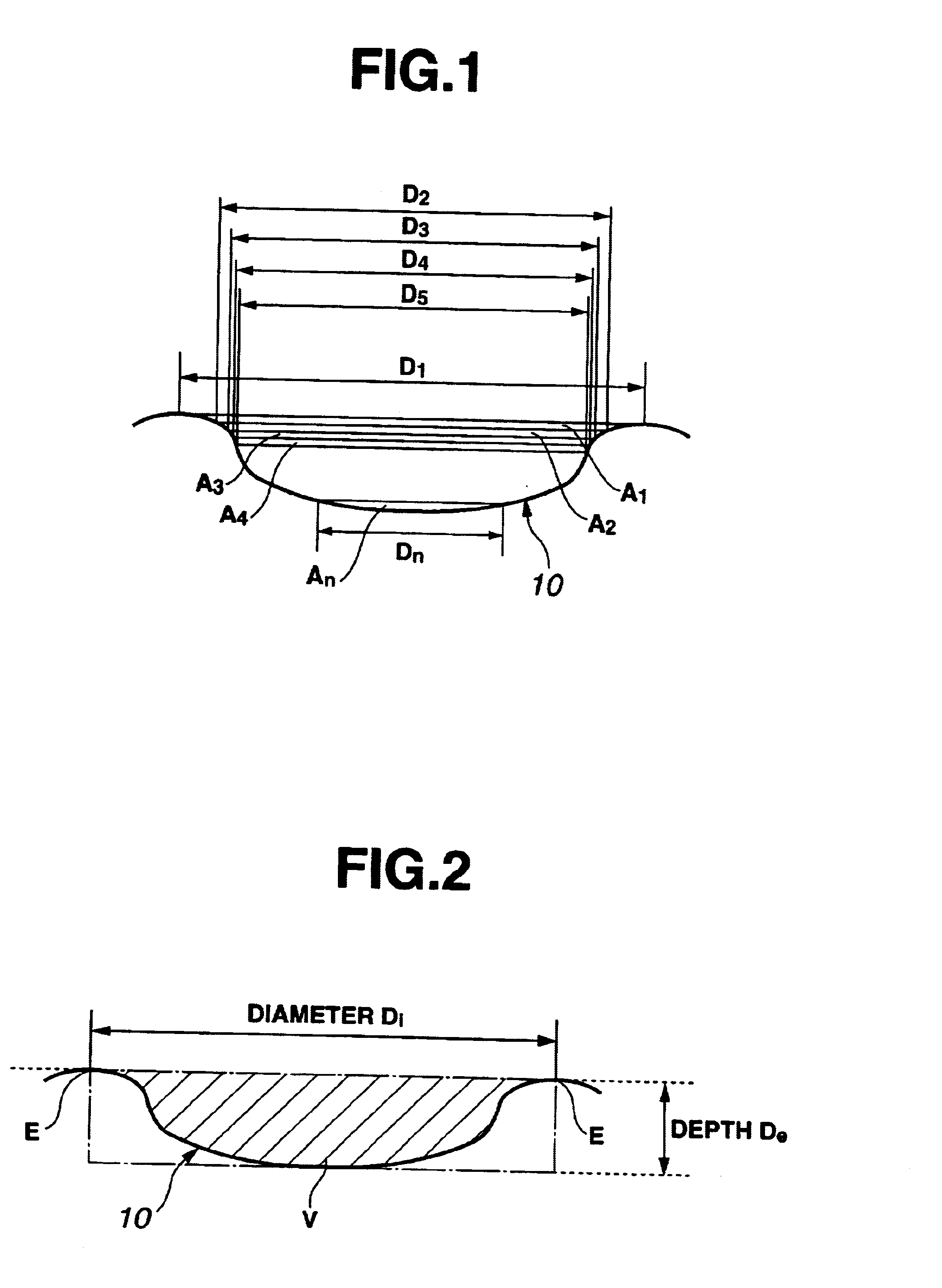

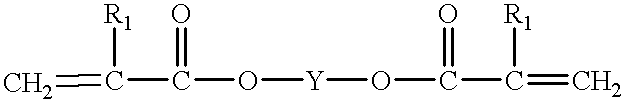

Multi-piece solid golf ball

InactiveUS6739986B2Stretching flight performanceExtended driving distancePolyurea/polyurethane coatingsGolf ballsLow speedHardness

In a multi-piece solid golf ball comprising a solid core and a cover of two inner and outer layers enclosing the solid core and formed on the surface with a plurality of dimples, the solid core in its entirety has a hardness distribution falling within the range of JIS-C hardness 50-85, the difference between maximum and minimum JIS-C hardnesses in the solid core falls within 5%, the cover inner layer has a JIS-C hardness of 70-90, the cover outer layer has a JIS-C hardness of 60-80, the sum of high-speed region dimple operative volumes HDOV of respective dimples is 170-310, the sum of low-speed region dimple operative volumes of respective dimples LDOV is 200-310, and the overall dimple volume is 260-360 mm<3>.

Owner:BRIDGESTONE SPORTS

Abrasion resistant urethane coatings

InactiveUS6228433B1Improve wear resistanceResistant to stainsPolyurea/polyurethane coatingsThin material handlingOligomerReactive diluent

A radiation curable and abrasion resistant coating composition is provided comprising: (a) 70% to 98% by weight of an urethane-acrylate oligomer; (b) 2% to 30% of fine particles of a filler capable of imparting abrasion resistance having an average particle size in the range of 1-20 microns; (c) optionally a reactive diluent; and (d) optionally an synthetic resin. The coatings when applied to wood floorings impart superior abrasion resistance.

Owner:PRISM ENTERPRISES

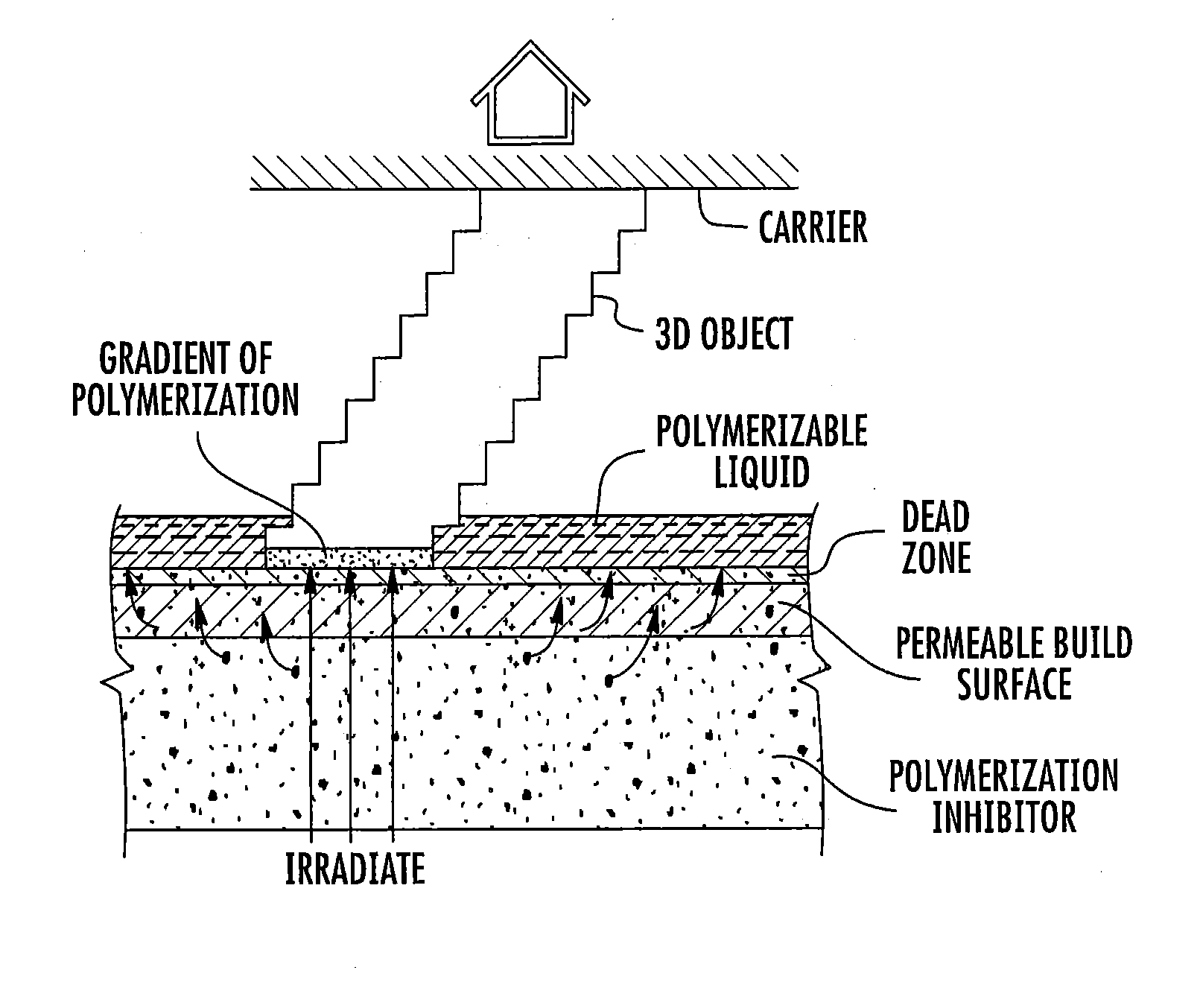

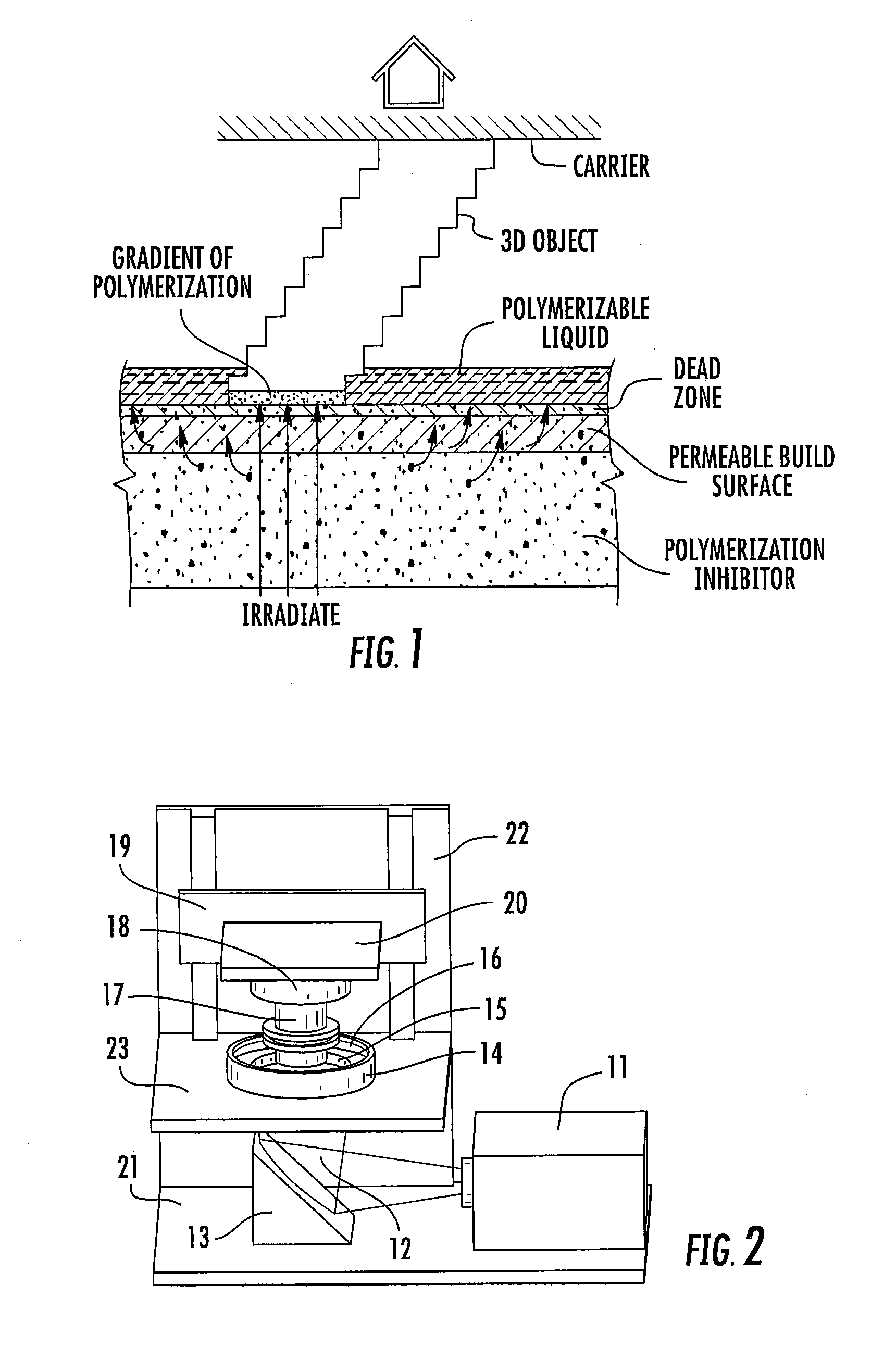

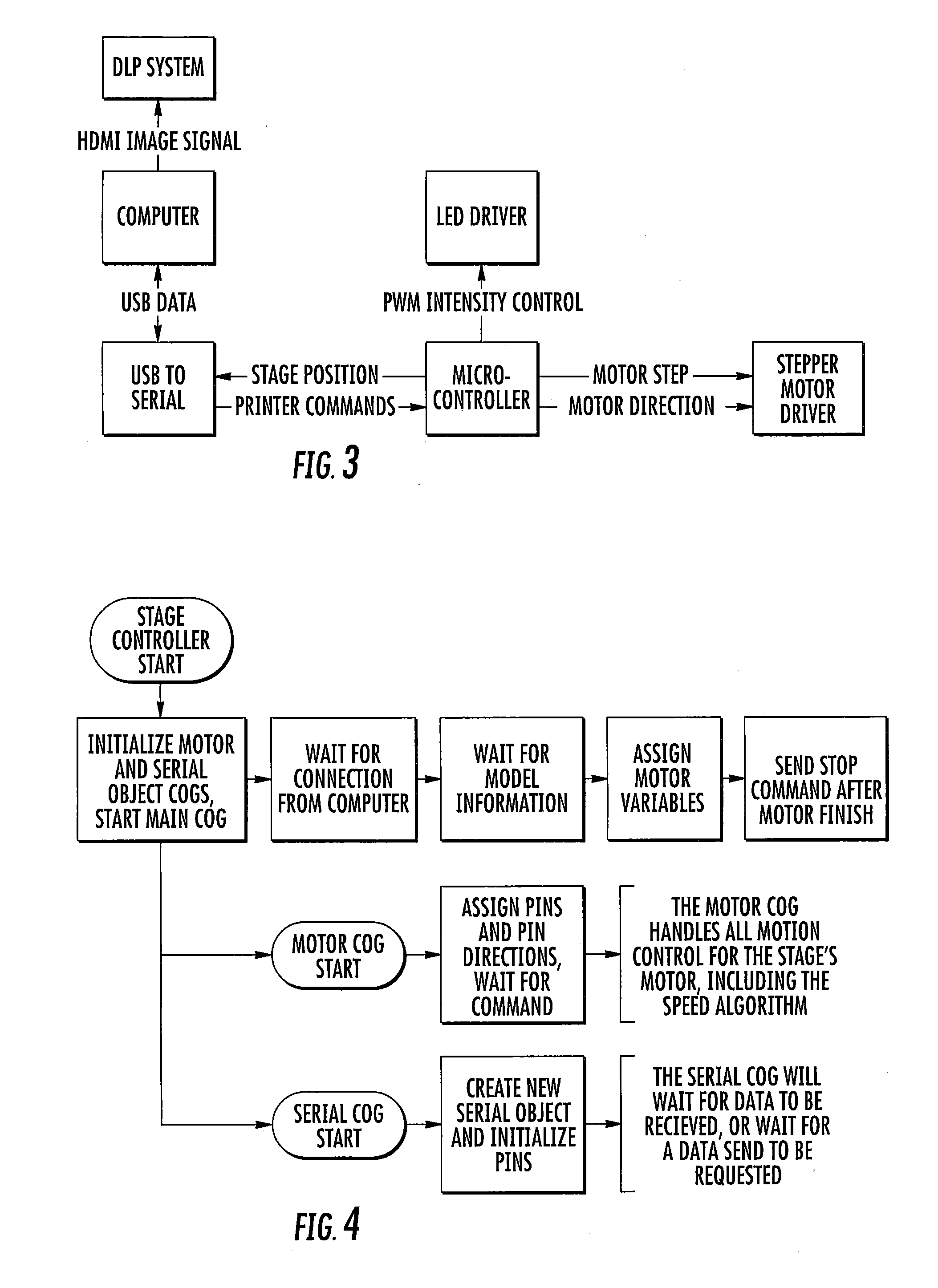

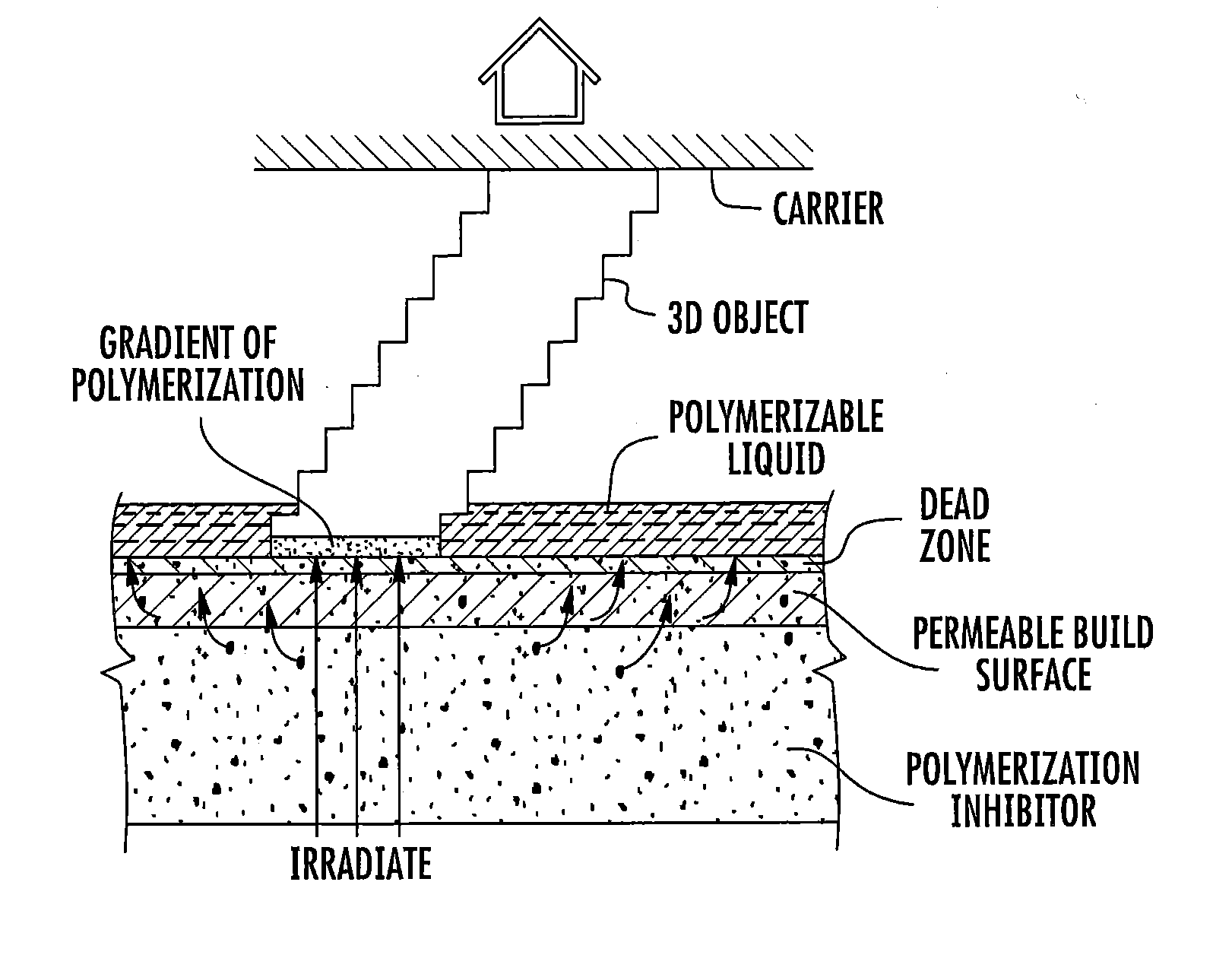

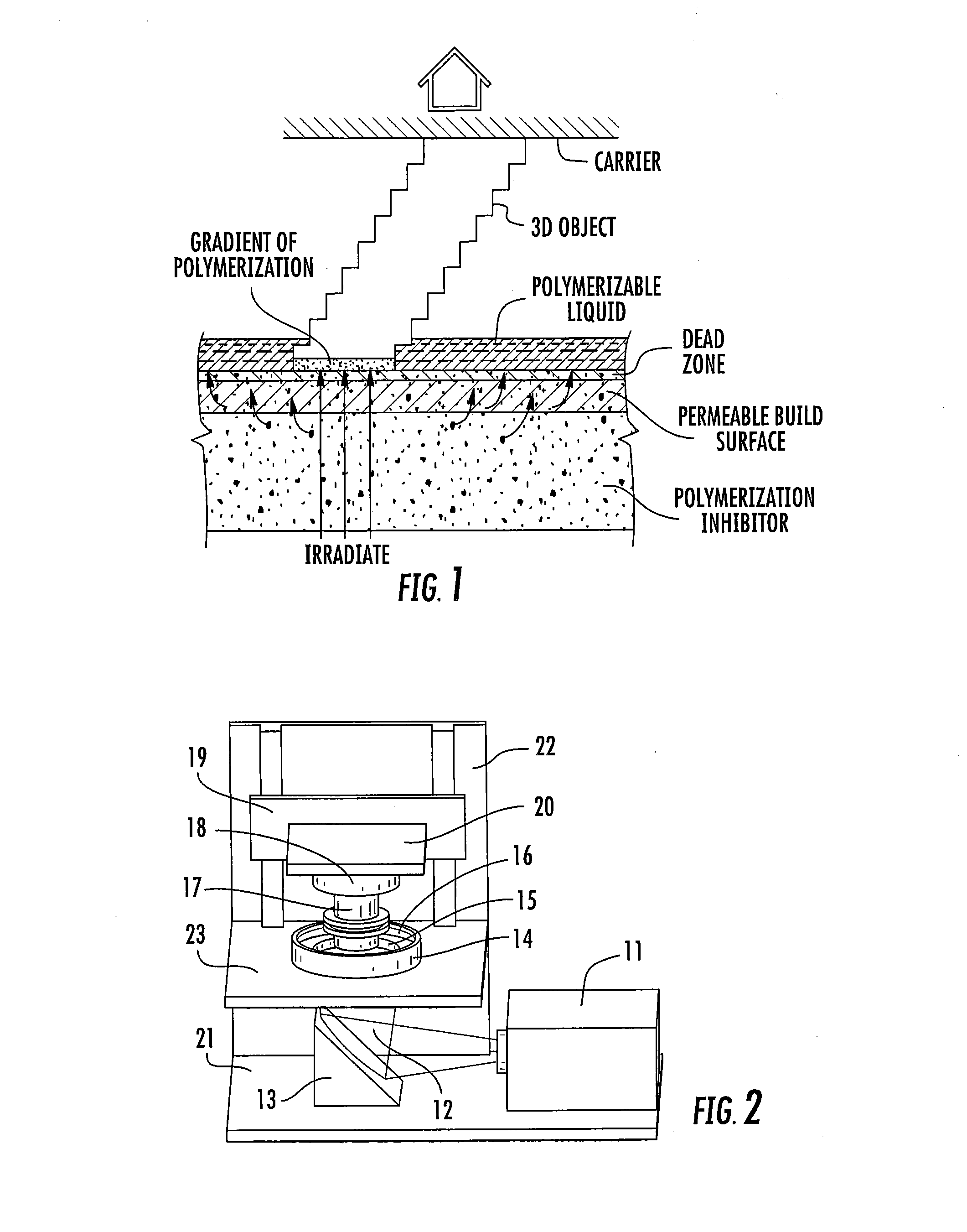

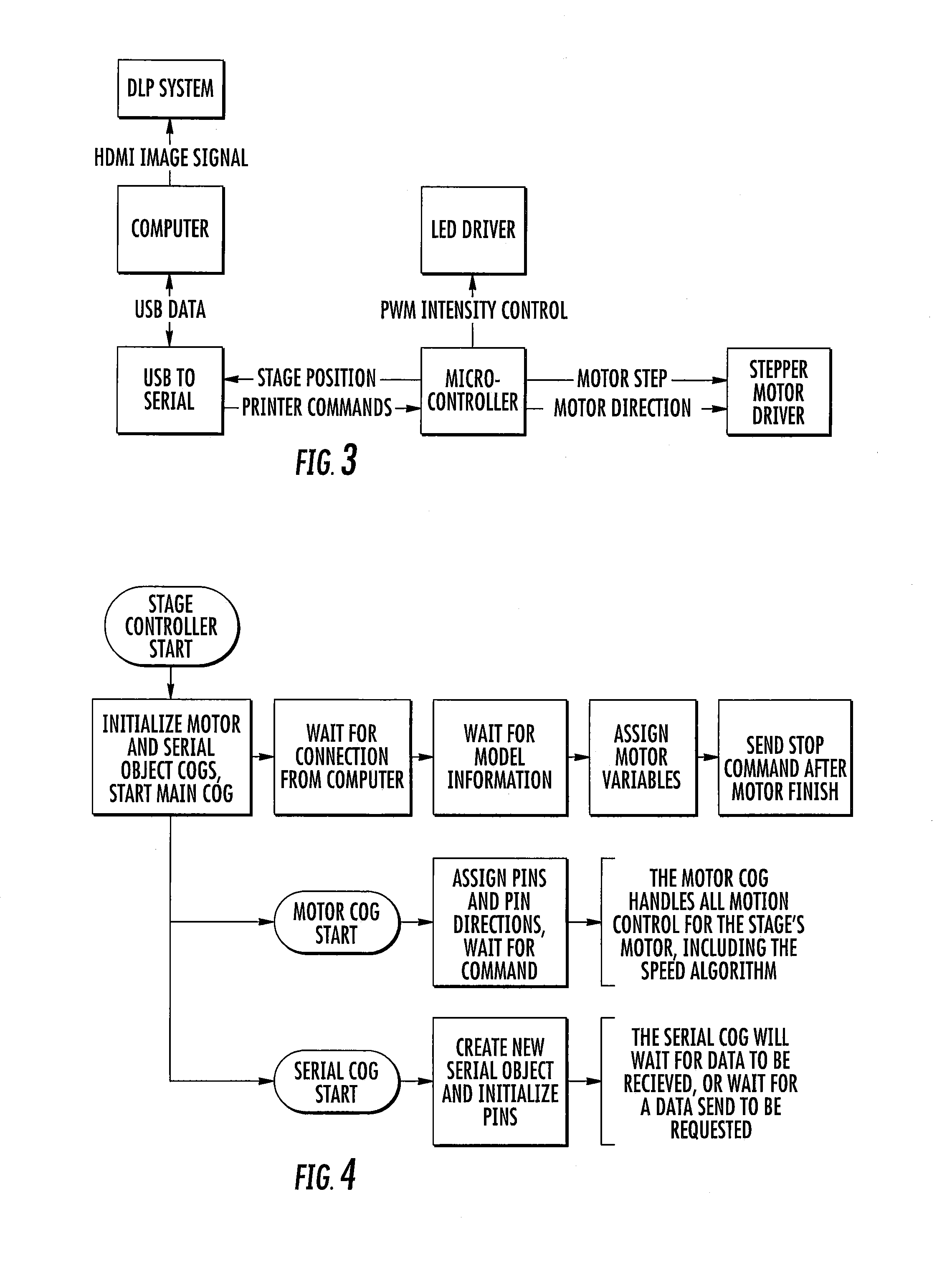

Methods of producing three-dimensional objects from materials having multiple mechanisms of hardening

ActiveUS20160136889A1Increased formationEnhance or speed the refilling of the build regionManufacturing enclosuresOptical articlesPolymer scaffoldChemistry

A method of forming a three-dimensional object is carried out by: (a) providing a carrier and an optically transparent member having a build surface, the carrier and the build surface defining a build region therebetween; (b) filling the build region with a polymerizable liquid, the polymerizable liquid including a mixture of (i) a light polymerizable liquid first component, and (ii) a second solidifiable component that is different from the first component; (c) irradiating the build region with light through the optically transparent member to form a solid polymer scaffold from the first component and also advancing the carrier away from the build surface to form a three-dimensional intermediate having the same shape as, or a shape to be imparted to, the three-dimensional object, and containing the second solidifiable component carried in the scaffold in unsolidified and / or uncured form; and (d) concurrently with or subsequent to the irradiating step, solidifying and / or curing the second solidifiable component in the three-dimensional intermediate to form the three-dimensional object.

Owner:CARBON INC

Reactive oligomers for isocyanate coatings

InactiveUS6221494B1Extended shelf lifeHigh glossAluminium compoundsSynthetic resin layered productsEpoxyOligomer

The invention is directed to a two-pack solvent-based ambient curable coating composition comprising a binder of a hydroxyl and crosslinking components. The hydroxyl component includes a linear or branched cycloaliphatic moiety-containing reactive oligomer or blend of oligomers with a weight average molecular weight not exceeding 3,000, a polydispersity not exceeding about 1.7 with at least 2 hydroxyl groups, at least 1, on average, being a primary hydroxyl group. The reactive oligomer is formed by the reaction of an oligomeric acid with monofunctional epoxy. The crosslinking component includes one or more of an oligomeric crosslinker containing at least 2 isocyanate groups. The coating composition of the invention is particularly suited in automotive refinish coatings.

Owner:AXALTA COATING SYST IP CO LLC

Radiation curable and jettable ink compositions

The present invention is directed to radiation curable and jettable ink compositions and particularly to such compositions which exhibit enhanced elongation, when cured at low doses, and are advantageously used, for example, in digital inkjet printing. The compositions include a polyfunctional component and a monofunctional monomer, and may optionally include an additional monofuctional component and / or chain transfer agent. The compositions have a viscosity at 25° C. of not greater than about 70 cP and are radiation curable to form a cured ink having an elongation of between about 40 and about 150%. In addition, the compositions, when cured at low dose, exhibit a tack free surface and a low coefficient of friction.

Owner:COLLINS INK CORP

Carbon black composition and usage thereof

InactiveUS20130029183A1Good dispersionInhibition formationPigmenting treatmentMagnetic materials for record carriersCyclohexanoneOrganic solvent

An aspect of the present invention relates to a carbon black composition, which comprises carbon black; an organic tertiary amine selected from the group consisting of an aliphatic tertiary monoamine and an alicyclic tertiary amine; and at least one organic solvent selected from the group consisting of methyl ethyl ketone, cyclohexanone, isophorone, and ethanol.

Owner:SOITEC SA +1

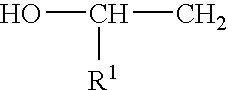

Biodegradable polyurethane and polyurethane ureas

ActiveUS20060051394A1Fast formingEasily degradableOrganic active ingredientsSurgeryPolyolInsertion stent

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

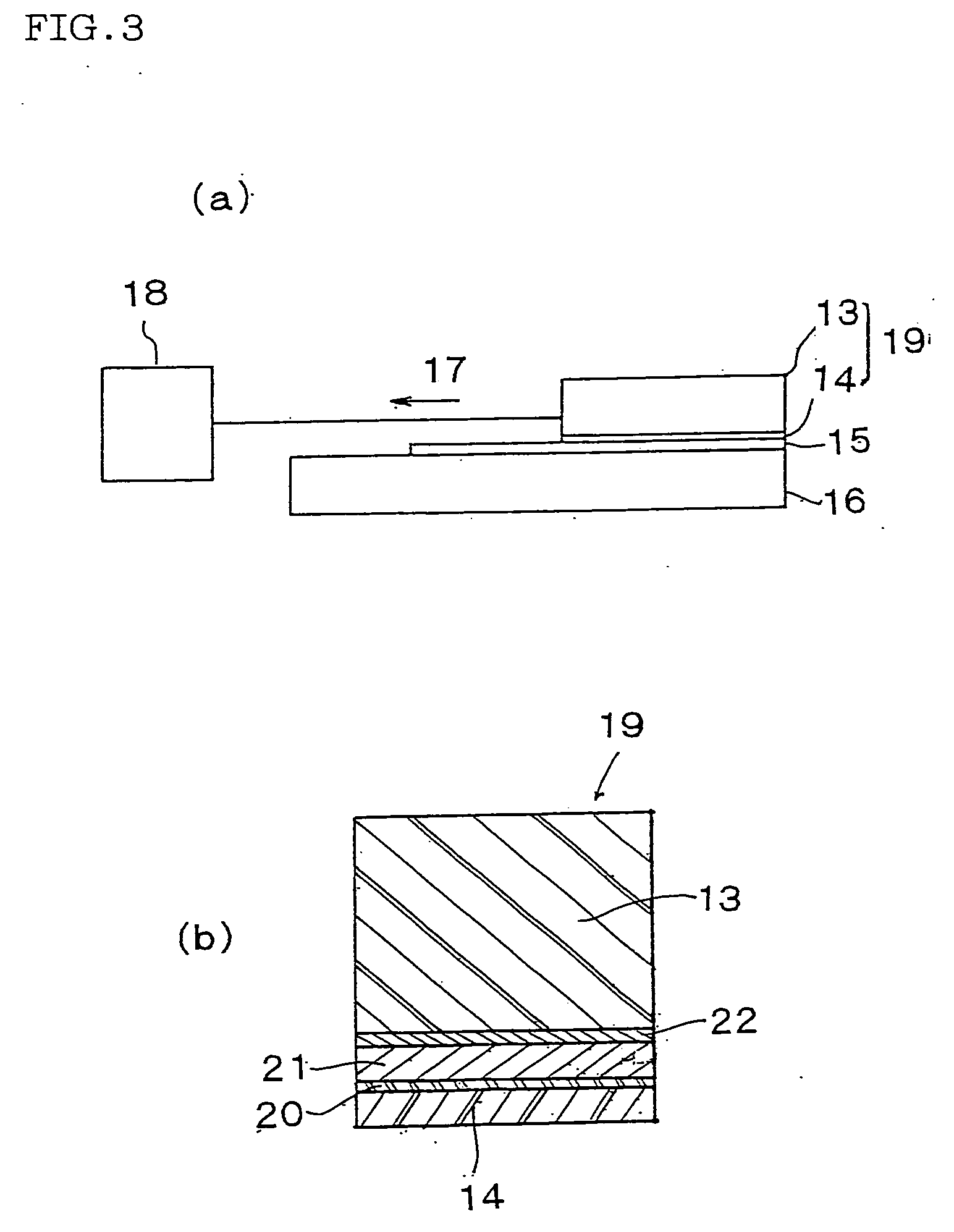

Grinding pad and method of producing the same

InactiveUS20050064709A1Reduce rateReduce hardnessLayered productsAbrasion apparatusAluminum substrateSemiconductor

The invention provides a polishing pad by which optical materials such as lenses, reflecting mirrors etc., or materials requiring a high degree of surface planarity, as in the polishing of silicone wafers, glass substrates or aluminum substrates for hard disks, or general metal polishing, can be flattened with stability and high polishing efficiency. The invention also provides a polishing pad for semiconductor wafers, which is superior in planarizing characteristic, is free from scratches and can be produced at low cost. There is provided a polishing pad which is free from dechucking error so that neither damage to wafers nor decrease in operating efficiency occurs. There is provided a polishing pad which is satisfactory in planarity, within wafer uniformity, and polishing rate and produces less change in polishing rate. There is provided a polishing pad which can make planarity improvement and scratch decrease compatible.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Biodegradable polyesters

InactiveUS6120895AMonocomponent copolyesters artificial filamentPolyurea/polyurethane coatingsFiberPolymer science

PCT No. PCT / EP97 / 04908 Sec. 371 Date Mar. 17, 1999 Sec. 102(e) Date Mar. 17, 1999 PCT Filed Sep. 19, 1997 PCT Pub. No. WO98 / 12242 PCT Pub. Date Mar. 20, 1998Biodegradable polyesters based on A) 95-99.99 mol % of at least one polyester A containing as monomeric building blocks of an acid component comprising a11) 20-95 mol % of at least one aliphatic or cycloaliphatic dicarboxylic acid or its ester-forming derivative and a12) 5-80 mol % of at least one aromatic dicarboxylic acid or its ester-forming derivative and at least one dihydroxy compound or at least one amino alcohol or their mixtures, and B) 0.01-5 mol % of a mixture comprising mono-, bi-, tri-, tetra- and higher-nuclear isocyanurates or corresponding compounds containing two, three or four functional groups capable of reacting with the end groups of polyester A, or mixtures of the isocyanurates and the corresponding compounds, as well as molding compositions comprising said polyesters, their manufacture and their use in the manufacture of moldings, filsm, fibers and coatings.

Owner:BASF AG

Aqueous compositions comprising polymeric duller particle

ActiveUS7829626B2Limit scopeImprove consistencyLiquid surface applicatorsLayered productsSingle stageTert-butyl acrylate

The present invention provides aqueous matte coating compositions comprising a binder component B) and a polymeric duller component A) composed of particles of one or more multi-stage copolymer or single stage crosslinked (co)polymer, e.g. crosslinked t-butyl (meth)acrylate, the duller component particles A) having an average diameter of 1-20 μm. Components A) and B) are compatible. Preferably, the duller component A) is acrylic; more preferably, components A) and B) are acrylic. The aqueous compositions provide matte coatings having haptic or feel (soft touch) properties, film and appearance properties, including burnish resistance and low color loss.

Owner:ROHM & HAAS CO

Articles with hydrophilic coating

InactiveUS6866936B2Favorable and associative interactionImprove wet strengthNon-fibrous pulp additionLiquid surface applicatorsWater basedHydrophilic coating

A water-based coating composition suitable for preparing hydrophilic surfaces on various articles is provided which includes a supporting polymer having functional moieties capable of undergoing crosslinking reactions, said supporting polymer soluble in or emulsified in an aqueous based medium; and a hydrophilic polymer, said hydrophilic polymer associated with the supporting polymer. The composition is characterized in that, when crosslinked at the functional moieties, the supporting polymer forms a three-dimensional network which substantially minimizes disassociation of the hydrophilic polymer.

Owner:SURFACE SOLUTIONS LAB

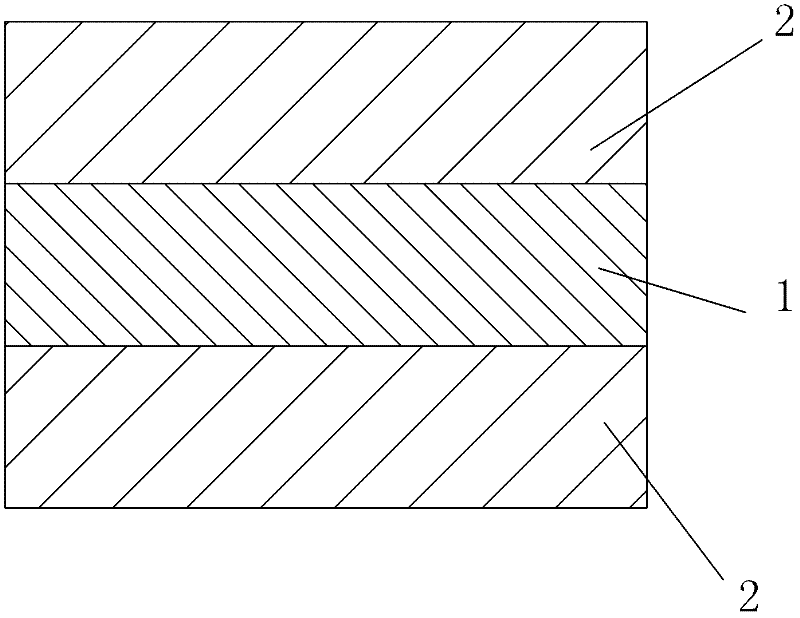

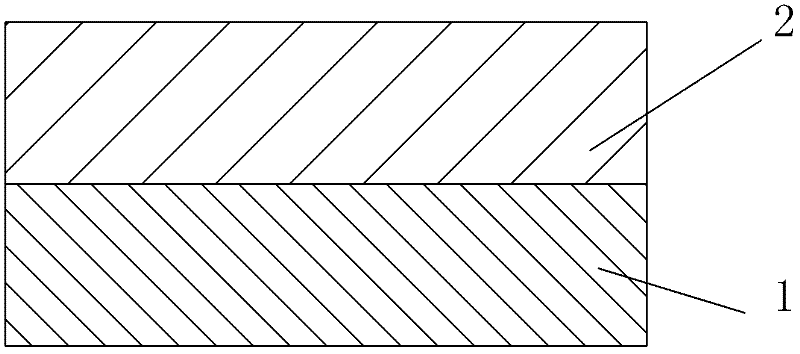

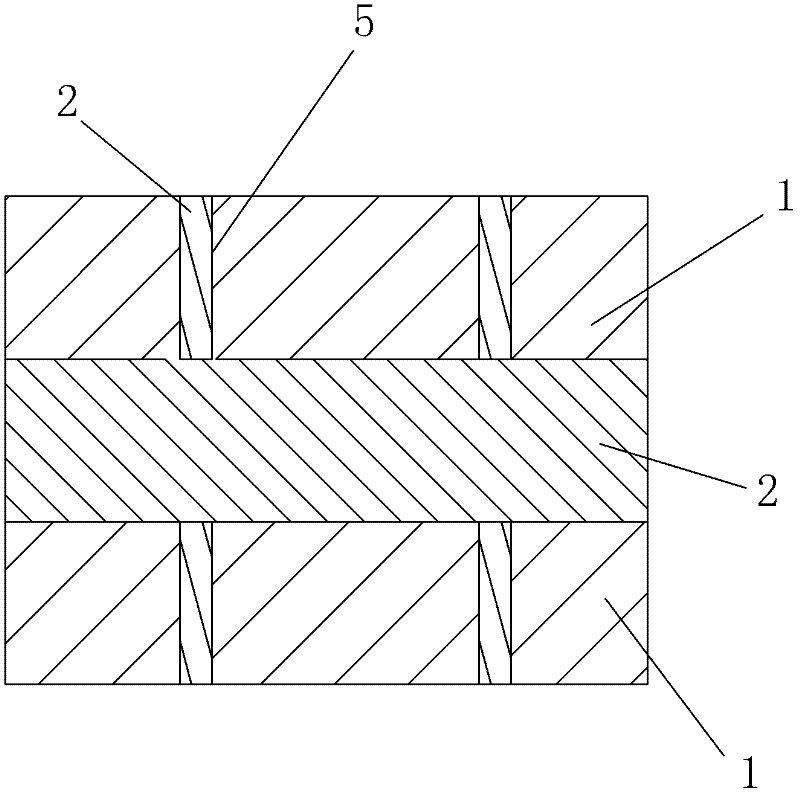

Weather-resistant and high thermal conductive coating, radiating solar rear panel and efficient solar cell panel

InactiveCN102516852AImprove thermal conductivityMeet service life requirementsPolyureas/polyurethane adhesivesPhotovoltaicsWeather resistanceConductive coating

The invention discloses a weather-resistant and high thermal conductive coating, a radiating solar rear panel and an efficient solar cell panel. The weather-resistant and high thermal conductive coating consists of 10 to 50 parts of weather-resistant resin, 5 to 30 parts of curing agent, 0.1 to 5 parts of organic filler, 30 to 80 parts of inorganic filler, and 30 to 100 parts of solvent. The radiating solar rear panel comprises a base layer, and the weather-resistant and high thermal conductive coating is arranged on at least one surface of the base layer or arranged between the base layers. The efficient solar cell panel comprises a solar front panel and the radiating solar rear panel, a solar cell circuit is arranged between the solar front panel and the radiating solar rear panel, and an encapsulation material is arranged on one side or two sides of the solar cell circuit. The weather-resistant and high thermal conductive coating can be directly coated on a base material and has high binding power and an excellent thermal conductive effect, and the weather resistance of the coating meets the requirement of a solar module for the service life of over 25 years.

Owner:ALLSTAE TECH ZHONGSHAN

Three-dimensional objects produced from materials having multiple mechanisms of hardening

InactiveUS20160160077A1Enhance or speed the refilling of the build regionIncreased formationManufacturing enclosuresLayered productsPolymer scienceCationic polymerization

A three dimensional object includes (a) a light polymerized first component; and (b) a second solidified component different from the first component. The object is preferably of a polymer blend formed from the first component and the second component, with the polymer blend as an interpenetrating polymer network, a semi-interpenetrating polymer network, or a sequential interpenetrating polymer network. In some preferred embodiments, the second component does not contain a cationic polymerization photoinitiator. In some preferred embodiments, the three dimensional object is produced by the process of continuous liquid interface production.

Owner:CARBON INC

Radiation curable composition comprising a urethane oligomer having a polyester backbone

InactiveUS6023547AOptical fibre with multilayer core/claddingPolyurea/polyurethane coatingsPolyesterOligomer

A radiation curable composition comprising a urethane oligomer with a polyester backbone which composition, when cured, has improved hydrolytic stability. The composition comprises a urethane oligomer, having a polyester backbone with a number average molecular weight of less than about 1000, wherein the polyester backbone is at least in part based on a diol component wherein at least one carbon at the beta -position with respect to a hydroxyl group bears two carbon-containing substituents having a total of at least three carbon atoms. Alternatively, when the composition comprises a urethane oligomer with a number average molecular weight of less than about 2000, having a polyester polyol backbone with a number average molecular weight of less than about 1000, the polyester backbone is at least in part based on a diol component wherein at least one carbon at the beta -position with respect to a hydroxyl group bears at least one carbon-containing substituent.

Owner:DSM IP ASSETS BV

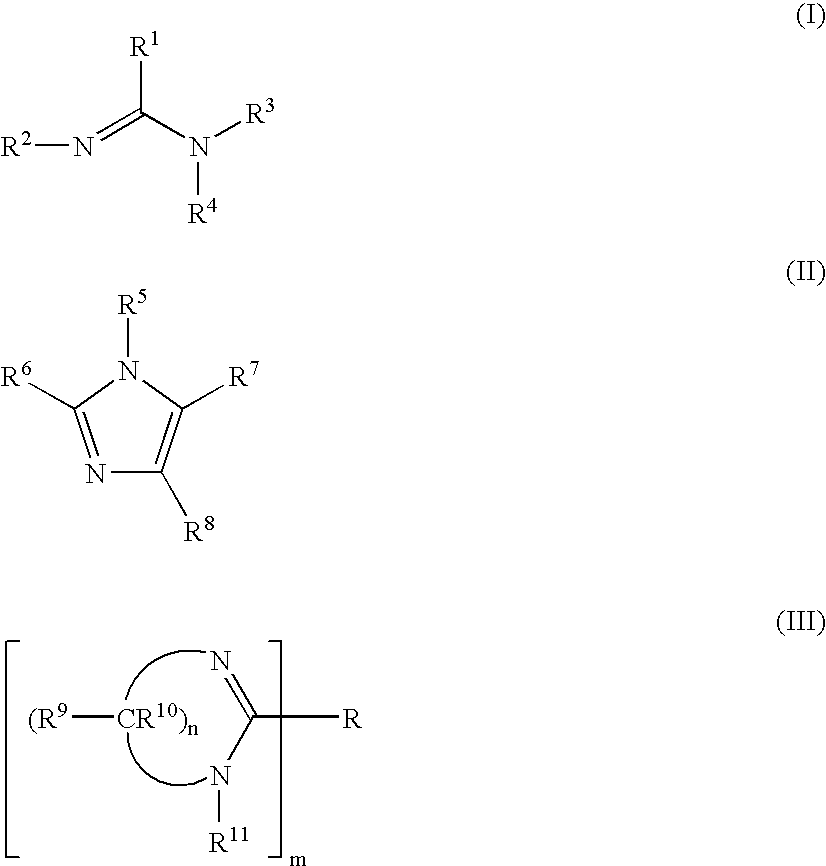

Organometallic compositions and coating compositions

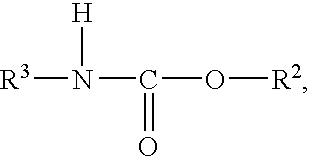

InactiveUS20060247341A1Reduce yellowingImprove moisture resistanceOrganic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsCarbamateZinc

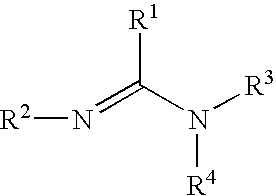

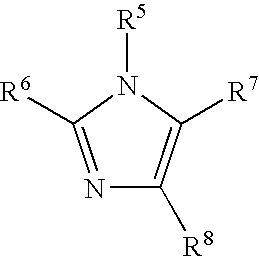

The present invention is directed to novel organometallic complexes as catalysts for the reaction of compounds with isocyanate and hydroxyl functional groups to form urethane and / or polyurethane and the process employing such catalysts. More particularly, the present invention is directed to novel complexes of zinc(II) with substituted amidines. These novel catalysts are useful for the production of urethanes and polyurethanes which are important in many industrial applications.

Owner:KING INDUSTRIES INC

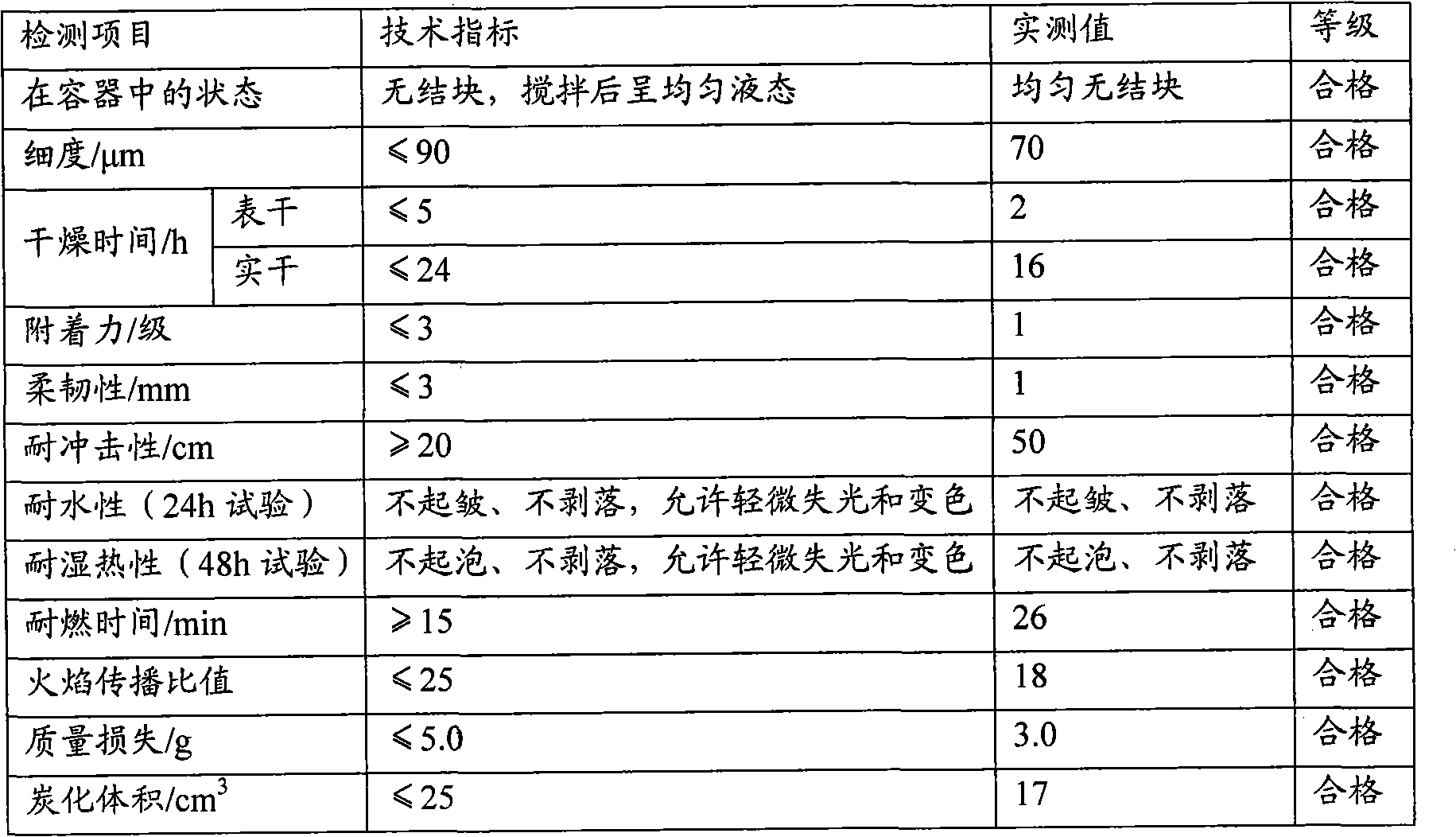

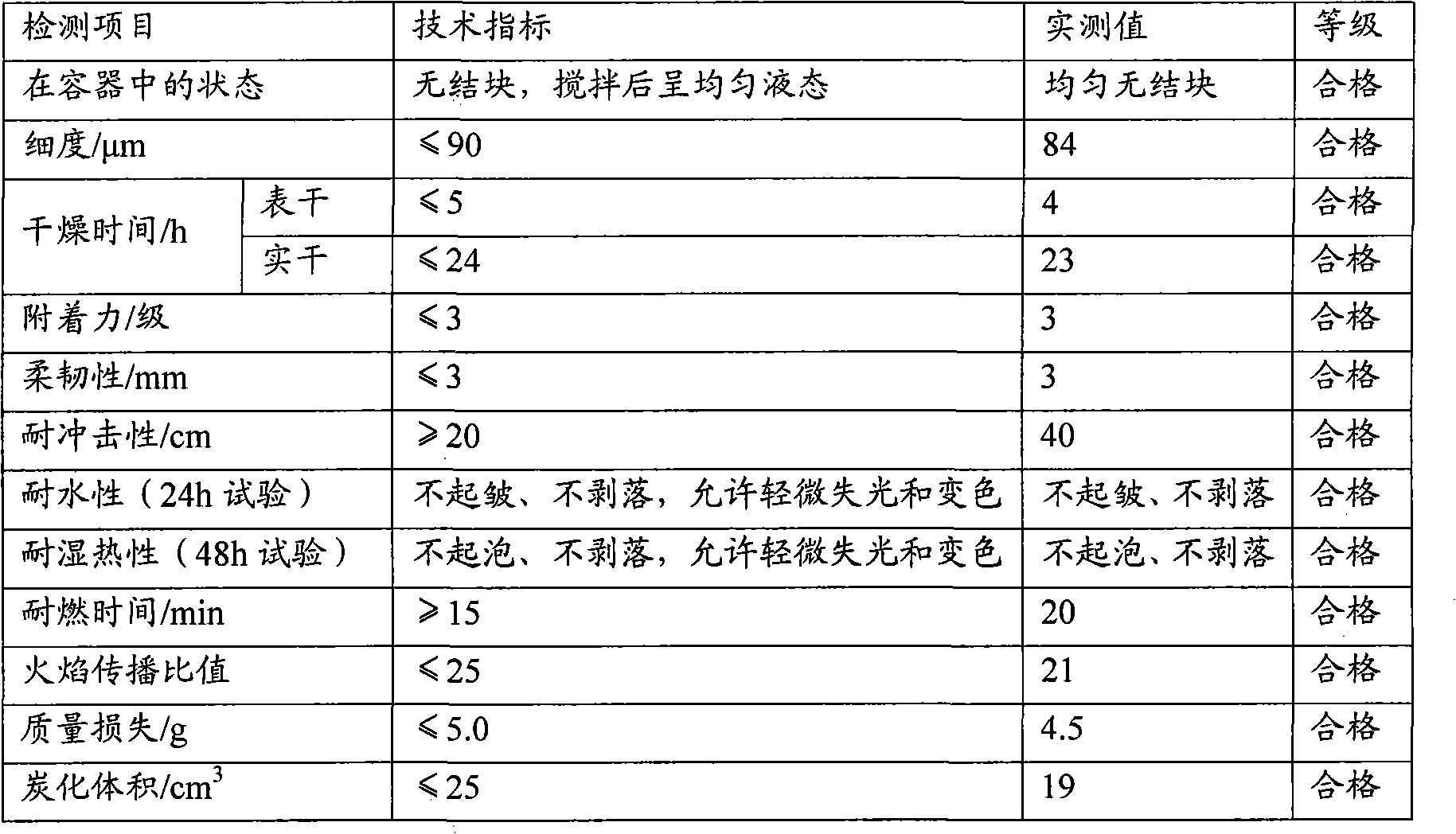

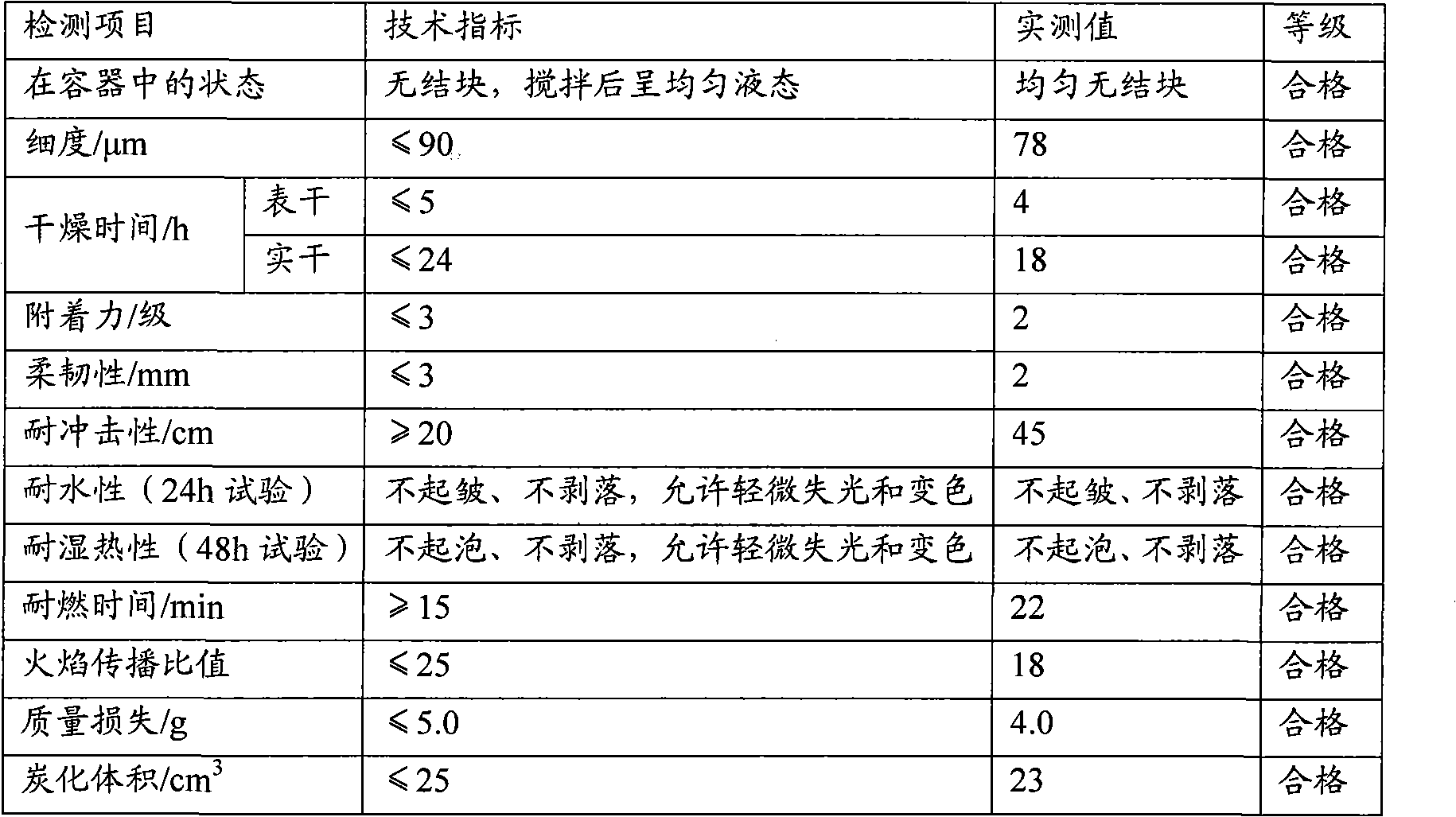

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

Polyurethane and preparation containing polyurethane

InactiveUS6884852B1Increase elasticityIncrease flexibilityOther chemical processesPolyureas/polyurethane adhesivesPolymer sciencePolyol

A polyurethane is produced by reacting at least components A and B, where a) a polyisocyanate or mixture of polyisocyanates is used as component A and b) a polyol or mixture of polymer is used as component B. Component B contains at least one polyether having a number average molecular weight of at least 4000 and a polydispersity of less than 1.5 and / or an OH functionality of between about 1.8 and about 2. Preparations containing such polyurethanes are useful as adhesives, coatings and sealants.

Owner:HENKEL KGAA

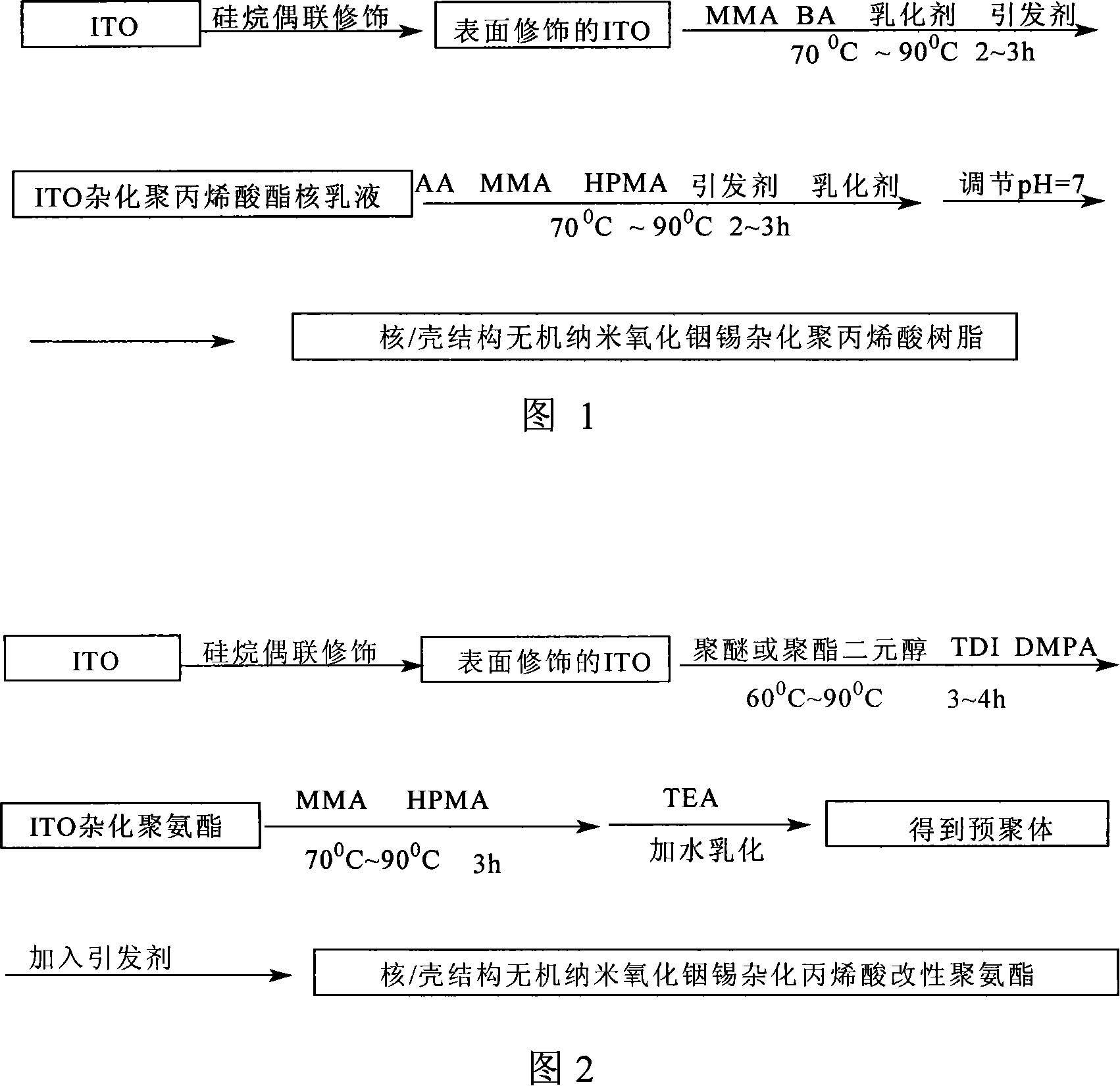

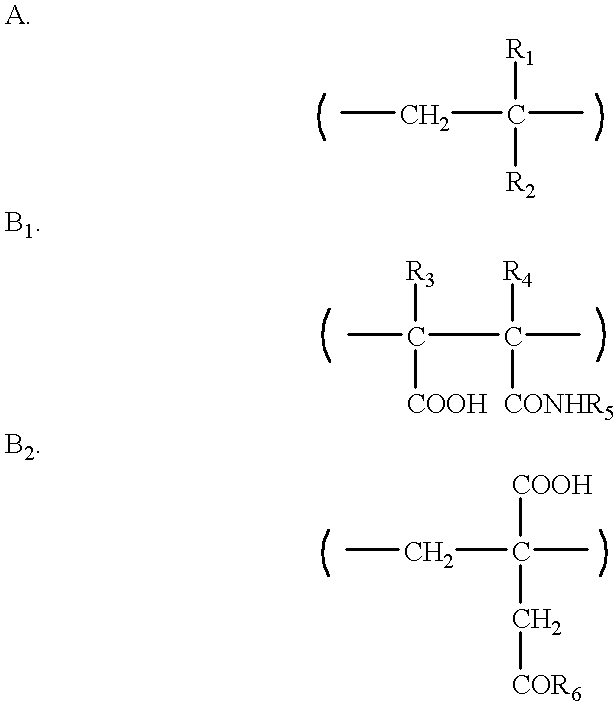

Nano transparent insulating paint and its preparing process

InactiveCN101108946AGood dispersionImprove stabilityFireproof paintsPolyurea/polyurethane coatingsInfraredIn situ polymerization

The invention relates to a nano transparent heat insulation coating, which comprises the following components: inorganic nano particle hybrid high molecular resin, coating additive and thinner. Wherein, the inorganic nano particle hybrid high molecular resin is the resin with core / shell structure and synthesized by inorganic nano heat insulation powder and high molecular resin through in-situ polymerization and the high molecular resin covers the nano heat insulation powder. The invention also provides a preparation method of the nano transparent heat insulation coating. The nano transparent heat insulation coating film forming material is the inorganic nano particle hybrid high molecular resin and is characterized by strong adhesive force, transparency and shielding infrared for heat insulation, which can be coated on the surfaces of glass, metals and cement and is especially for glass of cars or buildings. The invention adopts the inorganic nano particle hybrid high molecular resin with core / shell structure prepared through in-situ polymerization, which is simple and easy and has good coating properties.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

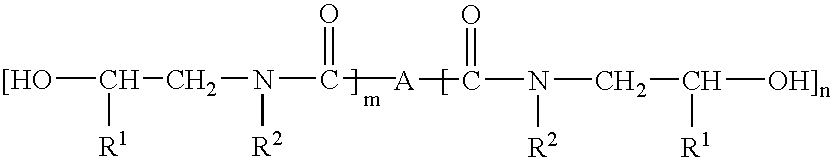

Flexible, flame-retardant, aqueous-processable photoimageable composition for coating flexible printed circuits

A flexible, flame-retardant, aqueous processable, photoimageable resin composition for forming a permanent, protective coating film for printed circuitry and a multilayer photoimageable element containing a layer of the photoimageable resin composition in combination with a low tack photoimageable resin sublayer and a temporary support film are disclosed. The photoimageable resin composition has excellent aqueous developability and provides a cured coating film having good flexibility, adhesion, solvent resistance, surface hardness, thermal resistance, electrical insulating properties and flame retardancy.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com