Method for preparing nano material

A nanomaterial and nanotechnology, applied in the field of preparation of nanomaterials, can solve the problems of high cost, small particle diameter, easy agglomeration and other problems, and achieve the effects of energy saving, high product quality and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

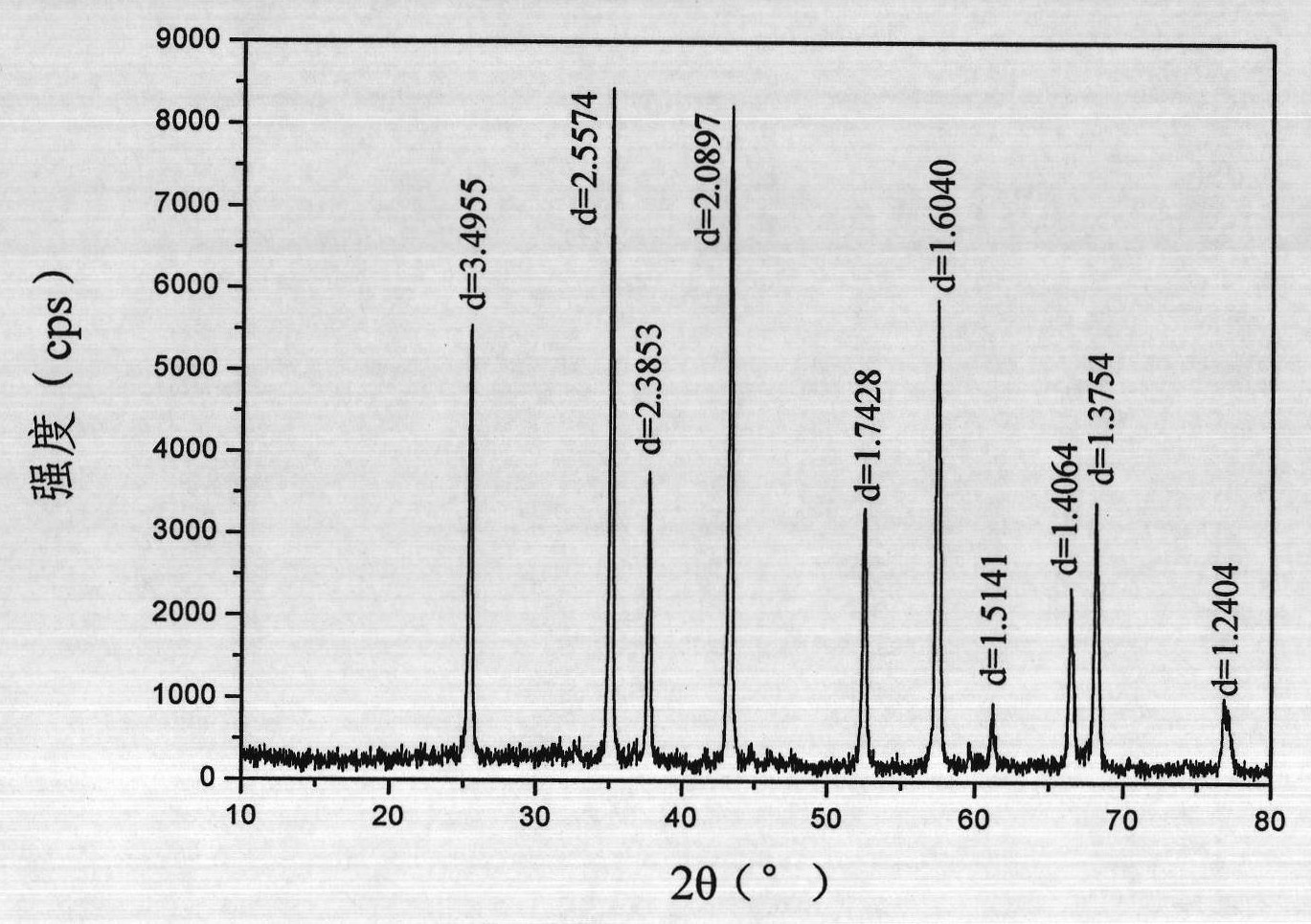

[0037] Embodiment 1: Preparation of nanometer α-alumina

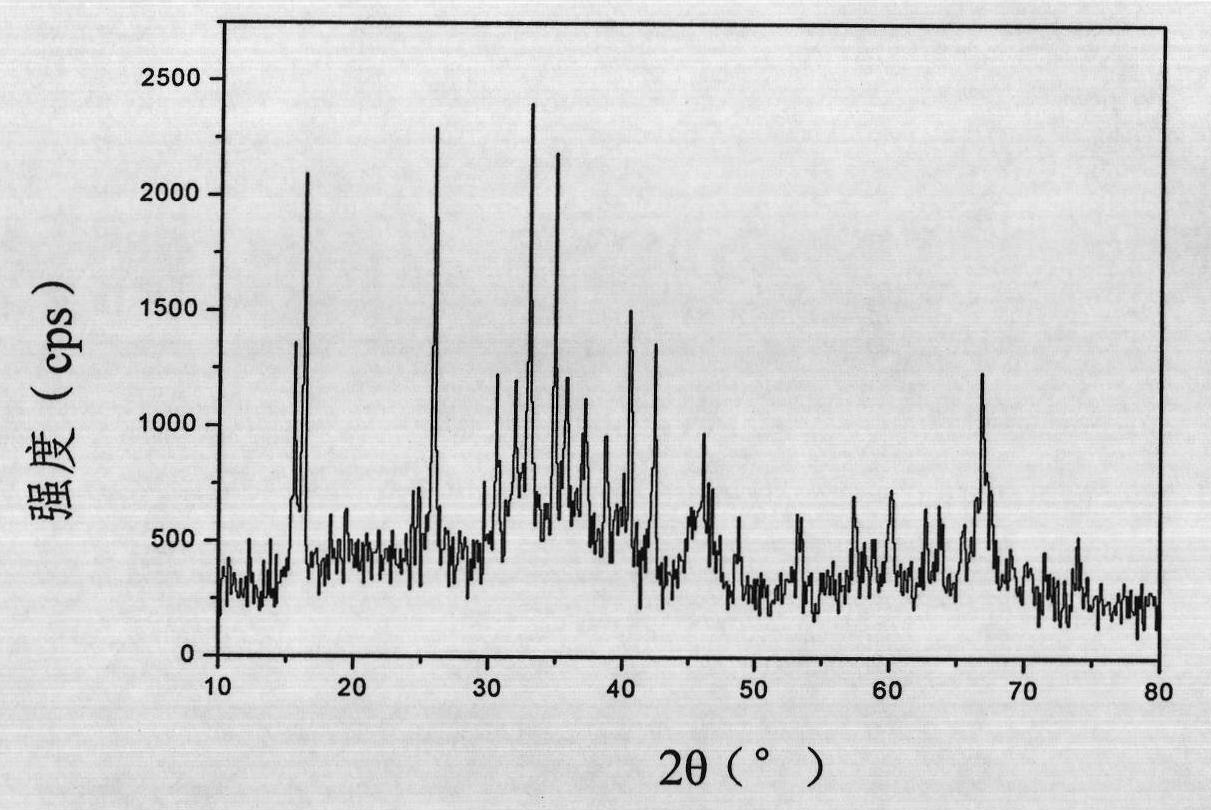

[0038] First prepare the precursor of nano pseudo-boehmite in the supergravity field: make the sodium metaaluminate solution and carbon dioxide gas contact and react in the supergravity to obtain the pseudo-boehmite suspension, and then perform aging, filtration, aging treatment, After the solid product is separated and dried, a solid nanoscale pseudo-boehmite precursor is obtained. Specifically, the gas-liquid ratio of sodium metaaluminate aqueous solution to carbon dioxide gas is 1-10:1, preferably 1-5:1; the carbon dioxide gas introduced consumes excess sodium hydroxide in the solution and destroys the aluminum Equilibrium system in sodium bicarbonate solution, resulting in pseudo-boehmite precipitate (AlOOH·nH 2 O). Therefore, the temperature for the reaction is 0-35°C, the rotational speed is controlled at 1000rpm, and the centrifugal acceleration in the supergravity field is 180-10000m / s 2 , preferably 1000-6000g...

Embodiment 11

[0043] Take a certain mass of sodium metaaluminate solution with a concentration of 0.15-0.30 mol / L, add 1-2% polyethylene glycol 400 organic polymer surface dispersant according to its mass ratio, and mix the mixed solution uniformly for use. CO 2 Gas backup. Start the spiral channel type rotating field supergravity bed to drive the reactor to rotate, control its speed at 1000-1200rpm, add the mixed liquid into the rotating reactor through the valve that can adjust the flow rate, adjust and control the mixed liquid flow rate to 400L / h, wait for After the flow stabilizes, open the CO 2 Gas valve, adjust the gas flow to make the gas-liquid flow ratio 1.5:1, so that CO 2 It also enters the rotating reactor, and carries out carbonization reaction with the existing sodium metaaluminate solution in the reactor, controls the reaction temperature below 35°C, measures the pH of the solution during the reaction, closes all valves when it reaches around 10.5, and the screw The channe...

Embodiment 12

[0047] The pseudo-boehmite was prepared according to the same method as in Example 1.1, except that the concentration of the sodium metaaluminate solution was 0.3-0.5 mol / L. Experiments show that: increasing the concentration of reactants will prolong the carbonization reaction time. When the concentration is higher than 0.5mol / L, the solution will return to alkali during the carbonization process, which is not conducive to the carbonization reaction to prepare nano-pseudo-boehmite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com