Patents

Literature

1238results about How to "Reduce turbidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

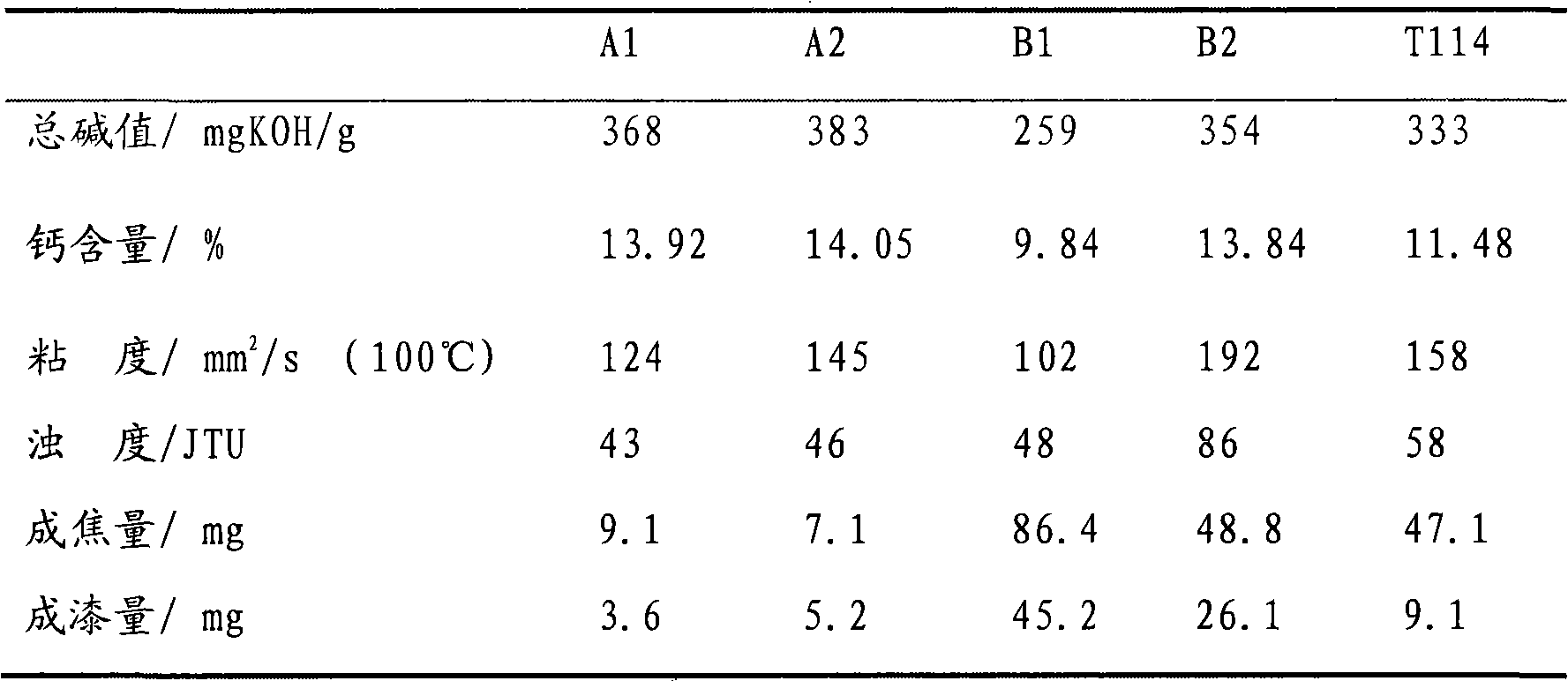

Preparation method for high-alkaline calcium naphthenate

ActiveCN101885677AAvoid aggregation and sedimentationHelps neutralize the reactionAdditivesCarboxylic acid salt preparationCalcium hydroxideAlkaline water

The invention relates to a preparation method for high-alkaline calcium naphthenate. In the method, calcium hydroxide and calcium oxide are taken as calcifying agents, pure water is replaced by alkaline aqueous solution, and a mode of multiple addition is adopted to prepare a calcium naphthenate product with the base number of more than or equal to 350 mgKOH / g. The product has the advantages of low viscosity and turbidity and better high temperature cleanliness.

Owner:CHINA PETROLEUM & CHEM CORP +1

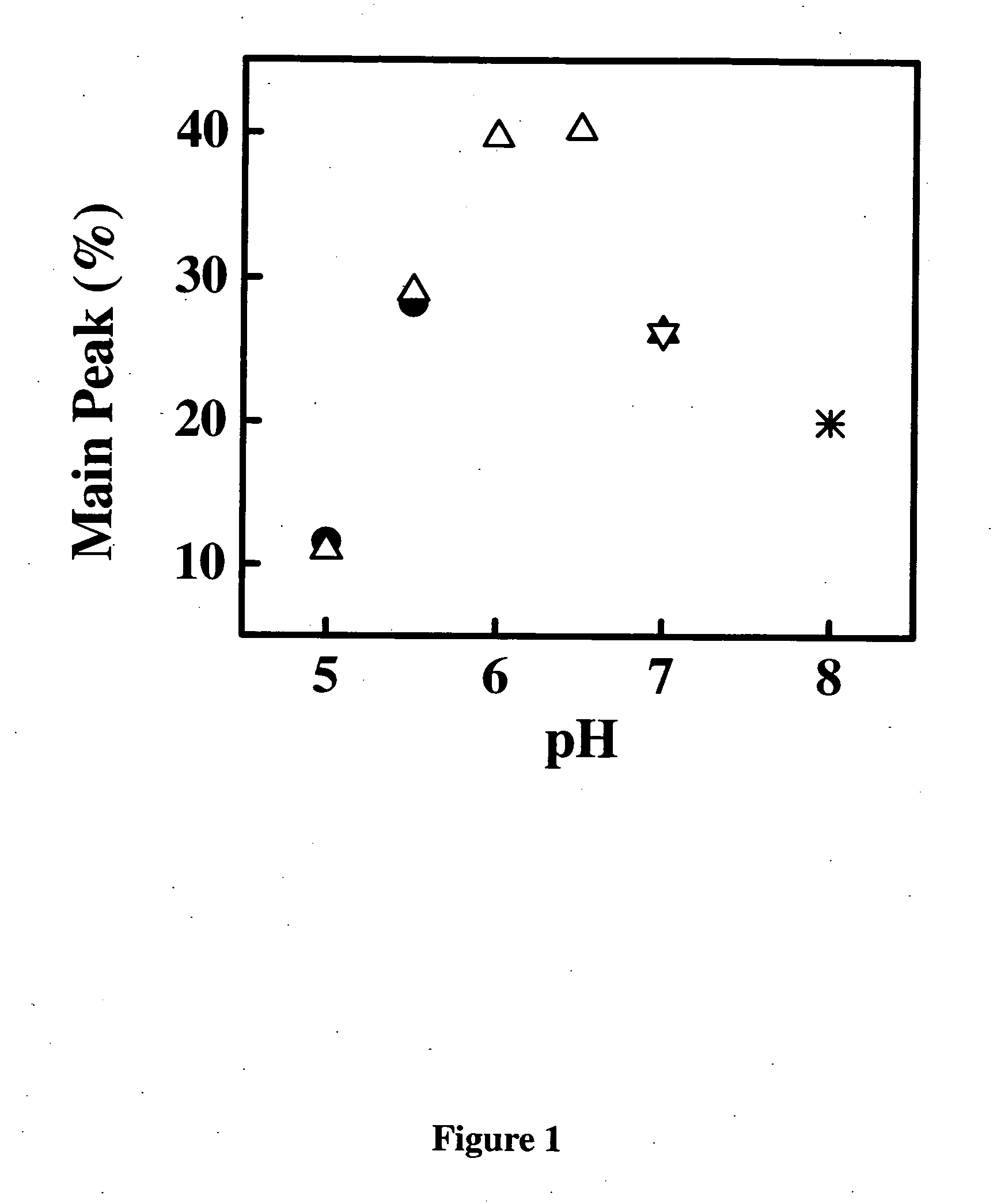

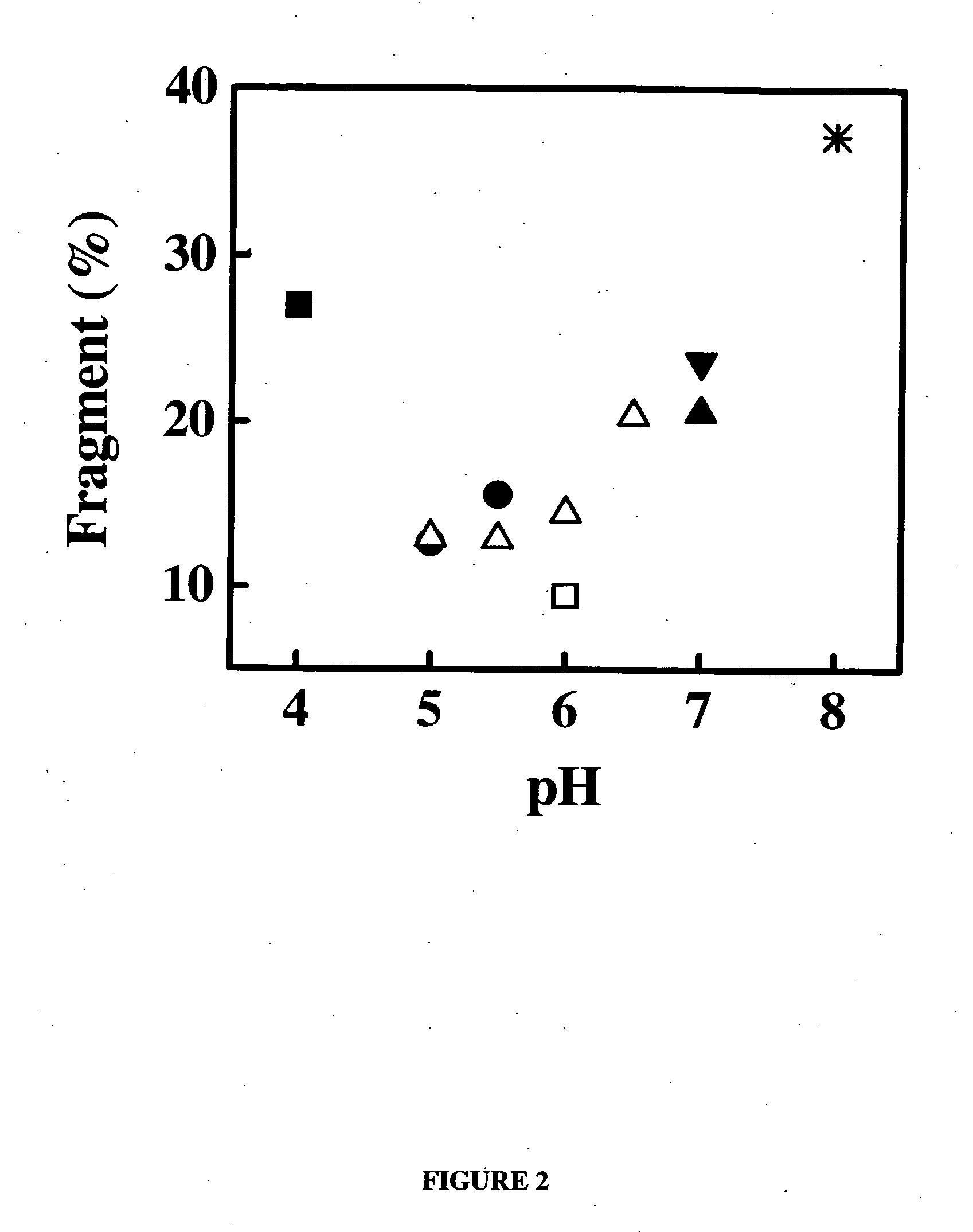

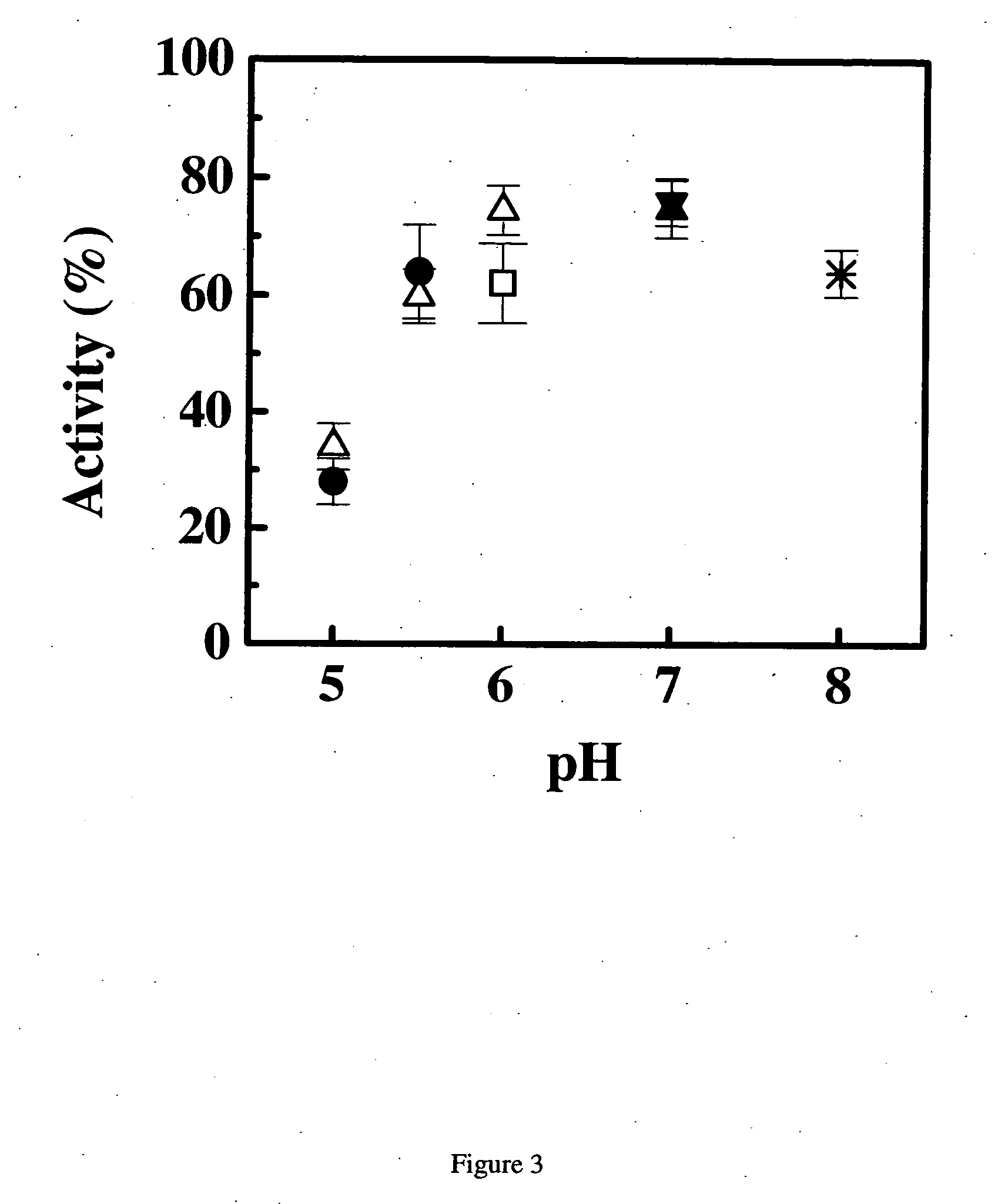

Methods of treating IgE-mediated disorders comprising the administration of high concentration anti-IgE antibody formulations

InactiveUS20050158303A1Speed up concentrationReduce turbidityOrganic active ingredientsBiocideIge mediatedAnti-IgE Antibody

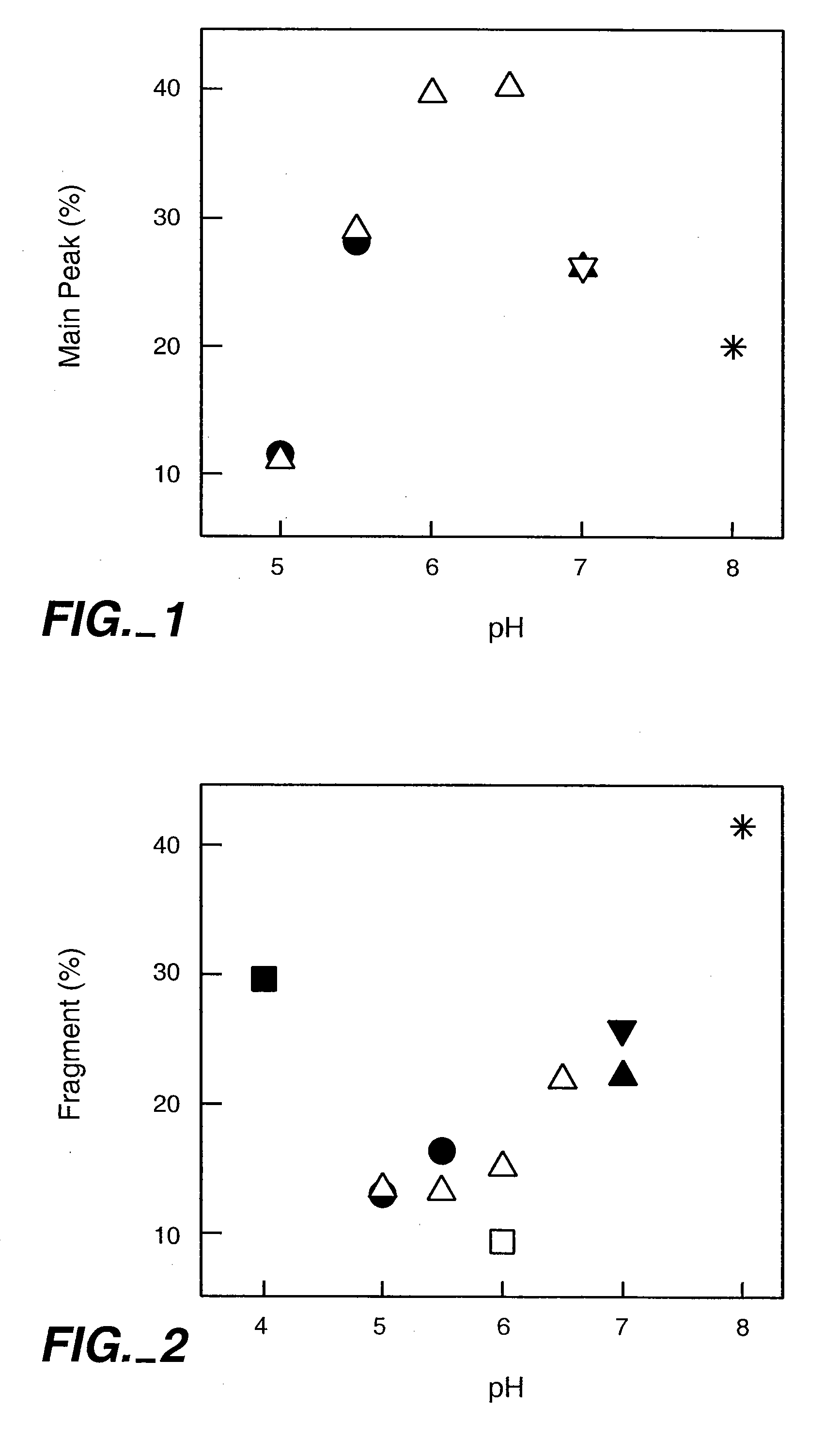

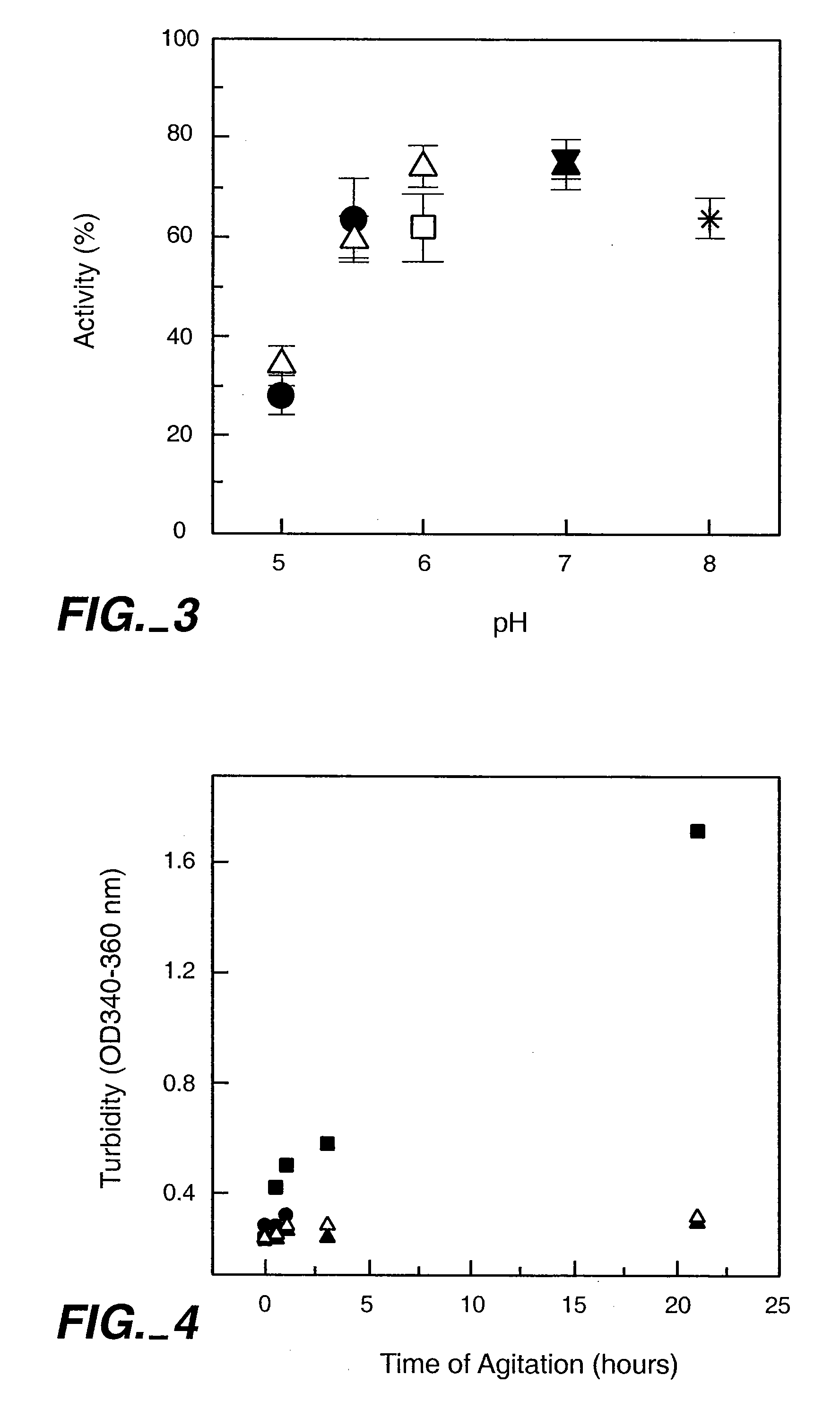

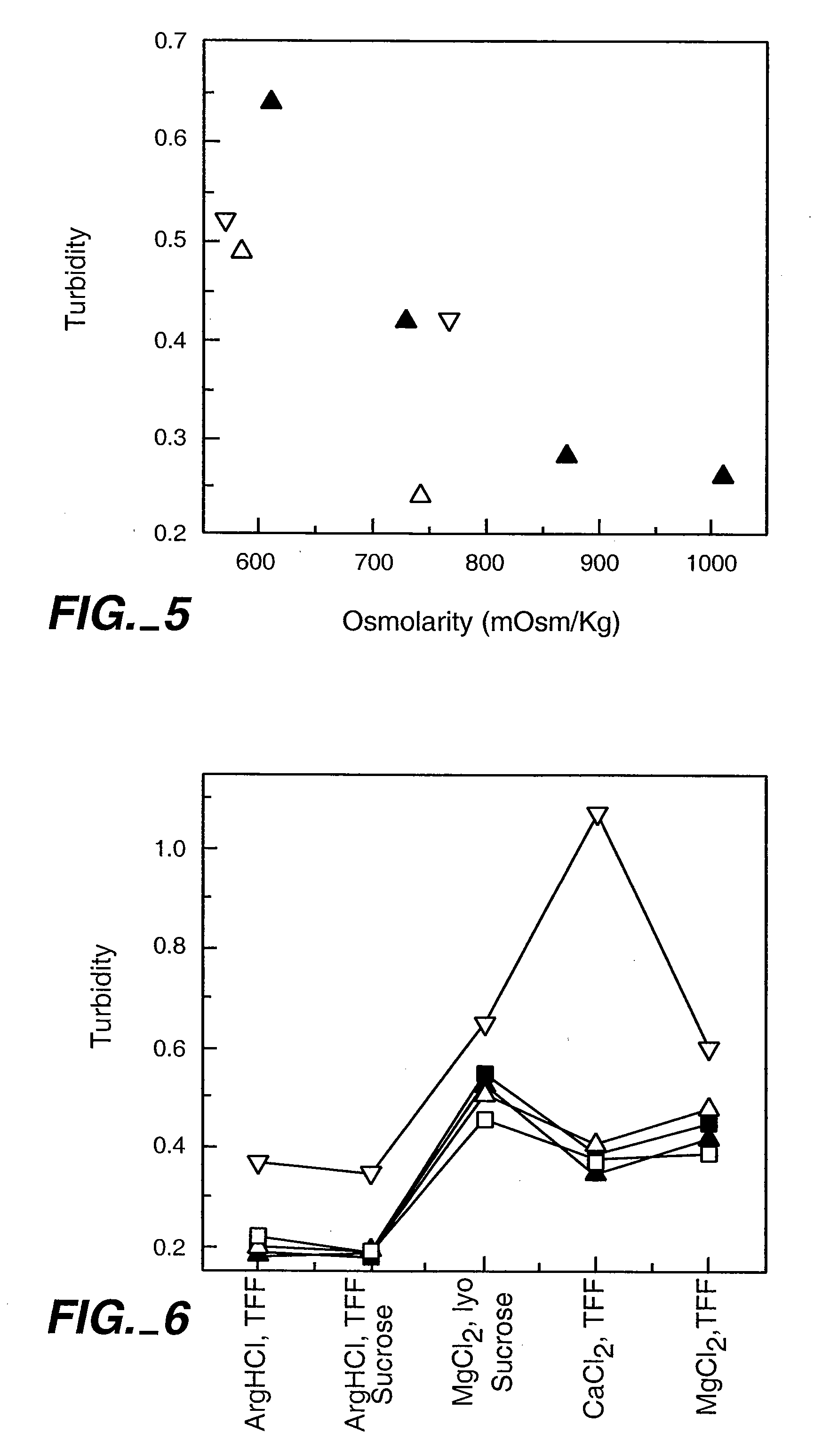

The present application relates to methods of treating IgE-mediated disorders comprising the administration of highly concentrated anti-IgE antibody formulations with reduced viscosity that are stable, relatively isotonic and are of low turbidity. The formulations are particularly suitable for subcutaneous administration.

Owner:GENENTECH INC +1

High concentration antibody and protein formulations

InactiveUS20070053900A1Speed up concentrationReduce turbidityAntipyreticAutomatic syringesDiseaseAntiendomysial antibodies

The present application relates to highly concentrated antibody and protein formulations with reduced viscosity that are stable, relatively isotonic and are of low turbidity. The formulations are particularly suitable for subcutaneous administration. The application further describes articles of manufacture containing such formulations and method for using them to treat disorders treatable by the formulated antibody or protein.

Owner:GENENTECH INC

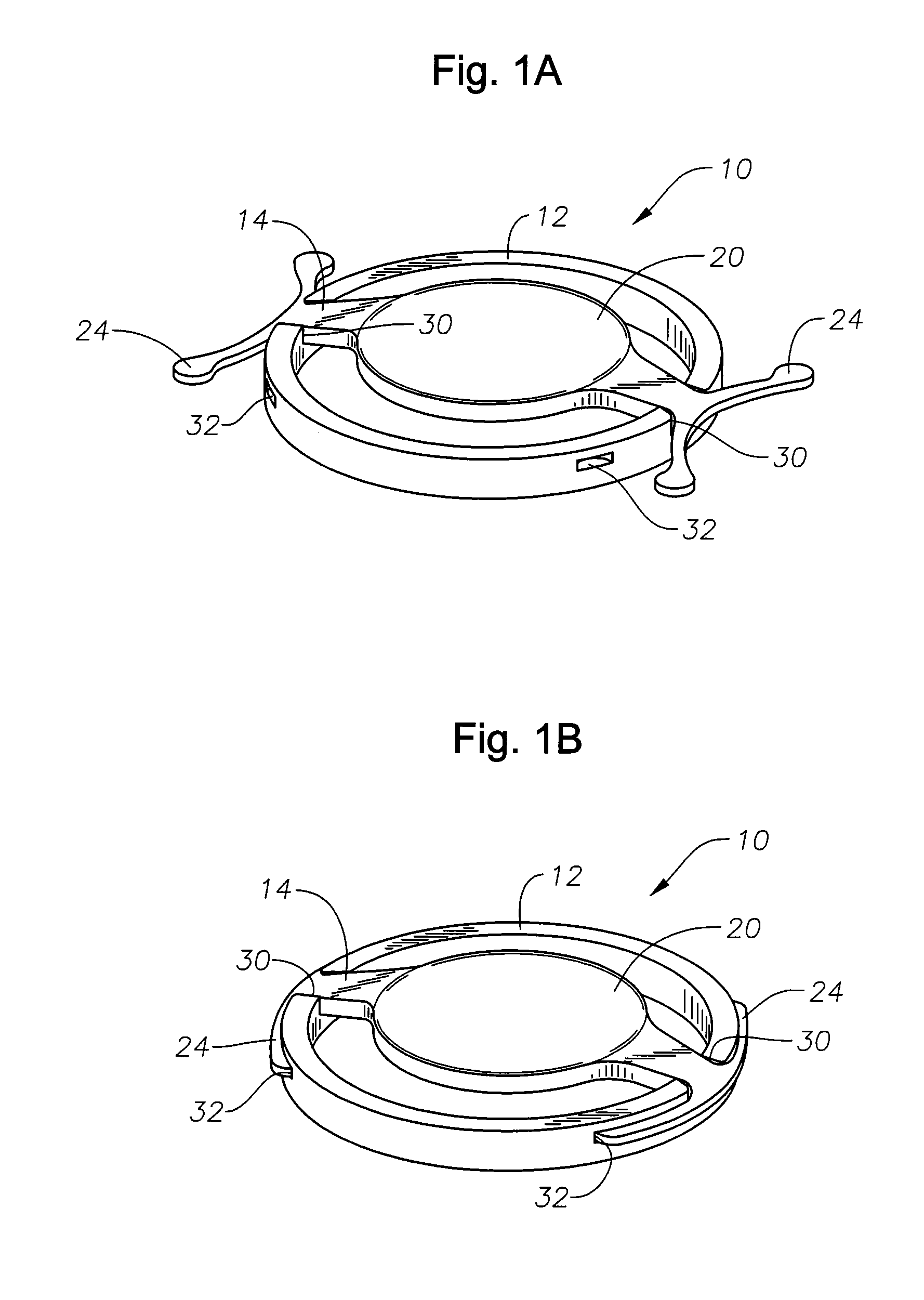

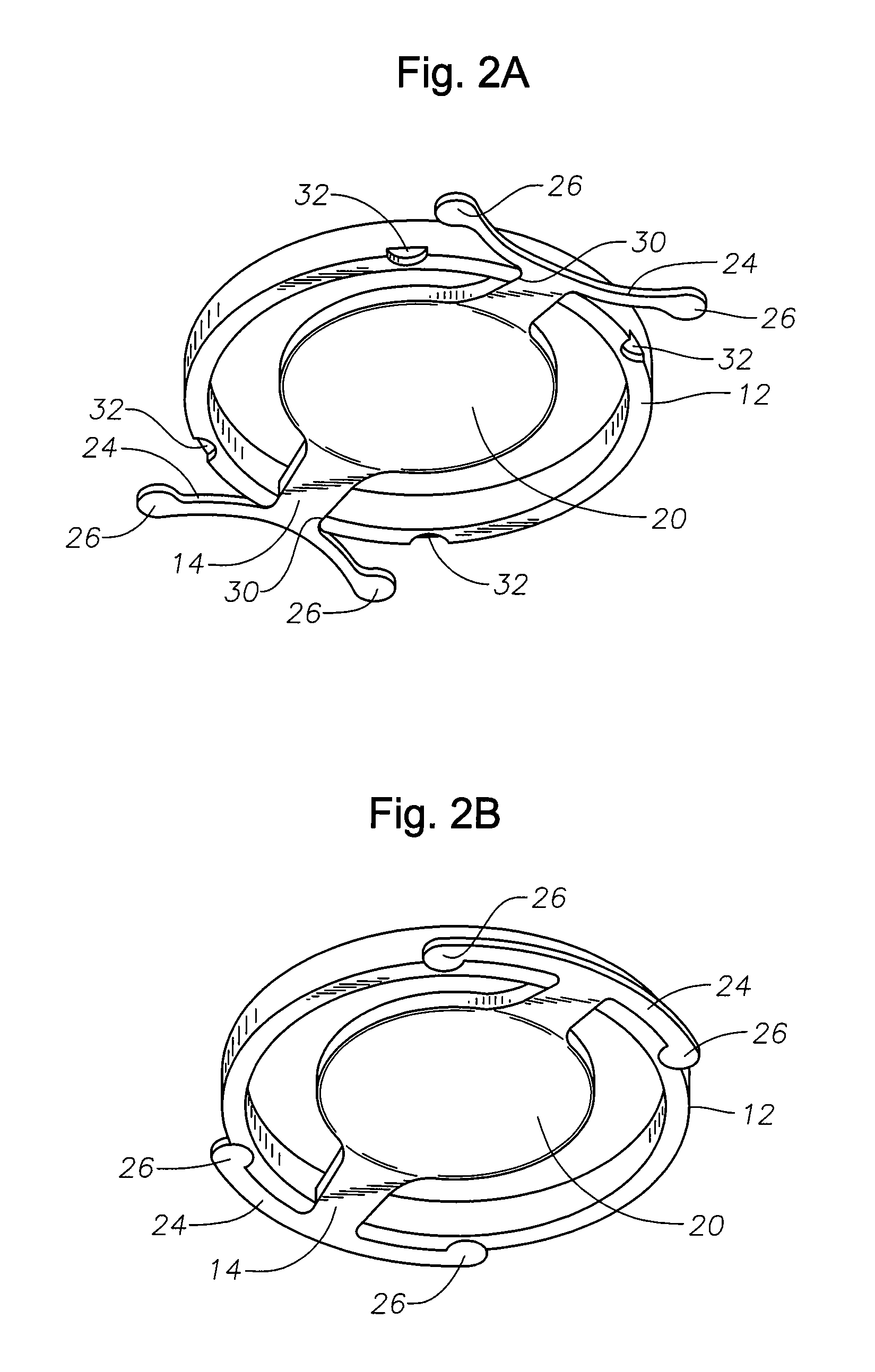

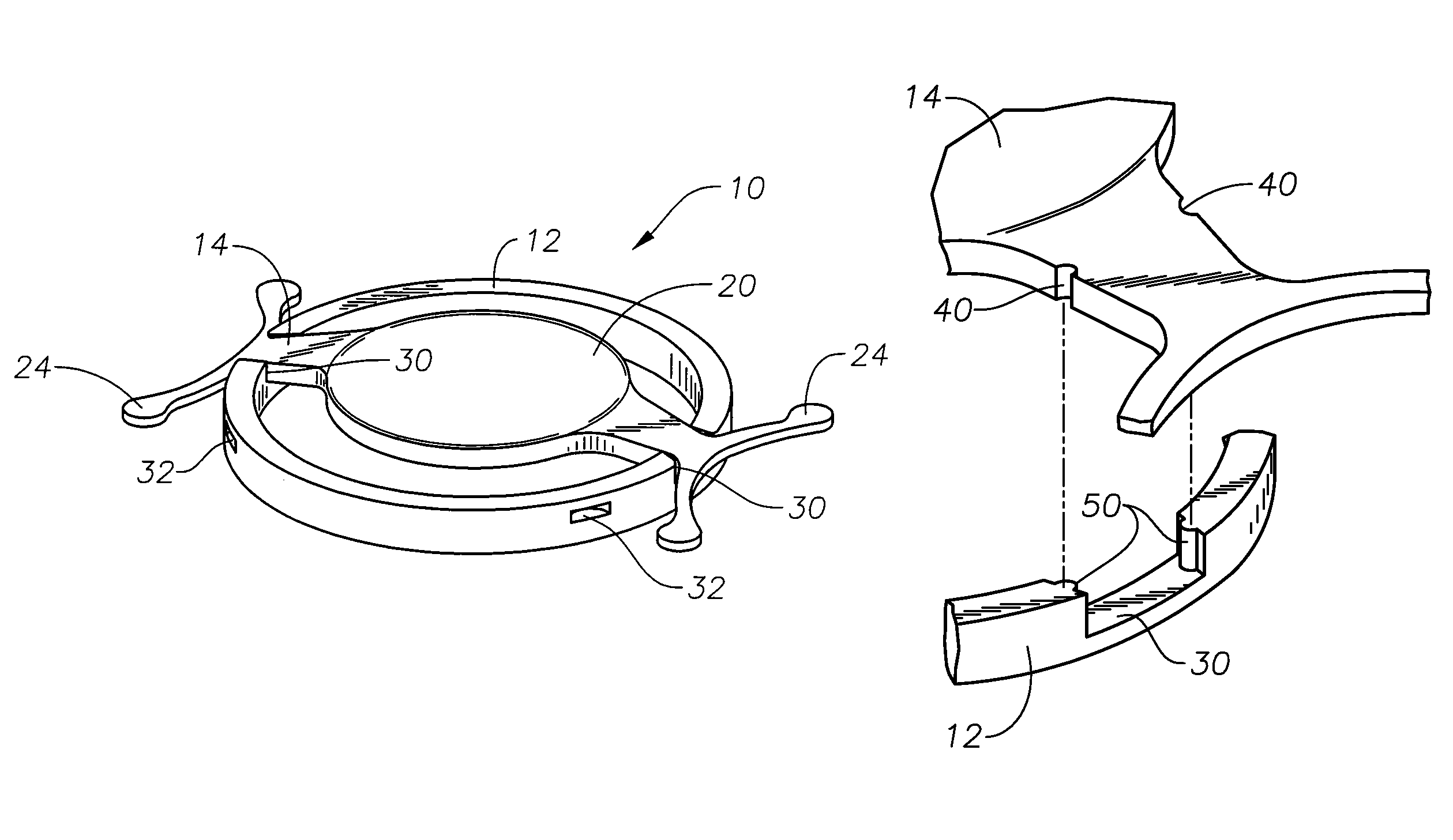

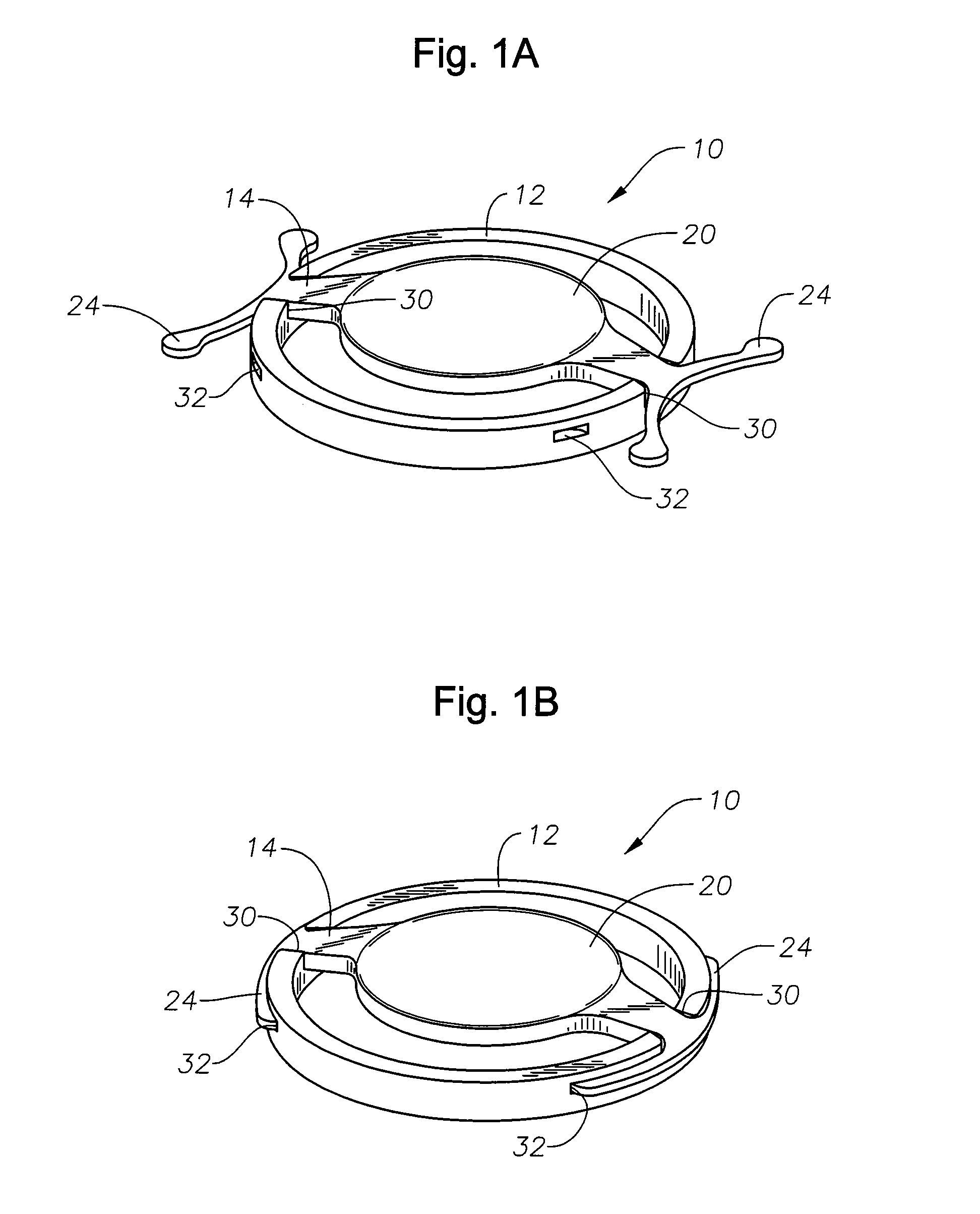

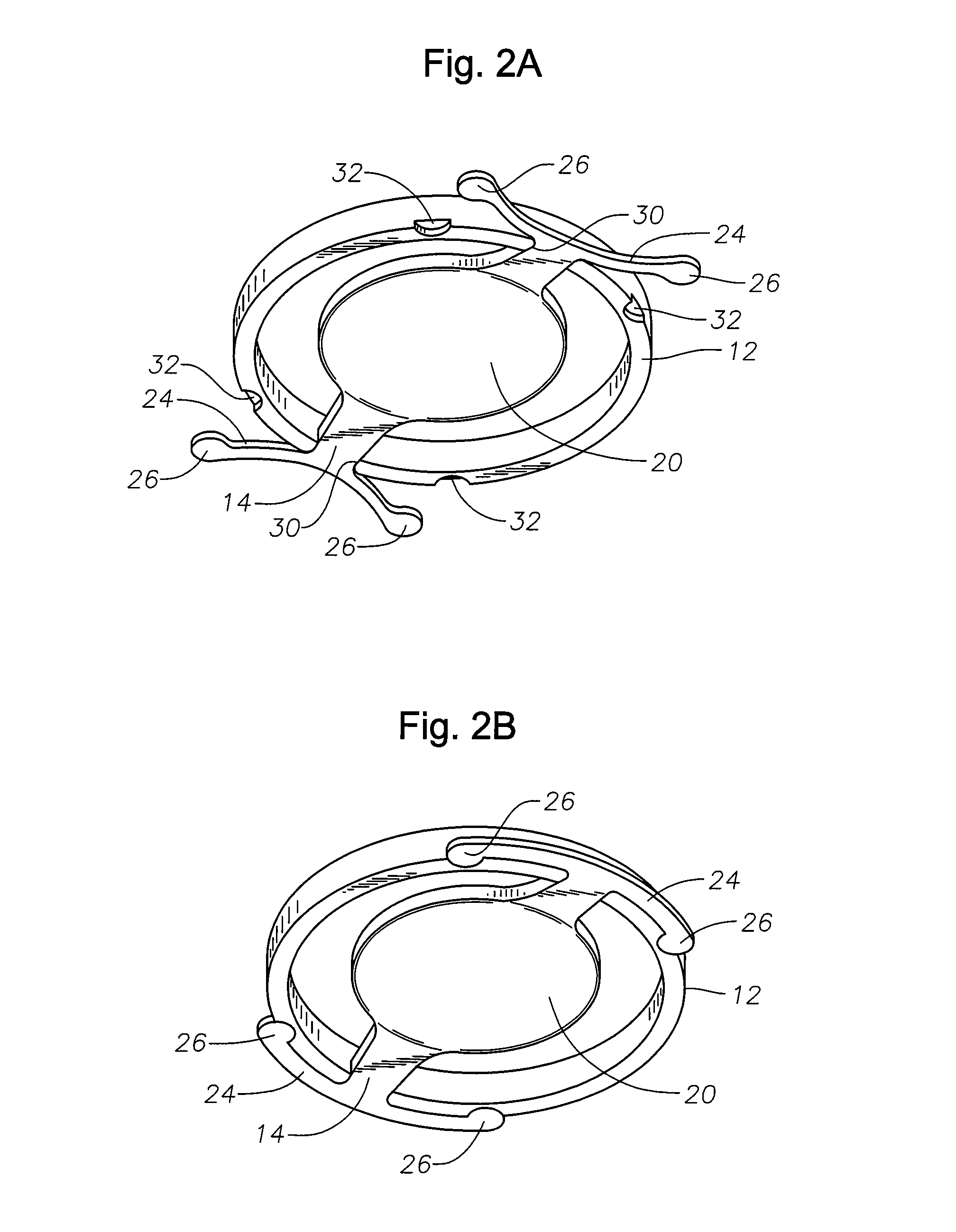

Single optic accommodative intraocular lens system

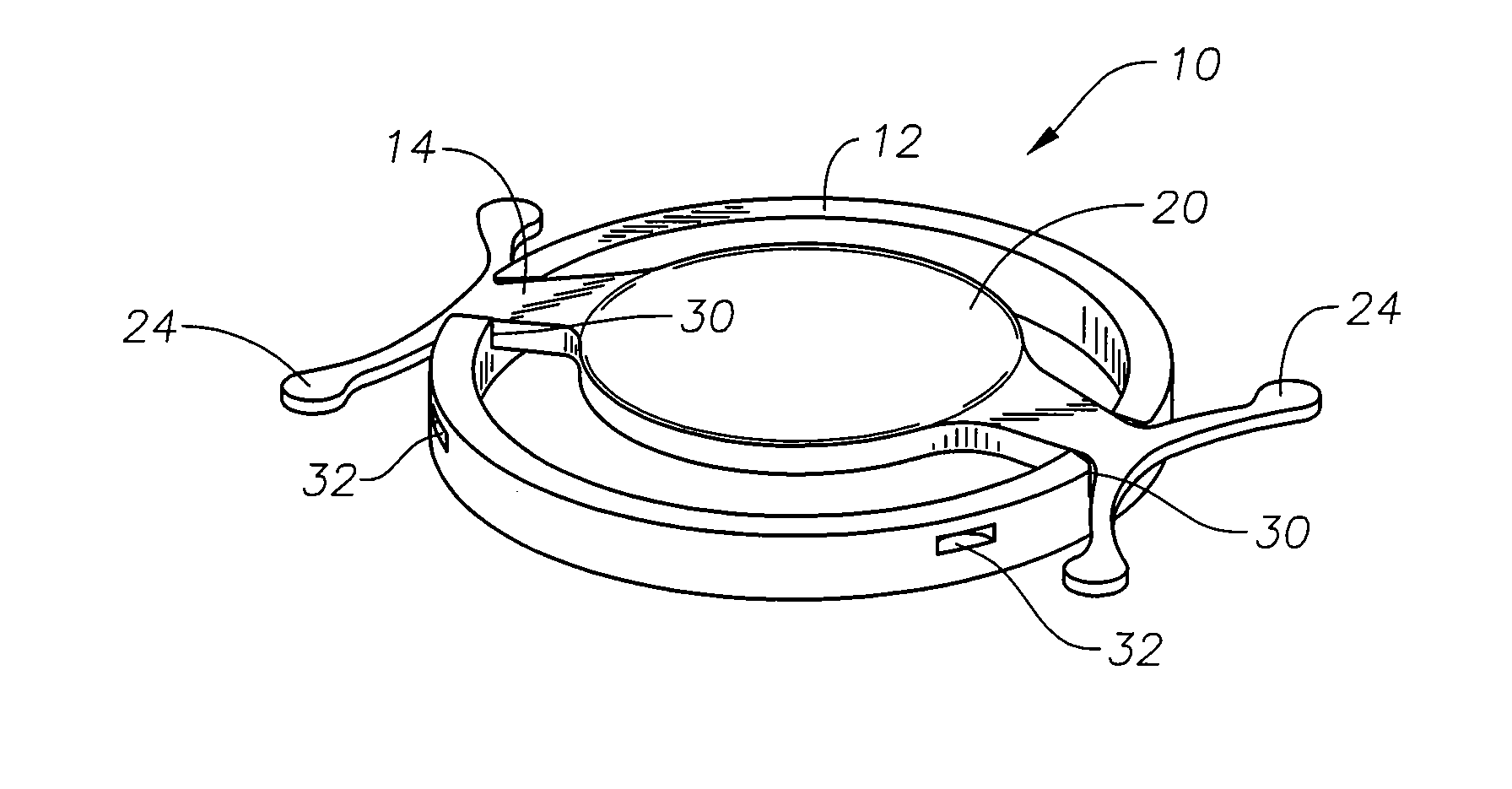

ActiveUS20100204788A1Add depthRestore accommodationGas turbine plantsIntraocular lensOphthalmologyCapsular ring

A single-optic accommodative lens system comprising two intraocular elements. The two intraocular elements are designed to be located within the capsular bag to extend depth of focus and / or restore accommodation following extraction of a natural lens. A first intraocular element comprises a circumferential capsular ring having interlock features to couple to and control the dynamic vault response of a second intraocular element. This second intraocular element comprises an intraocular lens (IOL) having an optic and a plurality of haptics and is designed to move axially in response to changes in the geometry of the eye capsule and thus provide a range of accommodative power. The IOL further comprises interlock features complementary to the interlock features of the first intraocular element for coupling the IOL to the capsular ring in a manner that provides for controlled movement of the IOL in response to capsular forces. Capsular force can be applied to the IOL from anterior, posterior and / or intermediate sections of the capsule equator, resulting in movement of the IOL and commensurate accommodation.

Owner:ALCON INC

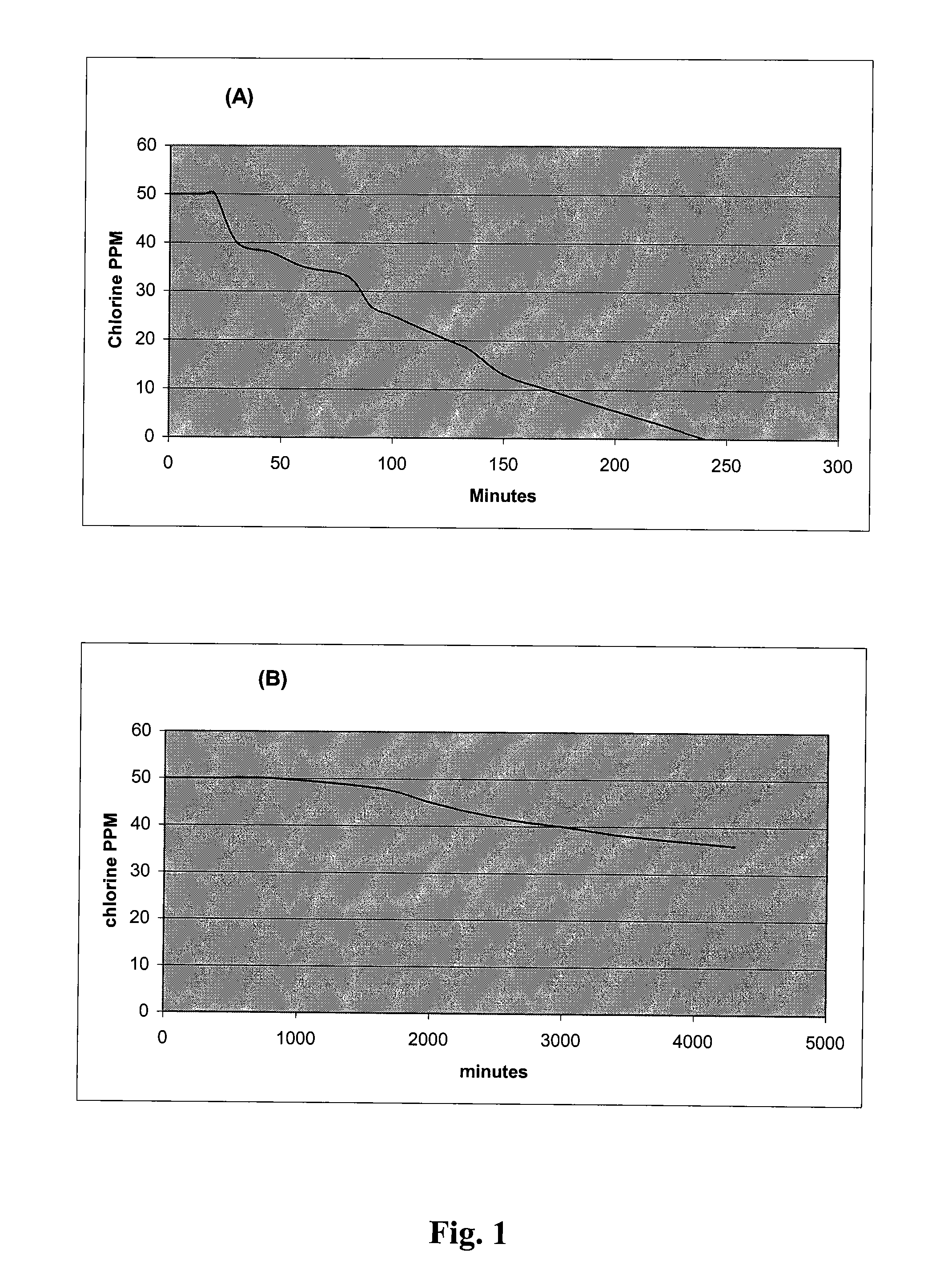

Biocidal compositions for treating water

InactiveUS6093422AEffective destructionEfficient Growth InhibitionOrganic active ingredientsBiocideCrosslinked chitosanSulfate zinc

The present invention is directed to a biocidal water treatment composition, water treatment apparatus, and method of treating water to reduce levels of pathogens. The composition contains sources of copper, zinc, and silver metal ions within a crosslinked polymer matrix. Examples of these ion sources include copper sulfate, zinc sulfate, and silver nitrate. An example of the crosslinked polymer matrix is crosslinked chitosan, which also serves to clarify the water and release the metal ions over time. The product is easy to manufacture, and allows the use of decreased halogen sanitizer, as well as decreased copper ion, thereby decreasing the likelihood of staining. The product simultaneously provides good bactericidal and algaecidal properties, despite low levels of copper ion and low chlorine levels.

Owner:ZODIAC POOL SYST

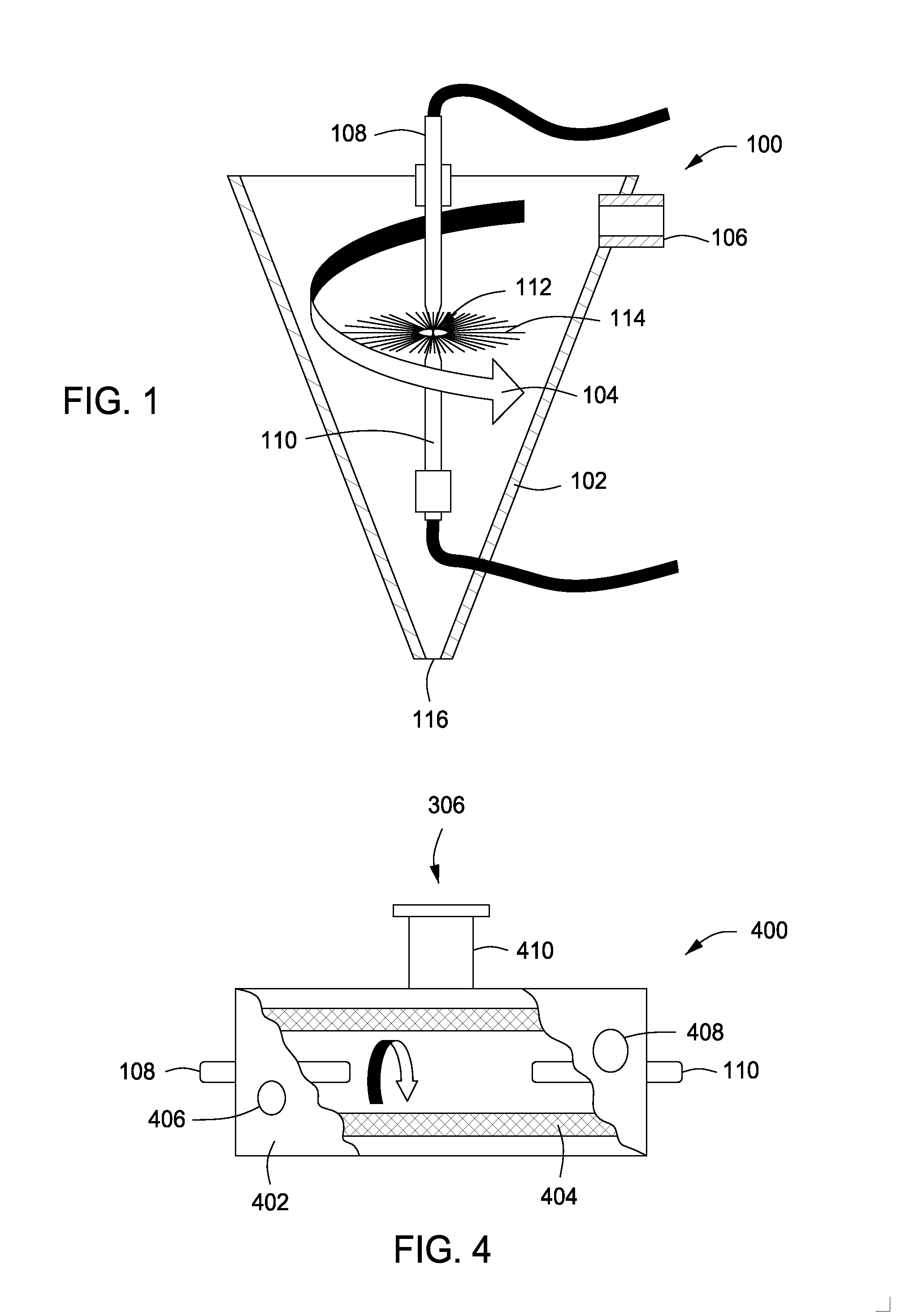

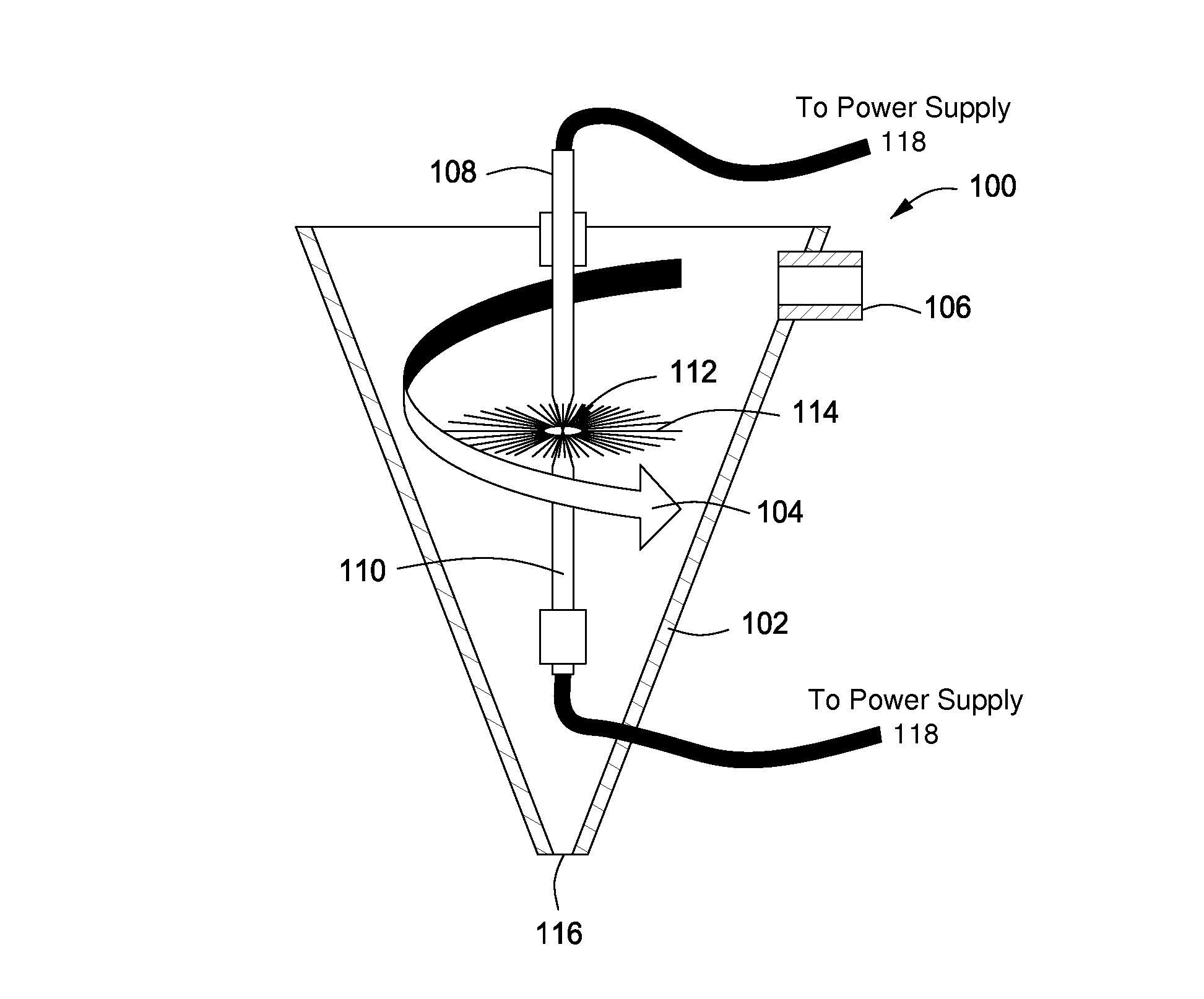

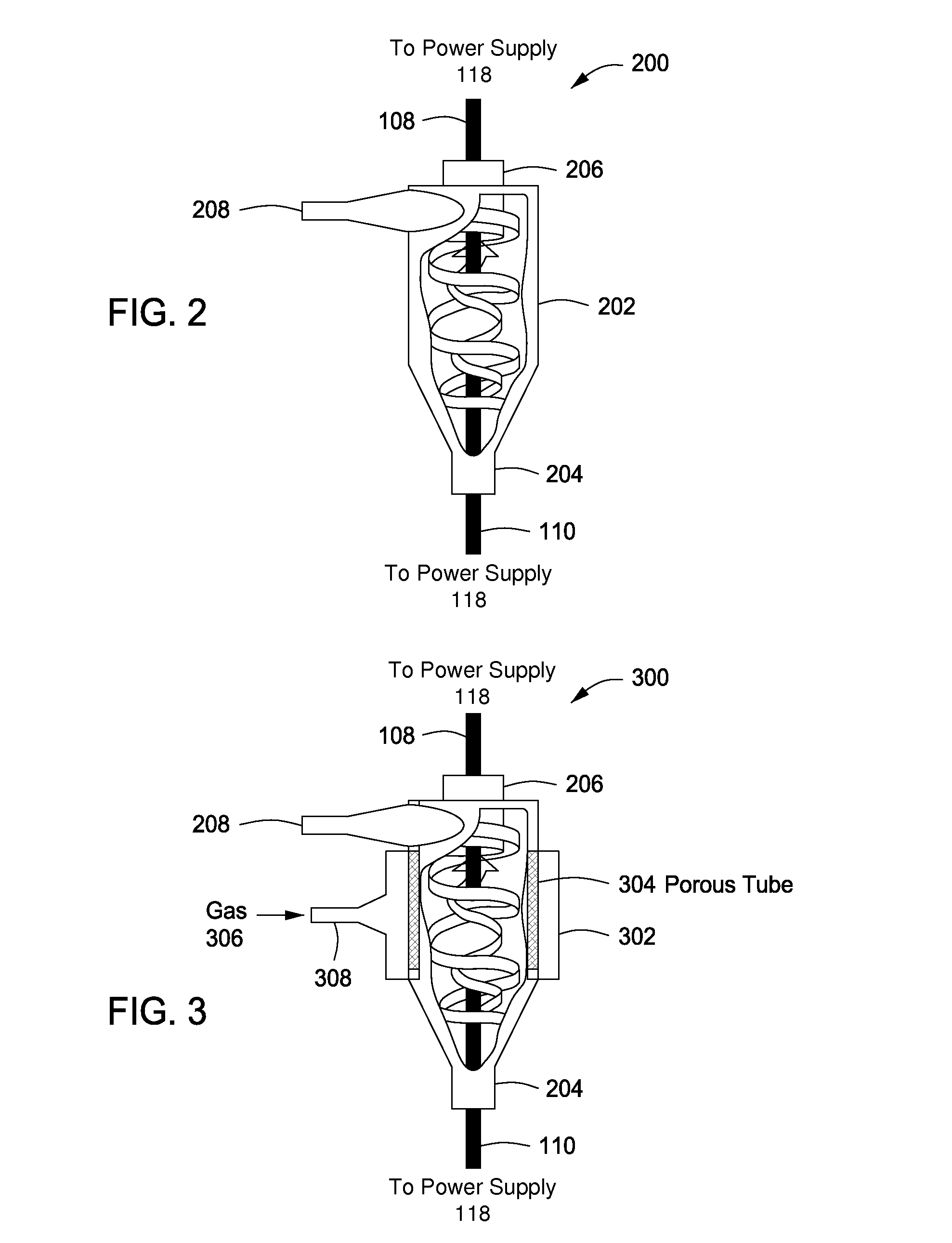

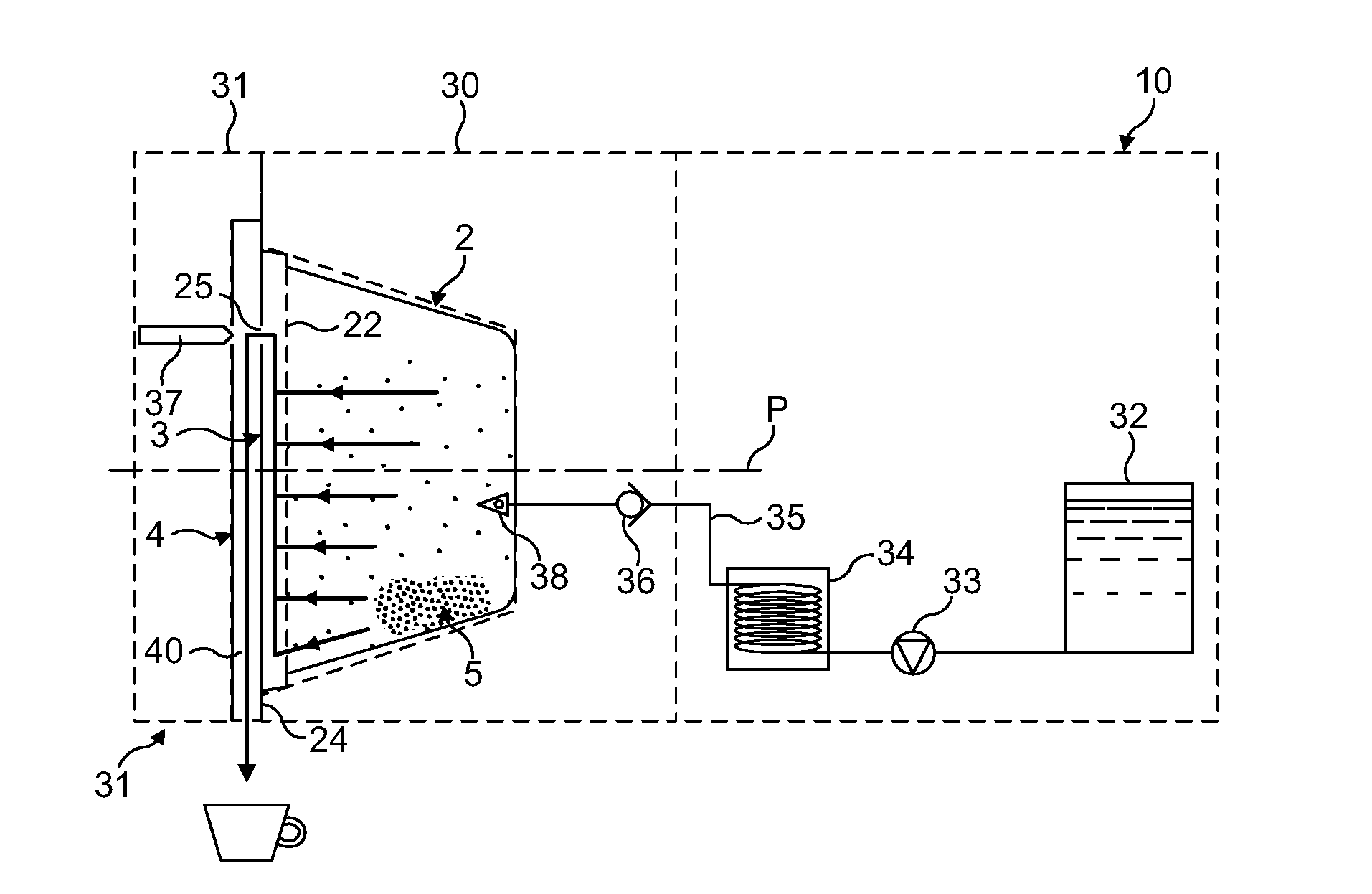

Apparatus for treating liquids with wave energy from an electrical arc

ActiveUS7857972B2Energy efficiencyReduce maintenanceWater distributersWaste water treatment from animal processingEngineeringEnergy source

The present invention provides a system, method and apparatus for treating a liquid by providing a wave energy source and creating a thin film of the liquid whirling around the wave energy source such that one or more wave energies irradiate the liquid. Likewise, the present invention provides a method of treating a liquid by providing three zones of wave energy and passing the liquid through the three zones of wave energy.

Owner:FORET PLASMA LABS

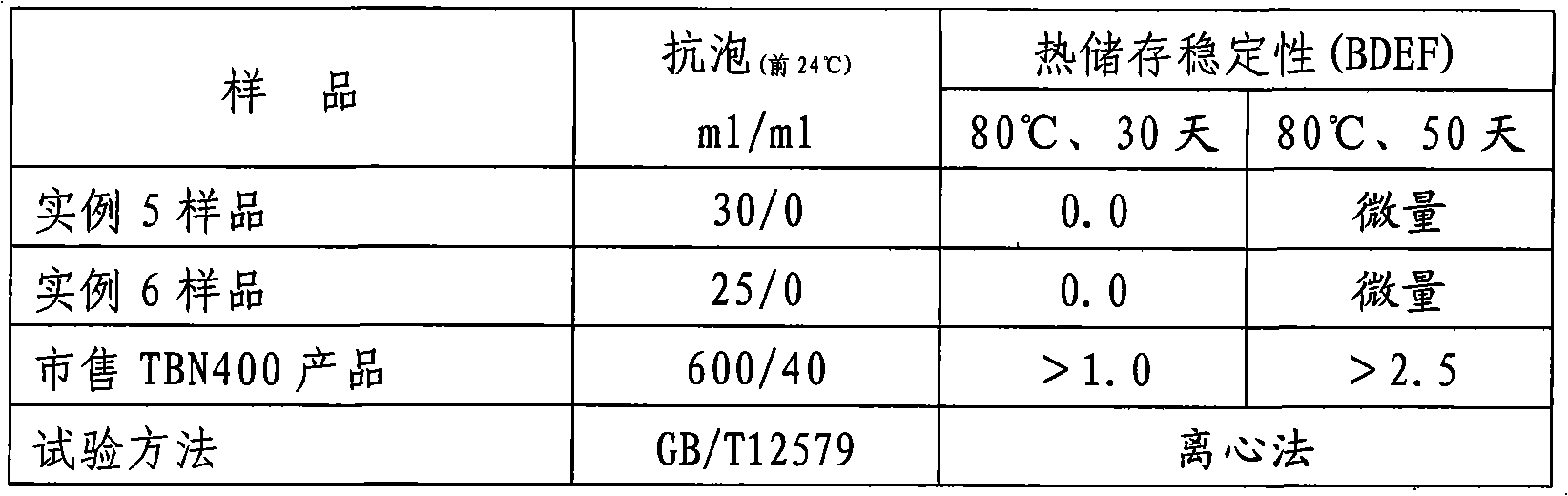

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

Ocular solutions

InactiveUS7083803B2Reduce inflammationReduce bacterial growthBiocideSenses disorderDiseaseEverolimus

Ocular solutions containing at least one macrolide antibiotic and / or mycophenolic acid provide anti-inflammatory, anti-cell proliferation, anti-cell migration, anti-angiogenesis, antimicrobial and antifungal effects. In one embodiment, the solution is administered intraocularly after cataract surgery before insertion of a replacement intraocular lens, resulting in reduced posterior capsular opacification which may eliminate the need for a subsequent surgery. The solution may be one that is invasively administered, for example, an irrigation or volume replacement solution containing at least one macrolide antibiotic such as tacrolimus, sirolimus, everolimus, cyclosporine, and ascomycin, or mycophenolic acid. The solution may be one that is non-invasively or topically administered in the form of drops, ointments, gels, creams, etc. and may include eye lubricants and contact lens solutions. The solution may contain a supratherapeutic concentration of agent(s) so that a therapeutic concentration of a topically administered solution accumulates in a diseased ocular structure sufficient to treat the disease.

Owner:PEYMAN GHOLAM A DR

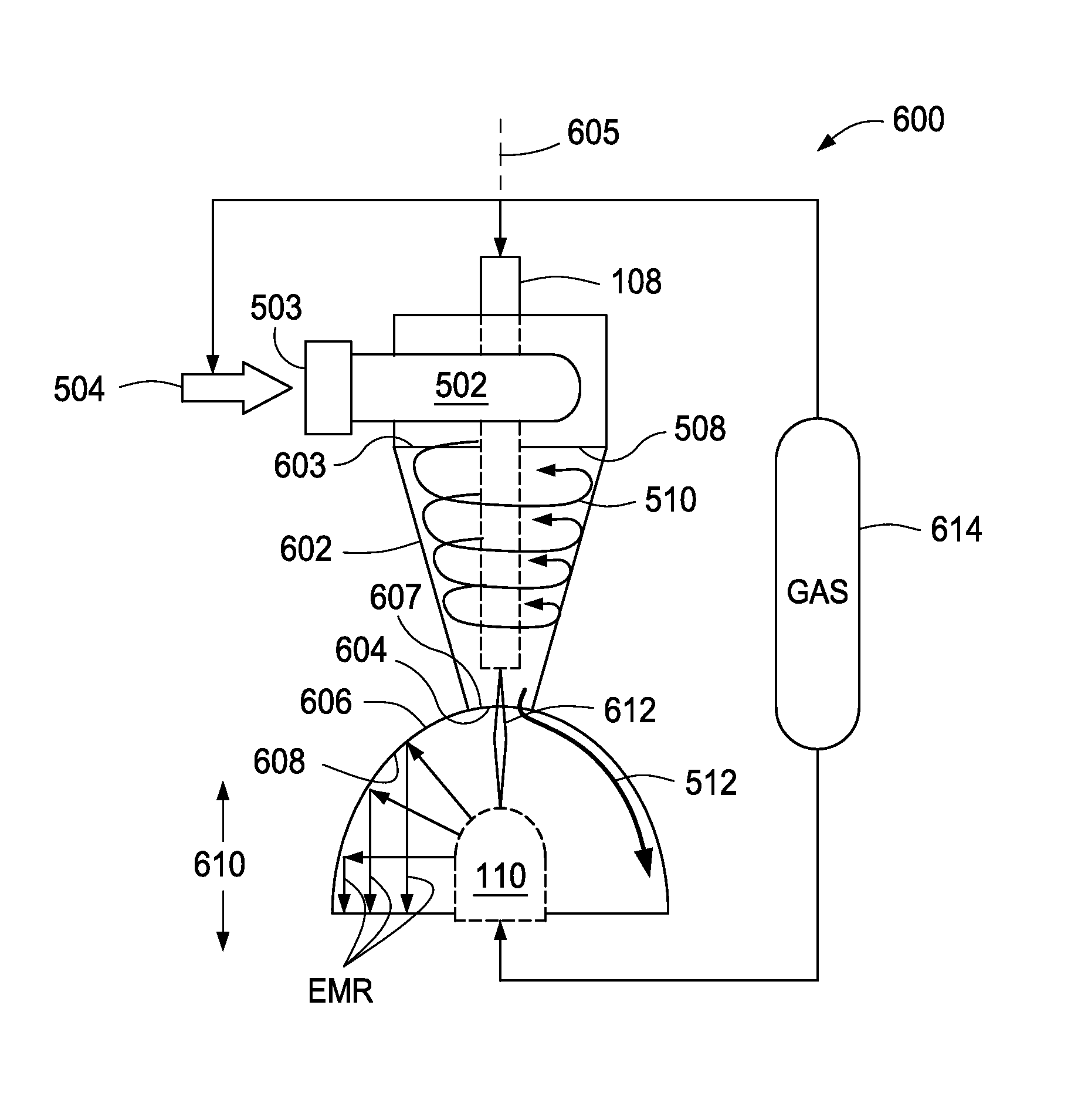

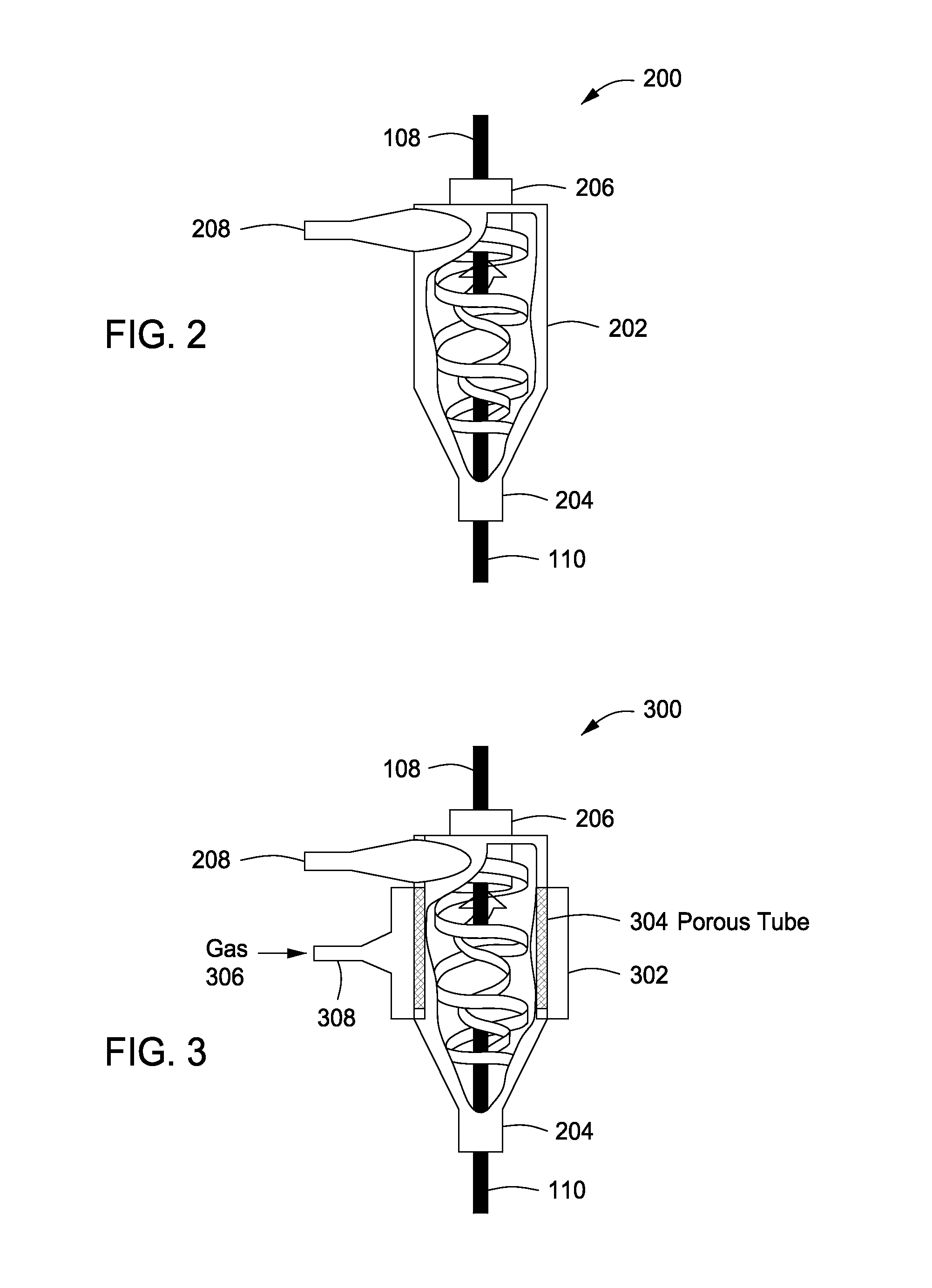

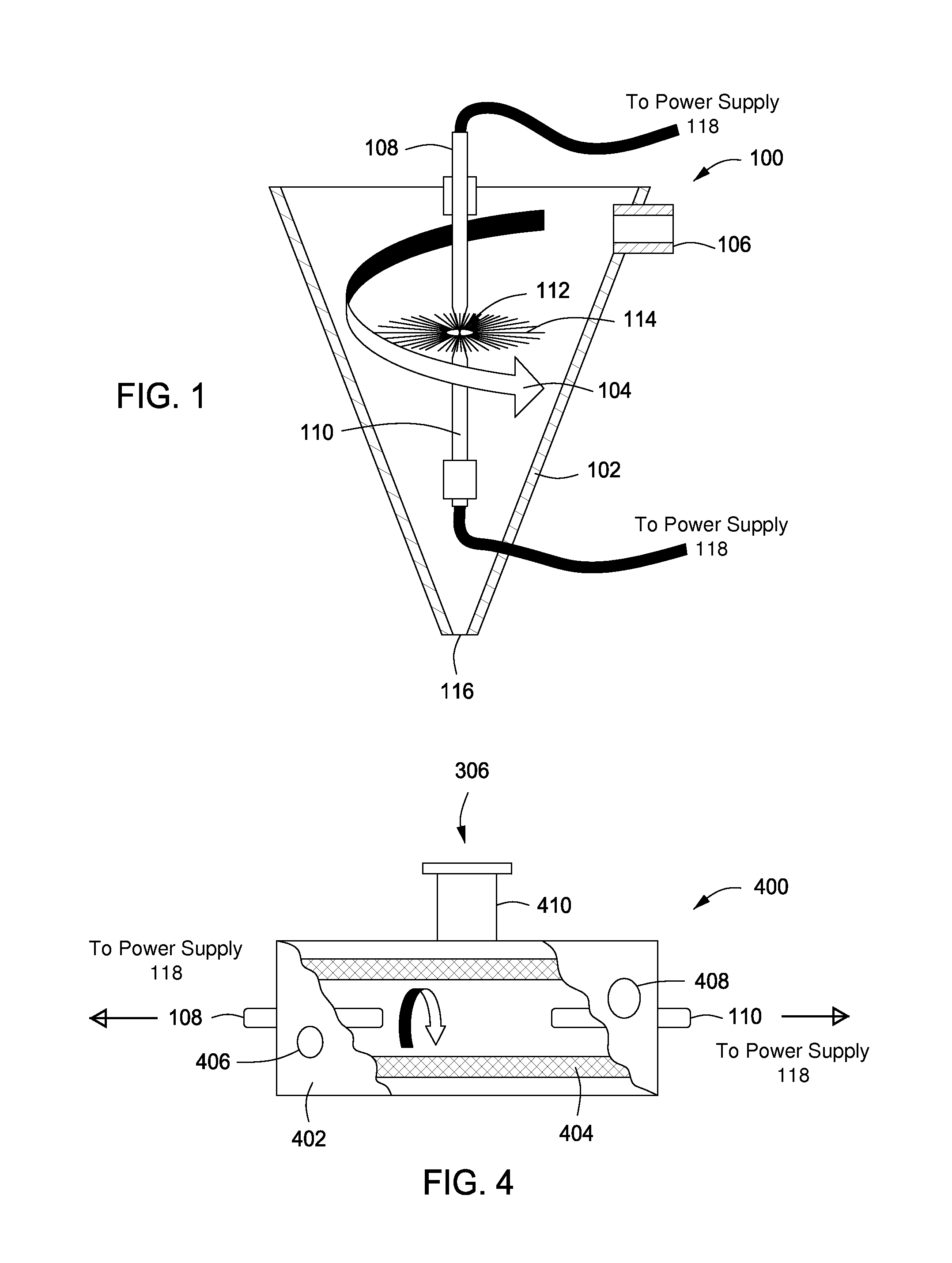

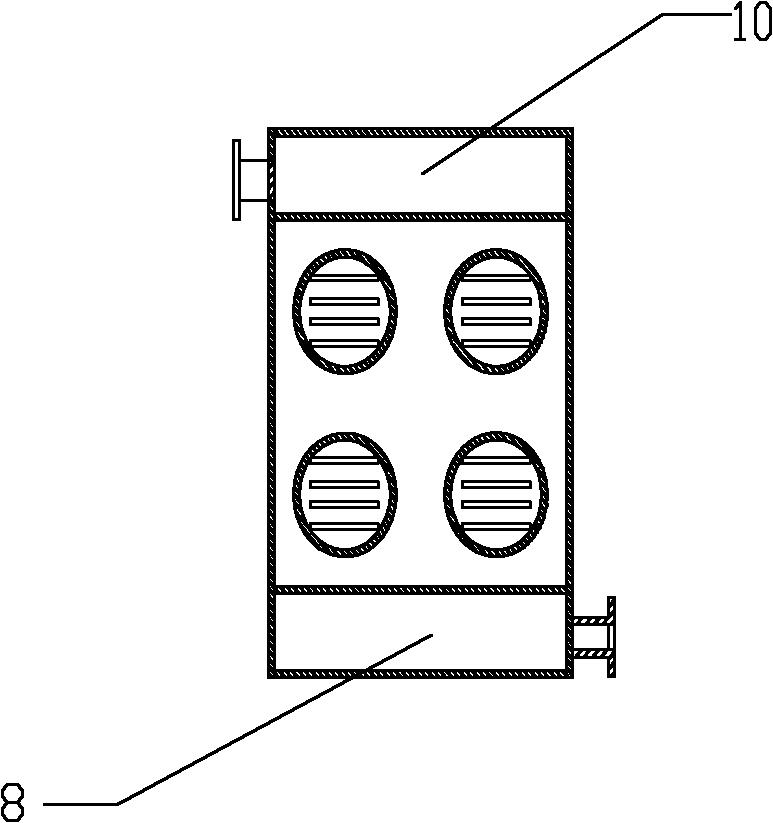

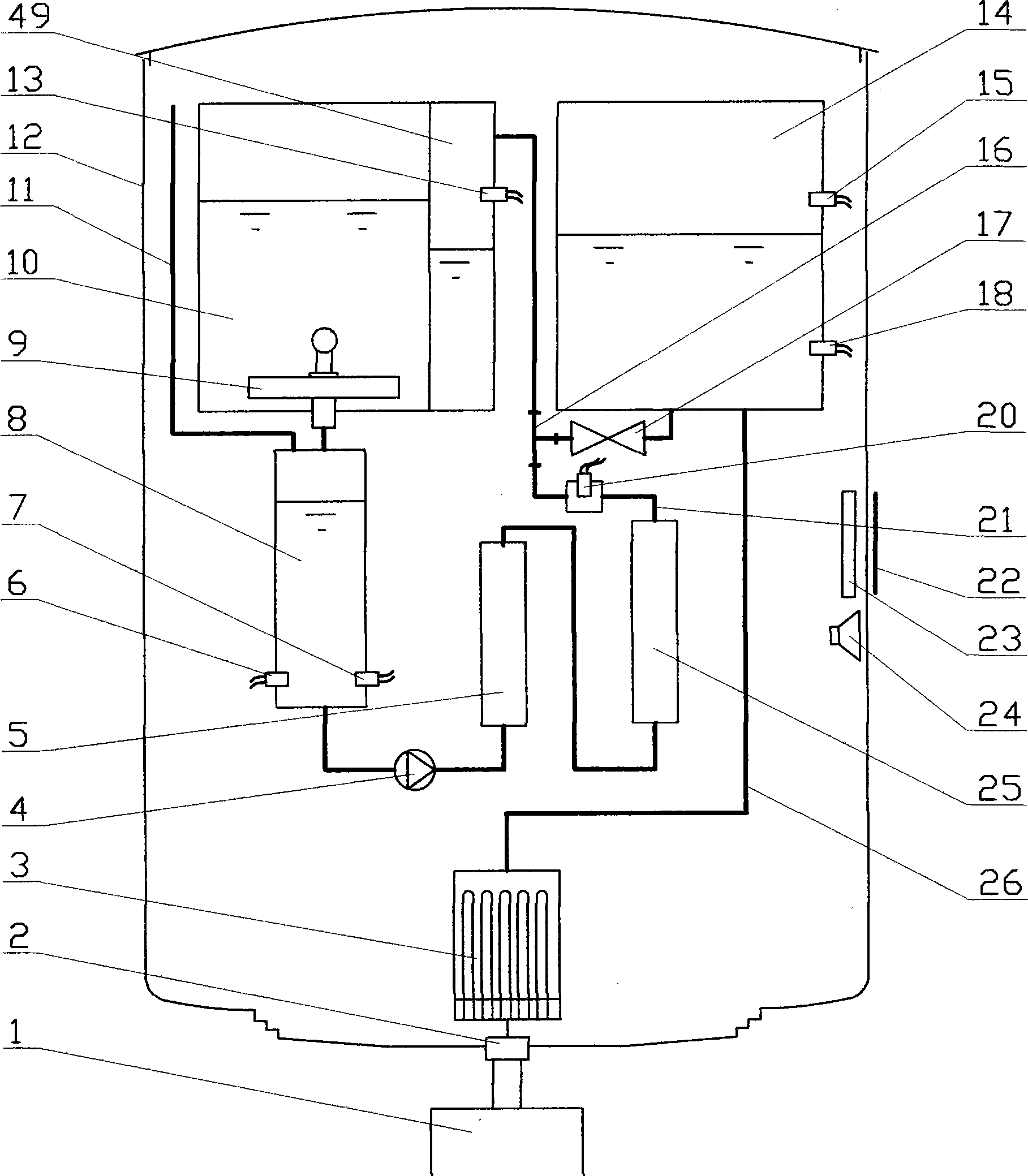

System for treating a substance with wave energy from an electrical arc and a second source

InactiveUS20110303532A1Energy efficiencyReduce maintenanceGeneral water supply conservationPaint waste treatmentSubstance useEngineering

A system for treating a substance using a storage vessel and two or more devices disposed in a top of the storage vessel. Each device has: (a) a volute or cyclone head, (b) a throat connected to the volute or cyclone head, (c) a parabolic reflector connected to the throat, (d) a first wave energy source comprising a first electrode within the volute or cyclone head that extends through the outlet into the opening of the throat along the central axis, and a second electrode extending into the parabolic reflector and spaced apart and axially aligned with first electrode, and (e) a second wave energy source disposed inside the throat, embedded within the throat or disposed around the throat. The substance is supplied to the inlet of the volute or cyclone head and is irradiated with one or more wave energies produced by the first and second wave energy sources.

Owner:FORET PLASMA LABS

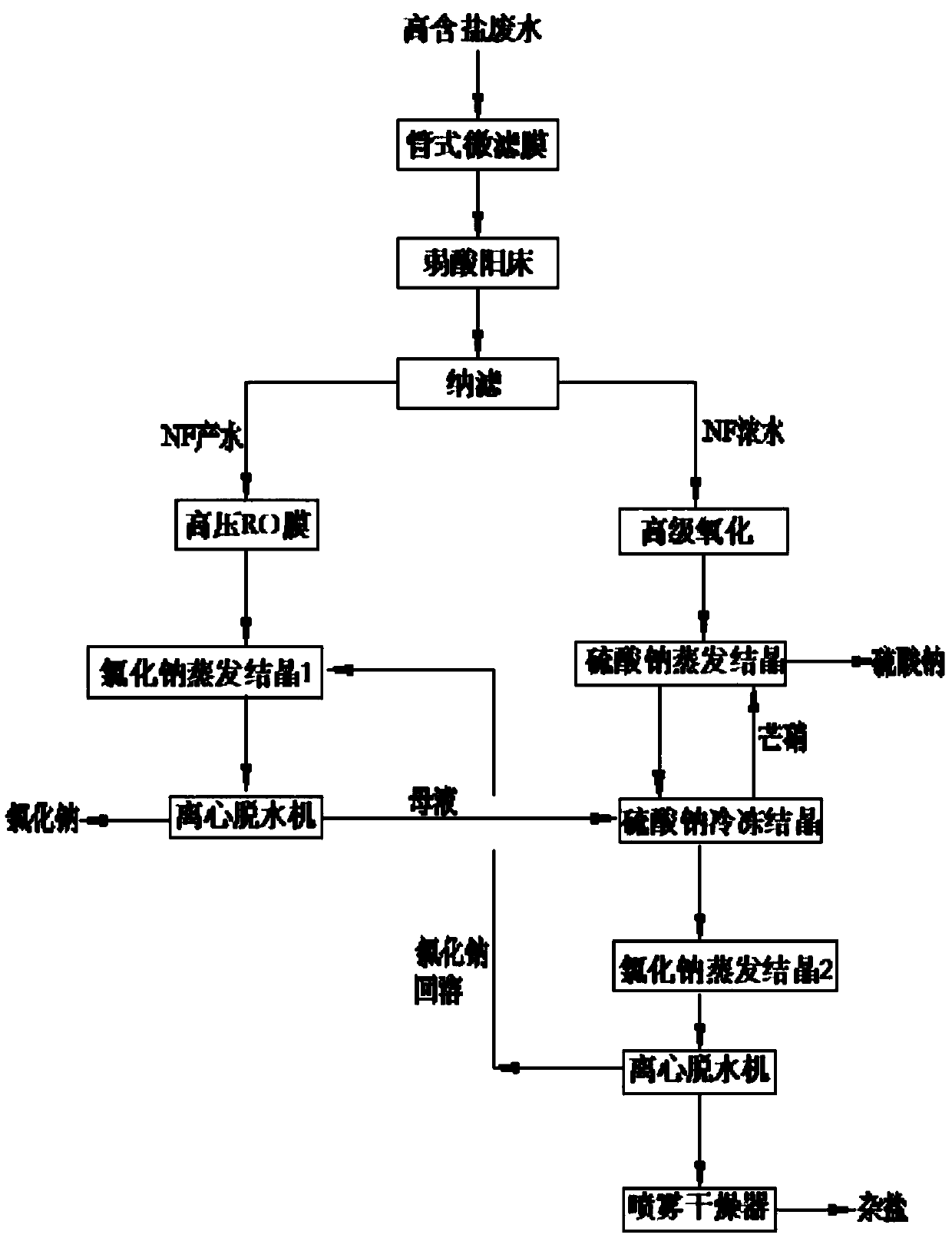

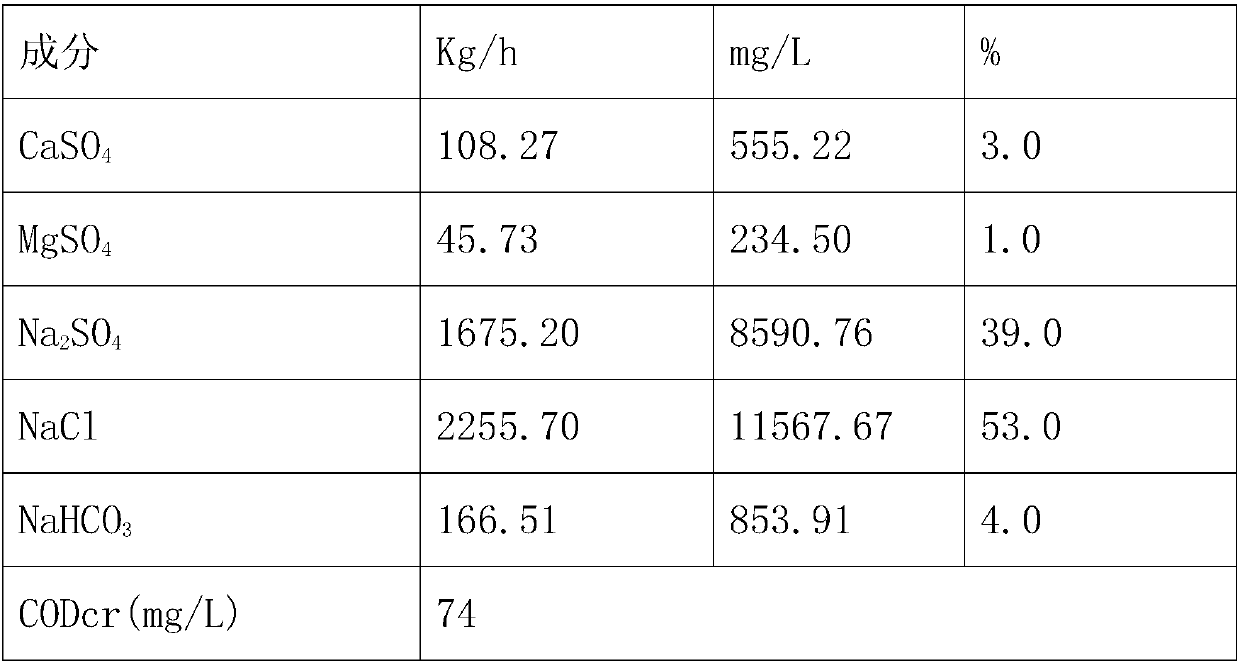

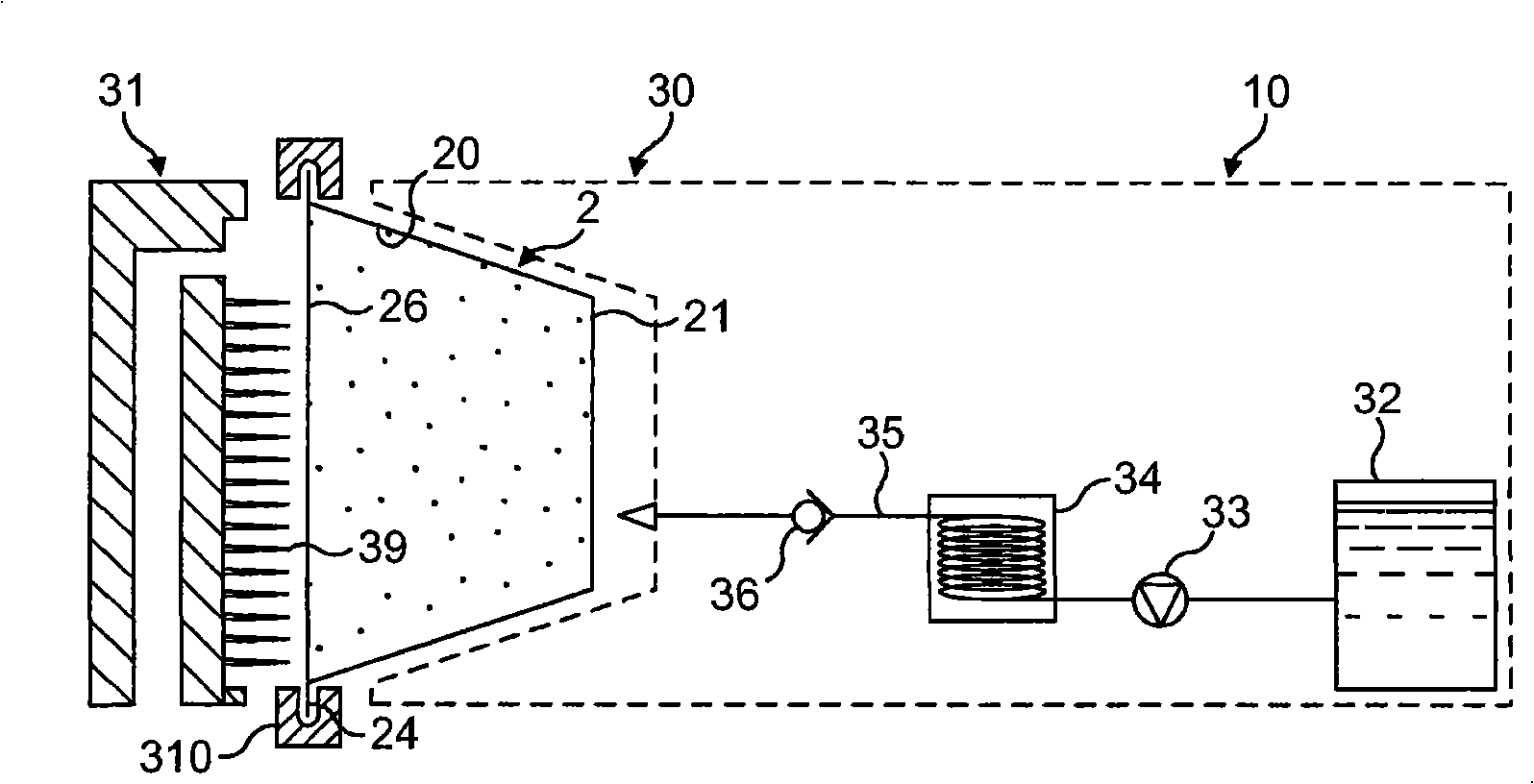

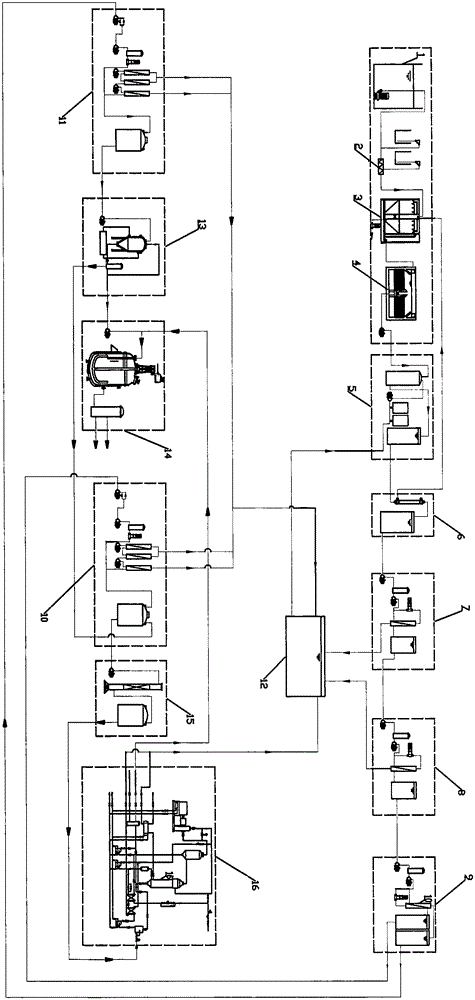

Resource technology and system for separating salt from high-salinity wastewater

InactiveCN107619144ASolve the problem of pipe blockageReduce energy consumptionMultistage water/sewage treatmentAlkali metal chloridesMirabiliteProduced water

The invention discloses a zero-drainage technology for recycling crystallizing salt from high-salinity wastewater and a treatment system thereof. The treatment system comprises a tubular microfiltration system, a weak acid resin hardness removal system, a nanofiltration membrane salt separating system, a nanofiltration concentrated water oxidizing system, a nanofiltration concentrated water sodiumsulfate evaporating and crystallizing system, a sodium sulfate freezing and crystallizing system and the like. The zero-drainage technology has the advantages that the pretreated wastewater is subject to nanofiltration primary salt separating, the salt component in the produced water is mainly sodium chloride, the sodium chloride with purity no lower than 98.5% is obtained by membrane concentration, evaporating and crystallizing, and the sodium sulfate with purity 99.1% or more is produced by MVR (mechanical vapor recompression) crystallizing after concentrated water oxidizing; a mother liquid after evaporating and crystallizing of sodium sulfate and a mother liquid after nanofiltration evaporating and crystallizing are mixed and frozen, so as to obtain mirabilite, and the mirabilite is converted into anhydrous sodium sulfate after sodium sulfate evaporating and crystallizing; at the premises of ensuring quality, the whole recycling rate of salt reaches 90% or above; finally, a smallamount of mother liquid is sprayed, dried and cured, and the zero-drainage effect of wastewater is realized.

Owner:侯新春 +1

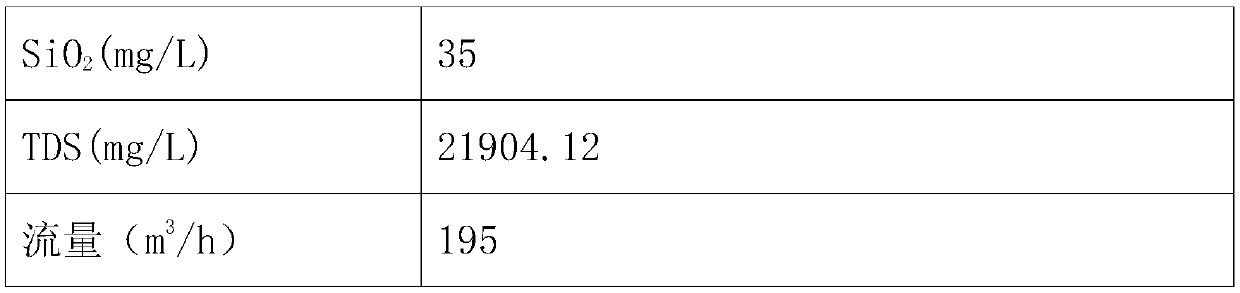

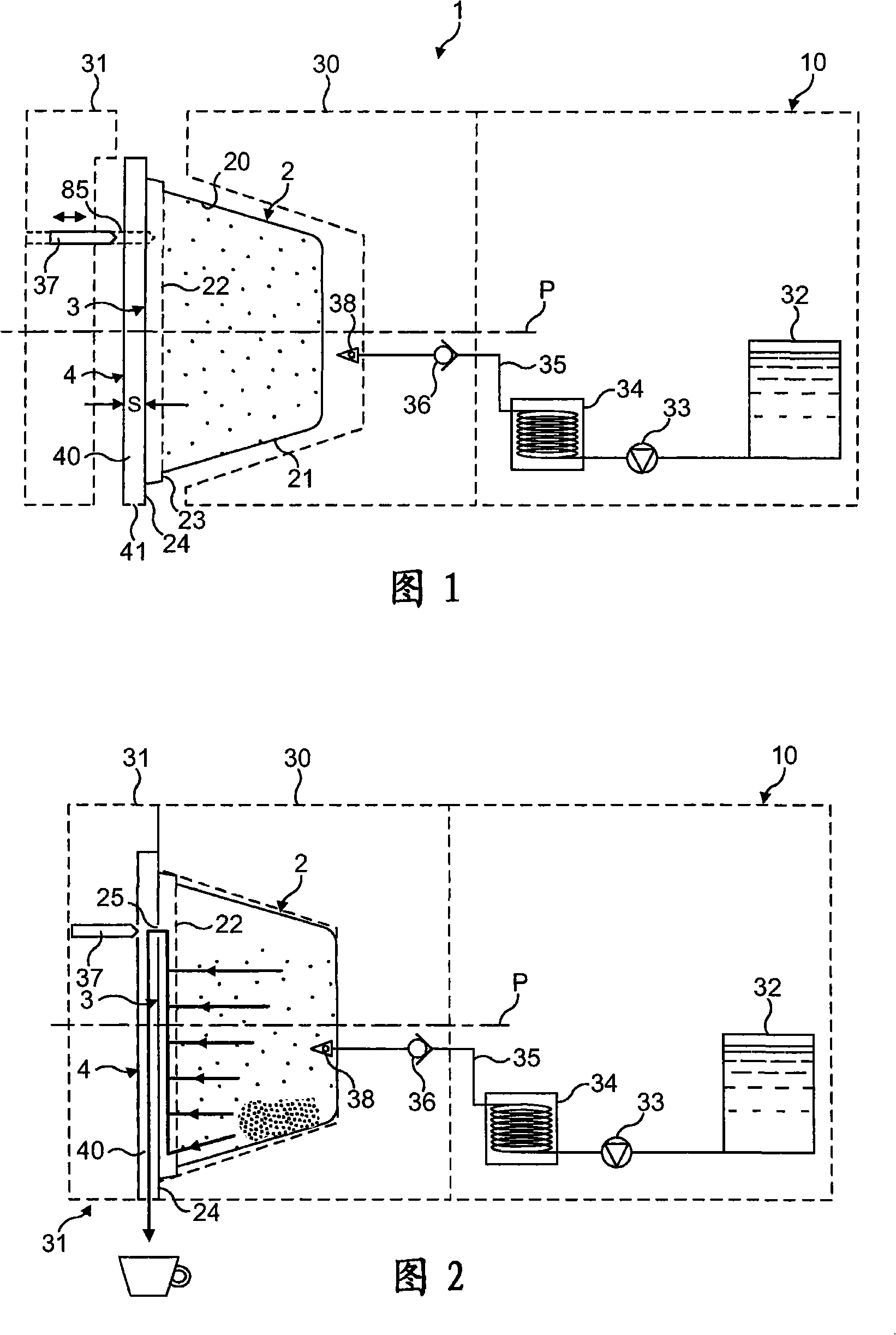

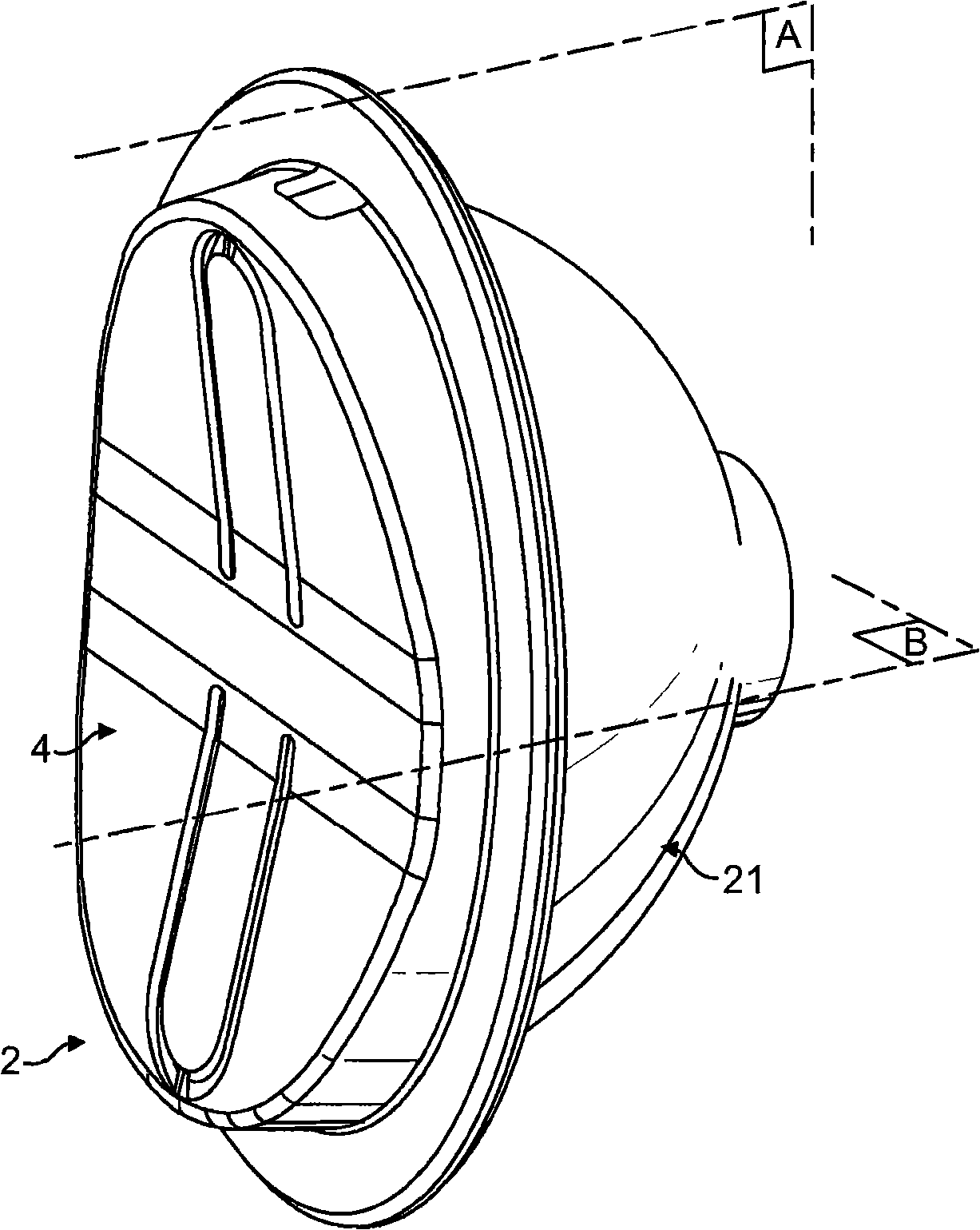

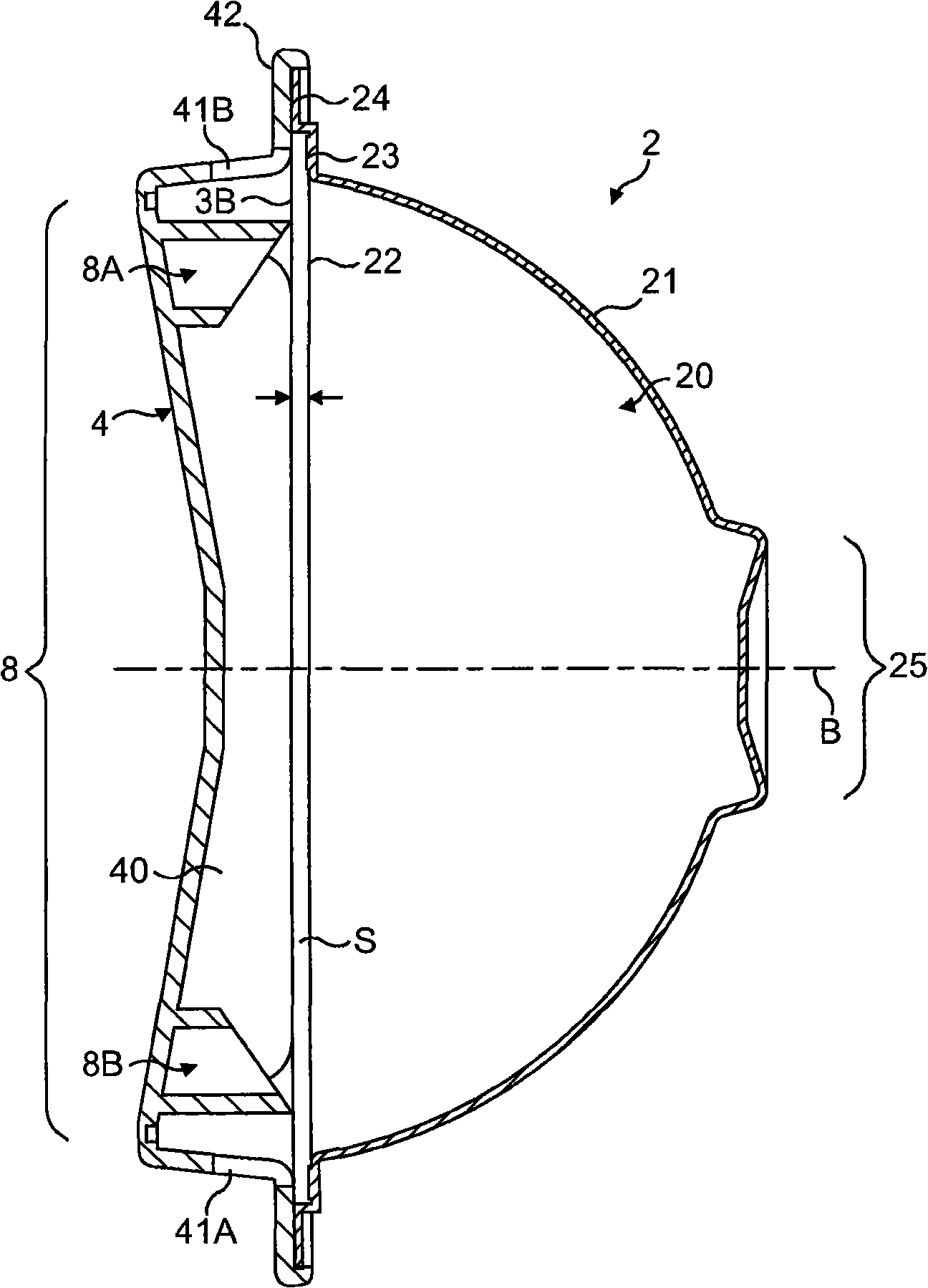

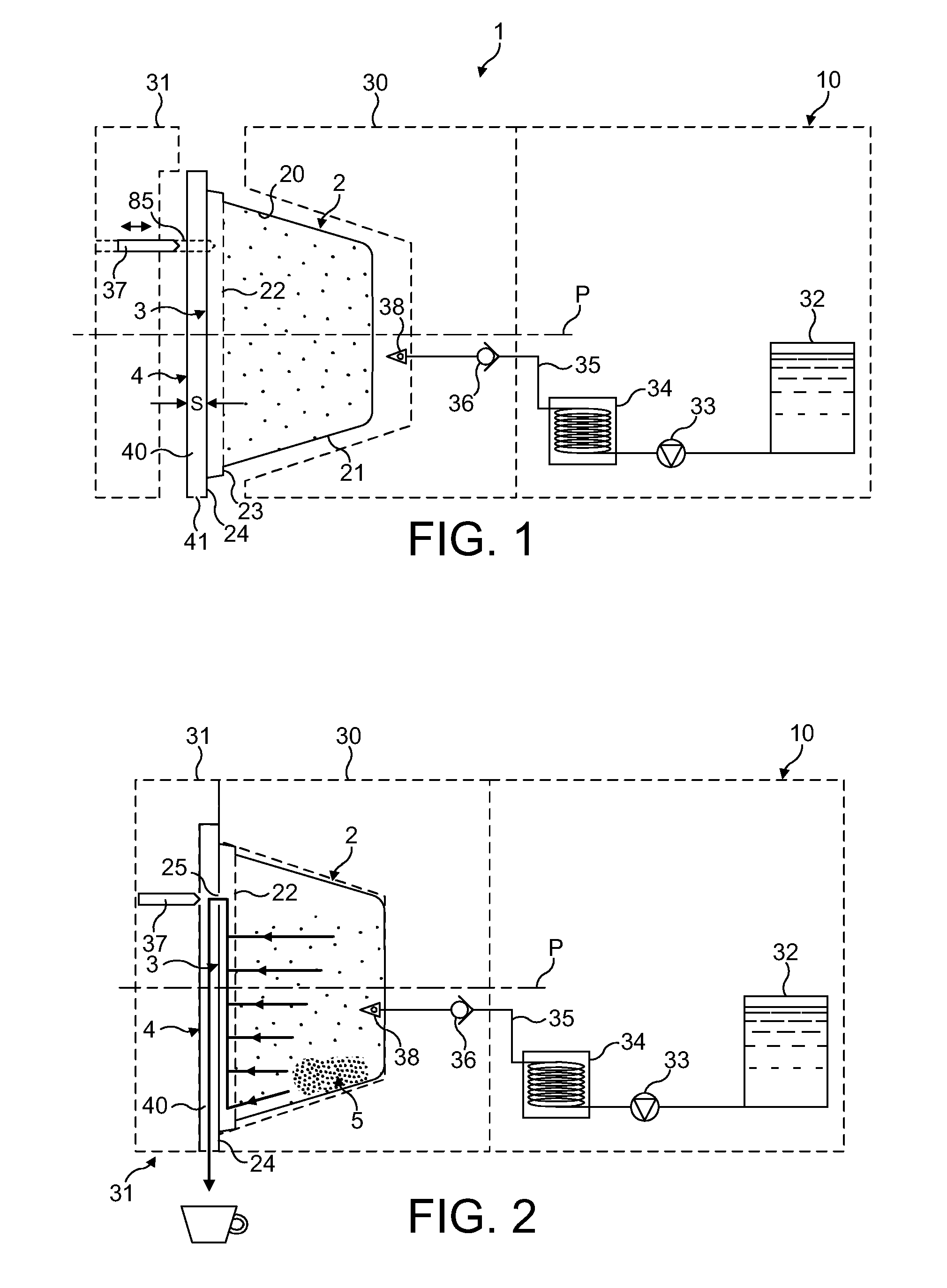

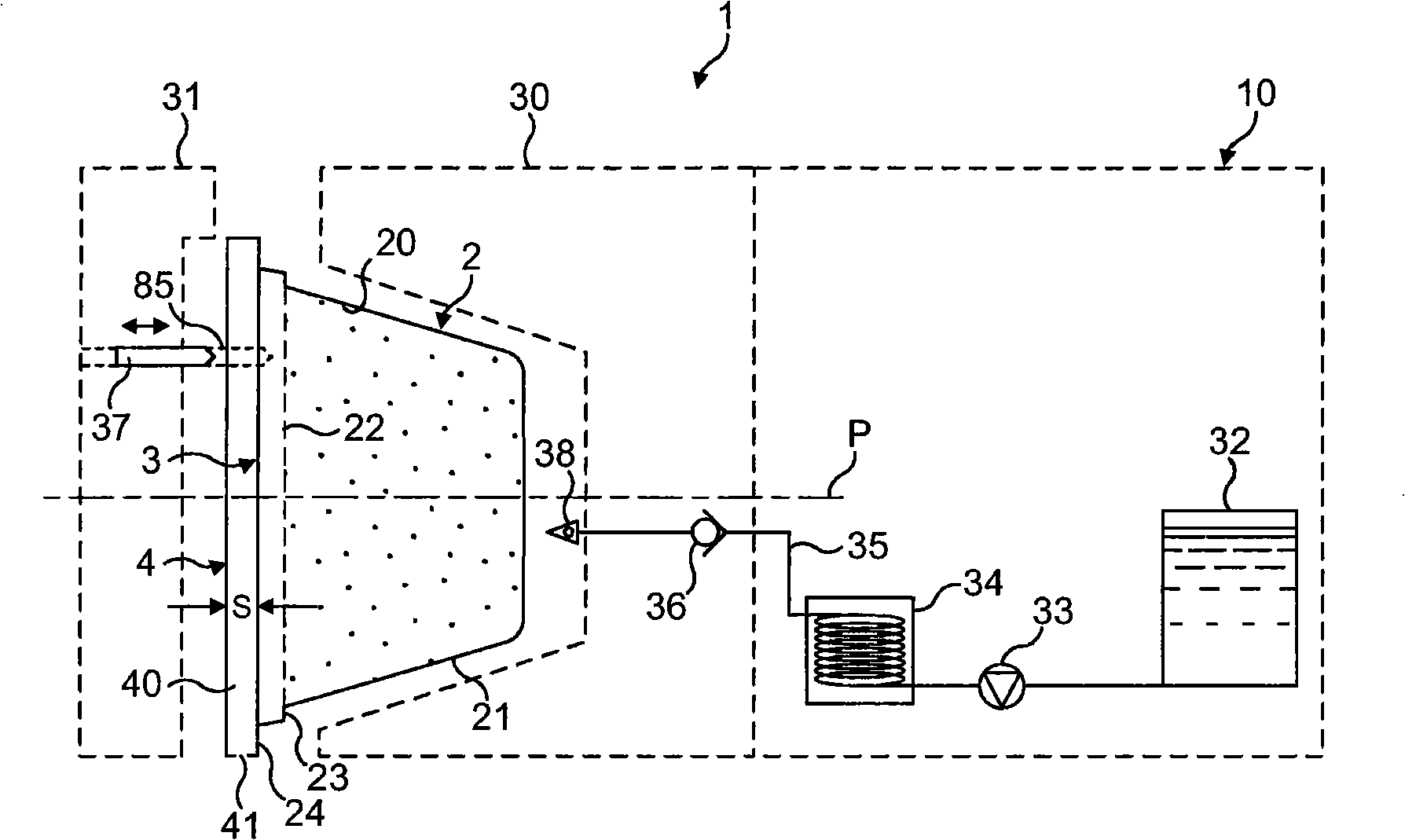

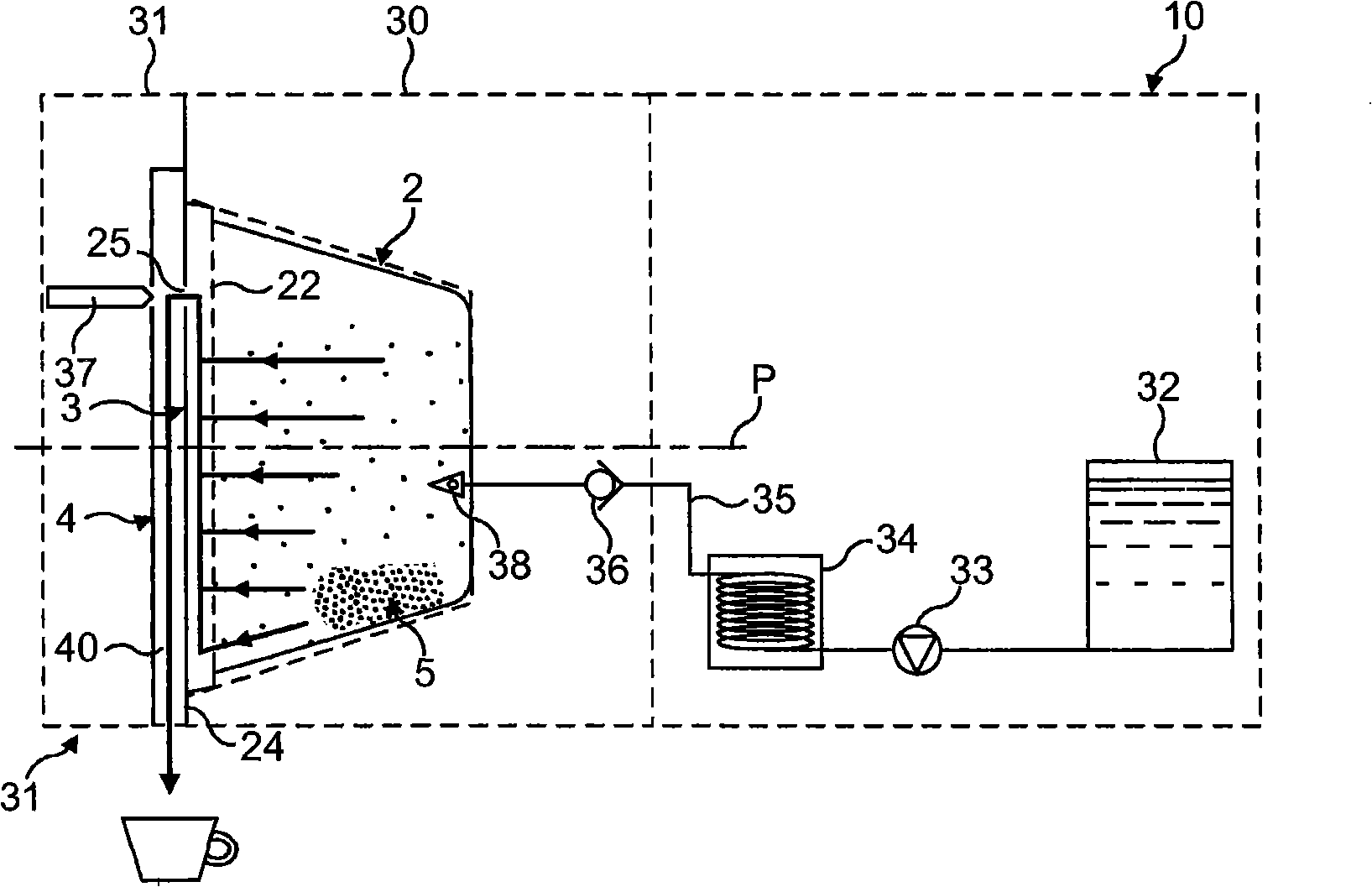

Capsule for the preparation of a beverage

ActiveCN101309840AImprove qualityReduce turbidityBeverage vesselsPackagingAdditive ingredientBiomedical engineering

Capsule for the preparation of a beverage in a beverage machine comprising an enclosure (20) containing one or more beverage ingredients, a filtering wall (22) delimiting at least one filtering side of the enclosure, wherein the capsule further comprises an overflow wall (3B) that is positioned in the path of the brewed liquid after the filtering wall and which comprises at least one overflow aperture or is associated with at least one puncture means (8A, 8B) or, respectively, puncture indication means capable of producing or, respectively, indicating at least one overflow aperture. The capsule of the invention is designed for delivering a brewed liquid at relatively low pressure and is more particularly suited for tea beverages.

Owner:SOC DES PROD NESTLE SA

Antimicrobial Compositions And Methods Of Use Thereof

ActiveUS20090192231A1Reduce discolorationReduce turbidityBiocideDead plant preservationBiotechnologyActive agent

The invention provides antimicrobial compositions comprising one or more acid and one or more organic diol. In one embodiment, the invention's compositions have an acidic pH. The compositions may optionally further contain one or more oxidizing agent (including stabilized oxidizing agent and / or unstabilized oxidizing agent), and / or one or more surfactant. In particular embodiments, the acid lacks one or both of —NH group and —NH2 group. The invention's compositions are useful in all stages of handling agricultural products, in hospitals, and in commercial and household applications.

Owner:SMARTWASH SOLUTIONS

Method for preparing a beverage from a capsule

ActiveUS8039034B2Quality improvementGreat tasteTea substituesTea alkaloid content reductionAdditive ingredientEngineering

A method for preparing a beverage through a capsule (2) inserted in a beverage machine; the capsule comprising an enclosure (20) containing one or more beverage ingredients, wherein a brewing fluid is introduced in the enclosure to brew the said one or more beverage ingredients, wherein a brewed liquid is filtered by a filtering wall (22) and delivered from the capsule, wherein the filtering wall extends from substantially the bottom of the enclosure and said filtering wall is associated to an overflow wall (3) that forces the brewed liquid to traverse at least one overflow aperture (25). The method is particularly suitable for brewing a tea containing capsule.

Owner:SOC DES PROD NESTLE SA

Ocular solutions

InactiveUS20060228394A1Reduce inflammationReduce bacterial growthAntibacterial agentsBiocideEverolimusOcular structure

Ocular solutions containing at least one macrolide antibiotic and / or mycophenolic acid provide anti-inflammatory, anti-cell proliferation, anti-cell migration, anti-angiogenesis, antimicrobial, and antifungal effects. In one embodiment, the solution is administered intraocularly after cataract surgery before insertion of a replacement intraocular lens, resulting in reduced posterior capsular opacification which may eliminate the need for a subsequent surgery. The solution may be one that is invasively administered, for example, an irrigation or volume replacement solution containing at least one macrolide antibiotic such as tacrolimus, sirolimus, everolimus, cyclosporine, and ascomycin, or mycophenolic acid. The solution may be one that is non-invasively or topically administered in the form of drops, ointments, gels, creams, etc. and may include eye lubricants and contact lens solutions. The solution may contain a supratherapeutic concentration of agent(s) so that a therapeutic concentration of a topically administered solution accumulates in a diseased ocular structure sufficient to treat the disease. The agent(s) may be formulated with polymers or other components for extended or slow release to provide a substantially constant concentration over the course of treatment.

Owner:MINU

Ocular solutions

InactiveUS7087237B2Reduce inflammationReduce bacterial growthAntibacterial agentsBiocideEverolimusMacrolide resistance

Containing at least one macrolide antibiotic and / or mycophenolic acid provide anti-inflammatory, anti-cell proliferation, anti-cell migration, anti-angiogenesis, antimicrobial, and antifungal effects. In one embodiment, the solution is administered intraocularly after cataract surgery before insertion of a replacement intraocular lens, resulting in reduced posterior capsular opacification which may eliminate the need for a subsequent surgery. The solution may be one that is invasively administered, for example, an irrigation or volume replacement solution containing at least one macrolide antibiotic such as tacrolimus, sirolimus, everolimus, cyclosporine, and ascomycin, or mycophenolic acid. The solution may be one that is non-invasively or topically administered in the form of drops, ointments, gels, creams, etc. and may include eye lubricants and contact lens solutions.

Owner:PEYMAN GHOLAM A DR

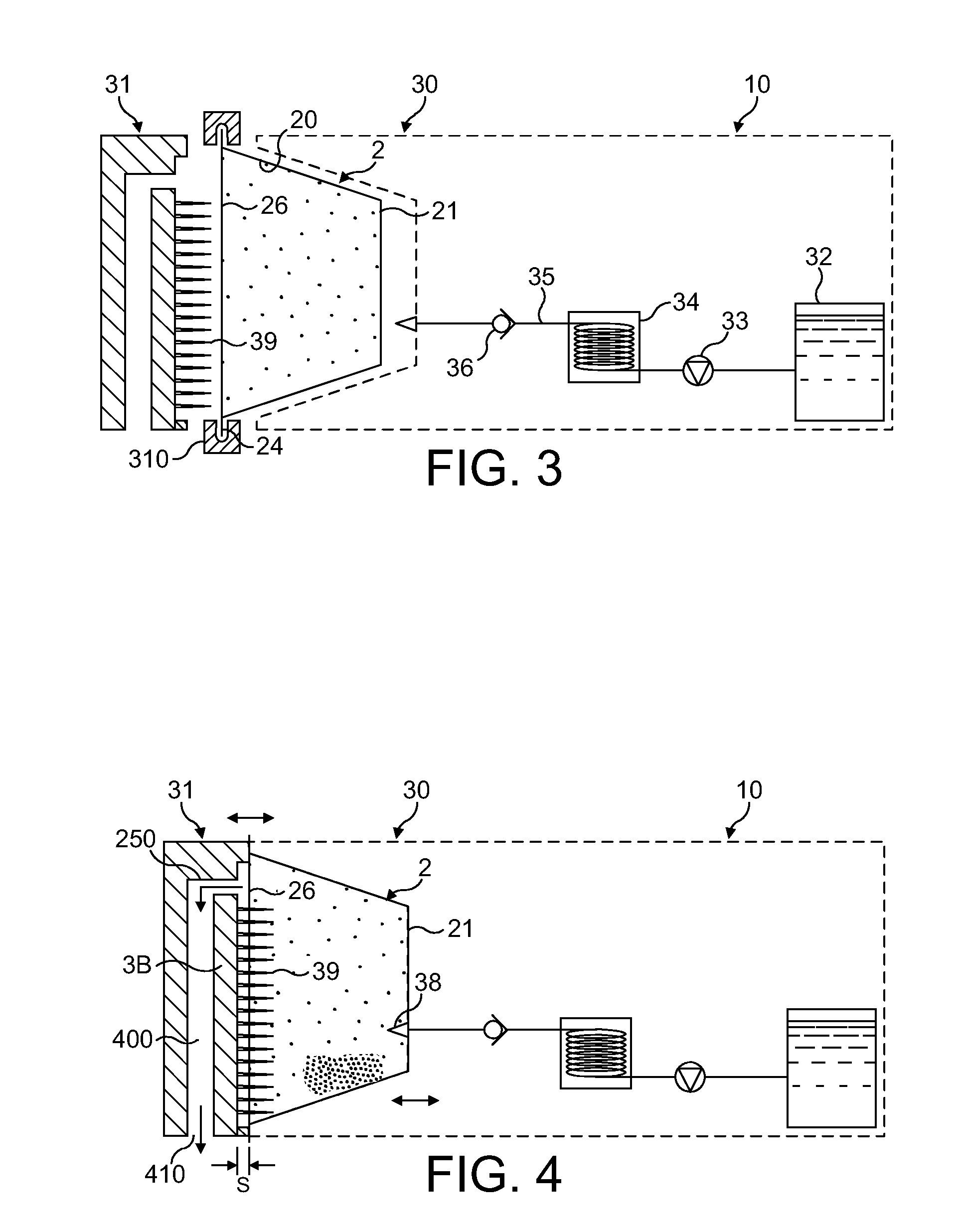

Flocculating agent for waste water treatment, and preparation method thereof

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

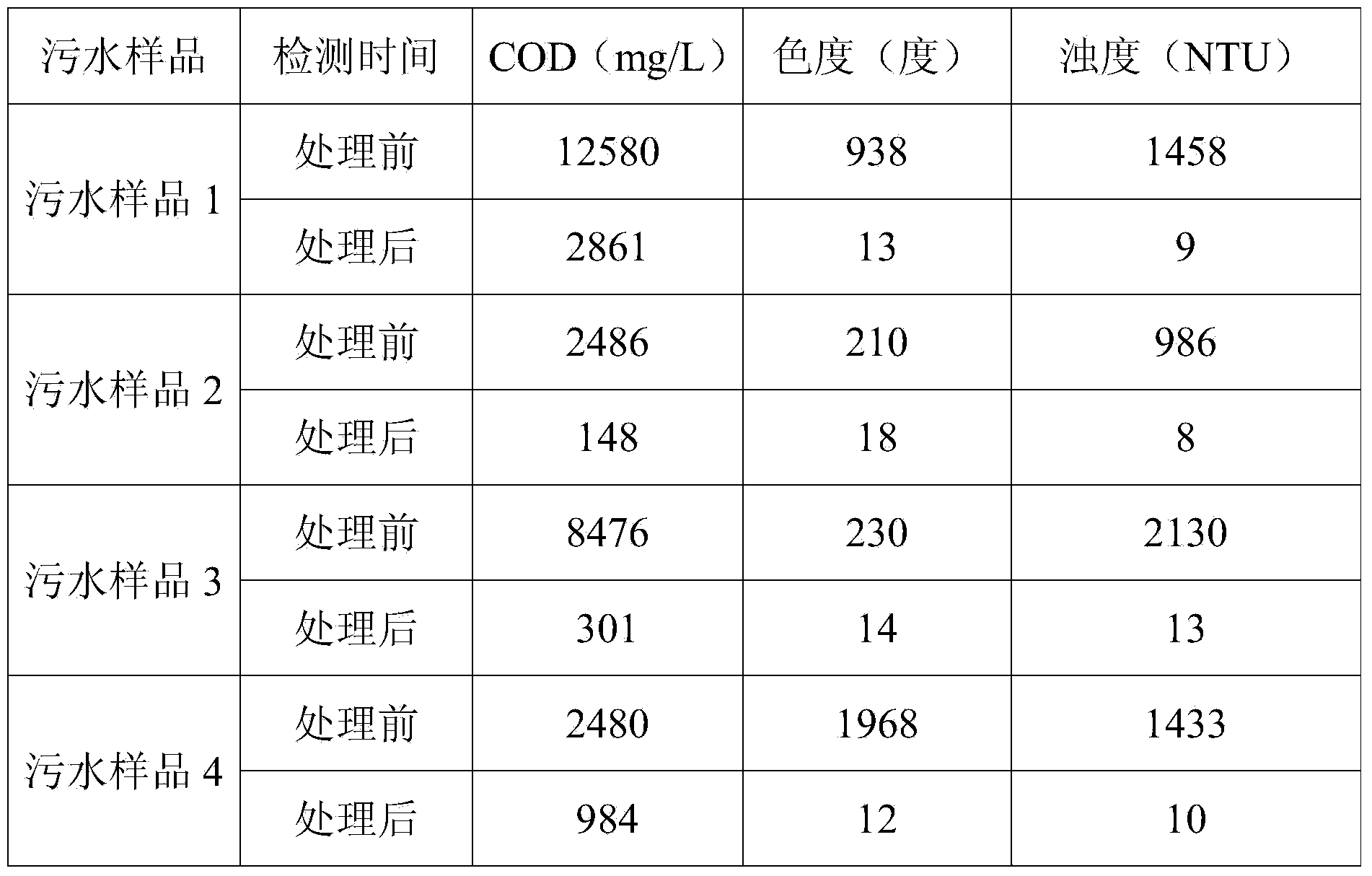

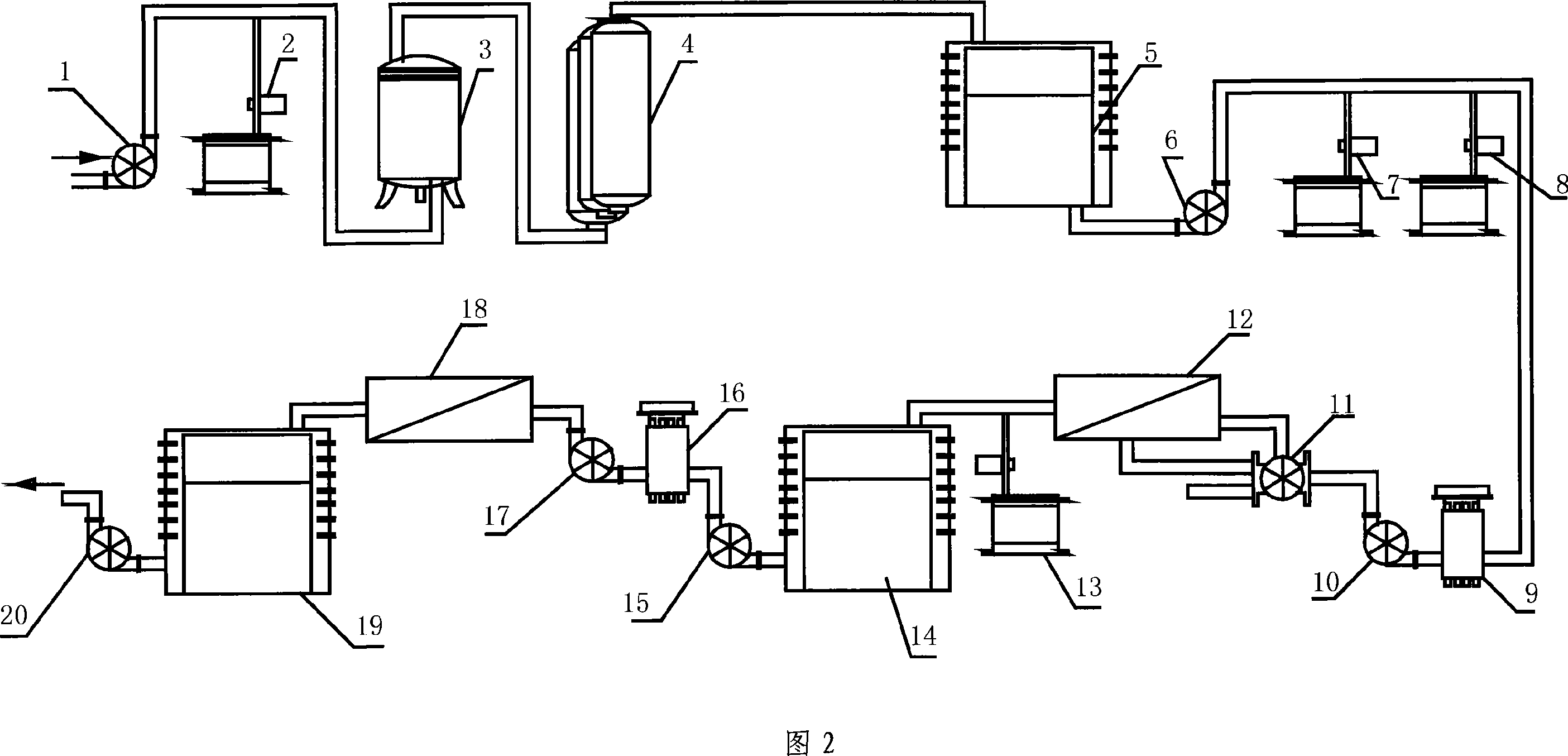

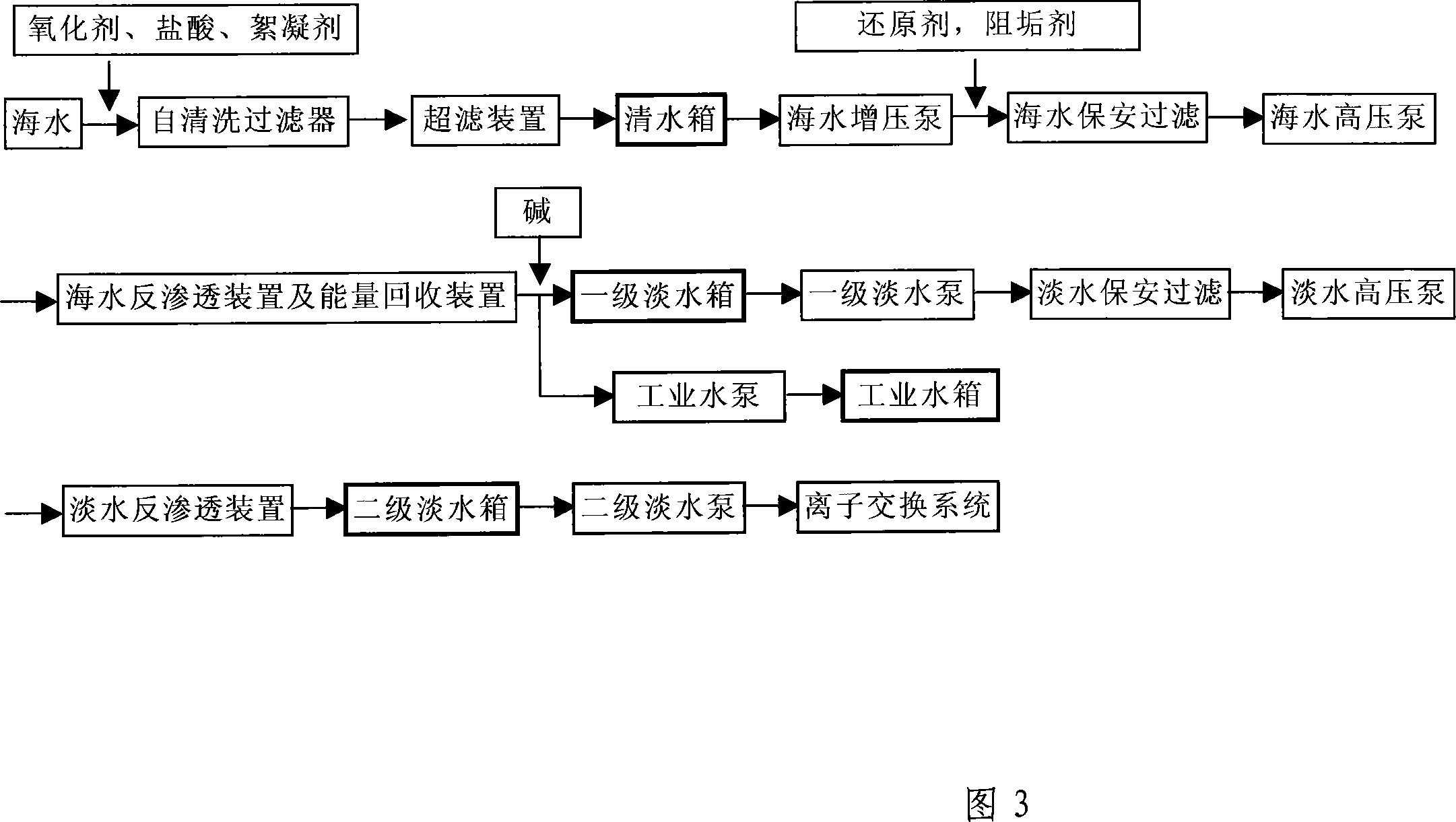

Membrane integration process for desalinizing sea water

InactiveCN101058470AImprove protectionAvoid harmGeneral water supply conservationSeawater treatmentWater desalinationSeawater reverse osmosis

The invention discloses a seawater desalinating technique through film integrated method, which comprises the following steps: passing the seawater through self-rinsing filter; predisposing the rinsed seaward into hyperfilter device; boosting the seawater through the boost pump; removing possible micro-particle in the inlet water of counter-osmosis system of the seawater through seawater safety filter; elevating the inlet pressure of the counter-osmosis system of the seawater; desalinating through counter-osmosis system of the seawater; removing micro-particle in the inlet water of counter-osmosis system of the fresh water through fresh water safety filter; elevating the inlet pressure of the counter-osmosis system of the fresh water; desalinating through counter-osmosis system of the fresh water. The invention reduces the adding quantity of the chemicals and rinsing times of reverse osmosis membrane effectively, which improves automatic degree with stable property and small equipment occupying area.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Method for preparing a beverage from a capsule

ActiveCN101309621AQuality improvementGreat tasteBeverage vesselsPackagingAdditive ingredientEngineering

A method for preparing a beverage through a capsule (2) inserted in a beverage machine; the capsule comprising an enclosure (20) containing one or more beverage ingredients, wherein a brewing fluid is introduced in the enclosure to brew the said one or more beverage ingredients, wherein a brewed liquid is filtered by a filtering wall (22) and delivered from the capsule, wherein the filtering wall extends from substantially the bottom of the enclosure and said filtering wall is associated to an overflow wall (3) that forces the brewed liquid to traverse at least one overflow aperture (25). The method is particularly suitable for brewing a tea containing capsule.

Owner:SOC DES PROD NESTLE SA

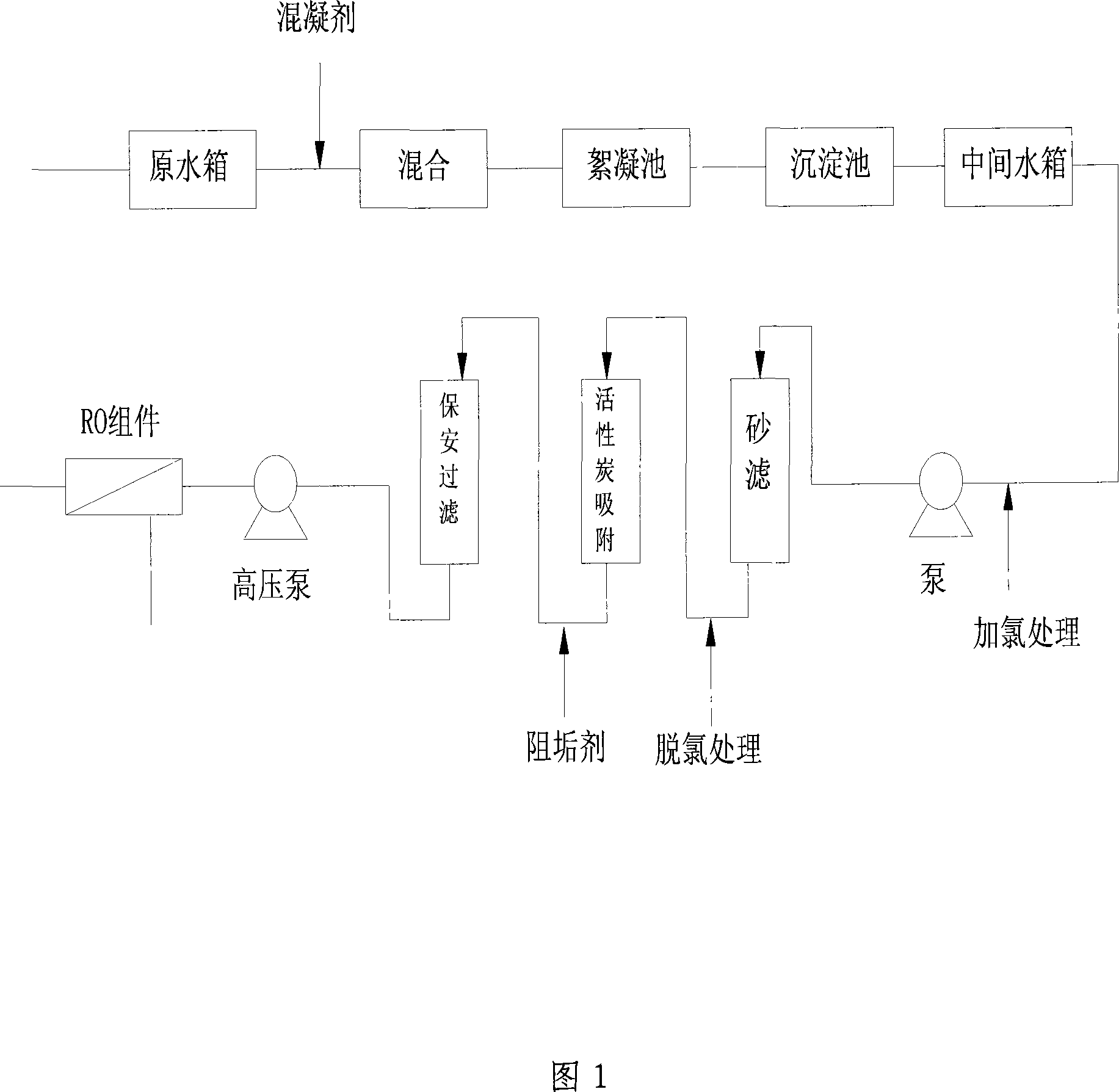

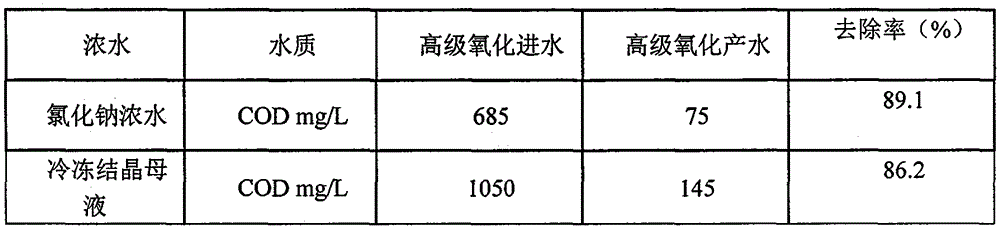

System for preparing potassium sulfate from high-salt-content industrial wastewater and technology of system

ActiveCN105645439AReduce turbidityReduce retentionTreatment involving filtrationWater/sewage treatment by ion-exchangeUltrafiltrationMirabilite

The invention relates to a system for preparing potassium sulfate from high-salt-content industrial wastewater and belongs to the field of water treatment. The high-salt-content industrial wastewater is pretreated through a regulating pool, a pipeline mixer, a high-density precipitate pool, a V-type filter pool, ion exchange resin and an ultrafiltration membrane system and then concentrated through a first section reverse osmosis membrane system and a second section reverse osmosis membrane system and then enters a nanofiltration membrane system for salt separation, nanofiltration produced water and thick water enter a plate-pipe type high-pressure flat sheet membrane system II and a plate-pipe type high-pressure flat sheet membrane system I respectively to be concentrated again, the concentrated thick water enters a freezing crystallization system for crystallization, crystals enter a potassium sulfate preparing system to be converted, freezing mother liquor and the concentrated nanofiltration produced water enter an advanced oxidizing system for oxidation and then enter an evaporative crystallization system for crystallization, and produced sodium sulfate crystal salt enters a potassium sulfate preparing system for conversion. The system has the advantages that the scale of the nanofiltration system is reduced, and investment cost is reduced; salt separation is thorough, and operation cost is low; the purity of the crystallization salt is high; mirabilite and sodium sulfateare converted into potassium sulfate, and the economic value is improved.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Method and system for washing

ActiveUS20050252255A1Improves bleaching performanceImproved cleaning performanceMaterial nanotechnologyTableware washing/rinsing machine detailsWater softeningElectrolysis

A washing system for use in cleaning or washing a soiled substrate or substrates, the system comprising: a. a washing zone for contacting and washing the soiled substrate with wash liquor; b. a feed supply for providing hot or cold feed water to the washing zone; c. a wash liquor cleanup and recycle zone in fluid communication with the washing zone d. an effluent storage and / or discharge zone; and optionally one or more of e. a product dispensing zone; f. means for sonically or ultrasonically treating the soiled substrate in the washing zone or in a washing pre-treatment zone; g. an electrolysis zone for electrolysing the feed water or wash liquor; h. a wash liquor disinfection zone; and i. a feed water softening zone; The wash liquor cleanup and recycle zone preferably comprises an ultrafiltration or microfiltration device having a cut-off in the range from about 1000 Daltons to about 1 μm, preferably from about 0.05 μm to about 0.5 μm, a lumen size of from about 1 to about 10 mm, preferably from about 2 to about 6 mm, more preferably from about 3 to about 5 mm, and a clean water flux of at least about 1000 L / m2.h.100 kp (RO water at 25° C.), preferably at least about 10,000 L / m2.h.100 kp.

Owner:THE PROCTER & GAMBLE COMPANY

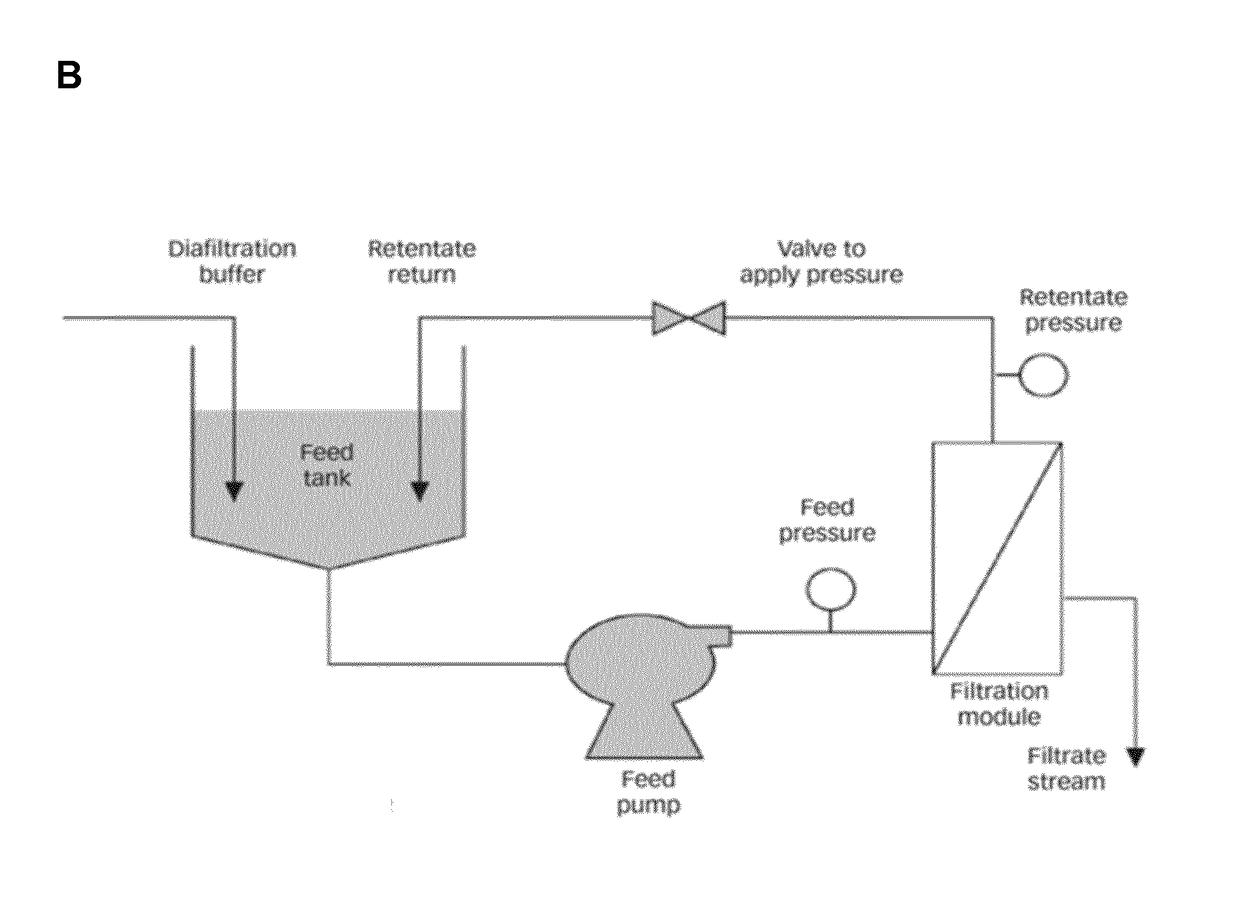

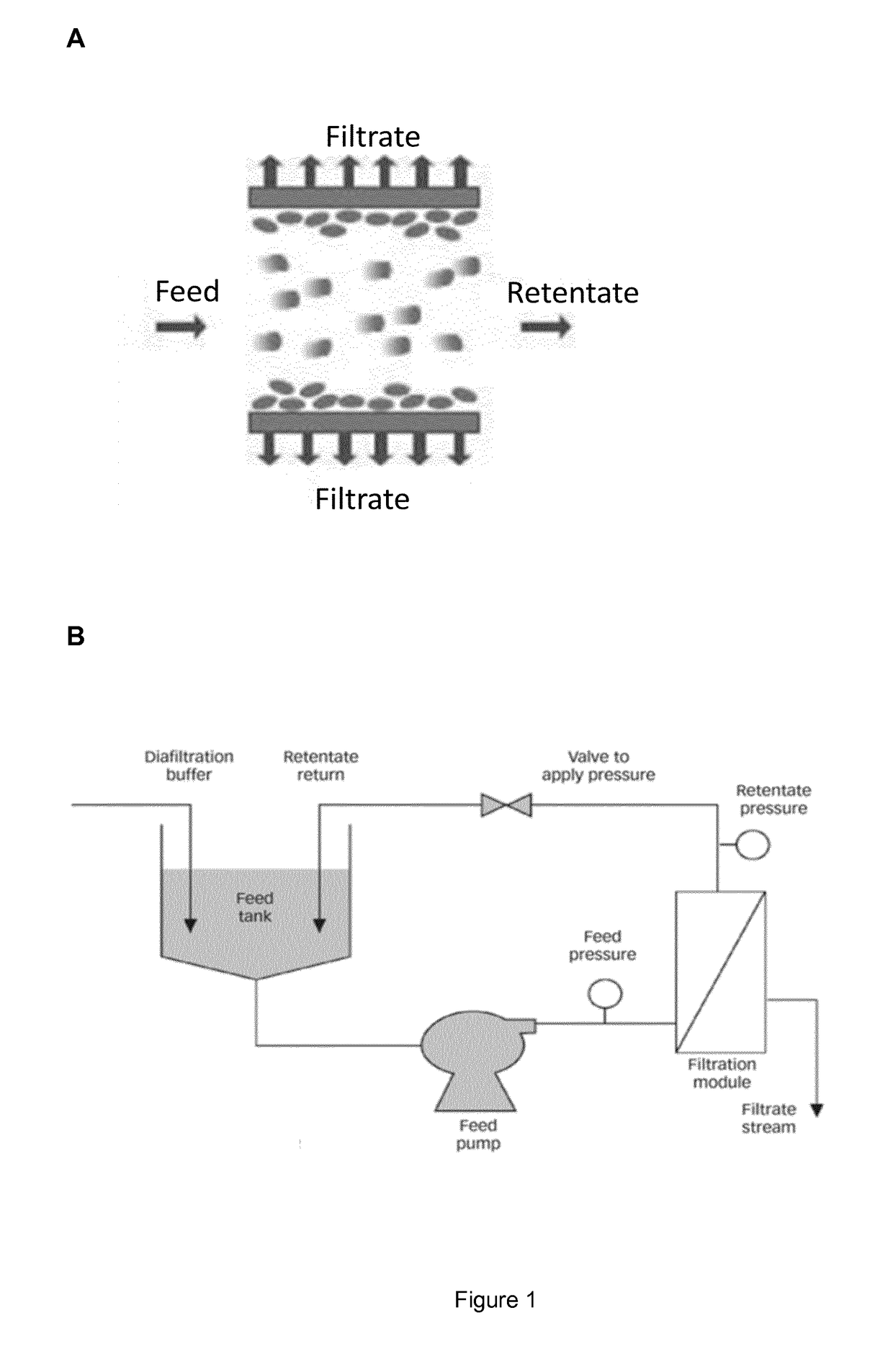

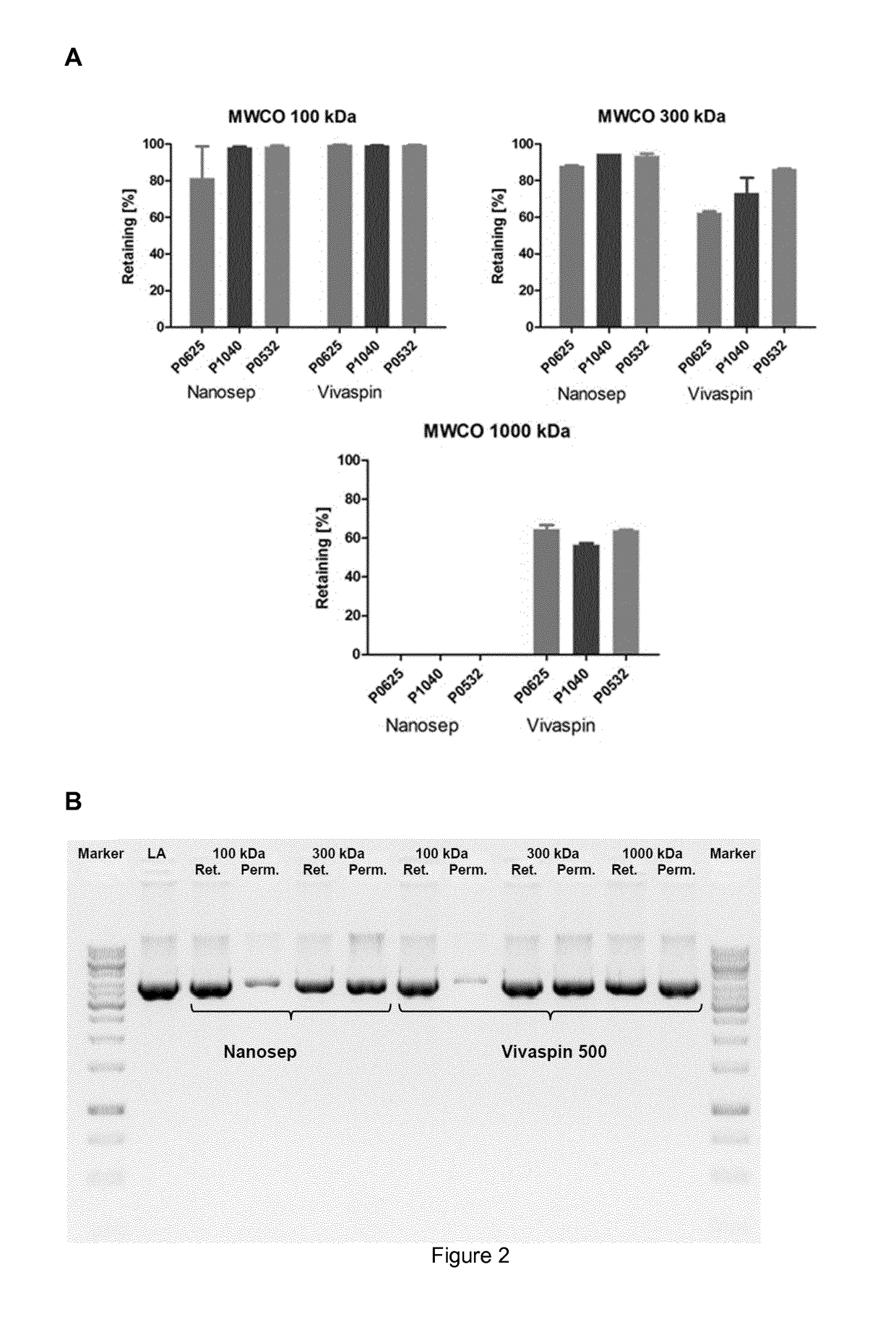

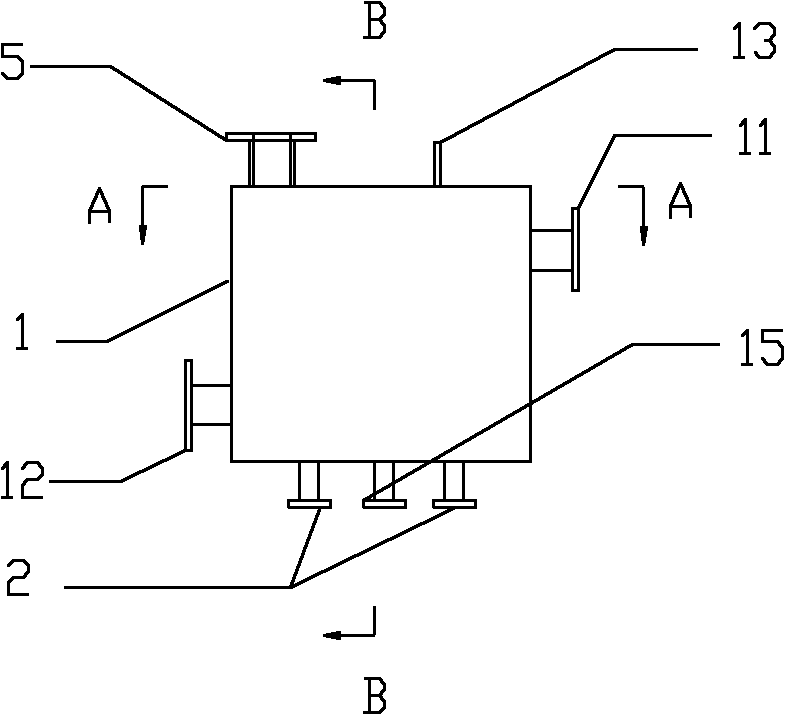

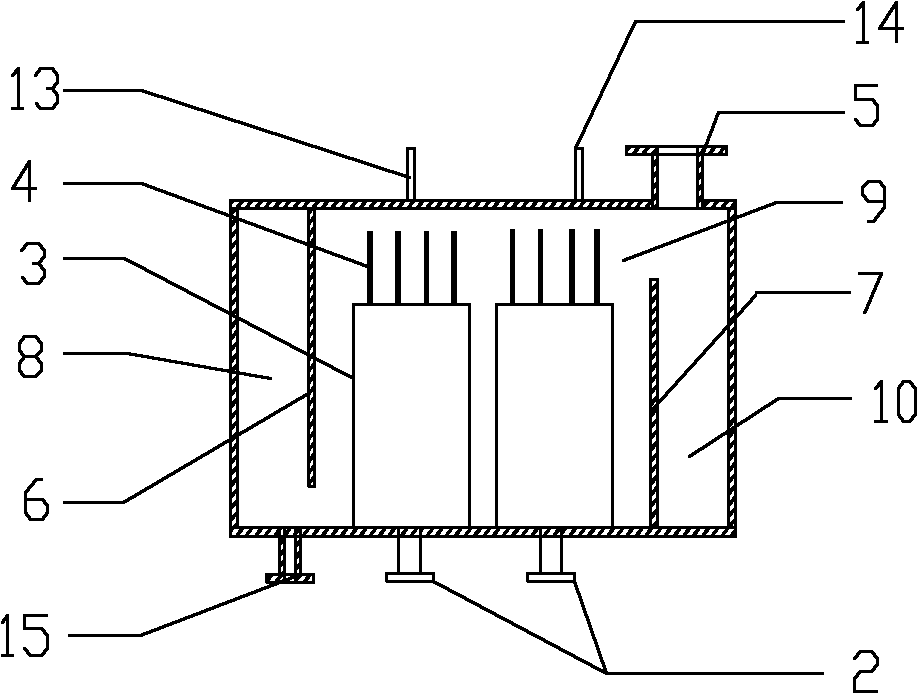

A method for producing and purifying rna, comprising at least one step of tangential flow filtration

ActiveUS20180298372A1Improve resolutionEffectively stopComponent separationUltrafiltrationDna encodingBiology

Owner:CUREVAC REAL ESTATE GMBH

Nano catalytic electrolysis flocculation device

InactiveCN102010038APromote aggregation and sedimentationReduce dosageWater treatment compoundsSpecific water treatment objectivesFlocculationWater discharge

The invention discloses a nano catalytic electrolysis flocculation device, relating to an electrolysis flocculation device. The nano catalytic electrolysis flocculation device has the advantages of extremely low working voltage between two adjacent electrodes, large current density, small energy consumption, high electrical efficiency and no electrode consumption and electrolysis, and integrates solid-liquid separation function and gas-liquid separation function. The bottom of a shell is provided with a water inlet; the shell is internally provided with a scum baffle and a watertight shutter; the scum baffle and one inner side of the shell form a water discharging chamber; a gap is reserved between the bottom of the scum baffle and the bottom of the shell; the scum baffle and the other inner side of the shell form a slag discharging chamber; a gap is reserved between the top of the watertight shutter and the top of the shell; a hydrogen exhaust port is arranged on the top of the shell; an electrolyzer is arranged between the scum baffle and the watertight shutter; the top of the electrolyzer is open and the gap is reserved between the top of the electrolyzer and the top of the shell; electrodes are installed in the electrolyzer; a gas-liquid separation chamber is formed in the shell on the upper part of the electrolyzer; and a drain outlet is arranged at the bottom of the shell and us positioned between the watertight shutter and the adjacent electrolyzer.

Owner:BOYING XIAMEN SCI & TECH

Single optic accommodative intraocular lens system

ActiveUS9078744B2Add depthRestore accommodationGas turbine plantsIntraocular lensCataract extractionLens extraction

A single-optic accommodative lens system includes two intraocular elements designed to be located within the capsular bag to extend depth of focus and / or restore accommodation following cataract extraction of a natural lens. A first intraocular element comprises a circumferential capsular ring having interlock features to couple to and control the dynamic vault response of a second intraocular element. This second intraocular element comprises an intraocular lens (IOL) having an optic and a plurality of haptics and is designed to move axially in response to changes in the geometry of the eye capsule and thus provide a range of accommodative power. The IOL further comprises interlock features complementary to the interlock features of the first intraocular element for coupling the IOL to the capsular ring in a manner that provides for controlled movement of the IOL in response to capsular forces.

Owner:ALCON INC

Stable beverage compositions containing tea polyphenols, flavonoids or catechins and methods

Ready-to-drink color and turbidity stable beverage compositions are provided. The beverage compositions contain from about 100 to about 2,700 milligrams per liter by total weight of the beverage composition of a tea material selected from the group consisting of tea solids, tea polyphenols, tea flavonoids, tea catechins and combinations thereof. The composition contains water, a total of no more than from about 0 to 100 milligrams per liter divalent cations and a turbidity of less than about 50 NTU and even less than 20 NTU for compositions containing 900 mg / l of tea solids. Preferably, the tea material contains less than about 450 milligrams divalent cations per 100 grams of the tea material. The beverage compositions of the invention are color and turbidity stable when packaged and stored under normal conditions.

Owner:PEPSICO INC

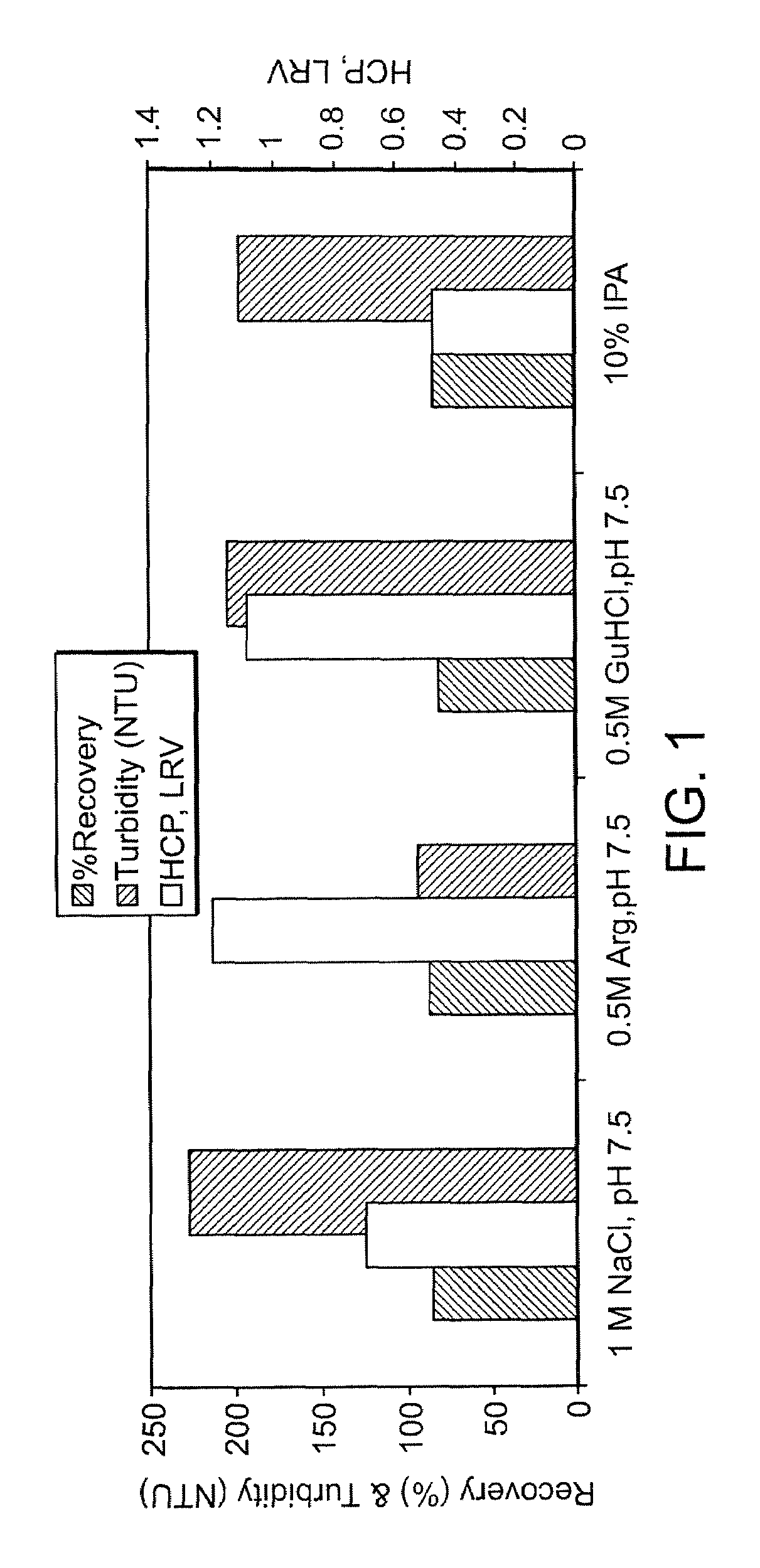

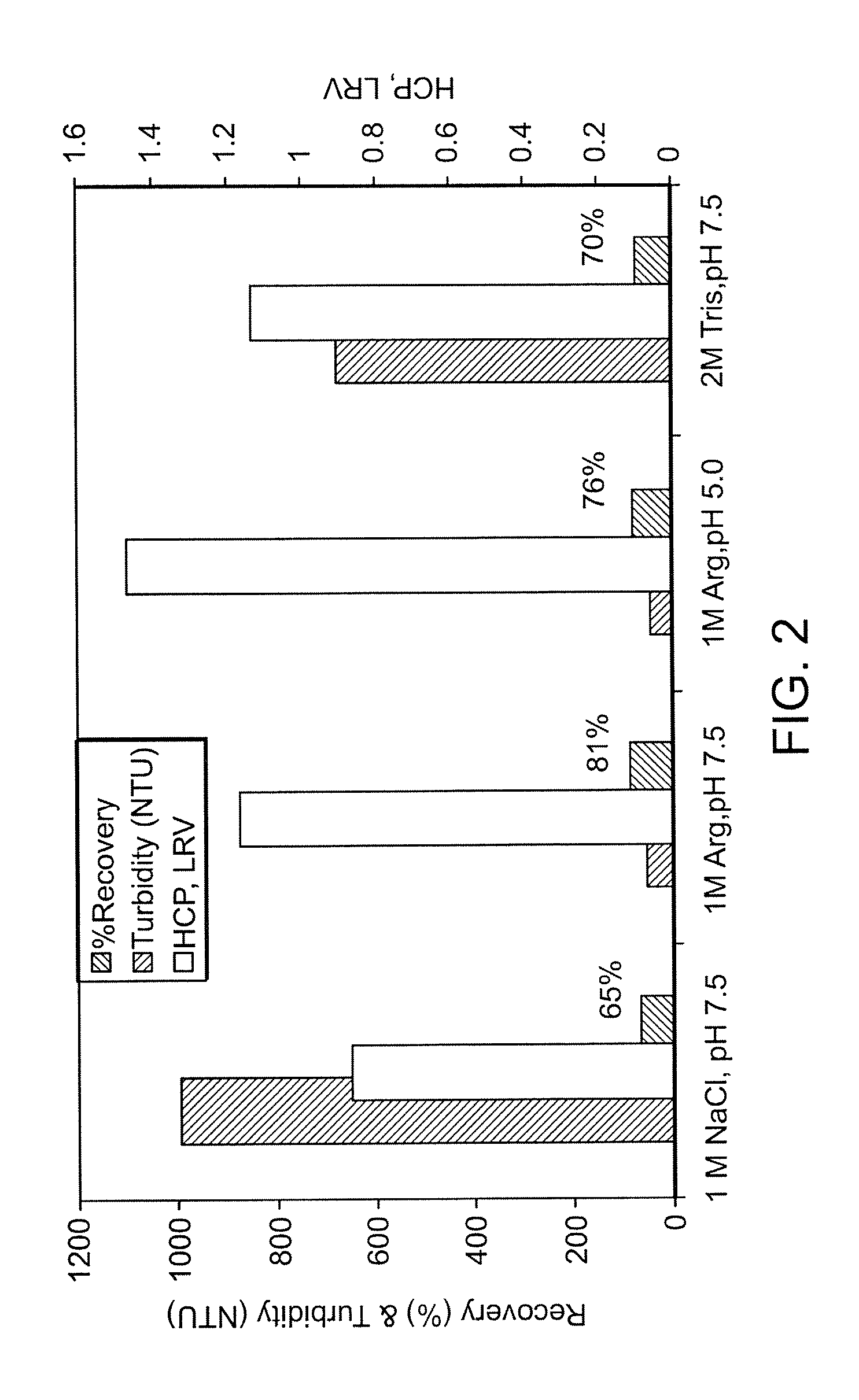

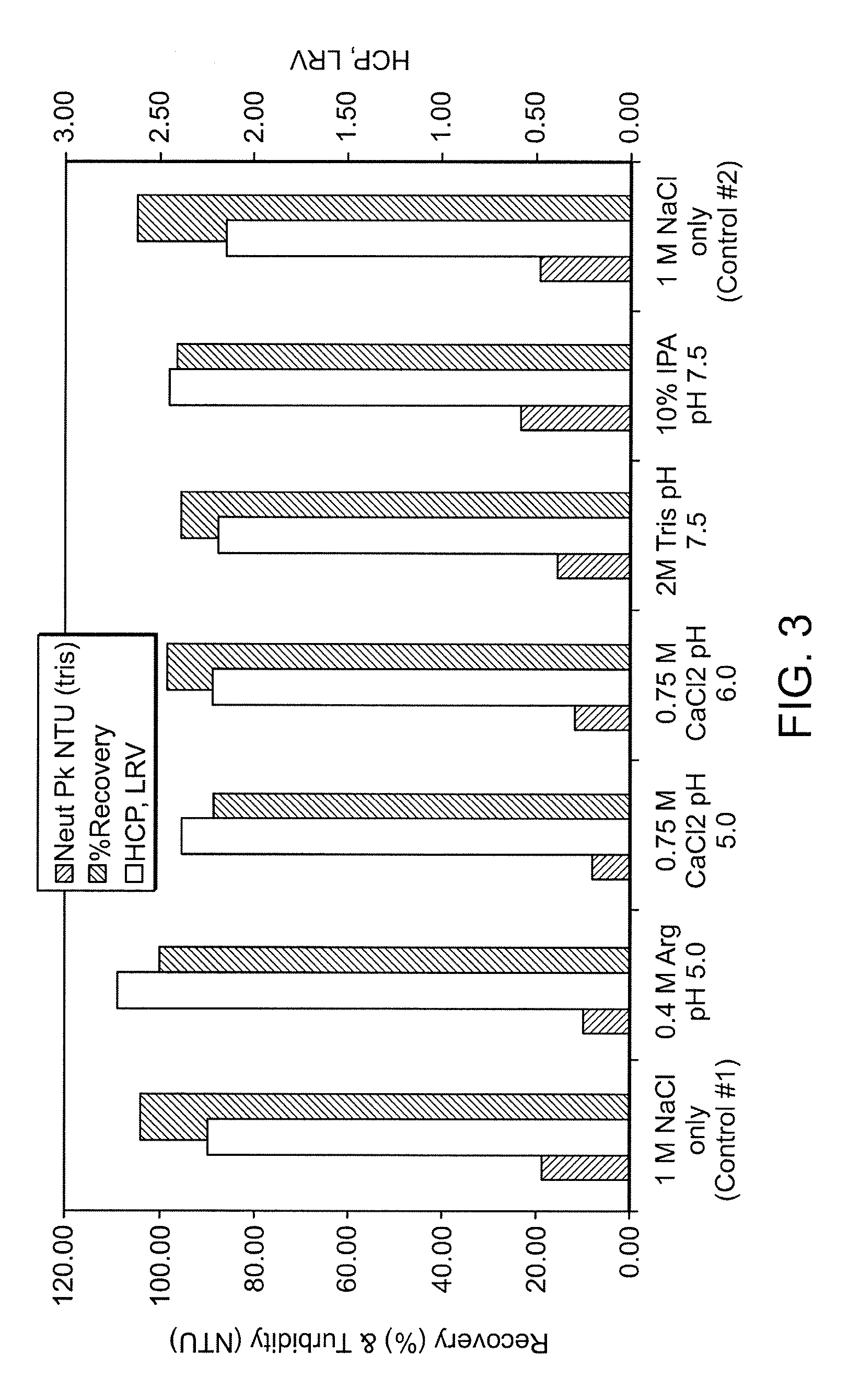

Arginine derivative wash in protein purification using affinity chromatography

ActiveUS7714111B2Reduce turbidityRaise the ratioDepsipeptidesPeptide preparation methodsArginineElution

The invention relates to methods for isolating a product and / or reducing turbidity and / or impurities from a load fluid comprising the product and one or more impurities by passing the load fluid through a medium, followed by at least one wash solution comprising an arginine derivative, and collecting the product using an elution solution. The invention further relates to a product prepared using a method as described herein.

Owner:WYETH LLC

Electro-adsorption demineralization water purifier

InactiveCN101412550AReduce turbidityReduced salt removal capacityDispersed particle separationAutomatic controlDesorption

The invention discloses an electro-absorptive desalination water purifier, which comprises a high-precision pretreatment filter element, an electro-absorptive filter element, an electrical control circuit board, and a water quality probe capable of detecting the content of salinity in water. After suspended substances and particulate matters in raw water are removed through the high-precision pretreatment filter element, then the salinity in the water is removed through the electro-absorptive filter element, the water quality probe is arranged in a water outlet pipeline of the electro-absorptive filter element; the water outlet pipeline is divided into two paths behind the water quality probe; and one path is a fresh water pipeline communicated with a water purification tank, while the other path is a sewage pipeline which is communicated with a sewage tank or is emptied. The water purifier has the advantages that the water purifier can realize the automatic control to the water quality of water outlet by controlling the electric conductivity of the water outlet; hardness components are contained in the salinity, so the desalination water purifier is also a water softener and is particularly suitable for hard water areas in the north of China; after the electro-absorptive filter element has saturated absorption, the electro-absorptive filter element can obtain the regeneration through the desorption, has small discharge capacity during the regeneration, and saves water resources; and concentrated water drained during the regeneration does not contain acid and alkali liquid, and does not pollute the environment.

Owner:黄樟焱

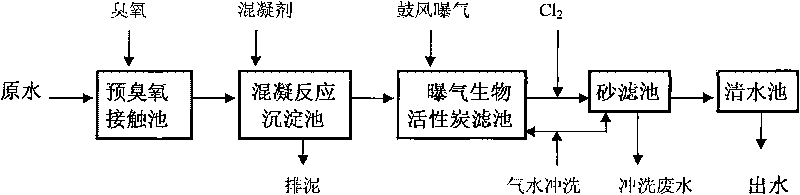

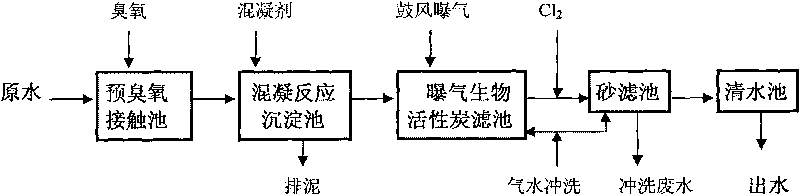

Feedwater treatment method by pre-ozonation and aerated biological activated carbon

InactiveCN101704609AAvoid breedingReduce qualityTreatment using aerobic processesMultistage water/sewage treatmentWater sourceWater quality

The invention discloses a method for applying pre-ozonation and aerated biological activated carbon processes to feedwater treatment. The method combines ozone pre-oxidation, an aerated biological activated carbon filter tank and a coagulation-sedimentation-sand filtering-disinfection conventional feedwater treatment process to produce drinking water, is a feedwater treatment process for improving water quality of feed water aiming at micro-polluted drinking water sources, and integrates the characteristics of an aerated biofilter biological pre-treatment process and an ozone biological activated carbon advanced water-purifying process. Raw water enters a pre-ozonation contact tank, a coagulation sedimentation tank and the aerated biological activated carbon filter tank orderly, is disinfected, enters a sand filtering tank, and finally flows into a clear water tank. Because the pre-ozonation contact tank and the aerated biological activated carbon filter tank are arranged in the conventional feedwater treatment process, the effect of removing organic matters, ammonia nitrogen, pathogenic microorganism, odor, chroma and the like is greatly improved, and the water quality safety of the method is obviously superior to that of the biological pre-treatment process and the ozone biological activated carbon advanced water-purifying process.

Owner:SOUTH CHINA UNIV OF TECH

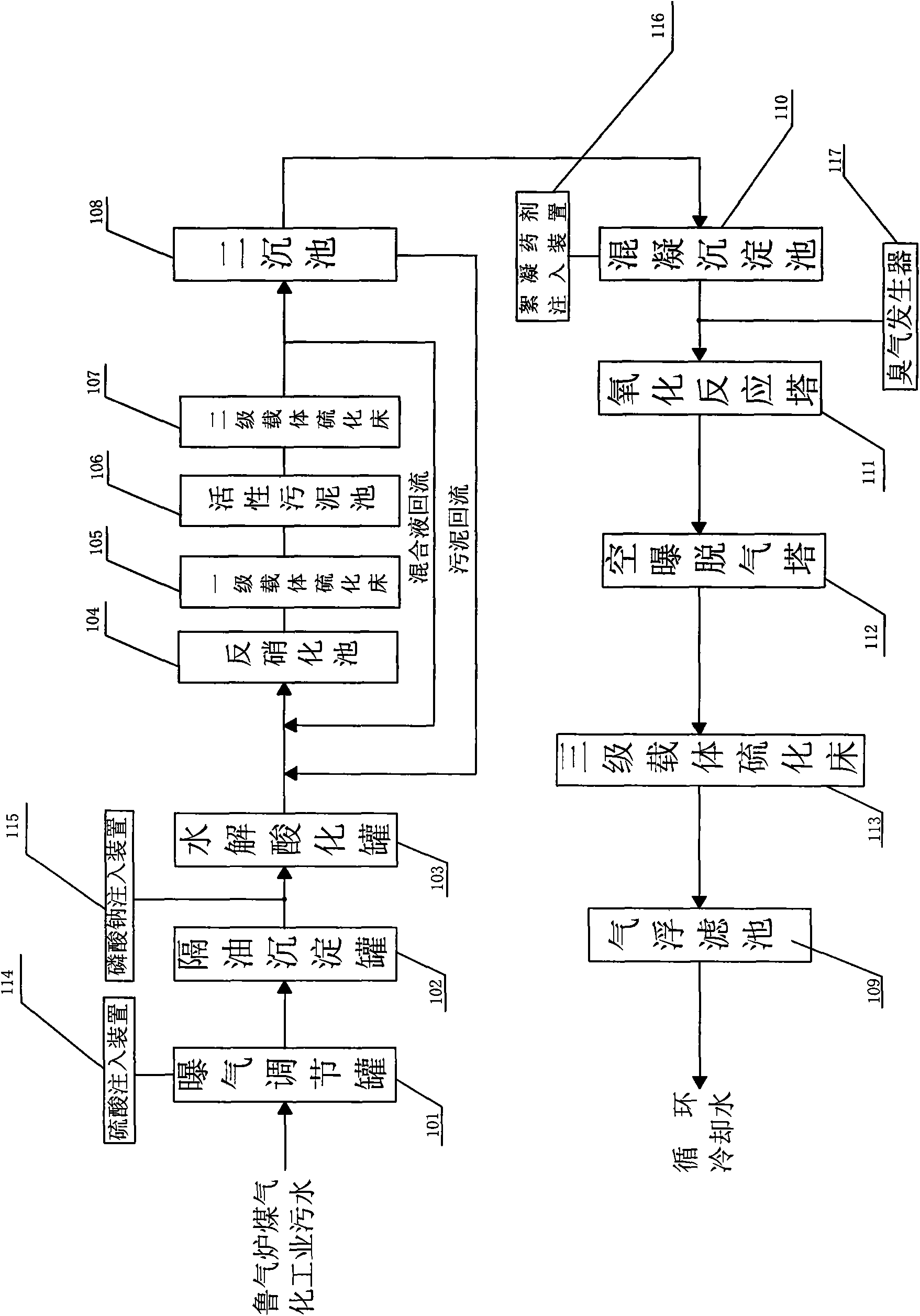

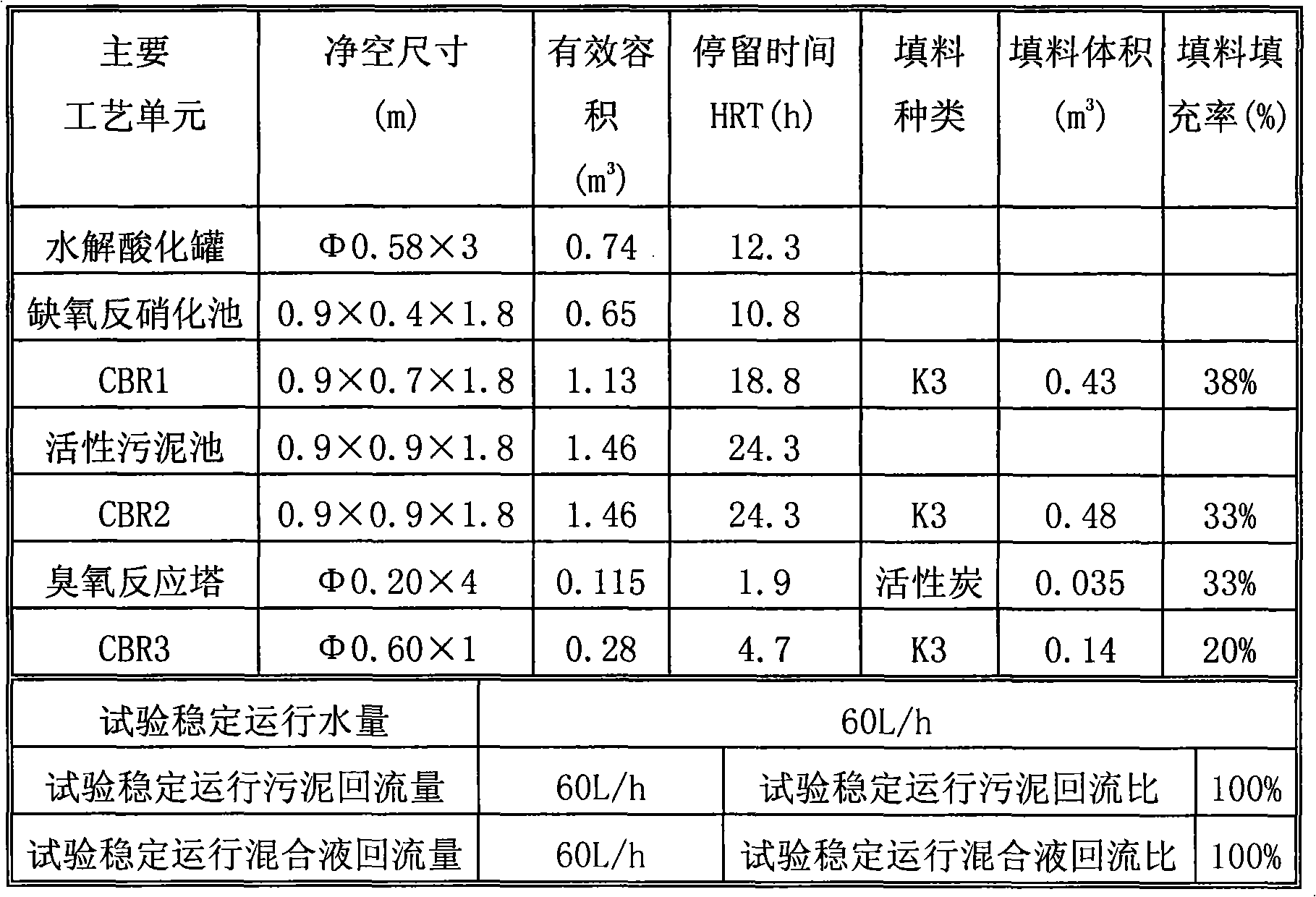

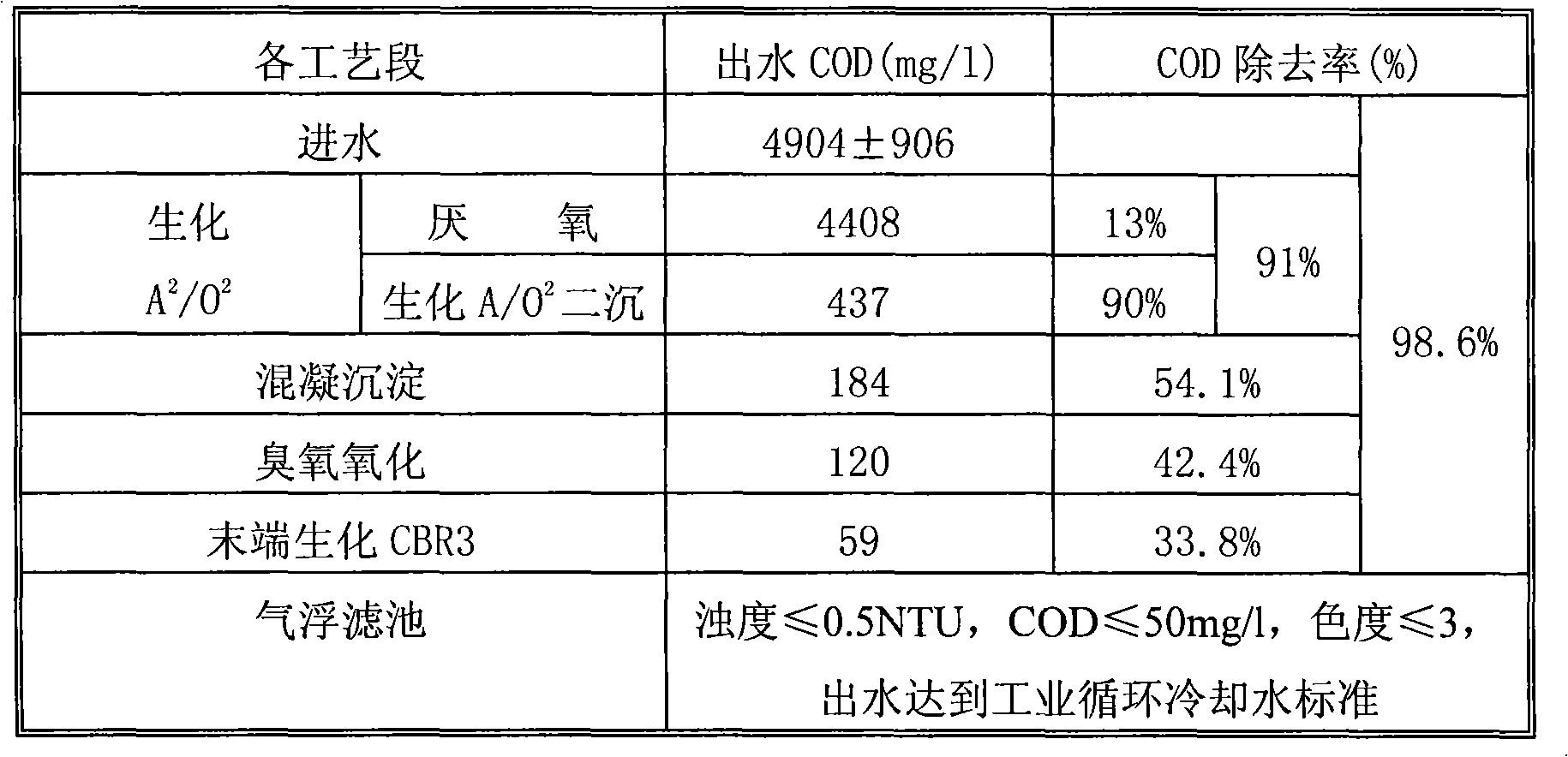

Lurgi furnace coal gasification wastewater treatment and reuse technology

ActiveCN101607777AImprove impact resistanceGuaranteed uptimeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterActivated sludge

The invention discloses a Lurgi furnace coal gasification wastewater treatment and reuse technology, comprising the steps of adopting aeration adjustment, oil separation and sedimentation, hydrolysis acidification, denitrification treatment, first order carrier fluidized bed decarburization, residual COD removement with activated sludge, second order carrier fluidized bed ammonia / nitrogen removement, sludge-water separation, precipitation, oxidation reaction, residual ozone removement, organic waste removement and floating filter treatment to treat the coal gasification wastewater of a Lurgi furnace coal gasification factory and obtaining water which can be reused. The invention has simple operation and low process cost and the treated effluent can be used as the cooling water of boiler furnaces, thus fully recycling the treated Lurgi furnace coal gasification wastewater.

Owner:DASMART ENVIRONMENTAL SCI & TECH (BEIJING) CO LTD

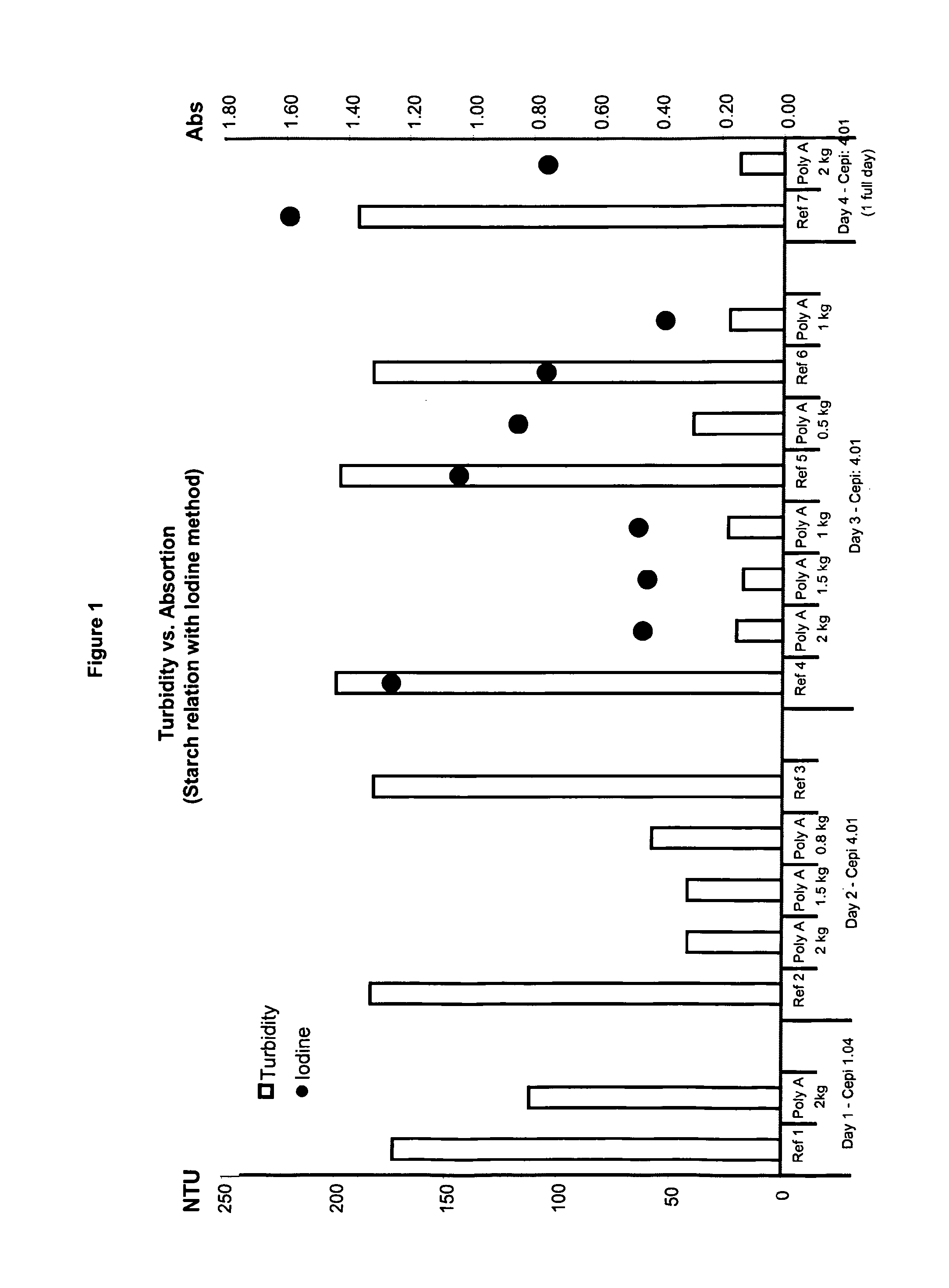

Method for increasing the advantages of starch in pulped cellulosic material in the production of paper and paperboard

ActiveUS8758562B2Avoid degradationPrevent degradationNatural cellulose pulp/paperSpecial paperCellulosePaperboard

The invention relates to a method for increasing the benefit from starch in pulped, preferably repulped cellulosic material at paper or paperboard manufacturing comprising the steps of (a) pulping a cellulosic material containing a starch; (b) treating the cellulosic material containing the starch with one or more biocides, preferably in the thick stock area; and (h) adding an ionic polymer and preferably, an auxiliary ionic polymer to the cellulosic material; wherein the ionic polymer and the optionally added auxiliary ionic polymer preferably have a different average molecular weight and preferably a different ionicity, wherein the ionicity is the molar content of ionic monomer units relative to the total amount of monomer units.

Owner:SOLENIS TECH CAYMAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com