Patents

Literature

31results about How to "Reduce flow turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

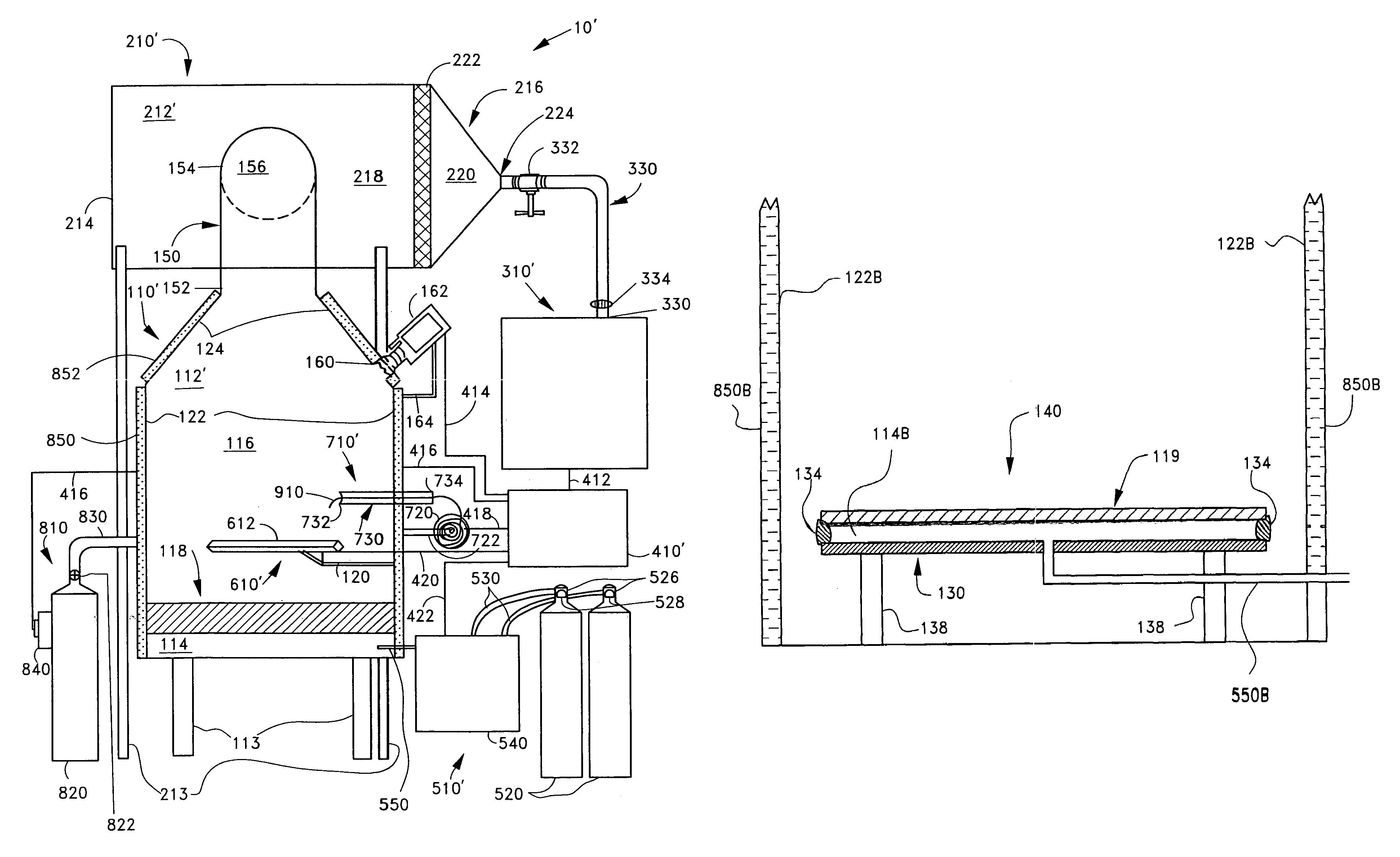

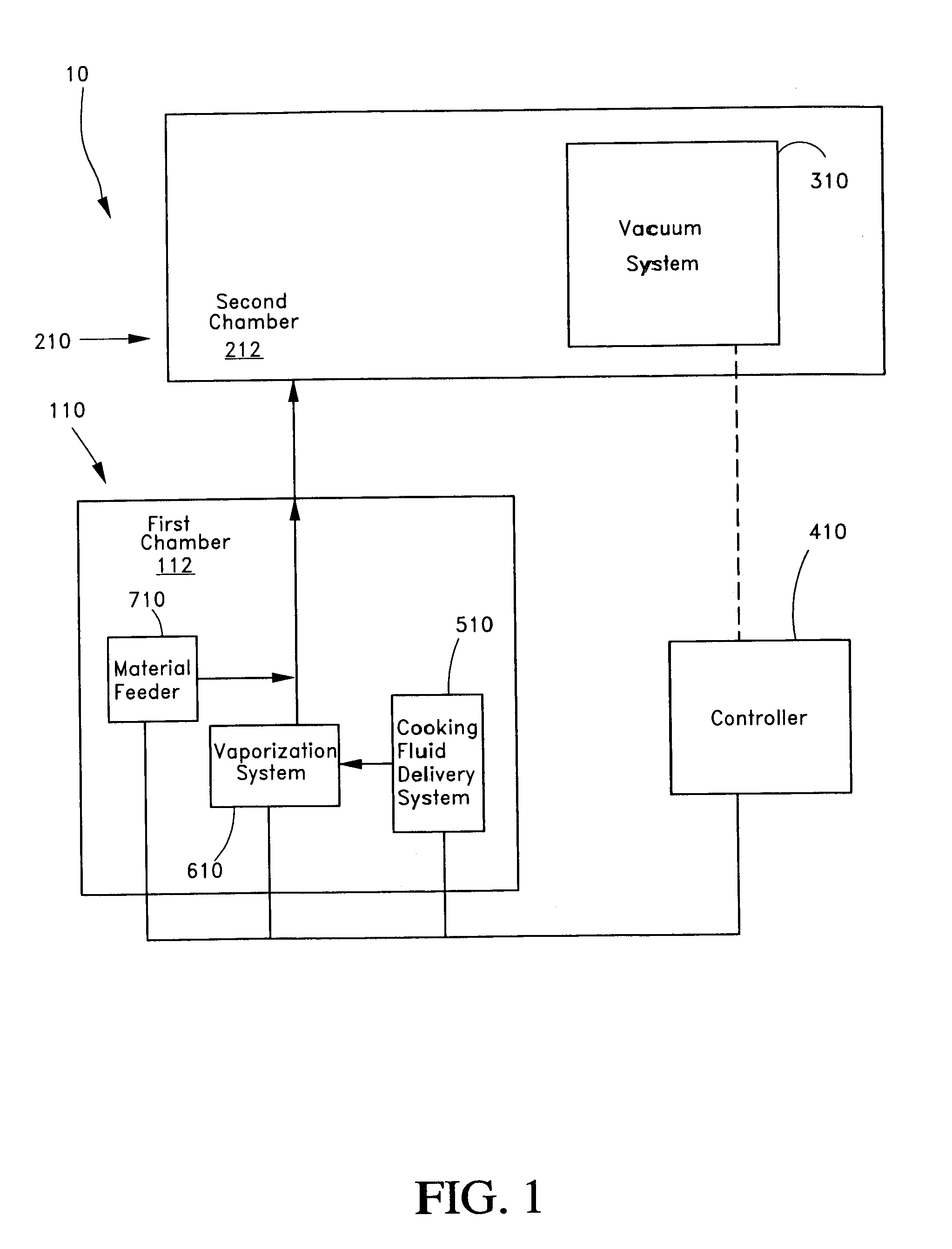

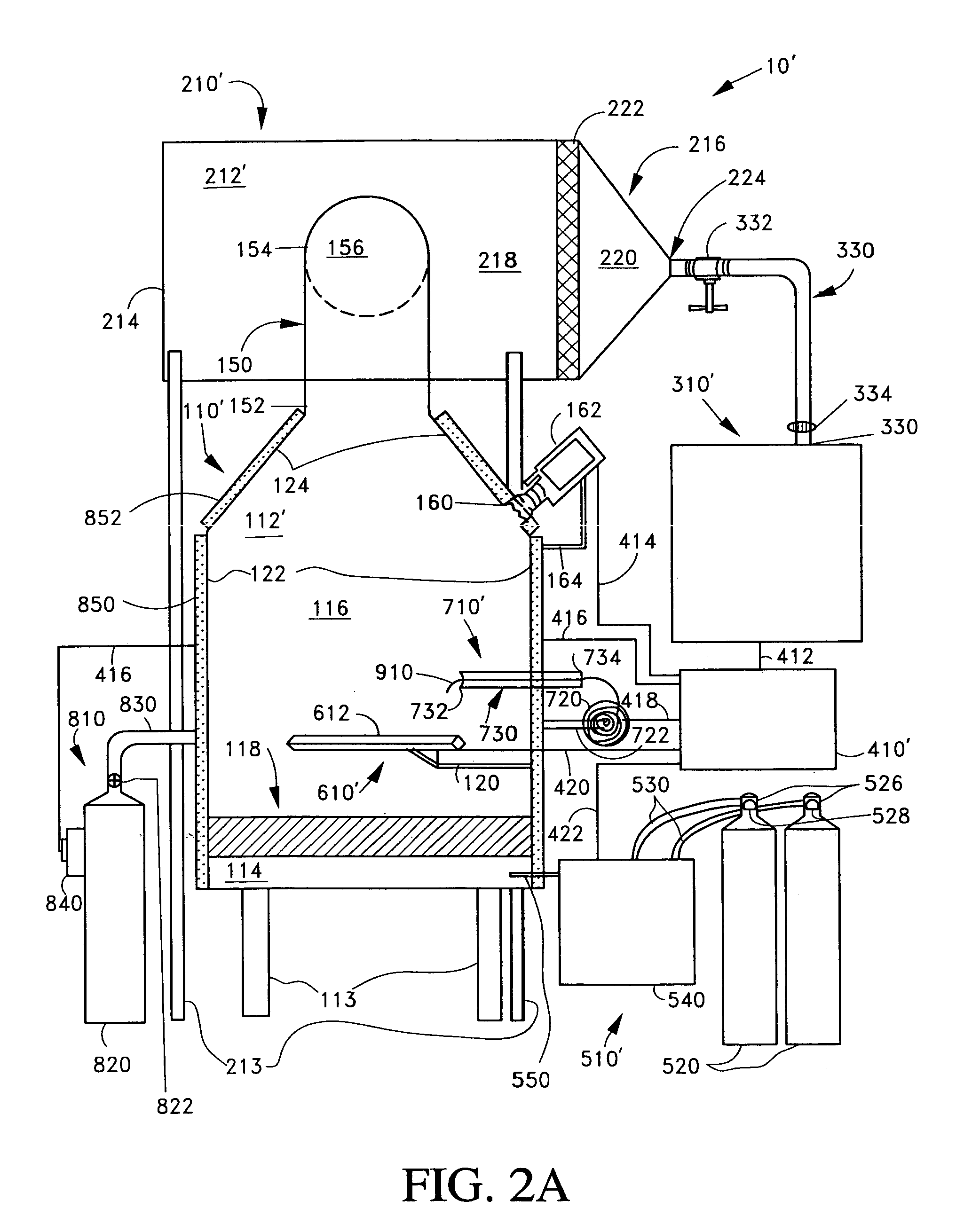

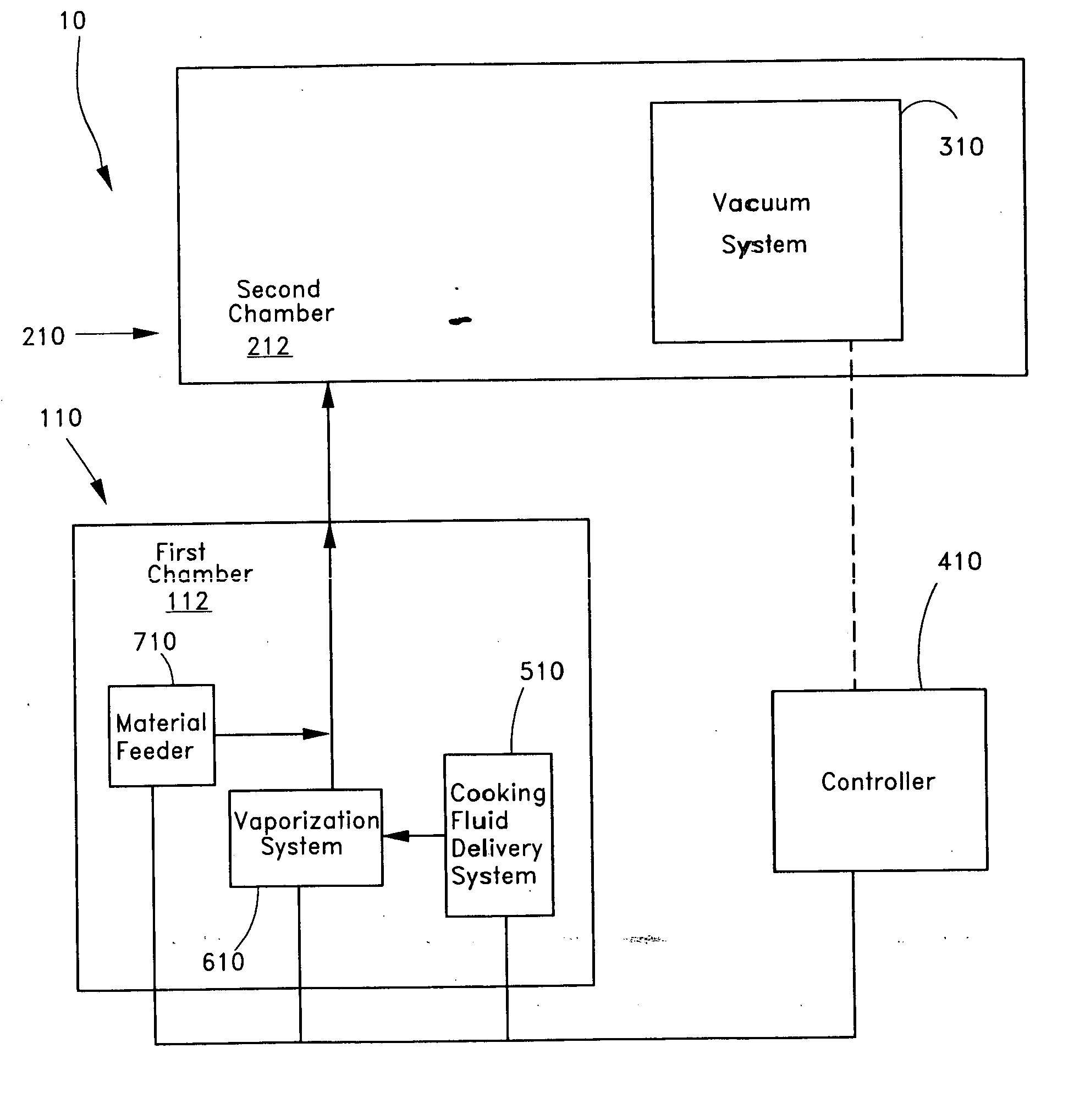

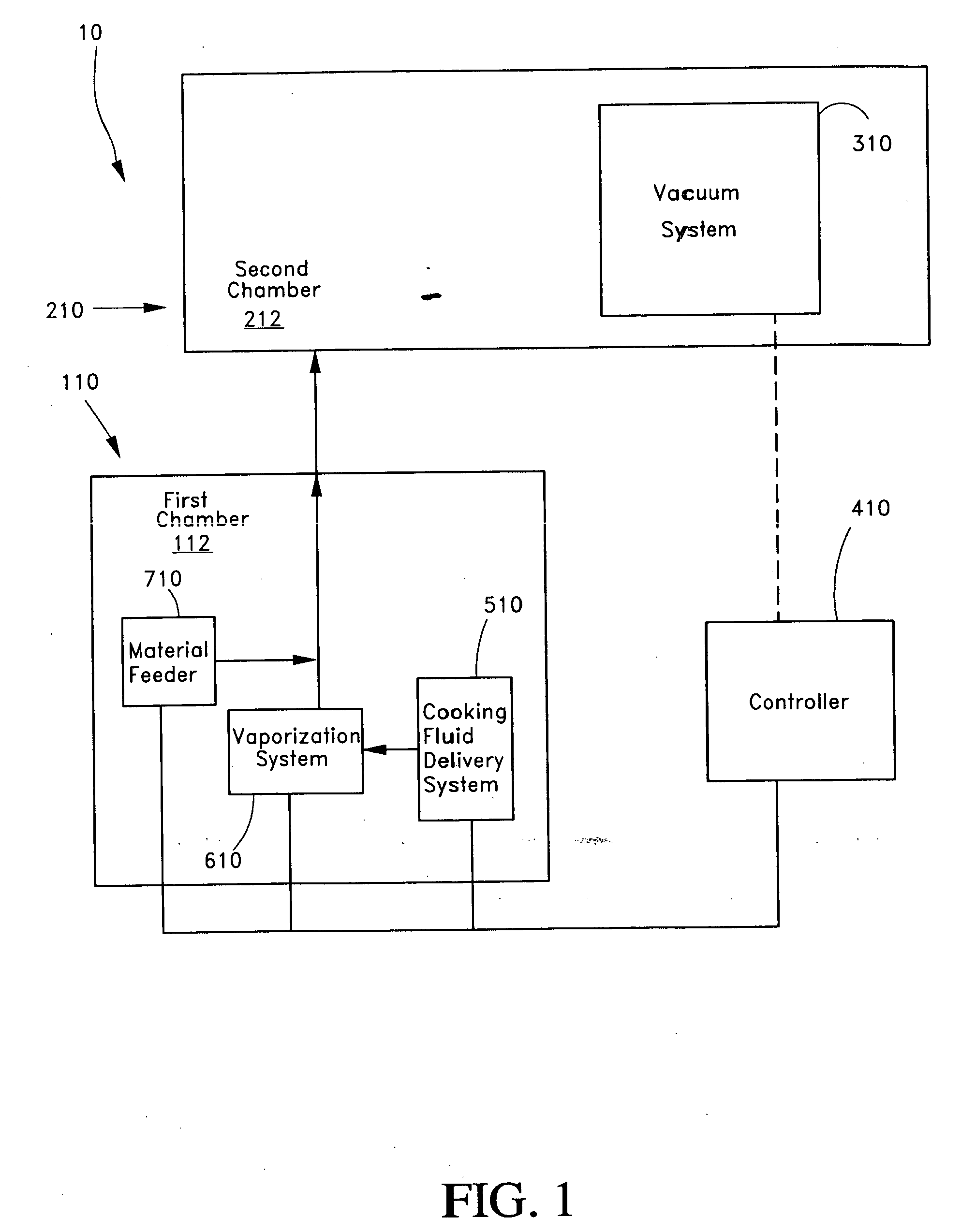

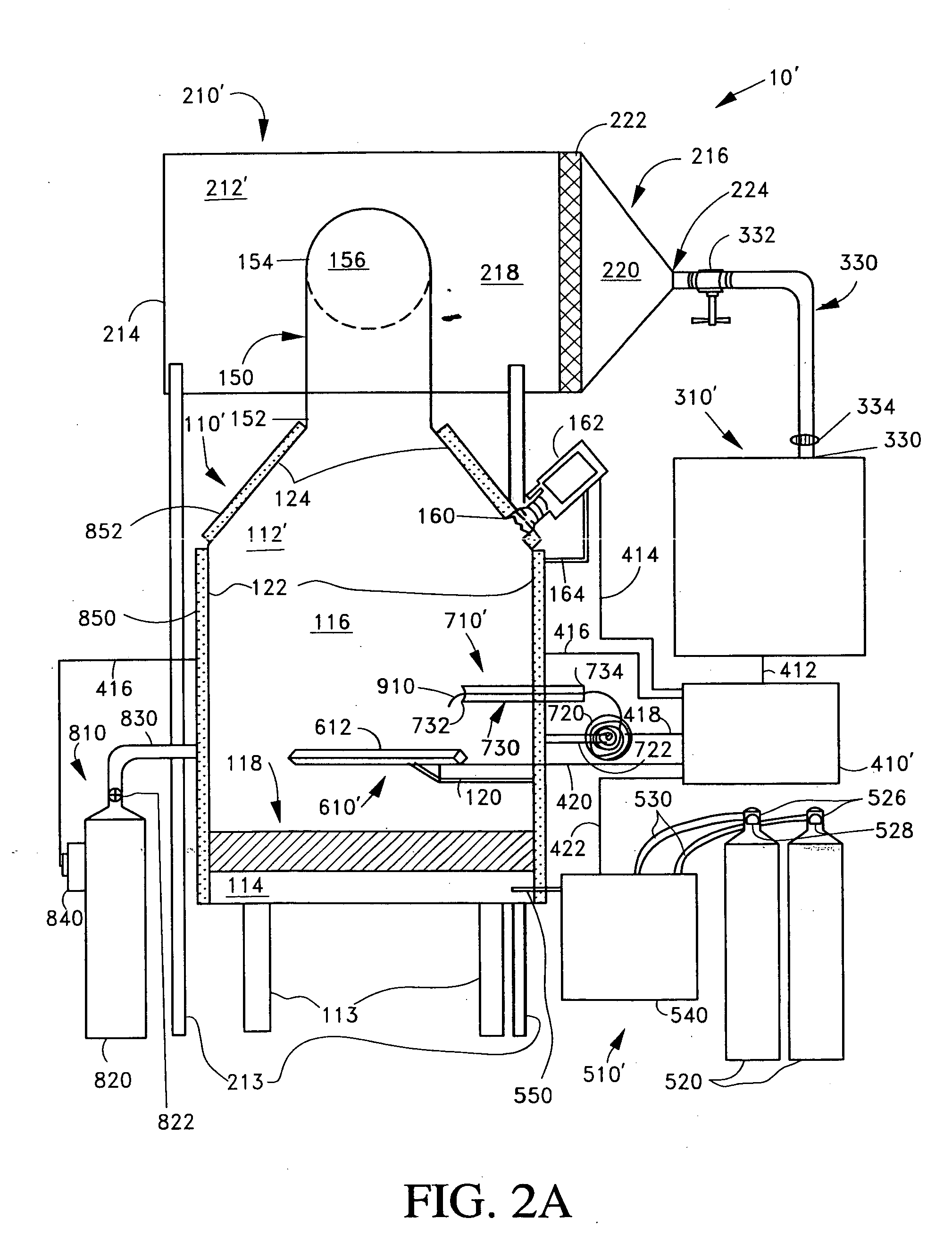

Method and apparatus for forming nano-particles

ActiveUS7282167B2Reduce flow turbulenceLarge particle sizeMaterial nanotechnologyTransportation and packagingMetallurgyCooling fluid

Nano-scale particles of materials can be produced by vaporizing the material and allowing the material to flow in a non-violently turbulent manner into thermal communication with a cooling fluid, thereby forming small particles of the material that can be in the nano-scale size range.

Owner:VIVAKOR INC +1

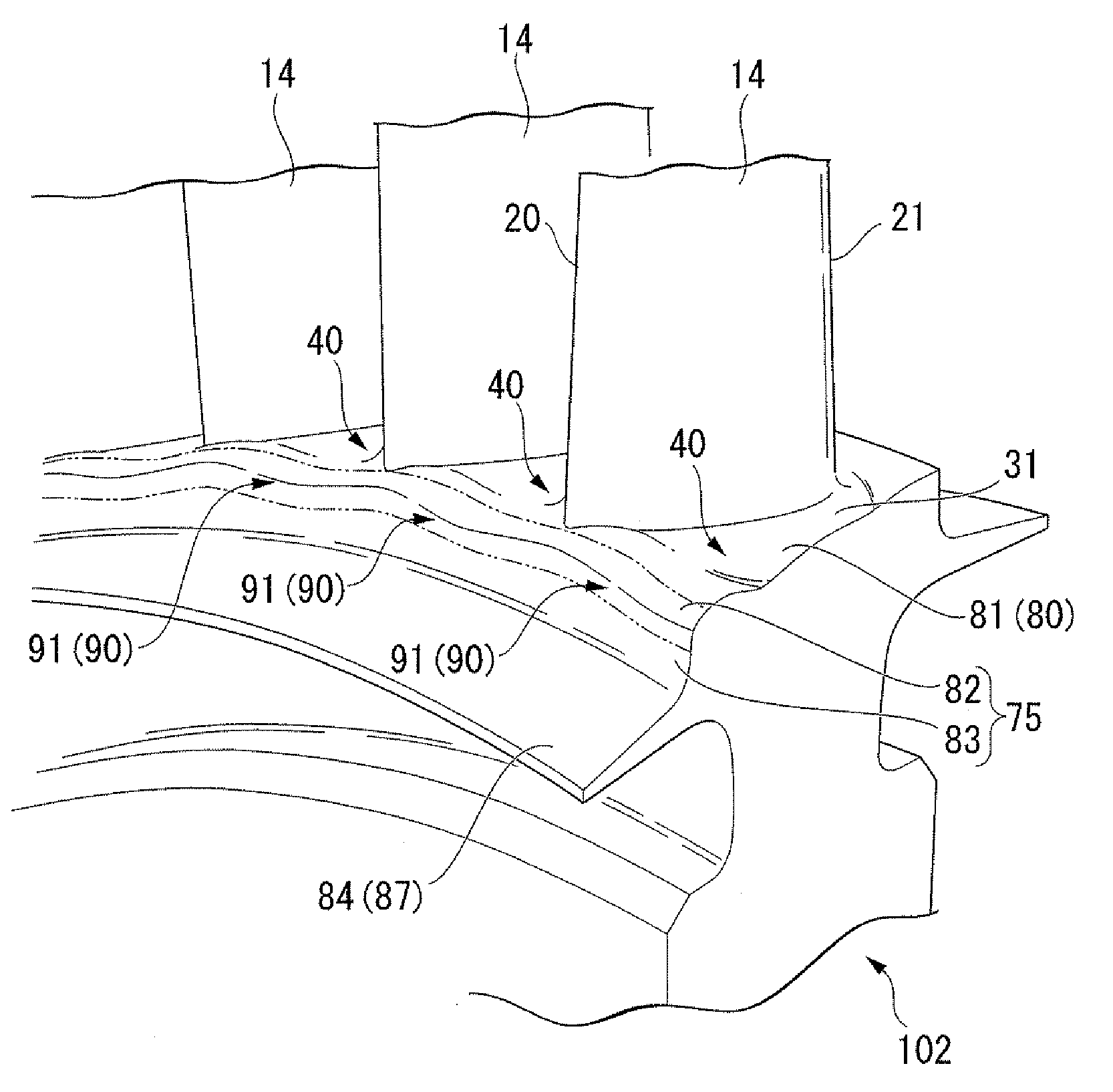

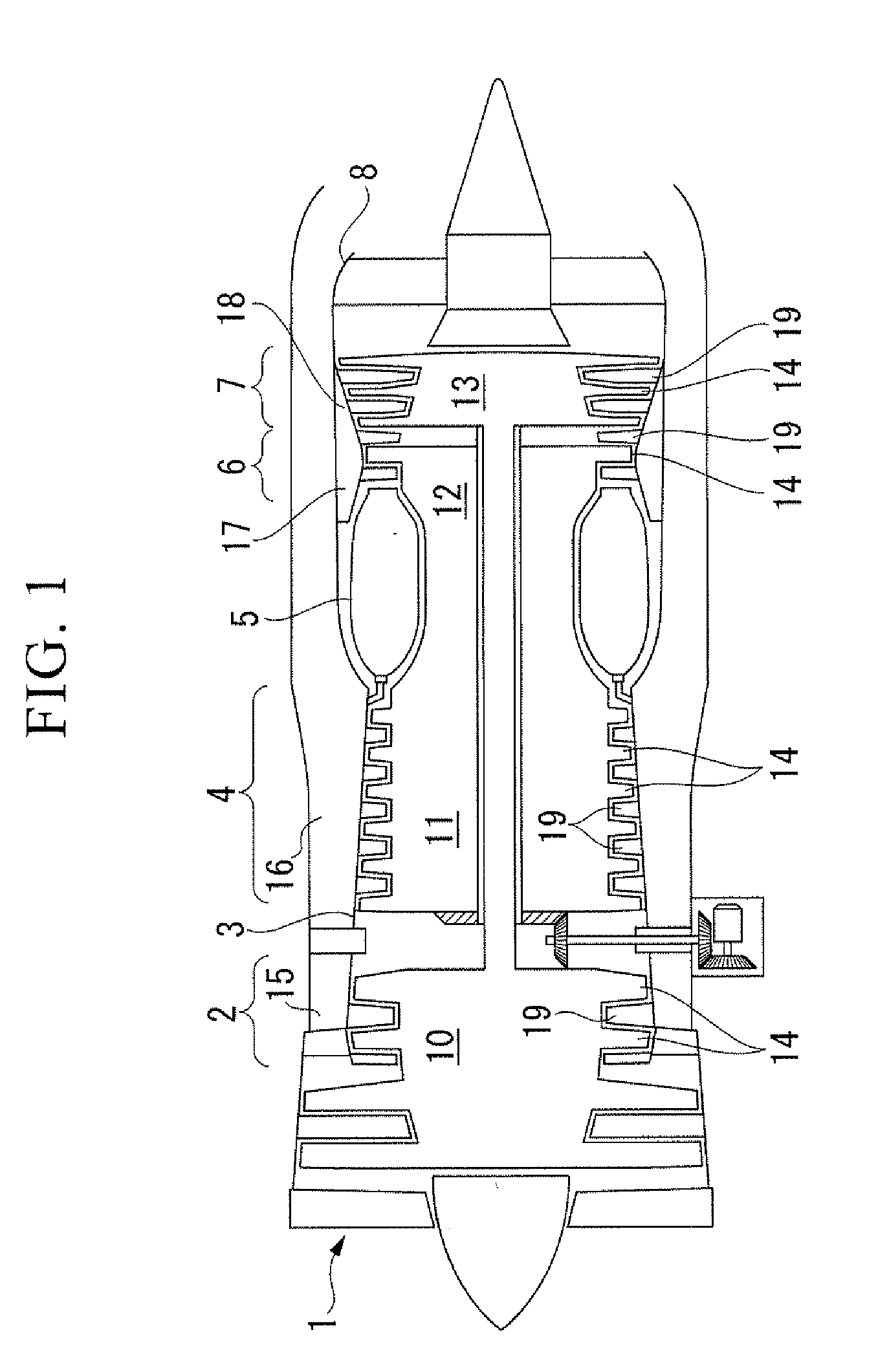

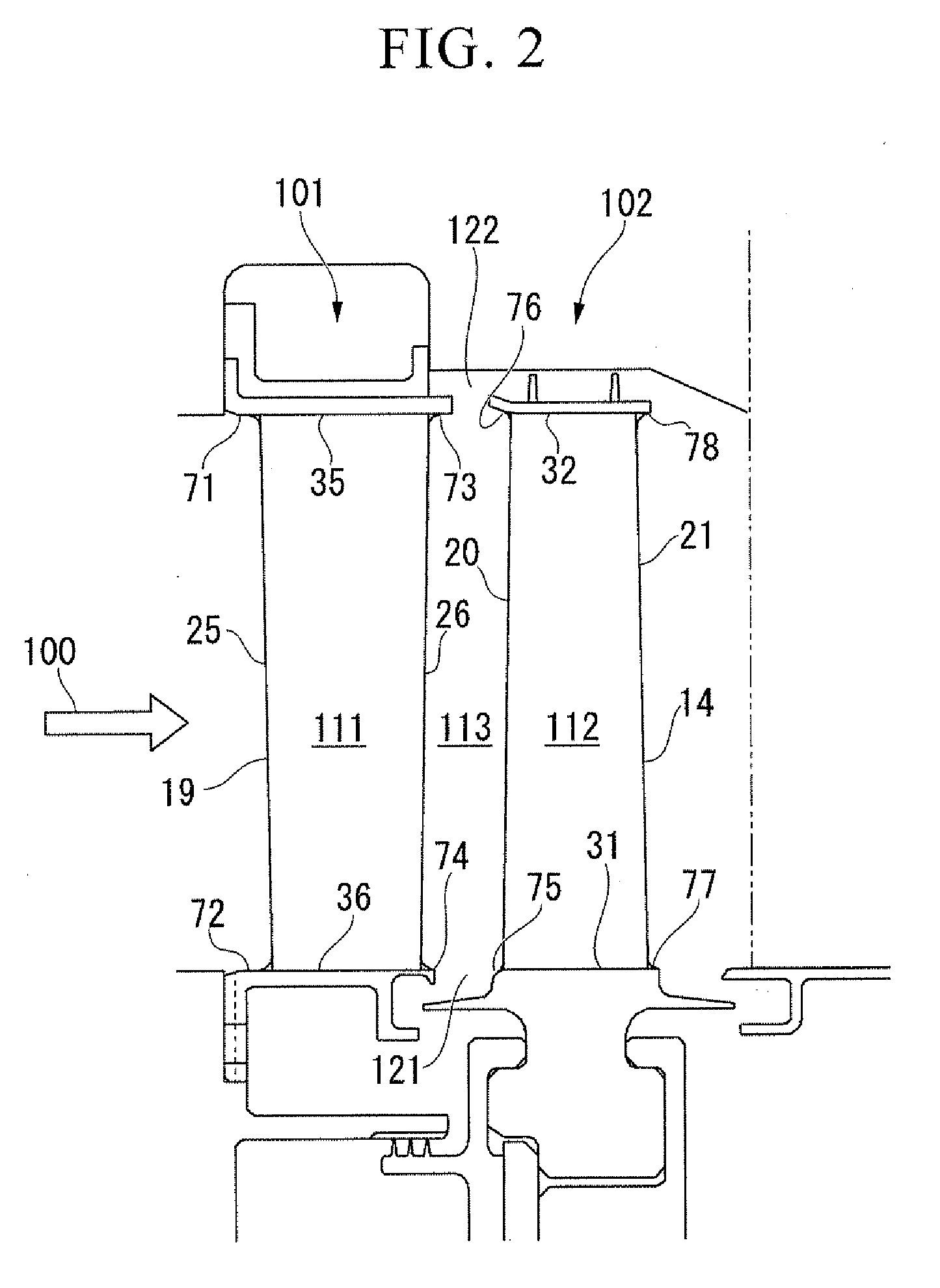

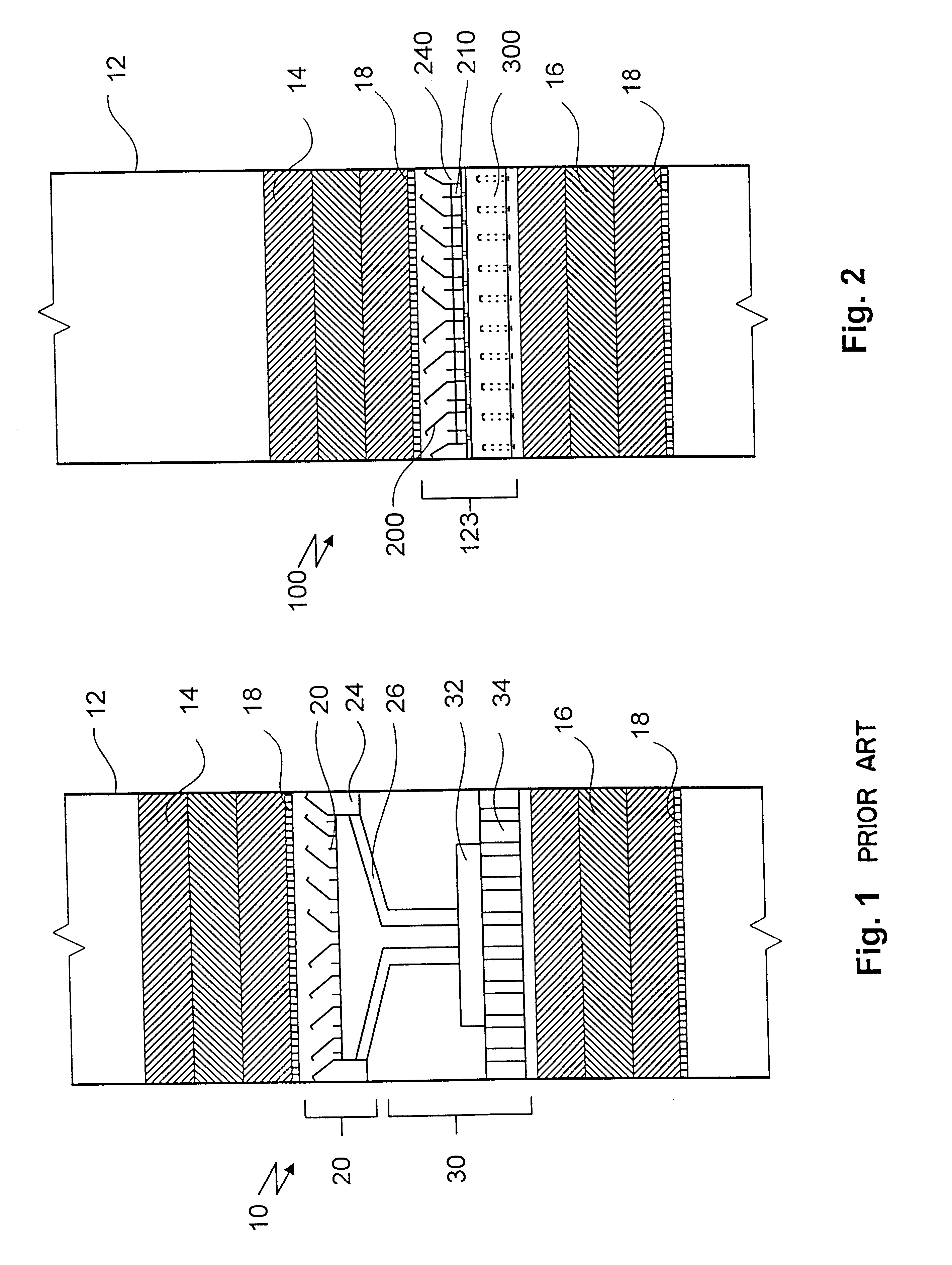

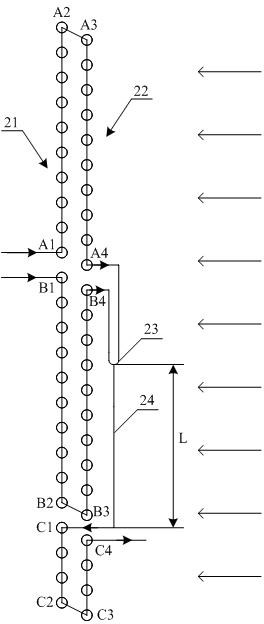

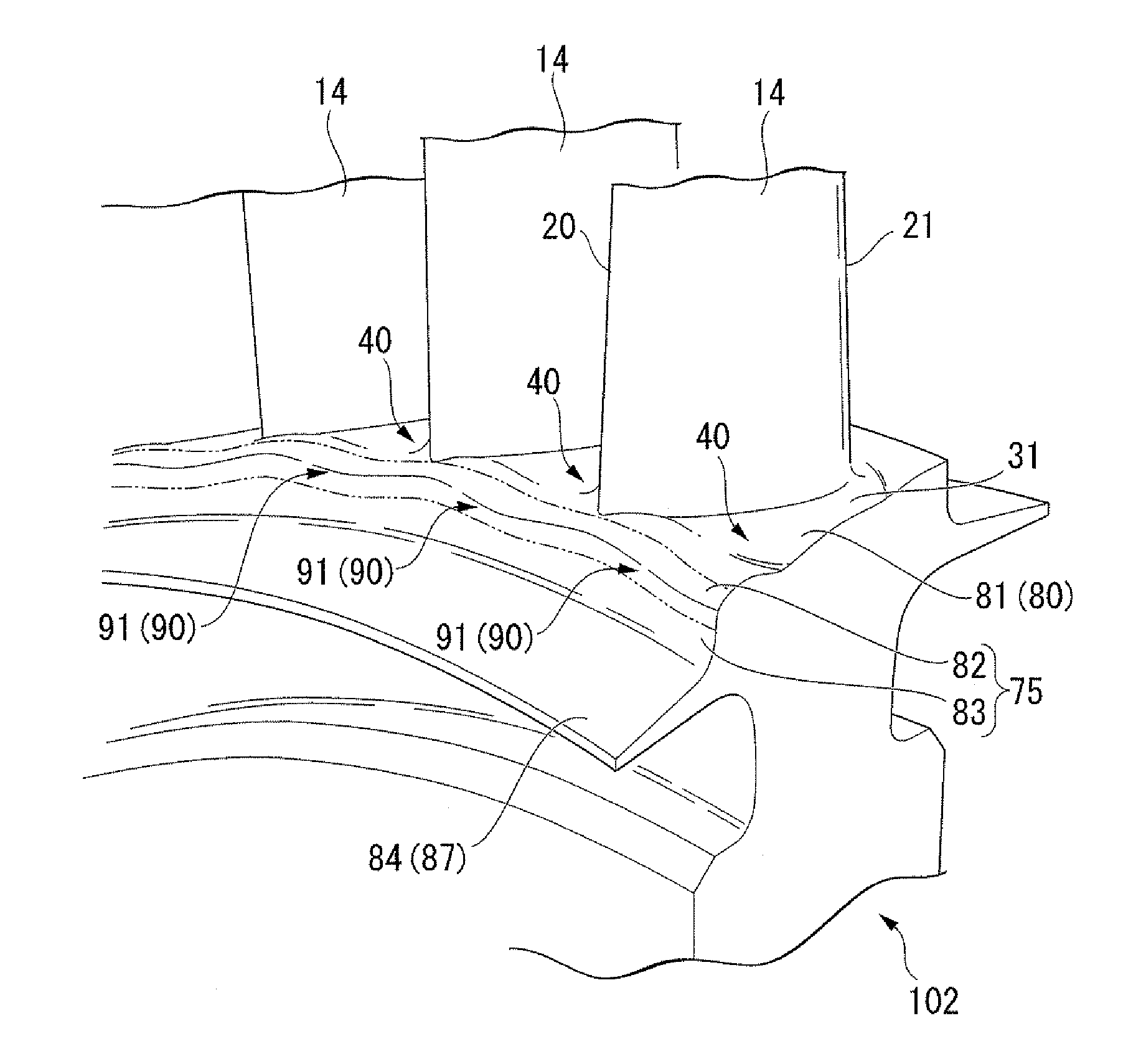

Wall of turbo machine and turbo machine

ActiveUS20100172749A1Reduce flow turbulenceEngine manufacturePump componentsRadial positionMechanical engineering

The invention relates to wall of a turbo machine having a cascade of blades. The wall includes: a first platform facing a first passage between blades in the cascade of blades; and a second platform facing a second passage between adjacent cascade of blades on an upstream side and cascade of blades on a downstream side, and having a circumferential outline having a distribution of radial positions. According to the invention, loss due to disturbance of flow through the gap of axially adjacent walls can be reduced.

Owner:IHI CORP +1

Method and apparatus for forming nano-particles

ActiveUS20060226564A1Improve particle size distributionReduce flow turbulenceMaterial nanotechnologyTransportation and packagingMetallurgyNanometre

Nano-scale particles of materials can be produced by vaporizing the material and allowing the material to flow in a non-violently turbulent manner into thermal communication with a cooling fluid, thereby forming small particles of the material that can be in the nano-scale size range.

Owner:VIVAKOR INC +1

Apparatus for the collection and distribution of liquid in a column

InactiveUS6527258B2Quality improvementReduce flow turbulenceCarburetting airUsing liquid separation agentEngineeringFluid power

The apparatus for the collection and distribution of liquid in a column having at least one lamella collector and a distributor outflow system which is arranged below it. A side passage is contained in the or in each lamella collector and liquid outflow openings are arranged in a combination, as a result of which a hydrodynamic equalization for a liquid to be distributed results.

Owner:SULZER CHEMTECH AG

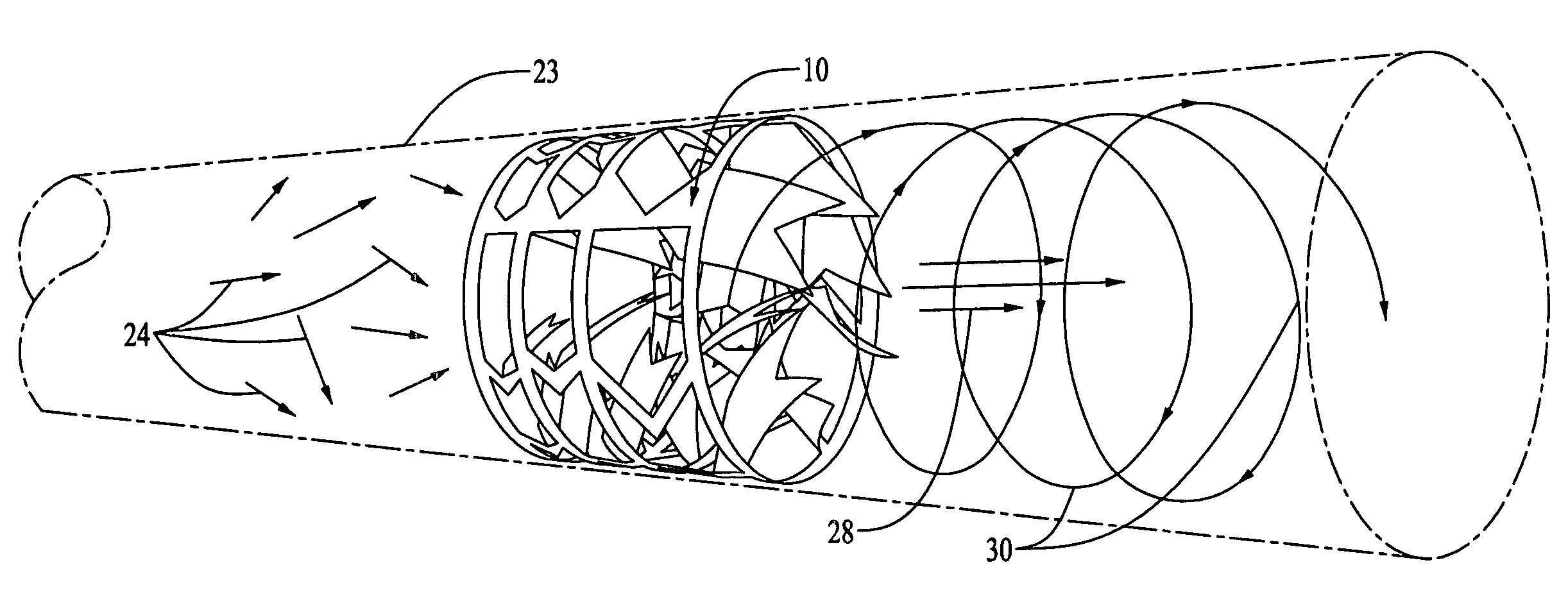

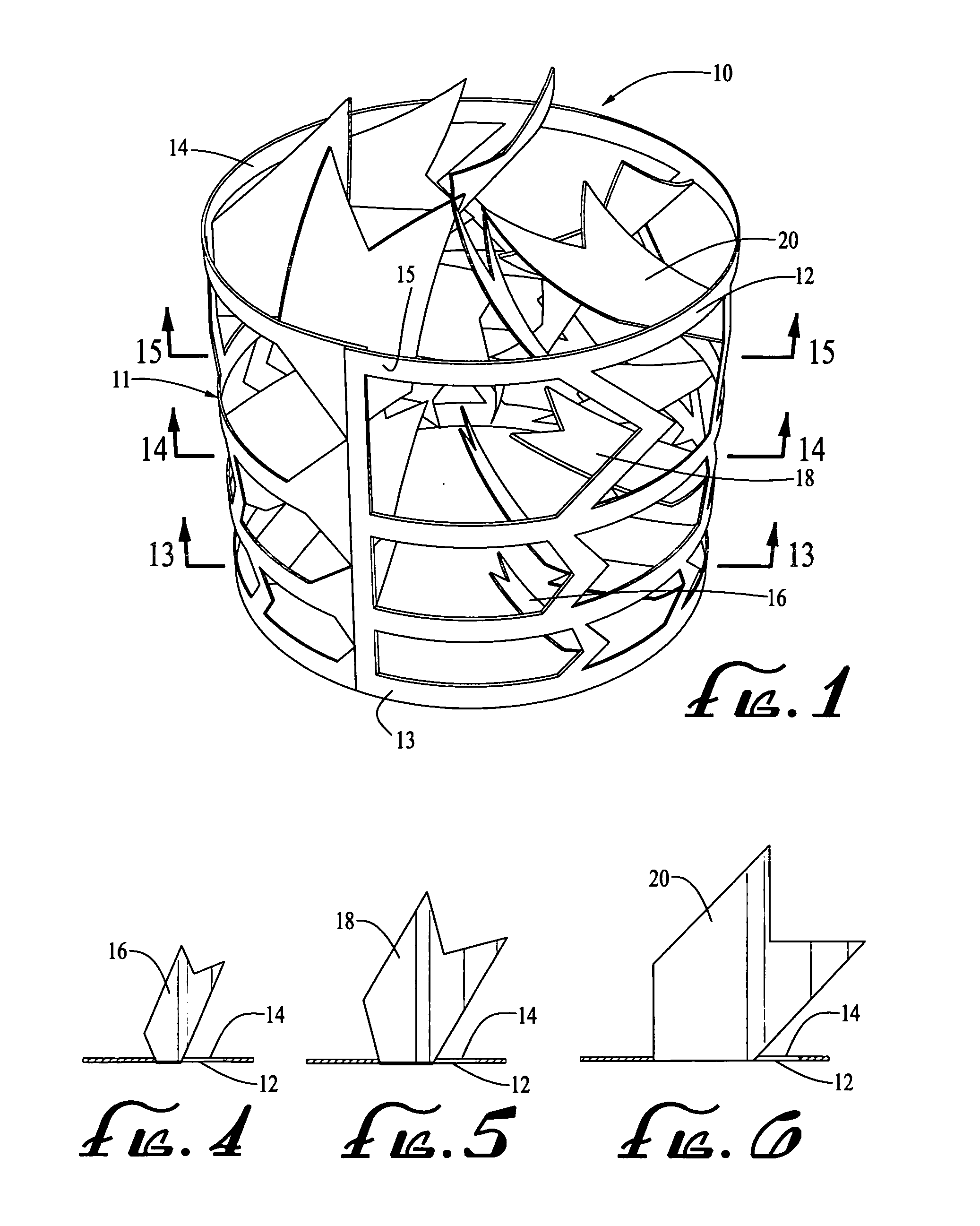

Turbine inverter

InactiveUS20080060712A1Reduce turbulenceReduce flow turbulenceFlow mixersTransportation and packagingEntry angleEngineering

Disclosed is a fluid flow diverting device comprising a hollow main body and a plurality of blades protruding into the interior of the main body. The blades are positioned along the interior surface of the main body in multiple layers. The blades of each successive layer have a larger surface area and a larger entry angle of approach than the blades of a previous layer. The fluid diverting device can be inserted into any enclosed medium where fluids typically flow. The arrangement of blades diverts the flow of fluid in a way that creates a low pressure flow in the center of the enclosed medium. This low pressure flow is surrounded by high pressure flow, resulting in an increase in the swirling of matter and a pull of matter toward the center of the medium.

Owner:GLUZMAN ELI +2

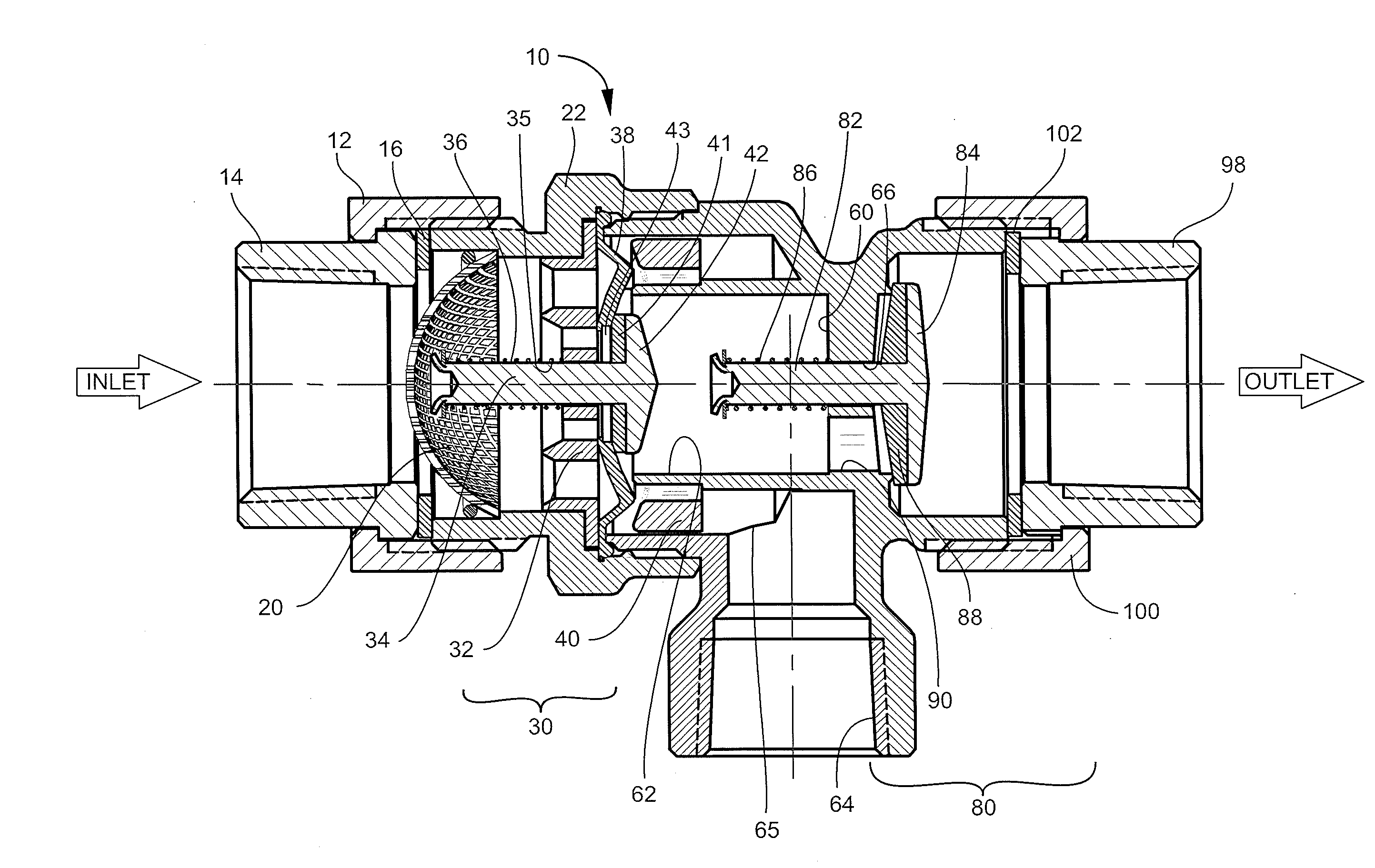

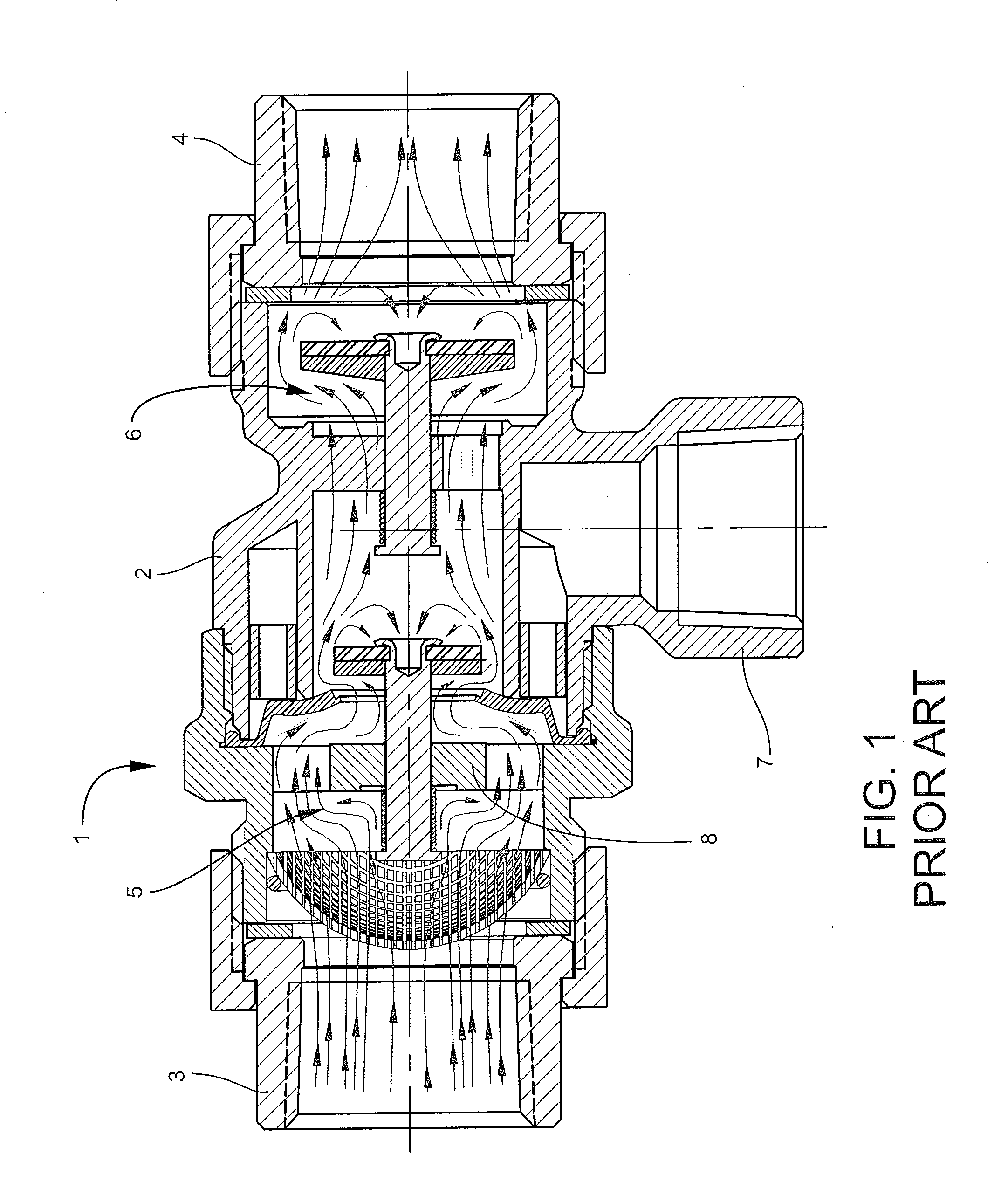

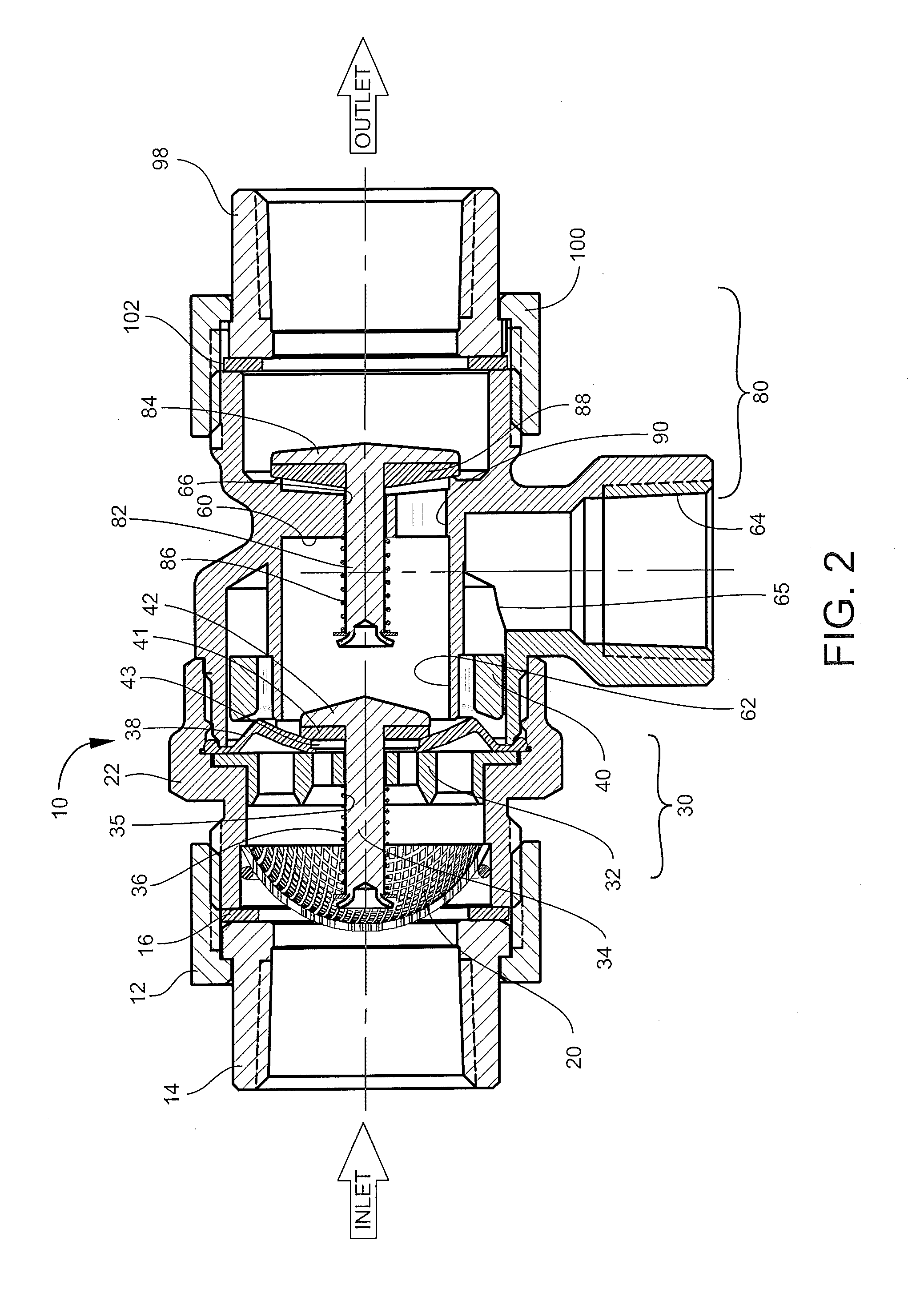

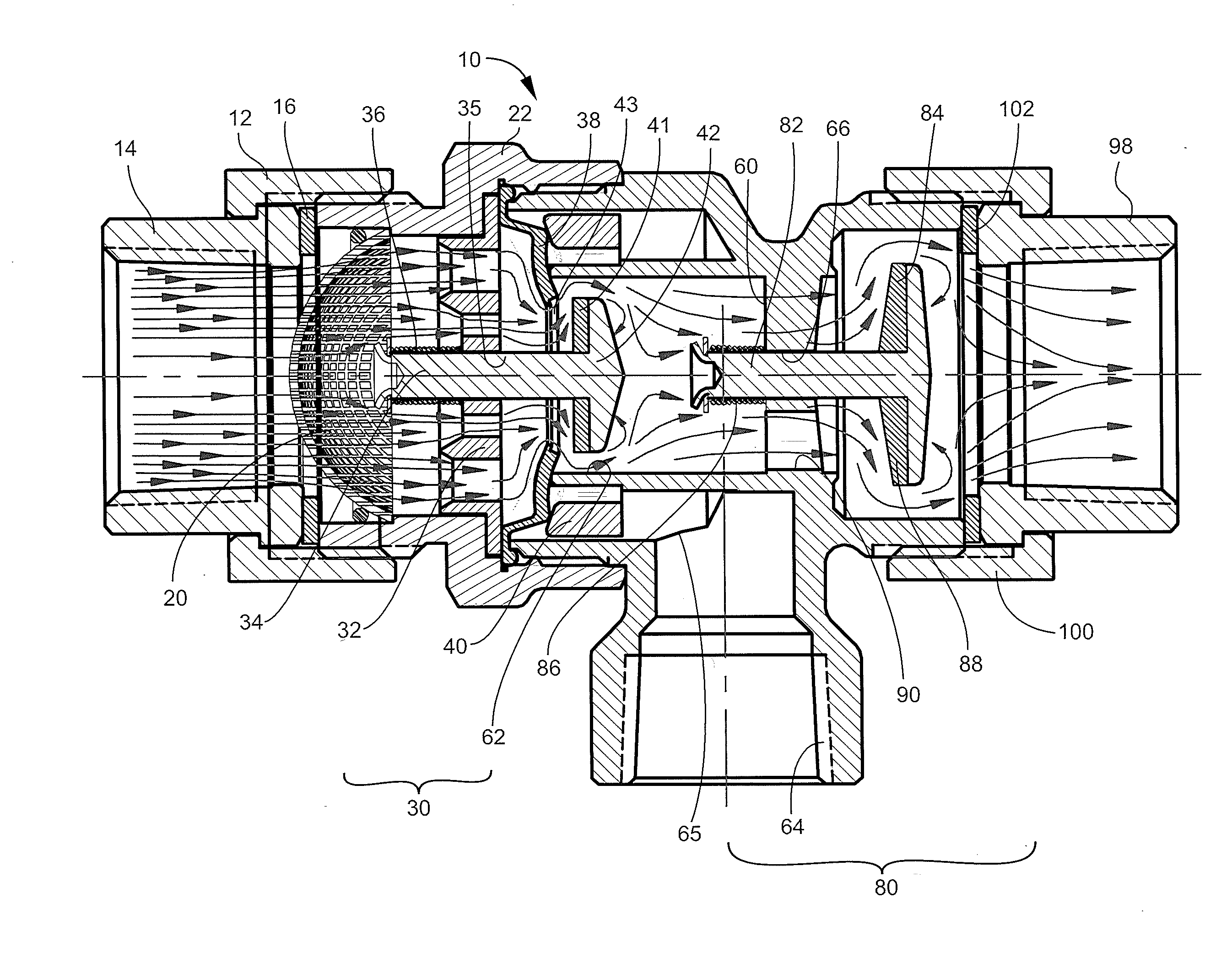

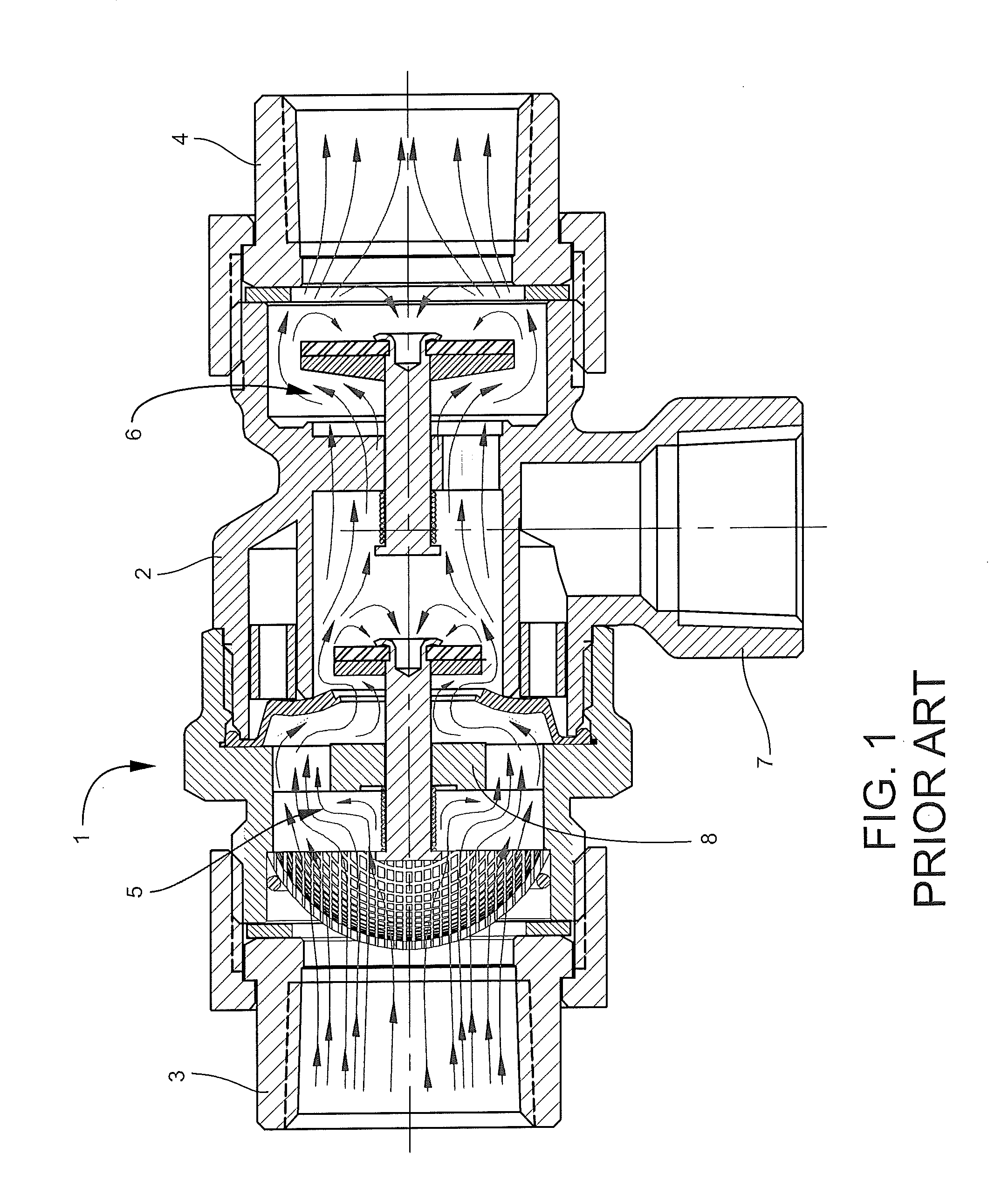

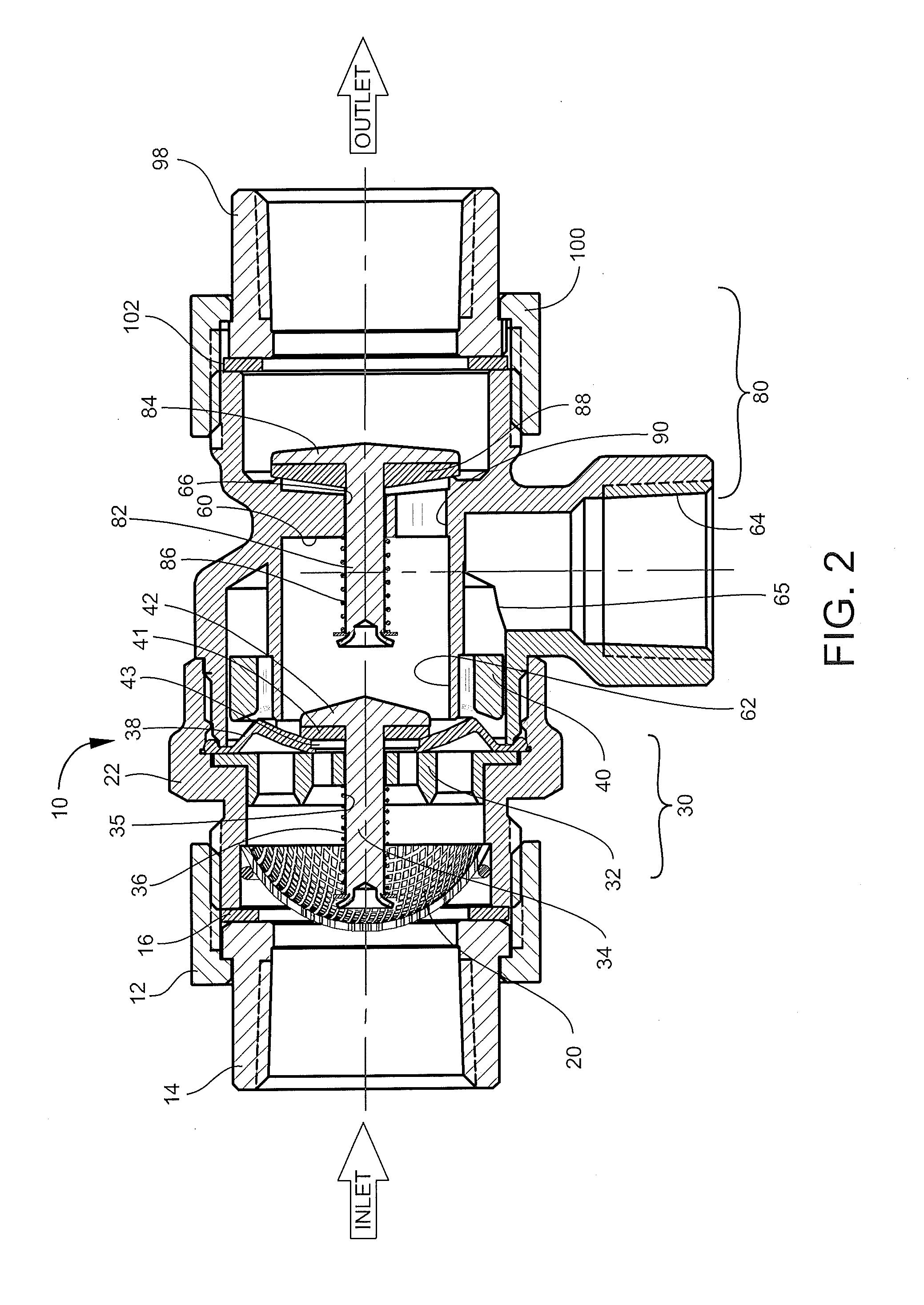

Dual check backflow preventer

ActiveUS20160178076A1Reduce flow turbulenceIncrease pressureCheck valvesDomestic plumbingBackflow prevention deviceEngineering

A backflow preventer that includes a housing having an inlet and an outlet adapted to be mounted in a liquid flow configuration in a liquid supply circuit. An upstream check disc assembly is positioned in the housing downstream of the inlet, and includes an upstream check plate supporting a downstream diaphragm. An upstream check disc is positioned downstream of the diaphragm and integrally formed with an upstream stem mounted in an aperture in a central hub formed in the check plate for movement between a normally open, flow position and a closed position preventing backflow of liquid through the inlet. A downstream check disc assembly is positioned in the housing downstream from the upstream check disc assembly. A vent discharges liquid to atmosphere upstream of the downstream check disc assembly.

Owner:CONBRACO IND

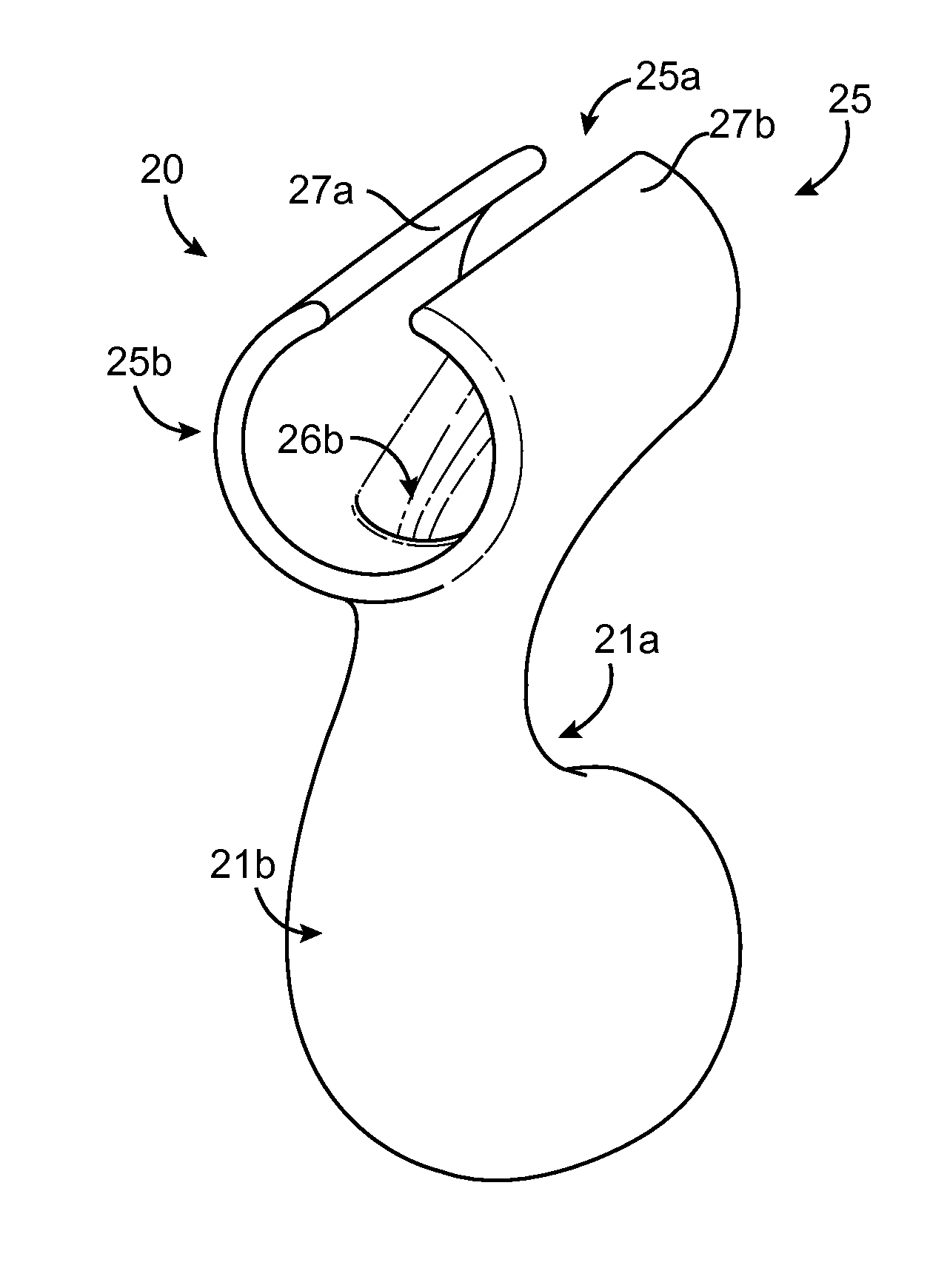

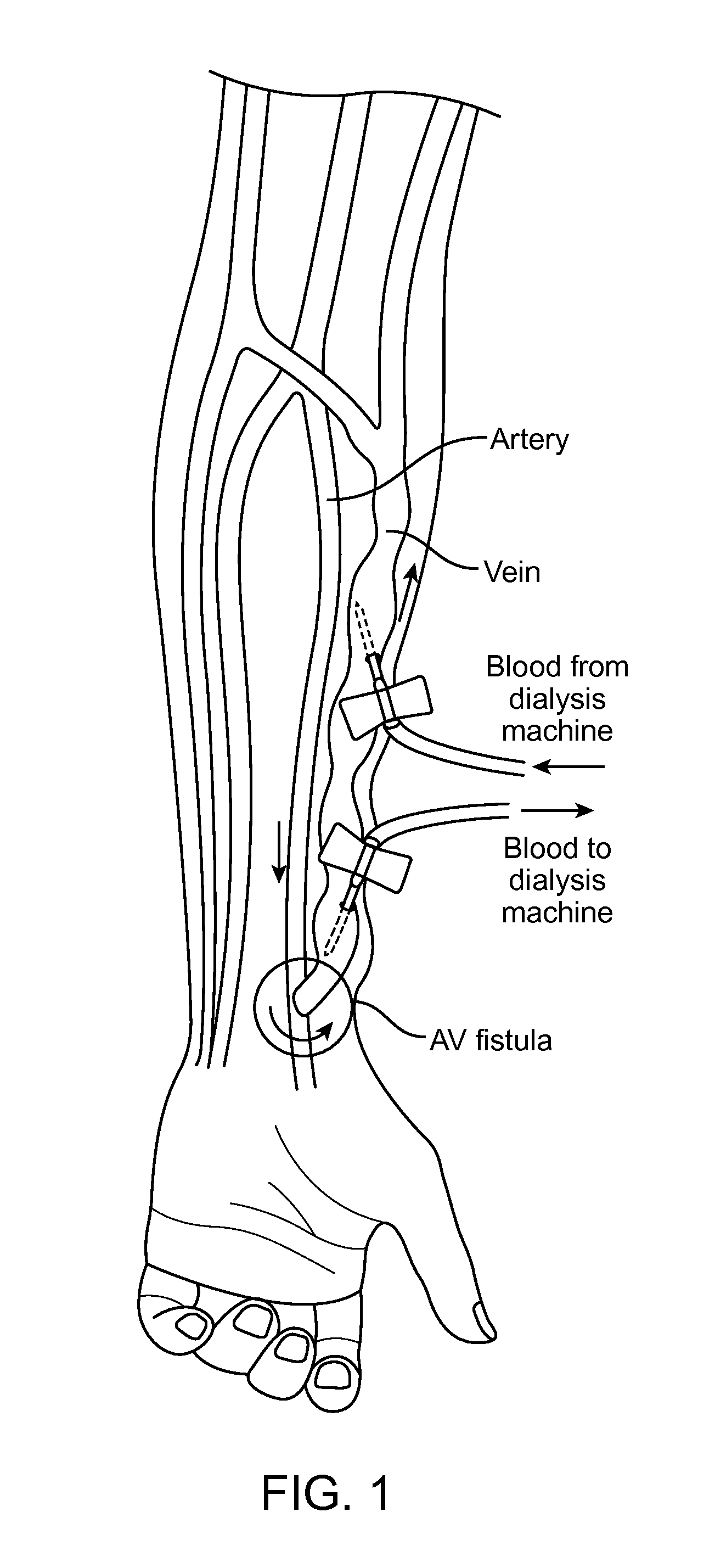

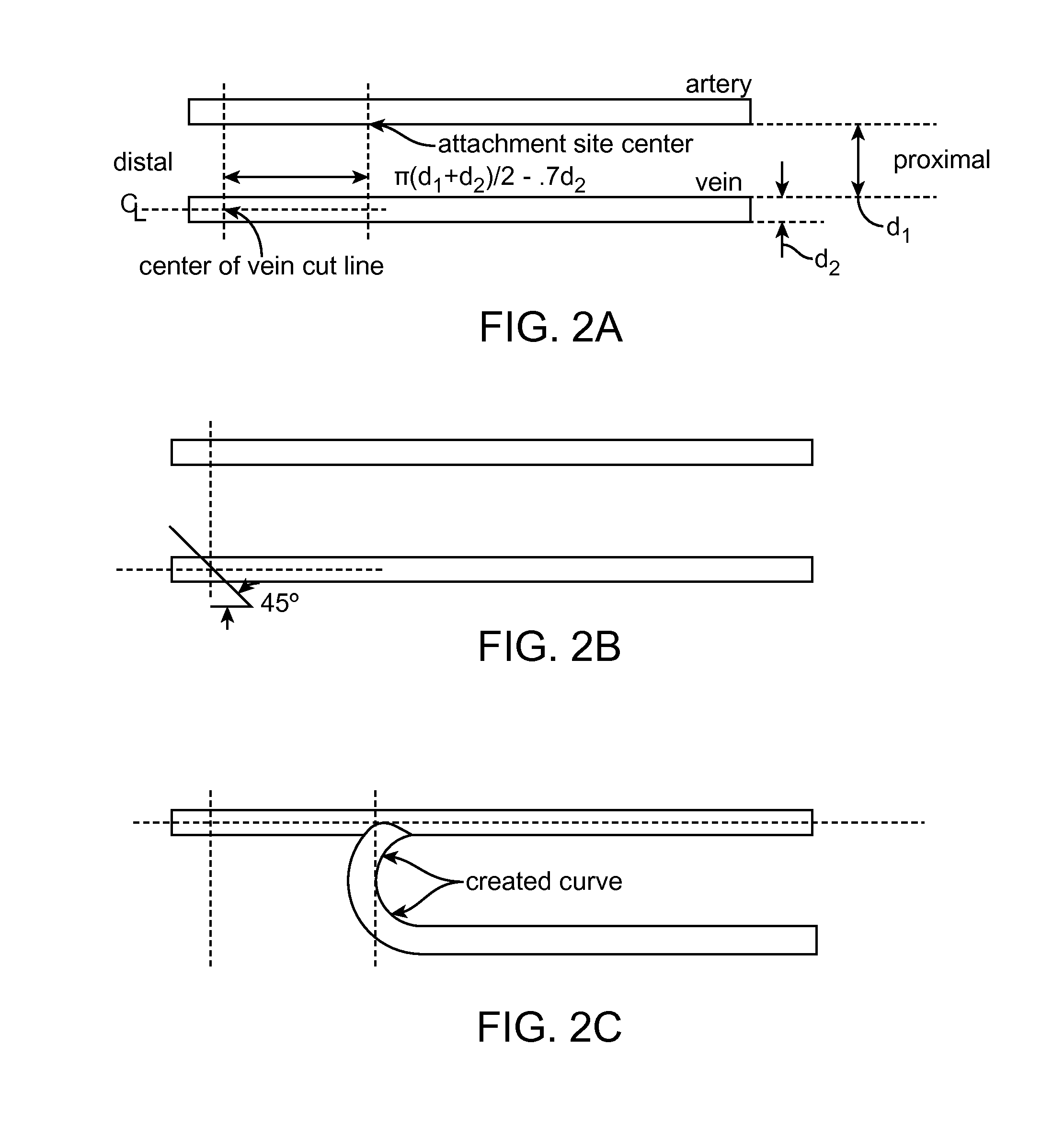

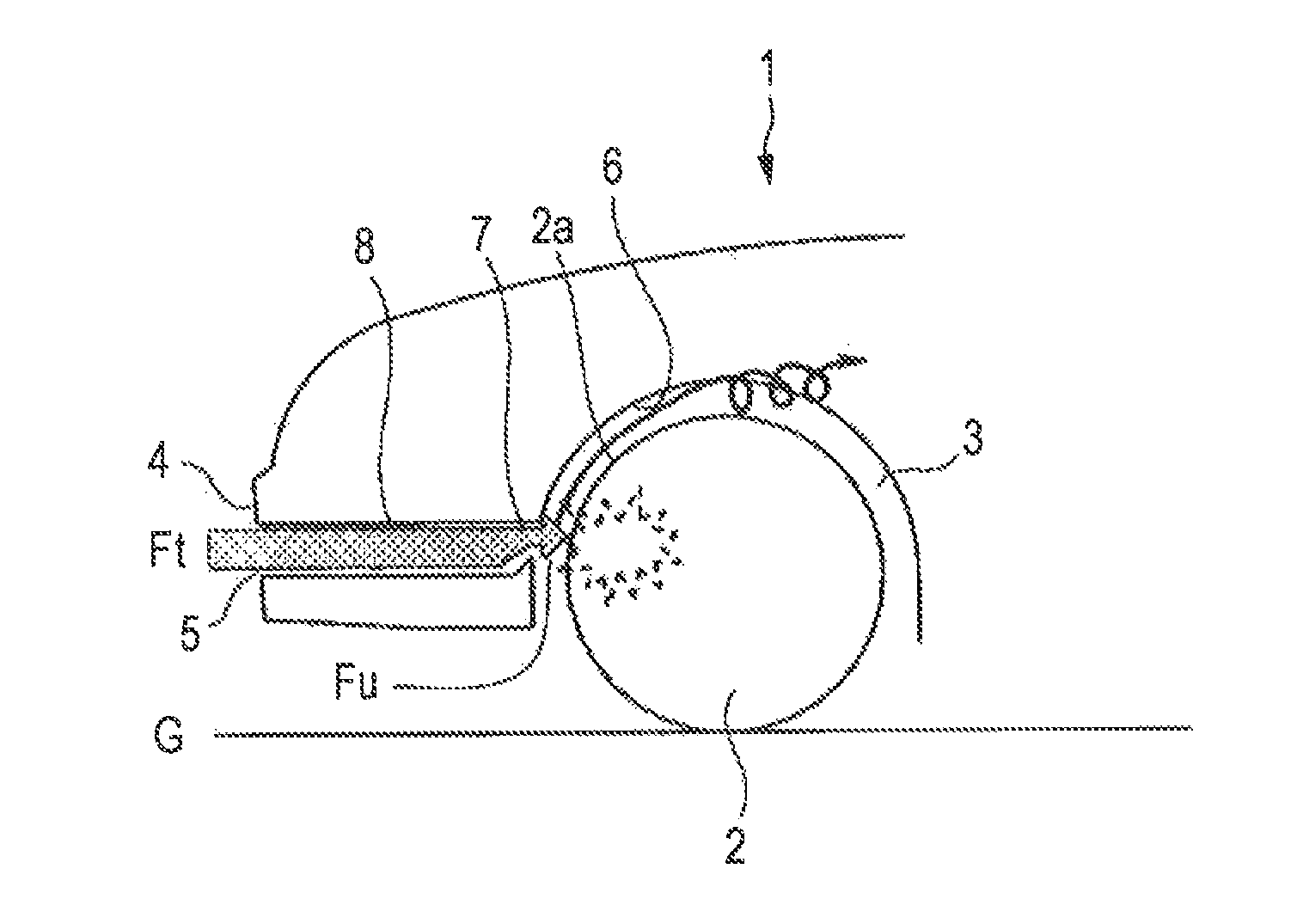

Extravascular devices supporting an arteriovenous fistula

InactiveUS20150119908A1Less acceleratedConvenient and smoothSuction devicesWound clampsEntrance angleVein

A medical device includes a curved tubular body configured for being used as an extravascular device to support vein maturation following the formation of an arteriovenous fistula. The tubular body is curved. The tubular body has an entrance angle of less than about 40 degrees to improve blood flow from the artery into the vein. And the tubular body includes a cuff or edge at the proximal end to stabilize the tubular body at the fistula.

Owner:ABBOTT CARDIOVASCULAR

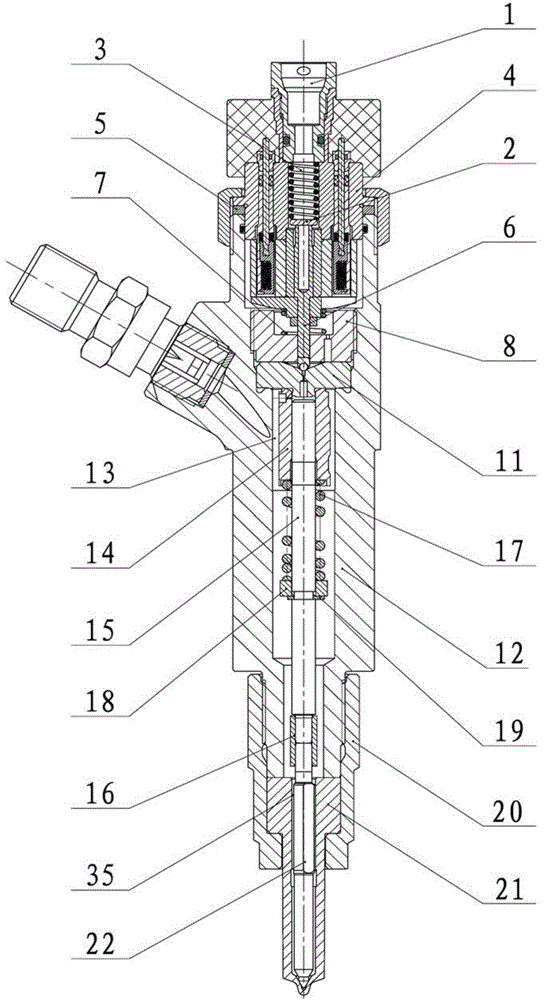

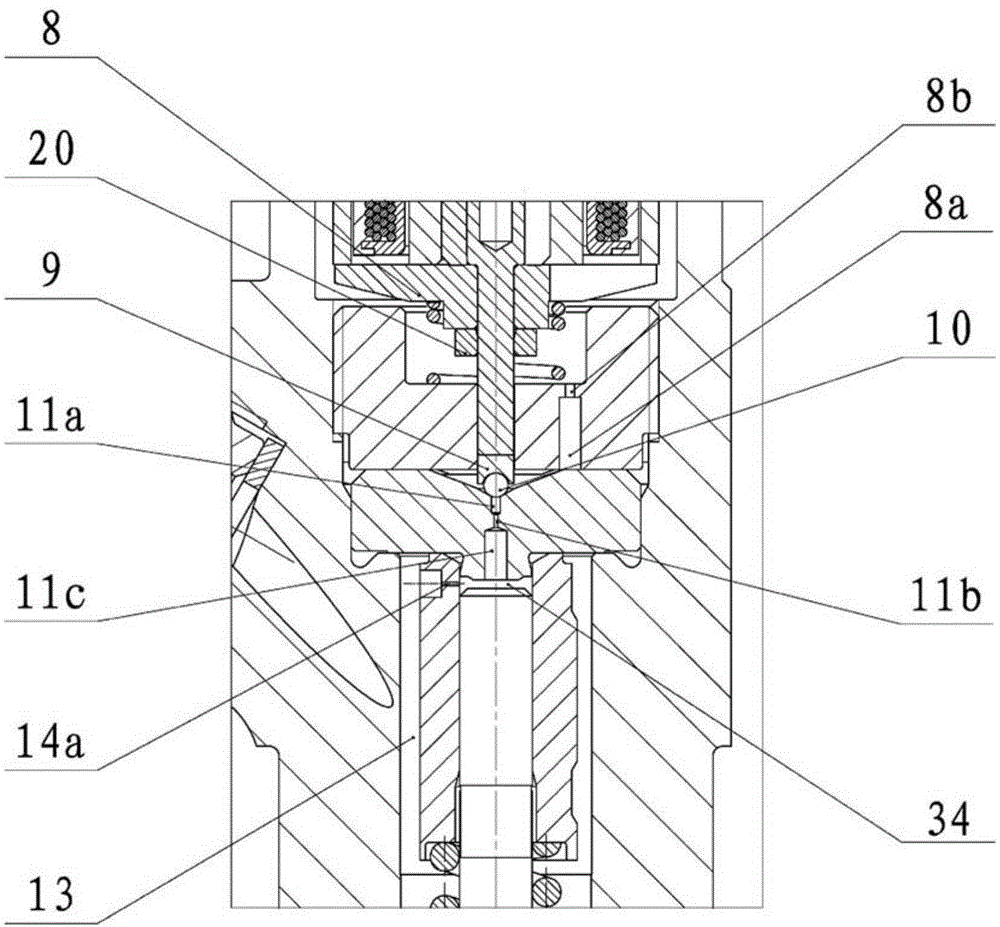

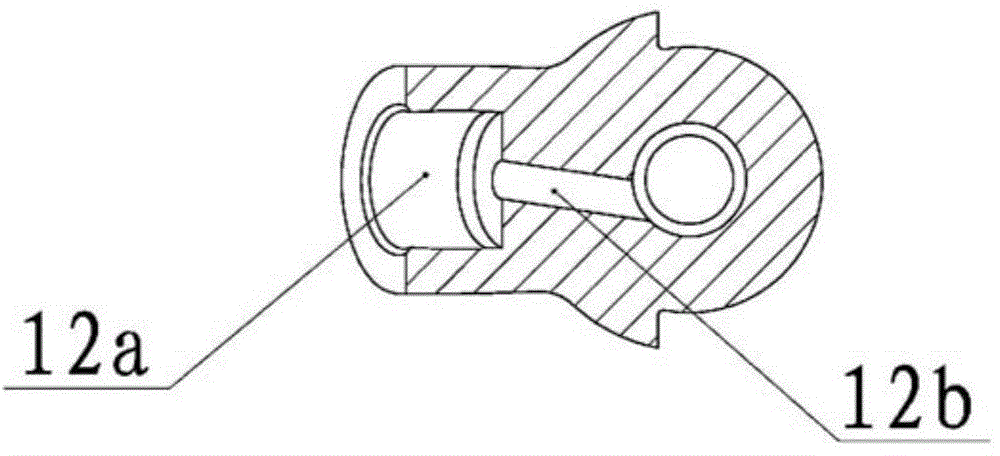

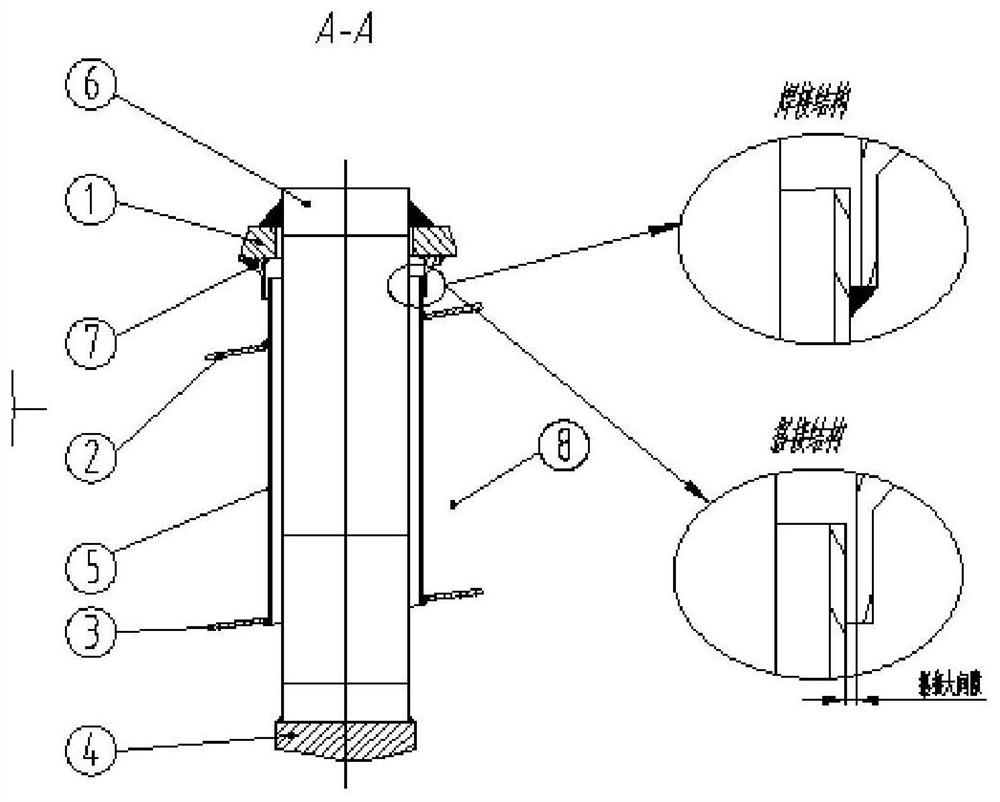

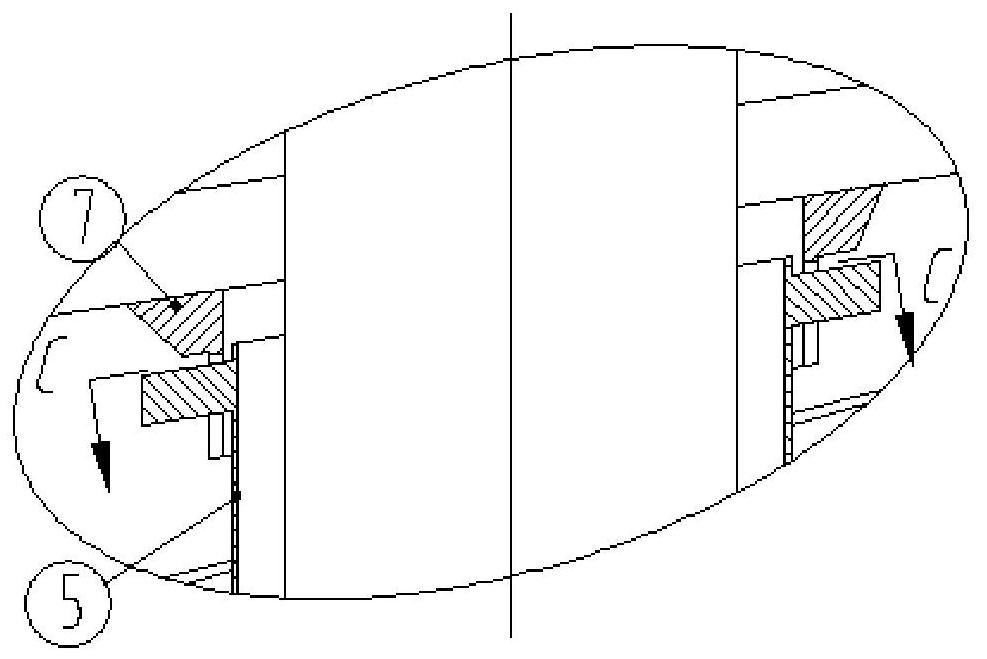

Middle hole pressure storage static leakage-free oil sprayer

ActiveCN104314725ASimple structureImprove sealingFuel injection apparatusMachines/enginesSolenoid valvePlunger

The invention discloses a middle hole pressure storage static leakage-free oil sprayer, comprising a high speed solenoid valve, a locking screw sleeve, a tapered surface ball valve type switch valve, a control plunger and barrel assembly, an oil sprayer spring, a spring seat, an opening check ring, an oil sprayer body, an oil sprayer assembly and an oil nozzle locking cap; the tapered surface ball valve type switch valve is arranged in a concave cavity in the upper end of the oil sprayer body; the upper end of the oil sprayer body is connected with the high speed solenoid valve by a locking nut; the lower end of the oil sprayer body is connected with the oil nozzle assembly by the oil nozzle locking cap; the control pole plunger and barrel assembly is arranged in a central hole formed along the axis of the oil sprayer body; the central hole of the oil sprayer body and the control pole plunger and barrel assembly form a middle hole pressure storage cavity. The oil sprayer is simple in structure, low in machining cost and convenient to mount, so the production efficiency and product percent of pass are improved.

Owner:钧风电控科技(大连)有限责任公司

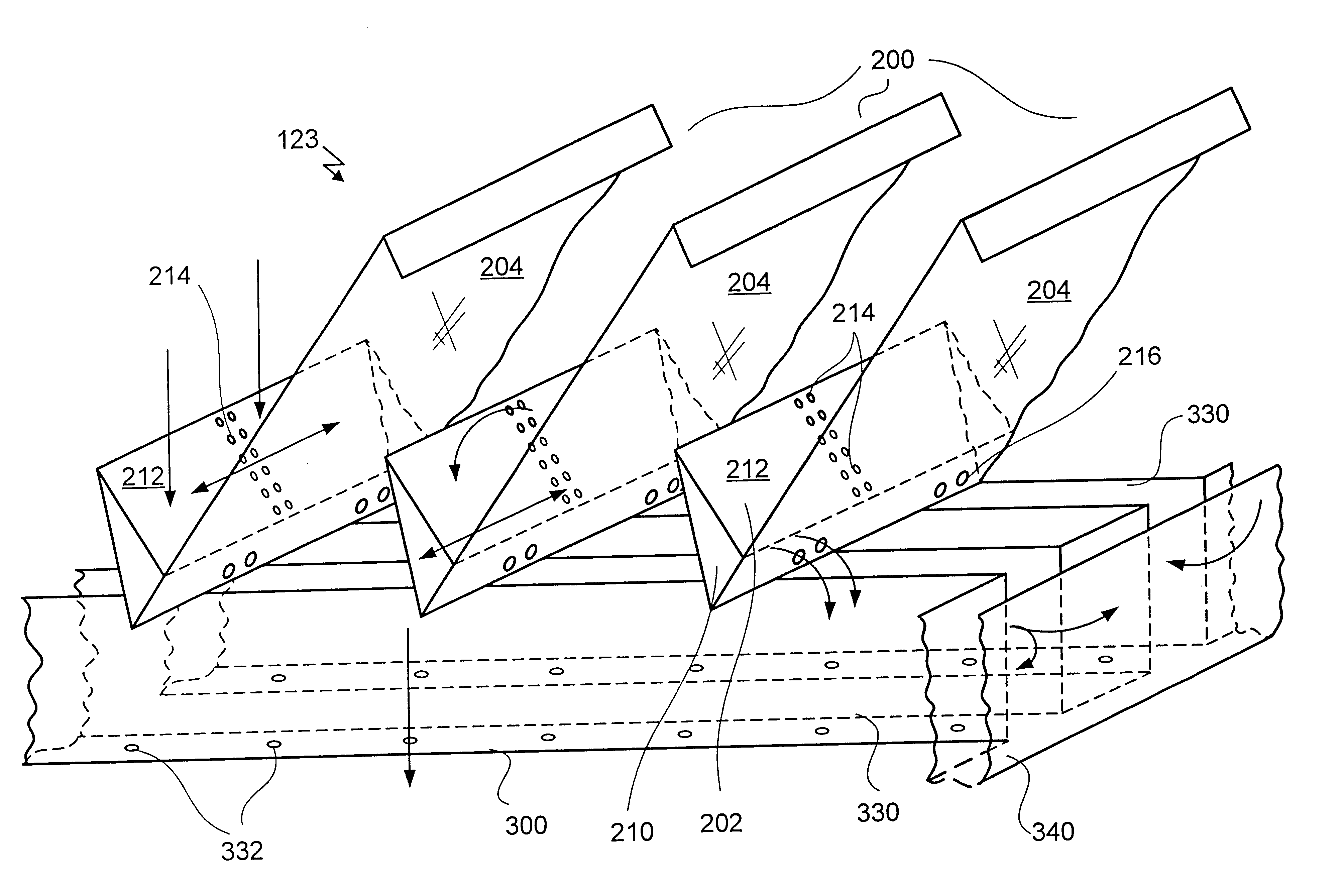

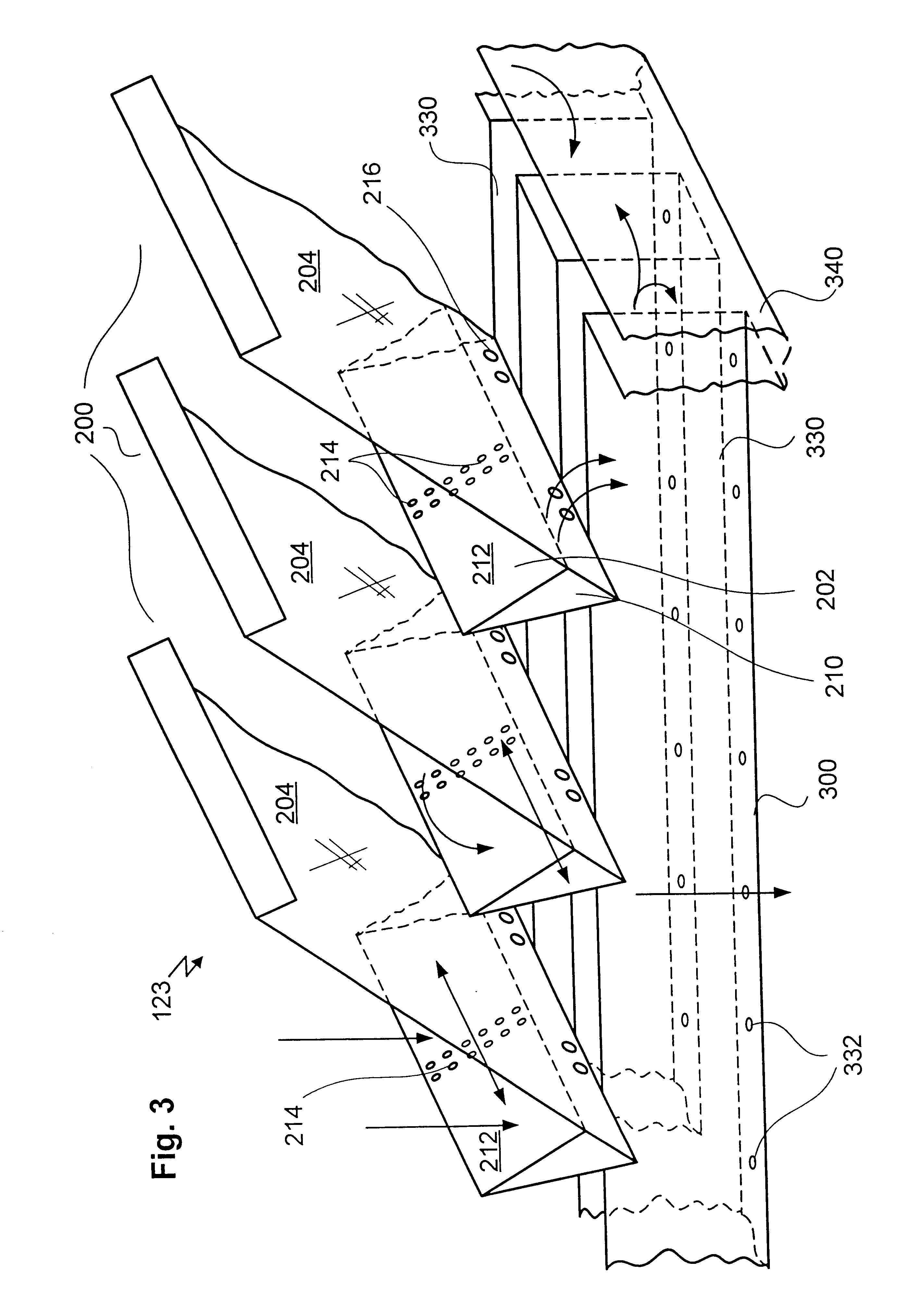

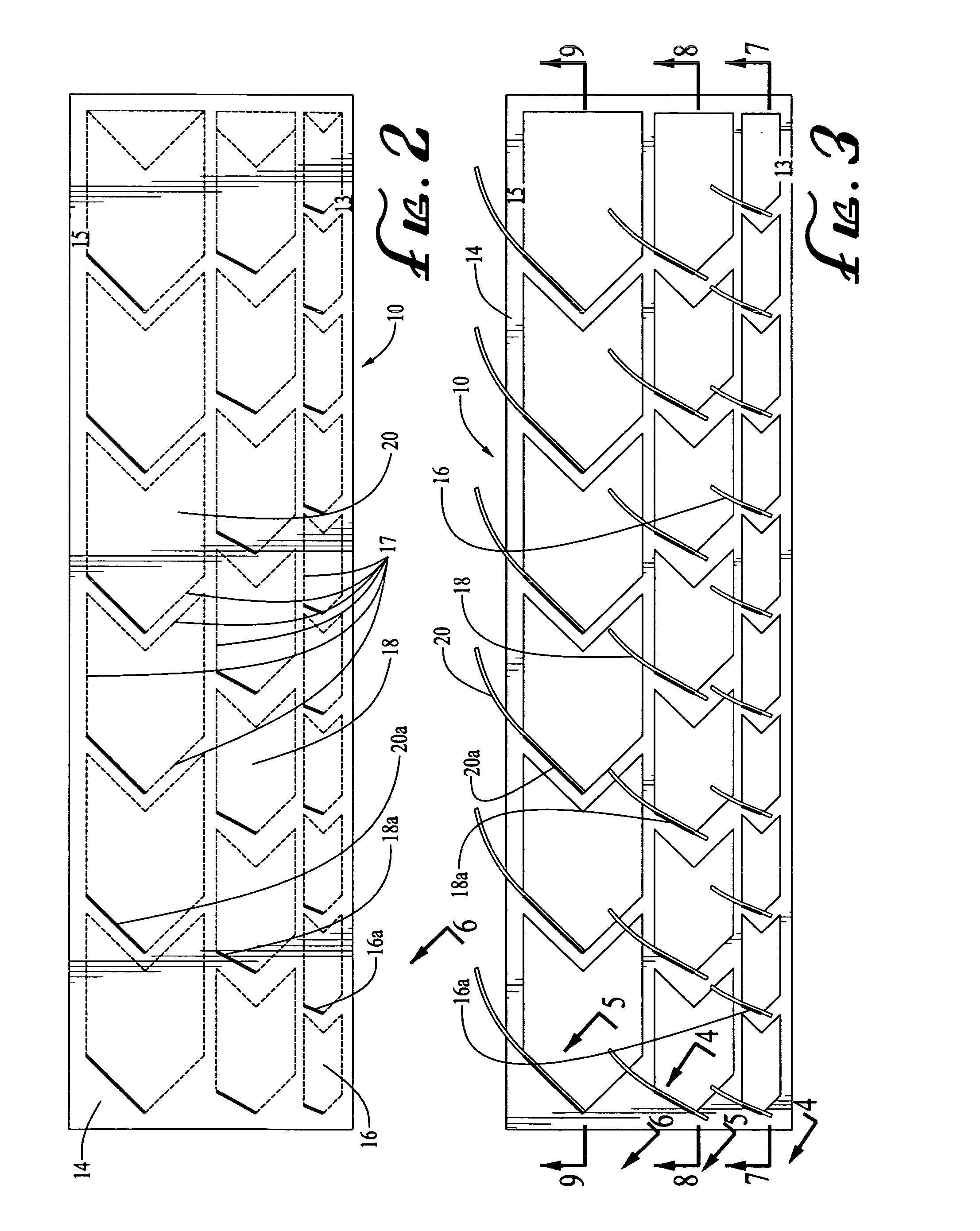

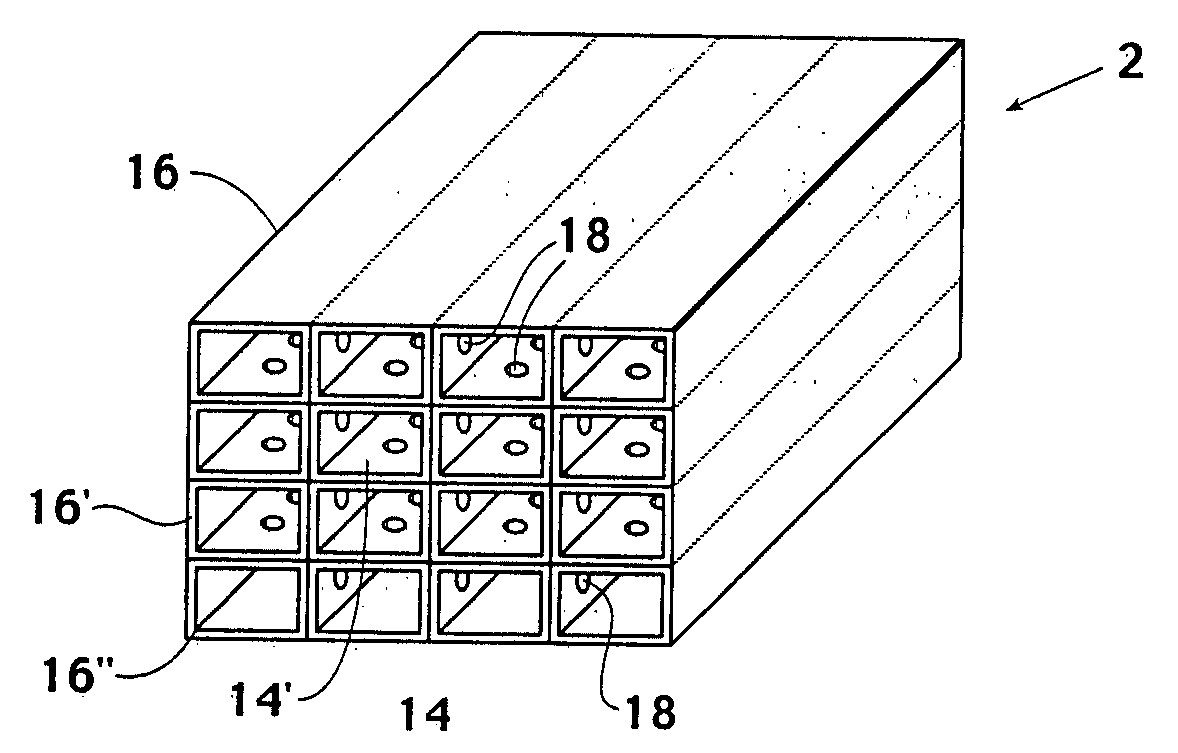

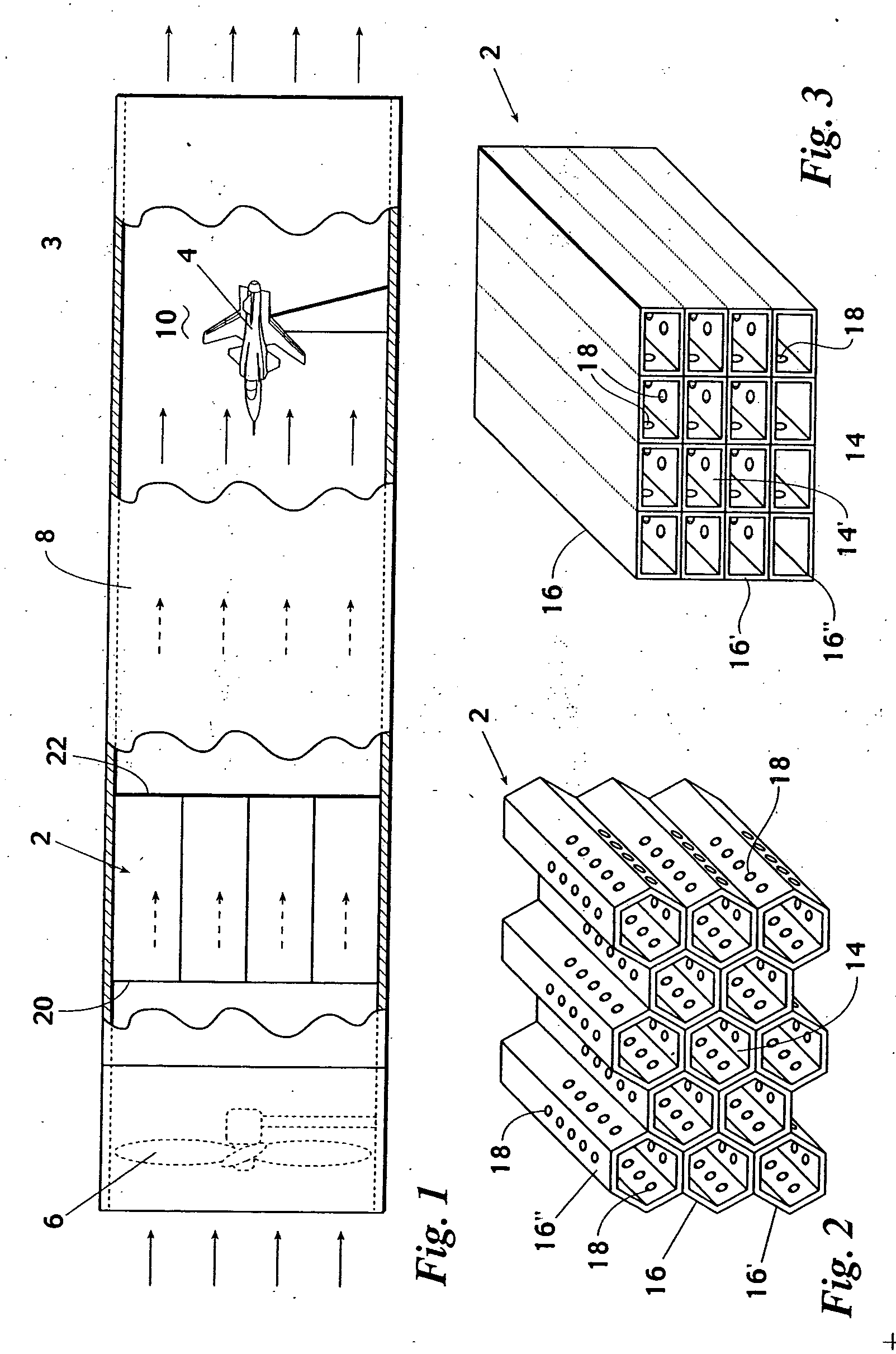

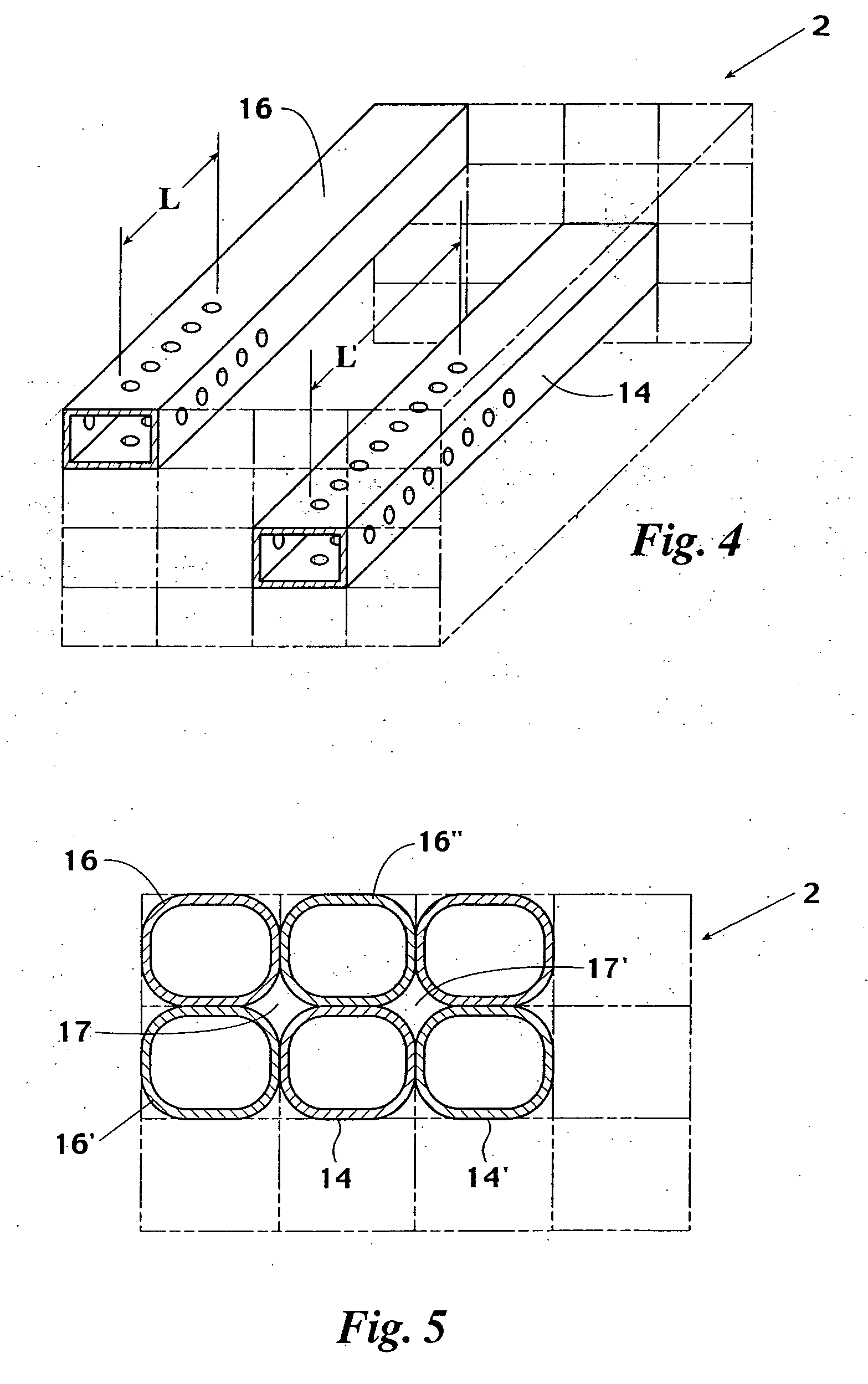

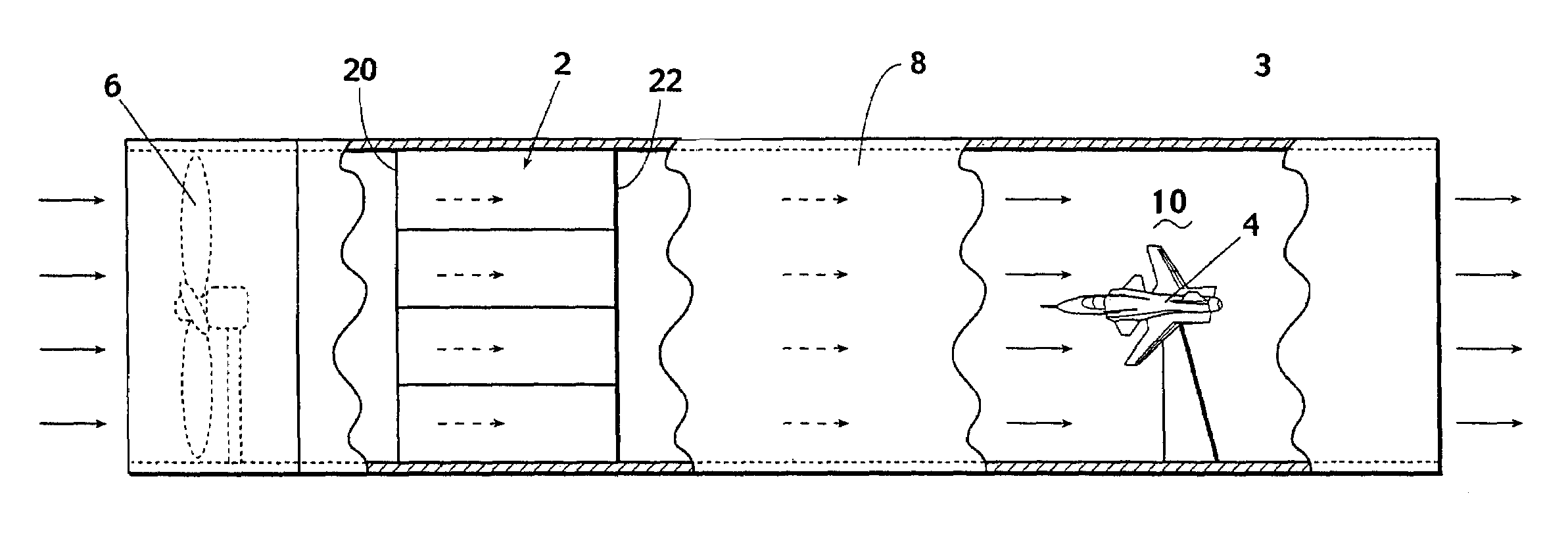

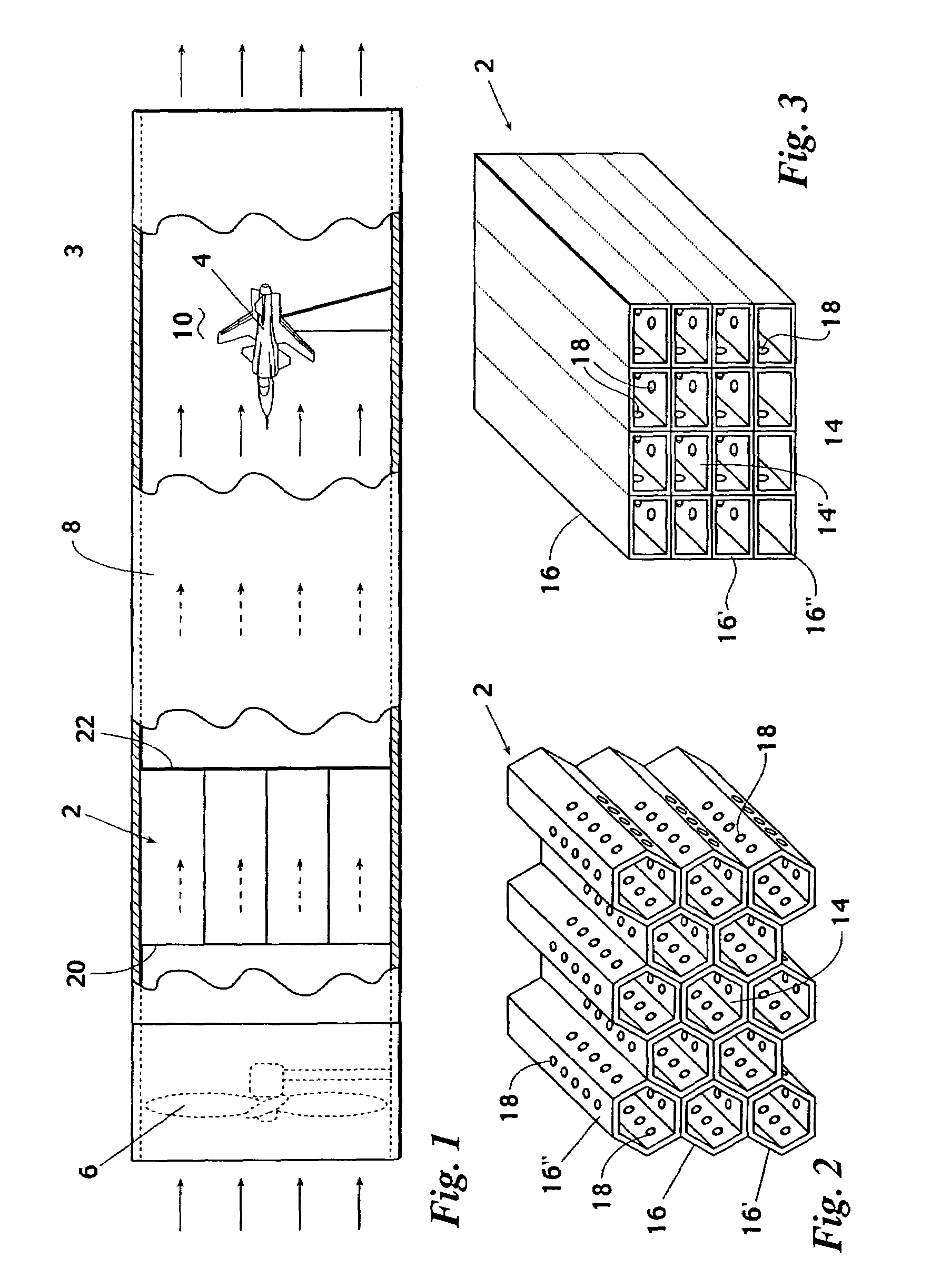

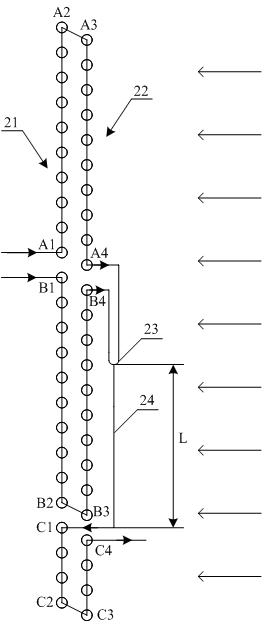

Structure and method for improving flow uniformity and reducing turbulence

InactiveUS20070137717A1Reducing lateral turbulenceReduce trafficAerodynamic testingFluid dynamicsEngineeringGuide tube

A structure for reducing turbulence and increasing flow uniformity in a flowing fluid in a wind tunnel, or a fluid channel, has a plurality of conduits or channels arranged into a conduit bundle. The conduit bundle has a number of parallel conduits with plurality of perforations on the inner side walls of the conduit. As the fluid flows through the conduit bundle the sides of the conduits reduce lateral turbulence while the perforations minimize pressure gradients in the flowing fluid in adjacent conduits, resulting in isotropic turbulence. The invention is particularly useful in testing aircraft, improving engine performance, and fluid mechanics applications.

Owner:VAKILI AHMAD D

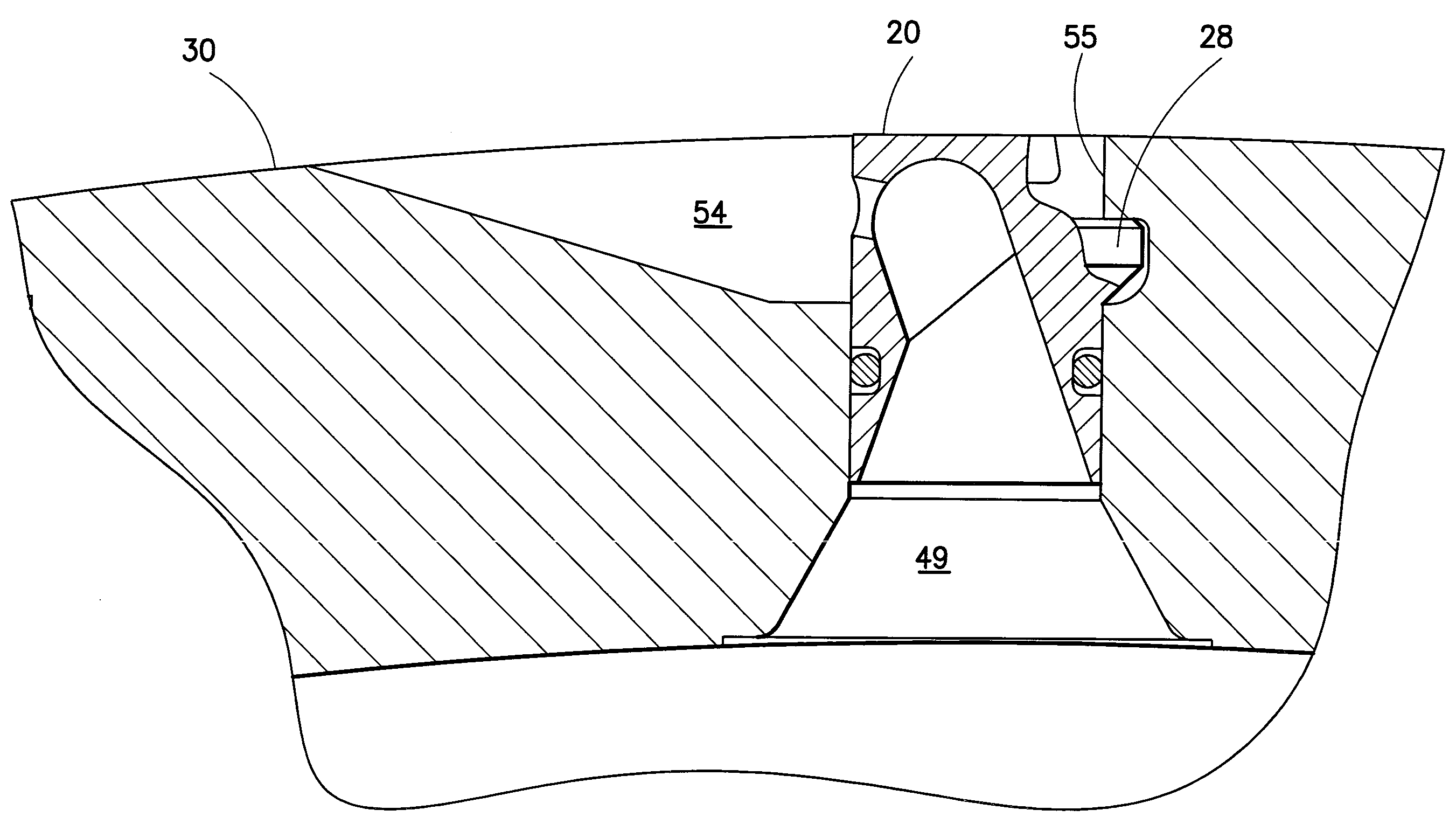

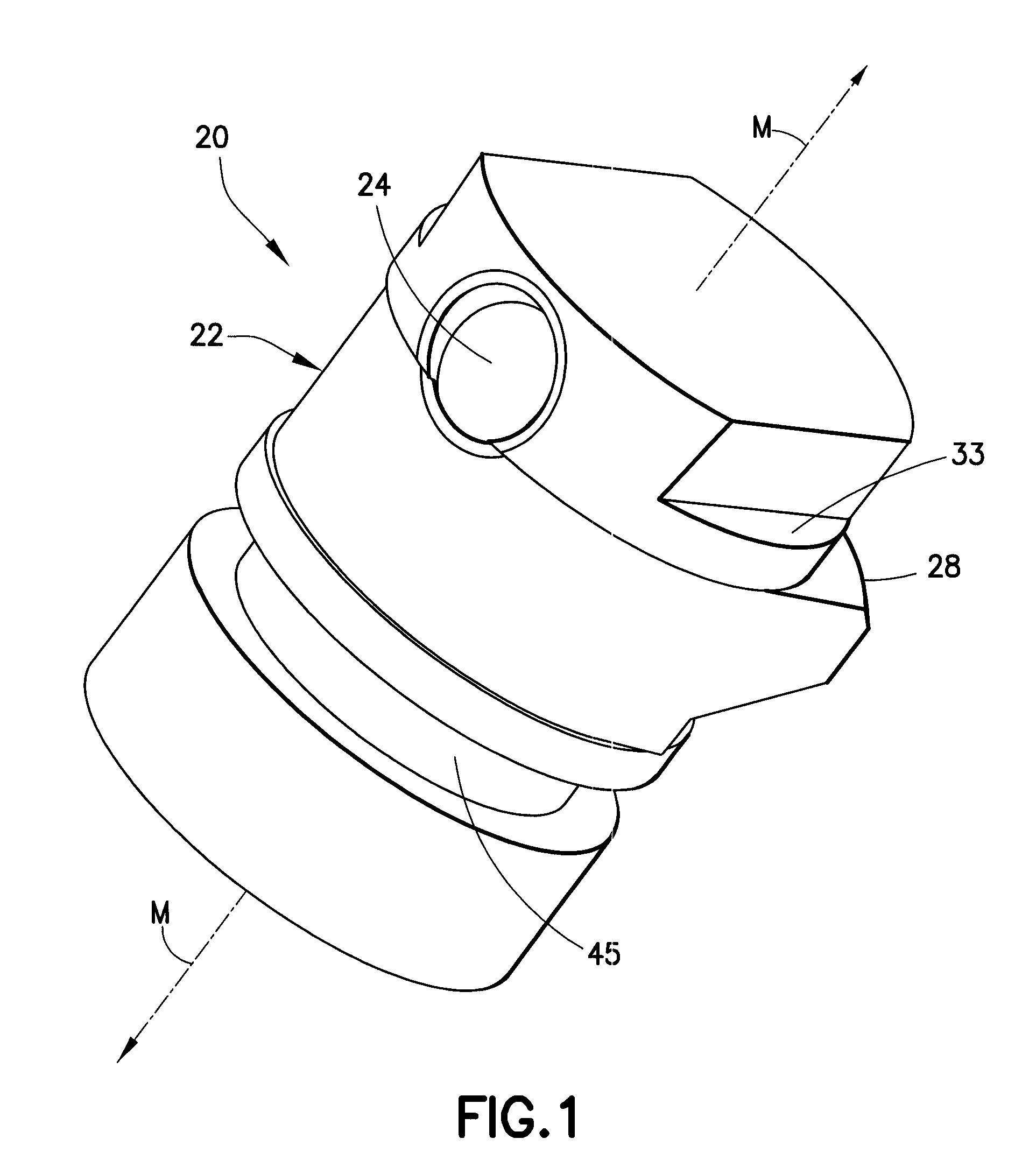

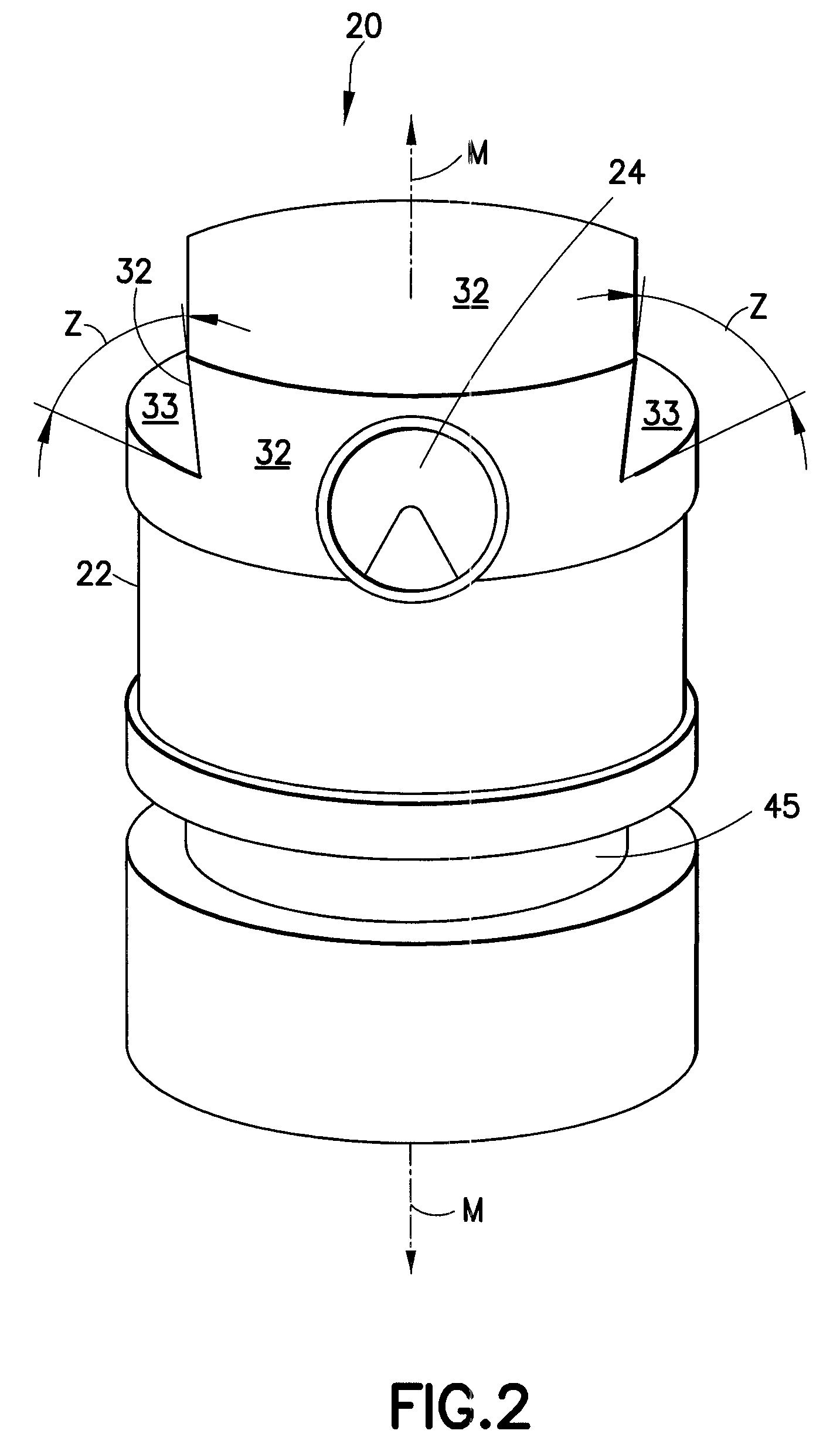

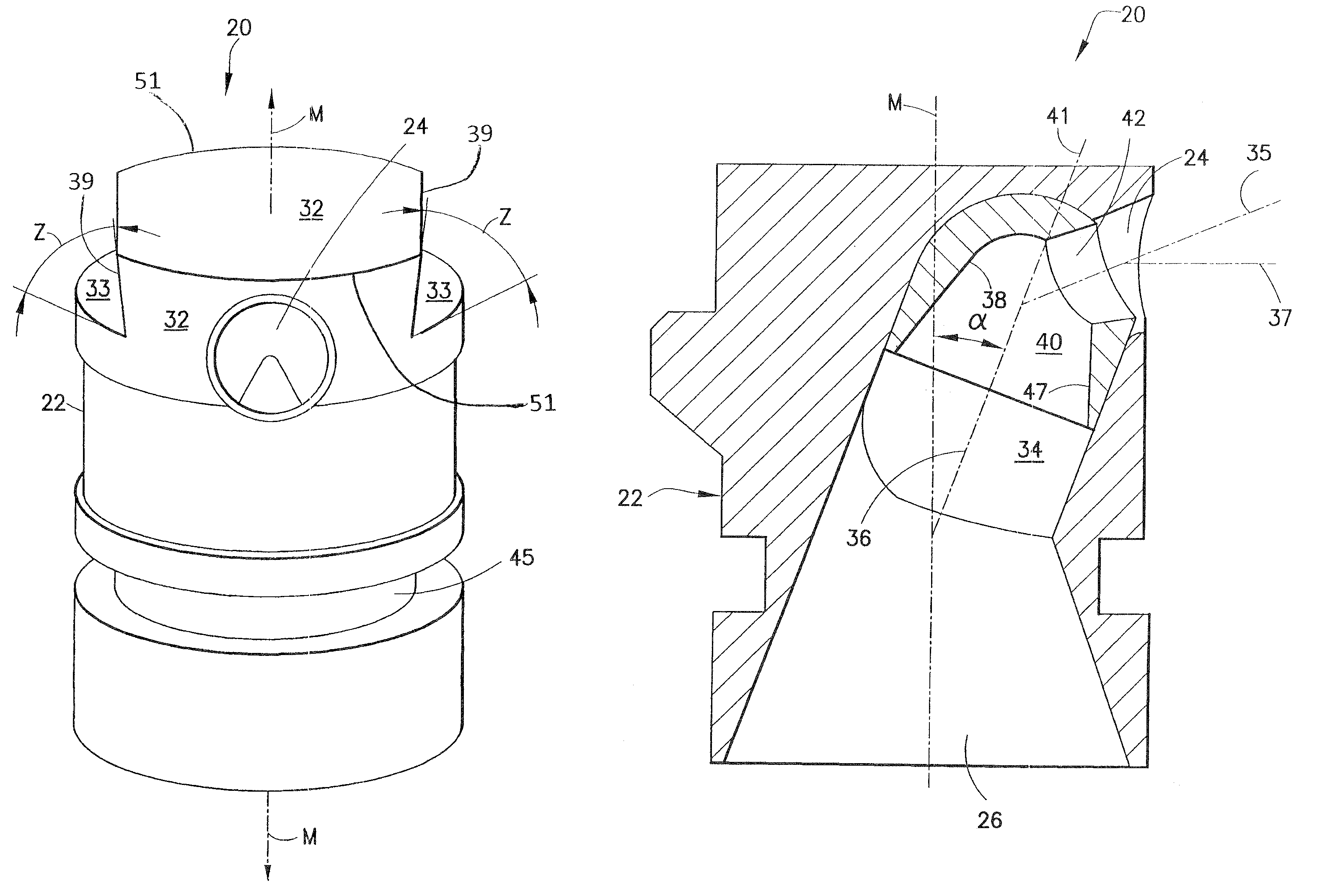

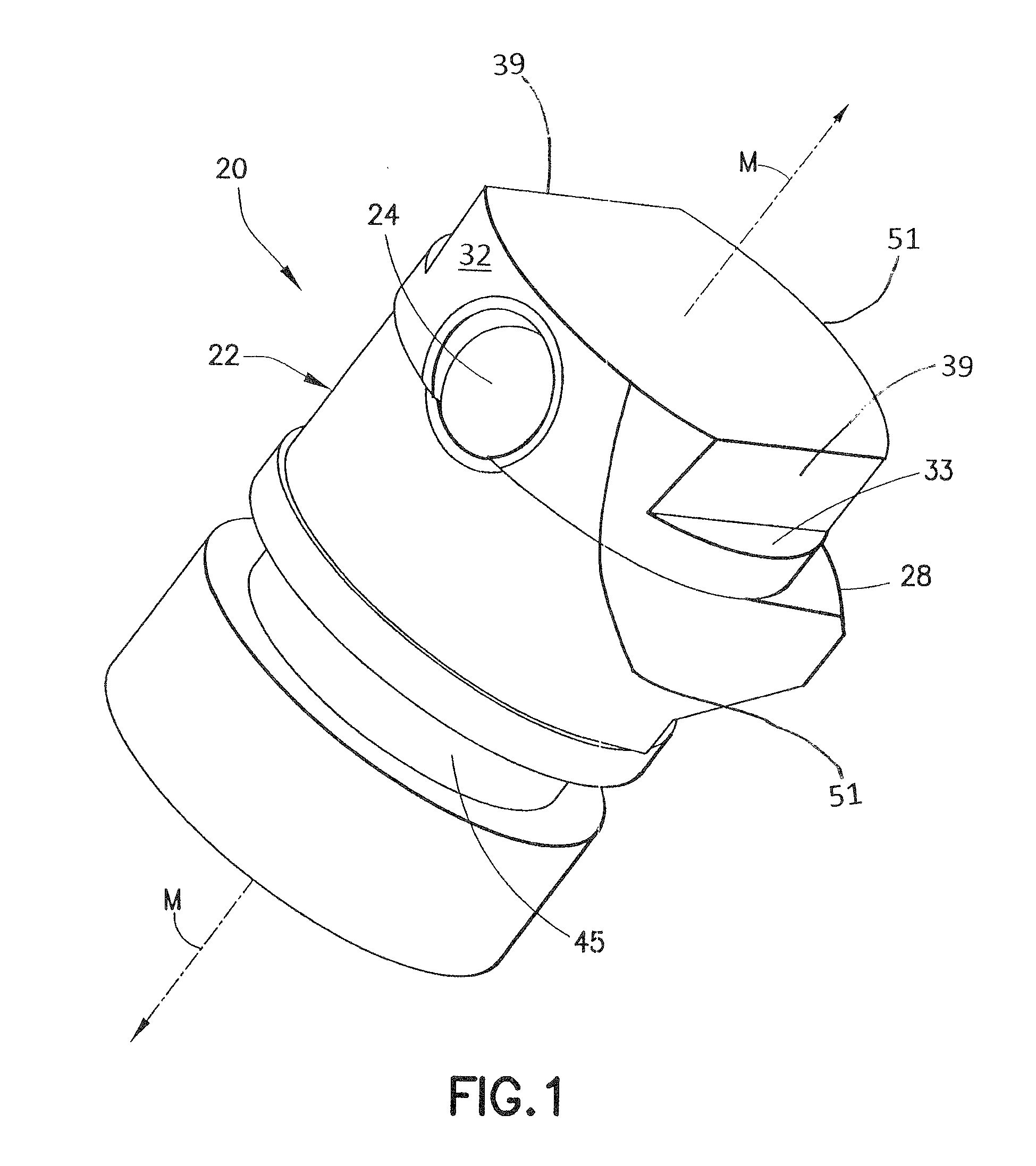

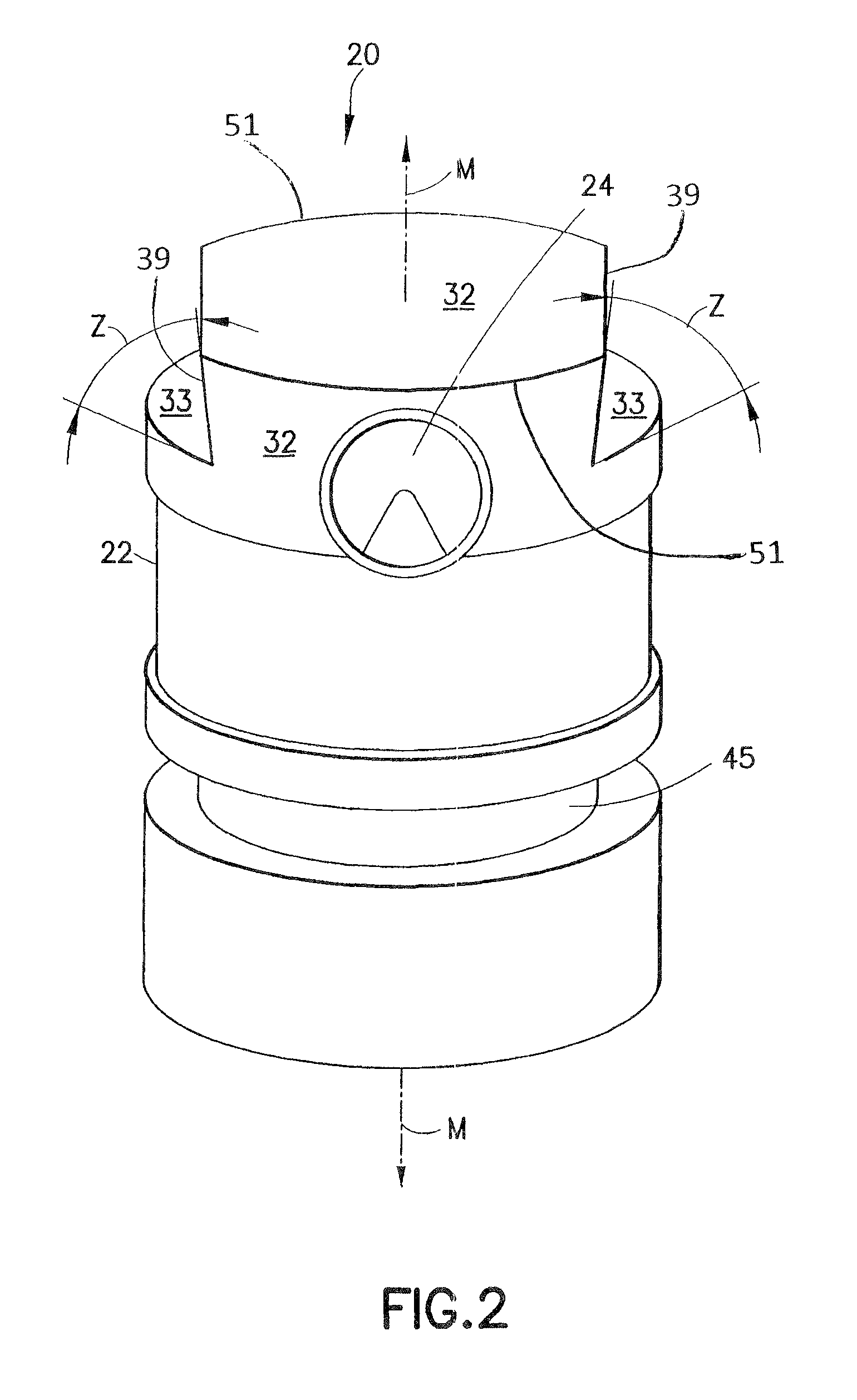

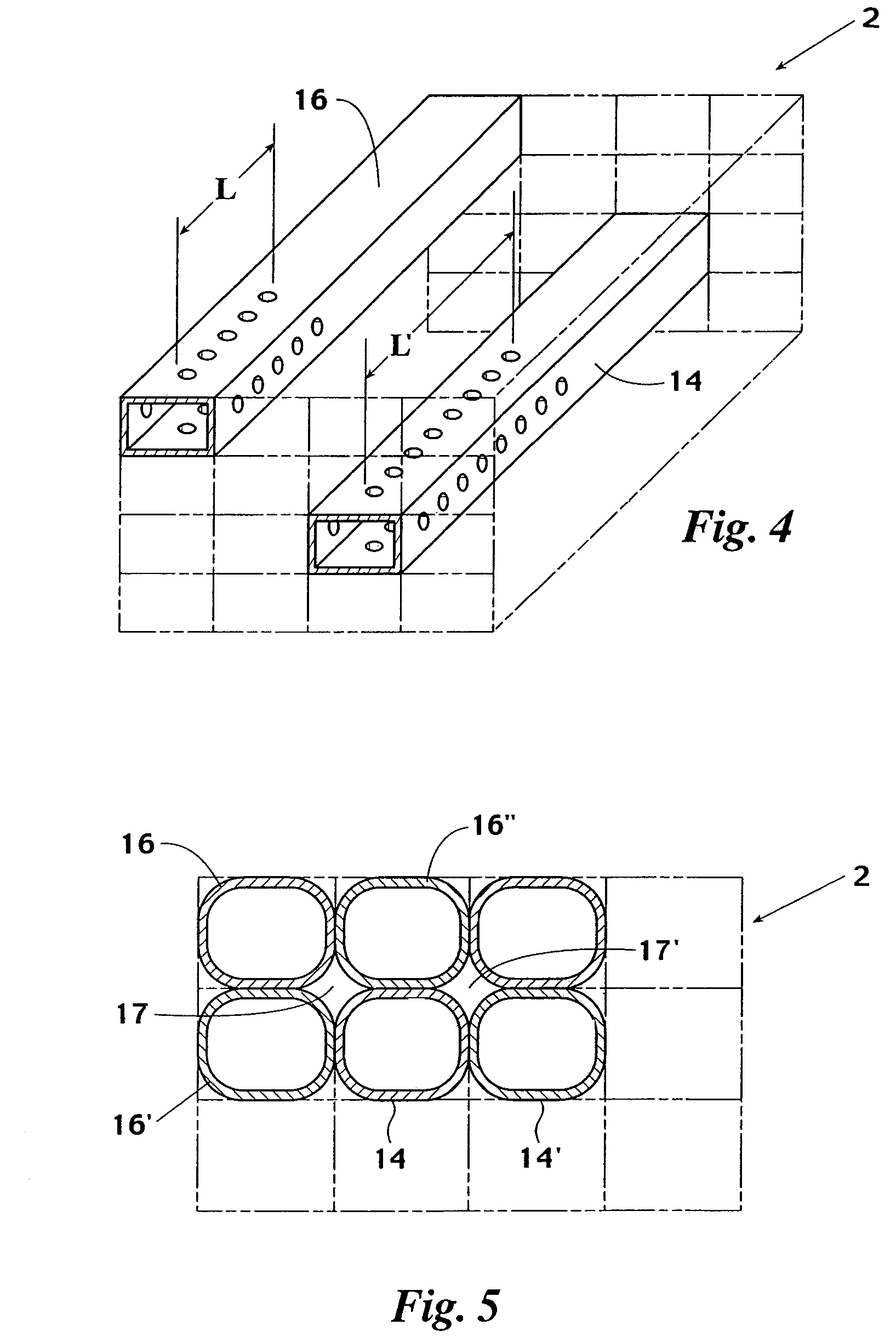

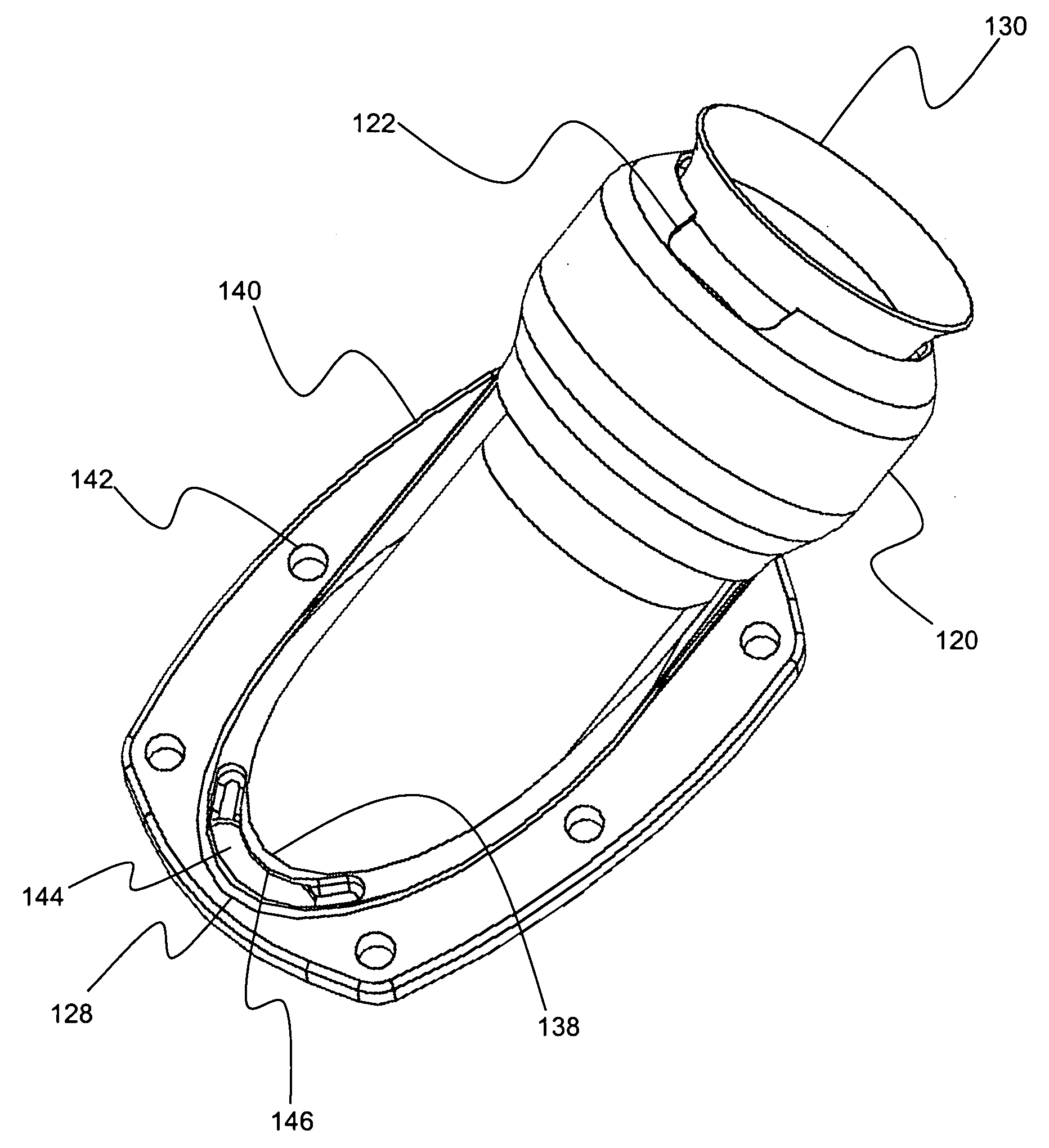

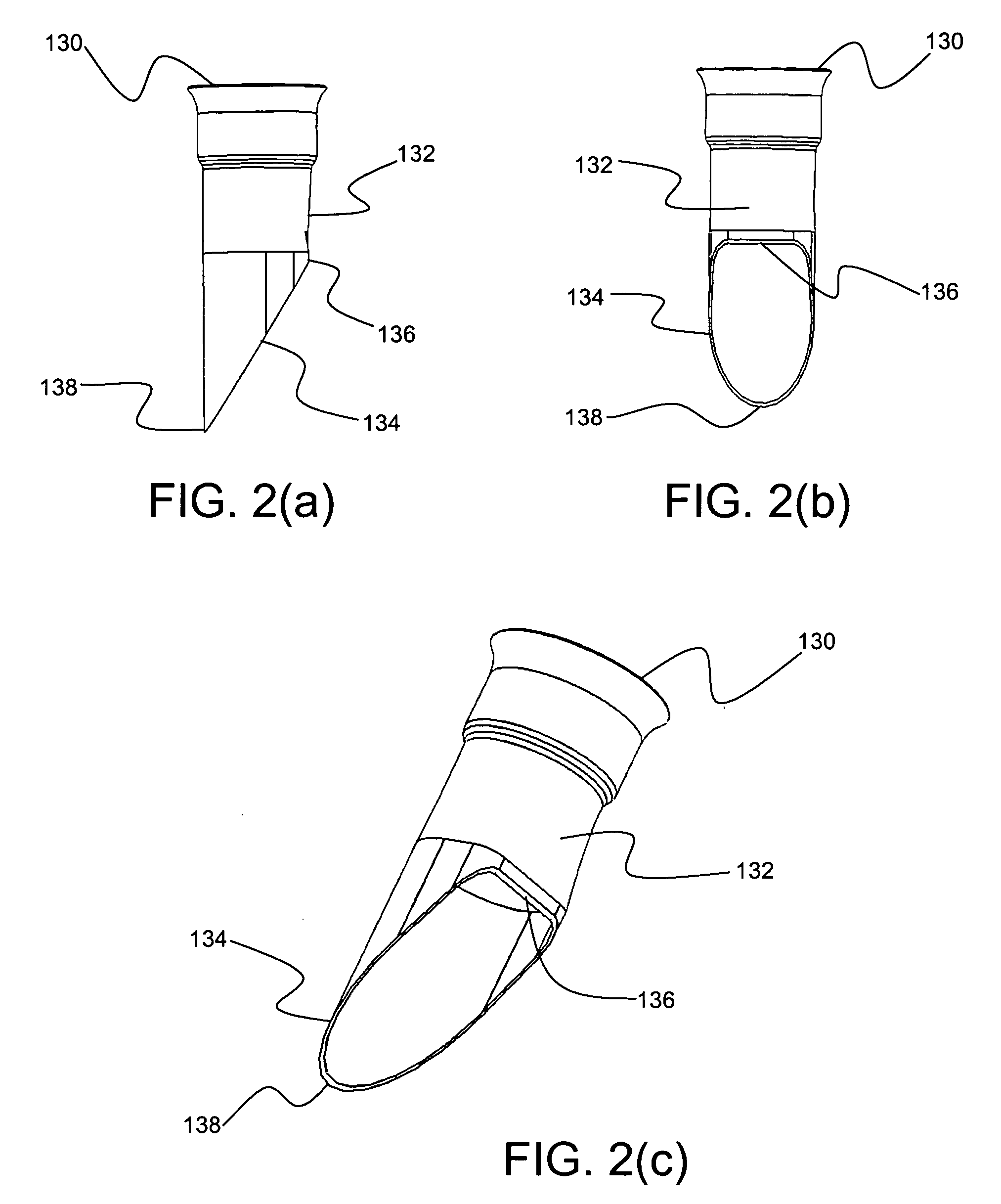

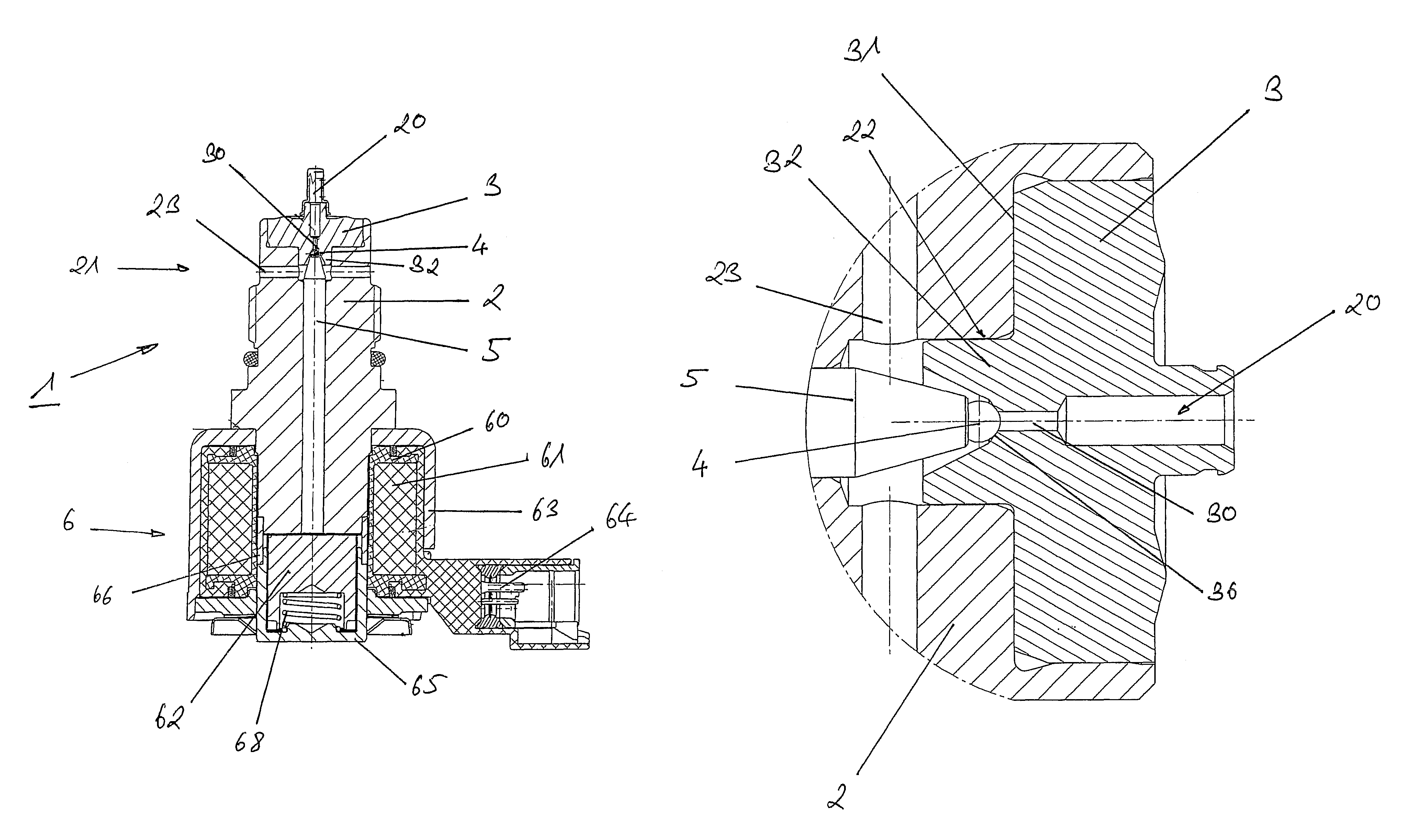

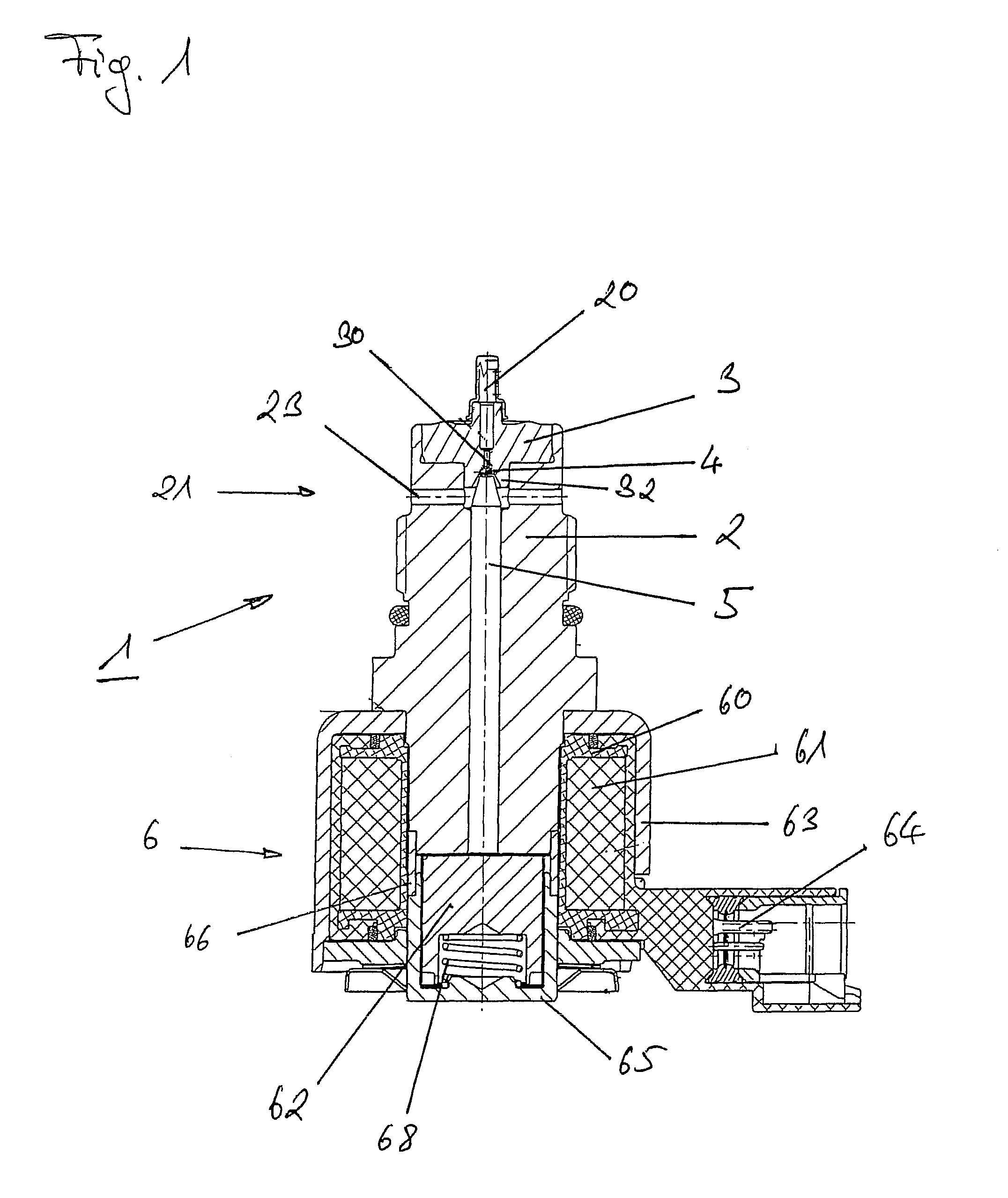

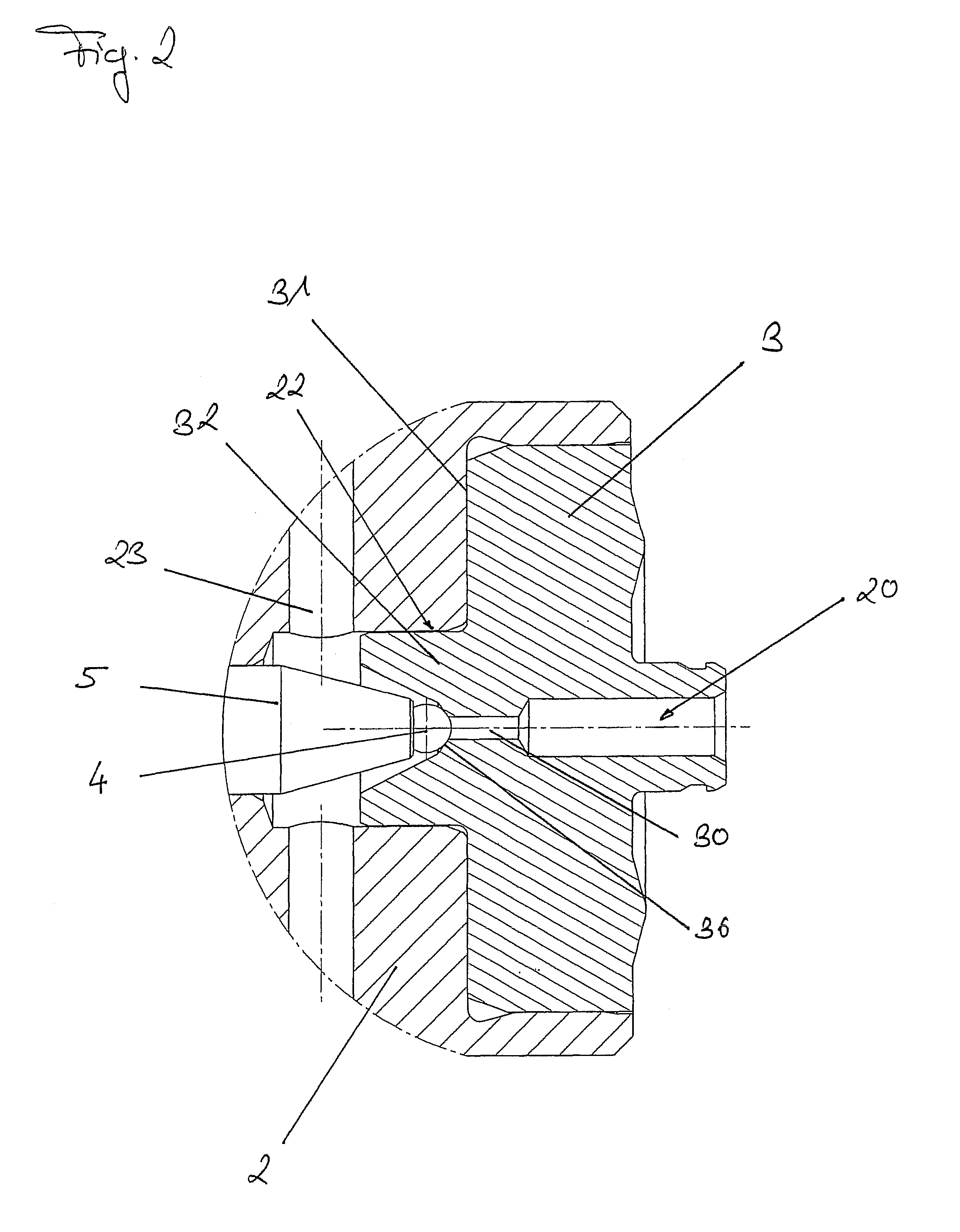

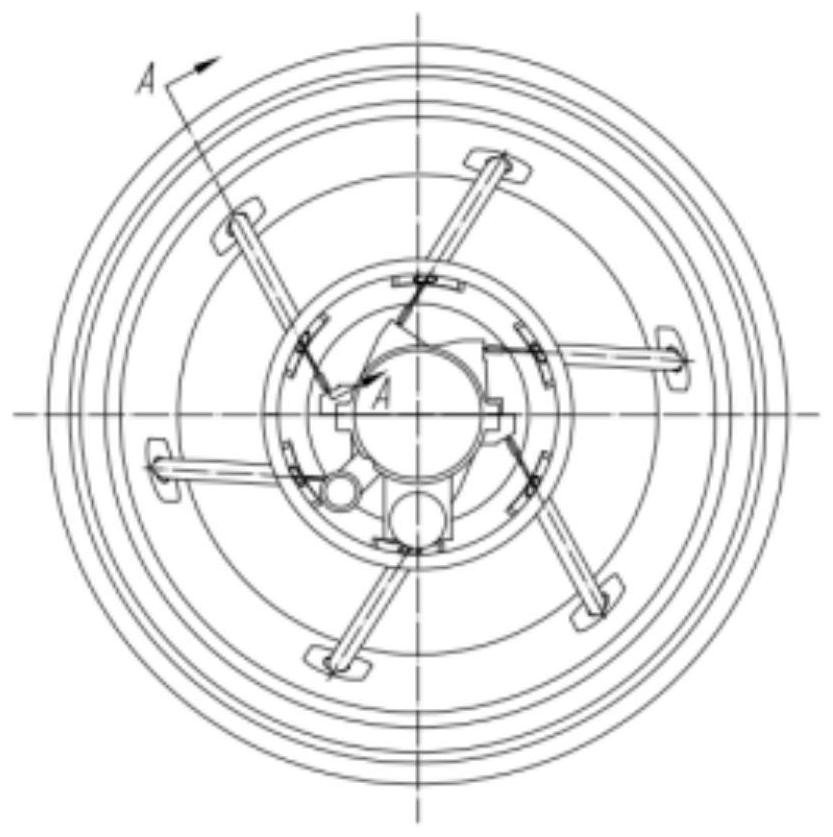

Centrifuge nozzle and method and apparatus for inserting said nozzle into a centrifuge bowl

ActiveUS20090140081A1Good flexibilityReduced Power RequirementsRotary centrifugesSpray nozzlesEngineeringCentrifuge

In a centrifuge nozzle (20) a nozzle body (22) defines an inlet in fluid communication with a nozzle outlet (24). The nozzle body (22) is adapted to be releasably positioned in an aperture defined by a centrifuge bowl assembly. A camming portion (28) projects outwardly from the nozzle body and defines a surface frictionally engageable with a portion of the bowl assembly. The nozzle body also defines a male mounting portion for slidably engaging a complimentarily shaped female slot defined by a nozzle insertion and extraction tool. The outlet of the nozzle is located adjacent to the male mounting portion.

Owner:ALFA LAVAL CORP AB

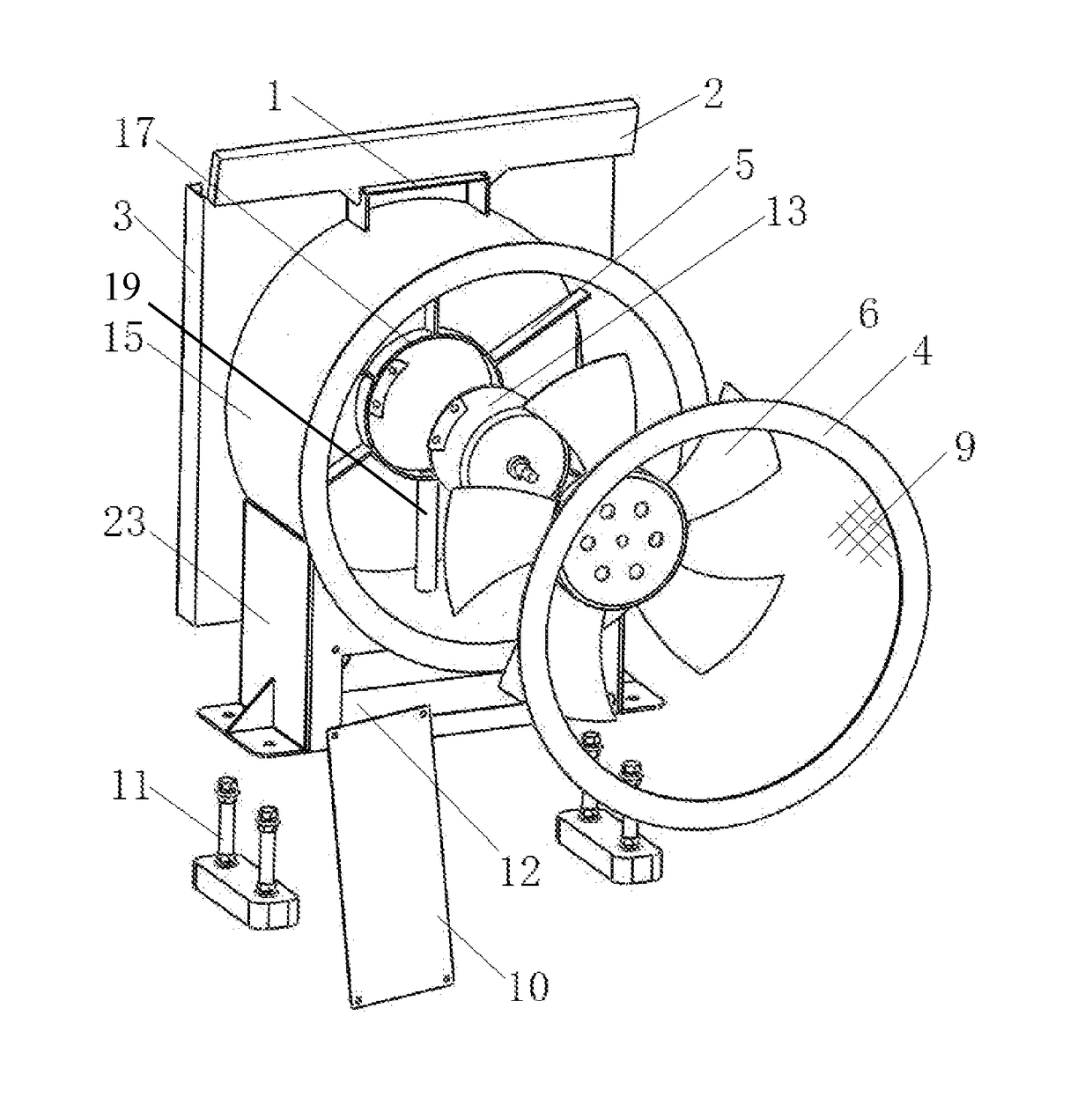

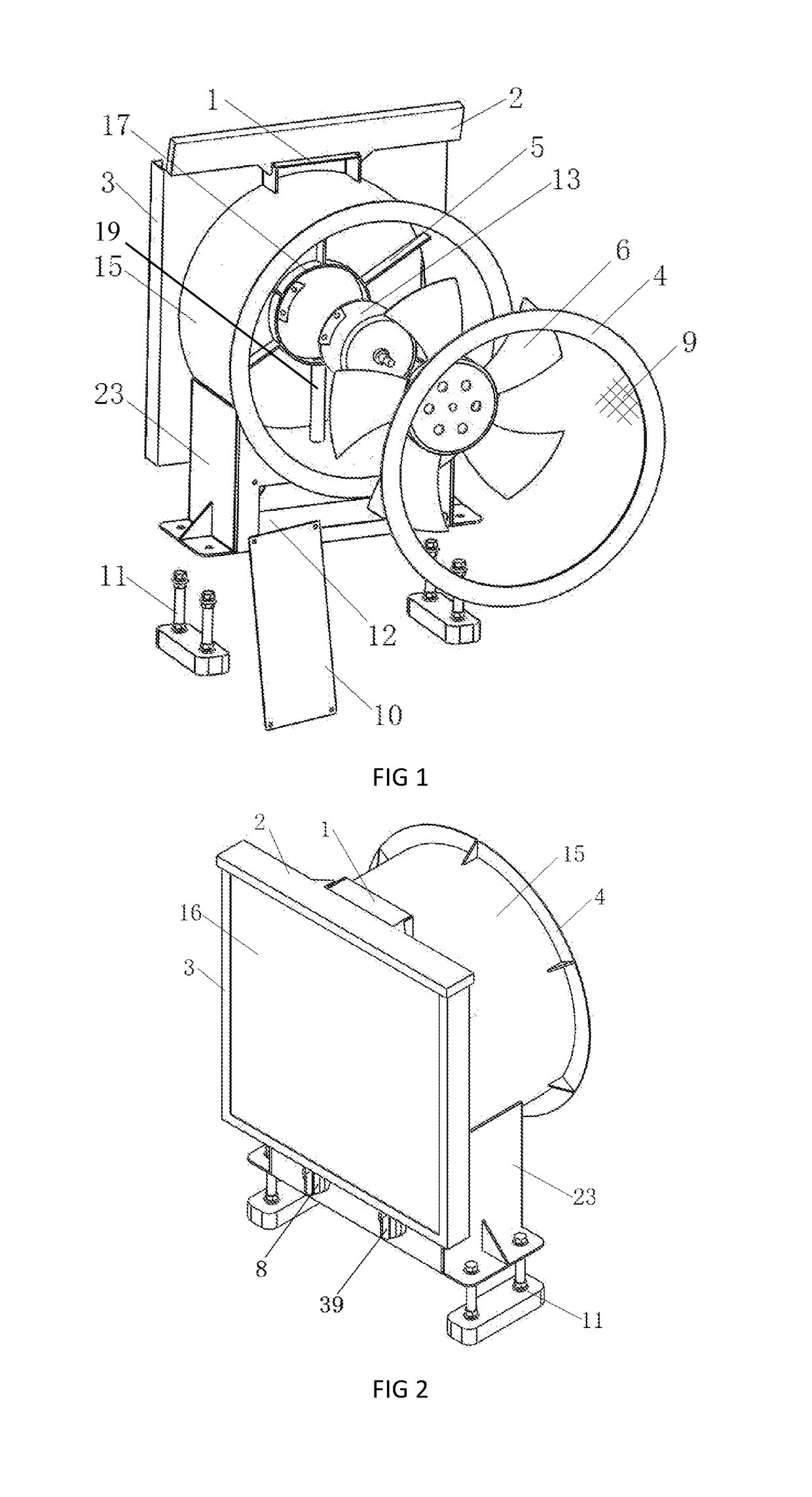

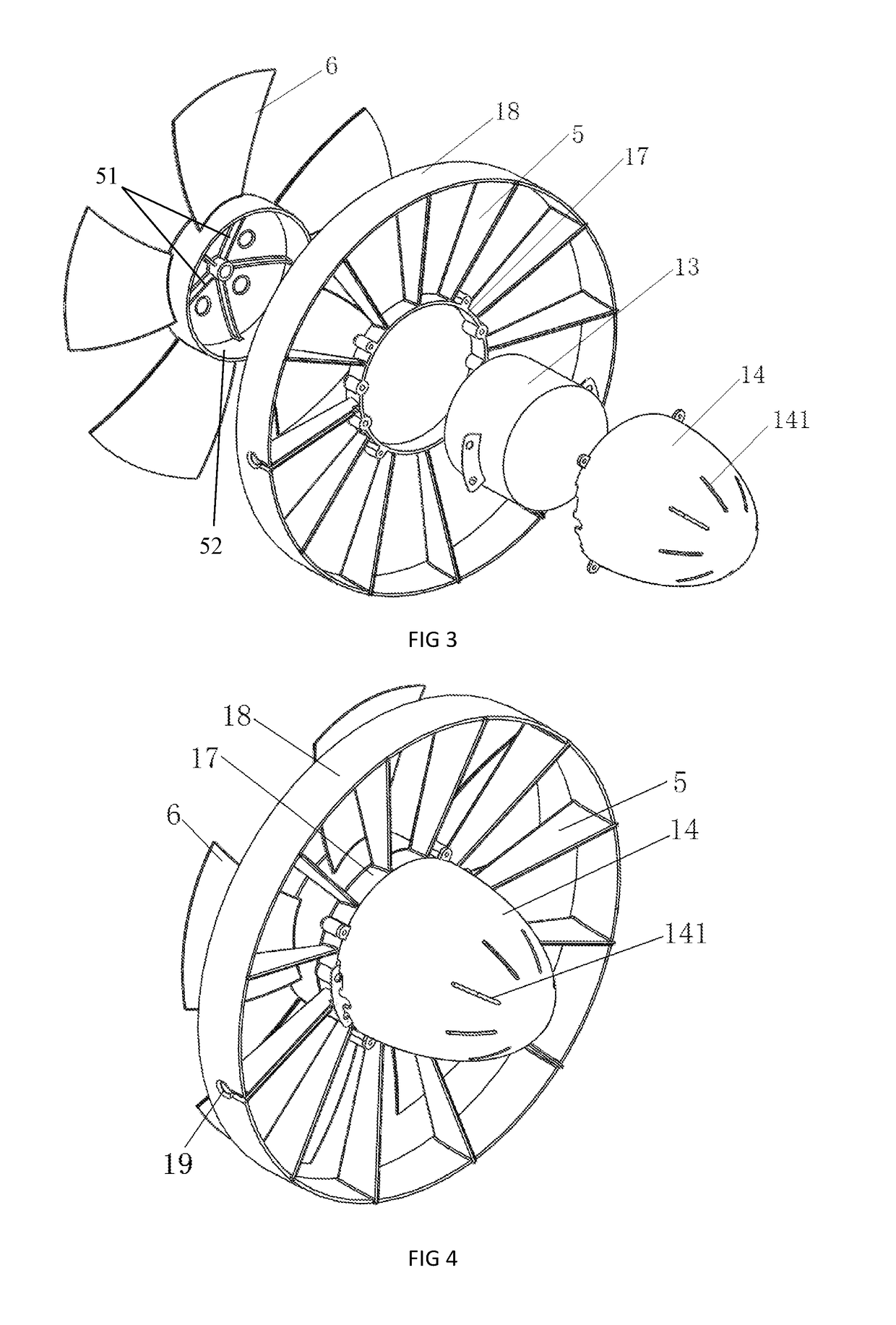

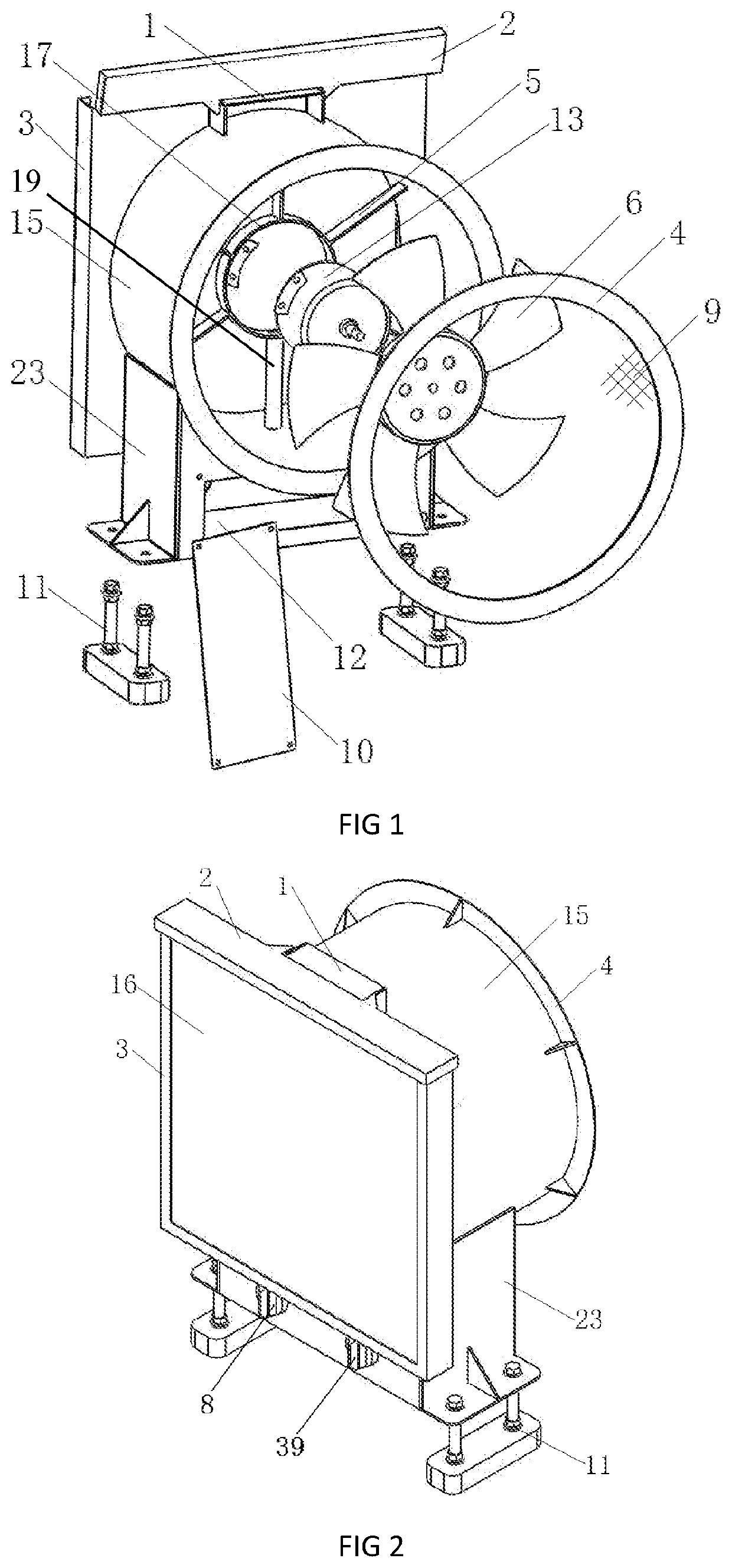

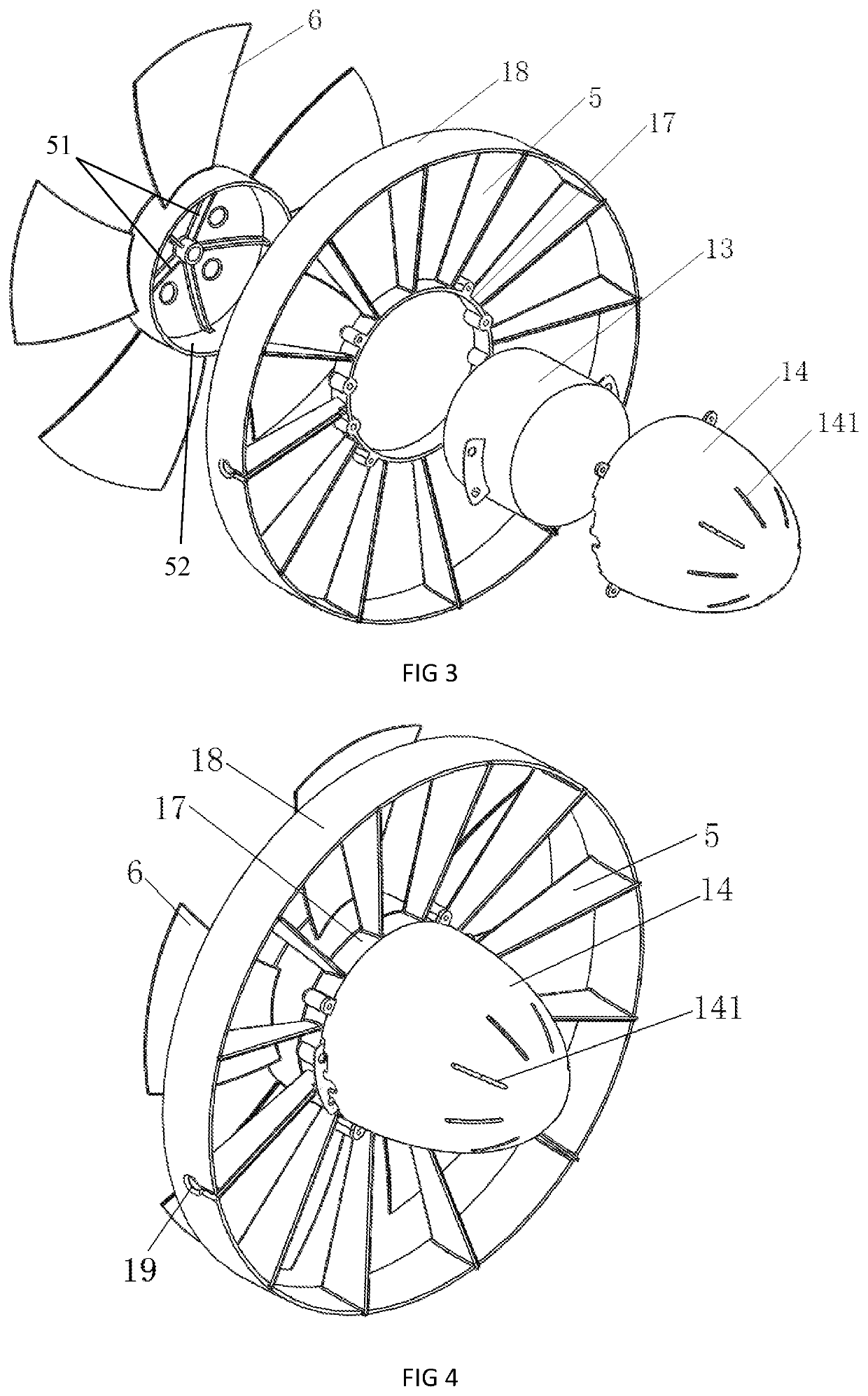

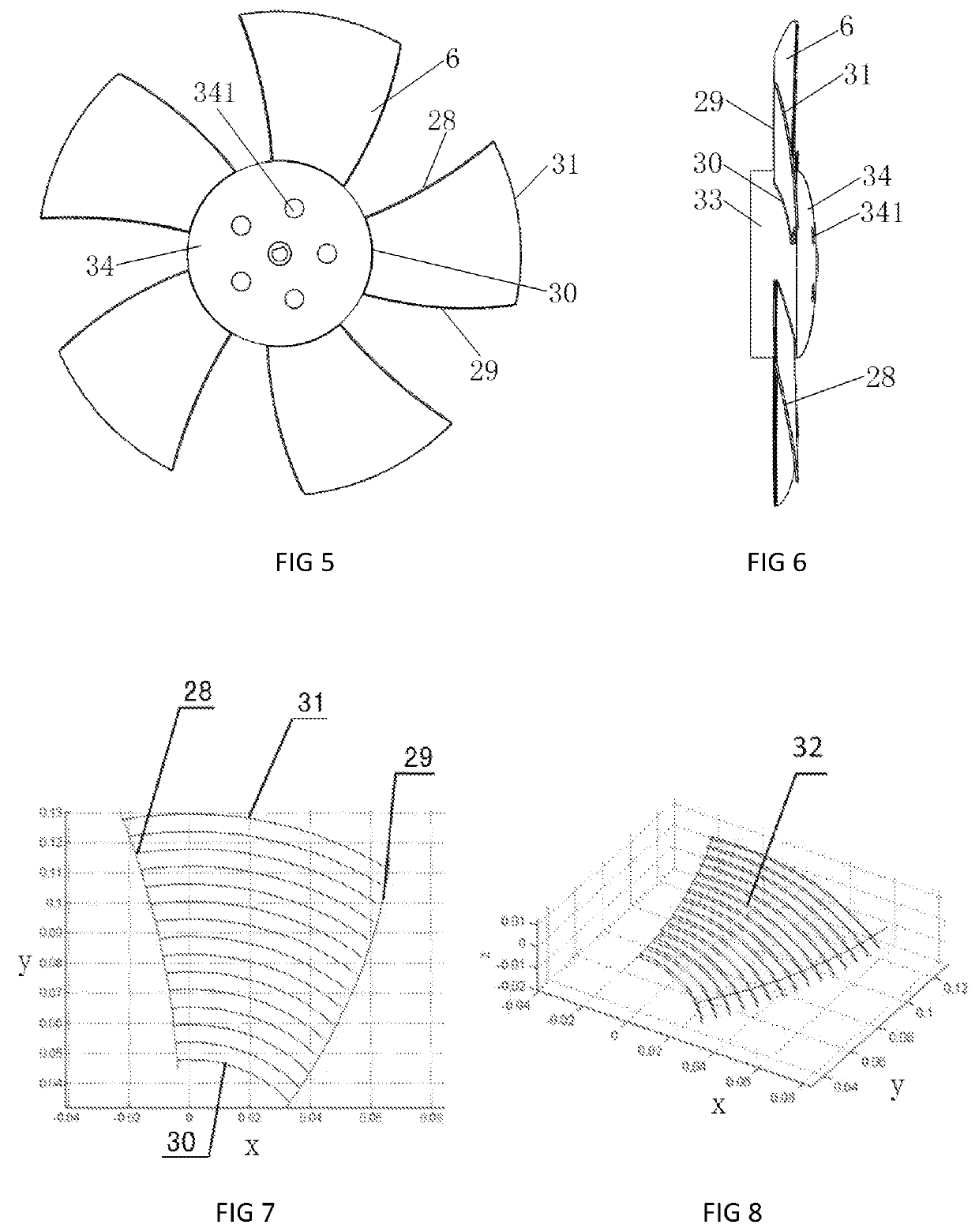

Air purifier

ActiveUS20180202465A1Reduce flow turbulenceImproves fanDispersed particle filtrationPump componentsTongue and grooveEngineering

An air purifier system characterized by a housing, a fan, and a motor, as well as a docking ring located at the outer edge of the inlet side of the air purifier system, a seat below the housing, a prefilter or barrier upstream of the fan, and a filter downstream of the fan. An air purifier system characterized by an upstream-to-downstream airflow path that includes an axial fan, a diffuser, and a filter, in that relative order, with an electric motor held along the centerline of the housing by one or more supports and / or guide vanes. A docking ring that facilitates attachment of a screen-like, mesh-like, cloth-like, or paper-like filter to a machine capable of air purification, characterized by having a large hole through which air passes and by attachment to the machine utilizing any tongue and groove system, for which installation and removal of the docking ring is achieved, in whole or in part, by rotation of said docking ring relative to the machine.

Owner:QINGDAO RANDALL AERODYNAMICS ENG LLC

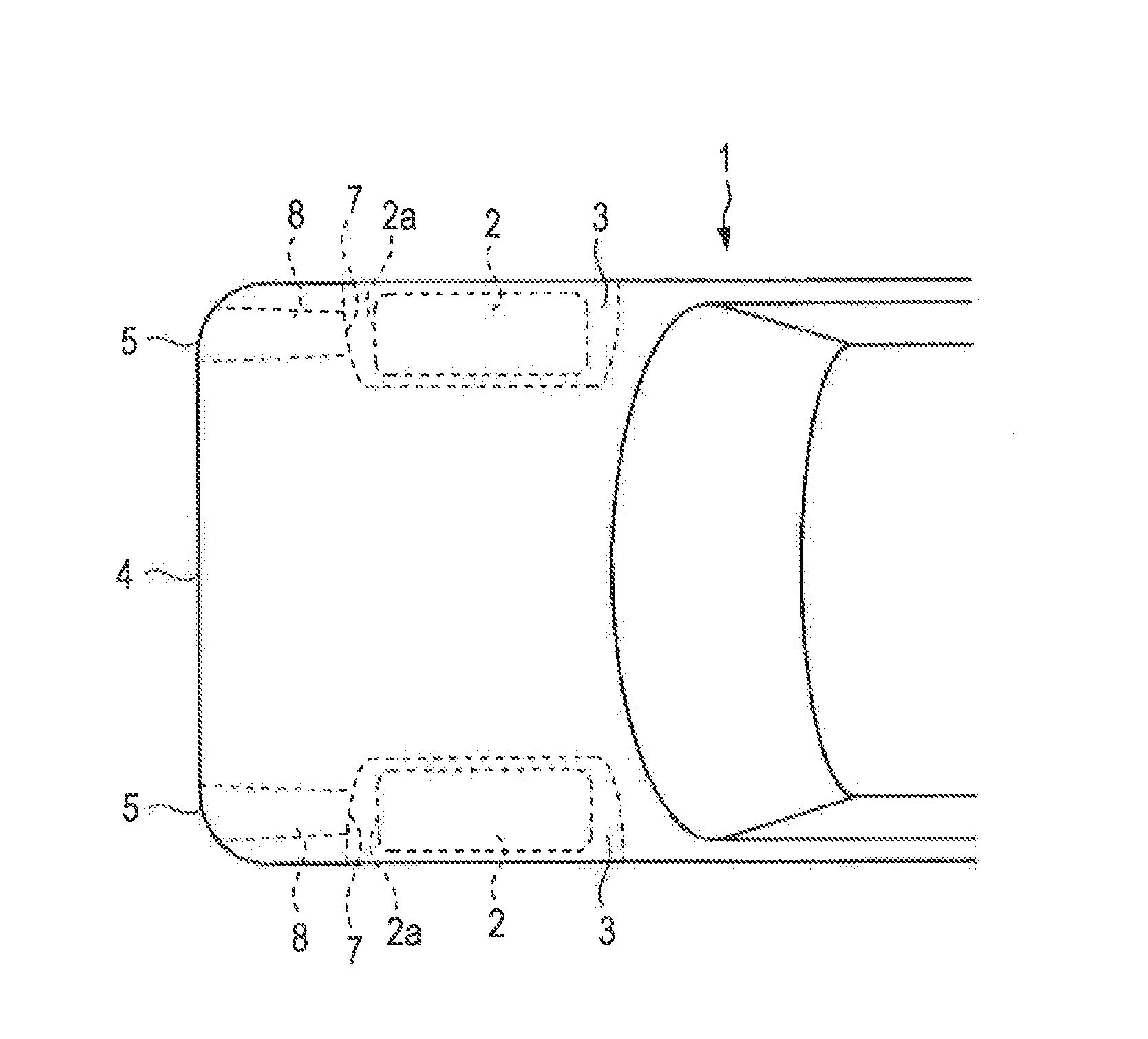

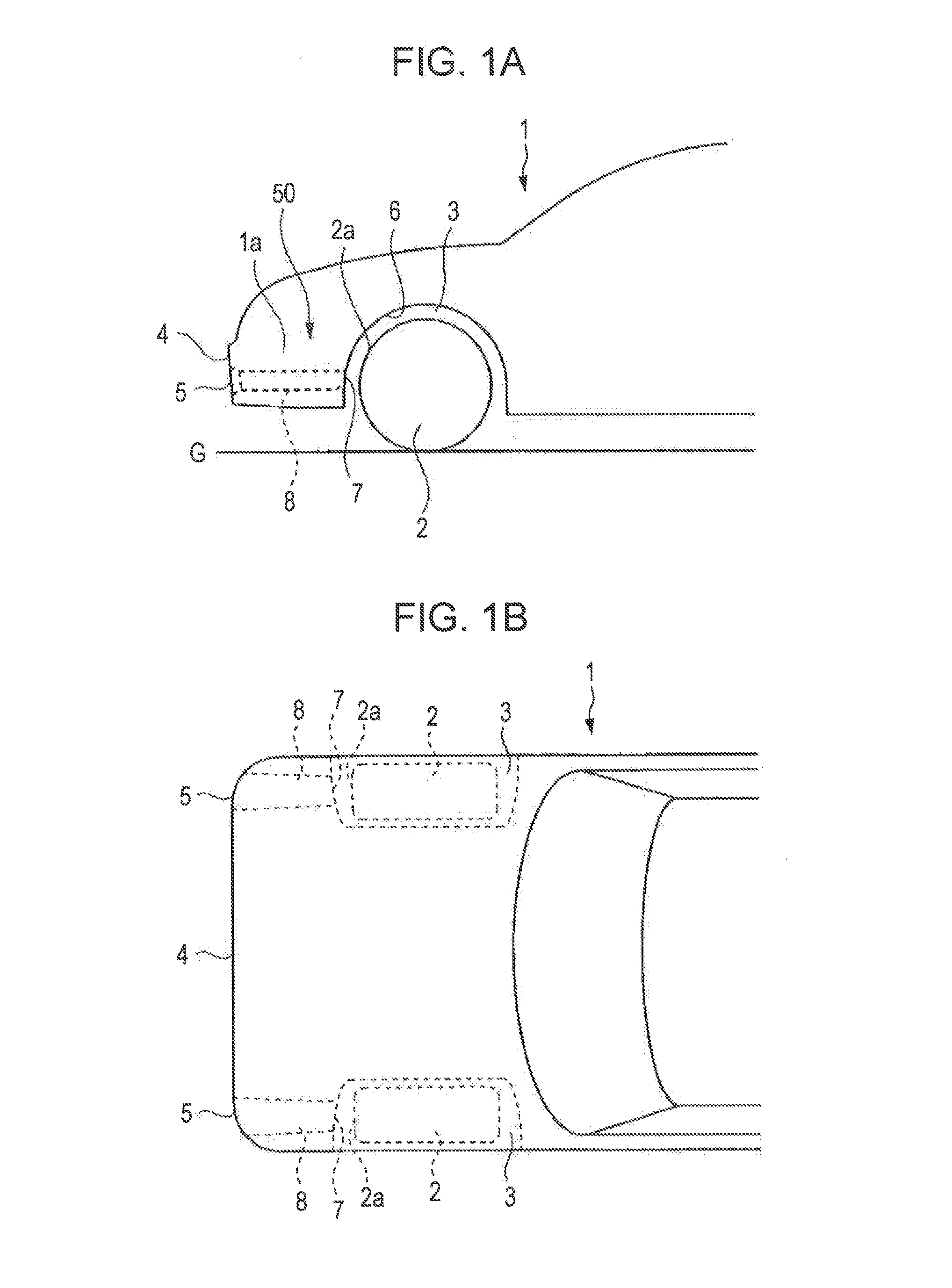

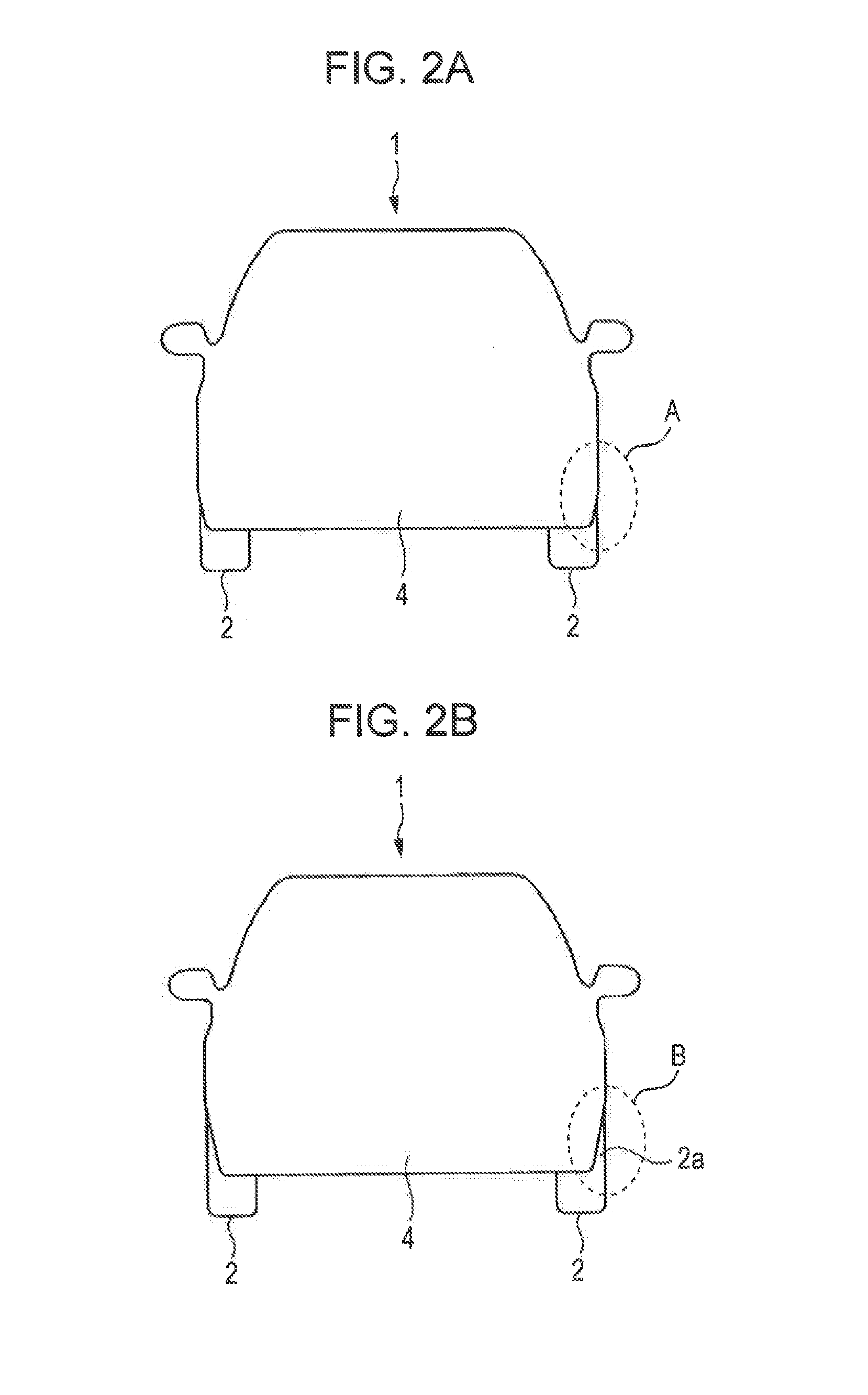

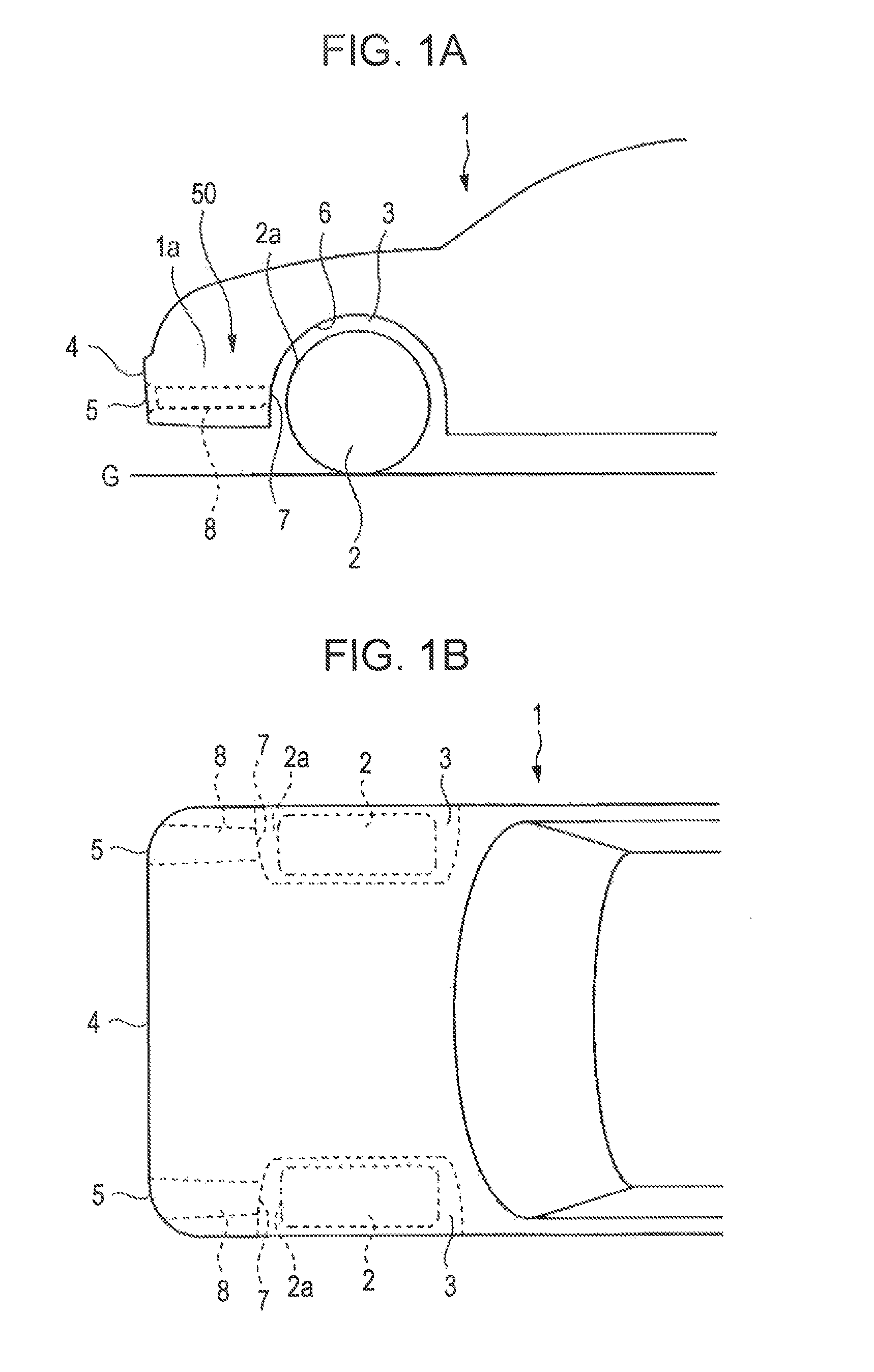

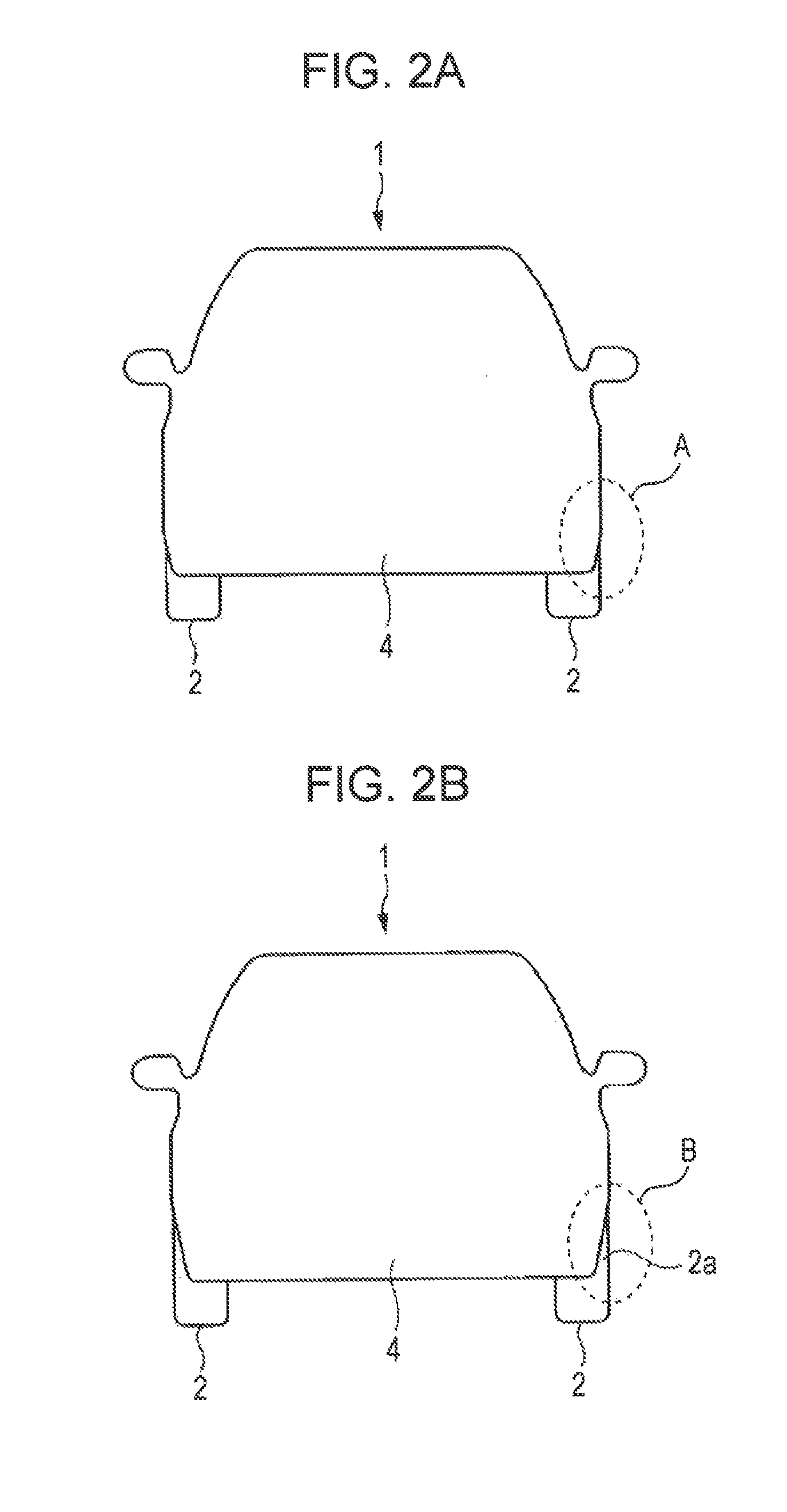

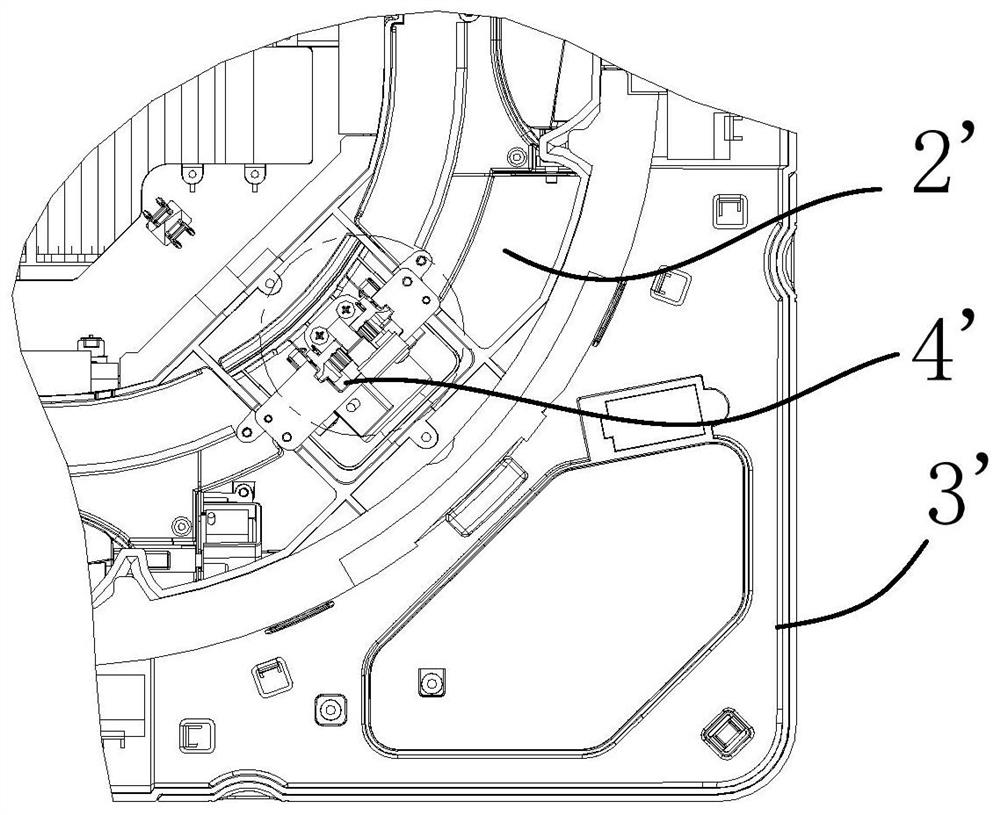

Rectifier of vehicle wheel house

InactiveUS20140175830A1Reduce turbulenceReduce flow turbulenceVehicle seatsWindowsEngineeringRectifier

A rectifier of a vehicle wheel house to rectify an air flow in the wheel house housing a wheel includes an air passage configured to introduce running wind from a forward position of a vehicle; and an air blowing port which is formed at a partition wall member included in a partition wall of the wheel house on the vehicle body side, and configured to allow the running wind through the air passage to strike an outer circumferential surface of the wheel.

Owner:SUBARU CORP

Centrifuge nozzle and method and apparatus for inserting said nozzle into a centrifuge bowl

ActiveUS8672243B2Good flexibilityReduced Power RequirementsRotary centrifugesSpray nozzlesEngineeringCentrifuge

In a centrifuge nozzle a nozzle body defines an inlet in fluid communication with a nozzle outlet. The nozzle body is adapted to be releasably positioned in an aperture defined by a centrifuge bowl assembly. A camming portion projects outwardly from the nozzle body and defines a surface frictionally engageable with a portion of the bowl assembly. The nozzle body also defines a male mounting portion for slidably engaging a complimentarily shaped female slot defined by a nozzle insertion and extraction tool. The outlet of the nozzle is located adjacent to the male mounting portion.

Owner:ALFA LAVAL CORP AB

Structure and method for improving flow uniformity and reducing turbulence

InactiveUS7249614B2Reducing lateral turbulenceReduce trafficAerodynamic testingFluid dynamicsEngineeringMaterial Perforation

Owner:VAKILI AHMAD D

D-shaped tube for header

InactiveUS20070209353A1Reduce turbulenceImprove heat transfer performanceExhaust apparatusSilencing apparatusWater flowInternal combustion engine

Disclosed is a water cooled exhaust assembly for use in association with an internal combustion engine in a marine environment. Inner and outer nested tubes are affixed to a mounting flange to form, in conjunction with an access port in the mounting flange, a cooling water flow channel to provide cooling of exhaust gases from the engine. The inner tube is formed with a flattened portion to produce a reduction in exhaust gas turbulence in the flow channel with a consequent increase in heat transfer capability.

Owner:COMPX INTERNATIONAL

Air purifier

ActiveUS10711804B2Reduce flow turbulenceImproves fanPump componentsDispersed particle filtrationAir purifiersStructural engineering

An air purifier system characterized by a housing, a fan, and a motor, as well as a docking ring located at the outer edge of the inlet side of the air purifier system, a seat below the housing, a prefilter or barrier upstream of the fan, and a filter downstream of the fan. An air purifier system characterized by an upstream-to-downstream airflow path that includes an axial fan, a diffuser, and a filter, in that relative order, with an electric motor held along the centerline of the housing by one or more supports and / or guide vanes. A docking ring that facilitates attachment of a screen-like, mesh-like, cloth-like, or paper-like filter to a machine capable of air purification, characterized by having a large hole through which air passes and by attachment to the machine utilizing any tongue and groove system, for which installation and removal of the docking ring is achieved, in whole or in part, by rotation of said docking ring relative to the machine.

Owner:QINGDAO RANDALL AERODYNAMICS ENG LLC

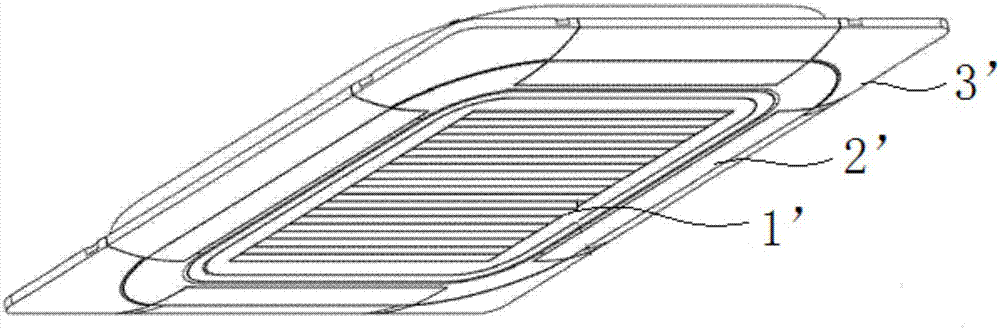

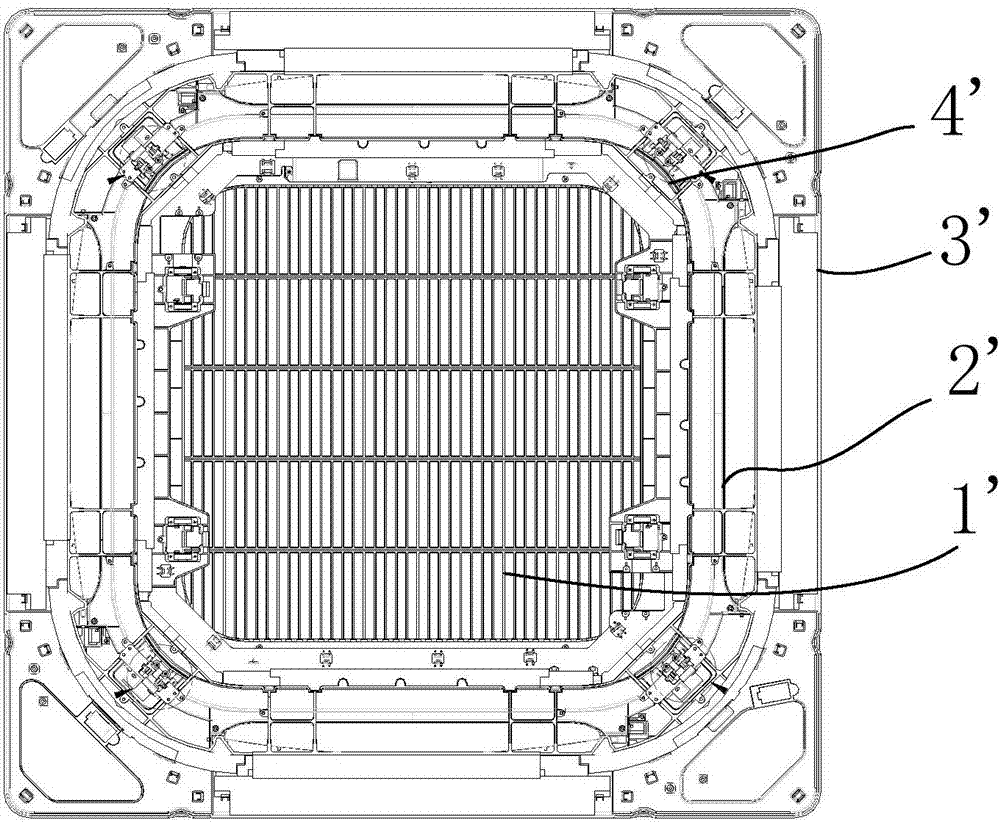

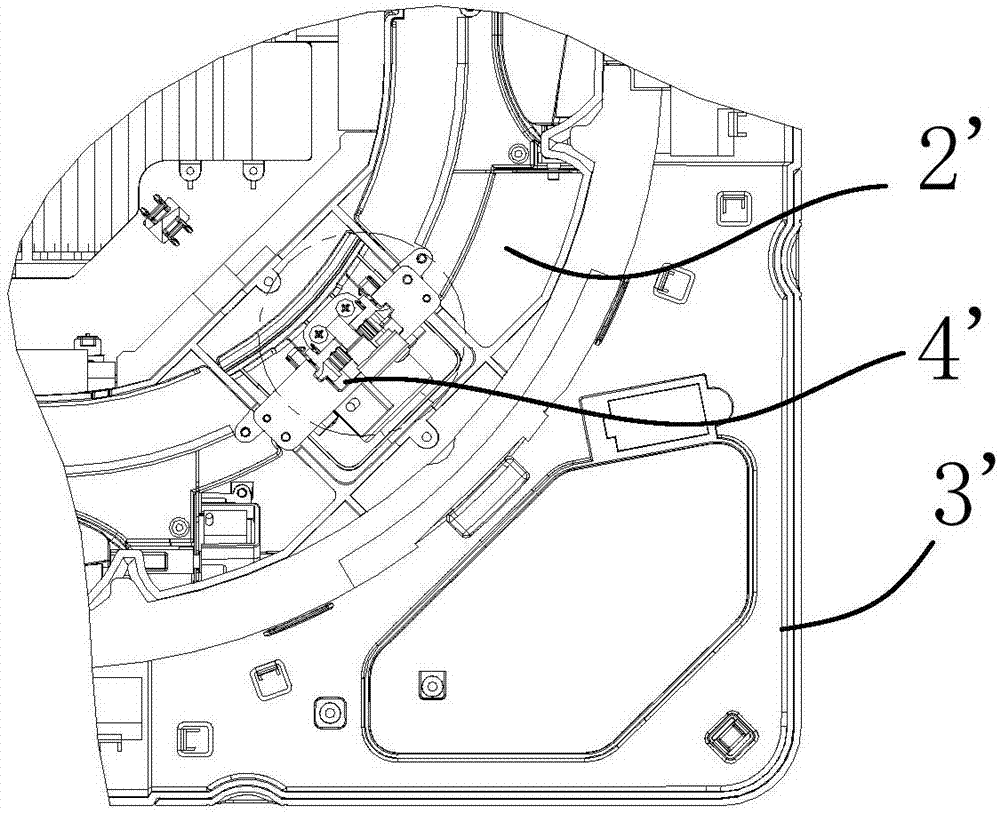

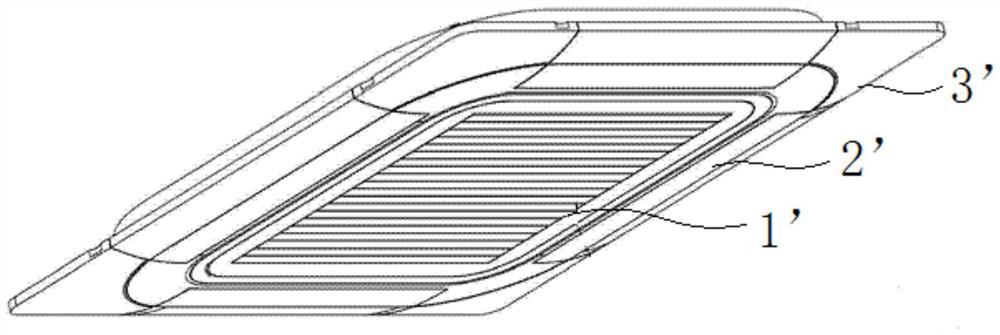

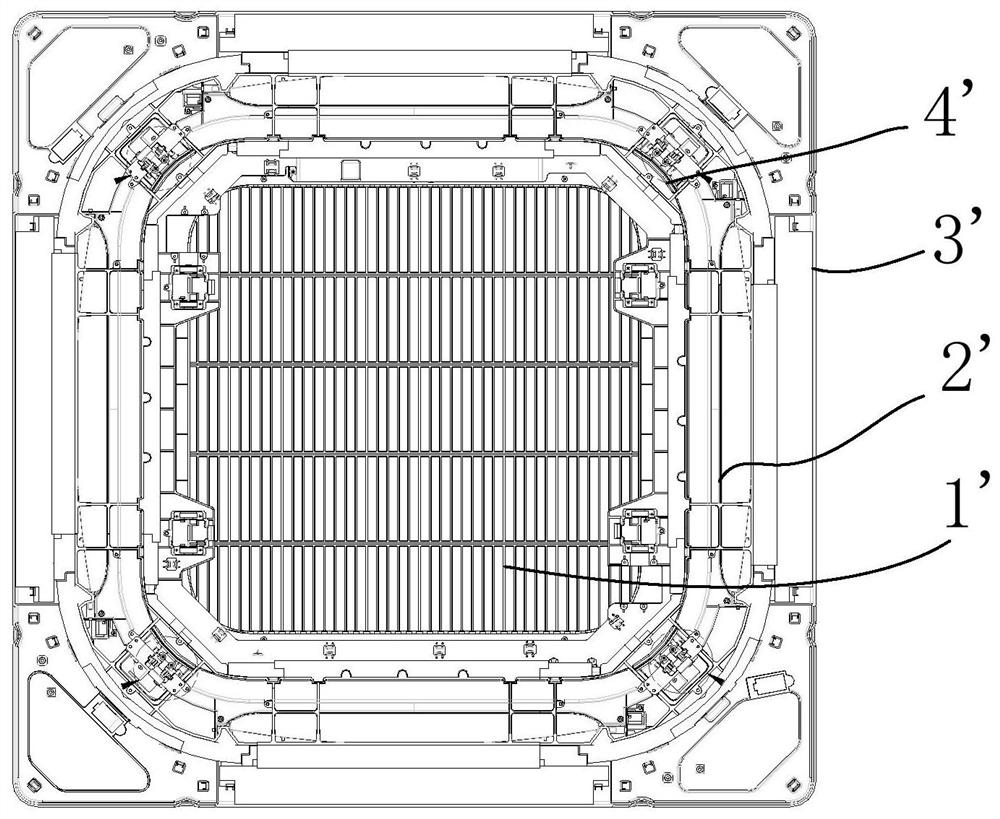

Ceiling-mounted air conditioner panel and ceiling-mounted air conditioner

ActiveCN106895494AReduce flow turbulenceIncrease air volumeLighting and heating apparatusNoise suppressionAir volumeAirflow

The invention relates to a ceiling-mounted air conditioner panel and a ceiling-mounted air conditioner, wherein the ceiling-mounted air conditioner panel comprises an air inlet frame, an air outlet frame and a driving device arranged at the side of the air inlet frame far away from an air outlet duct, and the air outlet frame is driven by the driving device to move to form an air outlet communicating with the air outlet duct. In the invention, the driving device is arranged far away from the air outlet duct and the air outlet so that the air outlet duct and the air outlet can communicate with each other, and airflow from the air outlet duct can be discharged from the air outlet smoothly, in favor of enhancing the air volume, and airflow disturbance is reduced effectively; noise generated in turbulence is eliminated, and the condensation problem of the air outlet can also be solved.

Owner:GREE ELECTRIC APPLIANCES INC

Outdoor machine condenser and air conditioner

ActiveCN102635984AEfficient removalImprove defrosting effectEvaporators/condensersSuper coolingFrost

The invention discloses an outdoor machine condenser and an air conditioner. The outdoor machine condenser comprises an inner row of condensation pipelines and an outer row of condensation pipelines, wherein first flow path refrigerating fluid inlets, second flow path refrigerating fluid inlets, first connecting pipe ports and super-cooling flow path refrigerating fluid inlets are sequentially arranged on the inner row of condensation pipelines from top to bottom; first flow path refrigerating fluid outlets, second flow path refrigerating fluid outlets, second connecting pipe ports and a refrigerating fluid main outlet are sequentially arranged on the outer row of condensate pipelines from top to bottom; and the refrigerating fluid main outlet is arranged at the upper end of the port at the bottom end of the outer row of condensation pipelines. Through raising the refrigerating fluid main outlet to be far away from the port at the bottom end of the outer row of condensation pipelines, the condensation pipeline at the bottom end, which is close to an outdoor machine chassis, has higher temperature and can effectively remove the residual frost at the bottoms of the chassis and the condenser, thus the freezing phenomenon is avoided, and the defrosting performance and overall operating performance of the air conditioner are favorably improved.

Owner:HAIER GRP CORP +1

Wall of turbo machine and turbo machine

ActiveUS9051840B2Reduce flow turbulenceEngine manufacturePump componentsRadial positionMechanical engineering

The invention relates to wall of a turbo machine having a cascade of blades. The wall includes: a first platform facing a first passage between blades in the cascade of blades; and a second platform facing a second passage between adjacent cascade of blades on an upstream side and cascade of blades on a downstream side, and having a circumferential outline having a distribution of radial positions. According to the invention, loss due to disturbance of flow through the gap of axially adjacent walls can be reduced.

Owner:IHI CORP +1

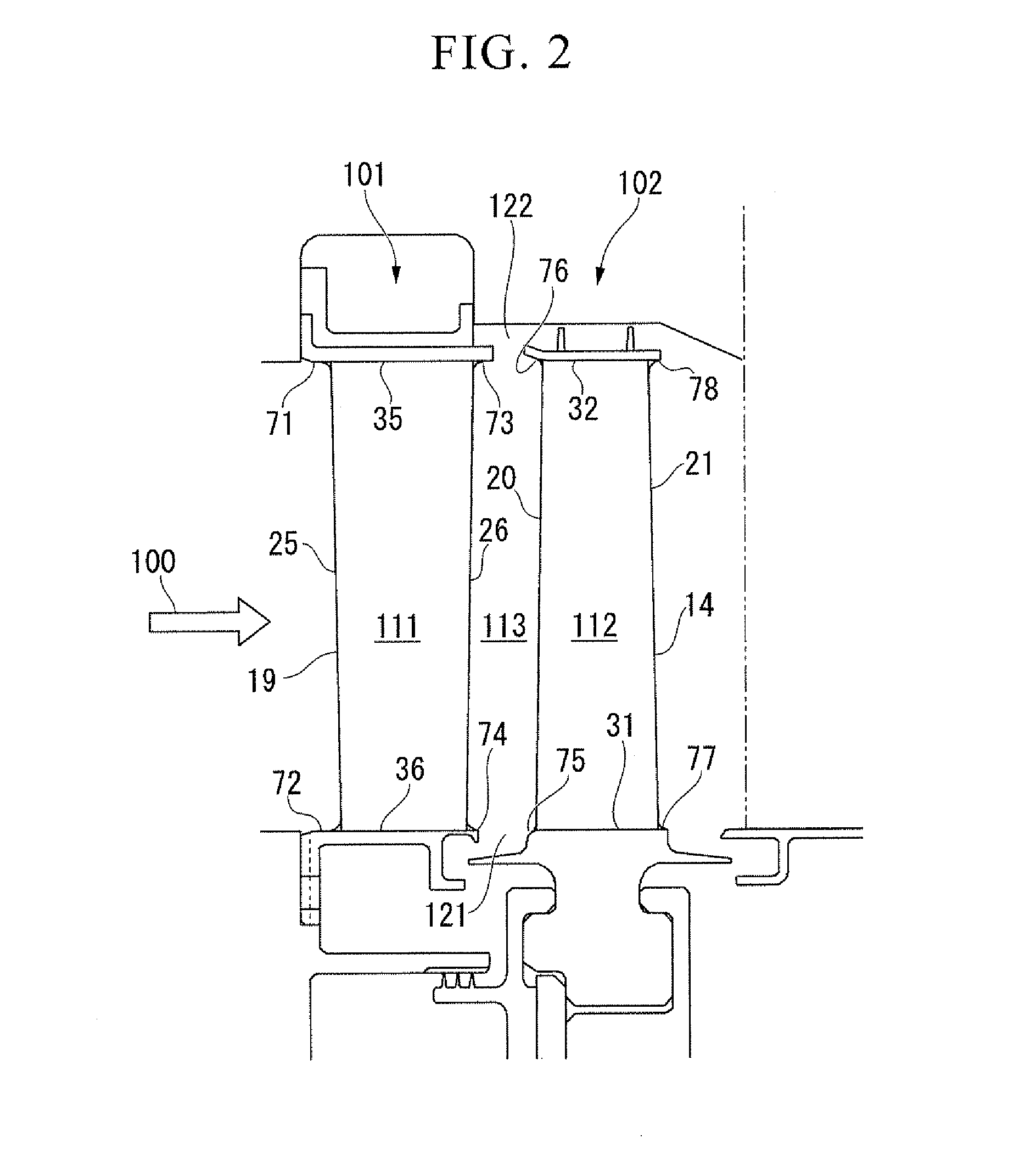

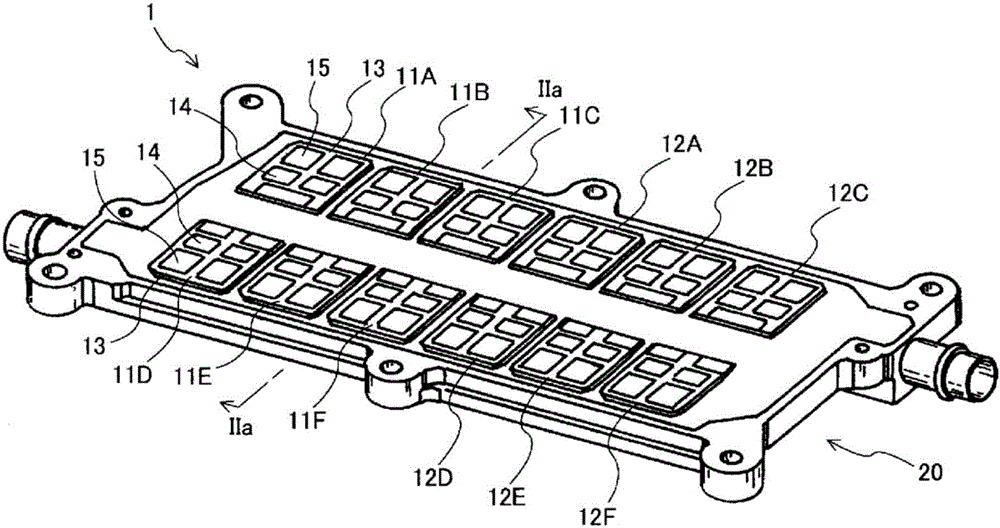

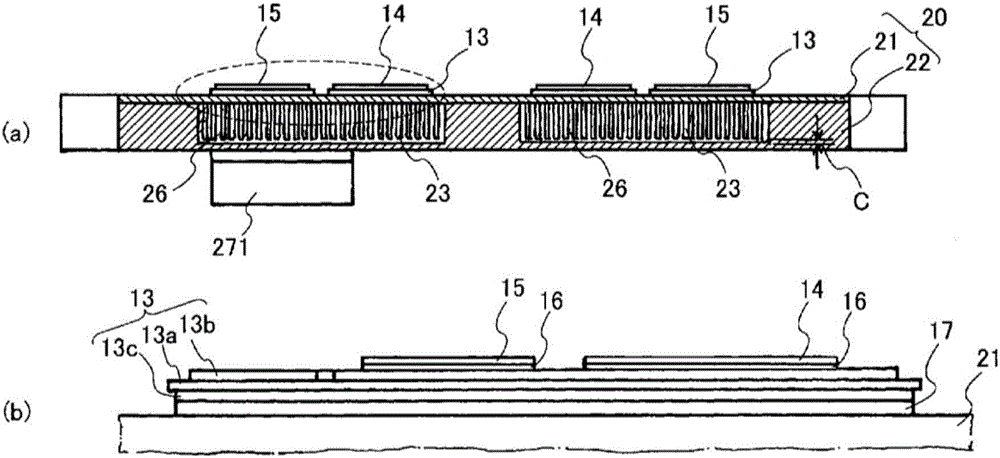

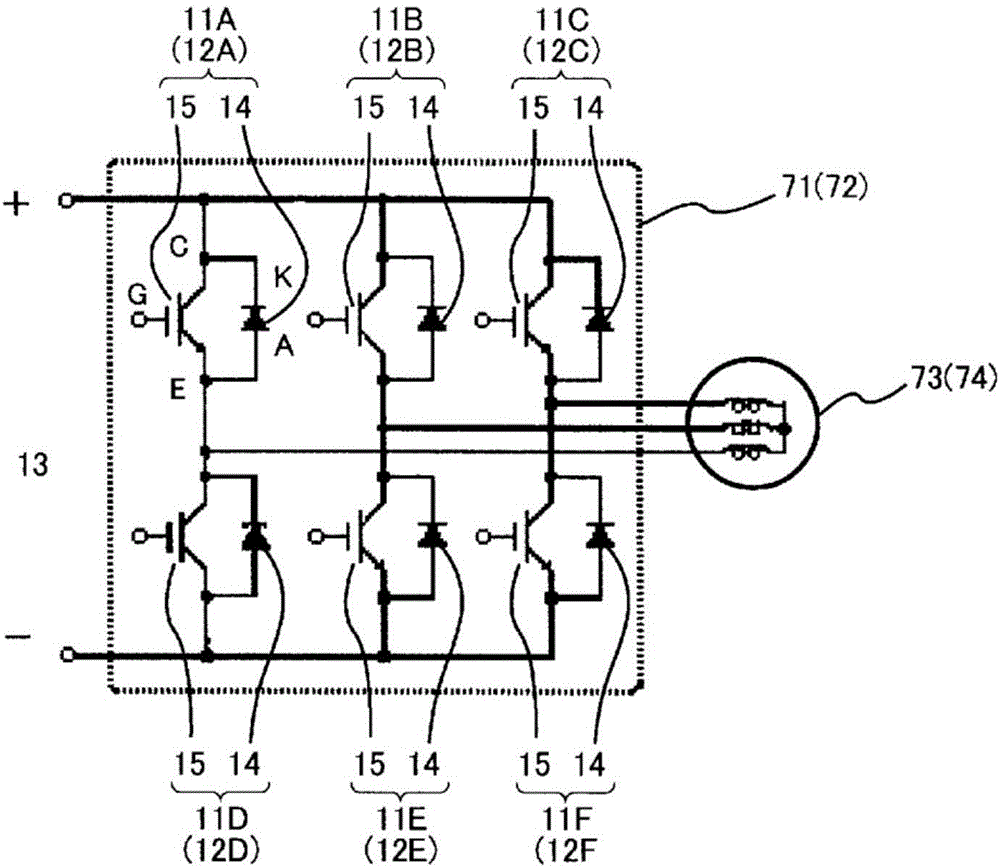

Semiconductor device

ActiveCN105940491AReduce flow turbulenceReduce disorderSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

A cooler (20) for a semiconductor device is provided with: an introduction part (27) and a discharge part (28) for a cooling liquid; an introduction path (24); a discharge path (25); and a cooling flow path (26). The introduction path (24) and the discharge path (25) are provided with asymmetric planar shapes. A part (271) connecting the introduction path (24) and the introduction part (27) faces the cooling flow path (26) in a section directly below a plurality of circuit boards (13) arranged on the cooler (20). A part (281) connecting the discharge path (25) and the discharge part (28) faces the cooling flow path (26) in a section directly below a plurality of circuit boards (13) arranged on the cooler (20).

Owner:FUJI ELECTRIC CO LTD

Dual check backflow preventer

ActiveUS9518669B2Reduce flow turbulenceIncrease pressureCheck valvesDomestic plumbingEngineeringDISC assembly

A backflow preventer that includes a housing having an inlet and an outlet adapted to be mounted in a liquid flow configuration in a liquid supply circuit. An upstream check disc assembly is positioned in the housing downstream of the inlet, and includes an upstream check plate supporting a downstream diaphragm. An upstream check disc is positioned downstream of the diaphragm and integrally formed with an upstream stem mounted in an aperture in a central hub formed in the check plate for movement between a normally open, flow position and a closed position preventing backflow of liquid through the inlet. A downstream check disc assembly is positioned in the housing downstream from the upstream check disc assembly. A vent discharges liquid to atmosphere upstream of the downstream check disc assembly.

Owner:CONBRACO IND

Rectifier of vehicle wheel house

InactiveUS9073583B2Reduce turbulenceReduce flow turbulenceSuperstructure subunitsVehicle body streamliningEngineeringRectifier

A rectifier of a vehicle wheel house to rectify an air flow in the wheel house housing a wheel includes: an air passage configured to introduce running wind from a forward position of a vehicle; and an air blowing port which is formed at a partition wall member included in a partition wall of the wheel house on the vehicle body side, and configured to allow the running wind through the air passage to strike an outer circumferential surface of the wheel.

Owner:SUBARU CORP

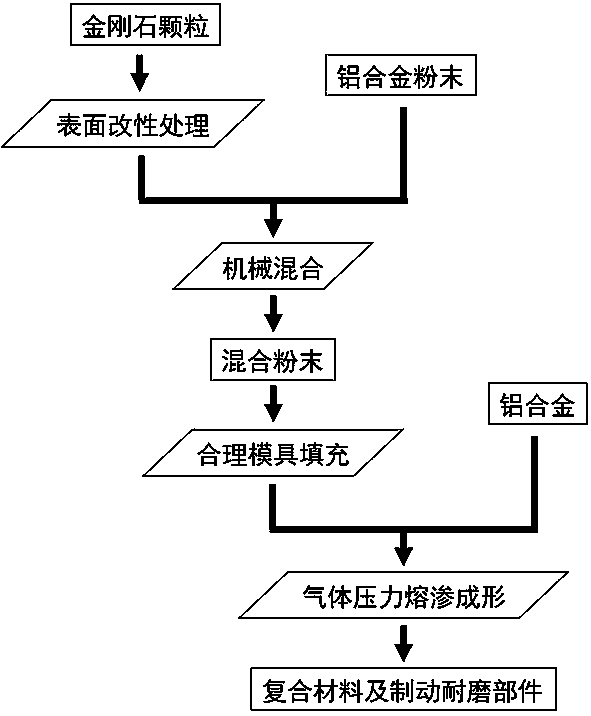

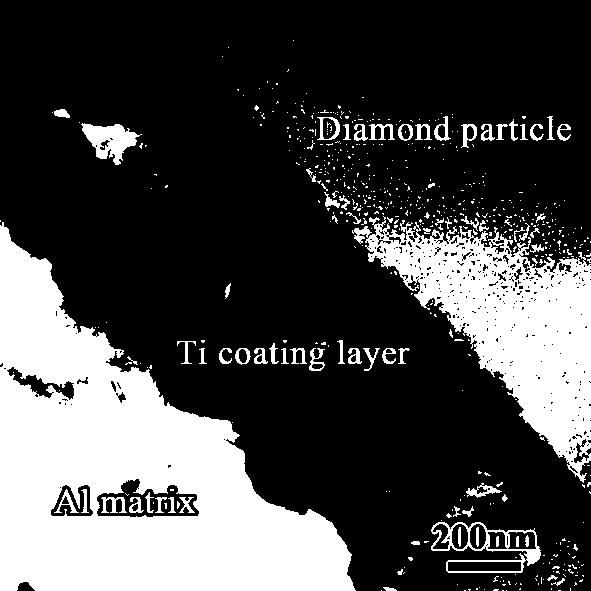

A diamond particle reinforced aluminum-based brake wear-resistant composite material and its preparation method

The invention relates to a diamond particle-reinforced aluminum-based brake wear-resistant material and a preparation method thereof, belonging to the field of wear-resistant materials. It is characterized in that the surface-modified 5-15μm diamond particles are mixed with Al-Cu alloy powder and placed in a forming mold. After vacuuming, use high-pressure gas to drive Al-Cu at 750-950°C and 0.1-2.0MPa. Si alloy melt infiltration forming, heat preservation and pressure holding for 5-30min, obtained composite material with a volume fraction of reinforcing phase of 5-25% applied to brake wear-resistant parts; realized precise control and optimization of the two-phase interface and microstructure of the composite material, Ensure that the excellent performance of the reinforced phase is stable and fully exerted under actual braking conditions. Compared with traditional steel materials, the composite material prepared by the present invention has significantly reduced density and greatly improved thermal conductivity while optimizing friction and wear characteristics, meeting the needs of braking materials and components for the development of transportation equipment in the direction of higher speed and lighter weight. Brand new requirement.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

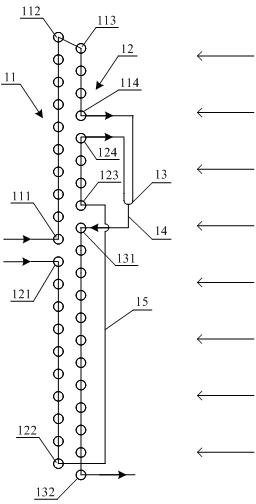

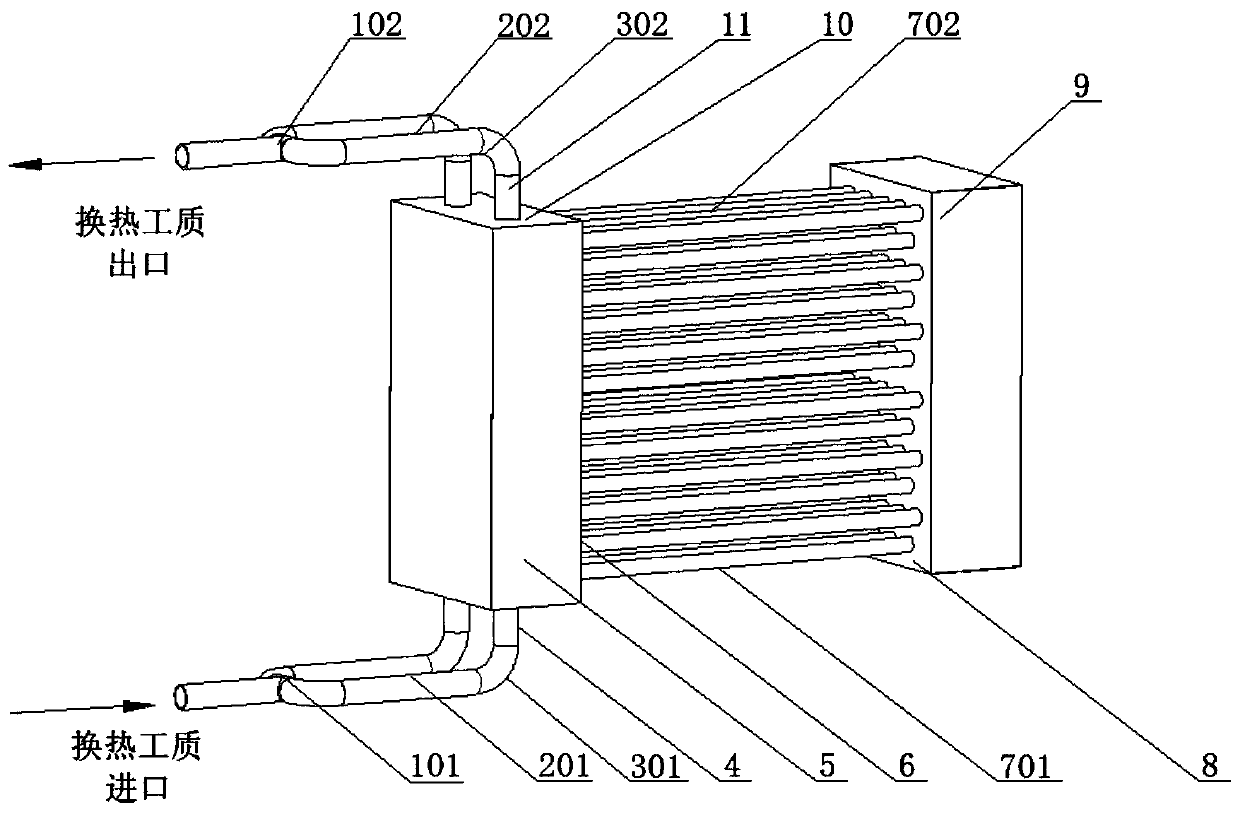

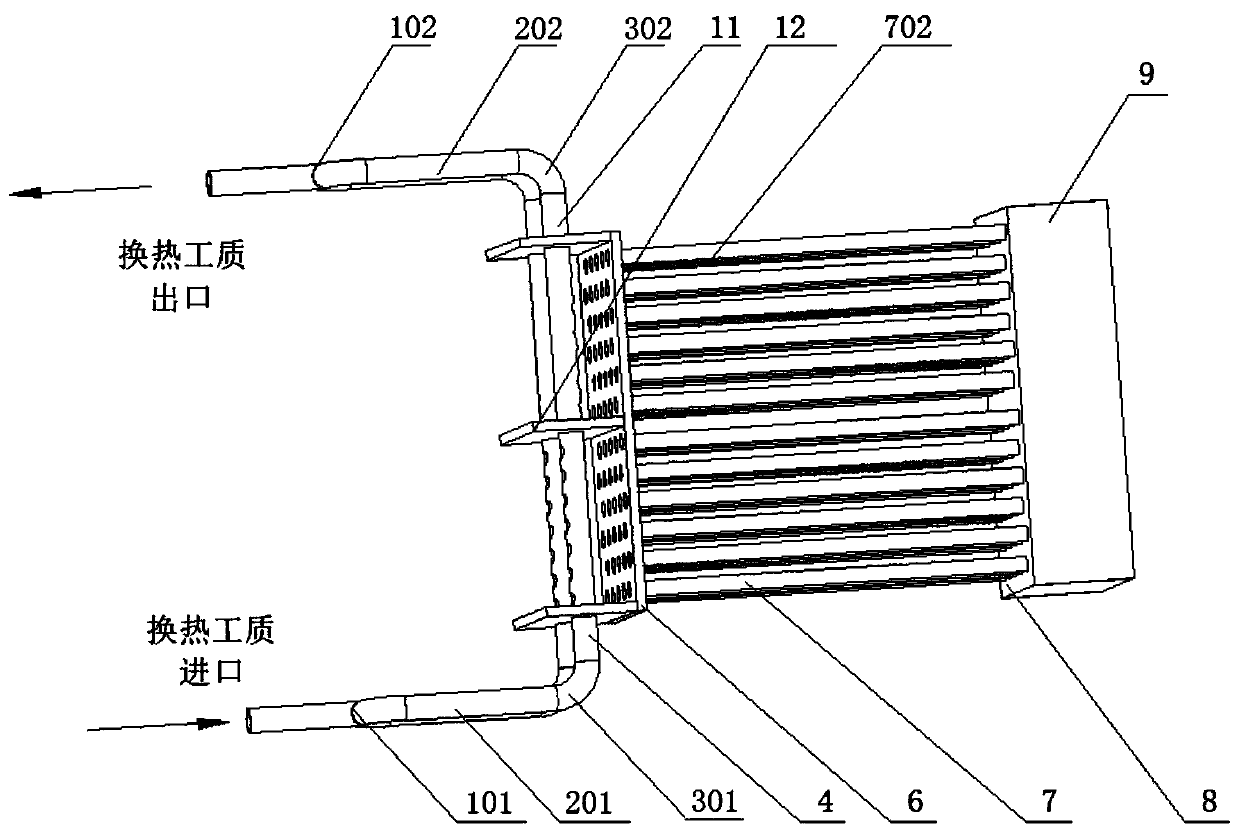

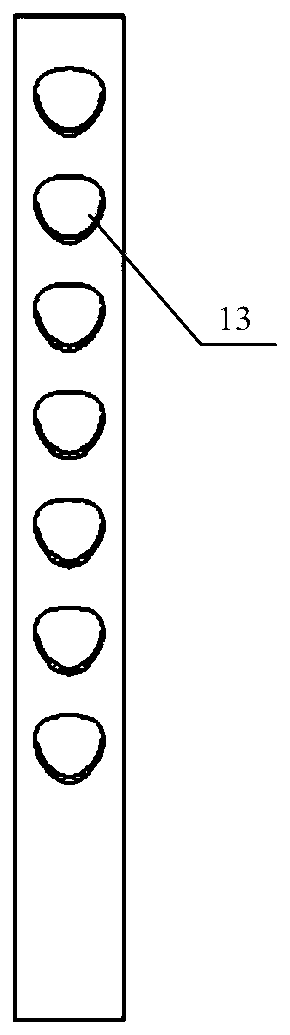

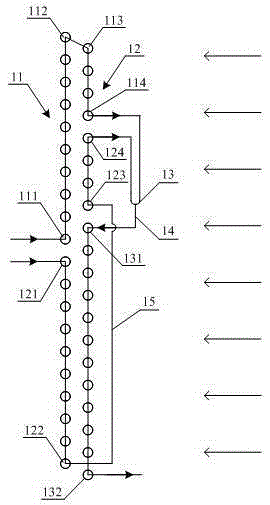

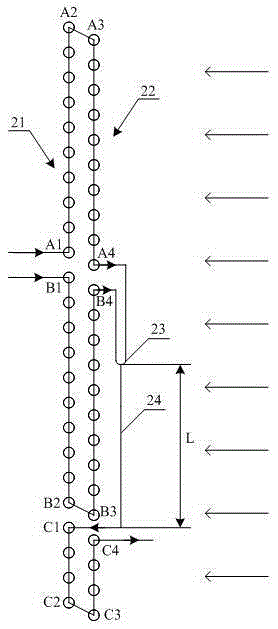

An inlet and outlet tube box for evenly distributing the flow in the tube of a tube heat exchanger

Owner:XI AN JIAOTONG UNIV

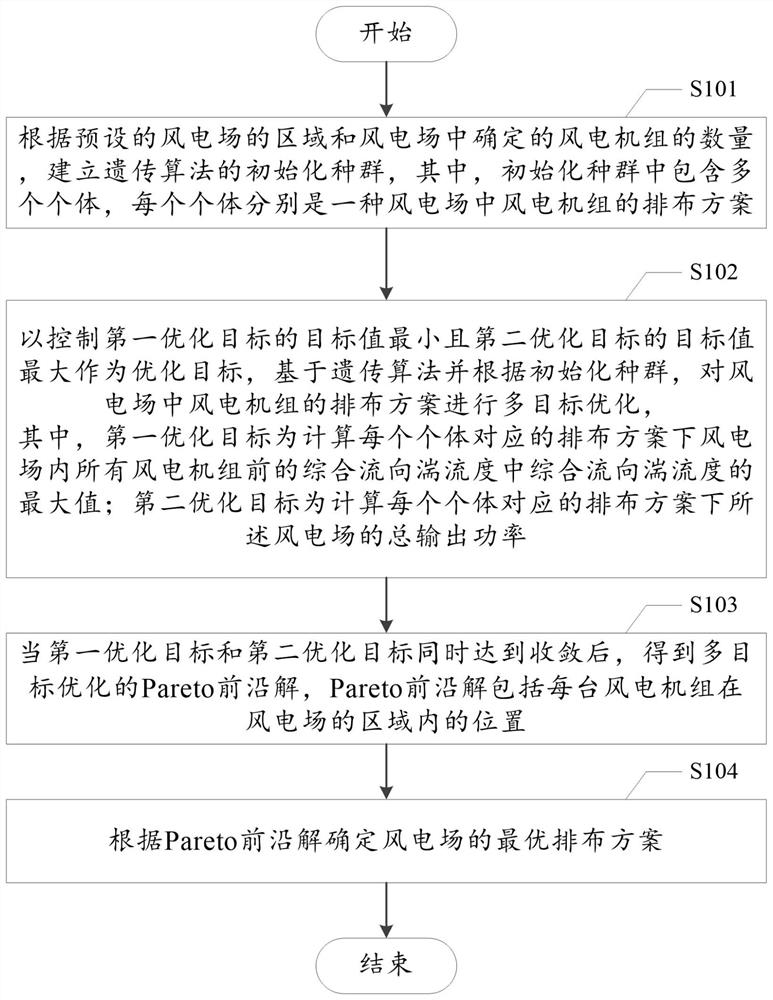

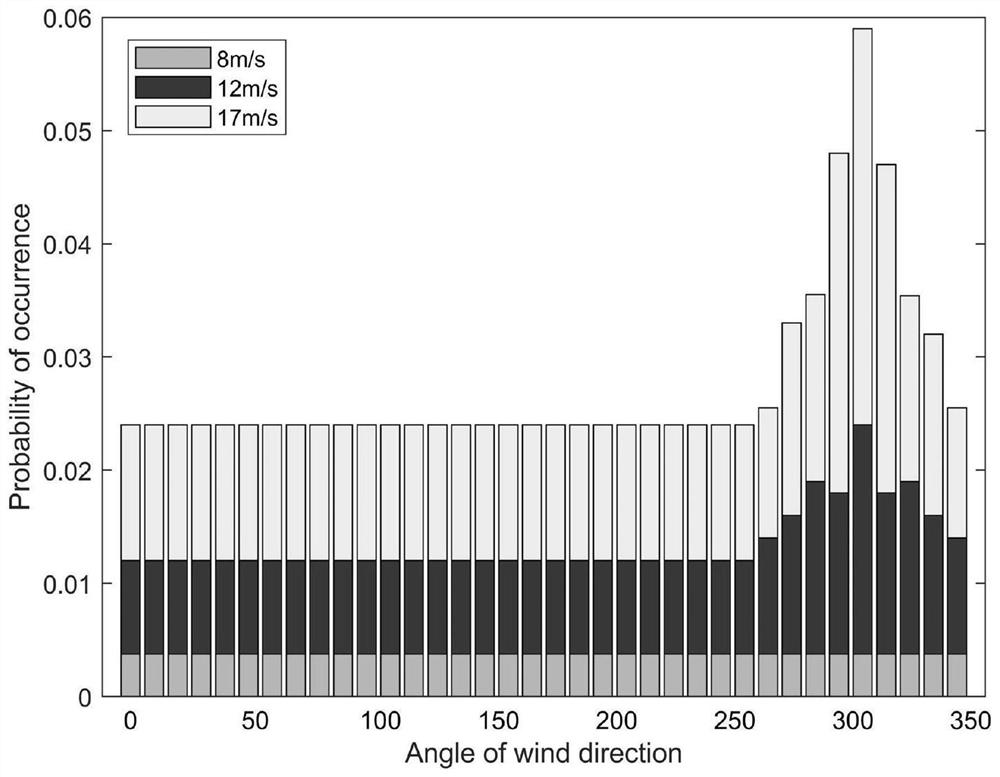

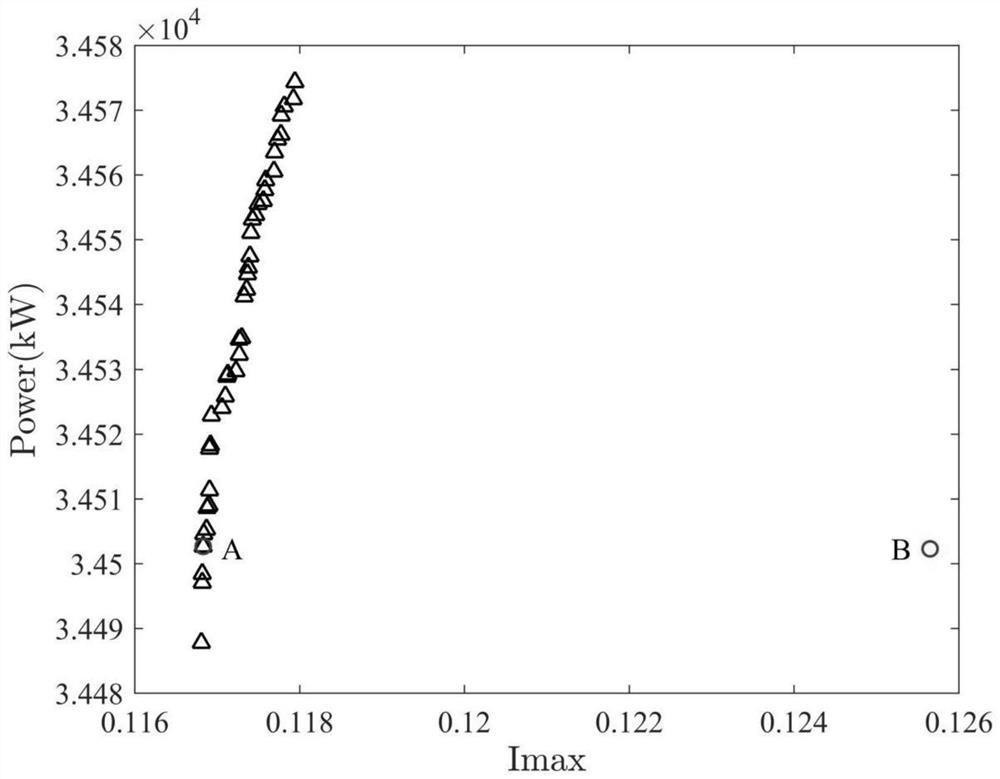

Multi-target arrangement optimization method and system for wind power plant positions

PendingCN114444784AIncrease output powerIncreased operating lifeForecastingInformation technology support systemGenetics algorithmsAtmospheric sciences

The invention relates to the technical field of wind power plant micro-siting, particularly provides a multi-target arrangement optimization method and system for wind power plant positions, and aims to solve the problems that in the existing wind power plant arrangement optimization process, the optimization target is single, and the influence of conditions such as wind conditions on the optimization process is not fully considered. In order to achieve the purpose, a genetic algorithm is applied, the target value of a first optimization target is controlled to be minimum, the target value of a second optimization target is controlled to be maximum, multi-target optimization is carried out on the arrangement scheme of the wind turbine generators in the wind power plant, a Pareto leading solution of multi-target optimization is obtained, and the arrangement optimization scheme of the wind power plant is determined. Through the configuration mode, in the optimization process of the arrangement scheme of the wind power plant, the total output power of the wind power plant and the front flow turbulence degree of the wind turbine generator are comprehensively considered, on the premise that the total output power of the wind power plant is ensured, the front flow turbulence degree of the wind turbine generator is reduced, and the service life of the wind power plant is prolonged; and the generating capacity of the whole life cycle is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Outdoor unit condenser and air conditioner

ActiveCN102635984BEfficient removalImprove defrosting effectEvaporators/condensersSuper coolingFrost

The invention discloses an outdoor machine condenser and an air conditioner. The outdoor machine condenser comprises an inner row of condensation pipelines and an outer row of condensation pipelines, wherein first flow path refrigerating fluid inlets, second flow path refrigerating fluid inlets, first connecting pipe ports and super-cooling flow path refrigerating fluid inlets are sequentially arranged on the inner row of condensation pipelines from top to bottom; first flow path refrigerating fluid outlets, second flow path refrigerating fluid outlets, second connecting pipe ports and a refrigerating fluid main outlet are sequentially arranged on the outer row of condensate pipelines from top to bottom; and the refrigerating fluid main outlet is arranged at the upper end of the port at the bottom end of the outer row of condensation pipelines. Through raising the refrigerating fluid main outlet to be far away from the port at the bottom end of the outer row of condensation pipelines, the condensation pipeline at the bottom end, which is close to an outdoor machine chassis, has higher temperature and can effectively remove the residual frost at the bottoms of the chassis and the condenser, thus the freezing phenomenon is avoided, and the defrosting performance and overall operating performance of the air conditioner are favorably improved.

Owner:HAIER GRP CORP +1

High pressure control valve

ActiveUS9297345B2Increase pressureReduce erosionOperating means/releasing devices for valvesWear reducing fuel injectionHigh pressureControl valves

Owner:KENDRION VILLINGEN GMBH

A Supporting Structure for Flow Channels in Exhaust Cylinders of Small and Medium-sized Gas Turbines

ActiveCN110273719BReduce working heat stressAvoid tearing and deformationMachines/enginesEngine componentsEngineeringCylinder block

The invention belongs to the technical field of exhaust cylinders of gas turbines, and in particular relates to a support structure for flow passages in exhaust cylinders of small and medium-sized gas turbines. The small and medium-sized gas turbine exhaust cylinder inner runner support structure includes an outer cylinder body (1), a bearing seat (4) and an inner runner (8), and is characterized in that it also includes a support cylinder (5), a symmetrical member support rod ( 6), and an elliptical hollow rounded platform guard plate (7); the support rod (6) passes through the inner flow channel (8) and one end is connected with the bearing seat (4), and the other end is connected with the outer cylinder body (1) connection; the support tube (5) is set on the outside of the support rod (6); Slides inside the guard (7) along its axis. The support structure provided by the invention reduces the working thermal stress of the inner runner of the exhaust cylinder, prevents deformation and tearing of the inner runner, increases the stability of the support of the inner runner, and reduces the thermal stress of the support rod.

Owner:HANGZHOU TURBINE POWER GRP

Patio machine panel and patio machine

ActiveCN106895494BReduce flow turbulenceIncrease air volumeLighting and heating apparatusNoise suppressionAir volumeStructural engineering

The invention relates to a patio machine panel and a patio machine, wherein the patio machine panel includes an air inlet frame, an air outlet frame and a driving device, and the driving device is arranged on a side of the air inlet frame away from the air outlet duct, and the The driving device drives the air outlet frame to move to form an air outlet communicating with the air outlet channel. In the present invention, the driving device is avoided from the air outlet and the air outlet, so that the air outlet and the air outlet can form a continuous passage, and the air flow can be blown out from the air outlet smoothly when blowing out from the air outlet, which can help to increase the air volume, and is effective It can reduce the turbulence of air flow, eliminate the noise generated by turbulent flow disturbance, and also improve the condensation problem of the tuyere during cooling.

Owner:GREE ELECTRIC APPLIANCES INC

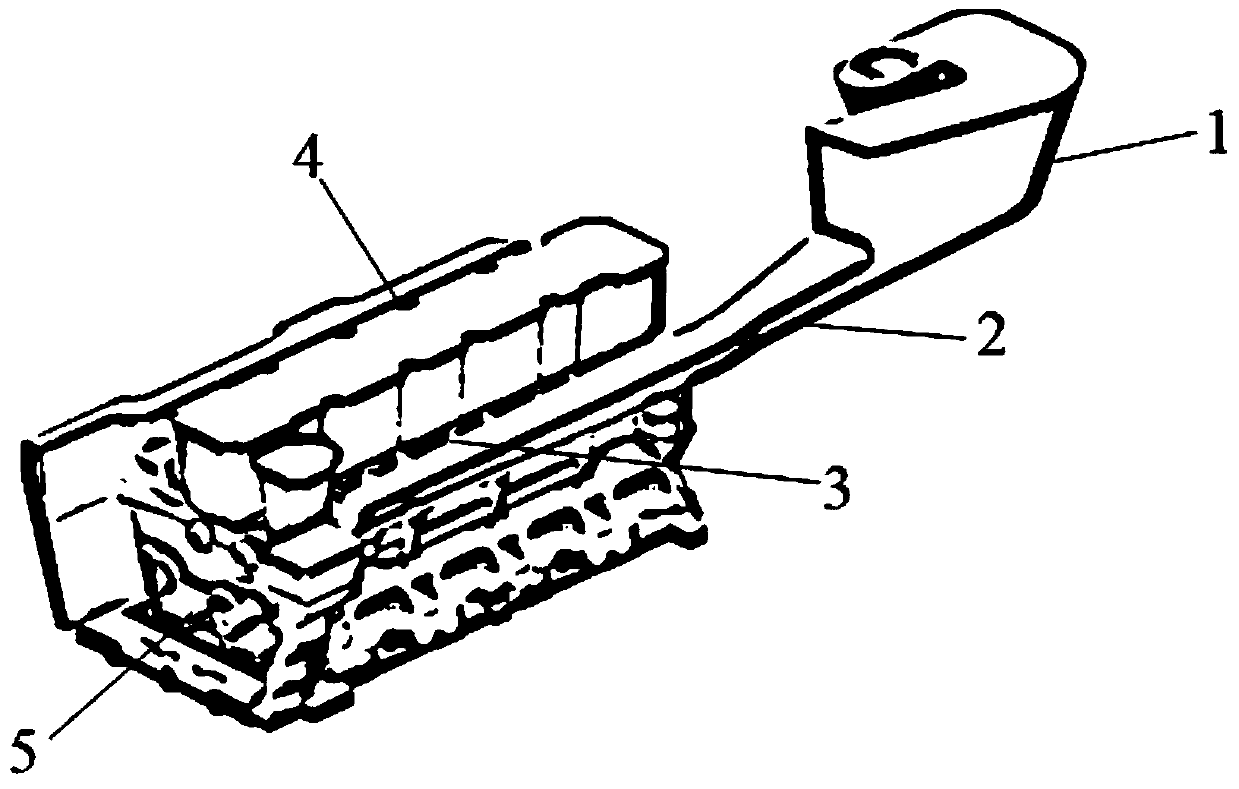

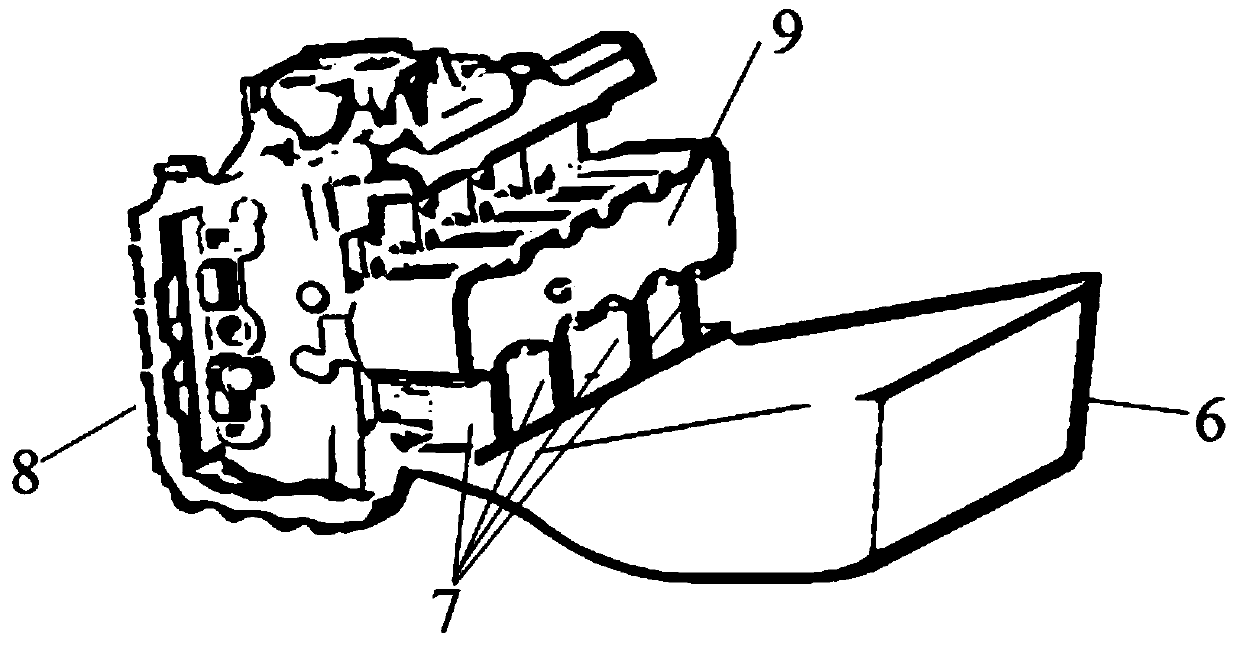

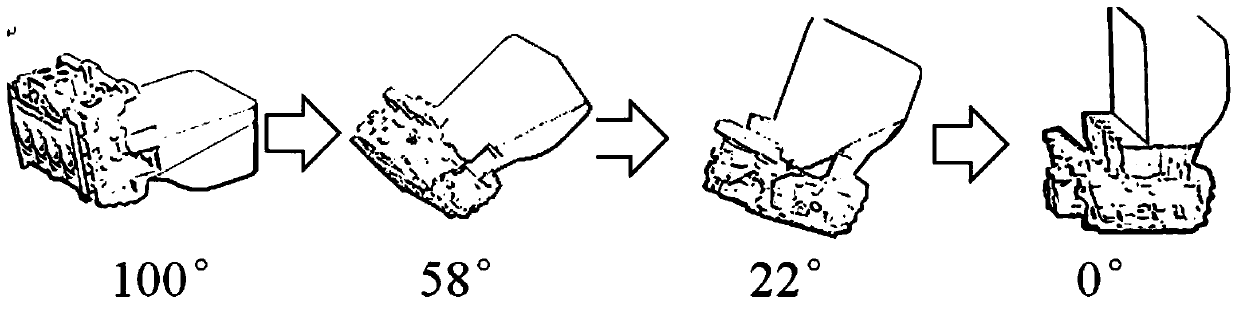

Method for preparing aluminum alloy engine cylinder cover by using tilted pouring process

InactiveCN111069575ASolve shrinkageSolve the problem of stomataFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention belongs to the technical field of aluminum alloy gravity casting, and relates to a method for preparing an aluminum alloy engine cylinder cover by using a tilted pouring process. As thealuminum alloy engine cylinder cover is prepared by using the tilted pouring process, during pouring, a mold is tilted by 100 degrees, molten aluminum flows into a pouring basin 6, the mold is tiltedfrom 100 degrees to 0 degree, the molten aluminum flows into a cylinder cover cavity B 8 from a gas inlet side inner runner B 7 under the action of gravity, when the mold is tilted to 0 degree, namelythe mold is horizontal, the molten aluminum fills the cylinder cover cavity B 8, and finally continuously fills a riser B 9, then the aluminum alloy engine cylinder cover is formed, wherein the weight of the mold riser selected by the tilted pouring process is 9215 grams, the adopted casting time is 13 seconds, the solidification time is 180 seconds to 190 seconds, and the temperature of coolingwater is 30 DEG C. According to the method, the tilted pouring process is applied to the aluminum alloy engine cylinder cover, winding of a molten aluminum punching molding path can be reduced, too many twists and turns are avoided, and gas entrapment, heat dissipation and pressure loss are avoided; and problems about shrinkage porosity and exhaust side cold shuts are effectively solved, and the leakage test qualification rate is improved.

Owner:CHINA FIRST AUTOMOBILE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com