Patents

Literature

94results about How to "Increased burst index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing antibacterial paper on the basis of interlayer self-assembling technology

InactiveCN102587196AIncreased tensile indexHigh folding resistanceNon-fibrous pulp additionPaper/cardboardCelluloseFiber

The invention discloses a method for preparing antibacterial paper on the basis of an interlayer self-assembling technology. In the method, cationic polyelectrolyte chitosan biguanide hydrochloride (CGH) with an antibacterial function, and anionic polyelectrolyte carboxymethyl cellulose sodium (CMC) are alternately deposited on the surface of a bleached kraft hardwood fiber to prepare a layered ordered self-assembled multilayer ultrathin film, which can improve the strength property of a paper sheet while endowing the paper sheet with a good antibacterial performance. Through the change of the environment and the technical conditions of an interlayer self-assembling system, multilayer film structures with different properties can be obtained on the surface of the bleached kraft hardwood fiber, the retention of an antibacterial agent on the fiber is improved, and the antibacterial effect of the paper sheet is enhanced; a layered ordered self-assembled nano-film is prepared by taking a negatively-charged fiber as a matrix and controlling the adsorption process of a reverse-phase ion system,; the preparation method is simple in production process, less in equipment investment and high in adaptability; the prepared antibacterial paper has better antibacterial performance and strength property; and antibacterial requirements of household paper and food packaging paper can be met better.

Owner:ZHEJIANG SCI-TECH UNIV

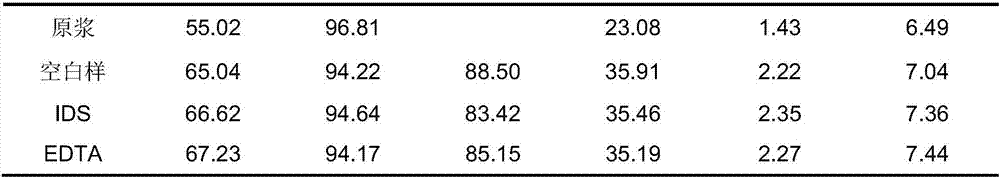

Method for removing metal ions of paper pulp and bleaching

The invention relates to a method for removing metal ions of paper pulp and bleaching and relates to a technique for removing metal ions of paper pulp and applications thereof in bleaching, belonging to the technical field of paper making. The method comprises the following steps of: (1) carrying out pretreatment for removing metal ions of the paper pulp, namely under the existence of Mg(CH(3)COO)2, Ca(CH(3)COO)2 and EDTA (disodium ethylene diamine tetraacetate), carrying out bleaching pretreatment to deoxidizing sulfate pulp; and (2) carrying out following no-pollution bleaching, carrying out following secondary bleaching treatment consisting of a peroxyacetic acid bleaching stage and a hydrogen peroxide bleaching stage on the paper pulp after the pretreatment for removing metal ions. The invention is simple and easy to operate and has obvious effect; the removal rate of the metal ions is high, and the removal rate of Mn is 80.5 percent. Compared with the conventional EDTA chelation treatment, the strength performance of the paper pulp can be improved; the Mg(CH3COO)2 and the Ca(CH3COO)2 can replace 60 percent of EDTA, consequently, the accumulative effect toxicity of the conventional chelating agent can be obviously reduced.

Owner:KUNMING UNIV OF SCI & TECH

Method for processing calcium carbonate by modifying starch

InactiveCN101747666AImprove retentionFracture lengthInorganic compound additionPigment treatment with macromolecular organic compoundsWood fibrePaper production

The invention relates to a method for processing calcium carbonate by modifying starch and provides a paper filler. In the invention, starch is used as the raw material, then 2.5-7.5g of starch is weighed and prepared into solution with a concentration of 5-10%, 0.2-0.7g of modifier is added to the solution, 1N sodium hydroxide is used to adjust pH value of the solution to 9 and then the solution is stirred for 30-40min at 60 DEG C.15-30g of calcium carbonate is added to the reaction liquid, the mixture is heated and boiled to 70-80 DEG C while being stirred, the reaction time lasts 20-40min.After the reaction is over, 1N hydrochloric acid is used to adjust the pH value of the reaction liquid to 7.Then the reaction liquid is heated, dried, pulverized to particles of 100 meshes in a drying oven, thus obtaining the filler. The paper filler of the invention features higher retention, long brisement and greatly improved burst index. Therefore the paper filler can remarkably improve paper strength, replace wood fiber and have the function of protecting the environment, reduce paper production cost and improve paper usability.

Owner:TIANJIN UNIV OF SCI & TECH

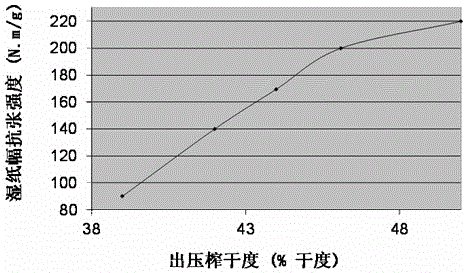

Preparation method for high-intensity corrugated paper

InactiveCN104480772AHigh strengthIncreased burst indexNon-fibrous pulp additionSecondary cellulose fibresCartonPapermaking

The invention discloses a preparation method for high-intensity corrugated paper, and relates to the technical field of papermaking. The preparation method comprises the steps: respectively weighing wood pulp and waste paper pulp, uniformly mixing the pulps, removing impurities, adding water to soak the pulps, transferring the pulp into a disperser for dispersion to obtain primary pulp, adding a polyacrylamide solution, performing papermaking to prepare paper, preheating the paper, applying glue, putting the paper into single jersey machine to obtain corrugated paper, and transferring the corrugated paper into a drying oven for drying. The high-intensity corrugated paper disclosed by the invention is mainly prepared by the wood pulp prepared by wood leftovers and the waste paper pulp, so that raw materials are readily available, wastes are turned into treasures, and the production cost is lower; in a papermaking process, polyacrylamide is added, so that the bursting index and the ring crush index of the corrugated paper are greatly increased; therefore, the corrugated paper is higher in intensity, and the service life of a corrugated carton is prolonged.

Owner:柳州市柳江区联华纸制品厂

Composite paper and production method thereof

InactiveCN107489067AHigh strengthIncreased burst indexFlexible coversWrappersGlass fiberPulp and paper industry

The invention discloses a composite paper and a production method thereof. The production method comprises the following steps: mixing raw wood pulp, barks, hemp, straws, glass fibers, an inorganic filler and limewater according to a weight ratio of 100:(20-30):(1-5):(2-5):(5-15):(15-25):(200-300), and boiling the obtained mixture to prepare a paper pulp; and washing, bleaching and beating the paper pulp, picking up paper, and squeezing and baking the paper to obtain the composite paper. In the invention, the raw wood pulp, barks, hemp, straws, glass fibers, an inorganic filler and limewater are mixed according to a specific ratio, and are boiled to prepare the paper pulp; and the inorganic filler added into the raw materials of the paper in the production method improves the strength of the produce paper and increases the burst index of the paper.

Owner:ANHUI YUEERWEI PLASTIC MACHINE CO LTD

Method for preparing powdery amphoteric guar gum derivative

ActiveCN101871180AImprove conversion rateMild reaction conditionsReinforcing agents additionPaper/cardboardPolymer scienceOrganic solvent

The invention discloses a method for preparing powdery amphoteric guar gum derivative having high degree of substitution, which adopts a semidry method and completes the cationization and anionized reactions of guar gum in a same reactor at the same time. The method comprises the following steps of: preparing sodium hydroxide into solution by using an alcohol / water mixture; spraying the solution into guar gum raw powder; adding a powdery quaternized reagent into the alkaline guar gum with stirring; and reacting the mixture with a carboxyalkylation reagent to obtain the product. The method has the advantages of completing the cationization and anionized reactions of the guar gum in the same reactor at the same time, no need for the separation and purification of intermediate products, directly performing subsequent reactions, fully utilizing reaction heat in a synthesis process, reducing energy consumption and solving the problems of high cost, difficult post treatment and low product degree of substitution of modified guar gum prepared by an aqueous method or an organic solvent method in the prior art along with characteristics of the semi-dry method.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Abrasion-resistant paper-plastic composite bag and preparation method thereof

InactiveCN106012668AIncreased burst indexHigh mechanical strengthNon-fibrous pulp additionCoatings with pigmentsHydrotalciteTricresyl phosphate

The invention discloses a preparation method of an abrasion-resistant paper-plastic composite bag. The preparation method includes the steps that 1, polyethylene resin, phenolic resin, polyurethane, glycerol, hydrotalcite, molybdenum disulfide, tricresyl phosphate and calcium stearate are mixed, are subjected to heat treatment and then are subjected to extrusion molding to obtain plastic particles; 2, the plastic particles are heated and applied to the surface of a paper layer to form a plastic covering layer so as to prepare abrasion-resistant paper-plastic composite paper; 3, the paper-plastic composite paper is processed into the abrasion-resistant paper-plastic composite bag. The abrasion-resistant paper-plastic composite bag prepared by means of the method has high burst index and high mechanical strength, the raw materials are easy to obtain, and quantitative production can be achieved.

Owner:TONGLING FOUNDER PLASTICS TECH

Whitewater processing method

ActiveCN103086534AReduce concentrationReduce turbidityMultistage water/sewage treatmentWater/sewage treatment by neutralisationCationic polymerizationPapermaking

The invention relates to a whitewater processing method comprising the steps that: the pH value of the whitewater is regulated to 8-14; a certain amount of a mixed solution of a flocculating agent and a cationic polymer is added to the whitewater, until the total mass concentration of the flocculating agent and the cationic polymer in the whitewater is 1000-3000ppm. In the mixed solution, the mass concentration of the flocculating agent is 1-5%, and the mass concentration of the cationic polymer is 0.1-0.5%. According to the invention, papermaking whitewater is processed by using the whitewater processing method provided by the invention, and is then used in preparing slurry. Therefore, paper one-time retention rate and filler retention rate can be substantially improved, and paper bursting index and tensile strength index are improved to a certain extent. Also, when the slurry is used in papermaking, concentration, turbidity, conductivity, and COD of collected under-mesh whitewater are greatly reduced, such that whitewater recycling time can be increased.

Owner:GOLD EAST PAPER JIANGSU

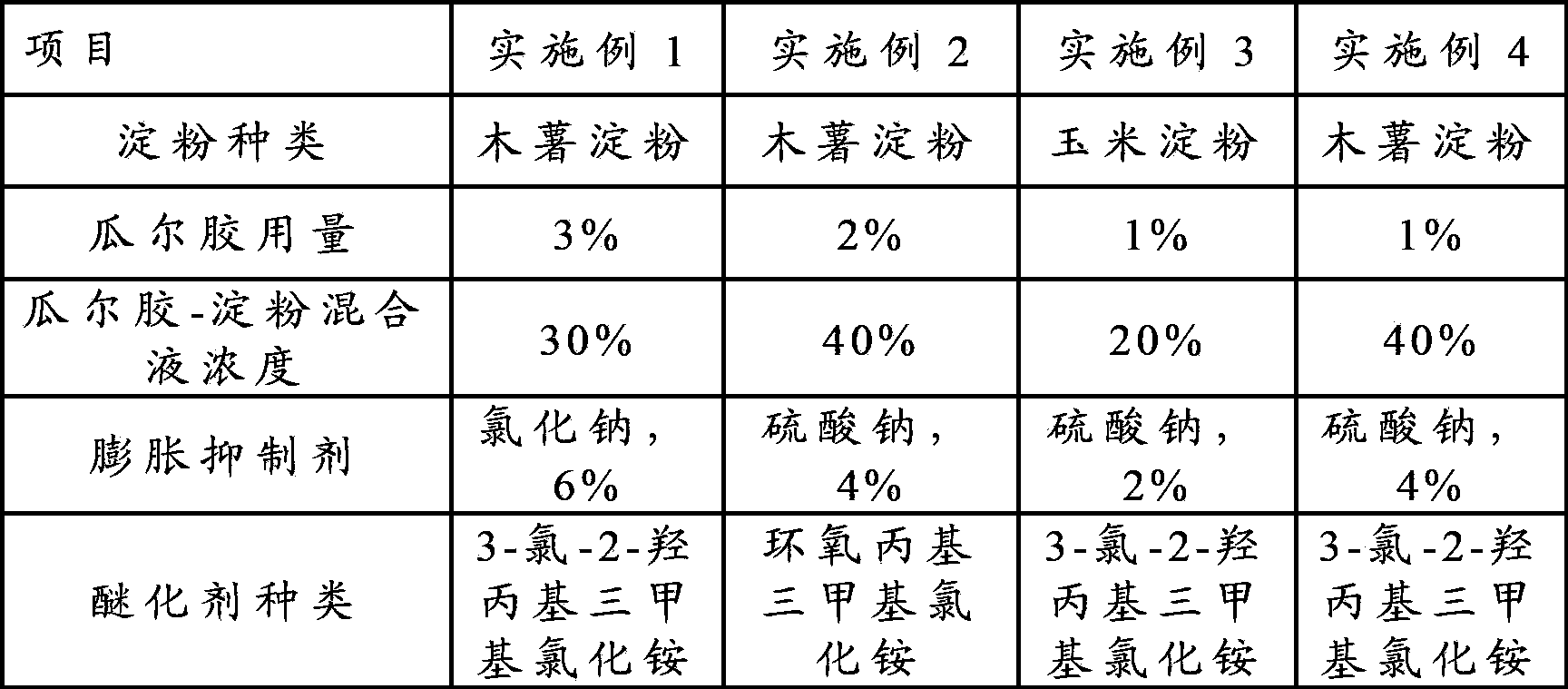

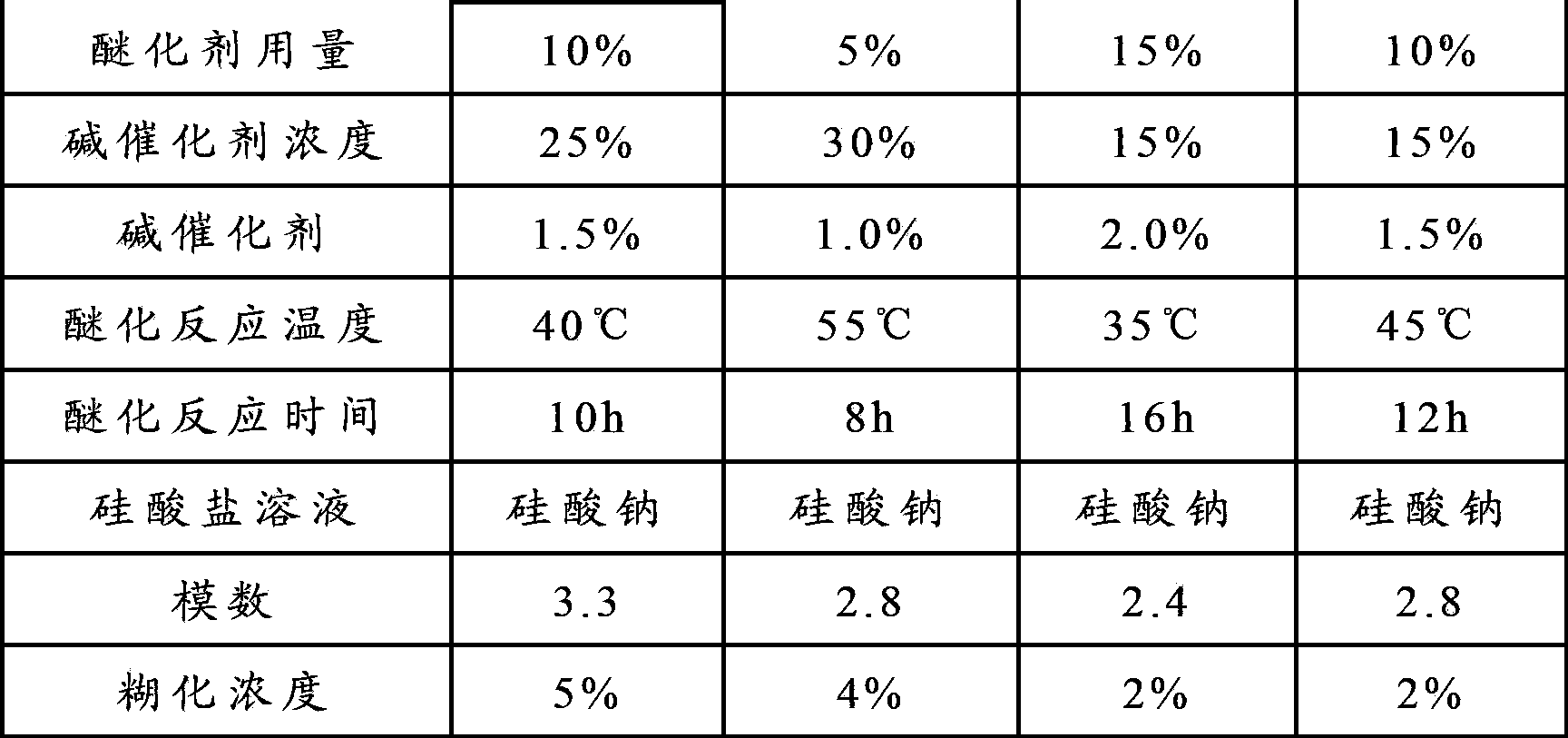

Starch composition, preparation method thereof and pulp using the starch composition

ActiveCN103741543AImprove retentionImprove water filtration performanceReinforcing agents additionPaper/cardboardGuar gumMetal

The invention provides a modified starch composition used in the paper-making field. The modified starch composition comprises reaction products by mixing guar gum, an etherified modified compound of starch, a metal silicate and water, wherein the etherified modified compound of starch is an etherified modified compound of original starch and a cationic etherifying agent pre-activated by an alkaline catalyst, the mass of the cationic etherifying agent in the cationic etherifying agent pre-activated by the alkaline catalyst is 5%-15% of the total dry mass of the original starch and the guar gum, the mass of the alkaline catalyst is 1.0%-2.0% of the total dry mass of the original starch and the guar gum; the dry mass of the guar gum is 1.0%-3.0% of the dry mass of the original starch, and the dry mass of the metal silicate is 10%-30% of the total dry mass of the original starch and the guar gum. The invention also provides a preparation method of the modified starch composition and pulp using the modified starch composition. The modified starch composition can effectively improve the retention and drainage properties of the pulp.

Owner:GOLD EAST PAPER JIANGSU

Moisture-resistant food bag and preparation method thereof

InactiveCN105924740AIncreased burst indexImprove moisture resistanceFlexible coversWrappersMolded pulpMoisture resistance

The invention discloses a preparation method of moisture-resistant food bags. The preparation method includes: 1) mixing polyethylene resin, phenolic resin, polyurethane, glass fibers, hydrotalcite, tricresyl phosphate and calcium stearate, and performing thermal treatment and extrusion molding to obtain plastic particles; 2) heating the plastic particles, and coating to the surface of a paper layer to form a plastic coating to obtain paper-plastic composite paper; 3) processing the paper-plastic composite paper into the moisture-resistant food bags. The moisture-resistant food bags made according to the method are excellent in moisture resistance, capable of preventing moisture deterioration of food in the bags and high in burst index.

Owner:TONGLING FOUNDER PLASTICS TECH

Preparation technology of kraft liner box board

ActiveCN109629286AGuaranteed StrengthGuaranteed brightnessSpecial paperPaper recyclingSurface layerPapermaking

The invention discloses a preparation technology for a kraft liner box board. The technology comprises the following steps of 1 pulping, 2 papermaking and 3 sizing. By adopting graded bottom layer slurry, core layer slurry and surface layer slurry, waste paper slurry is sufficiently utilized, and meanwhile the strength and brightness of formed paper are ensured; a filler is added into the bottom layer slurry, the strength of the bottom layer slurry is ensured, and a dry strength agent is added into the surface layer slurry, so that the formed paper tenacity is improved.

Owner:JIANGSU LEE & MAN PAPER MFG

Preparation method of case board paper

InactiveCN104452419ASolve processing problemsLow production costNon-fibrous pulp additionPaper/cardboardPulp and paper industryUltimate tensile strength

The invention discloses a preparation method of case board paper. The preparation method of the case board paper comprises the following steps: respectively crushing wood scraps and crop straws, grinding the wood scraps and the crop straws into crude fiber, adding water into the crude fiber and pulping, uniformly mixing, removing impurities, adding water and soaking the pulp, scattering the pulp to obtain raw pulp, adding the raw pulp into a polyacrylamide solution, making paper to obtain the paper, preheating the paper, applying glue to the paper, enabling the paper to pass through a single-side machine to obtain the case board paper, and drying the case board paper. According to the preparation method of the case board paper, the wood scraps and the crop straws are used as base raw materials, so that the waste is turned into wealth, so that not only the production cost is reduced, and also the problem of treatment of the wood scraps and the crop straws can be solved; polyacrylamide is added in the paper making process; the problem of low fiber strength of the crop straws is compensated; the breakage resistance index and the circular pressure index of the case board paper are improved.

Owner:柳州市柳江区联华纸制品厂

Rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process

ActiveCN103362009AHigh viscosityHigh folding resistancePulp bleachingCellulose material pulpingXylanasePre treatment

The invention discloses a rapid-growth poplar sodium hydroxide anthraquinone pulp biochemical method TCF bleaching process. The process is characterized in that the process comprises the steps that: (1) steaming is carried out, wherein rapid-growth poplar wood sheets are steamed in a steaming pot, such that an original pulp is obtained; washing and screening are carried out, such that paper pulp is obtained; (2) xylanase pretreatment is carried out; (3) TCF bleaching is carried out, wherein the treated paper pulp is bleached with one of the bleaching sequence selected from OP-Q-P, O1-O2P-Q-P and O1P-O2P-Q-P. According to the invention, paper pulp is pretreated by using xylanase, and bleaching is carried out with one of the three bleaching sequences of XOPQP, XO1O2PQP and XO1PO2PQP, such that paper pulp with higher whiteness and viscosity are obtained. Compared with paper pulp obtained by direct bleaching without xylanase pretreatment, the paper pulp provided by the invention has lower beating whiteness loss. A folding resistance is higher by 30-49 times, a burst index is higher by 0.3-0.6N.m.g<-1>, a breaking length is higher by 0.15-0.36KM, and a tearing index is not significantly changed. When a same or similar beating degree is reached, needed beating revolutions are less, and beating energy consumption can be saved by approximately 17.8%.

Owner:QILU UNIV OF TECH

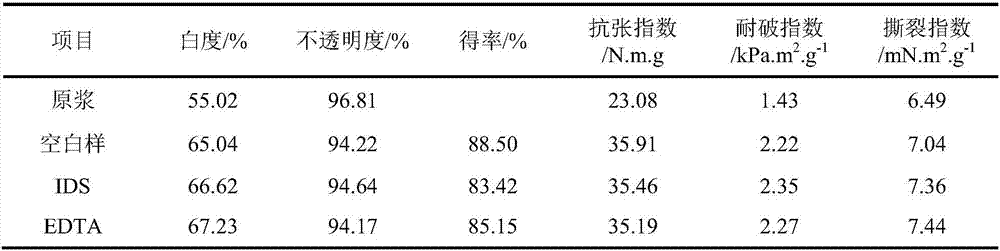

Method of applying green chelating agent in paper pulp hydrogen peroxide bleaching

The invention discloses a method of applying a green chelating agent in paper pulp hydrogen peroxide bleaching, and belongs to the technical fields of pulping and papermaking engineering. Specifically, after paper pulp is diluted to a concentration of 5%-10%, IDS with a mass percentage of 0.8%-1.2% of the absolute dry content of the paper pulp is added, mixing is performed uniformly, at the same time the chelation treatment temperature is controlled at 60-80 DEG C, and the reaction time is 50min-70min. According to the method provided by the invention, the IDS is used as the chelating agent for chelating treatment and pulp hydrogen peroxide bleaching, the bleaching effect is equivalent to that of hydrogen peroxide bleaching used conventional chelating agent EDTA, the whiteness of bagasse pulp can be improved by 2-4%, the tensile index can be improved by 5-6%, the burst resistant index can be improved by 20-23%, and the tear index can be improved by 8-10%; and the whiteness of waste paper deinking pulp can be improved by 2-4%, the burst index can be improved by 6-11%, and the tear index can be improved by 4-6%. The method provided by the invention can be used in the production process of paper pulp hydrogen peroxide bleaching.

Owner:SOUTH CHINA UNIV OF TECH

Paper-making pulping method by using kenaf aggregate

ActiveCN102021859AReduce dosageReduce pollutionNon-woody plant/crop pulpCellulose material pulpingPulp (paper)Sodium silicate

The present invention relates to a paper-making pulping method by using kenaf aggregates. Concretely, the present invention provides a paper-making pulping method by using kenaf aggregates which comprises the following steps: (a) soaking the kenaf aggregates in water or an aqueous solvent at a temperature of 70-100 DEG C for 5-180 min, cooling the soaked kenaf aggregates to the temperature of 5-50 DEG C, and pulverizing to obtain the pulverized kenaf aggregates; (b) soaking the kenaf aggregates obtained through step (a) at a temperature of 70-90 DEG C for 60-300 min with the presence of 2.0-7.0 wt% of sodium hydroxide, 2.0-5.0 wt% of hydrogen peroxide, 0.05-3.0 wt% of sodium silicate, and 0.05-2.0 wt% of magnesium sulfate; (c) performing the refining and latency procedure to the chemically treated pulp so as to obtain kenaf aggregate paper pulp.

Owner:SHANGHAI ZHONGWEI BIOCHEM

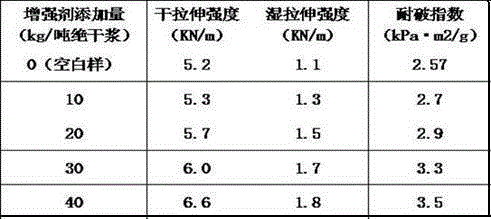

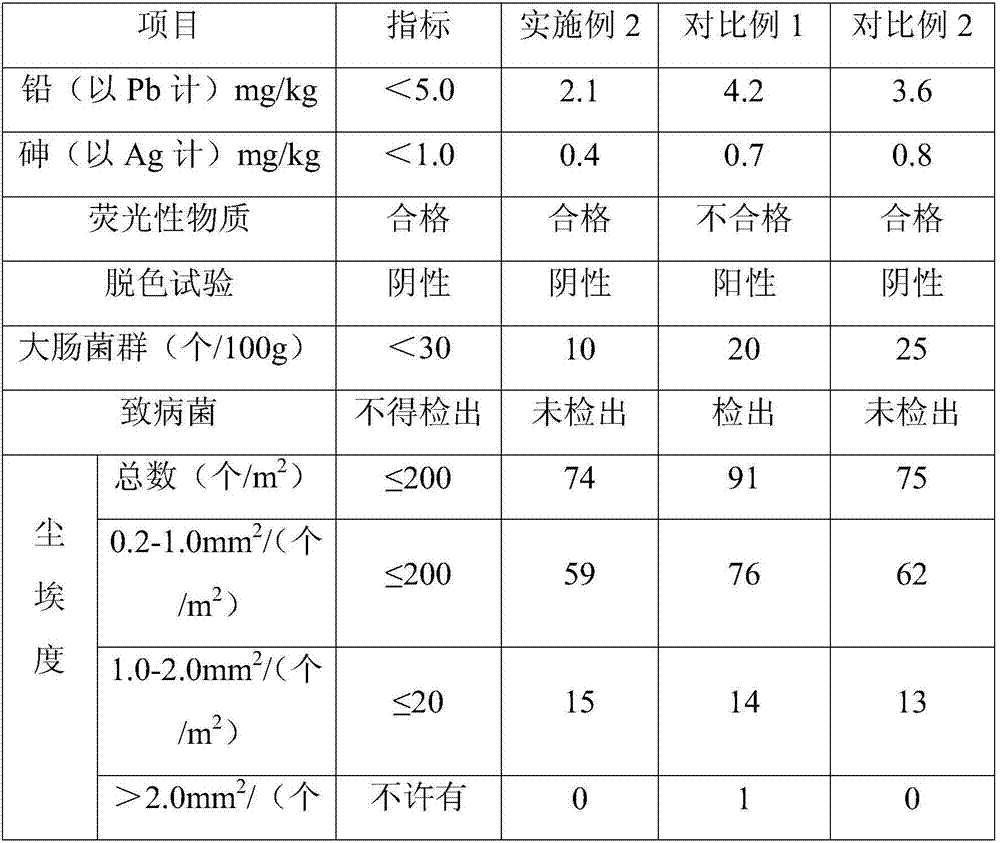

Preparation method of dry strength agent for food-grade paper

PendingCN113024719AHigh mechanical strengthIncrease binding areaReinforcing agents additionPaper/cardboardFiberCationic polymerization

The invention discloses a preparation method of a dry strength agent for food-grade paper, which comprises the following steps: (1) preparing the following raw materials in parts by weight: 40-55 parts of acrylamide, 0.3-1 part of anionic polymerization monomer, 1-3 parts of cationic polymerization monomer, 0.01-0.05 part of chelating agent, 0.05-0.2 part of inorganic acid, 0.1-0.5 part of molecular weight regulator, 0.03-0.1 part of initiator, 0.05-0.15 part of terminator and 40-60 parts of deionized water; and (2) adding an amide solution, anionic and cationic polymerization monomers, a chelating agent, inorganic acid, a molecular weight regulator and half of deionized water into a reaction kettle, and uniformly conducting stirring. According to the preparation method of the dry strength agent for the food-grade paper, the residual amount of the acrylamide monomer of the dry strength agent for the food-grade paper is less than 0.001%, and the dry strength agent can be safely suitable for the processes of production and manufacturing of the food paper, subsequent food processing and packaging and the like. The product can effectively increase the bonding area and bonding strength among fibers in papermaking paper under the condition of ensuring food safety, effective hydrogen bonding is formed, and the mechanical strength of the paper is remarkably improved.

Owner:青州金昊新材料有限公司

Degradable plastic layer material of paper plastic bag

The invention belongs to the technical field of degradable plastic layers of paper plastic bags and particularly relates to a degradable plastic layer material of a paper plastic bag. The material isprepared from, by weight, 22-26 parts of polyvinyl alcohol, 4-8 parts of vinyl acetate, 1-2 parts of N-isopropylacrylamide, 34-40 parts of modified corn starch, 3-5 parts of sodium-based montmorillonite, 0.2-1.0 part of boric acid and 0.2-0.6 part of plasticizer. Compared with the prior art, the degradable plastic layer material has the advantages that the corn starch is reasonably modified, the weather resistance of the material can be improved, the corn starch can be tightly bonded to a paper layer, the burst index and antibacterial property of the paper layer can be improved, the material has biodegradability, environmental pollution is avoided, a preparation method is simple, and the material is suitable for large-scale production.

Owner:合肥旭亚新材料科技有限公司

Glyoxal cross-linked polymer modified nano crystalline cellulose as well as preparation method and application thereof

InactiveCN105086322AEnhancement effect is goodImprove adsorption capacityReinforcing agents additionCross-linkCellulose

The invention discloses glyoxal cross-linked polymer modified nano crystalline cellulose. The glyoxal cross-linked polymer modified nano crystalline cellulose comprises two or more nano crystalline celluloses which are connected through a cross-linked polymer to form a nano crystalline cellulose cluster; the cross-linked polymer is formed by crosslinking a polymer formed through prepolymerization of nonionic monomers and a polymer formed through prepolymerization of cationic monomers via glyoxal; the nonionic monomers are selected from one or more of acrylamide, N,N-dimethyl acrylamide, N,N-diethyl acrylamide, N-vinylformamide and acrylonitrile; the cationic monomers are selected from one or more of methyl chloride or benzyl chloride quaternary ammonium salts of dimethyl diallyl ammonium chloride, dimethylaminoethyl acrylate and 2-(diethylamino)ethyl acrylate. The invention further provides application of glyoxal cross-linked polymer modified nano crystalline cellulose added into a paper machine's wet part as a papermaking additive.

Owner:赵迎辉

White paperboard and method for manufacturing same

ActiveCN105568748AIntensity effectReduce harmful ingredientsVegetable material additionPulp bleachingFiberPaperboard

The invention discloses a white paperboard and a method for manufacturing the same. The white paperboard comprises, by weight, 85-95 parts of mixed fibers, 6-8 parts of persimmon peel extract and 15-22 parts of semi-chemical pulp. The mixed fibers include mango tree fibers and bamboo fibers, a mass ratio of the mango tree fibers to the bamboo fibers is 15-16:2-3, the lengths of the mango tree fibers are 0.85 mm, and the widths of the mango tree fibers are 0.02 mm. The white paper board and the method have the advantages that the shortcoming of existing white paperboards in the aspect of elasticity can be overcome by the aid of the white paperboard with a low formaldehyde content, the white paperboard is difficult to fluff and high in smoothness, and printing ink is easy to attach onto the white paperboard.

Owner:苏州福羊自控科技有限公司

Method for deinking mixed office waste paper through composite biological enzyme

InactiveCN103485227APromote swellingReduce connectionsPaper recyclingWaste paper working-upPulp and paper industrySlurry

The invention discloses a method for deinking mixed office waste paper through composite biological enzyme. The method comprises the steps as follows: office waste paper is torn into 25*25 mm scraps with hands, and the scraps are soaked for 10 min and placed in a horizontal type hydrapulper for fluffing, so that standby pulp is obtained; the standby pulp is placed in the hydrapulper, water is added, the temperature is raised, the pH is adjusted, the composite biological enzyme and a surface active agent are added, and the mixture is mixed with the slurry; and finally, the slurry is poured into a flotation device, water is added for adjusting the slurry concentration to be 0.5%, the pH is adjusted to 8.0-8.5, an air pump and a slurry recycle switch of the flotation machine are switched on, and flotation is timed when a bubble pops out of a flotation tank; and after flotation, aeration and slurry recycle are stopped, and the slurry is poured into a filter bag to be squeezed, dried and dispersed for sheet making. According to the method, the waste paper dust degree is greatly reduced, the Eric value is decreased, and at the same time, the tensile index and the burst index of the paper are improved, so that the paper can have higher application values.

Owner:FUJIAN AGRI & FORESTRY UNIV

Method for preparing kraft liner cardboard paper by utilizing wastewater sludge

InactiveCN109594402AReduce usageIncreased burst indexWaste product additionSecondary cellulose fibresFiberCardboard

The invention discloses a method for preparing kraft liner cardboard paper by utilizing wastewater sludge. The method takes sludge obtained by wastewater treatment as a production raw material and thesludge is combined with waste paper pulp according to a certain ratio to prepare cardboard paper; the use amount of waste paper is reduced and the cost is saved; and the prepared kraft liner cardboard paper has relatively high burst index and ring crush index and has high smoothness, a great interlayer binding force and long service life. According to the method for preparing the kraft liner cardboard paper by utilizing the wastewater sludge, the quality of finished-product paper can be ensured through adding the wastewater sludge, a covering agent and a retention aid, and a filter aid and the quality index reaches enterprise standards; and the operation efficiency of a paper machine reaches 98 percent or more, the retention rate of fine fibers and filler can be maintained and the paper has a wide application prospect.

Owner:JIANGSU LEE & MAN PAPER MFG

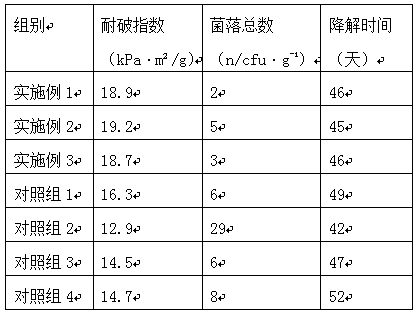

Method for improving strength of waste paper fiber by constructing nano-polyelectrolyte multilayer films

InactiveCN102242524AAchieve surface modificationImprove physical strengthReinforcing agents additionPaper/cardboardFiberCationic polyelectrolytes

The invention discloses a method for improve strength of waste paper fiber by constructing nano-polyelectrolyte multilayer films. In the method, a nanoscale polyelectrolyte multilayer film structure is formed on the surface of regenerated fiber by means of electrostatic layer-by-layer self-assembly of anionic and cationic polyelectrolyte on the surface of the waste paper fiber. The method has thebeneficial effects that by changing consumption of the polyelectrolyte, regulating and controlling the electrolyte multilayer film structure and adjusting the pH value of an electrostatic layer-by-layer self-assembly environmental system, the polyelectrolyte multilayer films with different properties can be obtained on the surface of the regenerated fiber so as to increase fiber bonding quantity;electrostatic attraction between anions and cations is taken as a film-forming driving force to prepare the ordered lamellar self-assembled multilayer ultra-thin films by means of alternate deposition of monomolecular layers in opposite ionic systems, and the preparation process has the advantages of simple conditions and strong adaptability and can realize surface modification of the waste paperfiber reused for a plurality of times; and strength of the finished paper prepared from the waste paper fiber after electrostatic layer-by-layer self-assembly modification is obviously enhanced, and drainage property of paper pulp is obviously improved.

Owner:湛江市吉城纸业有限公司

High-strength corrugated paper processing method

PendingCN109703109AHigh strengthIncreased burst indexMechanical working/deformationReinforcing agents additionPulp and paper industryUltimate tensile strength

The invention discloses a high-strength corrugated paper processing method comprising the following step I of preparing base paper pulp; the step II of adding reinforcing agents to the base paper pulp; the step III of performing heat treatment to base paper; the step IV of performing sizing treatment to the surface of the base paper; the step V of compounding the base paper through a corrugating machine to obtain corrugated paper; the step VI of performing cooling treatment after drying to obtain the high-strength corrugated paper. According to the processing method, the burst index and the ring crush index of the corrugated paper are improved, so that the corrugated paper is higher in strength, and the service life of a corrugated box is prolonged; and the market use requirements are met,and the promotion of products is benefited.

Owner:国腾彩色纸品(鹤山)有限公司

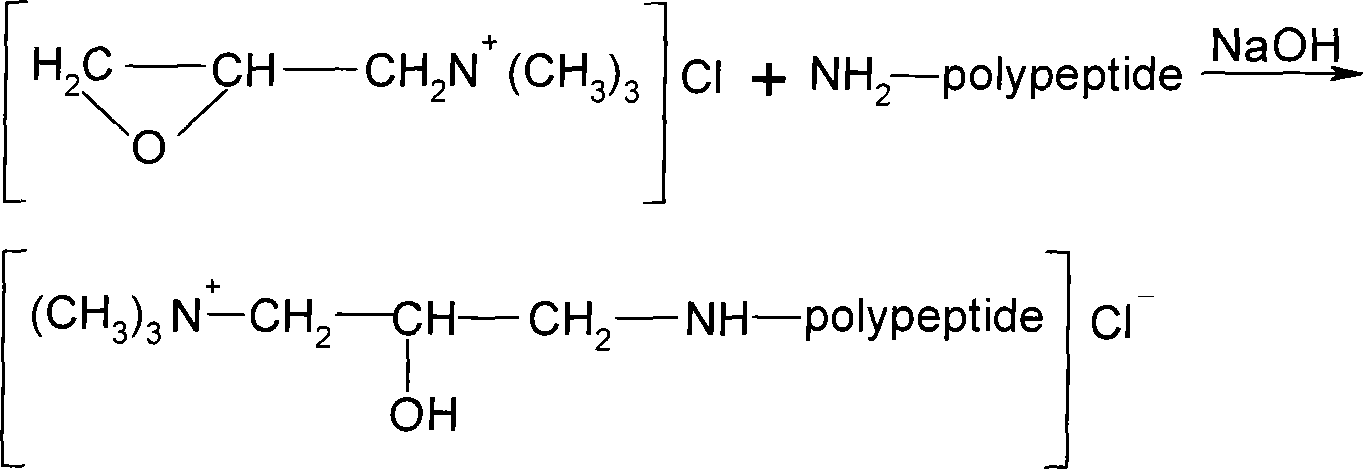

Quaternary ammonium glutelin protein synthetic method

InactiveCN101182687AImprove solubilityGood dispersionNon-fibrous pulp additionPaper/cardboardSolubilityFiber

The invention discloses a method for synthesizing quaternized gluten protein. Firstly, hypohalite is used to pretreat gluten protein. The mass ratio of gluten protein to hypohalite is 1:1-1:2. Convert the free amide groups on the gluten protein into fatty amino groups; then use cationic quaternary ammonium epoxy chloride with a mass ratio of 1:1 to 1:1.5 to carry out grafting reaction with the pretreated gluten protein to generate quaternary ammonium salts Cationic modified gluten protein. Through the pretreatment reaction of hypohalite, the content of fatty amino groups on the protein molecular chain can be increased, which is beneficial to the quaternization reaction, and the combination of protein and plant fiber can be improved; the solubility of gluten protein can be improved, and it is more suitable for plant fiber ( Pulp) for sizing.

Owner:SOUTH CHINA UNIV OF TECH

Production process of lightweight high-strength corrugated paper

InactiveCN112012047AIncreased burning difficultyImprove breathabilityDefoamers additionFlexible coversPaper productionProcess engineering

The invention discloses a production process of a light-weight high-strength corrugated paper, relates to the related field of corrugated paper production, and aims to solve the problems that the existing corrugated paper is insufficient in strength, and the strength of the corrugated paper is increased by adding a corrugated base paper layer, so that the light weight of the corrugated paper is influenced. The production process comprises the following steps: S1, soaking treatment, and then heating and cooking, S2, draining after cooling, crushing, primarily screening, grinding in a pulping machine, and screening again, S3, dividing of slurry into slurry A and slurry B, S4, preparation of mixed pulp A, papermaking, dehydrating and drying to prepare inner paper and surface paper, S5, preparation of mixed pulp B, papermaking, dehydrating and drying to prepare raw paper, S6, corrugating for forming a corrugated base paper, S7, cutting of an inner paper, two surface papers and two corrugated base papers, S8, preparation of an environment-friendly colloid, S9, sizing for fixing the corrugated base paper and the inner paper, S10, sizing for fixing the surface paper, S11, drying and thencooling, and S12, reinforcing agent spraying, and then drying.

Owner:LONG LI DE LD INTELLIGENT TECH CORP LTD

High strength packing paper board by mixed fibre of bluish dogbane and sorghum stalks and preparation method thereof

The invention belongs to a packing paperboard, specially relating to a bluish dogbane- sorghum stalk mixed fiber high-strength packaging paperboard and its preparing method, adopting the following raw materials in weight share: full-stalk bluish dogbane 1 share, sorghum stalks 1 shares, ammonium sulfite 0.3-0.4 share, magnesium oxide 0.03 share, where the liquor ratio is 1 : 2.5-3, and the rest water, cutting the full-stalk bluish dogbane and sorghum stalks into 20 mm-long segments, adding in water for predipping, placing in an evaporating ball or device at twice, deflating to a small extent to achieve the maximum filling quantity, cooking at 0.4Mpa-0.5Mpa at temperature 160-170 deg.C, where the cooking and heat-preserving time is 2-2.5 hours, reducing pressure and deflating, pouring in a bottom tank, making three-stage circulating wash, screening and milling, making paper, and the paperboard strength is largely improved, it can save large amount of timber, and beneficial to greening and environmental protection.

Owner:刘海博

Papermaking preparation method

InactiveCN102154919AReduce churnStrong adhesionNon-fibrous pulp additionPaper/cardboardPotassium persulfateCellulose

The invention discloses a papermaking preparation method which comprises the following steps: under the reaction temperature of 20-65 DEG C, dissolving sodium hydroxide and potassium persulfate in water, uniformly mixing, and reacting for 1-6 hours to obtain a pale yellow solution; adding modified starch with the concentration of 2-8% into the pale yellow solution, uniformly mixing, heating at 80-120 DEG C for 0.5-1h, and pasting to obtain a starch paste solution; adding the starch paste solution into pulp with the concentration of 2-7%, and uniformly mixing; adding the mixed pulp into polyanionic cellulose, and then extruding and concentrating by pulp extruding equipment, so as to enable the concentration of the pulp to be improved to 18-40%; and adding water into the concentrated mixed pulp to dilute, dispersing the pulp, and manufacturing paper. The papermaking preparation method disclosed by the invention remarkably enhances the drying strength and the tearing-resistance strength of the paper, remarkably improves the ring crush strength of the paper and the pulp drainage property, and improves the retention rate of superfine components.

Owner:JIANGMEN GAOLIYI TECH IND

Method for preparing water-resistant high-strength functional paper

InactiveCN101634123AImprove wet strengthImprove wet strength/dry strengthNon-fibrous pulp additionPaper/cardboardFolding endurancePolyethylene glycol

The invention provides a method for preparing water-resistant high-strength functional paper, which comprises the following steps: dehydrating tetrahydrofuran (THF) by adding anhydrous calcium chloride (CaCl2) for 24 hours; filtering to obtain anhydrous THF; adding polyethylene glycol to 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate (also known as isophorone diisocyanate, IPDI for short) to obtain a mixture A; adding the mixture A to the anhydrous THF; then, adding dibutyltin dilaurate as a catalyst, heating to 60 to 62 DEG C, and evenly stirring to obtain a mixed solution; impregnating paper with the mixed solution, and drying to remove the excessive organic solvent; and further heating and curing the paper to obtain the water-resistant high-strength functional paper. The modification of the invention to the body paper leads to average increases in the breaking length by 4.38 times, the folding endurance by 28.73 times and the burst index by 6.73, average wet strength / dry strength of 51% and average reduction in the opacity to about 60% from the original.

Owner:SHAANXI UNIV OF SCI & TECH

Non-wood unbleached pulp food warp paper and preparation method thereof

ActiveCN107090737ALow costReduce manufacturing costNon-fibrous pulp additionFlexible coversPaper sheetPapermaking

The invention discloses a non-wood unbleached pulp food wrap paper and a preparation method thereof. Slurry of the non-wood unbleached pulp food wrap paper is prepared from unbleached straw pulp and unbleached bamboo pulp, the fixed quantity of the wrap paper ranges from 45 g / m<2> to 65 g / m<2>, and the content of synthetic papermaking additives accounts for 0.5%-2.5% of oven dry stock. The wrap paper is safe and environmentally friendly, the natural color of plant fiber is kept, dust and chips do not exist, no hazardous substance is produced in a papermaking technology, the waste water treatment cost is lowered, and the production cost is low.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Paper-plastic composite material and preparation method thereof

InactiveCN107419597AHigh strengthIncreased burst indexPaper coatingSynthetic cellulose/non-cellulose material pulp/paperLow-density polyethyleneGlass fiber

The invention discloses a paper-plastic composite material and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing raw wood pulp, bark, hemp, straws, glass fibers, an inorganic filler and whitewash according to the weight ratio of 100 to (20 to 30) to (1 to 5) to (2 to 5) to (5 to 15) to (15 to 25) to (200 to 300), and then cooking to prepare paper pulp; washing, blenching and knocking the paper pulp, fishing paper, drying and baking paper to obtain composite paper; secondly, heating a low-density polyethylene film and then coating the surface of the composite paper with the film to form a plastic layer, thus obtaining the paper-plastic composite material. The paper-plastic composite material has excellent mechanical strength and good antibacterial properties.

Owner:ANHUI YUEERWEI PLASTIC MACHINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com