Large gas amount stray metallurgical off-gas wet dust collection and desulfuration method

A technology for smelting flue gas and wet dust removal, applied in the fields of smelting and chemical industry, can solve the problems of high equipment investment and operation cost, complicated process and poor economy, and achieve low processing cost, shortened process and environmental benefits. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

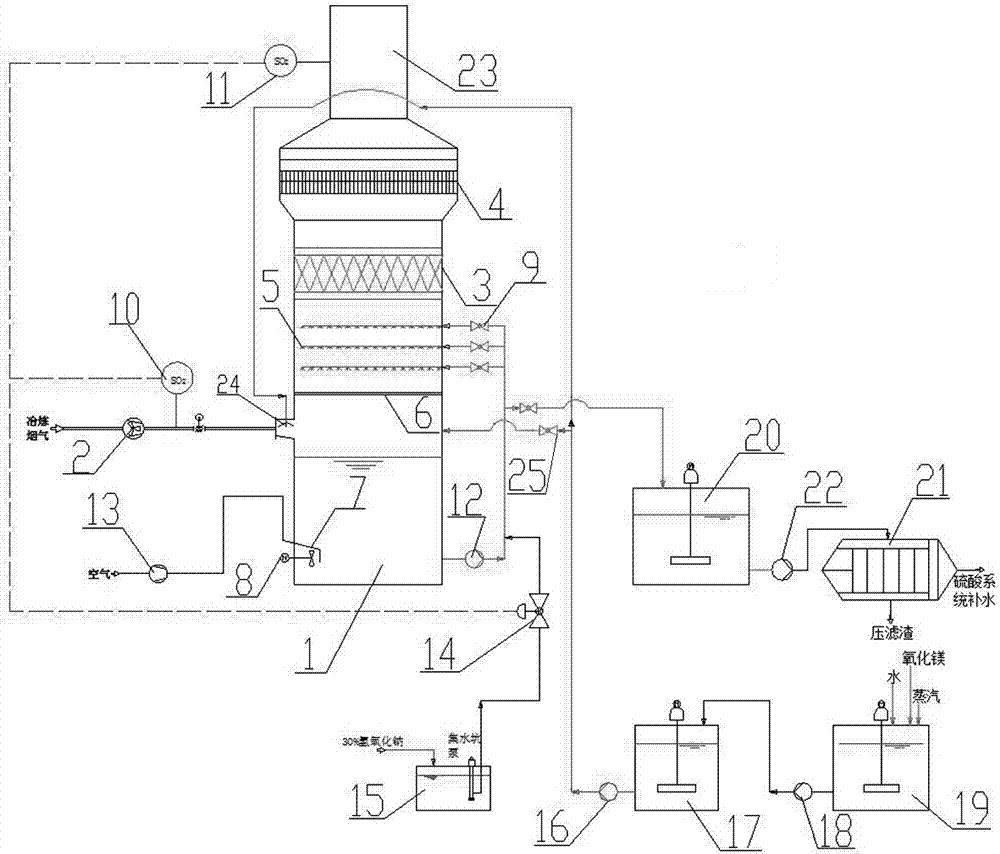

[0020] Preparation of magnesium hydroxide slurry: First, add the purchased qualified magnesium oxide powder and fresh water into the magnesium oxide aging tank 19 in a certain proportion, pass steam, start stirring, and aging for 2 hours to make 12% magnesium hydroxide slurry, which is oxidized The magnesium slaking pump 18 is delivered to the magnesium hydroxide slurry tank 17 for use. During normal production, the side stirring device 8 is turned on, the oxidation aeration device is turned on, and air is blown in by the air spray gun 7 . Turn on the absorption tower circulation pump 12 to deliver the magnesium hydroxide slurry to the multi-layer spray device 5, adjust the spray layer control valve 9, and open the three layers for spraying. Smelting stray flue gas (gas volume about 600,000 Nm 3 / h, SO 2 The concentration is 1057-3500mg / Nm 3 , the average is about 3000mg / Nm 3 , temperature 50±10°C) after being pressurized by the flue gas conveying fan 2, it enters the towe...

Embodiment 2

[0022] During abnormal production, the amount of smelting stray flue gas is about 400,000 Nm 3 / h, SO 2 The concentration is 6000-8500mg / Nm 3 , the average is about 7000mg / Nm 3 , temperature 200-280°C. The side stirring device 8 is turned on, the oxidation aeration device is turned on, and air is blown in by the air spray gun 7 . Turn on the magnesium hydroxide slurry pump 16, deliver the magnesium hydroxide slurry to the magnesium hydroxide slurry spray device 24 at the flue gas inlet to spray the flue gas to cool down, turn on the absorption tower circulation pump 12 to deliver the magnesium hydroxide slurry to the spray layer 5, adjust Each layer of spray layer control valve 9 is opened to spray on the second floor. After the smelting stray flue gas is pressurized by the flue gas conveying fan 2, after being cooled and washed by the magnesium hydroxide slurry spraying device 24, it enters the tower body from the middle and lower part of the desulfurization absorption to...

Embodiment 3

[0024] During abnormal production, the amount of smelting stray flue gas is about 400,000 Nm 3 / h,SO 2 The concentration is 835-2500mg / Nm 3 , the average is about 2000mg / Nm 3 , temperature 50±10°C. The side stirring device 8 is turned on, the oxidation aeration device is turned on, and air is blown in by the air spray gun 7 . Turn on the absorption tower circulation pump 12 to deliver the magnesium hydroxide slurry to the spray layer 5, adjust the single-layer spray layer control valve 9, and open the second layer for spraying. After being pressurized by the flue gas conveying fan 2, the stray flue gas from smelting enters the tower body from the middle and lower part of the desulfurization absorption tower 1, diffuses evenly through the flow-balancing efficiency tray 6, and mixes with the top-down air from the multi-layer spraying device 5. Magnesium hydroxide slurry reverse contact, magnesium hydroxide slurry will SO in the flue gas 2 absorb. After desulfurization, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com