Patents

Literature

492results about How to "Improve waterproof and moisture-proof performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

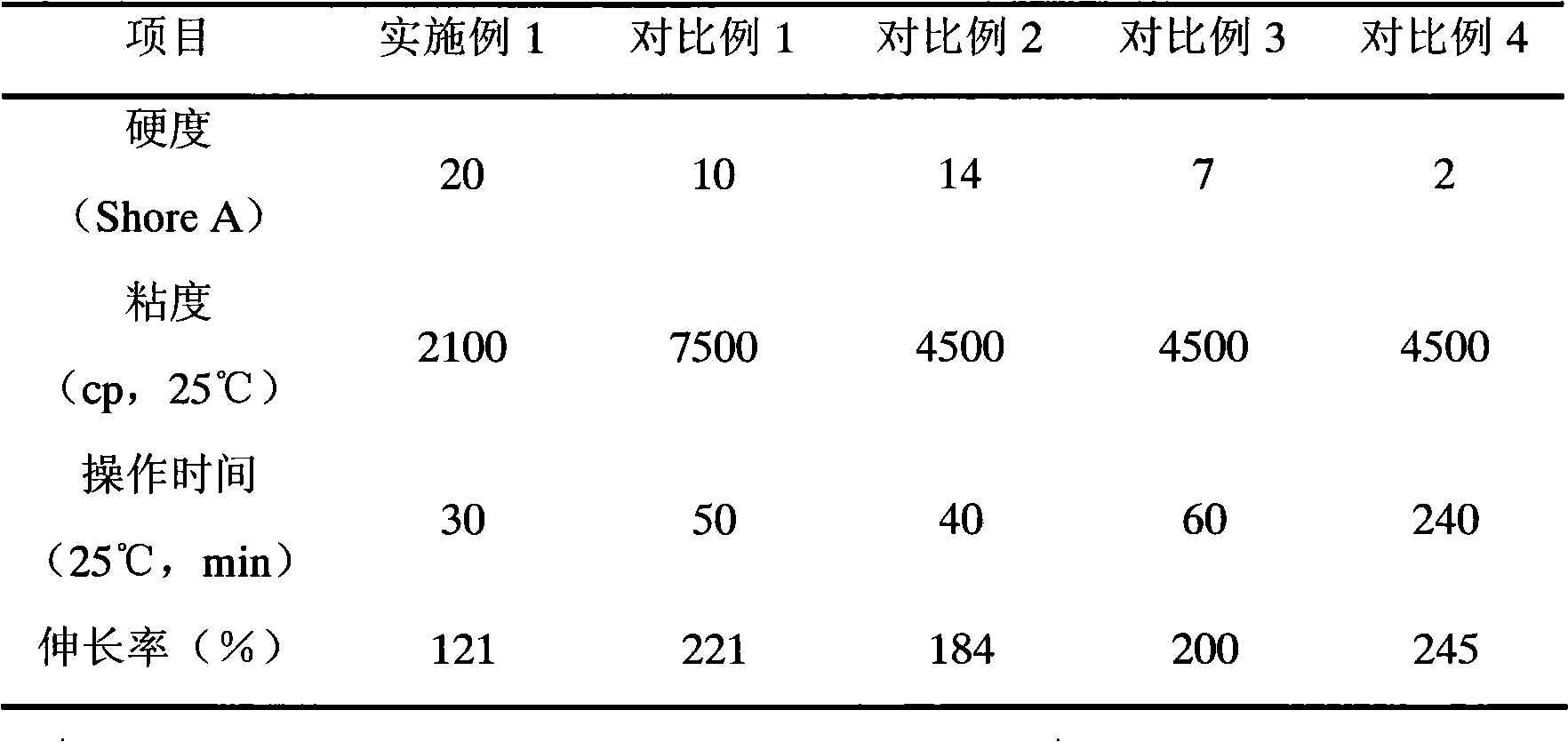

Low-hardness high-flexibility double-component condensed type organic silicon potting adhesive composition

InactiveCN101565600AGood waterproof and moisture-proof performanceImprove vulcanization effectNon-macromolecular adhesive additivesOther chemical processesPliabilityChemistry

The invention mainly relates to potting adhesive, in particular to a low-hardness and high-flexibility double-component condensed type organic silicon potting adhesive composition suitable for potting a light emitting diode (LED) display screen module. The composition comprises a component A and a component B, wherein the component A comprises a basic polymer, a filling material, a plasticizing agent and a deep curing agent; and the component B comprises a cross-linking agent, a tackifier and a catalyst. The component A and the component B are mixed according to designed proportion to have a cross-linking reaction so as to realize the effects of potting the LED display screen module, preventing adhesive layer cracking during repeatedly bending and folding LED tubes and providing excellent waterproof and dampproof properties.

Owner:GUANGZHOU HUITIAN FINE CHEM

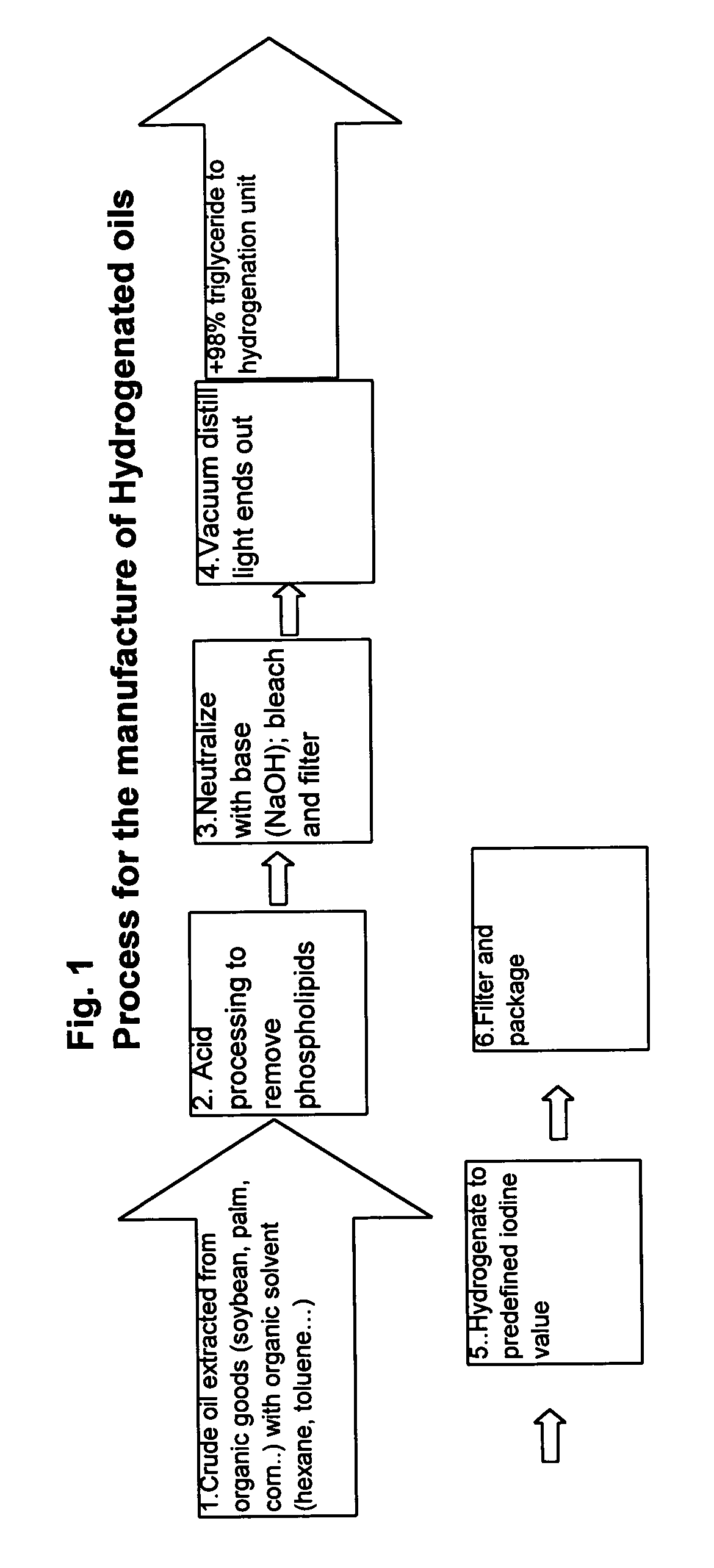

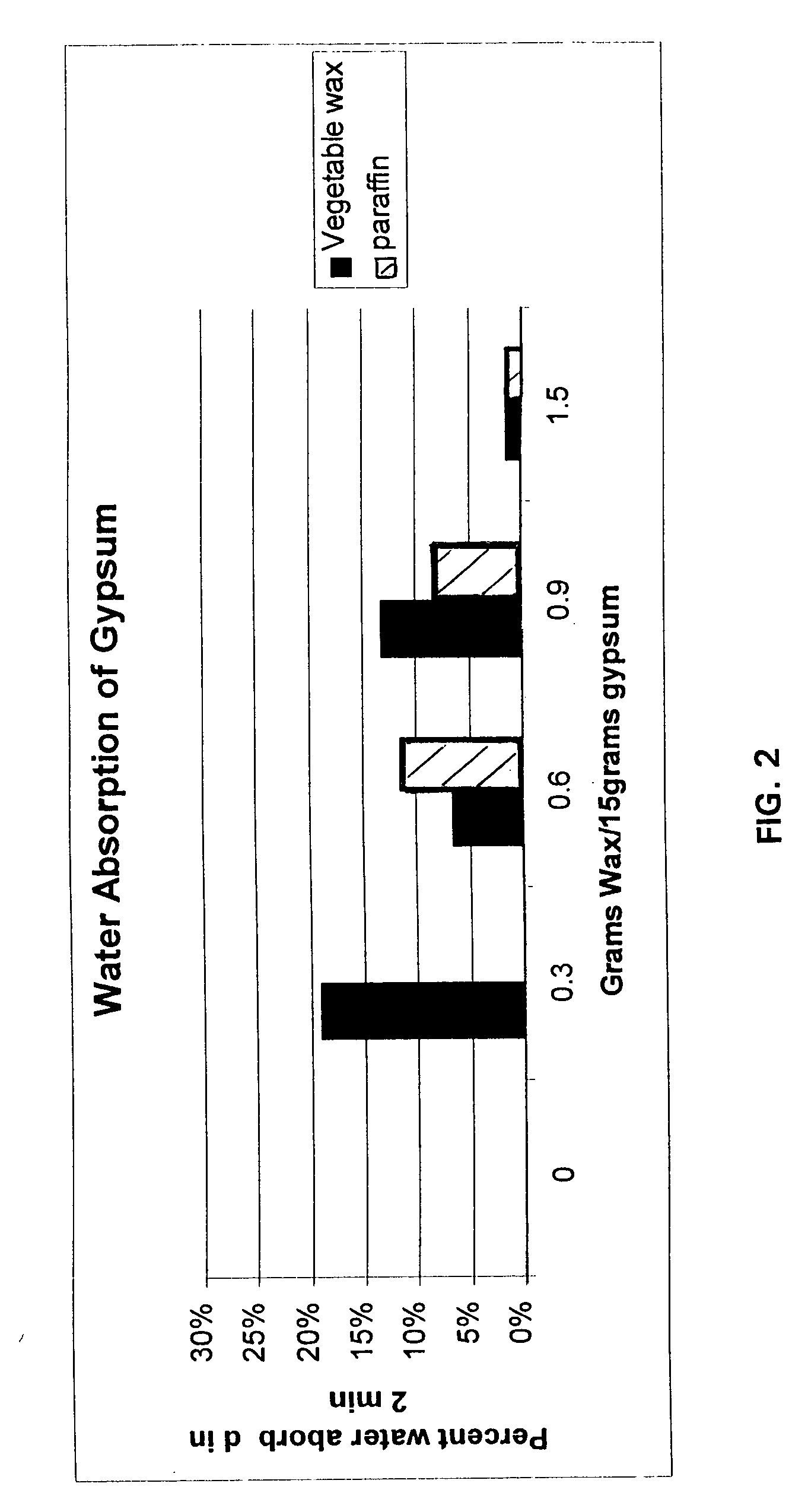

Additive to render gypsum board moisture resistant

InactiveUS20060196391A1Improve waterproof and moisture-proof performanceMore water resistantBuilding componentsCoatingsStearic acidMoisture barrier

Waxes prepared from hydrogenated plant oils, such as palm and soybean, are used to render gypsum board resistant to water. Unlike petroleum-derived waxes used for the same purpose, vegetable derived waxes are renewable and readily converted into forms such as emulsions or powder that facilitate incorporation into gypsum board manufacturing. Such water resistant materials are characterized by enhanced moisture barrier properties. The compositions have a low iodine value (between 2-5), and melting points between approximately 120-185 degrees F. (Mettler Drop Point). The wax comprises a triglyceride whose fatty acids are predominantly stearic acid (C18). The composition is used as an additive in the manufacture of water resistant gypsum board.

Owner:HRD CORP

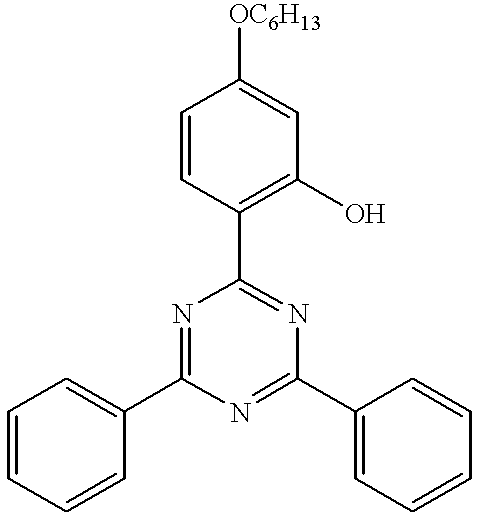

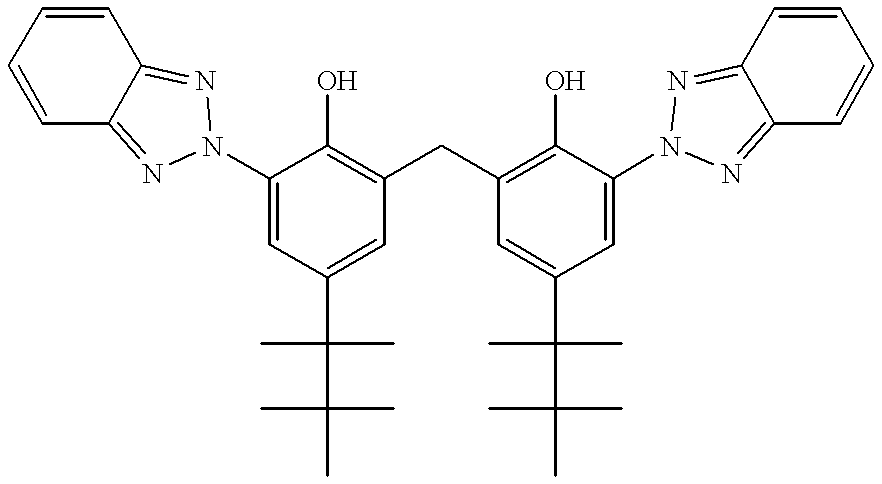

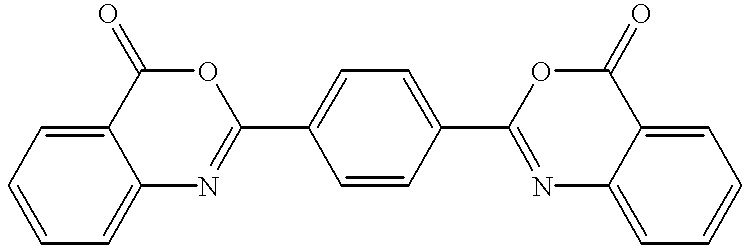

Hydrolysis-resistant, transparent, biaxially oriented film made from a crystallizable thermoplastic, and process for its production

InactiveUS6855758B2Maintain good propertiesLow shrinkageAluminium compoundsOrganic chemistryPolyesterThermoplastic

The invention relates to transparent, biaxially oriented and heat-set films having one or more layers and compris, as main constituent, at least one crystallizable thermoplastic, in particular a polyester, and also comprise at least one hydrolysis stabilizer. The hydrolysis stabilizer is preferably a phenolic compound, an oxazoline, and / or a monomeric or polymeric carbodiimide, where appropriate combined with an organic phosphite. It is preferably added in the form of a masterbatch. The film exhibits low longitudinal and transverse shrinkage. On exposure to moisture and heat it shows practically no embrittlement and retains its ultimate tensile strength. The additional functionality is preferably that the film has been made UV-resistant, or flame-retardant, or on one side or on both sides has been coated, or is sealable, and / or has been corona- or flame-treated. The film is generally produced by extrusion or coextrusion, the hydrolysis stabilizer being added in the form of a predried or precrystallized masterbatch.

Owner:MITSUBISHI POLYESTER FILM

Bamboo shoot skin plywood and production process thereof

InactiveCN103538123AReduce manufacturing costHigh strengthLaminationLamination apparatusHair removalPhyllostachys propinqua

Provided are bamboo shoot skin plywood and a production process of the bamboo shoot skin plywood. The bamboo shoot skin plywood adopts bamboo shoot skin of moso bamboo, phyllostachys parvifolia, dendrocalamus latiflorus, phyllostachys propinqua, phyllostachys viridi-glaucescens, overlord bamboo and others as raw materials, uses transparent polyester resin, and is manufactured through a panel material preparation and production process (including the steps of rinsing and hair removal, processing of a solution (70% of clean water, 27% of acetic acid and 3% of ethyl alcohol), water scrubbing, drying, flattening and mould pressing of a spliced picture), a base board production process (including the steps of rinsing and hair removal, drying, flattening, curtain weaving, spreading, gluing and hot pressing), and a third process (including the steps of splicing and spreading of a panel and the spliced picture, gluing, hot pressing of the panel on the surface of a base board, edge sawing, grading detection, and packaging and storage), can be used for the industry, the construction industry, furniture, floor boards, decoration, packaging and the like, and is multipurpose. The bamboo shoot skin plywood and the production process of the bamboo shoot skin plywood sufficiently reflect the concept of recycling waste materials, and solve many problems of existing plywood. The bamboo shoot skin plywood produced through the process is low in cost, high in strength, dampproof, waterproof, good in anti-mold property, not prone to deformation, low in carbon, environmentally friendly, durable, and capable of saving resources, and is a novel substitute product for the development of the plywood industry in our country.

Owner:CHIBI JIAXIANG BAMBOO SHOOT DEV

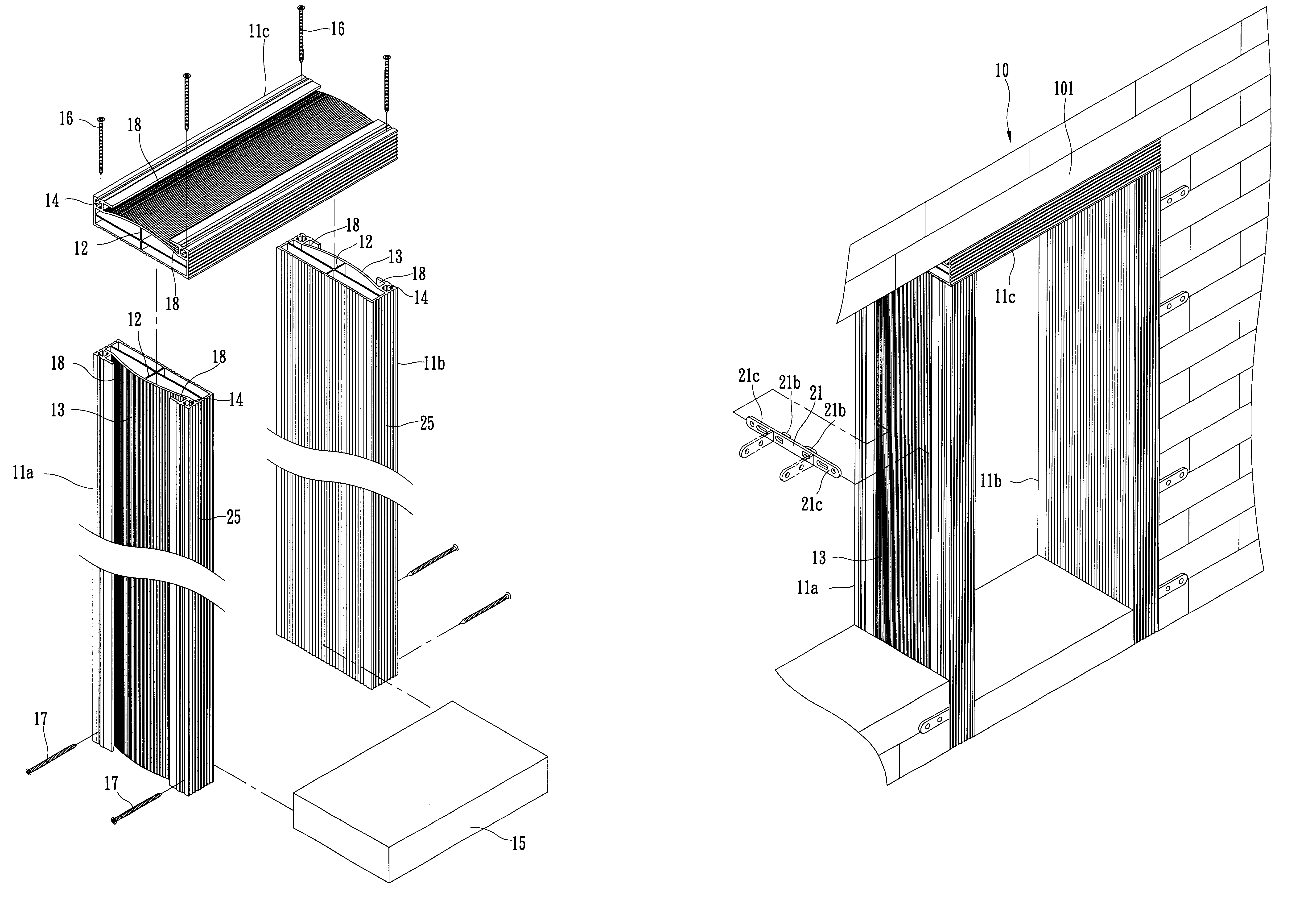

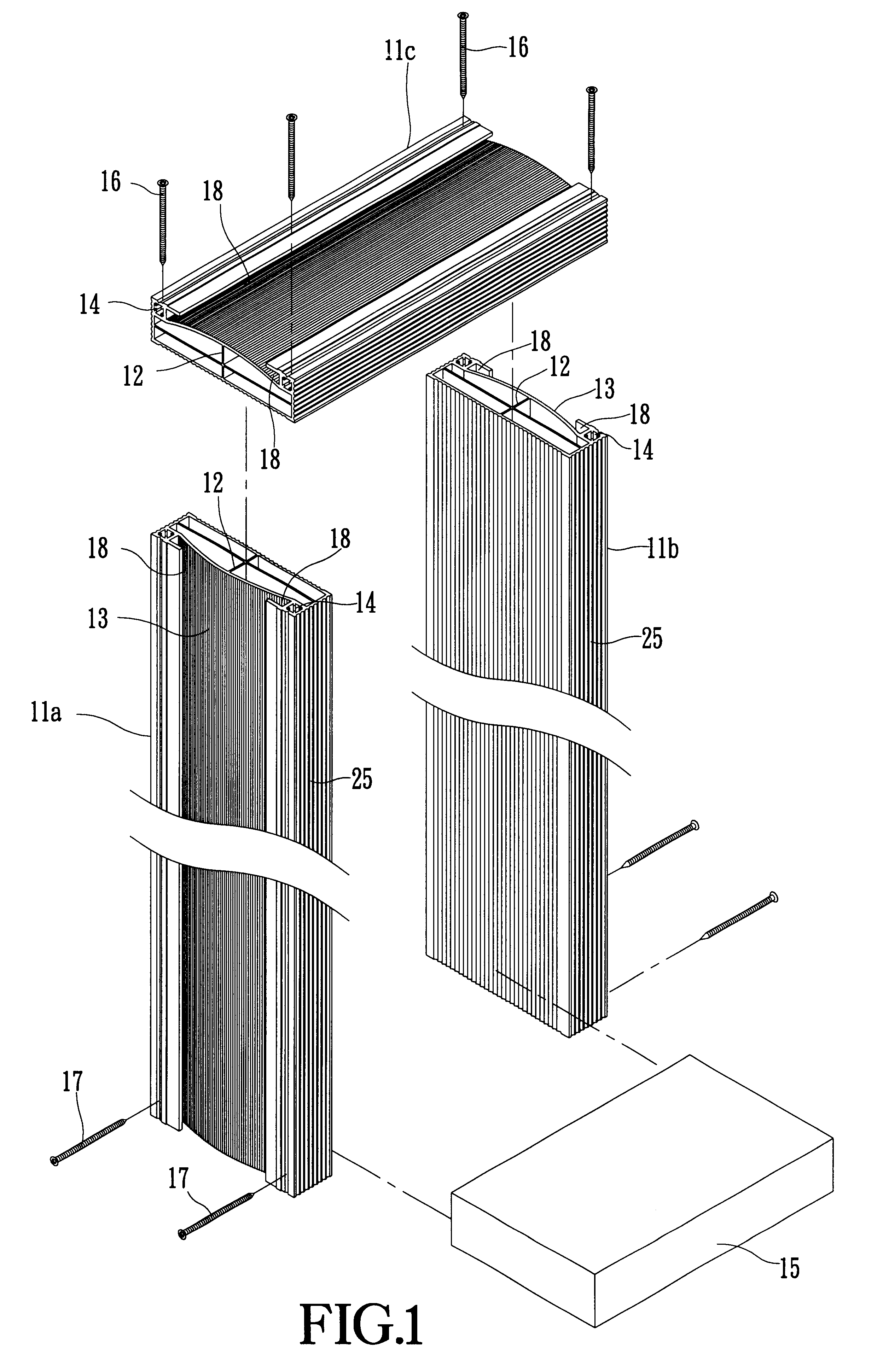

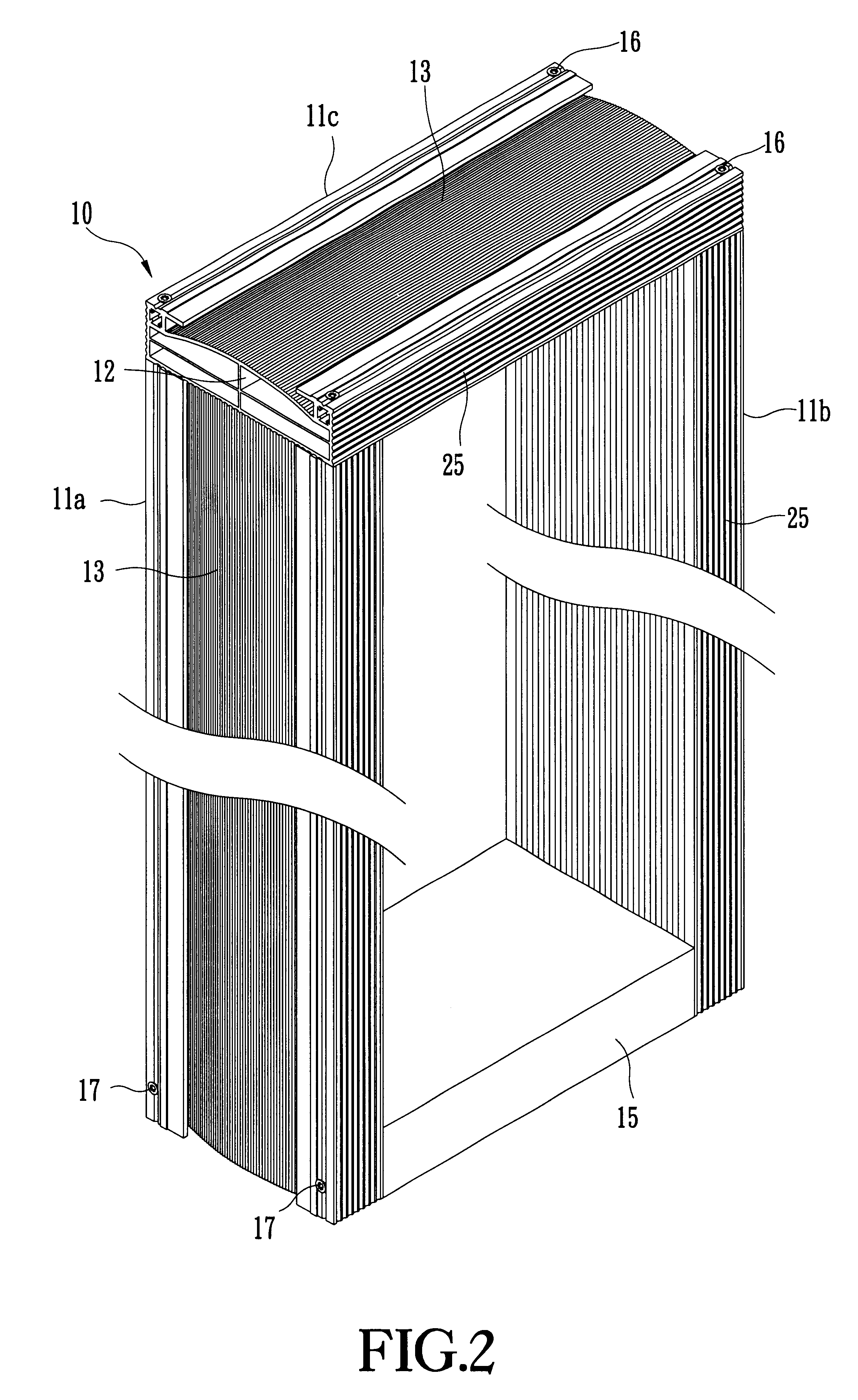

Auxiliary frame for improving conventional frame and method for working the same

InactiveUS6343448B1Easily rottedHigh strengthArched girdersBuilding roofsMetallic materialsEngineering

Owner:LIN CHUN CHEN

Paper pouring gate pipe for casting and manufacturing method of paper pouring gate pipe

The invention discloses a paper pouring gate pipe for casting. The paper pouring gate pipe for casting is prepared from organic fibers, inorganic fibers, sintered refractory, a binder, a waterproof and dampproof agent, an enhancer, a filter aid and a fluxing agent. The invention further discloses a manufacturing method of the paper pouring gate pipe for casting. According to the paper pouring gate pipe for casting and the manufacturing method of the paper pouring gate pipe for casting, compared with a refractory ceramic pouring gate pipe component adopted all the time, the paper pouring gate pipe for casting manufactured based on the paper pulp molding technology has the beneficial effects that the weight is low, operation is easy, little waste is generated after a casting is cast, treatment is easy, labor and time are saved, energy saving and environment friendliness are achieved, the environment is not polluted, and environment friendliness is achieved.

Owner:张新平

Preparation method for moisture-proof corrugated paper

InactiveCN104404816AWide variety of sourcesImprove waterproof and moisture-proof performanceLaminationLamination apparatusBenzeneWax

The invention discloses a preparation method for moisture-proof corrugated paper. The preparation method comprises the following steps: respectively weighing wood pulp and waste paper pulp; mixing the weighed wood pulp and the waste paper pulp till the mixture is uniform; removing impurities; adding water to soak the pulp mixture; carrying out scattering to obtain virgin pulp; adding a moisture-proof agent; carrying out paper making to obtain paper; conducting preheating and sizing on the paper; treating the preheated and sized paper with a single side machine to obtain corrugated paper; pasting a piece of wax-oil paper on the outermost layer of the corrugated paper; carrying out drying. The moisture-proof agent is prepared from the following raw materials in parts by weight: 25-30 parts of tapioca, 15-20 parts of allyl benzene, 13-18 parts of butenoic acid ester, 5-8 parts of paraffin, 2-5 parts of sodium dodecyl benzene sulfonate and 1-4 parts of silicon dioxide. The moisture-proof corrugated paper is wide in raw material resource and relative low in production cost. The preparation method has the advantages that the moisture-proof agent is added in the paper making process and the wax-oil paper is pasted on the outermost layer of the corrugated paper, so that the water-proof performance and moisture-proof performance of the corrugated paper are greatly improved.

Owner:柳州市柳江区联华纸制品厂

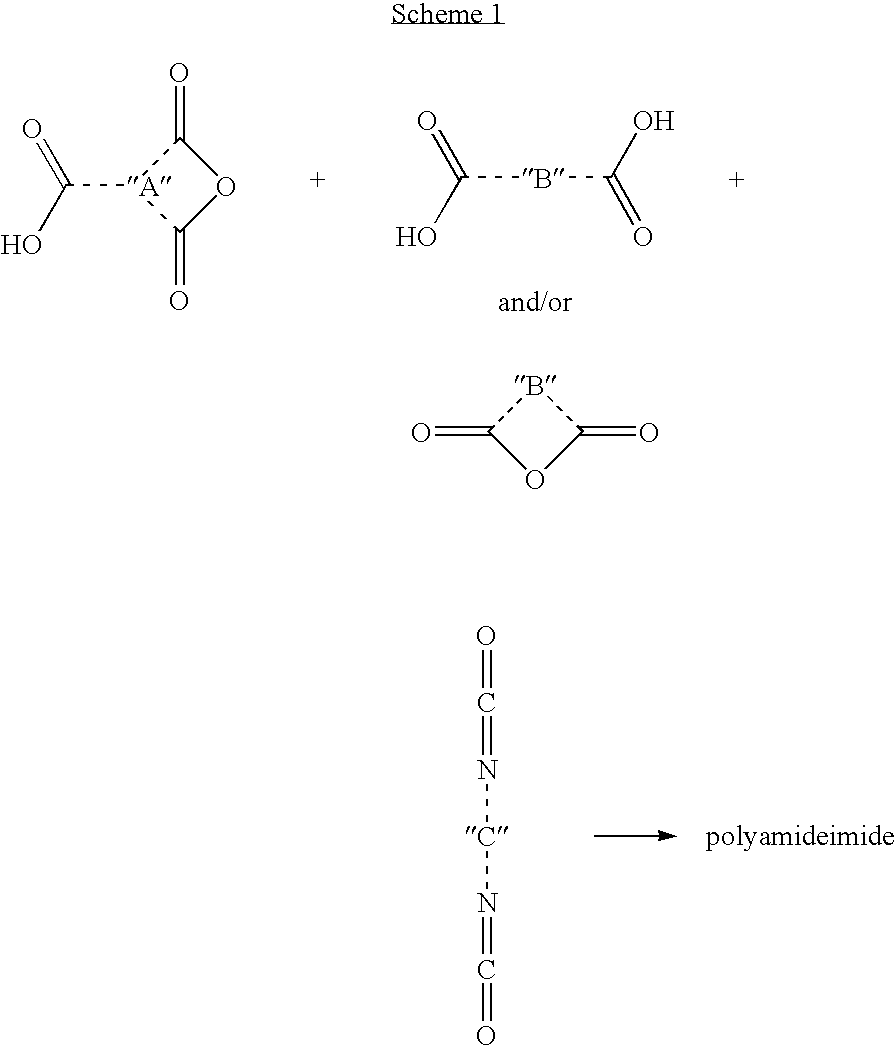

Polyamideimide compositions having multifunctional core structures

InactiveUS20050282010A1Improve toughnessIncrease stiffnessPlastic/resin/waxes insulatorsSynthetic resin layered productsPolyamide-imideMaterials science

Owner:GENERAL CABLE TECH CORP

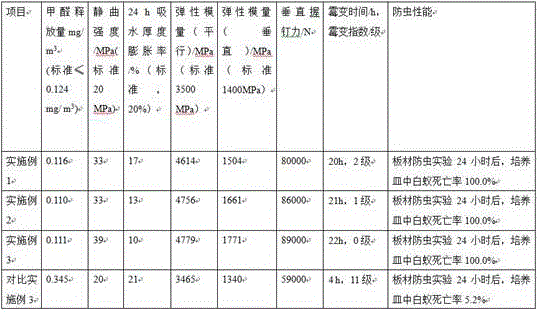

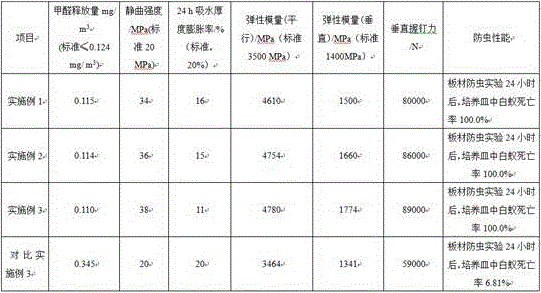

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

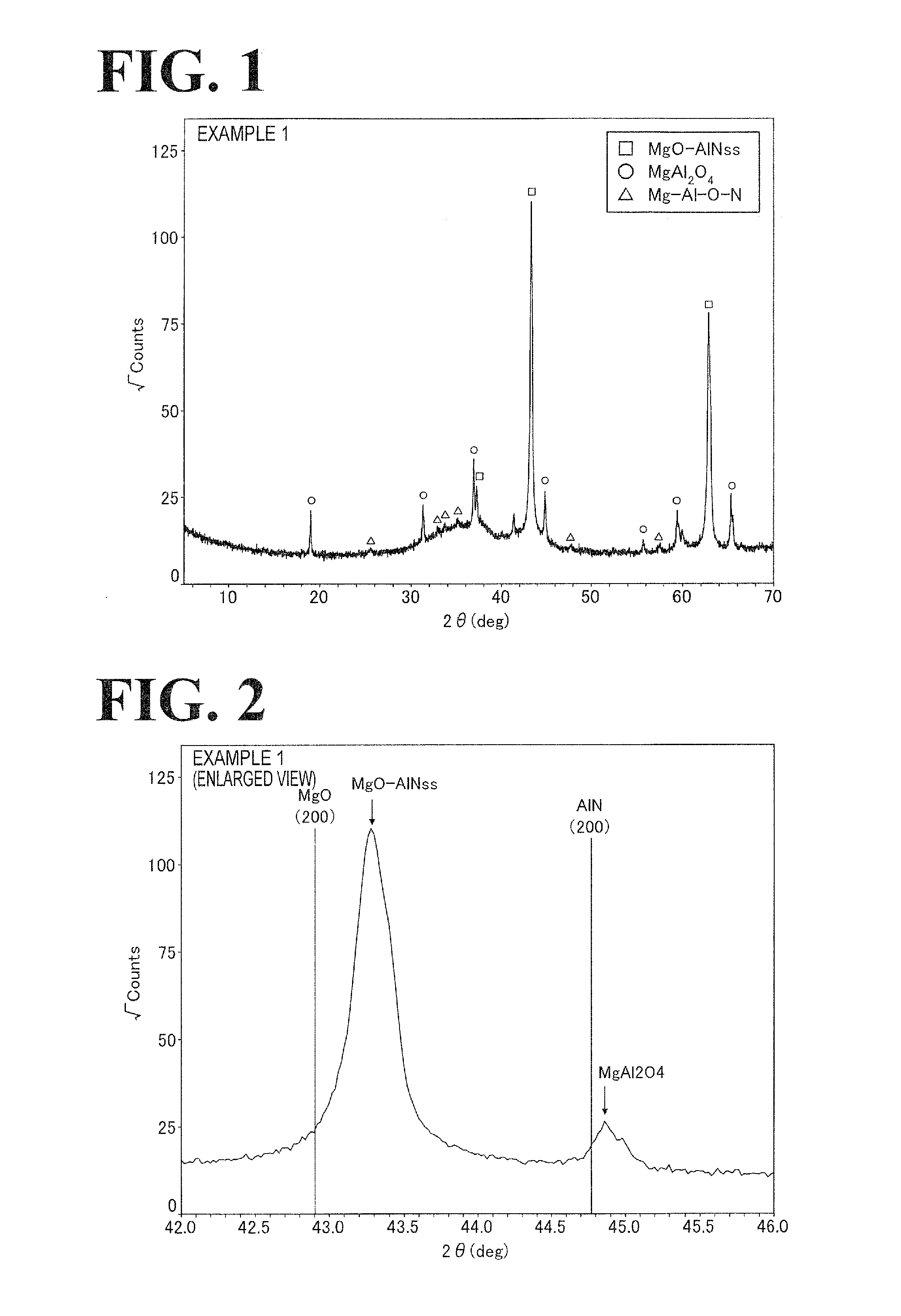

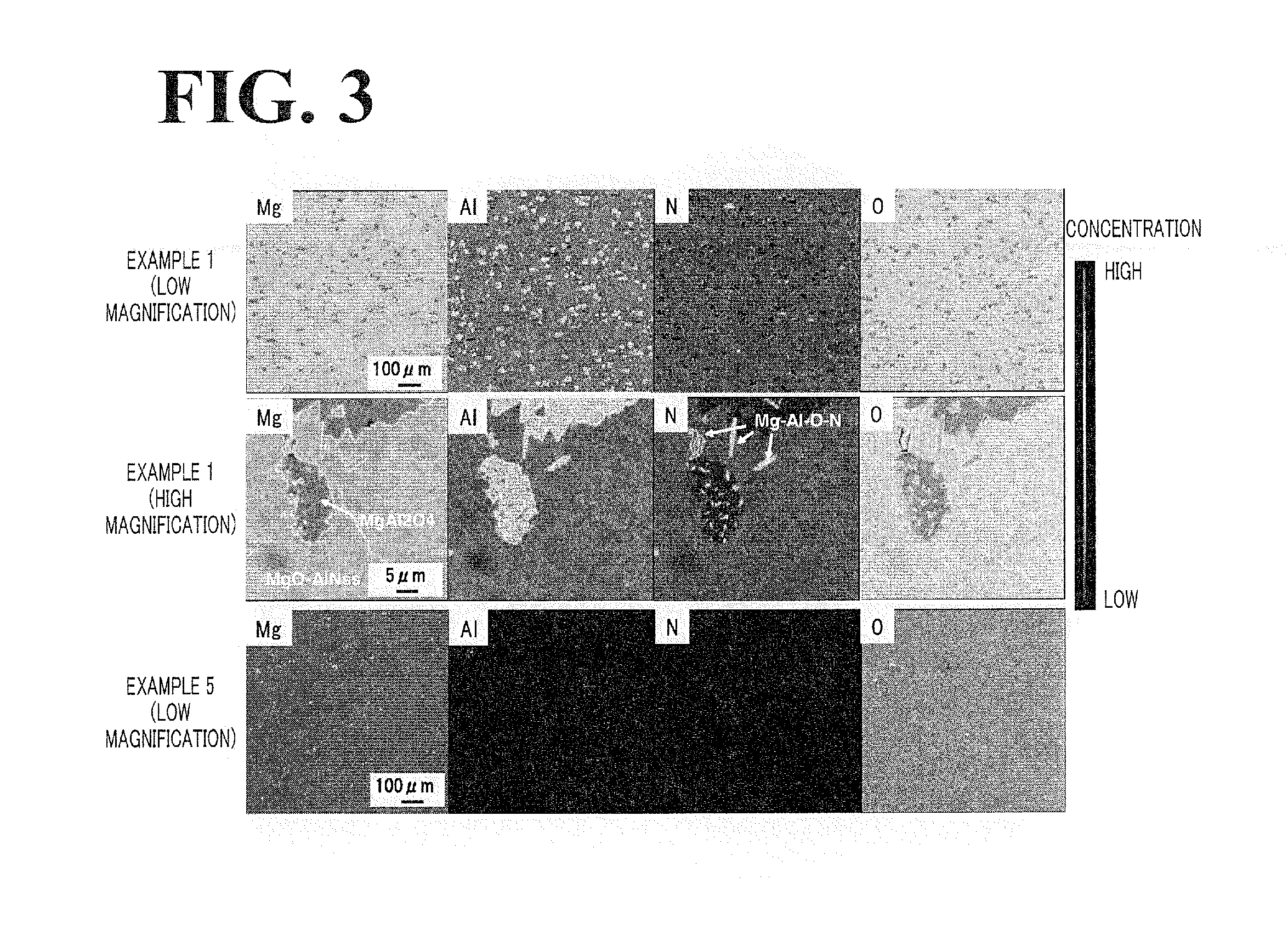

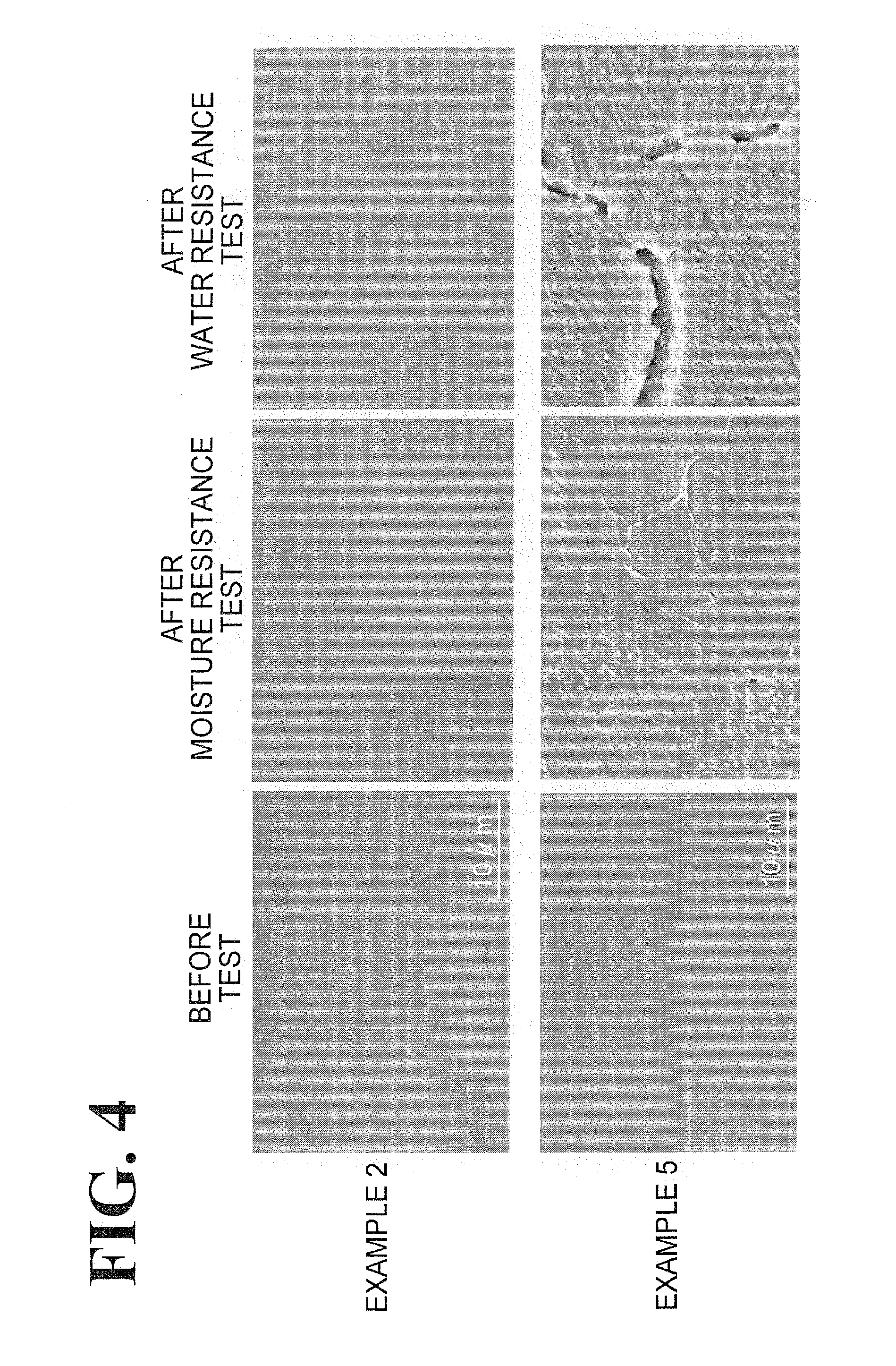

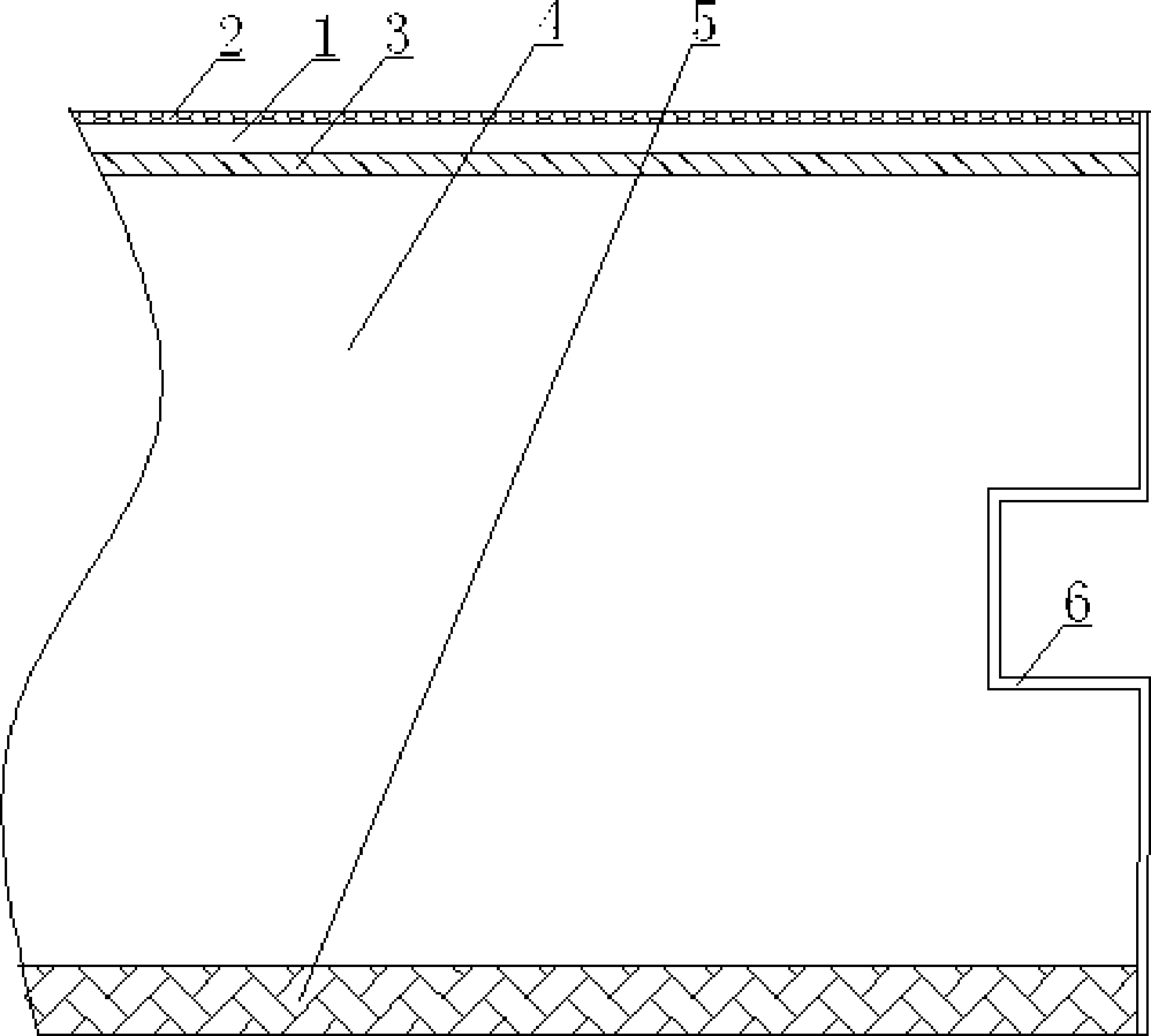

Ceramic material, member for semiconductor manufacturing equipment, sputtering target member and method for producing ceramic material

ActiveUS20120231945A1Improve moisture resistanceImprove water resistanceCellsVacuum evaporation coatingNitrogenSolid solution

A ceramic material according to the present invention mainly contains magnesium, aluminum, oxygen, and nitrogen, the ceramic material has the crystal phase of a MgO—AlN solid solution in which aluminum nitride is dissolved in magnesium oxide, the crystal phase serving as a main phase. Preferably, XRD peaks corresponding to the (200) and (220) planes of the MgO—AlN solid solution measured with CuKα radiation appear at 2θ=42.9 to 44.8° and 62.3 to 65.2°, respectively, the XRD peaks being located between peaks of cubic magnesium oxide and peaks of cubic aluminum nitride. More preferably, the XRD peak corresponding to the (111) plane appears at 2θ=36.9 to 39°, the XRD peak being located between a peak of cubic magnesium oxide and a peak of cubic aluminum nitride.

Owner:NGK INSULATORS LTD

Low-formaldehyde-emission abrasion-resistant and moisture-proof laminate wood flooring and production and laying method for laminate wood flooring

ActiveCN103243892AImprove water resistanceReduced degree of water swellingLamination ancillary operationsSynthetic resin layered productsFiberPolymer science

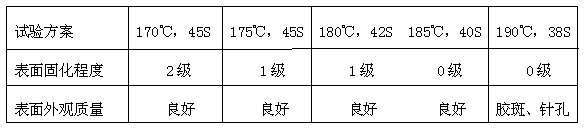

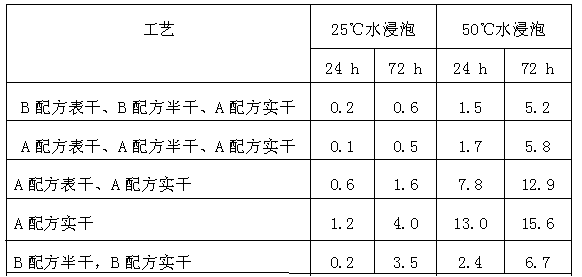

Disclosed are low-formaldehyde-emission abrasion-resistant and moisture-proof laminate wood flooring and a production and laying method for the laminate wood flooring. The laminate wood flooring is provided with an impregnated abrasion-resistant paper layer, an impregnated separation paper layer, an impregnated decorative paper layer, a high-density fiberboard layer and an impregnated balance paper layer successively from the surface layer to the bottom layer. Impregnated balance paper, a high-density fiberboard, impregnated decorative paper, impregnated separation paper and impregnated abrasion-resistant paper which are sacked successively are subjected to hot pressing at the temperature ranging from 175 DEG C to 185 DEG C and under the pressure in a range of 5MPa to 9MPa for 40S to 45S to be produced into a large semi-manufactured plate; the large semi-manufactured plate is subjected to splitting, healthy balance treatment and rabbet machining to be manufactured into small plates; the small plates are manufactured into laminate wood flooring by coating polyurethane lacquer at peripheral rabbet positions; and sawing section fibers of the flooring is subjected to the first coating through the polyurethane lacquer during laying, the polyurethane lacquer is dried till the lacquer surface is tacky but not sticky when touched with fingers, and the flooring is laid after the second coating is performed.

Owner:圣保罗家居科技有限公司

Waterproof coating of carton

ActiveCN102704330AGood chemical stabilityImprove insulation performanceCoatingsPaper forming aids additionParaffin waxEmulsion

The invention relates to a waterproof coating, in particular to a waterproof coating of a carton, which comprises the following components in weight part: 30-120 parts of paraffin micro-emulsion, 50-90 parts of simethicone, and 4-8 parts of emulsifier. The waterproof coating is prepared according to a method as follows: (1) heating the paraffin micro-emulsion to 50-180 degree C; (2) adding simethicone and stirring for 0.5-3 hours; and (3) adding the emulsifier, stirring at a high speed for 10-40 minutes, and cooling to the room temperature. The waterproof coating of the carton, disclosed by the invention, has no pollution on the human body and the environment, can be combined with the base material firmly, and has excellent waterproof property.

Owner:ANHUI JINDUN PAINT

UV-curing glass printing ink and UV-curing glass printing lacquer and process for printing glass substrates

A glass printing ink and glass printing lacquer are prepared, which contain at least one photoinitiator, at least one resin and at least one additional substance. The resin is an epoxy resin based on bisphenol A, diluted in a UV-curing monomer, or a resin with functional groups containing free functional amino, hydroxy, epoxy, acid, acid anhydride and / or acrylate groups, or a combination of the epoxy resin with the resin with functional groups. The at least one additional substance is a wax. The use of the glass printing ink and glass printing lacquer in printing a glass substrate and processes for the printing of a glass substrate are also described.

Owner:MARABU GMBH & CO KG

Formaldehyde-free-grade high-quality and high-density fiberboard and preparation method thereof

InactiveCN105128116AEliminate internal stressHigh bonding strengthFlat articlesDomestic articlesPolyurethane adhesiveSilanes

The invention discloses a formaldehyde-free-grade high-quality and high-density fiberboard. The formaldehyde-free-grade high-quality and high-density fiberboard is characterized by being prepared from, by weight, 42-45 parts of crop straw, an appropriate amount of sodium hydroxide with the concentration of 2%, 2-2.5 parts of a silane coupling agent kh450, 66-70 parts of ethyl alcohol with the concentration of 95%, 30-32 parts of timber leftover materials, 4-6 parts of diatom ooze, 3-4 parts of nanometer tourmaline powder, 5-6 parts of waterborne polyurethane adhesives, 1.5-2 parts of solid paraffin, 2-3 parts of soybean protein glue, 1-2 parts of polysorbate 80, 2-3 parts of urea and an appropriate amount of water. The technology is obtained by conducting innovation on the basis of an existing technology, the production cost can be reduced, the production efficiency can be improved, and the quality stability of the fiberboard can be improved. By means of waste materials such as straw of crops and wheat, environment pollution can be reduced, and the high added value of the product can be increased, for example, anion release and the adsorption effect; and the high-strength, high-quality and formaldehyde-free environment-friendly fiberboard is prepared.

Owner:ANHUI BAIYI FURNITURE

Wall surface heat insulating meterial

An insulating material for wall surface is prepared from the basic material which is light calcium carbonate particles coated by stearic acid, expanded pearlite, silicate cement, polyvinyl alcohol adhesive, carboxymethyl cellulose, Na-base bentone and polypropylene fibres. Its advantages are high mechanical performance, less deformation and high insulating effect.

Owner:武汉市鹏凌集团有限公司

Self-adhesive type ceramic composite belt and preparation method thereof

InactiveCN104476861ASelf-adhesiveImprove sealingSynthetic resin layered productsInsulated cablesCeramic compositePlatinum complex

The invention discloses a self-adhesive type ceramic composite belt. The self-adhesive type ceramic composite belt comprises a self-adhesive ceramic glue layer, a reinforcing layer and an isolating layer, wherein the reinforcing layer and the isolating layer are respectively positioned at the two sides of the self-adhesive ceramic glue layer; the self-adhesive ceramic glue layer and the reinforcing layer are fixed together; the self-adhesive ceramic glue layer is prepared from the following components in parts by weight: 60-100 parts of silicon rubber, 20-100 parts of white carbon black, 20-120 parts of ceramic powder, 1-20 parts of one or more of boric acid, boric anhydride, borate, polyborosiloxane or a boron-containing polymer, 1-20 parts of silicone oil, 0.00001-10 parts of platinum complex and / or platinum compounds, and 0.1-10 parts of a coupling agent. The self-adhesive type ceramic composite belt disclosed by the invention has self-adhesion, is mutually lapped and adhered during winding to achieve good sealing effects, has good moisture-proof and waterproof performances; during production, an isolating film is only needed to be added when the composite belt product is rolled, so that the process is simple and the production is easy.

Owner:常州市沃科科技有限公司

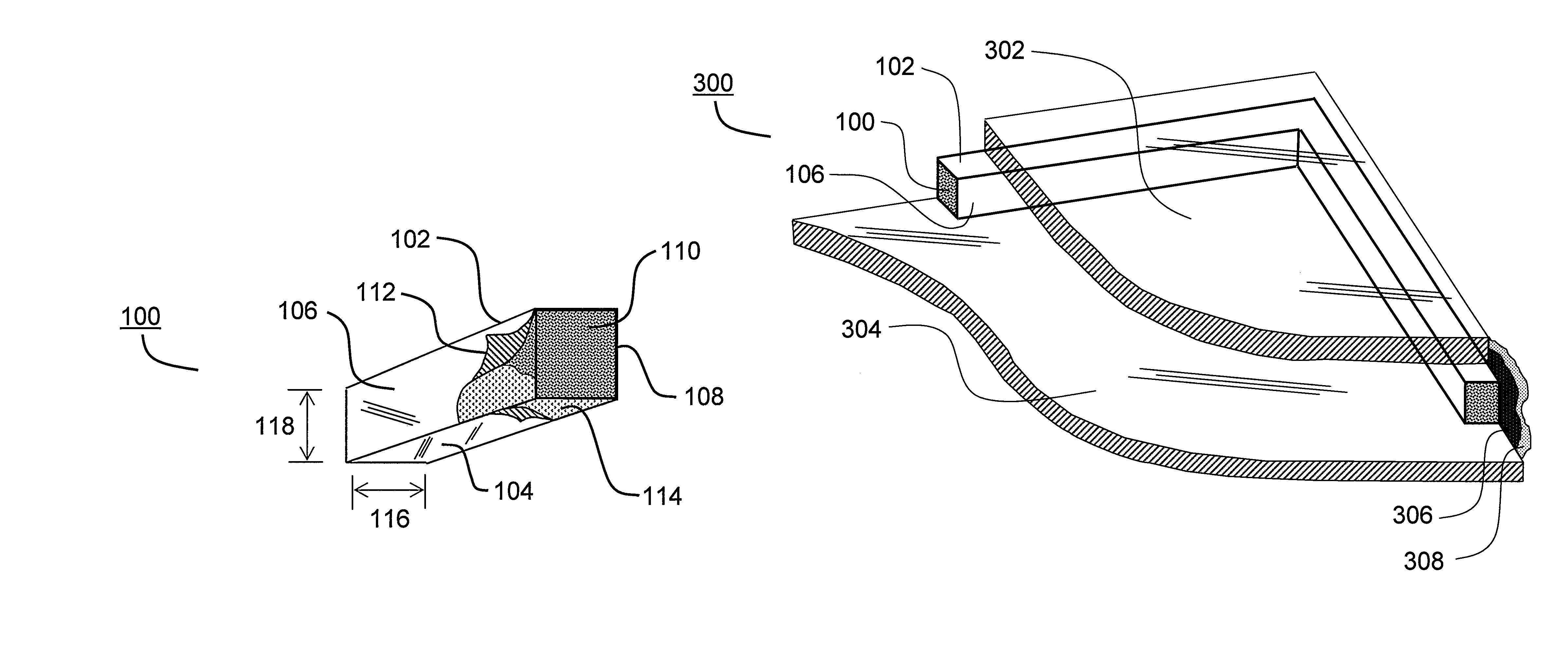

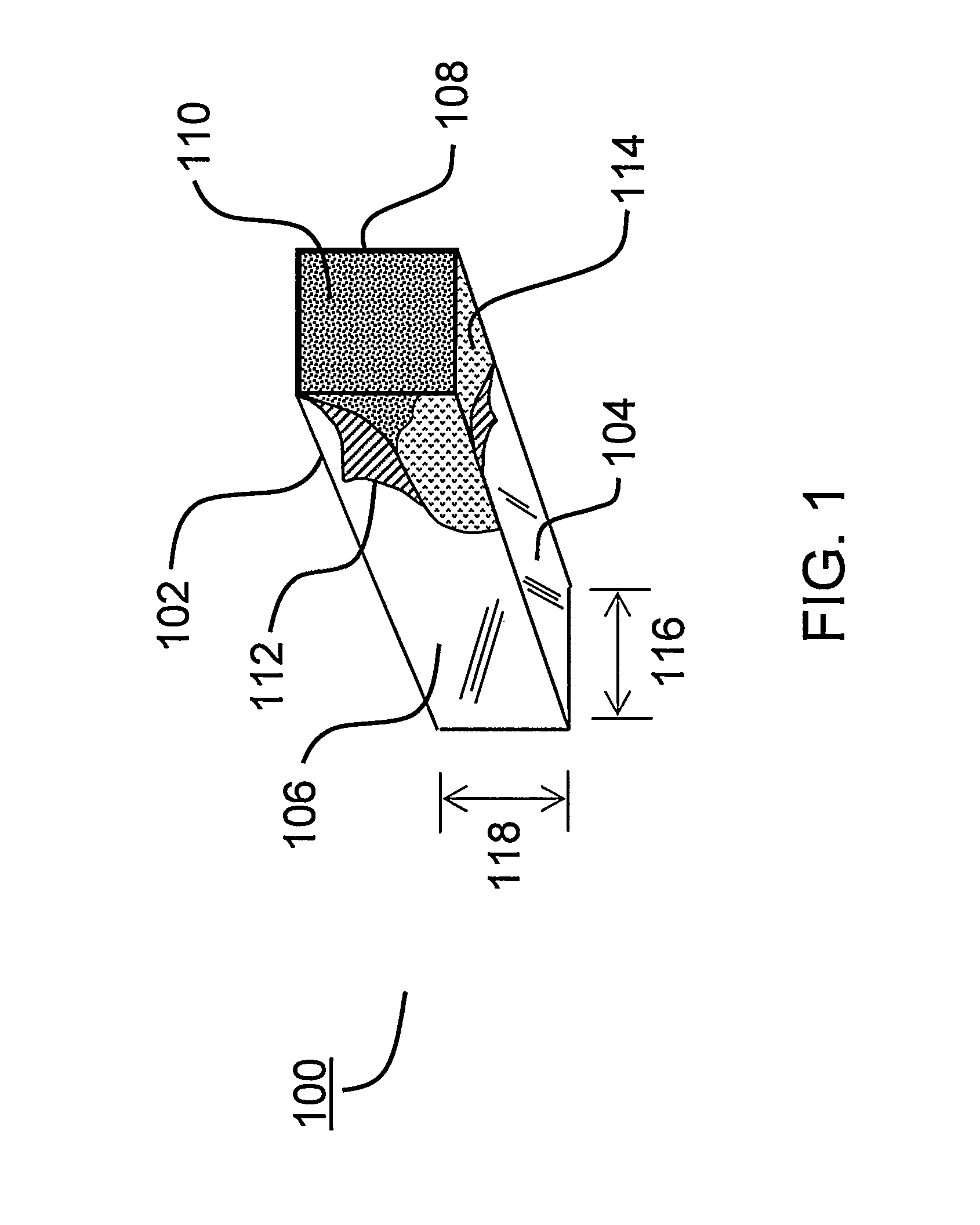

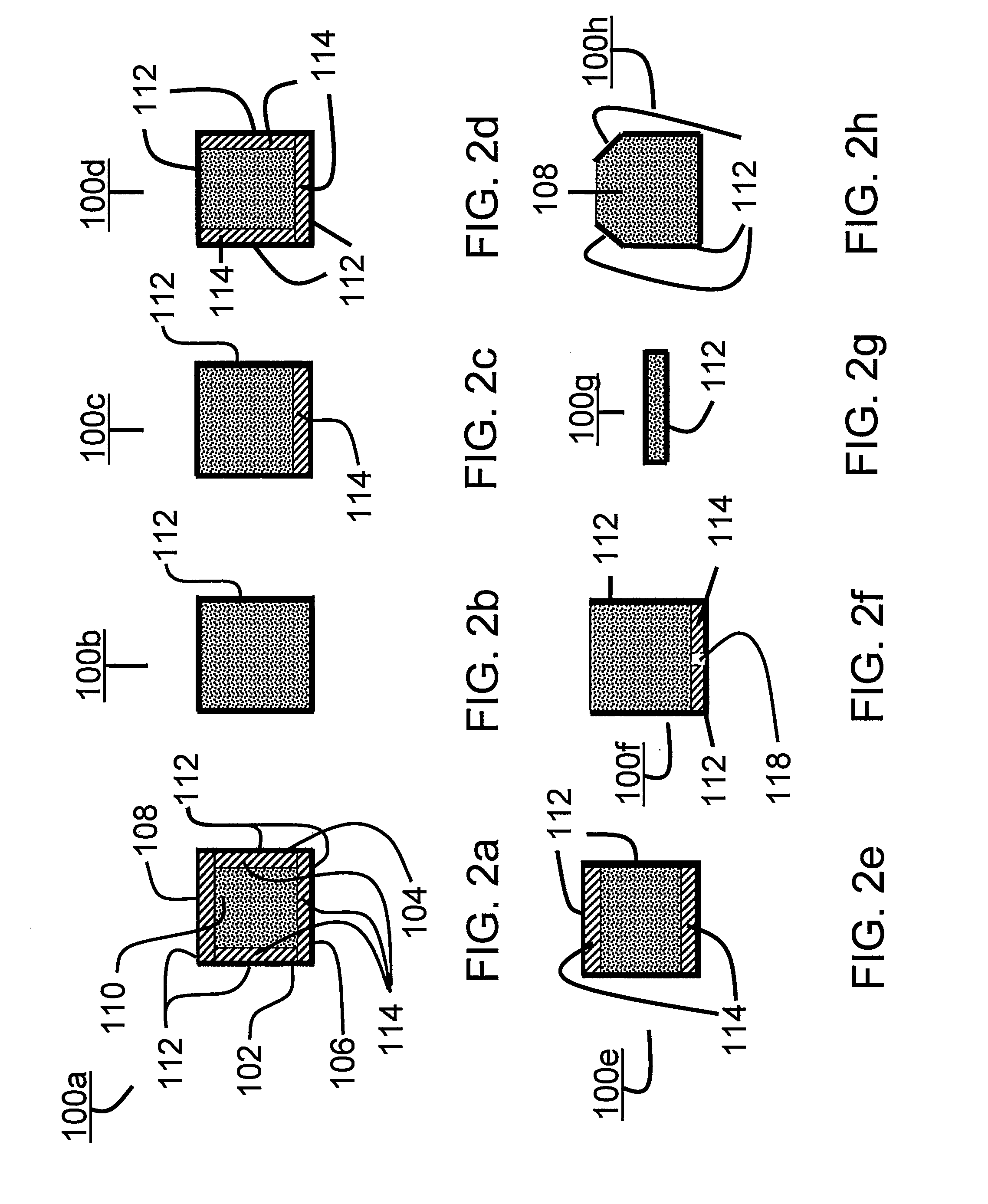

Encapsulated composit fibrous aerogel spacer assembly

An insulating spacer for creating a thermally insulating bridge between spaced apart panes of a multiple pane window unit comprises in one embodiment, a solid fiber-stabilized aerogel insulation material, hardened with a desiccant-impregnated hot melt adhesive. The spacer defines a thermally insulated space between the panes. Several embodiments of the insulating spacer of the present invention are disclosed. Insulated glass units using the disclosed insulating spacers and windows employing these insulated glass units have significantly better thermal performance than prior art insulated glass units and windows.

Owner:PACIFIC COAST BUILDING PRODS

Straw added fireproof high-density fiberboard and preparation method thereof

InactiveCN105082308AEliminate internal stressHigh bond strengthFlat articlesDomestic articlesScrapEmulsion

The invention discloses a straw added fireproof high-density fiberboard. The straw added fireproof high-density fiberboard is characterized by being composed of, by weight, 42-45 parts of crop straw, an appropriate amount of sodium hydroxide with the concentration being 2%, an appropriate amount of water, 1.5-2 parts of a silane coupling agent kh450, 66-70 parts of ethyl alcohol with the concentration being 95%, 30-32 parts of wood scraps, 4-6 parts of aluminum hydroxide, 2-3 parts of zinc borate, 7-8 parts of waterborne polyurethane adhesives, 1.5-2 parts of emulsion paraffin and 1-2 parts of pure acrylic emulsion. According to the straw added fireproof high-density fiberboard, while fibers are modified, the aluminum hydroxide, the zinc borate and other flame retardant components are added and attached to the surfaces of the fibers and in gaps, and the fireproof performance of the product is greatly improved. The straw added fireproof high-density fiberboard is simple and scientific in component matching, the technology is easy to industrially control, forming speed is high, and the manufactured fiberboard is good in waterproof and fireproof performance, uniform in density, free of deformation and suitable for application in the industries of furniture, building materials, packaging, decoration and the like.

Owner:ANHUI BAIYI FURNITURE

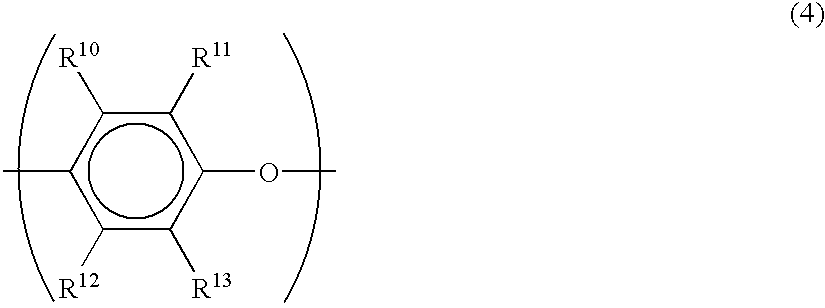

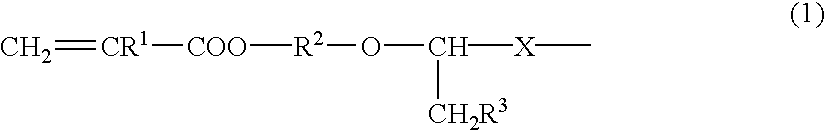

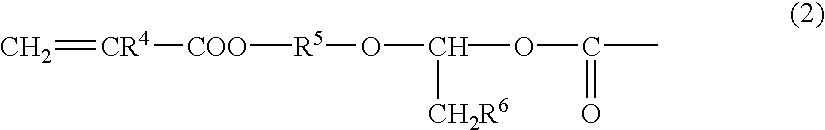

(Meth) acryloyl group-containing compound and method for producing the same

InactiveUS20030134926A1Improve film propertiesExcellent thermal decompositionImpression capsOrganic compound preparationVinyl etherMeth-

It is an object of the present invention to provide a compound having a (meth)acryloyl group that is suitably used in various applications, a process for producing such compound simply and under mild conditions, and an useful photo-curable composition and aqueous photo-curable composition comprising such compound. The present invention is related to a process for producing a compound having a (meth)acryloyl group which comprises reacting a compound having both a (meth) acryloyl group and a vinyl ether group with a compound having at least two functional groups capable of an addition reaction with said vinyl ether group, and to a compound having a (meth)acryloyl group which is obtained by an addition reaction of a functional group of a compound (A) having at least two functional groups and the vinyl ether group of a compound (B) having both a (meth)acryloyl group and a vinyl ether group, said functional groups of said compound (A) being selected from the group consisting of a hydroxyl group, a carboxyl group and a thiol group.

Owner:NIPPON SHOKUBAI CO LTD

Ecological sound-absorbing, sound-insulating and high-density fiberboard and preparation method thereof

InactiveCN105171884AHigh bonding strengthAvoid crackingDomestic articlesFlat articlesFiberPolyurethane adhesive

The invention discloses an ecological sound-absorbing, sound-insulating and high-density fiberboard. The ecological sound-absorbing, sound-insulating and high-density fiberboard is characterized by being prepared from, by weight, 42-45 parts of crop straw, a proper amount of sodium hydroxide with the concentration of 2%, 2-2.5 parts of silane coupling agents kh450, 66-70 parts of ethyl alcohol with the concentration of 95%, 30-32 parts of wood scraps, 7-8 parts of waterborne polyurethane adhesives, 1.5-2 parts of emulsified paraffin, a proper amount of water, 4-6 parts of zeolite molecular sieves, 2.5-3.5 parts of graphene, 5-7 parts of houttuynia cordata, 3-4 parts of complete flax plants and 1-2 parts of epoxidized soybean oil. The surfaces of the crop straw, wood scraps and other components used are properly processed on the basis of a traditional process, and a large number of forest resources can be saved. Meanwhile, the treating agents comprise the zeolite molecular sieves and the like and are matched with natural plant fibers to generate multi-pore components, so that the sound absorbing and insulation effects are enhanced. The product strength is high, quality stability is good, and the use range is wide.

Owner:ANHUI BAIYI FURNITURE

Waterproof and suncare straw wood composite high density fiberboard and preparation method thereof

InactiveCN104999539AImprove fusion effectImprove consistencyDomestic articlesFlat articlesFiberMethacrylate

The invention discloses a waterproof and suncare straw wood composite high density fiberboard. The waterproof and suncare straw wood composite high density fiberboard is characterized by being prepared by the following raw materials in parts by weight: 42-45 of crop straws, a proper amount of sodium hydroxide with a concentration of 2%, 2-2.5 of silane coupling agents kh450, 66-70 of ethanol with a concentration of 95%, 30-32 of wood leftovers, 3-4 of methyl sodium silicate, 3-5 of nanometer titanium dioxide, 7-8 of waterborne polyurethane adhesive, 1.5-2 of microcrystalline wax, 0.03-0.05 of ammonium persulfate, 2-3 of methacrylate, and a proper amount of water. The methyl sodium silicate is added when fibers are treated in the formula, the methacrylate, the microcrystalline wax and the like are added when the fibers are glued, and the raw materials coact to greatly enhance the product water resistance and to prevent the corrosion caused by water seepage; and meanwhile, the suncare nanometer titanium dioxide is added, so that the produced product can replace a plastic board or a wood board, or even can be used outdoors.

Owner:ANHUI BAIYI FURNITURE

Styrene-base wood-like material formula

The present invention relates to a styrene-base wood-like material formula, wherein the styrene-base wood-like material comprises, by weight, 100 parts of general purpose polystyrene, 20-40 parts of high impact resistance polystyrene (HIPS), 10-15 parts of a styrene butadiene rubber, 2-5 parts of an inorganic filling material, 0.5-1.5 parts of a foaming agent, 0.5-3 parts of a cell regulator, 0.2-0.5 part of an ultraviolet absorber, 0.5-3 parts of a lubricant, 0.4-0.7 part of a wood aroma agent, 0.7-1.3 parts of a dispersing agent, and 0.5-2 parts of a coloring agent. According to the present invention, compatibility between the main material and the auxiliary material is avoided, and the problems of large size difference, uneven distribution and the like of the cells in the traditional wood plastic wood-like material are solved so as to further improve water resistance and moisture resistance of the wood-like material, reduce material density and brittleness, improve mechanical strength and prolong a service life.

Owner:KOGEE OUTDOOR GRP

Stone plastic floor

InactiveCN103642148AImprove waterproof and moisture-proof performanceGuaranteed StrengthFlooringWear resistantEngineering

The invention provides a stone plastic floor with environmental protection and wear resistant performances, beauty and low cost, thereby solving many problems existed in stone and wood floor. The prepared floor contains PVC material, therefore the product has good waterproof and moistureproof performances, and the skid resistance is improved compared to common stone floor; the invention combines calcium powder and PVC, thereby keeping floor strength and simultaneously increasing floor toughness without fracture; simultaneously, waste heat extruded by an extruder is used for carrying out coating, and the coating effect is good, and the wear resistance of the present invention is improved; the floor prepared by the material has environmental protection effect without pollution. The sheet material provided by the invention not only can be used for floor, but also can be used for furniture, interior wall and exterior wall decoration materials, etc. with insect preventing, deformation preventing and other performances.

Owner:孔祥利

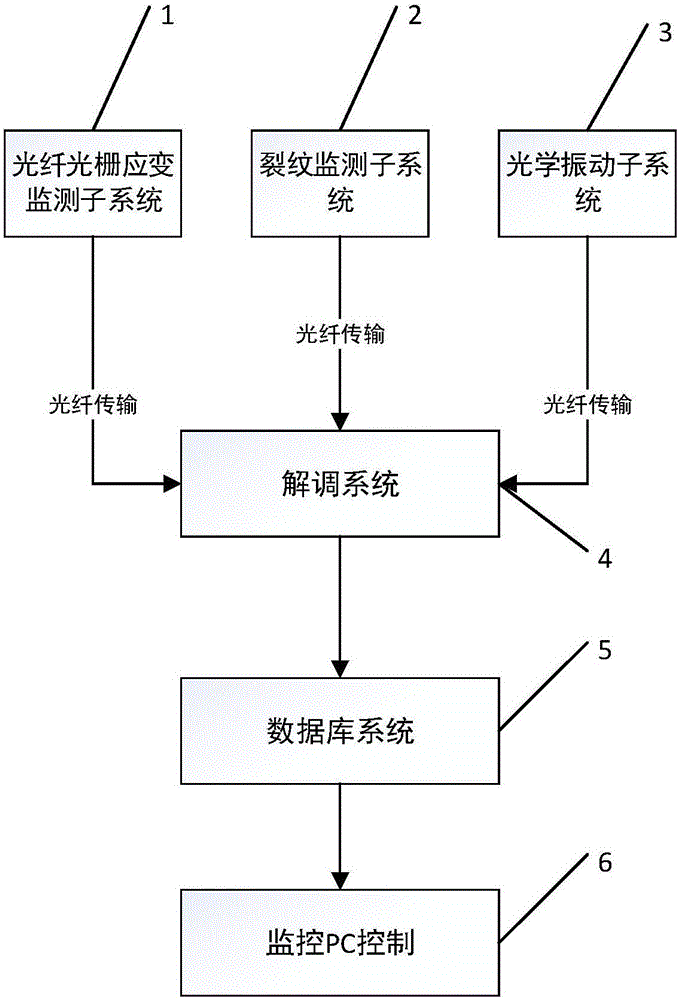

All-optical network ship lock miter gate health status monitoring system, and working method of system

ActiveCN106209223AFast transmissionImprove anti-interference abilityMeasurement devicesElectromagnetic receiversGratingMonitoring system

The invention discloses an all-optical network ship lock miter gate health status monitoring system, and a working method of the system. The monitoring system comprises an optical fiber grating strain monitoring sub-system, an optical fiber crack monitoring sub-system, an optical vibration monitoring sub-system, a demodulation system, a database management system, and a PC monitoring system. The system and the method provided by the invention have the advantages that optical fibers are used as a transmission medium, so that a high transmission rate, high anti-interference capability, and high stability and reliability in year-round operation are achieved, and power supply and loop forming are avoided; optical-electrical conversion of signals is only carried out after the signals enter the demodulation system, so that the waterproof and moisture-proof performances are greatly improved; the all-optical network system is constructed through a linear structure of sensors, the optical fibers, a demodulation device, network cables and a computer, so that the integration level is high, and uniform management, debugging and maintenance are facilitated; and through the system and the method, the safety and health statuses of a ship lock during the whole operation can be learned and understood in a real-time manner, and reasonable suggestions regarding ship lock overhauling and maintenance can be further provided.

Owner:DALIAN MARITIME UNIVERSITY

Aldehyde-free health decorative material and its preparation method

InactiveCN1836862AImprove waterproof and moisture-proof performanceImproved secondary processabilityWood working apparatusDomestic articlesFiberWood shavings

The present invention is no-aldehyde health decoration material and its production process. The no-aldehyde health decoration board is produced with no-aldehyde adhesive and at least one of bamboo / wood fiber, wood shavings, timber leftover and crop stalk through formaldehyde eliminating treatment. The technological process of producing the no-aldehyde health decoration board includes the steps of material treatment, mixing glue, applying glue, cold pressing to form blank, thermal pressing to settle and post-treatment. The no-aldehyde health decoration board has the advantages of no aldehyde, good moisture-proof and waterproof performance, good secondary machining performance and high stability, and is used in indoor decoration.

Owner:招燕萍

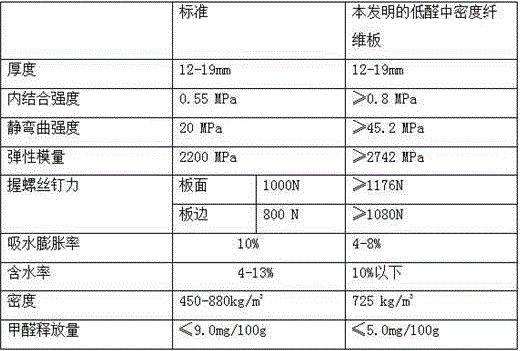

Method for producing low-formaldehyde medium-density fiberboard

ActiveCN105216086AImprove water resistanceGood alkali resistanceFlat articlesDomestic articlesEngineeringPulp and paper industry

The invention relates to a method for producing a low-formaldehyde medium-density fiberboard and belongs to the technical field of wood resource utilization. The method for producing the low-formaldehyde medium-density fiberboard comprises the technological steps of raw material slicing, impurity-removal and screening, boiling, waxing and hot grinding, gluing and drying, mat formation and hot pressing, and finished product obtaining. According to the method, residues, such as battens and waste veneer, generated during wood processing are used for producing the low-formaldehyde medium-density fiberboard, waste materials are recycled, and full utilization of wood resources is effectively achieved; the formaldehyde residual volume of low-formaldehyde urea formaldehyde resin adhesive used for producing the medium-density fiberboard is low, in this way, harm to the health of human bodies is reduced, and the bonding force is high; in addition, the fiberboard has good damp-proof performance and good water-proof performance, the internal structure of the board is uniform, the density is proper, the dimensional stability is high, the quality is stable, and the service life is long.

Owner:霸州市郭仕智能家居科技有限公司

High-performance wind-power generating facility coating prepared by taking organic fluorinated silicone modified elastic polyurethane-urea resin as substrate

InactiveCN101665655AHigh tensile strengthHigh resistivityPolyurea/polyurethane coatingsUreaWeather resistance

The invention discloses high-performance wind-power generating facility coating prepared by taking organic fluorinated silicone modified elastic polyurethane-urea resin as substrate. The high-performance wind-power generating facility coating is prepared from component A and component B according to proportion. The wind-power generating facility coating has toughness, attrition resistance, high elasticity, excellent mechanical property, yellowing resistance, good colour retention, high ultraviolet resistance, high weather resistance, favorable and excellent electrical insulation, chemical stability, moisture resistance and freeze resistance. In addition, the wind-power generating facility coating has high performance and moderate cost and can strongly protect the wind-power generating facility, reduce the maintenance frequency and lower the purchasing cost of the wind-power generating facility, thereby having extremely high implementation value and social and economic benefit.

Owner:西北永新涂料有限公司 +1

Wood reinforcement modification treatment agent for outdoor wood floor

ActiveCN104057507AImprove mechanical propertiesGood dimensional stabilityWood impregnation detailsFiberMoisture resistance

The invention relates to the field of wood modification treatment of wood floors, and particularly relates to a wood reinforcement modification treatment agent for an outdoor wood floor. The wood reinforcement modification treatment agent is prepared from the following raw materials in parts by weight: 10-12 parts by weight of silicone acrylic emulsion with a solid content of 50 percent, 4-5 parts by weight of 5-aminolevulinic acid, 12-15 parts by weight of tartaric acid, 0.01-0.02 part by weight of capsaicine, 1-2 parts by weight of azedarach, 15-18 parts by weight of white wine, 10-12 parts by weight of furfuryl alcohol, 25-28 parts by weight of urea, 4-5 parts by weight of borax, 5-6 parts by weight of polyether modified silicone oil, 2-3 parts by weight of sodium dodecyl benzene sulfonate, 350-380 parts by weight of water and 6-8 parts by weight of additive. According to the modification agent prepared by adopting the invention, active ingredients in the azedarach are simply and efficiently extracted, and raw materials such as the silicone acrylic emulsion, the furfuryl alcohol and the capsaicine are introduced, so that the prepared modification treatment agent is adsorbed and combined with wood fibers after penetrating into the wood, thus the mechanical property is improved, the size stability is good, the compressive strength is improved, the dewatering and the moisture resistance are prevented, the weather and ageing resistance are resisted, and microorganisms are difficult to propagate; the wood reinforcement modification treatment agent is especially suitable for making a wood floor for an outdoor environment, is more durable, and is strong in market competitiveness.

Owner:定远县林能木业有限责任公司

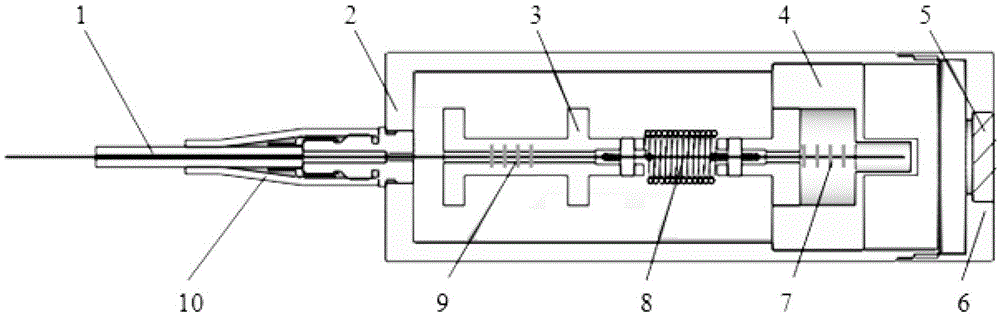

Fiber type osmotic pressure sensor with fine-tuning device and automatic temperature compensation

ActiveCN105606296AImprove anti-interference abilityHigh sensitivityFluid pressure measurement by optical meansGratingFiber type

The present invention discloses a fiber type osmotic pressure sensor with a fine-tuning device and automatic temperature compensation. The device comprises a protection shell and a permeable stone housing. The protection shell is equipped with a fiber fixed substrate. One end of the fiber fixed substrate is a rigid structure, and the other end of the fiber fixed substrate is an elastic structure. A temperature optical fiber is fixed at one end of the rigid structure, a pressure fiber grating is fixed at one end of the elastic structure, the connection part of the fiber fixed substrate and the pressure fiber grating is equipped with an elastic adjustment device, and the external part of the pressure fiber grating is the elastic film of the tail end of the fiber fixed substrate. The fiber type osmotic pressure sensor has the advantages of strong anti-interference ability, high sensitivity, high precision and stable performance, the automatic temperature compensation can be achieved, and the temperature and liquid pressure can be measured at the same time. The linear performance of the elastic film is good, good deformation can be generated under small pressure, and the sensitivity is excellent. The fiber type osmotic pressure sensor has a good protection structure and good waterproof and moisture-proof performance and can be applied to a harsh environment.

Owner:NANJING NARI GROUP CORP +1

Method for producing antiseptic oriented strand board through full-eucalyptus leftover materials

InactiveCN106239689AWhite colorGood film formingWood veneer joiningDomestic articlesDusting powdersOptoelectronics

The invention provides a method for producing an antiseptic oriented strand board through full-eucalyptus leftover materials. The method comprises the procedures of material preparing, drying, peel and impurity removing, sorting and storing, surface layer and core layer gluing, classified paving, preheating press forming, sanding facing and the like. A surface layer is coated with an isocyanate wood dust powder composite adhesive, a core layer is coated with an antiseptic composite urea-formaldehyde resin adhesive, and core layer wood shavings are of three-layer structures including a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and the surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction ranges from 34 MPa to 38 MPa, and the parallel elasticity modulus ranges from 4,610 MPa to 4,780 MPa; and the vertical elasticity modulus ranges from 1,500 MPa to 1,774 MPa, the water absorption thickness swelling rate in 24 h ranges from 11% to 16%, and the vertical nail holding force reaches up to 89,000 N. Meanwhile, through adding of an antiseptic agent, the problem that panels are prone to suffering from corrosion of wood-destroying fungi, moulds and white ants is thoroughly solved, and the service life of the panels is prolonged.

Owner:广西横县新威林板业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com