Patents

Literature

3183 results about "Sulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

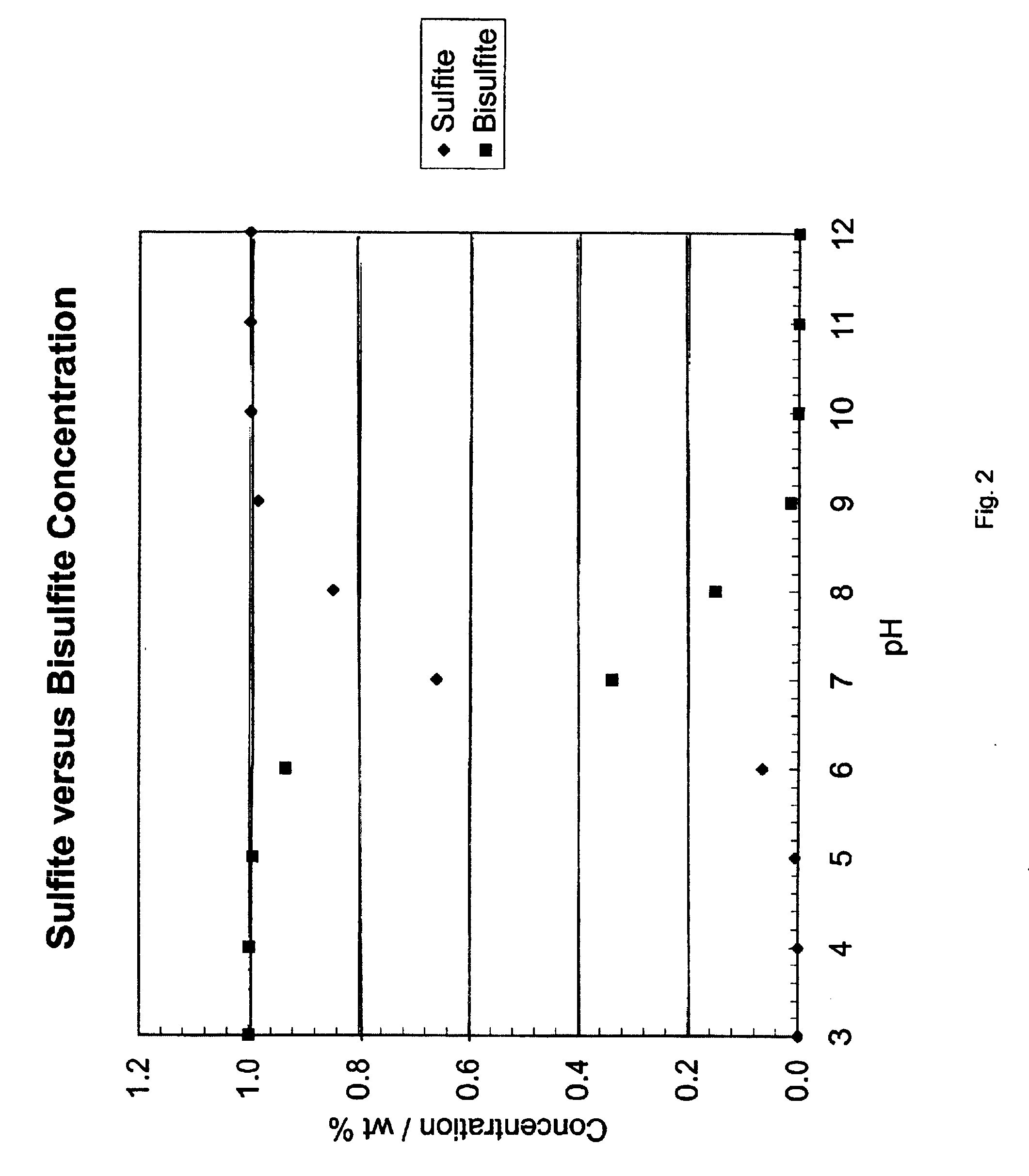

Sulfites or sulphites are compounds that contain the sulfite ion (or the sulfate(IV) ion, from its correct systematic name), SO²⁻₃. The sulfite ion is the conjugate base of bisulfite. Although its acid (sulfurous acid) is elusive, its salts are widely used.

High alkaline cleaners, cleaning systems and methods of use for cleaning zero trans fat soils

InactiveUS20100317559A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSulfiteCleansing Agents

The present disclosure relates to high alkaline cleaners, cleaning systems and methods for removing polymerized zero trans fat soils. The high alkaline cleaner of the present invention generally includes one or more alkaline wetting and saponifying agent(s), a chelating / sequestering system and a surface modifying-threshold agent system. In various embodiments, the cleaners may include, at least one cleaning agent comprising a surfactant or surfactant system and / or a solvent or solvent system and / or a cleaning booster such as a peroxide or sulfite type additive. The cleaners may also include one or more components to modify the composition form and / or the application method in some embodiments. All components described above may also be optimized optionally, to provide emulsification of a composition (both as a usable product or a concentrate that can be diluted to form a usable product). The use of the high alkaline cleaner of the present invention has demonstrated enhanced cleaning characteristics especially at higher temperatures (100° F. to about 200° F.) but also shows enhanced cleaning at ambient temperatures.

Owner:ECOLAB USA INC

Extended binder compositions

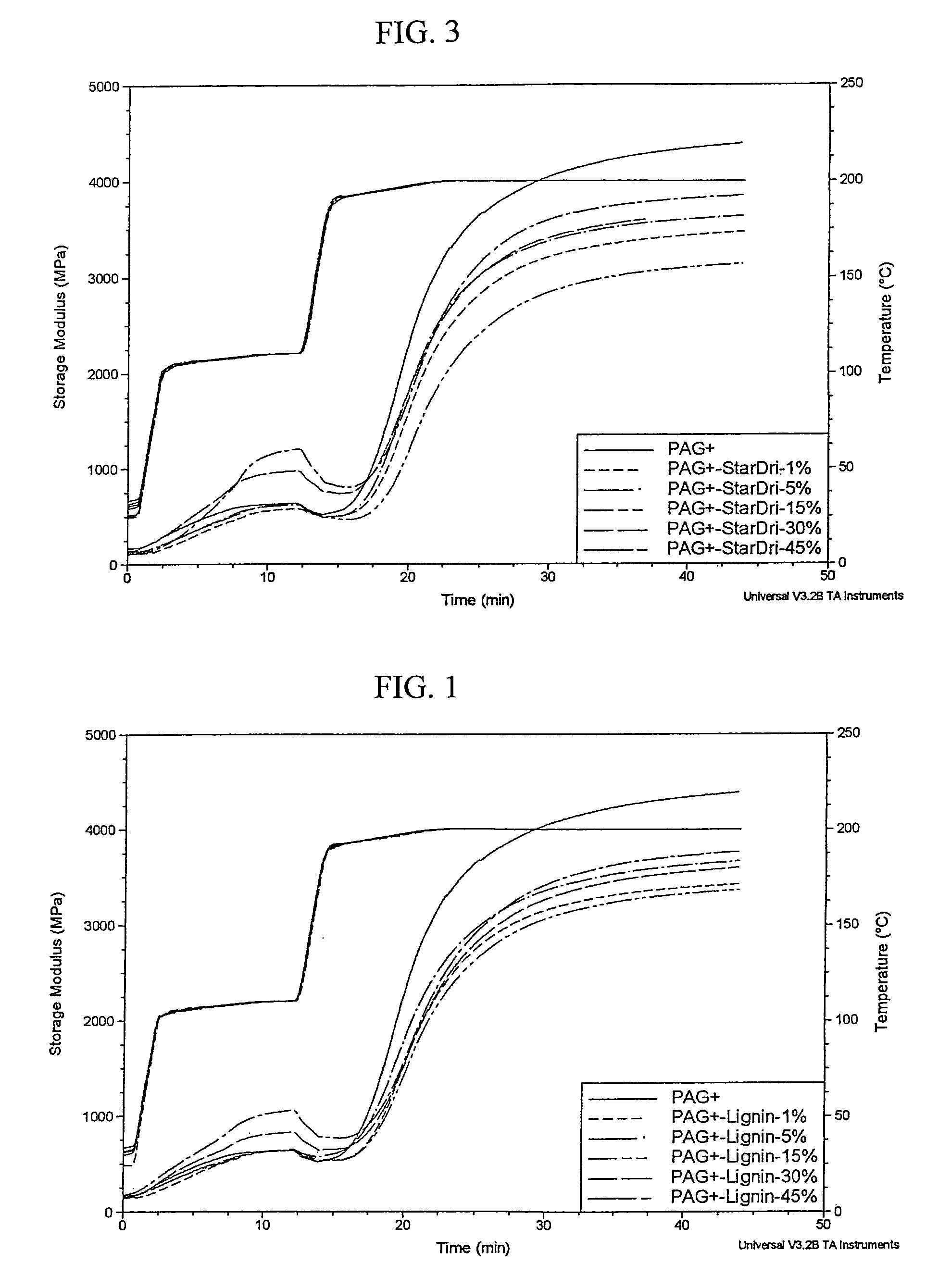

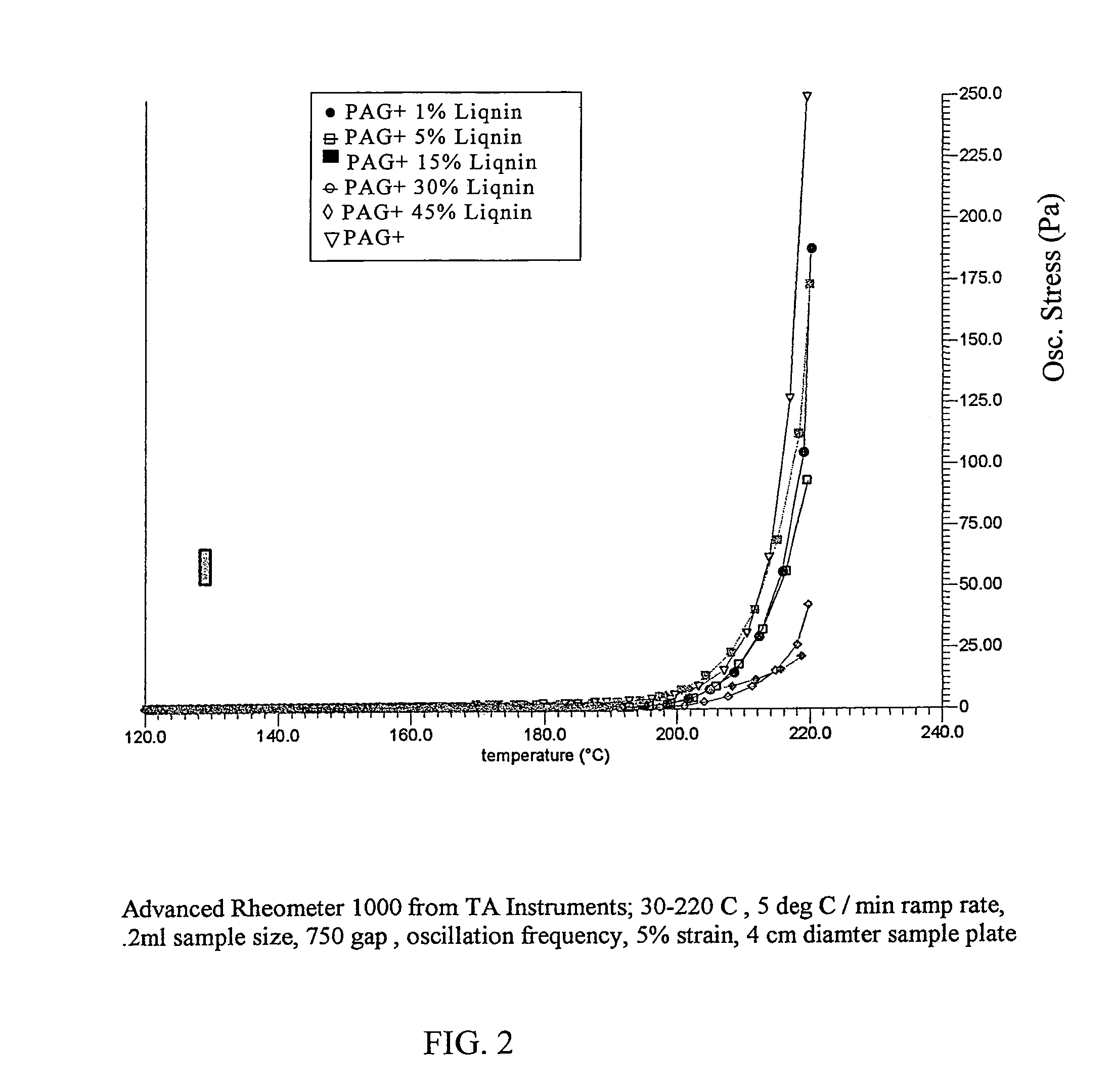

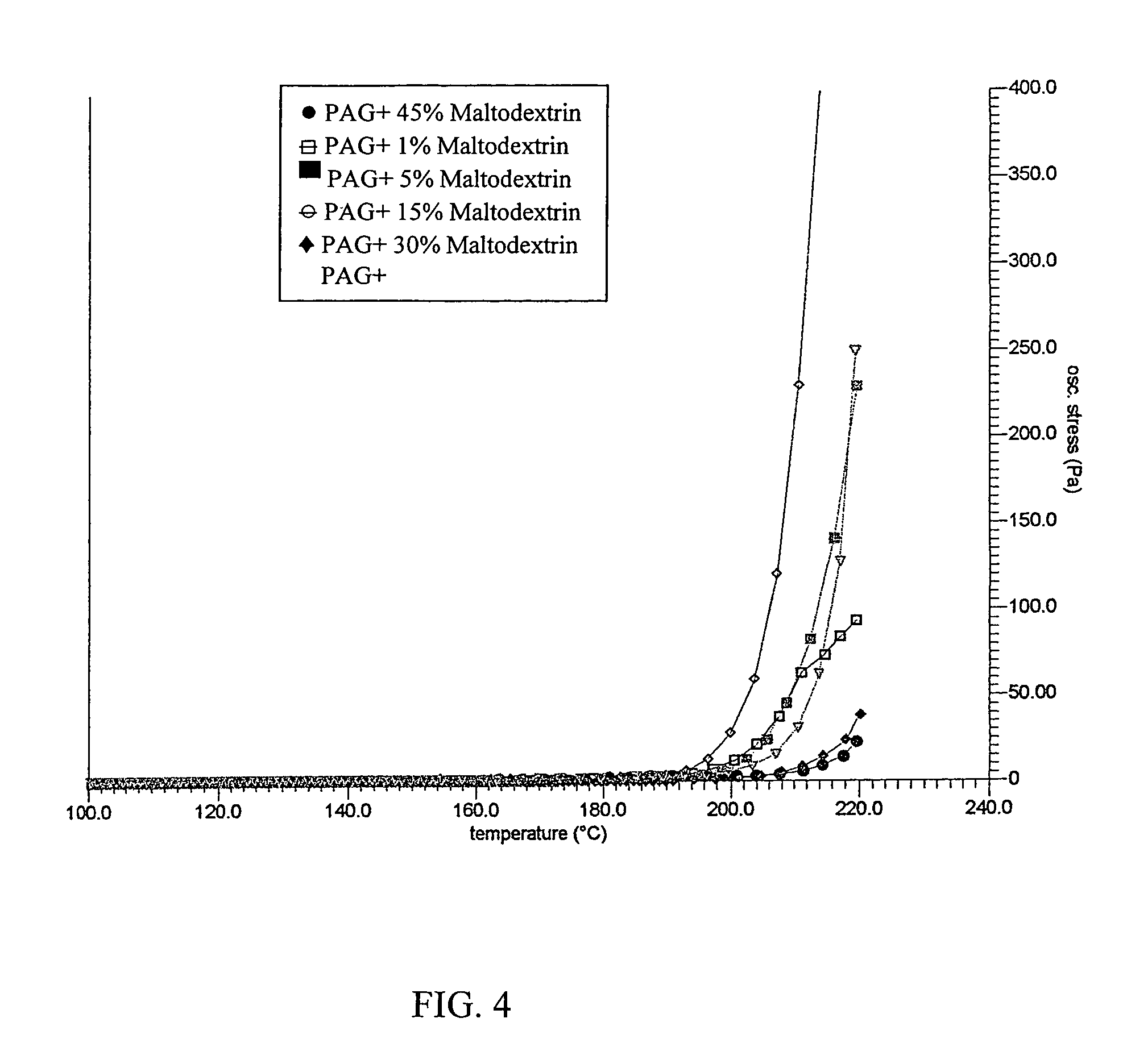

The present invention provides a variety of extended polyacrylic acid based binder compositions comprising a low molecular weight polyacrylic acid (typically hypophosphite or sulfite terminated), a crosslinking agent (such as triethanolamine or glycerol) and one or more water soluble materials, such as lignin, low molecular weight starch and soybean protein. The extended binder composition of the present invention provides a lower cost binder composition without degrading the performance and may be selected to alter one or more characteristics of the basic binder composition such binder wetting, emulsion compatibility, dust suppression and wash water flow properties.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

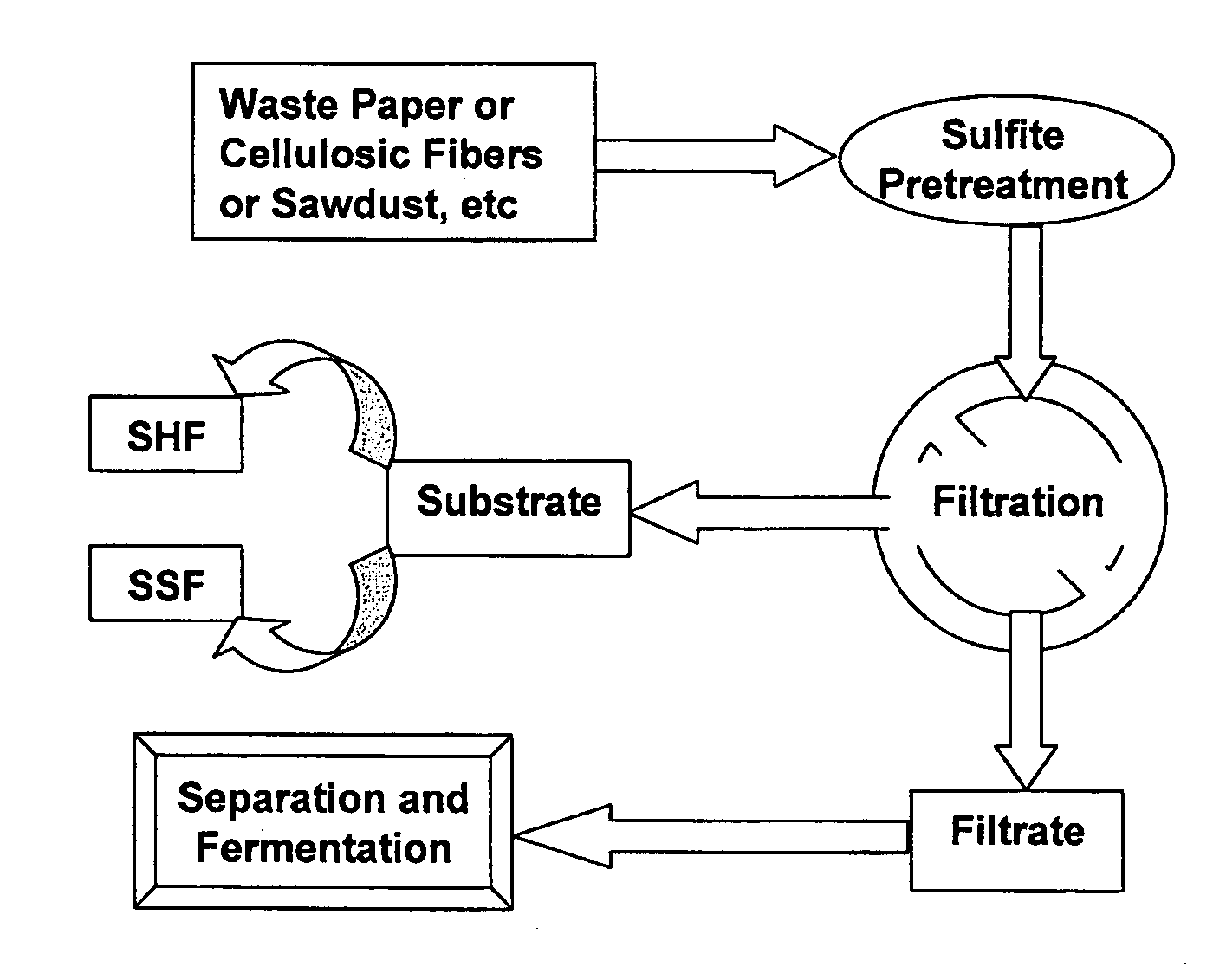

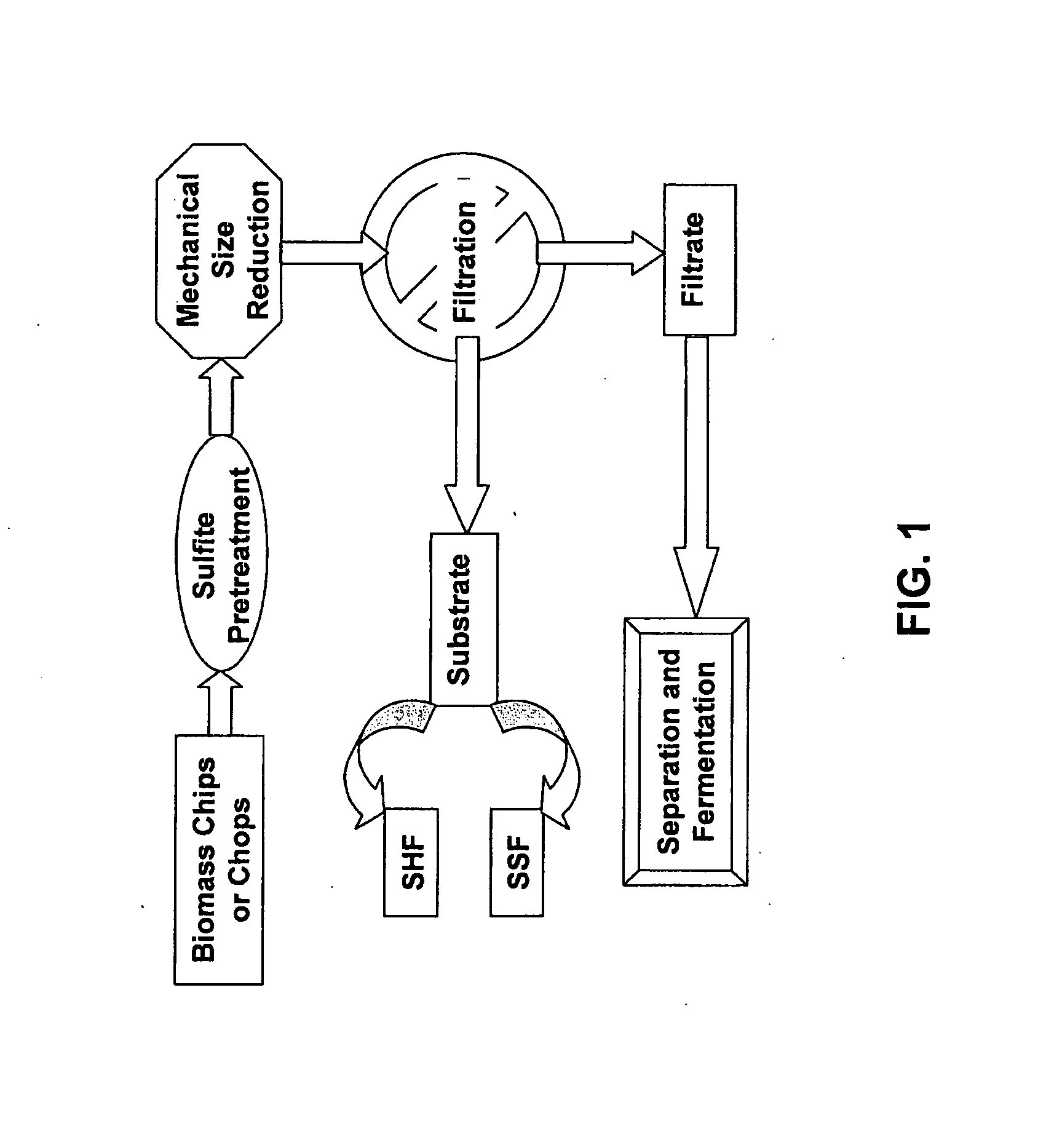

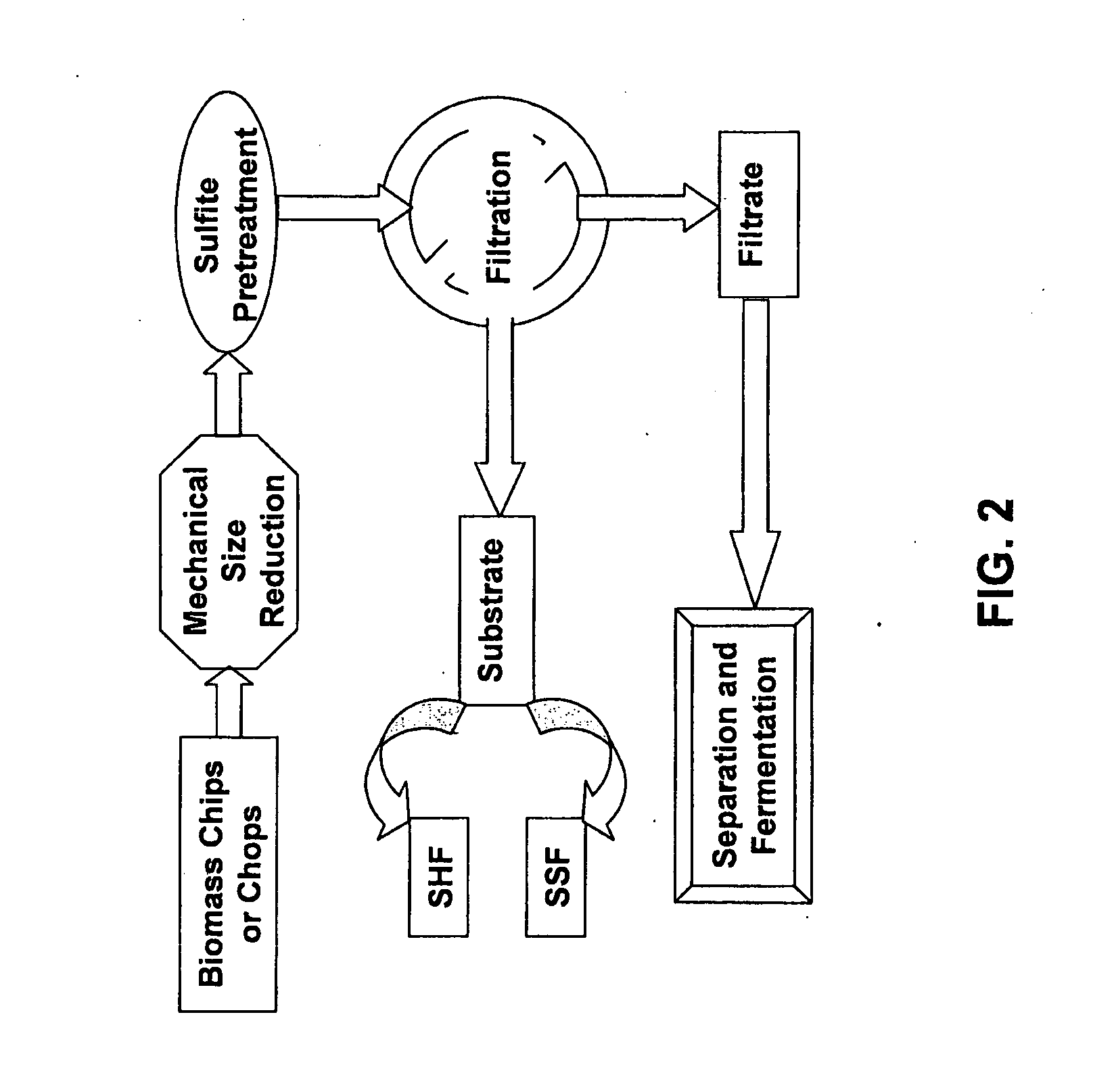

Sulfite Pretreatment For Biorefining Biomass

ActiveUS20090298149A1Save thermal energy consumptionImprove conversion efficiencyBiofuelsPaper recyclingCelluloseSulfite

The present invention relates to a method using sulfite pretreatment to overcome recalcitrance of lignocellulose (SPORL). More specifically, it relates to a sulfite-based chemical process for pretreating biomass in solutions to reduce access barriers of enzymes to the lignocellulose, resulting in efficient conversion through enzymatic saccharification.

Owner:US SEC AGRI +1

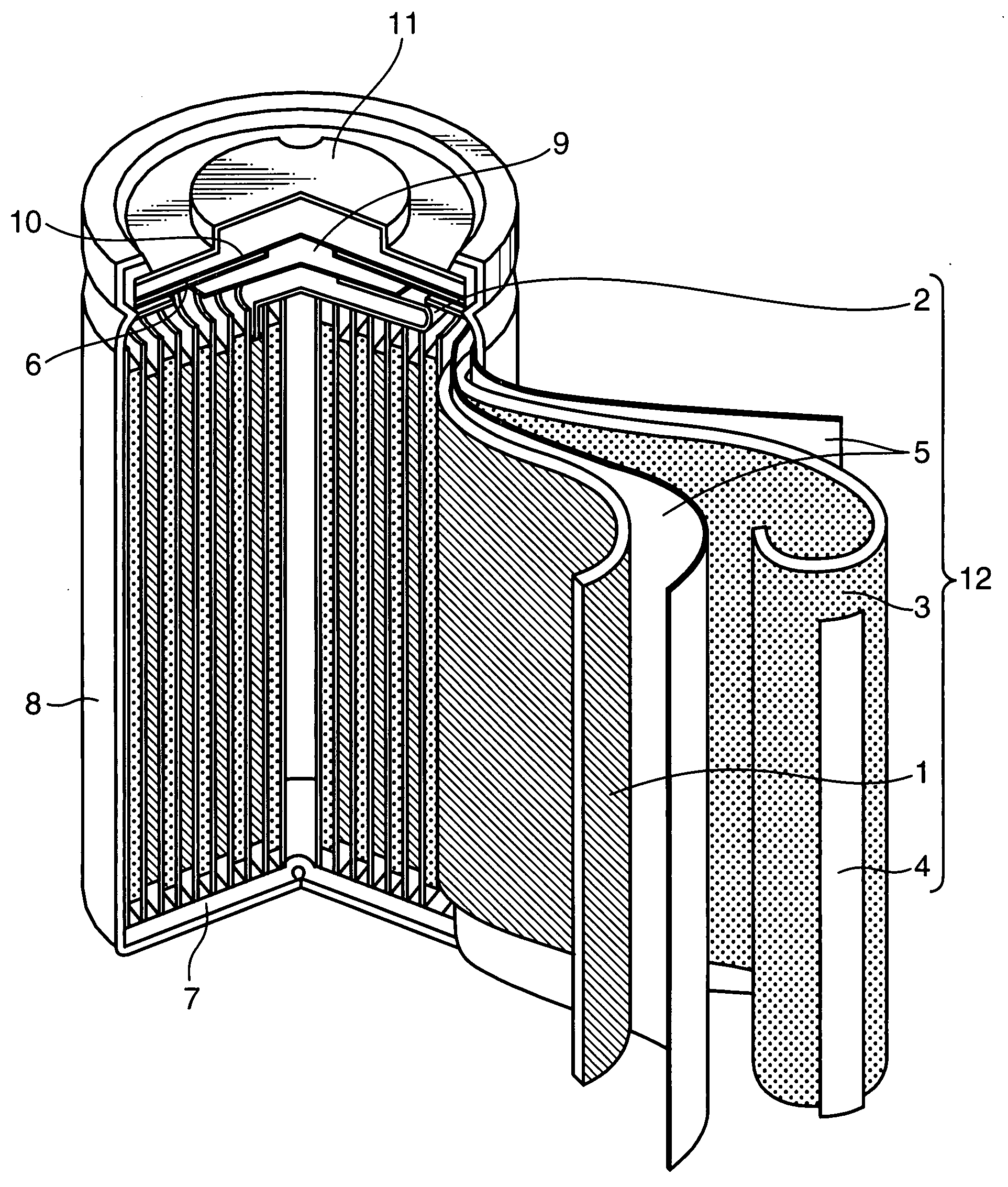

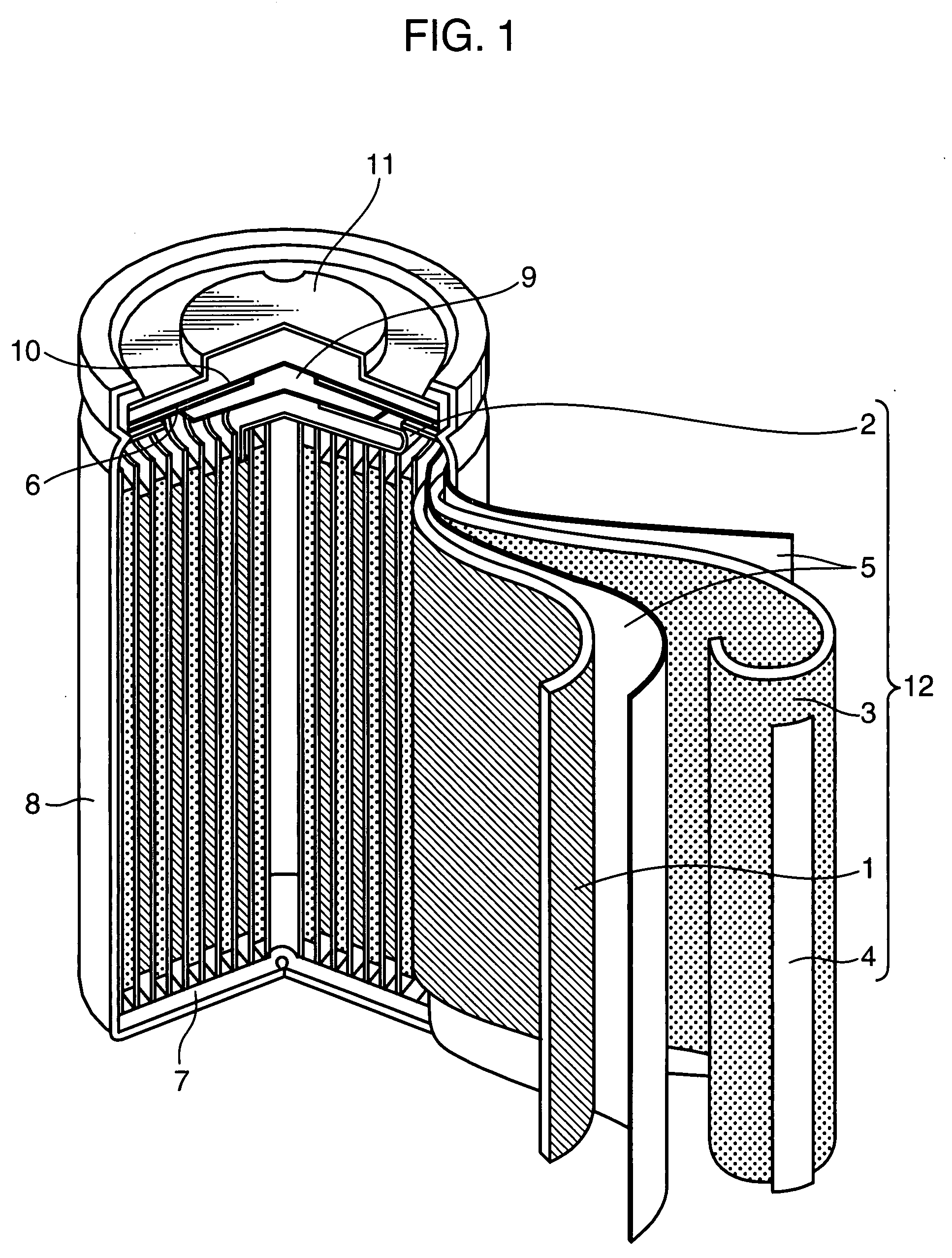

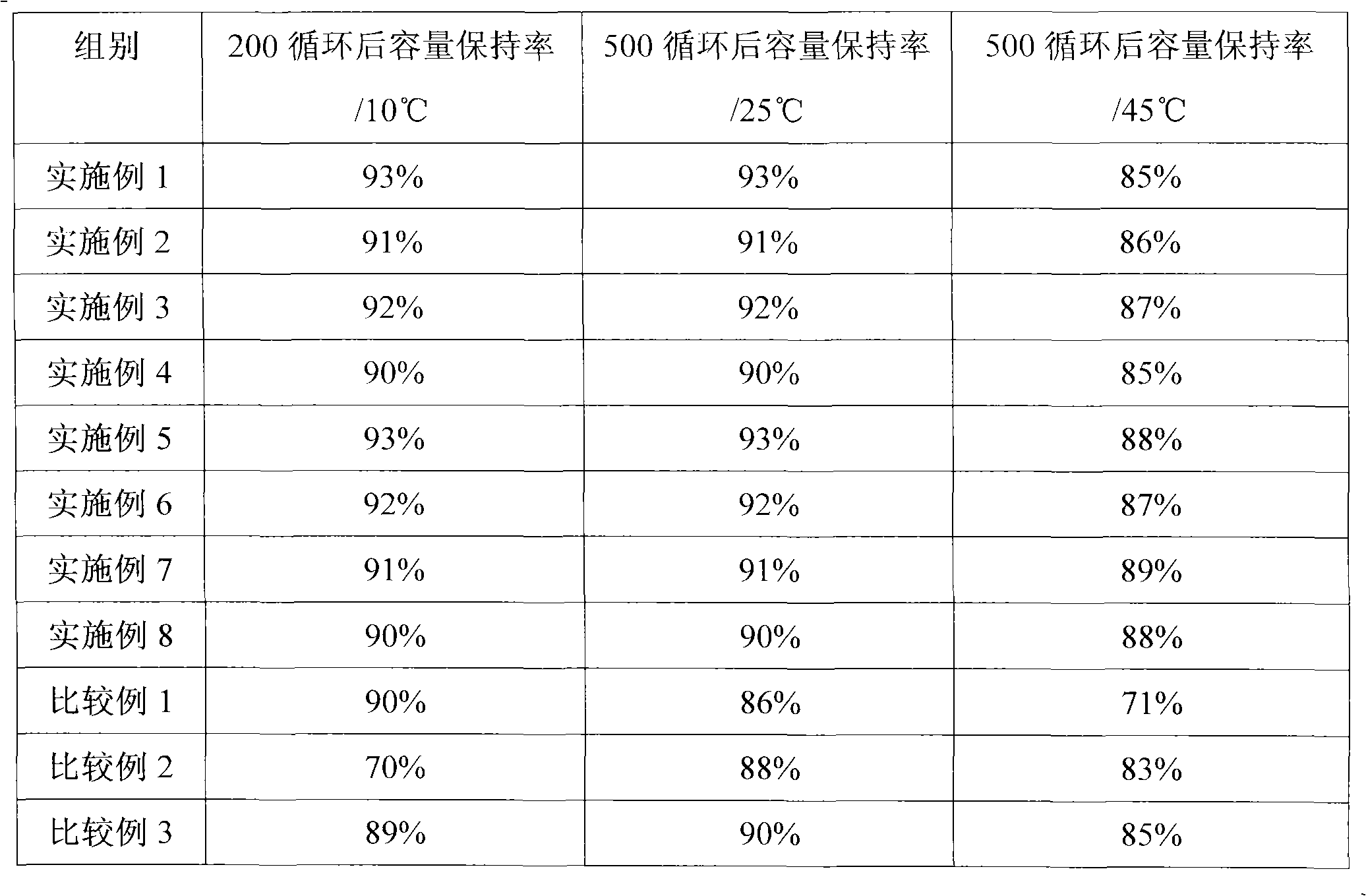

Nonaqueous electrolyte secondary battery and method of producing the same

InactiveUS20090142663A1Increase capacityGood discharge rate characteristicElectrode carriers/collectorsElectrolyte accumulators manufactureSulfitePropane sultone

A nonaqueous electrolyte secondary battery, comprising a positive electrode containing a transition metal-containing composite oxide as a positive electrode active material, a negative electrode containing a negative electrode active material allowing reversible insertion and extraction of lithium, a separator, and a nonaqueous electrolyte solution, wherein the nonaqueous electrolyte solution contains at least one additive (A) selected from the group consisting of ethylene sulfite, propylene sulfite, and propane sultone and at least one additive (B) selected from the group consisting of maleic anhydride, vinylene carbonate, vinylethylene carbonate, and LiBF4; and an end voltage of charge is 4.3 to 4.5 V.

Owner:PANASONIC CORP

Condensation products based on amino-s-triazines and the use thereof

In the proposed condensation product based on amino-s-triazines with at least two amino groups, formaldehyde and sulphite, the molar ratio of amino-s-triazine, formaldehyde and sulphite is 1:2.5-6.0:1.51-2.0 and the formiate content is less than 0.3 wt %. The condensation product is obtained by a) heating amino-s-triazine, formaldehyde and a sulphite in the molar ratio 1:2.5-6.0:1.51-2.0 in an aqueous solution at a temperature of 60-90° C. and a pH level of between 9.0 and 13.0 until the sulphite can no longer be detected; b) continuing the condensation at a pH level of between 3.0 and 6.5 and a temperature of 60-80° C. until the condensation product has a viscosity of 5-50 mm / s at 80° C.; and c) adjusting the pH level of the condensation product to 7.5-12.0 or carrying out thermal secondary treatment at a pH level of >10.0 and a temperature of 60-100° C. The product can be used as an additive for inorganic binders such as cement.

Owner:SKW POLYMERS GMBH

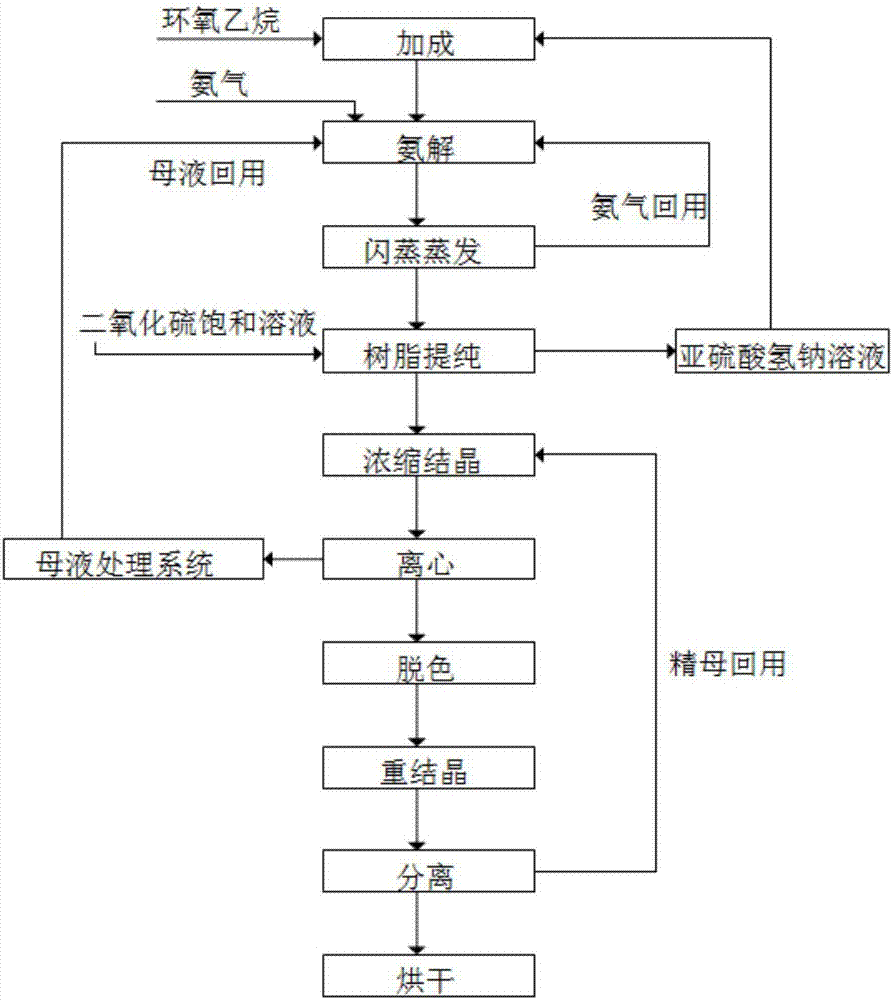

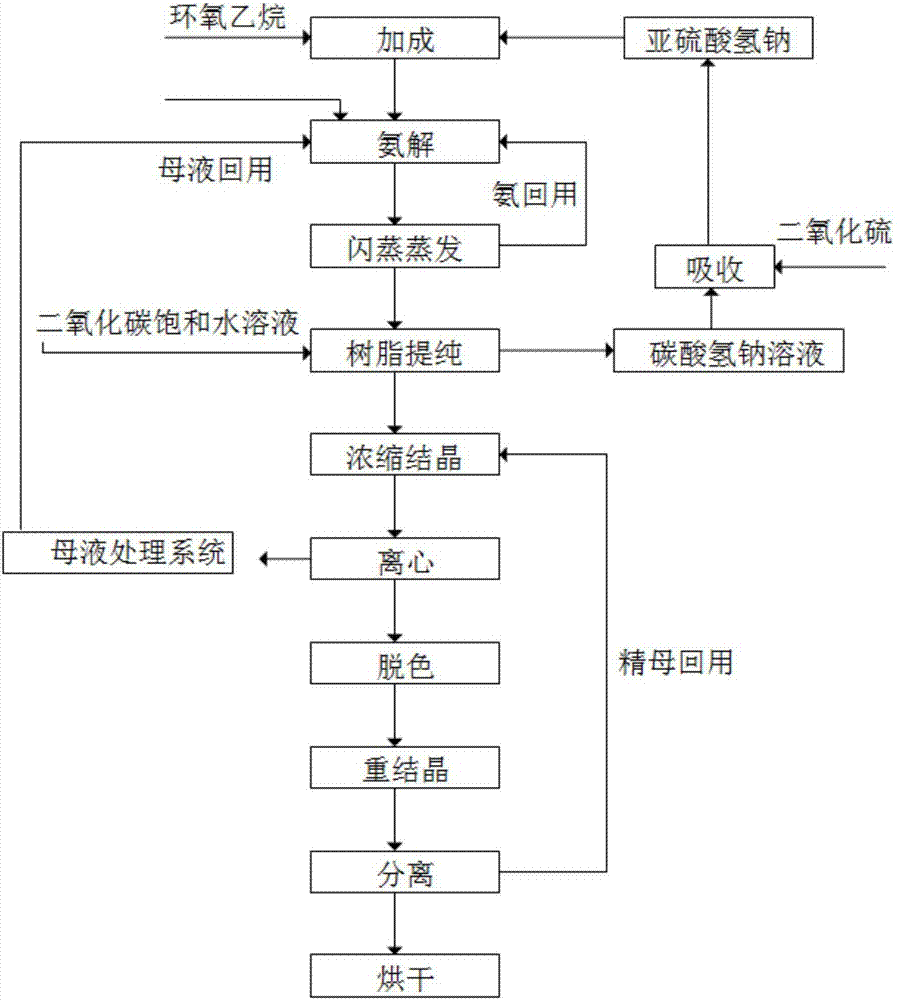

Method for cyclically producing taurine at high yield

ActiveCN107056659AReduce productionEfficient recyclingPhysical/chemical process catalystsOrganic compound preparationAfter treatmentHydrogen

The invention relates to a method for cyclically producing taurine at a high yield. The method includes the following steps that S1, ethylene oxide reacts with a sodium hydrogen sulfite solution to generate sodium hydroxyethyl sulfonate; S2, sodium hydroxyethyl sulfonate obtained in S1 is subjected to an ammonolysis reaction in ammonium hydroxide, flashing is carried out after the reaction is completed, and ammonia gas is recycled; S3, taurine-containing feed liquid of reaction liquid obtained after flashing in S2 is collected through an acid cation exchange resin column, the resin column is regenerated with a sulfur dioxide or carbon dioxide water solution after being inactivated, and eluant obtained during regeneration can be directly reused or reused after being treated with sulfur dioxide; S4, the feed liquid collected in S3 is subjected to after-treatment, and taurine is obtained. The method has the advantages that the generation amount of waste liquid in the whole process is small, part of substances are effectively and cyclically utilized in the process, the cost is reduced, the yield of taurine can reach 90% or above, meanwhile, the production process is relatively simple, and large-scale production is easy.

Owner:QIANGJIANG YONGAN PHARMA

Tobacco Raw Material

InactiveUS20170112183A1Enhanced smell and tasteTobacco preparationTobacco treatmentBiotechnologySulfite

Bleached tobacco raw material comprising less than about 4 weight-% fermentable carbohydrates, calculated on the dry total weight of the bleached tobacco raw material. Smoking tobacco composition comprising the bleached tobacco raw material. Smokeless tobacco composition comprising the bleached tobacco raw material. Nasal snuff comprising the smokeless tobacco composition. Oral smokeless tobacco product comprising the smokeless tobacco composition. A process for production of bleached tobacco raw material comprising: (a) treating tobacco raw material at acidic pH at about 70° C. to about 180° C. with sulfite ion; (b) defibrating the tobacco raw; and (c) treating the defibrated material with a bleaching agent at about 60° C. to about 90° C. Bleached tobacco raw material for use in the treatment of nicotine addiction.

Owner:WINNINGTON AB

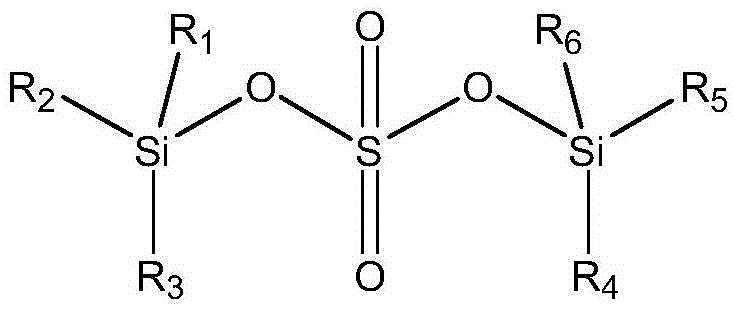

Power battery and lithium ion electrolyte thereof

InactiveCN104600362AImprove low temperature discharge performancePromote circulationSecondary cellsSilanesKetone solvents

The invention provides a power battery and a lithium ion electrolyte thereof. The lithium ion electrolyte comprises a non-aqueous organic solvent, lithium salt and an additive, wherein the additive comprises a first additive and a second additive, and the first additive comprises silane sulfate; the first additive accounts for 0.05 to 10% of the total weight of the electrolyte, and the second additive is an auxiliary additive and comprises one or more of vinylene carbonate, propane sultone, fluoroethylene carbonate, vinyl ethylene carbonate, ethylene sulfite, adiponitrile, and succinic anhydride in any proportion; the second additive accounts for 0.1-5wt% of the total weight of the electrolyte, and the non-aqueous organic solvent is a carbonic ester solvent, a carboxylic ester solvent, an ether solvent or a ketone solvent; and the lithium salt comprises primary lithium salt and secondary lithium salt.

Owner:SHENZHEN 3SUN ELECTRONICS

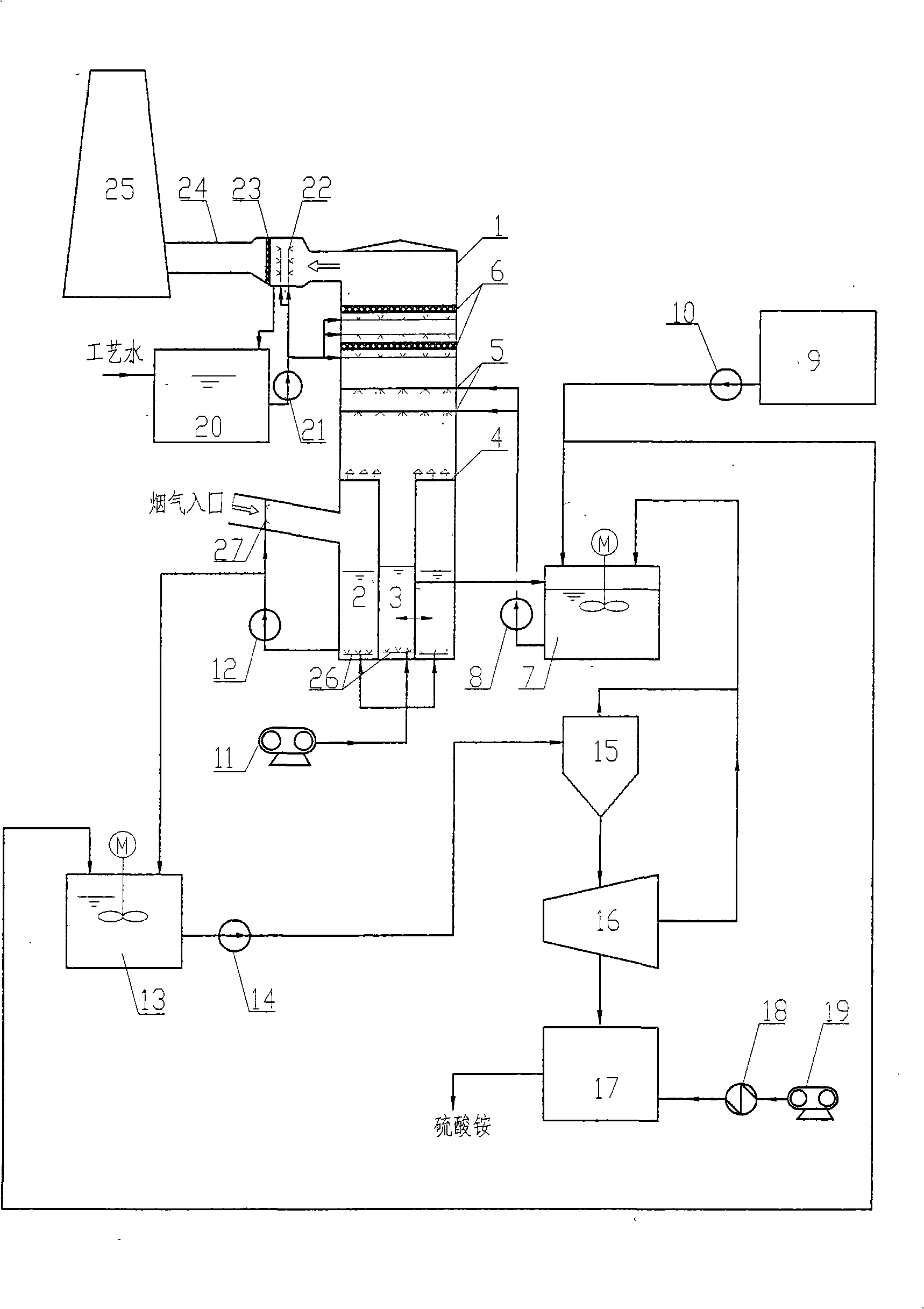

Water-solubility membrane

This invention provides a water-soluble film, which is a polyvinyl alcohol film containing a polyvinyl alcohol resin (A), has a time of dissolution in water of 20 C of not more than 60 sec in terms of a film thickness of 76 [mu]m and has a film b value of not more than 0.5 and, after standing at 80 C for 72 hr, a film b value of not more than 1.0, preferably a water-soluble film comprising a polyvinyl alcohol resin (A), at least two plasticizers (B), and a bisulfite (C), the content of the plasticizer (B) based on 100 parts by weight of the polyvinyl alcohol resin (A) being 5 to 50 parts by weight based on 100 parts by weight of the polyvinyl alcohol resin (A), the content ratio of the bisulfite (C) to the plasticizer (B) (C / B: weight ratio) being more than 0.02 and not more than 0.35. The water-soluble film composed mainly of PVA resin is less likely to cause coloration at the time of film formation and coloration with the elapse of time even upon contact with a chemical.

Owner:MITSUBISHI CHEM CORP

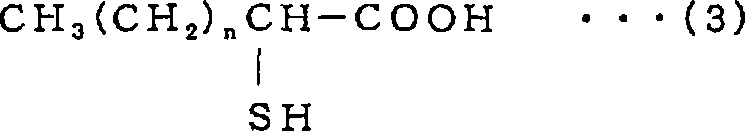

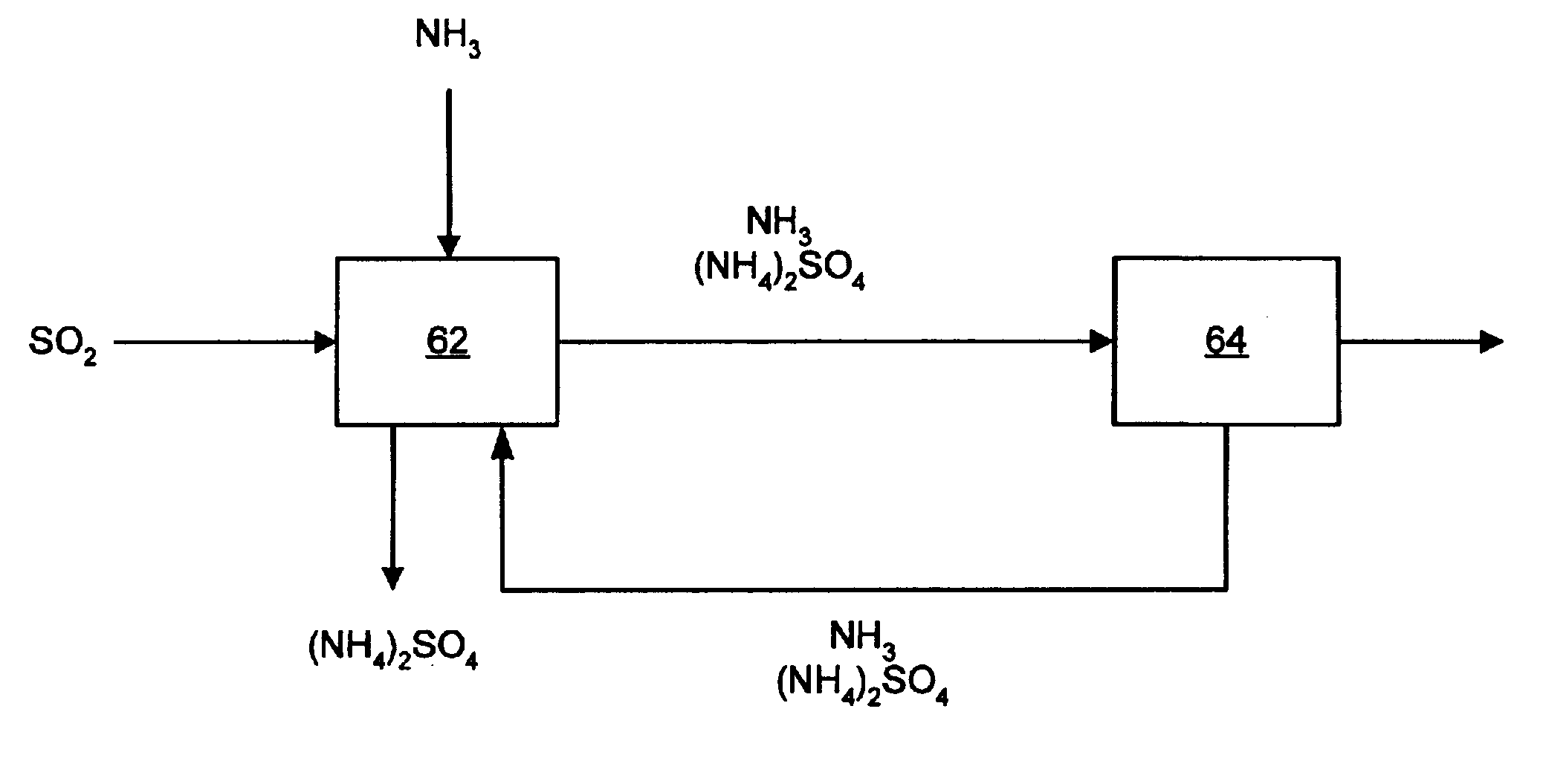

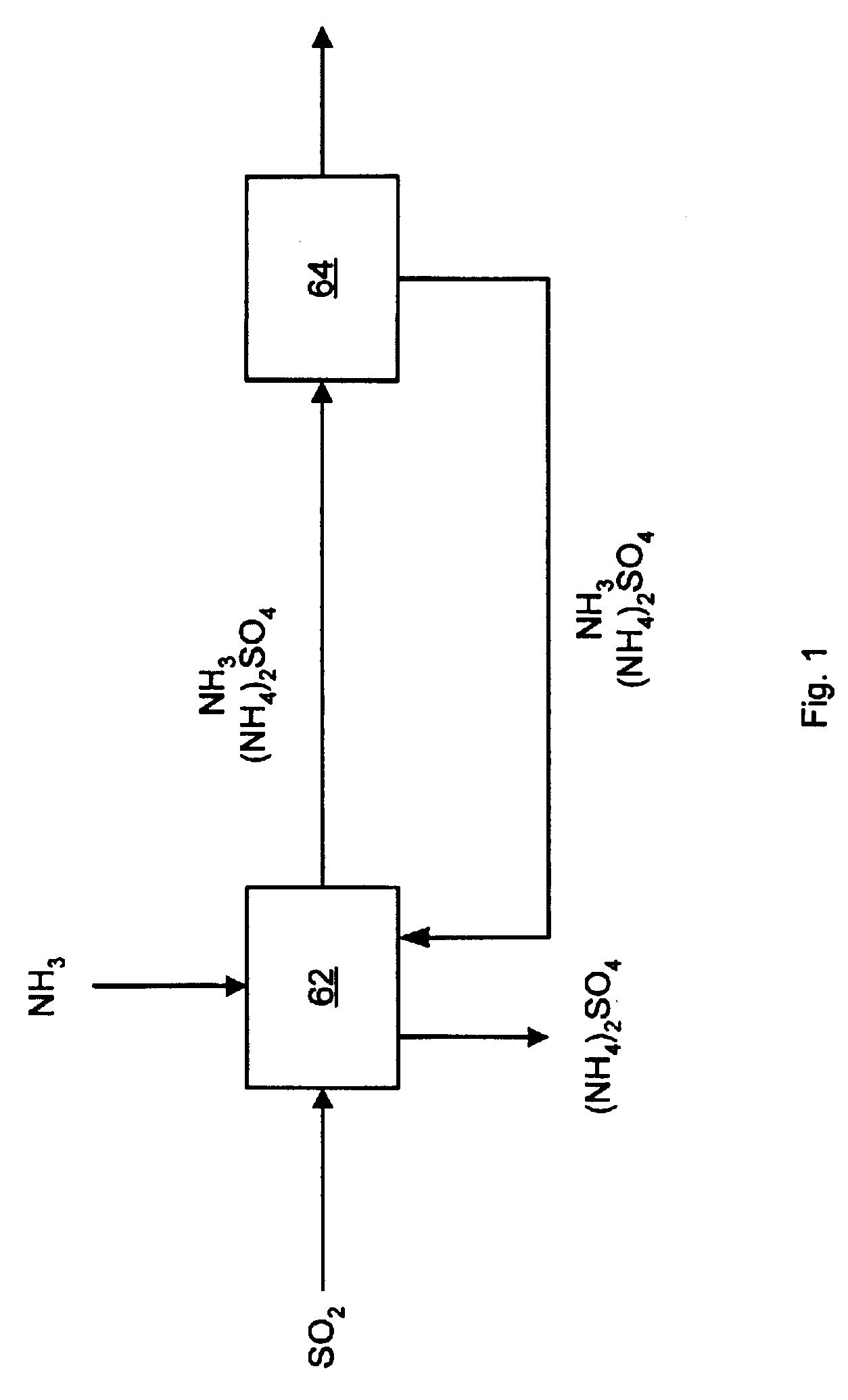

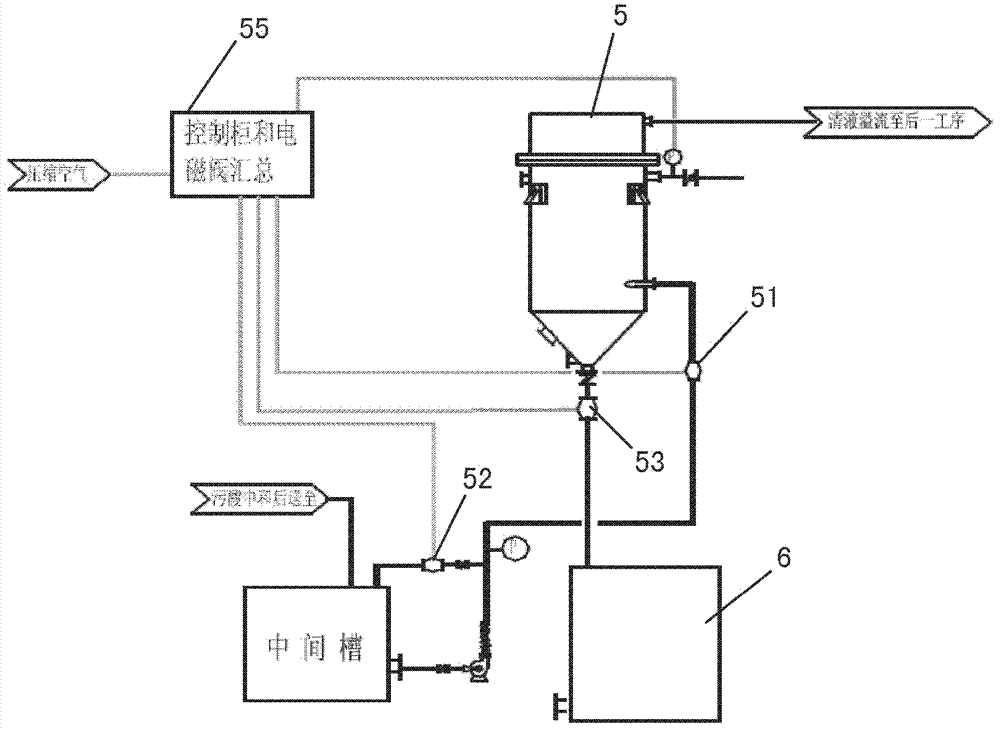

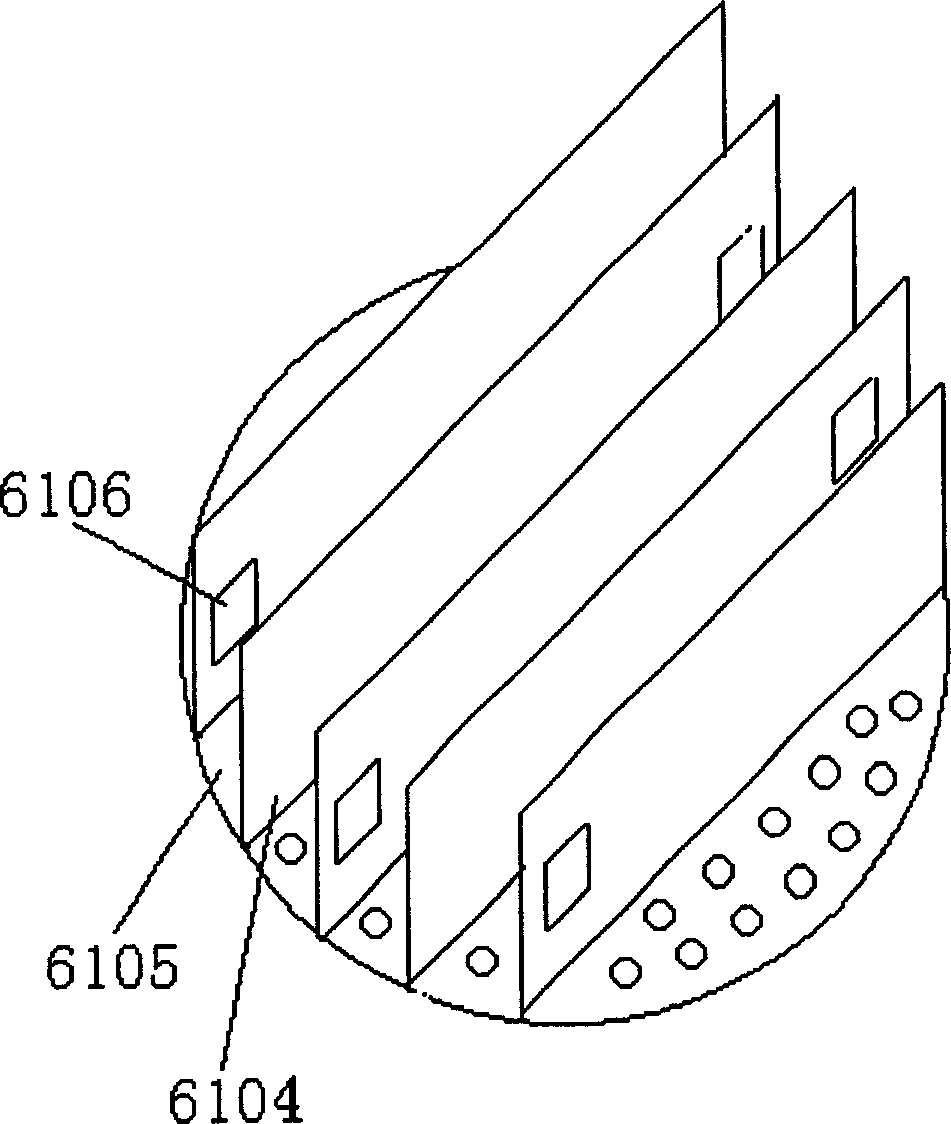

Segment-based ammonia flue gas desulfurization process and device thereof

InactiveCN101524620AHigh economic valueLow ammonia content in outlet flue gasDispersed particle separationProcess systemsPollution

A segment-based ammonia flue gas desulfurization process and a device thereof combine traditional absorption towers with a crystallization tower. A regeneration tank is arranged at the outside of the tower. The processes of absorption of SO2, sulfite oxidation, regeneration of desulfurization solution, crystallization of ammonium sulphate and ammonia volatilization are carried out respectively. The process system effectively improves the removal rate of SO2, improves the oxidation of the sulfite, strengthens the crystallization of the ammonium sulphate and reduces the escape of ammonia in outlet smoke. The standard discharge of the smoke can be realized after the smoke is processed by the system. The removal rate of SO2 is above 95 percent. The whole system process is simple and has no secondary pollution. And the by-product ammonium sulphate has high economic value and can be especially configured by enterprises with fixed ammonium sources.

Owner:山西晋丰节能环保工程设计有限公司 +1

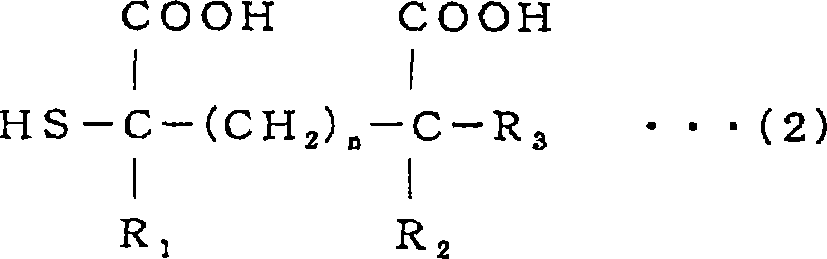

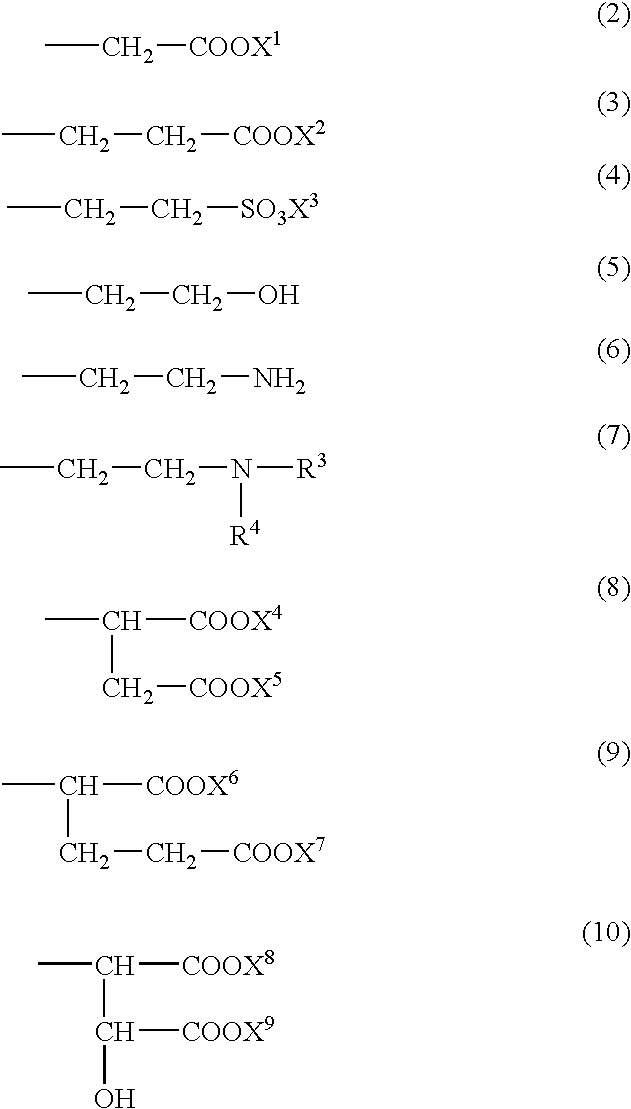

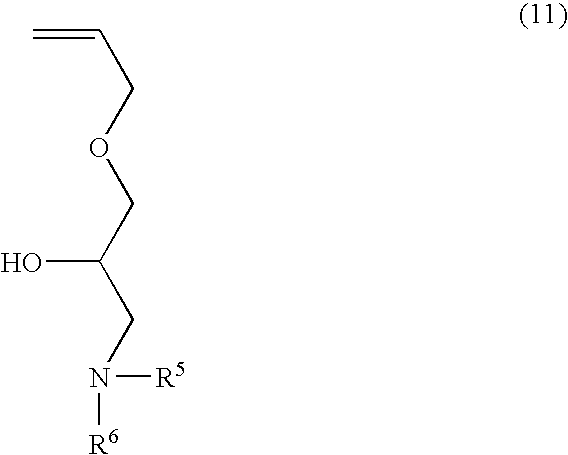

Amino Group-Containing Water-Soluble Copolymer

ActiveUS20080262192A1Improve quality performanceGood dispersionTransportation and packagingFibre treatmentSulfiteWater soluble

Owner:NIPPON SHOKUBAI CO LTD

Sulfur dioxide removal using ammonia

InactiveUS6605263B2Small sizeImprove efficiencyCombination devicesAmmonium sulfatesCorrosion resistant alloySulfite

Owner:POWERSPAN CORP

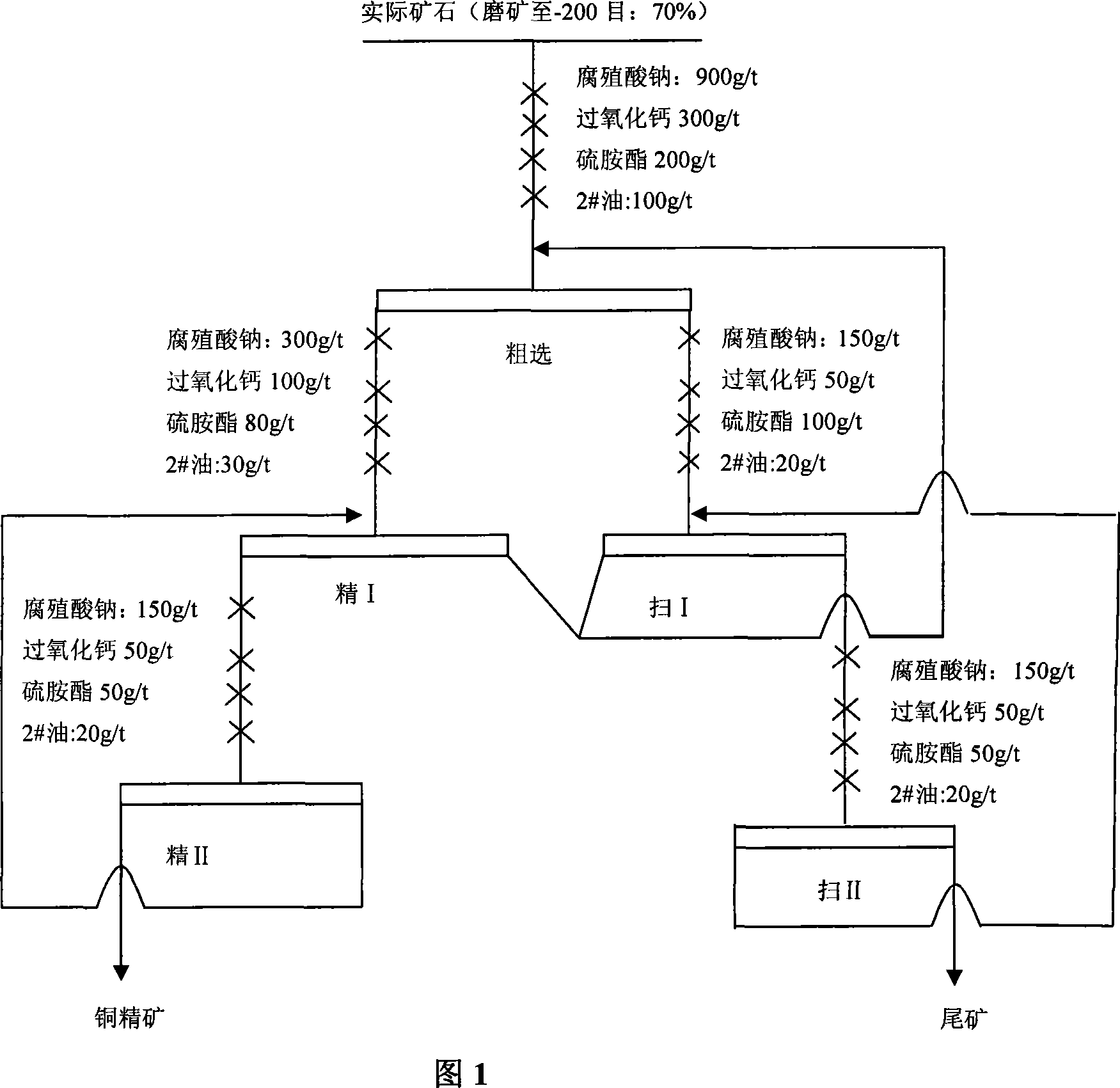

Highly effective composite restrainer of ferro-sulphur ore in complex vulcanizing ore and method of use thereof

The invention relates to a high-efficient combined inhabitor for pyrite in complex sulfide ores and the application method of the inhabitor. The inhabitor comprises calcium superoxide and HA-Na. The inhabitor of the invention can inhibit complex vulcanized iron-bearing minerals selectively, has better inhibition properties for magnetic pyrite, pyrite and arsonopyrite, and is an inhabitor of high selectivity. Compared with the prior inhibitors such as lime, cyanide, bichrome, potassium permanganate, sodium sulfide, sulphite, zinc sulphate and trisodium phosphate, the invention has the advantages of lower use level, good effects, no pollution, and other advantages.

Owner:CENT SOUTH UNIV

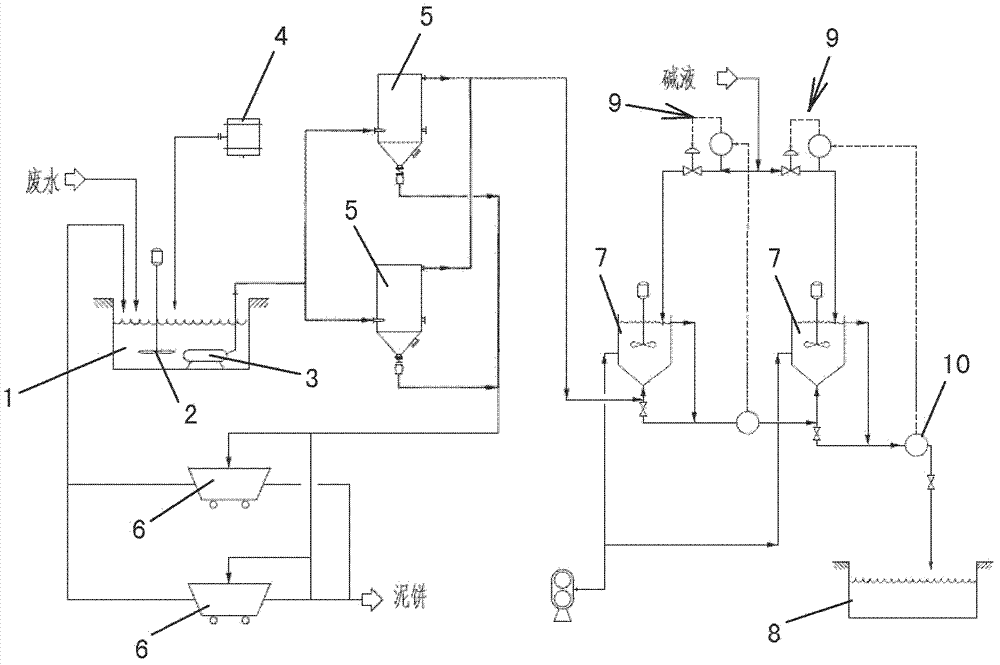

Catalytic cracking fume desulfuration wastewater treatment process

ActiveCN102815808AImprove effluent qualityEasy to operateMultistage water/sewage treatmentParticulatesChemical oxygen demand

A catalytic cracking fume desulfuration wastewater treatment process is characterized in that wastewater is discharged to a slurry pool and is mixed with a flocculating agent, a stirrer is used for stirring the wastewater and the flocculating agent, the wastewater and the flocculating agent are mixed evenly, the wastewater after being mixed is discharged to an expansion tube type filter and is subjected to the coagulation reaction at the lower end of the expansion tube type filter, small particulate matters in the wastewater are flocculated, large flocculating bodies are formed, the solid-liquid separation is achieved through the filtration of a filtering film, thick slag and supernatant fluid are obtained, the supernatant fluid is discharged to an oxidation tank further, the thick slag is subjected to back washing and enters a subsequent filtering box, the thick slag is concentrated and dewatered in the filtering box, mud cakes which are concentrated are transported outwards, the water of dehydration returns to the slurry pool again, is mixed with the wastewater and is processed again, the false chemical oxygen demand (COD) which contains sulfite and bisulfite is oxidized and removed by the supernatant fluid in the oxidation tank, and the sewage which meets standards is discharged. Compared with the prior art, the process has the advantages that the area occupied by devices is small, the operation cost is low, the solid and the liquid can be separated completely, the working environment of workers is good, device parameters can be set in accordance with parameters of different materials, and the application is wide.

Owner:CHINA PETROLEUM & CHEM CORP +3

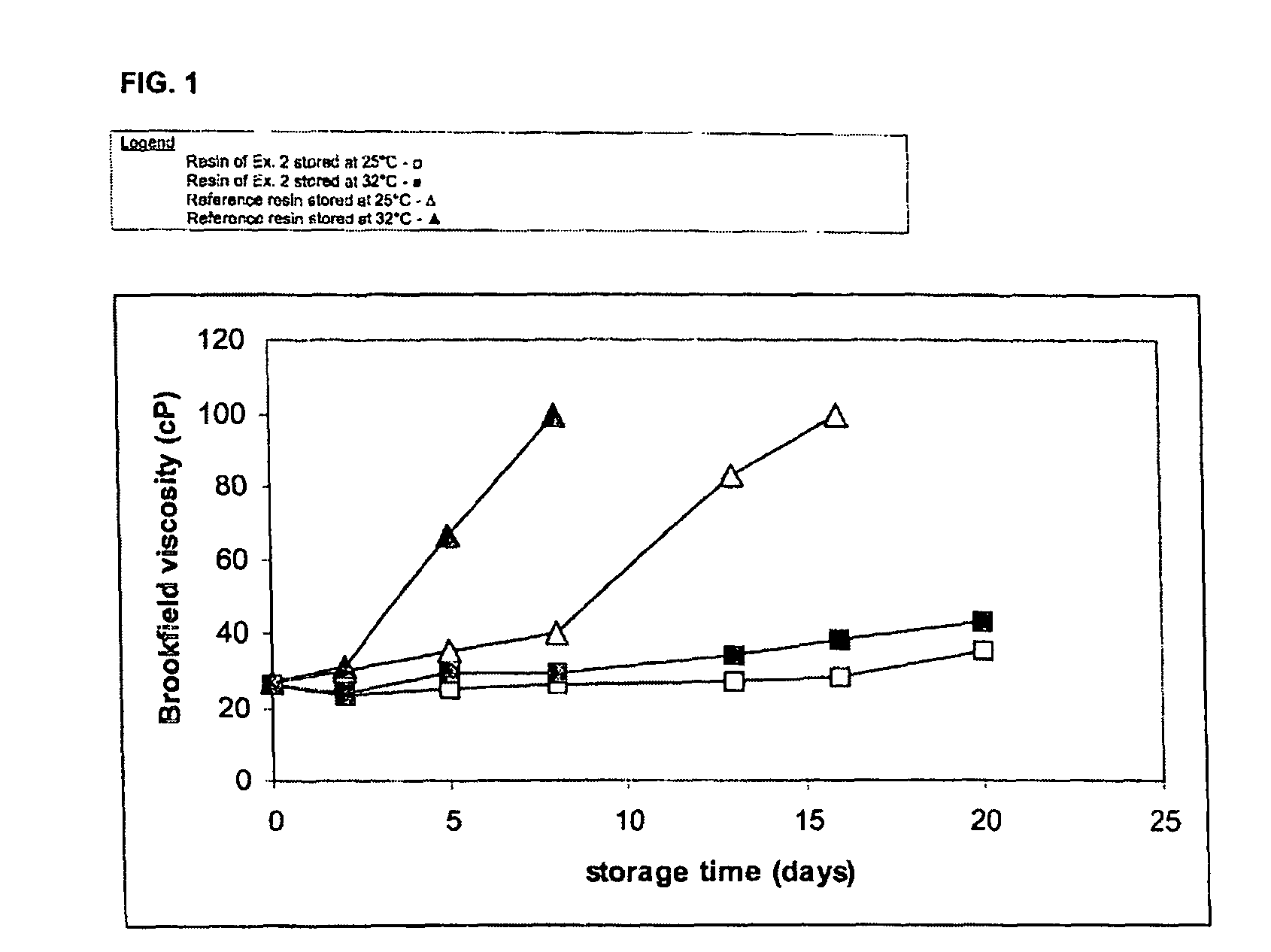

Reactive cationic resins for use as dry and wet strength agents in sulfite ion-containing papermaking systems

This invention relates to resins useful for imparting strength to paper, the process of incorporating these resins into paper and the paper produced containing the resins. In particular the invention relates to resins useful for imparting dry-strength and wet-strength to paper under conditions of high sulfite ion concentrations.

Owner:SOLENIS TECH CAYMAN

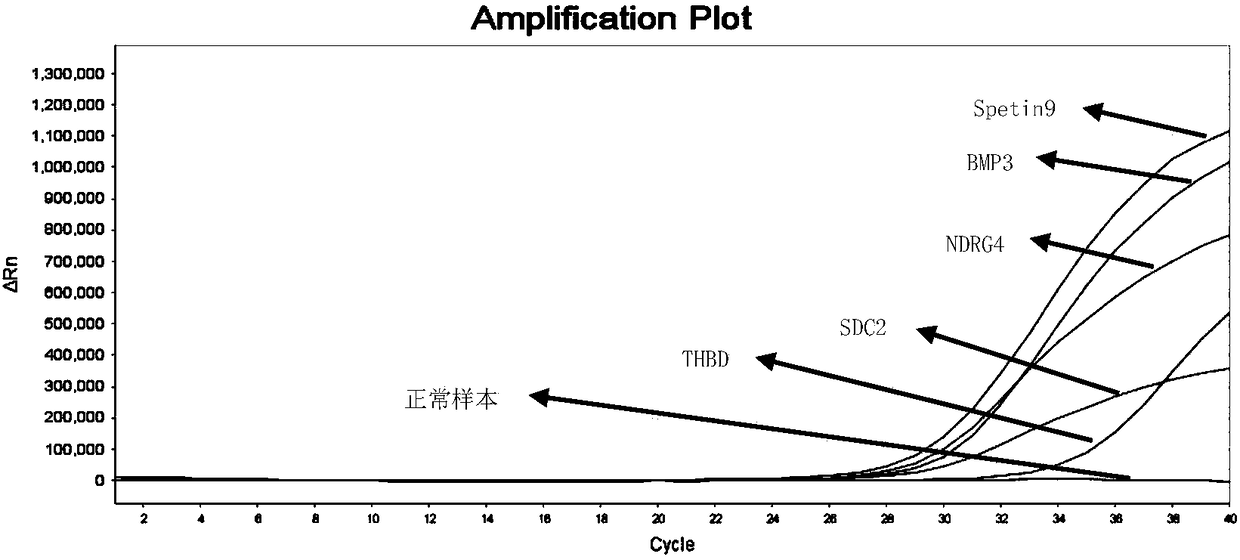

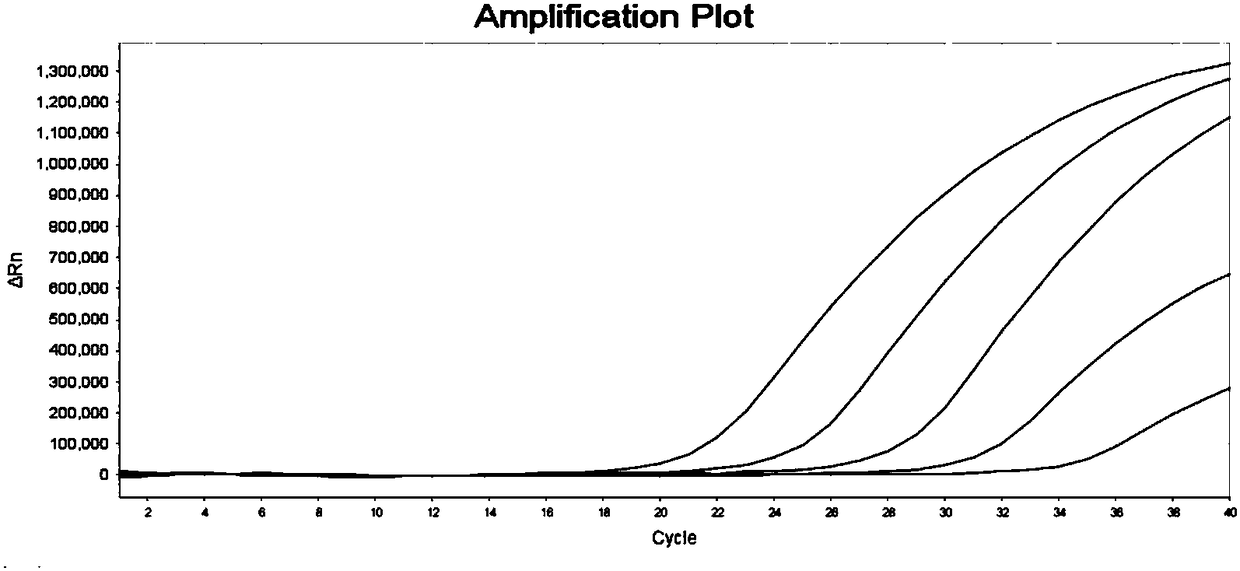

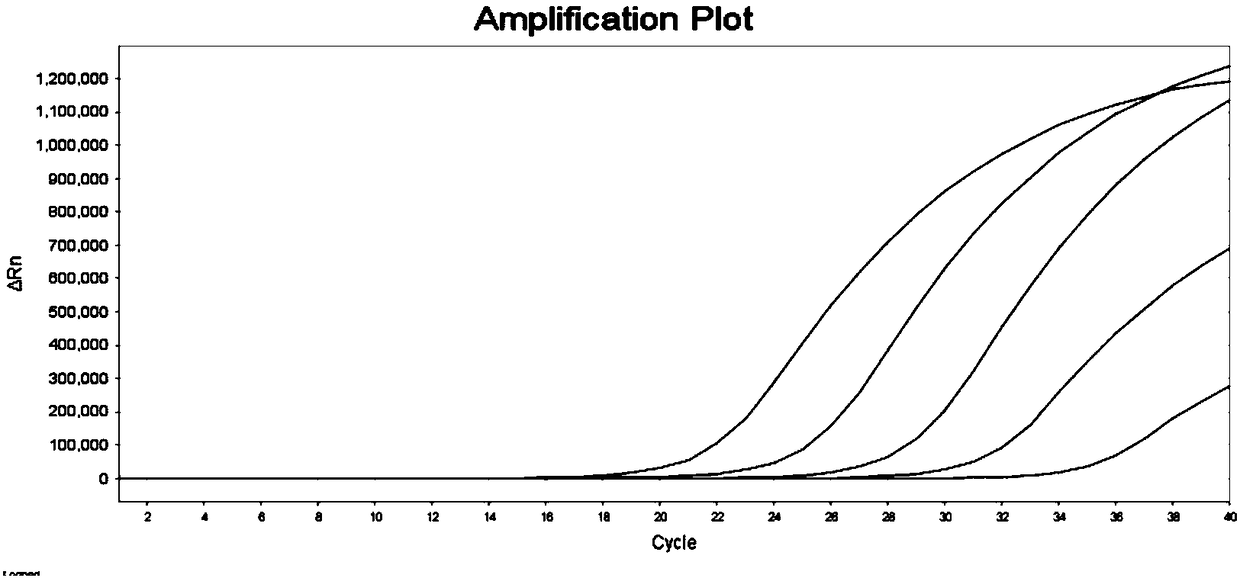

Primer pair, probe and kit used for noninvasive polygene methylation combination detection for early stage colorectal cancer and applications thereof

ActiveCN108103195AEasy to sampleSampling non-invasiveMicrobiological testing/measurementDNA/RNA fragmentationDNA methylationFluorescence

The invention relates to a primer pair and a probe used for noninvasive polygene methylation combination detection for early stage colorectal cancer, and includes the primer pair and the probe used for detecting methylation of genes Spetin9, NDRG4, BMP3, THBD and SDC2 and the primer pair and the probe for internal reference ACTB; the sequences of the primer pair and the probe are represented as the SEQ ID No.1 to the SEQ ID No.18. The invention also provides a kit containing the primer pair and the probe and applications thereof. The application method includes free DNA extraction from a plasma specimen, sulfite conversion, PCR amplification reaction, fluorescent signal detection and result determination. The kit and the method are suitable for methylation detection of the five genes Spetin9, THBD, SDC2, NDRG4 and BMP3 in human peripheral blood; compared with a conventional colorectal cancer diagnosis method, the application method fully utilizes the free DNA extraction from a plasma specimen, the DNA methylation and QPCR associated technologies, thus developing the kit having high sensitivity and specificity. The primer pair, probe and kit are used for performing early stage noninvasive screening to human colorectal cancer.

Owner:上海酷乐生物科技有限公司

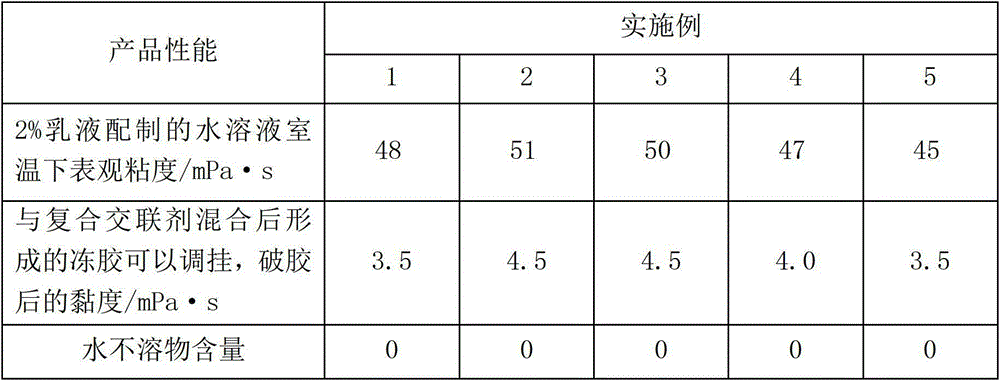

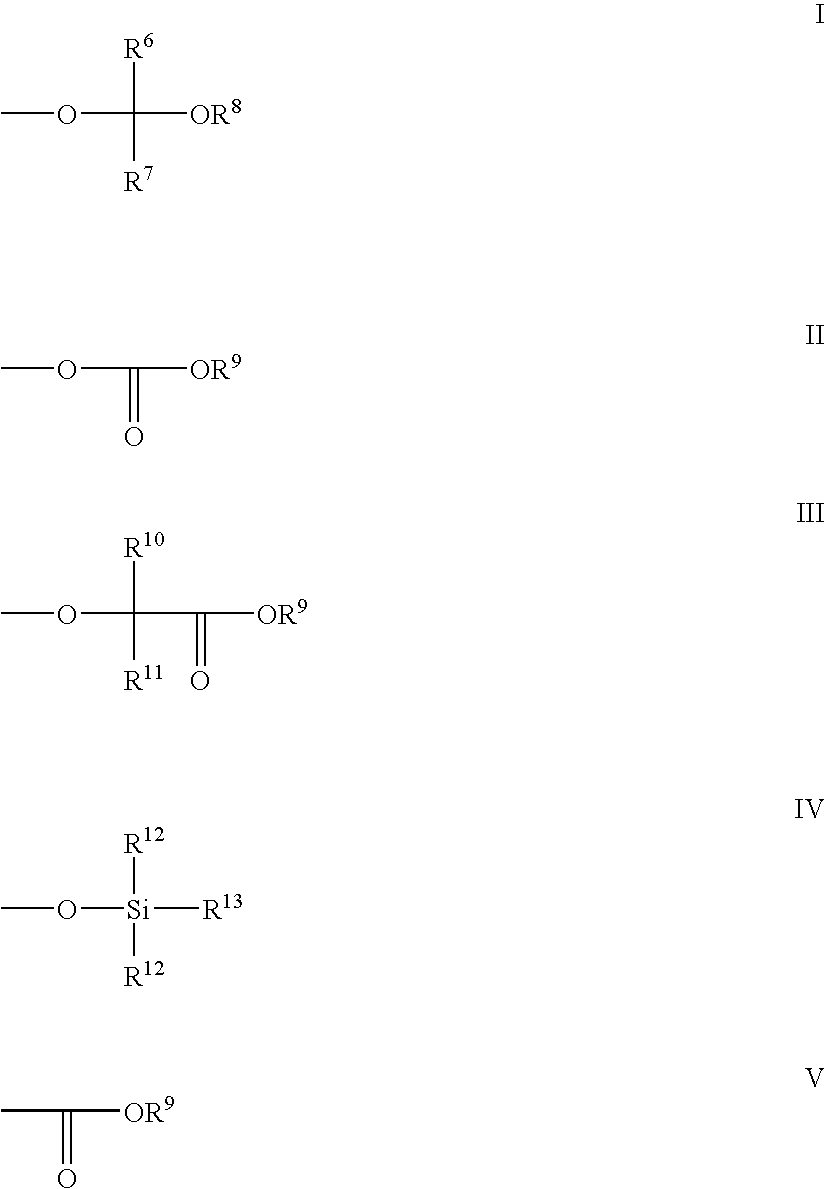

Inverse emulsion polymer thickener for fracturing fluid and preparation method thereof

ActiveCN103146372AAvoid harmMeet the fracturing constructionDrilling compositionPolymer sciencePersulfate

The invention relates to an inverse emulsion polymer thickener for a fracturing fluid and a preparation method thereof. The thickener is polymerized by water, 2-acrylamidyl-2-methyl sodium proparesulfonic acid liquid with mass fraction of 50%, alkyl acrylamide, acrylamide, a cationic monomer, N, N-methylene bisacrylamide, a tween-80 emulsifier, ethylene diamine tetraacetic acid disodium salt, 30% sodium hydroxide, white oil, acrylic ester, a span-80 emulsifier, sulfite, a peroxysulphate initiator, a water-soluble azo initiator and OP-15. According to the invention, raw materials are industrial products, and purification is not needed before reaction; polymerization is initiated by initiators by adding a complexing agent, and the preparation process is simple; the thickener provided by the invention is fast in dispersing, easy to prepare, free from pollution and harm, small in use level and good in stability, in particular resists high temperature of 220 DEG C, and is suitable for fracturing a high-temperature stratum; and the thickener is higher in shear resistance, can meet the fracturing construction of high flow, has high sand carrying performance, and is free from residue and is not harmful to the reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrofluoroalkanesulfonic acids from fluorovinyl ethers

InactiveUS20060276670A1Organic compound preparationSulfonic acids salts preparationVinyl etherHydrogen

Hydrofluoroalkanesulfonates of the general formula R—O—CXH—CX2—SO3M, where R is selected from the group consisting of alkyl groups, functionalized alkyl groups, and alkenyl groups; X is selected from the group consisting of hydrogen and fluorine with the proviso that at least one X is fluorine; and M is a cation, are made by reacting fluorovinyl ether with aqueous sulfite solution. Organic onium hydrofluoroalkanesulfonates are useful as ionic liquids and photoacid generators.

Owner:THE CHEMOURS CO FC LLC

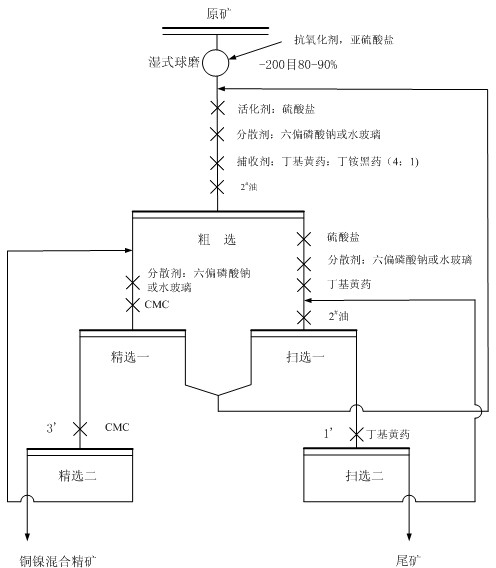

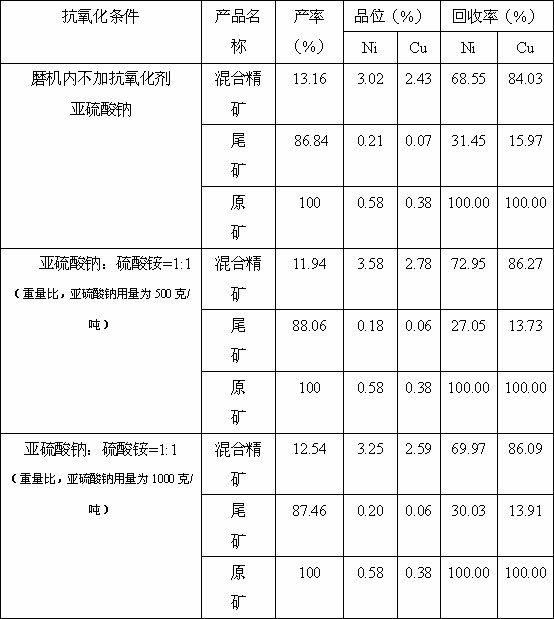

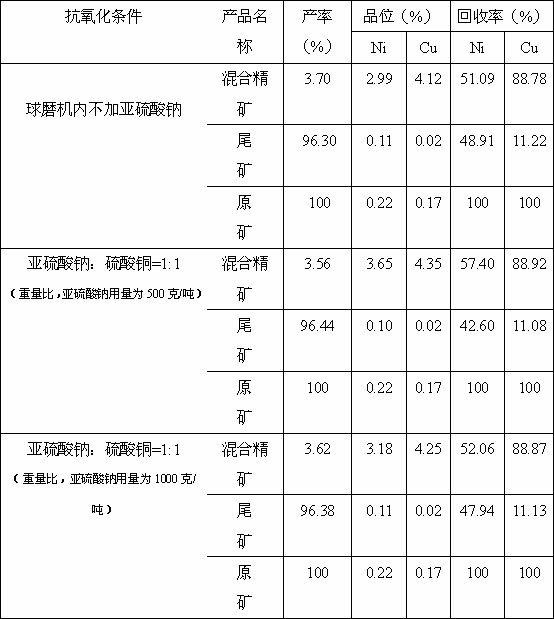

Flotation method for copper-containing nickel sulfide ore

InactiveCN102423728AGuaranteed not to be oxidizedImprove adsorption capacityFlotationAntioxidantPyrite

The invention discloses a flotation method for a copper-containing nickel sulfide ore. In order to solve the problem that nickel-containing sulfide is easily oxidized in the flotation process, the invention provides a flotation method which can ensure that the nickel-containing sulfide is not oxidized and can make a part of oxidized nickel ore activated, namely sulfite serving as an antioxidant of nickel sulfide is added during grinding operation of the copper-containing nickel sulfide ore, and sulfate serving as an activating agent with the same weight as the sulfite is added before flotation operation, so that the using amount of the antioxidant is sufficient, the requirement of preventing or delaying the nickel sulfide from being oxidized is met, and the nickel-containing sulfide such as pentlandite and the like is activated. Compared with the conventional flotation method in which the antioxidant is not added, the anti-oxidation method has the advantages that: the grade of a copper-nickel mixed concentrate can be improved by about 1 percent, the recovery rate of copper can be improved by 0 to 2 percent, and the recovery rate of nickel can be improved by 4 to 6 percent.

Owner:KUNMING UNIV OF SCI & TECH

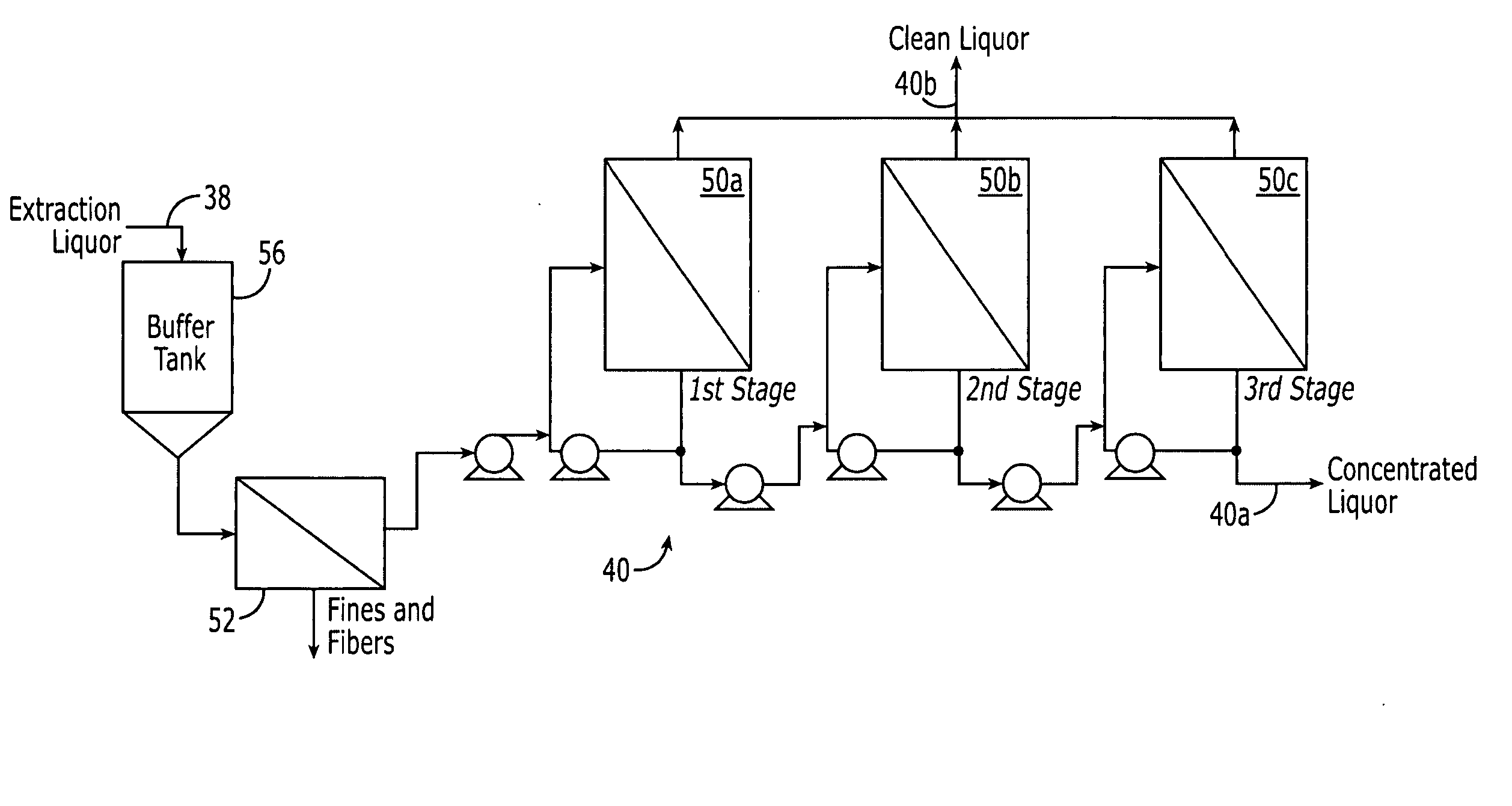

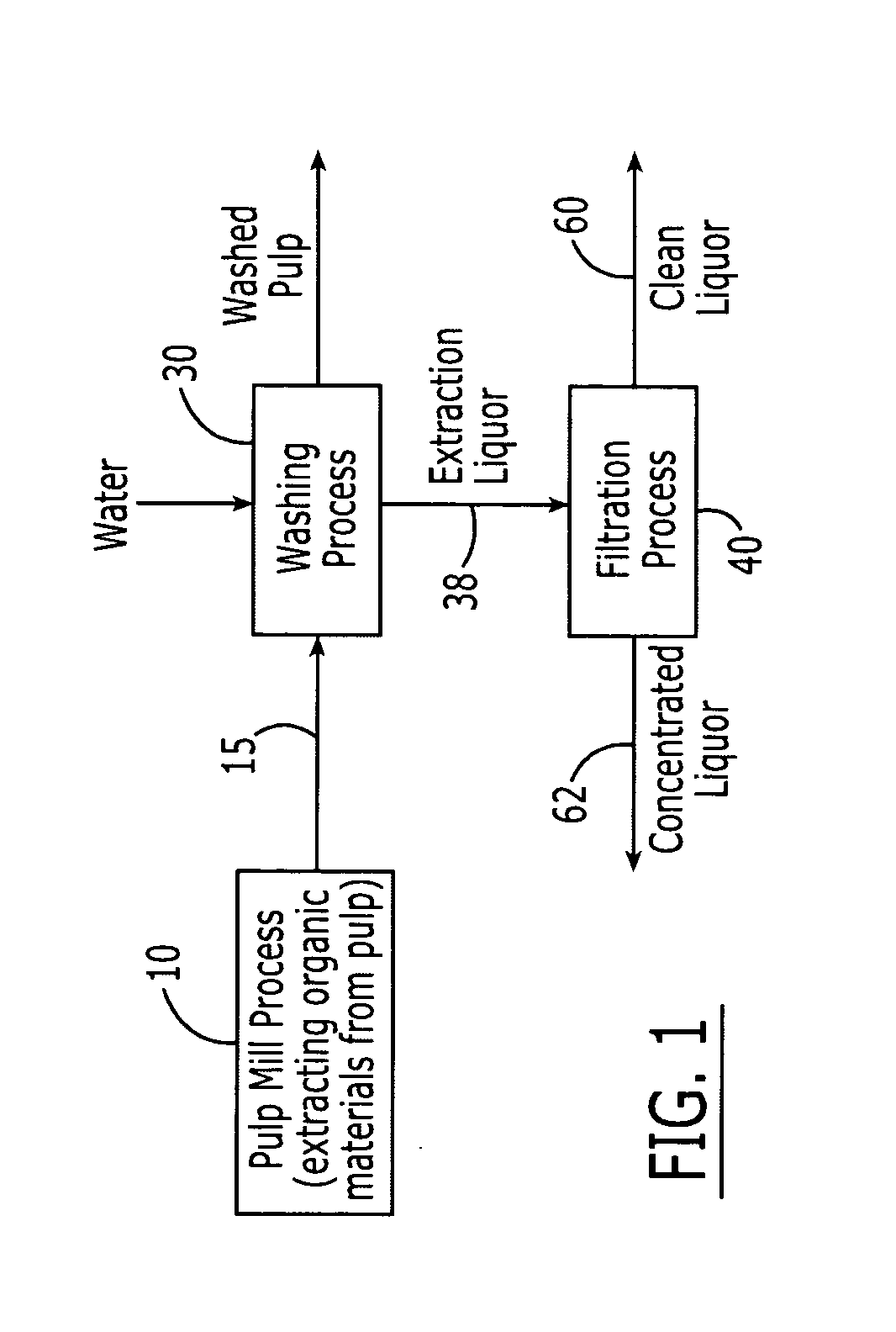

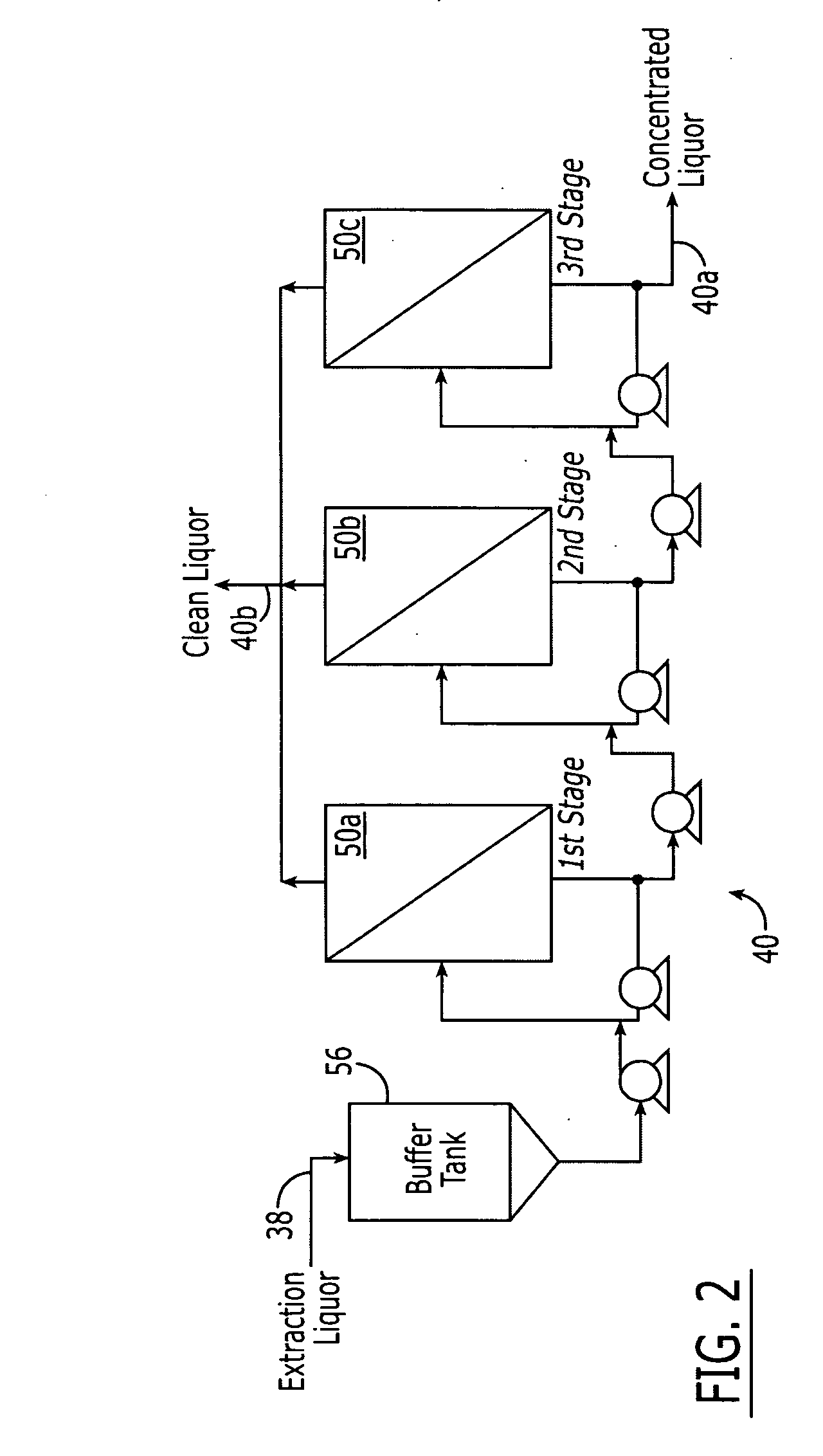

Method of concentrating pulp mill extracts

InactiveUS20060016751A1Reduce loadReduce processMembranesPulp liquors combustionWaste streamPulp mill

A process for separating organic components from a pulp mill waste stream comprising the steps of washing a cellulose pulp to obtain an aqueous extraction liquor containing organic components, and separating at least a portion of said organic components from the extraction liquor by passing the extraction liquor through at least one nanofiltration membrane. The process may be used in conjunction with a variety of pulp mill processes, including kraft cooking processes, hot caustic extraction processes, sulfite cooking processes, and bleaching processes.

Owner:RAYONIER PRODUCTS AND FINANCIAL SERVICES COMPANY

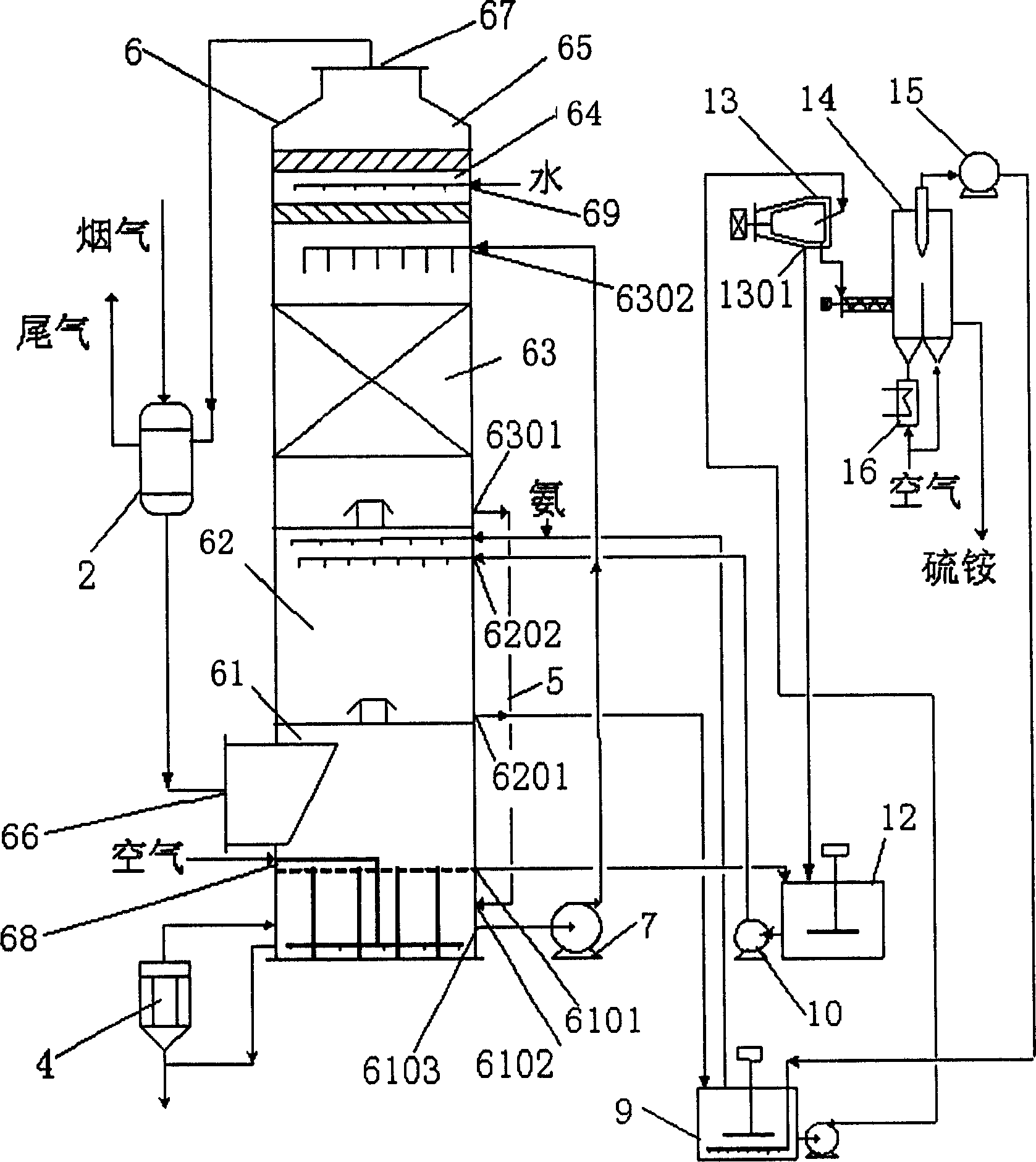

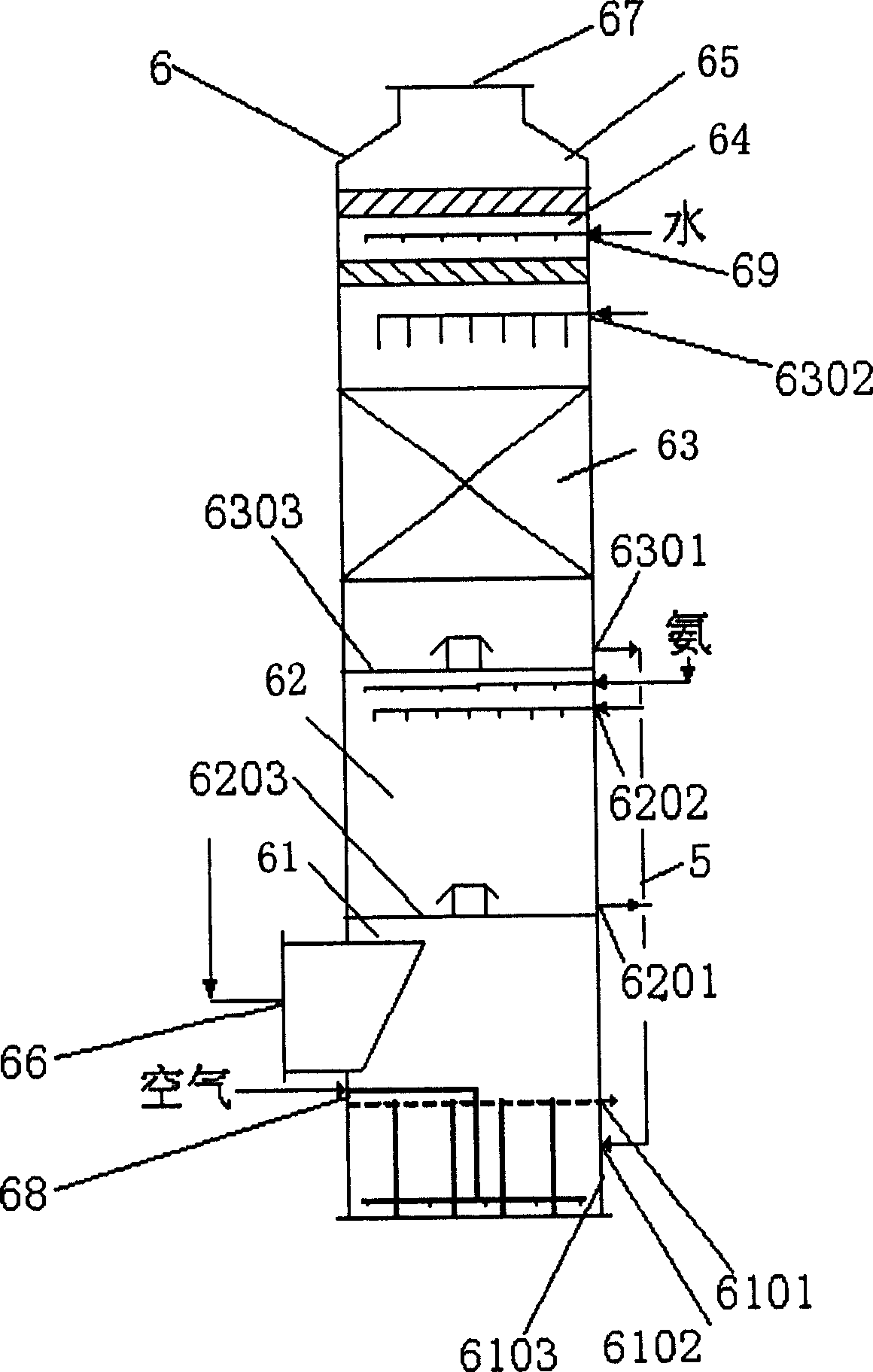

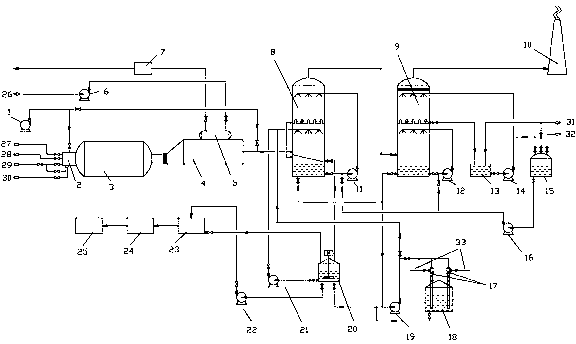

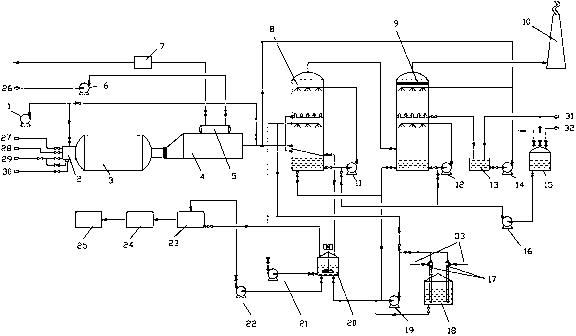

Removing and recovering process and device for SO2 in flue gas

InactiveCN1178735CReduce consumptionEasy to operateDispersed particle separationAmmonium sulfatesSulfateEnvironmental engineering

The present invention provides a method and apparatus for eliminating and recovering S02 from fume, including the following steps: l ) firstly, the fume containing low sulphur reacts with aqueous solution of ammonia, producing ammonia sulfite solution, ammonia / sulphur=1.3-1.8 (molar ratio), gas / liquid=2000-5000 (volume ratio); 2) the oxidizing reaction between the ammonium sulfite and air produces ammonia sulfate solution; 3) the ammonia sulfate solution is contacted heat fume, then the water-vaporized ammonia sulfate solution is delivered to crystallizer to be processed into ammonia sulfate fertilizer. The apparatus includes a desulphurizing tower, the desulphurizing tower includes S02 adsorption section, ammonia sulfite oxidizing section, ammonia sulfate solution condensing section, scrubbing section and demisting section. The apparatus can be operated easily. The cost can be reduced 10-30%.The vapor consumption can be reduced 90%. The concentration of S02 of fume can be reduced less than 10-100ppm. The quality of ammonia sulfate meets national standard.

Owner:EAST CHINA UNIV OF SCI & TECH

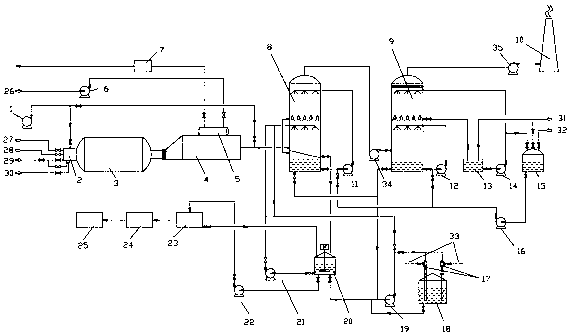

Device and process for recycling and treating hydrogen sulfide-containing chemical acid waste gas

InactiveCN103301732AReach the purpose of recyclingDispersed particle separationEnergy inputHigh heatSulfur dioxide

The invention belongs to the technical field of chemical waste gas treatment, and mainly relates to a device and a process for recycling and treating hydrogen sulfide-containing chemical acid waste gas. The process for recycling and treating hydrogen sulfide-containing chemical acid waste gas comprises the following steps of: igniting and completely burning the hydrogen sulfide-containing chemical acid waste gas into sulfur dioxide-rich high-temperature flue gas, recycling much heat and adjusting the temperature of the flue gas by cold air, and enabling the flue gas to enter an adsorption tower; completely absorbing the sulfur dioxide in the flue gas by utilizing an alkaline solution, removing less alkaline solution and sulfite contained in the flue gas absorbed by the alkaline solution, and exhausting the demisted pure flue gas to the atmosphere. The sulfite, which is generated by absorbing sulfur dioxide by the alkaline solution, is oxidized, concentrated, crystallized and dried to obtain side product sulfate.

Owner:义马煤业集团煤生化高科技工程有限公司 +1

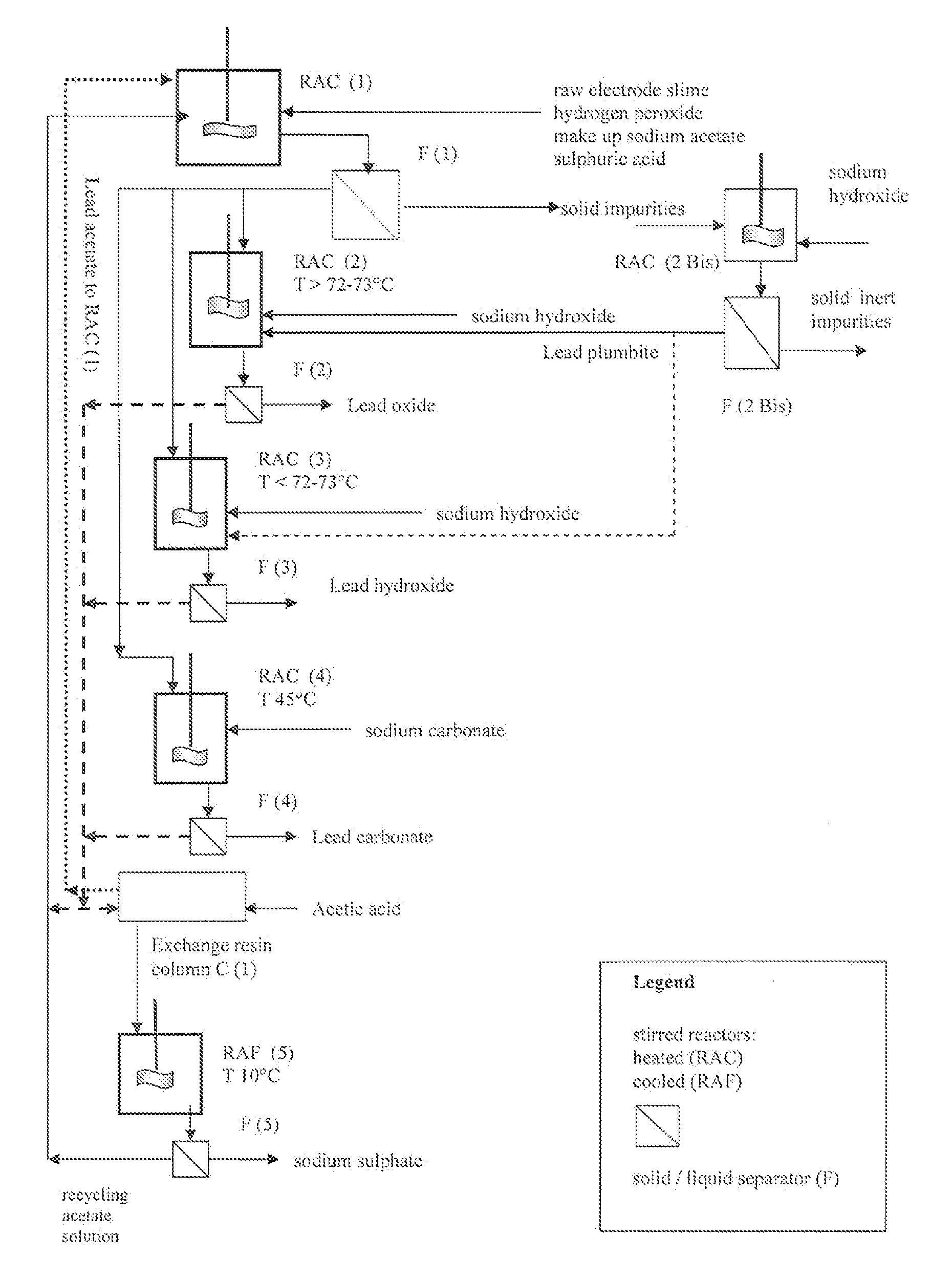

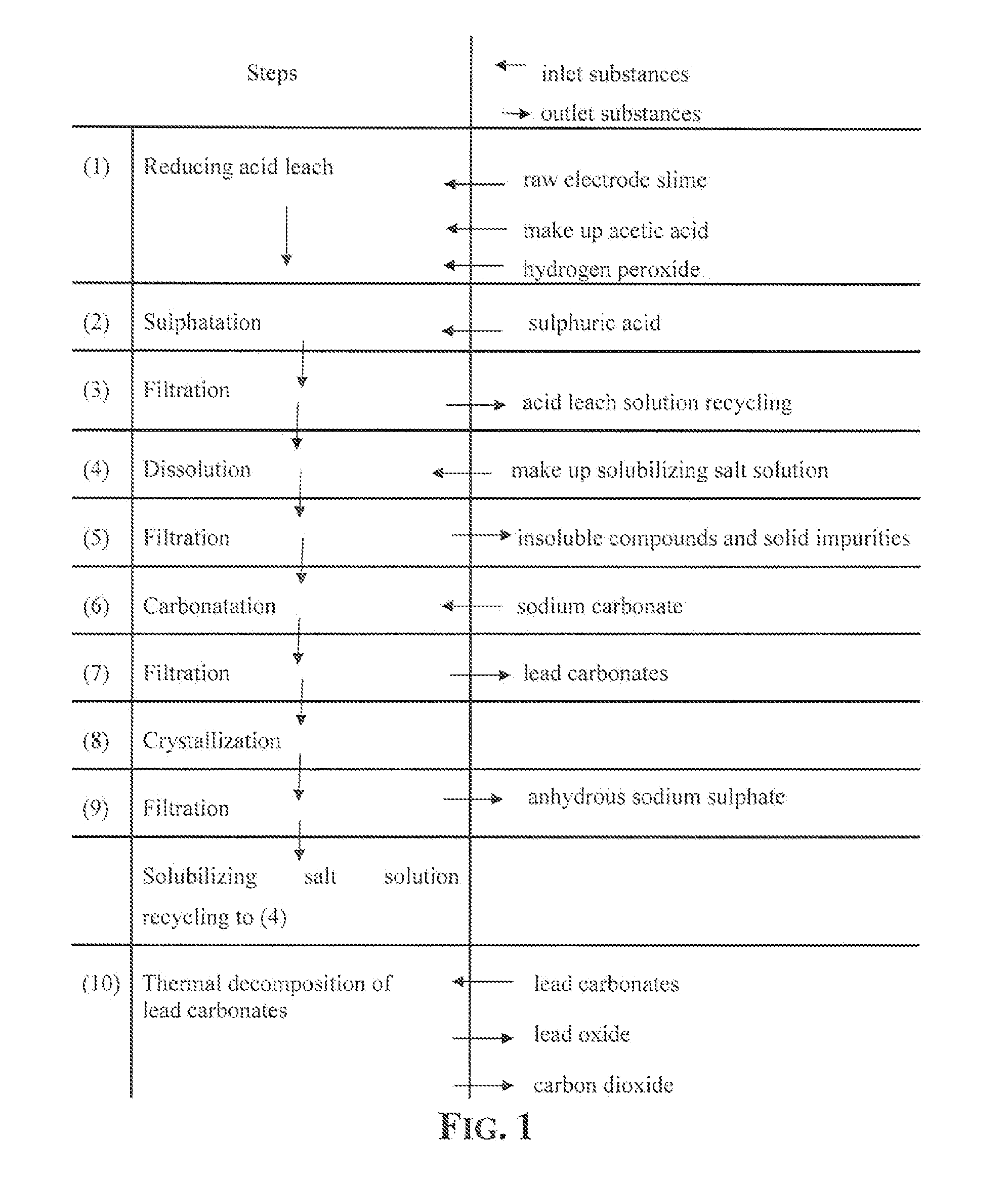

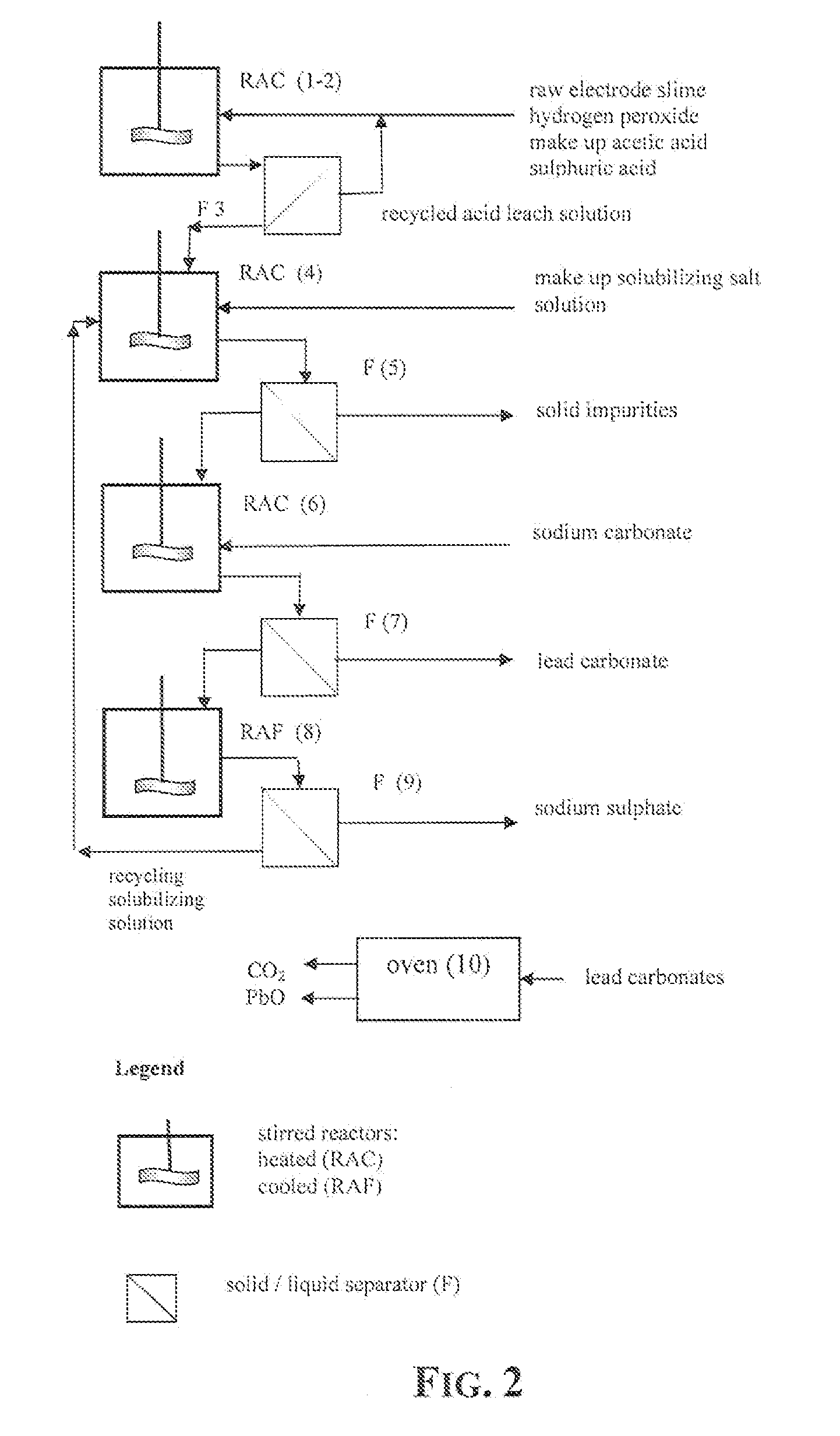

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

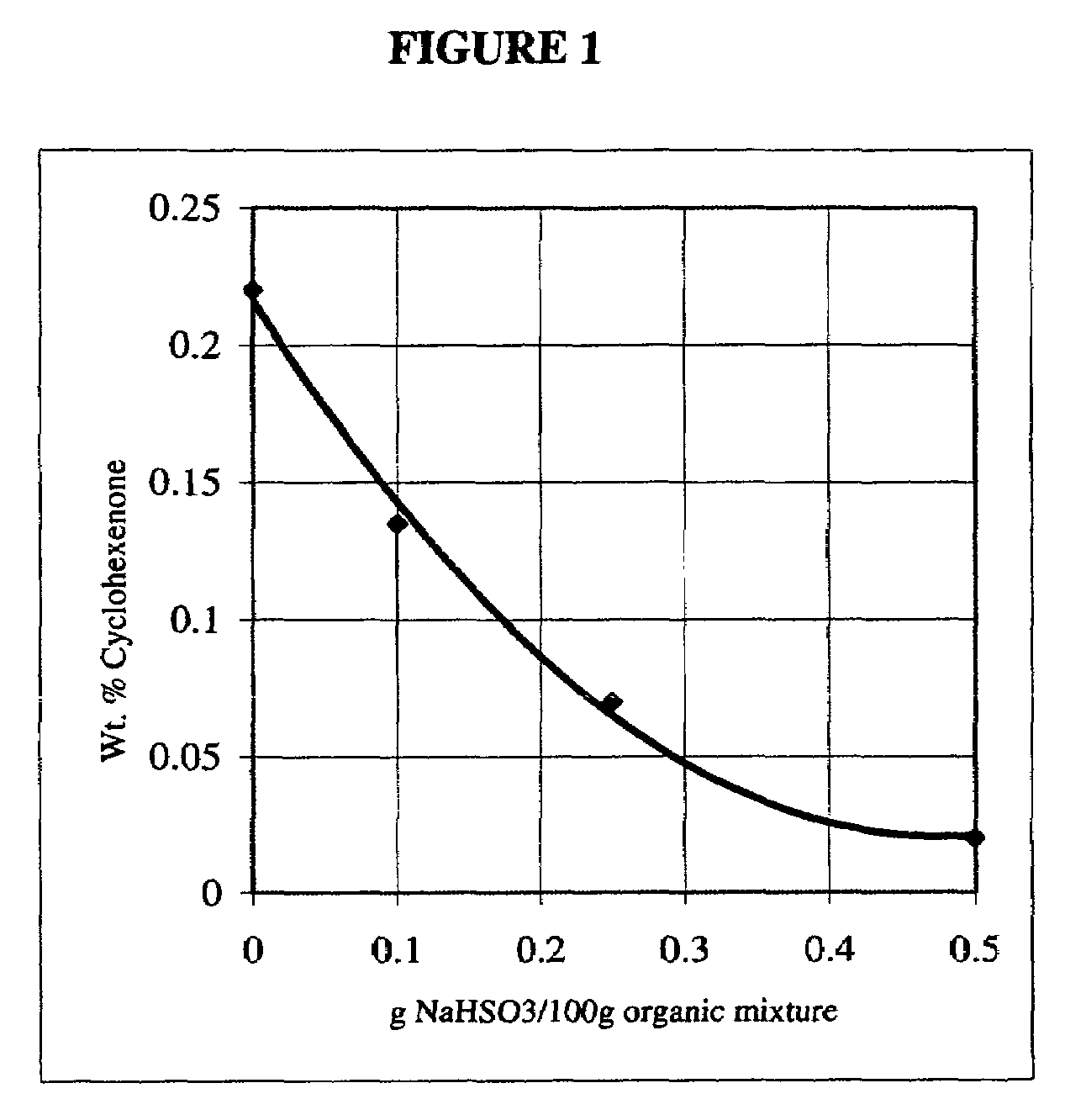

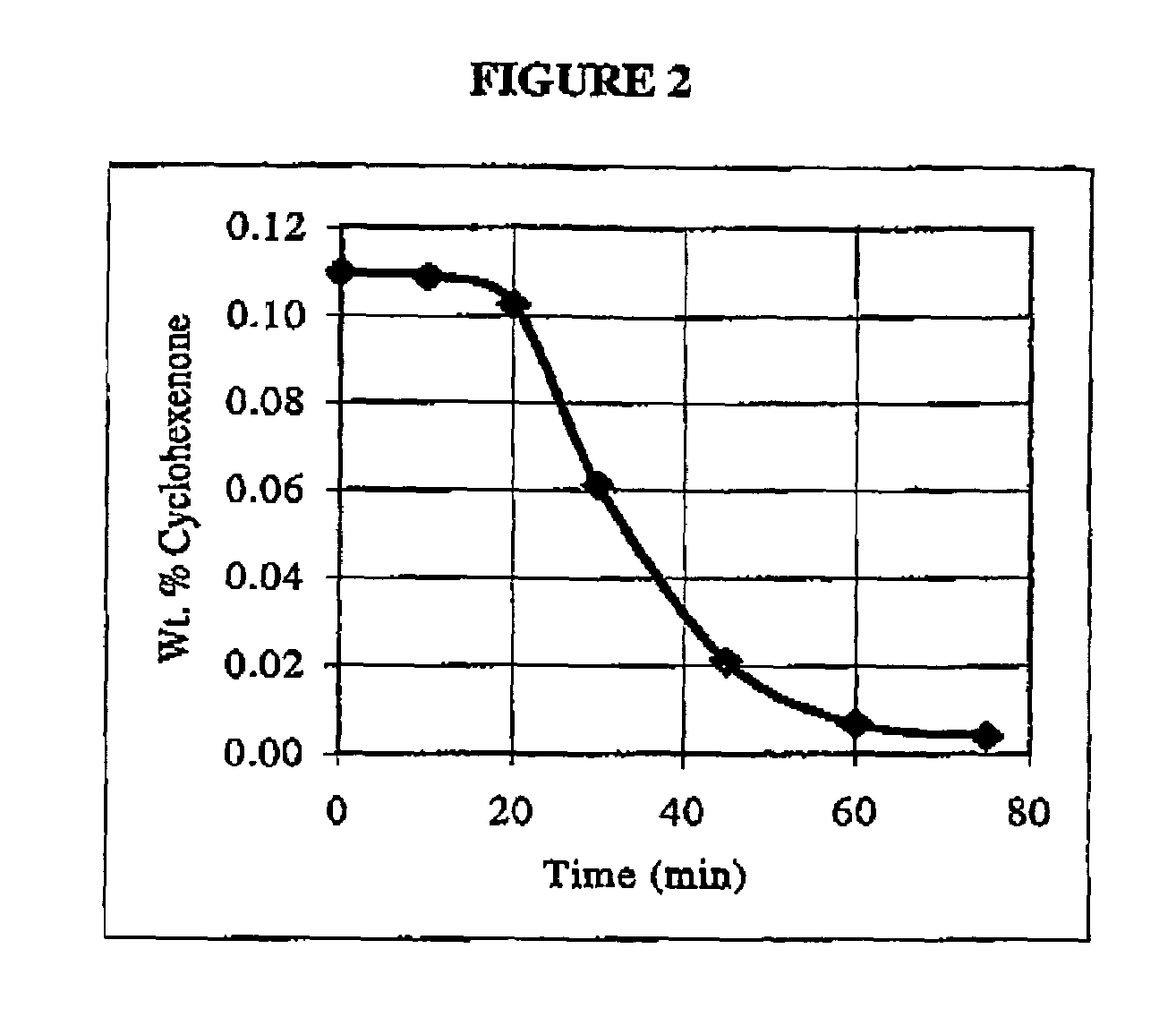

Method for reducing cyclohexenone content of a cyclohexenone-containing organic mixture

A method for reducing the concentration of cyclohexenone in a cyclohexenone containing organic mixture is disclosed. The method includes contacting an organic mixture comprising cyclohexenone with an effective amount of at least one of sulfurous acid, a salt of sulfurous acid, an alkali hydroxide, or a mixture of two or more of these compounds.

Owner:INVISTA NORTH AMERICA R L

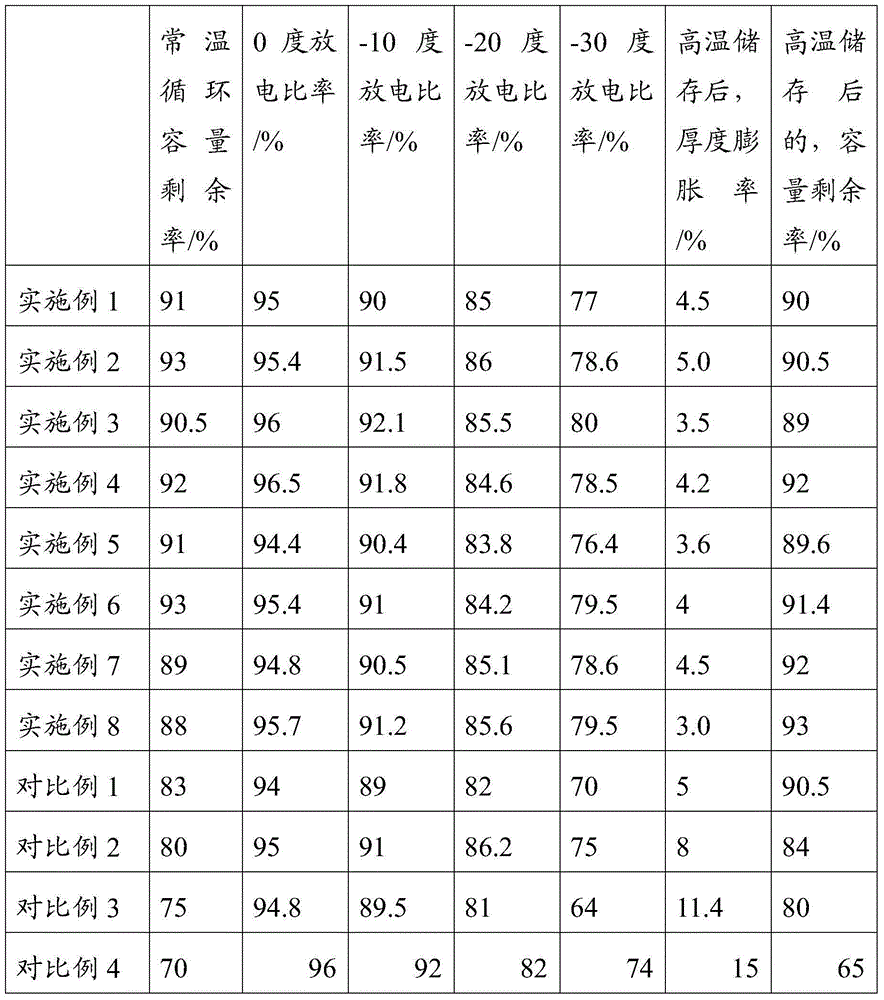

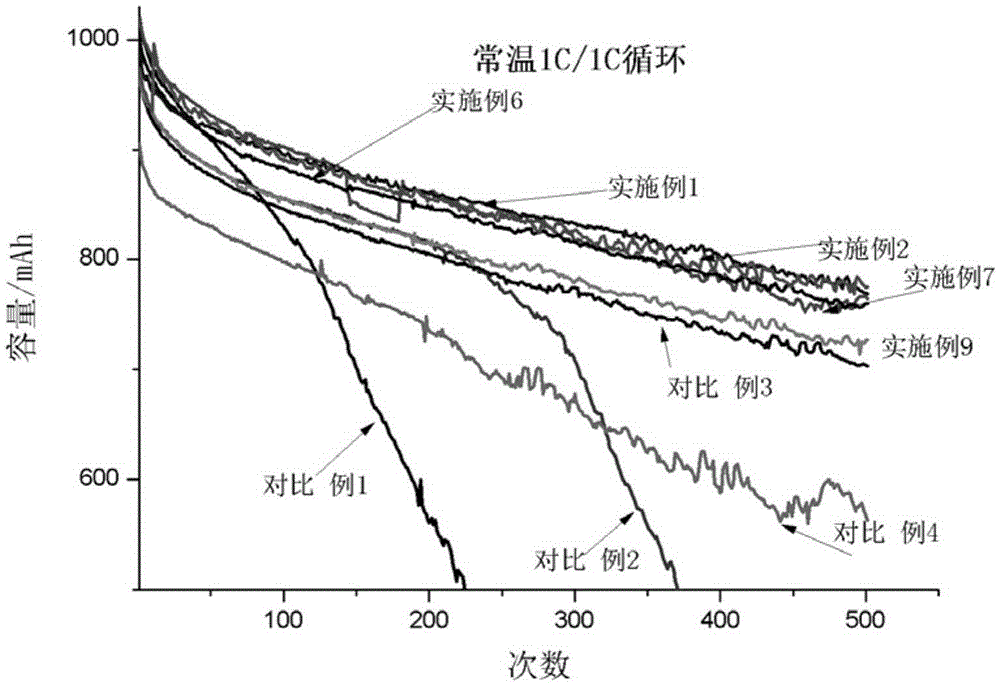

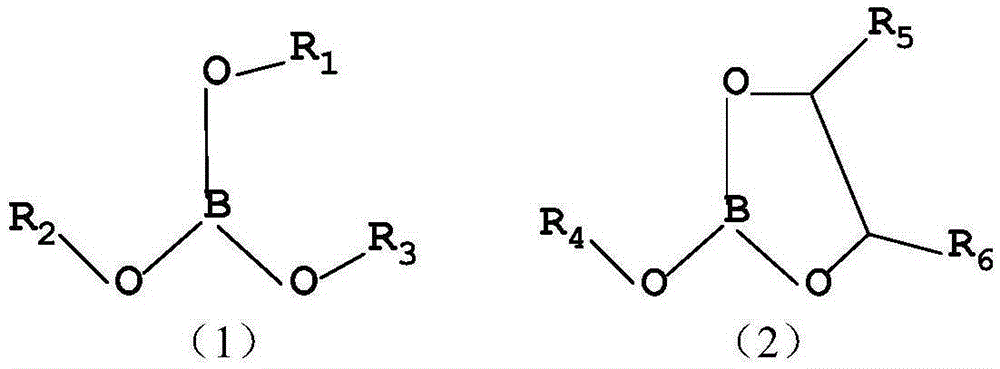

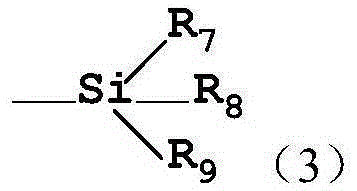

Matched silicon-carbon anode lithium-ion battery electrolyte and silicon-carbon anode lithium-ion battery

ActiveCN105406121AGood film formingImprove thermal stabilityCell electrodesSecondary cells servicing/maintenanceHigh temperature storageChemical structure

The invention relates to the technical field of the lithium-ion batteries, and in particular relates to a matched silicon-carbon anode lithium-ion battery electrolyte and a silicon-carbon anode lithium-ion battery. The lithium-ion battery electrolyte is composed of a non-aqueous organic solvent, a lithium salt and additives, wherein the additives comprise fluoroethylene carbonate, ethylene sulfite and a borate compound with a M type structure. Compared with the prior art, a SEI film formed on the surface of the electrode is more stable and compact through the synergistic effect produced by the combination use of more than three additives, the physical structure stability and chemical structure stability of the silicon-carbon anode surface are improved, so that the battery has good circulation performance and high-temperature storage performance, and meanwhile, the battery gas production is restrained.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

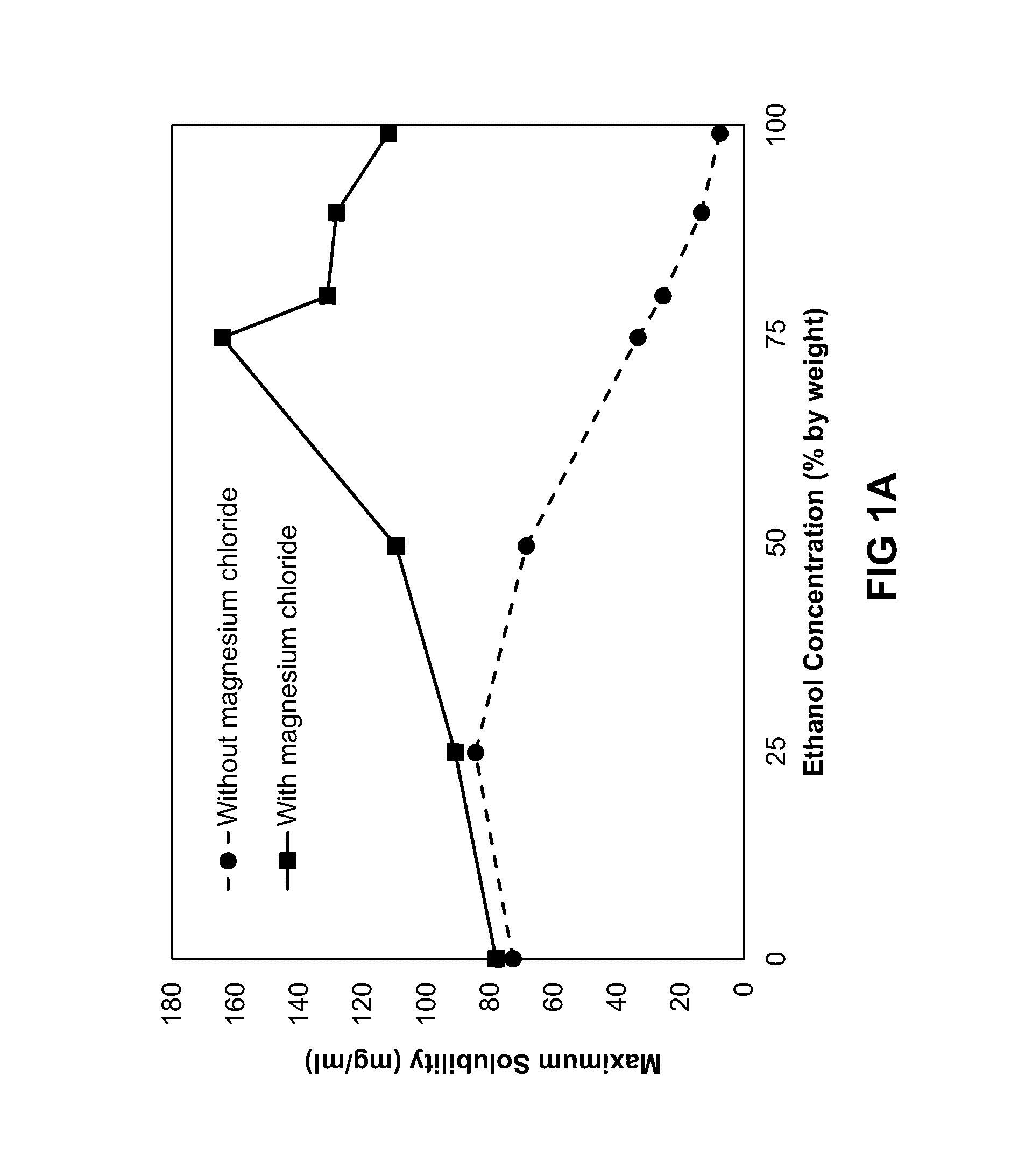

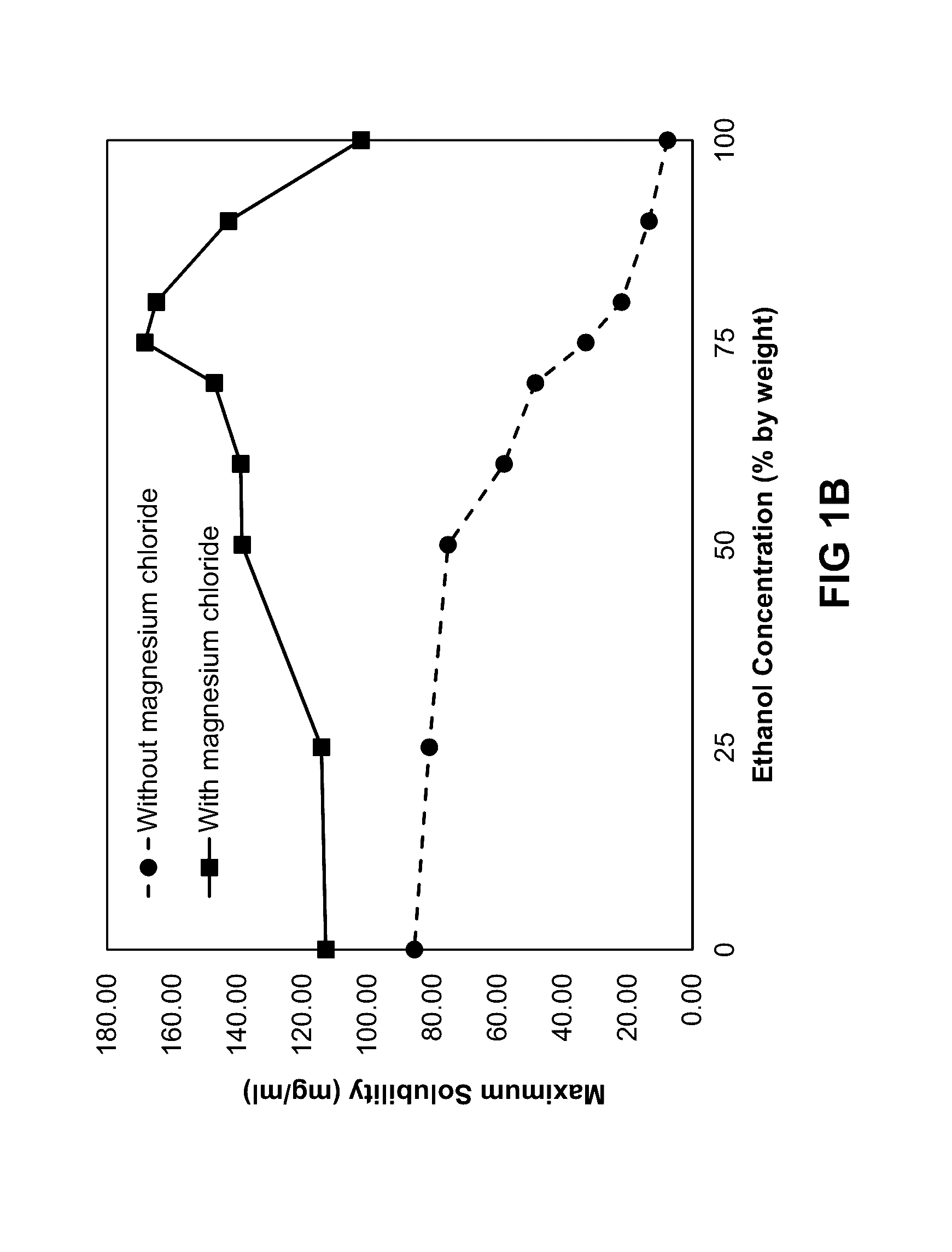

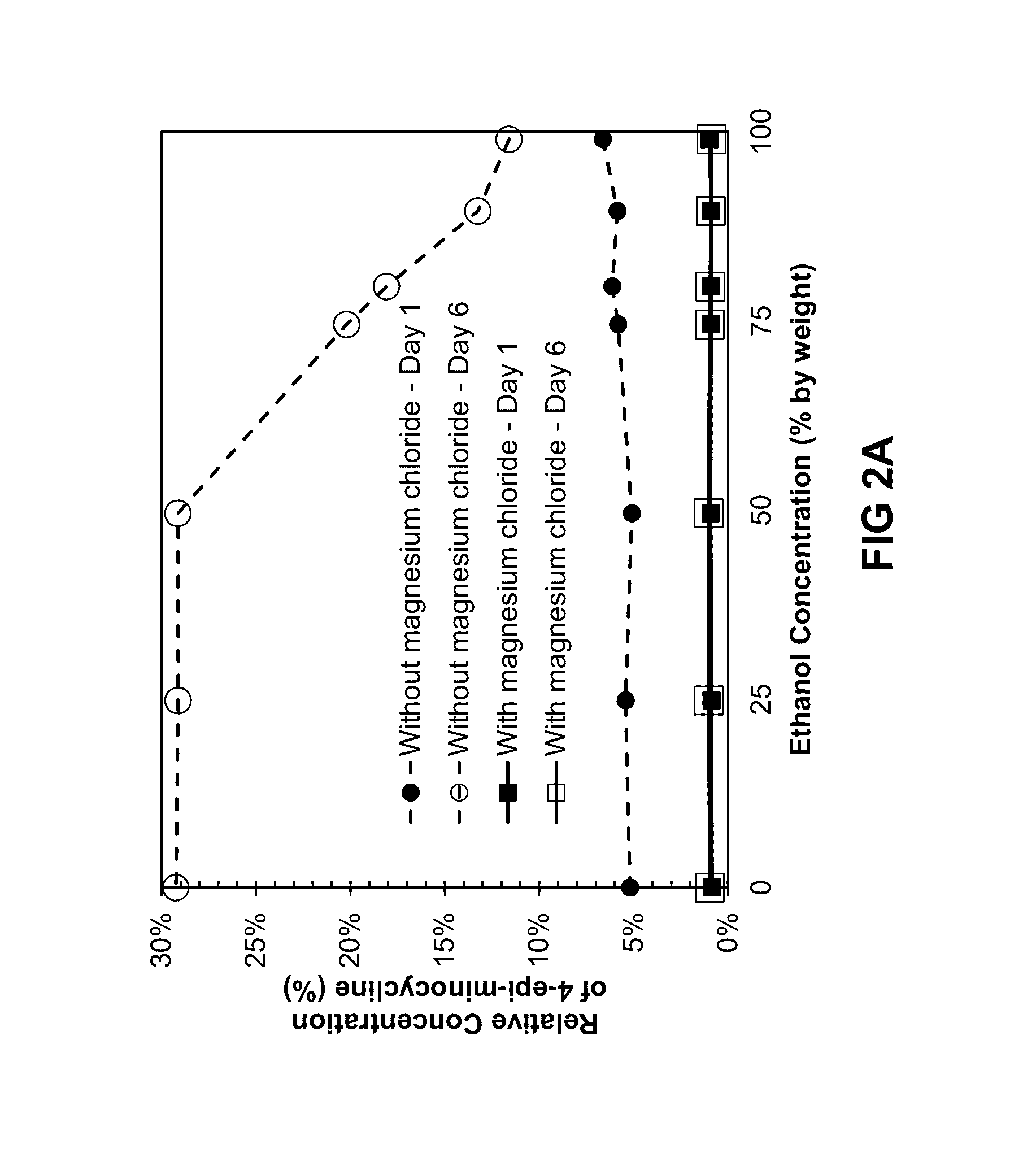

Pharmaceutical tetracycline composition for dermatological use

ActiveUS20160279152A1Prevent scalingAntibacterial agentsTetracycline active ingredientsMagnesium saltSolvent

Provided herein is a topical composition and related methods for making and using the composition. In a first aspect, the topical composition comprises minocycline, a magnesium salt, and a sulfite compound in a non-aqueous solvent. In yet another aspect, the topical composition comprises a tetracycline-class drug, a source of magnesium, a monohydric aliphatic alcohol, and a polyol, wherein (i) the ratio between the monohydric aliphatic alcohol and the propylene glycol is in the range of 1:1 to 99:1 by weight and (ii) the tetracycline-class drug is dissolved in the topical composition.

Owner:BIOPHARMX

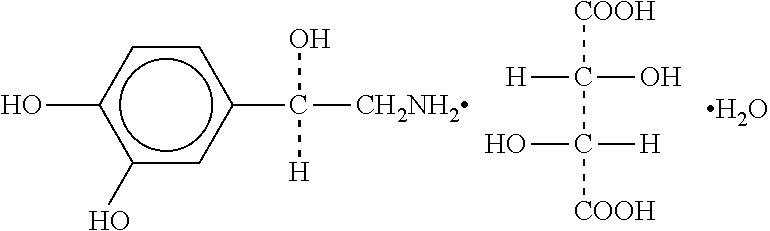

Parenteral dosage form of norepinephrine

The present invention relates to a ready-to-administer parenteral dosage form of norepinephrine which comprises an aqueous solution of norepinephrine, having an anti-oxidant which is not a sulfite anti-oxidant, wherein the dosage form is stable at room temperature for prolonged period of time.

Owner:SUN PHARMA INDS

Impregnated filter element, and methods

InactiveUS20060130451A1High molecular weightCombination devicesGas treatmentKetoneAldehyde formation

A contaminant-removal filter for removing carbonyl-containing compounds from a gas stream, such as air. Examples of common airborne carbonyl-containing compounds include ketones, including acetone, and aldehydes, including formaldehyde. The filter has a porous or fibrous body that includes a plurality of passages extending from a first, inlet face to a second, outlet face, the passages providing flow paths. The body has a reactant material impregnated throughout the substrate. The reactant material is a sulfite, bisulfite, oxidant, or derivative of ammonia, specifically high molecular weight and stable amines. Strong alkali (basic) materials are particularly suitable for aldehyde removal. The filter is free of any humectants.

Owner:DONALDSON CO INC

Clay molding sand for cast steel and preparation method thereof

The invention discloses clay molding sand for cast steel and a preparation method thereof. The clay molding sand is prepared from the following raw materials in parts by weight: 60-80 parts of quartz sand, 20-30 parts of forsterite sand, 8-12 parts of bentonite, 5-8 parts of composite powder, 4-6 parts of talcum powder, 2-3 parts of nanometer aluminum oxide, 3-5 parts of pine sawdust, 2-4 parts of alpha-starch, 1-2 parts of dextrin, 3-6 parts of calcium phosphate, 1.5-2.5 parts of sulfite lye and 4-8 parts of water. The molding sand is high-temperature resistant, high in strength and high in impact resistance, can be used for overcoming the defects on hot spot parts and avoiding sand adhesion, and a phenomenon that the sand mold is broken due to impact force of liquid steel casting is avoided. Moreover, the clay molding sand is low in air release amount, good in air permeability effect and high in liquidity, the defects of air holes, cold shut and shrinkage porosity in the casting can be effectively overcome, and the yield of the casting is improved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

Formation method of lithium ion battery

InactiveCN102637903AOvercoming the Leakage ProblemAvoid influenceFinal product manufactureSecondary cells charging/dischargingPower flowCurrent range

The invention belongs to the technical field of lithium ion batteries and particularly relates to a formation method of a lithium ion battery. The formation method comprises the following steps of: vacuumizing a battery to be injected and performing first injection on the battery; performing opening formation on the battery subjected to the first injection, wherein a formation current ranges from 0.1C to 1.5C; and performing second injection and encapsulation on the battery subjected to the formation, wherein electrolyte for the second injection comprises high-temperature additives including at least one of trimethylene sulfite, ethylene sulfate, succinonitrile and adiponitrile. Compared with the prior art, the formation method disclosed by the invention avoids the electrolyte leakage caused by quick gas production during deformation with a large current by virtue of the way of twice injection, and avoids the influence on the components of an SEI (Solid Electrolyte Interface) membrane due to adding the electrolyte additives once, thereby improving the low temperature performance of a battery cell; and as the battery cell has high temperature performance by virtue of the additives injected after the formation, and the formation time is shortened greatly, the process efficiency is enhanced greatly, and the production cost is reduced.

Owner:NINGDE AMPEREX TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com