Patents

Literature

1034results about "Flash distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for desalination of saline water, especially water, having increased product yield and quality

InactiveUS6508936B1General water supply conservationSeawater treatmentTotal dissolved solidsDistillation

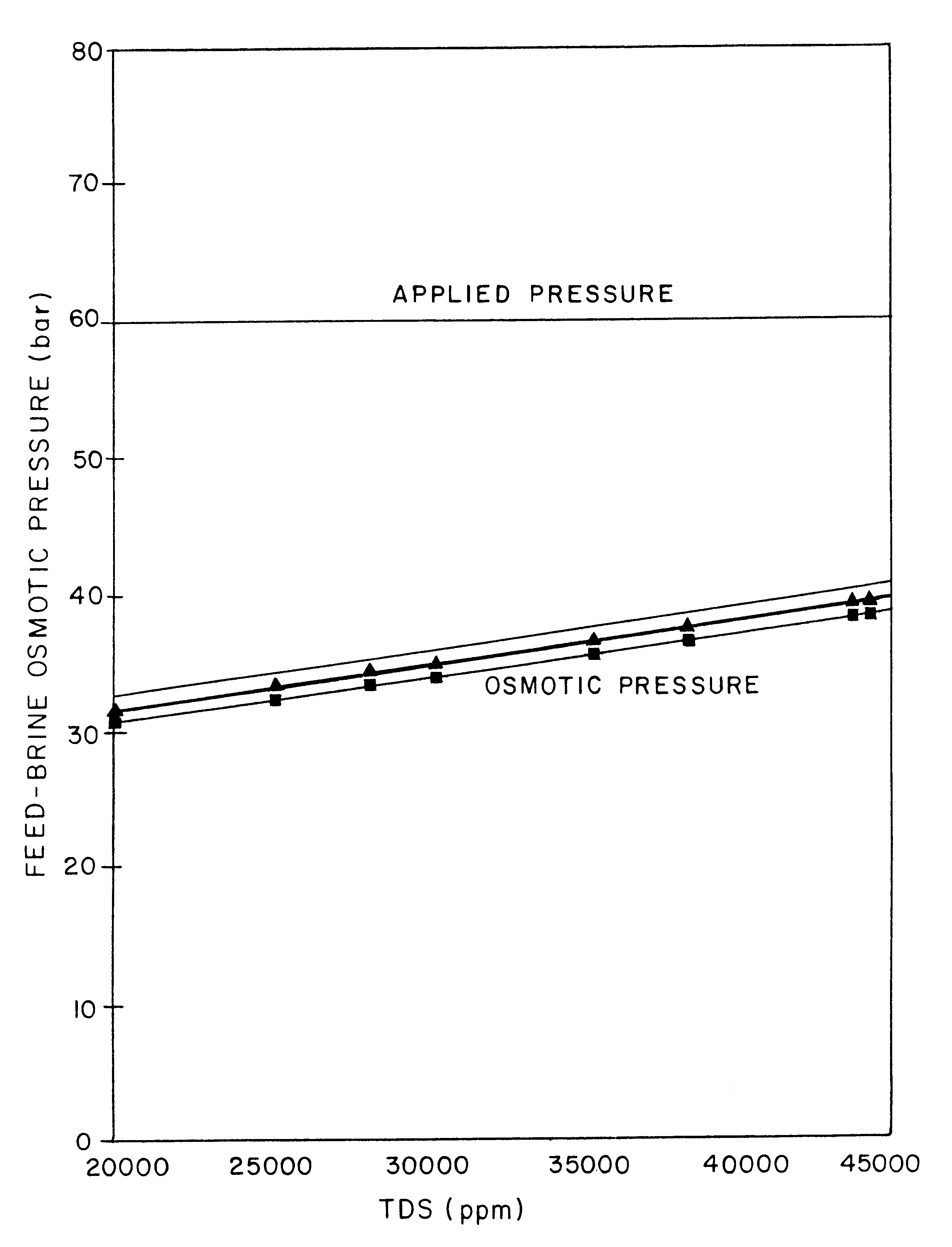

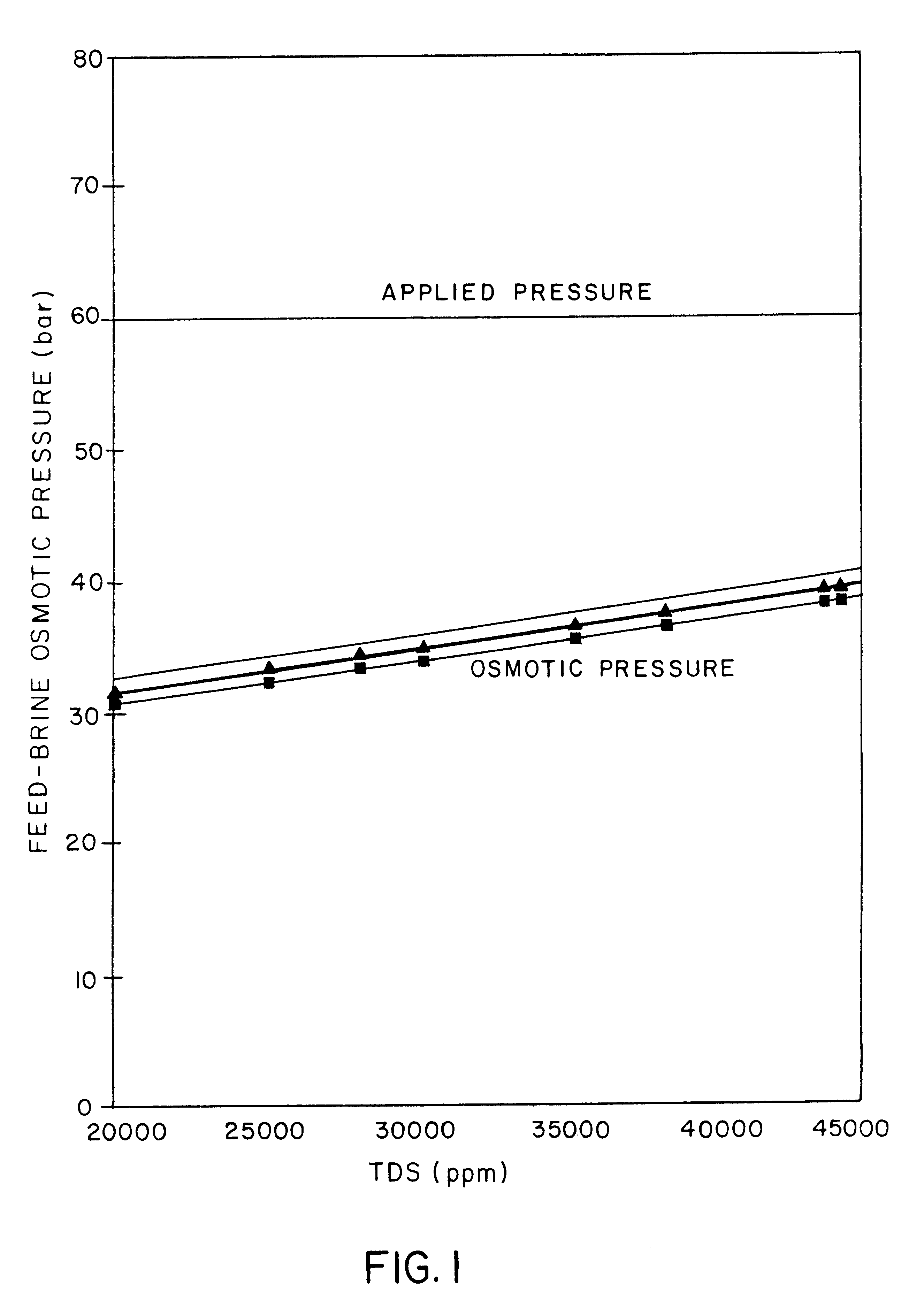

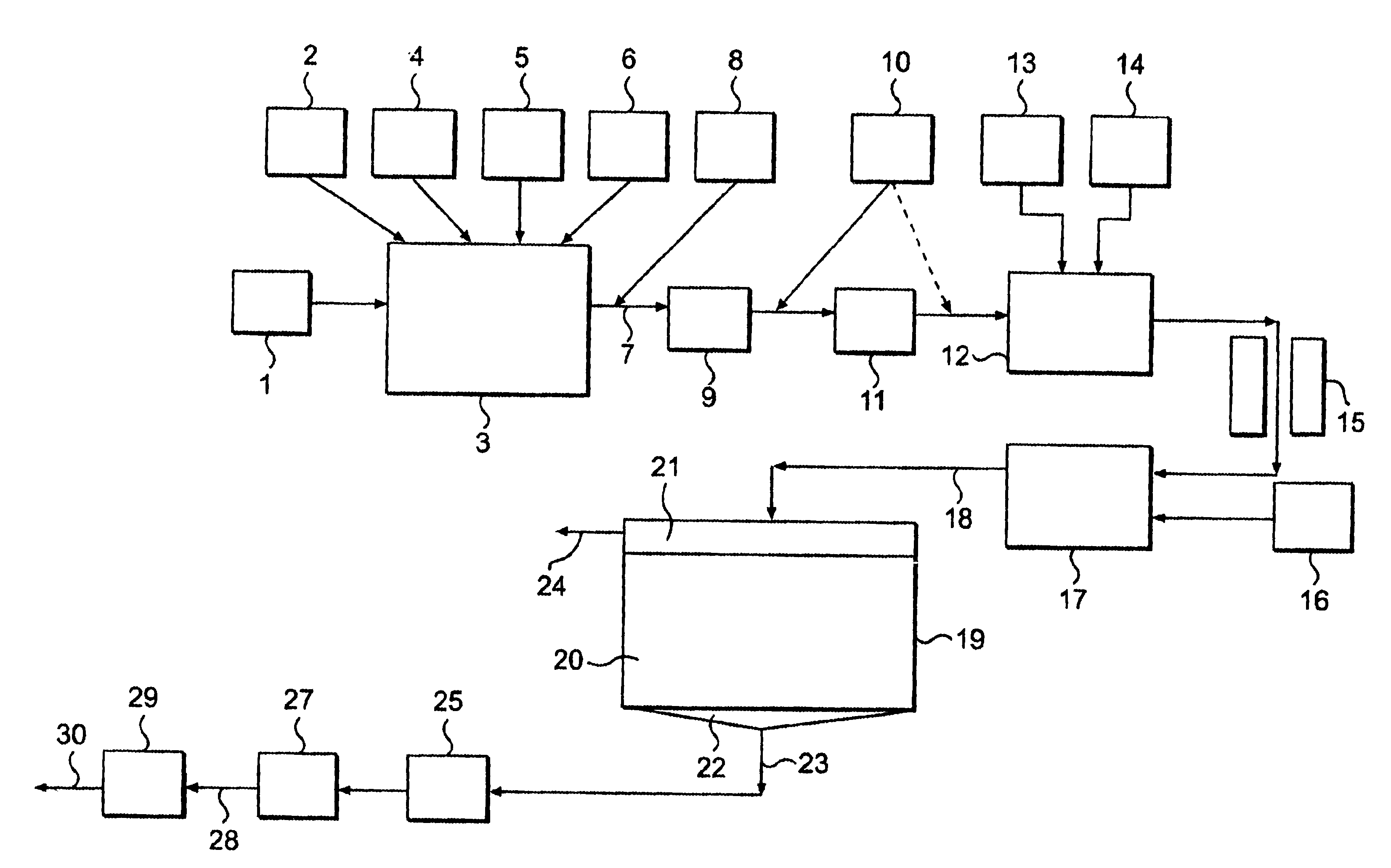

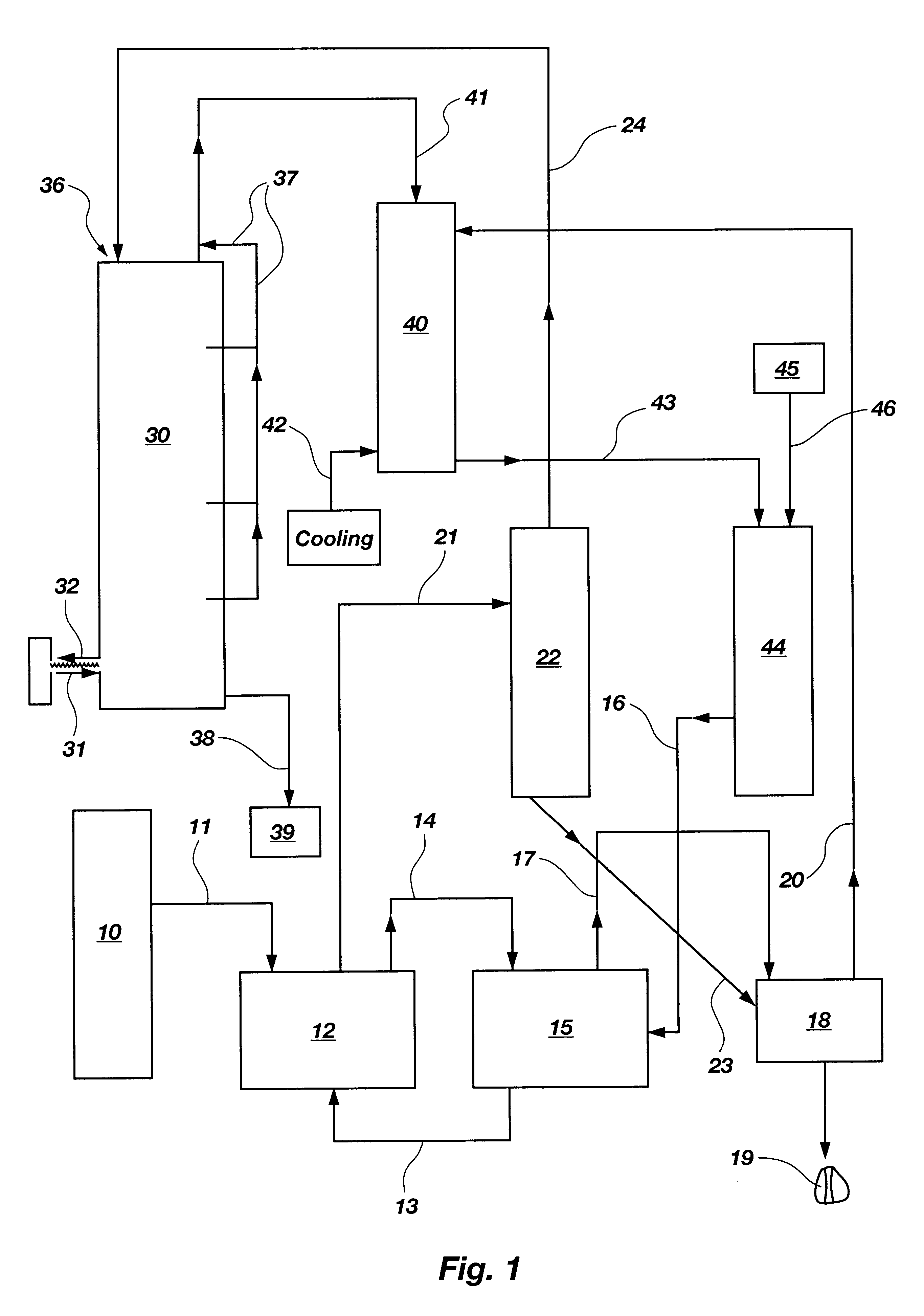

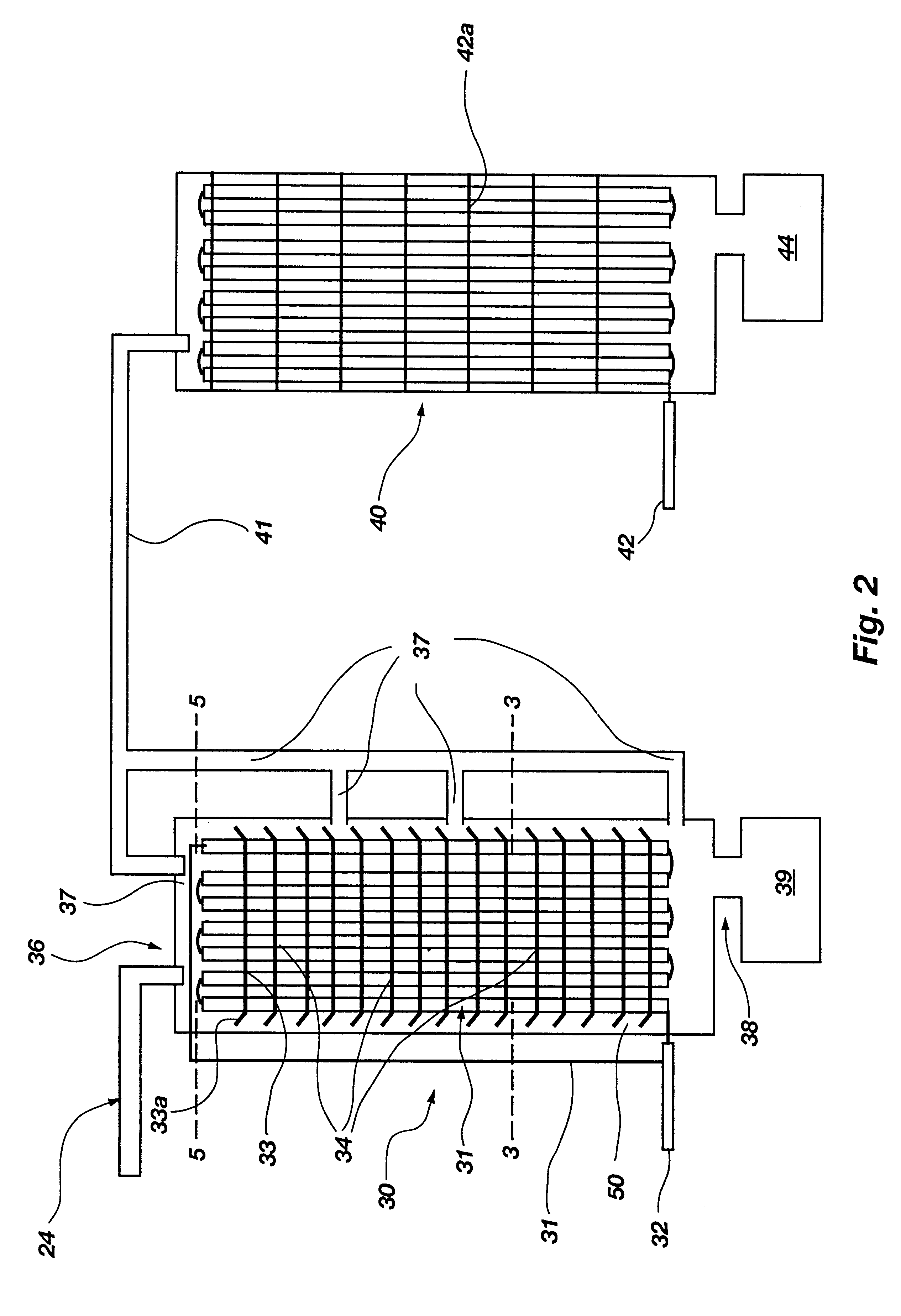

A desalination process is disclosed which combining two or more substantially different water treatment processes in a unique manner to desalinate saline water, especially sea water, to produce a high yield of high quality fresh water, including potable water, at an energy consumption equivalent to or less than much less efficient prior art desalination processes. In this process a nanofiltration step is synergistically combined with at least one of sea water reverse osmosis, multistage flash distillation. multieffect distillation of vapor compression distillation to provide an integrated desalination system by which sea water can be efficiently and economically converted to high quality potable water in yields which are at least 70%-80% greater than the yields available from the prior art processes. Typically a process of this invention using the nanofiltration initial step will produce, with respect to sea water feed properties, calcium, magnesium, sulfate and bicarbonate ion content reductions of 63%-94%, pH decreases of about 0.4-0.5 units and total dissolved solids content reductions of 35%-50%.

Owner:SALINE WATER CONVERSION CORP

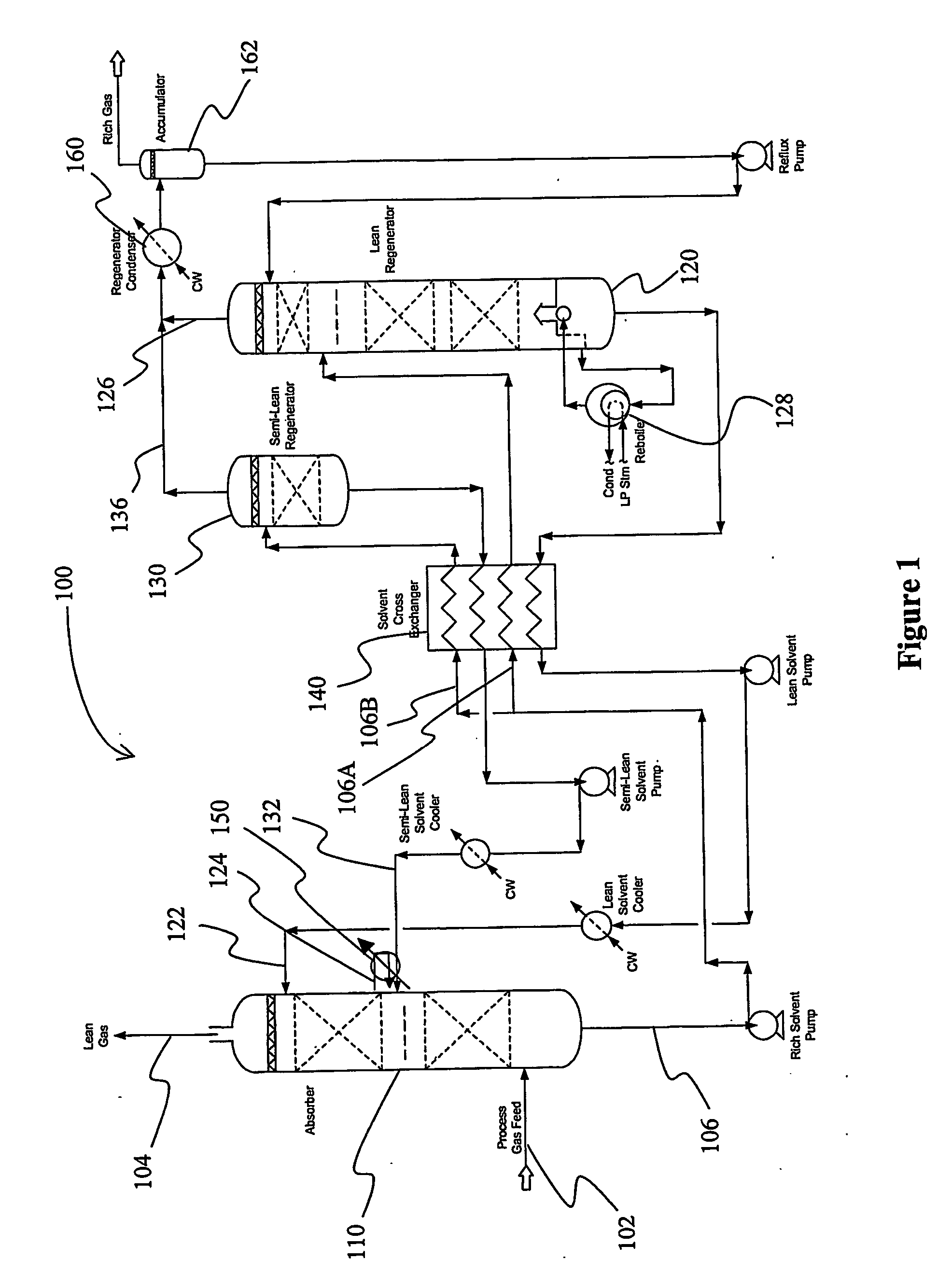

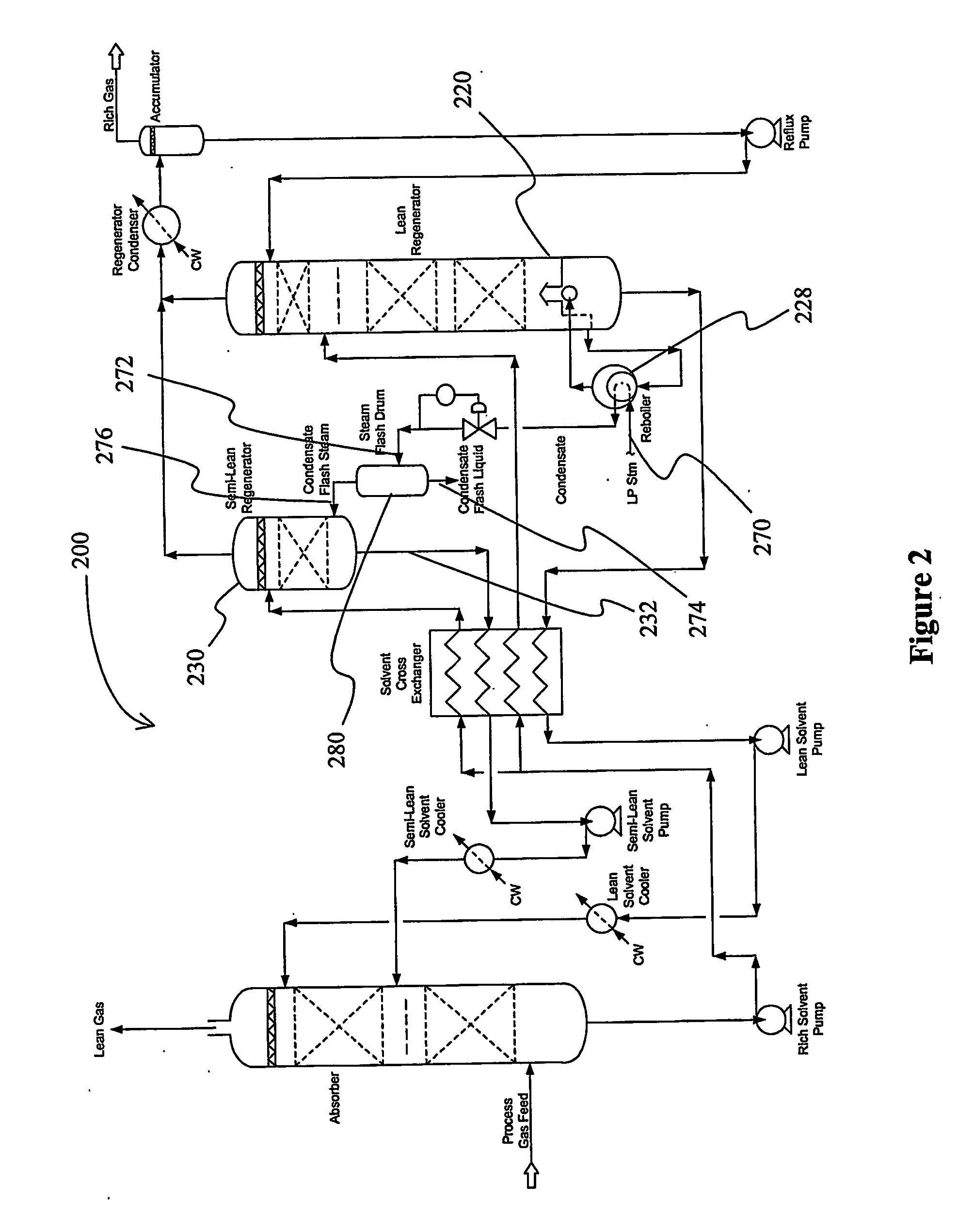

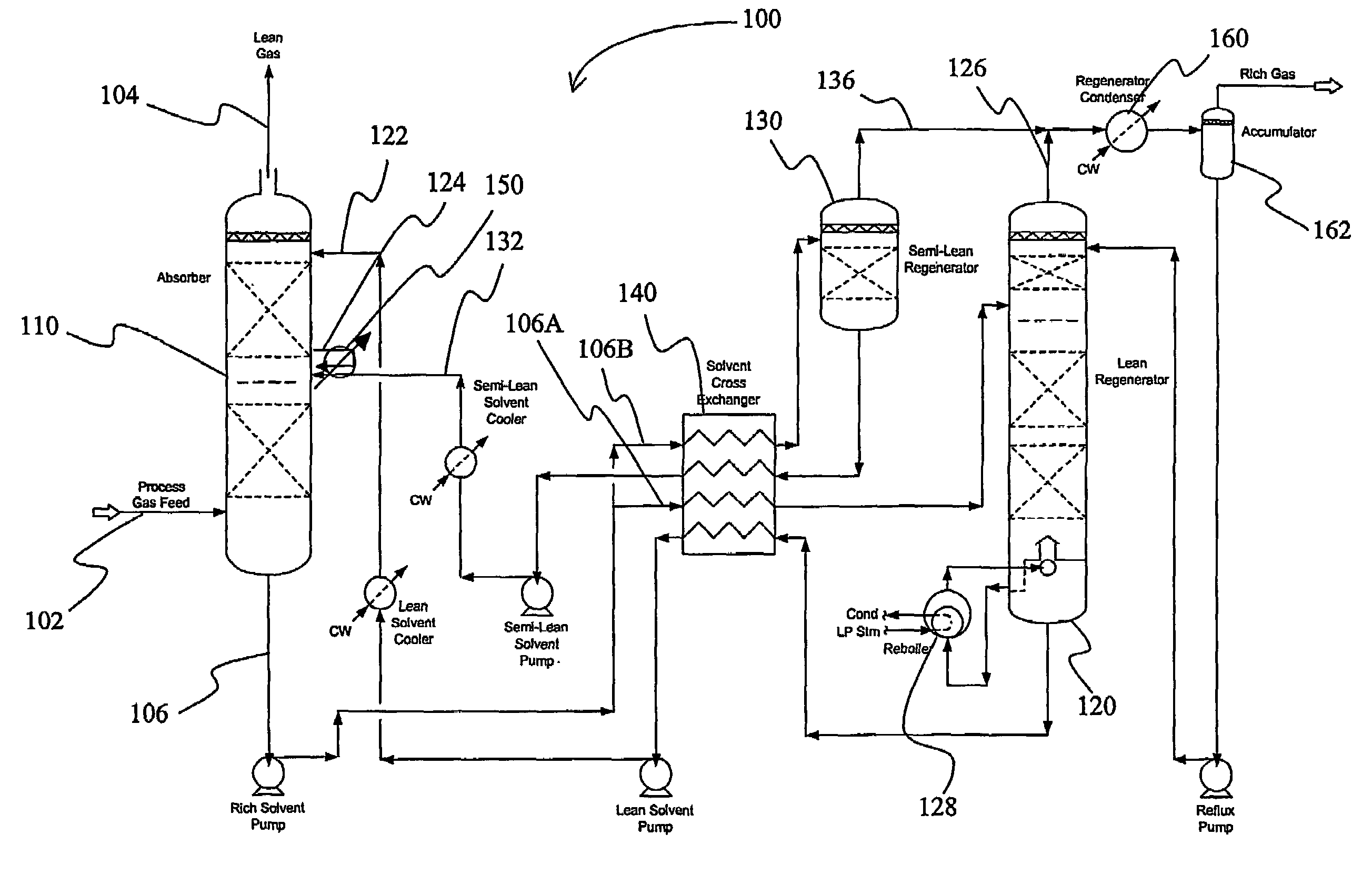

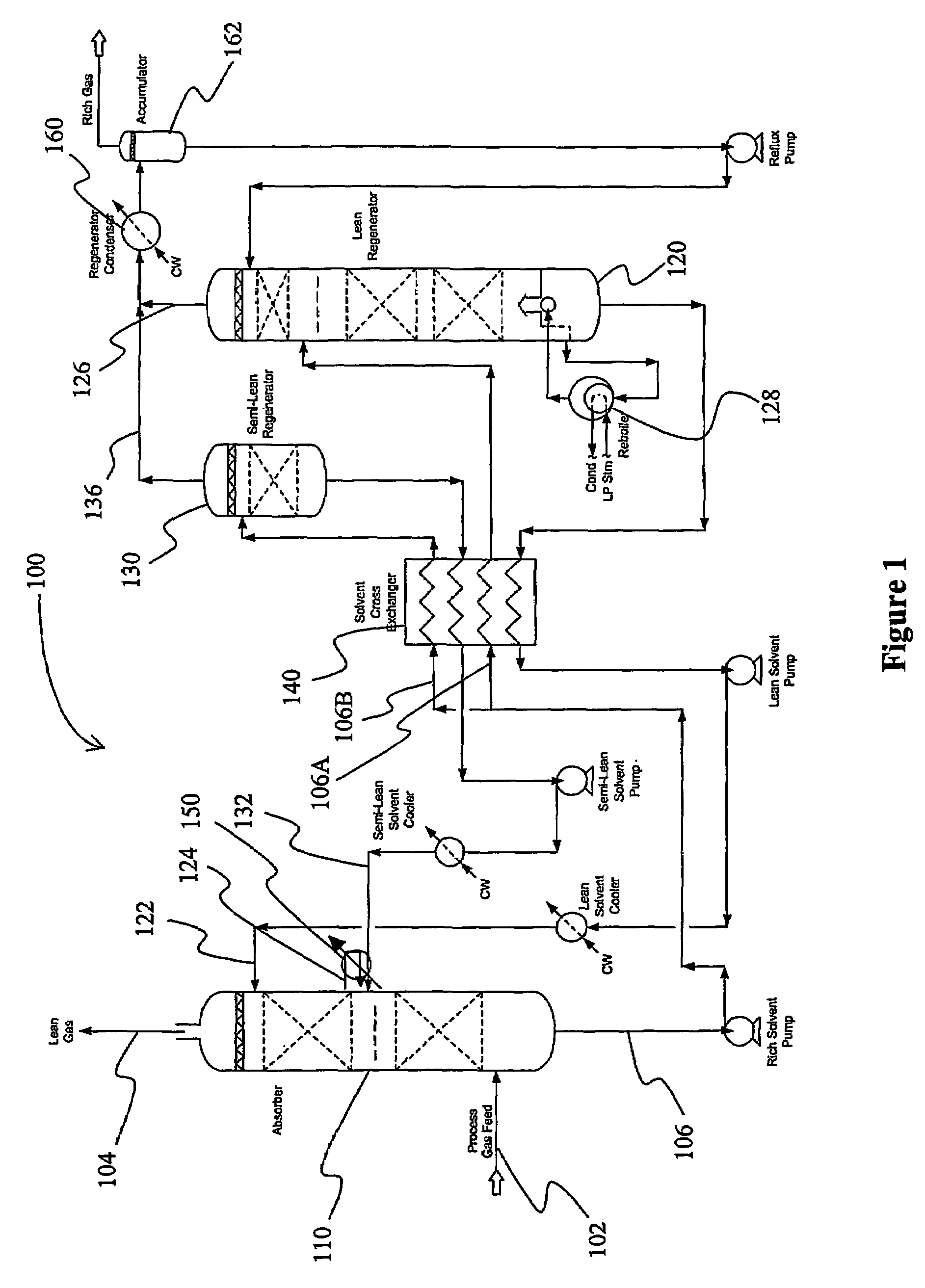

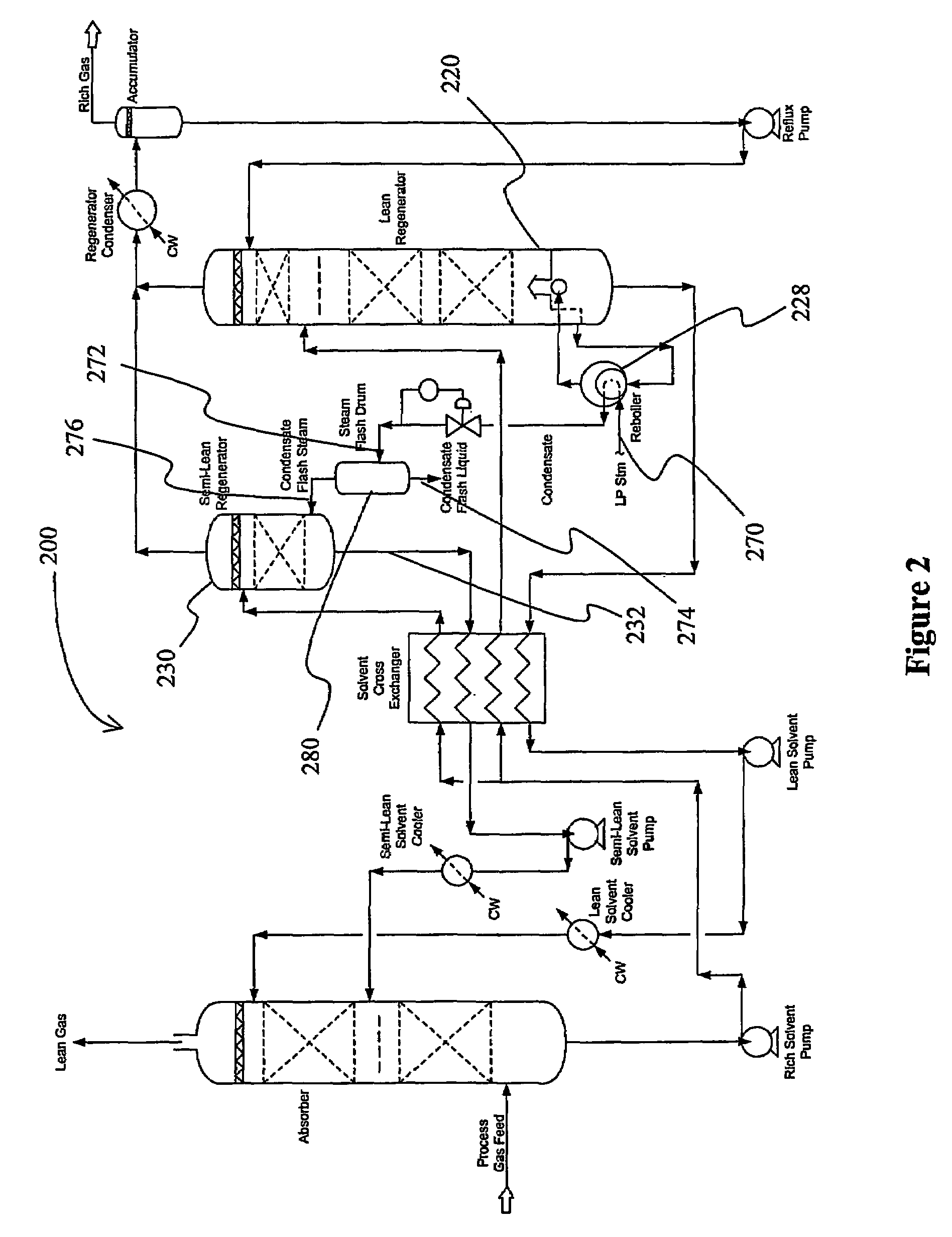

Split flow process and apparatus

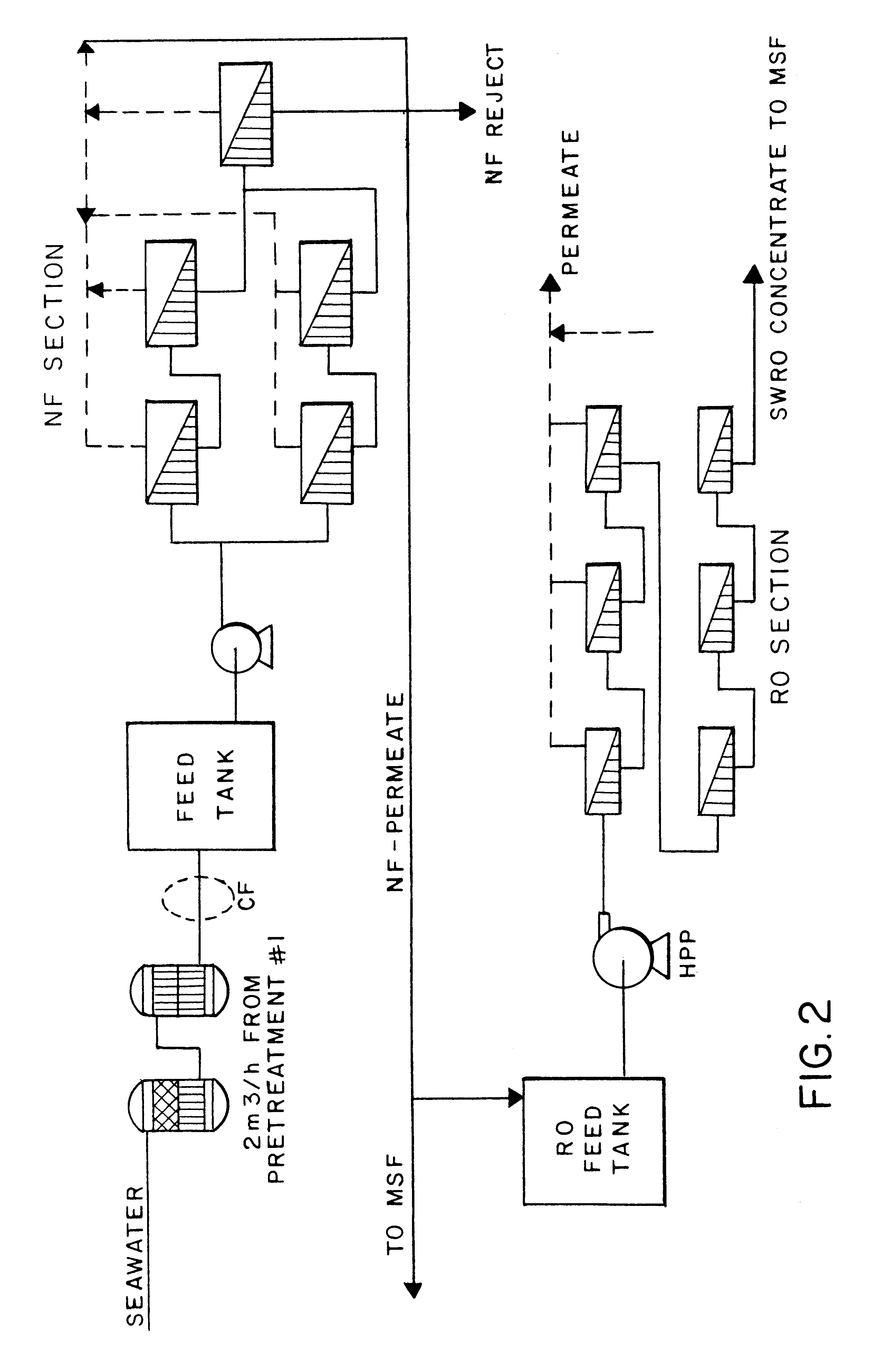

An acid gas removal plant includes an absorber that provides a rich solvent to two regenerators that independently generate a lean and a semi-lean solvent, wherein the semi-lean solvent is produced in one of the regenerators using heat and / or steam derived from the other regenerator. Further heat integration is particularly contemplated with power plants in which the power plant provides high-level heat to the acid gas removal plant and wherein the power plant receives low-level heat from the acid gas removal plant.

Owner:FLUOR TECH CORP

Toner processes

ActiveUS20080236446A1Improve blocking propertiesExcellent heat cohesionInksDevelopersPolyesterPolymer chemistry

A toner process comprising the aggregation and coalescence of an amorphous polyester, a crystalline polyester and a colorant, and wherein the coalescence is conducted at a temperature that is about lower than the melting point temperature of the crystalline polyester.

Owner:XEROX CORP

Process for the production of particles or powders

In a novel process for the production of particles or powders, a substance or mixture of substances to be treated is provided in a pressure vessel. A highly compressible fluid is dissolved under pressure in the substance or mixture of substances provided until a solution containing 5% to 90% by weight of said highly compressible fluid has formed. The melting point of said highly compressible fluid is at least around 40 K lower than the melting point of the substance or mixture of substances to be treated. The solution obtained by dissolving said highly compressible fluid in the substance or mixture of substances provided is adjusted to a temperature of up to around 50 K above or below the melting point under atmospheric pressure of the substance or mixture of substances to be treated and is then rapidly decompressed by means of a decompression device in such a way that the temperature falls, downstream of the decompression device, below the solidification point of the substance or mixture of substances to be treated and essentially all of the highly compressible fluid turns gaseous, whereby particles of the substance or mixture of substances provided form. Subsequently, the particles which have formed are removed from the stream of decompressed highly compressible fluid.

Owner:WEIDNER ECKHARD +2

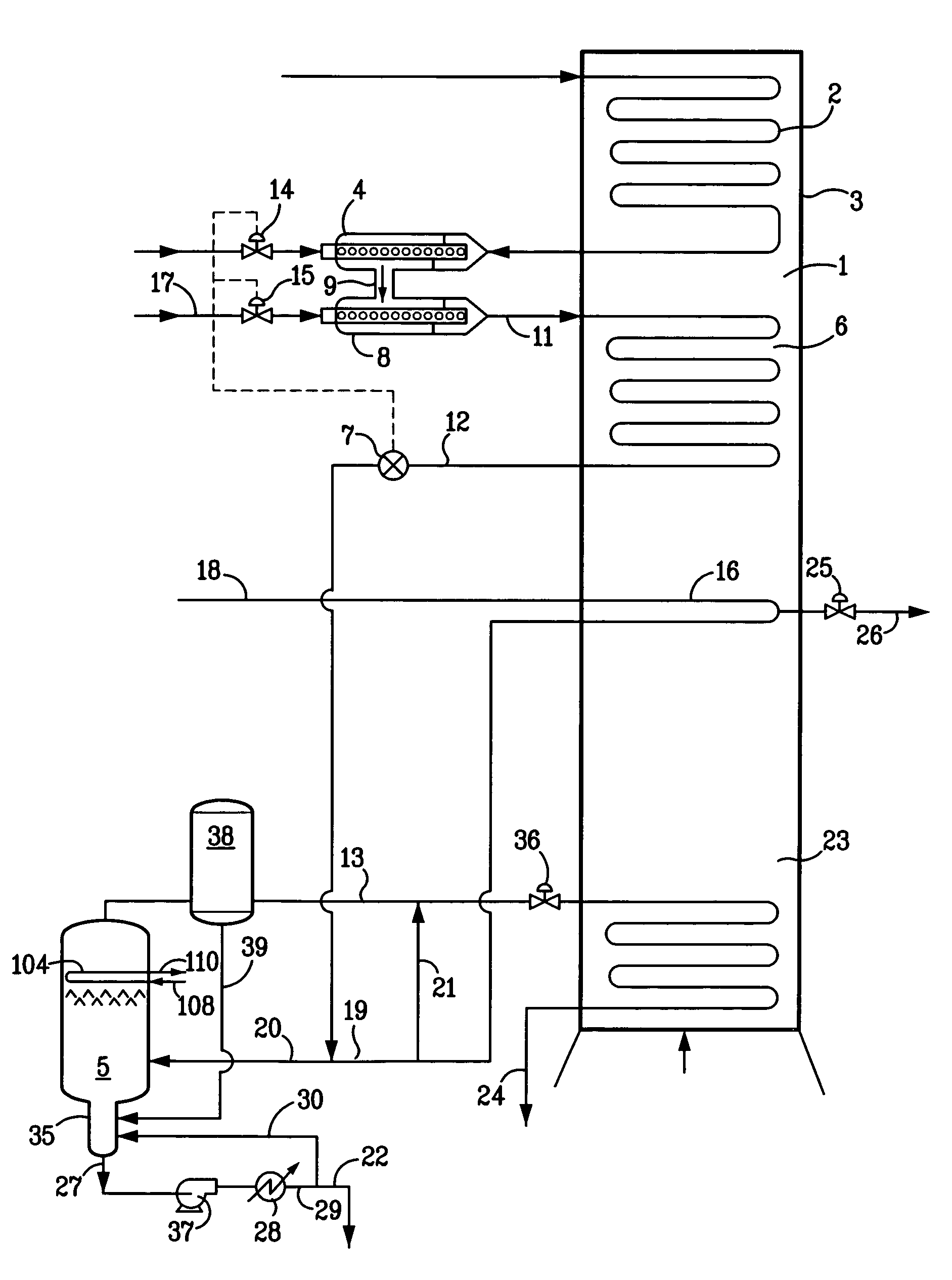

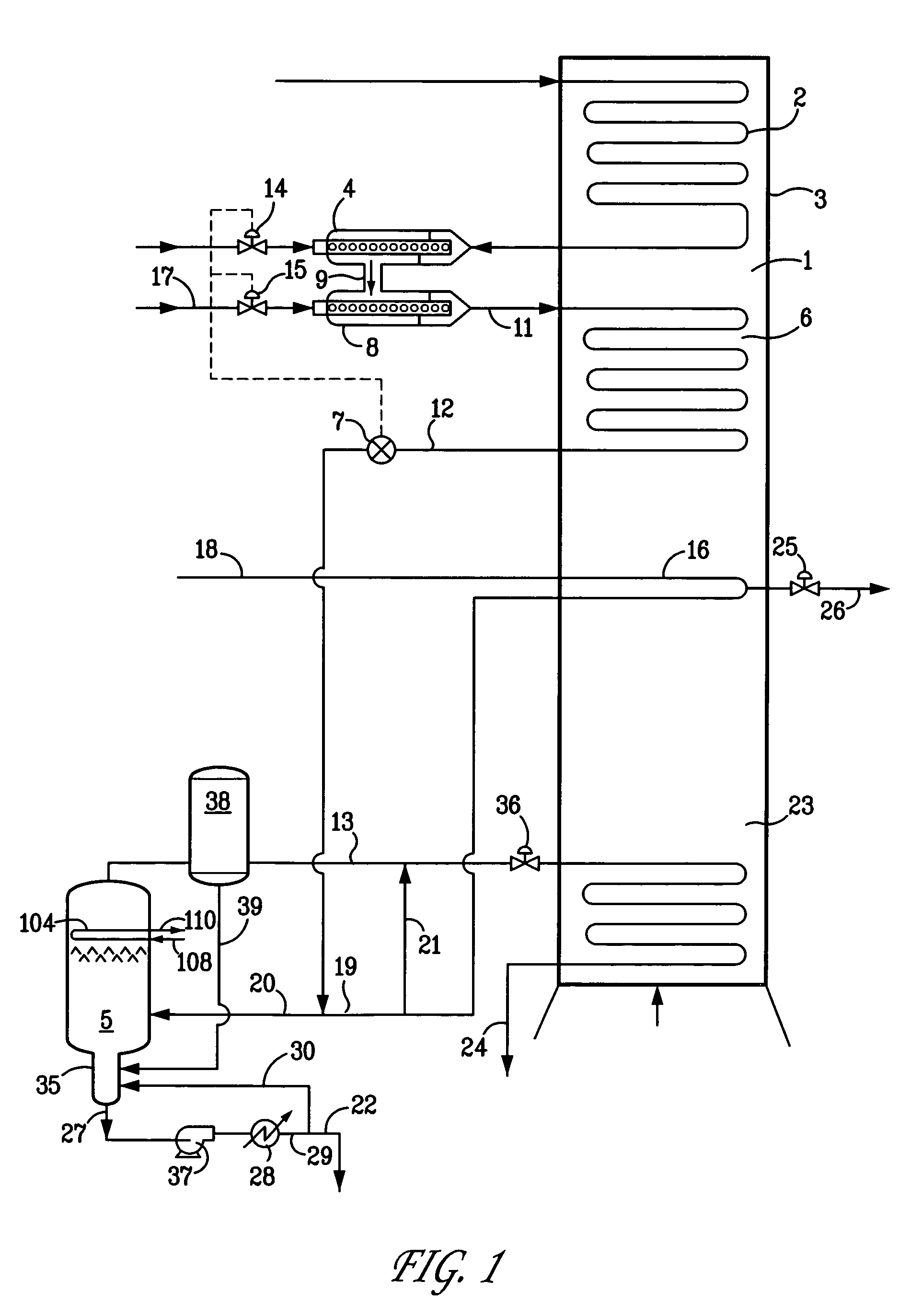

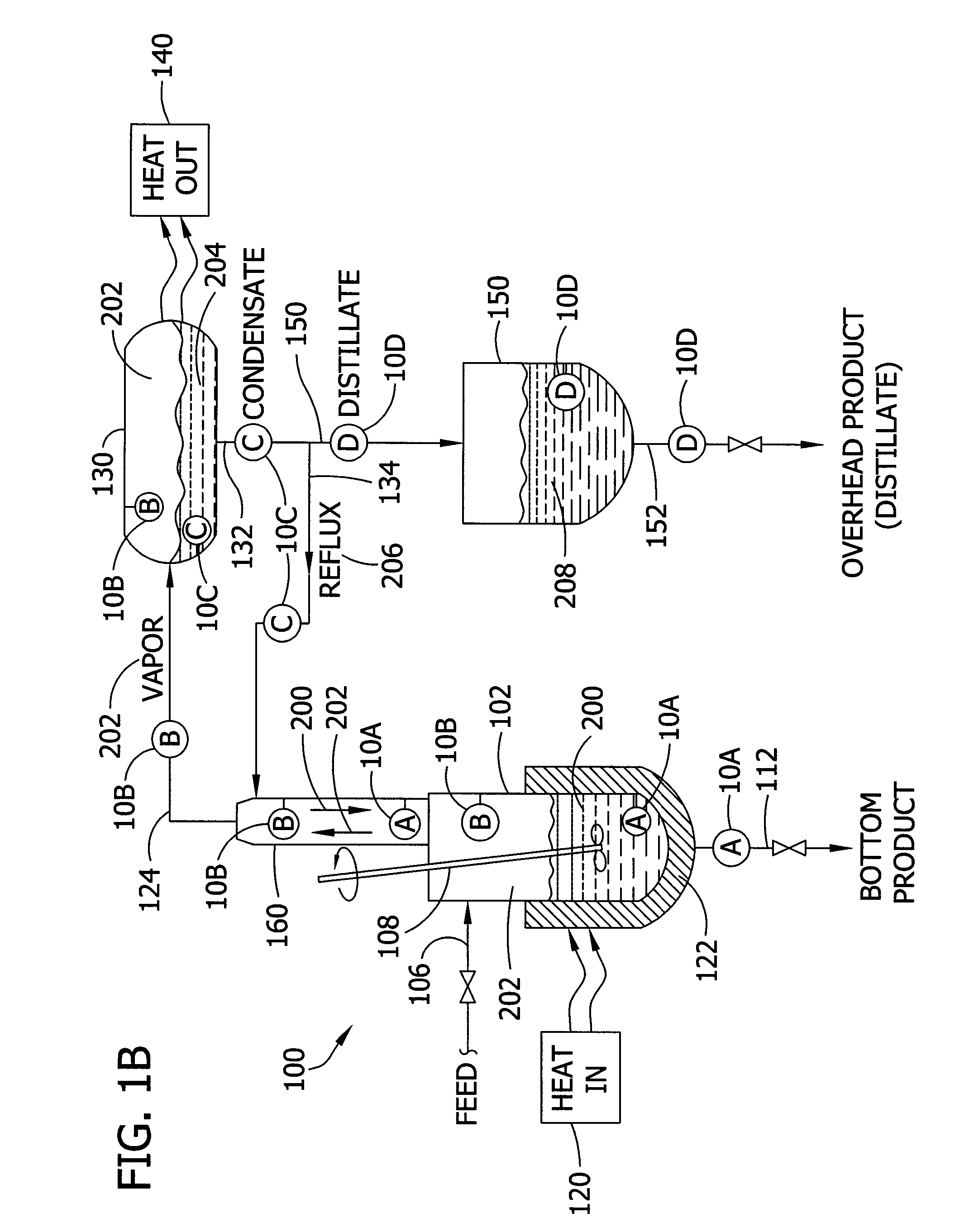

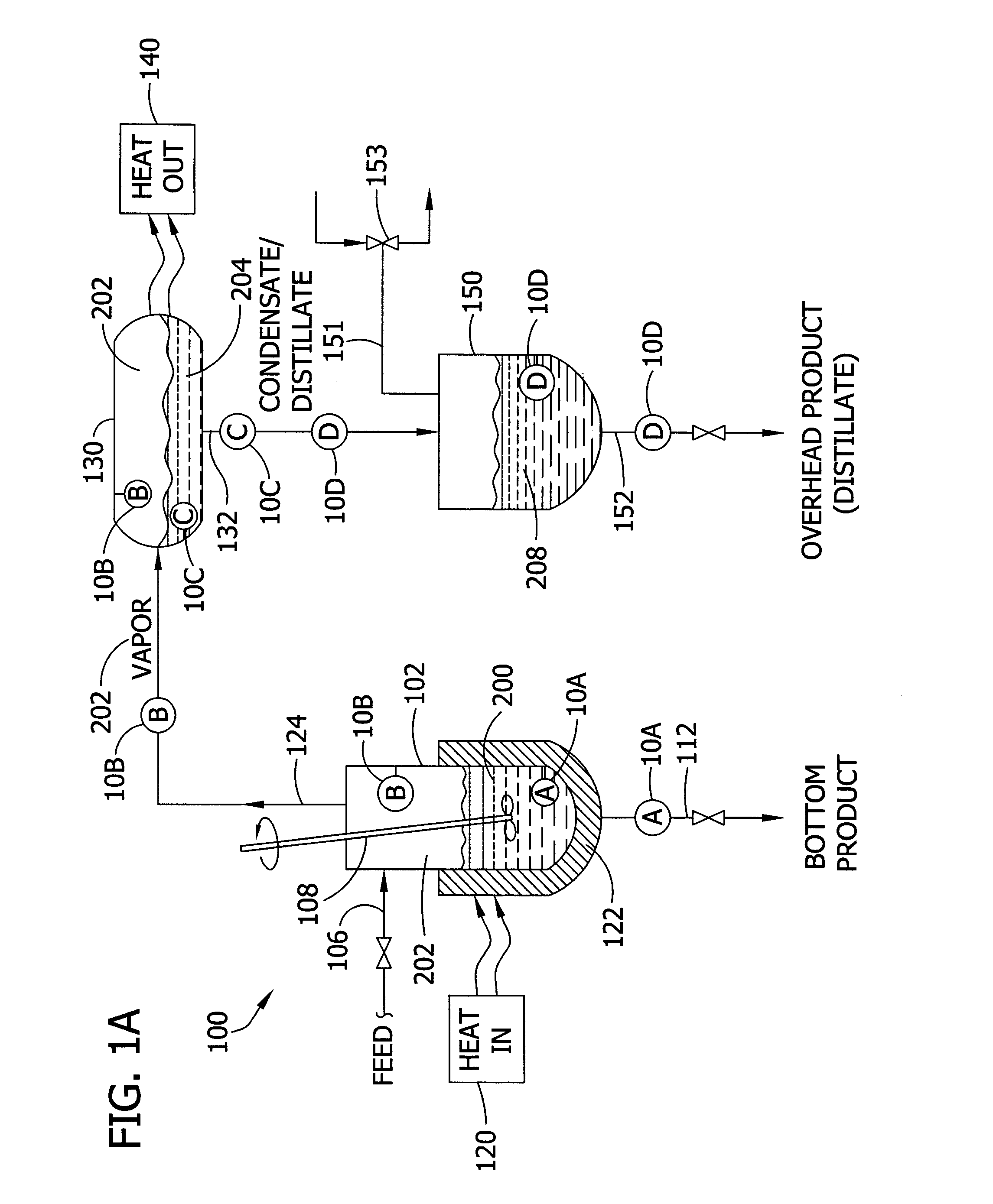

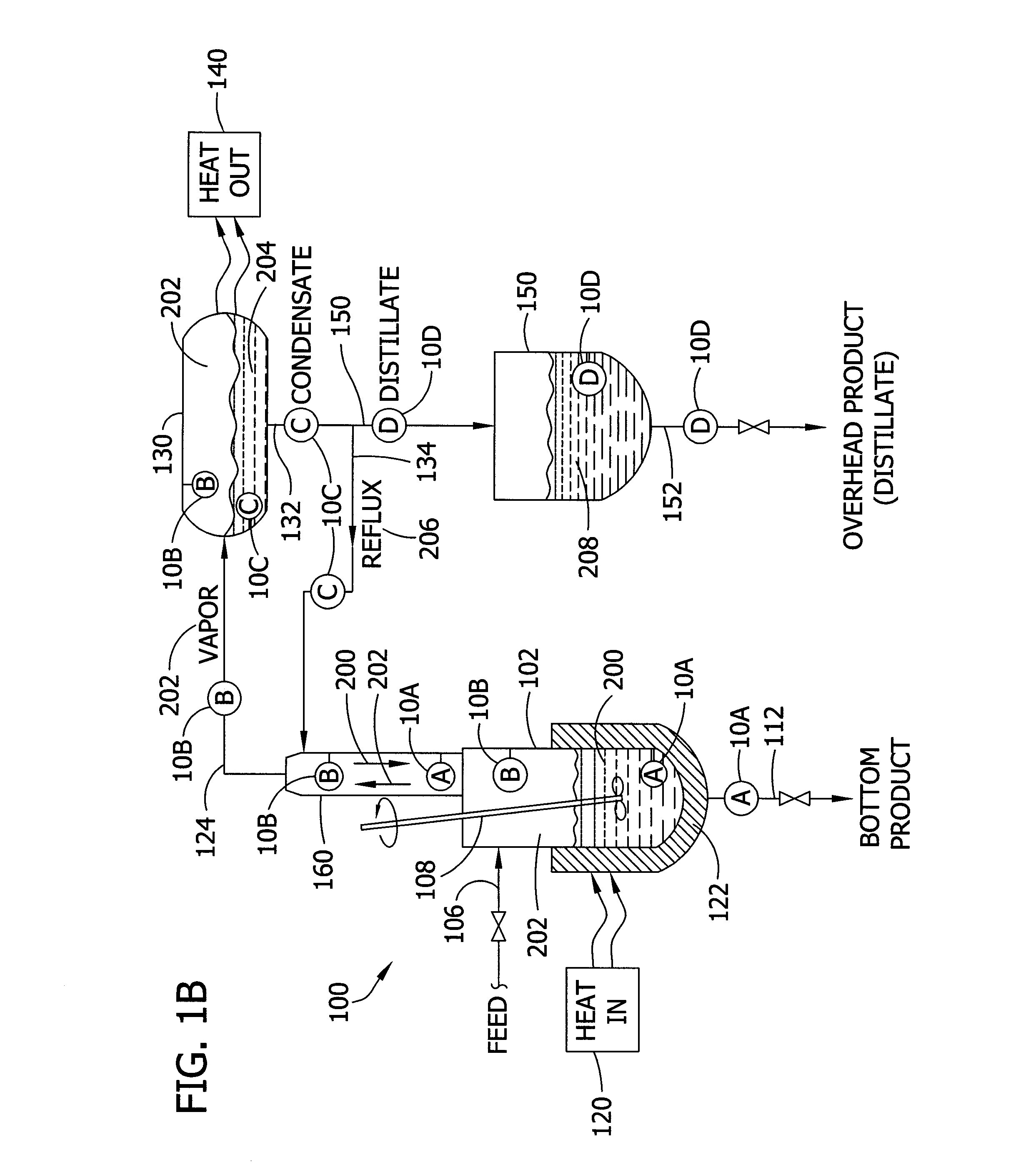

Cracking hydrocarbon feedstock containing resid utilizing partial condensation of vapor phase from vapor/liquid separation to mitigate fouling in a flash/separation vessel

A process is provided for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, optionally further heating the mixture, flashing the mixture within a flash / separation vessel to form a vapor phase and a liquid phase, partially condensing the vapor phase by contacting with a condenser within the vessel, to condense at least some coke precursors within the vapor while providing condensates which add to the liquid phase, removing the vapor phase of reduced coke precursors content as overhead and the liquid phase as bottoms, heating the vapor phase, cracking the vapor phase in a radiant section of a pyrolysis furnace to produce an effluent comprising olefins, and quenching the effluent and recovering cracked product therefrom. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

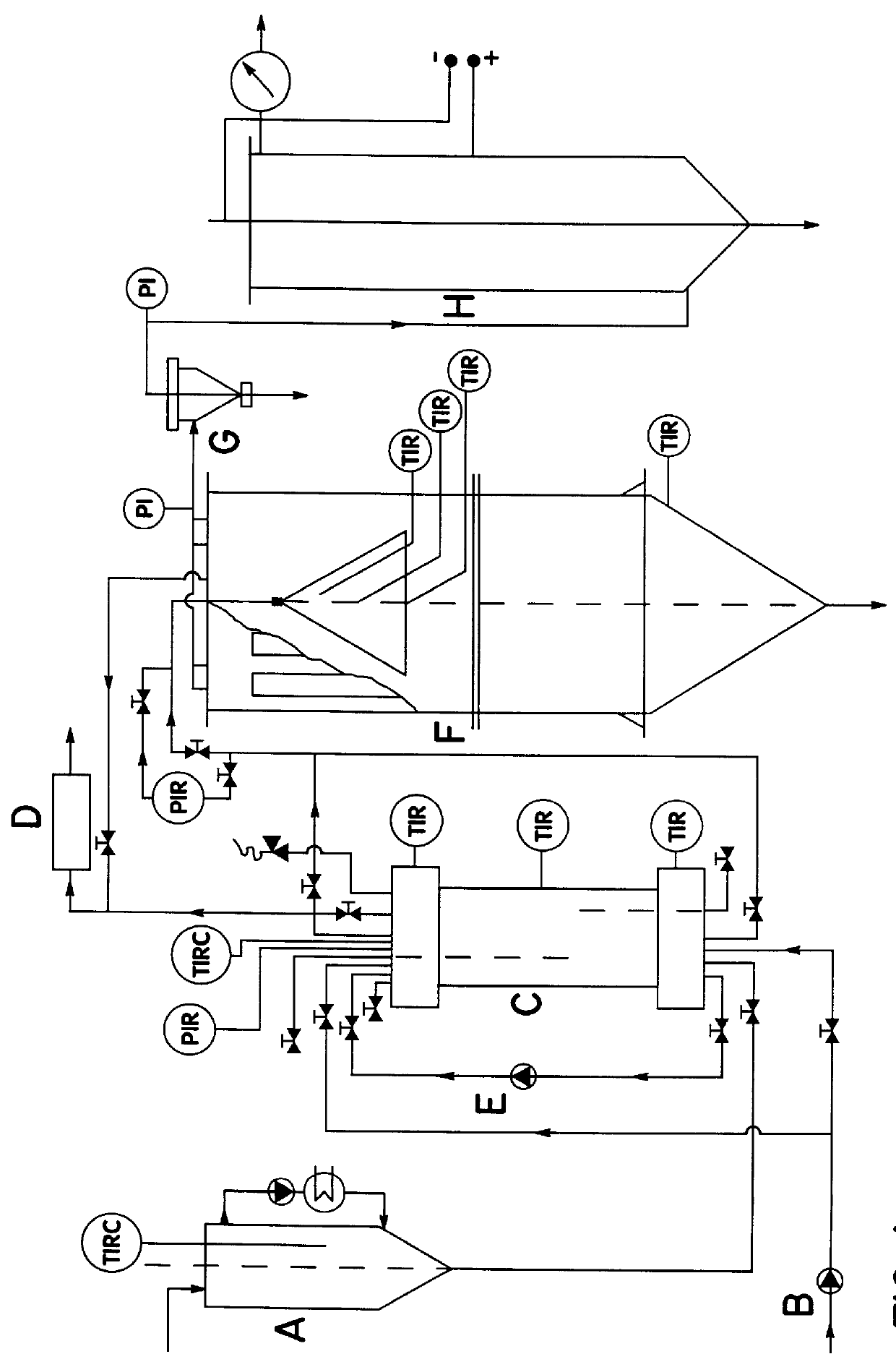

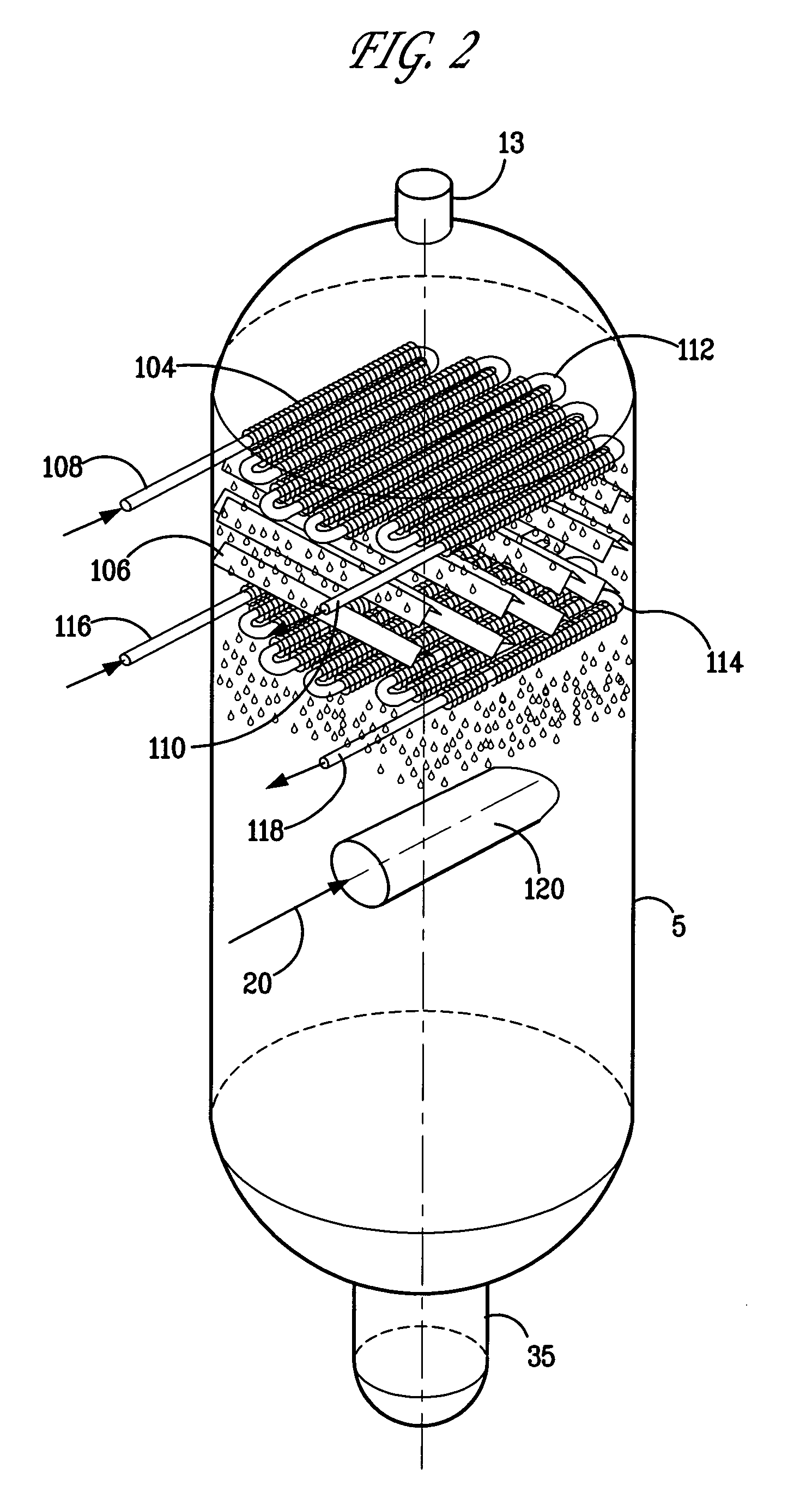

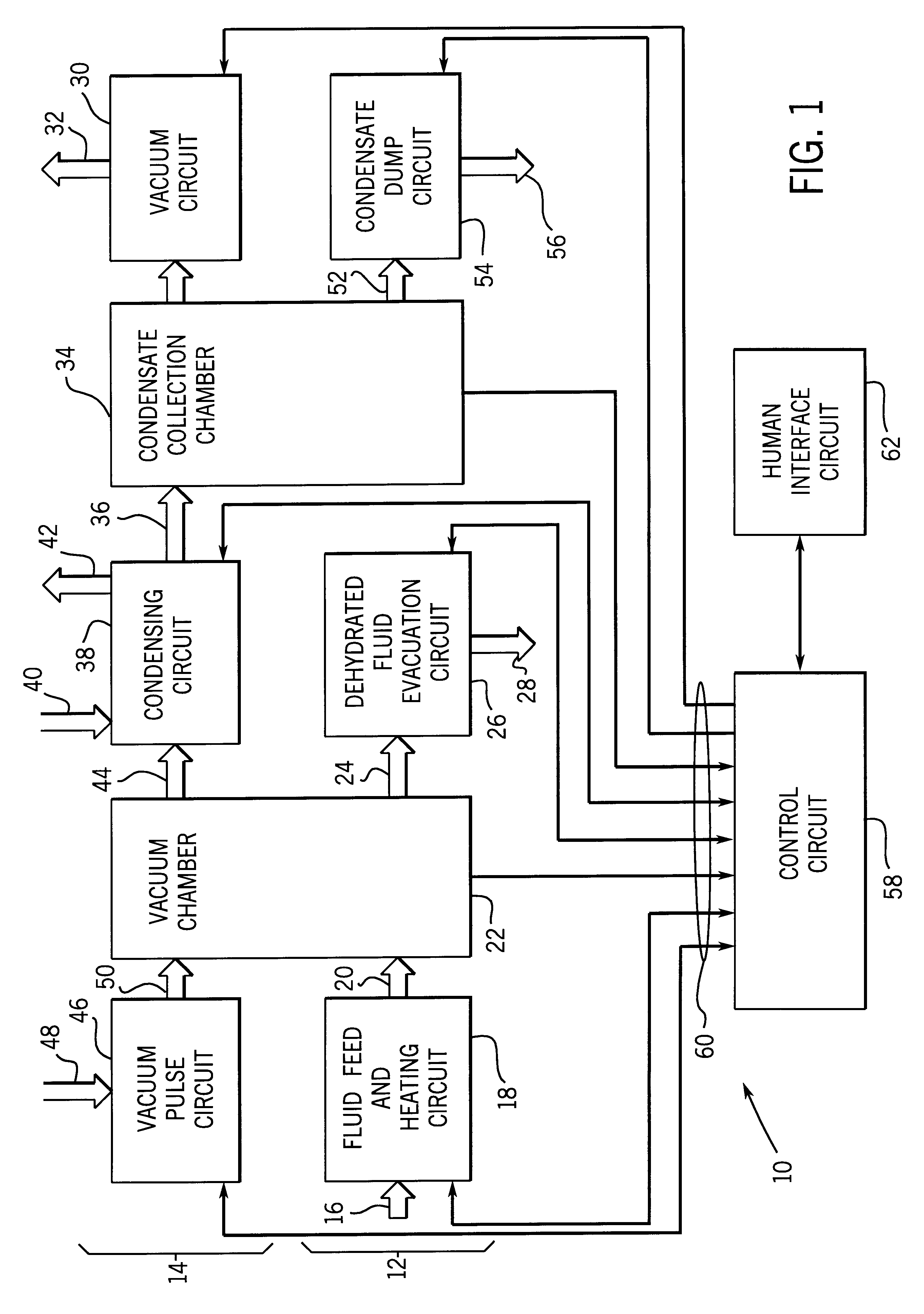

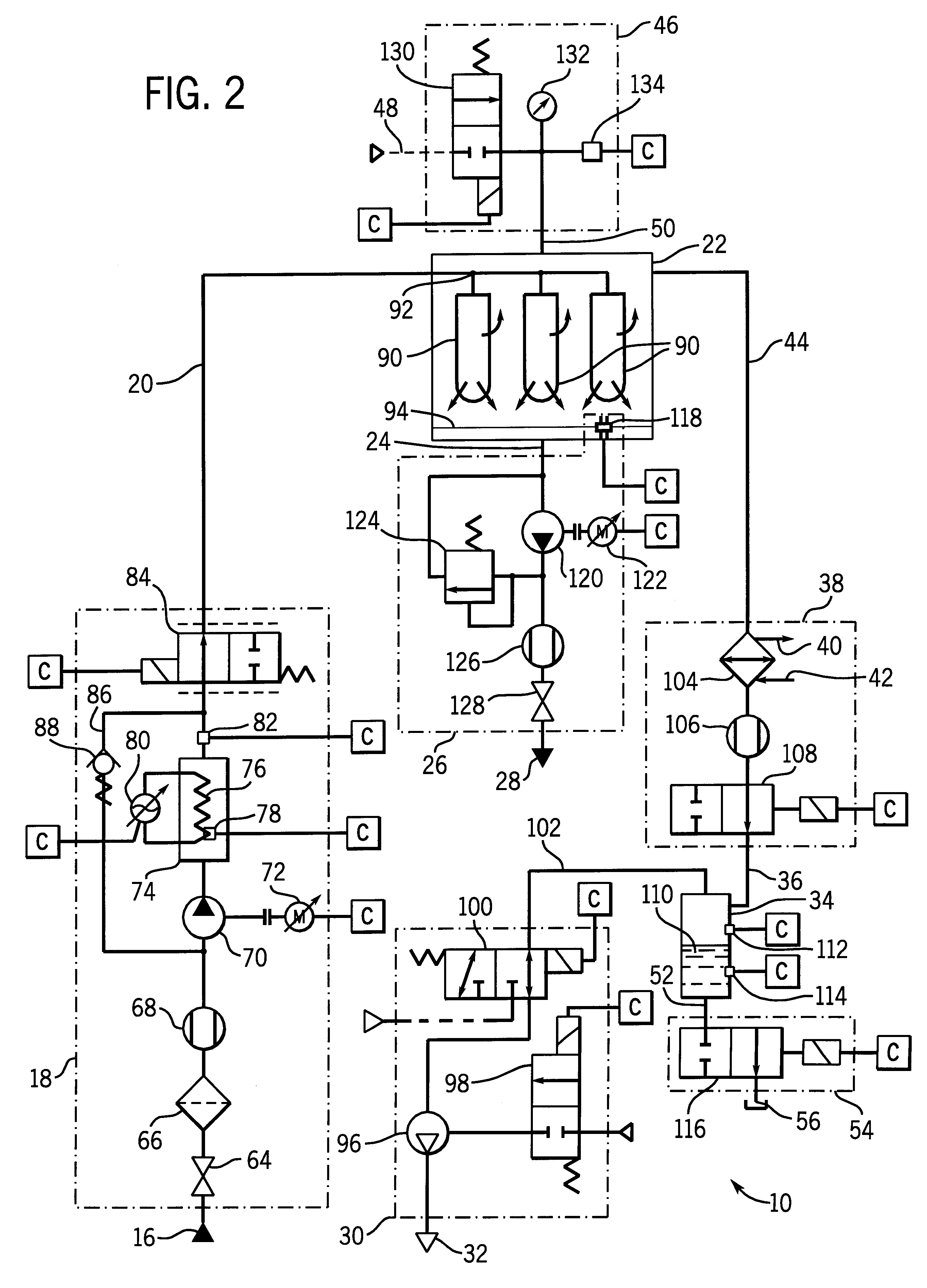

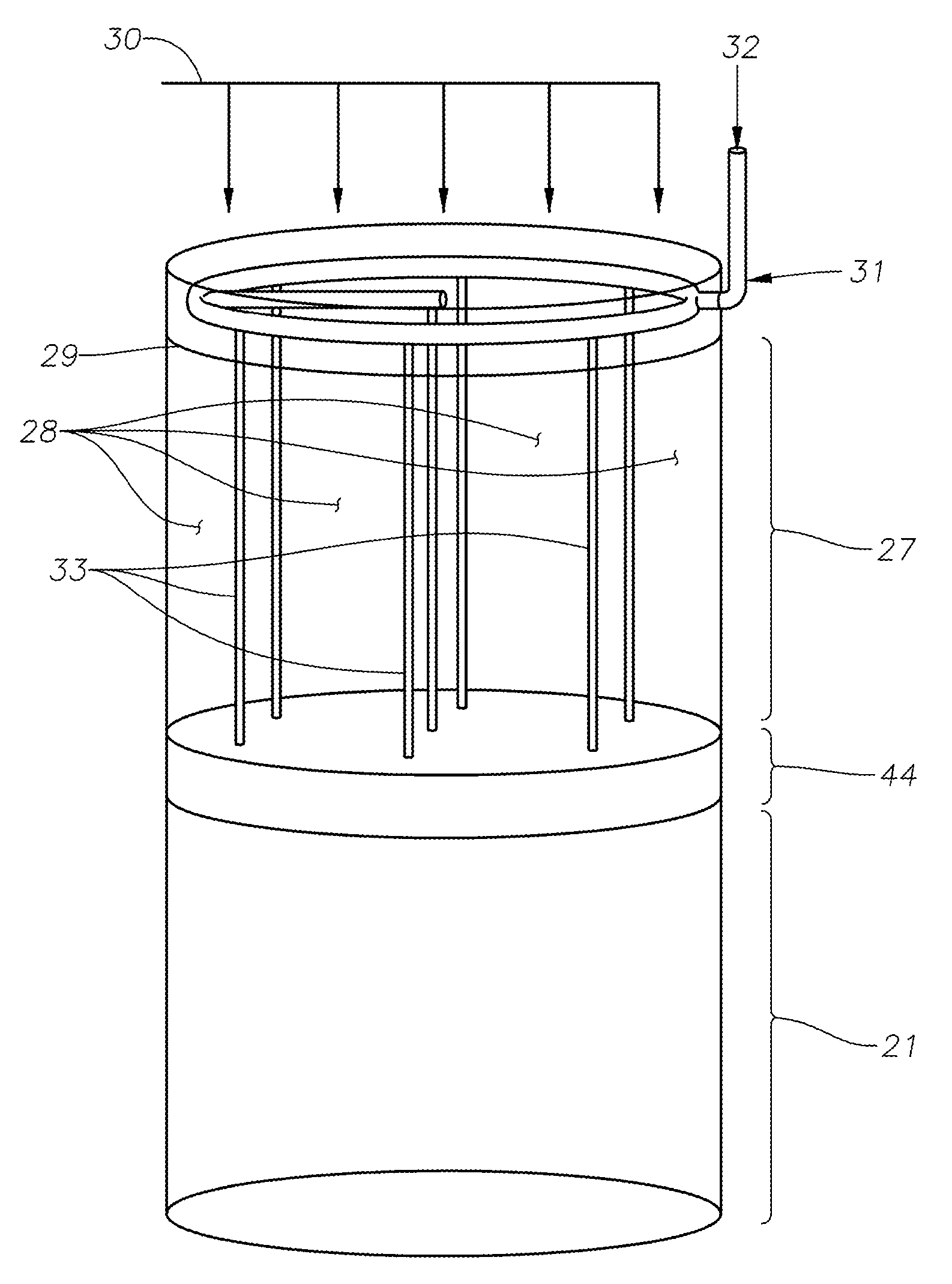

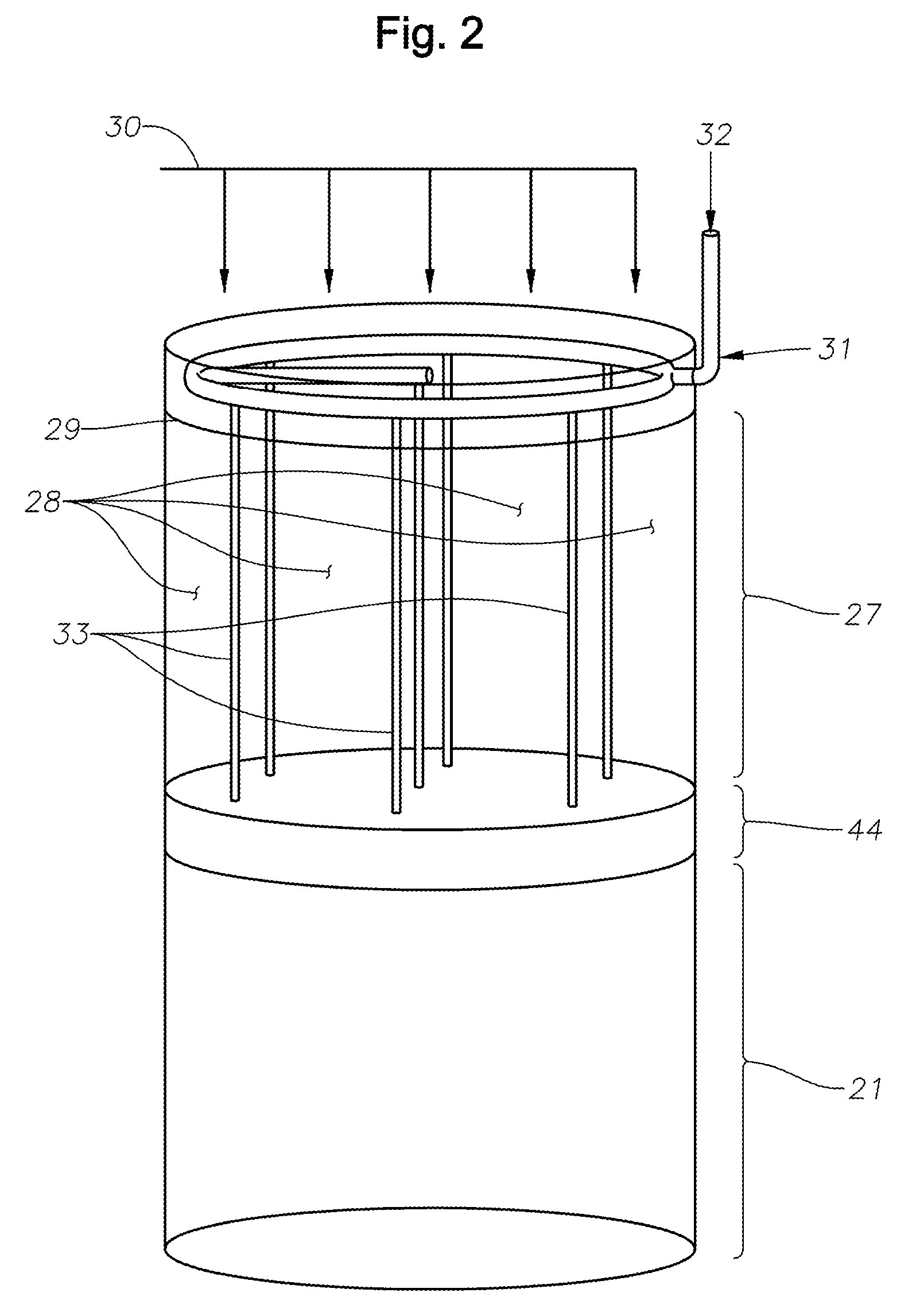

Apparatus for dehydrating oil

InactiveUS6224716B1Distillation regulation/controlEvaporation with vapour compressionVacuum pressureClosed loop

A system for dehydrating lubricating and hydraulic fluids includes a heating circuit and circuitry for creating a vacuum. The heating circuitry introduces a stream of heated fluid into a vacuum chamber in which a partial vacuum is drawn by the vacuum circuit. Aqueous components of the fluid stream are flashed in the vacuum chamber by virtue of the elevated temperature and reduced pressure. Dehydrated fluid is then collected and evacuated from the vacuum chamber. Vapor from the vacuum chamber, including the aqueous components of the fluid stream are collected, condensed and separately evacuated. The heating circuit limits surface temperature of a heating element in a closed-loop manner to avoid degradation of the fluid. The fluid stream is introduced into the vacuum chamber or is recirculated through the heating circuit to maintain a desired level of fluid temperature in a closed-loop manner. The system includes circuits for evacuating dehydrated fluid in a closed-loop manner and for automatically discharging condensate. The technique avoids undesirable foaming of dehydrated fluid within the vacuum chamber. A vacuum pulsing circuit is provided for periodically pulsing vacuum pressure within the vacuum chamber to aid in flashing aqueous components from the heated fluid stream.

Owner:OILQUIP

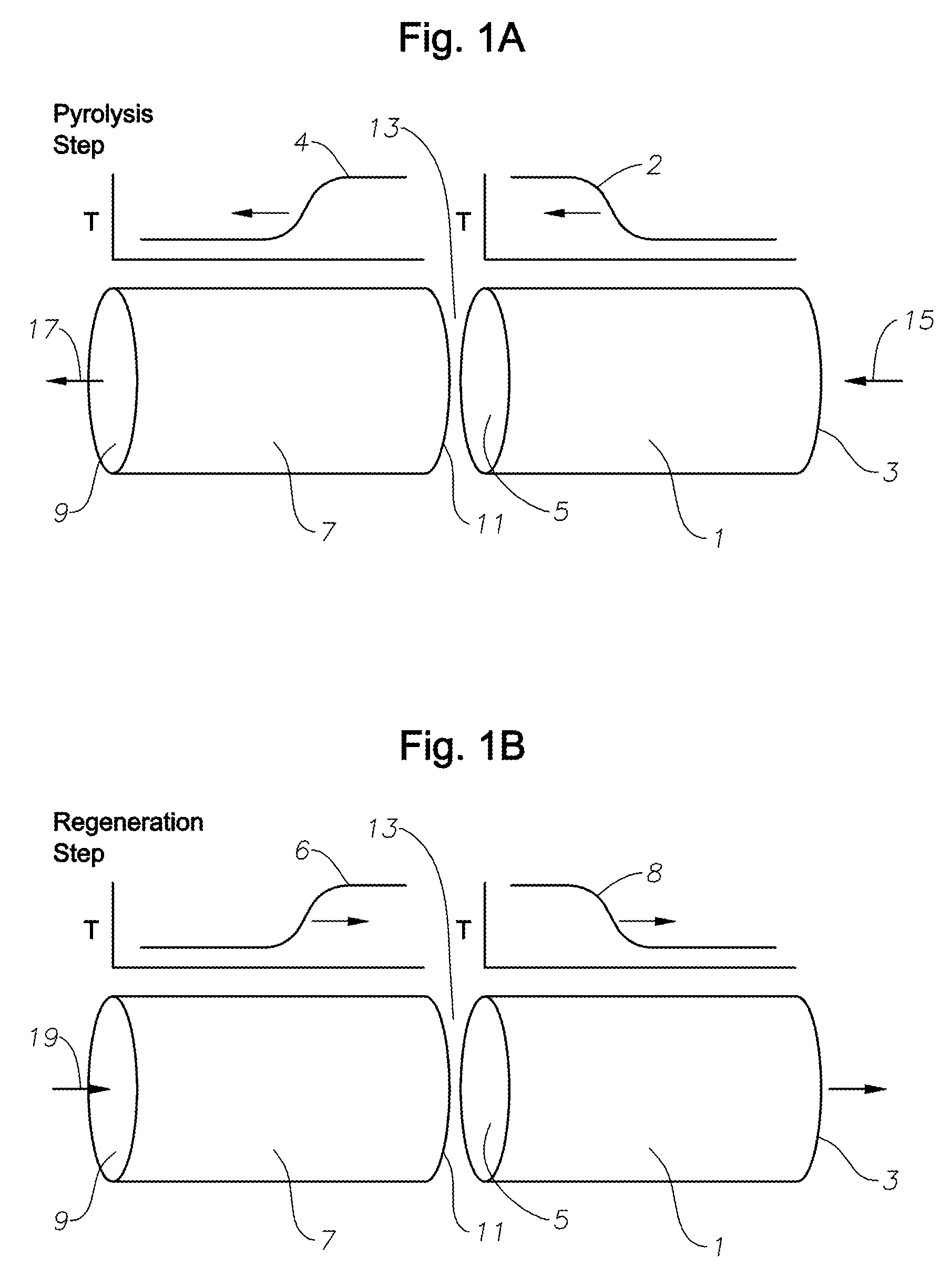

Pyrolysis reactor conversion of hydrocarbon feedstocks into higher value hydrocarbons

ActiveUS20090008292A1Thermal non-catalytic crackingCatalytic crackingReactor systemProcess engineering

In one aspect, the inventive process comprises a process for pyrolyzing a hydrocarbon feedstock containing nonvolatiles in a regenerative pyrolysis reactor system. The inventive process comprises: (a) heating the nonvolatile-containing hydrocarbon feedstock upstream of a regenerative pyrolysis reactor system to a temperature sufficient to form a vapor phase that is essentially free of nonvolatiles and a liquid phase containing the nonvolatiles; (b) separating said vapor phase from said liquid phase; (c) feeding the separated vapor phase to the pyrolysis reactor system; and (d) converting the separated vapor phase in said pyrolysis reactor system to form a pyrolysis product.

Owner:EXXONMOBIL CHEM PAT INC

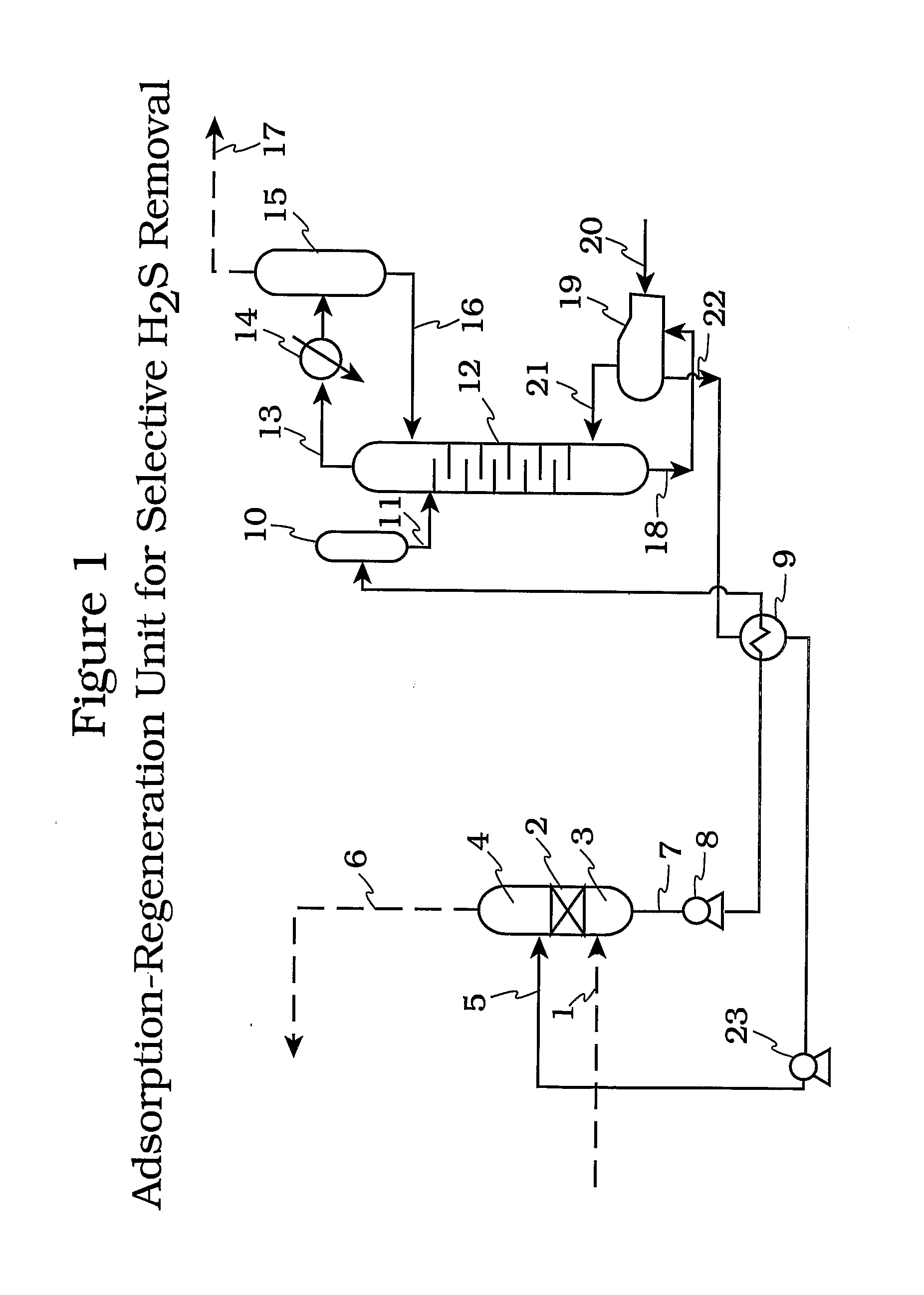

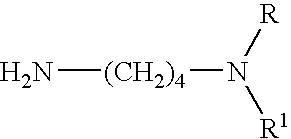

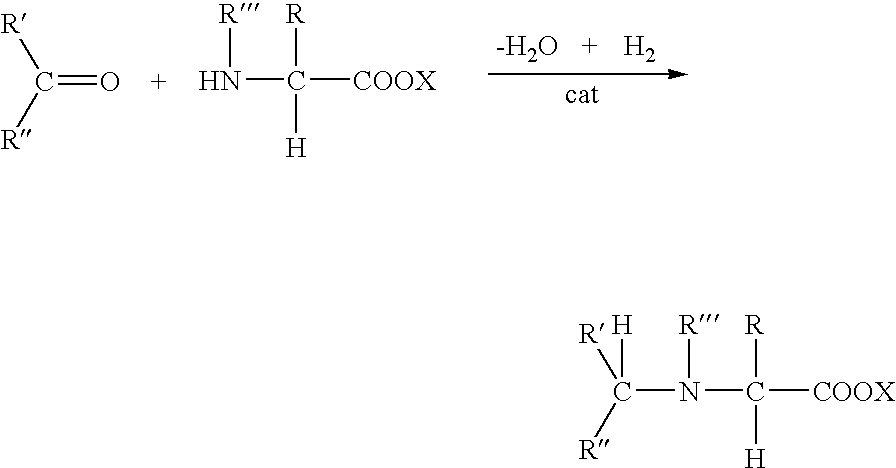

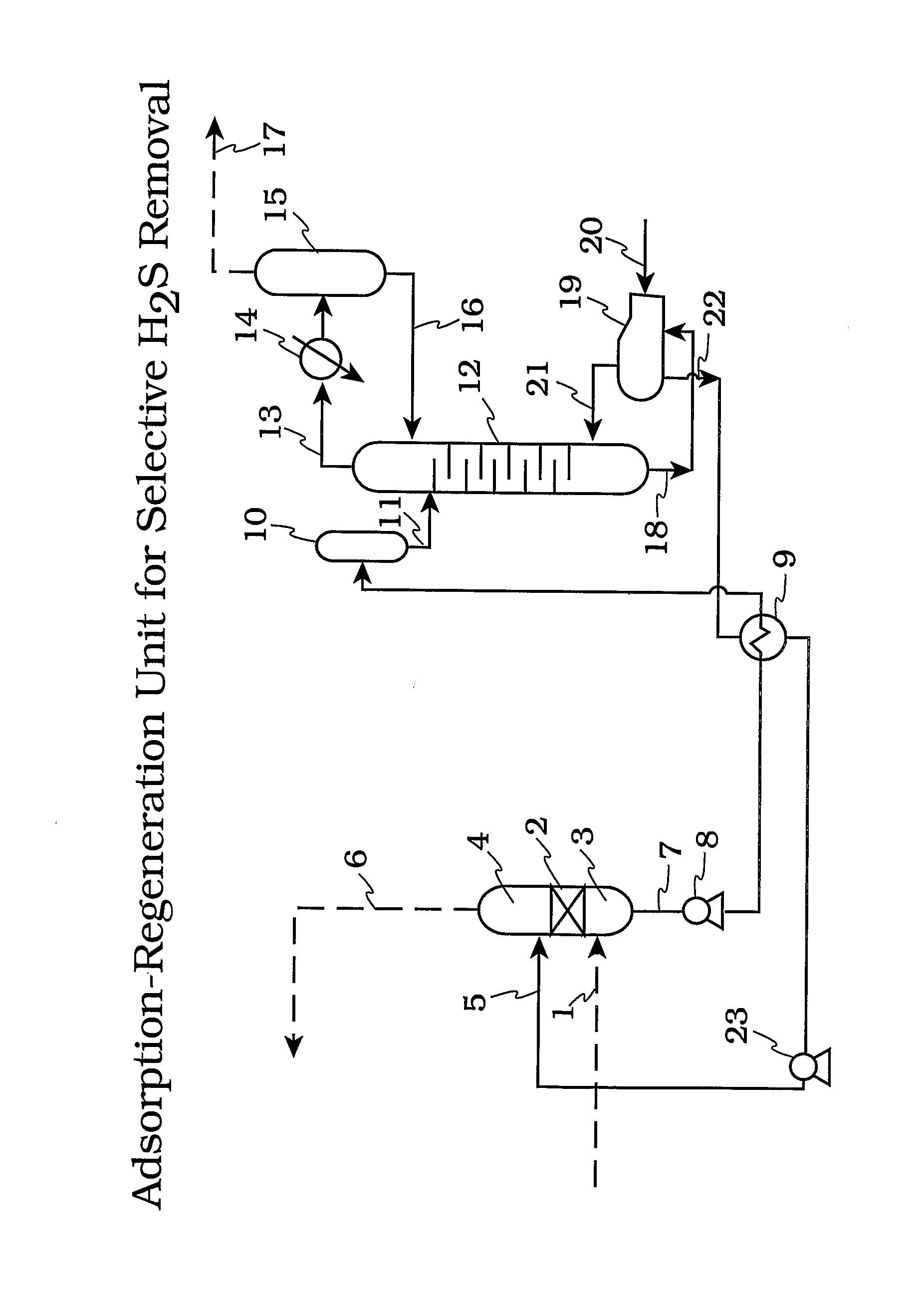

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

An acid gas absorbent comprising a metal sulfonate, phosphonate or carboxylate of a hindered amine and a process for the selective removal Of H2S as well as other acidic components such as carbon disulfide, carbonyl sulfide and oxygen and sulfur derivatives of C1 to C4 hydrocarbons from mixtures containing such acidic components and CO2 using said absorbent.

Owner:EXXON RES & ENG CO

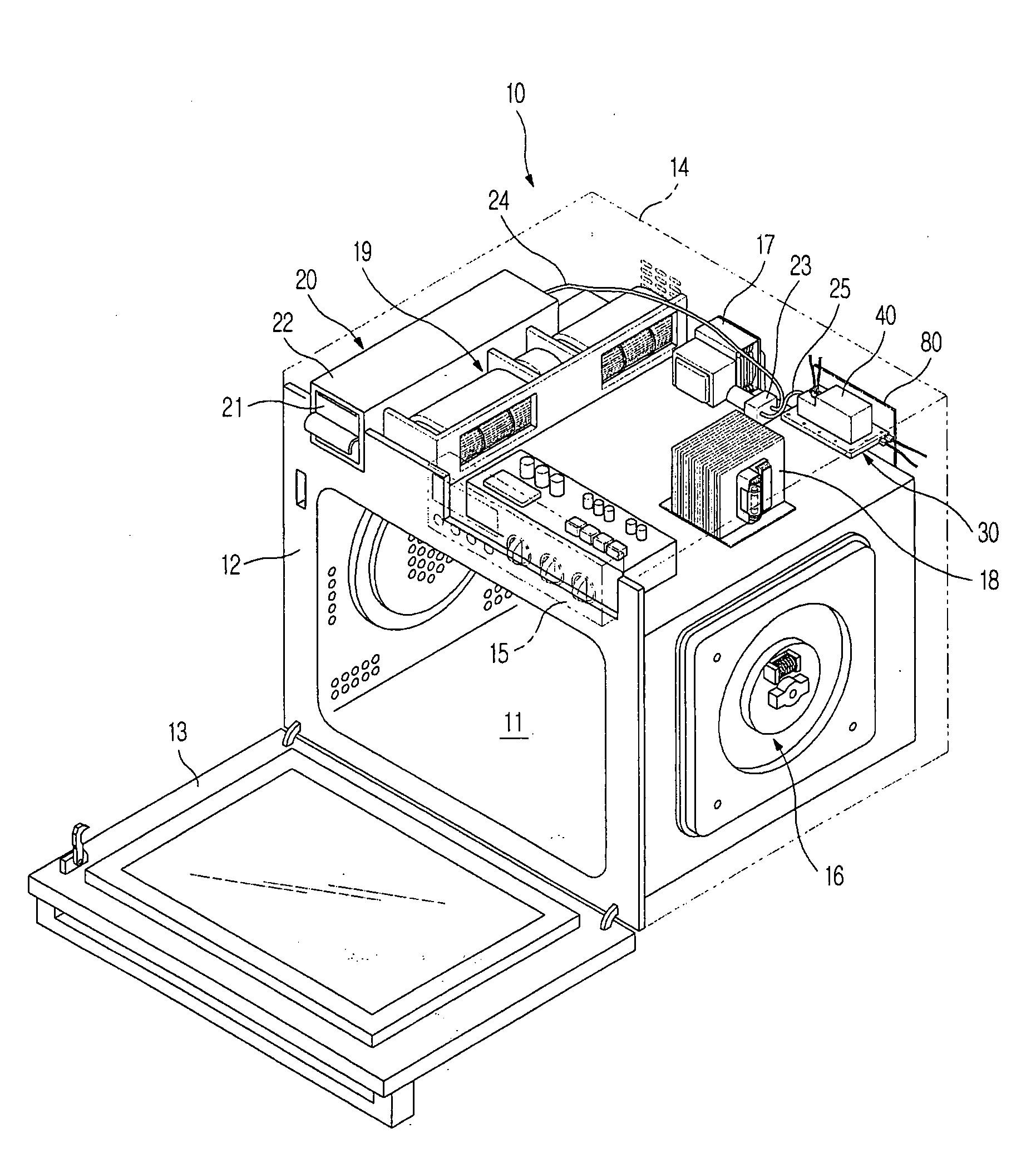

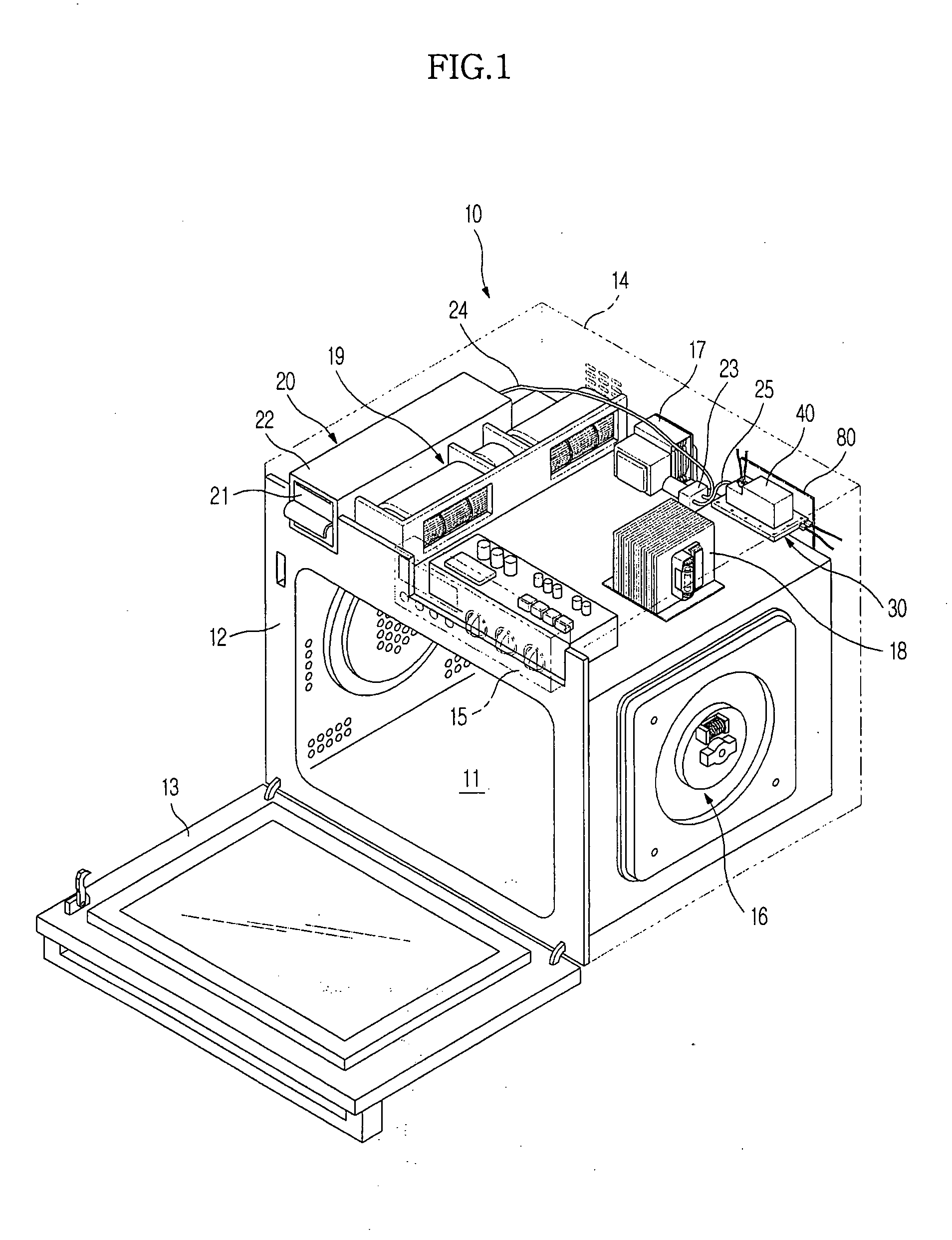

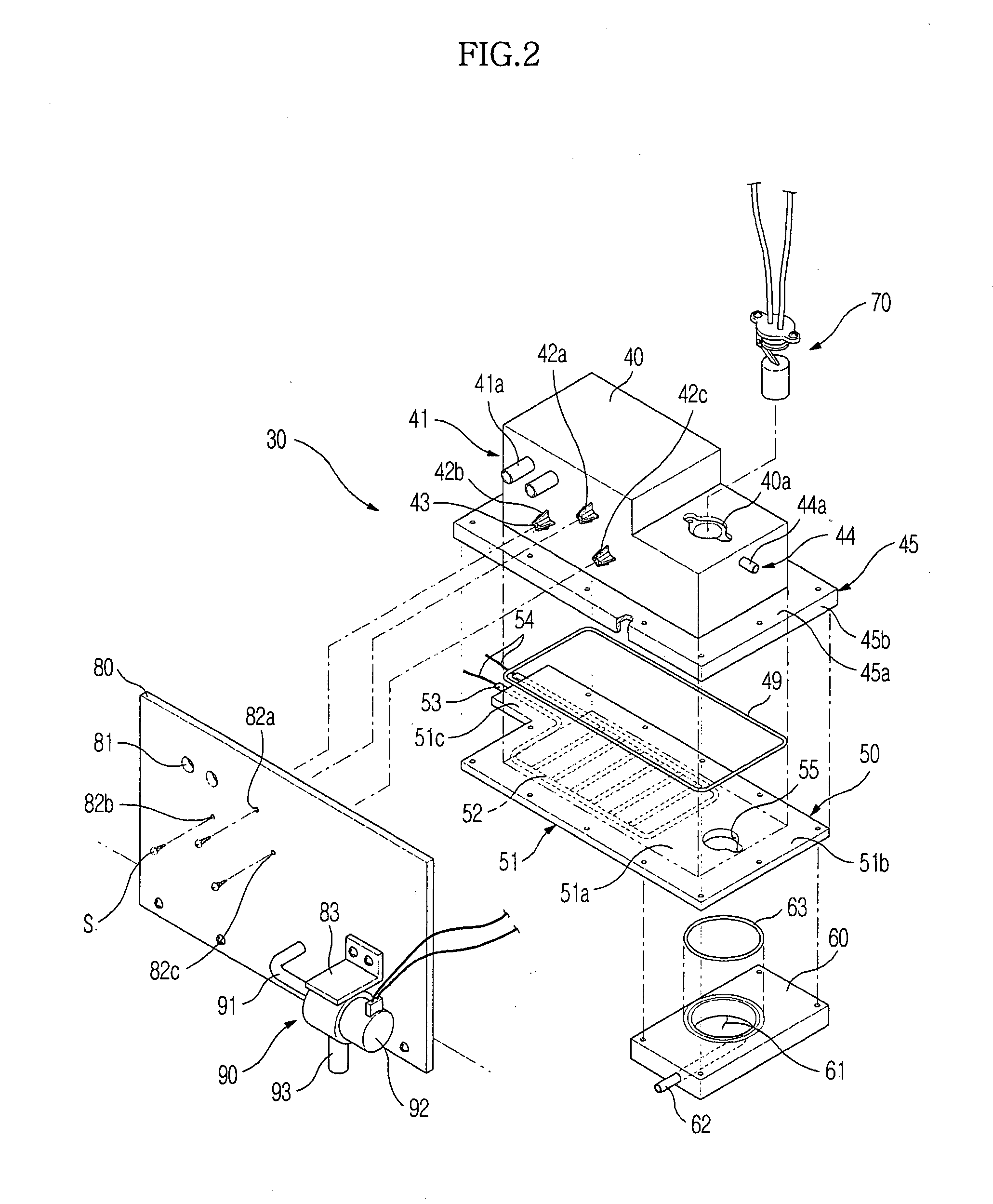

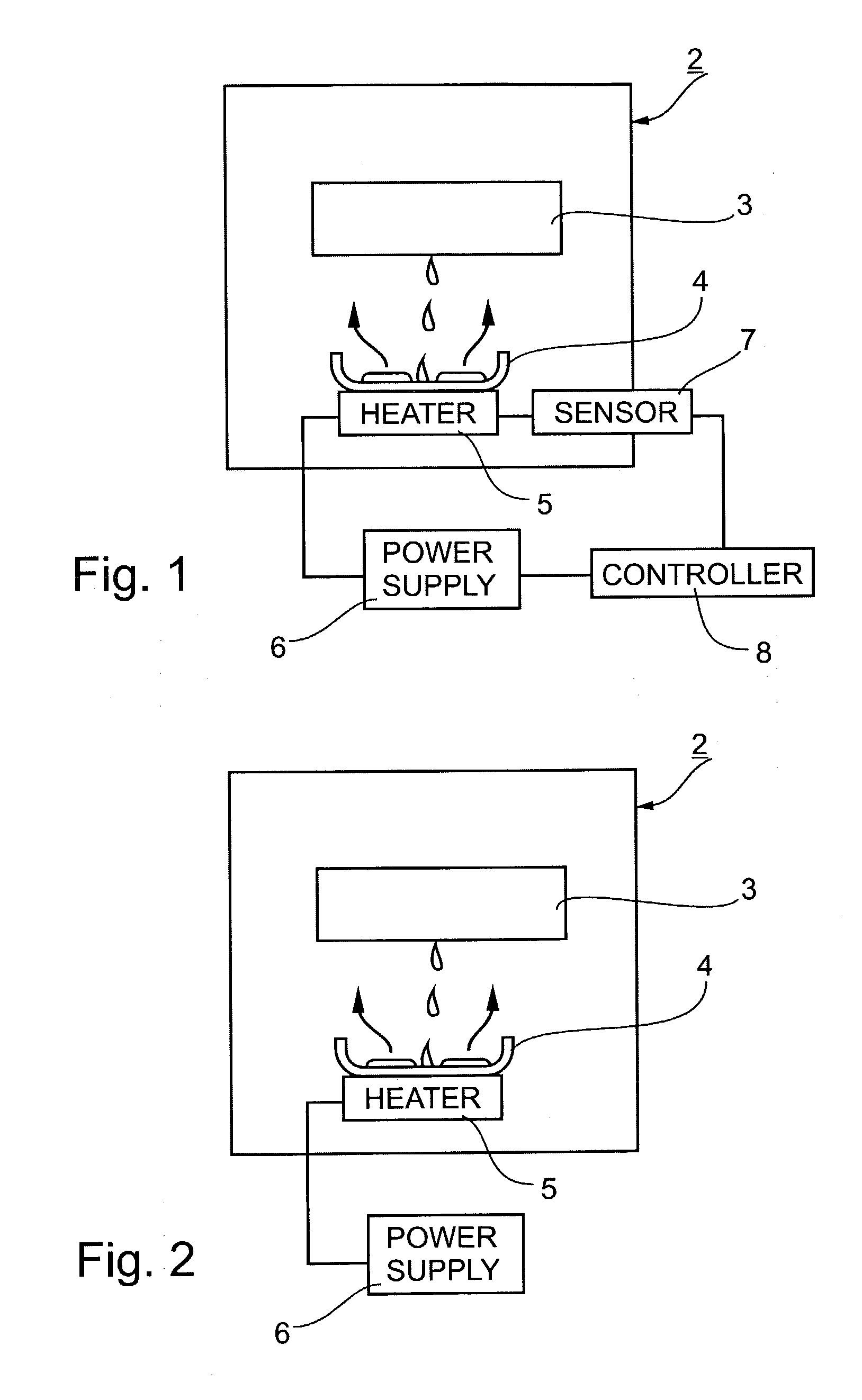

Steam generator and heating cooking apparatus having the same

A heating cooking apparatus including a body, a steam container, a steam heater, and a heater covering portion. The body has a cooking compartment in which food is disposed. The steam container includes a chamber, a water supply portion to supply water into the chamber, and a steam discharge portion to discharge steam generated in the chamber into the cooking compartment. The steam heater has a chamber bottom forming portion that is coupled to a lower end of the steam container so as to cover a bottom of the chamber and adapted to heat water supplied into the chamber. The heater covering portion is configured to cover a rim of the steam heater. Covering the rim of the steam heater using the heater covering portion alleviates the risk of power leakage accidents caused when water at the outside of a steam generator comes into contact with the steam heater.

Owner:SAMSUNG ELECTRONICS CO LTD

Liquid heating method and apparatus particularly useful for vaporizing a liquid condensate from cooling devices

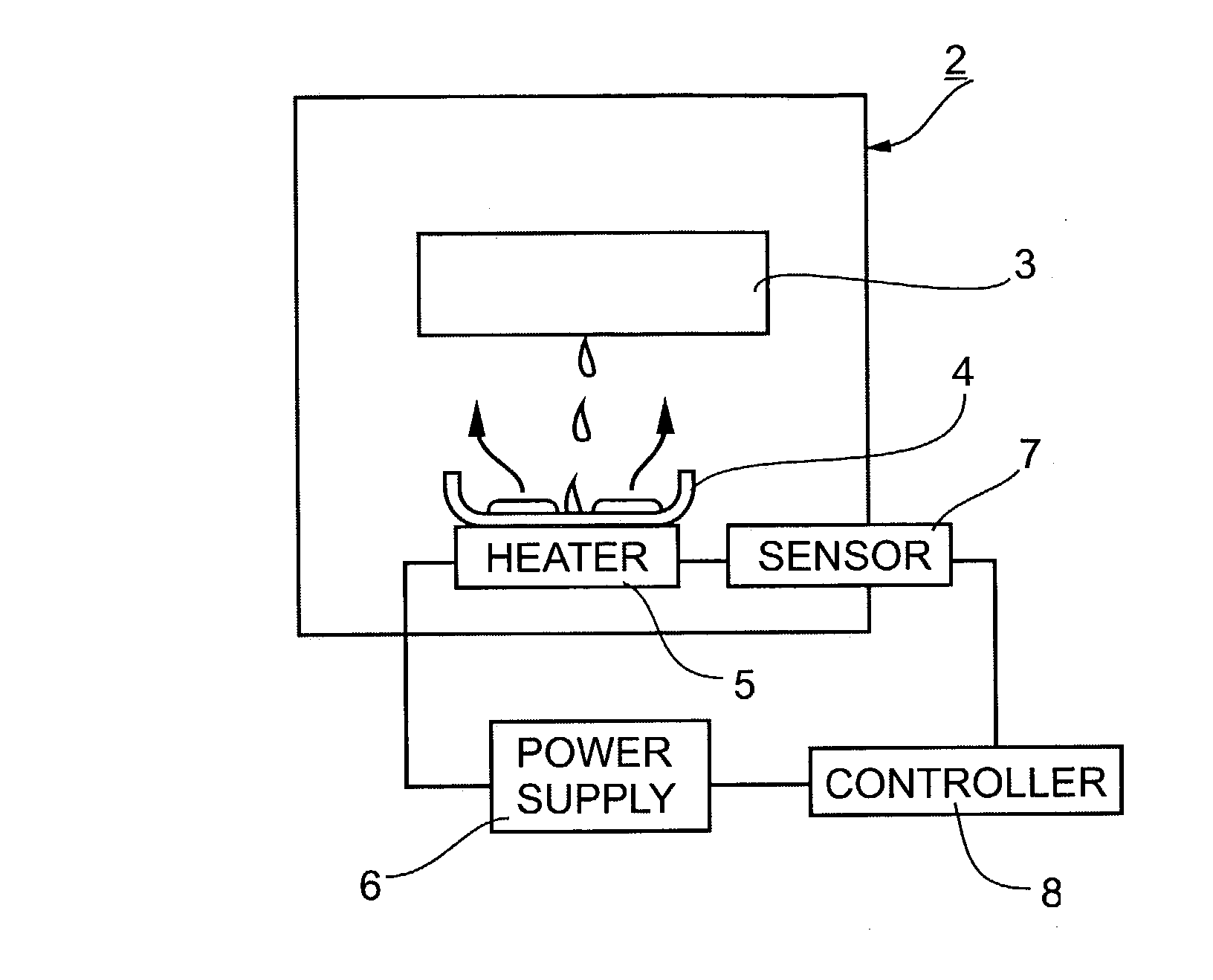

InactiveUS20030206730A1Minimize power consumptionRule out the possibilitySpace heating and ventilationSteam cooking vesselsElectrical resistance and conductanceBoiling point

A method and heating device for heating a liquid, particularly useful for removing liquid condensate from cooling devices, by wetting a heating plate with the liquid and controlling the electrical power supply to maintain the heating plate at a the predetermined temperature above the boiling point of the liquid, such that when the heating plate is not wetted by the liquid, the electrical power supply to the heating plate is automatically maintained at a relatively low value, but as soon as the heating plate is wetted by the liquid, the electrical power supplied to the heating plate is automatically increased until the liquid is completely evaporated. The heating plate is heated by one or more PTC thermistors in which the electrical resistance increases with temperature to automatically maintain the predetermined temperature. Besides evaporating liquid condensate, the heating device is described for use in many other applications including steam generation, space heating and plastic molding.

Owner:A T C T ADVANCED THERMAL CHIP TECH

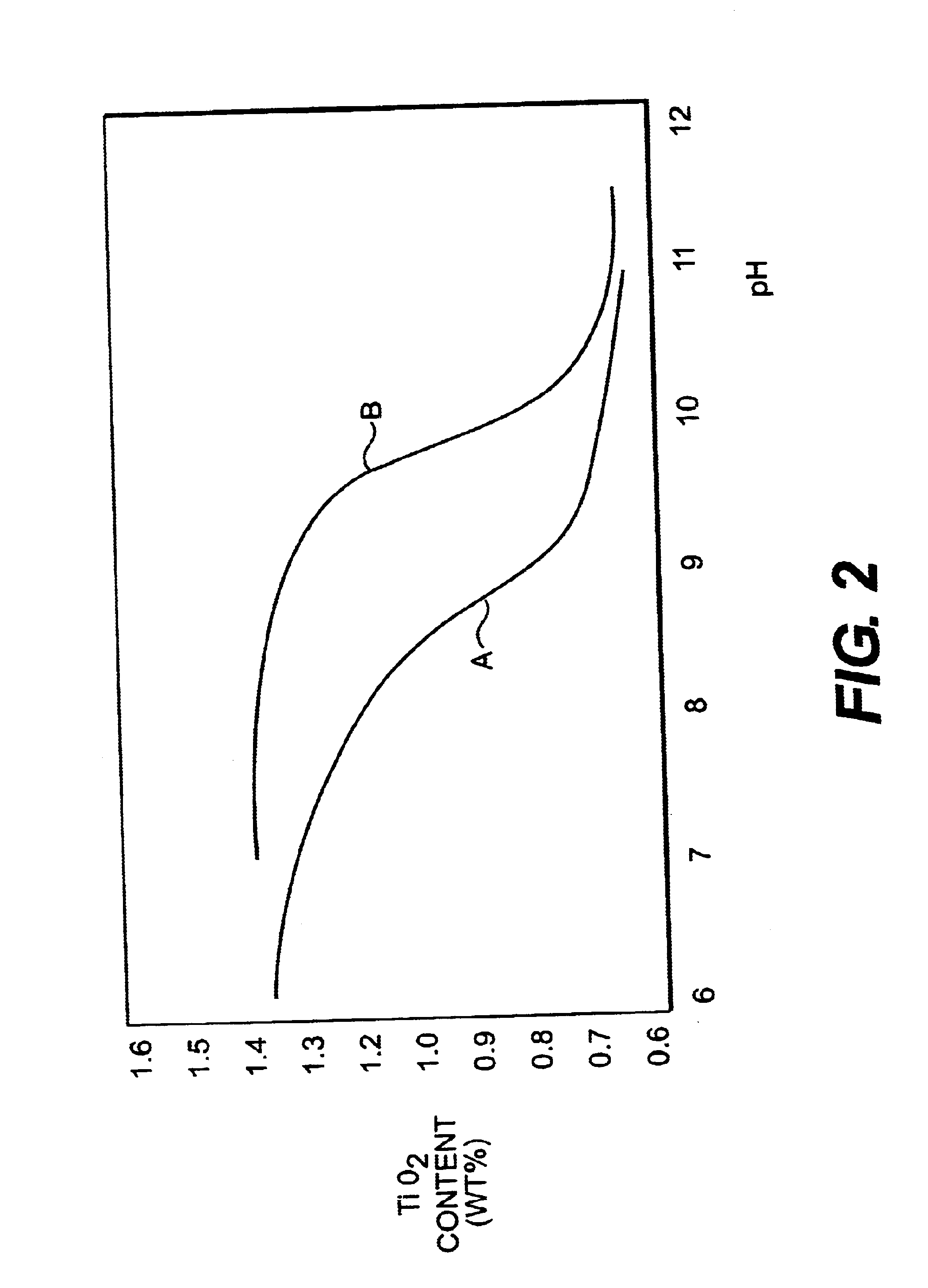

Method of treating an aqueous suspension of kaolin

InactiveUS6615987B1Improve effectivenessImproves floc formationPigmenting treatmentSedimentation separationFlocculationSolid particle

A method of treating a kaolin particulate material to improve its properties by removal of impurities which includes the steps of:(a) producing a dispersed aqueous suspension of a kaolin particulate material containing at least 0.1% by weight, based on the dry weight of the kaolin particulate material, of separable impurity by adding a dispersing agent to the kaolin particulate material to deflocculate solid particles of the material in the suspension;(b) conditioning the suspension prior to adding selective flocculation polymer thereto by allowing the suspension to age for a period of at least 30 minutes and optionally by adding one or more conditioning chemicals thereto;(c) adjusting the pH of the suspension to be at least about 9.5;(d) adding to the suspension at a pH of at least about 9.5 a selective flocculation polymer which facilitates separation of the separable impurity from the kaolin by flocculating the kaolin and allowing the separable impurity to be or remain deflocculated;(e) allowing the suspension at a pH of at least about 9.5 in a selective flocculation separator to separate into layers comprising a flocculated product layer and a deflocculated impurity layer containing the separable impurity; and(f) extracting the separated layers from the separator.

Owner:IMERYS USA INC

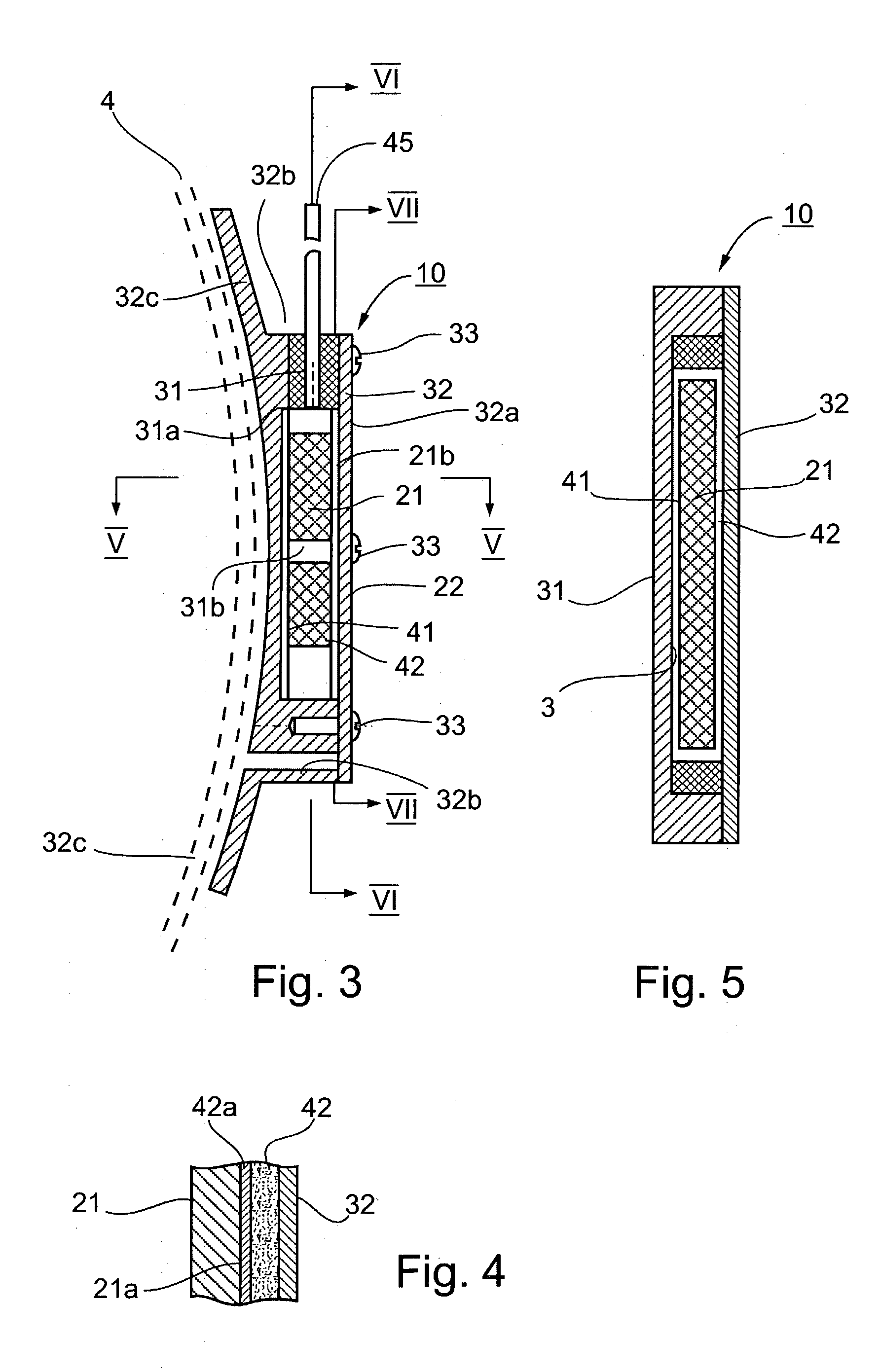

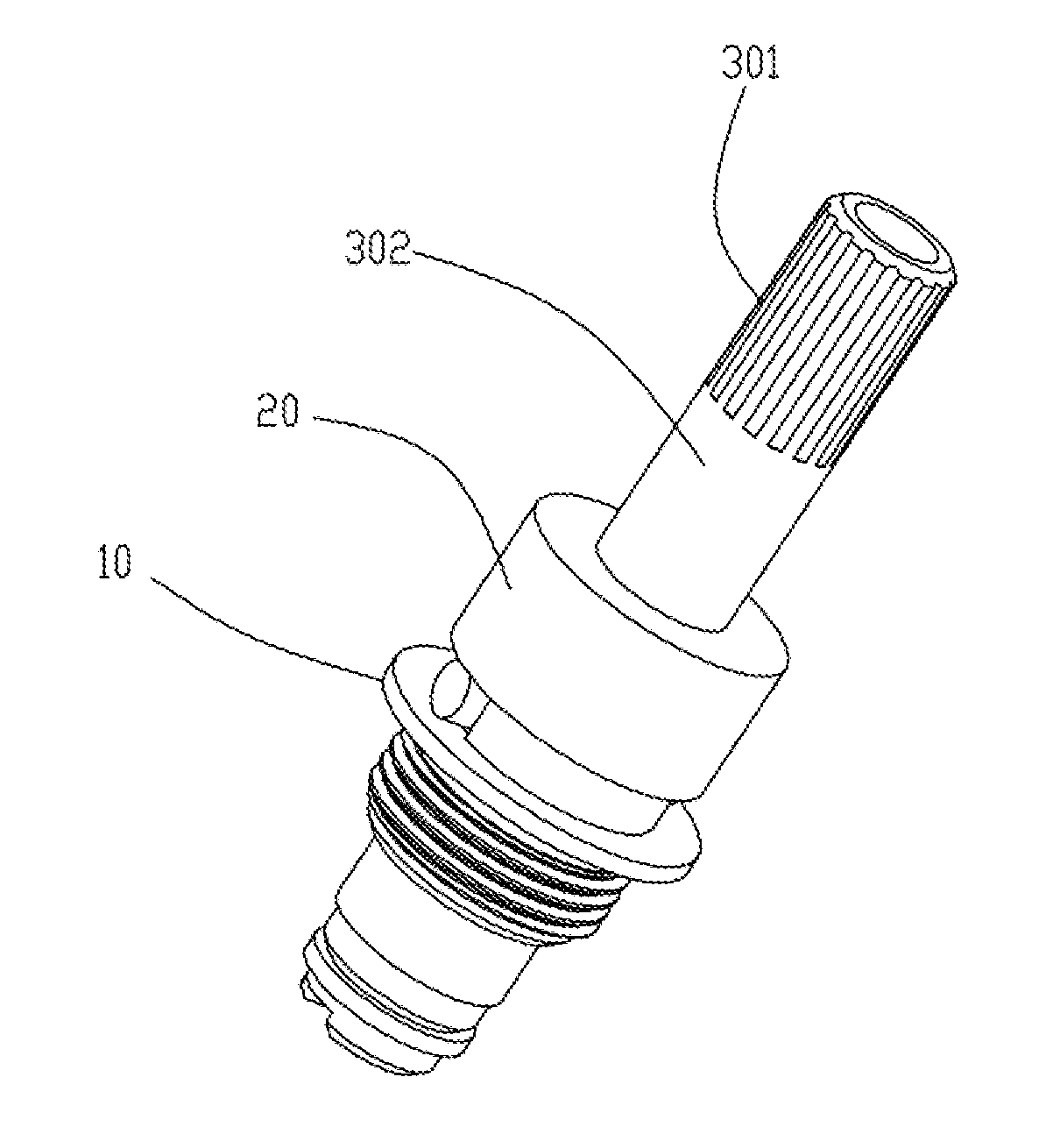

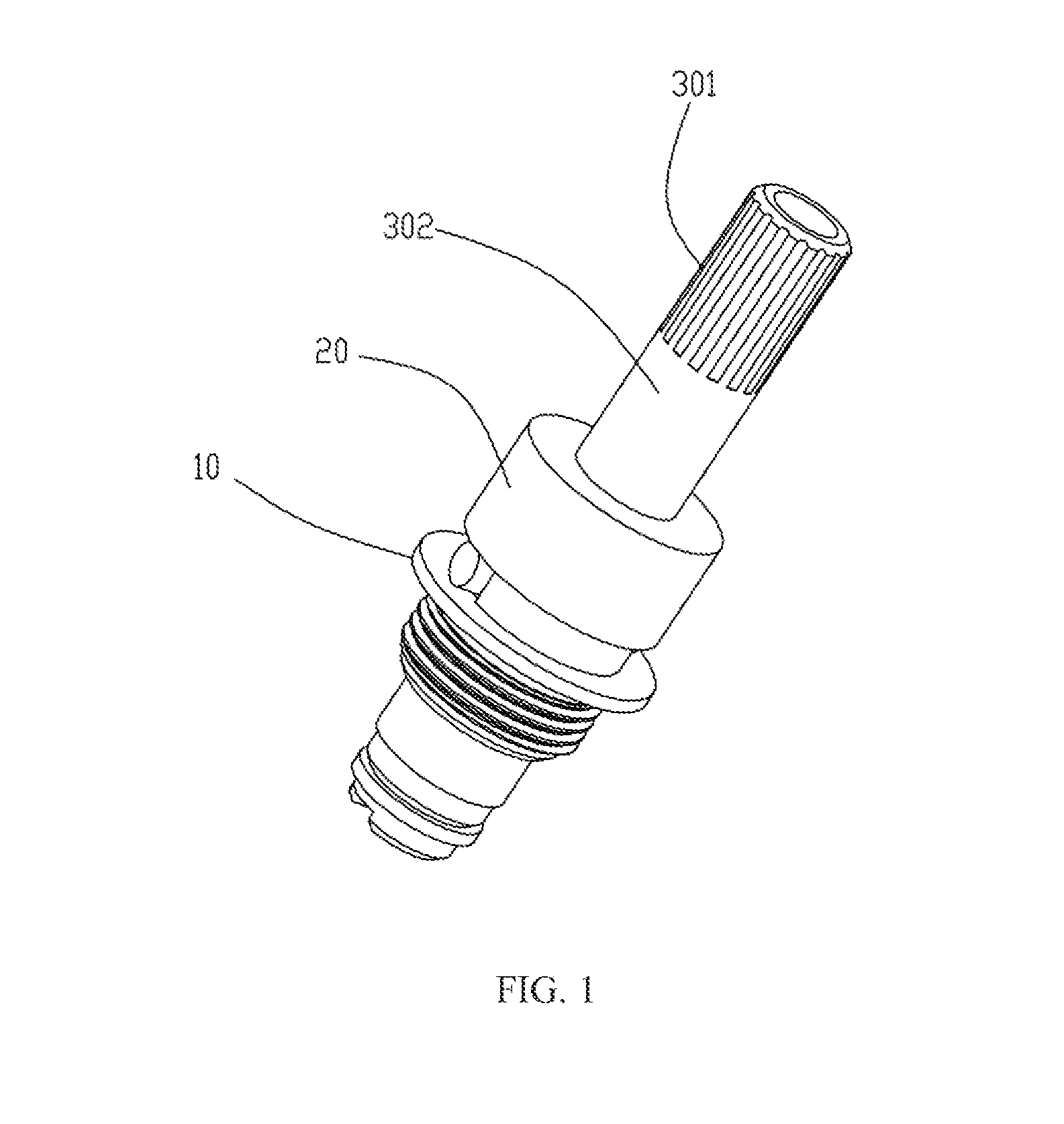

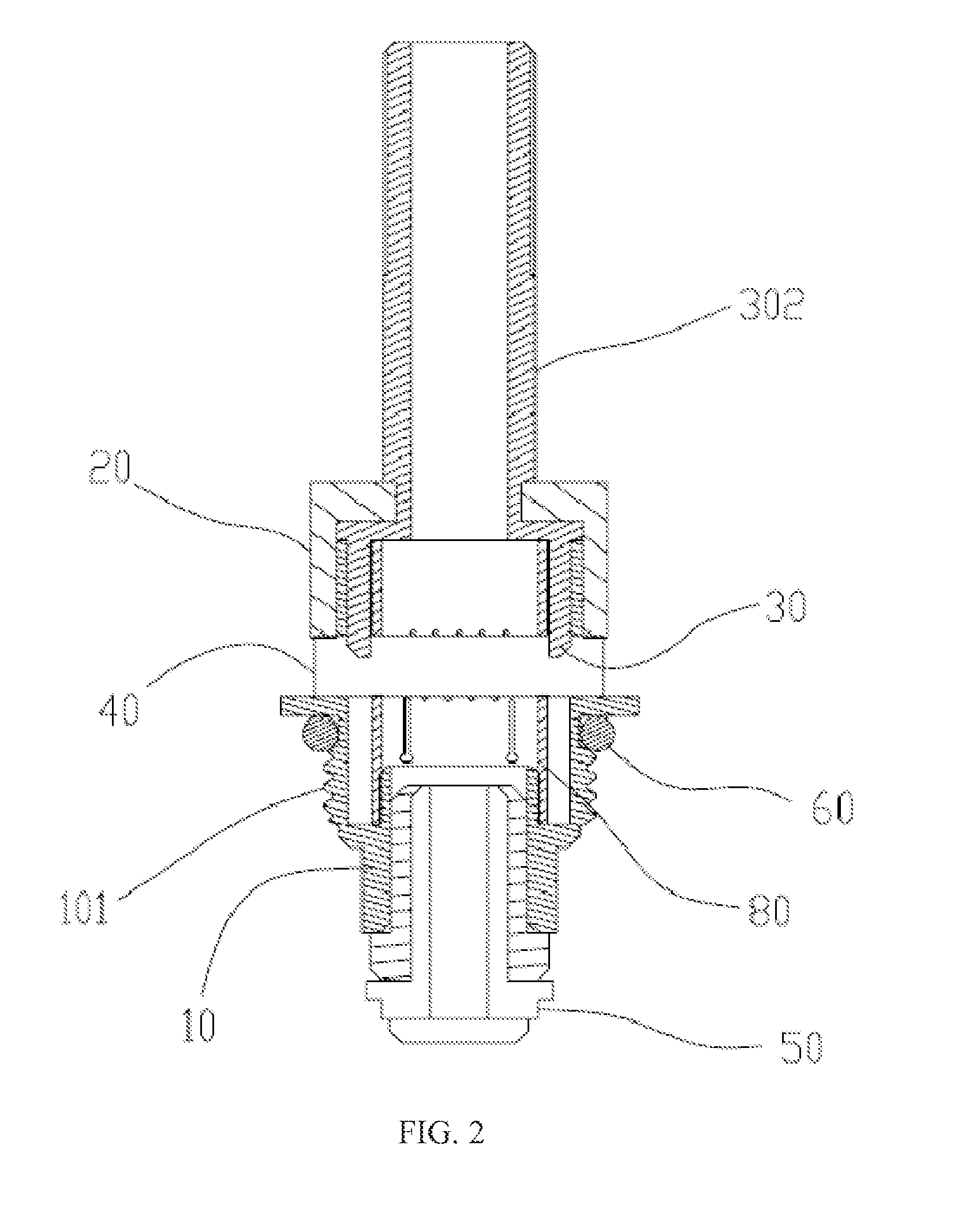

Atomizing assembly, atomizer and electronic cigarette having same

ActiveUS20150128977A1Performance of electronic is unsatisfactoryLow costSteam generation heating methodsHeater elementsElectronic cigaretteHeating element

An exemplary atomizing assembly includes a heating component, a holder, an electrode, and a cover. The heating component includes a liquid conducting element and a heating element in contact with the liquid conducting element. The holder includes two arms extending from a first end thereof The two arms and the cover cooperatively define a receiving space. The heating component is received in the receiving space. The electrode is arranged in the holder and is insulated from the holder. Two ends of the heating element are connected with the holder and the electrode respectively. The holder further includes a connection part arranged at an opposite second end, and the connection part is configured for detachably engaging with an external component.

Owner:SHENZHEN FIRST UNION TECH CO LTD

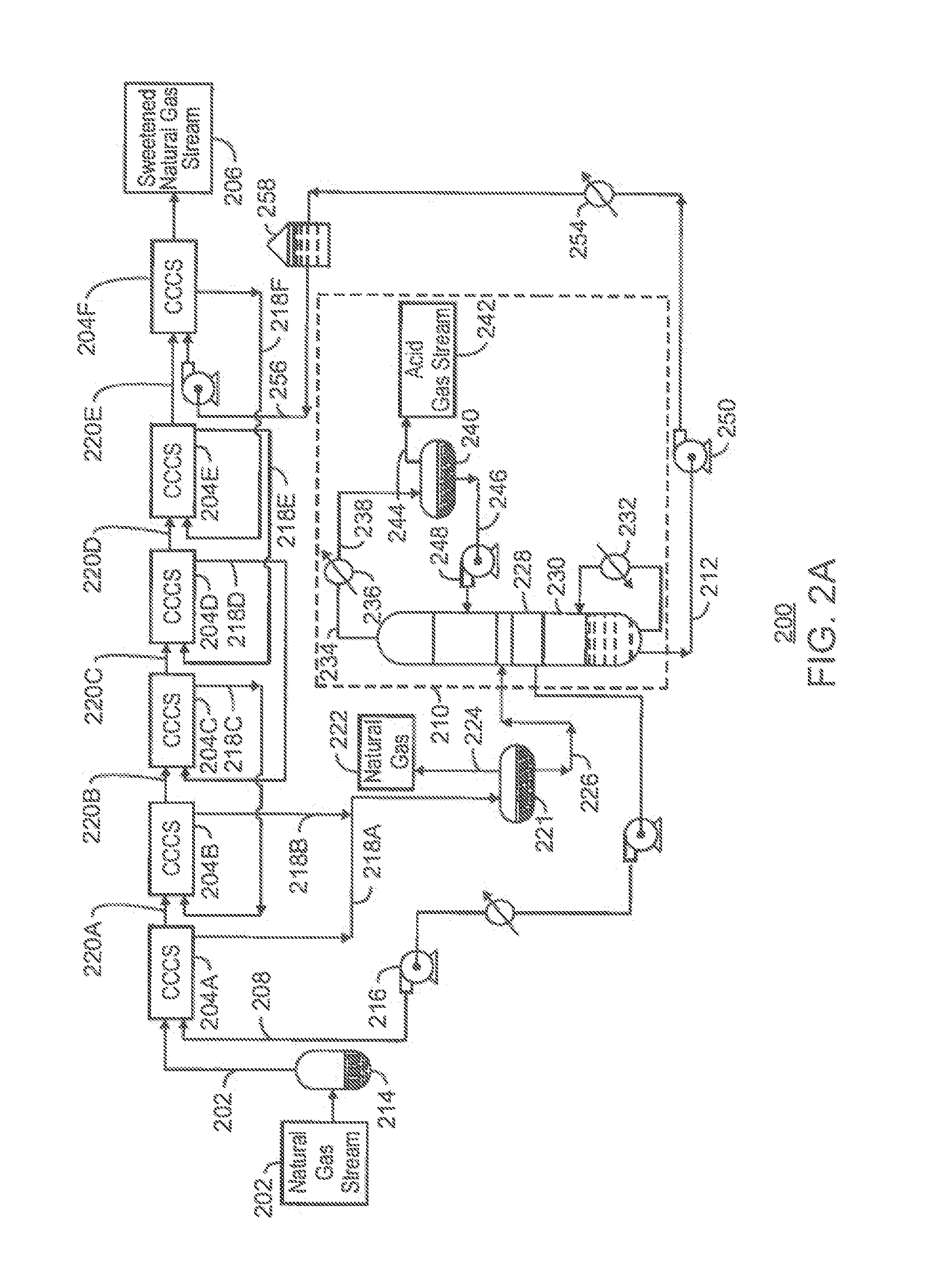

Split flow process and apparatus

An acid gas removal plant includes an absorber that provides a rich solvent to two regenerators that independently generate a lean and a semi-lean solvent, wherein the semi-lean solvent is produced in one of the regenerators using heat and / or steam derived from the other regenerator. Further heat integration is particularly contemplated with power plants in which the power plant provides high-level heat to the acid gas removal plant and wherein the power plant receives low-level heat from the acid gas removal plant.

Owner:FLUOR TECH CORP

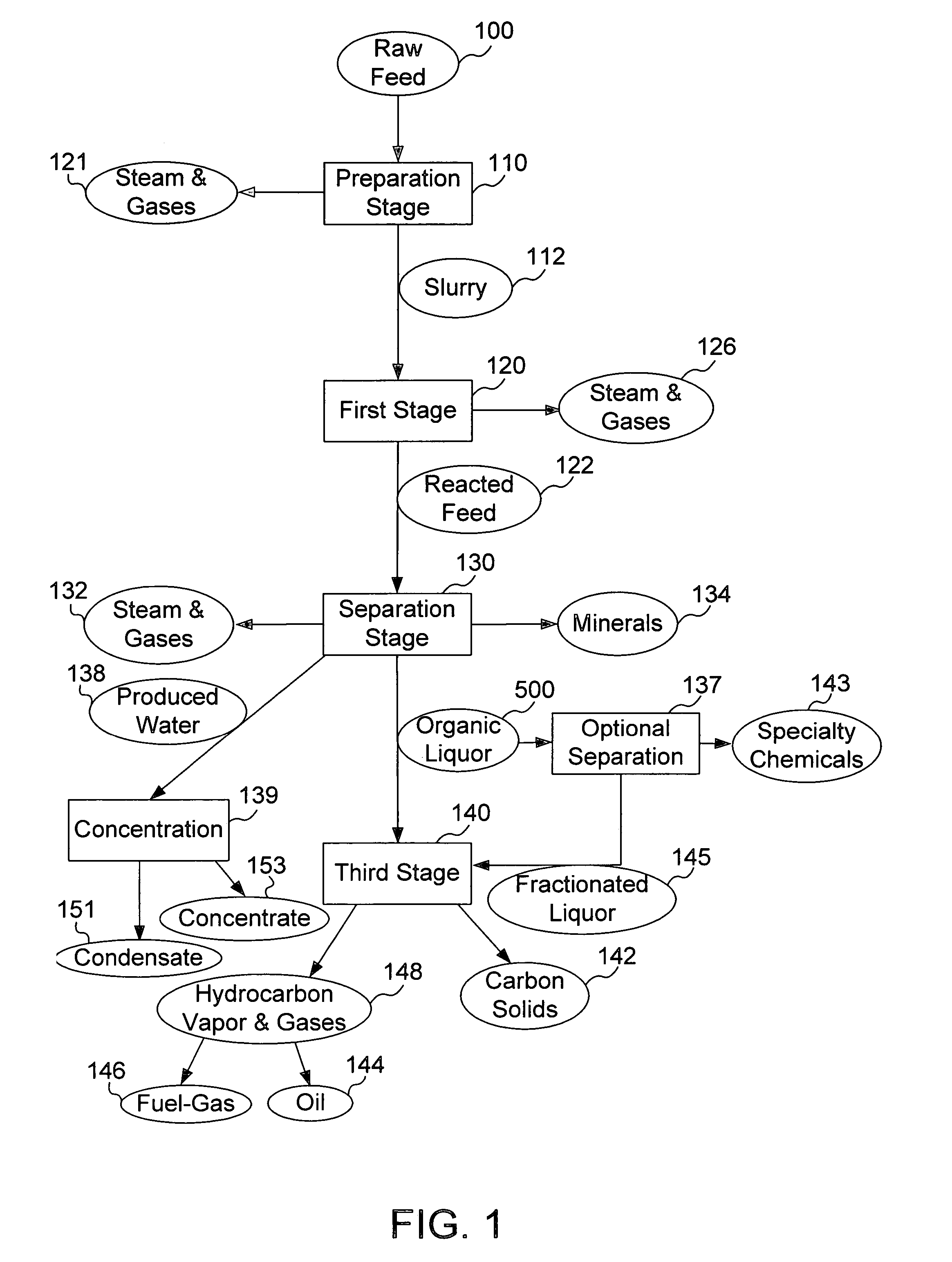

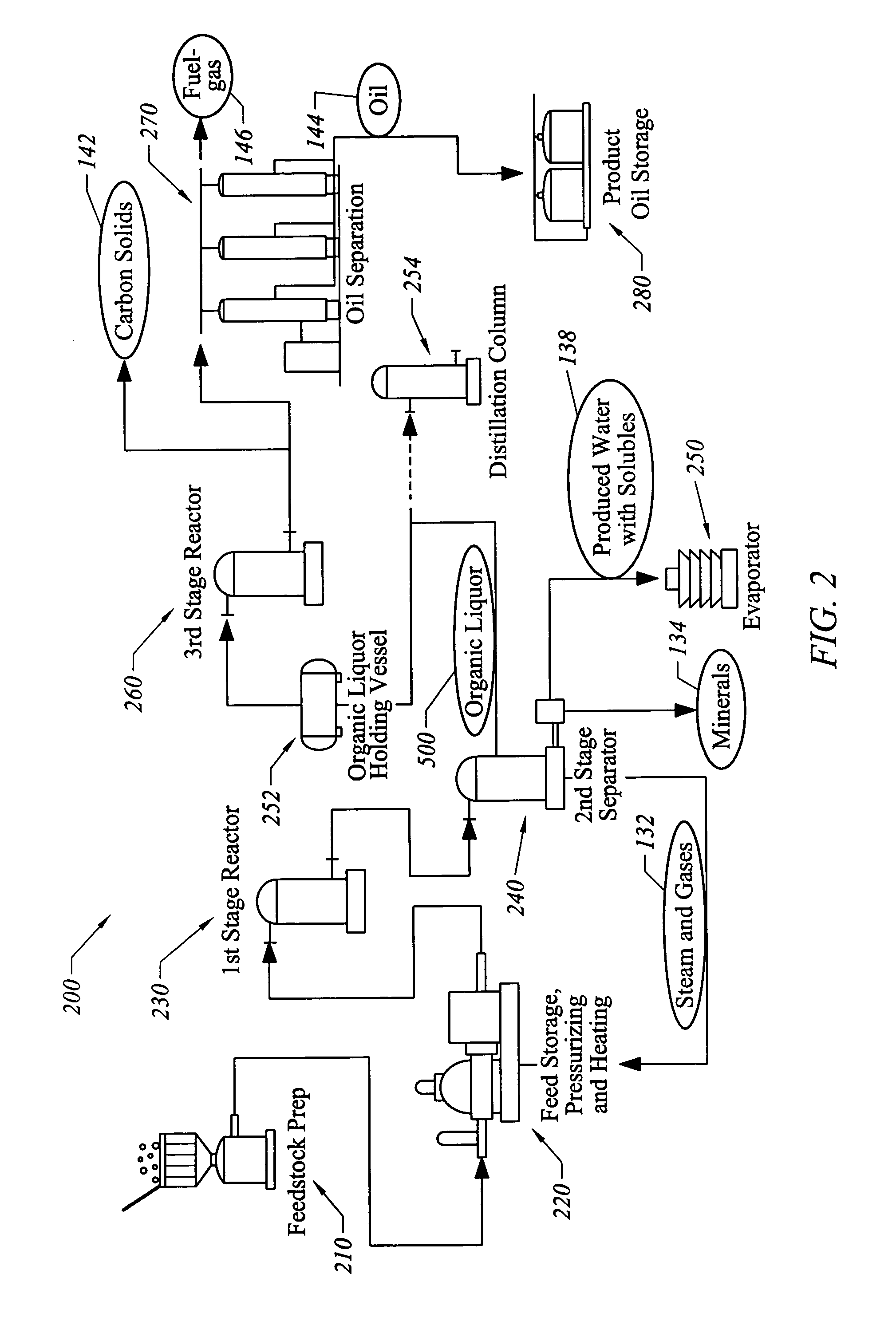

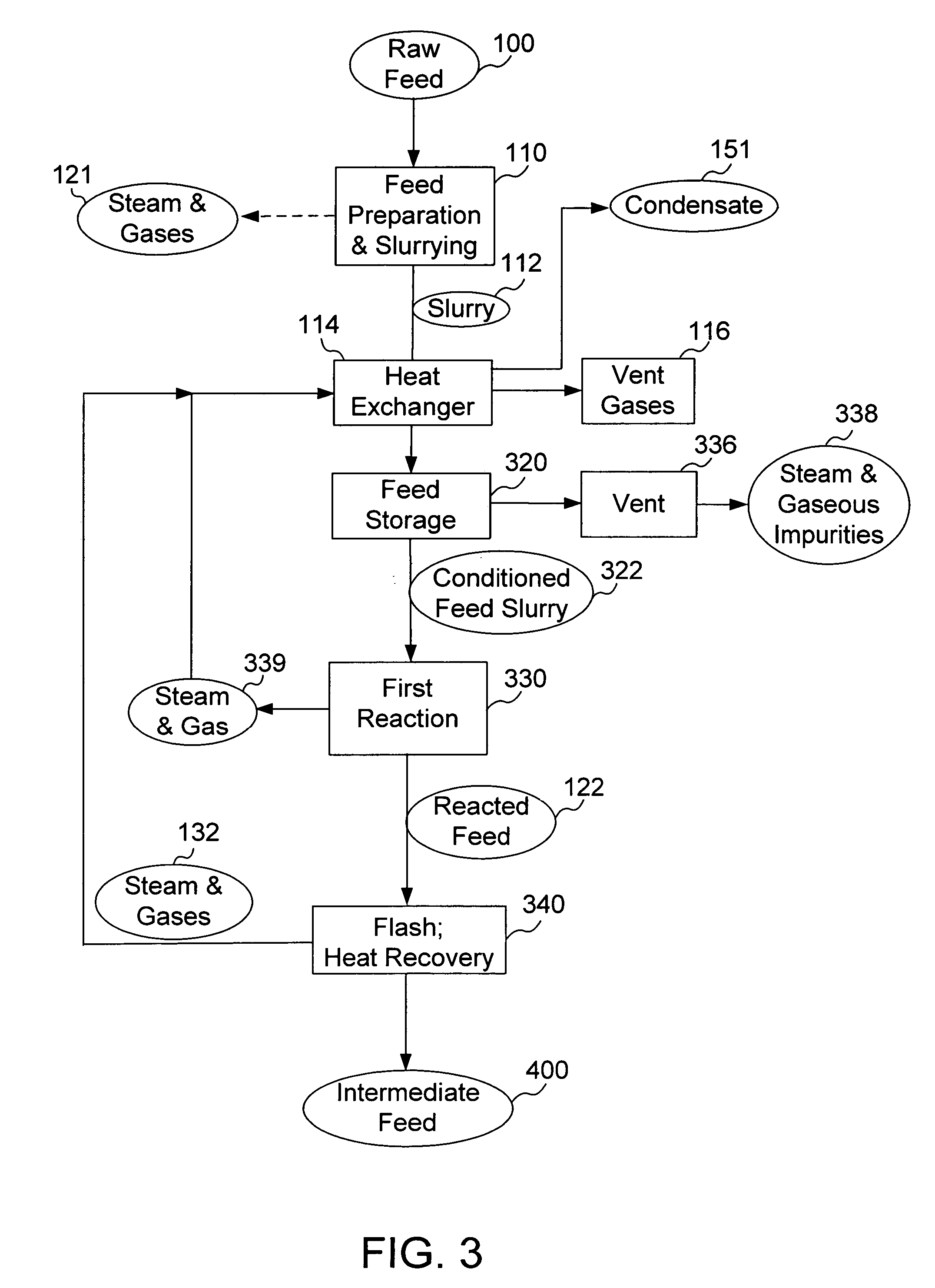

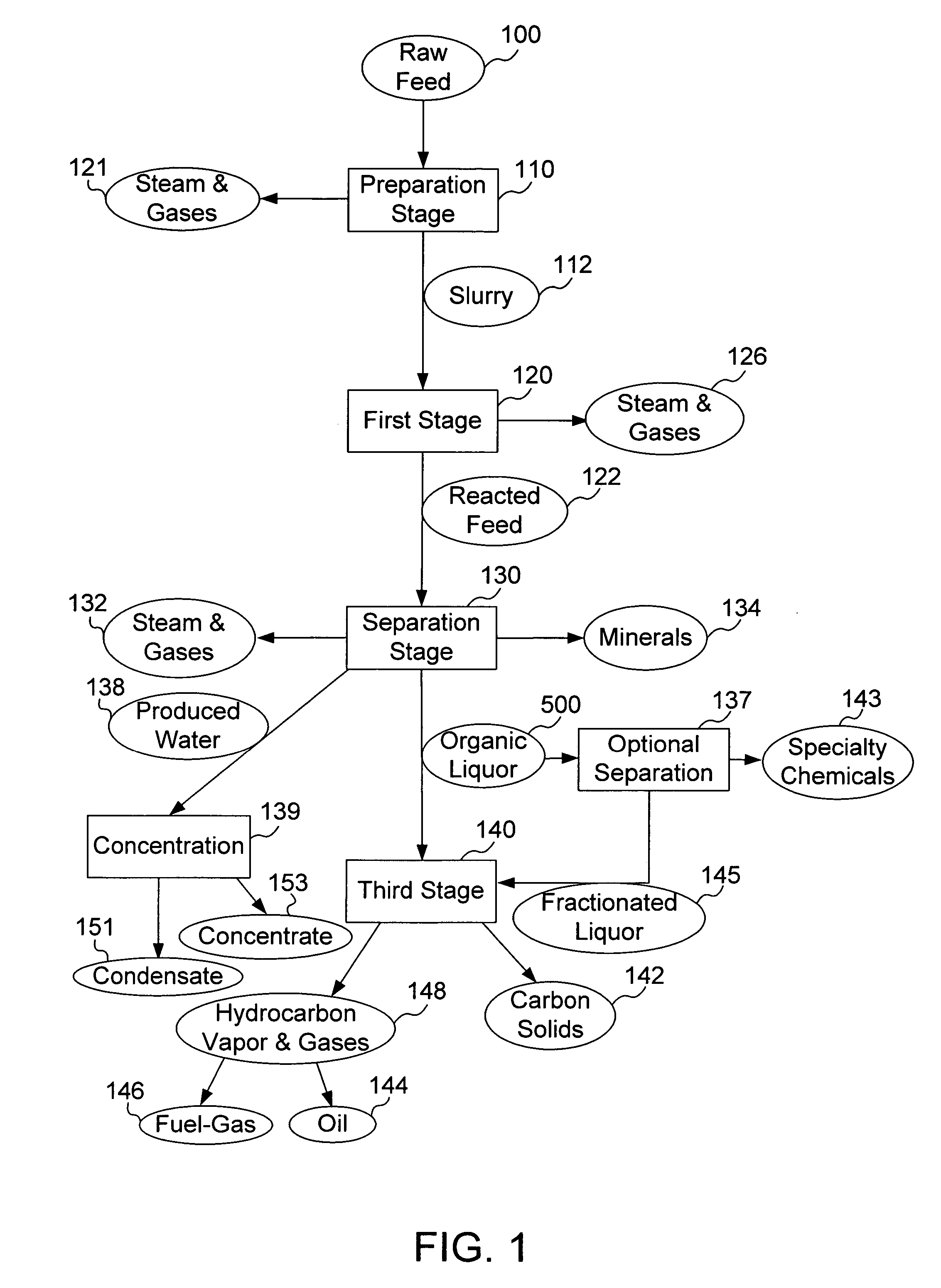

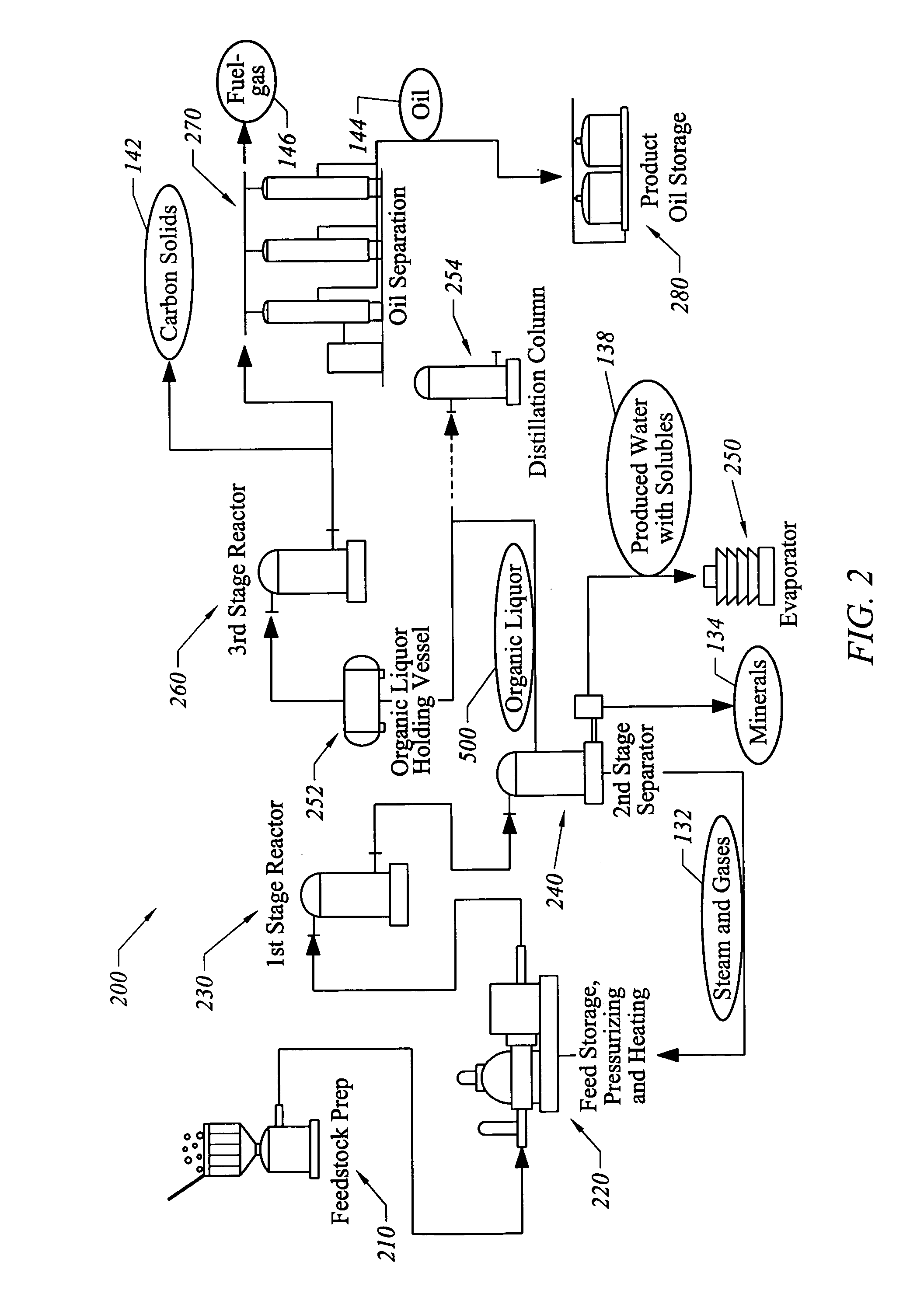

Apparatus and process for converting a mixture of organic materials into hydrocarbons and carbon solids

ActiveUS7476296B2Low viscosityInhibition formationAnimal corpse fertilisersMultiple-effect/fractional condensationSpeciality chemicalsHigh energy

Owner:SYNPET TEKNOLOJI GELISTIRME

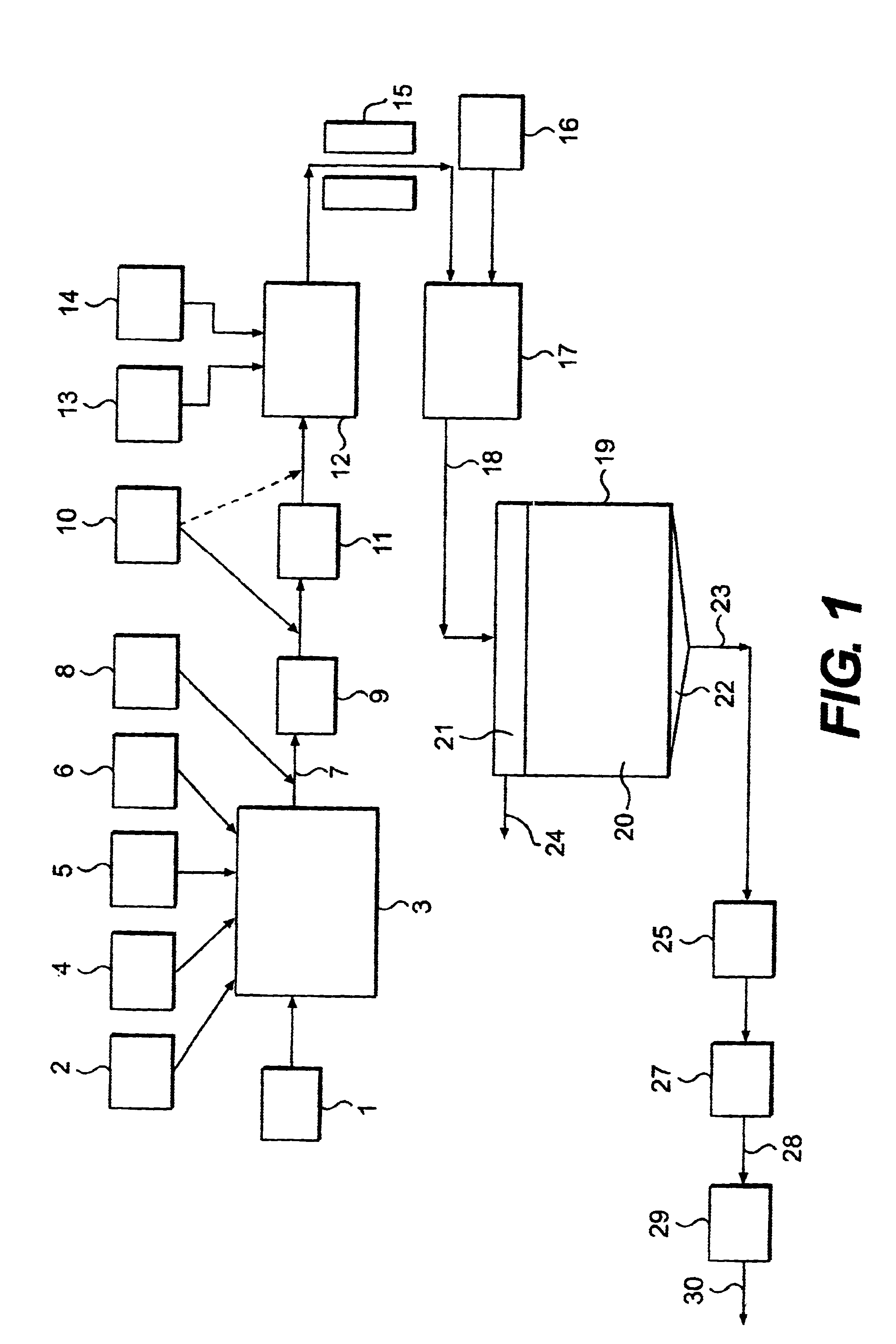

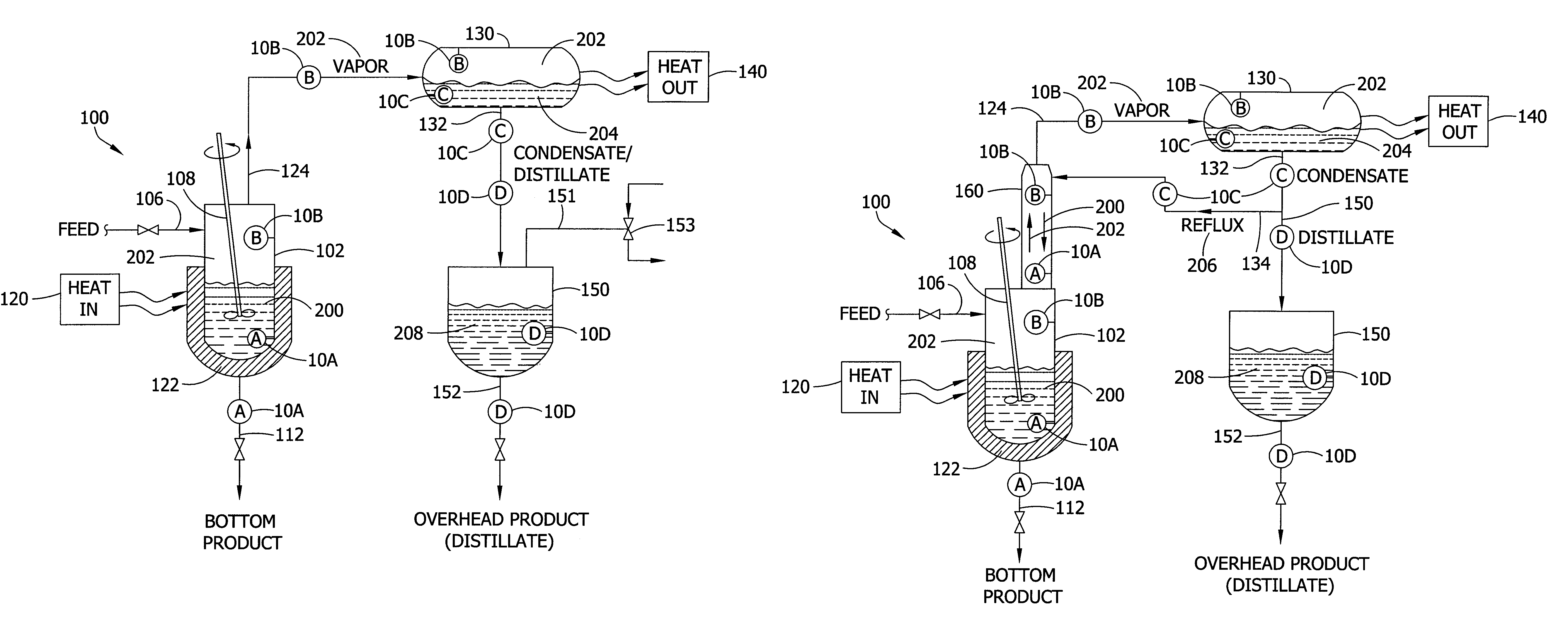

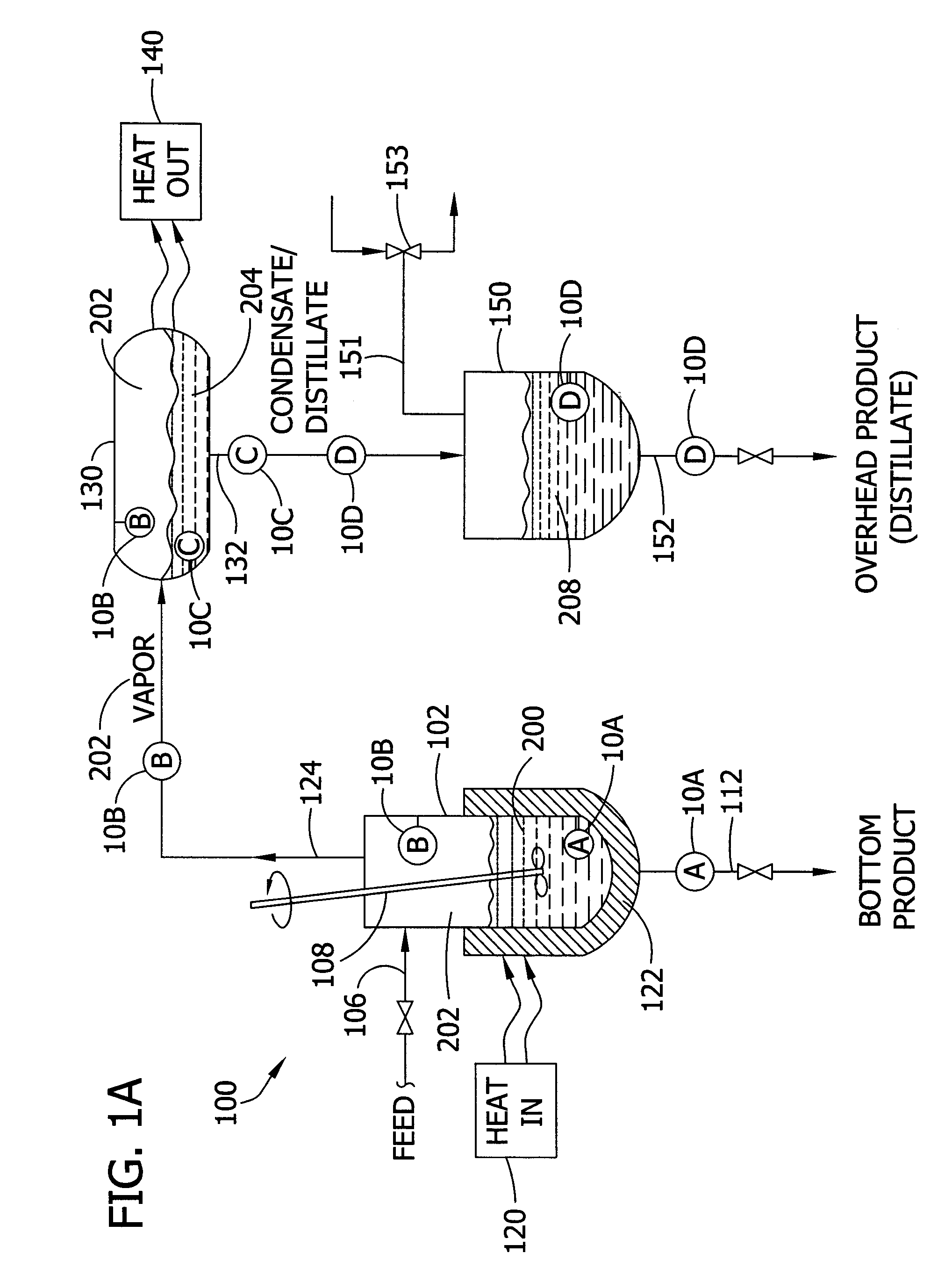

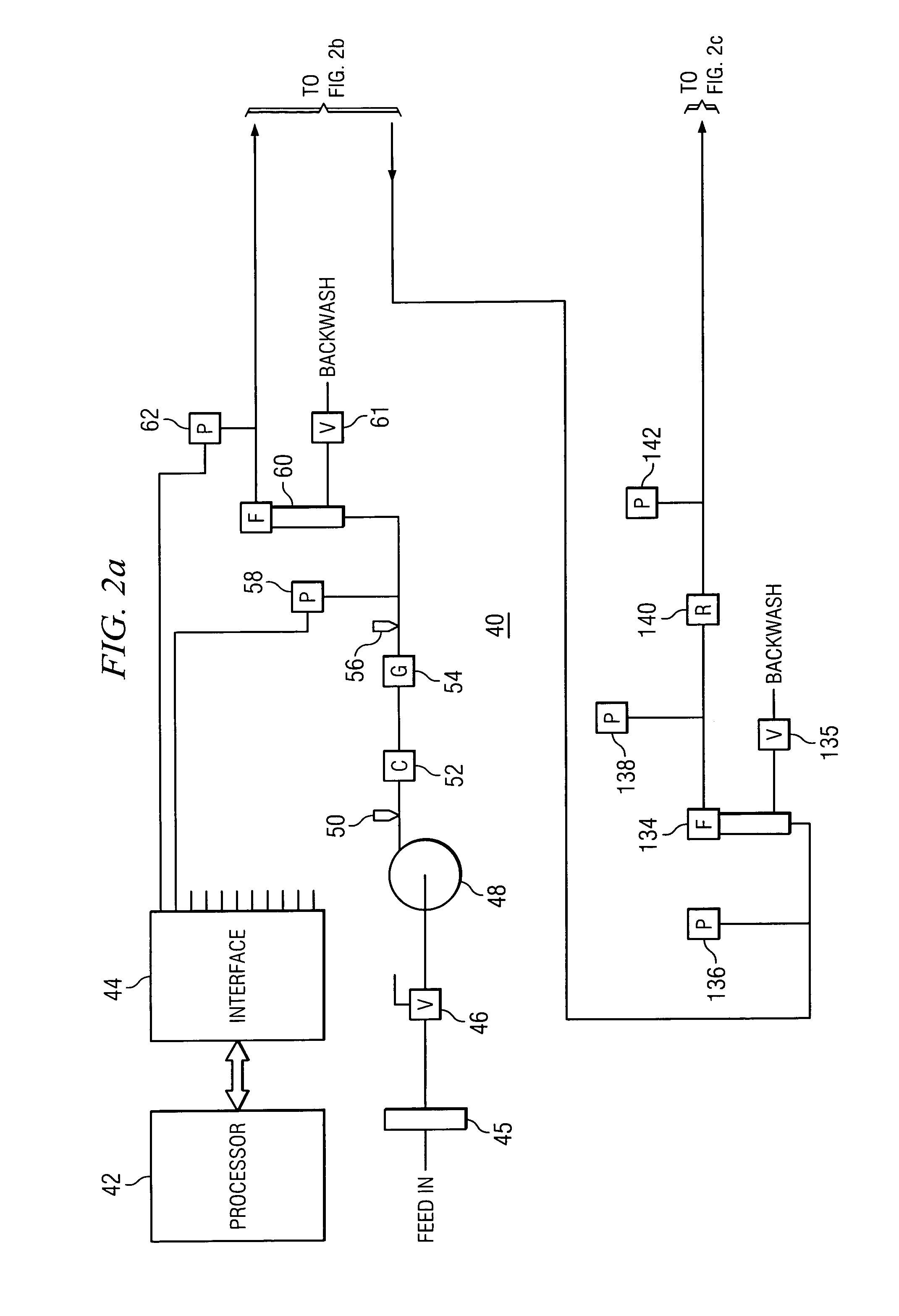

Systems for monitoring and controlling unit operations that include distillation

InactiveUS7603889B2High sensitivityHigh dielectric constantProcess control/regulationAnalysing solids using sonic/ultrasonic/infrasonic wavesDistillationUnit operation

Fluid sensor methods and systems adapted for monitoring and / or controlling distillation operations in fluidic systems, such as batch distillation operations or continuous distillation operations, are disclosed. Preferred embodiments are directed to process monitoring and / or process control for unit operations involving endpoint determination of a distillation, for example, as applied to a liquid-component-switching operation (e.g., a solvent switching operation), a liquid-liquid separation operation, a solute concentration operation, a dispersed-phase concentration operation, among others.

Owner:MEAS FRANCE

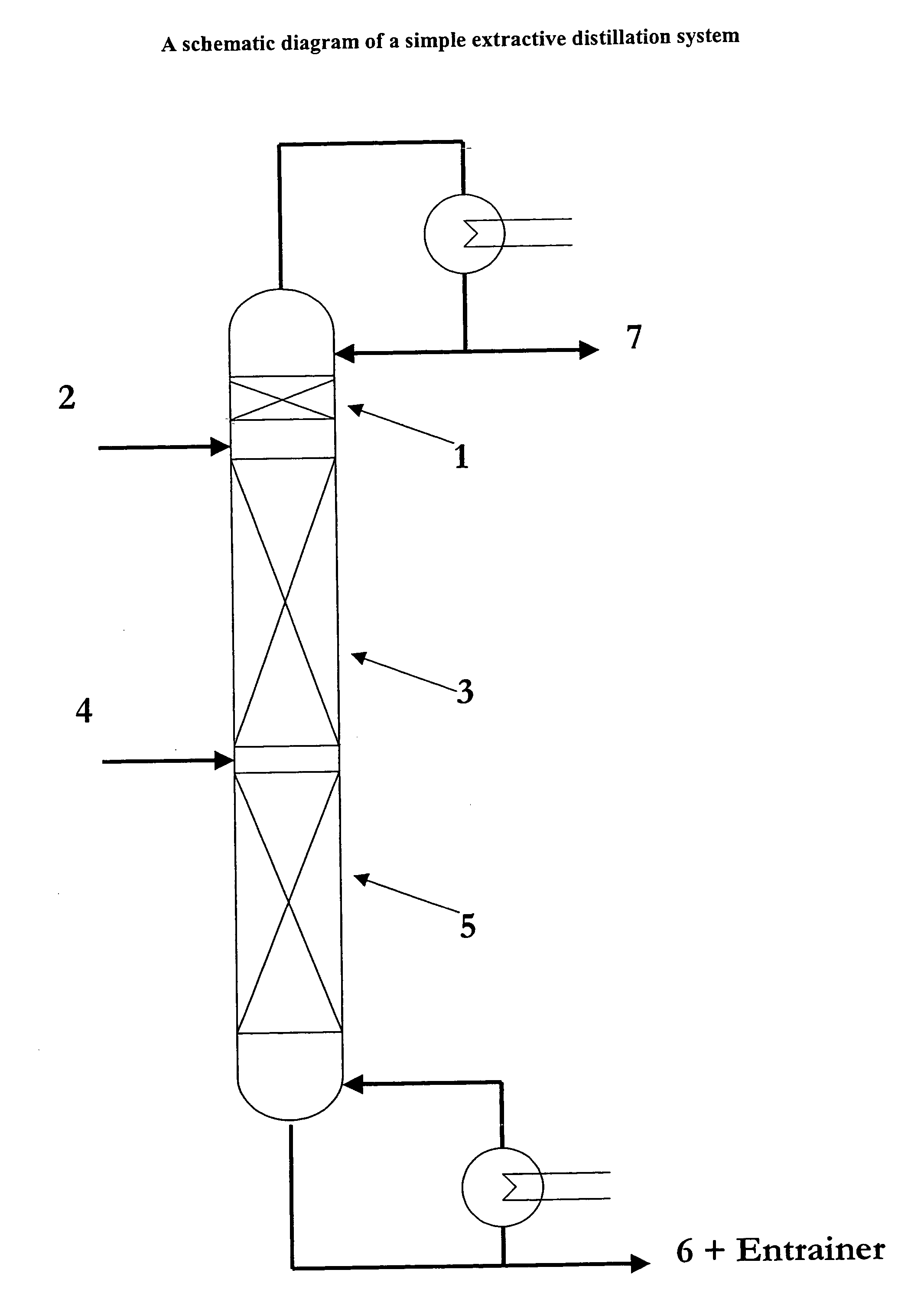

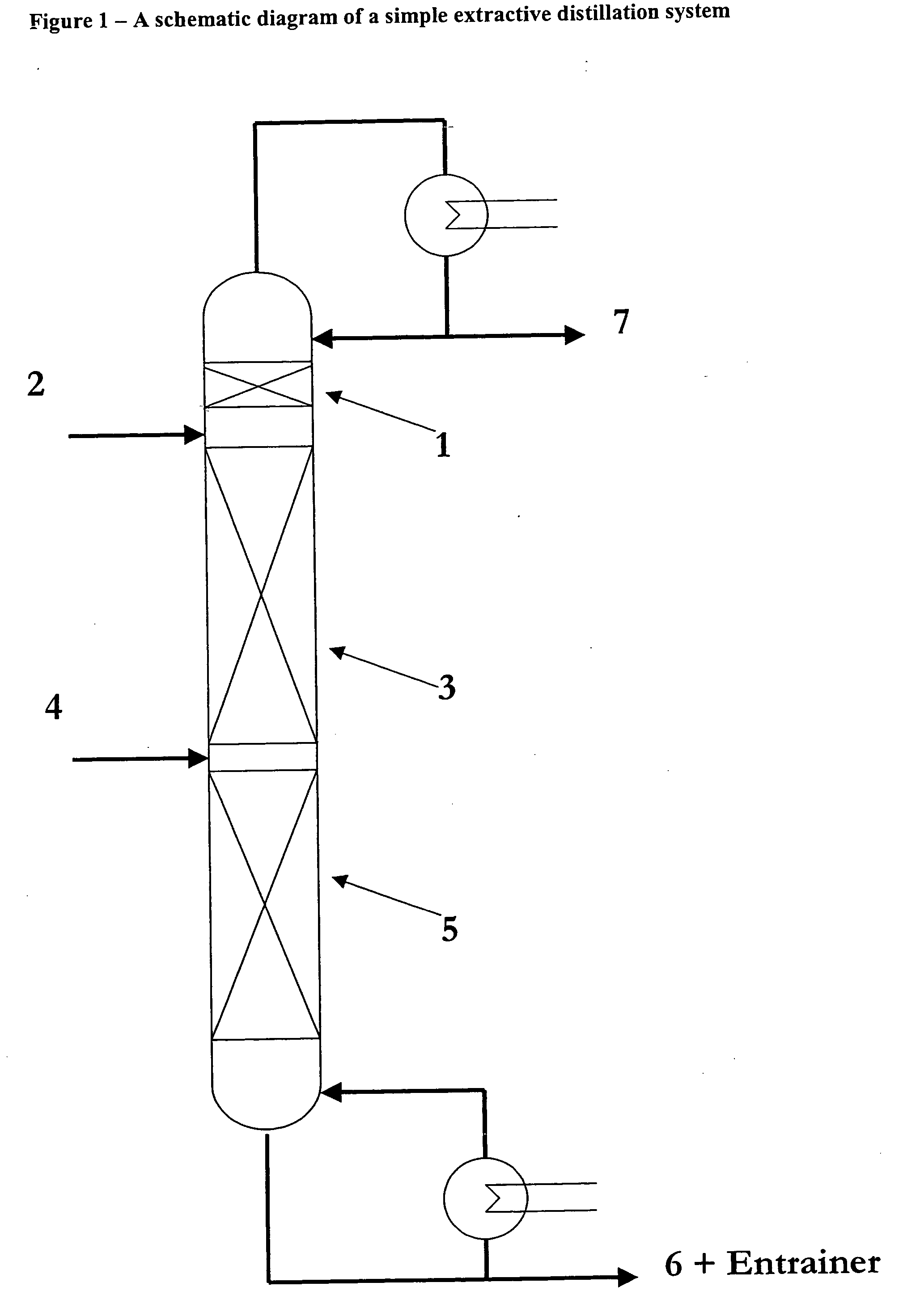

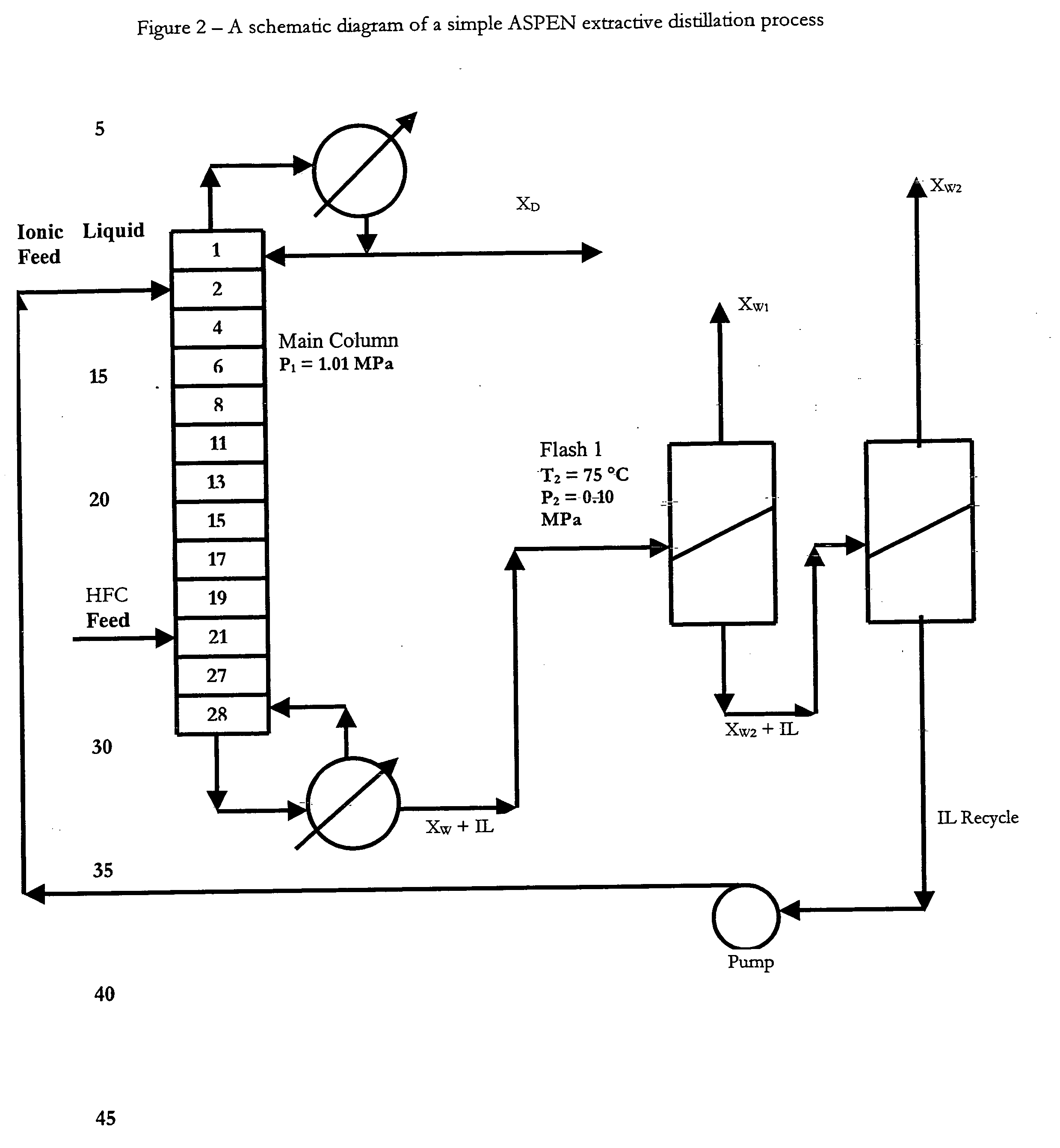

Utilizing ionic liquids for hydrofluorocarbon separation

InactiveUS20070131535A1Organic compounds purification/separation/stabilisationGroup 5/15 element organic compoundsPhysical chemistryOrganic chemistry

The present invention relates to a process for separating close-boiling and azeotropic components of mixtures, wherein said mixtures comprise at least one hydrofluorocarbon compound, using at least one ionic liquid.

Owner:THE CHEMOURS CO FC LLC

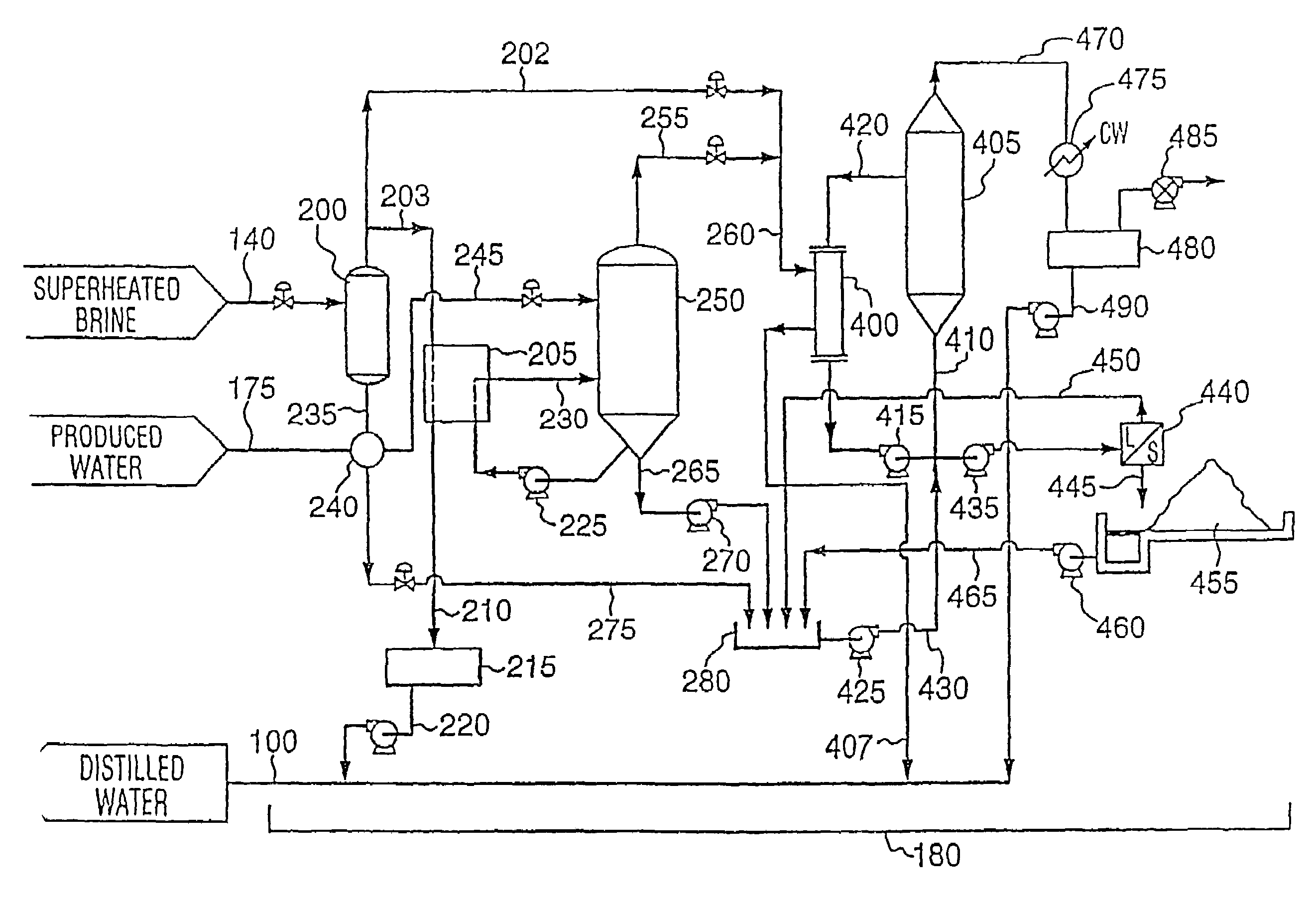

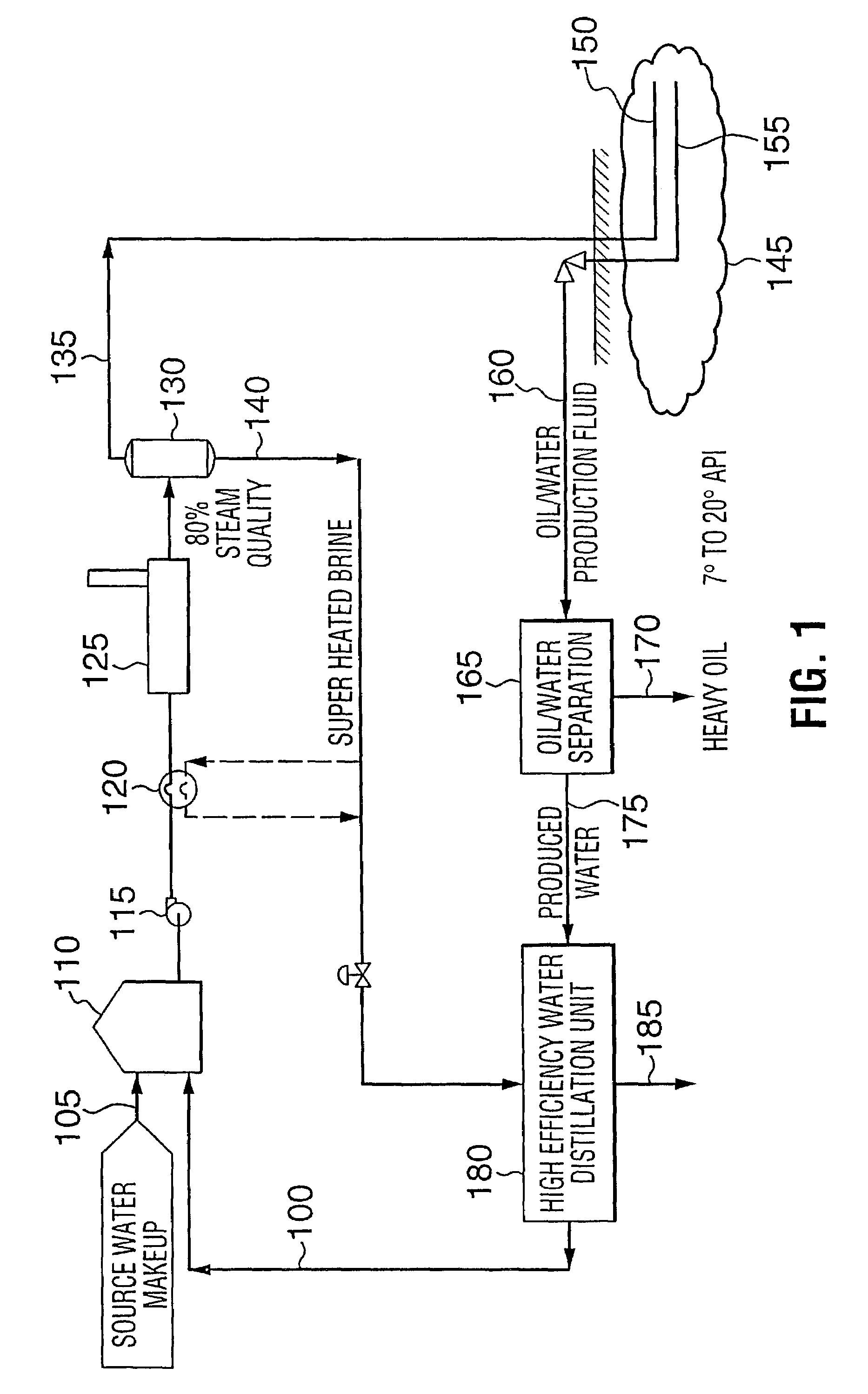

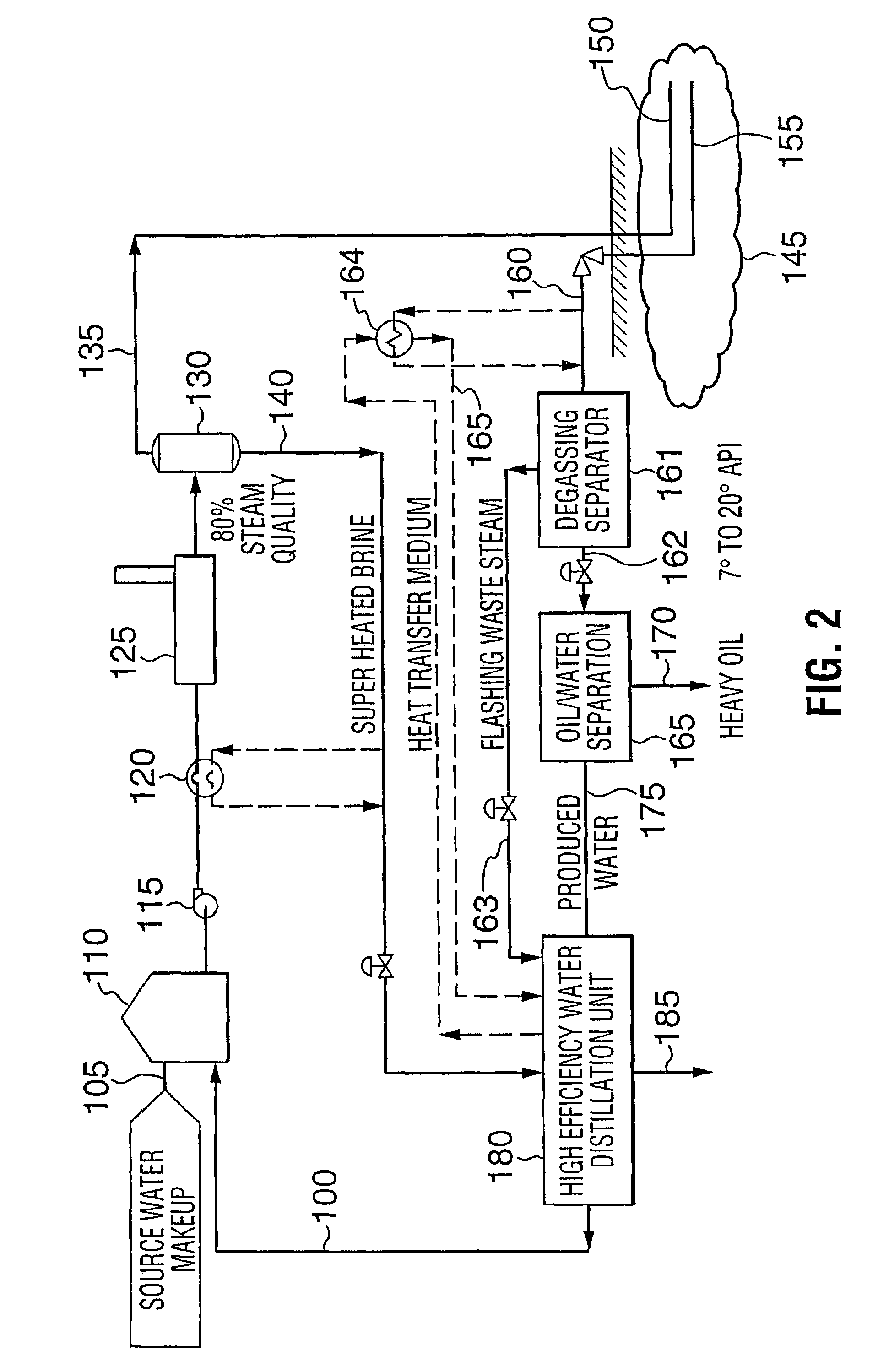

Water treatment process for thermal heavy oil recovery

There is disclosed a method and apparatus for treating produced water from a heavy oil thermal recovery unit to achieve water recovery and recycle levels of greater than 80% and as high as 100% to achieve zero discharge criteria. The method includes the initial steps of capturing the waste heat energy from the high pressure steam separator located downstream of the steam generators. Further, transferring the heat energy into a heated separator and reboiler exchanger to distill oil reservoir produced water and recover distilled water and a concentrated brine or solid product. The heated separator concentrated stream is circulated through the reboiler exchanger to maintain from 1% to about 50% mass vapour in the stream returning to the heated separator and prevent fouling and scaling. The apparatus includes a low pressure waste energy separator, heated separator and vapour compressor in combination with a forced circulation circuit to generate the distilled water.

Owner:FOUNTAIN QUAIL WATER MANAGEMENT LLC +1

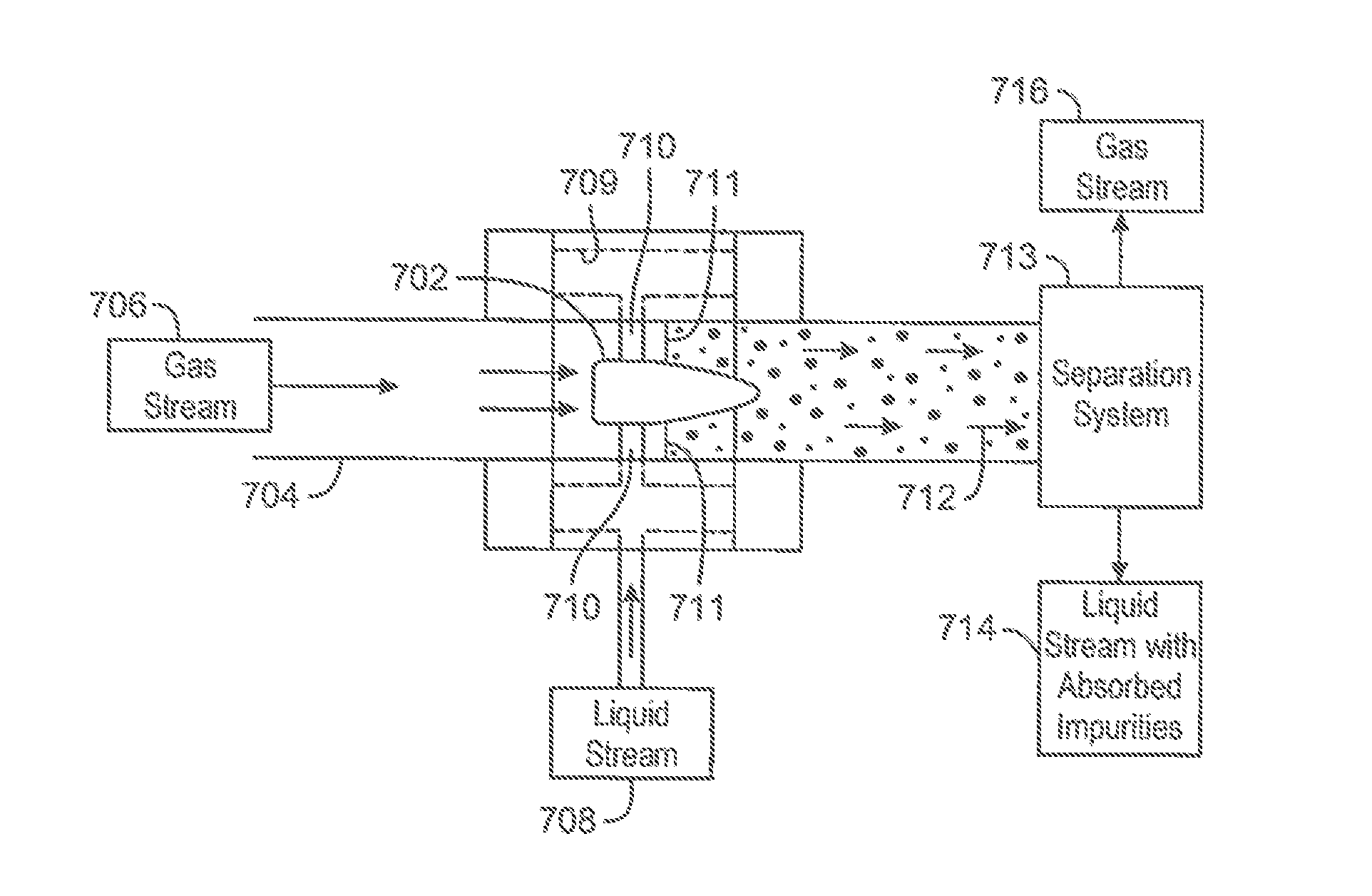

Contacting A Gas Stream With A Liquid Stream

ActiveUS20150352463A1Effective mergerOrganic compound preparationLighting and heating apparatusEngineeringContact system

A co-current contacting system is described herein. The co-current contacting system includes a co-current contactor located in-line within a pipe. The co-current contactor includes an annular support ring configured to maintain the co-current contactor within the pipe and a number of radial blades configured to allow a liquid stream to flow into the co-current contactor. The co-current contacts also includes a central gas entry cone configured to allow a gas stream to flow through a hollow section within the co-current contactor, wherein the co-current contactor provides for efficient incorporation of liquid droplets formed from the liquid stream into the gas stream. The co-current contacting system also includes a separation system configured to remove the liquid droplets from the gas stream.

Owner:EXXONMOBIL UPSTREAM RES CO

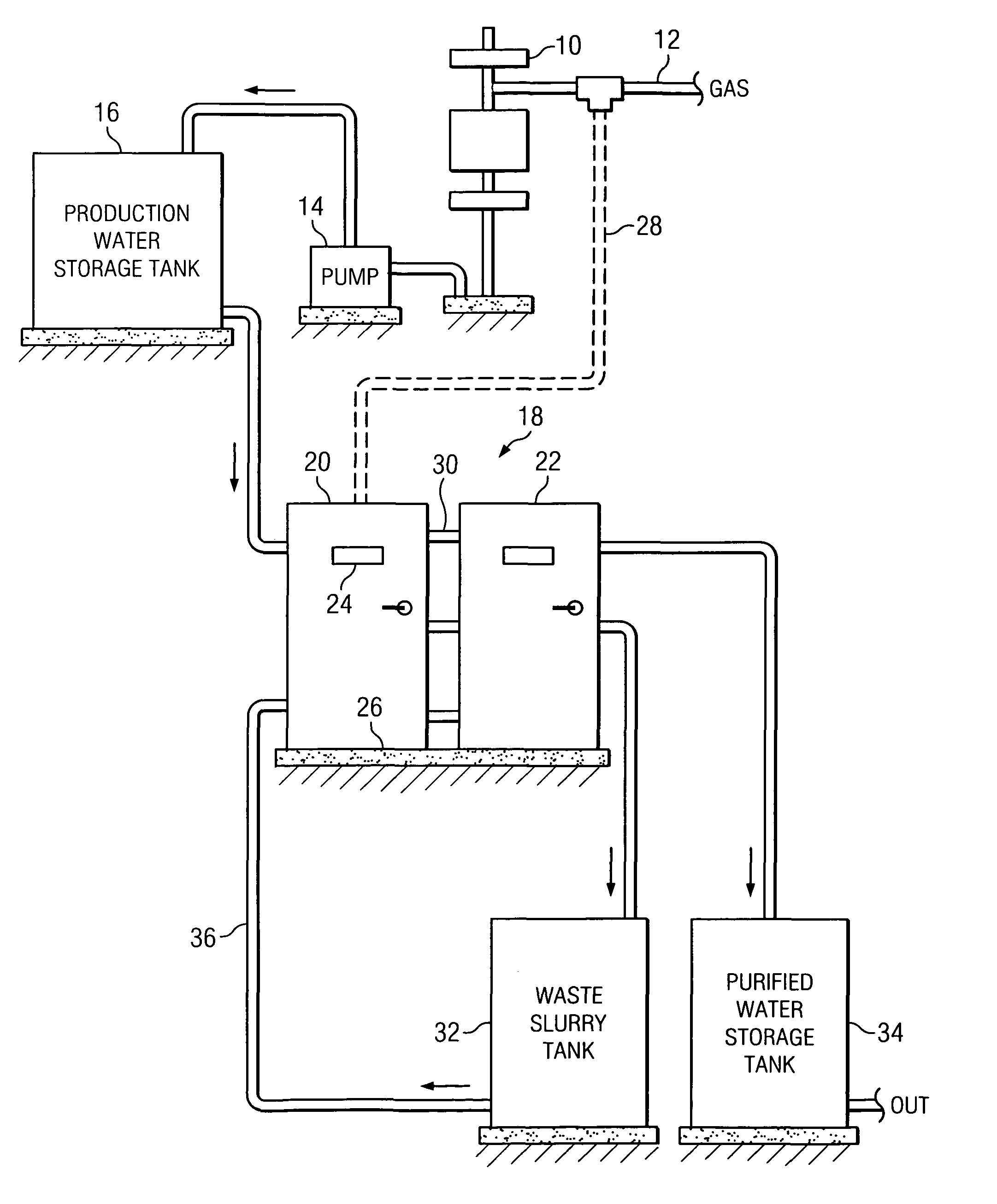

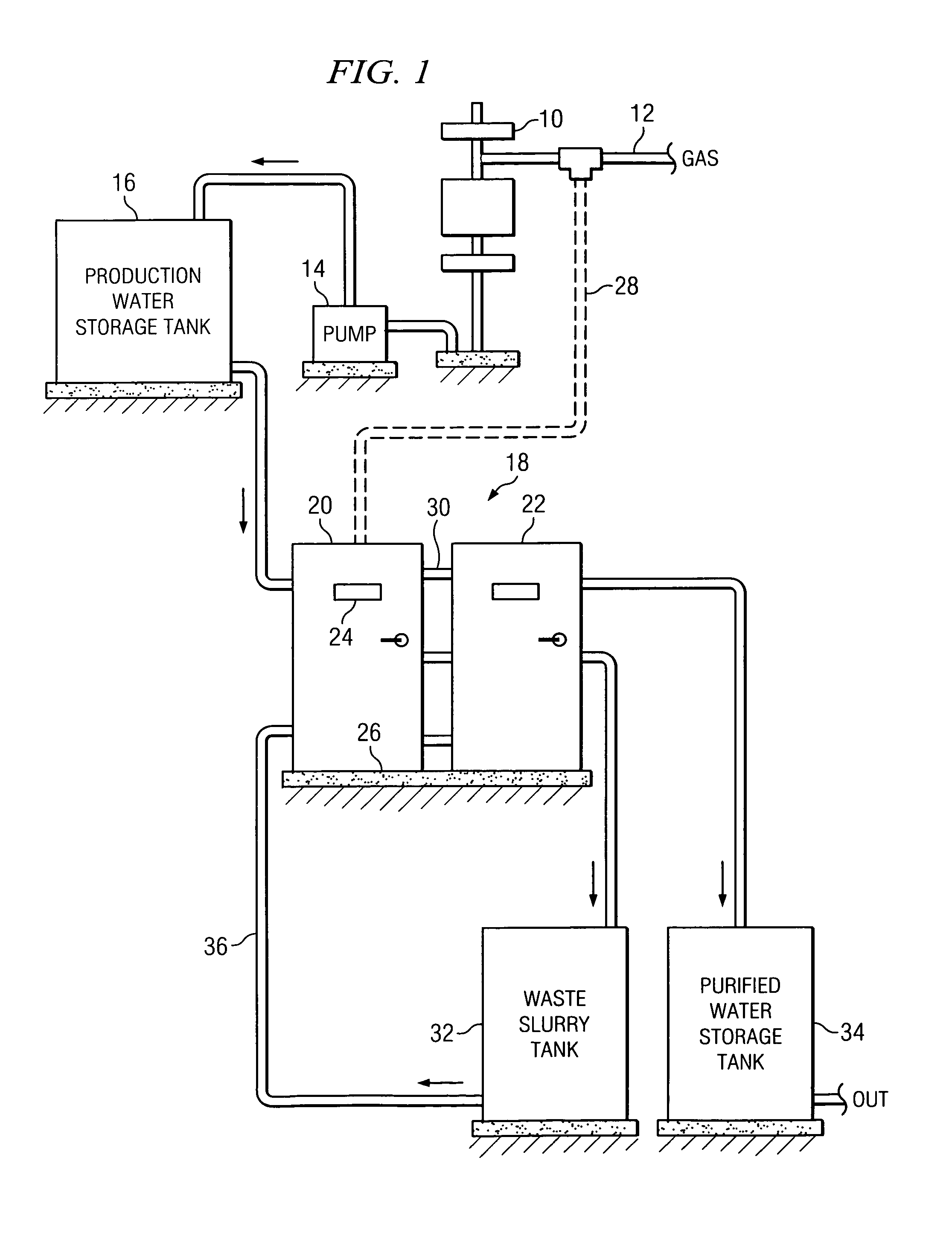

Method and apparatus for purifying water

ActiveUS8097128B1Improve efficiencyImprove throughputLiquid degasificationAuxillariesThermal energyInternal combustion engine

An efficient flash evaporation water purification system located at a hydrocarbon well site. An internal combustion engine uses hydrocarbon fuel from the well and drives a pump to pressurize production water from the well. The engine also generates thermal energy used to preheat the production water. An electrical generator is also driven by the engine to produce electrical power for the water purification system, as well as produce AC power for off-site consumers.

Owner:SHERRY RAYMOND C

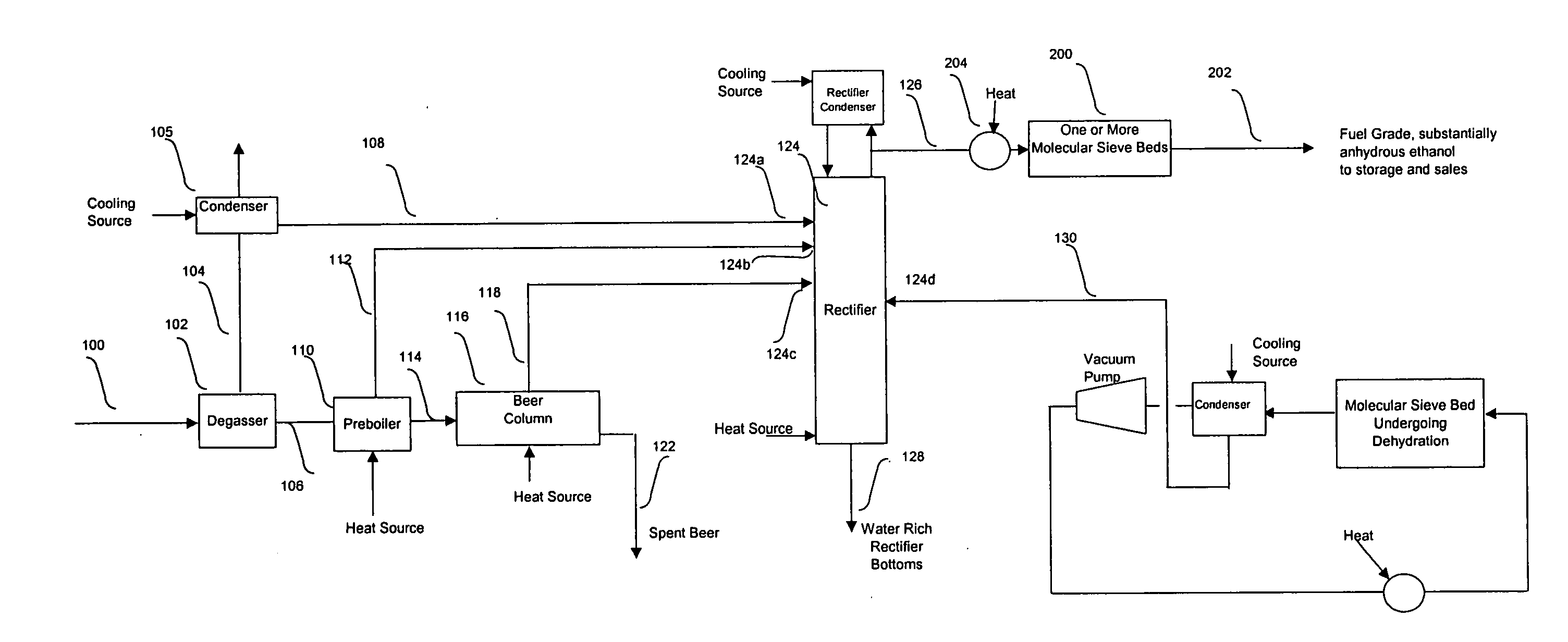

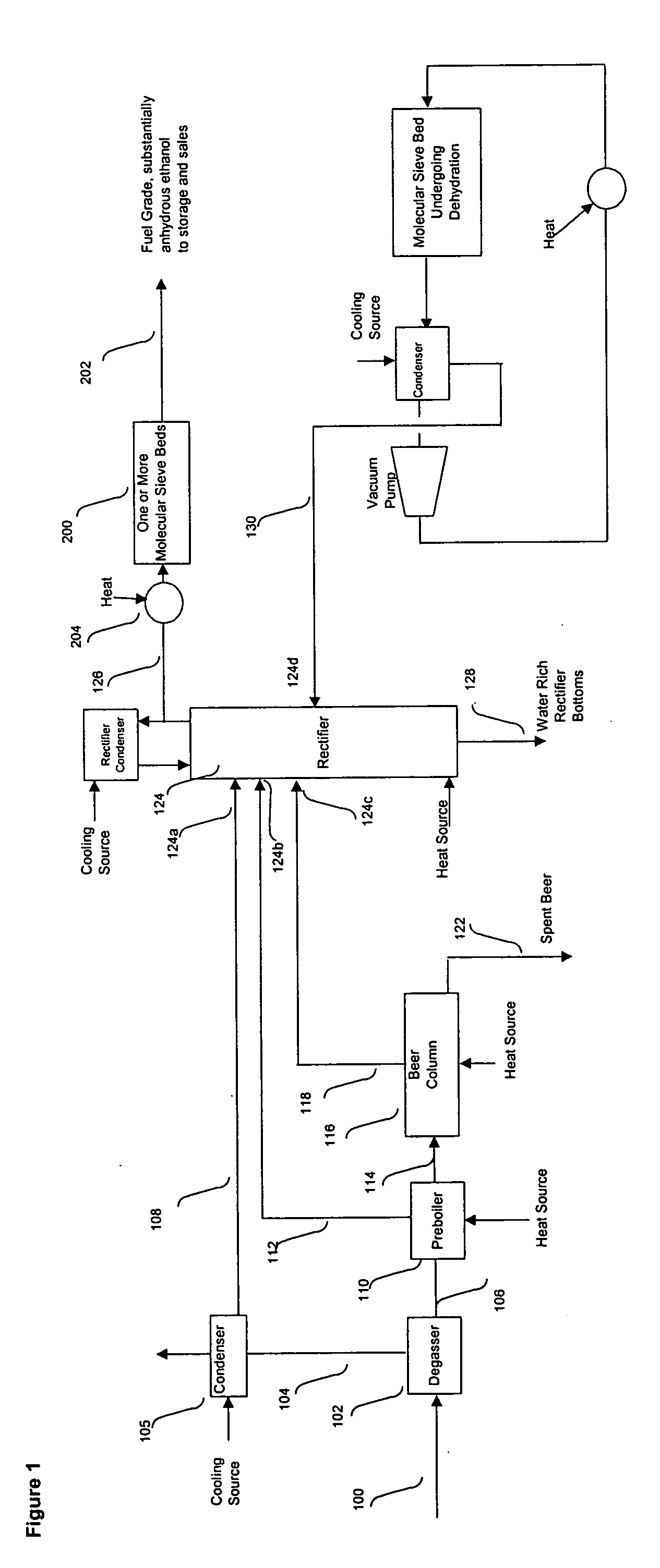

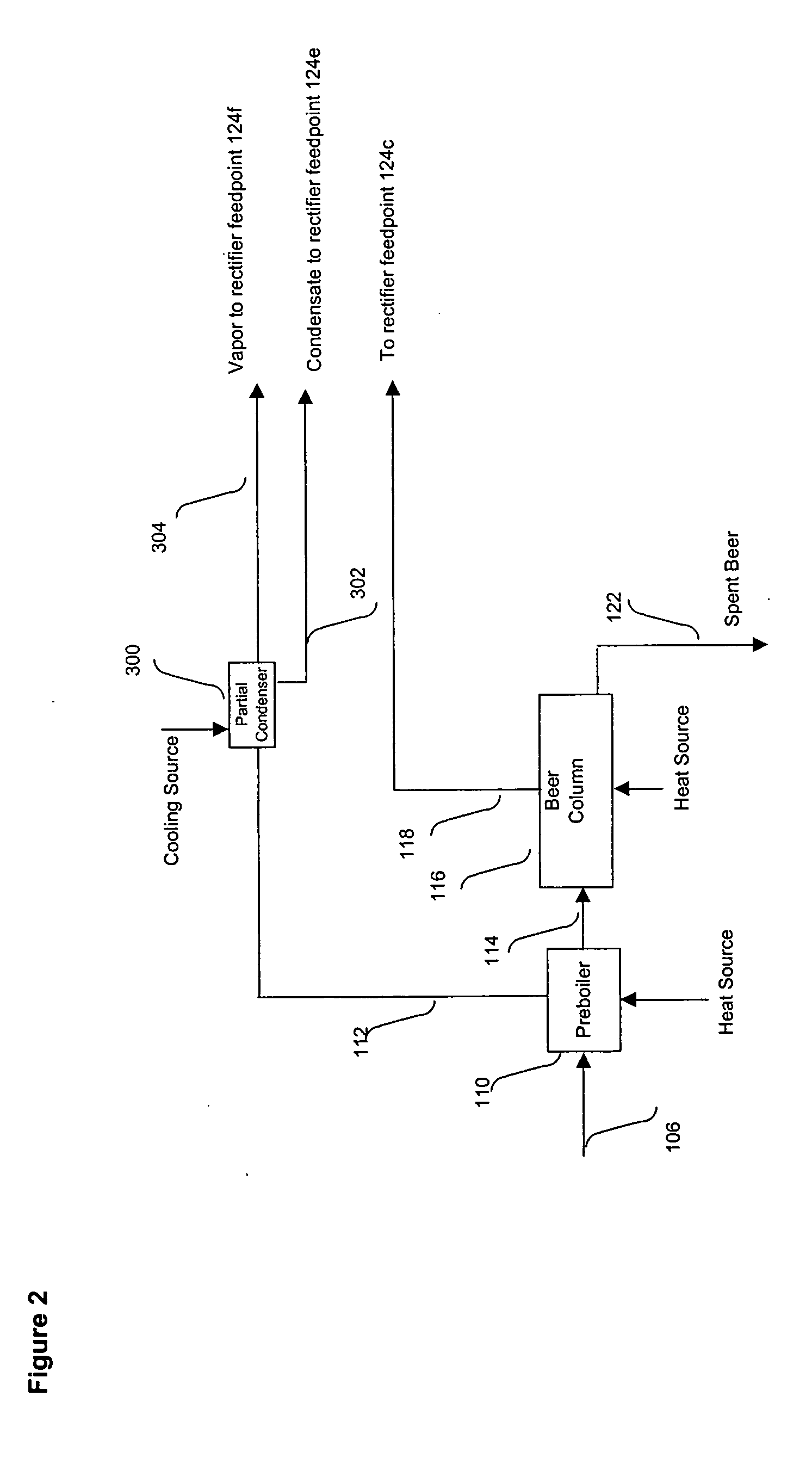

Process for providing ethanol

ActiveUS20070144886A1Using liquid separation agentSolid sorbent liquid separationWater vaporRectifier

The invention is a process for the purification of ethanol. In one embodiment the process comprises boiling a degassed beer feed (106) in a pre-boiler (110) to provide a vapor by-pass fraction (112) that by-passes the conventional beer column and is fed into the rectifier column (124). The process allows free capacity in the rectifier column of new or established plants to be filled by ethanol-water vapor and / or condensate streams that do not originate from the beer column.

Owner:SUSTAINABLE TECH CORP

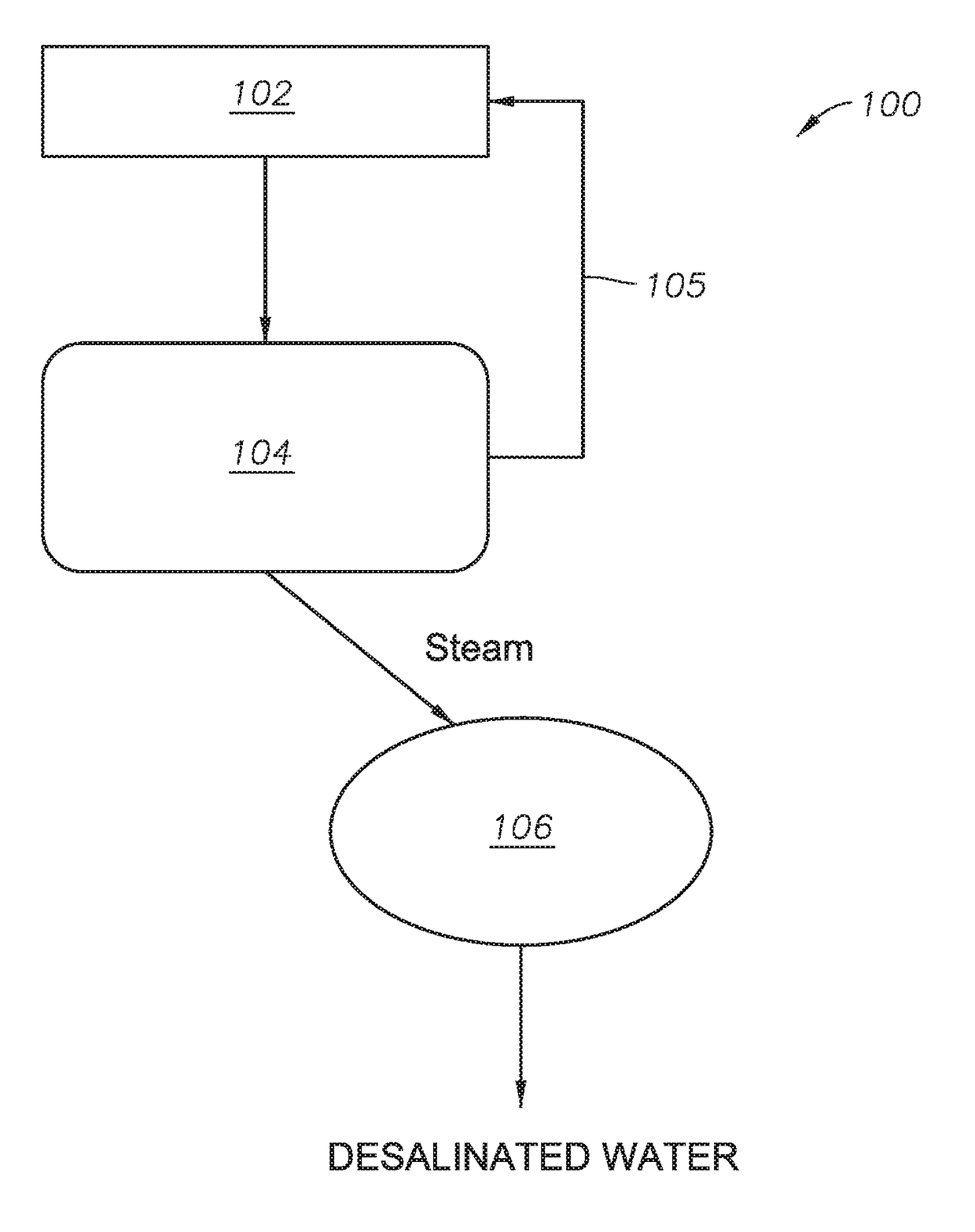

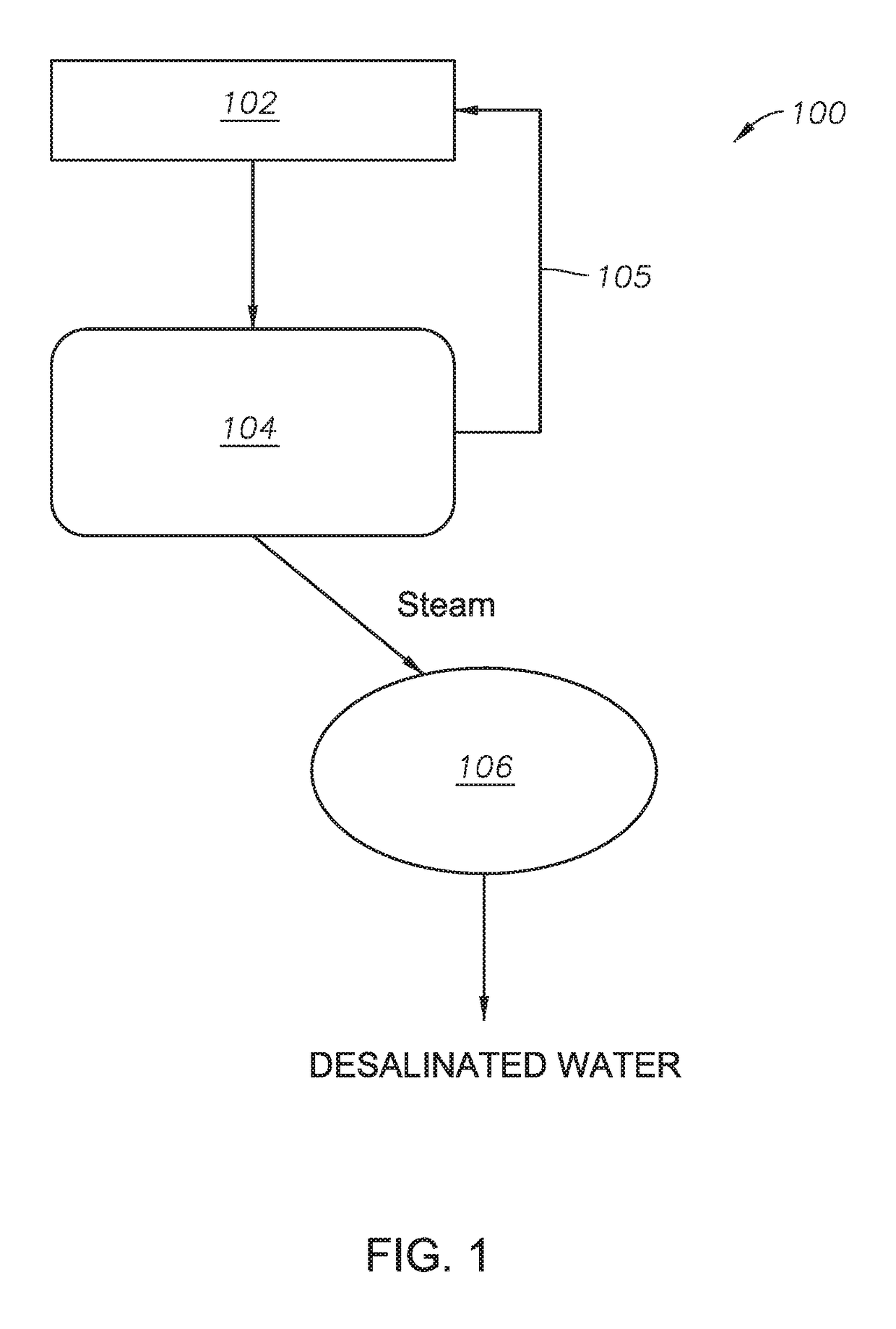

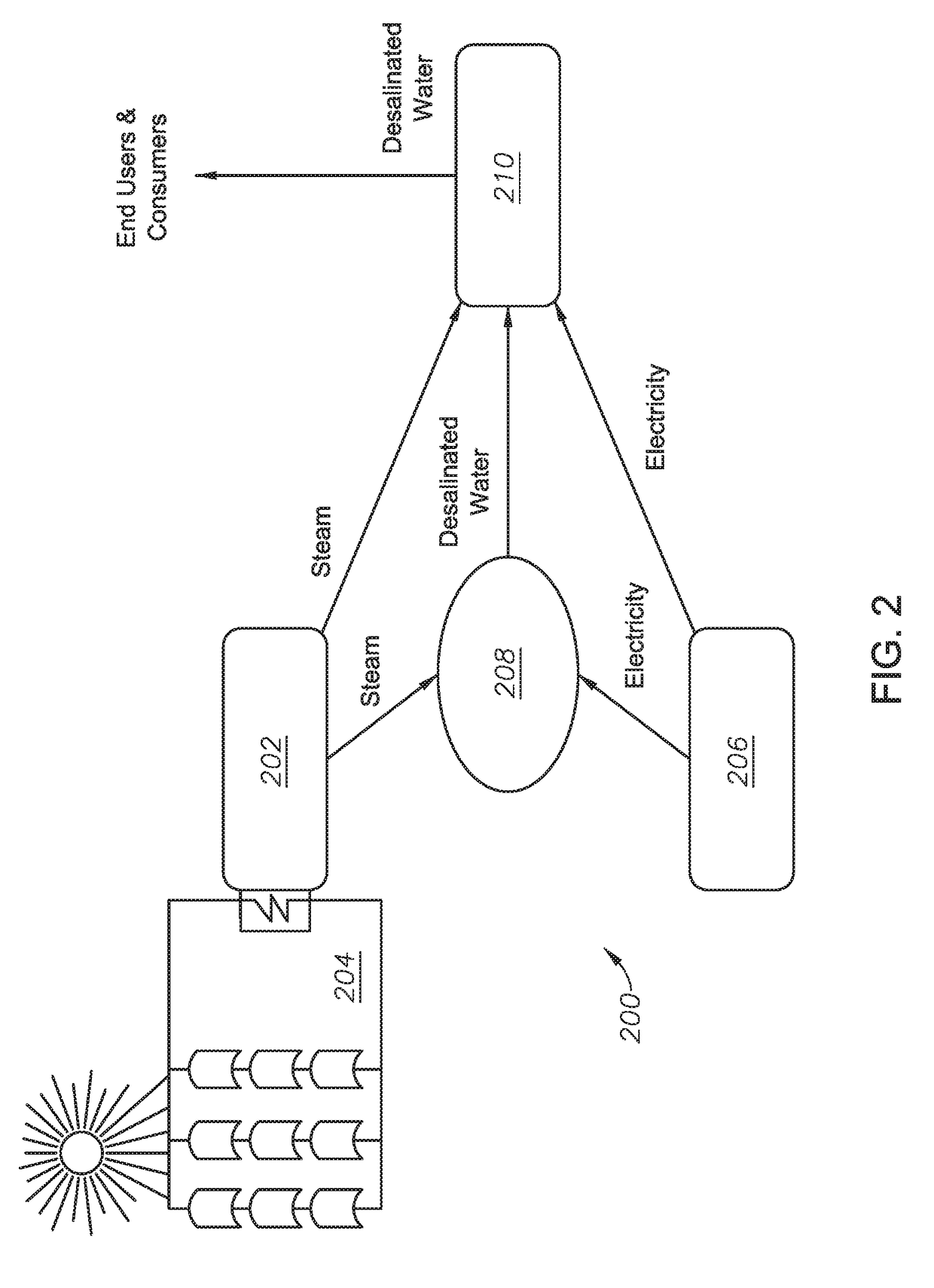

Coupling photovoltaic and concentrated solar power technologies for desalination

ActiveUS10065868B2Eliminate needSolar heating energyGeneral water supply conservationWater sourceEngineering

Systems and methods for the desalination of water are disclosed. A system includes a concentrated solar power (CSP) system, the CSP system operable to concentrate solar energy to increase temperature and pressure of a heat transfer fluid and operable to produce steam utilizing heat from the heat transfer fluid; a photovoltaic (PV) system, the PV system operable to collect solar energy to produce electricity; a desalination system in fluid communication with the CSP system and in electrical communication with the PV system, the desalination system operable to produce desalinated water from a salt water source utilizing the steam from the CSP system and electricity from the PV system; and a pump station in fluid communication with the CSP system and the desalination system, and in electrical communication with the PV system, the pump station operable to transmit the desalinated water to consumers for use.

Owner:SAUDI ARABIAN OIL CO

Monitoring and controlling unit operations

InactiveUS20070017291A1Efficiently sensingEffective monitoringProcess control/regulationAnalysing solids using sonic/ultrasonic/infrasonic wavesDistillationUnit operation

Fluid sensor methods and systems adapted for monitoring and / or controlling distillation operations in fluidic systems, such as batch distillation operations or continuous distillation operations, are disclosed. Preferred embodiments are directed to process monitoring and / or process control for unit operations involving endpoint determination of a distillation, for example, as applied to a liquid-component-switching operation (e.g., a solvent switching operation), a liquid-liquid separation operation, a solute concentration operation, a dispersed-phase concentration operation, among others.

Owner:MEAS FRANCE

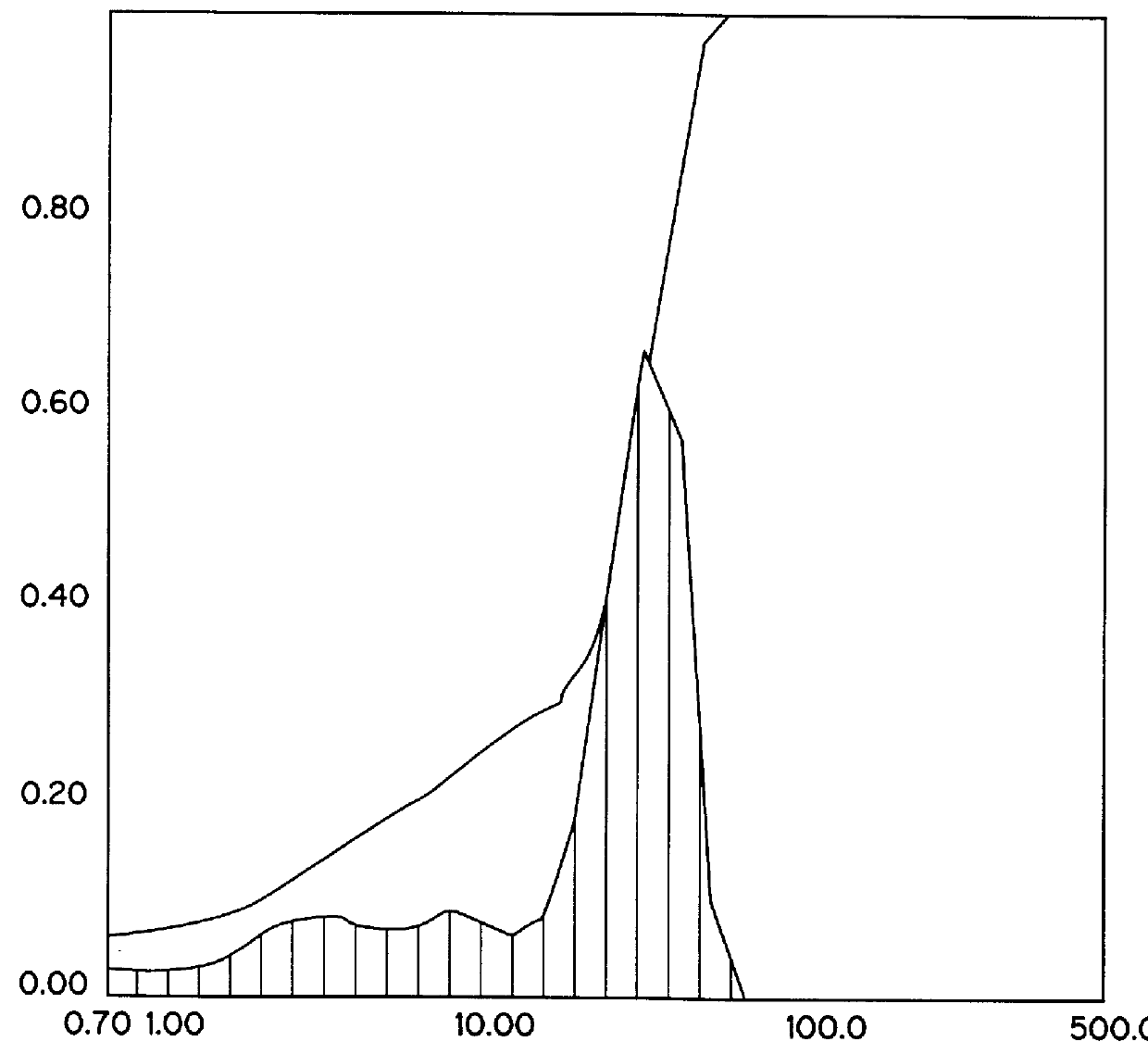

Method for the processing of a liquid reaction discharge of the cationic polymerization of isobutene

InactiveUS7038008B2Easy to useUndesired reactionWater/sewage treatment by centrifugal separationReversed direction vortexGas phaseCationic polymerization

A process for working up a liquid reaction discharge of the cationic polymerization of isobutene, which substantially comprises polyisobutene, unconverted isobutene and an inert diluent, in which the reaction discharge is heated and is let down into a flash container, is described, the reaction discharge separating, as a result of the flashing, into a polyisobutene-containing liquid phase and a gas phase containing the main amount of the isobutene contained in the reaction discharge and of the diluent.

Owner:BASF AG

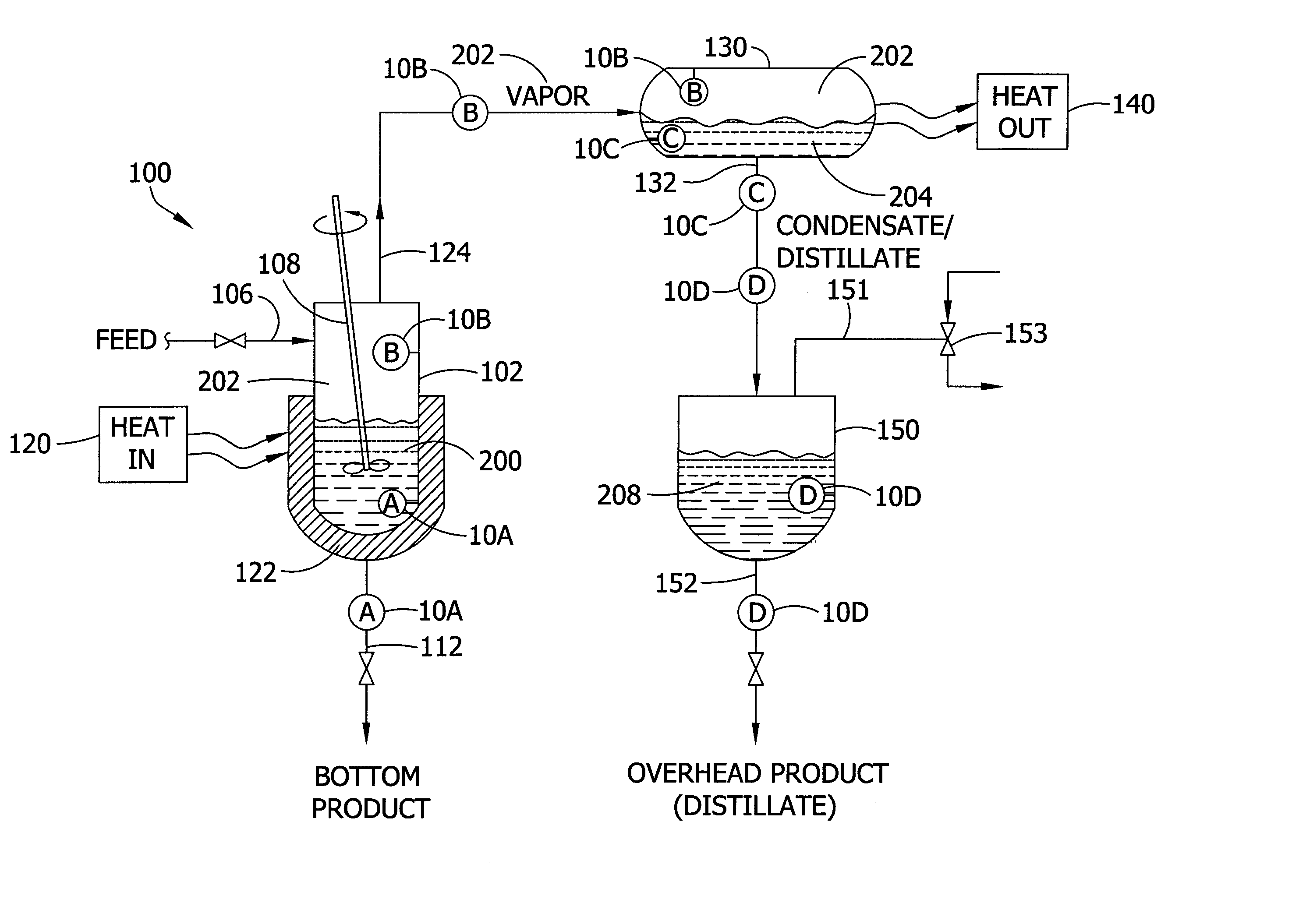

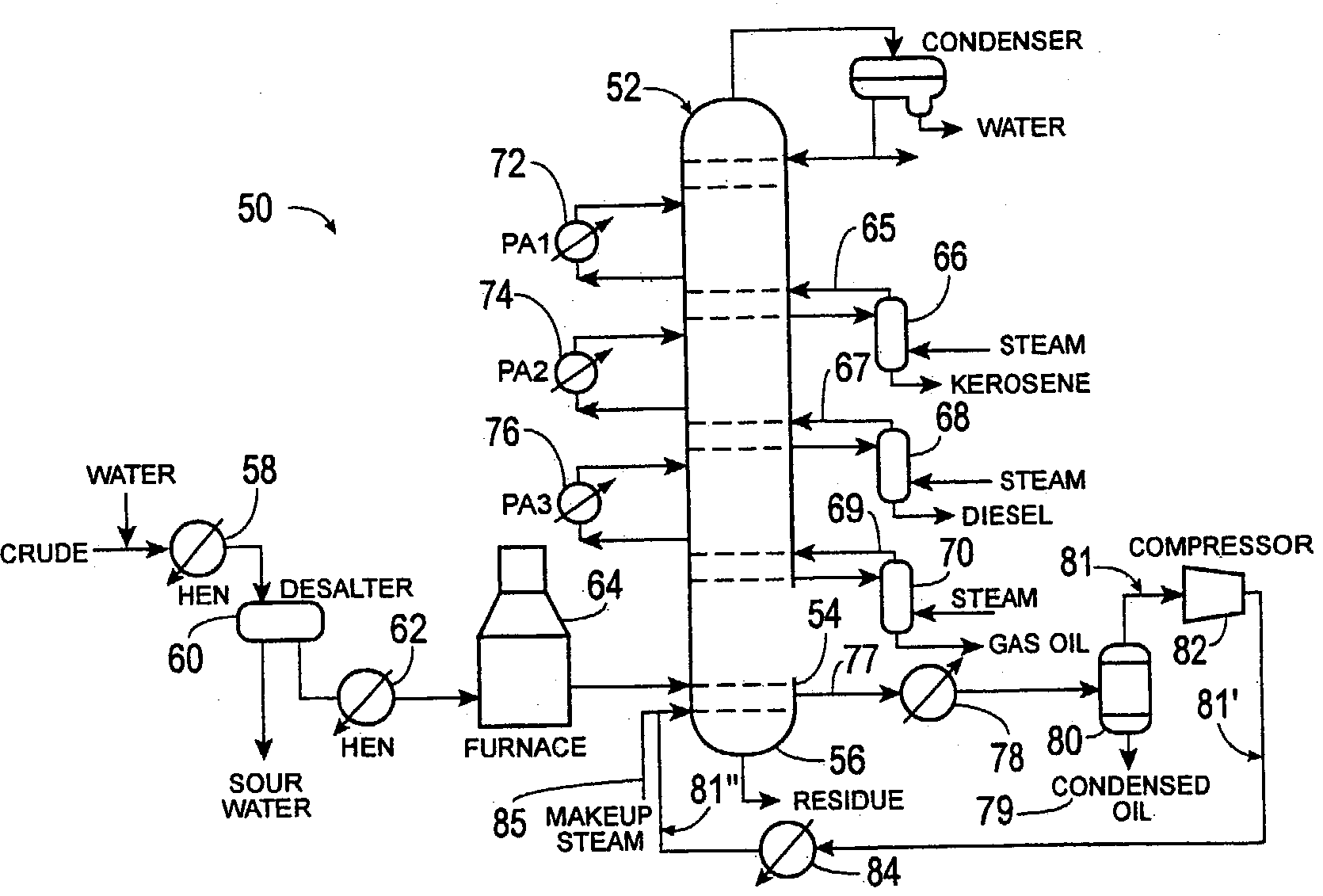

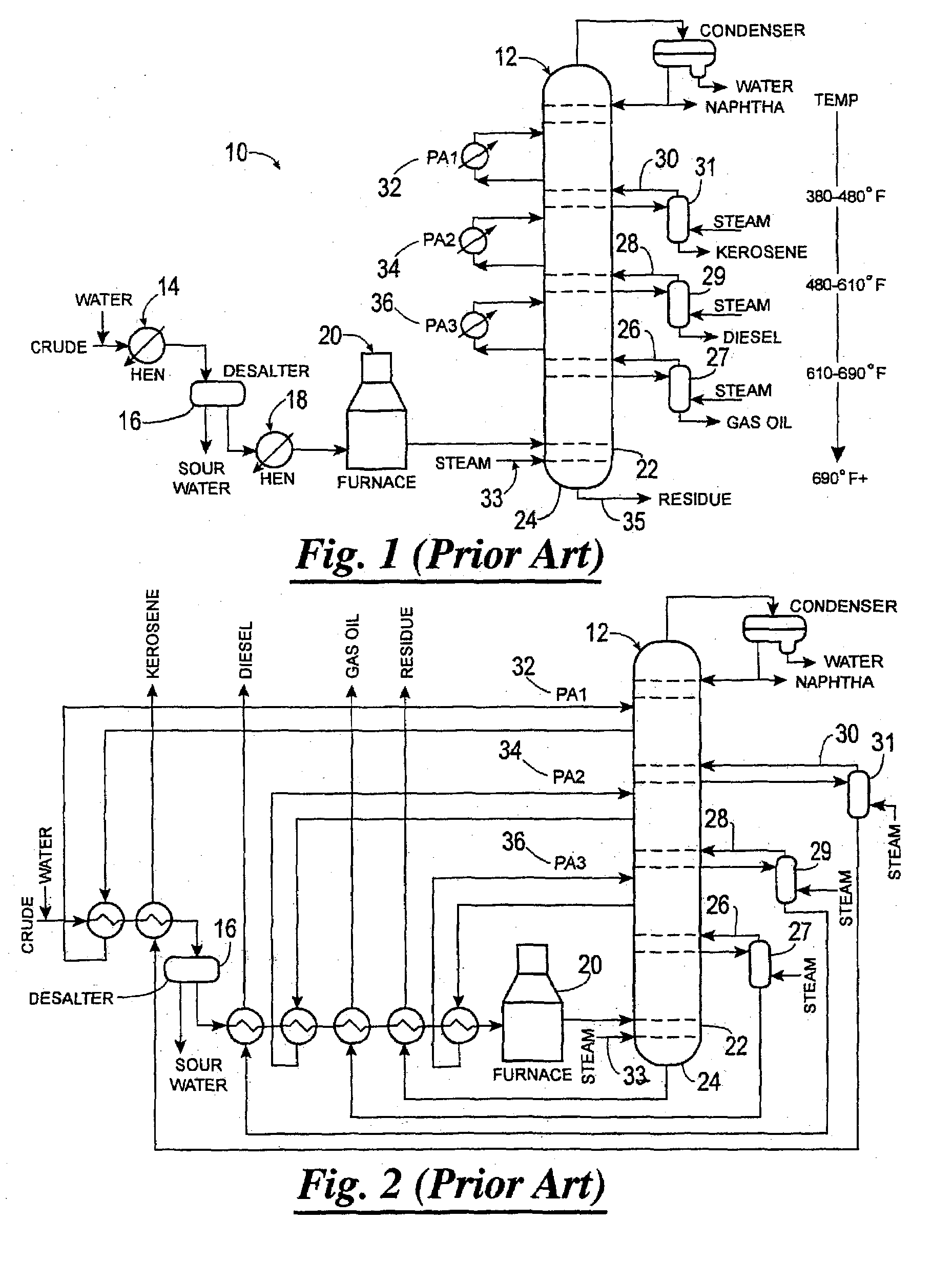

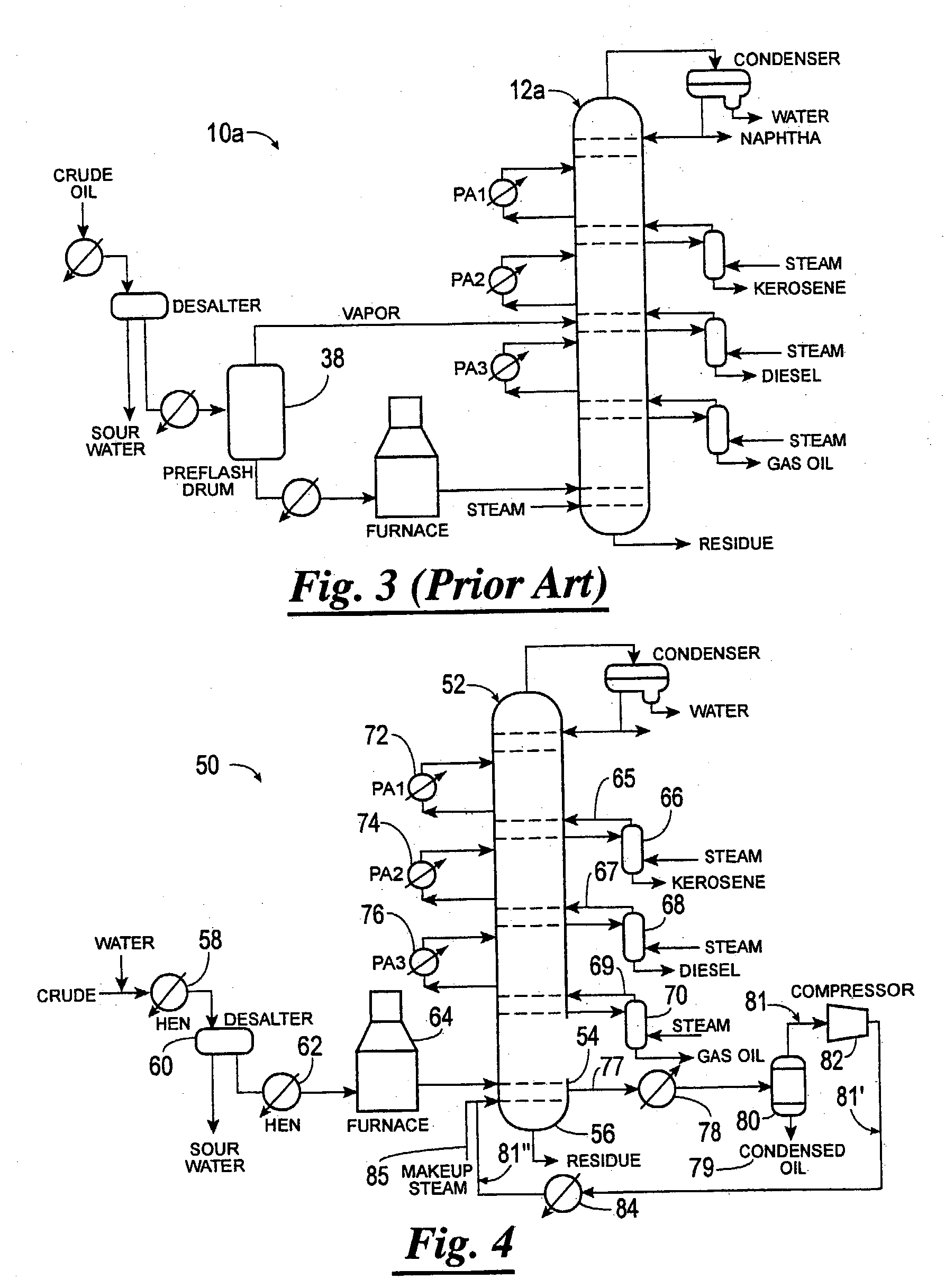

Method of increasing distillates yield in crude oil distillation

Methods of separating components of a mixture, such as crude oil, are disclosed which increase the yield of individual components while decreasing the yield of residue. In one method, a heated mixture is fed to a column, a vapor stream is withdrawn from the column and separated, and a portion of the vapor stream is recycled back to the column. In another method, a mixture is separated into streams composed substantially of components having light, intermediate or heavy molecular weight and / or low, intermediate or high boiling point, respectively, and the streams are fed into the column at different positions. In both methods, individual light, intermediate and / or heavy molecular weight and / or low, intermediate and / or high boiling point component streams are then selectively withdrawn from the column.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

Apparatus for separating particulates from a suspension, and uses thereof

InactiveUS7179379B2Stir wellDiscouraging decarboxylation reactionMultiple-effect/fractional condensationAnimal corpse fertilisersParticulatesSpeciality chemicals

The present invention includes an apparatus for separating particulates from a fluid in a suspension, comprising: a housing defining a frusto-conically shaped inner chamber with an inner wall, an inlet and a first outlet communicating with the chamber, and a second outlet; and a spinning assembly with a hollow interior mounted in the chamber, the assembly being shaped to define an annular gap with the chamber inner wall, the hollow interior communicating with the second outlet, and the hollow interior communicating with the annular gap for flow of fluid materials from the gap into the interior and out of the second outlet in response to rotation of the spinning assembly. The separator finds application in the preparation of waste products such as municipal sewage sludge for processes that produce useful materials including gas, oil, specialty chemicals, fertilizer, and carbon solids, in reliable purities and compositions, and with high energy efficiency.

Owner:AB CWT LLC

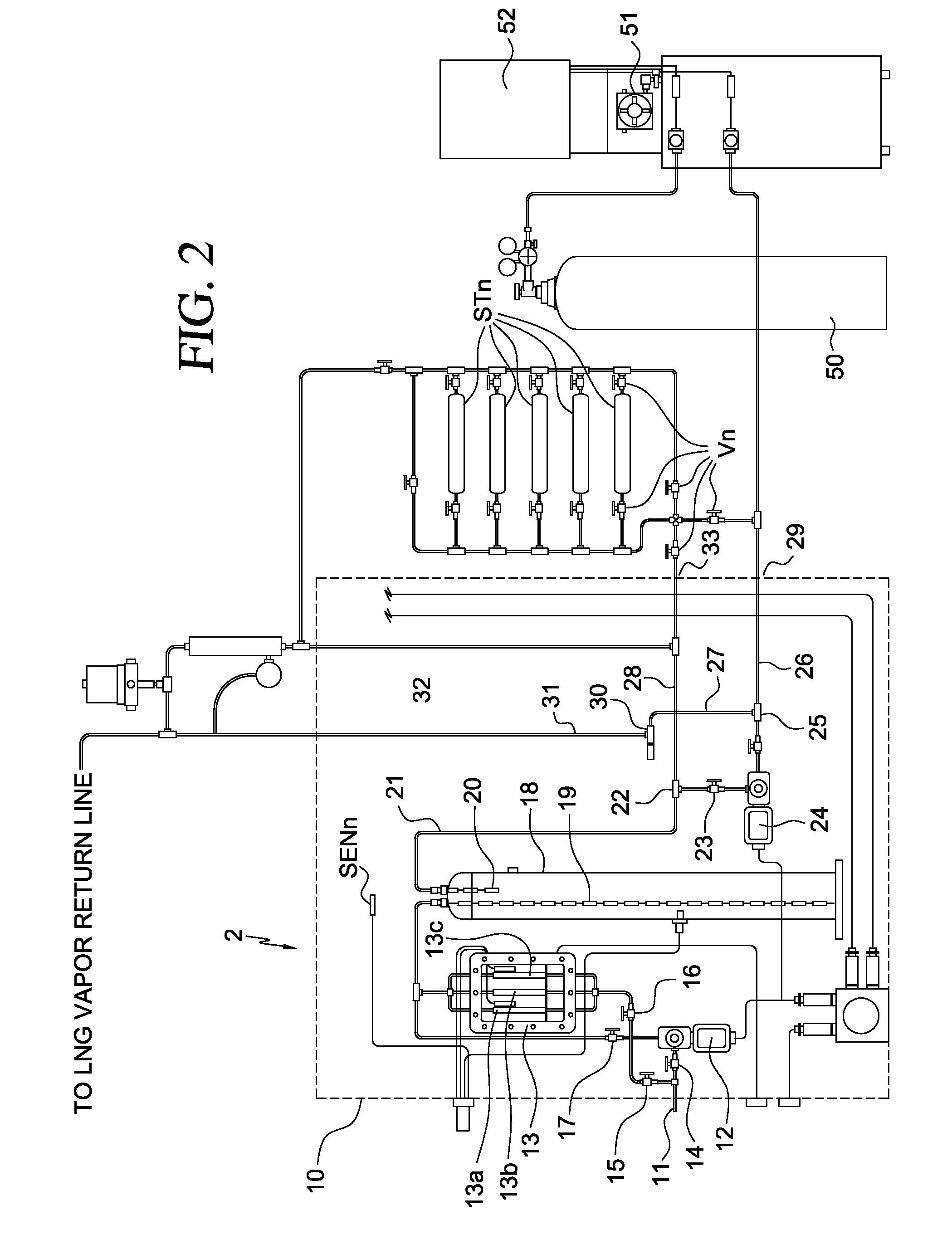

Liquid Gas Vaporization and Measurement System and Method

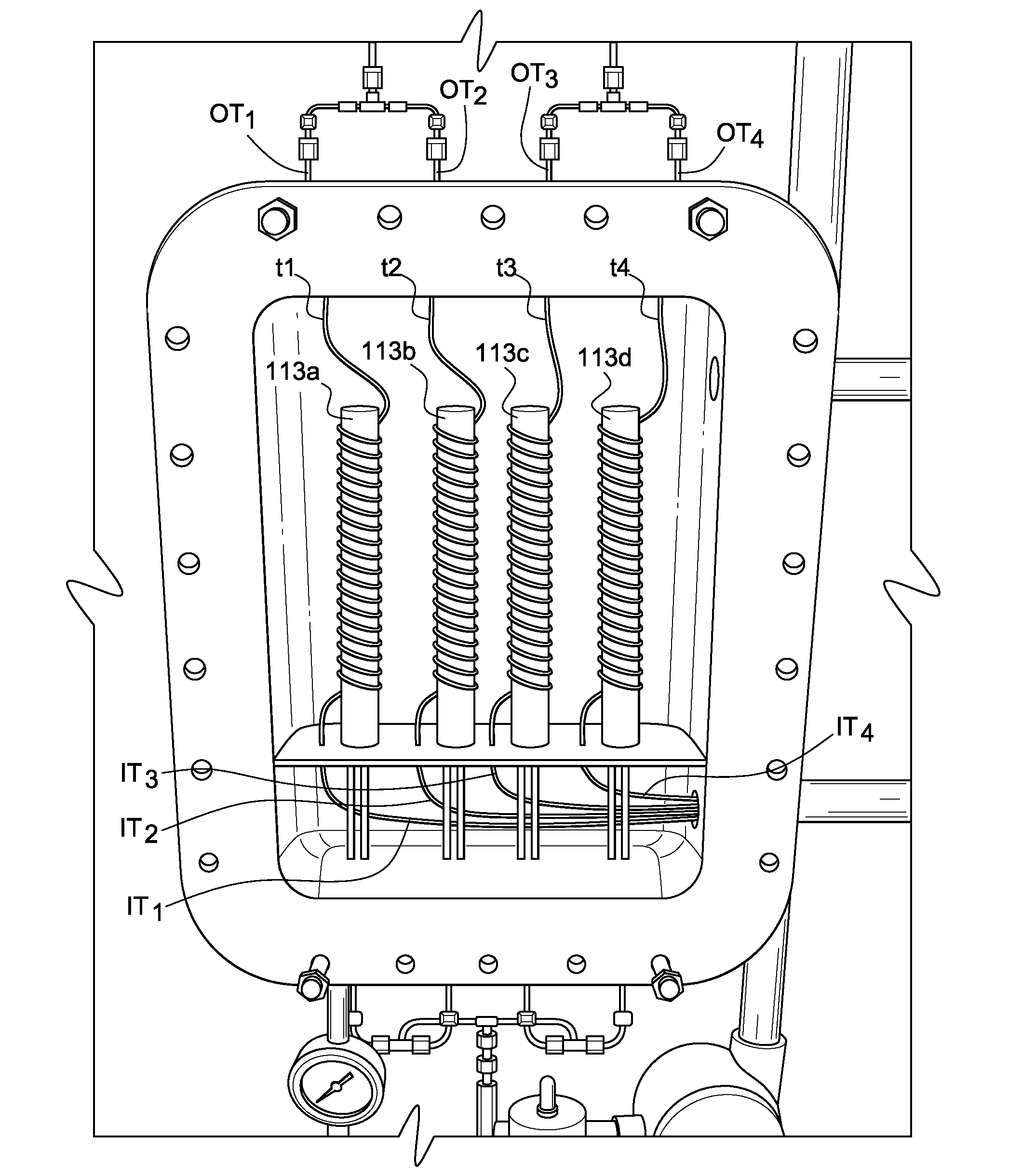

ActiveUS20090151427A1Efficiently flash vaporizeEfficiently and accurately sampling and measuringSpace heating and ventilationGas handling applicationsMass storageMeasuring instrument

A liquid gas vaporization and measurement system, and associated method, for efficiently vaporizing a continuous sample of liquid gas, such as liquid natural gas (LNG), and accurately determining the constituent components of the gas. A constant flow of liquid gas sampled from a mass storage device is maintained in a vaporizing device. Within the vaporizing device the liquid gas is flash vaporized within heated narrow tubing. The liquid gas is converted to vapor very quickly as it enters one or more independently operating vaporizer stages within the vaporizing device. The vapor gas is provided to a measuring instrument such as a chromatograph and the individual constituent components and the BTU value of the gas are determined to an accuracy of within + / −0.5 mole percent and 1 BTU, respectively.

Owner:MUSTANG SAMPLING

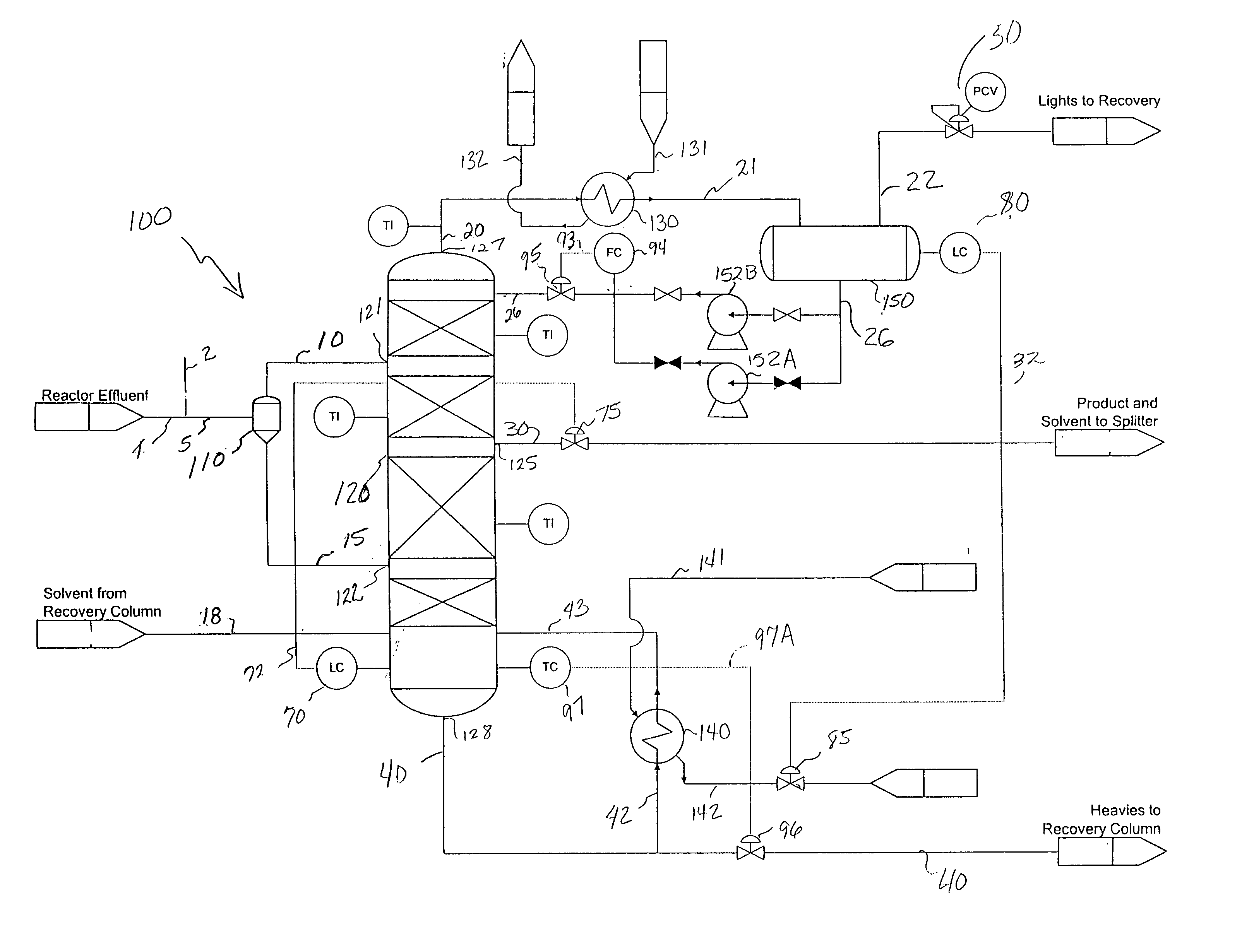

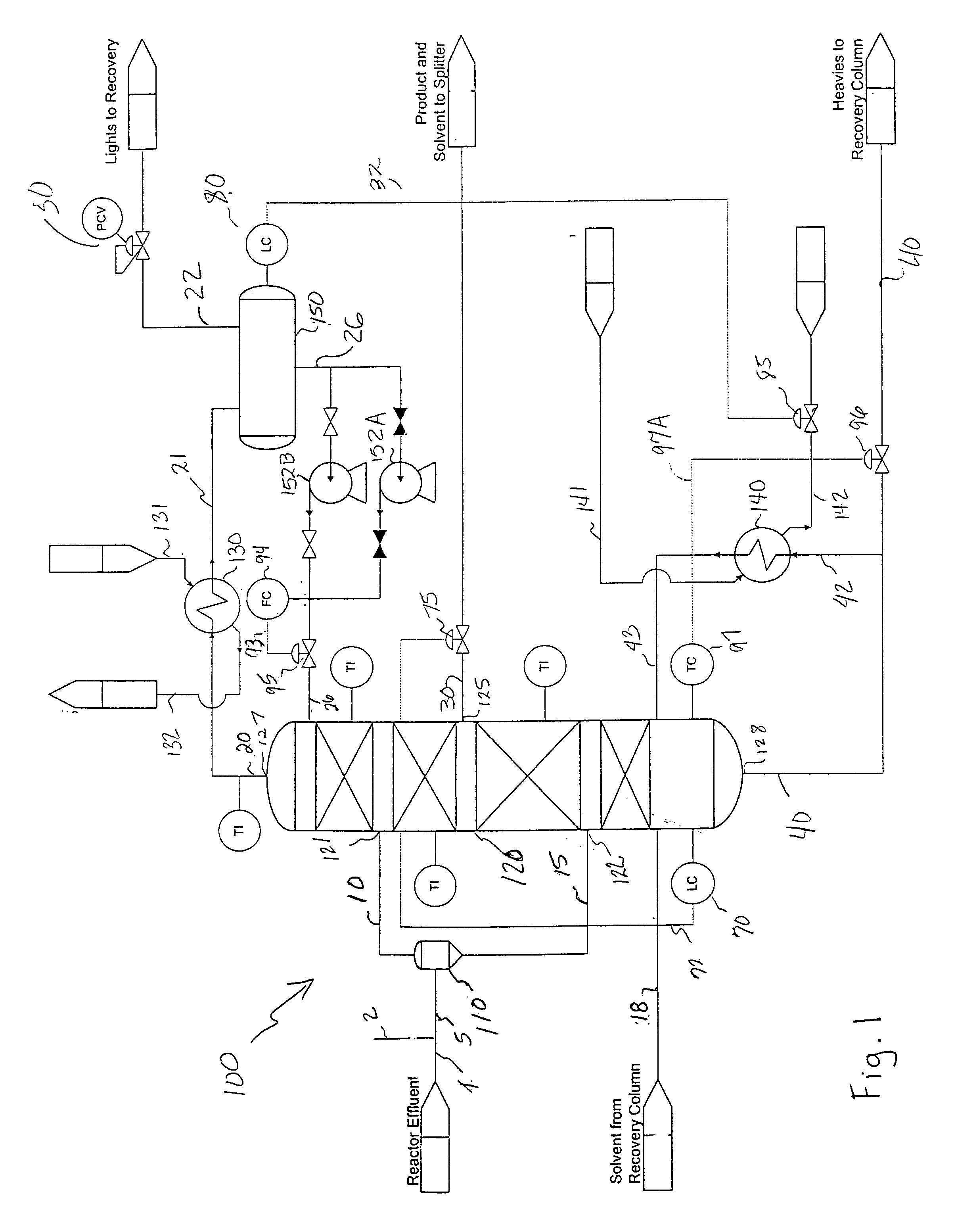

Method and system for separating an oligomerization reactor effluent

A method of separating an oligomerization reactor effluent, comprising: flashing the oligomerization reactor effluent into a liquid portion and a vapor portion, distilling the liquid and the vapor portions of the oligomerization reactor effluent and recovering an oligomerization product stream. A system for separating an oligomerization reactor effluent comprising liquid and vapor portions: a vapor / liquid separator to flash the oligomerization reactor effluent into a vapor portion and a liquid portion, and a distillation column in fluid communication with the vapor / liquid separator, wherein the distillation column has a side draw for withdrawing an oligomerization product stream and receives as separate feeds the vapor portion and the liquid portion from the vapor / liquid separator.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

Owner:EXXON RES & ENG CO

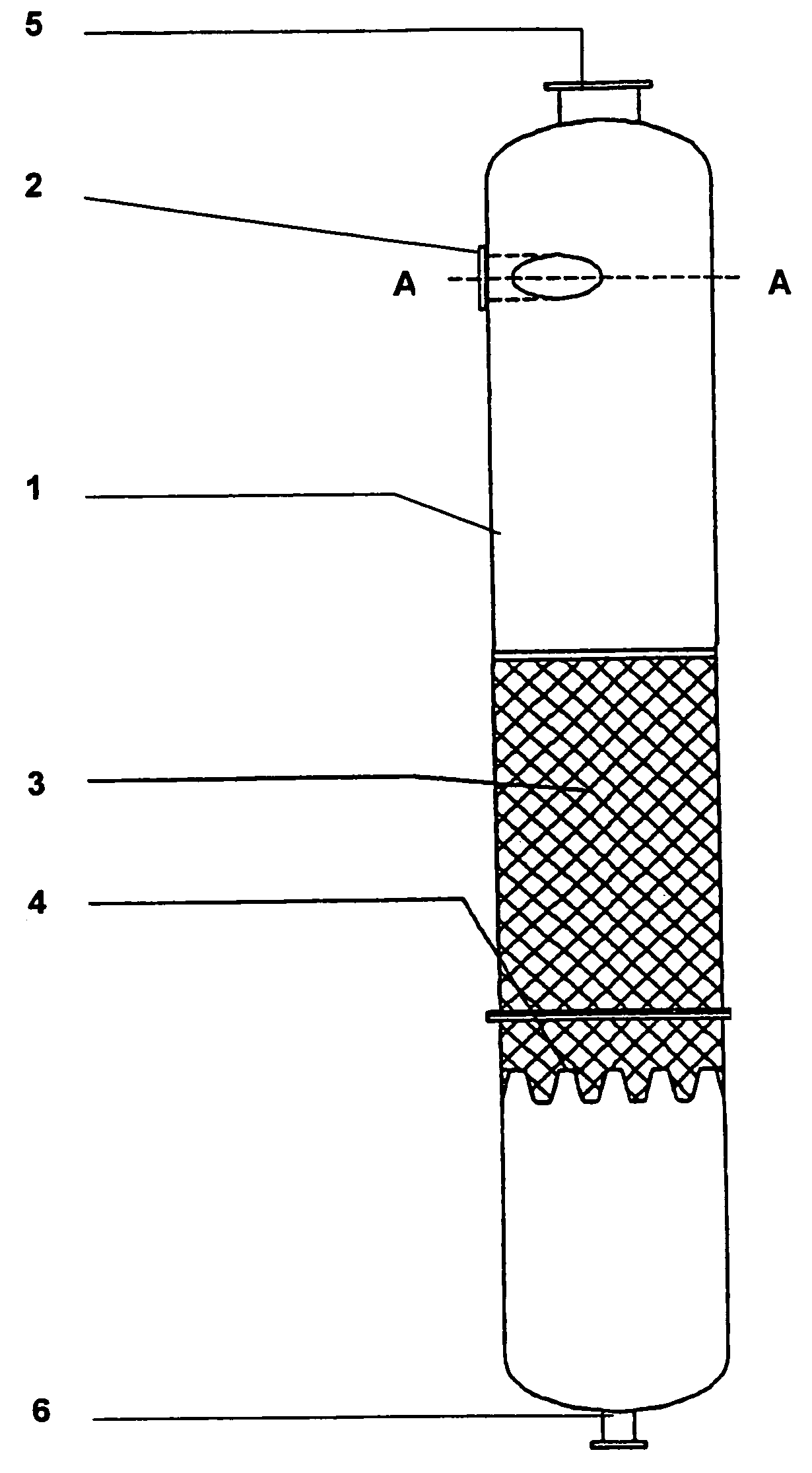

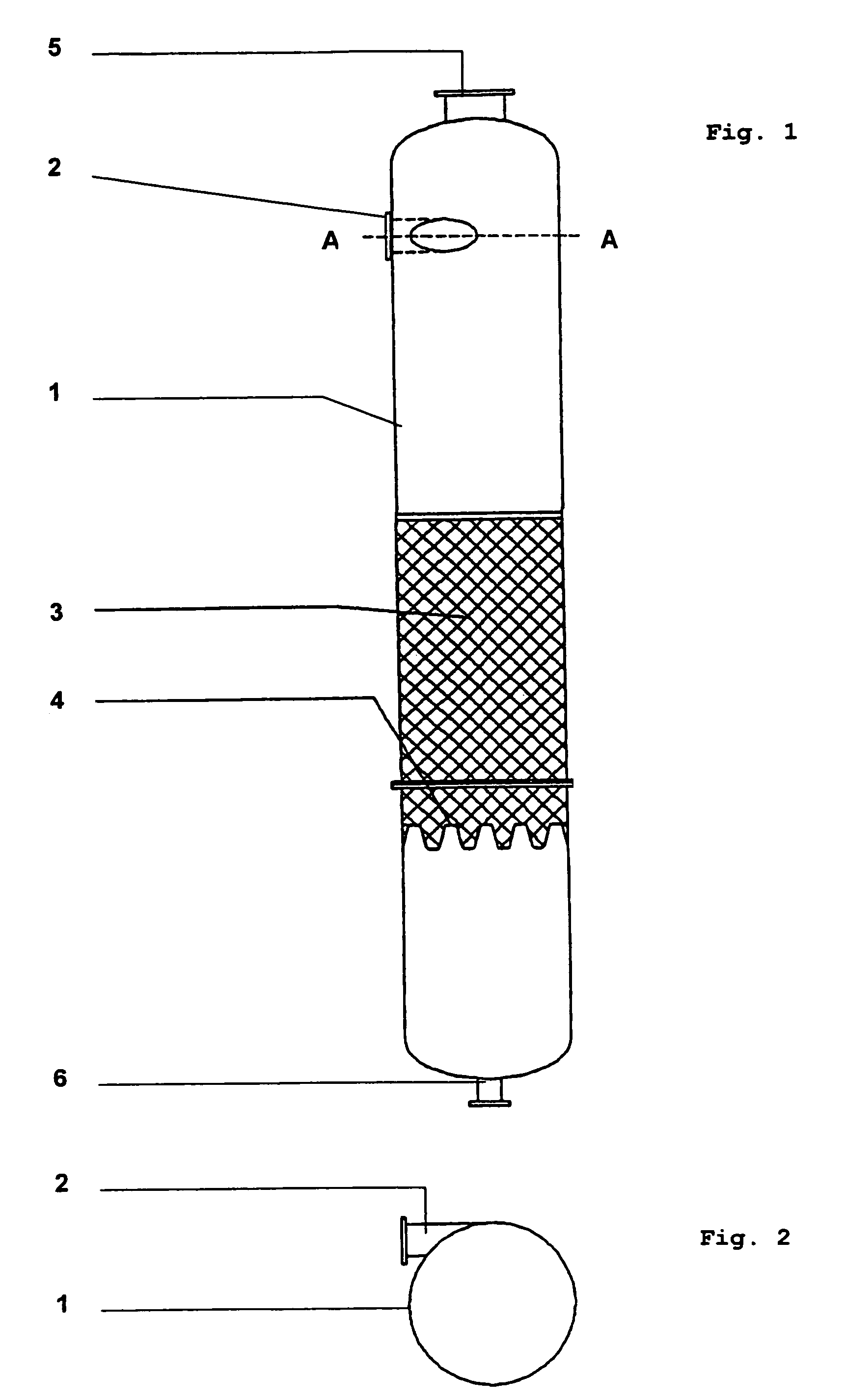

Solvent extraction of hydrocarbons from inorganic materials and solvent recovery from extracted hydrocarbons

InactiveUS6207044B1No pollution to the environmentIncrease surface areaLiquid organic insulatorsWorking-up pitch/asphalt/bitumen by chemical meansHydrocarbon solventsSolvent vapor

A process for the solvent separation of hydrocarbons from tar sand or contaminated soils comprises extracting the hydrocarbons from the sand or soil in a solvent extraction means to form a hydrocarbon rich solvent solution. The rich solvent is separated from the hydrocarbon in a process that utilizes flashing of the solvent in a heated flashing column at ambient pressure. The hydrocarbon is withdrawn from the bottom of the column and the flashed solvent vapors are strategicly withdrawn and passed into a condensation column from which the condensed solvent may be recycled. The flashing column is divided by a series of horizontal, vertically aligned apertured trays. The solution is introduced into the top of the column and the flashing operation is facilitated by the increase in the surface area of the solution as it flows by gravity from tray to tray. The column is maintained at a temperature, preferably above the boiling temperature of the solvent. The process is particularly adapted to the use of chlorinated hydrocarbon solvents and most particularly to the use of methylene chloride.

Owner:LUCENT TECH INC

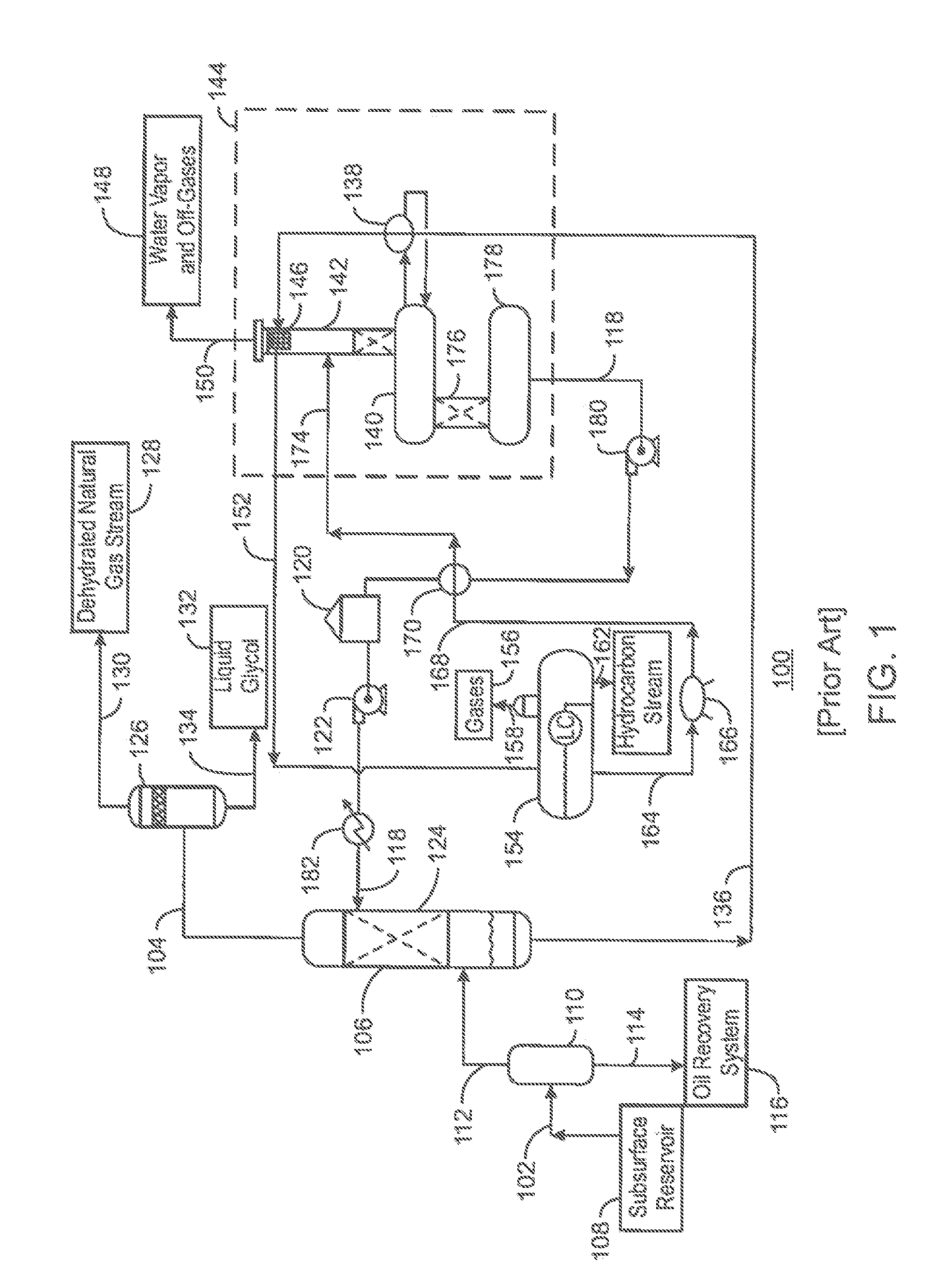

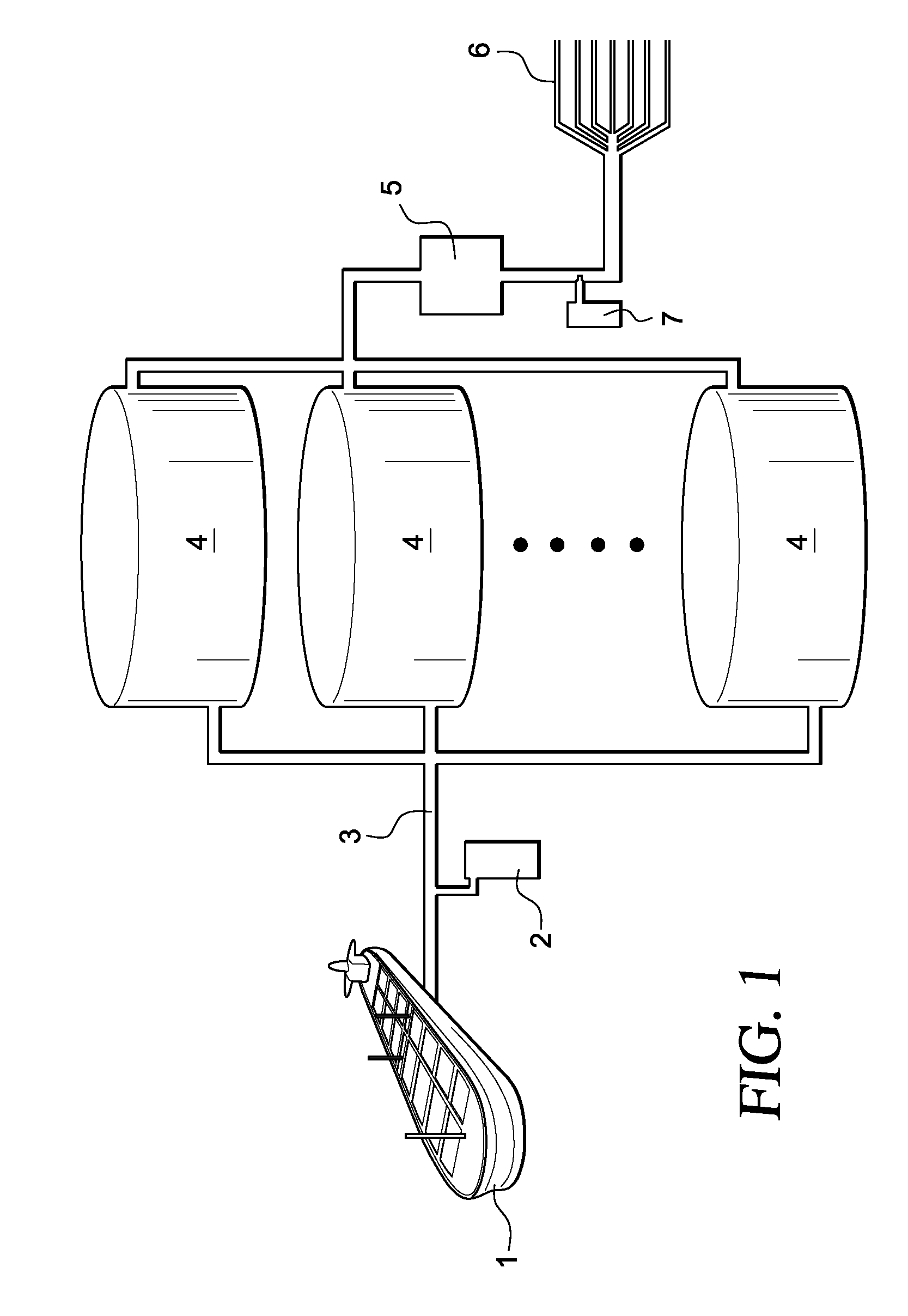

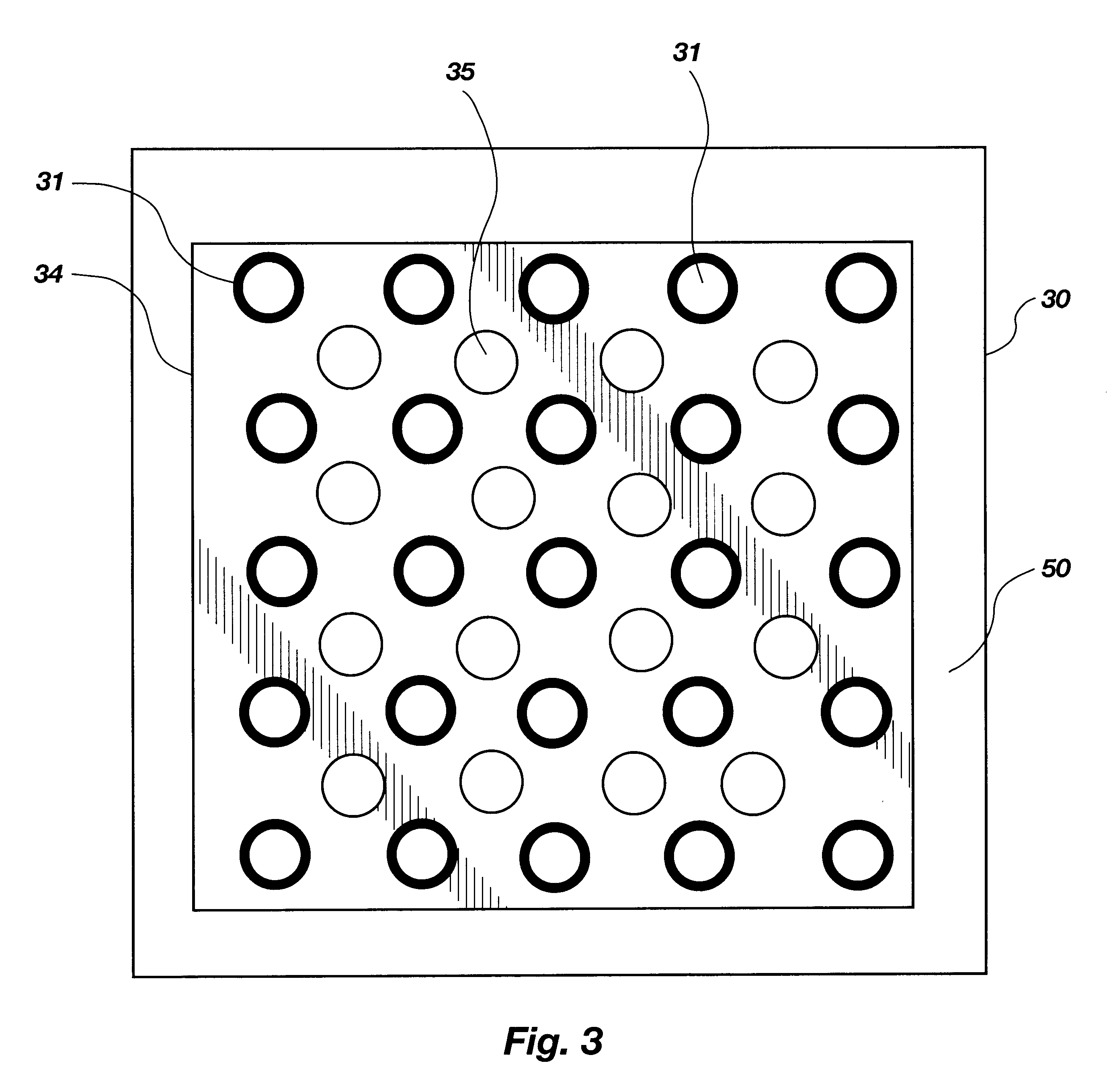

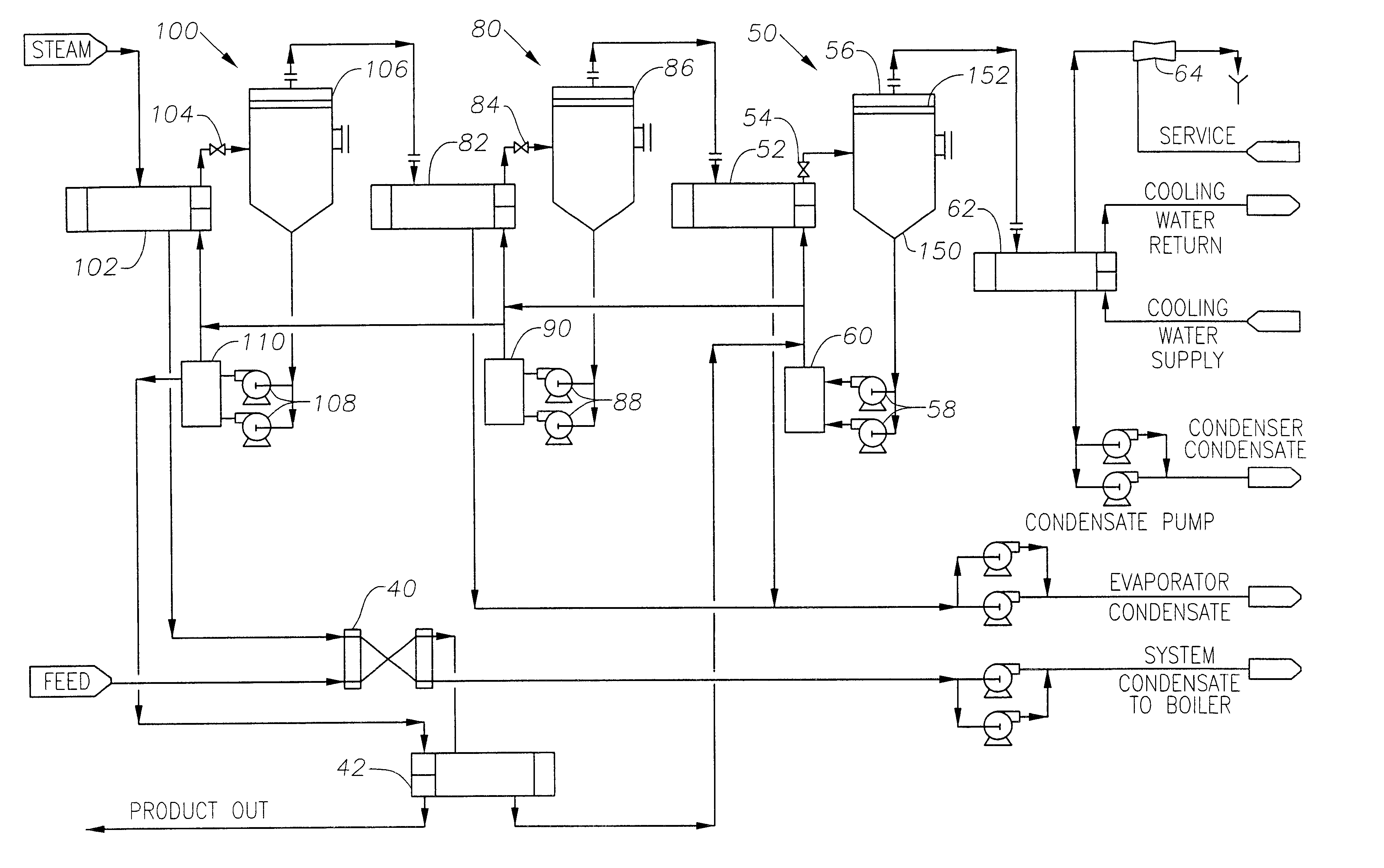

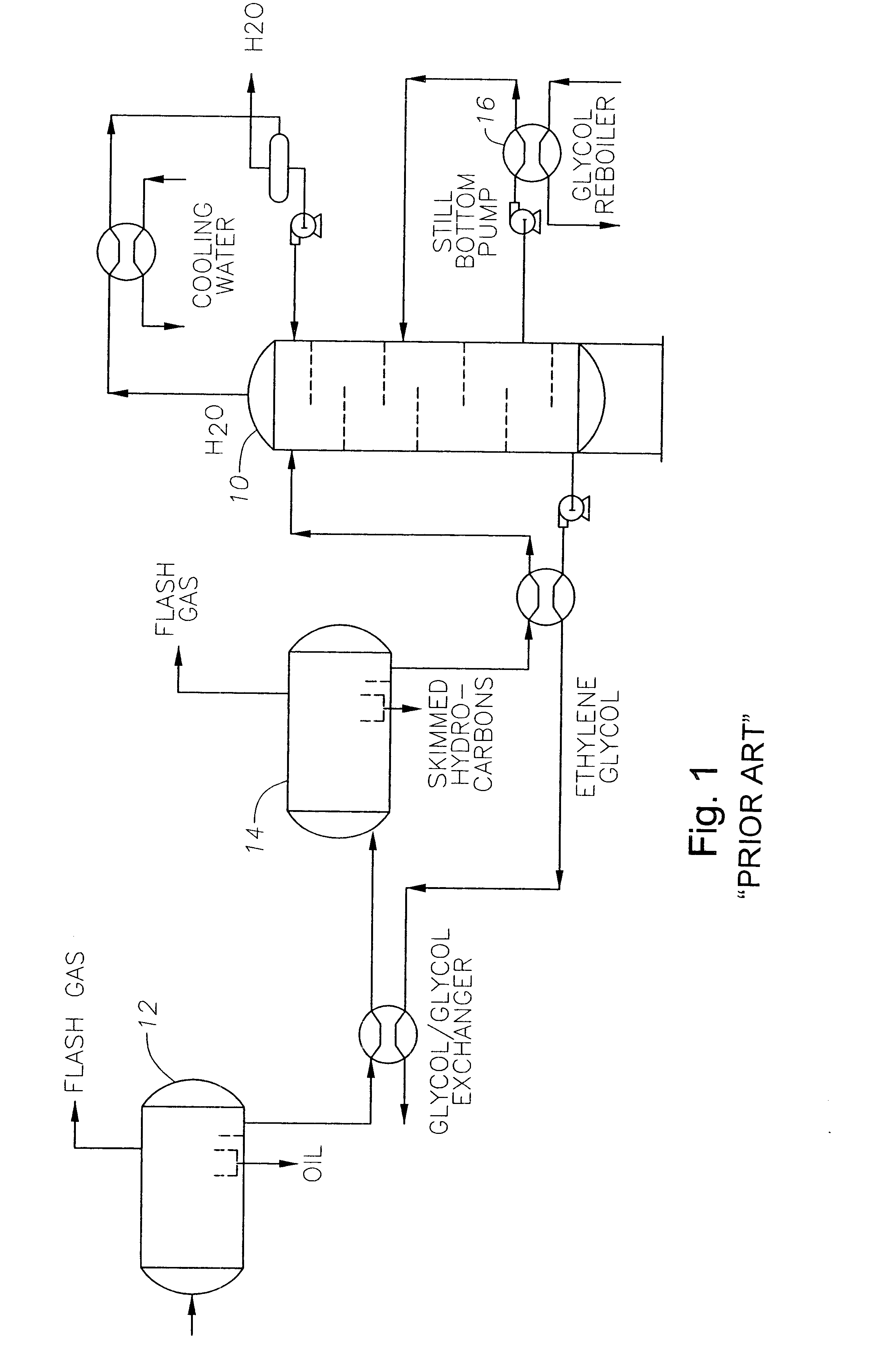

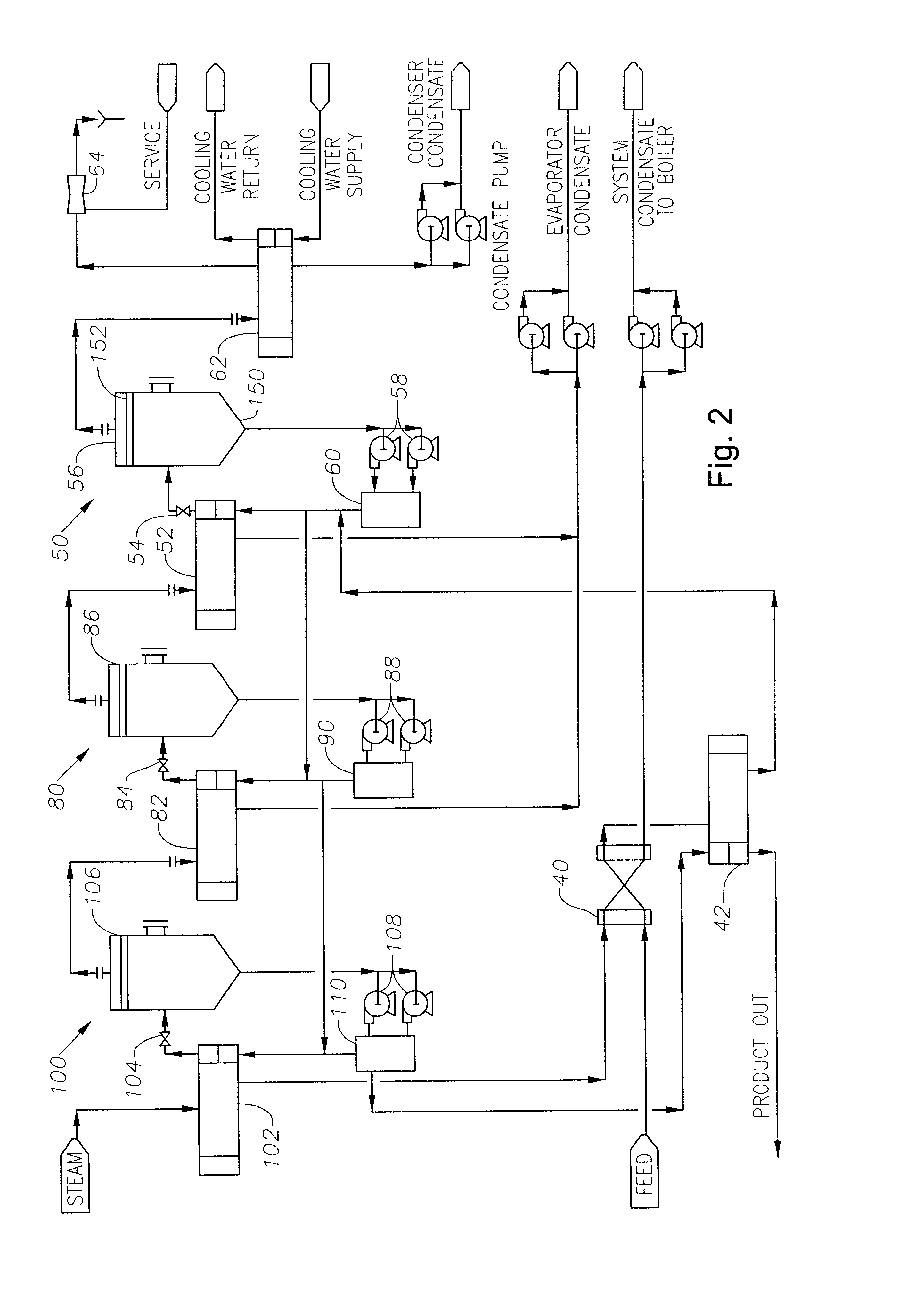

System for recovering glycol from glycol/brine streams

A system for recovering glycol from glycol and brine mixtures produced from oil or natural gas wells that combines energy efficiency with a capability for handling salt and other solids contained in the mixture. The system comprises three effect evaporator systems in series. Each effect evaporator system comprises an evaporator, a separator vessel, product pumps, and a solids removal system.The process utilizes the system to remove salt and other solids as well as excess water leaving a glycol stream that can be reused as a hydrate inhibitor. The process begins by preheating a glycol / brine stream comprising approximately fifty percent (50%) glycol. The stream is then subjected to three evaporation cycles. The first evaporation cycle comprises introducing the preheated stream into a suppressed boiling point evaporator where the stream is heated under a constant pressure. The stream pressure is then dropped to cause a portion of the water contained in the stream to vaporize or flash. The flashing stream is then introduced into a separator vessel where the water vapor is separated from the remaining liquid stream. The water vapor is removed from the separator and condensed. The remaining liquid glycol / brine stream is then pumped from the separator vessel through a solids removal system where precipitated salts and solids are removed. These steps are repeated two additional times. Each time the remaining liquid stream becomes more concentrated with glycol until the finished product is approximately ninety percent (90%) glycol.

Owner:TRANSOCEAN SEDCO FOREX VENTURES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com