Patents

Literature

186 results about "Hydroxyethyl sulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

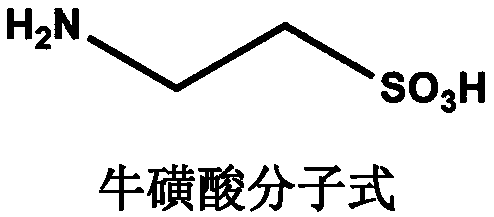

Sodium 2-hydroxyethyl sulfonate (also: sodium isethionate) is the sodium salt of 2-hydroxyethane sulfonic acid (isethionic acid), it is used as hydrophilic head group in washing-active surfactants, known as isethionates (acyloxyethanesulfonates) due to its strong polarity and resistance to multivalent ions.

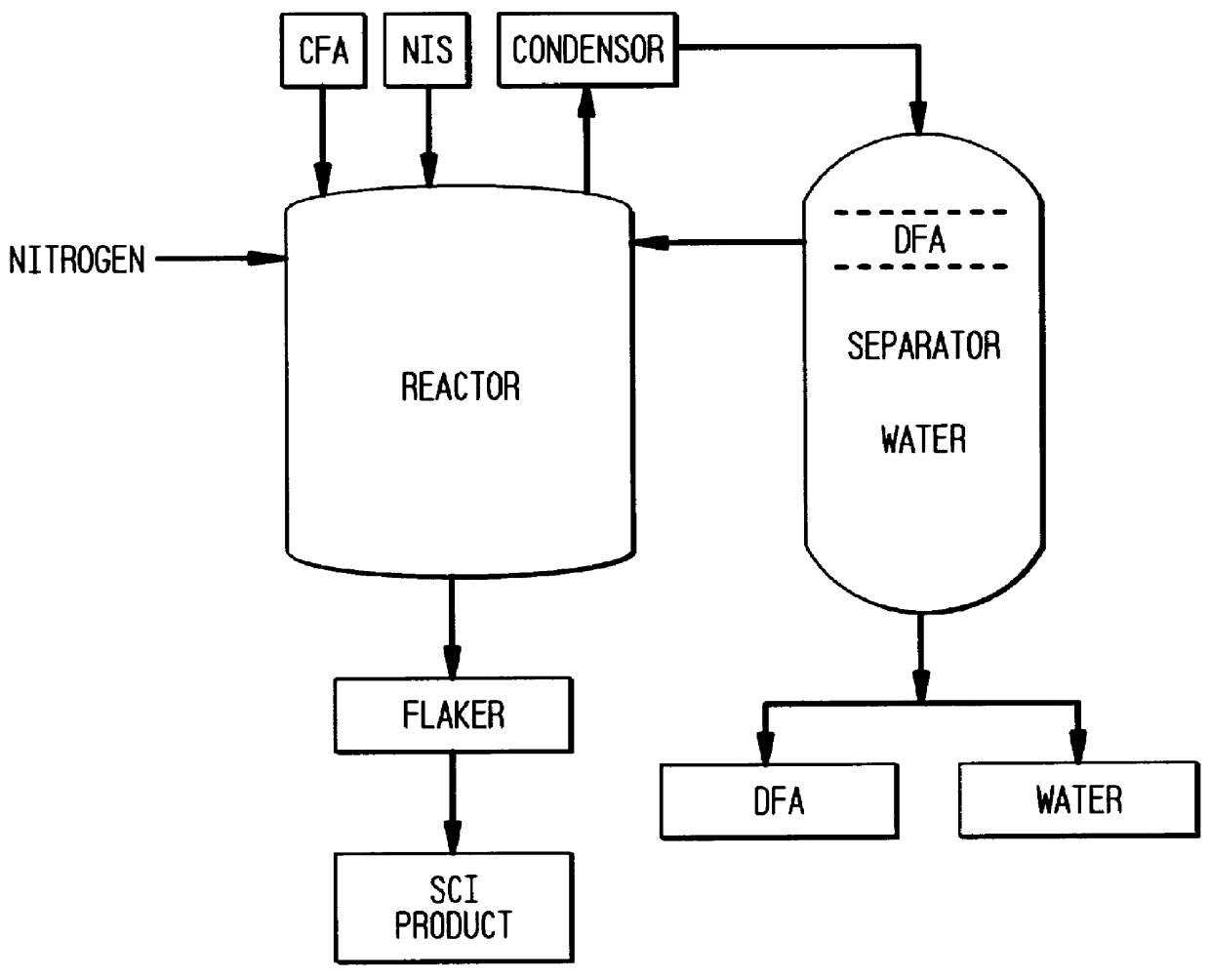

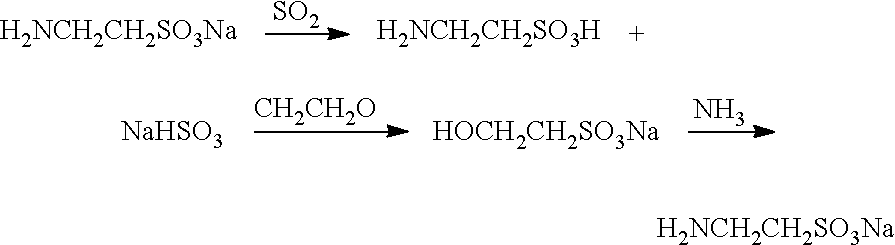

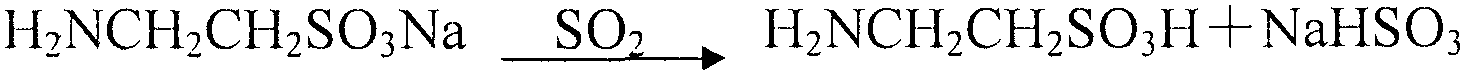

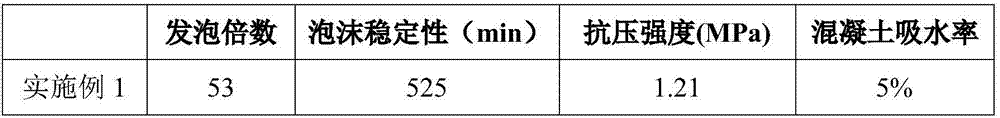

Synthesis of taurine

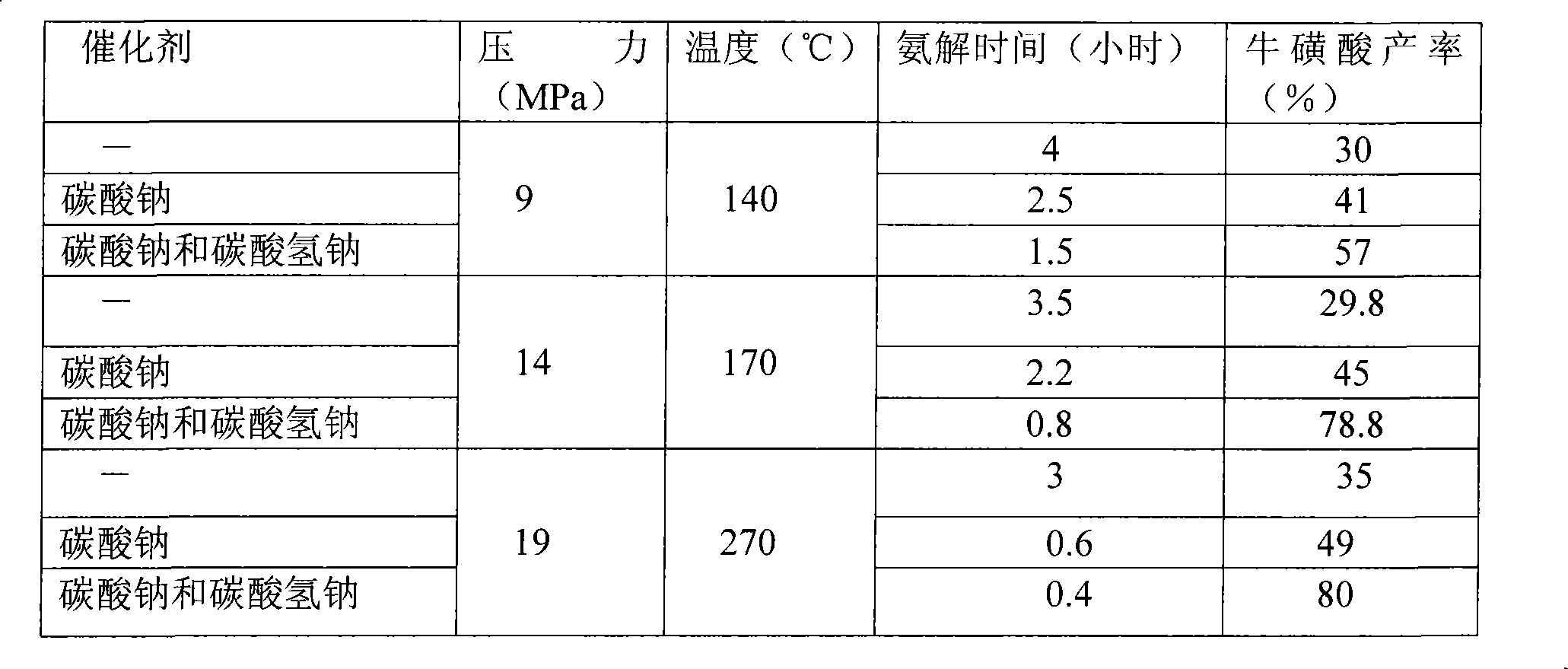

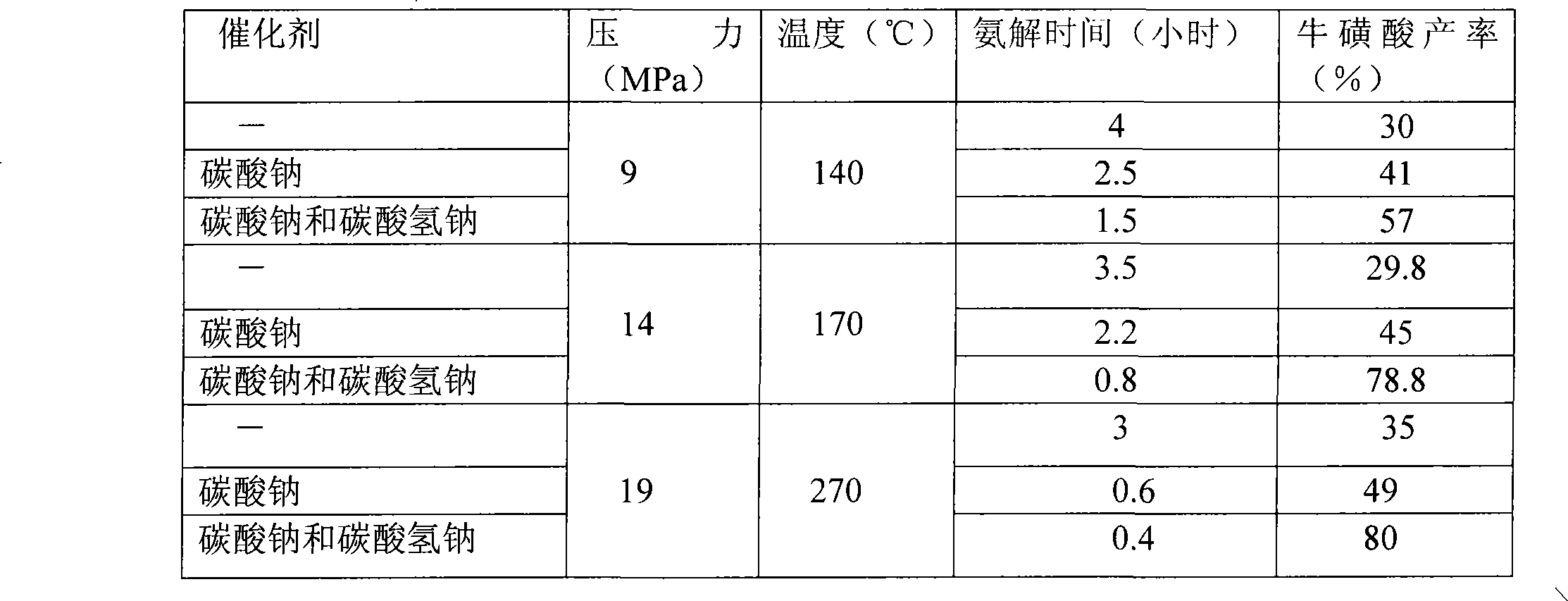

The invention relates to a method for synthesizing taurine, comprising the following steps: (1) according to the amount ratio of materials of 1:1 to 1:1.2, epoxy ethane and sodium bisulfite are subjected to addition reaction under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; (2) the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction under 14 to 21MPa and at a temperature between 160 and 280 DEG C to generate sodium taurate, and the mass concentration of ammonia in the reaction liquid is 20 to 30 percent; and (3) neutralization: namely, the sodium taurate is neutralized by sulphuric acid to generate the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production.

Owner:王代龙 +1

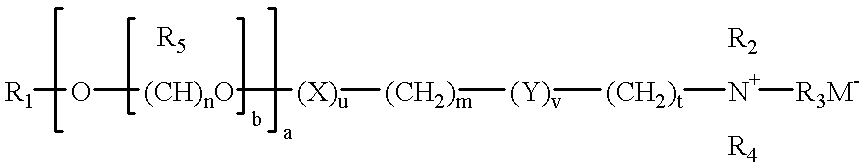

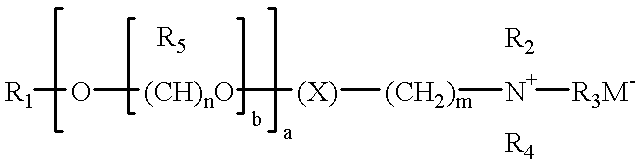

Stable multi-phased personal care composition

InactiveUS20060079418A1Increase depositionExcellent skin conditioningCosmetic preparationsHair cosmeticsPersonal careSodium laurate

A stable multi-phase personal care composition is described. The stable multi-phase composition comprises least two visually distinct phases; wherein at least one visually distinct phase comprises a cleansing phase comprising a surfactant component. The surfactant component comprises at least one anionic surfactant selected from the group consisting of ammonium lauryl sulfate, ammonium laureth sulfate, sodium lauryl sulfate, sodium laureth sulfate, sodium cocoyl sulfate, sodium laurate, sodium cocoyl isethionate, monomethyl branched surfactants and mixtures thereof. The visually distinct phases of the stable multi-phase personal care composition form a pattern.

Owner:THE PROCTER & GAMBLE COMPANY

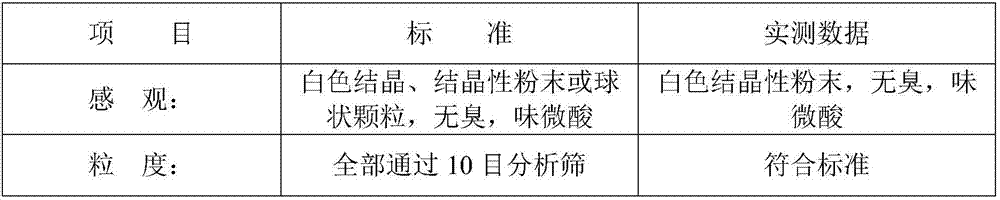

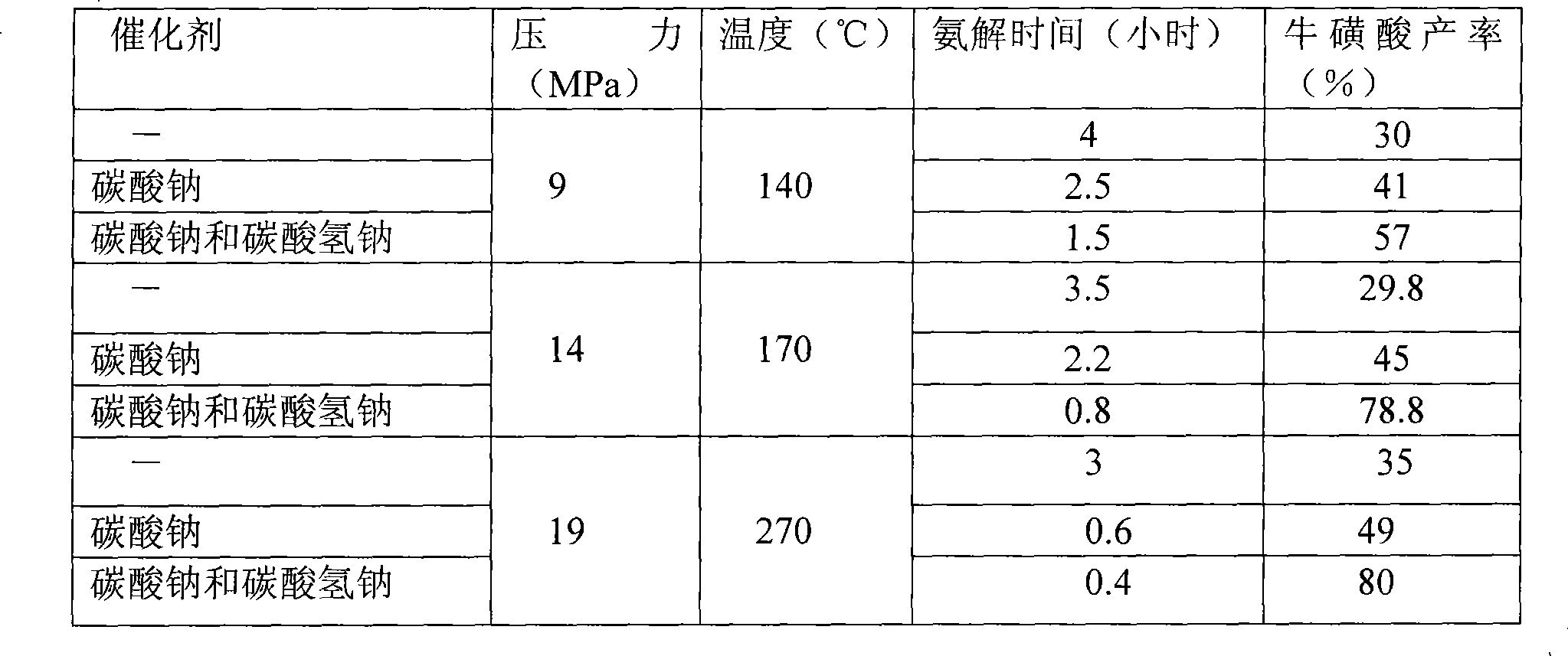

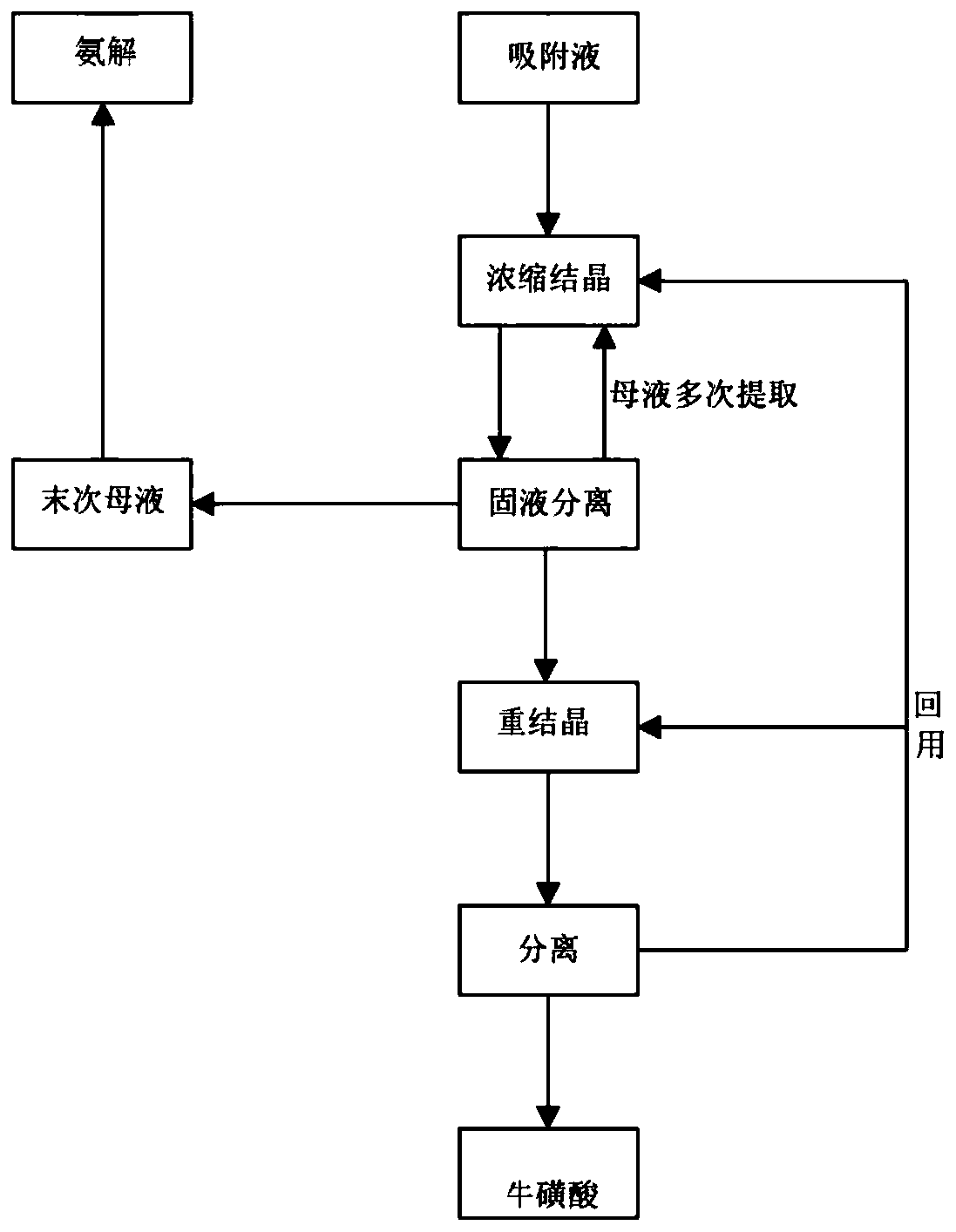

Method for preparing taurine

The invention relates to a method for preparing taurine, comprising the following steps: epoxy ethane and sodium bisulfite are reacted under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at a temperature between 75 and 85 DEG C to form hydroxyethyl sodium sulfonate; the hydroxyethyl sodium sulfonate and liquid ammonia are subjected to ammonolysis reaction at under 14 to 21MPa and at a temperature between 160 and 280 DEG C to form ammonolysis solution containing sodium taurate; and the ammonolysis solution is evaporated to remove ammonia, neutralized by sulphuric acid, concentrated, crystallized, separated, pre-dried in a boiling drying device or a vibration fluidization drying device, and then added into a microwave drying device to be dried and sterilized to obtain the taurine. The method for synthesizing the taurine has the advantages of short time, high yield and lower cost, and is easy for industrialized production. The water content of a taurine wet product can be reduced to below 0.30 percent through combined application of pre-drying of the boiling drying device or the vibration fluidization drying device and microwave drying, and simultaneously the device has the function of sterilizing.

Owner:王代龙 +1

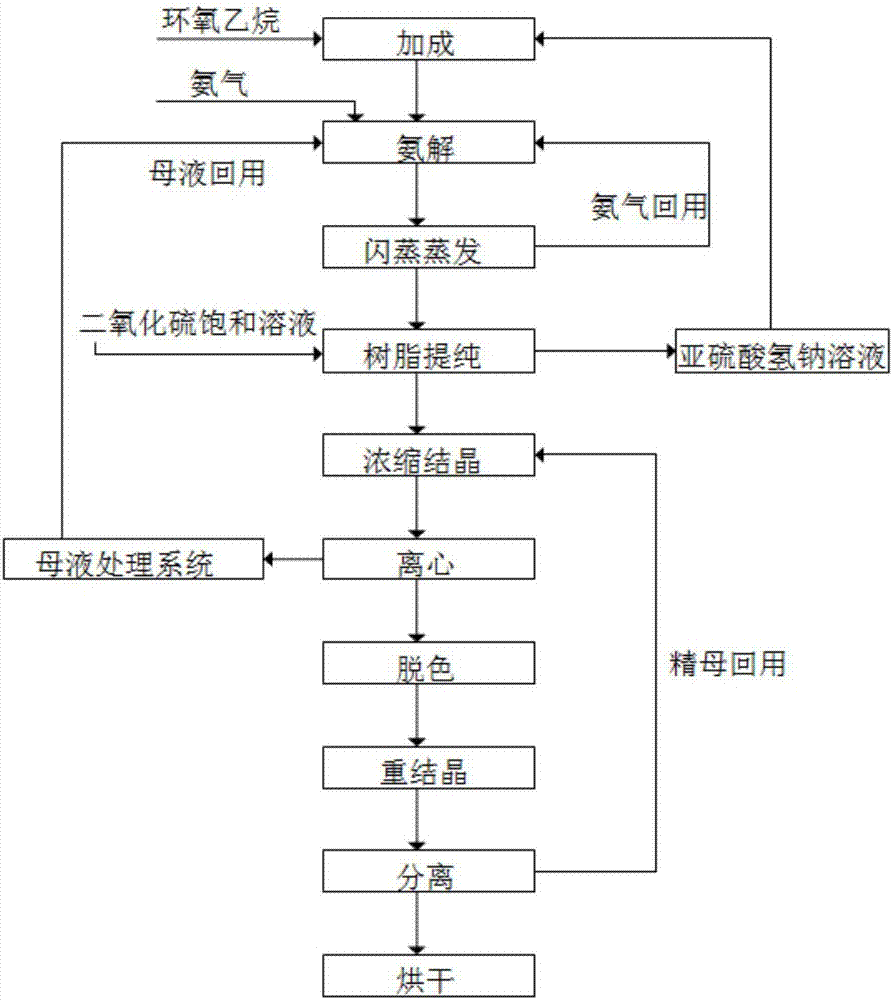

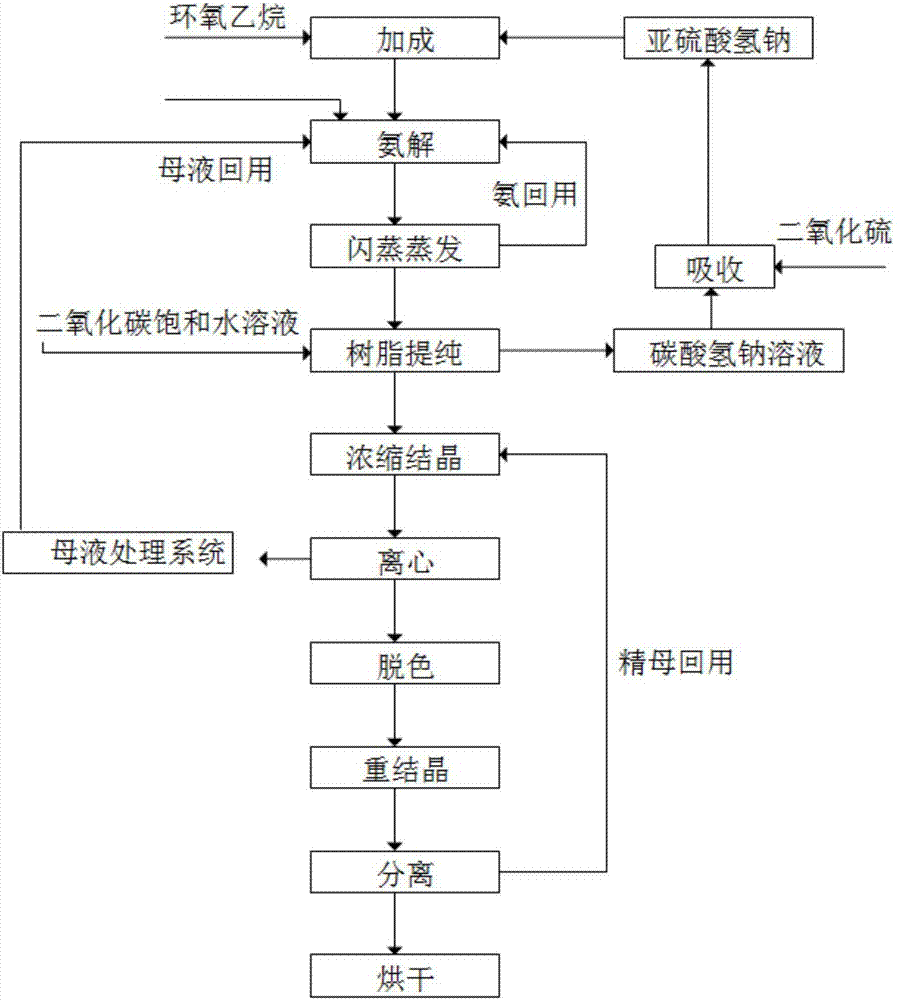

Method for cyclically producing taurine at high yield

ActiveCN107056659AReduce productionEfficient recyclingPhysical/chemical process catalystsOrganic compound preparationAfter treatmentHydrogen

The invention relates to a method for cyclically producing taurine at a high yield. The method includes the following steps that S1, ethylene oxide reacts with a sodium hydrogen sulfite solution to generate sodium hydroxyethyl sulfonate; S2, sodium hydroxyethyl sulfonate obtained in S1 is subjected to an ammonolysis reaction in ammonium hydroxide, flashing is carried out after the reaction is completed, and ammonia gas is recycled; S3, taurine-containing feed liquid of reaction liquid obtained after flashing in S2 is collected through an acid cation exchange resin column, the resin column is regenerated with a sulfur dioxide or carbon dioxide water solution after being inactivated, and eluant obtained during regeneration can be directly reused or reused after being treated with sulfur dioxide; S4, the feed liquid collected in S3 is subjected to after-treatment, and taurine is obtained. The method has the advantages that the generation amount of waste liquid in the whole process is small, part of substances are effectively and cyclically utilized in the process, the cost is reduced, the yield of taurine can reach 90% or above, meanwhile, the production process is relatively simple, and large-scale production is easy.

Owner:QIANGJIANG YONGAN PHARMA

Method of preparing taurine

The invention relates to method for preparing taurine, comprising the following steps: (1) reacting epoxy ethane with sodium sulfite under 0.05 to 0.1MPa, with pH value of 6.5 to 7.5 and at temperature between 75 and 85 DEG C to obtain hydroxyethyl sodium sulfonate; (2) carrying out ammonolysis reaction on the hydroxyethyl sodium sulfonate and liquid ammonia under 14 to 21MPa and at temperature between 160 and 280 DEG C to obtain ammonolysis solution containing sodium taurate; (3) introducing the ammonolysis solution into a single flash evaporator for primary flash evaporating at a temperature between 160 and 200 DEG C and under 1.3 to 2.0MPa; introducing the flash evaporated liquid into a secondary flash evaporating and falling film evaporator, using the primary flash vapor as a heating medium to carry out flash evaporating and falling film evaporating on the primary flash evaporated liquid in the secondary flash evaporating and falling film evaporator at a temperature between 110 and 140 DEG C and at 0.1 to 0.6MPa; evaporating and concentrating the flash evaporated liquid subjected to secondary flash evaporating and falling film evaporating with flash vapor and steam as heating media in a multi-effect flash evaporating and falling film evaporator; and (4) neutralizing the sodium taurate by sulphuric acid to obtain the taurine. The method for preparing the taurine has the advantages of short time, high yield and low cost, and is easy for industrialized production. In addition, by primary flash evaporating and secondary flash evaporating processes, almost all the ammonia and 40% to 60% of water in the flash evaporated liquid can be removed, thus having double effects of removing ammonia and condensing.

Owner:王代龙 +1

Detergent composition

InactiveUS20010026792A1Cosmetic preparationsCationic surface-active compoundsSodium bicarbonateWater contact

A wiping article is provided which includes an effervescent cleanser composition held within a pouch formed from a first and second substrate sheet. At least one of the substrate sheets must be water permeable. The effervescent composition is an intimate mixture of an acid material such as citric acid and an alkaline material such as sodium bicarbonate. Water contact causes the combination to effervesce. A dry surfactant such as sodium cocoyl isethionate in contact with the water and effervescing carbon dioxide results in a highly pleasant sudsing system. Skin benefit agents may be included within the composition. The effervescent action may improve deposition of the skin benefit agents onto the skin.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Cosmetic effervescent cleansing pillow

A wiping article is provided which includes an effervescent cleanser composition held within a pouch formed from a first and second substrate sheet. At least one of the substrate sheets must be water permeable. The effervescent composition is an intimate mixture of an acid material such as citric acid and an alkaline material such as sodium bicarbonate. Water contact causes the combination to effervesce. A dry surfactant such as sodium cocoyl isethionate in contact with the water and effervescing carbon dioxide results in a highly pleasant sudsing system. Skin benefit agents may be included within the composition. The effervescent action may improve deposition of the skin benefit agents onto the skin.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Fatty acid esters of hydroxyalkyl sulfonate salts and process for producing same

InactiveUS6069262ANegligible changeMaintain good propertiesOrganic compound preparationSurface-active detergent compositionsPersonal careHair care

Compositions of matter comprising fatty acid esters of hydroxyalkyl sulfonate salts, in particular sodium cocoyl isethionate (SCI) and process for preparing same. The esters are useful for personal care cleansing products, such as bar and liquid soaps, skin and hair care products.

Owner:INNOSPEC ACTIVE CHEM

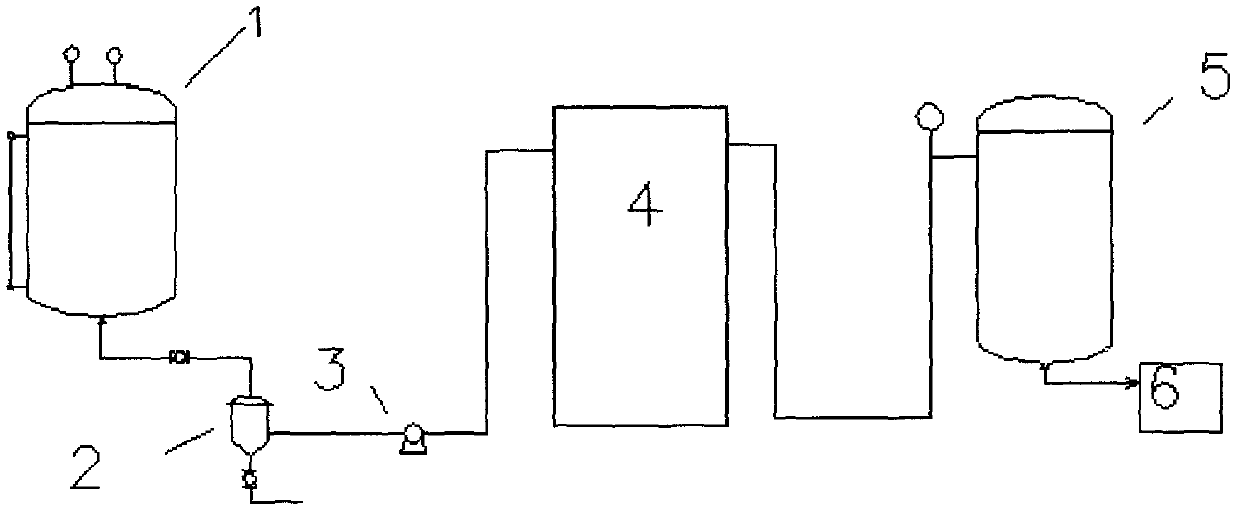

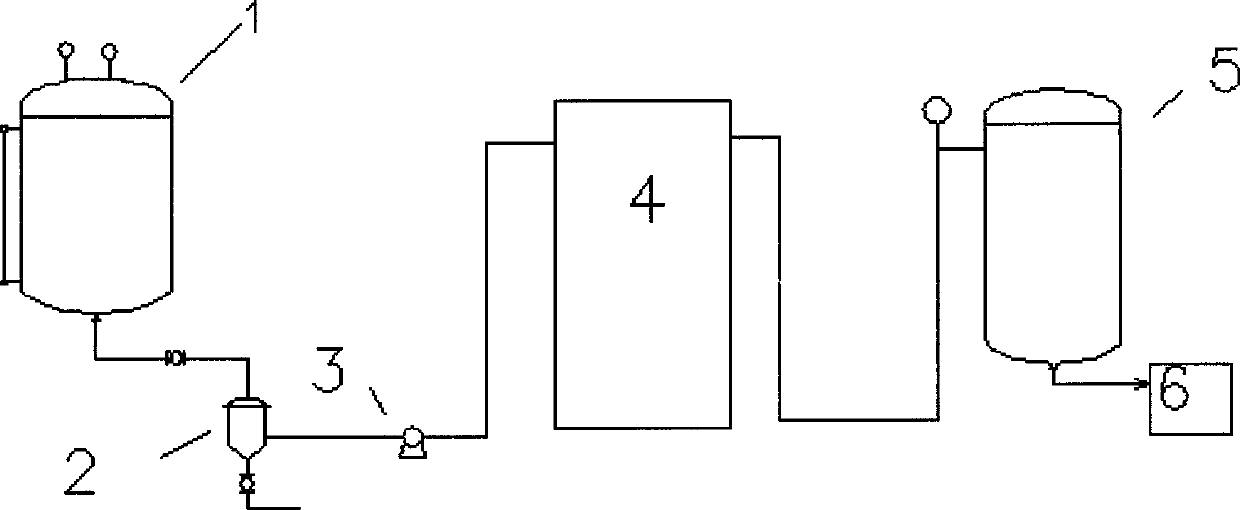

Device and method for continuously producing sodium methyl taurate in pipeline mode

InactiveCN102675160ALess energy consumptionStable concentrationSulfonic acids salts preparationHeat conductingDistillation

The invention relates to a device and a method for producing sodium methyl taurate, in particular to a device and a method for continuously producing sodium methyl taurate in a pipeline mode. The method comprises the following steps of: adding sodium hydroxyethyl sulfonate, water, methylamine and catalyst into a storage tank, pumping the materials into a continuous pipeline reactor through a boosting pipeline pump under the high pressure of 10 to 25MPa, heating to the temperature of between 150 and 300 DEG C through heat conducting oil, and reacting for 10 to 60 minutes in the pipeline reactor; and feeding the materials into an evaporator after reaction, performing multistage distillation, decolorizing, moisturizing, refining, and thus obtaining the qualified sodium methyl taurate. The device is simple and high in process safety, the reaction conditions are easy to control, continuous production is realized, the yield reaches over 90 percent, the sodium methyl taurate is stable in quality, and large-scale production can be realized with low investment in the industry.

Owner:HUANGGANG YONG AN PHARMA

Process for producing taurine

InactiveUS20140121405A1Easy to produceIncrease profitOrganic compound preparationSulfonic acids salts preparationEthylene oxideSODIUM TAURATE

The present disclosure provides a process for producing taurine, includes: adjusting a PH value of a sodium taurate solution by a S4+ compound; introducing ethylene oxide into the sodium taurate solution to produce sodium hydroxyethyl sulfonate; separating crude taurine before or after introducing the ethylene oxide to the solution; and adding ammonia to the sodium hydroxyethyl sulfonate reaction solution to be reacted with the reaction solution to reproduce sodium taurate. The process for producing taurine of the present disclosure makes use of the balances of the sodium bases in the system, recycles the mother liquor until the sodium taurate is reproduced out of the reactions in the mother liquor, and thus is capable of allowing taurine to be synthesized and extracted.

Owner:QIANGJIANG YONGAN PHARMA

Metal alloy electroplating liquid

The invention discloses a metal alloy electroplating liquid. The metal alloy electroplating liquid is composed of the following raw material components in parts: 30-40 parts of copper sulphate, 30-50 parts of aluminium sulphate, 50-60 parts of copper chloride, 50-60 parts of nickel hydroxide, 20-30 parts of cobalt sulphate, 30-40 parts of cobalt chloride, 10-15 parts of iron sulphate, 30-35 parts of ferrous chloride, 50-58 parts of cuprous oxide, 16-18 parts of hydrochloric acid, 15-20 parts of acetic acid, 3-4 parts of Tween-60, 4-5 parts of sodium hydroxyethyl sulfonate, 5-6 parts of allyl polyethenoxy ether, 6-7 parts of polyethylene glycol, 3-4 parts of ammonium lauryl sulphate, 5-8 parts of sodium lauryl sulphate and 200-300 parts of deionized water. The metal alloy electroplating liquid is good in stability, the surface of a plated film is high in brightness and smoothness, the flexibility of a plated layer is obviously improved, and the defects of burrs, roughness and the like on the outer surface of a plated part are basically eliminated.

Owner:梁胜光

Preparation method for taurine

ActiveCN103382170ASolve pollutionAvoid it happening againOrganic compound preparationSulfonic acids salts preparationSalt sodiumEthylene oxide

Owner:QIANGJIANG YONGAN PHARMA

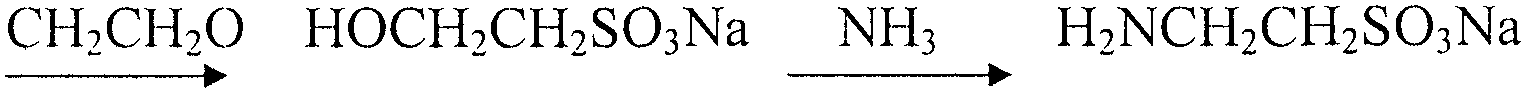

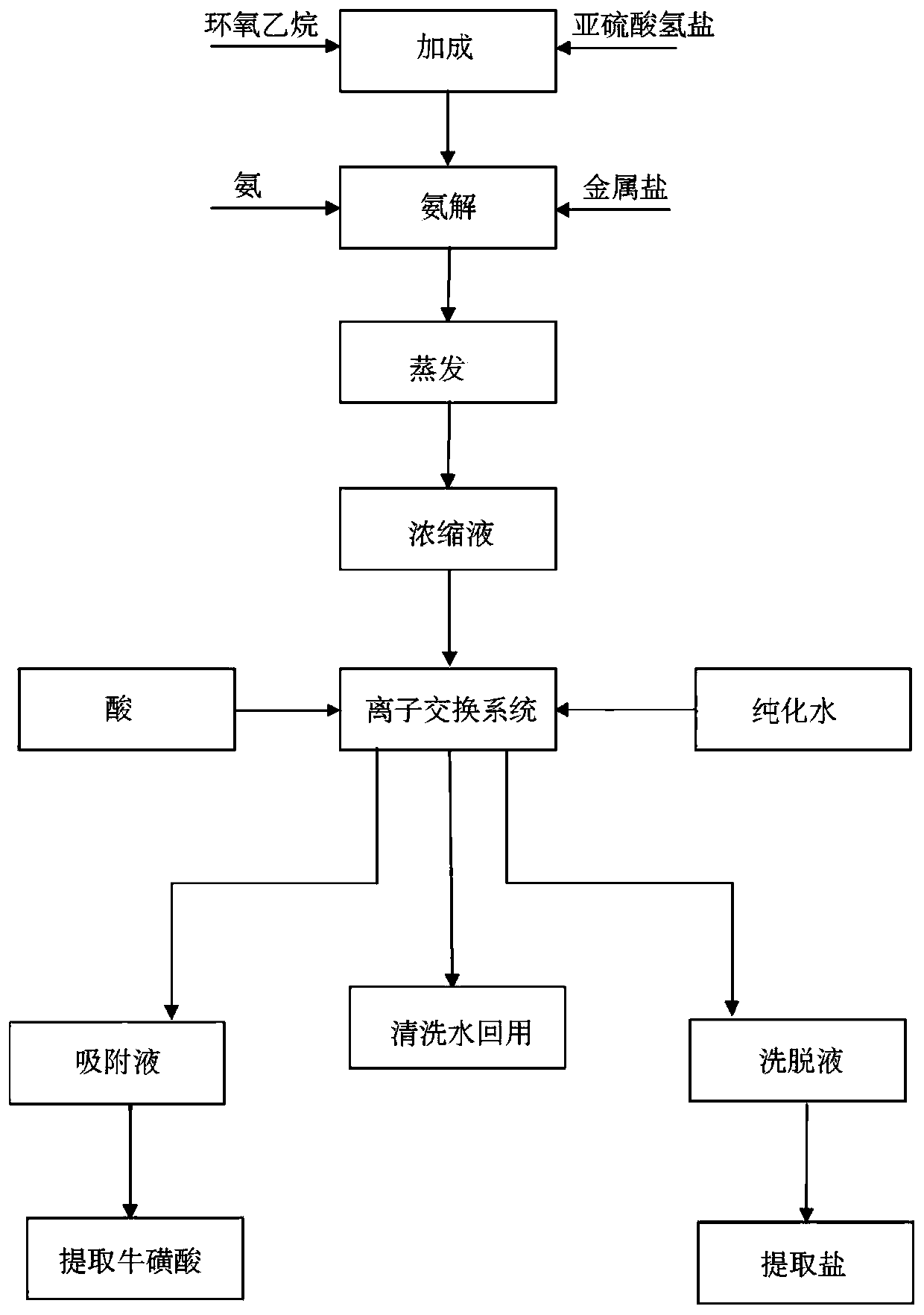

Method and system for preparing high purity taurine and salt

ActiveCN111471002AHigh purityGood crystal formOrganic compound preparationSulfonic acids salts preparationSulfonateEthylene oxide

The invention discloses a method and a system for preparing high-purity taurine and salt. The method comprises the following steps: reacting ethylene oxide with bisulfite to generate hydroxyethyl sulfonate; carrying out ammonolysis reaction on the hydroxyethyl sulfonate, ammonia and metal salt, evaporating to obtain a taurine salt concentrate, carrying out ion exchange on the concentrate in an ionexchange system to obtain an adsorption solution with taurine as a main component, independently collecting the adsorption solution, and extracting taurine from the adsorption solution; and eluting the adsorbed metal cations by using acid, independently collecting eluate, and extracting salt from the eluate or directly taking the eluate as a salt solution product. According to the method, materials of two target products are separated in advance after ammonolysis reaction, and then the target products are extracted respectively, so that the extraction process is very simple, interference on product separation when the two target products are in the same maternal system does not need to be considered at all, the process is simple, and the production cost is greatly reduced.

Owner:QIANGJIANG YONGAN PHARMA

Textile auxiliary containing antibiotic constituents and preparation method thereof

InactiveCN105714558AImprove antibacterial propertiesWith anti-fouling functionBiochemical fibre treatmentPolymer sciencePyrrolidinones

The invention discloses a textile auxiliary containing antibiotic constituents. The textile auxiliary comprises, by weight parts, 50-60 parts of sodium diethylhexyl sulfosuccinate, 45-55 parts of polyvinyl pyrrolidone, 40-50 parts of sodium dodecyl sulfonate, 30-40 parts of hydroxyethyl sulfonate, 30-40 parts of 2-hydroxyethyl salicylate, 25-35 parts of lupenyl palmitate, 25-35 parts of styrene maleic anhydride resin, 15-25 parts of trichloro-sym-diphenylurea, 15-25 parts of ethyl vanillin, 5-10 parts of zinc oxide, 5-10 parts of cross-linking agent and 5-10 parts of softening agent. The textile auxiliary containing the antibiotic constituents improves antibiotic effects of textile, and further has antifouling function. A corresponding preparation method is further disclosed.

Owner:WUJIANG FUHUIYUAN HOME TEXTILES CO LTD

Method for preparing 2-taurine

InactiveCN104016888AAvoid clumpingReduce demandOrganic compound preparationSulfonic acid preparationEthylene oxideSodium hydrogen sulphite

The invention discloses a method for preparing 2-taurine. The method comprises the following steps: reacting ethylene oxide with sodium hydrogen sulfite at 0.05-0.1MPa, pH value of 6.5-7.5 and temperature of 75-85 DEG C to prepare sodium hydroxyethyl sulfonate; performing ammonolysis reaction on the sodium hydroxyethyl sulfonate and liquid ammonia at 14-24 MPa and 160-280 DEG C to obtain an ammonolysis solution containing 2-taurine sodium, evaporating the ammonolysis solution to remove ammonia, neutralizing by using sulfuric acid, concentrating, crystallizing and separating, pre-drying in a boiling drying device or a vibration fluidized drying device, and then adding the dried product in a microwave drying device to dry and sterilize to obtain the 2-taurine, wherein the water content of the dry 2-taurine is reduced to be less than 0.05% in combination of the pre-drying of the boiling drying device or the vibration fluidized drying device and the far infrared of the microwave drying, and further the effect of sterilizing is achieved. The method disclosed by the invention is short in preparation time of the 2-taurine, high in yield, low in cost and easy for industrial production.

Owner:王代龙 +1

Preparation method of N-methyl sodium taurate

ActiveCN110903222AShorten the timeIncrease productivitySulfonic acids salts preparationMetal/metal-oxides/metal-hydroxide catalystsSulfonatePtru catalyst

The invention provides a preparation method of N-methyl sodium taurate. Firstly, sodium hydroxyethyl sulfonate is dissolved in water to form a homogeneous system solution. Secondly, methylamine and acatalyst are added into the homogeneous system solution, the reaction system is heated to react, and the catalyst is selected from Zn5 (Co3) 2 (OH) 6, Ni2ZrO4 and Zn5 (Co3) 2 (OH) 6 / Ni2ZrO4. Finally,the N-methyltaurine sodium sulfonate is obtained through demethylation, neutralization, crystallization separation and other steps. The yield of the N-methyltaurine sodium sulfonate can reach 85.0-95.0%, and the selectivity is greater than 98%.

Owner:WANHUA CHEM GRP CO LTD

Method for purifying sodium hydroxyethyl sulphonate

ActiveCN102050764ATo satisfy the market's needsSimple processOrganic compound preparationSulfonic acids salts preparationEpoxySolvent

The invention relates to a method for purifying sodium hydroxyethyl sulphonate, which is characterized by comprising the following steps of: preparing 40-45wt% of coarse product prepared by using 30-40wt% of newly-prepared sodium-bisulfite aqueous solution and epoxy ethane as raw materials; delivering the coarse product into a first effect evaporator for concentrating to 5-60wt% at the temperature of 80-120 DEG C; then delivering into a second effect evaporator for further concentrating and evaporating to 72-75wt% at the temperature of 100-130 DEG C; then delivering the concentrated solution to a continuous crystallizer, recrystallizing for 1-6 hours at the temperature of 20-80 DEG C, centrifugalizing crystal mush, delivering solids to next processing step, and respectively recovering a mother solution and a residual crystallization solution; obtaining the sodium hydroxyethyl sulphonate with the purity of larger than 99.5wt% when the content of glycol in the product is smaller than 0.1wt%; returning the recovered mother crystallization solution to the second effect evaporator for concentrating; and extracting the recovered residual crystallization solution with 3 times of anhydrous ethanol, then centrifugalizing, drying crystals at the temperature of 120 DEG C, and recovering and recycling the ethanol which is used as a solvent.

Owner:吉林众鑫化工集团有限公司

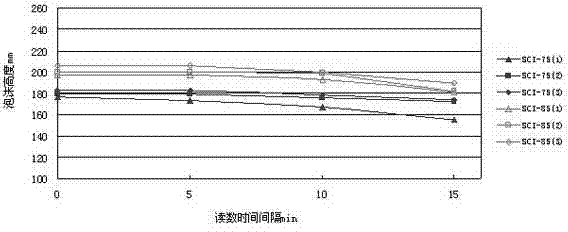

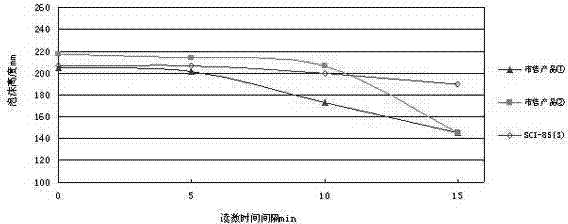

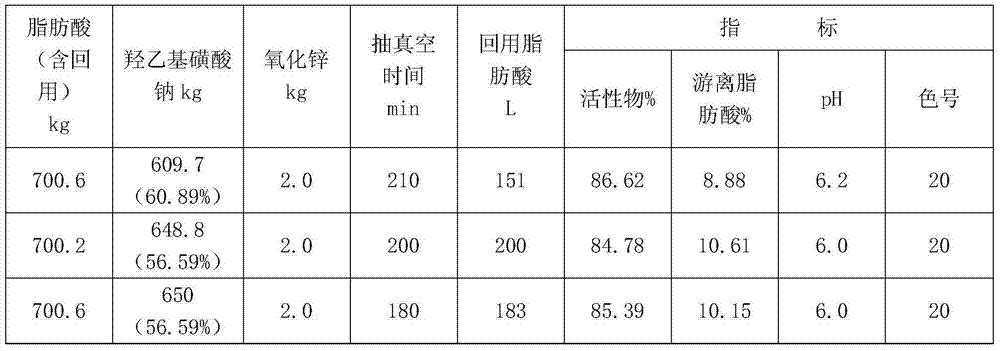

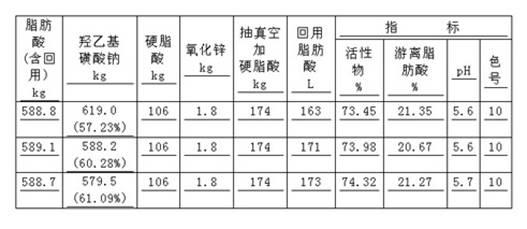

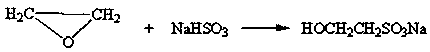

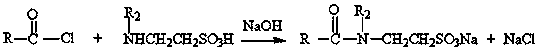

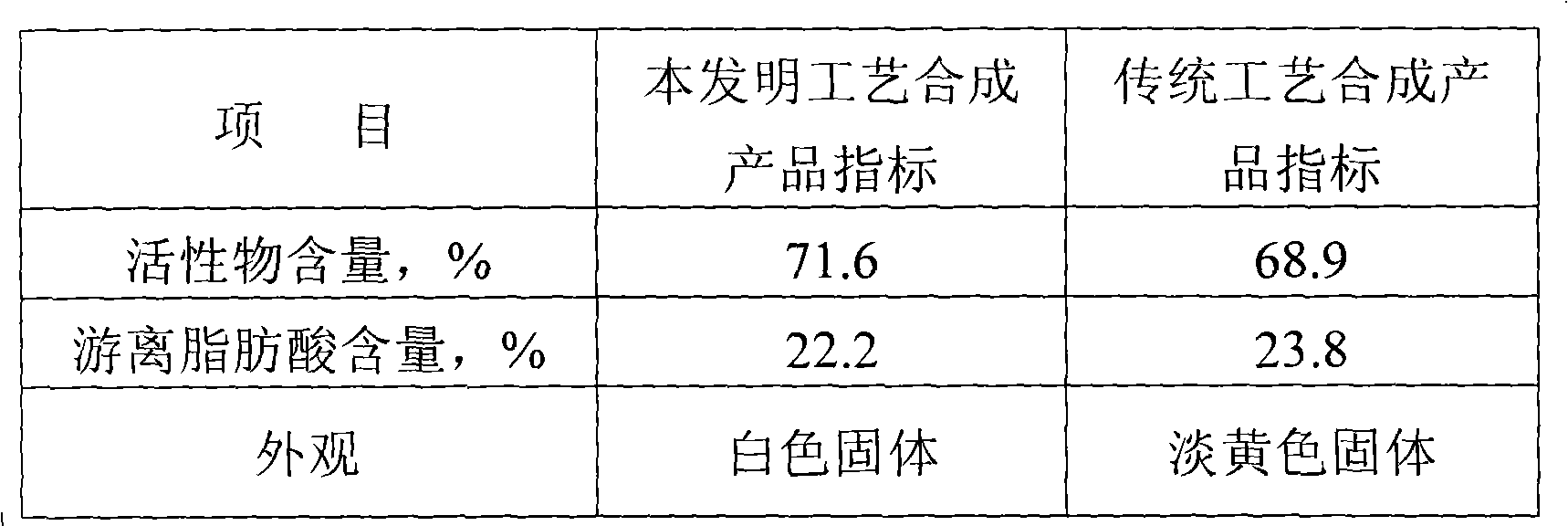

Preparation method of sodium hydroxyethyl sulfonate fatty acid ester

ActiveCN103483228ARich sourcesReduce pollutionSulfonic acids salts preparationVacuum pumpingIodo fatty acid

The invention relates to a preparation method for synthesizing esters from fatty acid and sodium hydroxyethyl sulfonate and particularly relates to a preparation method of sodium hydroxyethyl sulfonate fatty acid ester. According to the method, a finished product of sodium hydroxyethyl sulfonate fatty acid ester is prepared by adopting coconut oil acid, sodium hydroxyethyl sulfonate and zinc oxide as raw materials through performing preparation of the raw materials, esterification reaction, vacuum-pumping operation and other process steps. The preparation method provided by the invention has the advantages of simple process, rich sources of the raw materials, reproducibility, very low environmental pollution of a production process and no other wastes and byproducts, and is suitable for industrial mass production. The product is easy to be crushed into powder with the particle size of 200 meshes through a crushing machine and can be added into face washing powder, and experiments prove that the product has strong foamability and hard water resistance.

Owner:JILIN AEGIS CHEM

Hydroxyl compound type composite foaming agent and preparation method thereof

The invention relates to a foaming agent, specifically to a hydroxyl compound type composite foaming agent and a preparation method thereof. The hydroxyl compound type composite foaming agent at leastcomprises the following preparation raw materials in parts by weight: 2 to 20 parts of a nonionic surfactant, 1 to 5 parts of an anionic surfactant, 0.1 to 5 parts of a foam stabilizer, 0.5 to 1 partof a thickening agent and 69 to 96.4 parts of water, wherein the nonionic surfactant is one ore more selected from the group consisting of polyether polyol and lignin polyether polyol; and the anionic surfactant is one or more selected from the group consisting of a dodecyl anionic surfactant, lauryl sulfate triethanolamine, secondary alkyl sodium sulfonate, fatty alcohol sodium hydroxyethyl sulfonate, N-sodium lauroyl sarcosine, amide polyoxyethylene ether magnesium sulfate, dodecanol polyoxyethylene ether disodium sulfosuccinate, sodium alpha-olefin sulfonate, sodium fatty alcohol ether sulfate, sulfonates of ethoxylated fatty acid methyl ester, alcohol ether carboxylate, methyl stearate polyoxyethylene ether sodium sulfonate and isooctyl phosphate.

Owner:GUANGDONG SHENGRUI TECH CO LTD

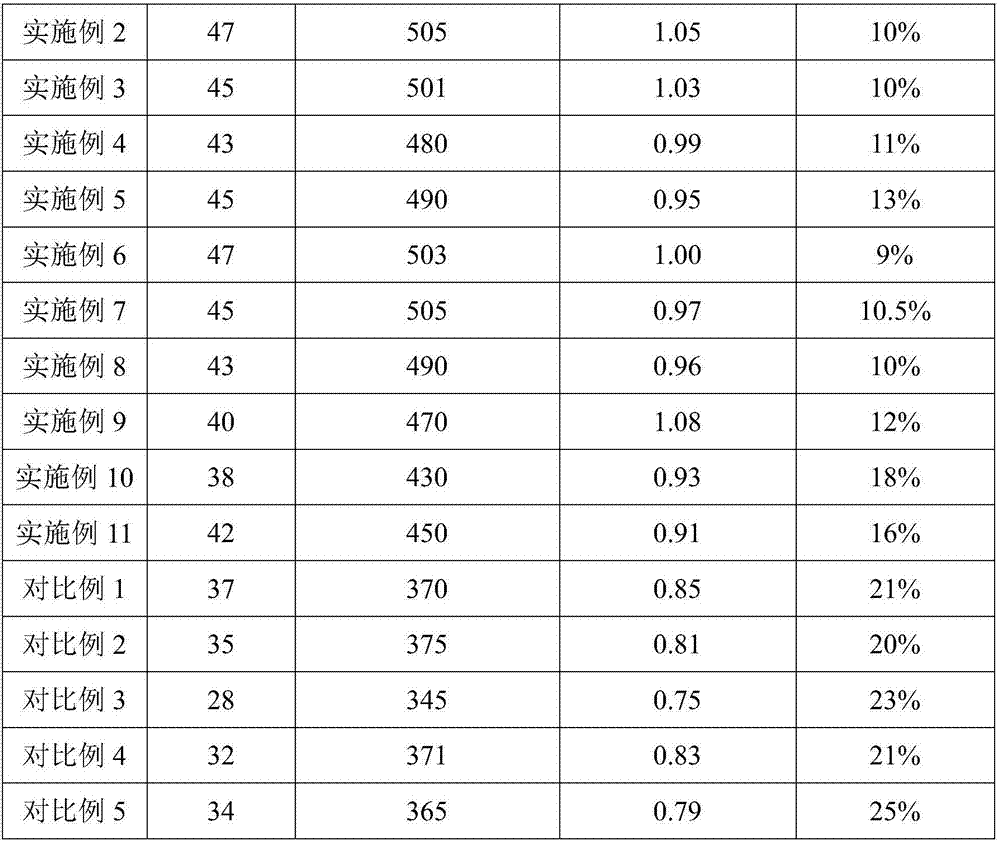

Low-pollution lignin dispersant for disperse dye as well as preparation method and application thereof

ActiveCN104356689AGood water solubilityImprove adsorption strengthOrganic dyesDisperse dyeDispersion stability

The invention discloses a low-pollution lignin dispersant for a disperse dye as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, dissolving an alkali lignin solid in water, adjusting the pH value to be 9.0-12.0 for preparing an alkali lignin aqueous solution with the mass concentration of 20%-50%, heating to 60-90 DEG C, and adding sodium hydroxyethyl sulfonate for reacting for 1-3 hours to obtain a sulfonated hydroxyethyl alkali lignin solution; adding a polarizing agent and a surface active material into the obtained sulfonated hydroxyethyl alkali lignin solution, uniformly stirring and adjusting the pH value to be 4.0-6.0 to obtain the low-pollution lignin dispersant. Compared with sodium lignin sulfonate and sulfomethylated lignin dispersants, the low-pollution lignin dispersant has the characteristics that the pollution rate of fibers and the reduction rate of the disperse dye are remarkably reduced, a dye system prepared from the dye dispersant has the characteristics that the dye-uptake rate of the fibers is greatly increased in comparison with sodium lignin sulfonate, and the dispersion stability of a prepared dye dispersion solution is superior to that of a naphthaline dispersant.

Owner:SOUTH CHINA UNIV OF TECH

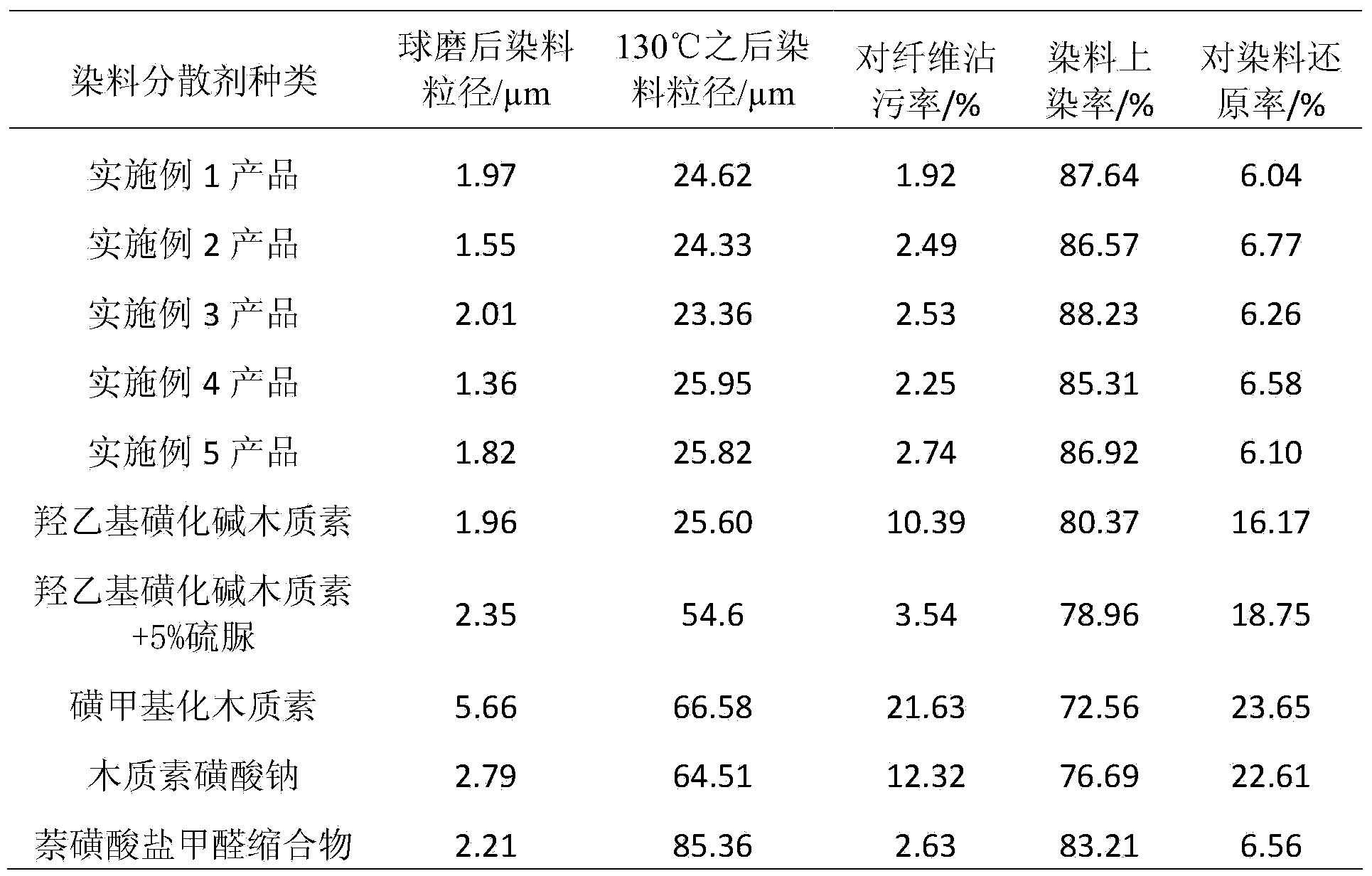

Taurine synthesis method

ActiveCN111320558AIssues that do not affect yieldHigh yieldOrganic compound preparationSulfonic acids salts preparationTaurine synthesisSodium Isethionate

The invention provides a safe and efficient taurine synthesis method. The taurine synthesis method comprises the following steps: adding sodium hydrogen sulfite and ethylene oxide to prepare sodium isethionate; carrying out ammonolysis on sodium hydroxyethyl sulfonate and liquid ammonia at a high temperature to obtain sodium taurate; acidifying sodium taurate, and carrying out crystallization to obtain a taurine pure product. Before addition reactions, impurities are filtered by a nano-filtration membrane, and the side reaction influence is eliminated. The method has the advantages of mild ammonolysis reaction conditions and shortened reaction retention time, and the industrial production is safe and efficient.

Owner:WANHUA CHEM GRP CO LTD

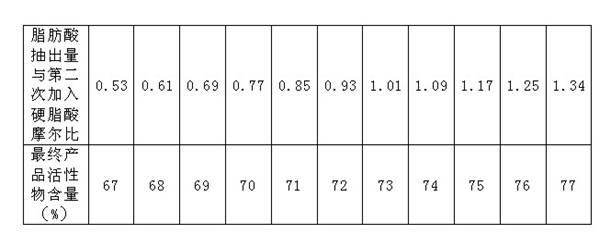

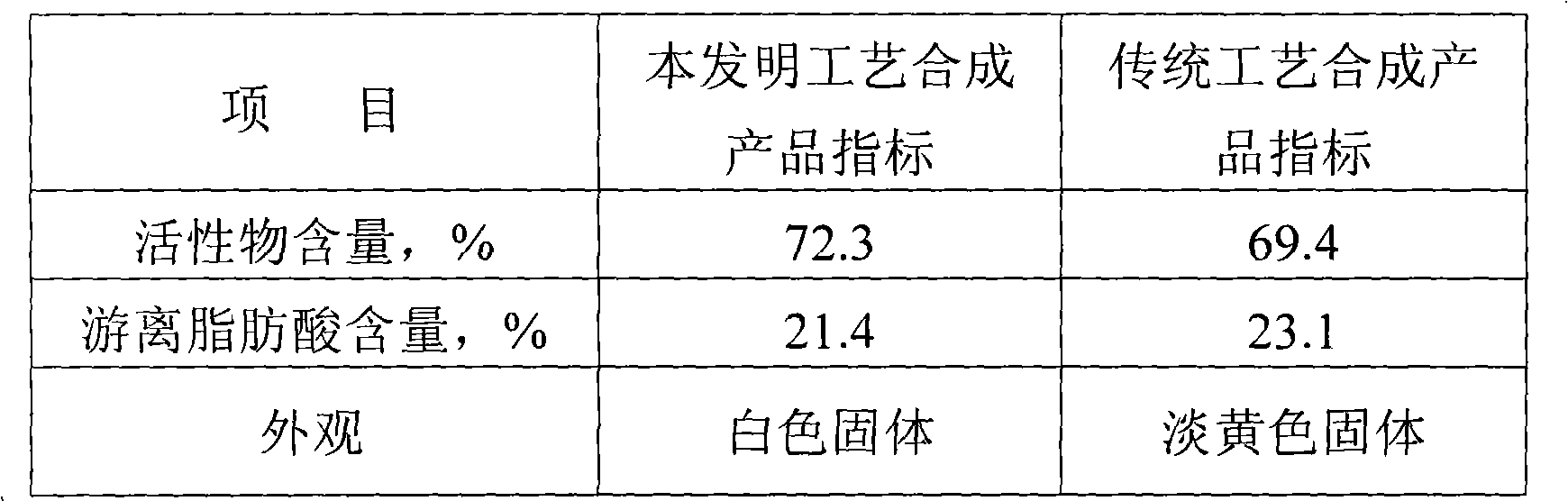

Preparation method for ethoxyl sodium sulfonate fatty acid ester

ActiveCN102584642AGuaranteed overdoseGuaranteed liquiditySulfonic acids salts preparationSulfonateShower gel

The invention relates to a preparation method for compounding an ester by using fatty acid and ethoxyl sodium sulfonate and especially relates to a preparation method for an ethoxyl sodium sulfonate fatty acid ester. The preparation method comprises the following steps: performing esterification reaction on coconut oleic acid (after being processed), stearic acid, ethoxyl sodium sulfonate and catalyst (ZnO), reducing the pressure, and adding the stearic acid for the second time, thereby obtaining the product of the ethoxyl sodium sulfonate fatty acid ester containing 65-77% of active matters.The aspects of color, smell and carbon number distribution cause the product to be better applied to preparation of the cleaning skin-care products, such as soap, facial cleaner, shower gel and shampoo.

Owner:JILIN AEGIS CHEM

Metal paint and preparation method thereof

InactiveCN102993791AHigh hardnessScratch resistantCoatingsPigment treatment with organosilicon compoundsGlycidyl methacrylateMeth-

The invention discloses a metal paint, which is prepared from the following raw materials in parts by weight: 180 to 190 parts of dodecenylsuccinic acid, 130 to 135 parts of propylene glycol, 210 to 215 parts of glycidyl methacrylate, 360 to 365 parts of 2-ethyl hexyl acrylate, 430 to 435 parts of methylpropanediol, 105 to 108 parts of phenolic resin, 85 to 90 parts of styrene, 100 to 110 parts of ethylenediamine, 300 to 310 parts of titanium dioxide, 20 to 30 parts of modified diatomite, 7 to 8 parts of formic acid, 100 to 105 parts of water, and 14 to 16 parts of sodium hydroxyethyl sulfonate. The raw materials are mixed, dispersed at a high speed, and grinded into nano-grade metal paint. The coating formed by the metal paint has the advantages of high hardness, scratch prevention, strong attachment, salt mist resistance, saline water resistance, acid and alkali resistance, water and oil resistance, recycling on oil paint film surface, paint film hurt prevention, super-strong paint film flexibility and the like. The service life of a conventional paint film can be between 5 and 8 years.

Owner:怀远县巨龙机械制造有限公司

Method for preparing taurine from sodium hydroxyethyl sulfonate

InactiveCN109535043AEasy to removePromote offenseSulfonic acids salts preparationSulfonic acid preparationTaurineAmmonia

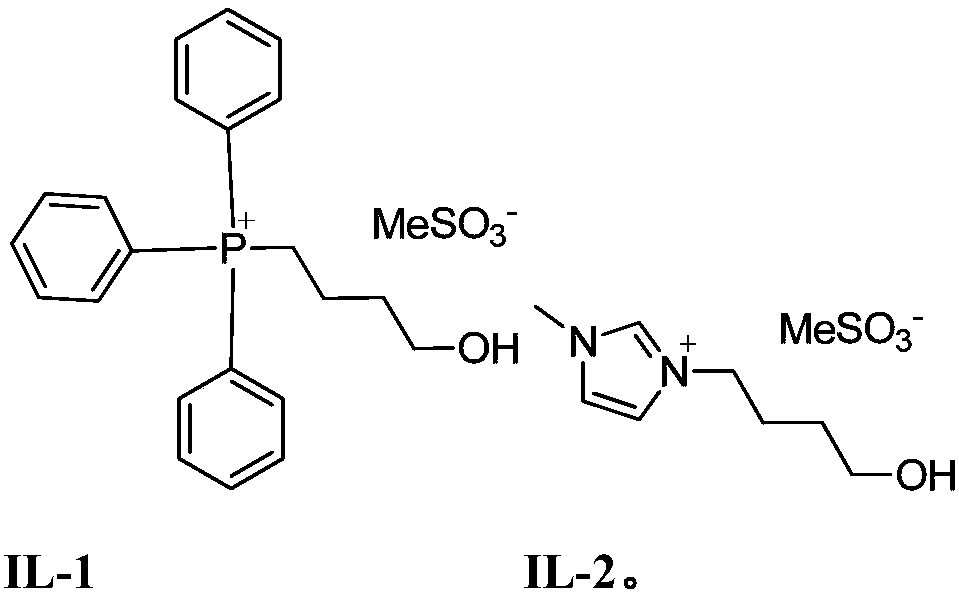

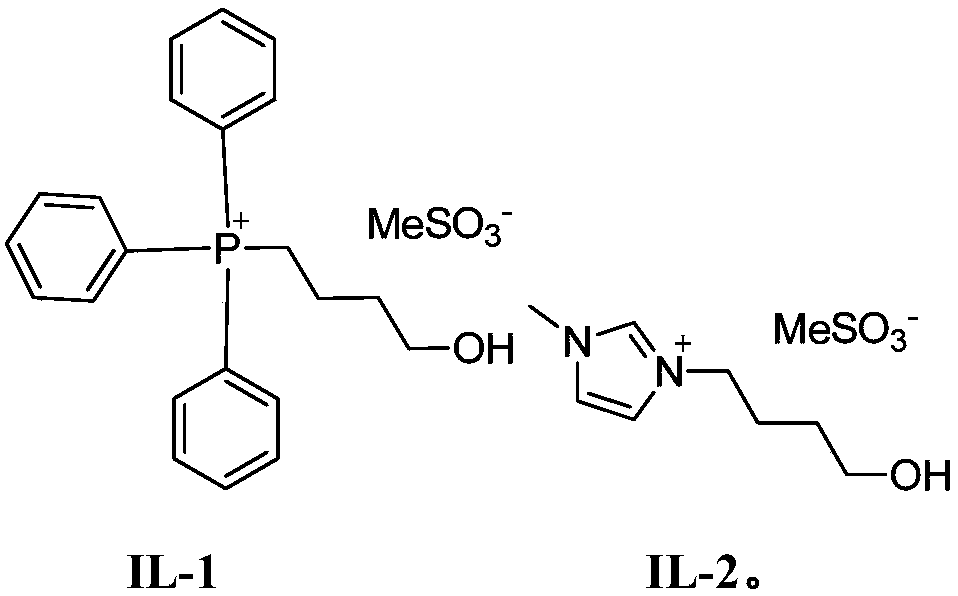

The invention provides a method for preparing taurine from sodium hydroxyethyl sulfonate. An ionic liquid homogeneous catalyst is adopted to catalyze an ammonolysis reaction of sodium hydroxyethyl sulfonate, and then steps of neutralization, crystallization separation and the like are carried out to obtain the finished taurine. Compared with a conventional alkaline catalyst, the ionic liquid homogeneous catalyst adopted in the process can significantly reduce the temperature and pressure of the ammonolysis reaction of the sodium hydroxyethyl sulfonate, so that the reaction time is shortened, and industrial production is facilitated.

Owner:WANHUA CHEM GRP CO LTD

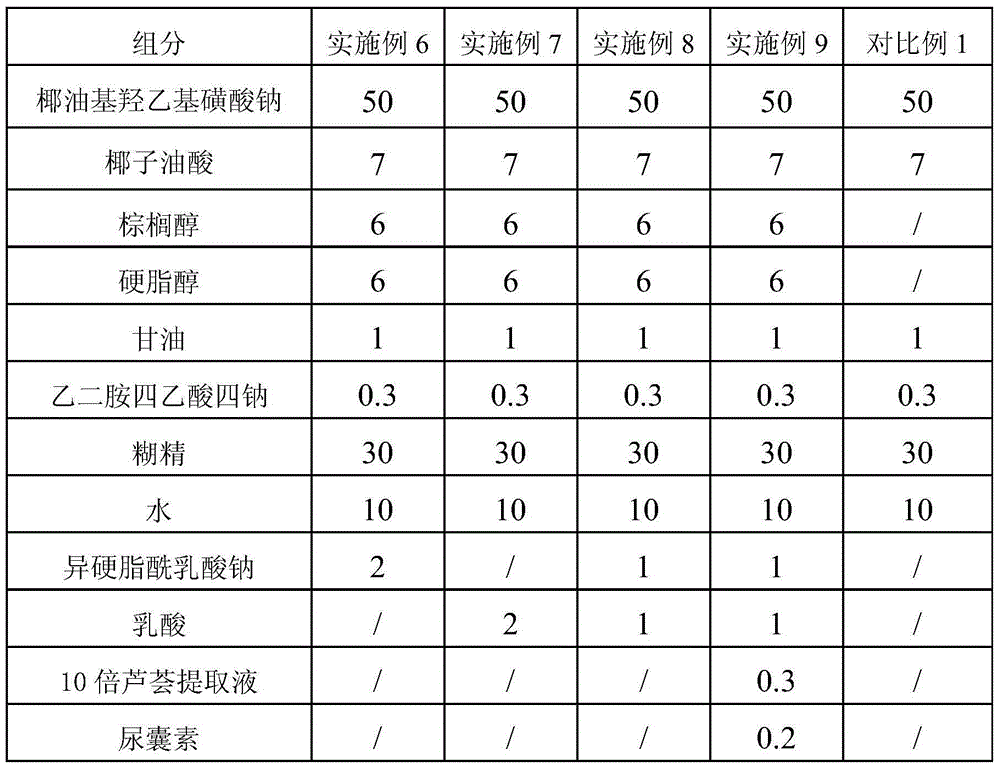

Neutral toilet soap capable of moisturizing and cleansing skin

ActiveCN104403855ALow degreasing powerMild performanceSurface-active non-soap compounds and soap mixture detergentsSkin careHydrogenGlycerol

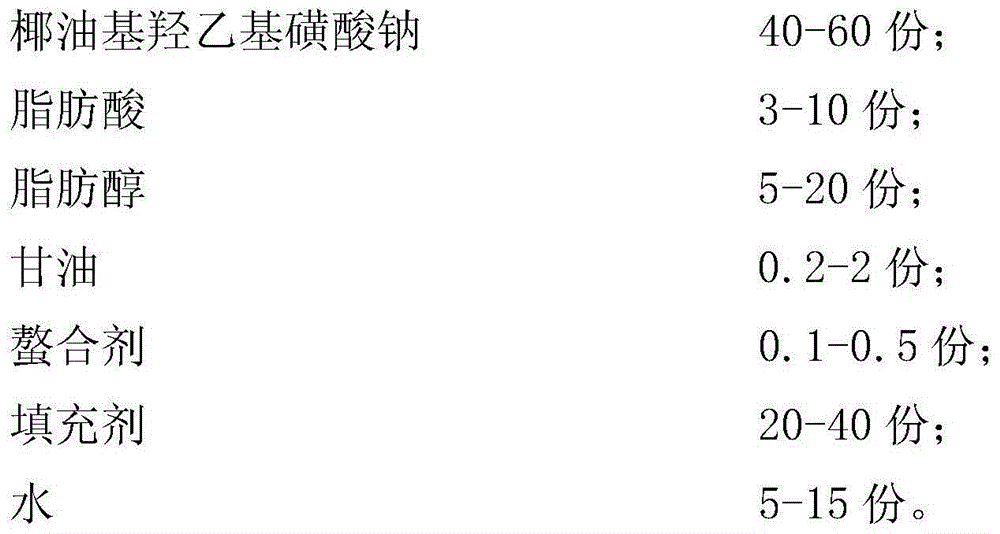

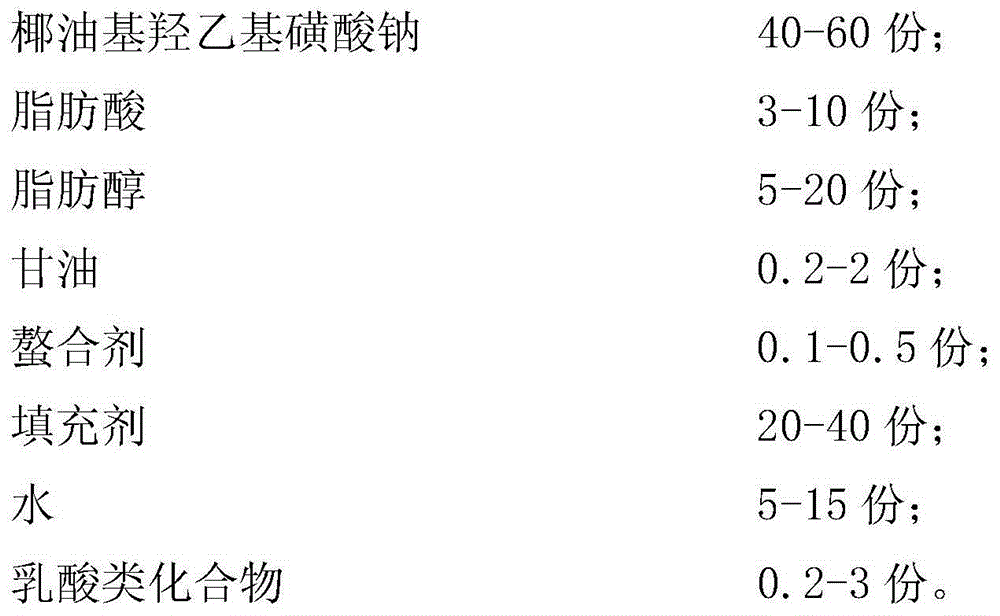

The invention discloses neutral toilet soap capable of moisturizing and cleansing skin. The neutral toilet soap capable of moisturizing and cleansing the skin comprises the following components in parts by weight: 40-60 parts of sodium cocoyl isethionate, 3-10 parts of fatty acid, 5-20 parts of fatty alcohol, 0.2-2 parts of glycerinum, 0.1-0.5 parts of chelating agents, 20-40 parts of filling agents and 5-15 parts of water. The PH (potential of hydrogen) value of the neutral toilet soap ranges from 4.5 to 6.5 and approaches the weak acid environment of the human skin. The neutral toilet soap can prevent stimulus to the skin in the cleansing process, has no granular feeling, is not likely to become pappy in water and is long in service life.

Owner:SHANGHAI SOAP FACTORY

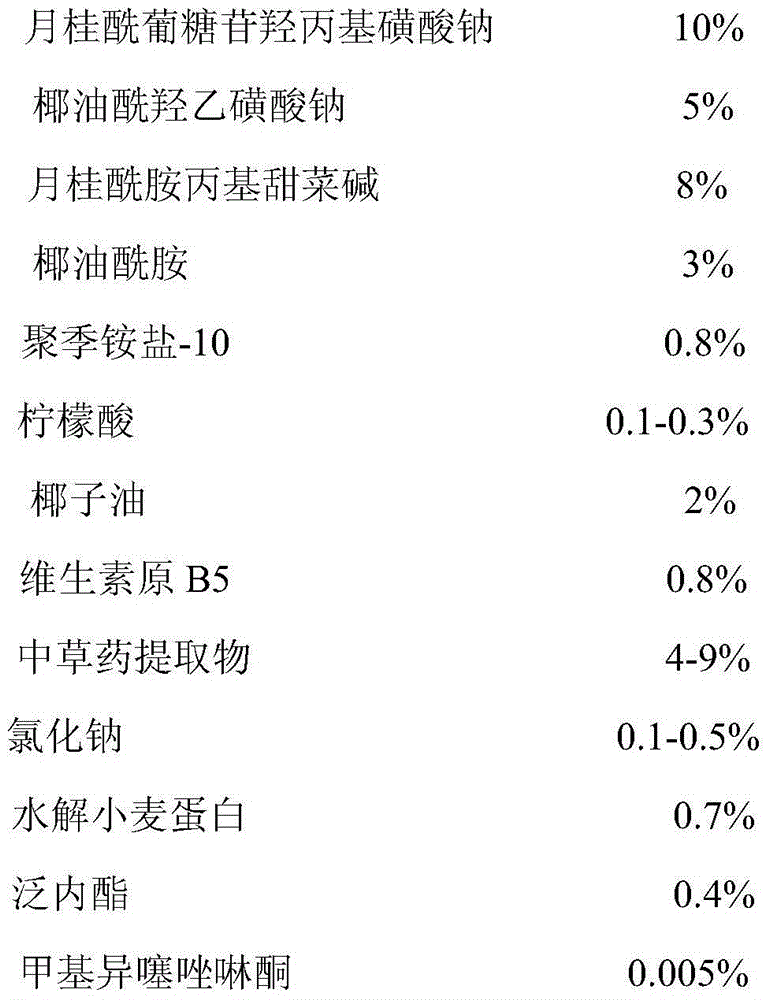

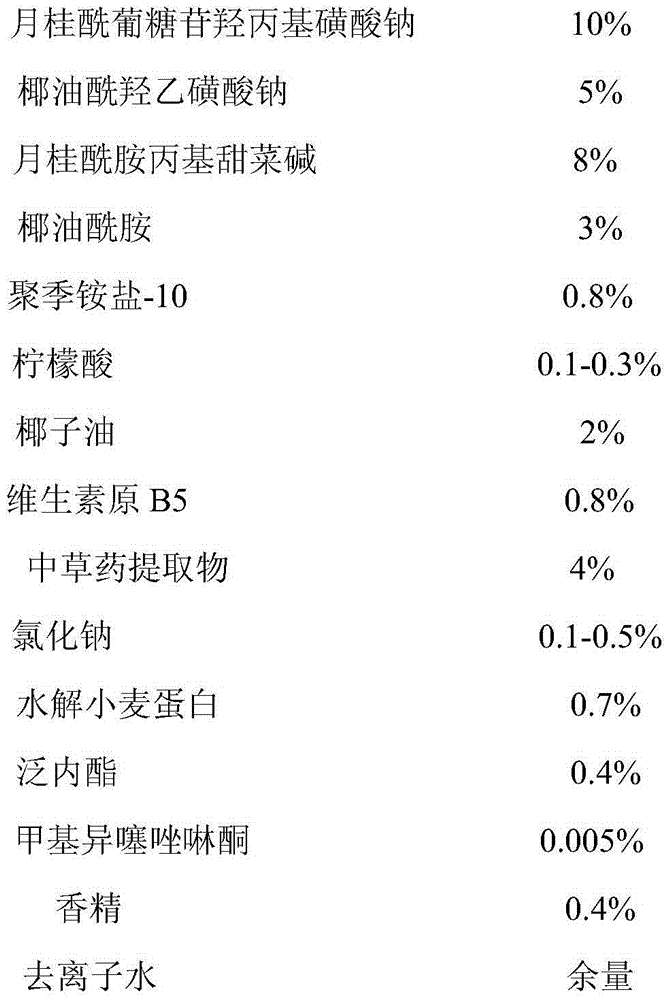

Traditional Chinese medicine shampoo capable of relieving itch and removing dandruffs

InactiveCN104095786AGood for healthImprove itchy headCosmetic preparationsHair cosmeticsHydroxyethyl sulfonateDandruff

The invention discloses a traditional Chinese medicine shampoo capable of relieving itch and removing dandruffs, belongs to the technical field of cosmetics, and aims to solve the problems that a user can easily have tolerance and the drug resistance to the existing shampoo capable of relieving itch and removing dandruffs. The traditional Chinese medicine shampoo comprises the following raw materials in percentage by mass: 10% of sodium laury glucosides hydroxypropyl sulfonate, 5% of cocoanutyl hydroxyethyl sulfonate sodium, 8% of (carboxymethyl)dimethyl-3-[(1-oxododecyl)amino]propylammonium hydroxide, 3% of coconutt diethanol amide, 0.8% of polyquaternium-10, 0.1-0.3% of citric acid, 2% of coconut oil, 0.8% of vitamin B5, 4-9% of traditional Chinese medicine extract, 0.1-0.5% of sodium chloride, 0.7% of hydrolyzed wheat protein, 0.4% of pantolactone, 0.005% of 2-methyl-4-isothiazolin-3-one, 0.4-0.6% of essence and the balance of deionized water. The traditional Chinese medicine shampoo is suitable for a user with oil, itch and dandruffs in hair.

Owner:卢磊

Anti-bacterial hand sanitizer containing folium artemisiae argyi extracts and preparation method thereof

ActiveCN105326681AImprove detergencyGood resistance to hard waterAntibacterial agentsCosmetic preparationsBiotechnologyAntimicrobial action

The invention belongs to the field of daily chemicals, and particularly relates to an anti-bacterial hand sanitizer containing folium artemisiae argyi extracts and a preparation method thereof. The anti-bacterial hand sanitizer containing the folium artemisiae argyi extracts is mainly prepared from fatty acid sodium hydroxyethyl sulfonate, seconary alkane sulphonate sodium, dodecyl polyglucoside, a moisturizing agent, the plant extracts, ethylene diamine tetraacetic acid tetrasodium, sodium chloride, citric acid, jojoba oil and water. The anti-bacterial hand sanitizer containing the folium artemisiae argyi extracts has the advantages of being soft, smooth and fine in foam, free of stimulation, harmless to hand, high in dirt-removing power and significant in anti-bacterial action and can achieve the effect of quickly and effectively cleaning the hands. Meanwhile, due to the fact that the moisturizing agent and the jojoba oil are added in the hand sanitizer, the hand sanitizer has the moistening and moisturizing effects on the skin after being used, and the phenomenon that the skin is dry and peeling after the hand sanitizer is used can be effectively prevented.

Owner:青春之艾(上海)健康科技有限公司

Bleaching agent for fabric and preparation method thereof

InactiveCN103696227AStrong bleaching abilityHas decontamination effectNon-ionic surface-active compoundsOrganic detergent compounding agentsFiberBleach

The invention relates to a bleaching agent for fabric and a preparation method thereof. The bleaching agent contains the following components by weight: 4-9 parts of fatty alcohol polyoxyethylene ether, 0.5-1.3 parts of hydroxyethyl sulfonate, 10-18 parts of sodium percarbonate, 2-4.4 parts of sodium hydroxide, 0.025-0.055 part of edetate, 4-11 parts of sodium sulfate, 7-16 parts of sodium hypochlorite, 0.01-0.03 part of manganese sulfate, 1.2-4 parts of sodium acrylate-maleic anhydride copolymer and 5.1-10.5 parts of water. According to the bleaching agent for fabric and the preparation method thereof provided by the invention, the bleaching agent has strong bleaching ability, does not damage clothing fibers, also has decontamination effect.

Owner:NANTONG CITY TONGZHOU DISTRICT DADA HEMP TEXTILE

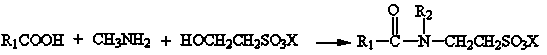

Method for synthesizing fatty acyl amino acid surfactant by using direct method

InactiveCN111004156AEasy to operateEasy to realize industrial productionTransportation and packagingSulfonic acids salts preparationSodium IsethionateSulfonate

The invention discloses a method for synthesizing a fatty acyl amino acid surfactant by using a direct method. The method comprises the following steps: (1) adding fatty acid, methylamine and hydroxyethyl sulfonate into a reactor; (2) closing the reactor, and slowly heating to 150-300 DEG C; (3) carrying out a heat preservation reaction for 2-10 hours; (4) distilling to remove unreacted methylamine; and (5) treating to obtain a finished product. According to the invention, fatty acid, methylamine and sodium isethionate are selected to be subjected to a direct reaction, impurities such as chlorine ions and the like are not introduced in the process, and the target product is obtained through the direct reaction, so that the purification steps such as acidification, salification and the likeare omitted, and the use and discharge of salt-containing wastewater or an organic solvent are reduced; and the operation is convenient, the industrial production is easy to realize, the product formof the prepared product can also be changed according to actual requirements, and the cost advantage and the application convenience advantage of the product are improved.

Owner:ZHANGJIAGANG GREAT CHEM

Microwave synthesis method of sodium fatty acyloxy isethionate

InactiveCN102180814ASimple heating equipmentFast heatingTransportation and packagingSulfonic acids salts preparationSodium IsethionateIodo fatty acid

The invention relates to a microwave synthesis method of sodium fatty acyloxy isethionate. The method provided by the invention has the characteristics of good product quality, simple processing equipment and low energy consumption. The technical scheme is as follows: the method sequentially comprises the following steps: 1. putting fatty acid and sodium isethionate into a special reaction bulb for microwaves in a mol ratio of 1:(1.0-1.3), heating to 180-200 DEG C by microwaves, reacting under the pressure of 10-100KPa for 30-60 minutes, and removing water generated in the reaction process by introducing nitrogen or vacuumizing; and 2. cooling the reaction product, and slicing to obtain the sodium fatty acyloxy isethionate. The fatty acid is a C8-C20 fatty acid or mixture thereof. In the reaction process, the N2 is introduced for protection and dewatering; and by using the number of bubbles as the counting unit, the flow rate of the N2 is 60-120 bubbles / min.

Owner:ZANYU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com