Preparation method of chiral separation membrane

A technology of chiral separation and chiral molecules, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of cumbersome preparation of chiral separation membranes, and achieve no chemical pollution, strong universality, The effect of simple implementation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

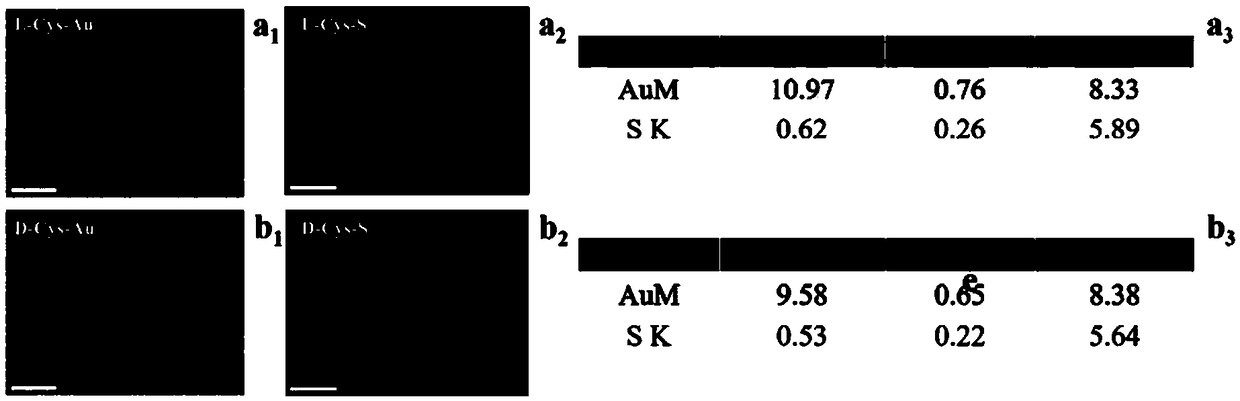

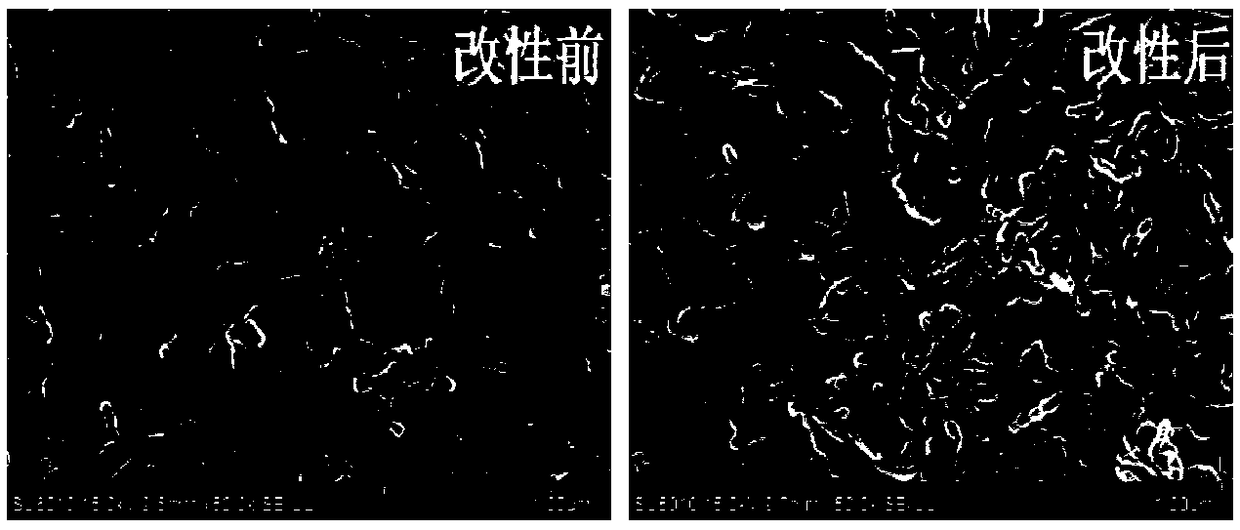

[0029] A preparation method of a chiral separation membrane with a compact surface layer and a pore size of 7 nm, the steps are as follows:

[0030] (1) Prepare two self-assembled micellar membranes of the same size formed by polymers containing carboxyl groups, with a concentration of 0.5mg / ml tetrachloroauric acid homogeneous solution;

[0031] (2) Put two ultrafiltration membranes of the same size into the above tetrachloroauric acid solution, shake at room temperature, and absorb for 6h;

[0032] (3) Then the adsorbed film is cleaned with deionized water;

[0033] (4) Prepare a sodium borohydride solution with a concentration of 0.1 mg / ml, put the cleaned membrane into the solution, shake at room temperature, and perform a reduction reaction for 8 hours;

[0034] (5) Take out the membrane, wash it with deionized water, and put the two membranes into two petri dishes respectively;

[0035] (6) The L-cysteine solution and the D-cysteine solution with a concentration of...

Embodiment 2

[0039] A preparation method of a chiral separation membrane with a micelle structure and a pore diameter of 11 nm, the steps are as follows:

[0040] (1) Prepare two self-assembled micellar membranes of the same size formed by a polymer containing pyridine, and prepare a homogeneous solution of 0.5mg / ml tetrachloroauric acid with a concentration;

[0041] (2) Put the above-mentioned two micellar films of equal size into the above-mentioned tetrachloroauric acid solution, shake at room temperature, and absorb for 6h;

[0042] (3) Then the adsorbed film is cleaned with deionized water;

[0043] (4) Prepare a sodium citrate solution with a concentration of 0.1 mg / ml, put the cleaned membrane into the solution, shake at room temperature, and perform a reduction reaction for 8 hours;

[0044] (5) Take out the membrane, wash it with deionized water, and put the two membranes into two petri dishes respectively;

[0045] (6) The L-cysteine solution and the D-cysteine solution wi...

Embodiment 3

[0052] A preparation method of a chiral separation membrane with a micelle structure and a pore size of 6.8nm, the steps are as follows:

[0053] (1) Prepare two identically sized blended membranes containing sulfonic acid groups, with a concentration of 1mg / ml tetrachloroauric acid homogeneous solution;

[0054] (2) Put the above-mentioned two micellar membranes of equal size into the above-mentioned tetrachloroauric acid solution, shake at room temperature, and absorb for 24h;

[0055] (3) Then the adsorbed film is cleaned with deionized water;

[0056] (4) Prepare an ethylenediamine solution with a concentration of 0.1 mg / ml, put the cleaned membrane into the solution, shake at room temperature, and perform a reduction reaction for 8 hours;

[0057] (5) Take out the membrane, wash it with deionized water, and put the two membranes into two petri dishes respectively;

[0058] (6) L-dopamine and D-dopamine solutions with a concentration of 5 mg / ml were prepared, and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com