Patents

Literature

161 results about "Carbohydrazide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

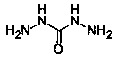

Carbohydrazide is the chemical compound with the formula OC(N₂H₃)₂. It is a white, water-soluble solid. It decomposes upon melting. A number of carbazides are known where one or more N-H groups are replaced by other substituents. They occur widely in the drugs, herbicides, plant growth regulators, and dyestuffs.

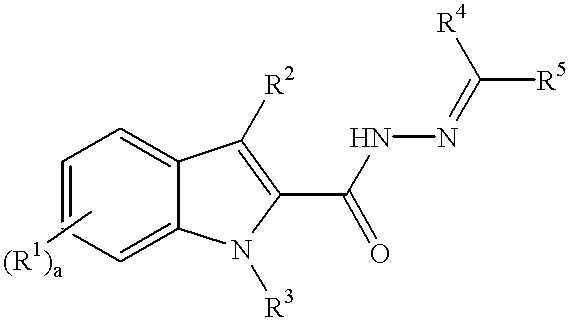

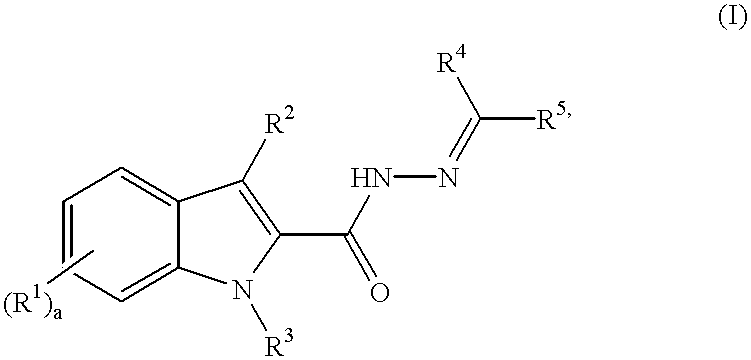

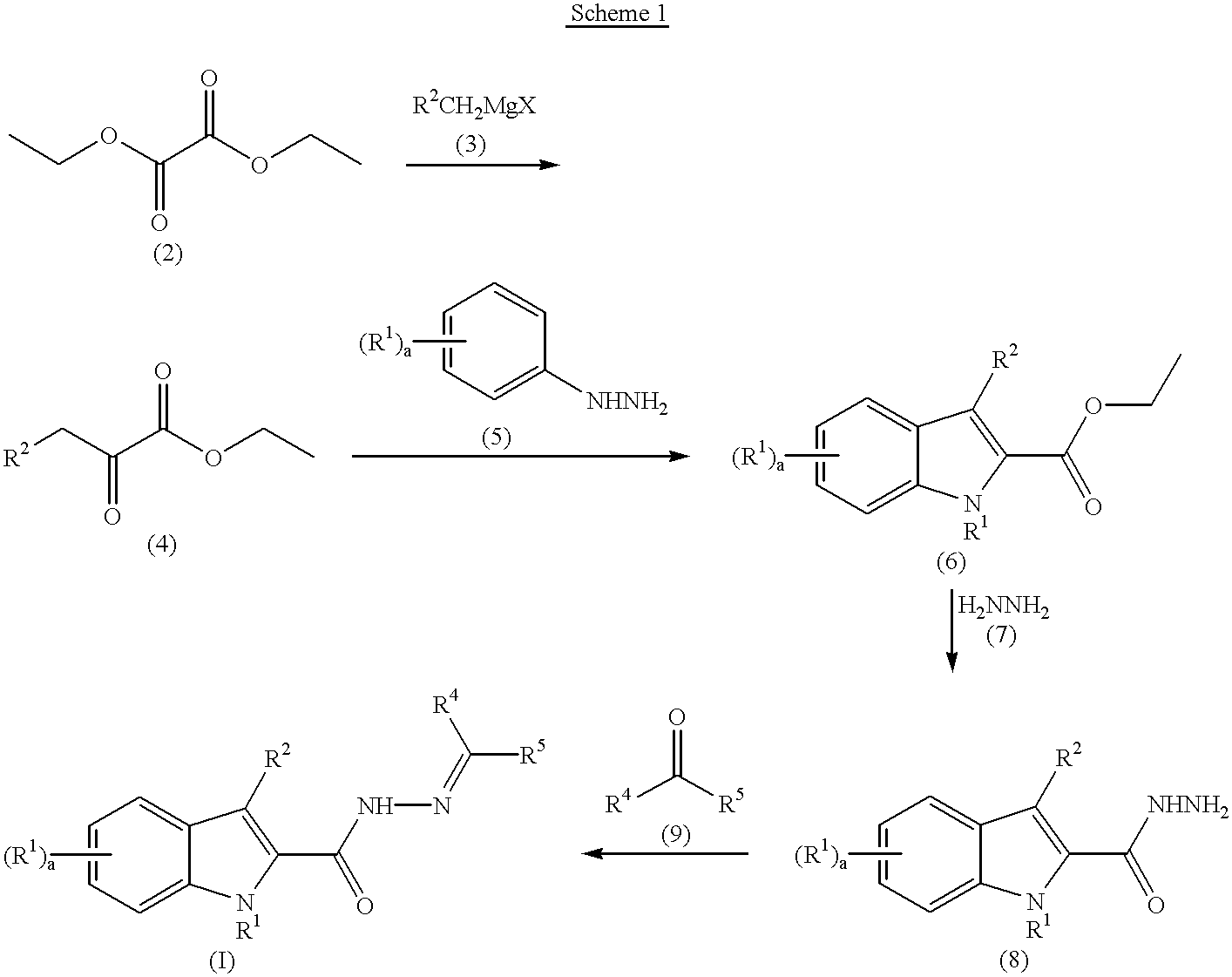

3-substituted indole angiogenesis inhibitors

3-Substituted indole carbohydrazides having the formula ##STR1## are useful for inhibiting angiogenesis. Also disclosed are angiogenesis-inhibiting compositions and methods of inhibiting angiogenesis in a mammal.

Owner:ABBVIE INC

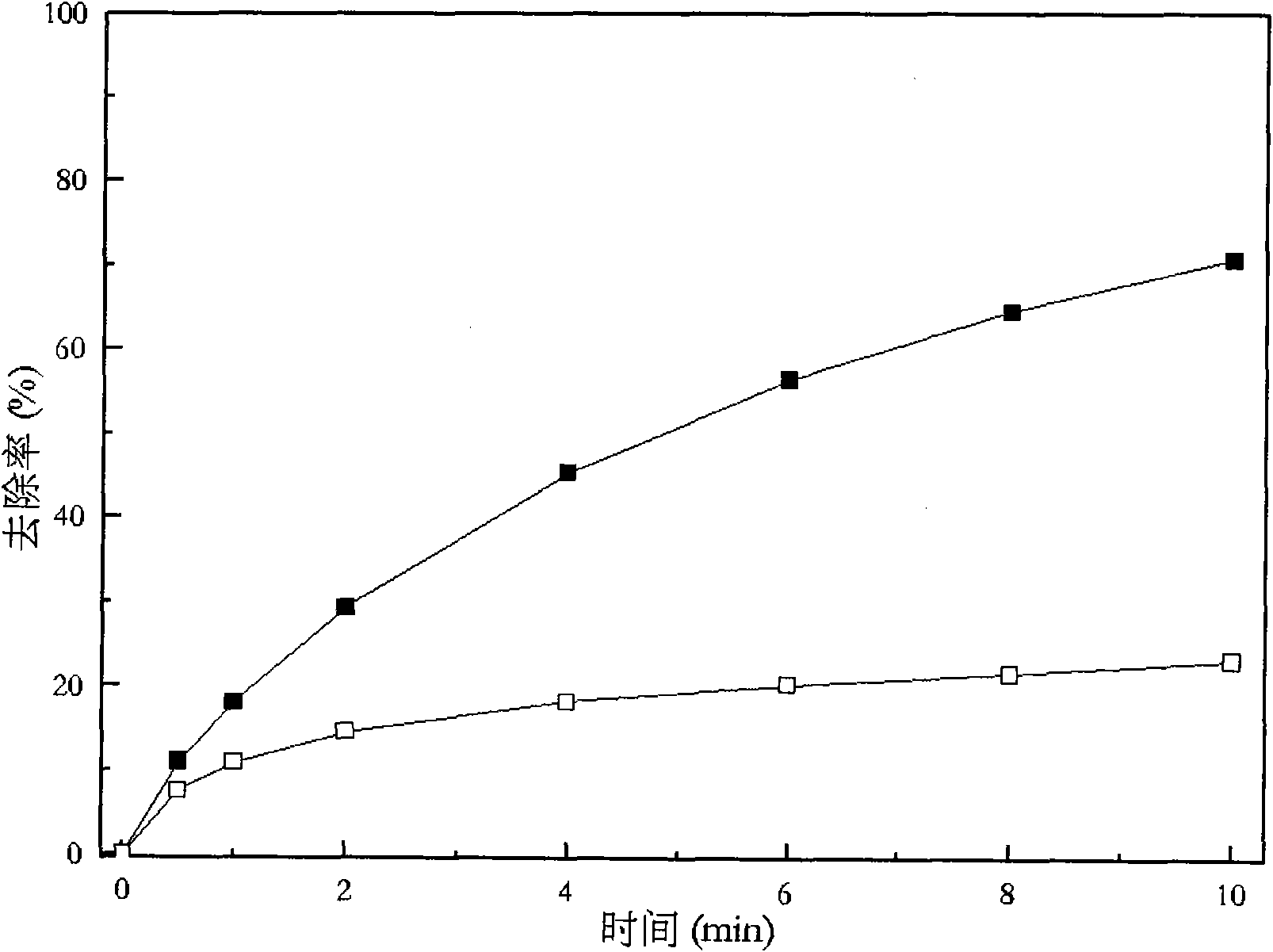

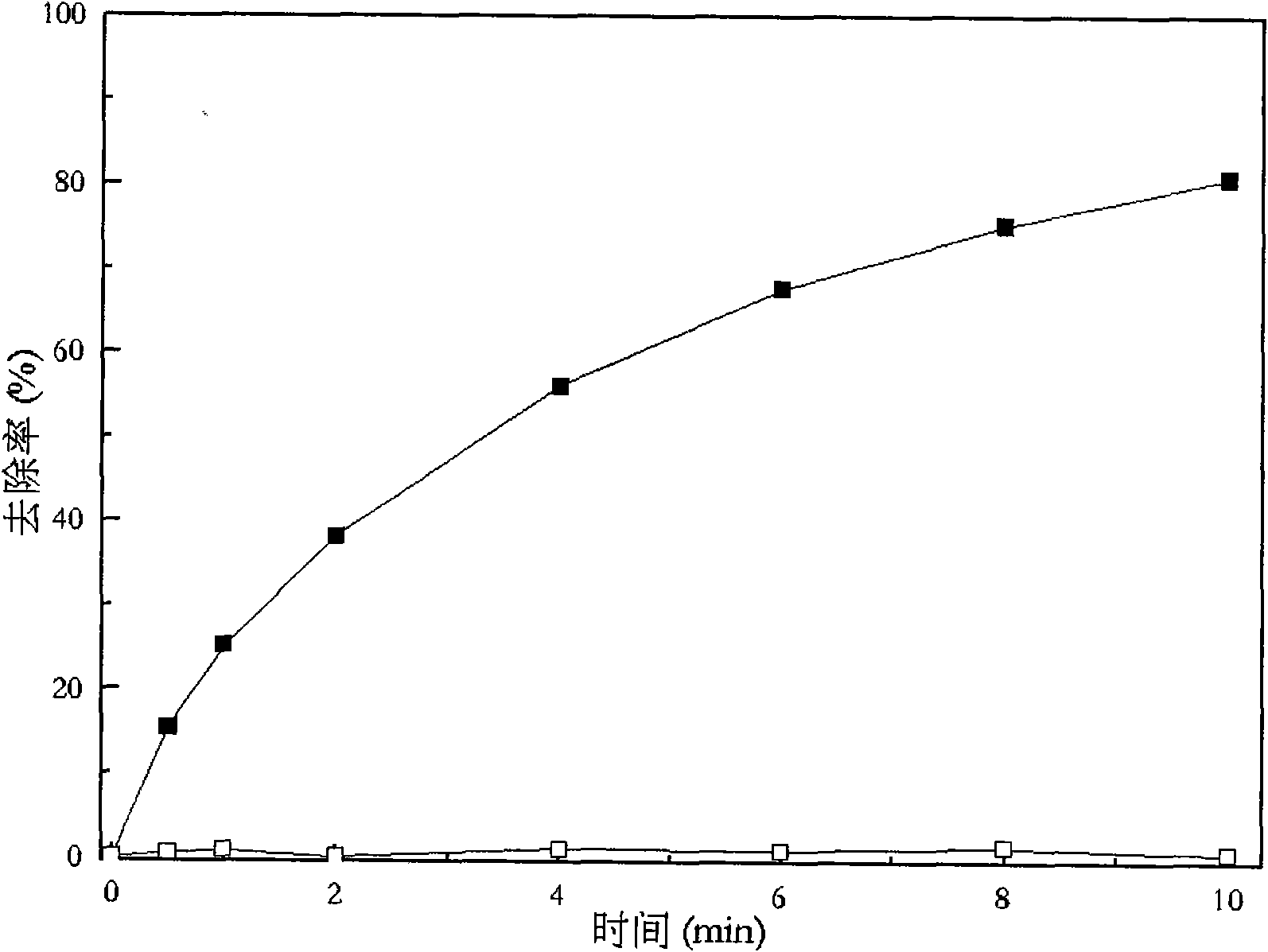

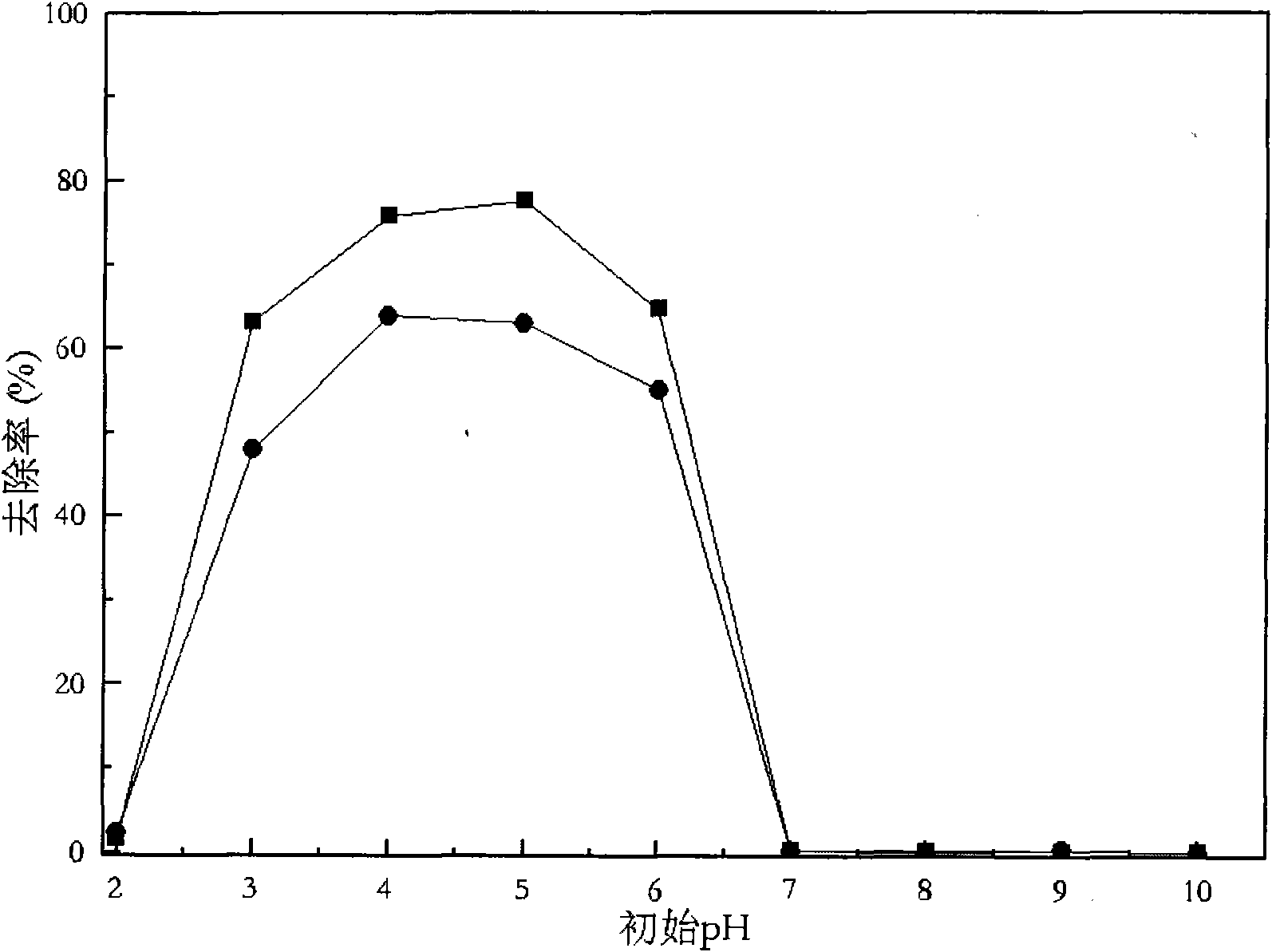

Fenton and Fenton-like system fortifier and using method thereof

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

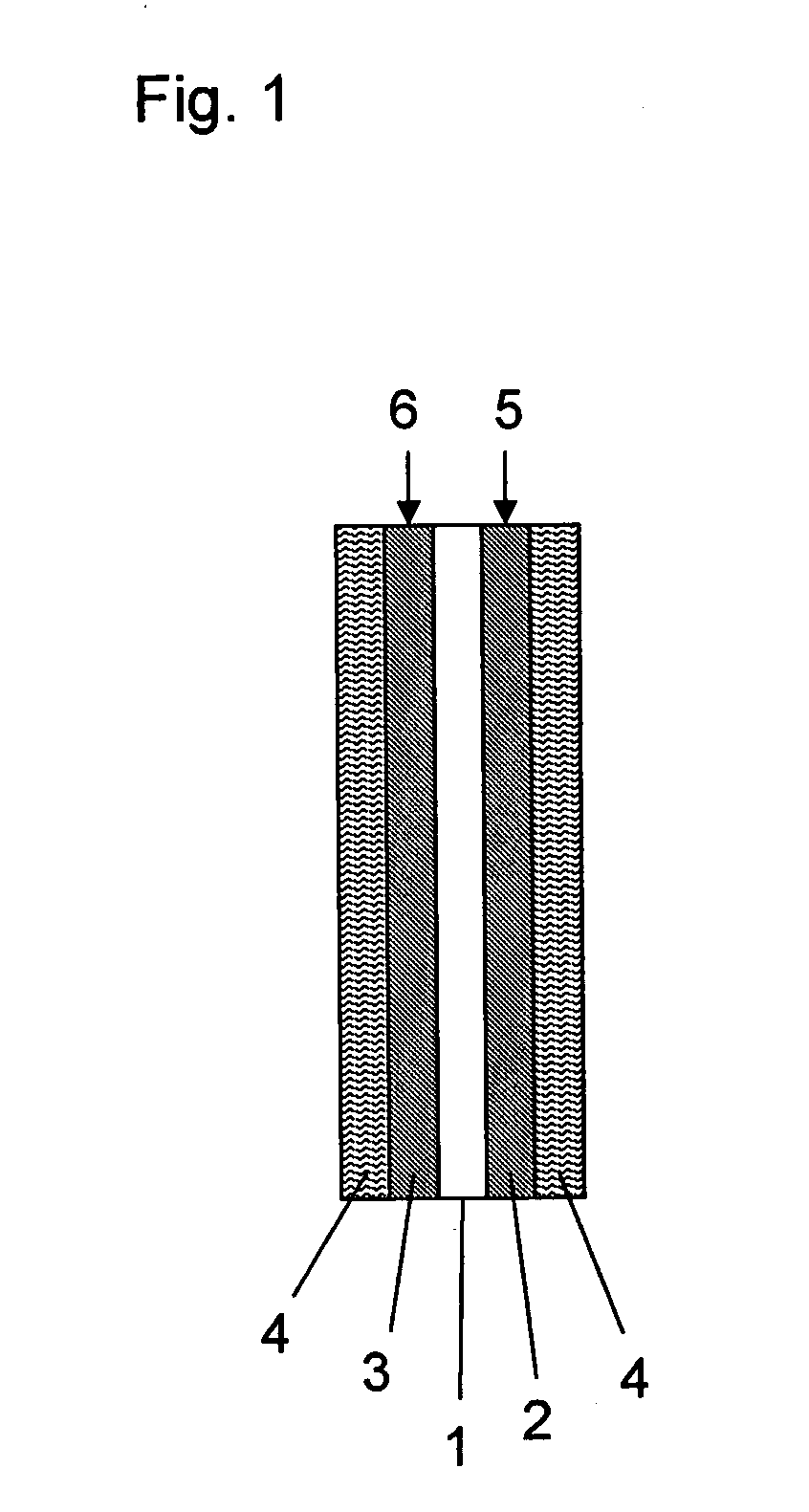

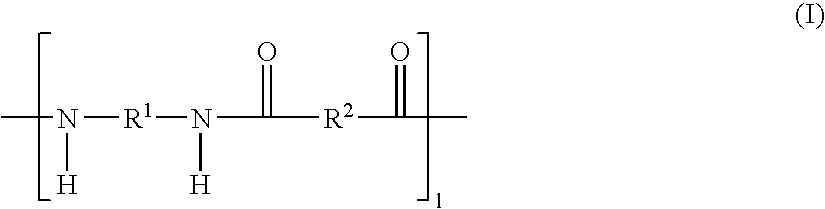

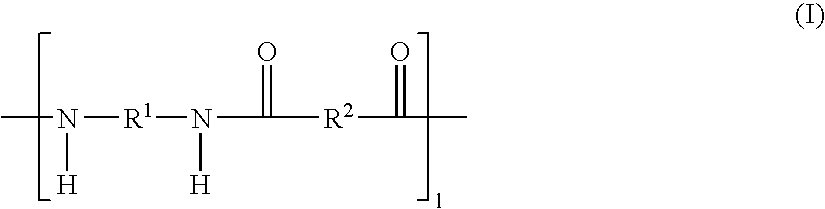

Aromatic polymer, film, electrolyte membrane and separator

InactiveUS20060204812A1High Young 's modulusHigh elongationFinal product manufactureFuel cell auxillariesChemical reactionAramides

An aromatic polymer containing aromatic polyamide structural units and aromatic carbohydrazide structural units at a specific ratio is disclosed. A film having a high Young's modulus, high elongation at break and low moisture absorption can be formed from such an aromatic polymer. Dehydration cyclization of a compound having a carbohydrazide structure can be conducted under mild conditions at low cost by causing the chemical reaction using a chemical which is selected from the acids and bases.

Owner:TORAY IND INC

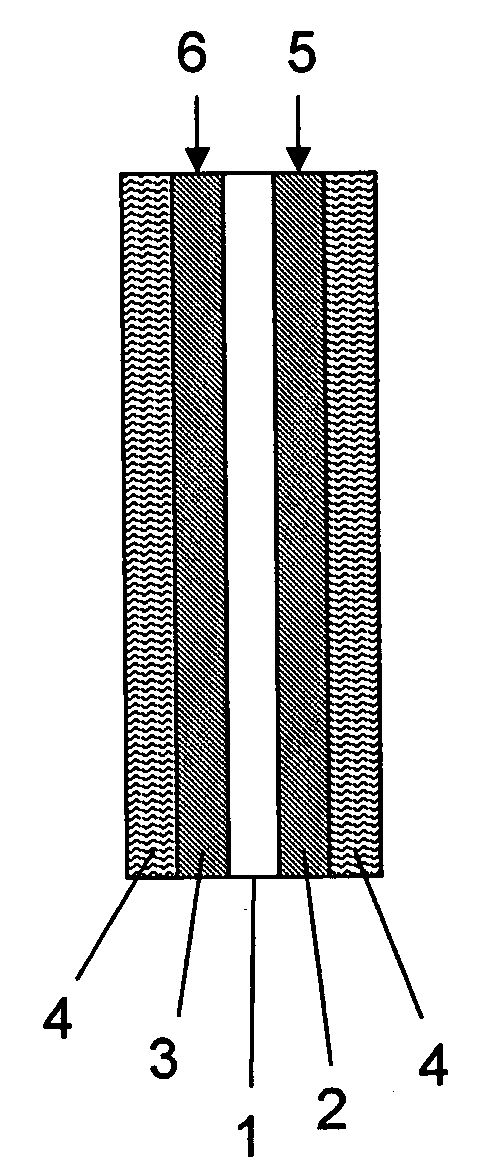

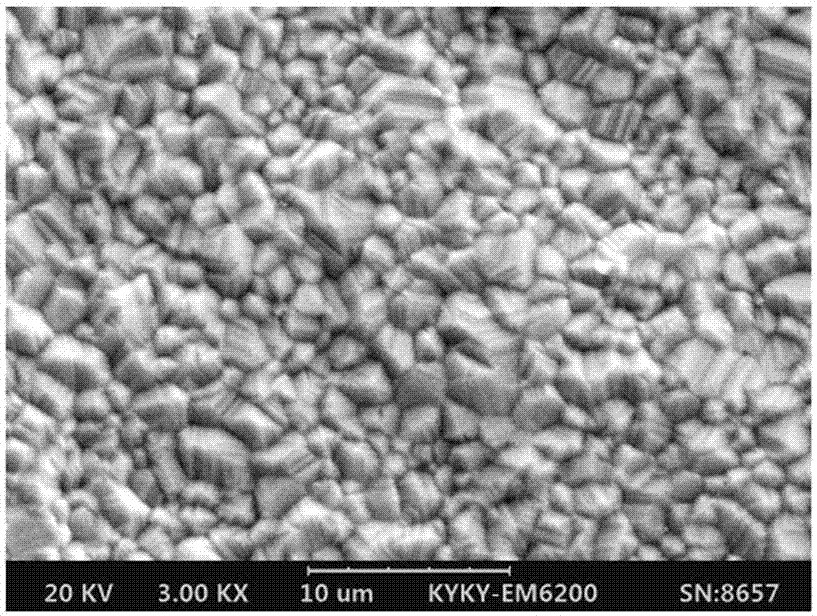

Film inhibitor and uses thereof

The invention discloses a filming corrosion inhibitor, which at least comprises 30 to 50 percent of octadecylamine, 20 to 30 percent of imidazoline amide, and reducing agent carbohydrazide being the rest, the above proportion is mass percentage. Under the condition that the temperature is 150 to 500 DEG C, the concentration of the filming corrosion inhibitor is 10 to 35 ppm, the pH valve is 7 to 11, and the time duration is 1 h to 10 min, the filming corrosion inhibitor can produce a compact protective film on the metal surface, and the function of preventing the metal to be corroded in the atmospheric environment is realized, especially the invention can be applied during the thermal power plant to stop the boilers for protection, the protective film with strong hydrophobicity and good erosion resistance can be produced on the metal surface inside the water vapor system of the thermal equipment, and the thermal equipment can be protect from being corroded for more than 8 months during the exposition in atmospheric environment, simultaneously, the invention has certain cleaning, uncovering, and removing function to the incrustation and the corrosion product on the metal surface of the thermal system, the probability of the thermal equipment corrosion and the four-tube blasting is reduced, the invention is advantageous for extending the acid pickling cycle of the boiler, the service life of the equipment is prolonged, the security is enhanced, and the economic benefit is increased.

Owner:WUHAN UNIV

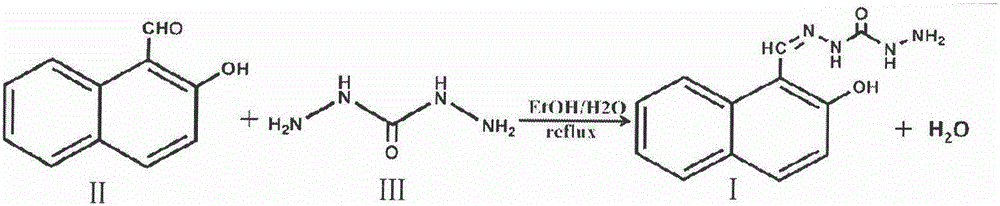

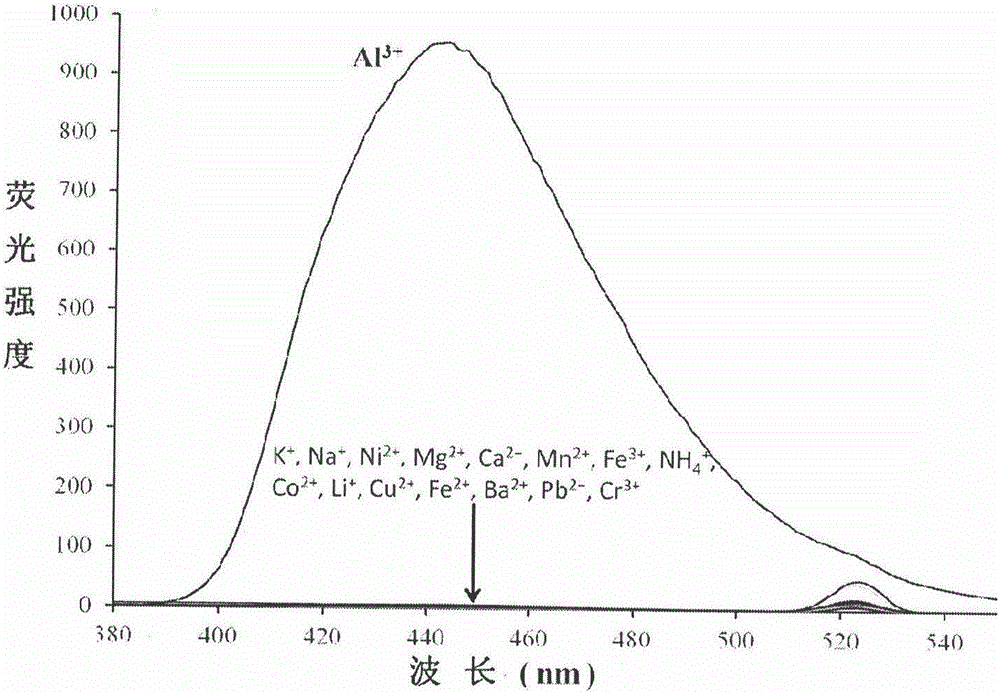

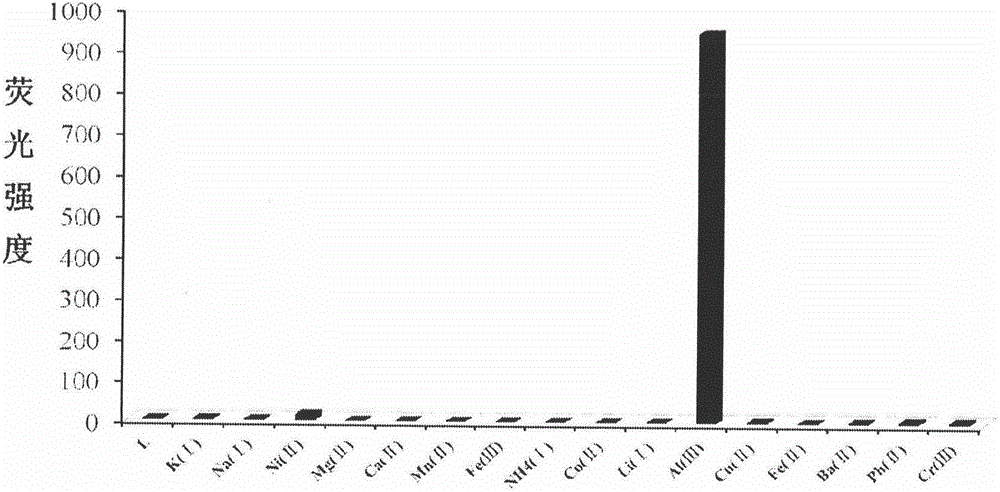

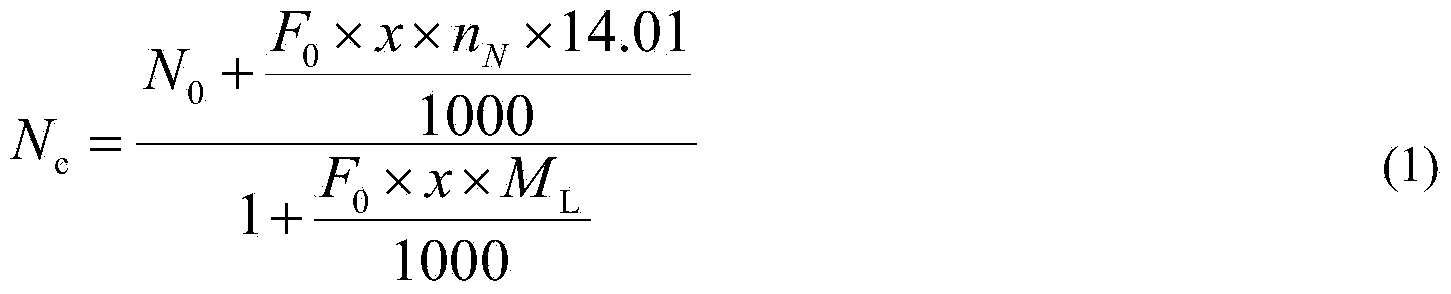

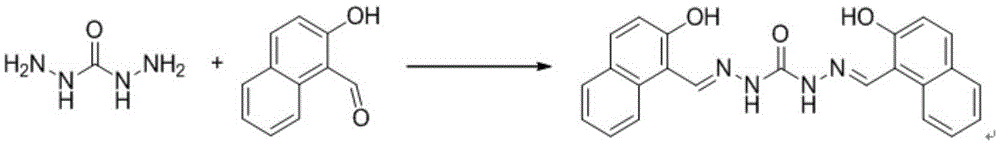

Preparation method of fluorescent probe and application of fluorescent probe in aluminum ion detection

InactiveCN105802608AGood choiceHigh sensitivityOrganic chemistryFluorescence/phosphorescenceAluminum IonReflux

The invention provides a preparation method of a fluorescent probe and an application of the fluorescent probe in aluminum ion detection. The fluorescent probe is obtained by virtue of a reaction in a heating reflux manner between 2-hydroxyl-1-naphthaldehyde and carbohydrazide. In the structure of the fluorescent probe provided by the invention, the N atoms on the C=N double bonds are influenced by a photo-induced electron transfer effect, and after the N atoms are combined with aluminum ions, the photo-induced electron transfer effect is inhibited, and planar conjugation is enhanced at the same time; two mechanisms together induce obvious enhancement of fluorescence emission; the fluorescent probe has good selectivity and sensitivity to the aluminum ions. High-selectivity identification of the aluminum ions is realized, a relatively good linear relation exists in a range of 5*10<-6> to 4*10<-5> mol / L, and the limit of detection is as low as 1.89*10<-8> mol / L, so that the fluorescent probe has a chromogenic sensing function.

Owner:WENZHOU MEDICAL UNIV

Gelled acid

Reducing agents or reducing agent precursors are provided for breaking ferric ion crosslinks in polymers in gelled acids used for diversion in matrix acidizing and used for leakoff control in acid fracturing. Previous reducing agents were very toxic to aquatic species or so active that they could be used only at low temperatures. The new reducing agents and reducing agent precursors are less reactive, less toxic, and leave less residue behind to impede fluid flow after the gel is broken after the treatment. Suitable compounds are sources of one or two hydrazines or sources of hydroxylamine. Such compounds are carbohydrazides, semicarbohydrazides, ketoximes, and aldoximes.

Owner:SCHLUMBERGER TECH CORP

Preparation method and application of composition for decomposing low-molecular aldehyde without illumination

The invention provides a preparation method and application of a composition for decomposing low-molecular aldehyde without illumination. The composition mainly comprises chitin, EDTA, carbohydrazide, glycerin, polyethylene glycol, dicyandiamide, sodium phytate, phytic acid, glucoside, sodium sulfanilate, mannitol, citric acid, sodium thiosulfate, modified starch, cellulose, gelatine powder, aluminum oxide, silica, diatomite and kaolin. The composition can be used for removing formaldehyde, acetaldehyde and other low-molecular aldehyde and harmful small polar molecules in gas-liquid-solid phase substances. The composition can be used for removing residual formaldehyde in decorative materials in buildings, and an aqueous solution and the gas state of the composition can be used for decomposing formaldehyde in the liquid phase and the gas phase. Solid of the composition can be added into materials such as indoor building materials, wallpaper glue, diatom ooze, seashell ooze, silicon balls, diatom balls, interior wall coating materials and water-based paint. According to a decomposing function of the composition, one part of the composition with the components can decompose 2 parts of formaldehyde solutions (40%), salt and water are generated, secondary pollution is avoided, illumination is of no need, and the formaldehyde decomposition rate can reach 99.7% or over.

Owner:崔文艳

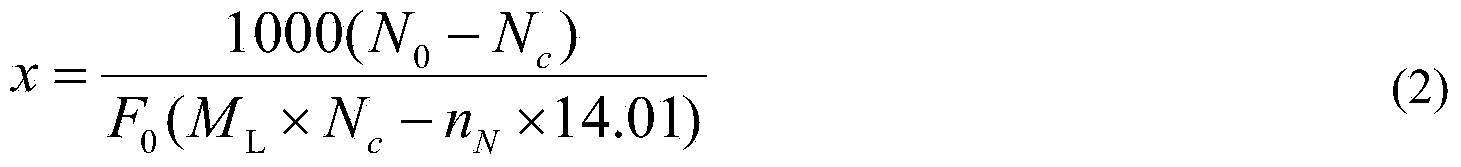

Synthetic method of chelating fiber with selective adsorption on Cr (VI)

InactiveCN104018346AExtensive sources of raw materialsWide variety of sourcesOther chemical processesFibre typesTetrafluoroethyleneFiber

The invention discloses a synthetic method of chelating fiber with selective adsorption on Cr (VI). The method comprises the following steps: 1) soaking acrylic acid grafted polytetrafluoroethylene fiber in N,N-dimethylformamide for 12-14 h by using acrylic acid grafted polytetrafluoroethylene fiber as a matrix; 2) adding ligand into the product obtained in the step 1), reacting with stirring at 30-50 DEG C for 11-14 h, wherein the ligand is carbohydrazide, and the molar ratio of functional group -COOH and ligand in the matrix is 1:4-6; and 3) filtering the product obtained in the step 2), washing the filter cake, drying the filter cake to a constant weight to obtain chelating fiber CHF with selective adsorption on Cr (VI) ions. The chelating fiber CHF fiber has good selective adsorption performance on Cr (VI) ions in the mixed heavy metal ion solution.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

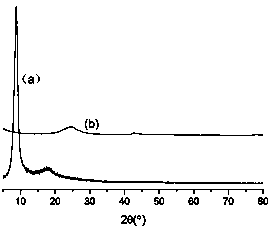

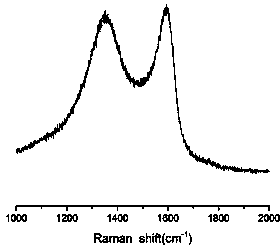

Graphene preparation method

The invention discloses a graphene preparation method. The mixed solution of thiourea dioxide and soluable alkali or carbohydrazide and the soluable alkali is taken as a reducing agent to perform reduction-oxidation on the graphene aqueous solution, and evenly dispersed graphene powder is obtained after washing and drying. The graphene preparation method, disclosed by the invention, solves the problems that hydrazine hydrate and other existing reducing agents are high-toxic and not thorough in reduction, and the graphene is liable to gathering in the graphene preparation process. The preparation method is simple and feasible, is rapid in reaction process and moderate in reaction condition and has no special requirements to equipment, and the prepared graphene is of high quality.

Owner:吴江市华诚电子有限公司

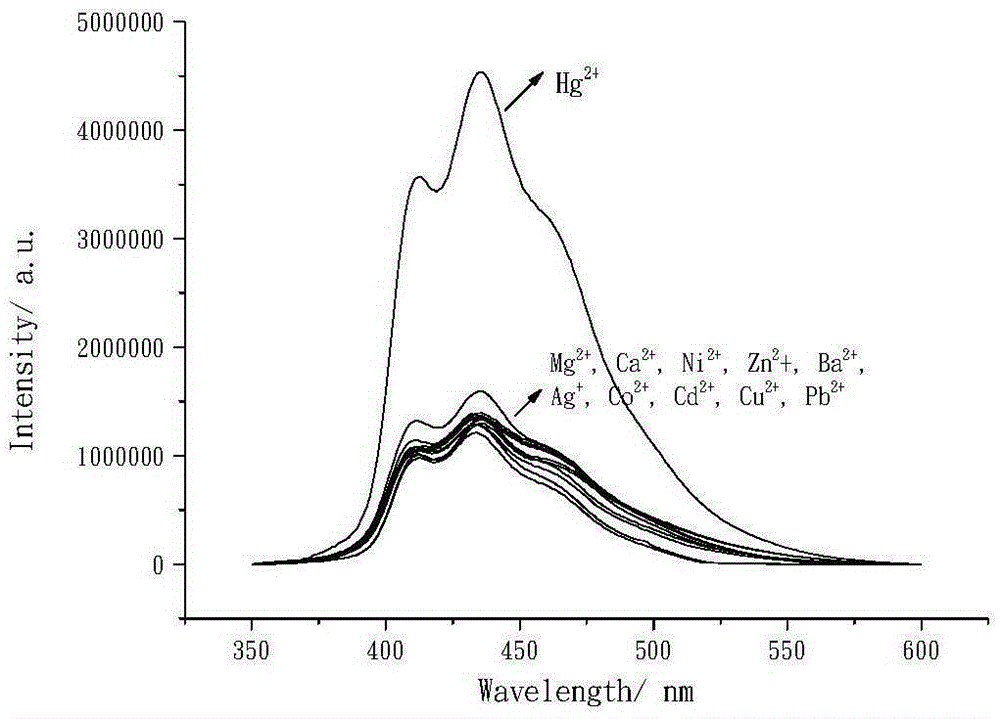

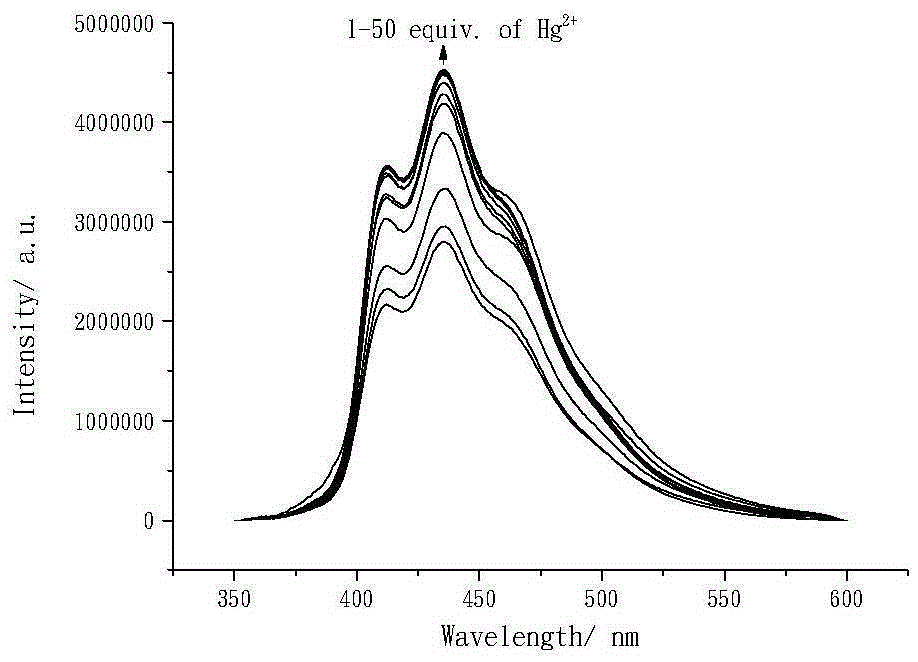

Preparation method and application of fluorescent probe

InactiveCN105241852ARealize quantitative detectionQuick checkFluorescence/phosphorescenceN dimethylformamideFluorescence

The invention relates to a preparation method and application of a fluorescent probe and belongs to the field of chemical sensing materials. The fluorescent probe is applied in the field of mercury ion detection. The preparation method comprises a step of dissolving carbohydrazide and hydroxylanthraldehyde in a mixture solution composed of ethanol and water and adding an acidic solution dropwisely to prepare the fluorescent probe, which is named Schiff base fluorescent sensing material. The Schiff base fluorescent sensing material then is applied in the mercury ion detection. The fluorescent probe, which is simple in structure and is easy to prepare, is very high in selectivity and sensitivity to Hg<2+> ion in a N,N-dimethylformamide solution. The fluorescent probe has fluorescence enhancement on the Hg<2+> ion and is 1*10<-5> mol / L in lowest detectable limit of the Hg<2+> ion concentration. The compound has high-sensitivity and high-selectivity fluorescent detection to the Hg<2+> ion without interferences caused by other ions, such as Ag<+>, Zn<2+>, Co<2+>, Ca<2+>, Cu<2+>, Ba<2+>, Pb<2+>, Mg<2+>, Ni<2+>, Cd<2+> and the like, so that the fluorescent probe can be applied widely in a Hg<2+> ion sensor with fluorescent channel detection.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

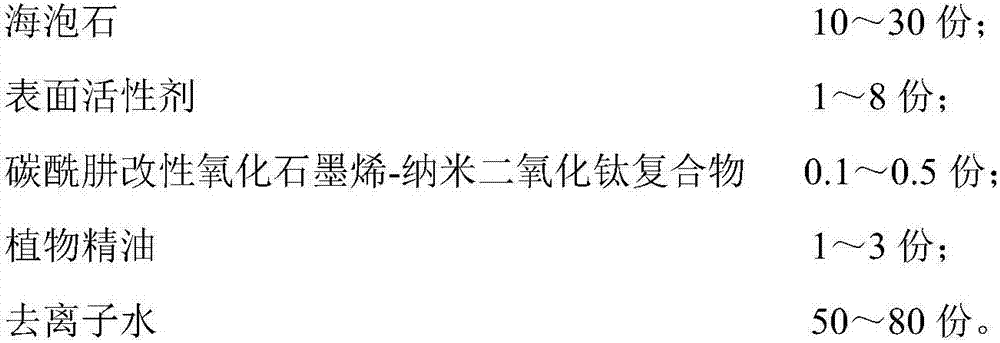

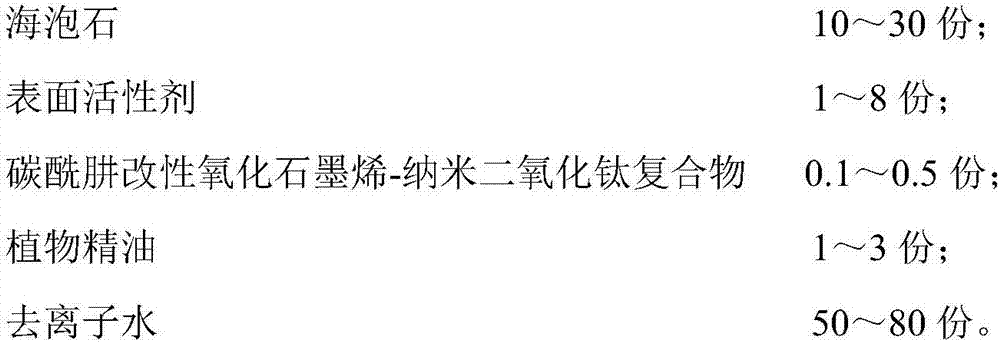

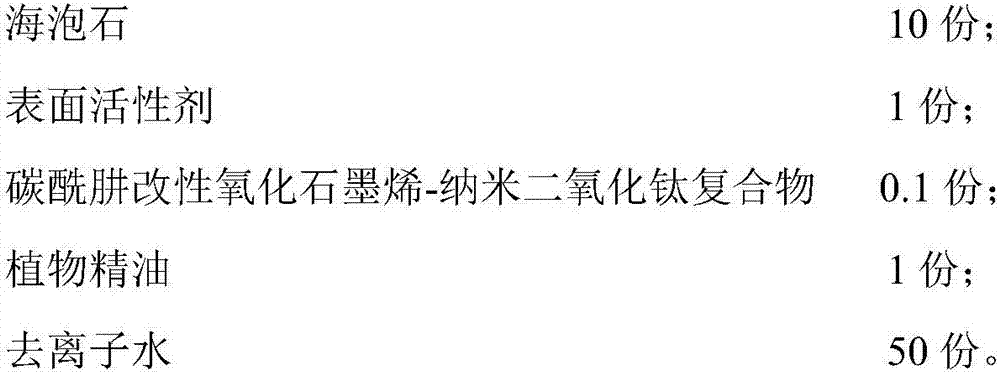

Environmental-friendly odor-removing formaldehyde composition and preparation method thereof

The invention relates to the field of odor removal, in particular to an environmental-friendly odor-removing formaldehyde composition and a preparation method thereof. The composition at least comprises the following raw materials in parts by weight: 10-30 parts of sepiolite, 1-8 parts of a surfactant, 0.1-0.5 part of a carbohydrazide modified graphene oxide-nano titanium dioxide compound, 1-3 parts of plant essential oil and 50-80 parts of deionized water. The preparation method of the environmental-friendly odor-removing formaldehyde composition at least comprises the following steps: uniformly mixing the sepiolite, the surfactant and the deionized water so as to obtain a mixed solution, further putting the carbohydrazide modified graphene oxide-nano titanium dioxide compound into the mixed solution, heating to be less than 50 DEG C, stirring to react for 1 hour, further adding the plant essential oil, uniformly stirring, and leaving to stand for 24 hours at 0 DEG C, so as to obtain the environmental-friendly odor-removing formaldehyde composition.

Owner:北京金逸科技有限公司

Biodegradable resin composition

ActiveUS20100063177A1Group 5/15 element organic compoundsConductive materialPhosphateCarboxylic acid

The invention relates to a biodegradable resin composition containing a biodegradable resin, a plasticizer and a crystal nucleus agent, the plasticizer being a compound containing two or more ester groups in the molecule thereof, wherein at least one alcohol component constituting the ester contains an alkylene oxide having 2 to 3 carbon atoms, added in the average amount of 0.5 to 5 moles per one hydroxyl group, and the crystal nucleus agent is a mixture of the following crystal nucleus agent (1) and crystal nucleus agent (2); the crystal nucleus agent (1) being the following crystal nucleus agent (1-1) or crystal nucleus agent (1-2): crystal nucleus agent (1-1): at least one selected from compounds having a hydroxyl group and an amide group in the molecule thereof; and crystal nucleus agent (1-2): at least one selected from hydroxy fatty acid esters; crystal nucleus agent (2): at least one selected from a metal salt of phenylphosphonic acid, a metal salt of a phosphate, a metal salt of an aromatic dialkyl sulfonate, a metal salt of rosinic acids, an aromatic carboxylic acid amide, rosinic acid amide, carbohydrazides, N-substituted ureas, salts of melamine compounds and uracils.

Owner:KAO CORP

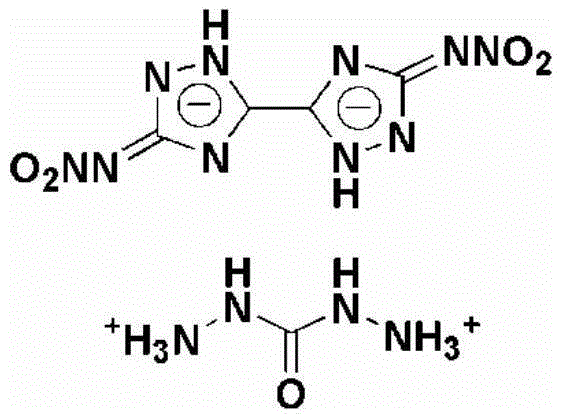

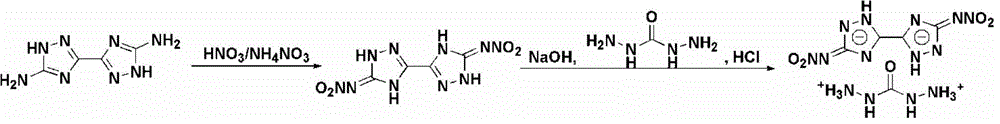

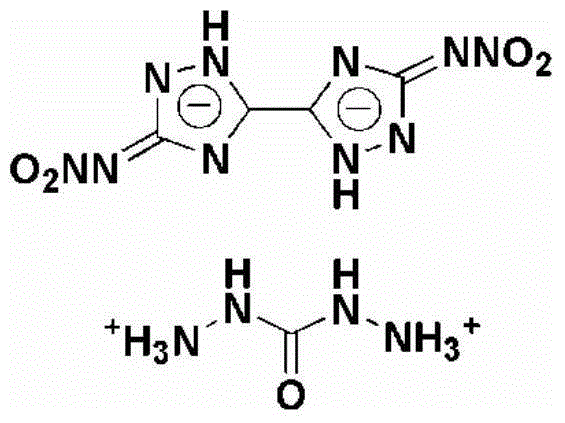

Method for synthesizing 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide

The invention discloses a method for synthesizing 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide. The carbohydrazide has the following structural formula, wherein the structural formula is as shown in the specification. In the method, 5,5'-diamino-3,3'-co-1,2,4-triazole serves as a raw material, and the method comprises the following steps: (1) adding the 5,5'-diamino-3,3'-co-1,2,4-triazole into a nitric acid and ammonium nitrate system in batches at the temperature of 0 DEG C, wherein a molar ratio of the 5,5'-diamino-3,3'-co-1,2,4-triazole, nitric acid to ammonium nitrate is 1:40: (4-8), stirring for 15 minutes, raising the temperature to 25 DEG C, reacting for 1.5 hours, pouring the reaction liquid into ice water, filtering, washing and drying to obtain 5,5'-dinitroamino-3,3'-co-1,2,4-triazole; and (2) adding the 5,5'-dinitroamino-3,3'-co-1,2,4-triazole, an aqueous liquid of sodium hydroxide and carbohydrazide into a reaction bottle under the temperature of 60 DEG C, wherein a molar ratio of the 5,5'-dinitroamino-3,3'-co-1,2,4-triazole, sodium hydroxide to carbohydrazide is 1:3:2.05, stirring for 20 minutes, dropwise adding 35 mass percent of hydrochloric acid until the pH value is 4-7, reducing the temperature to 25 DEG C, separating out a white product 5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide in the system. The method is mainly used for preparing the5,5'-dinitroamino-3,3'-co-1,2,4-triazole carbohydrazide.

Owner:XIAN MODERN CHEM RES INST

Liner for the protection of adhesive masses

ActiveCN103173150AMeasured value indication by color changeNon-macromolecular adhesive additivesSodium dithioniteIndium

In the case of a liner for the protection of adhesives, the protective effect is to be enhanced in respect of permeates originating from the environment and also permeates included during winding or stacking and other processing steps. This enhancement is accomplished through provision of a liner which comprises at least one adhesive release layer and at least one layer of a getter material capable of sorbing at least one permeable substance. The getter material is selected from lithium, beryllium, boron, sodium, magnesium, silicon, potassium, calcium, manganese, iron, nickel, zinc, gallium, germanium, cadmium, indium, cesium, barium, boron oxide, calcium oxide, chromium oxide, manganese oxide, iron oxide, copper oxide, silver oxide, indium oxide, barium oxide, lead oxide, phosphorous oxide, sodium hydroxide, potassium hydroxide, metal salts, metal hydrides, anhydrides of mono- and polycarboxylic acids, sodium dithionite, carbohydrazide, ascorbates, gallic acid, zeolites, carbon nanotubes, activated carbon, and carbodiimides, and mixtures of two or more substances selected from the above.

Owner:TESA SE

Preparation and application of 4-chlorine-3-ethyl-1-methyl-N'-(2-substituted phenoxy acetyl)-1H-pyrazol-5-carbohydrazide compounds

The invention discloses preparation and application of 4-chlorine-3-ethyl-1-methyl-N'-(2-substituted phenoxy acetyl)-1H-pyrazol-5-carbohydrazide compounds. The preparation comprises the following steps: carrying out backflow reaction on thionyl chloride and N-methyl-3-ethyl-4-chloride pyrazole carboxylic acid for 1h to obtain a compound (II), putting the mixed liquor of a compound (III), an organic solvent and an acid-binding agent in a round-bottom flask, dropwise adding the compound (II) at 20-30 DEG C while stirring, then heating up to backflow reaction, carrying out TLC tracing until the raw materials are completely reacted, stopping the reaction, respectively extracting by using 50ml of water twice, drying the organic layer by anhydrous NaSO4, evaporating out the solvent under reduced pressure, and carrying out recrystallization to obtain the target compound shown in the formula (I). According to the preparation and the application, the reaction conditions are mild, the postprocessing is convenient and the total yield of the reaction is as high as 81%; and the compound has a herbicidal activity, thus laying a foundation for the research and development of new pesticides.

Owner:YIFAN AGRI CHEM PLANT ZHEJIANG PROV

Anti-oxidative non-aqueous decarbonization solution for trapping carbon dioxide in mixed gas

ActiveCN109012090AImprove corrosion resistanceLow regeneration energy consumptionGas treatmentDispersed particle separationChemical reactionAbsorption capacity

The invention provides an anti-oxidation non-aqueous decarbonization solution for trapping carbon dioxide in a mixed gas, and belongs to the technical field of carbon dioxide gas trapping. The invention relates to a non-aqueous decarbonization solution, which is composed of a main absorption component N-ethylethanolamine and a solvent N, N-diethylethanolamine. The non-aqueous decarbonization solution has high boiling point, low viscosity and fast absorption rate for carbon dioxide. The absorption capacity is high and the product is easy to regenerate. By adding the antioxidants 2-butanone oxime, pyrogallol, carbohydrazide and N, N'-bis(salicylidene)-1,2-propylenediamine, the main absorption component and the solvent can be effectively prevented from being oxidized by oxygen, thus guaranteeing good performance and service life of the non-aqueous decarbonization solution. The non-aqueous decarbonization solution of the invention is mainly used for trapping carbon dioxide in various chemical reaction tail gases, tail gases from steel plants and cement plants, ore decomposition gas, combustion flue gas, natural gas, city gas and biogas, and has a broad application prospect.

Owner:DALIAN UNIV OF TECH

Electroless tin plating formula for printed circuit board

ActiveCN106939417AComplexation effectiveStrong complexationLiquid/solution decomposition chemical coatingThioureaTin plating

The invention discloses an electroless tin plating formula for a printed circuit board. The formula comprises the following components with the following concentrations: 10-30g / L of stannous ions, 70-130g / L of thiourea, 30-70g / L of methanesulfonic acid, 30-60g / L of citric acid, 20-50g / L of tetrasodium iminodisuccinate, 10-30g / L of carbohydrazide, 10-50mg / L of interfacial agent, 0.05-0.15g / L of bismuth acetate and 20-40g / L of polyamino polyether methylene phosphonate, wherein the component solutions are uniformly mixed and then prepared into an electroless tin plating solution; and the electroless tin plating solution has the following characteristics: tin is stable in tin deposition rate, bivalent tin is not liable to be oxidized into tetravalent tin, and the solution is high in stability. The formula disclosed by the invention contains many complexing agents, the stannous ions are not liable to be oxidized into tetravalent tin, the oxidization of oxygen dissolved in the plating solution can be cancelled by virtue of a reducing agent, the plating solution contains bismuth acetate, a plating layer is a tin-bismuth alloy, and the alloyed plating layer is not liable to grow tin whiskers; and moreover, the electroless tin plating solution has the following characteristics: tin is stable in tin deposition rate, bivalent tin is not liable to be oxidized into tetravalent tin, and the solution is high in stability.

Owner:SHENZHEN CHENGGONG CHEM

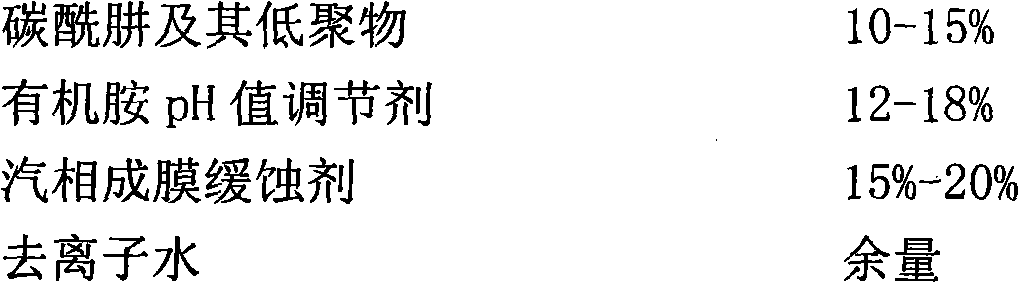

Boiler water-feeding multifunctional corrosion inhibitor and preparation method thereof

InactiveCN102181869ALow toxicityBroaden the deaeration temperature rangeScale removal and water softeningTO-18Oligomer

The invention relates to a boiler water-feeding multifunctional corrosion inhibitor and a preparation method thereof, belonging to the technical field of chemical products. The corrosion inhibitor comprises the following compositions in percentage by weight: 10 to 15 percent of carbohydrazide and oligomers thereof, 12 to 18 percent of organic amine pH value regulators, 15 to 20 percent of vapor phase film-forming corrosion inhibitors, and the balance of deionized water. The corrosion inhibitor provided by the invention shows a good synergistic effect, and the corrosion inhibiting purpose is achieved through various ways, such as deoxidizing, pH value regulation, vapor phase corrosion inhibiting and the like, so that the products are endowed with excellent corrosion inhibiting performance; and the corrosion inhibitor is applicable to wider temperature and pH value ranges, and has good industrial application prospect.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

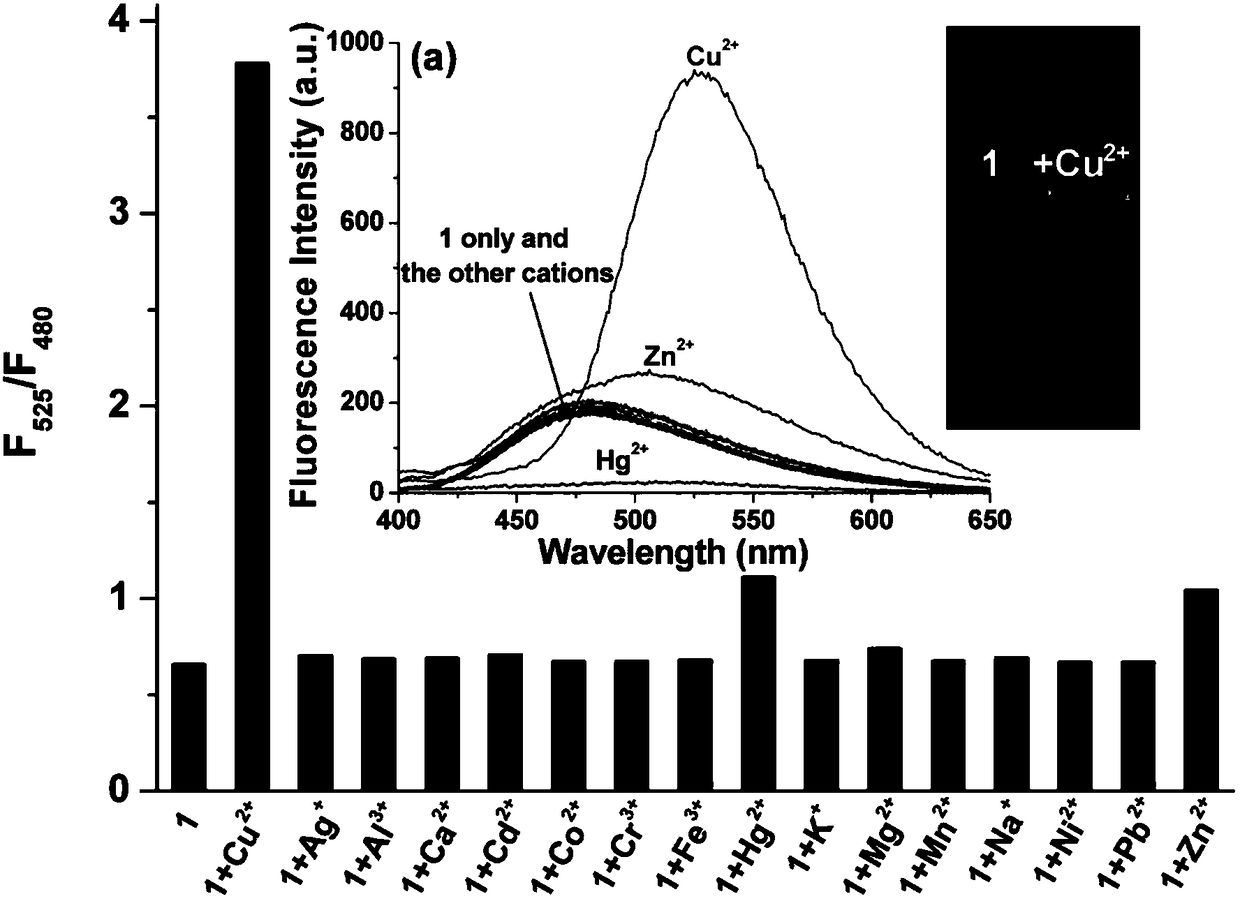

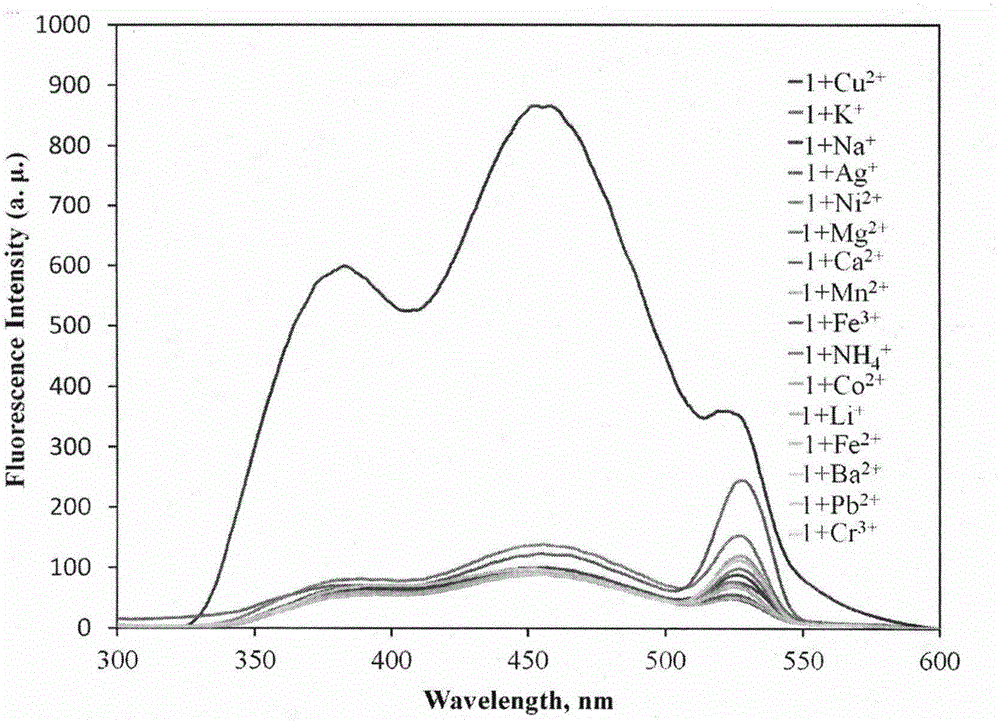

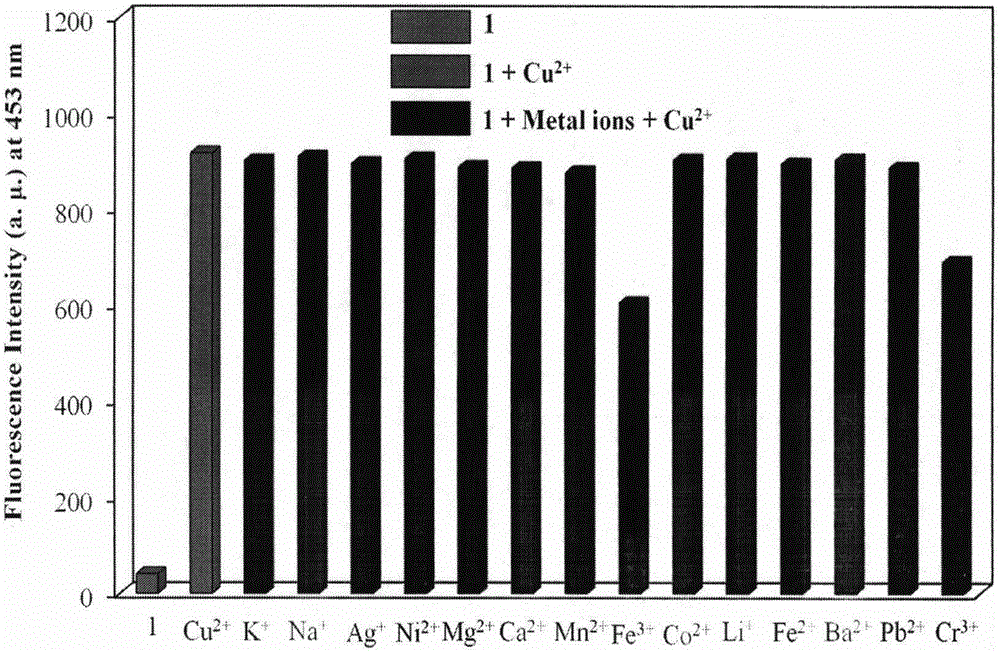

Novel fluorescent molecular probe for copper ions and application of novel fluorescent molecular probe

The invention provides a fluorescent probe for bivalent copper ions and a preparation method of the fluorescent probe. The method comprises the steps of dissolving 6-methoxyl-2-naphthaldehyde in a reaction flask by taking methanol as a solvent, and heating up to 40-50 DEG C; dissolving carbohydrazide by taking water as a solvent, then dropwise adding the dissolved carbohydrazide into the reaction flask, and carrying out reflux reaction for 3h; after the reaction, filtering and drying a mixed solution for removing the solvents to obtain the Schiff base fluorescent probe for the copper ions. The method is simple in operation, convenient and fast, low in cost of a needed intermediate and easy in control of reaction process; the product is easy to separate, high in yield and high in purity. The fluorescent probe has special recognition performance for the copper ions, thus having wide application prospect in the aspects of sensor technologies, photochemistry, electroluminescent devices, and the like.

Owner:WENZHOU MEDICAL UNIV

Biodegradable resin composition

ActiveUS20100210756A1Group 5/15 element organic compoundsConductive materialPolymer sciencePhosphate

The invention relates to a biodegradable resin composition containing a biodegradable resin, a plasticizer and a crystal nucleus agent, the plasticizer being a compound containing two or more ester groups in the molecule thereof, wherein at least one alcohol component constituting the ester contains an alkylene oxide having 2 to 3 carbon atoms, added in the average amount of 0.5 to 5 moles per one hydroxyl group, and the crystal nucleus agent is a mixture of the following crystal nucleus agent (1) and crystal nucleus agent (2); the crystal nucleus agent (1) being the following crystal nucleus agent (1-1) or crystal nucleus agent (1-2): crystal nucleus agent (1-1): at least one selected from compounds having a hydroxyl group and an amide group in the molecule thereof; and crystal nucleus agent (1-2): at least one selected from hydroxy fatty acid esters; crystal nucleus agent (2): at least one selected from a metal salt of phenylphosphonic acid, a metal salt of a phosphate, a metal salt of an aromatic dialkyl sulfonate, a metal salt of rosinic acids, an aromatic carboxylic acid amide, rosinic acid amide, carbohydrazides, N-substituted ureas, salts of melamine compounds and uracils.

Owner:KAO CORP

Aromatic polymer, film, electrolyte membrane and separator

InactiveUS7511112B2High Young 's modulusHigh elongationFinal product manufactureSolid electrolyte fuel cellsChemical reactionAramides

Owner:TORAY IND INC

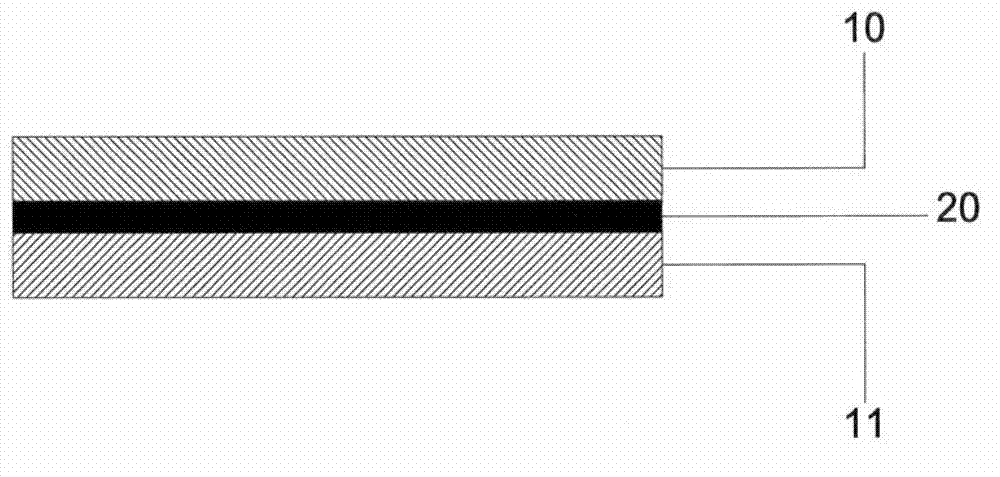

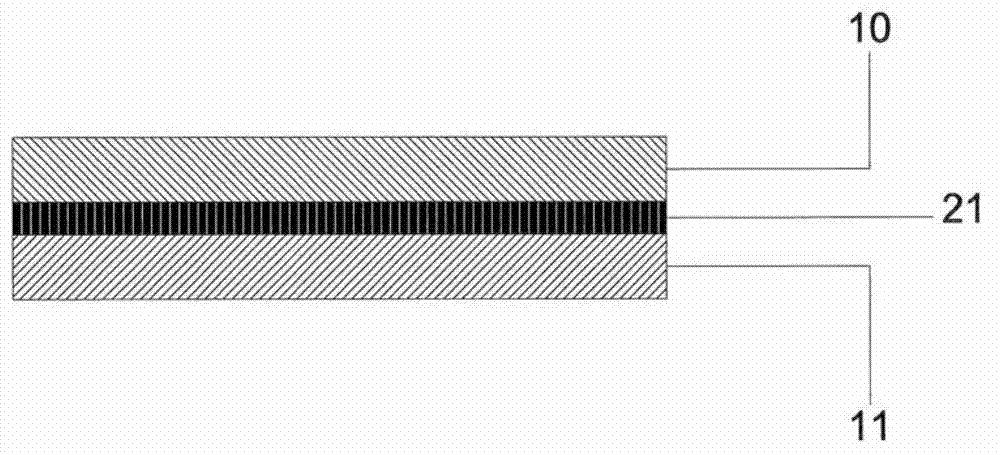

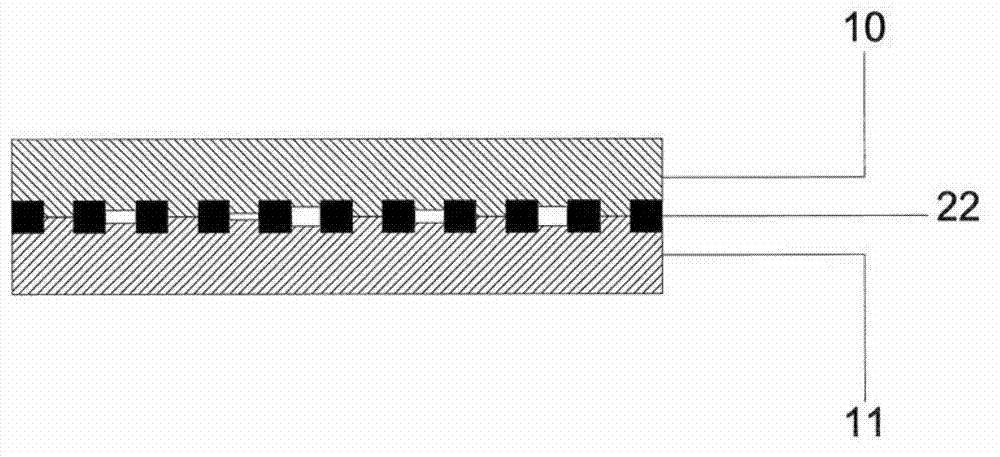

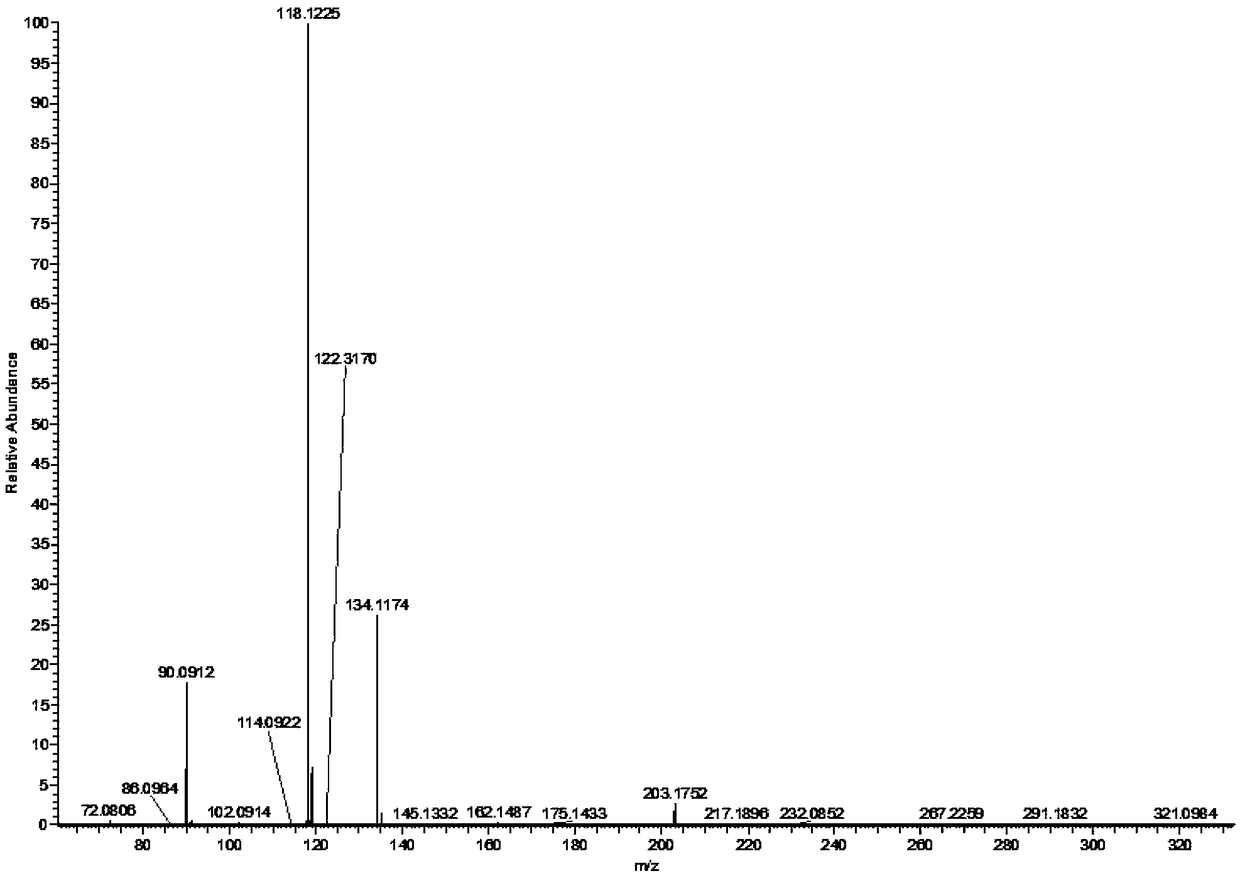

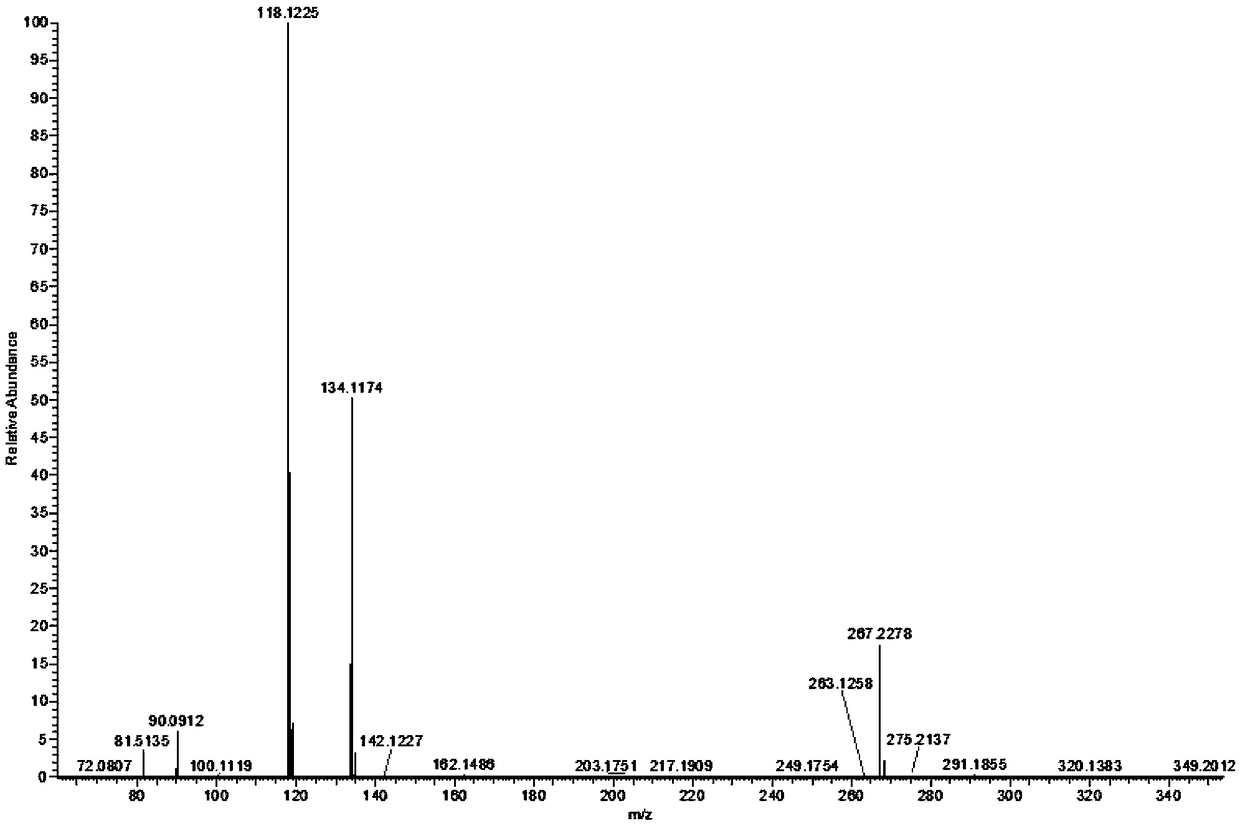

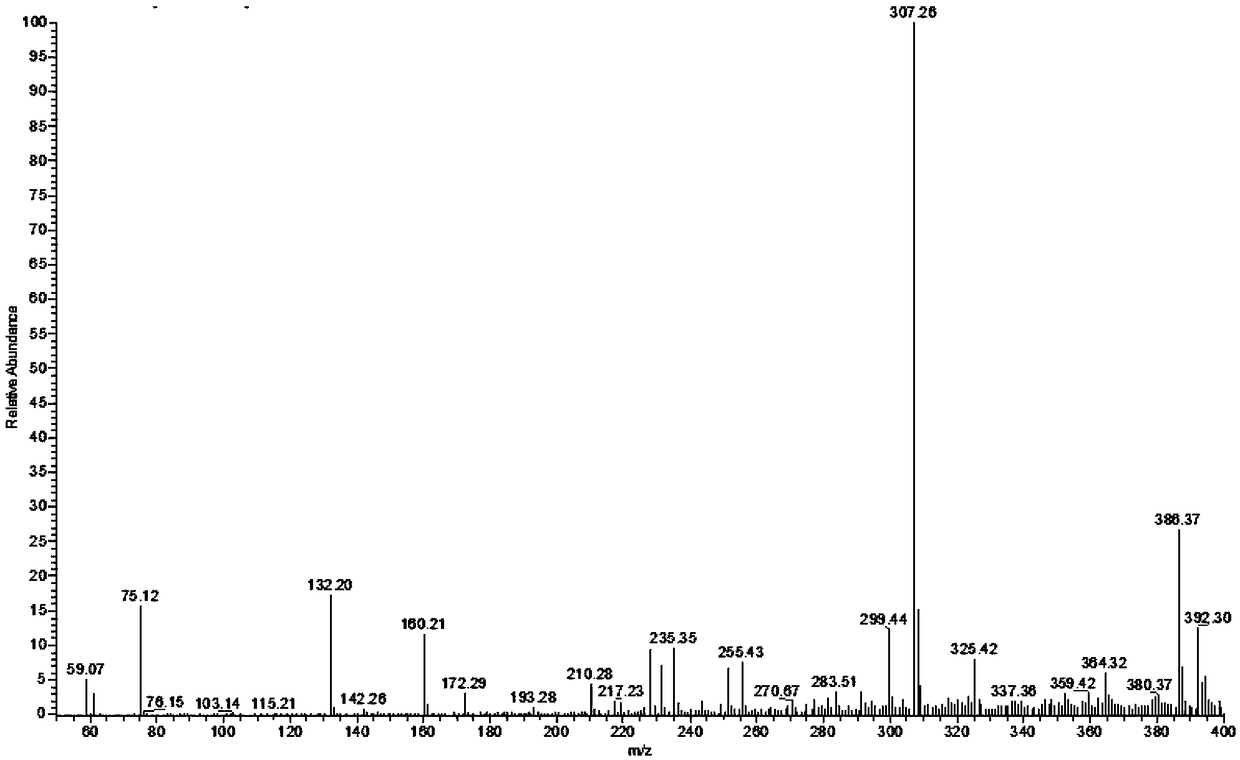

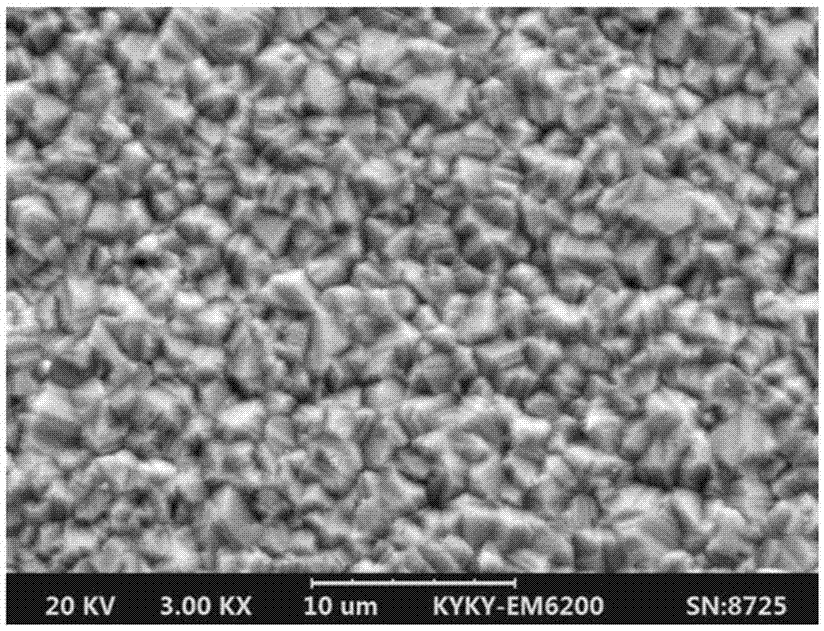

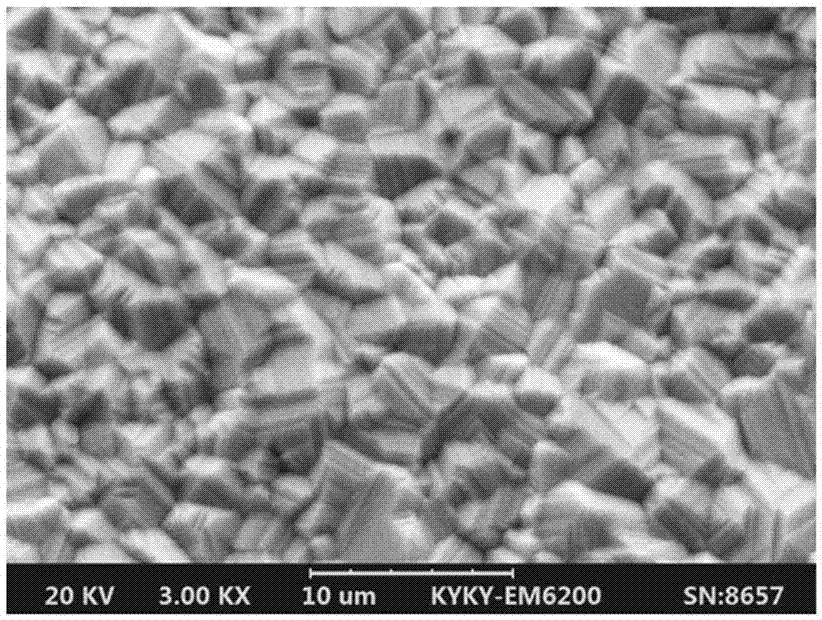

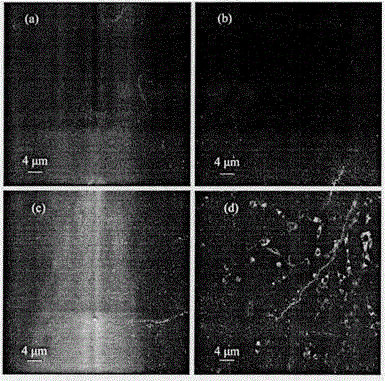

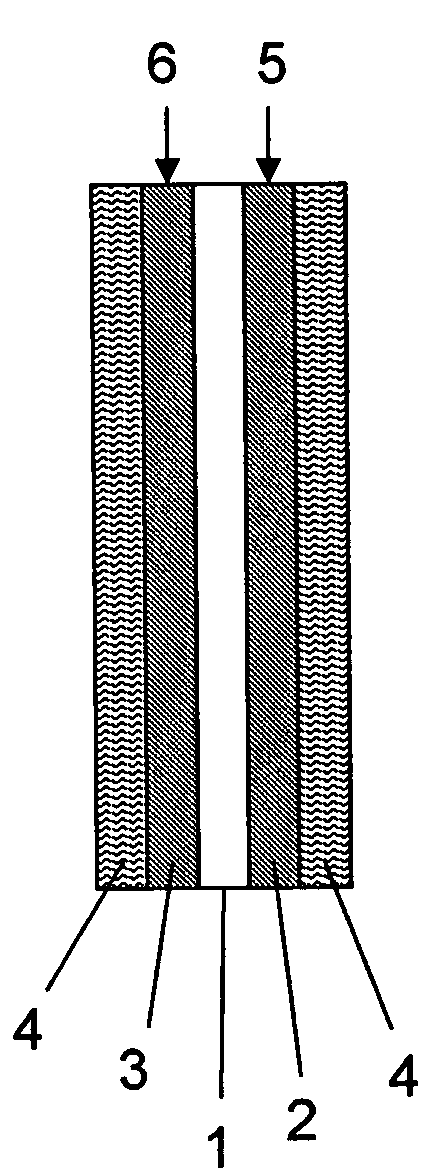

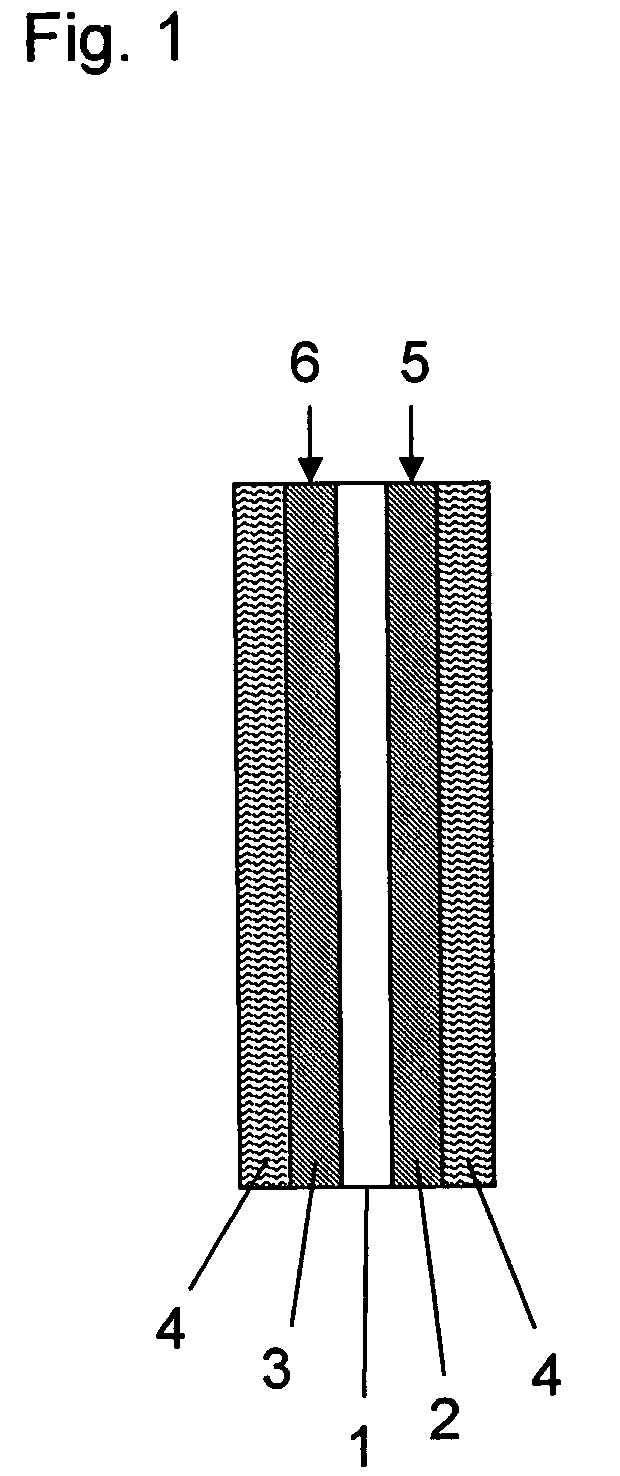

COMPOSITION FOR PREVENTION OR TREATMENT OF CANCER COMPRISING N-METHYLENENAPHTHO[2,1-b]FURAN-2-CARBOHYDRAZIDE DERIVATIVES AS AN ACTIVE INGREDIENT

The present invention relates to ethyl(2-methyl-3{(E)-[(naphtho[2,1-b]furan-2-ylcarbonyl)hydrazono]methyl}-1H-indole-1-yl)acetate, the novel mitosis inhibitor. The said ethyl(2-methyl-3{(E)-[(naphtho[2,1-b]furan-2-ylcarbonyl)hydrazono]methyl}-1H-indole-1-yl)acetate not only induces apoptosis by inhibiting tubulin polymerization in the course of mitosis but also displays an excellent anticancer effect in the multi-drug resistant cancer cells, so that it can be effectively used for the treatment of cell proliferative disease including various cancers.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

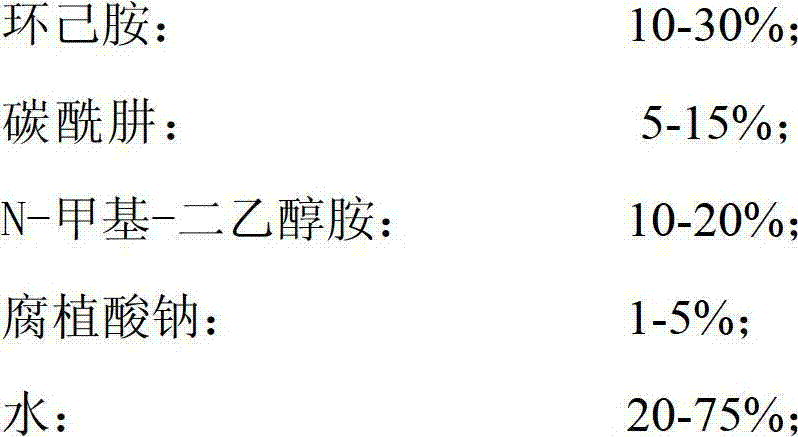

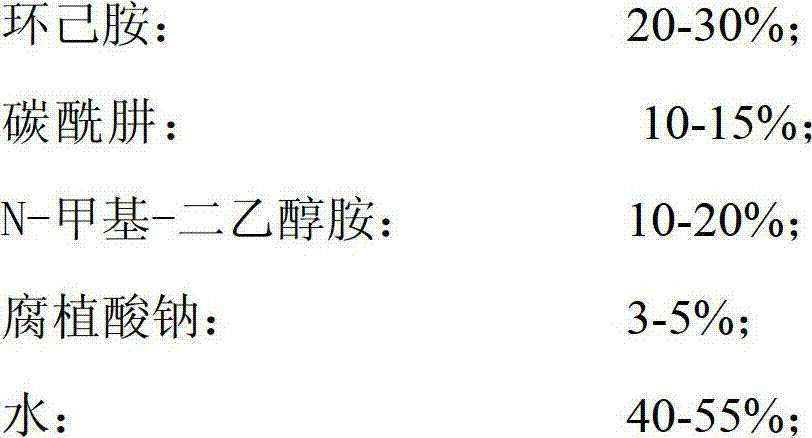

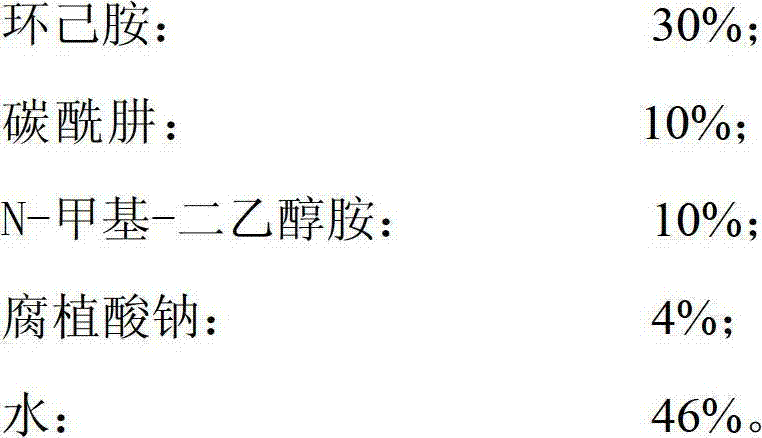

Multifunctional protective agent for boiler water supply system and preparation method thereof

InactiveCN102815797AAvoid corrosionEfficient removalScale removal and water softeningEngineeringPollution

The invention relates to a multifunctional protective agent for a boiler water supply system and a preparation method thereof. The protective agent comprises the following components expressed in mass percentage: 10 to 30% of cyclohexylamine, 5 to 15% of carbohydrazide, 10 to 20% of N-methyldiethanolamine, 1 to 5% of sodium humate and 20 to 75% of water, wherein the weight percentage of all the above-mentioned components sums to 100%. The protective agent provided by the invention is applicable to middle and low pressure boiler water supply processing systems and can effectively inhibit corrosion of a boiler, a furnace tube, a heat exchanger and a steam condensate system; the protective agent effectively controls stabilization of the pH value of water bodies in the boiler and the steam condensate system; and the protective agent effectively inhibits scale formation in the boiler, has stronger control and disperses generated scale which is then removed through pollution discharging by the boiler.

Owner:天津市瑞德赛恩新材料开发有限公司

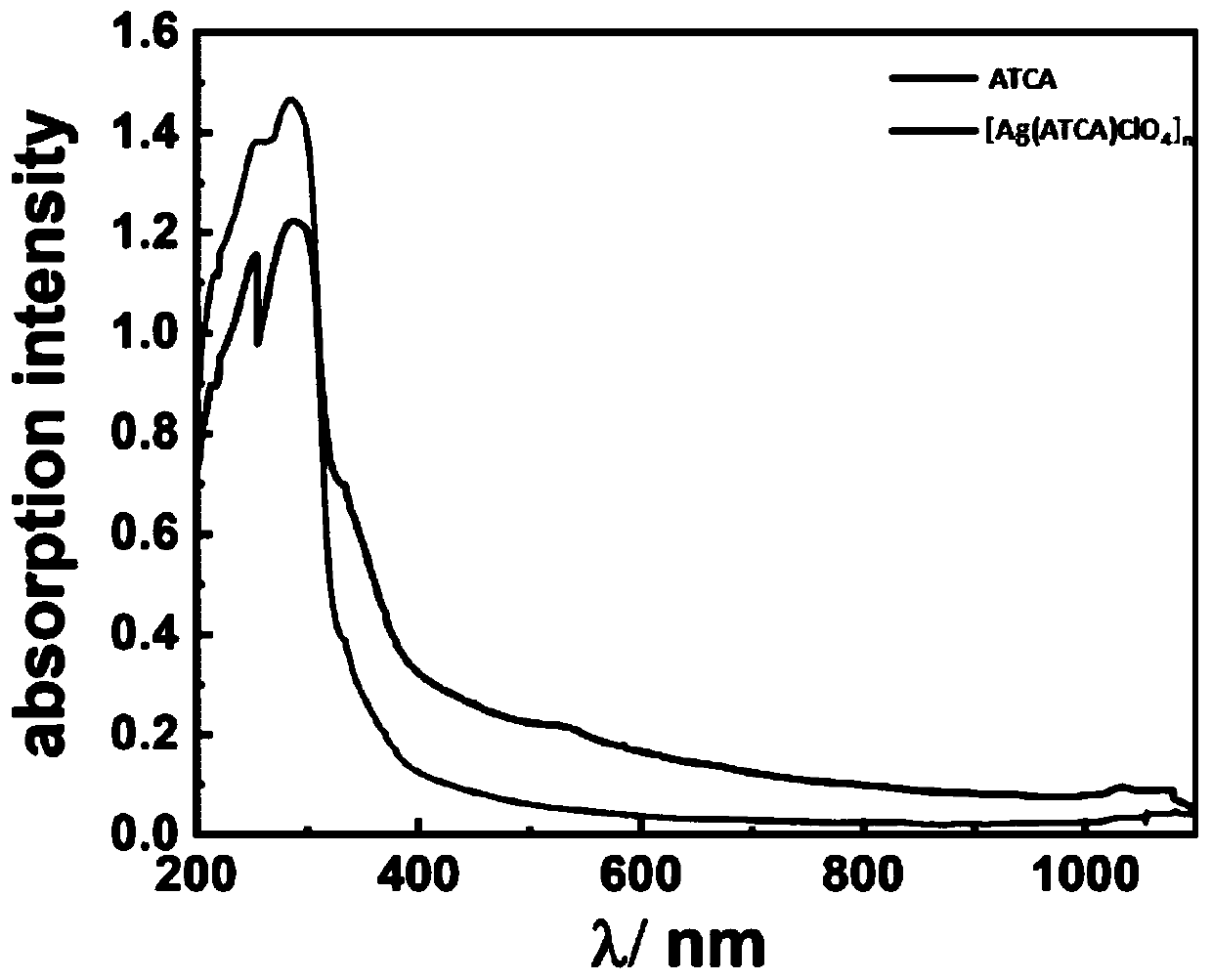

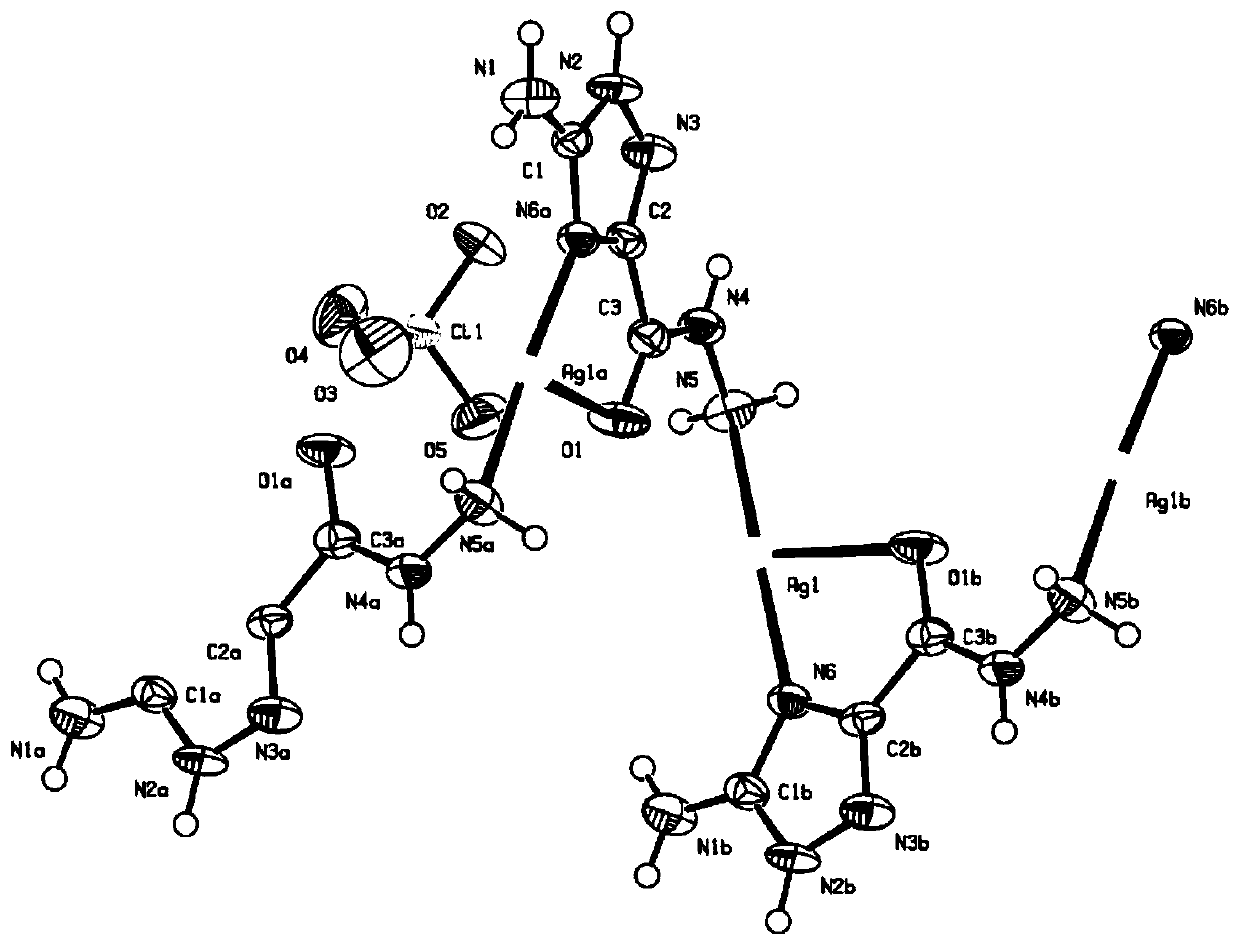

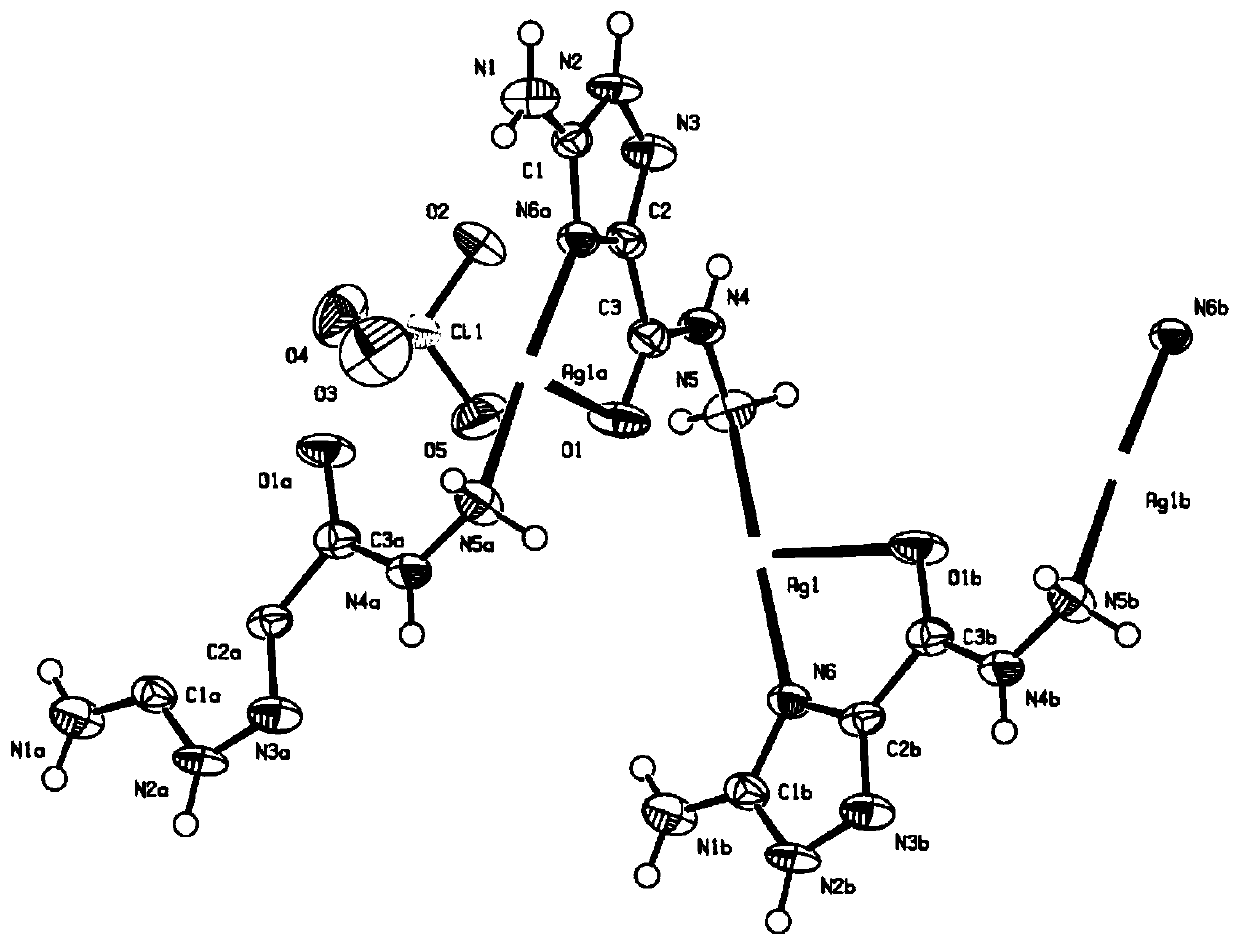

Application of silver-based cationic energy-containing metal organic framework as laser direct detonating agent composition

ActiveCN110452077AHigh ignition responseShorten ignition timeExplosive working-up apparatusMetal-organic frameworkGreen laser

The invention discloses application of a silver-based cationic energy-containing metal organic framework as a laser direct detonating agent composition. The energy-containing metal organic framework material with the chemical formula of [Ag(ATCA)ClO4]n is used as a core material, wherein ATCA in the formula is a neutral ligand of 3-amino-1H-1,2,4-triazole-5-carbohydrazide; meanwhile, a small amount of molybdenum disulfide is added as an assistant agent. According to the application of the silver-based cationic energy-containing metal organic framework as the laser direct detonating agent composition, the novel lead-free green laser detonating agent composition is more environmentally friendly. Meanwhile, the composition has a high ignition response to femtosecond lasers, the ignition timeof the composition is shorter, the ignition energy of the composition is lower, and the composition is better than detonating agents such as lead azide. A preparation method of the composition is simple in process flow, convenient to operate, mild in reaction condition and high in safety and product quality.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

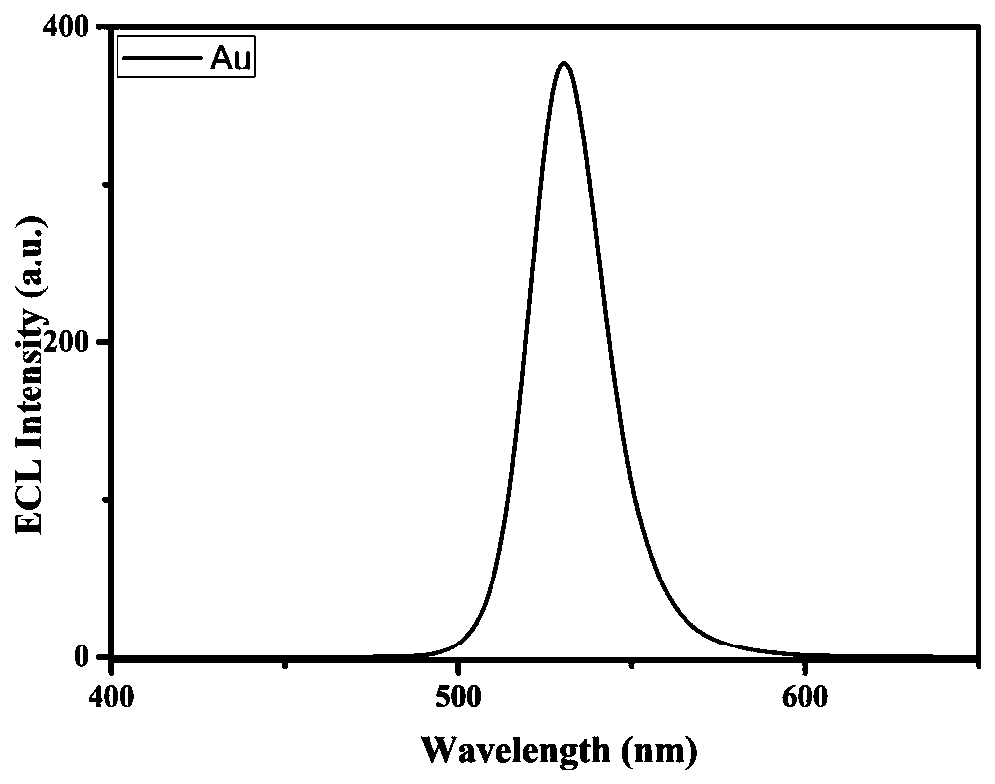

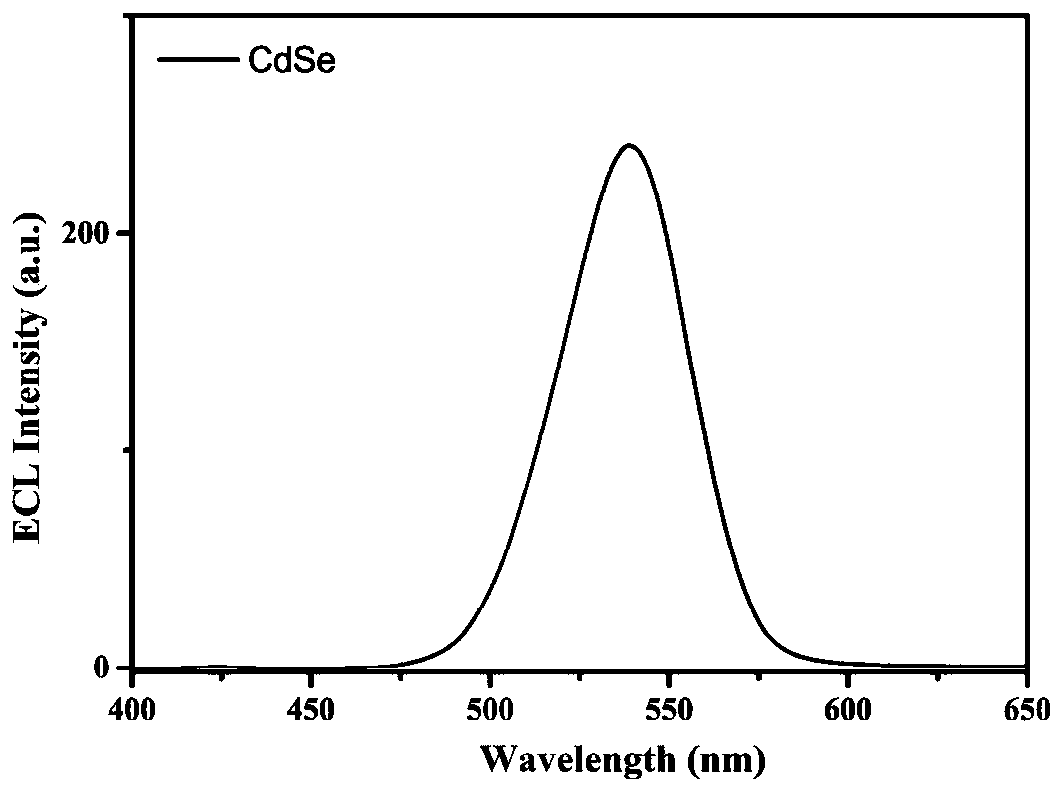

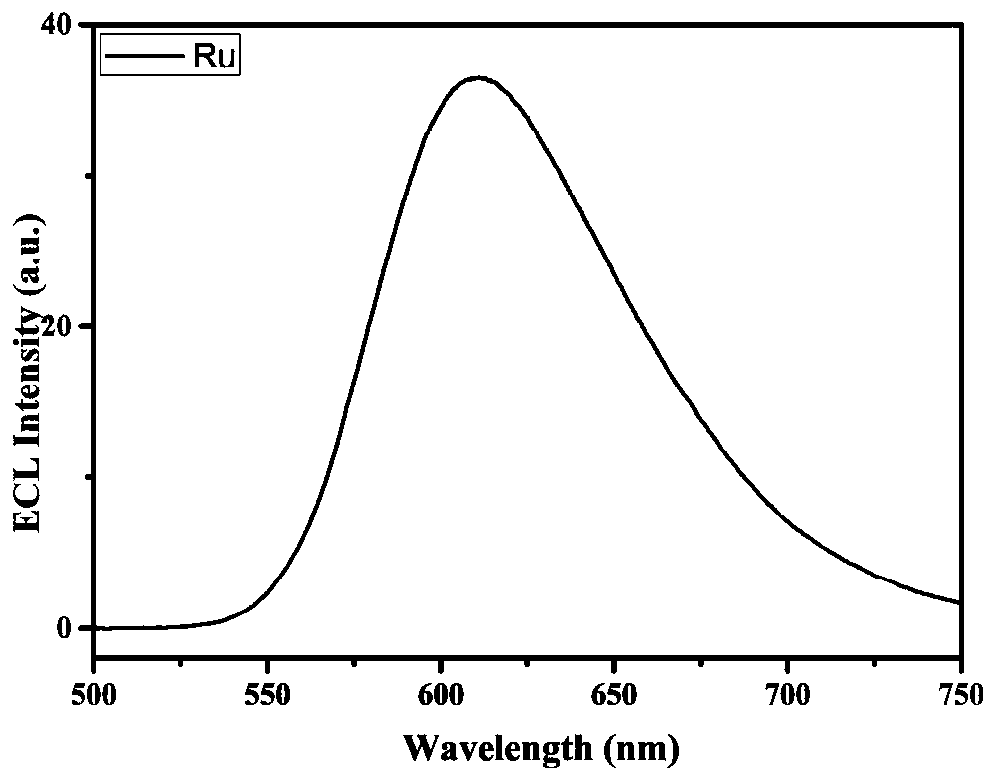

Broad-spectrum low-potential electrochemical luminescence system and construction method thereof

ActiveCN111139066ABroad-spectrumImprove electrode toleranceChemiluminescene/bioluminescenceLuminescent compositionsPropylaminePhotochemistry

The invention belongs to the field of analysis technical methods, and relates to a broad-spectrum low-potential electrochemical luminescence system and a construction method thereof. Low-toxicity carbohydrazide is used as a co-reactant, ruthenium bipyridine in a molecular form and a series of other substances in a nano-form, such as CdTe CdSe, Au and CuInS2 / ZnS quantum dots are immobilized on thesurface of a working electrode by using nafion, and anode electrochemical luminescence radiation close to 0.55 V is obtained in a water-phase buffer solution system close to physiological conditions.The luminescence potential of the system of the invention is obviously lower than the luminescence potential (1.2 V) of a classical ruthenium bipyridine / tripropylamine system, electrochemical interference can be effectively reduced, and the tolerance of an electrode material is improved.

Owner:SHANDONG UNIV

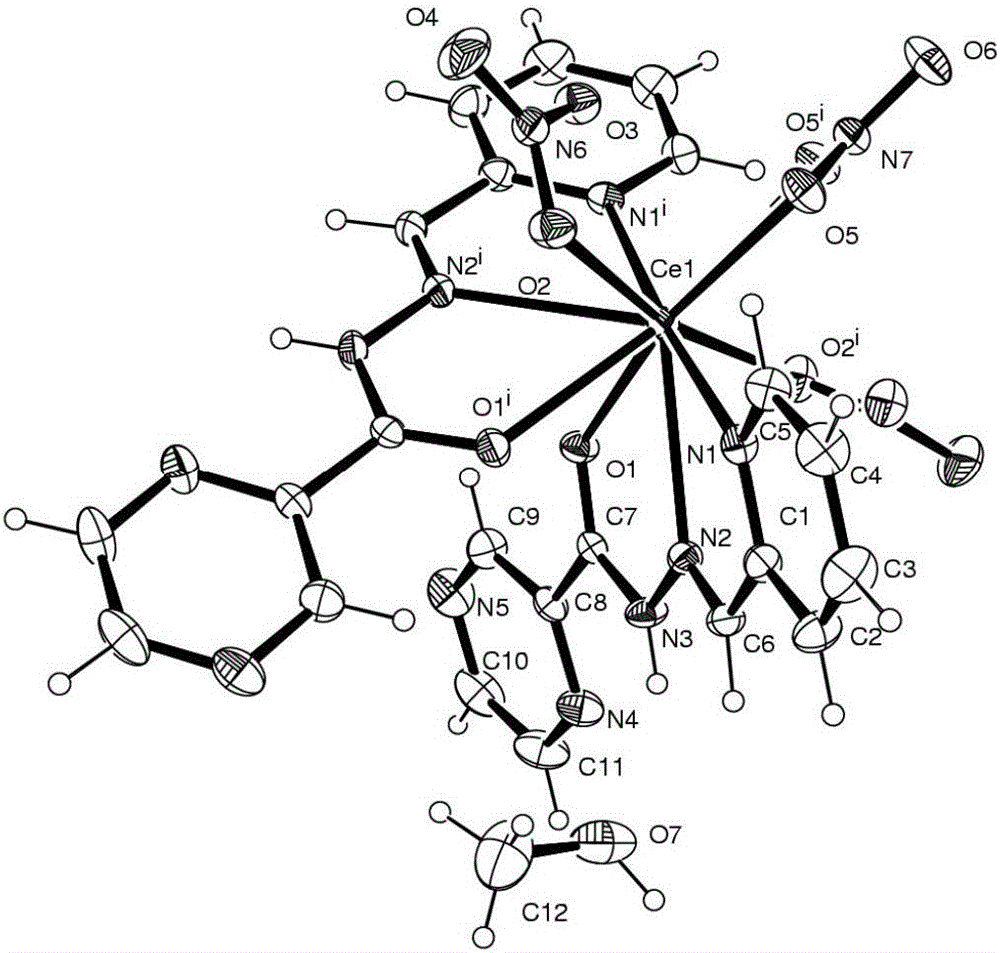

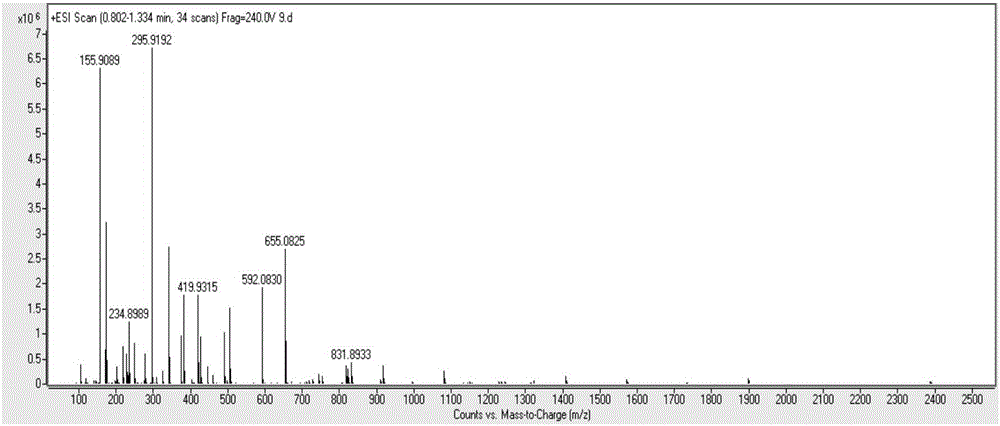

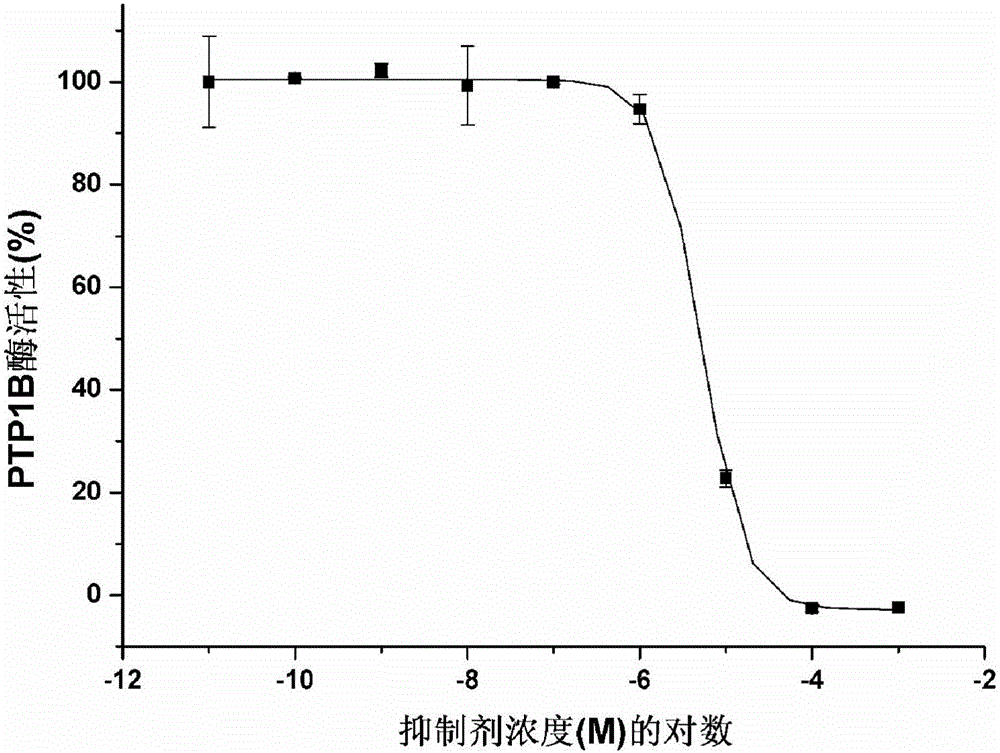

Rare-earth cerium Schiff base complex and preparation method and application thereof

InactiveCN106432308AHigh purityEasy to prepareMetabolism disorderGroup 3/13 organic compounds without C-metal linkagesFiltrationPyrazine

The invention provides a rear-earth cerium Schiff base complex and a preparation method and application thereof. The molecular formula of the complex is [Ce(HL)2(NO3)3], wherein HL is N'-(pyridine-2-methylene)pyrazine-2-carbohydrazide. The preparation method of the complex comprises the steps that a methanol solution of rear earth cerium salt is dropwise added into a methanol solution placed in a ligand of a round-bottom flask, heating reflux is conducted at the temperature ranging from 40 DEG C to 60 DEG C for 6-9 h, deep green clear liquid is obtained, filtration is conducted, light yellow blocky crystals are dissolved out from a filtrate, and the yield is 45%-75% or above. The complex has a good inhibiting effect on the activity of protein tyrosine phosphatase (PTP1B and TCPTP) and can serve as an inhibitor of the protein tyrosine phosphatase (PTP1B and TCPTP) for use.

Owner:SHANXI UNIV

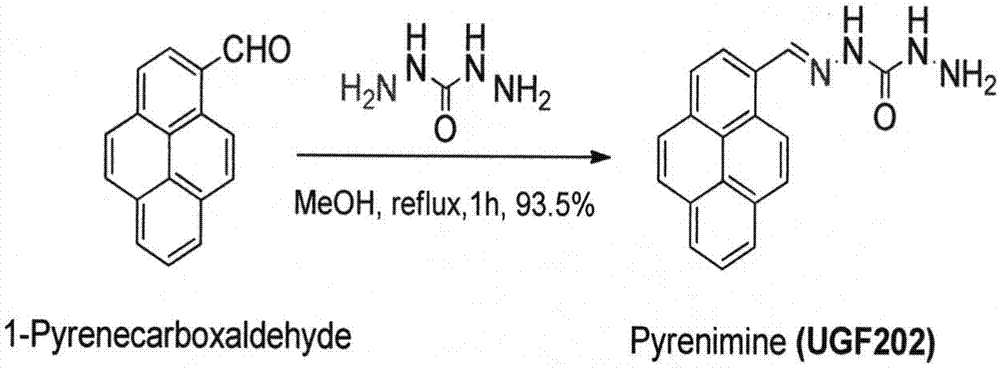

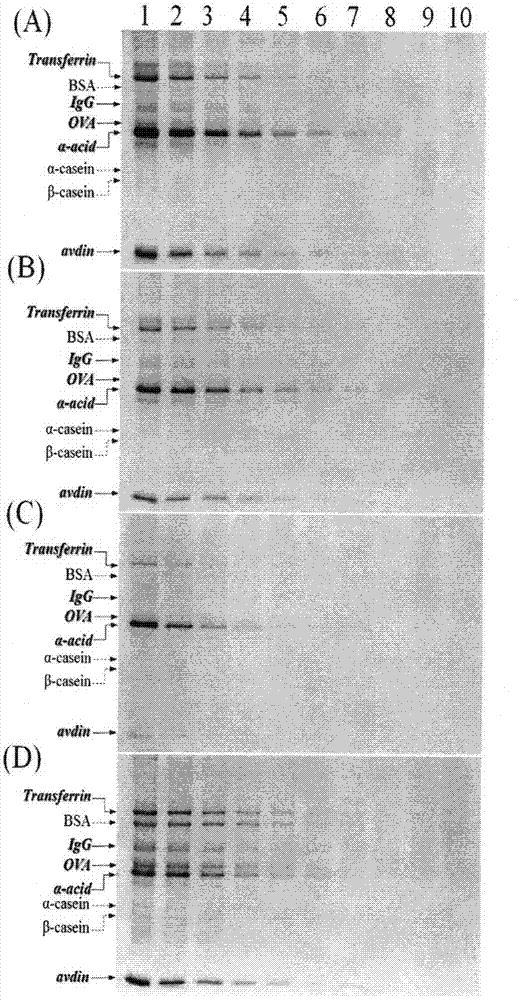

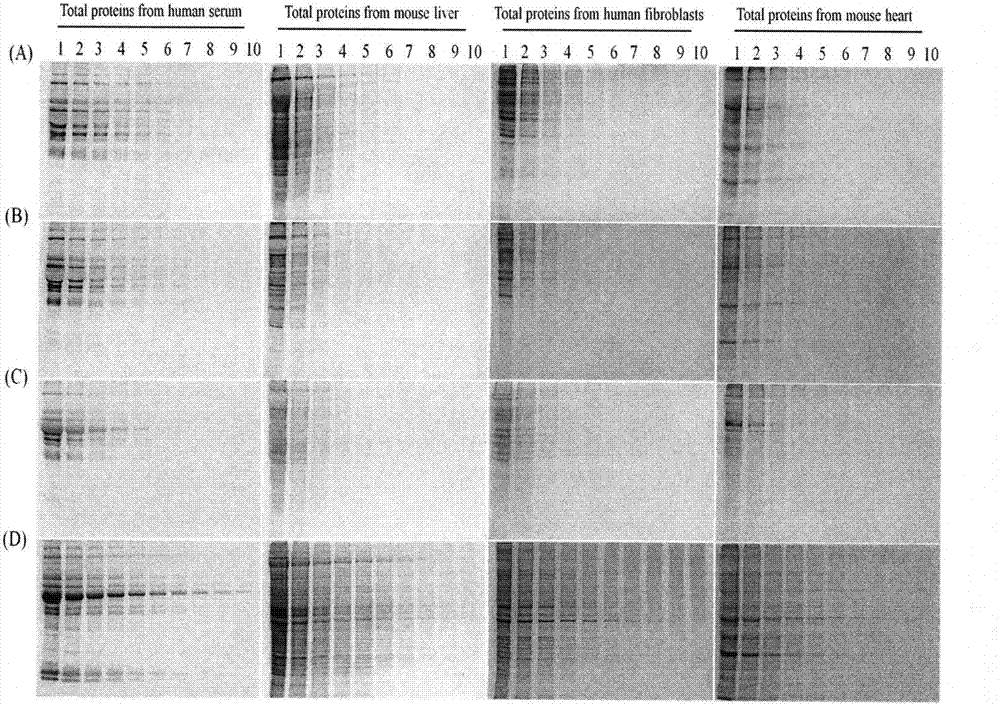

Synthesis of 1-pyrenyl-carbohydrazide and application of 1-pyrenyl-carbohydrazide in specific detection of glycoprotein

The invention relates to the field of specific fluorescence detection technology of glycoprotein in the research orientation and in particular relates to synthesis of 1-pyrenyl-carbohydrazide (UGF202) and application of derivatives of 1-pyrenyl-carbohydrazide in specific detection of glycoprotein. The invention provides a method for performing specific fluorescence detection on glycoprotein by virtue of 1-pyrenyl-carbohydrazide. The method comprises the following four steps: fixing gel containing a protein sample subjected to electrophoretic separation in a fixing solution; oxidizing with a periodic acid solution; washing with vitamin C aqueous solution; and staining. The method has extremely high sensitivity, can be used for detecting glycoprotein lowering to 0.5ng, has the advantages of high specificity, simple and convenient operation steps, time conservation, high reproducibility, good linear relation, high mass spectrum compatibility, safety in use and low cost and can be well applied to research of high-flux proteomics.

Owner:温州安得森生物科技有限公司

Preparation method of high-performance resin adhesive for rock wool sizing

ActiveCN103555235ASolve the lack of dilution differenceIncreased water dilutionAldehyde/ketone condensation polymer adhesivesPolyvinyl alcoholResin adhesive

The invention provides a preparation method of a high-performance resin adhesive for rock wool sizing, and relates to the field of resins. The high-performance resin adhesive is prepared from the following raw materials: phenol, concentrated sulfuric acid, formaldehyde, carbohydrazide, polyvinyl alcohol, liquid alkali and the like. The synthesis process of the high-performance resin adhesive comprises the following four reaction phases: in the first reaction phase, performing a sulfonation reaction on partial phenol and concentrated sulfuric acid at 100 DEG C to 110 DEG C so as to generate p-hydroxybenzenesulfonic acid; in the second reaction phase, condensing the majority of phenol remaining in the first reaction phase and p-hydroxybenzenesulfonic acid generated by the first reaction phase with formaldehyde under an alkali condition so as to generate a phenol formaldehyde resin adhesive; in the third reaction phase, adding carbohydrazide to be condensed with incompletely-reacted phenol, intermediates and formaldehyde so as to generate a phenol-carbohydrazide-formaldehyde resin adhesive; in the last reaction phase, adding polyvinyl alcohol to react with residual formaldehyde so as to generate a polyvinyl formal adhesive. The high-performance resin adhesive is long in storage life, high in water dilutability and low in free phenol and formaldehyde content, thereby being suitable for the fields of rock wool sizing and the like.

Owner:HEBEI SANKAISHENFA SCI & TECH CORP LTD +1

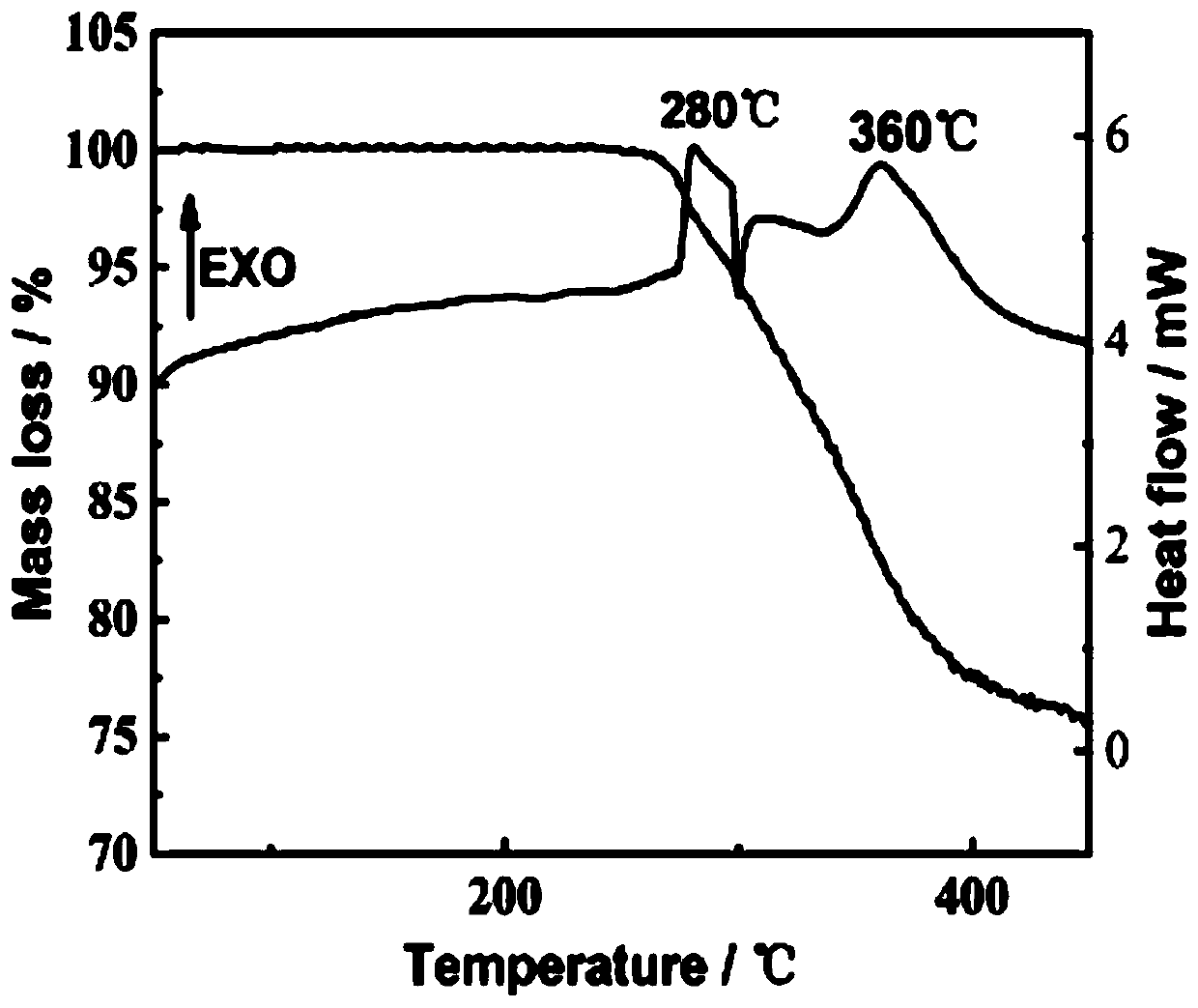

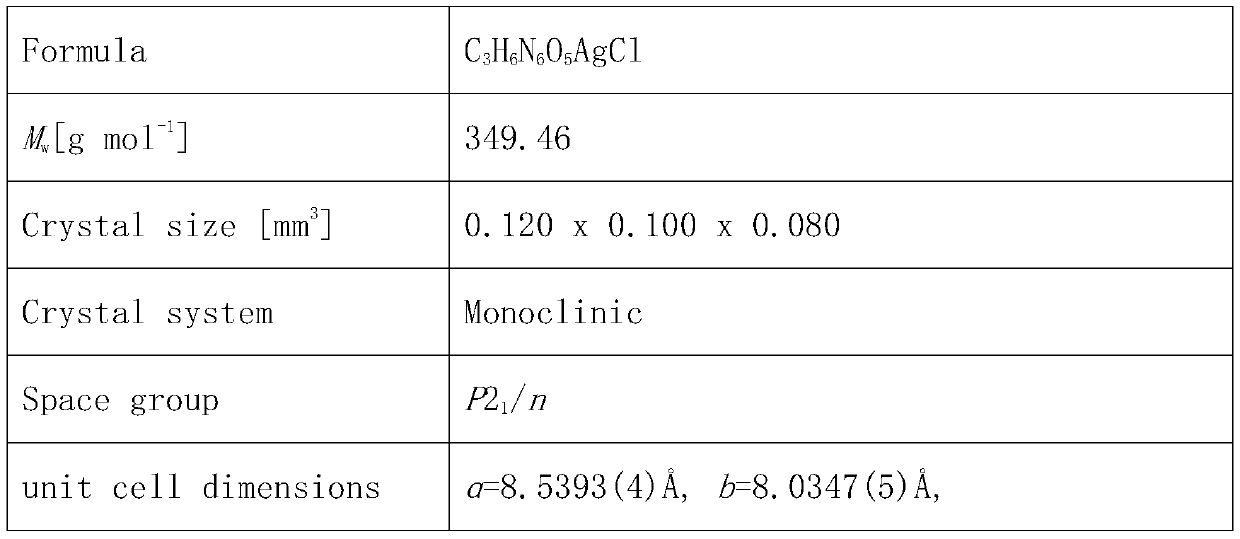

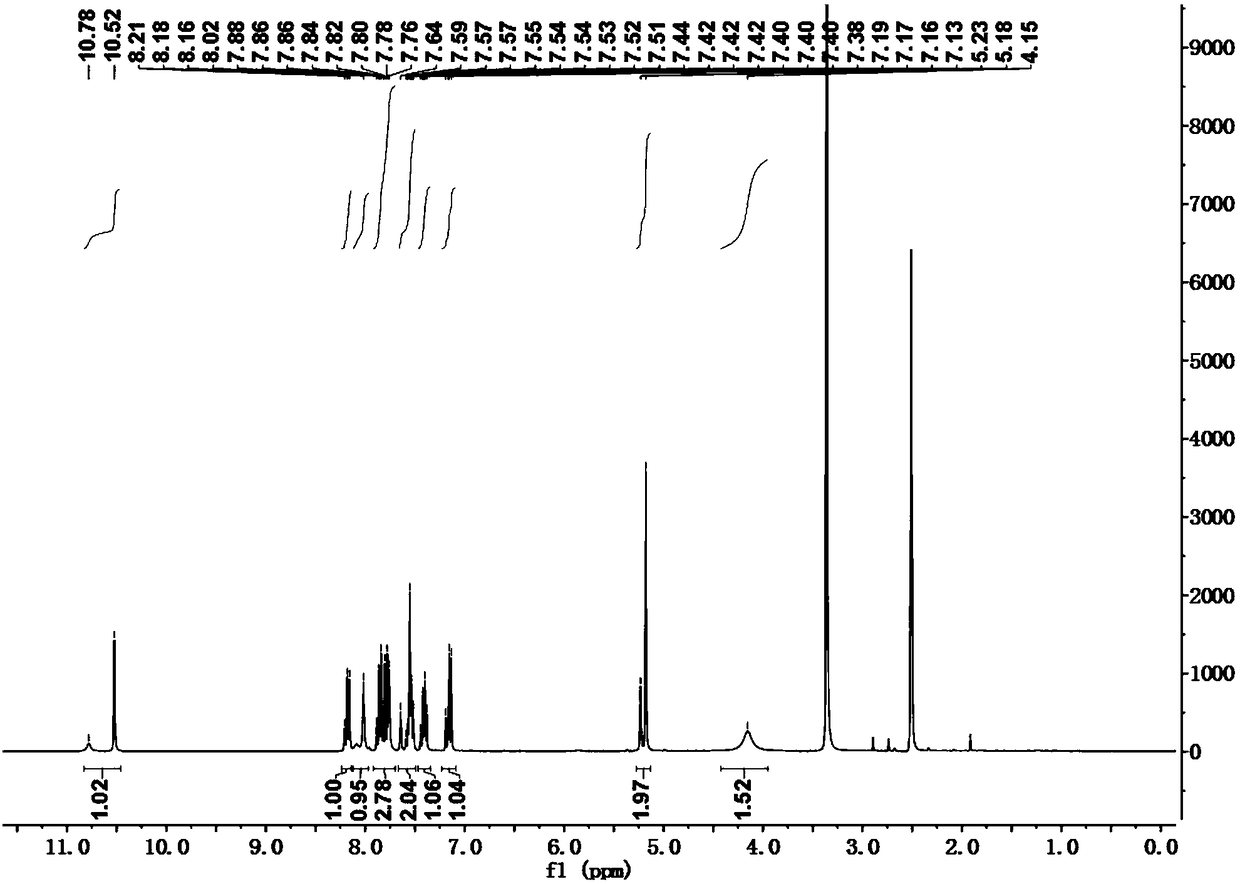

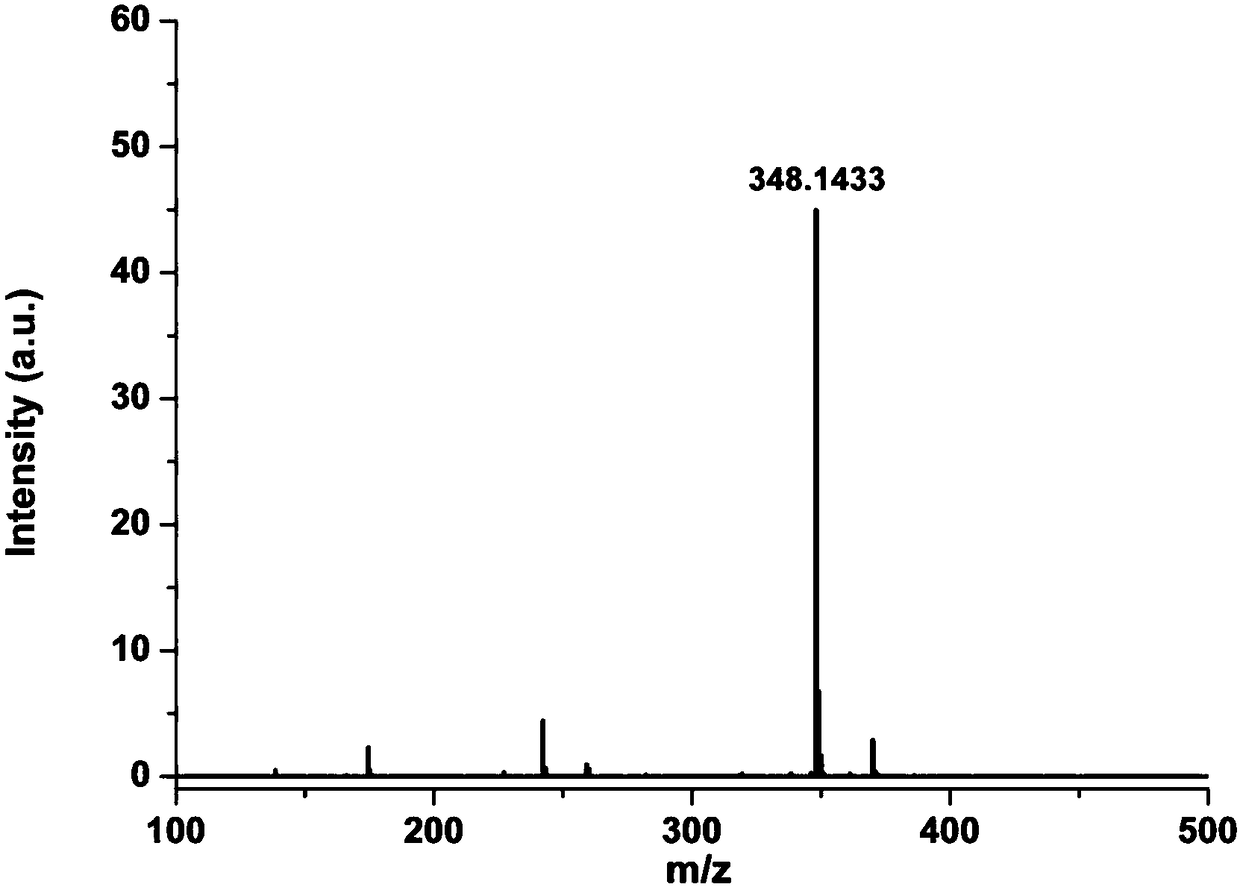

Insensitive energetic metal organic framework and preparation method thereof

ActiveCN110408048AImprove securityGood energy performanceExplosivesHydrazine compoundMetal-organic framework

The invention discloses a silver-based cationic energetic metal organic framework with the chemical formula of [Ag(ATCA)ClO4]n and a preparation method thereof. The preparation method comprises the following steps that step one, a commercial organic intermediate 3-amino-1H-1,2,4-triazole-5-carboxylic acid is taken as a starting raw material, and in absolute methanol, concentrated H2SO4 is taken asa catalyst for synthesis of 5-amino-1H-1,2,4-triazole-3-carboxylic acid methyl ester (MATC); step two, the MATC is utilized for reacting with hydrazine hydrate to prepare a target non-energetic nitrogen-rich ligand 3-amino-1H-1,2,4-triazole-5-carbohydrazide (ATCA); step three, a certain amount of ATCA is suspended in hot water and dissolved through heating, then a silver perchlorate solution withthe certain concentration is added, a certain amount of perchloric acid is dropwise added, then slow cooling evaporative crystallization is conducted, and the target product silver-based cationic energetic metal organic framework with the chemical formula of [Ag(ATCA)ClO4]n is obtained.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Naphthopyran carbazone derivative as well as preparation method and application thereof

InactiveCN108383823AThe synthesis method is simpleRaw materials are easy to getOrganic chemistryFluorescence/phosphorescenceOrganic solventSlag

The invention relates to a naphthopyran carbazone derivative as well as a preparation method and application thereof, and belongs to the technical field of organic synthesis. The preparation method ofthe naphthopyran carbazone derivative comprises the following steps of S1, adding 3H-naphtho[2,1-b]pyran-2-formaldehyde into an organic solvent to be dissolved; then, adding carbohydrazide to obtaina mixture; S2, performing backflow stirring reaction on the mixture obtained in the S1 at normal pressure; S3, after the reaction is completed, performing cooling to room temperature; separating out solid; performing reduced pressure filtering; taking filter slag; S4, washing filter slag obtained in the step S3 to obtain the naphthopyran carbazone derivative. The naphthopyran carbazone derivativehas high sensitivity and high selectivity when being used as a ratio fluorescence probe for detecting copper ions, particularly in application of convenient detection of copper ions in cells as a fluorescence probe.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![COMPOSITION FOR PREVENTION OR TREATMENT OF CANCER COMPRISING N-METHYLENENAPHTHO[2,1-b]FURAN-2-CARBOHYDRAZIDE DERIVATIVES AS AN ACTIVE INGREDIENT COMPOSITION FOR PREVENTION OR TREATMENT OF CANCER COMPRISING N-METHYLENENAPHTHO[2,1-b]FURAN-2-CARBOHYDRAZIDE DERIVATIVES AS AN ACTIVE INGREDIENT](https://images-eureka.patsnap.com/patent_img/2c8378f1-20a2-4e09-ae60-e4f0b1b26579/US20150182502A1-20150702-D00001.PNG)

![COMPOSITION FOR PREVENTION OR TREATMENT OF CANCER COMPRISING N-METHYLENENAPHTHO[2,1-b]FURAN-2-CARBOHYDRAZIDE DERIVATIVES AS AN ACTIVE INGREDIENT COMPOSITION FOR PREVENTION OR TREATMENT OF CANCER COMPRISING N-METHYLENENAPHTHO[2,1-b]FURAN-2-CARBOHYDRAZIDE DERIVATIVES AS AN ACTIVE INGREDIENT](https://images-eureka.patsnap.com/patent_img/2c8378f1-20a2-4e09-ae60-e4f0b1b26579/US20150182502A1-20150702-D00002.PNG)

![COMPOSITION FOR PREVENTION OR TREATMENT OF CANCER COMPRISING N-METHYLENENAPHTHO[2,1-b]FURAN-2-CARBOHYDRAZIDE DERIVATIVES AS AN ACTIVE INGREDIENT COMPOSITION FOR PREVENTION OR TREATMENT OF CANCER COMPRISING N-METHYLENENAPHTHO[2,1-b]FURAN-2-CARBOHYDRAZIDE DERIVATIVES AS AN ACTIVE INGREDIENT](https://images-eureka.patsnap.com/patent_img/2c8378f1-20a2-4e09-ae60-e4f0b1b26579/US20150182502A1-20150702-D00003.PNG)