Catalytic reaction method

A catalytic reaction and reaction technology, applied in the direction of chemical instruments and methods, chemical/physical/physical chemical mobile reactors, chemical/physical processes, etc., can solve the problem of rotating bed high gravity field device application has not yet been publicly reported, catalytic reaction Problems such as large equipment volume and low catalyst utilization rate can achieve the effect of reducing equipment volume, shortening residence time, and reducing equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] C in a rotating bed reactor 4 The fractions are fully hydrogenated. C 4 The full hydrogenation of fractions is a gas-liquid-solid three-phase reaction, and the material used is H 2 、C 4 Distillate, its main components are: butane, butene, butadiene and butyne, the catalyst used is Pt / Al 2 o 3 or Pd / Al 2 o 3, Temperature: 10~180°C, Pressure: 2~40atm, Speed 400~1500rpm. C 4 Distillate space velocity 10~100hr -1 , hydrogen / unsaturated bond mol / mol (hydrogen / (butene+2×butadiene+2×butyne+3×vinylacetylene)): 1.0~1.2, the circulation ratio of raw material and product: 5~9: 1.

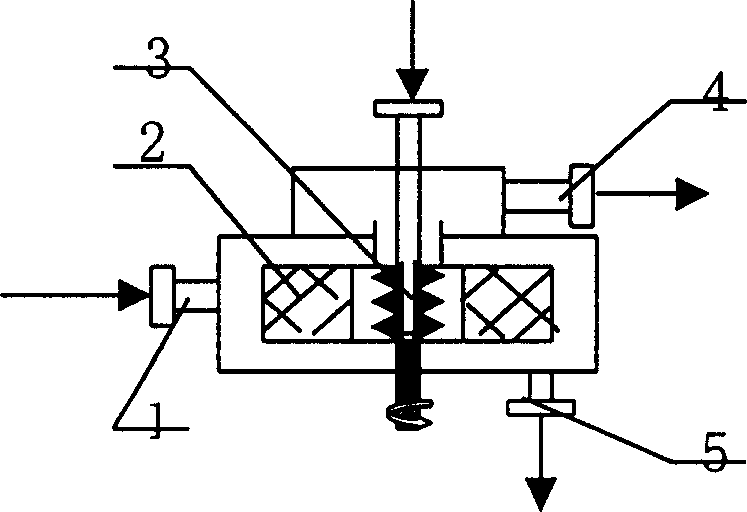

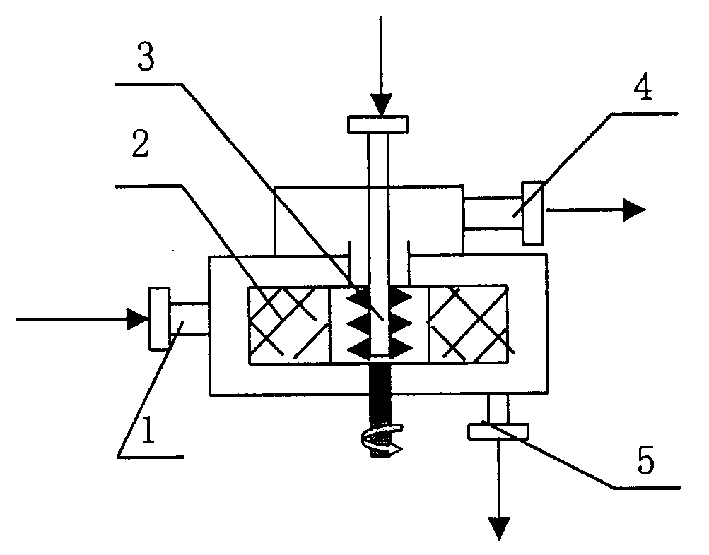

[0033] Such as figure 1 As shown, 30ml of catalyst is fixed on the rotor 2 of the rotary bed reactor, hydrogen is introduced into the reactor tangentially from the gas phase inlet 1, and the liquid phase C 4 The fraction is sprayed to the inner edge of the high-speed rotating catalyst layer by the liquid distributor 3, and the hydrogen and C 4 The distillate is strongly turbulent on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com