Patents

Literature

65results about How to "Easily degradable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

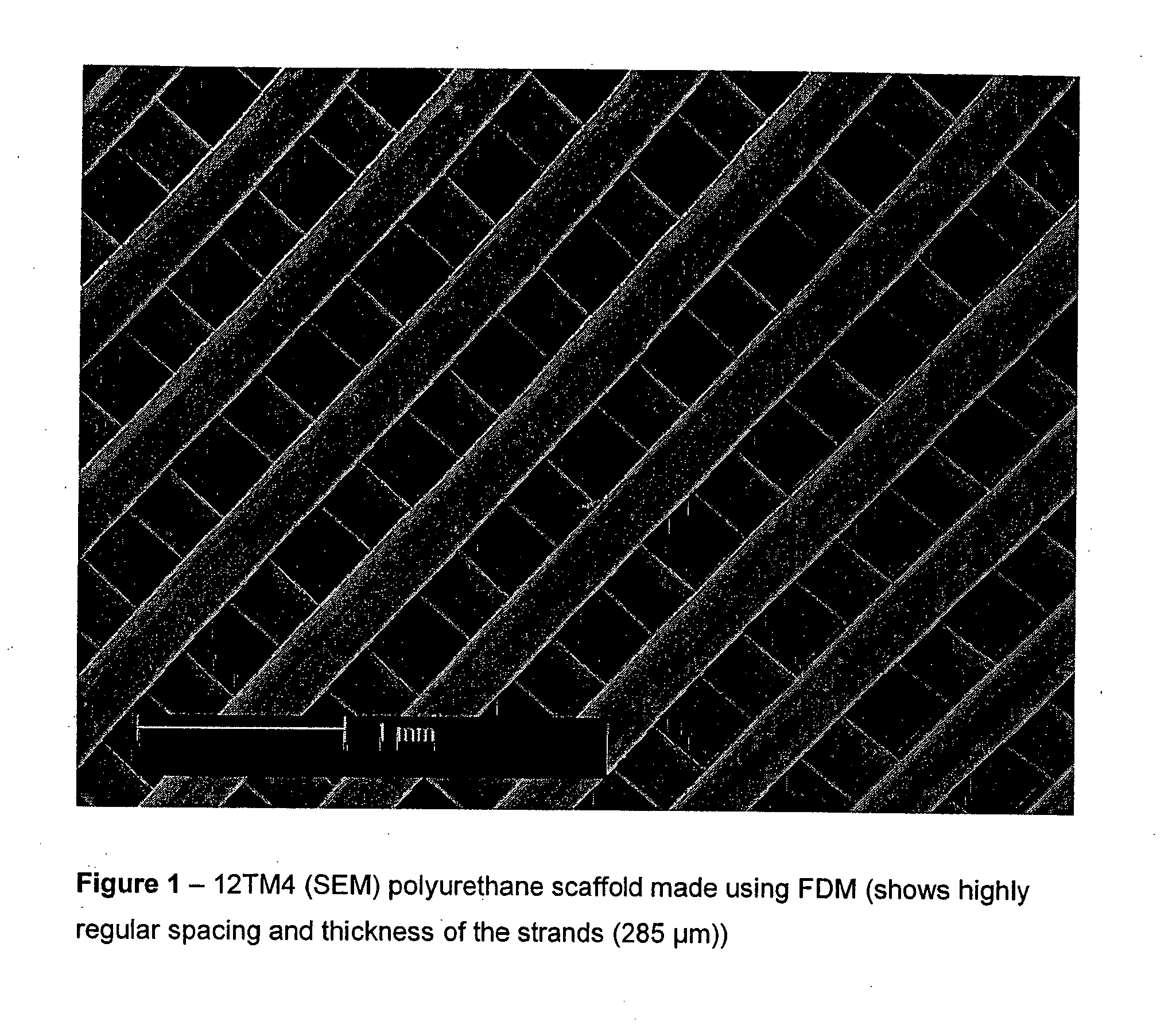

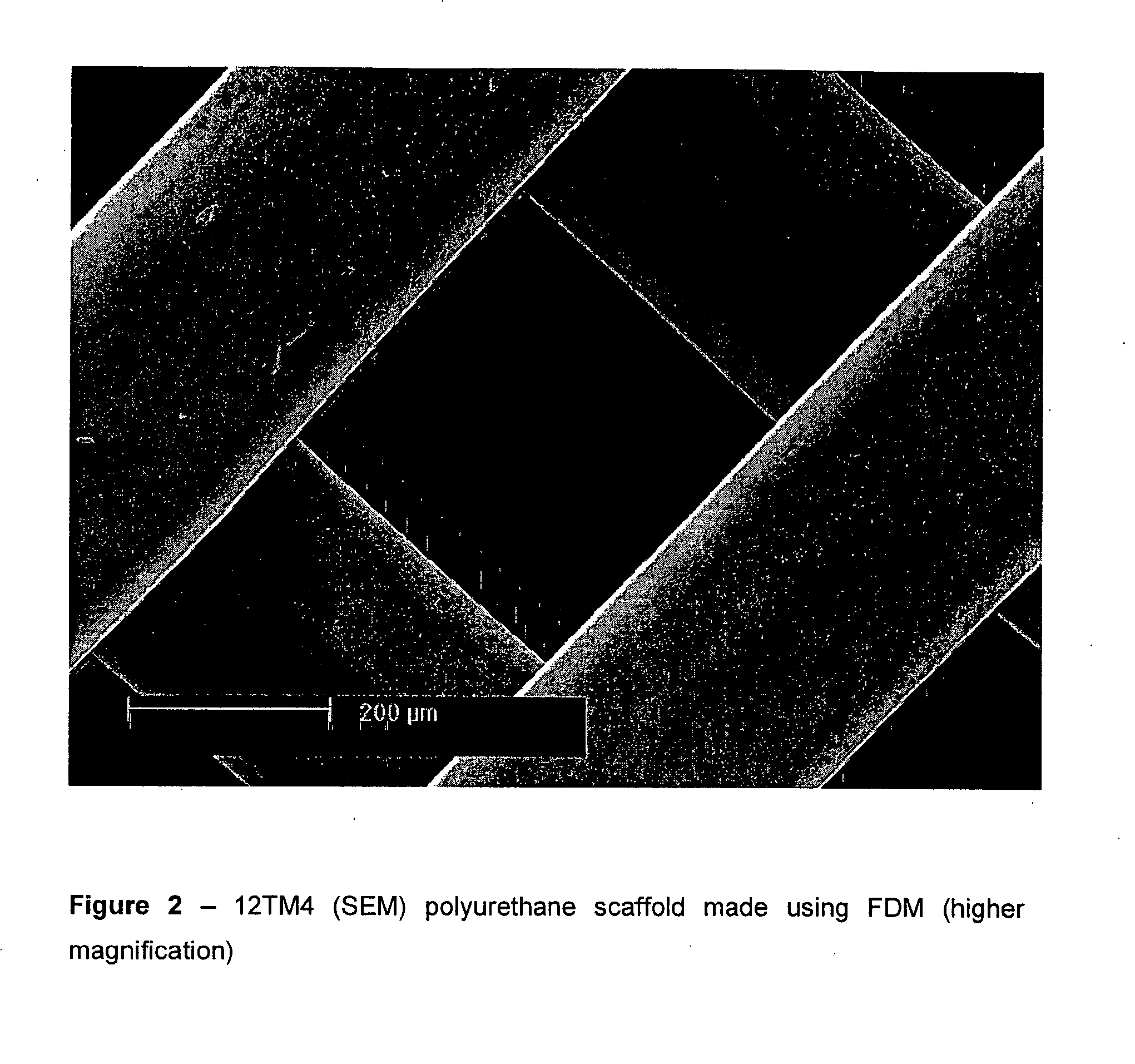

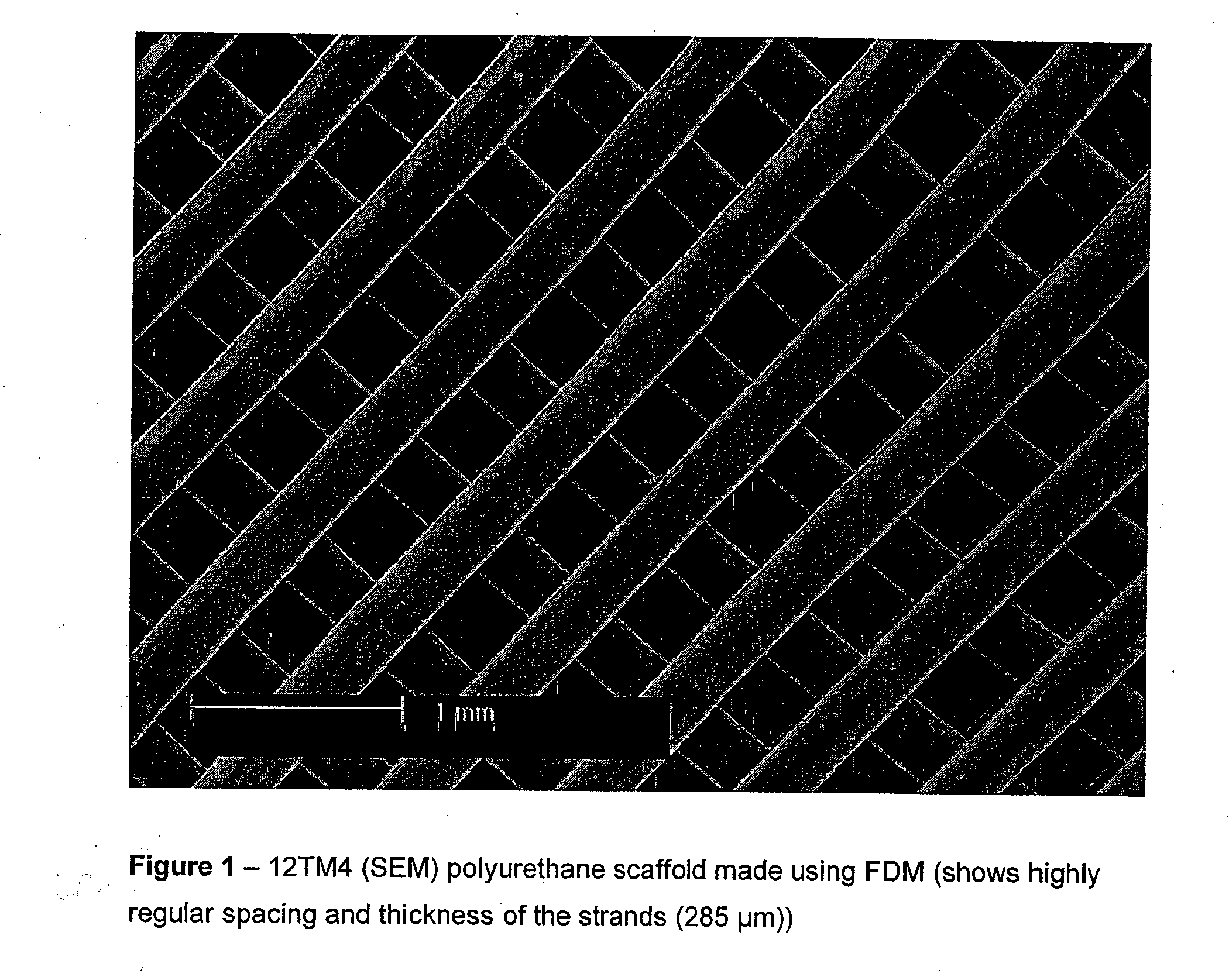

Biodegradable polyurethane and polyurethane ureas

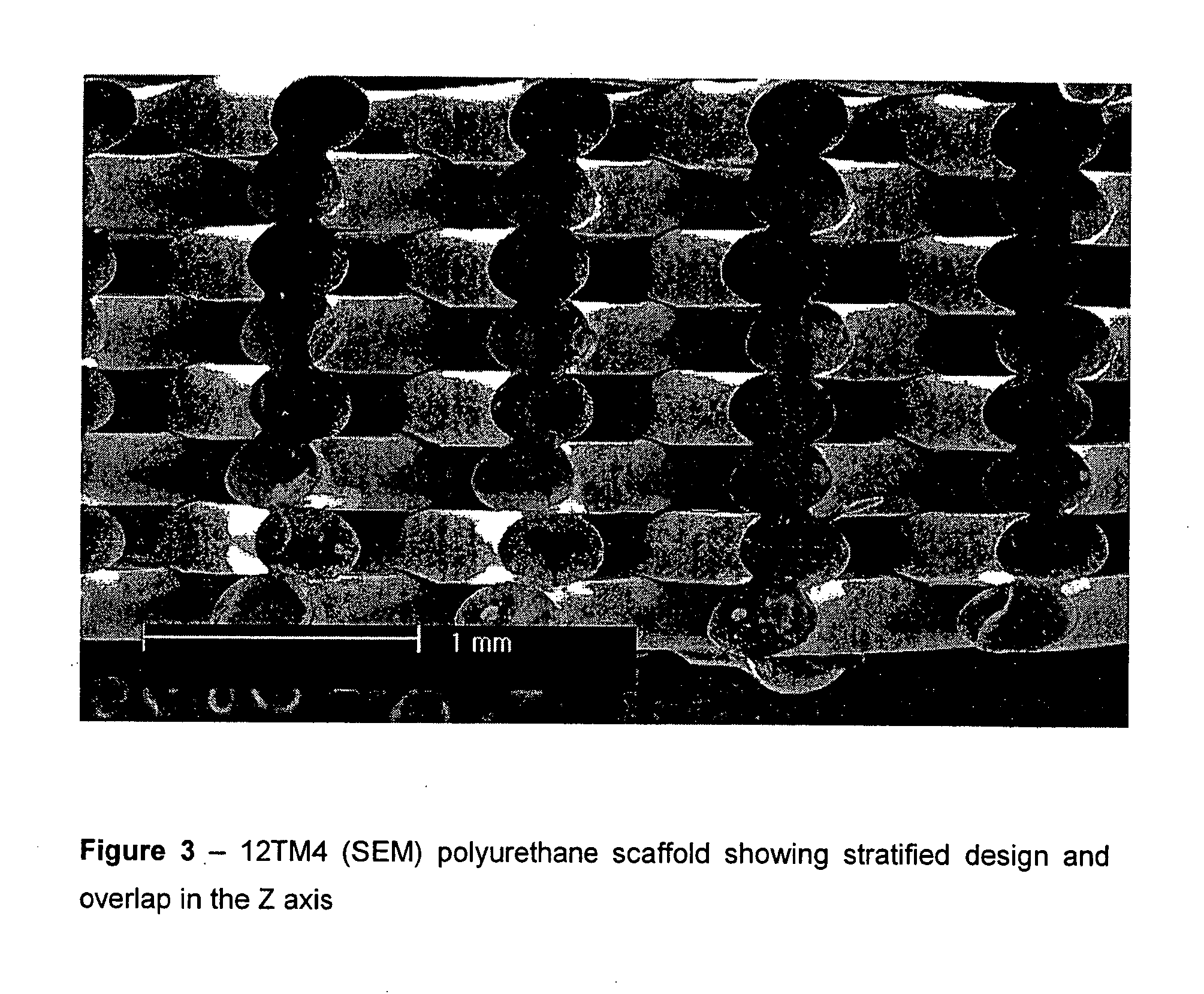

ActiveUS20060051394A1Fast formingEasily degradableOrganic active ingredientsSurgeryPolyolInsertion stent

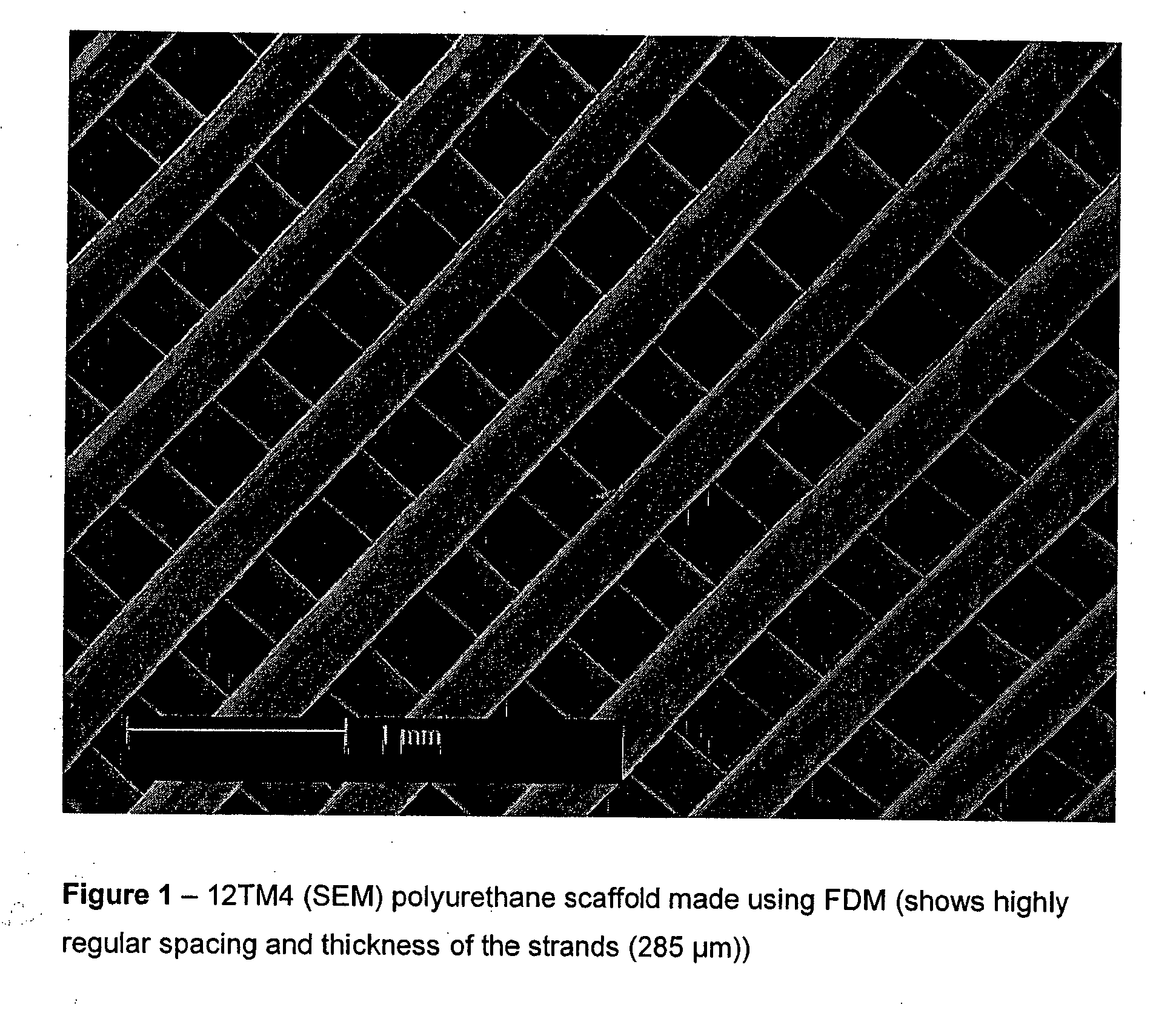

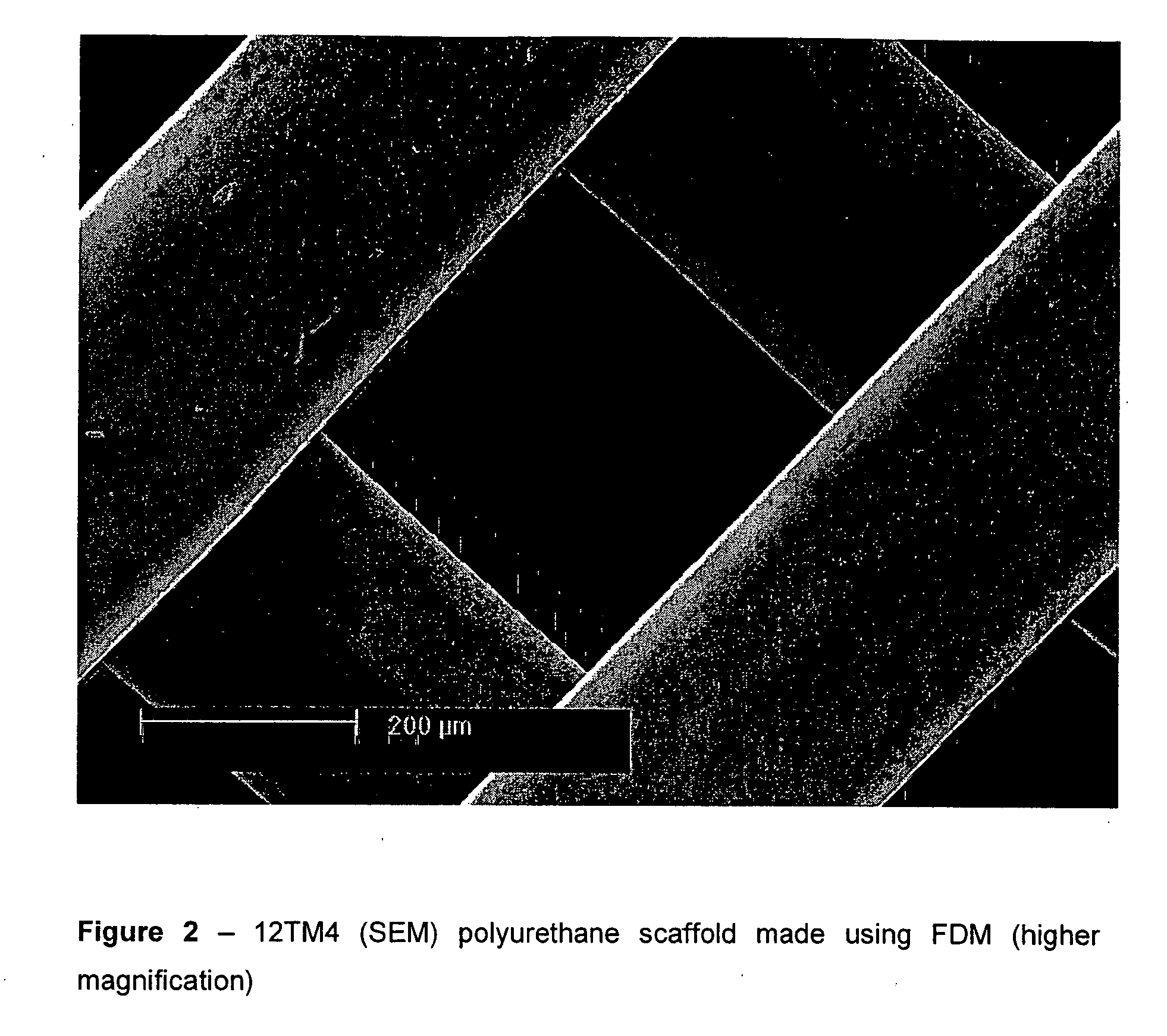

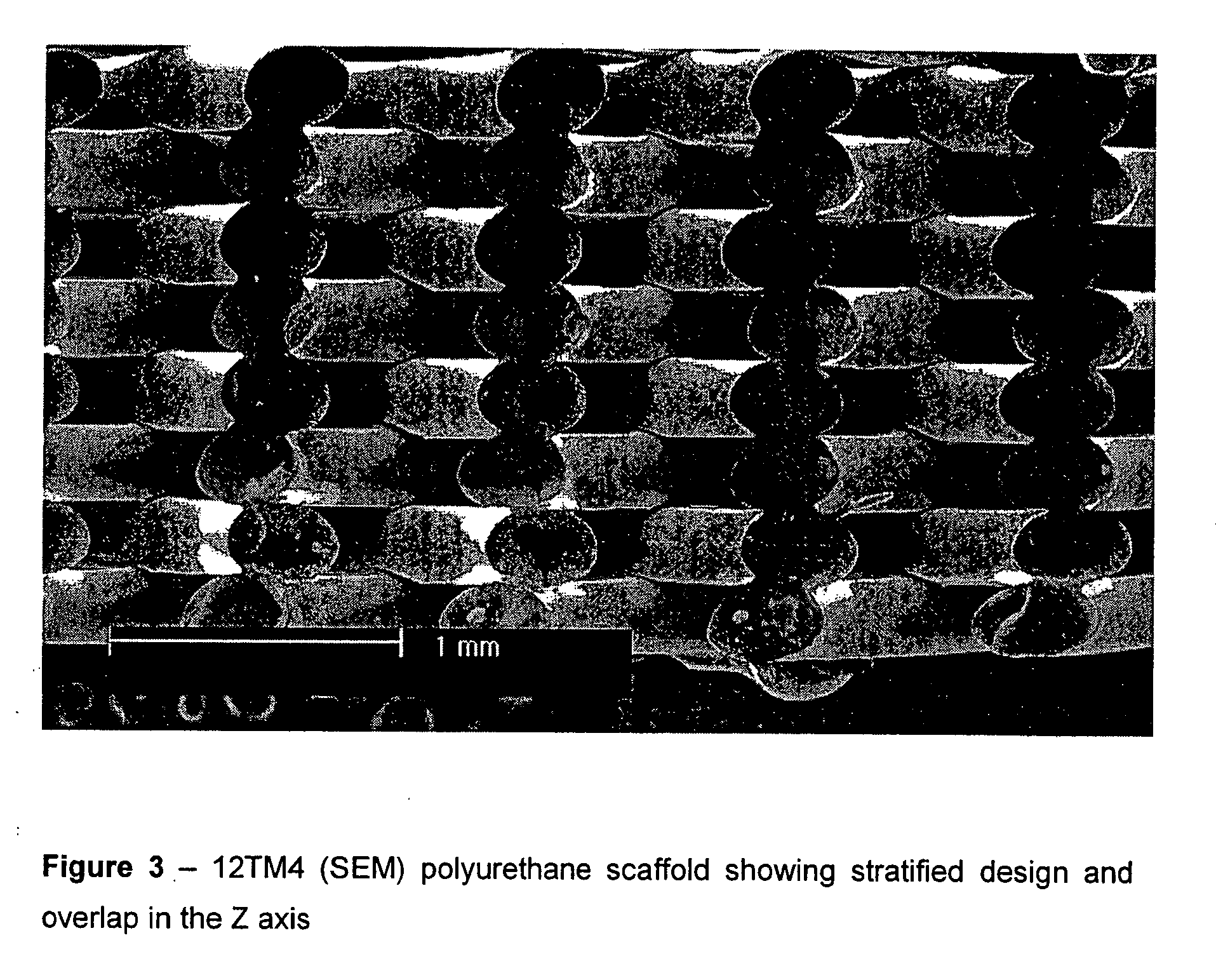

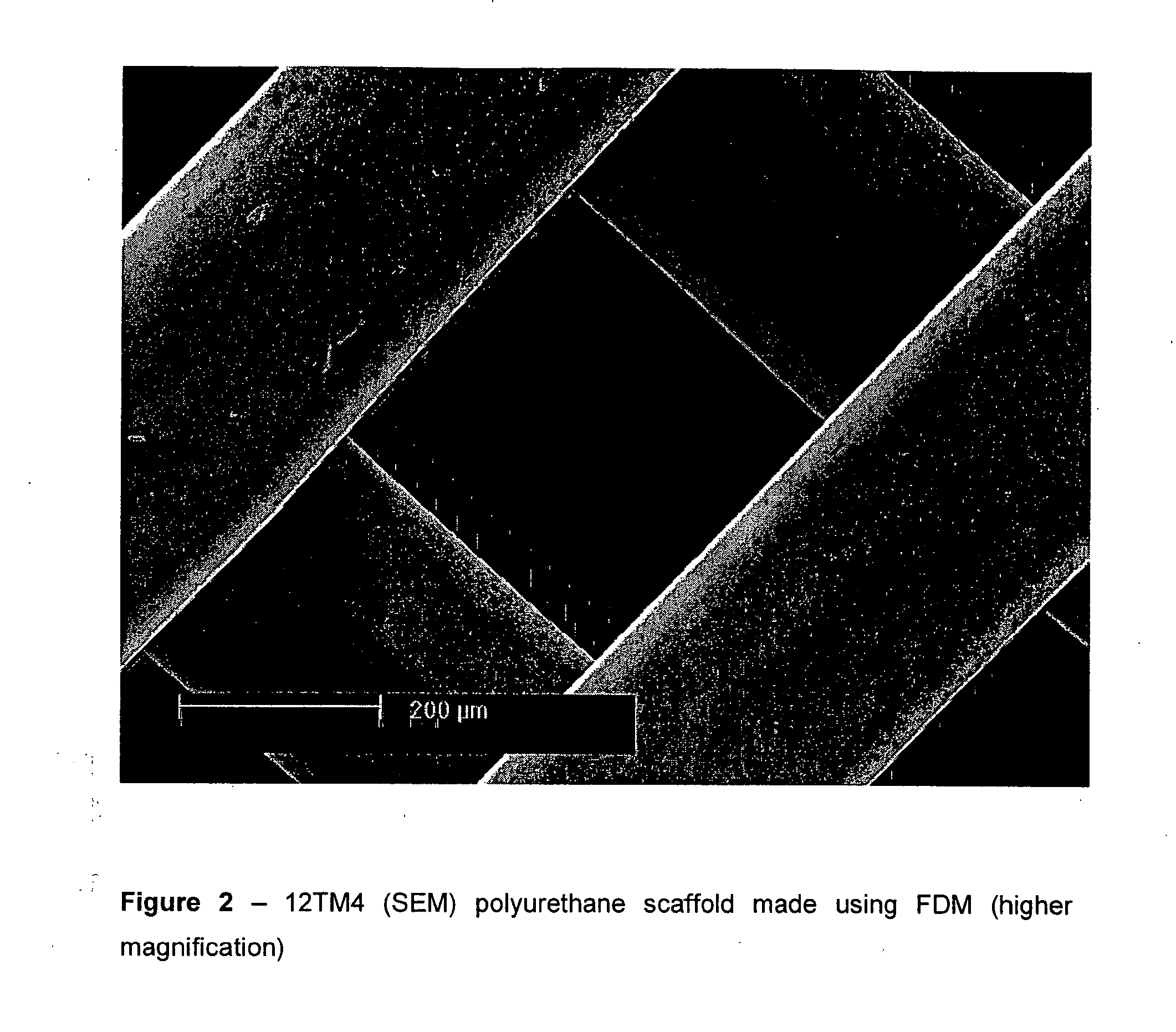

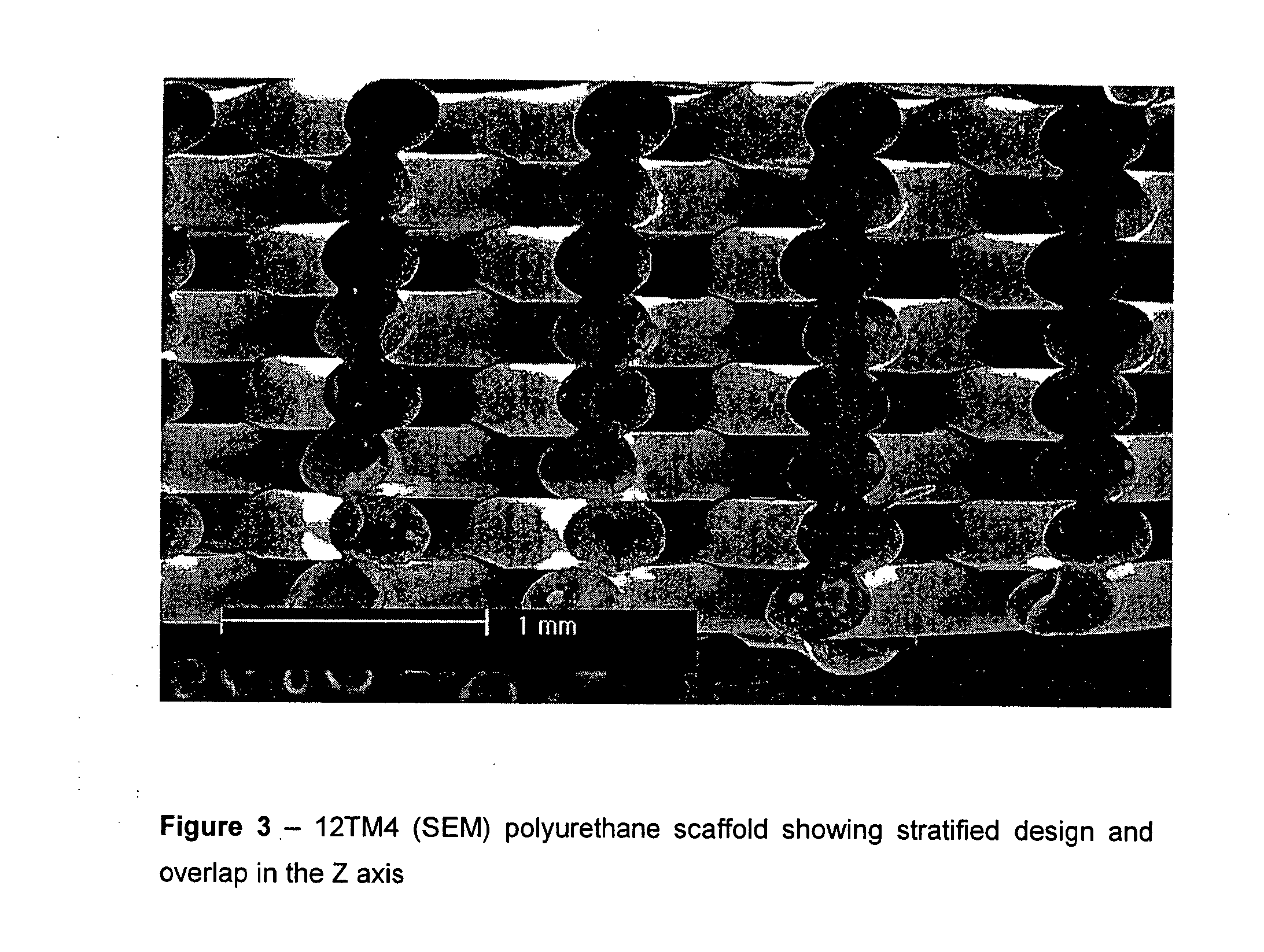

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Oxygen-scavenging filled polymer blend for food packaging applications

InactiveUS6037022AOxygen transmission propertyLow oxygenDomestic containersThin material handlingPaperboardFood packaging

The specification discloses a polymer blend especially well-suited for coating paperboard substrates used in food packaging, particularly acidic or acid-generating foods such as fruit and vegetable juices. The blend contains an acid-activatable oxygen scavenger dispersed in a film-forming synthetic polymer such as an EVOH copolymer. When placed as a film or layer on the side of the substrate inside the container in contact with the food the blend is effective to reduce the oxygen in the container over time to a very low concentration, replacing the same with carbon dioxide, for an excellent preservative effect.

Owner:INT PAPER CO

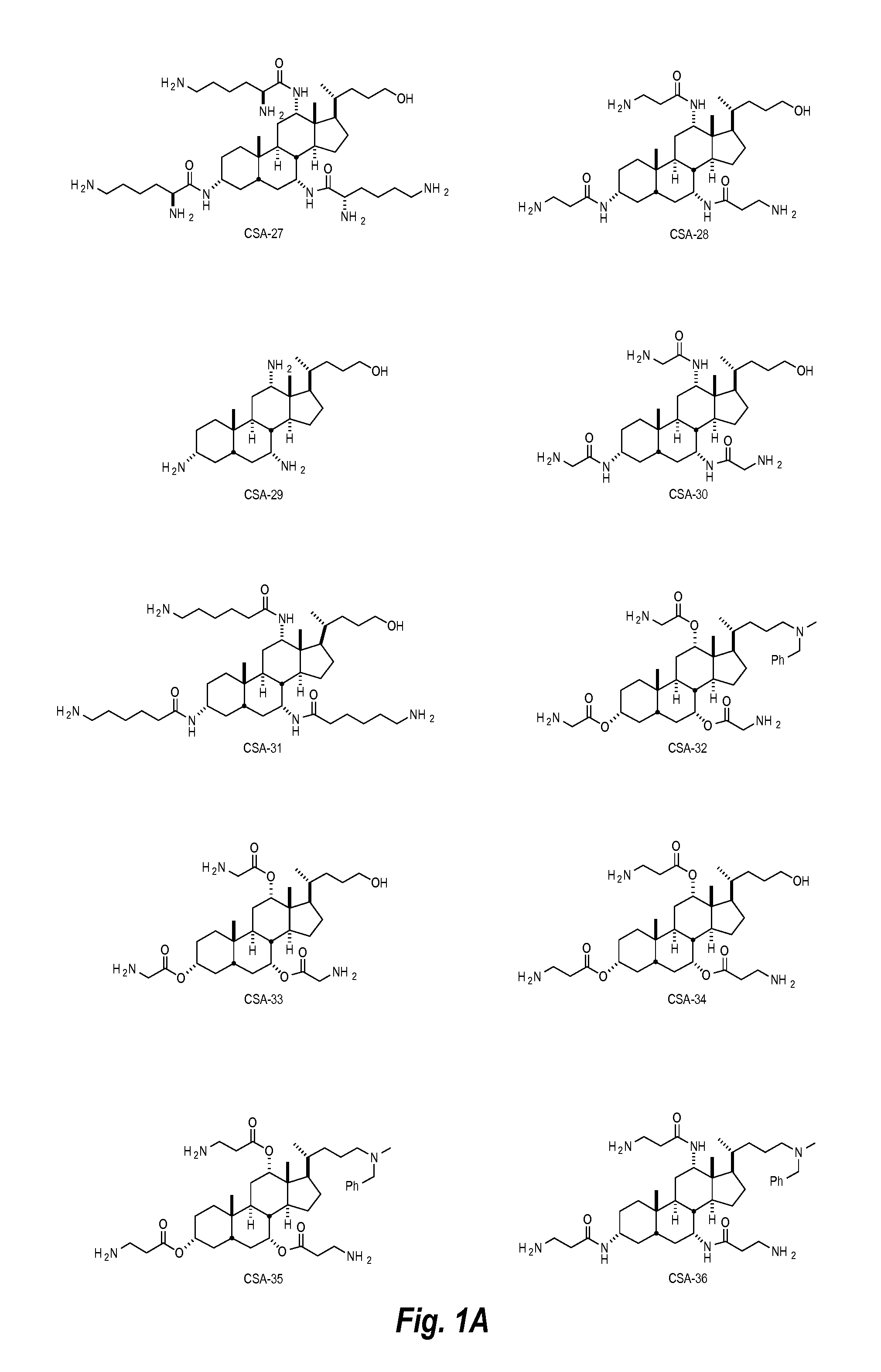

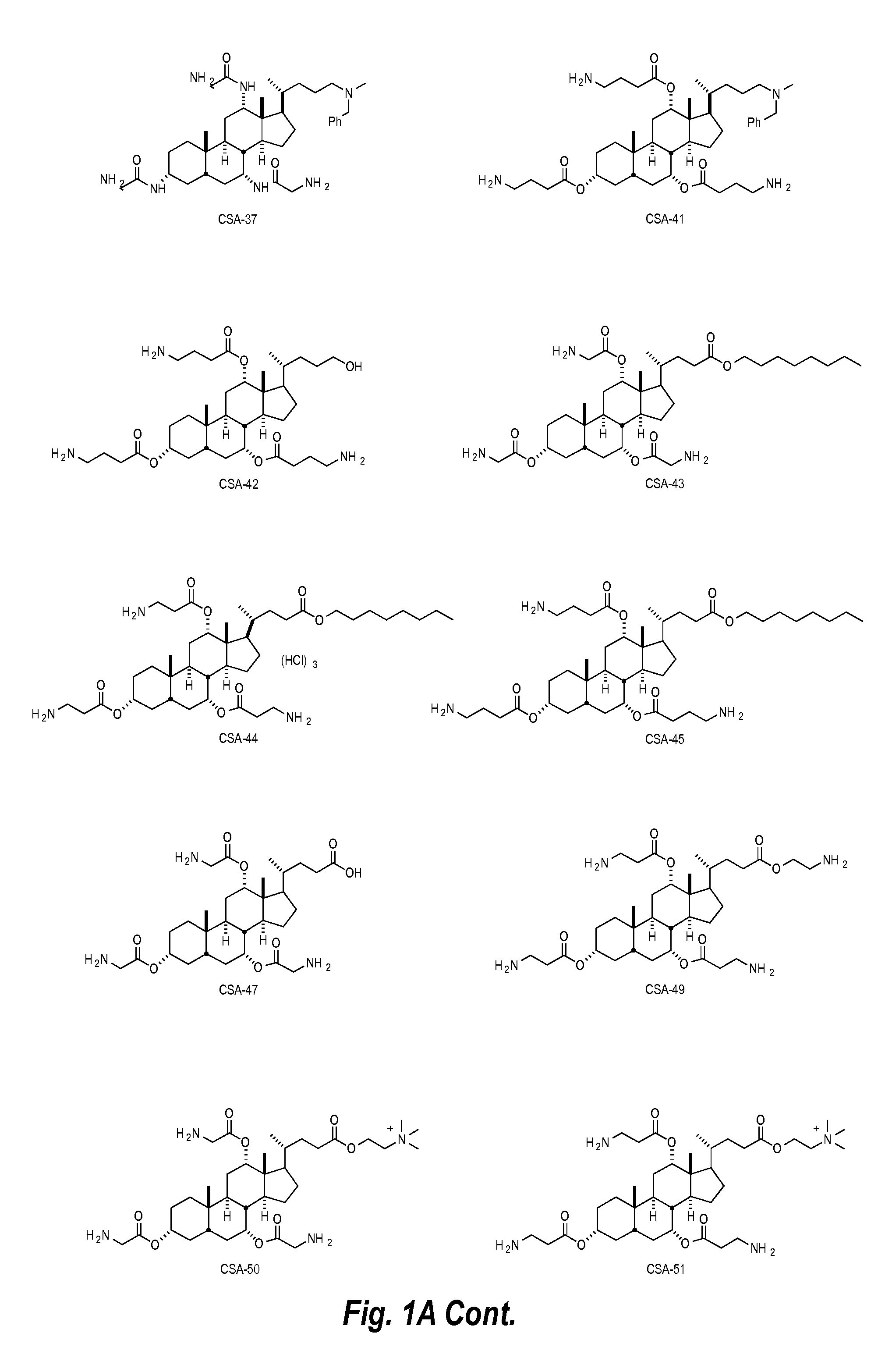

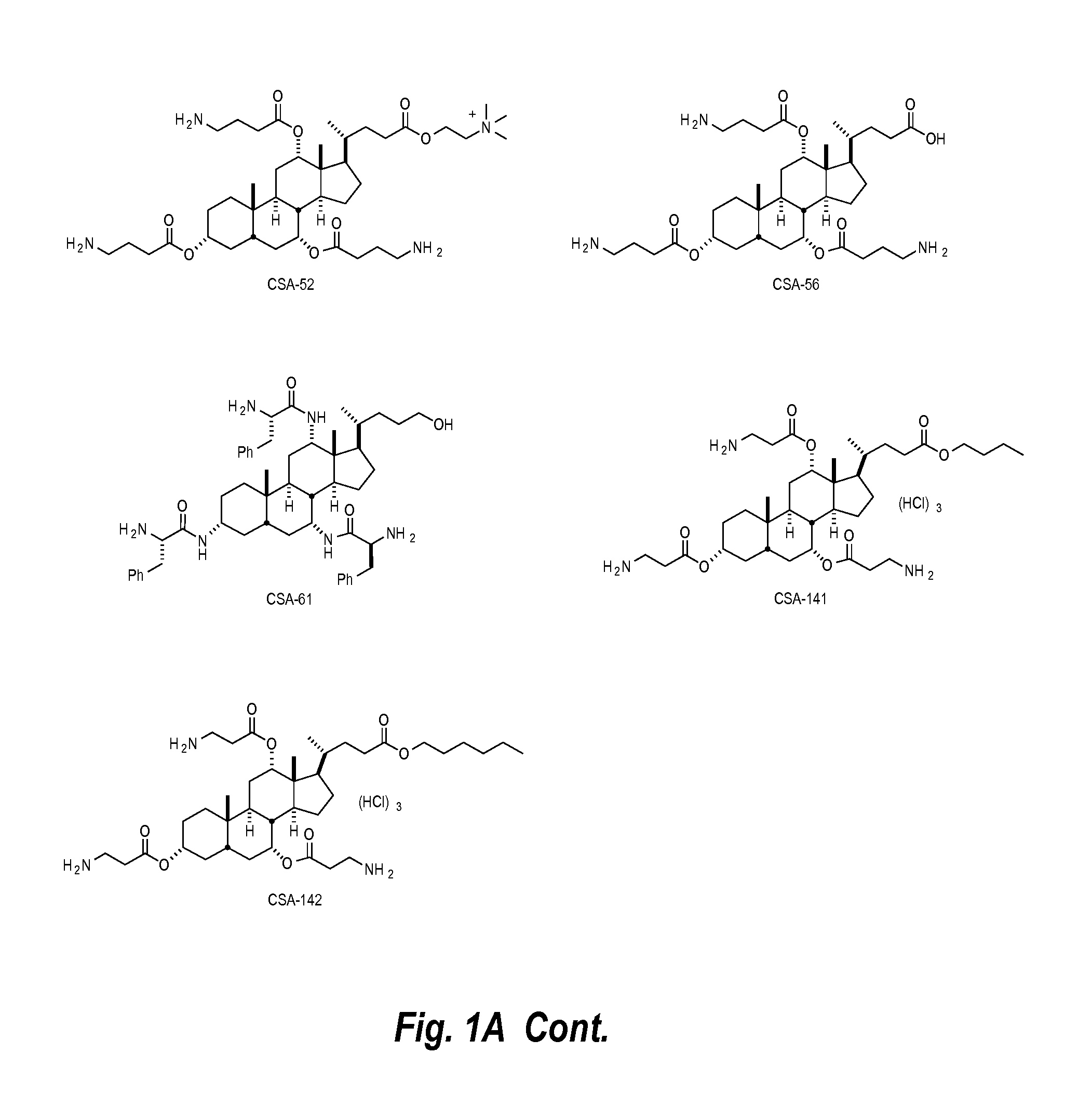

Anti-microbial food processing compositions including ceragenin compounds and methods of use

InactiveUS20130236619A1Damaging and altering quality characteristicLittle and riskOrganic active ingredientsPre-baking dough/flour preservationCerageninChemistry

Owner:BRIGHAM YOUNG UNIV

Biodegradable polyurethane and polyurethane ureas

ActiveUS20090081270A9Easily degradableEasily degradable hard segmentOrganic active ingredientsSurgeryPolyolInsertion stent

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

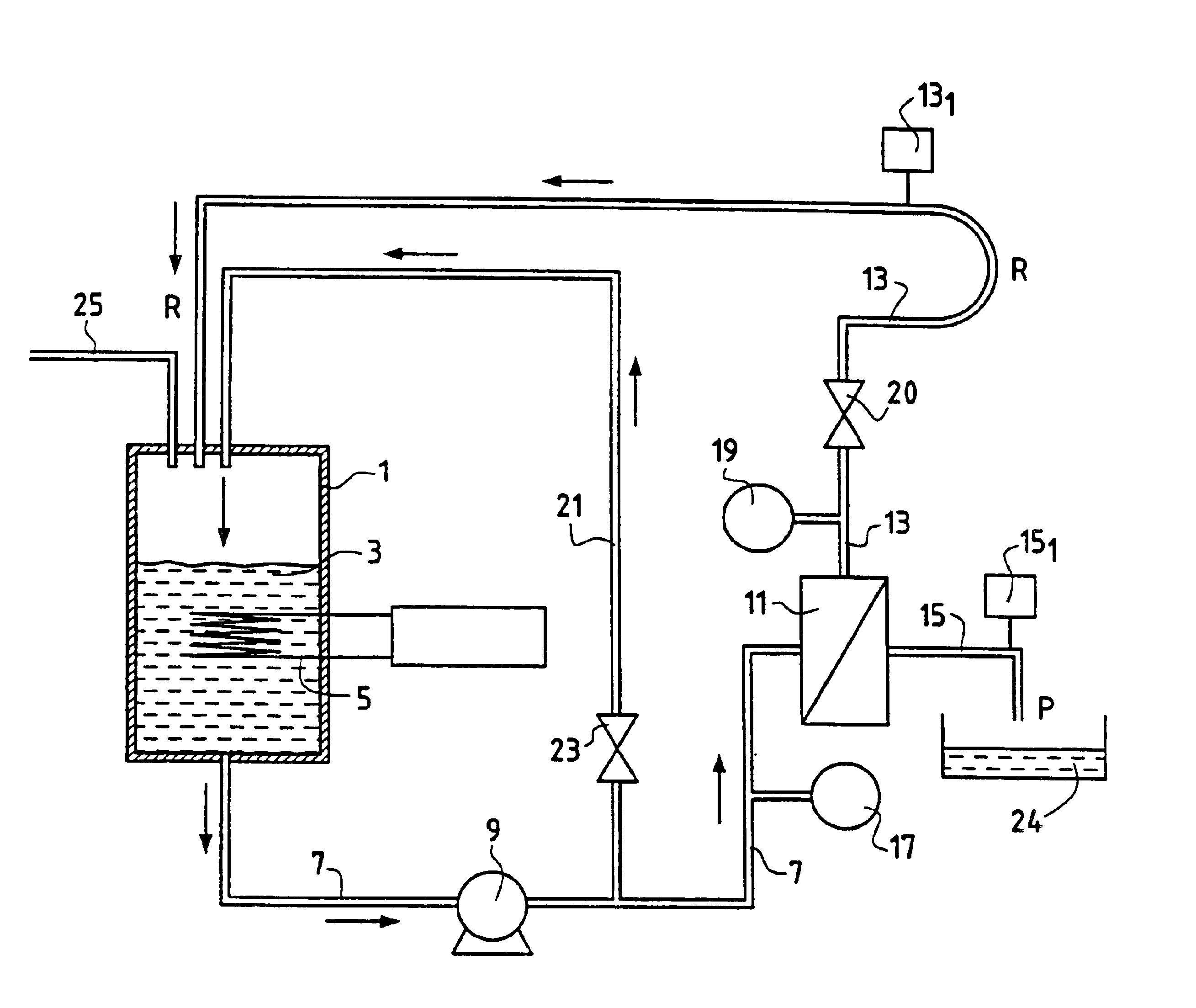

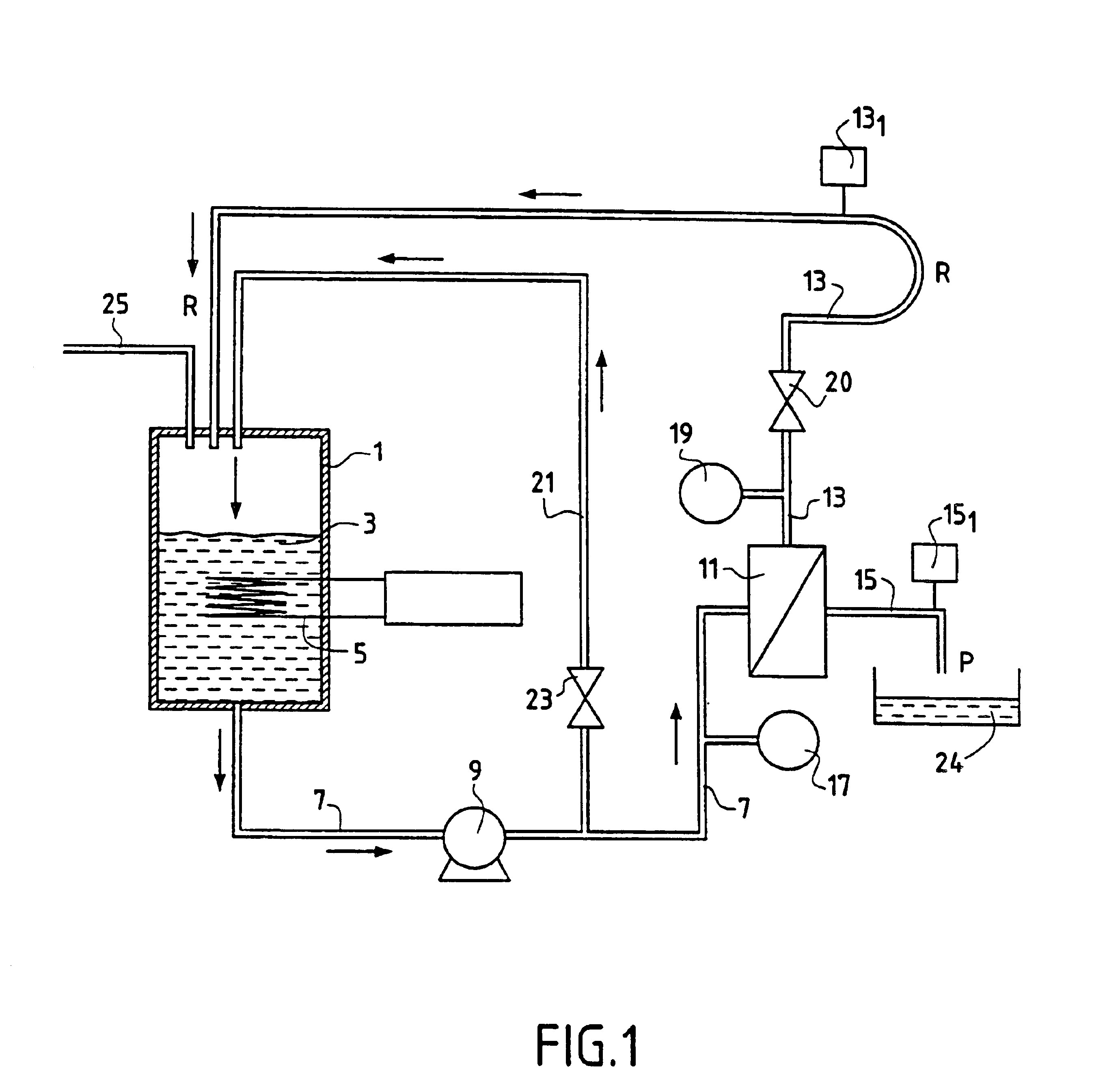

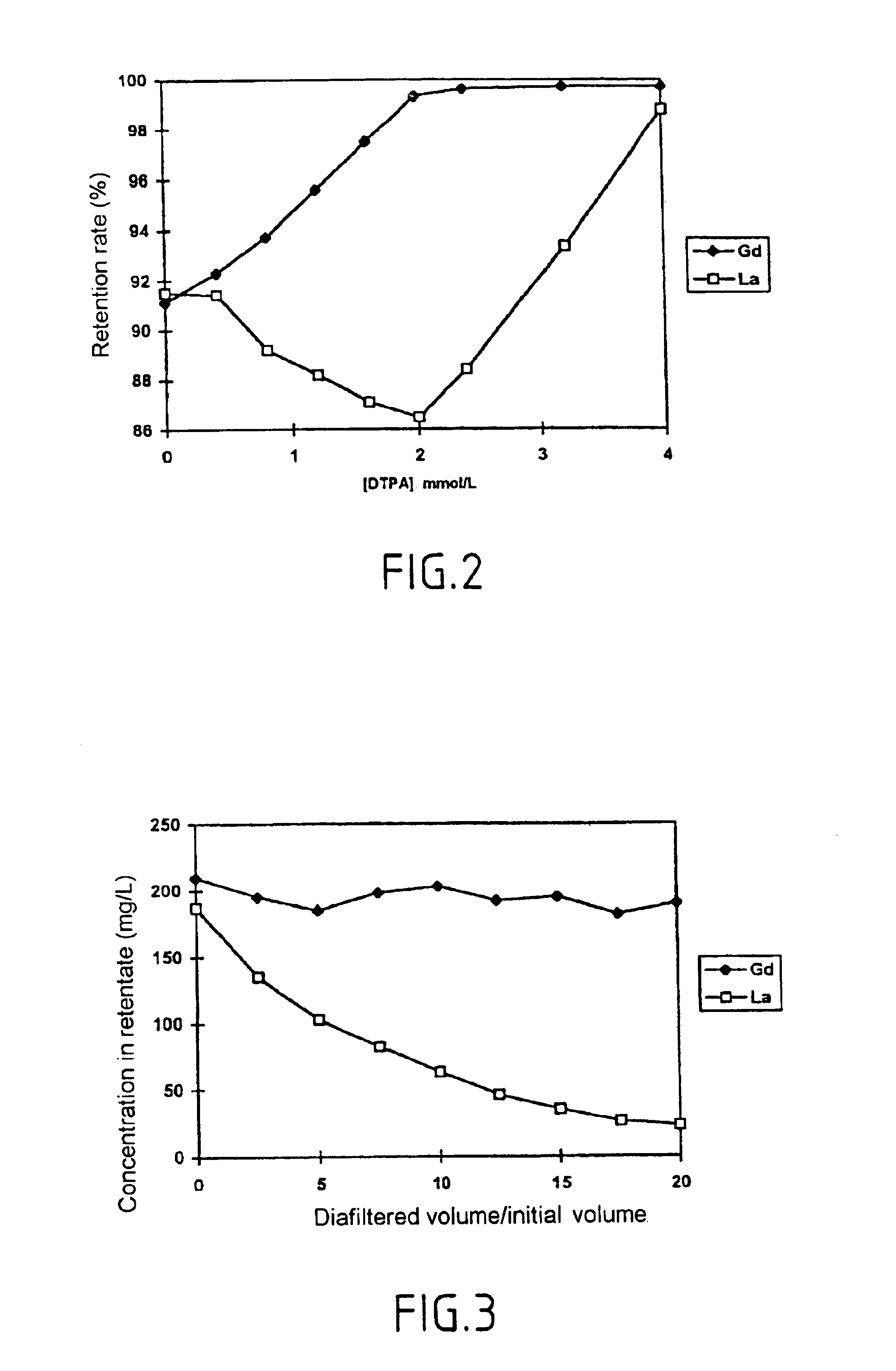

Method for separating in an aqueous medium lanthanides and/or actinides by combined complexing-nanofiltration, and novel complexing agents therefor

InactiveUS6843917B1Easy to implementEasily degradableMembranesOrganic chemistryWaste processingLanthanide

The invention relates to the separation of lanthanides and actinides by nanofiltration complexation. The object of the invention is to satisfy the existing need for a simple, efficient and economical technique for separating lanthanides and actinides. This object is achieved by a process consisting of using ligands of the polyamino acid type, such as EDTA or DTPA, for complexing lanthanides and / or actinides before separating them by nanofiltration. The invention further relates to novel polyamino acid ligands incorporating ligand structures additional to EDTA and DTPA. Application to the production of rare earths or nuclear waste processing, especially to recycling operations carried out on spent nuclear fuels is also discussed.

Owner:UNIV CLAUDE BERNARD LYON 1 +1

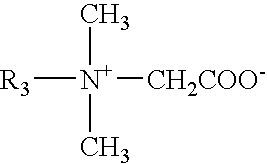

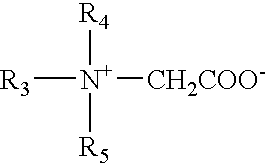

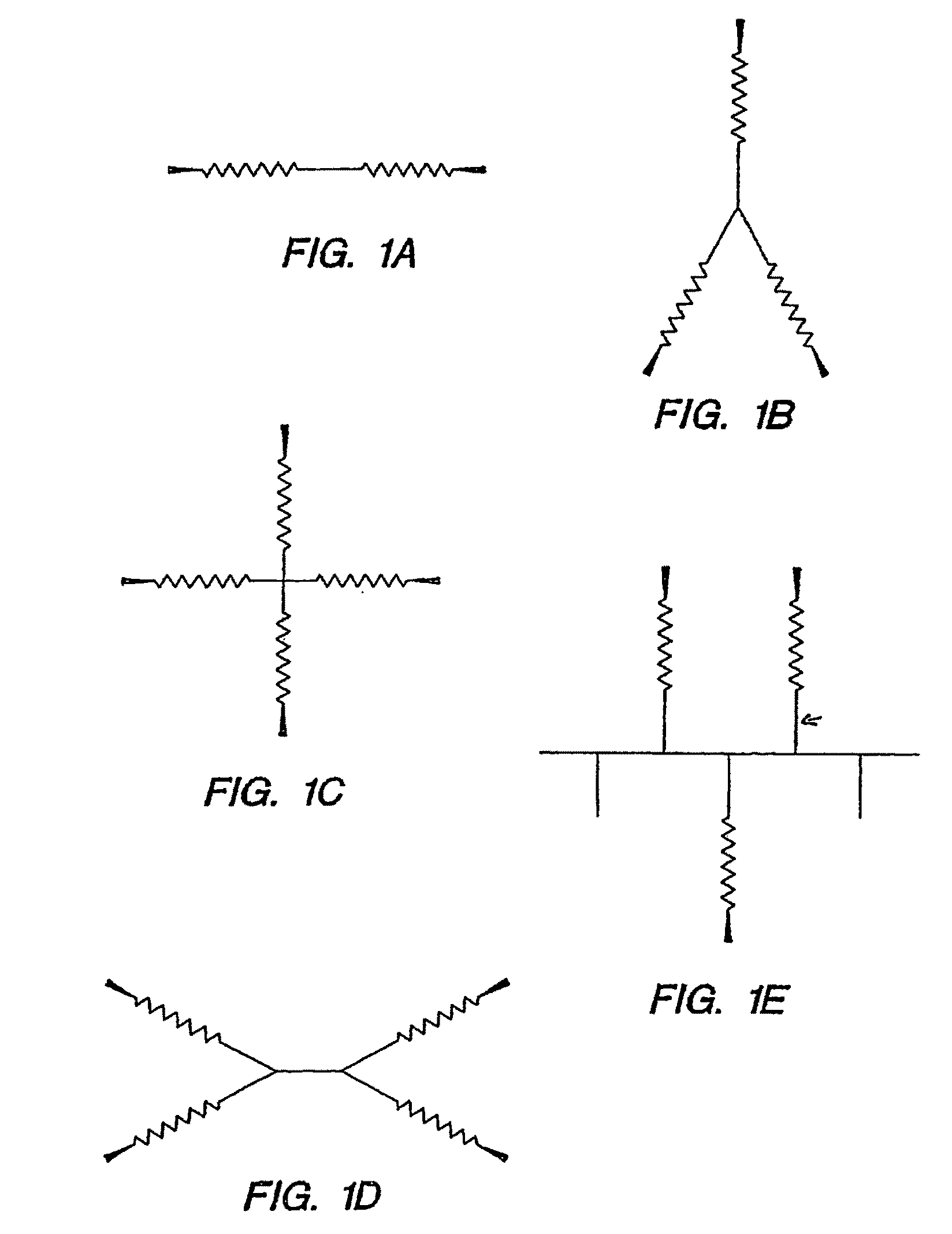

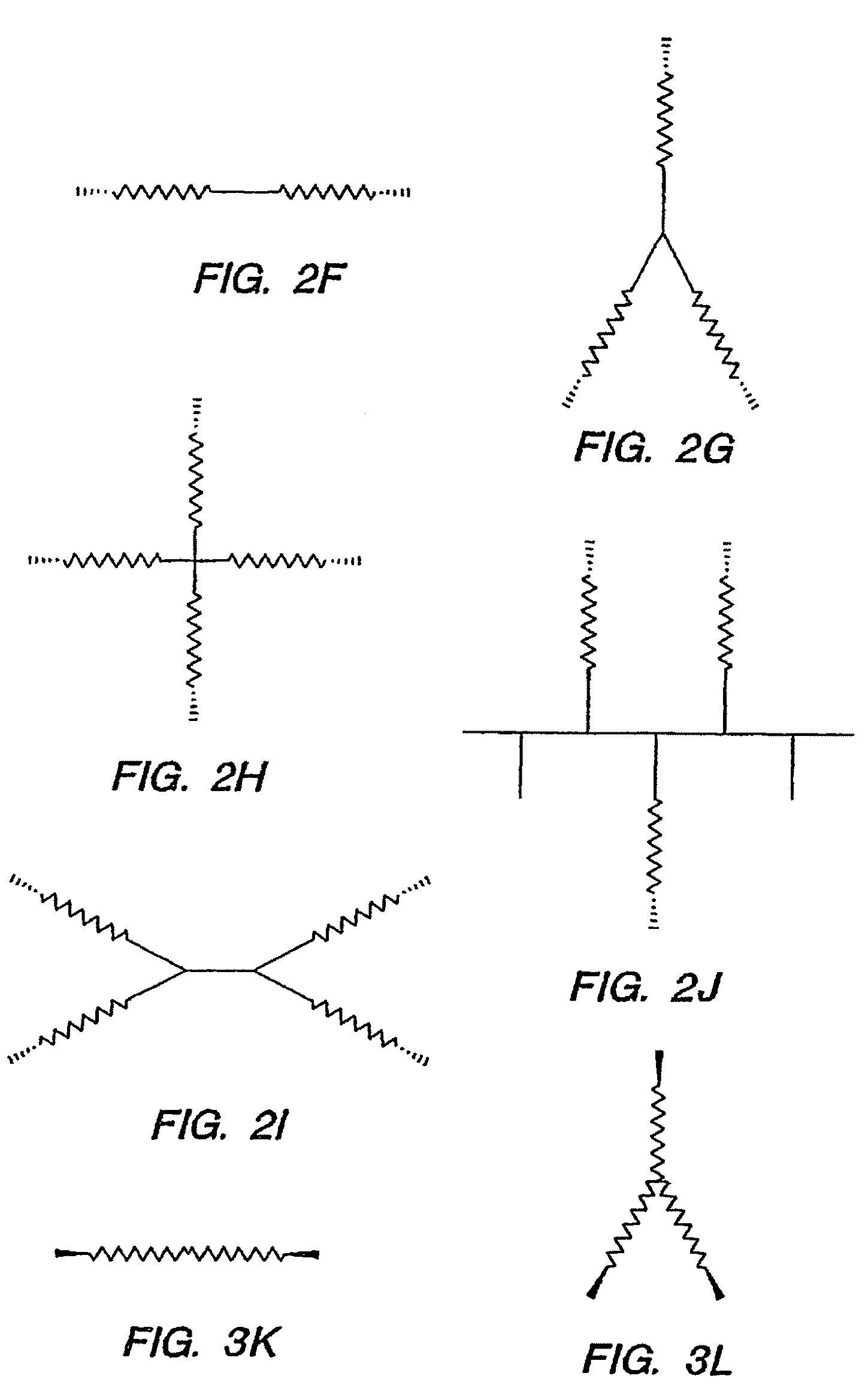

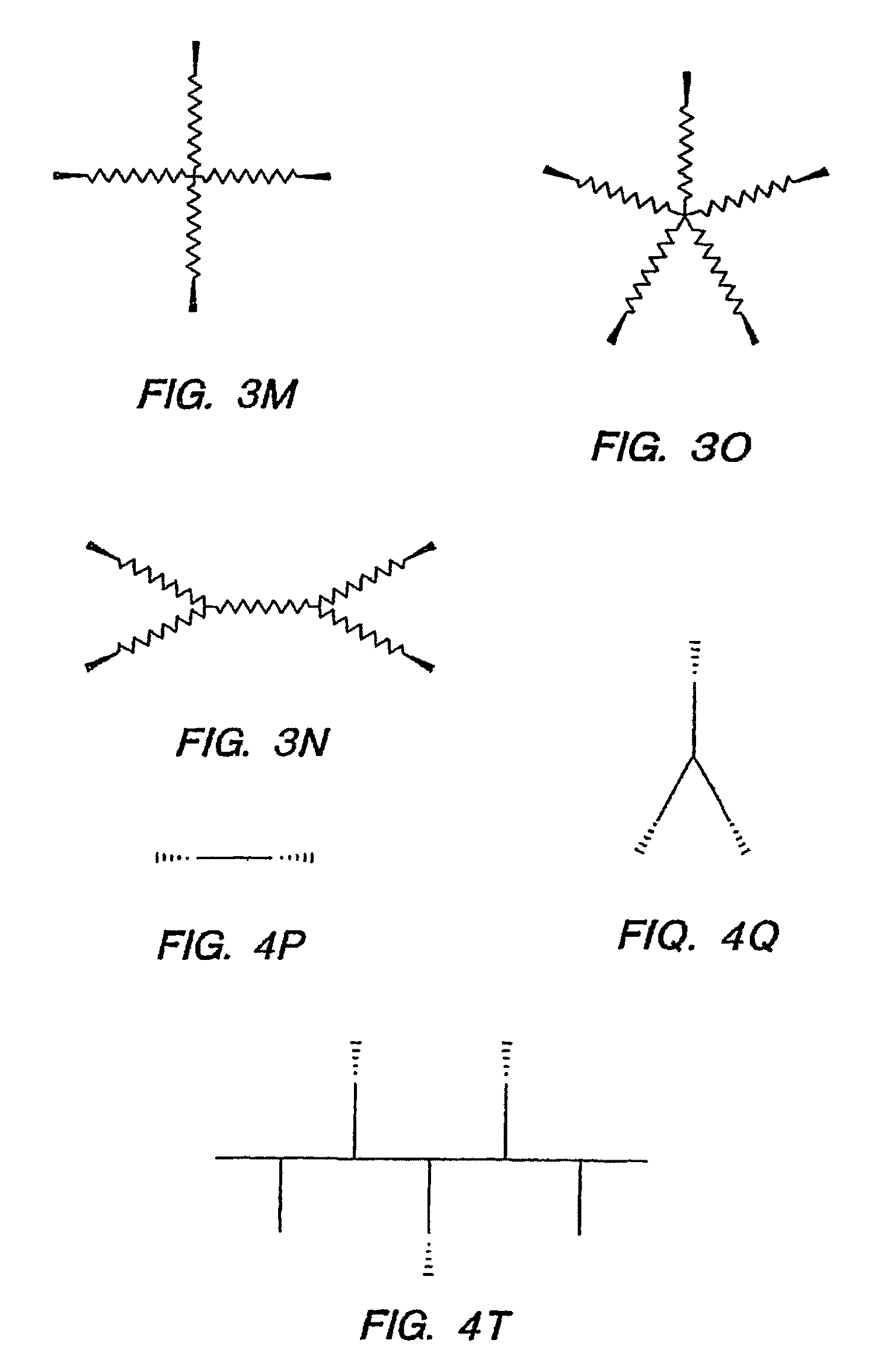

Fracturing liquid

InactiveUS20030168217A1Easily degradableStrong foaming capabilityFluid removalFlushingAlcoholAdditive ingredient

A subterranean fracturing fluid, which is relatively harmless to both the environment and subterranean formations includes an amphoteric surfactant, specifically a betaine surfactant and an organic electrolyte or an alcohol in an aqueous medium. Depending upon the proportions of the ingredients, the fluid can be foamed.

Owner:TRICAN WELL SERVICE

Biodegradable polyurethane and polyurethane ureas

ActiveUS20070275033A9Easily degradableEasily degradable hard segmentOrganic active ingredientsSurgeryPolyolInsertion stent

This invention relates to biocompatible, biodegradable thermoplastic polyurethane or polyurethane / ureas comprising isocyanate, polyol and a conventional chain extender and / or a chain extender having a hydrolysable linking group and their use in tissue engineering and repair applications, particularly as stents and stent coating.

Owner:POLYNOVO BIOMATERIALS PTY LTD

Amphoteric-cellulose-based composite material and application thereof

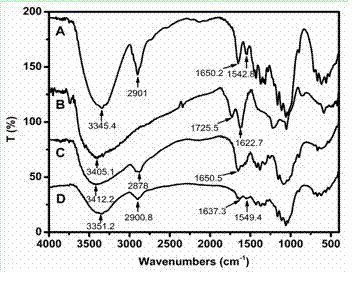

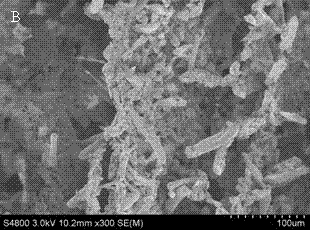

InactiveCN103497476ALarge specific surface areaImprove adsorption performanceOther chemical processesWater contaminantsComposite materialCellulose

The invention discloses an amphoteric-cellulose-based composite material and application thereof. Quaternary ammonium-sulfonic acid cellulose serves as a carrier, grapheme oxide and chitosan are loaded in a blending manner, binding force among the three is utilized, and a quaternary ammonium-sulfonic acid cellulose / grapheme oxide / chitosan composite porous material is obtained through freeze drying. The quaternary ammonium-sulfonic acid cellulose / grapheme oxide / chitosan composite porous material comprises, by weight, 5-8 parts of quaternary ammonium-sulfonic acid cellulose, 0.5-3 parts of grapheme oxide and 0.5-3 parts of chitosan, is safe, non-poisonous and good in biocompatibility and degradability, has an orderly three-dimensional porous structure, good mechanical strength and efficient adsorption capability, can be used for water absorption and oil removal and processing of heavy metal ion waste water and organic waste water, and hopefully serves as a filtering material such as an air purification material and a medical adsorption material for use.

Owner:SUZHOU UNIV

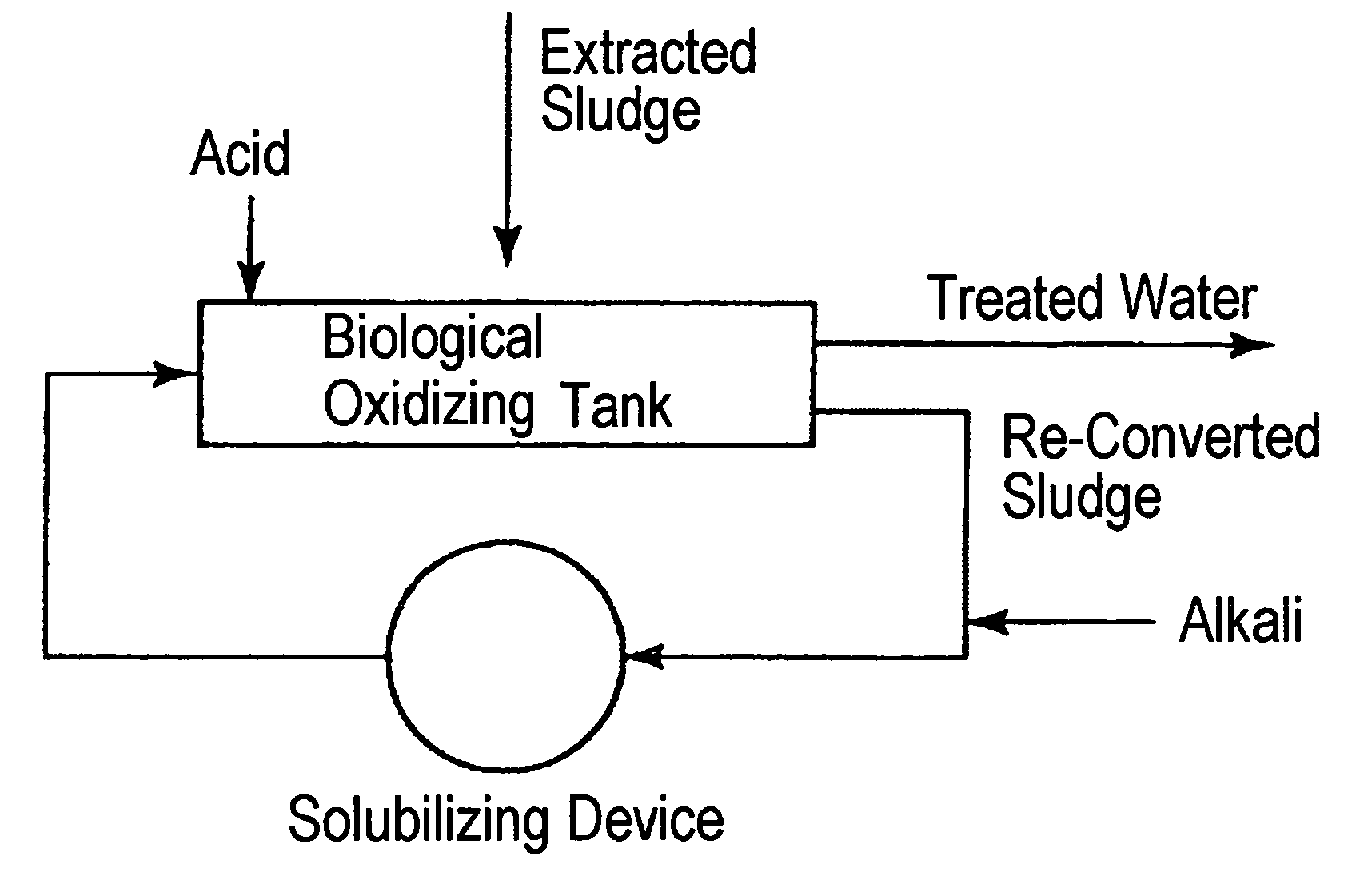

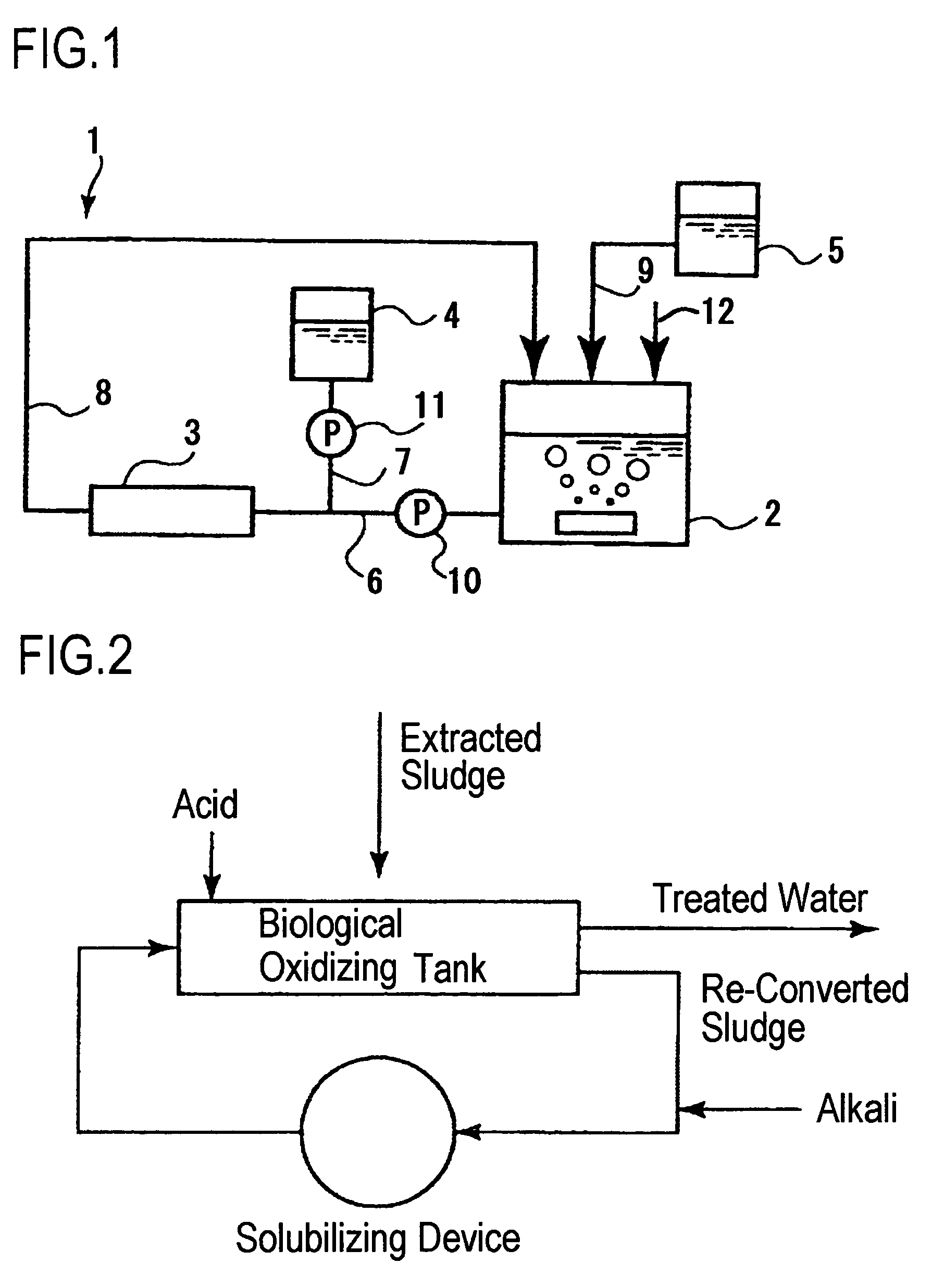

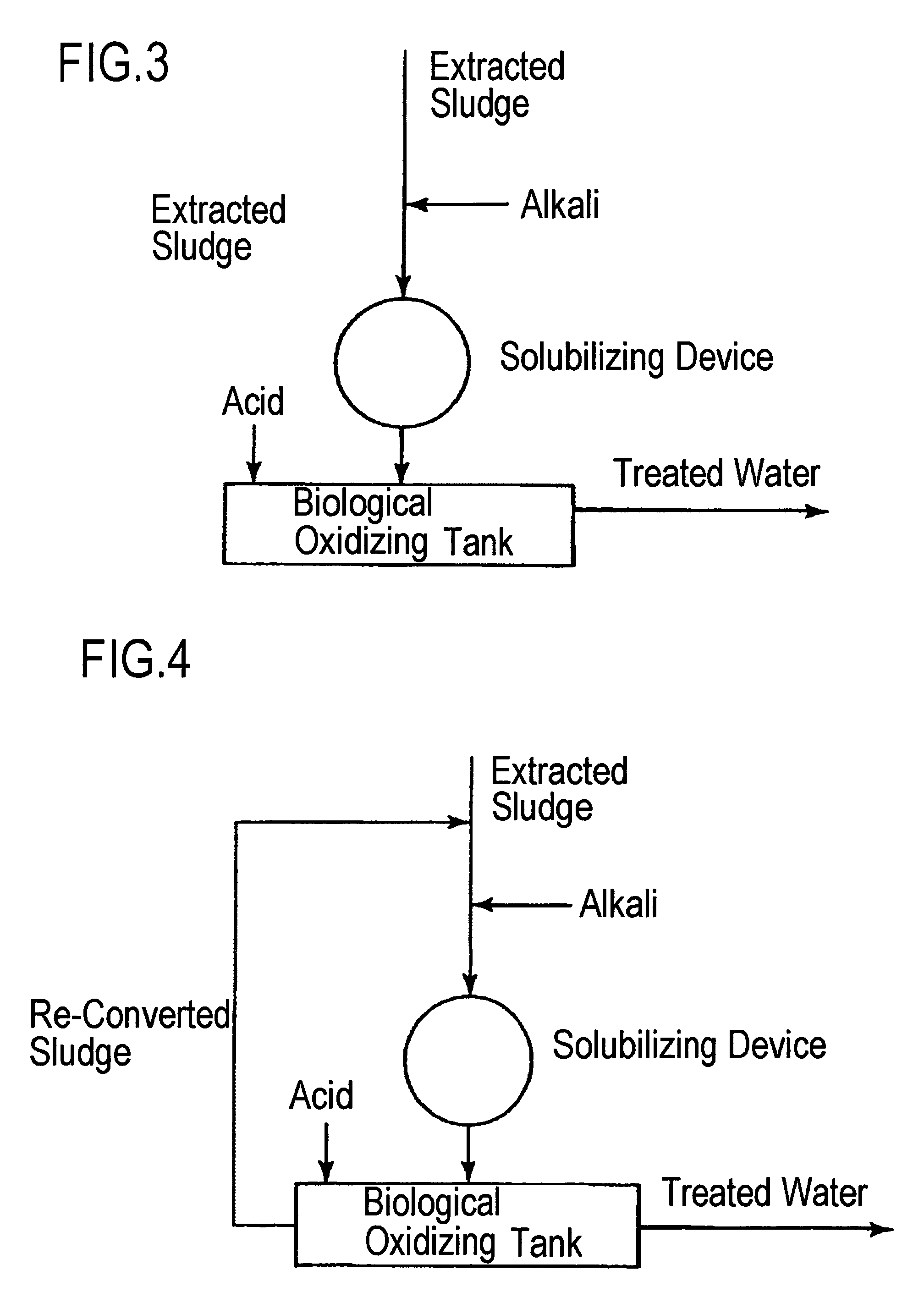

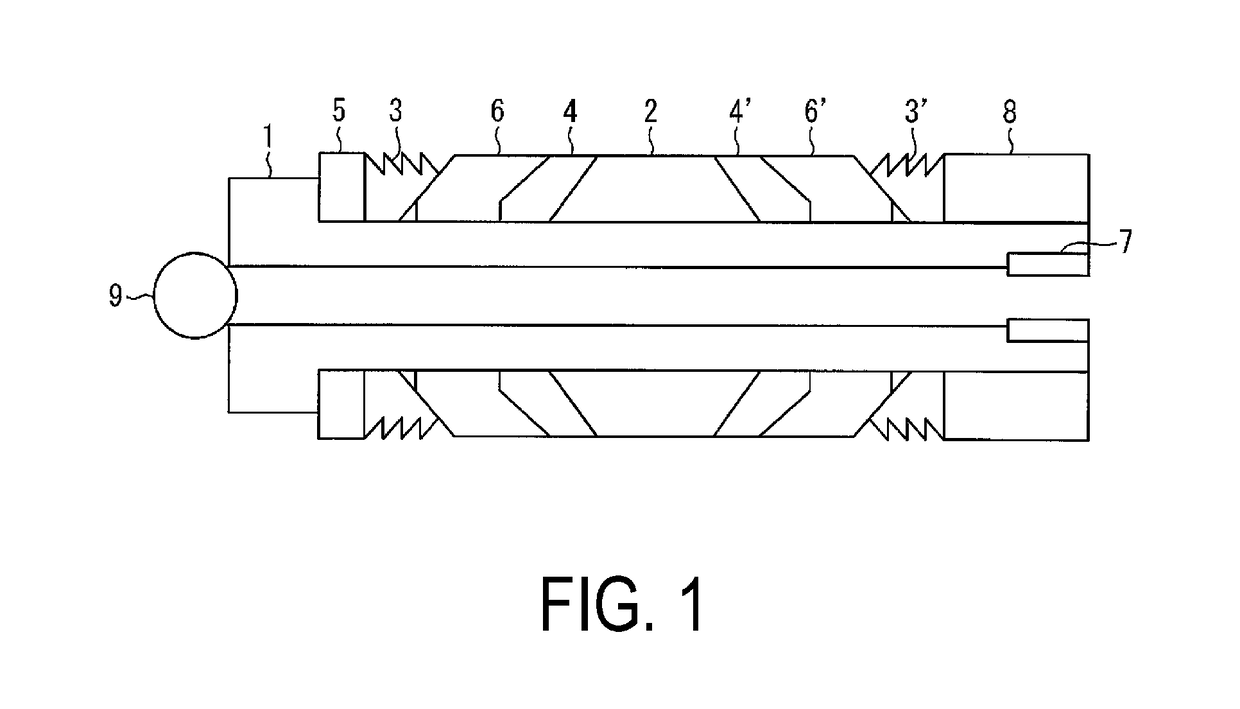

Method of reducing volume of sludge

InactiveUS7258791B2Lower the volumeReduce molecular weightSludge treatment by thermal conditioningTreatment using aerobic processesSteam pressureSludge

The pH value of excess sludge taken out from a biological oxidation tank (2) is adjusted to 8 to 14, and the pH-adjusted sludge is injected into a solubilizing device (3). The sludge taken out from the solubilizing device (3) is heated to 110° C. to 350° C. at a pressure higher than saturated steam pressure to solubilize the sludge to a state readily degradable by microorganisms. The solubilized sludge is returned to a biological oxidizing tank (2), and the pH value of the sludge in the biological oxidizing tank (2) to 5 to 9. The use of the above method of treating excess sludge and an apparatus therefore enables substantially reducing the volume of excess sludge with economic advantage.

Owner:KOGA TAKESHI

Biocompatible hydrogels made with small molecule precursors

InactiveUS8003705B2Easily degradablePrevent surgical adhesionBiocideFibrinogenWound dressingBlood vessel

Biocompatible crosslinked polymers, and methods for their preparation and use, are disclosed in which the biocompatible crosslinked polymers are formed from water soluble precursors having electrophilic and nucleophilic functional groups capable of reacting and crosslinking in situ. Methods for making the resulting biocompatible crosslinked polymers biodegradable, or not, are provided, as are methods for controlling the rate of degradation. The crosslinking reactions may be carried out in situ on organs or tissues or outside the body. Applications for such biocompatible crosslinked polymers and their precursors include controlled delivery of drugs, prevention of post-operative adhesions, coating of medical devices such as vascular grafts, wound dressings and surgical sealants. Visualization agents may be included with the crosslinked polymers. Embodiments that include hydrogels having isolated hydrolytically degradable esters are set forth. Embodiments including the use of low molecular weight amines to make degradable hydrogels are also set forth.

Owner:INCEPT LLC

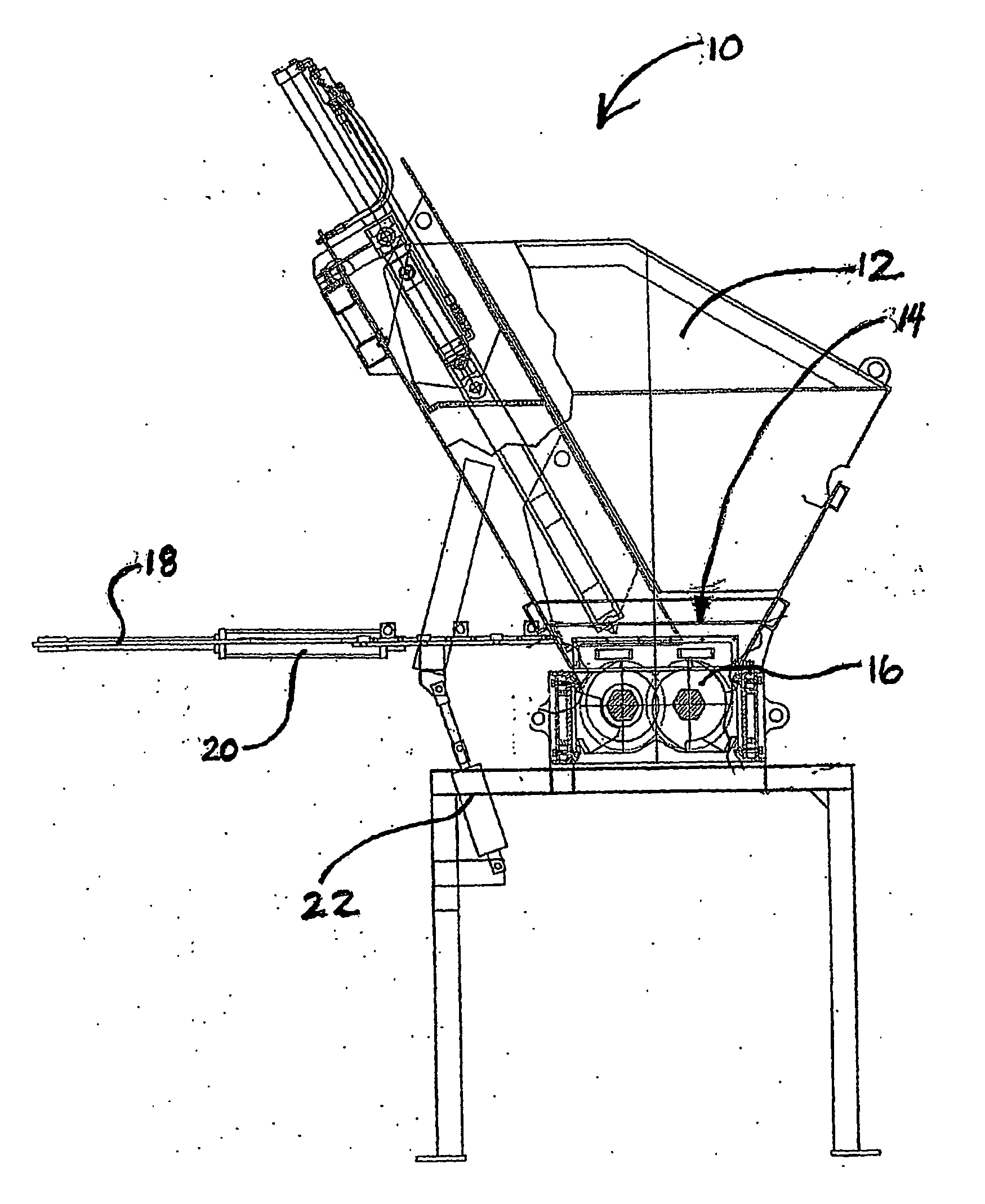

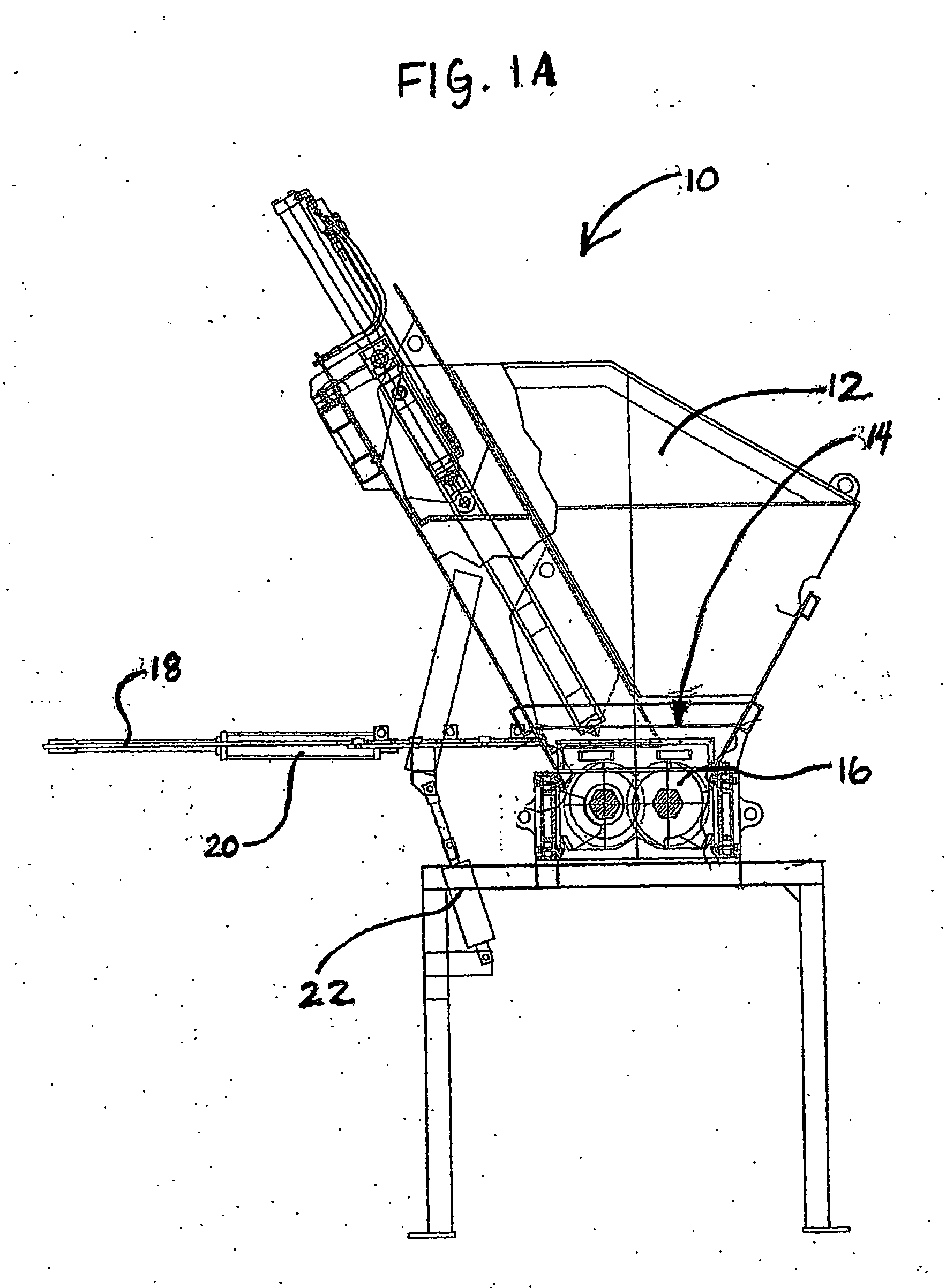

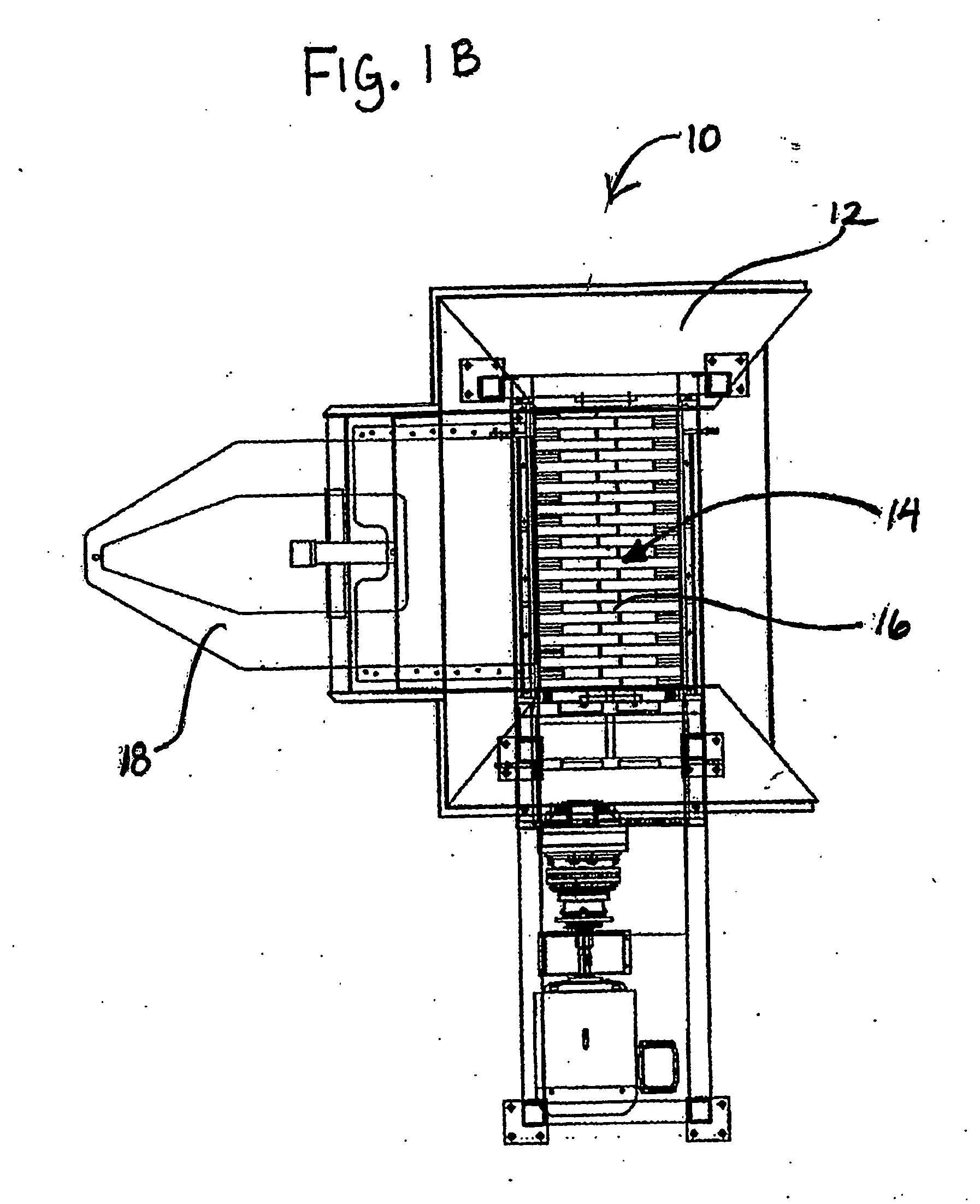

Apparatus and method for transforming solid waste into useful products

InactiveUS20070199613A1Easily degradableEasy to removeSolid waste disposalSolid materialPressure vesselWaste disposal

A system and method for processing solid waste disposal includes a hydrolyzer (80) and a injection assembly (30) for transferring waste to the hydrolyzer (80). The injection assembly (30) includes a sleeve (40), in which waste is compressed with a ram (37), and a movable gate (52), which opens to allow the compressed waste (68) to exit the sleeve (40) and enter the hydrolyzer (80). The hydrolyzer (80) includes a pressure vessel (84), a rotating shaft (108) contained within the vessel (84), and agitates attached to the shaft for moving and processing the material through the hydrolyzer (80).

Owner:BOULDIN CORP

Method for production of microcapsules using solid fat

InactiveUS20100297222A1Increase contentFood with easePowder deliverySenses disorderEmulsionOrganic solvent

A method for production of fine microcapsules which encapsulate a hydrophilic bioactive substance at a high content and can be used in wide range of applications such as foods and medical drugs, which method enabling efficient industrial production, is provided. A method for production of S / O type microcapsules including the steps of: (1) emulsifying and dispersing a mixture of a solid fat and an aqueous solution containing a hydrophilic bioactive substance at a temperature of at least the melting point of the solid fat to obtain a W / O emulsion; (2) removing moisture in the W / O emulsion at a temperature of at least the melting point and lower than the boiling point of the solid fat to obtain an S / O suspension; (3) adding the S / O suspension into an aqueous phase containing at least one selected from a surfactant (B), a thickening agent and a hydrophilic organic solvent, and permitting liquid droplet dispersion at a temperature of at least the melting point and lower than the boiling point of the solid fat to obtain an S / O / W emulsion; and (4) cooling the S / O / W emulsion to lower than the melting point of the solid fat to harden the solid fat, and further removing the moisture at a temperature lower than the melting point of the solid fat.

Owner:KANEKA CORP

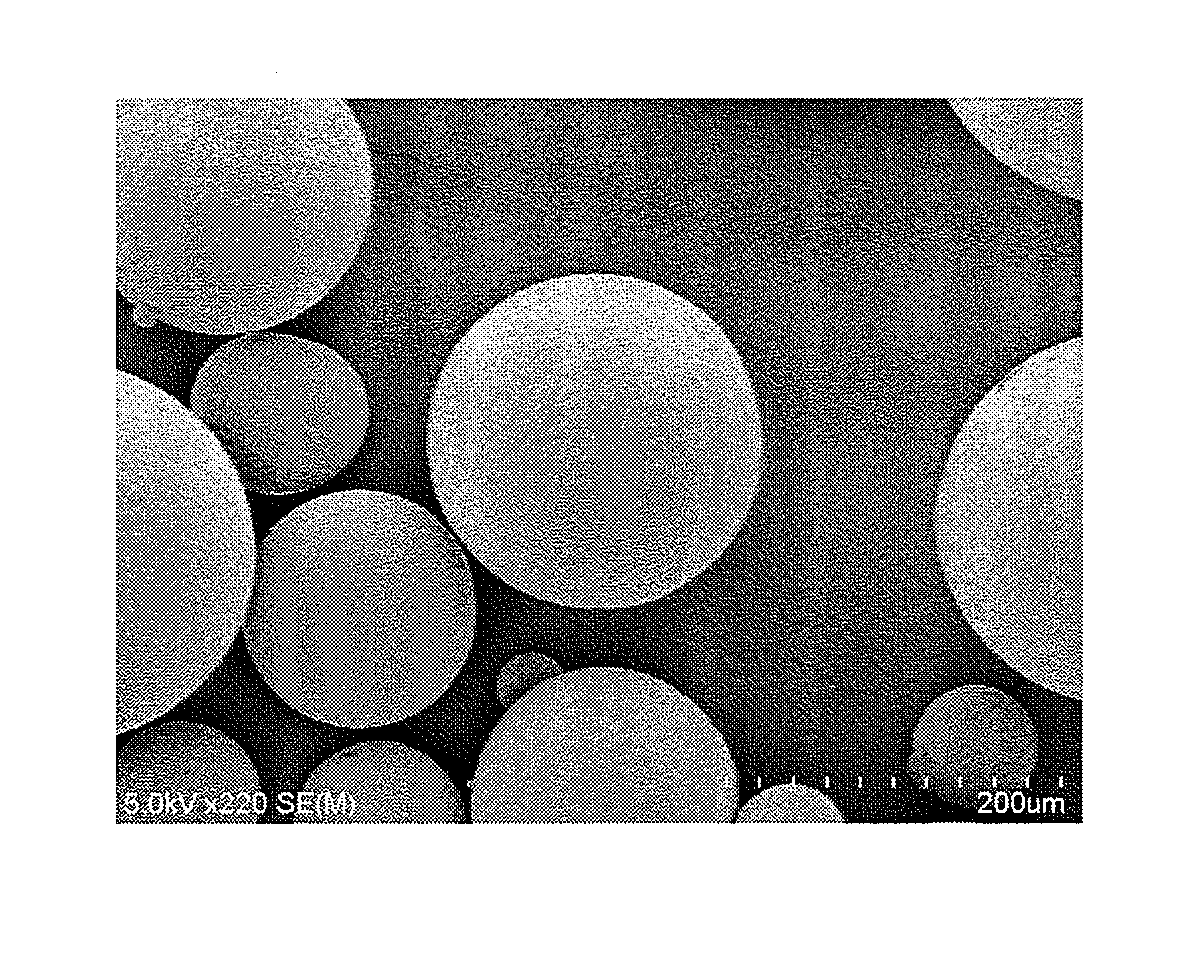

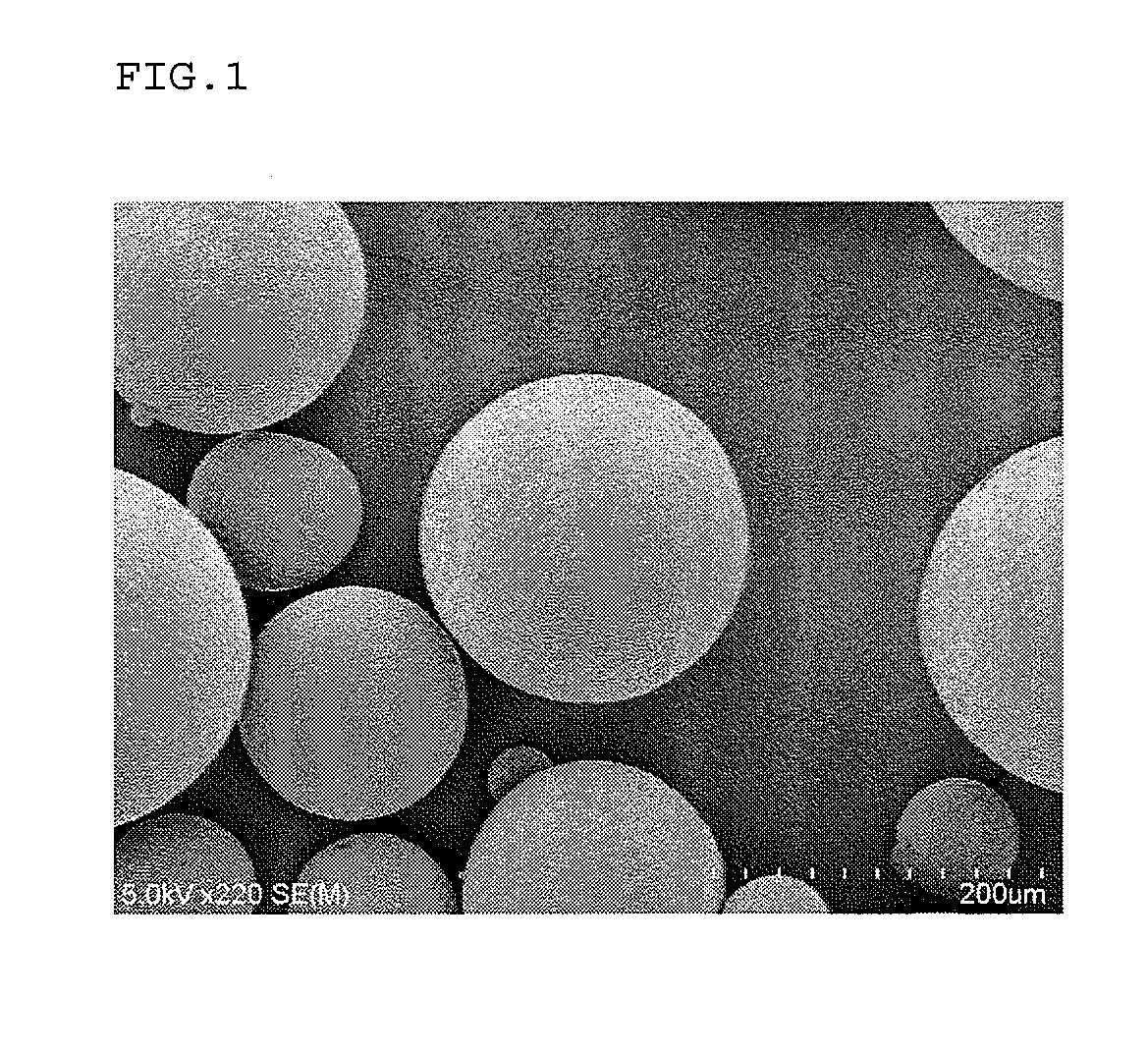

Stock shape for downhole tool component, downhole tool component, and downhole tool

ActiveUS20190017346A1High strengthEasily degradableFluid removalSealing/packingRare-earth elementMetallic materials

A stock shape for a downhole tool component includes a magnesium alloy including a phase containing 70 to 95 wt. % of magnesium in which 0 wt. % or more and less than 0.3 wt. % of a rare earth metal, a metal material other than the magnesium and the rare earth metal, and 0.1 to 20 wt. % of a degradation accelerator are distributed, and the stock shape has an average particle size of the metal material of 1 to 300 μm, tensile strength of 200 to 500 MPa, and a degradation rate in a 2% potassium chloride aqueous solution at 93° C. of not less than 20 mg / cm2 and not greater than 20000 mg / cm2 per day. Accordingly, a downhole tool having high strength and being readily degradable is established.

Owner:KUREHA KAGAKU KOGYO KK

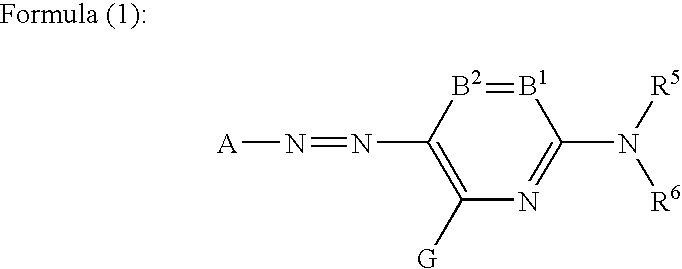

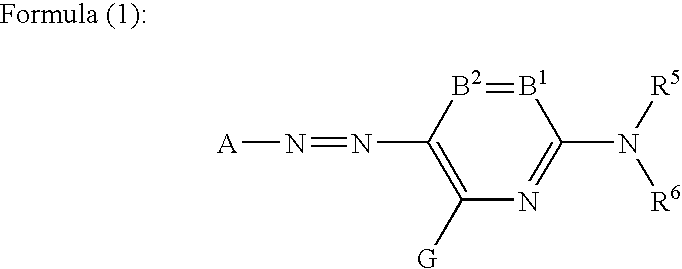

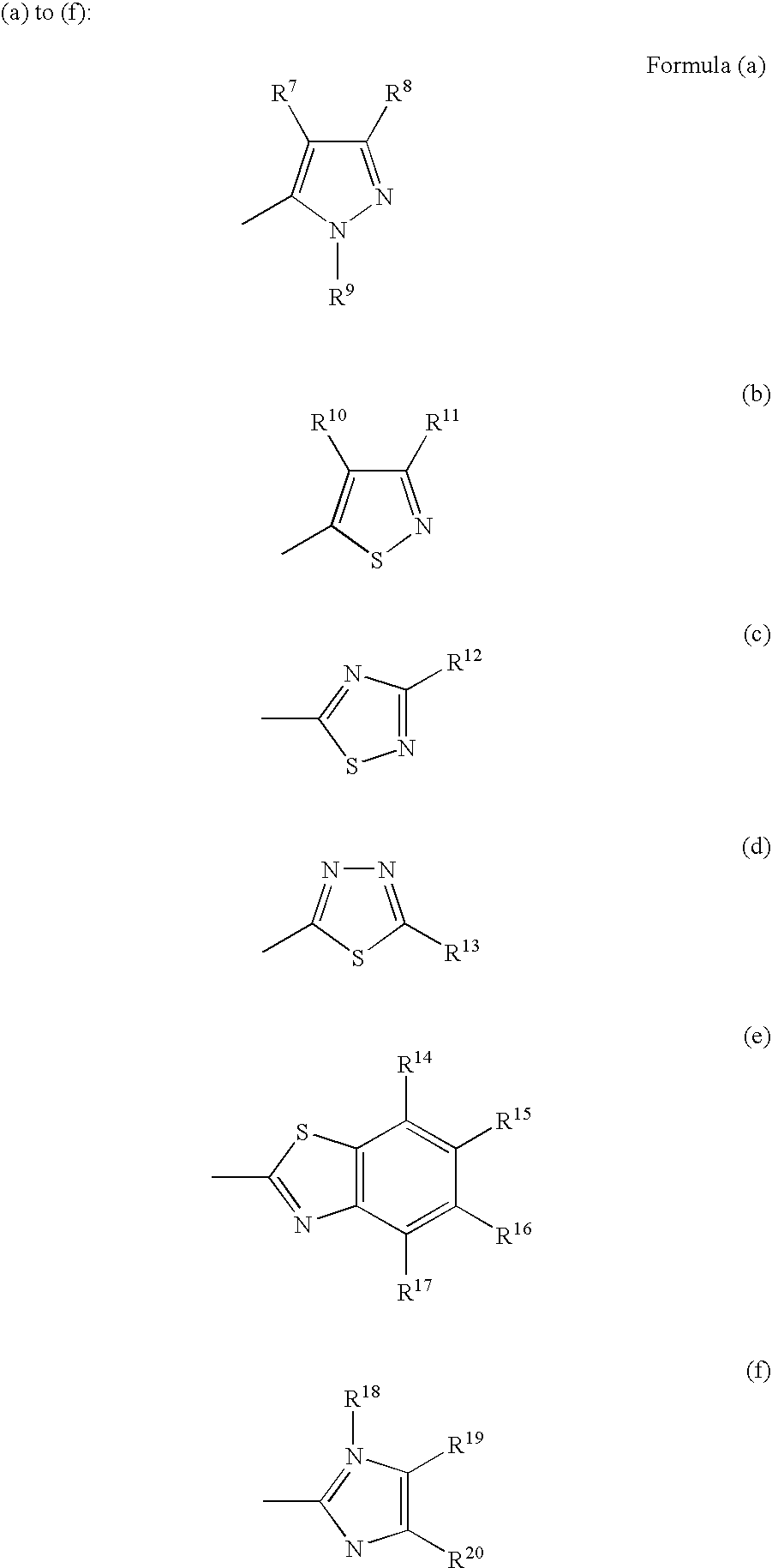

Ink for inkjet recording and method for inkjet recording

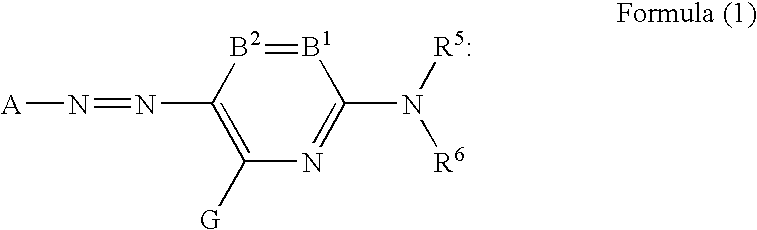

InactiveUS20050162492A1Excellent toneHigh fastnessMonoazo dyesMeasurement apparatus componentsOrganic solventImaging quality

An inkjet recording ink comprising an aqueous medium having dissolved or dispersed therein a magenta dye selected from azo dyes, wherein the magenta dye is a dye having an oxidation potential more positive than 1.0 V (vs SCE) and at the same time, a water-miscible organic solvent having a vapor pressure of 2,000 Pa or less at 20° C. is contained; and an inkjet recording method using the ink. By virtue of such a constitution, an inkjet recording ink and an inkjet recording method are provided, which can ensure high ejection stability, good color hue of the obtained image, no drying of the ink at the ink jet head, excellent fastness to light and water, image quality free from defective such as fineline bleeding under high-humidity condition, and good preservability of the image under severe conditions, and furthermore can ensure high storability and high ejection stability even after aging for a long time or under severe conditions.

Owner:FUJIFILM CORP +1

Sheet Filter Materials With Additives

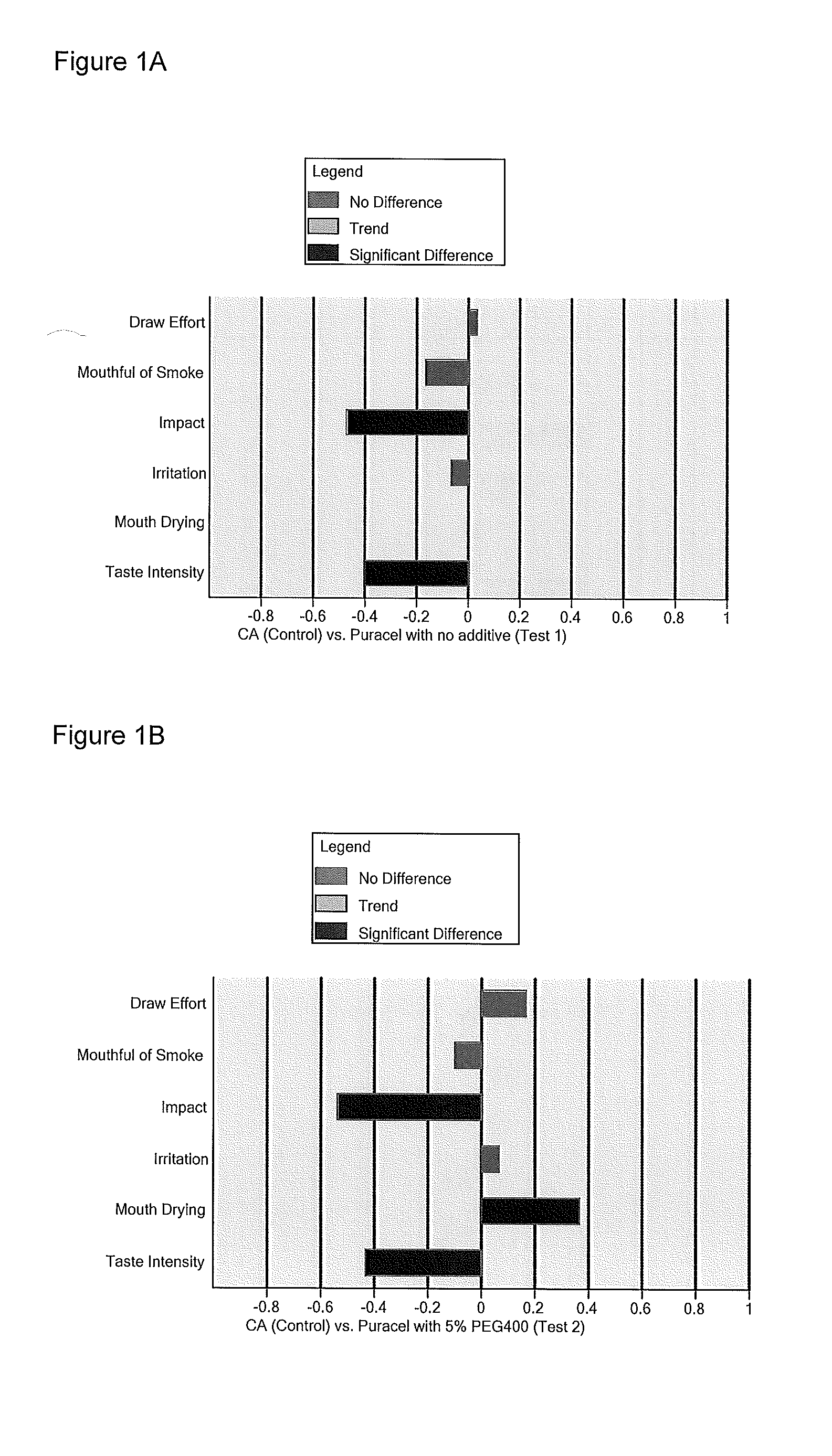

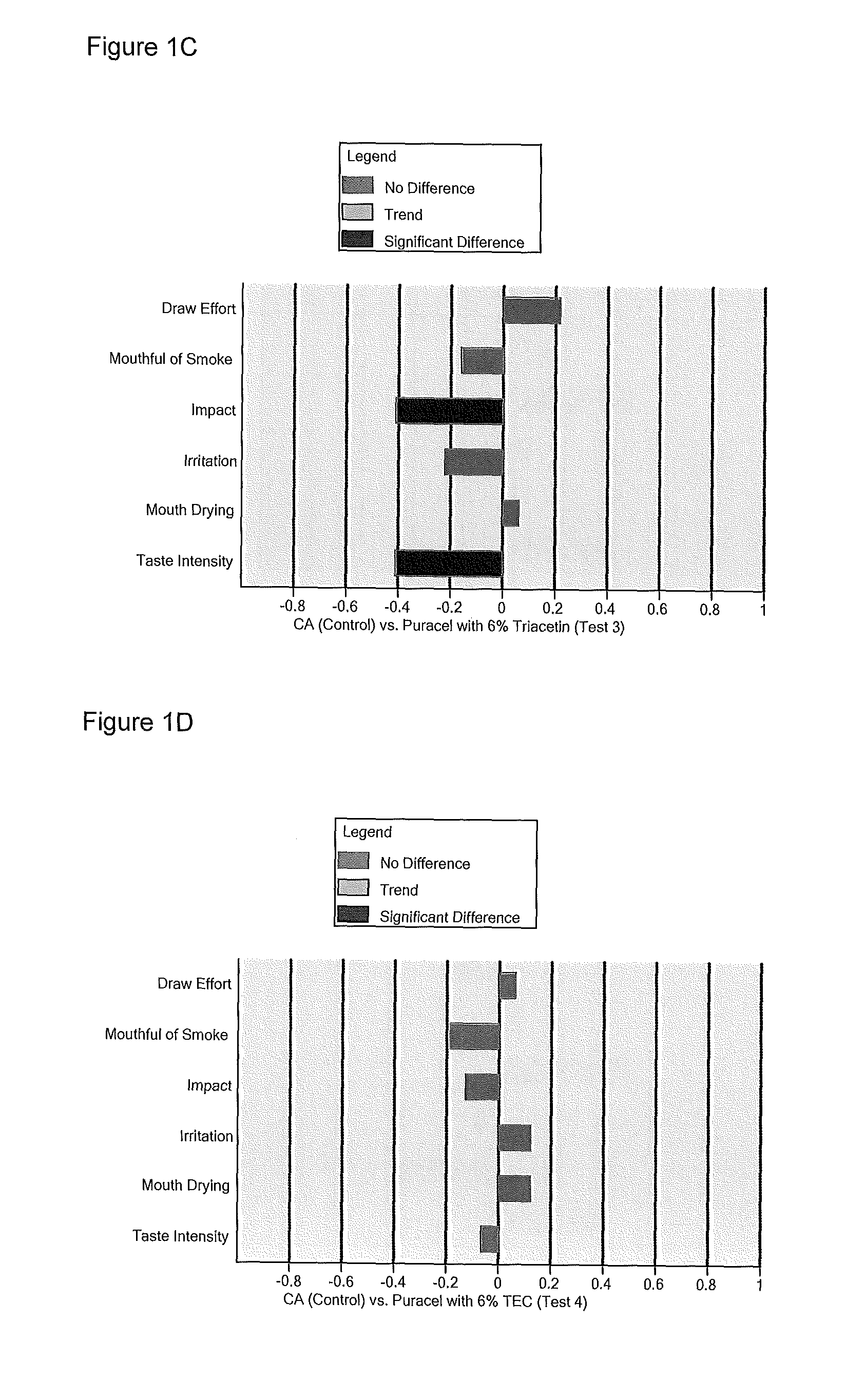

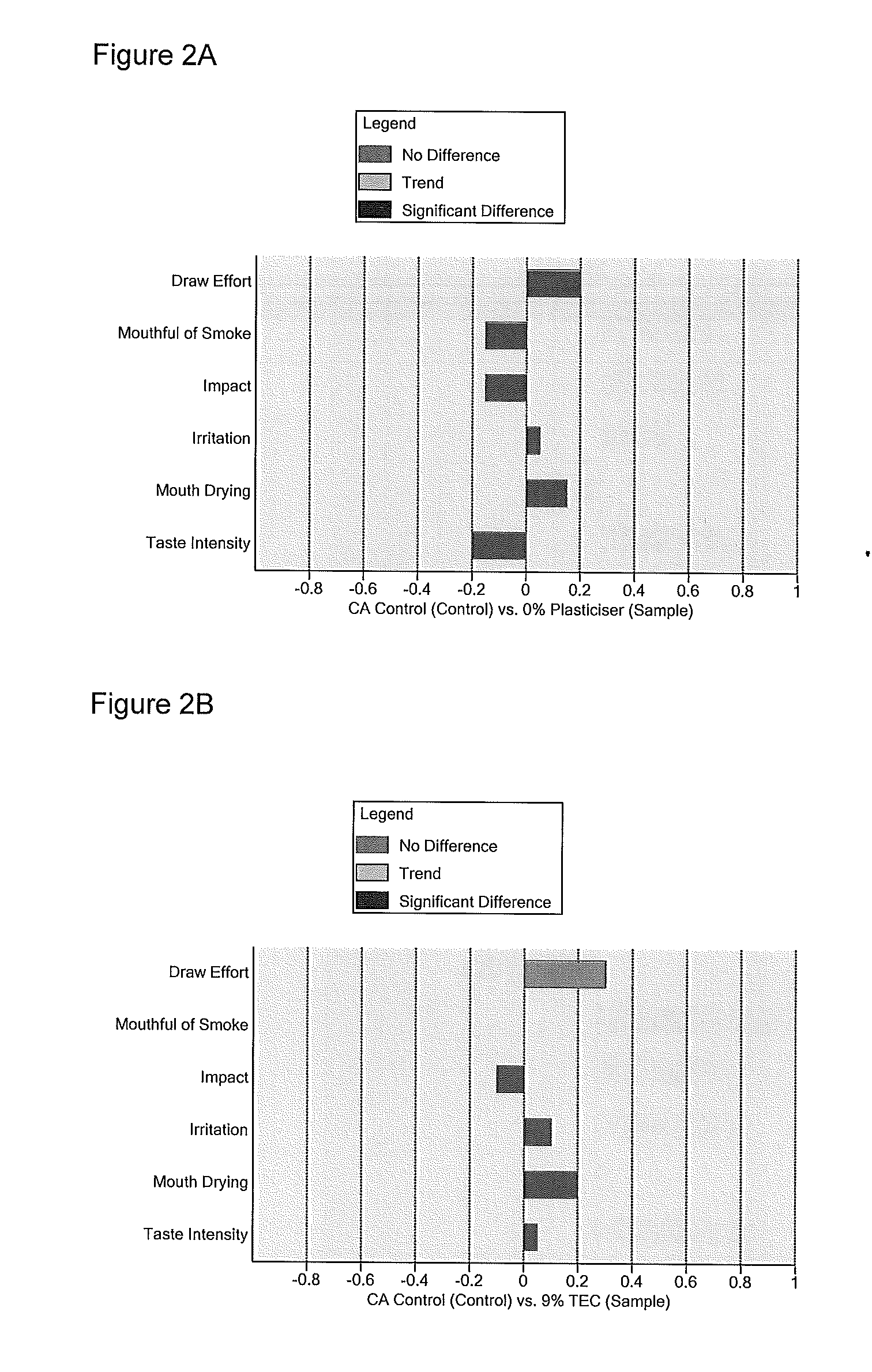

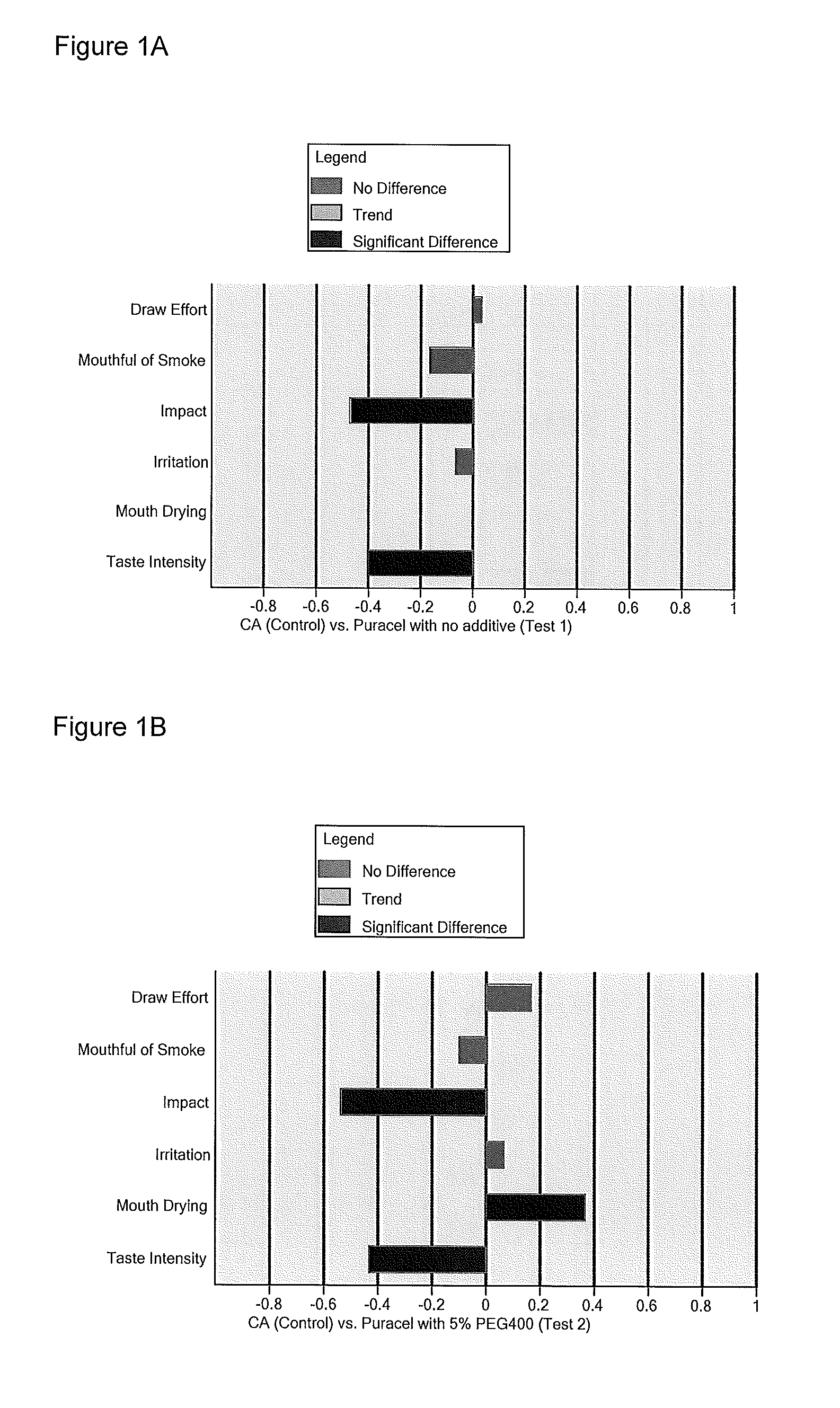

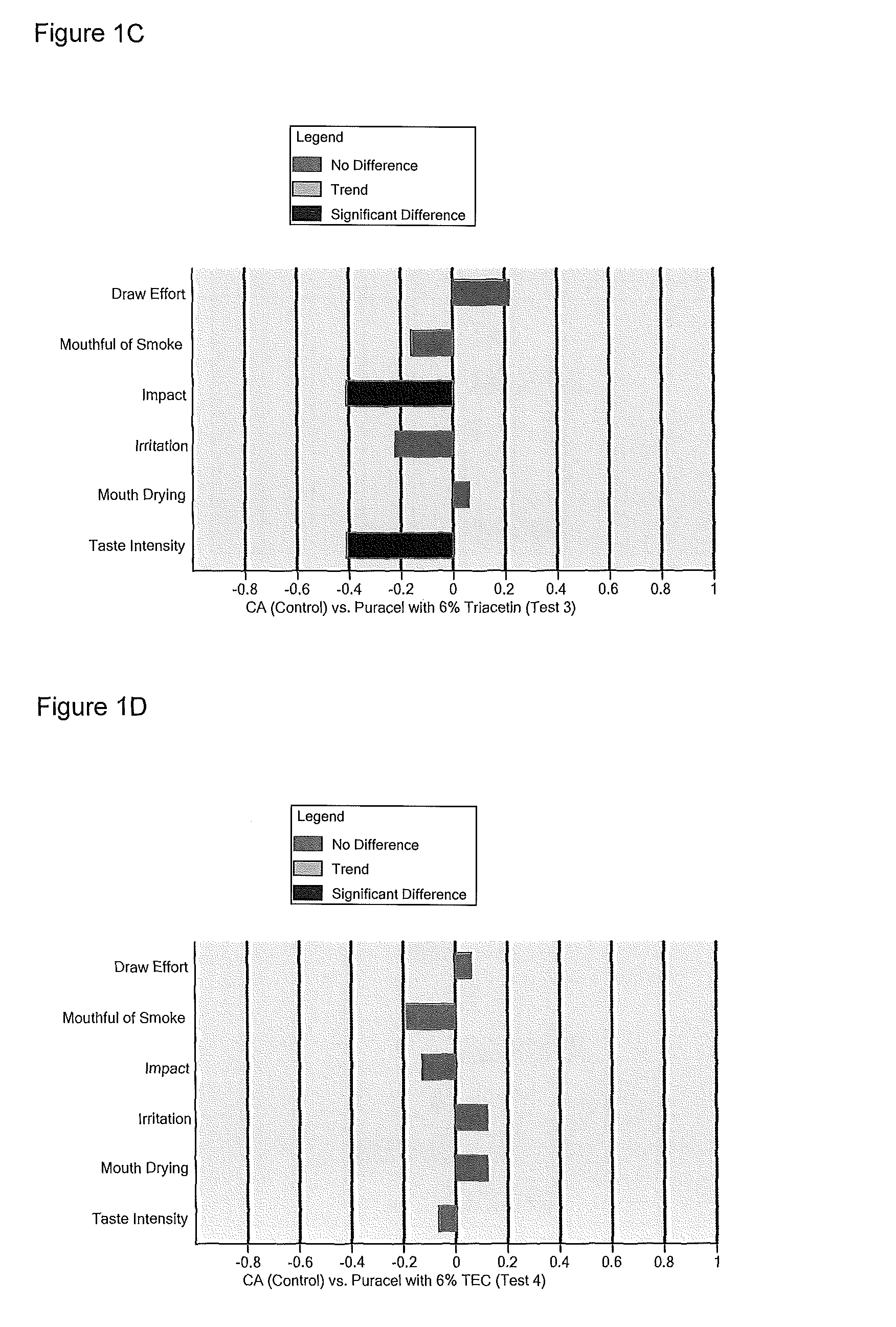

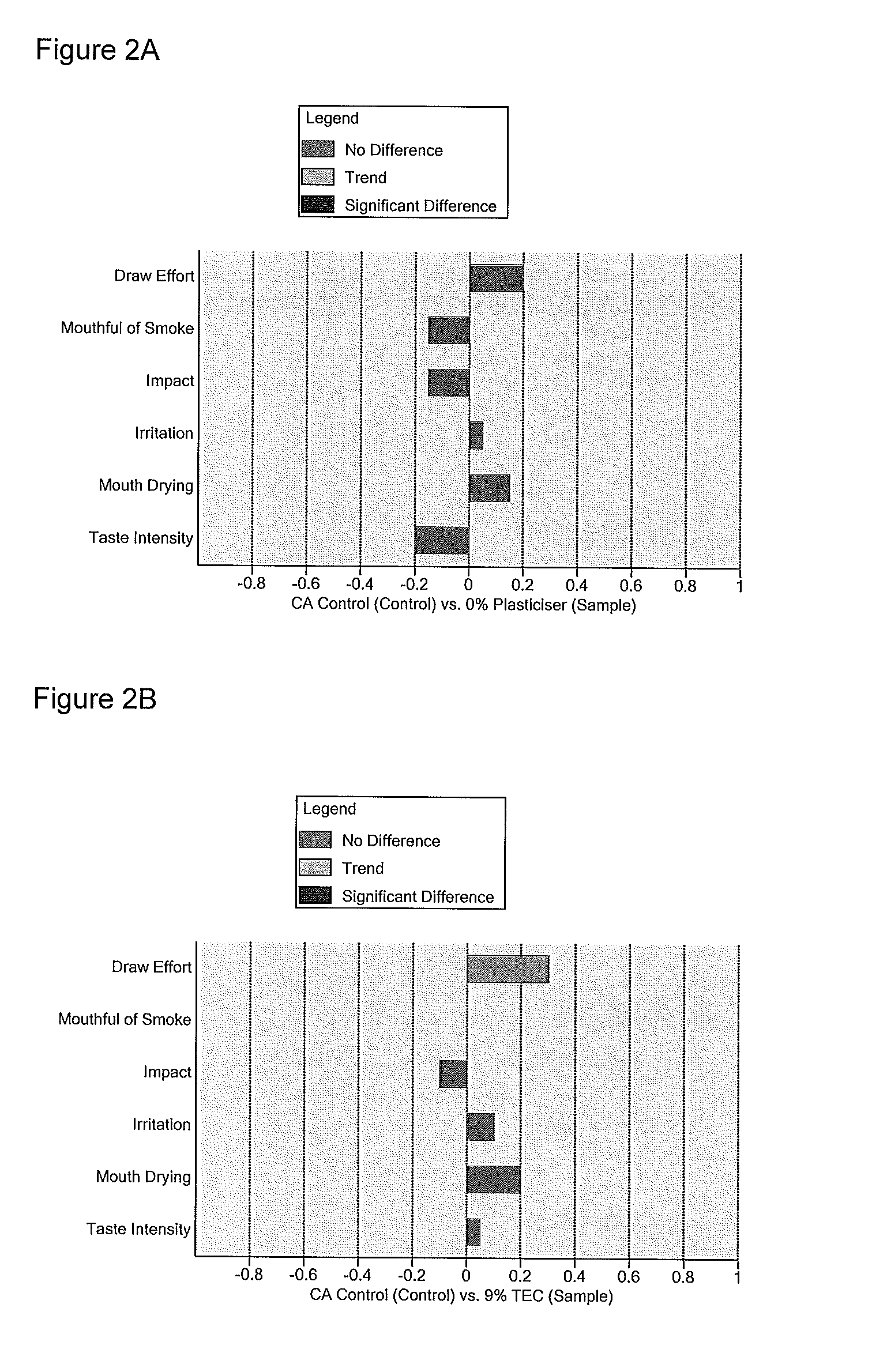

ActiveUS20130025611A1Improved taste characteristicEasily degradableTobacco treatmentCigar manufacturePolyethylene glycolEngineering

The present invention relates to the inclusion of additives in a filter element comprising a non-woven sheet material or paper as the filter material to increase the selective removal of semi-volatile compounds and to improve the taste characteristics of the smoke drawn through the filter element. The increased selective removal of semi-volatile compounds from the smoke being drawn through the filter element is provided by polyethylene glycol. TEC and / or triacetin are additives which have been found to improve the taste characteristics of smoke drawn through the filter element.

Owner:BRITISH AMERICAN TOBACCO (INVESTMENTS) LTD

Ink-jet recording ink and method of ink-jet recording

InactiveUS20050117006A1Excellent toneHigh fastnessMeasurement apparatus componentsInksWeather resistanceHue

An inkjet recording ink comprising an aqueous medium having dissolved or dispersed therein a dye having a specific property or structure, and containing at least one antiseptic is provided, which can ensure excellent ejection stability and color hue even after long-term aging of the ink and exhibit excellent weather resistance.

Owner:FUJIFILM CORP +1

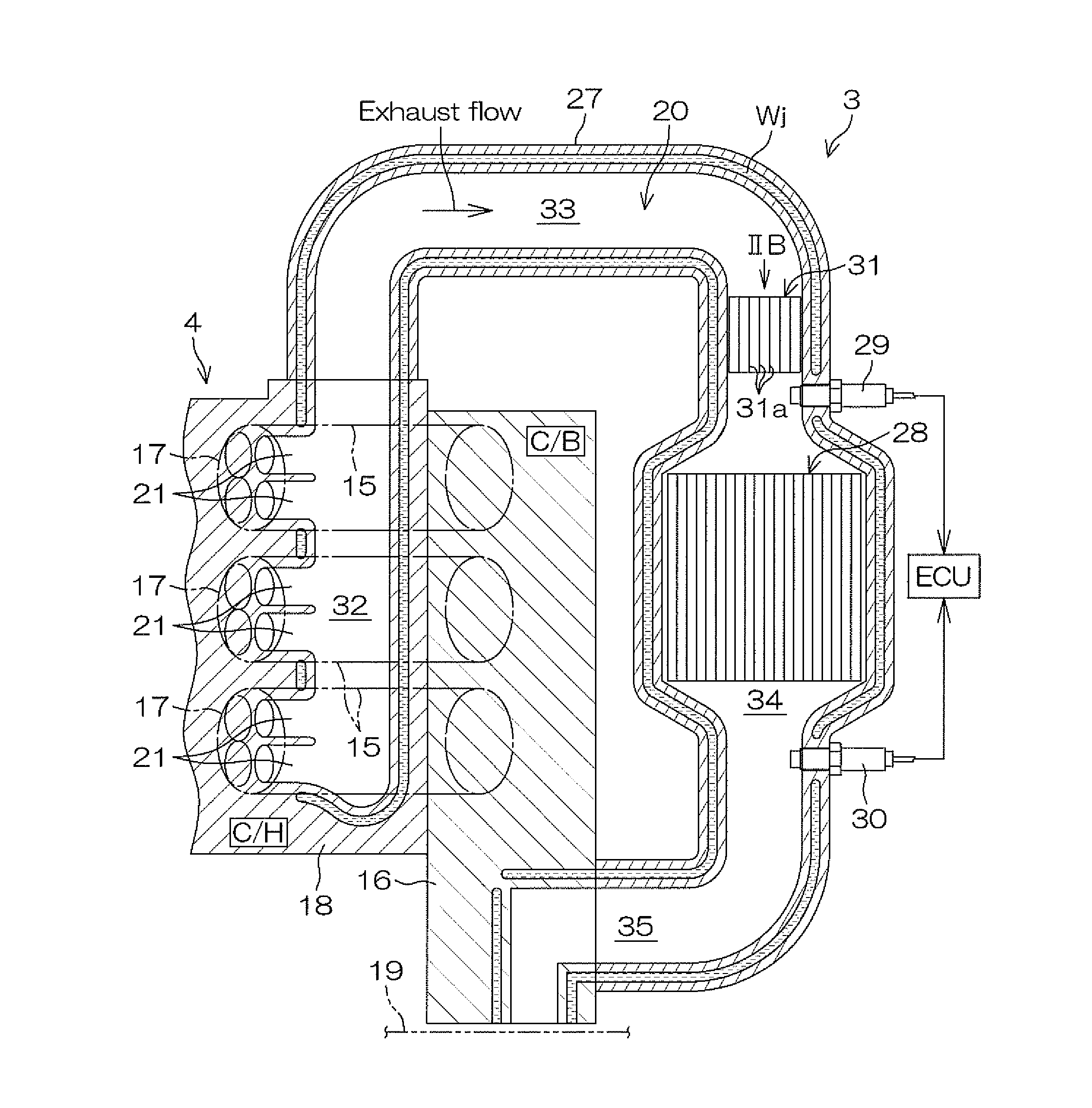

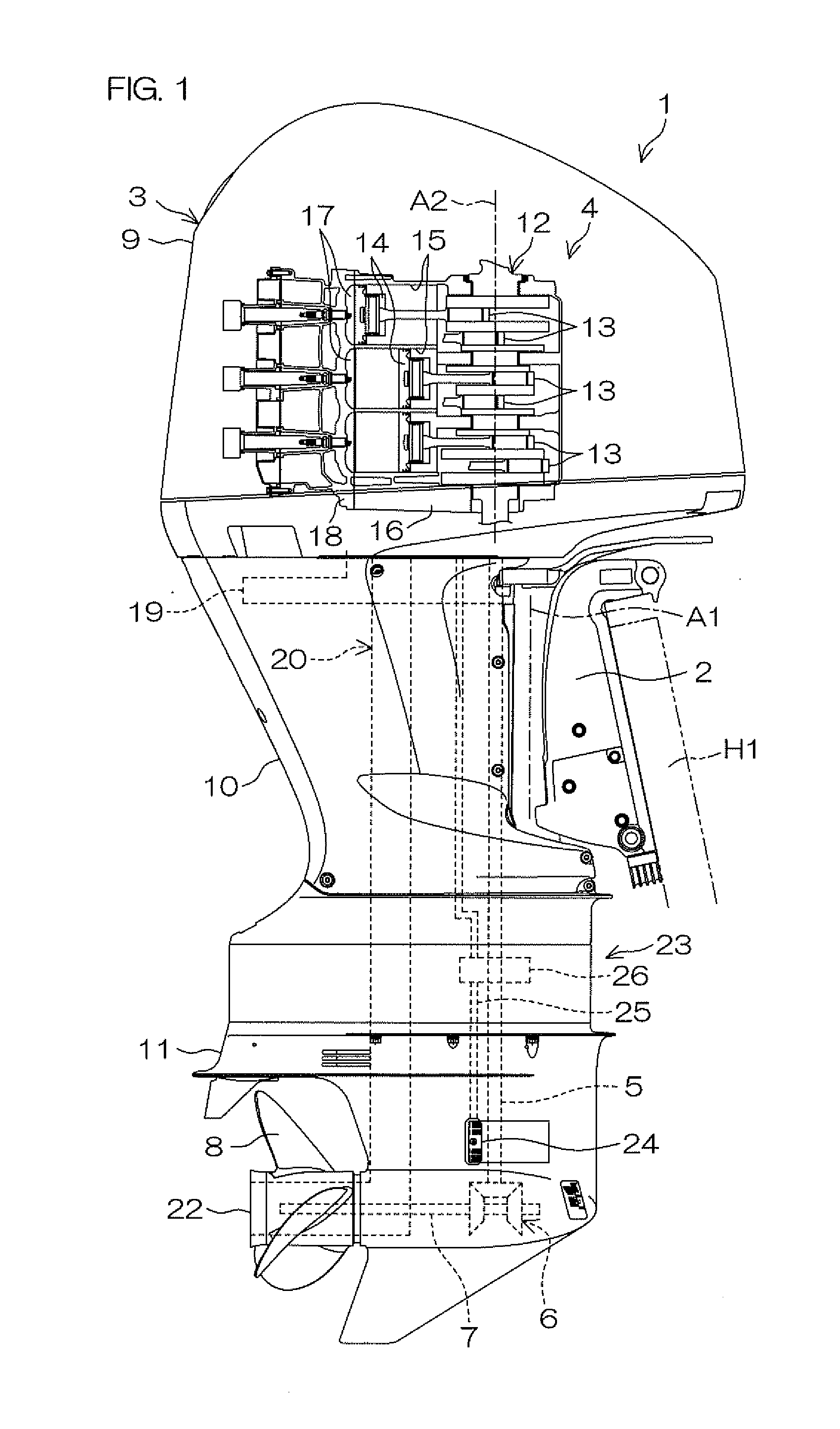

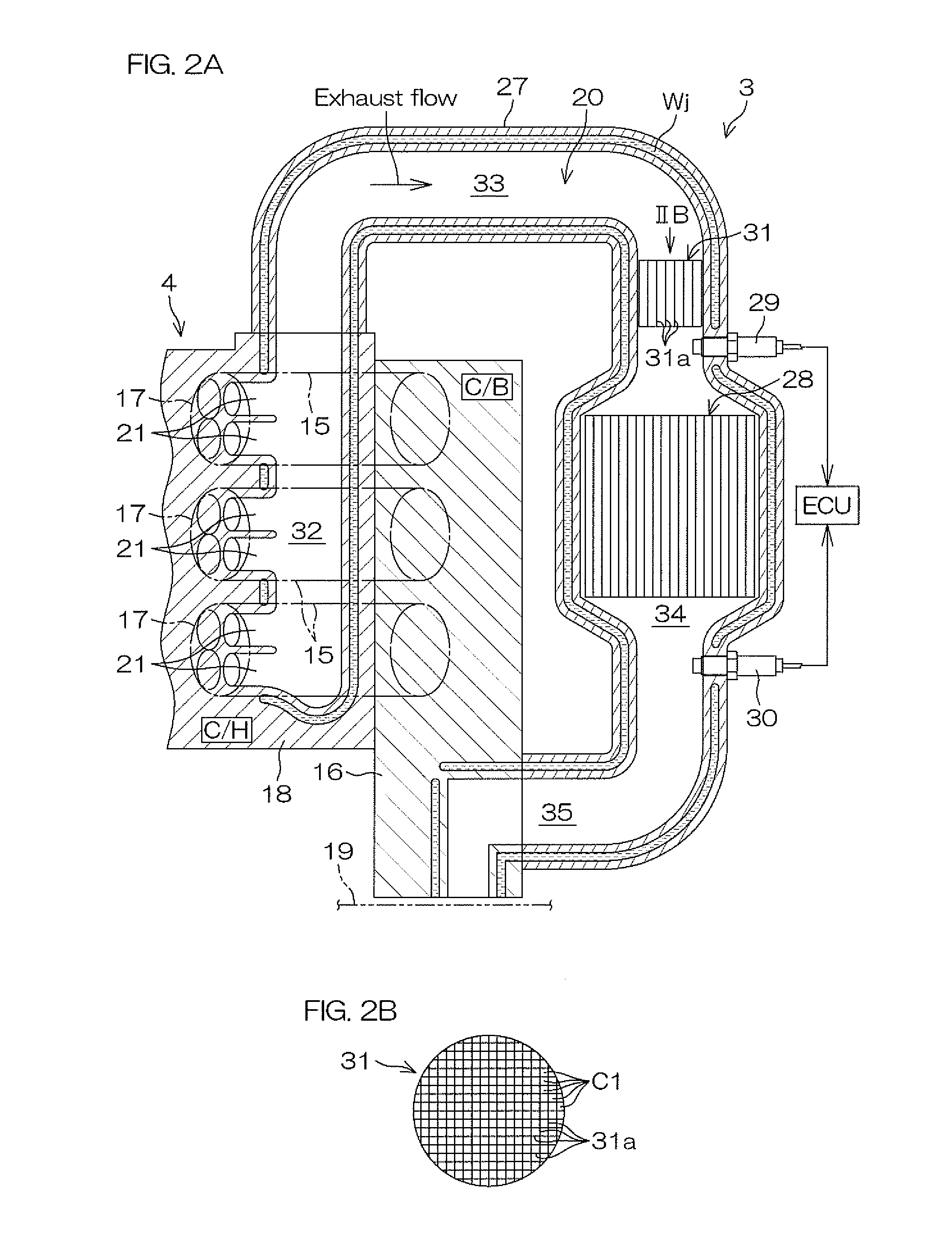

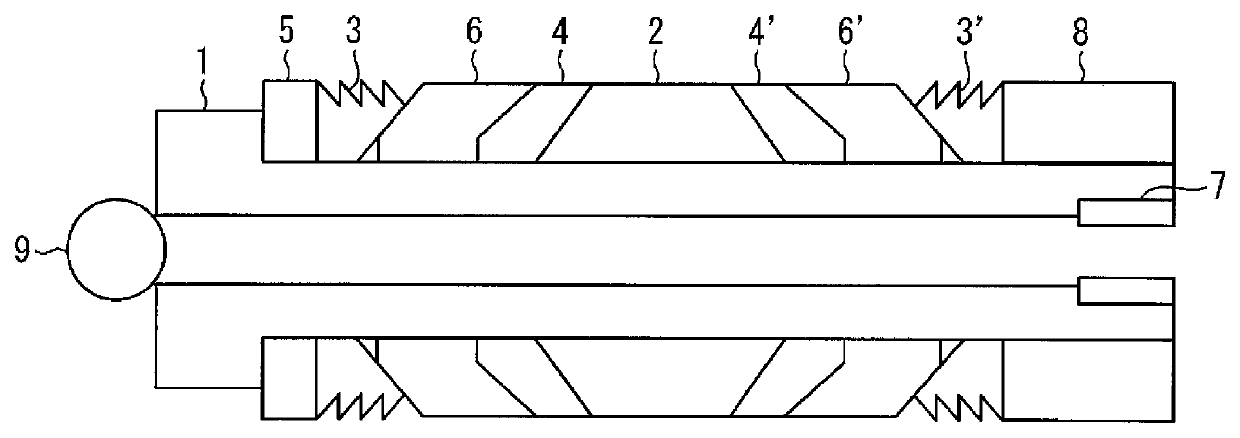

Vessel propulsion apparatus

ActiveUS20130203309A1Well formedLower performance requirementsExhaust apparatusPropulsion power plantsWater jacketAerospace engineering

A vessel propulsion apparatus includes an exhaust passage guiding exhaust generated at an engine, a water jacket cooling at least a portion of the exhaust passage, a cooling device supplying water outside the vessel propulsion apparatus to the water jacket, an exhaust sensor detecting a concentration of a component in the exhaust in the exhaust passage, and a non-catalytic porous member disposed in the exhaust passage at an upstream side relative to the exhaust sensor. The non-catalytic porous member is a porous member that does not hold a catalyst.

Owner:YAMAHA MOTOR CO LTD

Plastic cup and processing method thereof

The invention discloses a plastic cup and a processing method thereof, belonging to the technical field of a plastic product. The plastic cup consists of the following raw materials in parts by weight: 50-65 parts of polylactic acid, 10-18 parts of polycarbonate butanediol, 8-14 parts of polypropylene, 5-12 parts of chitosan fiber, 7-15 parts of sweet potato starch, 5-10 parts of light calcium carbonate, 3-9 parts of wollastonite, 2-5 parts of zinc oxide, 2-5 parts of aluminum hydroxide, 1-4 parts of stearic acid and 0-3 parts of a foaming agent. Polylactic acid and polycarbonate butanediol are taken as the main raw materials of the plastic cup disclosed by the invention; the plastic cup is characterized by easiness in degradation; the light calcium carbonate, wollastonite, zinc oxide and aluminum hydroxide are added for improving the strength and toughness of the plastic cup; the raw materials of the plastic cup are easily available, pure natural, safe and environmentally friendly; the preparation method is simple, the raw material cost is low and the requirement for mechanical equipment is low; the plastic cup is easy for large-scale popularization and application and has excellent economic benefits.

Owner:安徽金星包装有限公司

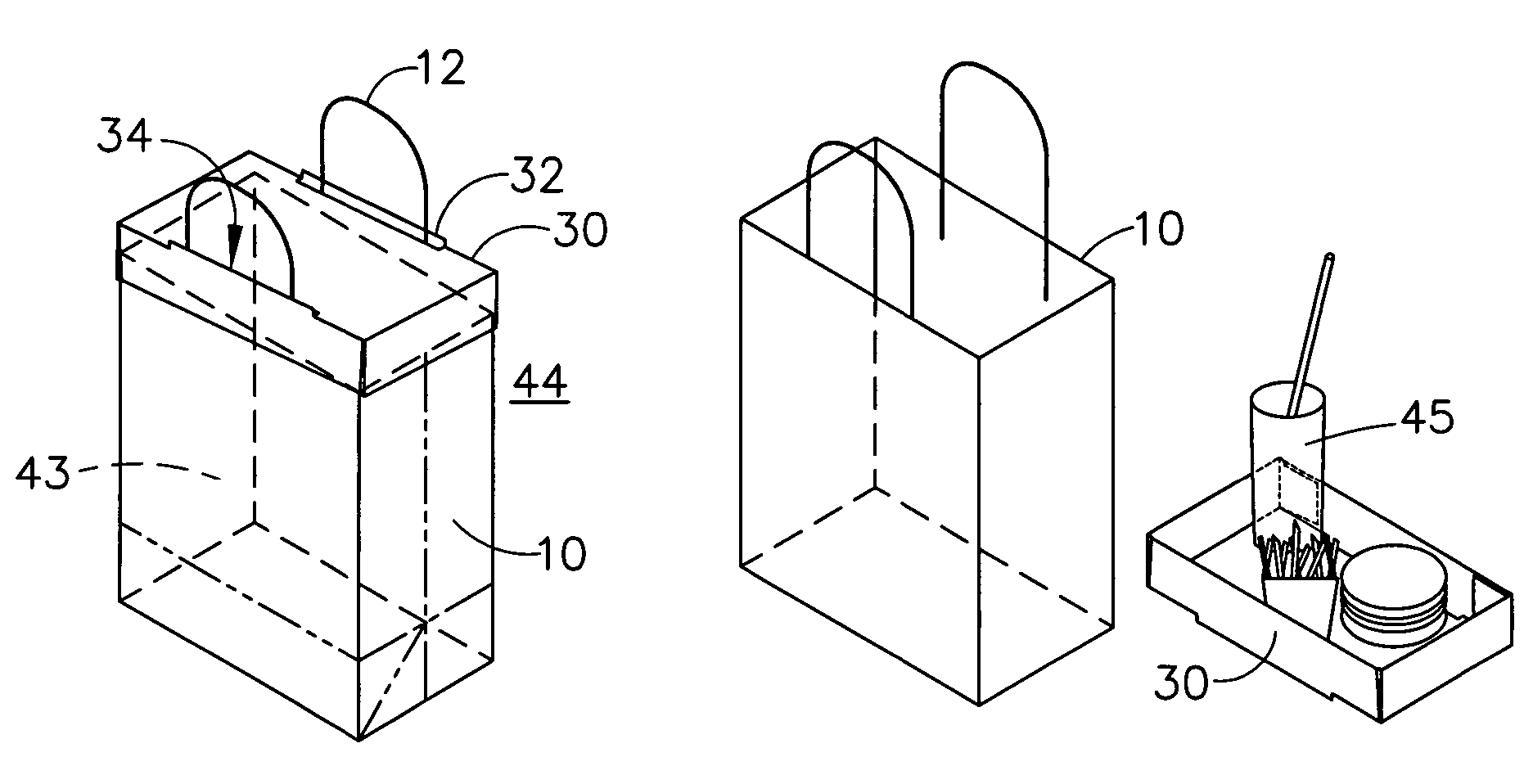

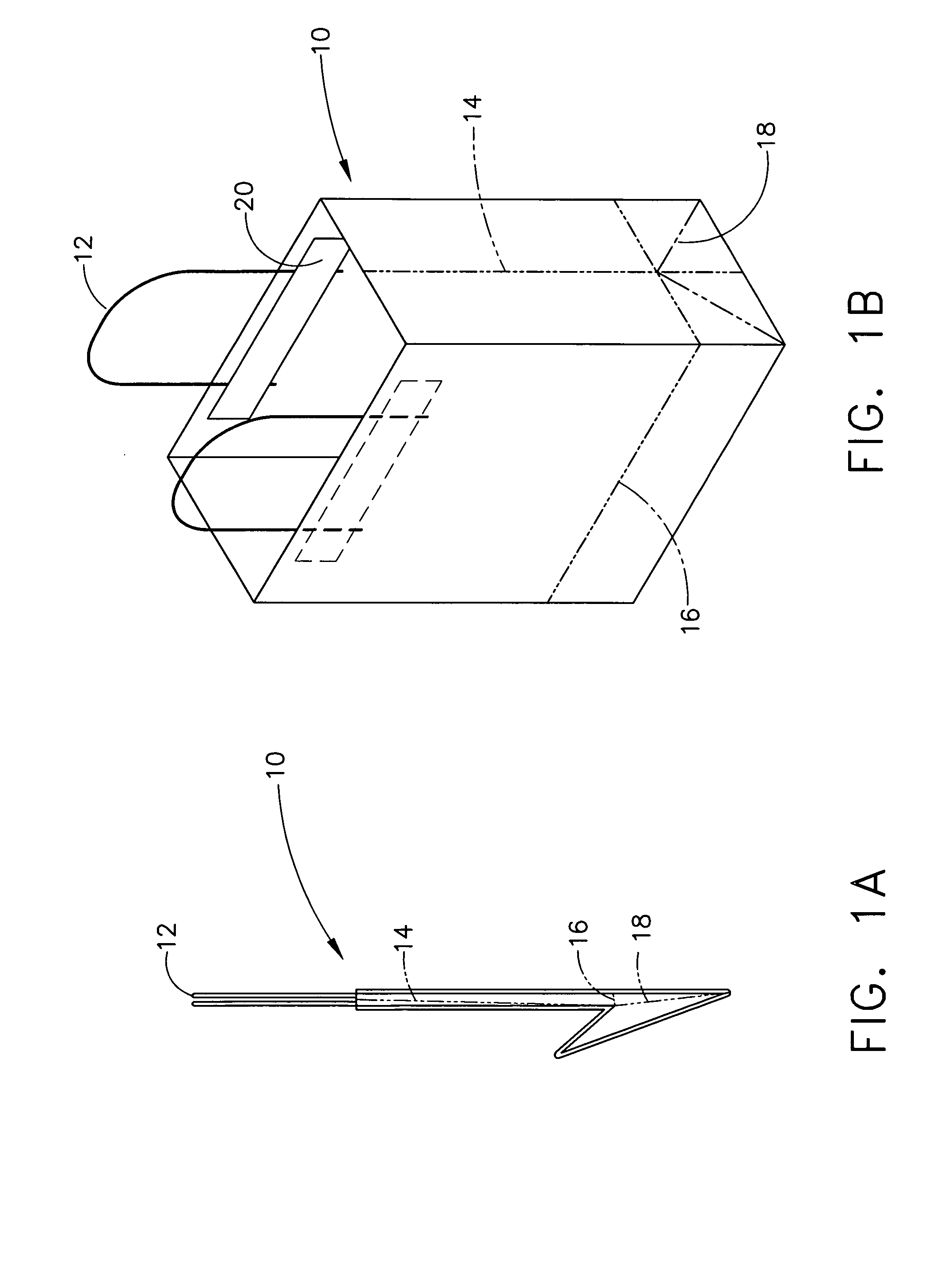

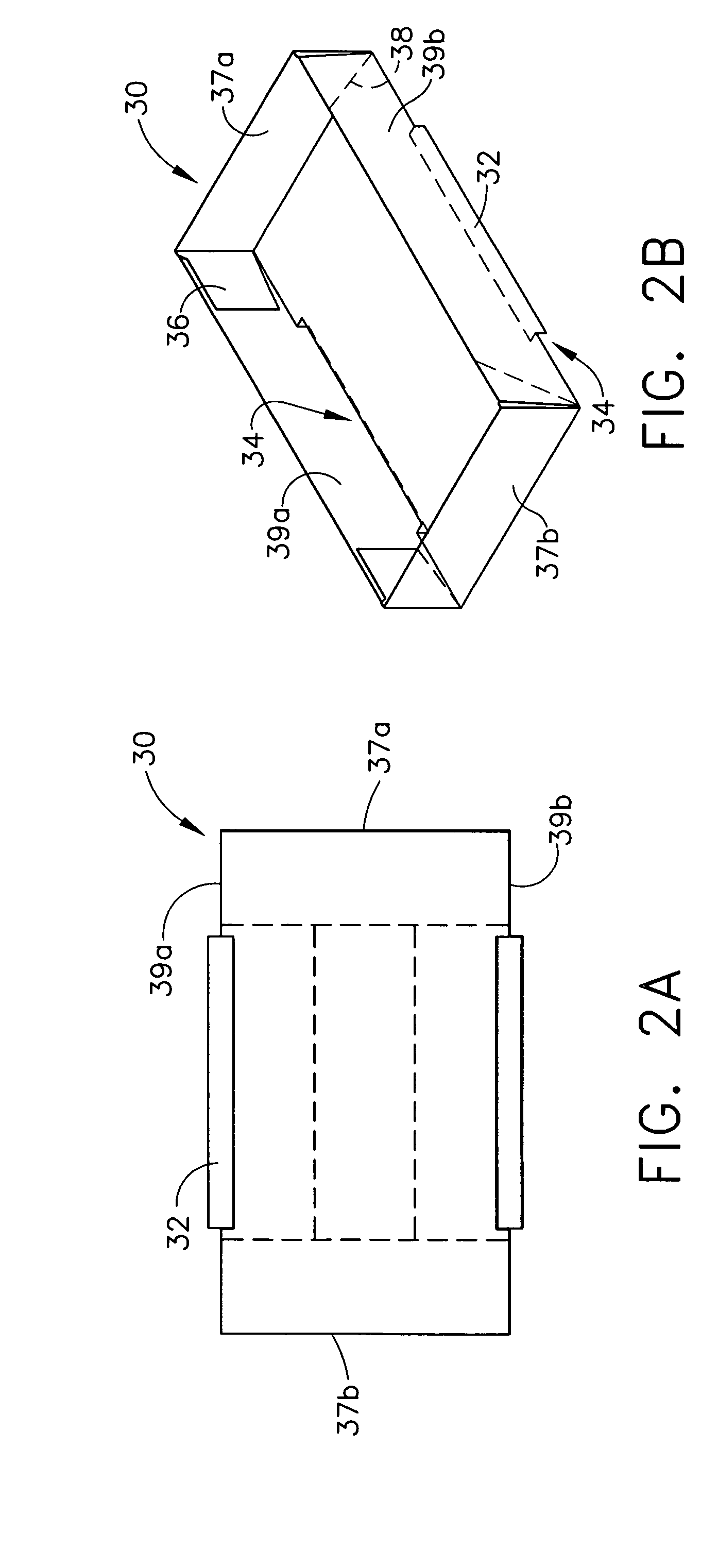

Bag topper device

InactiveUS7004628B2Improve structural rigidityLess-expensive to manufactureBox making operationsPaper-makingEngineeringBiomedical engineering

A product carrying and storage device that comprises a bag with handles and a bag topper device with handle openings in which contents are placed into the bag and the topper device is then guided onto the handles of the bag to protect and insulate the interior contents.

Owner:DURO BAG MFG

Additive for thermoplastics, use of and method for its manufacture, method for the manufacture of a thermoplastic containing such additive and thermoplastic so manufactured

An additive for thermoplastic materials is prepared to achieve controlled degradation and the manufacturing of very light coloured thermoplastics. The thermoplastics may be processed by film blowing, extrusion and injection molding. A ferric(III) salt is reacted with a C2o-C24 fatty acid or derivative under formation of a fat-soluble ferric (III) compound in a process where a suitable oxidizing agent ensures that all the iron in the end product is maintained in the ferric state.

Owner:NOR X IND

Ink for inkjet recording and method for inkjet recording

InactiveUS7287848B2Excellent toneHigh fastnessMonoazo dyesMeasurement apparatus componentsHigh humidityOrganic solvent

An inkjet recording ink including an aqueous medium having dissolved or dispersed therein a magenta dye selected from azo dyes, wherein the magenta dye is a dye having an oxidation potential more positive than 1.0 V (vs SCE) and at the same time, a water-miscible organic solvent having a vapor pressure of 2,000 Pa or less at 20° C. is contained; and an inkjet recording method using the ink.By virtue of such a constitution, an inkjet recording ink and an inkjet recording method are provided, which can ensure high ejection stability, good color hue of the obtained image, no drying of the ink at the ink jet head, excellent fastness to light and water, image quality free from defective such as fineline bleeding under high-humidity condition, and good preservability of the image under severe conditions, and furthermore can ensure high storability and high ejection stability even after aging for a long time or under severe conditions.

Owner:FUJIFILM CORP +1

Sheet filter materials with additives

ActiveUS9107454B2Good removal effectEasily degradableTobacco treatmentCigar manufacturePolyethylene glycolEngineering

The present invention relates to the inclusion of additives in a filter element comprising a non-woven sheet material or paper as the filter material to increase the selective removal of semi-volatile compounds and to improve the taste characteristics of the smoke drawn through the filter element. The increased selective removal of semi-volatile compounds from the smoke being drawn through the filter element is provided by polyethylene glycol. TEC and / or triacetin are additives which have been found to improve the taste characteristics of smoke drawn through the filter element.

Owner:BRITISH AMERICAN TOBACCO (INVESMENTS) LTD

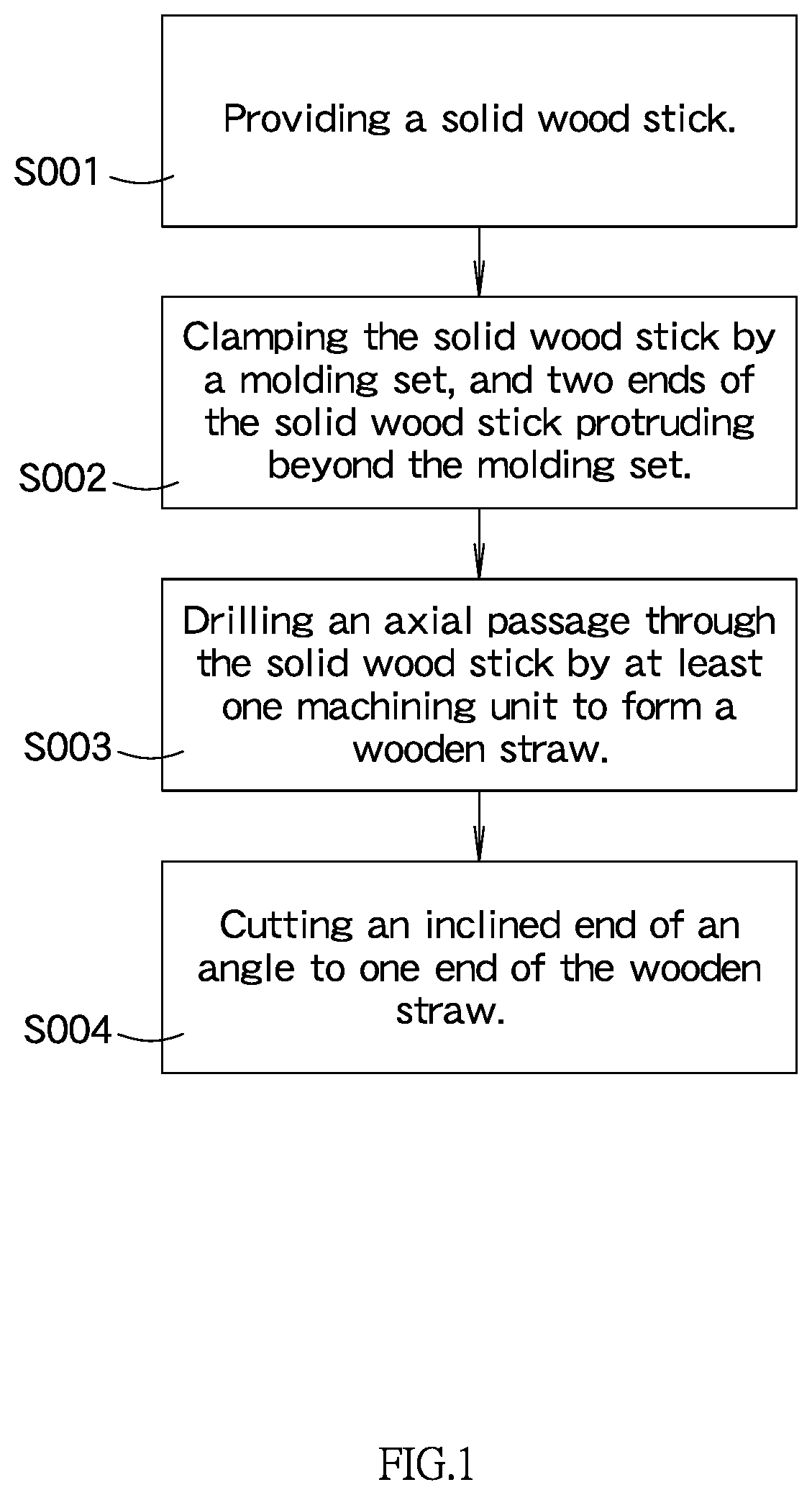

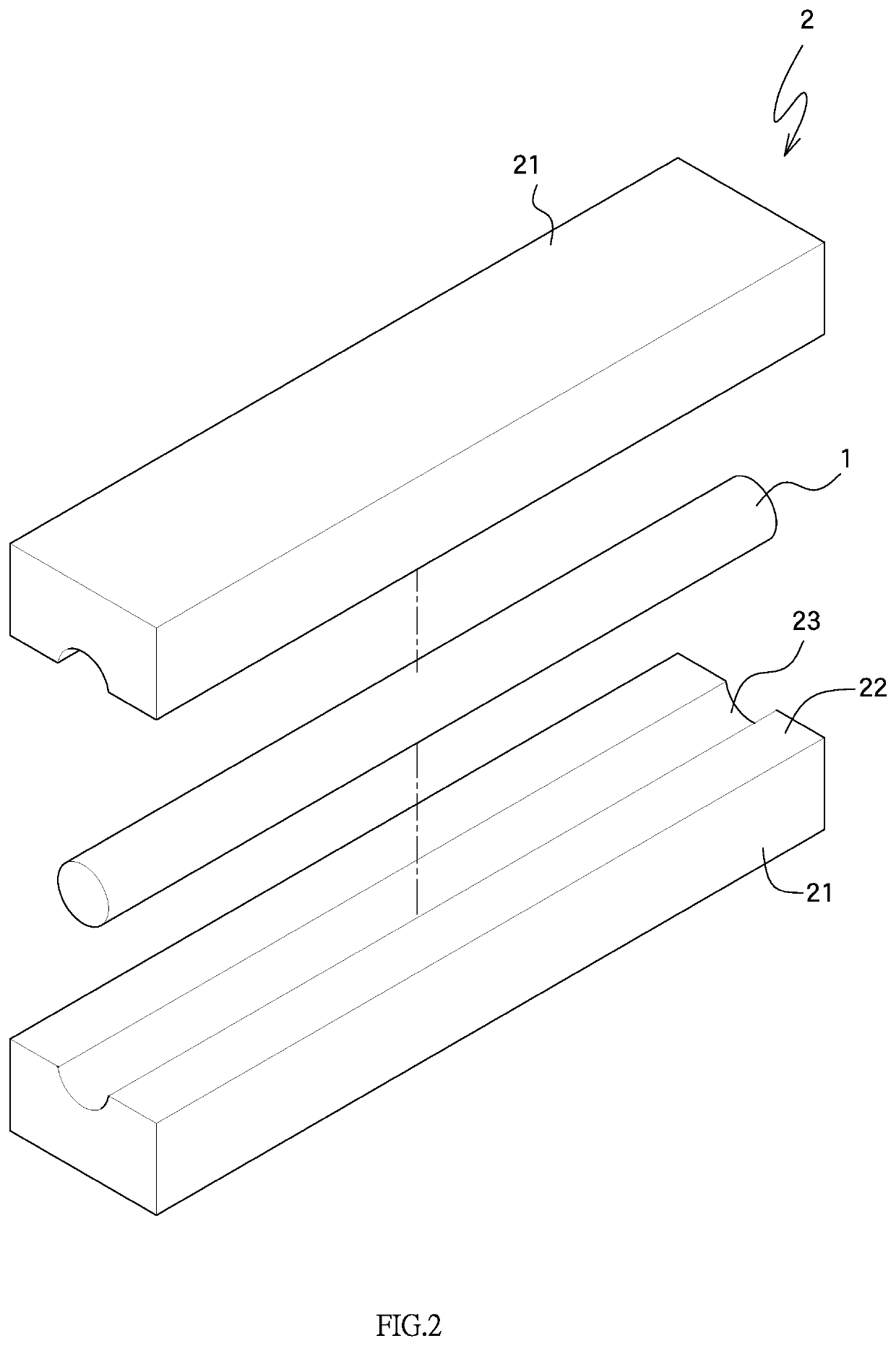

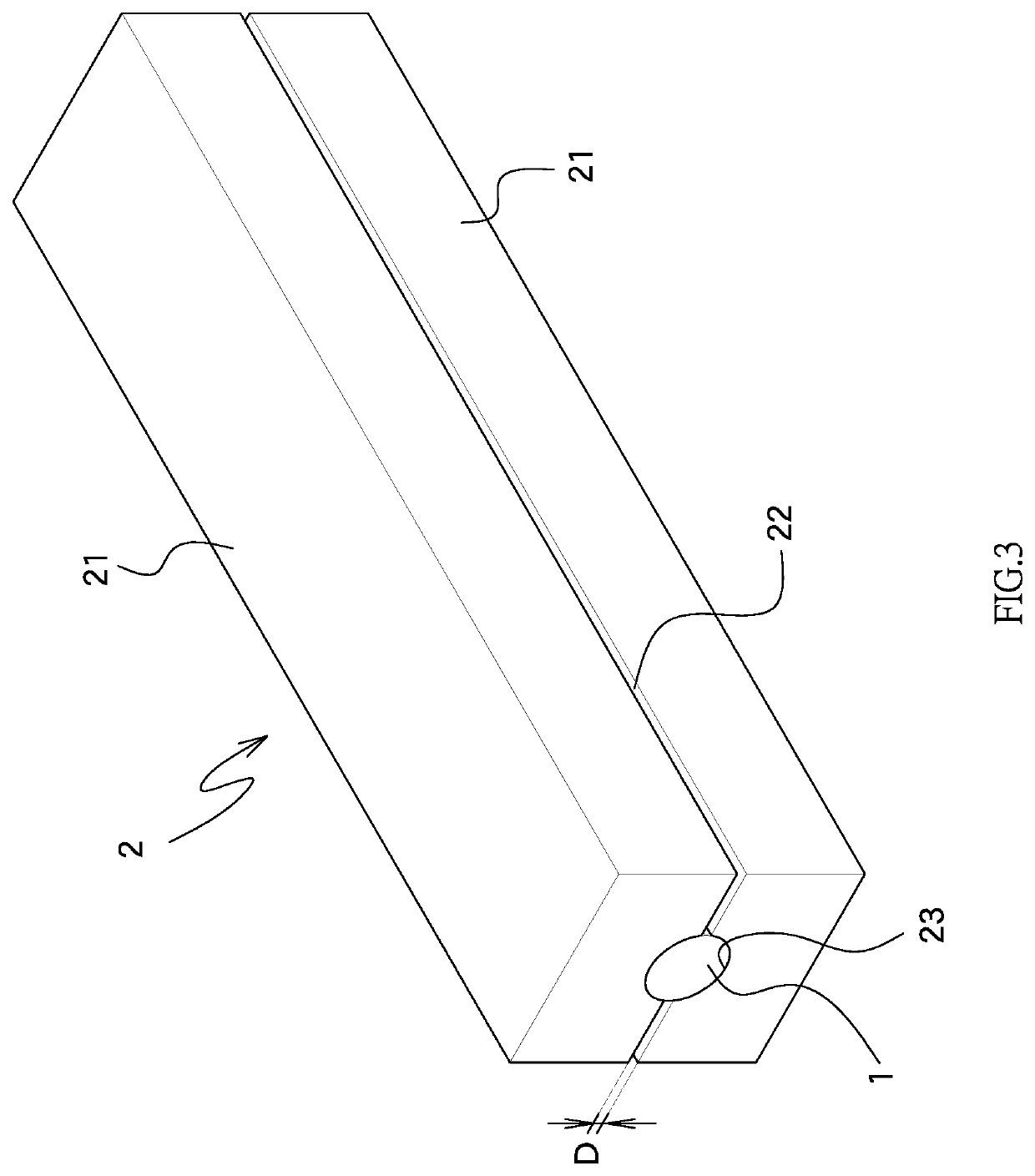

Method for making wooden straws and molding set for making the wooden straws

InactiveUS20200009759A1Easily degradableReduce manufacturing costDrilling machinesDwelling equipmentSolid woodPulp and paper industry

A method for making wooden straws from a solid wood stick includes a step of providing a solid wood stick; a step of clamping the solid wood stick by a molding set, and two ends of the solid wood stick protruding beyond the molding set, and a step of drilling an axial passage through the solid wood stick by at least one machining unit to form a wooden straw. The wooden straws are bio-degradable and durable. The wooden straws do not affect beverage taste and can be manufactured in mass production. The molding set for making the wooden straws includes two dies and each die includes a groove. The solid wood stick is accommodated in the two respective grooves. At least one machining unit is used to drill an axial passage through the solid wood stick to form the wooden straw.

Owner:JIANG JING HUAN

Method for enhancing high-quality gelatin yield

ActiveCN104593465ASignificant progressThe reaction temperature is easy to controlFermentationFiltrationViscosity

The invention discloses a method for enhancing high-quality gelatin yield, which comprises the following steps: regulating the pH value of a colloidal liquid obtained by a pretreatment process, adding biological proteinase by stages to perform colloidal extraction, adding a bamboo charcoal-chitosan composite into the obtained colloidal liquid to perform adsorption filtration, bleaching and sterilizing with hydrogen peroxide, carrying out impurity removal and concentrating by a membrane process, and finally, drying with a flat plate to obtain the gelatin finished product. The stage-by-stage enzyme addition and colloidal extraction are adopted to completely hydrolyze collagens, so that the gelatin yield is greatly enhanced; and the bamboo charcoal-chitosan composite adsorption filtration, H2O2 treatment, membrane-process impurity removal and concentration and other steps are performed to obtain the high-viscosity high-jelling-power gelatin product.

Owner:HUNAN ER KANG PHARMA

Coated controlled-release fertilizer for modifying urea into easily degradable film and production method of coated controlled-release fertilizer

The invention discloses a coated controlled-release fertilizer for modifying urea into an easily degradable film and a production method of the coated controlled-release fertilizer. The method comprises the following steps: heating common urea into a molten-state urea liquid, and uniformly mixing the molten-state urea liquid with a modifier and a curing agent; directly spraying the mixture on the surfaces of fertilizer particles for curing, reacting and forming a film, thereby obtaining a urea-modified coated controlled-release fertilizer which has smooth and dense film material surface and different water resistances. The product has excellent moisture controlled-release performance, the film material is low in cost, the film shell remained in soil is rapidly degraded, and the fertilizer belongs to the coated controlled-release fertilizer of which the film shell is easily degraded. In addition, the product is low in production cost, simple and convenient in production process flow and suitable for large-scale industrial production and popularization and application in gardening and field crops.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

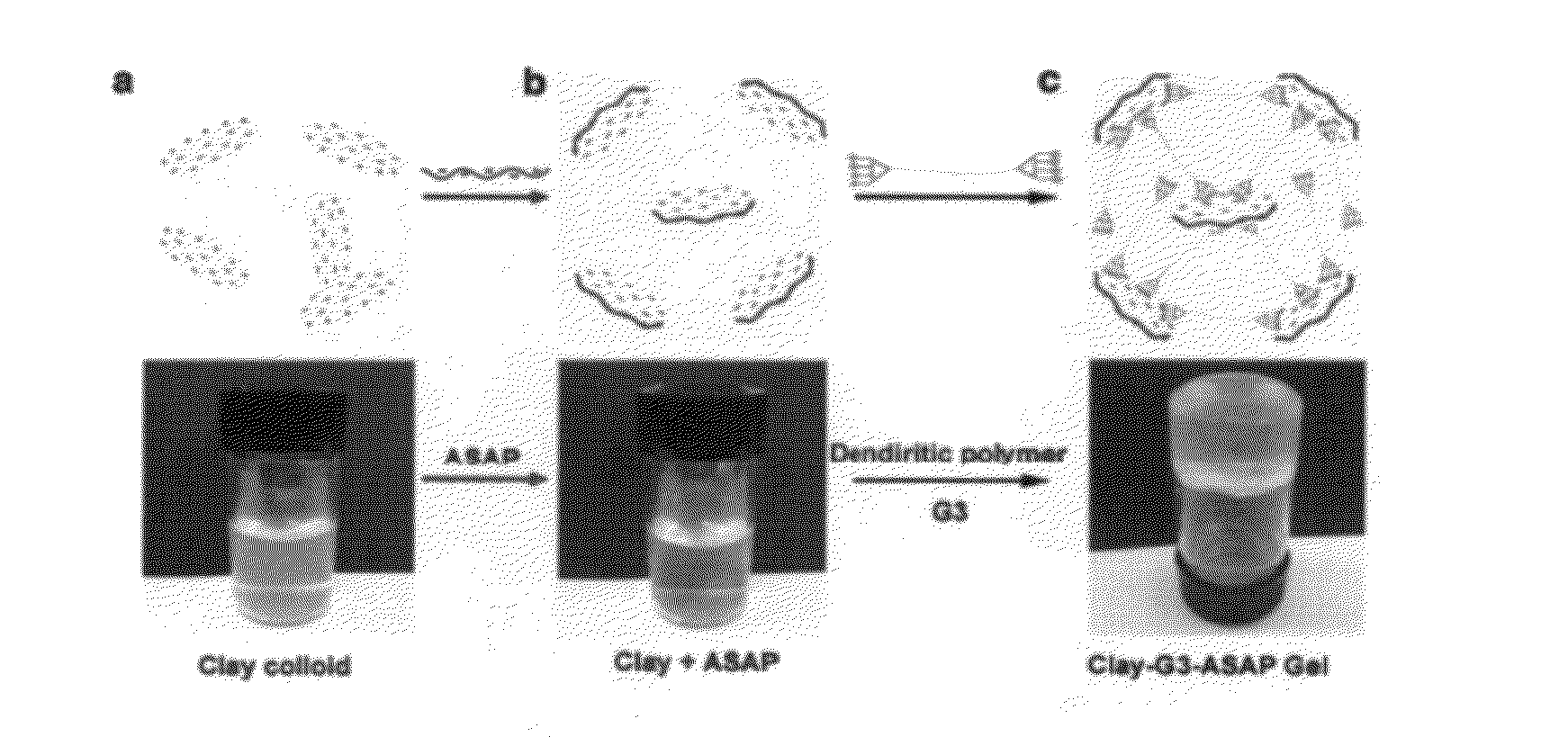

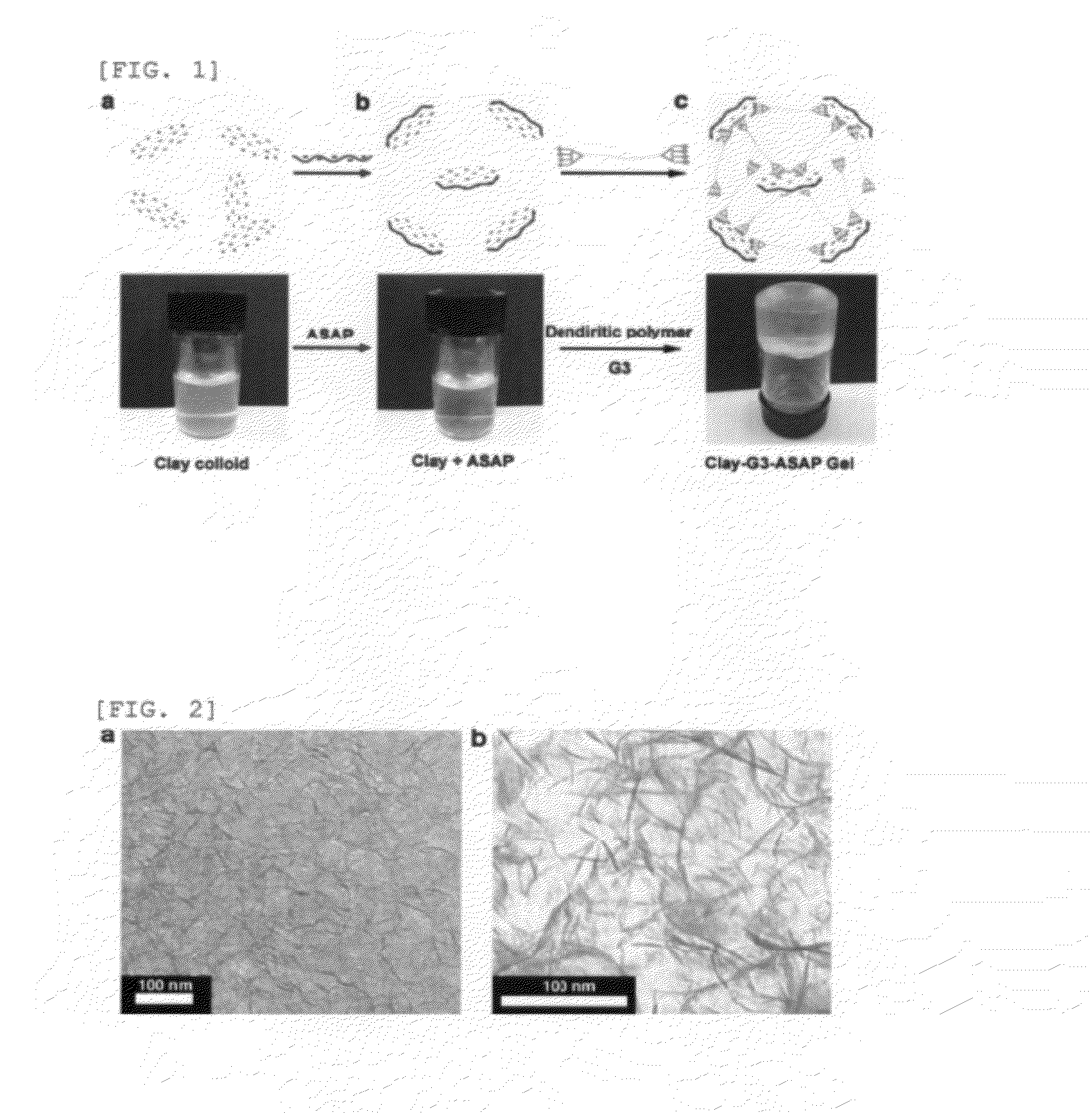

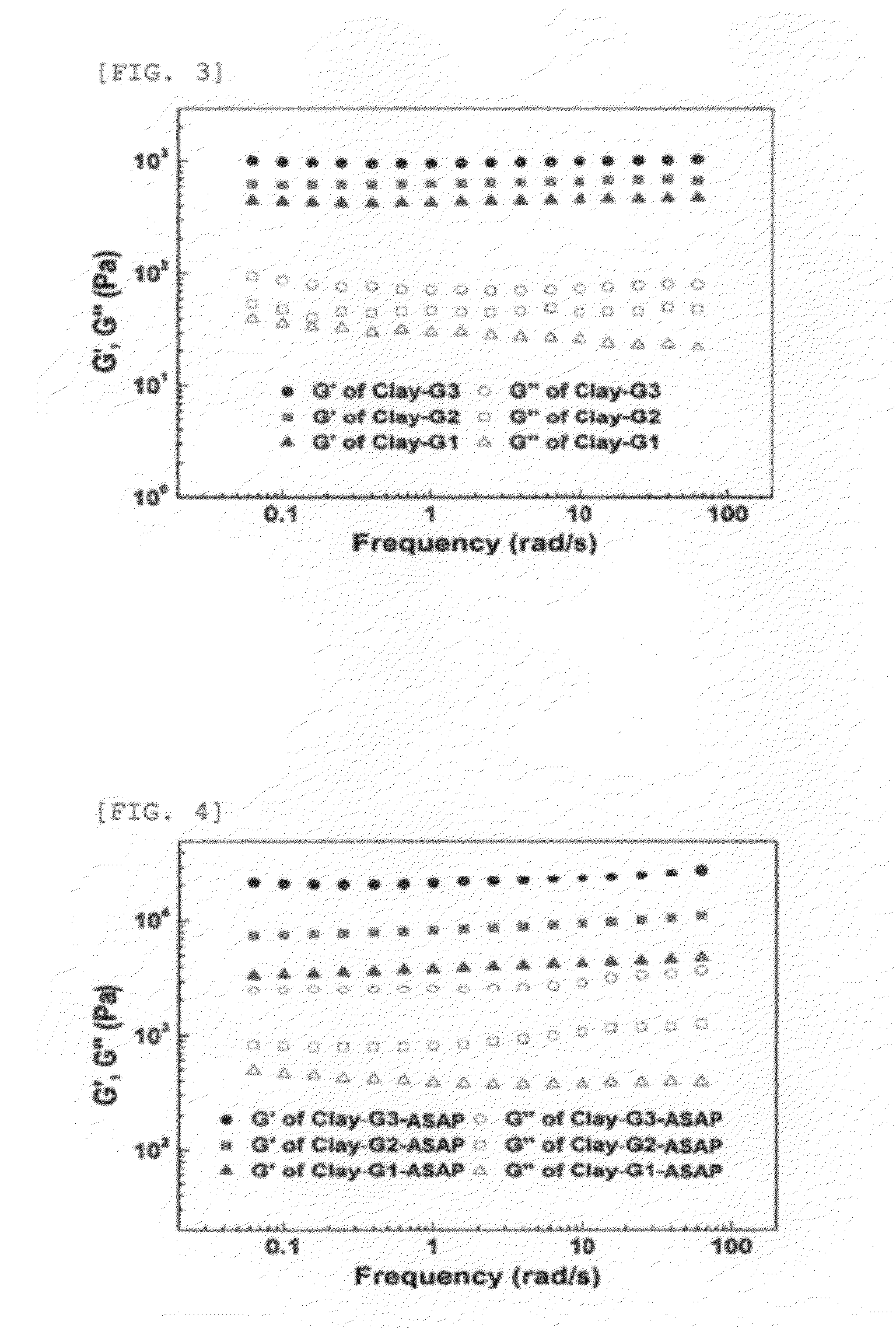

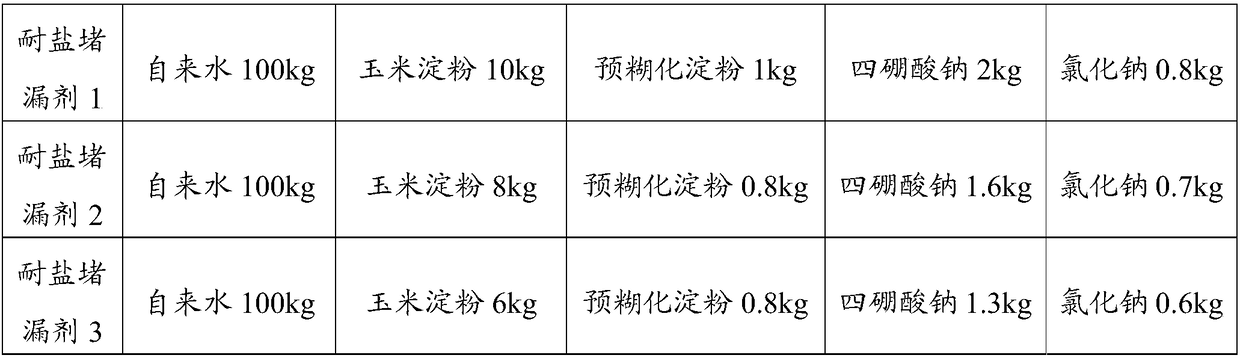

Polyionic dendrimer and hydrogel comprising same

InactiveUS20120101041A1Low mechanical strengthIncrease moisture contentCosmetic preparationsMaterial nanotechnologySelf-healingDendrimer

Provided is a hydrogel which comprises water as the main component at a high water content and has mechanical strength suitable for practical use and which exhibits high transparency and self-healing and shape-retaining properties. Also provided are both a material for the hydrogel and a novel polyionic dendrimer. A polyionic dendrimer which comprises a hydrophilic linear polymer as the core and polyester dendrons attached to both terminals of the linear polymer and in which cationic groups are bonded to the surfaces of the dendrons, said cationic groups being selected from the group consisting of guanidine group, thiourea group, and isothiourea group; a material for a hydrogel, which comprises the polyionic dendrimer and clay; and a hydrogel prepared using the material.

Owner:JAPAN SCI & TECH CORP

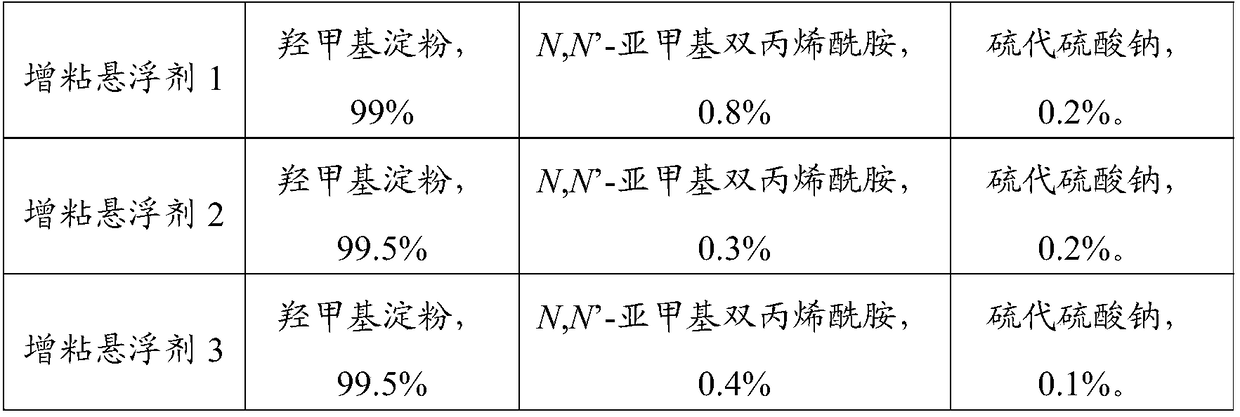

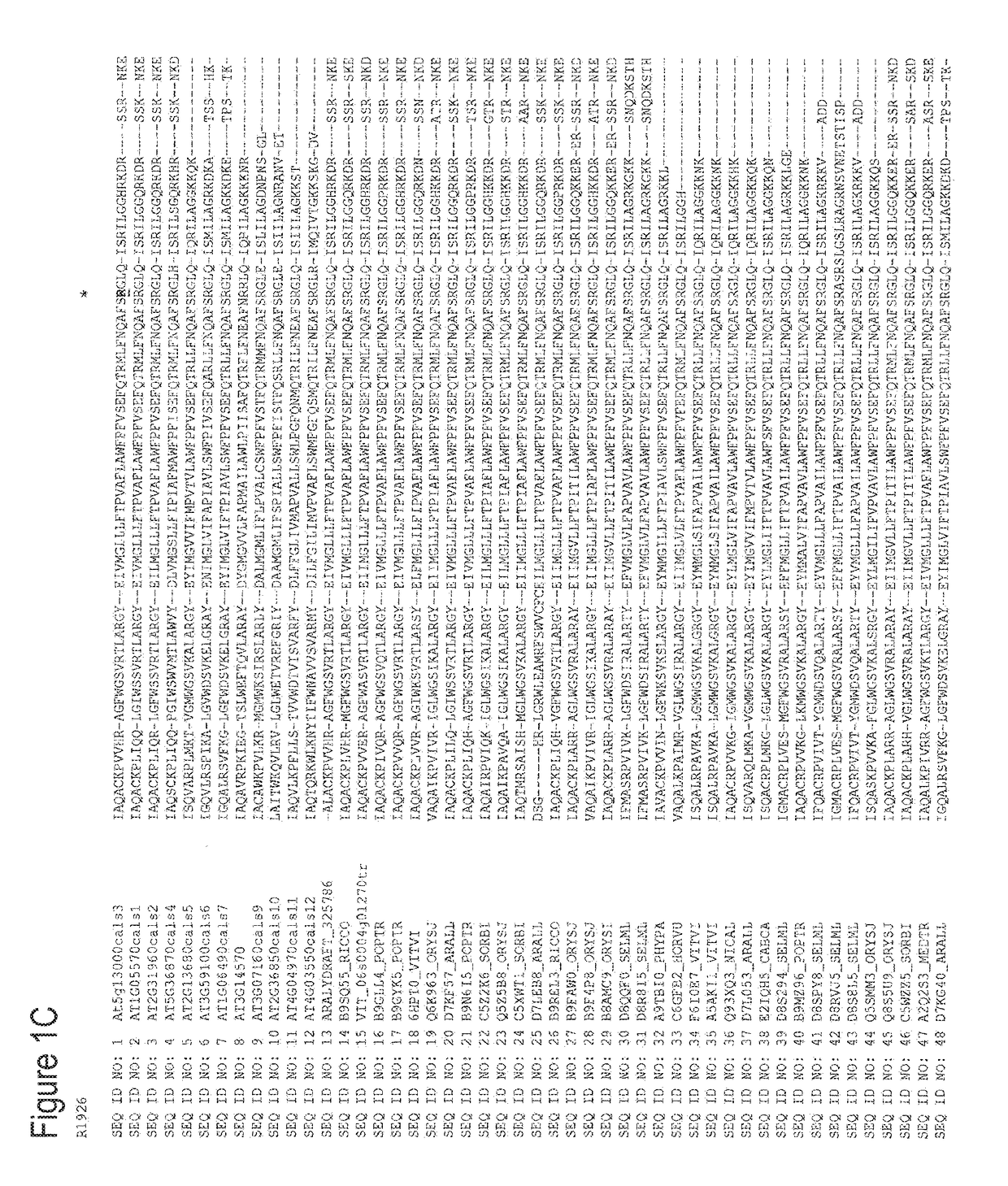

Modified brine workover fluid and preparation method thereof

ActiveCN109385258AEasy to flow backPrevent leakageDrilling compositionSuspending AgentsHydroxymethyl

The invention discloses a modified brine workover fluid and a preparation method thereof, belonging to the technical field of workover fluids for workover during oil-gas field development. The modified brine workover fluid comprises brine, a modifier for preventing brine from fouling, a salt-resistant plugging agent, a tackfying-suspending agent, a unidirectional pressure sealing agent for a drilling fluid and oil-soluble resin. The salt-resistant plugging agent is prepared from the raw materials by mass: 100 parts of water, 8 to 12 parts of natural starch, 0.8 to 2 parts of pregelatinized starch, 1 to 3 parts of sodium tetraborate and 0.7 to 1 part of sodium chloride. The tackifying-suspending agent comprises the following components by mass: 99.0% to 99.5% of hydroxymethyl starch, 0.3% to 0.8% of N,N'-methylenebisacrylamide and 0.1% to 0.2% of thiosulfate. The modified brine workover fluid has the advantages of good plugging effect, a wide plugging range, high salt resistance, easy degradability, etc.

Owner:PETROCHINA CO LTD

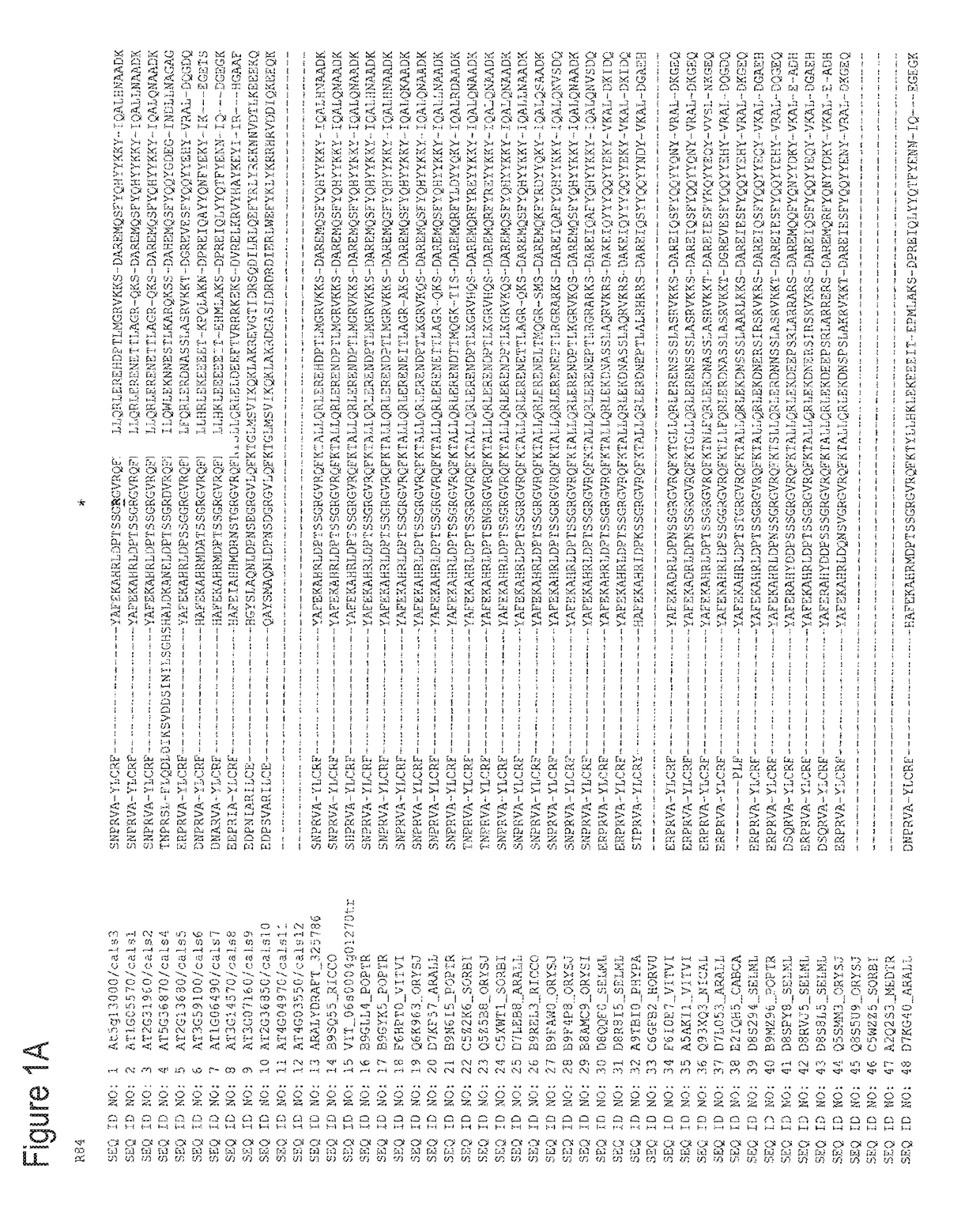

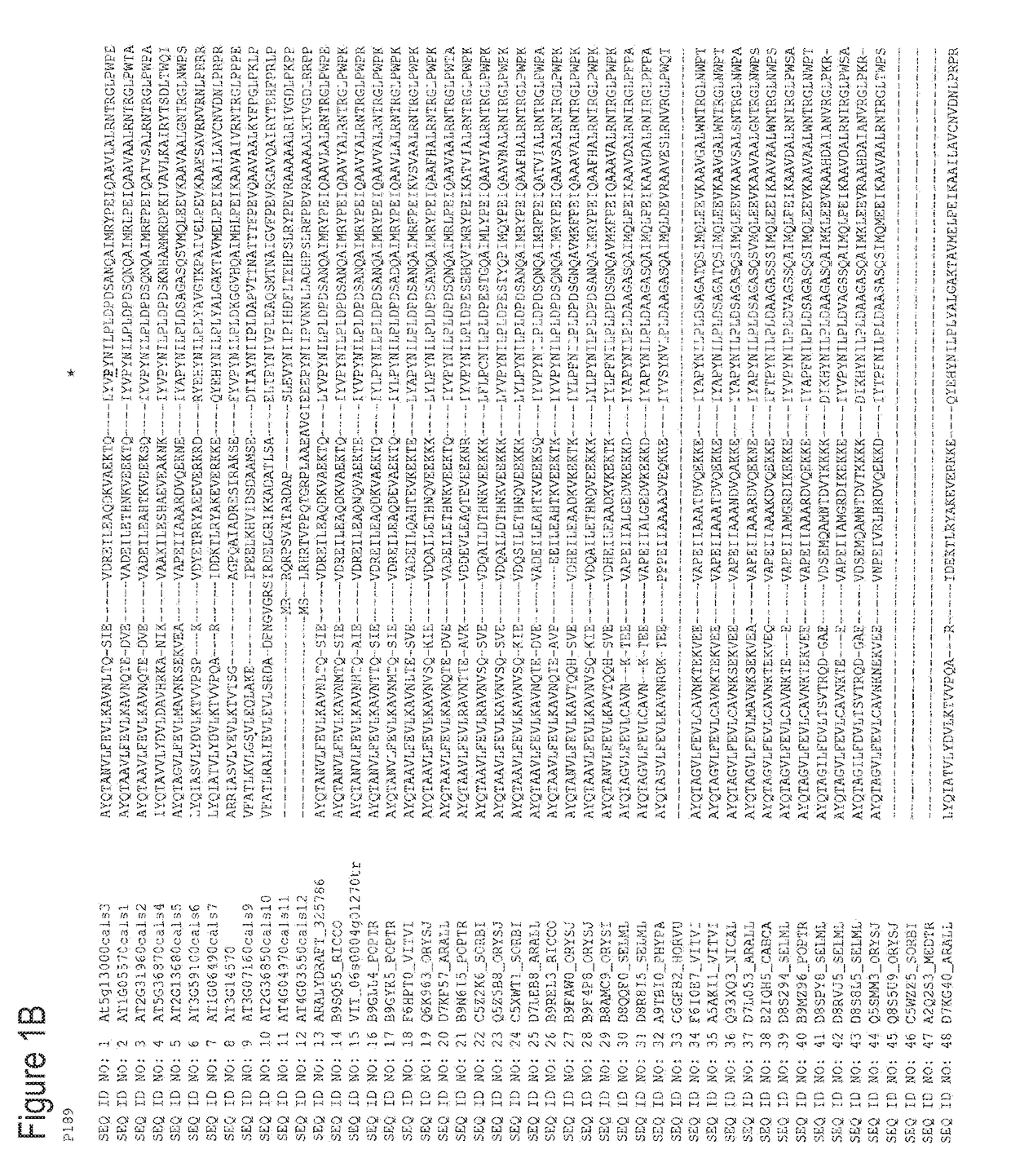

Polypeptide

ActiveUS9944908B2Enhances biosynthesis and accumulationImprove quality and quantityPowder deliveryPlant peptidesCalloseBiosynthesis

The present invention relates to a polypeptide, or a fragment thereof, capable of enhancing callose biosynthesis and / or accumulation, wherein at least one of the conserved amino acid residues selected from the group consisting of residue corresponding to R84 of SEQ ID NO: 1, residue corresponding to R1926 or SEQ ID NO: 1 and residue corresponding to P189 of SEQ ID NO: 1, of the polypeptide or a fragment thereof, is modified by a mutation selected from the group consisting of substitution and deletion.

Owner:UNIVERSITY OF HELSINKI +1

Stock shape for downhole tool component, downhole tool component, and downhole tool

A stock shape for a downhole tool component includes a magnesium alloy including a phase containing 70 to 95 wt. % of magnesium in which 0 wt. % or more and less than 0.3 wt. % of a rare earth metal, a metal material other than the magnesium and the rare earth metal, and 0.1 to 20 wt. % of a degradation accelerator are distributed, and the stock shape has an average particle size of the metal material of 1 to 300 μm, tensile strength of 200 to 500 MPa, and a degradation rate in a 2% potassium chloride aqueous solution at 93° C. of not less than 20 mg / cm2 and not greater than 20000 mg / cm2 per day. Accordingly, a downhole tool having high strength and being readily degradable is established.

Owner:KUREHA KAGAKU KOGYO KK

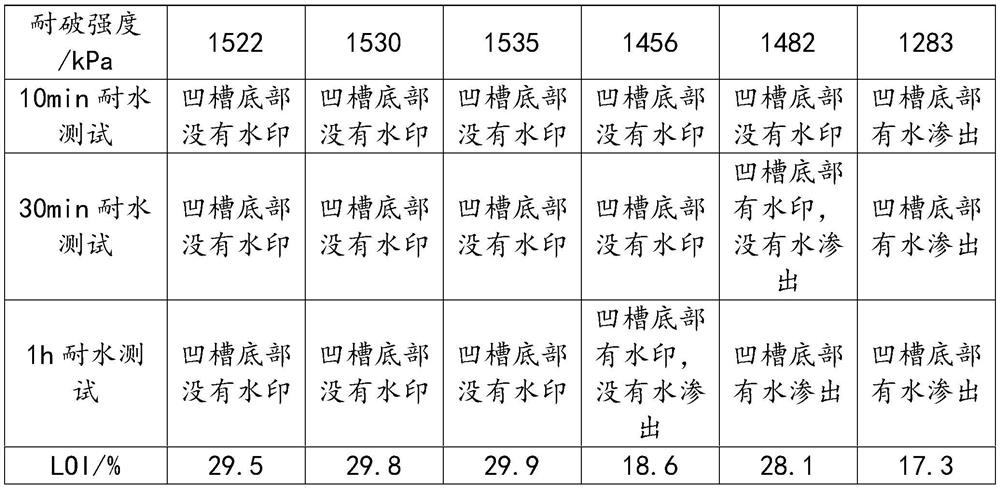

A waterproof and flame-retardant corrugated box and its production process

ActiveCN111441190BImprove mechanical propertiesImprove flame retardant performanceMechanical working/deformationWrappersFiberProcess engineering

The invention discloses a waterproof and flame-retardant corrugated box, which is made of waterproof and flame-retardant corrugated paper. The corrugated paper includes a base paper and a functional coating coated on the surface of the base paper. The base paper is modified by impregnating liquid; the corrugated paper The production process of the box is as follows: the first step, immerse the base paper in the impregnation solution, and dry it after ultrasonic; the second step, evenly coat the coating on the surface of the impregnated base paper, cure, and process it with corrugated rollers; the third step, nail box. In the present invention, the base paper is treated by impregnating the impregnating liquid, and the active ingredients in the impregnating liquid have a strong binding force with the fibers of the base paper, which can not only give full play to the flame retardant performance, but also form a cross-linked network structure to improve the mechanical properties of the base paper ; After being coated with functional coatings, the corrugated paper has good waterproof performance; moreover, the impregnating liquid and the raw materials of functional coatings are all environmentally friendly raw materials, and the base paper itself is made of ordinary wood. Therefore, the obtained corrugated paper is easy to degrade characteristics, in line with environmental protection requirements.

Owner:浙江一鸣包装印刷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com