Patents

Literature

274results about How to "Improve adsorption strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porous carbonaceous material, manufacturing method therefor and use thereof

InactiveUS6475461B1Facilitate dissociationImprove adsorption strengthPigmenting treatmentPhysical/chemical process catalystsElectrochemistryOxygen

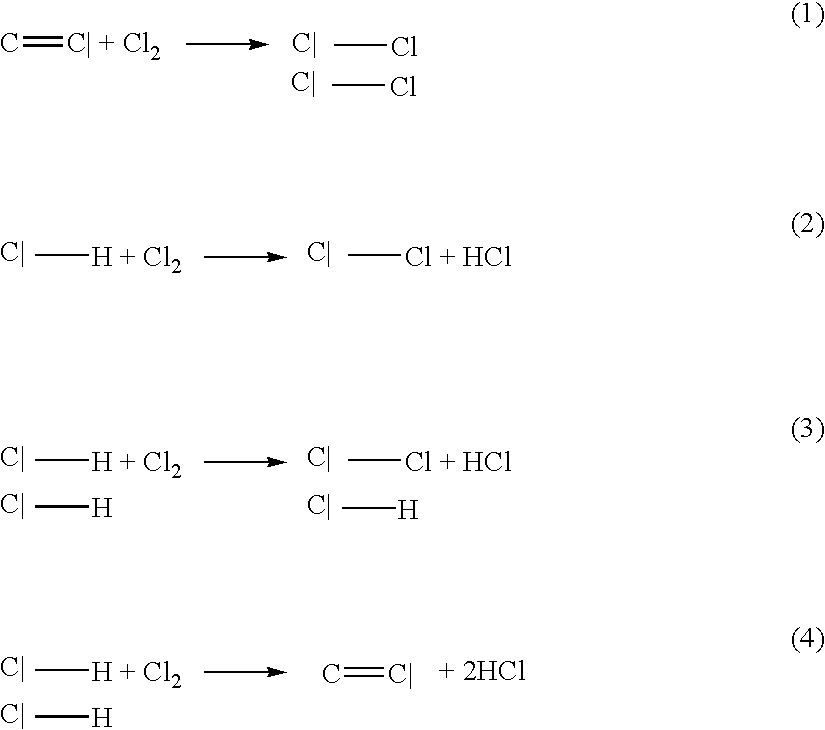

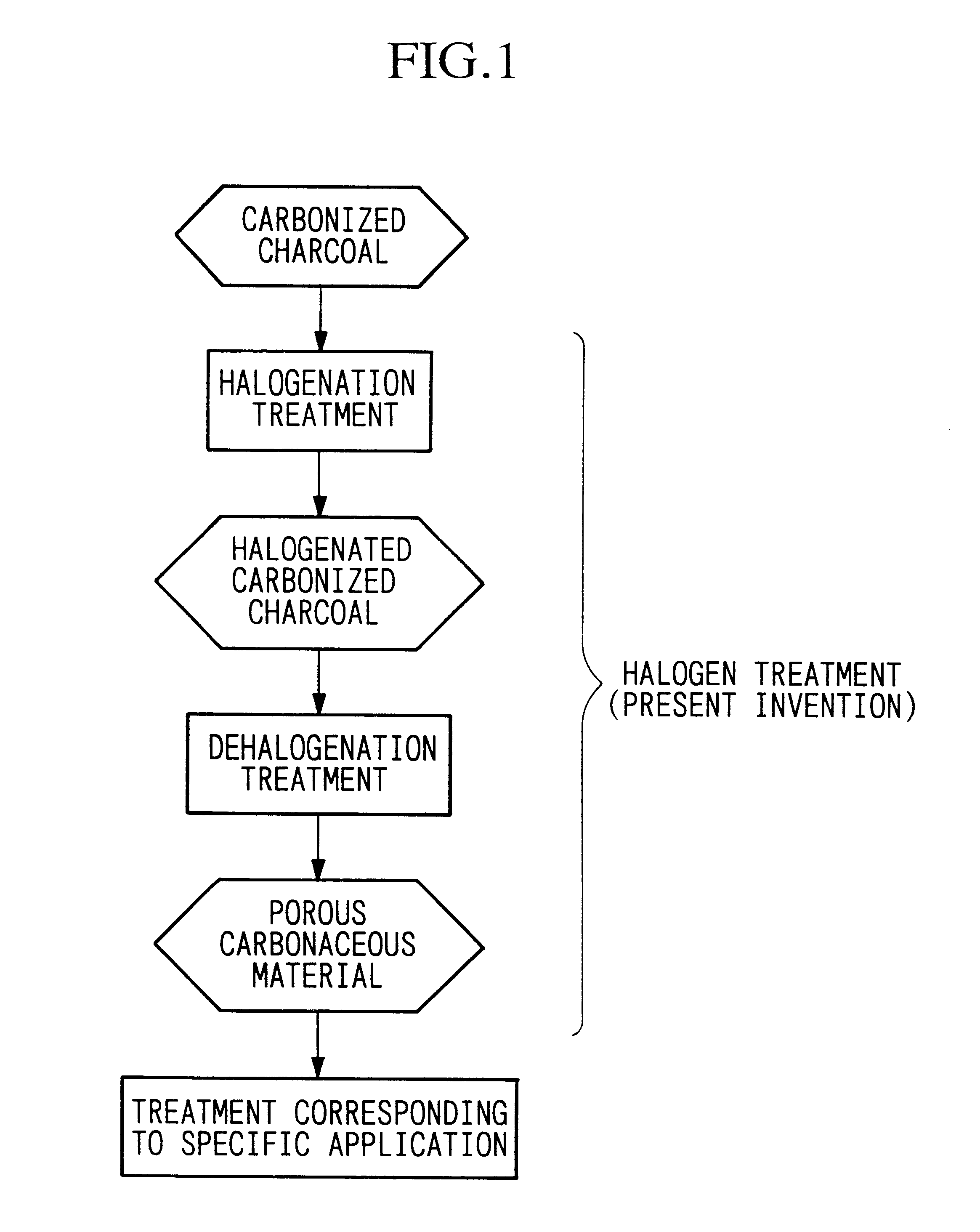

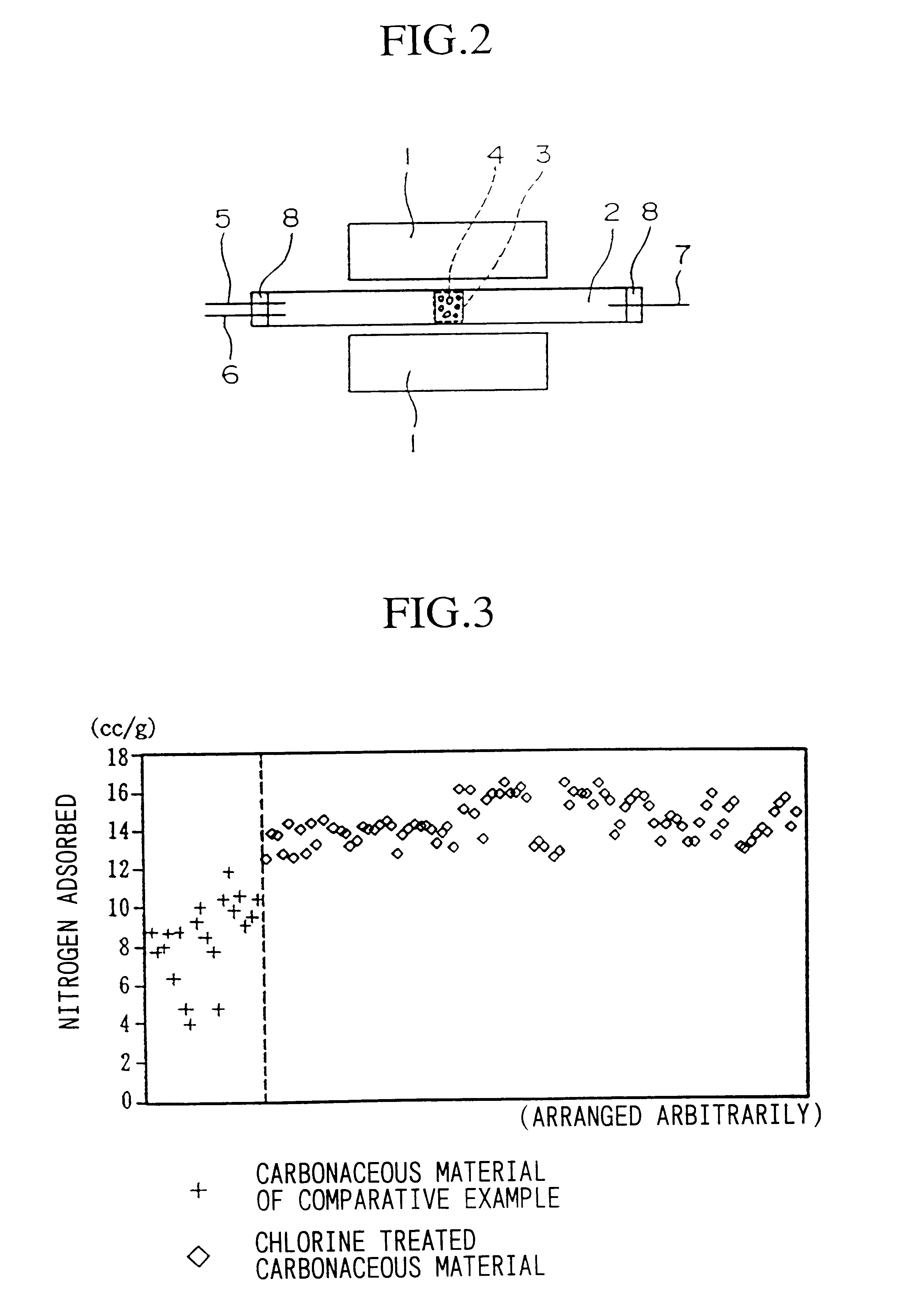

A halogen treatment is conducted comprising: a halogenation step wherein a halogenation heat treatment for preparing a halogenated carbonized charcoal is conducted in which the carbonized charcoal is brought into contact with halogen; and a dehalogenation step wherein a dehalogenation treatment is conducted in which a part of or all halogen atoms in the halogenated carbonized charcoal are eliminated. A porous carbonaceous material is obtained at a high yield, and the amounts of nitrogen, oxygen, carbon dioxide, and methane adsorbed by this porous carbonaceous material are large. When this porous carbonaceous material is used as an electrical double layer capacitor carbon, the electrostatic capacity is increased compared to conventional carbonaceous materials. Consequently, a carbonaceous material is obtained which has micopores and / or sub-micropores which are suitable for the adsorption of small molecules such as nitrogen, and for storage of electrochemical energy.

Owner:NIPPON SANSO CORP

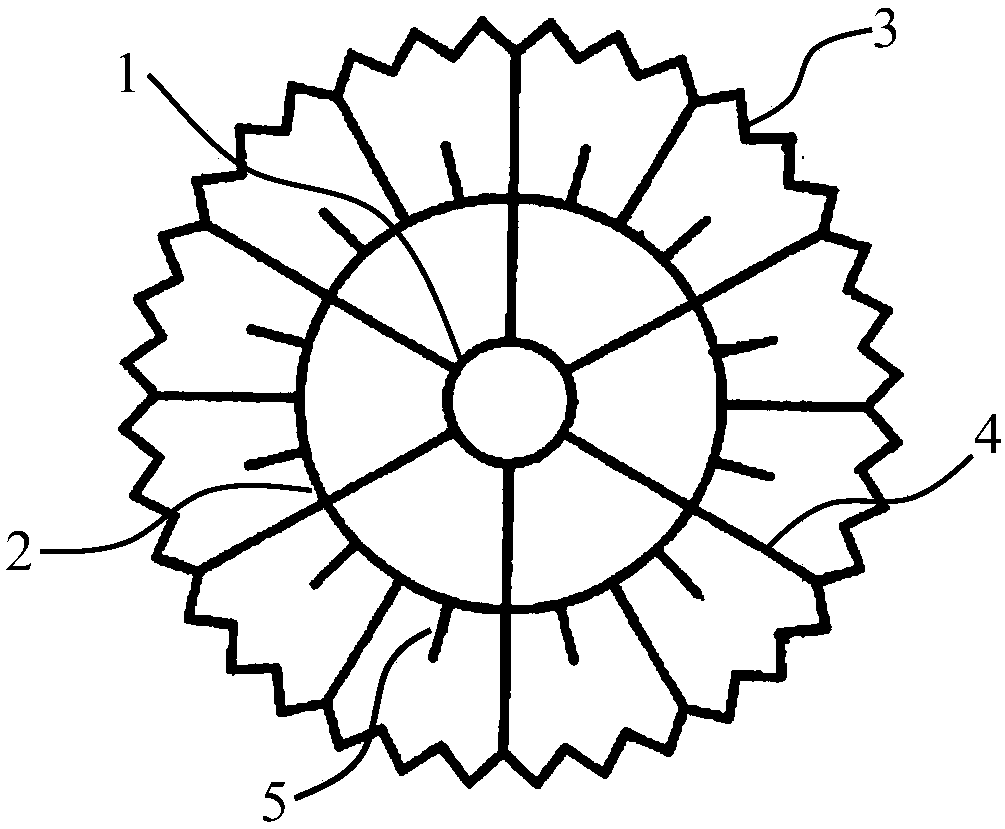

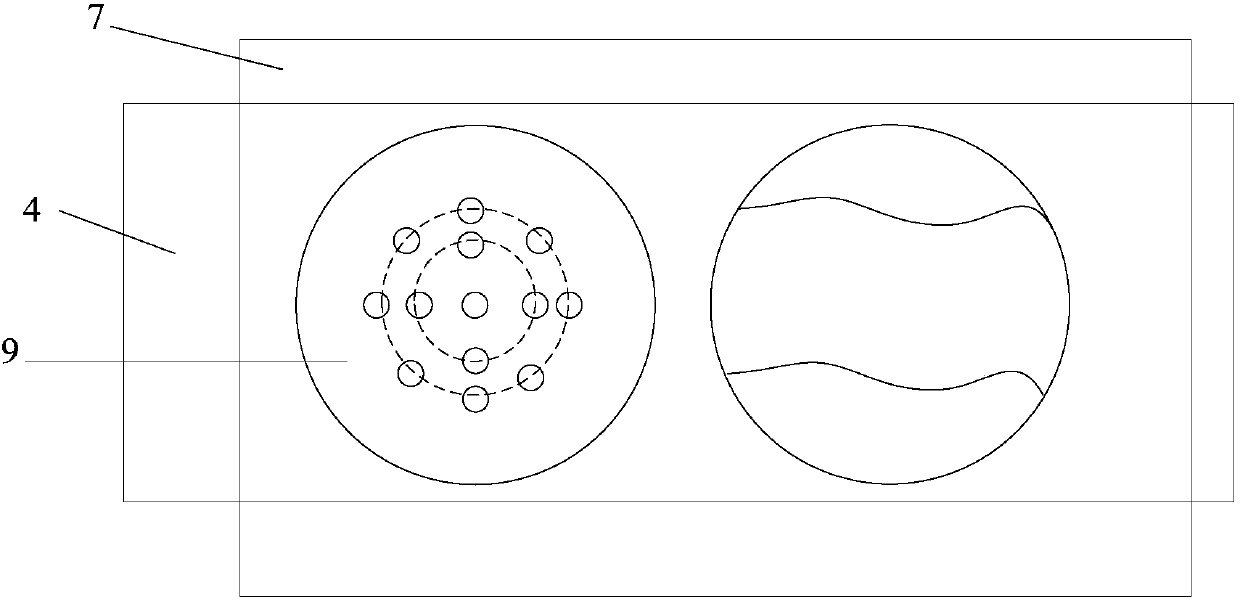

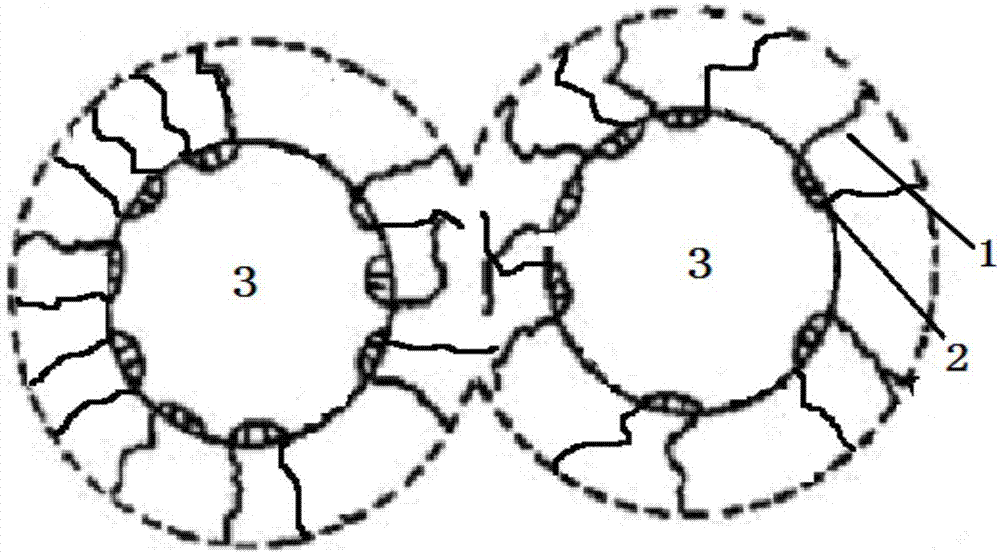

Hydrophilic carrier for microbial biofilm formation

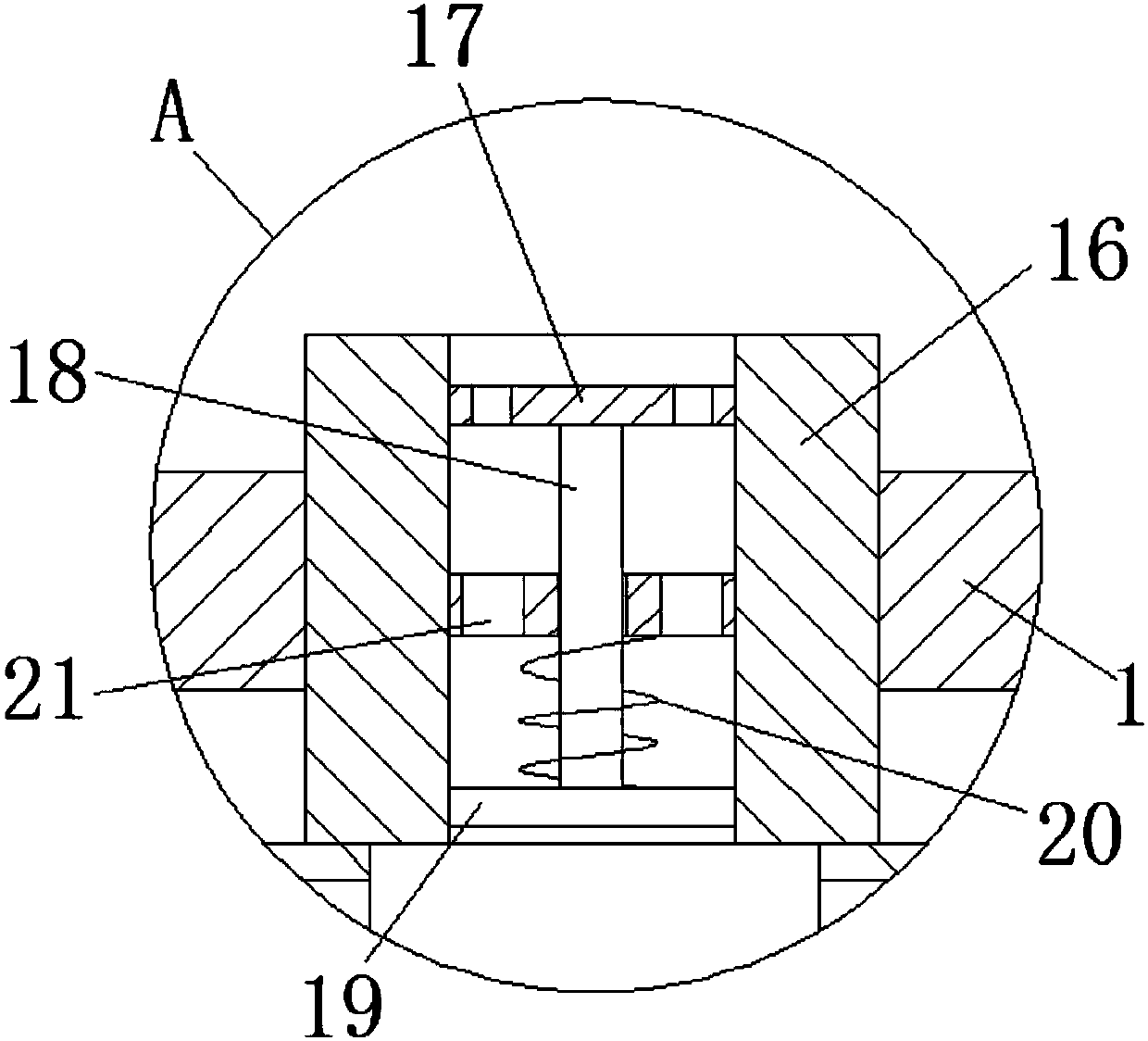

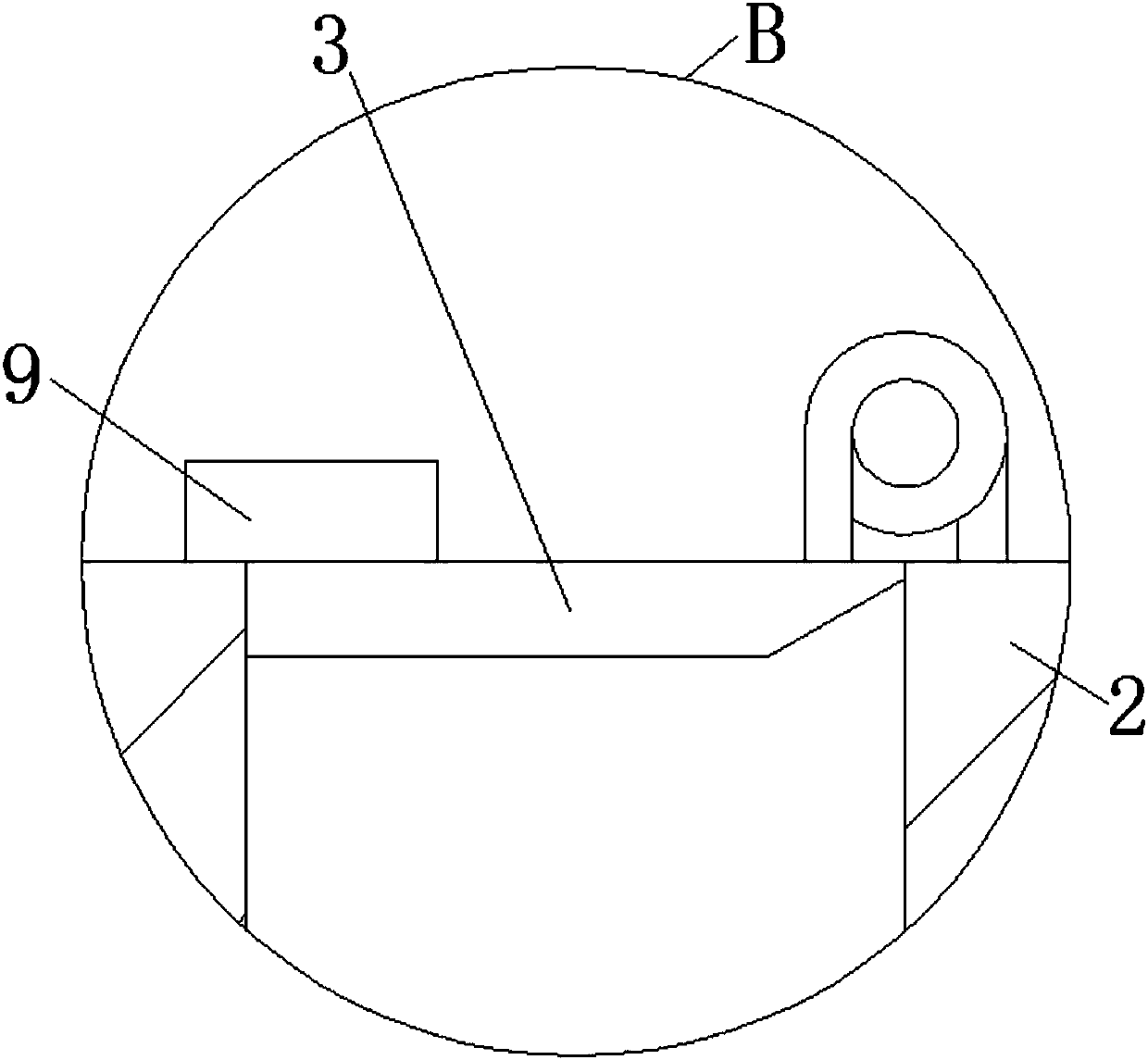

InactiveCN105621595ANot easy to fall offPromote sheddingTreatment with microorganism supports/carriersLow-density polyethyleneMicrobial Biofilms

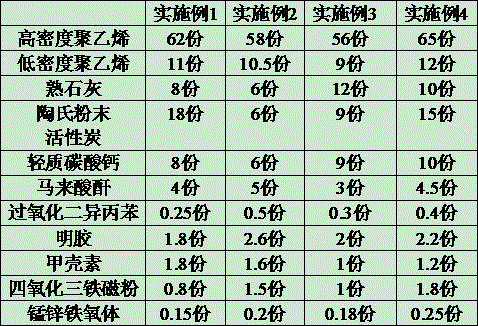

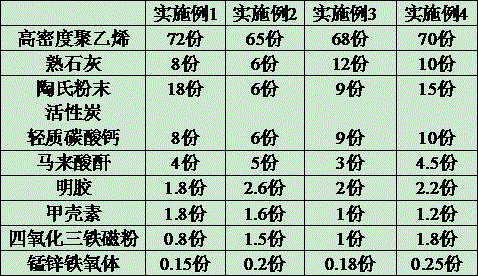

The invention discloses a hydrophilic carrier for microbial biofilm formation. The hydrophilic carrier comprises a hollow short tube, and a first concentric ring and a second concentric ring which are sequentially concentrically arranged outside the hollow short tube, wherein the surface of the outermost second concentric ring is toothed; and the microbial filler is composed of the following components in parts by weight: high-density polyethylene, low-density polyethylene, white lime, Dow powder activated carbon, light calcium carbonate, maleic anhydride, dicumyl peroxide, gelatin, chitin, ferroferric oxide magnetic powder and manganese-zinc ferrite. The density of the microbial filler is 0.96-0.98 g / cm<3>. The hydrophilic carrier for microbial biofilm formation prolongs the contact time between microbes and organic matters, so that the organic matters are degraded quickly and thoroughly; and the biological oxidation can restore the surface adsorption capacity of the activated carbon.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

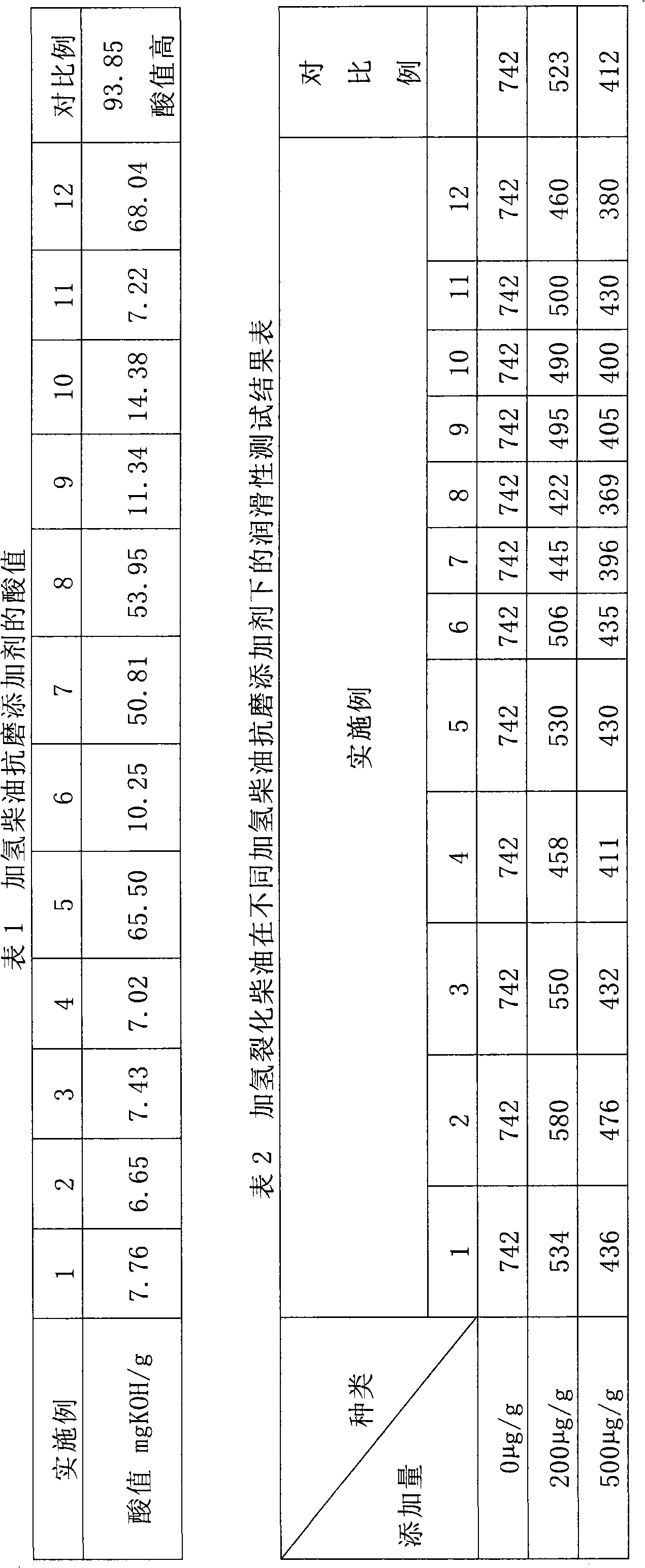

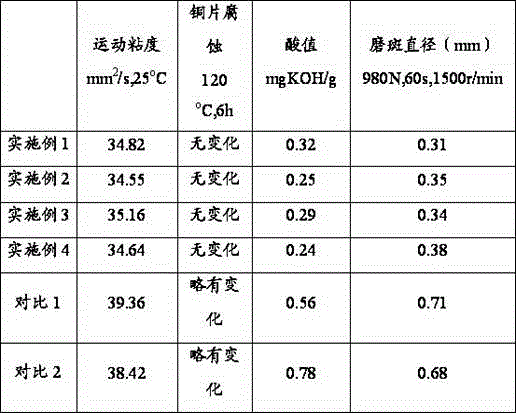

Wear-resistant additive for low-sulphur hydrogenated diesel

InactiveCN102031165AImprove adsorption strengthImprove responseLiquid carbonaceous fuelsFuel additivesGramChemistry

The invention relates to a wear-resistant additive for low-sulphur hydrogenated diesel, comprising a component A with an alcohol ester structure and also optionally comprising an auxiliary agent B with an alcohol ester structure, an auxiliary agent C with an ester structure, an assistant D or mixtures of B, C and D. The mass ratio of the component A to the component B to the component C and the component D is 100:0-42:0-10:0-0:10. Under the condition of adding 200 mug of wear-resistant additives to every gram of low-sulphur hydrogenated diesel, the diameter of a wearing crack of the low-sulphur hydrogenated diesel is reduced to 422 mum from 742 mum. By adopting plant oleic acid as the raw material, the wear-resistant additive for low-sulphur hydrogenated diesel in the invention has the advantages of low acid value, environmental protection and small addition.

Owner:EAST CHINA UNIV OF SCI & TECH

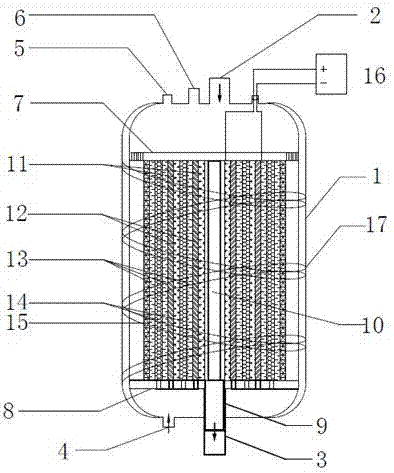

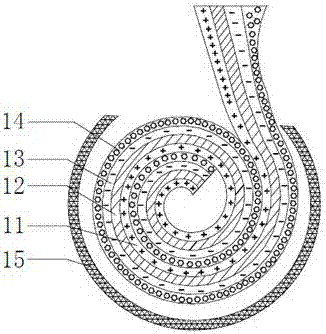

Spirally wound electrochemical water treatment reactor

ActiveCN107098442AFacilitated DiffusionEnhanced mass transferDispersed particle separationWater/sewage treatment by oxidationElectricityBarrel Shaped

The invention discloses a spirally wound electrochemical water treatment reactor. The spirally wound electrochemical water treatment reactor comprises a vertically-arranged long-barrel-shaped shell; the interior of the shell is reaction space; the shell is provided with a water inlet and a water outlet connected with the reaction space; an electrocatalytic oxidation assembly is arranged in the reaction space in the shell and divides the reaction space located between the water inlet and the water outlet; the electrocatalytic oxidation assembly is formed by compounding and spiral winding of a positive electrode layer, a positive / negative electrode insulating layer, a negative electrode layer and a supporting layer; the positive electrode layer and the negative electrode layer are both of a net structure; and the distance between the negative electrode layer and the positive electrode layer is in a range of effective distances allowing an electrocatalysis reaction to occur between the negative electrode layer and the positive electrode layer. The structure of the reactor provided by the invention is beneficial for saving space, enlarging a reaction area, increasing gas-liquid polyphase mass transfer efficiency and realizing high-efficiency, long-acting and low-consumption treatment of pollutants in water.

Owner:CHONGQING XINHE QIYUE TECH CO LTD

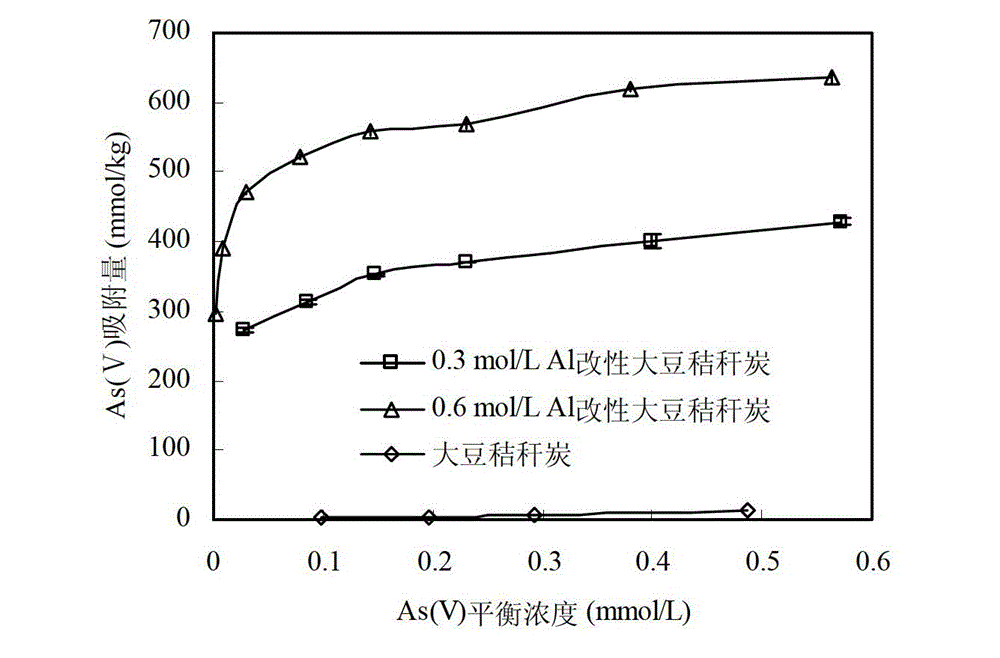

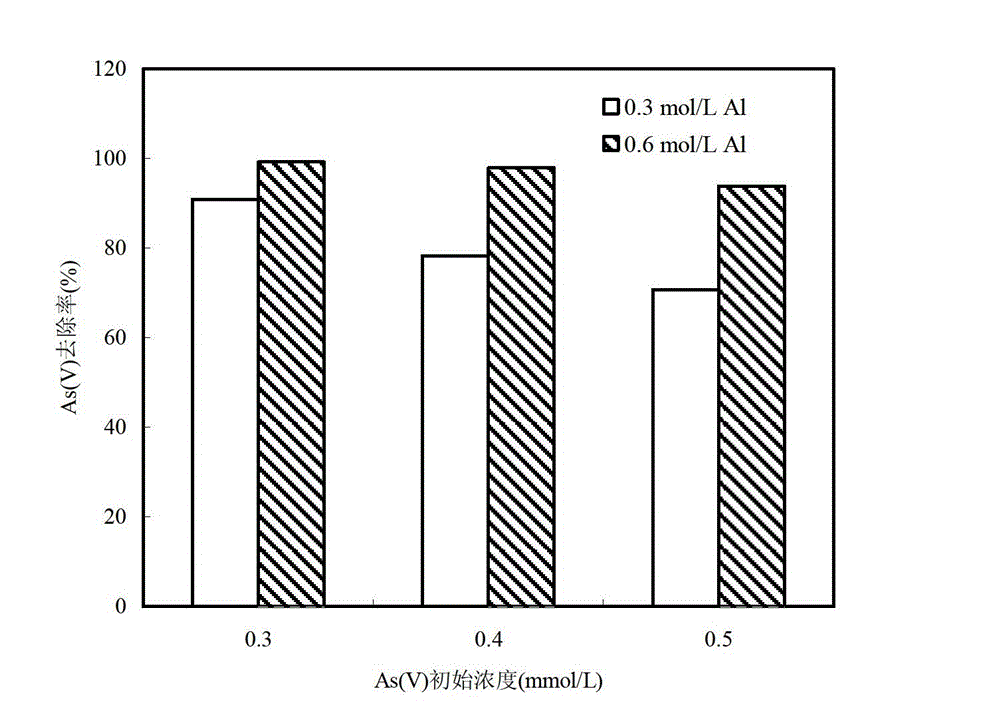

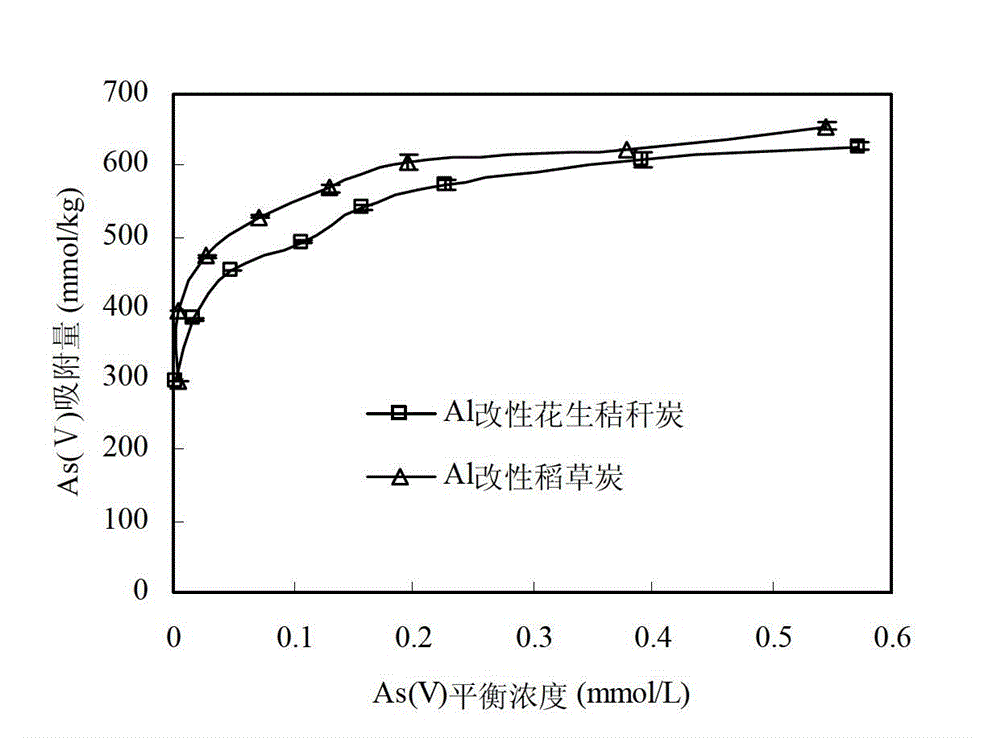

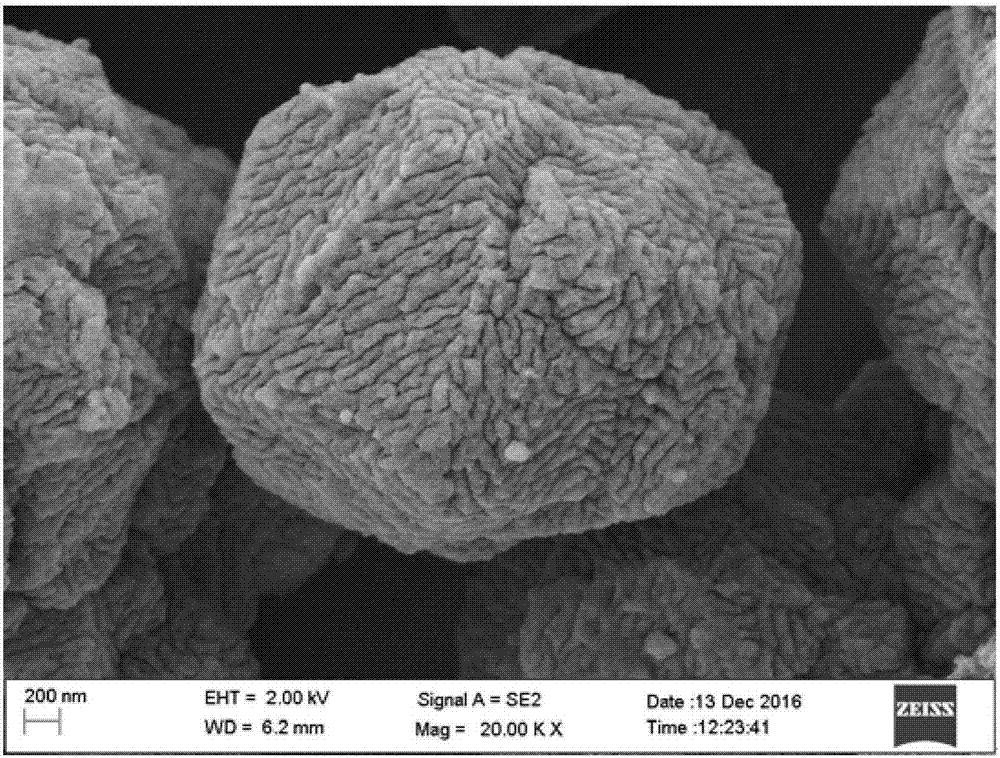

Aluminum modified straw biomass charcoal as well as preparation method and application thereof on removing arsenic in water body

InactiveCN102872803AImprove adsorption capacityImprove adsorption strengthOther chemical processesWater/sewage treatment by sorptionPulp and paper industrySand filter

The invention discloses aluminum modified straw biomass charcoal as well as a preparation method and an application thereof on removing arsenic in a water body. The straw biomass charcoal is formed by 350DEG C oxygen-controlled pyrolysis of peanut straws, soybean straws, rape straws, straws or other crop straws. The aluminum modified straw biomass charcoal is prepared by mixing and alkalifying straw biomass charcoal and 0.6mol / L of aluminum solution. A method for removing As (V) in the water body by the aluminum modified straw biomass charcoal comprises the following steps of: mixing the aluminum modified straw biomass charcoal with arsenic containing solution at the ratio of 1g / L in a reaction tank; continuously stirring for 2 hours; standing for 20 hours; stirring for 0.5 hours; after standing for 1.5 hours, separating the aluminum modified biomass charcoal from mixed liquor by a sand filtering device; discharging clear liquid; burning the biomass charcoal used for processing waste water after the biomass charcoal is subjected to air drying; and recovering ash contents and residues. The method is cheap and efficient and is free from secondary pollution.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Normal temperature catalytic material for efficiently removing VOCs

ActiveCN105080529ARapid enrichmentBulk enrichmentDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTio2 nanotubePolyvinyl alcohol

The invention relates to a formula of a catalytic material for efficiently removing VOCs and a preparation method of the catalytic material and belongs to the technical field of normal temperature catalysis and air purification. The efficient catalytic material is characterized by being prepared from a biological active carbon carrier with a high specific surface area, a non-noble metal catalytic component, a titanium oxide nanotube catalytic component and a macromolecular polymer template auxiliary. A preparation process of the material is characterized by comprising the steps of adding titanium dioxide and one or more of macromolecular polymers such as polyethylene glycol, polyvinyl alcohol, and polyaniline into a sodium hydroxide aqueous solution; carrying out hydrothermal reaction for 3-12 hours at 120-200 DEG C; then adding an aqueous solution containing one or more of non-noble metal ions such as Ce<4+>, Al<3+>, Zn<2+>, Mn<2+>, Fe<3+>, Co<2+>, Ni<2+>, and Cu<2+> to obtain a dispersed sol; immersing the biological active carbon with the high specific surface area for 4-10 hours at normal temperature; after solid liquid separation, carrying out sealed reaction on a solid wet material for 3-5 hours at 120-200 DEG C; and carrying out microwave drying on the material for 0.5-2 hours to obtain the final catalytic material. The catalytic material has the characteristics of being efficient in adsorption, quick to catalyze, long in service life and the like and can be used for satisfying the requirement of efficiently removing indoor VOCs for a long time (longer than 3000 hours) in a real environment.

Owner:江苏瑞丰科技实业有限公司

Hierarchical-pore nitrogen-doped carbon material and preparation method thereof

ActiveCN107051387AImprove adsorption capacityDiffusion fastGas treatmentOther chemical processesMetal-organic frameworkPhenol

The invention discloses a hierarchical-pore nitrogen-doped carbon material and a preparation method thereof and belongs to the field of material chemistry. The hierarchical-pore nitrogen-doped carbon material is prepared from components of raw materials as follows: a metal-organic framework material, a structure-directing agent, phenol, aldehyde, urea and an alkaline catalyst in the mass ratio being 1:(1-30):(0.5-20):(0.5-20):(0.1-10):(0.5-2). The mesoporous shell structure of the hierarchical-pore nitrogen-doped carbon material facilitates rapid dispersion of gas in pore passages, inside microporous cores facilitate gas adsorption, and meanwhile, the adsorption strength of pore passage surfaces and gas molecules is further improved as well through doping of nitrogen atoms in mesoporous shells and the microporous cores. Under the joint action of the mesoporous shell structure, the microporous cores and nitrogen atom doping, the provided hierarchical-pore nitrogen-doped carbon material has enhanced gas adsorption performance as compared with existing single-core and single-shell carbon materials.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

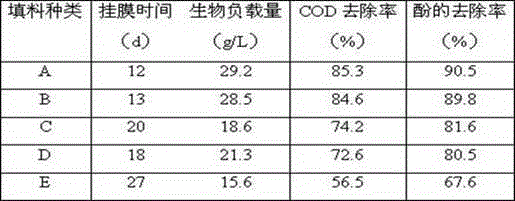

Suspended filler for quick biofilm culturing of microorganisms

InactiveCN105461083AFast film formationImprove processing efficiencyWater contaminantsSustainable biological treatmentBiocompatibility TestingBiology

The invention discloses a suspended filler for quick biofilm culturing of microorganisms. The suspended filler is prepared from, by weight, 65-75 parts of high-density polyethylene, 5-15 parts of slaked lime, 5-20 parts of Dow powdered activated carbon, 6-10 parts of light calcium carbonate, 3-5 parts of maleic anhydride, 0.2-0.6 part of dicumyl peroxide, 1.5-3 parts of gelatin, 1-2 parts of chitin, 0.8-2 parts of ferroferric oxide magnetic powder and 0.1-0.3 part of manganese zinc ferrite. The density of the suspended filler for quick biofilm culturing of microorganisms is 0.96-0.98 g / cm3. The biofilm culturing speed is high, disengagement does not occur easily, treatment efficiency is high, and the suspended filler is suitable for treating low-concentration organic matter and ammonia nitrogen in sewage and low-concentration organic waste water. The suspended filler has extremely high hydrophilia and biocompatibility, the filler has high adsorption strength on biological films, biofilm culturing time is remarkably shortened, and the COD and ammonia nitrogen removal rate is increased remarkably.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of suspended packing bioreactor and application thereof

ActiveCN104609567AHigh speedImprove efficiencyWater contaminantsSustainable biological treatmentSlagUltraviolet

The invention provides a preparation method of a suspended packing bioreactor. The preparation method comprises the following steps: (1) uniformly mixing 0.2-0.6 part by weight of magnetic powder, 7-10 parts by weight of recycled rubber powder, 3-12 parts by weight of zeolite, 2-8 parts by weight of maleic anhydride, 0.2-0.8 part by weight of dicumyl peroxide, 0.5-2 parts by weight of chitin, 3-5 parts by weight of powdered coke and 1-2 parts by weight of slag powder, adding 70-75 parts by weight of high density polyethylene, and stirring at high speed; (2) adding the above mixed materials into a screw pelletizer and pelleting; (3) putting the pelleted particles into a screw extruder and carrying out extrusion molding, carrying out vacuum setting, cooling, carrying out mechanical holing, and carrying out cutting forming; and (4) finally irradiating the packing bioreactor by short wave ultraviolet. According to the invention, hydrophily of the suspended packing bioreactor is greatly enhanced, surface adsorbing capacity is increased, biofilm adsorption strength is raised, biofilm culturing period is shortened, and the biofilm is not easy to fall off. The suspended packing bioreactor is suitable for processing low concentration organic wastewater and phenolic wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

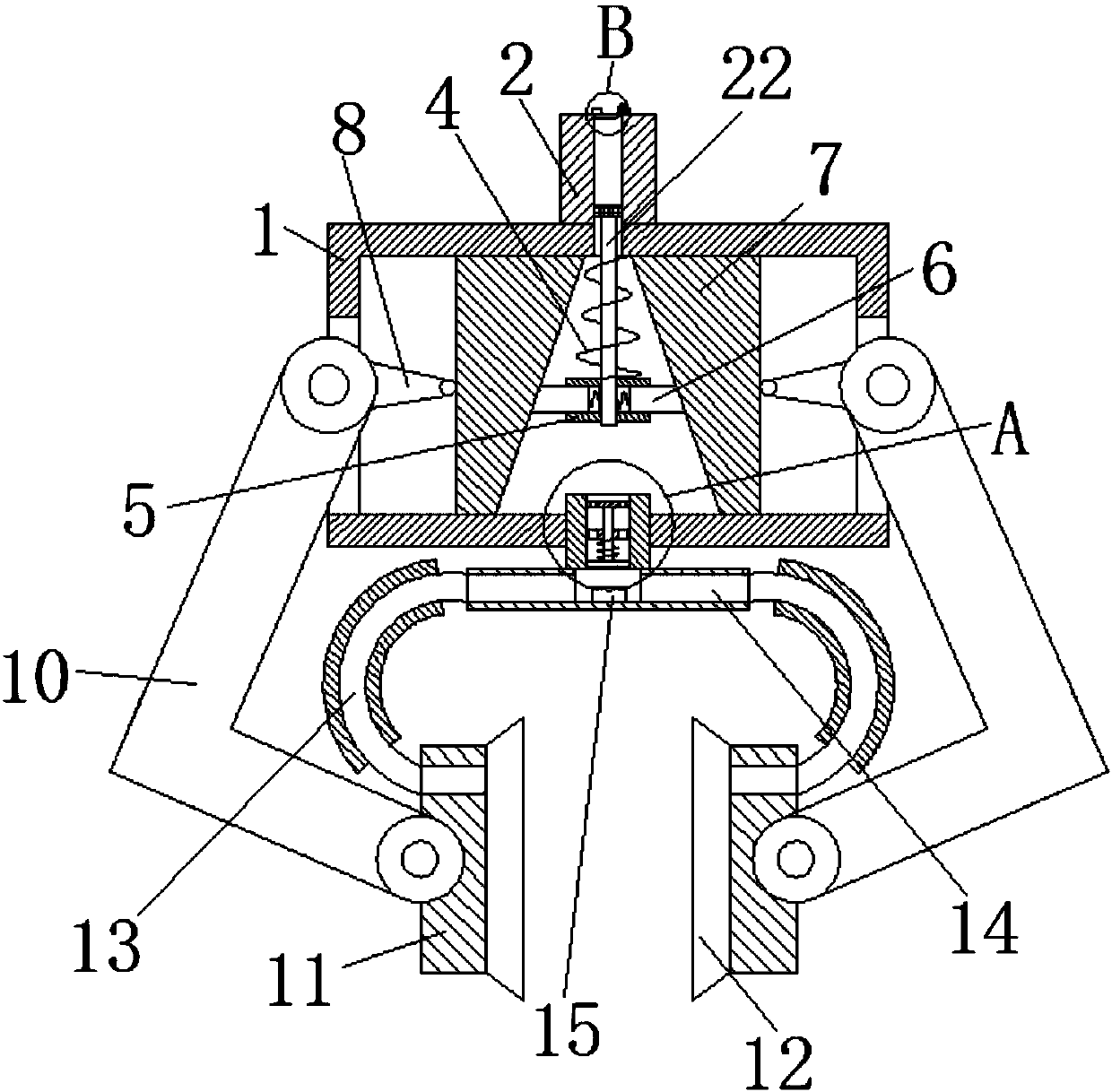

Gripper

InactiveCN107891440AImprove adsorption capacityImprove adsorption strengthGripping headsConveyor partsEngineeringThermal expansion

The invention discloses a gripping which comprises a mounting box, wherein a liquid inlet pipe is connected to the upper end face of the mounting box in a running-through manner, the liquid inlet pipeis fixedly connected with one end of an extension pipe in a inserted manner, the other end of the extension pipe reaches the inside of the mounting box, the upper end face of the liquid inlet pipe isfixedly connected with one end of a limiting block, the upper end face of the liquid inlet pipe is fixedly connected with one end of a torsion spring, and the other end of the torsion spring is fixedly connected with a rotating plate. When a fixed rod rotates, a propping plate is driven to push a trapezoid piston block to the center direction of the mounting box, and after liquid enters a connecting pipe, the liquid enters a sucker after being heated by electric heating iron, so that a to-be-adsorbed surface is moist and easy to adsorb; when the fixed rod rotates reversely, air can be suckedinto the liquid inlet pipe, high temperature liquid is cooled after entering the sucker, and due to thermal expansion and cold shrinkage, improvement of the adsorbing strength is facilitated, slippingis prevented, and grabbing success rate is increased.

Owner:新昌县羽林街道星捷轴承厂

Suspended microbial packing for wastewater treatment and preparation method thereof

InactiveCN105481083AFast film formationNot easy to fall offWater treatment compoundsTreatment with microorganism supports/carriersMaleic anhydrideBiomass

The invention discloses suspended microbial packing for wastewater treatment and a preparation method thereof. The suspended microbial packing is prepared from, by weight, 65-75 parts of high density polyethylene, 5-15 parts of slaked lime, 5-20 parts of Dow powdered activated carbon, 6-10 parts of light calcium carbonate, 3-5 parts of maleic anhydride, 1.5-3 parts of gelatin, 1-2 parts of chitin, 0.8-2 parts of ferromagnetic oxide powder and 0.1-0.3 part of manganese zinc ferrite. The suspended microbial packing is high in film formation speed, not prone to fall off, high in treatment efficiency and suitable for treatment of low-concentration organic matter and ammonia nitrogen in sewage and low-concentration organic wastewater. The biological packing has the extremely high hydrophilicity and biocompatibility, has the very high adsorption strength to a biological film and is beneficial for interception and accumulation of biomass on a packing carrier, and therefore the packing can better adapt to wastewater treatment under the low concentration condition.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

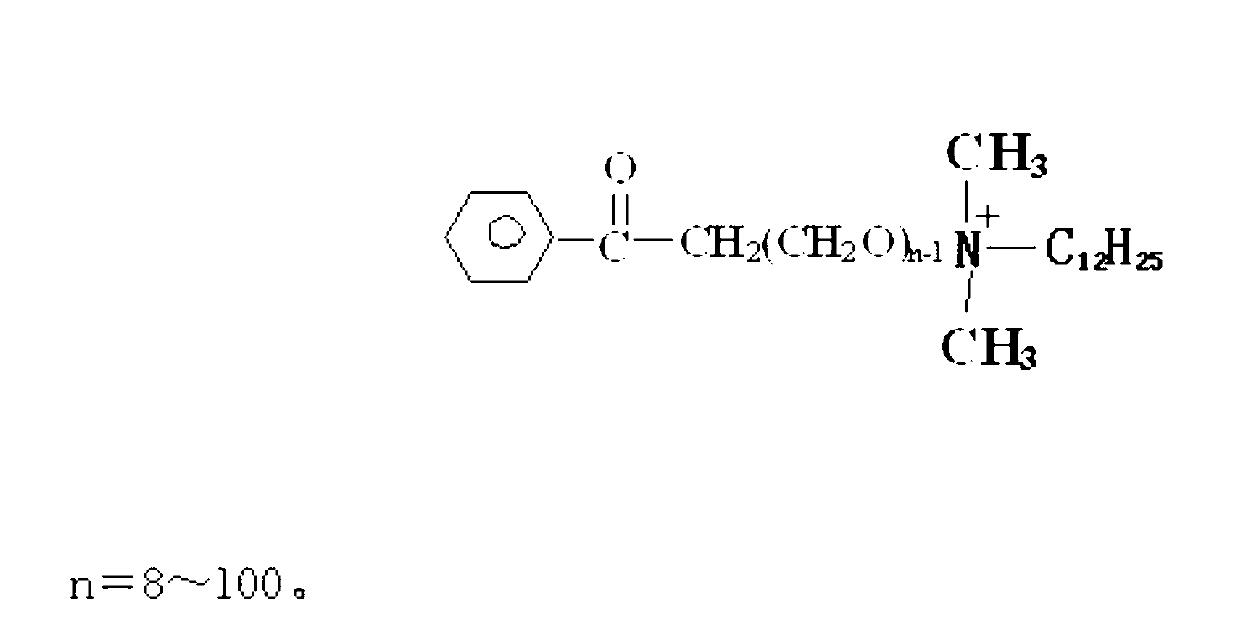

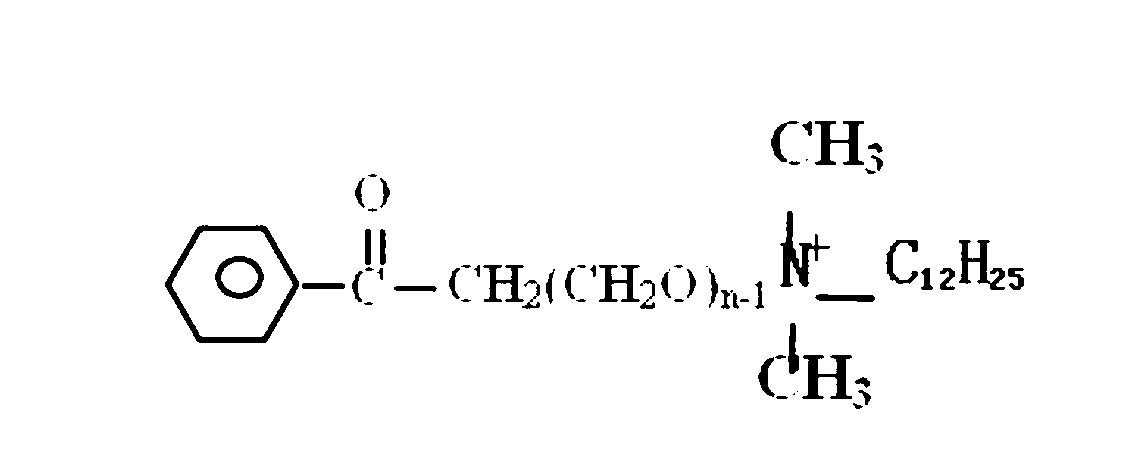

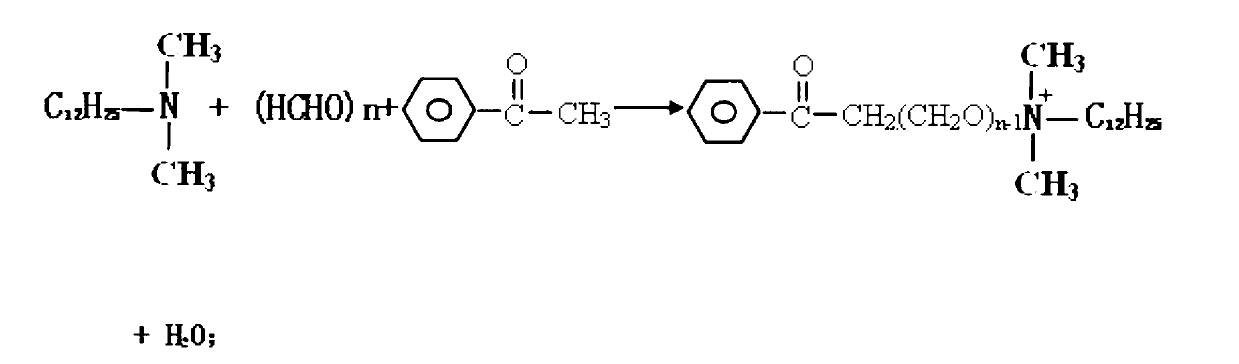

Mannich base acidifying corrosion inhibitor and preparation method thereof

InactiveCN102746840AImprove solubilityDoes not dissolve wellOrganic compound preparationBorehole/well accessoriesPotassium iodineSolvent

The invention provides a Mannich base acidifying corrosion inhibitor and a preparation method thereof. The molecular general formula of the Mannich base acidifying corrosion inhibitor is as follows. The preparation method comprises the following steps: proportionally pouring dodecyl dimethyl tertiary amine, polyformaldehyde and aromatic ketone into a reaction kettle, adding an ethanol solvent, slowly adding hydrochloric acid to regulate the pH value of the reaction solution, heating to 80+ / -5 DEG C, and refluxing for 5-7 hours while keeping the temperature, thereby obtaining the Mannich base; and compounding the Mannich base, acetic acid, propiolic alcohol and potassium iodide in a weight ratio of 6:2.5:0.5:1 to obtain the finished Mannich base acidifying corrosion inhibitor product. The existing raw materials for synthesizing the Mannich base acidifying corrosion inhibitor are changed to enhance the adsorption strength and compactness of the corrosion inhibitor protective film, thereby enhancing the corrosion inhibition effect of the acidifying corrosion inhibitor and lowering the acidifying operation cost.

Owner:天津中油科远石油工程有限责任公司

Large biofilm culturing amount MBBR suspended biofilm carrier and preparing method thereof

InactiveCN107758847AImprove hydrophilicityImprove impact resistanceSustainable biological treatmentBiological water/sewage treatmentBiocompatibility TestingVolumetric Mass Density

The invention discloses a large biofilm culturing amount MBBR suspended biofilm carrier and a preparing method thereof. The large biofilm culturing amount MBBR suspended biofilm carrier is prepared from, by weight, 65-75 parts of high density polyethylene, 5-15 parts of slaked lime, 5-20 parts of Dow powdered activated carbon, 6-10 parts of light calcium carbonate, 3-5 parts of maleic anhydride, 0.2-0.6 part of dicumyl peroxide, 1.5-3 parts of gelatin, 1-2 parts of chitin and 0.5-2 parts of magnetic powder; the density of the large-biofilm-culturing-amount MBBR suspended biofilm carrier is 0.96-0.98 g / cm<3>. The large-biofilm-culturing-amount MBBR suspended biofilm carrier is high in biofilm culturing speed, the biofilm does not easily shed, the treatment efficiency is high, and the biofilm carrier is applicable to treating low concentration organic matter, ammonia nitrogen and low concentration organic wastewater; the biofilm carrier has very high hydrophilicity and biocompatibility,the carrier itself has very high adsorption strength on biofilm and is beneficial to intercepting and accumulating biomass on the carrier.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of flotation method of carbonate mineral

InactiveCN102284372AImprove adsorption strengthReduce dosageFlotationFoaming agentPhysical chemistry

The invention provides a flotation method for carbonate minerals. The method comprises the following steps of: grinding, roughing, sifting and scavenging, namely after grinding, regulating the mass percentage concentration of flotation mineral slurry to 10 to 30 percent, adding acidic solution with the concentration of 0.01 to 5 mol / L until the pH value of the mineral slurry ranges from 0.1 to 5,adding a collecting agent in amount which is 0.002 to 0.05 percent of mineral solids in the mineral slurry, adding a foaming agent in amount which is 0.001 to 0.02 percent of mineral solids in the mineral slurry, stirring at a speed of between 30 and 120 revolutions / minute, and roughing, sifting and scavenging conventionally to obtain concentrates. In the flotation method, due to the addition of sulfuric acid, carbon dioxide microbubbles generated by reacting carbonates with the sulfuric acid are adsorbed to the surfaces of the minerals, so that mineral granules are adsorbed to float upwards under the bridging action of the microbubbles attached between the mineral granules and big bubbles. By the method, the using amount of the collecting agent and the foaming agent is reduced, the concentrate grades are improved by the selective adsorption of the bubbles, a process flow is simplified, and a high assorting index can be reached only by assorting once.

Owner:KUNMING UNIV OF SCI & TECH

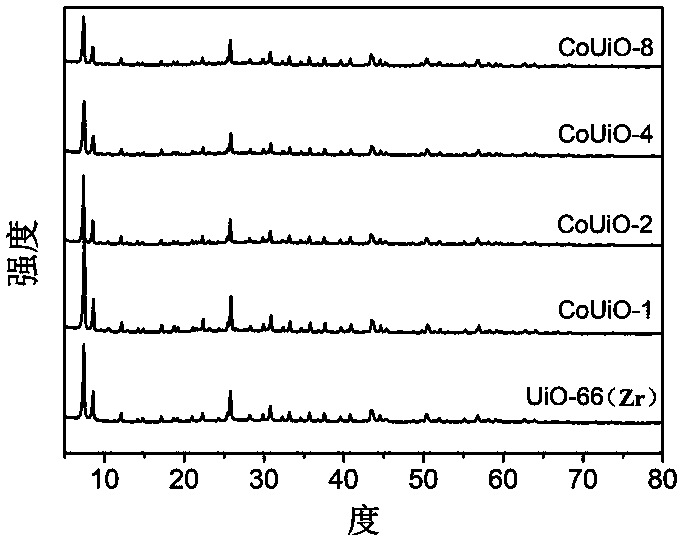

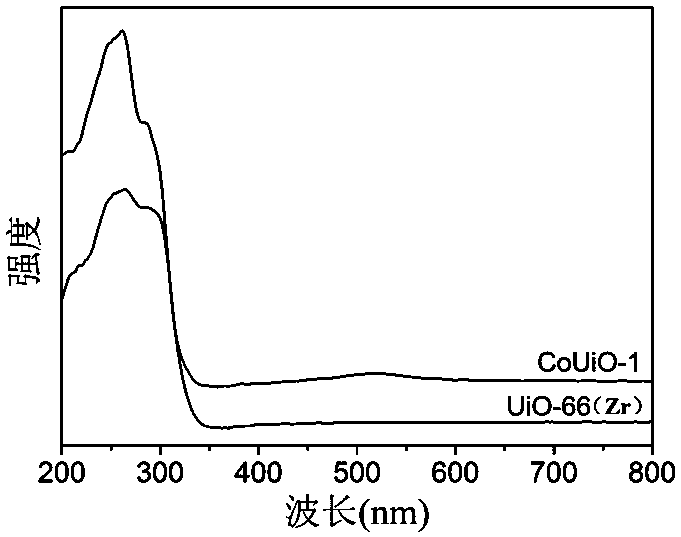

Method for treating antibiotic wastewater by using cobalt ion-doped metal organic framework material

ActiveCN108160042AImprove adsorption capacityEfficient degradationWater/sewage treatment by irradiationOther chemical processesMetal-organic frameworkWastewater

The invention discloses a method for treating antibiotic wastewater by using a cobalt ion-doped metal organic framework material. The method comprises the following steps: mixing the cobalt ion-dopedmetal organic framework material and the antibiotic wastewater, and performing oscillating adsorption to complete treatment to the antibiotic wastewater, wherein the cobalt ion-doped metal organic framework material comprises cobalt ions and UiO-66(Zr), and the cobalt ions are doped in the UiO-66(Zr). By the method for treating the antibiotic wastewater by using the cobalt ion-doped metal organicframework material, a treatment technology is simple, operation is convenient, equipment is simple, the cost is low, the treatment efficiency is high, the removing effect is good, the repeated utilization rate is high, and cleanness and no pollution are achieved; the method is a treatment method which can be widely applied and by which antibiotics can be effectively removed, and has a very high application value and a very high commercial value.

Owner:HUNAN UNIV

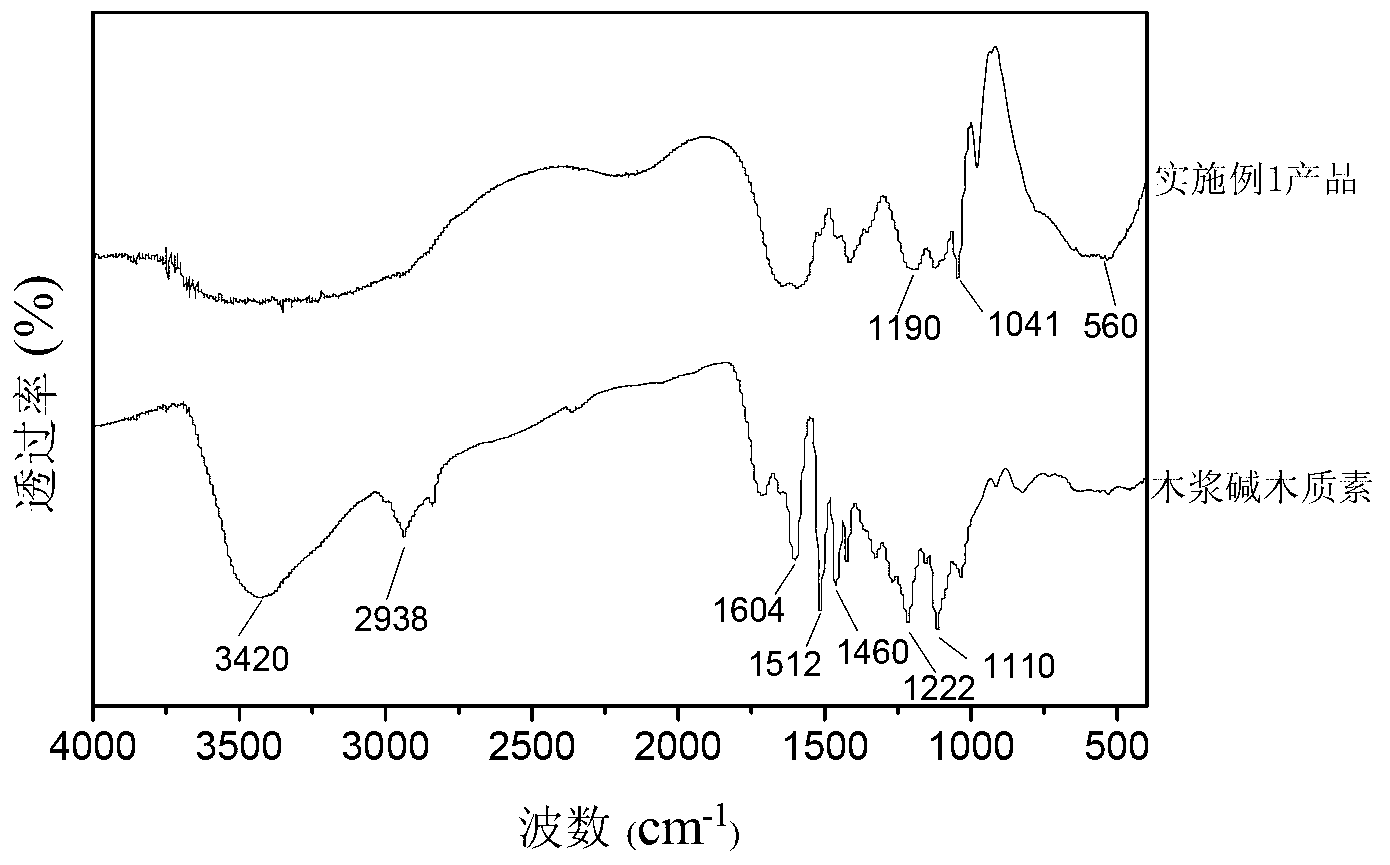

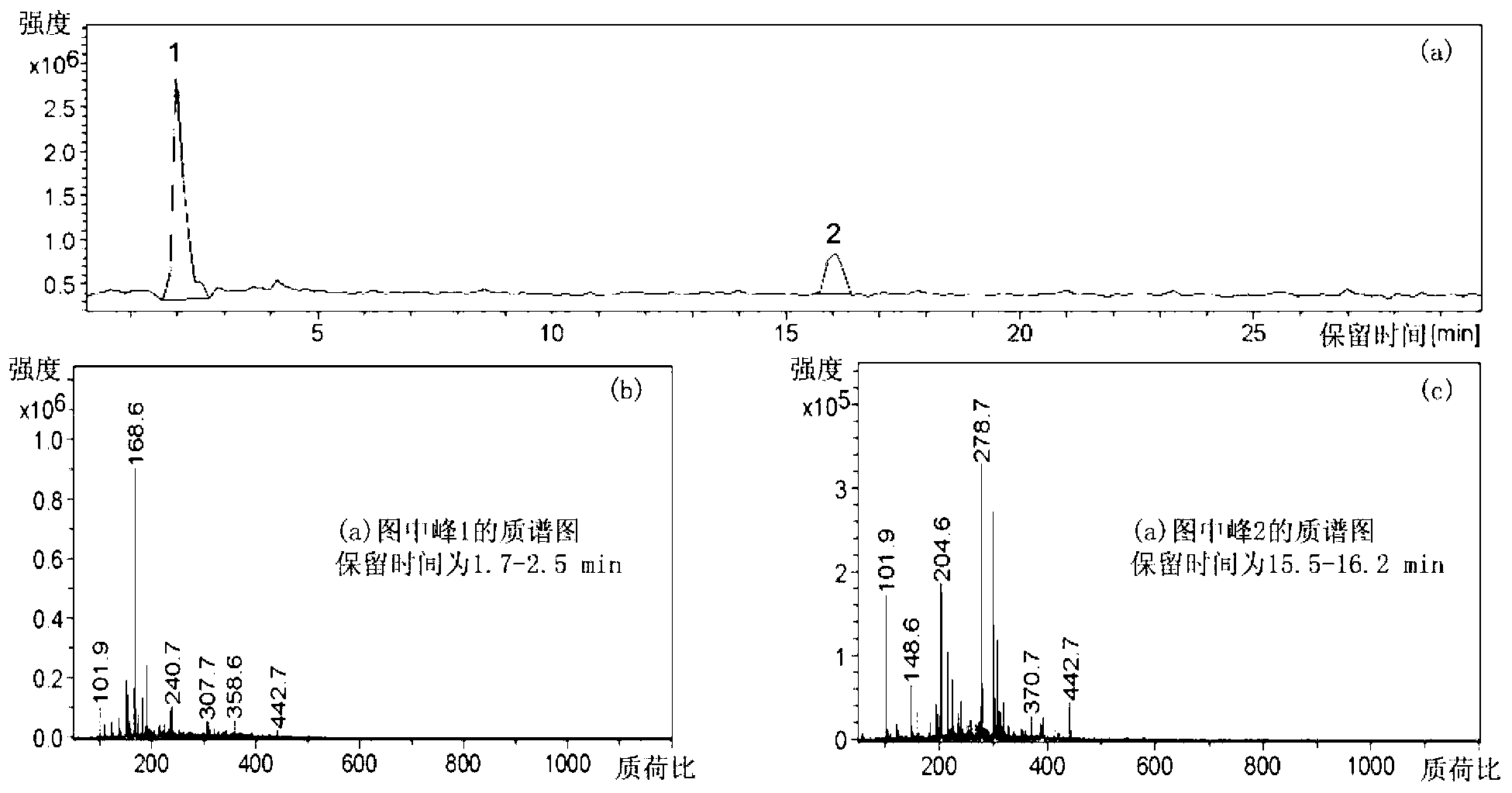

Lignin dispersant for phenol-water coal water slurry, and preparation method and application thereof

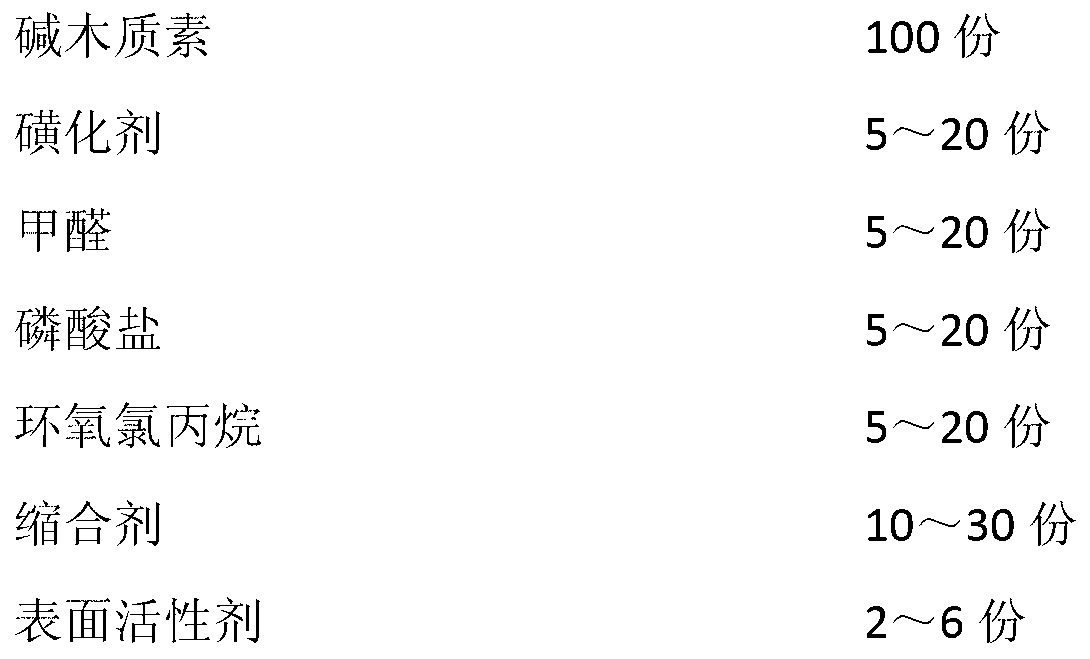

ActiveCN103265984AImprove stabilityExcellent dispersion viscosity reduction effectLiquid carbonaceous fuelsFuel additivesDispersion stabilityCoal water

The invention discloses a lignin dispersant for phenol-water coal water slurry, and a preparation method and application thereof. The preparation method comprises the following steps: adding a sulfonating agent into an alkaline alkali lignin solution, then adding formaldehyde, and reacting to obtain hydroxymethyl sulfonated alkali lignin; dissolving phosphate in water, adding epoxy chloropropane, and reacting to obtain a hydroxypropyl phosphate compound; and mixing the hydroxymethyl sulfonated alkali lignin and the hydroxypropyl phosphate compound, adding a condensing agent to perform condensation reaction, and then adding surfactant to obtain the lignin dispersant for phenol-water coal water slurry. The molecule of the lignin dispersant contains multiple hydrophilic functional groups such as sulfonic groups, phosphate groups and the like, so that the lignin dispersant has favorable dispersion / viscosity reduction capacity and stability for phenol-water coal water slurry in case of low consumption. The dispersion / viscosity reduction capacity of the lignin dispersant is far higher than that of the traditional lignosulfonate coal water slurry dispersant; and the dispersion stability of the prepared phenol-water coal water slurry is better in comparison with a naphthalene dispersant.

Owner:SOUTH CHINA UNIV OF TECH +2

Theaflavin matt glaze and manufacturing method thereof

The invention relates to ceramic glaze and a manufacturing method thereof, in particular to theaflavin matt glaze for an antique ceramic bottle and a manufacturing method thereof. The theaflavin matt glaze is characterized in that titanium dioxide, antimony oxide, nickel oxide and potassium dichromate are adopted as raw materials to be blended and calcined into theaflavin coloring materials, and then the theaflavin coloring materials are mixed with feldspar, quartz, Suzhou soil, boron frit, dolomite and calcite to be smashed into theaflavin matt glaze. A ceramic product which is calcined with the theaflavin matt glaze is simple and unsophisticated in glazing color, good in antique effect, uniform in color and applicable to top-grade bottles.

Owner:江苏省宜兴彩陶工艺厂

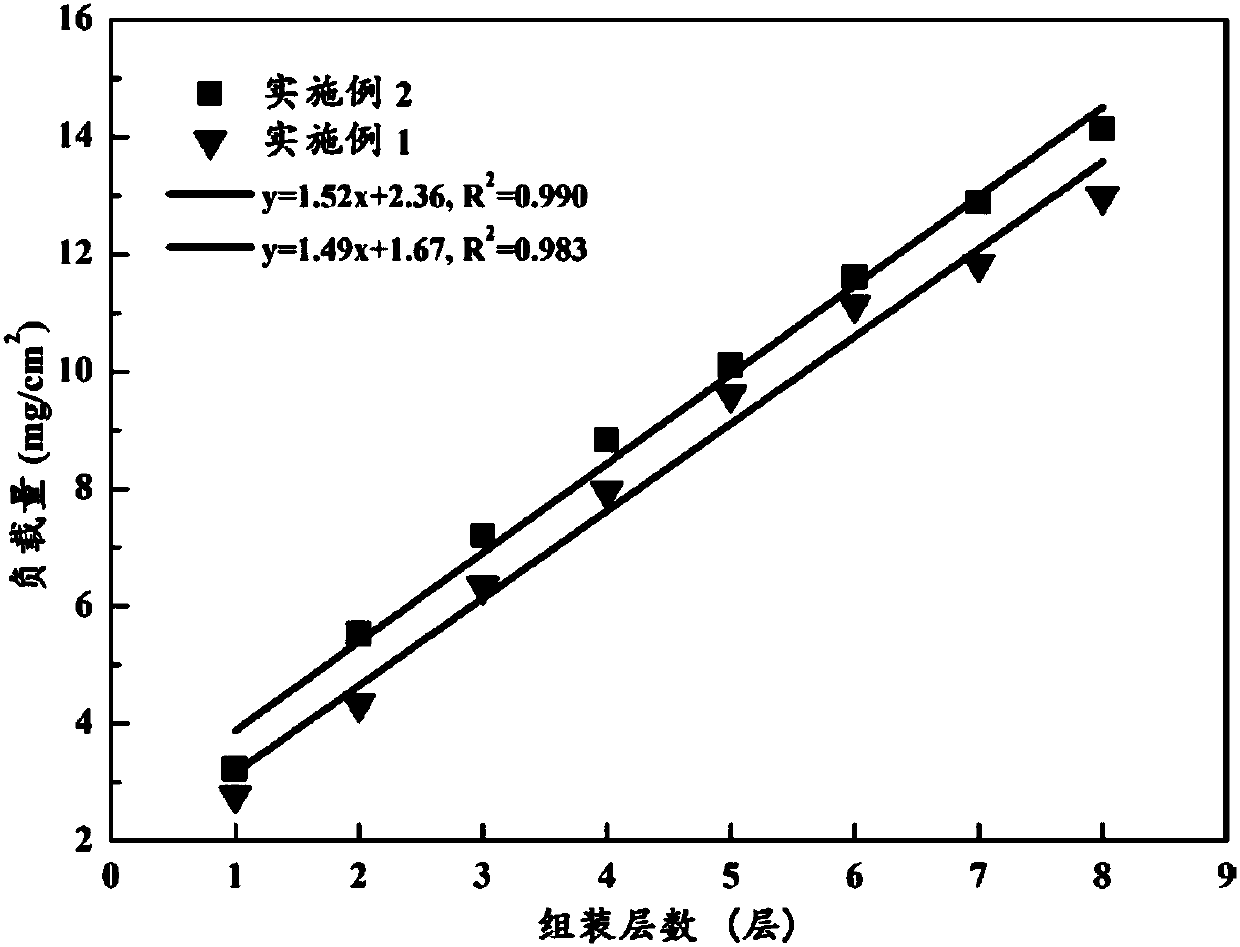

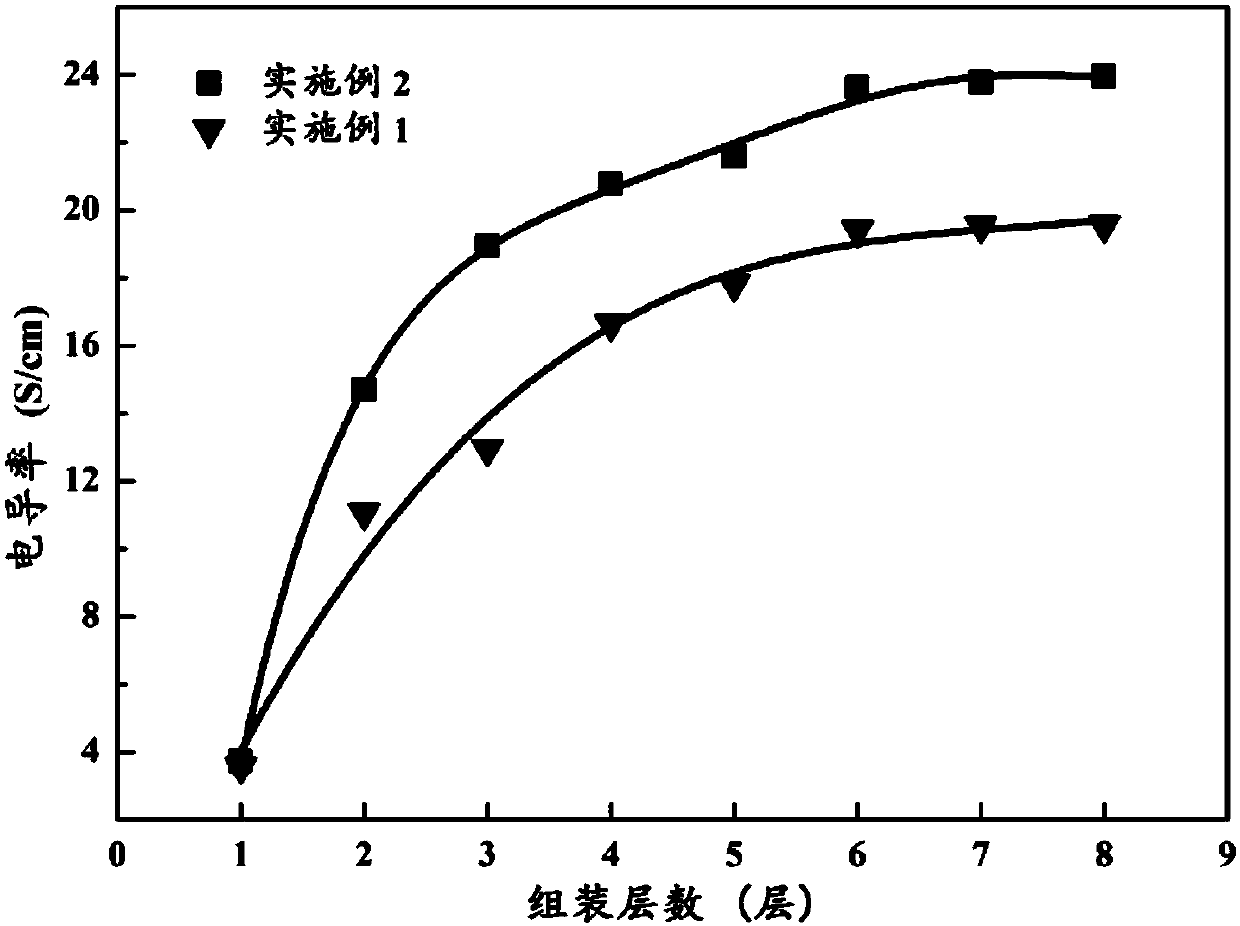

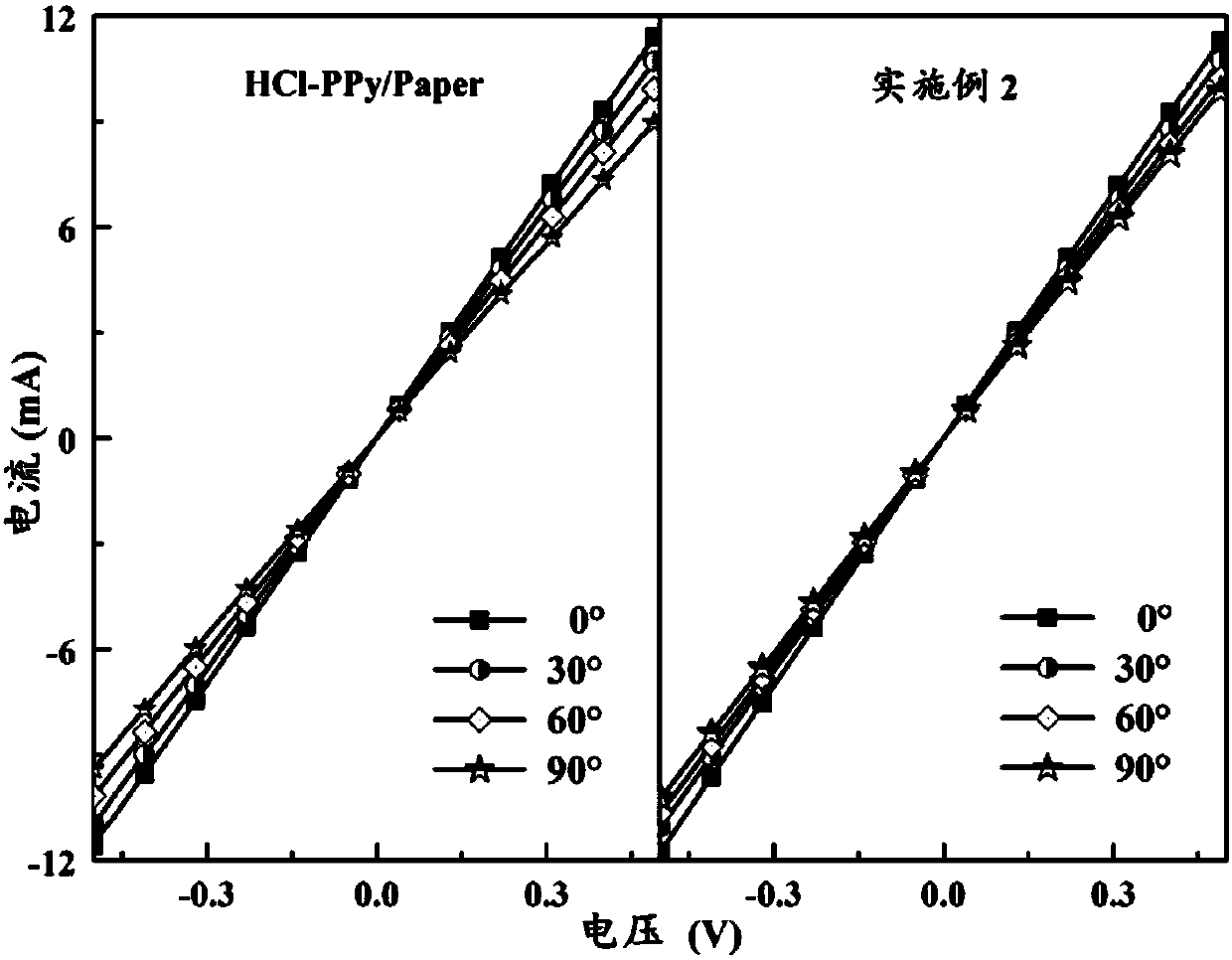

Lignosulfonic acid-reinforced polypyrrole conductive paper and preparation method thereof

ActiveCN107630390AImprove adsorption capacityImprove adsorption strengthSpecial paperNon-macromolecular organic additionUltrafiltrationPolypyrrole

The invention belongs to the technical field of functional materials and discloses a lignosulfonic acid-reinforced polypyrrole conductive paper and a preparation method thereof. The method comprises (1) separating a lignosulfonate through an ultrafiltration membrane and then purifying the lignosulfonate through a cation exchange resin to obtain lignosulfonic acid, (2) soaking a paper in the lignosulfonic acid for 10-30min, then soaking the paper in an aldehyde aqueous solution for 10-30min and heating the paper to 80-110 DEG C for a condensation reaction for 1-2h, (3) soaking the paper in a pyrrole solution for 10-30min, and (4) soaking the paper in a mixed solution of an oxidant and an inorganic acid for a reaction for 10-120min to obtain a self-assembled single-layer conductive paper andrepeating the above steps (2) to (4) to obtain a self-assembled multi-layer conductive paper. The lignosulfonic acid-reinforced polypyrrole conductive paper has high conductivity, good stability, adjustable loading capability and no dusting and can be used in the fields of surface heating materials, electromagnetic shielding materials and flexible electrode materials.

Owner:SOUTH CHINA UNIV OF TECH

Flotation method of zinc oxide ore

InactiveCN106111350AImprove stabilityReduce sheddingDifferential sedimentationFlotationFlocculationFoaming agent

The invention provides a flotation method of zinc oxide ore. The method comprises the steps that in the pretreatment process of flotation, the zinc oxide ore is crushed and levigated firstly, and the slurry concentration is adjusted to range from 15wt% to 20wt%; a scattering agent and a gangue mineral inhibitor are added in sequence, and then a flocculating agent is added for selective flocculation; then pregelatinized starch is added, the mixture is evenly stirred, and then sulfuric acid is added to adjust the pH value of slurry to 1-5; and a collecting agent and a foaming agent are added after stirring is carried out at a low speed for 2-5 minutes, and zinc concentrate is obtained through flotation according to a conventional process. Through addition of the pregelatinized starch, stability of selective floccules is enhanced, then the sulfuric acid is added so that tight absorption between smithsonite and carbon dioxide microbubbles generated through a reaction can be achieved, and then zinc minerals-floccules are recovered through conventional flotation, so that the beneficiation index of the ore is increased, and consumption of the collecting agent and the foaming agent can be effectively reduced.

Owner:FUZHOU UNIV

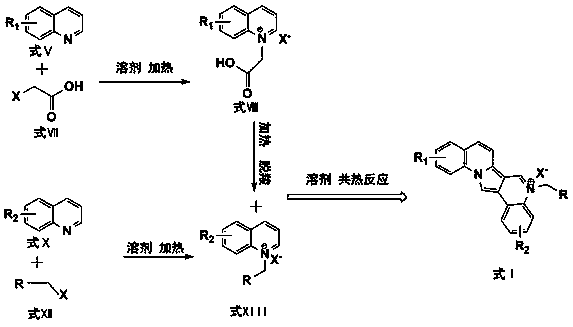

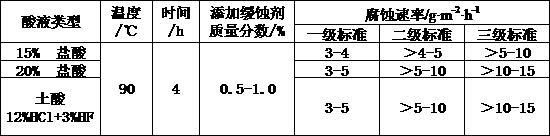

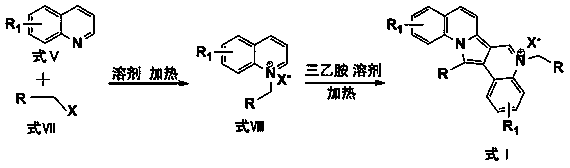

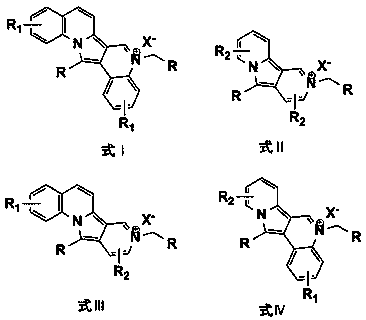

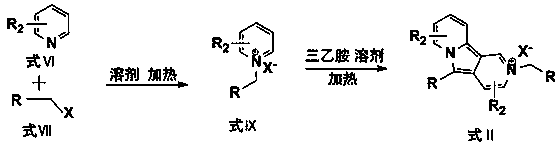

Acidification corrosion inhibitor based on interpolymer indolizine derivative as well as preparation method and application thereof

InactiveCN108440527AEfficient corrosion inhibitionGood corrosion inhibitionOrganic chemistryDrilling compositionAcetic acidQuaternary ammonium cation

The invention discloses an acidification corrosion inhibitor based on an interpolymer indolizine derivative as well as a preparation method and application thereof. The acidification corrosion inhibitor contains the interpolymer indolizine derivative; the interpolymer indolizine derivative is prepared by carrying out decarboxylation on heterocyclic alkali including (substituted) quinoline, (substituted) pyridine and the like, and carboxymethyl heterocyclic alkali quaternary ammonium salt obtained by alpha-haloacetic acid, and then carrying out intermolecular addition polymerization reaction onquaternary ammonium salt of the heterocyclic alkali including the (substituted) quinoline, the (substituted) pyridine and the like. The acidification corrosion inhibitor disclosed by the invention has relatively good corrosion inhibition performance under the condition that common corrosion inhibition synergists including alkynol and the like do not need to be compounded; the use amount of the acidification corrosion inhibitor is less and the acidification corrosion inhibitor can reach, even be better than the requirements of an acidification corrosion inhibitor performance testing method andfirst-grade to third-grade standards in evaluation indexes SY / T 5405-1996 when being independently used.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

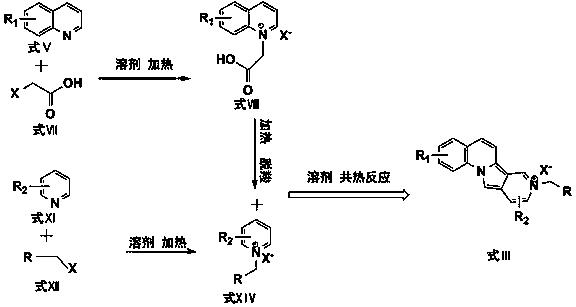

Acidizing corrosion inhibitor based on dimer indolizine derivative and preparation method and application of acidizing corrosion inhibitor

The invention discloses an acidizing corrosion inhibitor based on a dimer indolizine derivative and a preparation method and application of the acidizing corrosion inhibitor. The acidizing corrosion inhibitor contains the dimer indolizine derivative; and the dimer indolizine derivative is mainly obtained by further intermolecular dimerization of active alpha-cetyl trimethyl ammonium chloride of heterocyclic alkali such as (substituted) quinolone and (substituted) pyridine under alkali acceleration. The acidizing corrosion inhibitor has good corrosion inhibition under the condition that a common corrosion inhibition synergist such as alkynol does not need to be compounded, the use amount is small, and when the acidizing corrosion inhibitor is used independently, requirements of first-levelto third-level standard in an acidizing corrosion inhibitor performance testing method and an evaluation index SY / T 5405-1996 can be met and are even higher.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

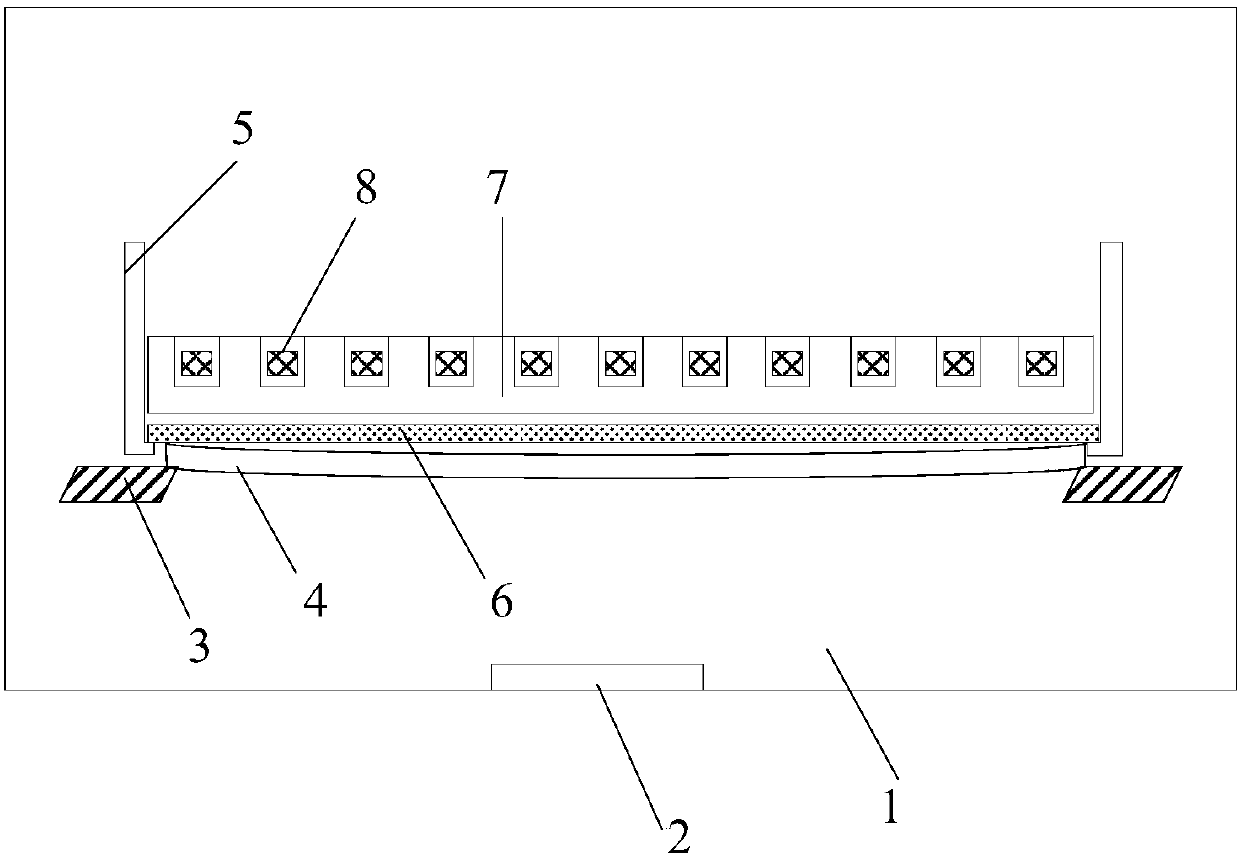

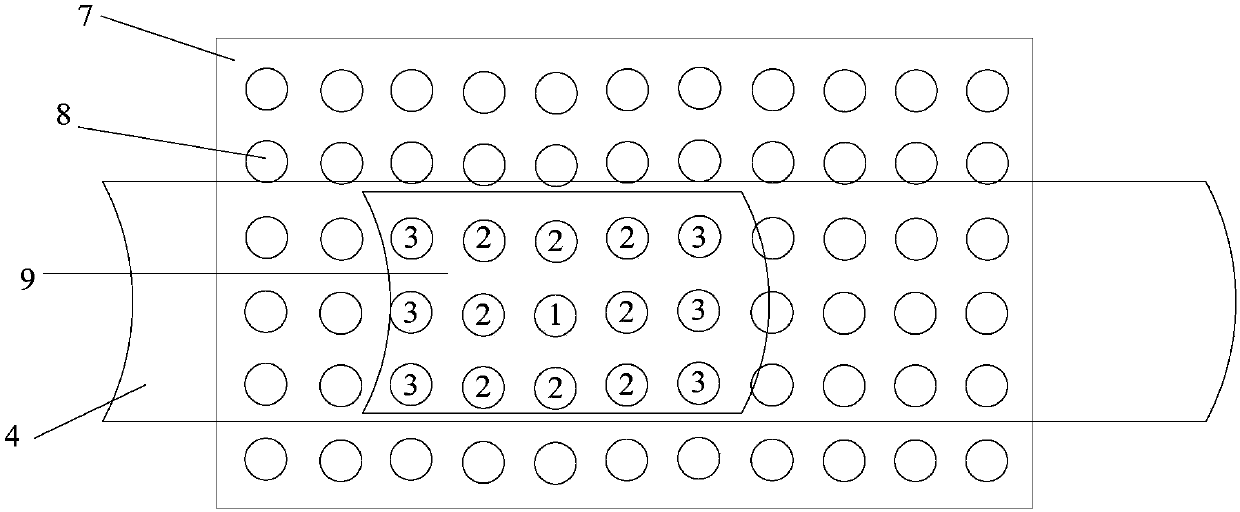

Evaporation device and method

ActiveCN107815649AImprove adsorption strengthEasy switch controlVacuum evaporation coatingSputtering coatingEvaporationEngineering

The invention discloses an evaporation device and method. The evaporation device comprises an evaporation base plate carrier. The evaporation base plate carrier is used for carrying an evaporation base plate. An electromagnetic module is arranged in the position, above the zone where the evaporation base plate is located, of the evaporation base plate carrier and comprises a plurality of electromagnetic units. The multiple electromagnetic units are used for energizing according to a preset sequence. According to the technical scheme provided by the invention, by arranging the multiple electromagnetic units for adsorbing metal masks, the problem that the whole metal masks are adsorbed, and consequently the metal masks are winkled or cannot be released due to winkling can be solved, meanwhile, the adsorption strength and switching can be better controlled through the electromagnetic units, and the position precision of patterns on the evaporation base plate can be improved.

Owner:BOE TECH GRP CO LTD +1

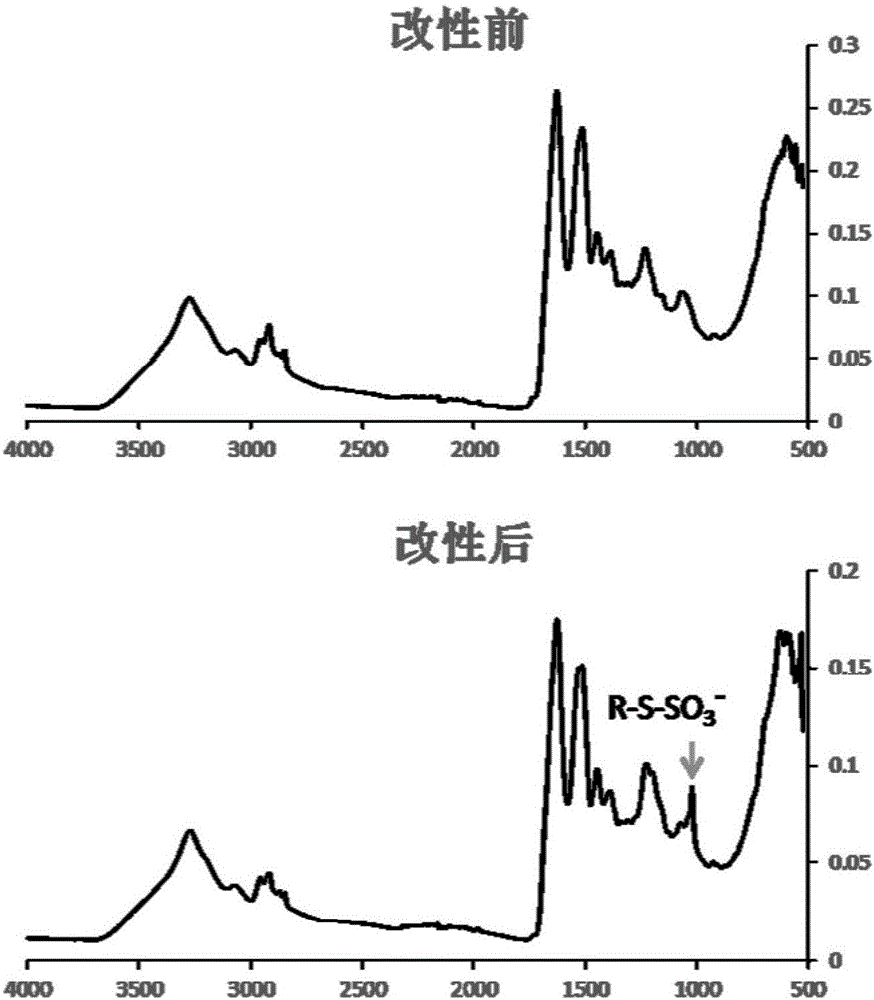

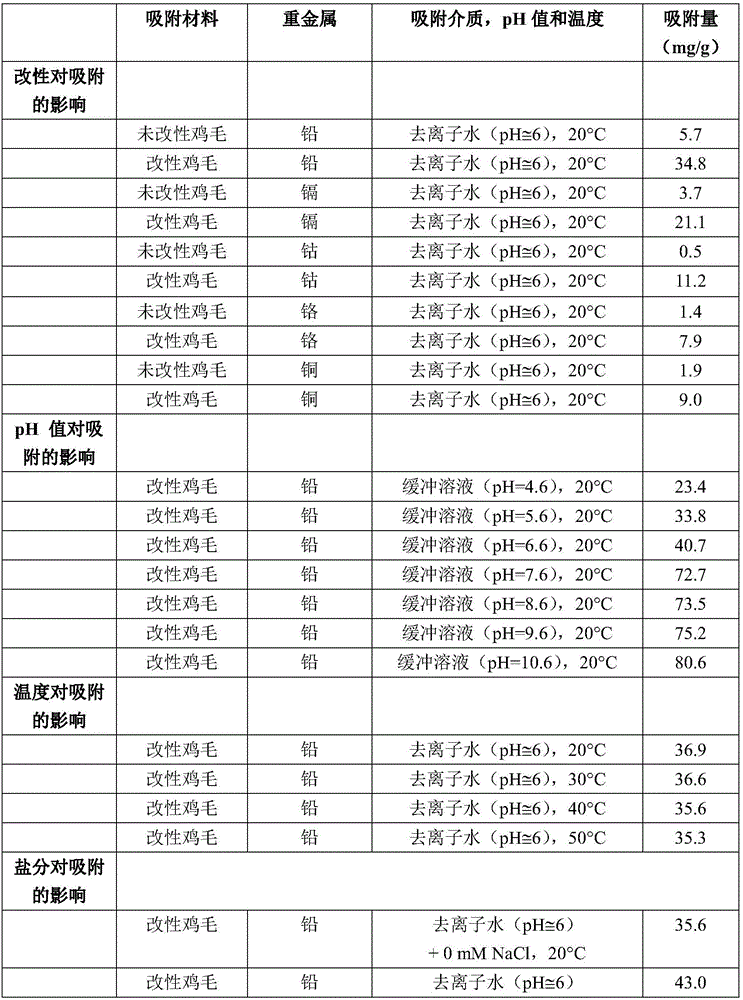

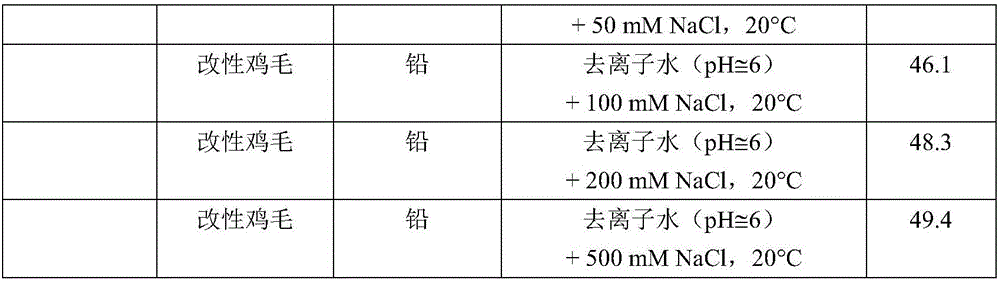

Keratin heavy metal adsorbent and preparation method thereof

InactiveCN106799212ADistinctive featuresLow priceOther chemical processesWater contaminantsSulfite saltSorbent

The invention provides a preparation method of a keratin heavy metal adsorbent. The preparation method comprises the following steps: step I, cleaning and smashing a keratin raw material; step II, carrying out oxidation reaction on the ready keratin raw material: taking the keratin raw material, and putting the keratin raw material in an oxidant aqueous solution to carry out oxidation reaction, wherein an oxidant is a potassium monopersulfate composite salt or a sodium monopersulfate composite salt; and step III, carrying out reduction reaction on the oxidized keratin material: taking the oxidized keratin material, putting the oxidized keratin material in an aqueous solution containing a reducing agent to carry out reaction, and drying the obtained keratin material to obtain the keratin heavy metal adsorbent, wherein the reducing agent is one of sodium sulfite, sodium metasulfite, sodium bisulfite, potassium sulfite, potassium metasulfite and potassium bisulfate. The prepared heavy metal adsorbent has certain selectivity, is high in adsorption efficiency, low in cost, simple and convenient to operate, mild in required condition and does not generate secondary pollution.

Owner:由永峰

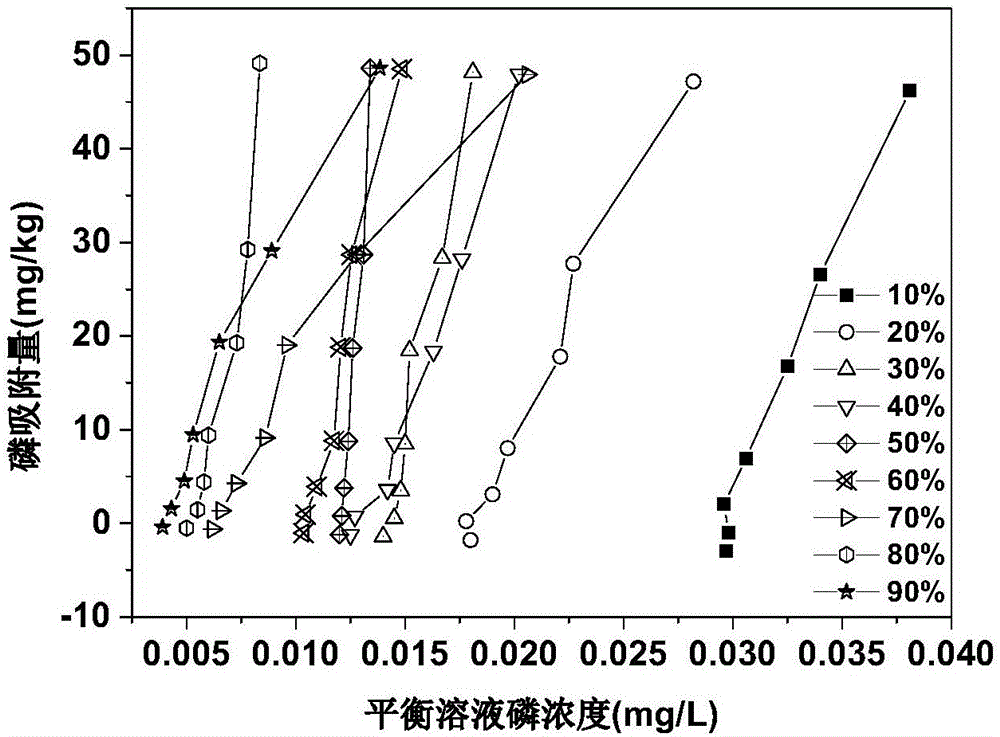

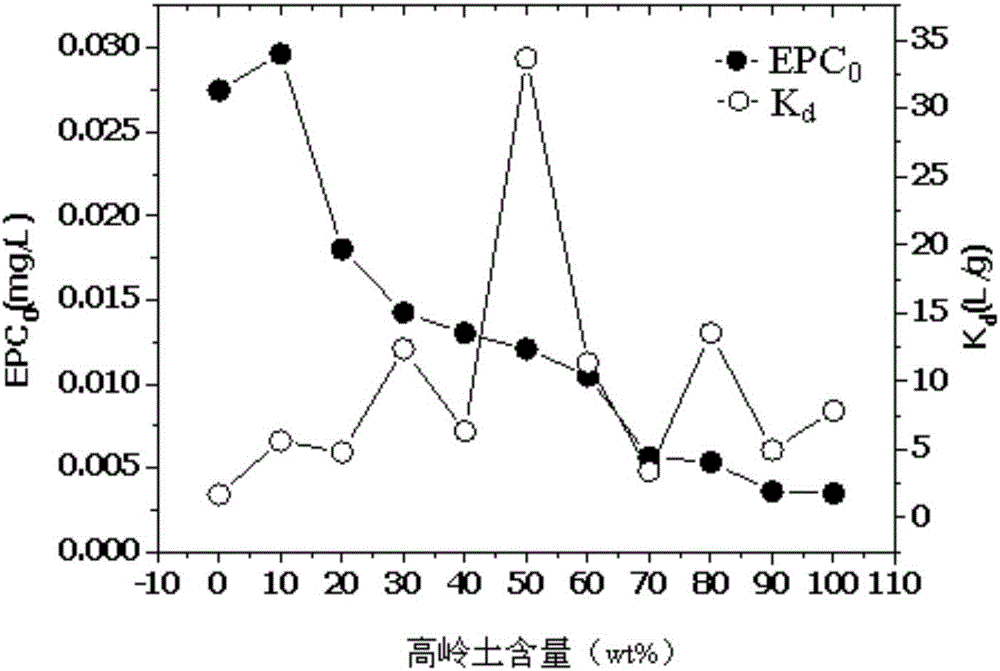

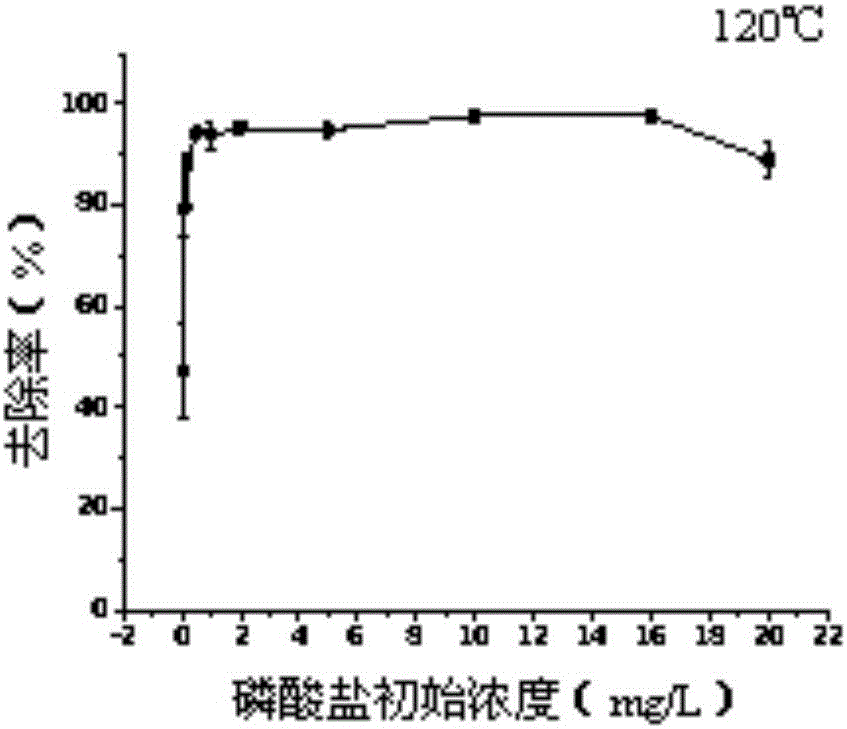

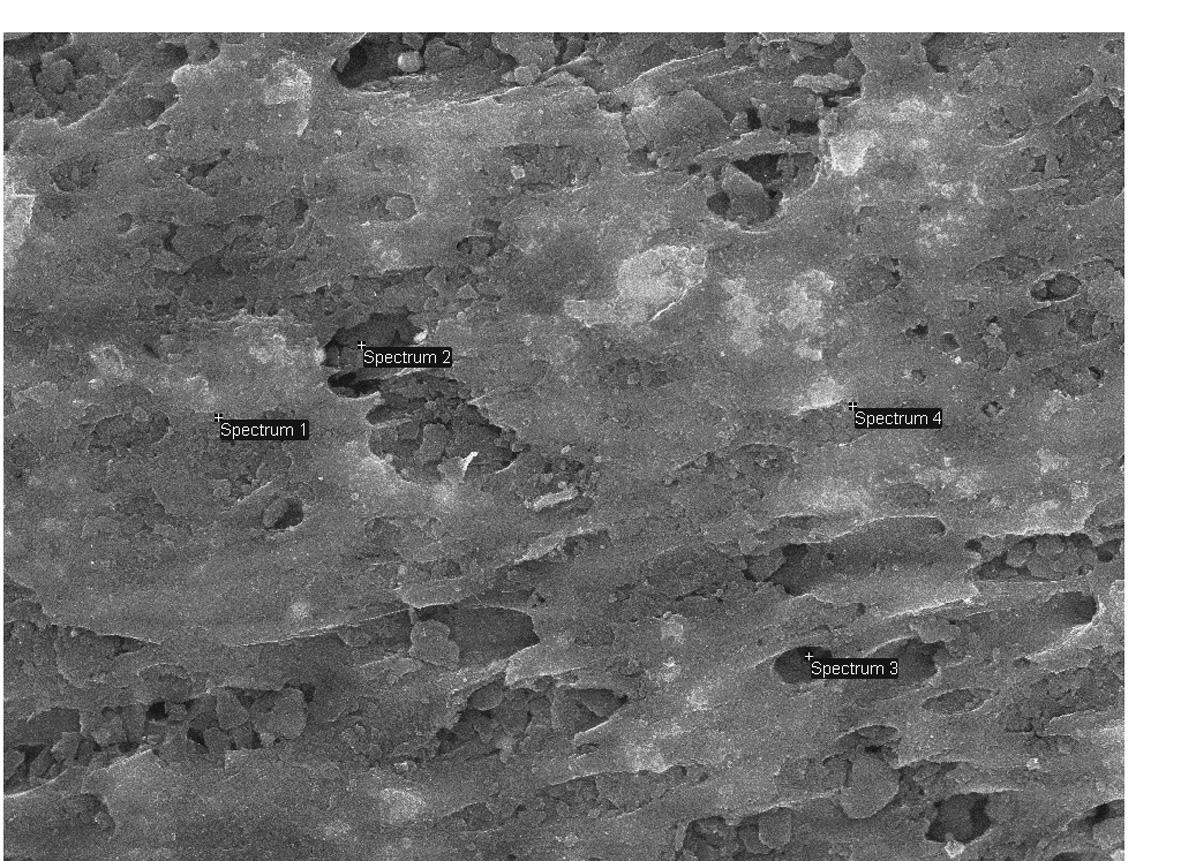

Preparation method and application of sediment-water interface phosphorus release control material

ActiveCN106277672ADecrease the adsorption-desorption equilibrium concentrationLess materialFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentIron saltsPhosphate

The invention provides a preparation method and application of a sediment-water interface phosphorus release control material. For the first time, a lake sediment and kaolin mixture is used as a basic raw material, and processes like oxidation, iron salt modification, granulation and calcination are adopted, so that adsorption-desorption balance concentration EPC0 value of the material to phosphate is remarkably lowered, linear distribution coefficient Kd value of the material is increased, and the material can effectively reduce sediment interstitial water phosphate concentration and can inhibit sediment-water interface phosphate release. The material itself has weak phosphate desorption capability and high adsorption and buffering capability, so that the material can truly realize effective obstruction and control on sediment-water interface phosphorus release. The material is low in material cost, high in social and economic benefit and safety, free of ecological risk to lake water, energy-saving and environment-friendly and has remarkable effect on controlling sediment-water interface phosphorus release in different lake areas of the Dian Lake in the process of application.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

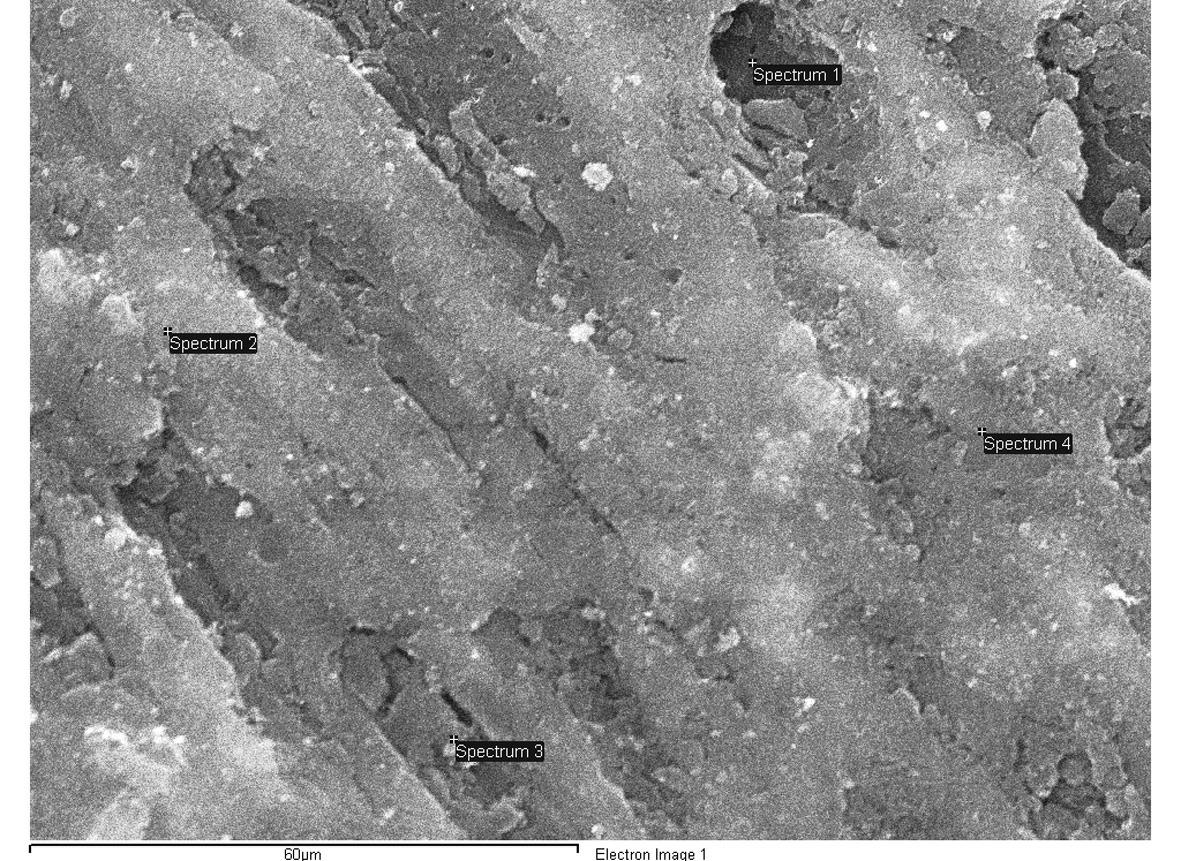

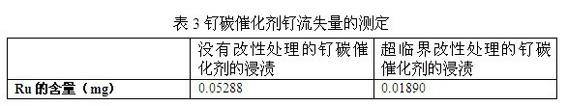

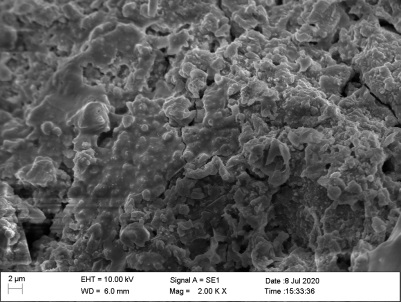

Ruthenium/carbon catalyst with activated carbon subjected to supercritical CO2 treatment as carrier and method for preparing catalyst

InactiveCN102489296AEvenly distributedReduce churnCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention relates to a ruthenium / carbon catalyst with activated carbon subjected to supercritical CO2 treatment as a carrier and a method for preparing the catalyst. The method comprises the following steps of: (1) putting a certain amount of activated carbon into a reaction kettle, and introducing CO2 by using a high-pressure injection pump to reach the pressure of 8.0 to 14.0MPa; (2) raising the temperature of the reaction kettle to be between 60 and 100 DEG C; (3) keeping the supercritical condition for 2 to 6 hours, reducing the temperature, and relieving the pressure to obtain modified activated carbon; and (4) impregnating a certain amount of modified activated carbon into a RuCl3 aqueous solution for 4 hours, drying at the temperature of 120 DEG C, putting the dried sample intoa quartz tube of a tube-type heating furnace, reducing by using hydrogen at the temperature of 200 DEG C for 2 hours and at the temperature of 300 DEG C for 1 hour, closing a temperature controller, cooling to room temperature, and thus obtaining the ruthenium / carbon catalyst. The activity of the ruthenium / carbon catalyst prepared by the method is obviously improved due to the action of supercritical treatment, and the defect of a supercritical organic medium is overcome.

Owner:ZHENGZHOU UNIV

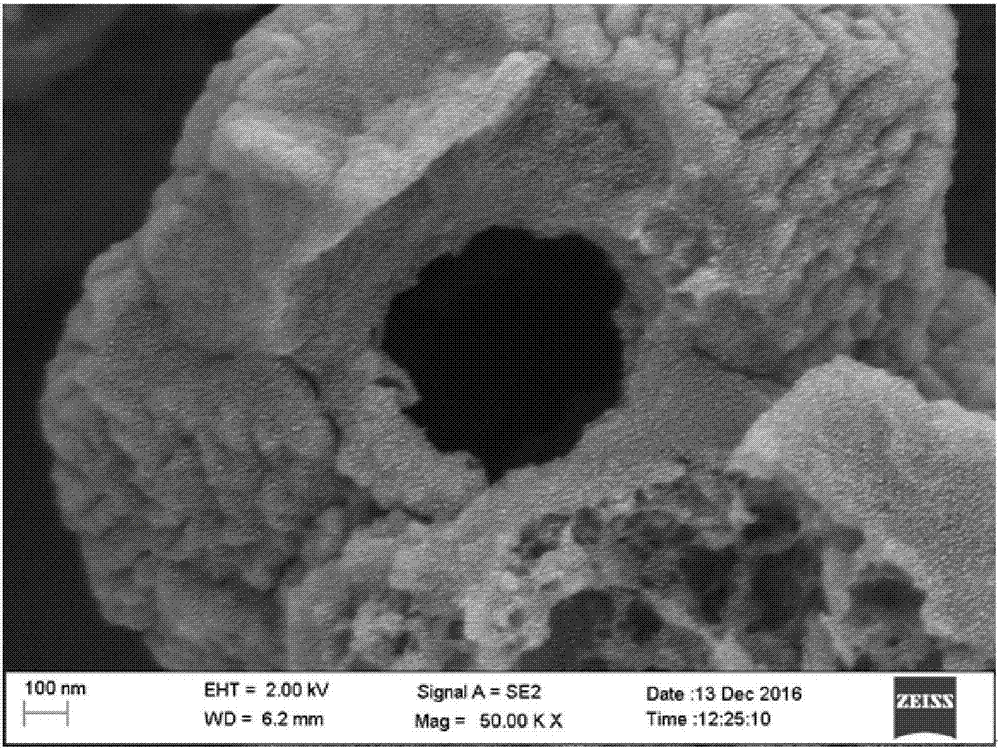

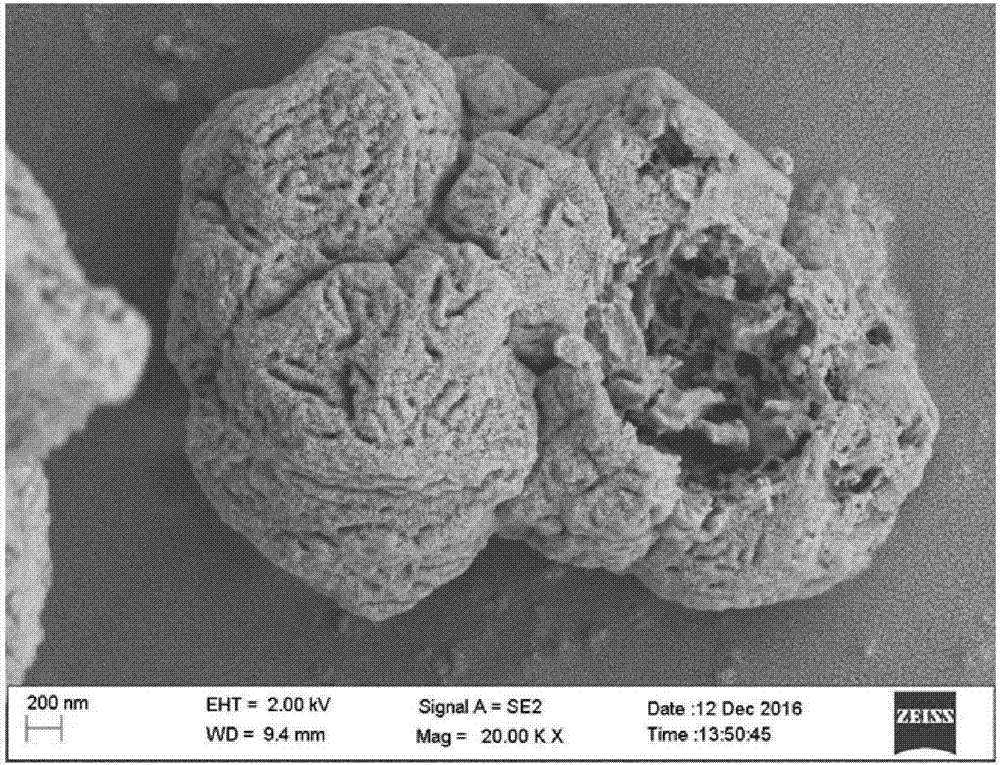

Preparation method and application of porous carbon reinforced microbial biofilm culturing carrier material

ActiveCN111892175AExtensive sources of materialsLow costSustainable biological treatmentBiological water/sewage treatmentBiomassEnvironmental chemistry

The invention discloses a preparation method of a porous carbon reinforced microbial biofilm culturing carrier material. The preparation method specifically comprises the following steps: mixing acidified biomass charcoal, a nano inorganic material, polyacrylamide and an amino starch adhesive, spraying a reaction medium, carrying out surface functional modification granulation, and carbonizing toobtain porous carbon; immersing porous carbon in activated sludge, and carrying out biofilm formation by adopting a continuous cyclic activated sludge supply method to obtain the microbial biofilm formation carrier material which can be applied to removal of nitrogen and phosphorus in a water body. Reaction media such as iron, calcium, lanthanum salt and the like permeate into premixed material molecules through high-temperature and high-pressure impregnation; metal colloid nanometer oxide is generated and loaded on the inner surface and the outer surface of the calcined and carbonized porouscarbon so that the adsorption active sites of the porous carbon and the adsorption capacity of nitrogen and phosphorus pollutants are enhanced, the requirement of biological coating on the surface ofthe carrier can be met within 36-48h in cooperation with the porous structure on the surface of the biochar, and the domestication time of subsequent active microorganisms is shortened.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES +1

Modification method of nano white carbon black

InactiveCN107266939AIncrease space densityImprove adsorption strengthPigment treatment with macromolecular organic compoundsDispersityIn situ polymerization

The invention provides a modification method of highly dispersed nano white carbon black used as rubber filler. According to the method, unsaturated acrylate polar monomers and acrylamide polar monomers are compounded, arylethene monomers are pre-emulsified, and highly dispersed nano white carbon black is prepared with an in-situ polymerization method. The method not only solves the problem that nano white carbon black is prone to agglomeration, but also solves the problem that nano white carbon black is agglomerated again due to long-term storage, nano white carbon black is endowed with super dispersity, and long-term storage stability is guaranteed. The modification method has the characteristics that fewer monomers are used, environmental pollution is small, the operation method is simple, the method is suitable for industrial production, and the like.

Owner:PETROCHINA CO LTD

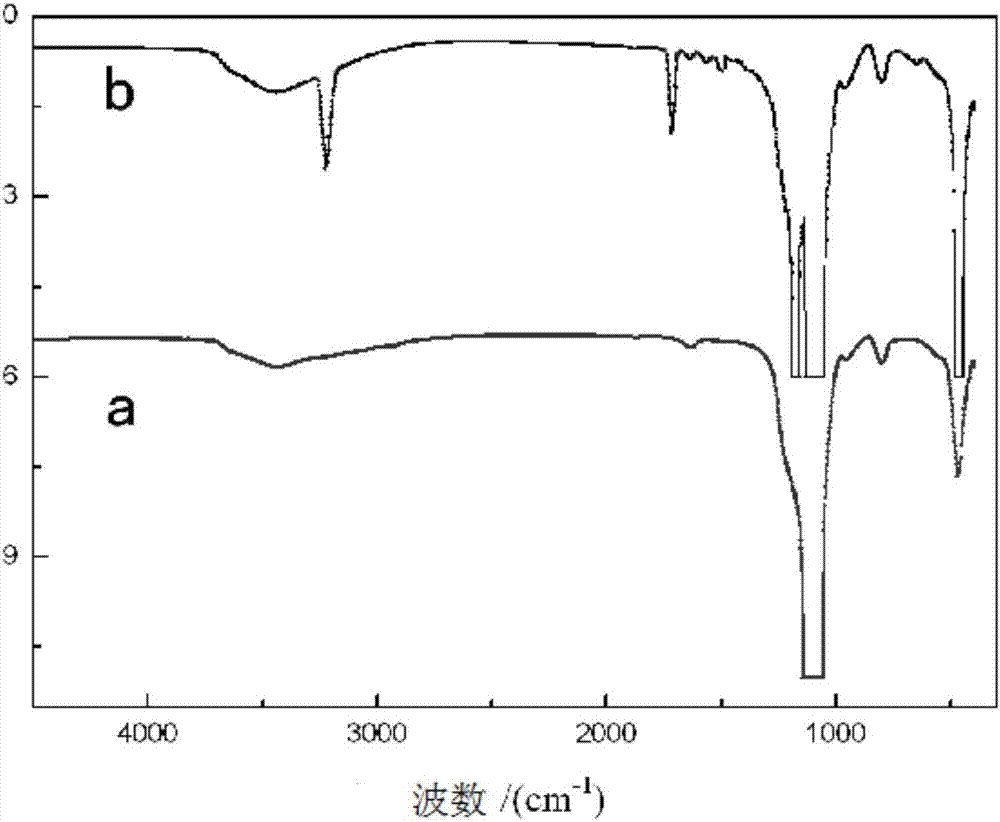

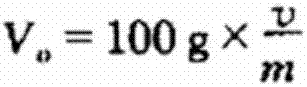

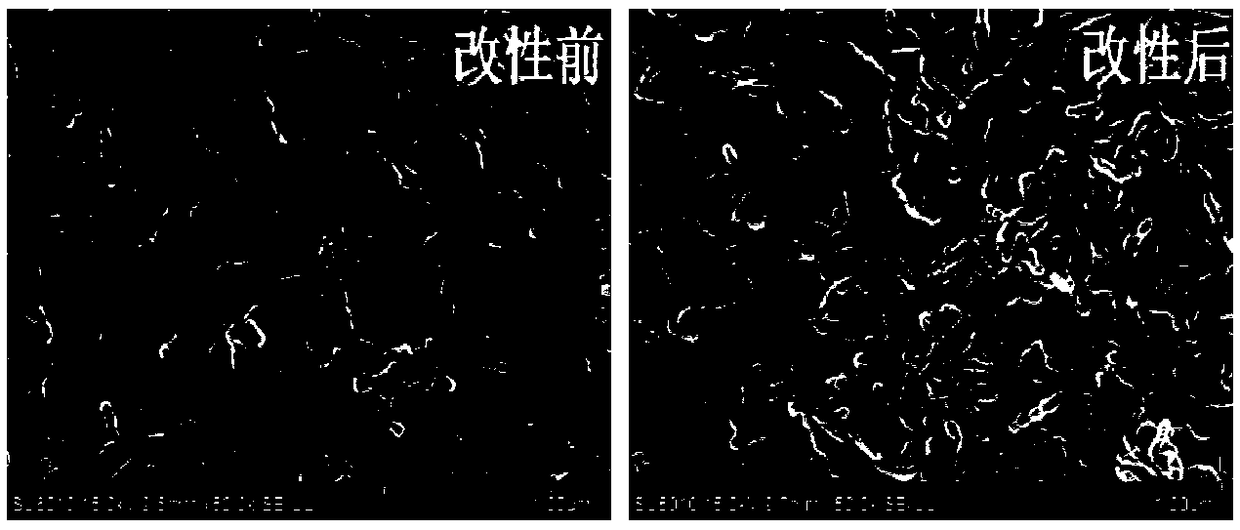

Preparation method of chiral separation membrane

The invention discloses a preparation method of a chiral separation membrane. The preparation method of the chiral separation membrane comprises the following steps: soaking a polymer membrane in an aqueous solution containing metal ions; taking out the polymer membrane a period of time later; transferring the polymer membrane into the aqueous solution containing a reducing agent; vibrating to enable the metal ions which are adsorbed to the surface of the membrane to be converted into metal elements; soaking the membrane loaded with metal in a chiral molecular solution which contains thiol anddiphenol structures; taking out the membrane a period of time later; and washing chiral molecules which are not adsorbed with deionized water to form the chiral separation membrane. The preparation method of the chiral separation membrane is simple and efficient, conditions are gentle, and large-scale application can be realized.

Owner:ZHEJIANG UNIV OF TECH

Thiadiazole-derivative/graphene-containing lubricating oil additive and preparation method thereof, and lubricating oil containing additive

The invention belongs to the field of chemical industry, and relates to a thiadiazole-derivative / graphene-containing lubricating oil additive and a preparation method thereof, and a lubricating oil containing the additive. The additive comprises thiadiazole derivatives, graphene, mercaptan, isopropanol, a 30 wt% formaldehyde solution, rare earth chlorides, alkali liquor and phenol substitutes. The nano graphene, which is used as the lubricating oil additive into the lubricating oil, has the functions of protection and repair, and forms a protective film, which can not be penetrated through even by hydrogen atoms, on the inner wall surface of the machine. When the graphene starts to be abraded, the hydrogen atoms jump and repair the crystal lattices, which indicates that the nano-graphene-added lubricating oil can keep permanently effective. The functional groups of the thiadiazole derivatives can form coordinate bonds and hydrogen bonds with graphene, thereby being beneficial to enhancing the dispersity of the graphene in the lubricating oil and the adsorption strength of the lubricating oil and graphene on the metal surface.

Owner:山东利特纳米技术有限公司

Preparation method of high-adsorption-capacity water treatment agent

InactiveCN107029678AEfficient releaseSimple processOther chemical processesWater/sewage treatment by sorptionWater bathsFiltration

The invention discloses a preparation method of a high-adsorption-capacity water treatment agent. The preparation method comprises the following steps that corncob powder is fed into tartaric acid for soaking, microwave irradiation treatment is performed, and filtration is performed to obtain a first pre-prepared material; vermiculite power, lauryl sodium sulfate, cocamidopropyl betaine and water are mixed evenly, heating is performed in a water bath, ultrasonic dispersion is performed, a succinimide solution is added, the pH value of a system is regulated with hydrochloric acid to 7.1-7.4, microcrystalline cellulose is added for stirring, suction filtration is performed, washing is performed to reach a neutral state, and drying and grinding are performed to obtain a second pre-prepared material; absolute ethyl alcohol and toluene are evenly stirred, the first pre-prepared material, the second pre-prepared material and methyltriethoxysilane are added, heating and stirring are performed, centrifugation is performed, flushing is performed with deionized water to make pH value neutral, and drying and smashing are performed to obtain the high-adsorption-capacity water treatment agent. The obtained high-adsorption-capacity water treatment agent is large in adsorption capacity and good in hydrophilcity.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com