Patents

Literature

141 results about "Magnesium sulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium sulfite is the magnesium salt of sulfurous acid with the formula MgSO₃. Its most common hydrated form has 6 water molecules making it a hexahydrate, MgSO₃·6H₂O. When heated above 40 °C (104 °F), it is dehydrated to magnesium sulfite trihydrate, or MgSO₃·3H₂O. The anhydrous form is hygroscopic, meaning that it readily absorbs water from the air.

Composite heavy metal polluted soil in-situ fixing method

ActiveCN102303041APromote mineralization reactionQuick fixContaminated soil reclamationWater insolubleMagnesium sulfite

The invention discloses a composite heavy metal polluted soil in-situ fixing method. The method comprises the following steps of: preparing a heavy metal polluted soil restoration agent by using 80 to 90 weight parts of bentonite or kaolin serving as a filling agent, 0.5 to 15 weight parts of ferrous sulfide, 0.5 to 5 weight parts of magnesium sulfate, 1.5 to 8 weight parts of magnesium sulfite, 1 to 5 weight parts of magnesium oxide, 2 to 10 weight parts of calcium hydroxide and 1 to 5 weight parts of phosphorus-containing preparation; and mixing the components and heavy metal polluted soil according to the weight ratio of 1:(5-20), and uniformly stirring to make the humidity of the soil kept between 15 and 30 percent, wherein heavy metal ions in the polluted soil are converted into water-insoluble metal sulfides, hydroxides, multi-metal co-precipitates, basic carbonates and phosphate minerals, the biological activity of heavy metal is lost, and the heavy metal is fixed in the soil. The restored soil meets the requirement of second-level standard values of 'Environmental Quality Standard for Soil' (GB 15618-1995) in China.

Owner:刘阳生

Fenton and Fenton-like system fortifier and using method thereof

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

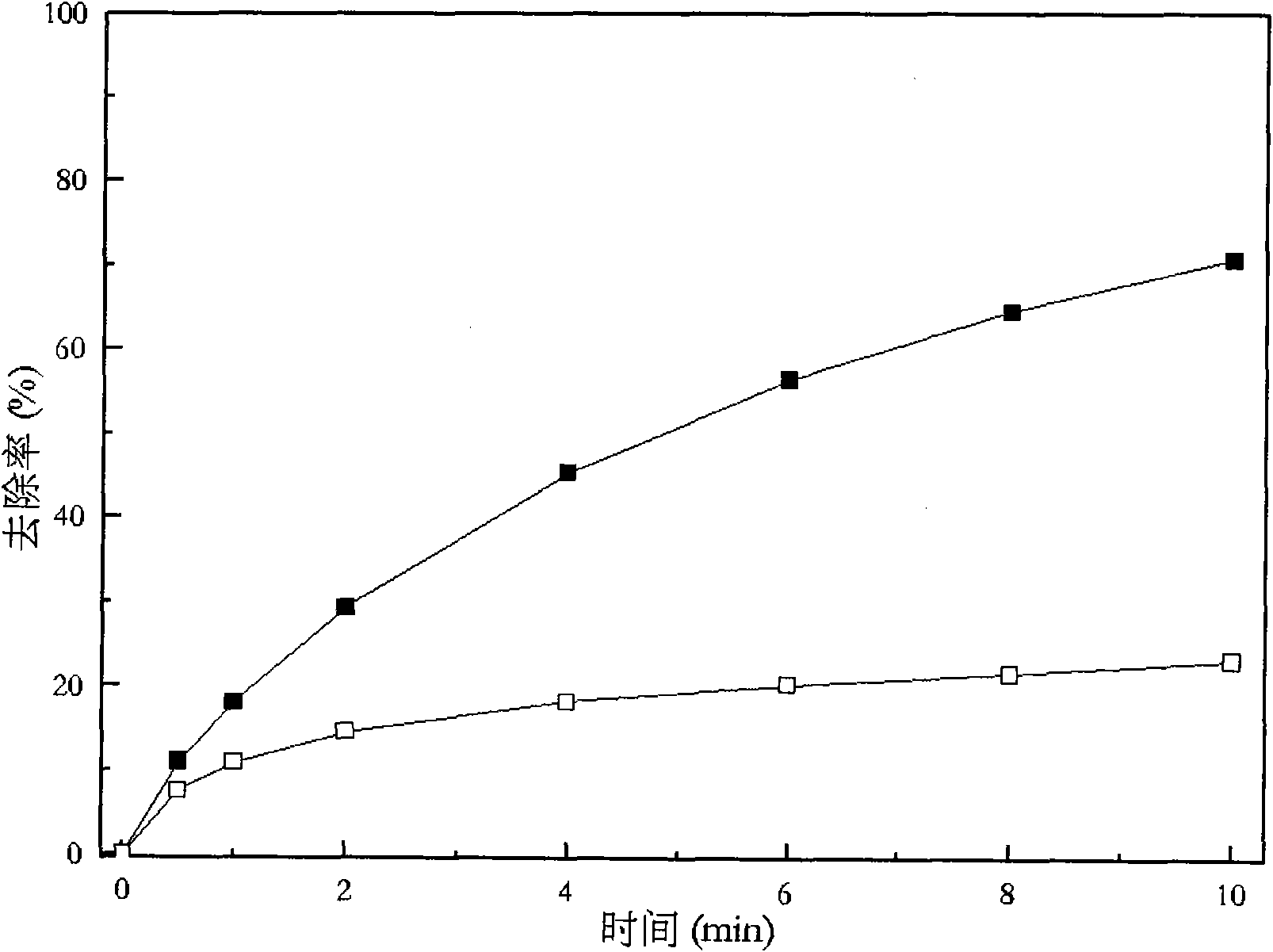

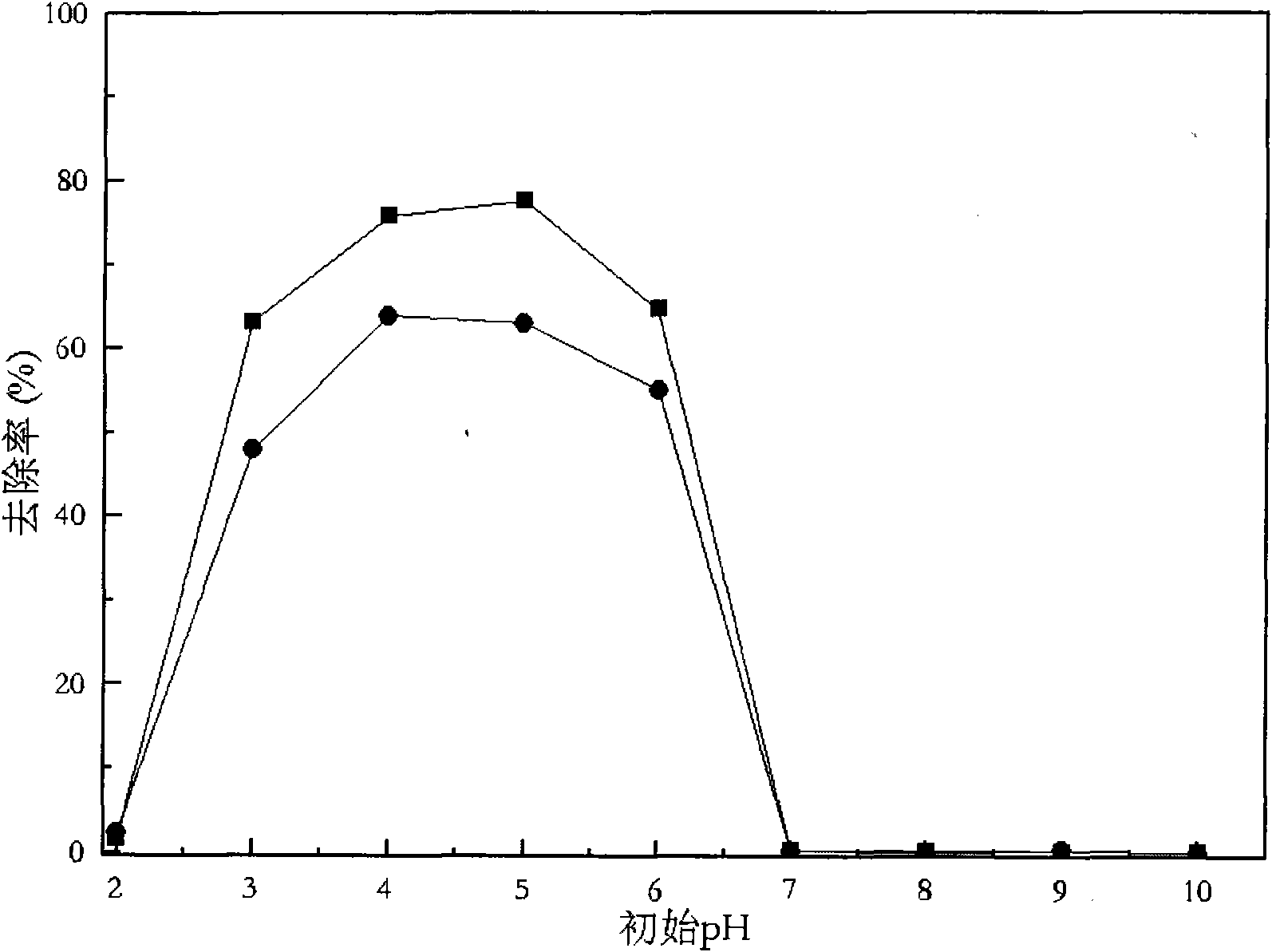

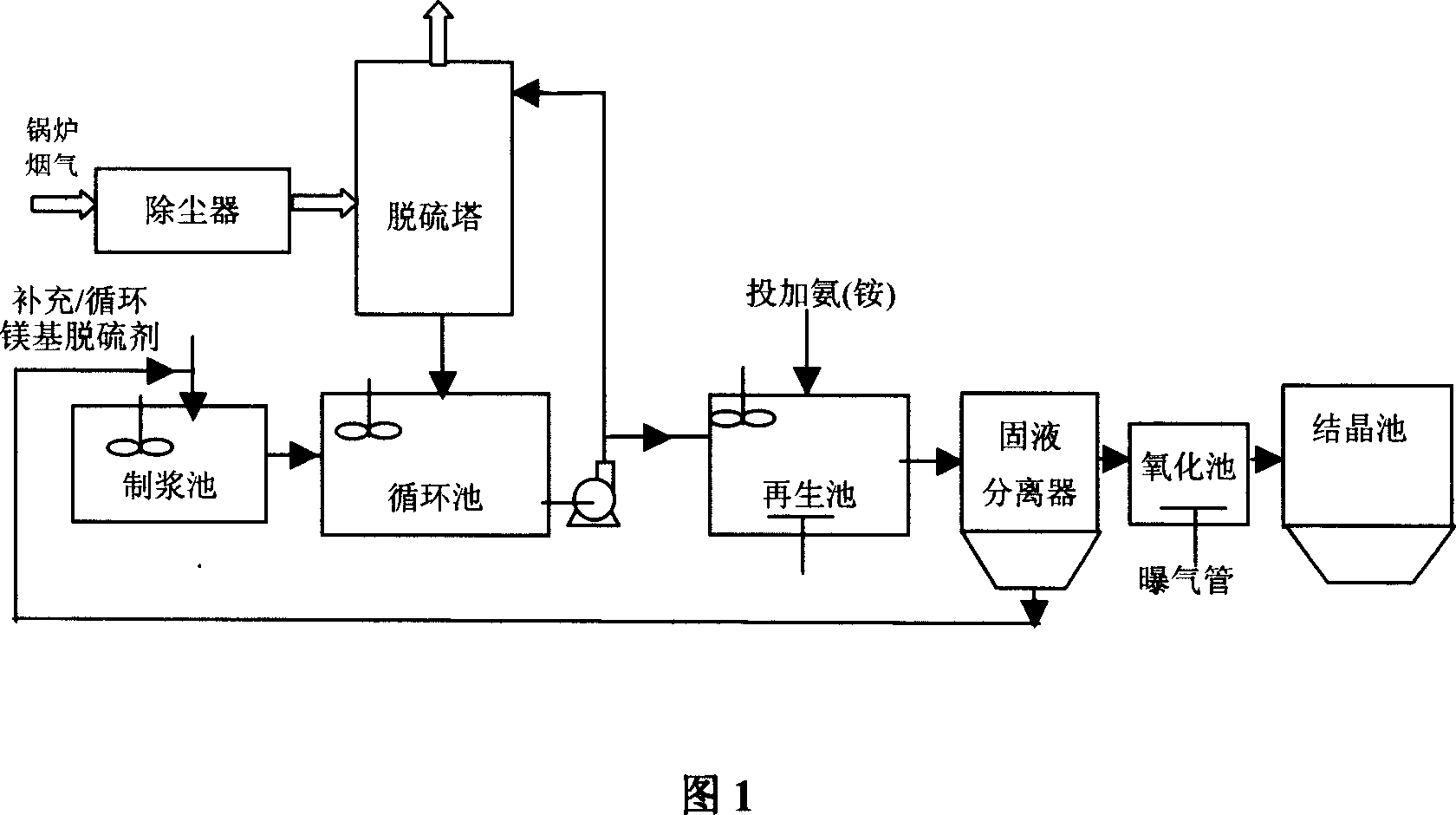

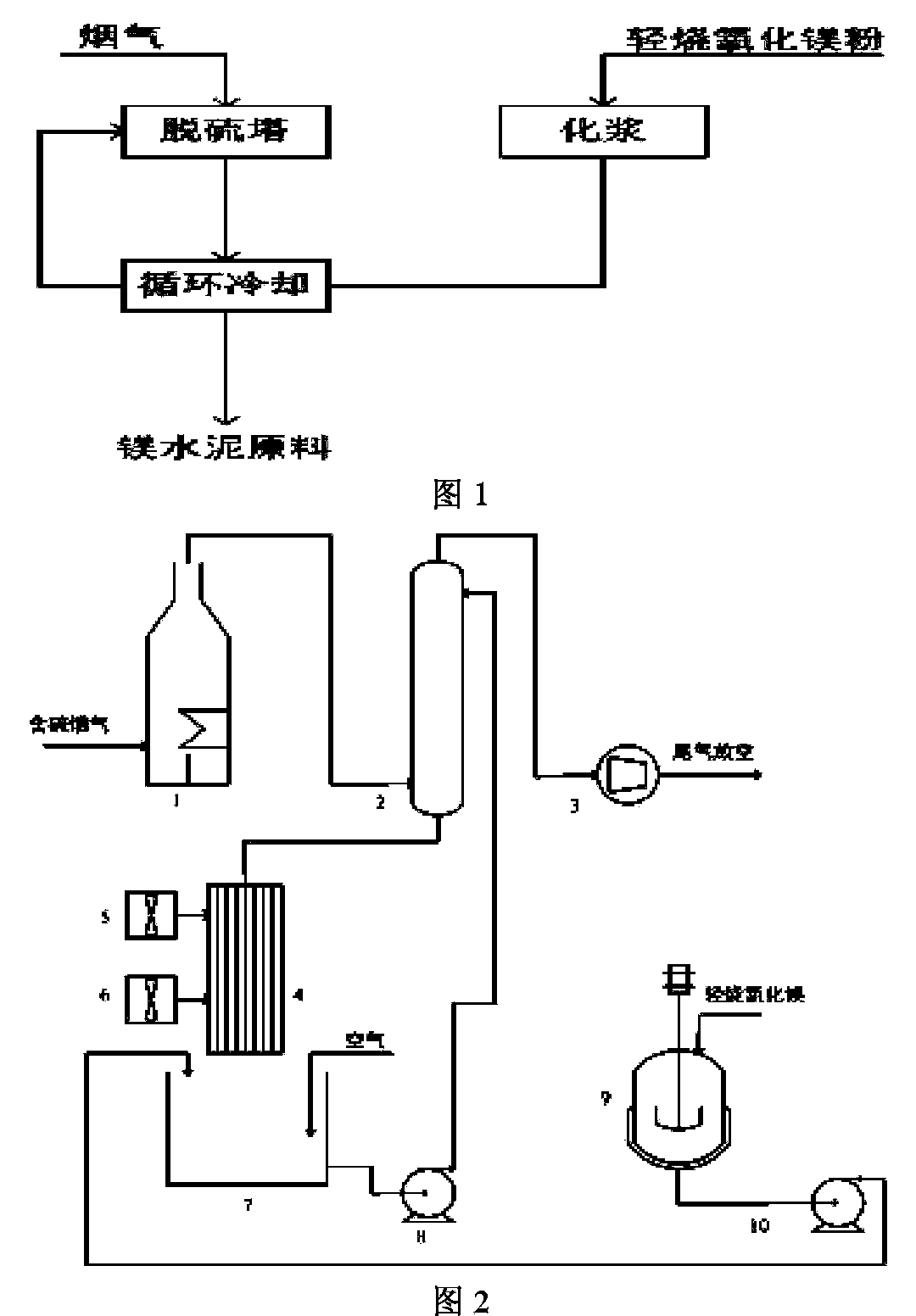

Method for using magnesium compound and ammonia to circulate regeneration flue gas desulfurization

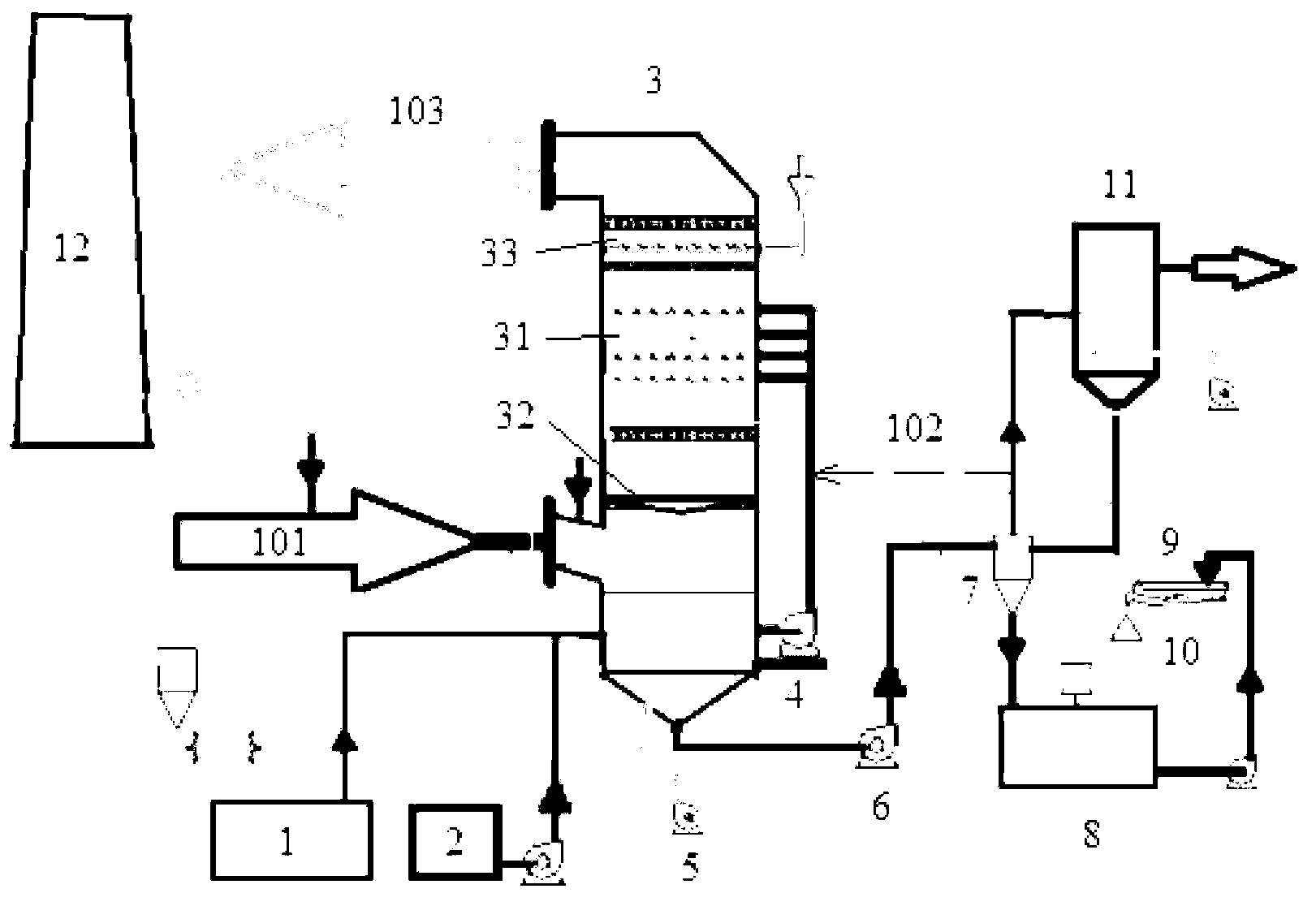

InactiveCN101053742AReduce desulfurization costThere is no secondary pollution problemDispersed particle separationMagnesium sulfiteCarbonate

The invention relates to a cyclic regeneration flue gas desulfurization method using magnesium compounds and ammonia. Firstly, the magnesium compounds and ammonia which is used as desulfurizer is made to be seriflux after mixed with water, and then is send to recycling tank and then to the thionizer using seriflux pump to absorb the sulfur dioxide therein via the contact with flue gas to get the purpose of desulfurization purification of the flue gas. Part of the desulfurization solution is drawn off and regenerated using ammonia or ammonium salt when the PH of the seriflux after absorbing the SO2 is low than 6.2. Regeneration uses the method of direct regeneration or oxydizing regeneration, and the precipitate such as magnesium sulphites, magnesium hydroxide or magnesium carbonate get after regeneration can be periodic duty. After concentrating crystallization, the ammiaonia sulfate of liquid phase can get the ammonium sulphate crystals, and is also made to be a composite Crystals of ammonium sulphate and magnesium sulfate. The invention reduces the desulfurization cost without secondary pollution at the precondition for ensuring the effect desulfurization of flue gas.

Owner:SHANGHAI JIAO TONG UNIV

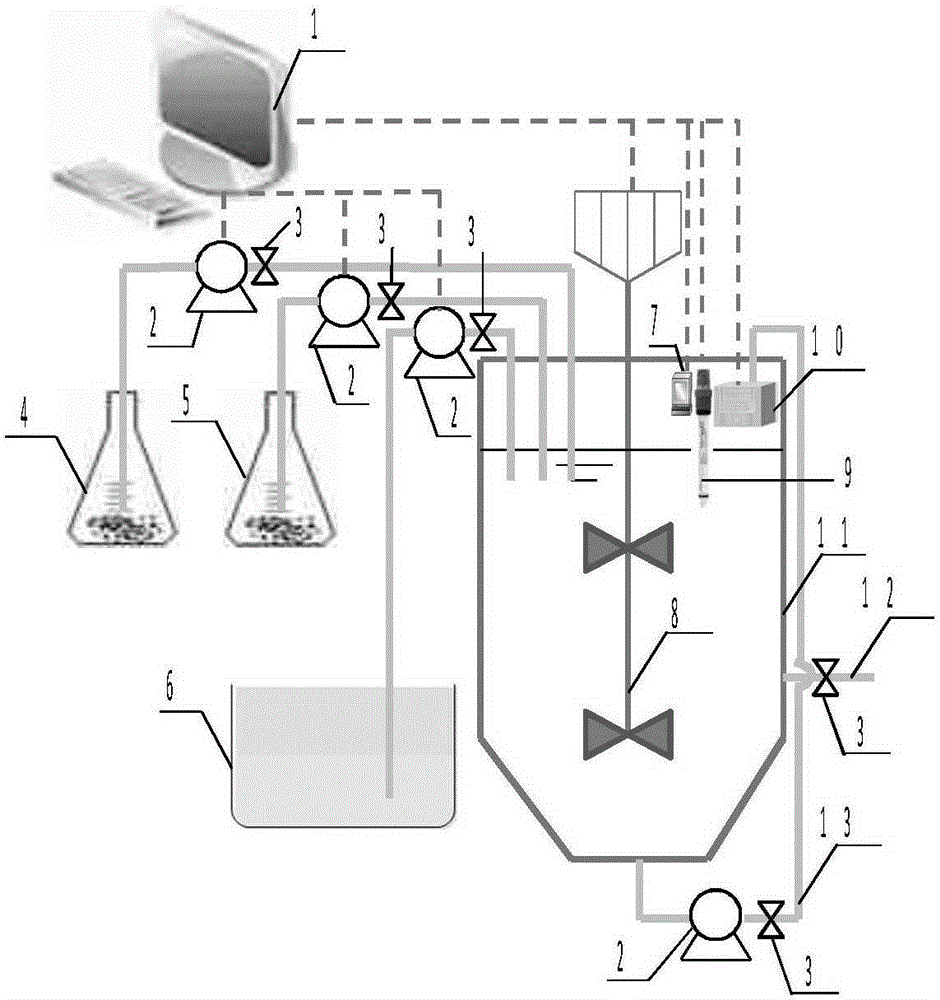

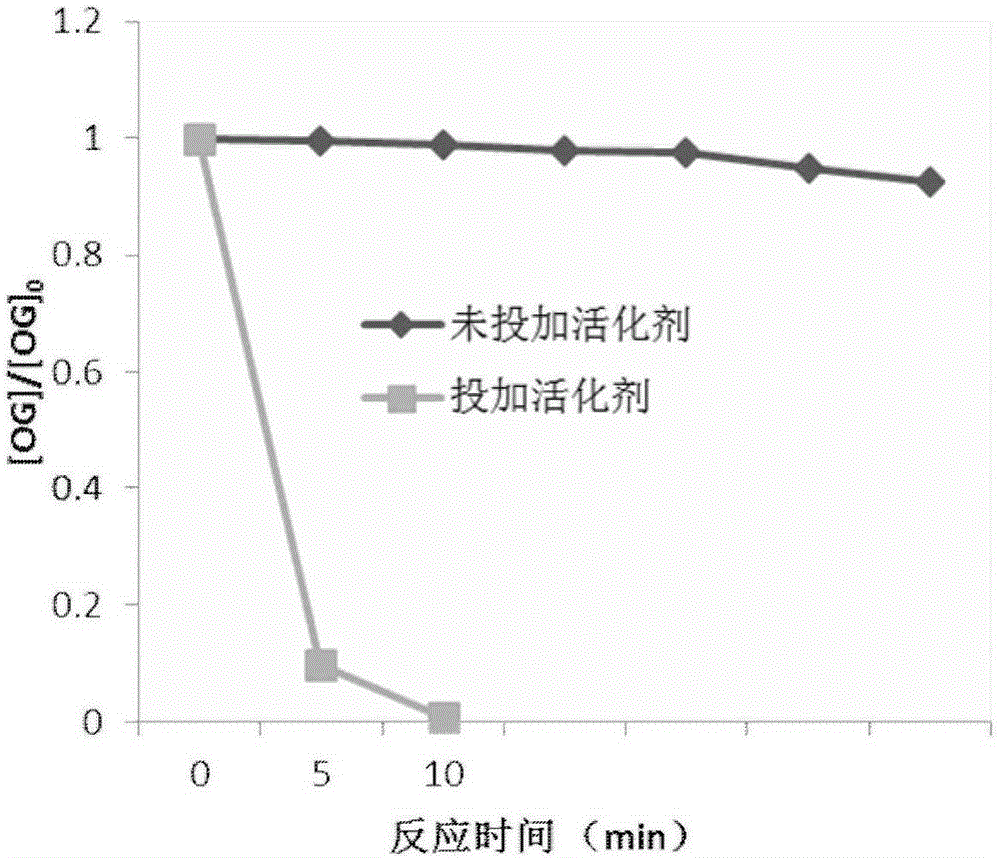

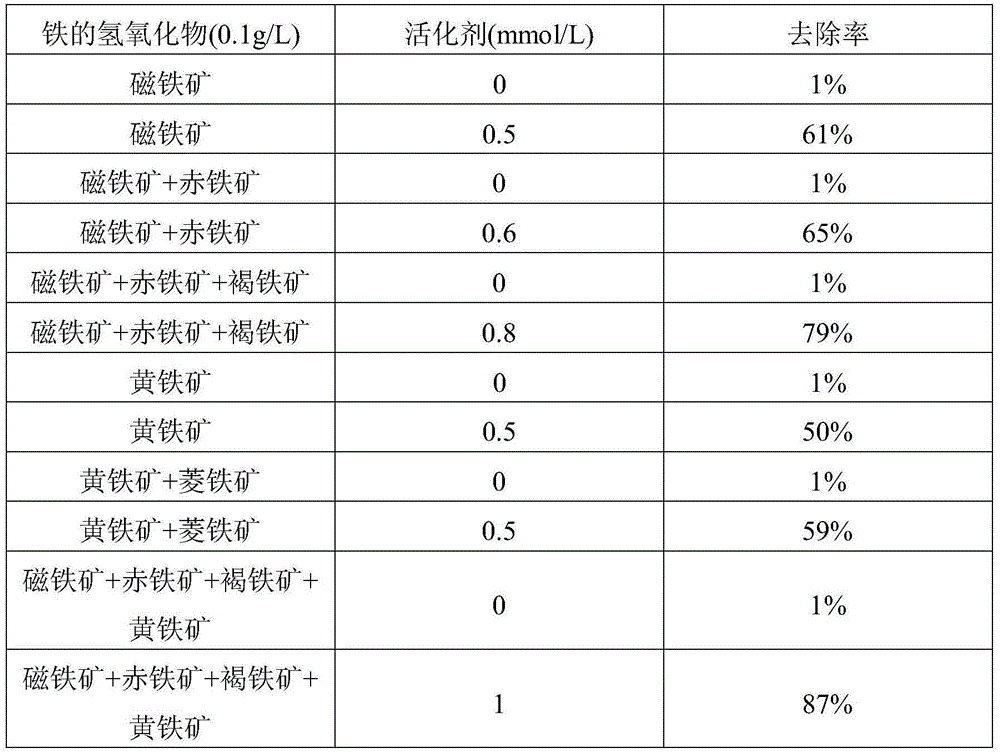

Method for recycling iron waste for fenton technology and water treating device of method

InactiveCN105174413AIncrease reaction rateRealize resource utilizationWater/sewage treatment by oxidationPotassium borohydrideSulfite salt

The invention discloses a method for recycling iron waste for the fenton technology. The method comprises the following steps that hydrogen peroxide, the iron waste and an activating agent are added to waste water to be treated, stirring is conducted so that the iron waste can be dispersed in a reaction system, a reaction is conducted, and then solid and liquid separation is conducted, wherein the activating agent is any one or a mixture of sodium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, sodium thiosulfate, potassium thiosulfate, calcium thiosulfate, magnesium thiosulfate, sodium borohydride, potassium borohydride, hydroxylamine hydrochloride and ascorbic acid. By means of the method, various kinds of iron waste are recycled, meanwhile, zero iron mud emission is achieved, and thus pollution to the environment is effectively reduced. The invention further provides a water treating device capable of achieving the method. By means of the method and the water treating device, the reaction speed of the iron waste in the fenton system is greatly increased, the effective pH range of the fenton system is expanded, meanwhile zero iron mud emission is achieved, and thus pollution to the environment can be easily reduced.

Owner:HOHAI UNIV

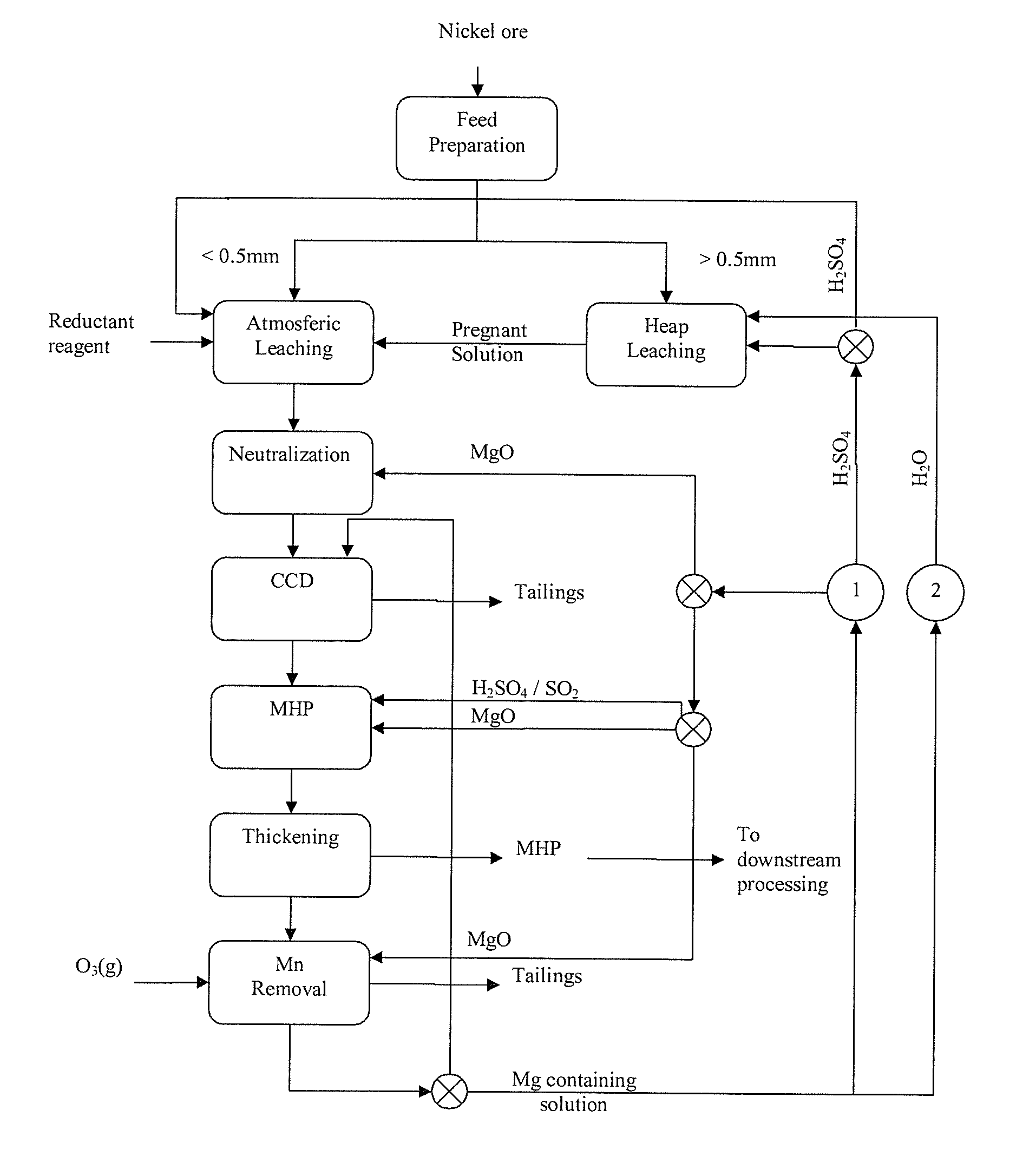

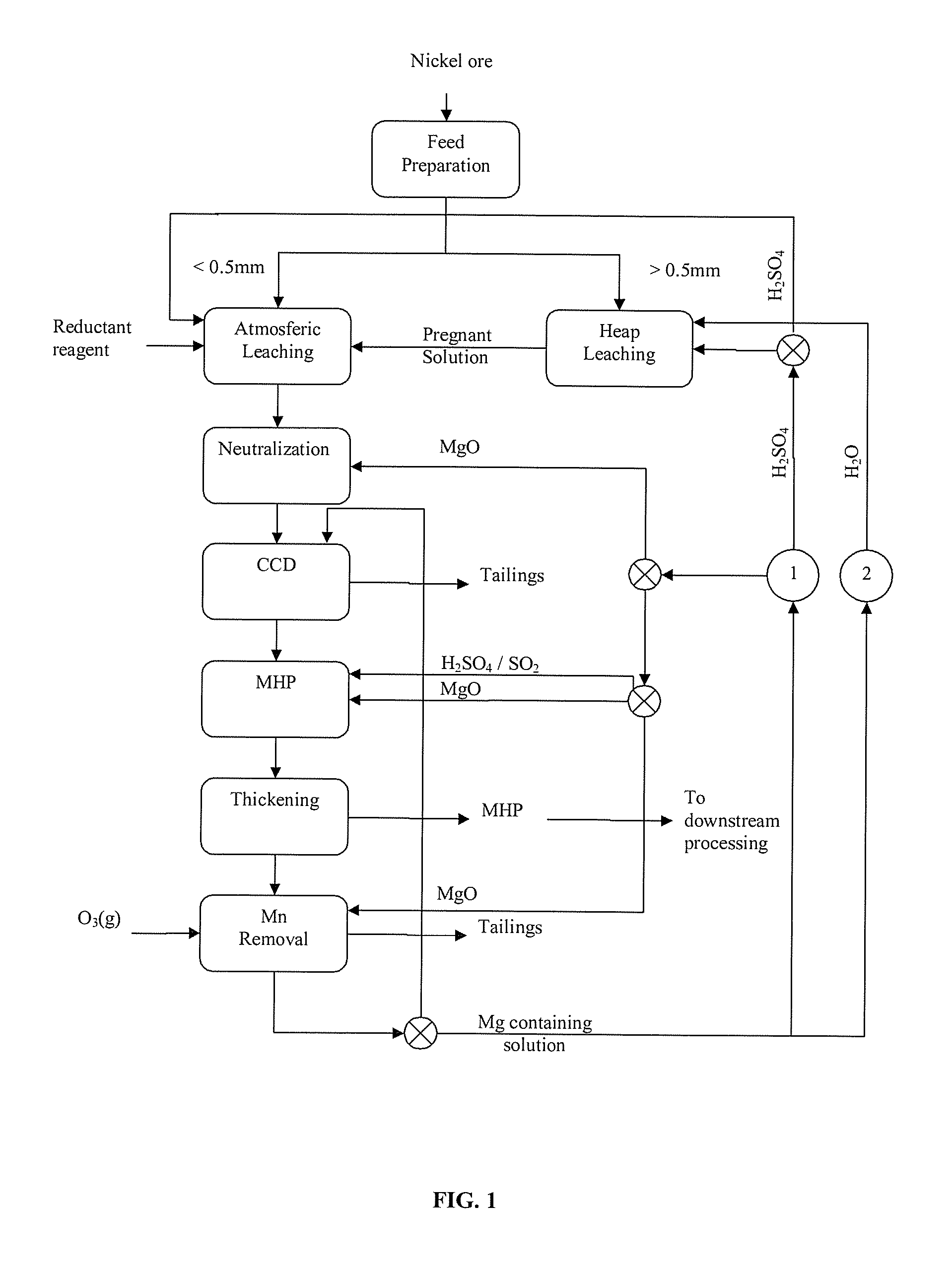

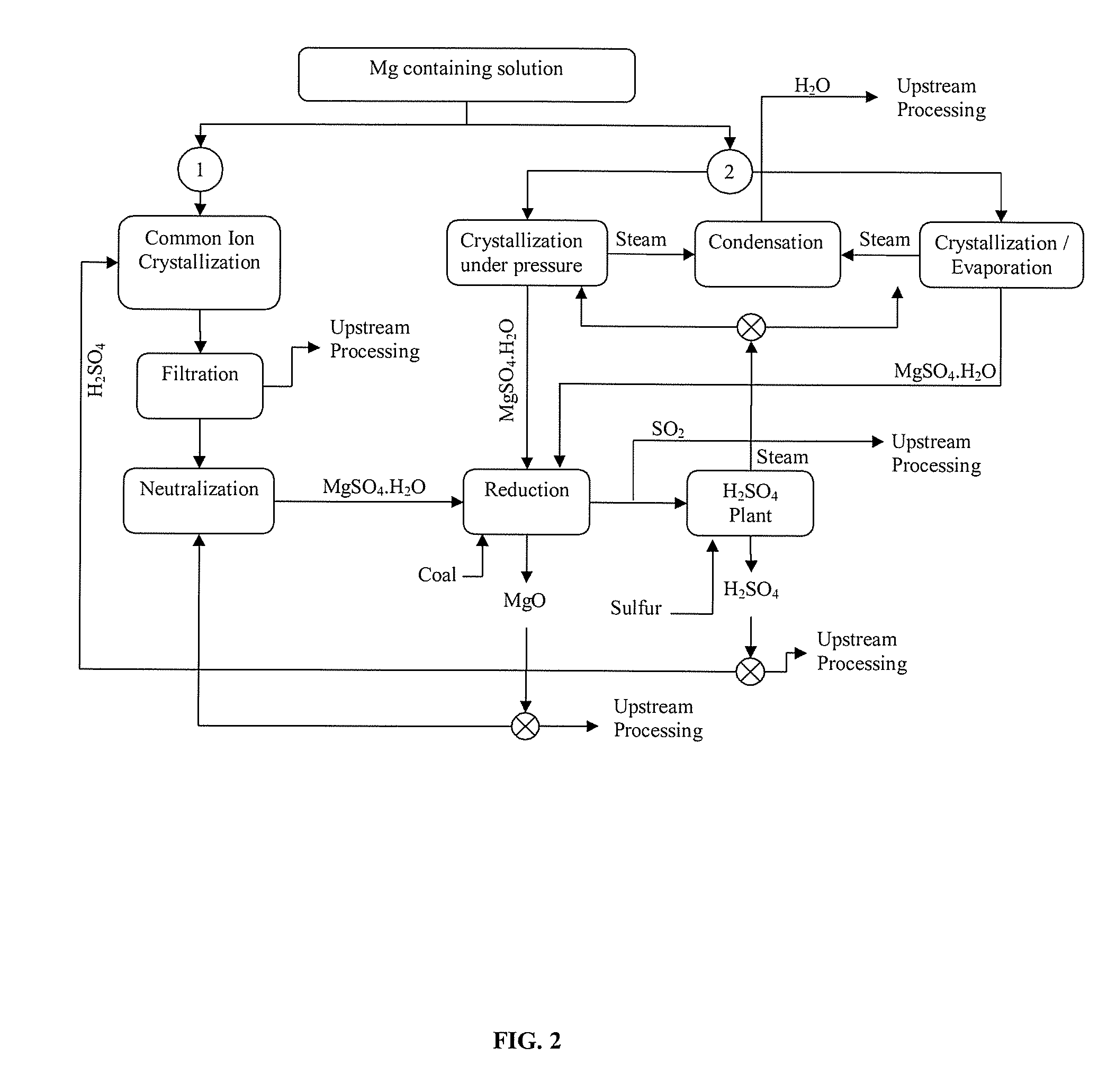

Magnesium recycling and sulphur recovery in leaching of lateritic nickel ores

ActiveUS20110110832A1Simplified logisticsReduce the amount requiredCalcium/strontium/barium sulfatesMagnesium sulfatesHigh magnesiumSulfur

The present invention resides in a process of recovering nickel and cobalt, regenerating the main raw materials, said process including the steps of: granulometric separation; leaching; neutralization; MHP production in only one stage and the pressure crystallization of magnesium sulphite.The process proposes a way to recovery nickel and cobalt from laterite ores through the atmospheric and heap leaching with staged addition of ore—by size separation—and H2SO4, decreasing the nickel losses and simplifying the neutralization circuit and producing a more purified MHP.The present process route is employed for nickel extraction, including the one from high magnesium containing lateritic ores.

Owner:VALE LIMITED

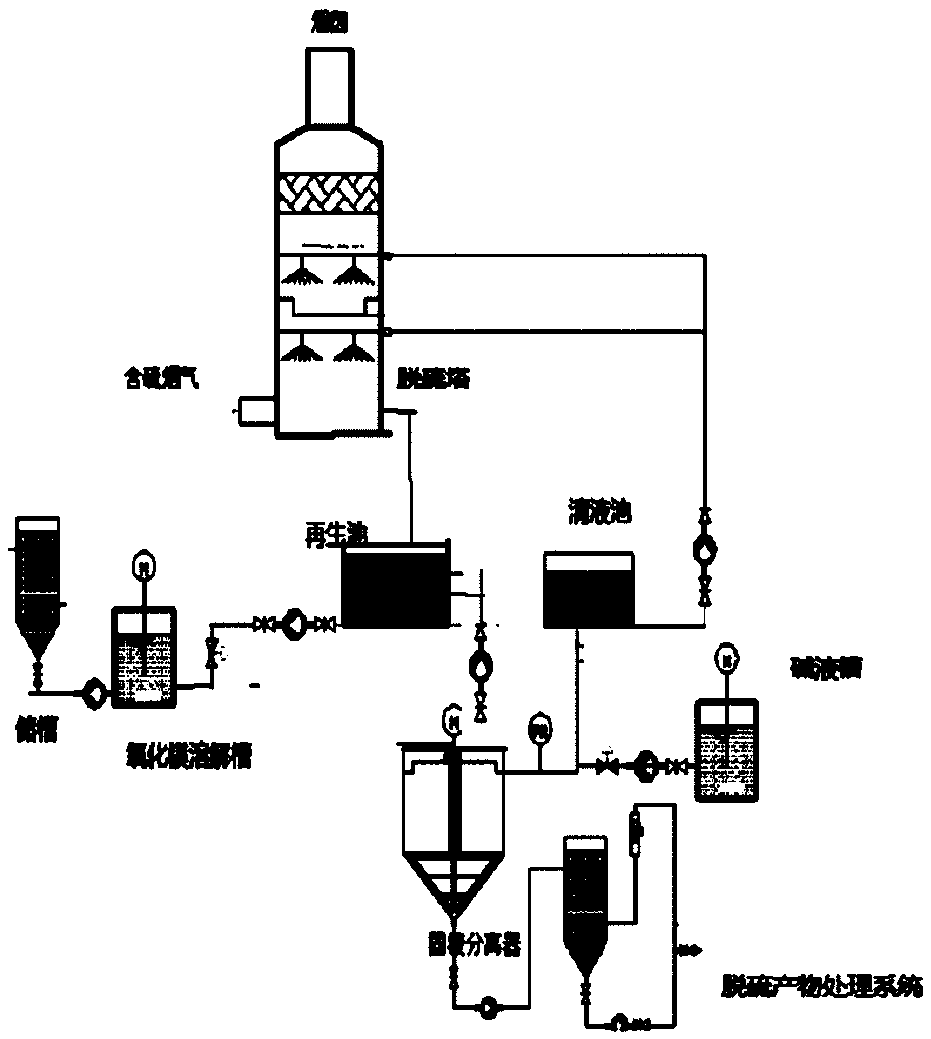

Technique for preparing magnesium sulfite during magnesium method desulfurization process

InactiveCN101254932AImprove solubilityReduce solubilityDispersed particle separationMagnesium sulfitesMagnesium sulfiteImpurity

The invention discloses a preparation method of magnesium sulfite during the desulphurization with magnesium oxide, which is capable of reducing the system water consumption and improving the yield of the magnesium sulfite. The preparation method includes: (1) removing impurities: guiding fume containing sulfur dioxide into a pretreatment device, removing partial fine powder dust, the hydrogen chloride and the hydrogen fluoride from the fume in the pretreatment device with atomized water sprayed from a spraying device, and loading the fume to a desulfurizing tower; (2) desulfurizing: allowing thje sulfur dioxide in the fume and the magnesium hydroxide slurry to react in the desulfurizing tower so as to remove the sulfur dioxide from the fume and further arranging the oxidation inhibitor simple substance or the sodium thiosulfate in order to prevent oxidation of the generated magnesium sulfite by the oxygen in the fume to obtain magnesium sulfate; and (3) separating: flocculating and settling the desulfurized slurry to obtain sediment, and performing the solid-liquid separation to obtain dried magnesium sulfite byproducts.

Owner:JIANGSU NEW ENVIRONMENTAL CORP

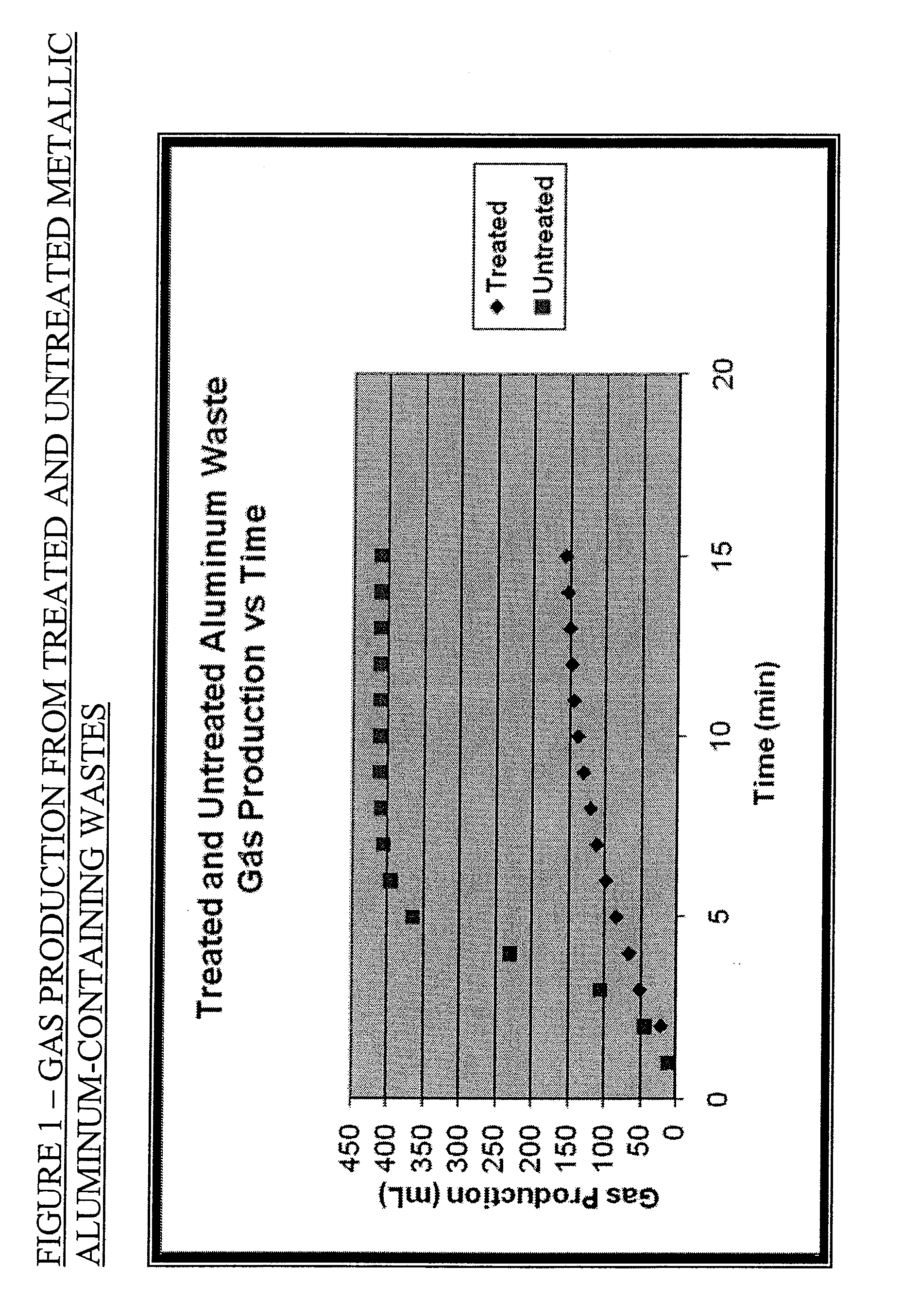

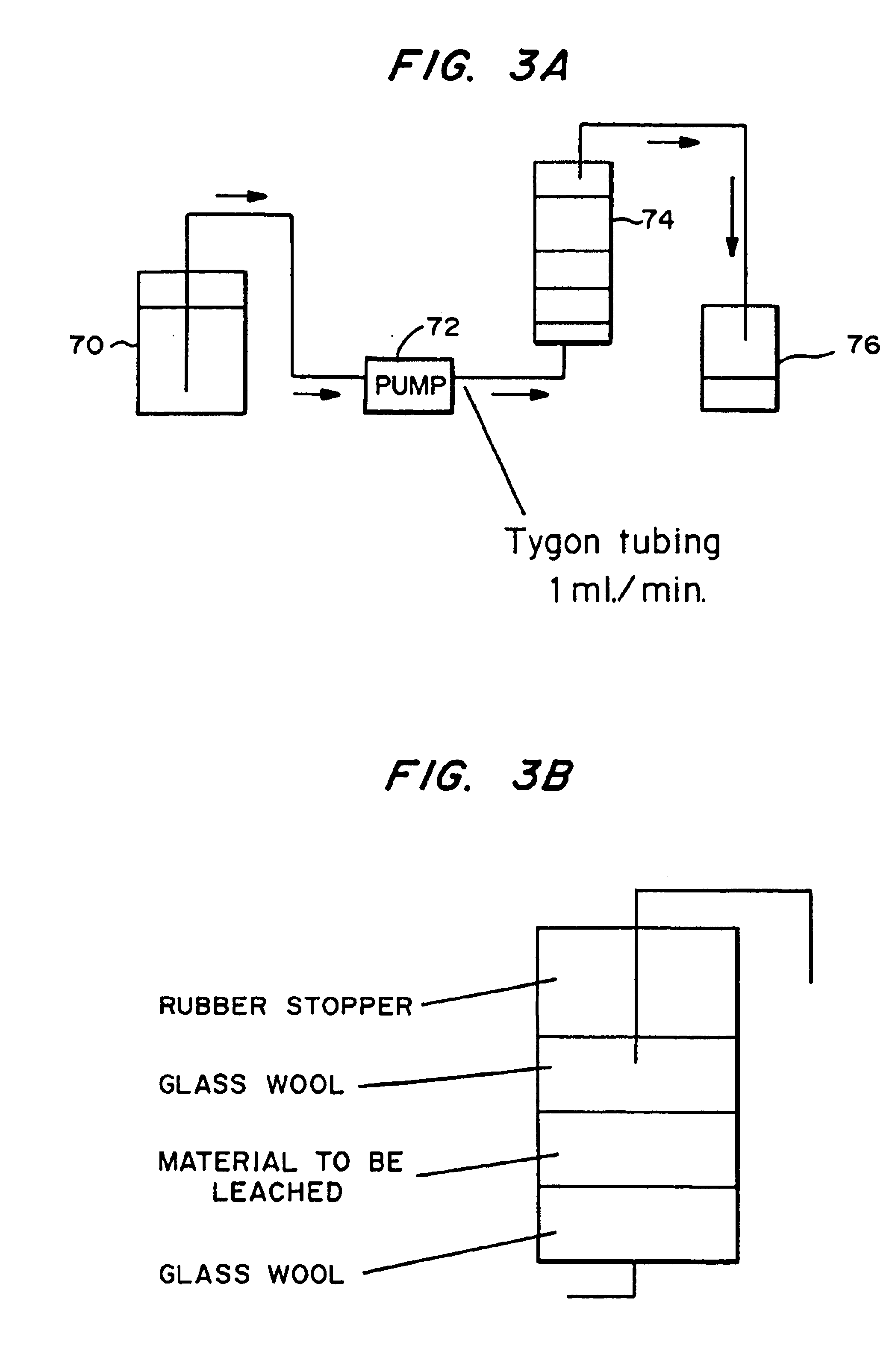

Method for Stabilization and/or Fixation of Leachable Metals

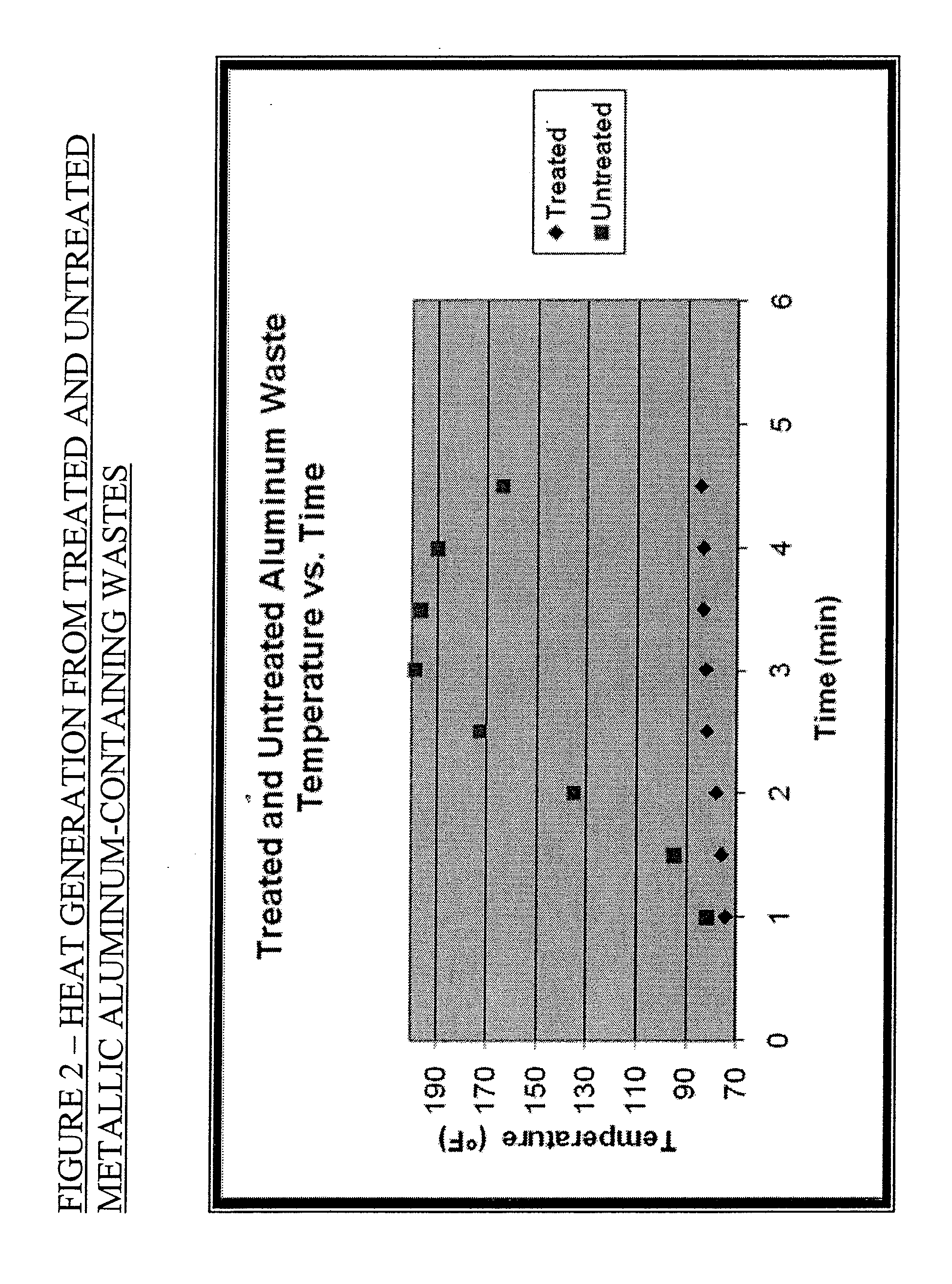

Methods for treatment a heavy metal-contaminated solid, semi-solid, liquid or gaseous matrix with magnesium oxide, magnesium sulfite, magnesium sulfate, magnesium chloride, magnesium hydroxide, and mixtures of any two or more of these. Methods for treatment of a solid or semi-solid waste containing unacceptable levels of leachable aluminum and reactive metallic aluminum-containing waste with magnesium oxide, magnesium sulfite, magnesium sulfate, magnesium hydroxide, magnesium chloride, and mixtures of any two or more of these.

Owner:REMEDIUM SERVICES GRP LLC

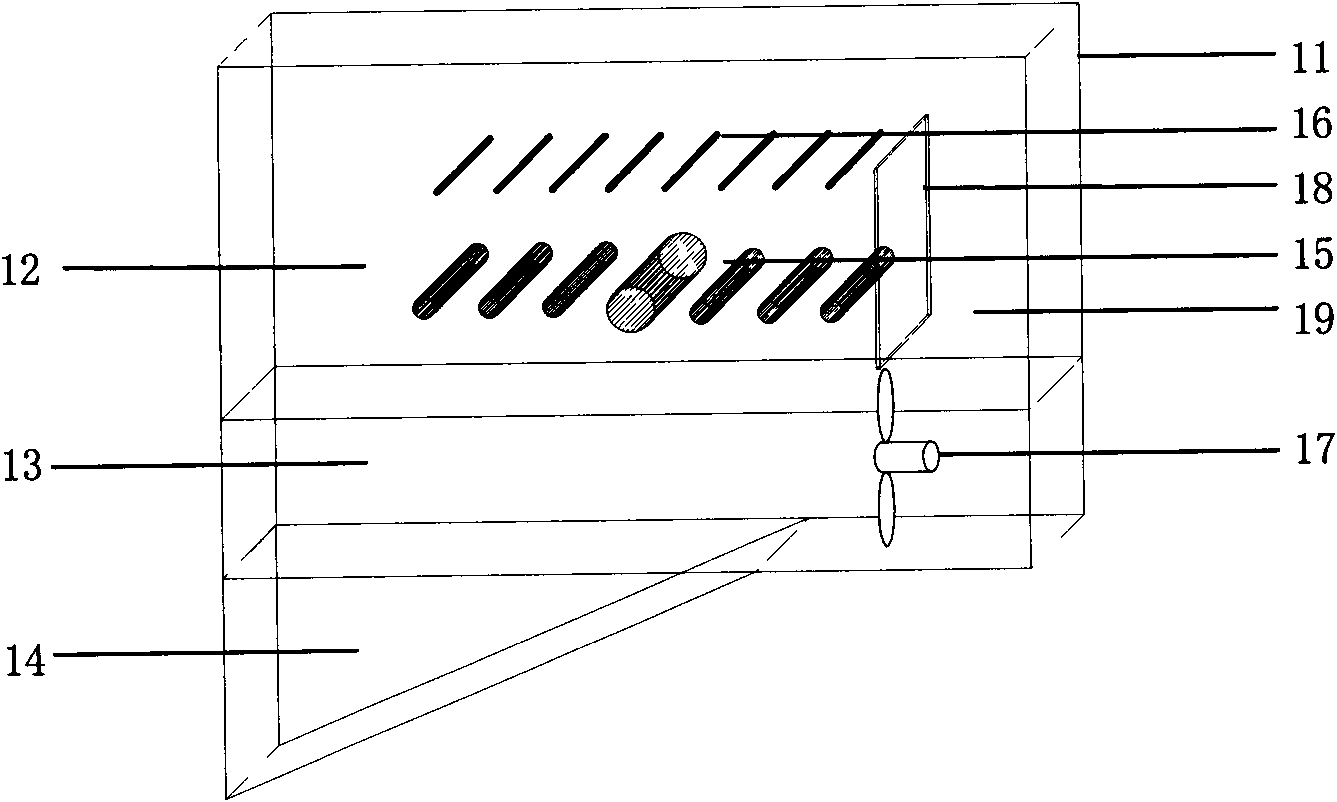

Method for dedusting and desulfurizing catalytic-cracking oil refining regenerated flue gas

The invention relates to a method for dedusting and desulfurizing catalytic-cracking oil refining regenerated flue gas. The method which utilizes a sodium alkali and magnesia combined sodium-magnesium method comprises the following steps: magnesium hydroxide slurry is prepared from magnesia firstly and is mixed with a sodium alkali solution according to a certain ratio so as to prepare a desulfurization solution, and the desulfurization solution is conveyed to each spraying layer from the bottom of a tower by a desulfurization circulating pump; the flue gas is subjected to spraying, humidifying and cooling at an entrance of a desulfurization tower, then rises from the bottom of the desulfurization tower and is subjected to enhanced dedusting, desulfurizing and acid mist trapping by a combination unit, and the flue gas flowing out of the combination unit is then subjected to deep desulfurizing and dedusting by an upper spraying zone; sulfur dioxide in the flue gas is converted into magnesium sulfite and sodium sulfite; desulfurizing waste liquid is subjected to adequate aeration and oxidation, and then, produced magnesium sulfate and waste residues are discharged by a residue slurry pump and enter a subsequent filtration and dewatering system; and slurry concentrated by a cyclone is subjected to dewatering by a filtering machine so as to obtain disposable solid wastes. Compared with the prior art, the method has the advantages that the cost of the desulfurizing liquid can be remarkably reduced, the wastewater output is reduced, and meanwhile, the dedusting and desulfurization of FCC (Fluidized catalytic cracking) regenerated flue gas can be realized efficiently.

Owner:SHANGHAI JIAO TONG UNIV

Magnesium base flue gas wet desulfurization catalyst

InactiveCN103949287AHigh activityIncrease concentrationOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationOrganic acidFlue gas

The present invention relates to a magnesium base flue gas wet desulfurization catalyst, which can be poured into a desulfurization absorption tower so as to prompt a desulfurization medium magnesium base compound well be dispersed in a desulfurization slurry, and contains an organic acid, an organic acid sodium salt and a metal sulfate. According to the present invention, the catalyst or synergist is added to the desulfurization absorption tower, such that the activity, the concentration and the mass transfer of the desulfurization element magnesium ions can be increased, and the oxidation process of magnesium sulfite can be accelerated so as to increase the sulfur dioxide removal rate and achieve the purposes of energy saving and emission reducing.

Owner:党晓军

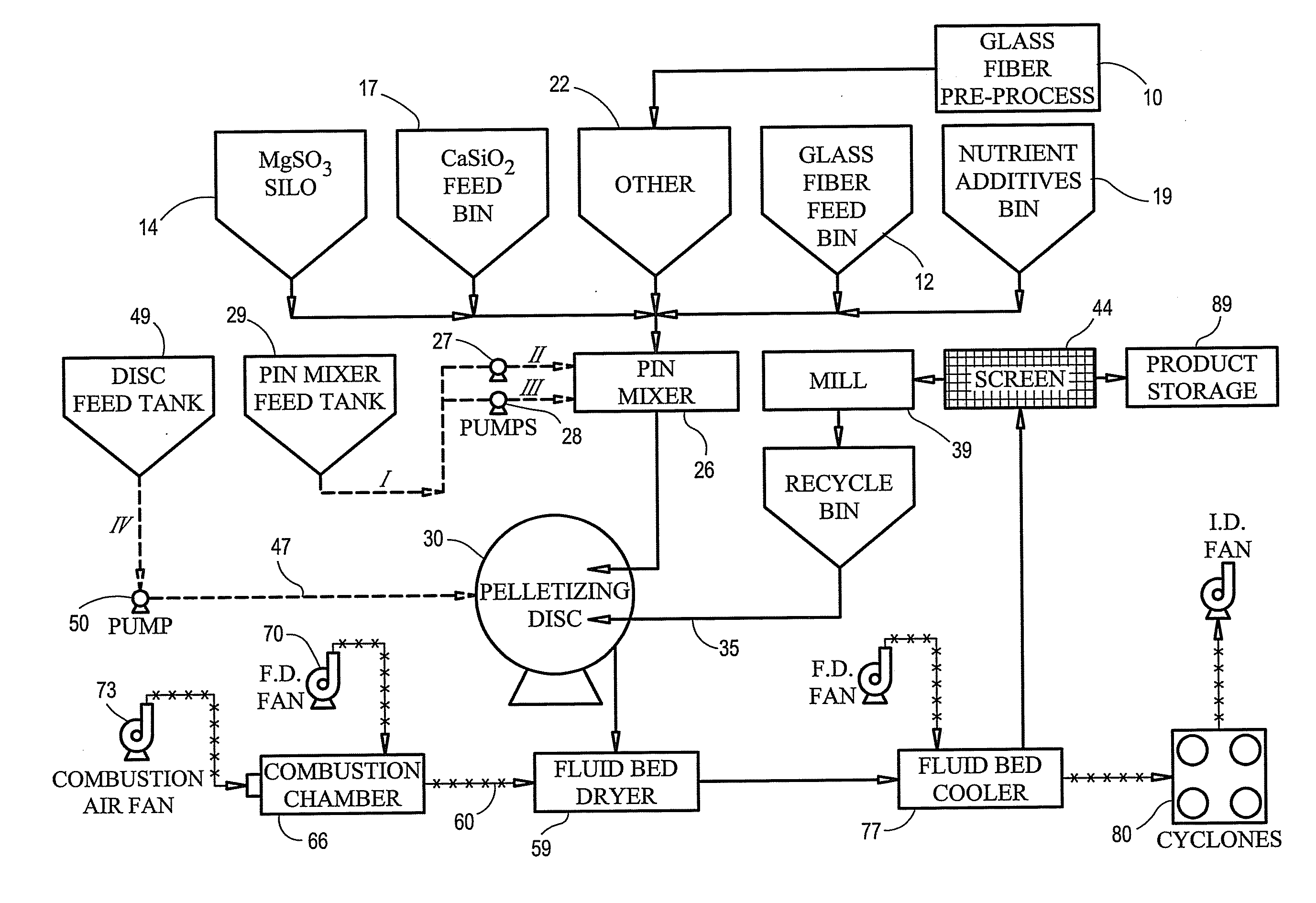

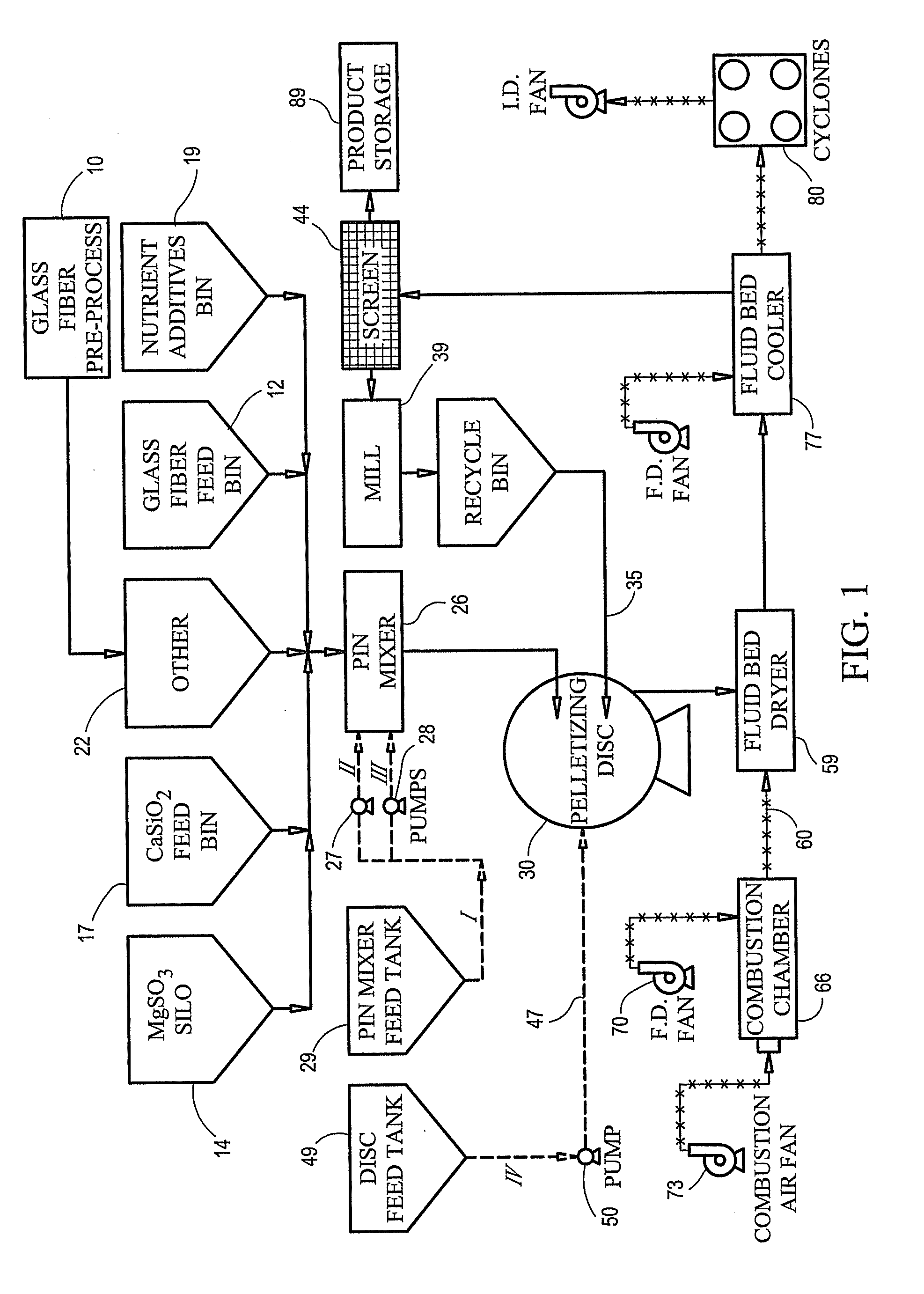

Soil enhancers

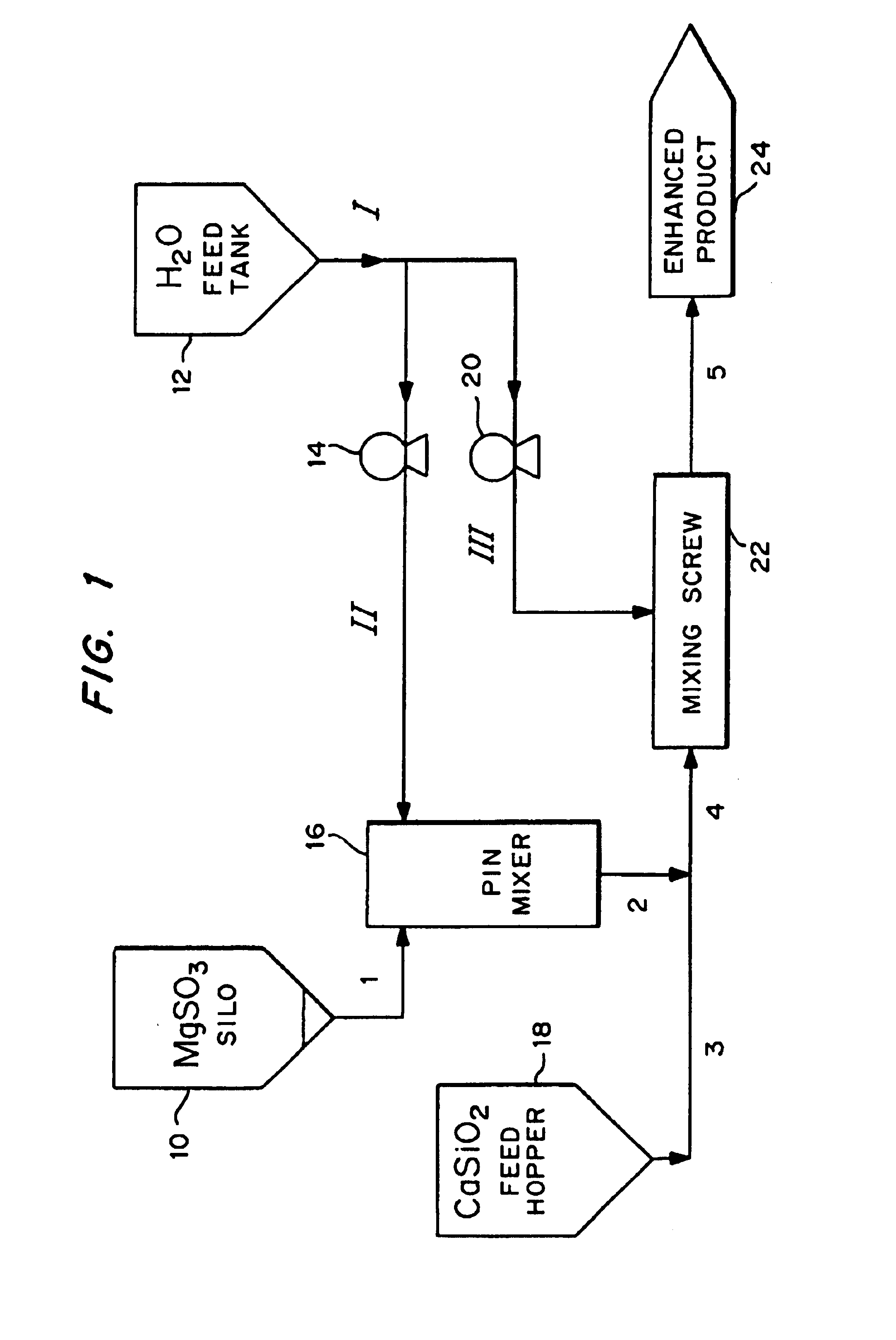

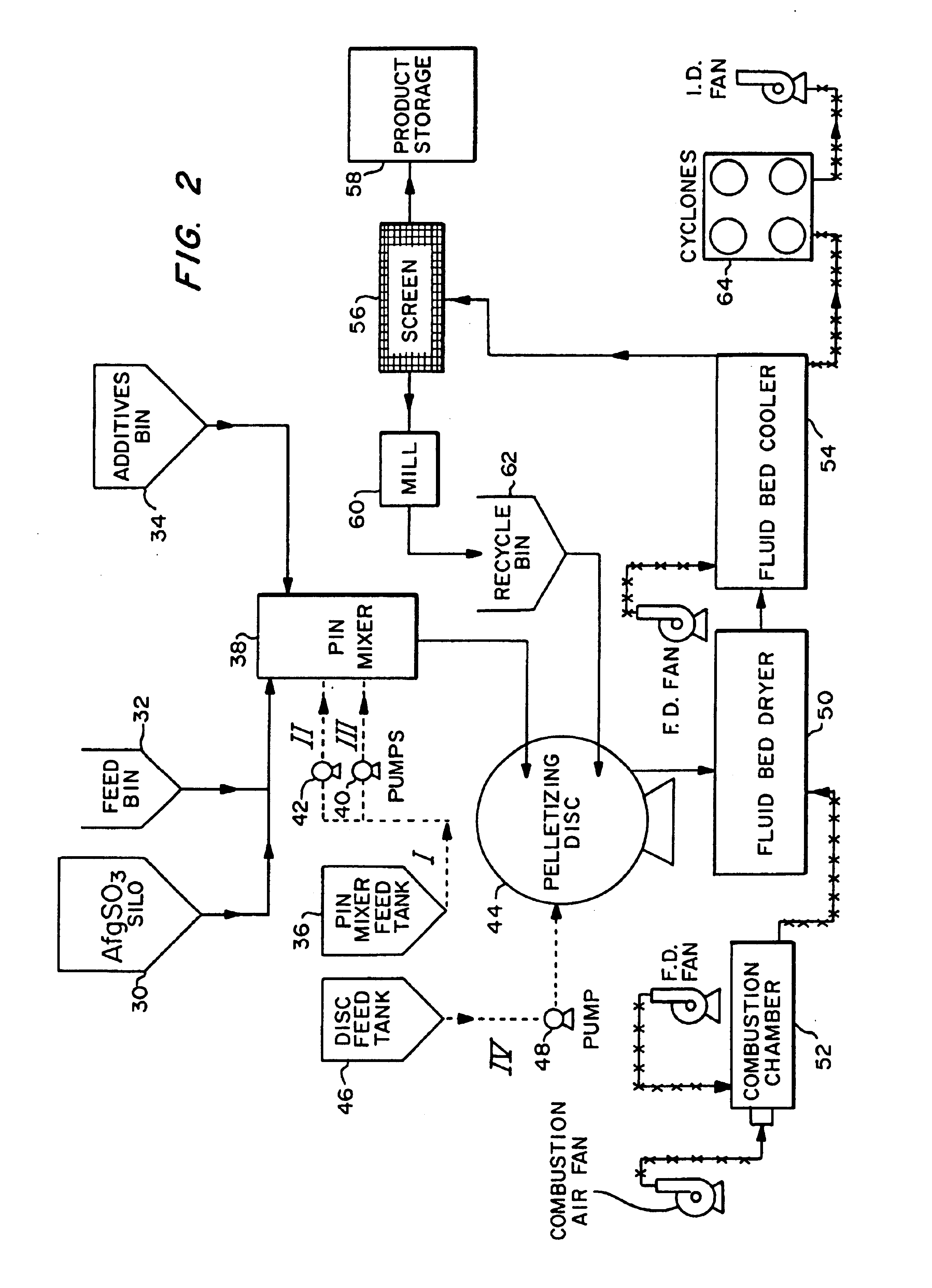

Compositions for increasing the amount of available silica, calcium, magnesium, and sulfur are described herein. The compositions contain calcium silicate (CaSiO2) and magnesium sulfite (MgSO3). Calcium silicate may be in the form of calcium silicate slag. Magnesium sulfite may be a by-product obtained from power plants. In one embodiment, the composition is in granular form and contains 65-90% (wt) calcium silicate slag, 20-30% (wt) magnesium sulfite, 0-5% (wt) expandible clay, and 2-10% (wt) residual moisture (H2O). In a preferred embodiment, the granules contain 31% (wt) silica, 22% (wt) calcium, 3% (wt) magnesium, and 4% (wt) sulfur. In a second embodiment, the composition is non granular and contains 75-90% (wt) calcium silicate slag, 10-20% (wt) magnesium sulfite and 0-10% (wt) H2O. The compositions may be applied to golf courses or residential or commercial lawns to improve the growth of grasses and their resistance to disease and insects. Alternatively, the compositions may be applied for use in agriculture for monocots, including grasses, sugarcane, cucumbers, rice, oats, corn, wheat, and barley, and dicots, such as citrus plants, cucumbers and tomatoes.

Owner:CALCIUM SILICATE

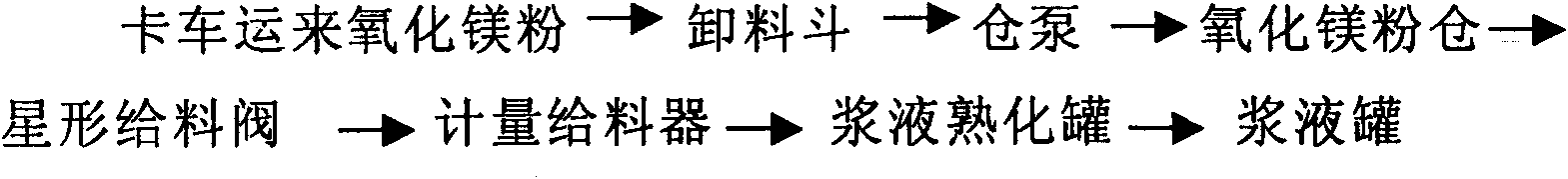

Improved magnesium method flue gas desulphurization technique

InactiveCN101628199AHigh desulfurization activityReduce energy consumptionDispersed particle separationWater vaporFlue gas

The invention provides an improved magnesium method flue gas desulphurization technique, which comprises the following steps: (a) mixing 1 portion of magnesium oxide desulfurizing agent with 2.3 to 5 portion of water and 0.1+ / -0.05 portion of water vapor in portion by weight at a temperature of between 0 and 20 DEG C so as to generate a magnesium hydroxide slurry; (b) ageing the magnesium hydroxide slurry obtained in the step (a) at a temperature of between 50 and 80 DEG C for 2 to 4 hours to obtain a desulfurizing agent slurry; and (c) spraying the desulfurizing agent slurry obtained in the step (b) to perform contact reaction with a flue gas containing sulfur dioxide so as to obtain a magnesium sulfite slurry or a magnesium sulfate slurry and the flue gas without the sulfur dioxide. The process has good reactivity and high desulphurization efficiency, and effectively avoids the problems of scaling, blockage and the like in a desulphurization system.

Owner:SINOPEC NINGBO ENG +1

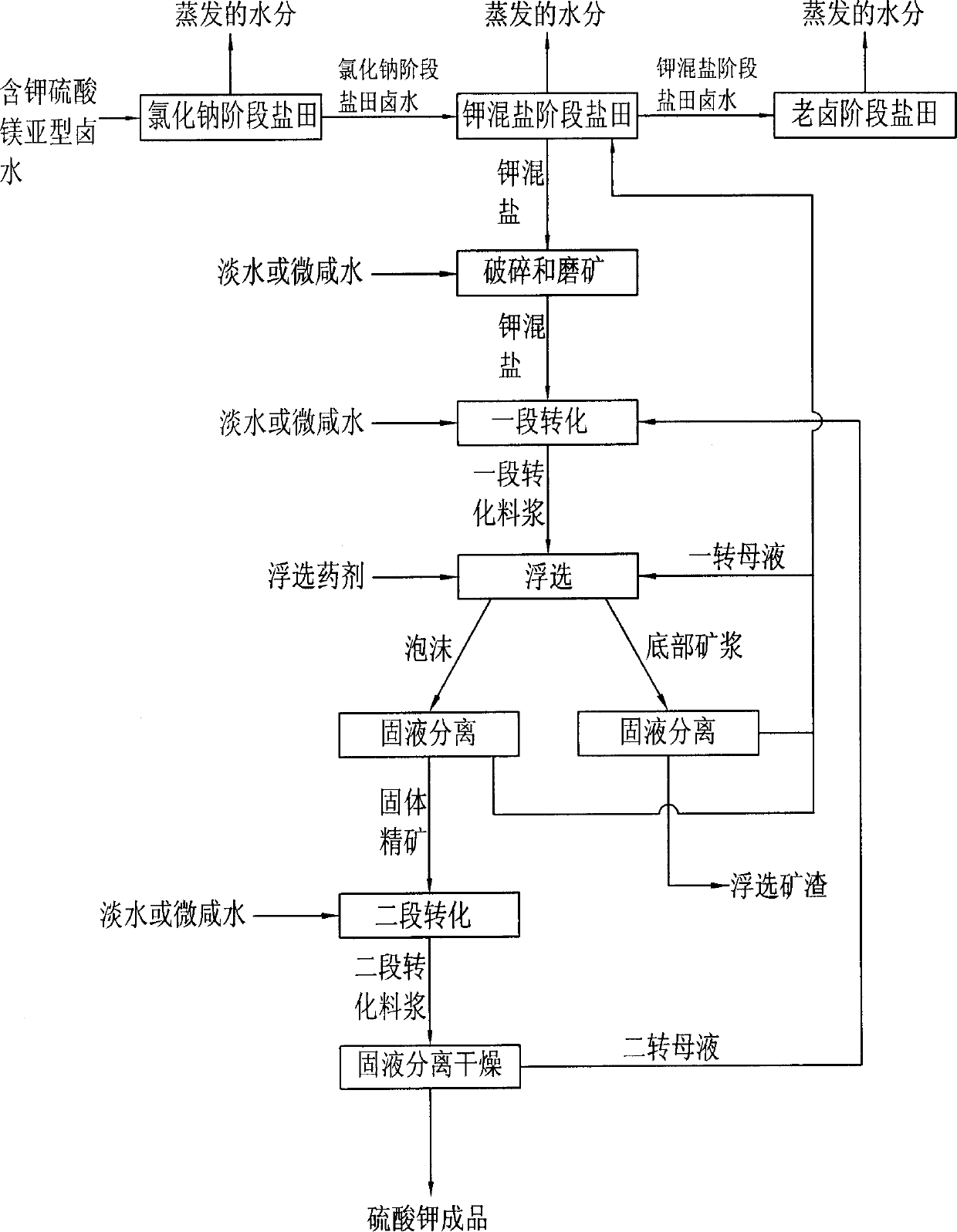

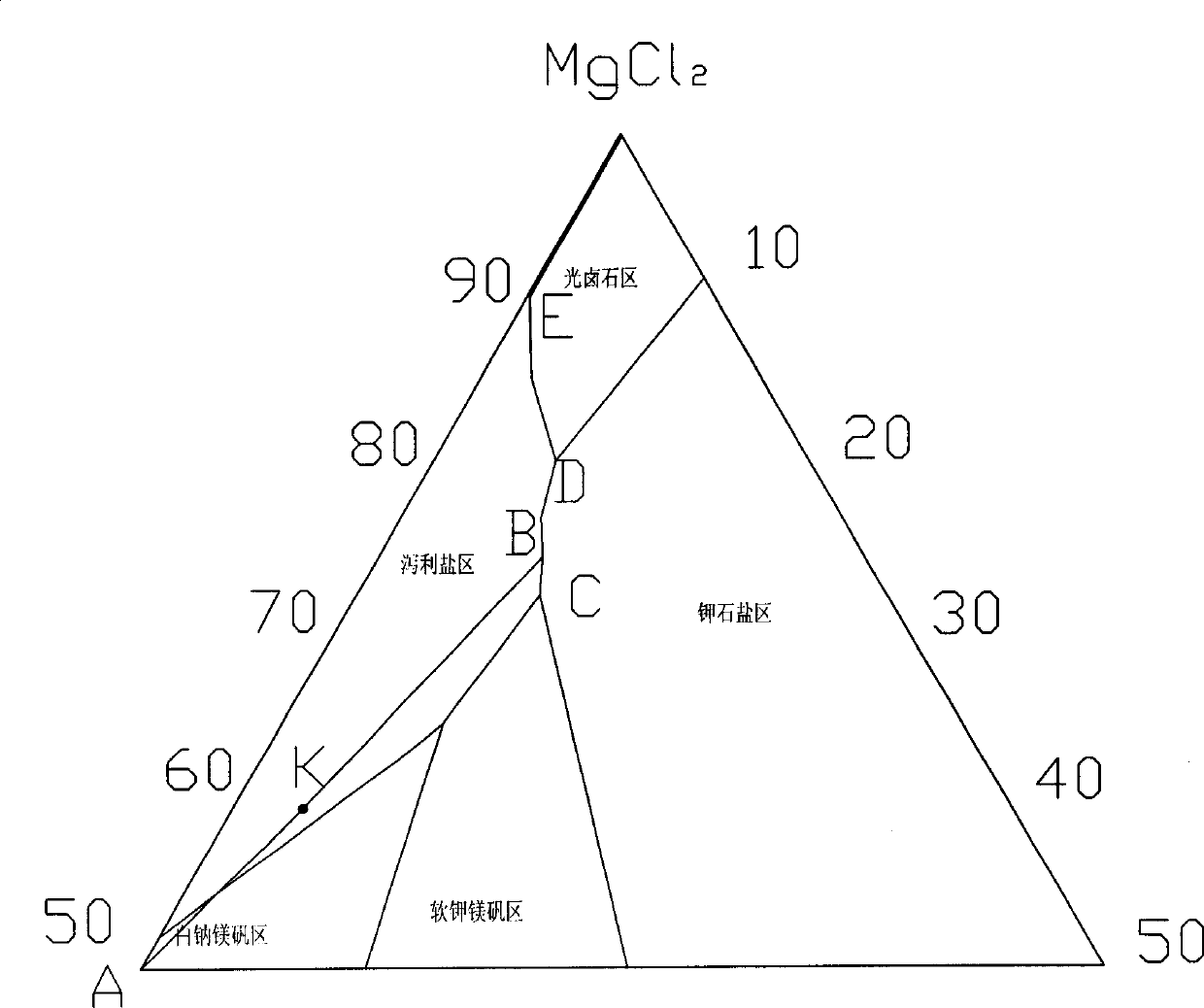

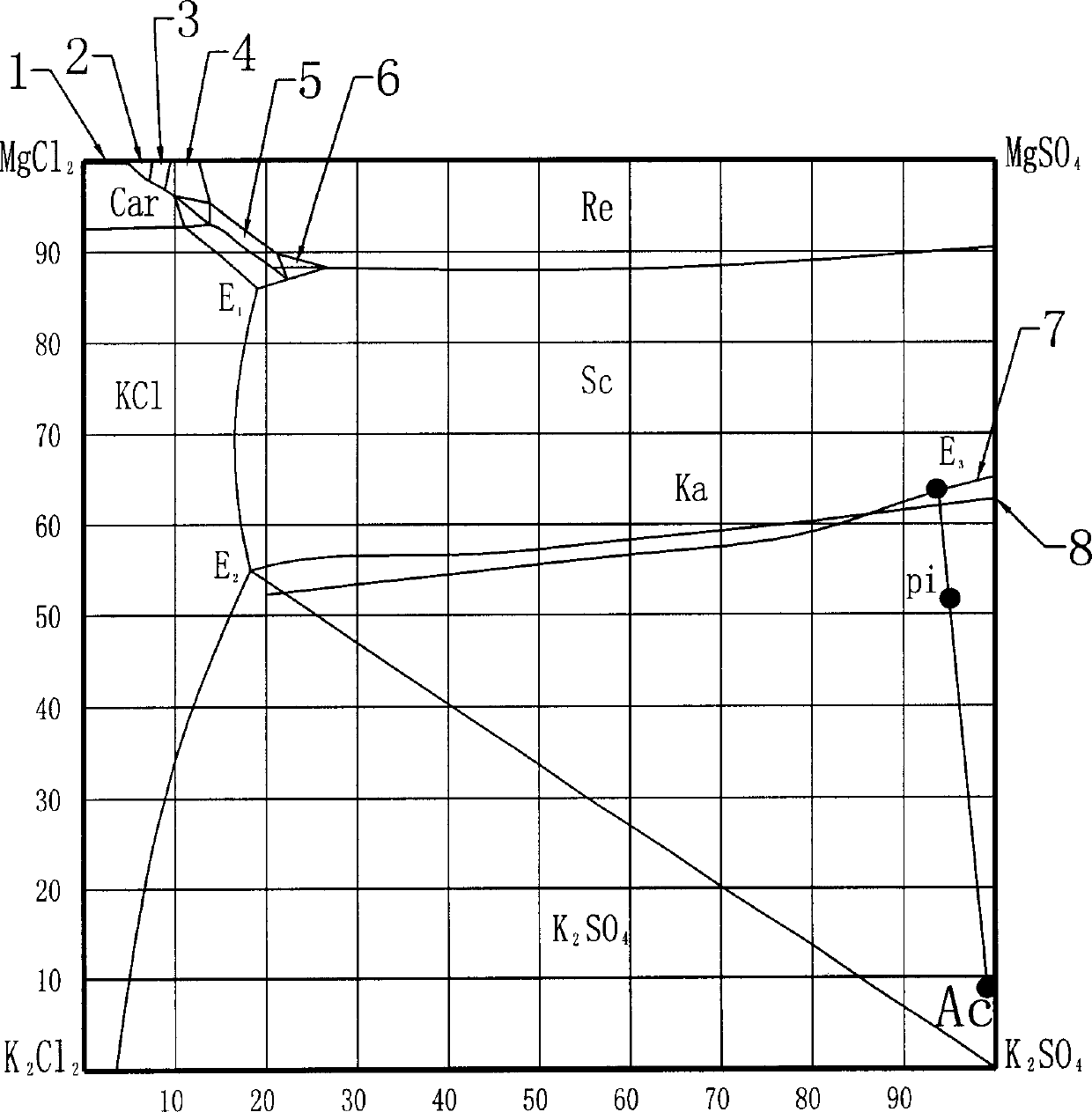

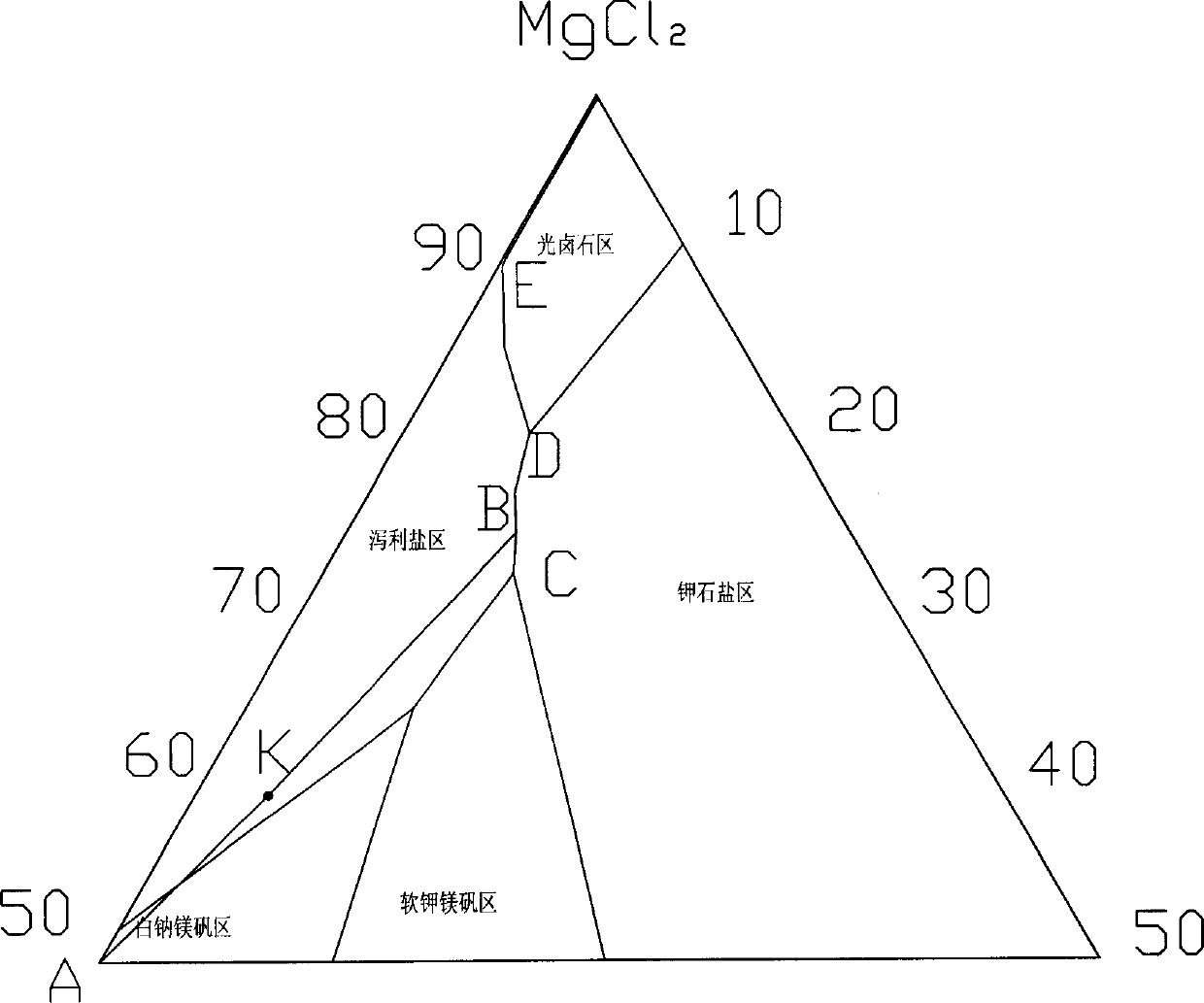

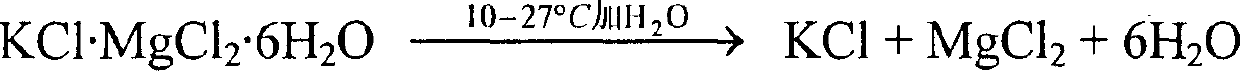

Improved process of preparing potassium sulfate with bittern containing potassium and magnesium sulfite

ActiveCN1810644AImprove processing stabilitySolve the problem of too much insoluble matterAlkali metal sulfites/sulfatesFresh waterMagnesium sulfite

The improved process of preparing potassium sulfate with bittern containing potassium and magnesium sulfite includes the following steps: 1. tedding bittern to obtain mixed potassium salt; 2. crushing and milling; 3. mixing the mixed potassium salt with fresh water or slight salty water in the weight ratio of 1 to 0.2-0.5 to prepare the first slurry and the first conversion reaction; 4. mixing the first converted slurry and floating chemical for floating to obtain solid concentrated mineral; 5. mixing the solid concentrated mineral and fresh water or slight salty water in the weight ratio of 1 to 1.0-1.5 to prepare the second slurry and the second conversion reaction; and 6. solid-liquid separation of the second converted slurry to obtain wet potassium sulfate and drying to obtain dry potassium sulfate product. The technological process has high stability, low water consumption, low mineral consumption, high comprehensive potassium ion recovering rate and low insoluble matter content in the product.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD

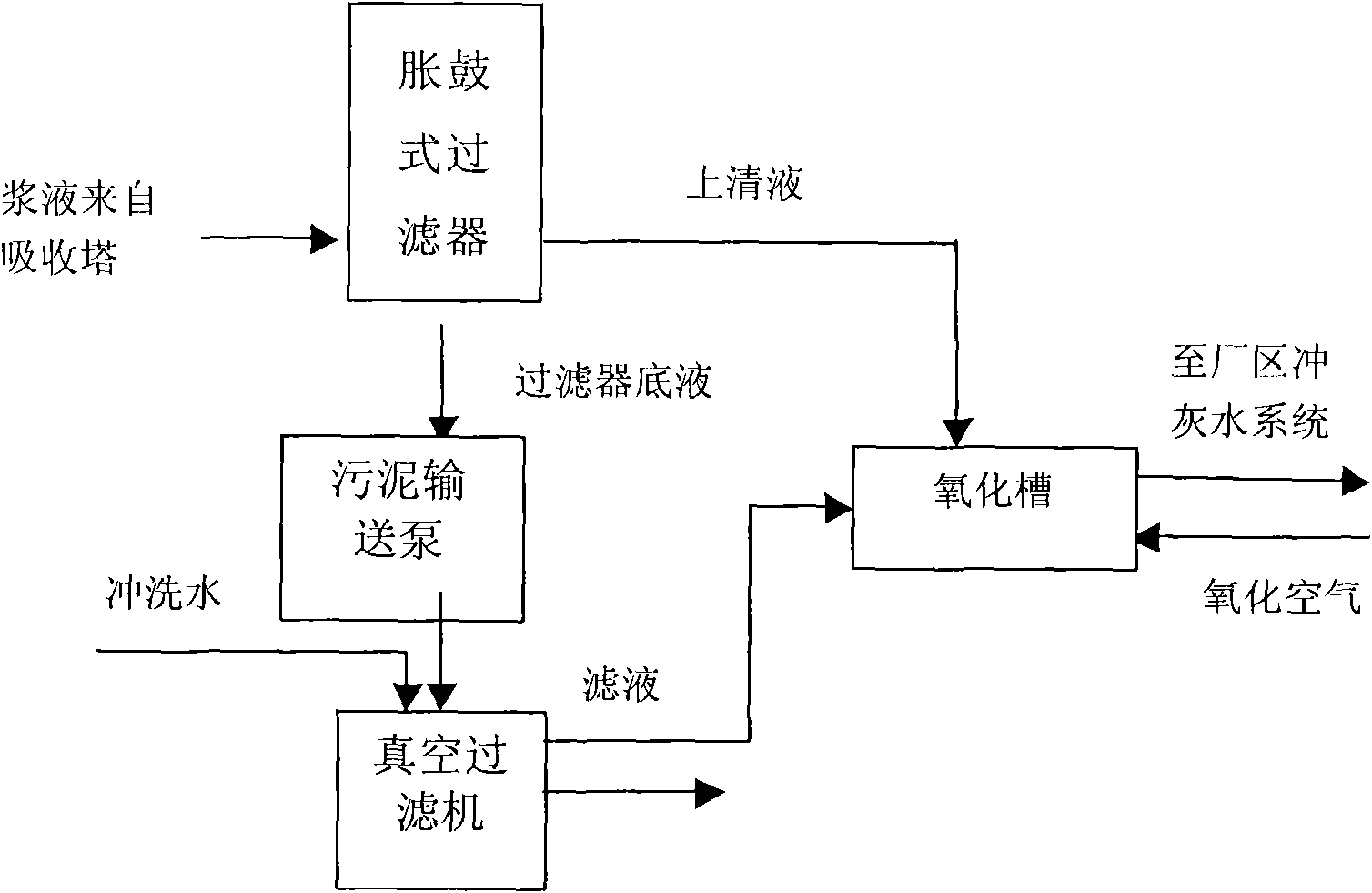

Magnesium desulfurization byproduct recovery process

InactiveCN102806004ALow impurity contentGuaranteed qualityDispersed particle separationMagnesium sulfatesRecovery methodFlue gas

The invention relates to a magnesium desulfurization byproduct recovery process, and provides a magnesium desulfurization byproduct recovery method. The method comprises the following steps: (1) carrying out oxidation in a desulfurization tower: introducing air to the desulfurization tower air and stirring, such that magnesium sulfite in a slurry is completely oxidized into magnesium sulfate; (2) increasing magnesium sulfate concentration in the desulfurization tower: controlling a water supply amount and a slurry discharge amount of the desulfurization tower, and adopting heat of flue gas in the desulfurization tower to carry out concentration on the desulfurized slurry so as to increase the magnesium sulfate concentration in the slurry to 30-35 wt%; (3) removing impurities: conveying the slurry from the step (2) to an expansion drum type filter to remove impurities; and (4) carrying out evaporation crystallization: conveying the filtrate from the step (3) into a two effect falling film evaporator to carry out evaporation crystallization to obtain a magnesium sulfate heptahydrate crystal.

Owner:CHINA PETROLEUM & CHEM CORP +3

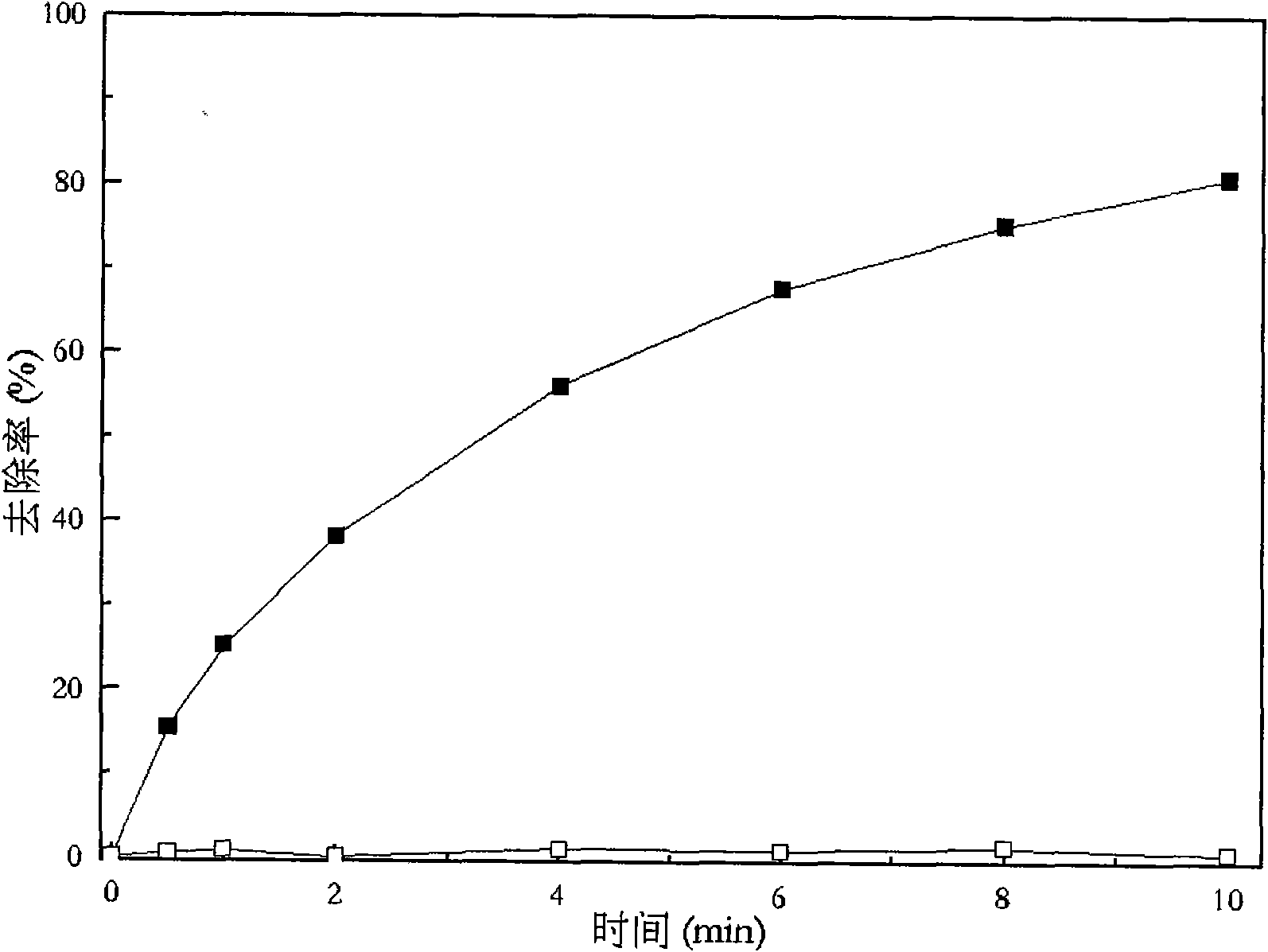

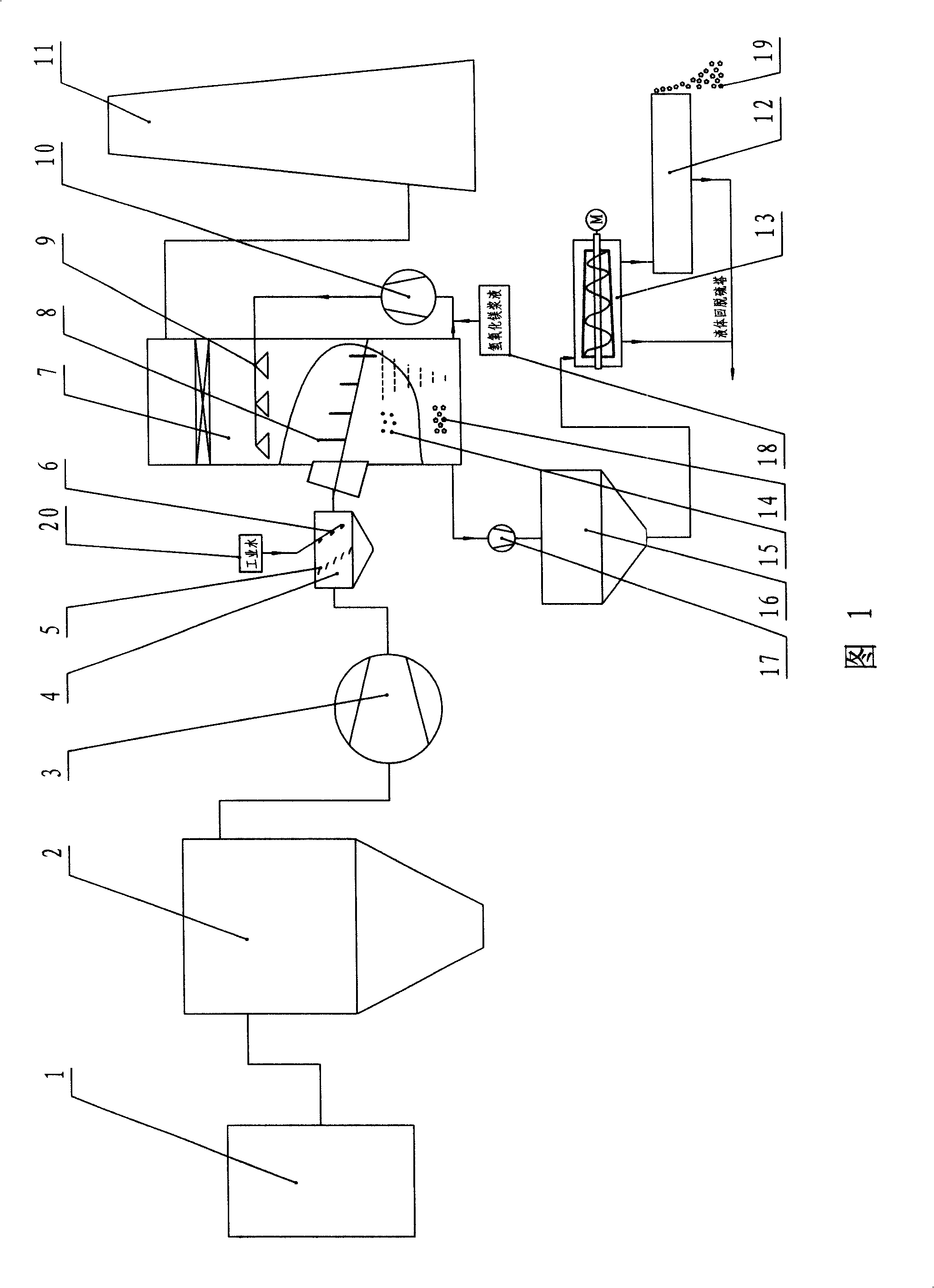

Technology for flue gas denitration by magnesium sulfite

InactiveCN103752151AImprove denitrification performanceAchieve efficiencyDispersed particle separationFlue gasMagnesium sulfite

The invention discloses a technology for flue gas denitration by magnesium sulfite. The technology comprises steps of (1) after removing dust in boiler flue gas, allowing the flue gas to enter a static mixer, simultaneously spraying ozone into the static mixer, reacting the ozone and the flue gas so as to obtain mixed gas; (2) sending the mixed gas into a denitration absorption tower from the bottom of an absorption tower, adding magnesium sulfite slurry into the kettle of the denitration absorption tower, pumping the magnesium sulfite slurry into the upper part of the denitration absorption tower by a circulating pump for spraying and circulating absorption so as to denitrify the mixed gas; and (3) discharging clean denitrified flue gas by a chimney. The technology adopts sulfite for absorbing, thus maintaining the higher level of denitration performance, and realizing high efficiency of nitric oxide in flue gas.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

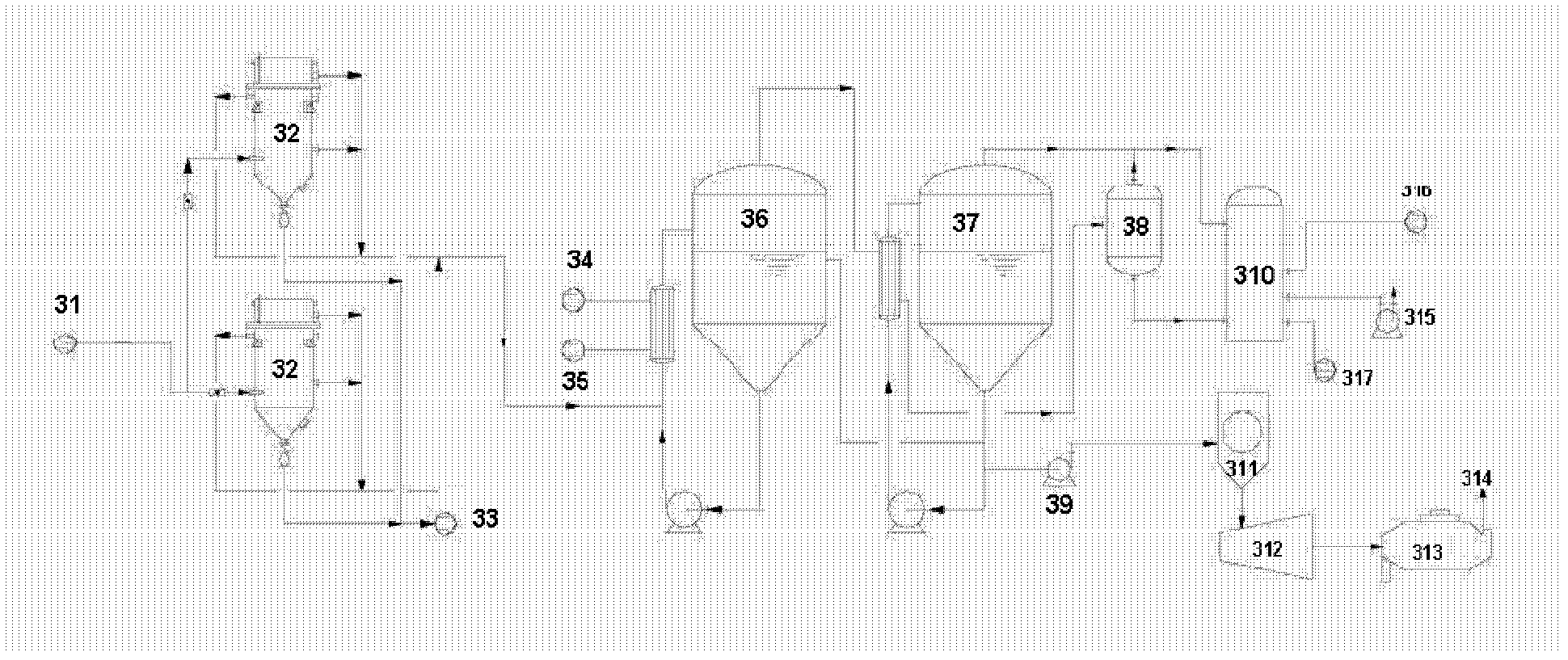

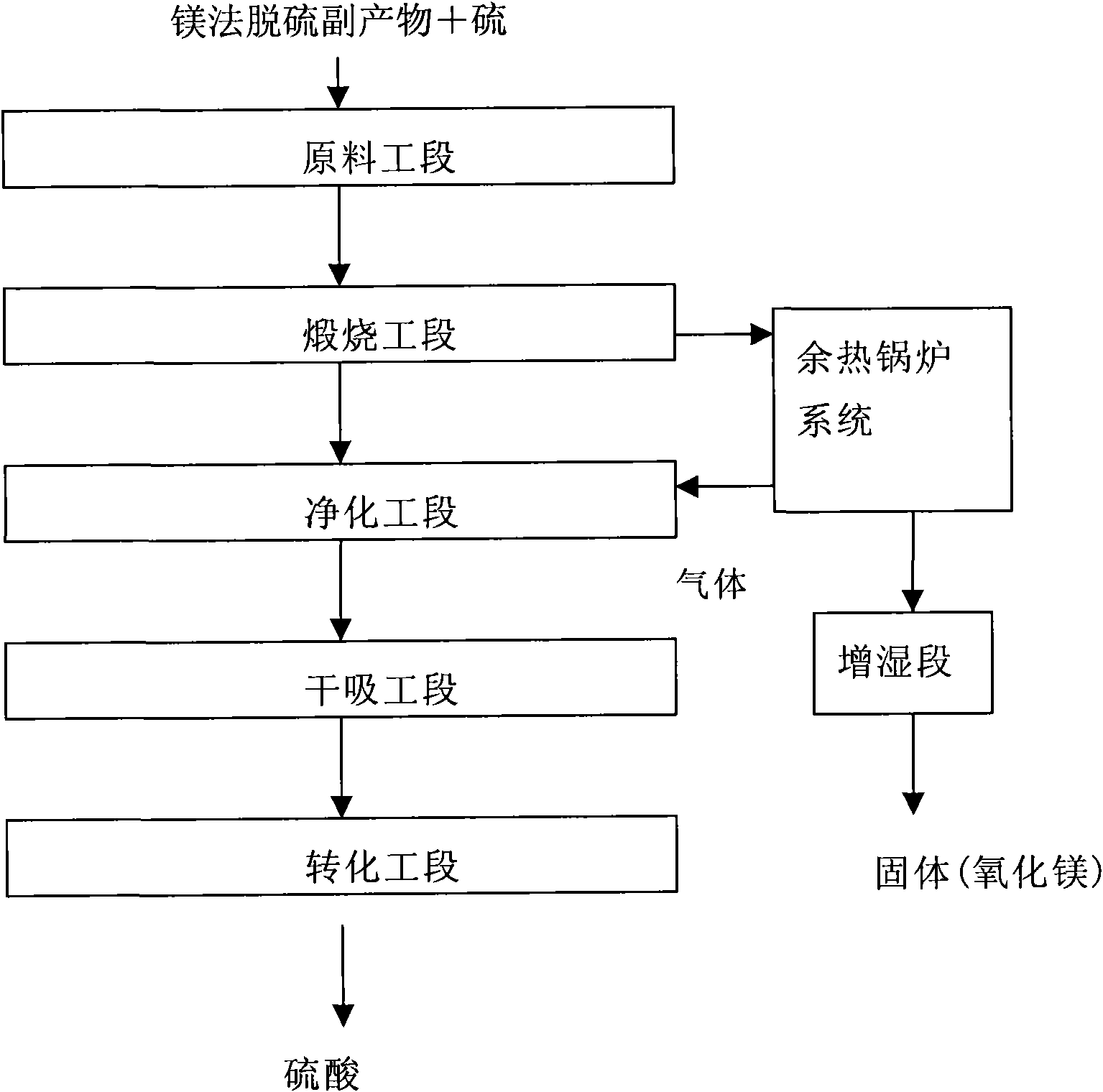

Technology for calcining and recycling magnesium desulfurizing byproduct containing magnesium sulfite

ActiveCN101624197ALow running costAchieving a circular economySulfur compoundsMagnesiaSulfurMagnesium sulfite

The invention provides a method for calcining and recycling magnesium desulfurizing byproducts, which comprises the following the steps: (a) providing the following components in portion by weight: 100 portions of magnesium desulfurizing byproducts containing magnesium sulfite and 10 to 35 portions of sulfur mixture; and (b) carrying out boiling calcination on the mixture of the step (a) at a calcining temperature of between 500 DEG C and 1,000 DEG C to decompose the mixture into gas products containing SO2 and solid products containing magnesium oxide.

Owner:SINOPEC NINGBO ENG +1

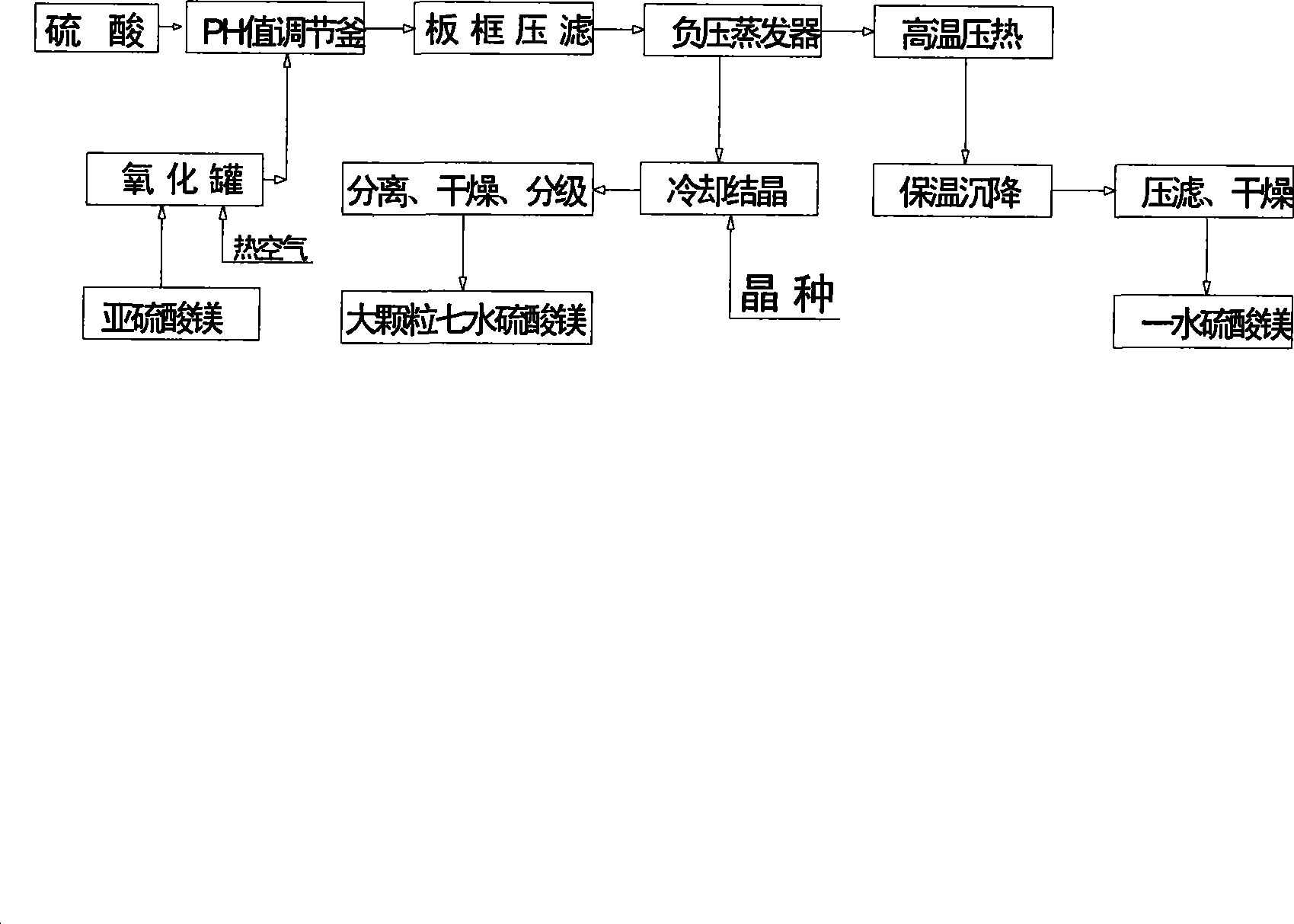

Method for producing large particles of heptahydrate magnesium sulfate and monohydrate magnesium sulfate from magnesium sulfate solution

InactiveCN101214980AImprove product qualityQuality improvementMagnesium sulfatesSocial benefitsPhysical chemistry

The invention discloses a method for producing magnesium sulfate, which is a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate from magnesium sulfate solution, in particular to a method for producing macroaggregated magnesium sulfate heptahydrate and magnesium sulfate mono-hydrate by employing solid containing magnesium sulfite (the chemical name is MgSO3) to obtain solution containing magnesium sulfate after oxidation treatment. The method of the invention comprises high temperature oxidizing magnesium sulfite, adding acid to adjust pH value, filtering solution, negative pressure evaporating and high temperature heating or seeding cooling for producing magnesium sulfate heptahydrate. The invention is simple in method and easy in operation. The product of magnesium sulfate produced by the method is high in product quality, and the selling price is increased. The method sufficiently employs byproduct of desulphurization process with magnesium as raw material, thereby decreasing the investment of environmental equipment in the desulphurization process with magnesium and operation cost, also decreasing the production cost of magnesium sulfate industry and achieving the win-win purpose of social benefit and economic benefit. The problems that in the existing method the product quality is low and macroaggregated magnesium sulfate heptahydrate can not be produced are resolved.

Owner:张荣阳 +2

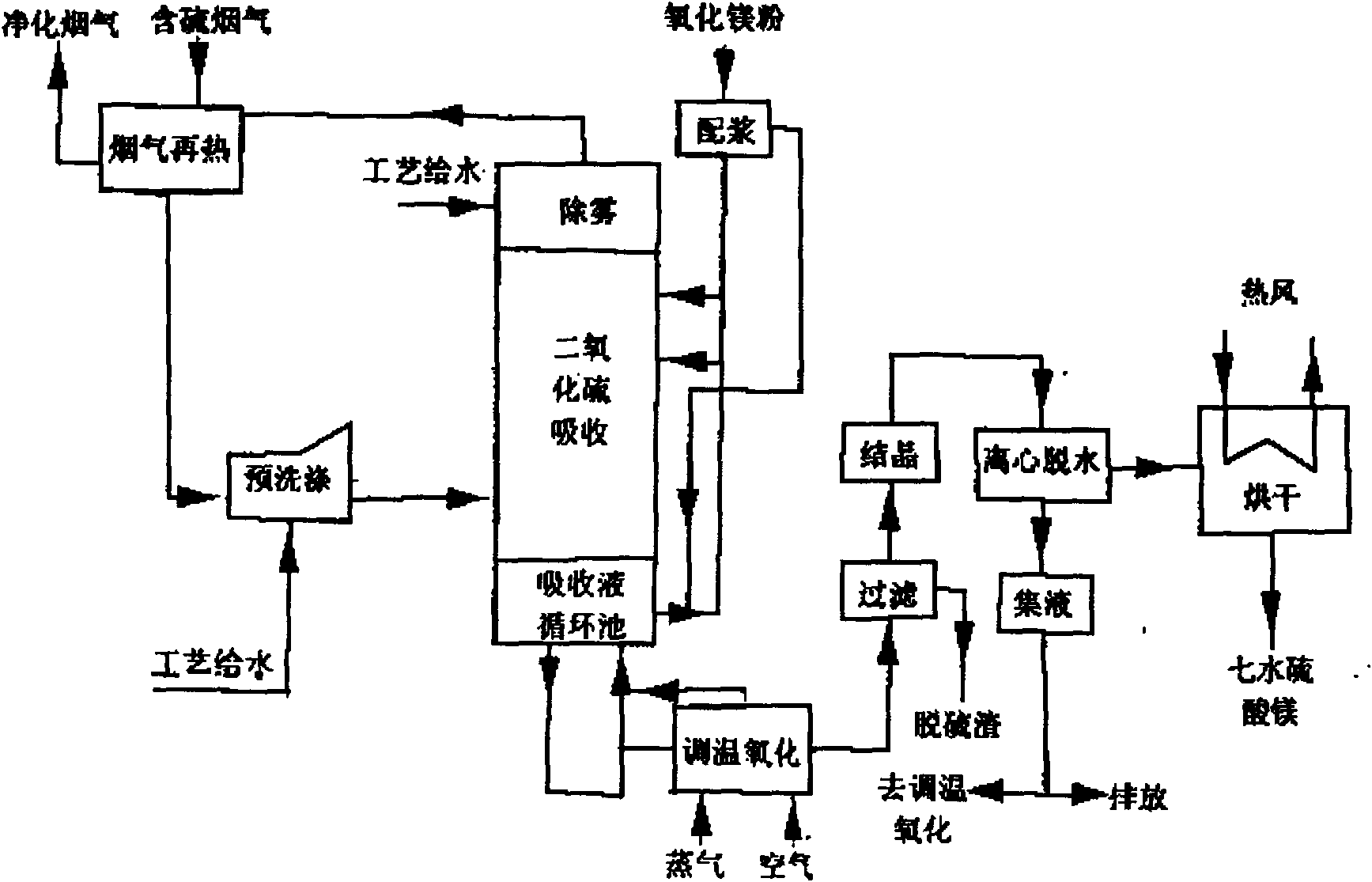

Recovery method of magnesium oxide flue gas desulfurization product

InactiveCN102078750ASmall processing rateReduce circulationDispersed particle separationMagnesium sulfitesRecovery methodResource utilization

The invention discloses a recovery method of a magnesium oxide flue gas desulfurization product, belonging to the technical field of resource utilization of flue gas desulfurization products and comprising the following steps of: inhibiting the oxidation of an absorption liquid during circulation desulfurization, facilitating the crystallization and the precipitation of MgSO3 (magnesium sulfite), pumping out concentrated slurry from the bottom of a circulation pool by using a centrifugal pump when the concentrated slurry is reached, filter-pressing the concentrated slurry into a solid through a plate frame, transporting the solid to a professional desulfurization product recovery plant, and reacting concentrated sulfuric acid with the MgSO3 to generate an MgSO4 (magnesium sulfate) serous liquid and an SO2 (sulfur dioxide) gas; and collecting the SO2 through a tiny negative pressure, drying, cooling, liquefying and canning the SO2, filtering, crystallizing and centrifugally dewatering the serous liquid so that the separation of solid-phase and liquid phase impurities is realized, and stoving to form an industrial product. By virtue of the method, the industrial production of MgSO4.7H2O and liquid-state SO2 is realized, a set of green chemical process is created with the flue gas desulfurization, the desulfurization, the recovery efficiency and the economic benefit are improved, and the technical and economical properties of the magnesium oxide flue gas desulfurization are comprehensively enhanced.

Owner:TSINGHUA UNIV

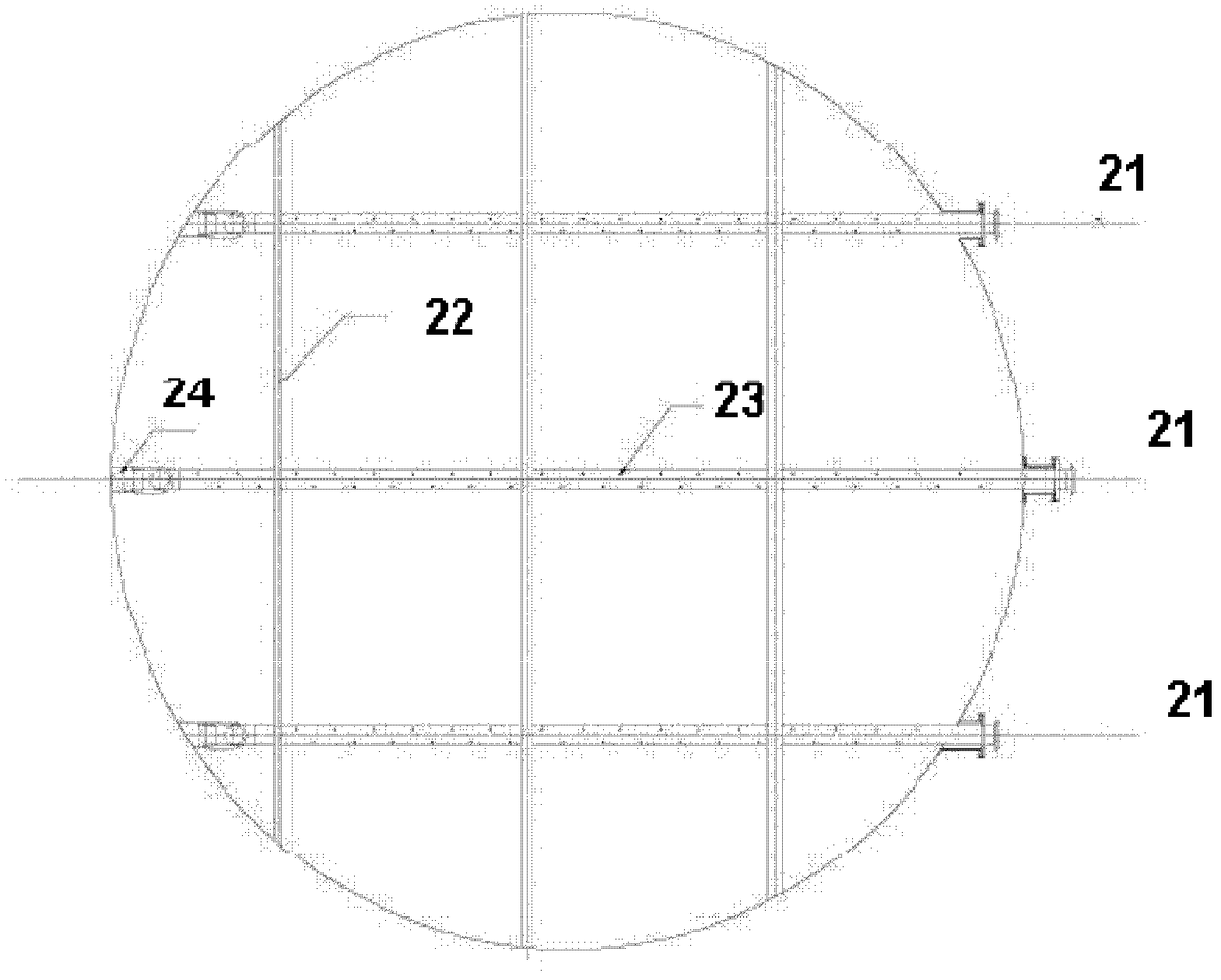

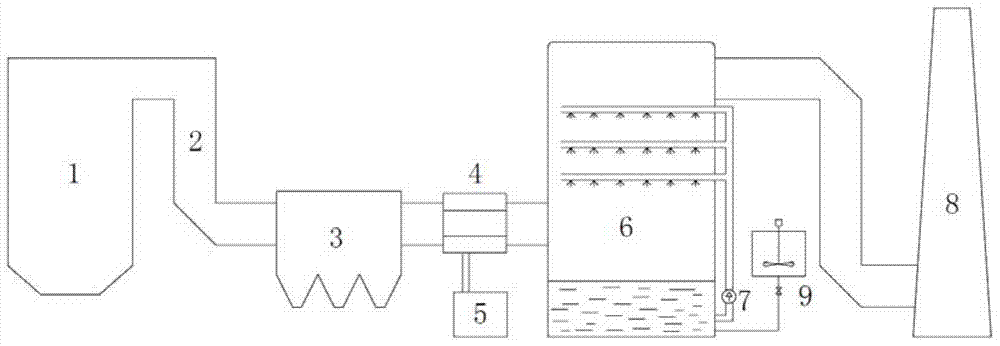

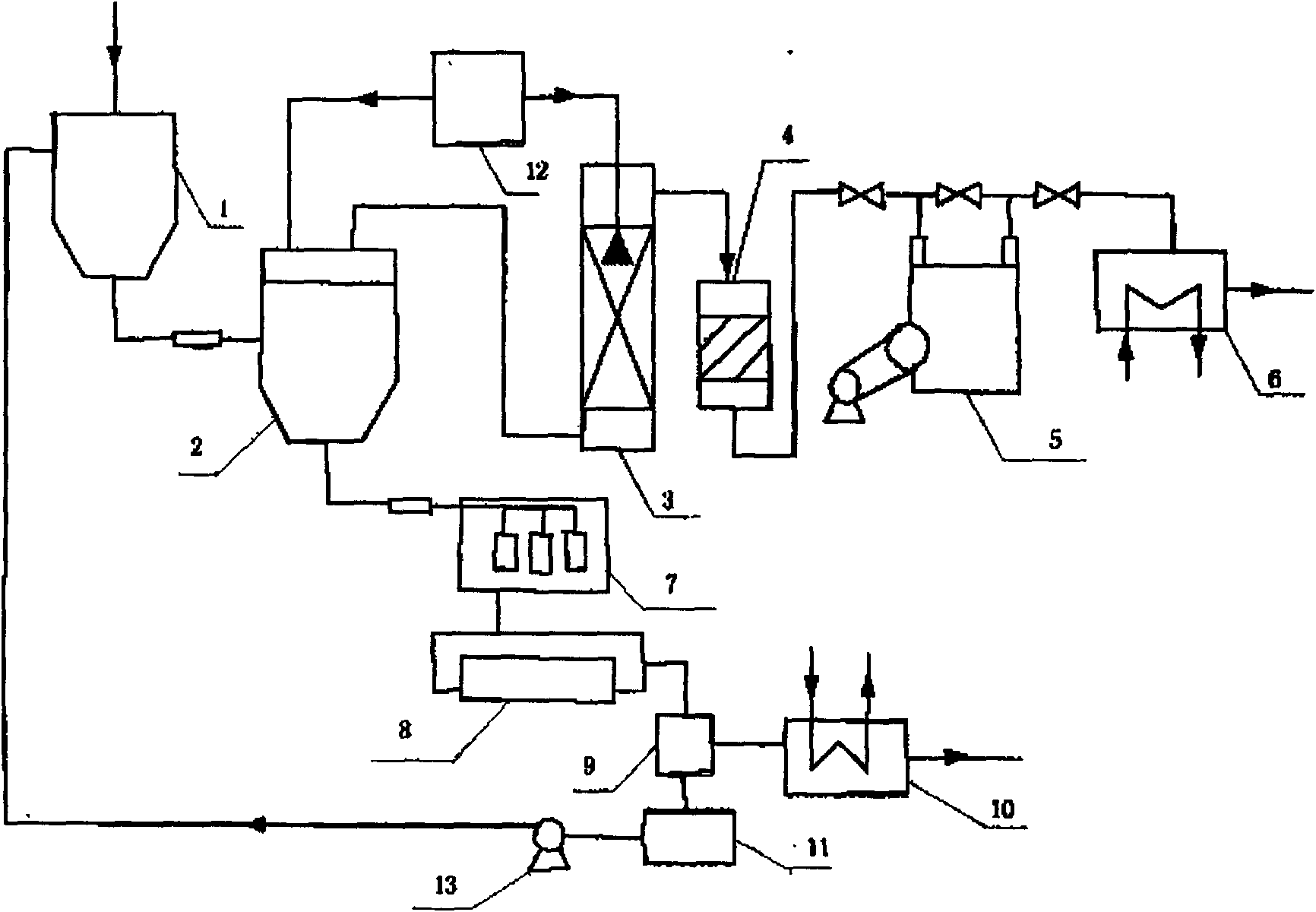

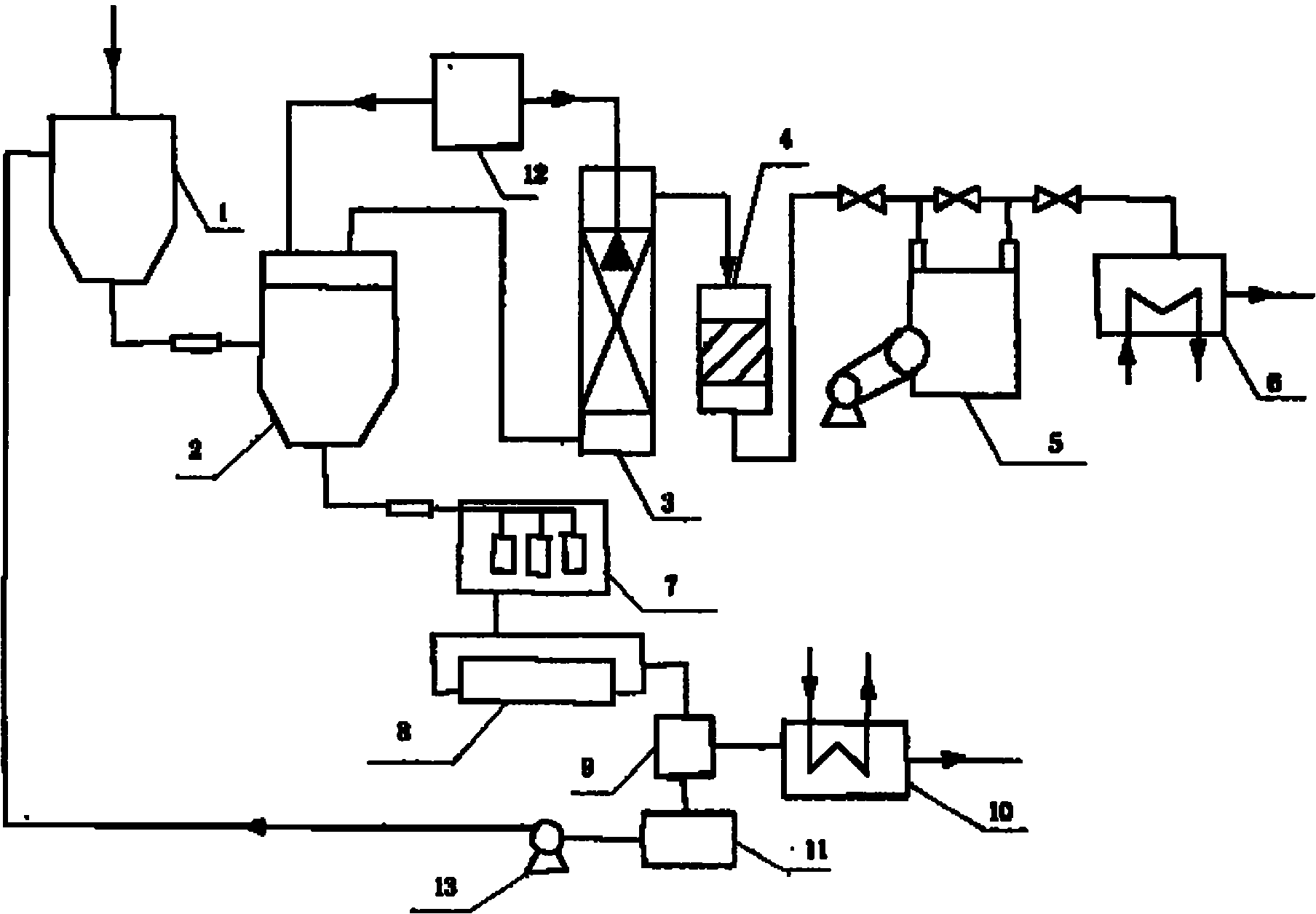

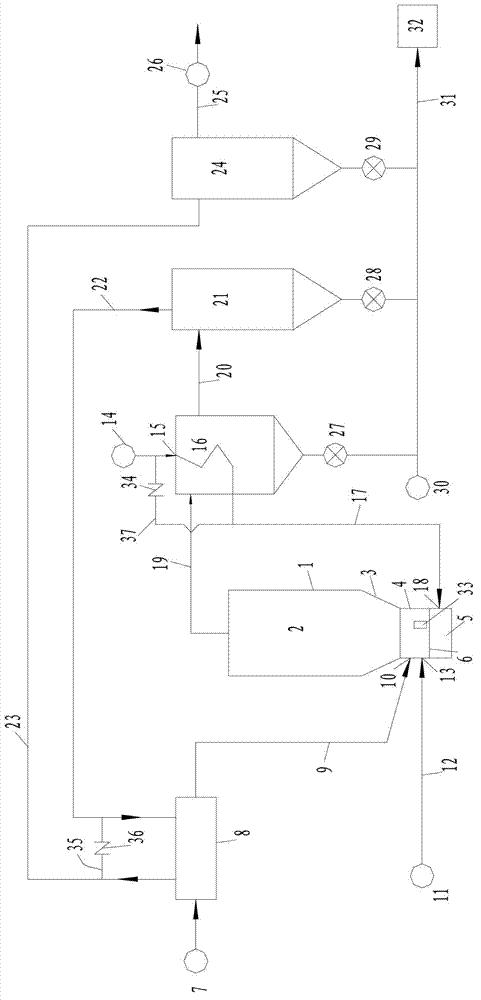

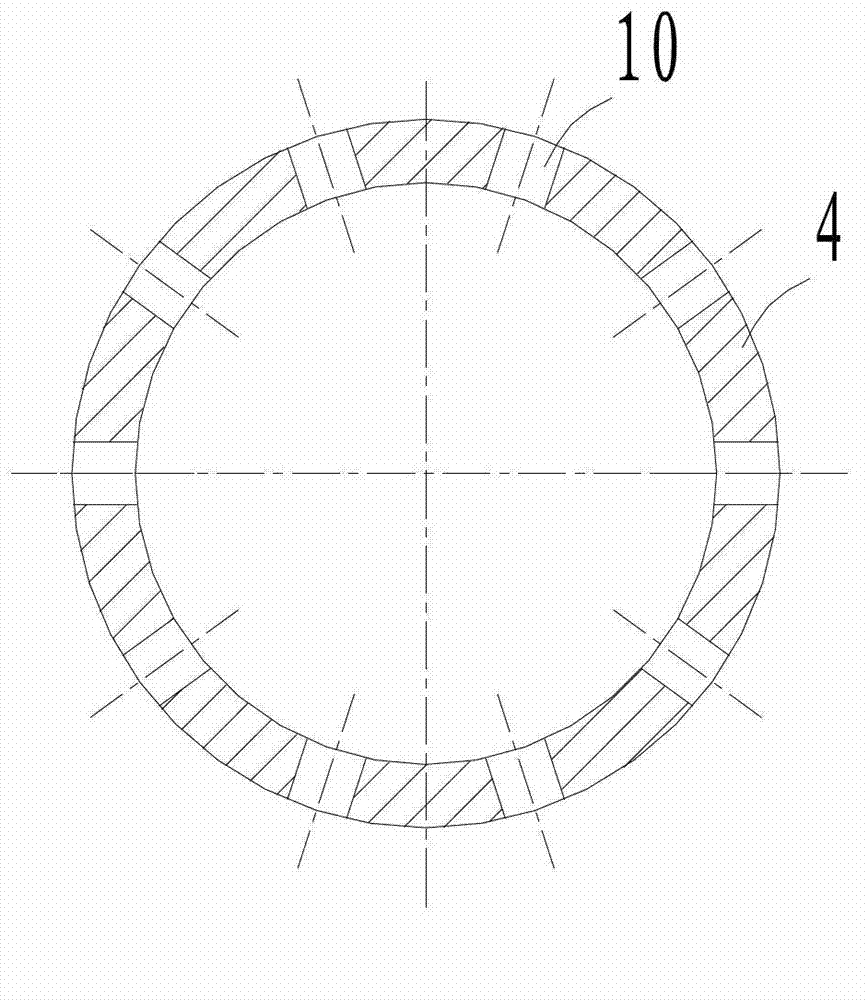

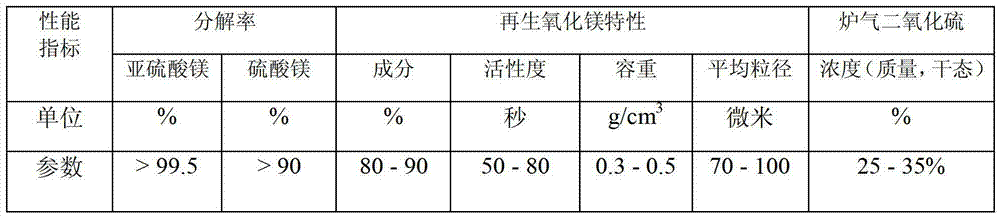

System and method for regenerating magnesium oxides and sulfur dioxides through decomposition of magnesium oxide desulphurization by-products

ActiveCN103111187AImprove productivityReduce volumeDispersed particle separationEnergy inputAir preheaterHigh concentration

Owner:SUNIC ENERGY & ENVIRONMENT TECH CHONGQING

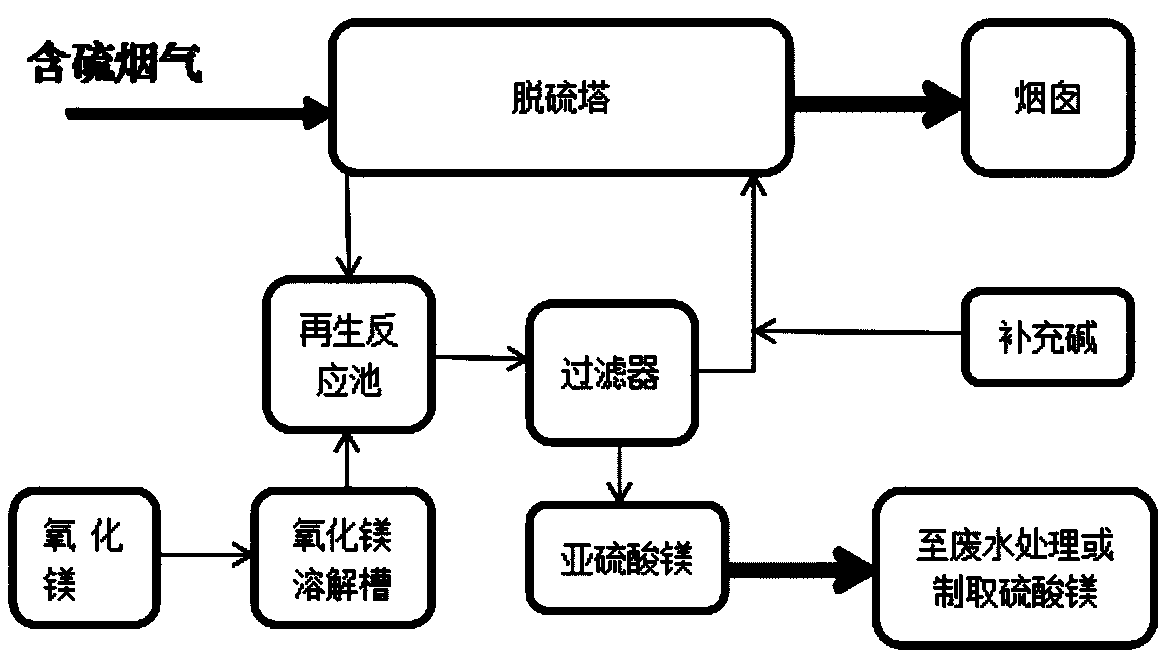

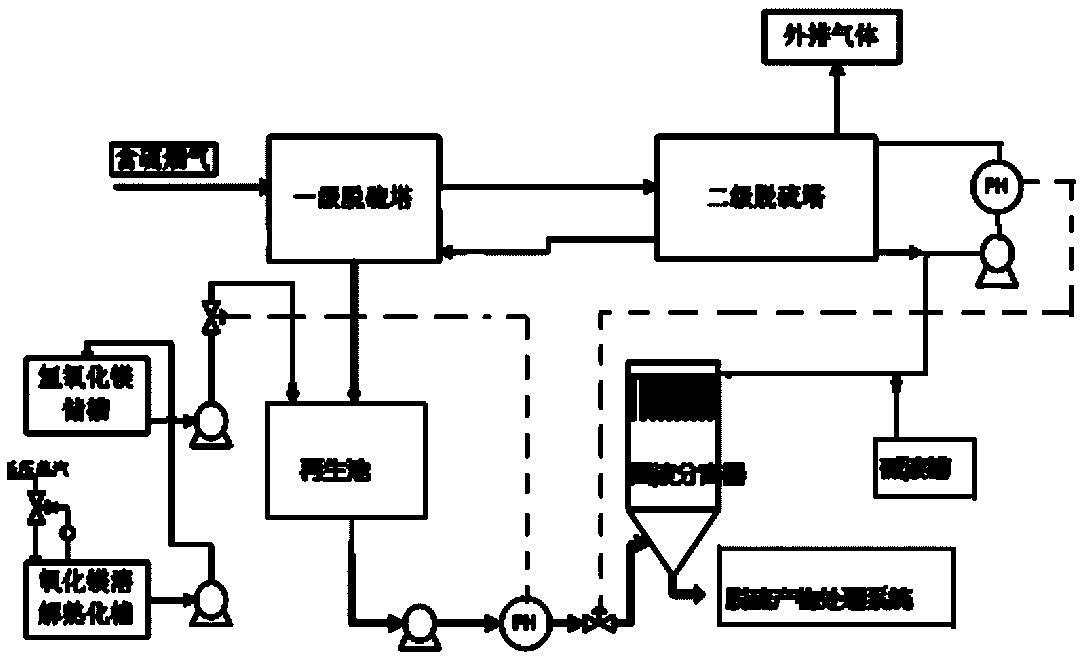

Novel dual-alkali flue gas desulfurization method and flue gas desulfurization system

InactiveCN105498503AImprove absorption efficiencyImprove desulfurization effectGas treatmentDispersed particle separationSulfite saltMagnesium sulfite

The invention provides a novel dual-alkali flue gas desulfurization method and flue gas desulfurization system, and relates to the technical field of flue gas purification. The method comprises the following steps of absorbing SO2 in flue gas to generate an absorption solution containing sodium sulfite and sodium bisulfite by taking sodium hydroxide or sodium carbonate as an absorbent, enabling the absorption solution to enter a regenerated reactor, regenerating the absorption solution in the regenerated reactor by using magnesium oxide or magnesium hydroxide, performing precipitation separation by virtue of a solid-liquid separator, enabling sodium sulfite or sodium hydroxide formed by regeneration to return to a desulfurization tower for flue gas absorption for recycling, enabling magnesium sulfite precipitates obtained by solid-liquid separation to enter a desulfurization product treatment system, and directly discharging magnesium sulfite or preparing magnesium sulfate. According to the method and the system, a sodium and magnesium dual-alkali method is adopted for flue gas desulfurization, so that a good desulfurization effect is achieved, oxidation is not required by the system, accumulation of sodium sulfate is avoided, and the system can run for a long time; moreover, the materials in the system can be regenerated and recycled, therefore alkali consumption is reduced, and the cost is reduced.

Owner:刘安明

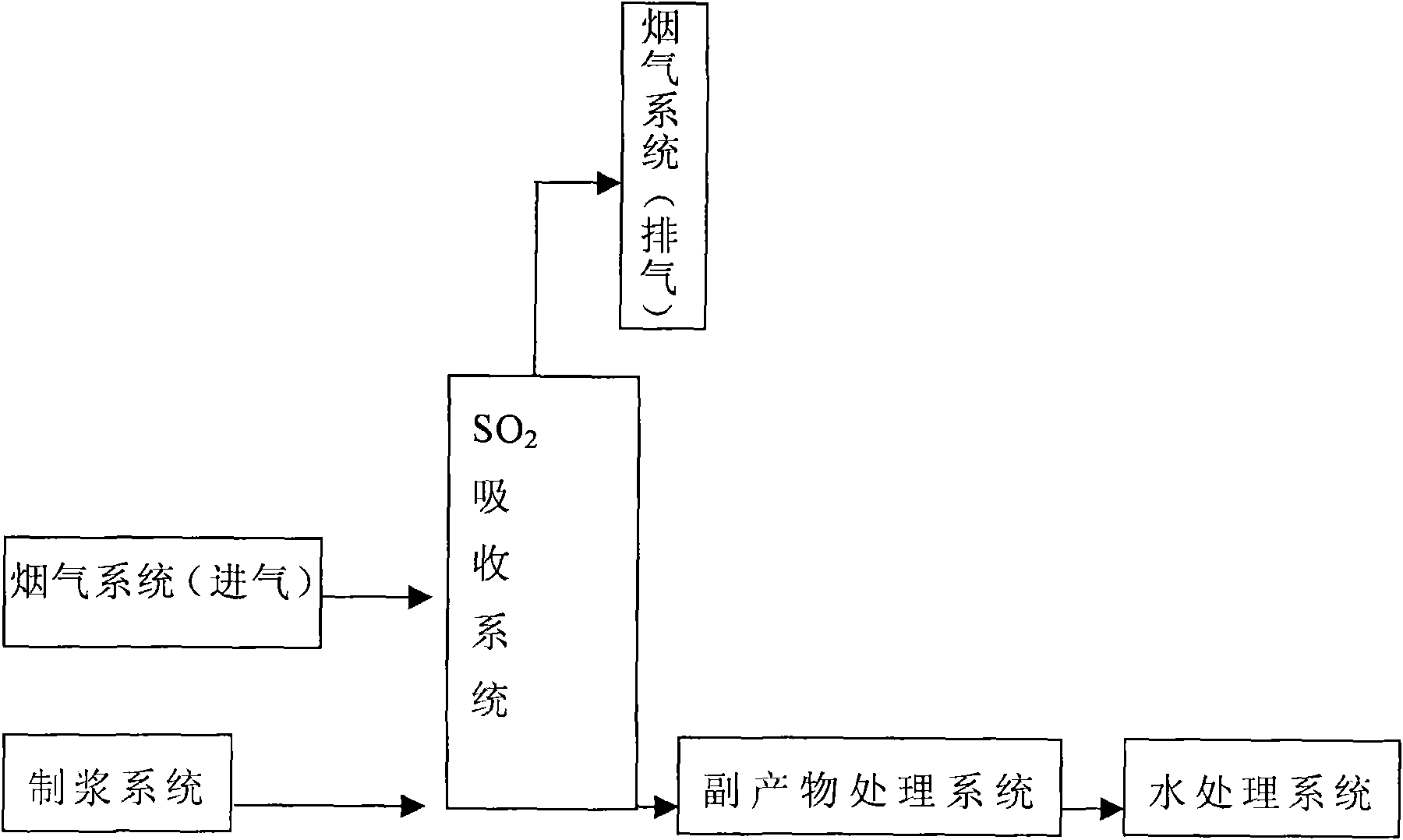

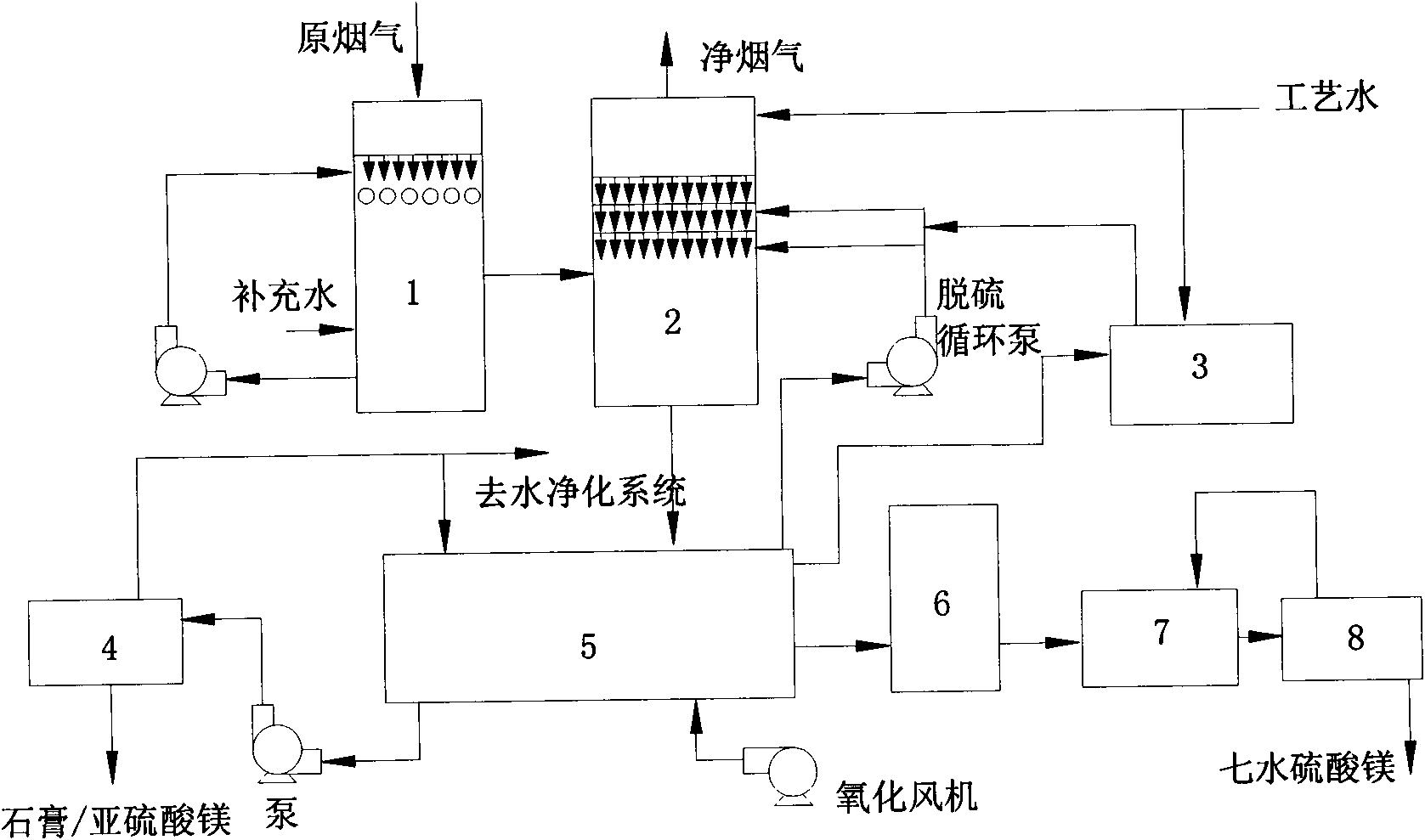

Flue gas desulfurization technology applicable to calcium and magnesium desulfuraters

InactiveCN101658760AGuaranteed high stability and reliabilityIncrease freedomDispersed particle separationProcess systemsMagnesium sulfite

The invention discloses a flue gas desulfurization technology applicable to calcium and magnesium desulfuraters, which comprises flue gas purification, desulfurater preparation, flue gas desulfurization, a combined tank, a dewatering system and a water purification system and is characterized in that the flue gas purification adopts an independent spray type flue gas purification tower; the desulfurater preparation takes calcium oxide or magnesium oxide as the desulfurater; the flue gas desulfurization adopts a three-layer spray system; and serosity absorbing sulfur dioxide enters a combined tank through self-flowing. The combined tank is internally provided with an oxidization area, a crystallization area and a precipitation area. When taking calcium oxide as the desulfurater, the main component of the by-product after dehydration is plaster; and when taking magnesium oxide as the desulfurater, fertilizers products such as magnesium sulfate or magnesium sulfite can be obtained. The flue gas desulfurization technology has the beneficial effect that the design of the multifunctional combined tank realizes the use of the calcium and magnesium desulfuraters in one set of process system, thus improving the degree of freedom and selectivity of the operation of the desulfurization system. The flue gas desulfurization technology is applicable to calcium and magnesium desulfuraters.

Owner:CECEP L&T ENVIRONMENTAL TECH

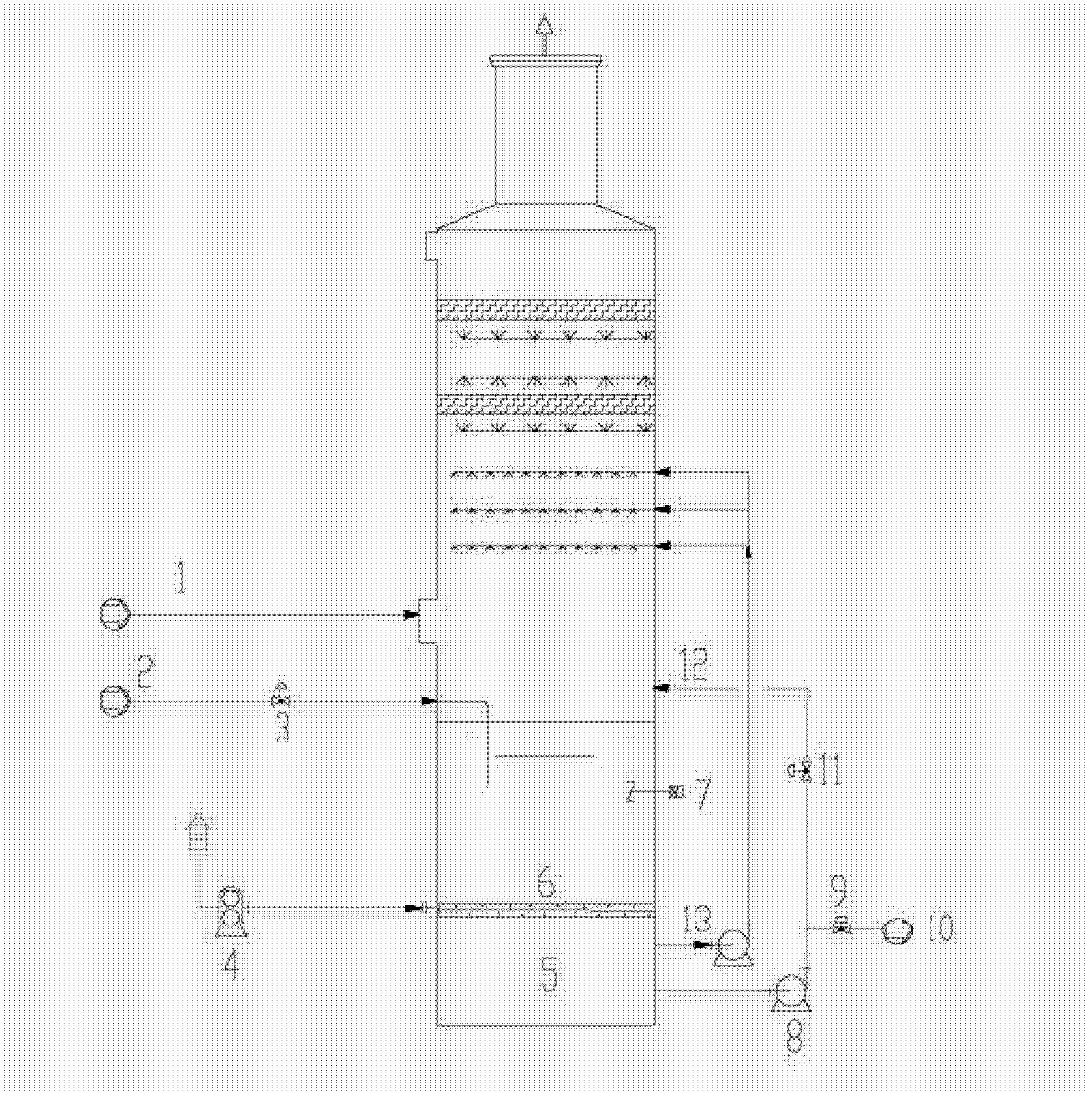

Light-calcined magnesia calcining furnace desulfurization technique and system

InactiveCN103446871ATypical Cleaning ProcessFriendly cleaning processDispersed particle separationFree coolingMagnesium sulfite

The invention provides a light-calcined magnesia calcining furnace desulfurization technique and system. The technique comprises steps as follows: light-calcined magnesia and water are added into a slurrying tank for slurrying, and the slurry enters a recycling tank; the slurry in the recycling tank is pumped to the top of a desulfurizing tower by a recycle pump and performs reflux absorption with fume which enters the bottom; the absorbed fume is discharged to air by a subsequent exhaust blower; the liquid on the bottom of the desulfurizing tower returns into a finned heat exchanger to be naturally cooled by an axial fan; the desulfurized solution enters the recycling tank; an air blower is additionally arranged in the recycling tank, and magnesium sulfite in the oxidizing solution also performs the function of further cooling; and when the solution concentration reaches 250 g / L, the solution is pumped to a magnesium cement construction material system to be used as a magnesium cement raw material. Only an ammonium chloride recycling process exists in the whole technical process, and thus, the technique is environment-friendly and clean.

Owner:新疆蓝天镁业股份有限公司

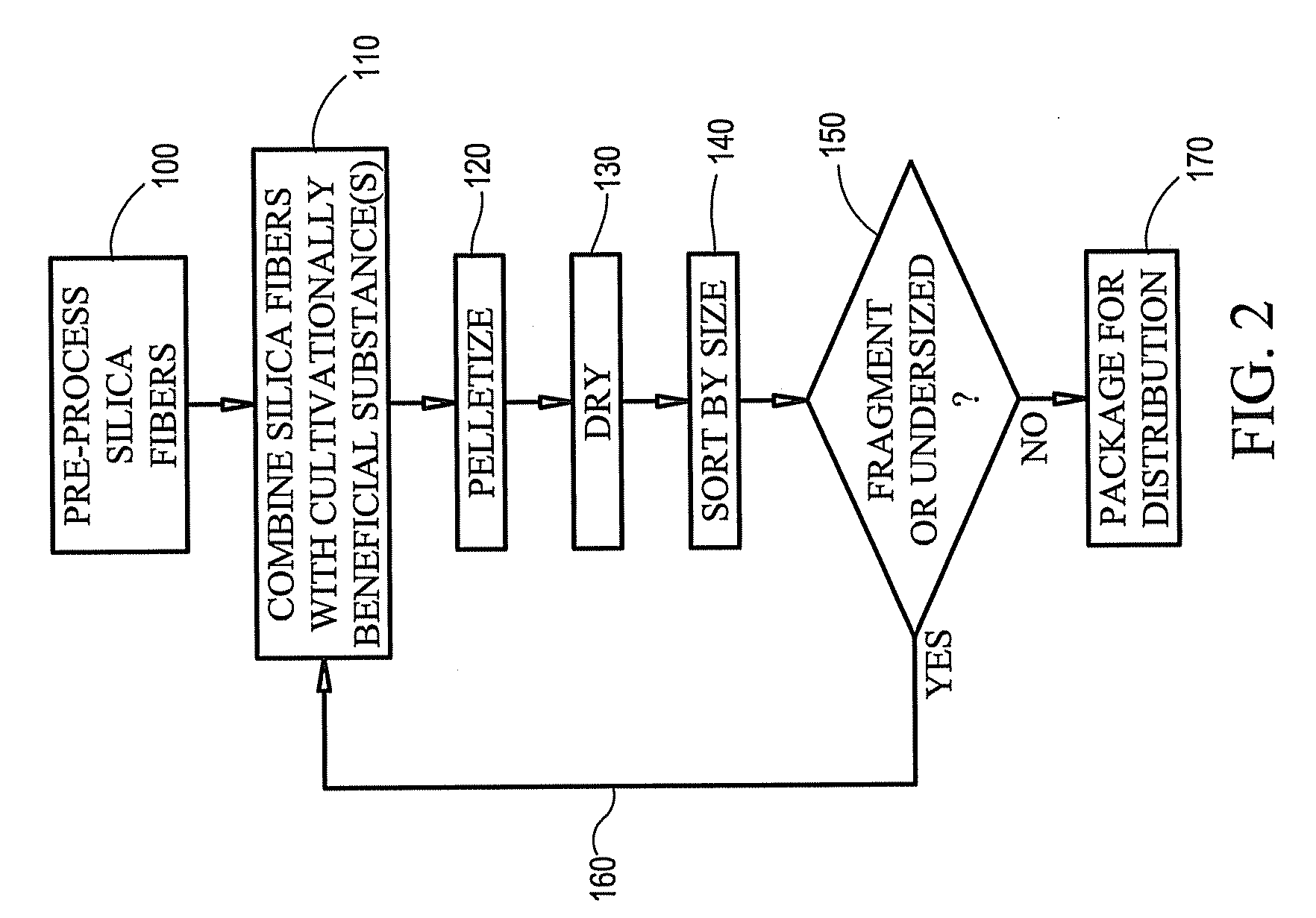

Agricultural pellet and method of making same

ActiveUS20090145191A1Improves Structural IntegrityModulating controlled release propertyCalcareous fertilisersBiocideCalcium silicateMagnesium sulfite

An economically efficient agricultural pellet of enhanced structural integrity comprises up to about 15% by weight of non-crystalline silica fibers blended with one or more other nutrient substances, such as calcium silicate and / or magnesium sulfite, such that the silica fibers to form an interlaced matrix dispersed throughout the body of the pellet. Fragmentation agent(s) and / or soil amendments may also be included. The silica fiber matrix provides both structural reinforcement and a source of bio-available silicon. In embodiments including calcium silicate, additional structural integrity is gained through pozzolonic bonding.

Owner:ELIZER MARK CONLEY +1

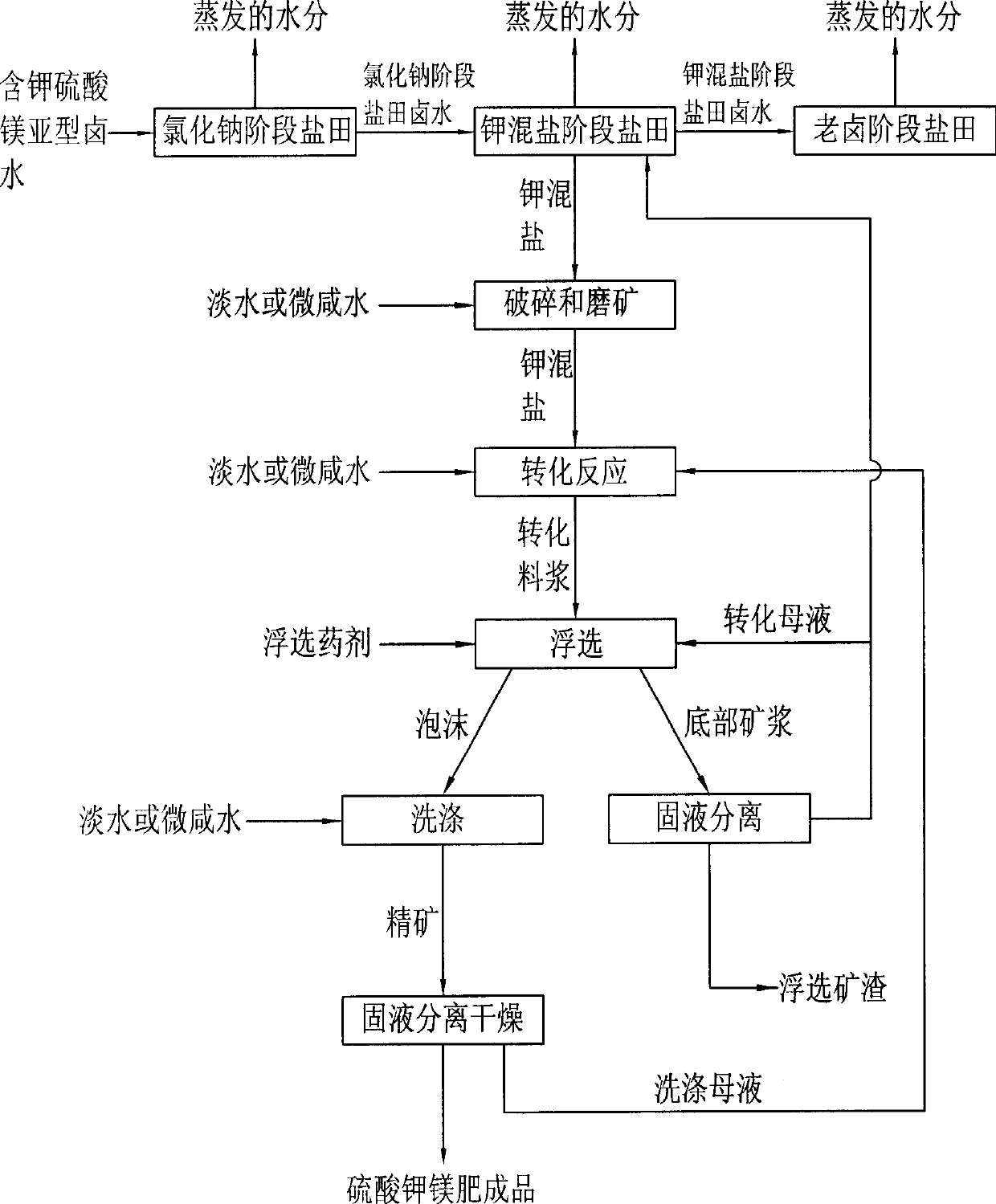

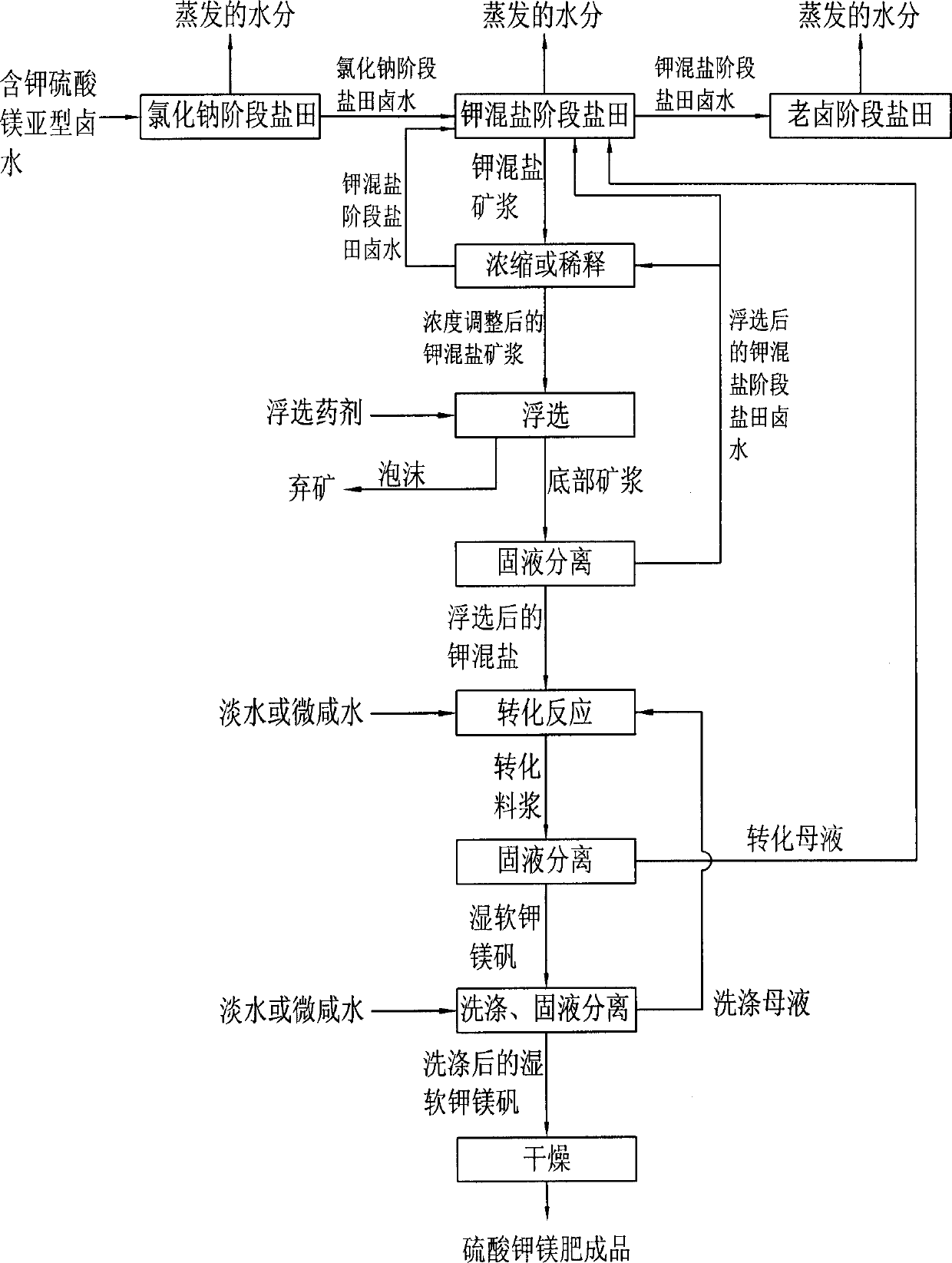

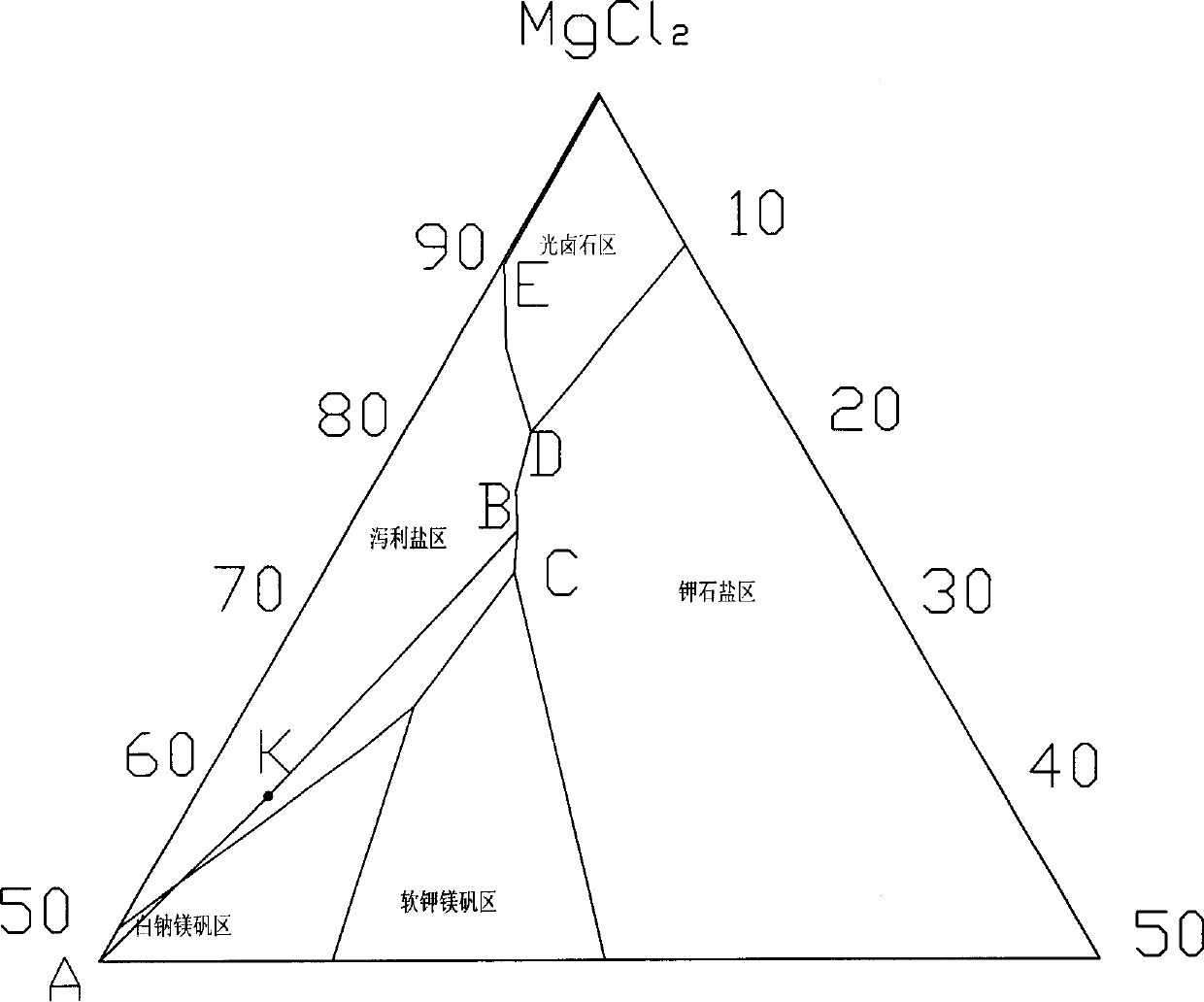

Improved process of preparing magnesium potassium sulfate fertilizer with bittern containing potassium and magnesium sulfite

ActiveCN1810730ASimple processImprove qualityMagnesium fertilisersPotassium fertilisersFresh waterMagnesium sulfite

The improved process of preparing magnesium potassium sulfate fertilizer with bittern containing potassium and magnesium sulfate includes the following steps: 1. spreading and shinning the bittern to form mixed potassium salt; 2. crushing and grinding the mineral of mixed potassium salt; 3. adding fresh water or slight salty water in the amount one 0.3-0.6 times the floated mixed potassium salt to convert the slurry; 4. mixing the slurry and floating chemical to float and obtain floated foamed concentrate; 5. washing the concentrate with fresh water or slight salty water; and 6. solid-liquid separating the concentrate to obtain solid concentrate and drying the solid concentrate to obtain magnesium potassium sulfate fertilizer product. The process of the present invention is simple, and has high quality of the produced magnesium potassium sulfate fertilizer.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD

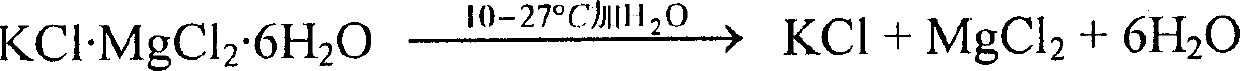

Process of preparing magnesium potassium sulfate fertilizer with bittern containing potassium and magnesium sulfite

ActiveCN1810729ASimple processAdded washing stepsMagnesium fertilisersPotassium fertilisersMagnesium sulfiteFresh water

The process of preparing magnesium potassium sulfate fertilizer with bittern containing potassium and magnesium sulfate includes the following steps: 1. spreading and shinning the bittern to form mixed potassium salt; 2. collecting mixed potassium salt slurry with pump; 3. regulating the concentration of the slurry to not higher than 20 %; 4. mixing the slurry and floating chemical to float; 5. adding fresh water or slight salty water in the amount one 0.3-0.6 times the floated mixed potassium salt to convert the slurry; 6. solid-liquid separating to obtain soft wet potassium and magnesium alum; 7. washing with fresh water or slight salty water and solid-liquid separating to obtain soft wet potassium and magnesium alum; and 8. drying to obtain magnesium potassium sulfate fertilizer. The process of the present invention is simple, has high quality of the produced magnesium potassium sulfate fertilizer, and is designed specially for water process collected bittern material.

Owner:SDIC XINJIANG LUOBUPO POTASH CO LTD

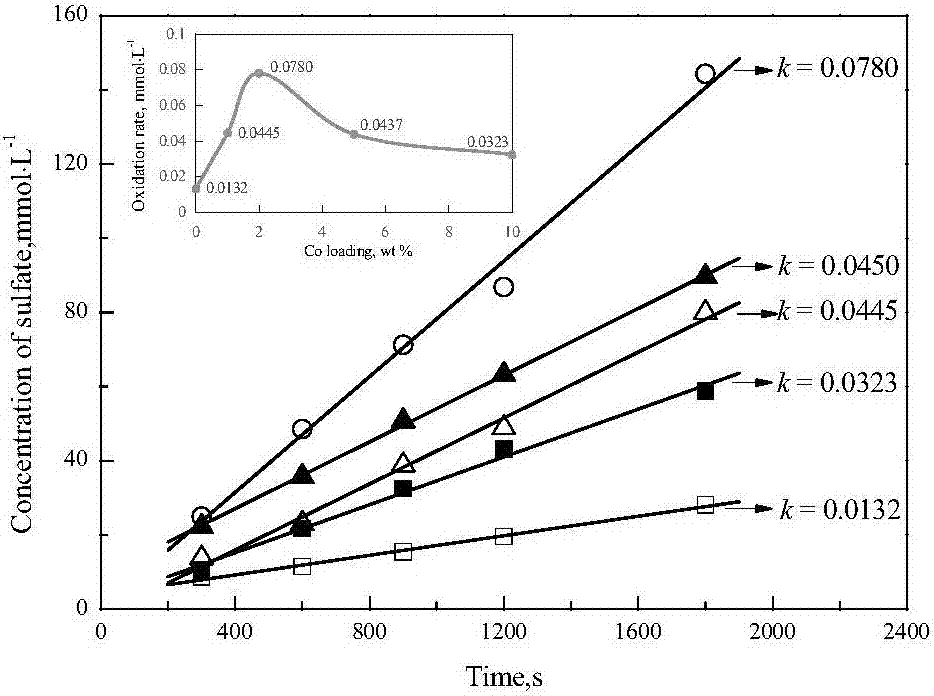

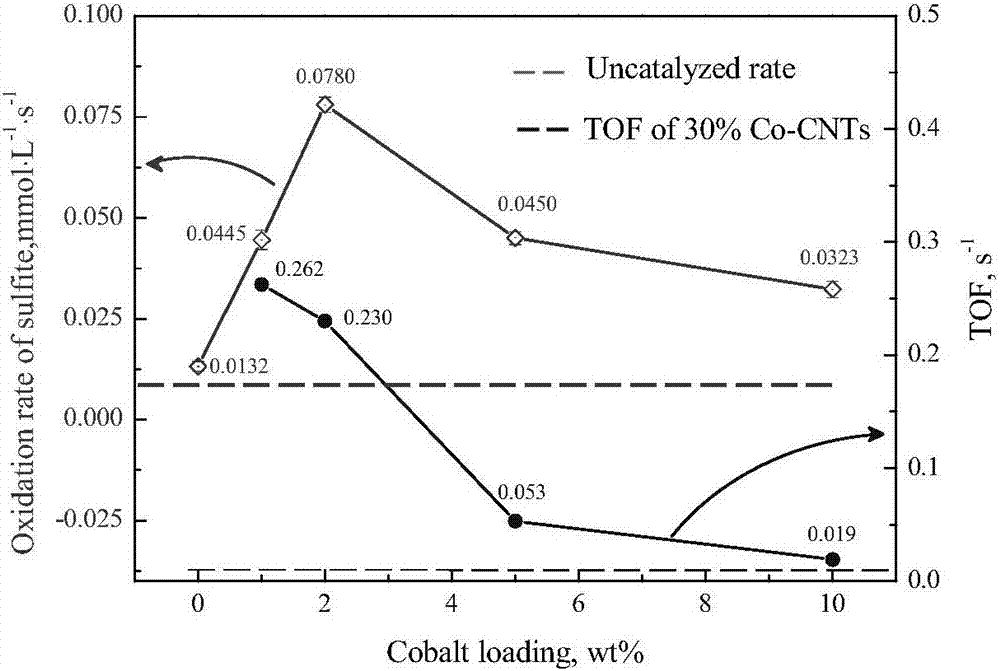

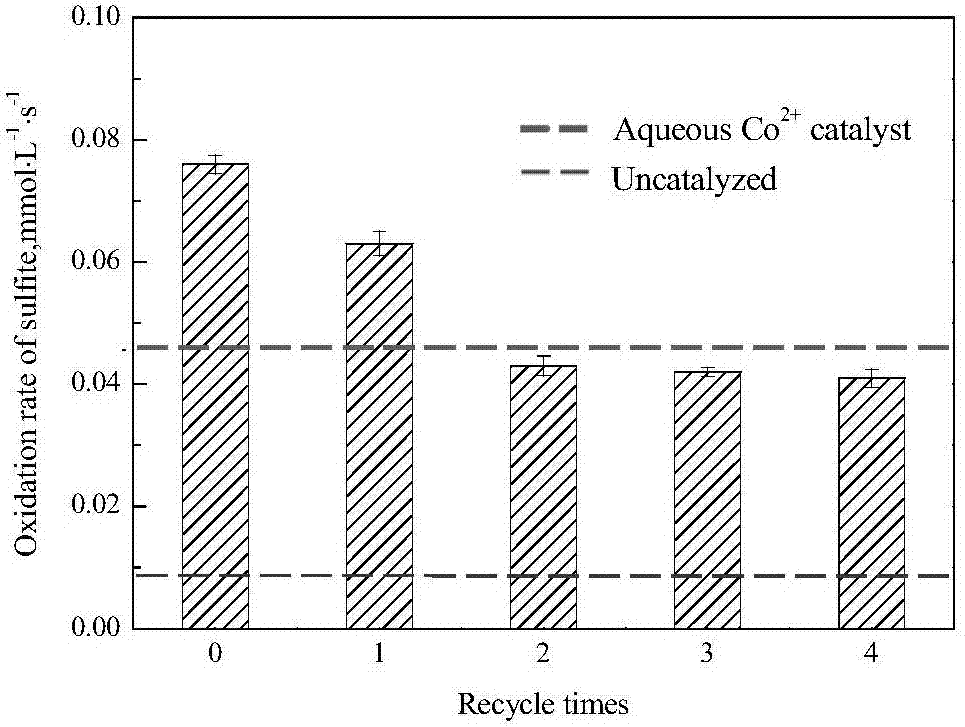

SBA15 catalyst loading cobalt base

ActiveCN107185581AIncrease oxidation rateSmall sizeMolecular sieve catalystsMagnesium sulfatesAlcoholRotary evaporator

The invention discloses an SBA15 catalyst loading a cobalt base. The loading amount of the cobalt base is 2%wt, and the cobalt base is highly dispersed inside pore canals of SBA15. The preparing method of the SBA15 catalyst comprises the steps of firstly weighing, by weight, 2 parts of solid powder of SBA15 and 0.1973 part of cobalt nitrate particles, dissolving the solid powder and cobalt nitrate particles into 100 parts (by weight) of absolute ethyl alcohol, and placing thee mixture into a beaker and conducting magnetic stirring for 5 h; secondly conducting still standing and crystallization for 24h; then placing the material obtained in the last step in a vacuum rotary evaporator to conduct evaporation drying for 2h, wherein the temperature is 60 DEG C; finally roasting the material in a muffle furnace at the temperature of 450 DEG C for 5h. The SBA15 catalyst loading the cobalt base is used for promoting oxidization of magnesium sulfite in a magnesia desulfurization process, the cost is lowered, and the catalysis efficiency is improved at the same time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

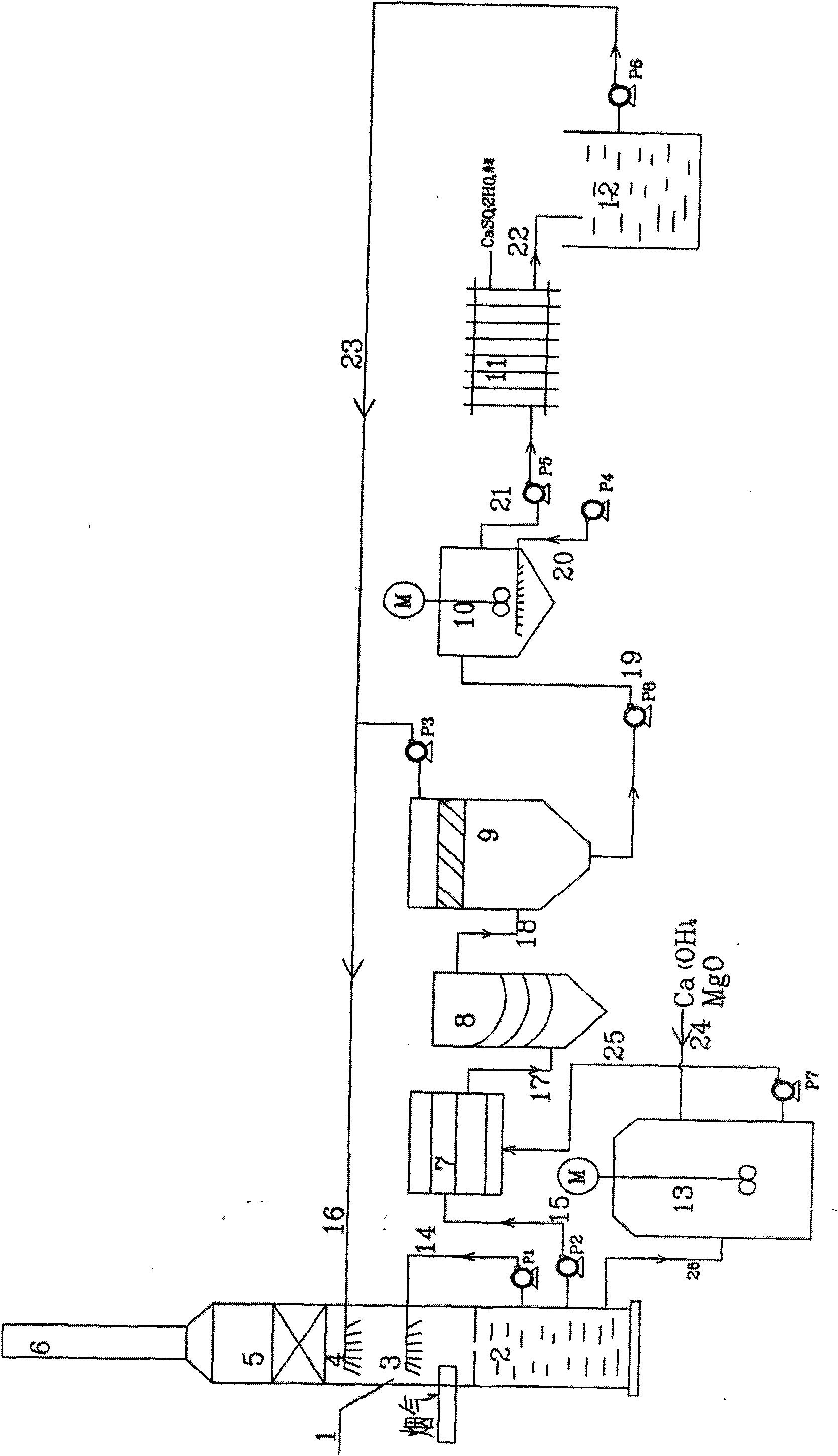

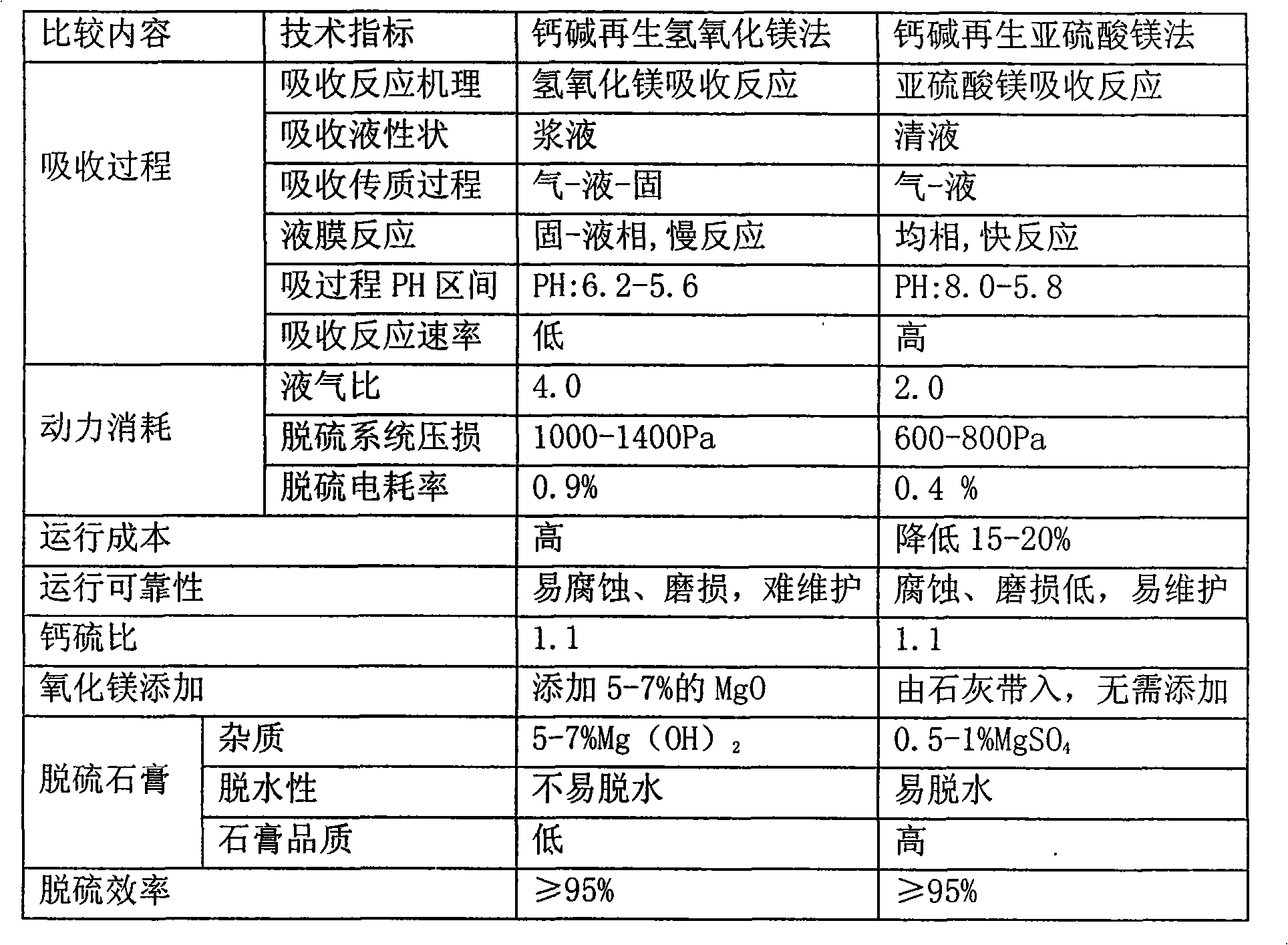

Flue gas desulfurization process through calc-alkaline regeneration magnesium sulfite cycle absorption method

ActiveCN101574619AIncrease the absorption reaction rateSolve the problem of using magnesium desulfurization process in areas lackingDispersed particle separationDecompositionSludge

The invention relates to a flue gas desulfurization process through a calc-alkaline regeneration magnesium sulfite cycle absorption method, which comprises the following steps: introducing flue gas containing sulfur dioxide into an absorption tower continuously, absorbing the sulfur dioxide in the flue gas circularly by using magnesium sulfite absorption liquid to convert magnesium sulfite into magnesium bisulfite, and then splitting part of the tower bottom absorption liquid to perform double decomposition reaction with calcium hydroxide to generate mixed slurry of magnesium hydroxide and calcium sulfate; splitting another part of the tower bottom absorption liquid which is put into a regeneration system outside the tower to perform regeneration with the generated mixed slurry of the magnesium hydroxide so that the magnesium bisulfite is regenerated into the magnesium sulfite; performing solid-liquid separation, reclaiming the mixed slurry of the magnesium sulfite and the calcium sulfate, and returning the filtrate to the absorption tower to perform cycle absorption; and introducing air to oxidize the reclaimed mixture of the magnesium sulfite and the calcium sulfate mixture so that the magnesium sulfite is oxidized into the magnesium sulfate, reclaiming the magnesium sulfate filtrate and returning the same to the cycle absorption, and comprehensively using sludge generated by filter pressing. The process adopts calc-alkali to regenerate the absorption liquid so that the absorption reaction rate is high.

Owner:江苏联慧资源环境科技有限公司

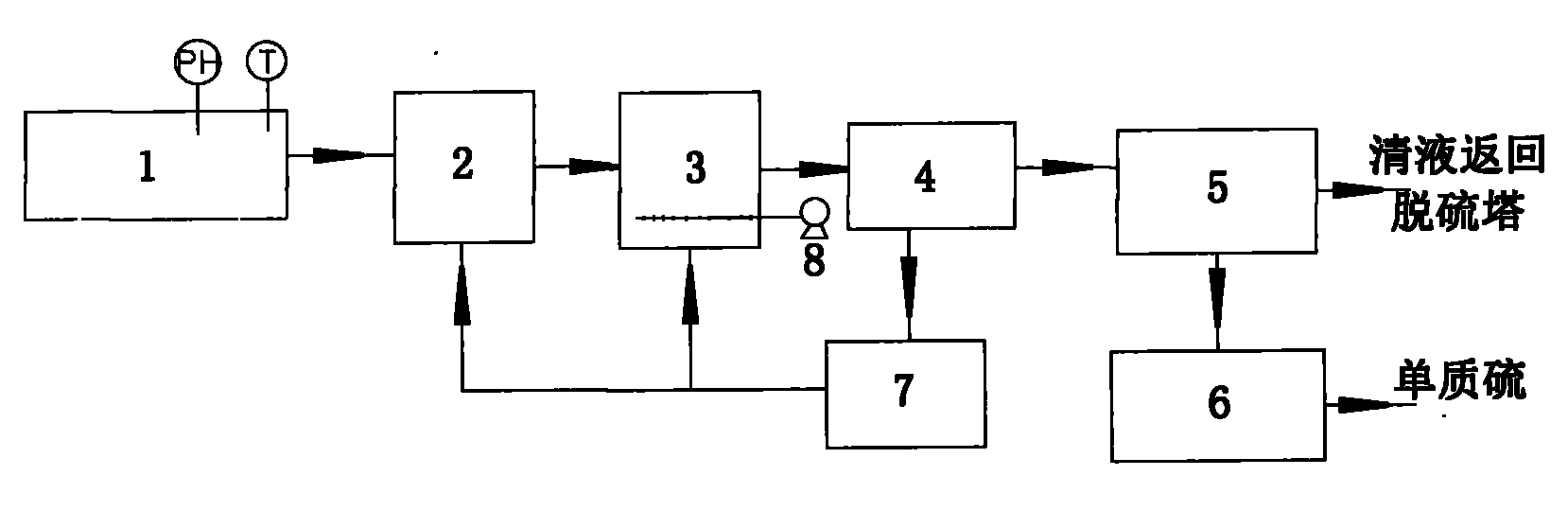

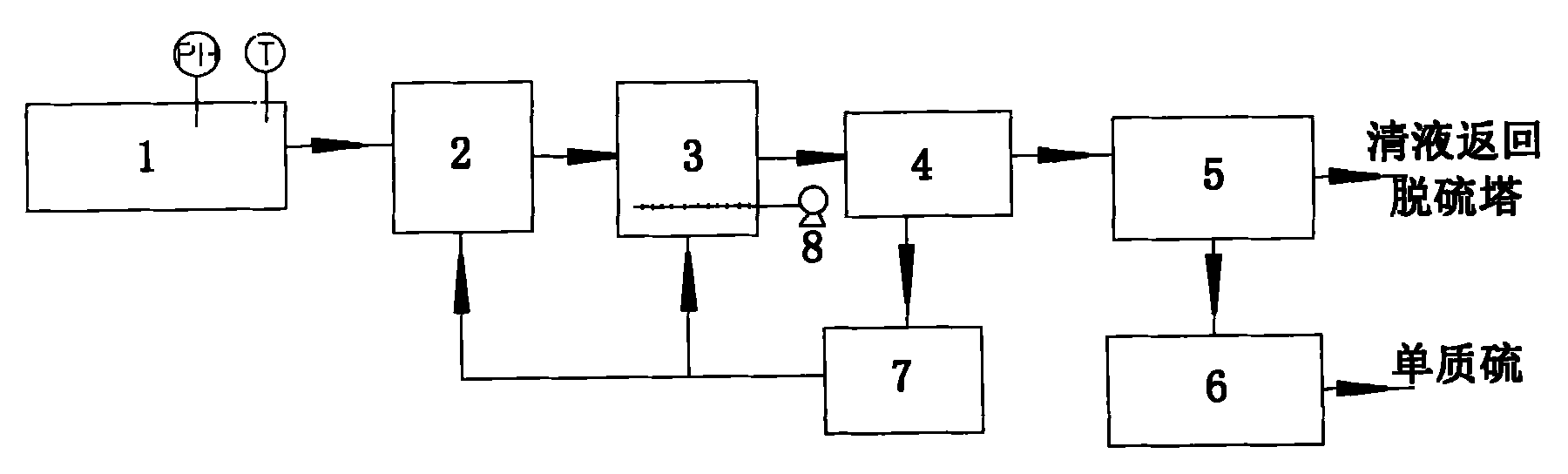

Method for treating wet magnesium desulfuration wastewater

ActiveCN102153228AReduce processingHarmlessSulfur preparation/purificationWaste water treatment from gaseous effluentsSulfate-reducing bacteriaSulfide

The invention discloses a method for treating wet magnesium desulfuration wastewater, which comprises the processes of slurry cooling, anaerobic reaction, aerobic reaction and elemental sulfur reclamation. The method is characterized by comprising the following steps of: delivering the slurry in an absorption tower in a cooling circulation tank to reduce the temperature of the slurry, regulating the pH value of the slurry by adding alkali liquor, discharging the cooled desulfuration slurry into a biological anaerobic reaction tank, reducing magnesium sulfite and magnesium sulfate in the slurry into sulfide or hydrogen sulfide under the action of efficient sulfate reducing bacteria, pumping the wastewater into an aerobic reaction tower, and oxidizing the magnesium sulfide or the hydrogen sulfide into elemental sulfur under the action of sulfur bacteria; and discharging the wastewater containing the elemental sulfur into a sedimentation tank, separating sludge and suspension, and dryingthe solid to obtain the elemental sulfur. By the treatment method provided according to the characteristics of high sulfite / sulfide solution of the magnesium desulfuration wastewater, the wastewater can be effectively treated, and reclamation, harmlessness and high value of wastes are realized at the same time. The method is suitable for treating the magnesium desulfuration wastewater.

Owner:CECEP L&T ENVIRONMENTAL TECH

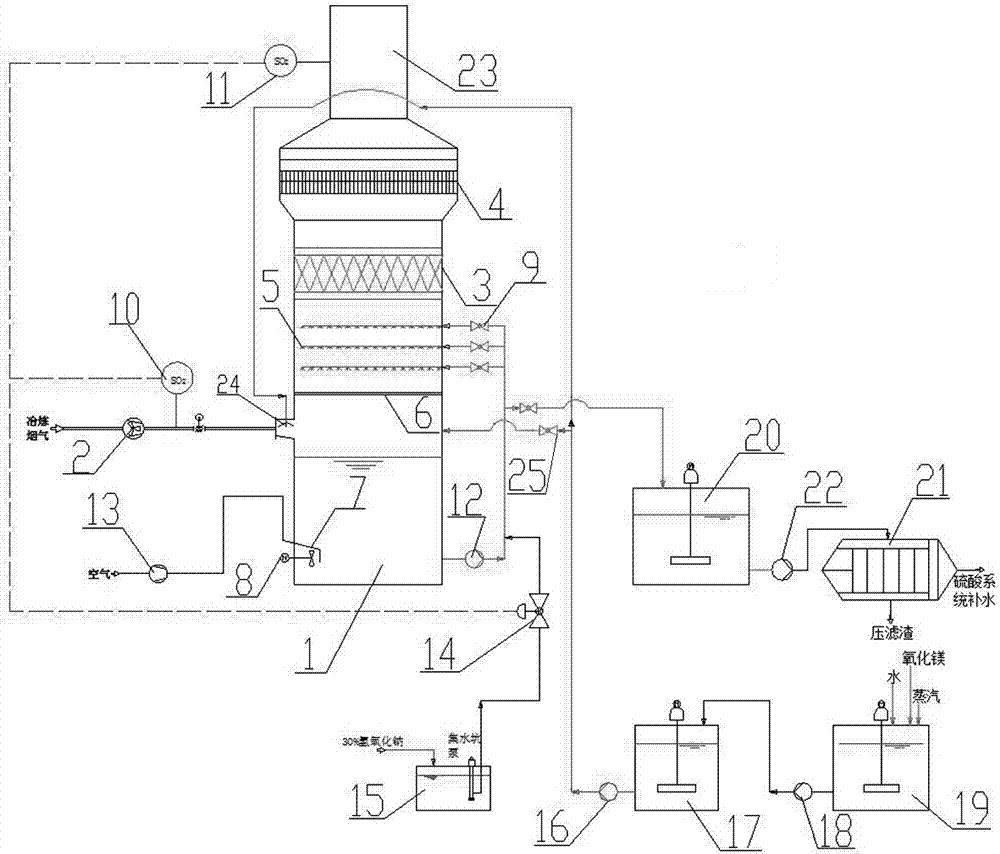

Large gas amount stray metallurgical off-gas wet dust collection and desulfuration method

PendingCN107185385AImprove adaptabilityAvoid depositionCombination devicesGas treatmentFiltrationPhysical chemistry

The invention discloses a large gas amount stray metallurgical off-gas wet dust collection and desulfuration method. According to the large gas amount stray metallurgical off-gas wet dust collection and desulfuration method, magnesium oxide is used for main adsorption, and sodium hydroxide is used for auxiliary adsorption, and the adding amount of sodium hydroxide is adjusted in time based on off-gas SO2 concentration; an adsorption-dedusting-demisting-evacuation integrated structure is adopted by an adsorption tower; a high temperature off-gas cooling device is arranged at a desulphurization adsorption tower inlet; a lateral stirring device and an aeration oxidation device are arranged at the bottom of the desulphurization adsorption tower; so that sparingly soluble magnesium sulfite in the adsorption tower can be converted into easily soluble magnesium sulfate effectively, and deposition of insoluble matters such as off-gas and magnesium oxide impurities is avoided; press filtration is adopted for treatment of a desulphurization liquid, so that separation of insoluble substances with magnesium sulfate solution is realized. Treatment effect is obvious, treatment cost is low, and requirements of treatment of complex metallurgical off-gas at high temperature period in large gas amount at high concentration SO2 are satisfied.

Owner:JINCHUAN GROUP LIMITED

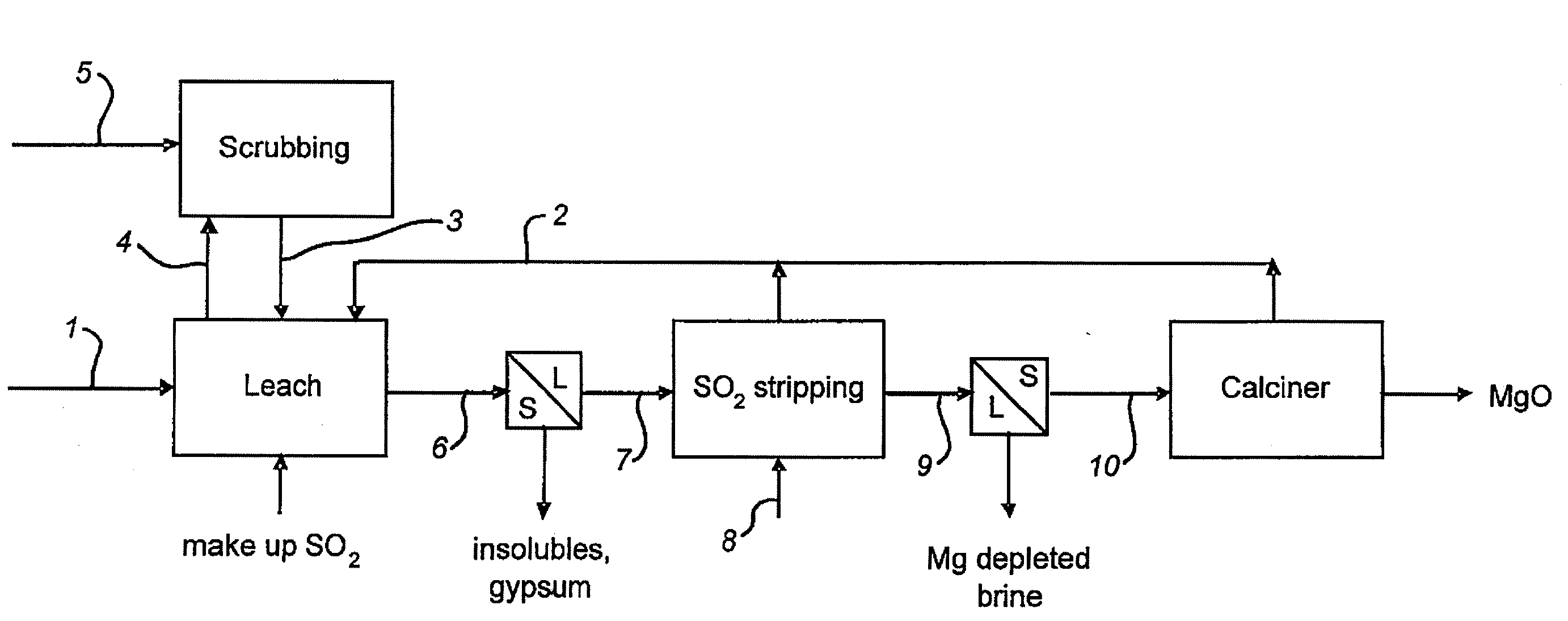

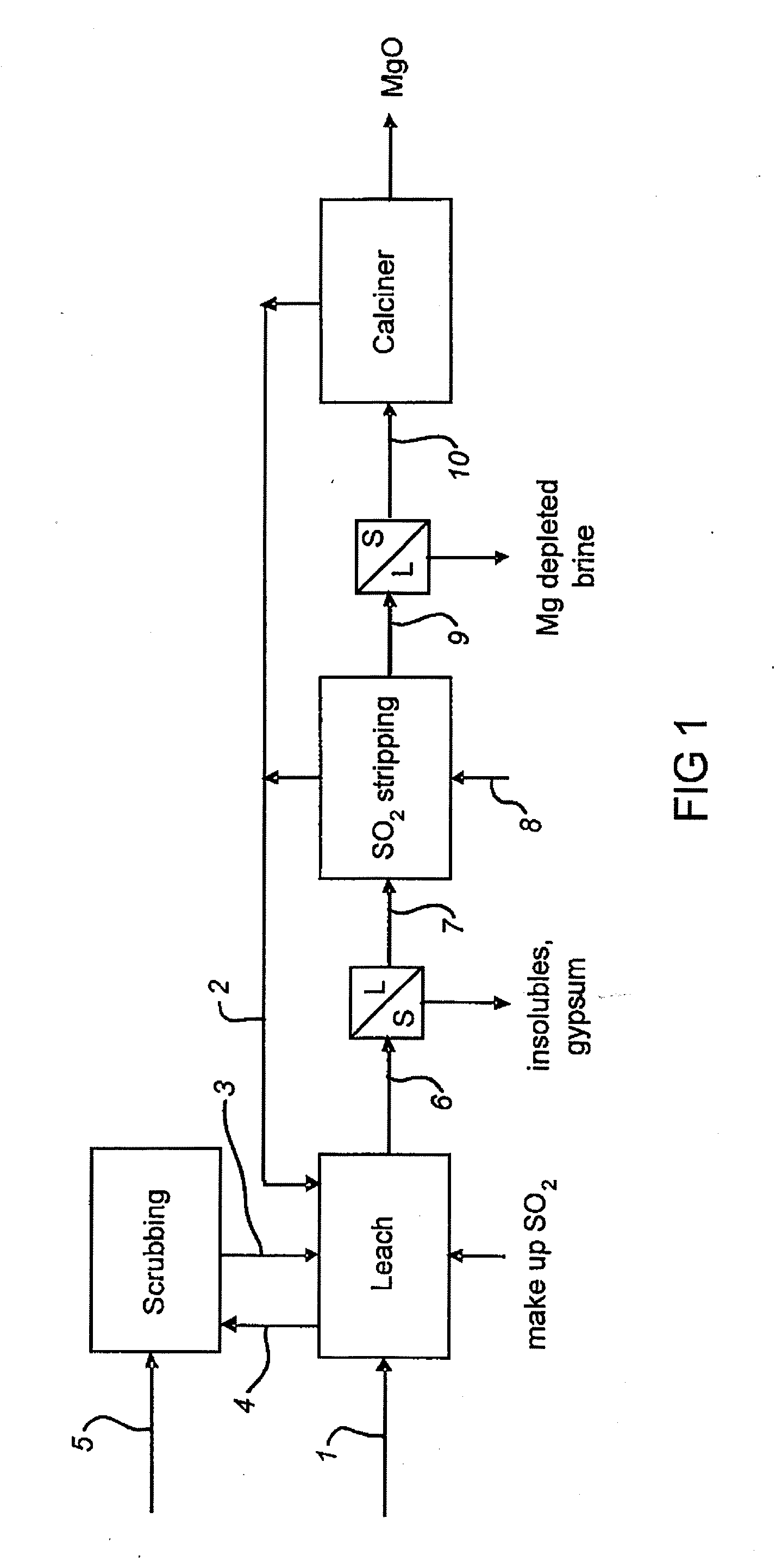

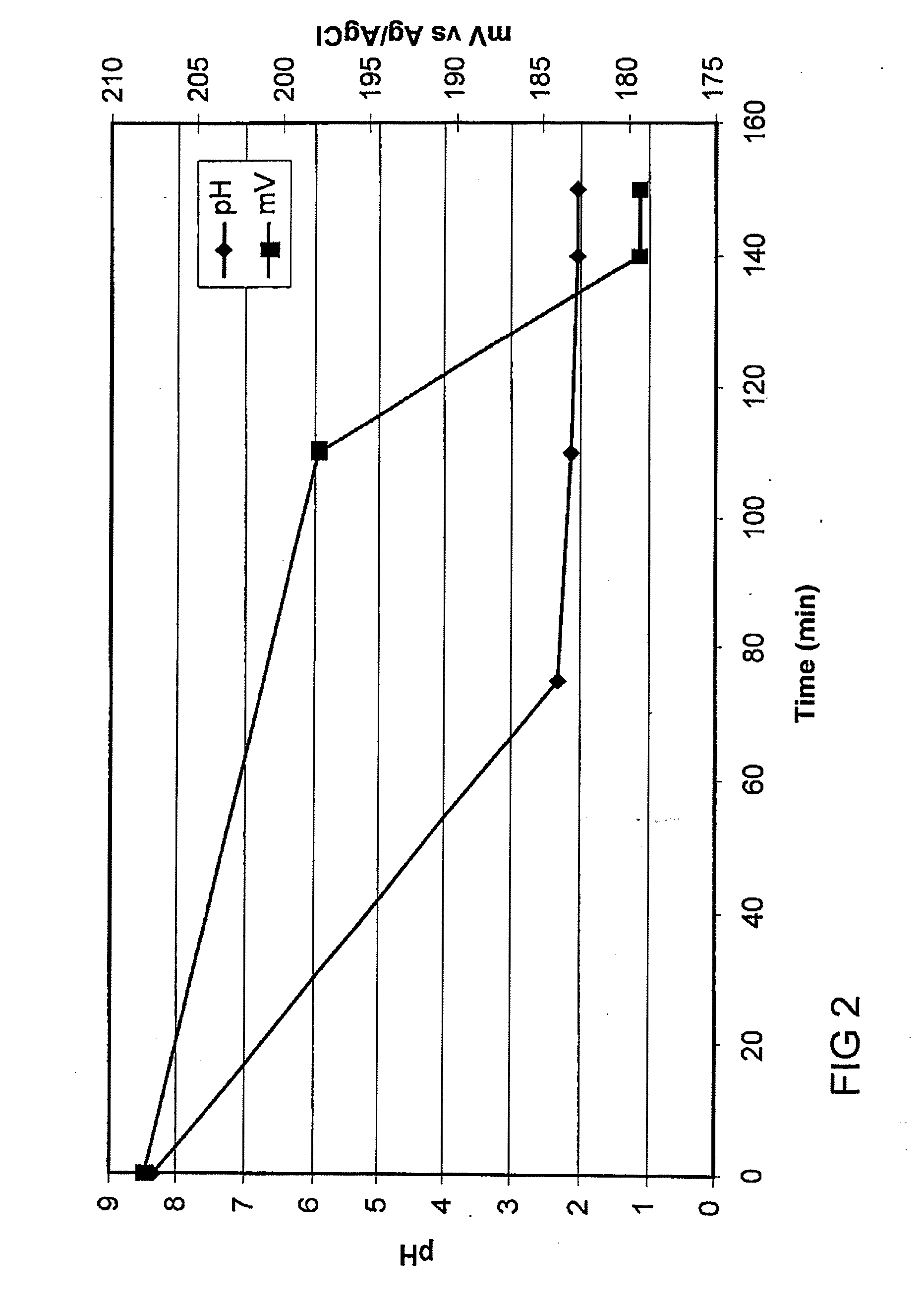

Process for the Production of Magnesium Oxide

InactiveUS20080025892A1Low costEasy to recycleCalcium/strontium/barium compoundsMagnesium sulfitesMagnesium saltPhysical chemistry

A process for the recovery of magnesium oxide from a source containing magnesium salts, said process including the steps of: (a) adding an alkali and sulfur dioxide to the source containing magnesium salts, in a leach step to form a magnesium bi-sulfite containing leachate;(b) separating the insoluble materials from the leachate; (c) stripping excess sulfur dioxide from the leachate and precipitating the magnesium as solid magnesium sulfite hydrate; (d) separating the solid magnesium sulfite hydrate from the magnesium depleted leachate; and (e) calcining the solid magnesium sulfite hydrate and recovering the magnesium as magnesium oxide.

Owner:BHP BILLITON SSM TECH PTY LTD

System and method for treating acidic wastewater produced in acid making with smelting gas

ActiveCN105384288AAchieve emission standardsEmissions up to standardWater aerationWater/sewage treatment by ion-exchangeMagnesium sulfiteSodium sulphide

The invention discloses a system and a method for treating acidic wastewater produced in acid making with smelting gas. The system and method disclosed by the invention are implemented through the steps that after a sodium sulfide solution and acidic wastewater are fed into a first-order reactor to react for removing part of heavy metals and arsenic in acid water, the obtained object enters a first-order thickener; bottom mud in the thickener, after being subjected to, is recycled, liquid supernatant and filtrate produced by a filter press enter a second-order reactor, and then the liquid supernatant, the filtrate, magnesium oxide absorption liquid discharged after being desulfurized in an environmental-friendly smelting gas gathering system and added into the second-order reactor, a prepared magnesium oxide solution, and a sulfuric acid in the acid water are subjected to a sufficient neutralization reaction by using magnesium oxide and magnesium sulfite contained in environmental-friendly gathered smelting gas desulfurized absorption liquid and a magnesium oxide solution; and an aluminum salt is added so as to reduce the heavy metal content of reaction liquid to a control range; the obtained object enters a second-order thickener, bottom mud in the thickener, after being subjected to filter pressing, is conveyed to a hazardous waste disposal site to carry out landfill disposal, and liquid supernatant and filtrate produced by the filter press enter a second-order reactor, after being subjected to deep treatment by using an iron carbonyl co-precipitation method and then reaching the standards, are recycled or discharged. According to the method, an effect of treatment of wastes with processes of wastes against one another is achieved, the pertinence is strong, the operation cost of environmental protection facilities is lowered, and the discharge amount of the system is reduced.

Owner:JINCHUAN GROUP LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com