Patents

Literature

28388 results about "Stearic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stearic acid (/ˈstɪərɪk/ STEER-ik, /stiˈærɪk/ stee-ARR-ik) is a saturated fatty acid with an 18-carbon chain and has the IUPAC name octadecanoic acid. It is a waxy solid and its chemical formula is C₁₇H₃₅CO₂H. Its name comes from the Greek word στέαρ "stéar", which means tallow. The salts and esters of stearic acid are called stearates. As its ester, stearic acid is one of the most common saturated fatty acids found in nature following palmitic acid. The triglyceride derived from three molecules of stearic acid is called stearin.

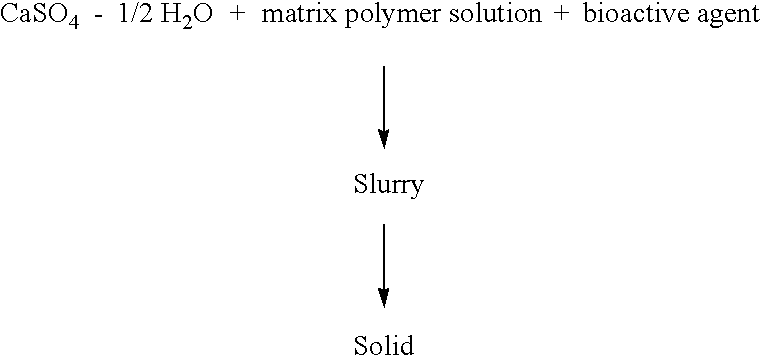

Resorbable matrices for delivery of bioactive compounds

This invention relates generally to the production and use of inorganic-conditioning agent complexes for the controlled release of compounds including medicinals. Advantageously, the inorganic used is calcium sulfate and the conditioning agent is calcium stearate.

Owner:ROYER BIOMEDICAL INC

Pharmaceutical composition and method for transdermal drug delivery

InactiveUS20050020552A1Increase concentrationImproves transdermal penetrationOrganic active ingredientsAerosol deliveryIsostearic acidHormones regulation

A pharmaceutical composition for transdermal administration of a hormone (e.g., testosterone), which includes isostearic acid as a penetration enhancer, and methods utilizing same for treating medical conditions in which elevating a hormone serum level is beneficial are disclosed.

Owner:AGIS INDUSTRIES (1983) LTD

Rubber composition and product thereof

The invention relates to a rubber combination, which comprises: 100 pars of rubber being a major constituent, 0-60 parts of anti-polyolefine, 1-5 parts of zinc oxide, 1-4 parts of stearic acid, 0.5-2 parts of age inhibitor, 0.5-2 parts of paraffinum, 20-150 parts of modification filling, 1-5 parts of process oil, 0.5-20 parts of softener, 0.5-3 parts of promoter, and 0.5-3 parts of sulfur. The rubber combination is molded, shaped, vulcanized so as to obtain various corresponding high performance products, in particular to tyre products, cord ply adhesive tapes and conveyor belt and has extensive use.

Owner:严晓敏

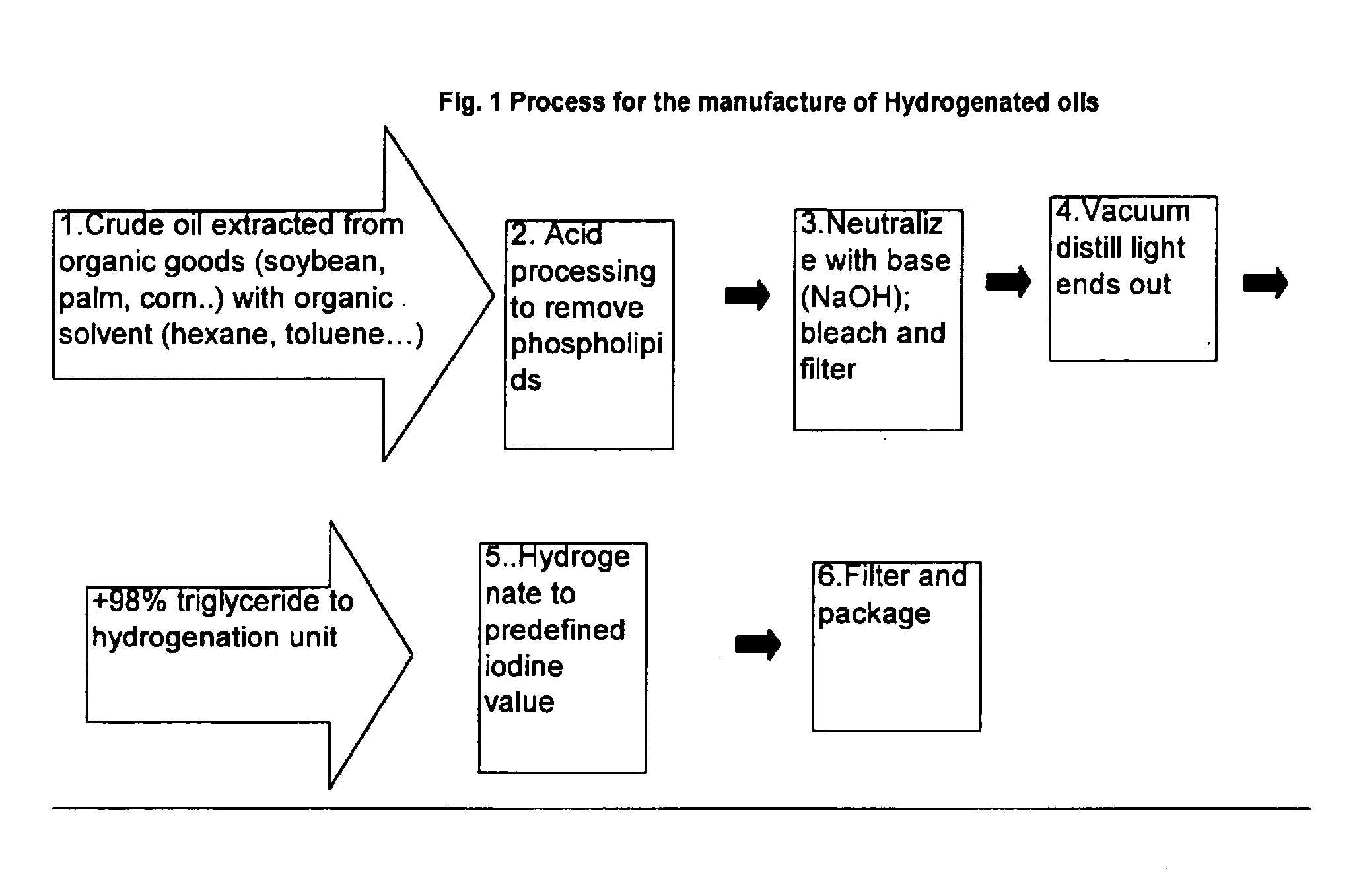

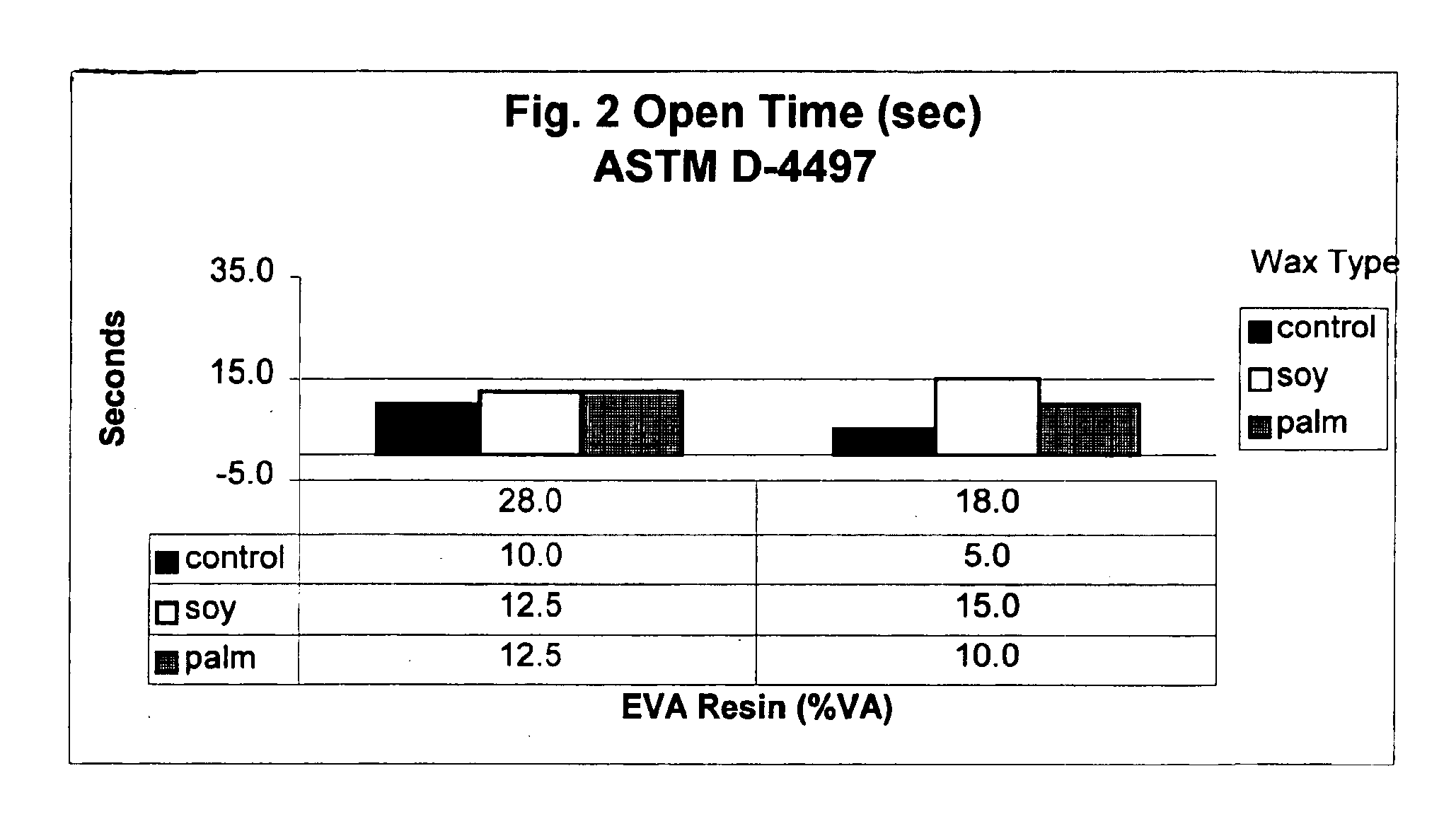

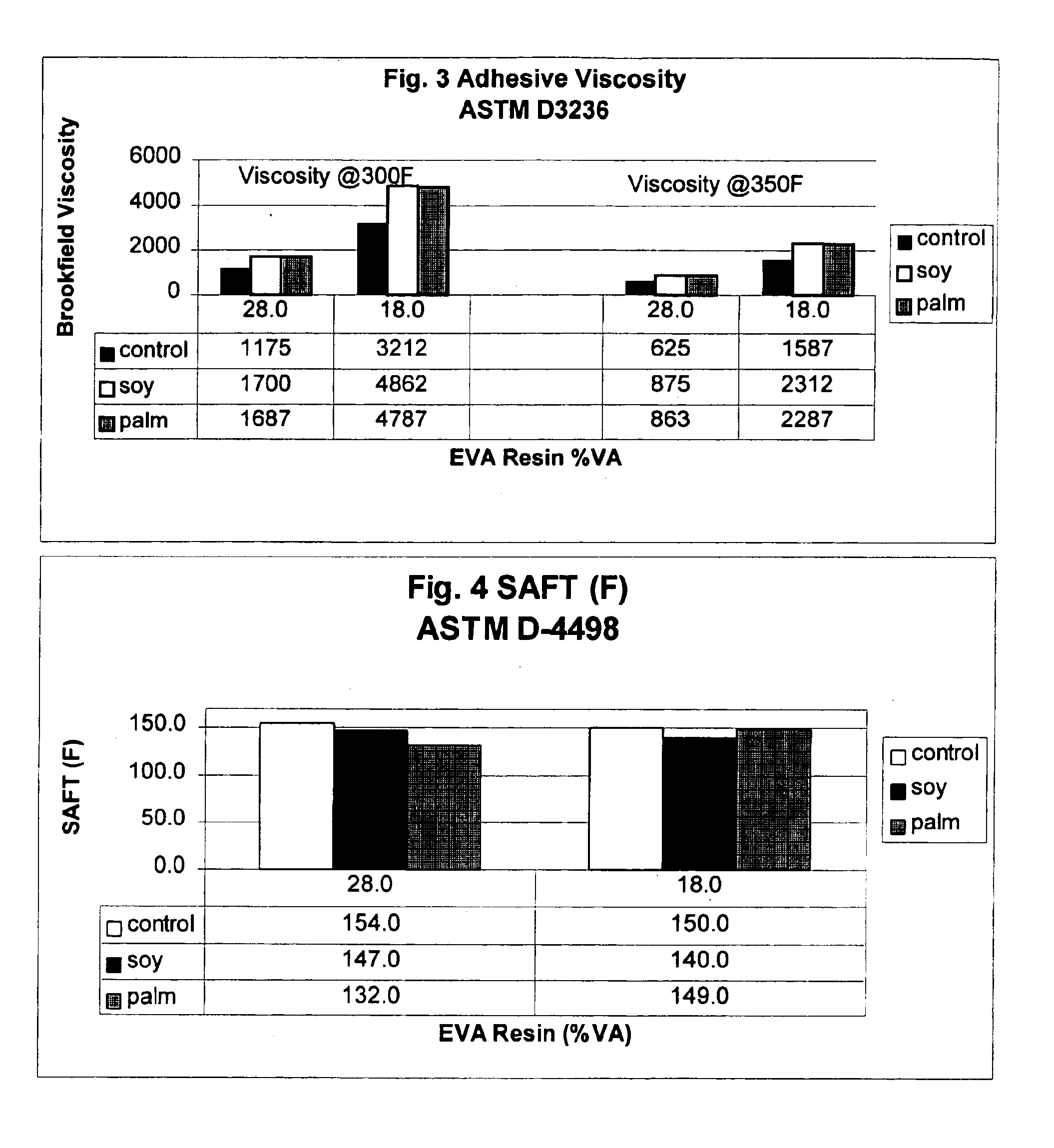

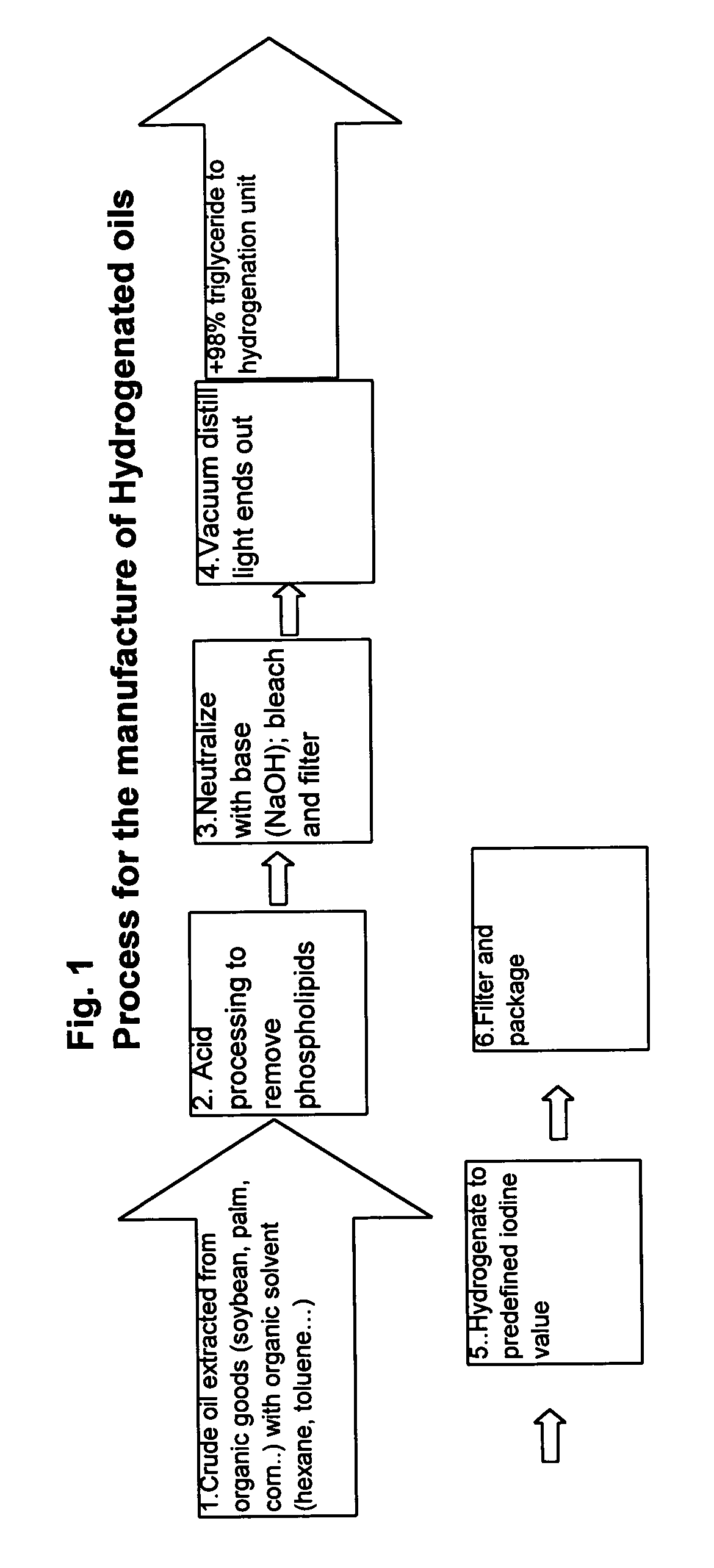

Wax for hot melt adhesive applications

InactiveUS6890982B2Produced economicallyProperty securityNon-macromolecular adhesive additivesFilm/foil adhesivesTG - TriglycerideStearic acid

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used as substitutes for petroleum derived waxes in hot-melt adhesive compositions. Unlike petroleum-derived or synthetic waxes, adhesive compositions comprising these waxes, which are obtained from naturally derived, renewable resources, achieve adhesion performance similar to conventional adhesives containing petroleum-derived waxes. The inventive waxes have a low iodine value (between 2-5), and melting points between approximately 120-165 degrees F. (Mettler Drop Point). These waxes comprise a triglyceride whose fatty acids are predominantly stearic acid (C18). The naturally derived waxes are used as an alternative to petroleum and synthetically derived waxes in the manufacture of adhesives used to bond paper, wood, glass, plastic and metal in a variety of manufacturing operations.

Owner:MARCUS OIL & CHEM

Novel wood plastic composite decorative building material and manufacturing method thereof

InactiveCN101955614AImproved performance characteristicsGood environmental characteristicsAntioxidantPolyvinyl chloride

The invention relates to a novel wood plastic composite decorative building material and a manufacturing method thereof. The novel wood plastic composite decorative building material comprises the following components in part by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 30 parts of mixture formed by mixing one or more of wood powder, bamboo powder, rice bran powder and crop straw powder in an arbitrary ratio, 30 parts of calcium powder, 5 to 10 parts of chlorinated polyethylene or MBS resin, 2 to 6 parts of rear earth compound stabilizer, 0.5 to 3 parts of polyethylene wax or oxidized polyethlene wax, 0.5 to 3 parts of stearic acid, 0.5 to 2.0 parts of foaming agent, 5 to 10 parts of blowing promoter, 0.5 to 1 part of antioxidant, 0.5 to 1 part of reinforcing agent, 1 to 3 parts of toner and 0.5 to 1 part of weather resistant agent. PVC plastic is modified by adding the auxiliaries, and the influence of unstable components (such as a vinyl chloride monomer, hydrogen chloride gas and the like) in the PVC on the performance of the building material is eliminated, so that the building material has better performance and environmental protection characteristics on the basis of keeping the original performance.

Owner:CHENGDU AOKINGTH TECH

Antioxidant and ultravioresistant polypropylene woven bag raw material

InactiveCN102766918AImprove antioxidant capacityImproves UV resistanceMonocomponent polyolefin artificial filamentArtifical filament manufactureUv absorberStearic acid

The invention discloses an antioxidant and ultravioresistant polypropylene woven bag raw material. The polypropylene woven bag raw material is added with anti-oxidant B215, anti-oxidant 1010, auxiliary anti-oxidant DLTP (dilauryl thiodipropionate) or DSTP (distearyl thiodipropionate), ultraviolet absorber UV531, light stabilizer GW-480, stearic acid, calcium stearate, calcium carbonate, mono-alkoxy titanate coupling agent YDH-101, and zinc stearate in powdered polypropylene, and then subjected to wiredrawing treatment in a drawing machine. Compared with the prior art, the raw material provided by the invention has advantages of good antioxidant and ultravioresistant properties, the raw material is particularly suitable for being used as woven bag raw materials, especially for being used as the raw material for manufacturing container bags.

Owner:尚勇

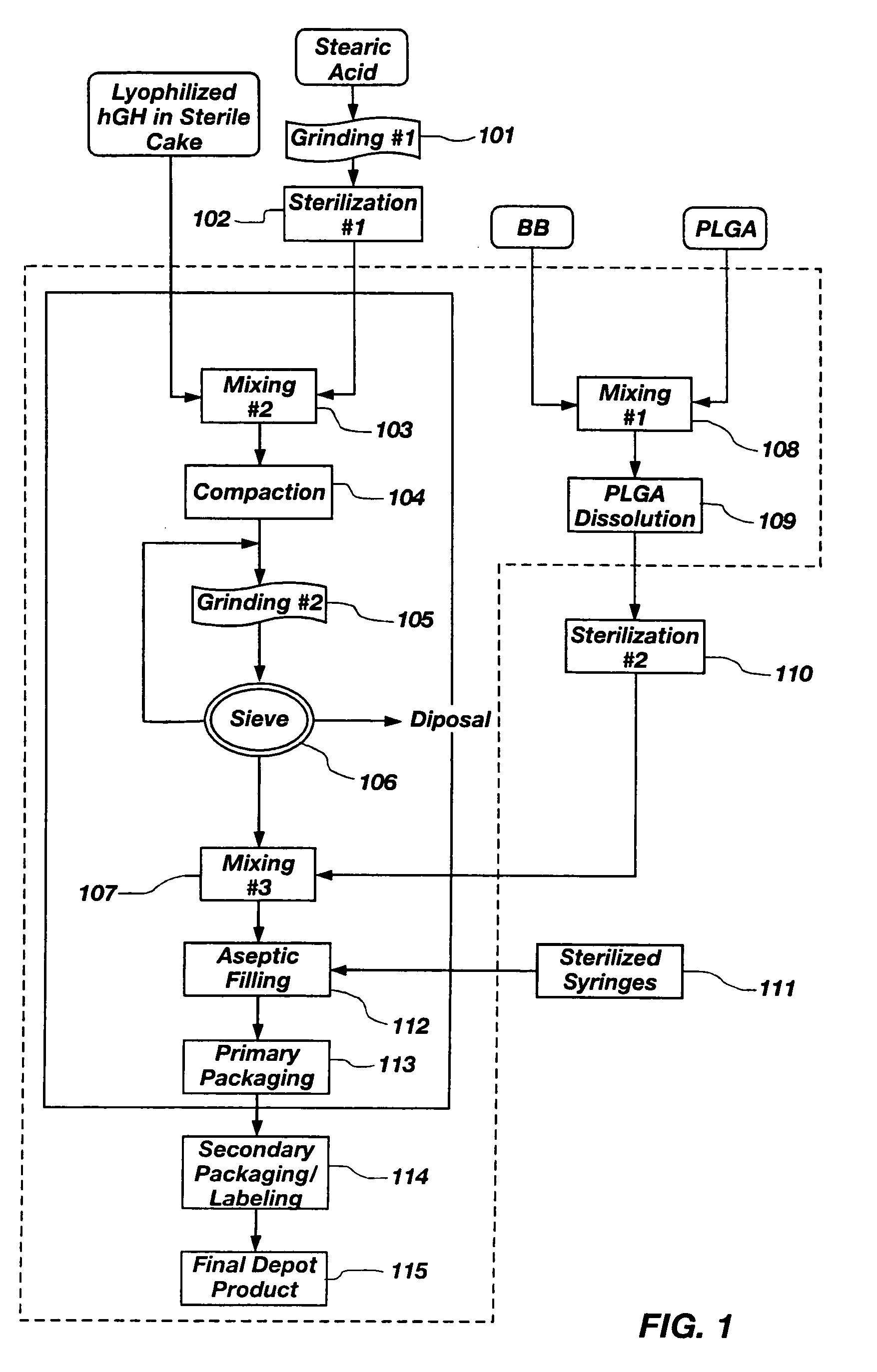

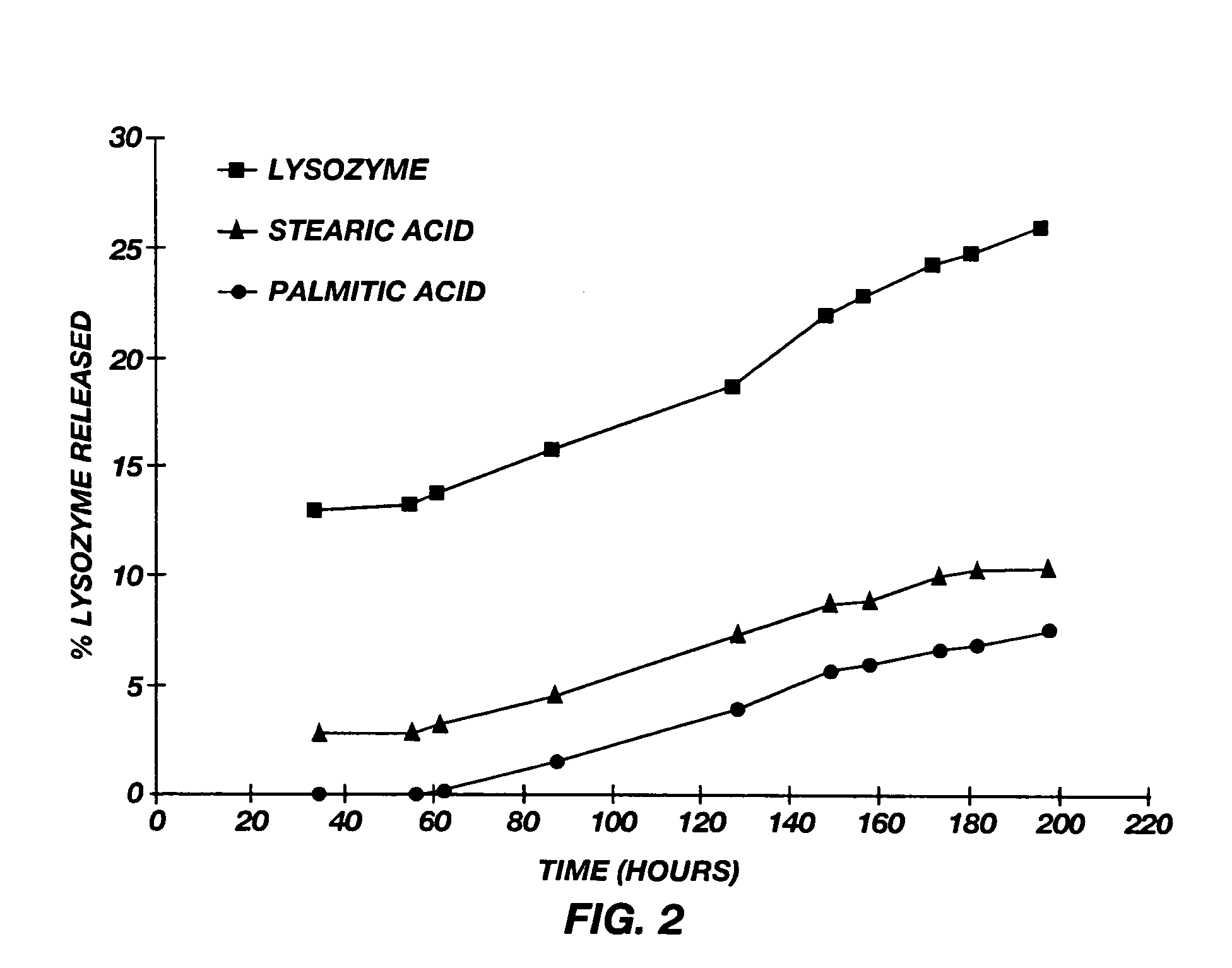

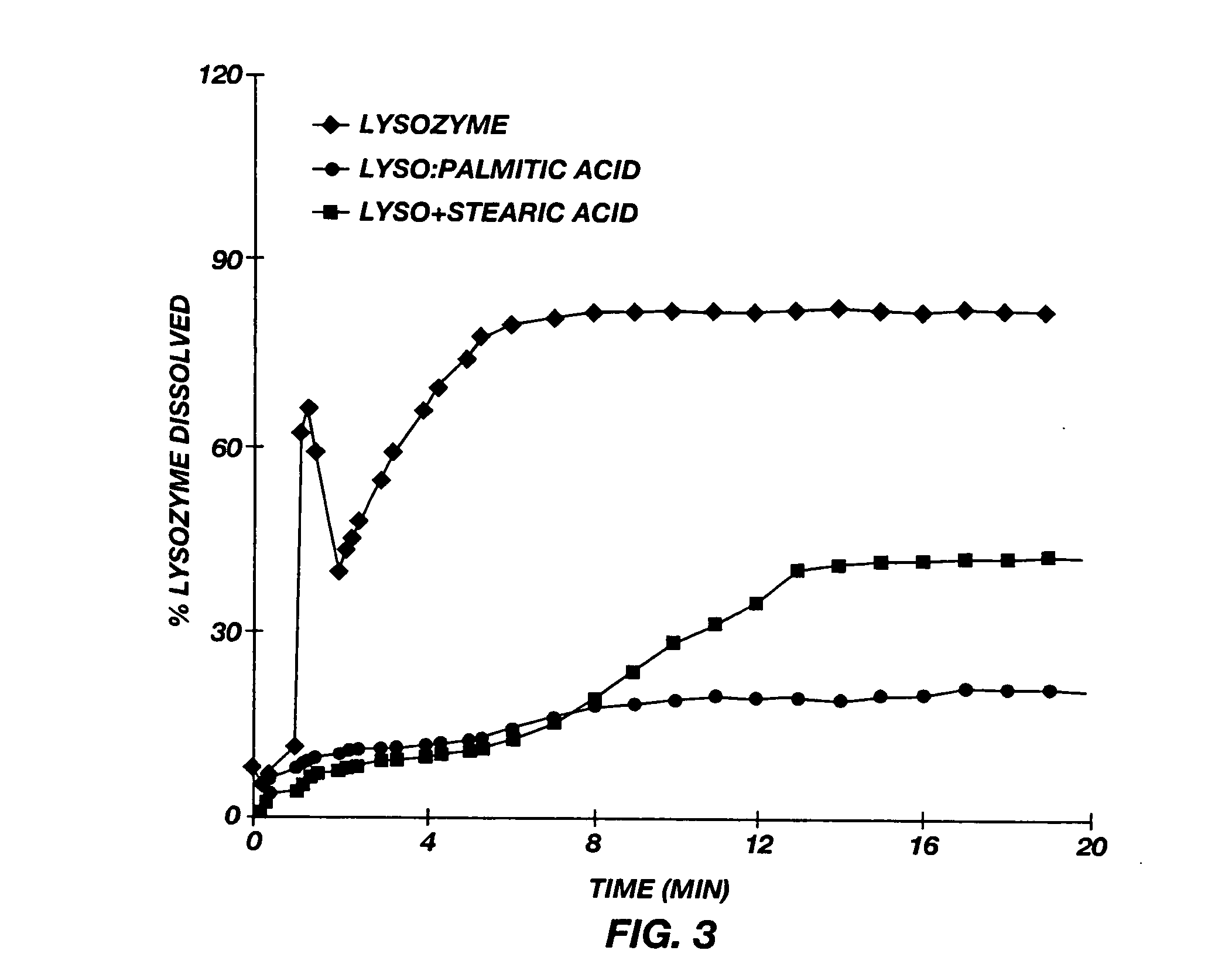

Implantable gel compositions and method of manufacture

Methods and compositions for reducing the burst of beneficial agent from implantable systems is described. Such systems utilize compressed particulates of a beneficial agent, optionally mixed with a dissolution rate modulator or an agent exhibiting a characteristic of low solubility in water, such as a mixture of stearic acid and palmitic acid, dispersed throughout a bioerodible and biocompatible carrier.

Owner:DURECT CORP

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

High-heat-conductivity rubber composite material and preparation method thereof

InactiveCN102504358AImprove thermal conductivitySimple preparation processRubber materialVulcanization

The invention discloses a high-heat-conductivity rubber composite material and a preparation method of the high-heat-conductivity rubber composite material. The high-heat-conductivity rubber composite material consists of the following ingredients in parts by mass: 100 of rubber, 4 to 6 of zinc oxide, 1 to 3 of stearic acid, 1 to 2 of anti-aging agents, 40 to 60 of carbon black, 1 to 1.5 of promoters, 1 to 3 of sulphur and 50 to 170 of heat conducting agents. The manufacture method comprises the following process steps that: the rubber is added into an open mill, the zinc oxide, the stearic acid, the anti-aging agents, the promoters, the carbon black and the heat conducting agents are sequentially added after the roll recovering, and finally, the sulphur is added. After rubber materials are uniformly mixed, the thin conduction is carried out, triangle bag packing and rolling are respectively carried out for five times, and the roll distance is regulated to 1.5mm for sheet output. The material sheets are placed into a mold, the vulcanization is carried out on a flat plate vulcanization machine, the vulcanization time is 15 to 20 minutes, the vulcanization temperature is 160 to 165 DEG C, and the vulcanization pressure is 10 to 12MPa. The material disclosed by the invention has an excellent physical and mechanical property and a high heat conduction factor.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

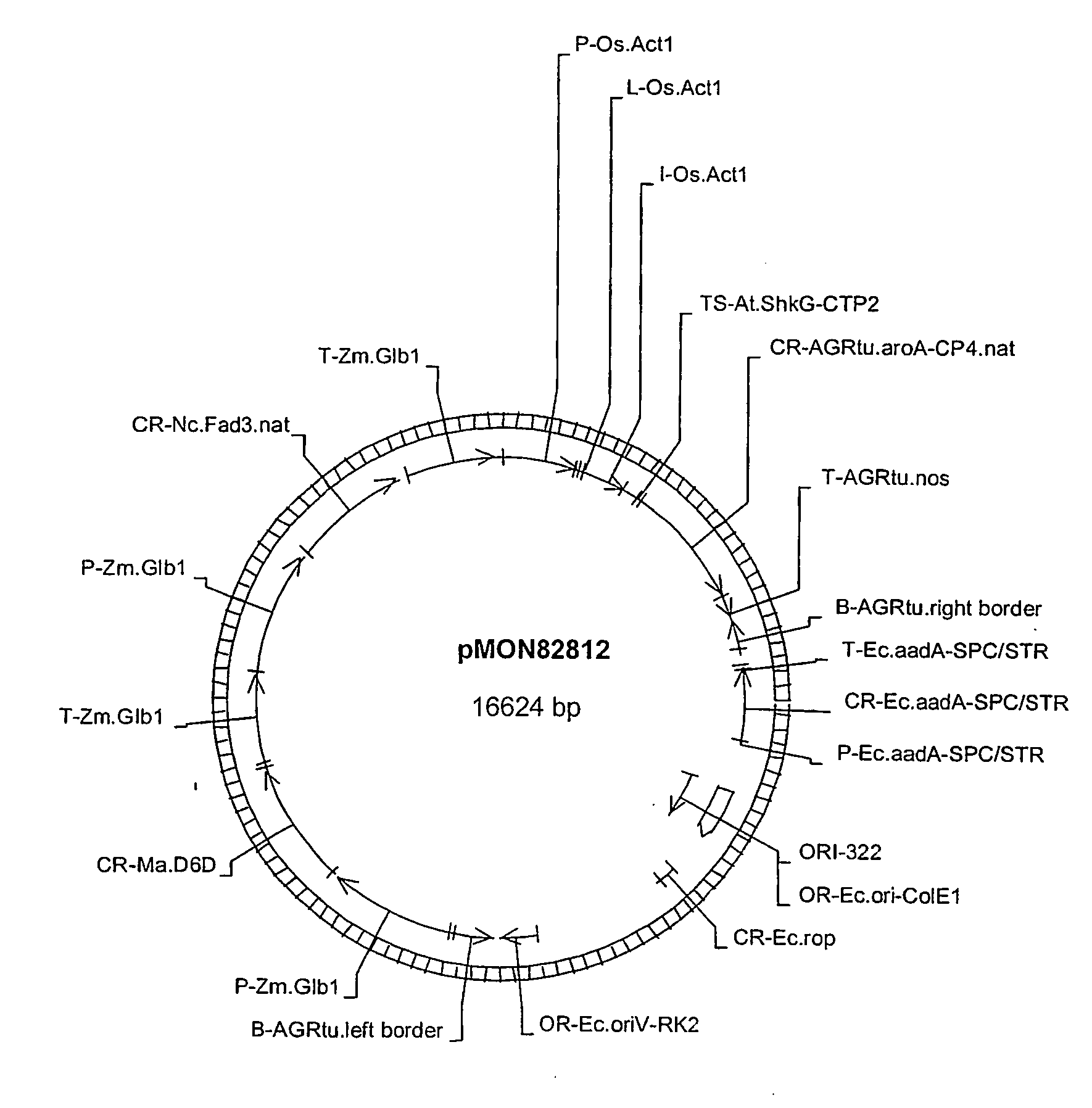

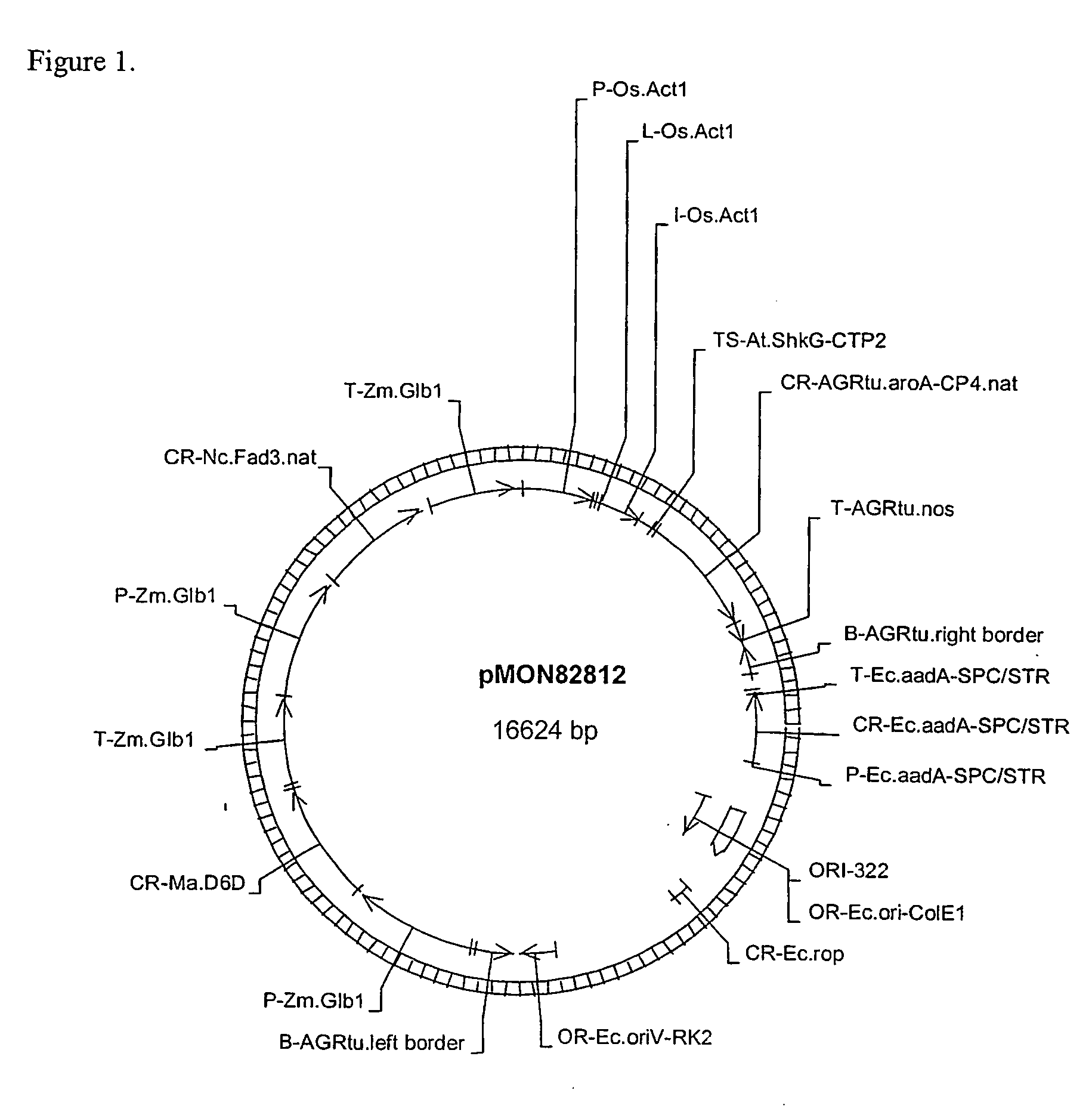

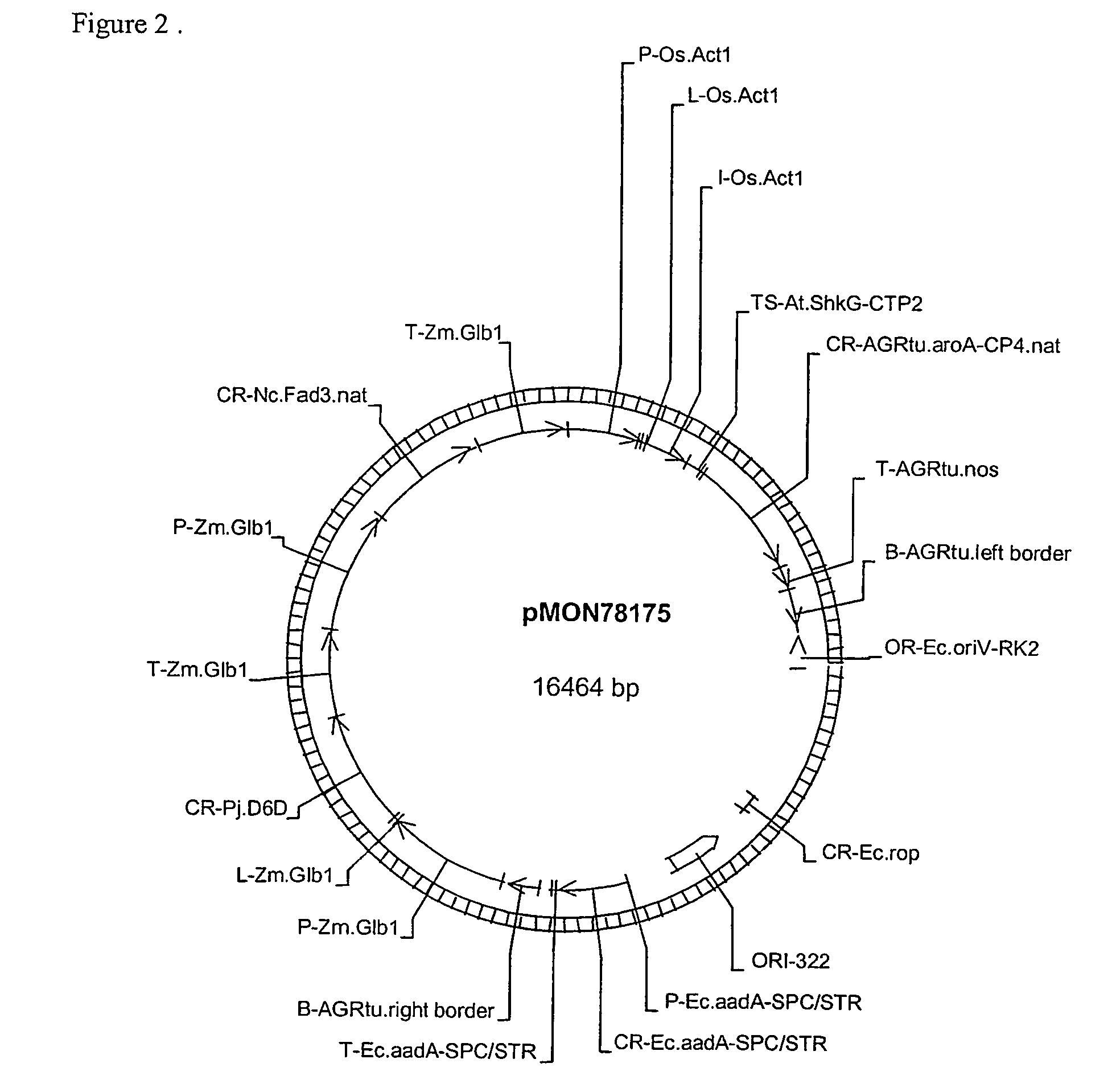

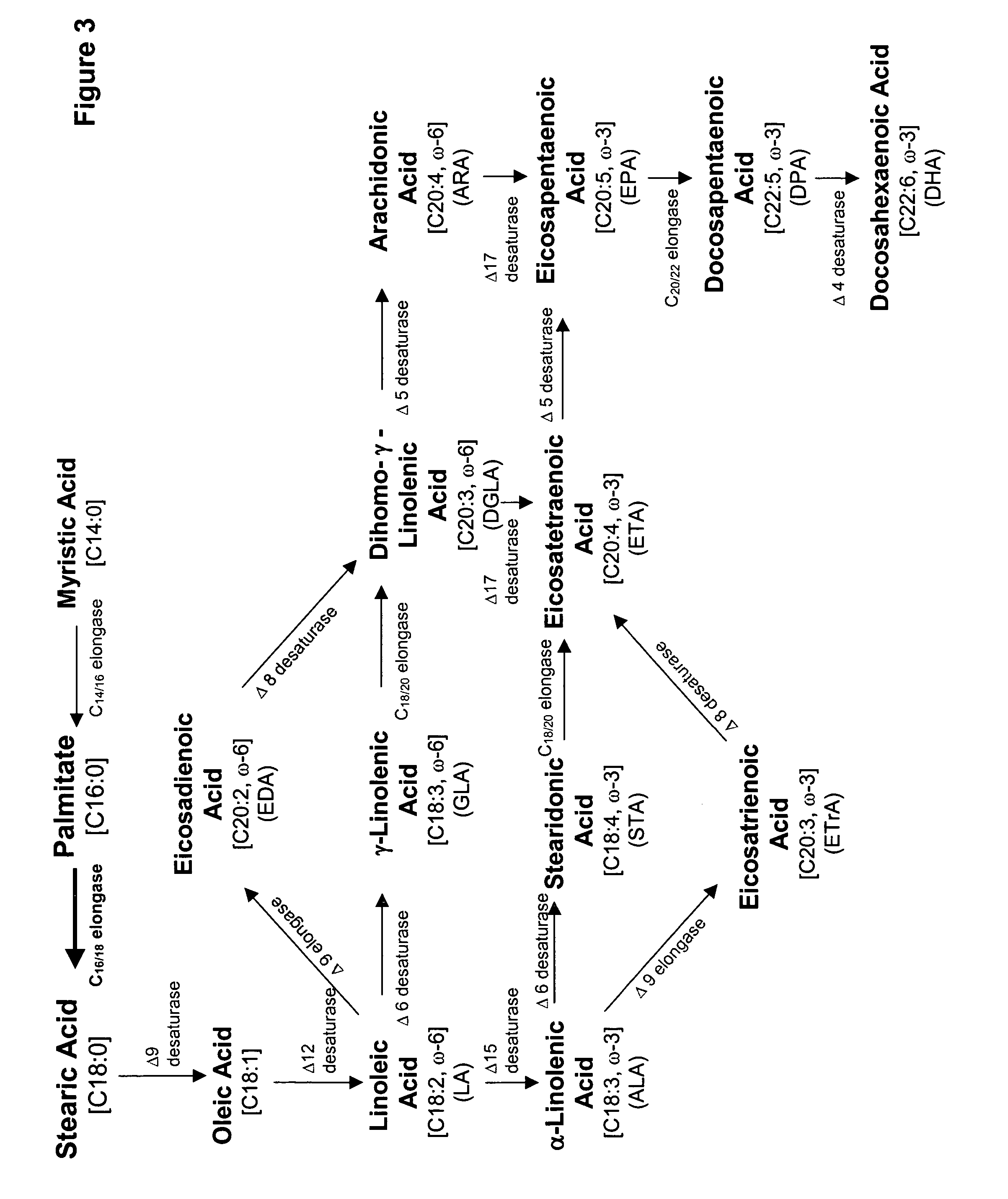

Expression of Fatty Acid Desaturases in Corn

ActiveUS20080260929A1High nutritional valueIncrease SDA contentBacteriaPeptide/protein ingredientsStearidonic acidGenetically modified maize

The invention relates generally to the expression of desaturase enzymes in transgenic corn plants and compositions derived therefrom. In particular, the invention relates to the production of oils with improved omega-3 fatty acid profiles in corn plants and the seed oils produced thereby. Such oils may contain stearidonic acid, which is not naturally found in corn plants and has been shown to have beneficial effects on health.

Owner:MONSANTO TECH LLC

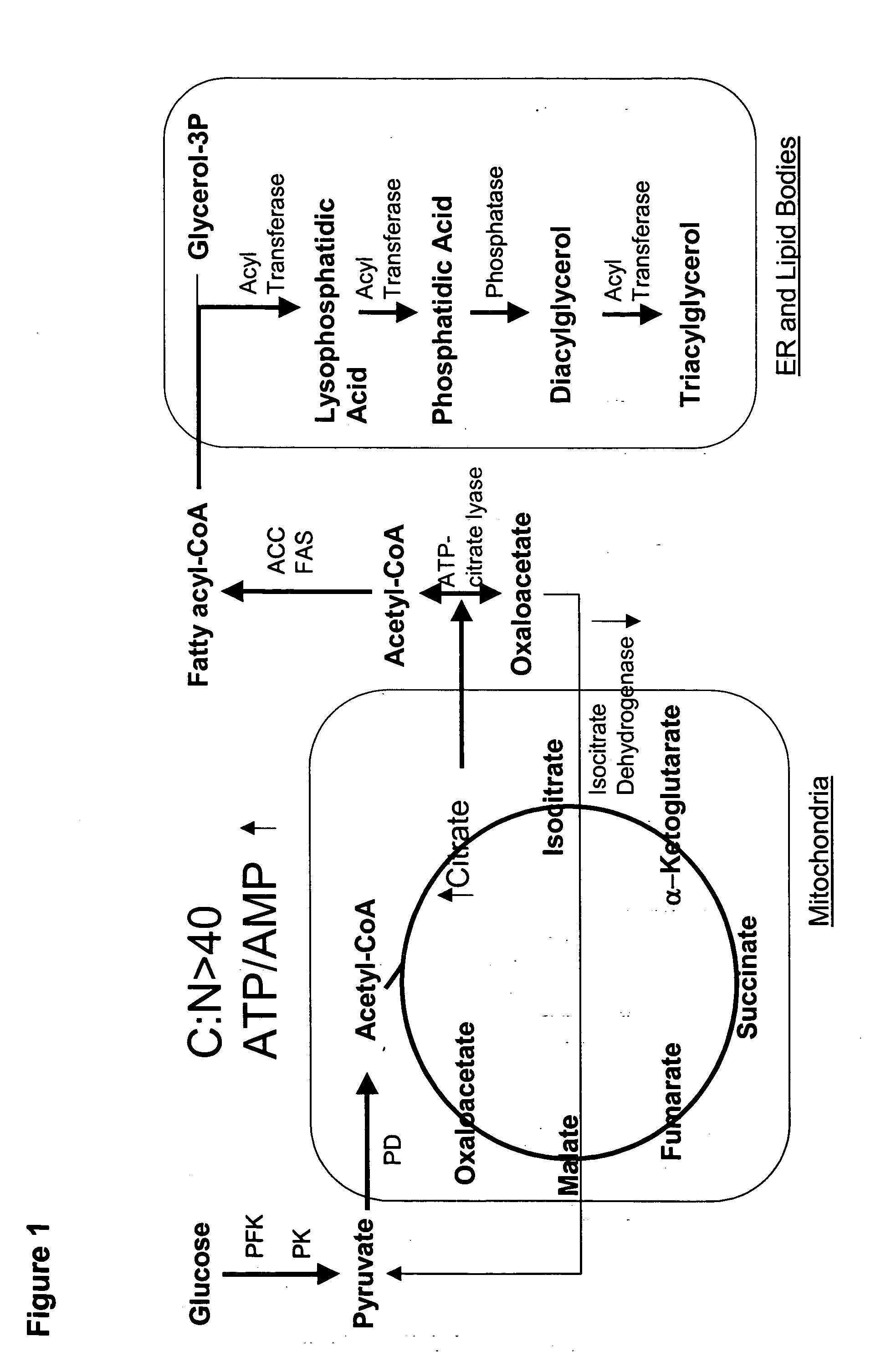

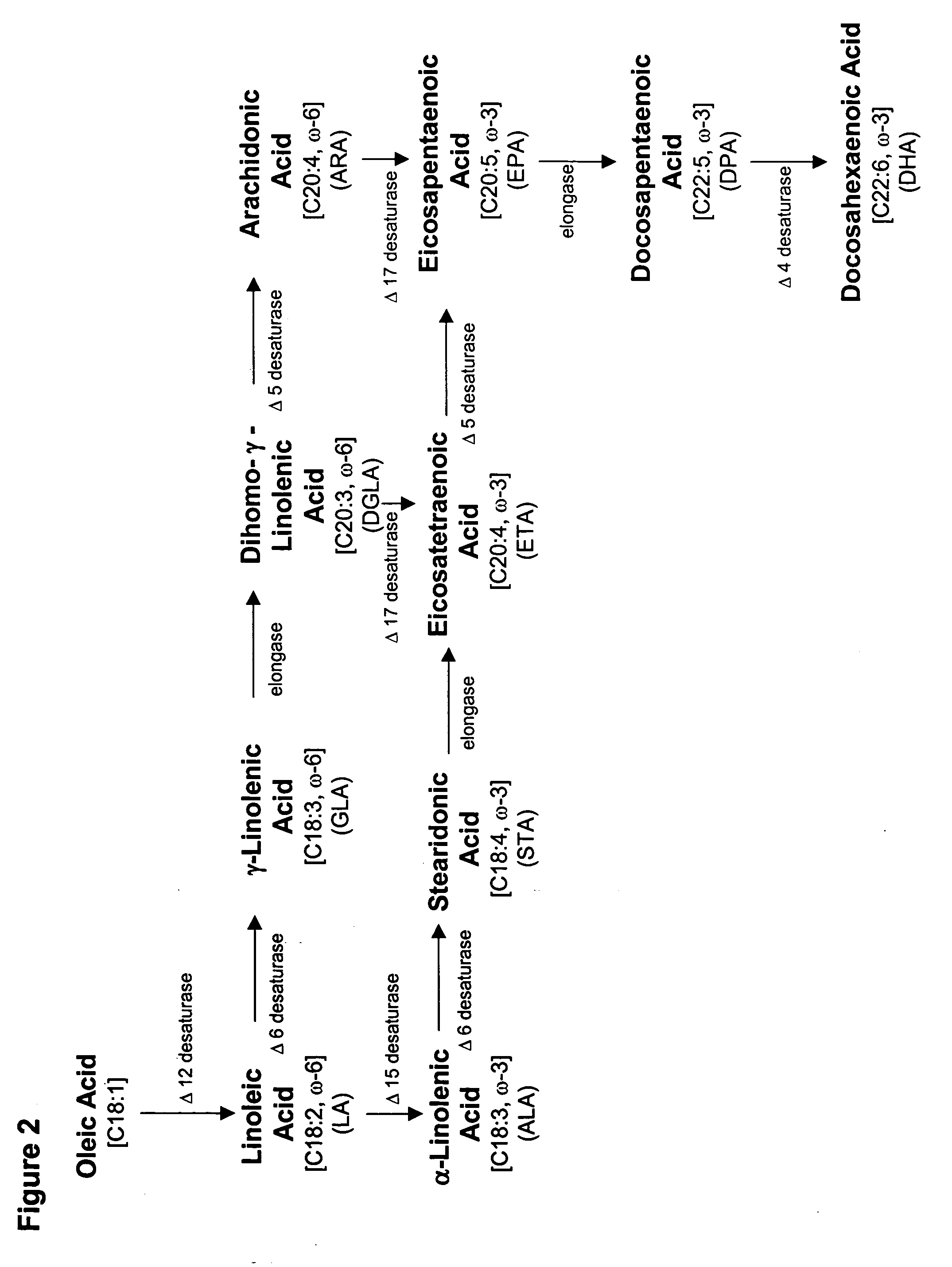

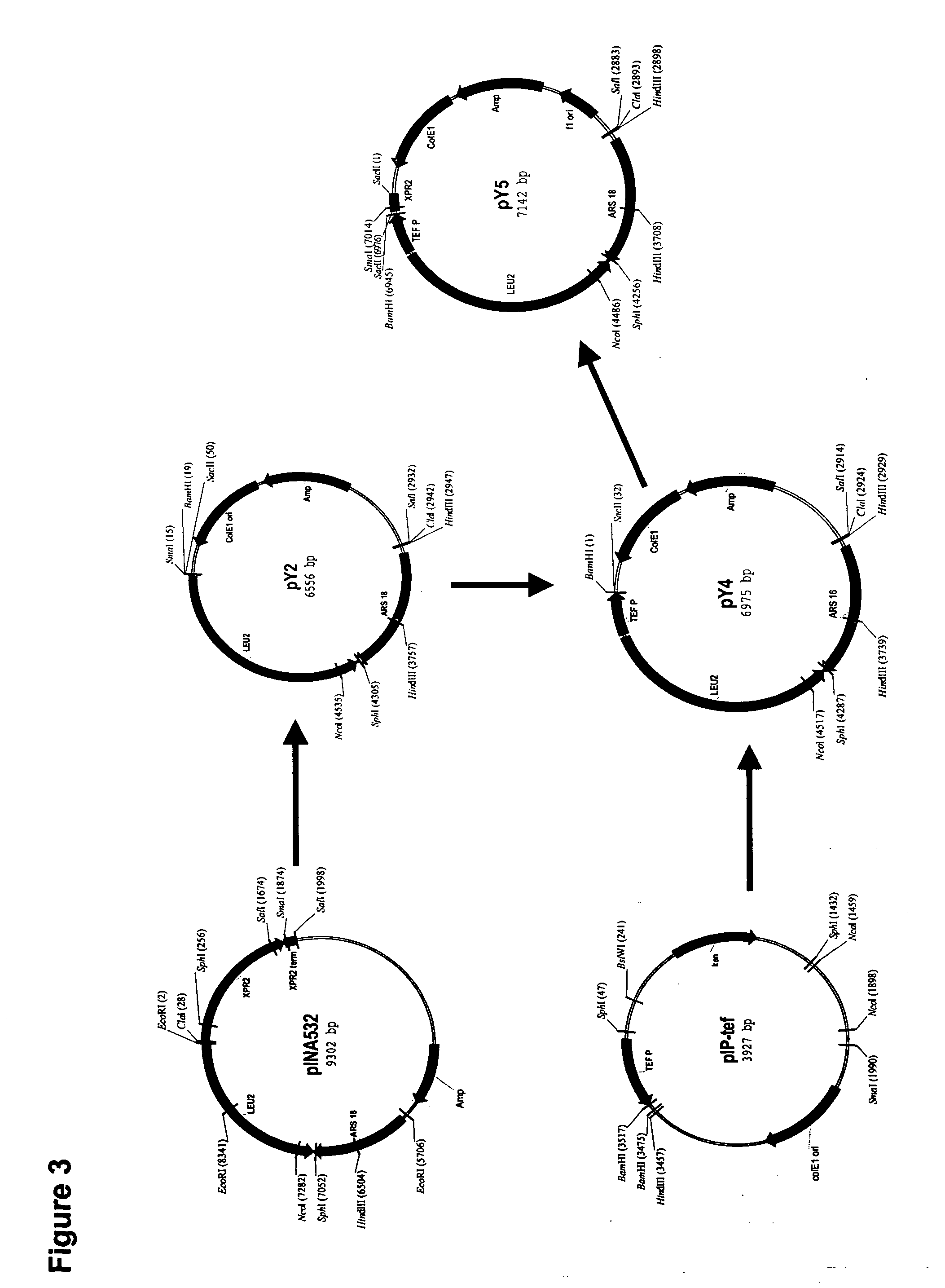

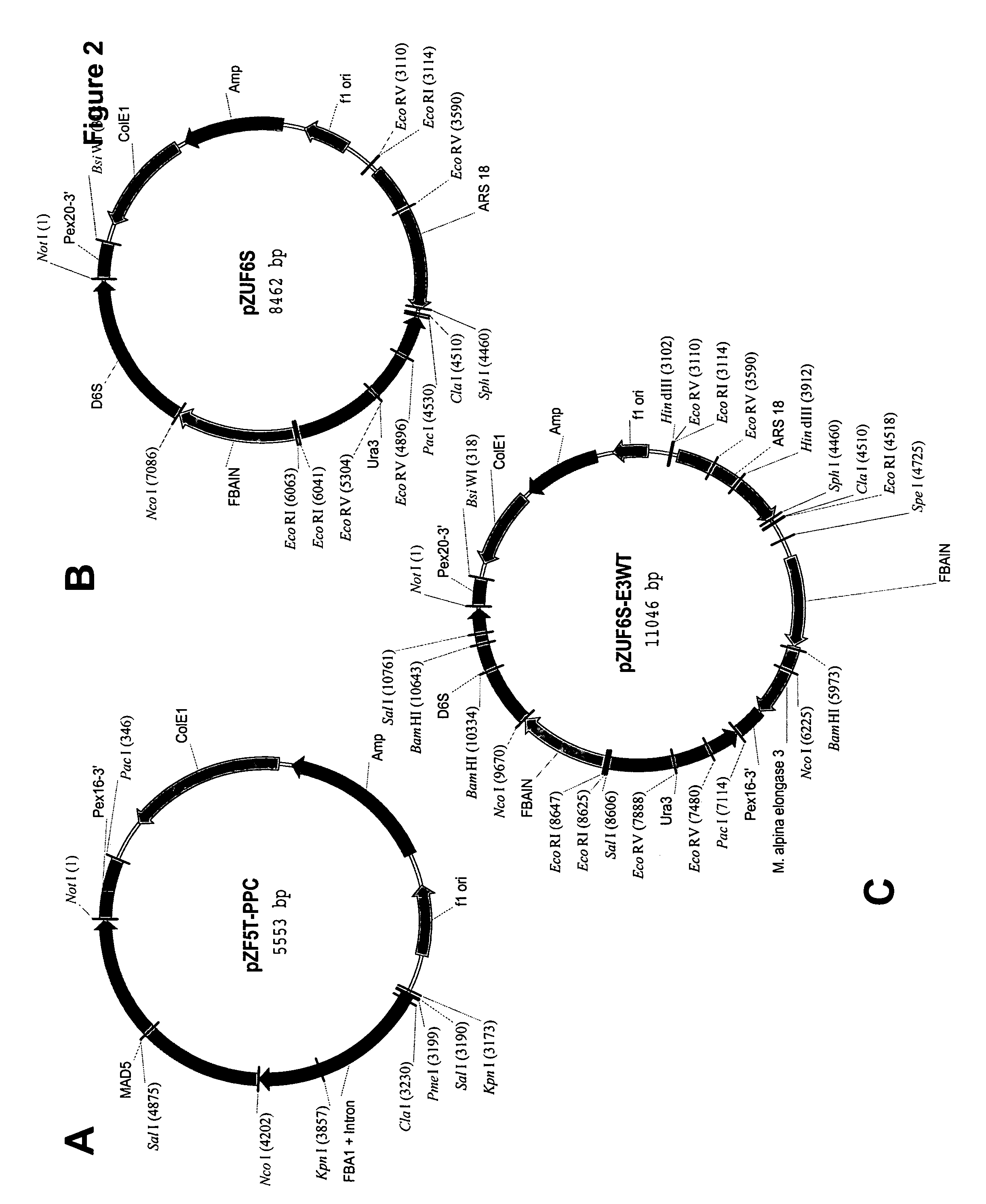

Production of polyunsaturated fatty acids in oleaginous yeasts

The present invention relates to methods for the production of ω-3 and / or ω-6 fatty acids in oleaginous yeast. Thus, desaturases and elongases able to catalyze the conversion of linoleic acid (LA) to γ-linolenic acid (GLA); α-linoleic acid (ALA) to stearidonic acid (STA); GLA to dihomo-γ-linoleic acid (DGLA); STA to eicosatetraenoic acid (ETA); DGLA to arachidonic acid (ARA); ETA to eicosapentaenoic acid (EPA); DGLA to ETA; EPA to docosapentaenoic acid (DPA); and ARA to EPA have been introduced into the genome of Yarrowia for synthesis of ARA and EPA.

Owner:DUPONT US HLDG LLC

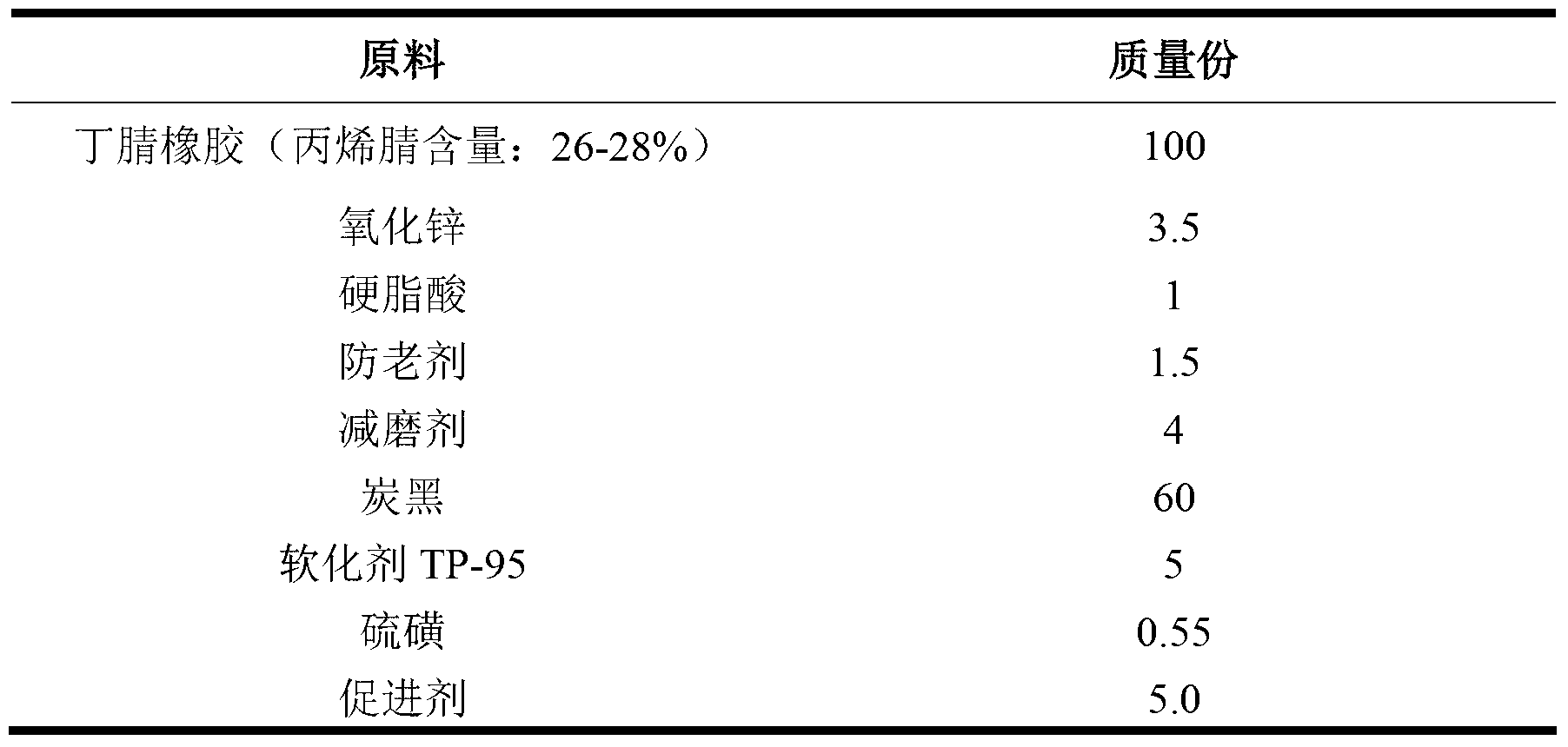

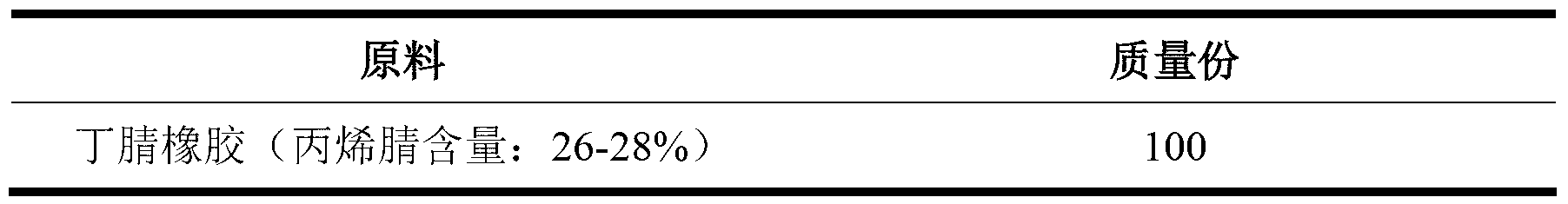

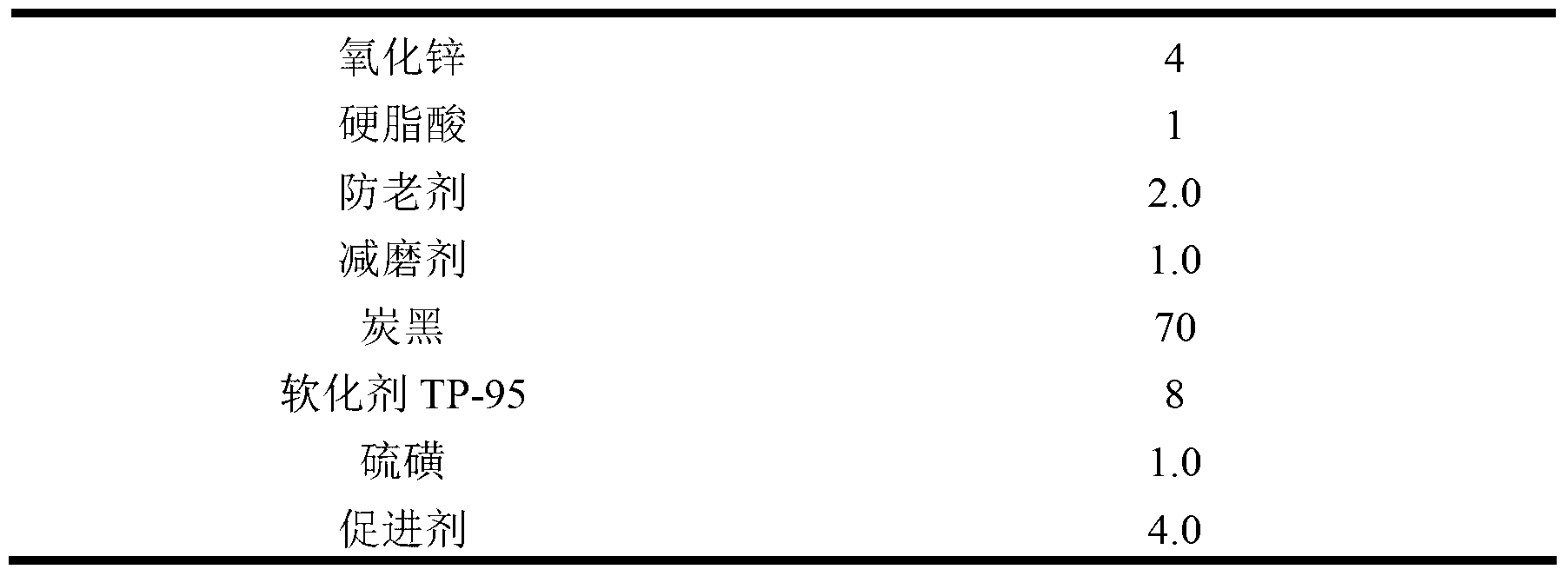

Cold-resistant wear-resistant nitrile rubber sealing material and preparation method thereof

ActiveCN103289150ACompatibility is reasonableImprove wear resistanceOther chemical processesPolymer scienceNitrile rubber

The invention discloses a cold-resistant wear-resistant nitrile rubber sealing material which comprises the following raw materials of: by weight, 100 parts of nitrile rubber, 3.5-8 parts of zinc oxide, 1 part of stearic acid, 1.5-3.5 parts of an antioxidant, 0.5-4.0 parts of an antifriction agent, 60-115 parts of carbon black, 2-10 parts of TP-95, 0.3-1.0 parts of a vulcanizing agent and 3.0-5.5 parts of an accelerant. A preparation method of the nitrile rubber sealing material comprises the steps of plasticating the nitrile rubber, adding the zinc oxide, the stearic acid, the antioxidant and the antifriction agent to carry out mixing, adding 1 / 2 of the carbon black to continue mixing after last mixing, then adding the residual carbon black and TP-95 to continue mixing, discharging glue stock and refining the glue stock with turning, obtaining a segment of rubber compound and placing the segment of the rubber compound, adding the rubber compound to a rubber covered roll of an open mill, adding the accelerant to carry out mixing, milling and packaging in a triangular bag, adjusting thickness and discharging material sheets. The nitrile rubber sealing material provided by the invention has better cold resistance and wear resistance.

Owner:GUANGZHOU JST SEALS TECH

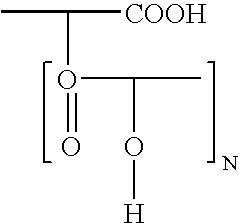

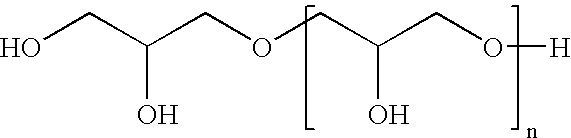

Emulsifier for highly liquid W/O emulsion based on partly crosslinked polyglycerol esters of polyhydroxystearic acid

ActiveUS20050031580A1Pleasant sensationImprove the immunityCosmetic preparationsBiocideBranched chain fatty acidsTO-18

The present invention relates to polyglycerol partial esers of polyhydroxystearic acid and polyfunctional carboxylic acids which are obtainable by esterification of a polyglycerol mixture with polyhydroxystearic acid where N=1 to 10, preferably 2 to 8, in particular 3 to 5 units and dimer fatty acids which have been obtained by catalytic dimerization of unsaturated fatty acids having 12 to 22 C atoms and have an average functionality of 2 to 3, and / or with aliphatic, linear or branched dicarboxylic acids having a chain length of 2 to 16 C atoms and additionally saturated or unsaturated, linear or branched fatty acids having 6 to 22 C atoms, preferably 12 to 18 C atoms, the degree of esterification of the polyglycerol mixture being between 20 and 75%, preferably 40 to 70%.

Owner:EVONIK DEGUSSA GMBH

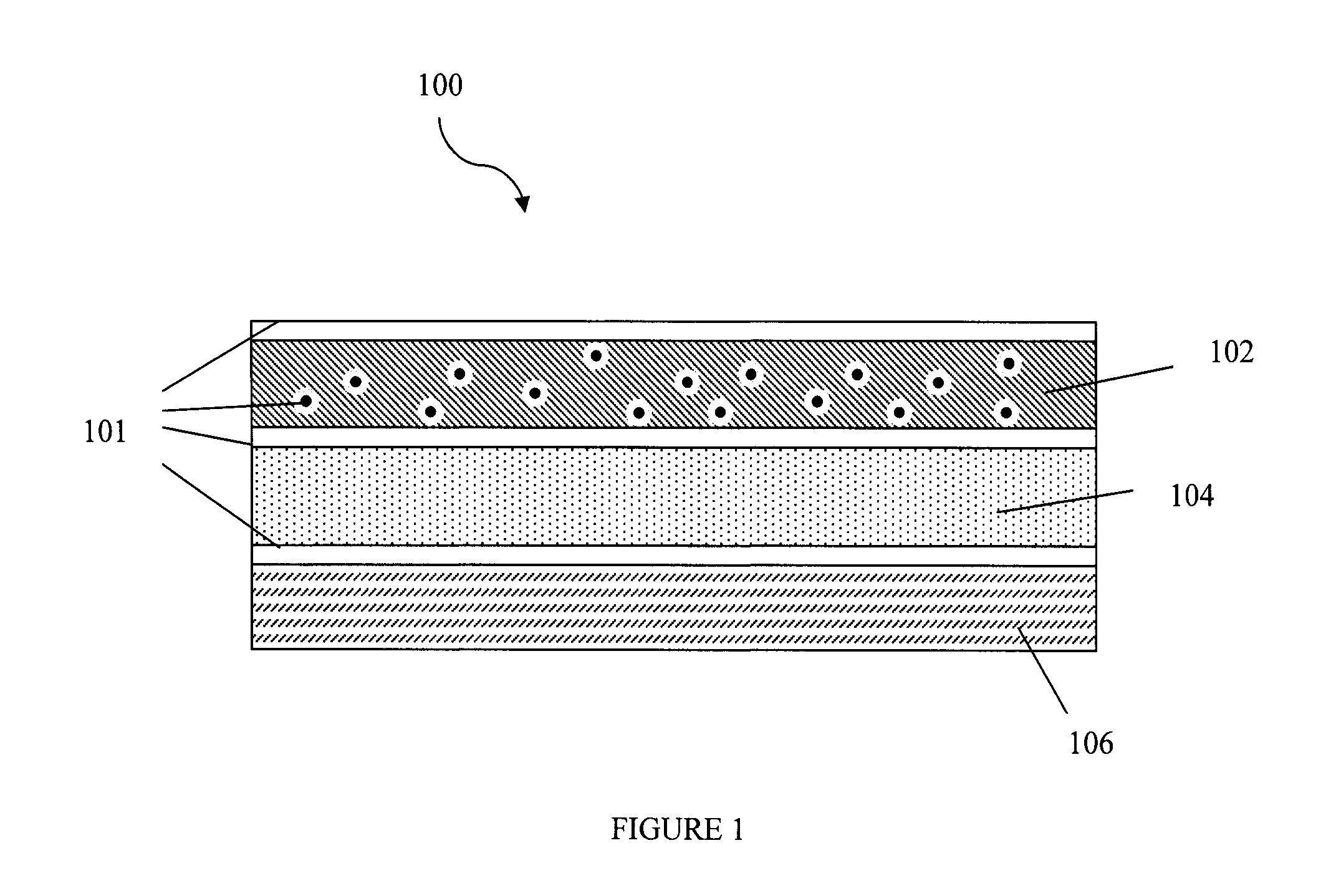

Solar cell

InactiveUS20090120490A1Improve conversion efficiencyReduce warpageNon-conductive material with dispersed conductive materialPhotovoltaic energy generationStearic acidSolar cell

A solar cell, comprising: a substrate, including p-n doping structure formed within said substrate; material attached to the back of said substrate, where said material includes glass mixture, aluminum material, organic medium and additive. Wherein said glass needs to be formed by combining two or more glasses: the main composition for post-mixed glass should include Al2O3, Bi2O5, B2O3, SiO2, PbO, Tl2O3 and other metal and non-metal oxides. For the material composition, aluminum powder content is 60˜80 mass %, with approximately 90 to 99.99% purity. Additives include C10˜C24 stearic acid, with the content of less than 5 mass %. The C10˜C24 stearic acid may include oleic acid. Organic medium content is roughly 20˜35 mass %. Wherein said organic medium includes 60˜90 mass % ether class organic solvent, 10˜20 mass % cellulosic resin and 1˜5 mass % of leveling agent, rheological agent or thixotropic agent.

Owner:GIGASTORAGE CORP

High-elasticity sneaker air cushion sole and production method thereof

The invention provides a high-elasticity sneaker air cushion sole and a production method thereof and researches a sneaker sole with high elasticity, high wear resistance and low hardness. The high-elasticity sneaker air cushion sole comprises a phylon (MD) midsole, an air cushion and a large sole which are sequentially and fixedly connected with one another from top to bottom, wherein an ethylene-vinyl acetate copolymer (EVA) cushion piece is assembled on a heel part of the air cushion; and the material formula of the MD midsole comprises the following components in parts by weight: 40-60 parts of EVA, 0-20 parts of ethylene propylene ternary gel, 0-30 parts of polyolefin elastomer (POE), 0-10 parts of talcum powder, 2.0-4.0 parts of a foaming agent, 0.6-1.0 part of a bridging agent, 1.0-2.0 part of a zinc oxide desulfurizing agent, 0.6-1.2 parts of stearic acid, 0.5-1.0 part of zinc stearate, 0.8-1.5 parts of a flow promotor and 0.3-0.8 part of a bridging addition agent.

Owner:新侨伟(福建)鞋服有限公司

Process for making an ink jet ink

A process for making an ink jet ink comprising: a) providing a dispersion containing a pigment, a hydrocarbon carrier, and a polyamine / fatty acid condensation polymer dispersant; b) mixing the pigment dispersion with rigid milling media less than 100 mu m; c) introducing the mixture of step (b) into a mill; d) milling the mixture from step (c) until the pigment particle size is below about 100 nanometers (nm); e) adding to the mixture during or after step d) or f) (below) a stabilizer selected from the group consisting of a polyether polyol; a modified polyester resin; an acrylic polymer; an alkylol ammonium salt of a block copolymer having acidic groups; ethoxylated triethanolamine; a high molecular weight block copolymer having an amine functionality; sorbitan sesquioleate; polyhydroxy stearic acid; butylated polyvinyl pyrrolidone; poly(vinylpyrrolidone / 1-hexadecene); and poly(p-tert-butylstyrene-co-styrene-co-2-sulfoethyl-lithium methacrylate); f) separating the milling media from the mixture milled in step (d); and g) diluting the mixture to obtain an ink jet ink having a pigment concentration suitable for ink jet printers.

Owner:EASTMAN KODAK CO

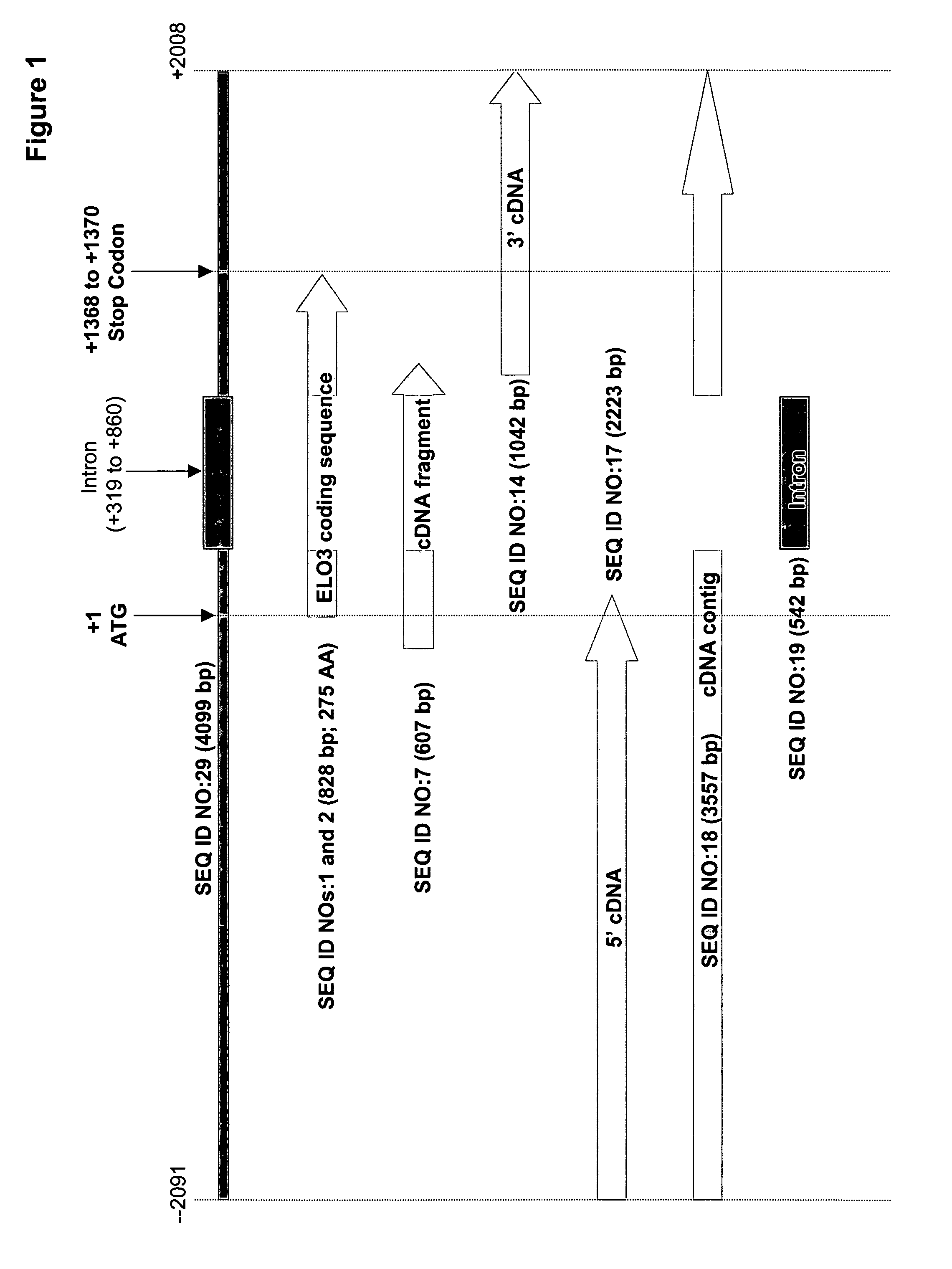

Mortierella alpina C16/18 fatty acid elongase

The present invention relates to a fungal C16 / 18 fatty acid elongase that is able to catalyze the conversion of palmitate (16:0) to stearic acid (18:0). Specifically, the nucleotide sequence of a Mortierella alpina C16 / 18 fatty acid elongase is provided (designated as “ELO3”). Methods of increasing microbial oil production, increasing carbon flux into the polyunsaturated fatty acid biosynthetic pathway and increasing the content of polyunsaturated fatty acids by over-expression of the C16 / 18 fatty acid elongase are described herein. Most desirably, the substrate specificity of the instant ELO3 will be particularly useful to enable accumulation of long-chain polyunsaturated fatty acids in oleaginous yeast, such as Yarrowia lipolytica.

Owner:DUPONT US HLDG LLC

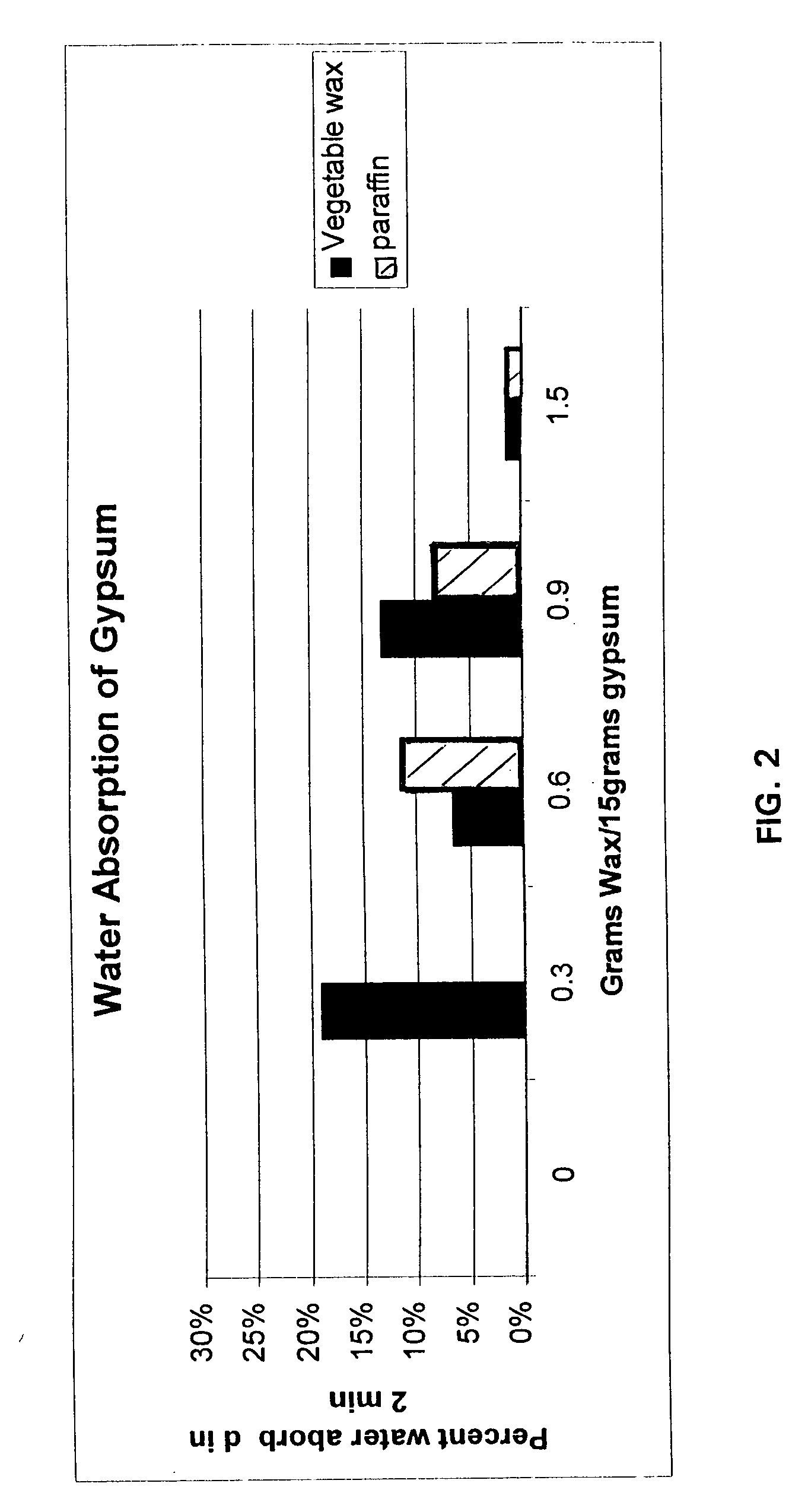

Additive to render gypsum board moisture resistant

InactiveUS20060196391A1Improve waterproof and moisture-proof performanceMore water resistantBuilding componentsCoatingsStearic acidMoisture barrier

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used to render gypsum board resistant to water. Unlike petroleum-derived waxes used for the same purpose, vegetable derived waxes are renewable and readily converted into forms such as emulsions or powder that facilitate incorporation into gypsum board manufacturing. Such water resistant materials are characterized by enhanced moisture barrier properties. The compositions have a low iodine value (between 2-5), and melting points between approximately 120-185 degrees F. (Mettler Drop Point). The wax comprises a triglyceride whose fatty acids are predominantly stearic acid (C18). The composition is used as an additive in the manufacture of water resistant gypsum board.

Owner:HRD CORP

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

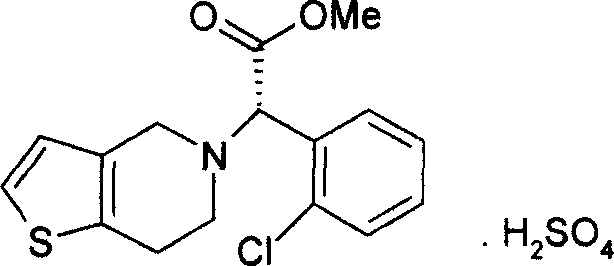

Clopidogrel sulfate solid preparation, and its preparing method

ActiveCN1935119AOrganic active ingredientsPharmaceutical delivery mechanismClopidogrel HydrochlorideSilica gel

The present invention relates to a solid preparation of clopidogrel hydrochloride and its preparation method. It is characterized by that in said sold preparation the palmitoleostearin and micropowder silica gel are added, and its preparation method adopts a grinding equivalent progressively-increasing method so as to raise the stability and safety of said solid preparation.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

Alumina carrier with composite pore structure and preparation method thereof

ActiveCN102614934AExtend your lifeHigh selectivityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPolymer scienceMicrosphere

The invention discloses a preparation method of an alumina carrier with a composite pore structure, which comprises the steps of mixing and roasting an aluminum-contained compound and a composite template, wherein the composite template comprises a mesoporous template selected from at least one of a polyethylene glycol-polypropylene glycol-polyethylene glycol triblock polymer, polyethylene glycol, dodecylamine, hexadecyl trimethyl ammonium bromide, lauric acid, stearic acid and fatty alcohol polyoxyethylene ether and a macroporous particulate template selected from polystyrene microspheres with the particle size of greater than 50nm, polymethyl methacrylate microspheres, biomaterial particles, asphalt particles or heavy oil residues; and the weight ratio of the mesoporous template to the macroporous particulate template to the aluminum-contained compound (by alumina) is 0.1-2:0.1-0.7:1. The invention also discloses the alumina carrier simultaneously having mesoporous tunnels and macroporous tunnels prepared through the method, wherein mesopores account for 40-90% of the total pore volume, and macropores account for 10-60% of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP

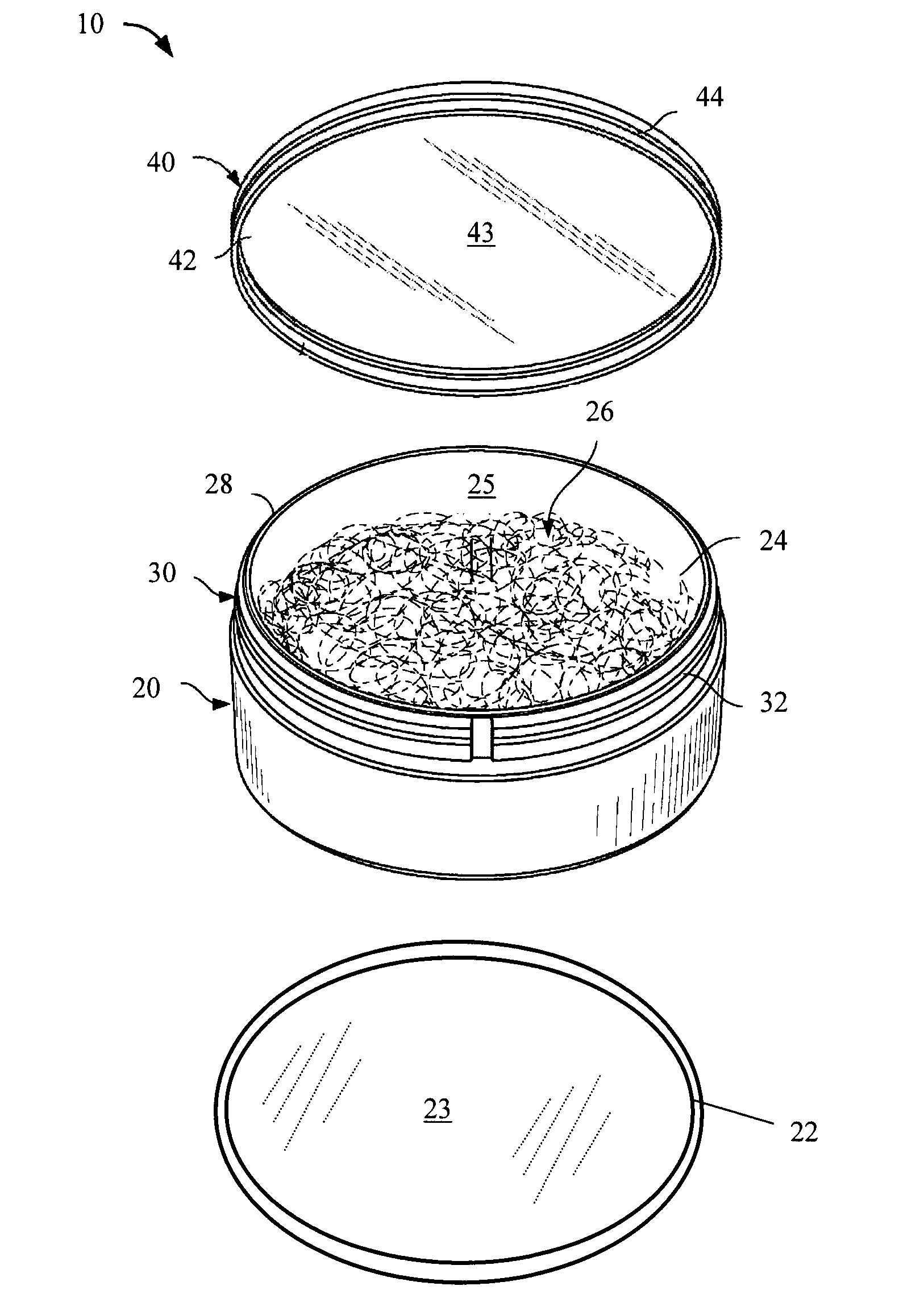

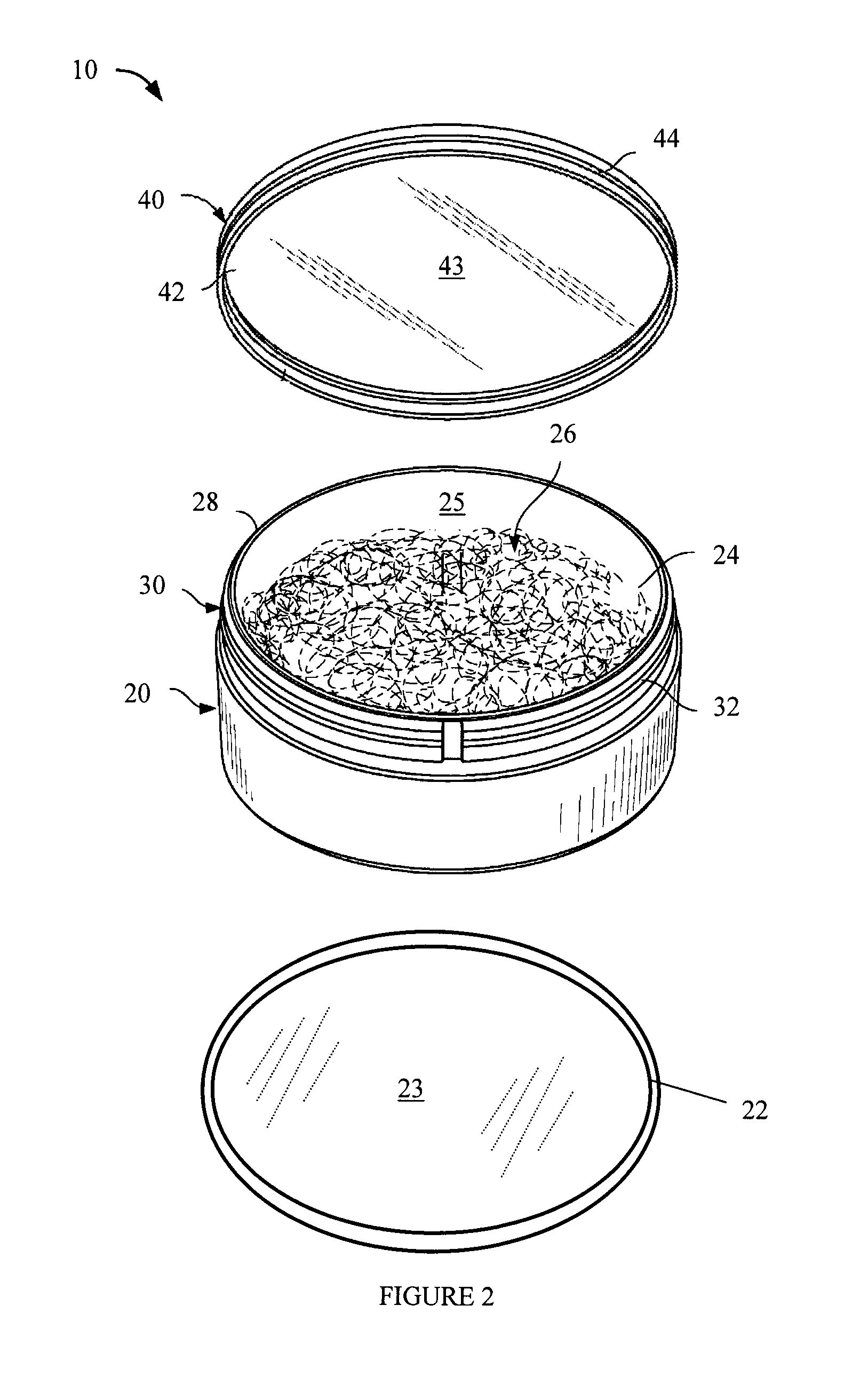

Transparent moisture barrier coatings for containers

Containers for smokeless tobacco products and other consumer and food products are provided. The containers include a layer of fibrous material, wherein the layer of fibrous material includes a moisture barrier layer imbedded within the layer of fibrous material or carried on an outer surface of the layer of fibrous material as a coating, the moisture barrier layer incorporating at least one of: (i) a triazine-containing compound; (ii) a nano-cellulose material; (iii) a nanoclay material; (iv) a polymer composition comprising one or more of a salt of one or more of myristic, palmitic and stearic acid, polyvinyl alcohol, and a C9-C18 fatty acid complex of a metal ion having an oxidation state of at least three; and (v) an inorganic oxide material.

Owner:R J REYNOLDS TOBACCO COMPANY

Topical skin care formulations

InactiveUS20110044920A1Improve visual appearanceExtended maintenance periodCosmetic preparationsBiocideCaprylyl GlycolStearic acid

Disclosed is a topical skin care composition that includes water, silymarin, hydrolyzed algin, palmitoyl tripeptide 8, ceramide 2, pomegranate extract comprising pomegranate sterols, glycerin, disodium EDTA, caprylic / capric triglyceride, shea butter, C12-15 alcohols benzoate, dimethicone, glyceryl stearate and PEG 100 stearate, cetyl alcohol, stearyl alcohol, stearic acid, butylene glycol, caprylyl glycol, and (s) a mixture of acrylamide / sodium acryloyldimethyl taurate copolymer, isohexadecane, and polysorbate 80.

Owner:MARY KAY INC

Steel-based copper alloy dual-metal sliding bearing and preparation method thereof

ActiveCN101649858ALow costImprove carrying capacityBearing componentsReflex reflectorsStearic acidLubrication

The invention discloses a dual-metal sliding bearing and a preparation method thereof. Carbon steel or stainless steel is taken as an outer layer material, and a powder metallurgy material taking a copper alloy as a basal body is taken as an inner layer material; the inner surface of the outer layer material is electroplated to form an electroplated copper layer with the thickness of 4-8 micrometres; the inner layer material comprises the following components by weight percent: 1%-20% of aluminum, 1%-8% of titanium, 1%-15% of stannum, 0.1%-5% of ferrum, 0.1%-2% of phosphorus, 0.1%-5% of nickel, at least one of 0.1%-2% of graphite and 0.1%-2% of molybdenum disulfide or 0.1%-2% of zinc stearate, and the balance of copper; and the bearing is impregnated with lubricating oil. The dual-metal sliding bearing has the advantages of low cost, high carrying capability, self-lubrication, excellent abrasion resisting capability, and the like, and can be widely applied to reciprocating swing positions of a swing arm, a bucket rod, a bucket, and the like of a large-tonnage and high-power excavator.

Owner:COB PRECISION PARTS

Xanthophyll micro-capsule and its preparation method

InactiveCN101288662AHydroxy compound active ingredientsAntinoxious agentsAntioxidantMagnesium stearate

The invention relates to a xanthophylls microcapsule and a preparation method thereof. The core material of the microcapsule is xanthophylls and the wall material is natural macromolecule chitosan or glutin, gum acacia and antioxidant. The technique has the following steps: the xanthophylls is dissolved in an organic solvent, which is added into a gum acacia solution containing emulsifier and antioxidant for uniform emulsion; the well emulsified gum acacia is added into the chitosan or glutin solution for being condensed into capsules, and the capsules are processed with magnesium stearate after solidification; the microcapsules with excellent dispersivity are obtained after drying. The microcapsule prepared by the technique has the grain diameter of 1-200 Mum. The preparation technique has simple process, mild preparation condition and easy popularization; the microcapsule prepared has good dispersivity and high stability and is suitable for industries such as food, health care products, feed, etc.

Owner:UNIV OF JINAN

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

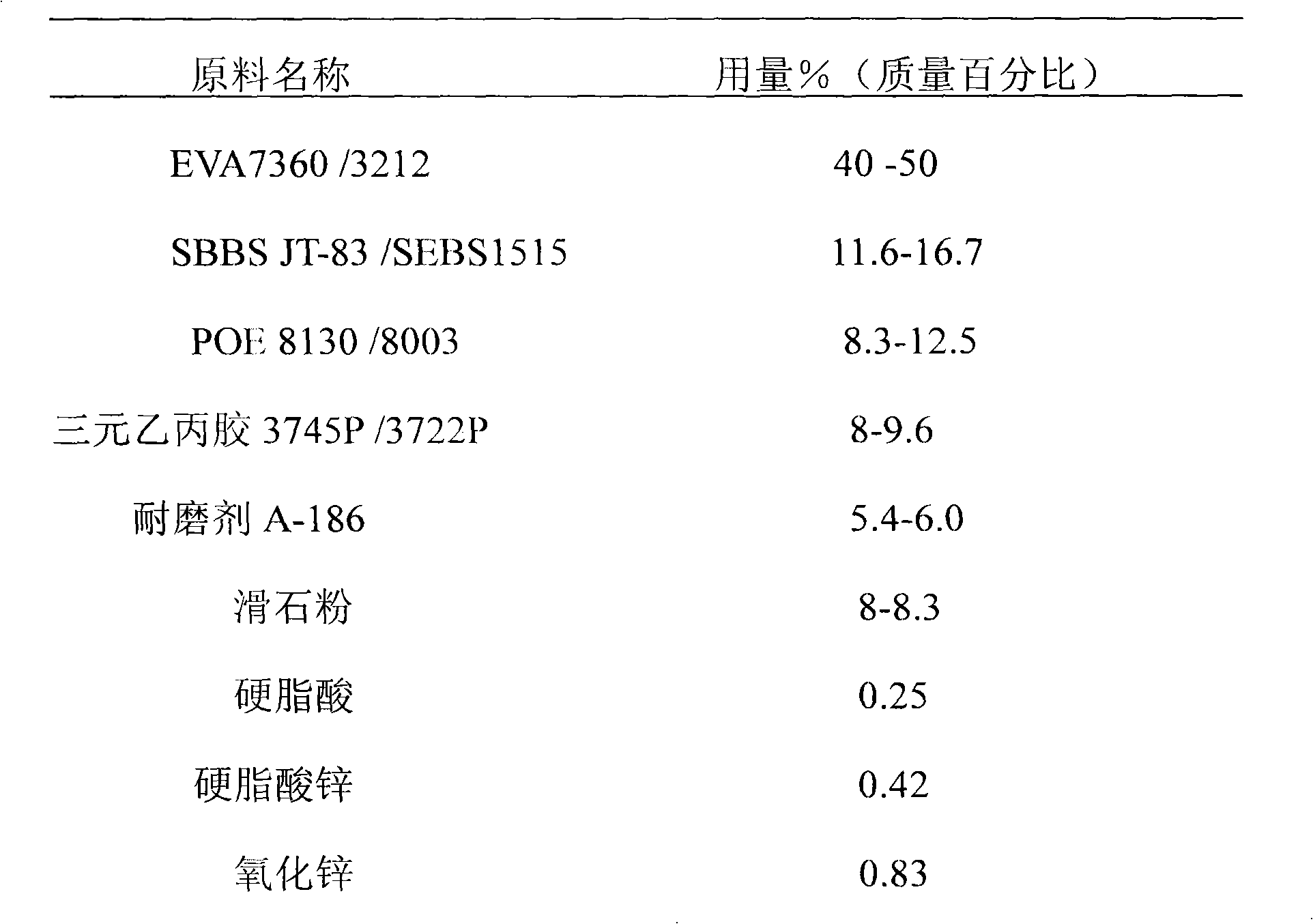

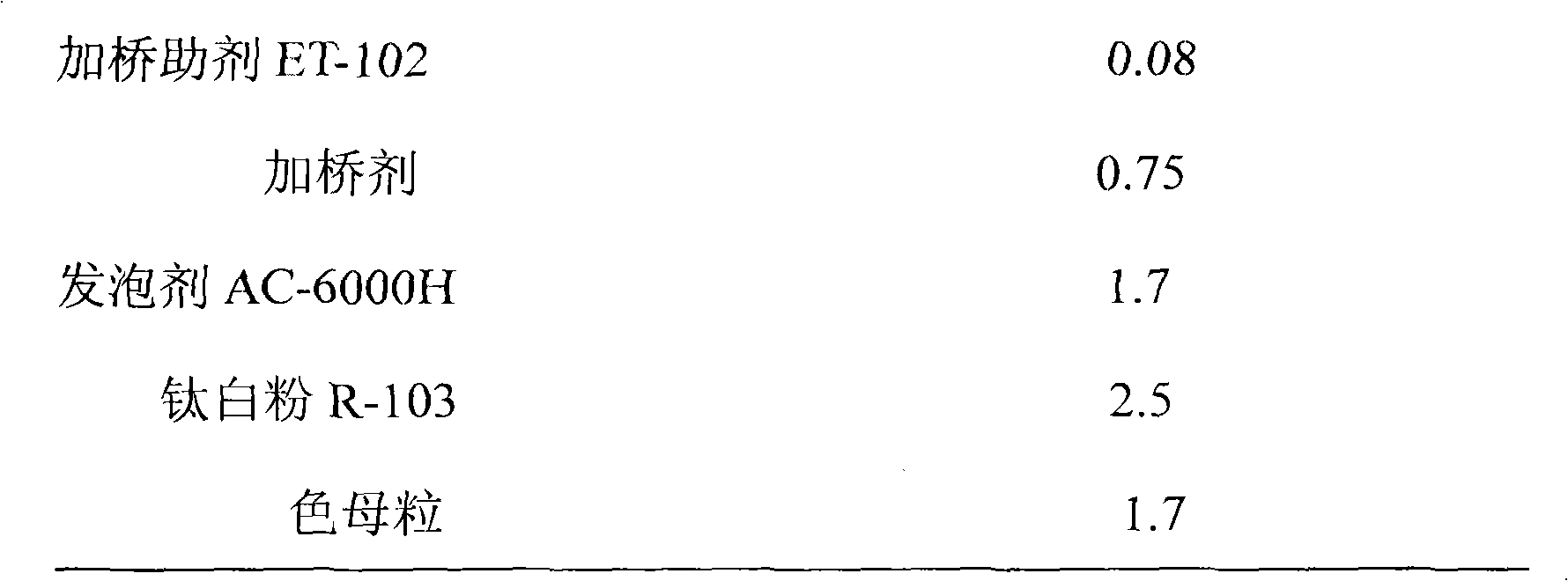

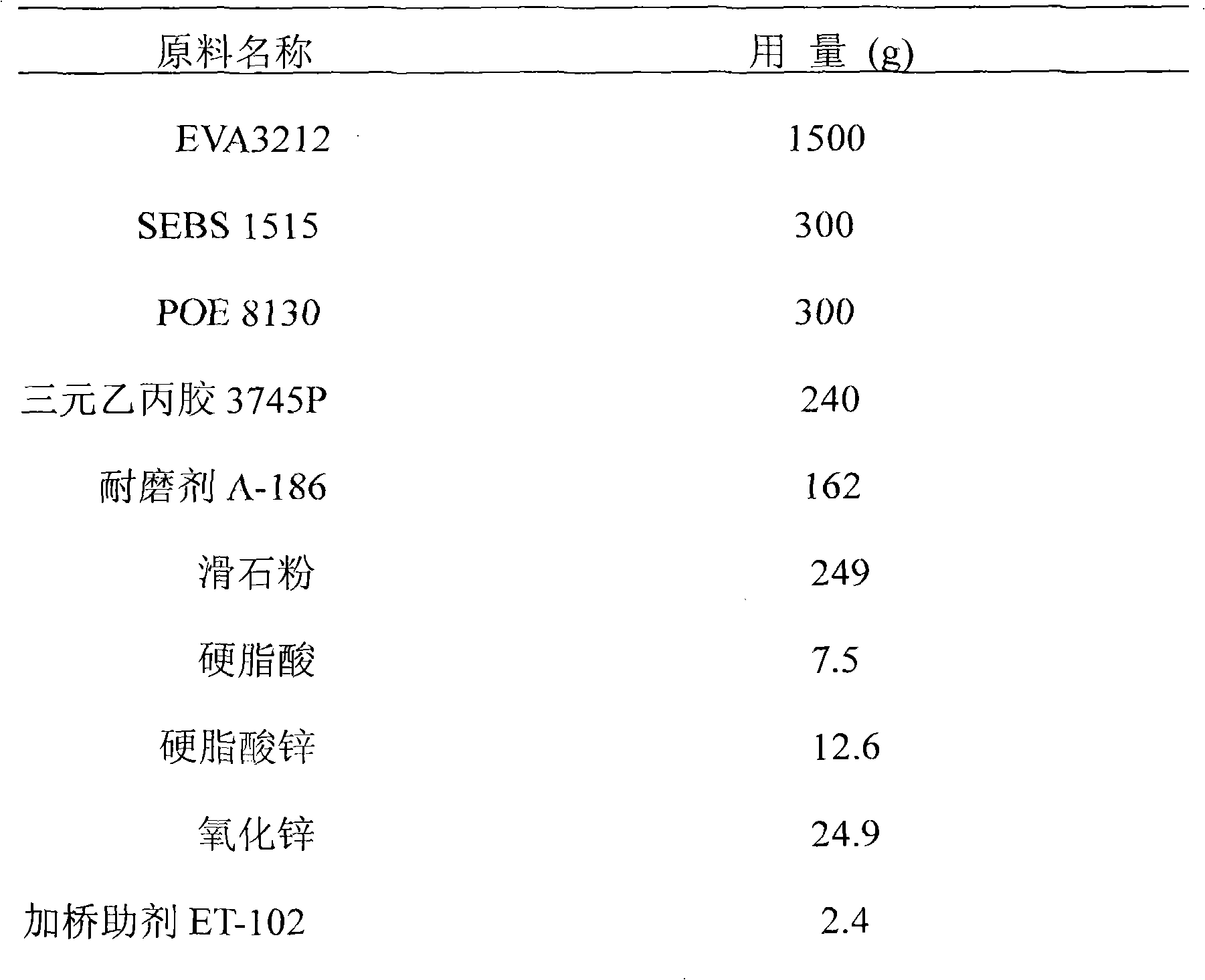

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Sealing strip using epdm rubber as host material

ActiveCN101230248AReduce viscosityInhibitionEngine sealsOther chemical processesPolyethylene glycolEPDM rubber

The invention discloses a sealing strip which takes EPDM as the host material and the preparing method, which is characterized in that the composition contains the following constituents (expressed by wt percent): EPDM 26 percent, zinc oxide 1-1.5 percent, stearic acid 1-6 percent, polyethyleneglycol 0.5-1.6 percent, hydrafil 10-32 percent, zinc borate 5-16 percent, orthophosphoric lipid 3-16 percent, black carbon 7-20 percent, paraffin oil 7-21 percent, calcium oxide 2-5 percent, sulfur 0.25-0.5 percent and accelerant 0.65-1.5 percent. The invention ensures the mechanical performance and extrusion performance, is convenient for extrusion, adopts the hydrafil, the zinc borate, and a inflaming retarding system; is the most realistic non-halogen inflaming retarding; can produce a lot of crystal water on the surface of the burning substance; can separate the burning substance from contacting oxygen, and then can perform the inflaming retarding effect; can inhibit the gases produced by the burning substance, accordingly does not produce smog.

Owner:DANYANG WANBEN AUTOMOTIVE PARTS

Recipe of breviscapine drop pills and preparing method

InactiveCN1408392AReduce the number of medicationsSmooth releaseUnknown materialsPill deliveryParaffin waxIce water

The breviscaping drop pill prepared via a solid dispersing process has the recipe comprising breviscapine 20-30 wt%, polyglycol-6000 40-60 wt%, stearic acid 10-30 wt% and poloxamer-188 5-25 wt%. The preparation process includes heating to smelt polyglycol-6000, adding stearic acid and poloxamer-188, adding breviscaping powder while stirring, transferring to dropping pipe while maintaining the temperature, dropping the molten into liquid paraffin in ice water bath to solidify into pill and washing out the liquid paraffin. The present invention has high biological utilization of medicine, delays the medicine release time and reduces medicine taking times.

Owner:HUAZHONG UNIV OF SCI & TECH +2

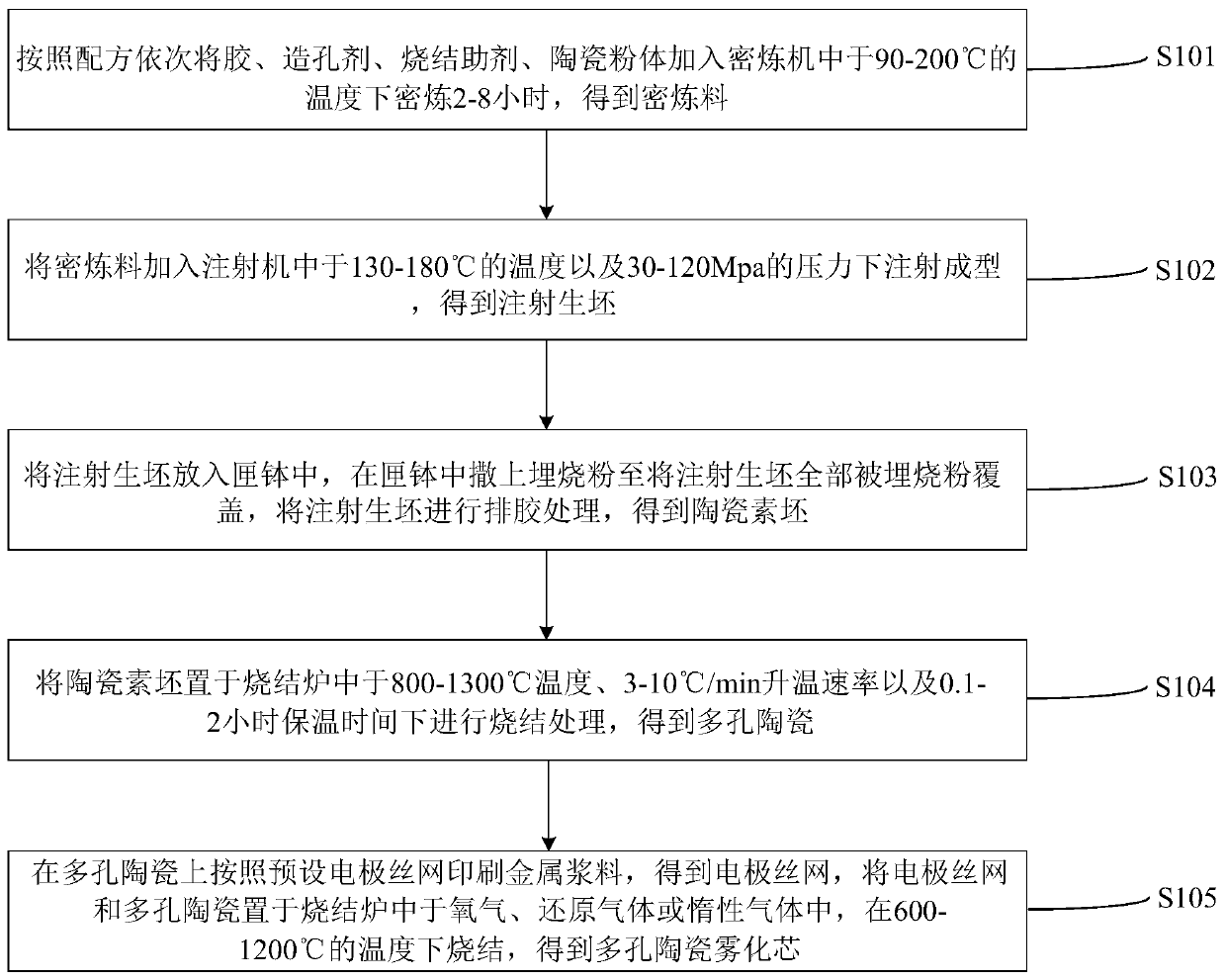

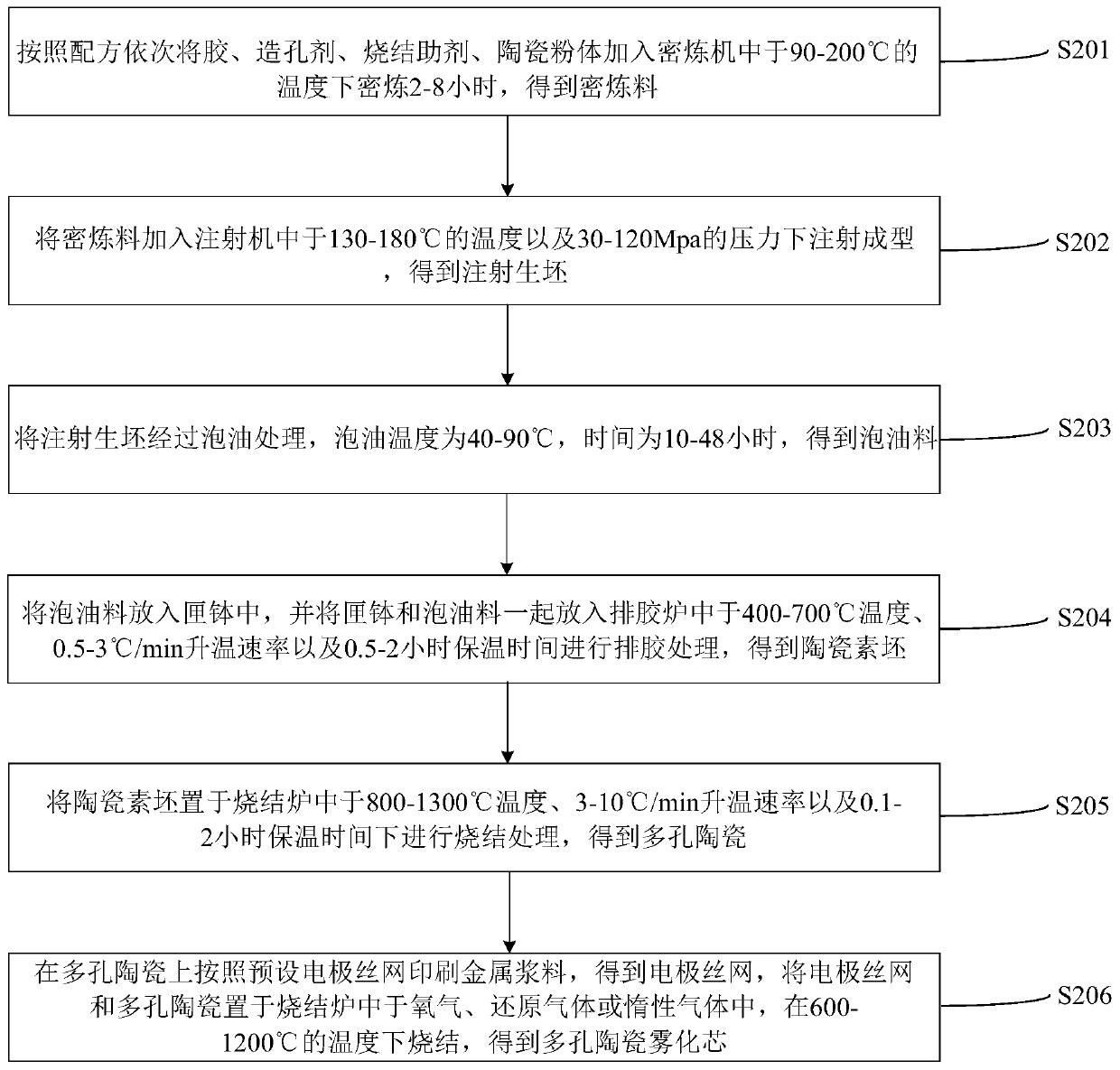

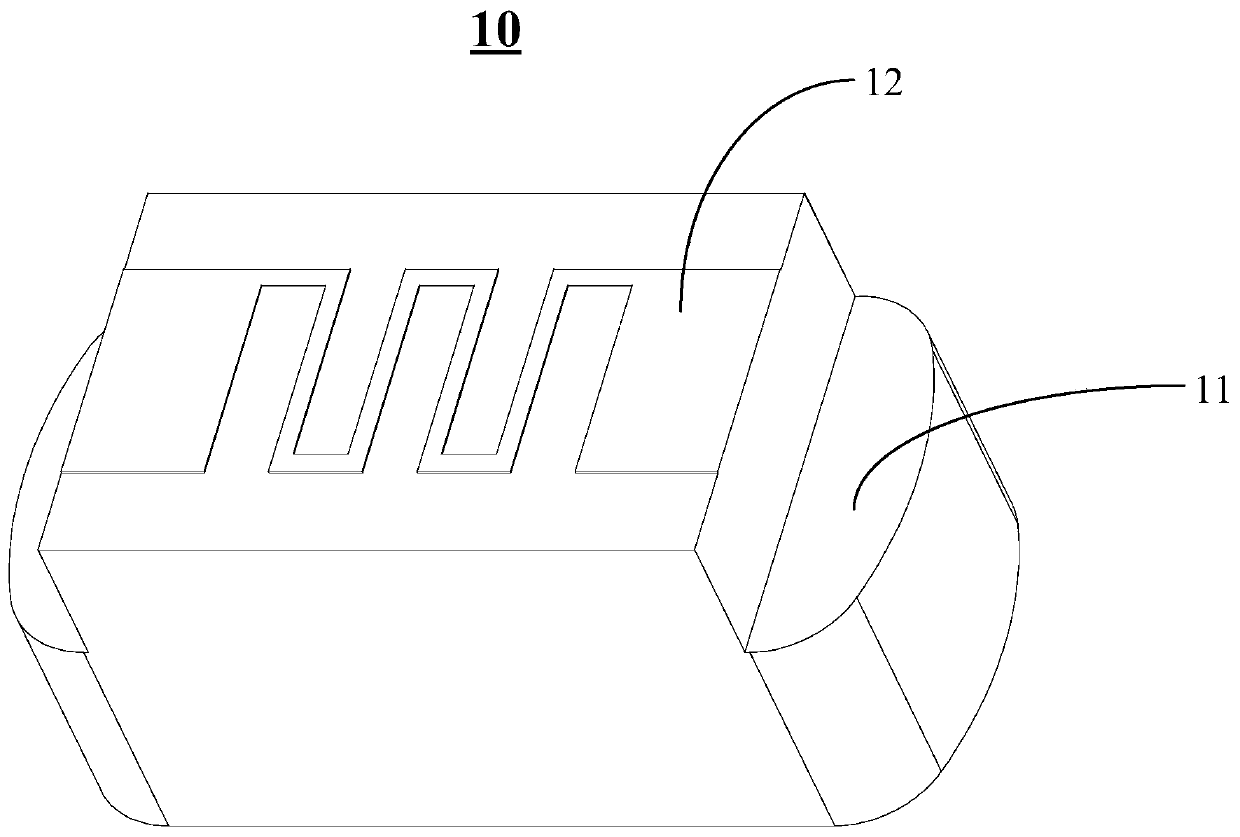

Porous ceramic for electronic cigarette, atomizing core containing porous ceramic and preparation method of atomizing core

InactiveCN111153686AImprove automationUniform structureTobaccoCeramicwareParaffin waxElectronic cigarette

The invention relates to the technical field of electronic cigarettes, and in particular, relates to a porous ceramic for an electronic cigarette, an atomizing core containing the porous ceramic and apreparation method of the atomizing core. The porous ceramic for the electronic cigarette is composed of the following components in percentage by mass: 35 to 60 percent of ceramic powder, 5 to 40 percent of a pore forming agent, 5 to 30 percent of a sintering aid and 15 to 35 percent of a glue, wherein the glue is composed of the following components in percentage by mass: 20 to 40 percent of PE, 20 to 40 percent of PP, 1 to 10 percent of PE wax, 15 to 40 percent of paraffin and 1 to 10 percent of stearic acid or oleic acid. Through the mode, the porous ceramic with a uniform structure and adjustable pore diameter and porosity is prepared by adopting an injection molding process, so that the requirements of users on different pore diameters and different porosities of the porous ceramiccan be met; through the specific feeding sequence and an internal mixer, the materials are mixed more uniformly, the forming size is stable and is close to the net size, secondary machining is not needed, forming is easy and automatic, the production efficiency is high, and the production cost is low.

Owner:东莞市陶陶新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com