Contacting a gas stream with a liquid stream

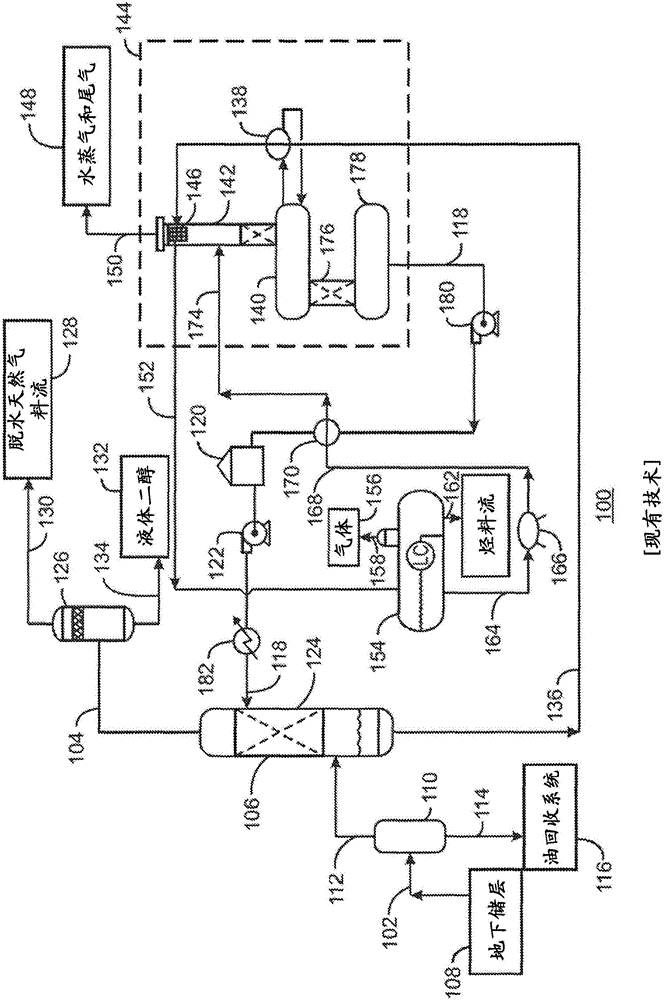

A liquid material flow and material flow technology, which is applied in the directions of gas fuel, distillation liquid distribution, fuel, etc., can solve problems such as difficulties, large tower base equipment transportation and installation difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

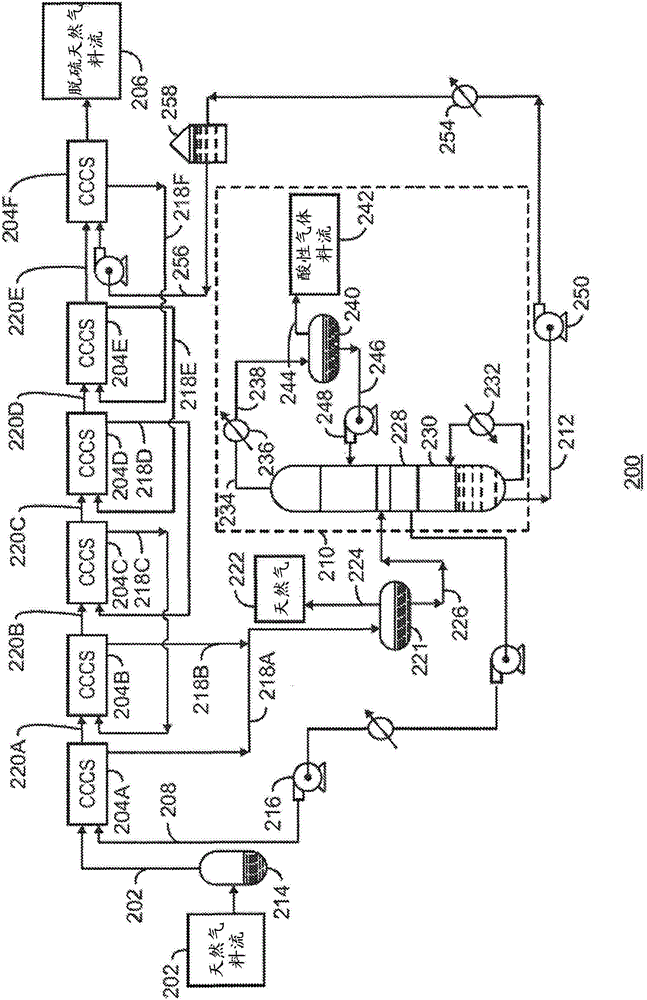

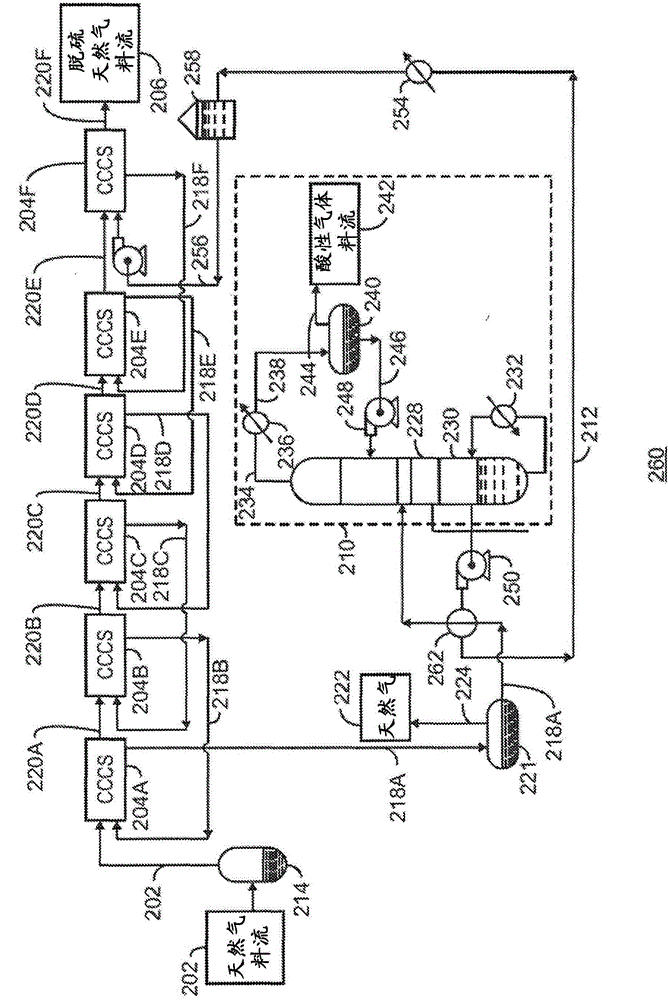

Embodiment approach

[0182] Embodiments of the invention may include any combination of the methods and systems shown in the following numbered paragraphs. This is not to be considered an exhaustive list of all possible embodiments, since many variations can be envisioned from the description.

[0183] 1. Parallel flow contact system, including:

[0184] A parallel flow contactor coaxially located in the pipe, the parallel flow contactor includes:

[0185] an annular support ring positioned to hold the co-current contactor inside the tube;

[0186] a plurality of radial vanes positioned to allow liquid streams to flow into the co-current contactor; and

[0187] a central gas inlet cone positioned to allow a gas stream to flow through the hollow portion inside the co-current contactor;

[0188] wherein the co-current contactor provides effective introduction of droplets formed from the liquid stream into the gas stream; and

[0189] A separation system arranged to remove at least one part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com