Patents

Literature

68results about How to "Realize quantitative production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

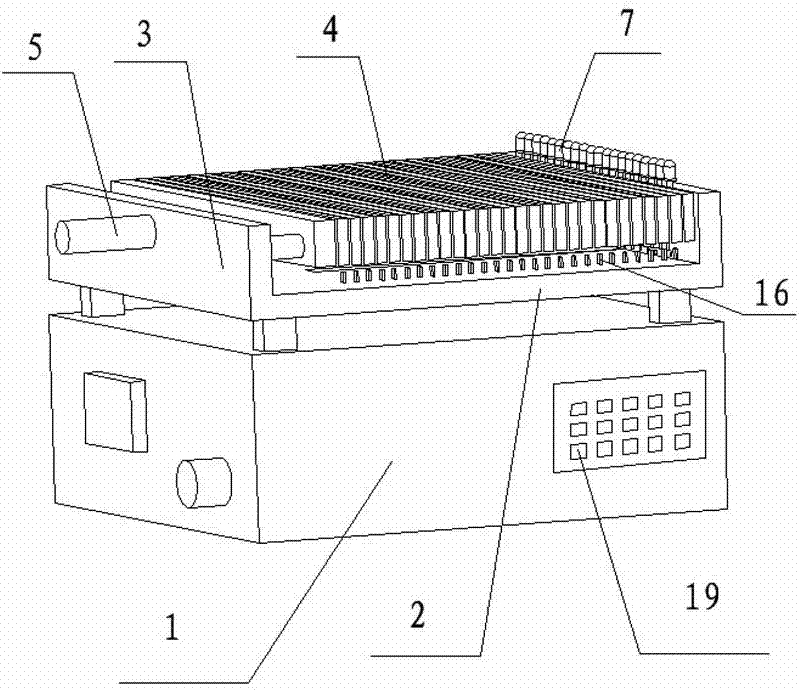

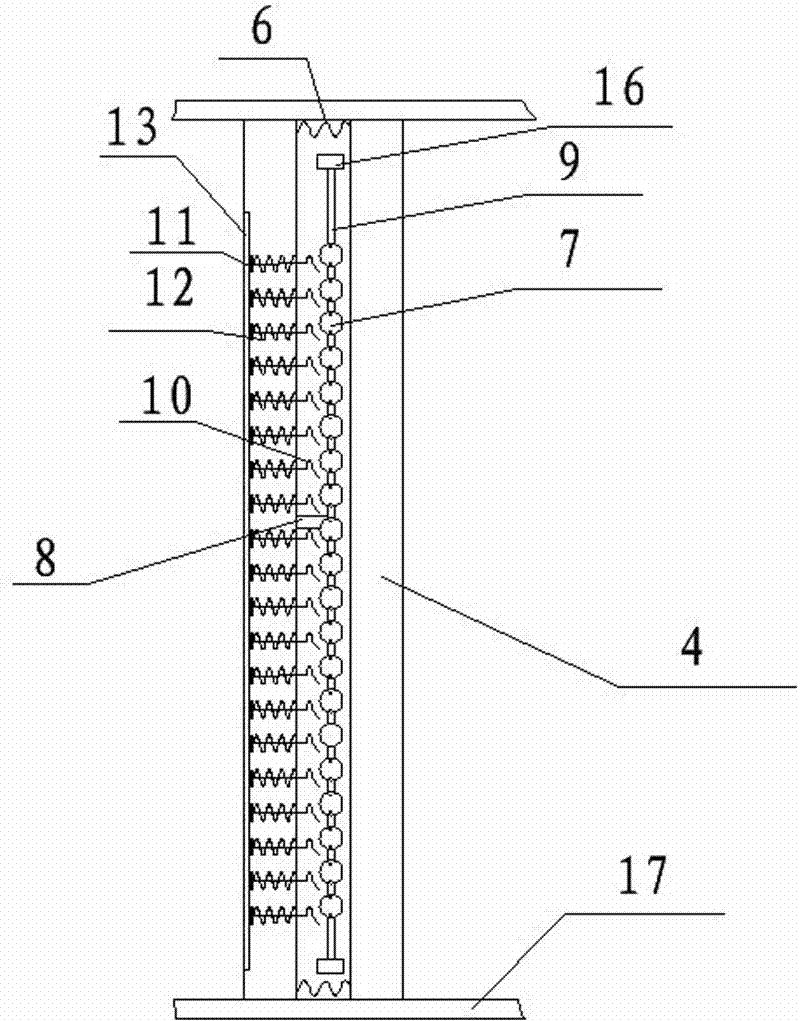

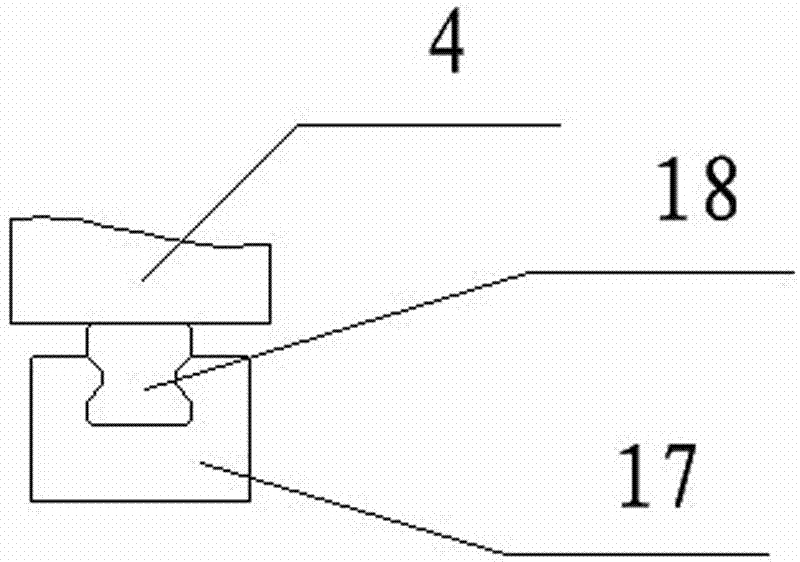

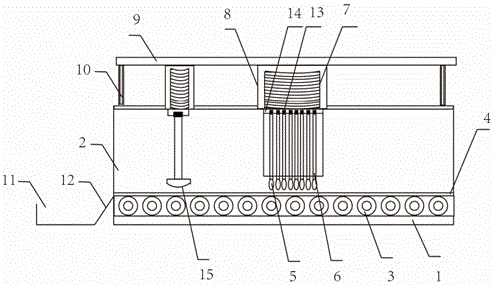

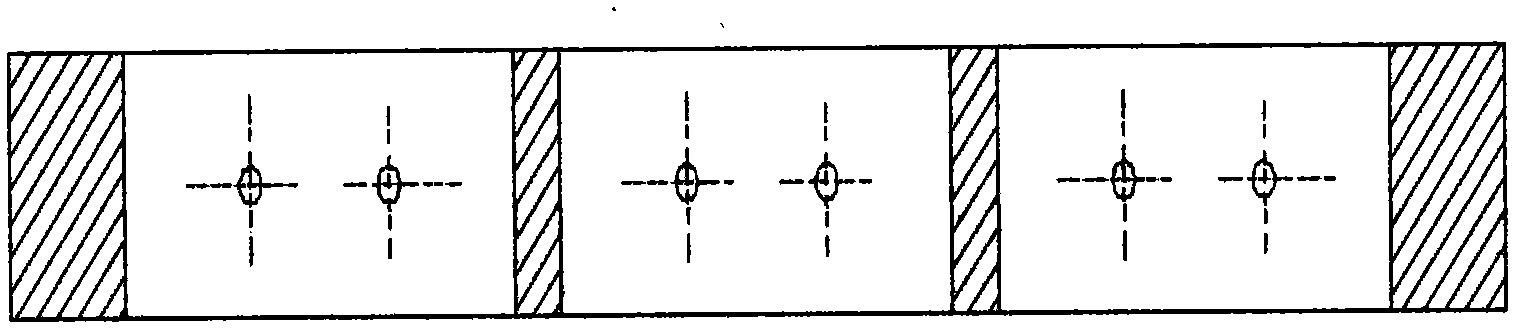

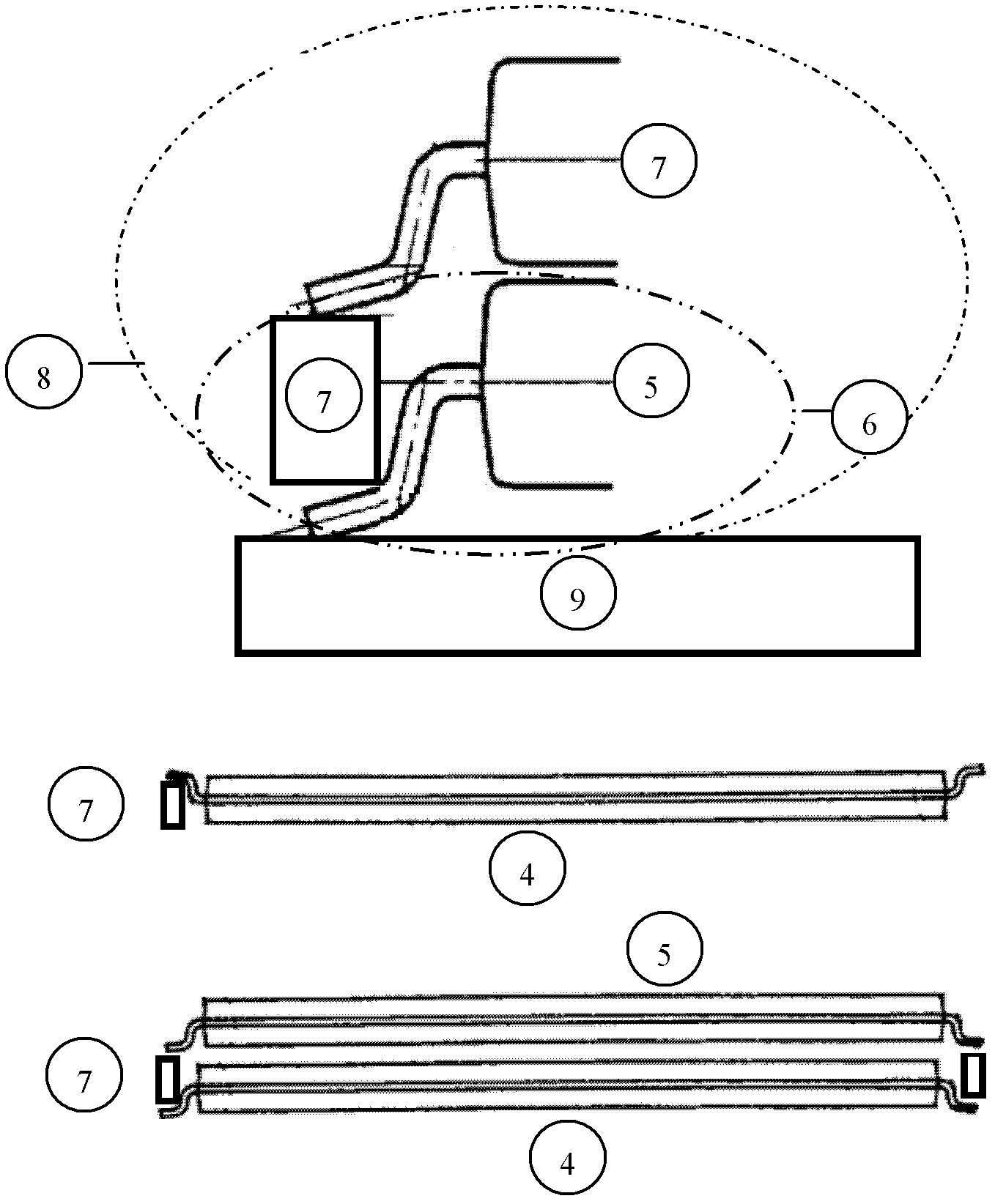

LED (Light Emitting Diode) ageing detection screening equipment and method

ActiveCN102172580AExtend detection timeImprove detection efficiencySortingIndividual semiconductor device testingPower flowControl system

The invention discloses LED (Light Emitting Diode) ageing detection screening equipment and method. In the equipment, a push rod is driven by a power device to make each splint press towards a corresponding LED row and a corresponding LED cathode pin is in contact with a corresponding cathode contact, so that electrification of LEDs is realized; meanwhile, detection screening of the LEDs is realized by using a PC (Personal Computer) machine. In the entire ageing process, rated voltage output by a circuit control system is kept at 24V, the rated current output is 50mA, current and voltage input to the LEDs are adjustable, and the rated current and rated voltage are supplied to the ageing of the LEDs for 20-60 minutes; through ageing, LEDs with electrical and process hidden troubles can be eliminated; and after ageing, the power device stops acting on the push rod and each splint returns to an initial position under the action of the acting force of a return spring, so that detection ofLEDs is realized and defective LEDs are eliminated.

Owner:JIANGMEN JIANGHAI DISTRICT KAIHUI PHOTOELECTRIC EQUIP CO LTD

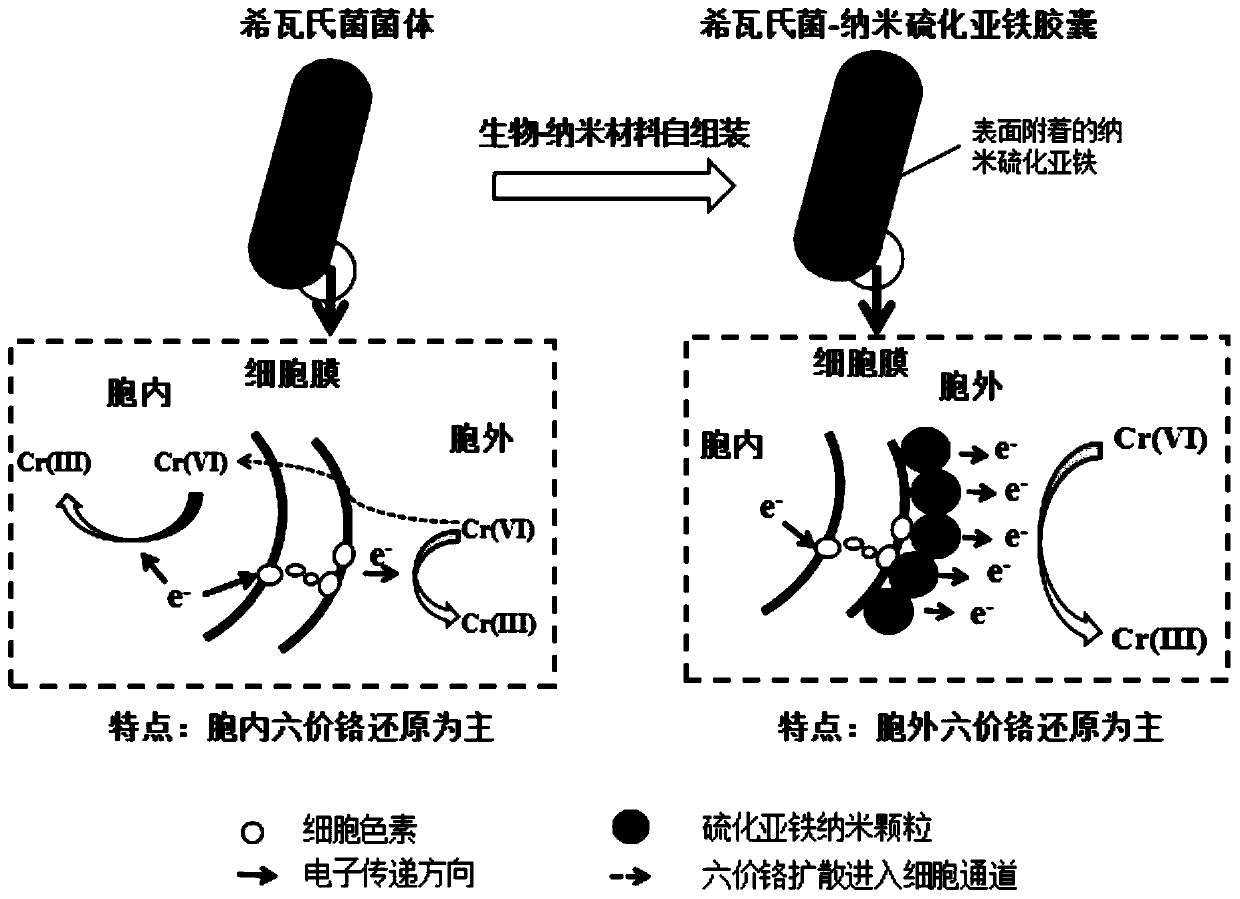

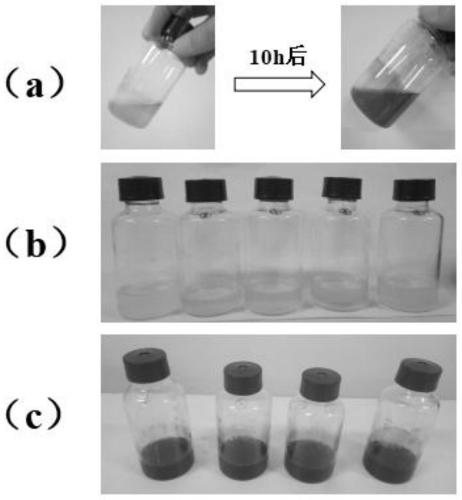

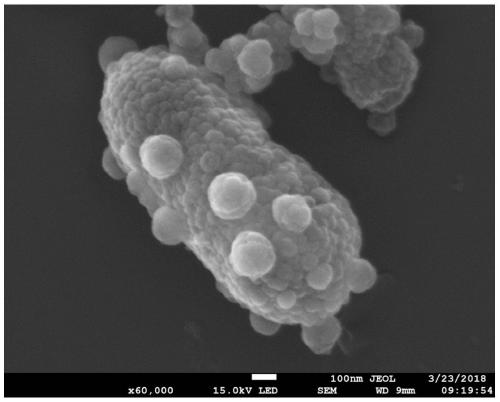

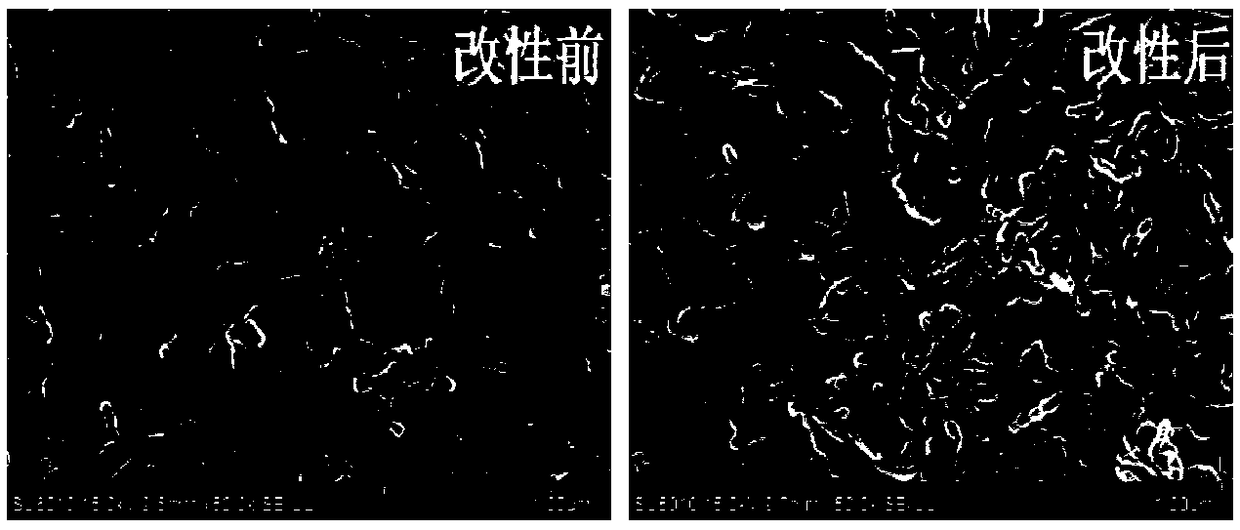

Preparation method and application of shewanella spp-nanometer ferrous sulfide capsules

ActiveCN109735527AEfficient multi-cycle processingImprove processing efficiencyWater contaminantsMicroorganism based processesChemistryHexavalent chromium

The invention belongs to the technical field of biology, and relates to a preparation method and application of shewanella spp-nanometer ferrous sulfide capsules. The method comprises the steps that an LB culturing medium and an M9 culturing medium are prepared, shewanella spp is inoculated to the LB culturing medium for culturing, and bacterial liquid is obtained; the LB culturing medium and theM9 culturing medium are mixed, sodium lactate, calcium chloride and magnesium sulfate are added, and reaction buffering liquid is obtained; then, the bacterial liquid is centrifuged, bacterial sludgeis added into the reaction buffering liquid until the OD 600 value is 0.05-5; then, a ferric chloride solution and a sodium thiosulfate solution are added into the reaction buffering liquid after inoculation of the bacterial sludge, and after culturing, centrifugation, washing and resuspending, the shewanella spp-nanometer ferrous sulfide capsules are obtained; in the process of synthesizing the capsules, the activity of the biological metabolism mechanism is fully utilized, the raw materials are simple and cheap, the application cost is low, and quantization production can be achieved; multi-period efficient removal for hexavalent chromium is efficiently achieved, and a new method is provided for efficiently processing heavy metal pollution.

Owner:JIANGSU UNIV

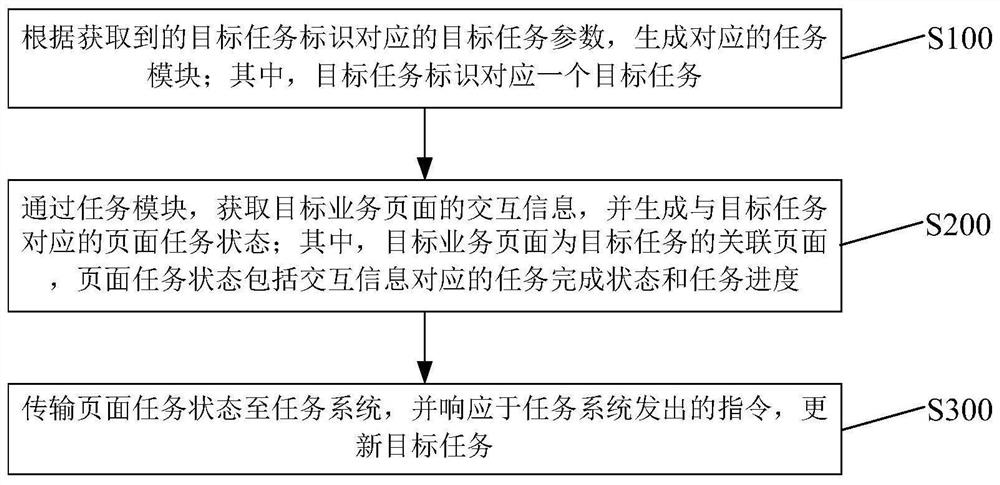

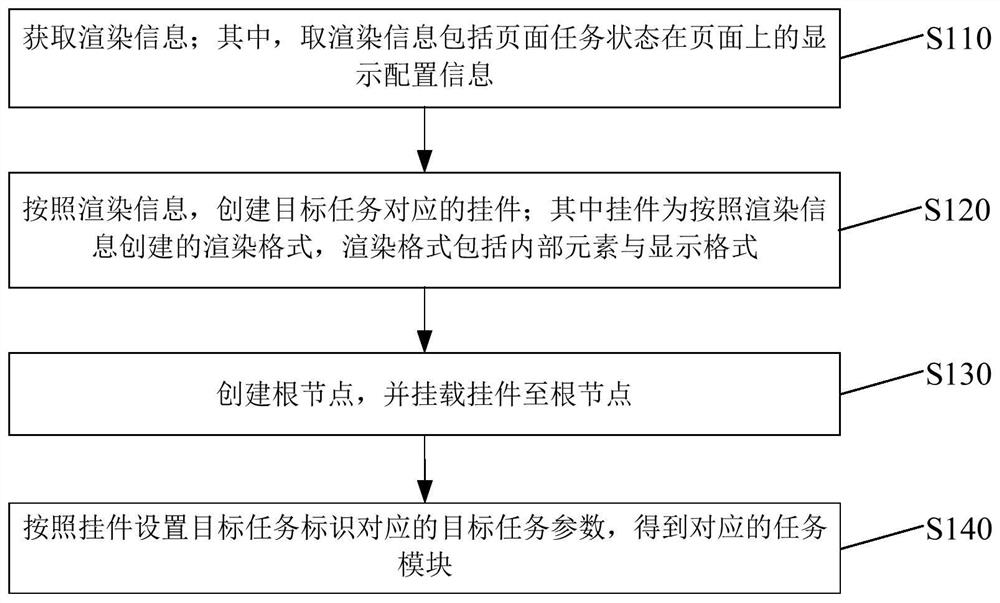

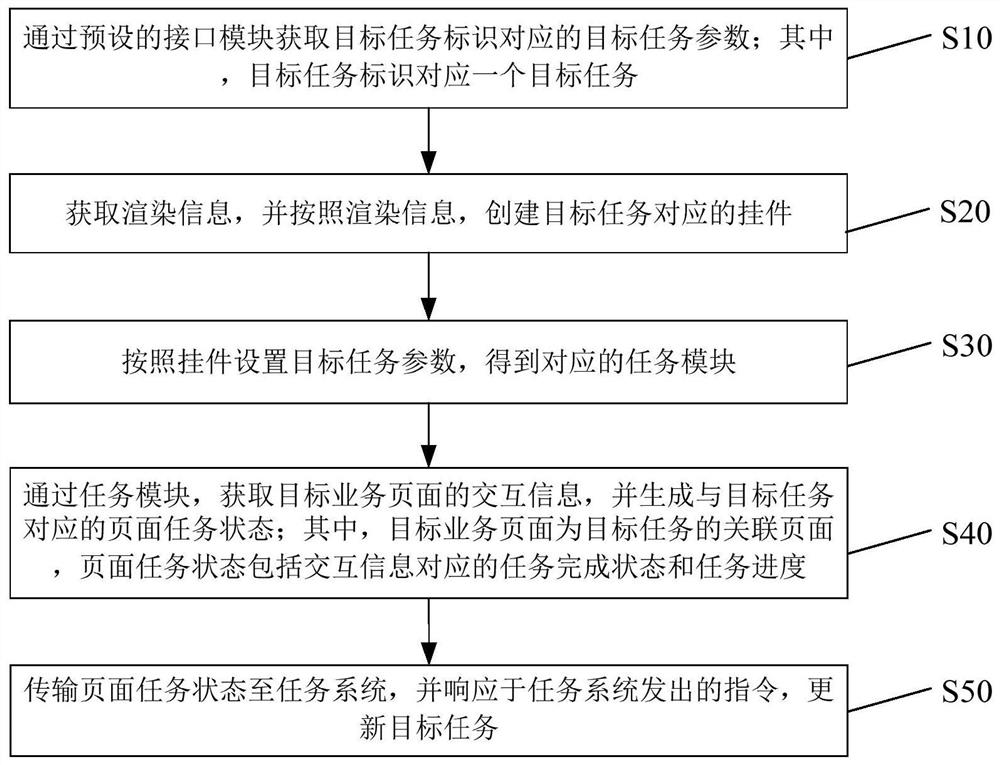

Page task access method, device and system, electronic equipment and storage medium

PendingCN111857928AAvoid duplication of workRealize quantitative productionExecution for user interfacesSoftware engineeringElectronic equipment

The invention relates to a page task access method, device and system, electronic equipment and a storage medium. The method comprises the steps of generating a corresponding task module according toan obtained target task parameter corresponding to a target task identifier, wherein the target task identifier corresponds to one target task; obtaining interaction information of the target businesspage through a task module, and generating a page task state corresponding to the target task, wherein the target business page is an associated page of the target task, and the page task state comprises a task completion state and a task progress corresponding to the interaction information; and transmitting the page task state to a task system, and updating the target task in response to an instruction sent by the task system. Therefore, the target task does not need to be excessively paid attention to in the development process of the business page, unnecessary repeated work is avoided, the business page can be rapidly accessed to a project system, and the purpose of quantitative production is achieved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Abrasion-resistant paper-plastic composite bag and preparation method thereof

InactiveCN106012668AIncreased burst indexHigh mechanical strengthNon-fibrous pulp additionCoatings with pigmentsHydrotalciteTricresyl phosphate

The invention discloses a preparation method of an abrasion-resistant paper-plastic composite bag. The preparation method includes the steps that 1, polyethylene resin, phenolic resin, polyurethane, glycerol, hydrotalcite, molybdenum disulfide, tricresyl phosphate and calcium stearate are mixed, are subjected to heat treatment and then are subjected to extrusion molding to obtain plastic particles; 2, the plastic particles are heated and applied to the surface of a paper layer to form a plastic covering layer so as to prepare abrasion-resistant paper-plastic composite paper; 3, the paper-plastic composite paper is processed into the abrasion-resistant paper-plastic composite bag. The abrasion-resistant paper-plastic composite bag prepared by means of the method has high burst index and high mechanical strength, the raw materials are easy to obtain, and quantitative production can be achieved.

Owner:TONGLING FOUNDER PLASTICS TECH

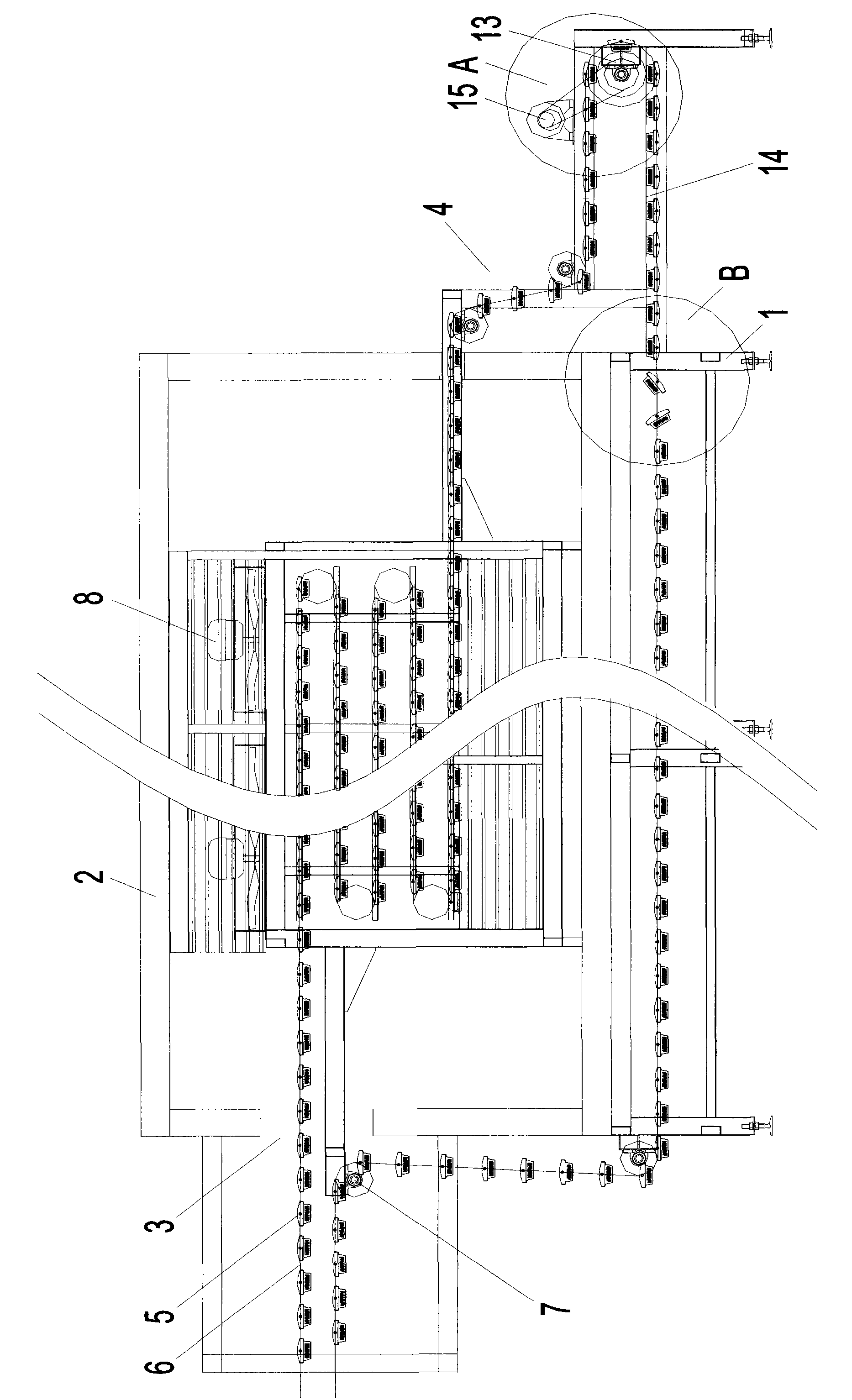

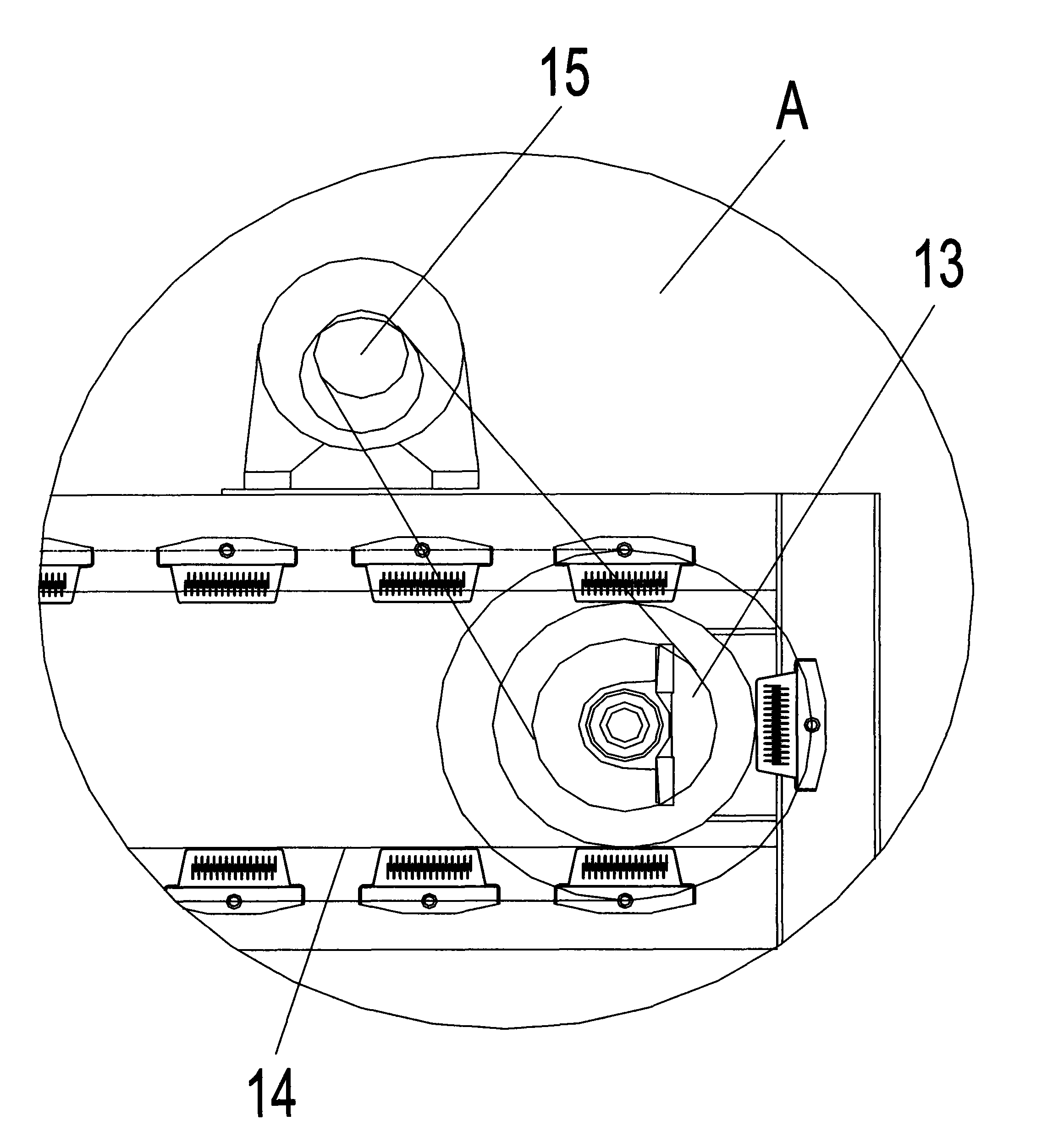

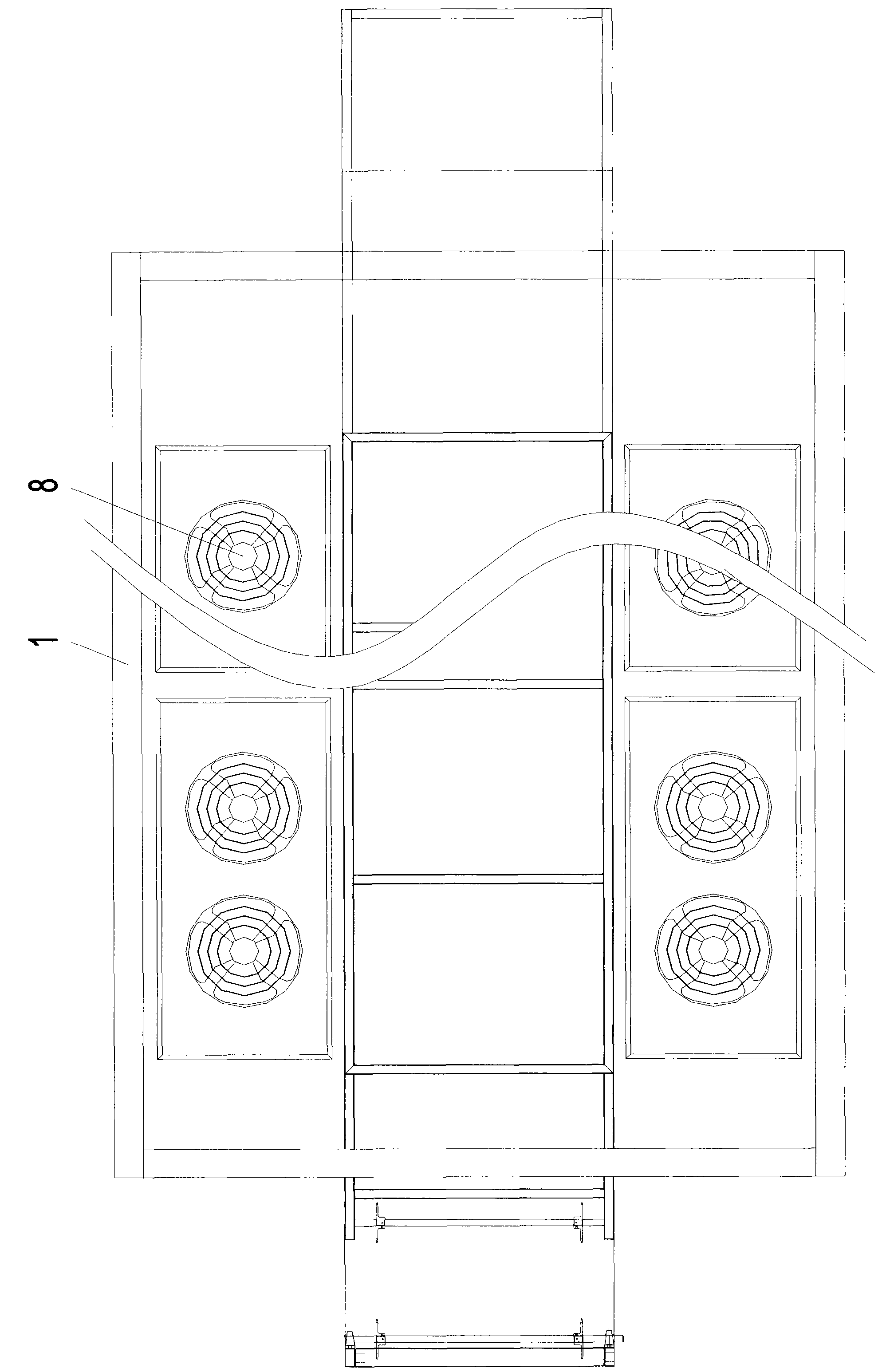

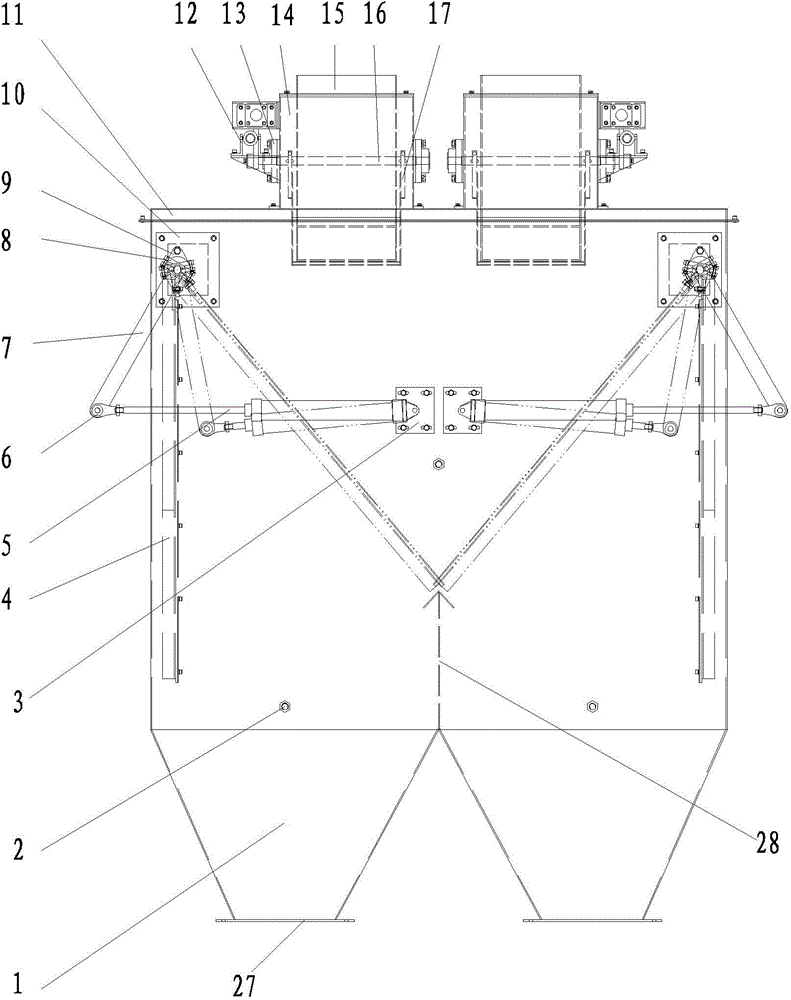

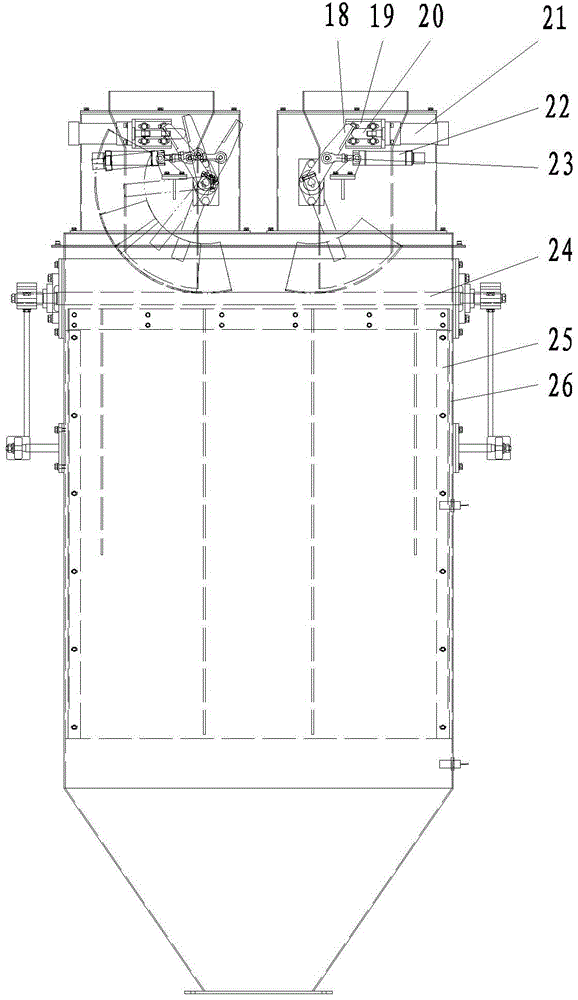

Instant freezer

ActiveCN103017448AHigh degree of automationSave manpower and material resourcesLighting and heating apparatusFood processingDelivery systemIn degree

The invention provides an instant freezer. The problems of a batch type instant freezing device used for producing in batches in the prior art that the production efficiency is low, the freezing effect is inferior, the energy resource is wasted and the quality of the product is different are solved. The instant freezer comprises a frame, an instant freezing cabin, a conveying system, a circulating fan and a charging basket turning device, wherein the instant freezing cabin is used for instantly freezing materials and comprises a cabin body, a feeding port and a discharging port; the cabin body is arranged on the frame; the feeding port is arranged at one end of the cabin body; the discharging port is arranged at the other end of the cabin body; the conveying system comprises a charging basket, a conveyer belt, and a transmission shaft; the charging basket is used for placing the materials, the conveyer belt is used for mounting the charging basket and passes by the instant freezing cabin, the transmission shaft is used for supporting the conveyer belt and changing a moving direction of the conveyer belt and is arranged on the frame; the circulating fan is used for causing the air in the cabin body to flow and enhancing the instant freezing effect and is arranged at the top in the cabin body; and the charging basket turning device is used for pouring the instantly frozen materials out of the charging basket and is arranged on the frame on one side of the discharging port. The instant freezer provided by the invention realizes the continuous production, is high in degree of automation, is labor-saving and material-saving, is energy-saving and environment-friendly, is high in production efficiency and is high in quality of products.

Owner:北京金田麦国际食品有限公司

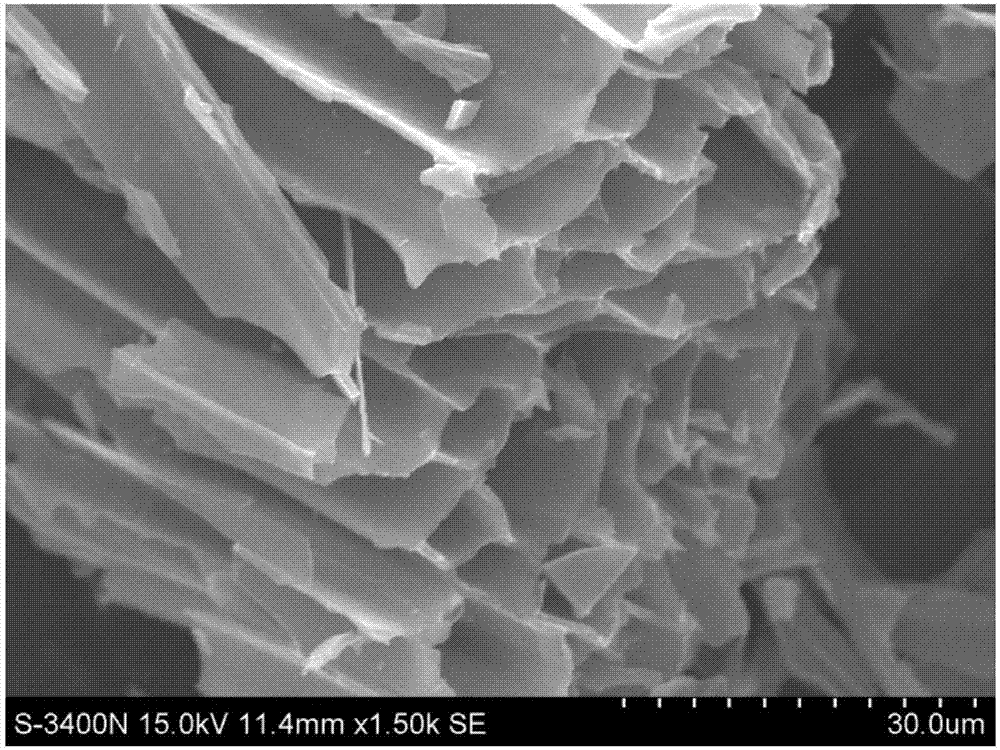

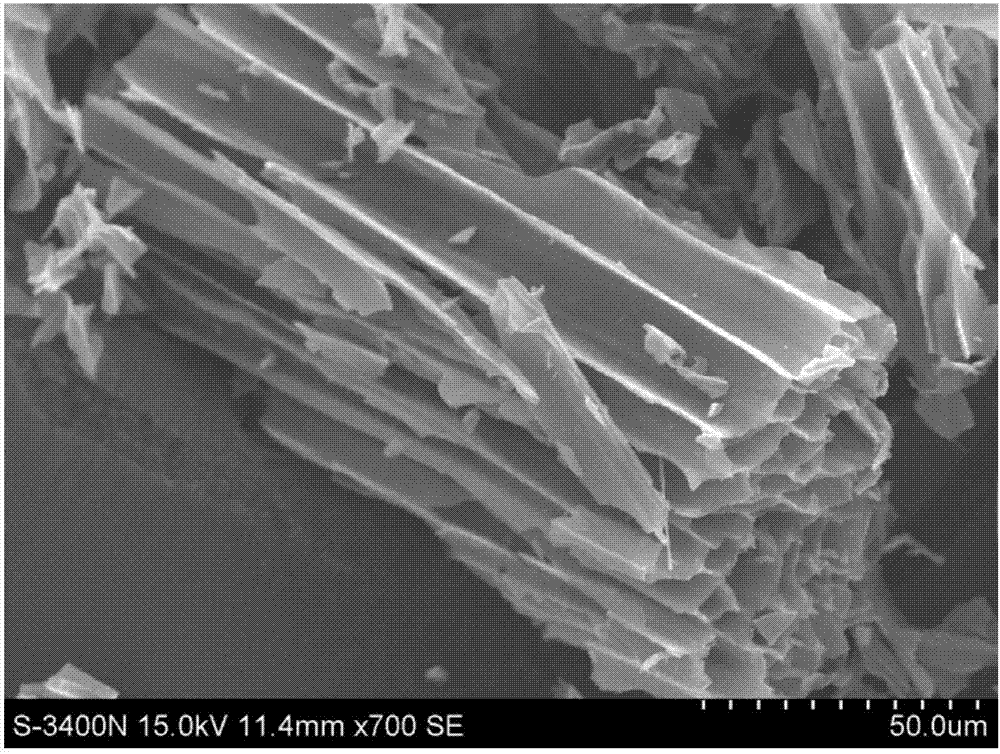

Preparation method for graphite film as well as product and application of graphite film

The invention relates to a preparation method for a graphite film. The method comprises the following steps: heating a PI film to temperature of 650-750 DEG C, keeping the temperature for 100-150 min,continuing to raise the temperature to 850-950 DEG C, keeping the temperature for 100-150 min, continuing to raise the temperature to 1250-1350 DEG C, keeping the temperature for 80-130 min, and performing cooling to obtain a carbonized film; and (2) performing graphitization: performing graphitization on the carbonized film obtained in the step (1) by adopting the following gradient heating procedure: heating the carbonized film to temperature of 1550-1650 DEG C, keeping the temperature for 20-60 min, continuing to raise the temperature to 1750-1850 DEG C, keeping the temperature for 20-90 min, continuing to raise the temperature to 2300-2400 DEG C, keeping the temperature for 20-90 min, performing heating to temperature of 2750-2900 DEG C, and performing cooling to obtain the graphite film with high orientation, high crystallinity and high conductivity.

Owner:SHUZHOU GU CARBON NEW MATERIAL

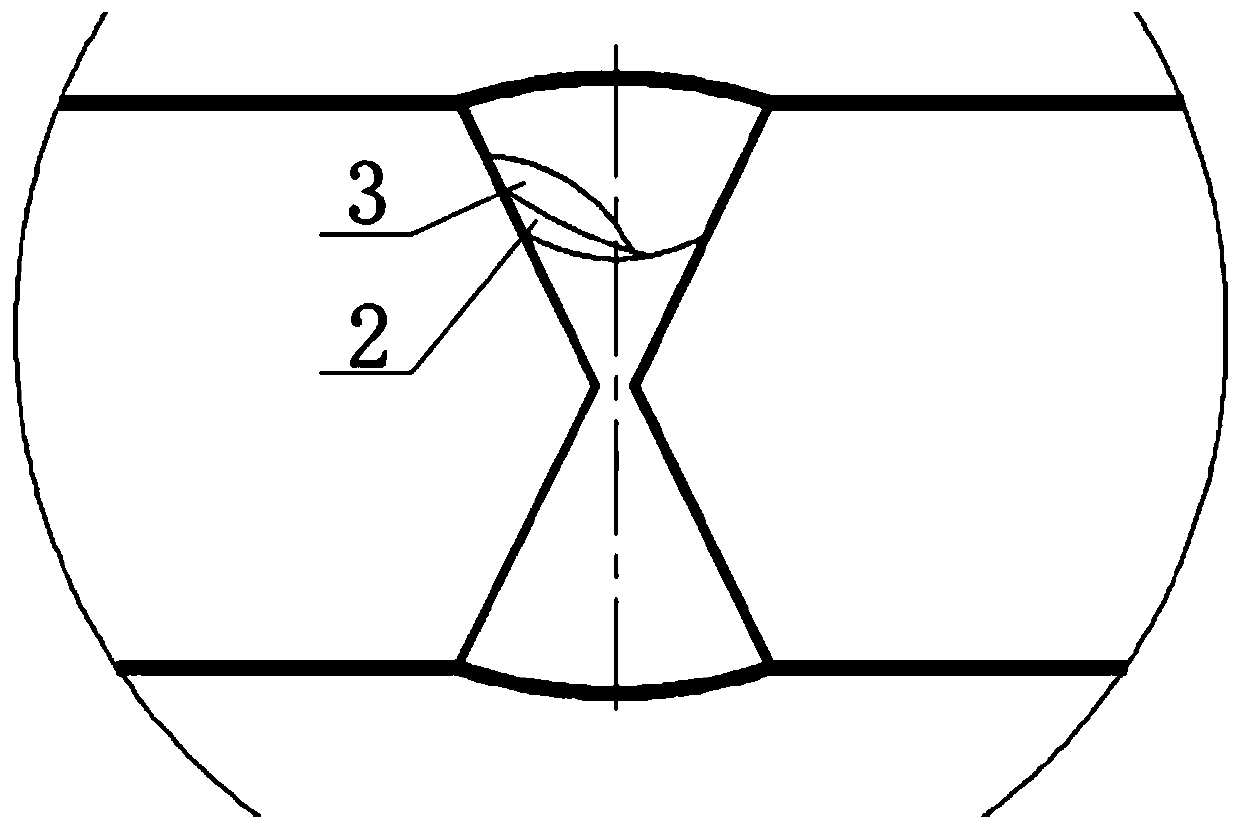

Manufacturing method of weld defect testing plate for austenitic stainless steel having unfused defects

ActiveCN110722255AMeet training application needsSolve the technical problems of unfused defectsElectrode supporting devicesWelding/soldering/cutting articlesShielded metal arc weldingSS - Stainless steel

The invention discloses a manufacturing method of a weld defect testing plate for austenitic stainless steel having unfused defects. The manufacturing method comprises the following steps of: fittingup one pair of steel plate welding parts after chamfering to-be-welded positions of the steel plate welding parts; carrying out backing welding by adopting gas tungsten arc welding and subsequently carrying out filling welding by adopting shielded metal arc welding; manufacturing unfused defects at corresponding welding seam metal layers according to preset quantity and position of the unfused defects by adopting gas metal arc welding; and after the unfused defects are manufactured, regulating the welding parts to be flat positions of welding, welding a layer of welding surface at the upper surface or the side surface of the unfused defects so as to implement after-treatment by adopting gas metal arc welding, and filling the other positions by adopting shielded metal arc welding. The manufacturing method of the weld defect testing plate for the austenitic stainless steel having unfused defects, disclosed by the invention, can realize manufacturing of unfused defects at any position inthe welding seam so as to meet the application requirements of simulative testing plates for a contrast test of various detection methods or training for testers.

Owner:WUHAN YIYE STEEL STRUCTURE

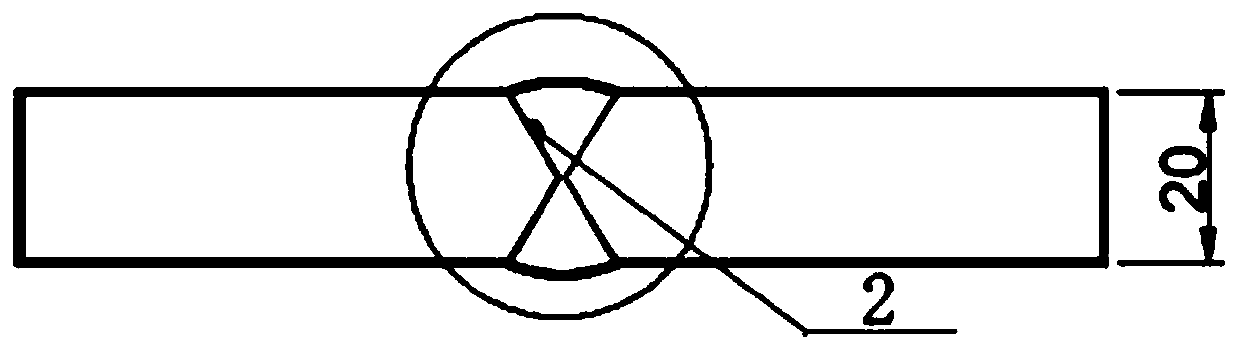

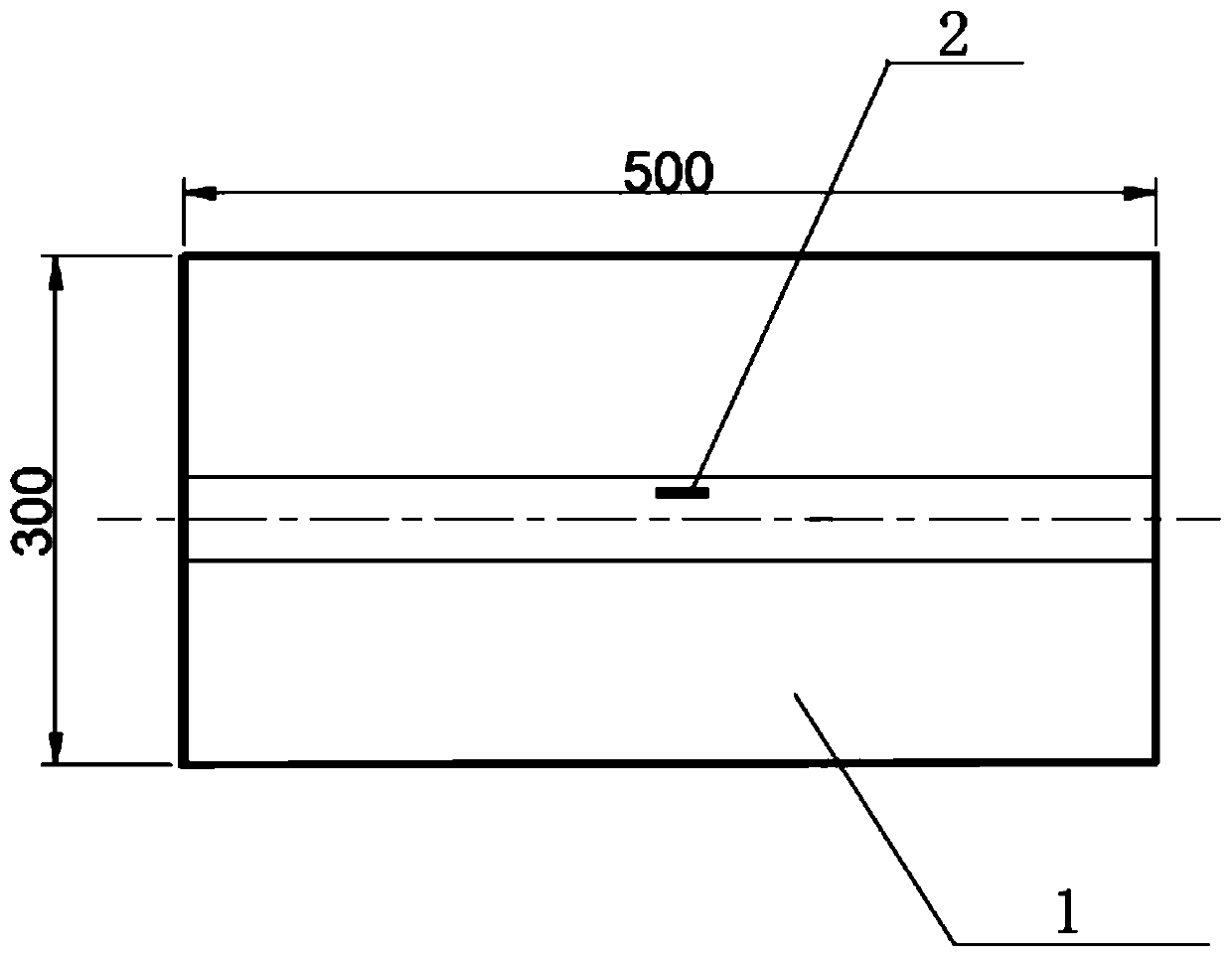

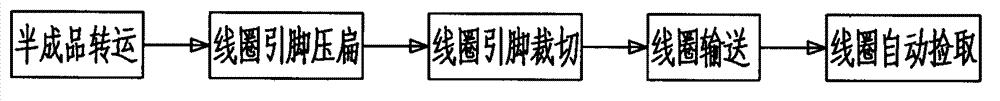

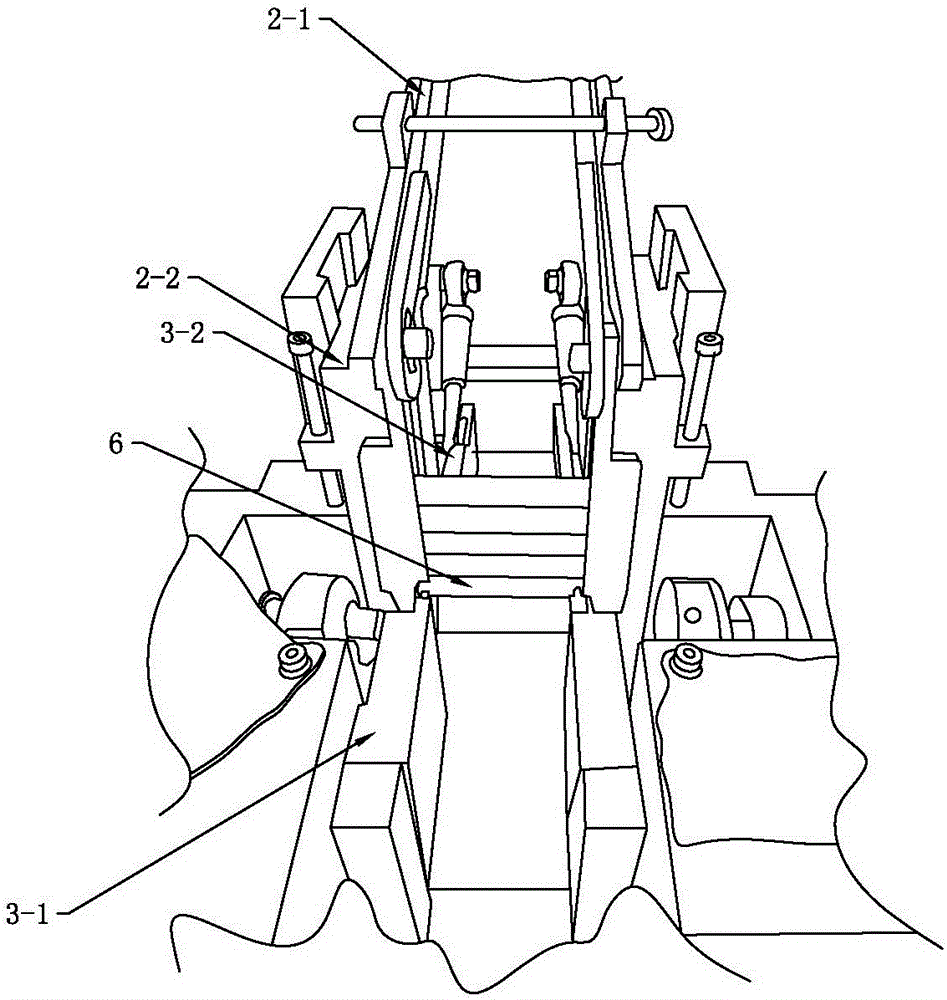

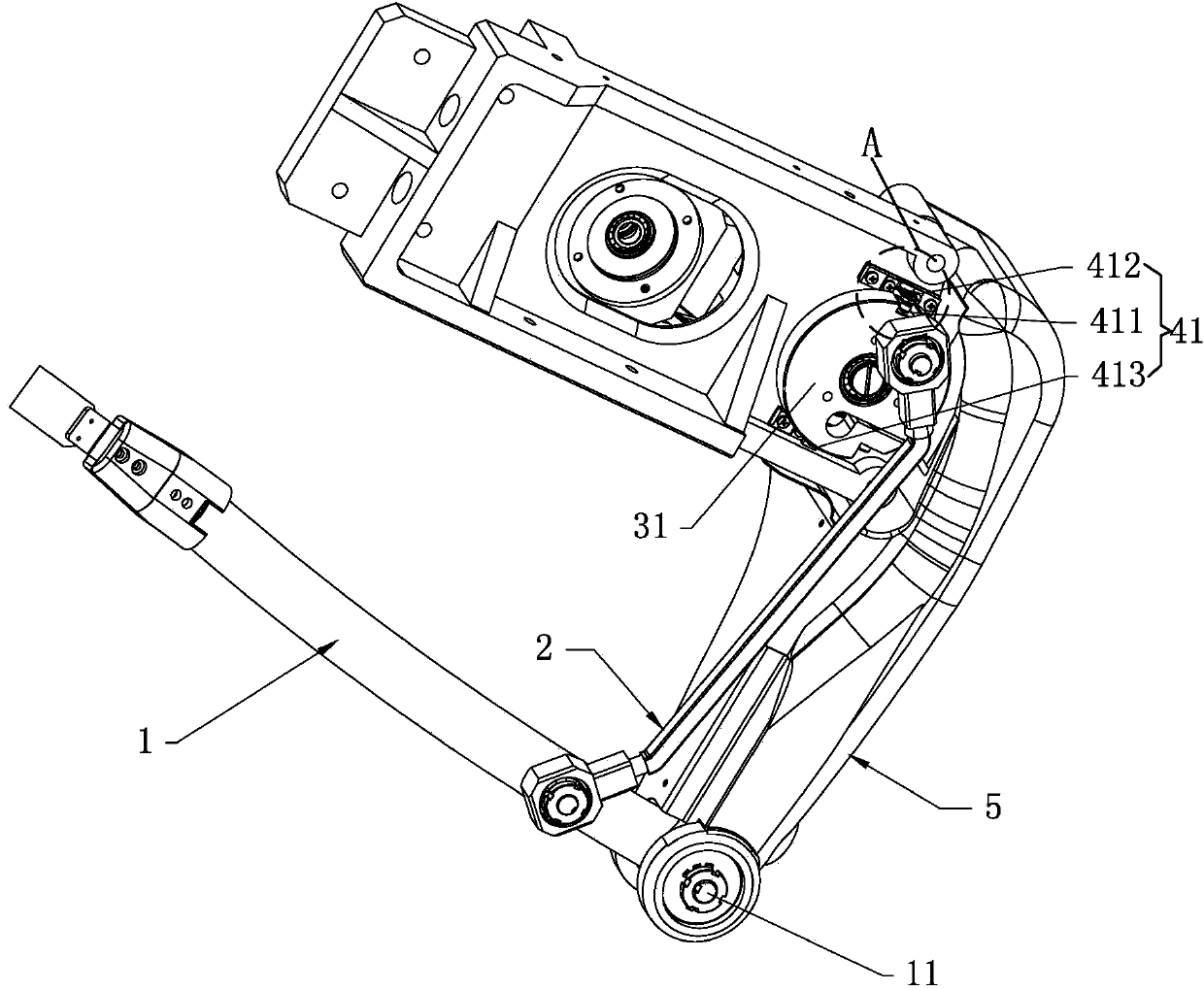

Coil forming machine

ActiveCN102760569AShort lateral movement distanceFast reciprocating motionManufacturing stator/rotor bodiesCoils manufactureManipulatorWork in process

The invention discloses a coil forming machine, comprising a semi-finished product transfer arm, a coil pin flattening device, a coil pin trimming device, a coil conveying device and a coil automatic picking device, wherein the semi-finished product transfer arm comprises left and right guide rails fixedly arranged on the body of a processing machine, left and right slide blocks arranged along the left and right guide rails, upper and lower guide rails fixedly connected with the left and right slide blocks, upper and lower slide blocks sliding along the upper and lower side rails, and pneumatic chucks fixedly connected with the upper and lower side blocks; and the coil automatic picking device comprises a picking mechanism, a bearing mechanism and an accounting mechanism. The transfer arm of the coil forming machine has short transverse displacement distance and quickly performs reciprocating motion, so that the transferring time of the semi-finished products is reduced greatly, and the production efficiency is improved. The picking mechanism of the coil forming machine is an automatic picking mechanism, and automatically sleeves the coils on a core bar after picking the coils, so that the whole process from picking and placing the coils is finished automatically, the picking speed is high, labor force is saved, and production efficiency is improved.

Owner:昆山广辉精密五金有限公司

Moisture-resistant food bag and preparation method thereof

InactiveCN105924740AIncreased burst indexImprove moisture resistanceFlexible coversWrappersMolded pulpMoisture resistance

The invention discloses a preparation method of moisture-resistant food bags. The preparation method includes: 1) mixing polyethylene resin, phenolic resin, polyurethane, glass fibers, hydrotalcite, tricresyl phosphate and calcium stearate, and performing thermal treatment and extrusion molding to obtain plastic particles; 2) heating the plastic particles, and coating to the surface of a paper layer to form a plastic coating to obtain paper-plastic composite paper; 3) processing the paper-plastic composite paper into the moisture-resistant food bags. The moisture-resistant food bags made according to the method are excellent in moisture resistance, capable of preventing moisture deterioration of food in the bags and high in burst index.

Owner:TONGLING FOUNDER PLASTICS TECH

Antibacterial food bag and preparation method thereof

InactiveCN106087504AHigh burst resistanceImprove antibacterial propertiesNon-fibrous pulp additionPaper/cardboardFiberFishing

The invention discloses a preparation method of an antibacterial food bag. The method includes the steps that firstly, raw materials and limewash are mixed and cooked to obtain pulp; secondly, the pulp is subjected to washing, bleaching, ramming, paper fishing and drying to prepare antibacterial paper; thirdly, the antibacterial paper is processed into the antibacterial food bag, wherein the raw materials include bark, chitin fiber, aloe, fructus forsythiae, folium isatidis and selfheal. The antibacterial food bag prepared through the method has high breaking resistance and antibacterial performance. The raw materials in the preparation method are easy to obtain. The antibacterial food bag can be produced on a large scale.

Owner:TONGLING FOUNDER PLASTICS TECH

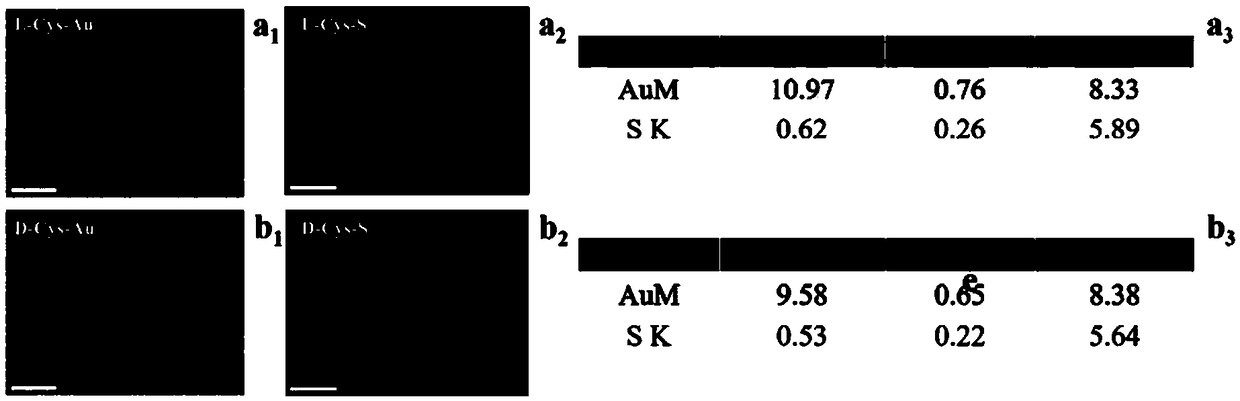

Preparation method of chiral separation membrane

The invention discloses a preparation method of a chiral separation membrane. The preparation method of the chiral separation membrane comprises the following steps: soaking a polymer membrane in an aqueous solution containing metal ions; taking out the polymer membrane a period of time later; transferring the polymer membrane into the aqueous solution containing a reducing agent; vibrating to enable the metal ions which are adsorbed to the surface of the membrane to be converted into metal elements; soaking the membrane loaded with metal in a chiral molecular solution which contains thiol anddiphenol structures; taking out the membrane a period of time later; and washing chiral molecules which are not adsorbed with deionized water to form the chiral separation membrane. The preparation method of the chiral separation membrane is simple and efficient, conditions are gentle, and large-scale application can be realized.

Owner:ZHEJIANG UNIV OF TECH

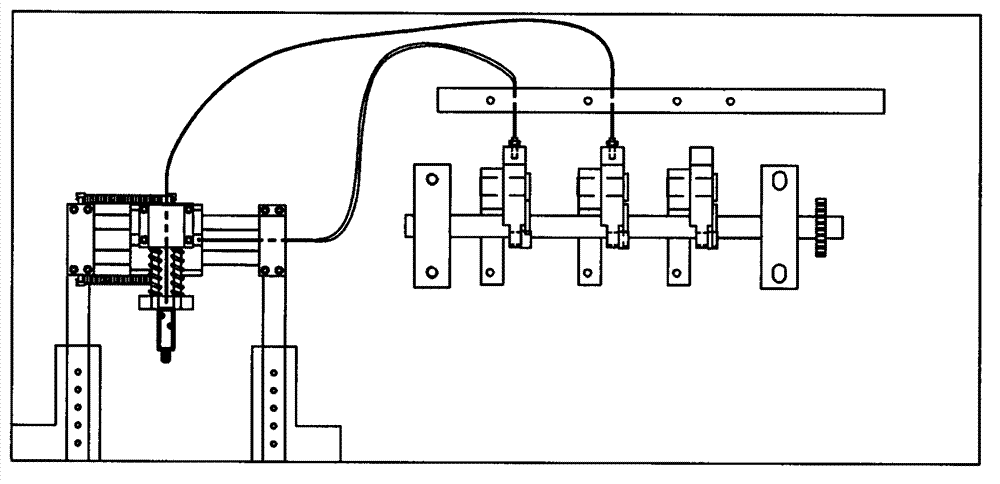

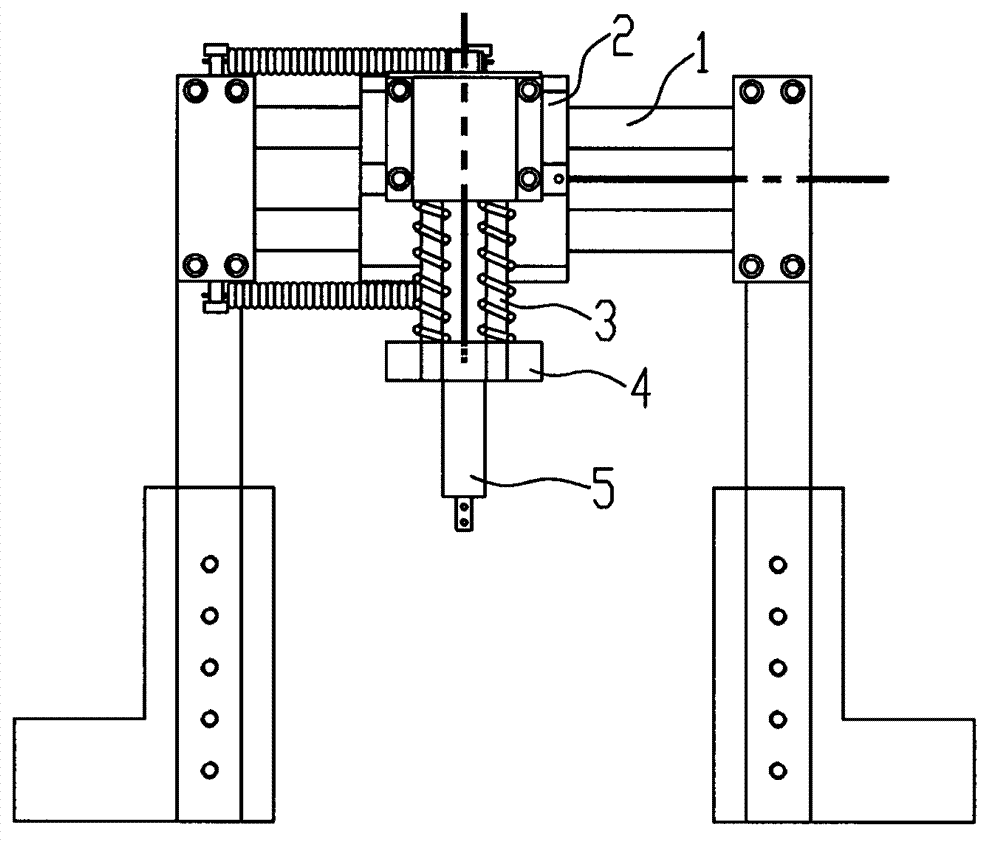

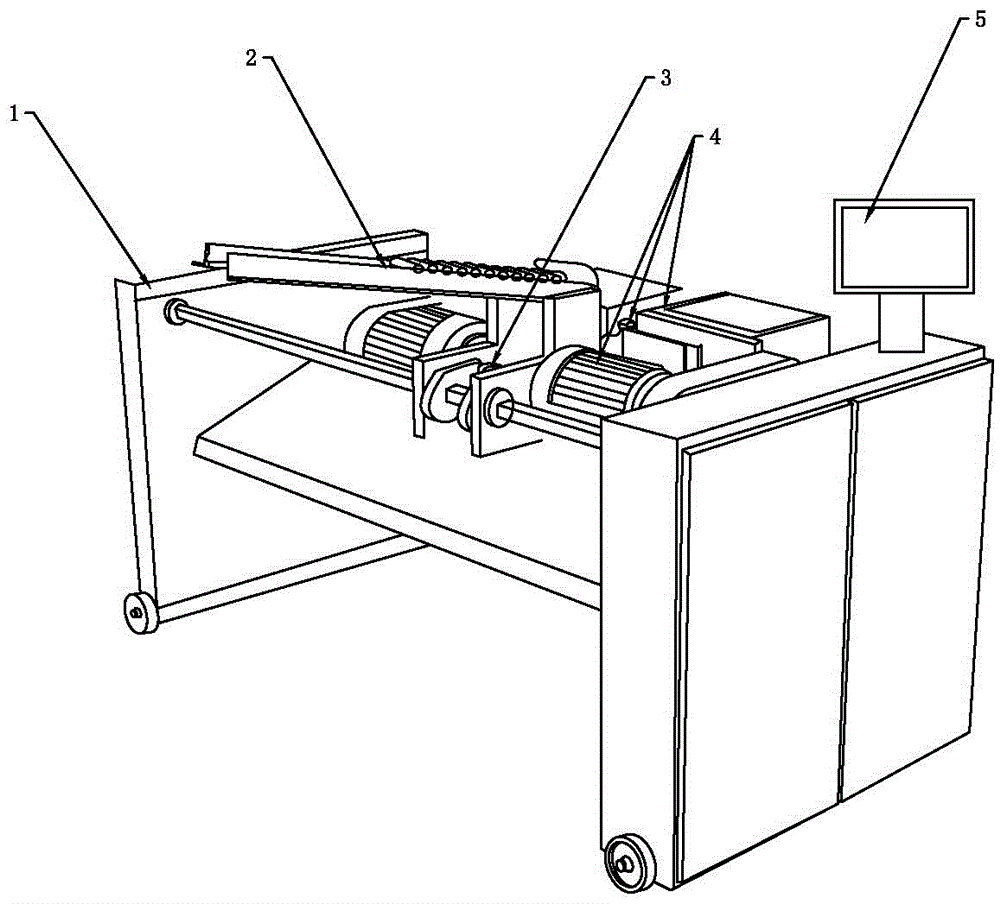

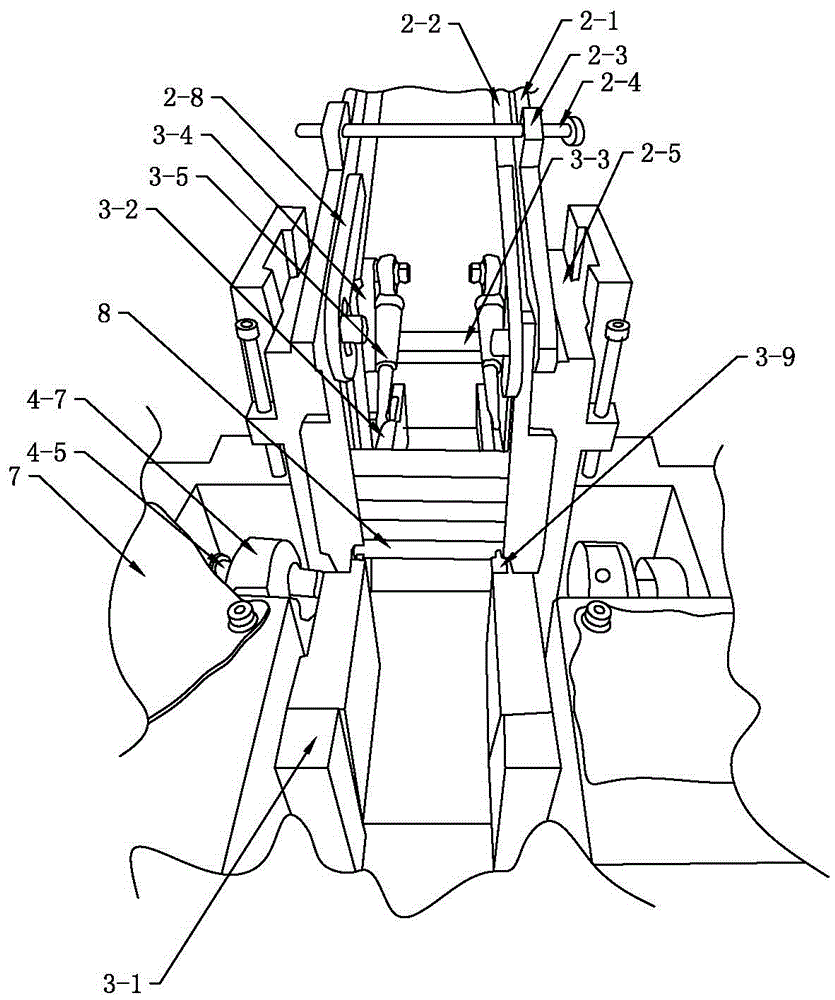

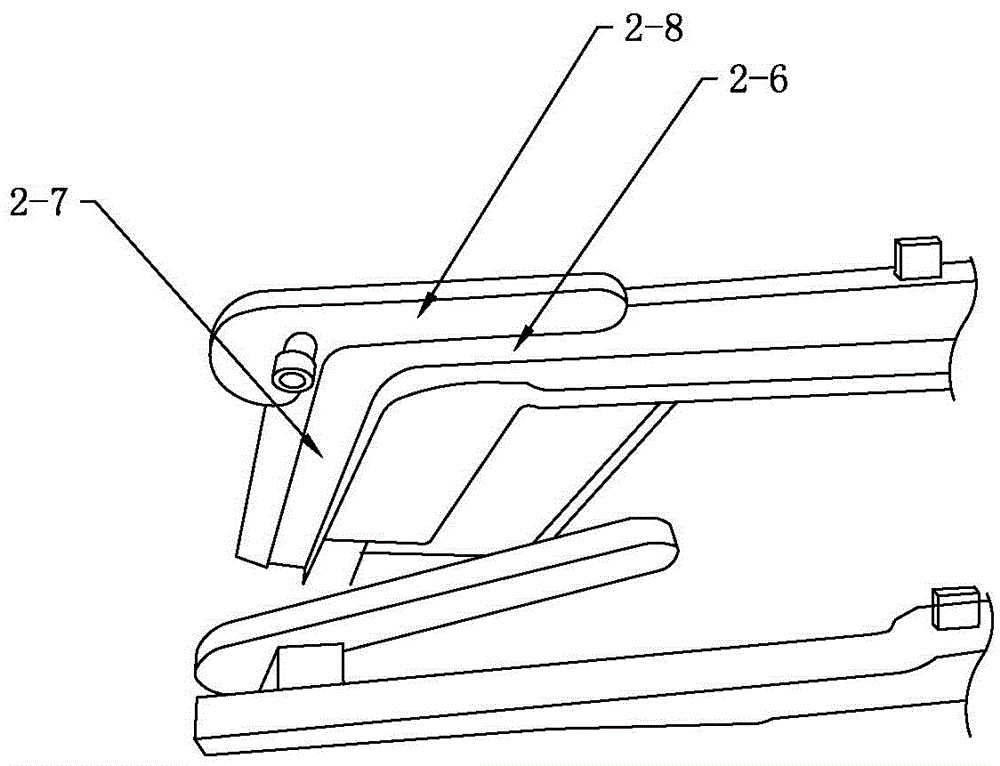

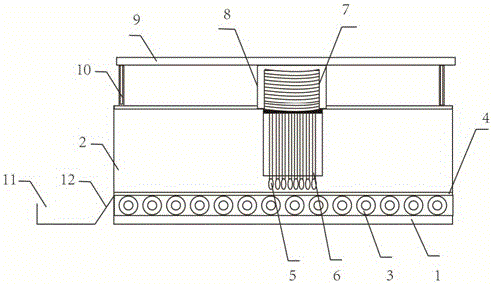

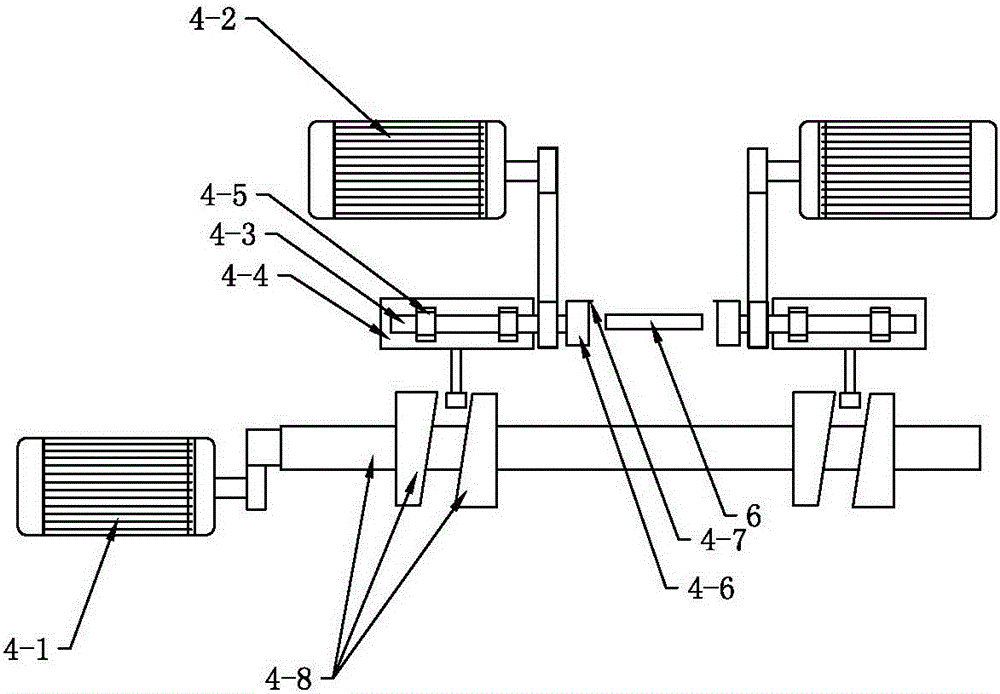

Full-automatic double-head chamfering machine

ActiveCN106180840ARealize quantitative productionTimely replenishmentMeasurement/indication equipmentsMilling equipment detailsMicrocomputerProduction line

The invention discloses a full-automatic double-head chamfering machine. The chamfering machine comprises a machine body support, a feeding mechanism, a clamping mechanism, a rotary cutting mechanism, a light sensing system, an infrared pulse counter, a discharging receiving device and a microcomputer; the high-performance microcomputer is used for controlling the full-automatic double-head chamfering machine to run, a worker issues production plane and process control to the full-automatic double-head chamfering machine composed of all chamfering devices through a control center of the microcomputer, a man-machine interactive interface in the microcomputer is mainly composed of a displayer and an I / O device; the worker inputs production operation instructions through the interface and receives various kinds of state and warning information fed back in the production line debugging and running process, the feeding mechanism, the clamping mechanism, the rotary cutting mechanism, the light sensing system, the infrared pulse counter and the discharging receiving device are automatically and efficiently controlled to achieve efficient feeding, in-time material supplementing, precise positioning and stable chamfering rotary cutting, improve production efficiency and ensure the product chamfering machining product, quantitative production and in-order material collection are achieved, and therefore packaging is facilitated.

Owner:茂名华粤机电设备有限公司

Anti-corrosion plastic bag and preparation method thereof

InactiveCN105949573AStrong acid and alkali resistanceWide range of usesFlexible coversWrappersPolypropylenePlastic bag

The invention discloses an anti-corrosion plastic bag and a preparation method thereof. The preparation method comprises the steps that 2, raw materials are mixed and subjected to heat treatment to obtain a mixture; 2, the mixture is subjected to extrusion molding to obtain an anti-corrosion plastic film; 3, the anti-corrosion plastic film is processed into the anti-corrosion plastic bag, wherein the raw materials comprise polyethylene resin, polypropylene resin, polyurethane, Makrolon, starch, filling materials, a plasticizer and a stabilizer. The anti-corrosion plastic bag prepared through the method has high corrosion resistance, and is wide in application range, the raw materials in the method are easy to prepare, and mass production can be achieved.

Owner:TONGLING FOUNDER PLASTICS TECH

Medium and trace element composition for water-soluble fertilizer, water-soluble fertilizer and preparations and application thereof

InactiveCN106673803AImprove the mixing effectImprove stabilityCalcareous fertilisersMagnesium fertilisersTrace element compositionNutrient content

The invention relates to the field of agricultural fertilizers, in particular to a medium and trace element composition for a water-soluble fertilizer, the water-soluble fertilizer and preparations and application thereof. The medium and trace element composition comprises a medium and trace element, a thickening substance and an anti-frosting substance, wherein the medium and trace element comprises at least one of calcium, magnesium, iron, manganese, molybdenum, copper, zinc and boron; the thickening substance comprises at least one of polysaccharide thickeners and inorganic polymeric thickeners; the anti-frosting substance comprises at least one of alcohols and inorganic salts. The thickening substance contained in the medium and trace element composition can improve the blending performance and the stability of a finished product; the contained anti-frosting substance can improve the frosting resistance of a suspended water-soluble fertilizer as the finished product, so that the suspended water-soluble fertilizer does not separate out salt in the case of -20 DEG C. Through application of the formula of the medium and trace element composition, a pertinent customized fertilizer formula with different nutrient contents can be formed, so that different needs of different crops in different regions are met, and soil testing for formulated fertilization is achieved.

Owner:北京天辰云农场有限公司

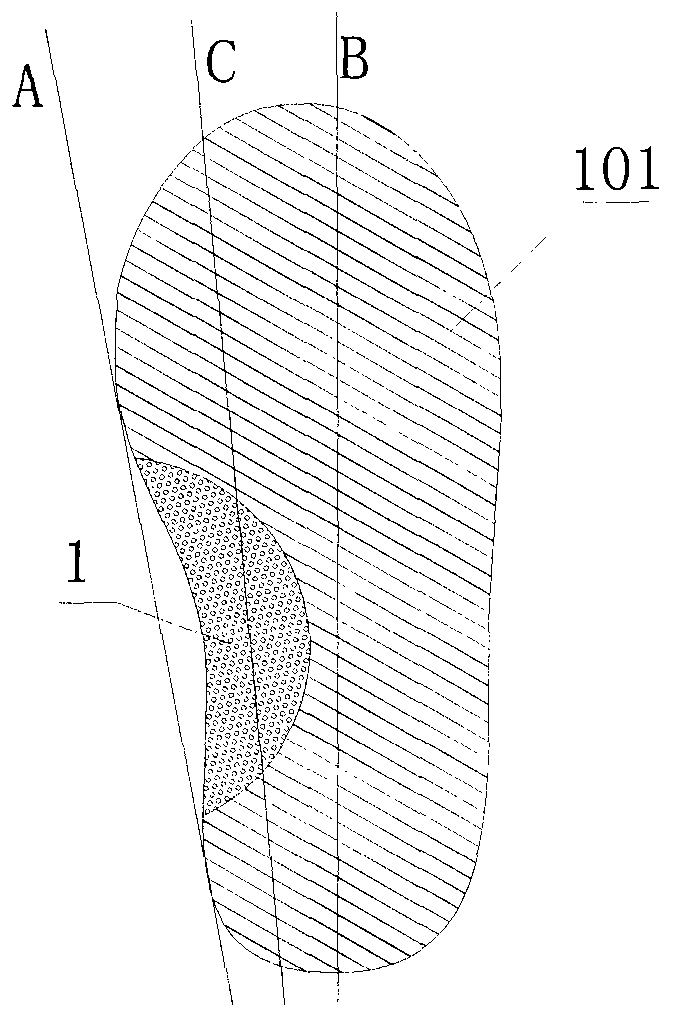

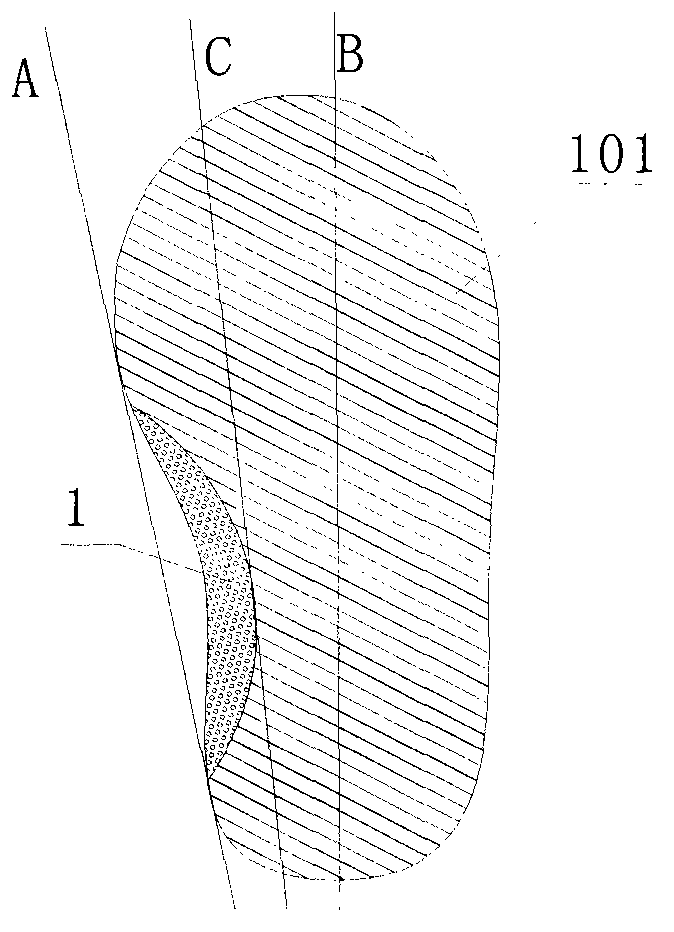

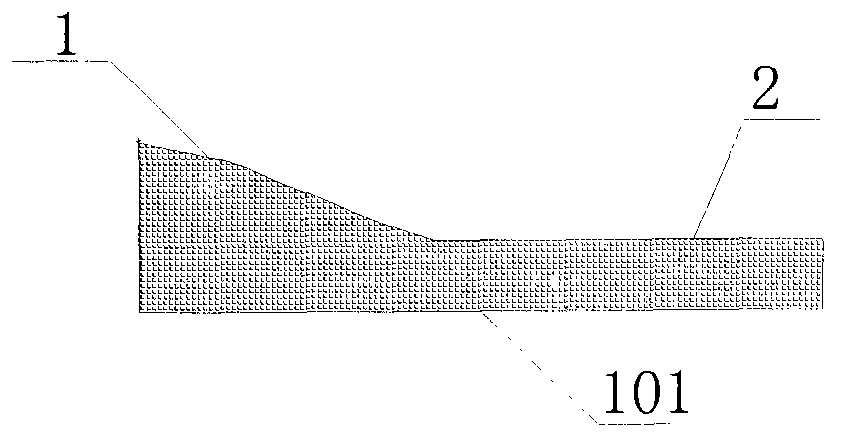

Shoe and industrial production method for part and custom shoe matched with sole

The invention relates to a part matched with a sole, and further relates to an industrial production method for a customer shoe and the shoe including the part and produced by adopting the above method. The part is regionally divided according to different sole forms, and corresponding protrusions are arranged according to the different sole forms to be matched with the sole form. The industrial production method includes: producing the corresponding part or a semi-finished product of the shoe or a finished product according to the sole forms, detecting sole parameters, comparing the parameters, selecting a corresponding matched shoe or producing the semi-finished product into the finished product. The shoe with a protecting function is produced according to foot anatomical structures and physiological characteristics according to different crowds. The shoe produced by the above method is almost the same as the one produced by being detected before production in the prior art in comfortableness, sole pressure is uniformly distributed, production cost is lowered, production efficiency is improved, and quantitative production can be smoothly realized.

Owner:曹晶晶

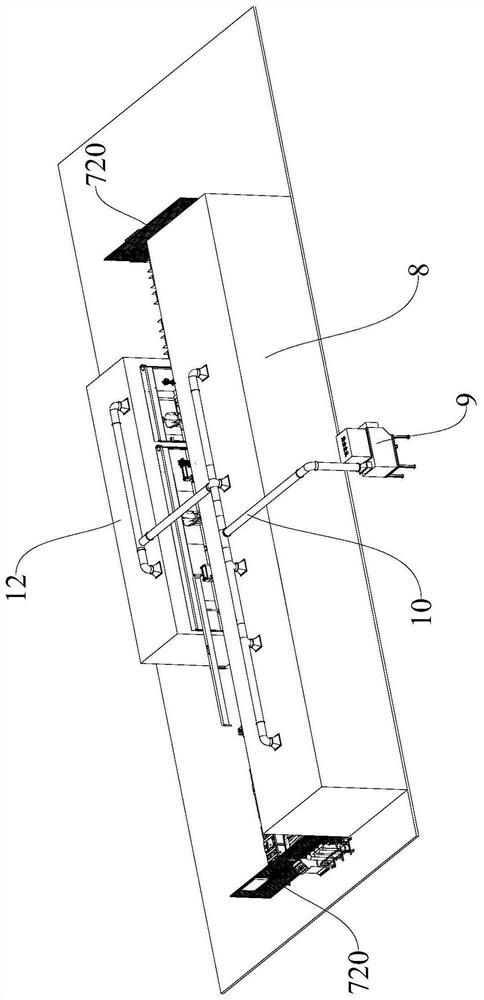

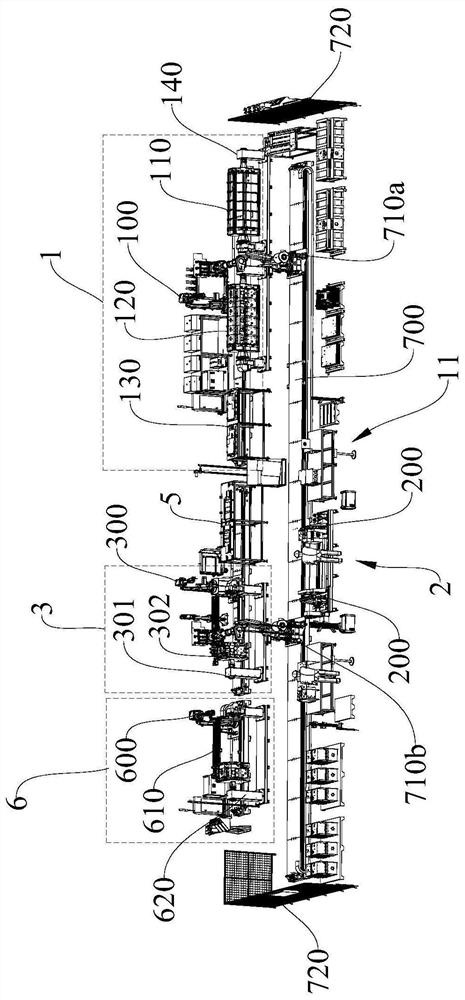

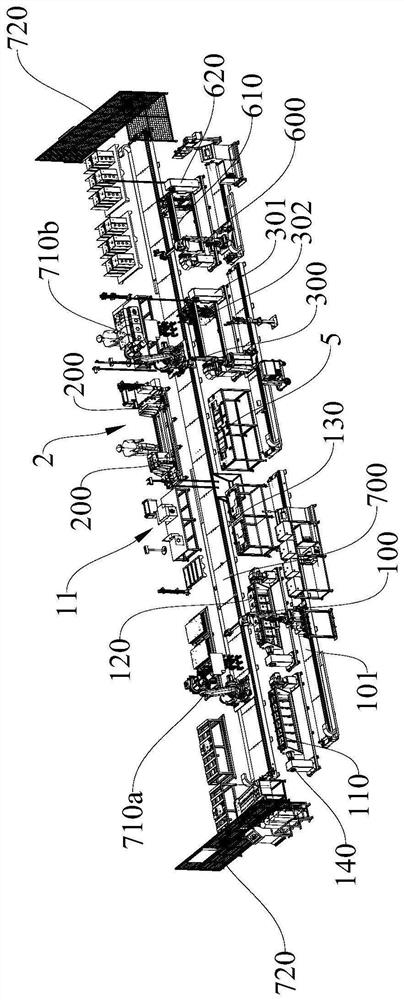

Inflatable ring main unit production line and production method

PendingCN113601193ARealize quantitative productionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineStructural engineering

The invention is used for the field of welding production lines, and particularly relates to an inflatable ring main unit production line and a production method. The inflatable ring main unit production line comprises a stud welding workstation, an assembling spot welding station and a CMT welding workstation, wherein the stud welding workstation comprises a stud welding robot, a front panel bracket, a bottom panel bracket and side panel brackets, wherein the stud welding robot can move among the front panel bracket, the bottom panel bracket and the side panel brackets; the assembling spot welding station is provided with an assembling clamp; and the CMT welding workstation is provided with a sealing welding robot. In the production process, the stud welding robot welds studs, then panels are assembled, subjected to spot welding and positioned, and a cabinet body is subjected to sealing welding through the sealing welding robot, so that the whole cabinet body is welded completely, and a large amount of manpower is saved. The inflatable ring main unit production method comprises the following steps: welding studs on the front and back surfaces of the front panel, the front and back surfaces of the bottom panel and the front surfaces of the side panels; assembling the front panel, the bottom panel and the side panels into a cabinet body structure, carrying out spot welding fixing, and then carrying out full welding sealing; and grinding and polishing hole sites in the cabinet body.

Owner:广州创研智能科技有限公司

Method for industrialized treatment of livestock and poultry manure and domestic sludge by using earthworms

InactiveCN105985000AGuaranteed continuous high yieldOvercome the defects of not being able to do EIABiological sludge treatmentAnimal husbandryFecesSludge

The invention relates to a method for industrialized treatment of livestock and poultry manure and domestic sludge by using earthworms. According to the method, firstly, the livestock and poultry manure is subjected to dry-wet separation so as to obtain dry livestock and poultry manure, then, the dry livestock and poultry manure is blended with the domestic sludge so as to obtain culture base soil which is suitable for earthworm living, and finally, the earthworms are cultured by adopting the culture base soil and take the culture base soil as food, so that the culture base soil is consumed, and meanwhile, new earthworms are obtained through propagation and can be cyclically placed into the culture base soil for treating the livestock and poultry manure and domestic sludge of next batch. According to the method for treating the livestock and poultry manure and the domestic sludge, the operation is simple, the cost is relatively low, and heat or harmful substances are not generated, so that the method has relatively high environment-friendly performance, and a living environment for people is beautified.

Owner:TAIZHOU CHUNGUANG ECOLOGICAL AGRI DEV

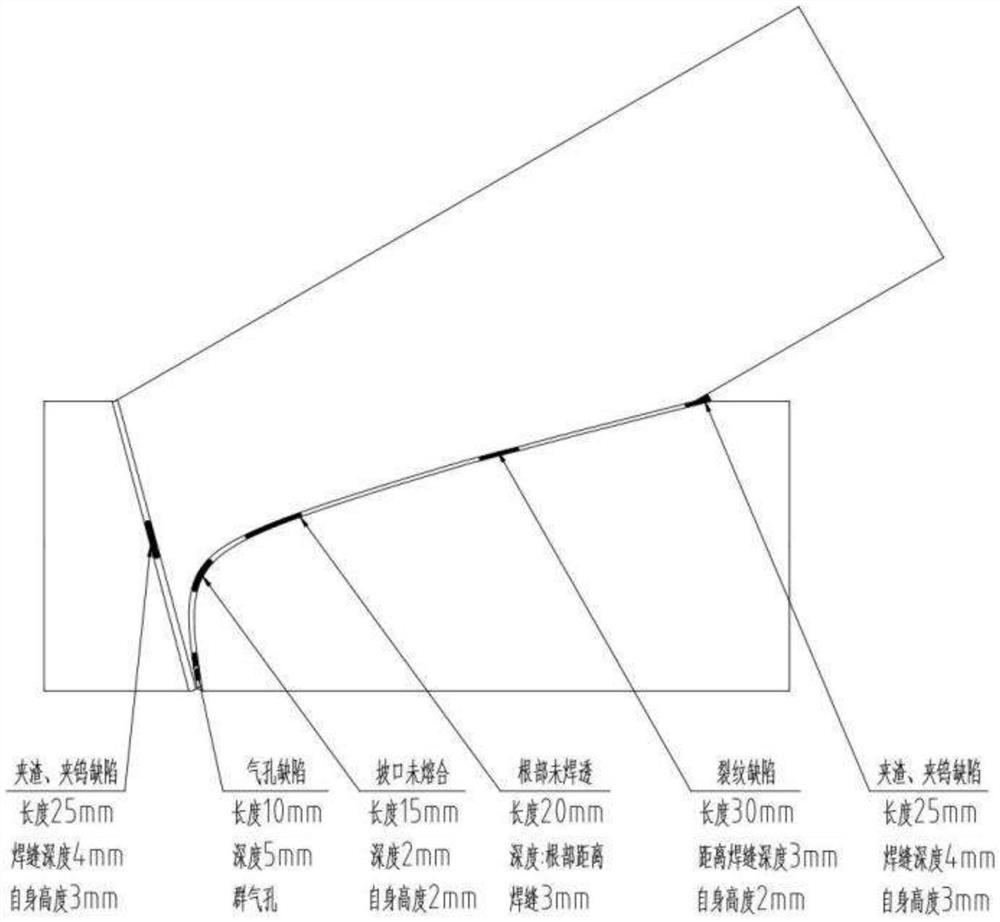

Manufacturing method of ultrasonic detection test piece for complex structural parts with various welding defects

ActiveCN112318068ARealize quantitative productionMeet training application needsNuclear energy generationPreparing sample for investigationSlag (welding)Welding defect

The invention discloses a manufacturing method of an ultrasonic detection test piece for complex structural parts with various welding defects. The manufacturing method comprises the following steps that groove single edges on the welding surfaces of two base materials to be welded are correspondingly processed, and pretreating is carried out; the single grooves of the two base materials to be welded are aligned to form a complete groove; after the base metal to be welded forms the complete groove, argon tungsten-arc welding is adopted for bottoming; shielded metal arc welding is adopted for filling; different types of defects are manufactured on the corresponding weld metal layers through consumable electrode gas shielded welding, welding slag and the like according to the preset number and positions of cracks, slag inclusion, tungsten inclusion, air holes, incomplete groove fusion and incomplete root penetration; the remelting area of the weld joint is refined, cosmetic welding is conducted on the surface of the weld joint, and a structural test piece with various welding defects is obtained; and after the defect is manufactured, the weldment is adjusted to a flat welding position, and a layer of convex weld is welded to the upper face or the side face of the incomplete fusion defect through consumable electrode gas shielded welding for aftertreatment.

Owner:SHENYANG AEROSUN FUTAI EXPANSION JOINT

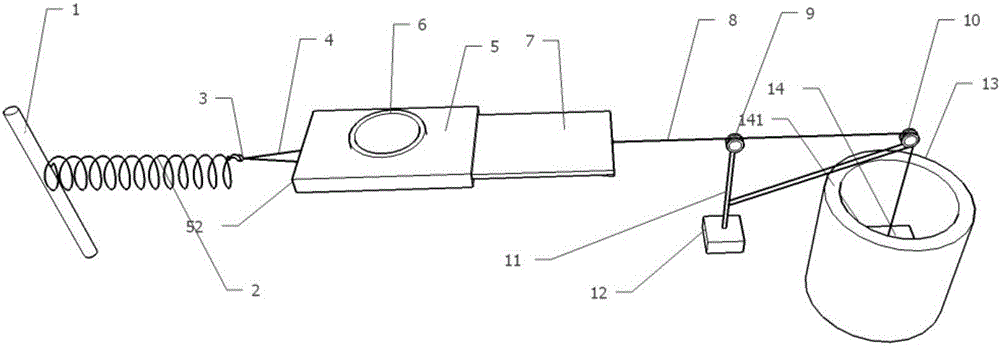

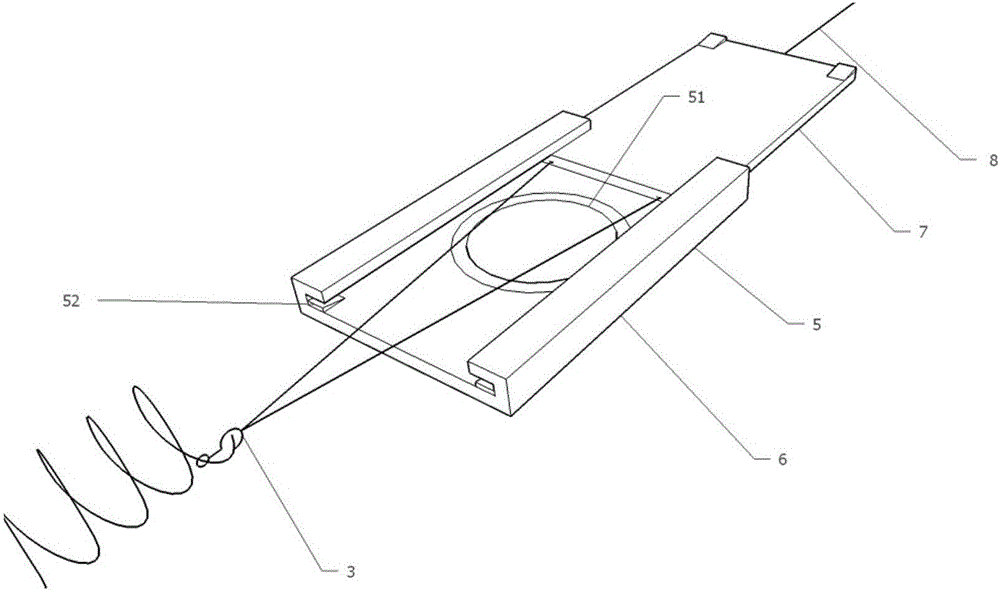

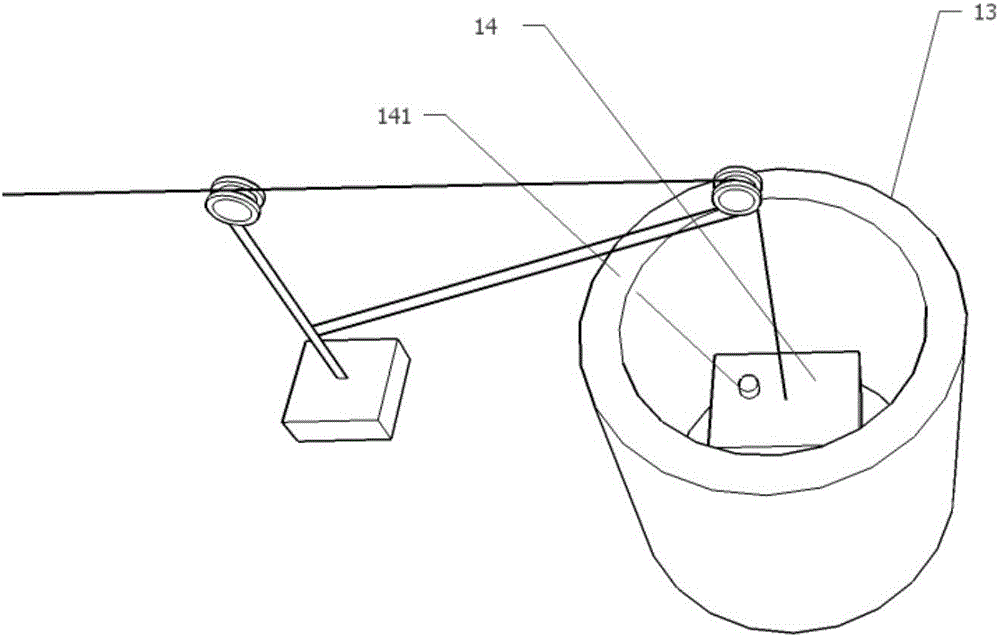

Assembly type farmland automatic water irrigation and stop device

InactiveCN106702986ASimple structureRealize quantitative productionConstructionsIrrigation ditchesRubber ringWater discharge

The invention discloses an assembly type farmland automatic water irrigation and stop device, which comprises parts such as a spring support post, a low-elasticity spring, a spring hook, a water discharging pipe opening, a gate moving groove, a cuboid gate, a gate towing rope, pulleys, a pulley support frame, a pulley support table, a buoy, a buoy towing rope and an observation well. The assembly type farmland automatic water irrigation and stop device has the advantages that the automatic water irrigation and stop can be realized according to a preset water level; the quantitative and punctual farmland water supply is realized; the efficient and feasible effects are achieved; the labor is saved; the gate can be sealed by a wedge-shaped body and a rubber ring; water cannot easily leak; the quantitative production can be realized; the assembly type use is realized.

Owner:HOHAI UNIV

Cutting machine suitable for different kinds of vegetables

The invention discloses a cutting machine suitable for different kinds of vegetables. The cutting machine comprises a base for supporting the cutting machine and a box located on the base, and further comprises a conveying device located inside the box and used for conveying vegetables and a cutting device used for cutting vegetables. The conveying device comprises rollers and a platform for supporting fruits. The cutting device comprises cutters, connection rods and a cylinder, wherein a protective sleeve is arranged outside the cylinder; the cutters include the transverse cutters and the longitudinal cutters; the cutters are inserted into clamping grooves through connection rods; the clamping grooves are formed in a fixing block; the fixing block and the cylinder are fixedly connected; a supporting frame is arranged outside the box and fixedly connected with the protective sleeve; and the supporting frame is connected with the box through fixing rods. The cutting machine is simple in structure, reasonable in design and high in mechanical intensity, achieves automatic production and quantitative production, and improves the production efficiency; and meanwhile through the clamping grooves in the fixing block and the placement positions of the cutters in the clamping grooves, the cutting length and width of vegetables are adjusted.

Owner:天津市真如果食品工业有限公司

Slicing device for fruits

InactiveCN105835103ASimple structureHigh mechanical degreeMetal working apparatusEngineeringMechanical engineering

The invention discloses a fruit slicing device, which is characterized in that it comprises a base for supporting the slicing device, a box body located on the base, and a conveying device and a cutting device for transporting fruit in the box, the conveying device comprising rollers and a support The platform of the fruit, the cutting device includes a cutting piece, a connecting rod and a cylinder connected with the cutting piece through the connecting rod, the outer surface of the cylinder is provided with a protective cover, the cutting piece is provided with several, and the cutting pieces are perpendicular to the platform. The spacing is arranged in parallel, the cutting piece is fixedly connected to the cylinder through the connecting rod, the outer side of the box is provided with a support frame, the support frame is fixedly connected to the protective sleeve, the support frame is connected to the box body through a fixed rod, and a collection box is provided on the left side of the box body. The collection box and the box are connected by a chute. The invention has the advantages of simple structure and high mechanical degree, realizes automatic production, can meet the requirements of rapid cutting, realizes quantitative production and improves production efficiency.

Owner:天津市真如果食品工业有限公司

Chamfering machining control method for axle workpieces

ActiveCN106670554AEnsure the efficiency of chamferingReduce operating energy consumptionMilling equipment detailsMicrocomputerMachine control

The invention discloses a chamfering machining control method for axle workpieces. A microcomputer is used for controlling running of components of a chamfering machine, multiple photosensitive sensors are utilized for determining whether the workpieces are arranged in place or not, detection on the shapes of the end faces of the workpieces happens before the workpieces fall to the clamping position, the end face shapes obtained through detection are recognized by the microcomputer through photovoltaic conversion, and accordingly the rotating speed of a cutting spindle and the feeding speed of a blade are controlled in combination with the material trademark of the workpieces. On the other hand, a feeding detection sensor is used for detecting a feeding station of a feeding roller table and sending information about whether the workpieces exist or not to the microcomputer, wherein if no workpieces exist, equipment is reminded of material supplementing, pausing or standby is conducted, the equipment is prevented from idling for a long time, and running energy consumption of a production line is reduced. Meanwhile, a light sensation counter is utilized for automatically counting the number of the chamfered workpieces and transmitting data to the microcomputer, quantitative production is achieved, the later counting workload is reduced, and quantitative conveying and packaging are convenient.

Owner:GUANGDONG MINGHAO HIGH STRENGTH FASTENERS

Automatic weighing and packaging production line tailing processing system

ActiveCN104527998ARealize quantitative productionAchieve the perfect combinationPackaging automatic controlSolid materialProduction lineEngineering

The invention belongs to the technical field of weighing and packaging, and particularly relates to an automatic weighing and packaging production line tailing processing system. The tailing processing system comprises a bin, two discharging holes are formed at the bottom of the bin, and a bin cover is fixed at the top of the bin and is provided with at least a set of feeding mechanisms. The two ends, in the length direction, of the upper portion of an inner cavity of the bin are both provided with a rotating shaft in a rotating mode. Each rotating shaft is fixedly connected with a turning plate which is arranged in the direction of the shaft diameter inside the bin. Both ends of each rotating shaft penetrate out of the inner cavity of the bin. The outer wall surface of the bin is provided with two sets of material flowing direction control devices. Each set of material flowing direction control devices is connected with one rotating shaft and drives the rotating shaft to rotate correspondingly during work. By means of the tailing processing system, the purpose of inventory reduction or even zero inventory can be achieved.

Owner:WUXI NAITE ELECTROMECHANICAL INTEGRATING TECH

Preparation method of luffa sponge nitrogen-doped carbon nanomaterial

The invention discloses a preparation method of a luffa sponge nitrogen-doped carbon nanomaterial. The preparation method comprises the following specific steps: (1) collecting luffa sponge, drying and grinding into powder; (2) adding the luffa sponge ground into powder into a guanidine hydrochloride solution for soaking, and then drying to obtain a precursor; (3) calcinating the precursor to obtain a pre-carbonized product; (4) adding the pre-carbonized product into a KOH solution for soaking, drying, and then calcinating at high temperature; (5) utilizing a hydrochloric acid solution to soak a product after calcinating at high temperature, filtering, washing to a neutral state and drying to obtain the luffa sponge nitrogen-doped carbon nanomaterial. The preparation method disclosed by the invention has the beneficial effects that the luffa sponge is utilized as the precursor to prepare the nitrogen-doped carbon nanomaterial, the luffa sponge is rich in source, a preparation process technology is simple, safe, reliable and free of pollution to environment, and quantified production is obtained.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

Method and device for metering number of noodles sliced by sliced noodle robot

ActiveCN103766429ARealize quantitative productionDough shaping and cutting apparatusCounting mechanisms/objectsEngineeringFood products

The invention is suitable for the technical field of preparation of beverage and food products, and provides a method and a device for metering the number of sliced noodles. The number of sliced noodles is accurately metered by detection of the reciprocating frequency of a noodle slicing cutter, the conditions of the resistance borne by the noodle slicing cutter during the noodle slicing or the number of the sliced noodles passing through a video detecting and controlling system, so that the problems that the amount of the noodles in each bowl or each pot is uneven and the numbers of the sliced noodles are unequal during the noodle slicing process are thoroughly solved. The quantitative preparation and the cooking standardization of the sliced noodles are realized.

Owner:SHENZHEN ALLOVE INTELLIGENT CATERING TECH

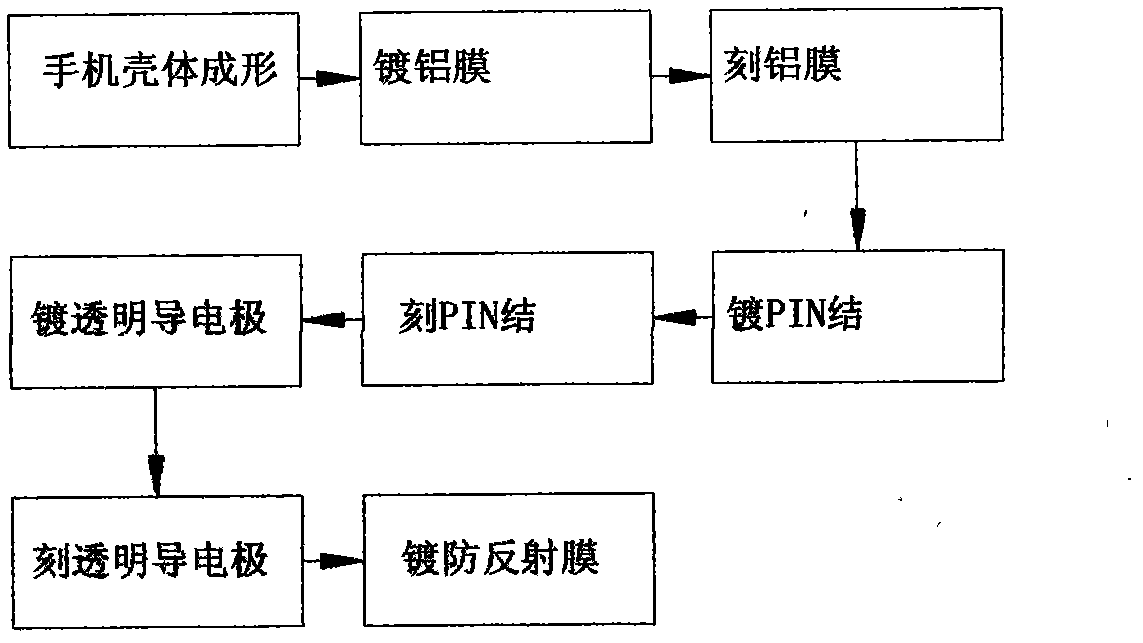

Method for preparing thin film solar cell on mobile phone casing

InactiveCN102867888ARealize quantitative productionSimple processFinal product manufactureSemiconductor devicesEvaporationEngineering

The invention discloses a method for preparing a thin film solar cell on a mobile phone casing. The method mainly comprises the processing steps of: forming a back casing, plating an aluminum film, etching the aluminum film, plating a non-crystal silicon PIN (Personal identification number) junction, etching the PIN junction, plating a transparent conductive electrode, etching the transparent conductive electrode, and plating an anti-reflection film, wherein the back casing forming step adopts a traditional plastic forming method to integrate an output electrode and a bypass diode with the casing; the aluminum film plating step mainly adopts vacuum film plating modes, such as evaporation film plating mode or sputter film plating mode; the non-crystal silicon PIN junction adopts a PECVD (Plasma-enhanced chemical vapor deposition) film plating mode; the transparent conductive electrode adopts the sputter film plating mode; all the three etching processing steps adopt a laser scribing mode; and the anti-reflection film adopts the sputter film plating mode. By utilizing the method disclosed by the invention, a solar cell structure capable of complementing electric energy for a mobile phone cell can be produced in large scale, and the standby time of the mobile phone can be prolonged.

Owner:刘莹

Method for producing sodium sulfide of low-sulfur sodium hydride

ActiveCN108946674ARealize quantitative productionAlkali metal sulfides/polysulfidesInlet channelSulfur

The invention relates to a method for producing sodium sulfide of low-sulfur sodium hydride. The method comprises the following steps: S1) dissolving a certain amount of inorganic base and water in astirring tank, thus obtaining an inorganic base solution with a concentration of 350-400g / L; S2) selecting a certain amount of sodium sulfide alkali liquor, concentrating into a sodium sulfide solution with a concentration of 20%, adding the inorganic base solution acquired in the step S1 and a co-precipitator with concentration of 90-100g / L, respectively adding into three inlet channels in a three-channel mixer, and mixing and uniformly stirring at 60-70 DEG C; S3) introducing a mixed solution acquired in the step S2 from an outlet of the three-channel mixer into a settling tank, settling andseparating precipitate, and settling for 3-5h, thus obtaining supernatant liquor and a bottom precipitate. According to the invention, a three-way pipe with Venturi tube and spiral mixing pipe is arranged for mixing the raw materials, and meanwhile, the concentration and dosage of the raw materials are controlled so as to obtain the reaction power of complete reaction and the sodium sulfide of low-sulfur sodium hydride; the method is simple and convenient; the method can realize mass production.

Owner:ZHUSHAN COUNTY QINBA BARIUMSALT CO LTD

Powder metallurgy preparation method of fine-particle diamond copper-based composite heat dissipation material

ActiveCN112941431AImprove sintering densitySolve engineering application problemsCarbide siliconPowder metallurgy

The invention discloses a powder metallurgy preparation method of a fine-particle diamond copper-based composite heat dissipation material. The method comprises the following step that S1, 4.2%-11.6% of fine-particle diamonds, 1%-5% of water-atomized superfine CuSn15 bronze powder, 0.1%-0.5% of composite nickel / copper plated carbon fibers / silicon carbide whiskers and the balance electrolytic copper powder are weighed according to weight percent. The powder metallurgy production technology that after the fine-particle diamonds and the copper powder are mixed, a composite heat dissipation substrate with the heat conductivity larger than 550 W / mK is prepared through two times of sintering is adopted, the method has the advantages of being low in cost, stable in process and capable of achieving quantitative production, and the engineering application difficulty that heat dissipation substrates with the thickness smaller than or equal to 2 mm are difficult to produce in a quantitative manner in the prior art can be solved.

Owner:JILIN UNIV

Anti-odor food bag and preparation method thereof

InactiveCN106087589AHigh burst resistanceImprove the anti-odor effectFlexible coversWrappersGlass fiberChrysanthemum Flower

The invention discloses an anti-odor food bag and a preparation method thereof. The preparation method comprises the steps that 1, raw materials are mixed with whitewash, cooking is conducted, and paper pulp is obtained; 2, the paper pulp is subjected to material washing, bleaching, ramming, paper fishing and drying to obtain anti-odor paper; 3, the anti-odor paper is processed into the anti-odor food bag; the raw materials comprise bark, glass fibers, aloes, cactuses, chlorophytum comosum, dianthus chinensis L., chrysanthemum flowers and canna indica L.. The anti-odor food bag prepared through the preparation method can effectively inhibit odor, caused by mildew, of contained food. Meanwhile, the raw materials in the preparation method are easy to obtain, and industrial production of the anti-odor food bag can be achieved.

Owner:TONGLING FOUNDER PLASTICS TECH

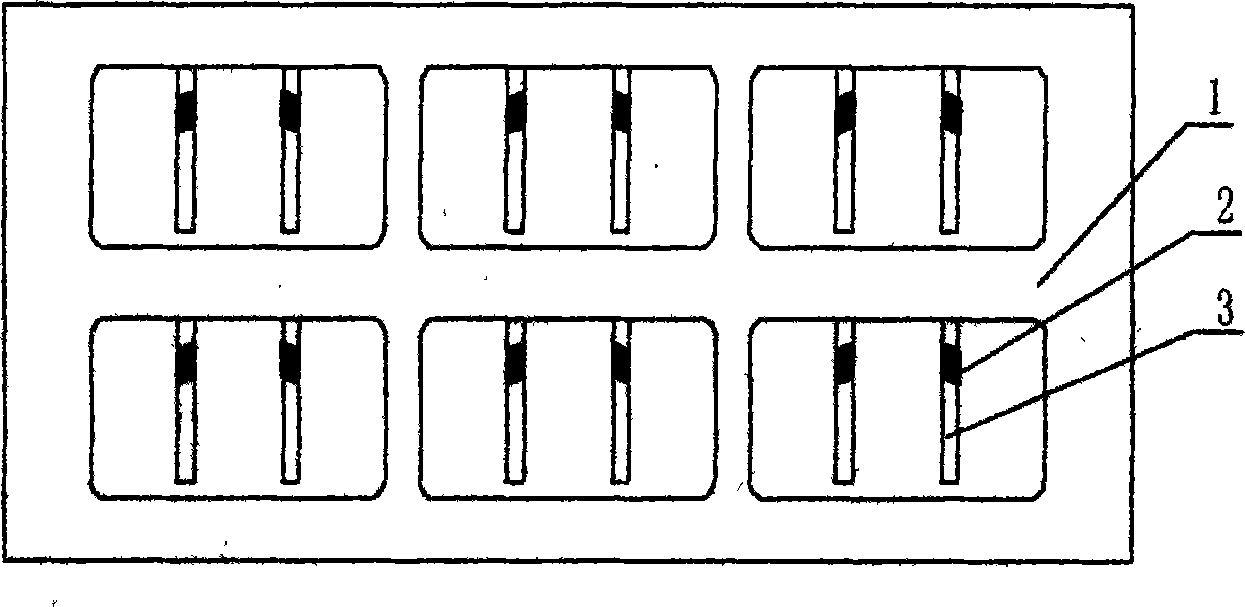

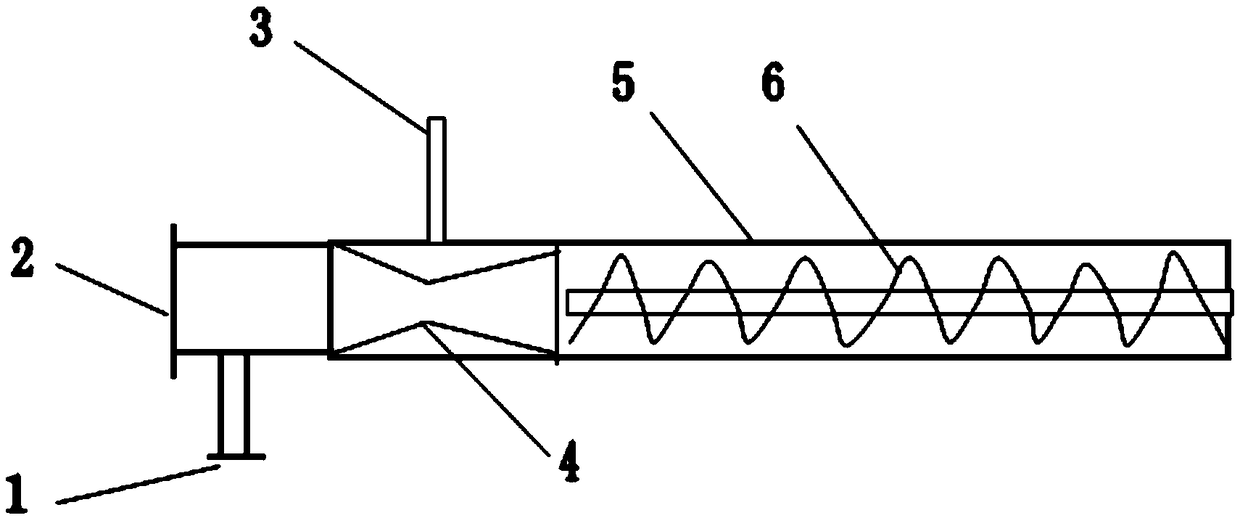

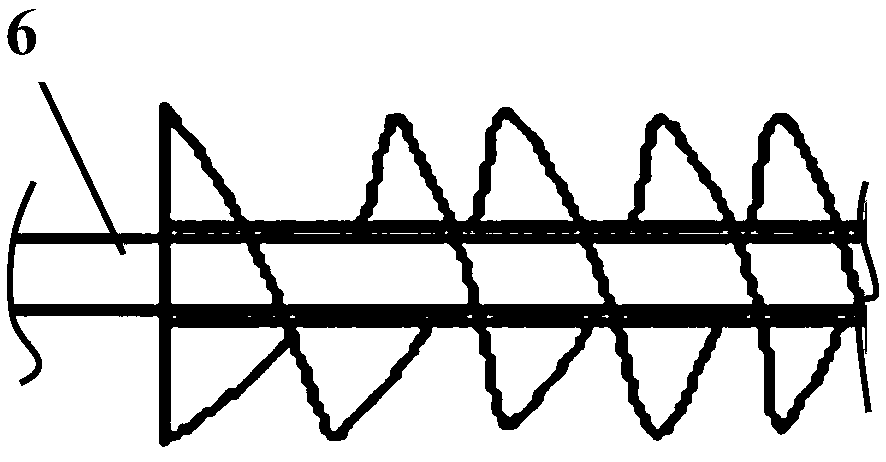

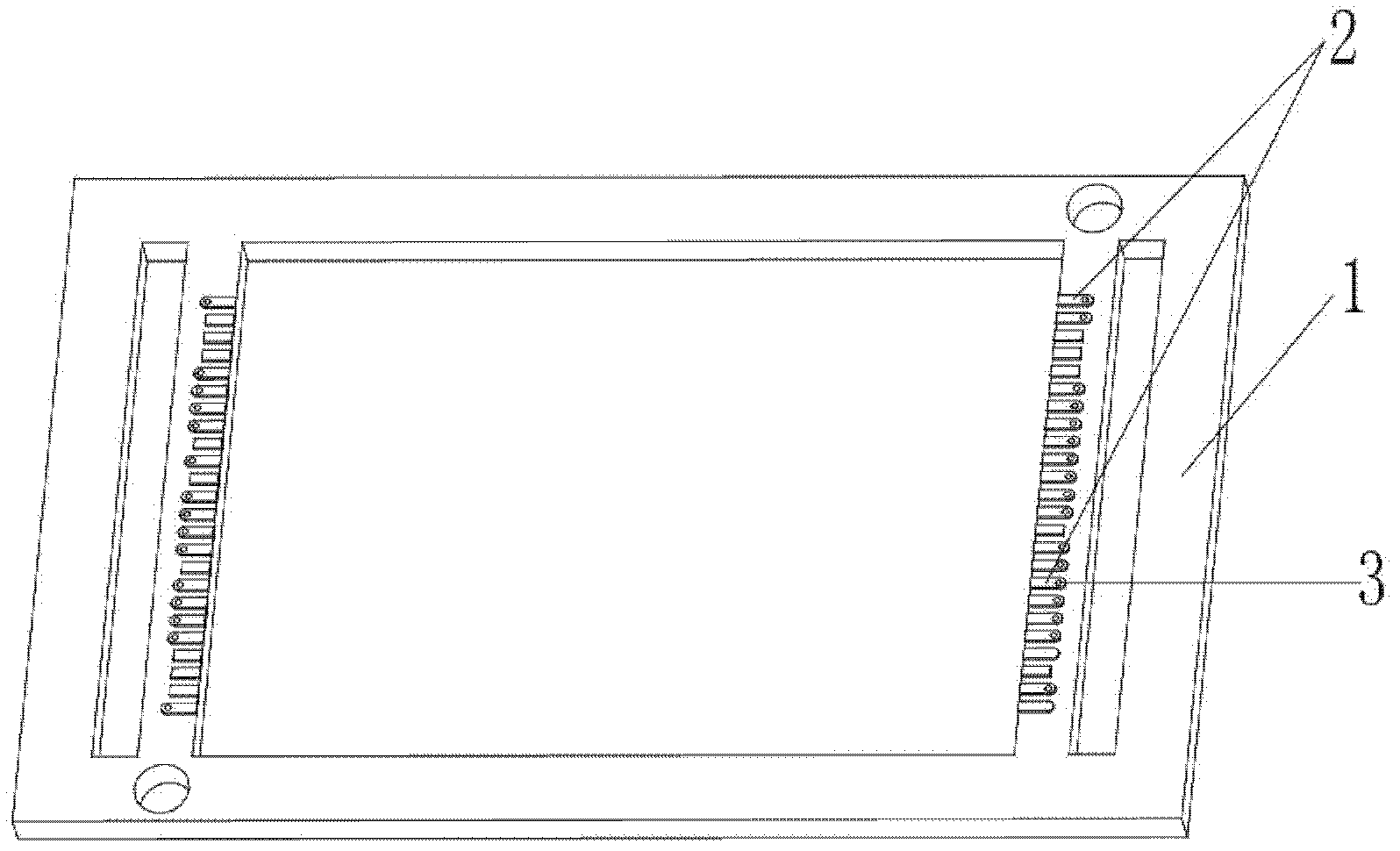

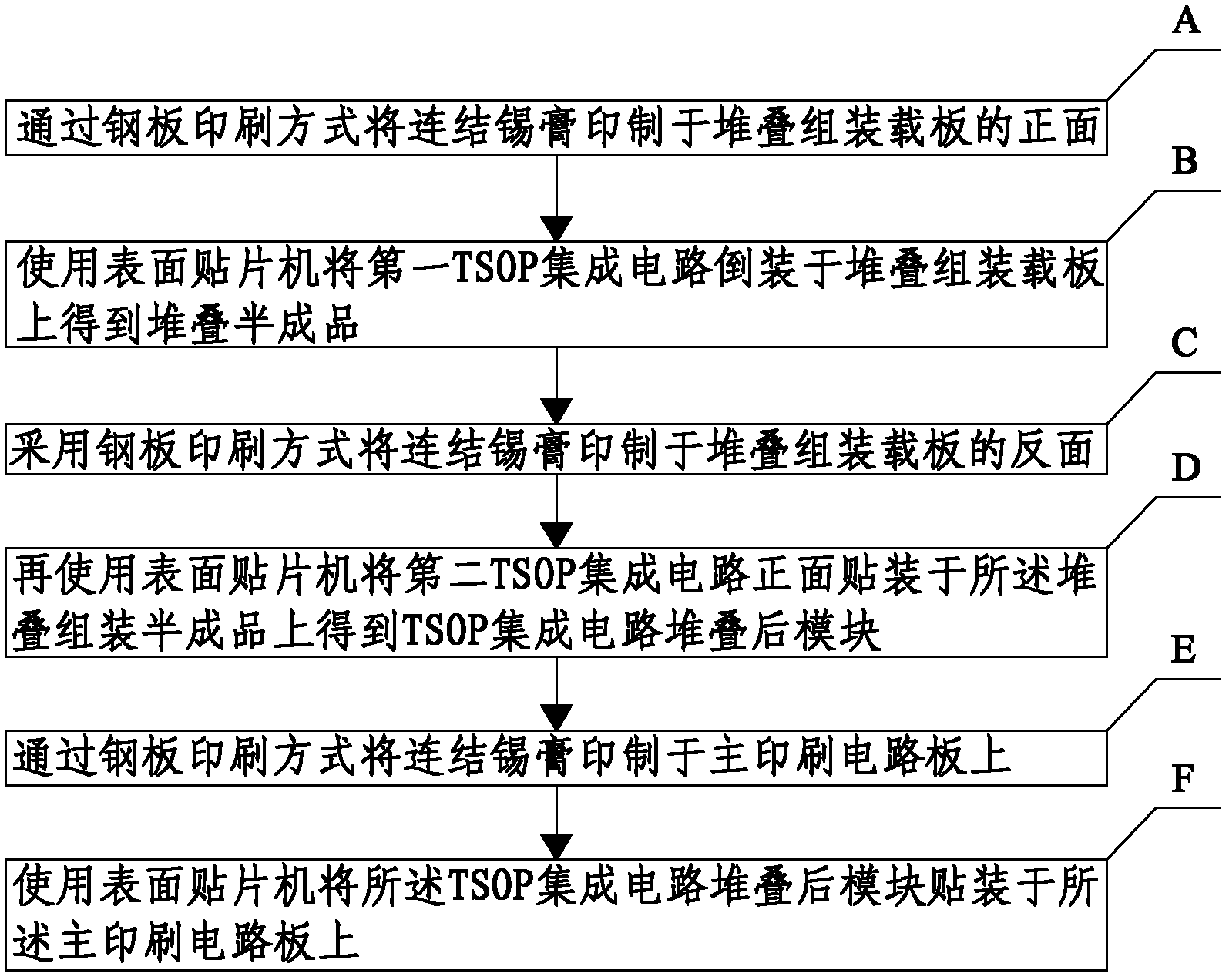

Stacked-assembled substrate and stacked assembly method of TSOP (Thin Small Outline Package) integrated circuits

ActiveCN102548215ARealize quantitative productionIncrease production capacityPrinted circuit assemblingElectrical connection printed elementsThin Small Outline Package

The invention discloses a stacked-assembled substrate and a stacked assembly method of TSOP (Thin Small Outline Package) integrated circuits. The stacked-assembled substrate comprises a printed circuit board, wherein the front and the back of the printed circuit board are provided with TSOP welded pads. Through holes are arranged on the TSOP welded pads and are used for electrically connecting two TSOP integrated circuits stuck on the front and the back of the printed circuit board through the TSOP welded pads. The TSOP integrated circuits are stacked and assembled through the stacked-assembled substrate, so that the quantitative production of the TSOP integrated circuits can be realized, the capacity is increased, and the cost of products is reduced. According to the stacked-assembled substrate, the product yield of assembly production can be increased, and after-sales services are convenient. In addition, the method uses the existing equipment and does not need replace special or higher-end equipment to support output, and therefore the cost is further controlled.

Owner:SUZHOU ETRON TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com