Patents

Literature

225 results about "Supergravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In theoretical physics, supergravity (supergravity theory; SUGRA for short) is a modern field theory that combines the principles of supersymmetry and general relativity; in contrast to non-gravitational supersymmetric theories such as the Minimal Supersymmetric Standard Model. Supergravity is the gauge theory of local supersymmetry. Since the supersymmetry (SUSY) generators form together with the Poincaré algebra a superalgebra, called the super-Poincaré algebra, supersymmetry a gauge theory makes gravity arise in a natural way.

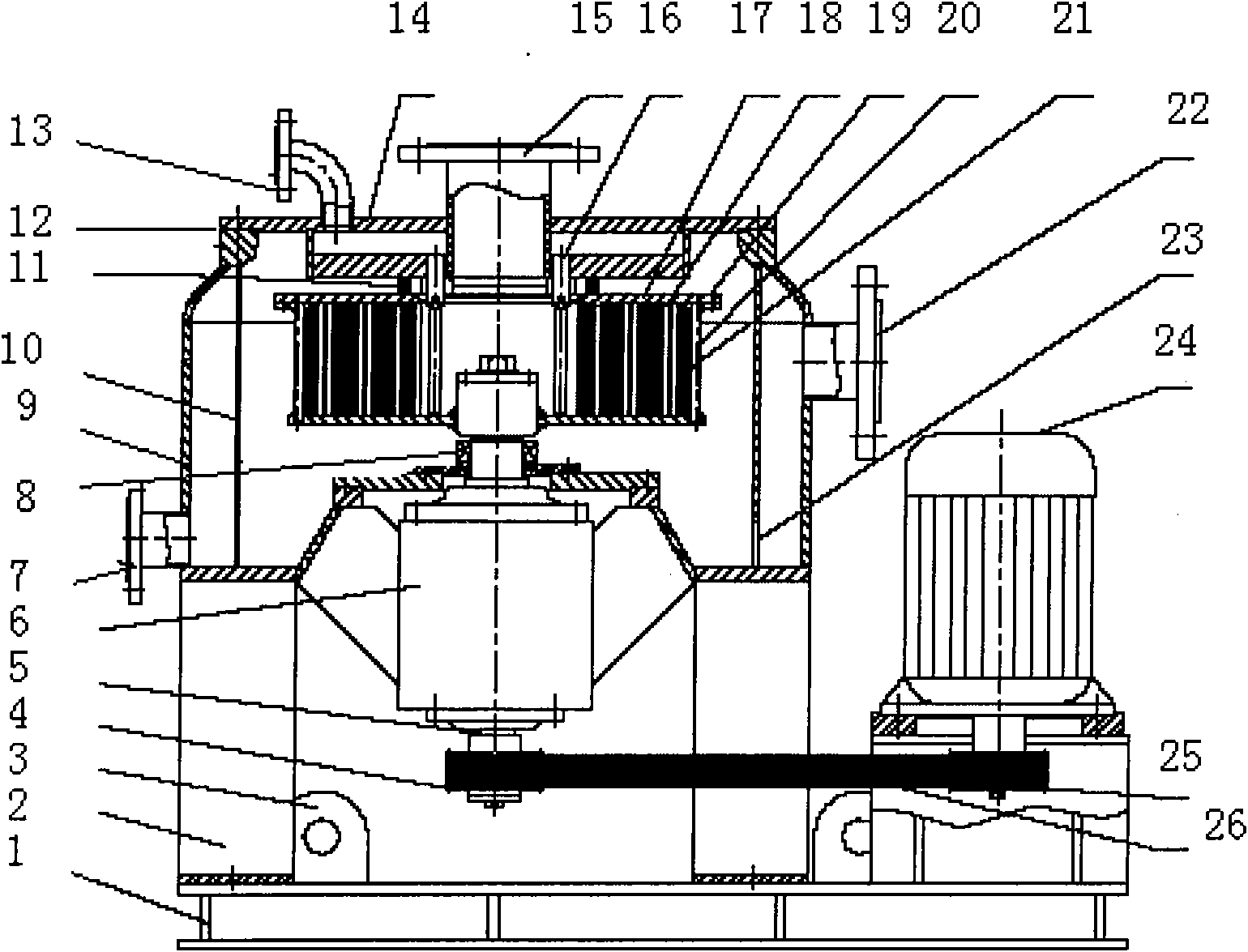

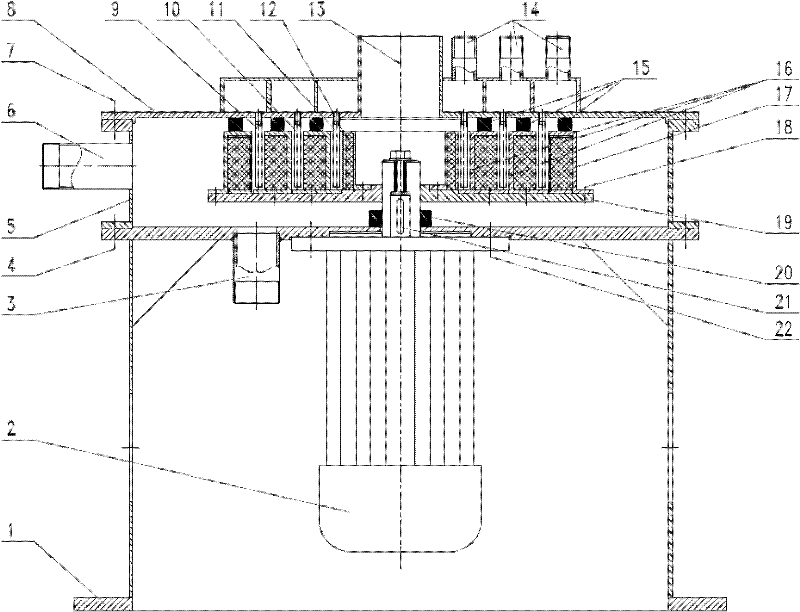

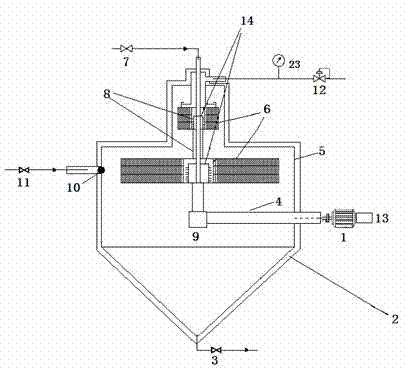

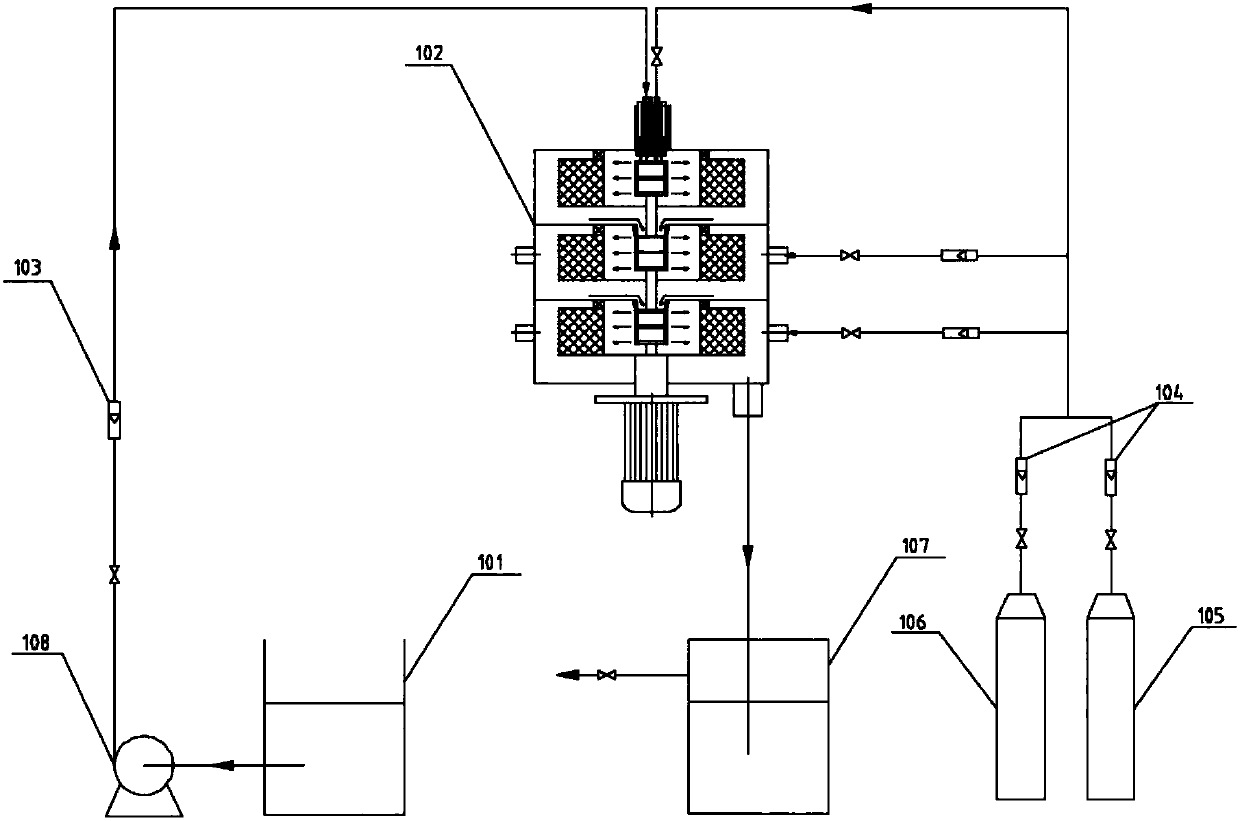

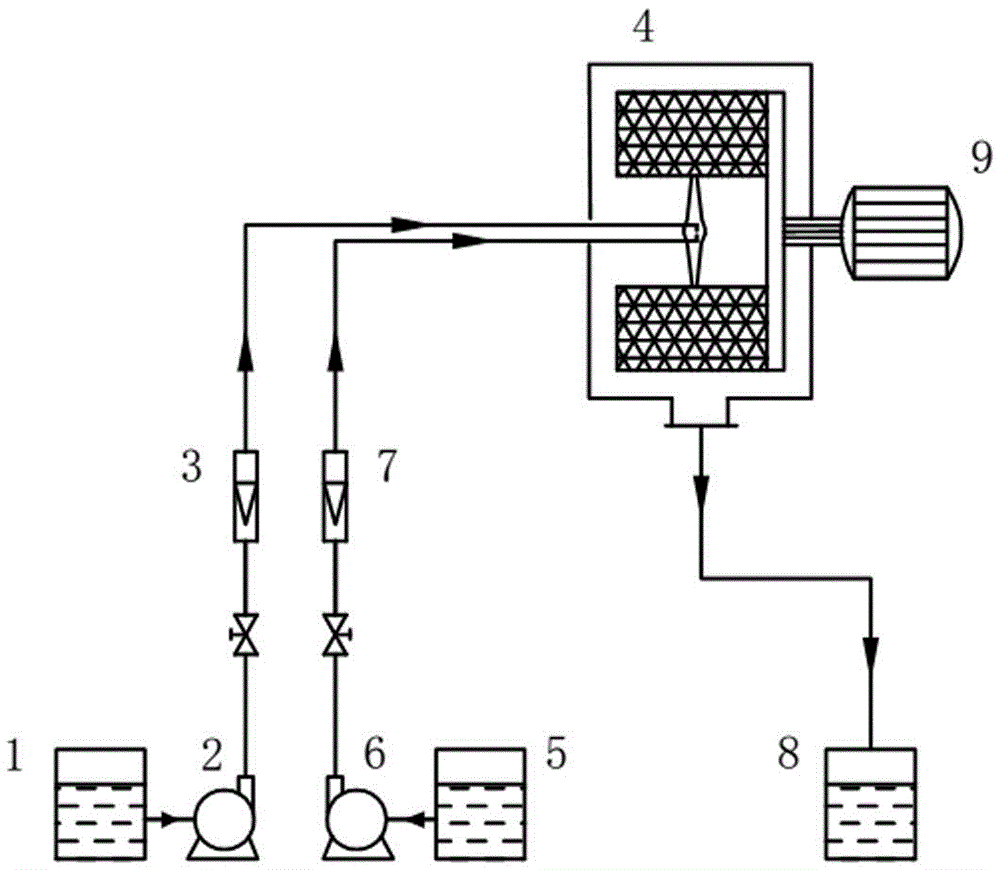

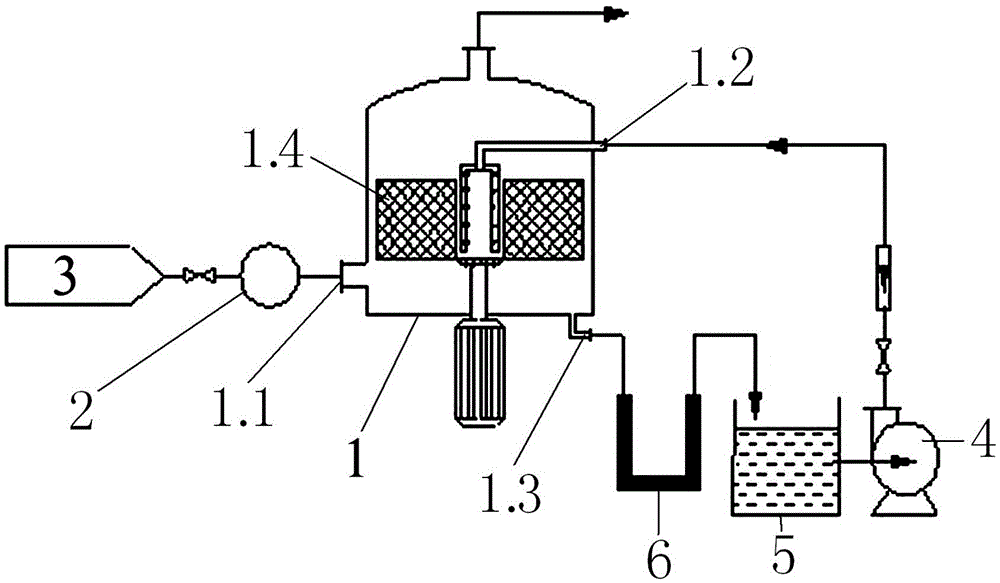

Supergravity revolving bed device and application in carbon dioxide collecting and passivating process

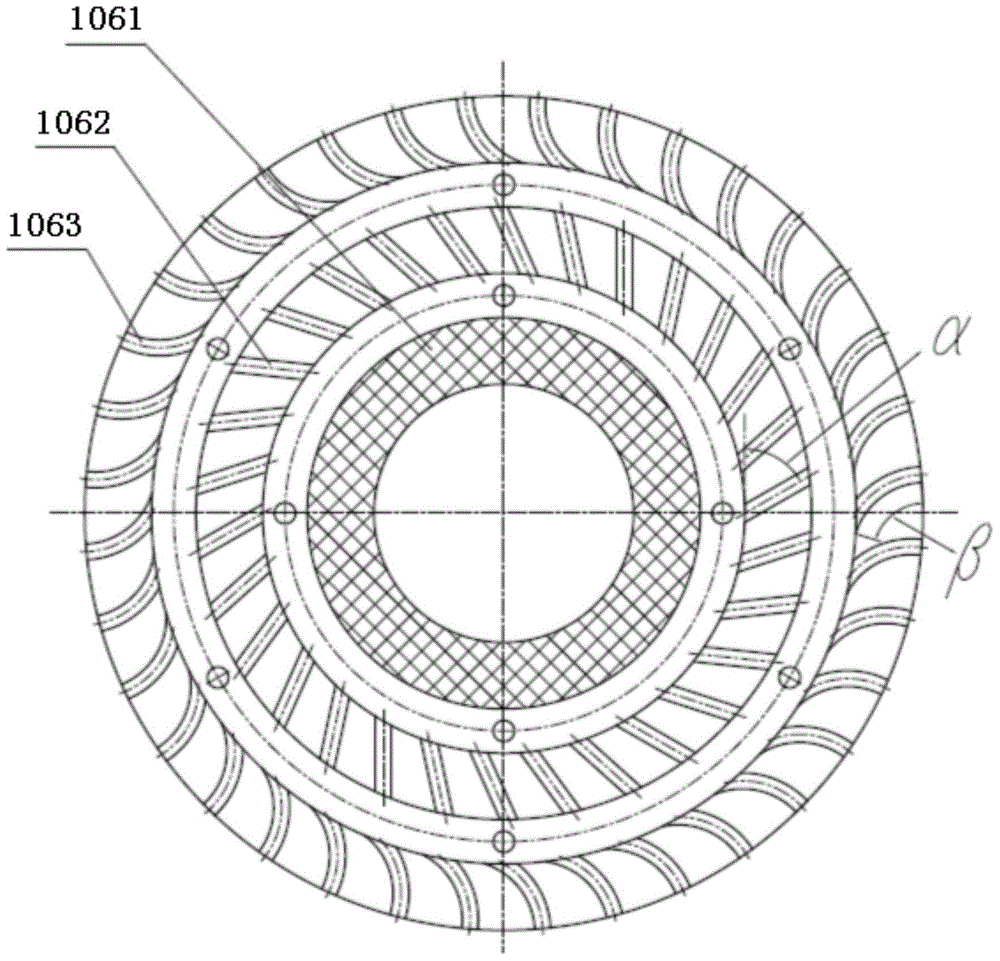

ActiveCN101549274AGreat operating flexibilityImprove mass transfer efficiencyDispersed particle separationChemical/physical/physico-chemical processesDesorptionFilling materials

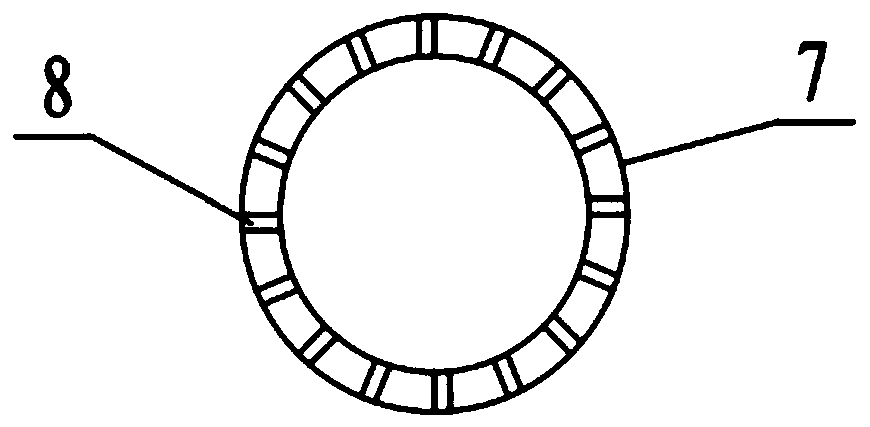

The invention relates to a supergravity revolving bed device and an application in a carbon dioxide collecting and passivating process. A filling layer of a rotor of the revolving bed device consists of material filling layers and blade layers which are arrayed at intervals in a concentric ring mode along a radial direction, and the material filling layers in the rotor ensure that fluid generates a large number of new surface areas, and the blade layers in the rotor can regulate and control the flowing direction of the fluid so as to ensure that end effect areas are formed when the fluid enters a next layer for filling materials. In the carbon dioxide collecting and passivating process, the processes of absorption and desorption of the carbon dioxide are carried out in the revolving bed device so as to ensure that the carbon dioxide in flow industrial tail gas and associated gas is efficiently collected and passivated for in situ recovery. Compared with a conventional process using tower equipment to collect and passivate the carbon dioxide, under the condition of reaching the same absorption and desorption effects, the invention saves the equipment investment by 30 percent and reduces the floor space by 50 percent and the operation cost by 10 percent. The revolving bed device has large operation elasticity, stable operation and practical values for industrial use.

Owner:BEIJING UNIV OF CHEM TECH +1

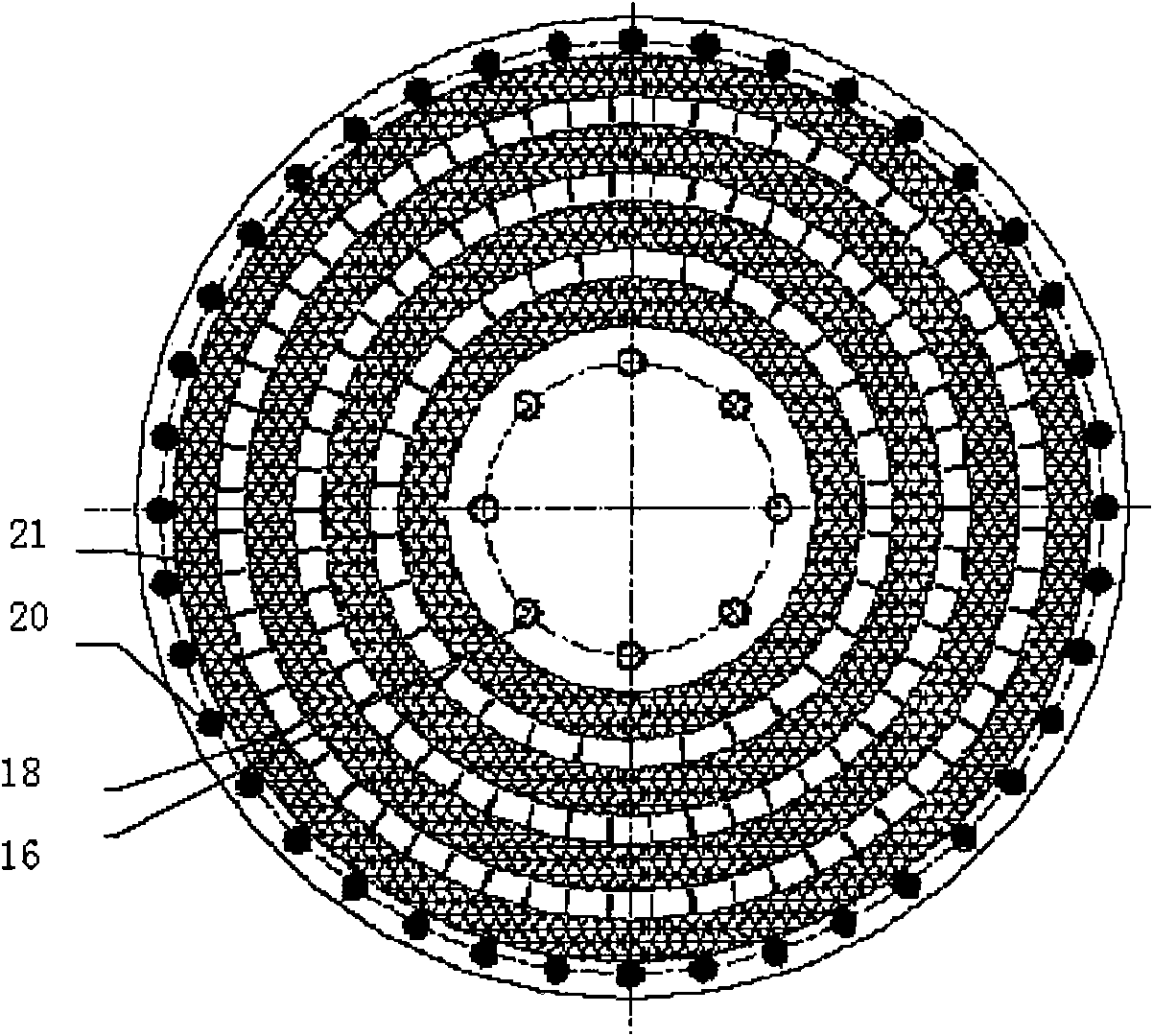

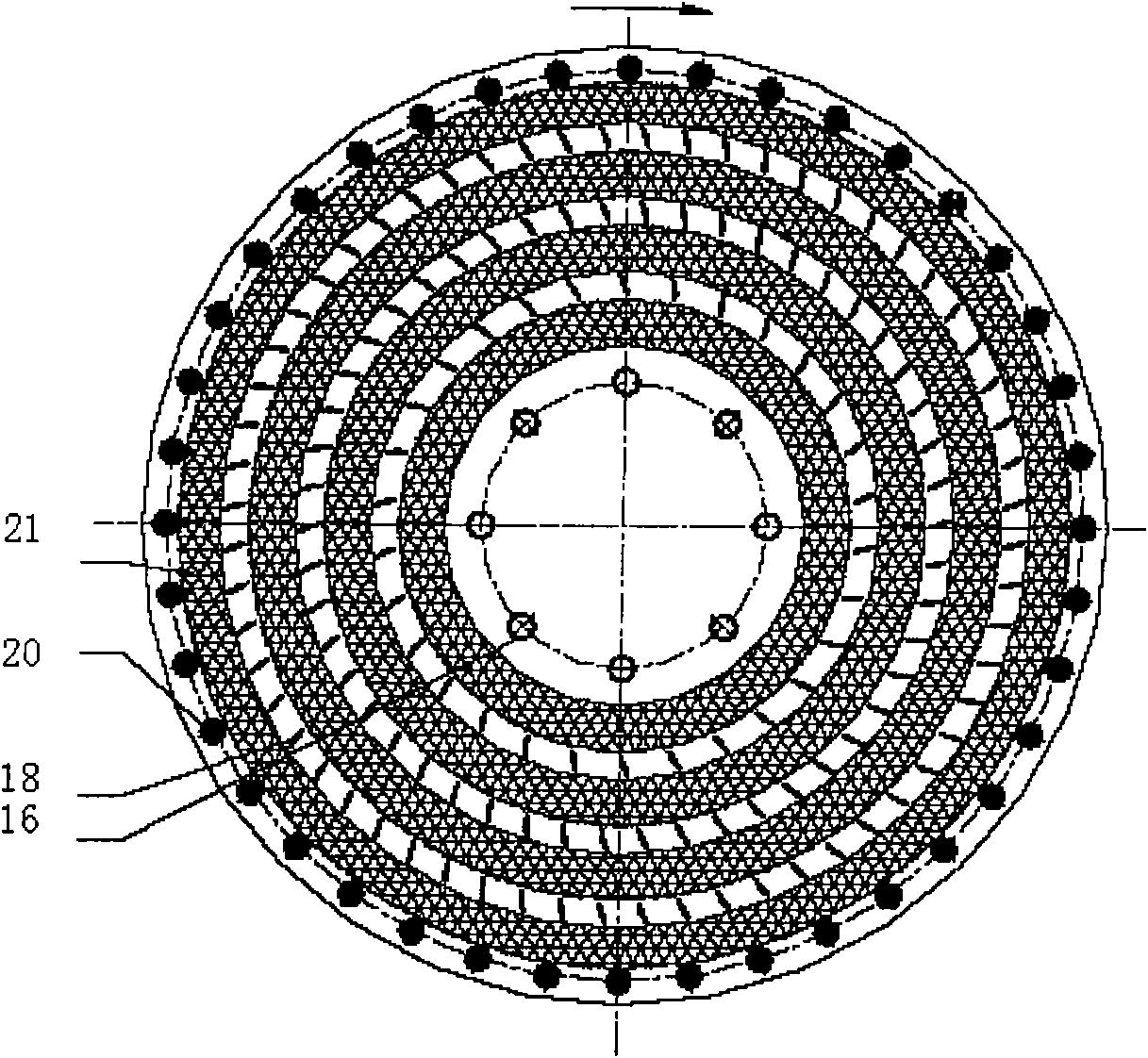

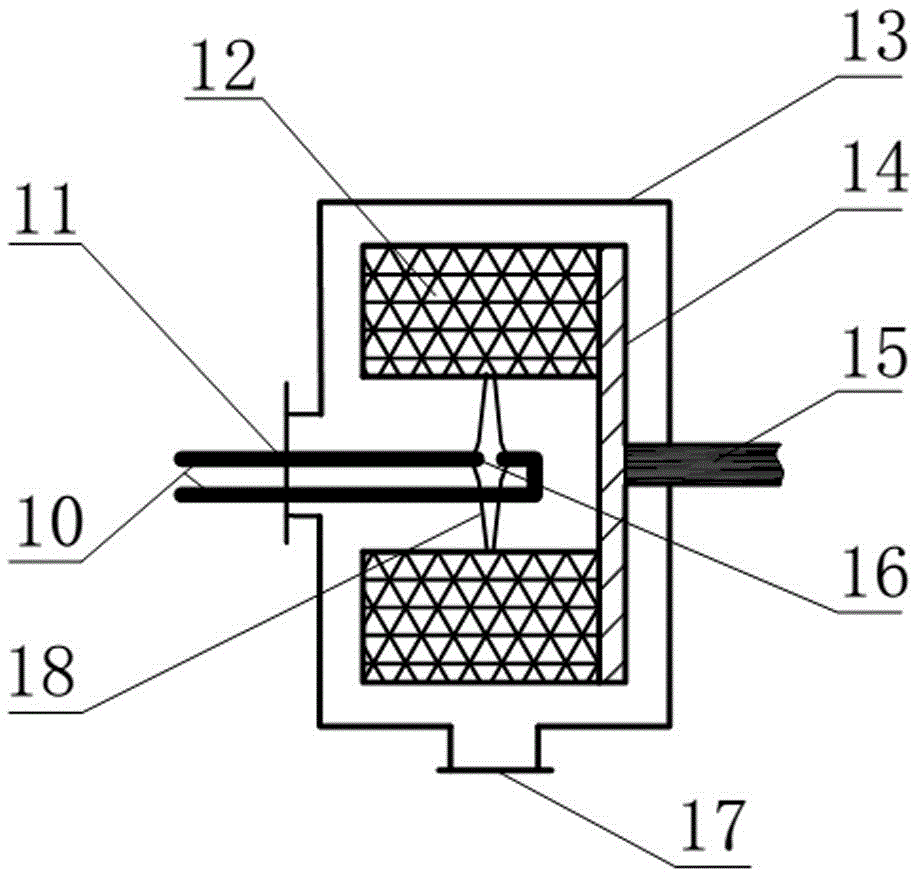

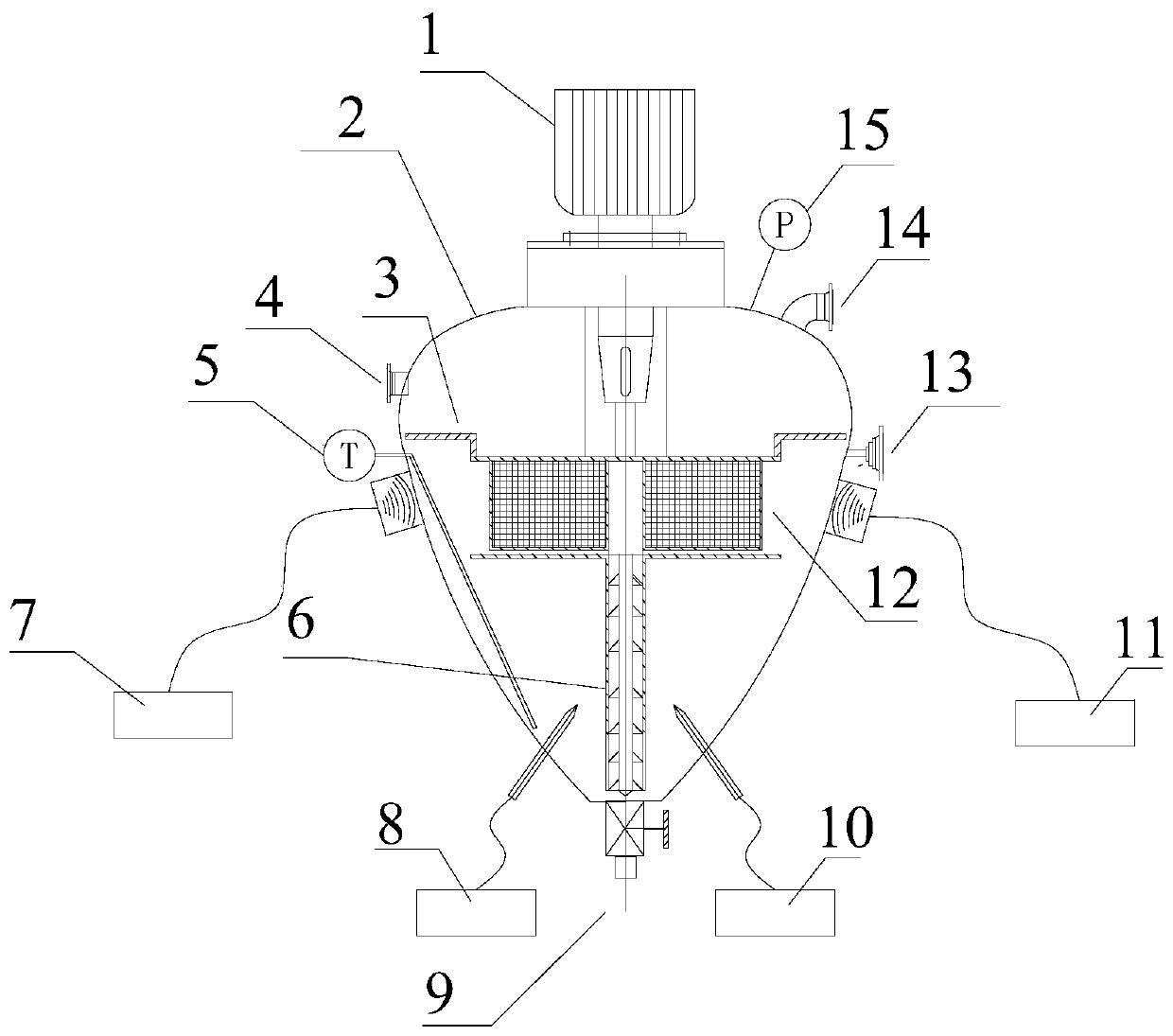

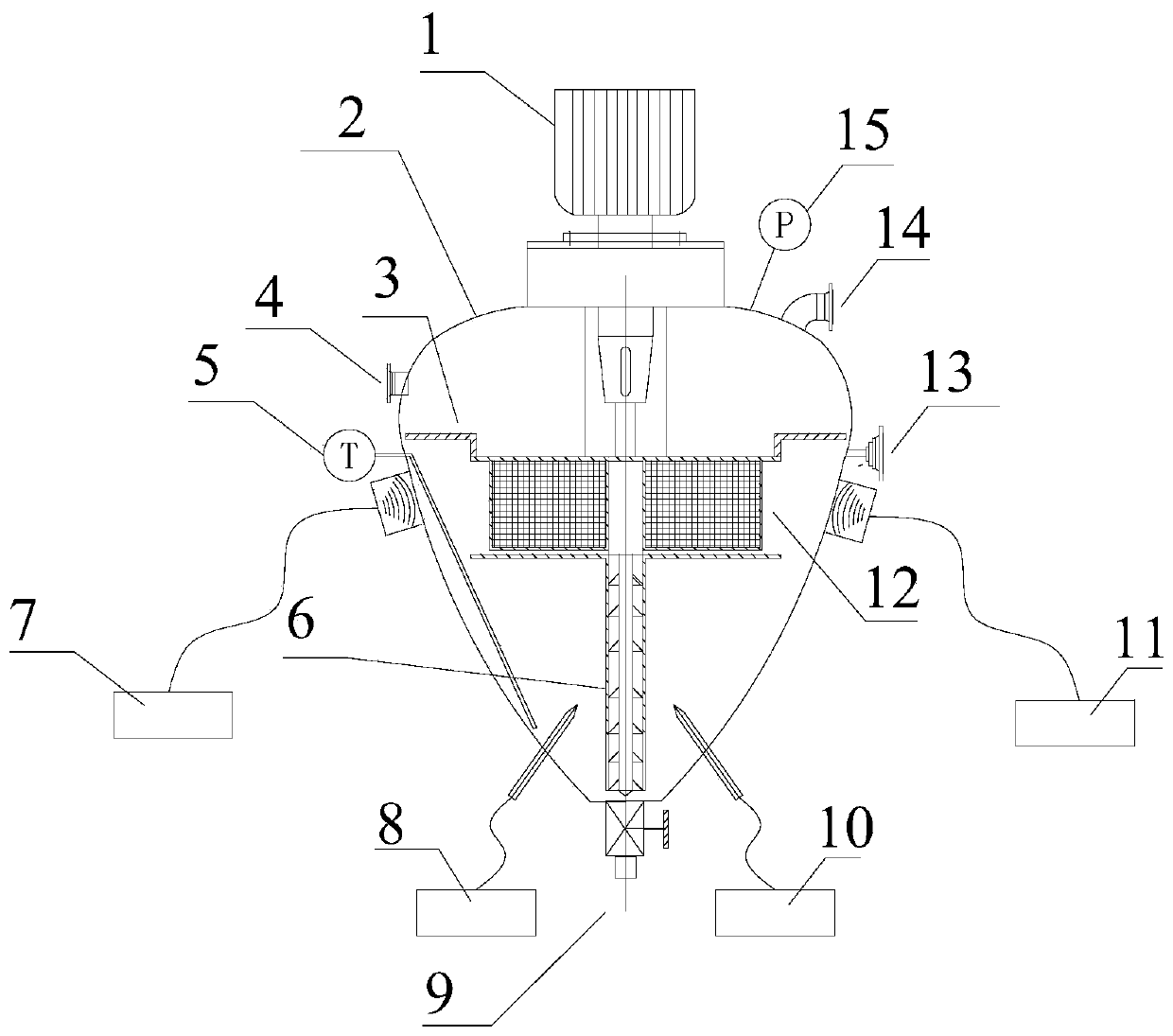

Ultrasonic coupling supergravity rotary packed bed and application thereof

ActiveCN105080436ASelf-cleaningWith substantial expansionMixersEnergy based chemical/physical/physico-chemical processesCouplingEngineering

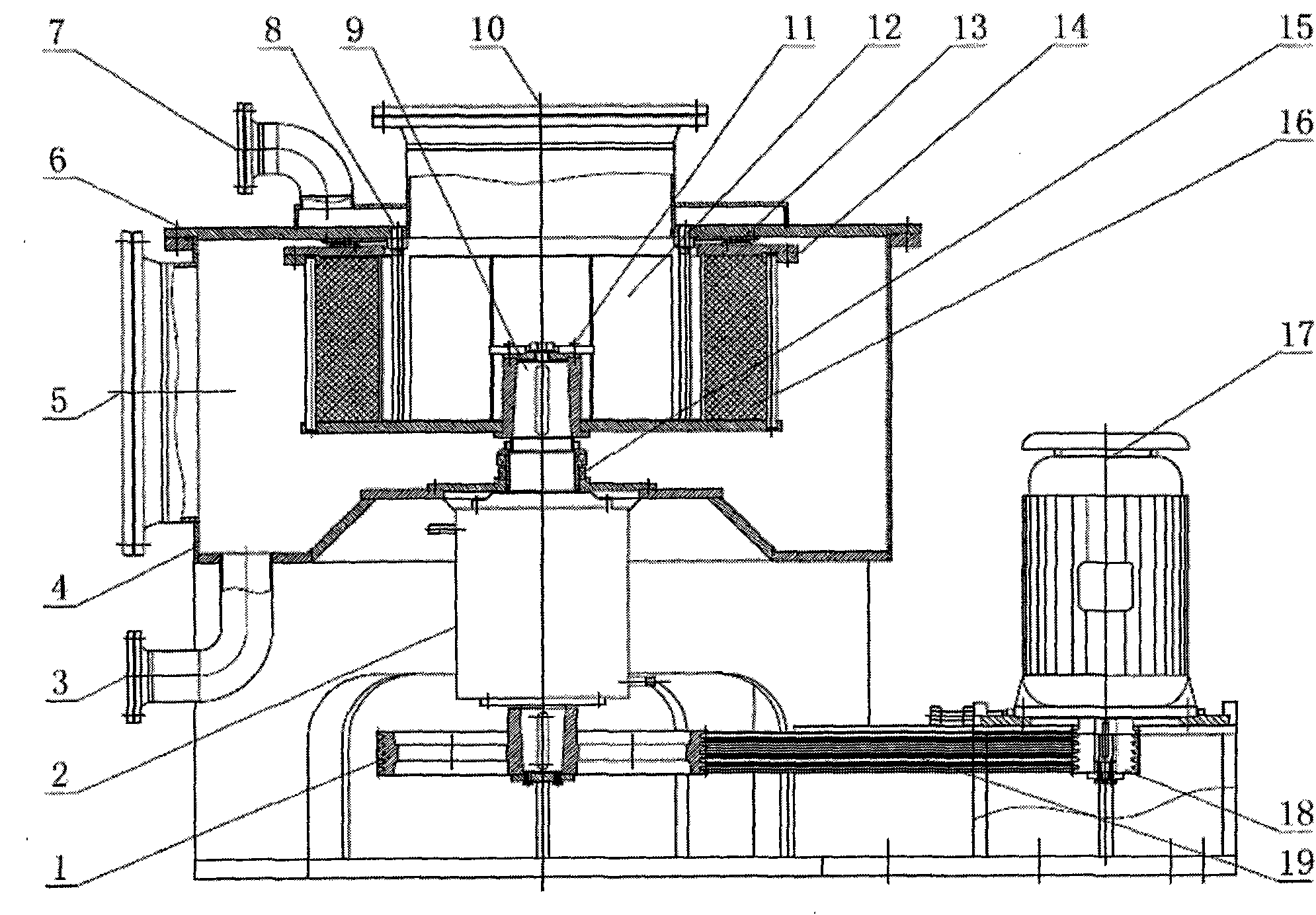

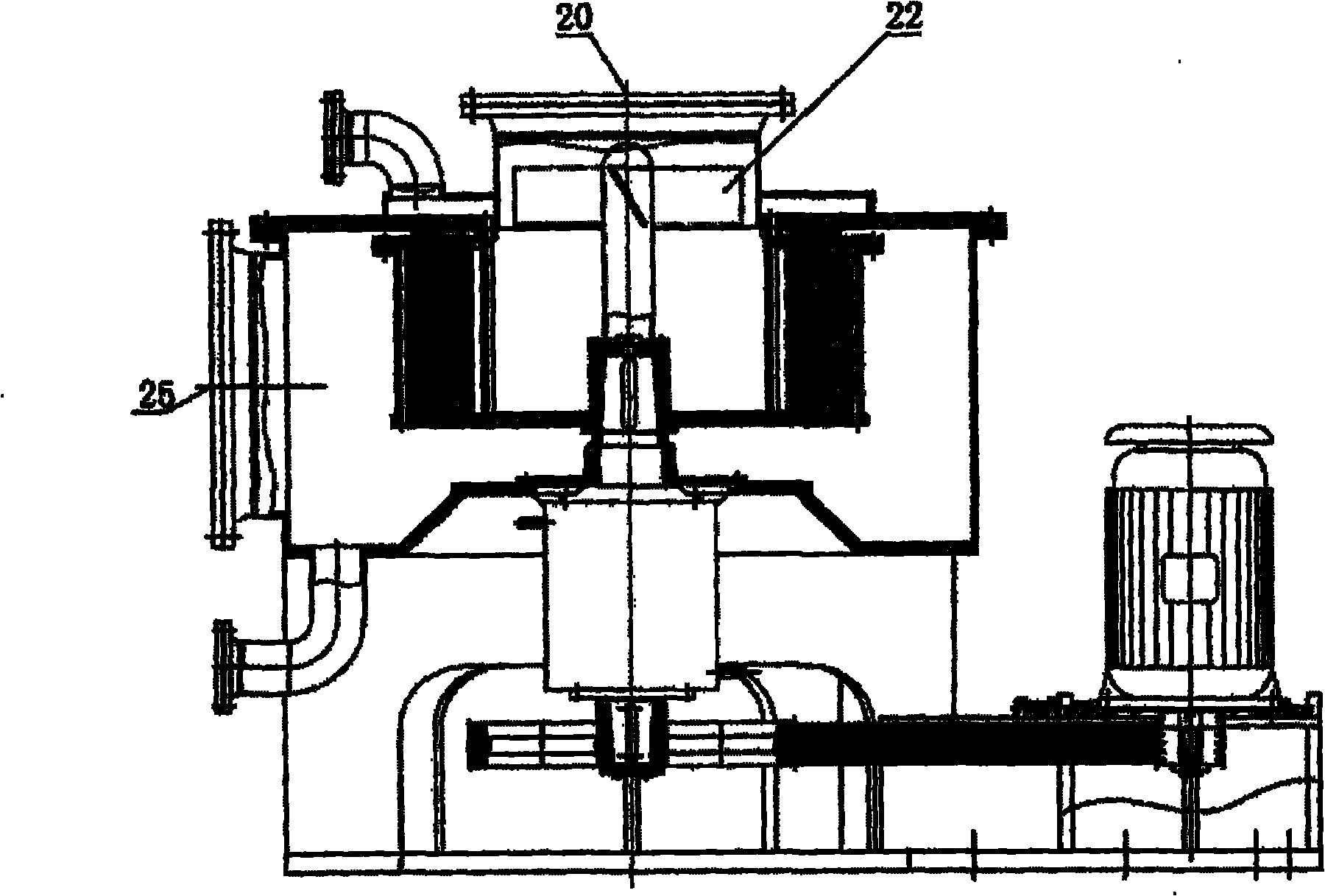

The invention discloses an ultrasonic coupling supergravity rotary packed bed which comprises a housing, an end cover, a rotator and a transmission device, wherein the housing and the end cover form a sealed cavity; the sealed cavity is internally provided with the rotator which is provided with a filler ring; the rotator is connected with the transmission device out of the sealed cavity through a rotary shaft; a gas inlet and a liquid outlet are formed on the housing; a gas outlet and a liquid input distributor are arranged on the end cover, the gas input distributor penetrates and extends to a central cavity of the rotator from the end cover and is close to the inner edge of the filler ring of the innermost inner ring; the filler ring is composed of multiple reaction filler rings which are concentrically arranged with different diameters or multiple blade rings are concentrically arranged with different diameters or multiple reaction filler rings and blade ring which are concentrically arranged in a combined manner with different diameters; a functional bade which penetrates and extends from the end cover is arranged in annular space between two adjacent filler rings. According to the device and process disclosed by the invention, the efficiency is 1.1-3 times that of the efficiency without ultrasonic waves at different ultrasonic frequencies, and the device and process can be applied to processes such as reaction, emulsification and the like. The ultrasonic coupling supergravity rotary packed bed disclosed by the invention has the advantages of being less in equipment investment, low in energy consumption, small in occupied space of equipment and the like.

Owner:BEIJING UNIV OF CHEM TECH

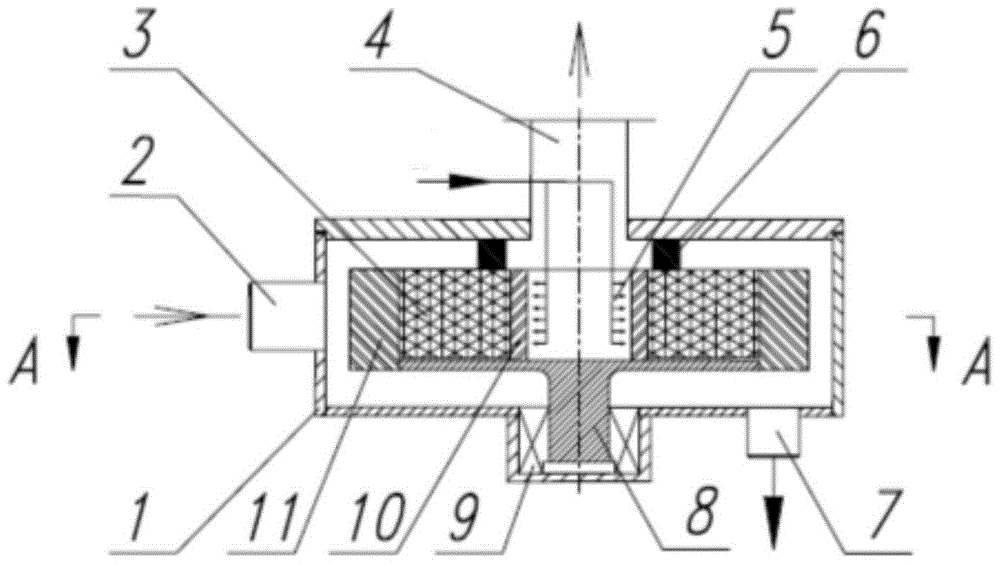

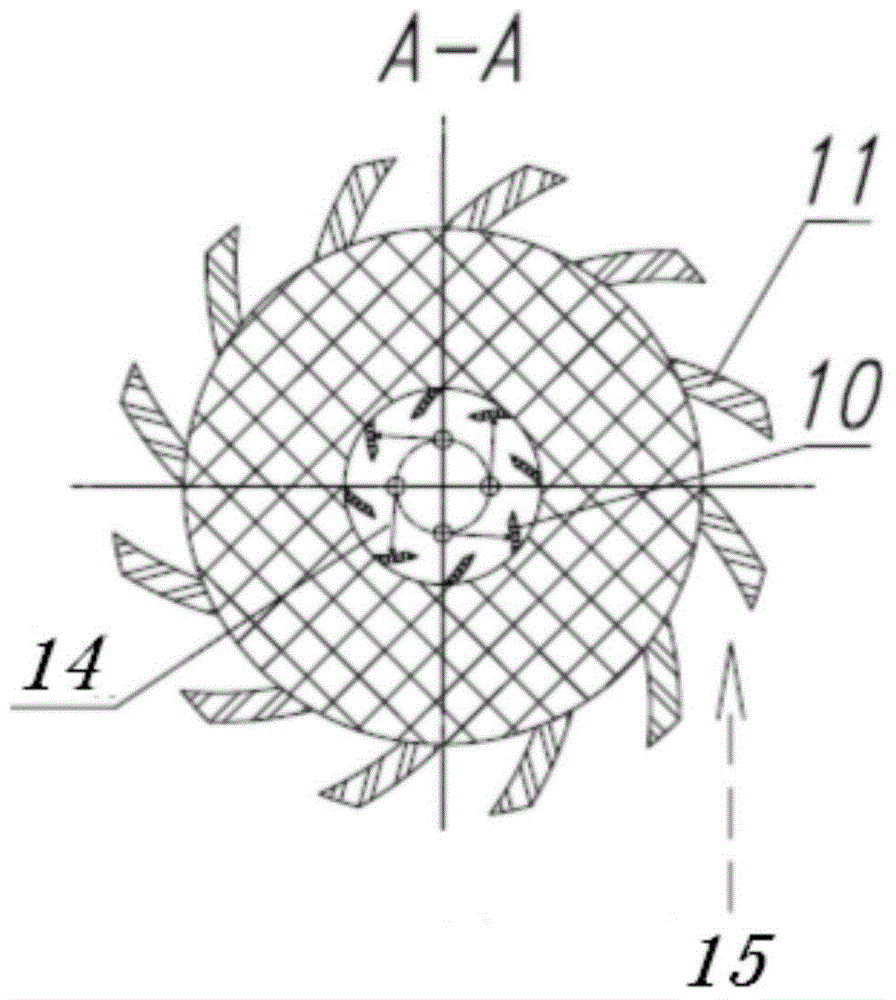

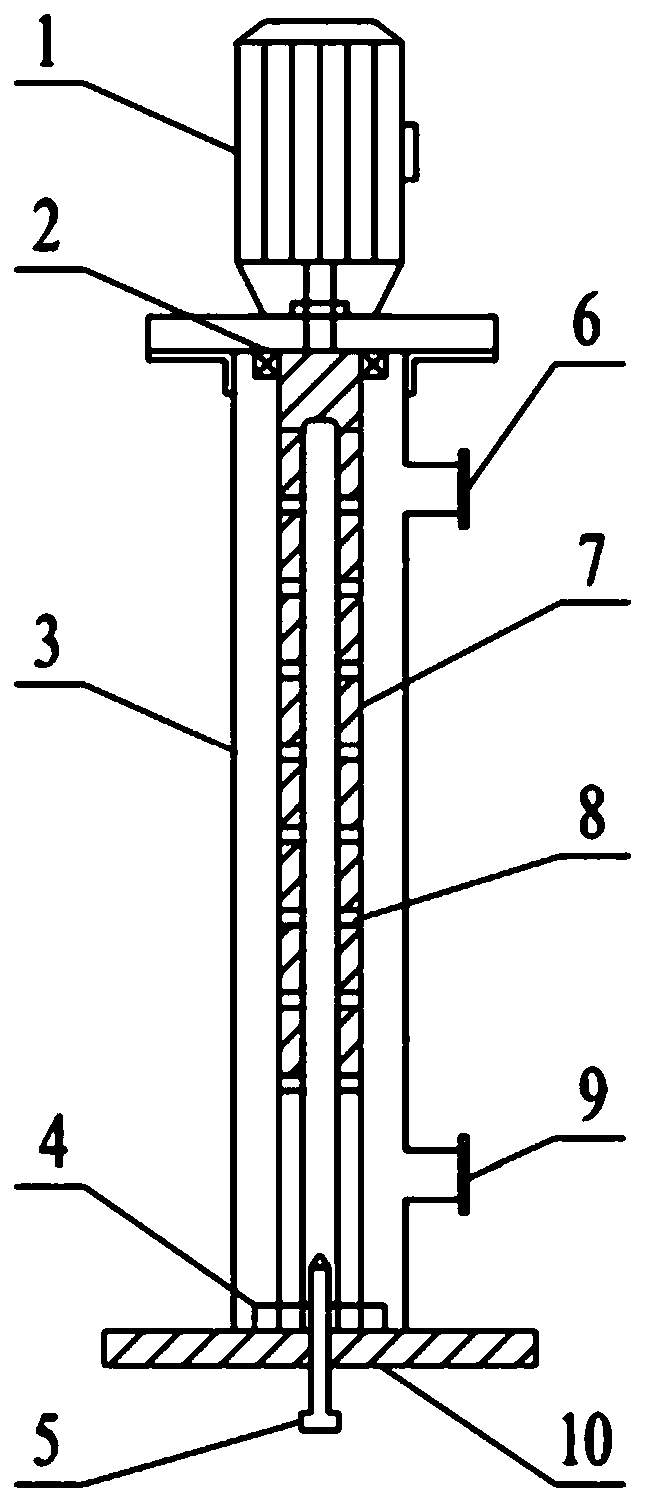

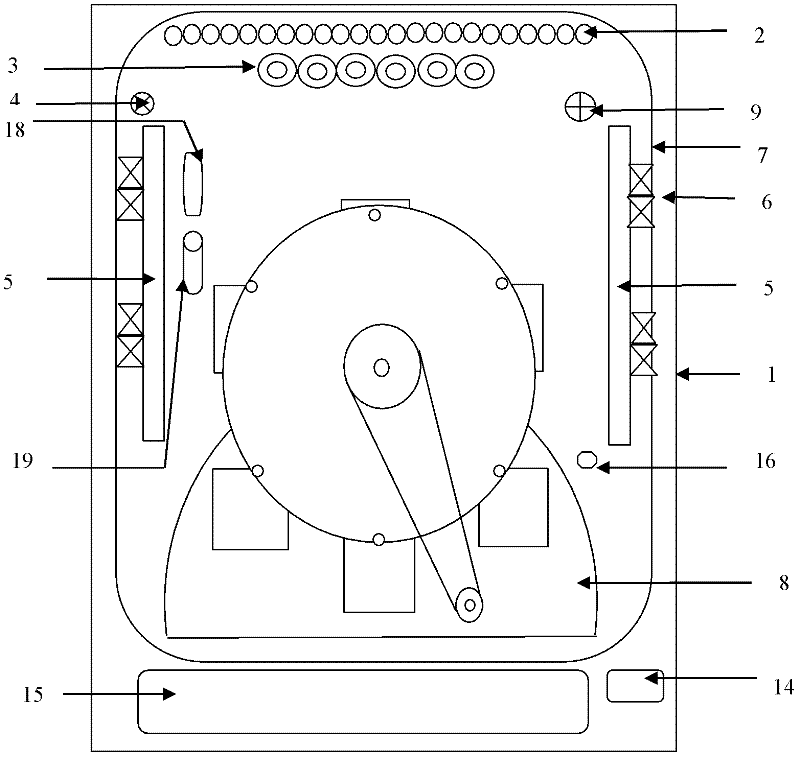

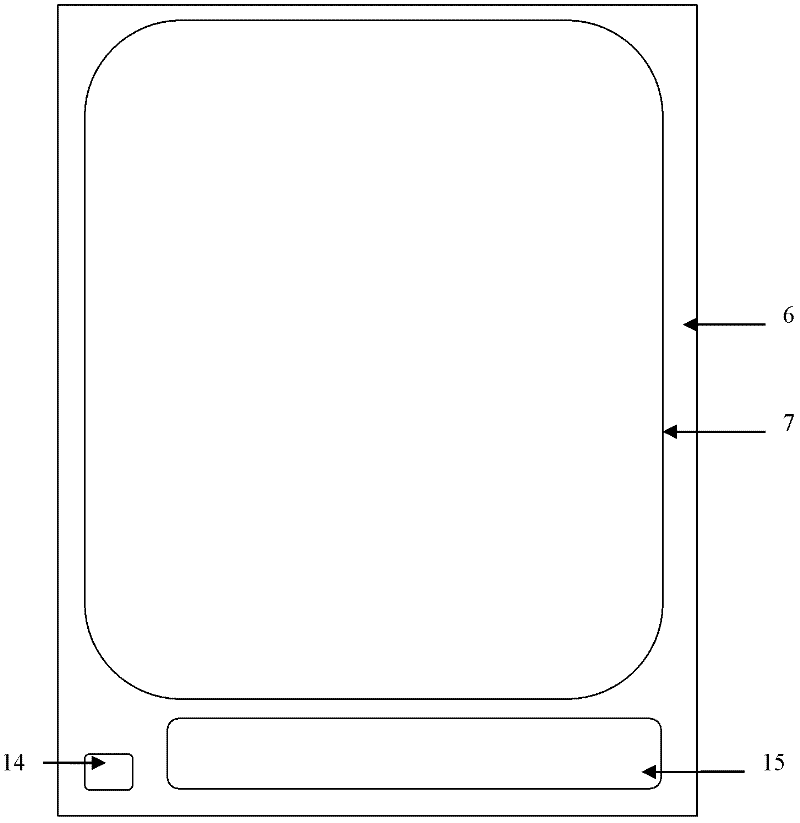

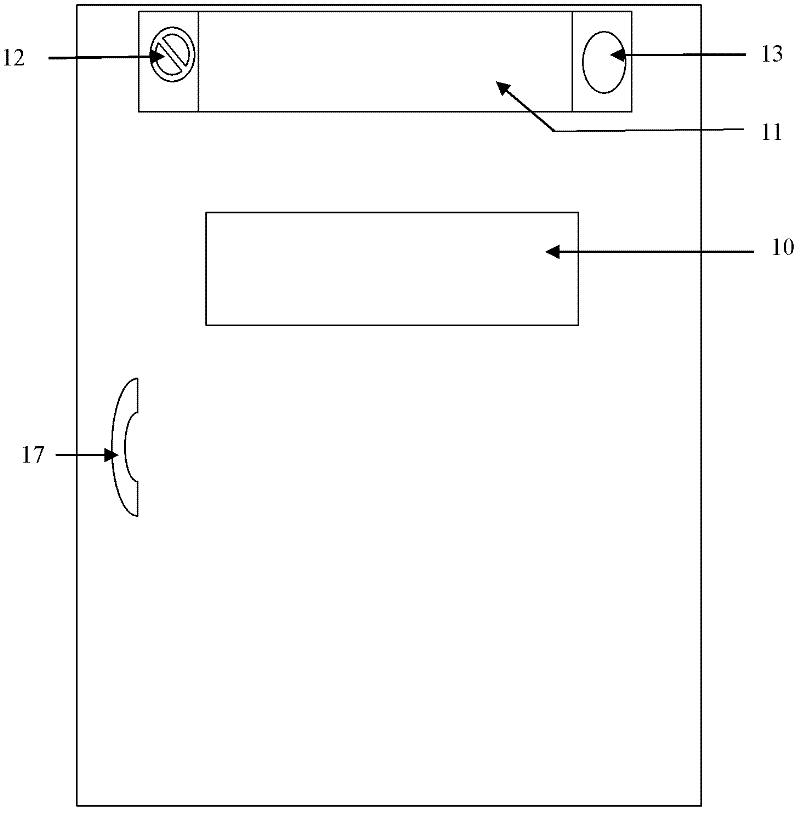

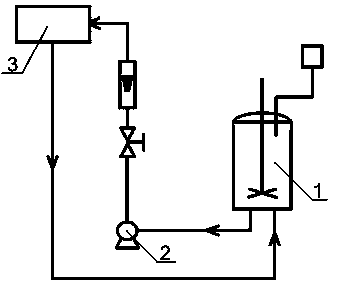

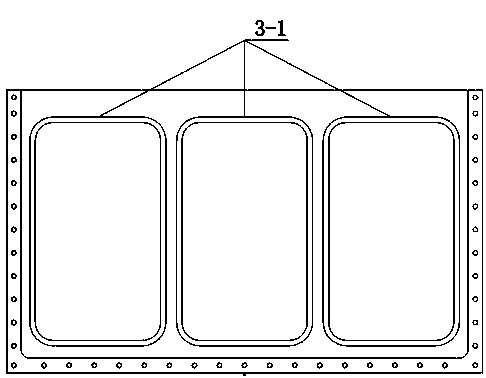

Novel passive super-gravity rotary bed device

InactiveCN104549100AMeets the requirement to omit the motorReduce energy consumptionTransportation and packagingUsing liquid separation agentEngineeringHigh pressure

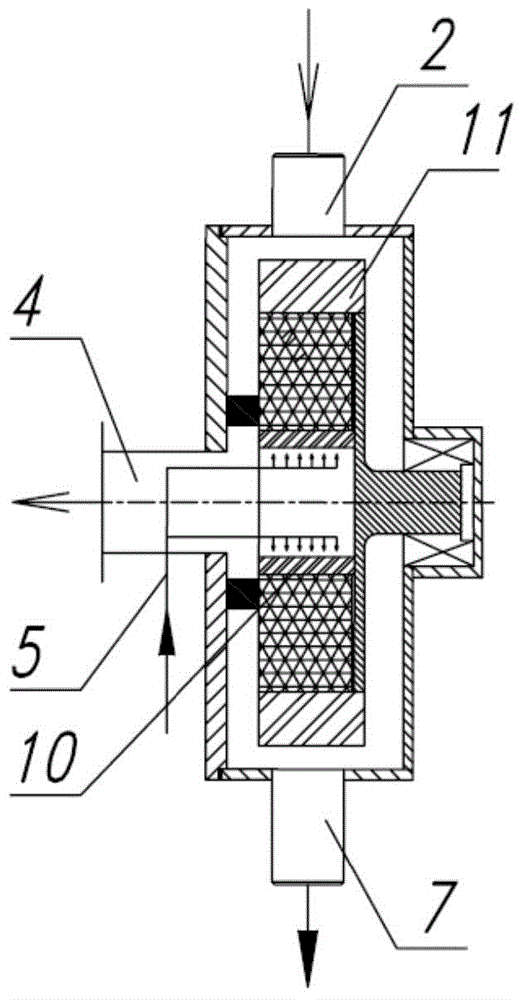

A passive supergravity rotating bed apparatus, comprising a housing (1), a rotor (3), a rotary shaft (8), a first gas conduit (2), a second gas conduit (4), liquid separators (5), and a liquid outlet (7). The rotor (3) is disposed within the housing (1) and is rotatably connected to the housing (1) by means of the rotary shaft (8). The first gas conduit (2), the second gas conduit (4), and the liquid outlet (7) are disposed on the housing (1). The liquid separators (5) are disposed at the inner edge of the rotor (3). Blades (10, 11) are provided on the inner edge of the rotor (3), the outer edge of the rotor (3), or on the inner and outer edges of the rotor (3). High-pressure fluid pushes the blades (10, 11), thereby driving the rotor (3) to rotate. Hence, no electric motor is required to drive the rotor.

Owner:BEIJING UNIV OF CHEM TECH +1

Low-pressure-drop nano/microstructure filler revolving bed supergravity device and application thereof

ActiveCN102120172AGas phase pressure drop is smallImprove mass transfer efficiencyDispersed particle separationChemical/physical/physico-chemical stationary reactorsPorosityEngineering

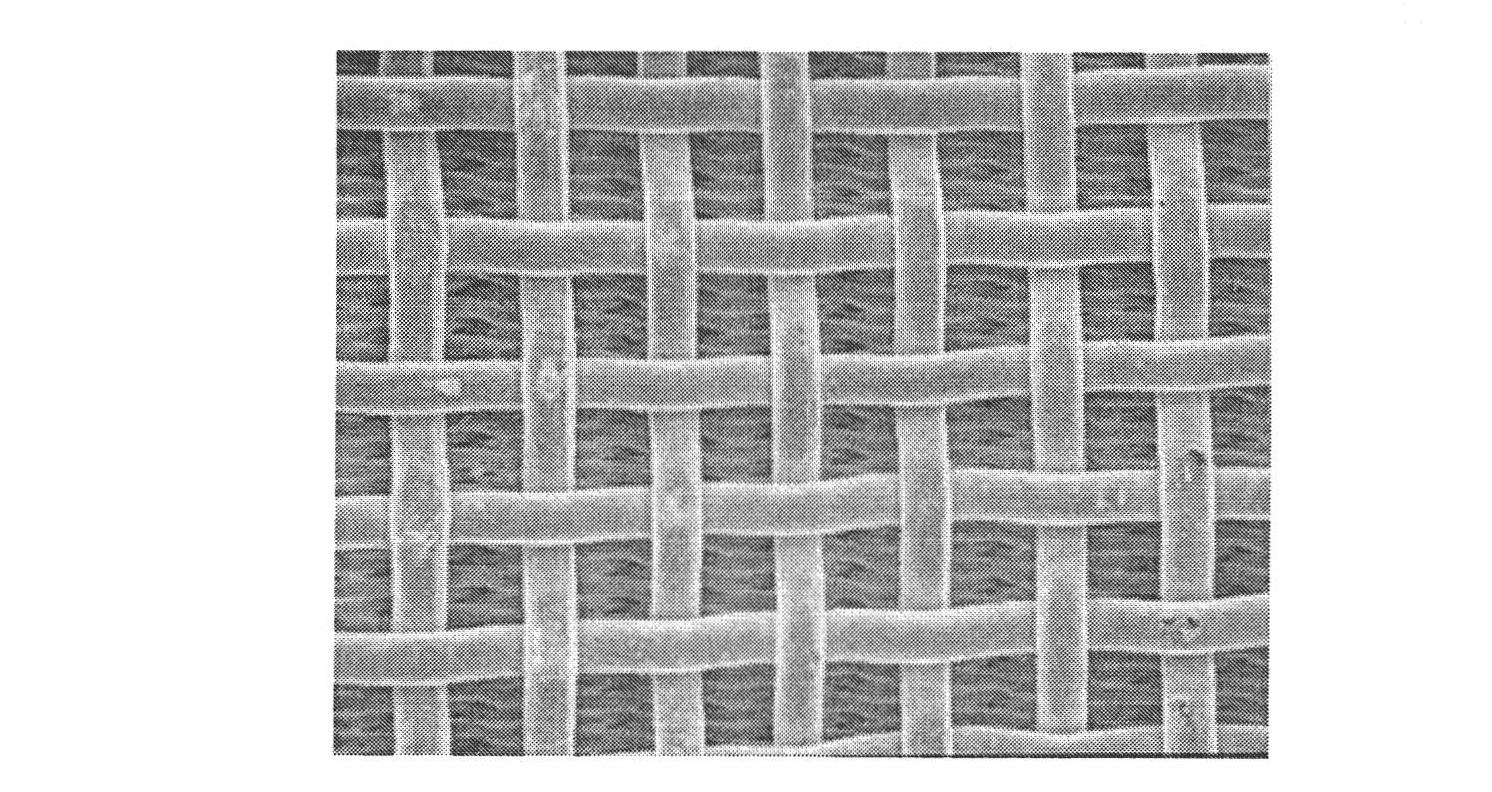

The invention discloses a low-pressure-drop nano / microstructure filler revolving bed supergravity device and application thereof and belongs to the technical field of supergravity. The supergravity device comprises a rotating part formed by arranging a rotor and a filler in a closed shell, wherein the shell and an upper cover have a liquid inlet, a liquid outlet, a gas inlet and a gas outlet; and a liquid distributor extending into a central cavity of the rotor is arranged in the liquid inlet. In the device, the filler in the rotating part is a structuralized SiC, sintered ceramic and powder sintered titanium-based alloy filler with a nano / microstructure, the runner diameter of the structuralized filler is 0.1 to 5mm, the porosity is 55 to 97 percent, the surface of the filler has a 0.01 to 3-micrometer convexoconcave nano / microstructure, and the specific surface area of the filler is 200 to 2,000m<2> / m<3>. When the device is used for deeply removing sulfur dioxide from industrial gases such as sulfuric acid industrial tail gas with low-pressure-drop requirement, the pressure drop of the supergravity device is lowered by 40 to 80 percent, and the harmful gas content after treatment is lower than 20 to 100ppm.

Owner:BEIJING UNIV OF CHEM TECH +1

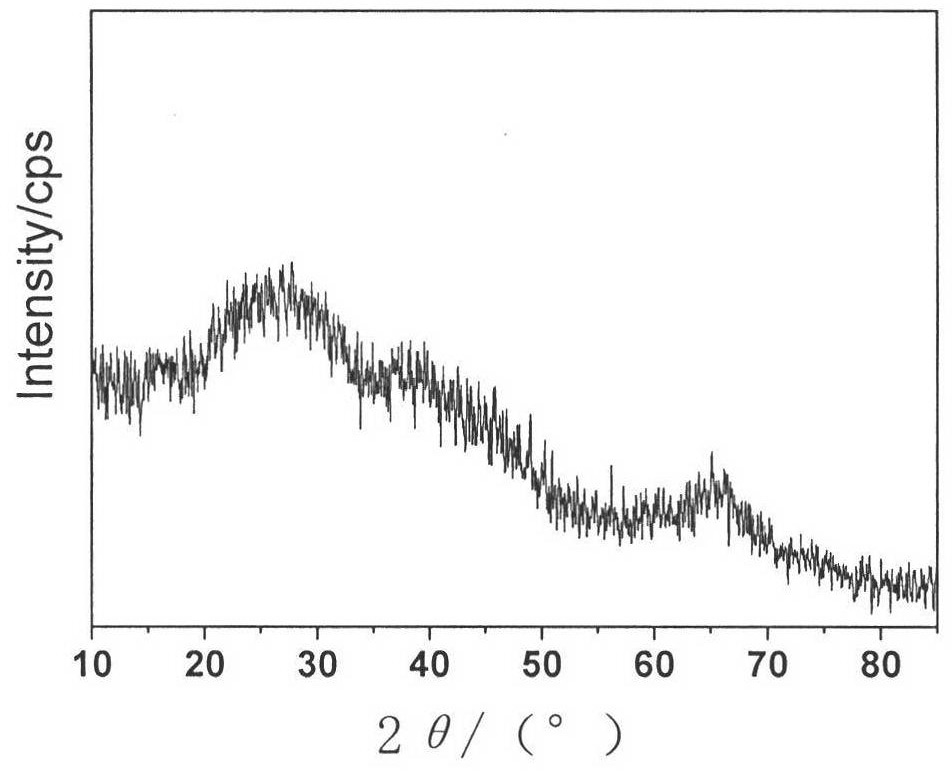

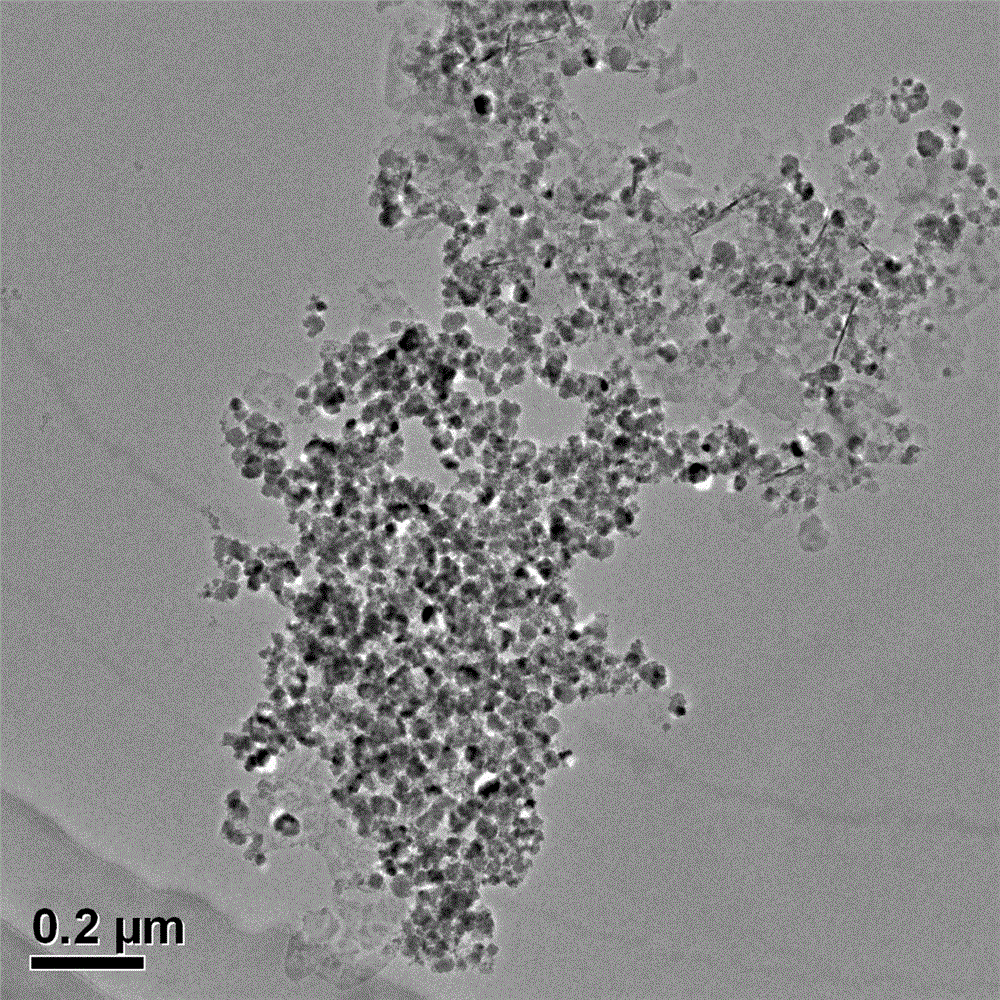

Method for preparing nano material

InactiveCN102030352AThe method is scientific and reasonableImprove product qualityZinc oxides/hydroxidesNanotechnologyChemical reactionDecomposition

The invention relates to a method for preparing a nano material, which comprises the step of: preparing a nano material precursor and a nano material. The method for preparing the nano material precursor comprises the step of: placing reacting raw materials in a supergravity filed reactor for gas-liquid reaction or liquid-liquid reaction to obtain the nano material precursor. The method for preparing the nano material comprises the step of heating and roasting the nano material precursor with a microwave field to ensure that the nano material precursor generates decomposition or recrystallization to obtain the nano material. The method for preparing the nano material precursor also comprises the step of: in a process of accelerating and enhancing the mass transfer with the supergravity filed, enabling a metal salt water solution in the reactor to be uniformly mixed with a liquid precipitator or gas precipitator in a molecule size manner for chemical reaction to obtain the nano material precursor of carbonate materials or nano oxyhydrate materials or hydrous oxide materials of the metal, wherein the prepared nano material is used as a nano metal oxide. The method has the advantagesof scientific and reasonable structure, high quality of products, energy saving, no secondary pollution and the like.

Owner:XIANGTAN UNIV

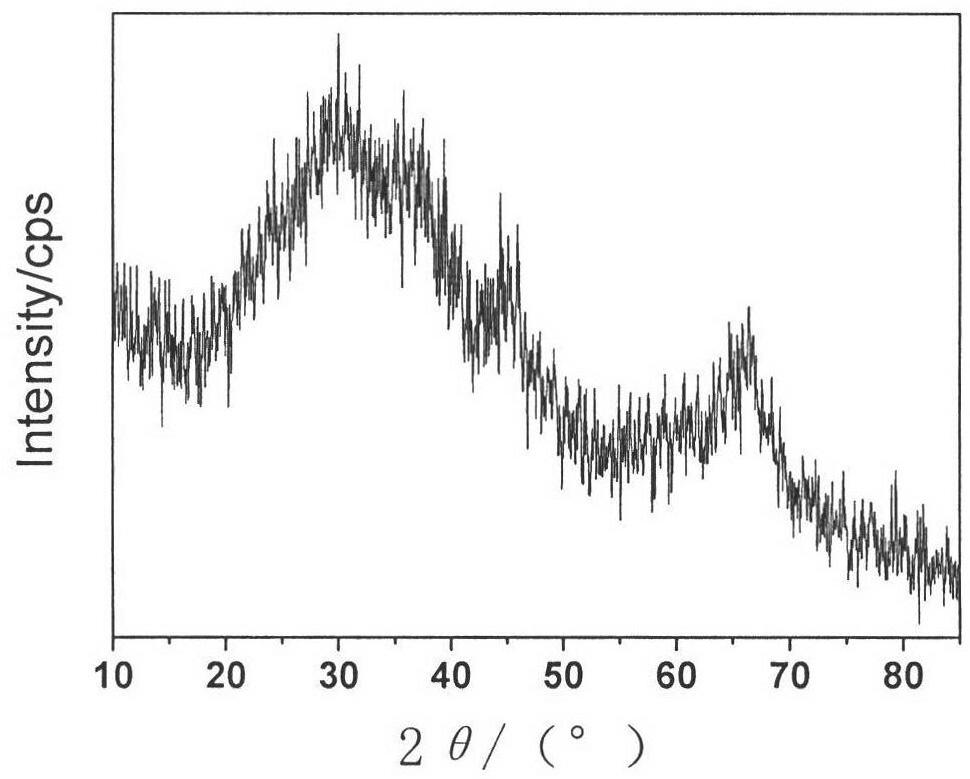

Preparation method of nano alpha-Fe2O3

InactiveCN107601574ARegular shapeGood dispersionMaterial nanotechnologyFerric oxidesDispersitySolvent

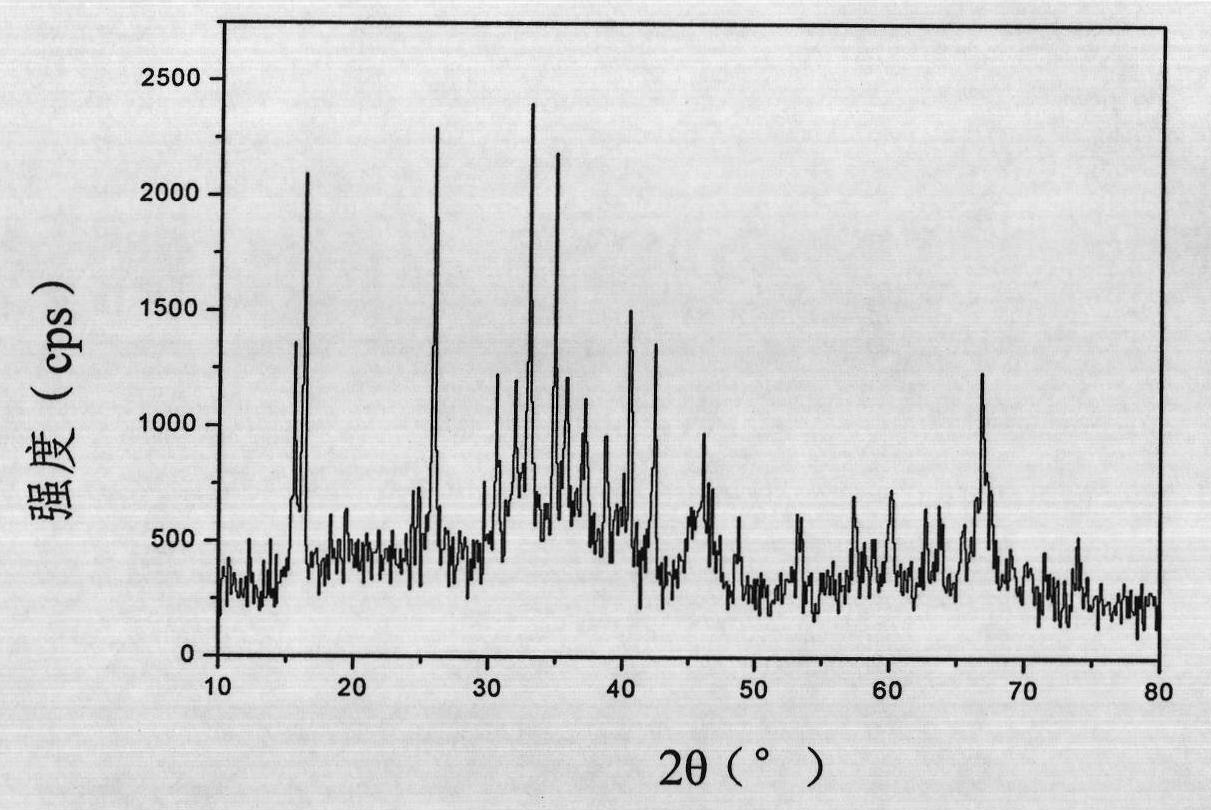

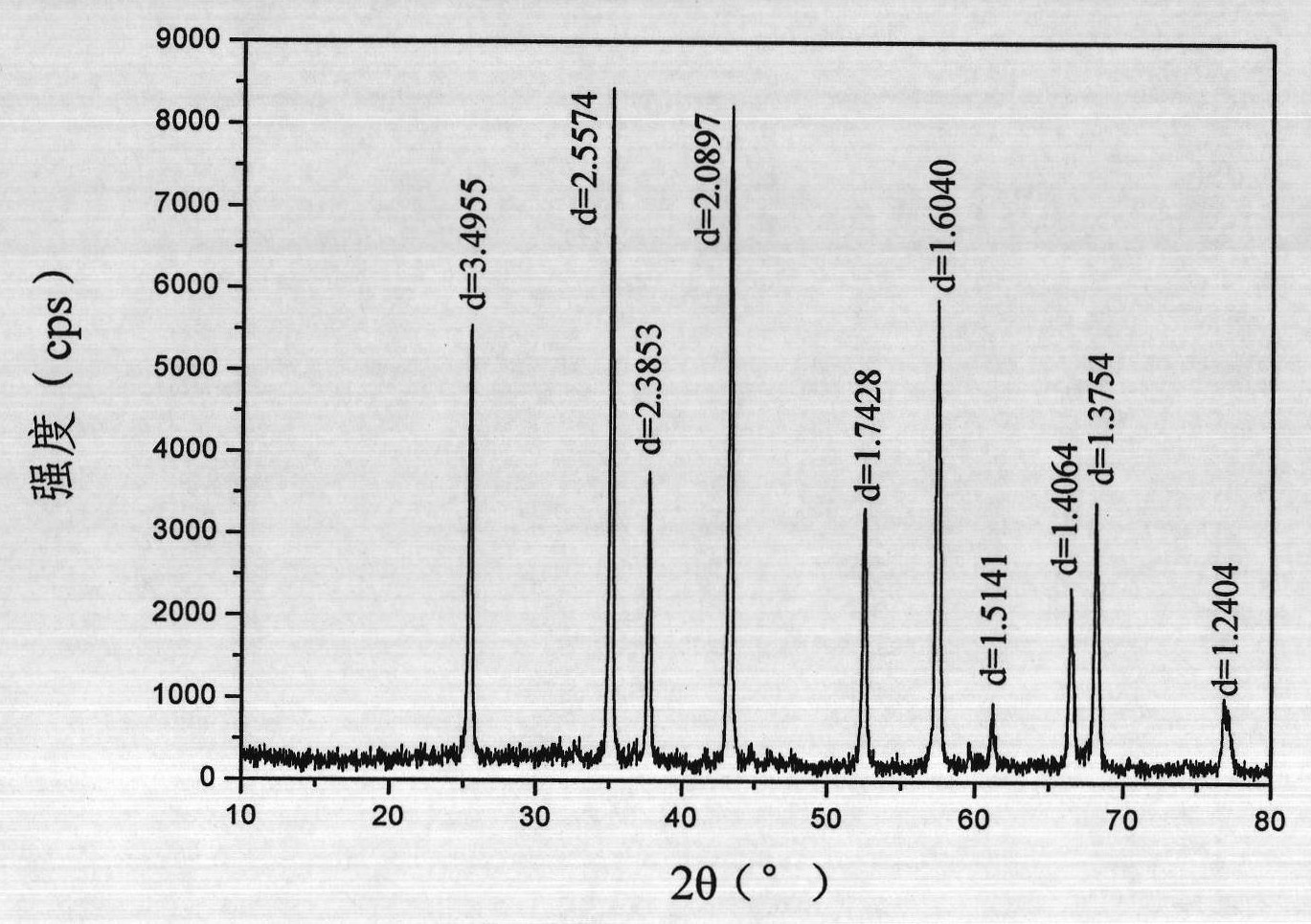

The invention discloses a preparation method of nano alpha-Fe2O3 and belongs to the crossing field of chemical engineering and materials. Ferric salt, alkali, water, an organic solvent and other raw materials are pre-mixed in a supergravity rotating packed bed, a uniformly mixed precursor suspension is put in a hydrothermal kettle for heating, and nano alpha-Fe2O3 is obtained through washing, centrifugation, drying and other steps. The micromixing characteristic can be strengthened on the basis of the supergravity rotating packed bed, micromixing of a ferric salt solution and an alkaline solution is strengthened through the supergravity rotating packed bed, so that rapid and homogeneous nucleation of a reaction system is realized, a precursor suspension containing uniform crystal nucleusesis obtained, a solvothermal method is adopted in the later crystallization process, the product morphology and size are effectively regulated by changing the rotating speed of the rotating bed, the solvent type, the concentration of the alkaline solution and other parameters, and 15-30 nm nano alpha-Fe2O3 with regular particle morphology, good dispersity, small size and uniform particle size distribution is prepared.

Owner:BEIJING UNIV OF CHEM TECH

Supergravity nano-microbubble generating device and reaction system

ActiveCN109701457AIncrease gas holdupSmall particle sizeLiquid-gas reaction as foam/aerosol/bubblesFlow mixersMicrobubblesGas phase

The invention provides a supergravity nano-microbubble generating device and a reaction system. In the device, a liquid phase is a continuous phase, and a gas phase is a dispersed phase; gas enters the interior from a hollow shaft, and primary shearing is carried out on the gas through shearing action of aeration micropores for forming bubbles; then the bubbles are quickly separated from the surface of the rotating shaft under the action of the rotating shaft which rotates at a high speed; and secondary shearing is carried out under the strong shearing force of a super-gravity environment generated by the rotating shaft to form nano-microbubbles. The nano-microbubbles have the advantages of being fast and stable and having a small average particle size, the average particle size of the formed nano-microbubbles is in a range of from 800 nm to 50 microns, and the range of the average particle size of the bubbles can be adjusted and controlled by adjusting the rotating speed of the rotating shaft. According to the device, on one hand, the problem that a liquid phase in a conventional supergravity device is discontinuous and a liquid phase containing nano-microbubbles cannot be formedis solved, and on the other hand, the problem that nano-microbubbles are clustered on the surface of a static microporous medium is solved.

Owner:BEIJING UNIV OF CHEM TECH

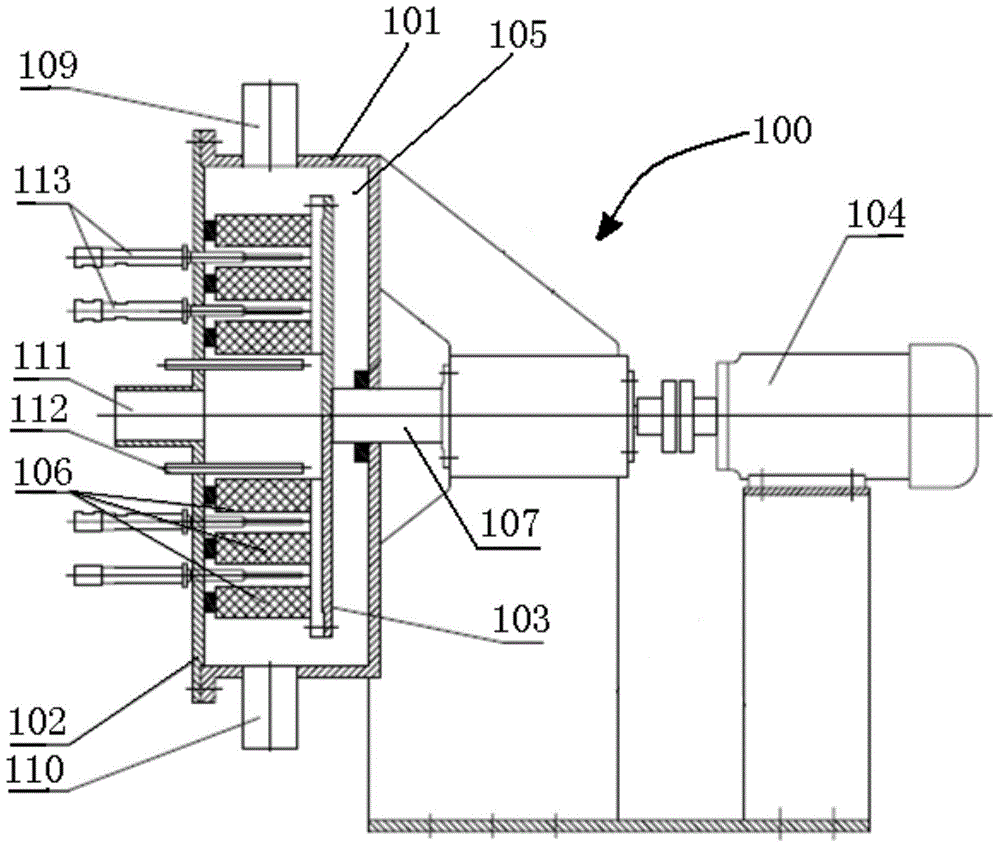

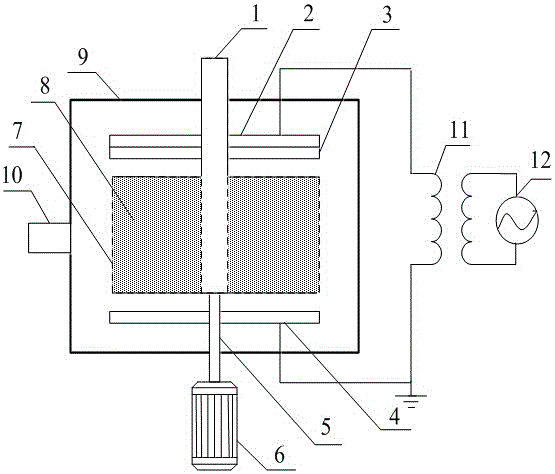

Device and method for cooperatively removing gaseous pollutants by plasma-supergravity coupling

ActiveCN105032136AImprove joint removal efficiencyReduce removal costsDispersed particle separationChemical reactionHigh energy

The invention discloses a device and a method for cooperatively removing gaseous pollutants by plasma-supergravity coupling. According to the device and the method disclosed by the invention, multiple gaseous pollutants are decomposed and oxidized by using high-energy electrons and active groups generated by low-temperature plasma discharge; in a process that the gaseous pollutants flow through a solid adsorbent reactor rotating at high speed, gas containing the pollutants are in sufficient contact with a solid adsorbent by means of a supergravity effect generated by high-speed rotation of gas and solid, to generate a gas phase-solid phase adsorption and chemical reaction to finish substance conversion and purification processes between multiple gaseous pollutants and the solid adsorbent, and thus the pollutants are converted into non-toxic and pollution-free substances. The device and the device are applicable to dry-process combined removal of multiple pollutants in flue gases and various wastes gas generated by combustion, gasification, incineration and the like in the fields of energy resources, chemical engineering, building materials, metallurgy and the like containing multiple gaseous pollutants.

Owner:SOUTHEAST UNIV

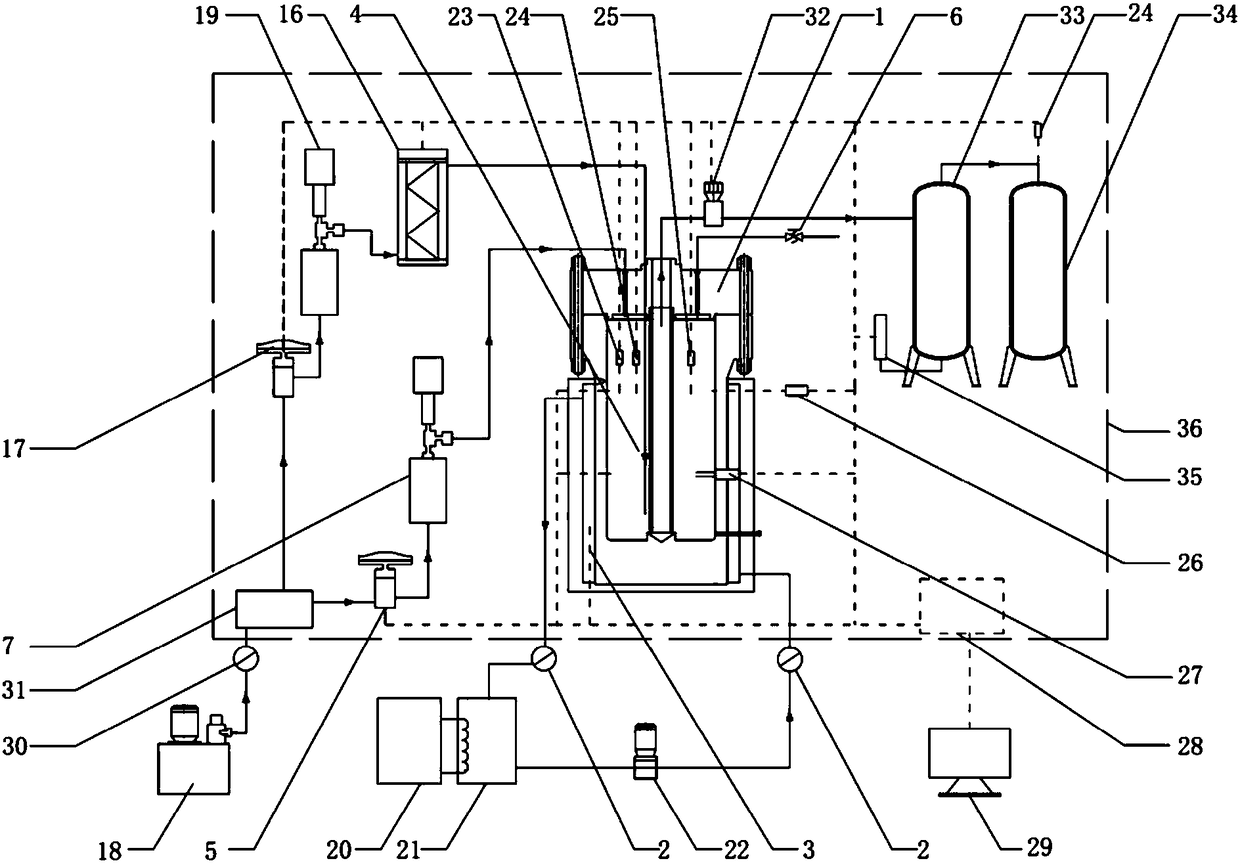

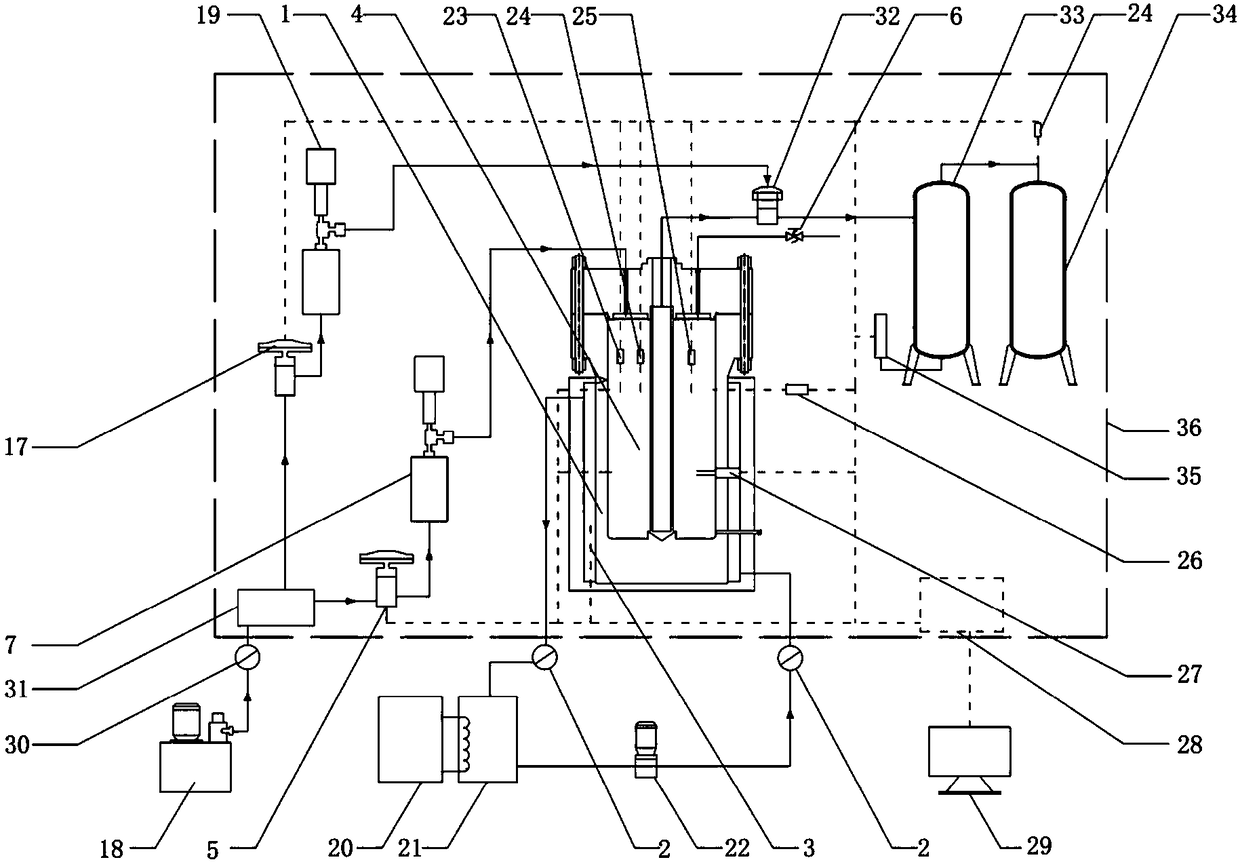

Natural gas hydrate heat shock method mining simulation device under supergravity condition

ActiveCN108386164AEffective guidanceImprove toleranceConstructionsFluid removalTemperature controlWater baths

The invention discloses a natural gas hydrate heat shock method mining simulation device under a supergravity condition. A hydraulic oil station is connected to a confluence plate through an oil pathcentrifuge rotation joint to be divided into two paths, wherein two paths are respectively connected to a high-pressure reactor through a supergravity hydraulic pressure control module and a supergravity heat shock module; a supergravity gas-liquid separation module is directly connected to the high-pressure reactor; a kettle body temperature control module is connected to the high-pressure reactor through a water bath passage centrifuge rotation joint; sensors in the high-pressure reactor, the supergravity hydraulic pressure control module, the supergravity heat shock module, the supergravitygas-liquid separation module and the kettle body temperature control module are all connected with a data collection box. According to the natural gas hydrate heat shock method mining simulation device, the cataclysm process of on-site natural gas hydrate heat injection mining can be truly simulated, and a scientific support is provided for a natural gas hydrate heat injection mining simulation experiment.

Owner:ZHEJIANG UNIV

Method for preparing nano alumina

InactiveCN102328941AUniform particle sizeUniform particle size distributionNanotechnologyAluminium oxides/hydroxidesNano al2o3Inorganic materials

The invention belongs to the field of inorganic material preparation and relates to a method for preparing nano alumina, and in particular relates to a method for preparing nano alumina by using a supergravity method. Aiming at the defects in the prior art, a method, which has simple process and low cost, is safe to operate and is easy to industrial product on large scale, for preparing nano alumina is provided. The method adopted in the invention has simple process and low cost, prepared alumina has high purity and uniform particle size, and is easy to achieve large-scale industrial production.

Owner:XIANGTAN UNIV

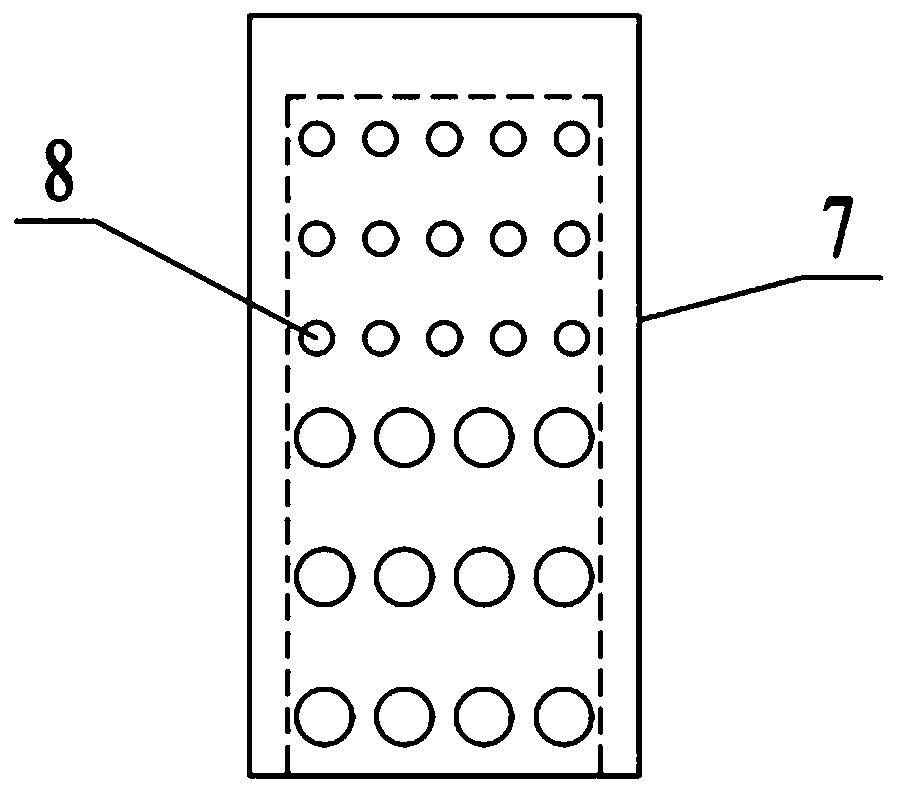

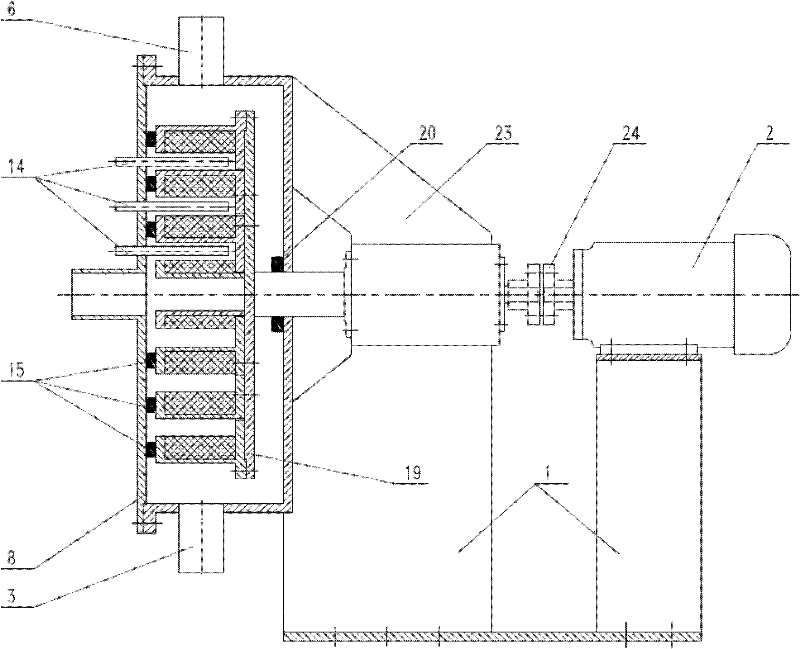

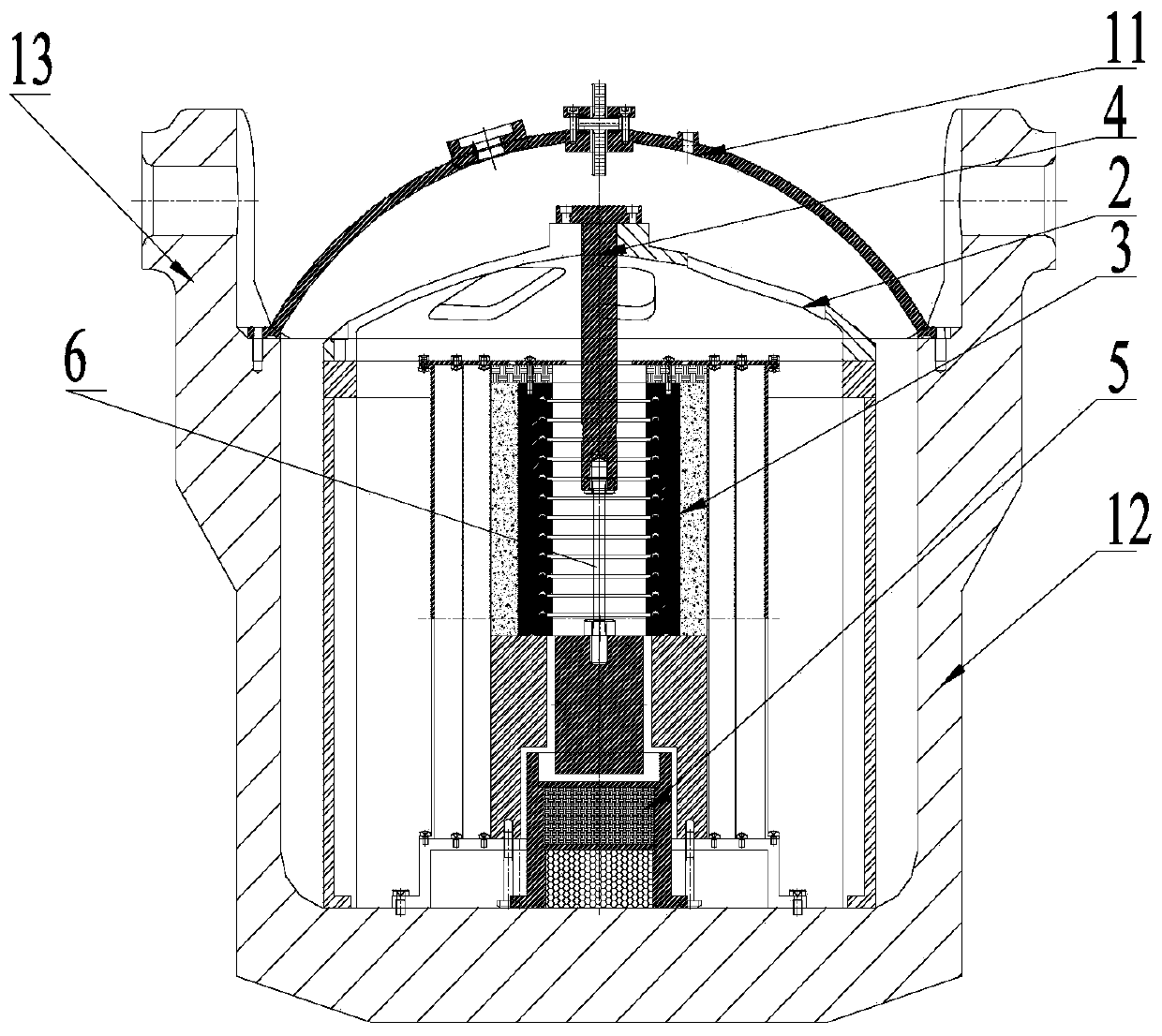

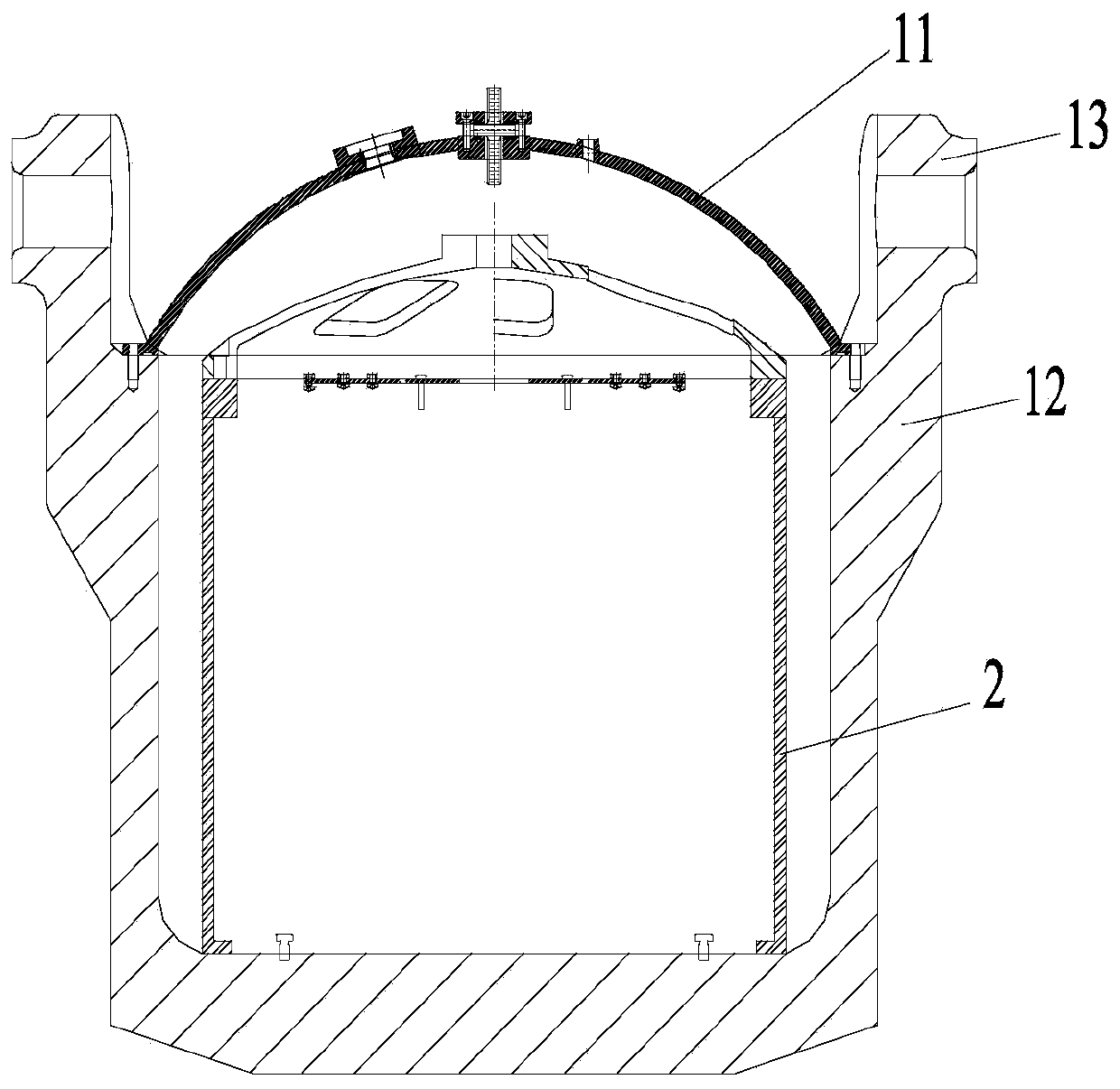

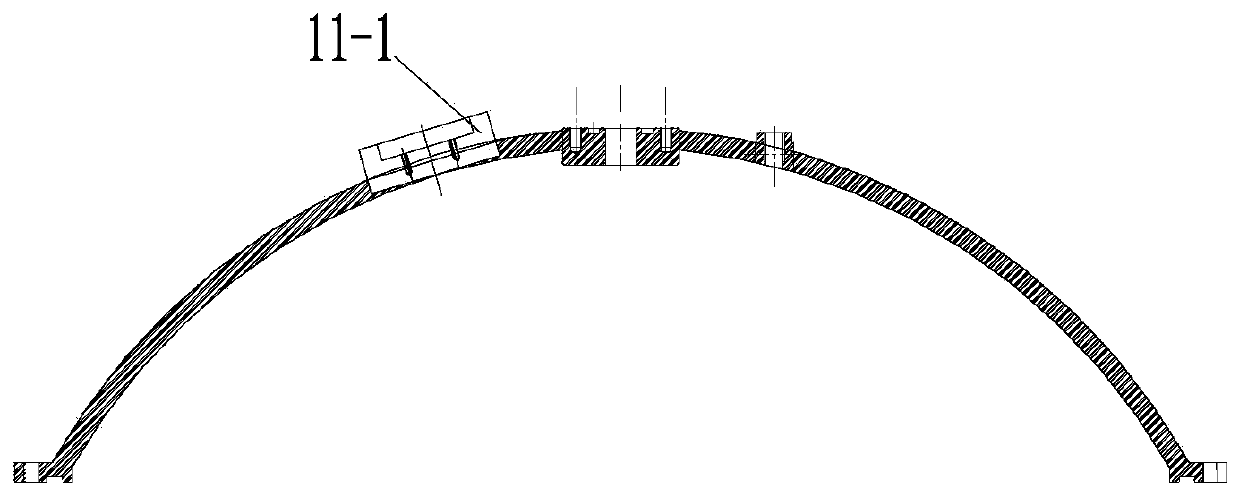

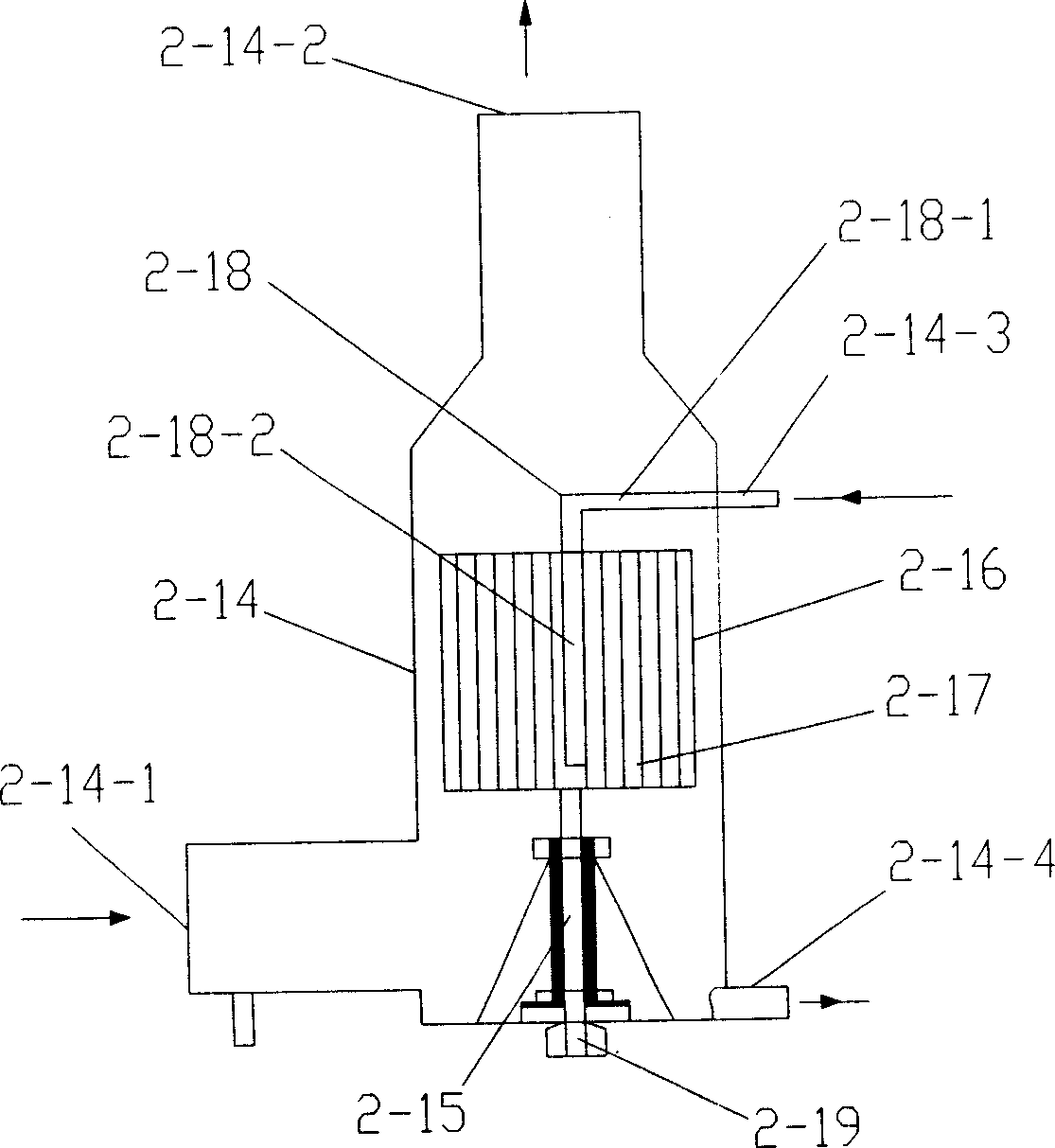

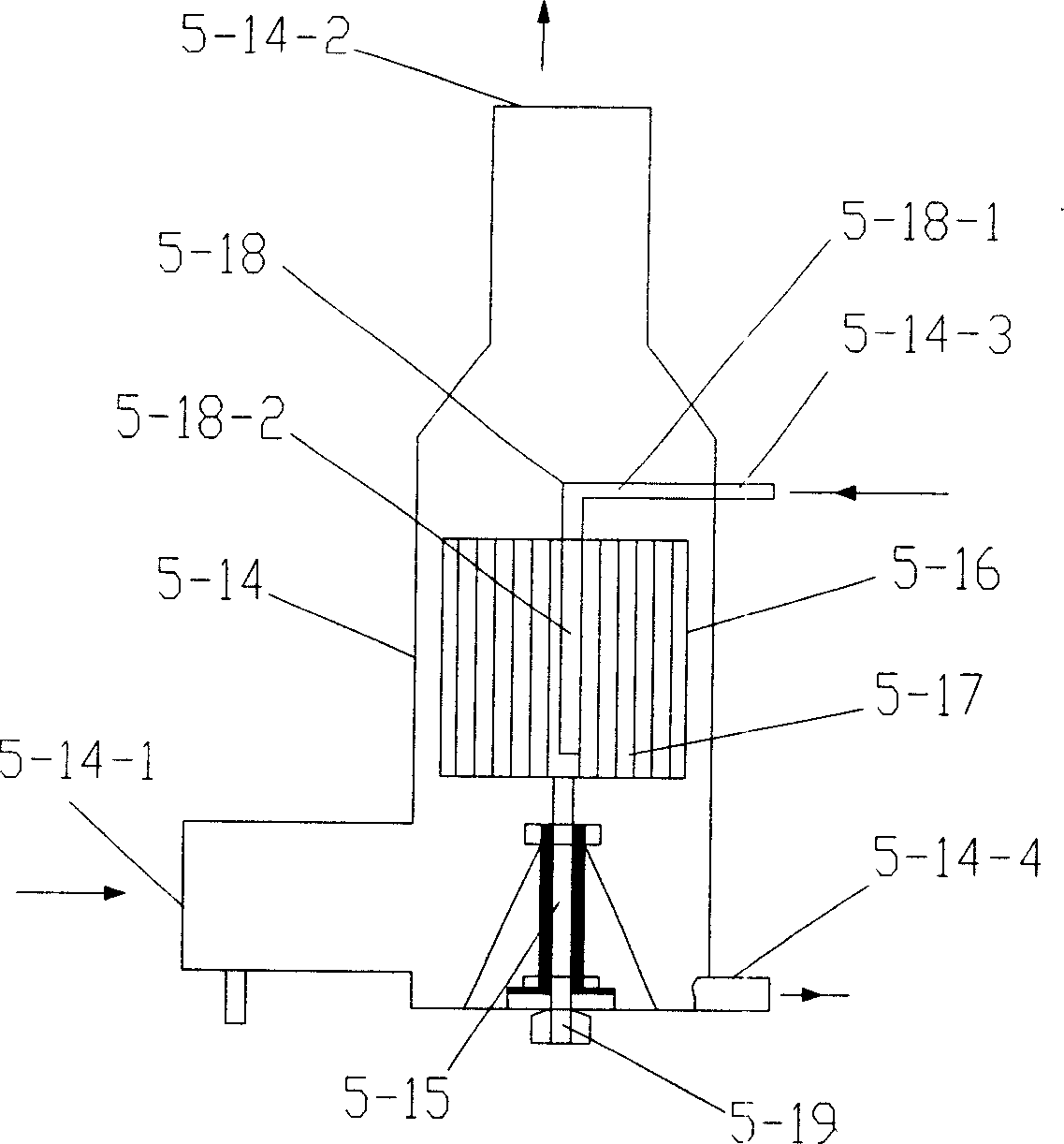

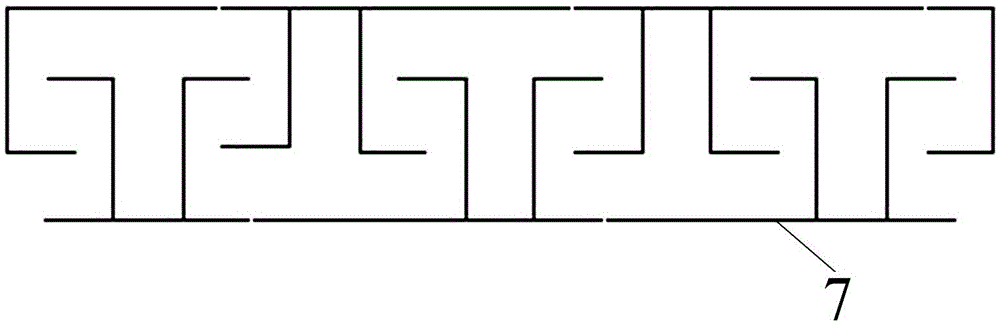

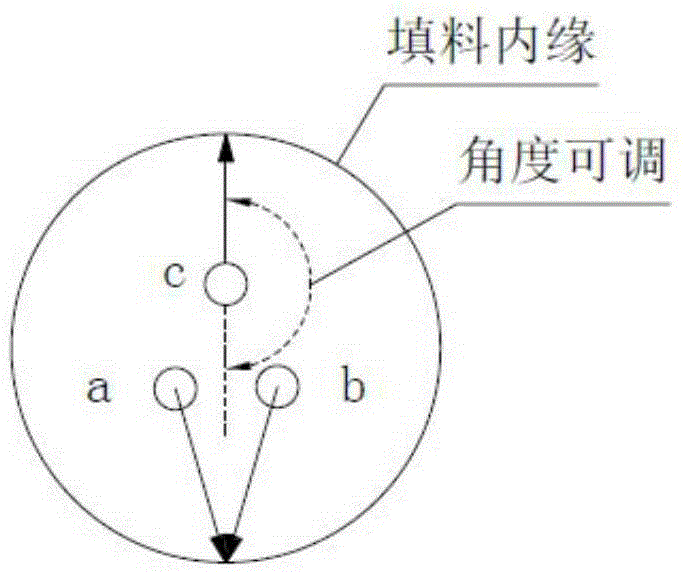

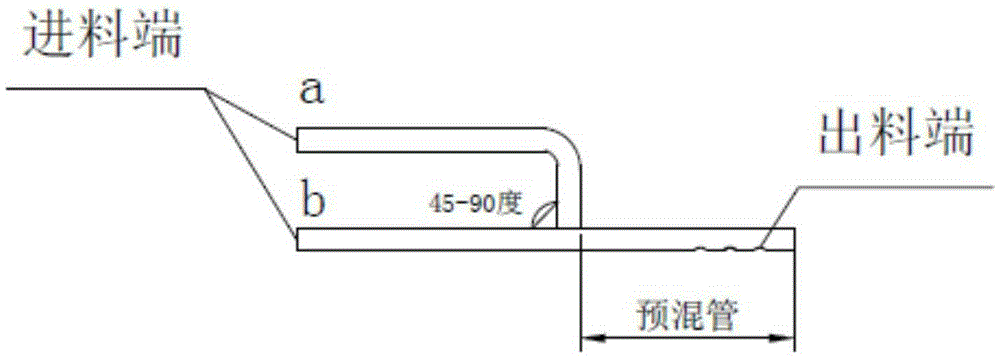

A high-gravity rotating bed device with staged liquid feeding and enhanced rotor end effect

ActiveCN102258880AImprove mass transfer effectTake advantage ofDispersed particle separationChemical/physical/physico-chemical stationary reactorsCENBOLRetention time

The invention discloses a supergravity rotating bed device adopting sectional type liquid feeding mode to strengthen the rotor end effect, belonging to the technical field of supergravity. The device disclosed by the invention comprises a closed shell, wherein a rotating shaft penetrating through each shell section is arranged in the center of the shell; a filler layer is arranged in a rotor; a liquid inlet, a liquid outlet, a gas outlet and a gas inlet are formed on a cavity; multiple liquid feeding shower pipes which are concentrically distributed are radially fixed in a sectional mode on the lower end surface of a cavity gland; the filler layer comprises multiple sections of annular filler layers which are distributed in a radial parallel mode along the rotating shaft; and the liquid feeding shower pipes are distributed between every two adjacent sections of annular filler layers. Multiple end effect regions are manufactured on rotor filler layers by adopting a sectional type liquid feeding mode, thereby enabling all fillers to be fully utilized and achieving the purpose of strengthening mass transfer; and the mass transfer efficiency can be improved by 40-60%. The device disclosed by the invention is suitable for a reaction system requiring long reaction retention time and large mass transfer coefficients and is particularly suitable for gas-liquid absorption systems and the like which include viscous fluid transfer courses and are difficult to implement. The device disclosed by the invention can be used for a vertical rotating bed or a horizontal rotating bed.

Owner:BEIJING UNIV OF CHEM TECH

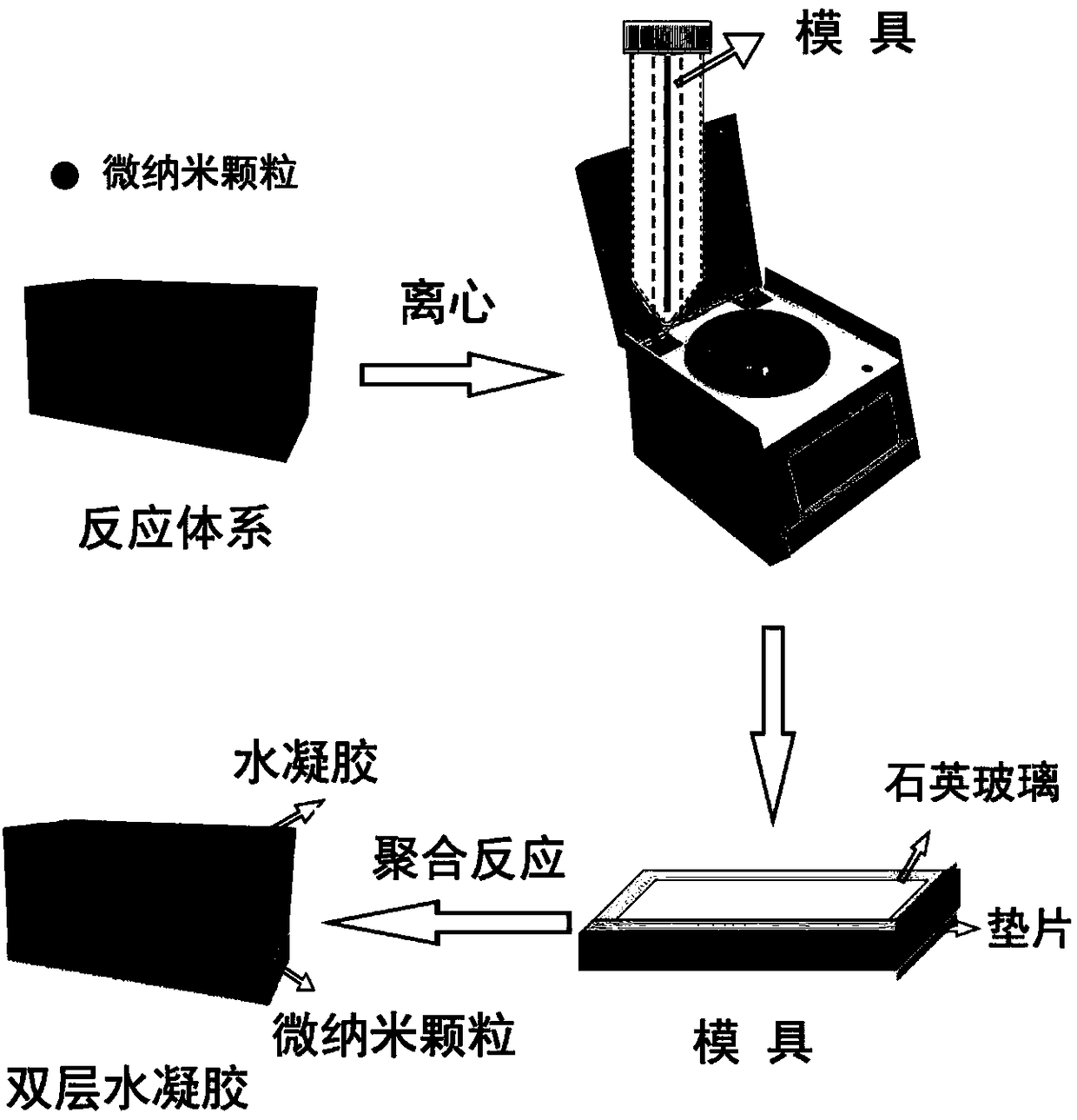

Method of preparing self-driving gradient-composition hydrogel through supergravity and application of the hydrogel

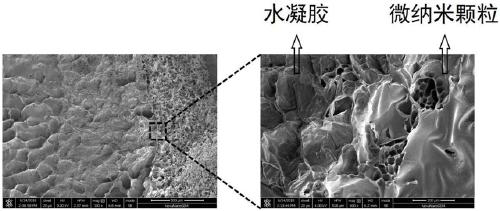

InactiveCN109280183ASimple methodLow costTissue regenerationProsthesisFunctional monomerMicro nanoparticles

The invention discloses a method of preparing self-driving gradient-composition hydrogel through supergravity and an application of the hydrogel. The method includes: mixing micron-nano particles witha gelatable functional monomer water solution with uniform dispersion, thus obtaining a mixed hydrogel system; centrifuging the mixed hydrogel system, centrifugal rotary speed being 1000-4000 rpm andcentrifugal time being 1-10 min, so that by accurately controlling the rotary speed and centrifugal time of a centrifuge, the micron-nano particles are separated and are gradient-dispersed; performing further gelation to prepare the self-driving gradient-composition hydrogel. The method is simple, low in cost and high in efficiency, has good universality and is green and environment-friendly. Theinvention also discloses the application of the self-driving gradient-composition hydrogel to tissue engineering and intelligent drivers.

Owner:ZHEJIANG UNIV OF TECH

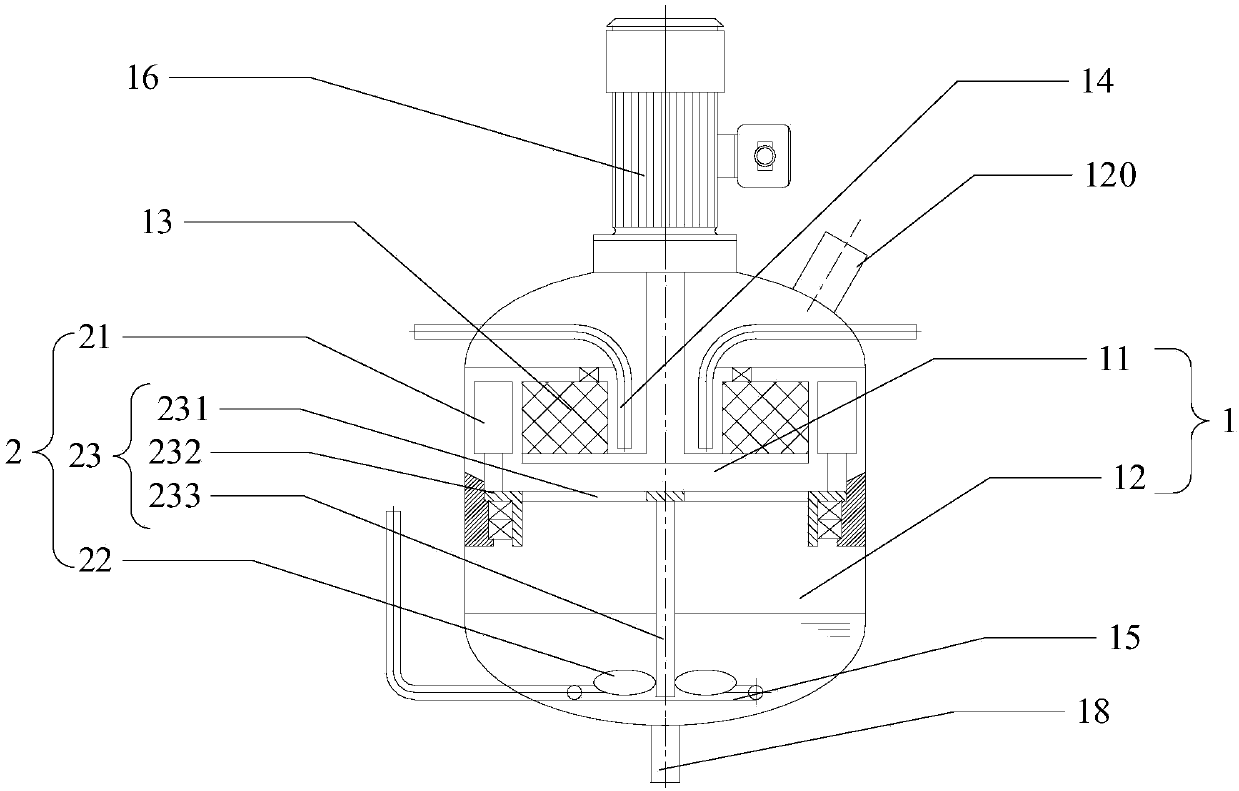

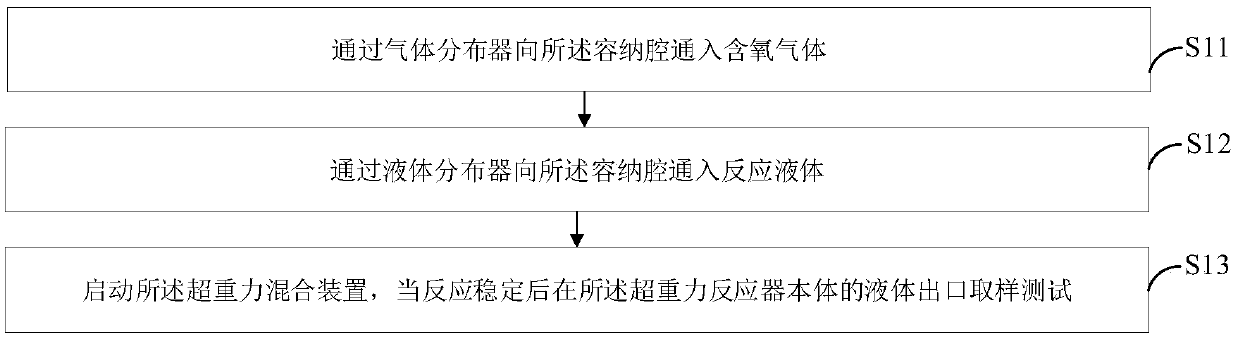

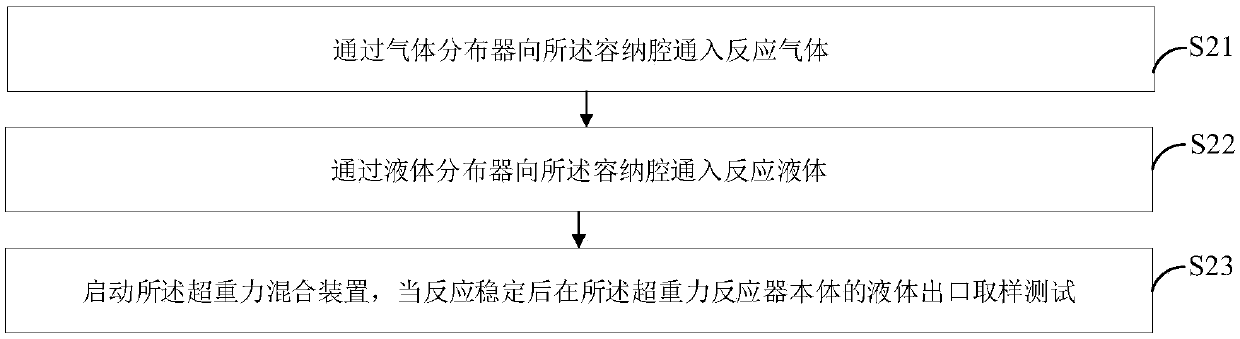

Supergravity device for fully utilizing energy, oxidation method and system

ActiveCN109647315AEfficient use ofEnhanced gas-liquid mass transferOrganic compound preparationChemical/physical/physico-chemical stationary reactorsHypergravityEngineering

The invention provides a supergravity device for fully utilizing energy, an oxidation method and system, wherein the device comprises a supergravity reactor body and a passive turbulent flow part, a collision part of the passive turbulent flow part is impacted after liquid is thrown out of a rotating chamber, the collision part rotates and driving the bottom passive turbulence part to rotate so asto strengthen the gas-liquid mass transfer of the reaction system; the contact area of liquid and gas is increased through the hypergravity reactor to strengthen mass transfer in the upper cavity, the mixing between gas and liquid is improved through rotation in the lower cavity, the reaction time is prolonged, the mass transfer and the mixing are further strengthened, the energy is efficiently utilized, and the problem of leakage of the reaction cavity caused by collision of the high-speed rotating fluid to the reaction cavity is avoided; furthermore, a differential environment of two-stageenhanced mass transfer and reaction can be formed, the requirement of a special reaction system can be met, and a new idea is provided for reaction differential control.

Owner:BEIJING UNIV OF CHEM TECH

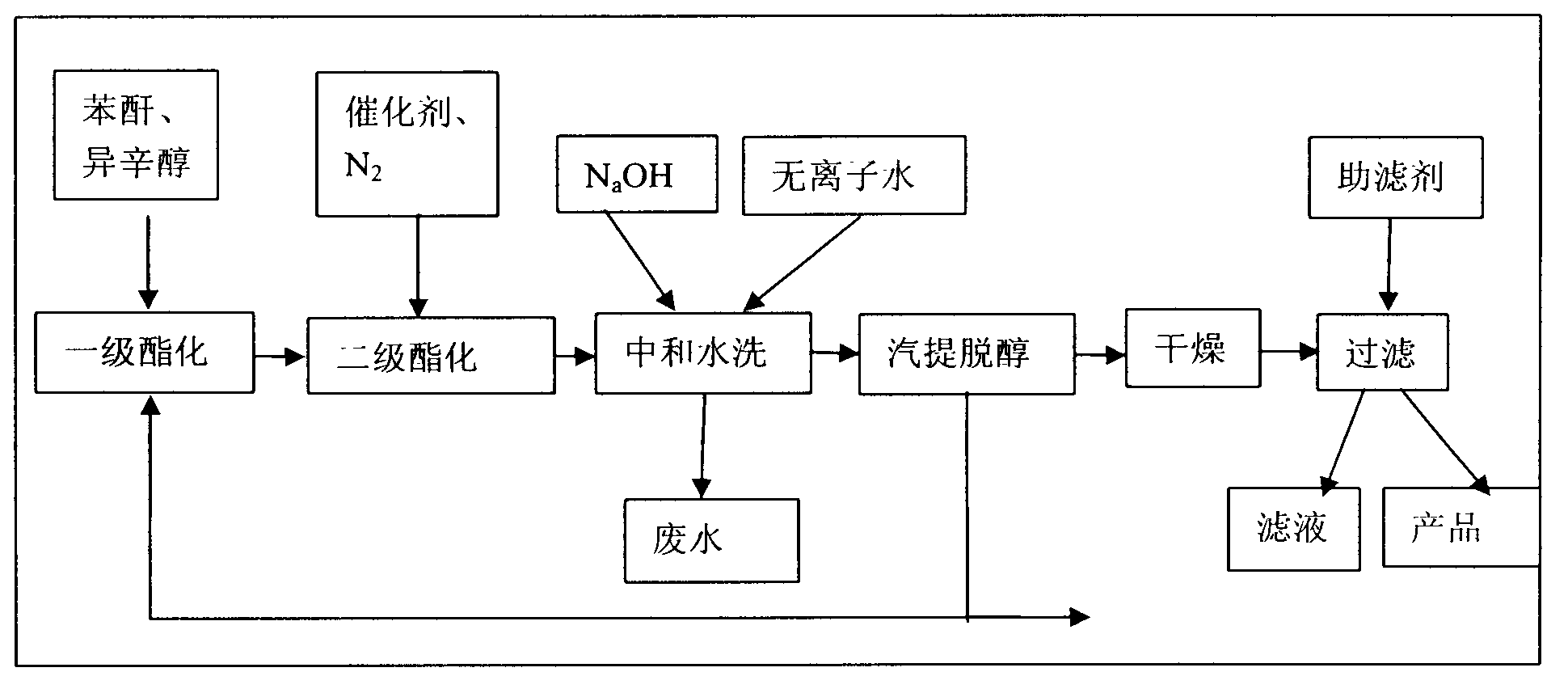

Preparation method of dioctyl phthalate (DOP)

InactiveCN104072372ASimple processImprove product qualityOrganic compound preparationCarboxylic acid esters preparationDistillationPhthalate

The invention discloses a preparation method of dioctyl phthalate (DOP). The preparation method comprises the following steps: adding the raw materials including phthalic anhydride and superfluous isooctyl alcohol to a reaction kettle, adding concentrated sulfuric acid as a catalyst, controlling the temperature in the reaction kettle to be 0-150 DEG C, reacting for 16-20 hours, neutralizing the catalyst and unreacted phthalic anhydride with an alkaline solution after the reaction is completed, standing for layering and then carrying out washing with clear water for several times. After alcohol-containing wastewater is collected, alcohols are recovered with a recovery tower and are reused. A lower ester layer after layering is heated to recover alcohols at reduced pressure (isooctyl alcohol is recovered by using a supergravity bed and is reused). After activated carbon is added for decoloration, the finished product of DOP is obtained through filter pressing by adopting a plate-and-frame filter press. The preparation method has the beneficial effects that the superfluous alcohol serves as a water-carrying agent, so that the esterification reaction is gradually carried through to the end, the technological process is simplified and the product quality is good; relative to a process of distillation in a rectifying tower, the preparation method has the advantages that the supergravity bed is used to recover isooctyl alcohol in the process, so that the energy consumption is effectively reduced and the process has better environment-friendly significance.

Owner:池银萍

Artificial climate box capable of simulating multiple complex environment conditions

ActiveCN102553663ARealize simulationFlexible control of temperature and humidityHeating or cooling apparatusEnclosures/chambersX-rayEngineering

Owner:BEIHANG UNIV

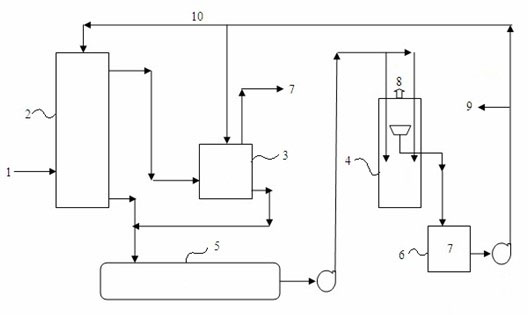

Preparation method of high-modulus potassium silicate inorganic nano-resin

ActiveCN103421368AThorough responseReduce formationAlkali metal silicate coatingsAnti-corrosive paintsPotassium silicateSolid content

A preparation method of high-modulus potassium silicate inorganic nano-resin includes: a step of mixing raw materials and a step of preparing high-modulus potassium silicate inorganic nano-resin. The step of mixing raw materials includes: adding low-modulus potassium silicate solution into a mixer first, mixing to form vortexes, adding water, silica sol, stabilizer and coupling sequentially, and mixing well to obtain premix. The step of producing the high-modulus potassium silicate inorganic nano-resin includes: heating the premix to 40-80 DEG C, and allowing the heated premix to engage in circular reaction in a reaction system of a mixer, a circulating pump and a supergravity rotary packed bed to obtain the high-modulus potassium silicate inorganic nano-resin. The nano-resin is 5.3-6.2 in modulus, 26-30% in solid content, 5-20nm in particle size, and 98.5-99% in yield. The preparation method has the advantages that product quality and storage stability are improved, reaction time is shortened and energy consumption is reduced.

Owner:WUDA JUCHENG STRUCTURE CO LTD

Column and machine combined gas desulphurization process device and desulphurization method thereof

InactiveCN102604687ADifficulties in improving storage and transportationDifficulty improvingGas purification by liquid washingElutionProcess engineering

The invention discloses a column and machine combined gas desulphurization process device which comprises desulphurization equipment and regenerative equipment. The desulphurization equipment comprises secondary desulphurization equipment comprising a packing absorbing column and a spiral-flow type supergravity desulphurization machine; sulfurous gas firstly enters the packing absorbing column for desulphurization, and then enters the spiral-flow type supergravity desulphurization machine for desulphurization firstly and then discharging; desulphurization solution enters the packing absorbing column and the spiral-flow type ultragravity desulphurization machine from tops for convection elution with the sulfurous gas, is discharged from the bottoms when the convection elution is finished, and then enters the regenerative equipment for regeneration; regenerative desulphurization solution is recycled; and waste fluid produced enters a subsequent salt extraction process for salt extraction treatment. The technology and the device can not only be suitable for gas with high hydrogen sulfide content, but also meet the index of the hydrogen sulfide content of desulfurated gas; sulfur foam is not produced during the desulphurization operation, and sulfur is not produced; the desulphurization equipment is efficient, and has light weight and low cost; and the desulphurization operation does not cause environment pollution and secondary pollution.

Owner:JIANGSU ZHONGXIAN GRP CO LTD

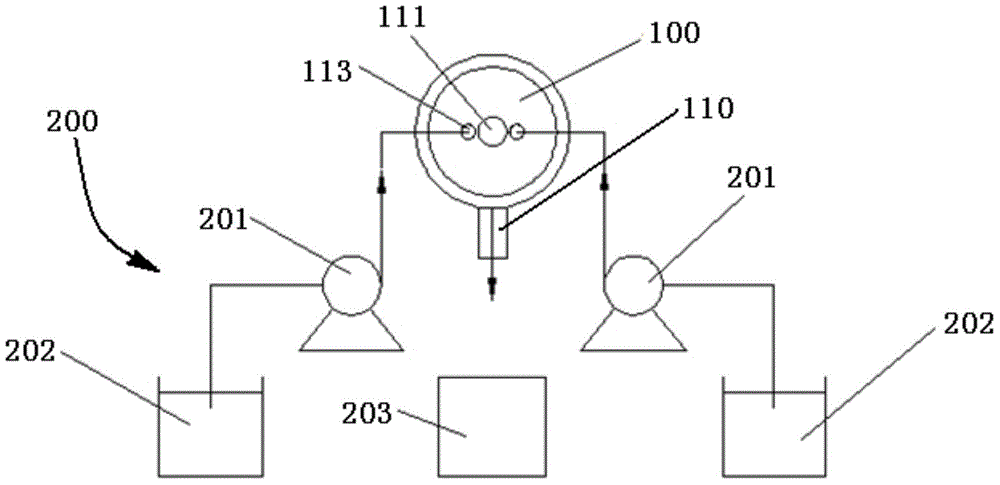

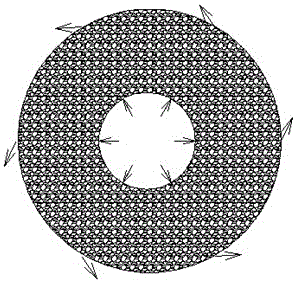

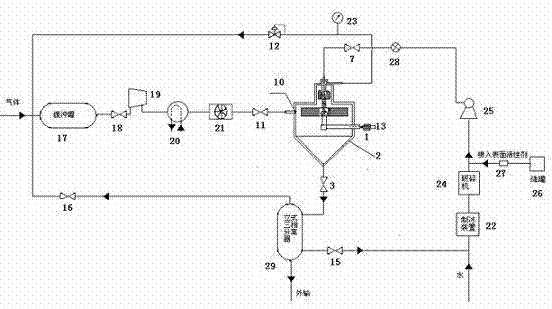

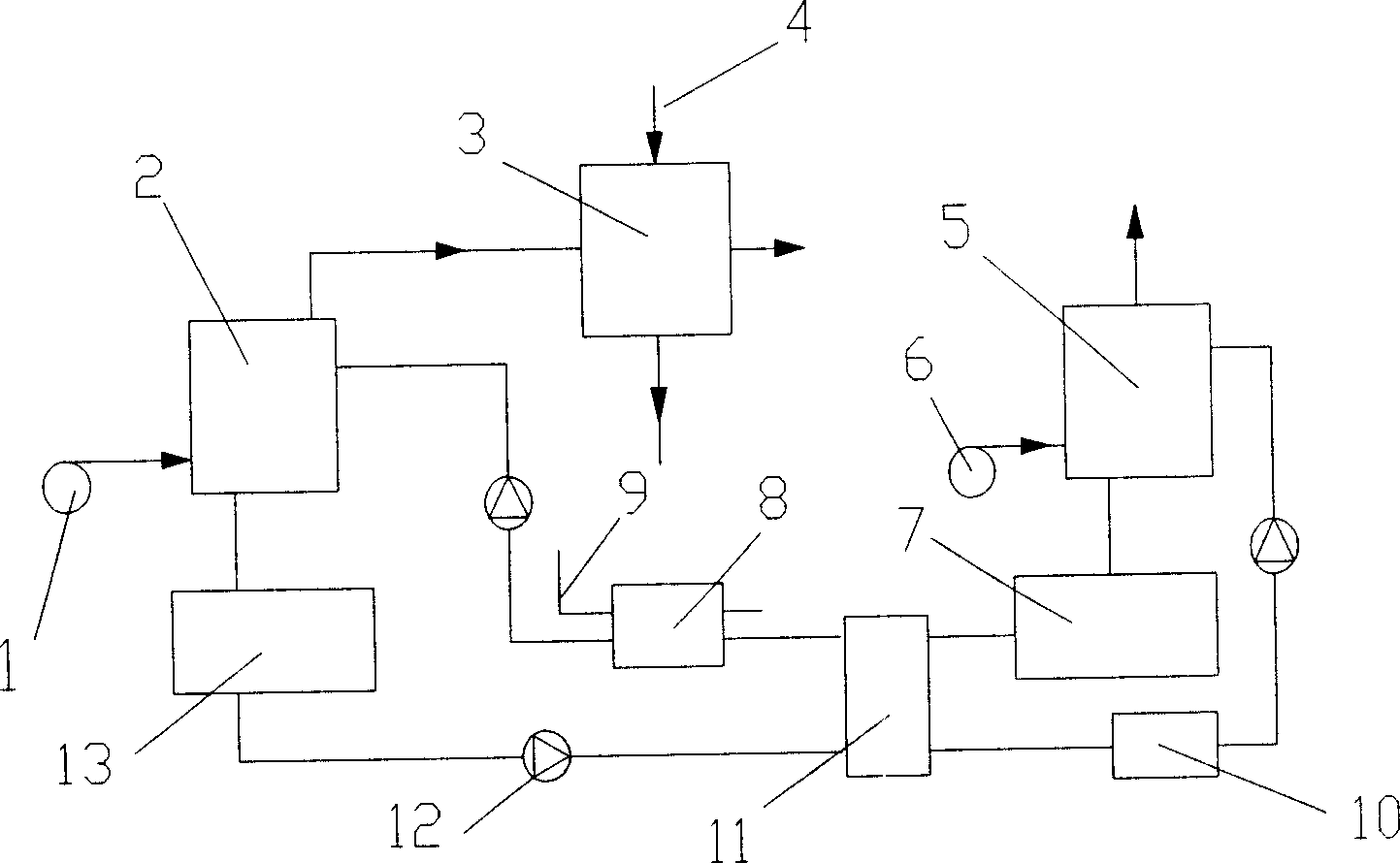

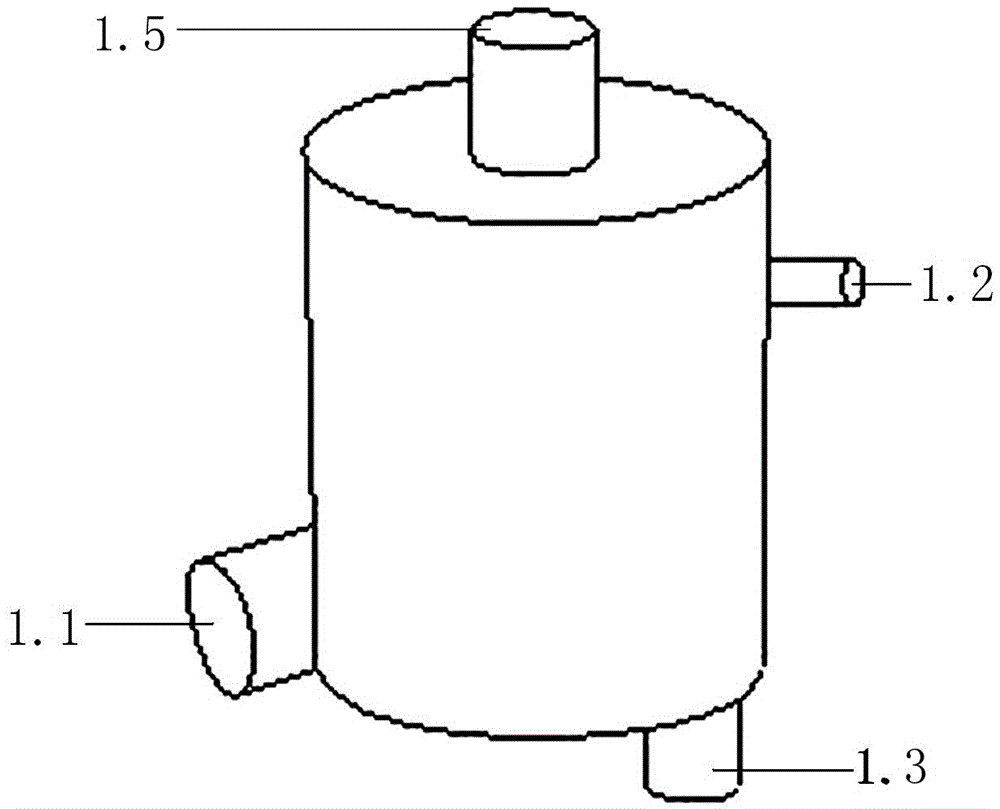

Supergravity hydrate synthesis device

ActiveCN103285781AUniform inflowHigh synthesis efficiencyChemical/physical processesBuffer tankThree-phase

The invention relates to the technical field of hydrate synthesis, storage and transportation and particularly relates to a supergravity hydrate synthesis device. The supergravity hydrate synthesis device comprises a cut-off valve, a one-way liquid valve, a nozzle, a one-way gas valve, a pressure regulating valve, a gas buffer tank, a compressor, a condenser, a turbine flowmeter, an ice maker, a pressure gauge, a pulping machine, a slurry pump, a surfactant storage tank, a Laval spraying valve, a mass flowmeter, a vertical three-phase separator and a supergravity reactor. The supergravity hydrate synthesis device adopts a supergravity technology for enhancing the heat transfer and mass transfer in a hydrate synthesis process, so that the reaction time is shortened, the equipment size decreases, the production cost is reduced, and a tapered outlet is formed so as to be helpful to the outflow of generated hydrates.

Owner:南通东湖国际商务服务有限公司

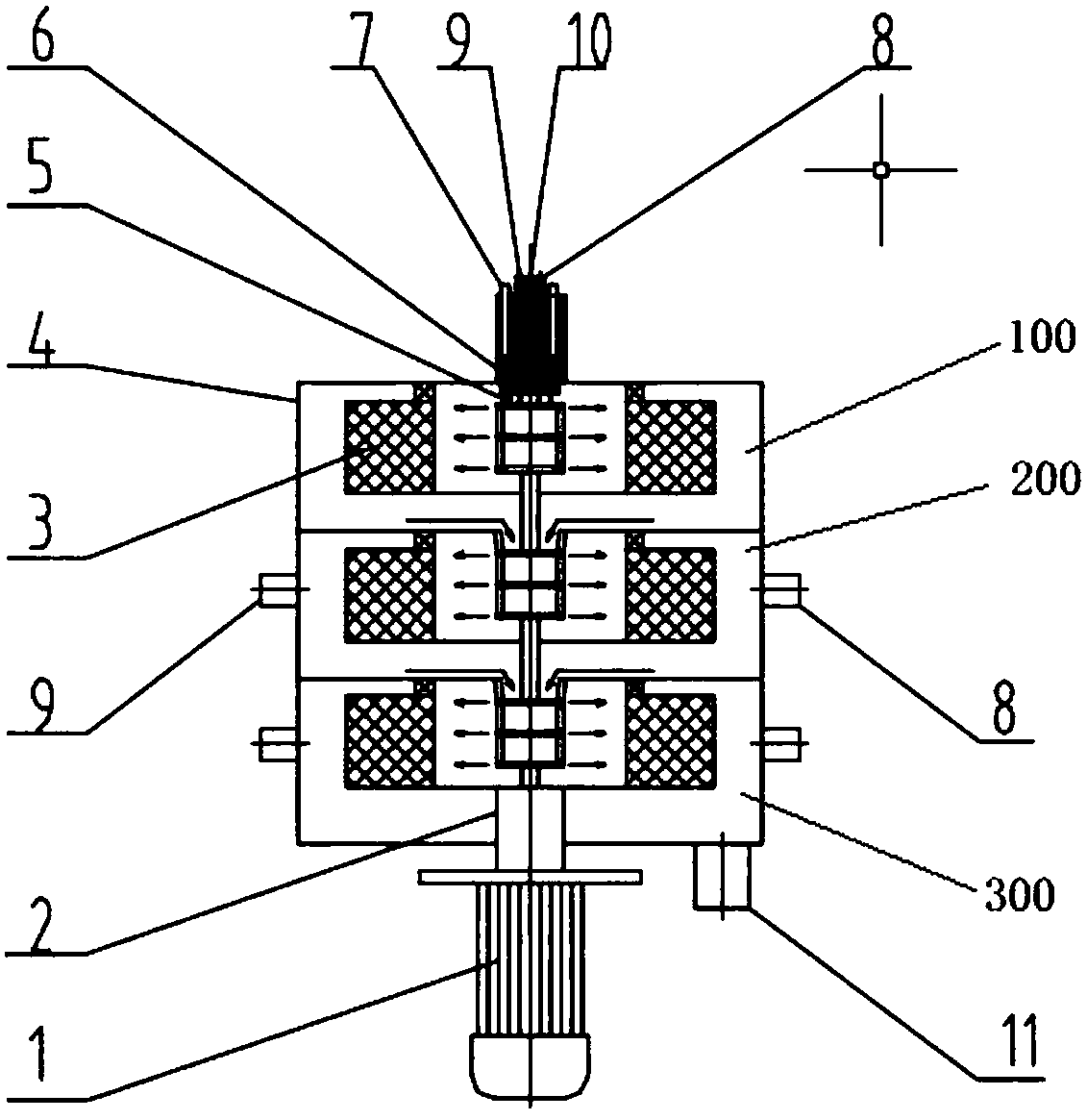

Method for hydrogenation of heavy oil with multistage supergravity reactor

ActiveCN107699276AExtension of timeSlow ascentEnergy based chemical/physical/physico-chemical processesHydrocarbon oils treatmentFuel oilStart up

The invention discloses a method for hydrogenation of heavy oil with a multistage supergravity reactor. The method comprises the following steps: starting up a motor of a supergravity reactor, drivingrotating discs of all stages to rotate, and meanwhile, turning on an ultrasonic probe of a charging chamber; loading hydrogen gas and heavy oil to the charging chamber, and carrying out gas-liquid two-phase efficient mixing, so as to form a gas-liquid mixture; and spraying the gas-liquid mixture to a rotating disc of a first-stage rotor from the lower end of the charging chamber under the actionof gas pressure and gravity, spinning the gas-liquid mixture to flow through a catalyst in the rotor by using a centrifugal force of the rotating disc so as to complete a gas-liquid-solid three-phasehydrogenation reaction process, conveying a reaction product to a rotating disc of a second-stage rotor from a liquid outlet of the bottom of the first-stage rotor, enabling the reaction product to enter the second-stage rotor for a reaction, and carrying out operation in such a manner until a reaction product enters an N-th rotor, is subjected to a reaction and then is discharged from the reactorfrom a liquid outlet of the bottom of a shell. According to the method disclosed by the invention, the deasphaltenizing percent can reach 50% or more, the demetalization percent can reach 80% or more, the desulfurization percent can reach 88% or more, and the denitrification percent can reach 45% or more.

Owner:BEIJING UNIV OF CHEM TECH

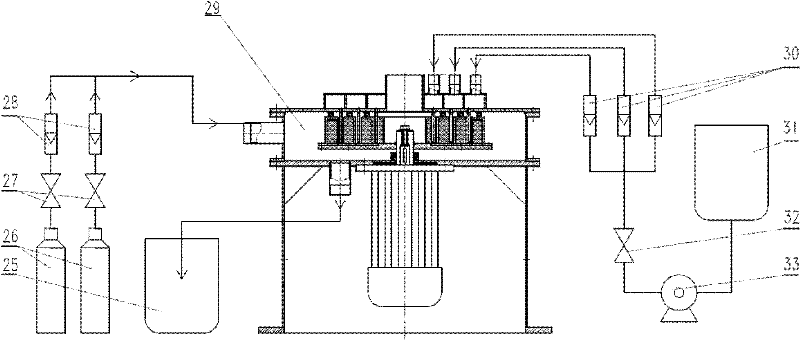

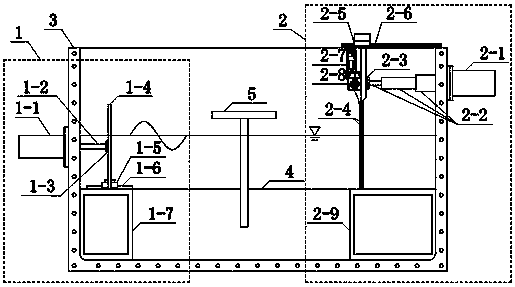

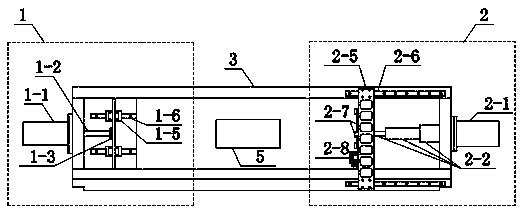

Supergravity simulation system for depressurization production of natural gas hydrates

ActiveCN108490151ALarge hypergravity centrifugal accelerationControl pressureEarth material testingEducational modelsWater bathsTemperature control

The invention discloses a supergravity simulation system for depressurization production of natural gas hydrates. A hydraulic oil station is connected with a flow converging plate by an oil-way centrifuge rotating joint and is then divided into two paths; the two paths are connected with a high-pressure reactor through a supergravity water pressure control module and a supergravity mining controlmodule respectively; a kettle body temperature control module is connected with the high-pressure reactor through a water-bath passage centrifuge rotating joint; the high-pressure reactor, the flow converging plate, a data acquisition box, the supergravity water pressure control module and the supergravity mining control module are all arranged on a supergravity centrifuge located in a supergravity centrifuge air-conditioning chamber; the hydraulic oil station, a computer and the kettle body temperature control module are arranged out of the supergravity centrifuge air-conditioning chamber; and sensors in the high-pressure reactor, the supergravity mining control module, the supergravity water pressure control module and the kettle body temperature control module are all connected with thedata acquisition box. The supergravity simulation system of the invention can truly simulate catastrophic process in mining of natural gas hydrates and provide scientific support for simulation experiments of natural gas hydrate mining.

Owner:ZHEJIANG UNIV

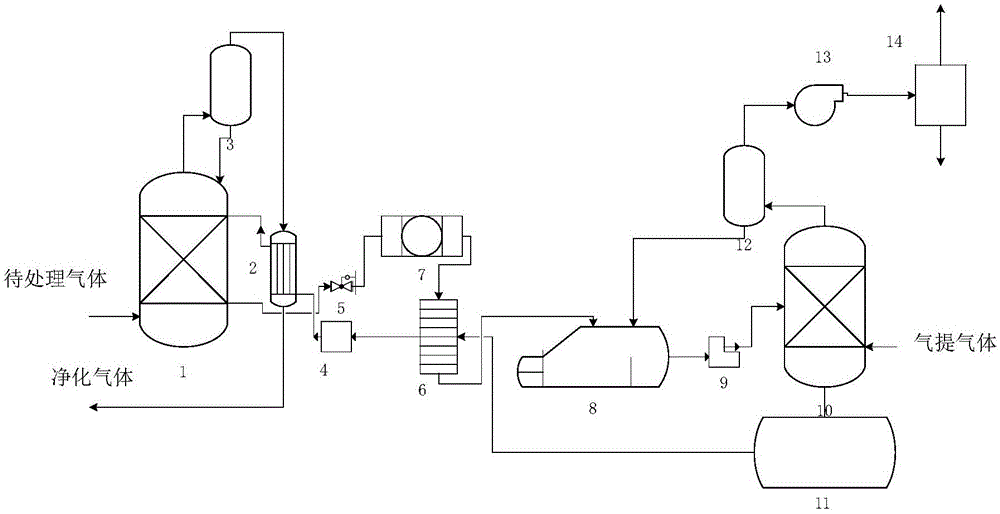

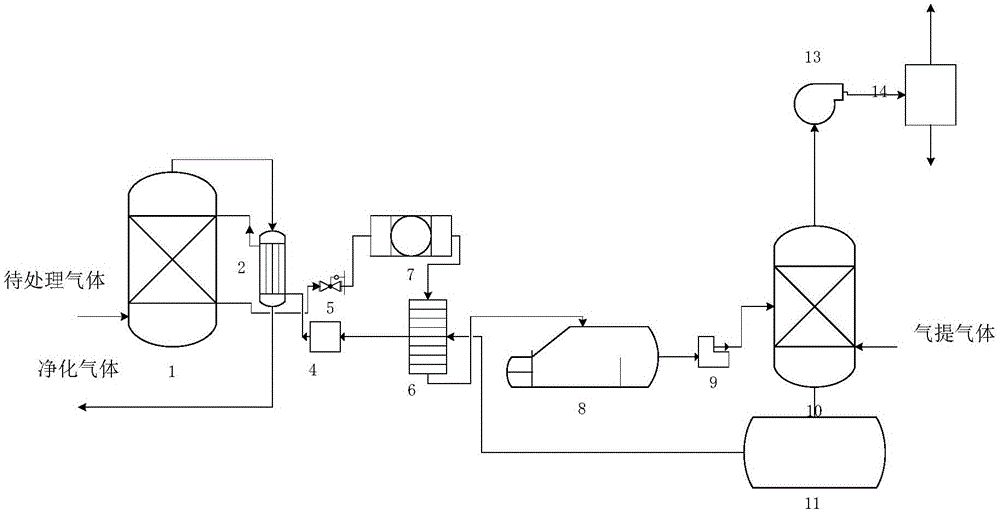

Method for removing acidic components and water from gas in one step

ActiveCN106422667AAvoid degradationIncrease surface areaDispersed particle separationAlcoholGas phase

The invention relates to the field of deacidification and dehydration and provides a method for removing acidic components and water from gas in one step. The method includes the steps that to-be-treated gas containing the acidic components and the water makes contact with an absorbent for deacidification and dehydration so as to obtain gas without the acidic components and the water and a rich absorbent absorbing the acidic components and the water, then the rich absorbent is subjected to regeneration, and a poor absorbent obtained after regeneration circulates and is used in the deacidification and dehydration process, wherein the absorbent is an amino compound or a mixture of an amino compound and an alcohol compound. The regeneration process includes the step that the rich absorbent is sequentially subjected to heating and supergravity desorption and regeneration to obtain the poor absorbent serving as liquid-phase effluent and the gas containing the acidic components and the water and serving as gas-phase effluent. The aim of deacidification and dehydration in one step in the same procedure can be achieved, and efficient regeneration of the rich absorbent at low temperature is achieved.

Owner:BEIJING SIJIANTONG TECH&DEV

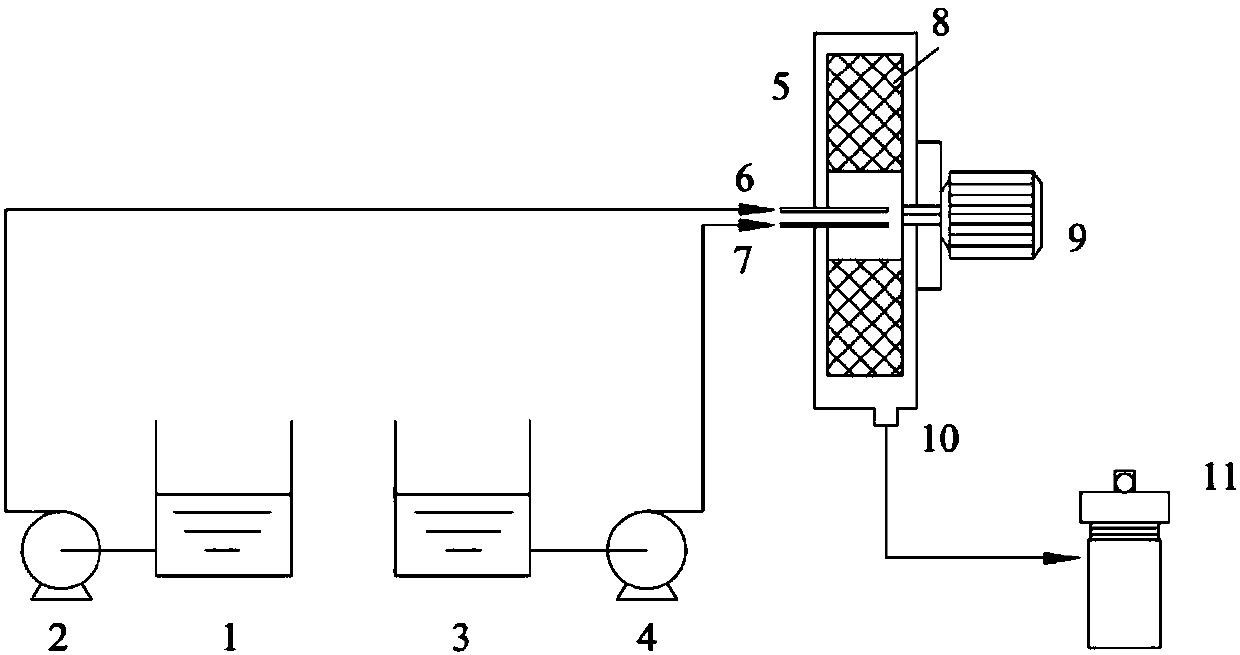

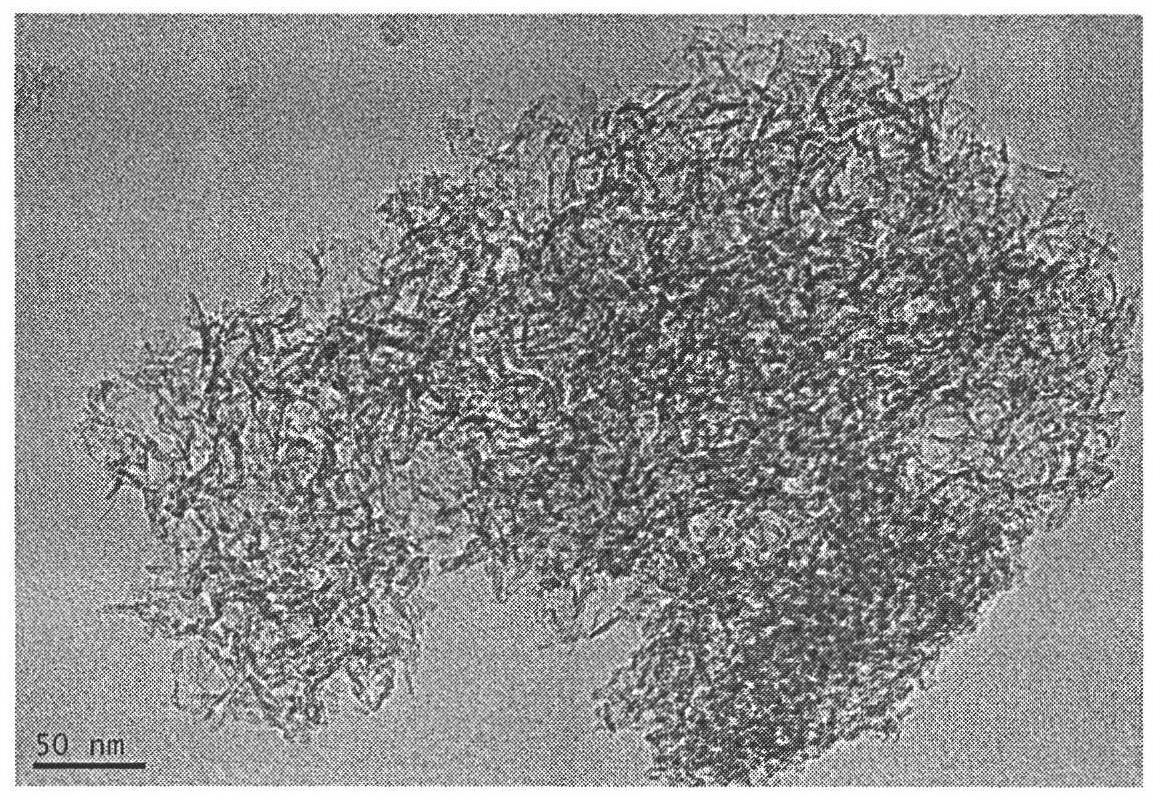

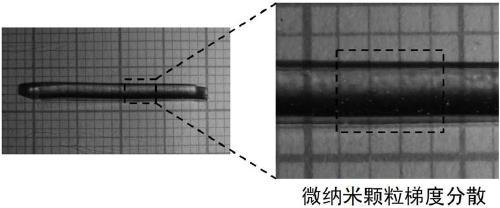

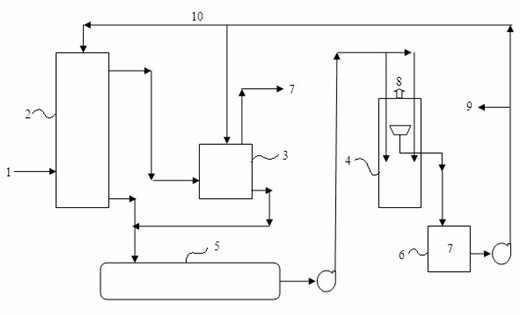

Method and device for supergravity on-line preparation of nano zero-valent iron and synchronous treatment on nitrobenzene wastewater

ActiveCN105858856AAvoid feedingEasy to prepareNanostructure manufactureWater contaminantsRetention timeFerrous salts

The invention belongs to the technical field of preparation of nano materials and nitrobenzene wastewater treatment, particularly relates to a method and a device for supergravity on-line preparation of nano zero-valent iron and synchronous treatment on nitrobenzene wastewater, and aims to solve the problems that conventional nano zero-valent iron is complex in preparation process, conditions are rigorous, the preparation process is not easy to amplify, nanoparticles are easy to agglomerate, oxidize and deactivate in the processes of drying, storage and use, and the like. The method comprises the following steps: enabling a ferrous salt containing nitrobenzene wastewater solution and a KBH4 or NaBH4 aqueous solution to react in an impinging stream device for collision, feeding into a rotating packed bed for mixing and reacting, and implementing preparation of nano zero-valent iron and treatment on the nitrobenzene wastewater by using the nano zero-valent iron simultaneously. The method and the device have the advantages that the situation that the nano zero-valent iron can be reacted with nitrobenzene only after being completely developed into large particles in a conventional method is avoided, the nano zero-valent iron can be relatively sufficiently utilized, the amount can be remarkably reduced, multiple steps of reaction is reduced to one step, the reaction can be implemented rapidly, the retention time is shortened, continuous operation can be achieved, and the method and the device are applicable to nitrobenzene wastewater treatment which is large in treatment volume and heavy in treatment task.

Owner:ZHONGBEI UNIV

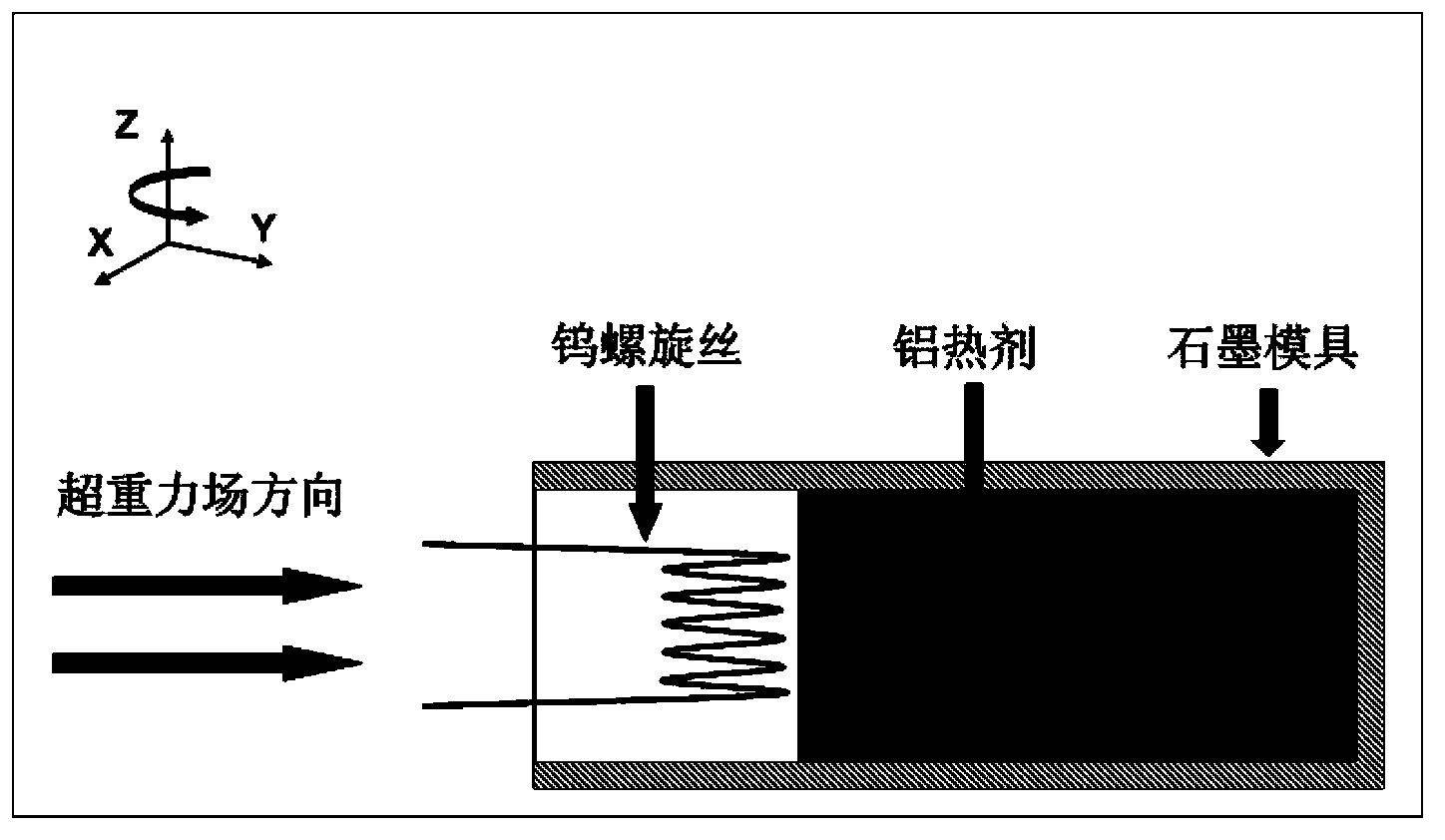

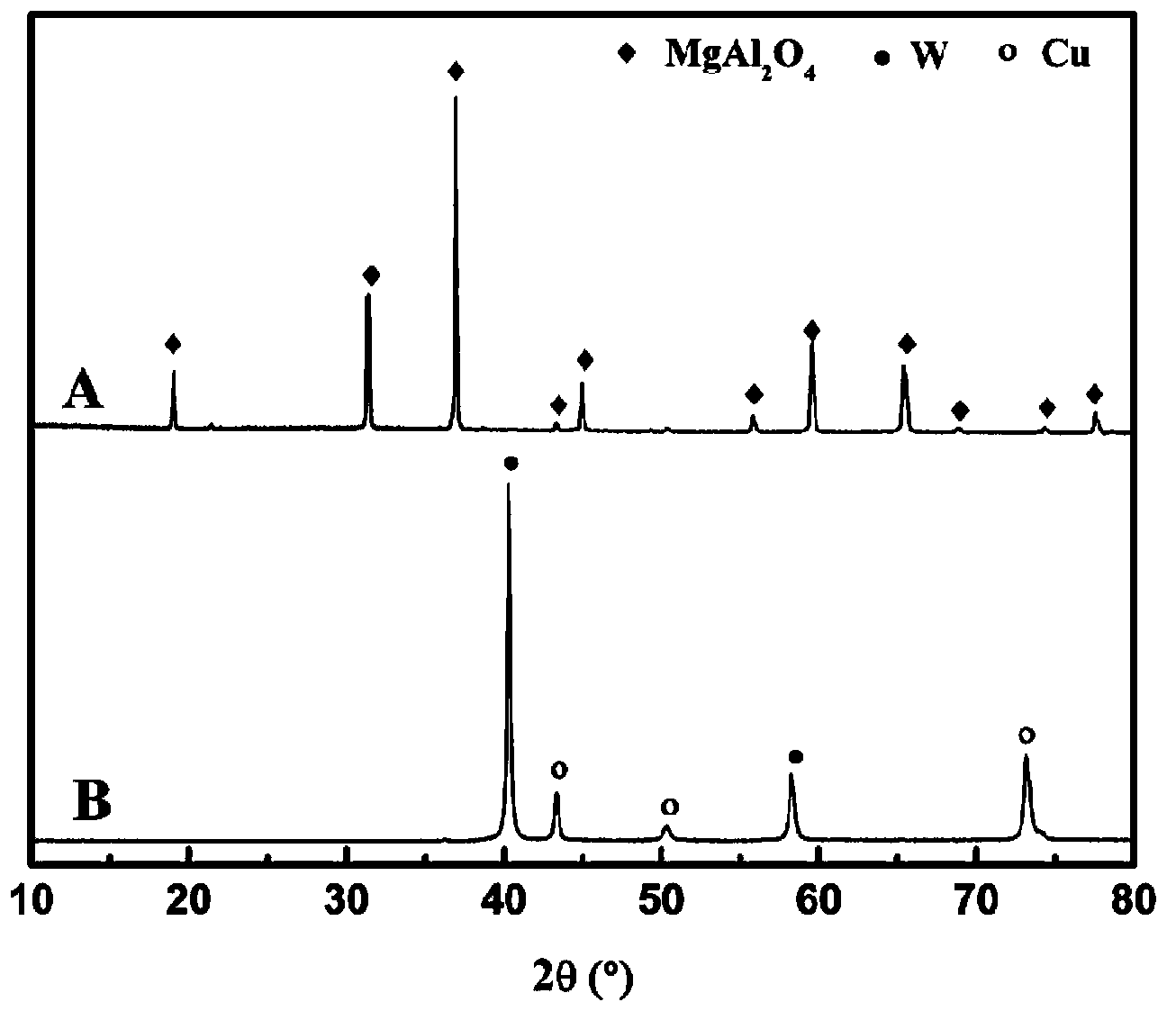

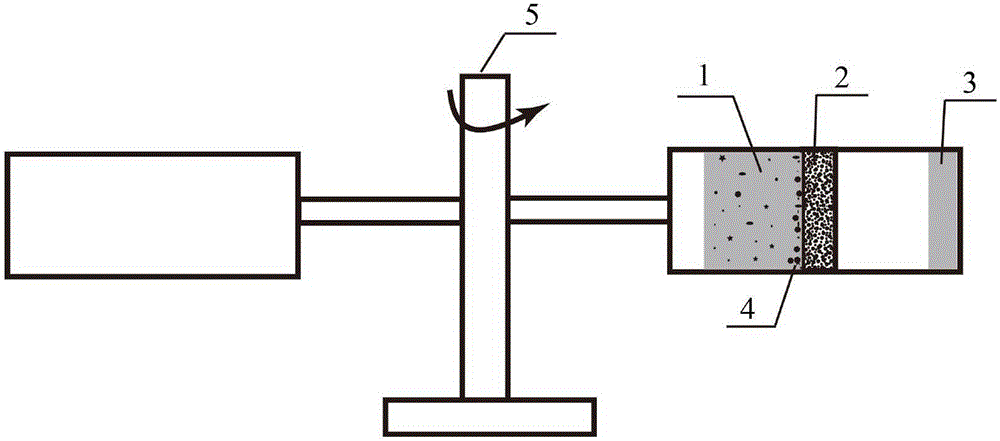

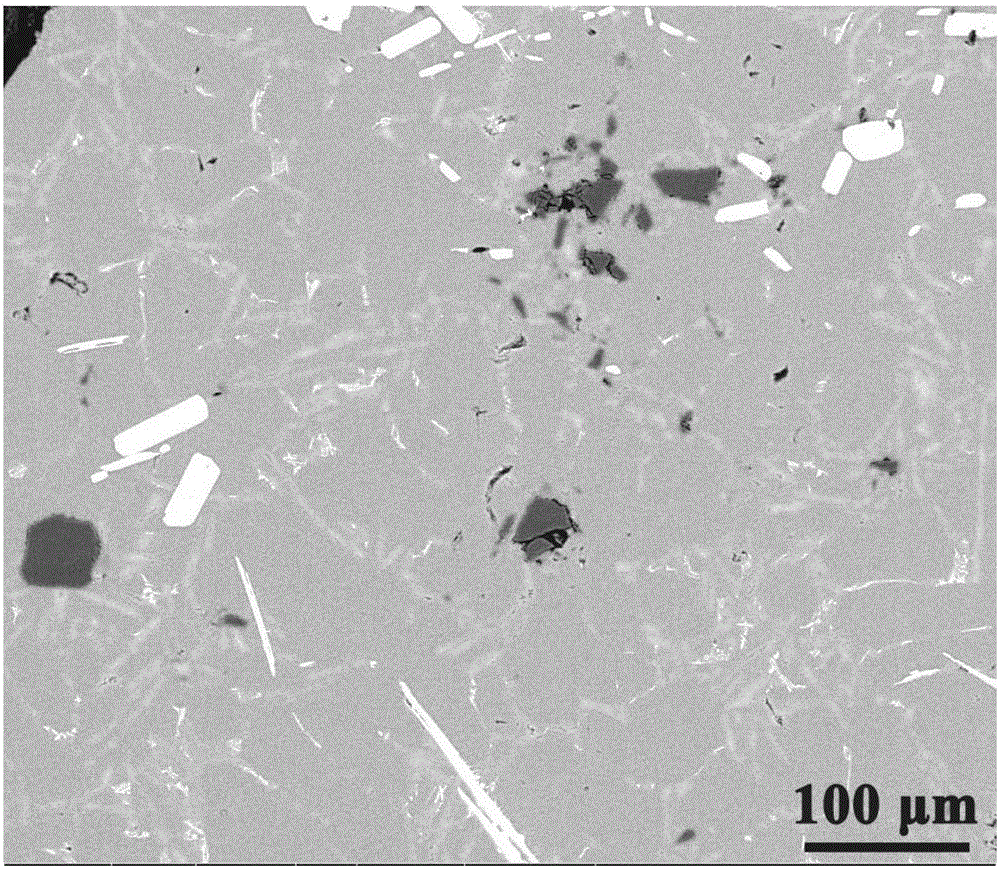

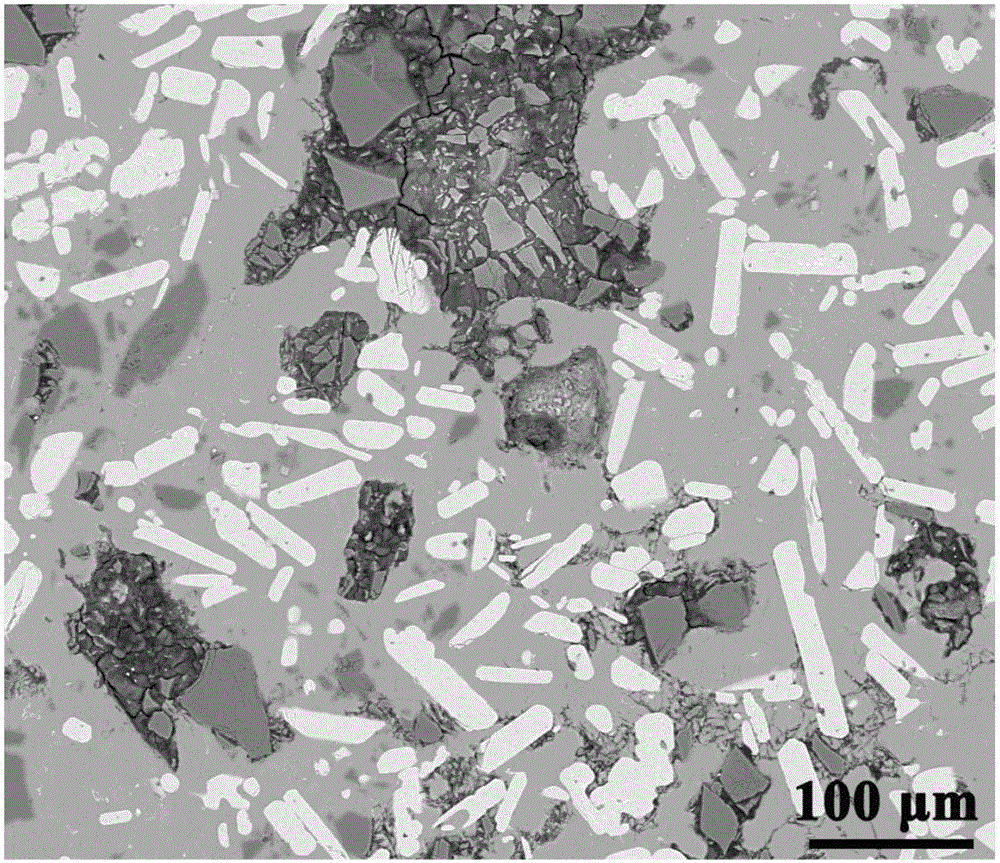

Thermite for hypergravity-assisted combustion synthesis of copper-based composite material

The invention belongs to the technical field of combustion synthesis preparation, and in particular relates to a thermite for hypergravity-assisted combustion synthesis of a copper-based composite material. According to the thermite provided by the invention, the formula employs a CuO powder with particle size in gradient distribution and an Al powder with particle size in gradient distribution, combustion rate and heat release amount in the preparation of the copper-based composite material is controlled by adding a Cu2O powder, a Cu powder, a MgO powder and a CaF2 powder, so as to realize stability and controllability of thermit reaction in the supergravity field. The thermite provided by the invention has the advantages of low sputtering rate, high heat release amount, stability and controllability, and is suitable for hypergravity-assisted combustion synthesis of various copper-based composite materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for purifying aluminum and aluminum alloy melt through supergravity filtering and recombination

InactiveCN105886789AEfficient separationSimple processProcess efficiency improvementPhysical fieldNon-metallic inclusions

The invention provides a method for removing inclusions in aluminum and aluminum alloy melt through supergravity filtering and recombination. The method belongs to a novel technology for purifying metal melt through a physical field. A supergravity field is produced by utilizing the rotation of a centrifuge, and supergravity filtering treatment is carried out on aluminum melt by adopting a filter. After supergravity filtering, oxide inclusions and impurity elements in the aluminum melt can be thoroughly separated from an aluminum matrix. By utilizing a supergravity filtering and recombination purifying method, non-metallic inclusions and impurity elements in the aluminum and aluminum alloy melt are rapidly removed, and the cleanliness of the aluminum melt is obviously improved. Compared with common filtering in actual production, the method can adopt the filter with a smaller hole diameter in the supergravity field, so that smaller inclusions can be removed without affecting the filtering rate of the melt.

Owner:UNIV OF SCI & TECH BEIJING

Material performance testing system under suspension type multi-field coupling action in supergravity environment

PendingCN110261216AIn line with the concept of high strength and light weightShort experiment preparation periodStrength propertiesMulti fieldEngineering

The invention discloses a material performance testing system under the suspension type multi-field coupling action in a supergravity environment. The material performance testing system comprises a hoisting sealed cabin, a bearing frame, a high-temperature furnace, a mechanical testing device and a buffer device; the bearing frame and the high-temperature furnace are fixedly installed inside the hoisting sealed cabin, the bearing frame covers the high-temperature furnace, the buffer device is installed at the bottom inside the high-temperature furnace, the upper end and the lower end of the mechanical testing device are connected to the top of the bearing frame and the bottom of the high-temperature furnace, and the sample is connected and installed at the tail end of the mechanical testing device. The material performance testing system solves the problem of material dynamic performance testing under the coupling action of volume force-surface force-temperature under the high-speed rotation state, and is simple in structure, convenient to operate, safe and reliable.

Owner:ZHEJIANG UNIV

Super gravity liquid absorption dehumidifying and regenerating system

InactiveCN1683056ALarge amount of processingImprove efficiencyLighting and heating apparatusDispersed particle separationEngineeringRegenerative system

The supergravity liquid absorbing dehumidifying and regenerating system includes supergravity absorber and supergravity regenerator, the supergravity absorber is communicated with indoor air, and the supergravity regenerator is communicated with outdoor air. Between the supergravity absorber and the supergravity regenerator, there are connected cold liquid storing tank, heat exchanger, regenerating heater, hot storing tank and cooler. The supergravity absorber and the supergravity regenerator are also connected separately to indoor fan and outdoor fan. The supergravity absorber and the supergravity regenerator may be cross flow type or reverse flow type. The present invention has simple structure, low cost, high safety and reliability, high adjustability, high work efficiency, and other advantages.

Owner:SOUTH CHINA UNIV OF TECH

Ultrasonic microwave coupling hypergravity reaction device and system

ActiveCN109967013AEnhanced mass transferGood dispersionEnergy based chemical/physical/physico-chemical processesMicro nanoDispersity

The invention provides an ultrasonic microwave coupling hypergravity reaction device and system. On the one hand, the dispersing and mixing effects of the whole device can be further improved, so thatthe reaction device has extremely high dispersing and mixing effects, and gas obtained after supergravity and microwave coupling exists in liquid in a micro-nano level bubble form; on the other hand,the purpose of uniform heating can be achieved for a heating system; meanwhile, an ultrasonic feed-in unit is arranged at the bottom of a second cavity, solid-liquid or gas-liquid dispersion can be enhanced, a supergravity unit and the microwave feed-in unit are also used, the dispersity of the gas in the liquid is good, and the gas bubbles reach the micro-nano level, so that the difficulty of liquid overflowing caused by ultrasonic mechanical vibration improved, the defect that the staying time of the gas in the liquid is short due to ultrasound is overcome, and the device is especially suitable for gas-liquid, gas-liquid-solid and other multi-phase reaction systems.

Owner:BEIJING UNIV OF CHEM TECH

Device and method for removing fine particles in gas in supergravity manner

ActiveCN105642062AReduce the cushioning forceExtended stayCombination devicesUsing liquid separation agentHigh concentrationLiquid storage tank

The invention belongs to the technical field of supergravity dedusting, aims at solving the problem that existing supergravity dedusting methods are low in fine particle removing rate, high and unstable in energy consumption, prone to causing packing blockage when being used for treating high-concentration dust-containing gas and incapable of realizing continuous running and provides a device and a method for removing fine particles in gas in a supergravity manner. A gas inlet of a supergravity rotating packing bed is connected with a dust-containing gas source through a vortex shedding flowmeter, a liquid inlet is connected with a liquid storage tank through a liquid pump, a liquid outlet is connected with the liquid storage tank through a U-shaped liquid sealing device, the gas inlet is tangentially arranged outside a shell of the supergravity rotating packing bed, a square diversion inlet plate is mounted at the gas inlet, a packing layer is arranged in the supergravity rotating packing bed, and packing is plastic Pall ring packing. Total dedusting efficiency is up to 99.6%, grading efficiency is remarkably improved, and the device and the method are more suitable for removing the fine particles in the gas. The device is lower in economic cost, more stable in running, low in energy consumption, suitable for industrial application, free of blockage, supportive of continuous running, light in weight and convenient to transport.

Owner:ZHONGBEI UNIV

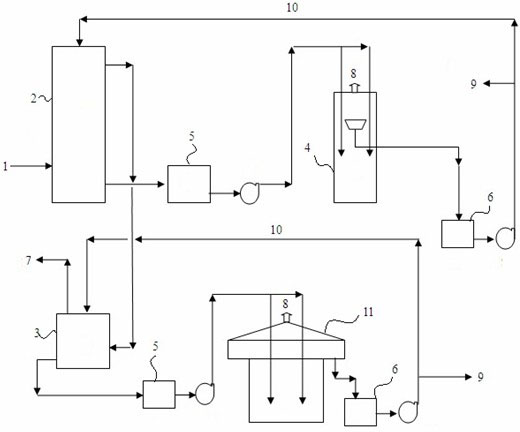

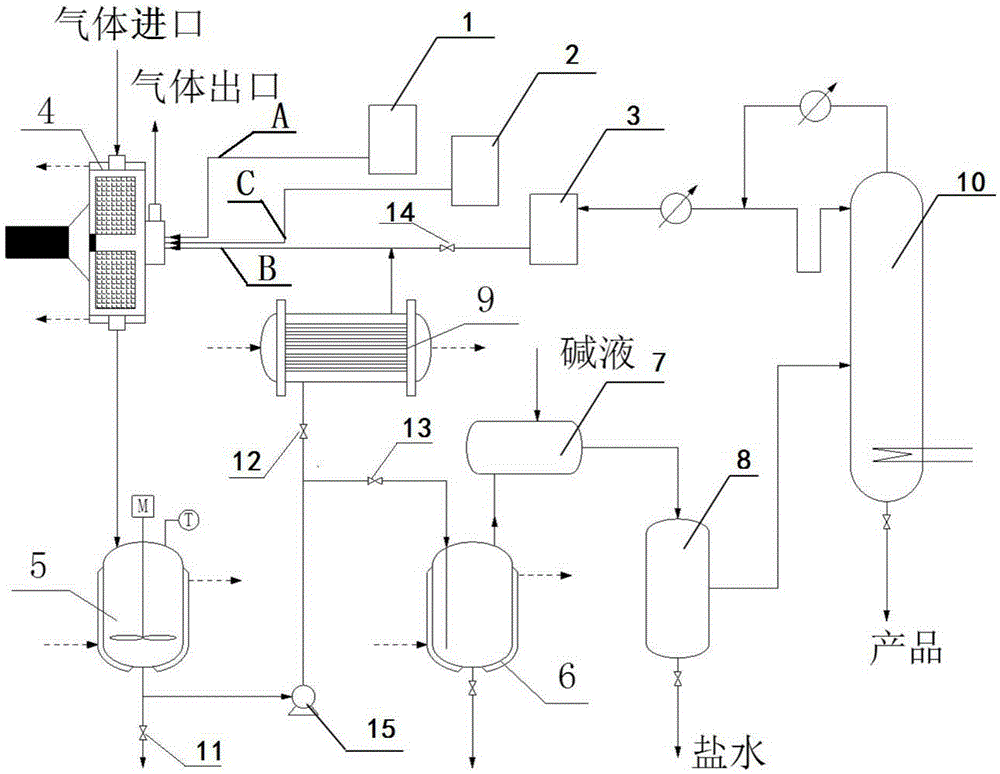

System device for preparing sulphonate surfactant through supergravity sulfonating method and application

InactiveCN106606991AShort stayNot easy to bring outTransportation and packagingSulfonic acids salts preparationSolventSide reaction

The invention discloses a system device for preparing a sulphonate surfactant through a supergravity sulfonation method and application. The system device comprises batching systems, a supergravity reaction system, heat removing systems and a post-processing system. The batching systems comprise the sulfonation agent batching system, the organic solvent for heat removing batching system and the raw material waiting for being sulfonated batching system; the supergravity reaction system comprises a supergravity reactor and a feeding device; the heat removing systems comprise the outer heat removing system and the cold shock heat removing system; and the post-processing system comprises a circulating stirring system, a circulating pump, an overflow aging system, a neutralization system, a water-separating system and a solvent recovery system. The system device is adopted to conduct a sulfonation reaction, diluted gaseous or liquid sulfur trioxide serves as a sulfonating agent, so that the reaction is controllable, and the reaction heat quantity can be removed timely. According to the system device for preparing the sulphonate surfactant through the supergravity sulfonation method, the supergravity technology is applied in the process of sulfonation quick reaction, so that raw materials can be evenly distributed rapidly, the occurrence probability of a side reaction is reduced, and the product quality is improved.

Owner:BEIJING UNIV OF CHEM TECH

Hydraulic driving type push plate wave making test device under supergravity condition

PendingCN109186937AWell formedImprove reliabilityHydrodynamic testingHydraulic cylinderElectric machine

The invention discloses a hydraulic driving type push plate wave making test device under a supergravity condition. A wave making unit and a wave absorbing unit are respectively arranged at the innerwalls of the left side and the right side of a model box filled with liquid; a wave making hydraulic cylinder and a wave absorbing hydraulic cylinder are respectively arranged on the outer walls of the left side and the right side of the model box; a seabed model is arranged in a groove formed between a bottom stop block of the wave making unit and a bottom stop block of the wave absorbing unit; amarine structure model is buried in the seabed model; and two sets of hydraulic driving systems outside the model box respectively provide hydraulic power for the wave making hydraulic cylinder and the wave absorbing hydraulic cylinder through a centrifugal machine rotary joint. The device is suitable for high-frequency large wave making under the supergravity condition; the push plate type wavemaking is adopted, a power conversion system from a hydraulic driving system to a wave making plate has simpler and more reliable form than a conventional wheel disc type power conversion system driven by a servo motor; and during a test process, a distance between the wave absorbing plate and the wall of the model box and an aperture ratio of the wave absorbing plate are both adjustable, the simulation of waves under different working conditions can be met, and the wave absorbing efficiency is improved.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com