Apparatus for the collection and distribution of liquid in a column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

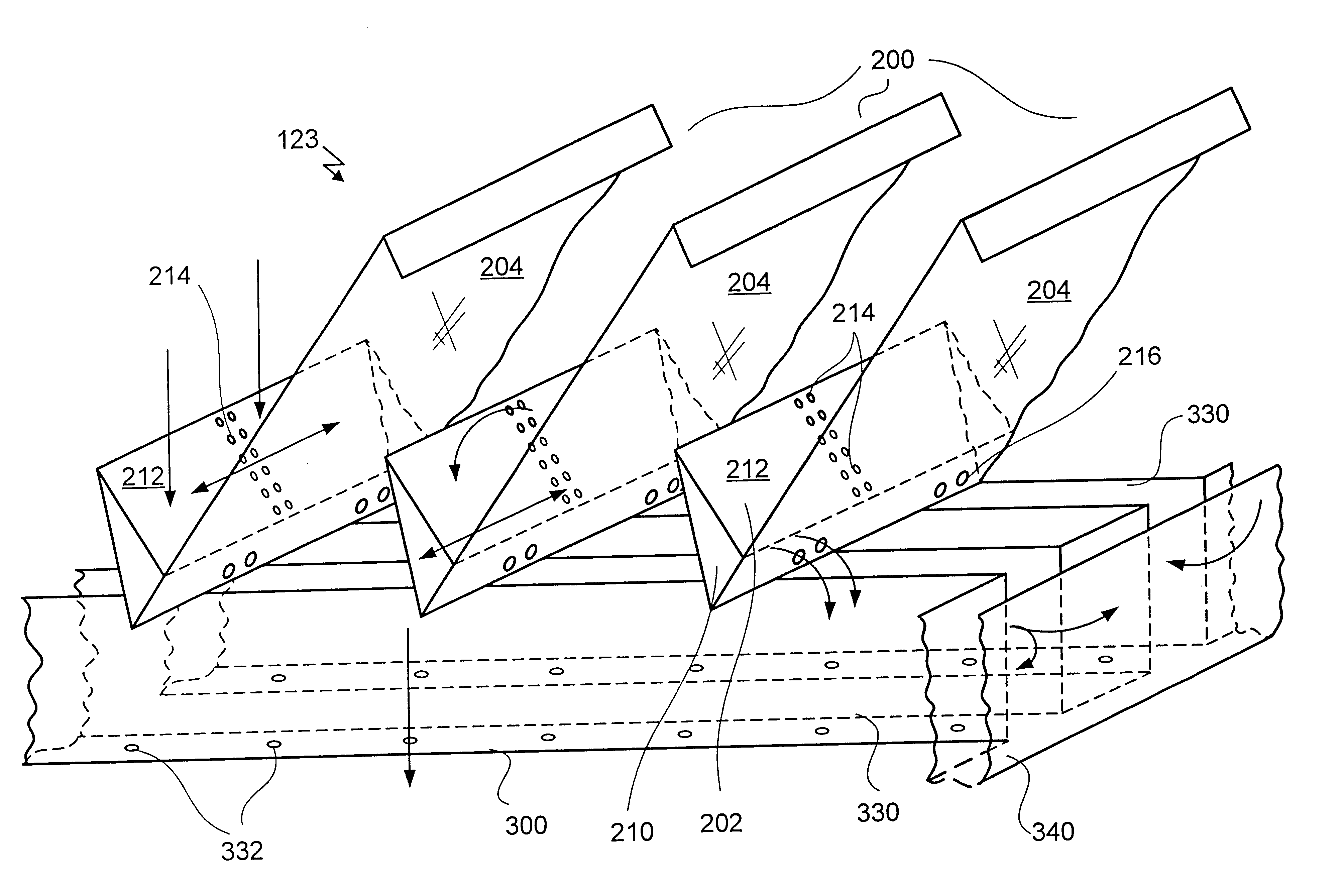

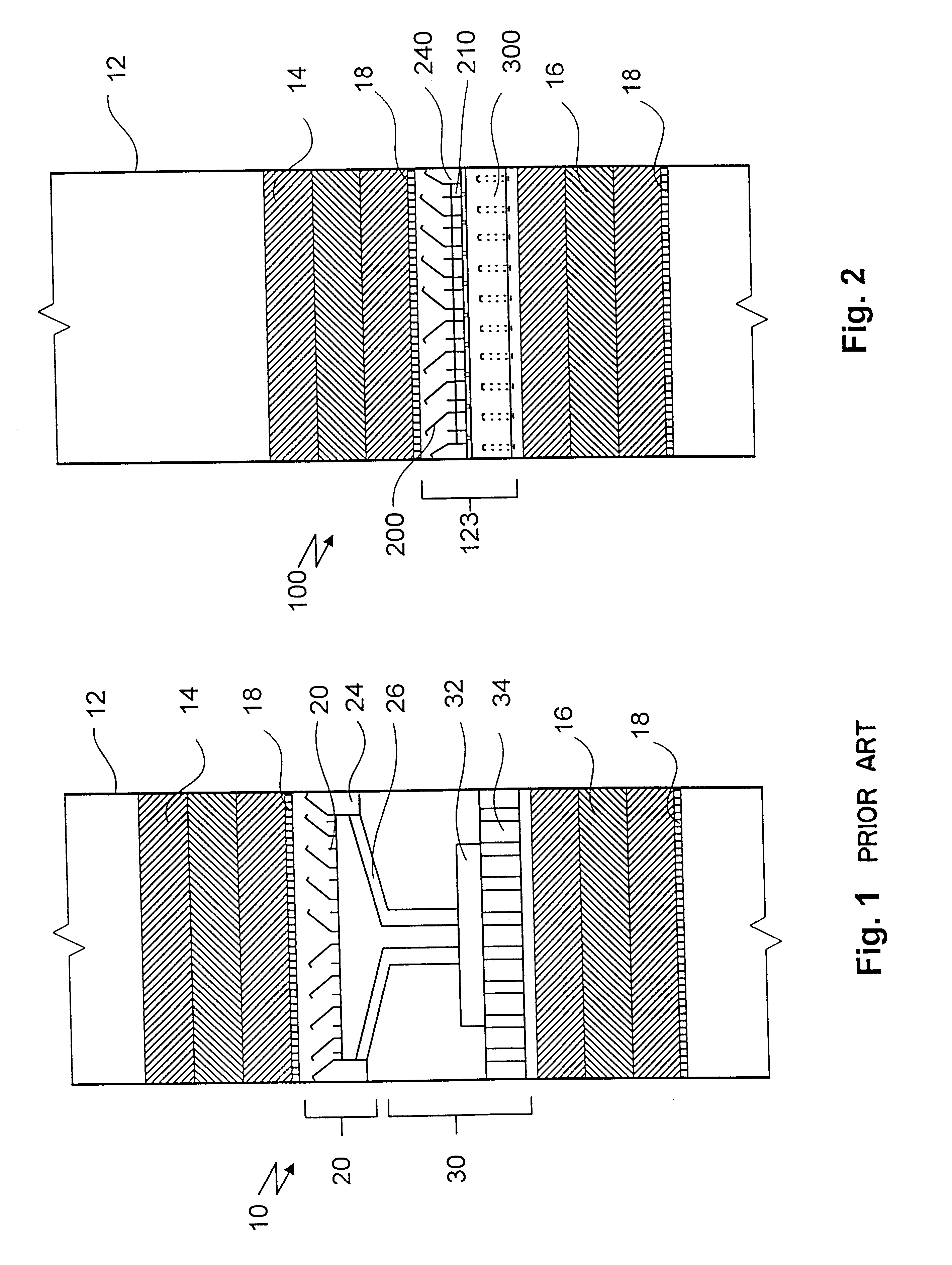

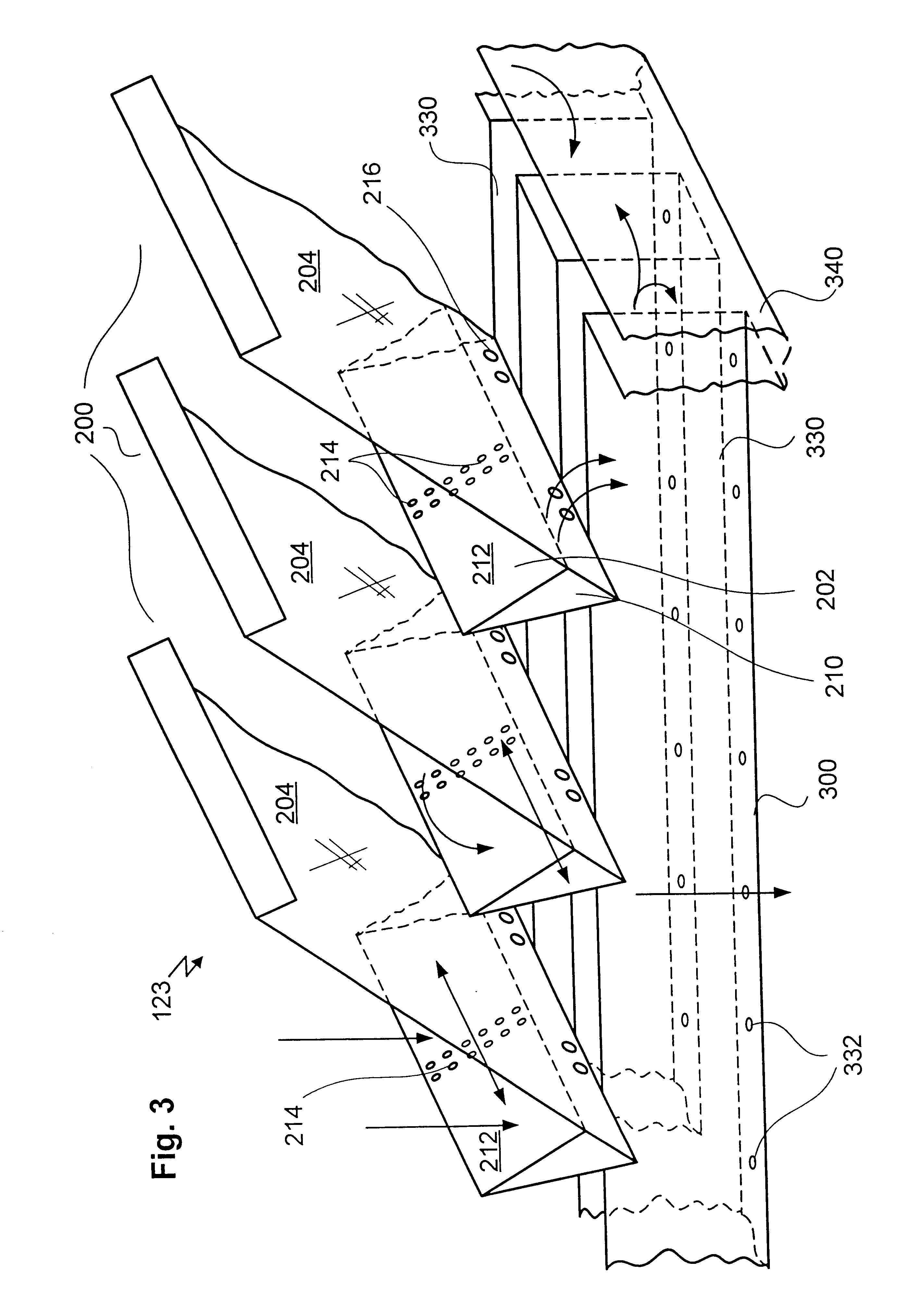

In FIG. 1 the schematic illustration of a conventional redistributor station 10 is illustrated. In this the column chute 12, the upper packing bed 14, the lower packing bed 16 and the redistributor stations placed between them can be seen. The latter consists of a collector apparatus 20 and a completely separate distributor apparatus 30. The liquid is conducted from the collector apparatus 20 to the mainly central inlet of the pre-distributor 32 or distributor 34 through at least one elongate and downwardly directed down pipe 26. Then the liquid is to be uniformly distributed over the lower packing bed 16 with the help of at least one distributor stage.

FIG. 2 is the schematic illustration of a redistributor station 100 with a compact collector and distributor apparatus 123 in accordance with the invention. The illustration comprises the column chute 12, as in FIG. 1, an upper and lower packing bed 14 and 16. The reduction of the space between the upper and lower packing bed in compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com