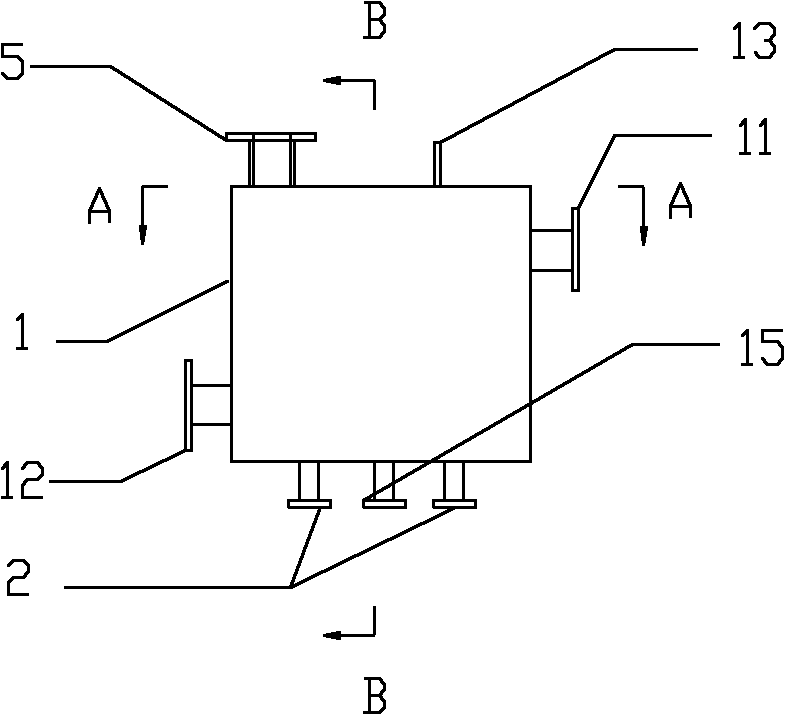

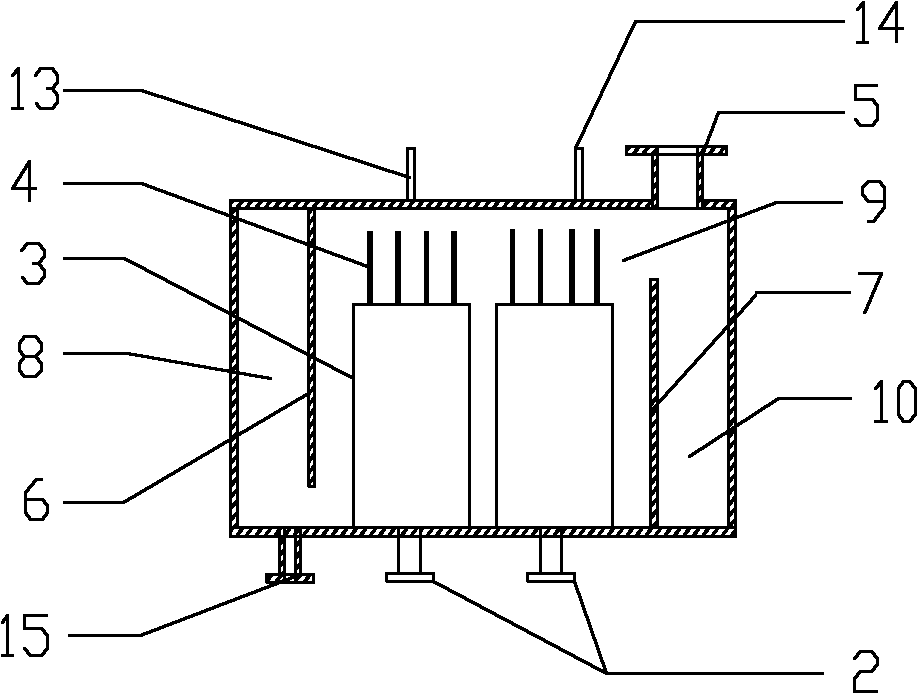

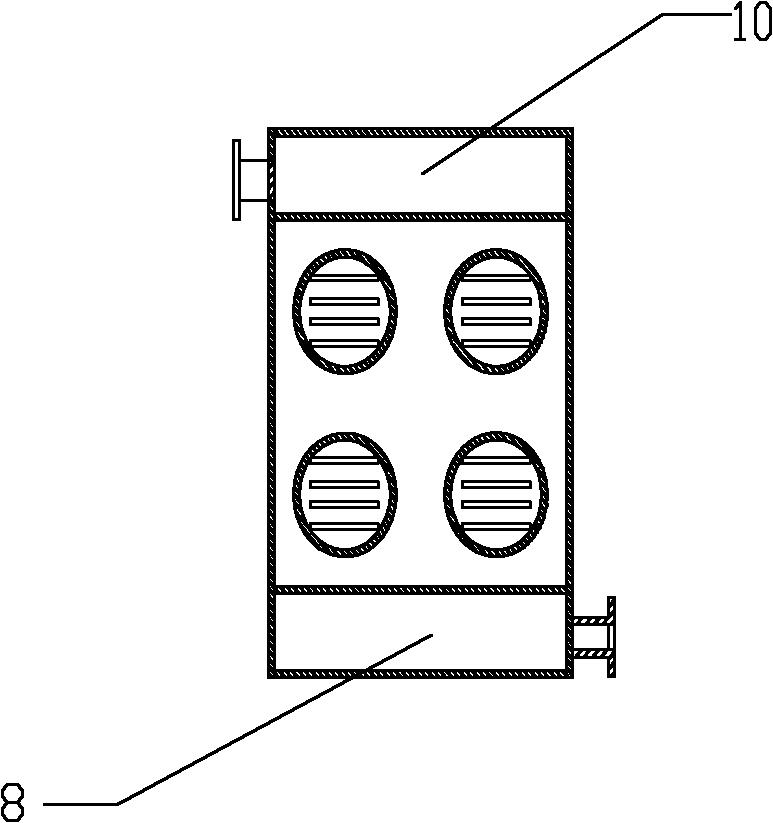

Nano catalytic electrolysis flocculation device

A technology of electrolytic flocculation and nanocatalysis, which is applied in chemical instruments and methods, water treatment of special compounds, special treatment targets, etc., can solve problems such as high energy consumption, high overpotential, and channeling, and achieve high electrocatalytic activity, The effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Treatment effect on fresh water purification and disinfection

[0063] Pump fresh water into the nano catalytic electrolysis flocculation device for electrolysis, the voltage between the two electrodes is 5-8V, and the electrolysis density is 10-200mA / cm 2 The catalytic electrolysis machine keeps the residence time of fresh water in the nano-catalytic electrolytic flocculation device at 0.5-1min, and the electricity consumption of fresh water electrolysis is controlled at 0.009-0.010 degrees / m 3 . The effects before and after treatment are shown in Table 1 (indices of untreated fresh water) and Table 2 (indices of fresh water treated by nanocatalytic electrolytic flocculation device).

[0064] Table 1

[0065] serial number

project

index

serial number

project

index

1

smelly and smelly

No smell

5

COD (mg / L)

9

[0066] 2

pH

6.9

6

0.5

3

...

Embodiment 2

[0070] The treatment effect on the purification and disinfection of seawater

[0071] Pump seawater into the nano-catalytic electrolysis flocculation device for electrolysis, the voltage between the two electrodes is 3-5V, and the electrolysis density is 10-260mA / cm 2 The catalytic electrolysis machine keeps the residence time of seawater in the nano-catalytic electrolysis flocculation device at 0.5-1min, and the electricity consumption of seawater electrolysis is controlled at 0.003-0.004 degrees / m 3 . The effects before and after treatment are shown in Table 3 (indices of untreated seawater) and Table 4 (indices of seawater after purification and disinfection treatment by nanocatalytic electrolysis device).

[0072] table 3

[0073] serial number

[0074] Table 4

[0075] serial number

[0076] 1

Embodiment 3

[0078] Treatment effect on printing and dyeing advanced treatment wastewater

[0079] The printing and dyeing advanced treatment wastewater from the secondary sedimentation tank treated by A / O flows into the nano-catalyzed electrolytic flocculation device for electrolysis, the voltage between the two electrodes is 3-6V, and the electrolysis density is 10-300mA / cm 2 Catalytic electrolysis, keeping the residence time of wastewater in the nano-catalytic electrolytic flocculation device is 2-5 minutes, and the electricity consumption of wastewater electrolysis is controlled at 0.8-1.0 degrees / m 3 . The effects before and after treatment are shown in Table 5 (indices of comprehensive printing and dyeing wastewater in the untreated mixing pool) and Table 6 (indices of printing and dyeing wastewater after nanocatalytic electrolysis treatment).

[0080] table 5

[0081] serial number

project

unit

measured value

serial number

project

unit

measured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com