Patents

Literature

3775 results about "Small particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

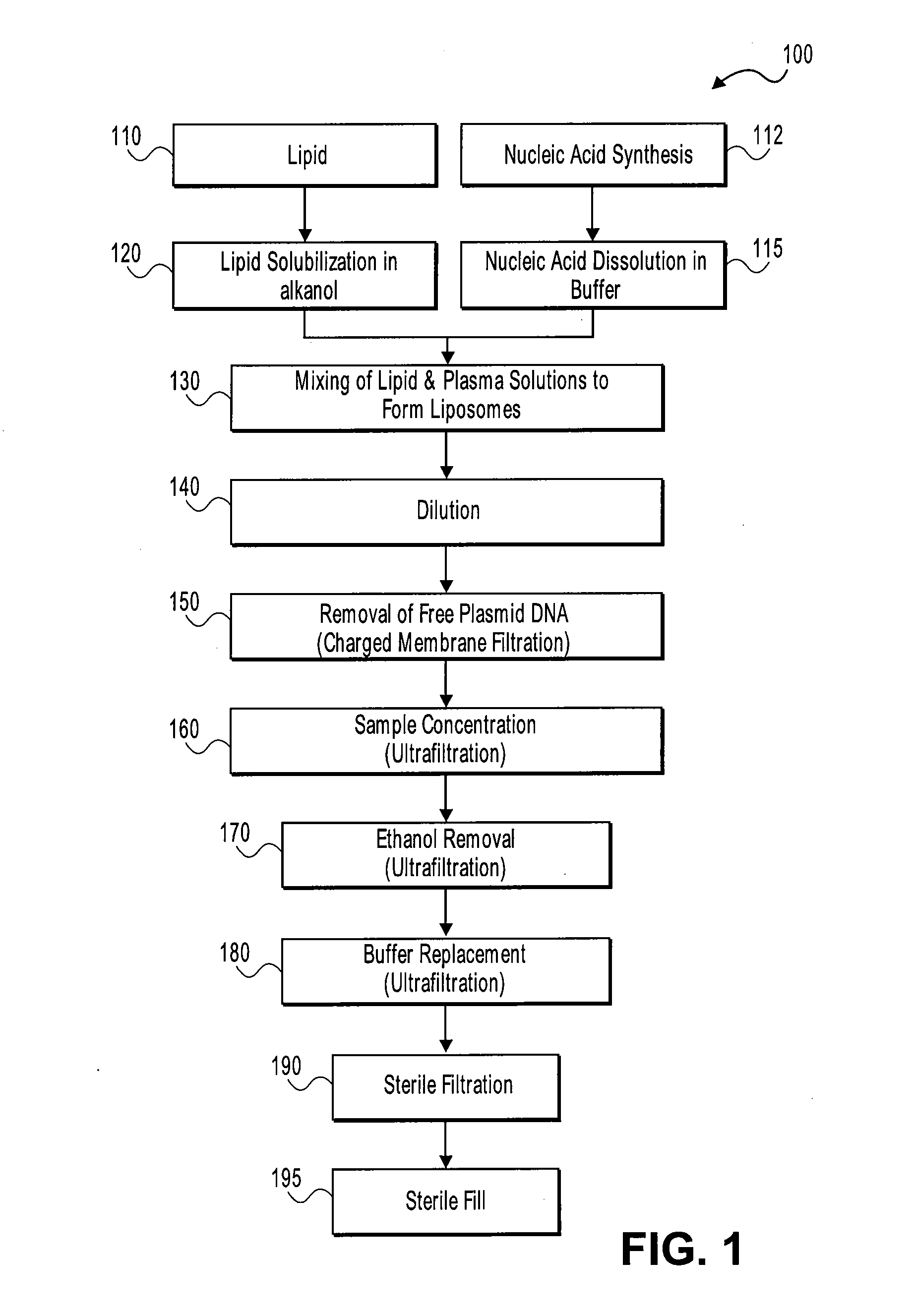

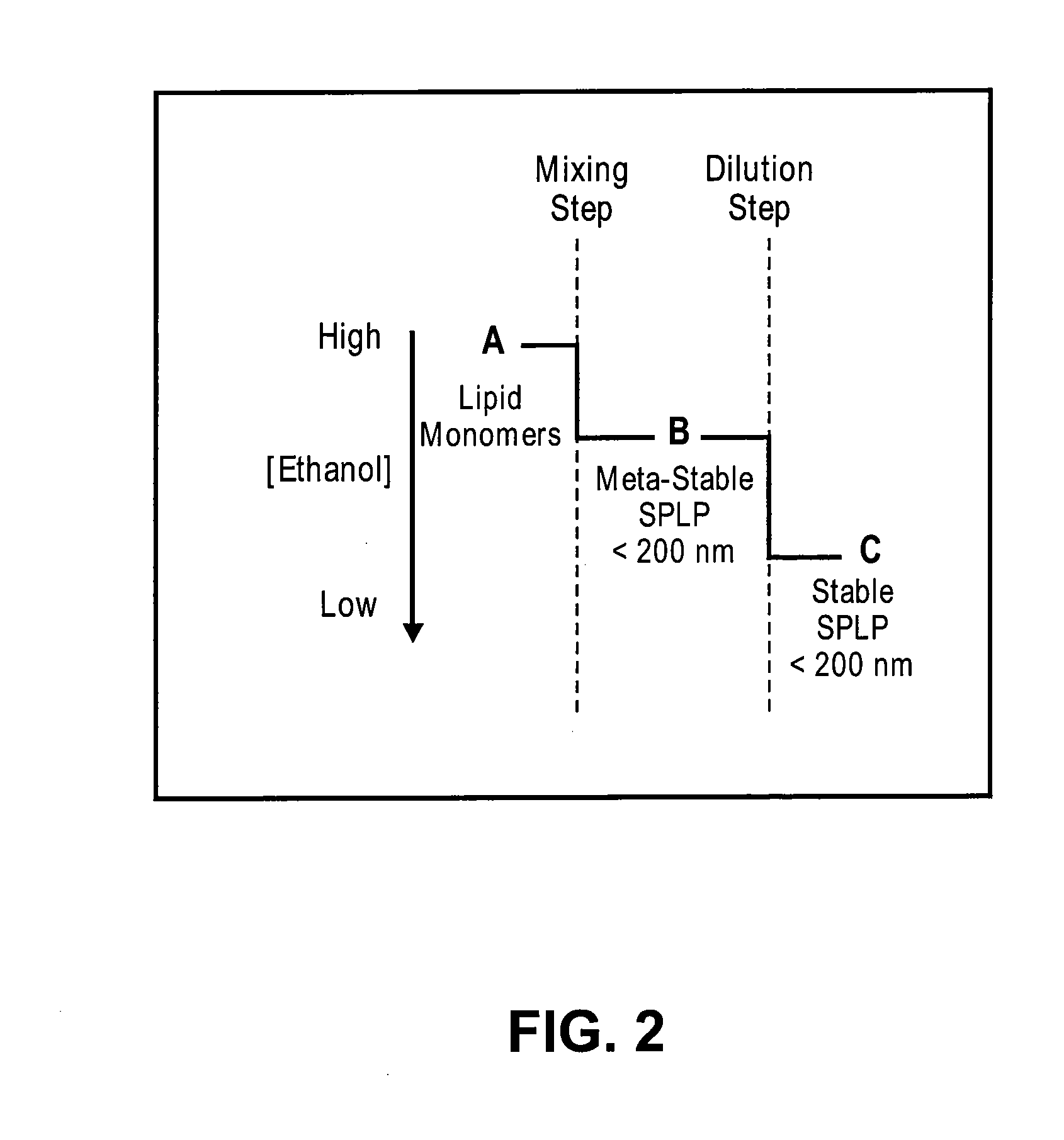

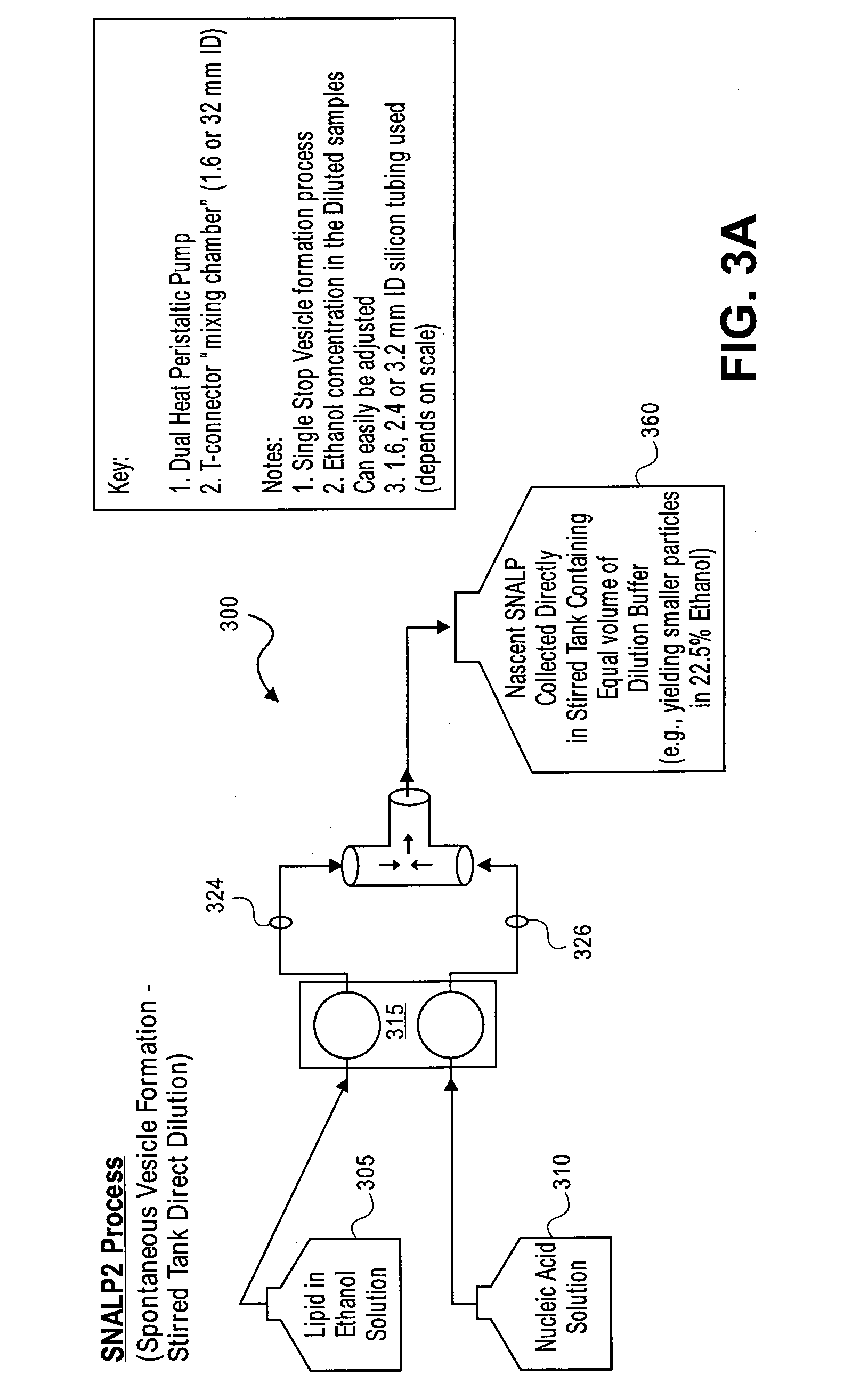

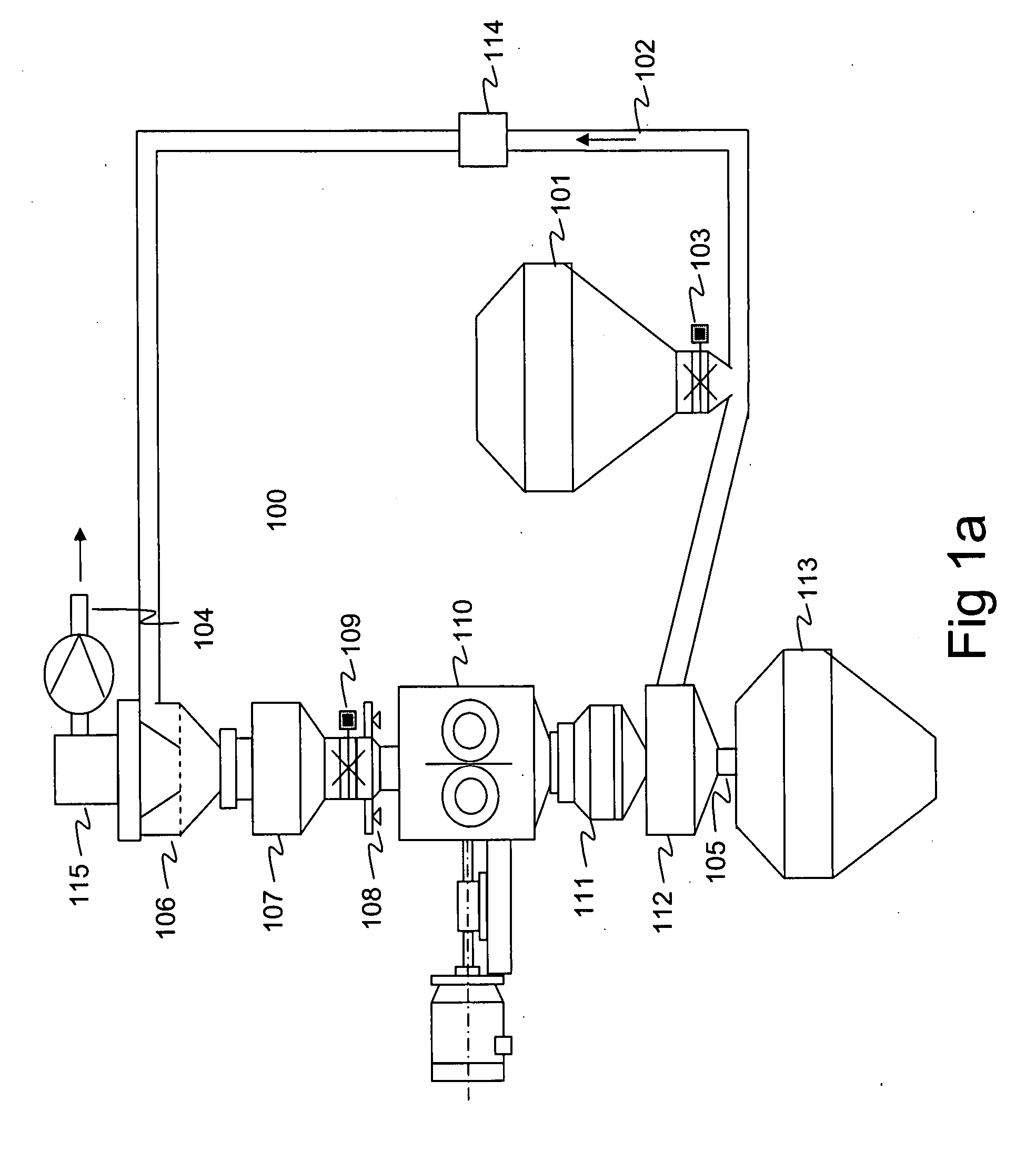

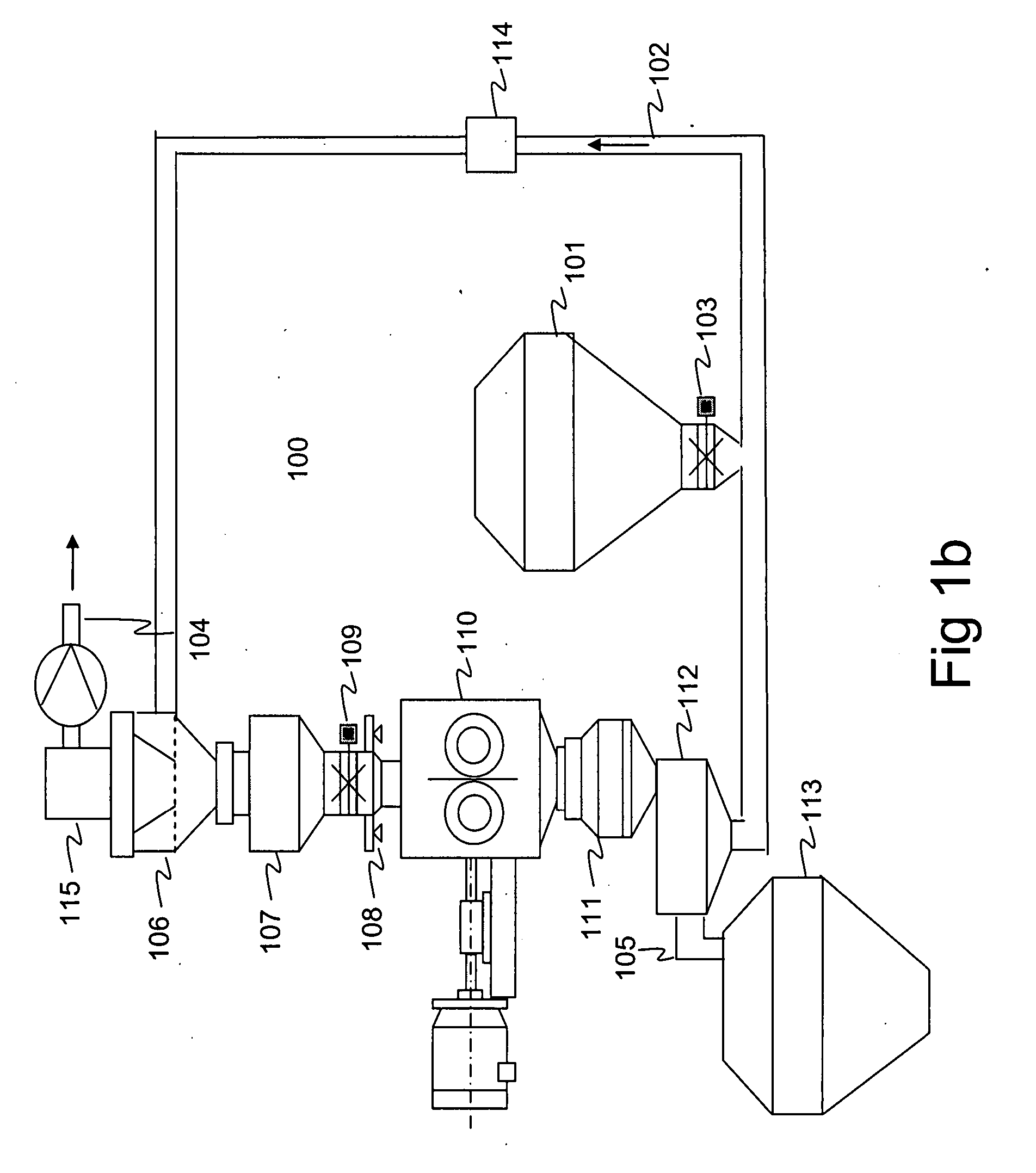

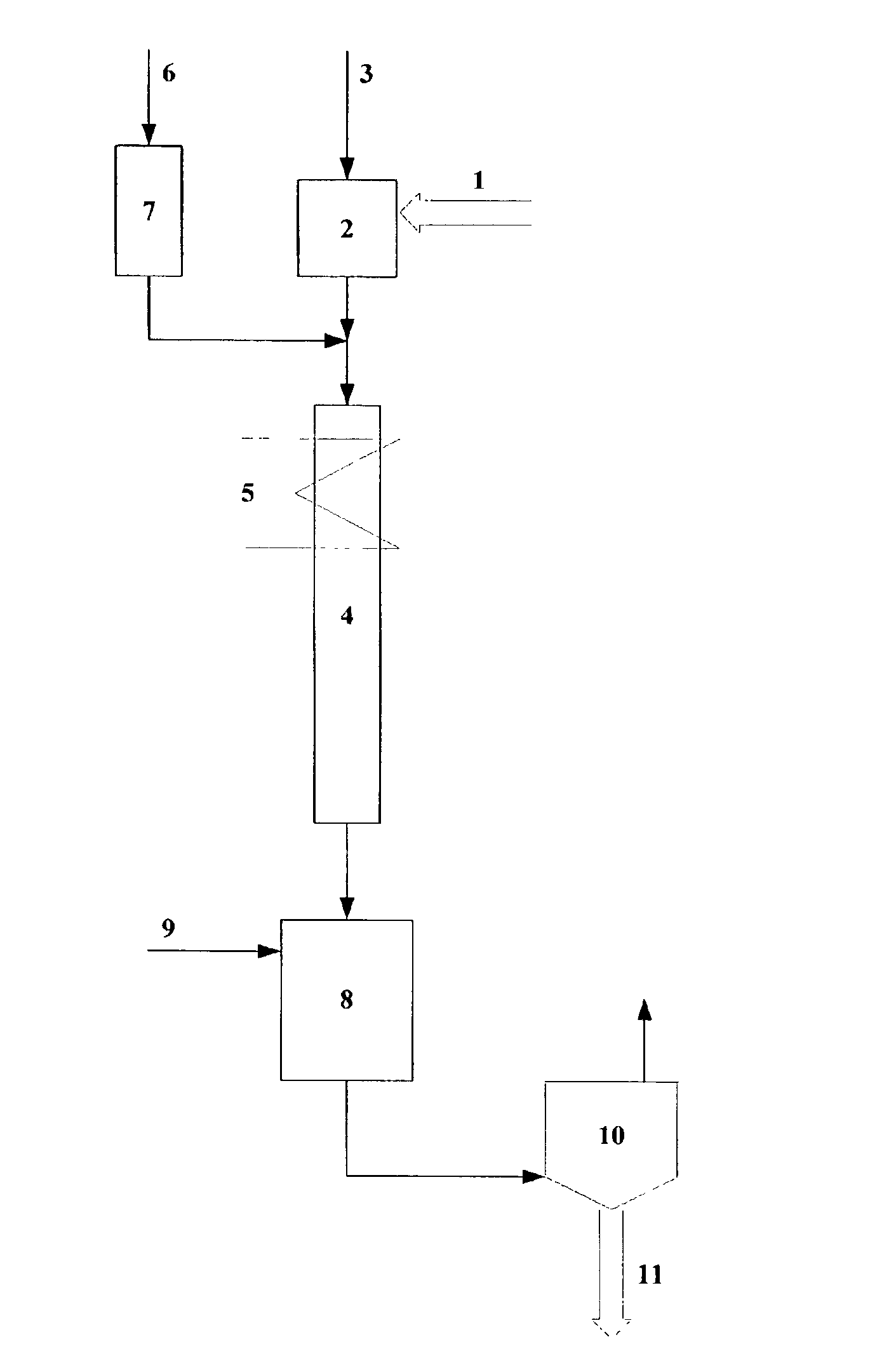

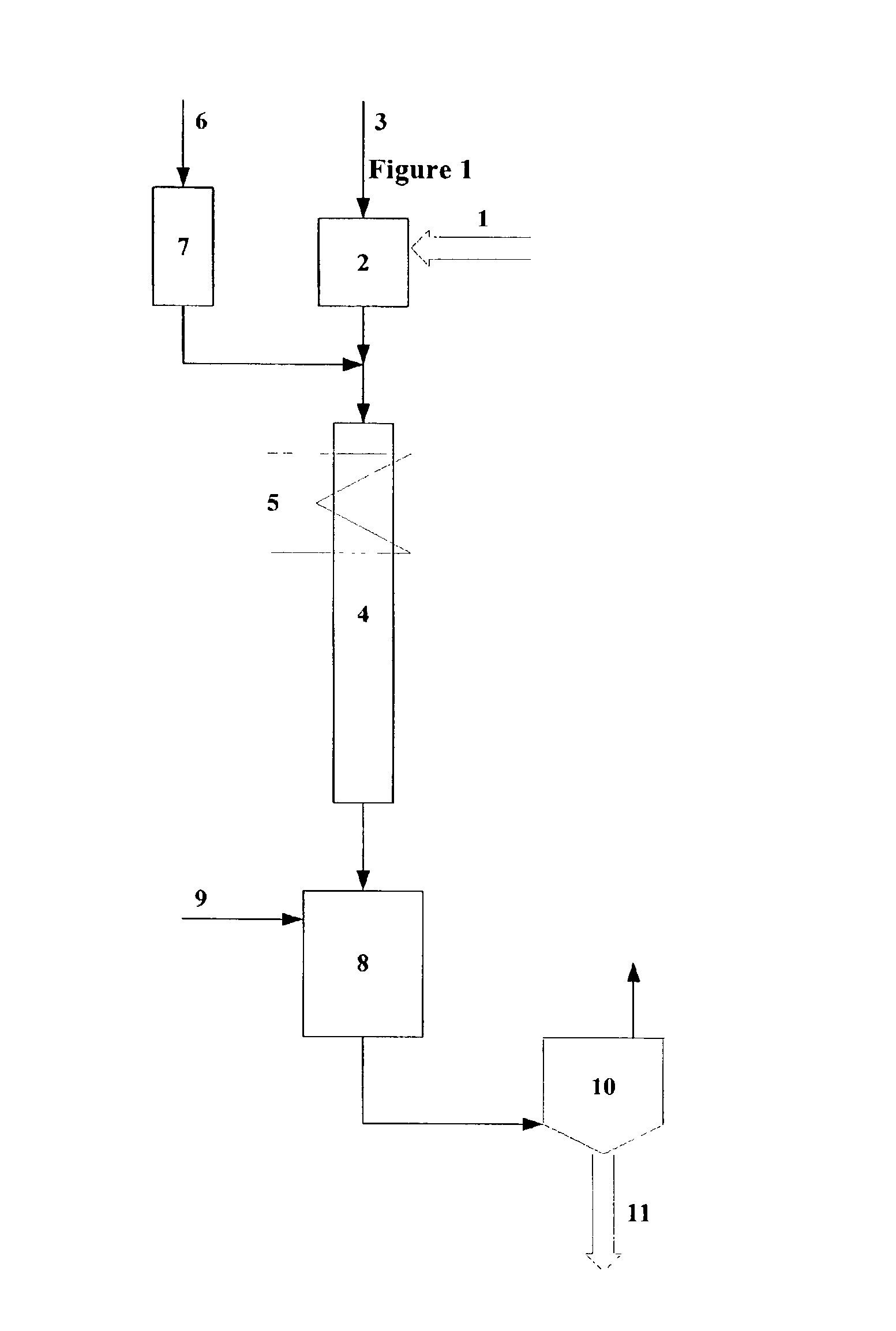

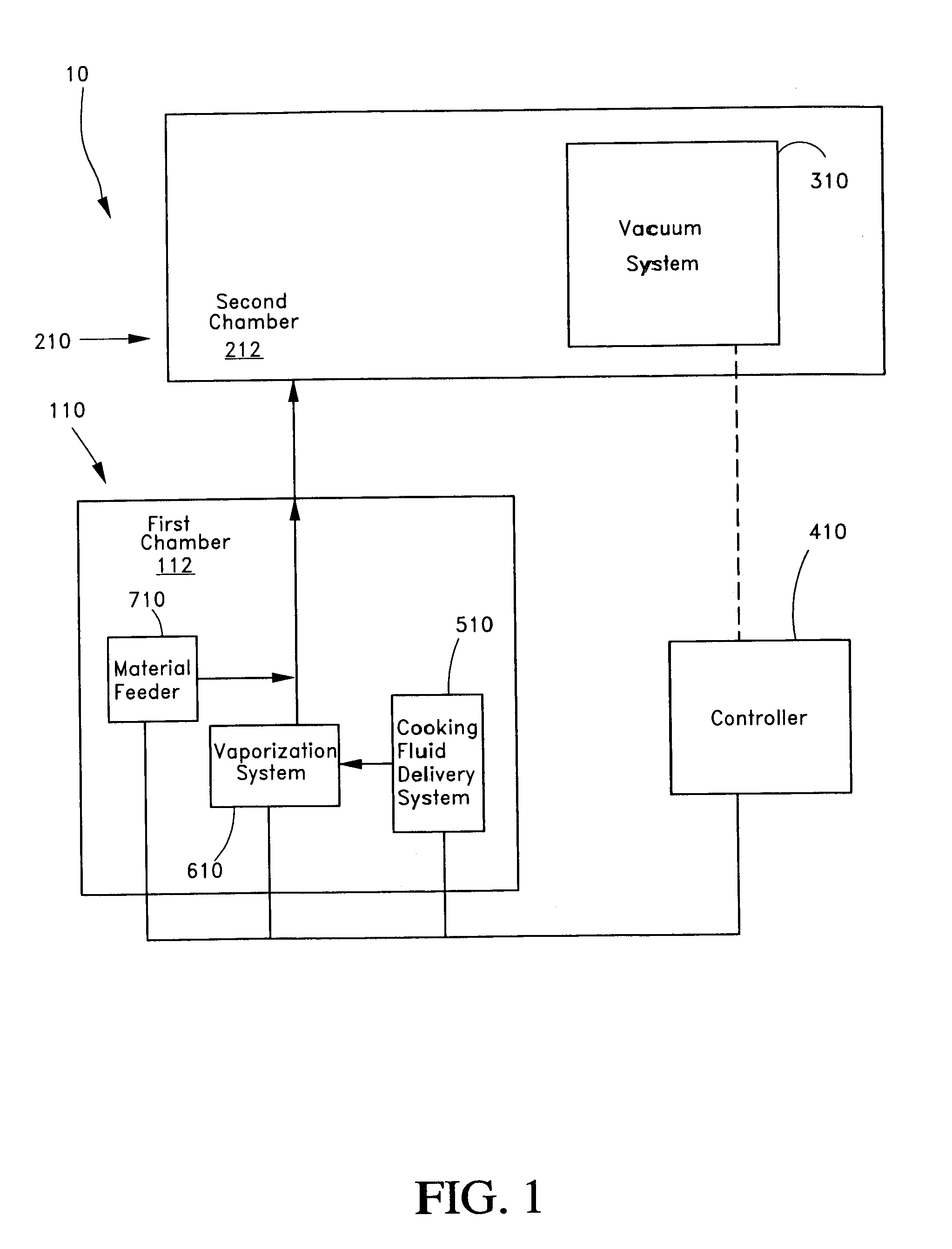

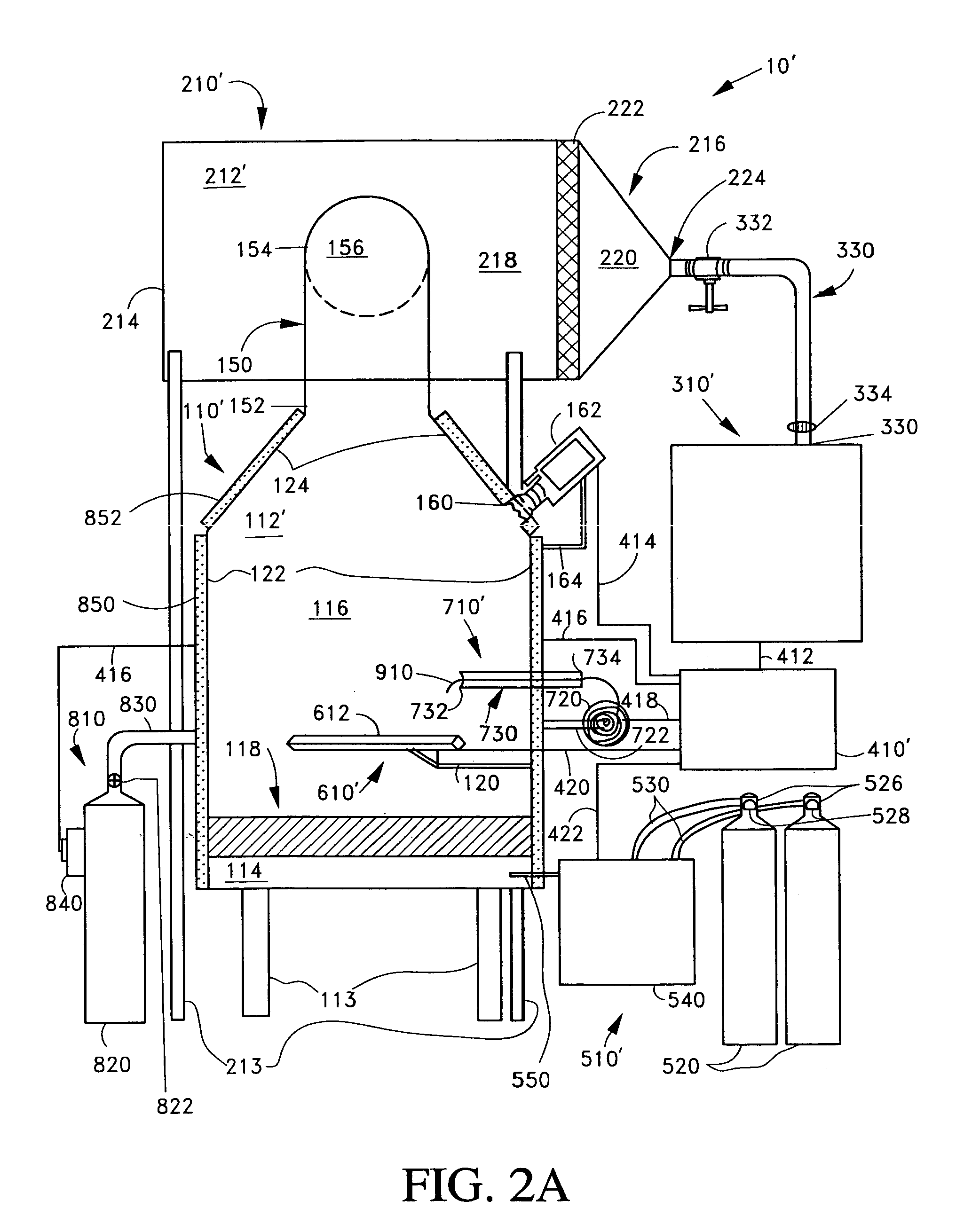

Systems and methods for manufacturing liposomes

ActiveUS20070042031A1Fast preparationOrganic active ingredientsMicroencapsulation basedLipid formationBuffer solution

The present invention provides apparatus and processes for producing liposomes. By providing a buffer solution in a first reservoir, and a lipid solution in a second reservoir, continuously diluting the lipid solution with the buffer solution in a mixing chamber produces a liposome. A therapeutic agent, such as nucleic acid, is included in one of the buffer solution or the lipid solution. Upon mixing a liposome encapsulating the therapeutic product is substantially instantaneously formed. Thereafter the liposome solution formed is immediately diluted with buffer solution to enhance homogeneity and maintain small particle size.

Owner:ARBUTUS BIOPHARMA CORPORAT ION

Milled particles

InactiveUS6634576B2Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

A process for milling a solid substrate in the milling chamber of a dispersion or media mill in the presence of a two or more compositions of milling media bodies is disclosed wherein all milling media bodies contribute to the grinding of the solid substrate and wherein at least one composition of media bodies provides fragments of milling media bodies that are retained with the milled solid substrate particles in the form of a synergetic commixture produced in the milling process. More specifically, a process is disclosed for preparing a synergetic commixture comprising small particles of a solid substrate and small particulates of a first material of a desired size comprising the steps of (a) providing to the milling chamber of a media mill a contents comprising a pre-mix of a solid substrate, a fluid carrier, a plurality of milling bodies of a first material having a fracture toughness Kc1, and a plurality of milling bodies of a second material having a fracture toughness Kc2; (b) operating the media mill to grind the solid substrate and degrade at least a portion of the milling bodies of first material to produce a dispersion in the fluid carrier comprising a synergetic commixture of small particulates of the first material and small particles of the solid substrate having a desired size equal to or less than a size Sp; (c) separating the dispersion from any milling bodies and solid substrate particles having a size larger than Sp; and (d) optionally removing the fluid carrier from the dispersion to form a synergetic commixture free of fluid and comprising the particles and the small particulates, wherein KC2 is greater than KC1.

Owner:RTP PHARMA +1

Milled particles

InactiveUS20020047058A1Increase incorporationOptimal for incorporationPowder deliveryInorganic non-active ingredientsParticulatesPolymer science

Owner:RTP PHARMA +1

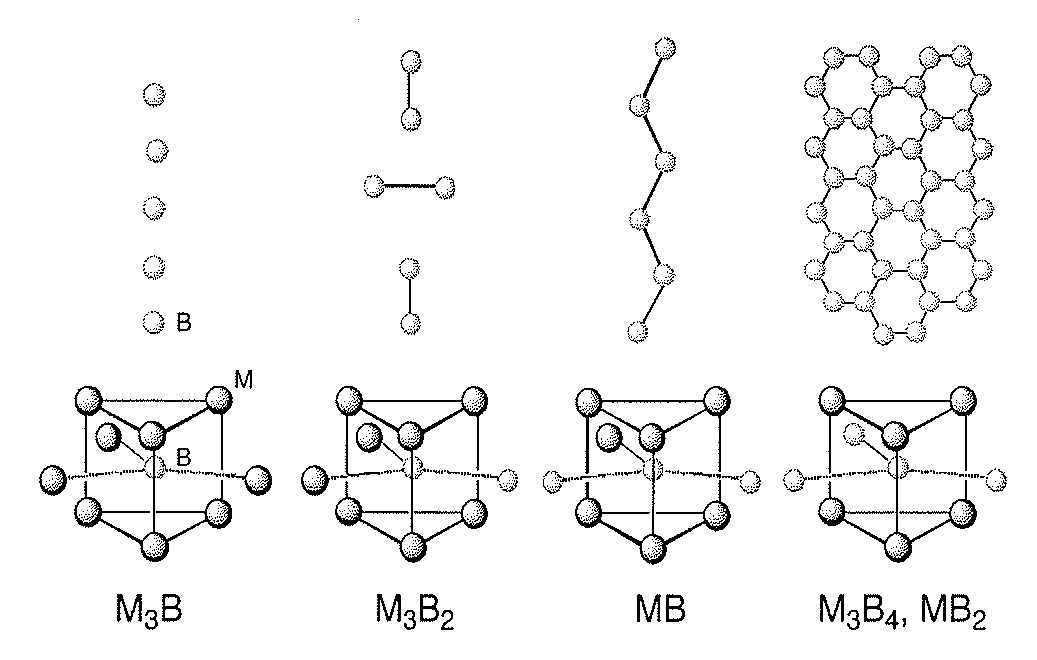

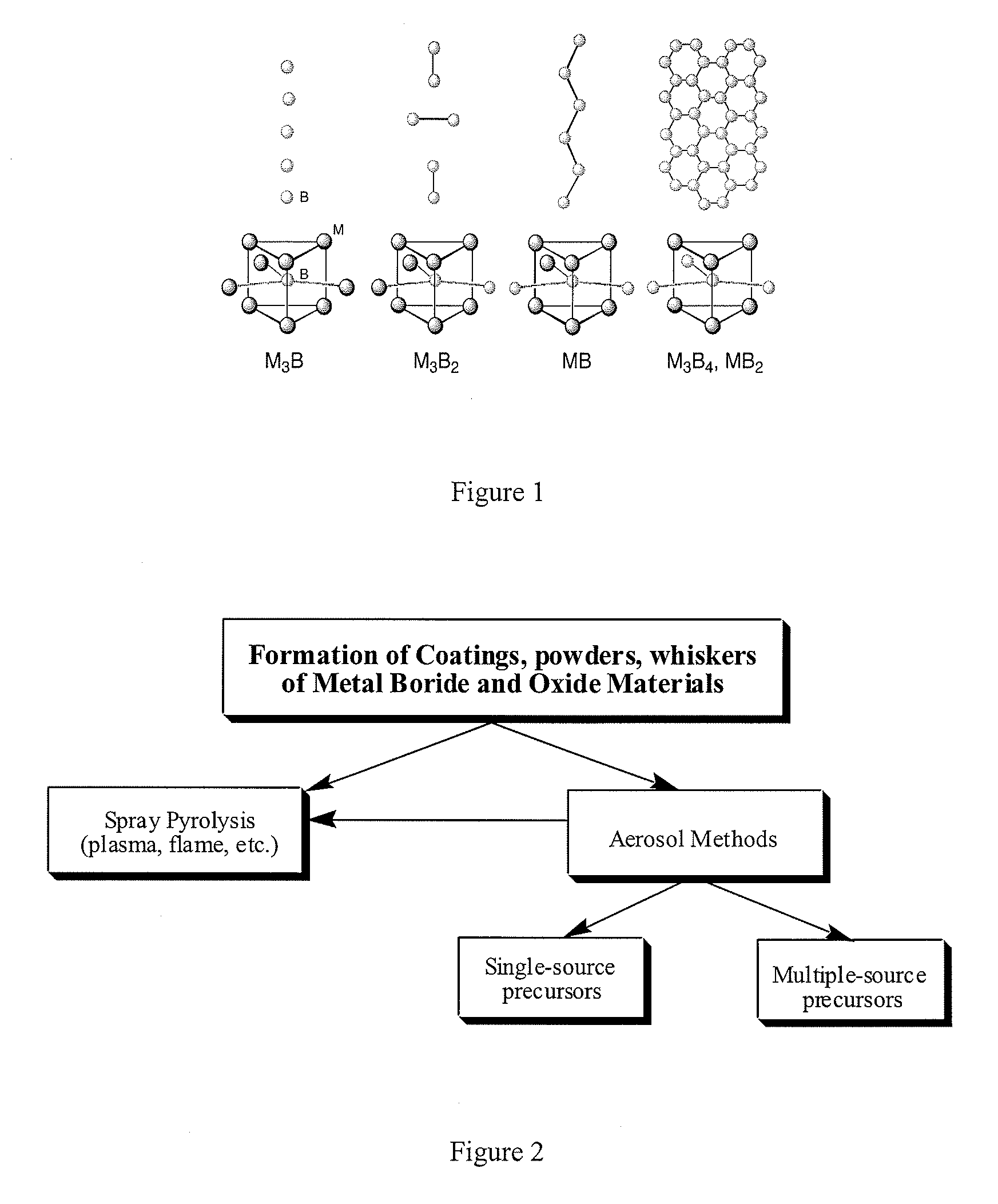

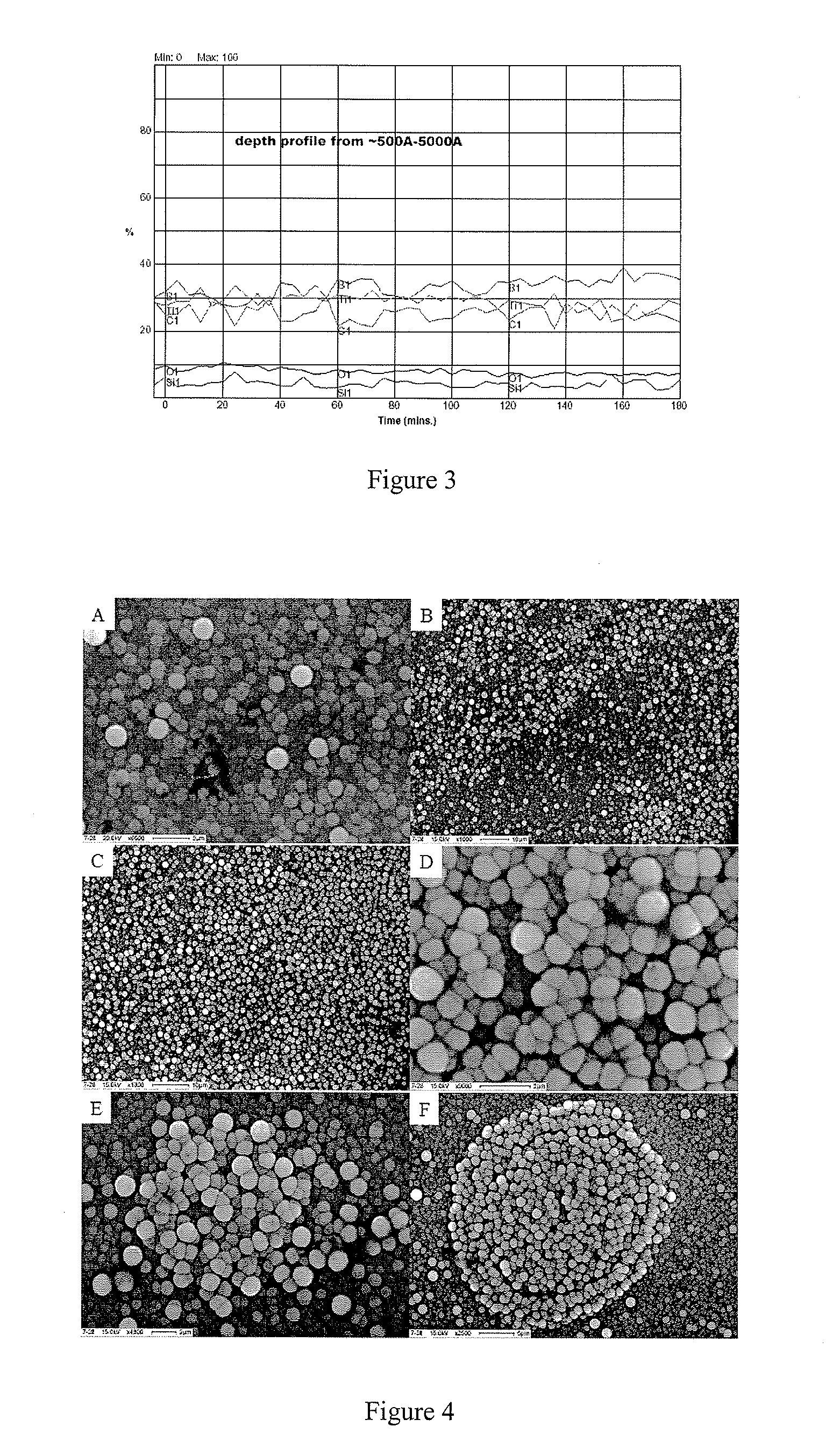

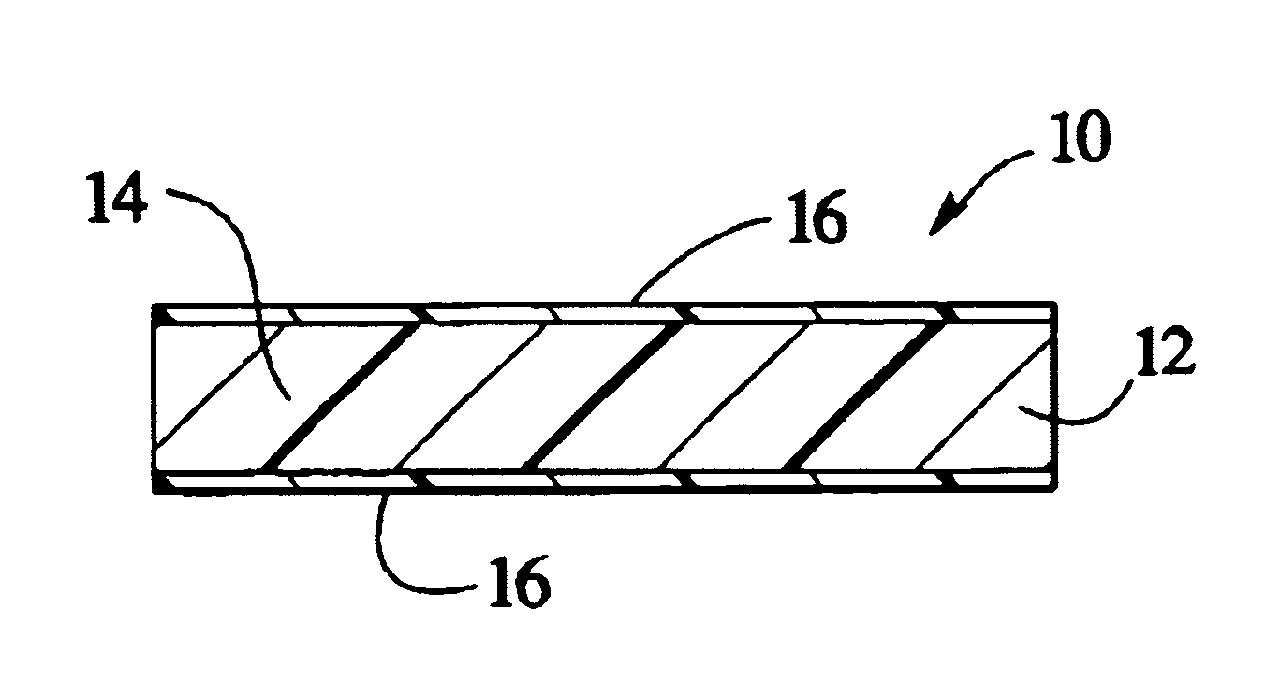

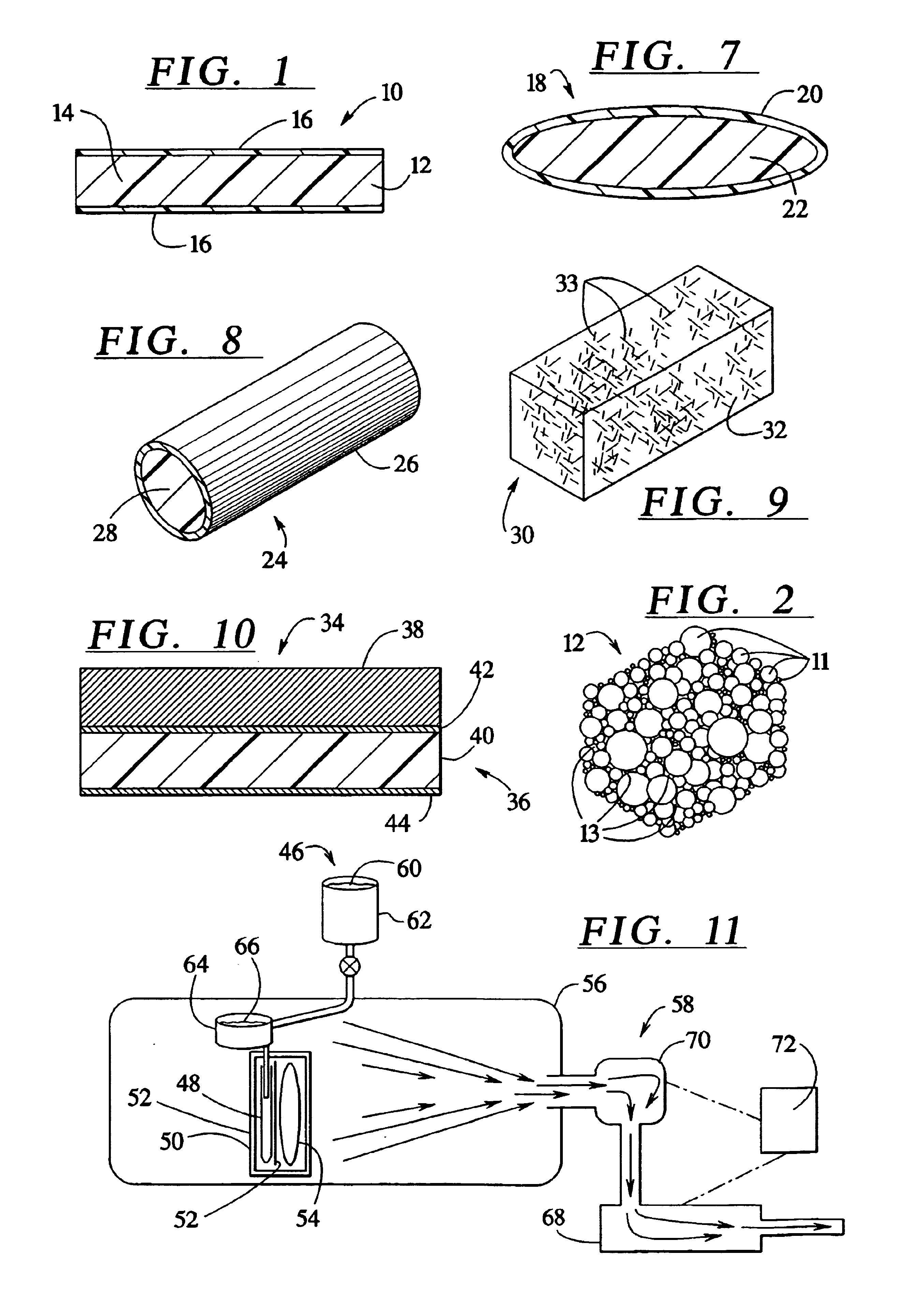

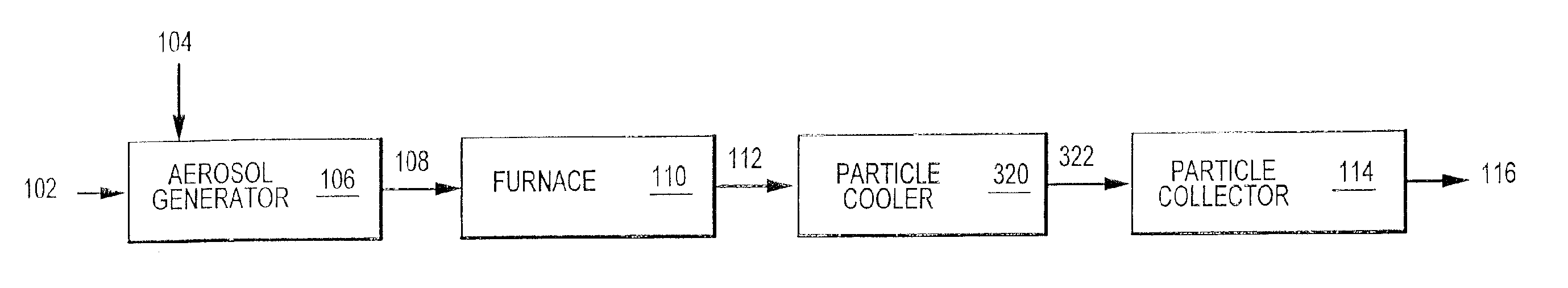

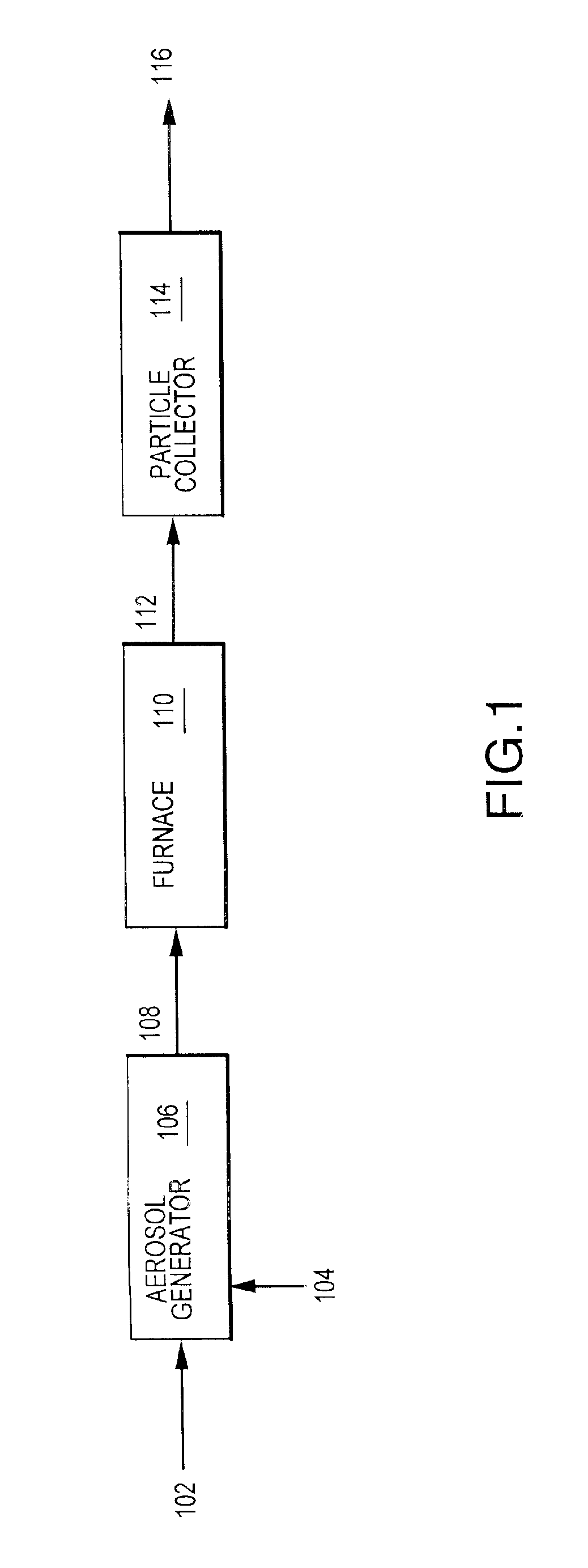

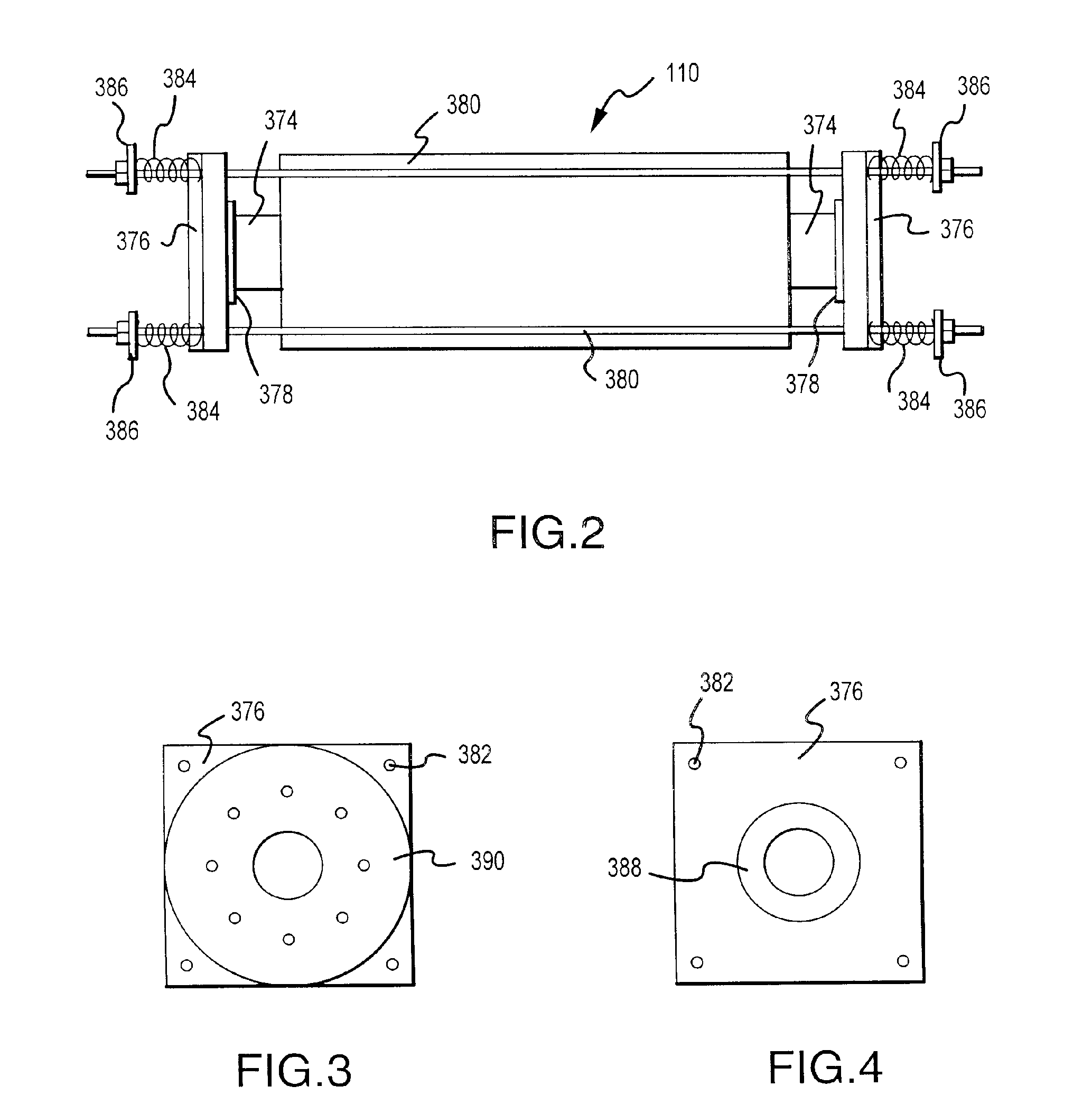

Systems and Methods of the Formation of Solid State Metal Boride and Oxide Coatings

InactiveUS20080003425A1Easy to implementMolten spray coatingLayered productsCelsius DegreeMicrometer

A system and method for the formation of novel small particles, thin films, and coatings of solid state metal boride material. The metal boride materials may be formed using aerosol methods and / or spray pyrolysis to form a generally uniform, thin film coating of boride compound spheres. Boride solutions or compounds are sprayed via a gas nebulizer in a reactor containing a substrate and heated to approximately 900° Celsius. The boride compounds form uniform, spherical particles of approximately one micrometer in diameter. The boride compounds are extremely strong, non-reactive, dense, and, when prepared as films or coating, adhere very well to substrates, such as metals.

Owner:SYRACUSE UNIVERSITY

Composite materials

InactiveUS7037865B1Remarkable strength and other propertyImprove material performanceSynthetic resin layered productsCellulosic plastic layered productsFiberHigh density

New composite materials having a high density of small particles, such as hollow microspheres, in a matrix material are disclosed. The microspheres are densely packed in the matrix material such that adjacent microspheres are positioned in contact with each other or very close together. Fiber flanking may be provided on the opposite sides of a layer of a core of composite material having the small particles and matrix material. Also disclosed are methods of making and using the composite materials.

Owner:JAMES HARDIE TECH LTD

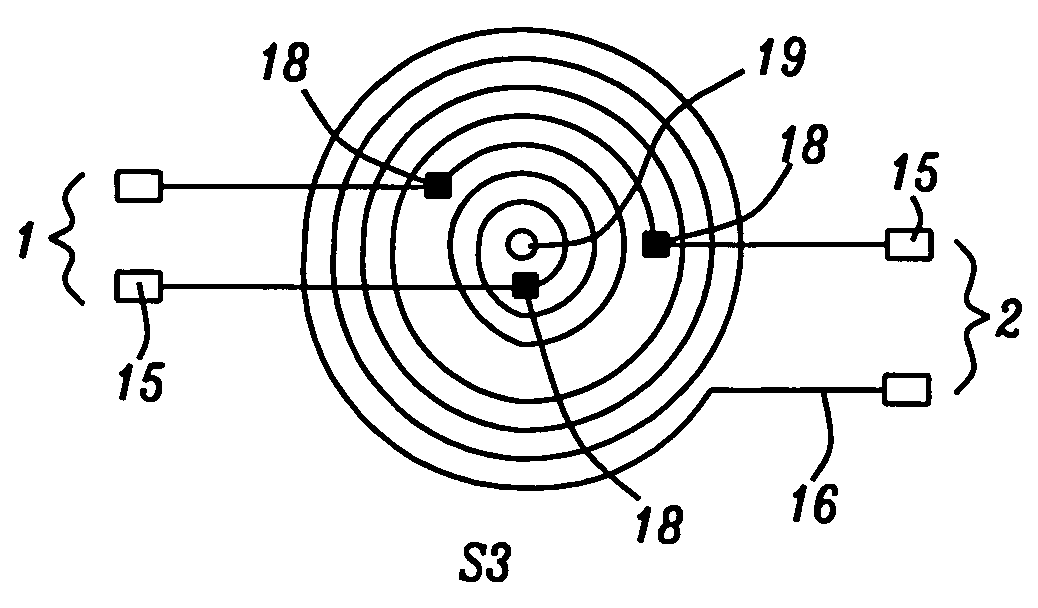

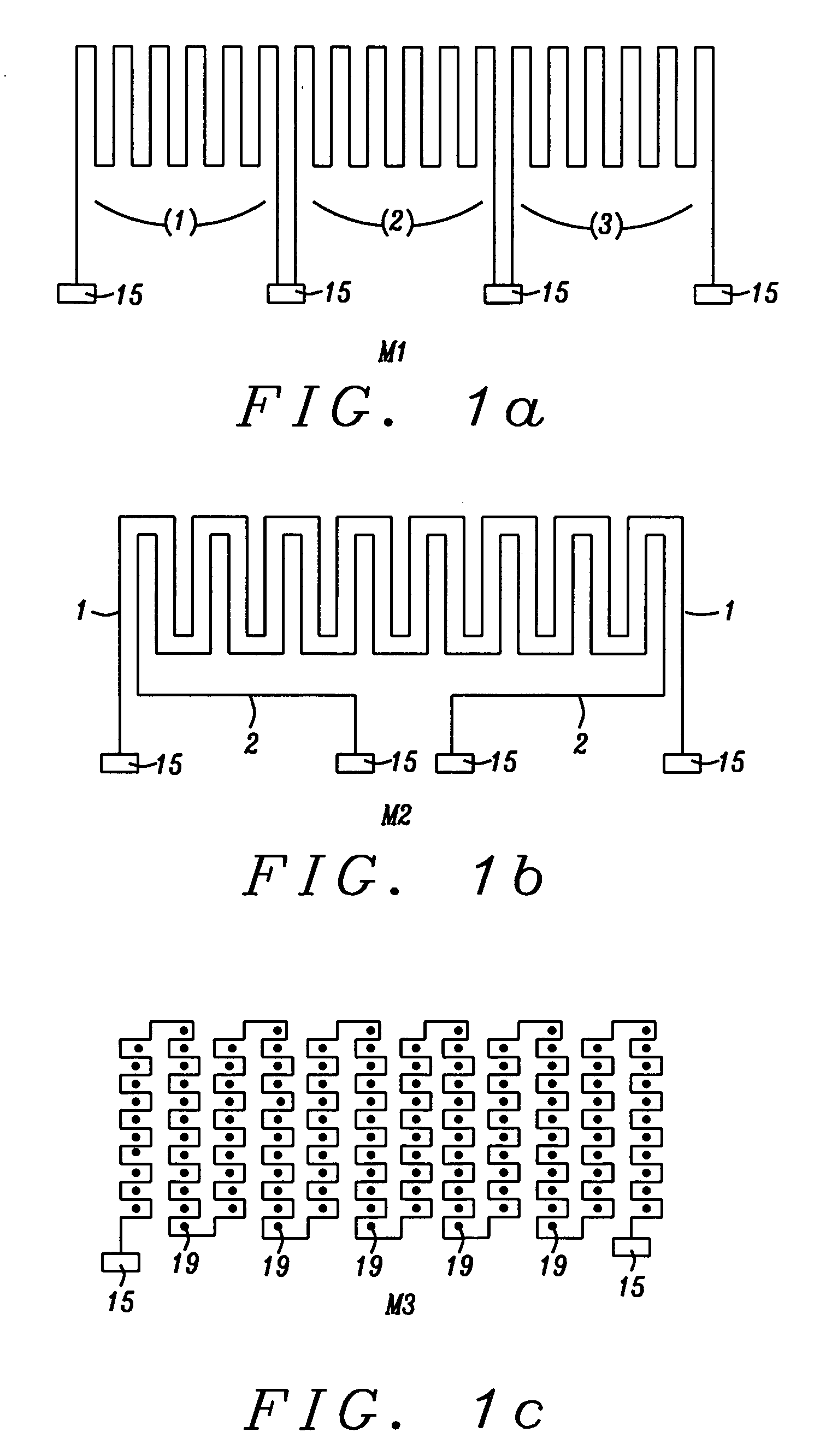

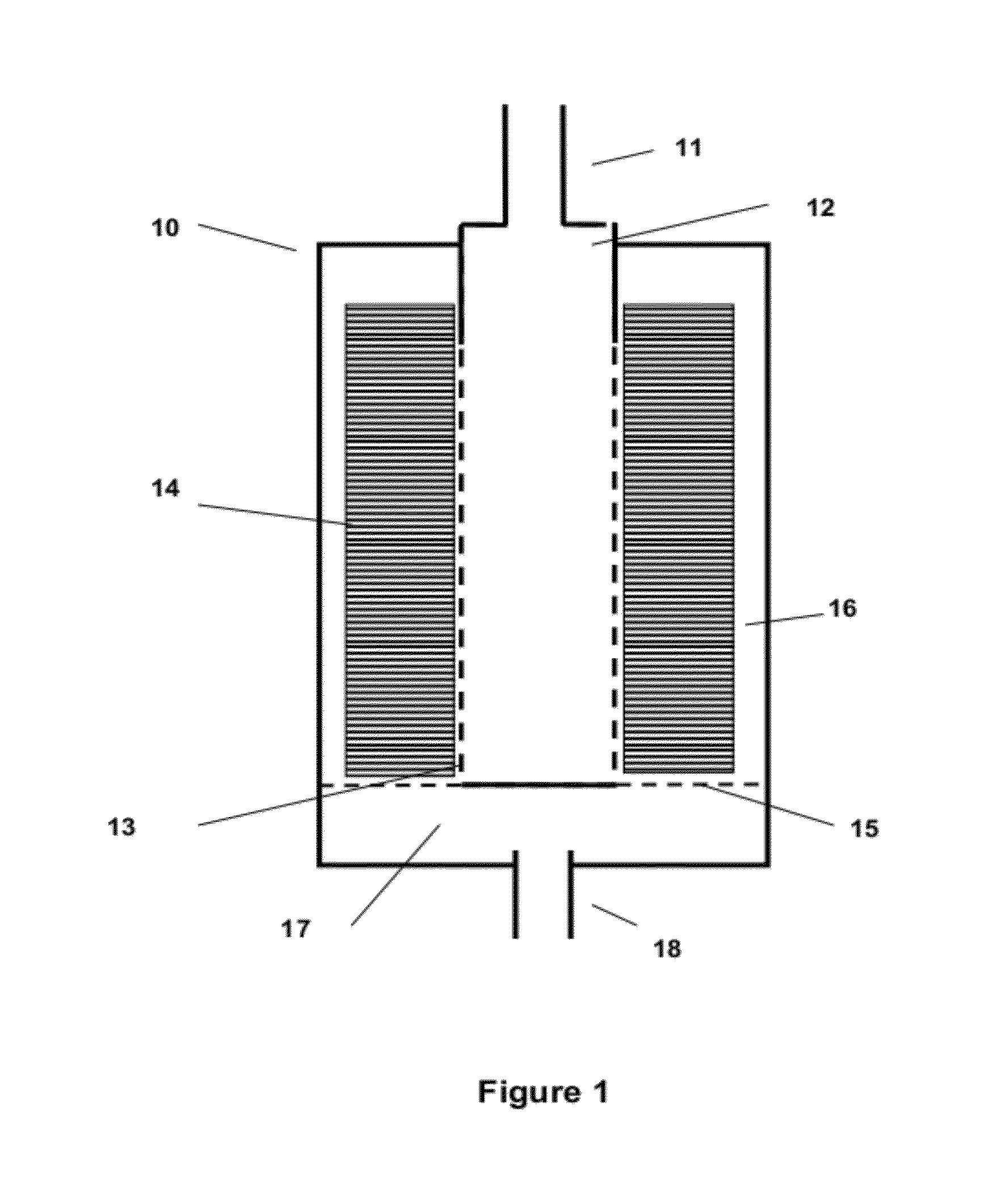

Microfabricated system for magnetic field generation and focusing

InactiveUS20050275497A1Easily of circuitryWell formedTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesDielectricMicro coil

A method of forming, in or on a Si substrate, planar micro-coils with coil windings of high aspect ratio (>3) and a wide variety of geometric shapes. The micro-coils may be formed on a Si substrate and be embedded in a dielectric, or they may be formed in trenches within a Si substrate. The micro-coils may have field enhancing ferromagnetic pillars rising above the micro-coil plane, formed at positions of maximum magnetic field strength and the micro-coils may also include magnetic layers formed beneath the substrate and contacting the pillars to form a substantially closed pathway for the magnetic flux. The substrate may be thinned to membrane proportions. These micro-coils produce strong magnetic fields with strong field gradients and can be used in a wide variety of processes that involve the exertion of strong magnetic forces at small distances or the creation of magnetic wells for trapping and manipulating small particles.

Owner:AGENCY FOR SCI TECH & RES +1

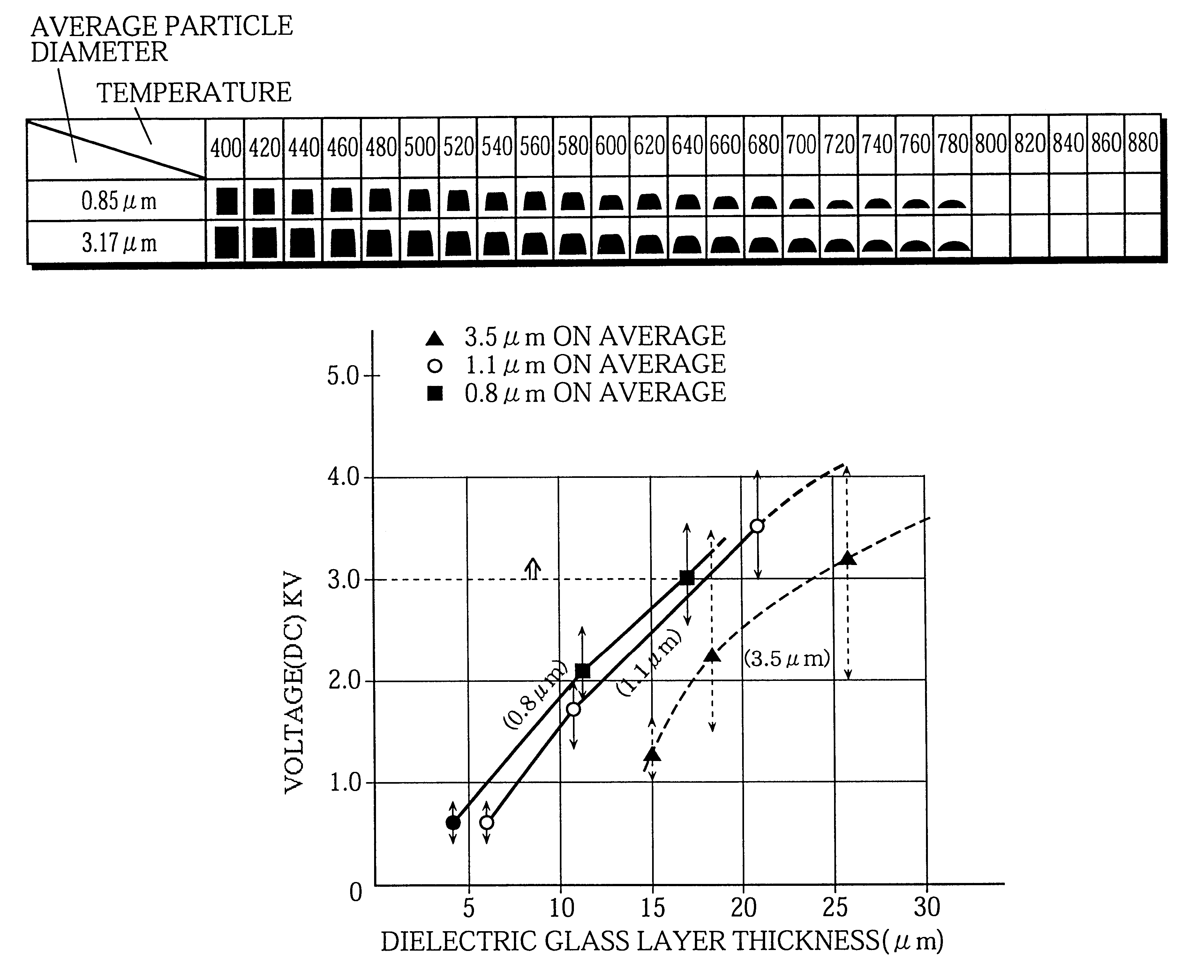

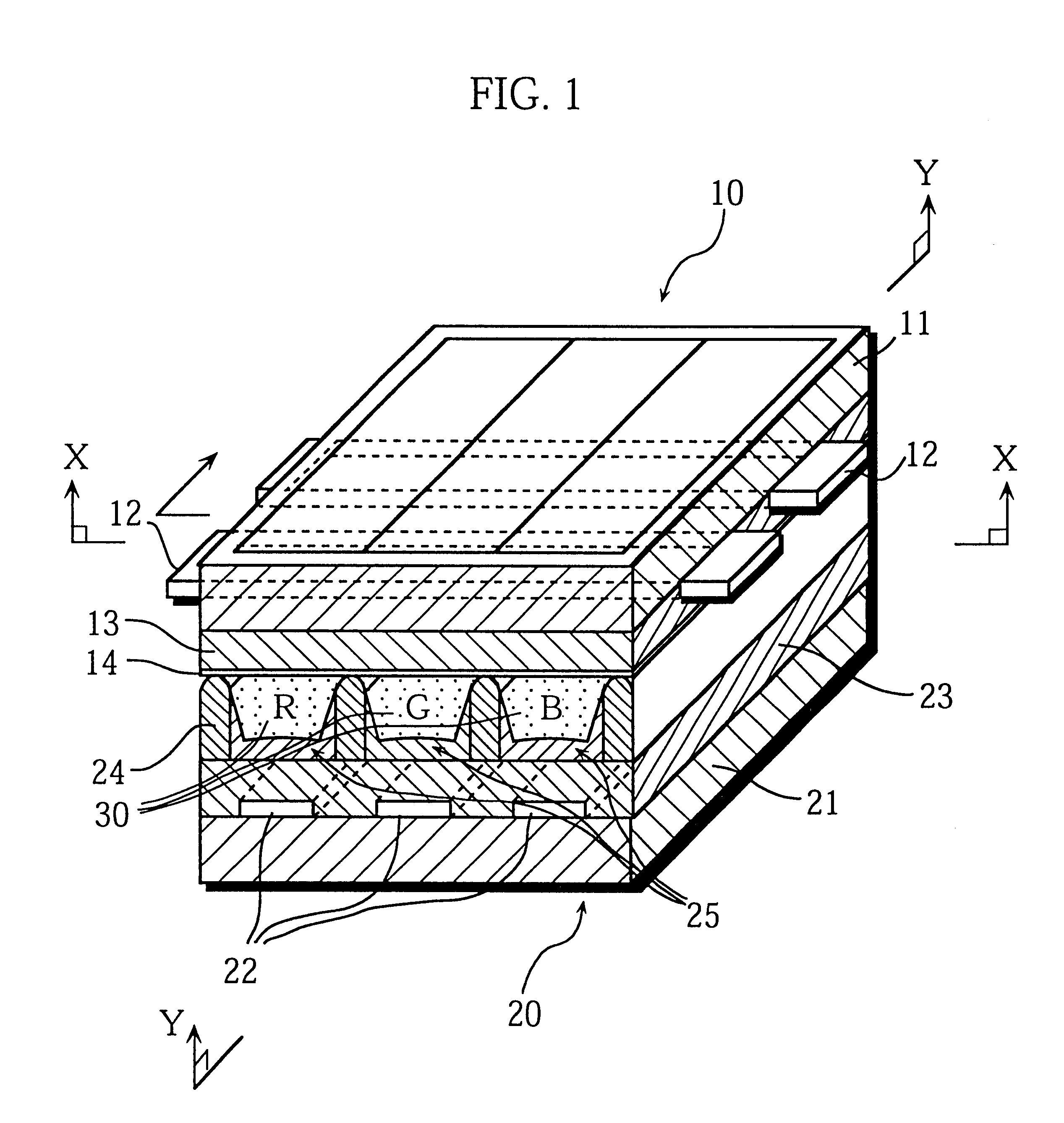

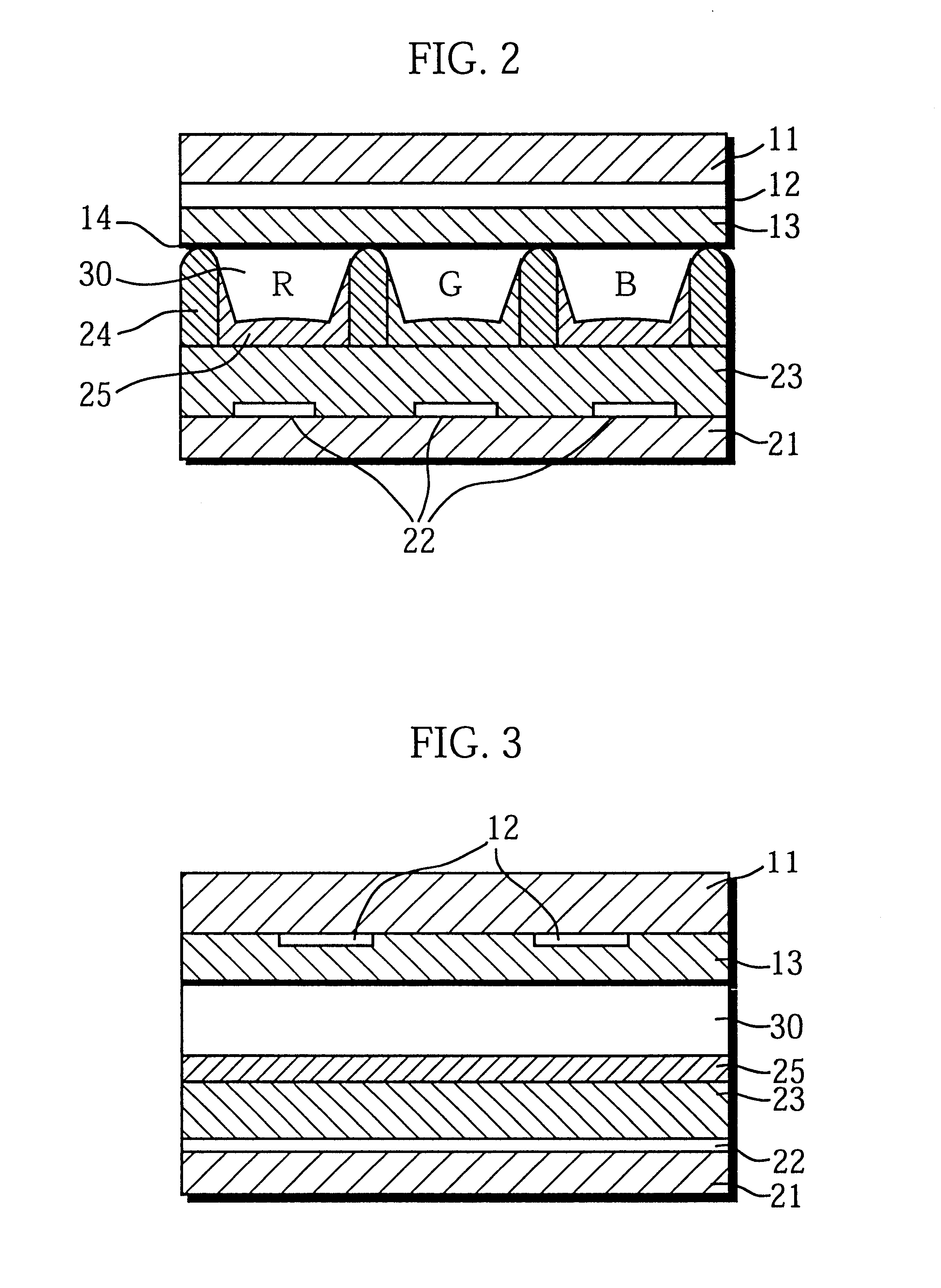

Manufacturing method of plasma display panel that includes adielectric glass layer having small particle sizes

InactiveUS6439943B1Alternating current plasma display panelsVessels or leading-in conductors manufactureScreen printingMetallurgy

The object of the present invention is to provide a high-intensity, reliable plasma display panel even when the cell structure is fine by resolving the problems such as a low visible light transmittance and low voltage endurance of a dielectric glass layer. The object is realized by forming the dielectric glass layer in the manner given below. A glass paste including a glass powder is applied on the front glass substrate or the back glass substrate, according to a screen printing method, a die coating method, a spray coating method, a spin coating method, or a blade coating method, on each of which electrodes have been formed, and the glass powder in the applied glass paste is fired. The average particle diameter of the glass powder is 0.1 to 1.5 mum and the maximum particle diameter is equal to or smaller than three times the average particle diameter.

Owner:PANASONIC CORP

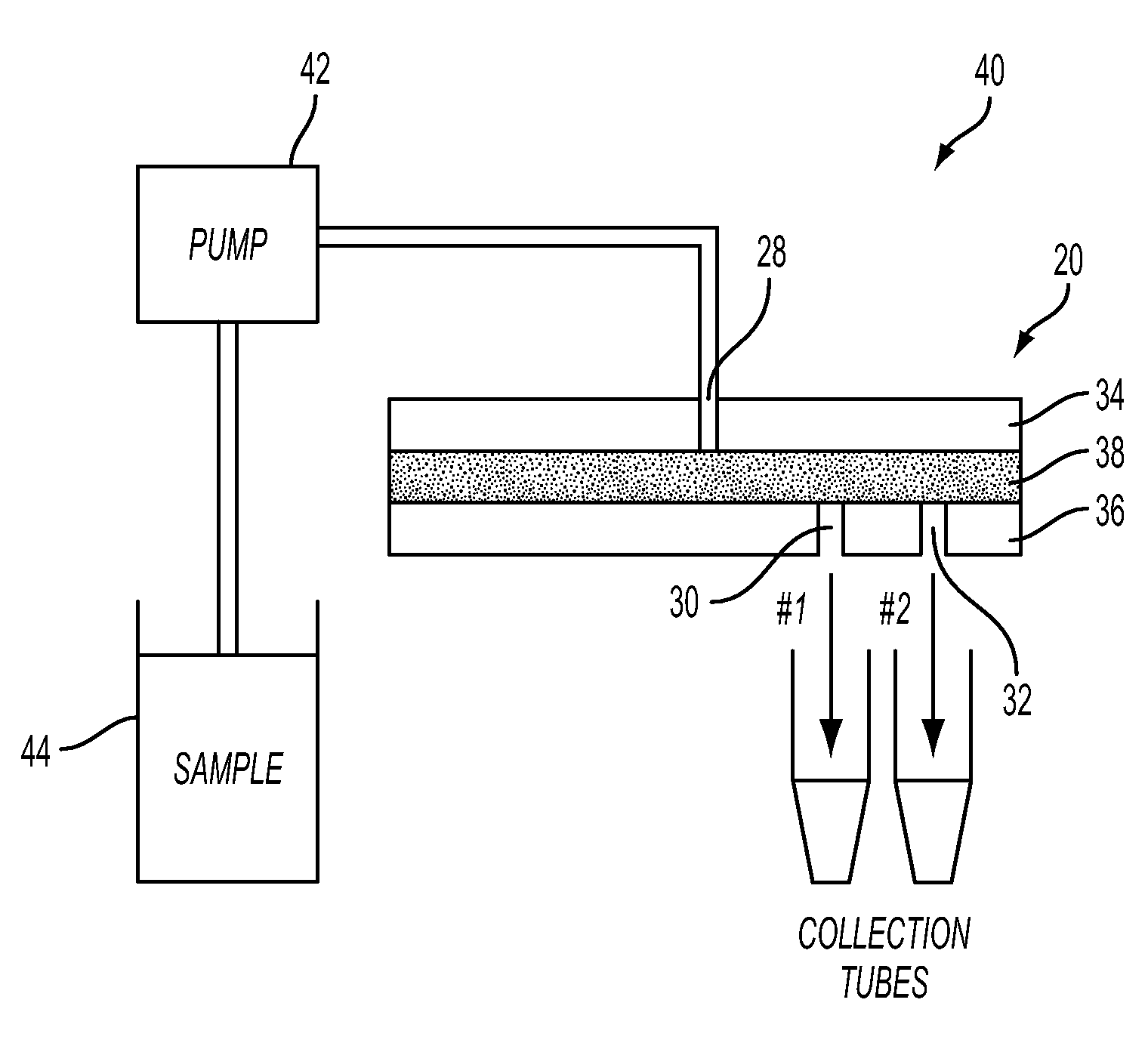

Particle separation and concentration system

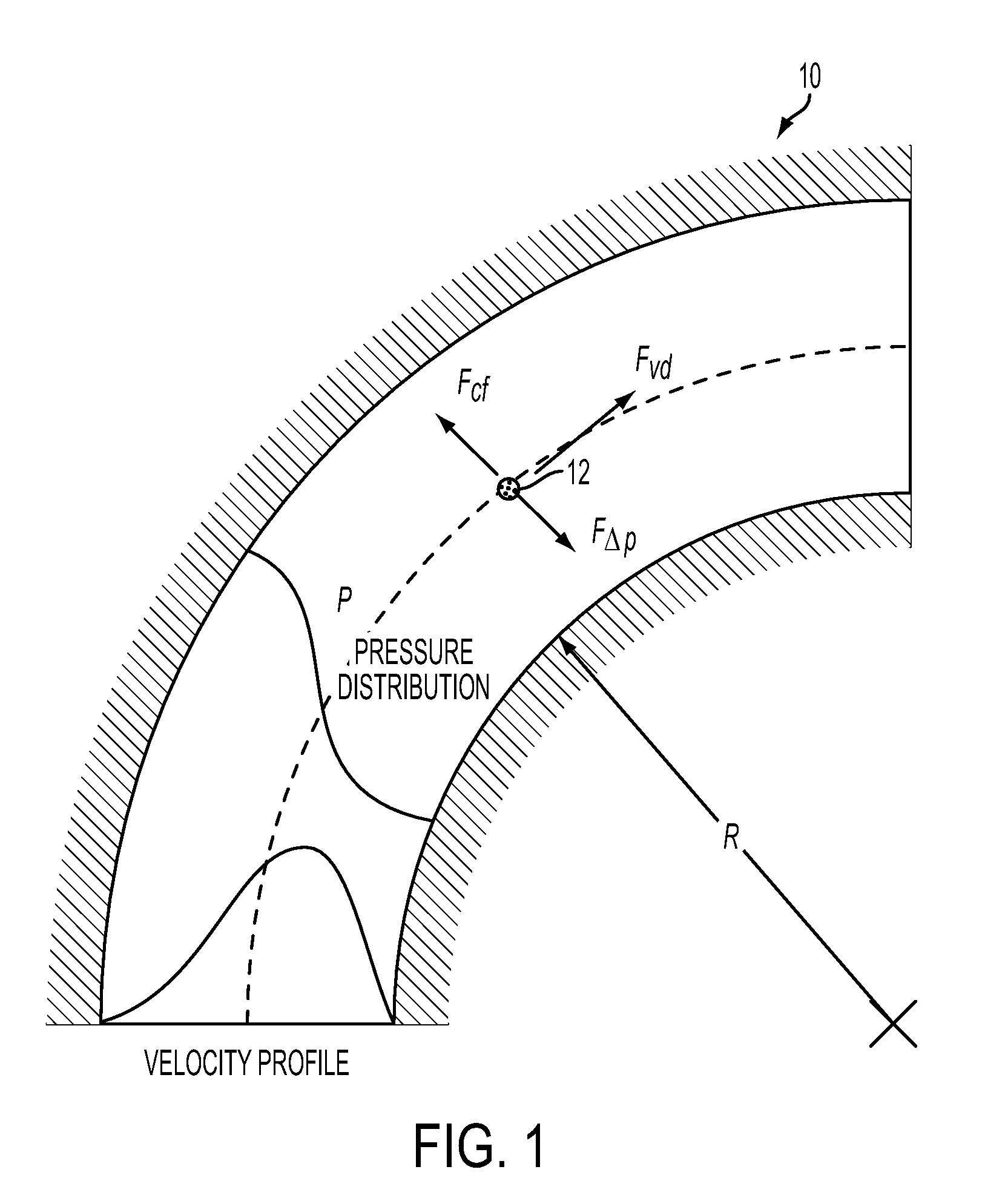

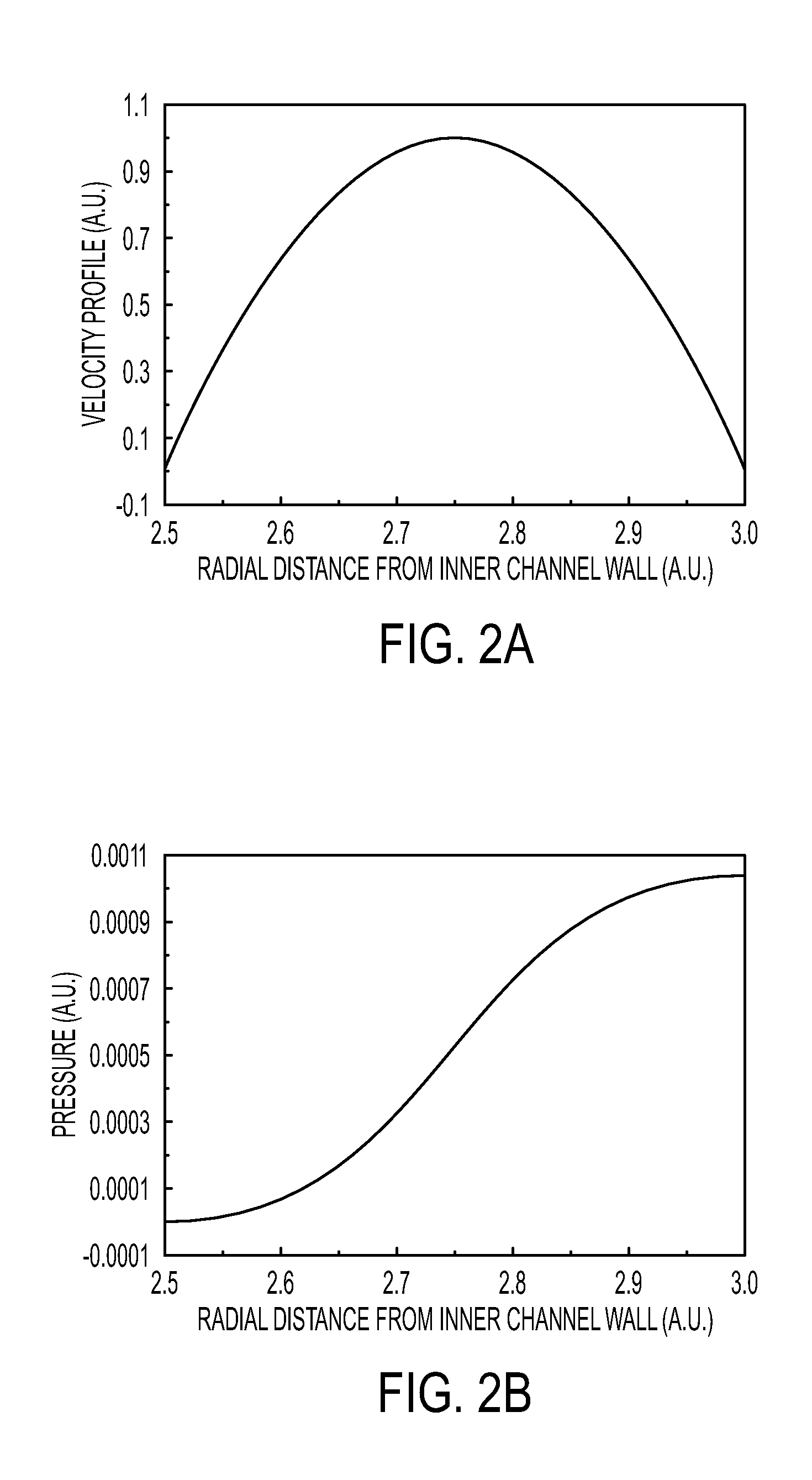

This invention is based on size and mass separation of suspended particles, including biological matter, which are made to flow in a spiral channel. On the spiral sections, the inward directed transverse pressure field from fluid shear competes with the outward directed centrifugal force to allow for separation of particles. At high velocity, centrifugal force dominates and particles move outward. At low velocities, transverse pressure dominates and the particles move inward. The magnitudes of the two opposing forces depend on flow velocity, particle size, radius of curvature of the spiral section, channel dimensions, and viscosity of the fluid. At the end of the spiral channel, a parallel array of outlets collects separated particles. For any particle size, the required channel dimension is determined by estimating the transit time to reach the side-wall. This time is a function of flow velocity, channel width, viscosity, and radius of curvature. Larger particles may reach the channel wall earlier than the smaller particles which need more time to reach the side wall. Thus a spiral channel may be envisioned by placing multiple outlets along the channel. This technique is inherently scalable over a large size range from sub-millimeter down to 1 μm.

Owner:XEROX CORP

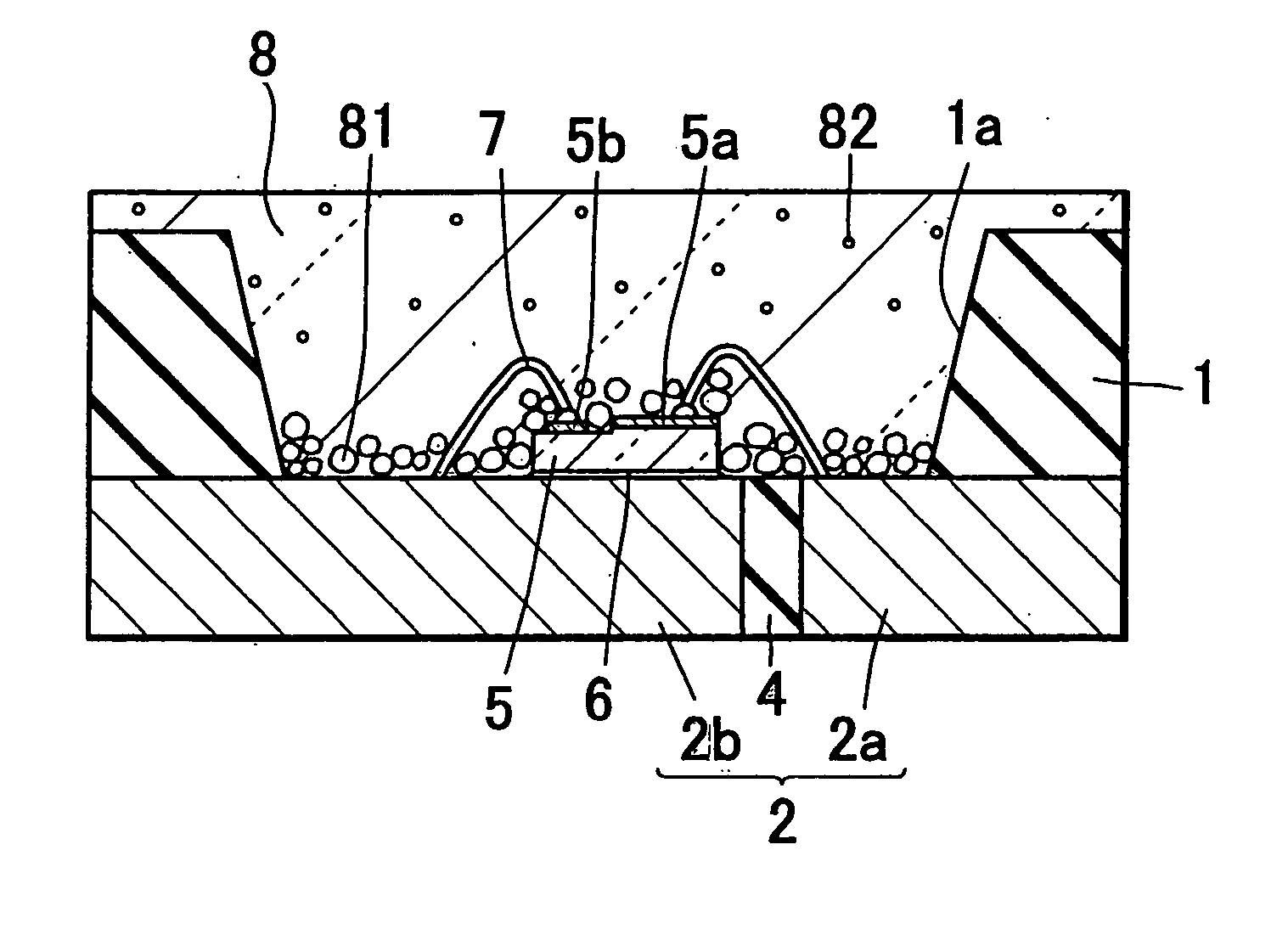

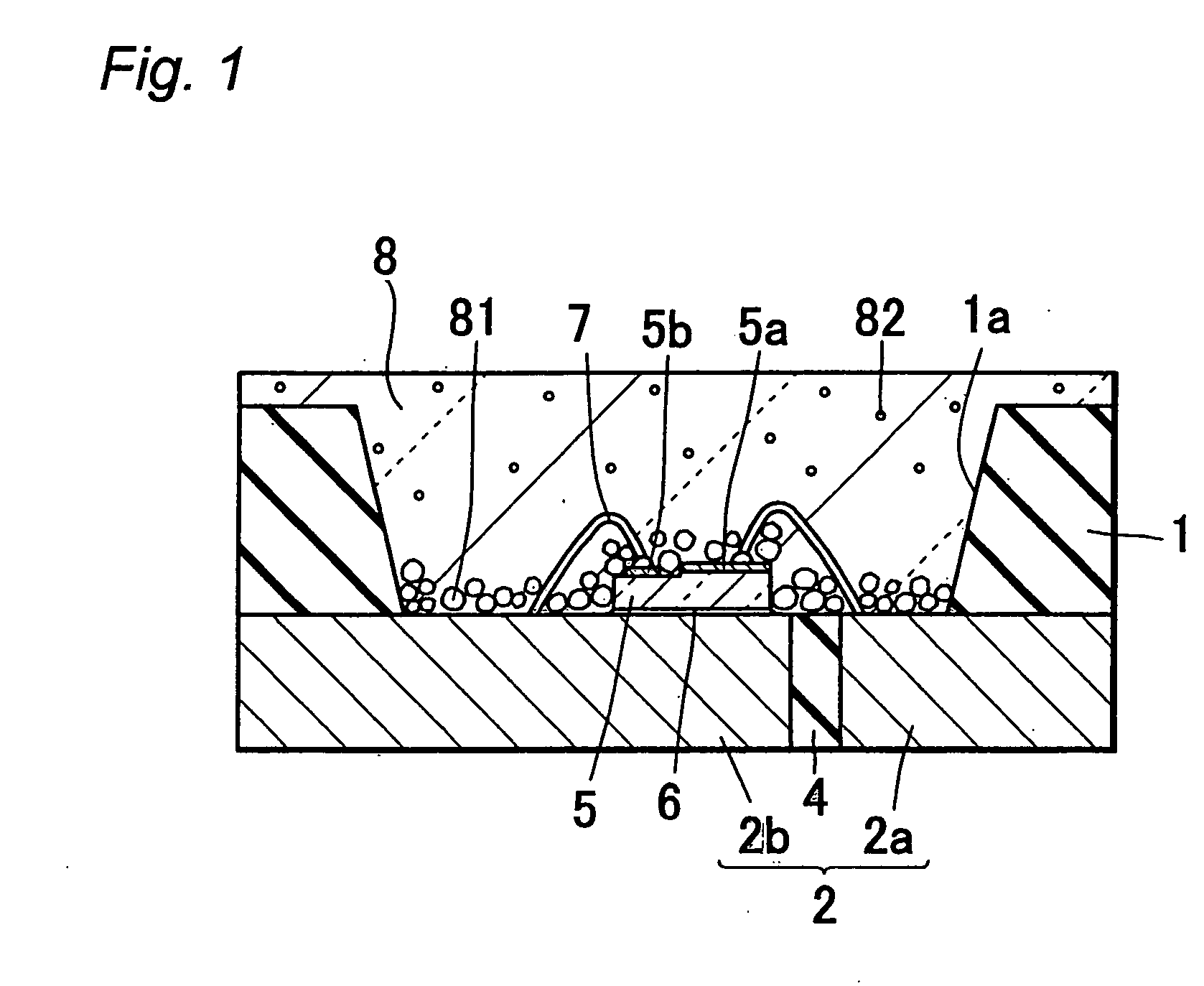

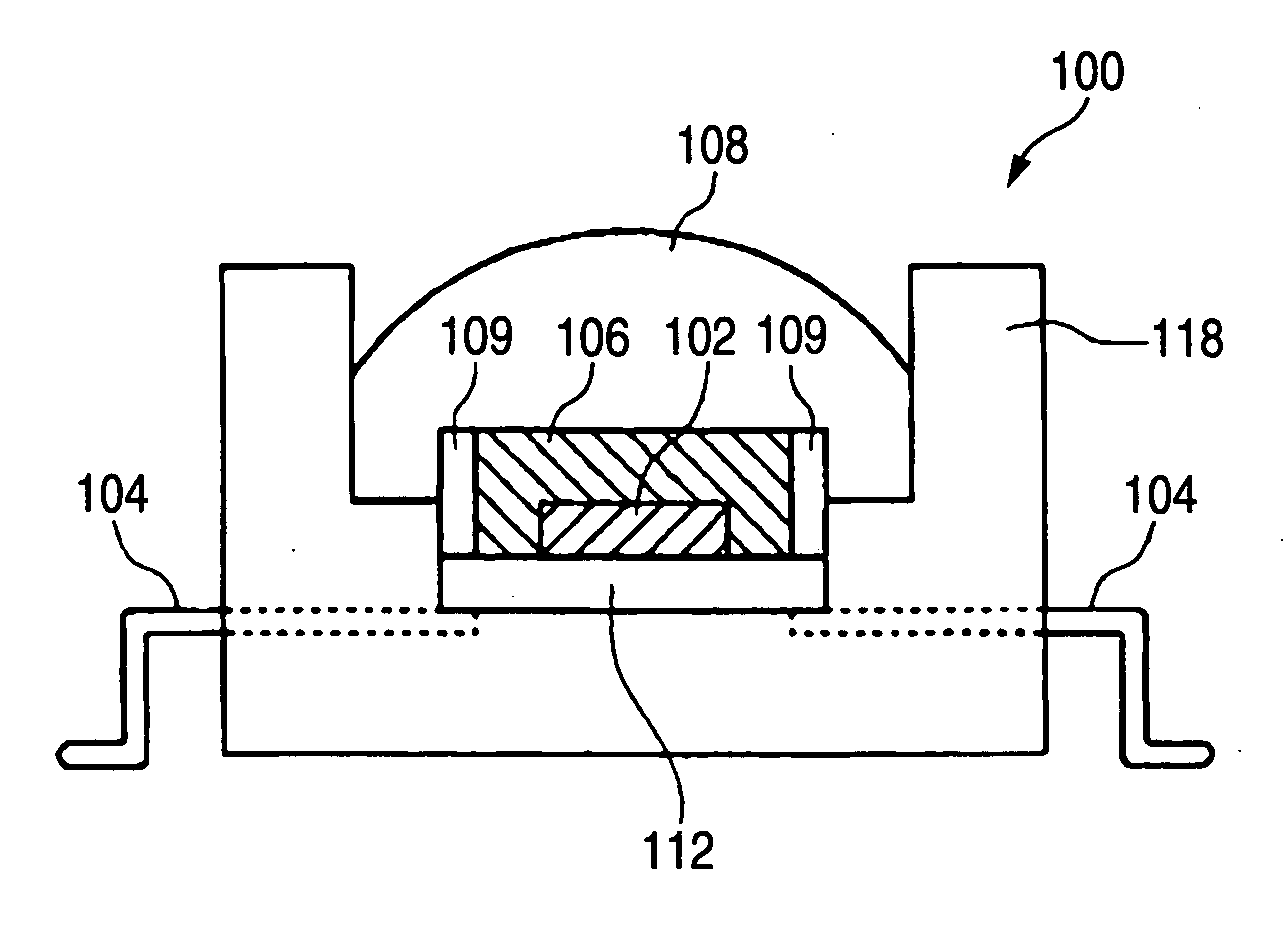

Light emitting diode, optical semiconductor device, epoxy resin composition suited for optical semiconductor device, and method for manufacturing the same

InactiveUS20050224821A1Light emission characteristicSuppress the variation in the chromaticity of the light emittedDischarge tube luminescnet screensLamp detailsEpoxyLength wave

A light emitting diode comprising an LED chip having a light emitting layer made of a nitride compound semiconductor and a light transmitting resin that includes a fluorescent material which absorbs at least a part of light emitted by the LED chip and emits light of a different wavelength, wherein the fluorescent material includes a fluorescent particles of small particle size and a fluorescent particles of large particle size, the fluorescent particles of large particle size being distributed in the vicinity of the LED chip in the light transmitting resin to form a wavelength converting layer, the fluorescent particles of small particle size being distributed on the outside of the wavelength converting layer in the light transmitting resin.

Owner:NICHIA CORP

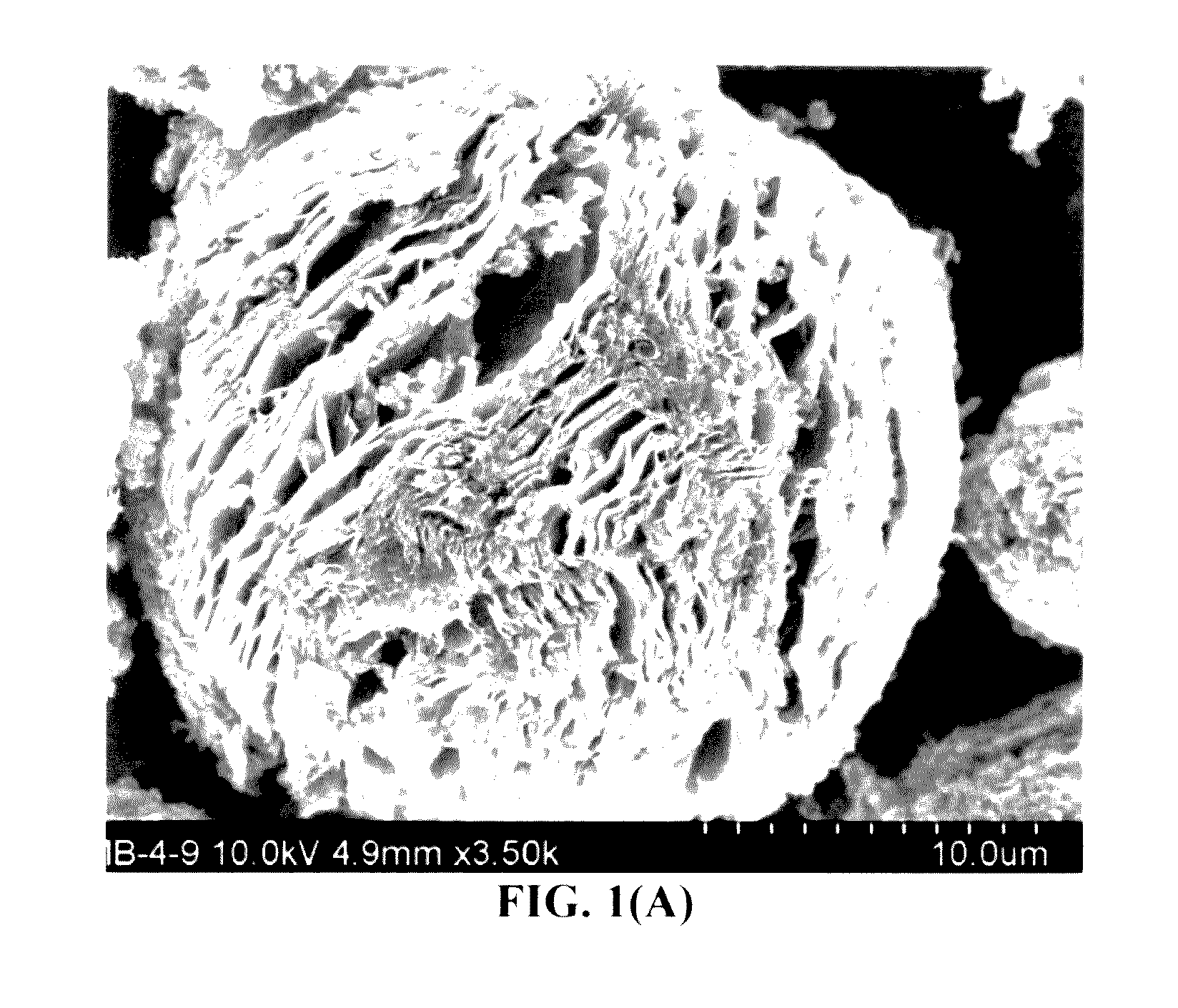

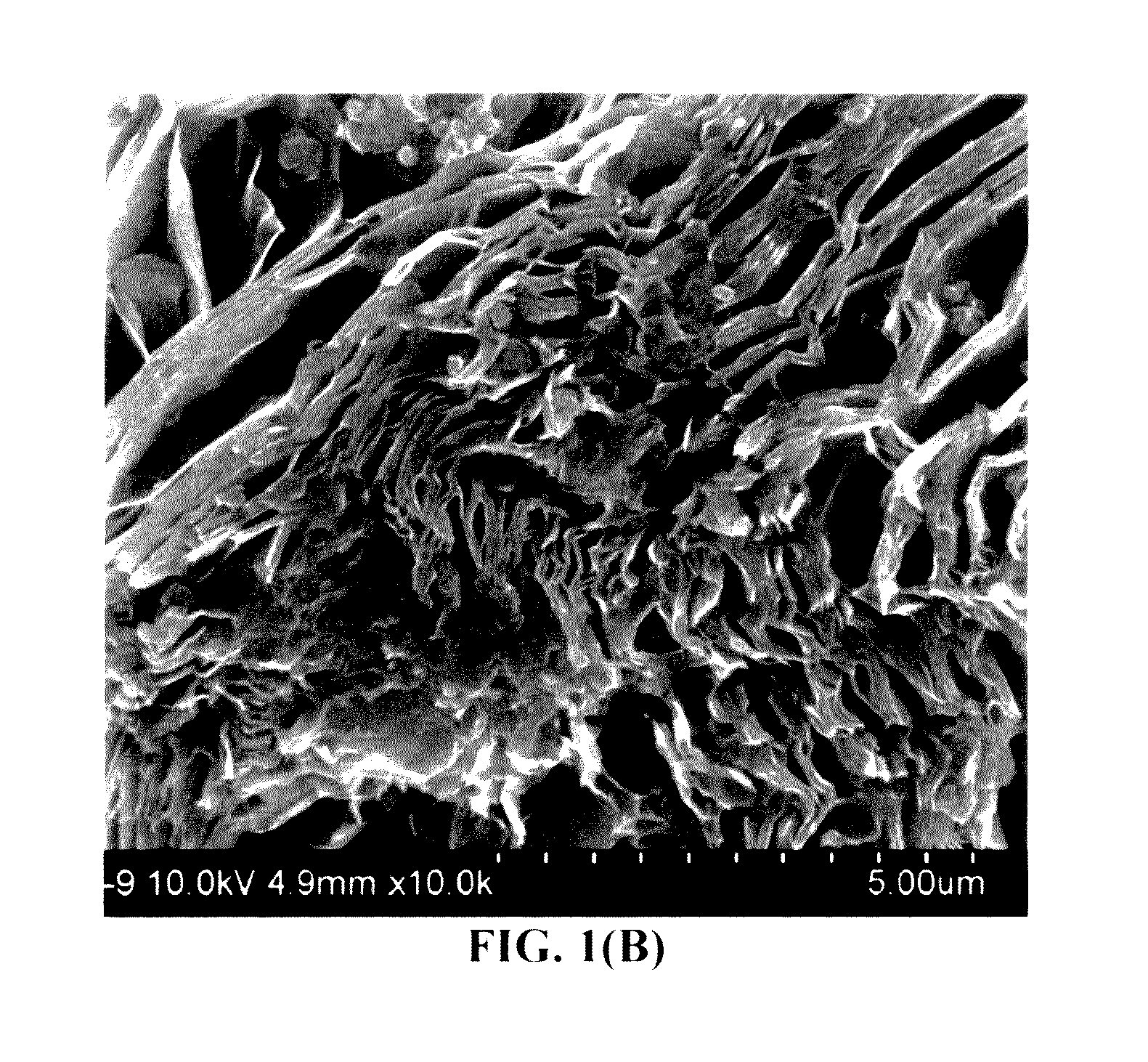

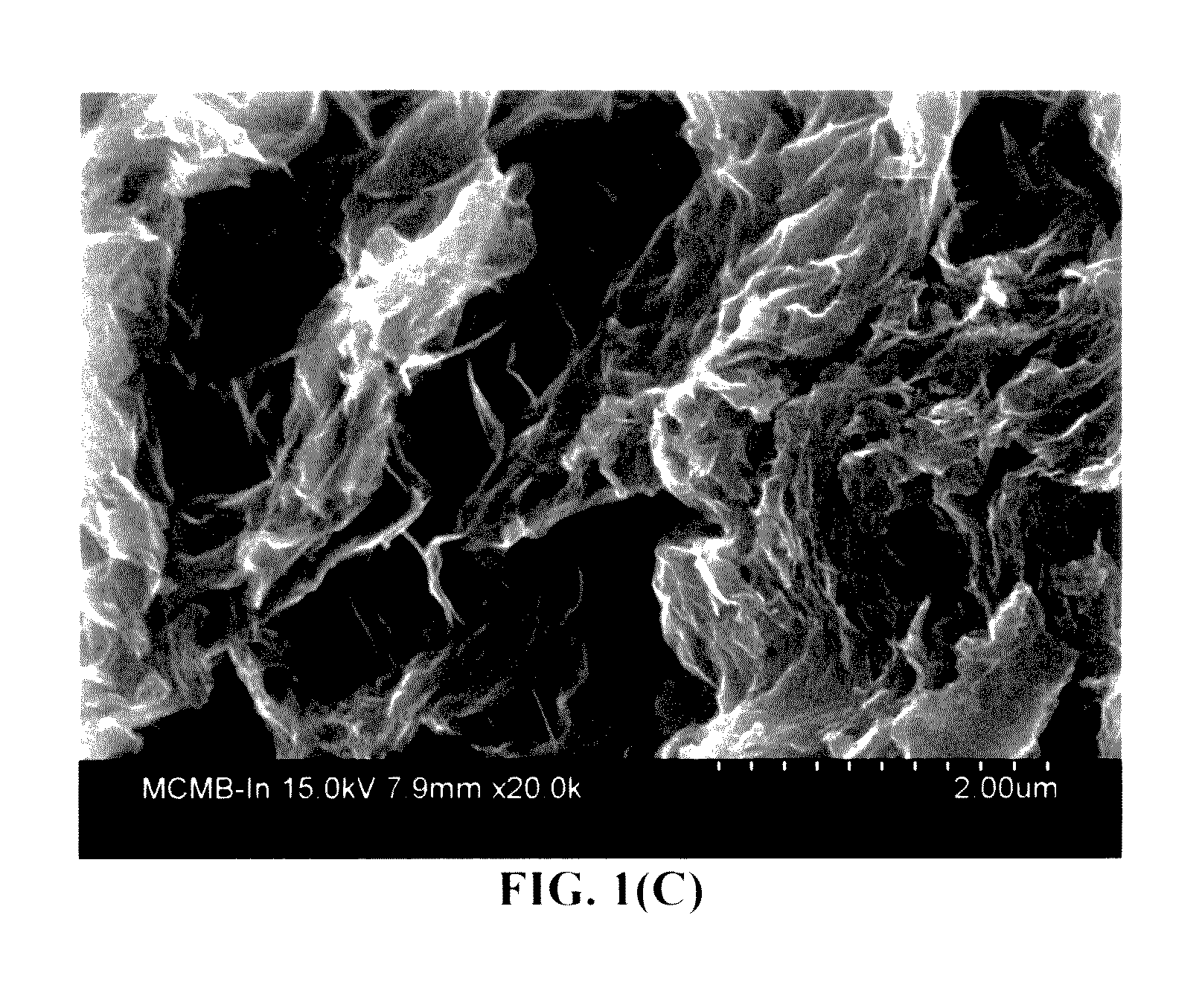

Transition metal sulfide/graphene composite material, and preparation method and application thereof

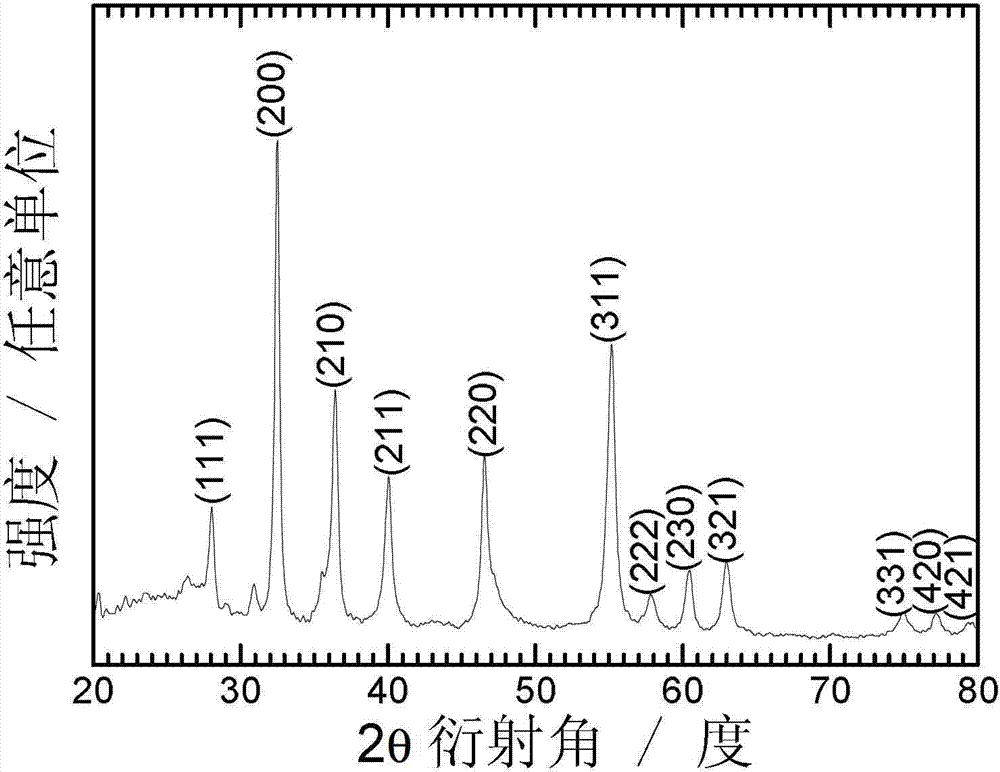

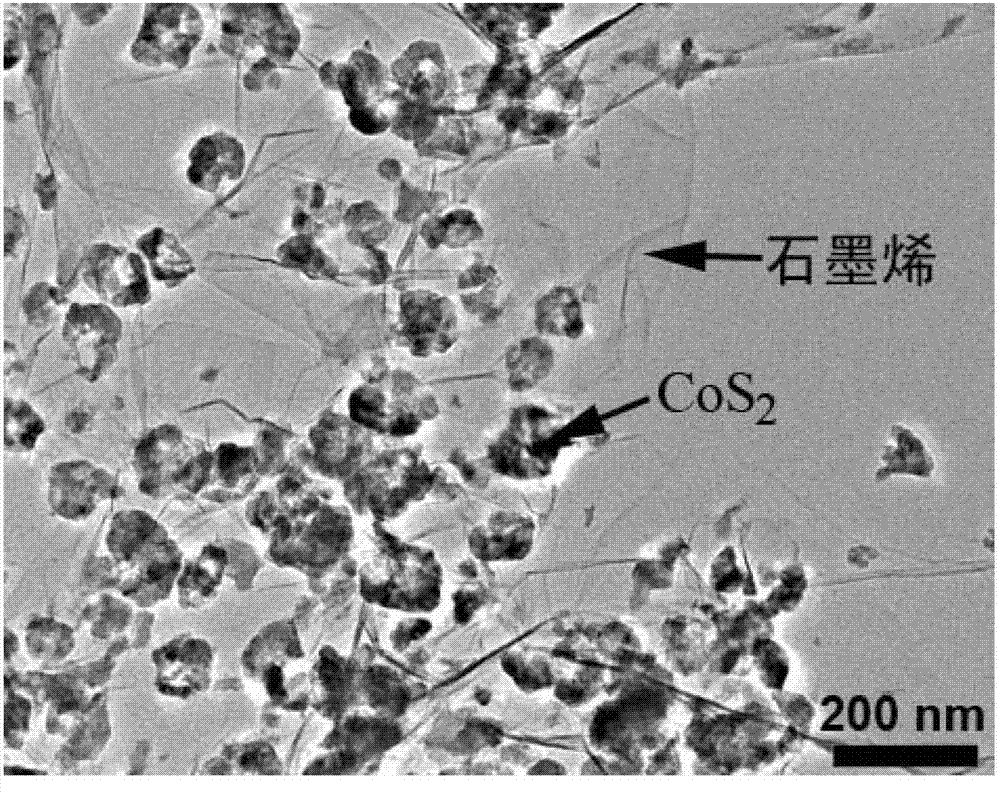

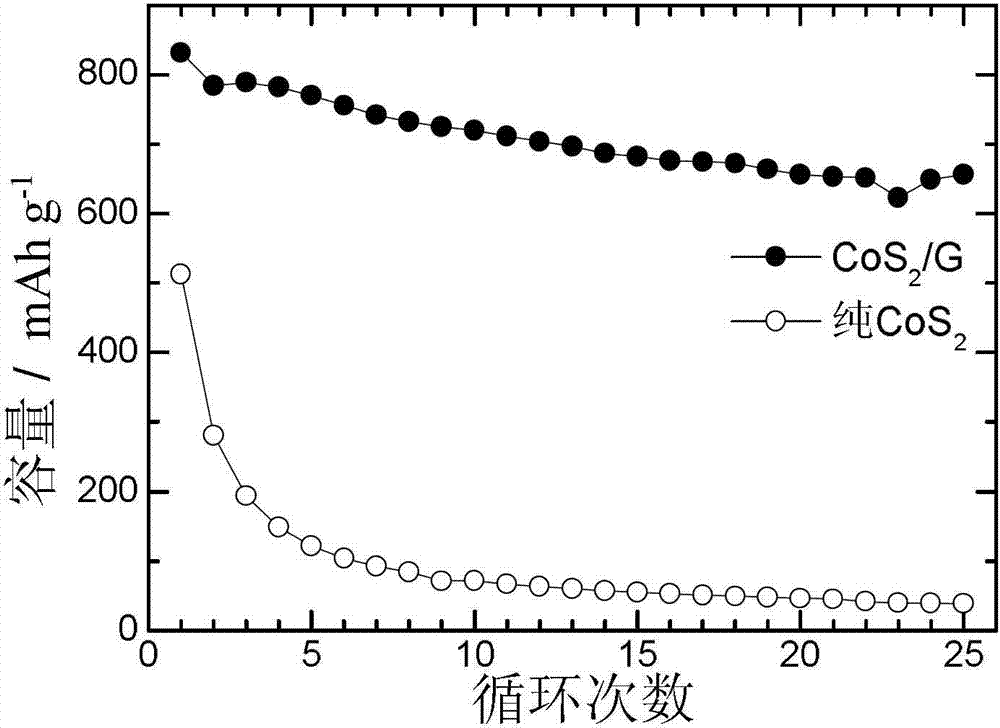

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

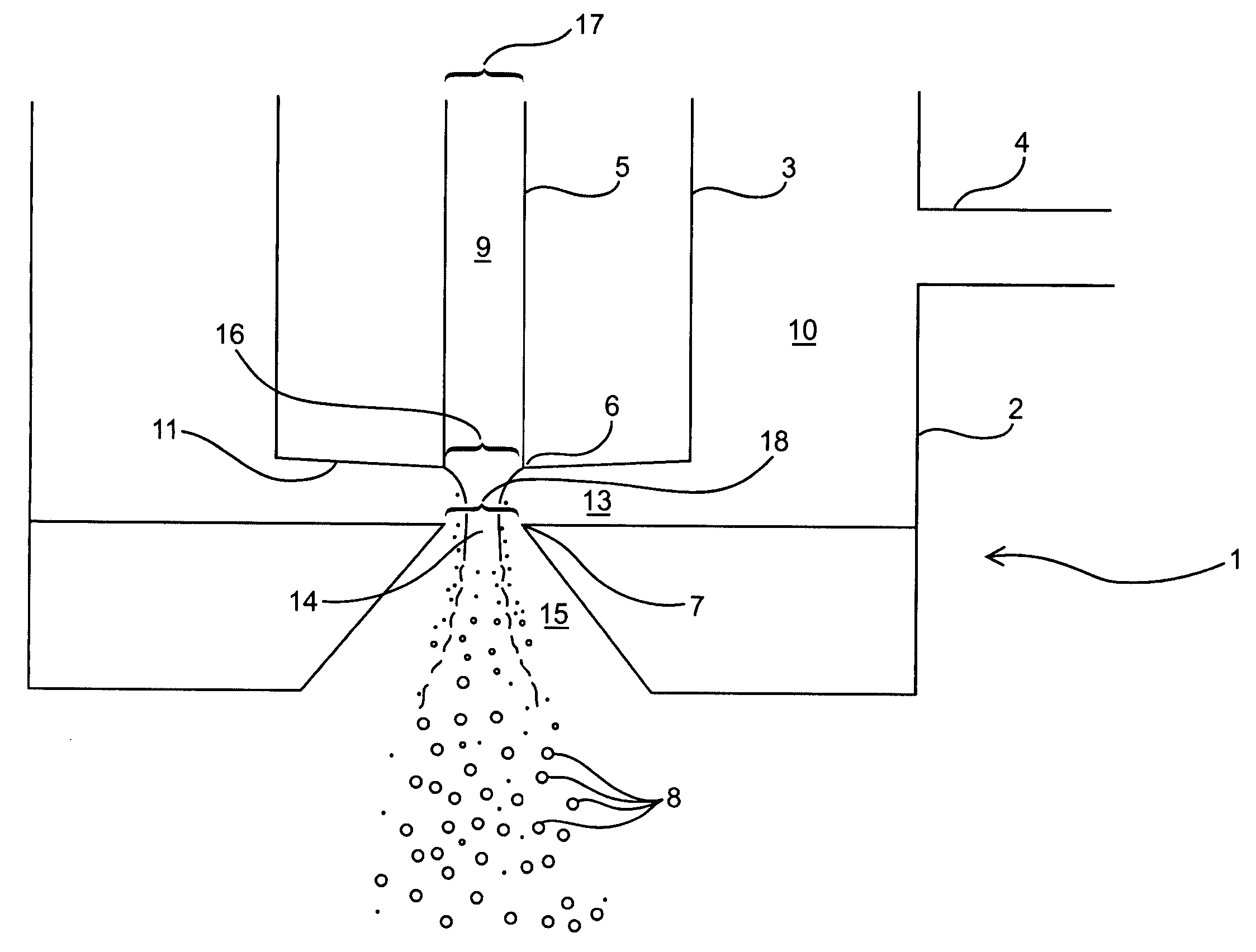

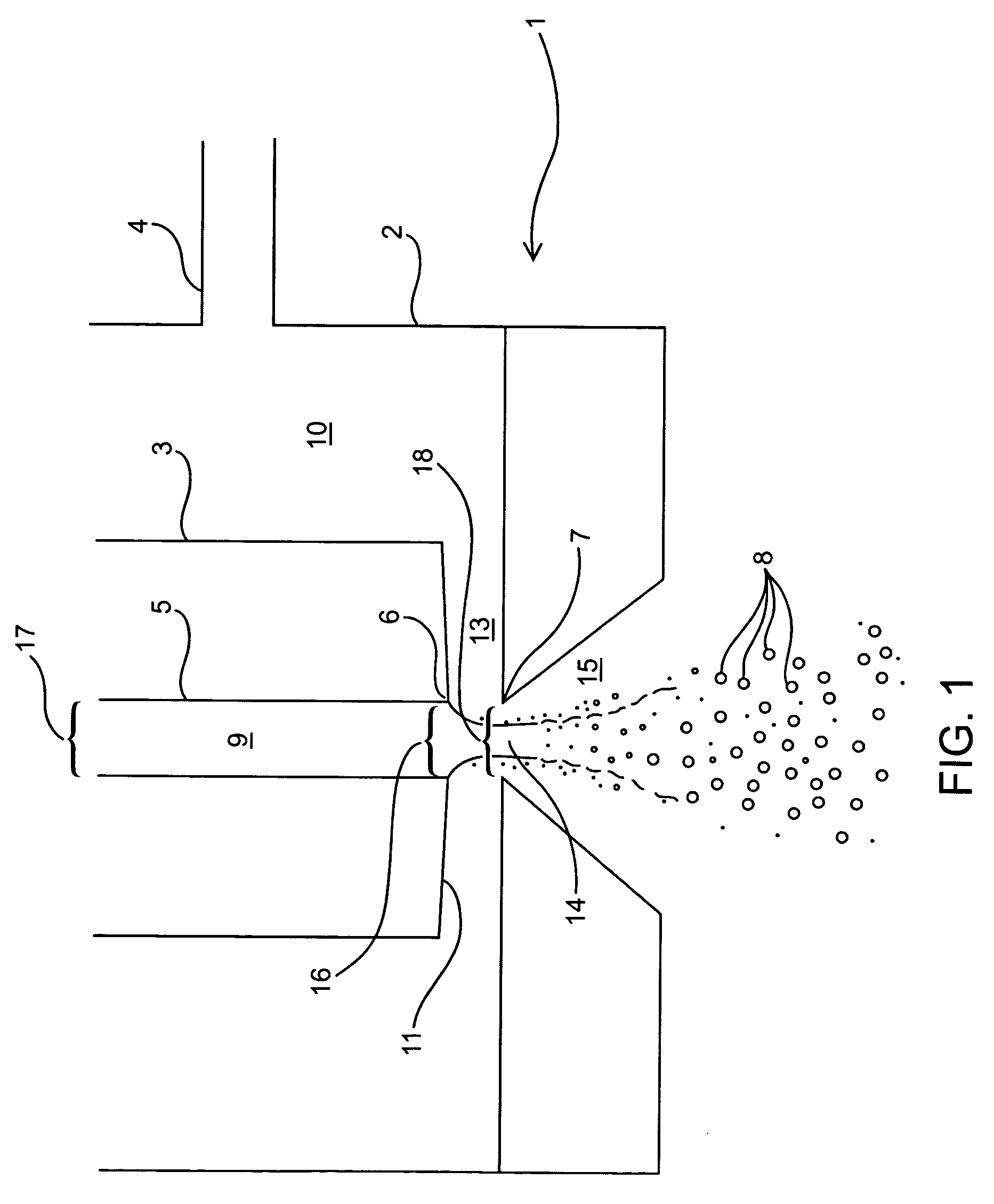

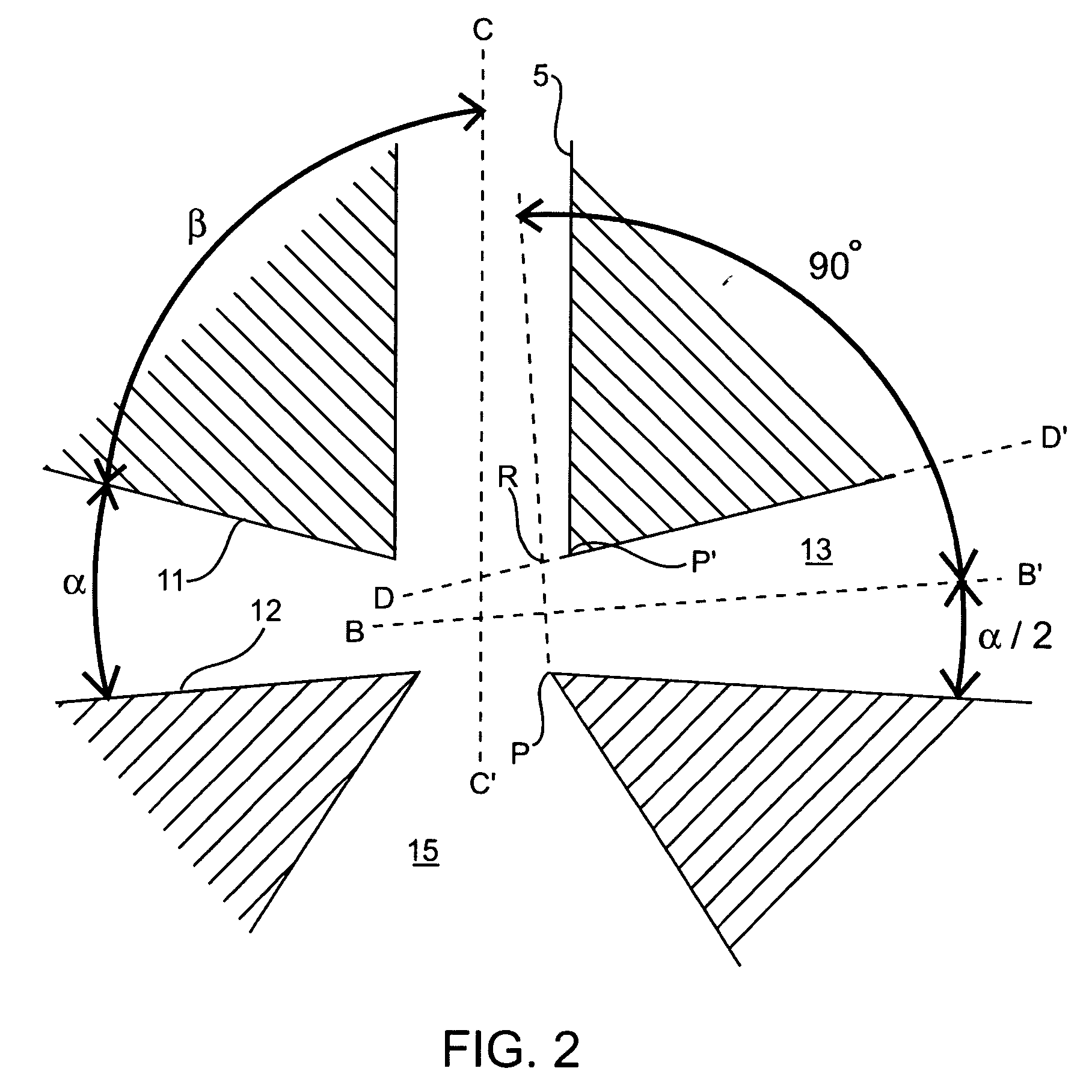

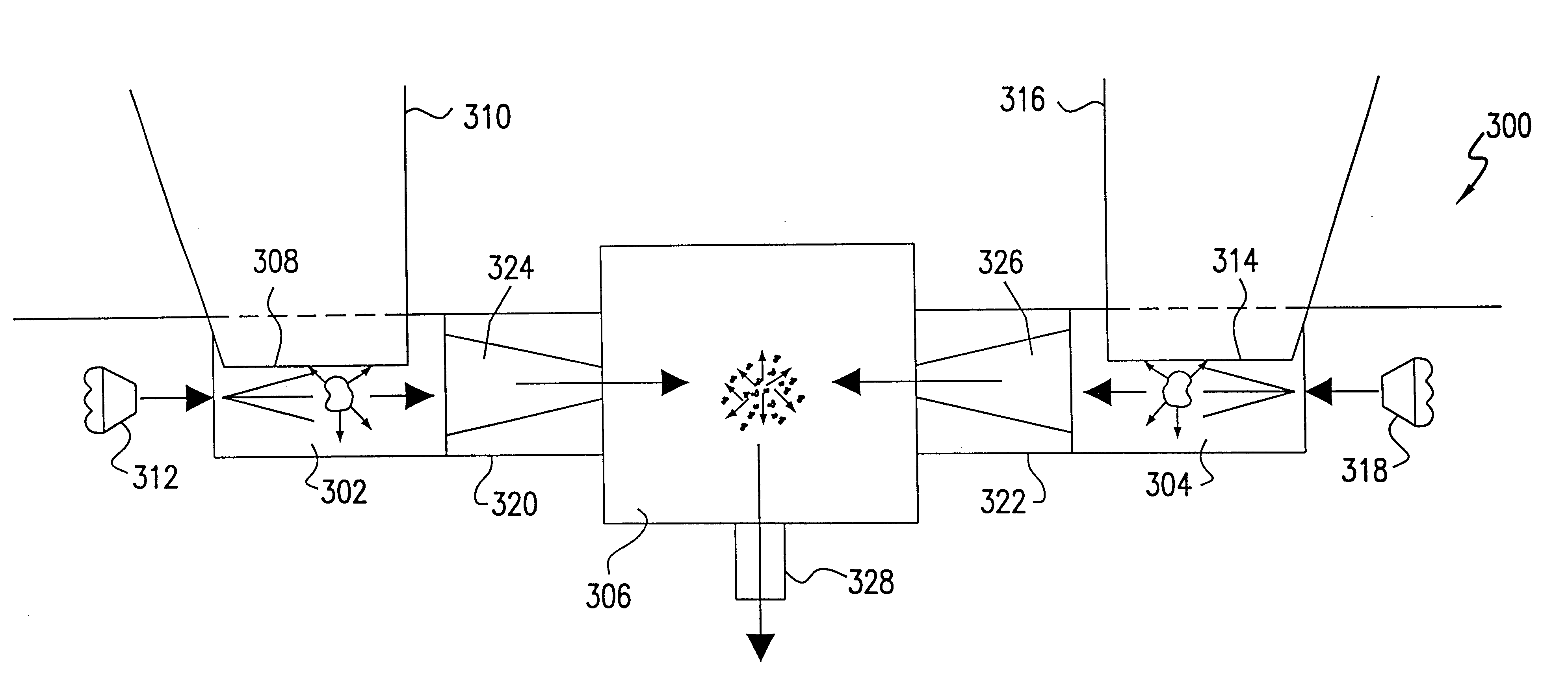

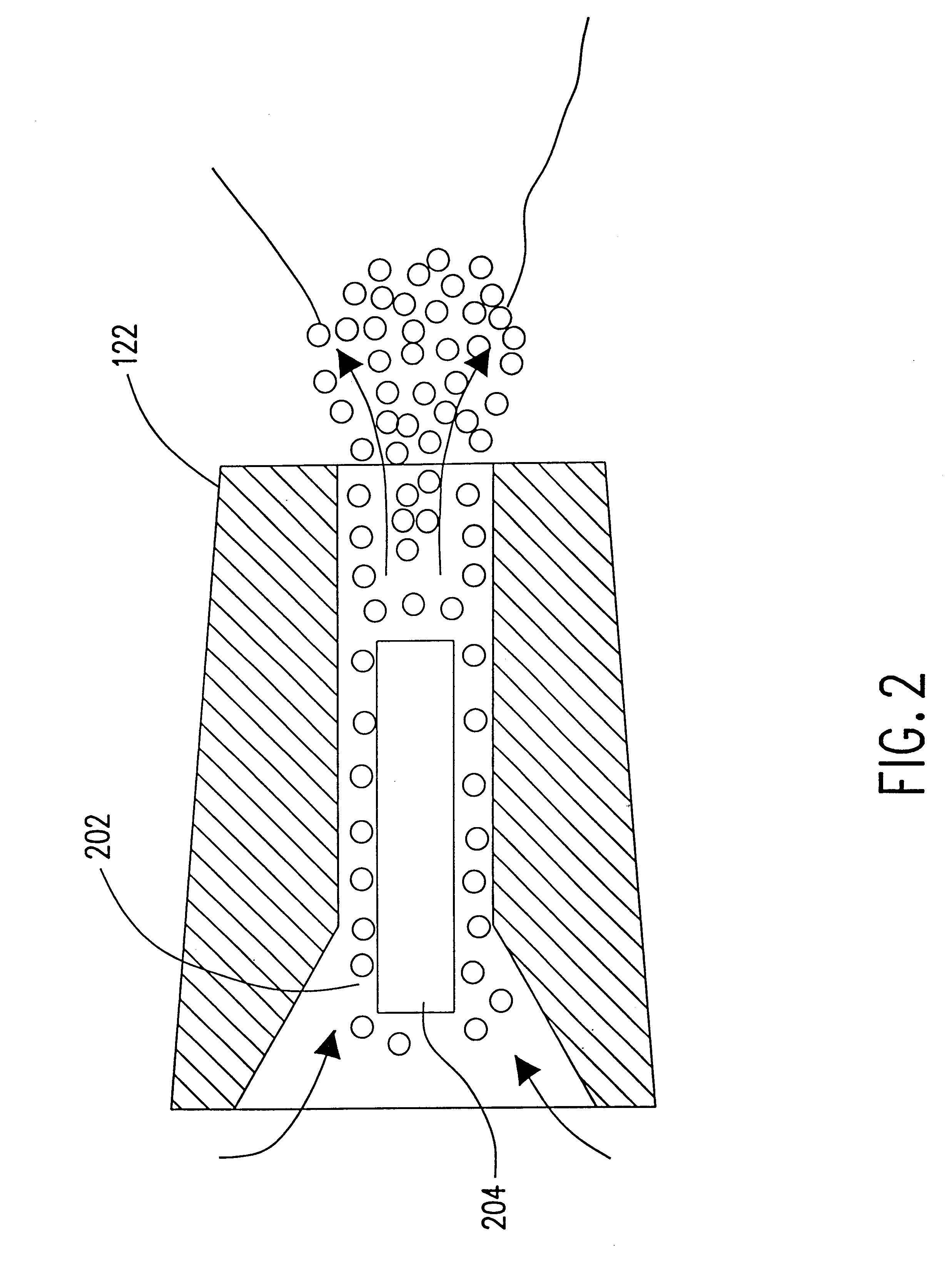

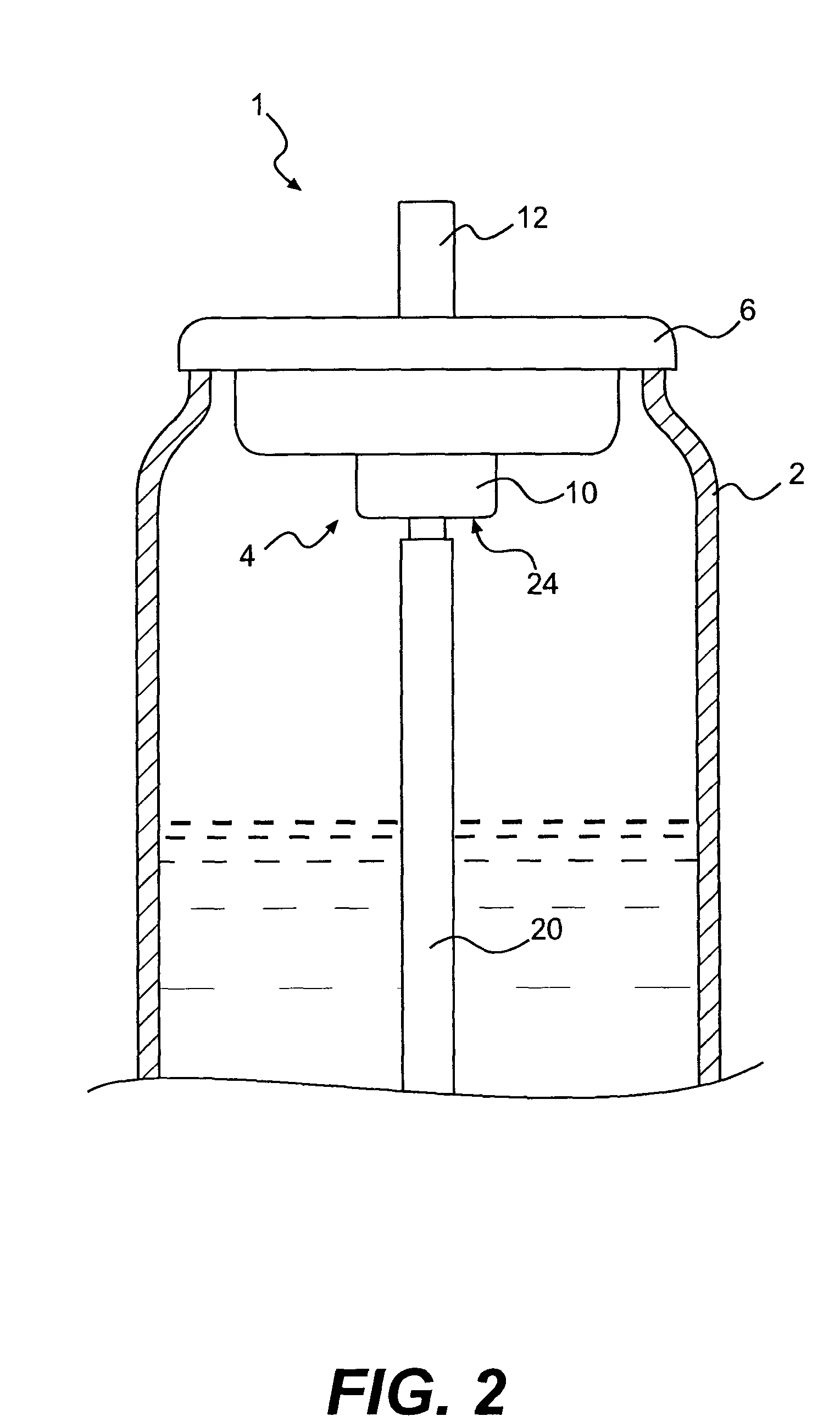

Aerosol created by directed flow of fluids and devices and methods for producing same

InactiveUS20060169800A1Efficient deliveryEasy to manufactureSpray nozzlesLiquid spraying apparatusEngineeringSmall particle

A method of creating small particles by a technology referred to here as “violent focusing” is disclosed, along with devices for generating such violent focusing. In general, the method comprises the steps of forcing a first fluid out of an exit opening of the feeding channel to create a fluid stream. The exit opening is positioned such that the fluid flowing out of the channel flows toward and out of an exit orifice of a pressure chamber which surrounds the exit opening of the feeding channel, and is filled with an atomizing fluid. An atomizing fluid such as a gas is directed towards the first fluid stream in approximately orthogonal directions and surrounding the circumference of the first fluid stream from all sides. The first fluid flow is broken into particles which have dimensions which are smaller than the dimensions of this fluid stream.

Owner:ARADIGM +1

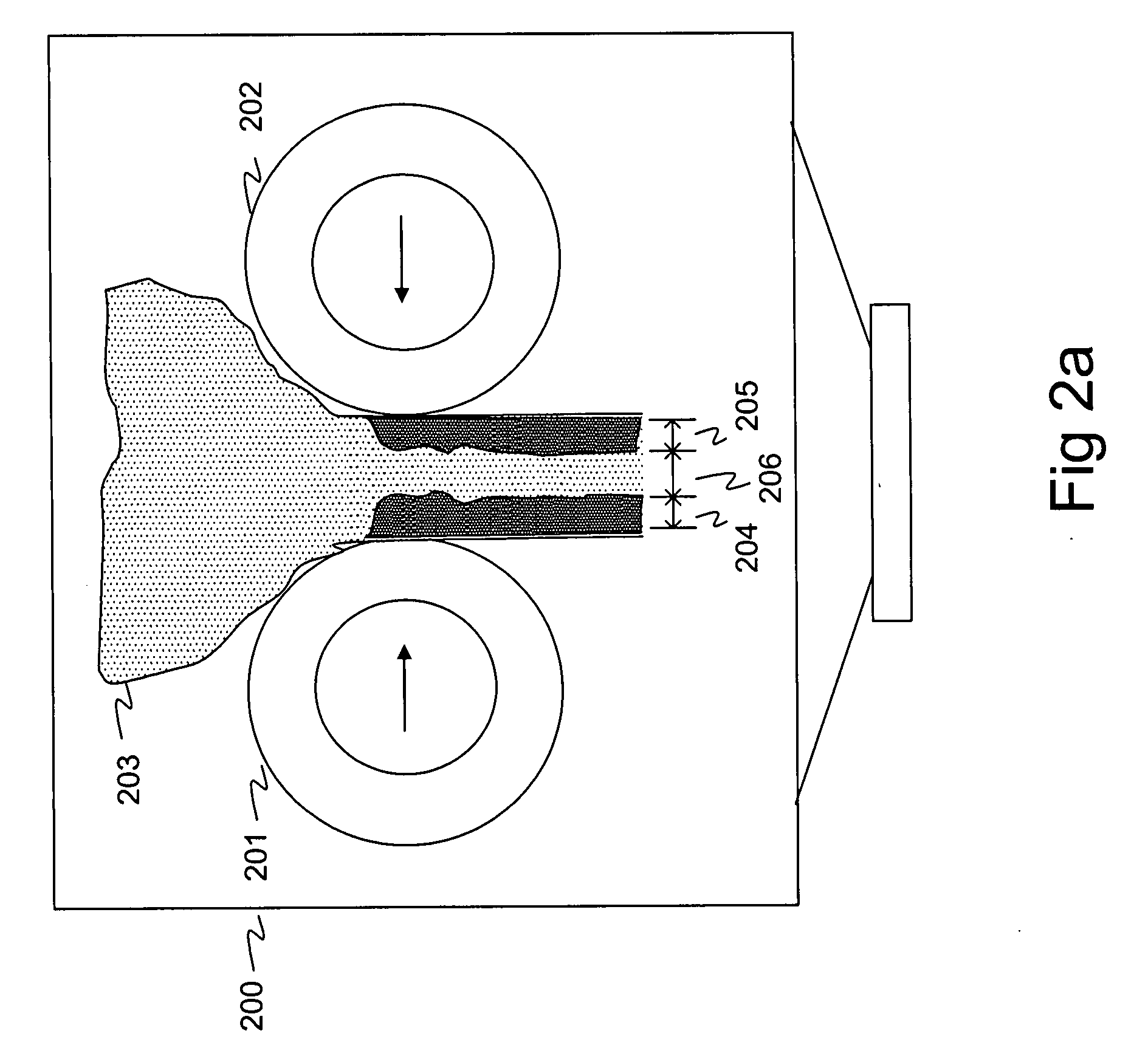

Granules, tablets and granulation

ActiveUS20080111269A1Quick cureEasy to assemblePowder deliveryElectrostatic separationMaterials scienceAirflow

The invention provides, inter alia, a method for producing granules from a powder, characterized in that a low compaction force is applied to the powder to produce a compacted mass comprising a mixture of fine particles and granules and separating fine particles from the granules by entraining the fine particles in a gas stream. Also provided are apparatus for use in the process and tablets formed by compression of the resultant granules.

Owner:ATACAMA LABS OY

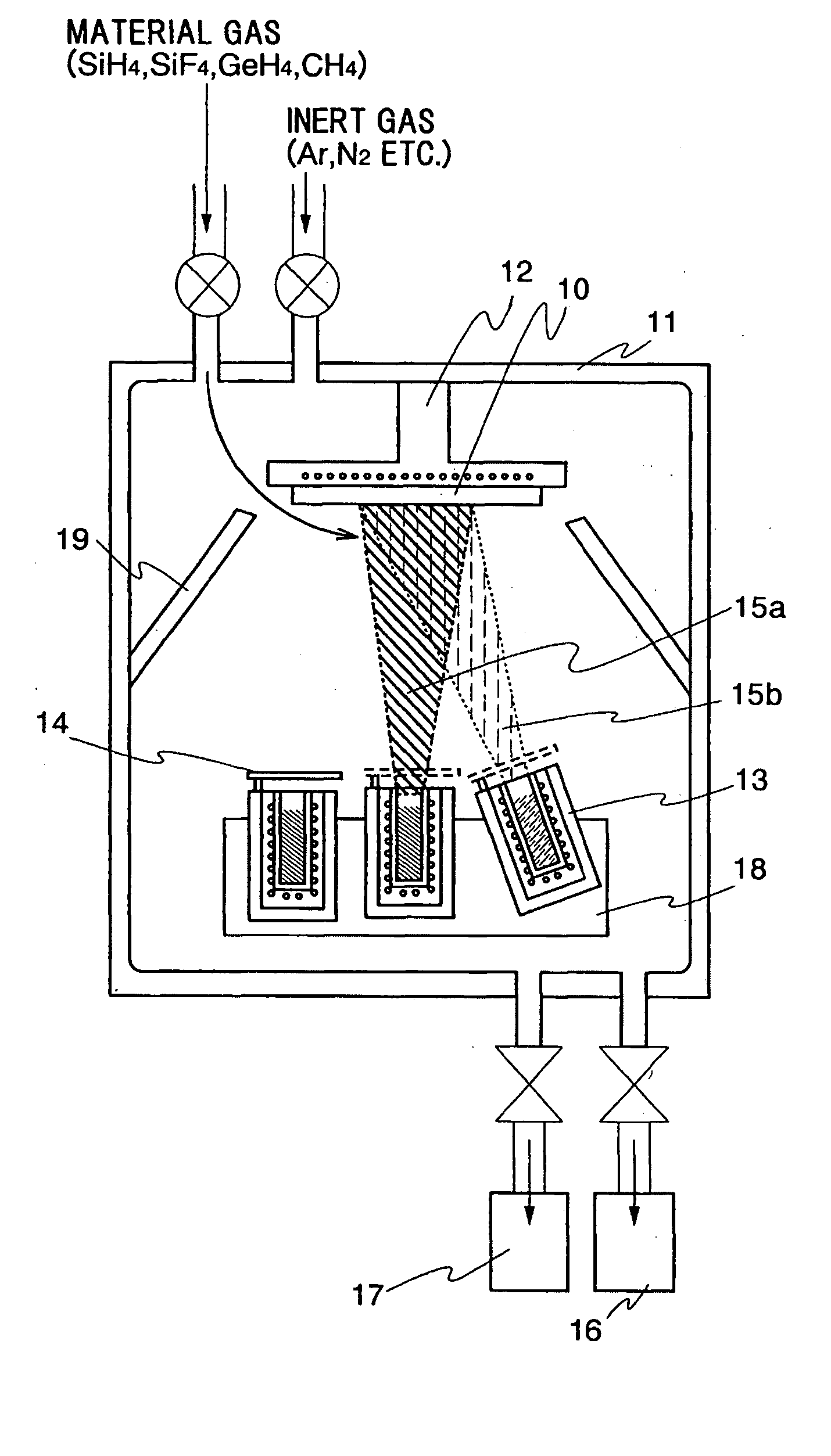

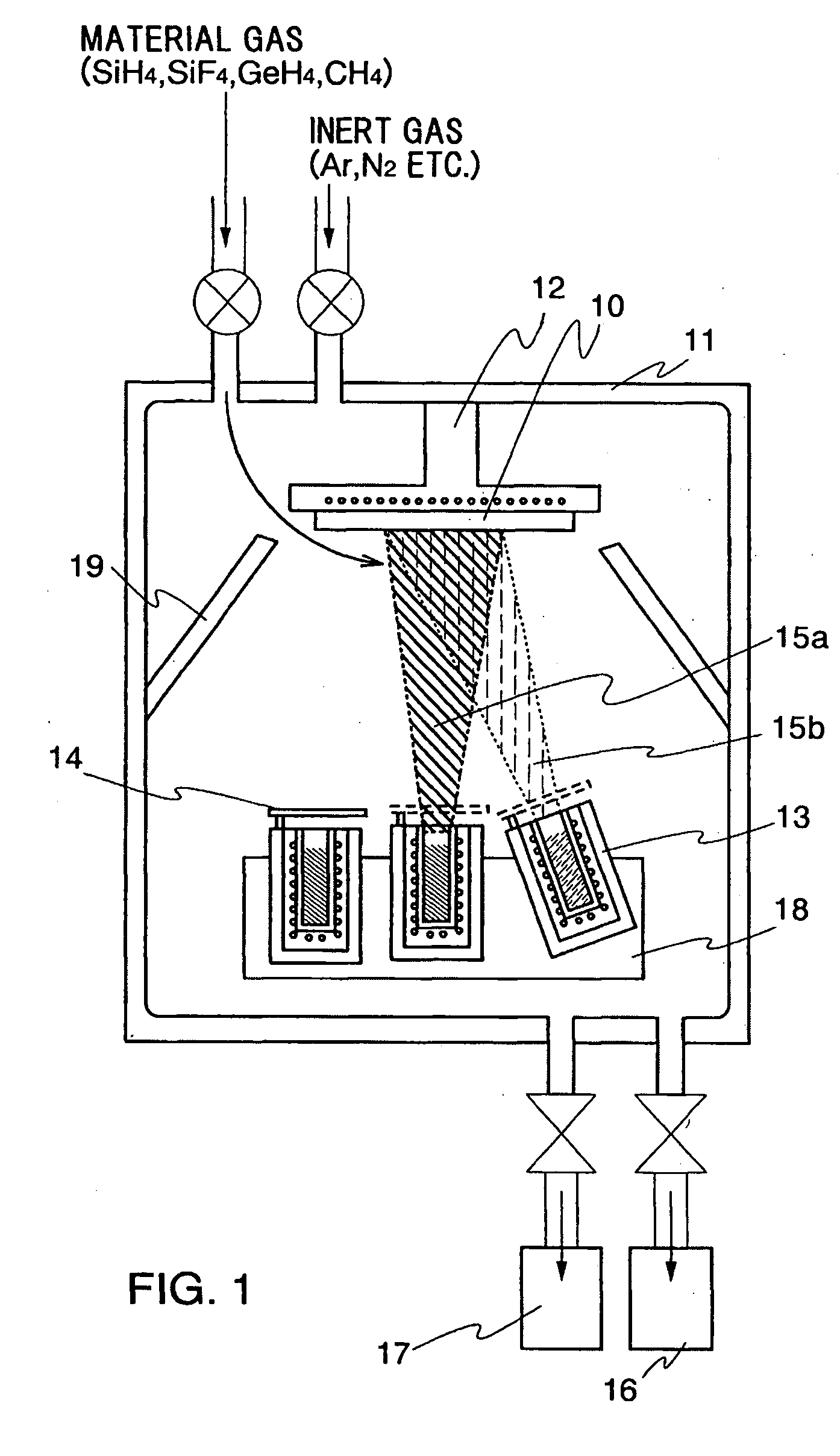

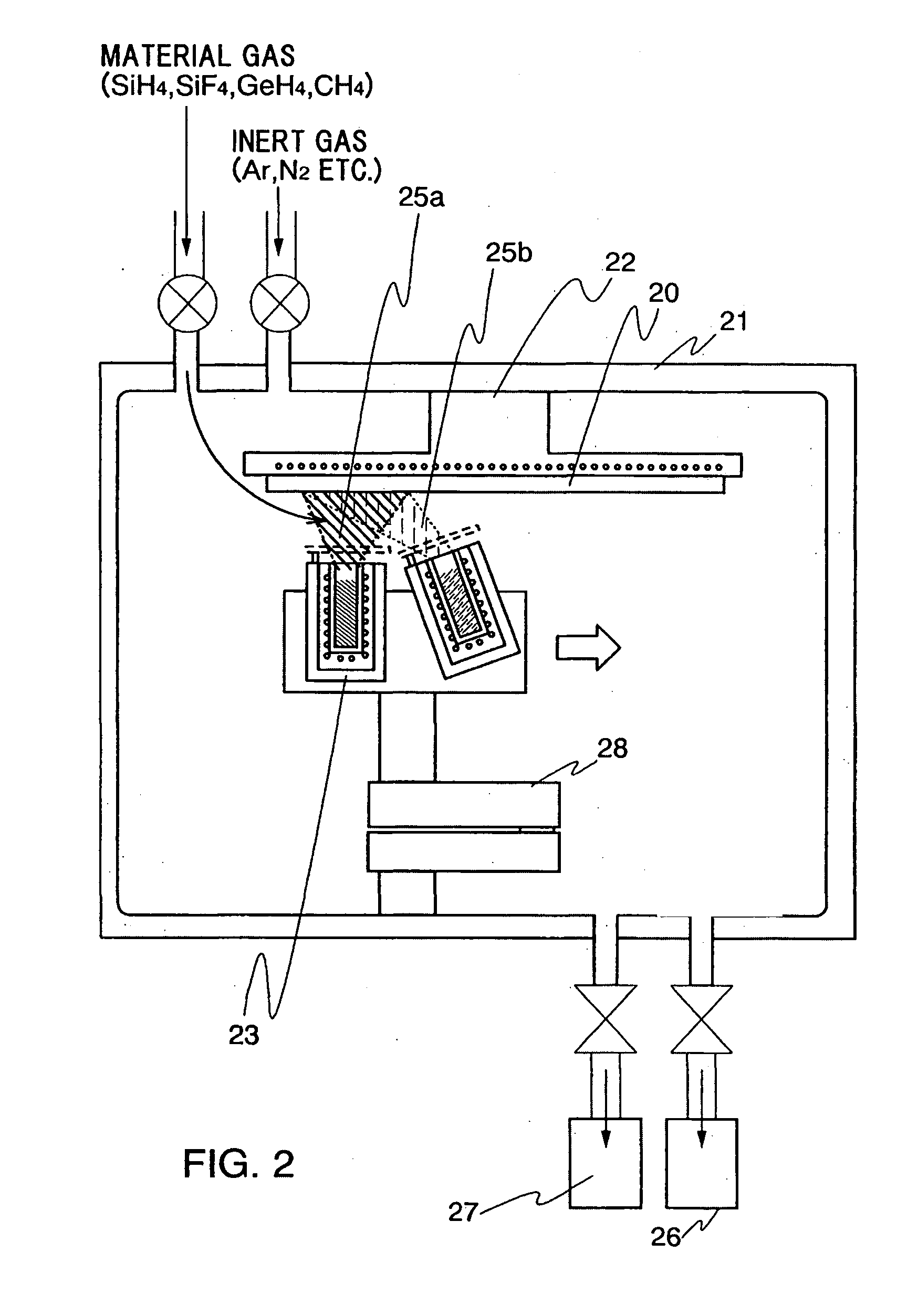

Light-emitting device, film-forming method and manufacturing apparatus thereof, and cleaning method of the manufacturing apparatus

InactiveUS20050016462A1Small surface areaGas discharge is preventedElectroluminescent light sourcesVacuum evaporation coatingSilanesMetallurgy

This invention provides a new film forming method in which, on the occasion that pressure is decreased by pressure decreasing means which was connected to a film forming chamber, and a film is formed by evaporating an organic compound material from a deposition source in the film forming chamber, minute amounts of gas (silane series gas) which comprises smaller particles than particles of the organic compound material, i.e., a material with a smaller atomic radius are flowed, and the material with a small atomic radius is made to be included in an organic compound film.

Owner:SEMICON ENERGY LAB CO LTD

Noble metal-containing supported catalyst and a process for its preparation

The invention provides a noble metal-containing supported catalyst which contains one of the noble metals from the group Au, Ag, Pt, Pd, Rh, Ru, Ir, Os or alloys of one or more of these noble metals in the form of noble metal particles on a powdered support material. The particles deposited on the support material have a degree of crystallinity, determined by X-ray diffraction, of more than 2 and an average particle size between 2 and 10 nm. The high crystallinity and the small particle size of the noble metal particles lead to high catalytic activity for the catalyst. It is particularly suitable for use in fuel cells and for the treatment of exhaust gases from internal combustion engines.

Owner:UMICORE AG & CO KG

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

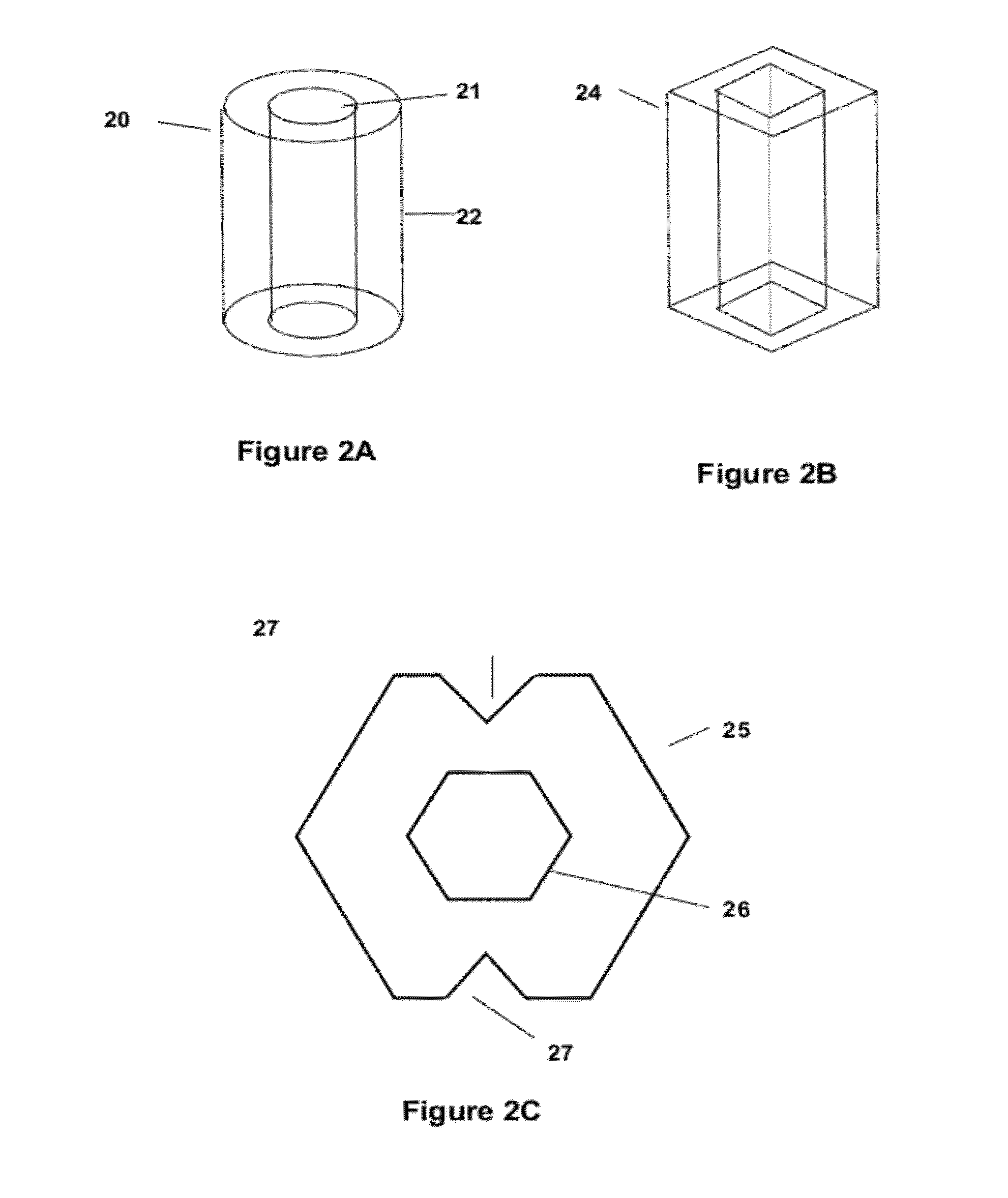

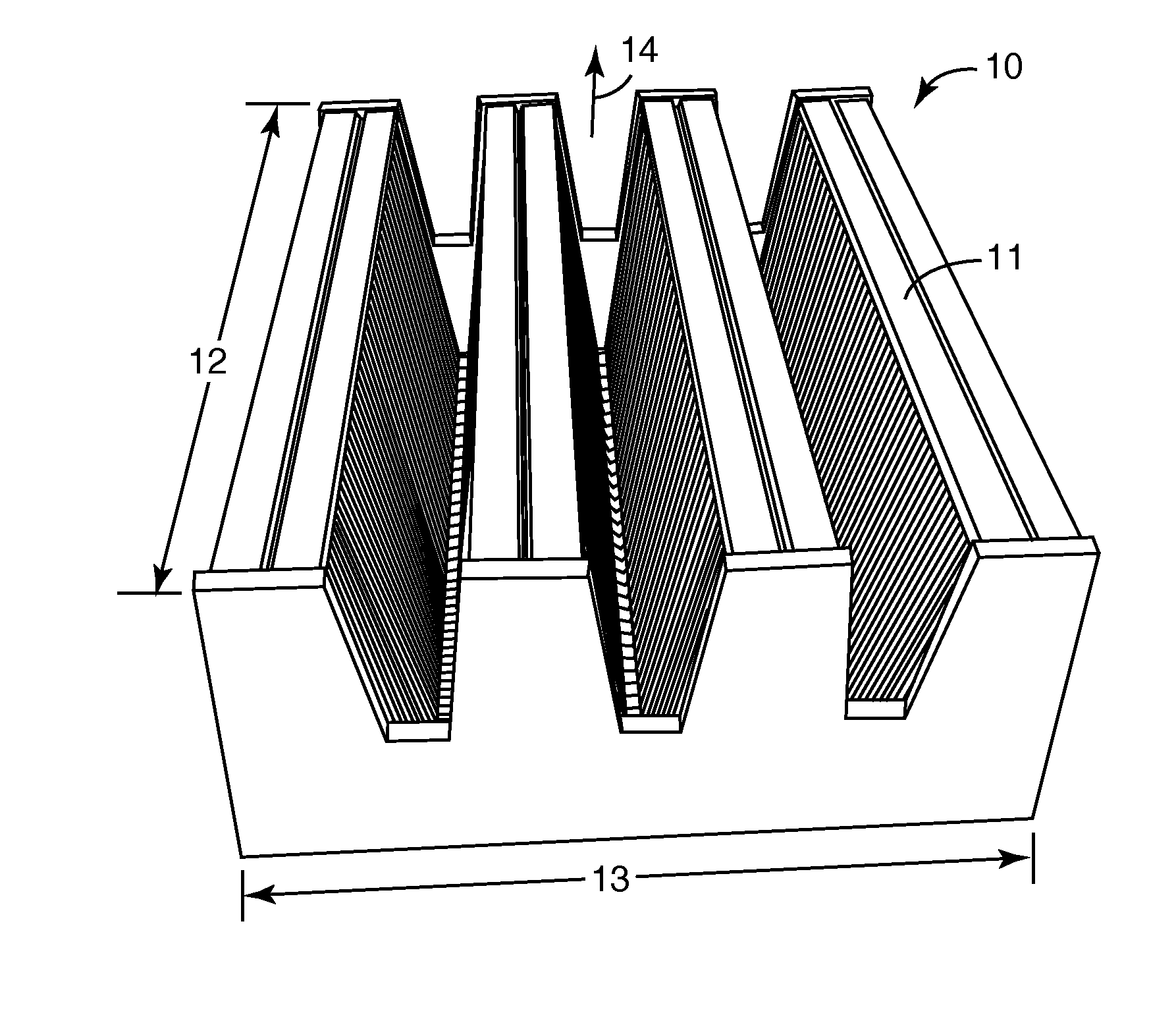

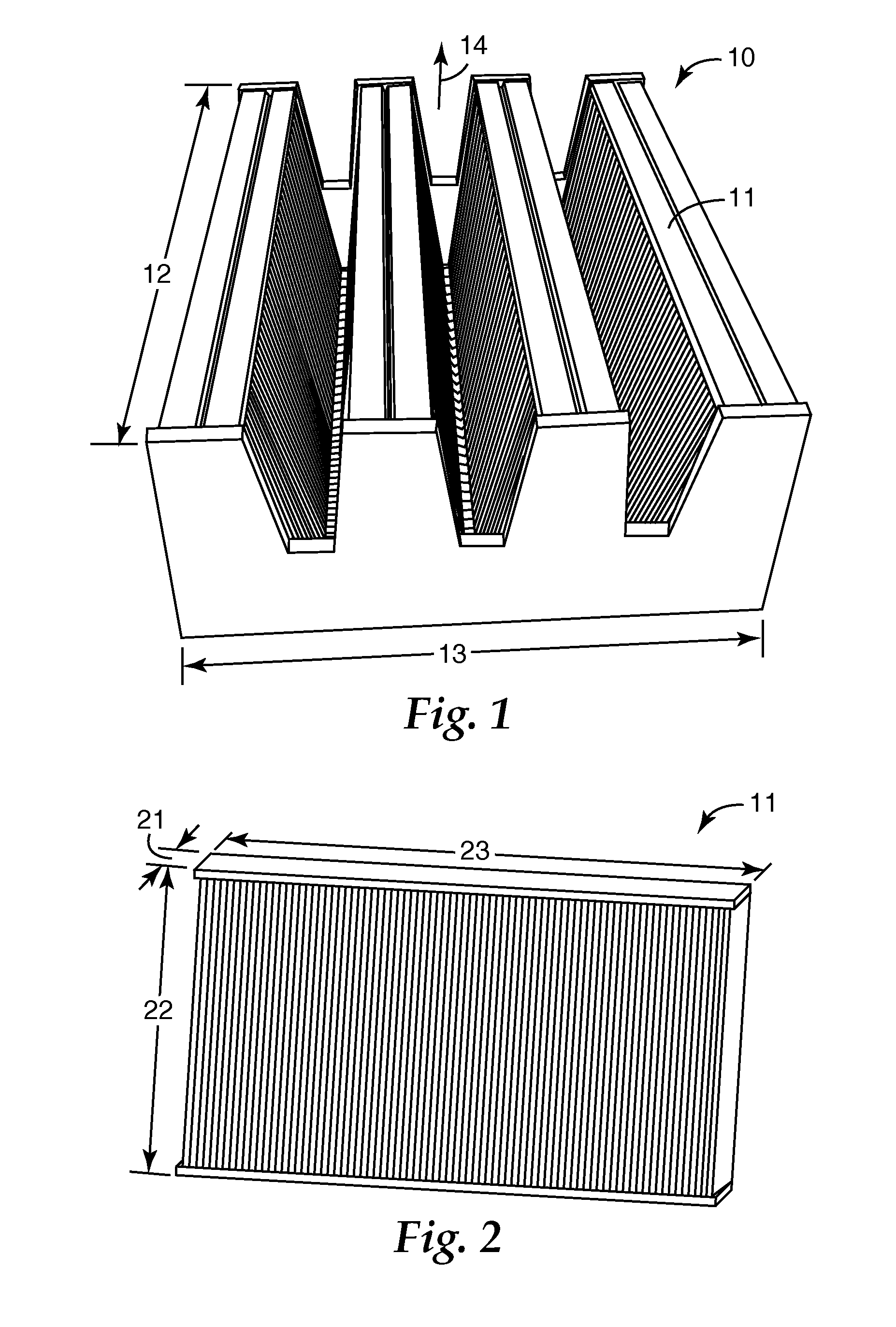

Gas Purification Process Utilizing Engineered Small Particle Adsorbents

ActiveUS20120222555A1Great diffusion rateLower Level RequirementsCarbon compoundsSulfur compoundsParticulatesSorbent

A gas separation process uses a structured particulate bed of adsorbent coated shapes / particles laid down in the bed in an ordered manner to simulate a monolith by providing longitudinally extensive gas passages by which the gas mixture to be separated can access the adsorbent material along the length of the particles. The particles can be laid down either directly in the bed or in locally structured packages / bundles which themselves are similarly oriented such that the bed particles behave similarly to a monolith but without at least some disadvantages. The adsorbent particles can be formed with a solid, non-porous core with the adsorbent formed as a thin, adherent coating on the exposed exterior surface. Particles may be formed as cylinders / hollow shapes to provide ready access to the adsorbent. The separation may be operated as a kinetic or equilibrium controlled process.

Owner:EXXON RES & ENG CO

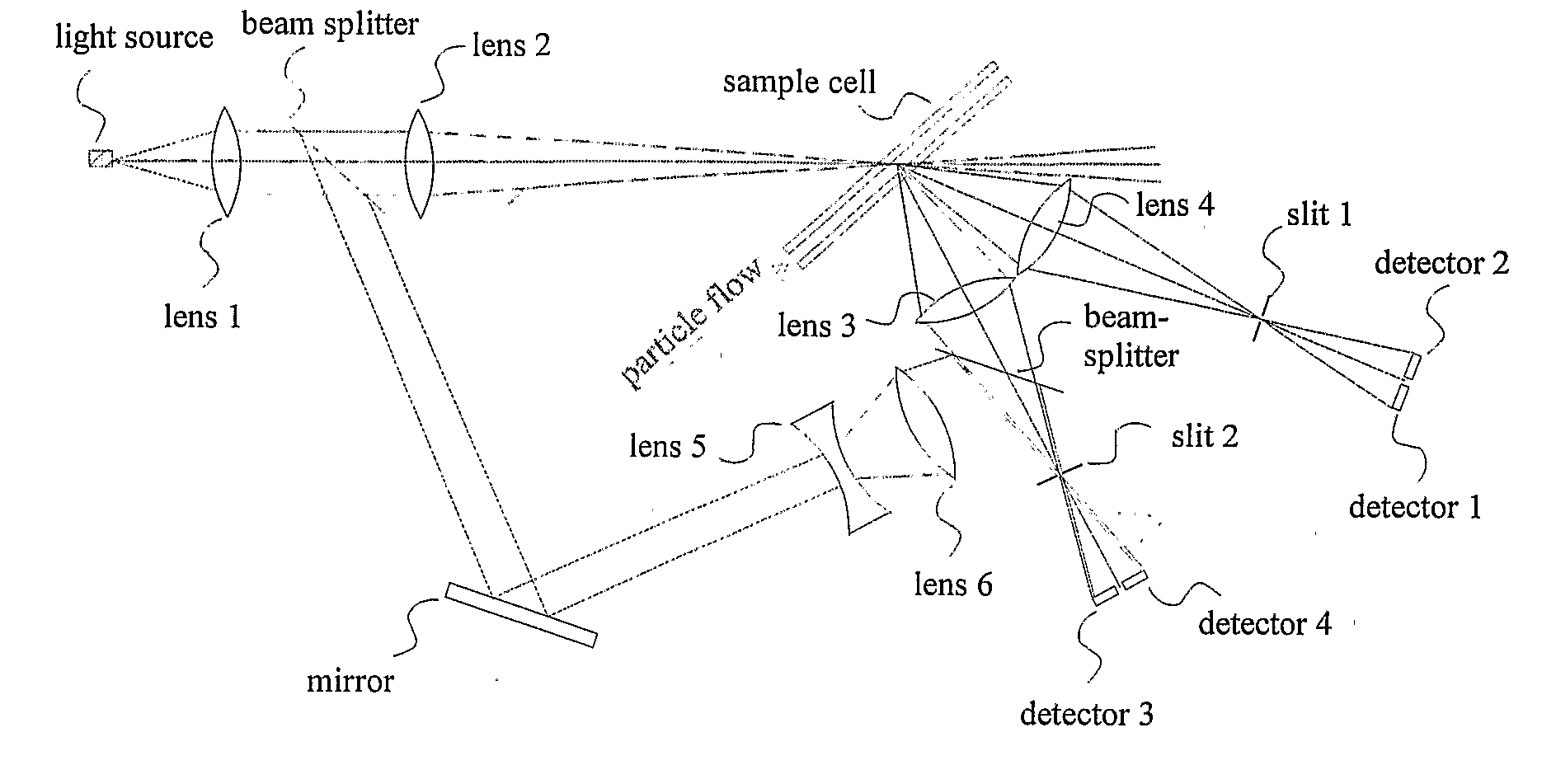

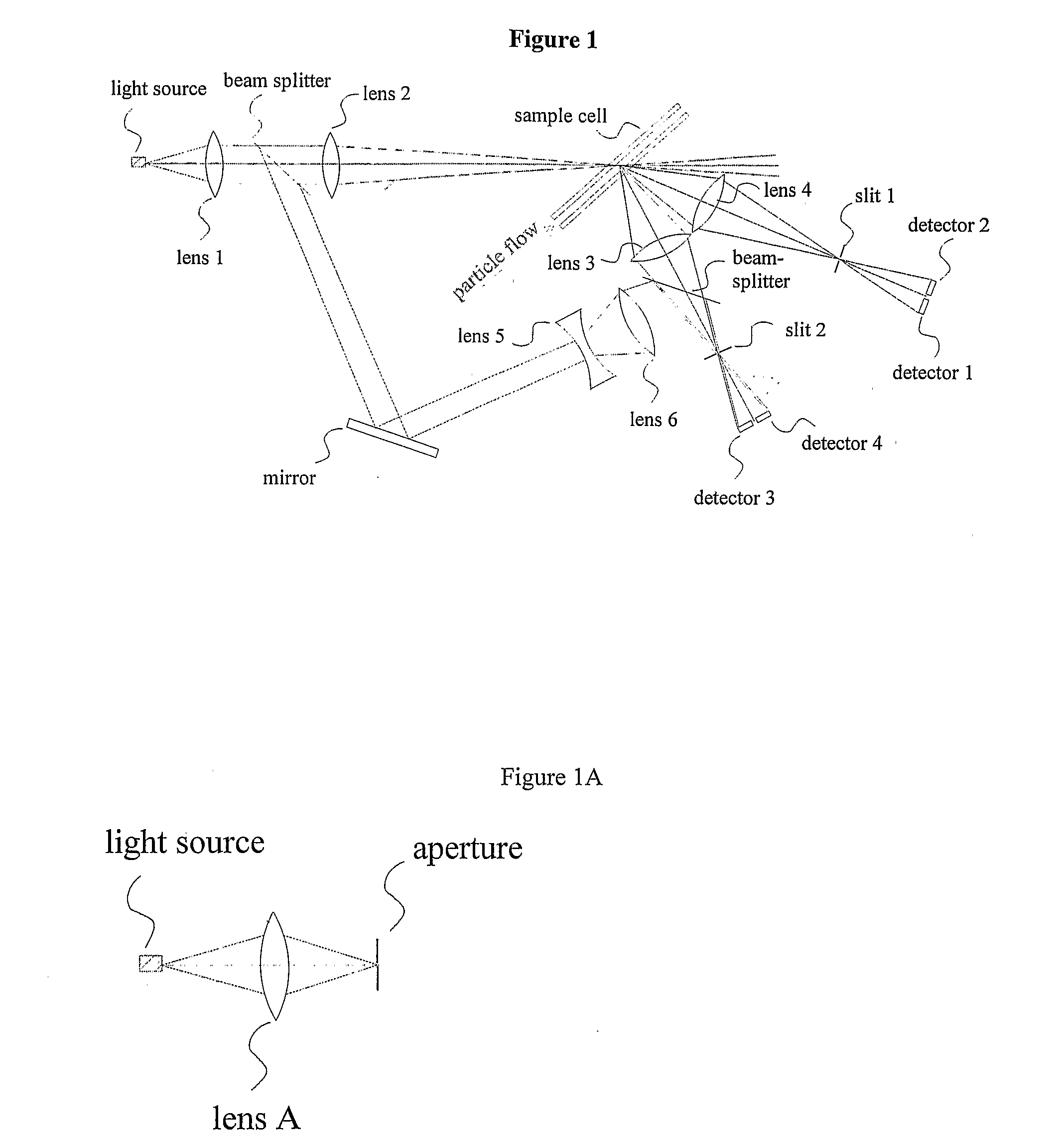

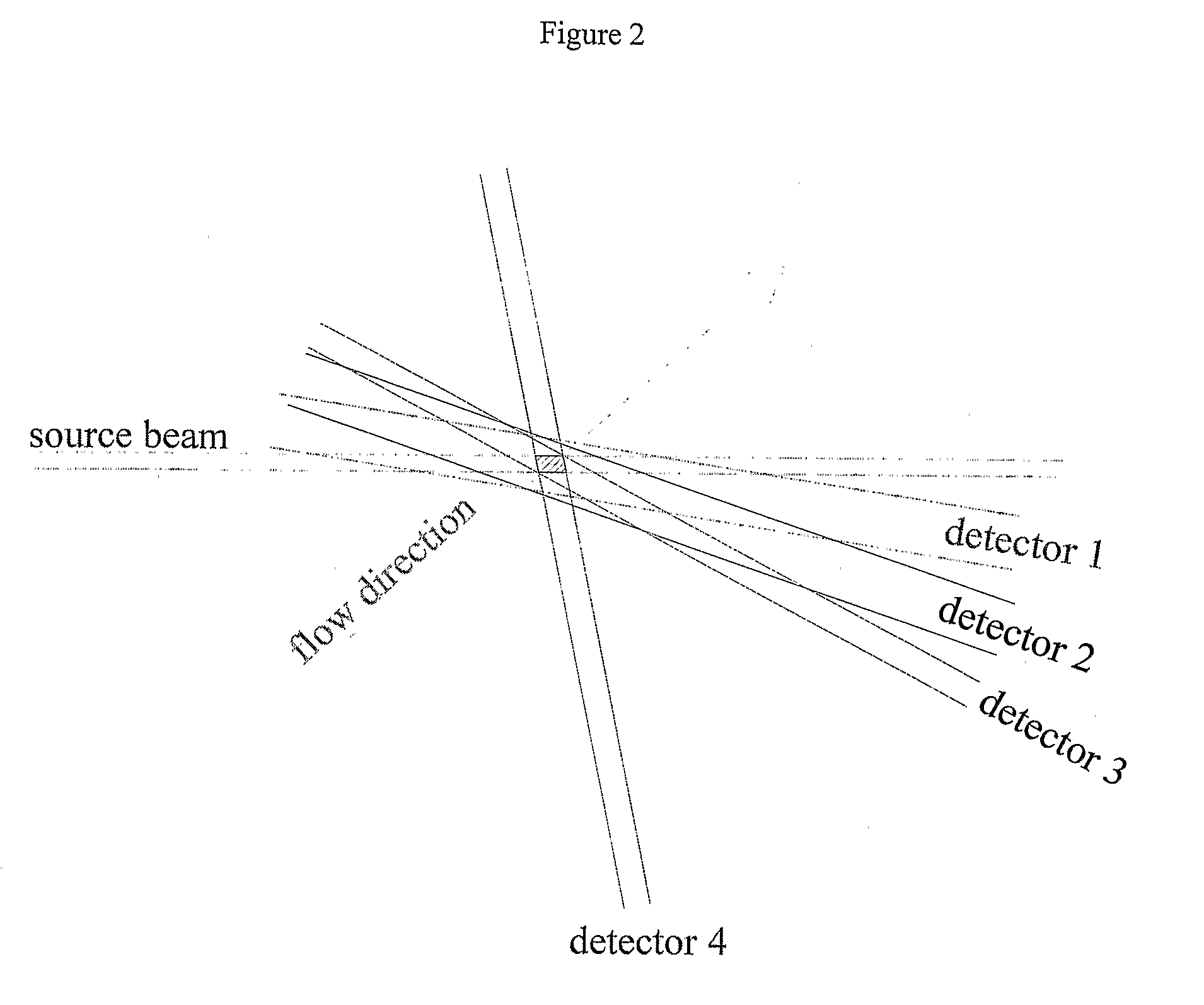

Methods and apparatus for determining the size and shape of particles

An instrument for measuring the size distribution of a particle sample by counting and classifying particles into selected size ranges. The particle concentration is reduced to the level where the probability of measuring scattering from multiple particles at one time is reduced to an acceptable level. A light beam is focused or collimated through a sample cell, through which the particles flow. As each particle passes through the beam, it scatters, absorbs, and transmits different amounts of the light, depending upon the particle size. So both the decrease in the beam intensity, due to light removal by the particle, and increase of light, scattered by the particle, may be used to determine the particle size, to classify the particle and count it in a certain size range. If all of the particles pass through a single beam, then many small particles must be counted for each large one because typical distributions are uniform on a particle volume basis, and the number distribution is related to the volume distribution by the particle diameter cubed.

Owner:TRAINER MICHAEL

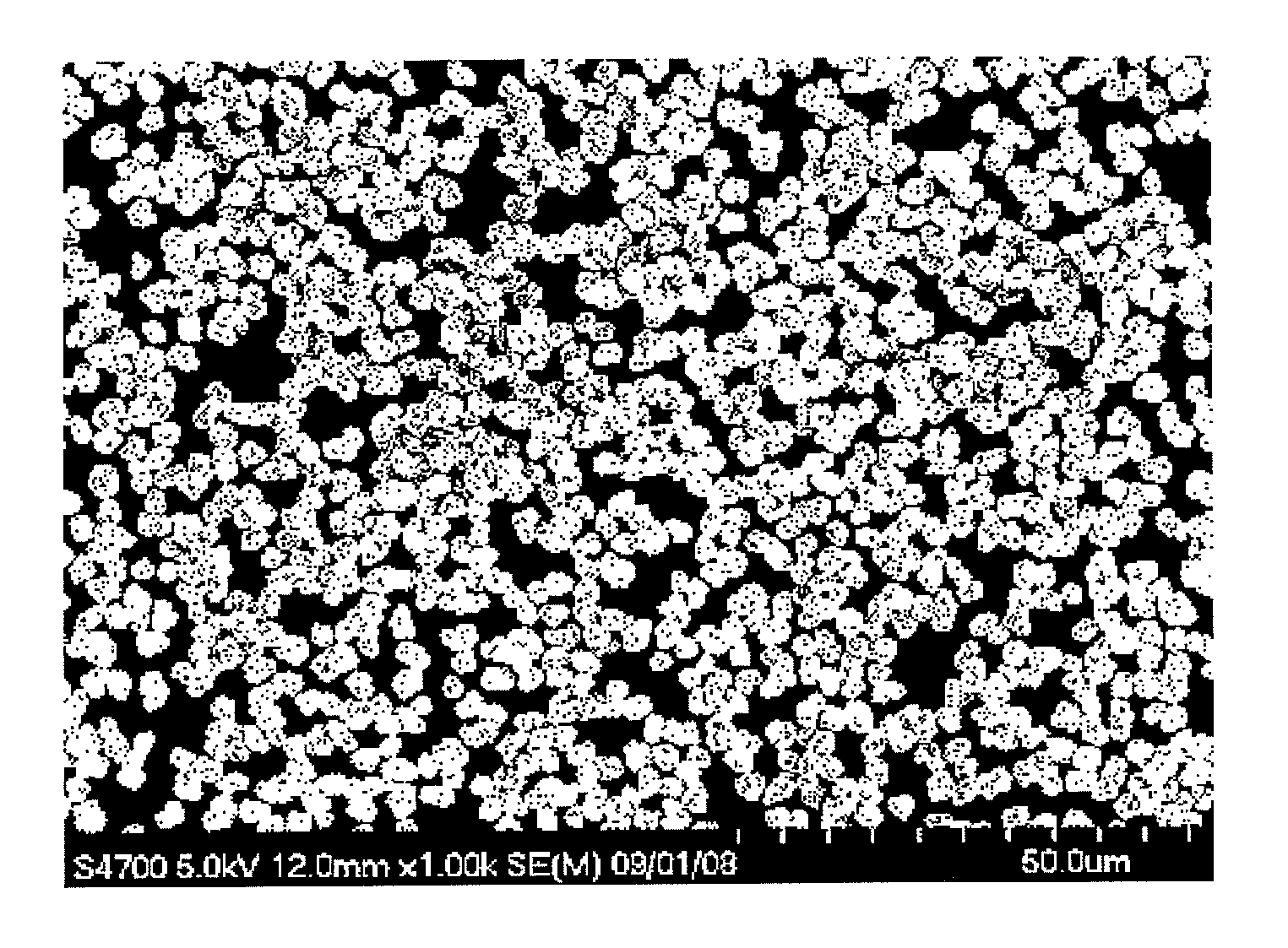

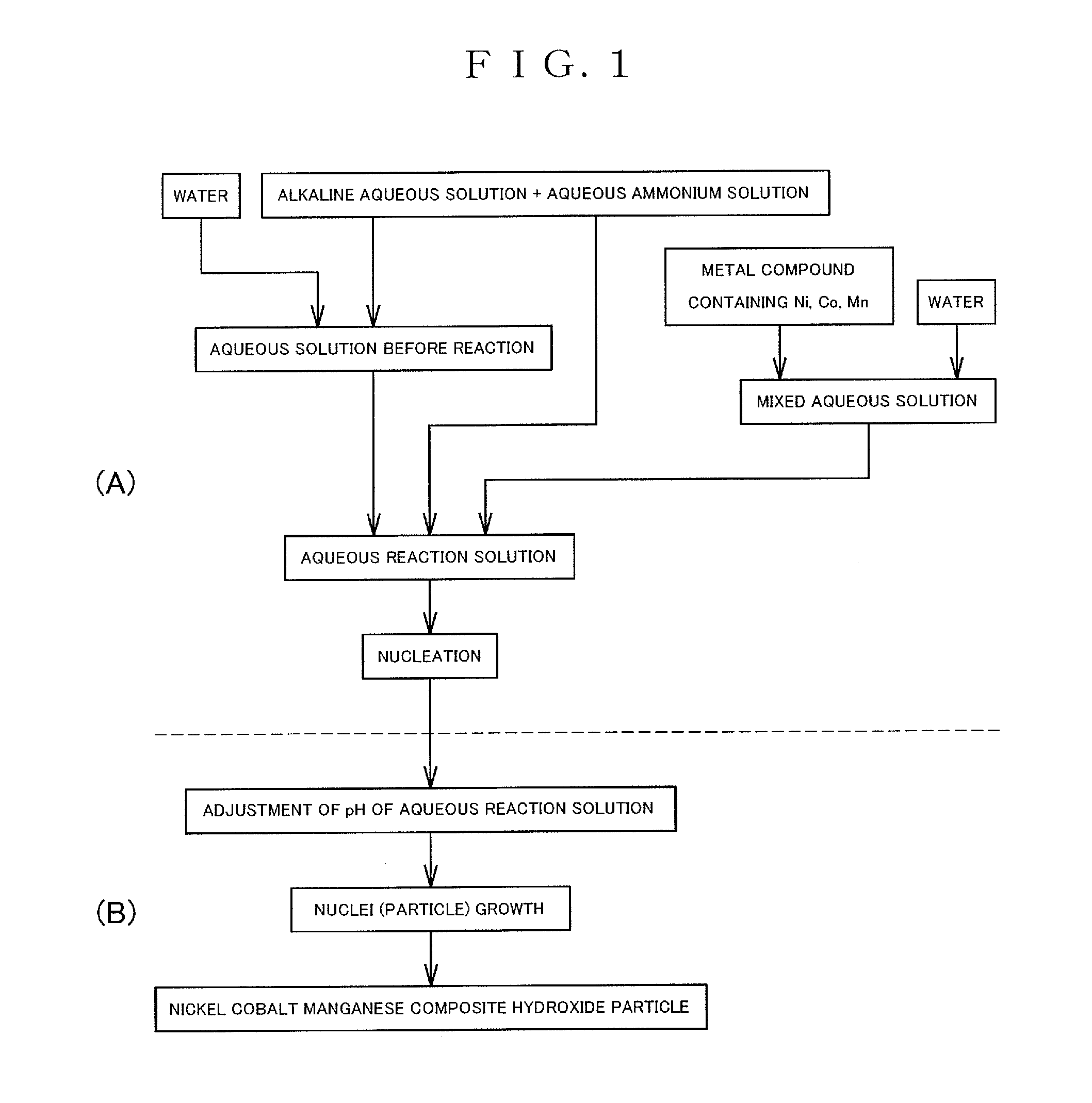

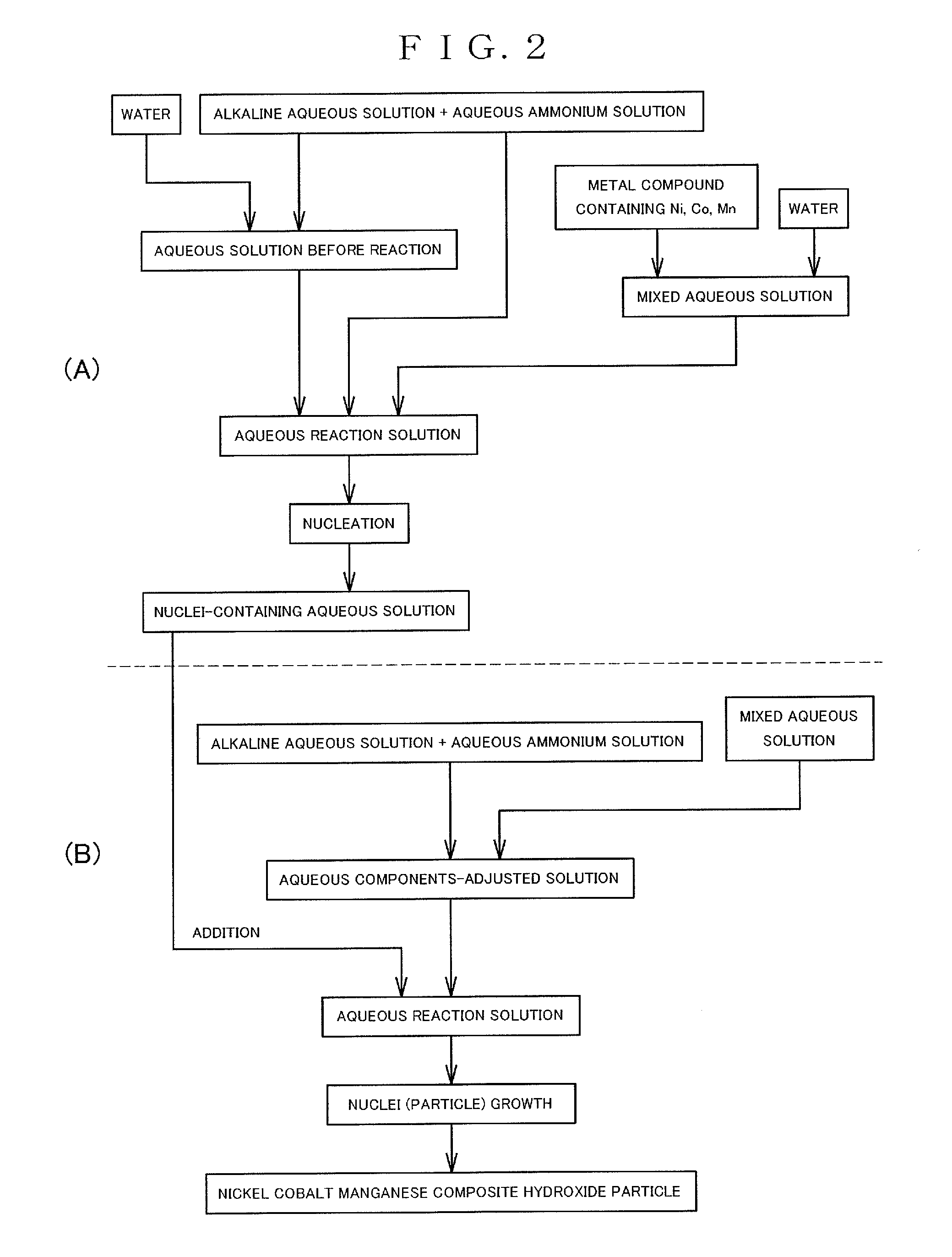

Nickel-cobalt-manganese complex hydroxide particles and method for producing same, positive electrode active material for nonaqueous electrolyte secondary battery and method for producing same, and nonaqueous electrolyte secondary battery

ActiveUS20120270107A1Growth inhibitionFast executionNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLiquid temperatureManganese

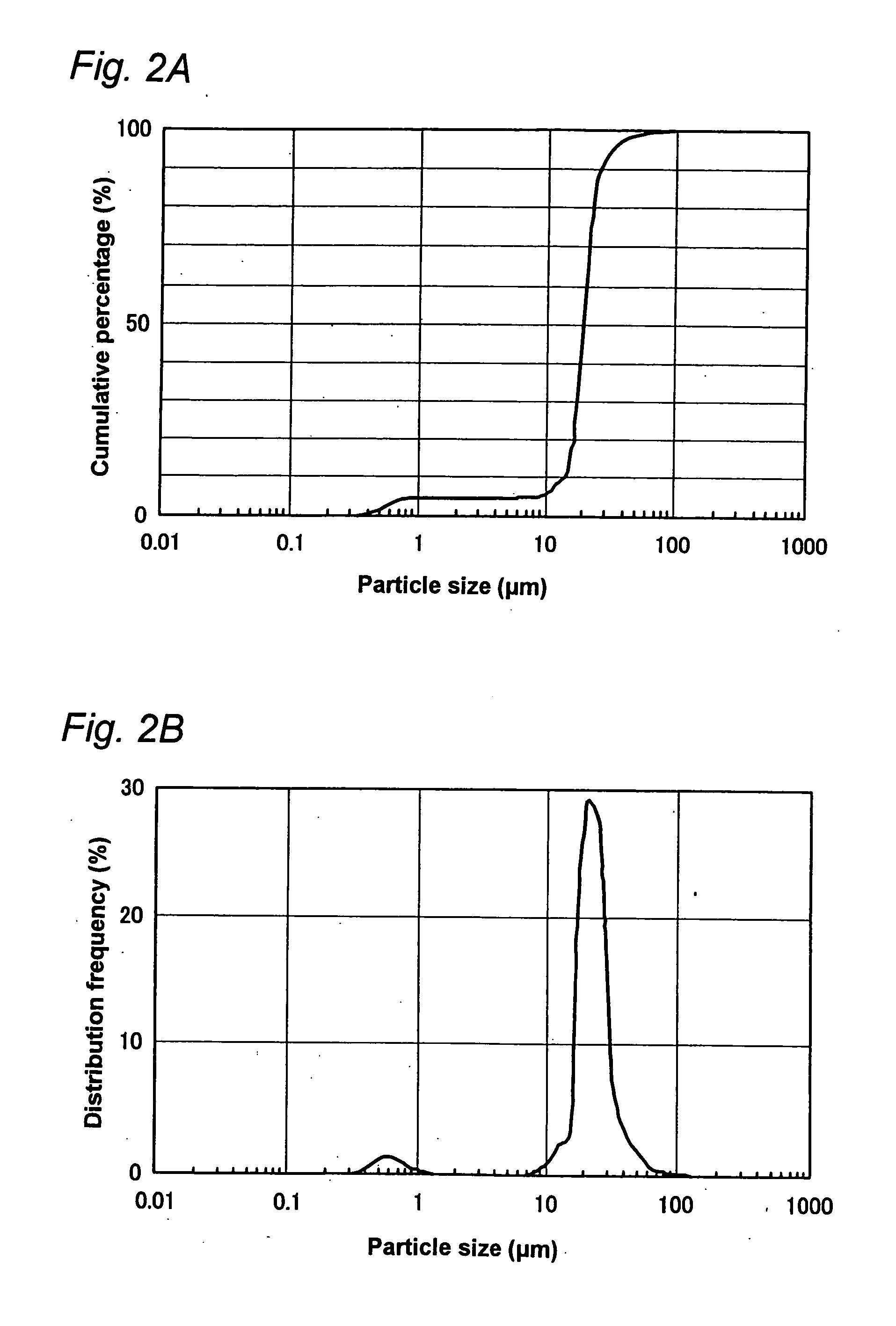

An object of the present invention is to provide nickel cobalt manganese composite hydroxide particles having a small particle diameter and a uniform particle size distribution, and a method for producing the same.[Solution]A method for producing a nickel cobalt manganese composite hydroxide by a crystallization reaction is provided. The method includes: a nucleation step of performing nucleation by controlling a pH of an aqueous solution for nucleation including metal compounds containing nickel, cobalt and manganese, and an ammonium ion donor to 12.0 to 14.0 in terms of the pH as measured at a liquid temperature of 25° C. as a standard; and a particle growth step of growing nuclei by controlling a pH of an aqueous solution for particle growth containing nuclei formed in the nucleation step to 10.5 to 12.0 in terms of the pH as measured at a liquid temperature of 25° C. as a standard.

Owner:SUMITOMO METAL MINING CO LTD +1

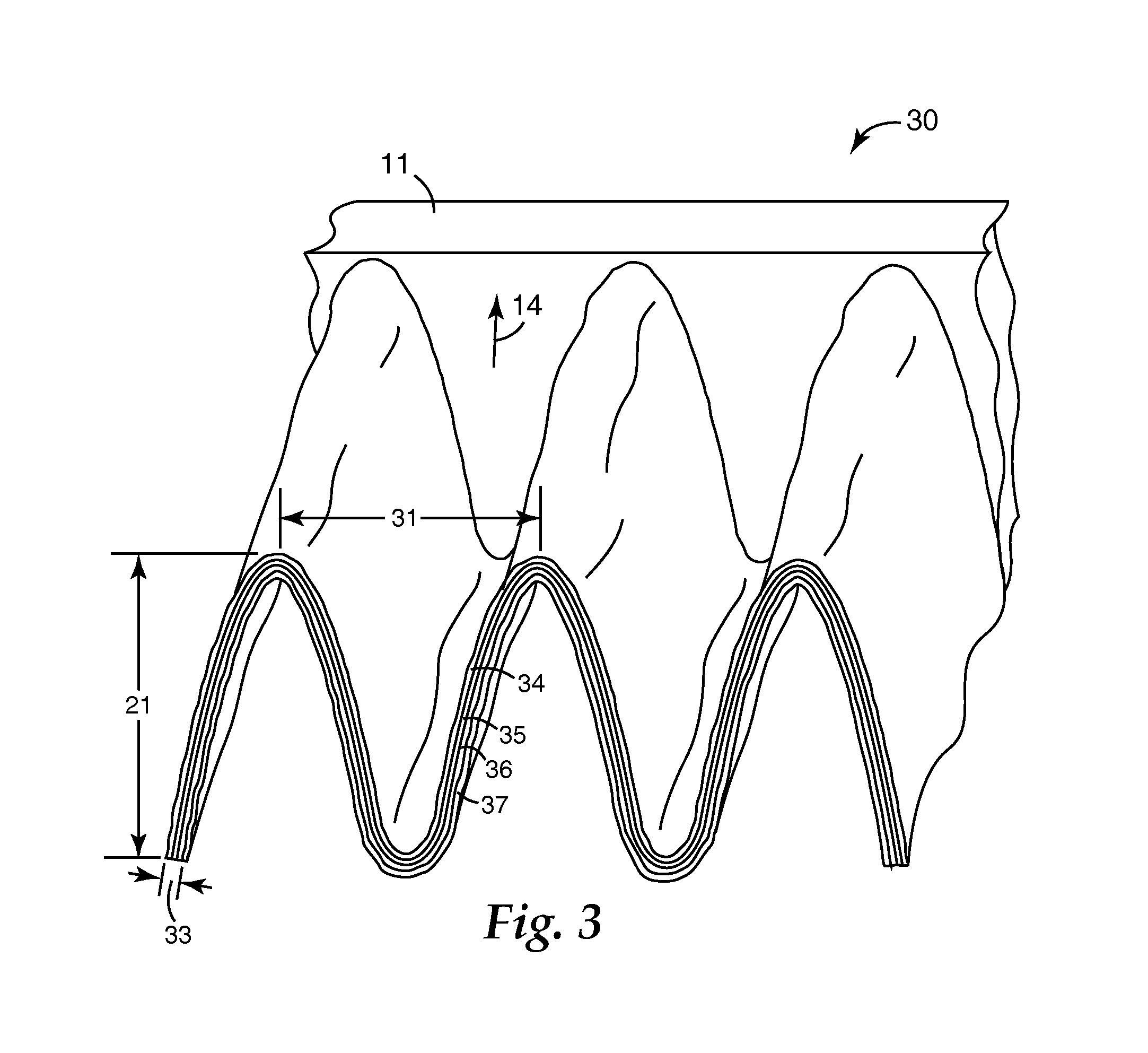

High efficiency HVAC filter

InactiveUS20080017038A1Lose weightLittle efficiencyMaterial nanotechnologyDispersed particle filtrationFiberGram

There is provided a pleated HVAC type filter containing a pleated filter media laminate of a melt blown nonwoven media containing layer and a nanofiber filter media layer. The melt blown nonwoven media containing layer has an upstream face and a downstream face, where the downstream face is laminated to the nanofiber filter media layer. The melt blown nonwoven media further has a very low basis weight of less than 30 grams / m2 and a thickness of less than 1 mm, the filter media laminate, which includes supporting scrim layers, has a basis weight of less than 200 grams / m2 and a thickness of less than 3 mm where the filter media laminate is pleated to a pleat density of at least 1 pleats / cm and has an initial pressure drop of less than 0.45 inches of water, a small particle efficiency, relative to 0.3 to 1.0 micron particles, of greater than 70 percent, the nanofiber filter media comprising a nanofiber web on a support backing, wherein the nanofibers have a diameter of less than 1.0 microns and an efficiency relative to 0.8 micron PSL particles of greater than 30 percent.

Owner:3M INNOVATIVE PROPERTIES CO

Method of creating ultra-fine particles of materials using a high-pressure mill

Owner:CORNERSTONE TECH

Active cathode layer for metal-sulfur secondary battery

ActiveUS20160294000A1Perfect sulfur utilization efficiencyIncrease loadElectrode carriers/collectorsSecondary cellsLithiumPolysulfide

A preloaded cathode layer, comprising: (A) An integral porous structure having massive surfaces greater than 100 m2 / g or pores with a size from 1.0 nm to 100 nm, wherein multiple conductive particles, platelets or filaments, without a conductive filler, form a 3-D conductive network; and (B) a metal polysulfide preloaded in the pores or deposited on the massive surfaces, selected from: (a) an MxSy, (x=1-3 and y=1-10) wherein M is a metal element selected from a non-lithium alkali metal, an alkaline metal selected from Mg or Ca, a transition metal, a metal from groups 13 to 17, or a combination thereof, or (b) Li2S6, Li2S7, Li2S8, Li2S9, or Li2S10, wherein the metal polysulfide contains a thin coating or small particles with a thickness or diameter less than 20 nm and occupies a weight fraction of from 1% to 99%.

Owner:GLOBAL GRAPHENE GRP INC

Composite particles and method for production thereof and use thereof

InactiveUS20060116279A1Improve photocatalytic activityImprove efficiencyPigmenting treatmentMaterial nanotechnologyFiberUltraviolet

A composite particle comprised of a larger particle and, supported thereon, smaller particles wherein the smaller particles are photocatalyst-containing fine particles with an average particle diameter of 0.005-0.5 μm as calculated from a BET specific surface area, and the larger particle has an average particle diameter of 2-200 μm as measured by the laser diffraction-scattering particle size measuring method. The smaller particle is preferably a composite particle of titanium dioxide with an inorganic compound exhibiting no catalytic activity, such as silica, or a particle containing a Brφonsted acid salt, especially on the surface thereof; and an advantageous method for producing the above composite particles wherein the above larger particles and smaller particles are dry mixed by a ball-mill or mixed by rotation of blades or by shaking, with an energy constant controlled within a specific range. A composition comprising an organic polymer and the above composite particles can give a shaped article, such as fiber, film or a molding, exhibiting ultraviolet ray-screening function.

Owner:SHOWA DENKO KK

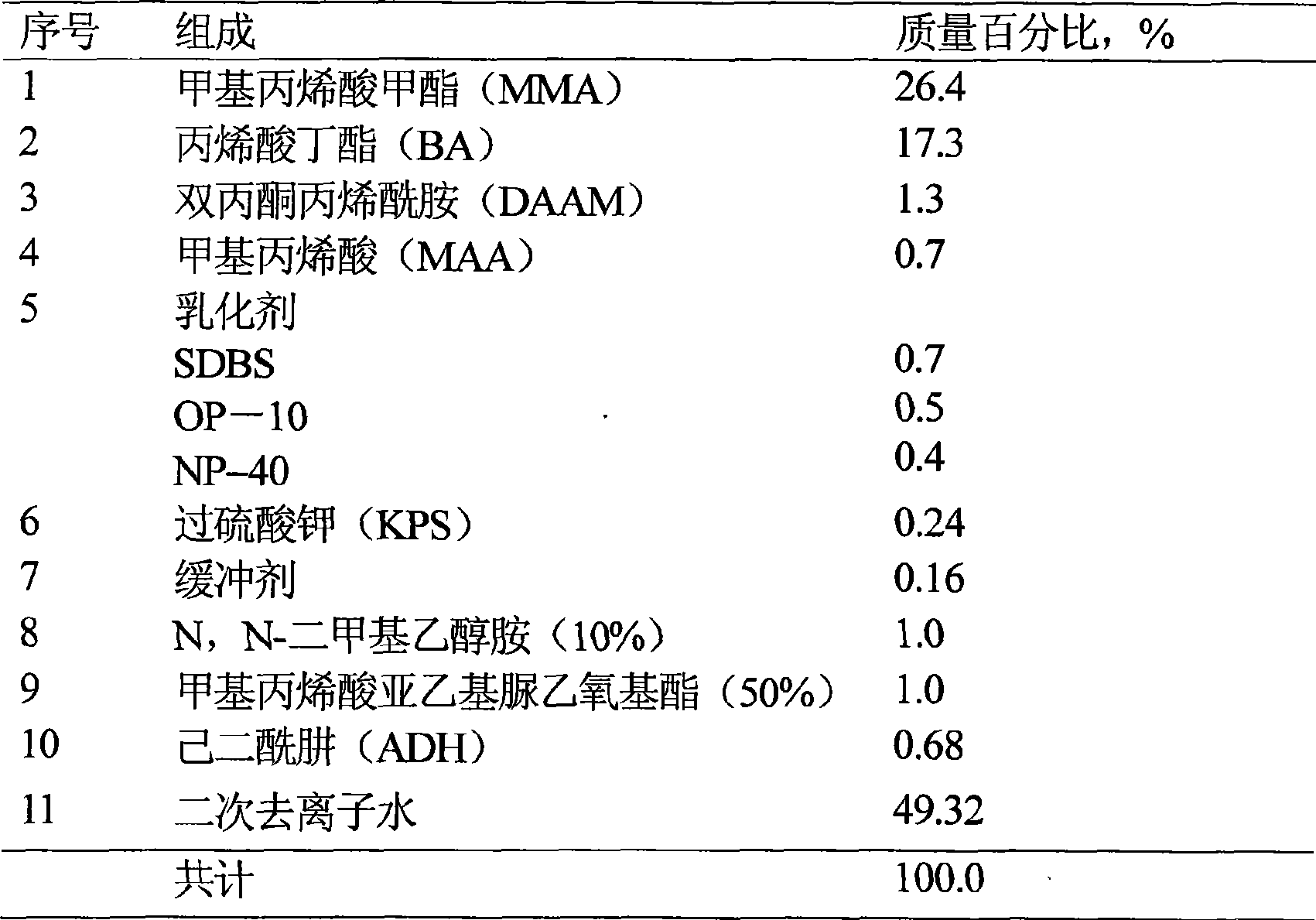

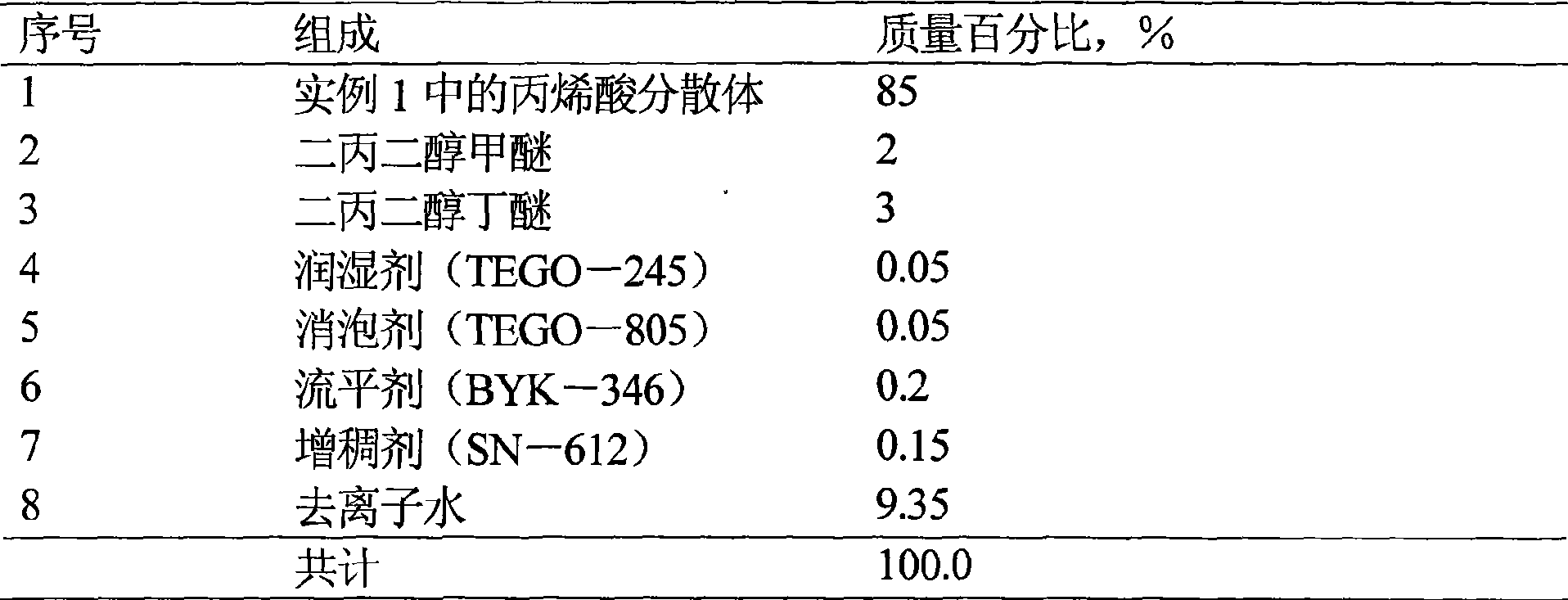

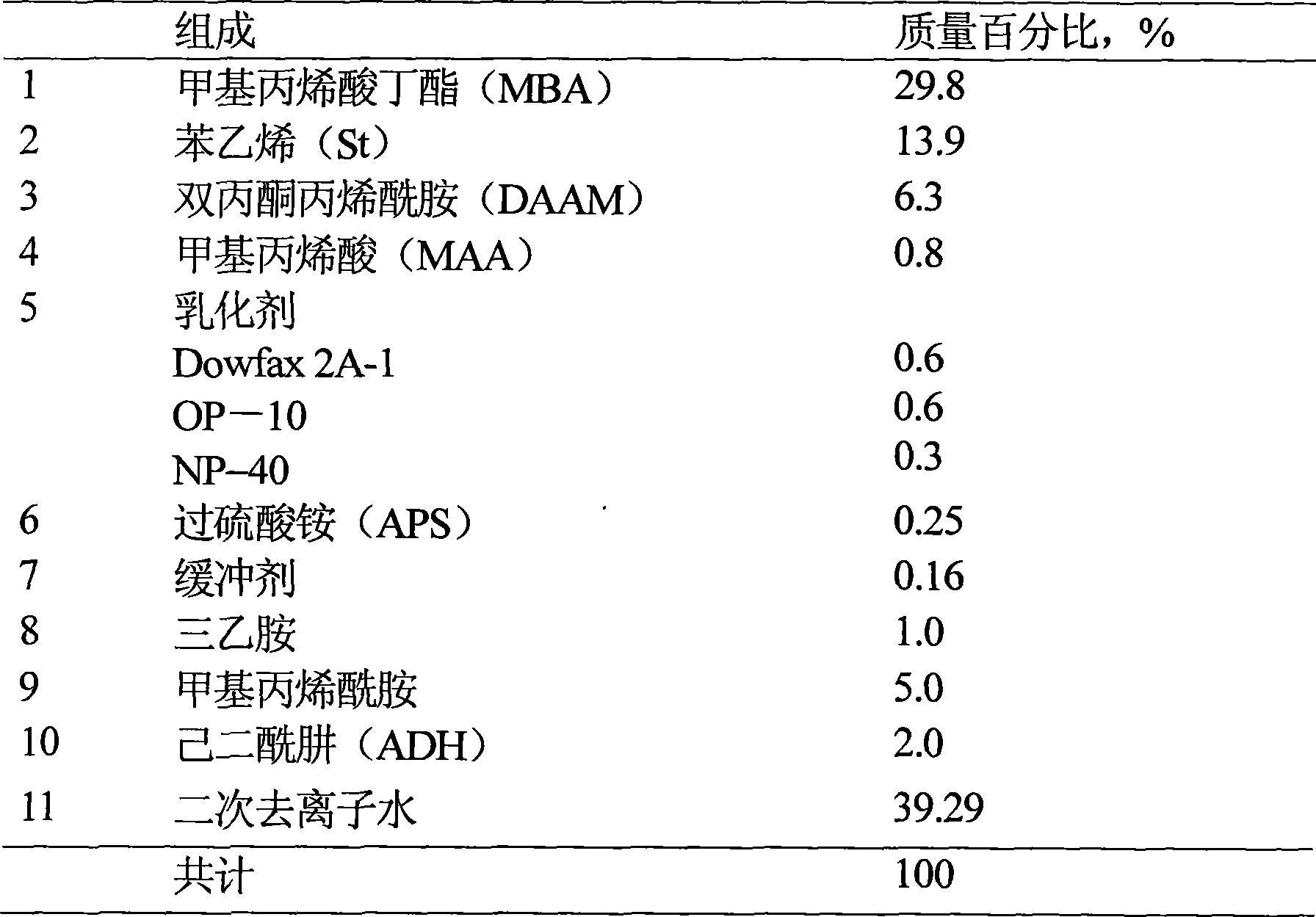

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

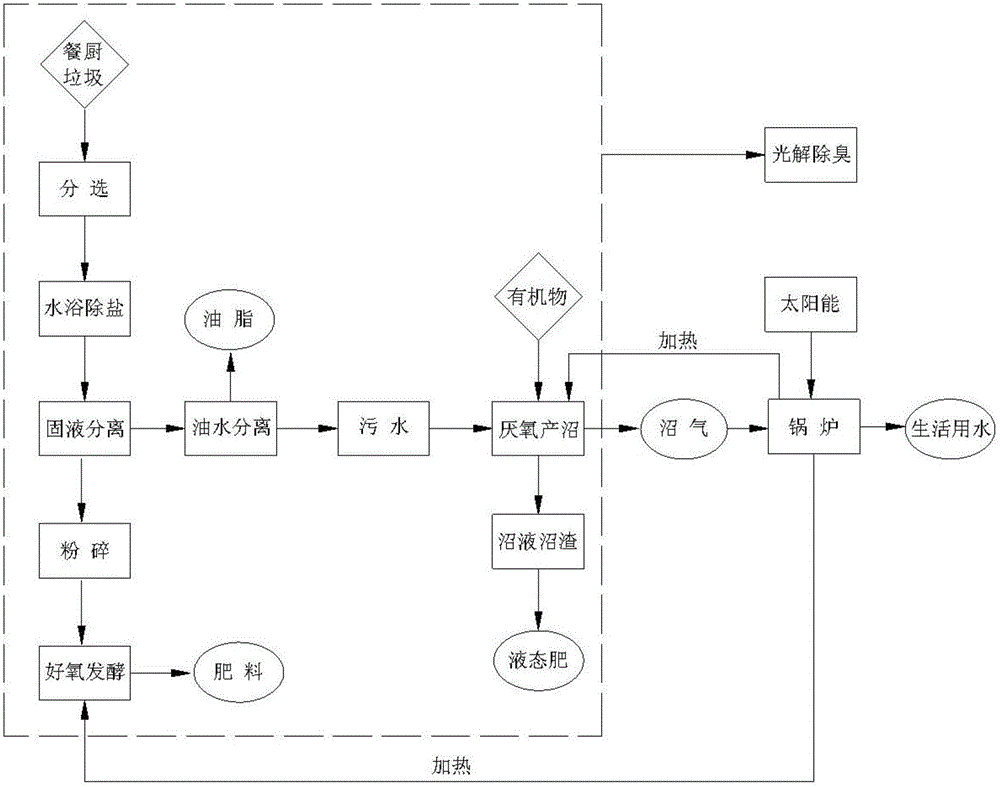

Resource-based and harmless treatment method for kitchen waste

InactiveCN104030738AEfficient removalGrowth inhibitionBio-organic fraction processingClimate change adaptationWater bathsLiquid waste

Relating to the technical field of resource recovery and recycling, the invention discloses a resource-based and harmless treatment method for kitchen waste. The method is directed at the problems of high salt content in fertilizer products, easy cause of soil salinization, and large equipment investment for anaerobic fermentation of total waste in existing kitchen waste treatment methods. The method comprises the steps of: (a) kitchen waste sorting; (b) water bath desalting: adding water, and conducting heating and stirring to dilute salt; (c) solid-liquid separation: dehydrating the waste; (d) solid material aerobic fermentation: crushing the dehydrated solid material into small particles, and conducting aerobic fermentation and drying treatment to obtain an organic fertilizer; and (e) waste liquid anaerobic fermentation: conducting oil-water separation on the waste liquid, recovering grease, subjecting sewage to anaerobic fermentation, making the produced biogas residue and biogas slurry into a liquid fertilizer, and taking the produced biogas as the fuel of a biogas boiler. The method provided by the invention is particularly suitable for resource-based and harmless treatment of kitchen waste.

Owner:习建华 +1

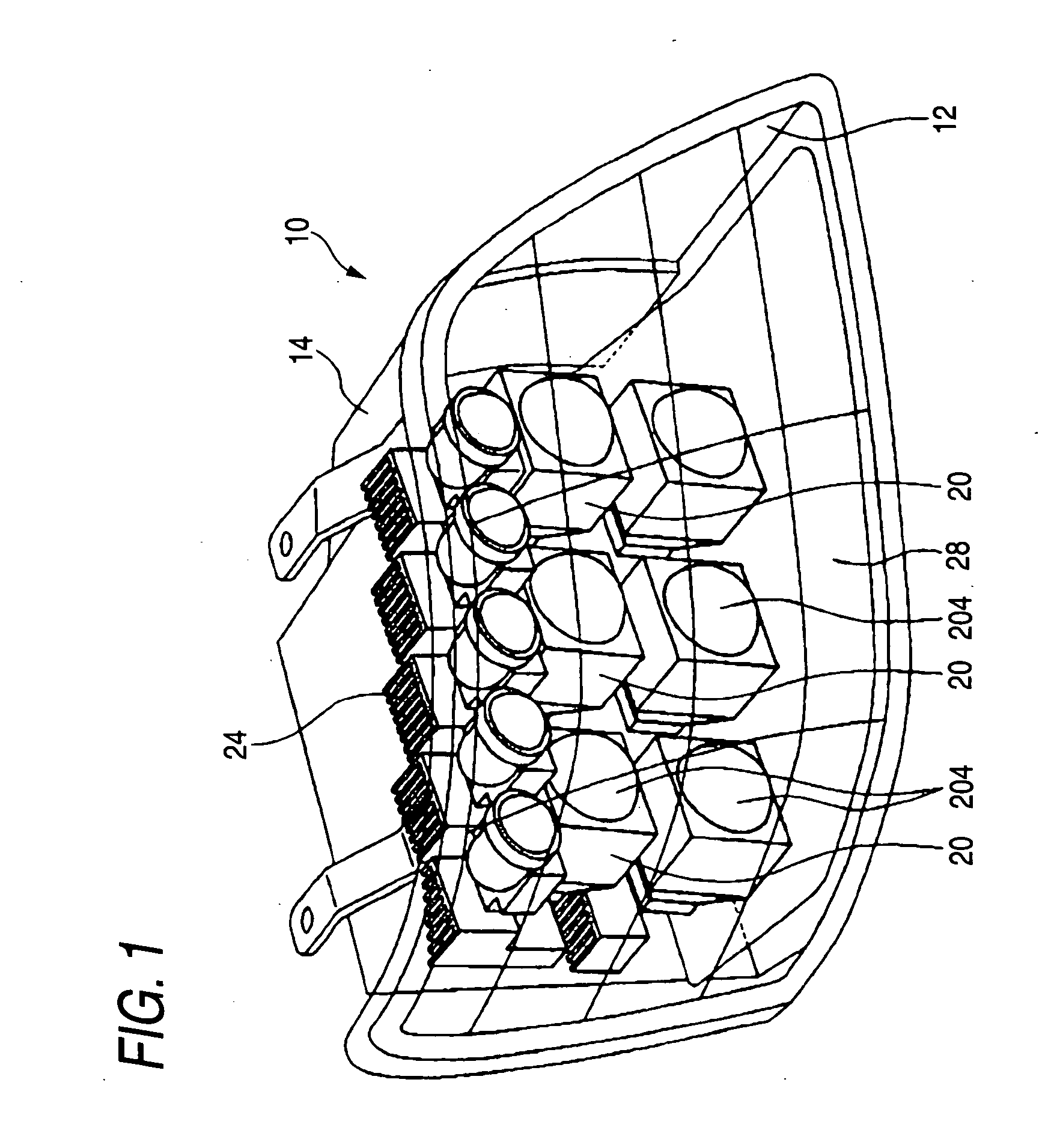

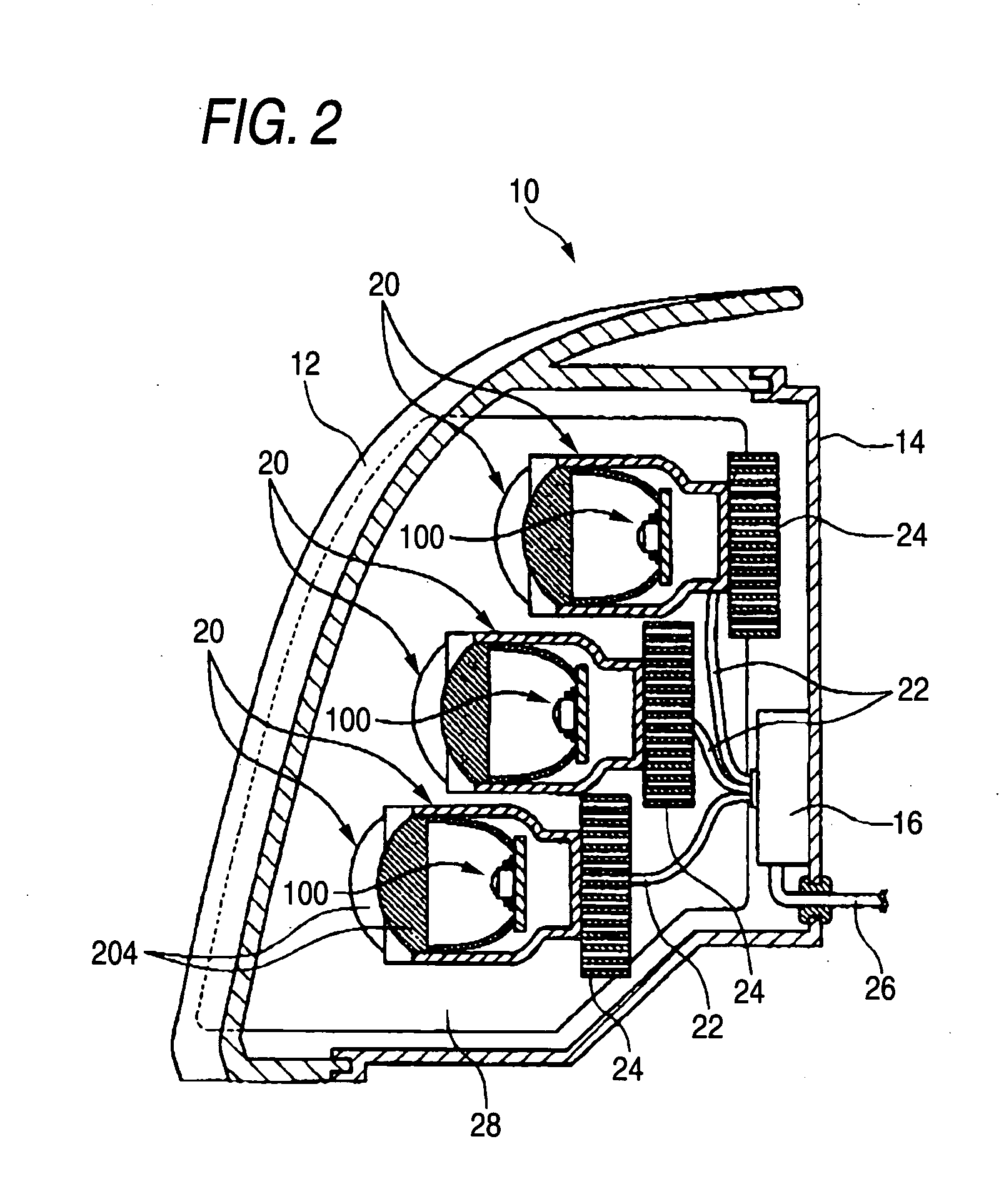

Light emitting apparatus and vehicle lamp

InactiveUS20060255716A1High luminous efficiencyEfficient extractionMaterial nanotechnologyDischarge tube luminescnet screensPhosphorRefractive index

A light emitting apparatus includes a device protective layer including a transparent binder (A) and particles (B), and a light emitting device coated with the device protective layer, characterized in that the transparent binder (A) contains one or more ceramics, and the particles (B) have a smaller particle diameter than the wavelength of the light produced by the light emitting device, and characterized in that the refractive index of the device protective layer is preferably 1.4 or more, the particle diameter of the particles (B) is 100 nm or less, and the device protective layer contains a phosphor therein. The light emitting apparatus can form a vehicle lamp high in luminous efficiency.

Owner:KOITO MFG CO LTD

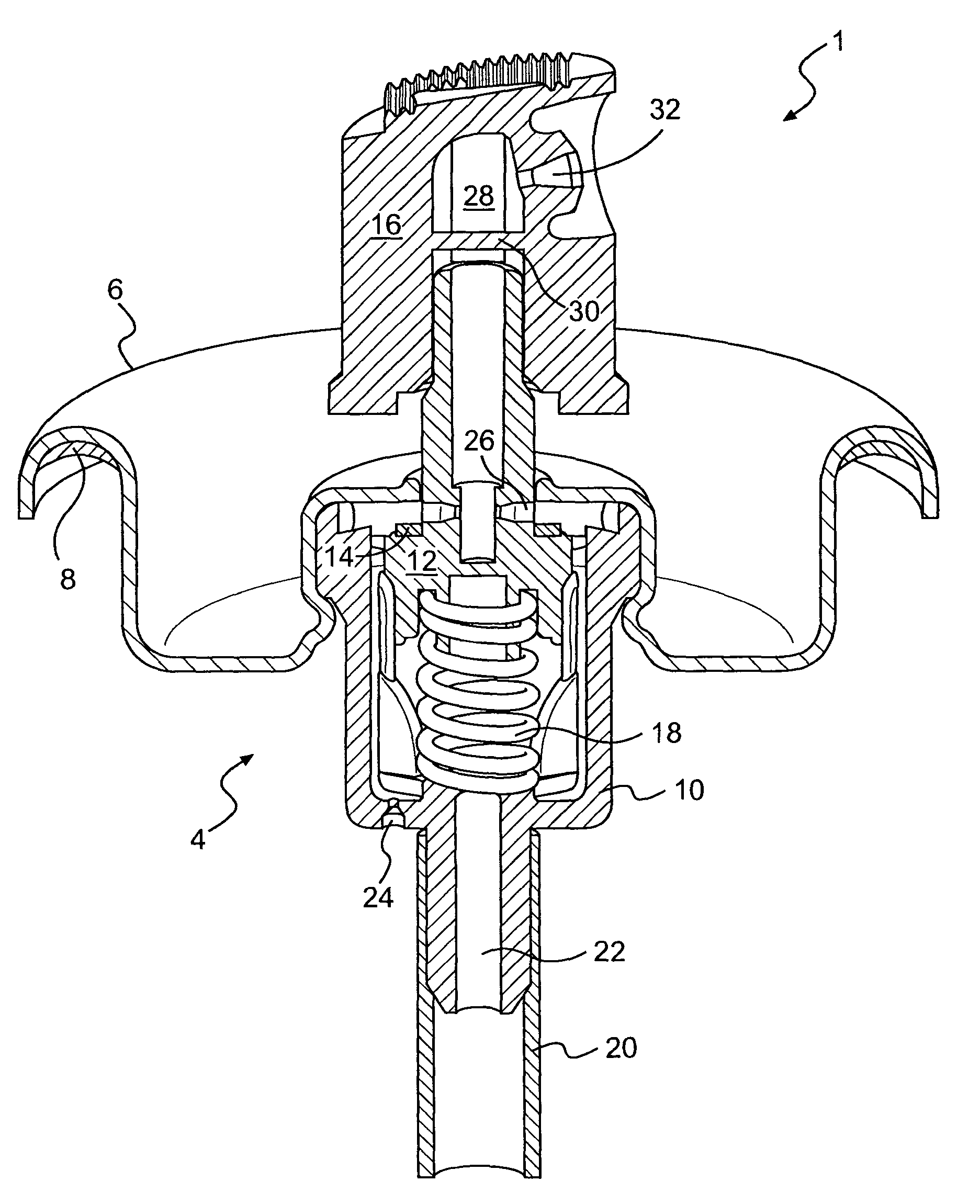

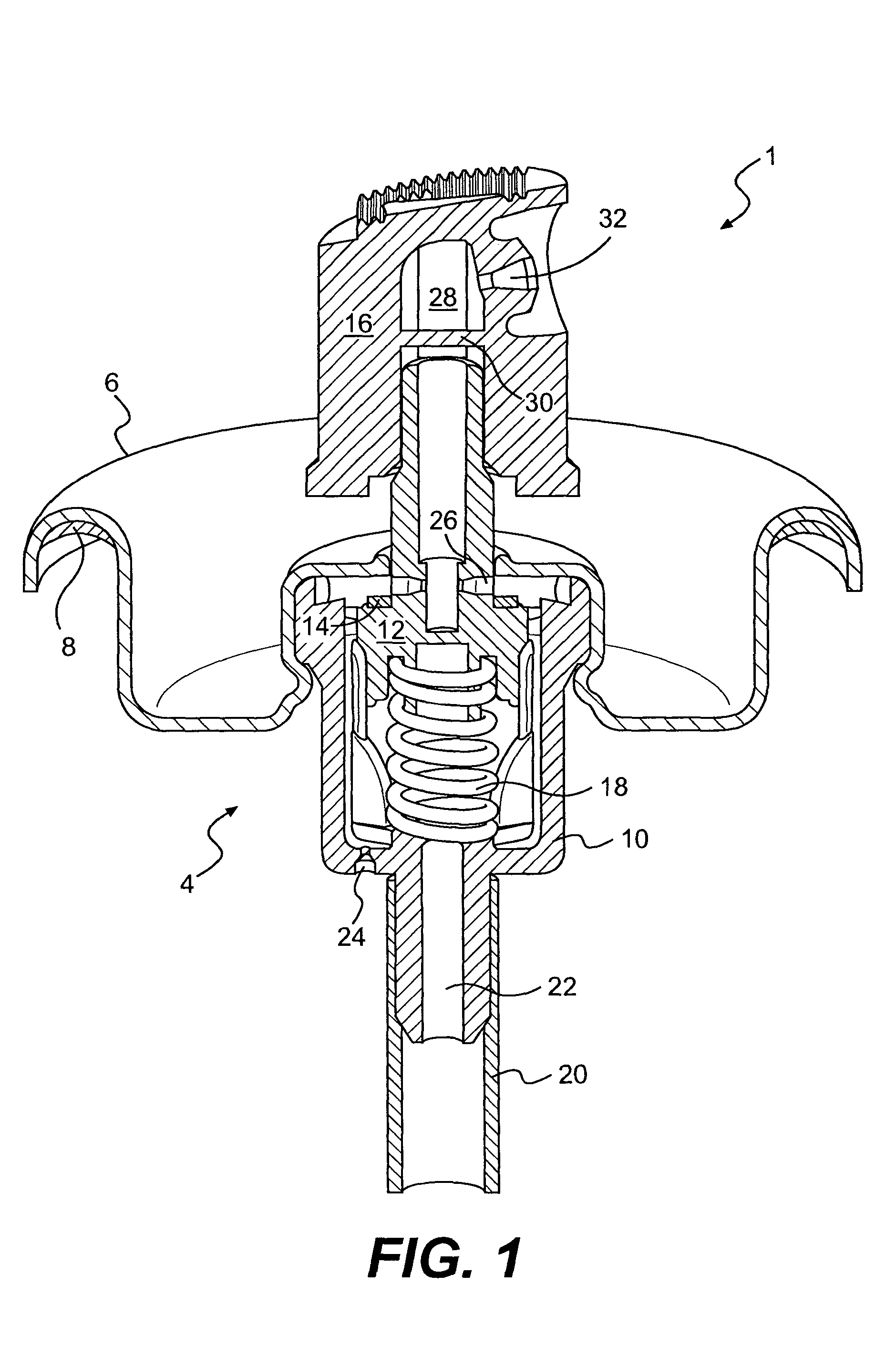

Aerosol dispenser assembly having low volatile organic compound (VOC) content

InactiveUS7014127B2Satisfactory particle sizeSatisfactory spray rateLiquid spraying apparatusLiquid dispensingLiquid productMechanical engineering

An aerosol dispenser assembly (1) has a container (2) holding a liquid product and a liquefied gas propellant for propelling the liquid product from the container, the propellant being present in a quantity of at most about 25% by weight of the contents of the container (2). A valve (4) is attached to the container (2) for selectively dispensing the liquid product from the container (2) as a mist. The assembly (1) is configured such that the mist has a small particle size, is dispensed at an expeditious rate, and very little product is retained in the container (2) when the propellant is depleted.

Owner:SC JOHNSON & SON INC

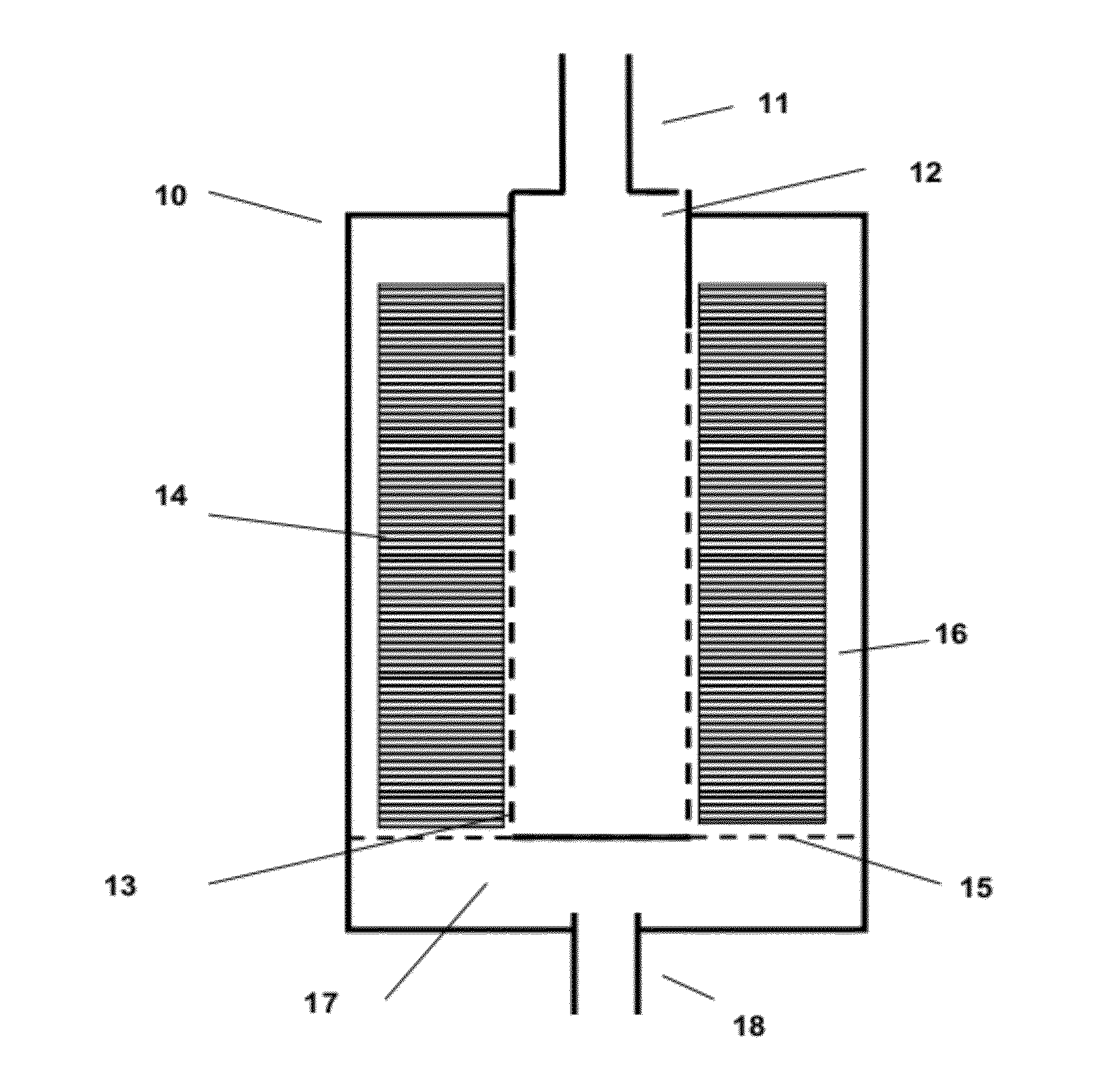

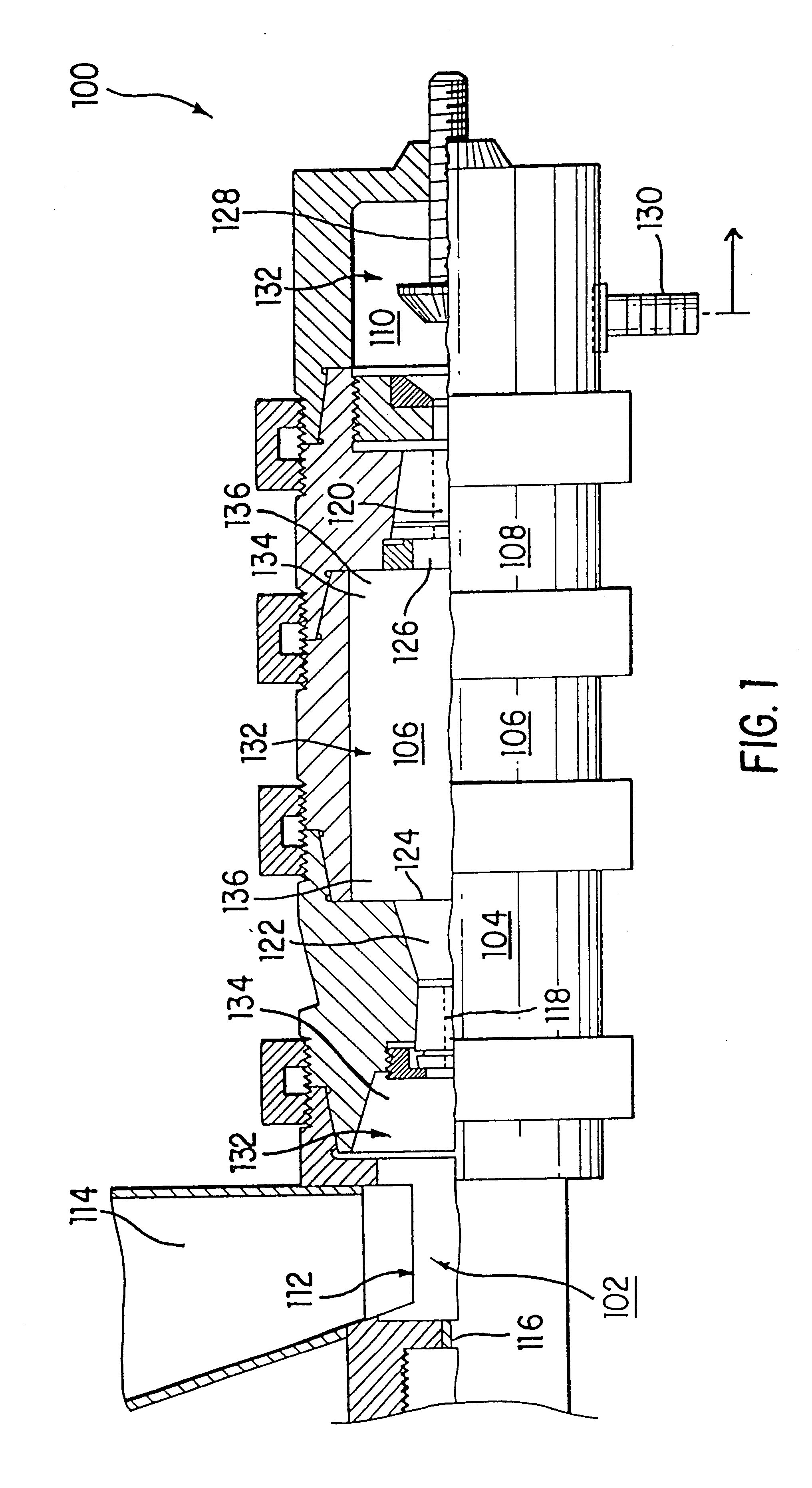

Method and apparatus for forming nano-particles

ActiveUS7282167B2Reduce flow turbulenceLarge particle sizeMaterial nanotechnologyTransportation and packagingMetallurgyCooling fluid

Nano-scale particles of materials can be produced by vaporizing the material and allowing the material to flow in a non-violently turbulent manner into thermal communication with a cooling fluid, thereby forming small particles of the material that can be in the nano-scale size range.

Owner:VIVAKOR INC +1

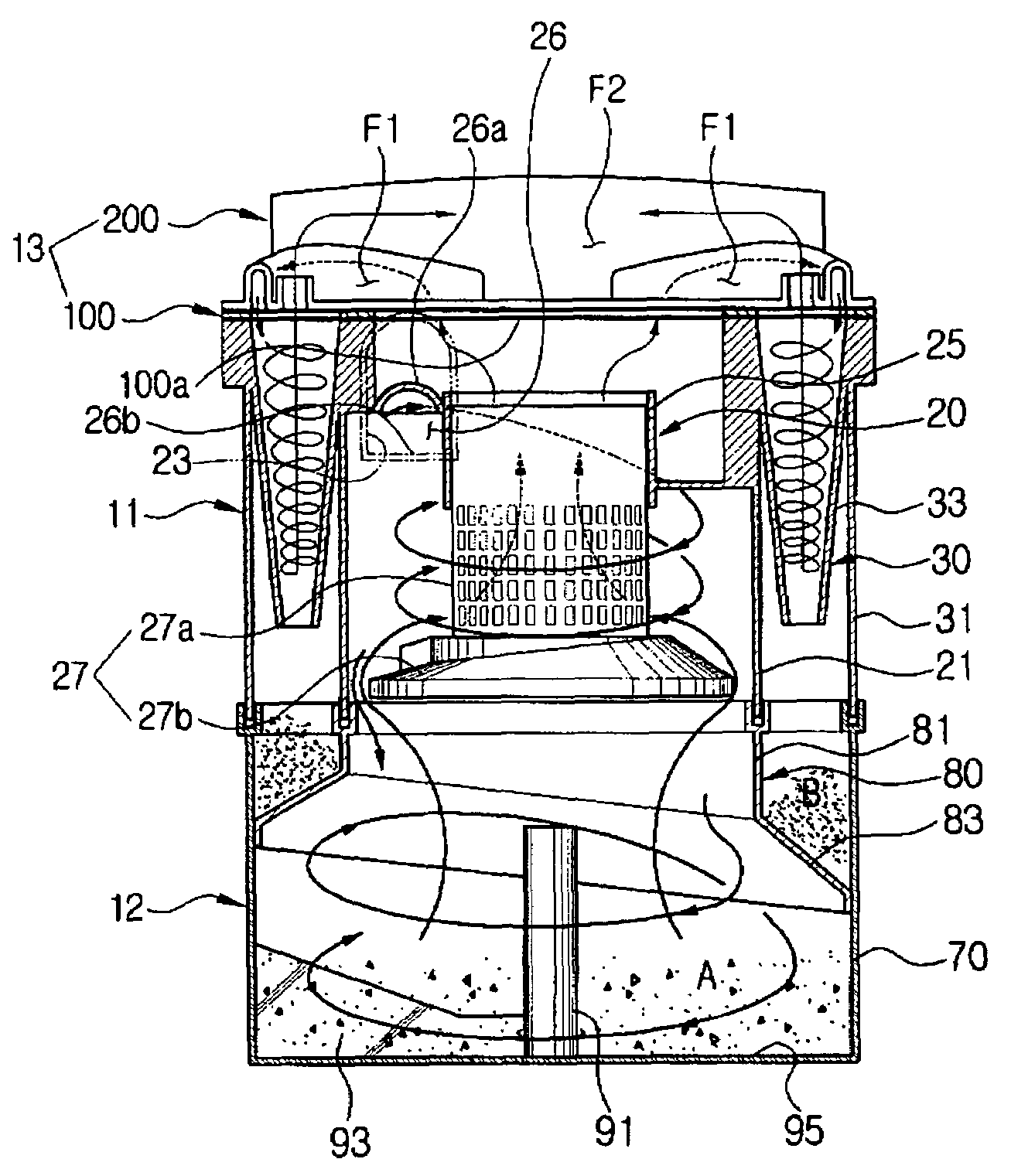

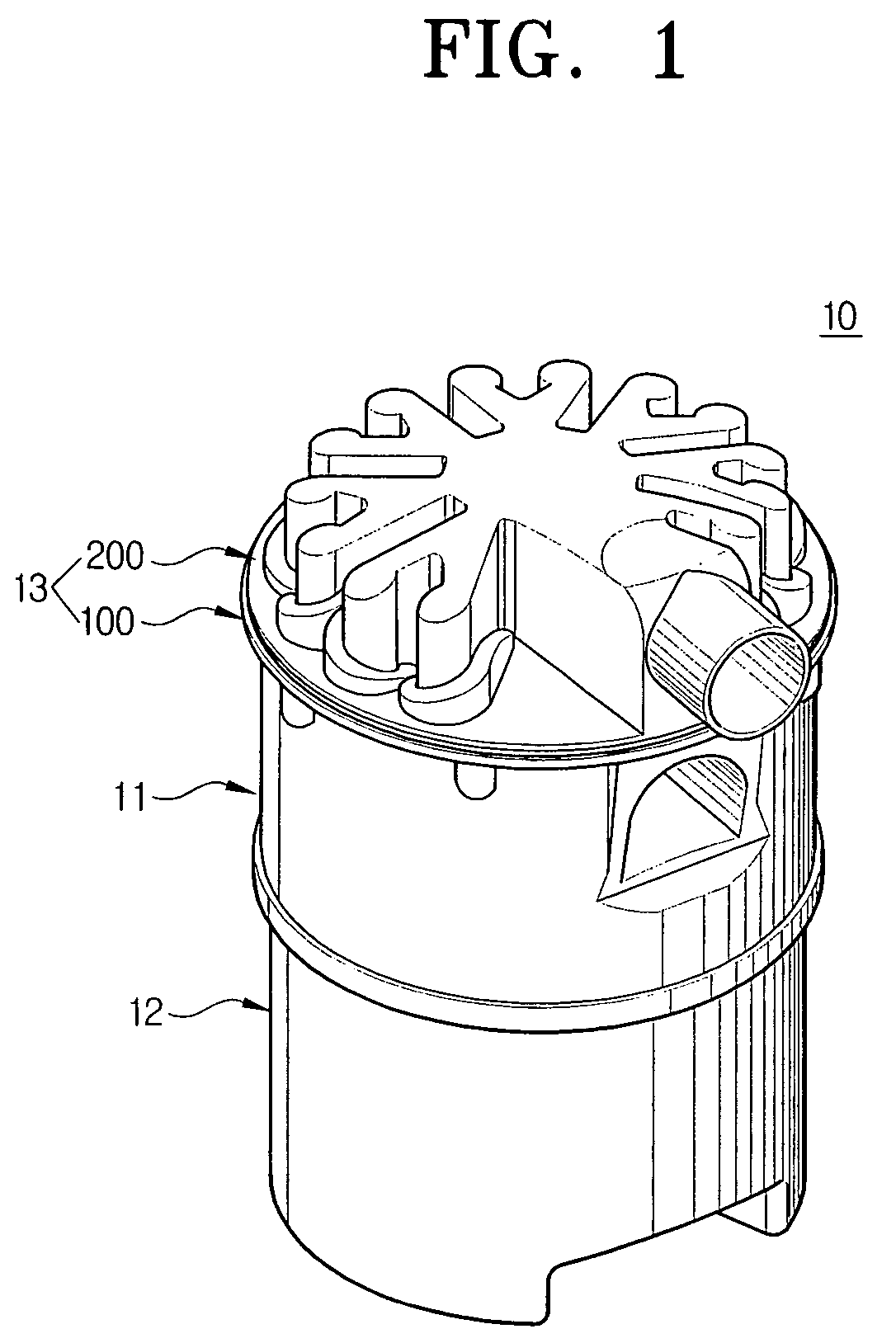

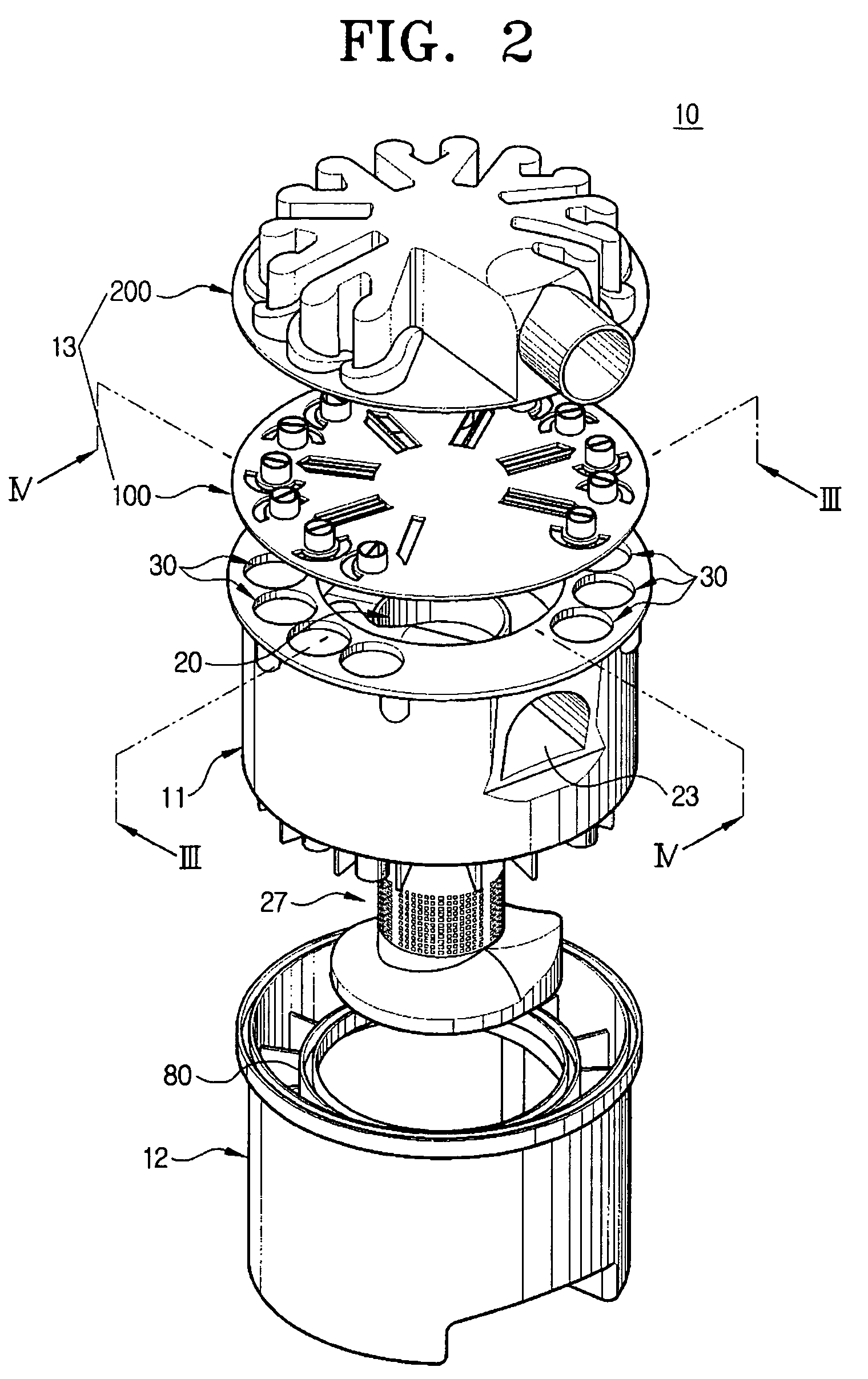

Multi cyclone dust-collecting apparatus

InactiveUS7335242B2Reduce in quantityImprove manufacturabilitySuction filtersReversed direction vortexCycloneEngineering

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

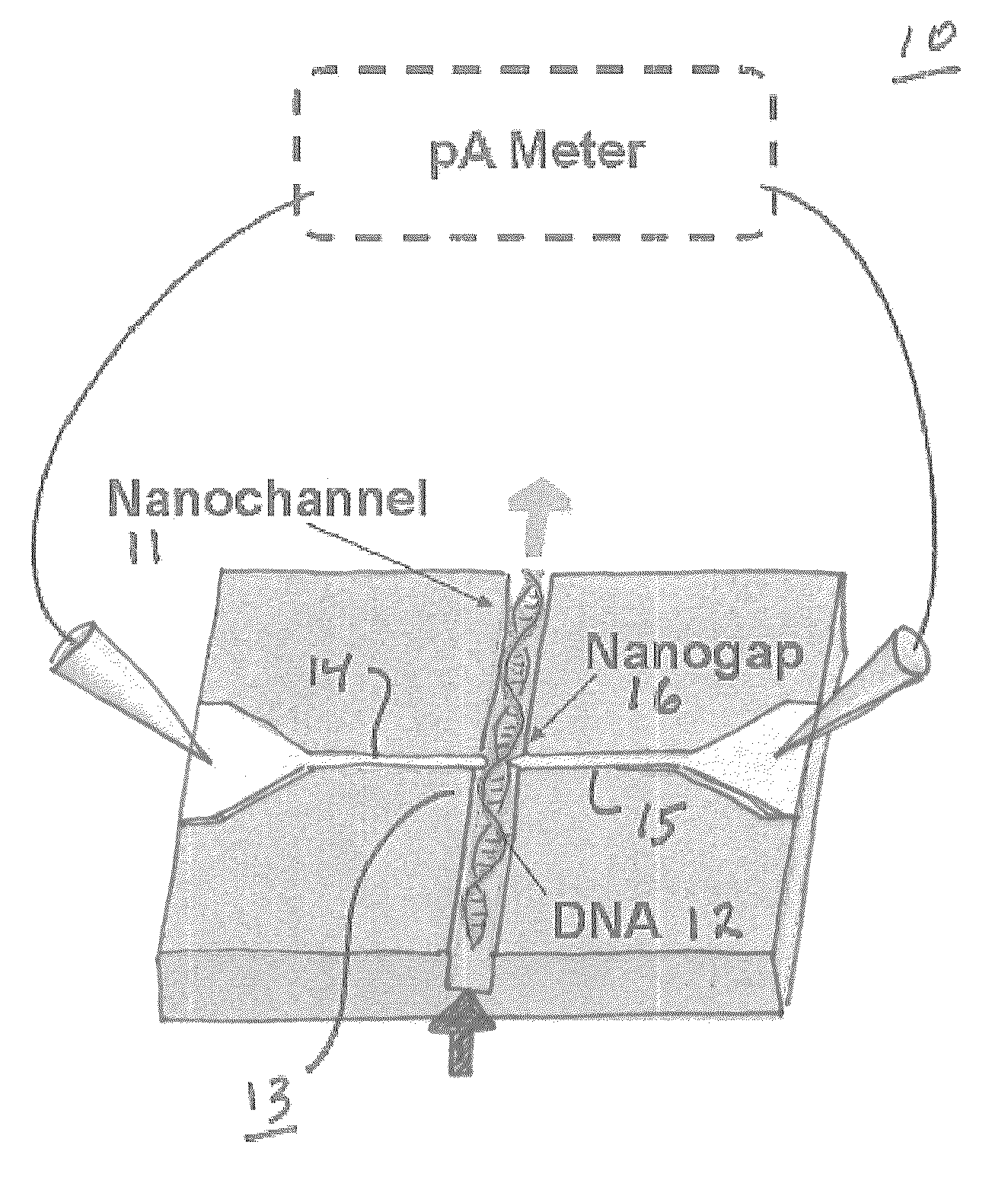

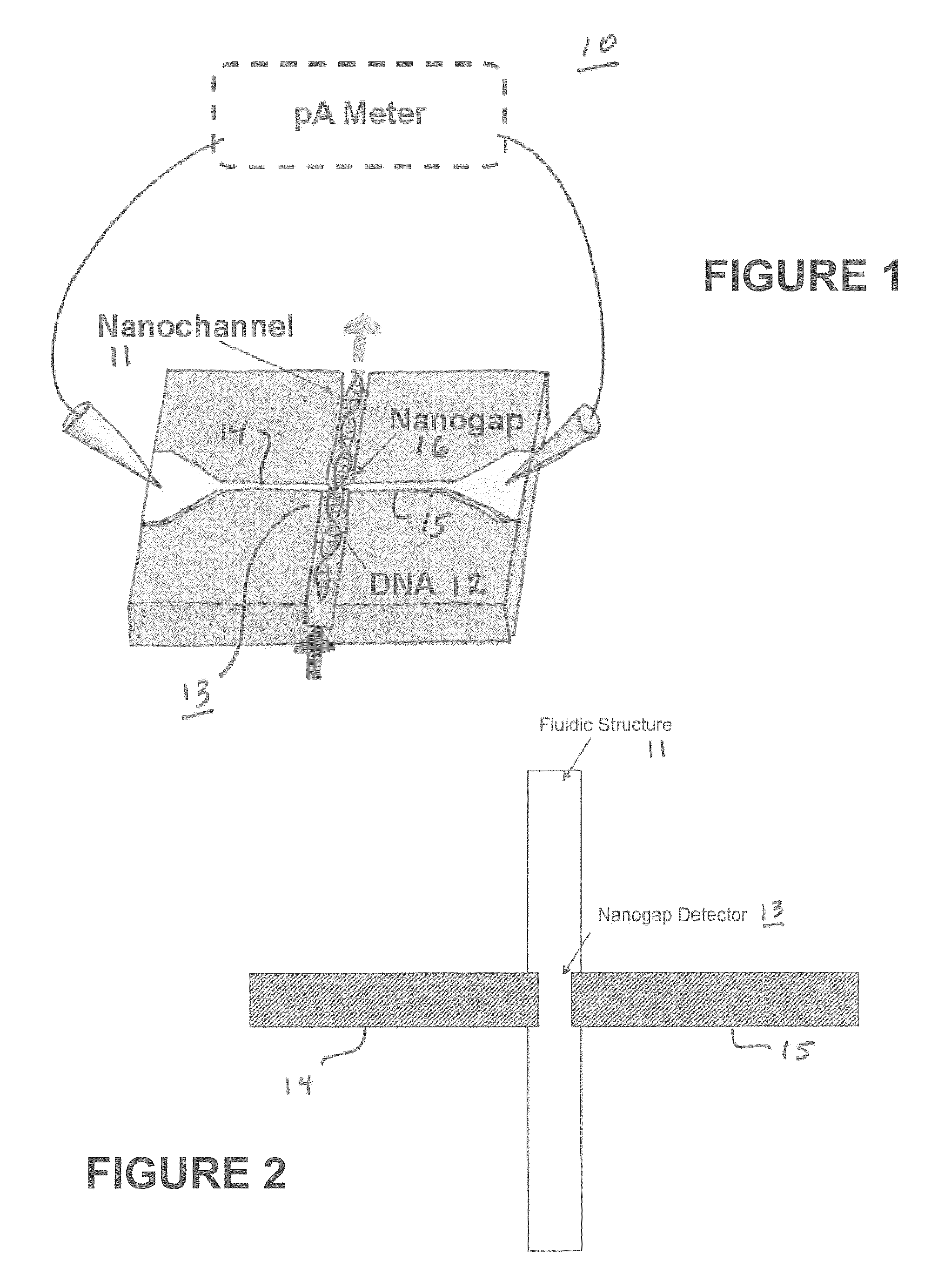

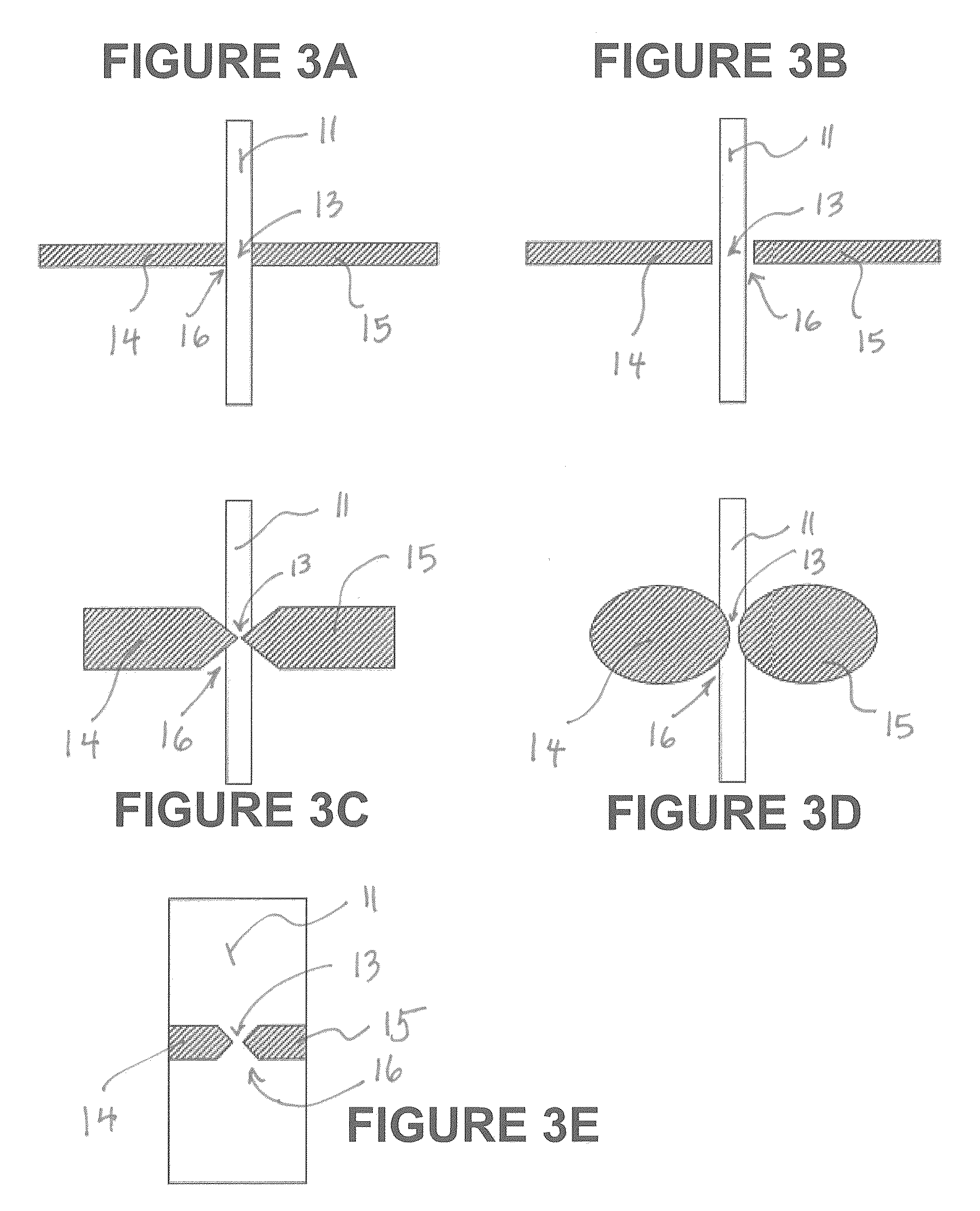

Electronic Detectors Inside Nanofluidic Channels For Detection, Analysis, and Manipulation of Molecules, Small Particles, and Small Samples of Material

ActiveUS20100267158A1Decorative surface effectsMicrobiological testing/measurementSmall sampleSmall particle

The present invention provides methods and apparatus that can manipulate, detect, and / or analyze single molecules, single small particles or single small samples of matter passing through a nanoscale gap within a nanofluidic channel of a detector.

Owner:NANONEX

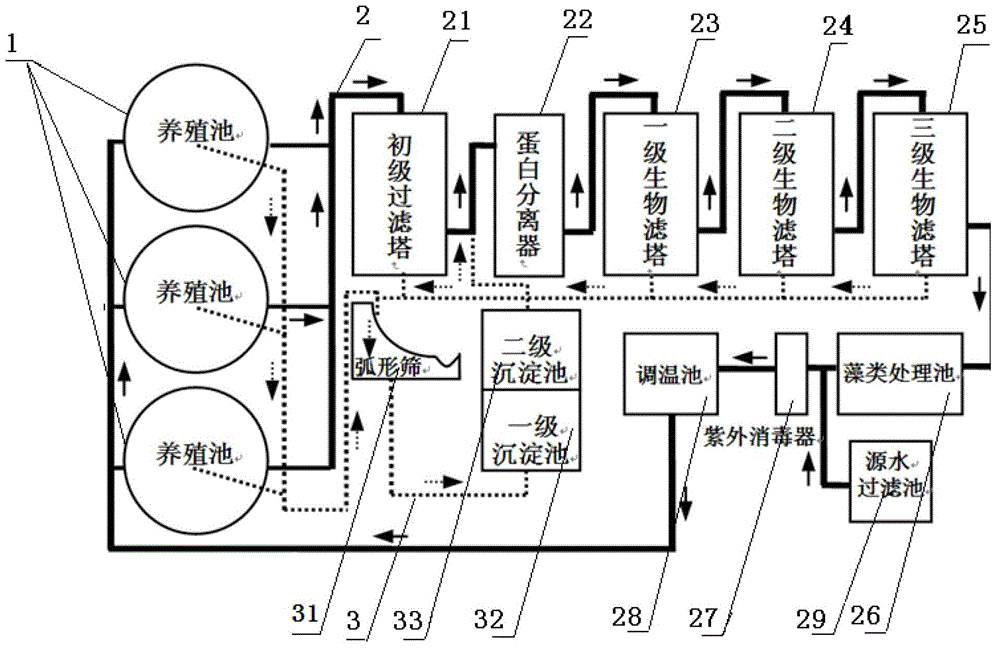

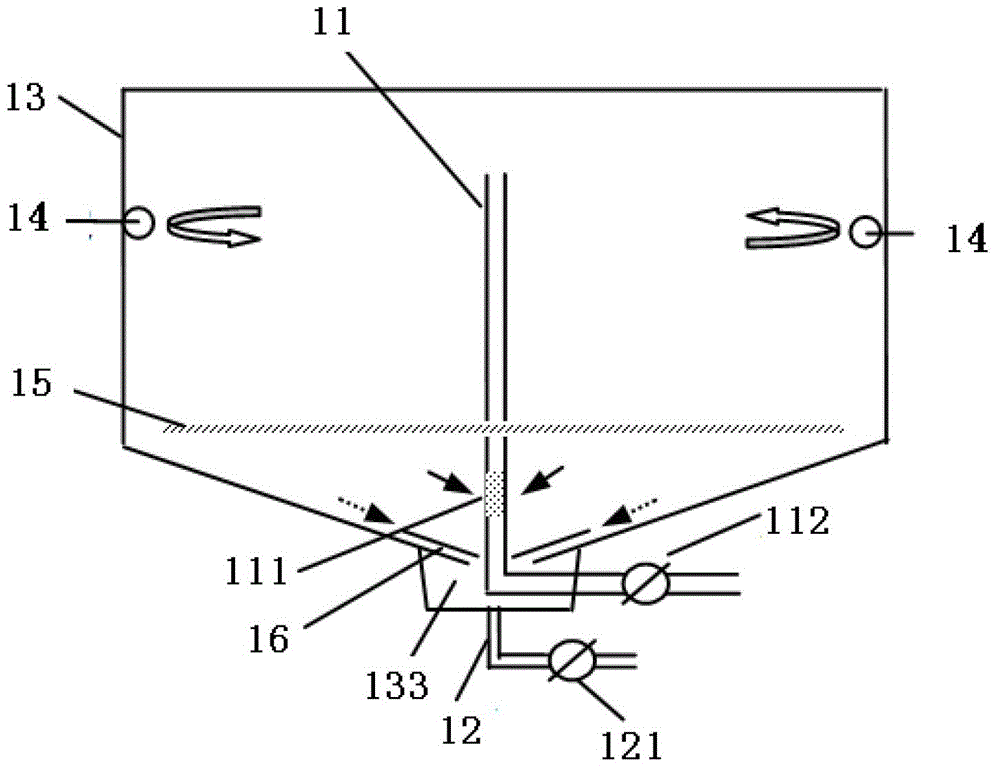

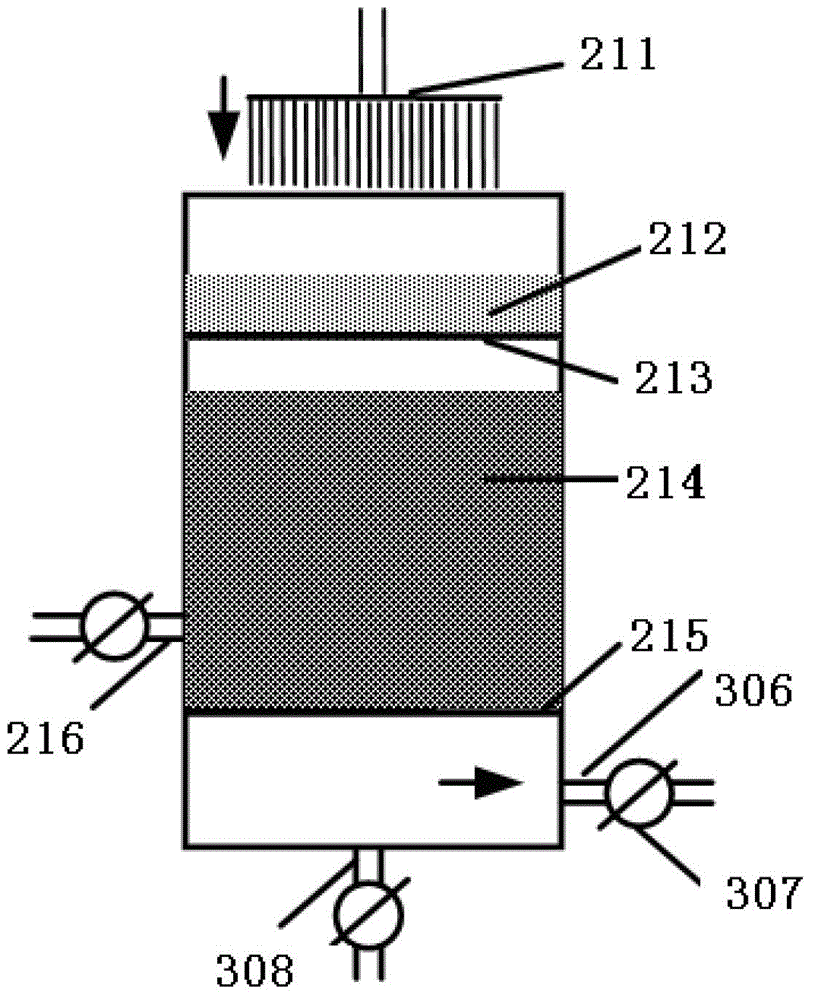

Ecological seawater rare fish factorization circulating water aquaculture system

InactiveCN102742536AReduce flow rateEfficient retentionPisciculture and aquariaResource utilizationBiological filter

The invention discloses an ecological seawater rare fish factorization circulating water aquaculture system which comprises an aquaculture pond, a primary filter tower, an albumen segregator, a primary biological filter tower, a secondary biological filter tower, a tertiary biological filter tower, an algae treating pond, a source water filter pond, a UV (Ultraviolet) sterilizer, a temperature adjusting pond, an arc-shaped sieve, a primary sedimentation pond and a secondary sedimentation pond. A bidirectional drainage system is adopted by the aquaculture pond, the water containing less smaller particles at the lower part of the pond and the water containing more larger particles at the bottom of the pond are respectively drained and then input into different processing units for recycle. Molluscs, sea cucumbers and algae are drawn into aquaculture waste, wastewater disposal and resource utilization by the circulating water aquaculture system, so that the circulating water aquaculture system has an obvious ecological characteristic. The ecological seawater rare fish factorization circulating water aquaculture system has the advantages of high treatment efficiency of aquaculture wastewater and rubbish, simpler equipment, low energy consumption, high backwash efficiency, resource utilization of aquaculture wastewater and rubbish, less circulation supplement water, high treatment efficiency of inorganic nutrient salt in the water and high economic additional value.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com