Patents

Literature

111results about How to "Self-adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Two-component sealing silica gel with low viscosity and high thermal conductivity and preparation method theref

InactiveCN101962528AEasy to moveGuarantee job stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer scienceAdhesive

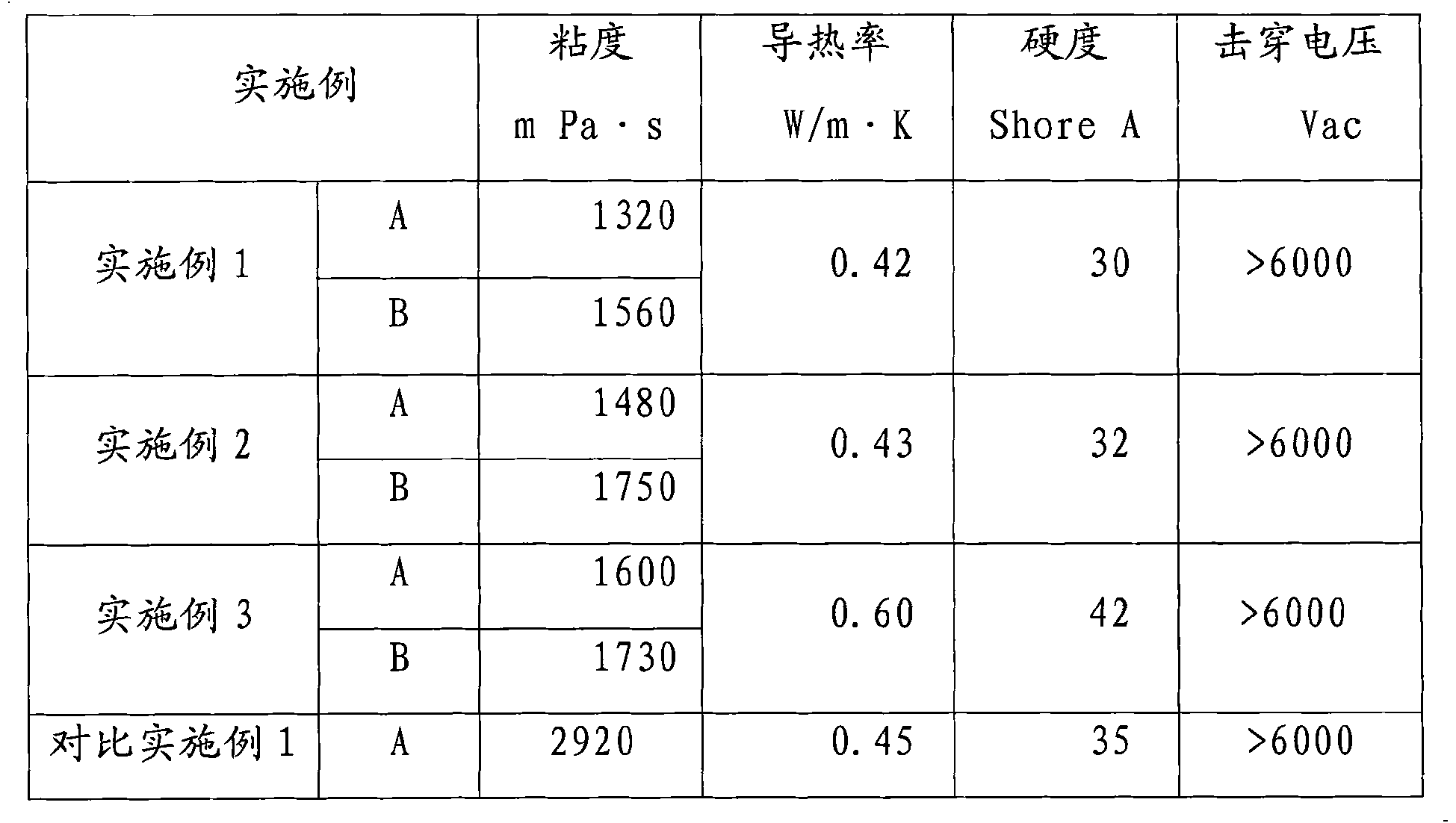

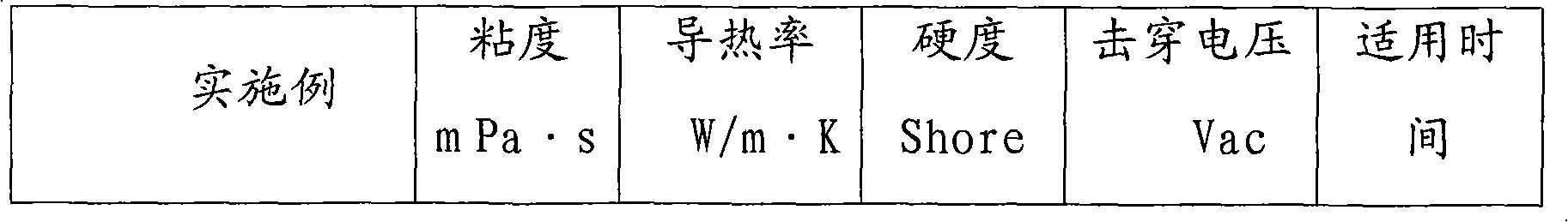

The invention relates to a two-component sealing adhesive with low viscosity and high thermal conductivity and a preparation method thereof. The two-component sealing adhesive consists of a component A and a component B in a weight ratio of 100:80-100:125, wherein the component A comprises the following raw materials by weight percent: 40.00%-90.00% of thermal conductive powder, 4.50%-50.00% of low-viscosity liquid silicone oil, 0.50%-10.00% of silicane curing agent and 0.00-5.00% of toner; and the component B comprises the following raw materials by weight percent: 40.00%-90.00% of thermal conductive material, 9.50%-54.00% of low-viscosity liquid silicone oil, 0.04%-1.00% of catalyst and 0.00-5.00% of toner. The preparation method comprises the following steps: weighting all the raw materials according to the weight persentages to prepare the component A and the component B; and when in use, mixing the component A and the component B evenly in a weight ratio of 100:80-100:125, and curing to obtain the sealing adhesive of the invention.

Owner:YANTAI DARBOND TECH

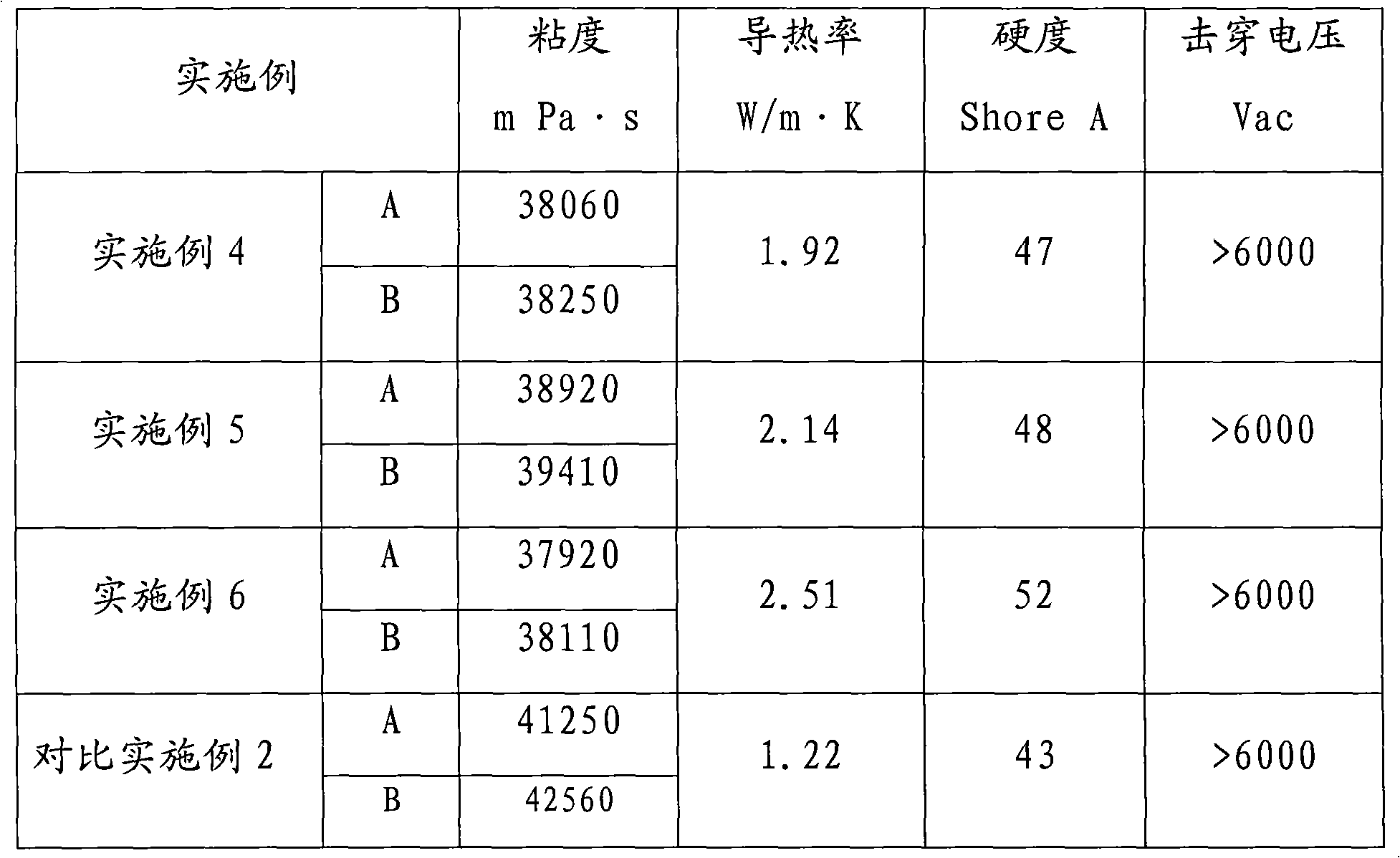

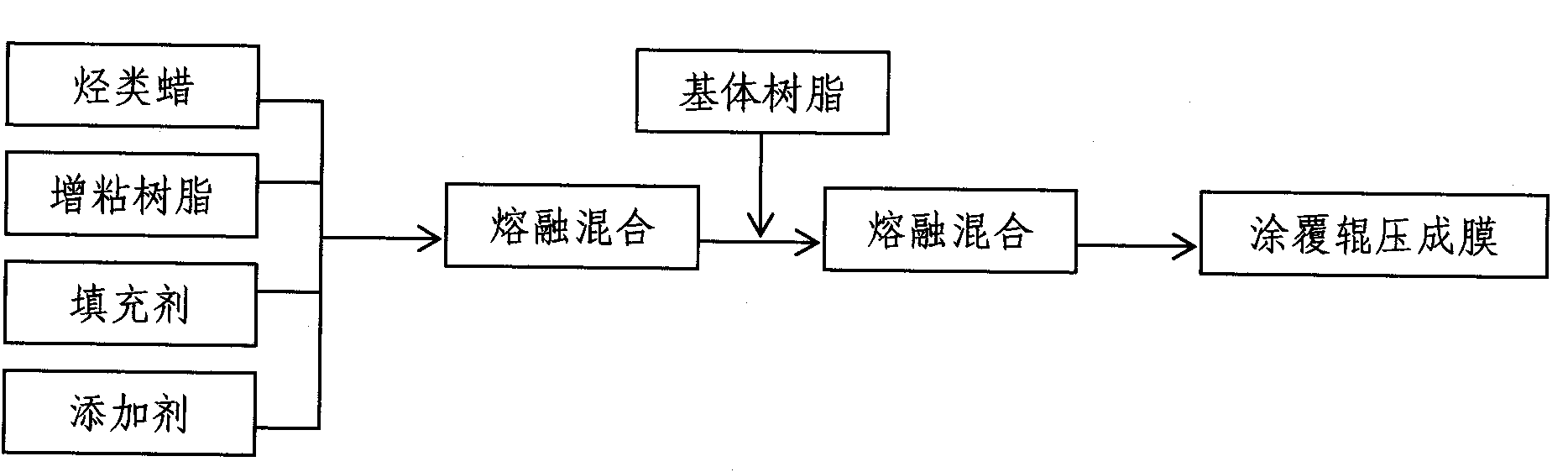

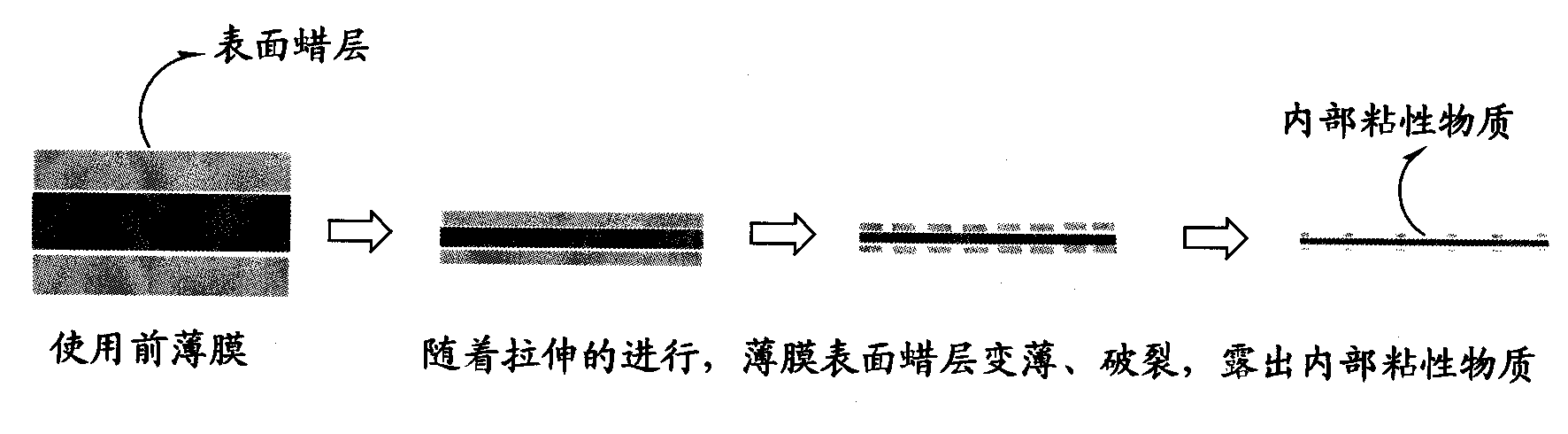

Thermoplastic elastic self-sealing film and preparation method thereof

The invention discloses a thermoplastic elastic self-sealing film and a preparation method thereof. The film is mainly prepared from the following components in part by weight: 100 parts of matrix resin, 100 to 140 parts of wax, 10 to 100 parts of thickening agent and 1 to 30 parts of filler. The preparation method comprises the following steps of: fusing and mixing the components except the matrix resin in a ratio; adding the matrix resin, and performing fusing and mixing; and delivering the obtained melt to a hot melt T-shaped crack die head for coating, rolling and forming the film. The thermoplastic elastic self-sealing film has the advantages of no stickiness on the original surface of the film, easy packaging and transporting, no stickiness to hands, and ideal permeability and resilience; and the preparation process is simple and easy to operate.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

Reactive self-adhered ethylene-propylene-diene monomer waterproof roll

ActiveCN104017512ASelf-adhesiveSelf-healingNon-macromolecular adhesive additivesFilm/foil adhesivesPolyethylene terephthalate glycolWear resistant

The invention relates to a reactive self-adhered ethylene-propylene-diene monomer waterproof roll which consists of a surface waterproof layer, a middle self-adhering layer and a bottom isolating layer, wherein the surface waterproof layer is formed by co-mixing ethylene-propylene-diene monomer rubber, zinc oxide, sulfur, stearic acid, highly wear-resistant carbon black, processing oil and an accelerator DM, the middle self-adhering layer is an active self-adhered sizing material which is formed by co-mixing asphalt, a softener, a tackifier, butyl rubber IIR (Isobutylene-Isoprene Rubber), butadiene styrene rubber, an activator and filler, and the bottom isolating layer is a PET (Polyethylene Terephthalate) thin film. As the middle self-adhering layer which contains asphalt and active macromolecular active components and has the active reactive self-adhered sizing material is arranged in the upper layer on the inner surface of the surface waterproof layer which takes ethylene-propylene-diene monomer as a main material, so that edges of the roll and the roll and the base layer of concrete are directly adhered by the middle self-adhering layer without any adhesives in match. The generated waterproof layer has a service life effect which is equal to that of a main body material, so that the roll is an ideal upgrading product of existing single ethylene-propylene-diene monomer waterproof roll.

Owner:上海北新月皇新材料集团有限公司

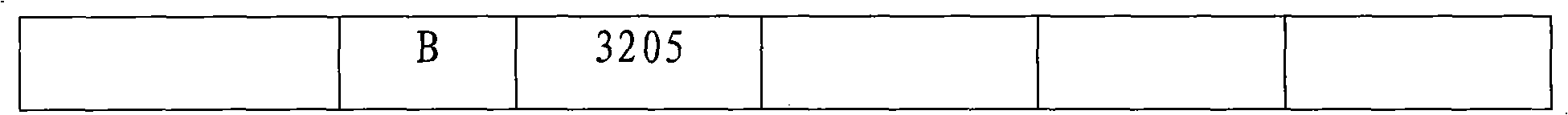

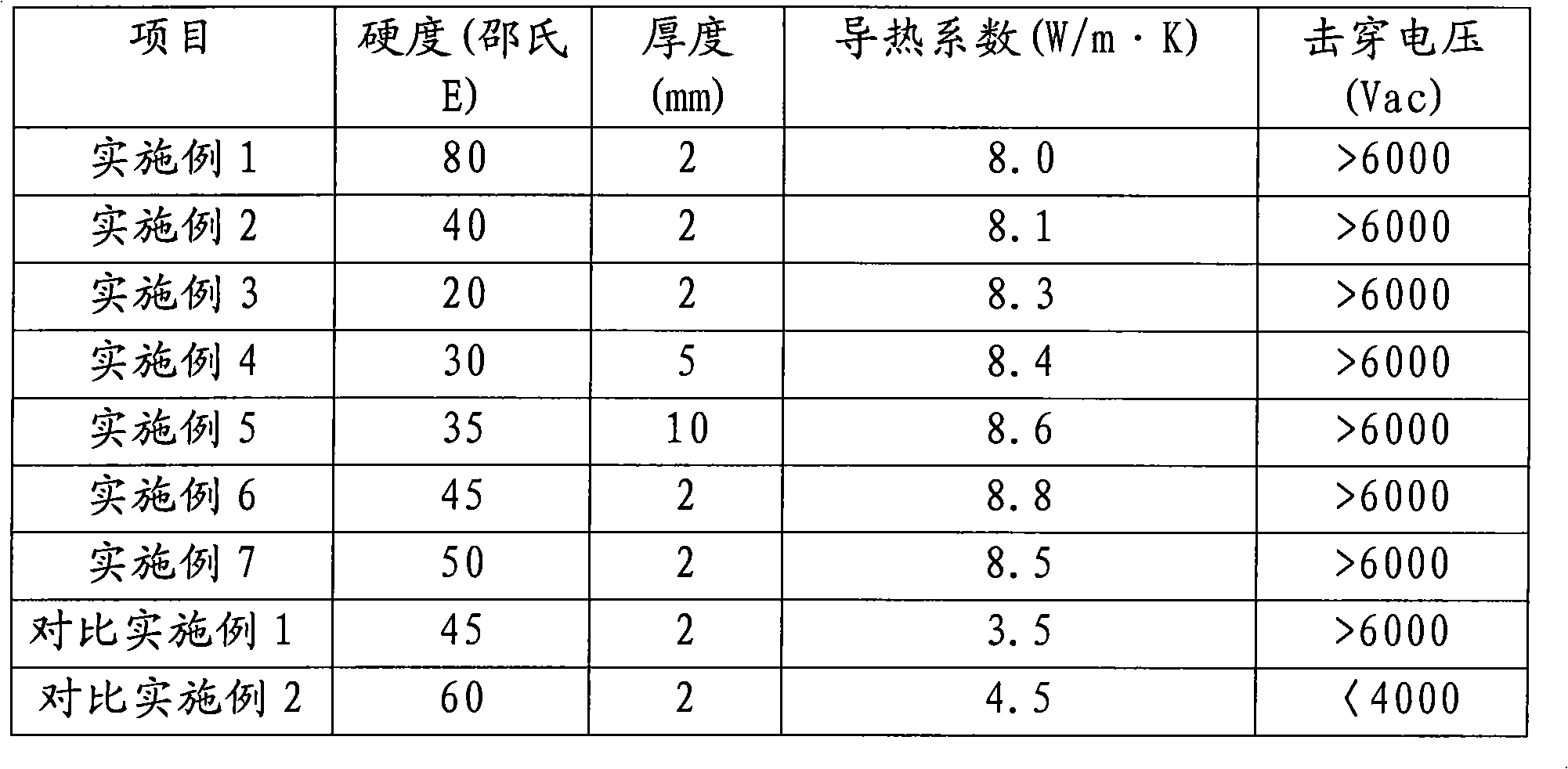

Macromolecule thermal-conducting composite material and preparation method thereof

InactiveCN101921489AGood thermal conductivity performanceLow costHeat-exchange elementsPolyresinRaw material

The invention relates to a macromolecule thermal-conducting composite material and a preparation method thereof. The macromolecule thermal-conducting composite material comprises two parts of matrix resin and a heat conductive filler with the weight proportion of 100:700-110:1100. The matrix resin comprises the following raw materials in percentage by weight: 95-99 percent of organic silicon resin, 1-4 percent of curing agent and 0.1-1 percent of catalyst; and the heat conductive filler comprises the following raw materials in percentage by weight: 70-95 percent of spherical filler and 5-30 percent of needle-like filler. The preparation method comprises the steps of: sequentially adding the organic silicon resin, the curing agent and the catalyst into a mixer, mixing to obtain the matrix resin; then mixing the matrix resin with the heat conductive filler by the proportion of 100:700-100:1100, wherein in the process of the heat conductive filler addition, 70-95 percent of the spherical filler is added firstly and the 5-30 percent of needle-like filler is added subsequently; and stirring for mixing, smearing to form a film, and curing to obtain the composite material.

Owner:YANTAI DARBOND TECH

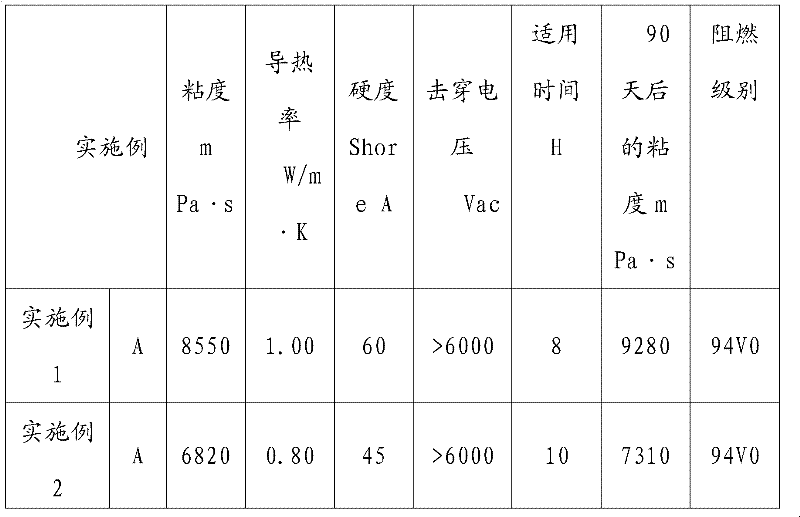

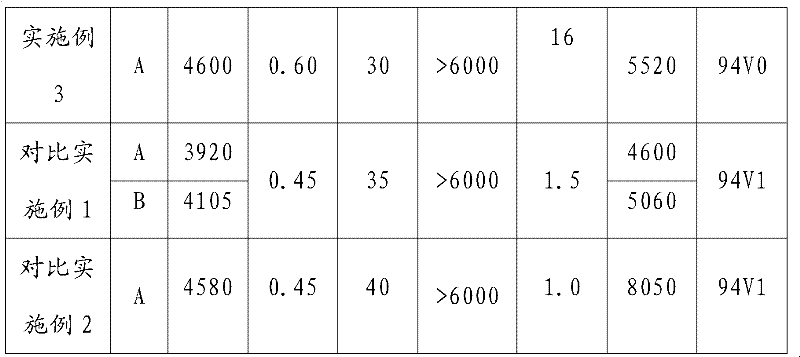

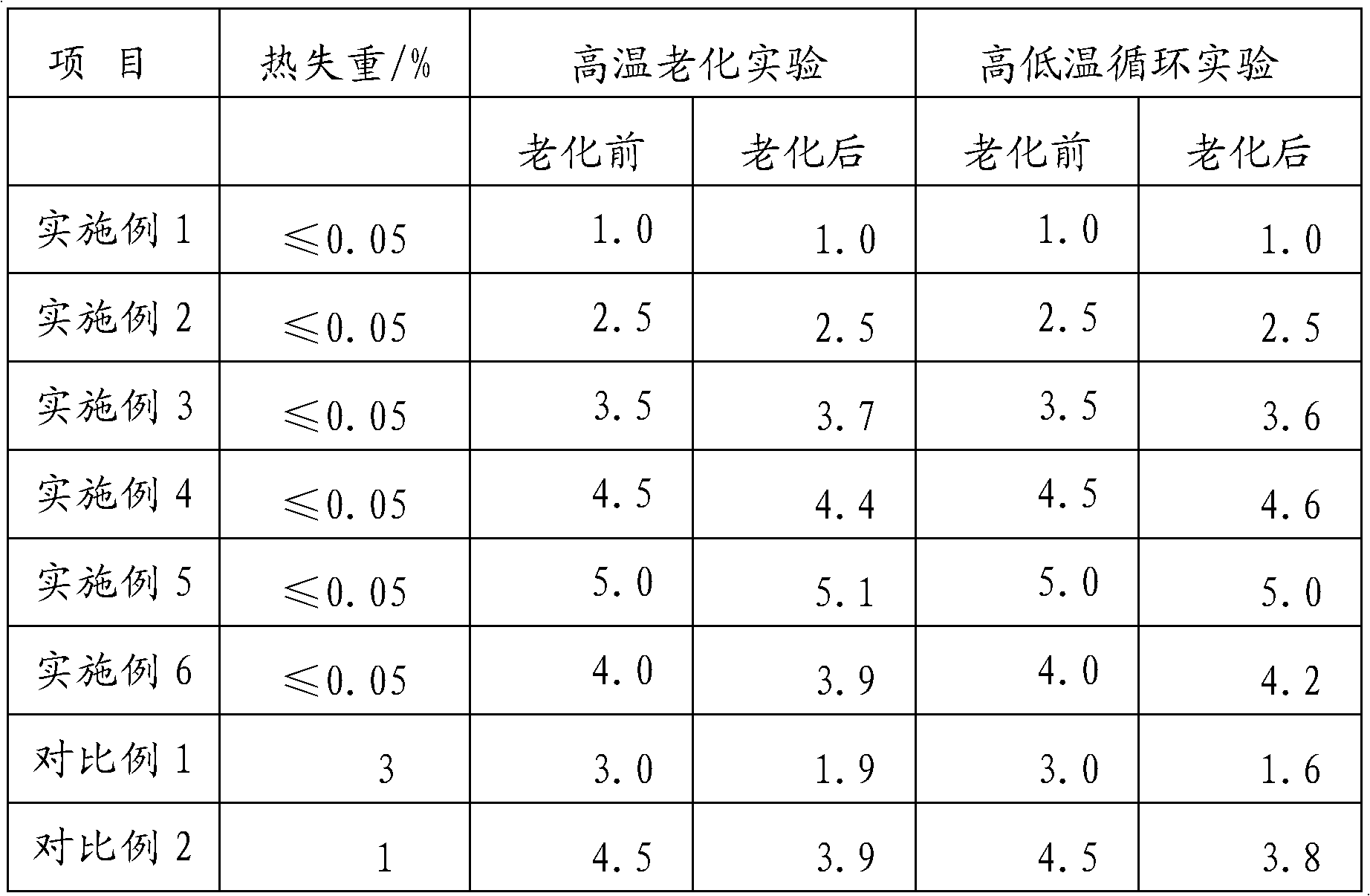

High temperature curing monocomponent heat-conduction flame-retardation electronic pouring sealant and preparation method thereof

InactiveCN102516930AWill not polluteImprove temperature resistanceNon-macromolecular adhesive additivesOther chemical processesViscous liquidSilica gel

The invention relates to a high temperature curing monocomponent heat-conduction flame-retardation electronic pouring sealant and a preparation method thereof. The preparation method concretely comprises the following steps: 1, sequentially adding liquid silicon oil, a silane crosslinking agent, a microcapsule type catalyst, a toner, and heat-conduction flame-retardation powder to a stirring machine, and stirring for 0.2-1h to obtain a viscous liquid; and 2, stirring the viscous liquid obtained in step 1 for 2-3h under conditions that the vacuum degree is -0.08MPa--0.1MPa to obtain the high temperature curing monocomponent heat-conduction flame-retardation electronic pouring sealant. The high temperature curing monocomponent heat-conduction flame-retardation electronic pouring sealant of the invention has the advantages of enough long operation time, waste phenomenon reduction, solution of a bubble problem generated by mixing in the two-component silica gel applying process, and construction convenience.

Owner:YANTAI DARBOND TECH

Polylactic acid self-curled and self-bonded composite cigarette tow and preparation method thereof

InactiveCN108642601AAvoid mechanical propertiesAvoid heat damageTobacco smoke filtersArtificial filament heat treatmentPlasticizerSingle fiber

The invention discloses a polylactic acid self-curled and self-bonded composite cigarette tow and a preparation method thereof. The preparation method comprises the following steps: drying polylacticresin; adding a spinning assistant for the polylactic resin into conventional polylactic resin, adding the spinning assistant to polylactic resin containing a plasticizer, and performing melting plasticization to obtain a polylactic resin melt; spraying the melt from a spinneret hole to form single composite fibers; cooling a polylactic acid two-component cigarette tow; oiling the two-component tow, and carrying out drafting and tension heat setting to obtain the polylactic acid self-curled and self-bonded composite cigarette tow. The single fibers in the tow is one of a side-by-side, orange-slice, sheath-core and sea-island composite structures, one of the components of the side-by-side type or the orange-slice type structure is the polylactic resin containing the plasticizer, and the remaining component is the conventional polylactic resin and a composition thereof. The preparation method has the advantages of simplification of the production process, avoiding of mechanical and thermal damages, increase of the rod yield of the polylactic fiber tow, and reduction of the production cost; and the polylactic acid self-curled and self-bonded composite cigarette tow has a good biodegradability.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

Moulded-in-place high molecular thermal conductive composite material and preparation method thereof

InactiveCN101985519AImprove performanceImprove high temperature resistanceHeat-exchange elementsPolyresinMaterials science

The invention relates to a moulded-in-place high molecular thermal conductive composite material and a preparation method thereof. The thermal conductive composite material consists of a base resin and a thermal conductive filler in a weight ratio of 100:300-100:1,100, wherein the base resin consists of the following raw materials in percentage by weight: 95 to 99 percent of organic silicone resin, 1 to 4 percent of curing agent, 0.1 to 1 percent of catalyst and 0.01 to 0.1 percent of stabilizing agent; and the thermal conductive filler consists of the following components in percentage by weight: 70 to 100 percent of spherical filler A and 0 to 30 percent of filler B. The method comprises the following steps of: sequentially adding the organic silicone resin, the curing agent, the catalyst and the stabilizing agent into a stirrer, uniformly blending the raw materials to obtain the base resin, and blending the base resin and the thermal conductive filler in the weight ratio of 100:300-100:1,100, wherein the thermal conductive filler is prepared by uniformly stirring 70 to 100 percent of spherical filler A and 0 to 30 percent of filler B; and uniformly stirring, vacuumizing, defoaming and packing the mixture to obtain the moulded-in-place high molecular thermal conductive composite material.

Owner:YANTAI DARBOND TECH

High-temperature cured two-component pouring sealant and preparation method thereof

InactiveCN102093838AEasy to moveApplicable for a long timeNon-macromolecular adhesive additivesOther chemical processesHeat conductingSealant

The invention relates to a high-temperature cured two-component pouring sealant and a preparation method thereof, and the heat-conducting pouring sealant is prepared by an A component and a B component according to the weight ratio of 100: 80-100: 125, wherein the A component comprises the following raw materials by weight percent: 45.00%-85.00% of heat-conducting powder, 14.00%-50.00% of low-viscosity liquid silicon oil, 0.15%-15.00% of silane curing agent, 0.005-0.02% of inhibitor, and 0.00-5.00% of color toner; and the B component comprises the following raw materials by weight percent: 45.00%-85.00% of heat-conducting material, 14.00%-55.00% of the low-viscosity liquid silicon oil, 0.04%-1.00% of catalyst and 0.00-5.00% of the color toner. The preparation method of the heat-conducting pouring sealant comprises the following steps: respectively preparing the A component and the B component, uniformly mixing the A component with the B component according to the weight ratio of 100: 80-100: 125 during the use, and heating and curing for 2 hours at the temperature of 60-80 DEG C for preparation.

Owner:YANTAI DARBOND TECH

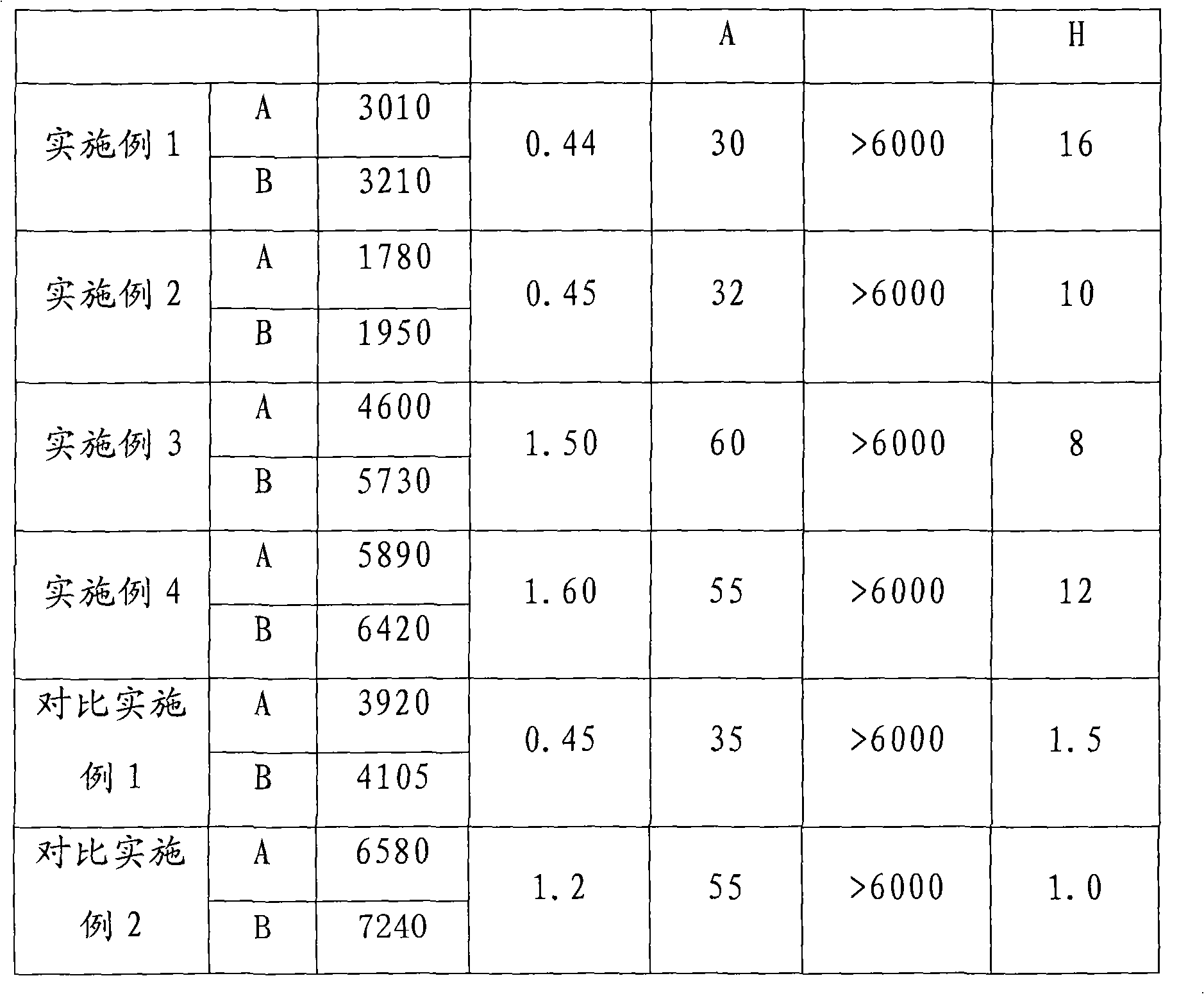

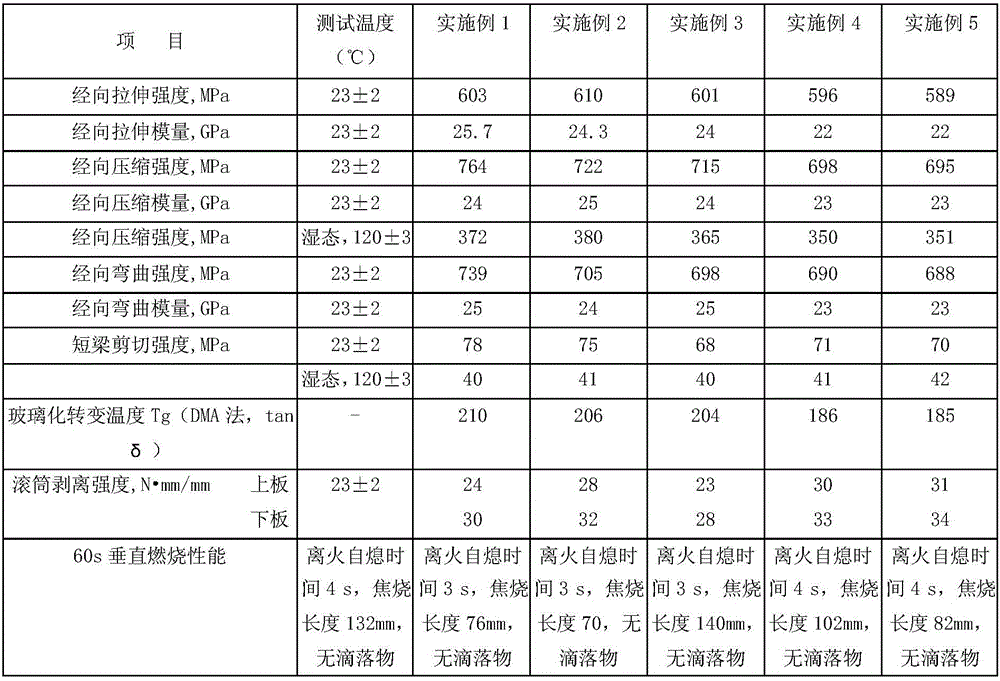

Flame-retardant and heat-resistant epoxy resin for self-adhesive prepreg

InactiveCN106046680AHeat resistantHeat-resistant epoxy resin also has the ability to cure at medium temperatureEpoxyVitrification

The invention belongs to the technical field of preparation of prepreg, and particularly relates to a flame-retardant and heat-resistant epoxy resin for self-adhesive prepreg. The resin for the prepreg consists of an epoxy resin mixture component A and a curing agent mixture component B. The epoxy resin mixture component A accounts for 50-80 parts by weight of the resin, and the curing agent mixture component B accounts for 10-40 parts by weight of the resin. The prepreg is prepared by a hot melt adhesive dipping reinforcing material of a composition; a composite material is formed by the prepreg. The viscosity of the prepreg is moderate, and the processability is good; the storage time at the normal temperature is 3 months. The prepreg can be cured completely within 2 hours at the temperature of 135 DEG C. The glass-transition temperature of the cured composite material is 180-210 DEG C; heat resistance and flame retardance of the composite material are good. The resin for the hot melting prepreg provided by the invention has been toughened and modified, the self-adhesive property of the prepreg is good, honeycombs can be adhered directly, adhesive films are not required, the process can be simplified, and the weight can be reduced.

Owner:AVIC COMPOSITES

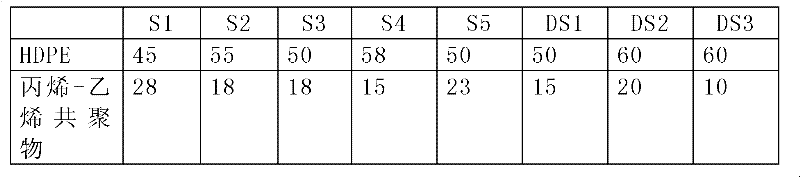

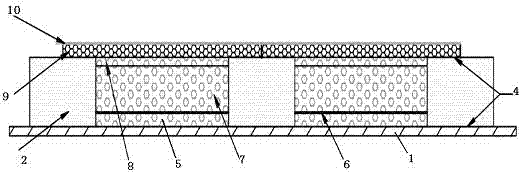

First-aid dressing used for traumatic wounds in cold area and preparation method of dressing

InactiveCN102755664AEasy to carryEasy way to treat woundsAntibacterial agentsAntipyreticTraumatic woundDressing change

The invention relates to a first-aid dressing used for traumatic wounds in a cold area and a preparation method of the dressing. The first-aid dressing comprises a medicinal film protective layer, a medicinal film layer, a heating layer, a back lining layer and a heating protective layer which are arranged in sequence; and the first-aid dressing can reach a heating temperature of 28 to 38 DEG C within 1-2 hours and can heat continuously for 4-6 hours. The first-aid dressing is prepared by the following steps: 1, preparing traditional Chinese extract and a matrix, and mixing to obtain a medicinal film plaster; 2, preparing heating material, bagging to obtain the heating layer; 3, preparing the heating protective layer and the back lining layer; and 4, preparing the first-aid dressing, packaging and disinfecting. The first-aid dressing can be used for pre-hospital first aid of a wounded person, can cover and protect the wound from further being infected, can enable the medicinal layer to reach a higher temperature through the internal heating material even in a cold area with a lower temperature, has a long time of curative effect, greatly reduces the dressing change frequency and shortens treatment cycle, facilitates disinfection and sterilization more, and alleviates the pains of the wounded person.

Owner:HENAN UNIV OF SCI & TECH

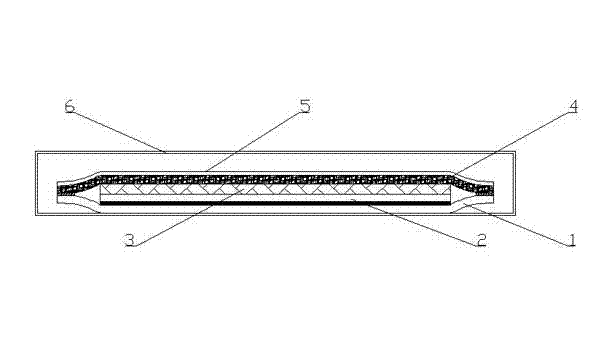

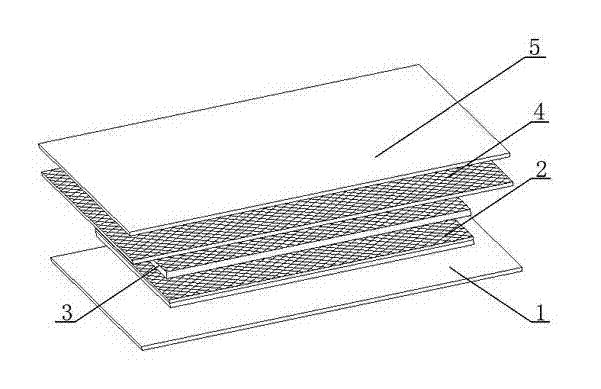

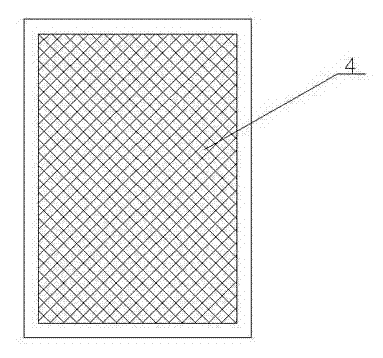

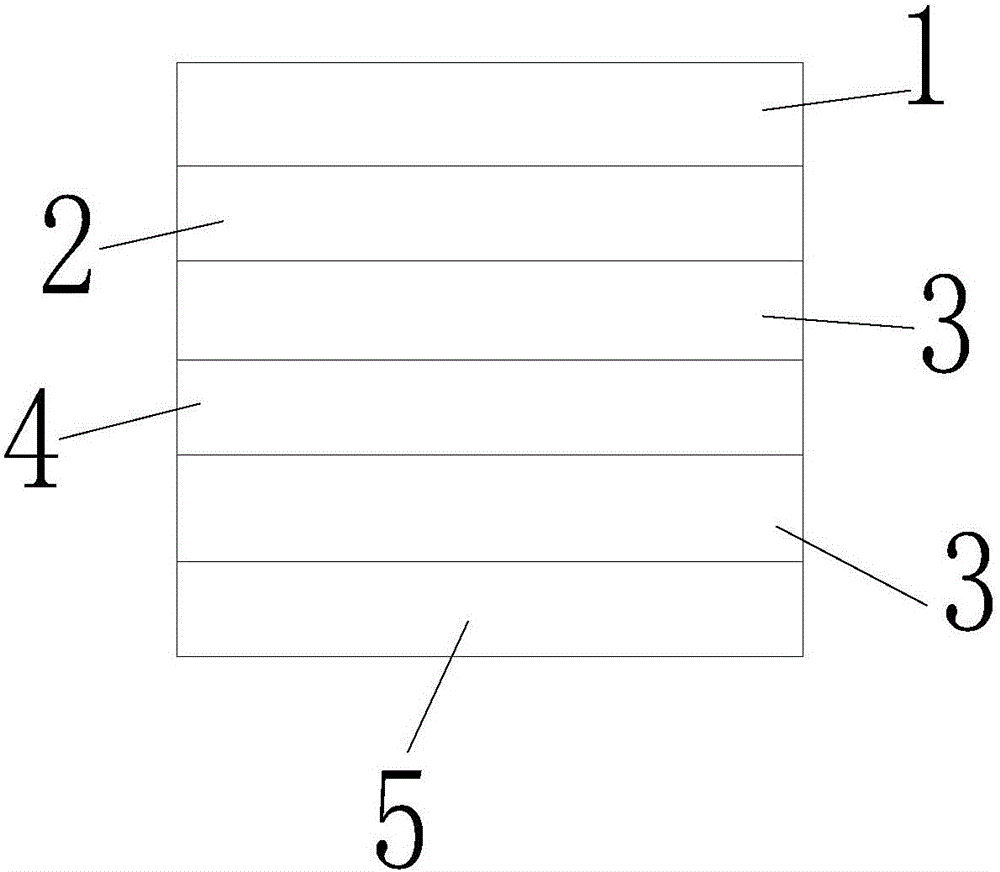

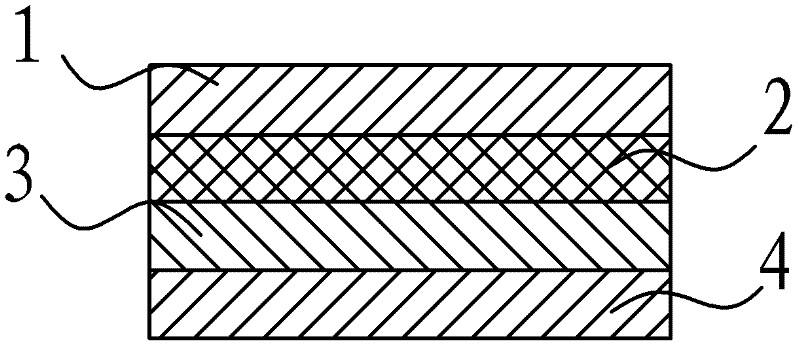

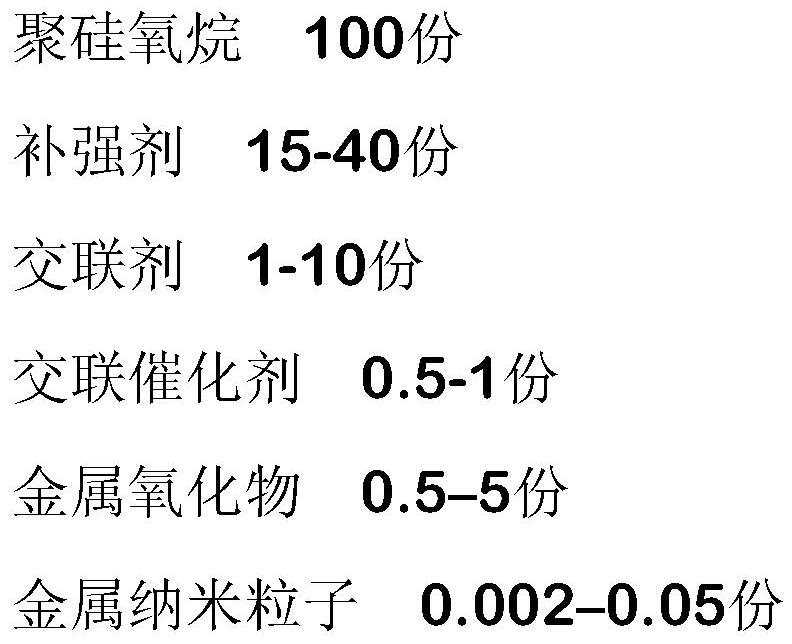

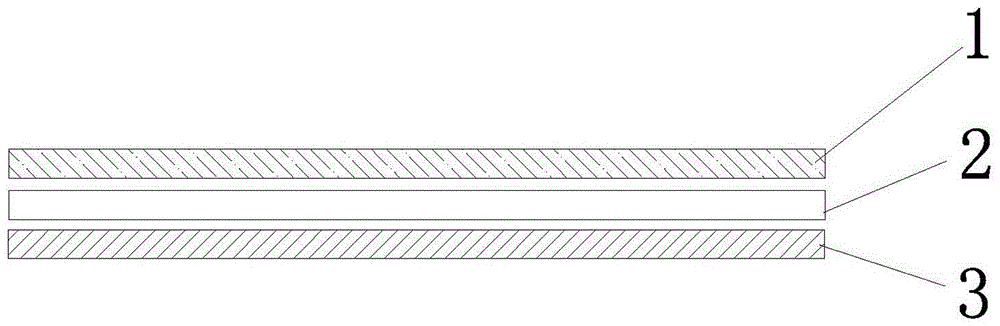

Self-adhesive type ceramic composite belt and preparation method thereof

InactiveCN104476861ASelf-adhesiveImprove sealingSynthetic resin layered productsInsulated cablesCeramic compositePlatinum complex

The invention discloses a self-adhesive type ceramic composite belt. The self-adhesive type ceramic composite belt comprises a self-adhesive ceramic glue layer, a reinforcing layer and an isolating layer, wherein the reinforcing layer and the isolating layer are respectively positioned at the two sides of the self-adhesive ceramic glue layer; the self-adhesive ceramic glue layer and the reinforcing layer are fixed together; the self-adhesive ceramic glue layer is prepared from the following components in parts by weight: 60-100 parts of silicon rubber, 20-100 parts of white carbon black, 20-120 parts of ceramic powder, 1-20 parts of one or more of boric acid, boric anhydride, borate, polyborosiloxane or a boron-containing polymer, 1-20 parts of silicone oil, 0.00001-10 parts of platinum complex and / or platinum compounds, and 0.1-10 parts of a coupling agent. The self-adhesive type ceramic composite belt disclosed by the invention has self-adhesion, is mutually lapped and adhered during winding to achieve good sealing effects, has good moisture-proof and waterproof performances; during production, an isolating film is only needed to be added when the composite belt product is rolled, so that the process is simple and the production is easy.

Owner:常州市沃科科技有限公司

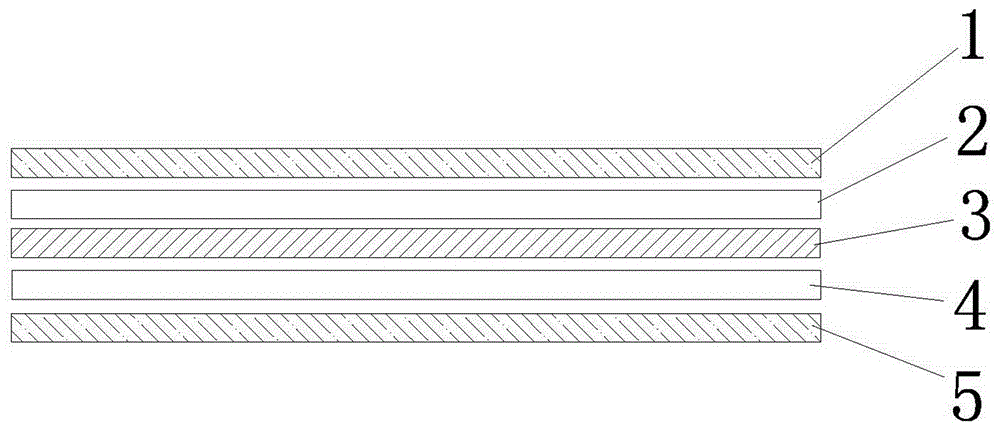

Adhesive tape used as shielding cover and application of adhesive tape

InactiveCN106010338AReduce surface resistancePlay a cooling effectMagnetic/electric field screeningFilm/foil adhesivesConductive coatingOxidation resistant

The invention discloses adhesive tape used as a shielding cover and application of the adhesive tape. When used as the shielding cover, the adhesive tape is excellent in shielding effect, thin and light. The adhesive tape comprises a release layer, a conductive adhesive layer, a fiber layer, a conductive adhesive layer, a conductive base body layer and an anti-oxidization conductive coating which are sequentially connected. The thickness of the adhesive tape is 0.03-0.3 mm. The conductive base body layer is a copper foil layer, an aluminum foil layer, a conductive fabric layer or a stainless steel layer. The thickness of the conductive base body layer is 0.005-0.25 mm. The adhesive tape can achieve electricity conductivity, shielding, grounding, anti-oxidization, heat conductivity and the like at the same time.

Owner:昆山汉品电子有限公司

Inorganic binder employing waste glass

InactiveCN1337927ASelf-adhesiveCovering/liningsCeramic shaping apparatusArtificial stoneSodium silicate

The present invention relates to a binder composition comprising a glass powder with a particle size of at least less than 0.15 mm and an alkali activator containing at least one alkali metal and at least one silicate. Preferably, a sodium silicate with a SiO2:Na2O weight ratio between about 1.6:1 to about 2.0:1. Mixed with water, the binder composition can be cured at ambient temperature, but rapidly yields a very high strength at an elevated temperature between about 40° C. to about 120° C. Preferably, between about 70° C. to about 90° C. The invention further provides a method of making artificial stone using glass as a sole binder and aggregate.

Owner:苏州格拉斯通绿色建材科技有限公司

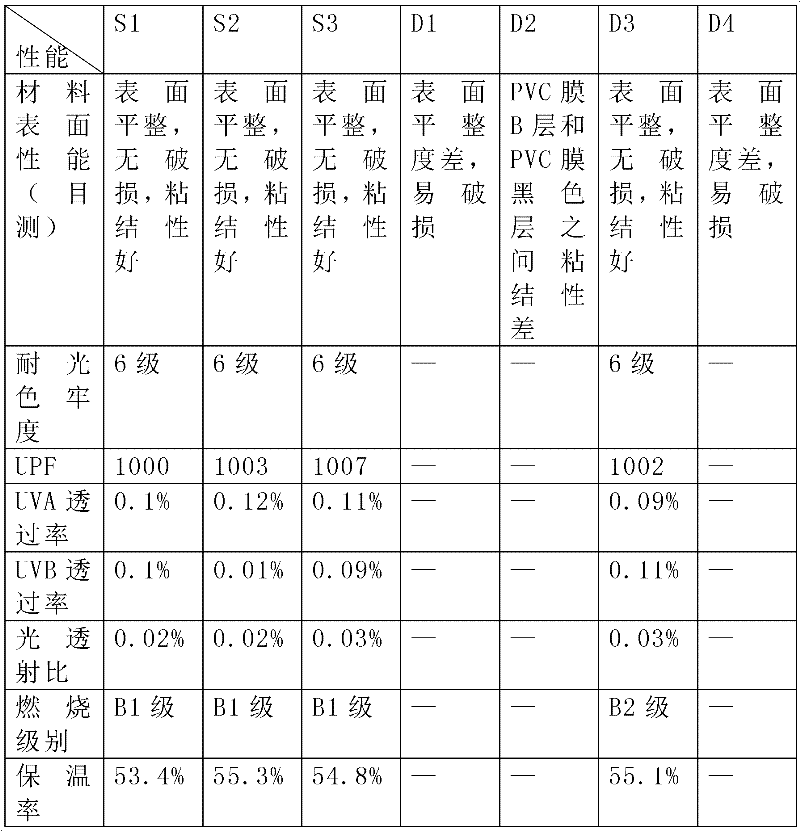

Glass fiber/PVC (polyvinyl chloride) composite membrane material and preparation method thereof

ActiveCN102555352AWith shadingWith heat insulation effectSynthetic resin layered productsLaminationFiberGlass fiber

The invention provides a glass fiber / PVC (polyvinyl chloride) composite membrane material. The glass fiber / PVC composite membrane material comprises a first PVC membrane layer, a second PVC membrane layer, a glass fiber base fabric layer and a third PVC membrane layer from bottom to top in sequence, wherein the second PVC membrane layer is a black PVC membrane layer. The invention also provides a preparation method for the glass fiber / PVC composite membrane material. The glass fiber / PVC composite membrane material provided by the invention has good shading and thermal insulation performances on the premise of ensuring good comprehensive color fastness and combustion performances. The preparation method for the glass fiber / PVC composite membrane material, provided by the invention, is simplified in the process and easy to perform.

Owner:NINGBO XIANFENG NEW MATERIAL

Method for preparing high hear conduction intermediate phase asphalt base charcoal materials

ActiveCN1631993AEliminate the composite processSimple processPigmenting treatmentFibre chemical featuresFiberBand shape

A method for preparing high heat conducting interphase bitumen material, uses band-shaped interphase bitumen fiber which is not melton in 180-280deg.C, with the speed to increase temperature being 0-150deg.c im 1-5deg.C / min, 150deg.C the final temperature being 0.2-0.6deg.C / min, and be dept in the final temperature for 1-3h, then be stamped to form the product in the pressure of 20-100MPa and temperature of 200-300deg.C, through charring and graphitization to generate the high heat conducting material. The invention has simple technique, avoids interference of filler or sticker and can be made into high heat conducting carbon material directly.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Hydrogen-sensitive discoloration detection adhesive tape, and preparation method and application thereof

InactiveCN111662650AMake up for positioningMake up for the disadvantage of finding small leaks difficultDetection of fluid at leakage pointNon-macromolecular adhesive additivesAdhesiveEngineering

The invention relates to a hydrogen-sensitive discoloration detection adhesive tape, and a preparation method and application thereof, concretely relates to a self-adhesive tape, concretely relates toa self-adhesive tape capable of generating color change under hydrogen contact, and further relates to a preparation method and an application method of the self-adhesive tape. The self-adhesive tapeis intrinsically safe, simple and convenient to fix, and simple and visual in a visual representation mode, the position of a leakage point can be indicated through local discoloration, the defects that the positioning capability of a pressure loss hydrogen leakage detection leakage detection point is limited and tiny leakage is difficult to find are overcome, the defect that electronic hydrogendetection equipment is high in layout cost is overcome, a common hydrogen leakage detection method is supplemented, the time cost for finding the leakage position after leakage occurs is greatly reduced, the emergency response is improved, and extremely high application and popularization value is achieved.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

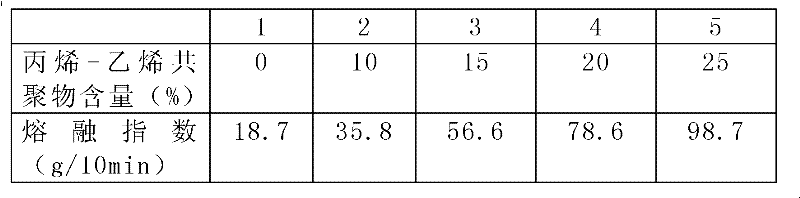

Polyethylene-based thermoplastic elastomer and preparation method and composite plastic thereof

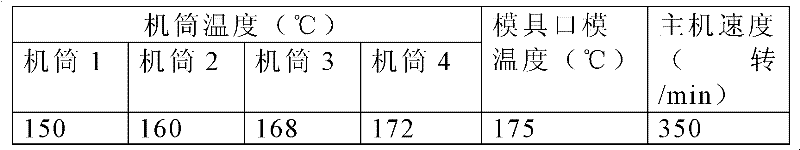

The invention provides a polyethylene-based thermoplastic elastomer. Based on total mass, the polyethylene-based thermoplastic elastomer contains the following components: 45 to 70 weight percent of high density polyethylene, 15 to 30 weight percent of propylene-ethylene copolymer, 10 to 20 weight percent of ethylene-vinyl acetate copolymer, 2 to 10 weight percent of silicone flame retardant, and 2 to 10 weight percent of ammonium polyphosphate. The invention also provides a preparation method for the polyethylene-based thermoplastic elastomer and a thermoplastic composite plastic using the polyethylene-based thermoplastic elastomer. The provided polyethylene-based thermoplastic elastomer has ultrahigh flowability and good flame-retardant property.

Owner:NINGBO XIANFENG NEW MATERIAL

Shockproof, anti-skidding and antistatic protective film

ActiveCN103753913AAdjust densityAdjust intensitySynthetic resin layered productsPolyethylene terephthalateCompanion animal

The invention discloses a shockproof, anti-skidding and antistatic protective film. The shockproof, anti-skidding and antistatic protective film comprises a protective layer, a using layer and a releasing layer, wherein the protective layer consists of an optical PET (Polyethylene Terephthalate)film and a low-mucilage-glue layer; the using layer mainly consists of a polyurethane foam layer, an antistatic priming coat, an optical PET film and a middle- and high-mucilage-glue layer; the releasing layer mainly comprises an optical PET releasing membrane; the polyurethane foam layer comprises some or all of waterborne polyurethane, sealed hollow expansion spheres, open air bubbles and fluorescent particles. The shockproof, anti-skidding and antistatic comprehensive protective film prepared by the invention is used for protecting the back of a cell phone; the shockproof function of the PU foam layer provides a certain drop-resistant effect for the cell phone; the flexibility and self-adsorption of the PU foam layer can prevent the cell phone from moving after being stressed when the cell phone is put on an object evenly; fluorescent particles in the PU foam layer can glow at night.

Owner:YIDONG ELECTRONICS CHANGSHU

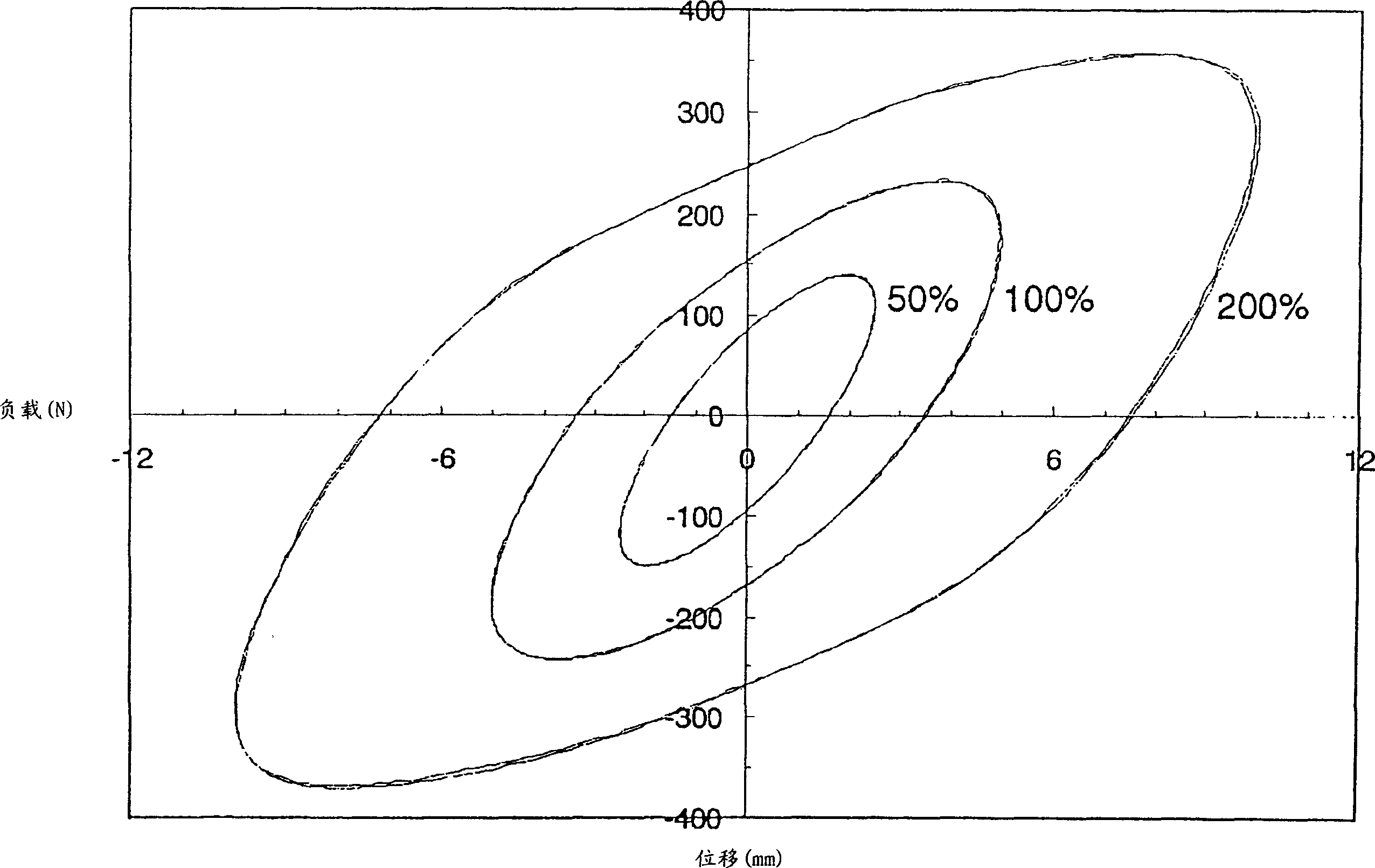

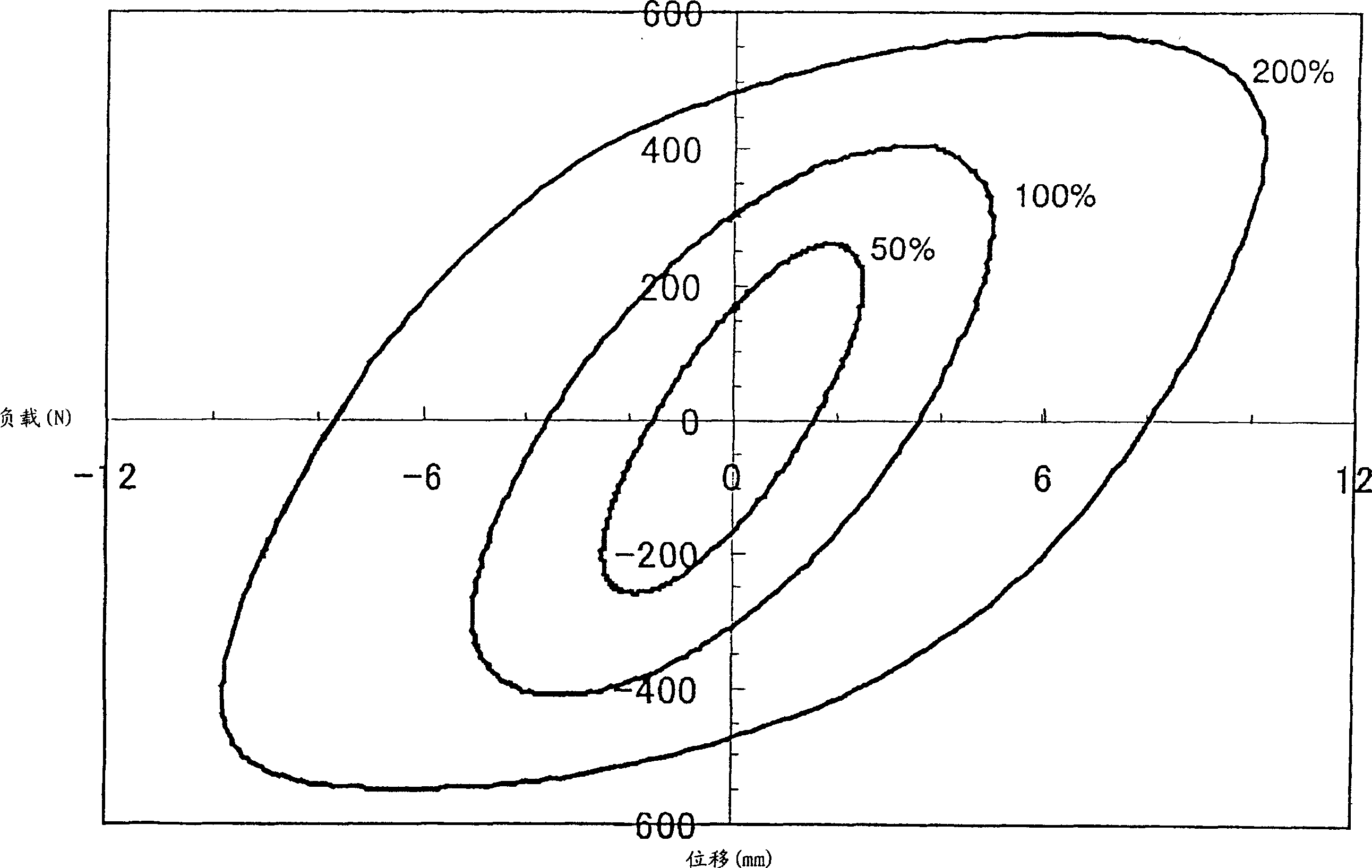

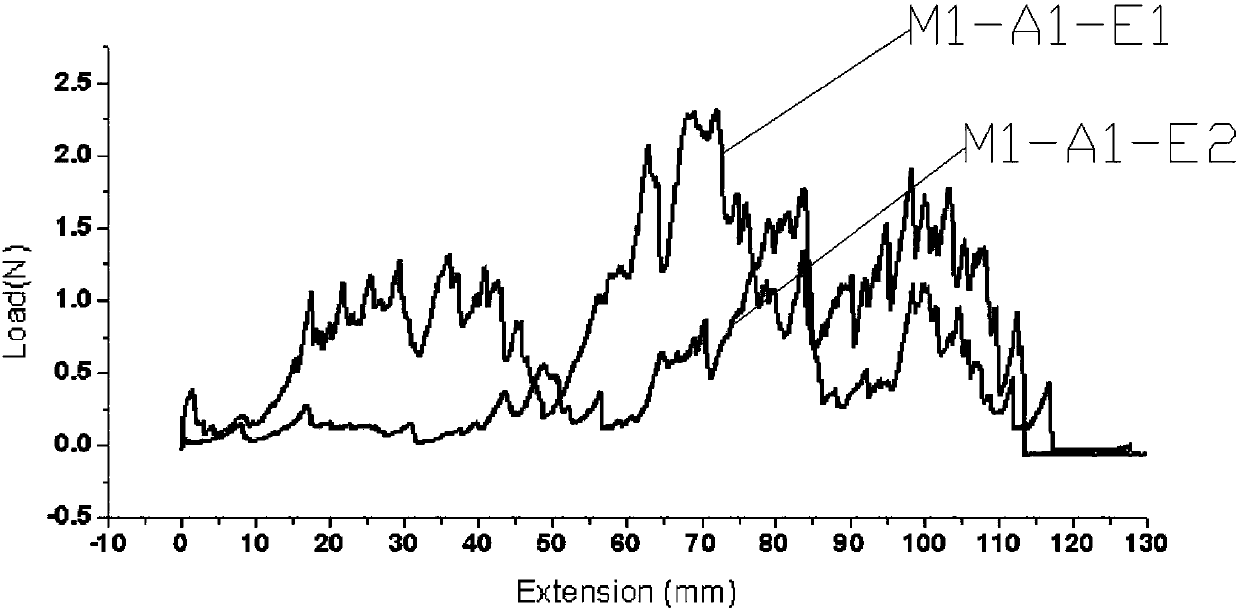

Vibration damper composition

InactiveCN1422317AImprove the attenuation effectGood deformabilityOther chemical processesFilm/foil adhesivesDynamic viscoelasticityRoom temperature

The present invention has for its object to provide a damping material which, despite a high damping capacity at and around room temperature, has a small temperature dependence of rigidity at and around room temperature and a damping material having hot-melt processability and a good balance between damping capacity and temperature dependence of rigidity at and around room temperature. This invention provides a damper material composition wherein the ratio of the storage modulus (G') value at 0 DEG C to the corresponding value at 40 DEG C as found by the measurement of dynamic viscoelasticity in the shear mode, namely (G'0 DEG C / G'40 DEG C), is not greater than 15 and the loss tangent (tan delta) value as found by said measurement is not smaller than 0.4 at 0 DEG C to 40 DEG C.

Owner:KANEKA CORP

Aerogel composite material with heat insulation and stealth functions and preparation method thereof

ActiveCN112661483AReduce heat radiation effectGood insulation performanceOther chemical processesFiberInsulation layer

The invention provides an aerogel composite material with a heat insulation and stealth function and a preparation method of the aerogel composite material, and belongs to the technical field of aerogel composite materials. The aerogel composite material comprises a nano-fiber aerogel matrix layer, a nano-fiber aerogel conductive layer and a nano-fiber aerogel heat insulation layer. According to the invention, under the condition of not using an adhesive, the effective fixation of aerogel particles and the tight combination between the base material and each functional layer can be realized by utilizing the unique hydrophilicity and pore structure of the nanofibers, and the heat insulation performance of the base material layer and the heat insulation layer is utilized; the electromagnetic shielding and controllable heat transmission performance of the conducting layer can achieve the heat insulation and electromagnetic infrared double-shielding synergistic function, and the invention has application prospects in the fields of national defense military industry and functional textiles.

Owner:广东广纳新材料有限公司

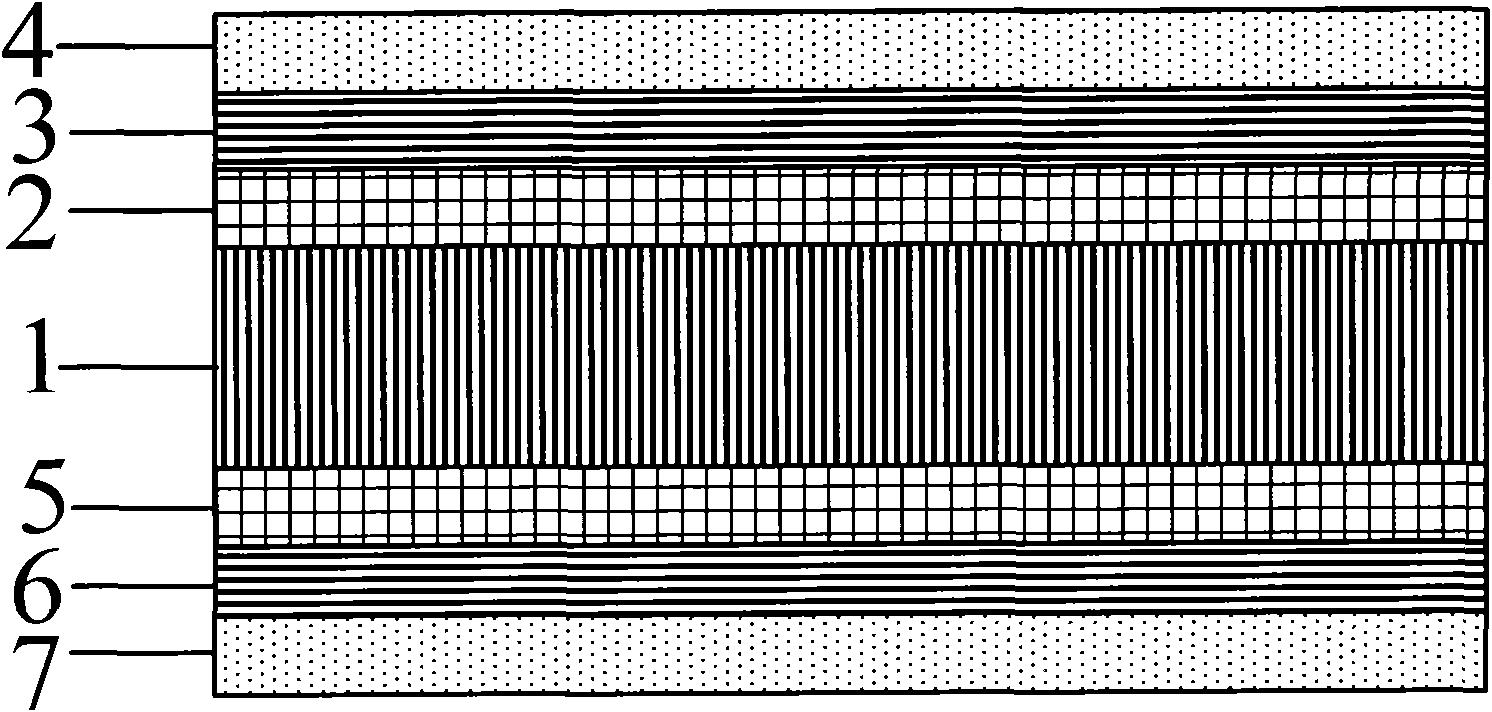

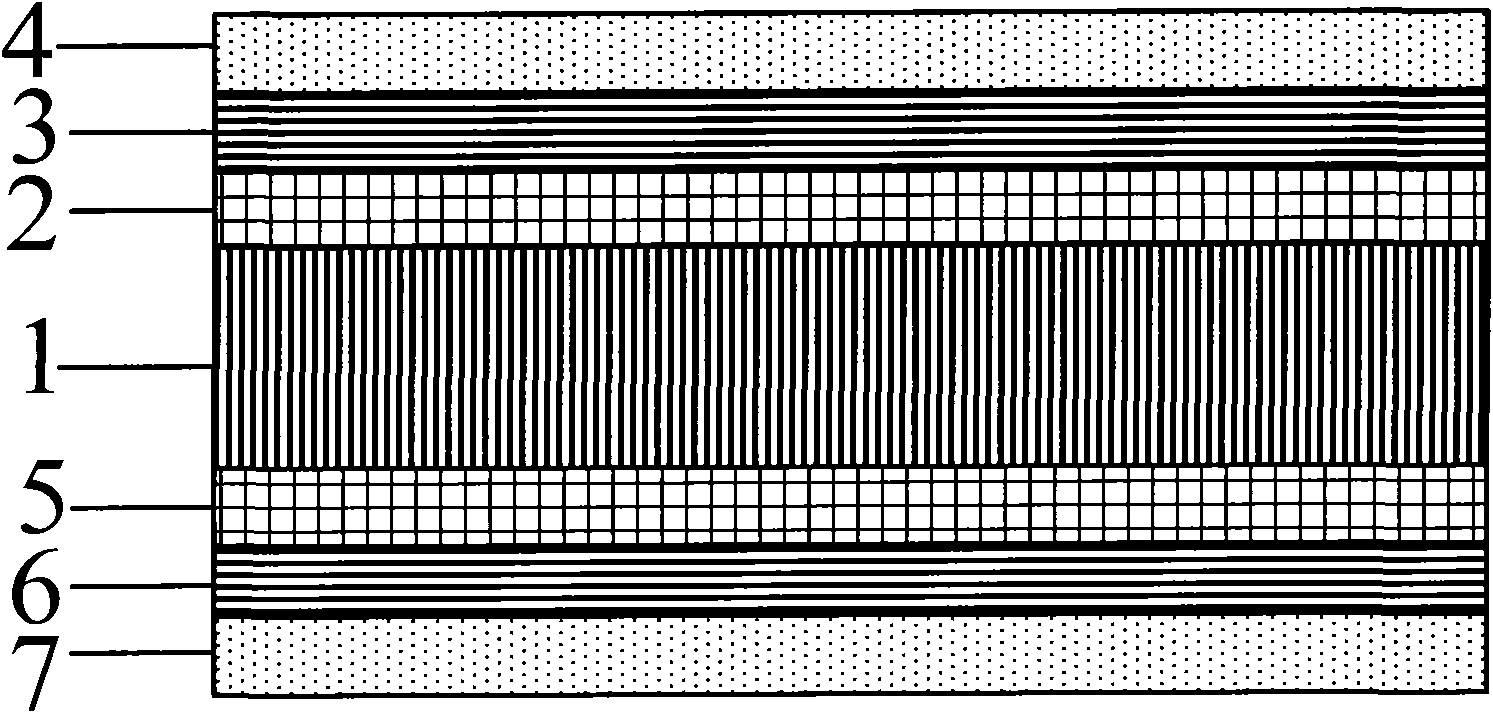

Breathable water-repellent type self-adhering bandage

The invention relates to a breathable water-repellent type self-adhering bandage. In the invention, with polyurethane sponge as a substrate, the front surface of the polyurethane sponge is compounded with an elastic non-woven fabric through a composite adhesive layer, a self-adhering adhesive layer is coated on the surface of the elastic non-woven fabric, the back surface of the polyurethane sponge is also compounded with an elastic non-woven fabric through a composite adhesive layer, and a self-adhering adhesive layer is coated on the surface of the elastic non-woven fabric. The bandage has the advantages of ventilation, water-repellence, comfort and the like without piquant to skin, can be independently used and can also be used in conjunction with an ordinary self-adhering bandage.

Owner:SUZHOU MEDSPORT PROD

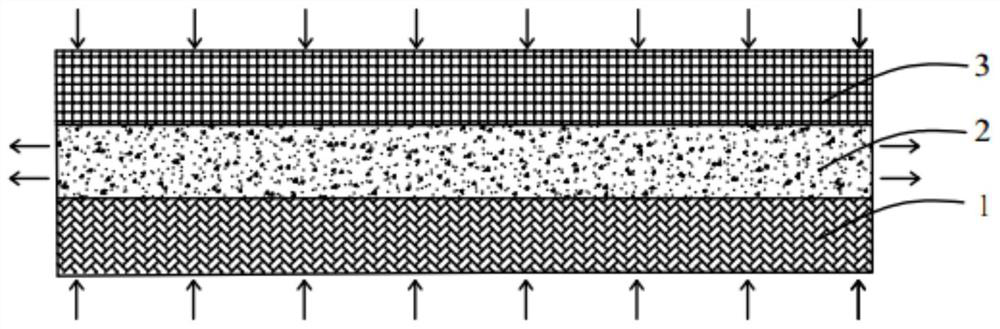

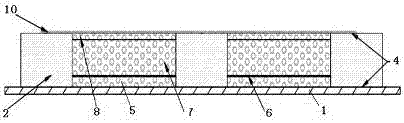

Self-adhered type anti-neutron composite shielding material as well as preparation method and application thereof

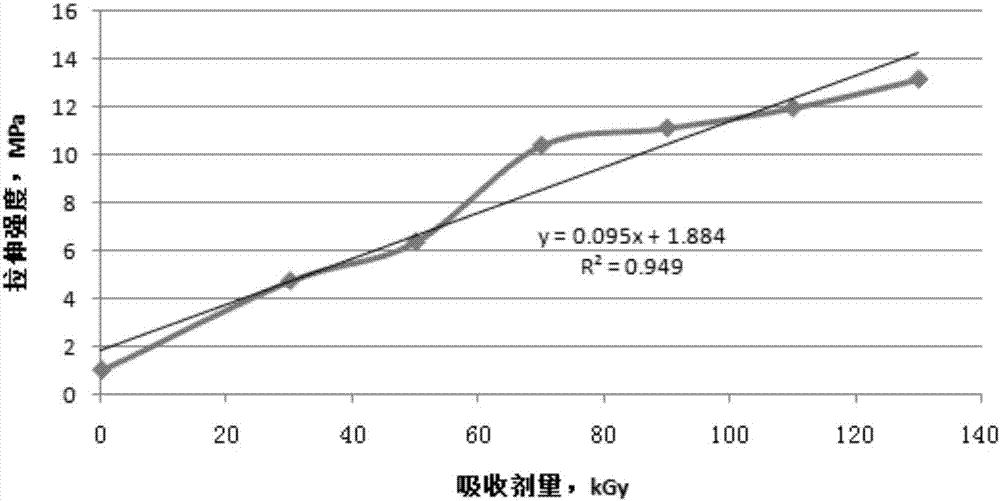

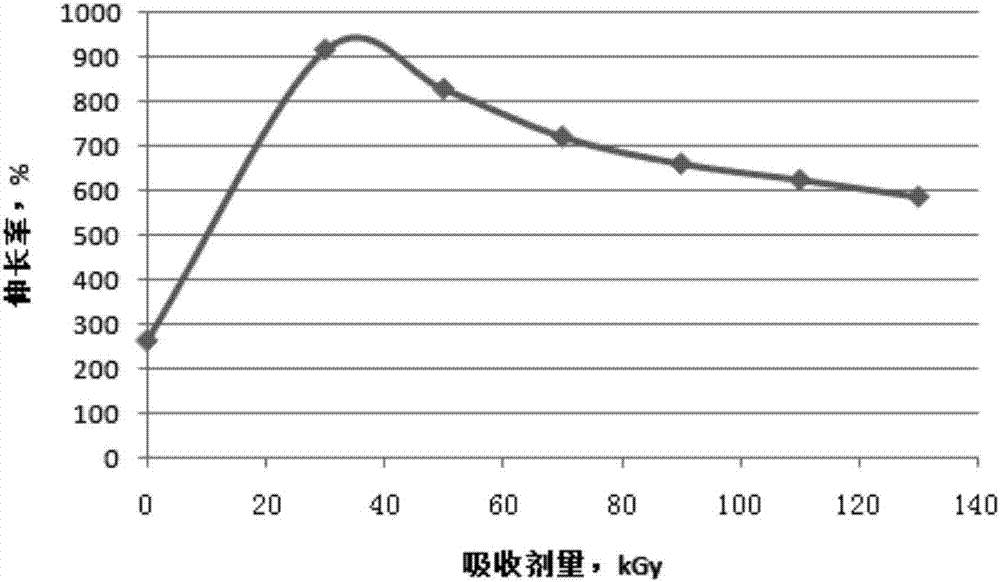

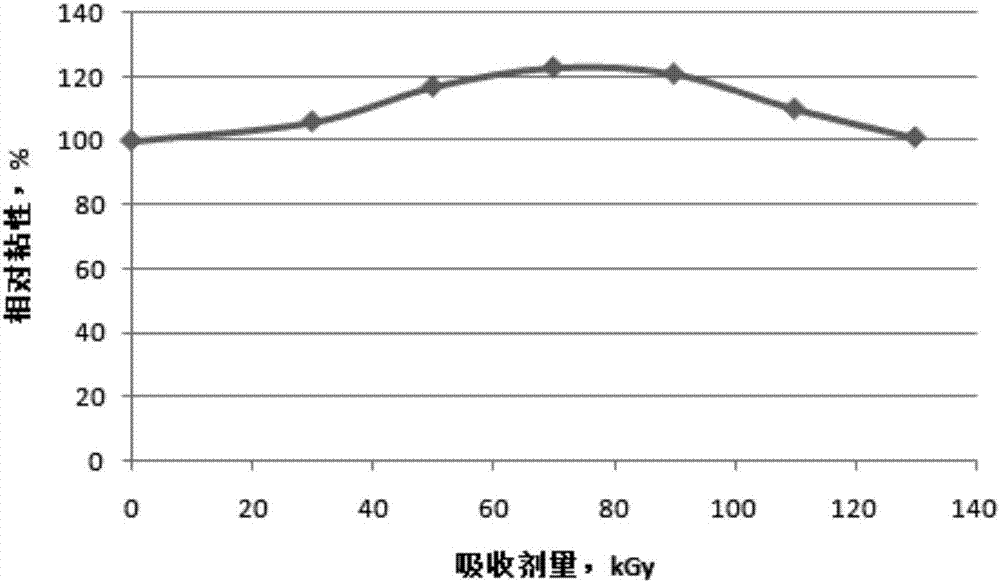

ActiveCN107082965AControl the degree of pre-crosslinkingImprove shielding effectShieldingFlat articlesVulcanizationActive agent

The invention provides a self-adhered type anti-neutron composite shielding material as well as a preparation method and application thereof. The shielding material is prepared from the following raw materials in parts by weight through radiation pre-crosslinking treatment: 100 parts of a rubber susbtrate, 5-50 parts of a tackifying agent polymer, 10-100 parts of a reinforcing agent, 20-200 parts of an anti-neutron additive, 0-50 parts of a softening agent, 0.5-10 parts of a vulcanizing agent, 0.5-5.0 parts of a vulcanization promoter, 0.5-10 parts of a vulcanization activator and 0-5.0 parts of an anti-aging agent. The invention further provides a preparation method of the shielding material and application of the shielding material in complex equipment or irregular parts. The self-adhered type anti-neutron composite shielding material provided by the invention has certain initial crosslinking degrees and self adhesion properties, is good in shape flow property, can be cured by self after being shaped, and has appropriate mechanical strength.

Owner:BEIJING RADIATION APPL RES CENT

Preparation process of silica gel product with color dots

InactiveCN108219175AGood stabilityAvoid visual fatigueLiquid surface applicatorsCoatingsChemistryOil pressure

The invention relates to the technical field of oil pressure production, and particularly relates to a preparation process of a silica gel product with color dots. The preparation process of the silica gel product with the color dots comprises: a step I, selection of a main material; a step II, selection of an auxiliary material; a step III, mixing; a step IV, vulcanization molding; a step V, spray-coating of hand-feeling paint. As liquid AB glue is adopted as the main material and a granular material whose color is different from that of the liquid AB glue is adopted as the auxiliary material, an obtained multicolor silica gel product not only can meet the requirement on an apparent surface, but also can meet the requirement on the interior of a non-apparent surface; moreover, the apparent colors of the silica gel product are difficultly influenced by the external factors of friction and the like to fall; the silica gel product has the advantage of being good in stability; in addition, as the auxiliary material whose color is different from that of the main material liquid AB glue is the granular material, the obtained multicolor silica gel product is enabled to be indistinct in color, and can be used for avoiding visual fatigue; moreover, the multicolor silica gel product subjected to the vulcanization molding is interspersed with uniformly distributed granules, and a novel visual perception is given to a person.

Owner:DONGGUAN SINCO ELECTRONICS

Conductive heat-sensitive pressure-sensitive adhesive tape

InactiveCN106479386AWith thermal expansion blocking functionWith blocking safety protection functionPressure sensitive film/foil adhesivesElectrically-conducting adhesivesMicrosphereHeat sensitive

The invention discloses a conductive heat-sensitive pressure-sensitive adhesive tape. The adhesive tape comprises a release material layer and a conductive heat-sensitive adhesive layer which is arranged on one surface of the release material layer, wherein the conductive heat-sensitive adhesive layer is formed by spreading an adhesive which is formed by adding conductive particles and expanded microspheres into acrylic pressure-sensitive adhesive and uniformly stirring the mixture. The pressure-sensitive adhesive tape has features of good flexibility, self-adhesion of the pressure-sensitive adhesive, low-temperature rapid irreversible blocking, thinner thickness and excellent shielding function, excellent electric conduction performance can be kept at normal temperature, and the tape can expand within 3-6 seconds when the temperature reaches a certain temperature and the blocking can be completed, the expansion compressive strength can be up to 100-200 psi / square inch.

Owner:SHENZHEN MEIXIN ELECTRONICS

Fireproof insulating layer for cryogenic storage tank

The invention discloses a fireproof insulating layer for a cryogenic storage tank. The fireproof insulating layer for the cryogenic storage tank comprises the cryogenic storage tank, a plurality of prefabricated foam blocks, coating foam, injection molding foam and foam glass, wherein the multiple prefabricated foam blocks are pasted on the surface of the cryogenic storage tank at intervals in the transverse and longitudinal directions through cryogenic adhesive; the first layer of injection molding foam, an anticracking layer, the second layer of injection molding foam and the coating foam are pasted to the portion, between the prefabricated foam blocks, of the surface of the cryogenic storage tank sequentially from inside to outside, and the coating foam is sprayed to the surface layers of the injection molding foam; the foam glass is pasted to the outer surfaces of the prefabricated foam blocks and the outer surface of the coating foam through the cryogenic adhesive; and a stainless steel coating is also pasted to the outer side of the foam glass.

Owner:酷泰克保温科技江苏有限公司

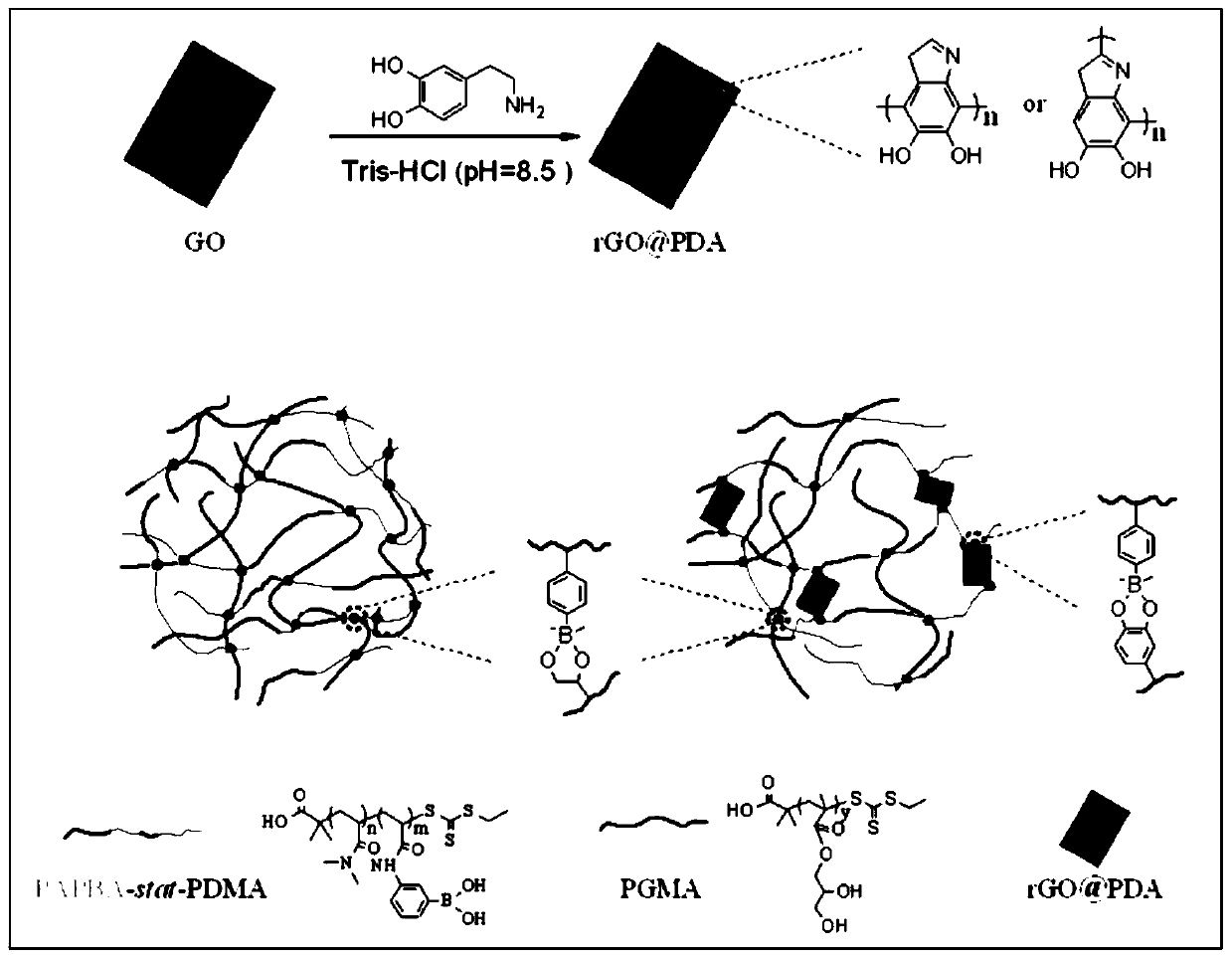

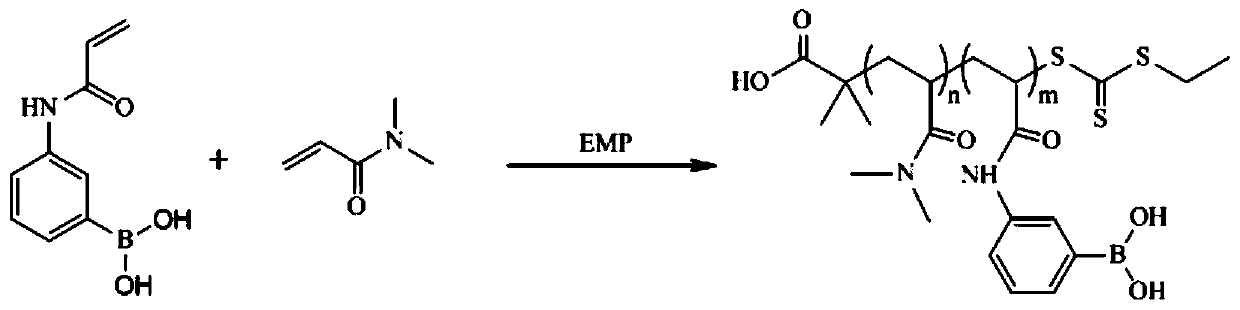

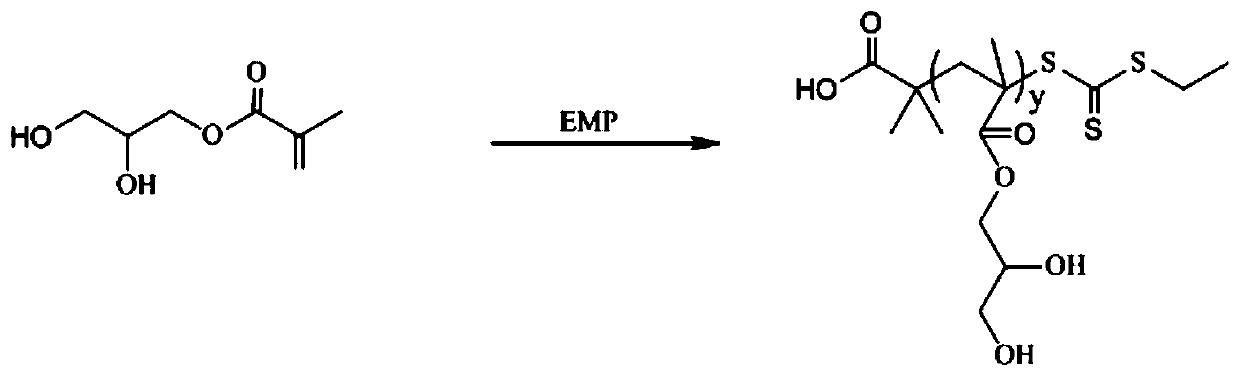

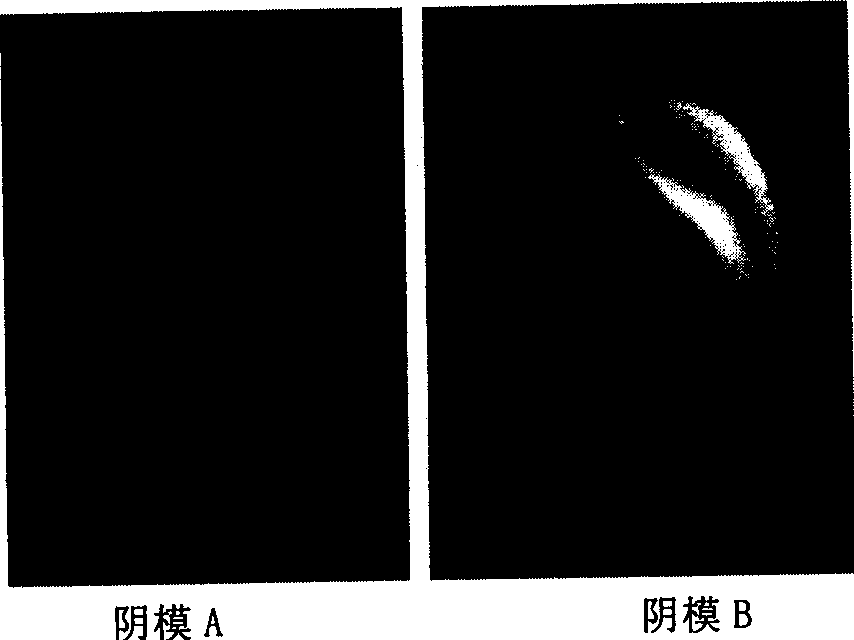

Nano composite hydrogel and preparation method and application thereof

The invention designs a novel multifunctional nano composite hydrogel, which has injectability, self-healing, and good mechanical strength, irritant reaction and adhesiveness. The multifunctional nanocomposite hydrogel is prepared by using a diol-containing polymer (PGMA) and a phenylboronic acid-containing polymer (PAPBA-STAT-PDMA) as precursors and adding a certain amount of poly-dopamine-coatedmodified nanoparticles (rGO @ PDA). In alkaline environment, a hydrogel network can be easily realized through the interaction of the phenylboronic acid- containing polymer and the diol- containing polymer. Compared with a pure polymer hydrogel without the poly-dopamine- coated modified nanoparticles (rGO @ PDA), the storage modulus (G') of the obtained nanocomposite hydrogel is significantly improved, and the nanocomposite hydrogel has adhesiveness.

Owner:XIANGTAN UNIV

Porous scaffold with complex contour and its preparing process

A porous scaffold with complex contour similar to the damaged tissue or organ is prepared from the biodegradable and biocompatible high-molecular material through designing the both flexible and rigid composite mould and the solvent-based cold press / particle infusion. Its advantages are simple and feasible preparing process and high porosity (more than 90%).

Owner:FUDAN UNIV

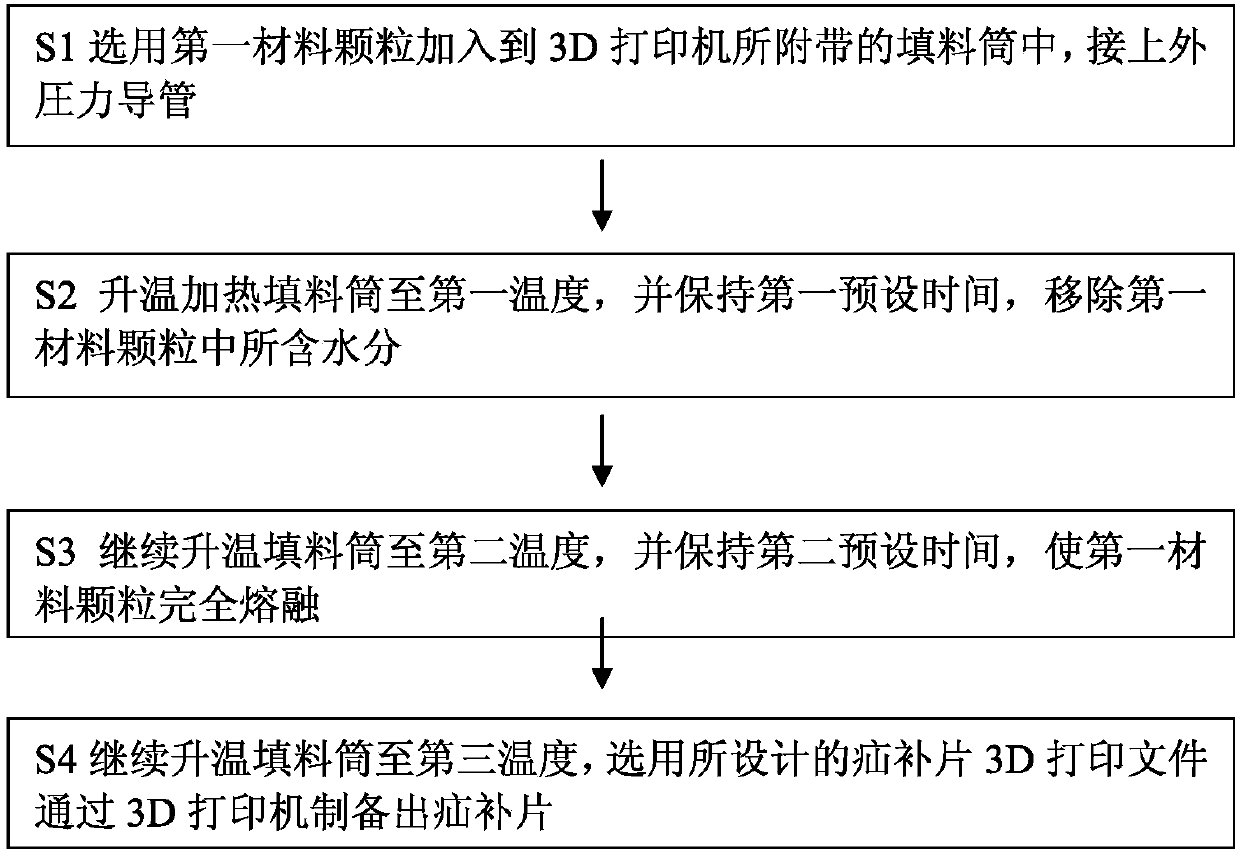

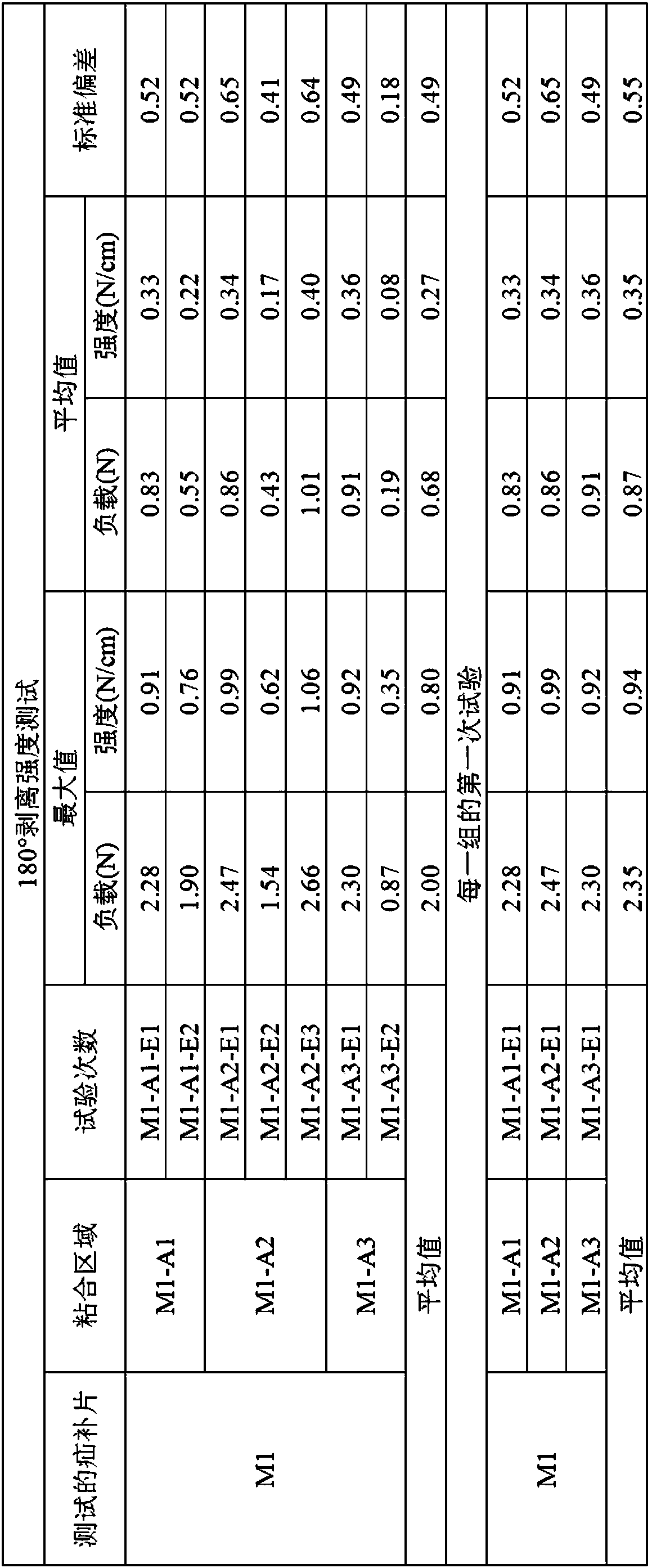

Hernia mesh and preparation method thereof

ActiveCN107756781AAperture controllableControlled BiocompatibilityAdditive manufacturing apparatusSurgeryBiocompatibility TestingUltimate tensile strength

The invention specifically relates to a hernia mesh and a preparation method thereof, belonging to the field of medical supplies. The preparation method for the hernia mesh comprises the following steps: S1, selecting first material particles, adding the first material particles into an accessory filler drum of a 3D printer, and connecting the filler drum with an external pressure conduit; S2, heating the filler drum to a first temperature, and maintaining the filler drum at the temperature for a first preset time to remove moisture in the first material particles; S3, continuing heating the filler drum to a second temperature and then maintaining the filler drum at the temperature for a second preset time to allow the first material particles to be completely fused; and S4, continuing heating the filler drum to a third temperature, selecting a designed 3D printing file for the hernia mesh and printing the hernia mesh via the 3D printer. The hernia mesh prepared in the invention has controllable pore sizes, biocompatibility, tensile strength and elasticity; the preparation method for the hernia mesh is convenient and fast and can reduce the making cost of the hernia mesh; and the hernia mesh can reduce foreign body sensation and discomfort for patients.

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

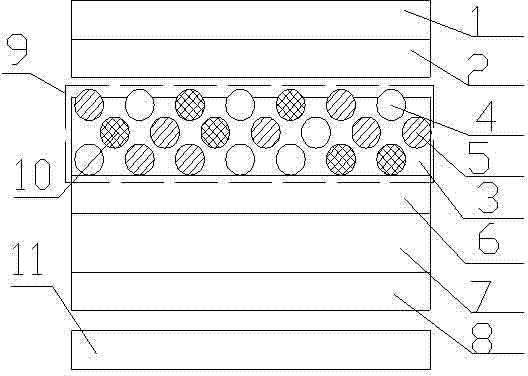

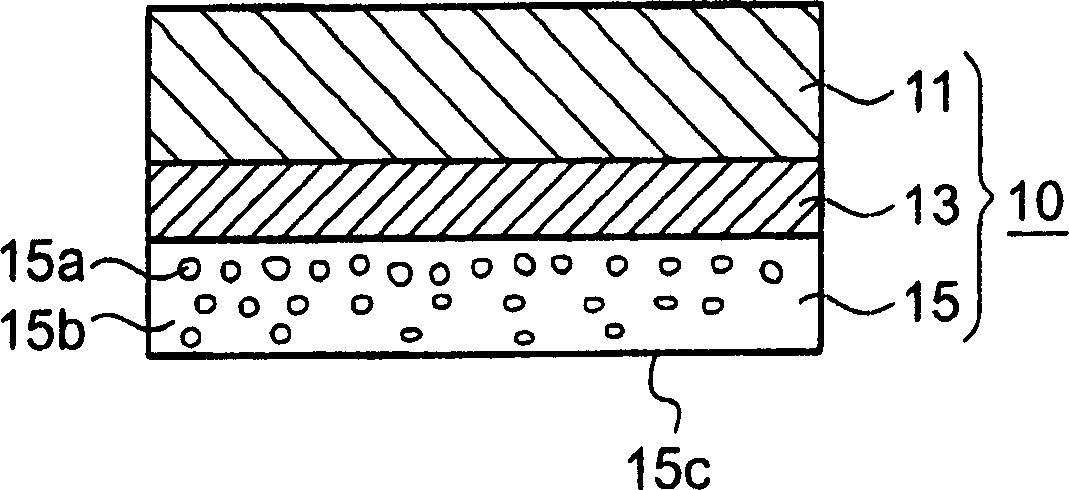

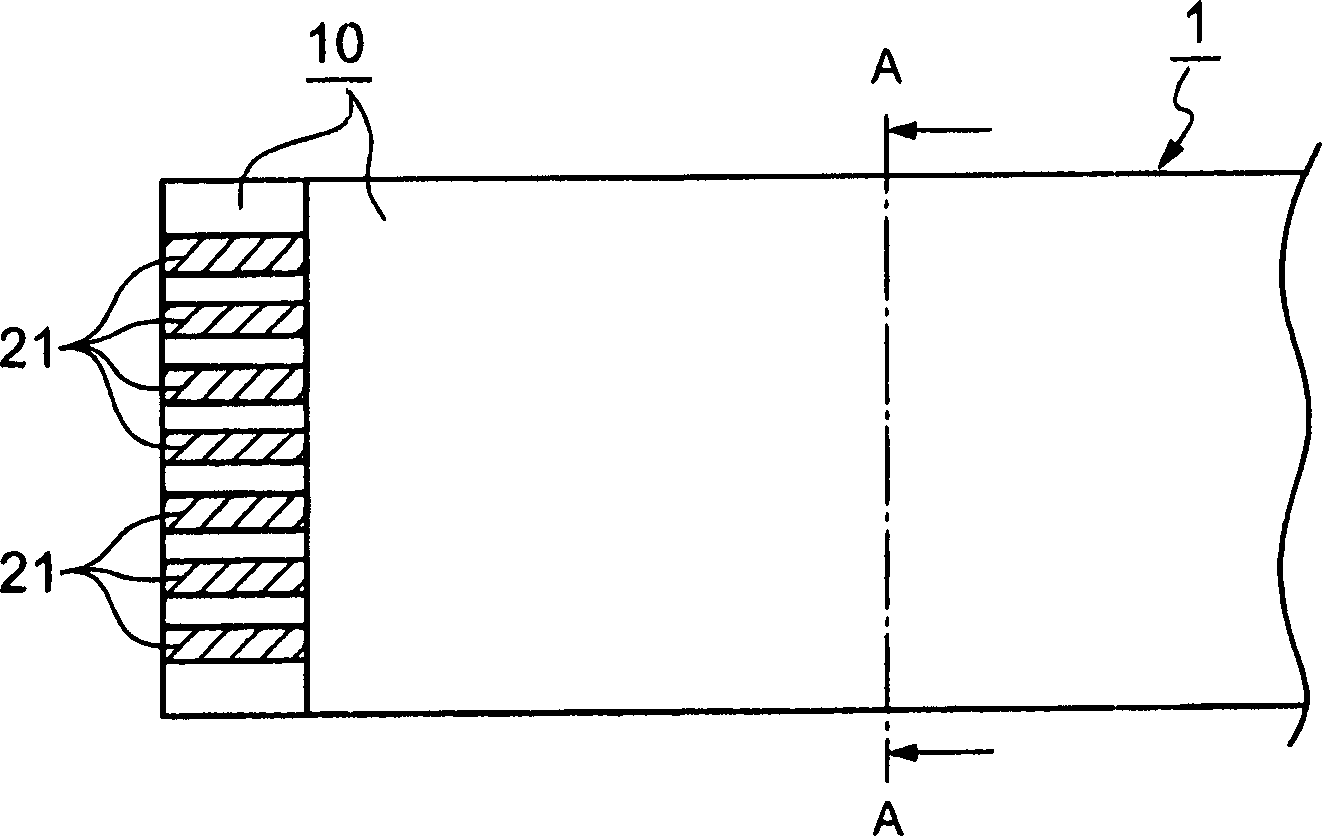

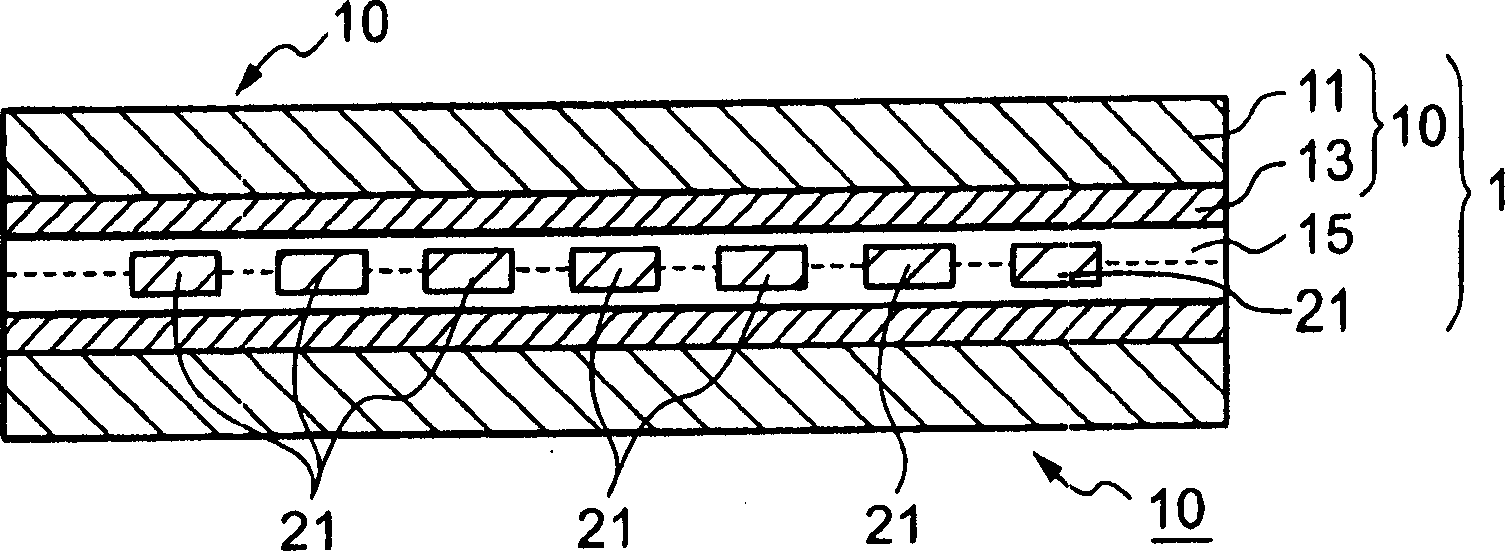

Flat-cable-coating material and flat cable

InactiveCN1806297AFlame retardantHeat-sealablePlastic/resin/waxes insulatorsNon-macromolecular adhesive additivesThermal adhesiveMaterials science

A flat cable covering material which has a base material film and, provided on one surface thereof, a thermal adhesive layer (P + V) containing at least a filler (P) and a thermoplastic resin (V), wherein the mass proportion (P) / (P + V) is distributed in a graduated manner in the direction of the thickness of the thermal adhesive layer, preferably, is gradiatedly distributed in such a manner that the mass proportion decreases from the base material film side to the side of the surface of the thermal adhesive layer in the range of (P) / (P + V) = 90 to 50 mass %, or wherein the filler (P) component comprises a hydrated metal compound (P1) and the mass proportion (P1) / (P) is gradiatedly distributed in such a manner that the mass proportion (P1) / (P) decreases from the base material film side to the side of the surface of the thermal adhesive layer in the range of (P1) / (P) = 80 to 0 mass %.

Owner:DAI NIPPON PRINTING CO LTD

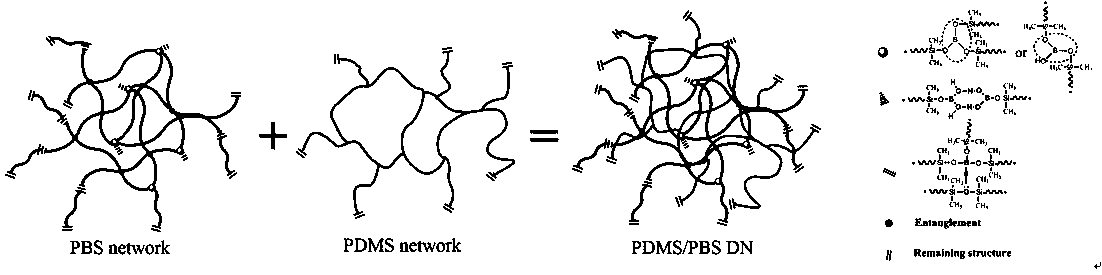

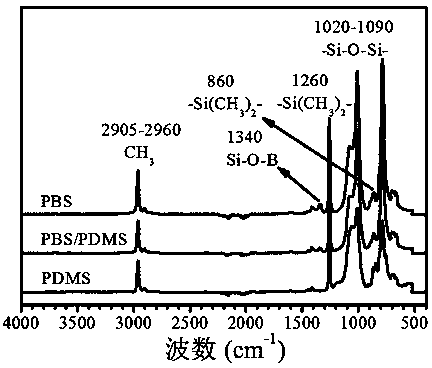

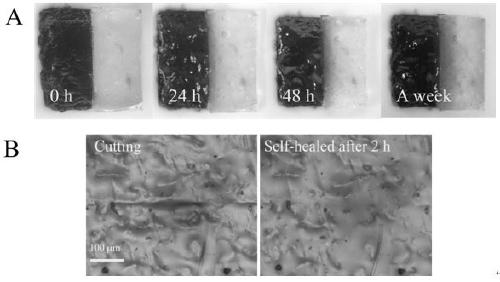

Preparation method of self-repairing electrode material based on supramolecular double-network structure

InactiveCN110415889ABiocompatibleThe synthesis method is simpleApparatus for manufacturing conducting/semi-conducting layersDouble networkSynthesis methods

The invention relates to a self-repairing electrode material, in particular to a preparation method of a self-repairing electrode material based on a supramolecular double-network structure. In the invention, the synthesis method for preparing the self-repairing electrode material is simple and efficient; the material has biocompatibility, not only has self-repairing mechanical properties and rheological properties, but also can drive a conductive network to be self-repaired; and the process is not limited, does not need external stimulation and can be carried out at any temperature. Accordingto the method, the performance of the material can be controlled by changing the ratio of the two networks, so that the material has targeted application. The self-repairing material prepared by themethod can completely recover electrical properties within 25 minutes at normal temperature, has self-adhesiveness, and is convenient to be compounded with a conductive material to prepare a human body electrode material attached to the skin.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com