Patents

Literature

359results about "Liquid distribution in distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

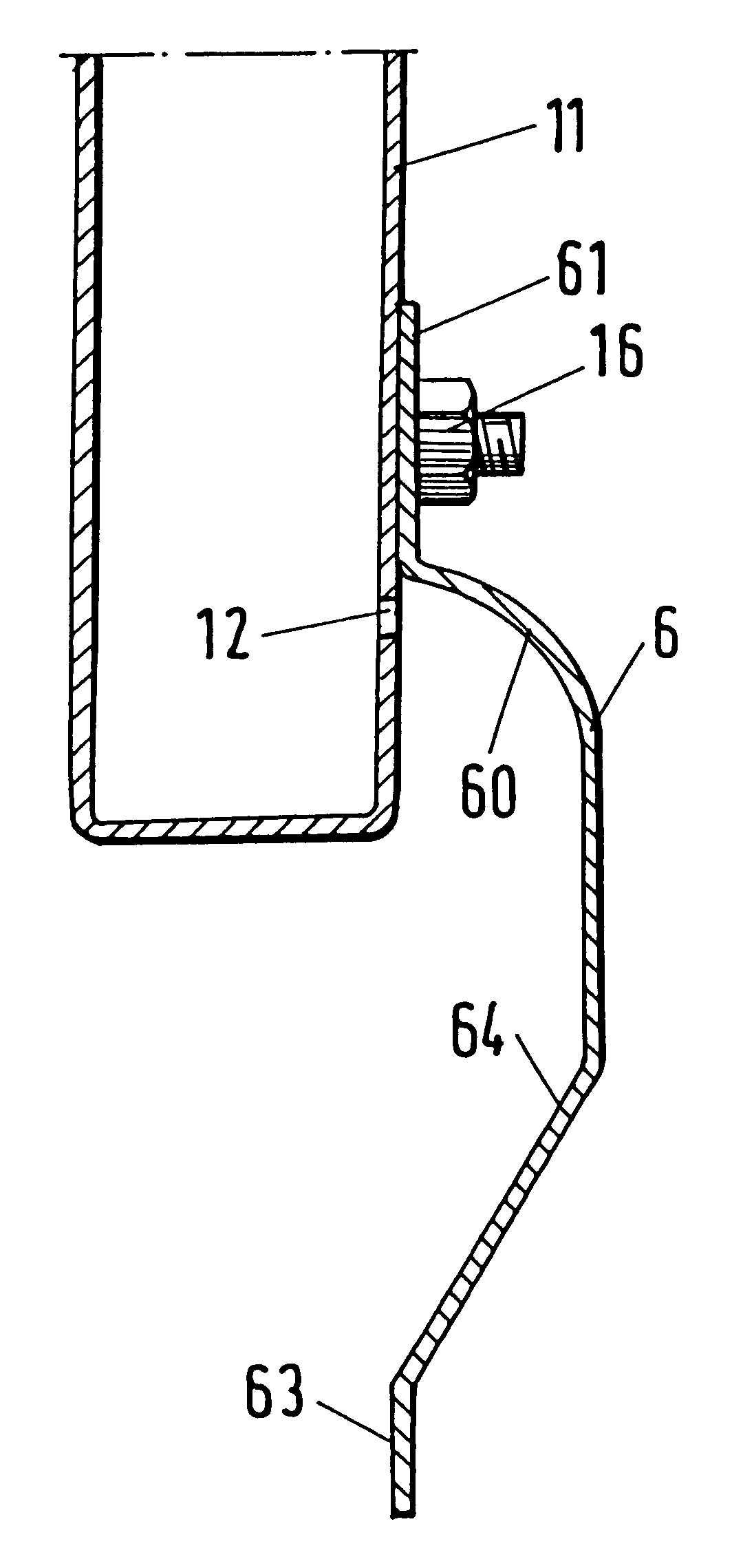

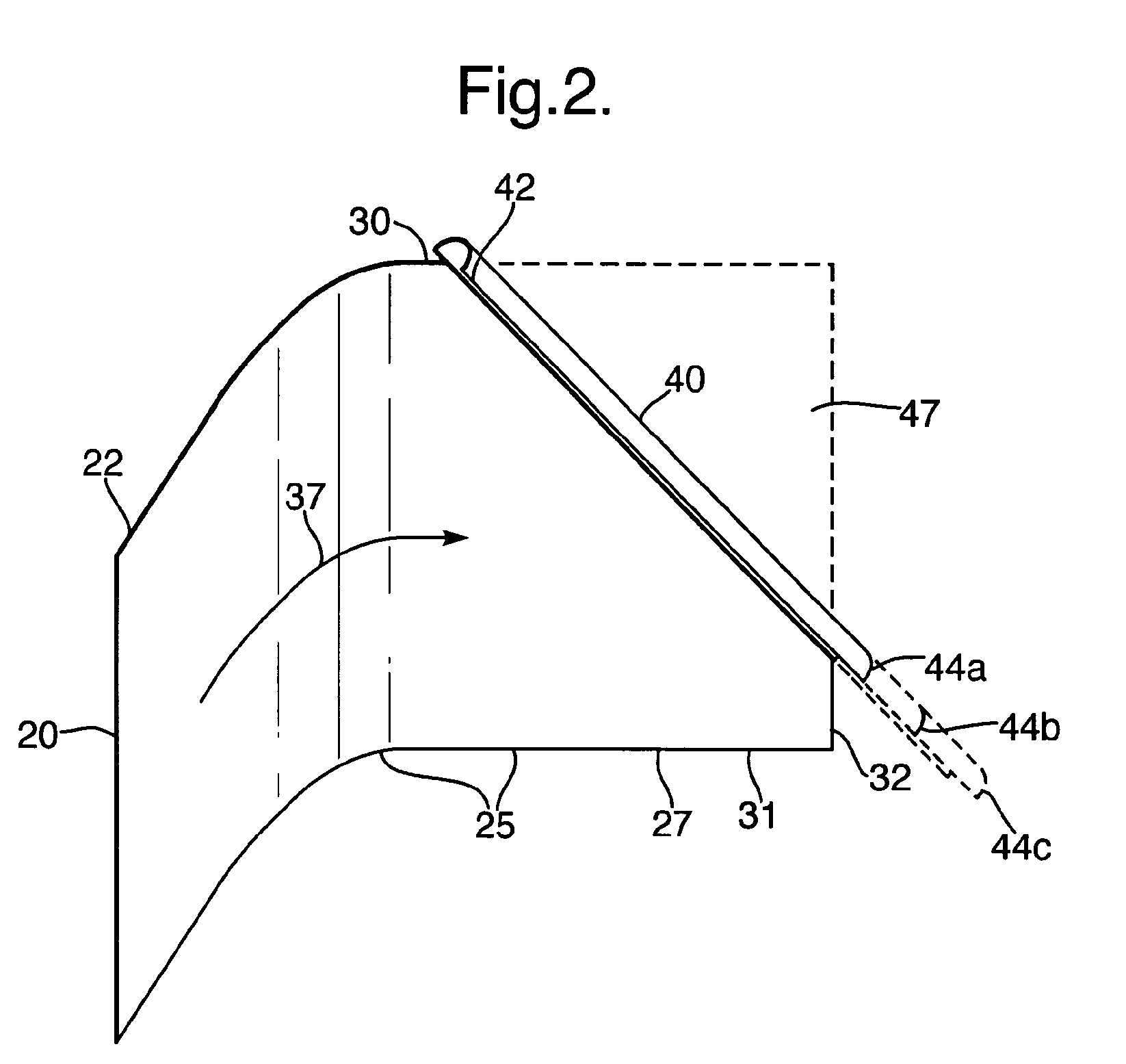

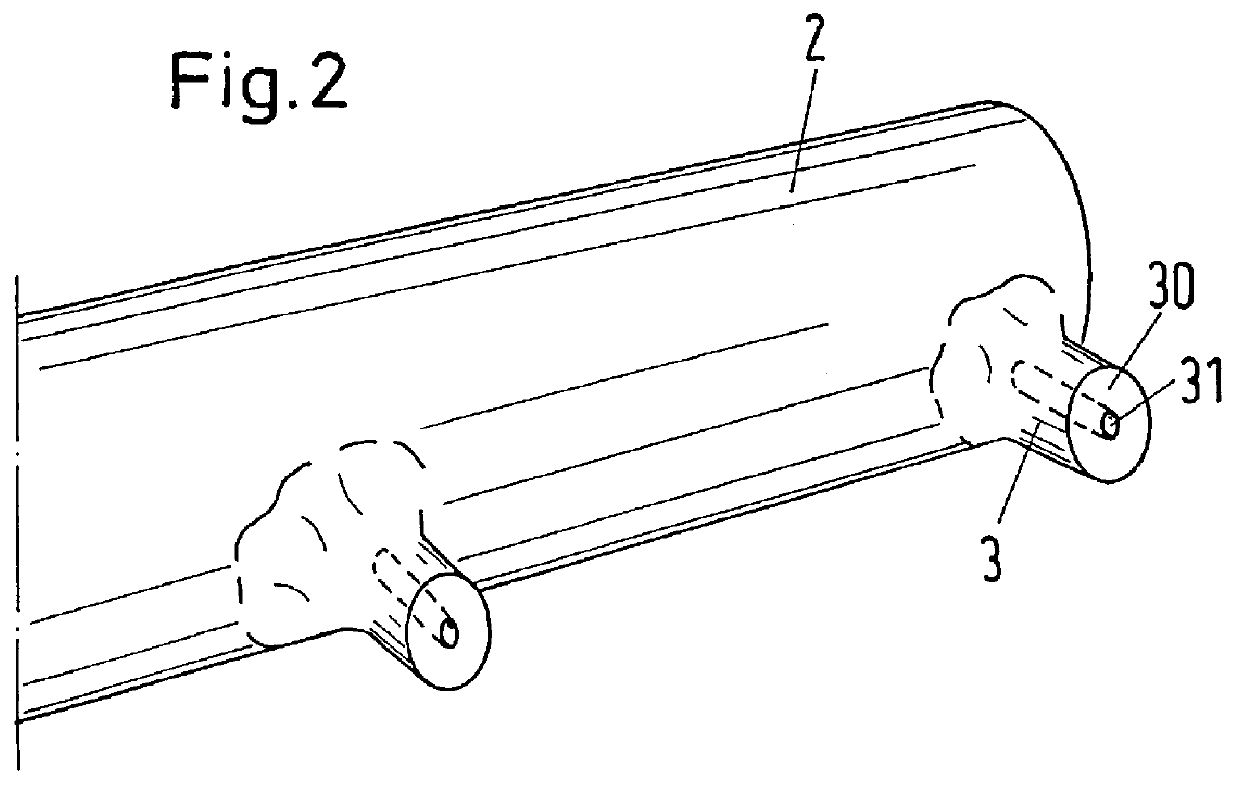

Liquid distributor for packing columns

InactiveUS6293526B1Obstruct passageCarburetting airUsing liquid separation agentLiquid jetEngineering

A liquid distributor for packing columns. The liquid distributor includes at least one tubular or trough-like distributor member including outlet openings for an output of liquid in the form of jets. Screens are arranged ahead of the outlet openings onto which the incident liquid jets are deformed to liquid films flowing off. The outlet openings screen the outlet openings against an upwardly flowing gas flow. In the event of a maximum output of liquid, the liquid jets are incident onto the screens at angles that are less than 60°, and even as much as less than 10°.

Owner:SULZER CHEMTECH AG

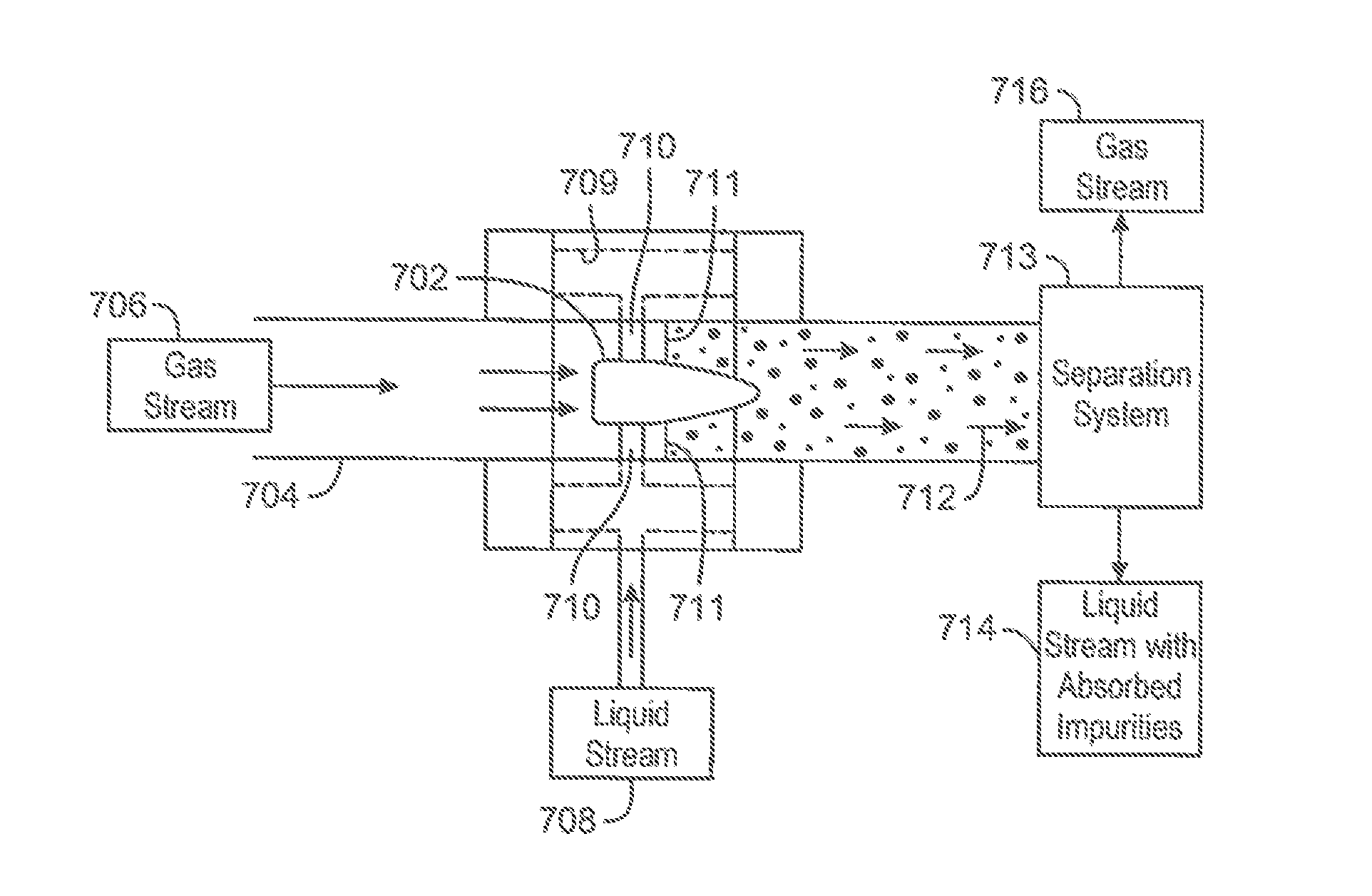

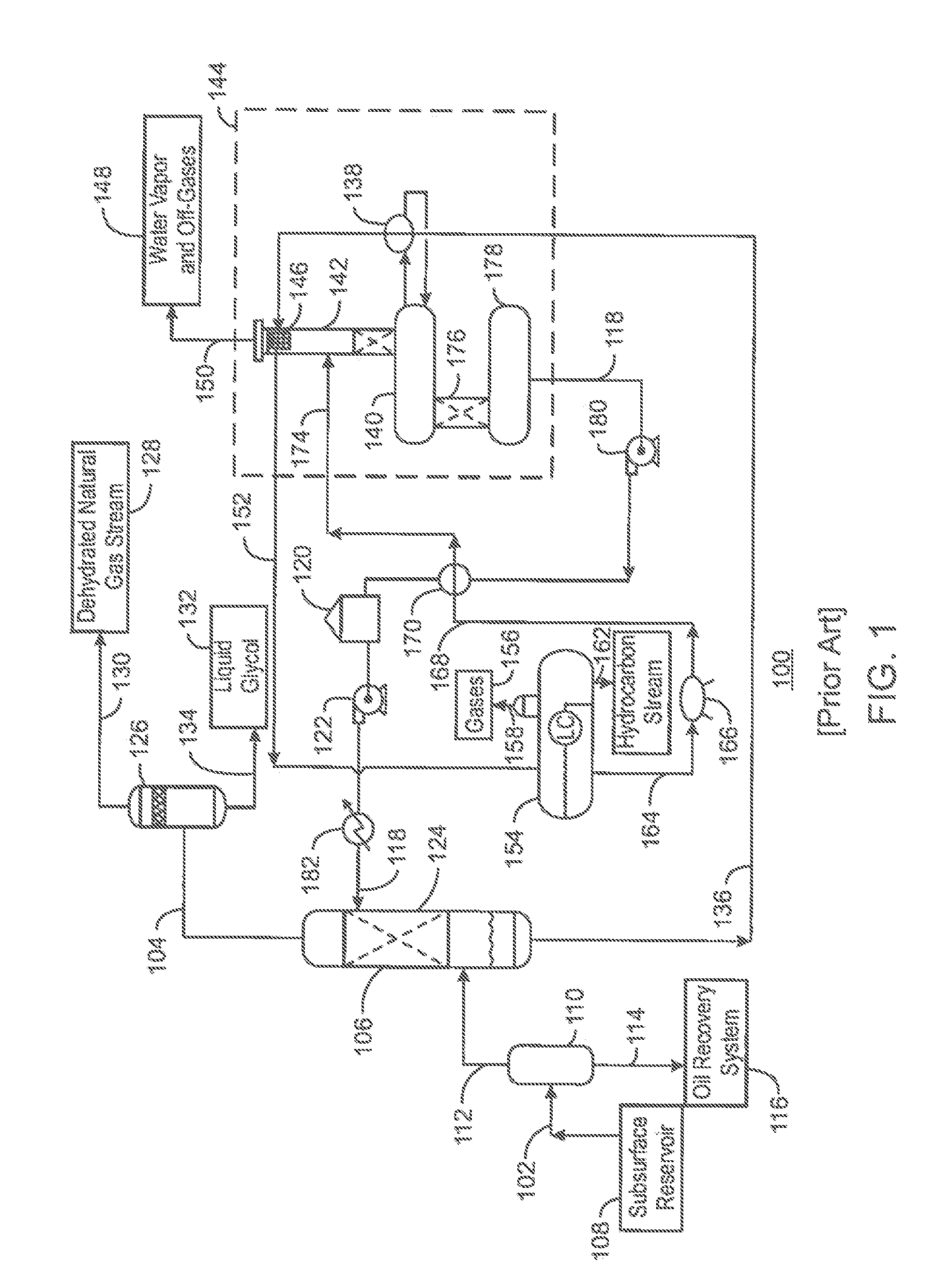

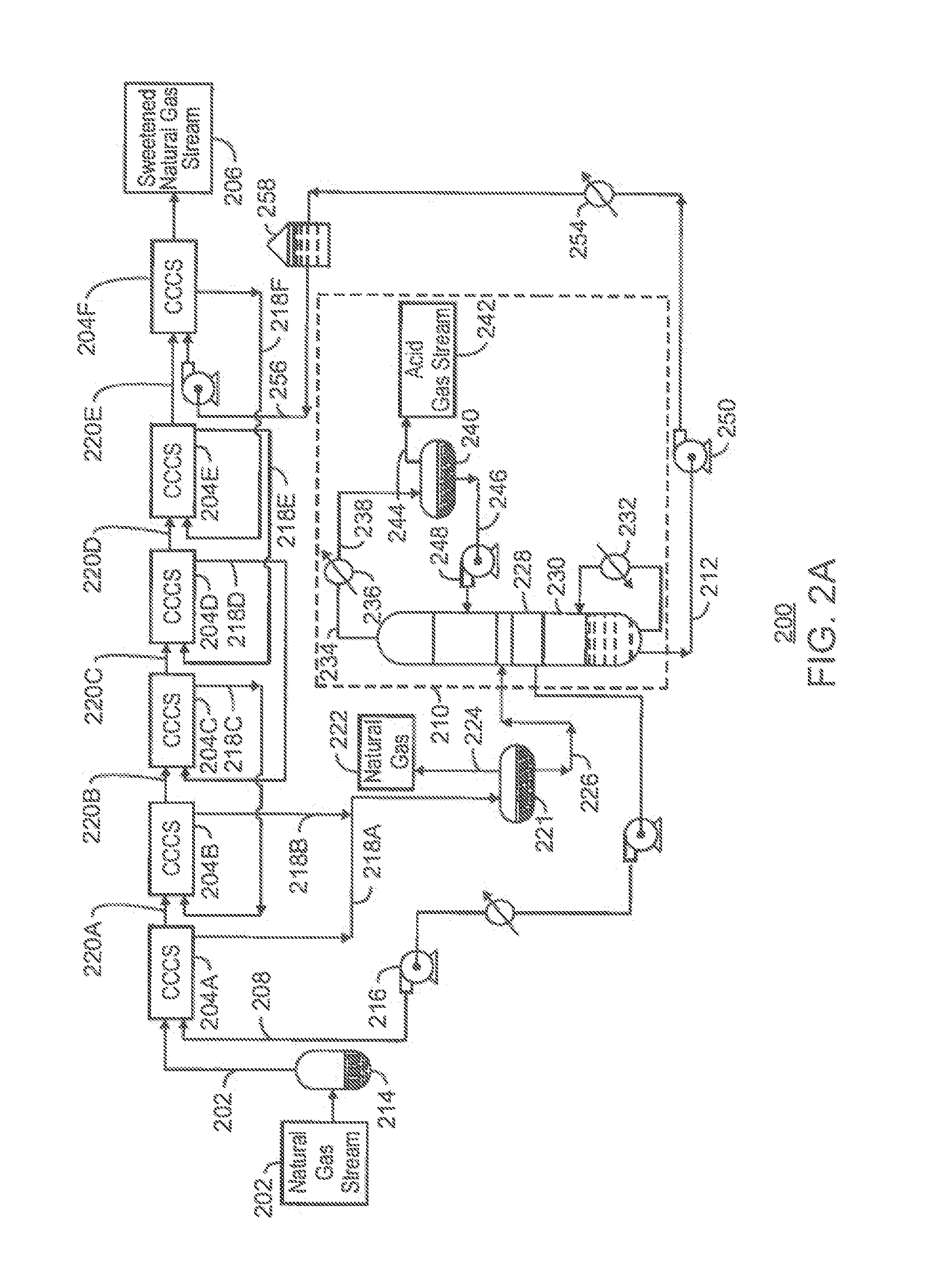

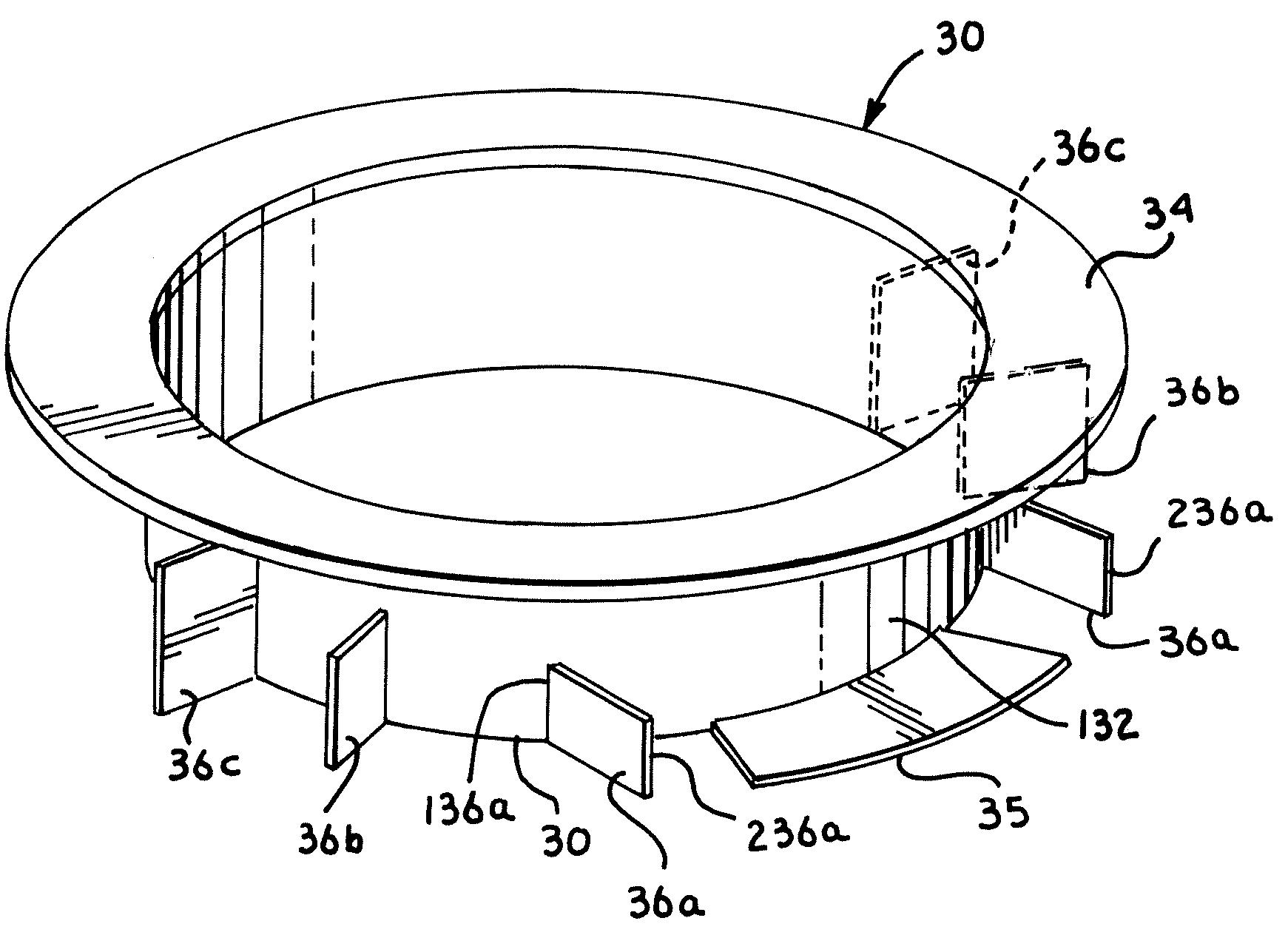

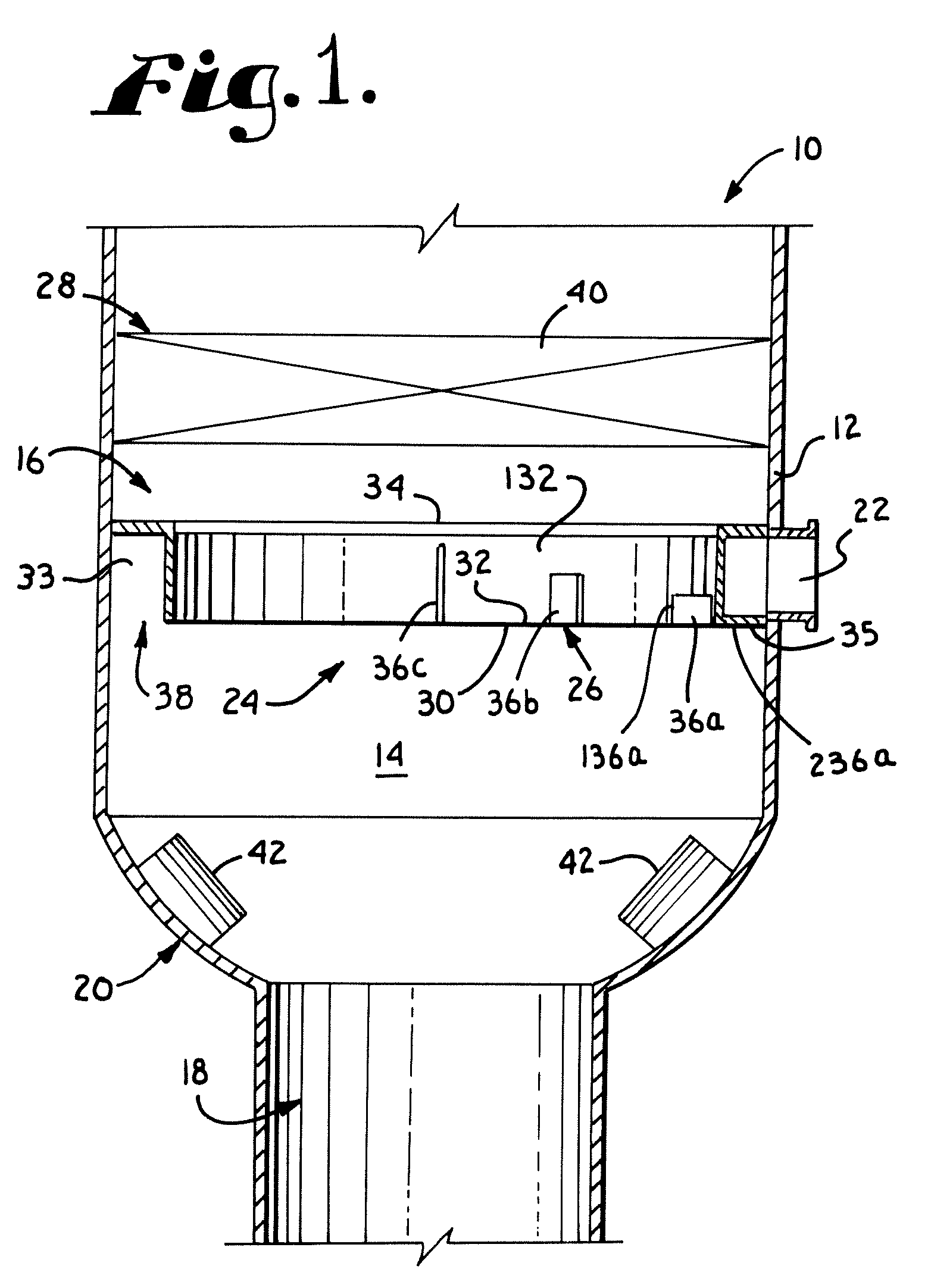

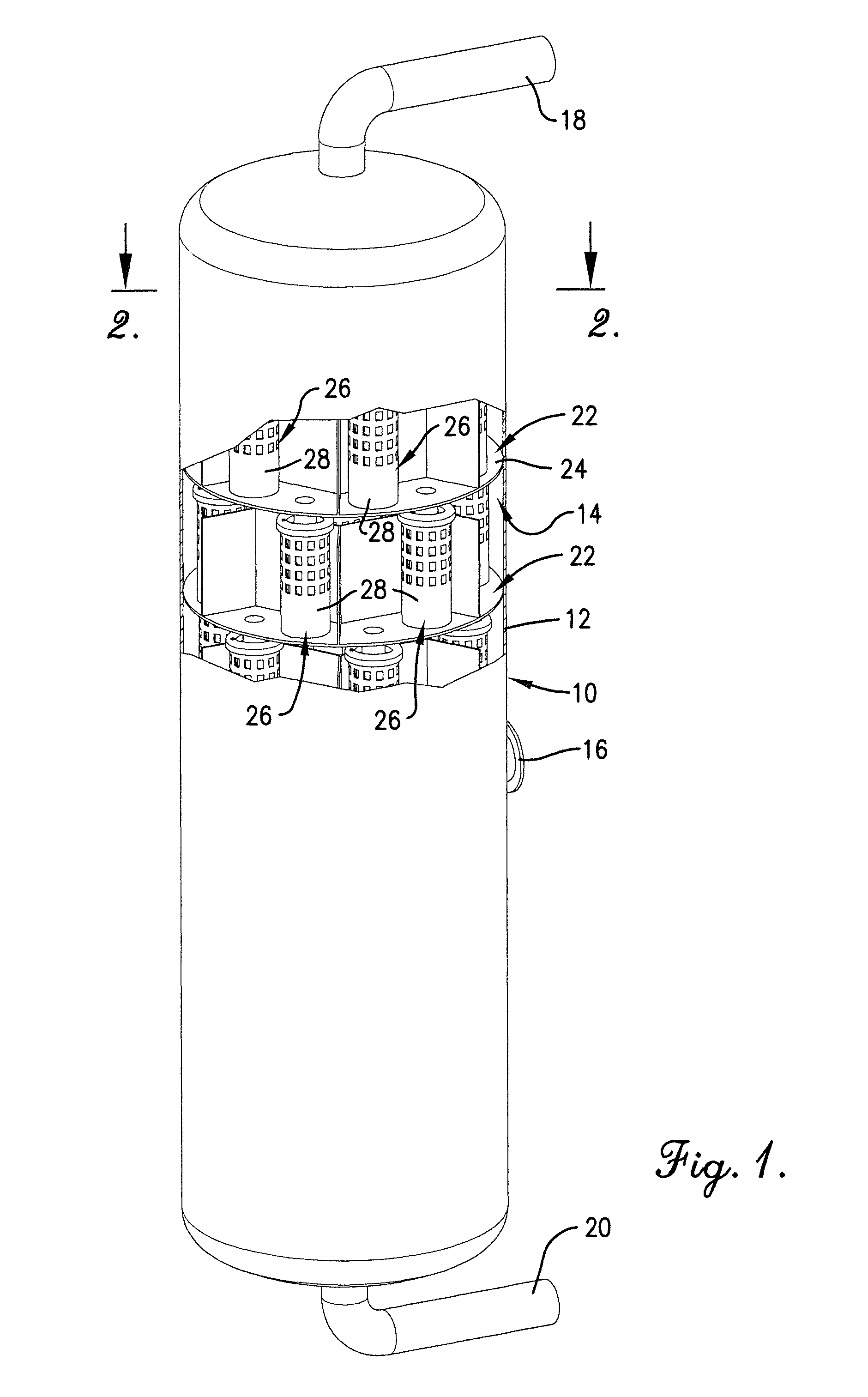

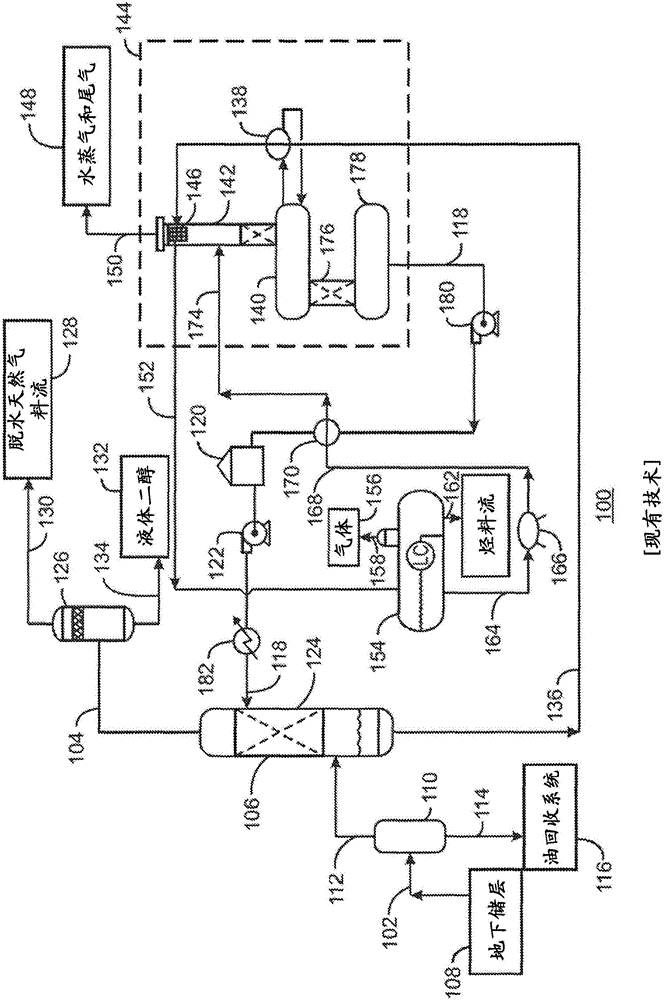

Contacting A Gas Stream With A Liquid Stream

ActiveUS20150352463A1Effective mergerOrganic compound preparationLighting and heating apparatusEngineeringContact system

A co-current contacting system is described herein. The co-current contacting system includes a co-current contactor located in-line within a pipe. The co-current contactor includes an annular support ring configured to maintain the co-current contactor within the pipe and a number of radial blades configured to allow a liquid stream to flow into the co-current contactor. The co-current contacts also includes a central gas entry cone configured to allow a gas stream to flow through a hollow section within the co-current contactor, wherein the co-current contactor provides for efficient incorporation of liquid droplets formed from the liquid stream into the gas stream. The co-current contacting system also includes a separation system configured to remove the liquid droplets from the gas stream.

Owner:EXXONMOBIL UPSTREAM RES CO

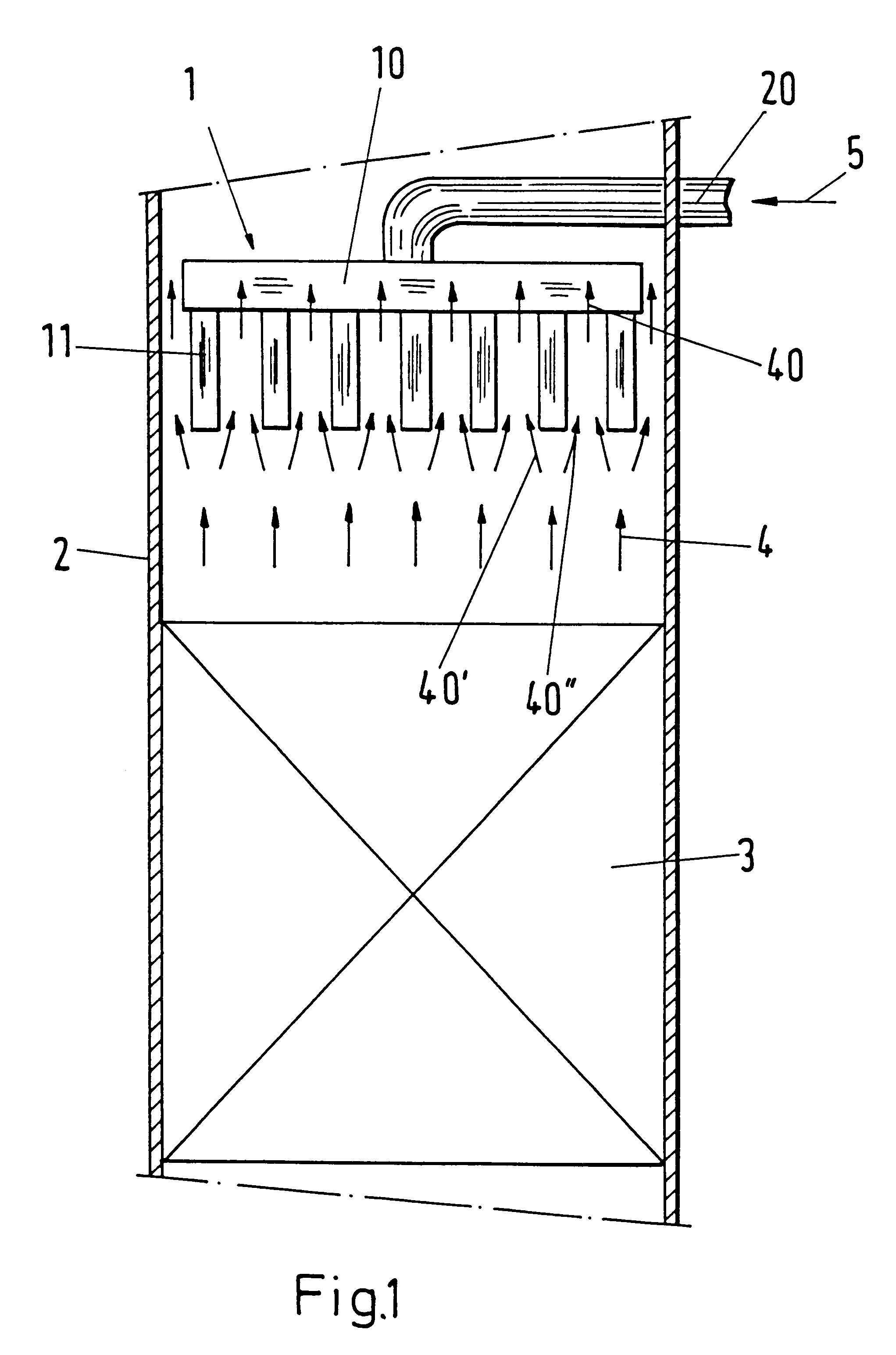

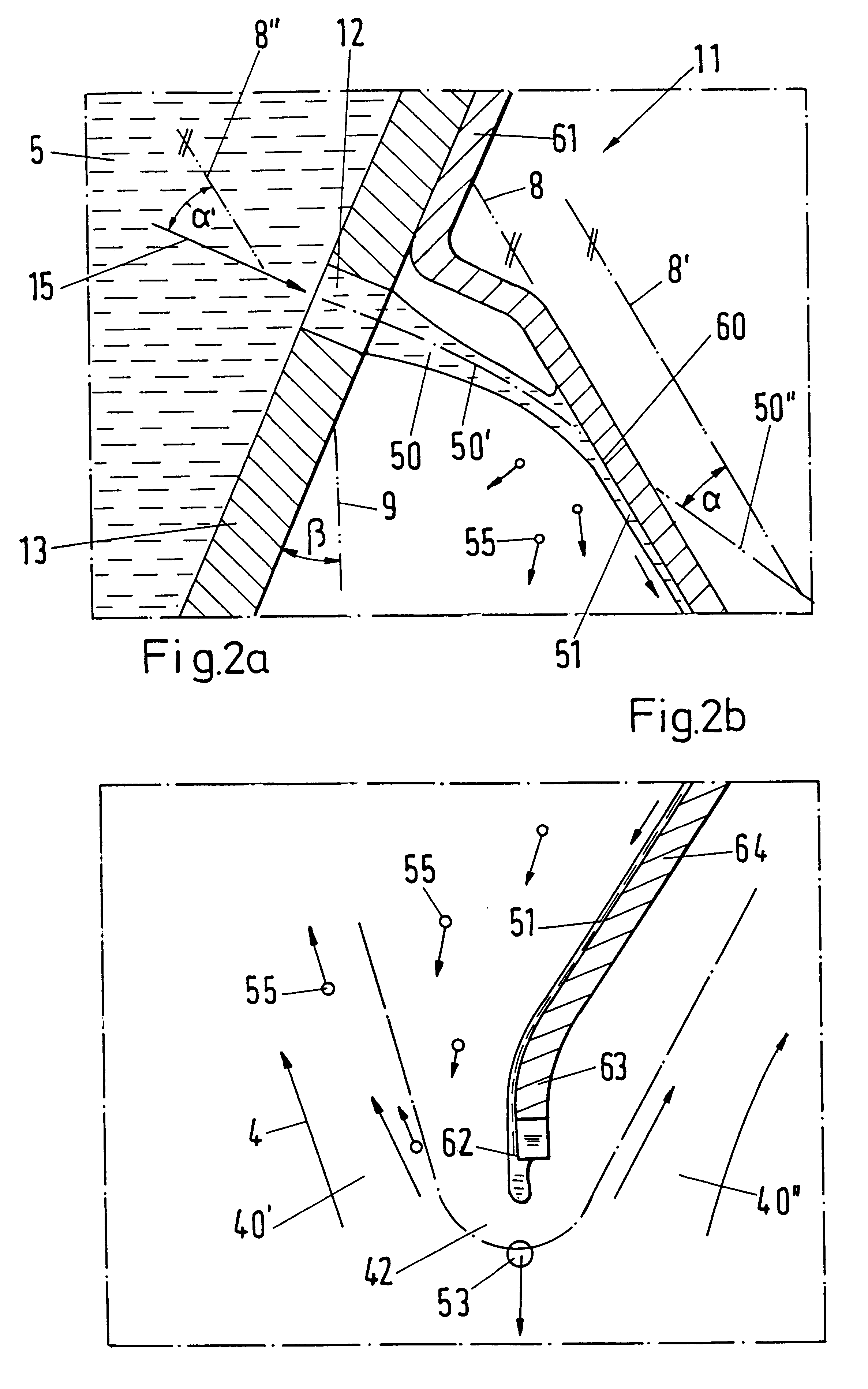

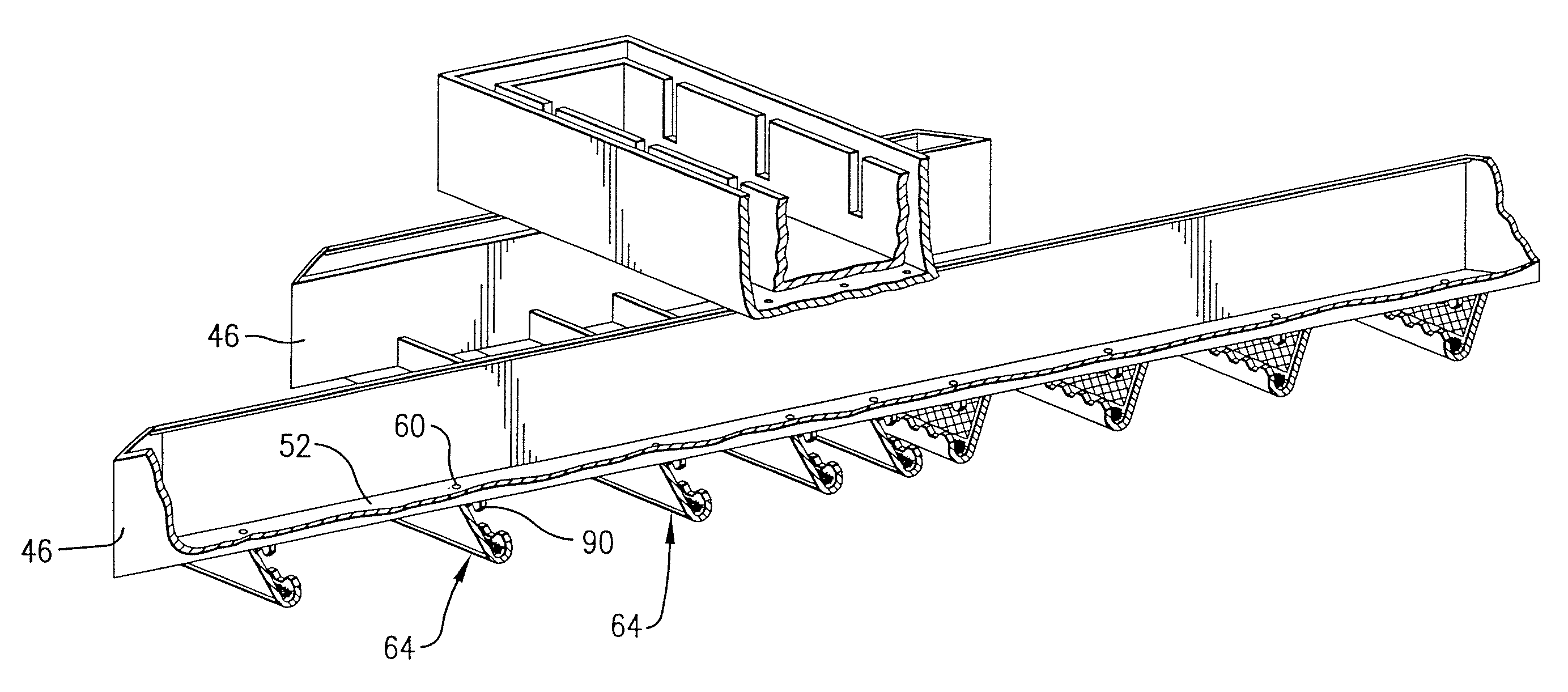

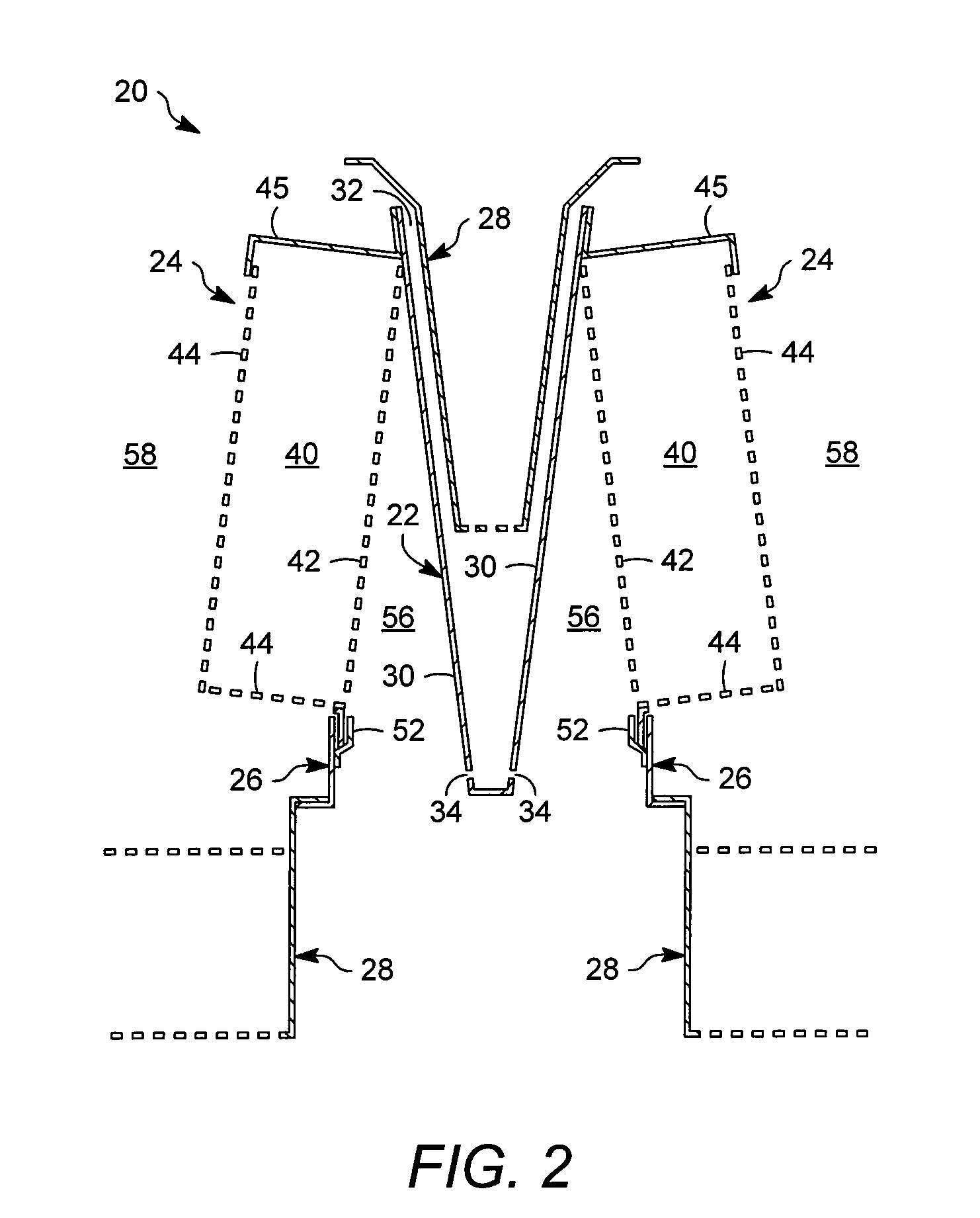

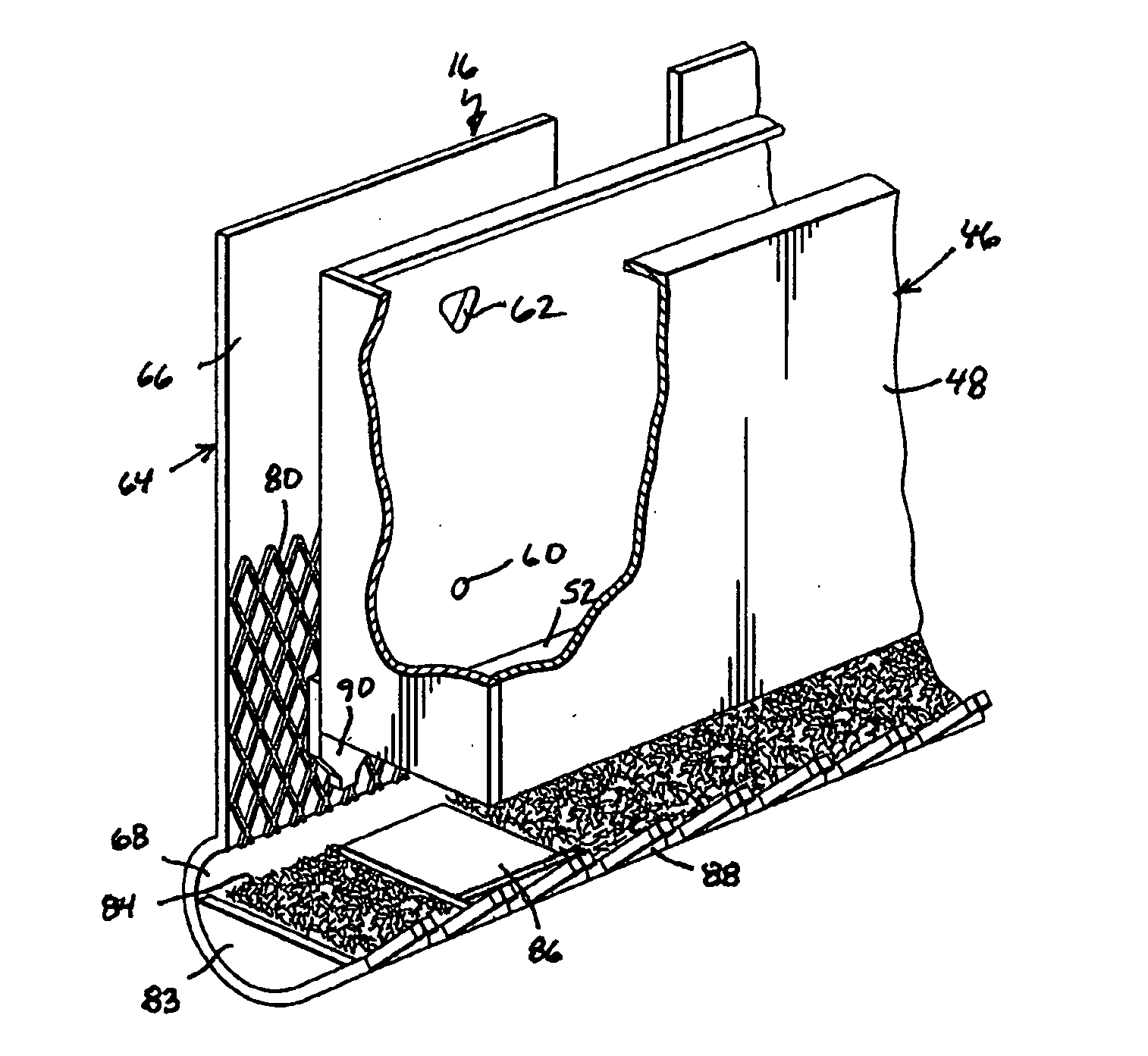

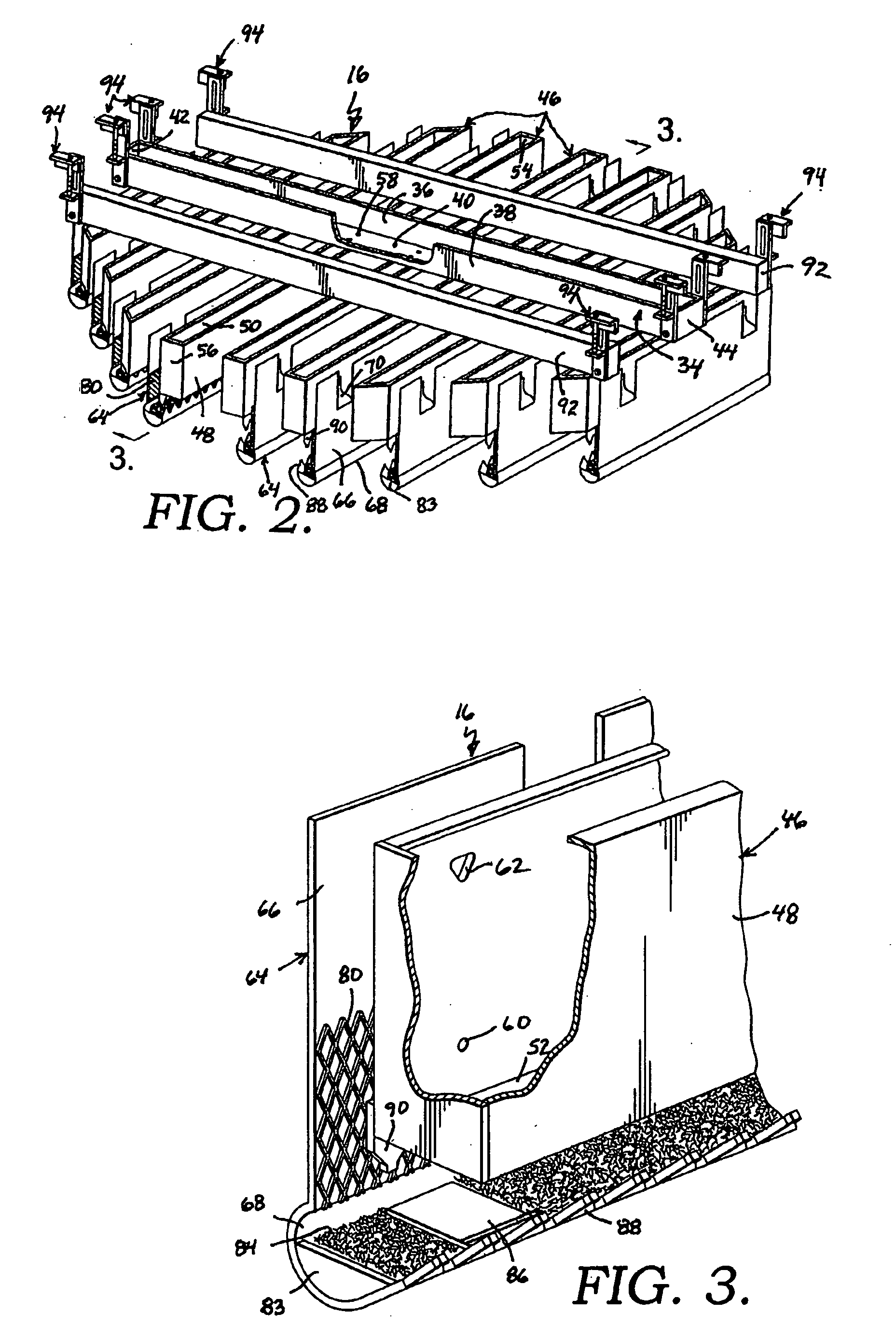

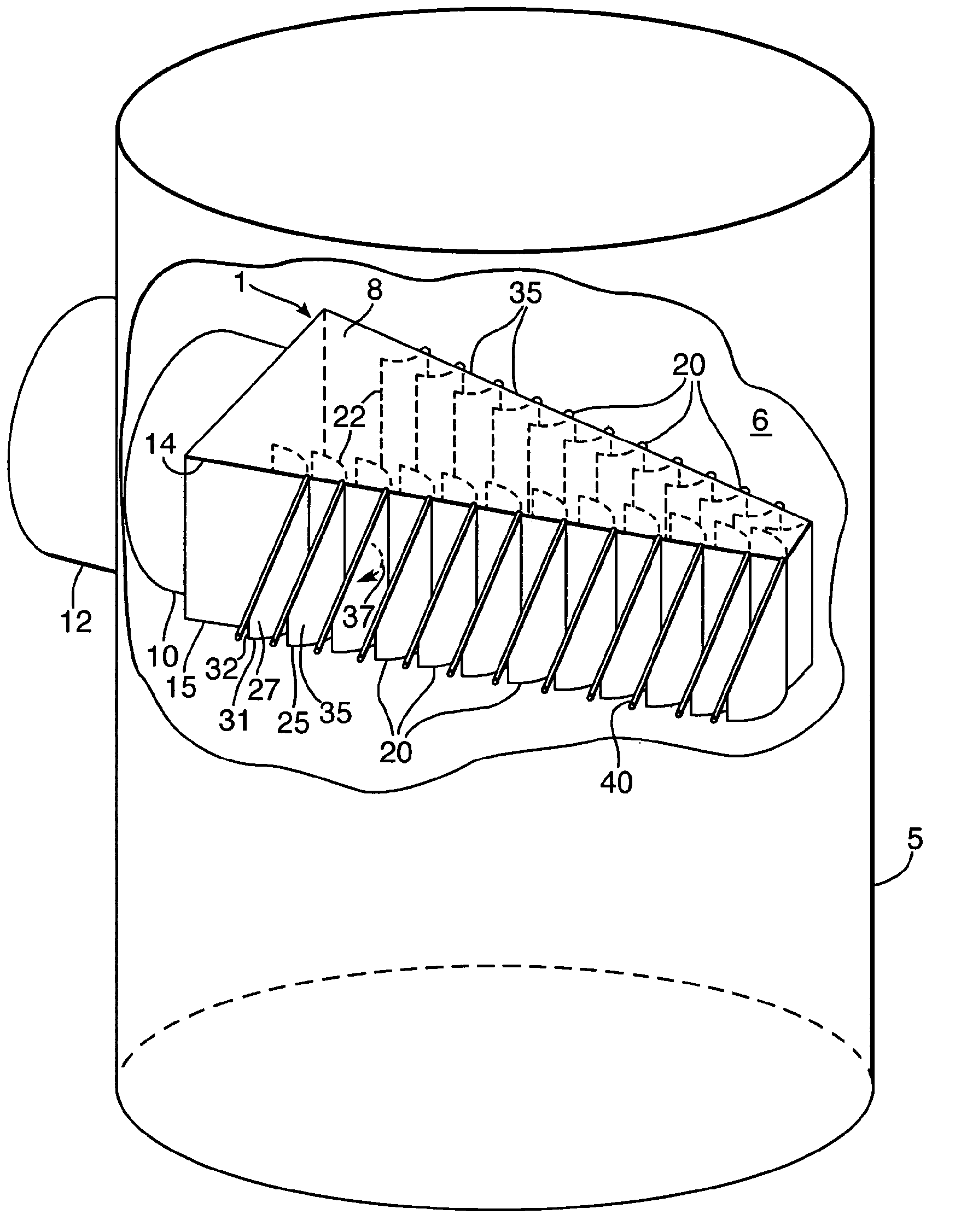

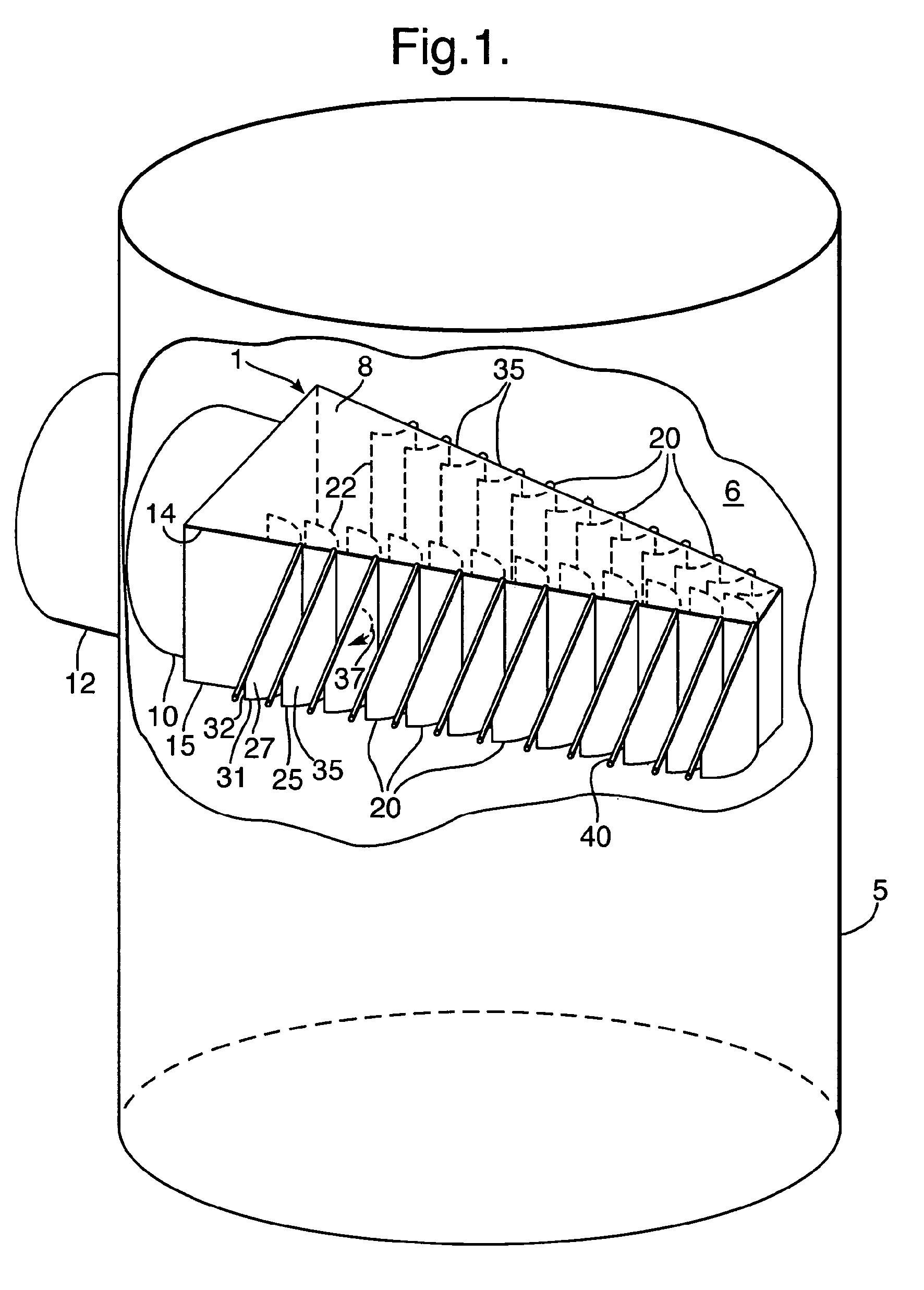

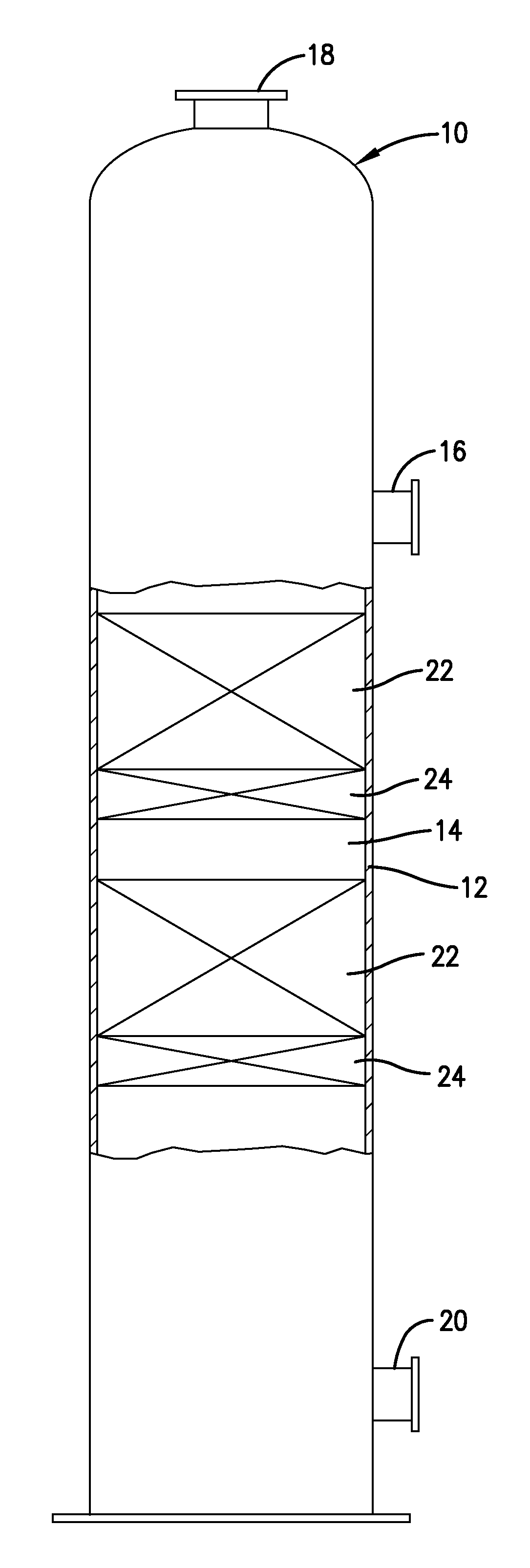

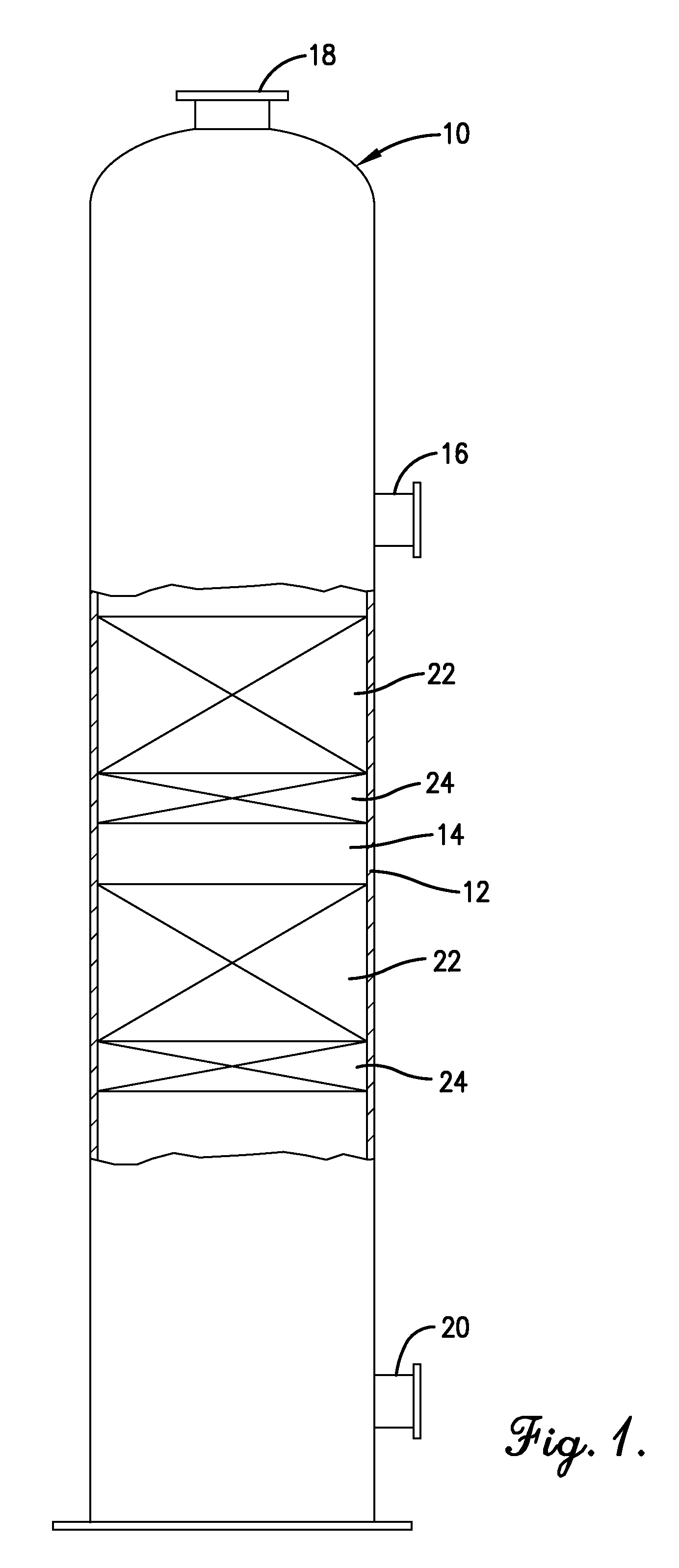

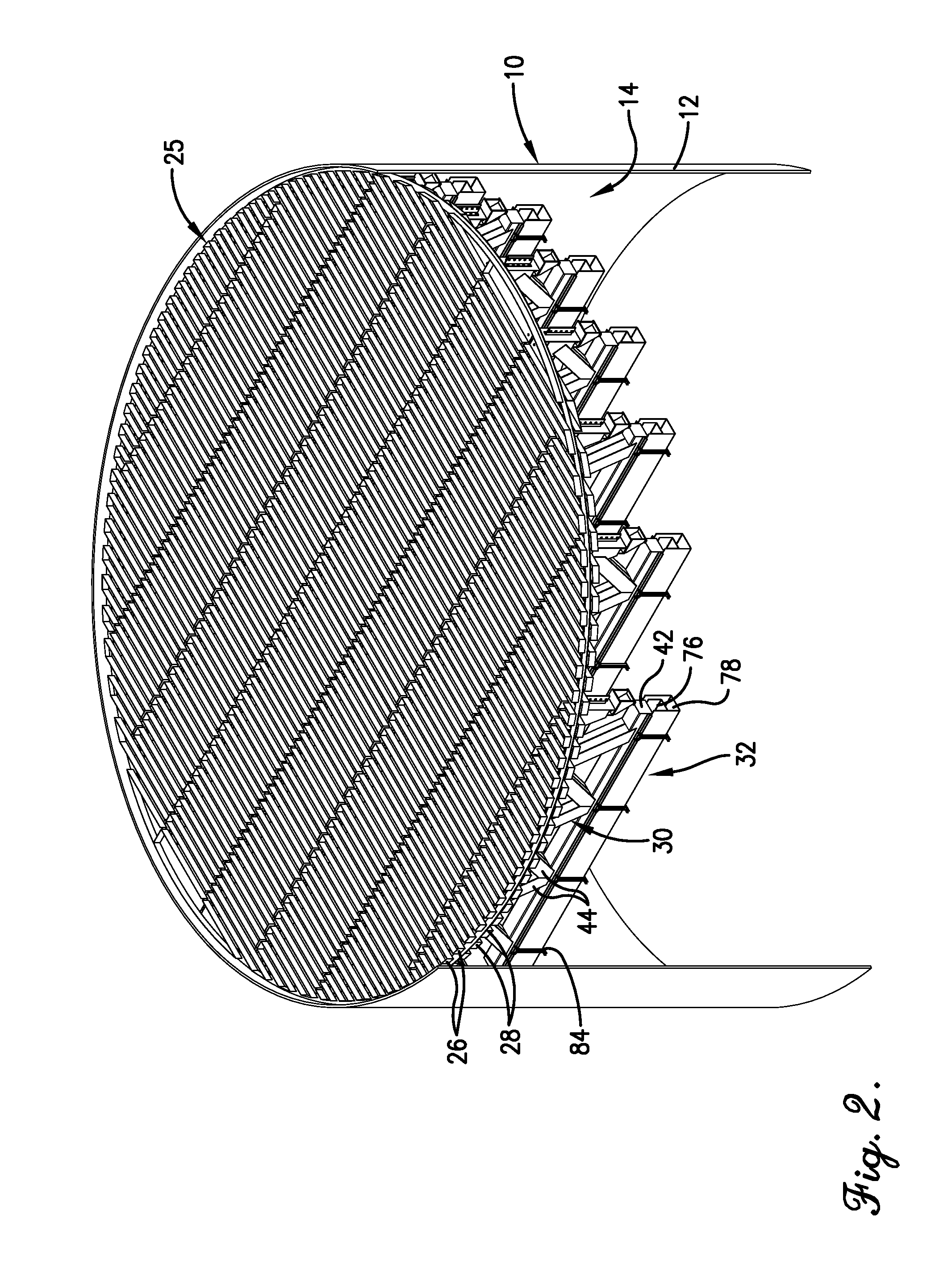

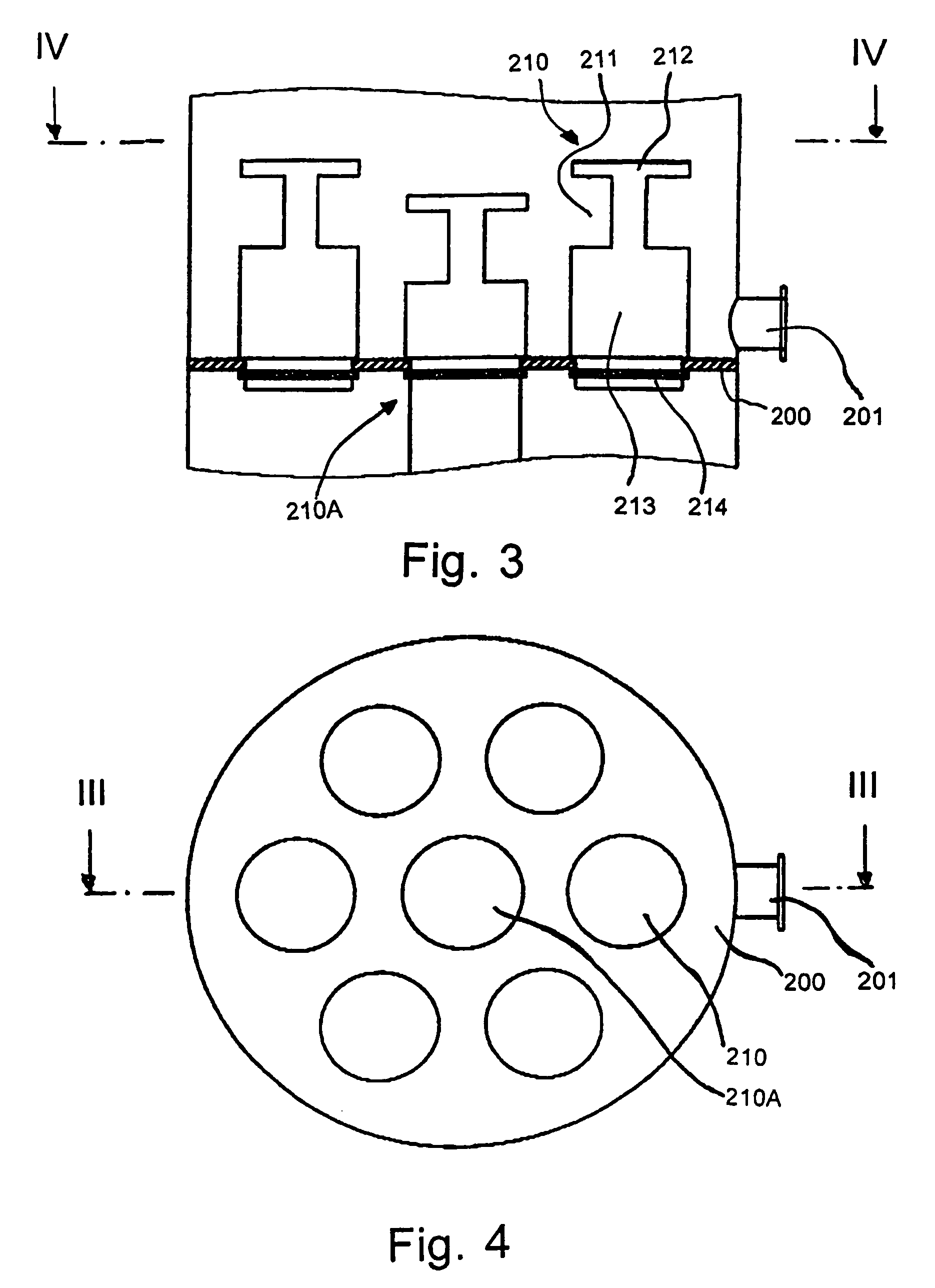

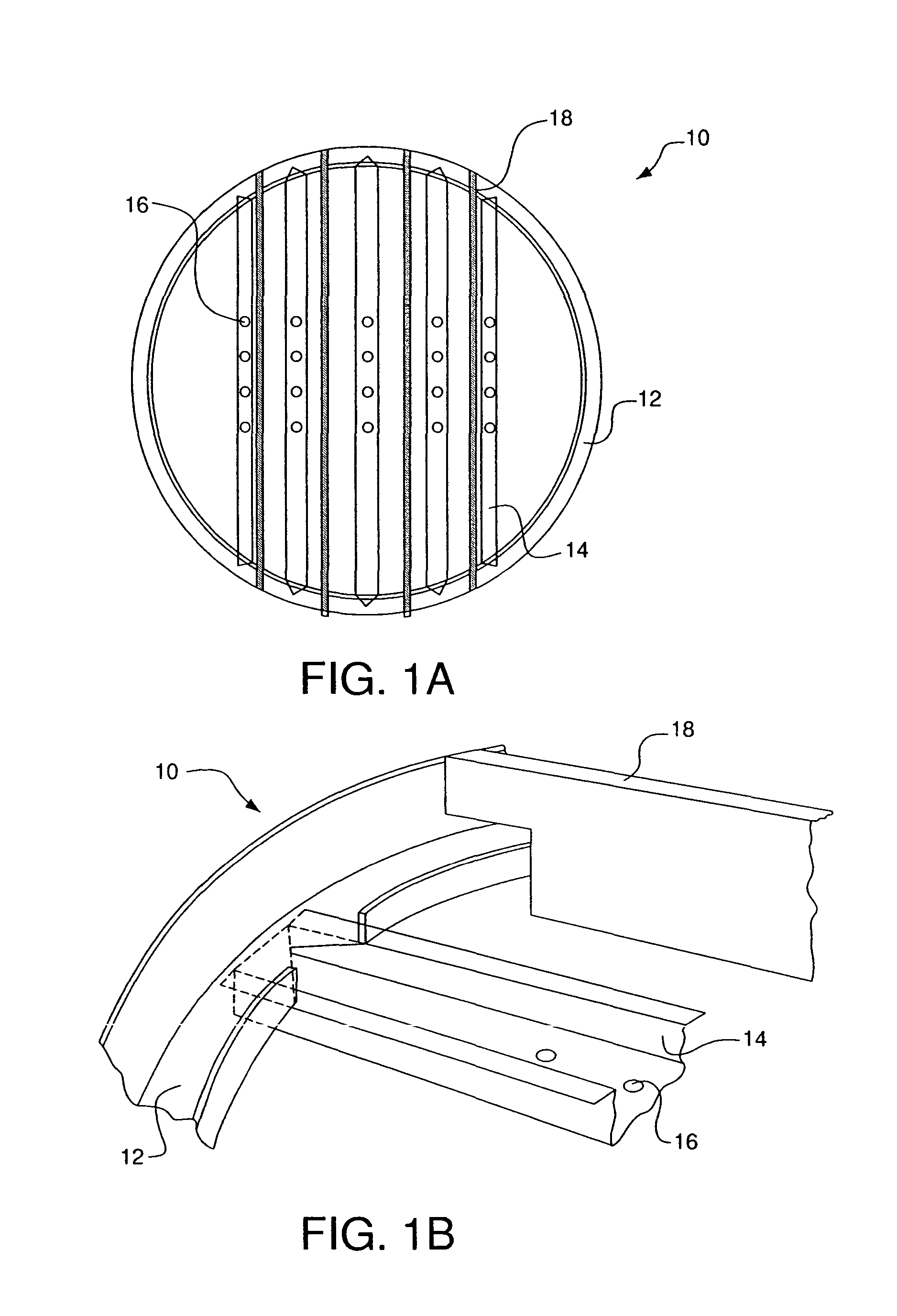

Liquid distributor for use in mass transfer column

ActiveUS7125004B2Facilitate horizontal distribution of liquidImprove distributionCarburetting airLiquid handlingInterior spaceEngineering

A flow distributor for liquid descending in a vertically elongated process column having an internal space. The distributor is made up of an elongated liquid distribution trough configured and arranged for being mounted in a process column in a position to extend across the internal space thereof. The trough has outer walls defining an elongated, longitudinally extending internal fluid distribution chamber and includes outlet holes which extend through the walls at locations permitting liquid to escape laterally outwardly from the trough. The distributor also includes a baffle distributor structure made up of an elongated, downwardly extending distributor plate member disposed adjacent the trough in a position such that at least a portion of a surface thereof is contacted by liquid escaping from said hole. The distributor also includes an elongated, fluid receiving element attached at a lower edge portion of said plate member presenting an elongated fluid distribution channel extending longitudinally of the plate member.

Owner:KOCH GLITSCH INC

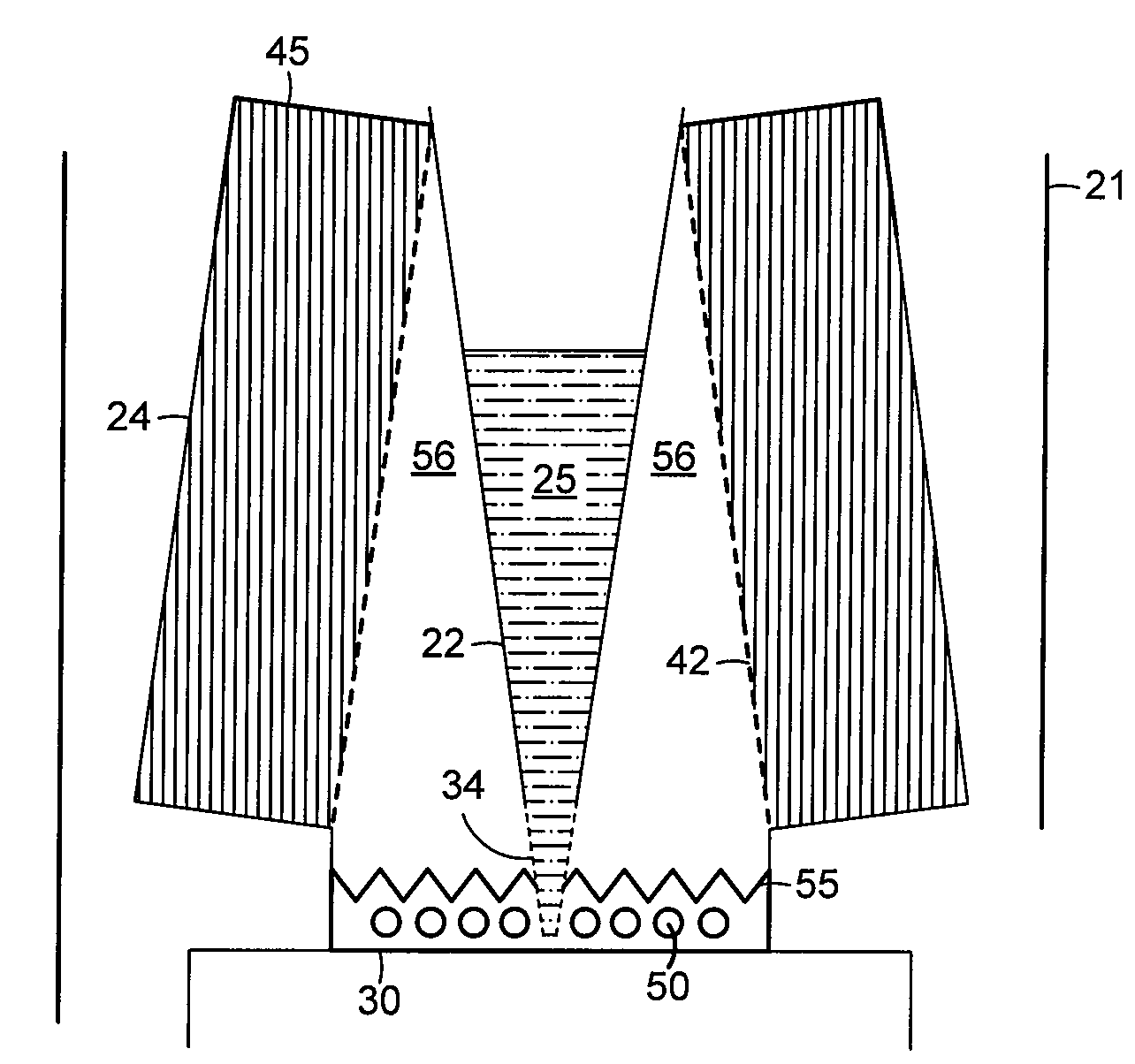

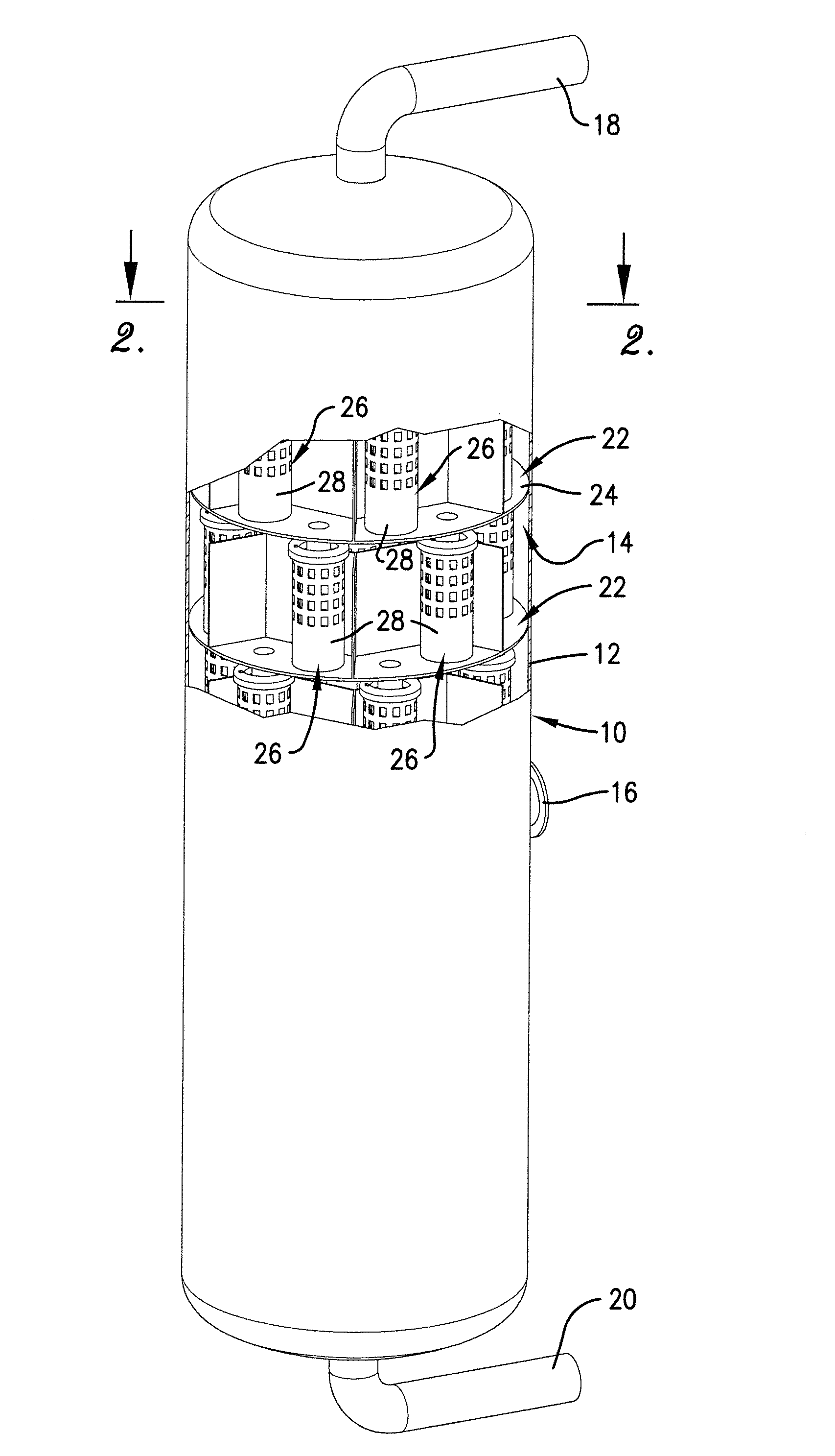

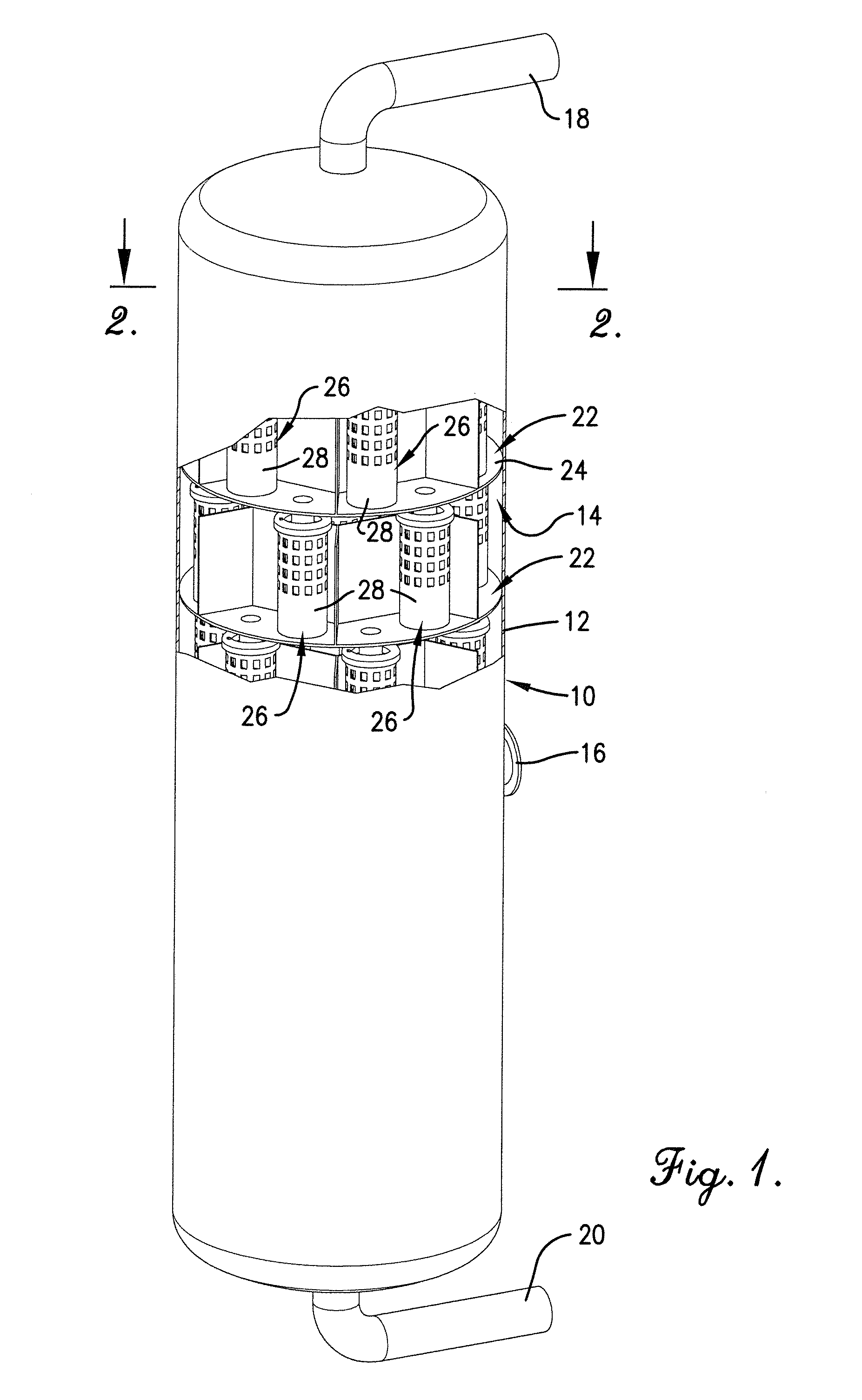

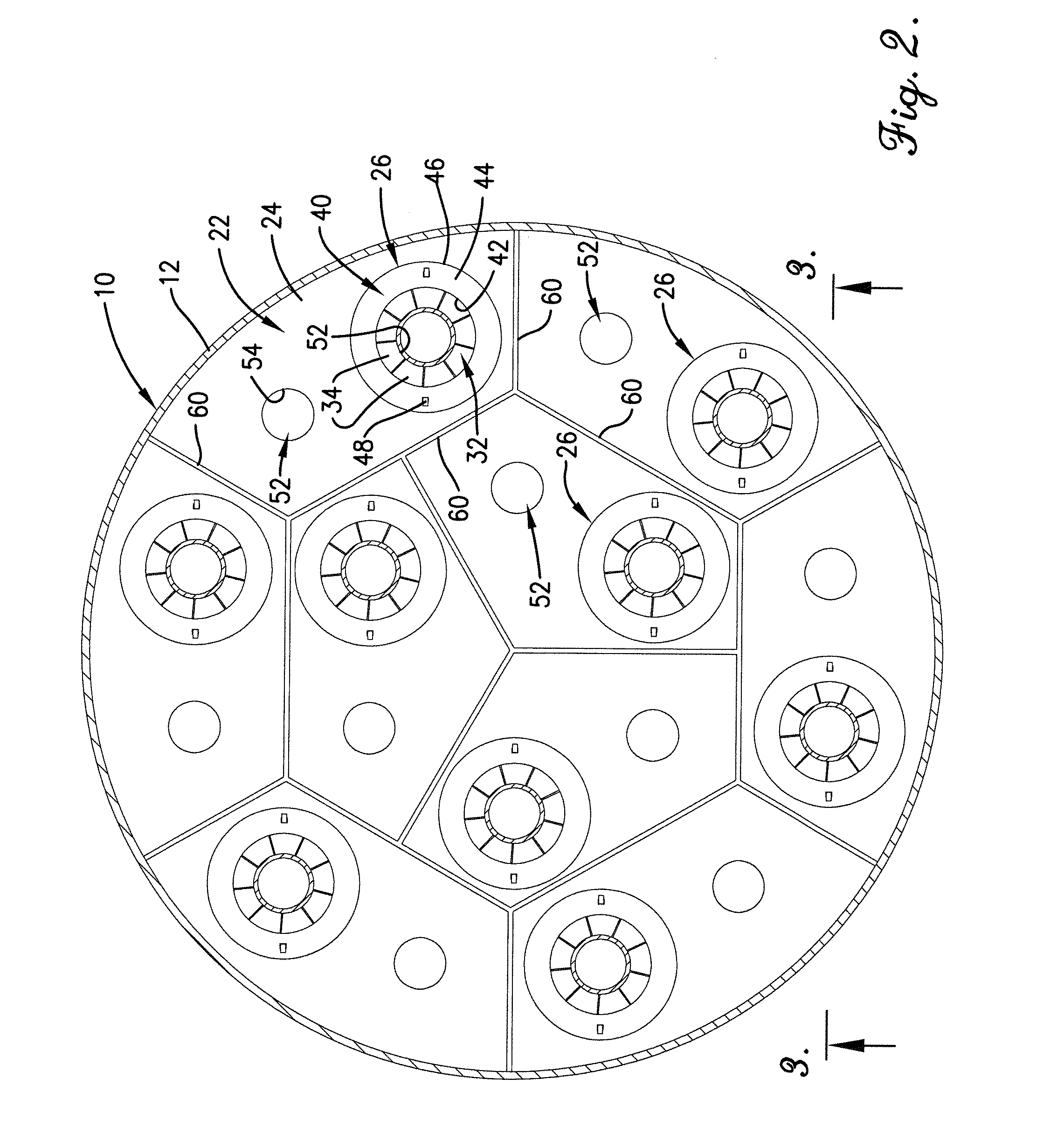

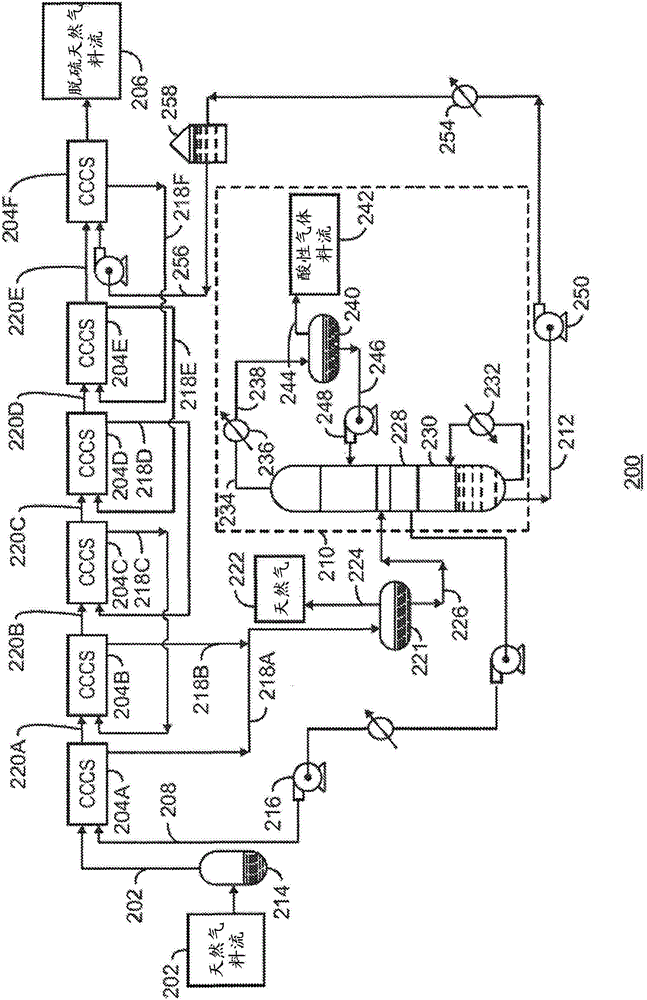

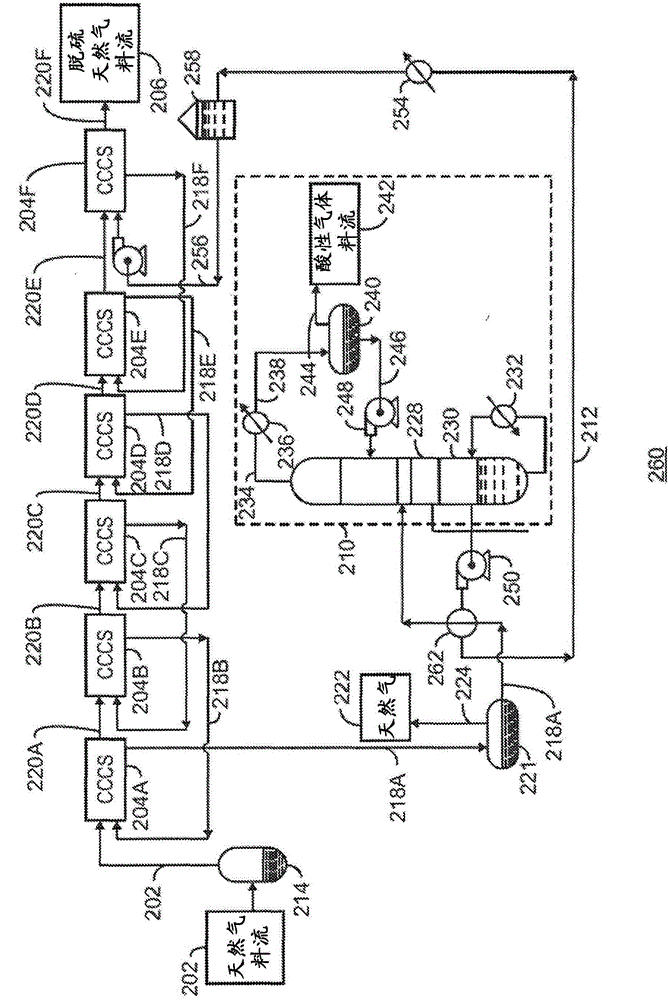

Vapor-liquid contacting in co-current contacting apparatuses

InactiveUS20100162891A1Reducing liquid handling capabilityLarge capacityCarburetting airLiquid degasificationVapor liquidEngineering

Improved contacting modules and apparatuses containing the modules, for carrying out vapor-liquid contacting, are described. In representative contacting modules, liquid (and possibly vapor) are discharged into co-current flow channels in a non-uniform manner (e.g., from only one side of the channels). Particular contacting modules comprise at least one liquid downcomer and a demister, wherein the liquid downcomer and an inlet surface of the demister define a co-current flow channel and wherein liquid is discharged from an outlet of the downcomer. The use of one or more added liquid distribution devices to more uniformly distribute the discharged liquid improves vapor-liquid contacting efficiency in the co-current flow channel and consequently vapor-liquid mass transfer and approach to equilibrium for the contacting stage.

Owner:UOP LLC

Liquid distributor for use in mass transfer column and method employing same

ActiveUS20050189663A1Facilitate horizontal distribution of liquidImprove distributionCarburetting airLiquid handlingInterior spaceEngineering

A flow distributor for liquid descending in a vertically elongated process column having an internal space. The distributor is made up of an elongated liquid distribution trough configured and arranged for being mounted in a process column in a position to extend across the internal space thereof. The trough has outer walls defining an elongated, longitudinally extending internal fluid distribution chamber and includes outlet holes which extend through the walls at locations permitting liquid to escape laterally outwardly from the trough. The distributor also includes a baffle distributor structure made up of an elongated, downwardly extending distributor plate member disposed adjacent the trough in a position such that at least a portion of a surface thereof is contacted by liquid escaping from said hole. The distributor also includes an elongated, fluid receiving element attached at a lower edge portion of said plate member presenting an elongated fluid distribution channel extending longitudinally of the plate member.

Owner:KOCH GLITSCH INC

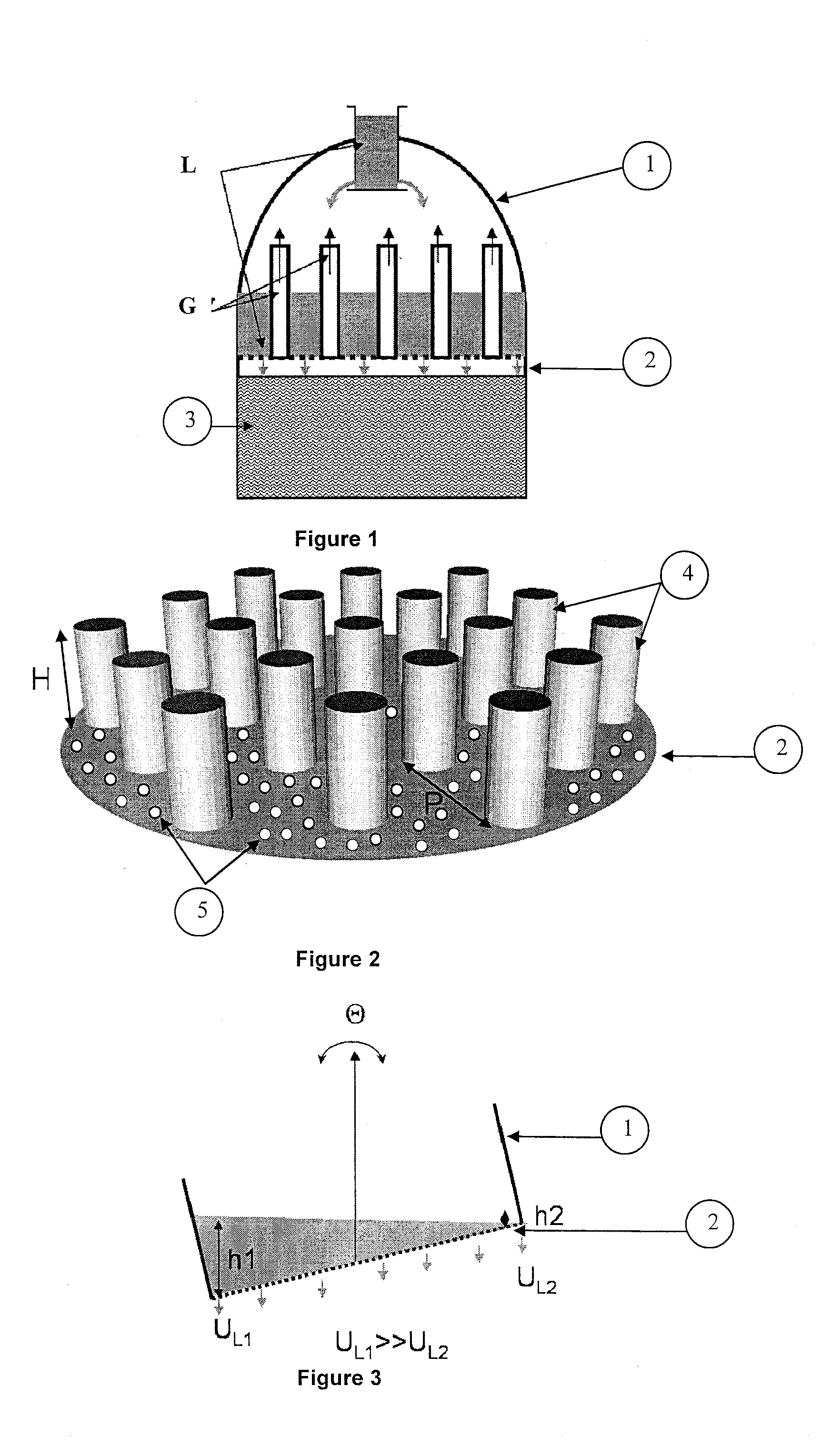

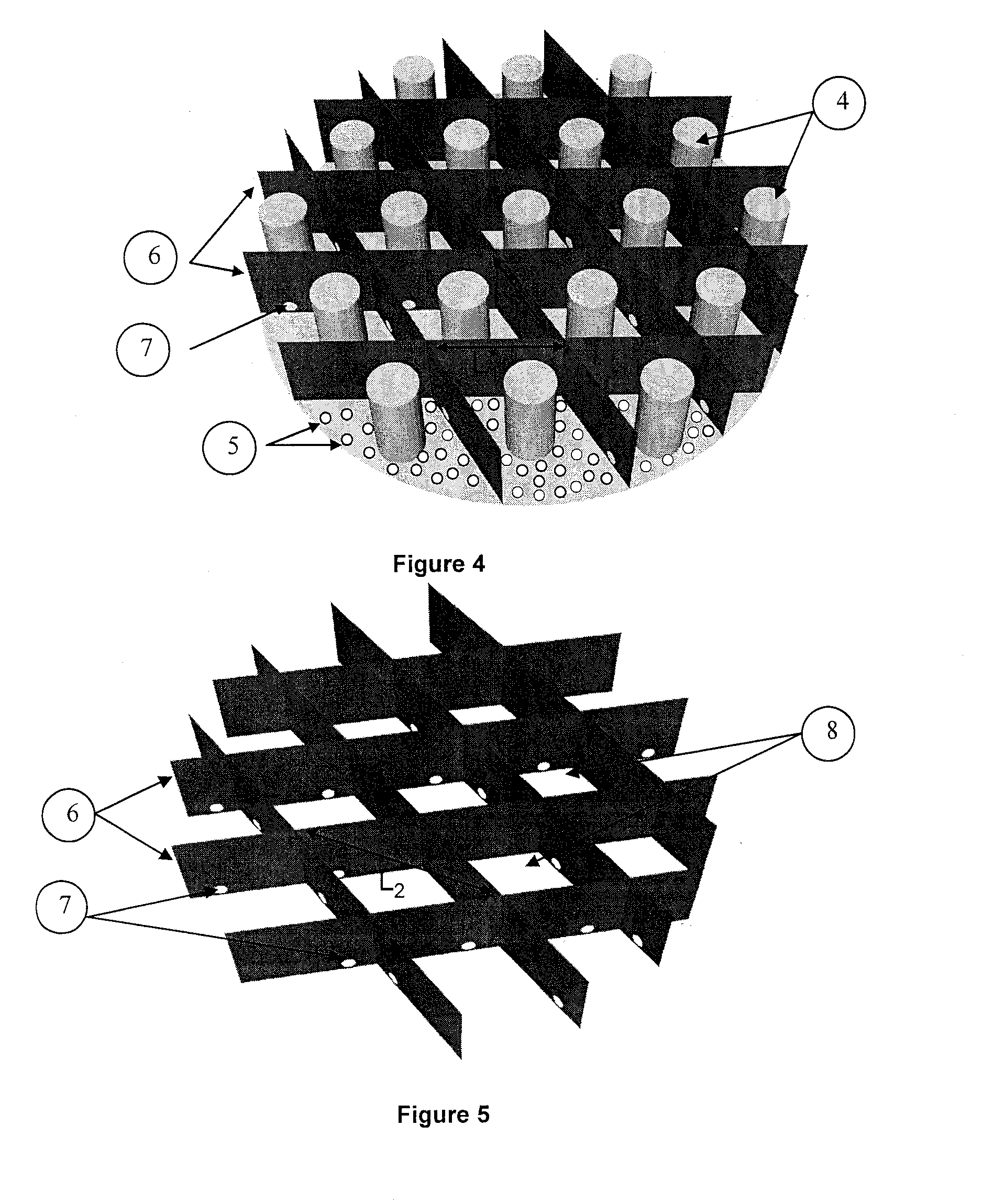

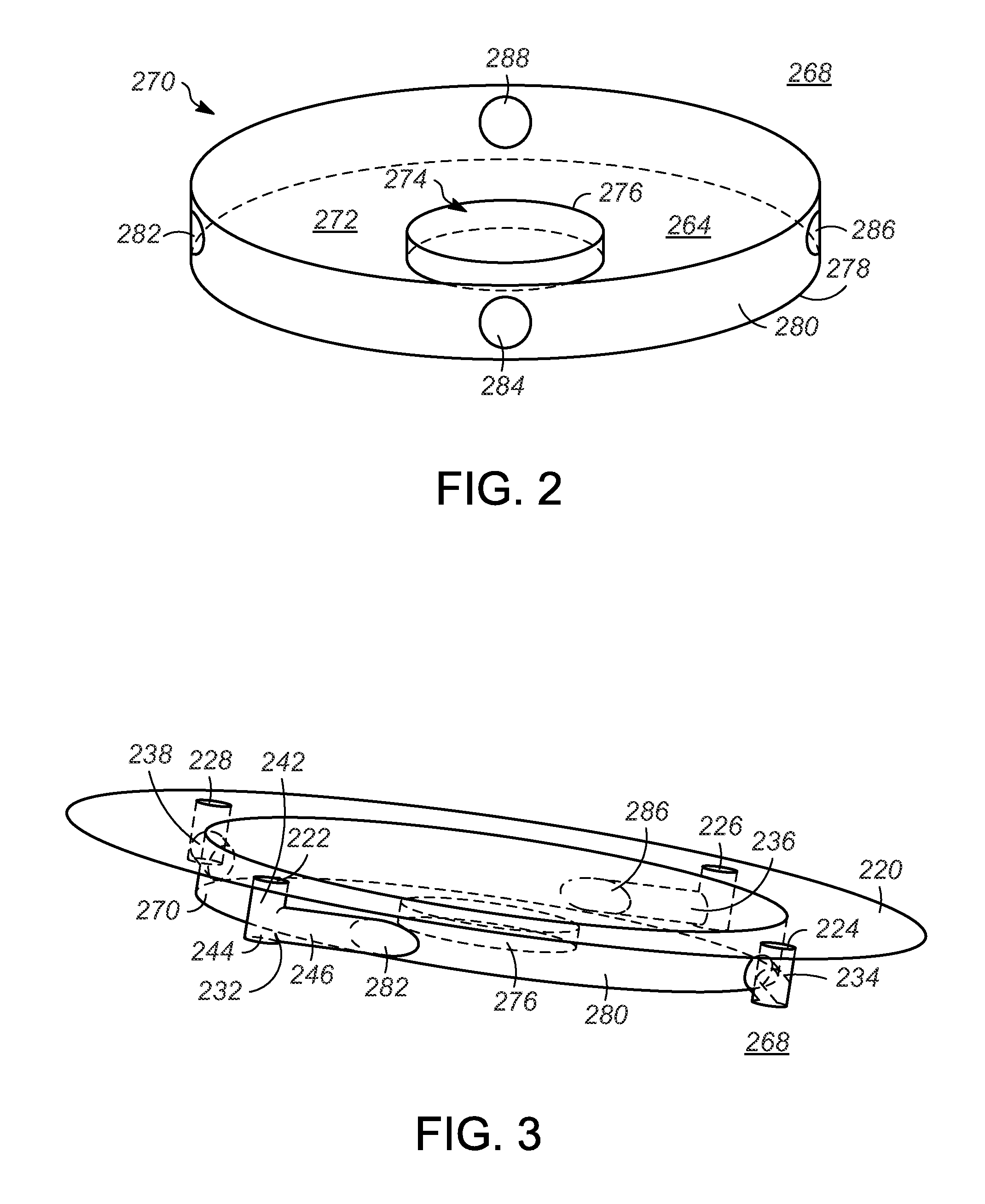

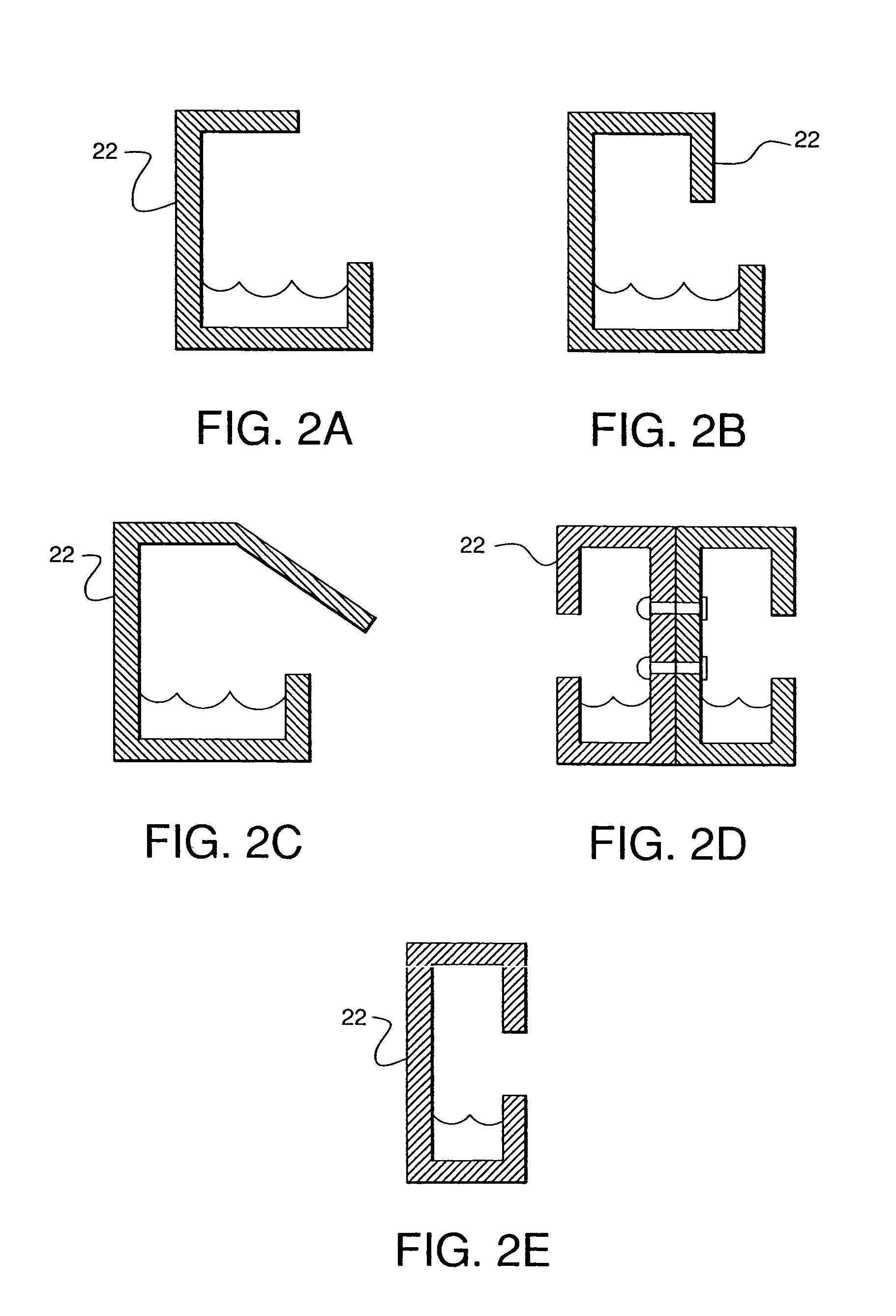

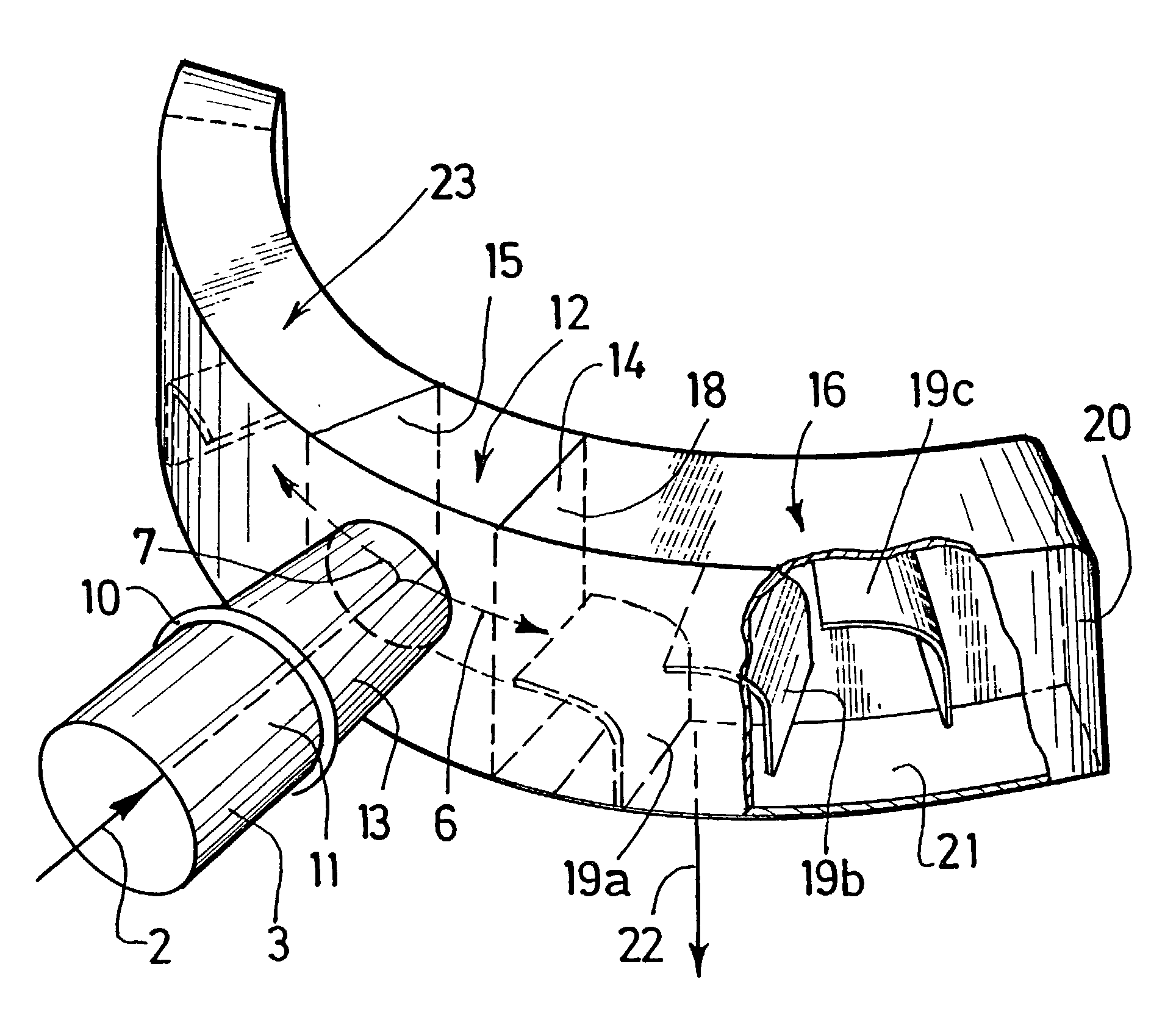

Partitioned distributor tray for offshore gas/liquid contact column

ActiveUS20130277868A1Using liquid separation agentFuel re-atomisation/homogenisationDistillationDistributor

The invention is a distributor tray for a column (1) for heating and / or material exchange between a gas (G) and a liquid (L), comprising at least one wall (6) defining compartments (8) on one of the surfaces of the tray. The walls are perforated (7) to allow part of the liquid to flow between compartments (8). Each compartment comprise at least one means (5) providing passage of the liquid through the tray and at least one means providing passage of the gas through the tray. The invention also relates to a gas / liquid contact column, a gas treatment unit, a CO2 capture unit, a distillation unit, and an offshore floating barge comprising the distributor tray. The invention also relates to a method of manufacturing such a tray

Owner:INST FR DU PETROLE

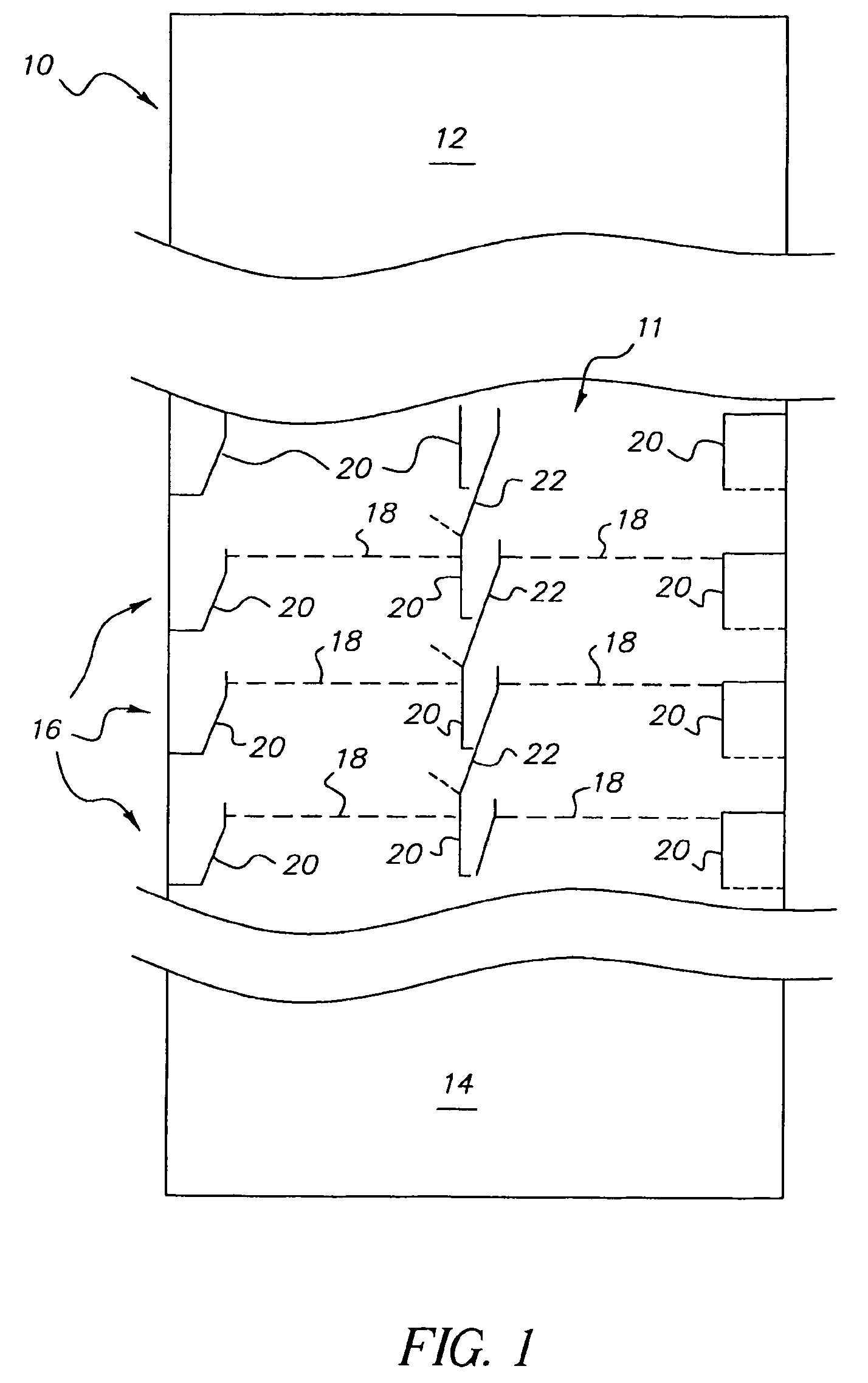

Fractionation apparatus with low surface area grid above tray deck

The flooding capacity of a fractionation tray (2) is increased by the addition of at least one layer of low surface area grids (3) above the inlet to the downcomers (6,12) located on the tray (2). The grids (3) extend upward for a distance equal to one to four times the depth of the downcomers. The grids may rest upon the top edge of the downcomers or on the tray decking between the top portions of the downcomer sidewalls.

Owner:UOP LLC

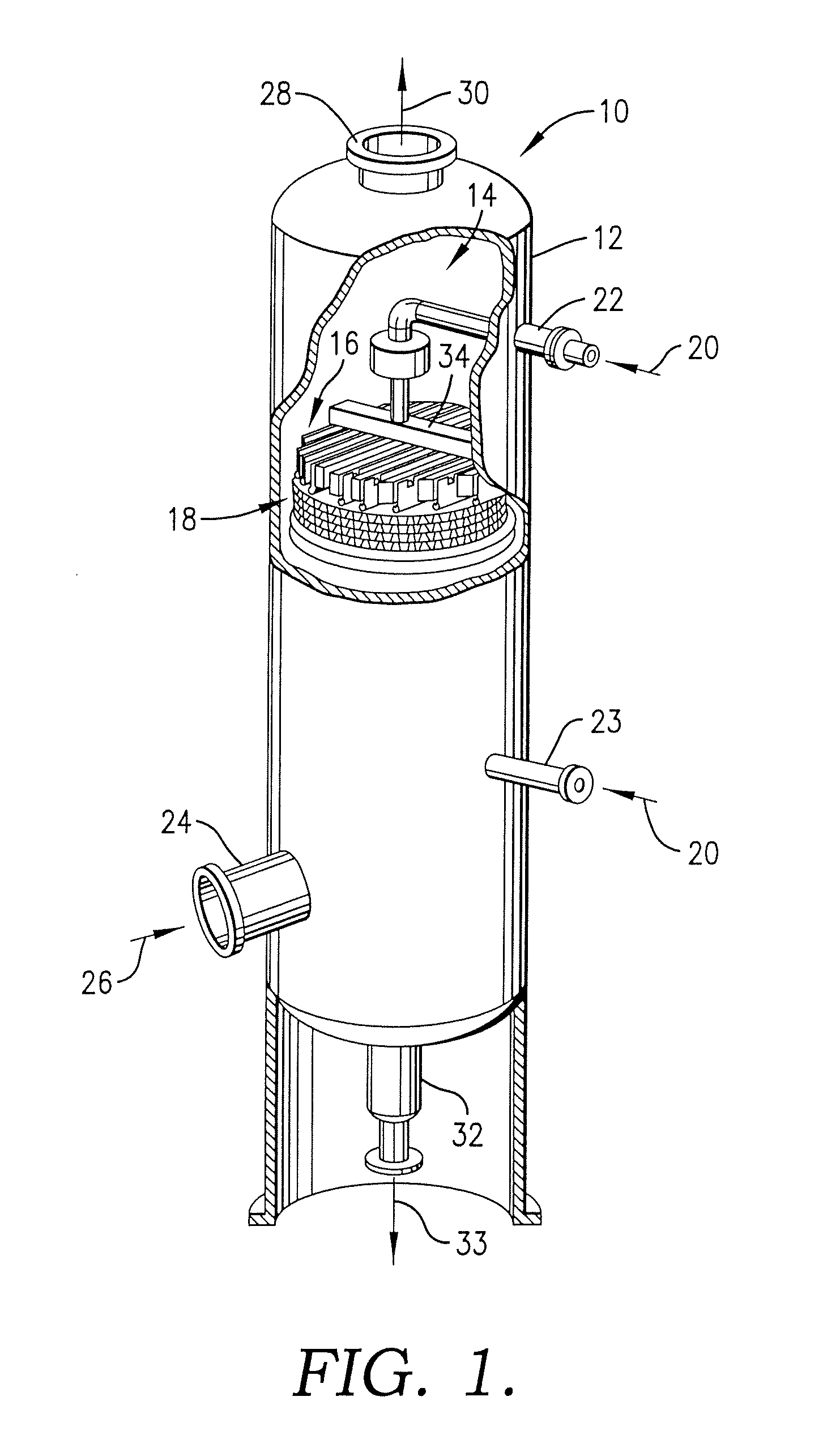

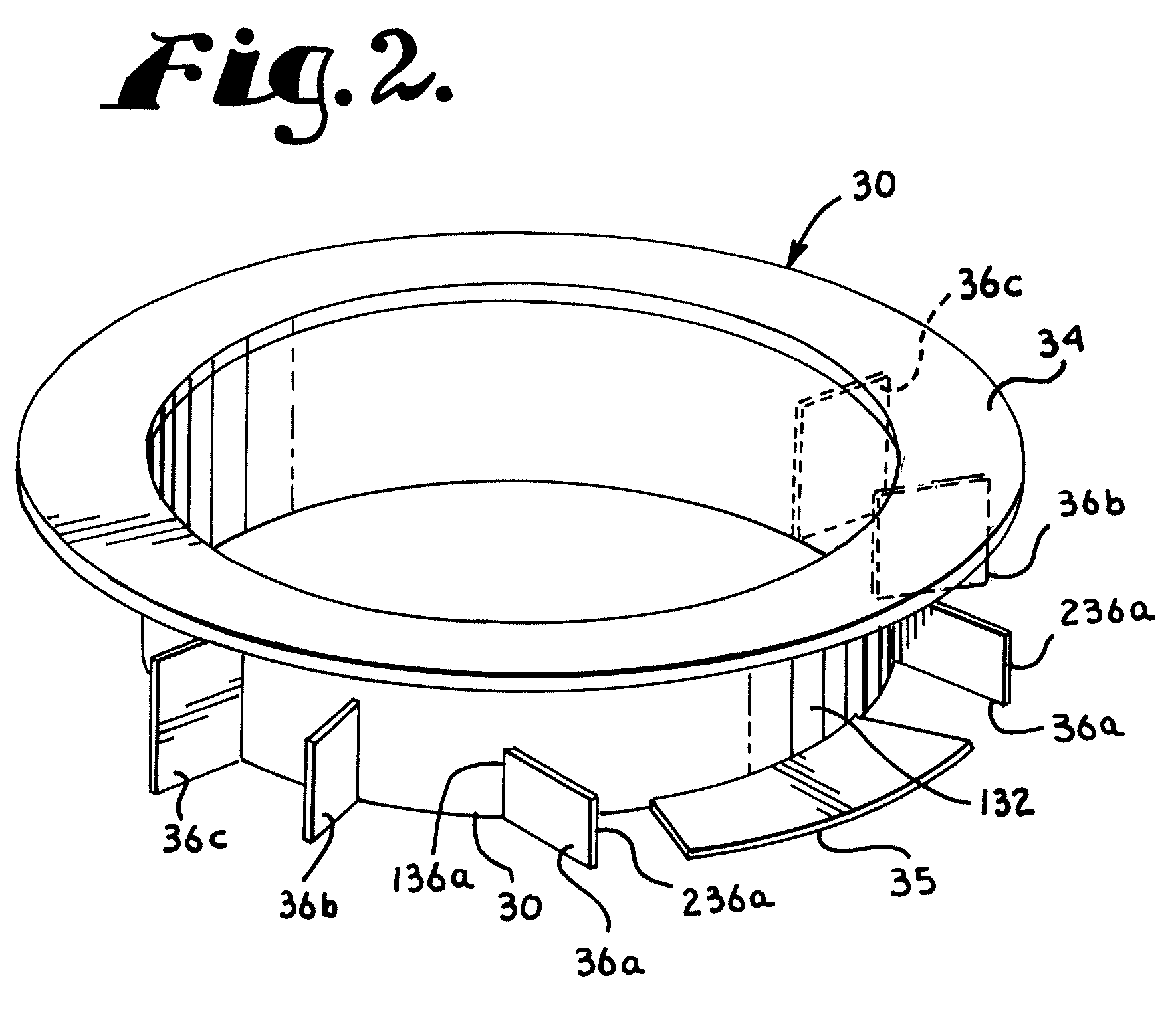

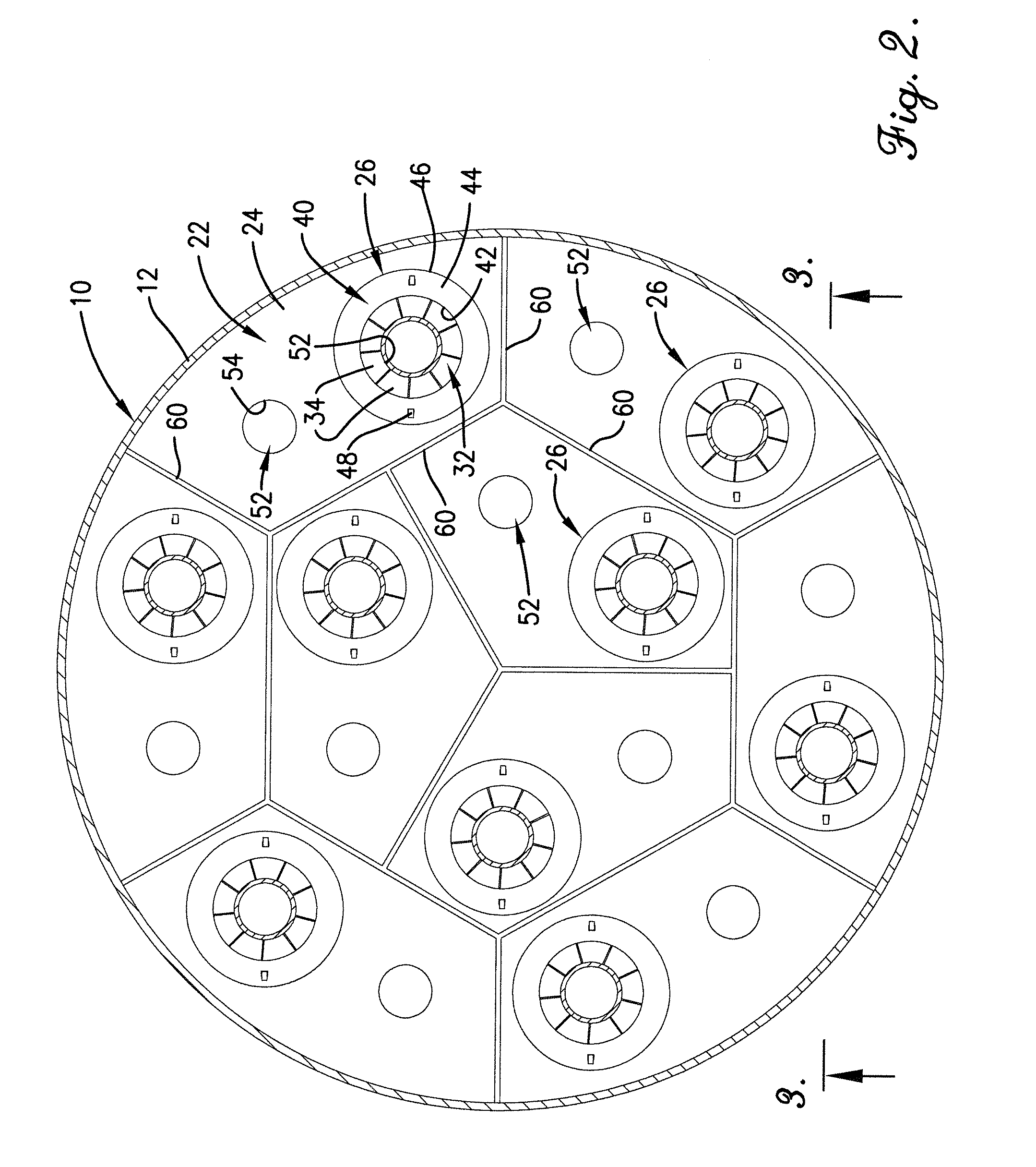

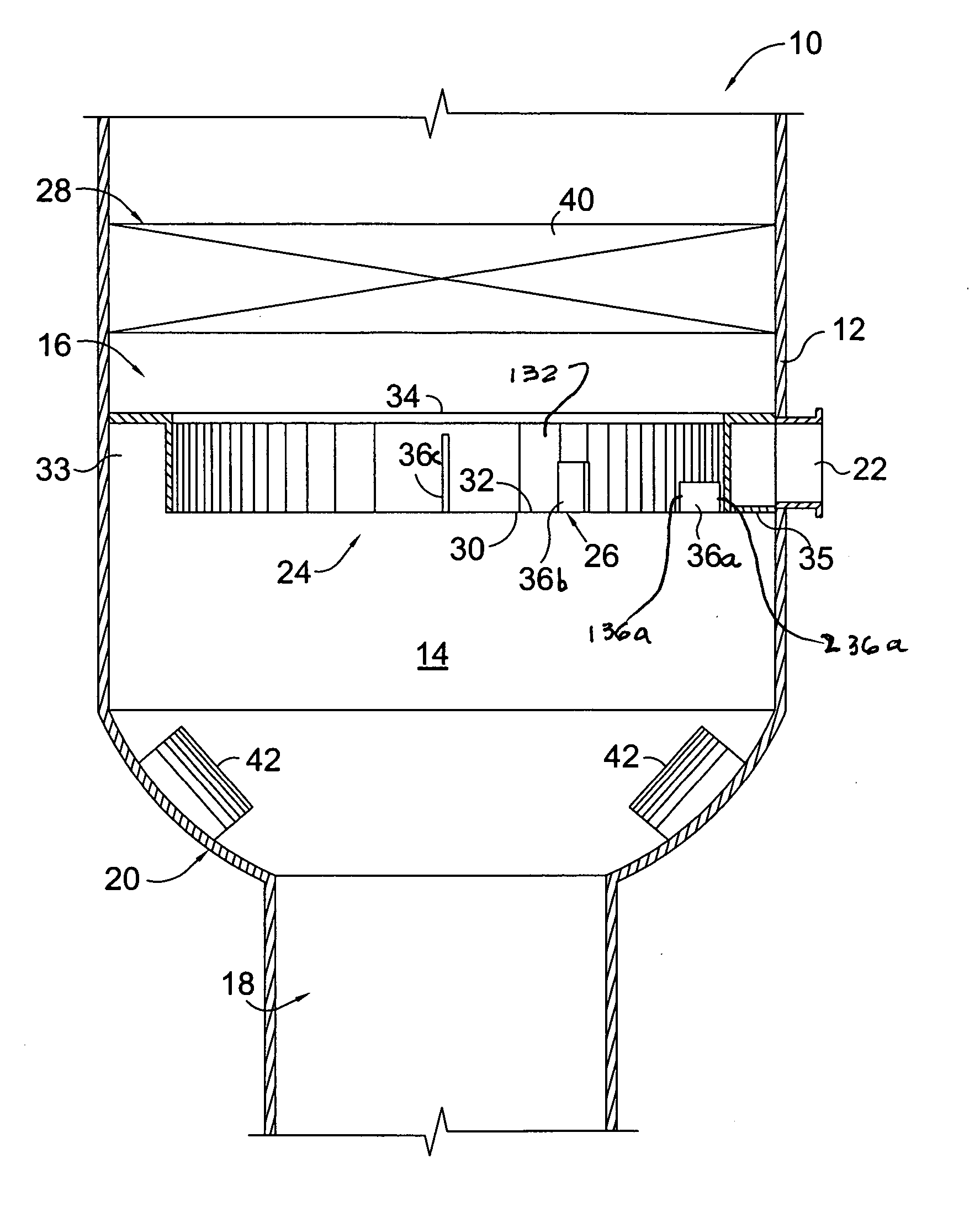

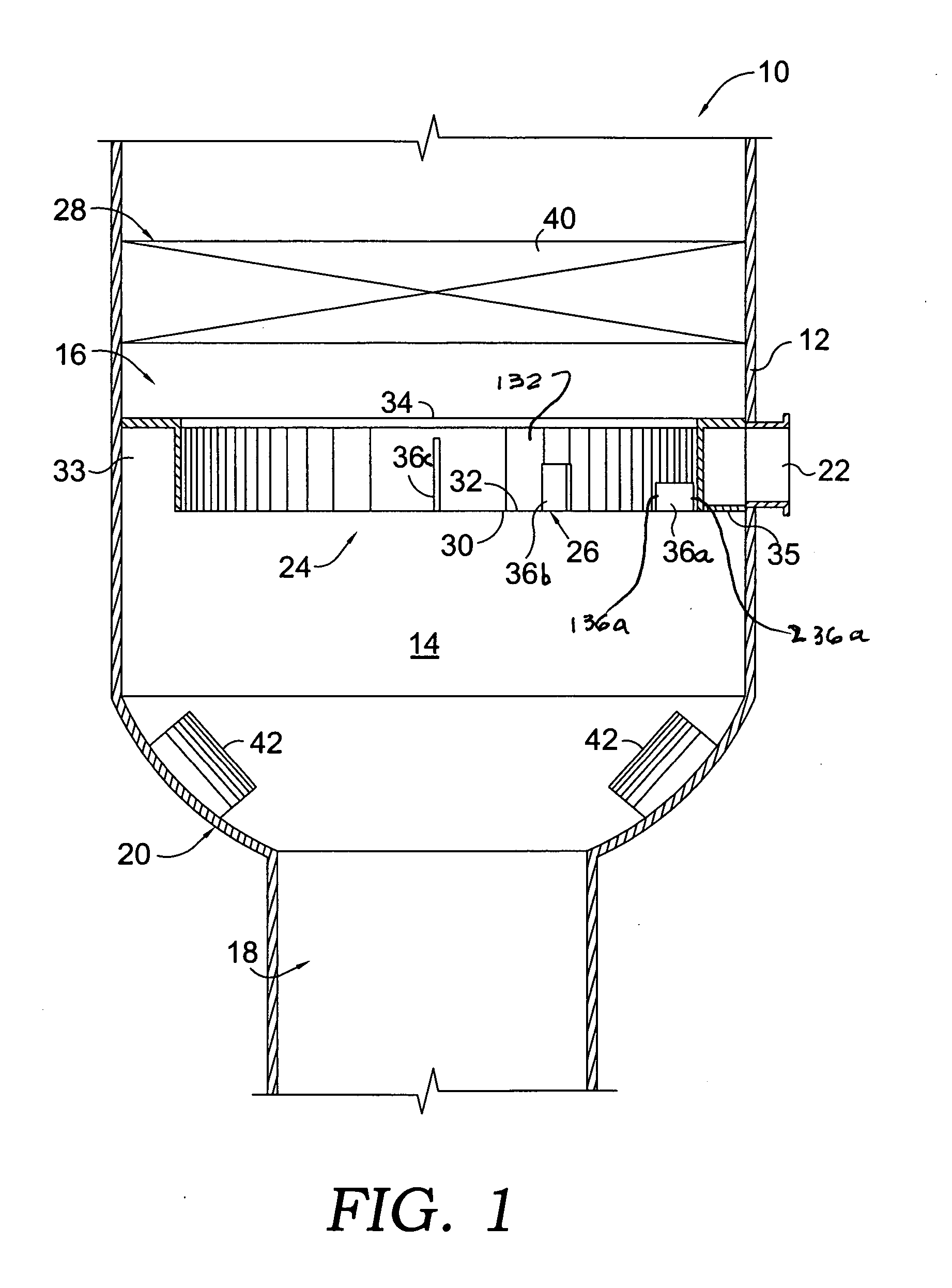

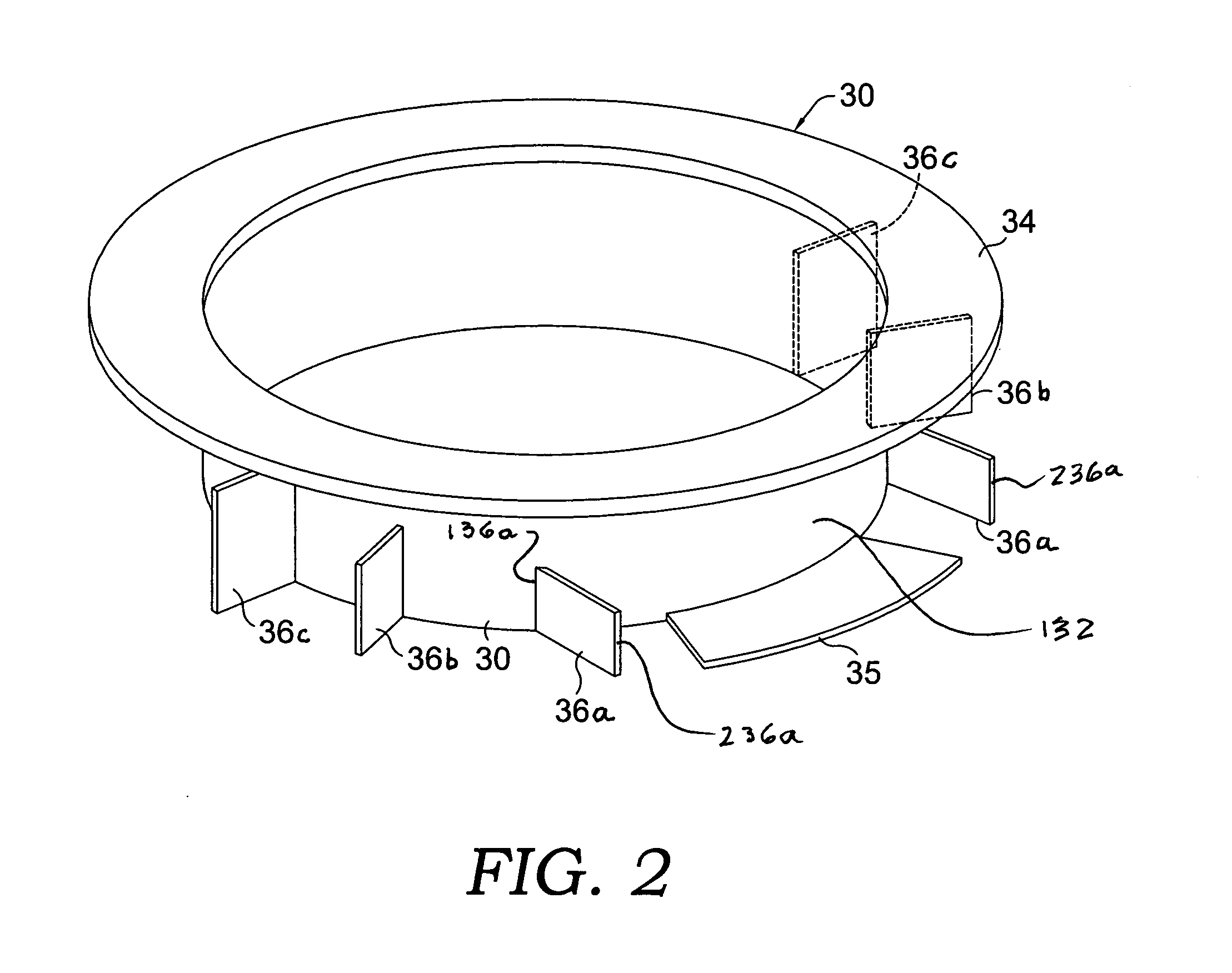

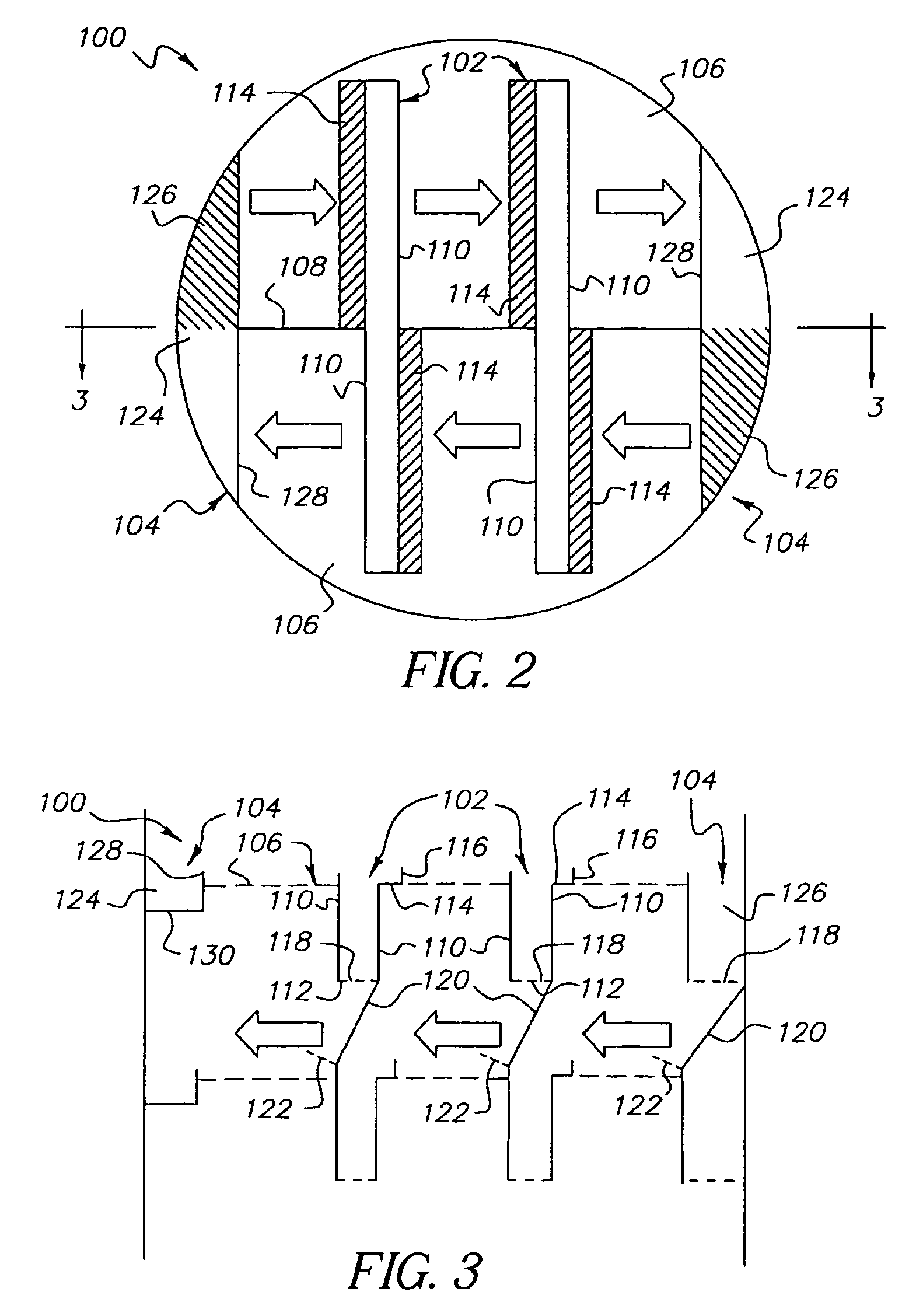

Fluid stream feed device for mass transfer column

InactiveUS20050029686A1Reduce the amount requiredLower overall pressure dropCarburetting airUsing liquid separation agentStream flowMixed phase

A mass transfer column includes a feed device that is used to de-entrain liquid and more uniformly distribute vapor across a horizontal cross section of the column after a vapor or mixed phase stream has been directed into the column through a radially oriented feed nozzle. The feed device includes an annular passageway formed in the spacing between the column shell and an inner wall spaced inwardly from the shell. A deflector with oppositely directed deflecting surfaces is positioned at an inlet from the feed nozzle to the annular passageway and splits the vapor or mixed phase stream into two roughly equal streams that flow in opposite circumferential directions in the annular passageway. At least one pair of turning vanes is spaced on opposite sides of the deflecting surfaces in the annular passageway to create subpassages through which the vapor or mixed phase stream flows. The subpassages reduce the amount of vapor or mixed phase stream flow that impacts against the inner wall of the feed device at the inlet. The turning vanes unexpectedly reduce the pressure drop that occurs as the vapor or mixed phase stream is redirected from its radial entry direction to the circumferential direction in the annular passageway. By reducing the pressure drop, improvements in product yield and vapor distribution can be achieved.

Owner:KOCH GLITSCH INC

Fluid Inlet Device, Use, and Method of Retrofitting

A fluid inlet device suitable for introducing a mixture of liquid and gas into a vessel, which fluid inlet device comprises an inlet flow channel having an inlet end for receiving the mixture of liquid and gas; and a plurality of curved guiding vanes placed one behind the other along the inlet flow channel, wherein each vane comprises an intercepting part extending towards the inlet end of the inlet flow channel, and an outwardly directed deflecting part defining a generally convex side and a generally concave side of the curved vane, wherein the deflecting parts of two consecutive vanes form an outlet channel of the inlet device and define a main direction of gas flow in the outlet channel, and wherein at least one of the vanes is provided with a liquid catcher channel extending from an upstream position with respect to the vane to a downstream position, and wherein a virtual line along the vane between the upstream position and the downstream position deviates from the main direction of gas flow; the use of the fluid inlet device for introducing a mixture of liquid and gas into a gas-liquid contacting vessel; and liquid catcher channels as well as their use in a method of retrofitting an a fluid inlet device.

Owner:SHELL USA INC

Liquid Collector and Redistributor For Packed Columns

An apparatus for collecting / redistributing a flow of liquid descending in an exchange column containing a layer of packing that includes: a plurality of horizontally spaced longitudinal members, each member having an inner side and an upper end adjacent a bottom of the layer of packing; at least one plate vertically spaced from the bottom of the layer of packing, each plate adapted to collect a portion of the flow of the descending liquid and having opposing ends connected to the inner sides of a pair of the longitudinal members; and at least one vapor riser in fluid communication with the plate and adapted to receive and transmit at least a portion of a stream of a vapor ascending in the exchange column from below to above the plate, each vapor riser having a cap vertically spaced apart from the bottom of the layer of packing.

Owner:AIR PROD & CHEM INC

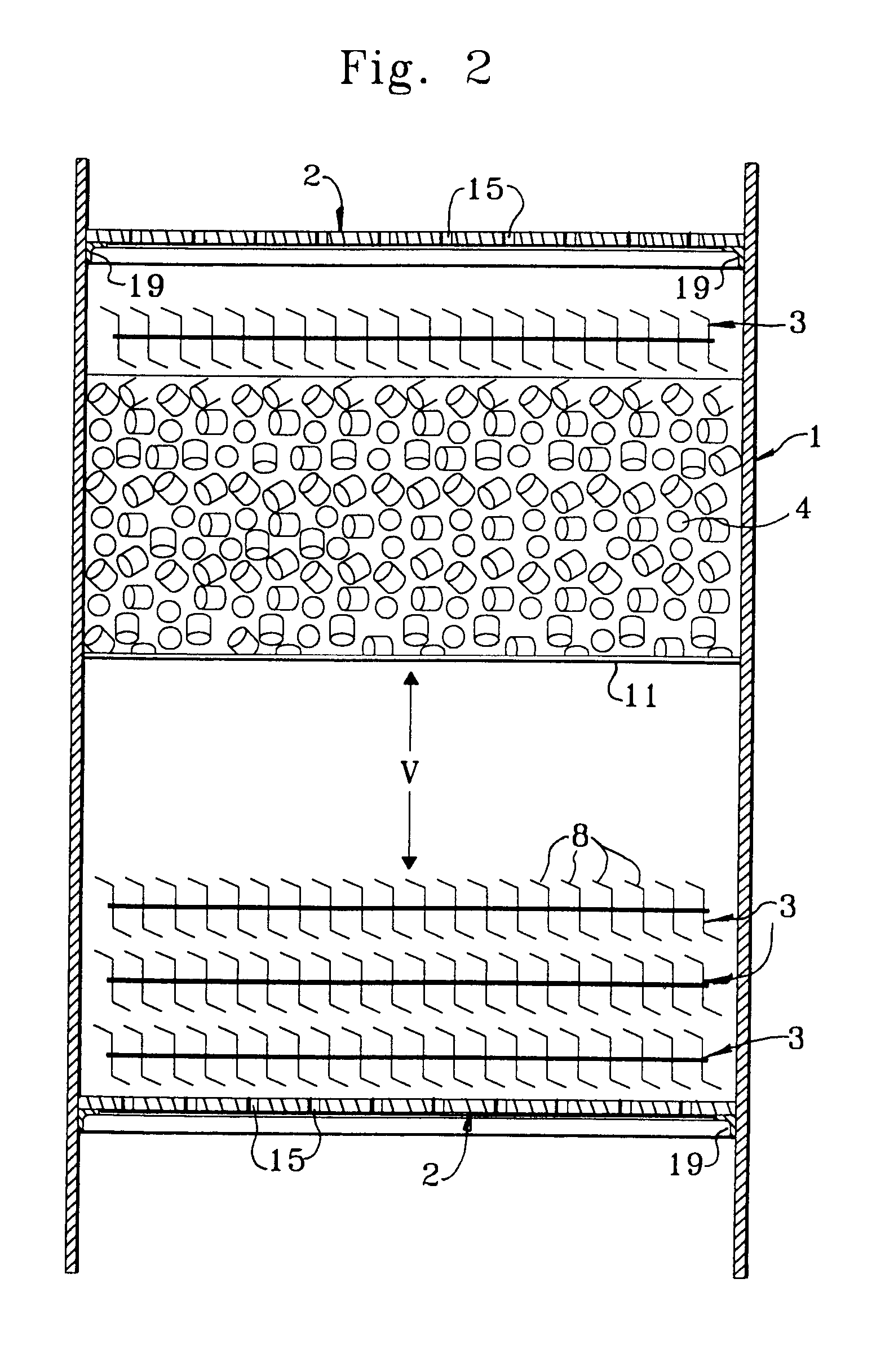

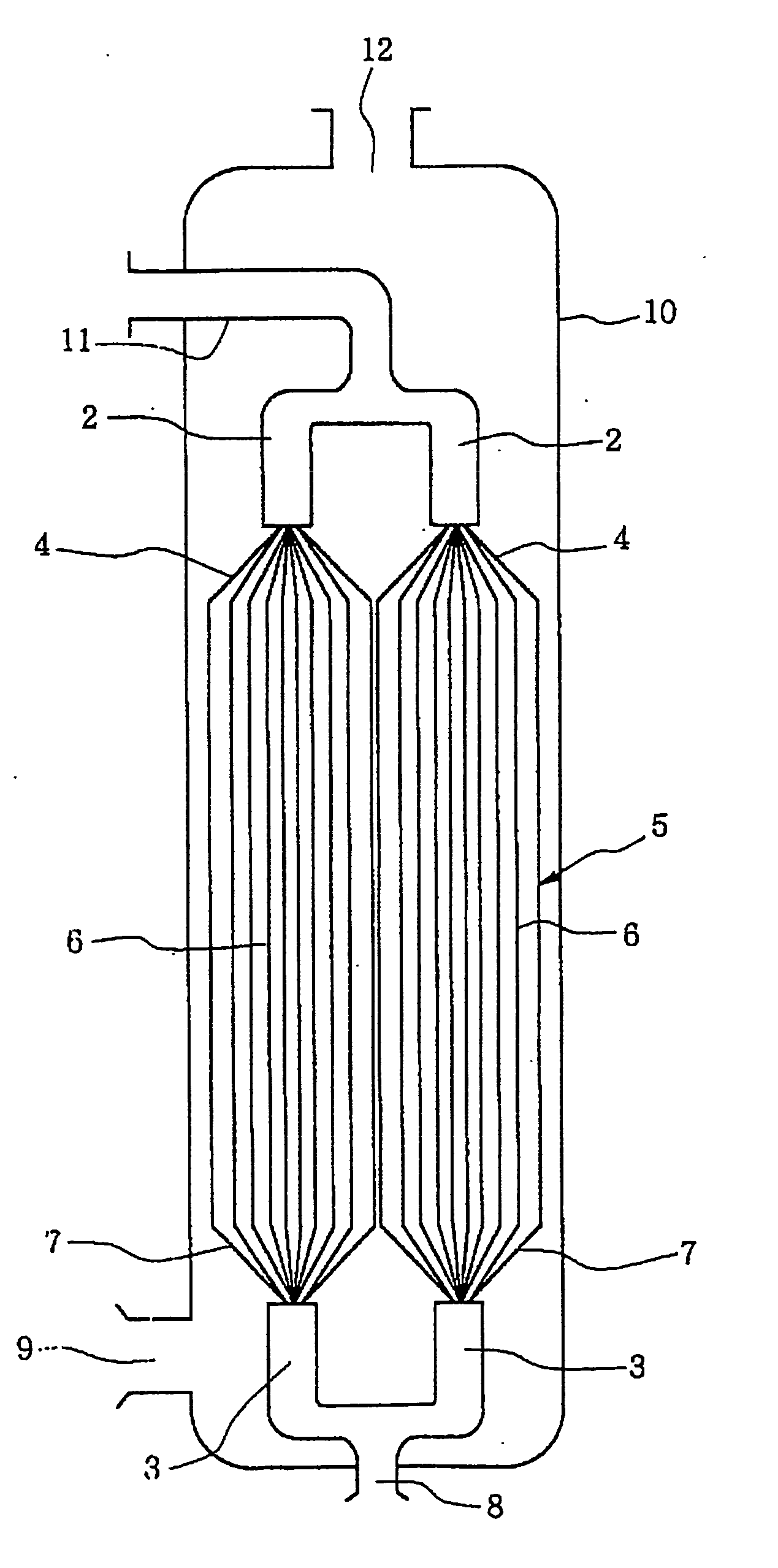

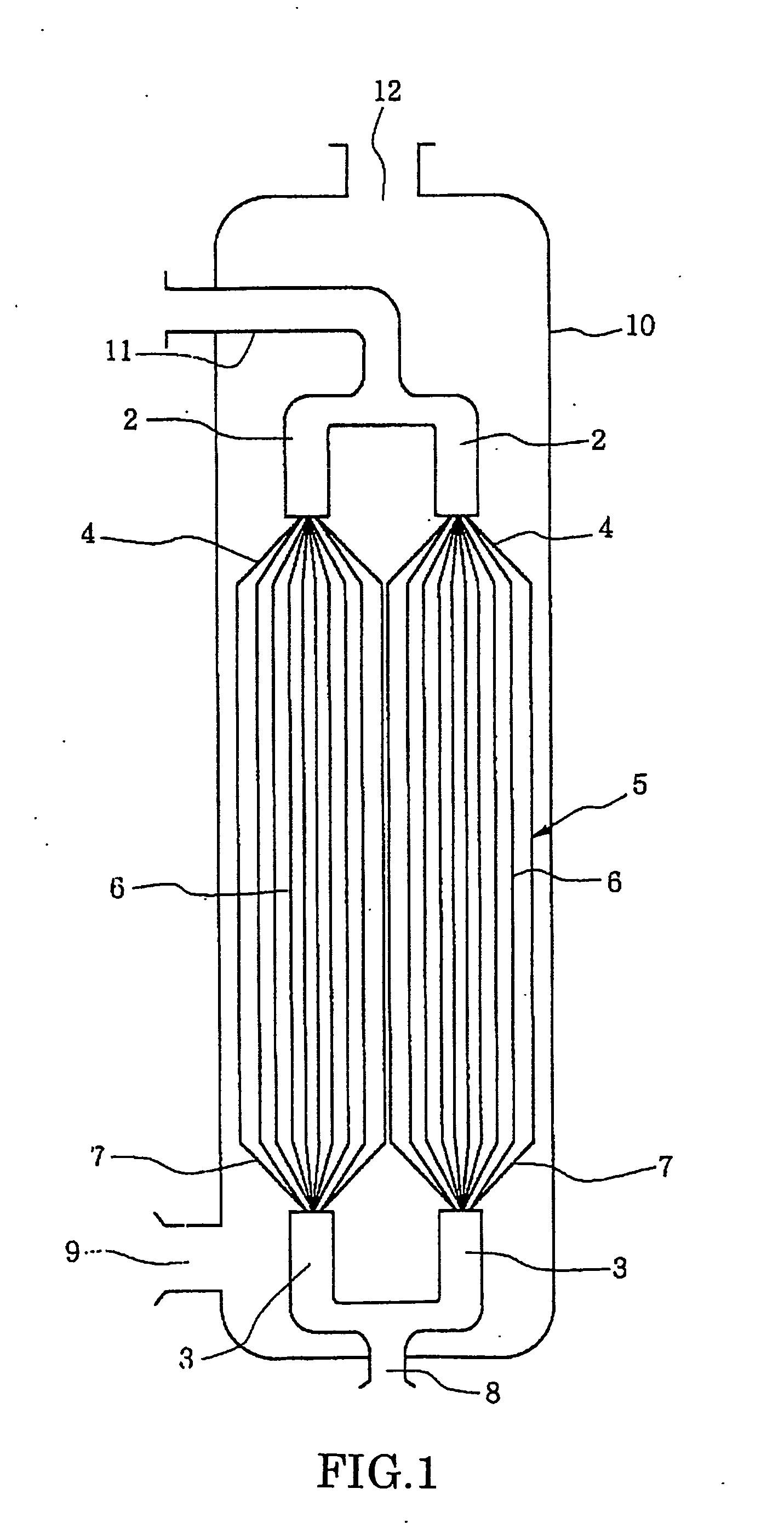

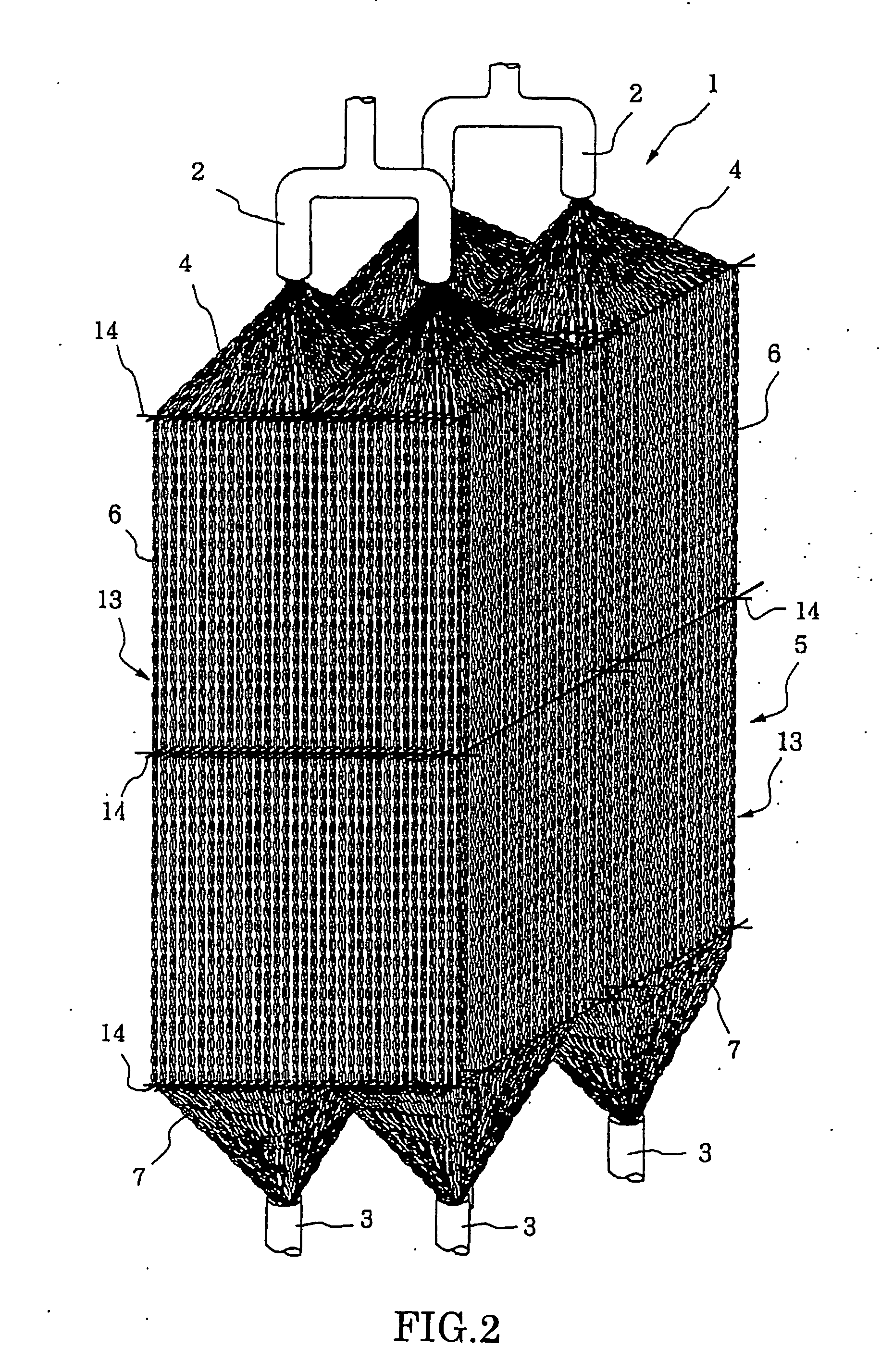

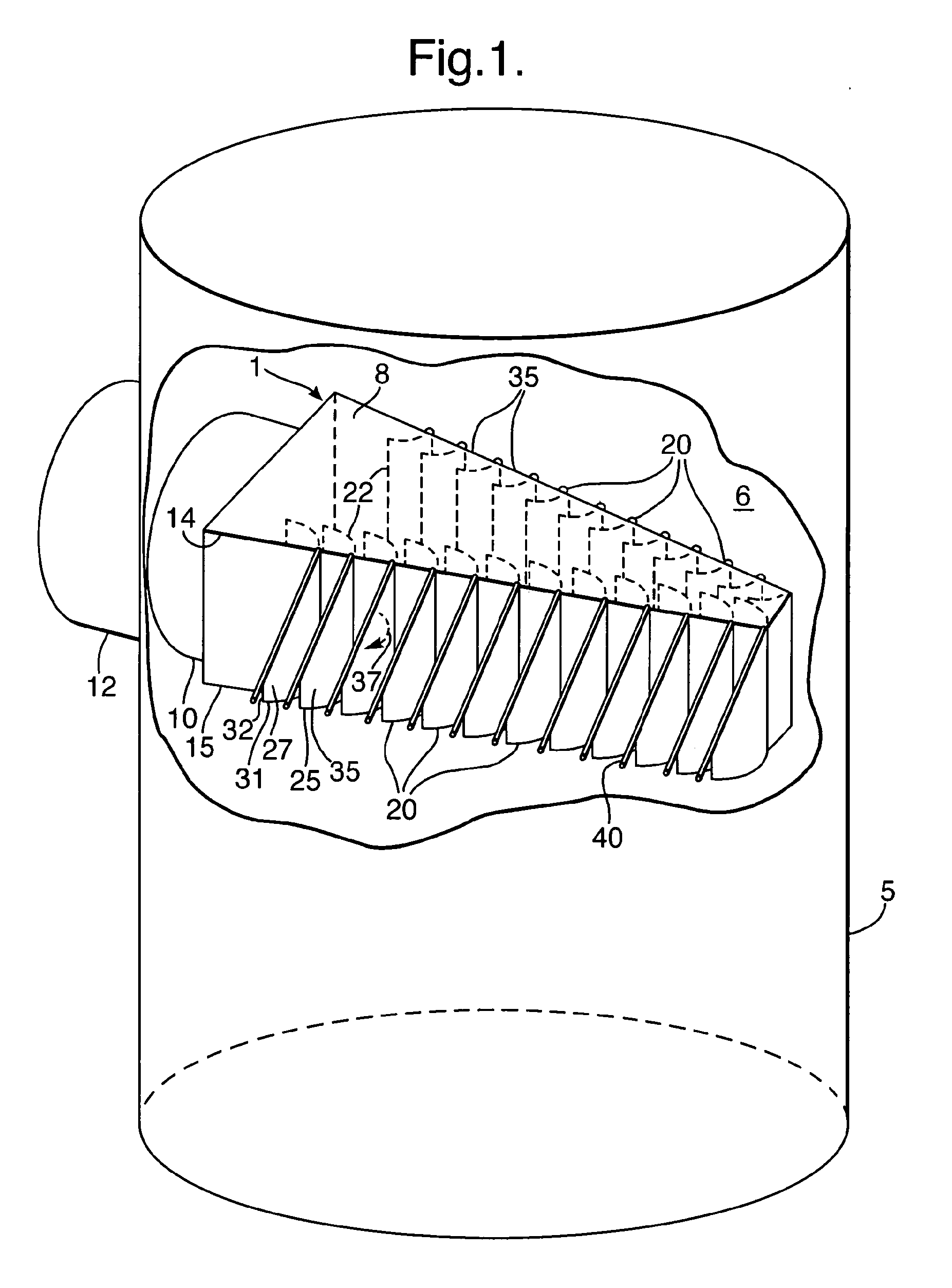

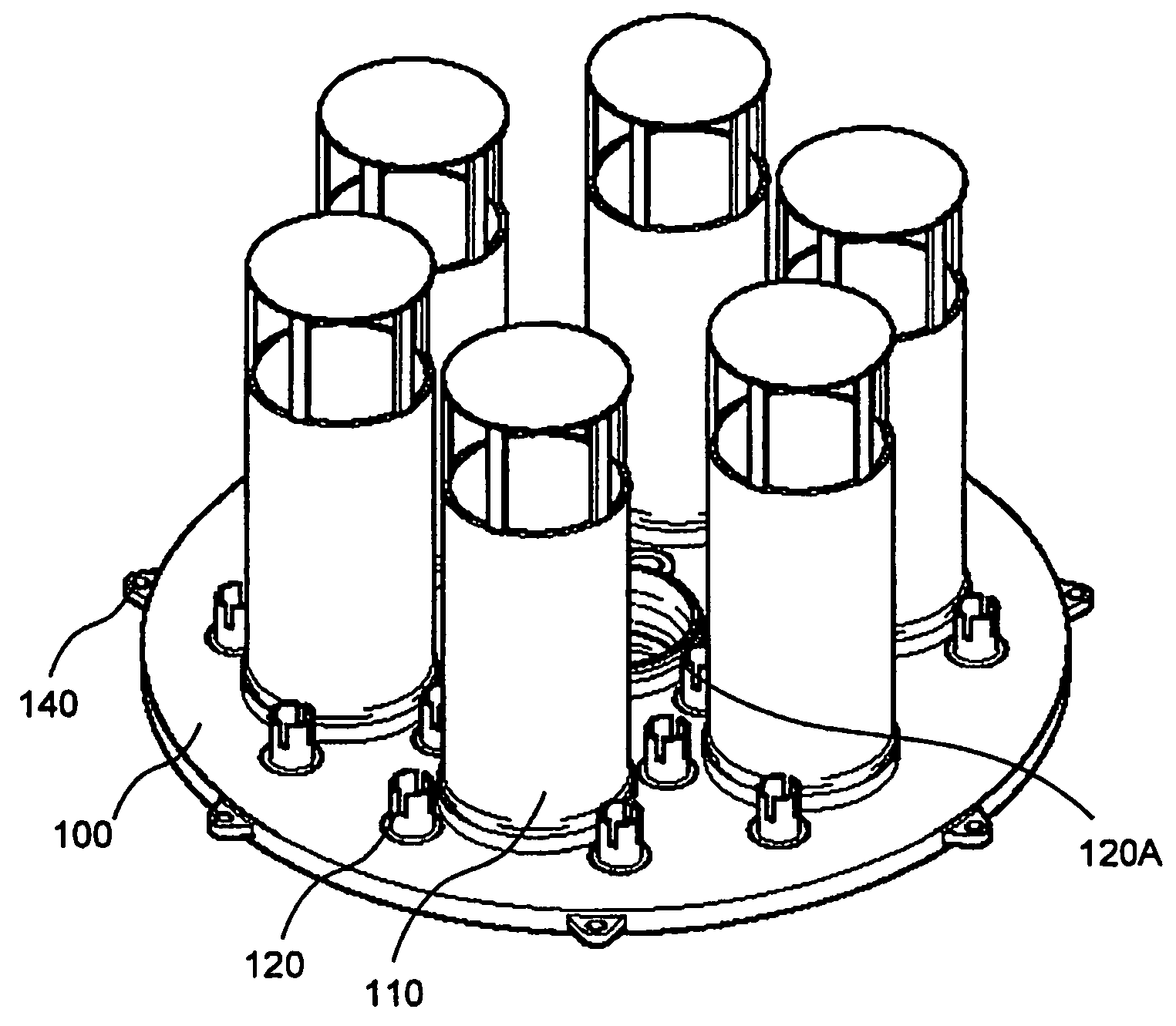

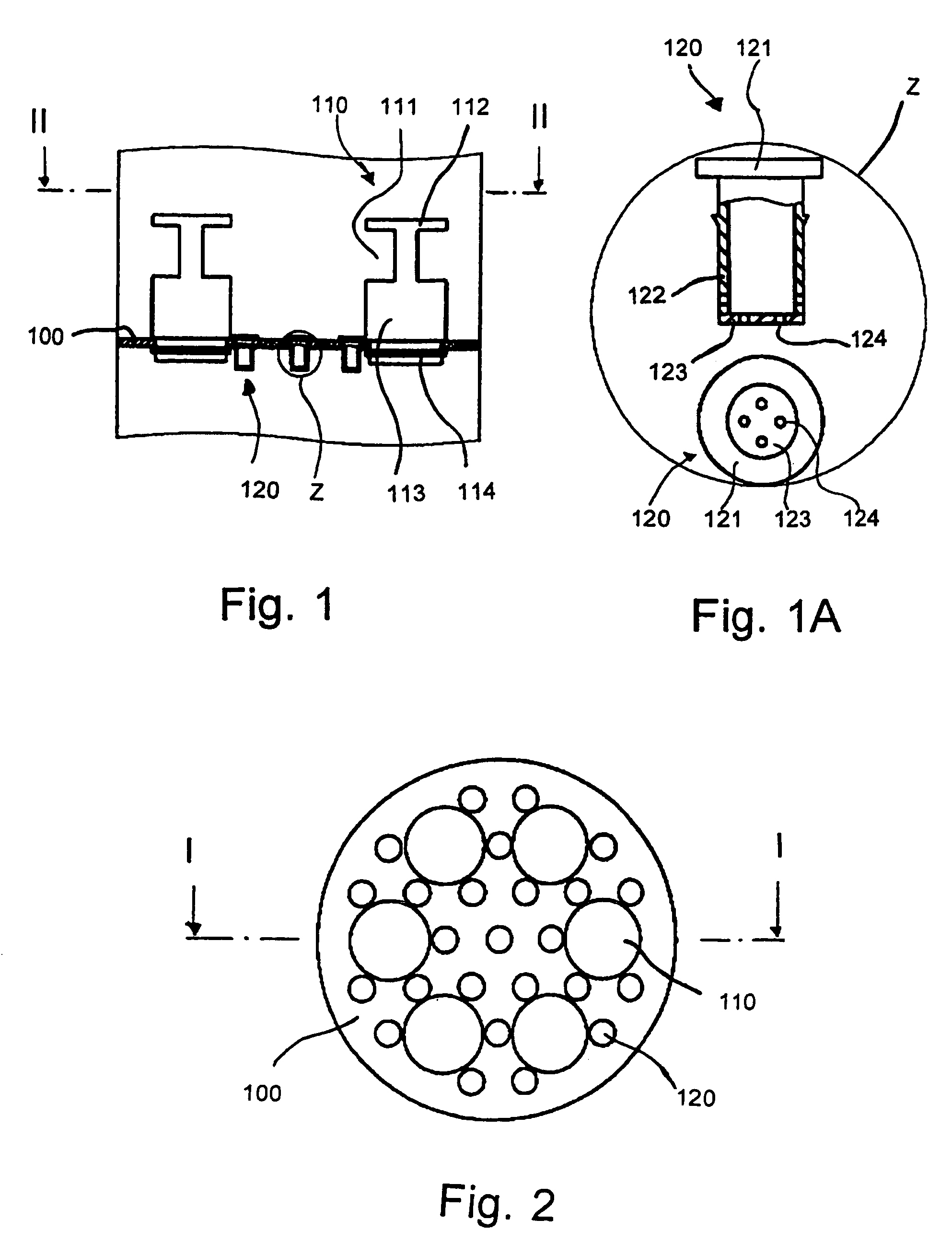

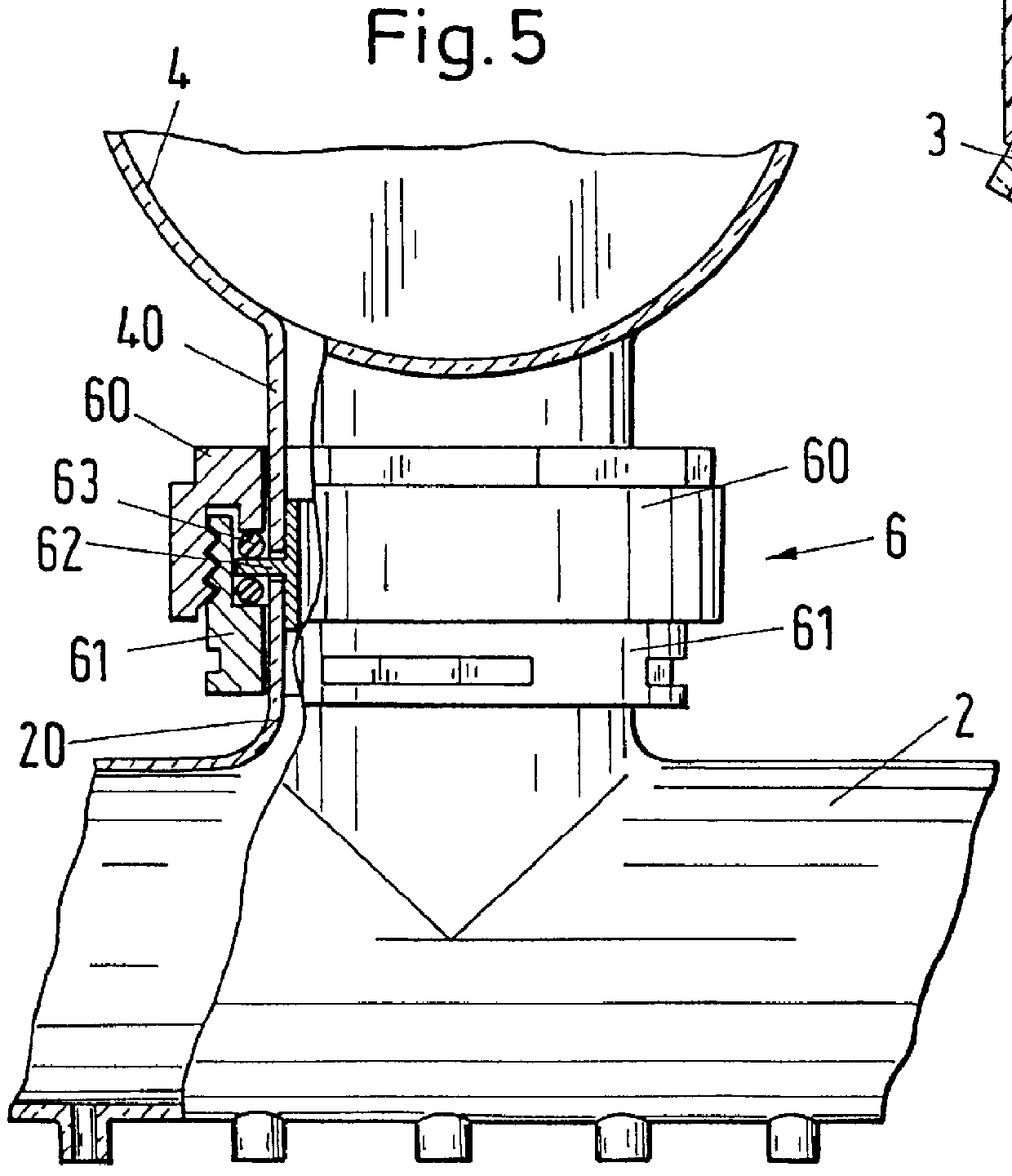

Reactor with packing mean

InactiveUS20070194471A1Eliminate driftSpeed up the flowUsing liquid separation agentLiquid distribution in distillationEngineeringDistributor

There is provided a liquid-gas contact device which has a liquid distributor (2) provided in the upper portion of the device, a liquid collector (3) provided in the lower portion of the device and an internal structure between the liquid distributor (2) and the liquid collector (3) which defines a plurality of flow paths. The liquid-gas-contact device includes a column packing (5) constituting the internal structure made of a plurality of column packing constituting elements (6) each of which extends vertically in parallel to each other in a non-contact state and in a non-contact state with an inner wall of the device, a plurality of adaptors (4) connecting the liquid distributor (2) with the column packing (5) for supplying liquid from the liquid distributor (2) to the column packing (5), and a plurality of collectors (7) connecting the column packing (5) with the liquid collector (3) for supplying liquid from the column packing (5) to the liquid collector (3).

Owner:NAGAOKA TADAYOSHI

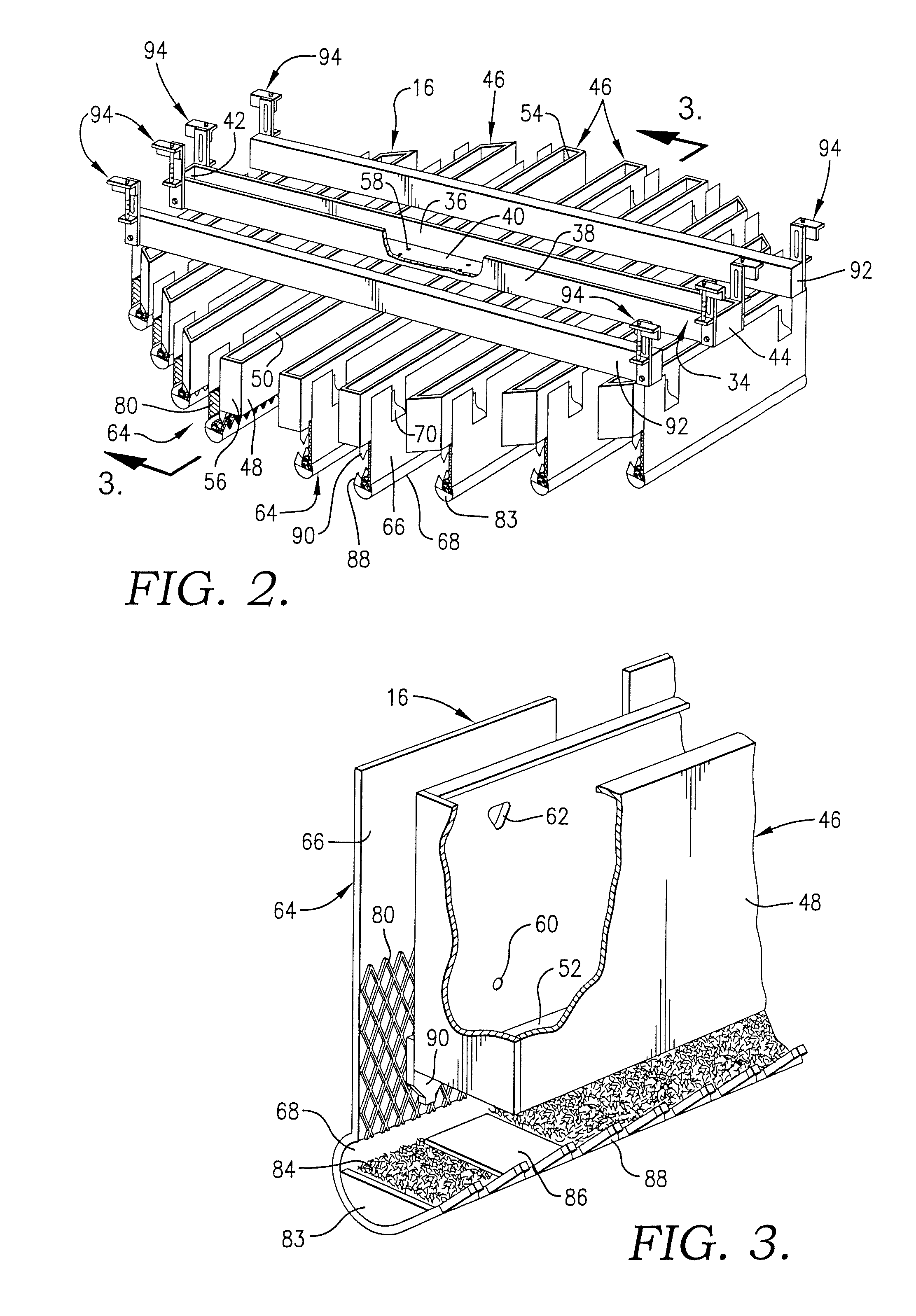

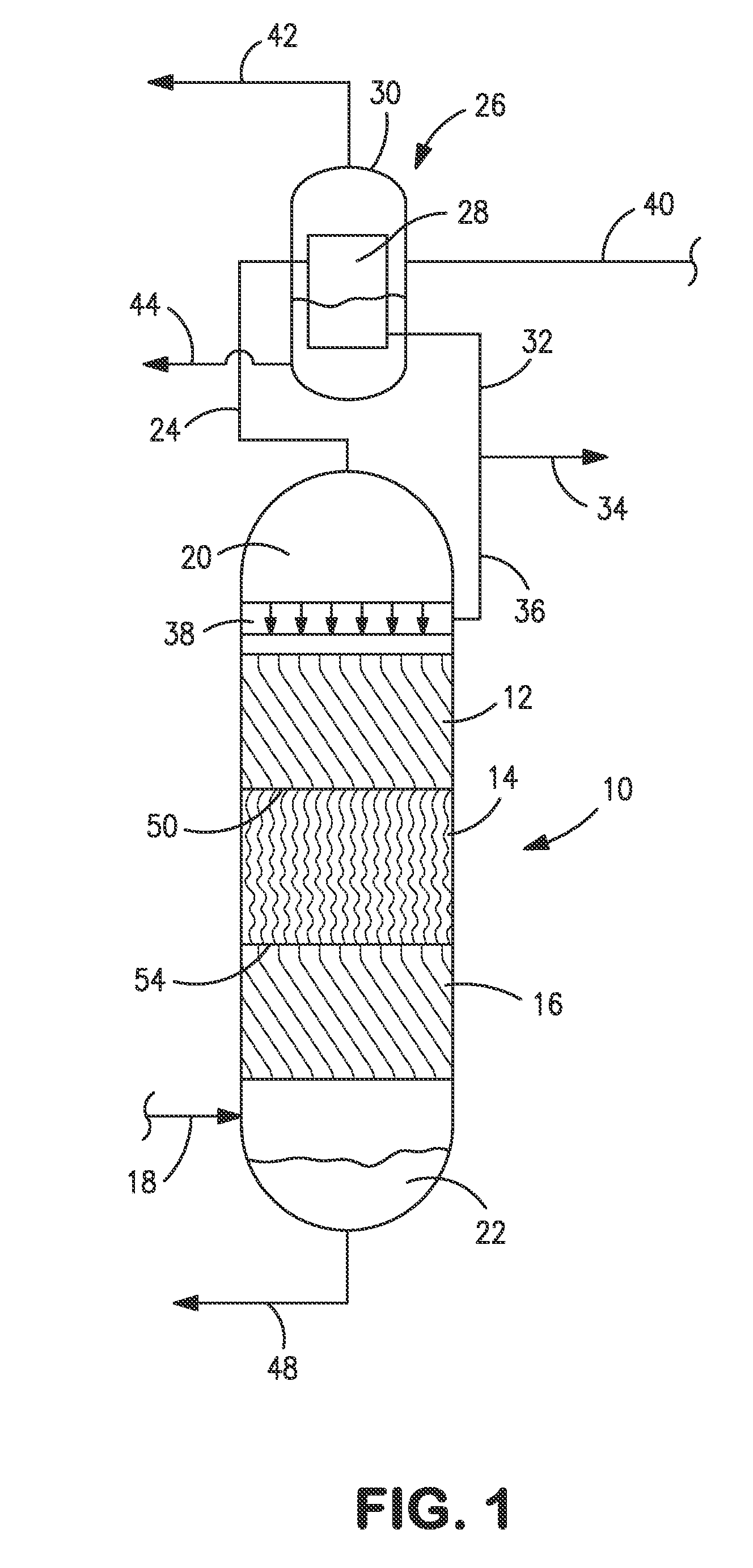

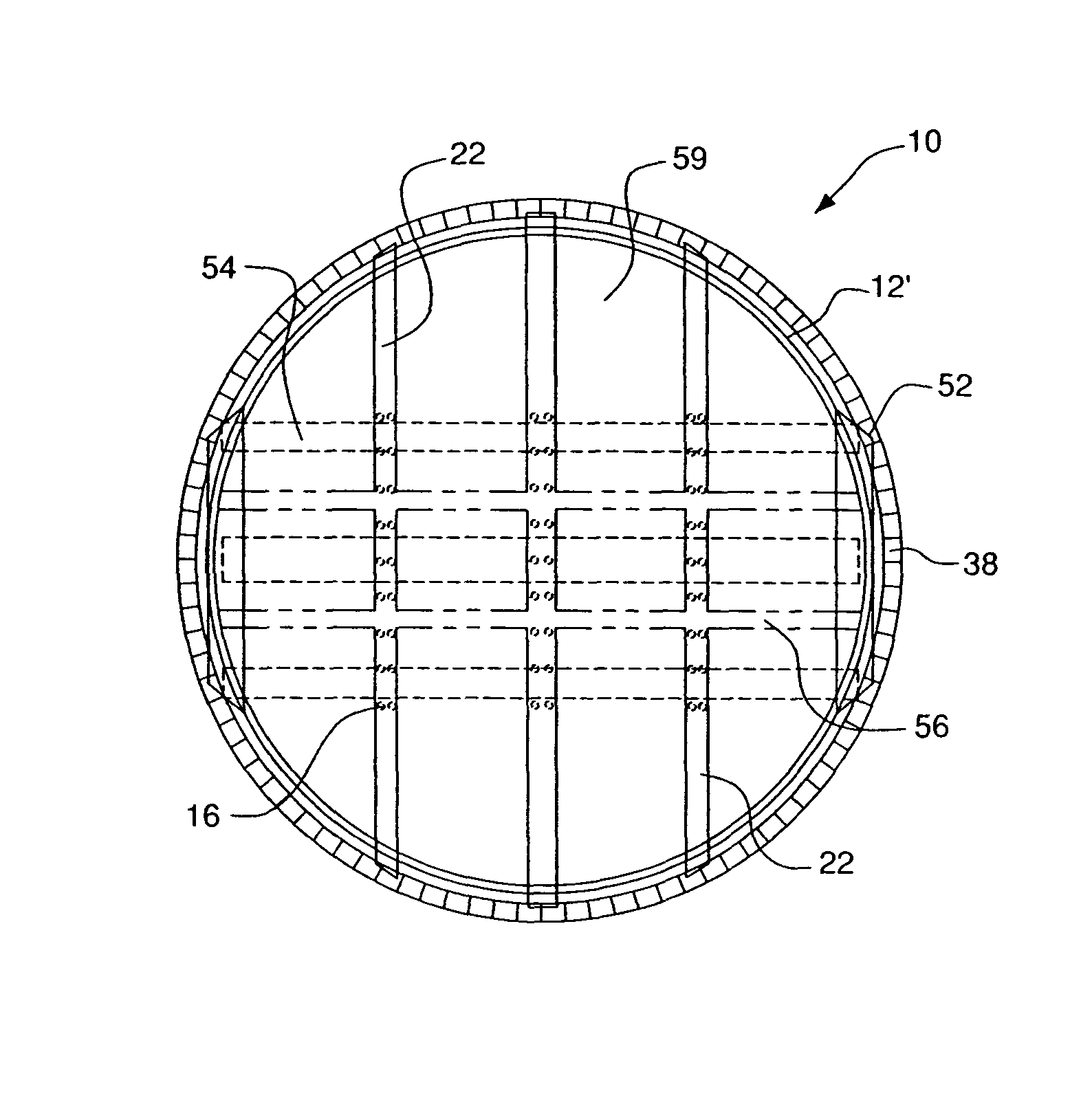

Liquid collection and distribution device for mass transfer column and process involving same

ActiveUS20120111717A1Improve its compositional uniformityImprove uniformityLiquid degasificationMixing methodsLiquid liquid partitionFilling materials

A liquid collection and distribution device is provided to support a bed of packing material and to collect liquid exiting the bed and redistribute it to an underlying bed of packing material with improved compositional and volumetric flow uniformity. The liquid collection and distribution device includes a liquid collector, a liquid distributor, and a lattice-type framework positioned between and supporting the liquid collector and the liquid distributor. In addition to supporting the liquid collector and liquid distributor, the framework has internal fluid passages that convey the liquid from the liquid collector to the liquid distributor while shielding the liquid from ascend vapor or gas flow.

Owner:KOCH GLITSCH INC

Apparatus and method for treating a fluid

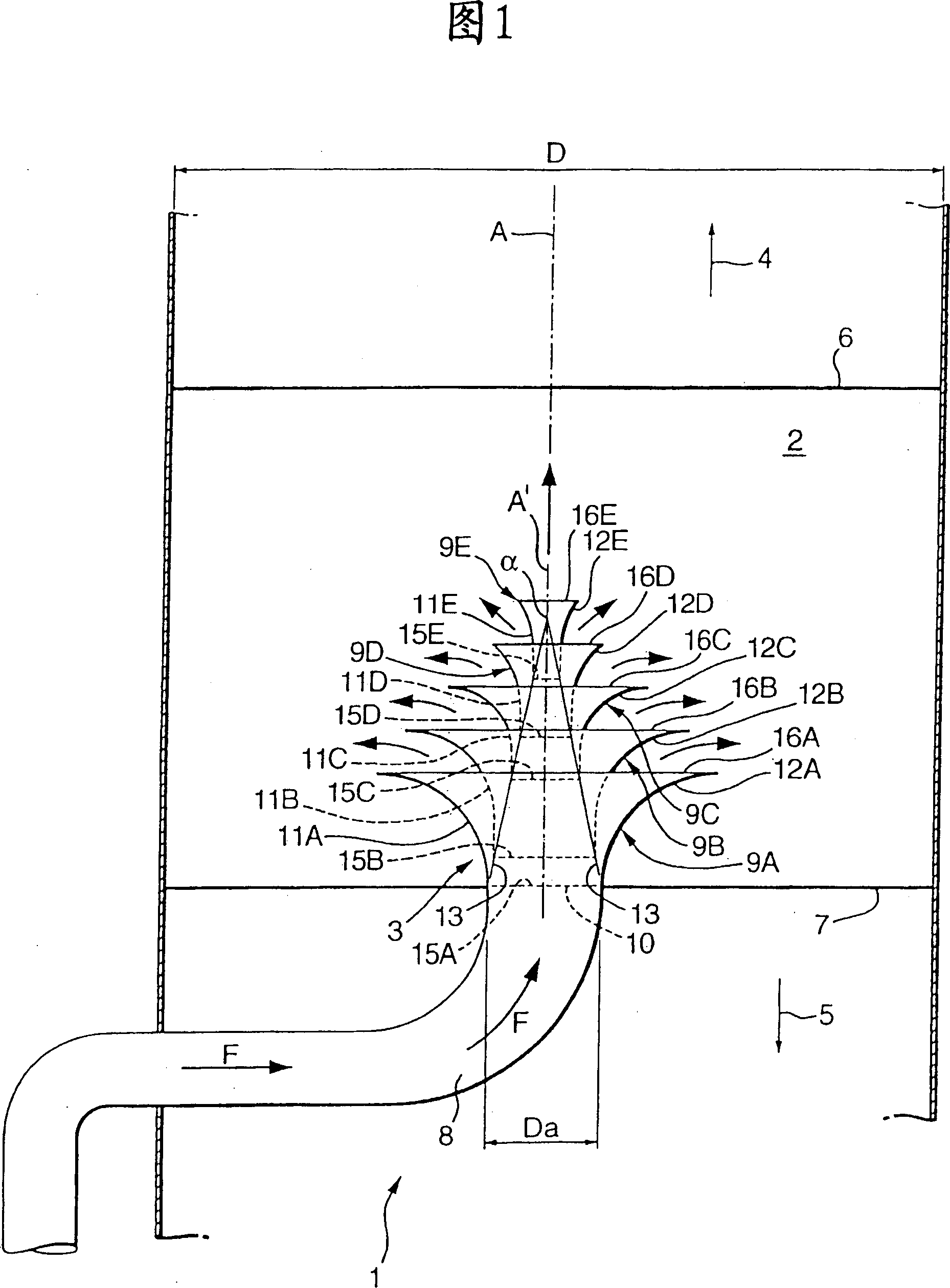

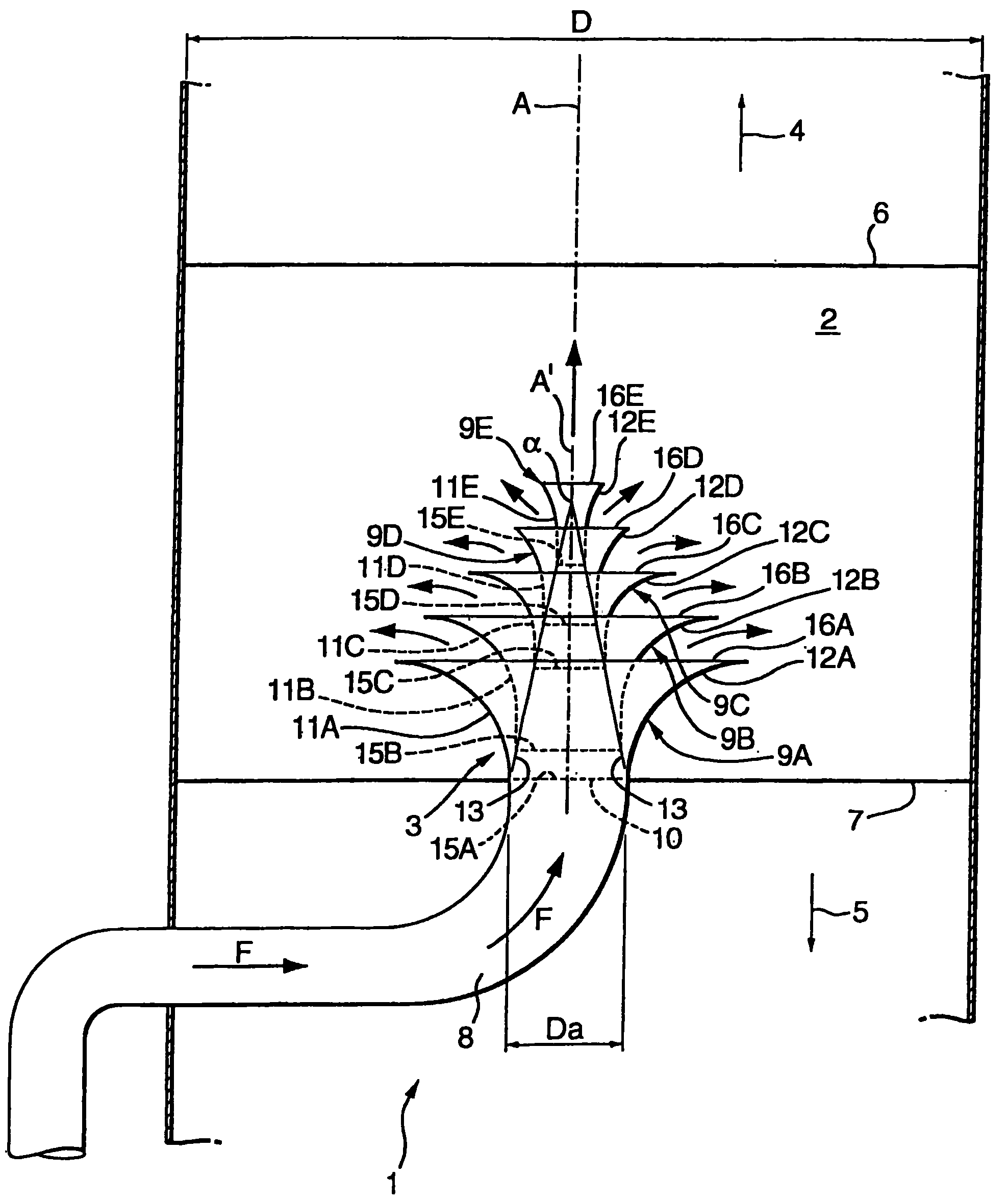

InactiveCN1306977CReduce eddy currentSpray nozzlesLiquid distribution in distillationLeading edgeTrailing edge

An apparatus for treating a fluid, comprising at least one treating zone (2), and a fluid inlet (3) and separation device disposed therein for introducing a separated mixture of liquid and gas into the treating zone (2). The fluid inlet (3) device comprises a series of coaxially disposed circumferential vanes (9A-9E), wherein each circumferential vane curvedly extends between an intercepting part having a substantially axially directed leading edge and a deflecting part having a substantially radially outwardly extending trailing edge, and wherein the central axis (A') of the inlet device (3) extends parallel or coaxial with an upwardly extending axis of the treating zone (2). The invention further relates to a fluid inlet device (3), to a use of the fluid inlet device, and to a method for treating a fluid.

Owner:SHELL INT RES MAATSCHAPPIJ BV

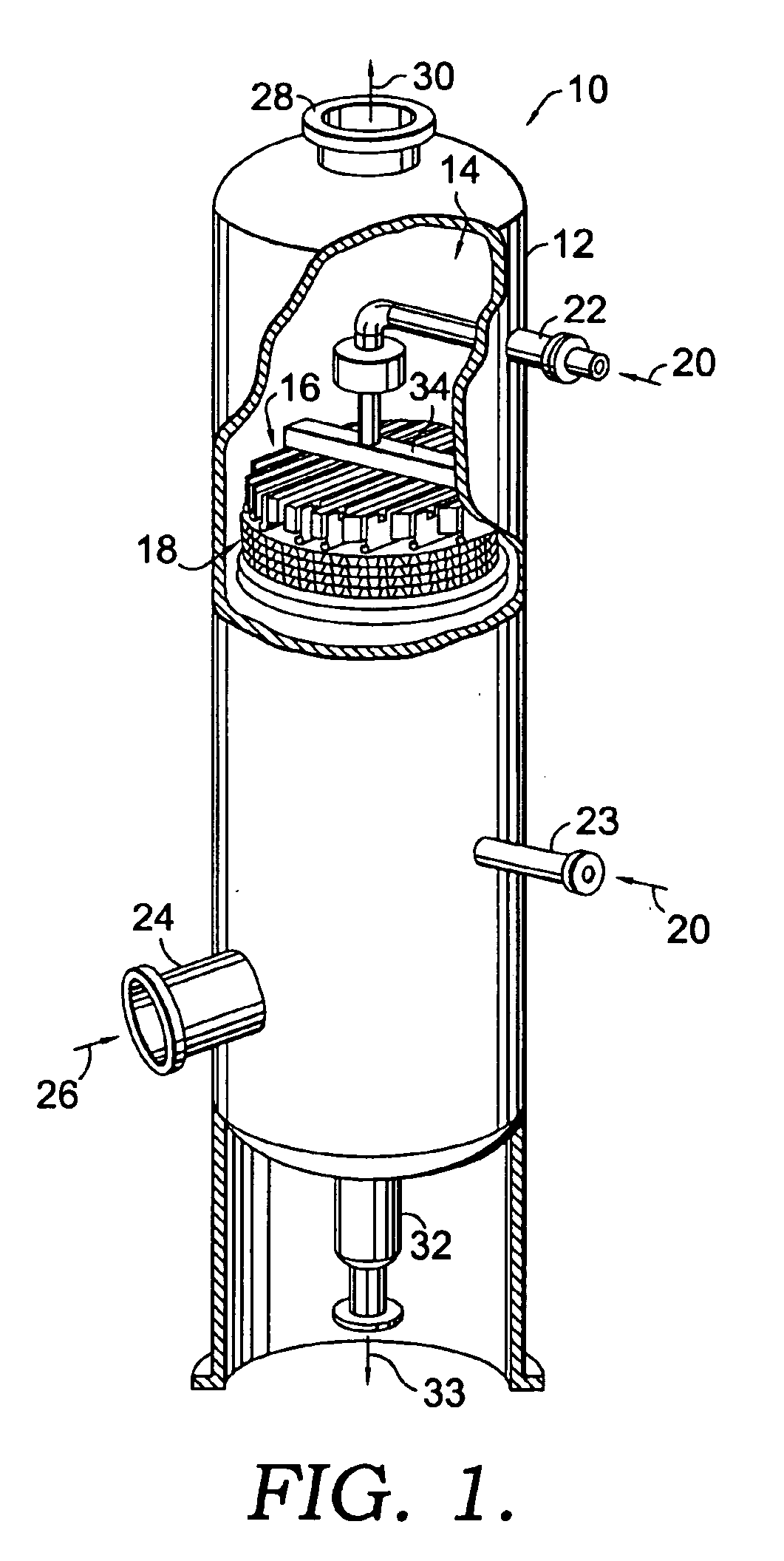

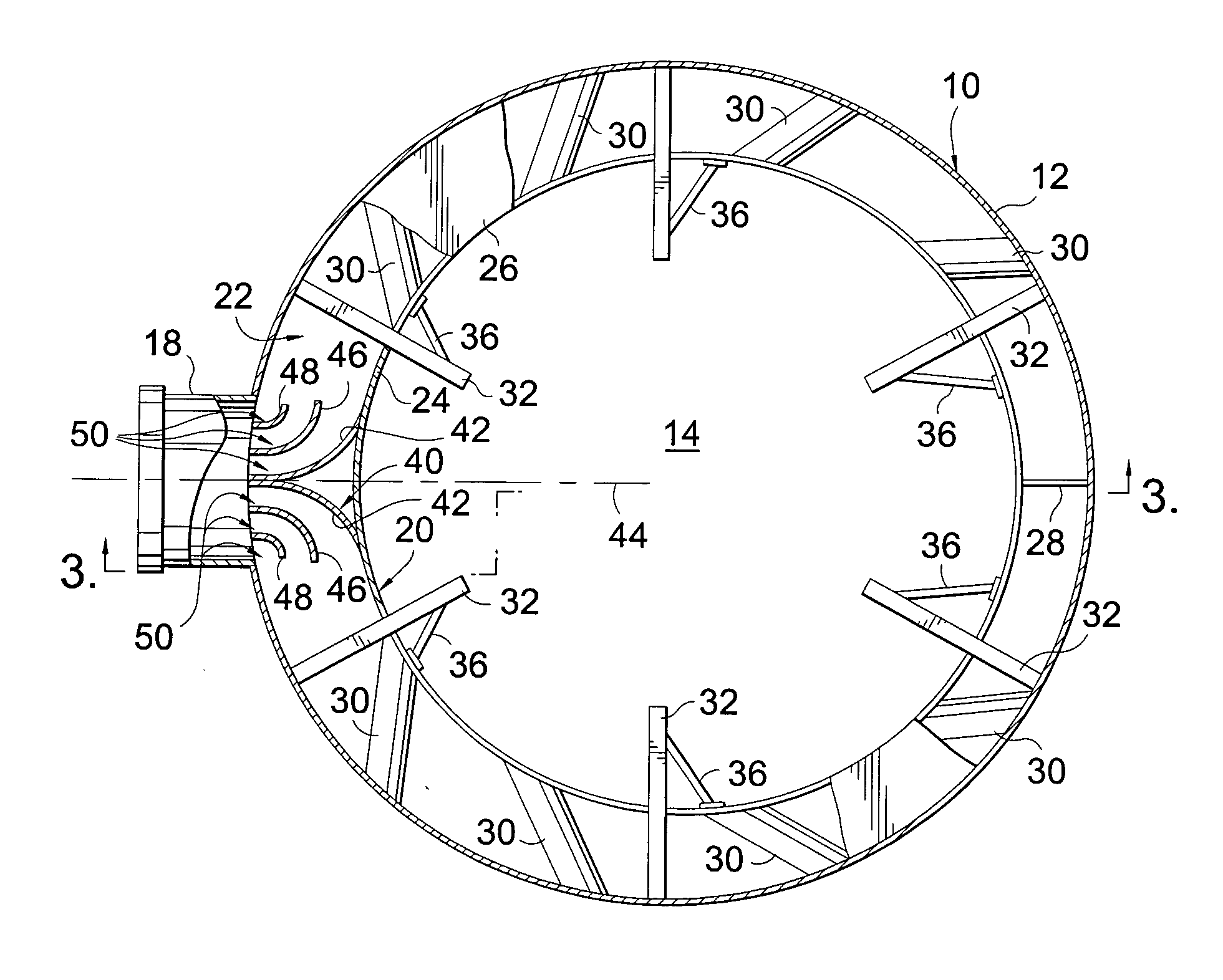

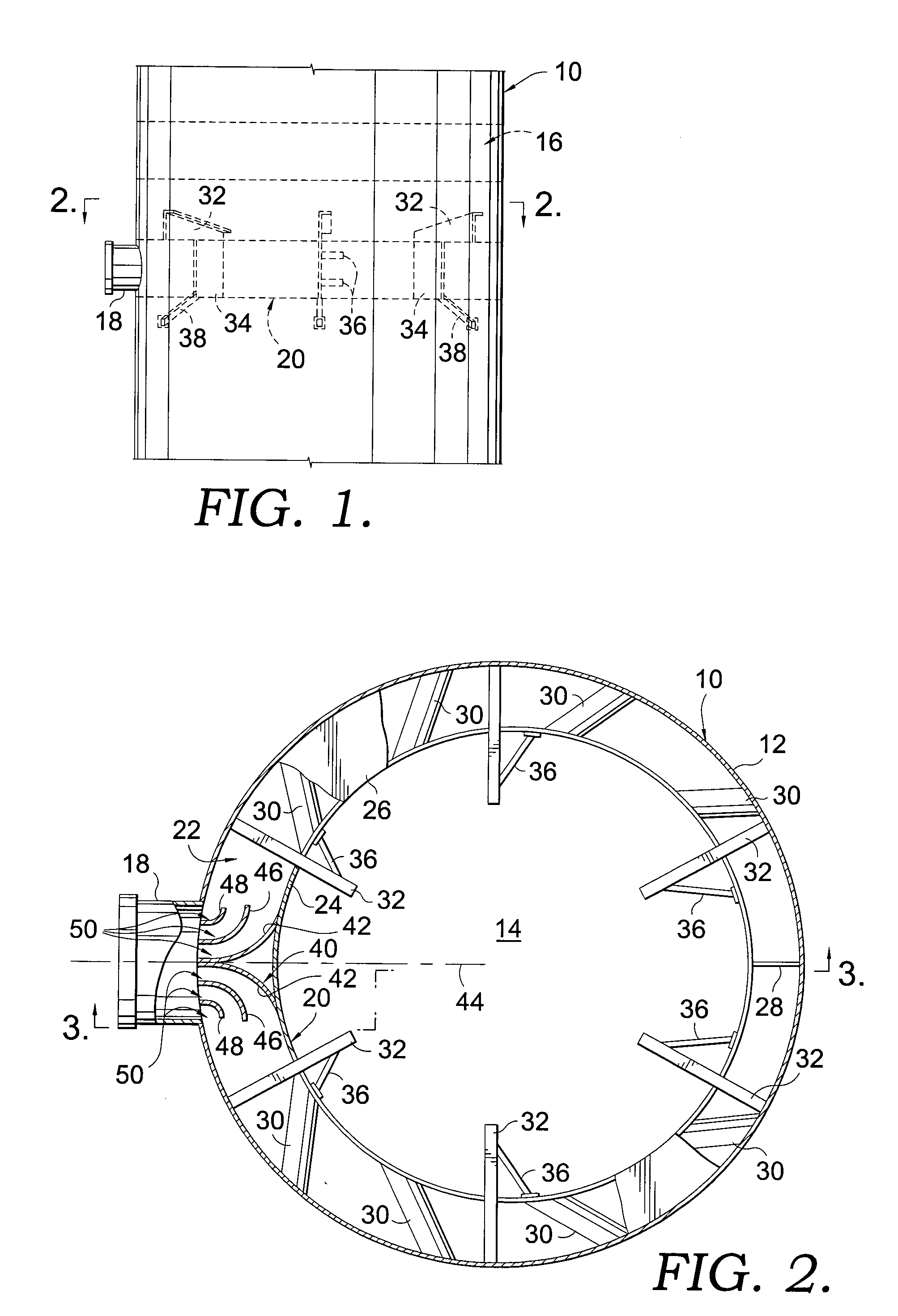

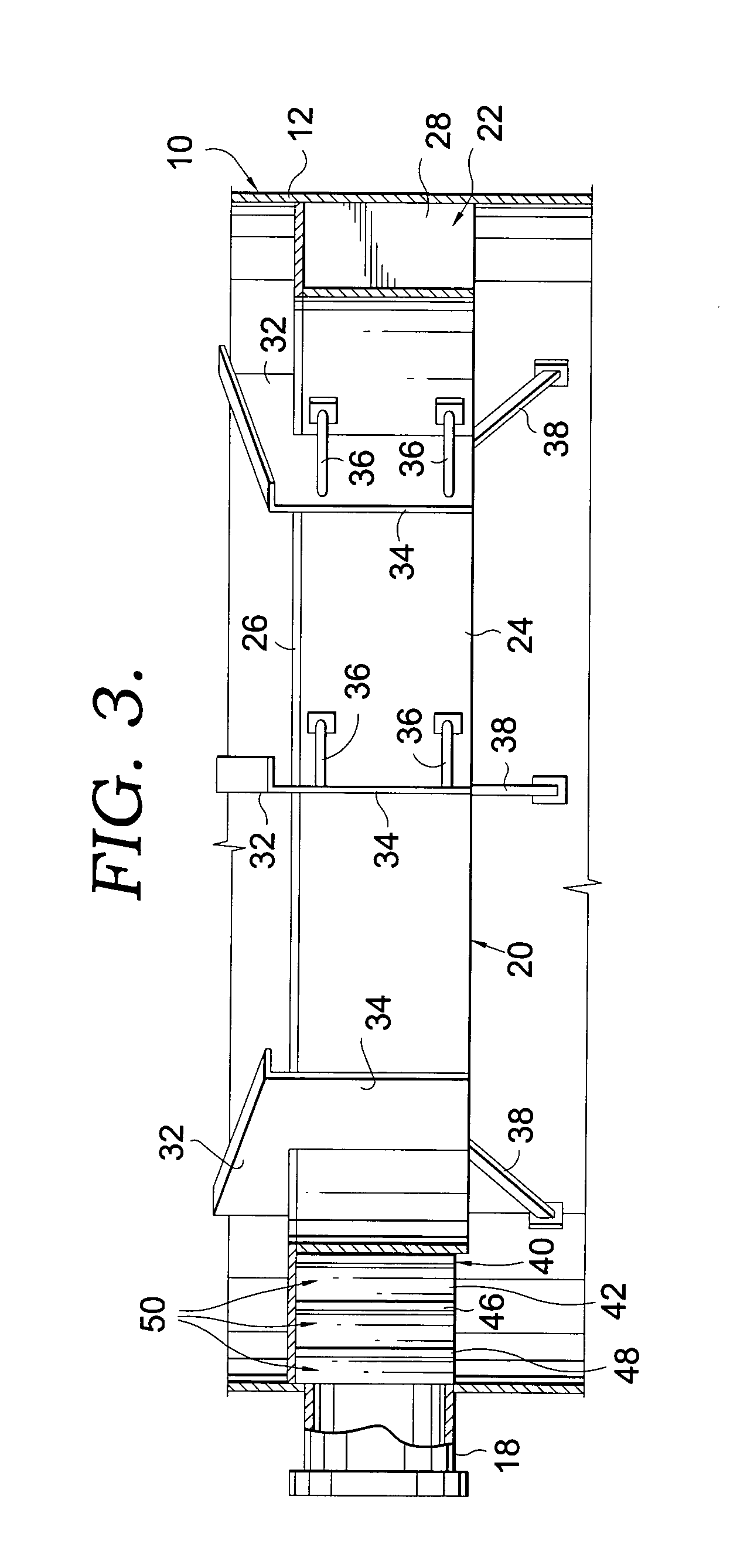

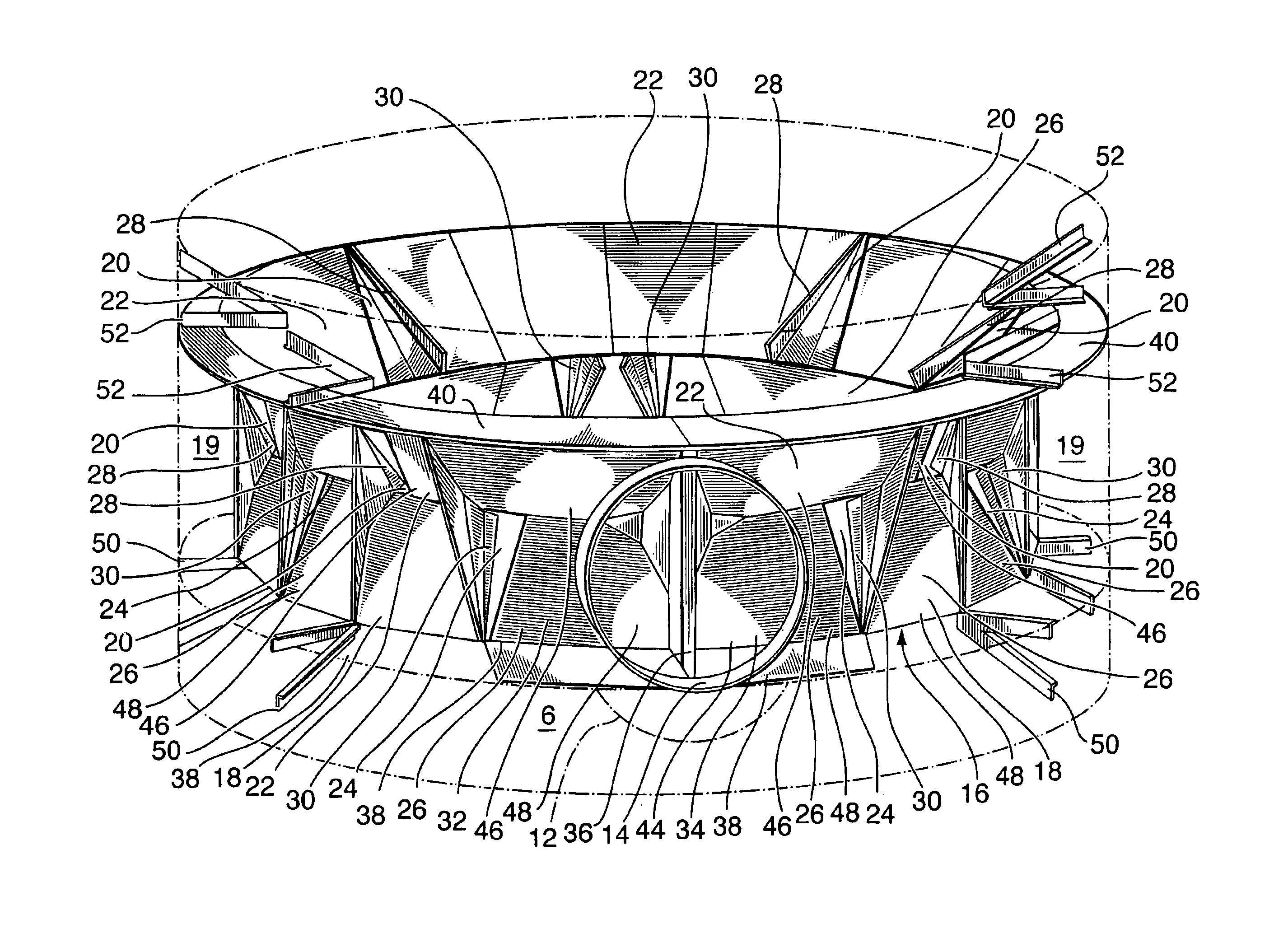

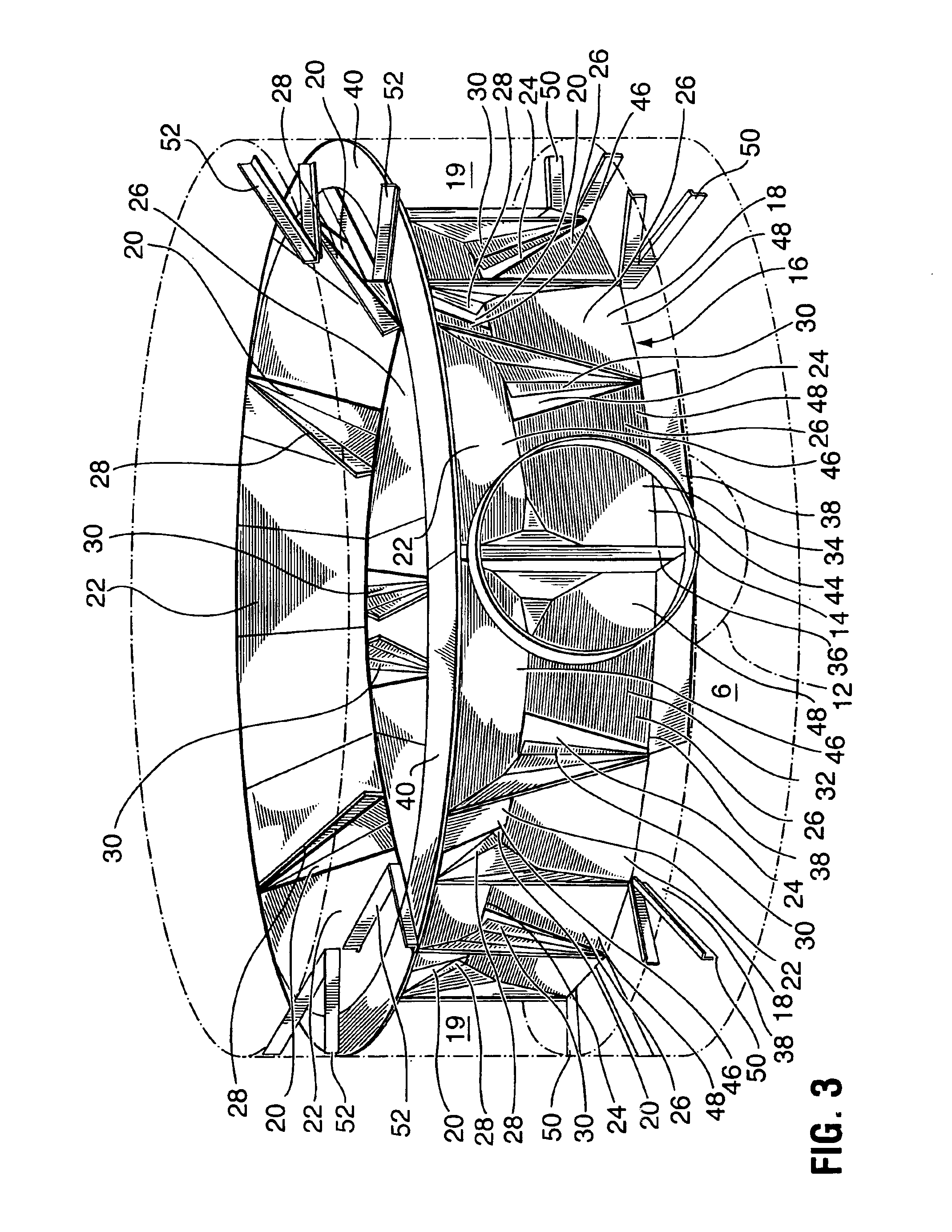

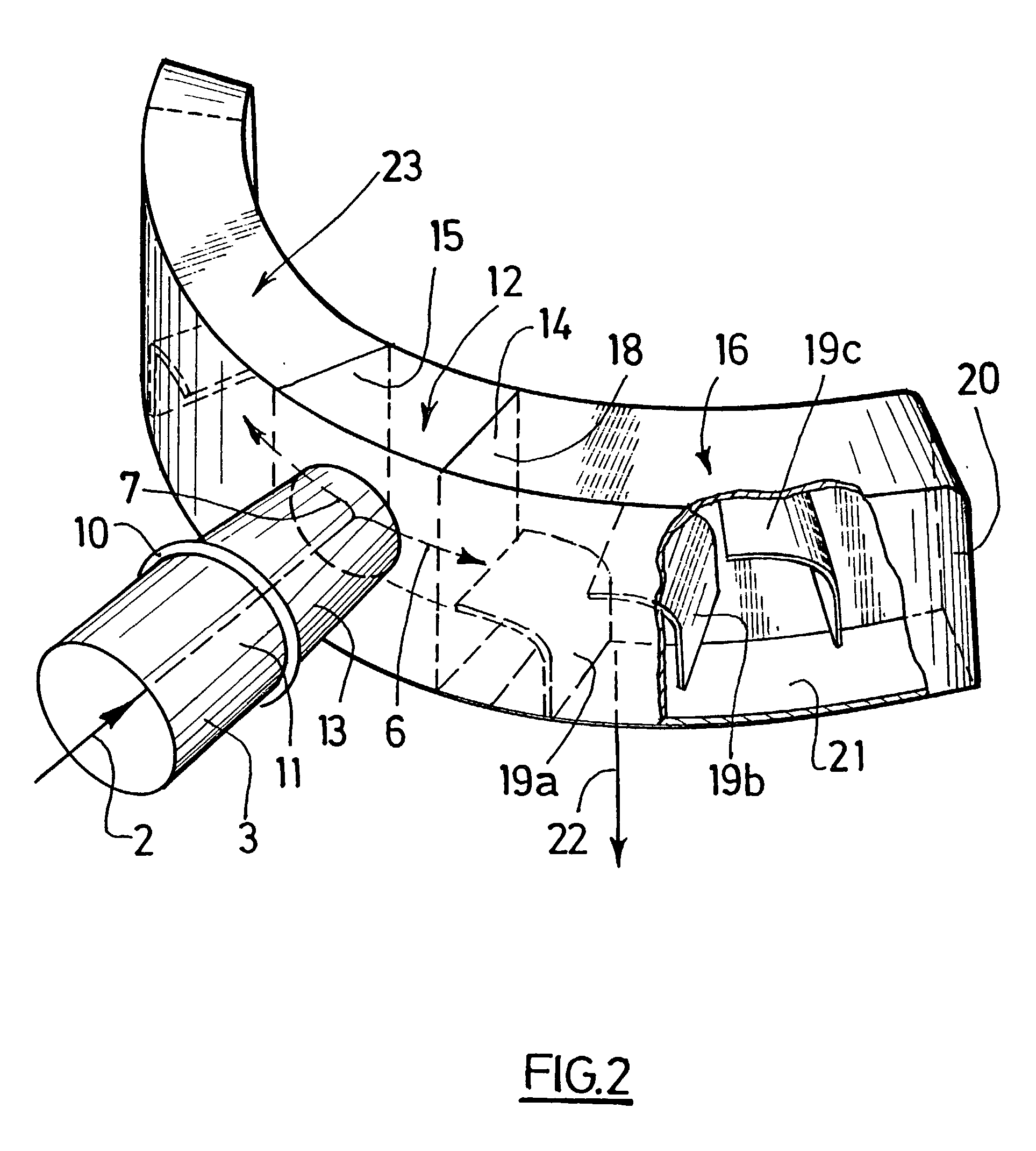

Method and apparatus for facilitating more uniform vapor distribution in mass transfer and heat exchange columns

ActiveUS7104529B2Transportation and packagingUsing liquid separation agentEngineeringCircular segment

A vapor horn device for use in an elongated, generally upright mass transfer and / or heat exchange column having an internal region comprises an elongated, generally arcuate wall arranged to be located within the internal region and disposed to extend around a longitudinal axis of the column. The arcuate wall includes an inlet area positioned for being contacted by a vapor or mixed phase stream entering the column and causing the stream to flow along an outer surface of the arcuate wall and generally around the axis. The device also includes a primary elongated vane extending outwardly from the outer surface of the arcuate wall. This primary vane has an inner end located adjacent the outer surface of the inner wall and an outer end disposed in spaced relationship relative to the outer surface of the wall. The vane is disposed at a tangential angle relative to the direction of flow of the stream such that the inner end of the vane is further downstream than the outer end thereof whereby any portion of the stream impinging on the primary vane is redirected toward the outer surface of the arcuate wall. The device also desirably includes one or more vanes that extend radially outwardly from the inner wall.

Owner:KOCH GLITSCH INC

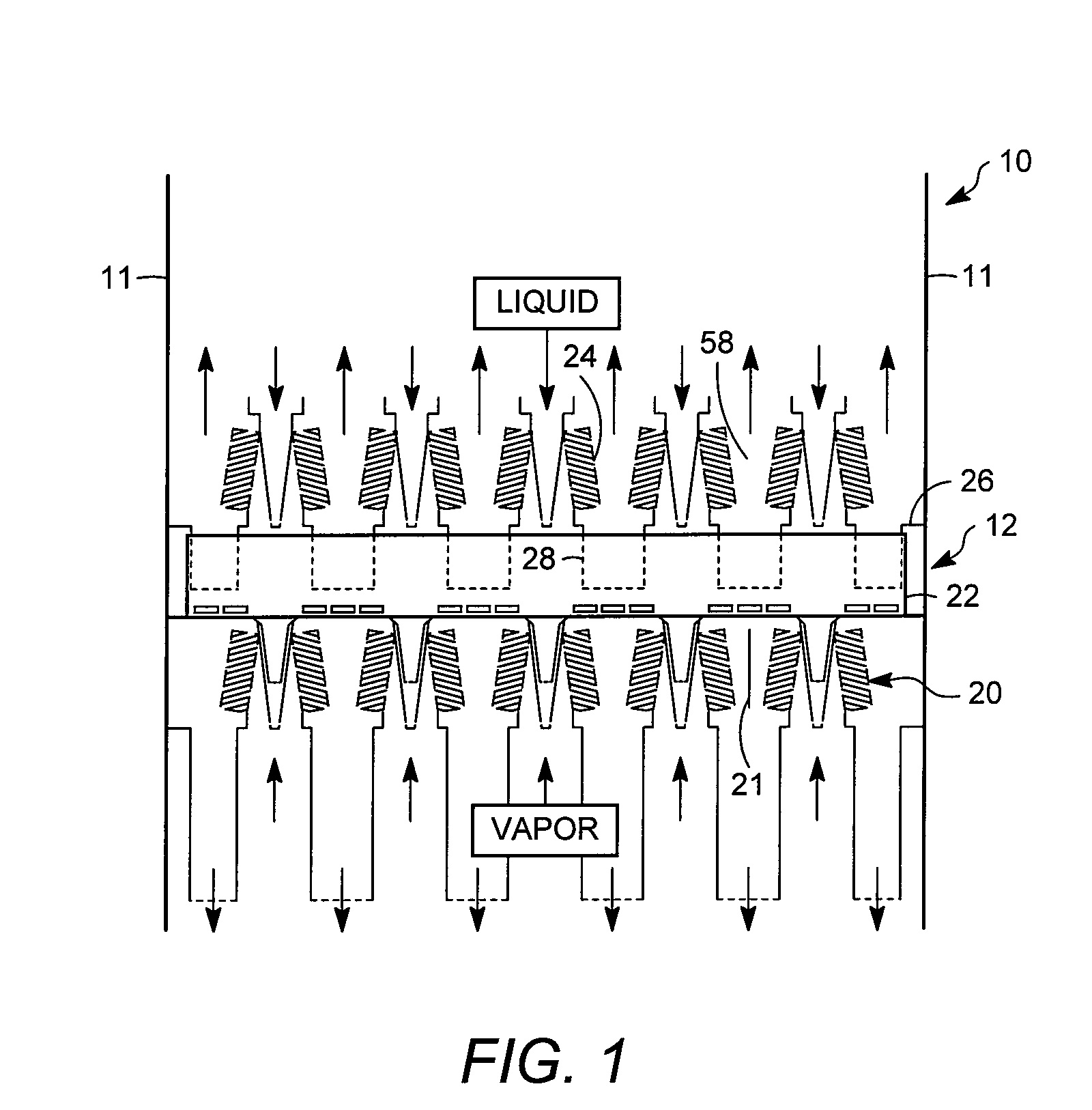

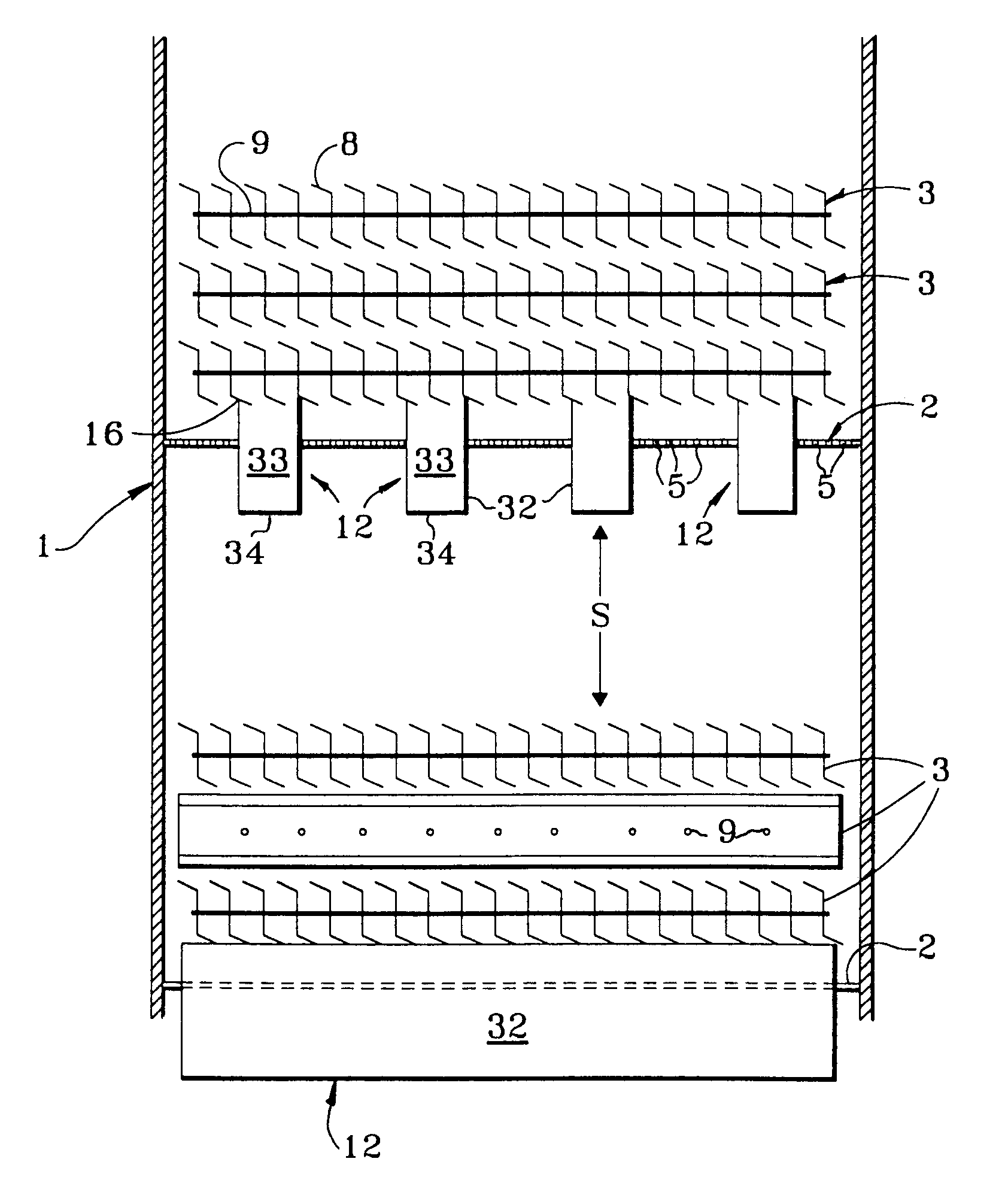

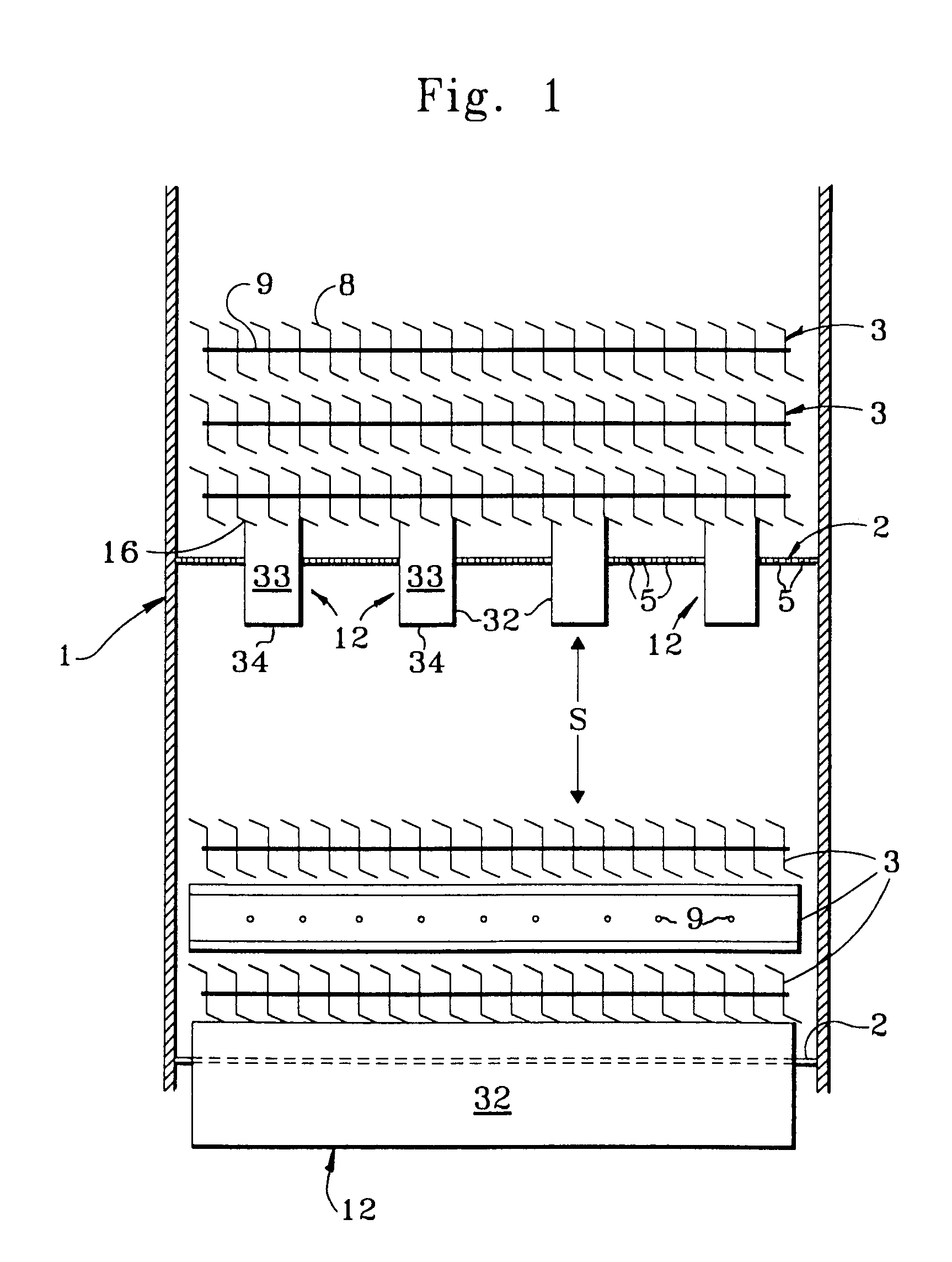

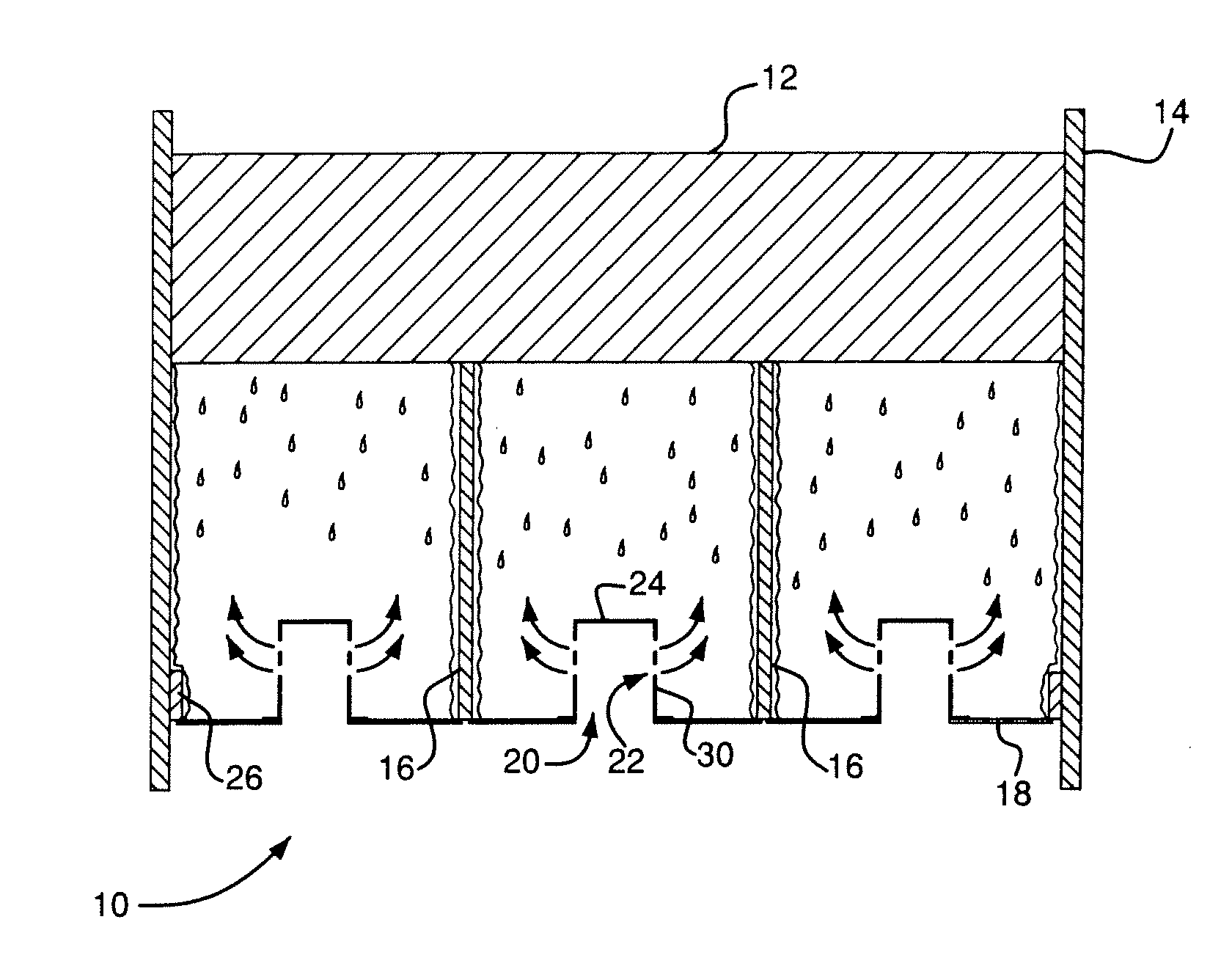

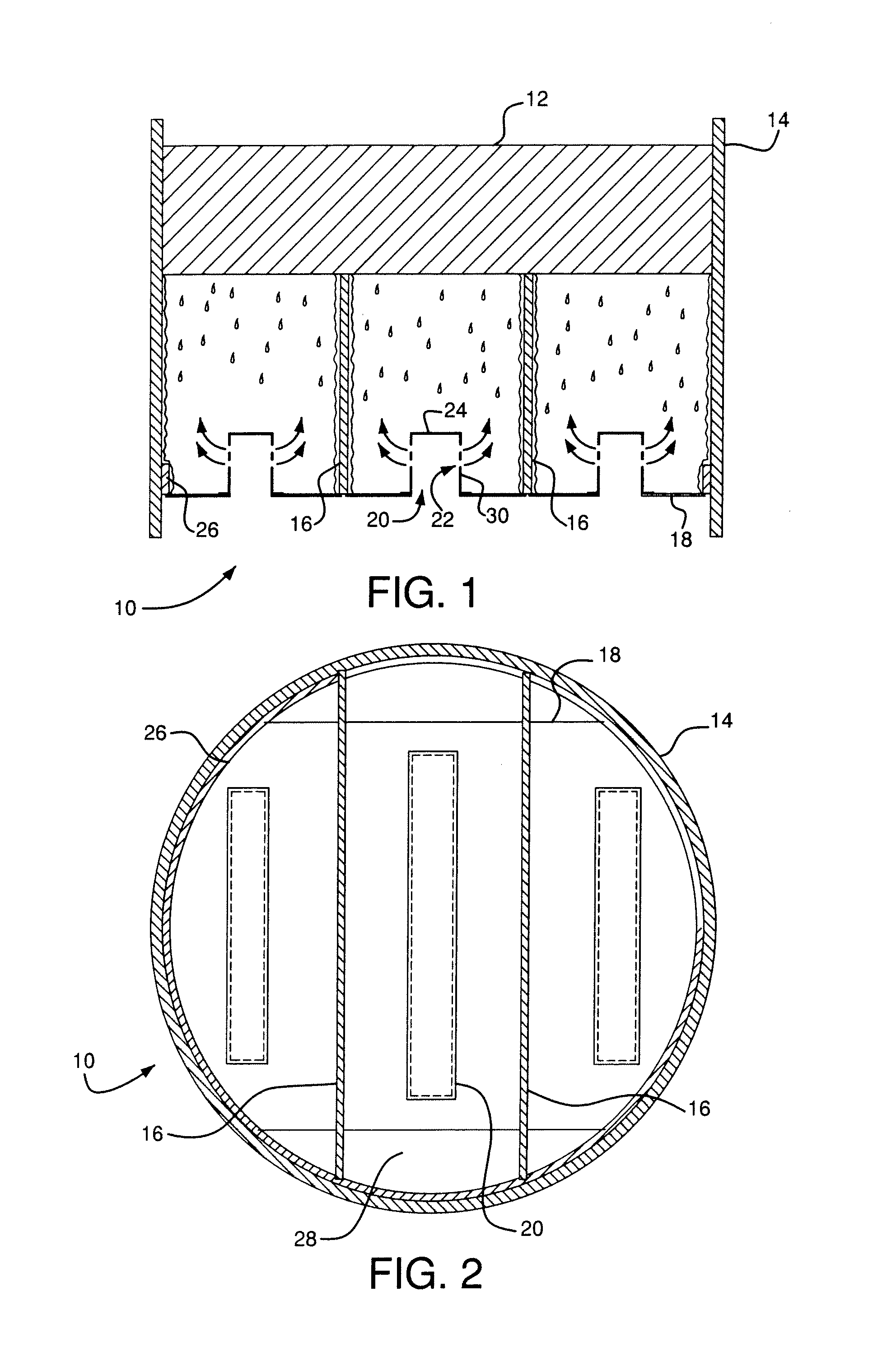

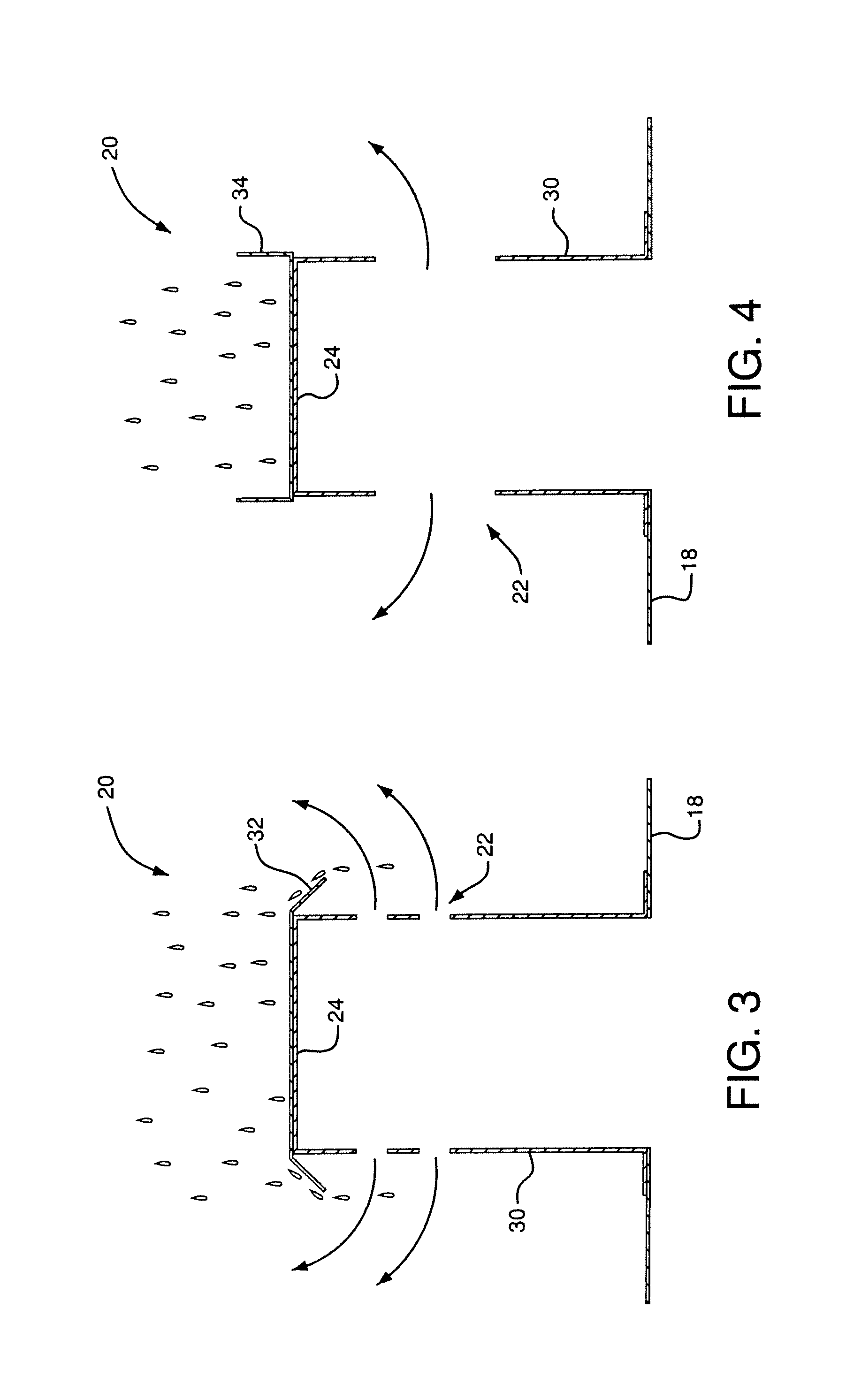

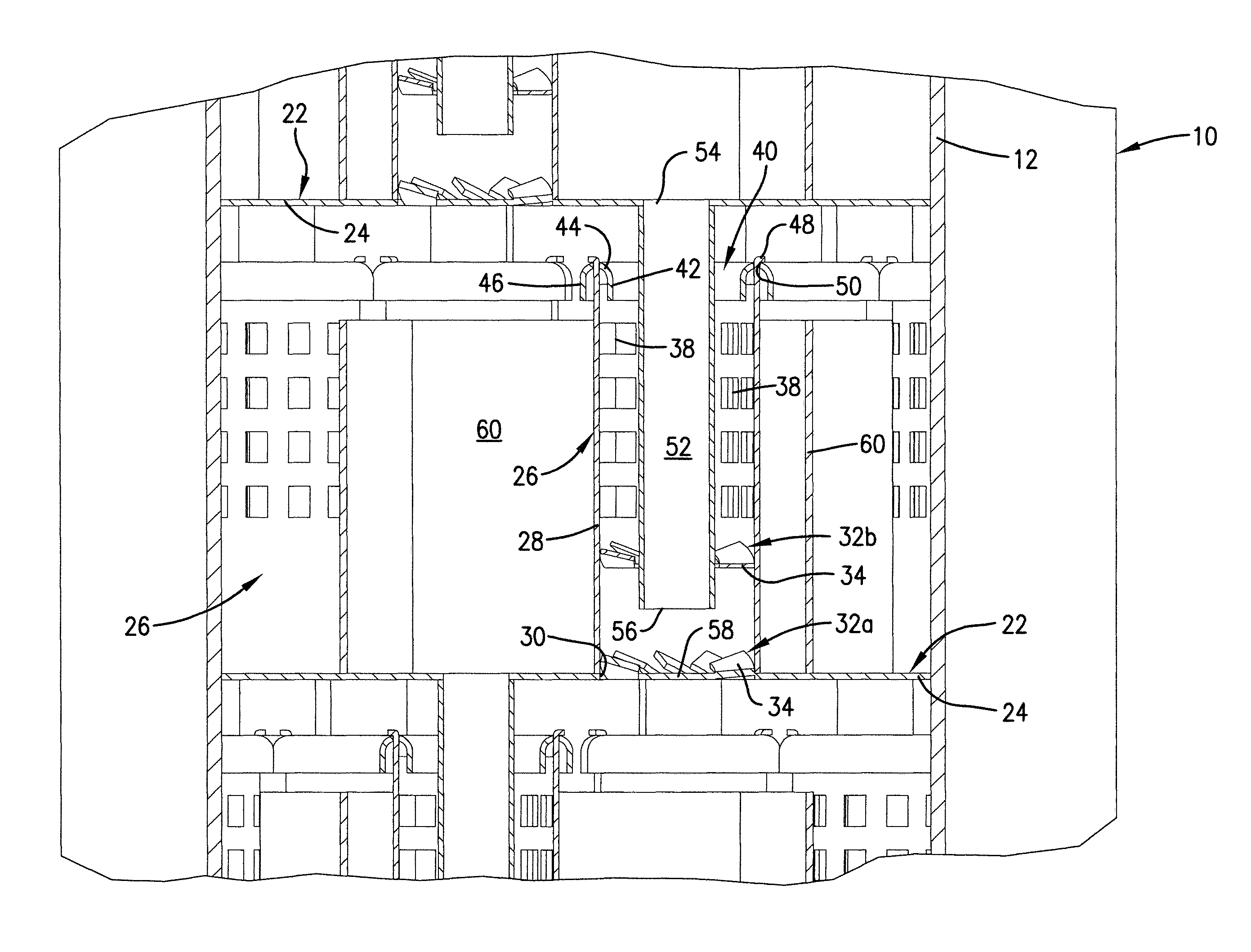

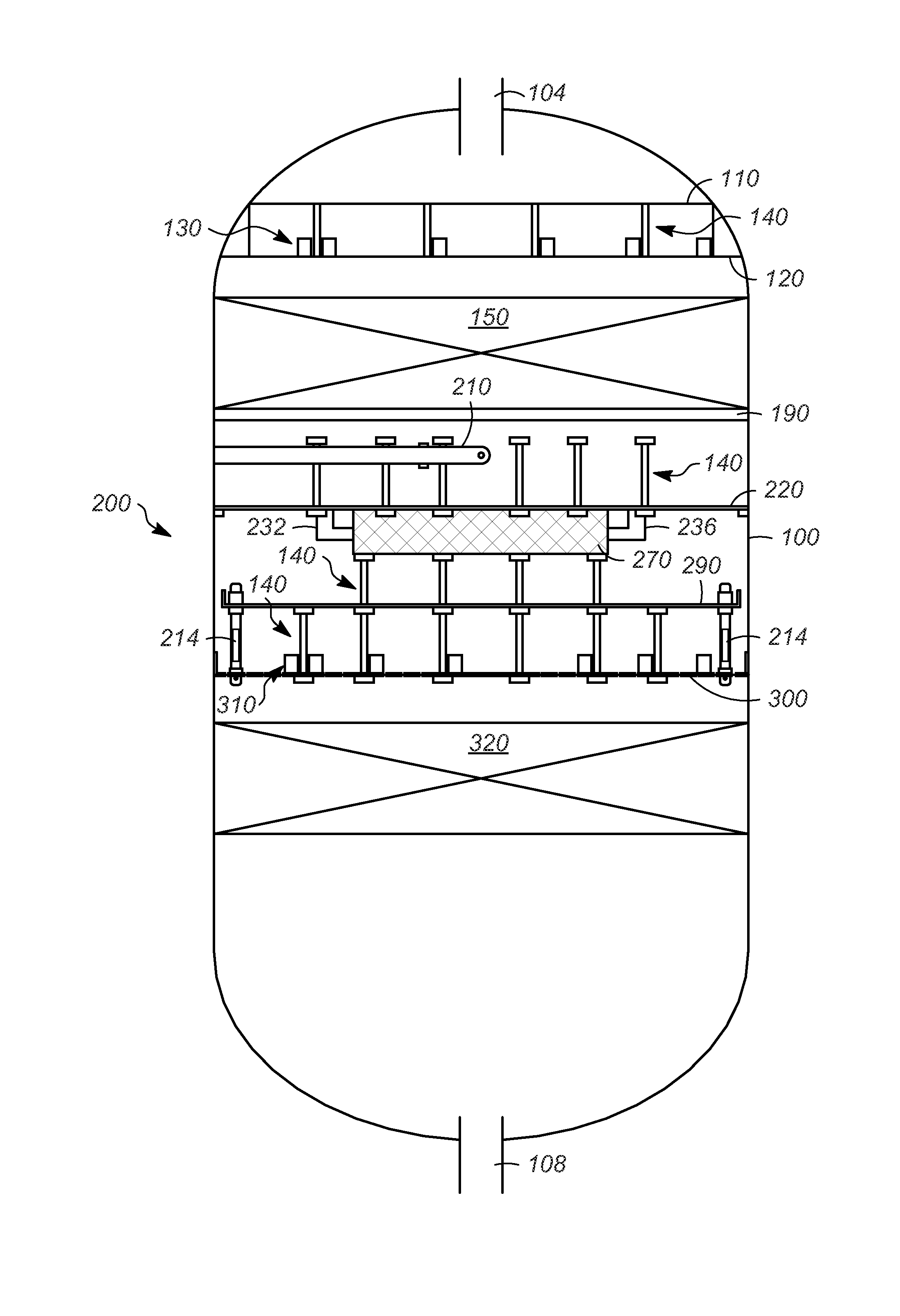

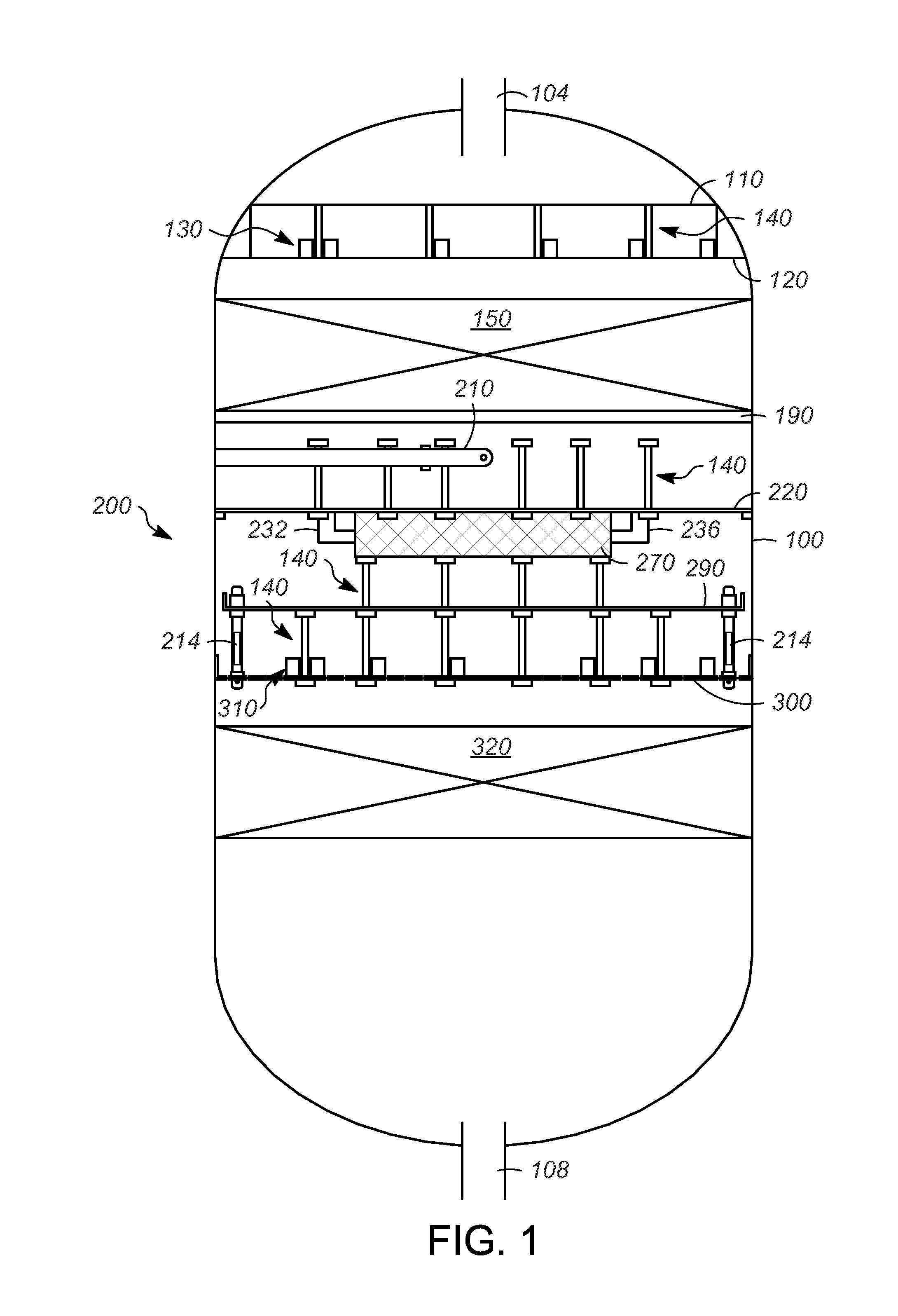

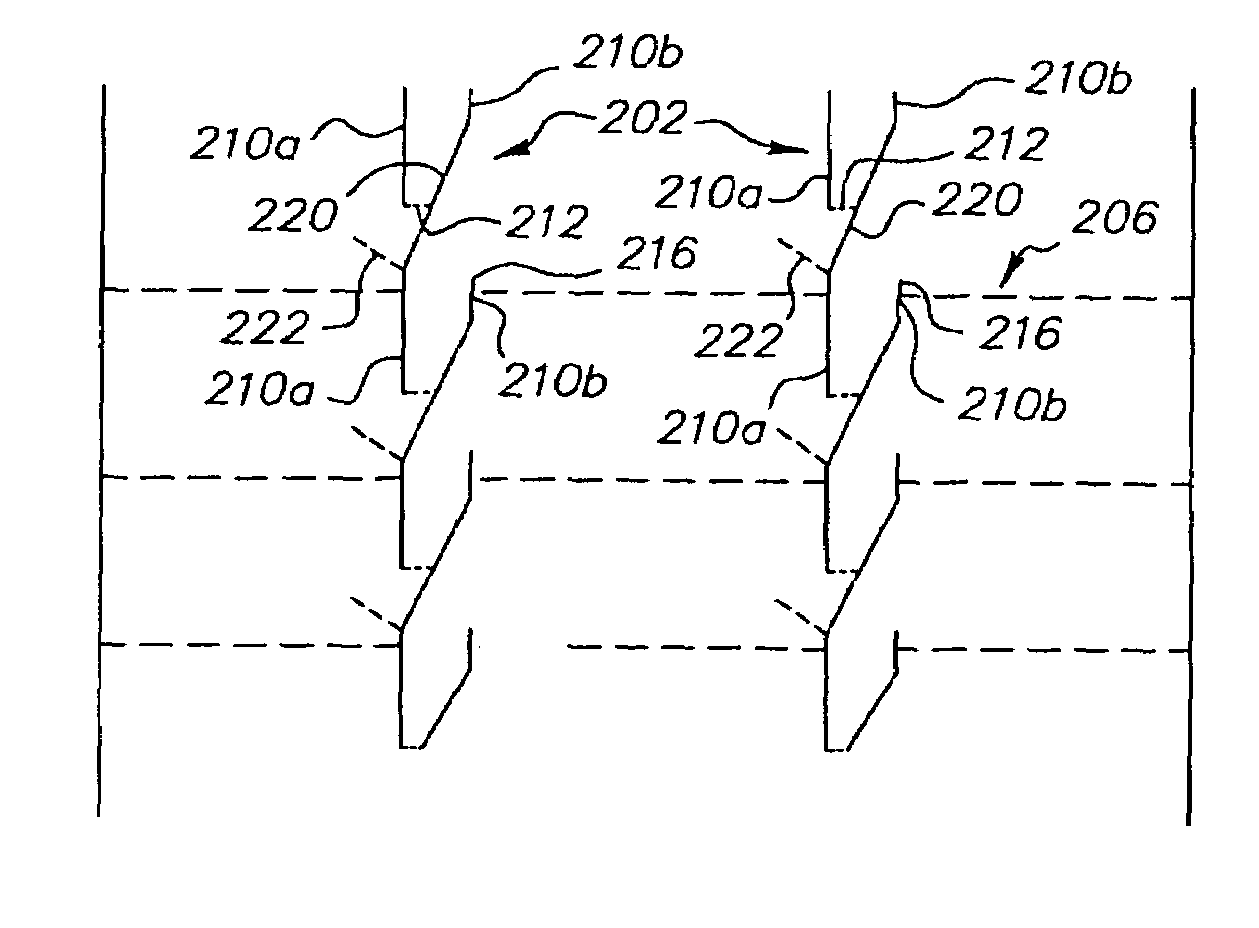

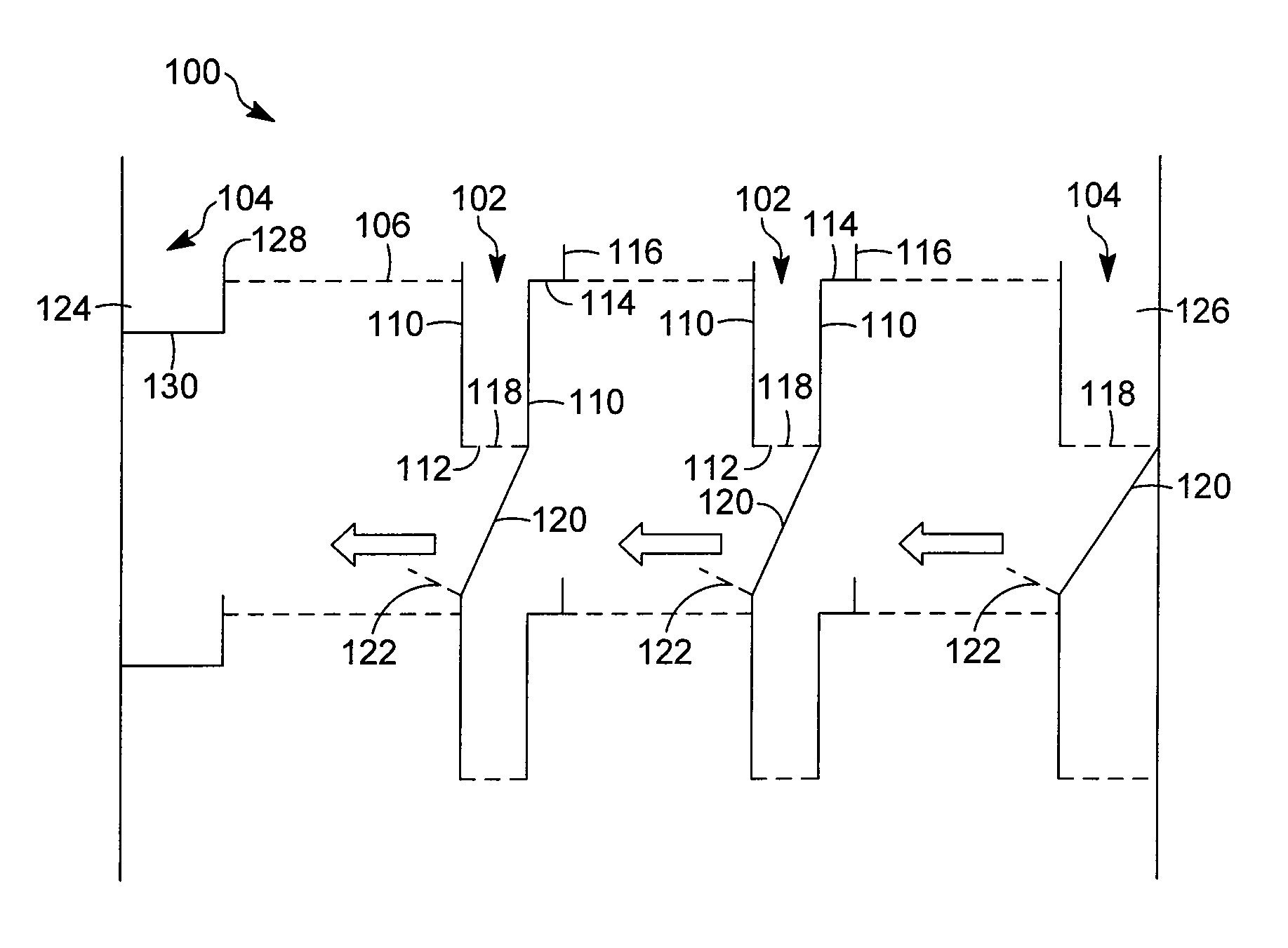

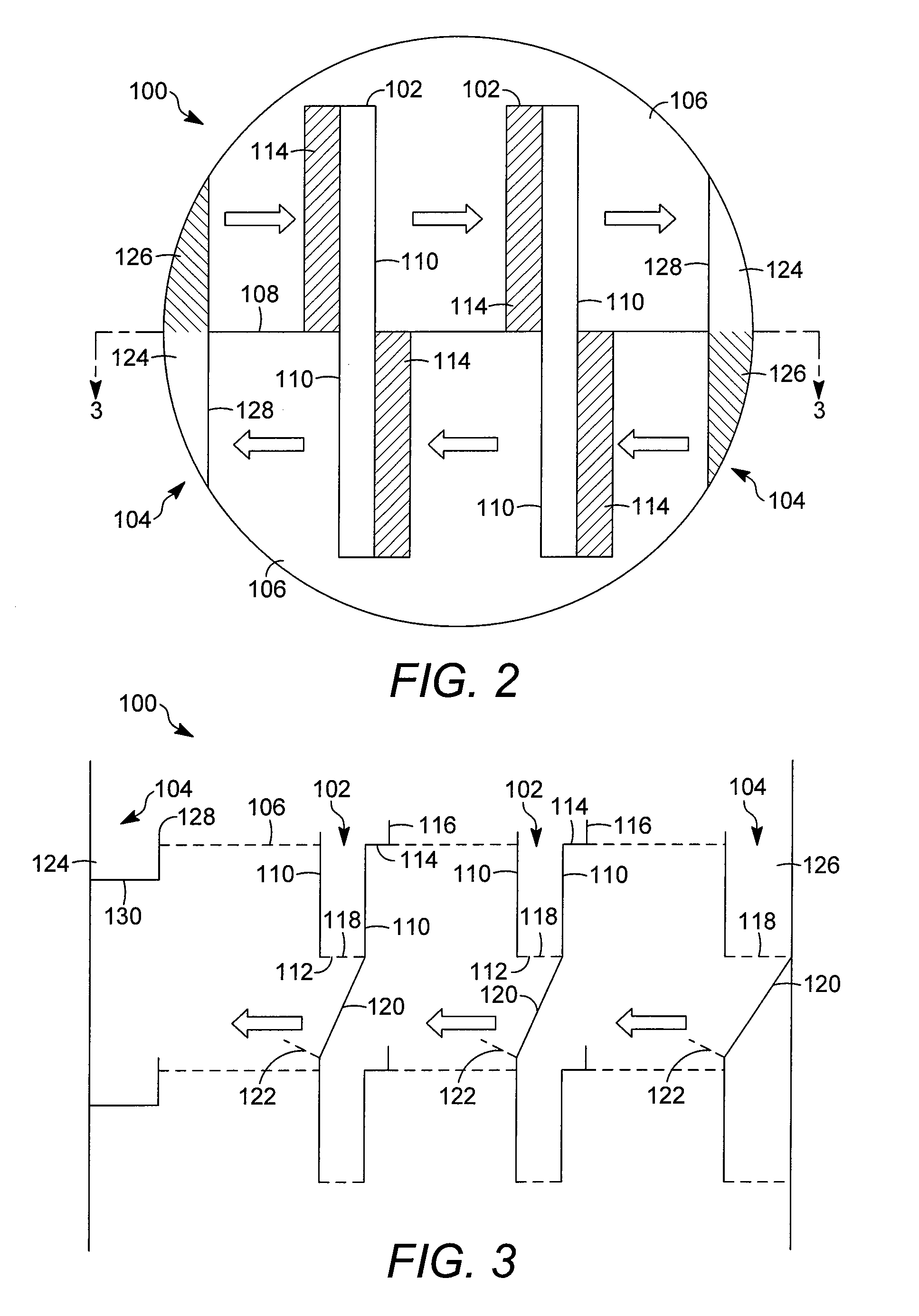

Contact tray and method employing same

ActiveUS20120175792A1Avoid communicationPromote exchangeCombination devicesLiquid degasificationWaste management

A contact tray is provided with a tray deck and dividing walls which form groupings of one or more cans and one or more downcomer inlets distributed across the tray deck. The cans have walls that surround vapor openings in the tray deck that permit upward passage of a vapor stream into the cans. Downcomers extend downwardly from the downcomer inlet and are positioned for delivering a liquid stream into the center of cans positioned on a tray deck of an underlying contact tray. Discharge openings are provided in the walls of the cans to allow the liquid stream to exit the cans. The dividing walls direct the exiting liquid stream into the downcomer inlets in the same grouping and prevent or impede the liquid stream from flowing to a low side of the tray deck.

Owner:KOCH GLITSCH INC

Contact tray and method employing same

ActiveUS8500105B2Avoid communicationPromote exchangeCombination devicesLiquid degasificationWaste management

A contact tray is provided with a tray deck and dividing walls which form groupings of one or more cans and one or more downcomer inlets distributed across the tray deck. The cans have walls that surround vapor openings in the tray deck that permit upward passage of a vapor stream into the cans. Downcomers extend downwardly from the downcomer inlet and are positioned for delivering a liquid stream into the center of cans positioned on a tray deck of an underlying contact tray. Discharge openings are provided in the walls of the cans to allow the liquid stream to exit the cans. The dividing walls direct the exiting liquid stream into the downcomer inlets in the same grouping and prevent or impede the liquid stream from flowing to a low side of the tray deck.

Owner:KOCH GLITSCH INC

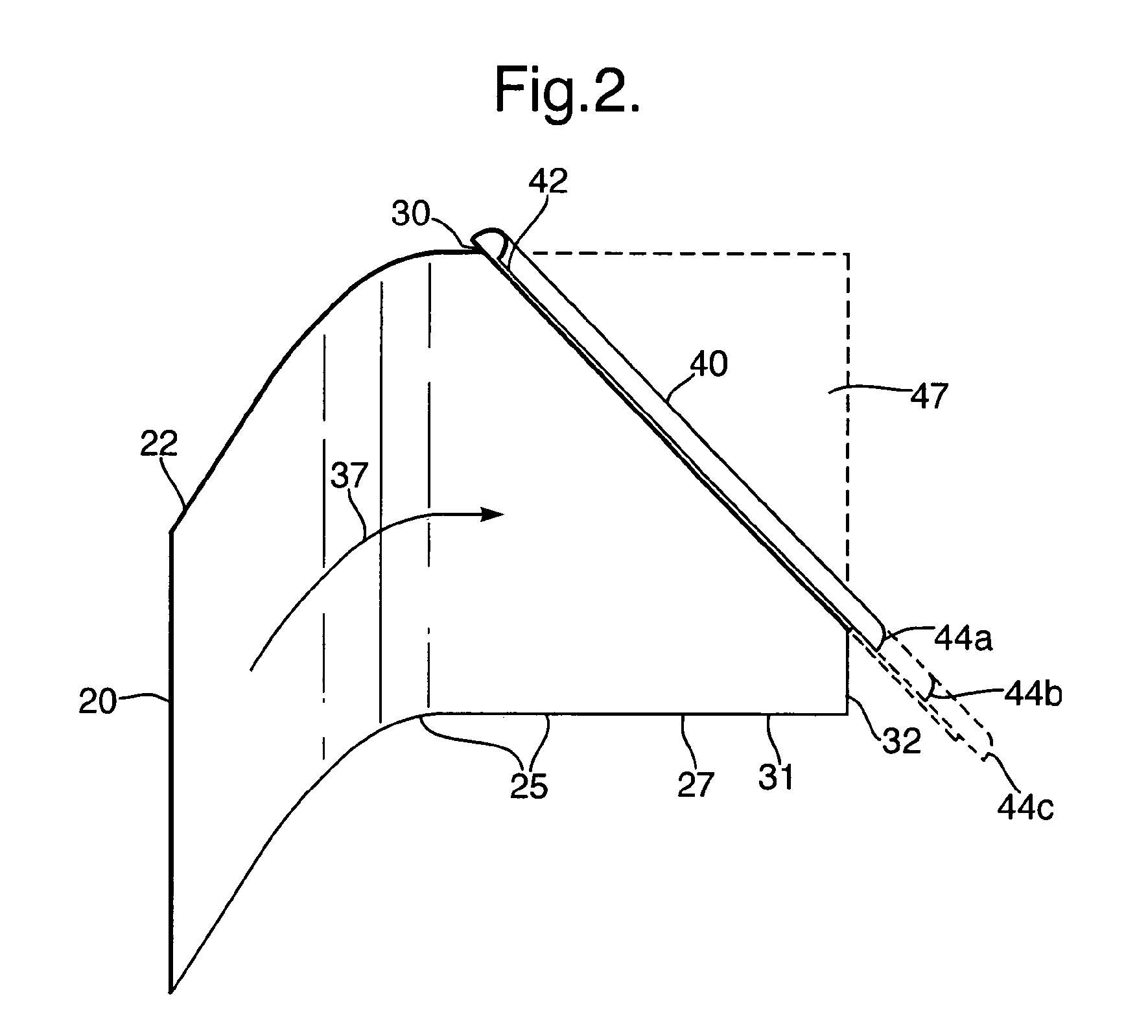

Fluid Inlet Device, Use, and Method or Retrofitting

A fluid inlet device (1) suitable for introducing a mixture of liquid and gas into a vessel, which fluid inlet device comprises a guide member having a surface on which surface a liquid film is present during normal operation, and having a main direction of gas flow along the surface; and wherein the guide member (20) is provided with a liquid catcher channel (40) extending from an upstream position with respect to the guide member (20) to a downstream position, and wherein a virtual line along the guide member between the upstream position and the downstream position deviates from the main direction of gas flow; the use of the fluid inlet device for introducing a mixture of liquid and gas into a gas-liquid contacting vessel; and a method of retrofitting a fluid inlet device.

Owner:SHELL OIL CO

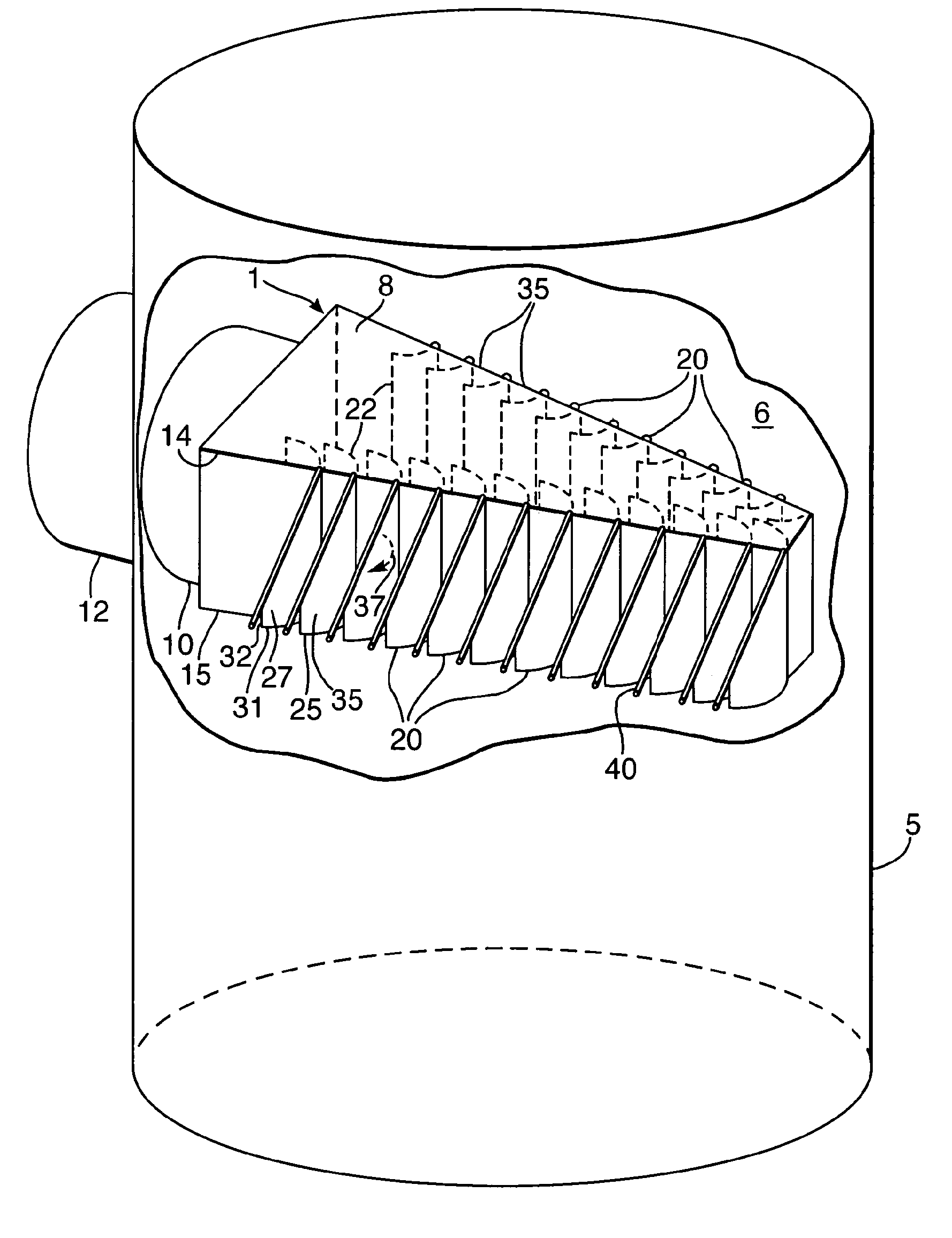

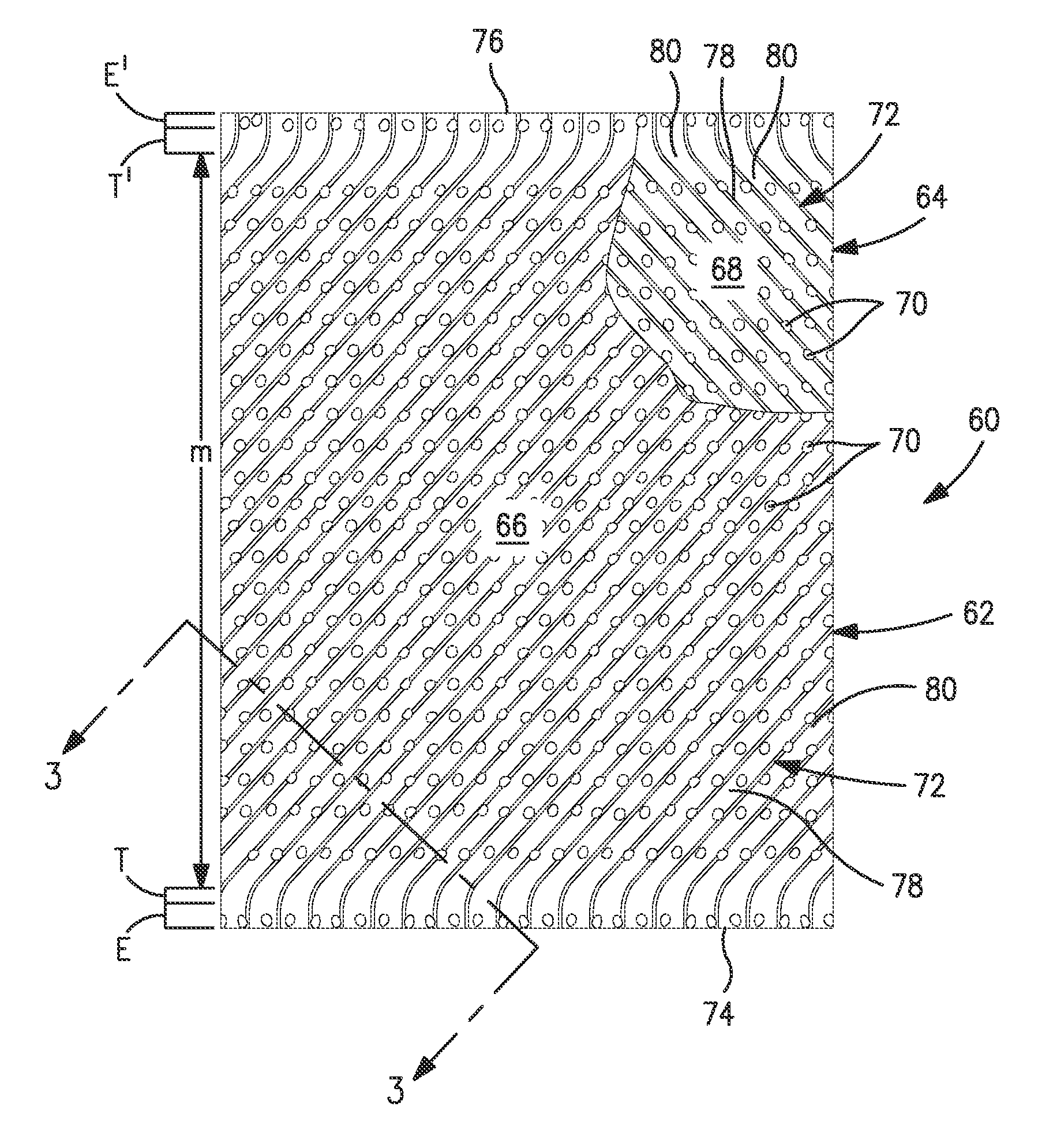

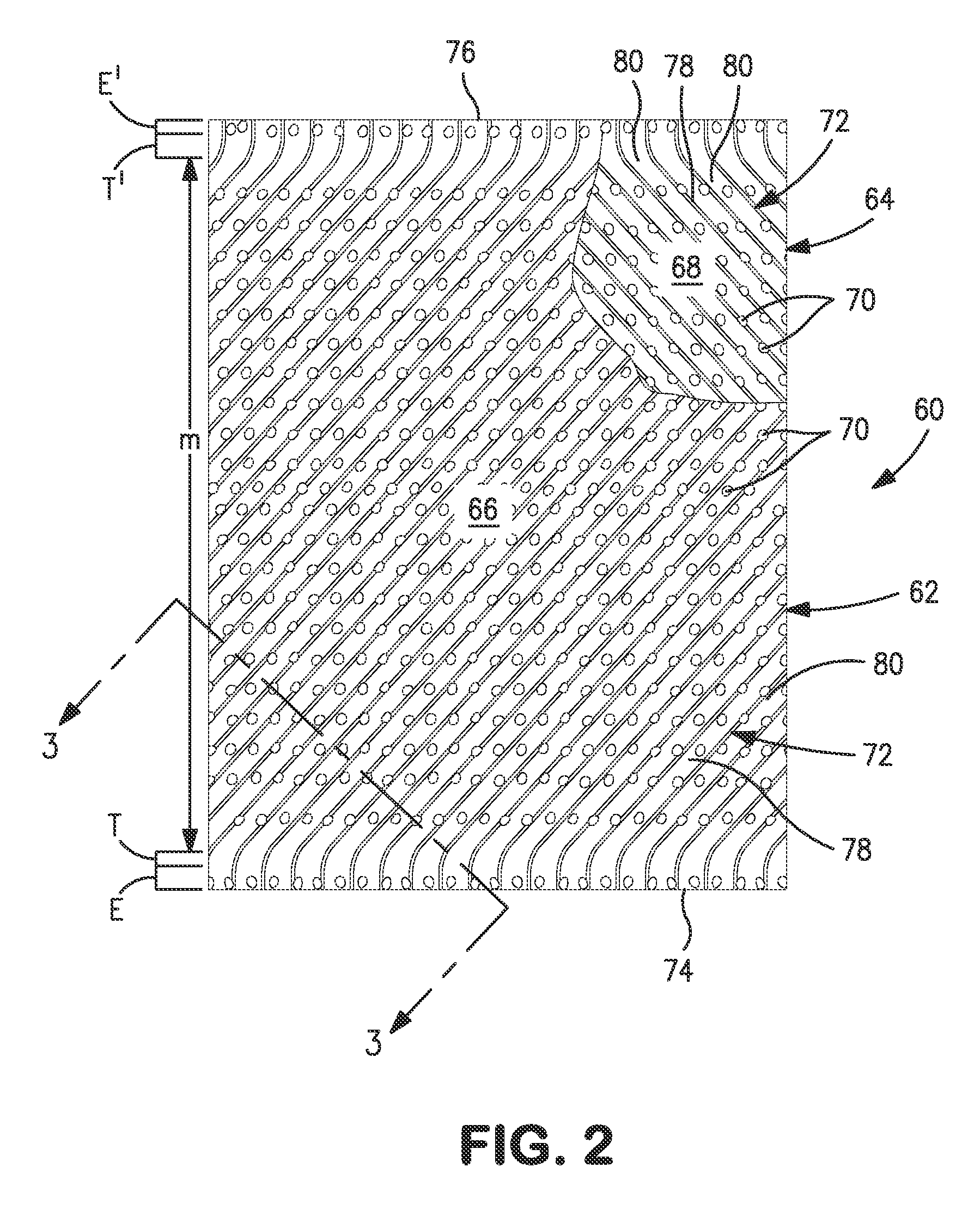

Structured packing and method

ActiveUS9295925B2Lower resistanceReduce the average velocitySolidificationLiquefactionInternal pressureAcute angle

A structured packing formed of a plurality of corrugated, rectangular sheets and a method relating to the use thereof. End regions of the corrugations are provided with straight, parallel corrugations extending inwardly from opposed edges of the sheets and a right angles thereto to reduce pressure drop at the interfaces between packing layers and thereby increase hydraulic capacity. Contact is promoted between descending liquid and ascending vapor phases within a main region of the corrugations that have straight, parallel sections of the corrugations oriented at an acute angle to the opposed edges. Transition regions having arcuate sections of the corrugations connect corrugations within the main and end regions to reduce internal pressure drop within the structured packing and thereby further reduce pressure drop at the interfaces and further increase the hydraulic capacity.

Owner:PRAXAIR TECH INC

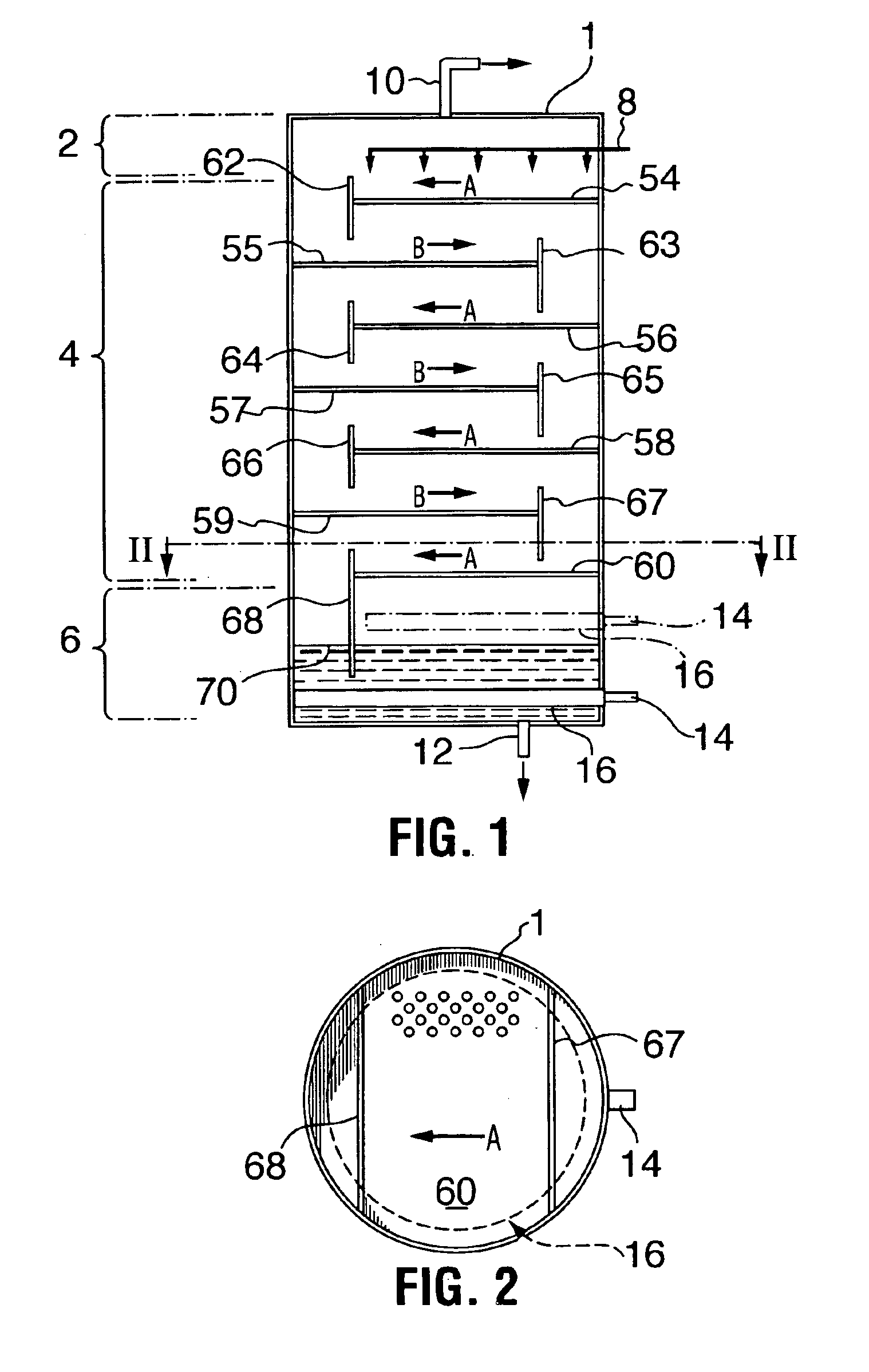

Gas/liquid contacting apparatus

The lower, liquid collecting section of a gas / liquid contacting column has an entrained substance depleting duct extending therearound wherein gas, for example, steam is fed by the duct into the lower section, steam depleted by gravity of liquid droplets, is deflected upwardly by deflectors in the duct through duct openings into a central, upper region of the lower section, while steam with the droplets is deflected downwardly by deflectors in the duct through other duct openings towards a liquid pool in the lower section. Any other liquid and / or solids entrained in the gas (steam) are also deflected downwardly in this manner.

Owner:AMT INT INC

Column tray

InactiveUS7234692B2High free cross-sectionLow costMixing methodsUsing liquid separation agentDistributorBiomedical engineering

A column tray assembly includes a tray having passages formed therein. The tray is a multifunction tray and is configured to receiving appropriate superstructures which can be selected according to the respective use of the assembly. Superstructures which communicate with the passages are mounted to the tray. The superstructures have gas penetration holes embedded in such way that, when the superstructures are mounted to the tray, the orifices of the gas penetration holes extend in a perpendicular manner in relation to the tray. The tray and the superstructures are formed from the same or different corrosion-resistant materials or combination of materials. The tray may also be provided with smaller holes for the discharge of liquid, into which holes distributor cups, or the like are inserted. These smaller holes may be closed for specific purposes.

Owner:QVF ENG GMBH

Method and apparatus for facilitating more uniform vapor distribution in mass transfer and heat exchange columns

ActiveUS20050146062A1Evenly distributedReduction in ascending vapor velocityUsing liquid separation agentTransportation and packagingEngineeringCircular segment

A vapor horn device for use in an elongated, generally upright mass transfer and / or heat exchange column having an internal region comprises an elongated, generally arcuate wall arranged to be located within the internal region and disposed to extend around a longitudinal axis of the column. The arcuate wall includes an inlet area positioned for being contacted by a vapor or mixed phase stream entering the column and causing the stream to flow along an outer surface of the arcuate wall and generally around the axis. The device also includes a primary elongated vane extending outwardly from the outer surface of the arcuate wall. This primary vane has an inner end located adjacent the outer surface of the inner wall and an outer end disposed in spaced relationship relative to the outer surface of the wall. The vane is disposed at a tangential angle relative to the direction of flow of the stream such that the inner end of the vane is further downstream than the outer end thereof whereby any portion of the stream impinging on the primary vane is redirected toward the outer surface of the arcuate wall. The device also desirably includes one or more vanes that extend radially outwardly from the inner wall.

Owner:KOCH GLITSCH INC

Process for contacting one or more fluids and a reactor relating thereto

ActiveUS20120241006A1Efficient mixingWell mixedPhysical/chemical process catalystsFluid dynamicsContact timeBiomedical engineering

One exemplary embodiment can be a process for contacting one or more fluids in a vessel. The process may include passing one or more fluids into a chamber from an overhead tray and providing a conduit outside the chamber coupling a respective spillway to a respective hole for increasing contact time inside the conduit. Typically, the chamber forms one or more sidewalls forming at least one hole and the overhead tray forms at least one spillway.

Owner:UOP LLC

Parallel flow fractionation tray

ActiveUS7204477B2Improve efficiencyIncrease capacityCarburetting airEngine sealsVapor liquidChemical compound

Owner:UOP LLC

Wall-flow redistributor for packed columns

An apparatus for collecting and redistributing a flow of a liquid descending in an exchange column containing a layer of structured packing and having a longitudinal axis, a cross-sectional area, and an inner wall having an inner perimeter, includes: a wall-flow collector located above the layer of structured packing, the wall-flow collector having an outer perimeter adjacent the inner perimeter of the inner wall and being adapted to collect at least a portion of the liquid descending on or near the inner wall of the exchange column; a transmission means for transmitting at least a portion of the collected liquid collected by the wall-flow collector toward the longitudinal axis a substantial distance across the cross-sectional area of the exchange column; and a dispensing means for dispensing at least a portion of the portion of the collected liquid from the transmission means to the layer of structured packing.

Owner:AIR PROD & CHEM INC

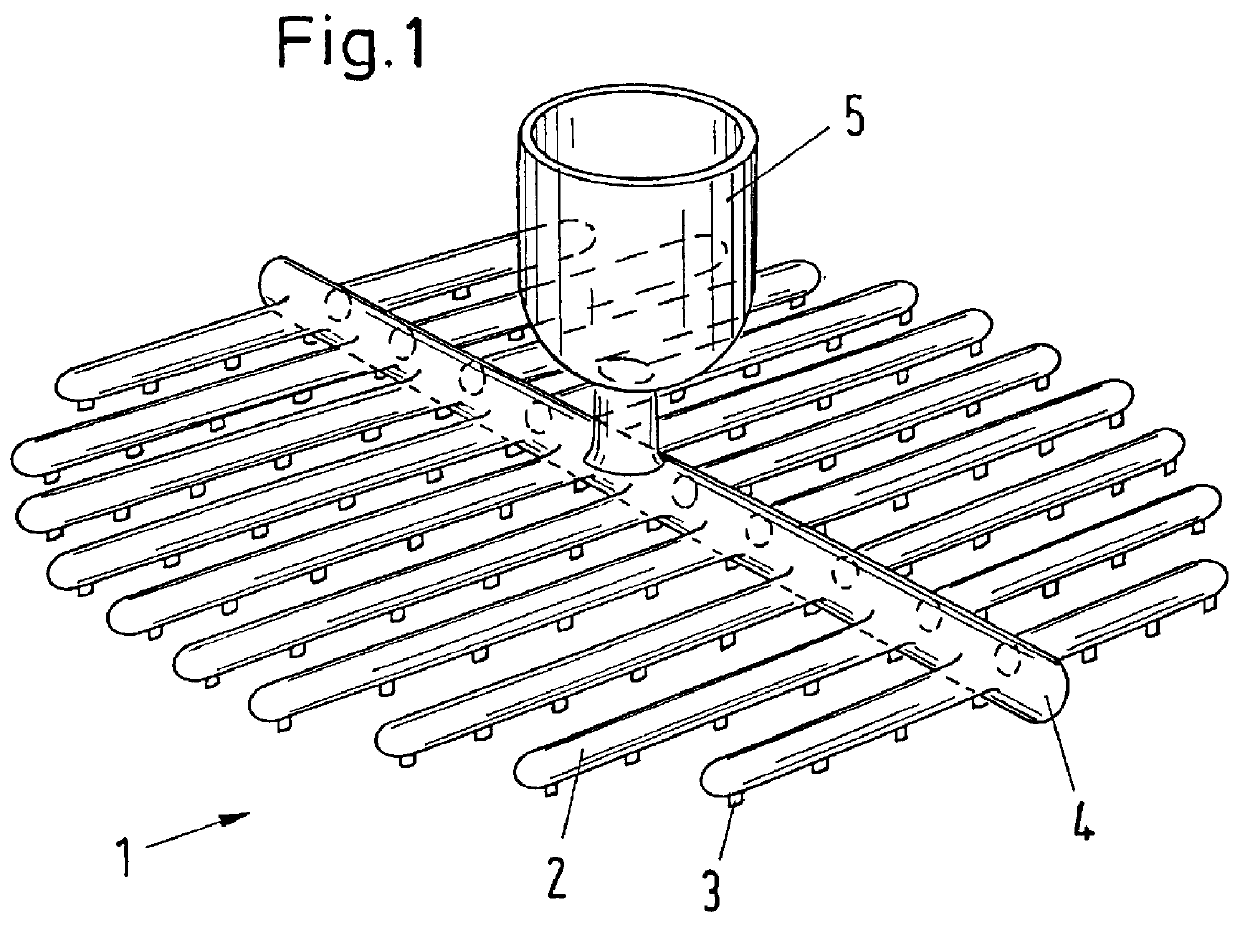

Distributor device for a column

InactiveUS6042090AReduce generationLess disturbingFlow mixersUsing liquid separation agentEngineeringDistributor

The distributor device for a column includes a system of distributor tubes and nozzles for a fluid. The outlet apertures of the nozzles are preferably all arranged at the same height. At least a portion of the nozzles are manufactured of similar glass tube pieces. Each outlet aperture has a border which is formed by an edge produced by a milling cut and is otherwise untreated or by an untreated, broken glass edge.

Owner:SULZER CHEMTECH AG

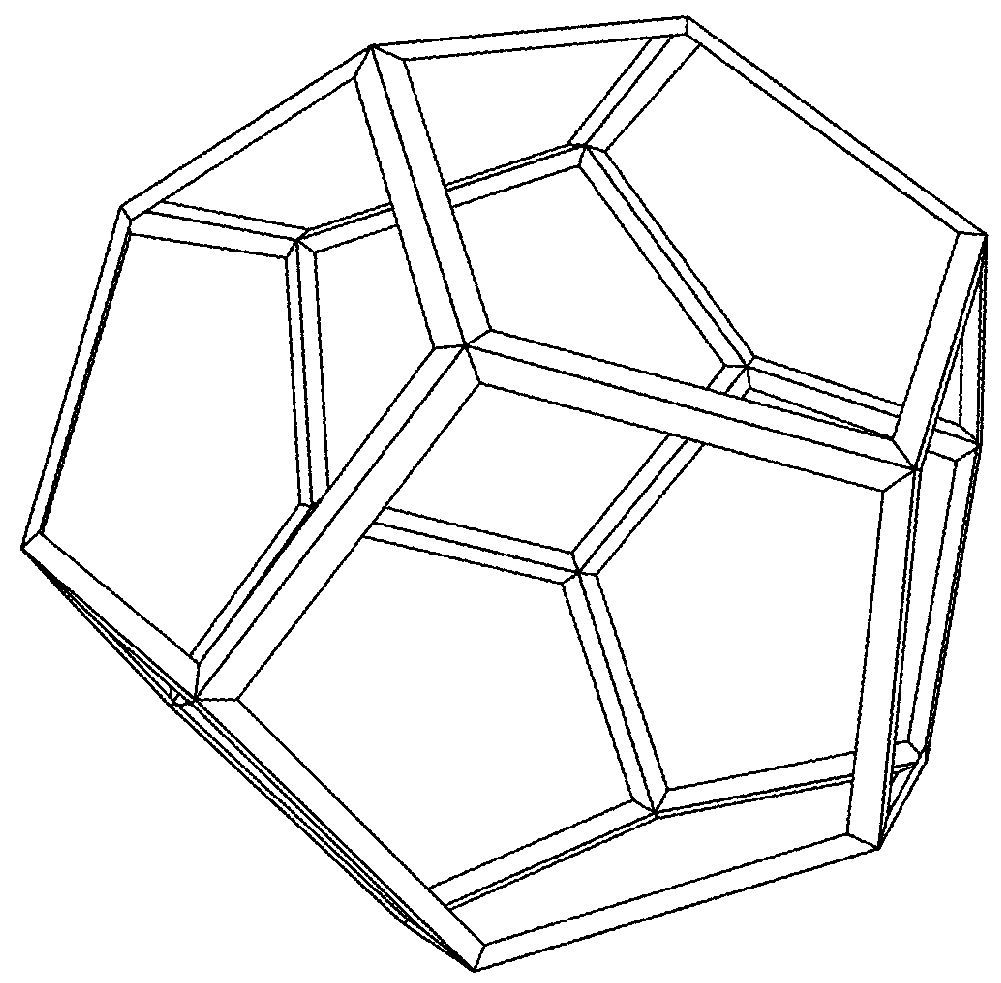

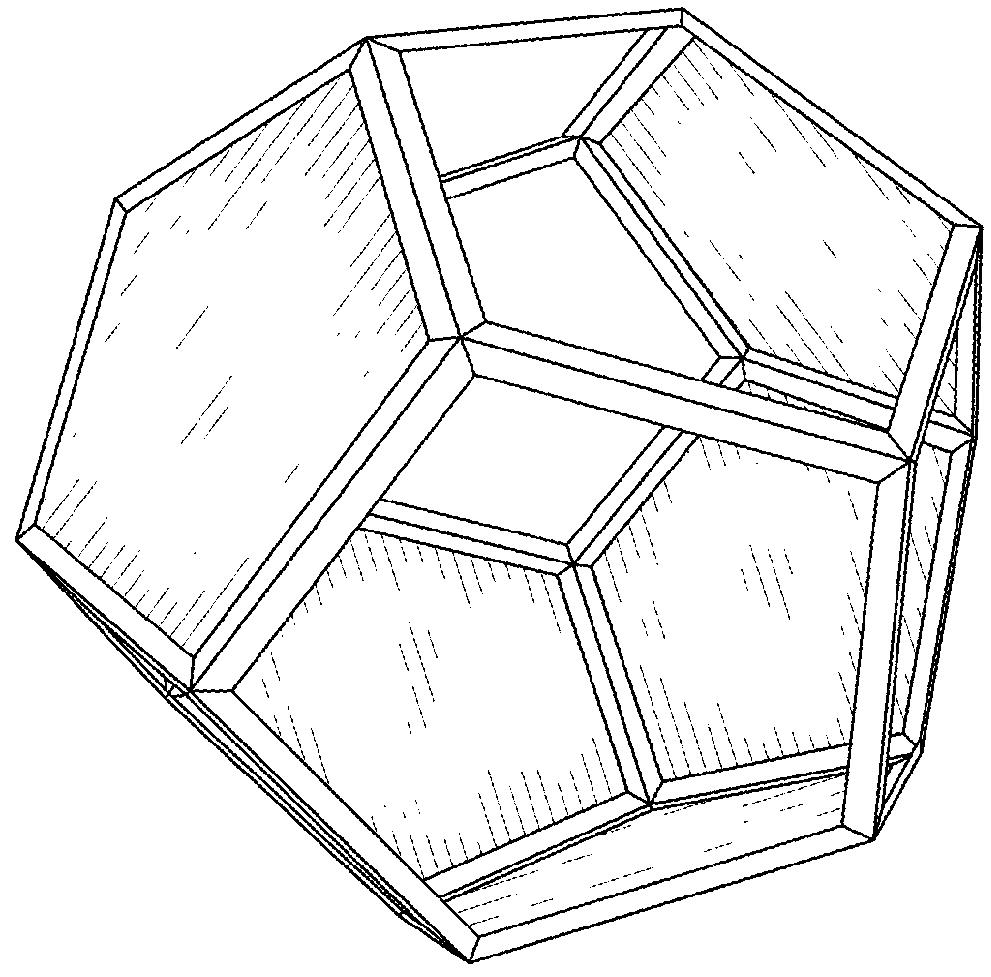

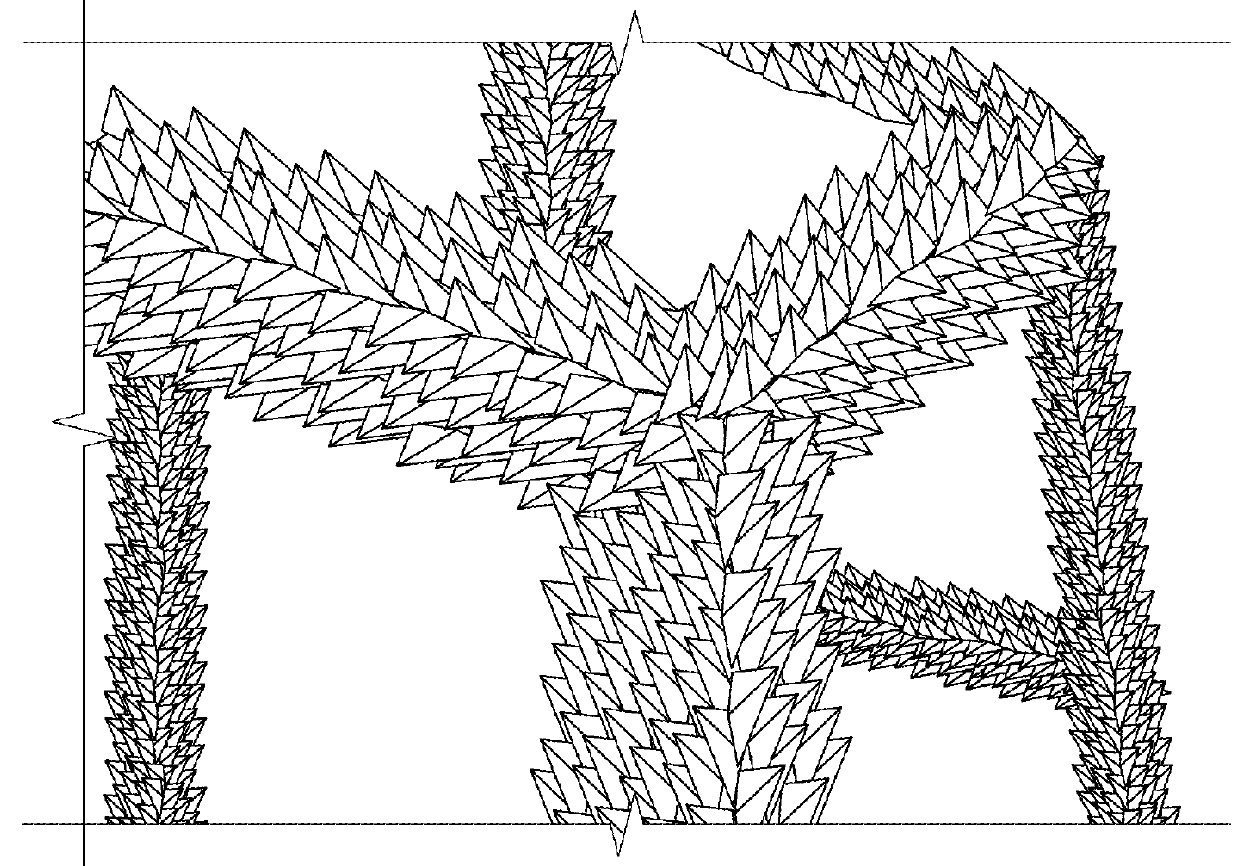

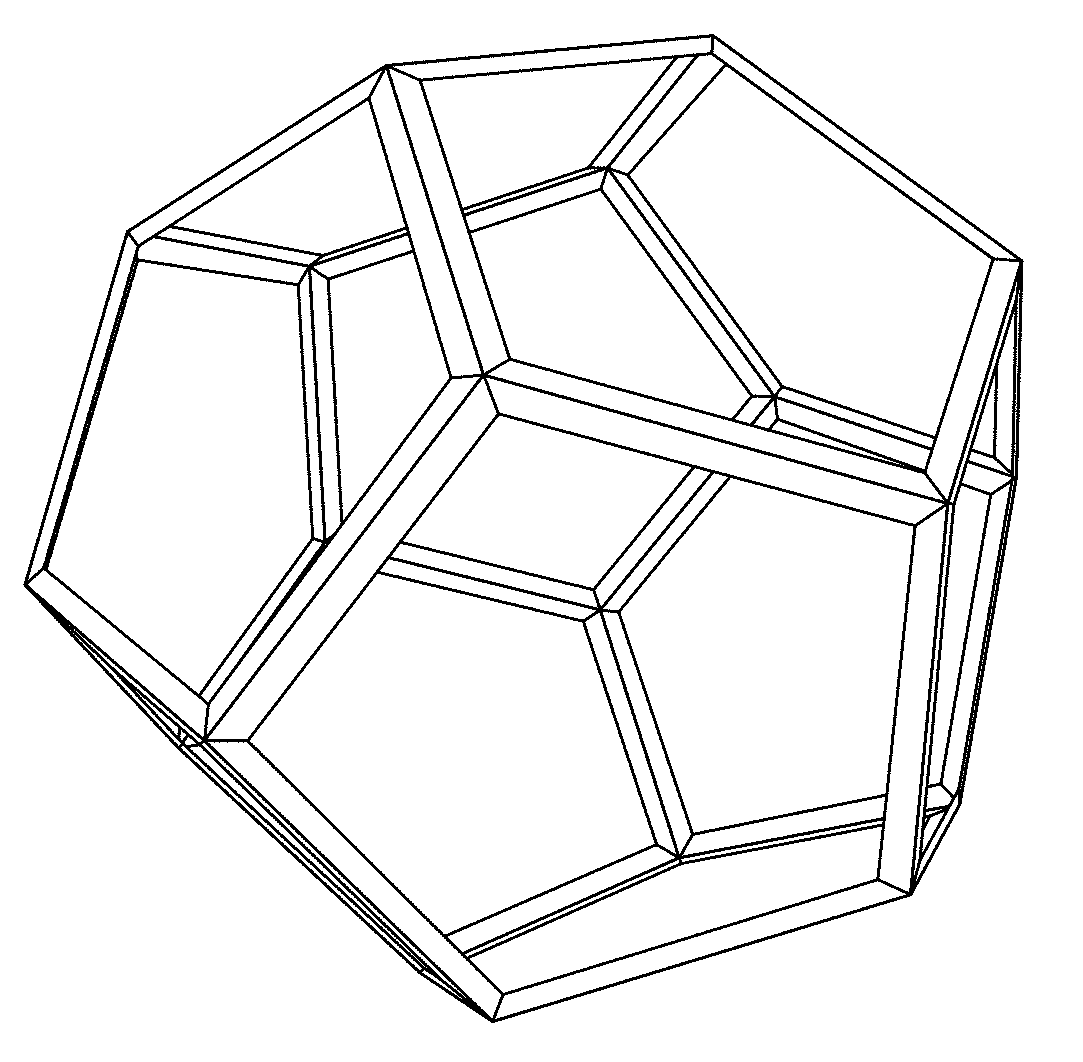

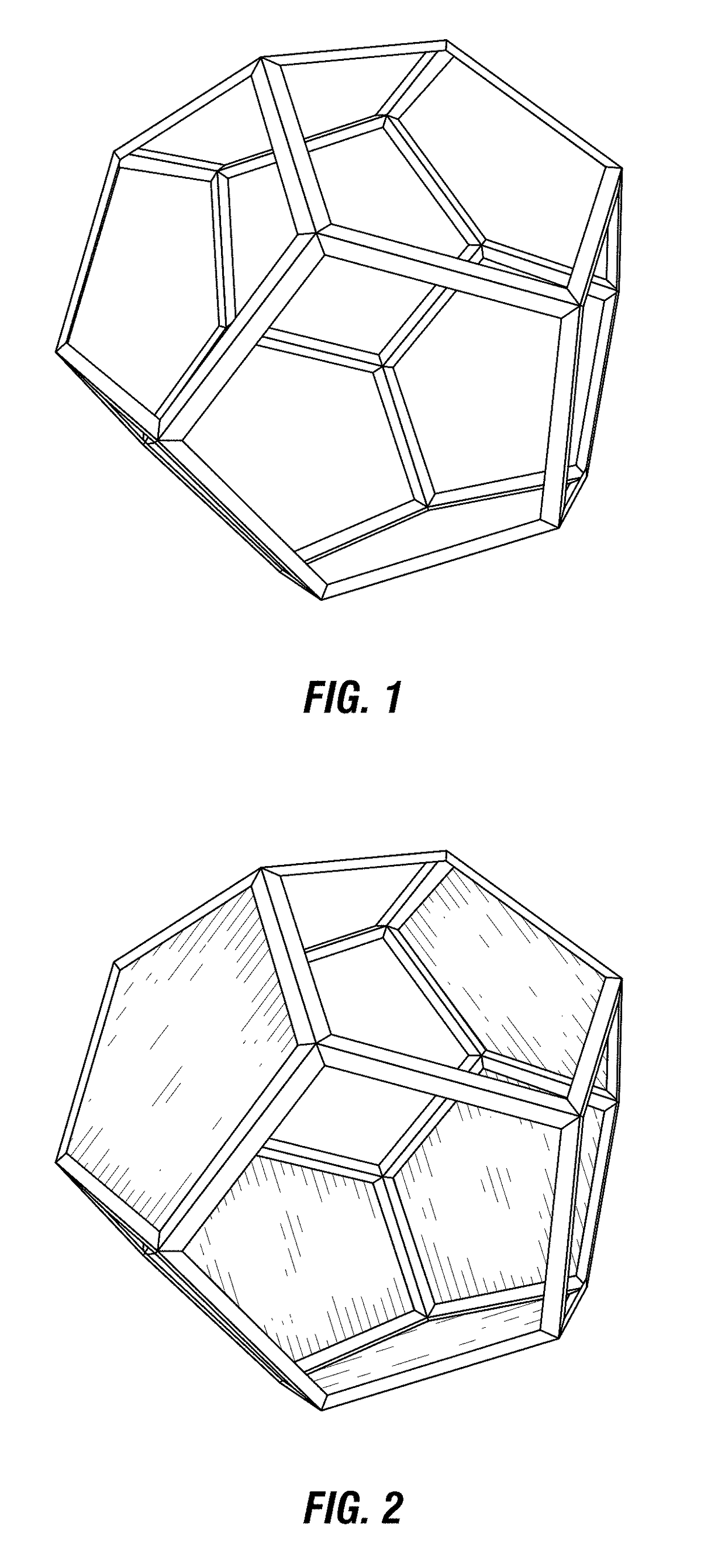

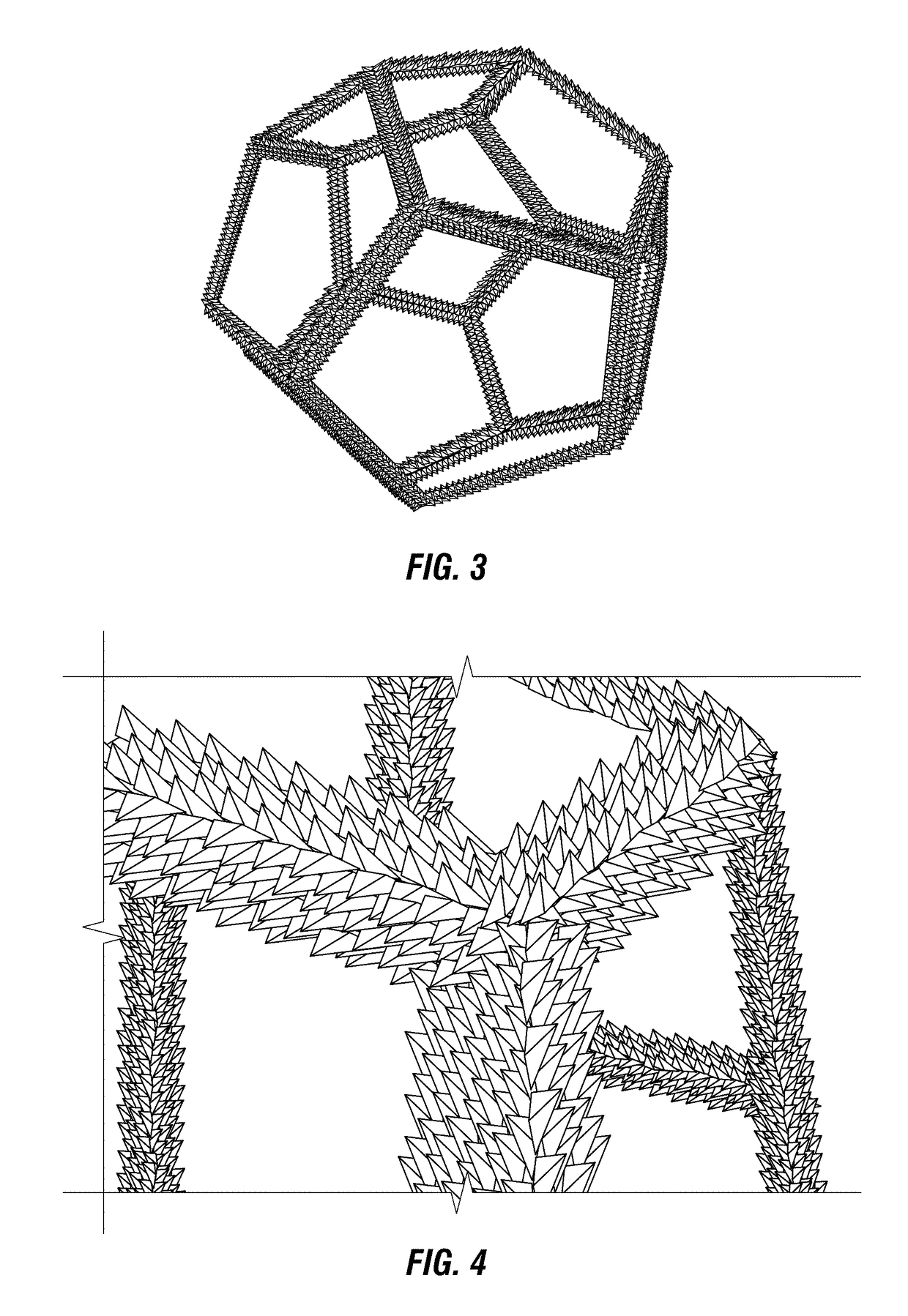

Structured elements and methods of use

InactiveUS20180093207A1Facilitate flow division and distributionUndesired attenuationLiquid distribution in distillationChemical/physical/physico-chemical processesFluteFiber

Owner:CRYSTAPHASE PRODS

Structured elements and methods of use

ActiveUS20170189834A1Facilitate flow division and distributionUndesired attenuationLiquid distribution in distillationChemical/physical/physico-chemical processesFluteFiber

Structured elements with capabilities for stream flow division and distribution and mitigation of undesired species that exceed those of conventionally available materials are provided. The structured elements provide increased opportunities for surface attraction, retention and coalescence of undesired species in a process stream. The functional contact surfaces of the structured elements can include one or more of the faces of cells, the surfaces of struts connecting cells, the surfaces of nodes connecting struts, and the surfaces of asperities or irregularities caused by channels, flutes, spikes, fibrils or filaments in or on the material surfaces.

Owner:CRYSTAPHASE PRODS

Contacting a gas stream with a liquid stream

A co-current contacting system is described herein. The co-current contacting system includes a co-current contactor located in-line within a pipe. The co-current contactor includes an annular support ring configured to maintain the co-current contactor within the pipe and a number of radial blades configured to allow a liquid stream to flow into the co-current contactor. The co-current contacts also includes a central gas entry cone configured to allow a gas stream to flow through a hollow section within the co-current contactor, wherein the co-current contactor provides for efficient incorporation of liquid droplets formed from the liquid stream into the gas stream. The co-current contacting system also includes a separation system configured to remove the liquid droplets from the gas stream.

Owner:EXXONMOBIL RESEARCHK & ENG CO

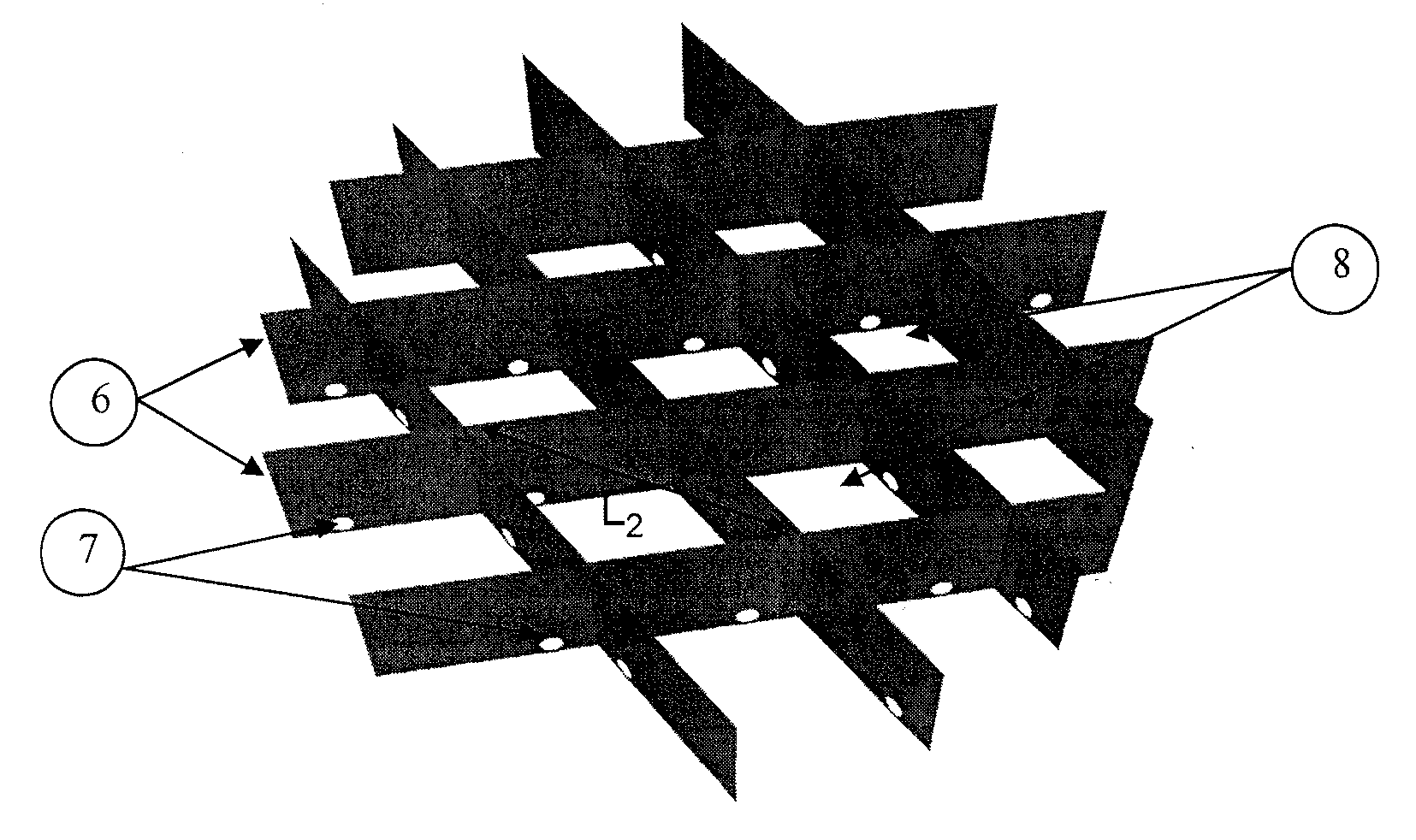

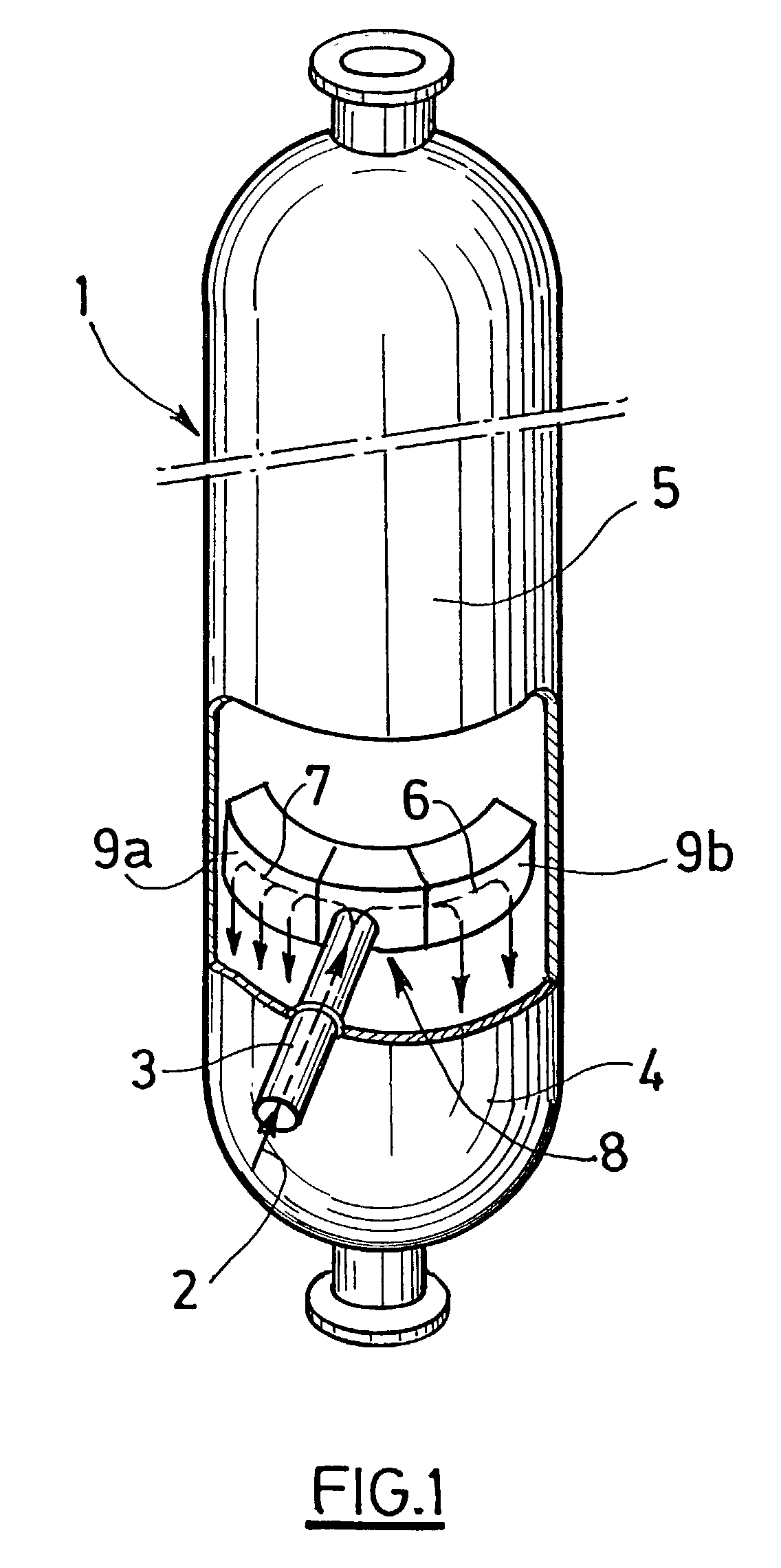

Method and device for introducing a liquid-vapor mixture into a radial feed cylindrical fractionating column

InactiveUS6997445B2Reduce entrainmentEqually distributedCarburetting airMixing methodsFractionating columnPetroleum

A method and device for introducing a liquid-vapor mixture into a radial feed cylindrical fractionating column (1). The method includes separating the liquid-vapor mixture into two opposite and horizontal flows (6, 7), and directing the flows toward the lower part (4) of the column (1) to reduce the entrainments of liquid toward the upper part (5) of the column. The device includes elements (9a, 9b) for separating the liquid-vapor mixture into two opposite and horizontal flows and elements for directing the flows toward the lower section of the column. The elements cooperate to reduce the entrainment of liquid toward the upper section of the column. The method and device can be applied in the oil industry, namely in crude oil refineries as well as in chemistry and petrochemistry.

Owner:TOTAL RAFINAGE DISTRIBUTION SA

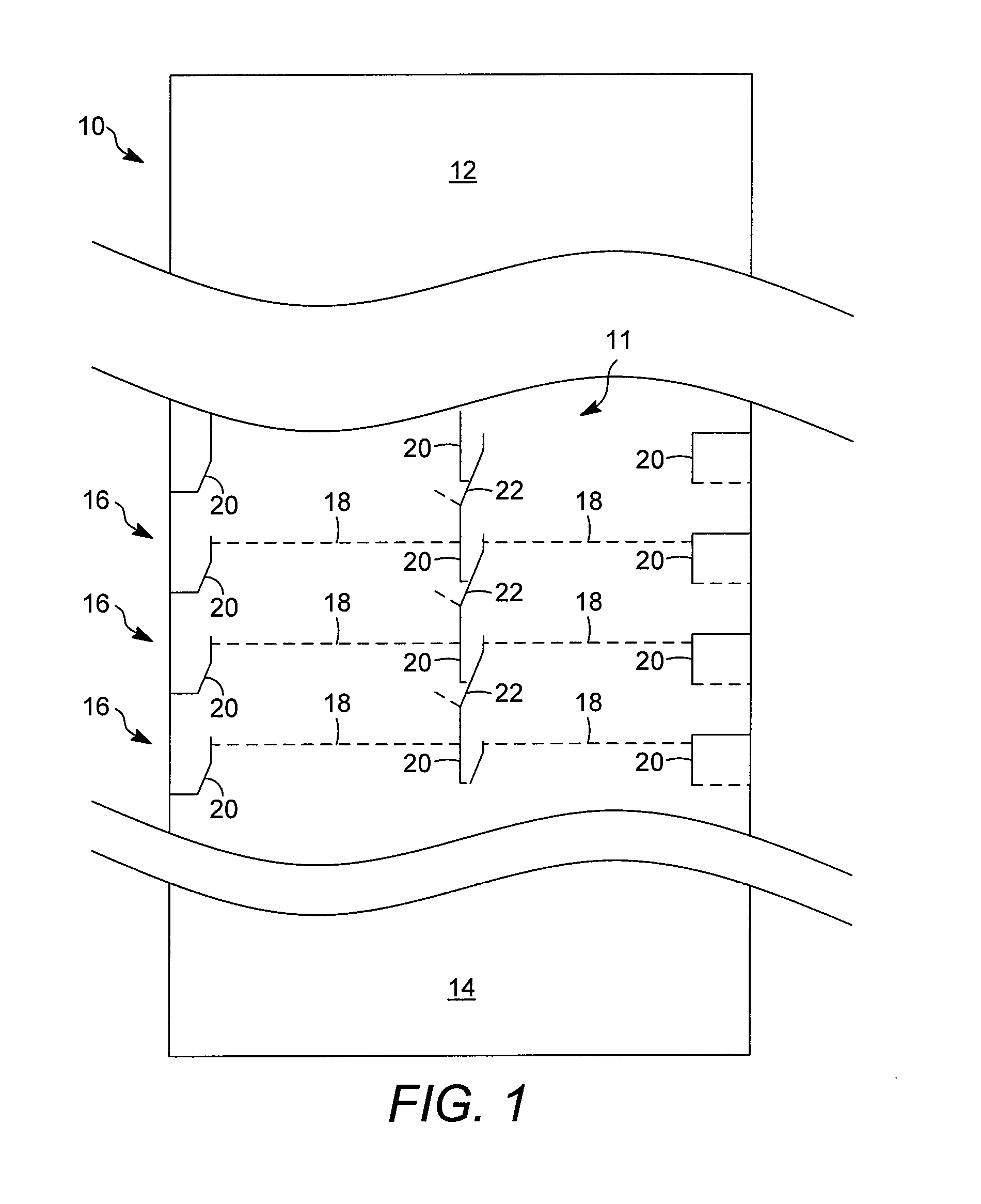

Fluid distribution to parallel flow vapor-liquid contacting trays

Fluid distribution systems, and particularly those for distributing liquids into apparatuses containing parallel flow trays for carrying out vapor-liquid contacting, are described. Representative fluid distribution systems comprise one or more extended troughs having a plurality of outlet spouts that are aligned for distribution to a vapor-liquid contacting deck zones of a parallel flow stage. The trough(s) may be orthogonal to liquid distribution pans which are in alignment with outlet spouts (e.g., in discrete outlet spout zones) of the trough(s).

Owner:UOP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com