Patents

Literature

74results about How to "Little effect of viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-viscosity and high-heat conduction epoxy resin electronic potting adhesive

InactiveCN101974302AImprove thermal conductivityRapid heat buildupNon-macromolecular adhesive additivesOther chemical processesEpoxyAdhesive

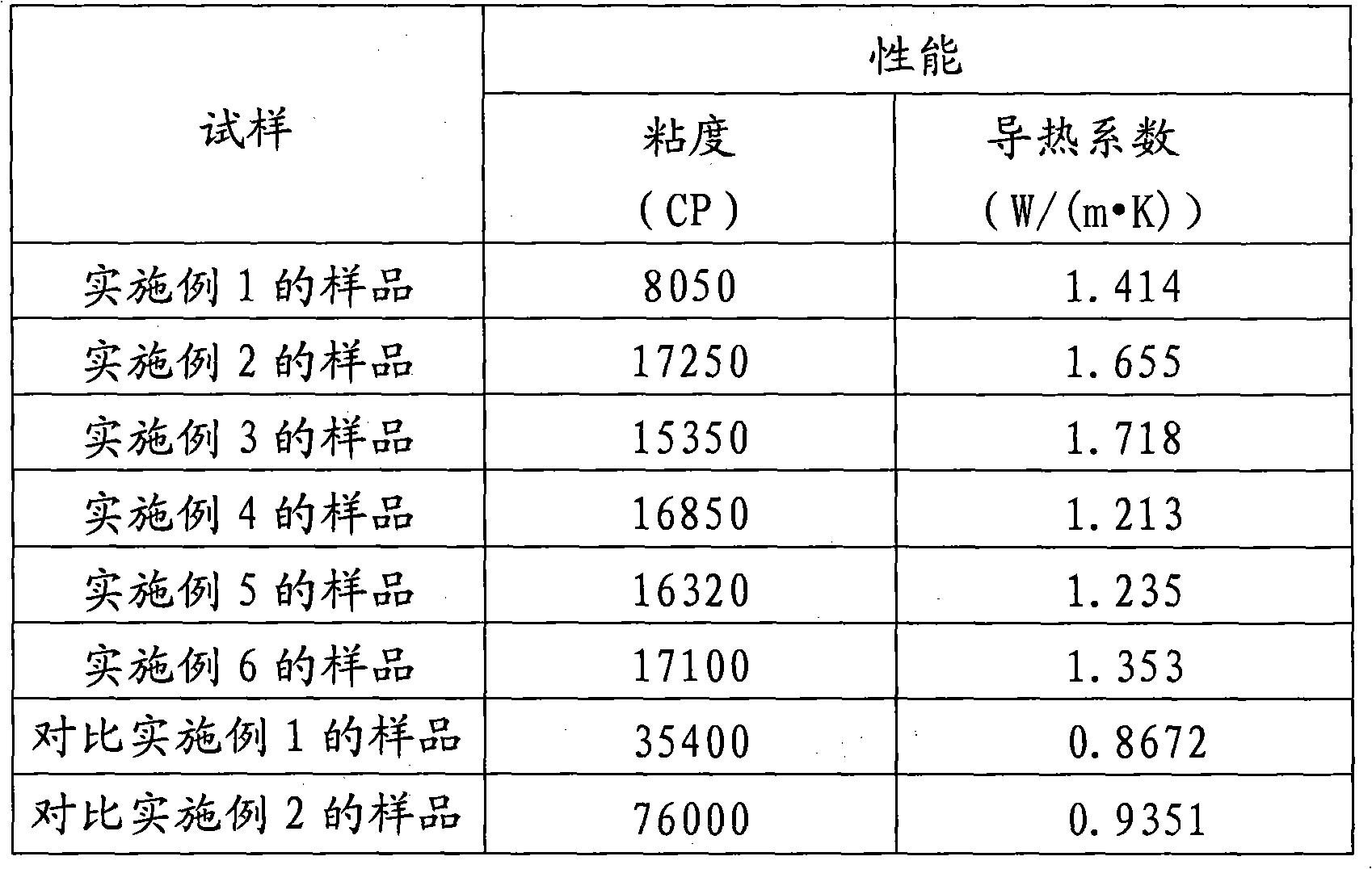

The invention relates to a low-viscosity and high-heat conduction epoxy resin electronic potting adhesive which is formed by mixing a component A with an amine curing agent according to the weight ratio of 100:5-12, wherein the component A comprises the following raw materials in weight ratio: 70-85 parts of spherical alumina powder, 10-20 parts of epoxy resin, 2-4 parts of active thinner, 2.5-5 parts of toughening agent and 0.1-0.5 parts of coupling agent. The invention has the advantages that the spherical alumina of the potting adhesive has higher filling amount compared with non-spherical alumina, the viscosity is less affected, the fluidity is favorable and the construction is convenient; the potting adhesive has good dispersibility and is difficult to sedimentate; a condensate has high heat conductivity and can quickly dissipate accumulated heat of heating parts and components; a high-filling filler can reduce a thermal expansion coefficient and a volumetric shrinkage rate and is very suitable for potting parts and components; and the price is cheaper compared with boron nitride and aluminum nitride, and the cost is low.

Owner:YANTAI DARBOND TECH

Cleaning fluid for cleaning plasma etching residue

InactiveCN101290482AImprove cleaning efficiencyEfficient and stable cleaning effectNon-surface-active detergent compositionsDetergent mixture composition preparationSilanesSolvent

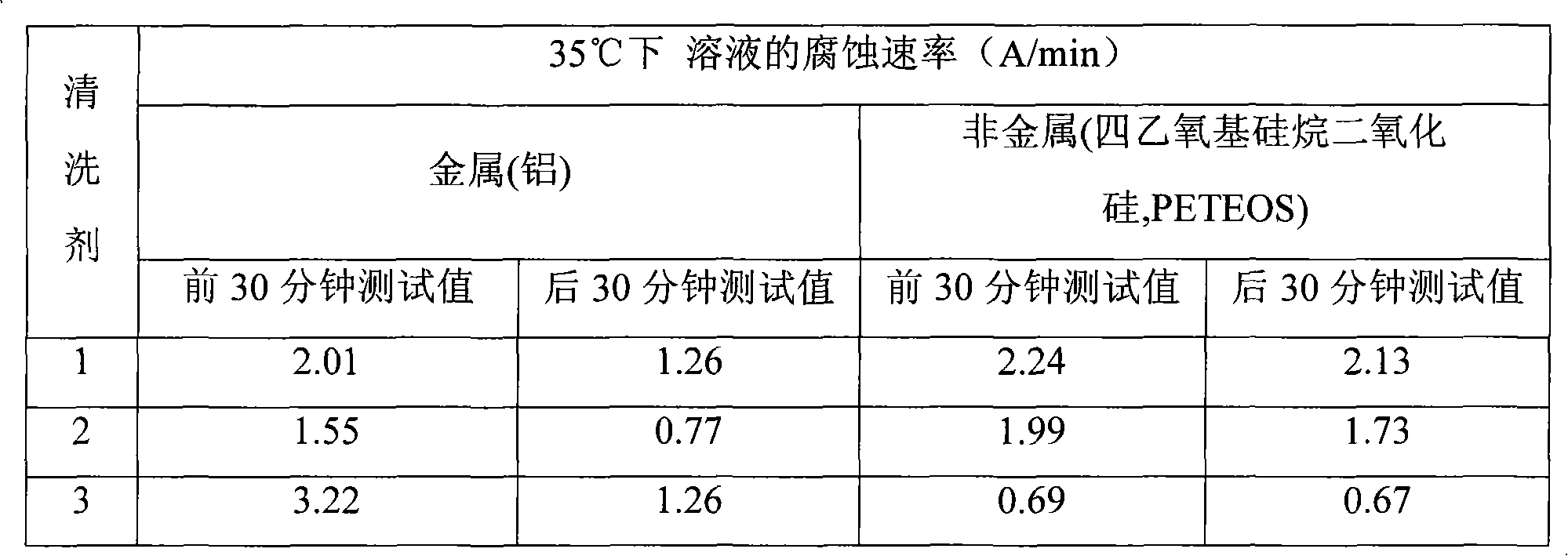

The invention discloses washing liquid used in the semiconductor industry to wash plasma etching residues. The washing liquid contains citric acid / citrate buffer solution, fluorides, macromoledular corrosion inhibitor, anti-freeze agent and solvent. The washing liquid can effectively wash the plasma etching residues during the process of manufacturing a semiconductor, have low etching velocity on nonmetals and metal substrates such as Si, SiO2, tetraethoxy silane silicon dioxides (PETEOS), low-medium materials, Ti, Al, Cu and so on, is safe and harmless to the environment and the human body, and has good application prospect in the microelectronic field such as washing of semiconductor wafers and so on.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

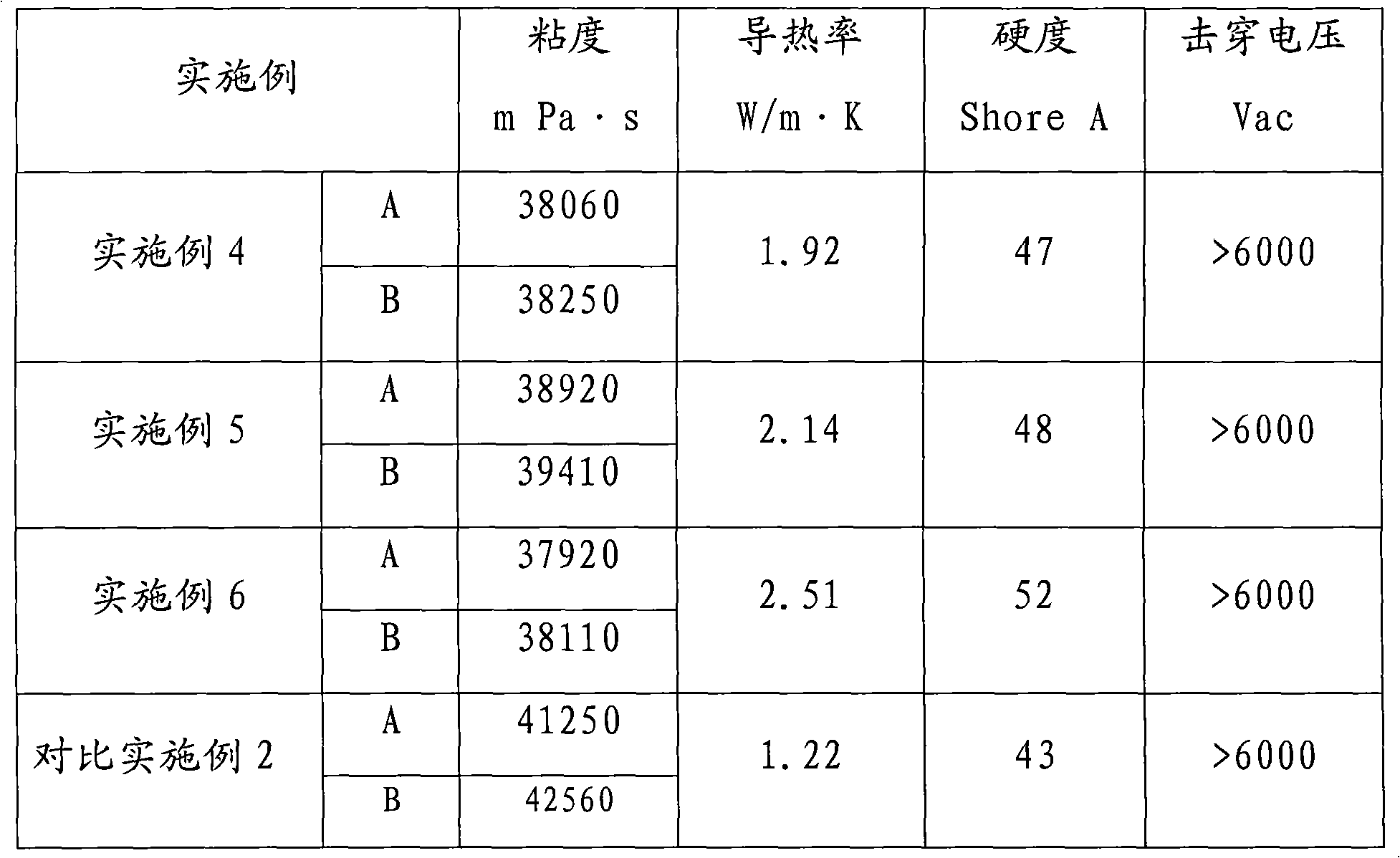

Two-component sealing silica gel with low viscosity and high thermal conductivity and preparation method theref

InactiveCN101962528AEasy to moveGuarantee job stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer scienceAdhesive

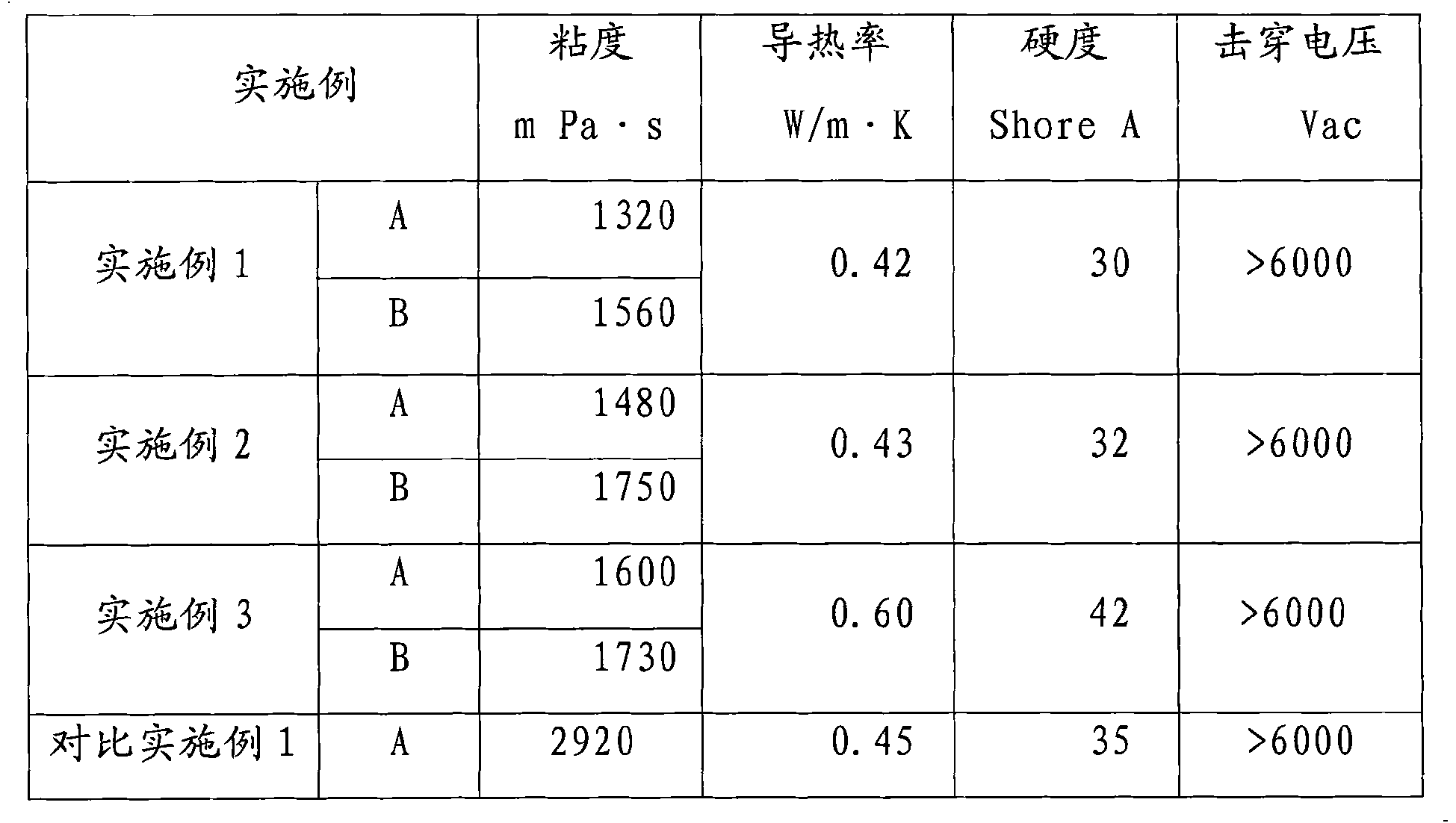

The invention relates to a two-component sealing adhesive with low viscosity and high thermal conductivity and a preparation method thereof. The two-component sealing adhesive consists of a component A and a component B in a weight ratio of 100:80-100:125, wherein the component A comprises the following raw materials by weight percent: 40.00%-90.00% of thermal conductive powder, 4.50%-50.00% of low-viscosity liquid silicone oil, 0.50%-10.00% of silicane curing agent and 0.00-5.00% of toner; and the component B comprises the following raw materials by weight percent: 40.00%-90.00% of thermal conductive material, 9.50%-54.00% of low-viscosity liquid silicone oil, 0.04%-1.00% of catalyst and 0.00-5.00% of toner. The preparation method comprises the following steps: weighting all the raw materials according to the weight persentages to prepare the component A and the component B; and when in use, mixing the component A and the component B evenly in a weight ratio of 100:80-100:125, and curing to obtain the sealing adhesive of the invention.

Owner:YANTAI DARBOND TECH

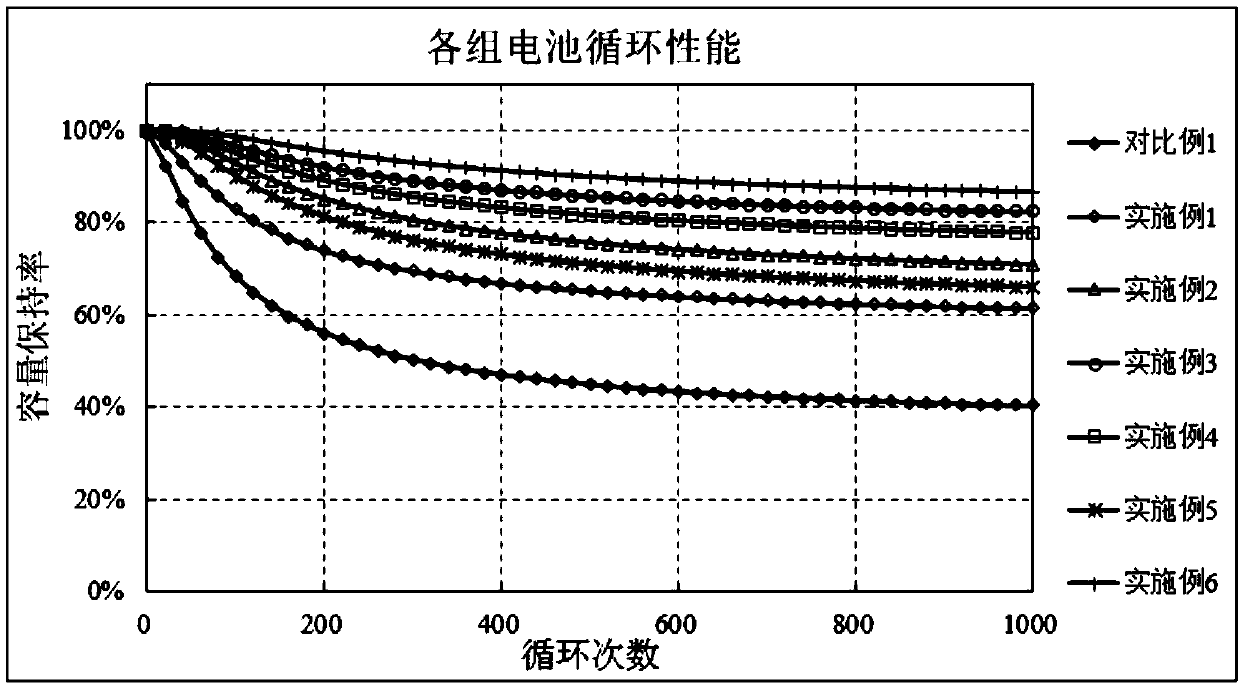

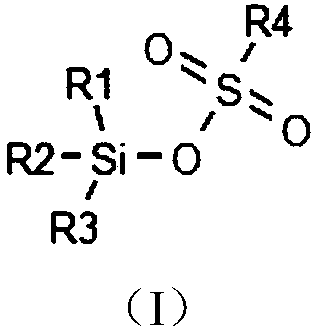

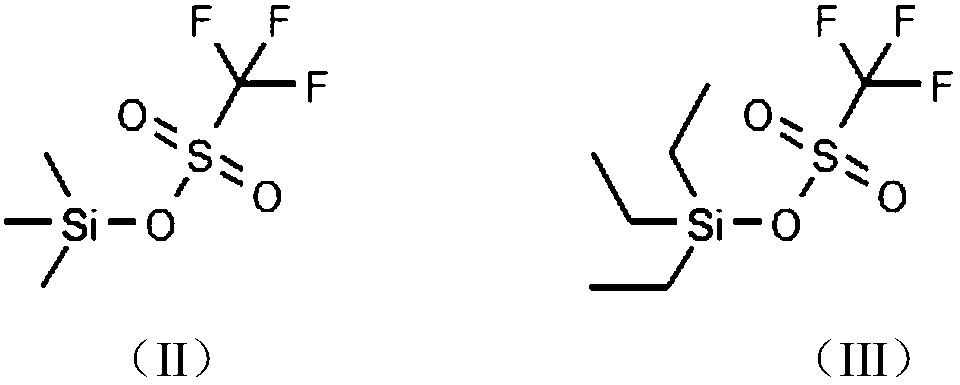

Electrolyte and lithium-ion battery using the same

ActiveCN109585925ALower oxidation potentialImprove toughnessSecondary cellsOrganic electrolytesCyclic processSilanes

The invention discloses an electrolyte and a lithium-ion battery using the same. The electrolyte comprises a non-aqueous solvent, a lithium salt and additives, wherein the additives comprise vinylenecarbonate, vinylethylene carbonate and fluoroethylene carbonate, and further comprises sulfonate and / or sulfate compounds containing silane functional groups, wherein the alkyl groups in the silane functional groups are independently selected from alkanes or olefins of which the number of carbon atoms is 1-3, or the alkanes or olefins of which the number of halogen-substituted carbon atoms is 1-3.The sulfonate or sulfate compounds can generate a dense and tough passivation film on the surface of a positive electrode material, effectively suppress the oxidation reaction in the system, and playa positive electrode protection role. And meanwhile, the compounds can synergize with other additives to form a dense and stable SEI film on the surface of a negative electrode, effectively prevent the reduction reaction of the electrolyte on the surface of the negative electrode and the deposition of transition metal, improve the interface between the negative electrode and the electrolyte, slowdown the secondary reaction of the electrode interface in a storage or circulation process, and further improve the battery performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Process for preparing rust-bearing rust-proof heavy-duty coating

ActiveCN102690558AHigh solid contentLittle effect of viscosityAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceHeavy duty

The invention relates to a process for preparing a rust-bearing rust-proof heavy-duty coating and belongs to the technical field of rust-bearing rust-proof heavy-duty coating preparation. The process comprises the following steps: 1) stirring; 2) grinding; 3) dispersing; 4) preparing a resin; 5) preparing the coating; and 6) stirring. The production process is simple and quick, and the produced coating has high permeability, high solid content and low viscosity and can passivate active and harmful iron compounds in a rust layer into harmless fillers.

Owner:PENGLAI WEIYANG NEW MATERIALS

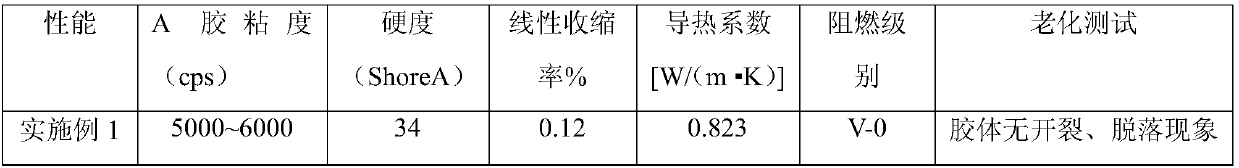

Low-shrinkage heat-conducting flame-retardant double-component condensed type organosilicone pouring sealant, and preparation method and application thereof

InactiveCN107760256AFast curingHigh copy numberNon-macromolecular adhesive additivesMacromolecular adhesive additivesHeat conductingPlasticizer

The invention belongs to the technical field of encapsulating materials, and discloses a low-shrinkage heat-conducting flame-retardant double-component condensed type organosilicone pouring sealant, and a preparation method and application thereof. The organosilicone pouring sealant consists of a component A and a component B, of which the weight ratio of (10:1) to (5:1), wherein the component A consists of the following raw materials in parts by weight: 100 parts of a base adhesive, 30 to 80 parts of a plasticizer A, 0.01 to 3 parts of a coloring material and 0.1 to 1 part of a curing accelerant; and the component B consists of the following raw materials in parts by weight: 80 to 300 parts of a crosslinking agent, 10 to 60 parts of a coupling agent, 0.5 to 1.5 parts of a catalyst and 100to 500 parts of a plasticizer B. The base adhesive consists of the following raw materials in parts by weight: 100 parts of liquid silicone rubber, 3 to 10 parts of reinforcing filler, 20 to 80 partsof heat-conducting filler, 20 to 100 parts of flame-retardant filler, 3 to 10 parts of a surface treating agent and 3 to 20 parts of functional filler.

Owner:GUANGZHOU MECHANICAL ENG RES INST

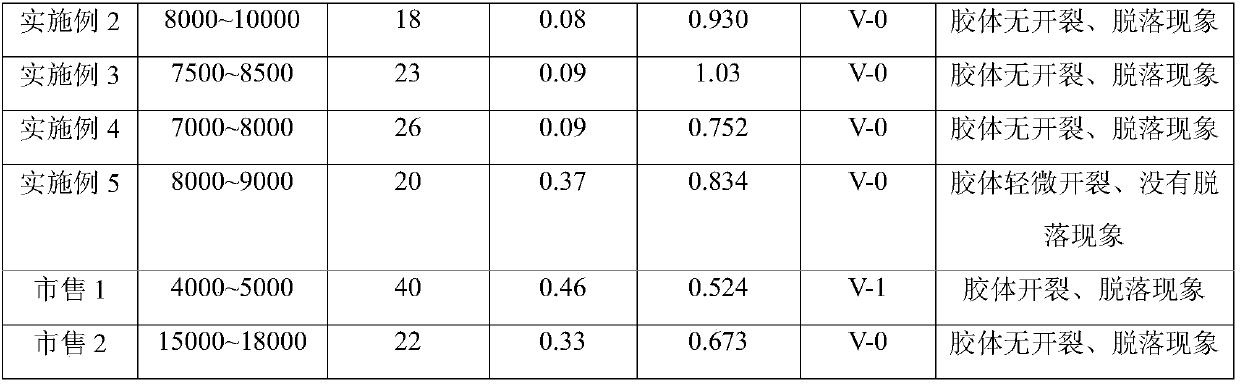

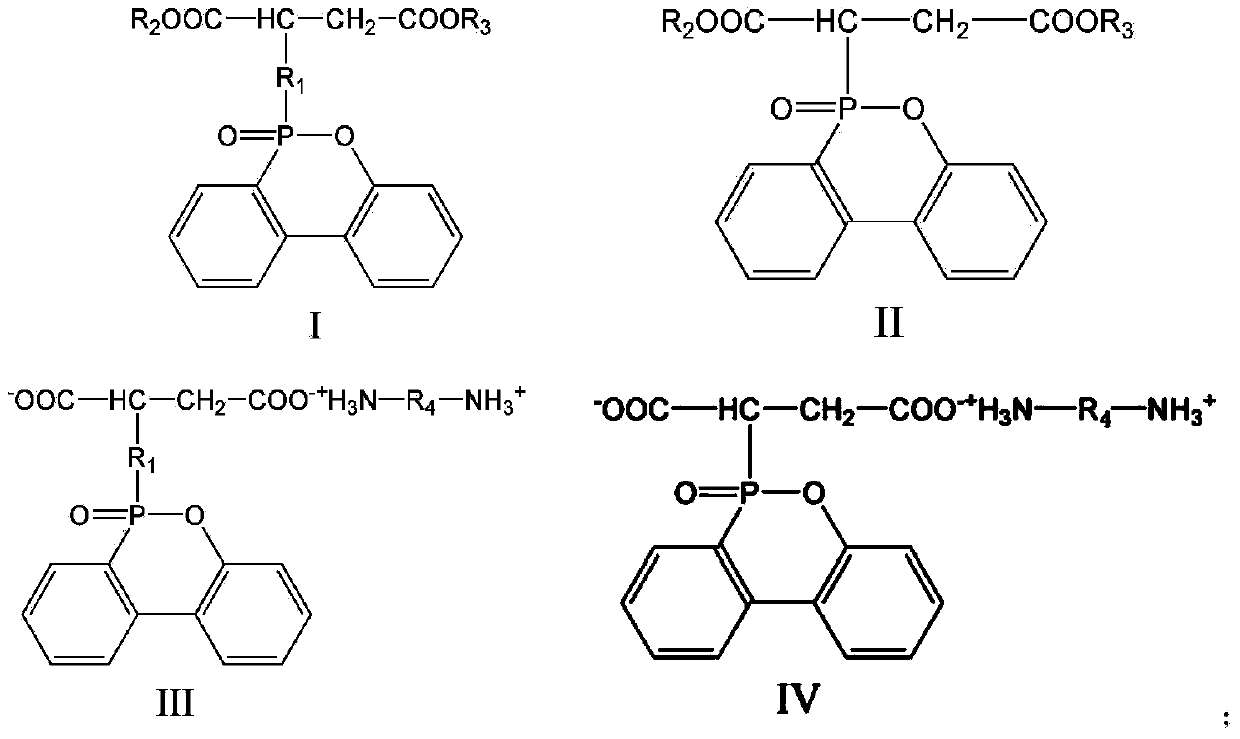

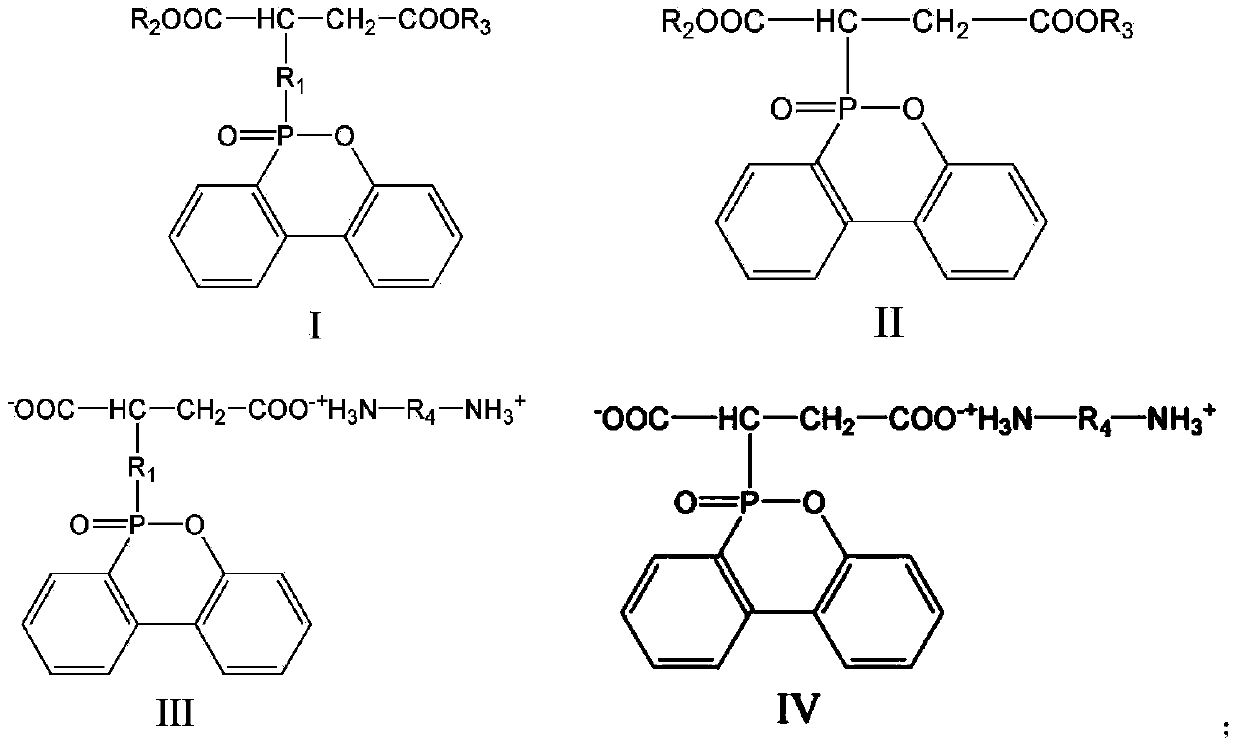

Nylon resin and preparation method thereof

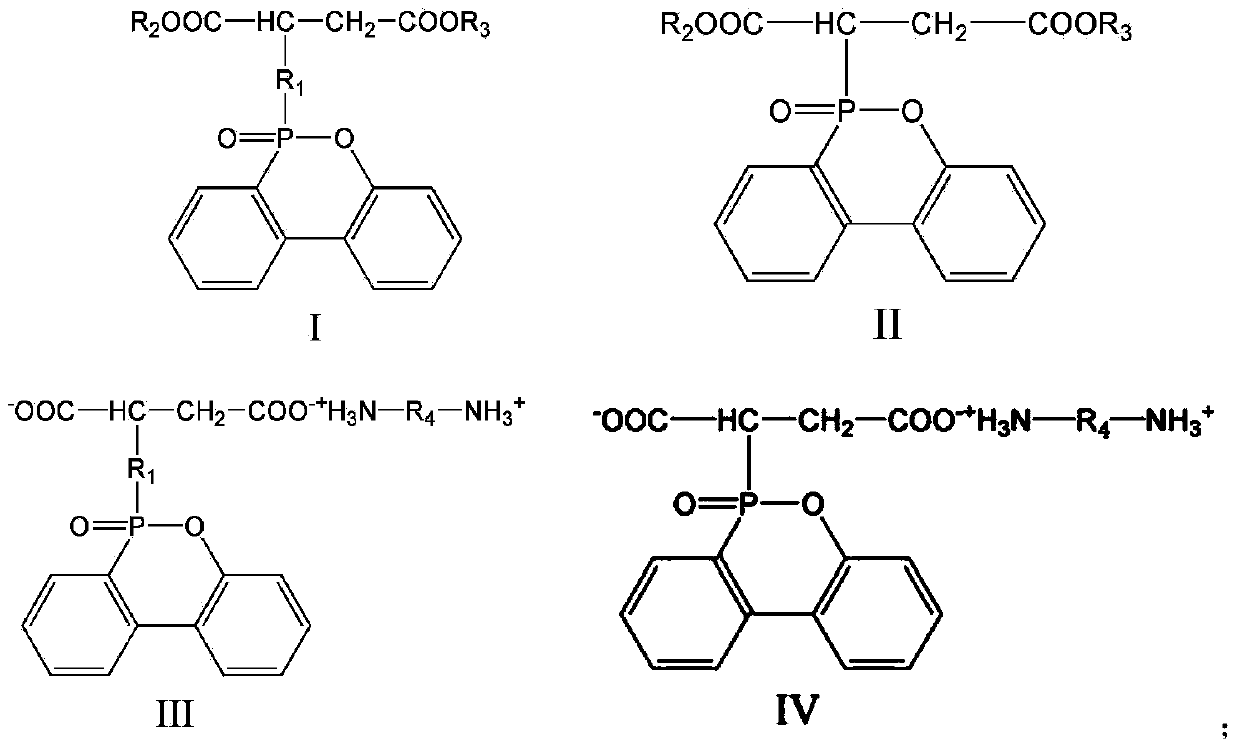

ActiveCN103694468ALittle effect of viscosityGood mechanical propertiesPolymer scienceCarboxyl radical

The invention provides a preparation method of nylon resin, which comprises the following steps of mixing a polymer monomer, a catalyst, a reaction type flame retardant and a charring agent, and performing a condensation polymerization reaction to obtain the nylon resin, wherein the polymer monomer is one or more of compounds containing amino and carboxyl and lactam, or the polymer monomer is diacid and diamine; the reaction type flame retardant is one or more of the compounds with the structures of formulas (I)-(IV). According to method provided by the invention, the reaction type flame retardant is a phosphorus-containing flame retardant; after being copolymerized with a monomer, the reaction type flame retardant is stably stored in the polymer without being transferred or lost and has a permanent flame retardant property. Moreover, the reaction type flame retardant is polymerized in a polymer, causes little influence on the viscosity of the nylon resin and has excellent mechanical properties.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Metallic powder injection molding adhesive

The invention relates to a binder which comprises the following components according to weight percentage: 15 percent to 25 percent of chlorinated polyethylene, 15 percent to 25 percent of polyformaldehyde, 3 percent to 10 percent of rubber, 20 percent to 30 percent of petroleum wax, 15 percent to 25 percent of Brazil wax (palm wax), 1 percent to 5 percent of stearic acid and 1 percent to 5 percent of epoxidized soybean oil. In the forming technique of metal powder, the binder can improve the strength of blank, reduce the damage of the blank and improve the finished yield and the production efficiency.

Owner:PINGHU HAITE ALLOY

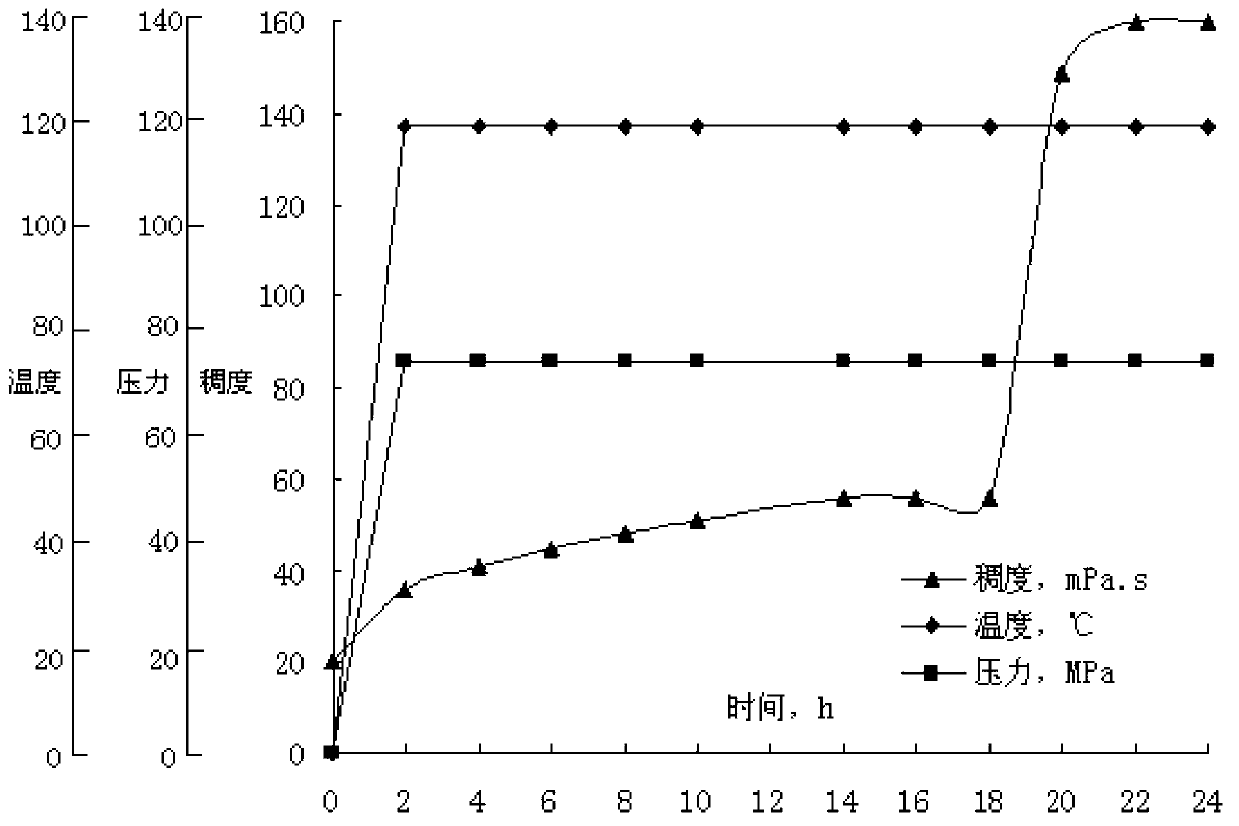

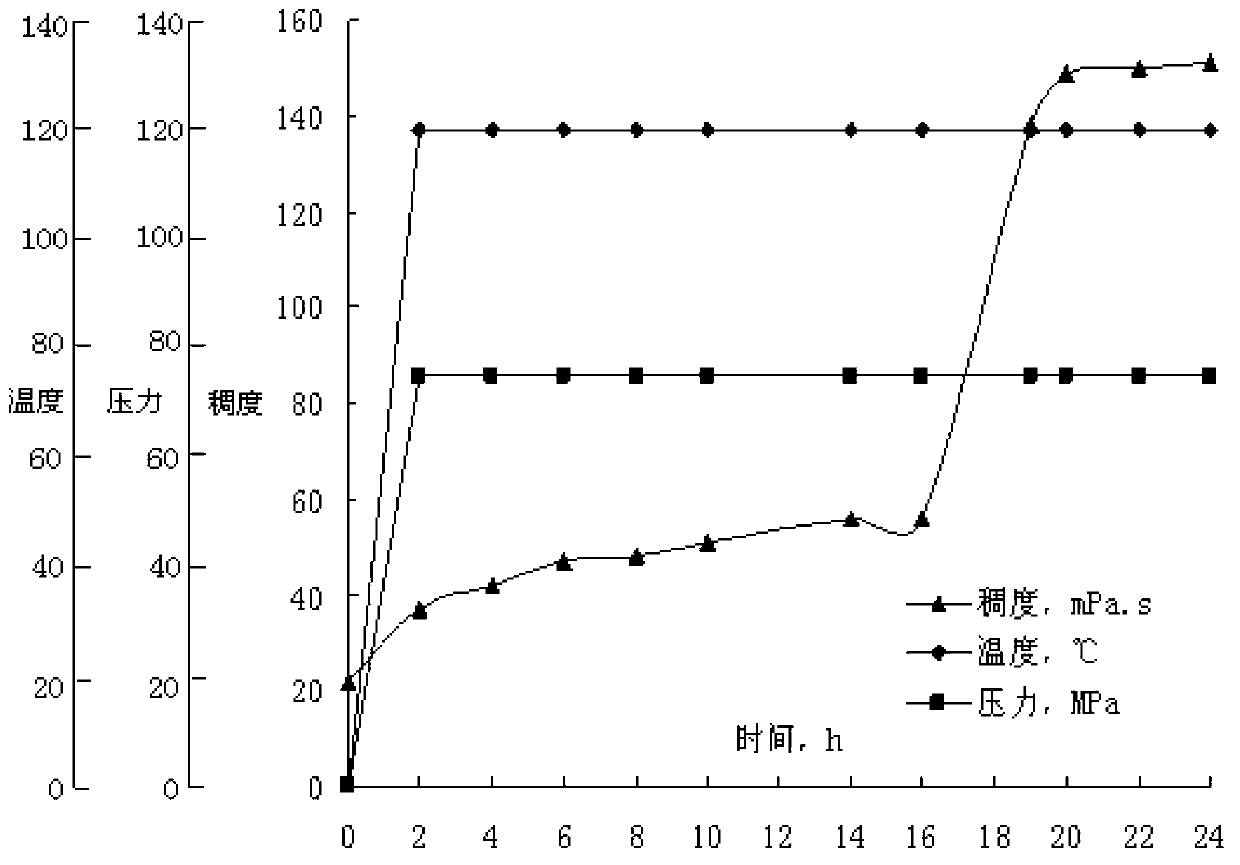

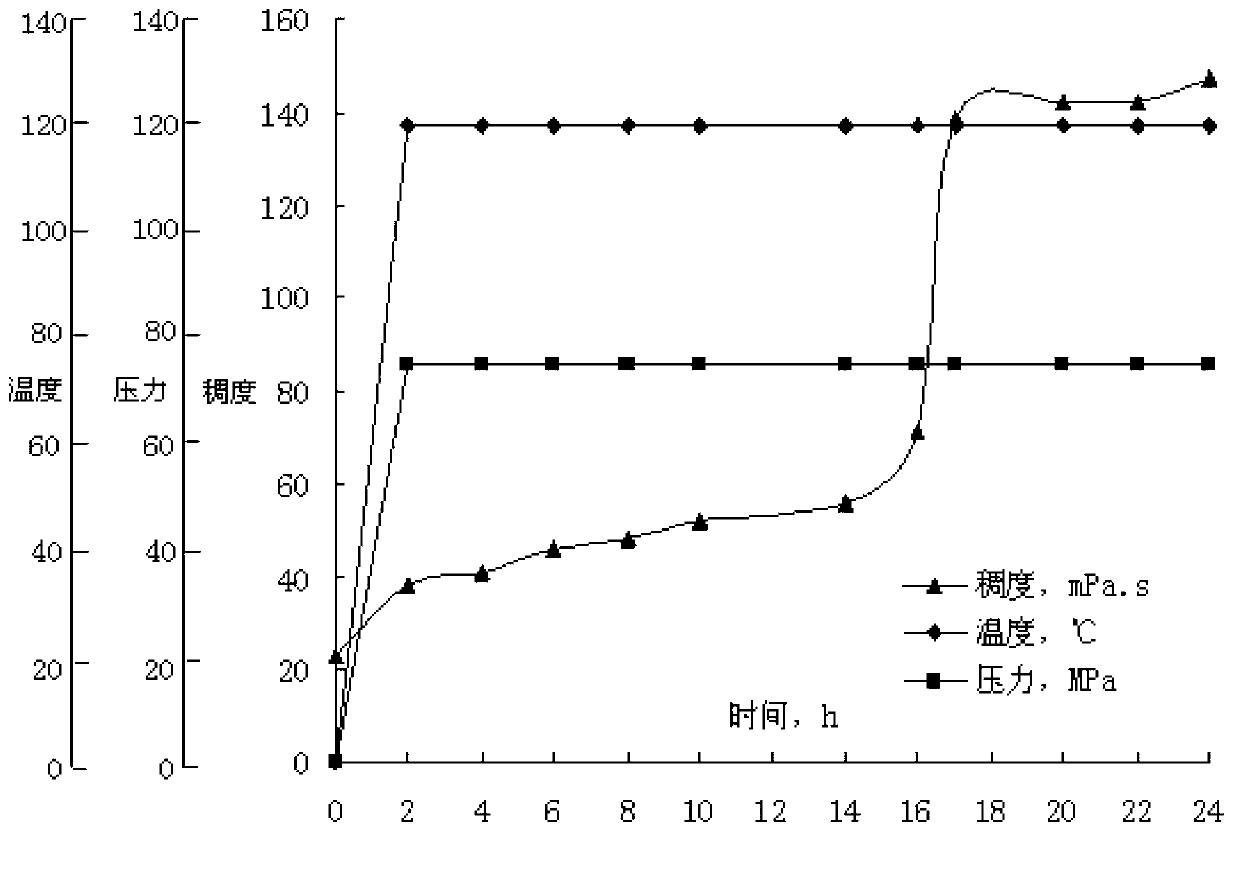

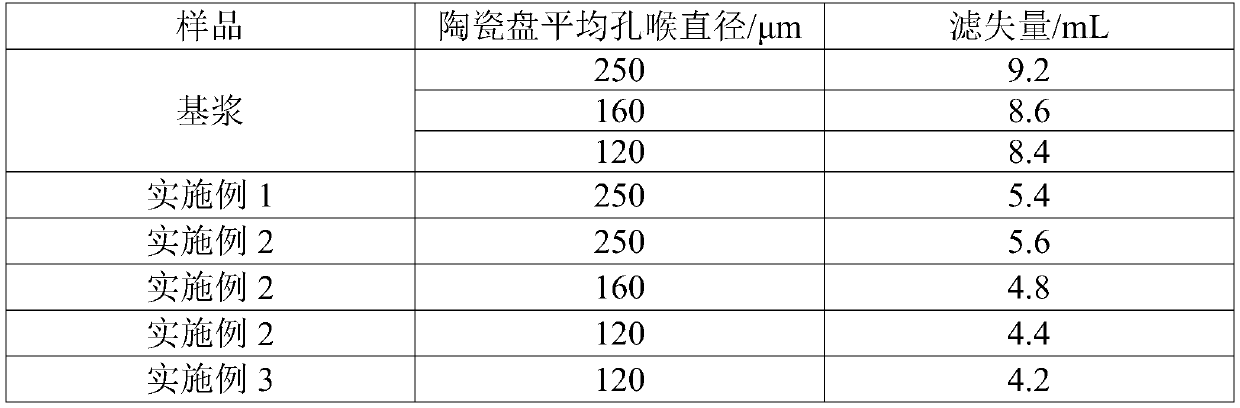

Heat-resistant and salt-resistant profile controlling agent and preparation method thereof

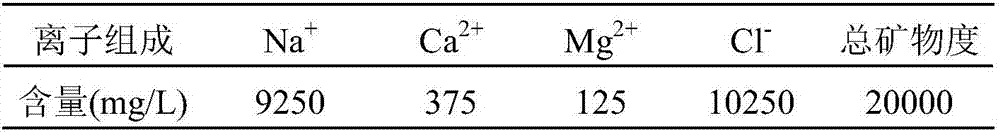

ActiveCN102994057AGood temperature and salt resistanceAdjustable densityDrilling compositionMaterials scienceSlurry

The invention discloses a heat-resistant and salt-resistant profile controlling agent, comprising waste slurry, a slurry curing agent, a strength modifier, a dispersant, a retarder and water. Based on the weight of the waste slurry as 100%, the profile controlling agent comprises 6-12 wt% of the slurry curing agent, 6-12 wt% of the strength modifier, 0.1-1.5 wt% of the dispersant, 0.02-0.15 wt% of the retarder and 6-12 wt% of water. The invention also relates to a preparation method of the heat-resistant and salt-resistant profile controlling agent. The heat-resistant and salt-resistant profile controlling agent is obtained by the steps of adding the slurry curing agent, the strength modifier, the dispersant, the retarder and water in the waste slurry, based on the weight of the waste slurry, and standing for 66-78 hours. The invention also provides an application of the waste slurry in preparing the heat-resistant and salt-resistant profile controlling agent.

Owner:CHINA PETROLEUM & CHEM CORP

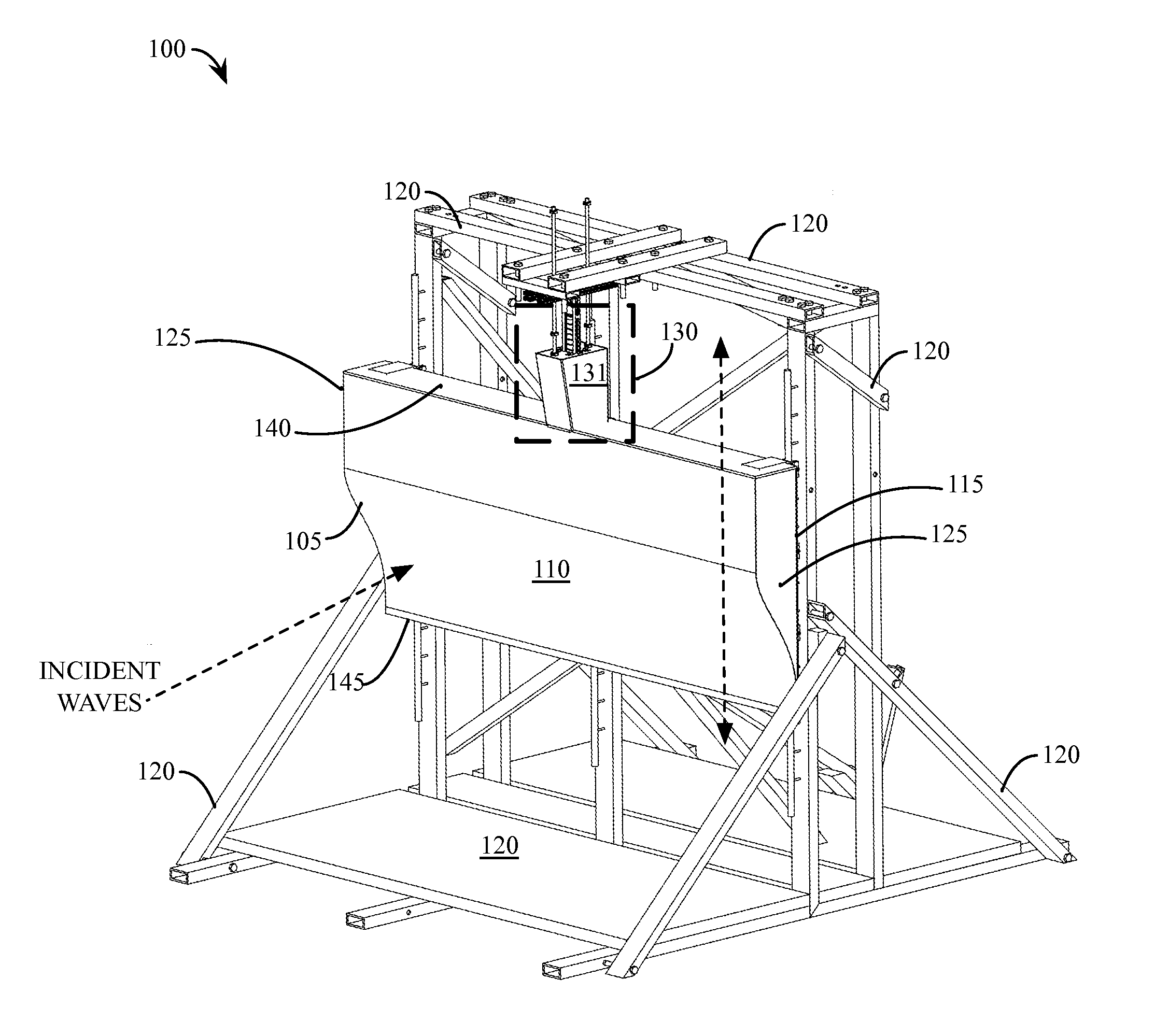

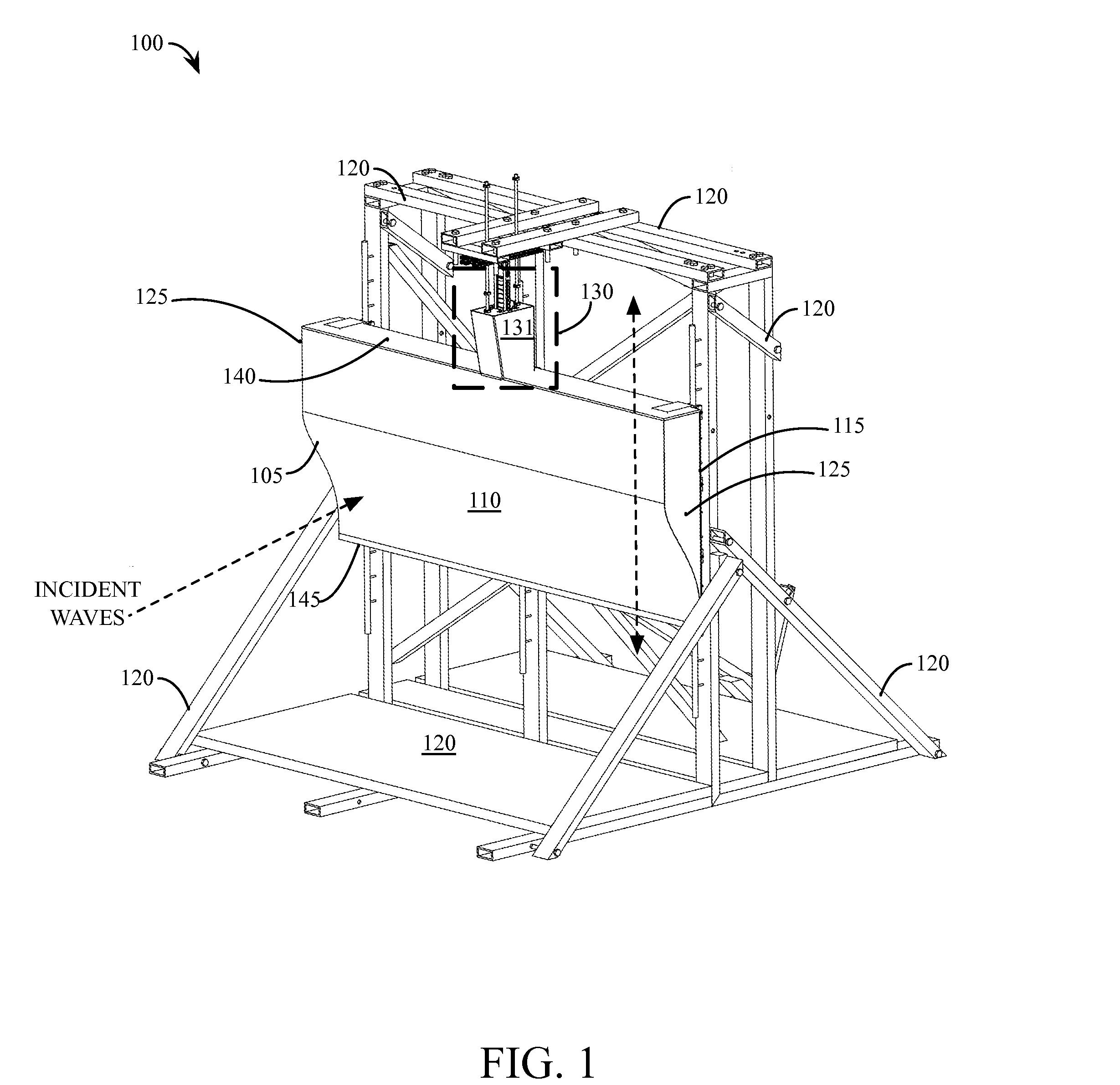

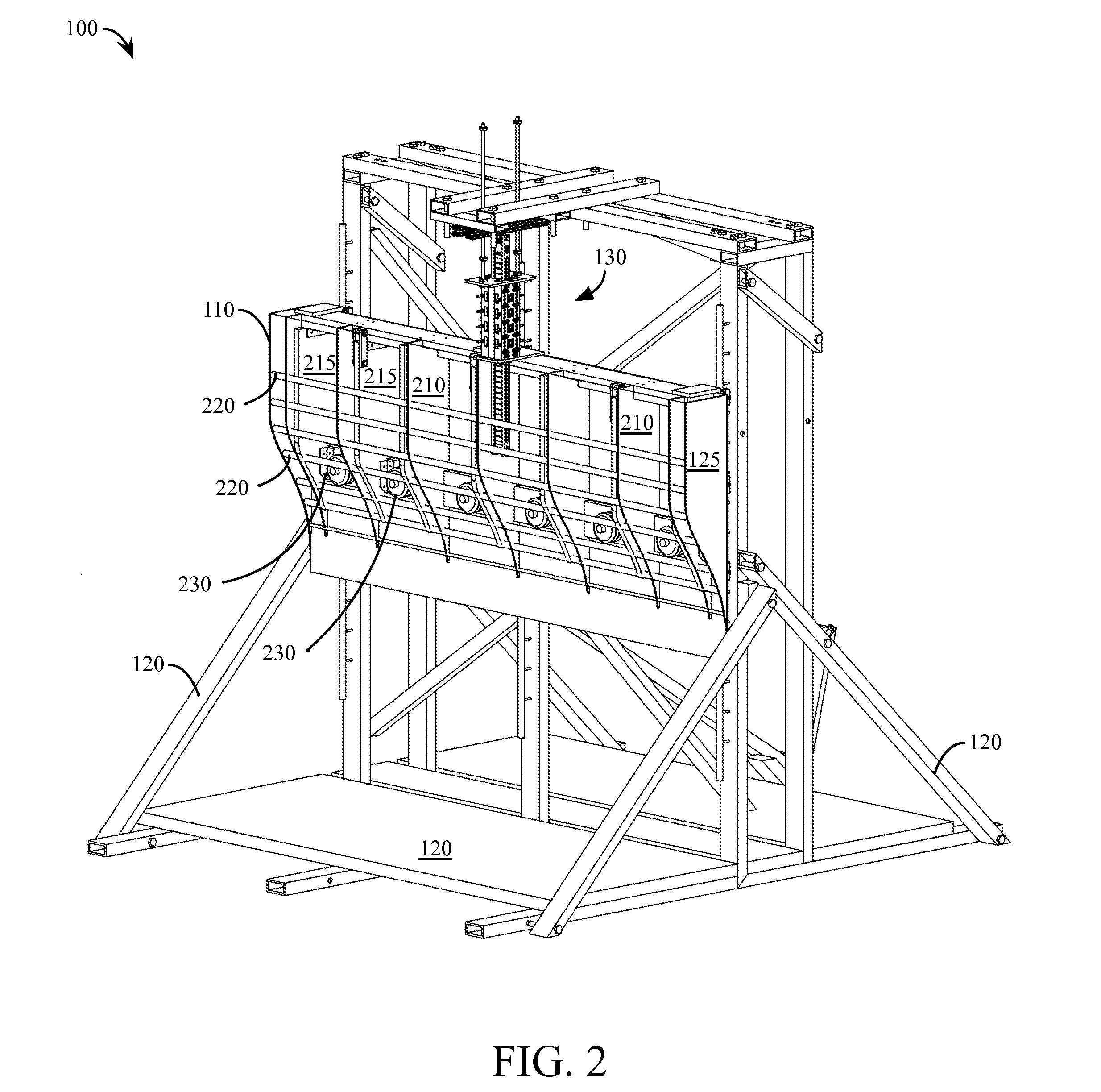

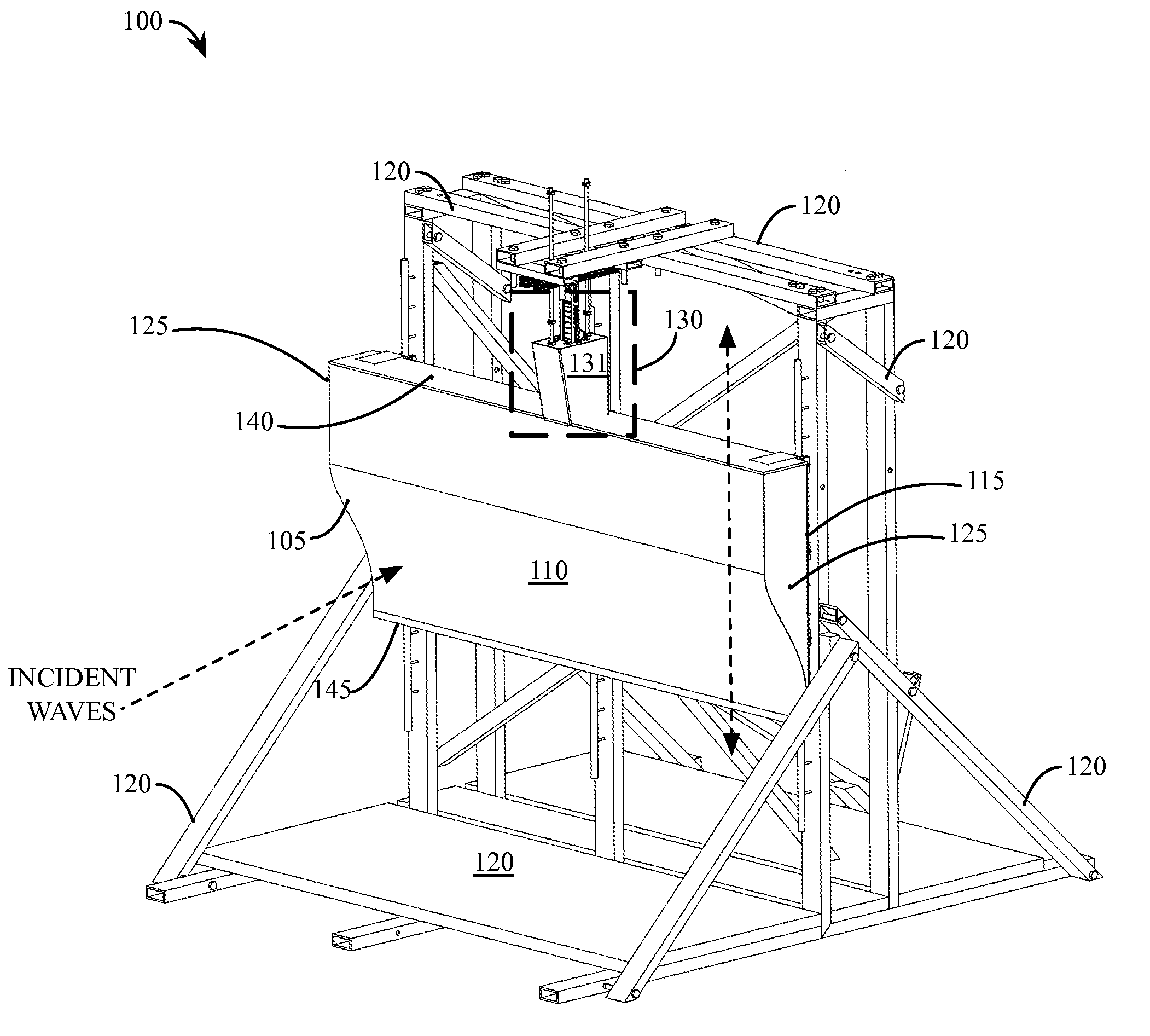

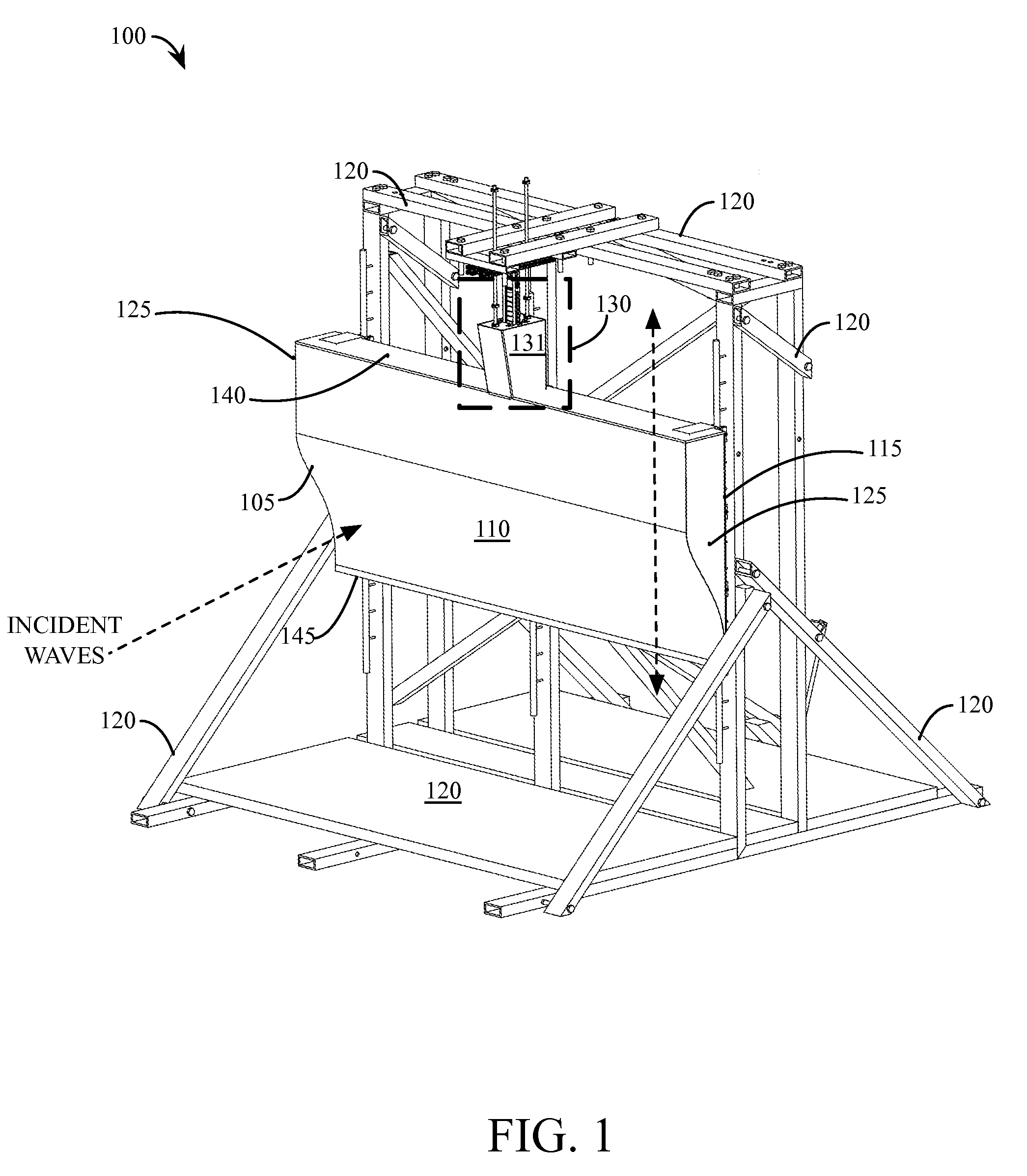

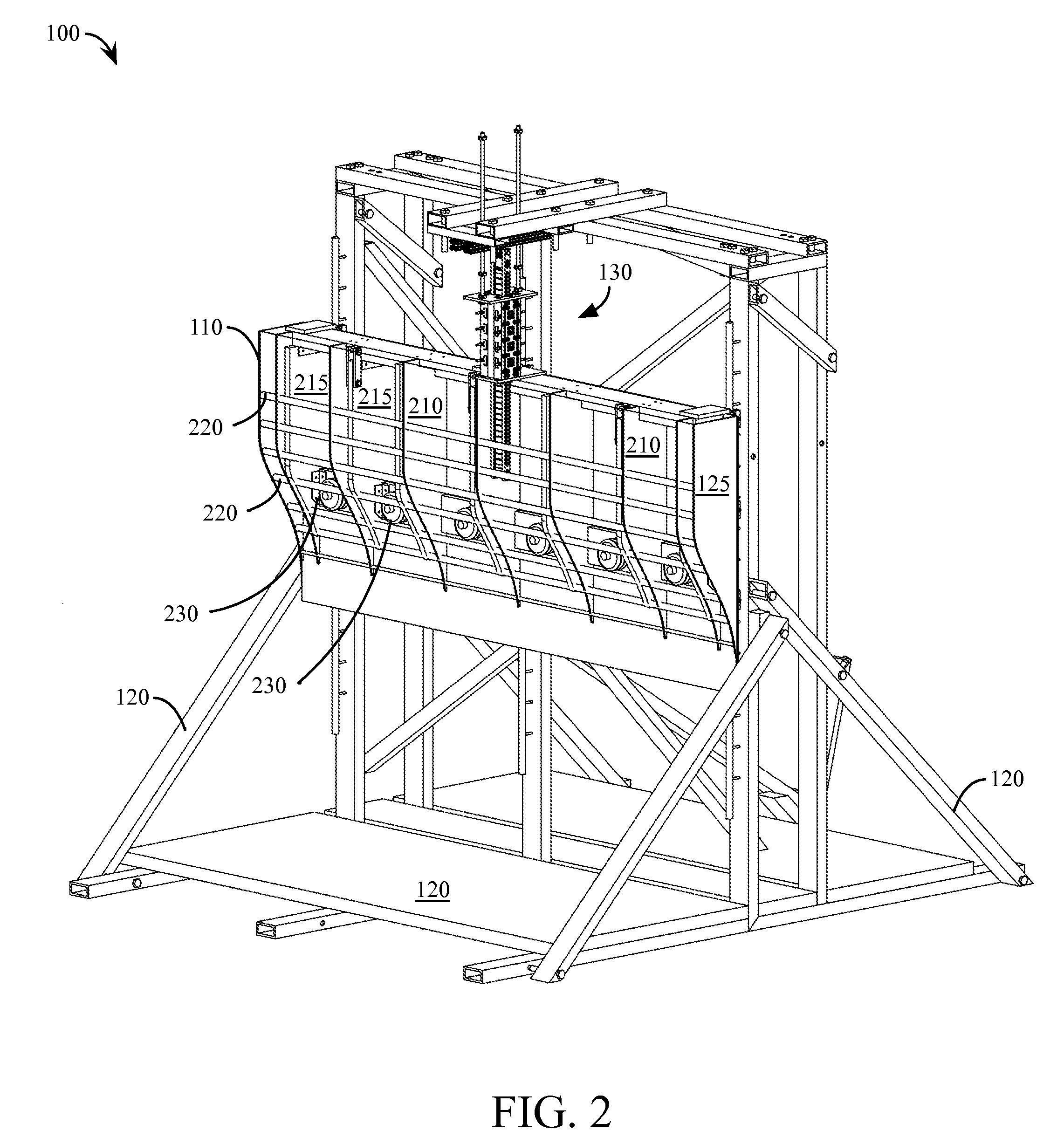

Energy-capturing floating breakwater

InactiveUS20150091304A1% efficiency of energy captureLittle effect of viscosityMachines/enginesEngine componentsSingle degree of freedomPermanent magnet linear generator

Disclosed is a single degree of freedom (DOF) apparatus of extremely high efficiency, which also serves as an effective floating breakwater. The apparatus comprises a unique asymmetric heaving floating body that exhibits minimal influence from viscosity effects. The asymmetric heaving floating body is coupled to a Permanent Magnet Linear Generator (“PMLG”) that serves as a power take off (“PTO”) system. A support structure used to install the apparatus in a desired location is also disclosed. The support structure is designed so as to restrain lateral force and pitching moment. Similarly, the asymmetric floating body is designed to minimize viscosity effects when in motion and for effectively transferring incident wave energy to the PTO. At least one preferred embodiment of the present invention may be referred to by the name “Berkeley Wedge.”

Owner:MADHI FARSHAD +2

Method for achieving continuous pad-dry-cure dyeing of polyester

The invention discloses a method for achieving continuous pad-dry-cure dyeing of polyester. The method comprises the steps of padding of the polyester in a dyeing solution, drying, curing and water processing. The dyeing solution comprises liquid disperse dye, prepolymer A, prepolymer B, prepolymer C, a synthetic thickener and a penetrating agent. The method has the advantages that the dyeing uniformity is good, the dye is not prone to migration in the drying process, the relative fixation rate of the dye is high, the dyefastness is good, colored wastewater discharge almost does not exist, processing equipment is conventional equipment, and the method is a continuous dyeing processing technology achieving energy conservation and emission reduction.

Owner:SUZHOU UNIV

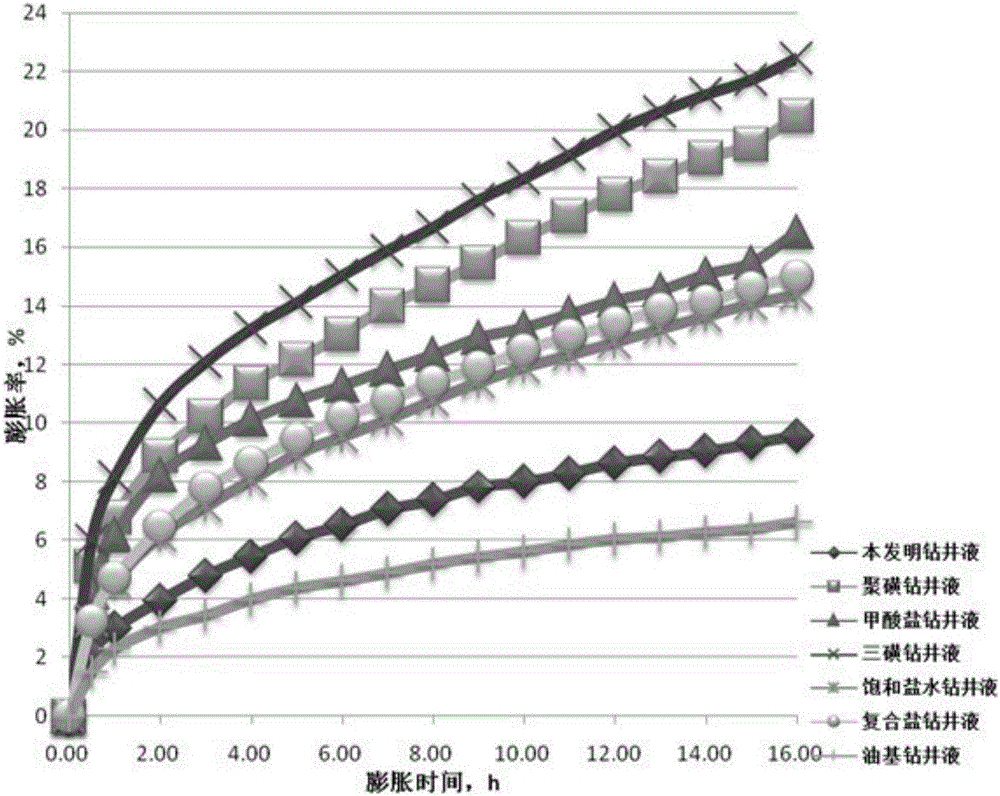

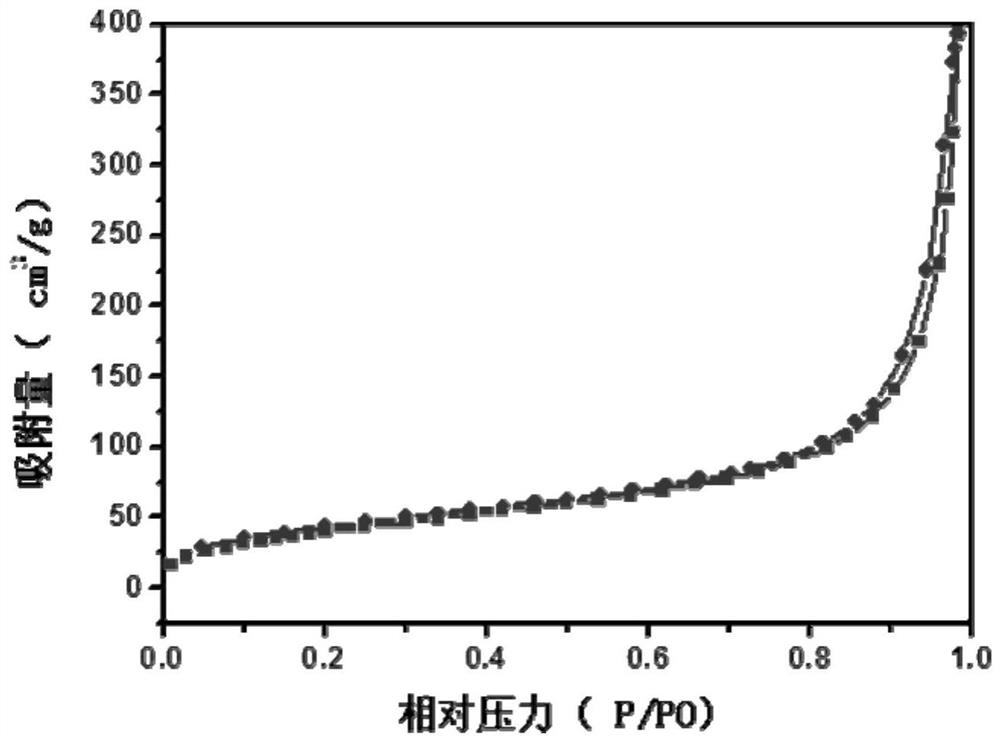

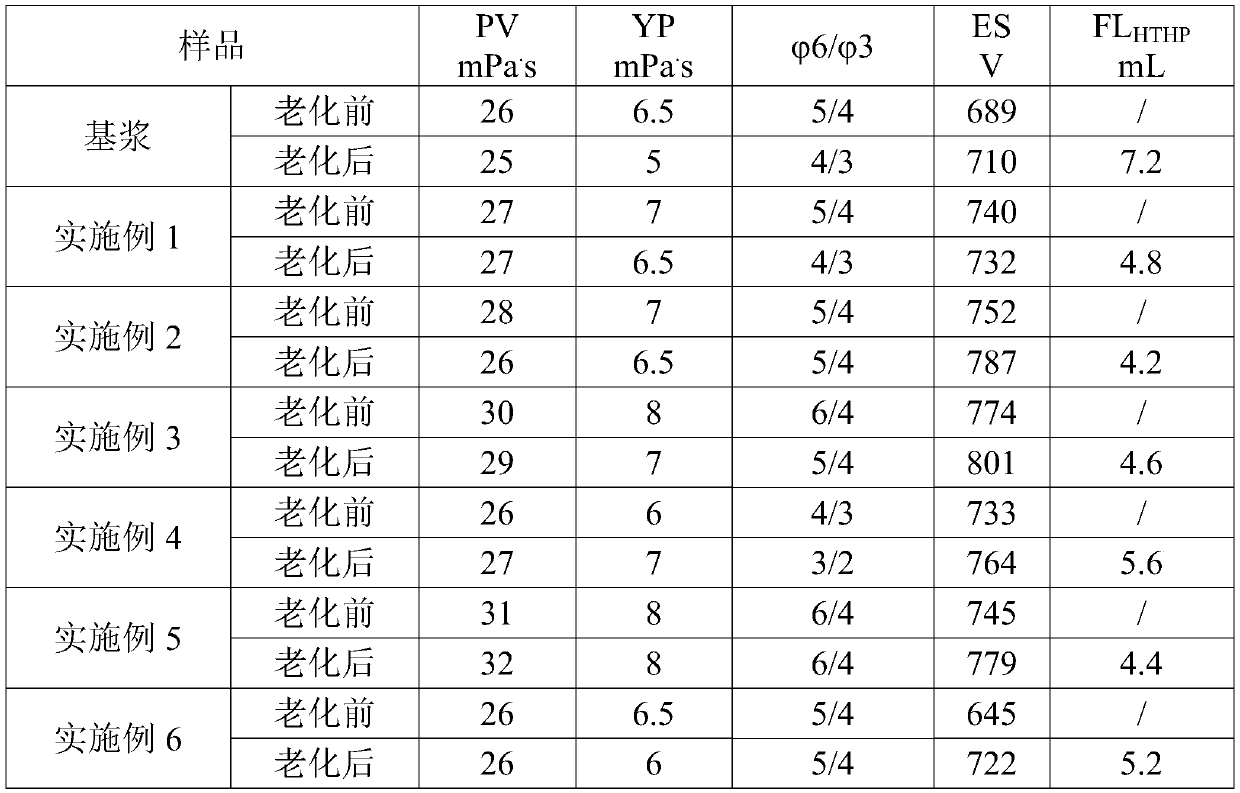

High-density water-based drilling fluid for shale gas horizontal well

ActiveCN105969323AGood sealingEnhanced inhibitory effectDrilling compositionWater basedHorizontal wells

The invention provides high-density water-based drilling fluid for a shale gas horizontal well. The high-density water-based drilling fluid is prepared from, by mass, 3.0%-6.0% of temporary shielding agent, 1.0%-5.0% of inhibitory anti-collapse agent, 2%-5% of solid lubricant, 1.0%-5.0% of balling cleaner, 10%-25% of potassium chloride, 0.1%-0.5% of sodium hydroxide, 1.0%-4.0% of filtrate reducer, 0.2%-0.5% of fluid type modifier, 50%-80% of barite and the balance water. The prepared high-density water-based drilling fluid for the shale gas horizontal well still has excellent blocking and inhibiting performance under the conditions of shale and carbonaceous mudstone, still has good lubricating performance, de-filtration performance and rheological performance under the high-density high-solid-phase condition, can meet the requirements of the shale gas horizontal well, a carbonaceous mudstone horizontal well and construction of other horizontal wells on instable formation for the water-based drilling fluid, and replaces oil-based drilling liquid, and low-cost development of shale gas resources is promoted in the political and economic environment of long-term low oil price.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Cleaning liquid composition for plasma etching residues in semi-conductor industry

InactiveCN101126053AImprove corrosion inhibitionApplicable environment is goodOrganic detergent compounding agentsDetergent mixture composition preparationSolventPolymer

The invention discloses a cleaning liquid combination used for removing plasma-etching residue in semiconductor industry. The cleaning liquid comprises amount of solvent used for effectively washing, buffer aqueous solution, fluoride, antifreeze agent, polymer inhibitor. The cleaning liquid combination of the invention can effectively clean plasma-etching residue in semiconductor industry without eroding SiO2, PETEOS, silicon, low medium material and some metals such as Ti, Al and Cu.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Preparation method of boron-modified phenolic aerogel

PendingCN112175230AHigh compressive strengthLow thermal conductivityHexamethylenetetramineFlight vehicle

The invention relates to a preparation method of a boron-modified phenolic aerogel. The method comprises the following steps of: dissolving linear phenolic resin, tributyl borate and other organic boric acids in an ethanol solution, adding a cross-linking agent hexamethylenetetramine, carrying out an initial low-viscosity sol-gel process to obtain a boron composite phenolic wet gel, and carrying out normal-pressure drying to obtain the boron modified phenolic aerogel. And tributyl borate and other organic boron sources can be uniformly mixed in the solution, so that the viscosity of the systemis unchanged or slowly rises, thereby effectively ensuring the stability of the glue injection process. In addition, boron particles form boron oxide in the ablation application process, and the boron oxide permeates into gaps of the phenolic aerogel to fill the gaps of the phenolic aerogel and melt and coat a phenolic matrix. The prepared boron-modified phenolic aerogel has the advantages of good specific surface area, oxidation resistance, low heat conductivity coefficient and density, good processability and the like, can maintain the original shape and performance at high temperature, andis expected to be applied to the field of external thermal protection of high-speed aircrafts.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Oil-based drilling fluid blocking agent and preparation method thereof

The invention discloses an oil-based drilling fluid blocking agent and a preparation method thereof. The oil-based drilling fluid blocking agent is prepared from a solid state mixture being 60 to 150meshes prepared by compounding oil-containing plant residue materials containing rich plant fiber and auxiliary materials accounting for 0.2 to 1 percent of the oil-containing plant residue materials,wherein the oil-containing plant residue materials are residue left after the grease removal from the oil-containing plant; the auxiliary materials are at least one kind of materials from calcium carbonate powder, magnesium stearate powder, talcum powder, superfine silica powder and calcium hydrophosphate powder with the mesh number being smaller than or equal to 60 meshes. The blocking agent isobtained through proportionally mixing the oil-containing plant residue materials and then performing drying, crushing, grinding and sieving. The preparation method is simple; the raw materials can beeasily obtained; the cost is low. The oil-based drilling fluid blocking agent has the characteristics of water absorption and oil absorption expansion, deformation capability, degradability, oleophilic performance and easy dispersion; the influence on the viscosity of the drilling fluid is small; waste materials can be reused; the cost is low; the environment is protected.

Owner:CNPC BOHAI DRILLING ENG

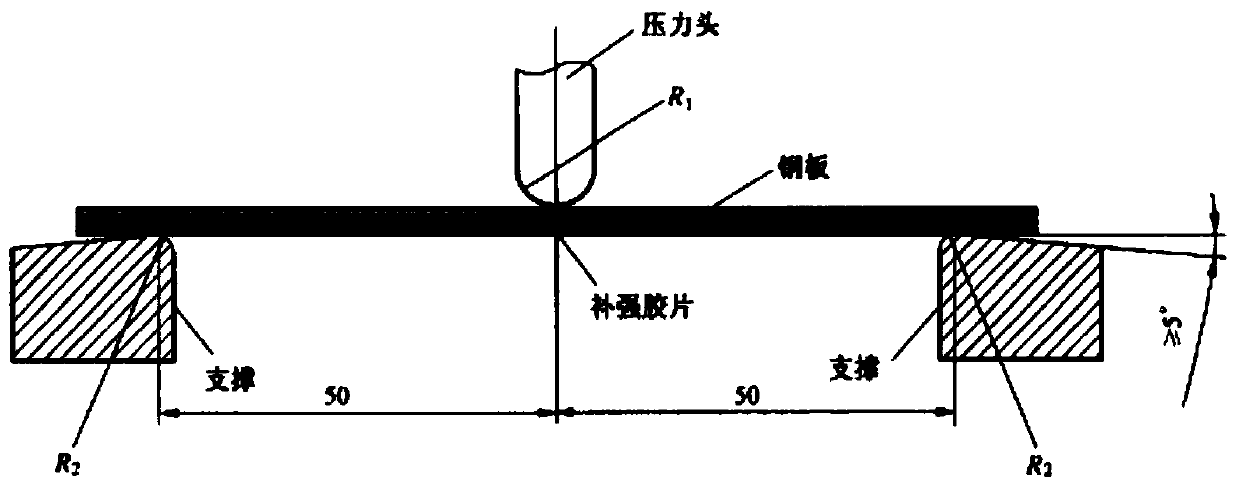

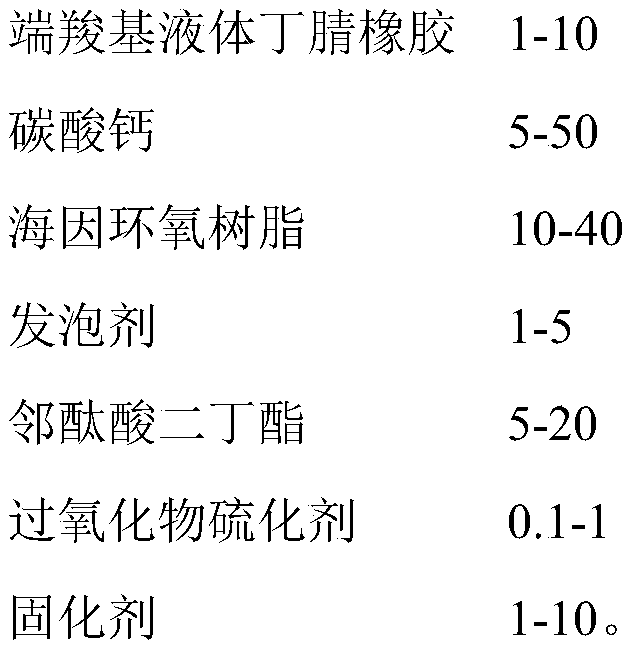

High-foaming reinforcing rubber sheet

ActiveCN111423836AGood compatibilityHigh initial adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceNitrile rubber

In order to solve the problems of fixed thickness and unsatisfactory reinforcing effect of conventional automobile reinforcing rubber sheets, the invention provides a high-foaming reinforcing rubber sheet. The reinforcing rubber sheet is composed of the following substances in parts by mass: 1-10 parts of carboxyl-terminated liquid nitrile rubber, 5-50 parts of calcium carbonate, 10-40 parts of hydantoin epoxy resin, 1-5 parts of a foaming agent, 5-20 parts of dibutyl phthalate, 0.1-1 part of a peroxide vulcanizing agent and 1-10 parts of a curing agent. The reinforcing rubber sheet of the invention has the advantages that the reinforcing rubber sheet is lighter and is beneficial for promoting lightweighting of an automobile; the strength of the reinforcing rubber sheet can be improved through microcellular foaming, and under a foaming condition, reinforcing multiplying power can also reach 5-6 times; meanwhile, due to the existence of a mesoporous structure, damping effect is better,the stress of the reinforcing rubber sheet during epoxy curing can be dispersed due to the existence of micropores; the reinforcing rubber sheet has better conformability during application, and doesnot causes deformation of a steel plate.

Owner:重庆钧业新材料科技股份有限公司

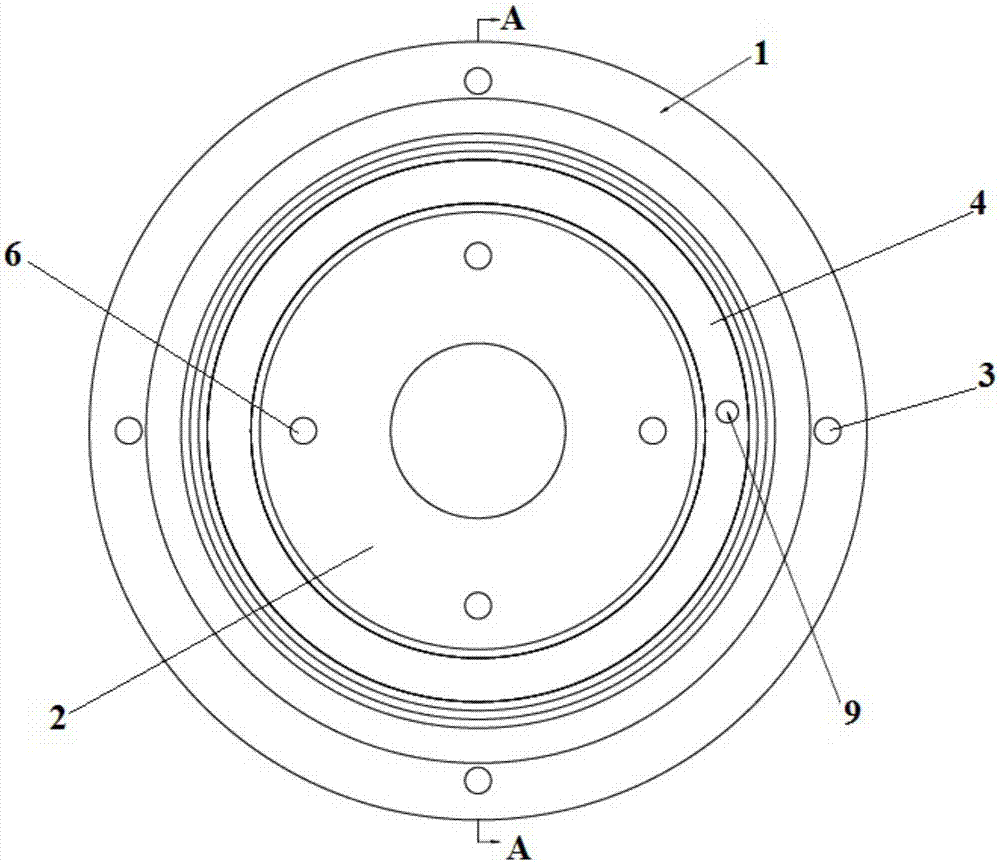

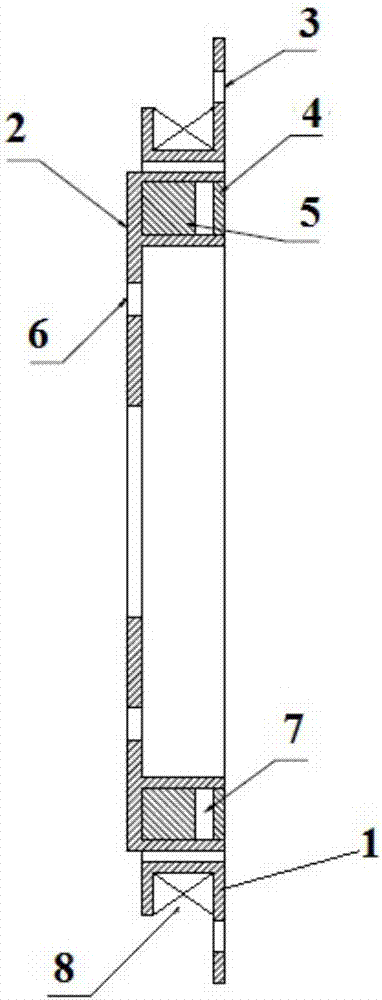

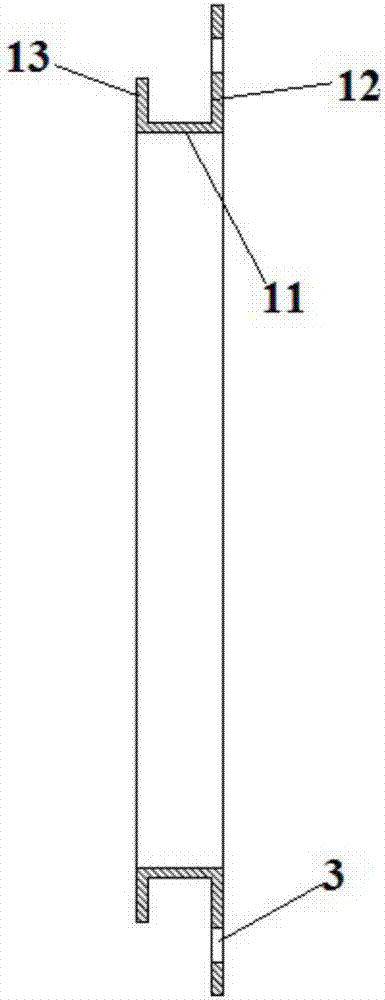

Self-adaptation magnetorheological fluid torsion damper

ActiveCN106870621AEfficient consumptionAvoid resonanceRotating vibration suppressionSpringsElectricityResonance

The invention relates to a self-adaptation magnetorheological fluid torsion damper. The self-adaptation magnetorheological fluid torsion damper comprises a damper shell fixedly connected with a crankshaft, a coil support arranged on the outer side of the damper shell in a sleeving manner and fixedly connected with an engine shell, an electromagnetic coil wound around the coil support, a current controller electrically connected with the electromagnetic coil, and a magnetorheological fluid damping unit arranged on the damper shell in the circumferential direction and used in cooperation with the electromagnetic coil. In the work state, the current controller adjusts the current of the electromagnetic coil, the electromagnetic coil generates a magnetic field with the corresponding intensity, accordingly, friction damping of the magnetorheological fluid damping unit is changed so that energy for torsion vibration can be consumed, and resonance is avoided. Compared with the prior art, the self-adaptation magnetorheological fluid torsion damper is simple and compact in overall structure, small in size and good in sealing performance, friction damping is adjustable, the torque adjusting effect is good, and safety and reliability are achieved.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation technology of on-rust antirust heavy duty anticorrosion paint

InactiveCN104693990AHigh solid contentLittle effect of viscosityAnti-corrosive paintsPolyurea/polyurethane coatingsSolid contentHeavy duty

The invention relates to a preparation technology of on-rust antirust heavy duty anticorrosion paint and belongs to the technical field of on-rust antirust heavy duty anticorrosion paint preparation. The preparation technology comprises the following steps of 1, stirring, 2, grinding, 3, dispersion, 4, resin preparation, 5, paint preparation and 6, stirring. The preparation technology has simple processes and can produce the paint with high permeability, high solid content and low viscosity. The paint can go through a rust layer and passivate active and harmful iron compounds in the rust layer into a harmless filling material.

Owner:QINGDAO HUICHENG PETROCHEM TECH

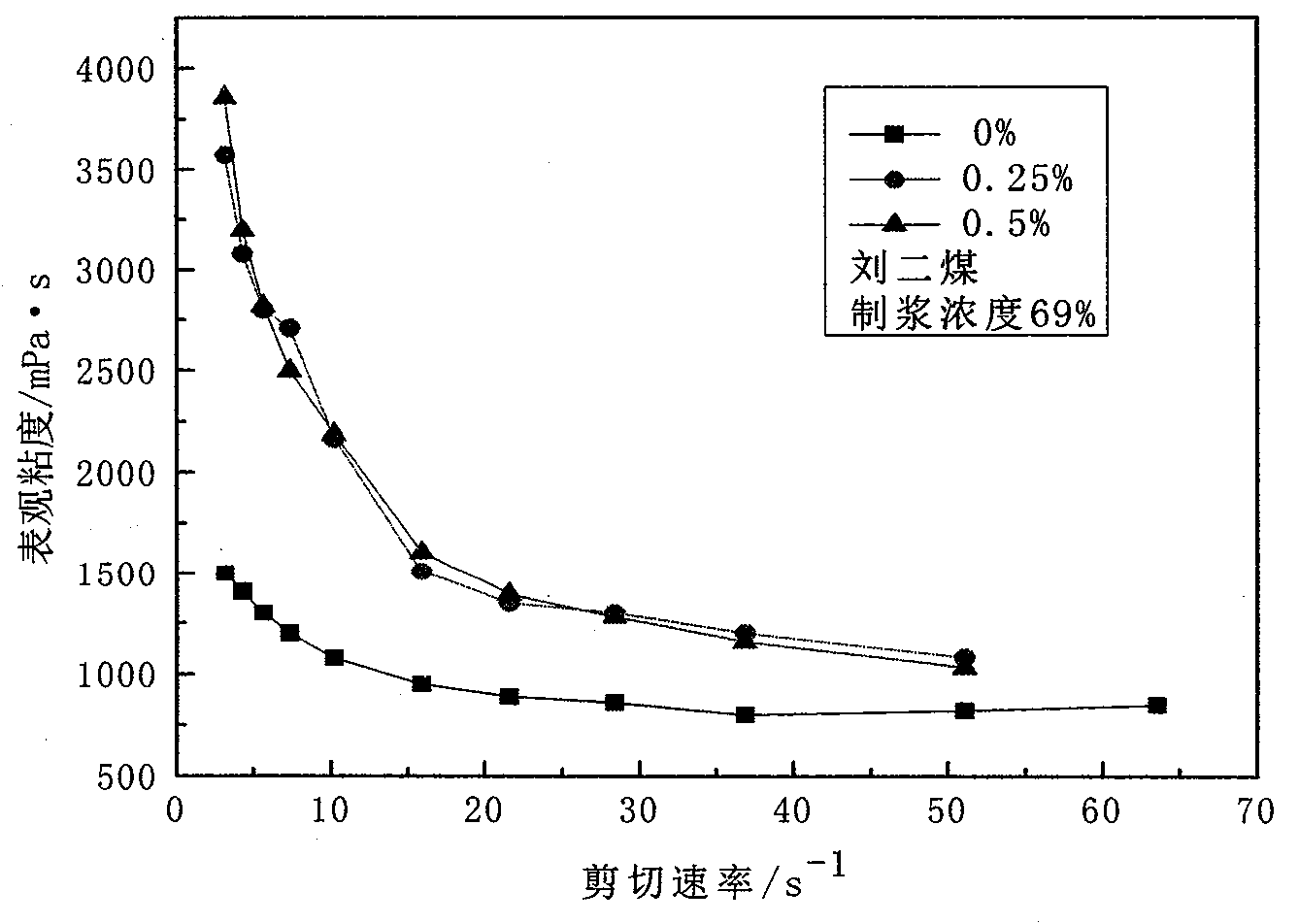

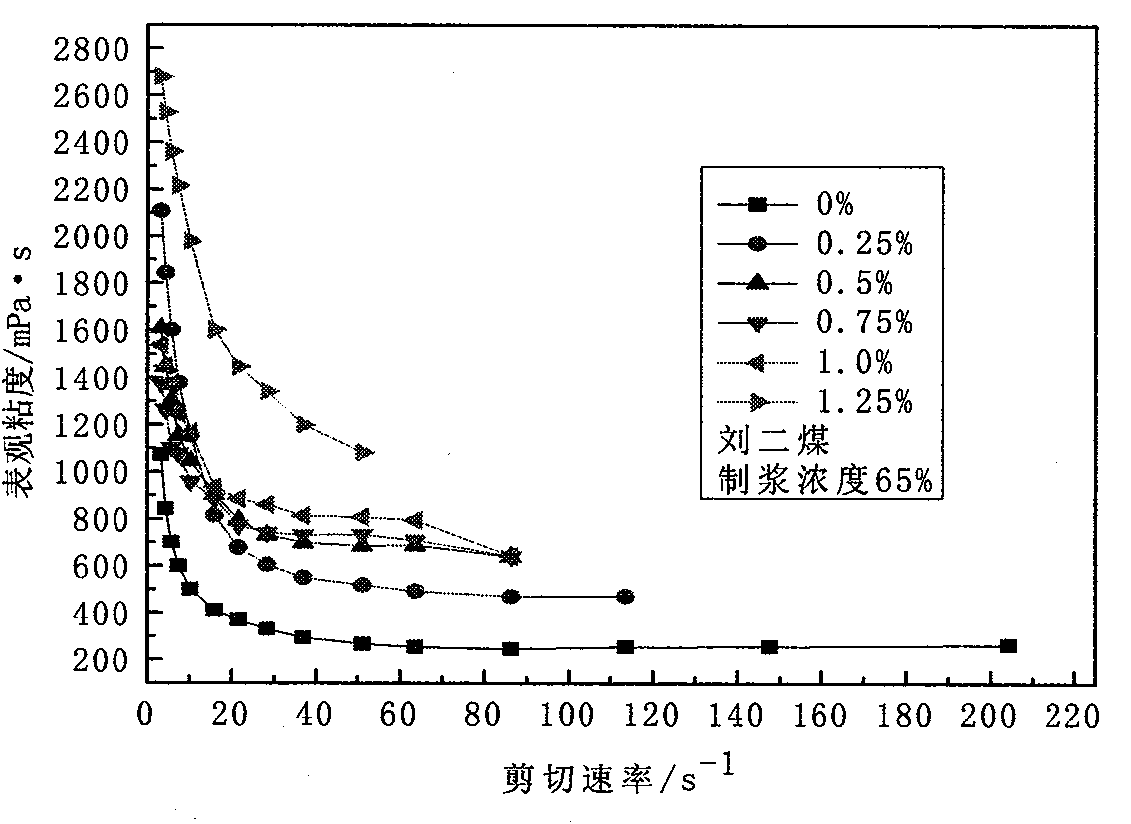

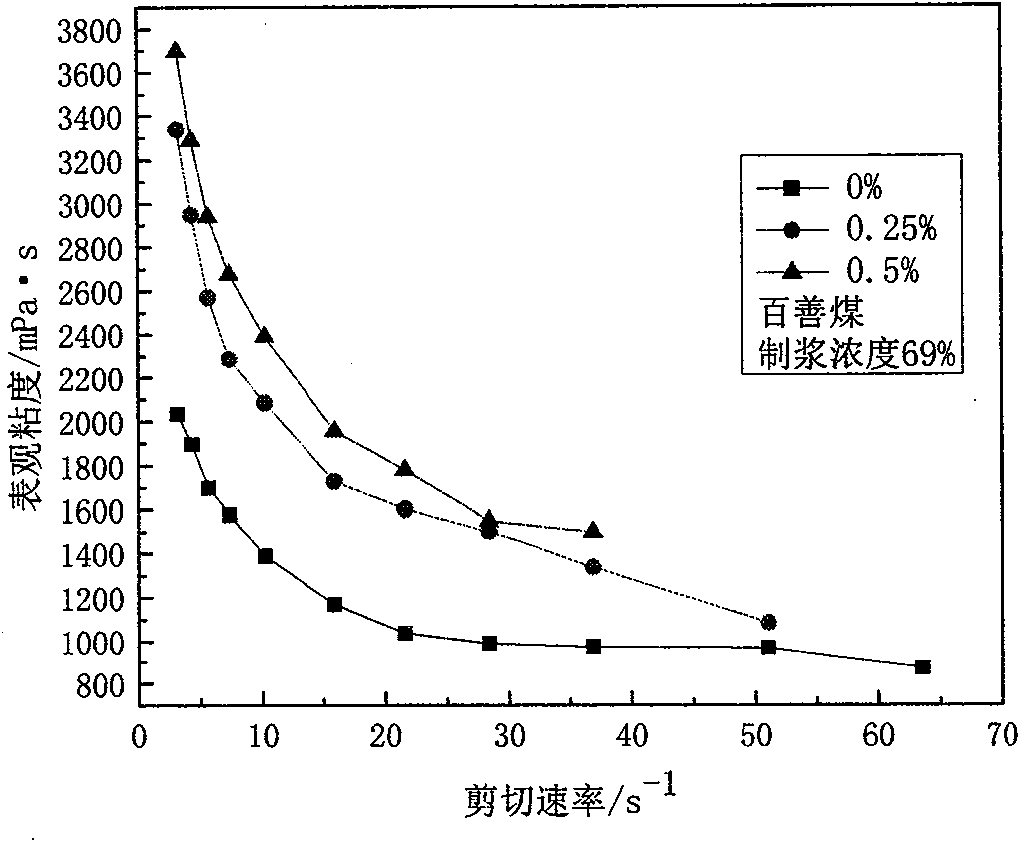

High-stability coal water slurry and preparation method thereof

InactiveCN101831329ALittle effect of viscosityLow water separation rateLiquid carbonaceous fuelsLump/pulverulent fuel preparationCoal waterCoal slurry

The invention relates to high-stability coal water slurry and a preparation method thereof. The coal water slurry contains coal powder, an additive, a stabilizer and water and has the mass concentration of 64-70 percent, wherein antibiotic fungi residues are adopted as the stabilizer, the addition of a fungi residue dry base is 0.1-1.5 percent of the total mass of a coal powder dry base and the fungi residue dry base, the addition of the additive is 1.0-2.0 percent of the mass of the coal water slurry, and the rest is water, and the antibiotic fungi residue comprises lincomycin wet bacteria residues, gentamicin wet bacteria residues and penicillin wet bacteria residues. In the preparation process of the coal water slurry, the antibiotic fungi residues are added, have less viscosity influence on the coal water slurry, but can remarkably decrease the syneresis rate of the coal water slurry and improve the stability of the coal water slurry, the slurry can be placed for a long time, and the requirements for pumping, atomizing, transporting in various modes, combusting and gasifying can be met. The method has low cost, not only can improve the stability of the coal water slurry, but also provides a new path for solving the problem of environmental pollution due to the antibiotic fungi residues.

Owner:ANHUI HUAIHUA

A kind of method of continuous heat-melt dyeing of polyester

The invention discloses a method for continuous heat-melt dyeing of polyester, which comprises the steps of padding the polyester with a dyeing solution, drying, baking and washing with water. The dyeing solution includes liquid disperse dye, prepolymer A, prepolymer B, prepolymer C, synthetic thickener and penetrant. The advantage of this method is that the uniformity of dyeing is good, the dye does not migrate during drying, the relative fixation rate of the dye is high, the color fastness is excellent, and there is almost no discharge of colored wastewater, and the processing equipment is all conventional equipment. Continuous dyeing processing technology for energy saving and emission reduction.

Owner:SUZHOU UNIV

Process for preparing rust-bearing rust-proof heavy-duty coating

ActiveCN102690558BHigh solid contentLittle effect of viscosityAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceHeavy duty

The invention relates to a process for preparing a rust-bearing rust-proof heavy-duty coating and belongs to the technical field of rust-bearing rust-proof heavy-duty coating preparation. The process comprises the following steps: 1) stirring; 2) grinding; 3) dispersing; 4) preparing a resin; 5) preparing the coating; and 6) stirring. The production process is simple and quick, and the produced coating has high permeability, high solid content and low viscosity and can passivate active and harmful iron compounds in a rust layer into harmless fillers.

Owner:PENGLAI WEIYANG NEW MATERIALS

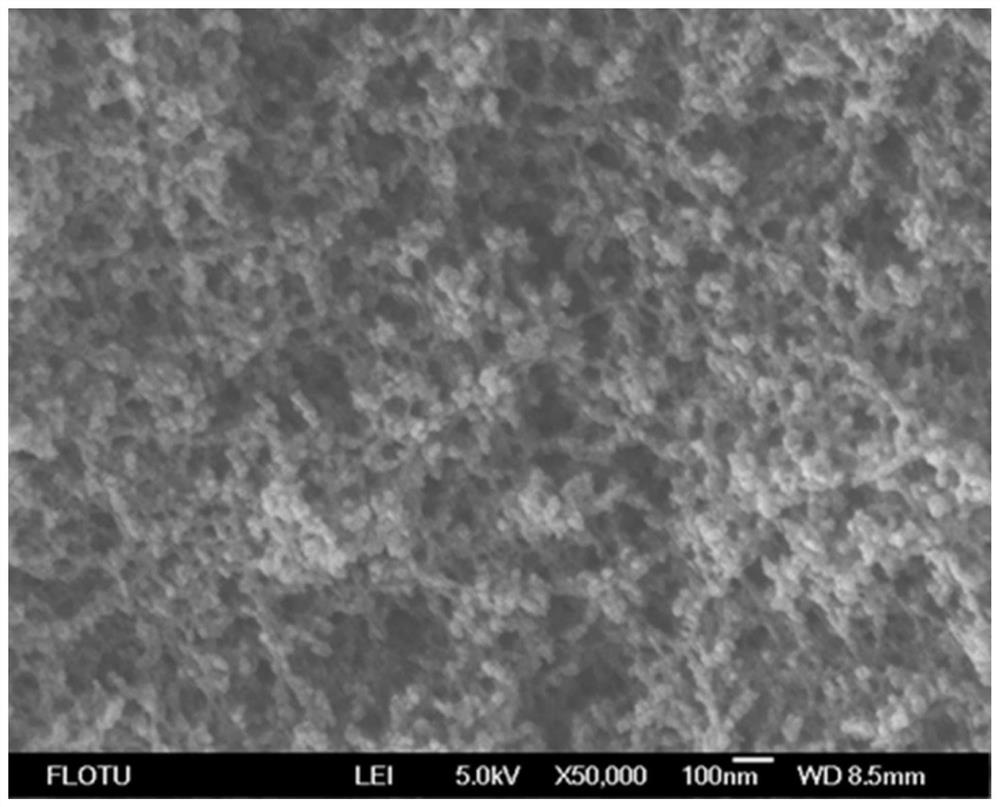

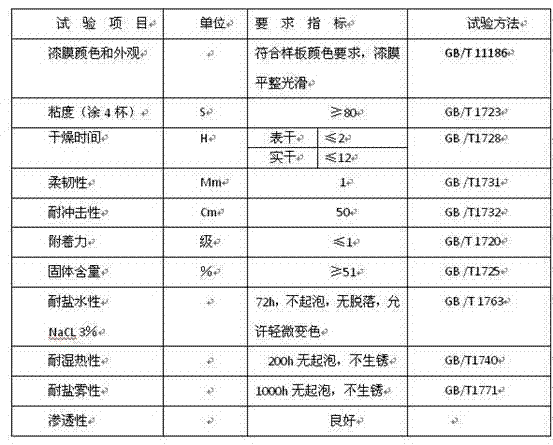

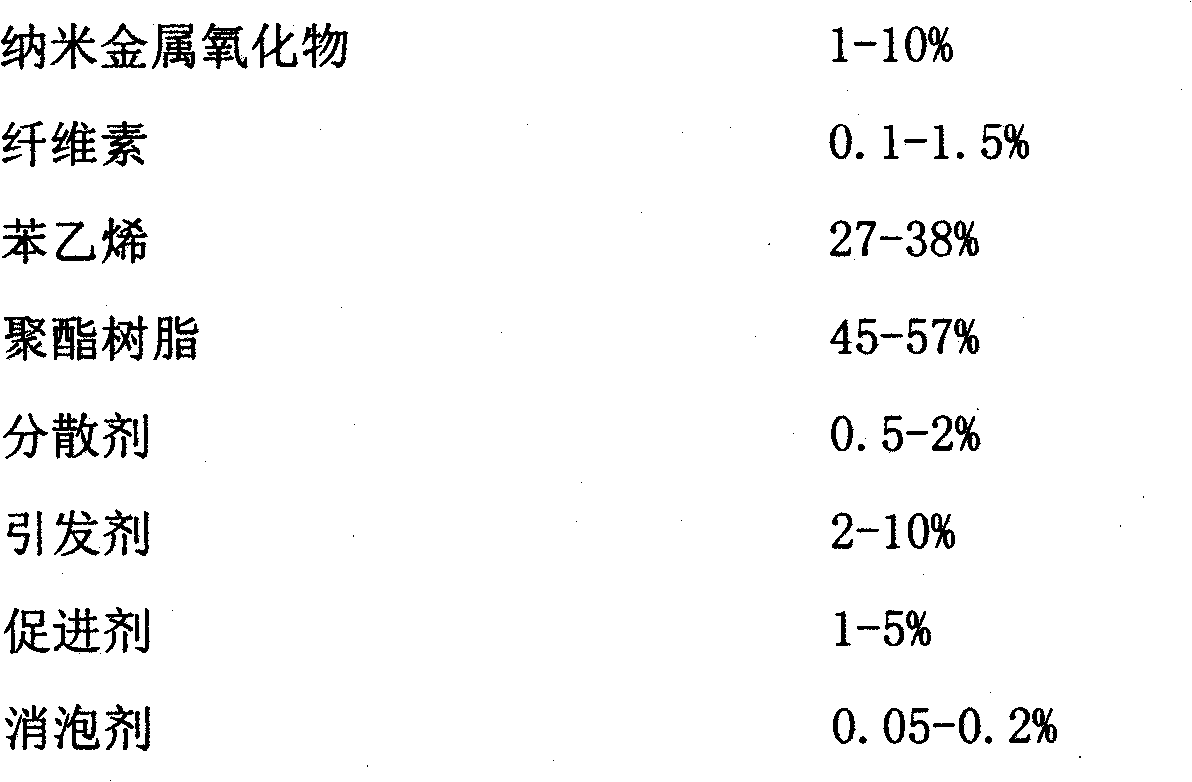

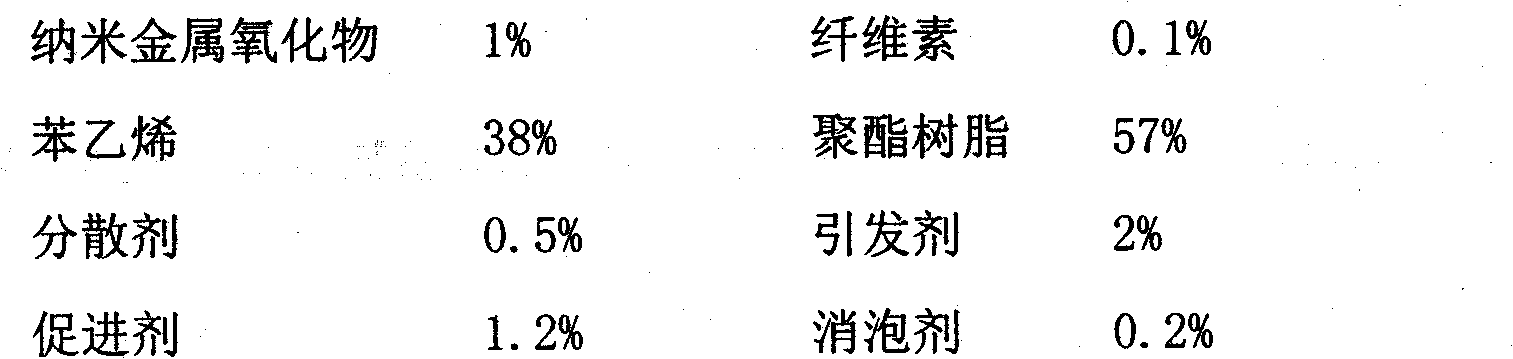

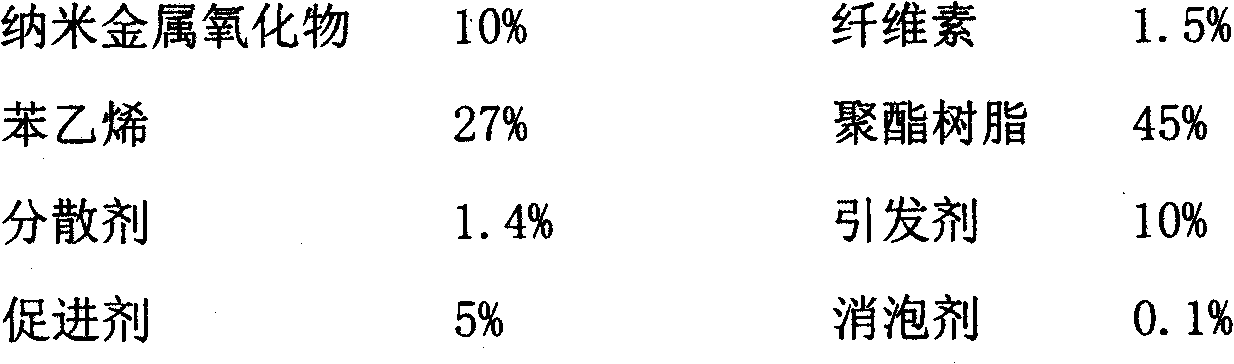

Special nanometer composite seal paint for woodware and preparing method thereof

The invention relates to special nanometer composite seal paint for woodware and a preparing method thereof, and belongs to the technical field of coating. The special seal paint is composed of nanometer metal oxide, cellulose, styrene, polyester resin, a dispersing agent, an initiating agent, an accelerating agent and a defoaming agent. The method provided by the invention comprises the following steps of: carrying out organic modification on the surface of nanometer metal oxide, preparing nanometer slurry, adding polyester resin, the defoaming agent, the initiating agent and the accelerating agent, and stirring and mixing uniformly to obtain the product. The method provided by the invention has short process flow, is simple, convenient and safe to operate and has small pollution to environment; and the product prepared by the method provided by the invention has the characteristics that the nanometer metal oxide has good dispersion stability, good permeability and levelling property, high hardness, strong adhesive force and the like. The method can be widely applied to preparation of nanometer composite paint for woodware, and the product prepared by the preparation method is particularly suitable to be used as the seal paint of woodware.

Owner:CHONGQING UNIV

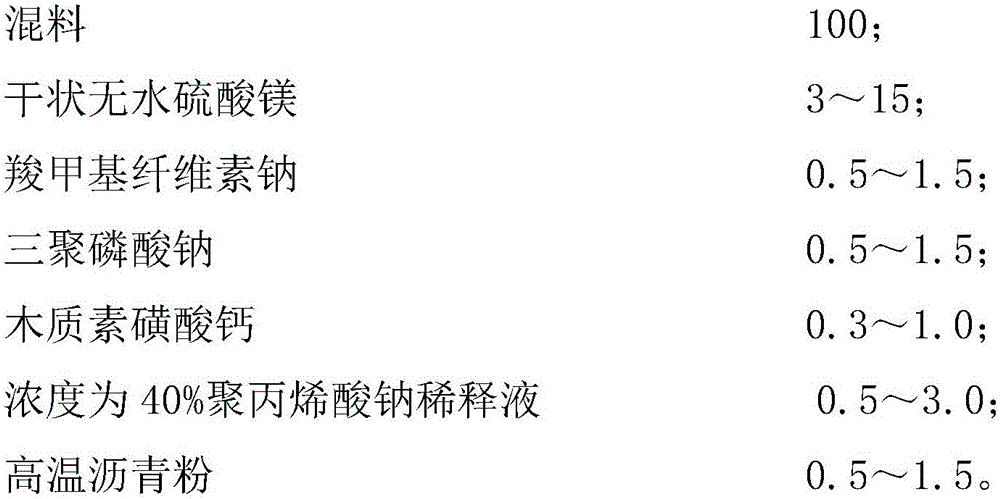

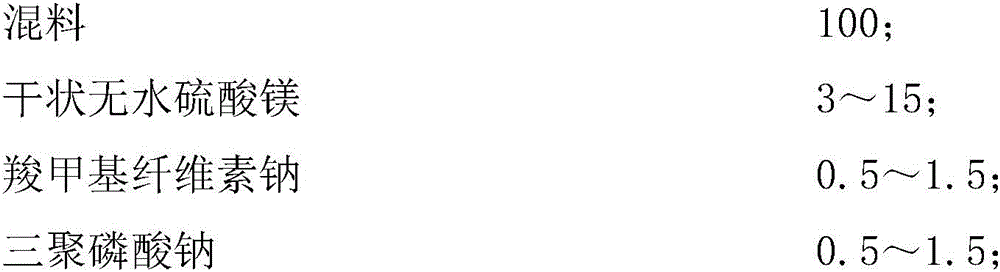

Novel high-viscosity high-fluidity magnesium refractory mortar

The invention discloses novel high-viscosity high-fluidity magnesium refractory mortar, which is prepared from the following raw materials in parts by weight: 100 parts of mixed material, 3 to15 parts of dry anhydrous magnesium sulfate, 0.5 to 1.5 parts of sodium carboxymethyl cellulose, 0.5 to 1.5 parts of sodium tripolyphosphate, 0.3 to 1.0 part of calcium lignosulphonate, 0.5 to 3.0 parts of sodium polyacrylate with the concentration of 40% and 0.5 to 1.5 parts of high-temperature asphalt powder. The novel high-viscosity high-fluidity magnesium refractory mortar has the advantages of being high in bonding strength, excellent in workability, stable in volume, good in high temperature performance, good in erosion resistance and washing-out resistance and capable of avoiding bleeding; the viscosity of the refractory mortar is obviously improved, and the fluidity of the refractory mortar is improved on the premise of not increasing the water addition amount; thus, the purpose of prolonging the service life of brick bodies, linings and a furnace is achieved.

Owner:北京利尔高温材料股份有限公司

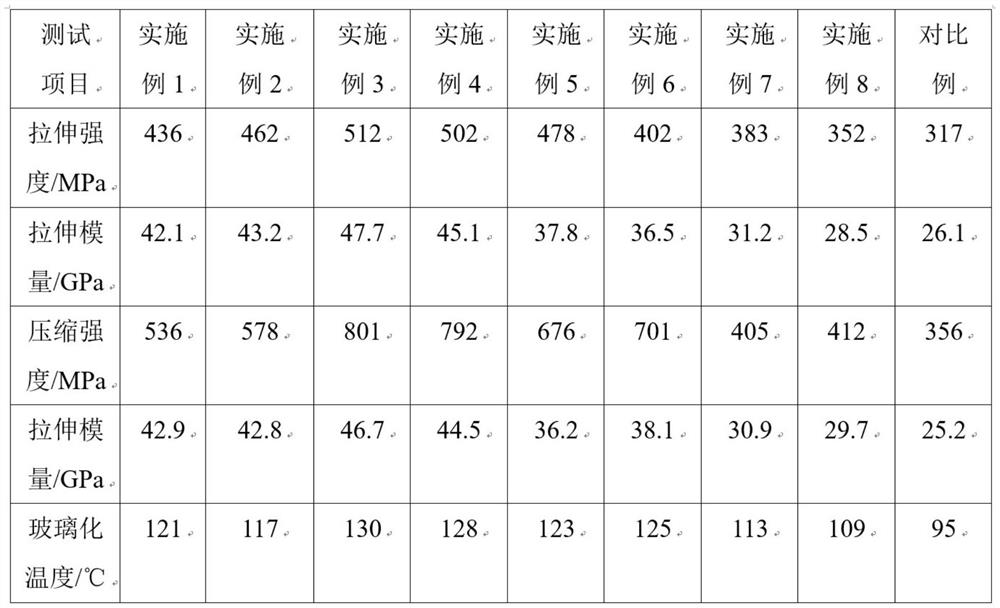

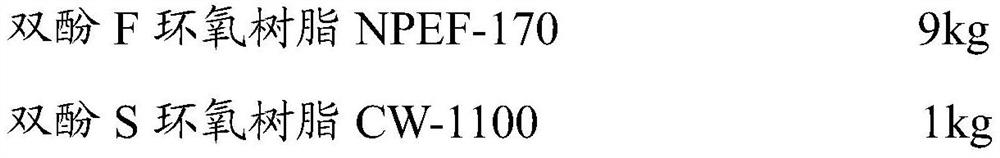

Epoxy resin composition capable of being rapidly cured at medium and low temperatures, epoxy resin-based composite material and preparation method thereof

ActiveCN113292819AFast medium and low temperature curing speedHigh glass transition temperaturePolymer scienceFirming agent

The invention provides an epoxy resin composition capable of being rapidly cured at medium and low temperatures, an epoxy resin-based composite material and a preparation method thereof. The epoxy resin composition capable of being rapidly cured at medium and low temperatures comprises the following components in parts by weight: 100 parts of epoxy resin, 0.1-5 parts of an imidazole accelerant, 2-40 parts of filler, 30-200 parts of an anhydride curing agent, 1-40 parts of a toughening agent and 0.5-10 parts of a release agent. According to the epoxy resin composition capable of being rapidly cured at medium and low temperatures, the epoxy resin-based composite material and the preparation method of the epoxy resin-based composite material, the medium and low temperature curing time of the epoxy resin-based composite material can be obviously shortened through cooperation of the anhydride curing agent, the imidazole accelerant and other raw materials in the epoxy resin composition; meanwhile, the pultrusion speed of the composite material in a pultrusion process is remarkably improved, and the composite material is excellent in mechanical property and high in glass transition temperature.

Owner:北玻院(滕州)复合材料有限公司

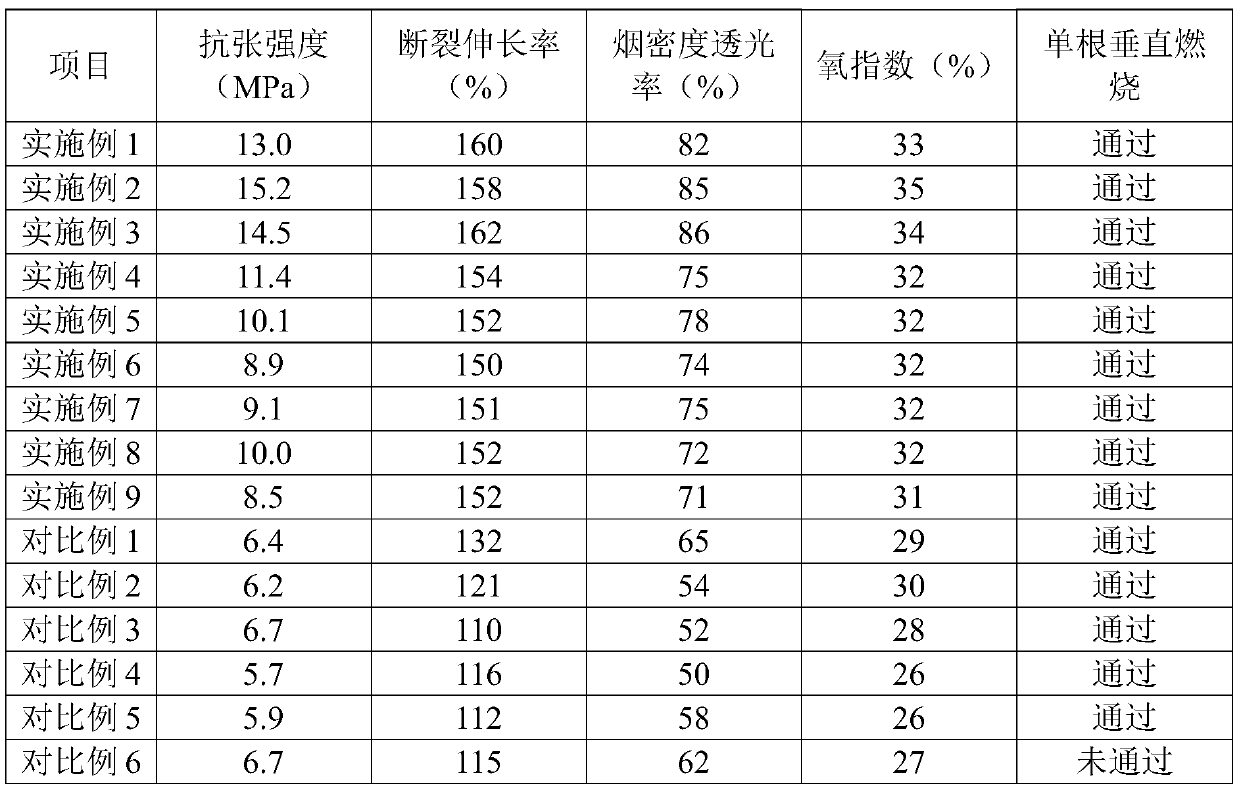

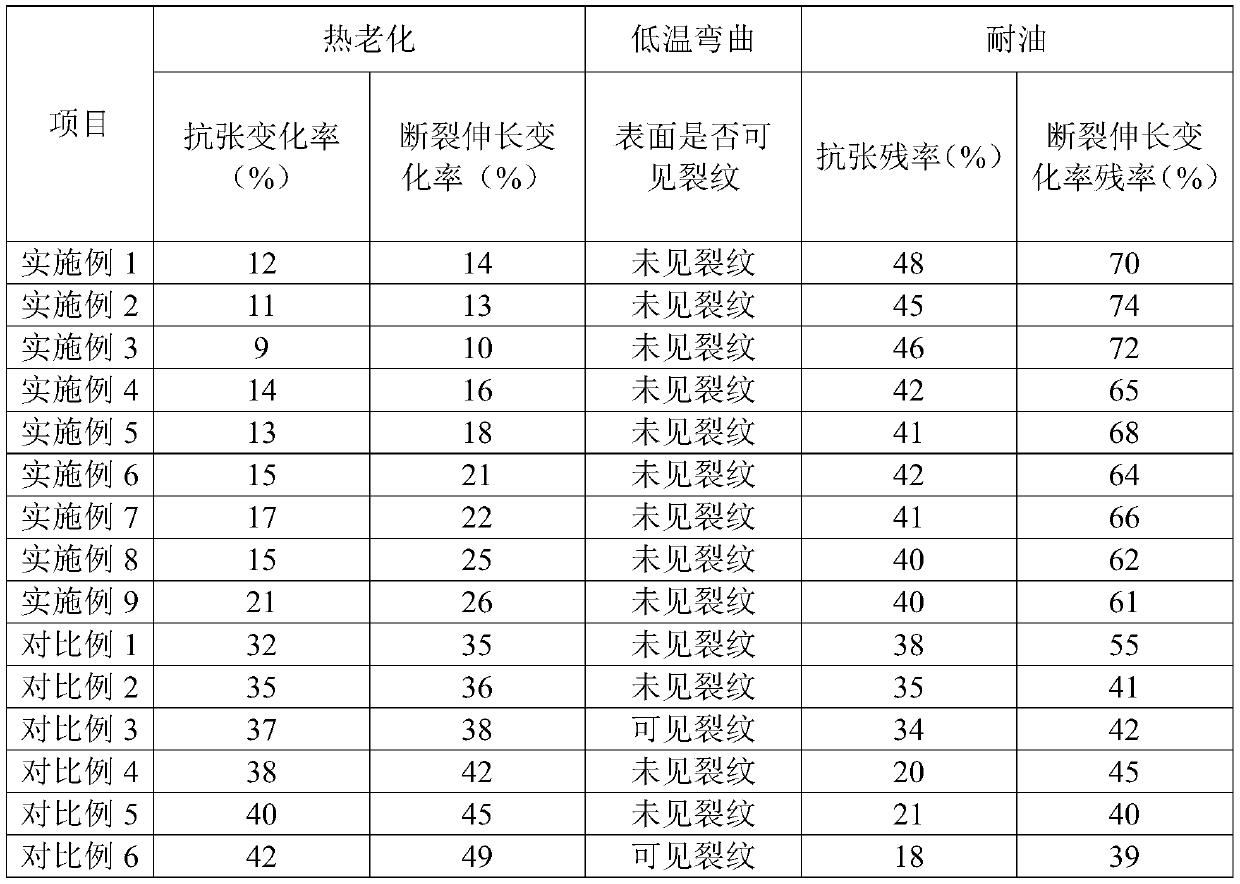

Photovoltaic cable sheath material and preparation method thereof

ActiveCN111073109ACompact dendritic spherical structureCompact structurePlastic/resin/waxes insulatorsPolymer scienceElectric cables

The invention provides a photovoltaic cable sheath material and a preparation method thereof. The photovoltaic cable sheath material comprises the following components in percentage by weight: 20-40%of hyperbranched polyethylene, 40-60% of a flame retardant, 5-10% of maleic anhydride grafted EVA, 1-5% of a stabilizing agent, 1-5% of silicone master batch and 1-5% of a silane coupling agent. The photovoltaic cable sheath material has extremely high insulation resistance, excellent flame retardance, good mechanical strength and smoke density light transmittance, can completely meet the performance requirements in the IEC62930 standard through single vertical combustion, and can be applied to the field of photovoltaic cables.

Owner:JIANGSU DASHENG POLYMER

Deoxidant for oil-displacing polymer and preparation method of deoxidant

ActiveCN107955595ALittle effect of viscosityThe effect of reducing viscosityDrilling compositionMicroballoon preparationHydroxypropylmethyl celluloseDeoxygenation

The invention relates to a deoxidant for an oil-displacing polymer and a preparation method of the deoxidant, and belongs to the technical field of oilfield chemistry. The preparation method comprisesthe following steps: reacting sulfuric acid with carbohydrazide to prepare carbohydrazide sulfate; dispersing the carbohydrazide sulfate, thiourea and isoascorbic acid into an acetone solution of hydroxypropyl methyl cellulose phthalate, taking a mixture as a dispersion phase and taking white oil dissolved with a surfactant as a continuous phase; adding the dispersion phase into the continuous phase under stirring to prepare stable emulsion; on the basis of the stable emulsion, raising the temperature to evaporate acetone and obtain a microcapsule deoxidant. A deoxidant product disclosed by the invention has the advantages of good deoxygenation effect, controllable deoxygenation time, small influence on the viscosity of a polymer and suitability for being used as a deoxygenation aid for ahigh-temperature oil displacing polymer.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

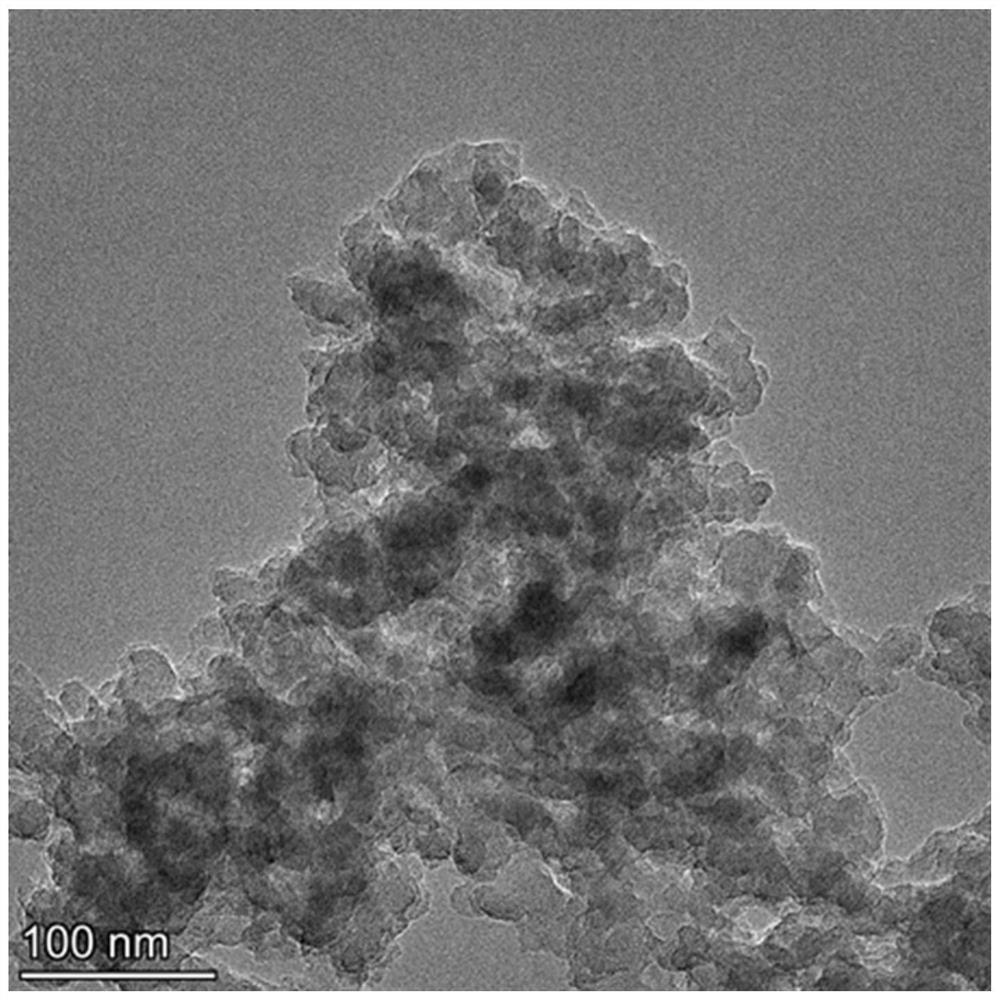

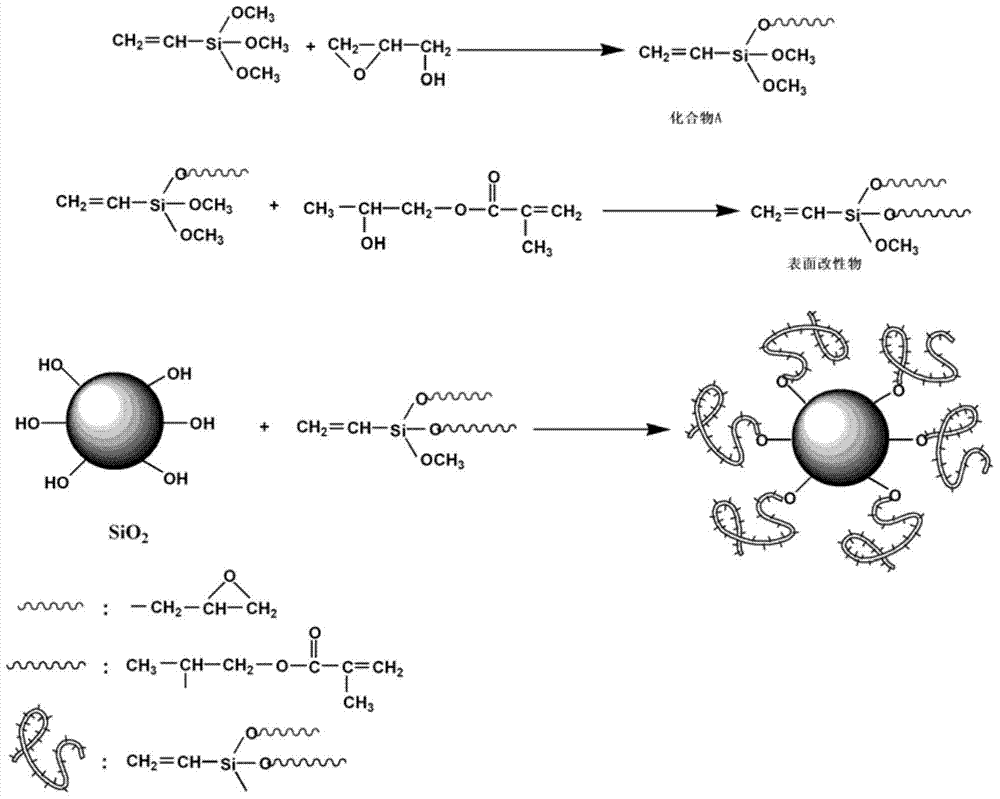

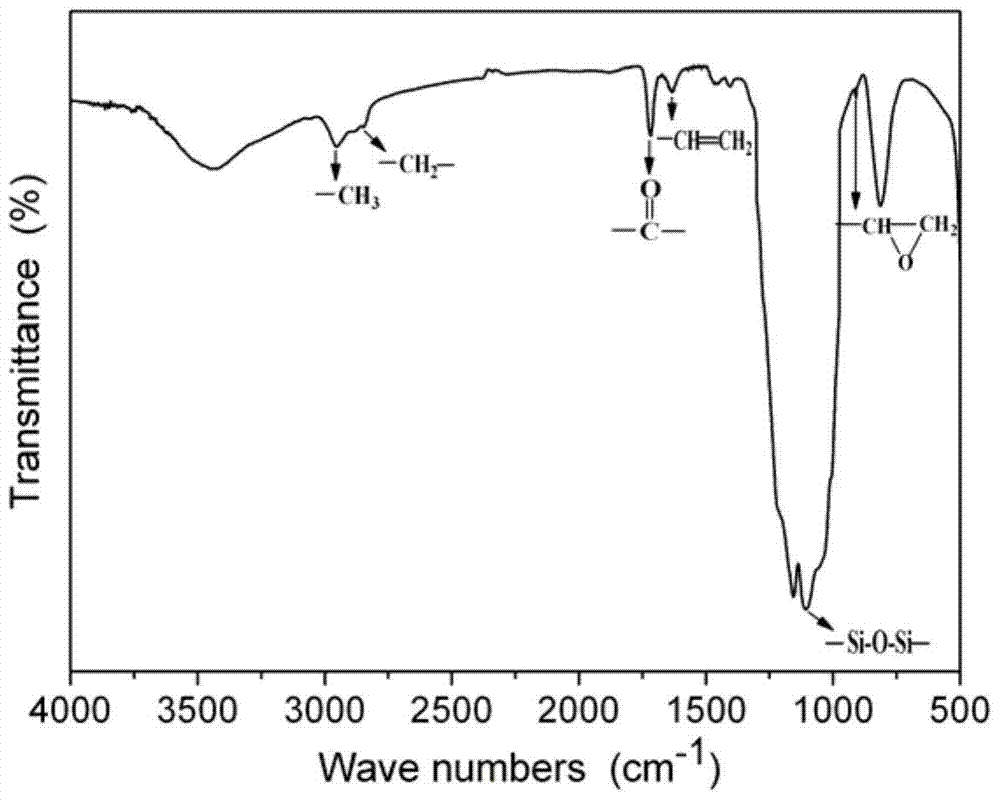

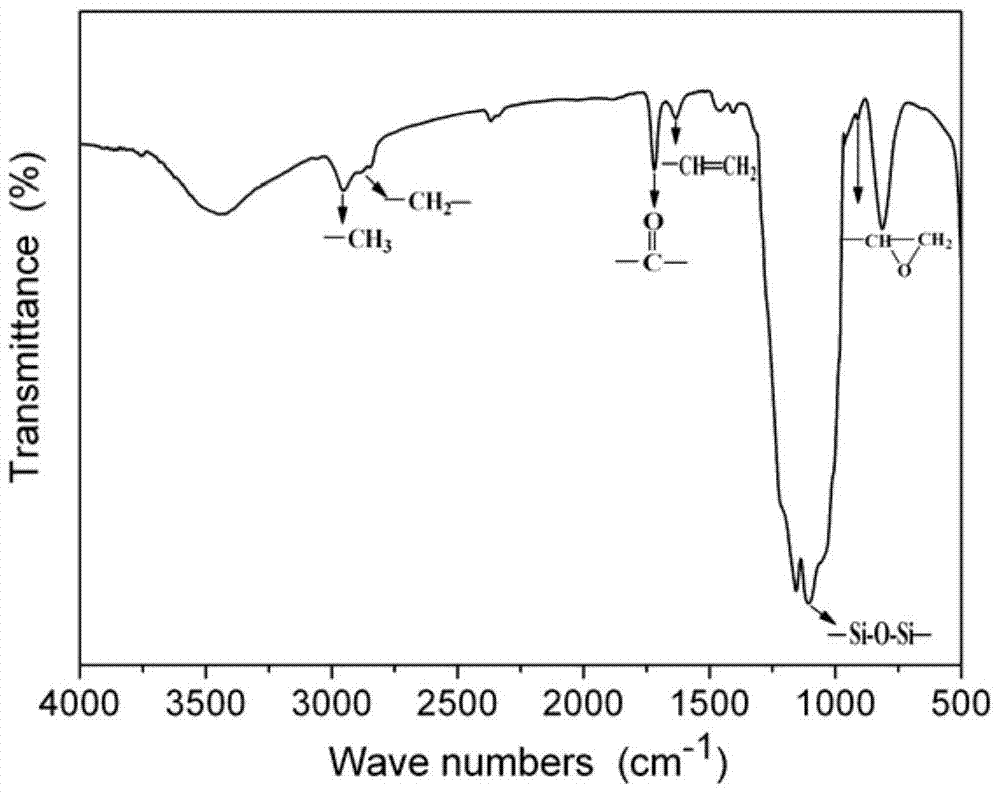

A kind of modified nano silicon dioxide, its preparation method and application

ActiveCN104829870BLower surface energyEasy to disperseGroup 4/14 element organic compoundsChemistryDouble bond

The invention relates to a modified nano-silica, its preparation method and application. In the presence of a catalyst, a nano-silica dispersion liquid with a mass fraction of a surface modification and nano-silica of 15% to 60% is prepared. React at 130°C-160°C to obtain the modified nano-silica, wherein the added amount of the surface modifier is 5%-40% of the mass of the nano-silica, and the structural formula of the surface modifier is: . Compared with ordinary nano-silica, the nano-silica grafted with double bonds and epoxy groups on the surface of the present invention has significantly improved dispersibility and dispersion stability, and has little influence on the viscosity of the system; the double bonds and epoxy groups on the surface have high Reactive, able to participate in the curing crosslinking reaction of the matrix resin, increase the crosslinking density of the system, and meet the requirements of nano-modified epoxy polyesterimide impregnated resins for surface-treated nano-silica particles.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

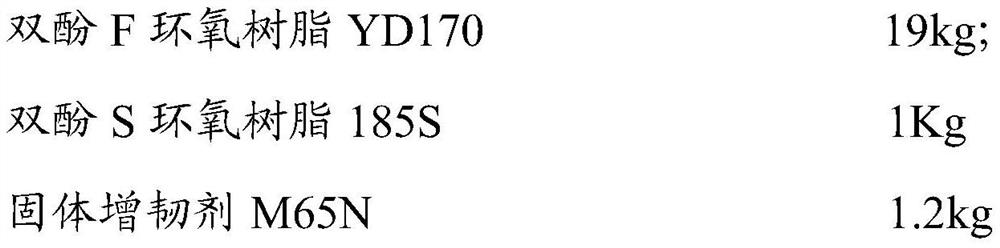

High-toughness liquid molding resin based on phase state control technology, composite material and preparation method thereof

The invention provides high-toughness liquid molding resin based on a phase state control technology, a composite material and a preparation method thereof. The liquid molding resin comprises 60-75% of liquid thermosetting resin, 20-30% of a curing agent and the balance of a toughening agent. A reinforcing phase of the composite material is fiber fabric, and a resin phase is liquid molding resin. According to the preparation method of the composite material, a phase state control technology is utilized, the adopted flexibilizer can generate phase change along with temperature change and resin curing, along with temperature rise, the flexibilizer can be dissolved in matrix resin to form a uniform and stable mixture, the uniform and stable mixture is uniformly distributed in the matrix resin, and in the liquid forming process, the toughening agent cannot be filtered out by the fiber and can permeate to the periphery of the fiber along with the matrix resin, along with further increase of the temperature, the matrix resin and the curing agent are subjected to a cross-linking reaction, the compatibility of the toughening agent and the matrix resin is reduced, the toughening agent and the matrix resin are subjected to phase separation, and the toughening agent and the matrix resin are uniformly distributed in the composite material, so that the toughness of the composite material is improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

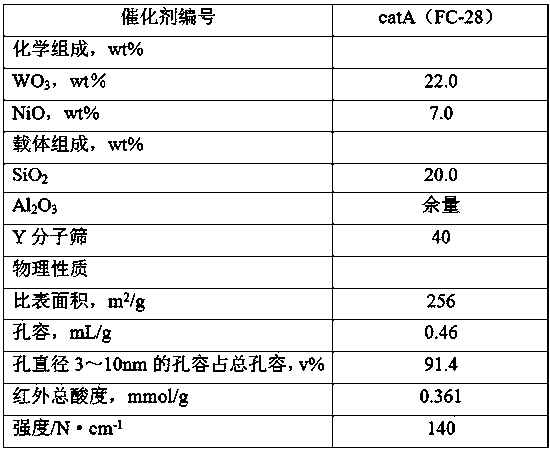

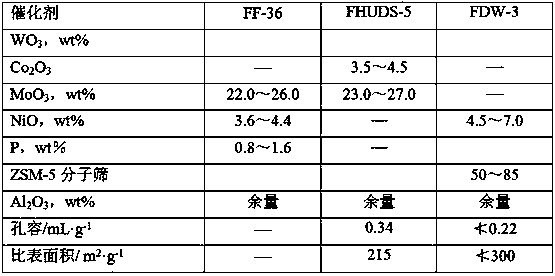

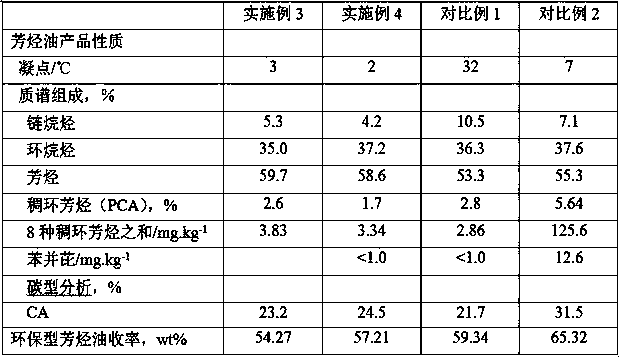

Production method of environment-friendly aromatic hydrocarbon oil for tires

ActiveCN111378498AAdaptableReduce lossesTreatment with hydrotreatment processesPolycyclic aromatic hydrocarbonProcess engineering

The invention discloses a production method of environment-friendly aromatic hydrocarbon oil for tires. The environment-friendly tire aromatic hydrocarbon oil meeting the European Union standard can be produced by taking positive-sequence furfural extract oil with a relatively high condensation point as a raw material and adopting a hydrotreatment-hydrodewaxing-solvent extraction combined process.The method comprises the following steps: performing hydrotreatment on raw materials under mild conditions to saturate polycyclic aromatic hydrocarbon, performing hydrodewaxing to reduce the condensation point to 0-10 DEG C, and finally performing shallow extraction to obtain the environment-friendly aromatic hydrocarbon oil for tires. The method expands sources of raw materials for producing theenvironment-friendly aromatic hydrocarbon oil, and has the characteristics of strong raw material adaptability and mild process conditions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Energy-capturing floating breakwater

InactiveUS9416766B2Little effect of viscosityEnergy efficiencyMachines/enginesEngine componentsEngineeringPermanent magnet linear generator

An apparatus comprises an asymmetric heaving floating body that resists influence from viscosity effects. The asymmetric heaving floating body is coupled to a Permanent Magnet Linear Generator (“PMLG”) that serves as a power take off (“PTO”) system. A support structure for the apparatus is designed so as to restrain lateral force and pitching moment. Similarly, the asymmetric floating body is designed to minimize viscosity effects when in motion to transfer incident wave energy to the PTO.

Owner:MADHI FARSHAD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com