Patents

Literature

317 results about "Continuous distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

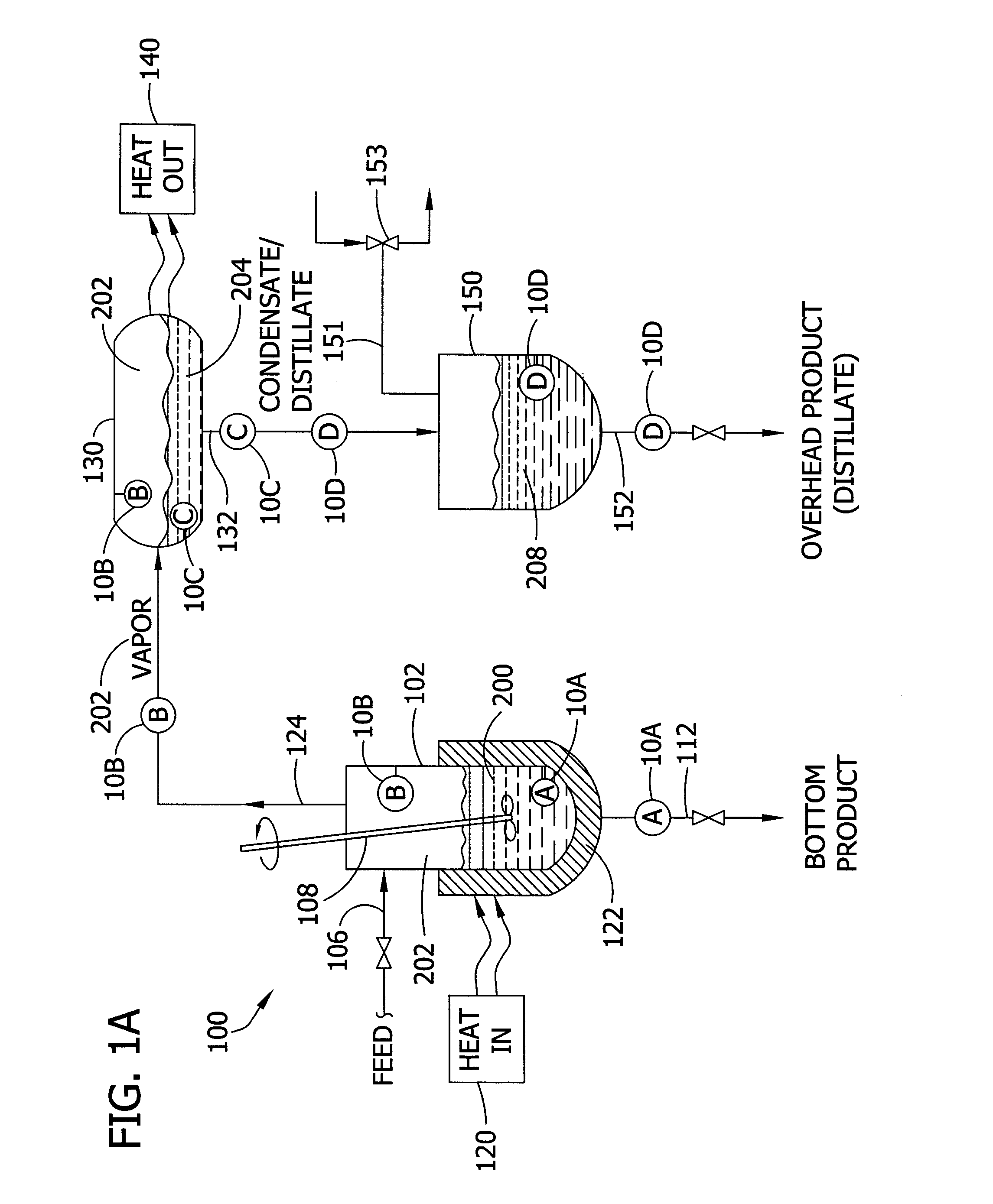

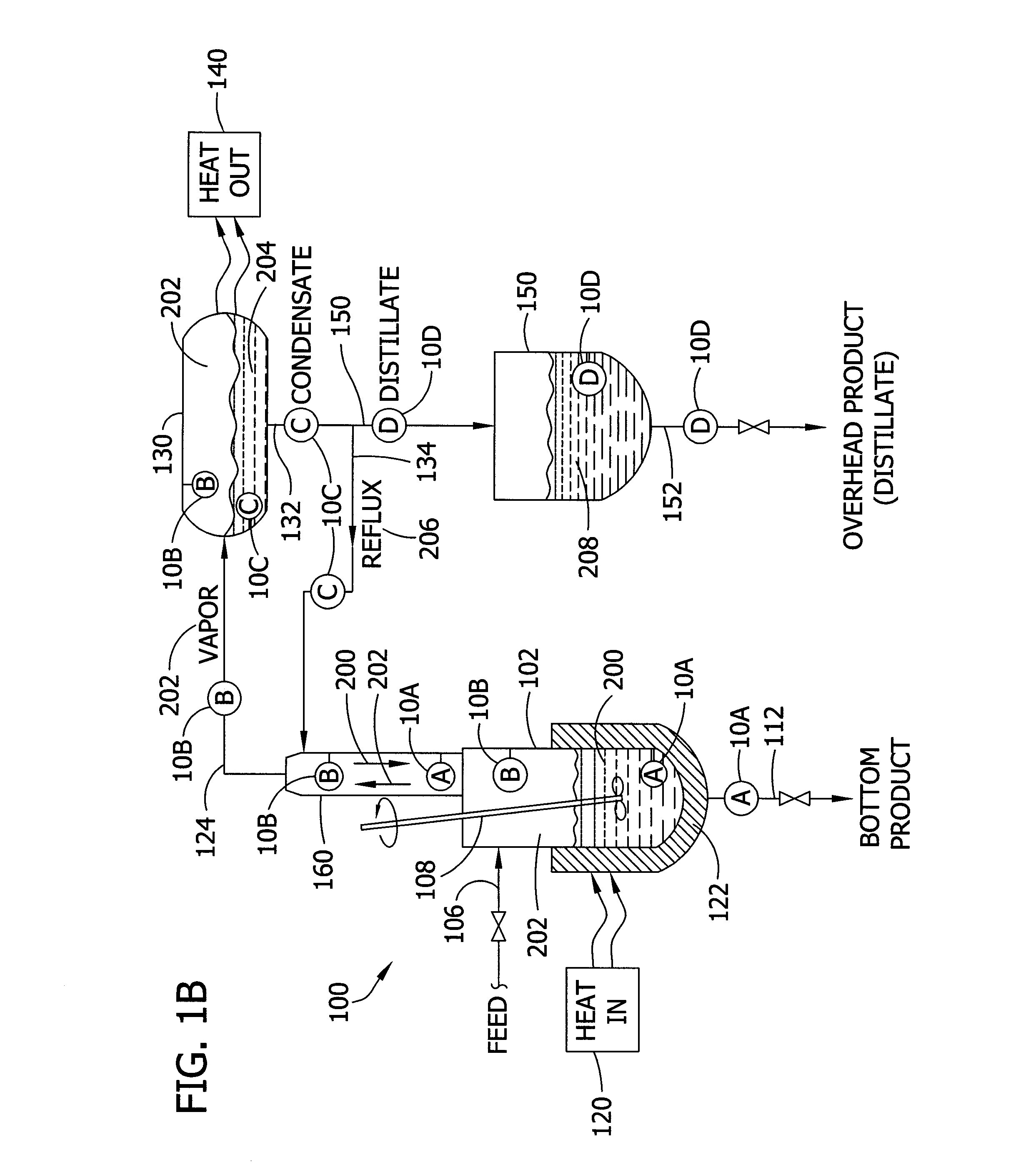

Continuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously (without interruption) fed into the process and separated fractions are removed continuously as output streams. Distillation is the separation or partial separation of a liquid feed mixture into components or fractions by selective boiling (or evaporation) and condensation. The process produces at least two output fractions. These fractions include at least one volatile distillate fraction, which has boiled and been separately captured as a vapor condensed to a liquid, and practically always a bottoms (or residuum) fraction, which is the least volatile residue that has not been separately captured as a condensed vapor.

Systems for monitoring and controlling unit operations that include distillation

InactiveUS7603889B2High sensitivityHigh dielectric constantProcess control/regulationAnalysing solids using sonic/ultrasonic/infrasonic wavesDistillationUnit operation

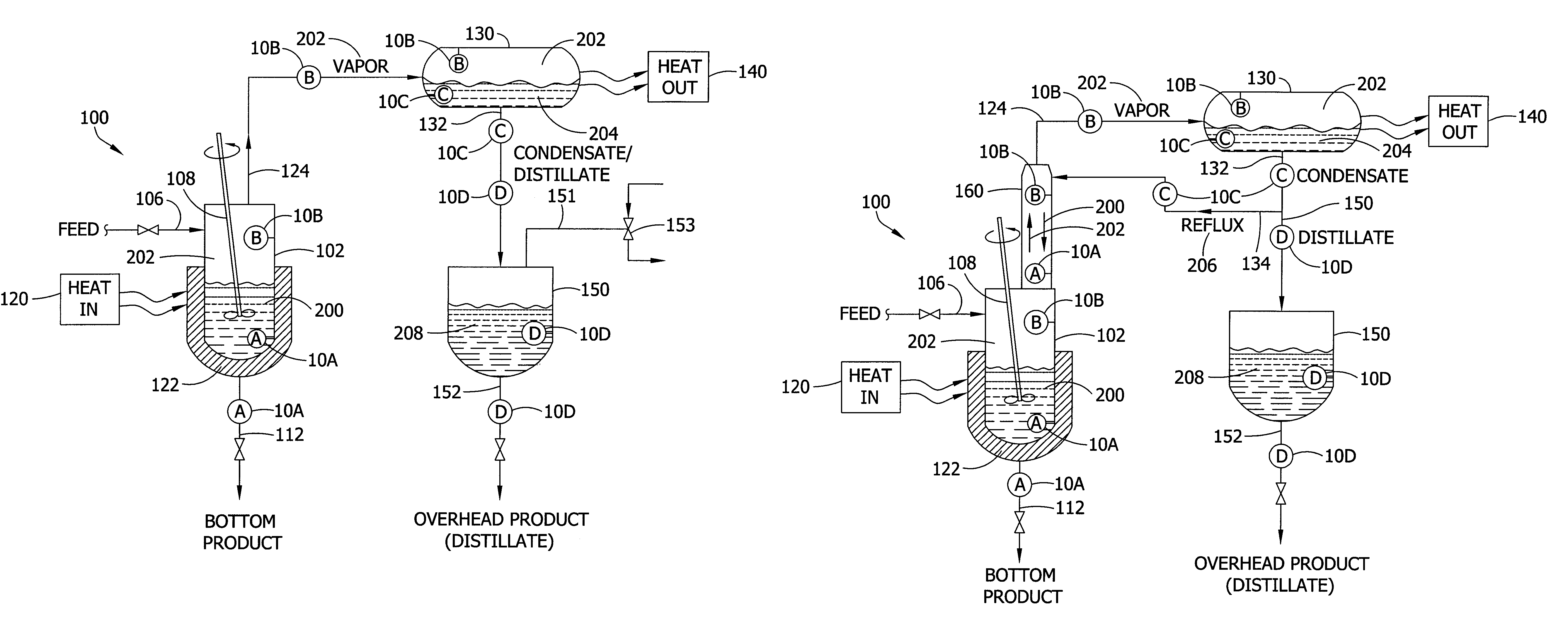

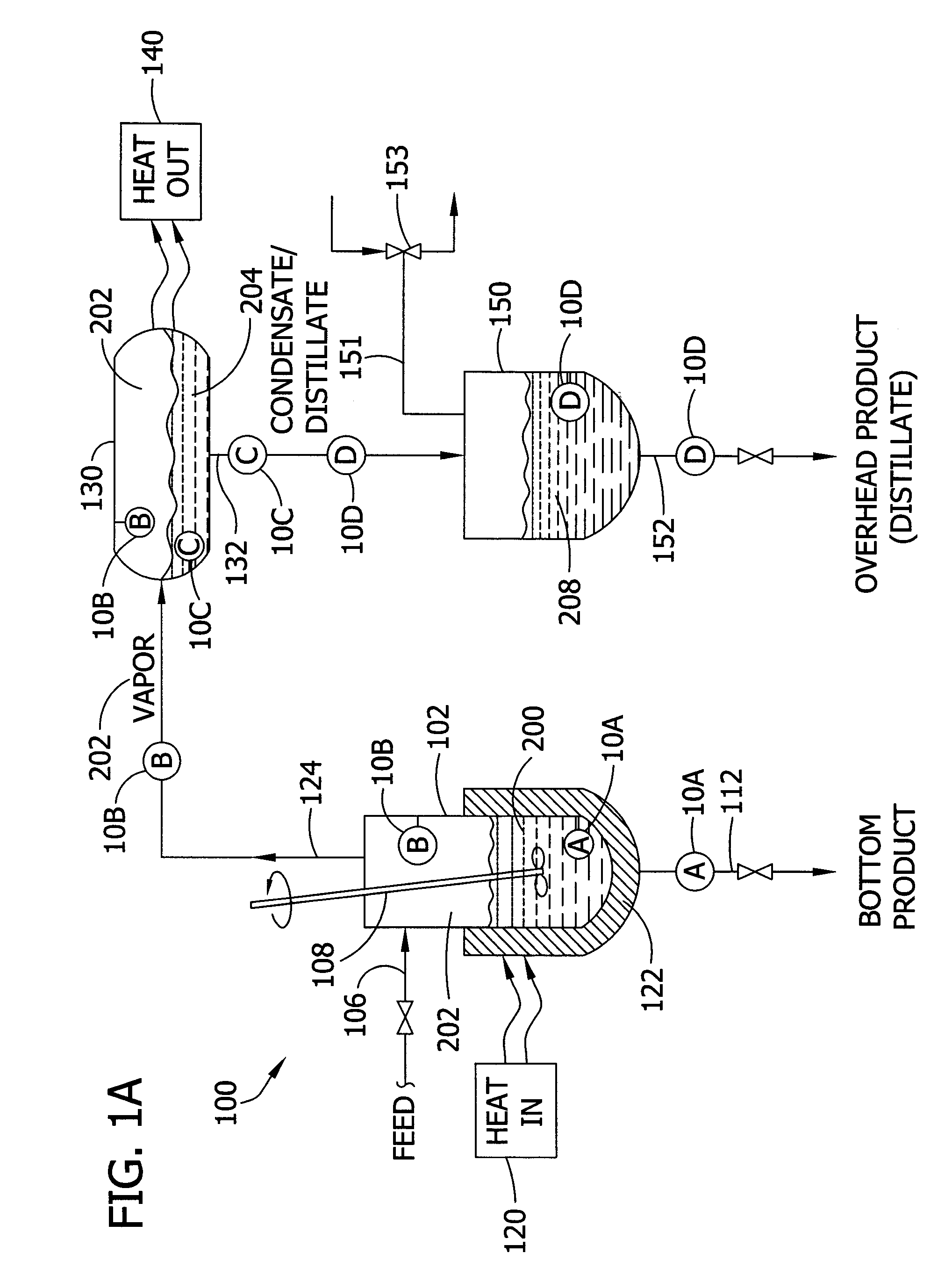

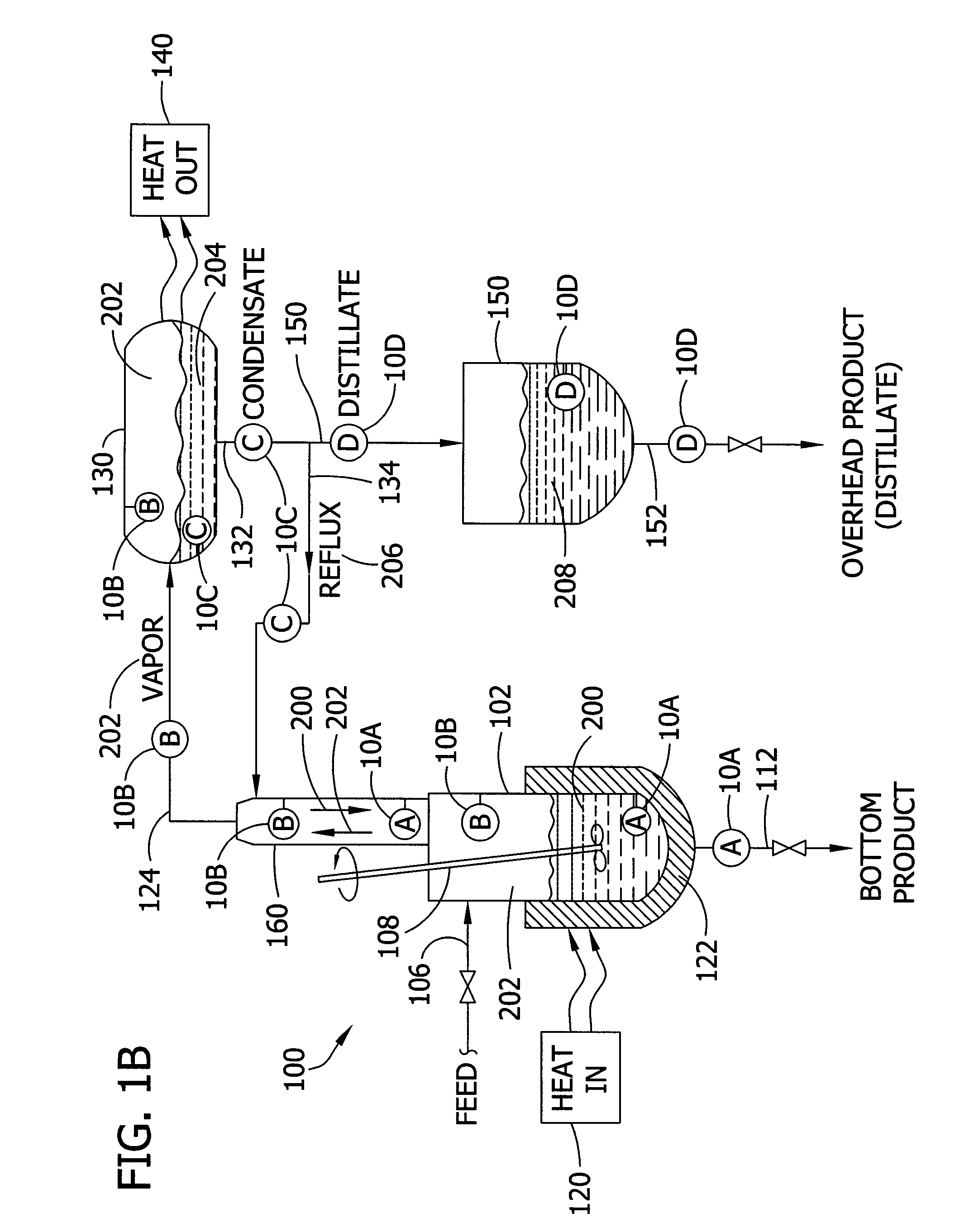

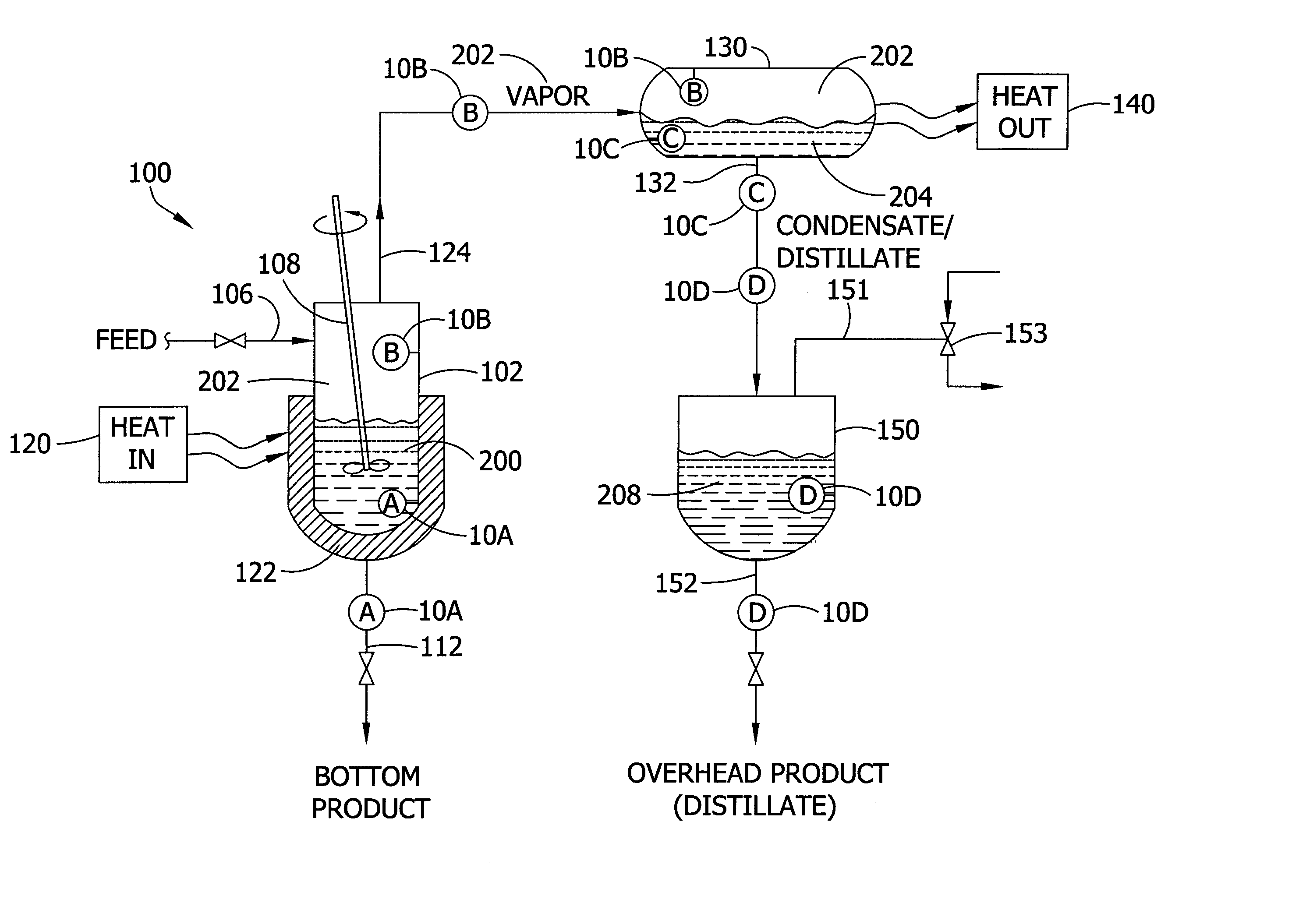

Fluid sensor methods and systems adapted for monitoring and / or controlling distillation operations in fluidic systems, such as batch distillation operations or continuous distillation operations, are disclosed. Preferred embodiments are directed to process monitoring and / or process control for unit operations involving endpoint determination of a distillation, for example, as applied to a liquid-component-switching operation (e.g., a solvent switching operation), a liquid-liquid separation operation, a solute concentration operation, a dispersed-phase concentration operation, among others.

Owner:MEAS FRANCE

Monitoring and controlling unit operations

InactiveUS20070017291A1Efficiently sensingEffective monitoringProcess control/regulationAnalysing solids using sonic/ultrasonic/infrasonic wavesDistillationUnit operation

Fluid sensor methods and systems adapted for monitoring and / or controlling distillation operations in fluidic systems, such as batch distillation operations or continuous distillation operations, are disclosed. Preferred embodiments are directed to process monitoring and / or process control for unit operations involving endpoint determination of a distillation, for example, as applied to a liquid-component-switching operation (e.g., a solvent switching operation), a liquid-liquid separation operation, a solute concentration operation, a dispersed-phase concentration operation, among others.

Owner:MEAS FRANCE

Process for the extraction of squalene, sterols and vitamin e contained in condensates of physical refining and/or in distillates of deodorization of plant oils

InactiveUS20110220483A1High priceEasy to useFatty acid esterificationMetabolism disorderSterolVegetable oil

The invention describes a global method for extracting sterols, vitamin E, squalene and other vegetable hydrocarbons from deodorization distillates of vegetable oils. After esterification of the free fatty acids, followed by trans-esterification of the combined fatty acids (glycerides and sterides) with the same short alcohol, three successive distillations allow successive recovery of a first fraction of the hydrocarbons, the main fraction of alkyl esters, and then the heaviest alkyl esters with squalene. The third distillate will be used for producing squalene and a second fraction of hydrocarbons. The residue of the third distillation will be used for producing sterols and vitamin E. By using bio-ethanol, vegetable glycerol and the vegetable hydrocarbons of the method, with the method it is possible to extract each of the four unsaponifiables without any solvent of petroleum origin and claim the labels of products obtained by natural physical and chemical methods.

Owner:SOPHIM

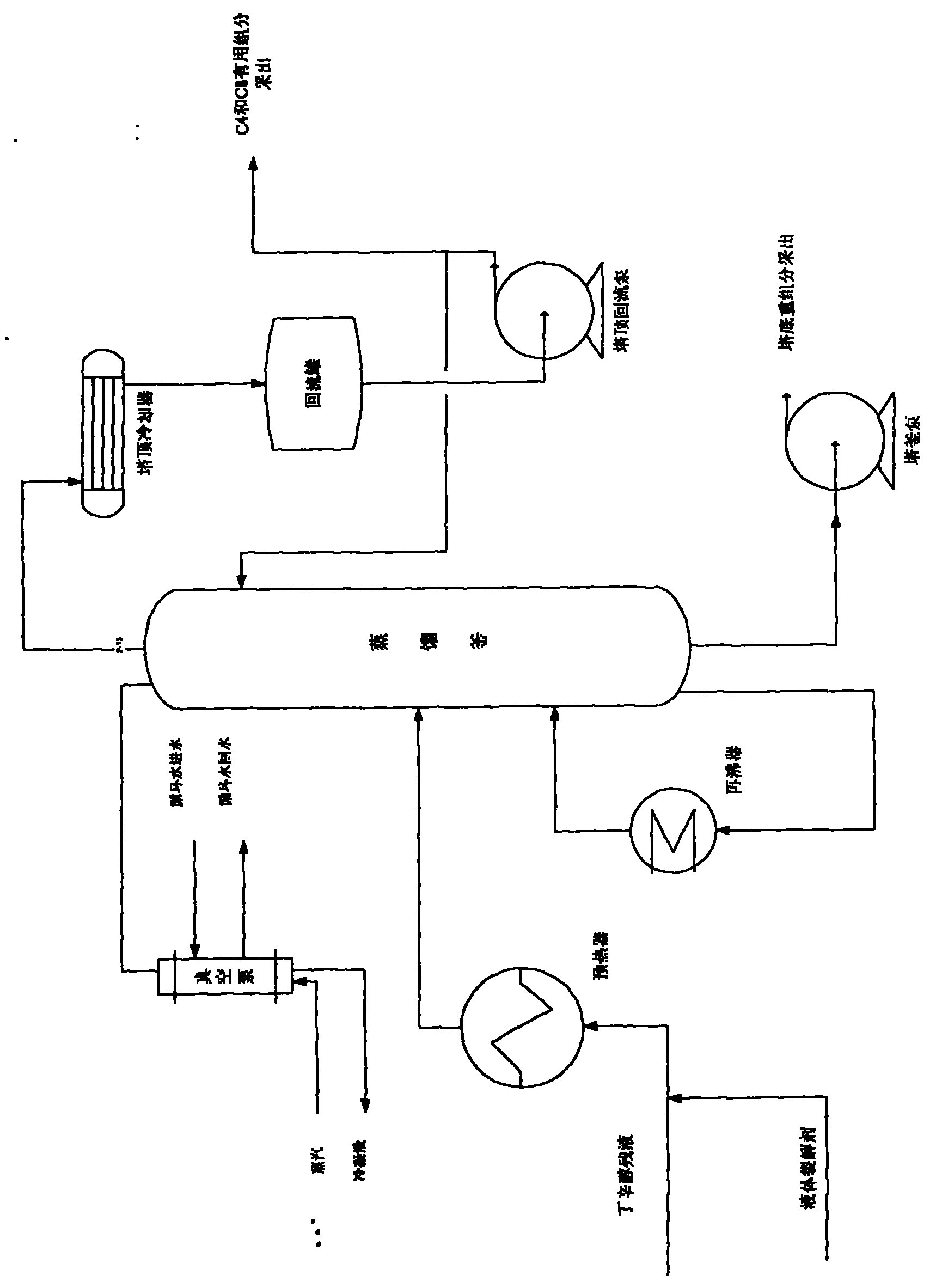

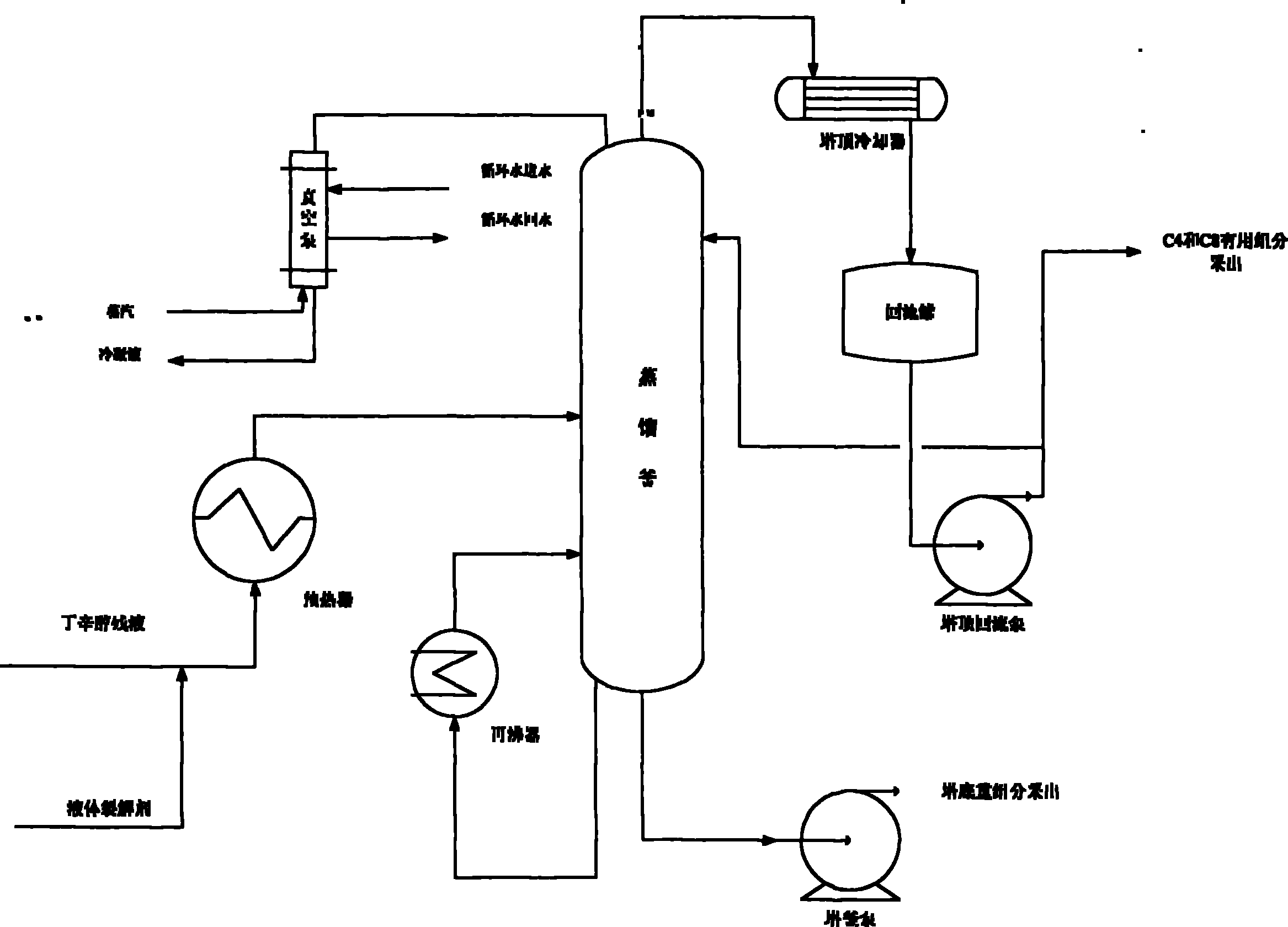

Production technology for cracking butyl octanol residual liquid into C4 and C8 by means of alkaline liquid cracking agent

ActiveCN101892066AReasonable useEmission reductionThermal non-catalytic crackingFractionationPotassium hydroxide

The invention relates to production technology for cracking butyl octanol residual liquid into C4 and C8 by means of an alkaline liquid cracking agent. The technology is characterized by comprising the following steps of: preparing the alkaline liquid cracking agent, wherein the alkaline liquid cracking agent consists of sodium hydroxide, potassium hydroxide, water, isopropanol, ethylene glycol, potassium permanganate, ethanol, barium nitrate and diboron trioxide; preheating the alkaline liquid cracking agent and the butyl octanol residual liquid through a preheater and adding into a distilling still, wherein the tower bottom temperature of the distilling still is between 200 and 280 DEG C, the tower top temperature is between 130 and 190 DEG C, and the tower top pressure is between 0.08 and 0.1Mpa below zero; and extracting the C4 and C8 generated by cracking from the tower top of the distilling still, pumping the C4 and C8 into a fractionating column at the downstream for fractionation, and extracting a small amount of uncracked heavy components from a tower bottom pump. The production technology has the advantages of high production capacity, high cracking selectivity, high content of the cracked useful components, low cost, simple process, and batch distillation or continuous distillation.

Owner:山东瑞利尔石油装备有限责任公司

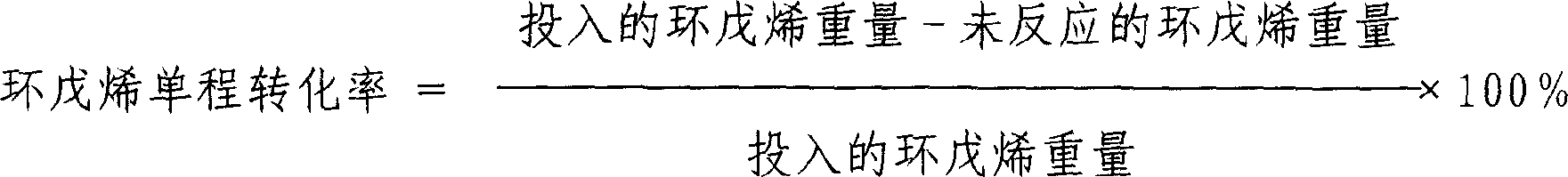

Cyclopentanol preparing and refining method

ActiveCN1676504AEasy to refineHigh selectivityOrganic compound preparationPreparation by hydroxy group additionHydration reactionCyclopentene

This invention is a making and refining method of cyclopentanol, which includes: 1) the materials comprises cyclopentene, phenylic acid solvent, water activator continuously pass through catalyst fixed bed to carry out hydration reaction, and the volume space velocity is 2-15hr to the power -1, the mole ratio of cyclopentene and water is 0.8-5.0, the weight ratio of phenylic acid and cycloamylene is 0.5-1.0. the intensity of activator is 0.01-0.2wt%, the reaction temperature is 130-180deg.C, the reaction pressure is 1.0-3.0MPa, the catalyst is strong acid cation exchange resin with sulfo group anchored on the surface, and the activating solvent is trialkylamine; 2)the reacted materials cool to house temperature and demix into oil phase and aqueous phase, the oil phase materials through continuous distilling separation procedure get non-reacting cycloamylene, refined cyclopentanol and phenylic acid full of solvent. The strong points of this invention are that the conversion of cyclopentene and selectivity of cyclopentanol are high, and the refining of cyclopentanol is simple and low energy consumption.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Improved process for producing alkylphenols thermoplastic resin

ActiveCN101338013AImprove the production processImproved economical production processSpecial tyresAlkylphenolReaction speed

The invention relates to an improved process for alkyl phenol-formaldehyde thermoplastic tackifying resin. Liquid formaldehyde and solid formaldehyde are added, while water generated by a condensation reaction is continuously distilled out. The reaction speed of the condensation reaction of alkyl phenol and the formaldehyde is reduced due to water in the system, so the production efficiency as well as the production output is improved.

Owner:SINO LEGEND CHINA CHEM

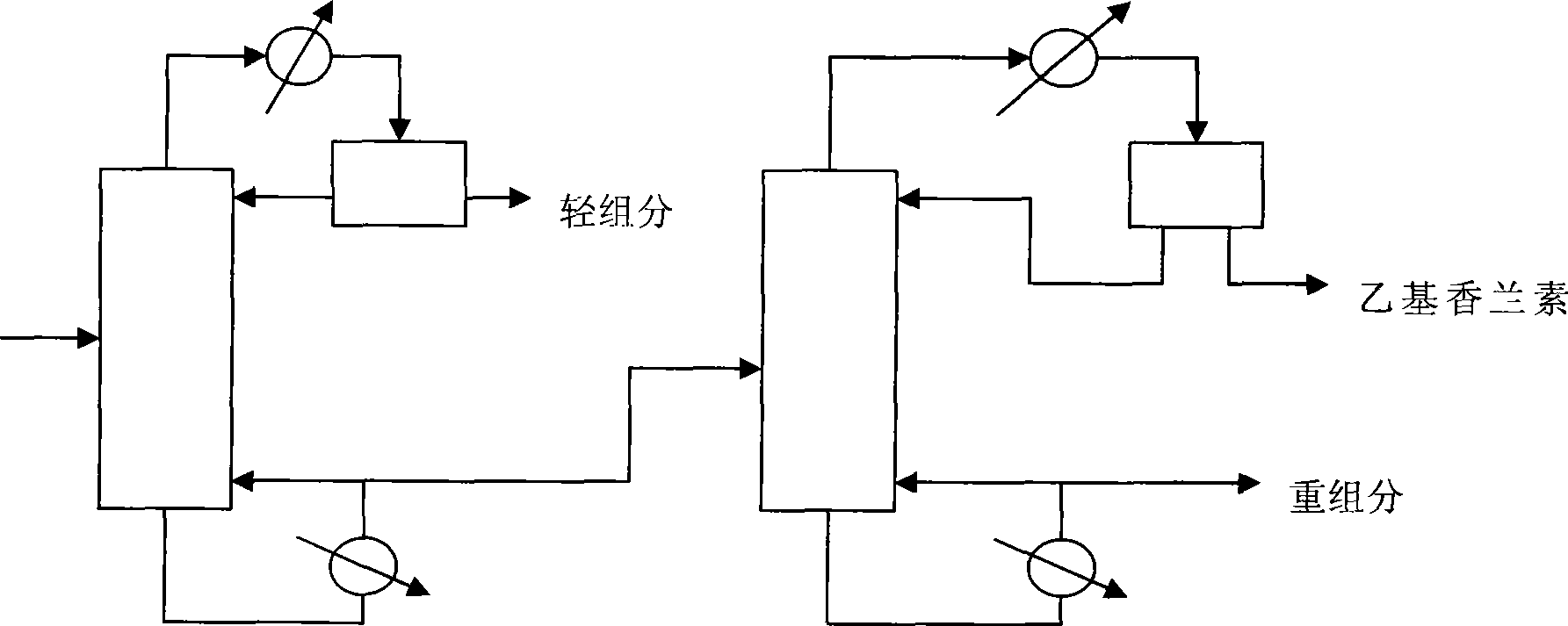

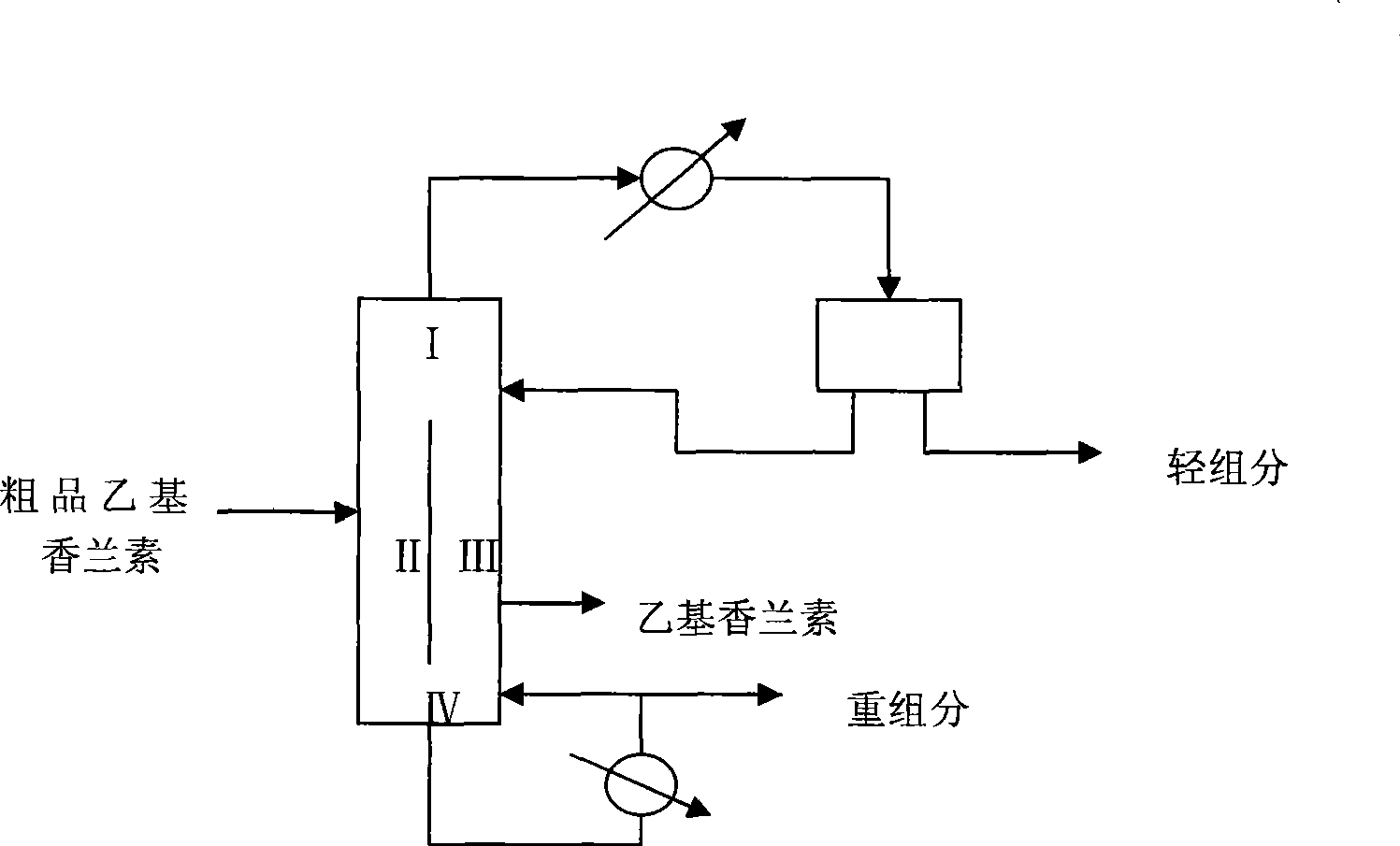

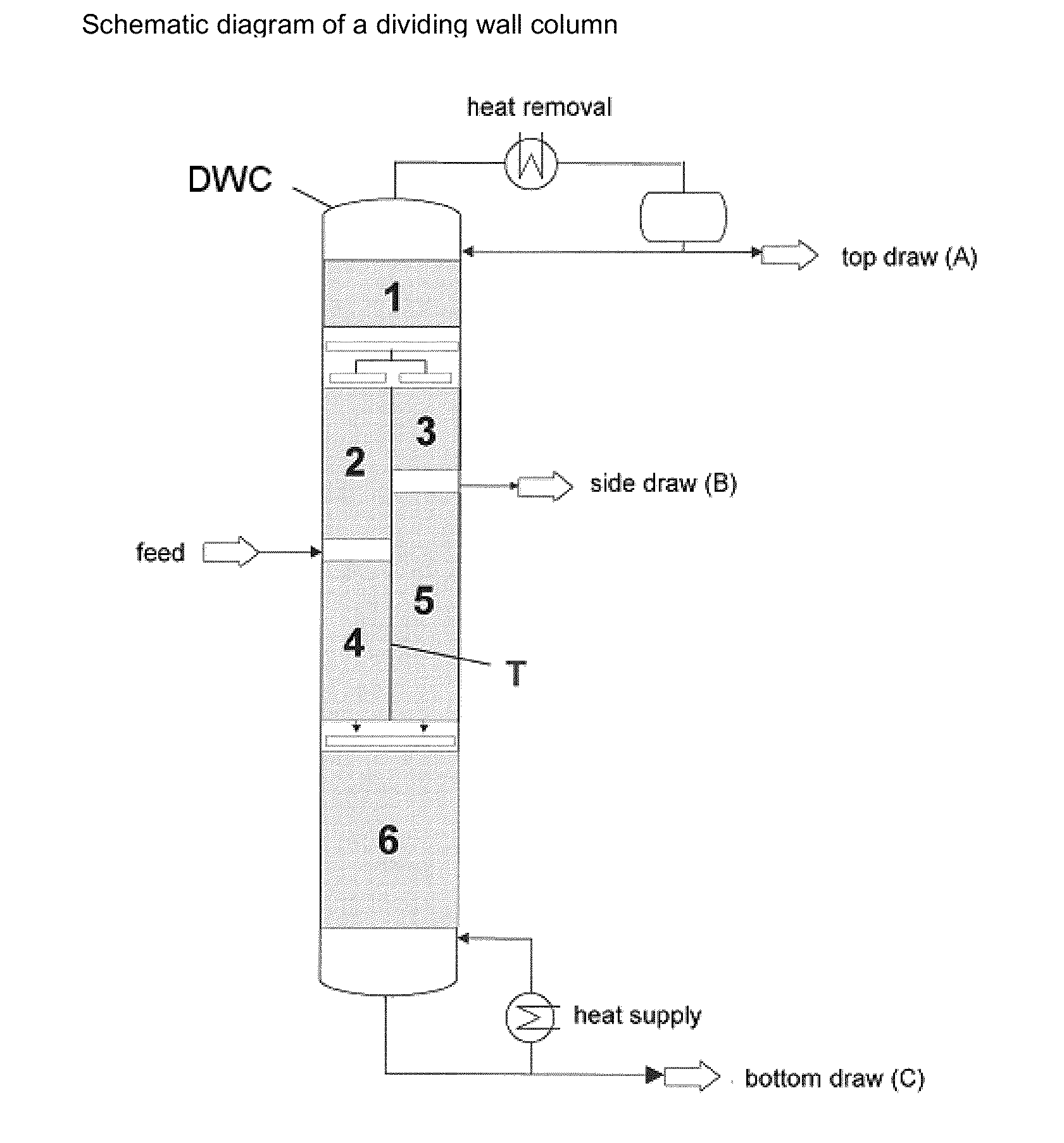

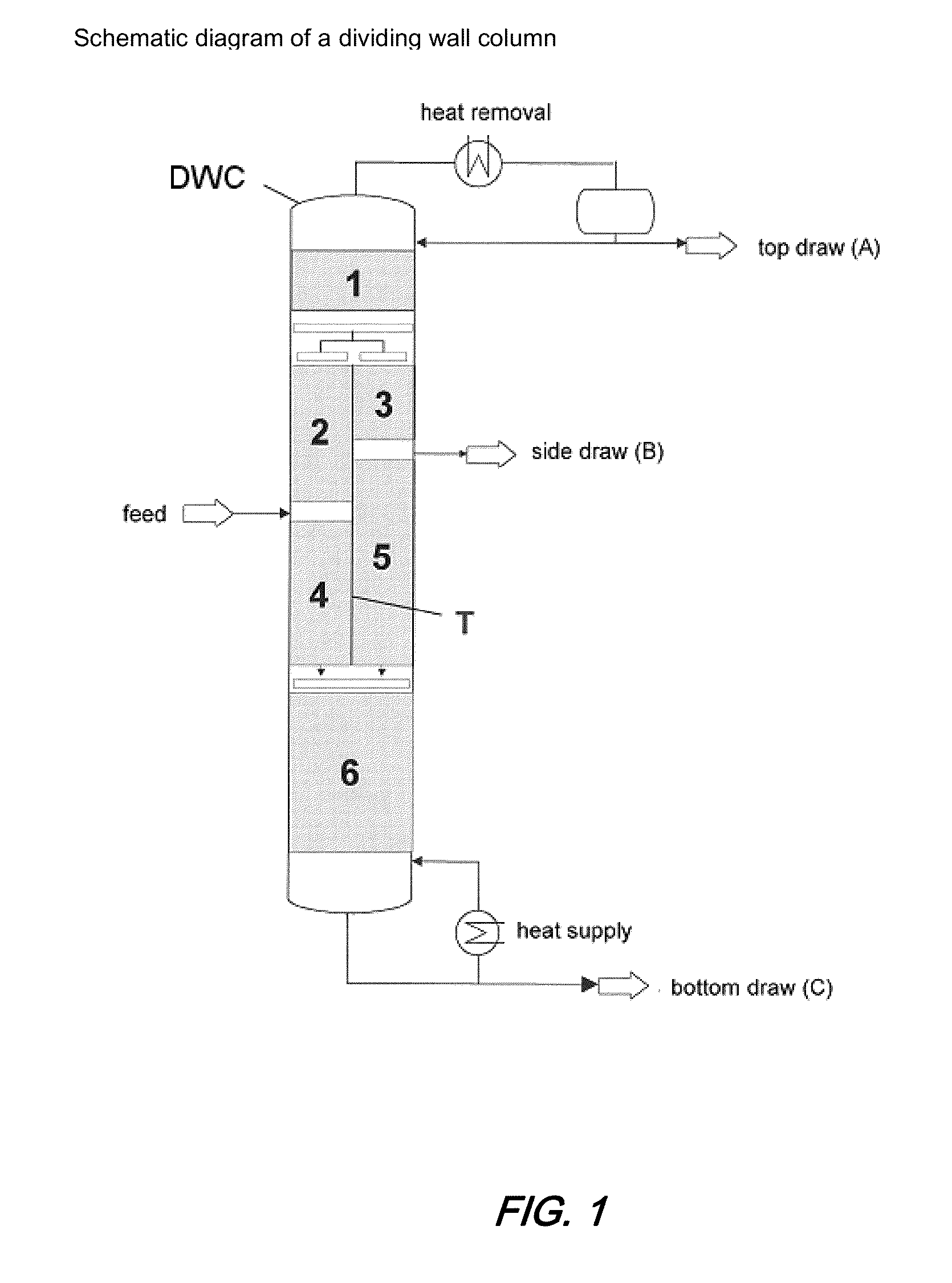

Method and apparatus for separating and purifying ethyl vanillin by decompression and continuous distillation in dividing wall column

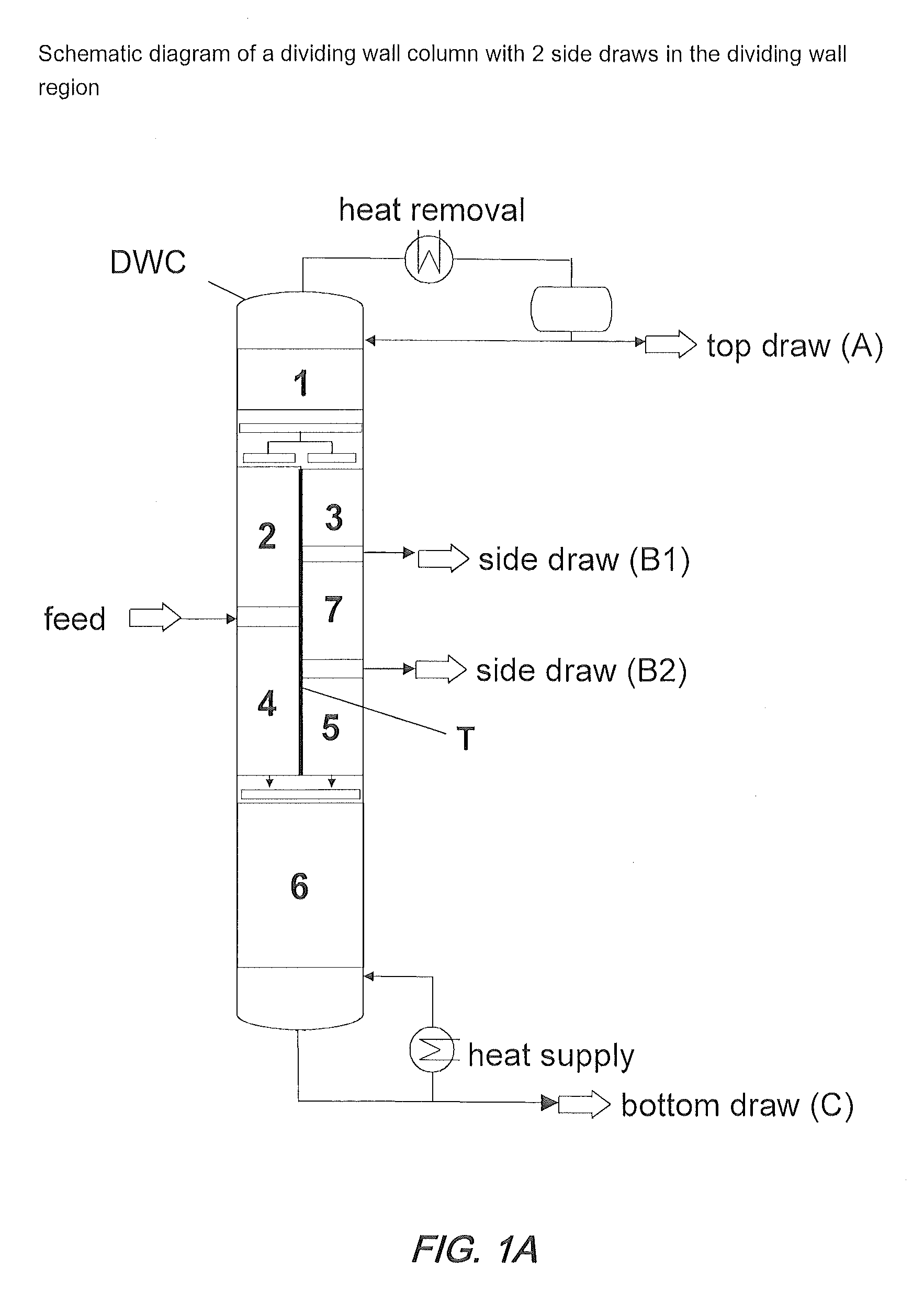

InactiveCN101417930AImprove efficiencyShort heating timeCarbonyl compound separation/purificationFractional distillationHigh energyDistillation

The invention relates to a method and device for separating and purifying vanillin by comparting wall tower to reduce pressure and continuous distillation. A vertical wall which is arranged in the middle and lower part of a distillation tower divides the tower into four areas, which are area one, area two, area three and area four. The coarse ethyl vanillin waiting to be separated, is put in from the middle and upper part of the area two which mainly finishes the separation of ethyl vanillin from the heavy components; the area three is the area in which ethyl vanillin is separated from light components, and the pure components ethyl vanillin is obtained from the lateral line in the middle and lower part of the area three; the area one is the public distillation section of the area two and the area three, and the light components is obtained from the top of the area one; the area four is the public distillation section of the area two and the area three, and the heavy components is obtained from the bottom of the area four. The single column continuous distillation of coarse ethyl vanillin is realized and high-purity ethyl vanillin is obtained from the lateral line. The invention overcomes the disadvantages of the high demand for equipment in the molecular distillation, and high energy consumption and low yield in the double tower pressure reduction continuous distillation method, and has the advantages of 'low invest, low energy consumption, high yield and high purity', large spreading and applying value and high social and economical benefits.

Owner:HUNAN ASTAR BIO CHEM TECH

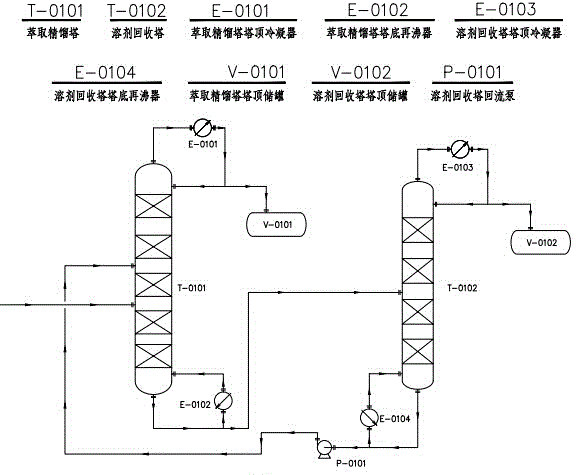

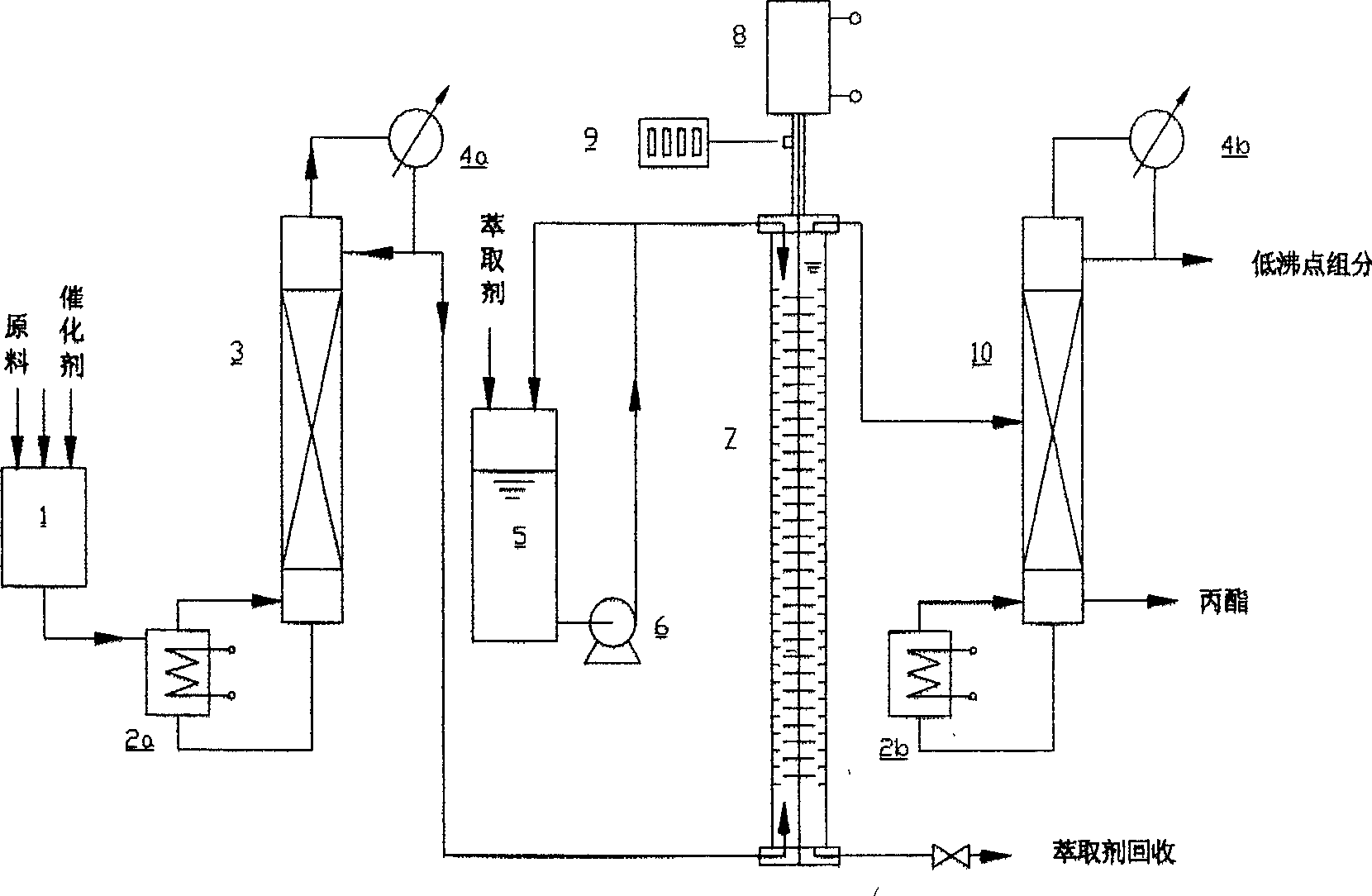

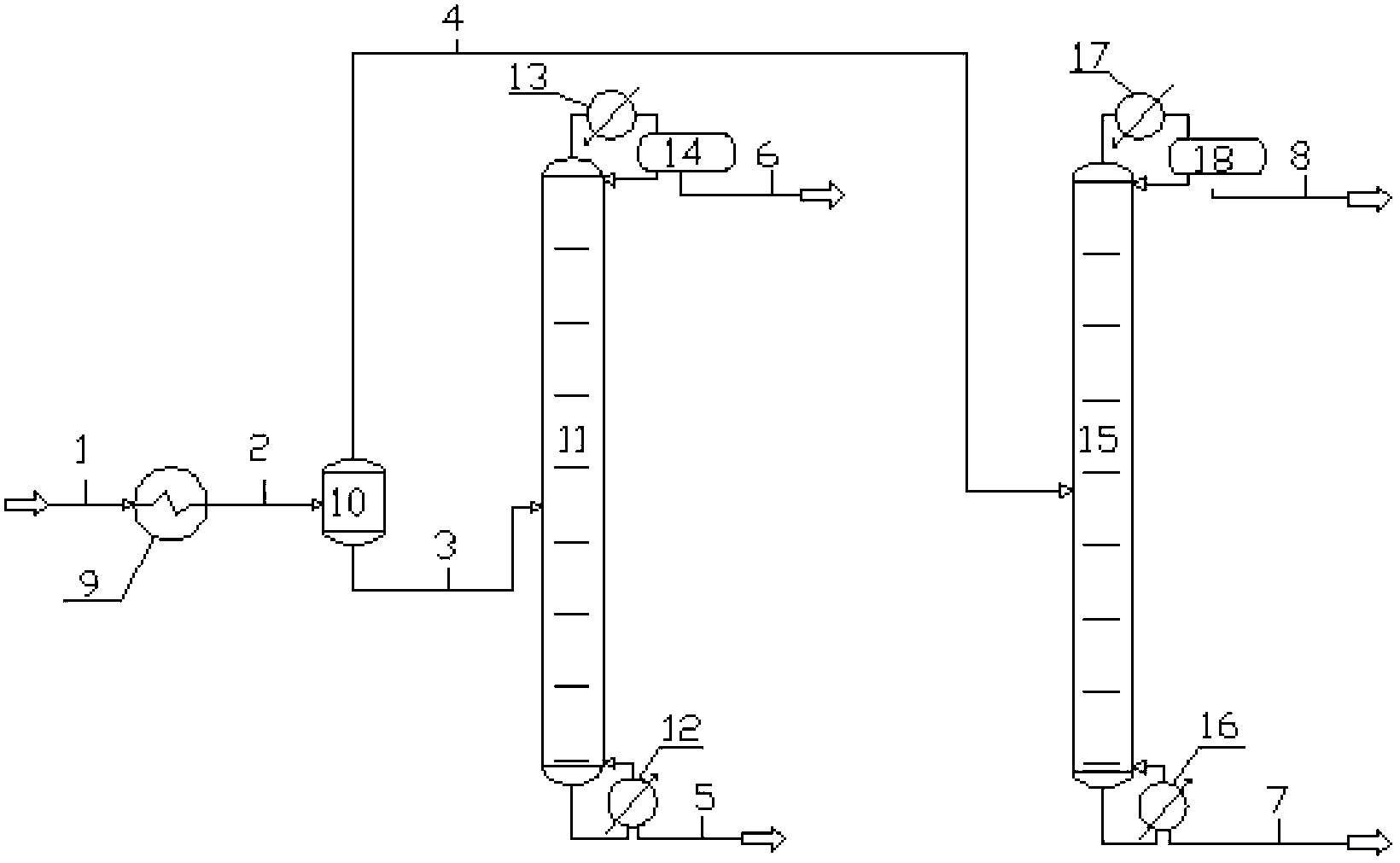

Method for continuous extraction distillation separation of dimethyl carbonate-methanol azeotropic mixture

InactiveCN105037162AHigh purityEasy to separateOrganic compound preparationHydroxy compound preparationN dimethylformamideDistillation

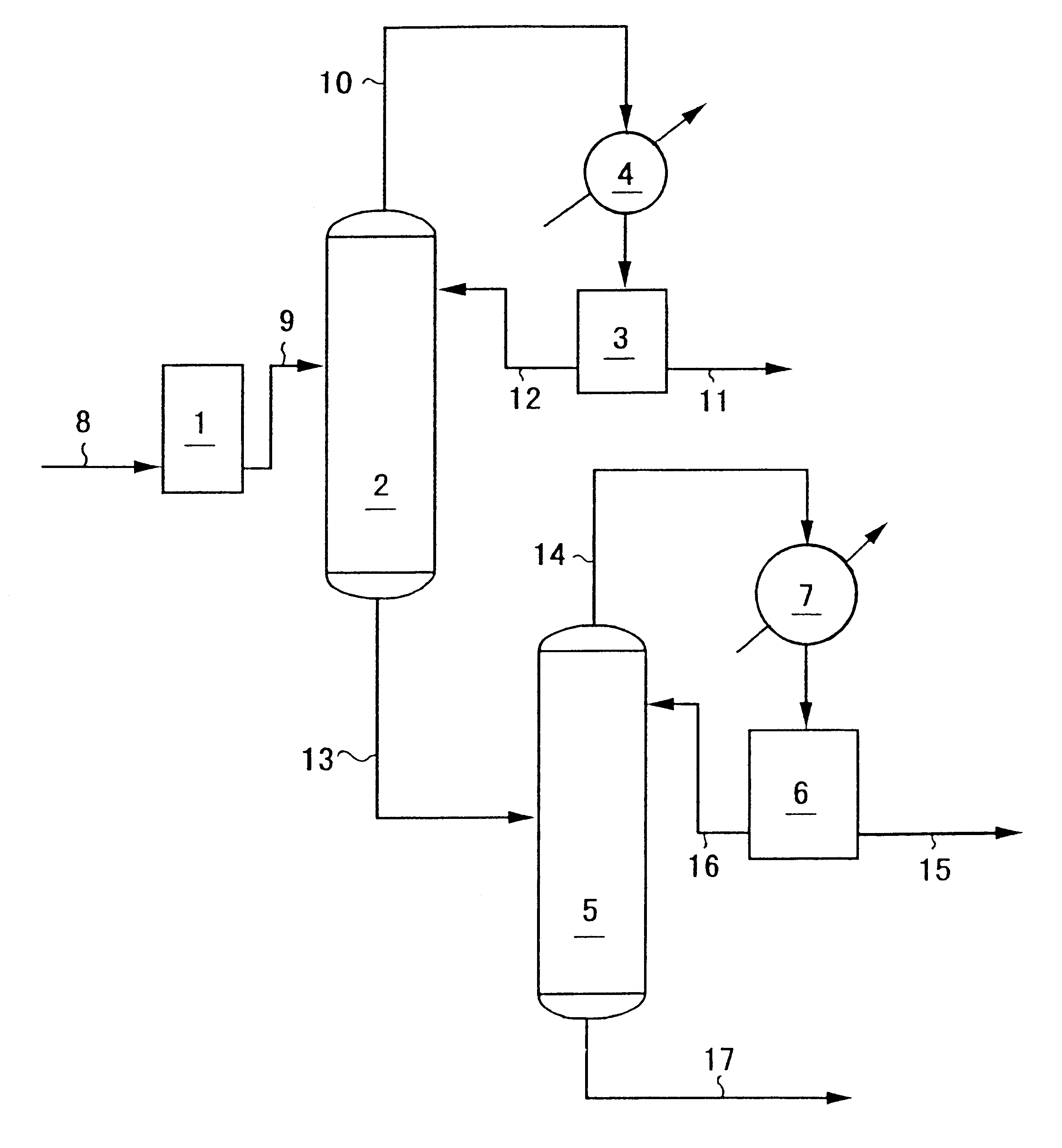

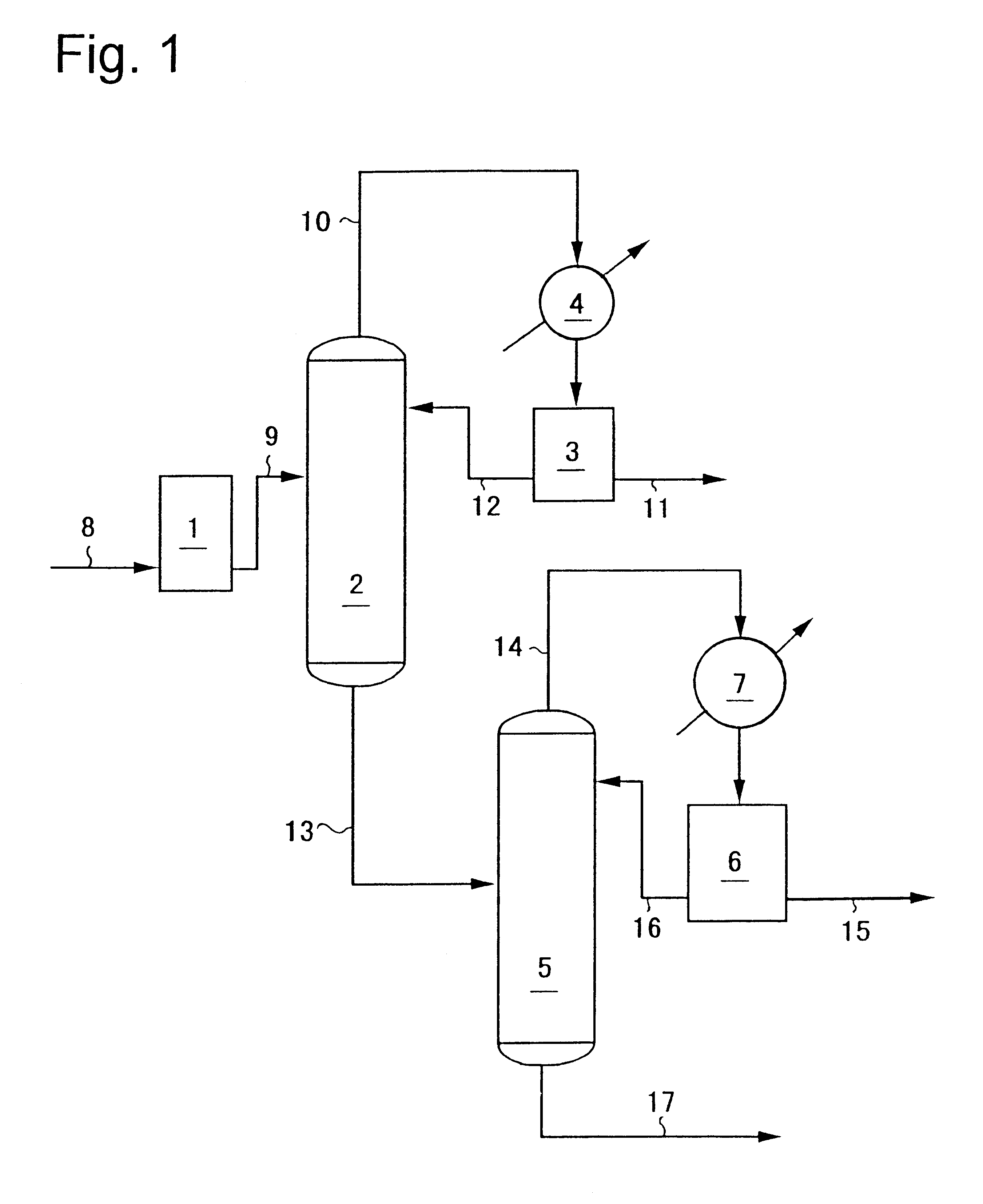

The invention discloses a method for continuous extraction distillation separation of a dimethyl carbonate-methanol azeotropic mixture, and belongs to separation technologies of the dimethyl carbonate-methanol azeotropic mixture. According to the method, N,N-dimethylformamide, N-formylmorpholine or a mixture consisting of N,N-dimethylformamide and N-formylmorpholine in any proportion is used as an extracting agent. The operation condition of an extraction distillation tower and a solvent recovery tower are that the pressure is a normal pressure or reduced pressure, the ratio of a distillate at the top of the extraction distillation tower to the extracting agent is (0.5:1)-(10:1), and the feed (mass) ratio of the extracting agent to a mixture is (1:10)-(5:1). Two distillation towers are used in the method to achieve cycle utilization of the extracting agent. Methanol meeting requirements is obtained at the top of the extraction distillation tower, and the distillate at the bottom of the tower enters the solvent recovery tower; high-purity methyl carbonate is obtained at the top of the solvent recovery tower, and a high-purity extracting agent is obtained at the bottom of the tower; and a pump is used for pumping the extracting agent into the extraction distillation tower for cycle utilization. The method has the advantages that the extracting agent is adopted to destroy a dimethyl carbonate-methanol azeotropic system, and the aims of separating high-purity dimethyl carbonate and methanol and ensuring cycle utilization of the extracting agent are achieved. The continuous distillation has the advantages of high tower efficiency, high yield and the like.

Owner:UNIV OF JINAN

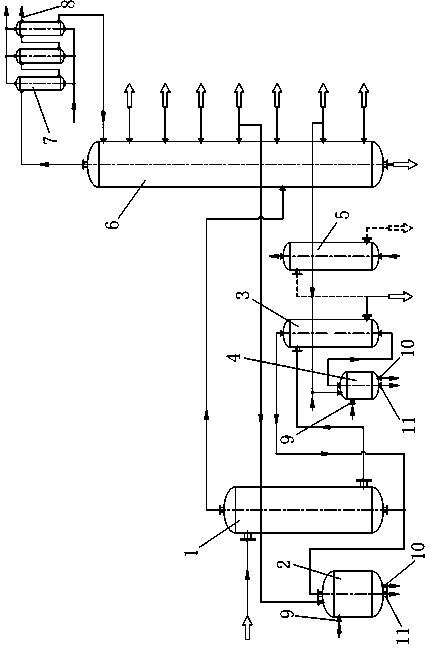

High-efficiency energy-saving white wine continuous distillation method and device

ActiveCN104178406AReduce consumptionEfficient separationAlcoholic beverage preparationAlcoholHigh energy

The invention discloses a high-efficiency energy-saving white wine continuous distillation method, which solves the problems of incapability of continuous production, very low efficiency and high energy consumption in the existing white wine distillation mode, and the problems of incapability of large-scale production and dependence of operation on experience in the distillation process. The device comprises a first distillation kettle, a second distillation kettle, a third distillation kettle, a first reboiler, a second reboiler, a distillation tower and a condenser set. The device can perform uninterrupted distillation on vinasse, thereby enhancing the distillation efficiency; and the device can implement the traditional technique of leaving out the beginning and the end, and can effectively separate aldehydes, methanol, other impurity alcohols and other substances harmful to the human body in the vinasse, thereby promoting the improvement of the white wine quality and being more beneficial to health of the drinker.

Owner:易治虎

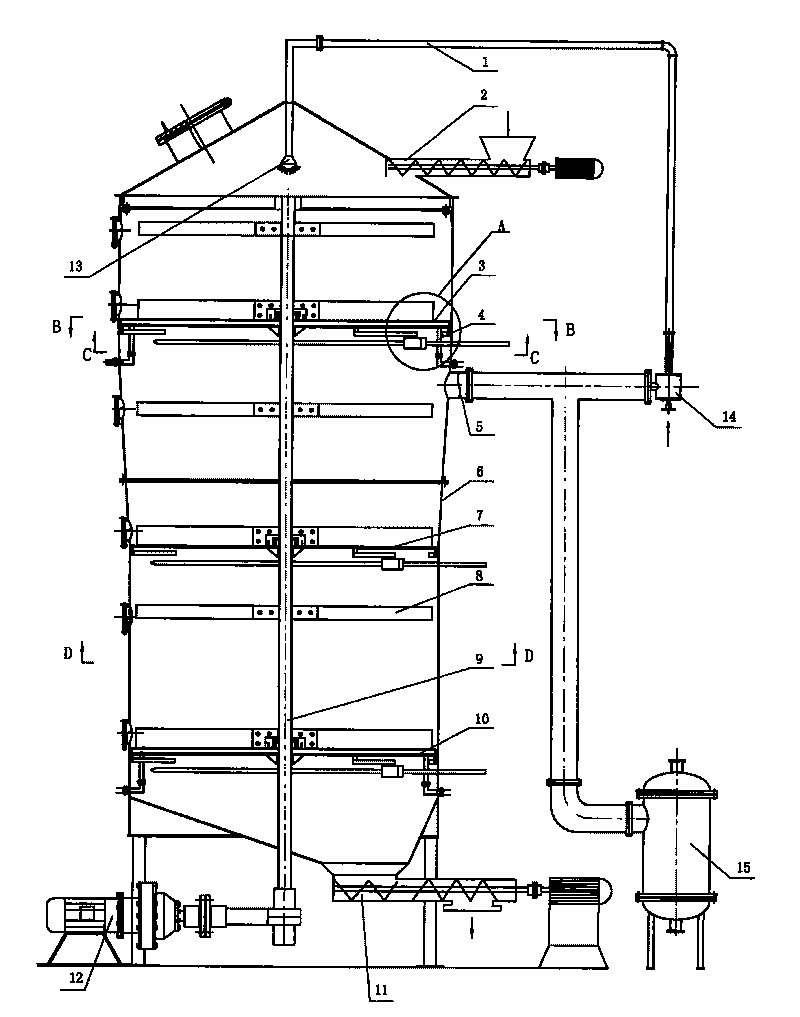

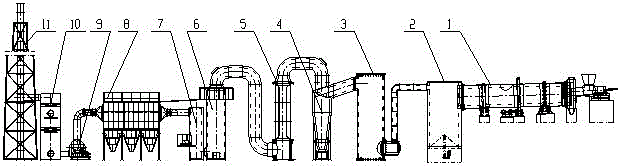

Process and system for producing ethanol through solid-state continuous fermentation and distillation of sorgo straws

ActiveCN101724661AUniform and complete fermentationHigh yieldBioreactor/fermenter combinationsBiological substance pretreatmentsDifferential pressureDistillation

The invention relates to a process and a system for producing ethanol through solid-state continuous fermentation and distillation of sorgo straws, wherein the process comprises a raw material pulverizing and preprocessing step, a strain adding step, a solid-state fermentation step and a solid-state distillation step; the solid-state fermentation step is continuously finished in a multilayer multisection solid-state continuous fermentation device, and the solid-state distillation step is continuously finished in a multilayer differential pressure type solid-state continuous distillation device, thereby radically overcoming the abuse that the past solid-state fermentation and distillation processes can not continuously produce, realizing continuous, mass and automated production and processing, greatly improving the production efficiency of preparing the fuel ethanol from the sorgo straws, and achieving the purposes for lowering the production cost, improving the yield and improving the economic benefit; an adopted continuous production system device is particularly suitable for industrialized large-scale production, thereby promoting the generalization and the application of a biological energy source technology.

Owner:天津实发中科百奥工业生物技术有限公司 +1

Devices and method for continuous distillative separation of a mixture containing one or more alkanolamine(s)

InactiveUS20140061020A1Organic compound preparationDistillation regulation/controlAlkanolamineRadiochemistry

Apparatus and processes for continuous distillative separation of a mixture comprising one or more alkanolamine(s) are described. The separation is performed in one or more dividing wall column(s) and the alkanolamine or the alkanolamines is / are withdrawn as a side draw stream or side draw streams (side fraction(s)).

Owner:BASF AG

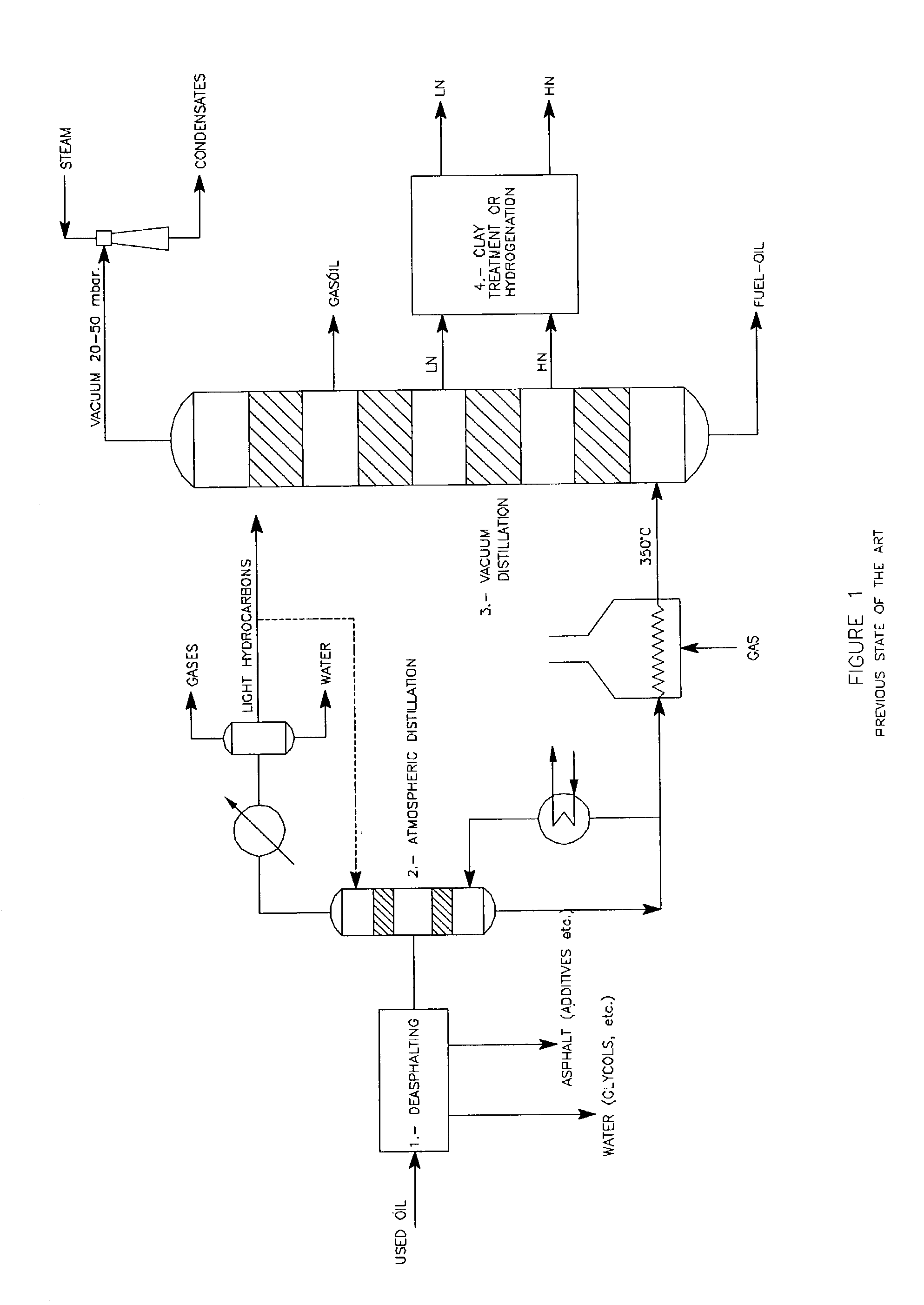

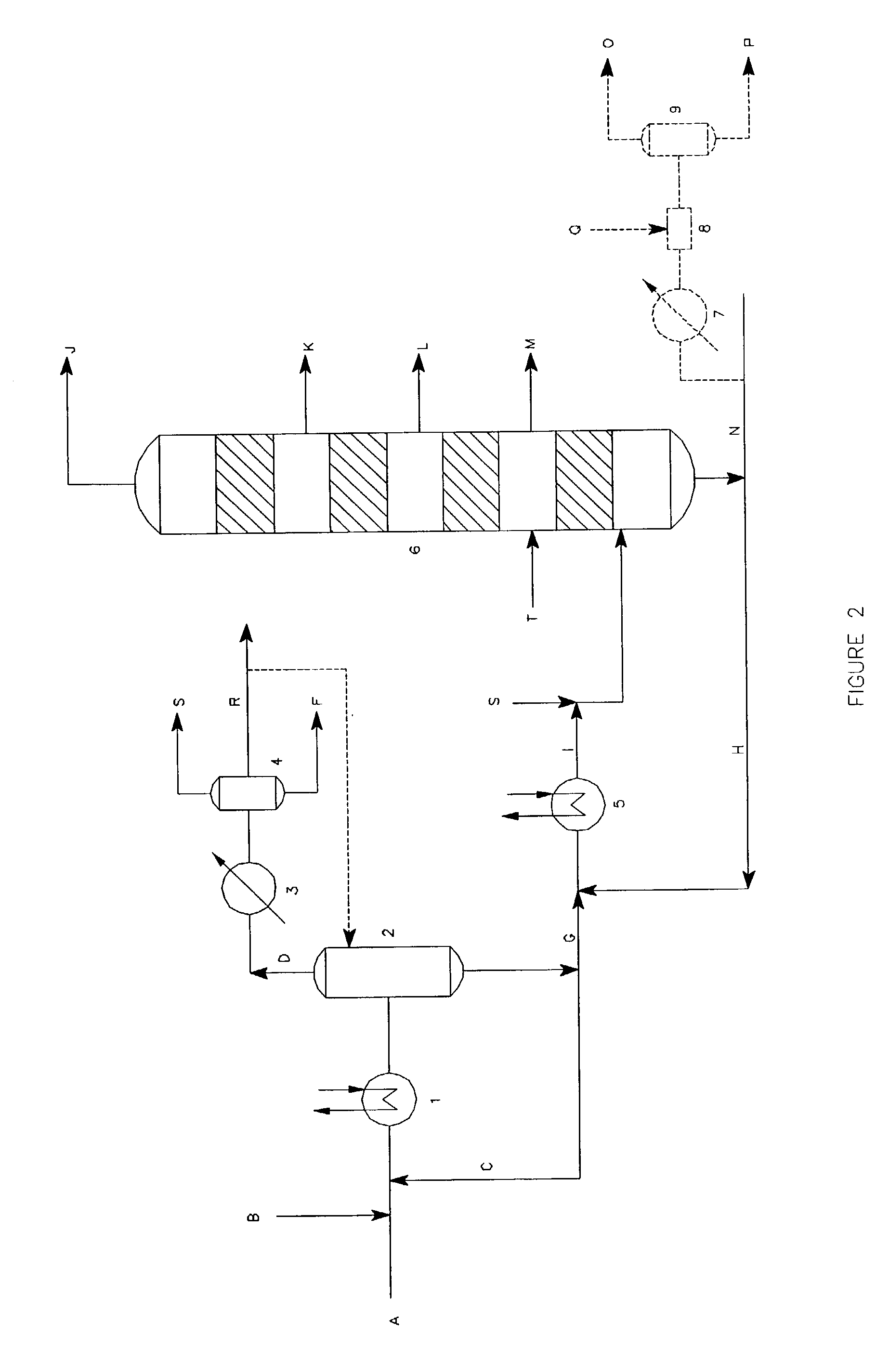

Process for re-refining used oils by solvent extraction

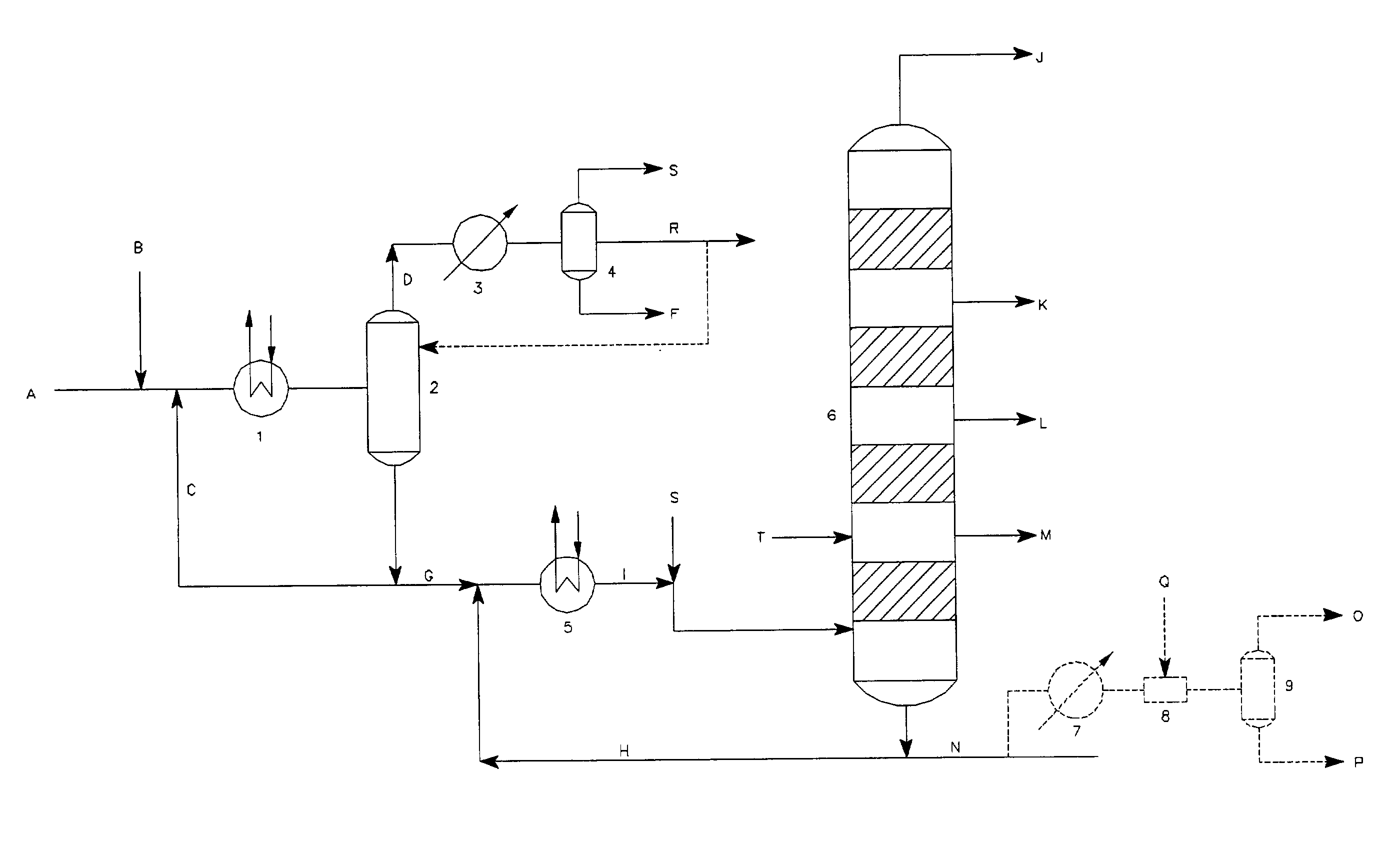

InactiveUS7226533B2No corrosionExpedited distillationWorking-up pitch/asphalt/bitumenTreatment with plural serial refining stagesWaste oilFuel oil

A process to re-refine used petroleum oils by extraction with aliphatic solvents, wherein after eliminating the extract solvent, the process consists of the following treatments, (a) flash, continuous vaporization, at atmospheric pressure or near atmospheric pressure, to separate the light fractions, in the presence of small amounts of a basic compound or a reducing agent or a combination of both and (b) continuous distillation, in a fractionating column, of the bottom liquid obtained in stage (a), under vacuum and moderate temperatures, in the presence of a basic compound or a reducing compound or a combination of both, with recirculation from the bottom of the column to its feed; separating, as lateral extractions, the vacuum gas-oil or spindle oil and the lubricant bases and, as bottom product, a fuel-oil or asphaltic component.

Owner:SENER GRUPO DE ING SA

Method for producing biological diesel oil

InactiveCN101230288AShort reaction timeLower conversion rateBiofuelsLiquid hydrocarbon mixture productionOil and greaseVegetable oil

The invention discloses a production method of biological diesel oil, which takes oil feet acidified oil of vegetable oil, animal fat, drain oil and restaurant waste oil as material; and contains four steps of grease no-catalysis high-pressure hydrolysis, fatty acid gas-phase esterification, neutralization dealcoholization and washing, fatty acid methyl ester high-vacuum continuous distillation, etc. The production method of the invention has the advantages that the reaction time is short, the raw material conversion rate is high, the production cost is low, and the product quality is high; therefore the invention is applicable for industrial production.

Owner:新疆协力新能源有限责任公司

Differential pressure type solid continuous distillation process

ActiveCN101721831AReduce the time required for distillation operationsShorten the timeSteam distillationDifferential pressureDistillation

The invention relates to a differential pressure type solid continuous distillation process, comprising the steps of: placing solid materials on a tower plate in a distillation tower, introducing vapor to the bottom of the tower plate for heating, collecting vapor by vaporizing materials from an outlet pipe at the upper part of the tower plate, and condensing the collected vapor by a condenser toobtain the product, wherein the heating process comprises a preheating loop, a distilling loop and a residual distilling loop. In the invention, the distillation process has scientific and reasonabledesign, realizes fast and efficient continuous distillation process by arranging different operation conditions in each loop, has the advantages of simple operation, large processing load, high production efficiency, high yield and the like, and can efficiently guarantee the consistency stability of the final product of distillation simultaneously.

Owner:天津实发中科百奥工业生物技术有限公司 +1

Method for preparing and purifying propyl acetate

InactiveCN1733685AOrganic compound preparationCarboxylic acid esters preparationAcetic acidPropyl acetate

The invention relates to a method for preparing and purifying propyl acetate, which comprises charging quantitative acetic acid, n-propanol (or isopropanol) and acidic homogeneous catalyst continuously into a pre-reactor, loading into esterification tower, obtaining crude ester on the top of the tower, loading the crude ester into a liquid-liquid rotating disc extraction tower, extracting and purifying with aqueous solution extracting agent of salts, recycling the extract phase and loading into rectifying tower for continuous distillation, thus obtaining n-propyl acetate or isopropyl acetate whose content is above 99.5% on the bottom of the tower.

Owner:SHANGHAI WUJING CHEM

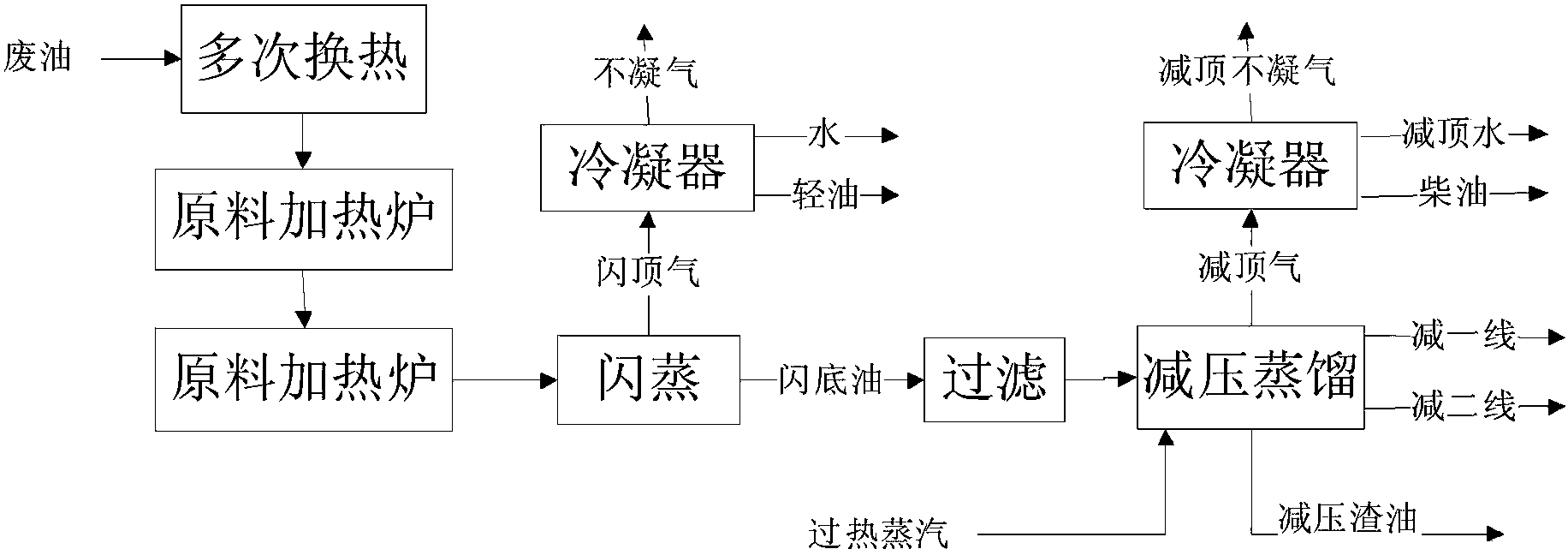

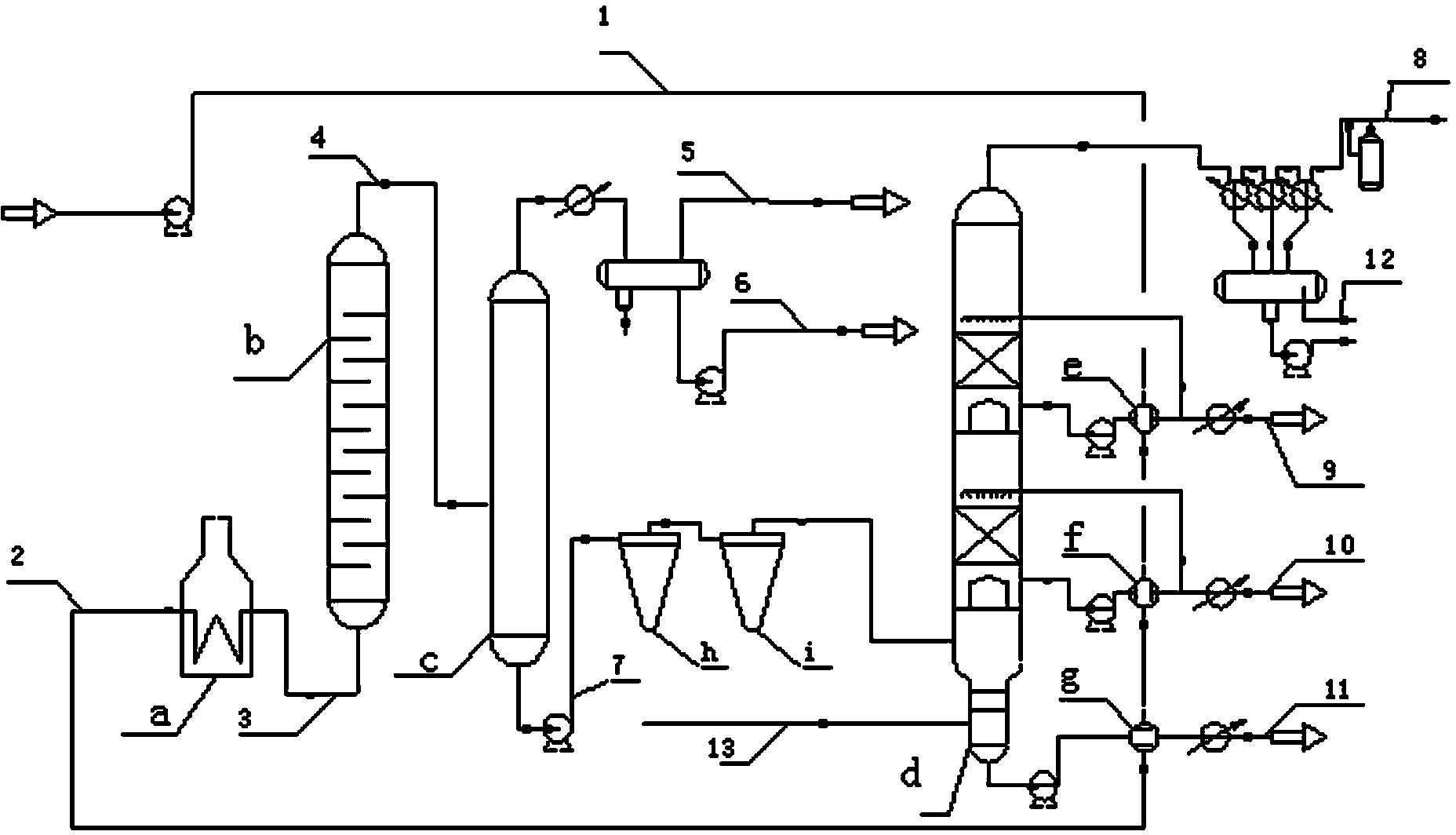

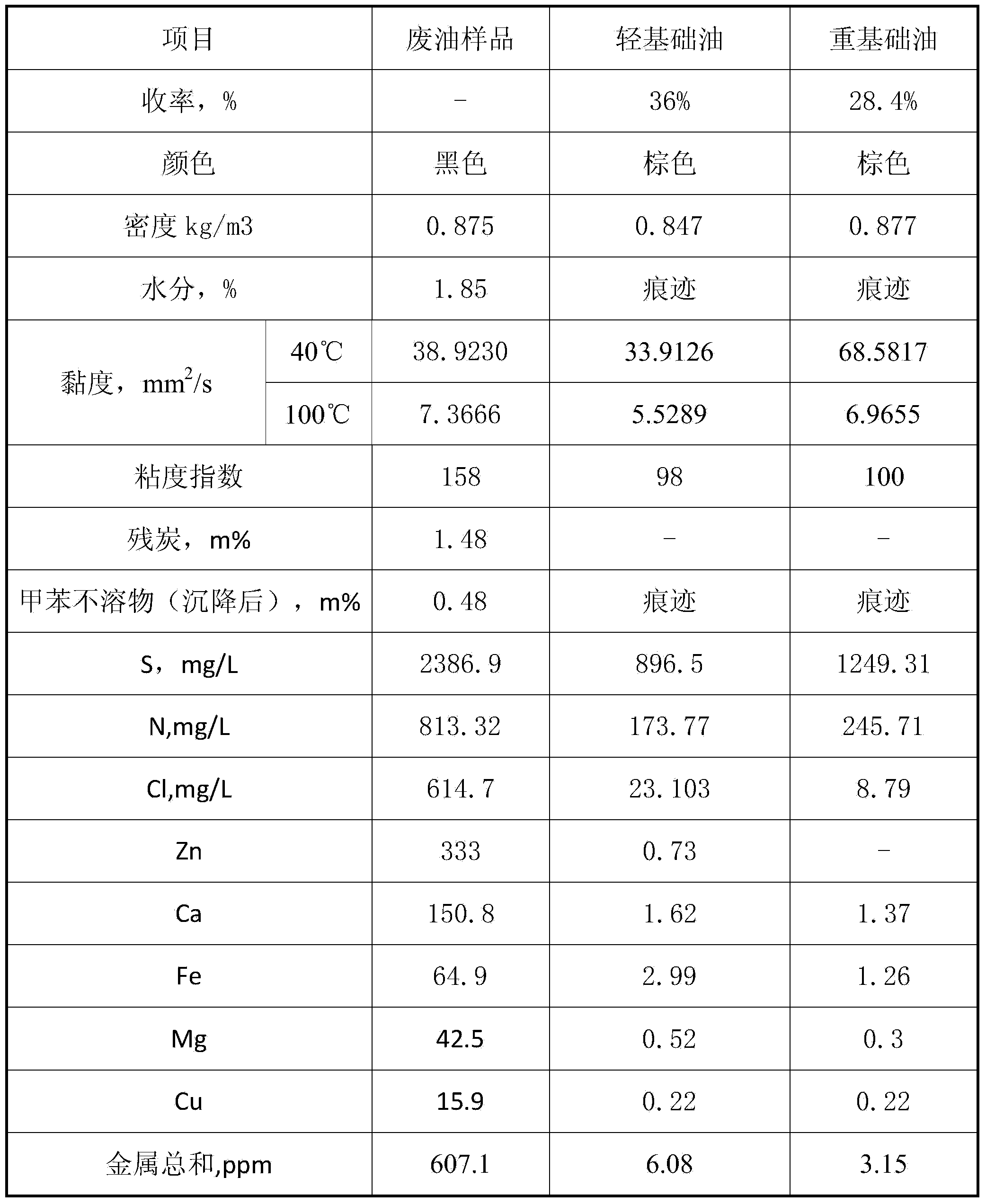

Continuous distillation technology used for regeneration of spent lubrication oil

InactiveCN104099171AEffectively breakEffectively break the clean dispersion in waste oilLubricant compositionOrganic acidDistillation

The invention discloses a continuous distillation technology used for regeneration of spent lubrication oil. The continuous distillation technology includes a heat exchange process of the spent lubrication oil and distilled cut fraction, a visbreaking heat treatment process and a flash distillation-reduced pressure distillation process. By means of visbreaking heat treatment, clean dispersing additives in the spent lubrication oil can be broken down effectively to enable suspended impurities such as metal in the spent lubrication oil to be deposited more easily, and part of metal salt additives and corrosive organic acid can be decomposed or deteriorated. By means of flash distillation-reduced pressure distillation, light components and base oil fractions can be pulled out effectively. Additionally, an optimized heat exchange system is capable of lowering energy consumption caused by continuous distillation, the total pull-out rate of the technological spent lubrication oil is more than 85%, the continuous distillation technology is good in technological economy, low in impurity content (particularly in metal content), and distilled products can serve as quality raw materials for subsequent hydrofining directly.

Owner:四川省中明环境治理有限公司 +1

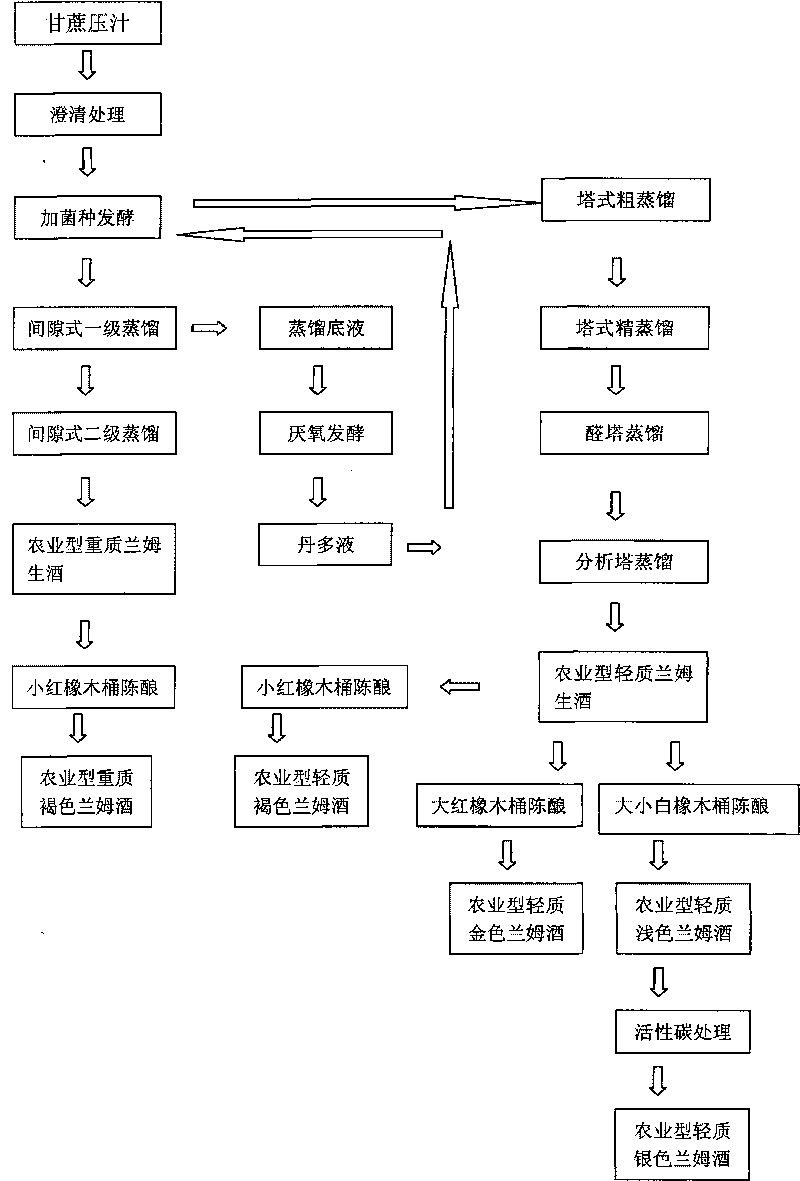

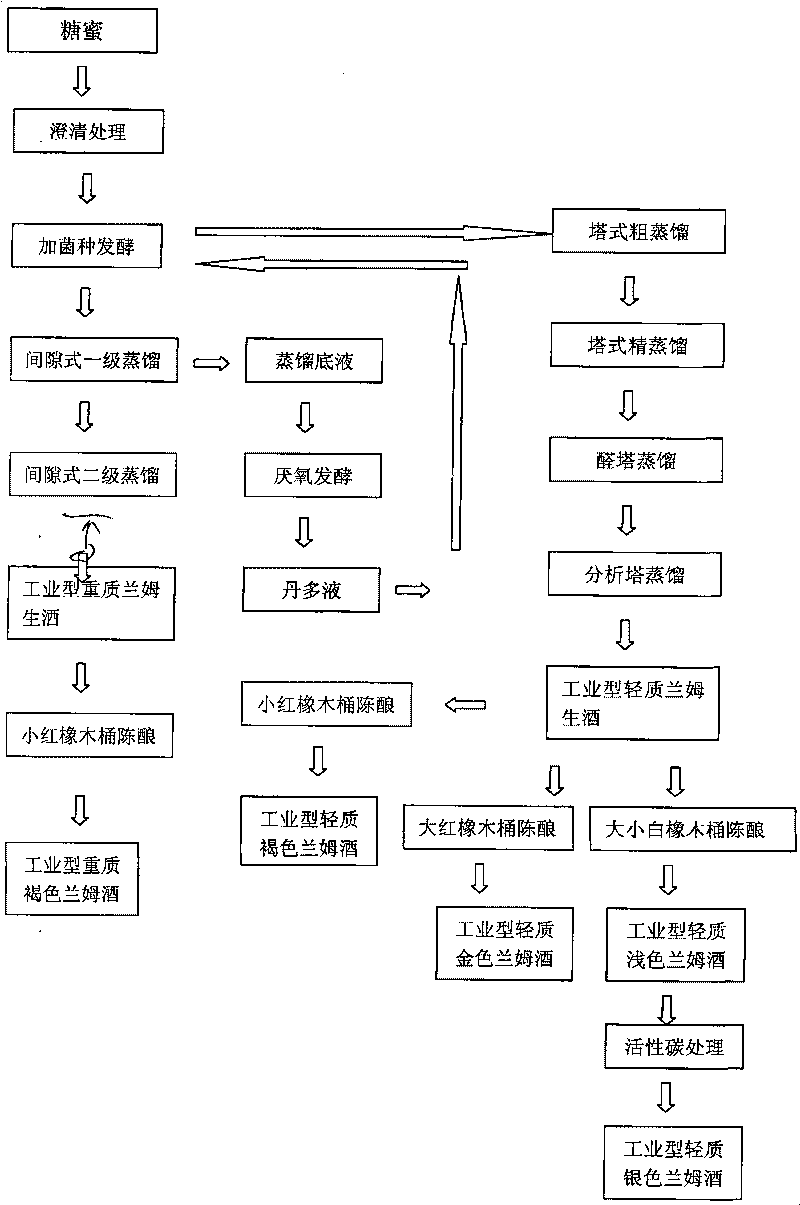

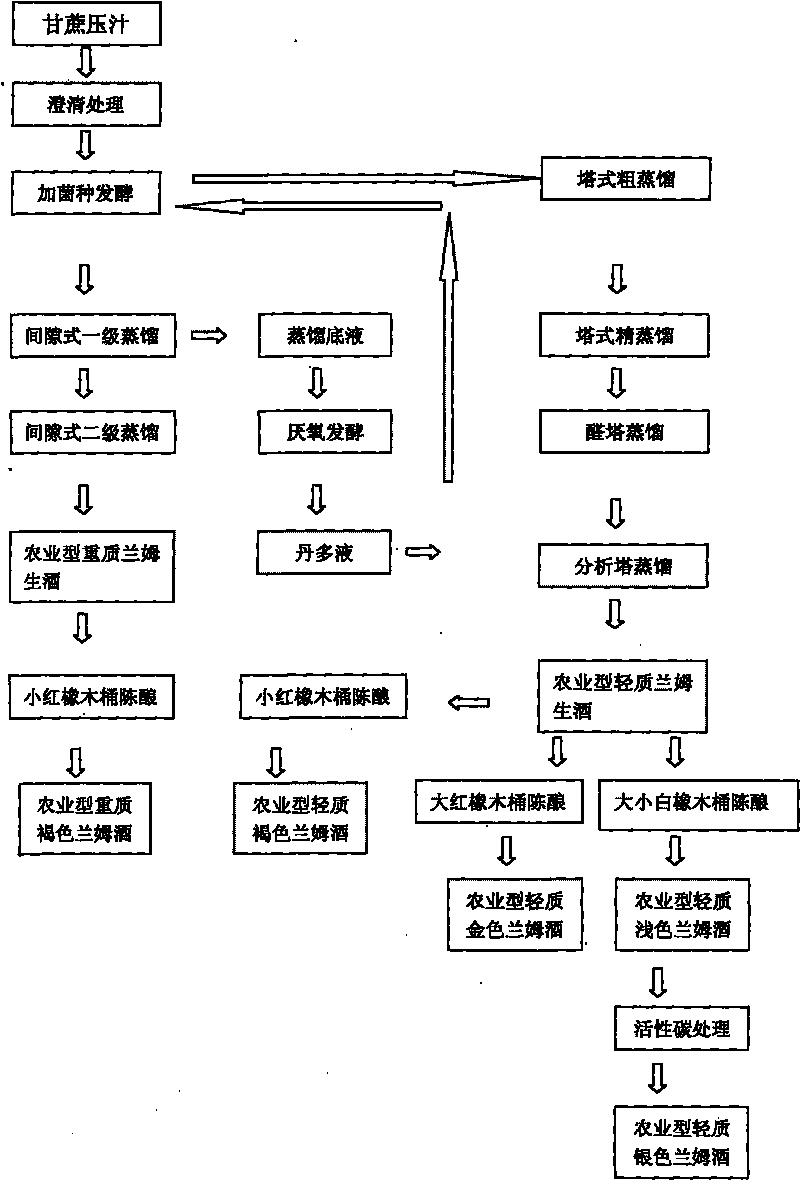

Method for producing compound rum from sugarcane juice and sugarcane molasses

The invention relates to a method for producing compound rum from sugarcane juice and sugarcane molasses, comprising the following steps: injecting yeast sample solution into unfermented solution to ferment the unfermented solution to obtain manure fermented solution; distilling and condensing part of the fermented solution in a clearance copper kettle-type distiller to obtain heavy raw rum; feeding the remaining fermented solution into a tower-type continuous distillation system to be distilled and condensed to obtain light raw rum; and injecting both the heavy raw rum and the light raw rum to an oak barrel to be aged. The method for producing compound rum from sugarcane juice and sugarcane molasses meet the international requirement for the characteristics, the fragrance, the flavor, the taste, the color and other traditional indexes of the rum, guarantees the economic and social benefits, fills the blank that no rum is produced in China and provides a favorable condition to diversify the life of people.

Owner:南宁海酩威科技有限公司

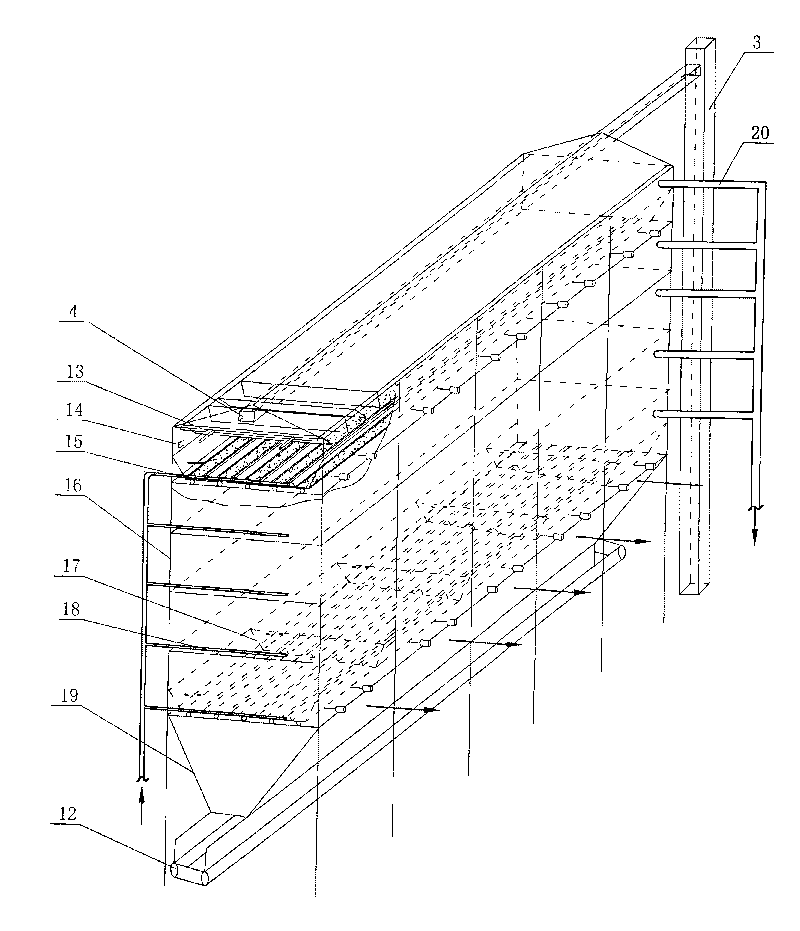

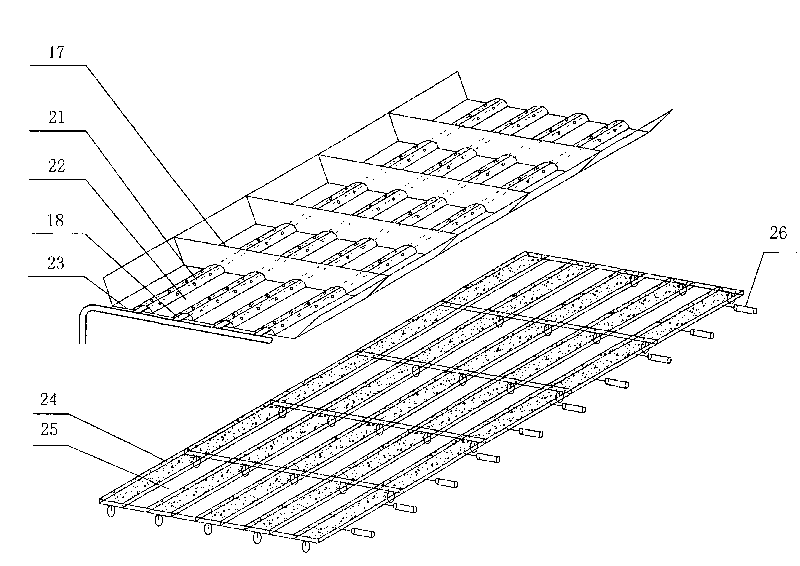

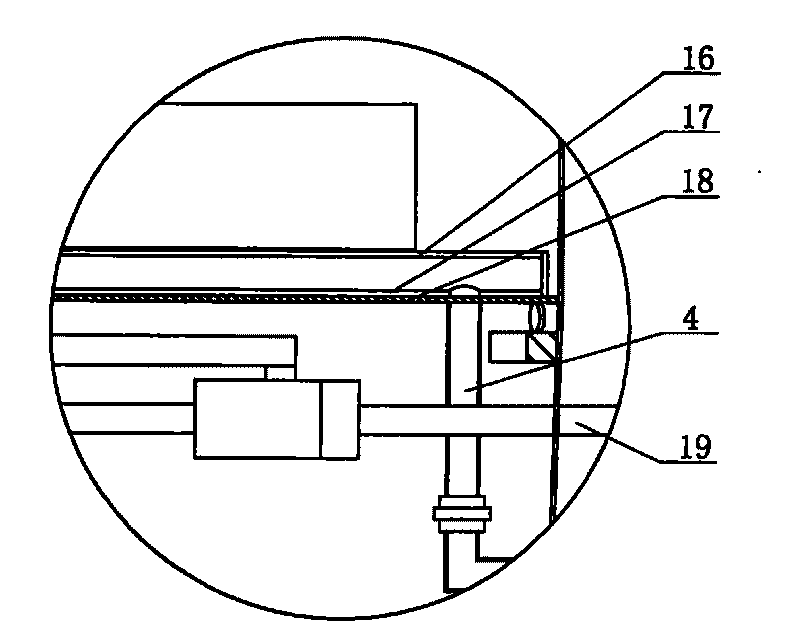

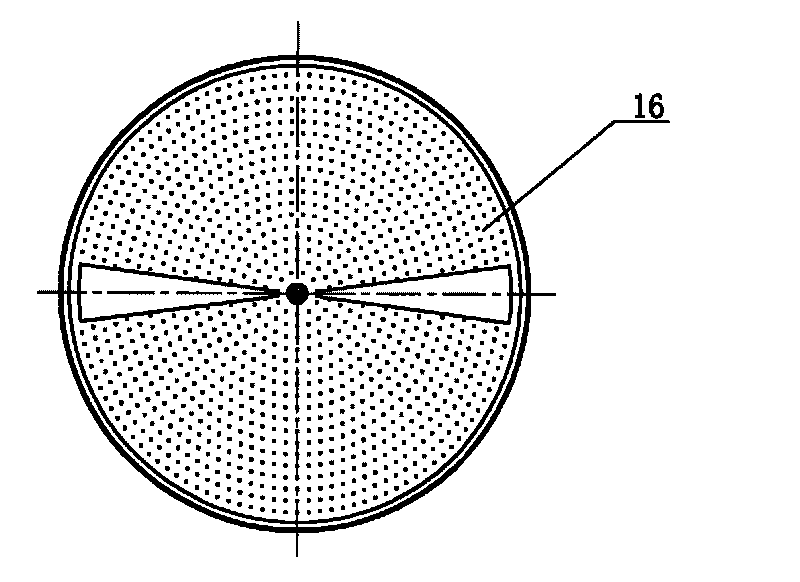

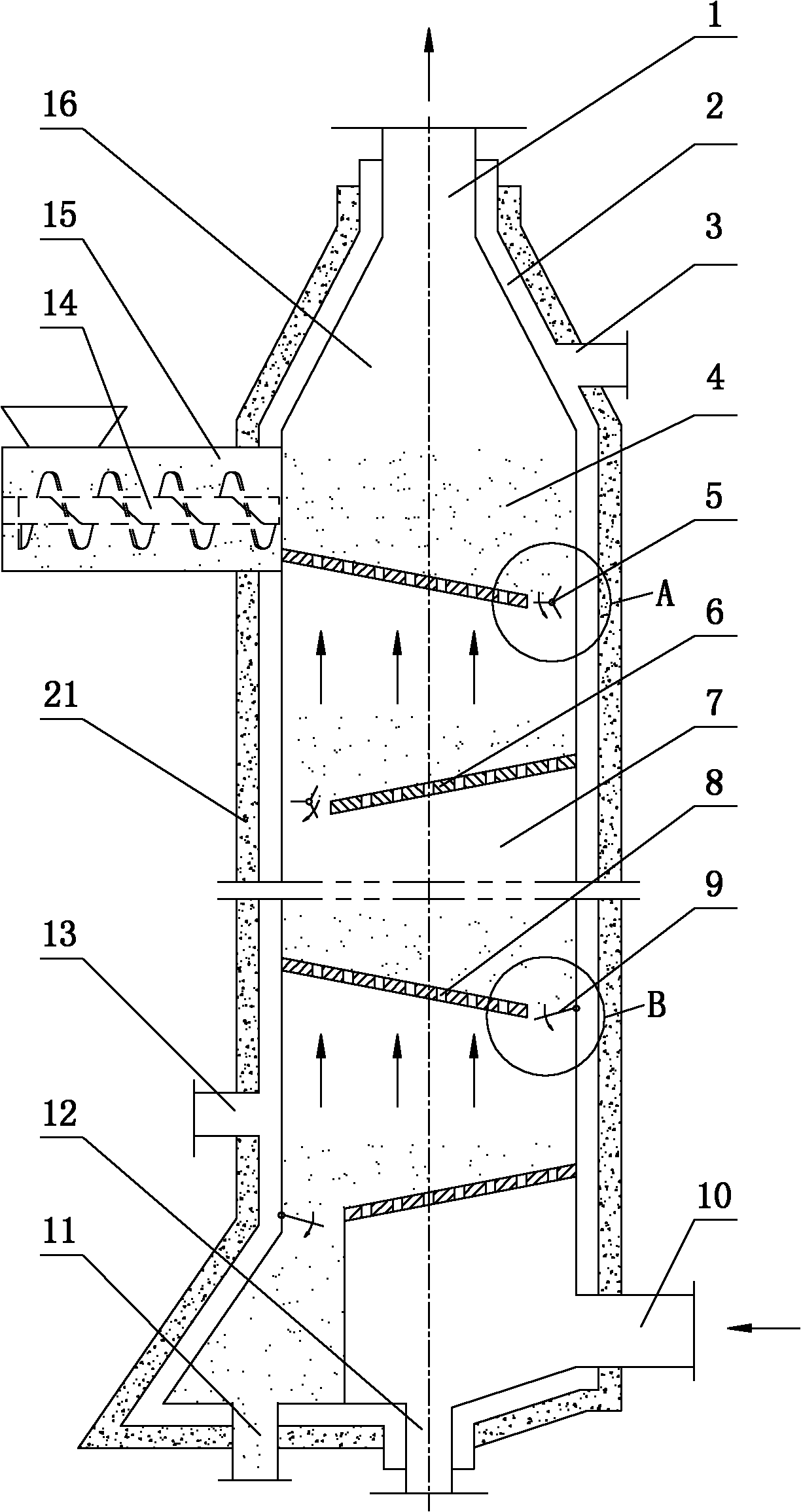

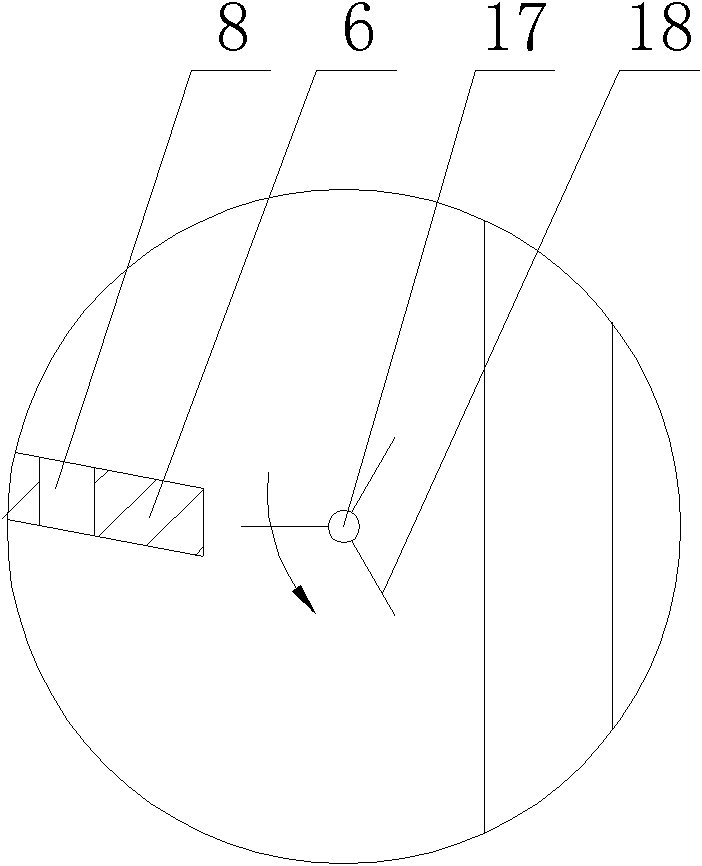

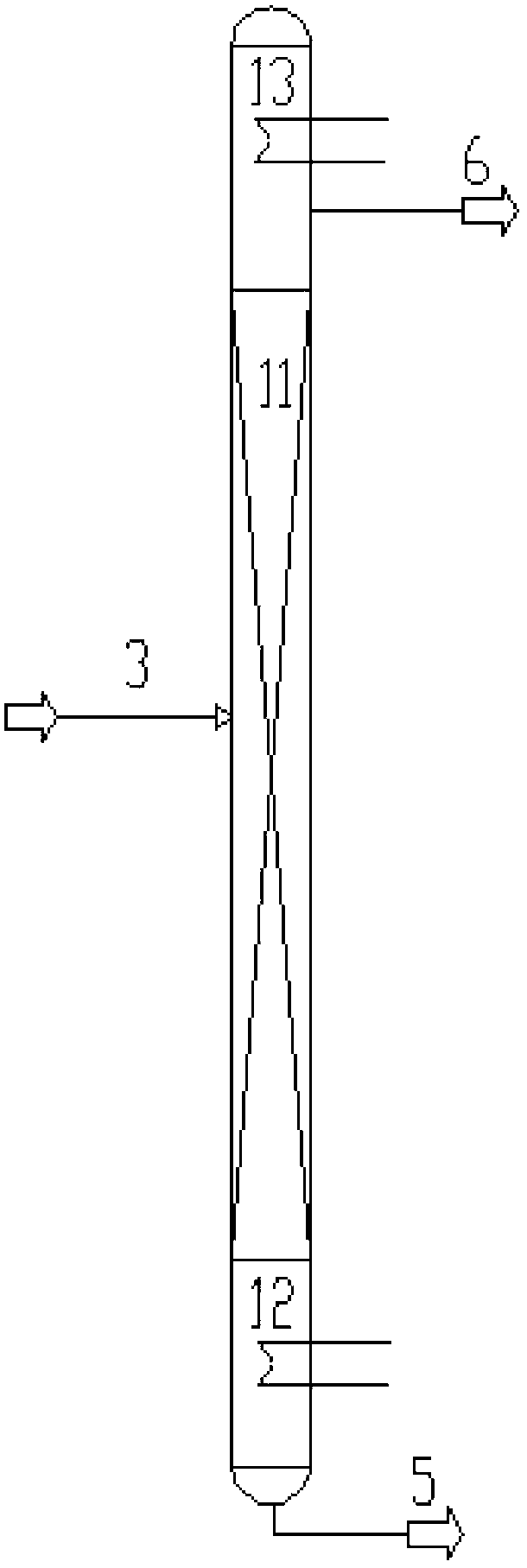

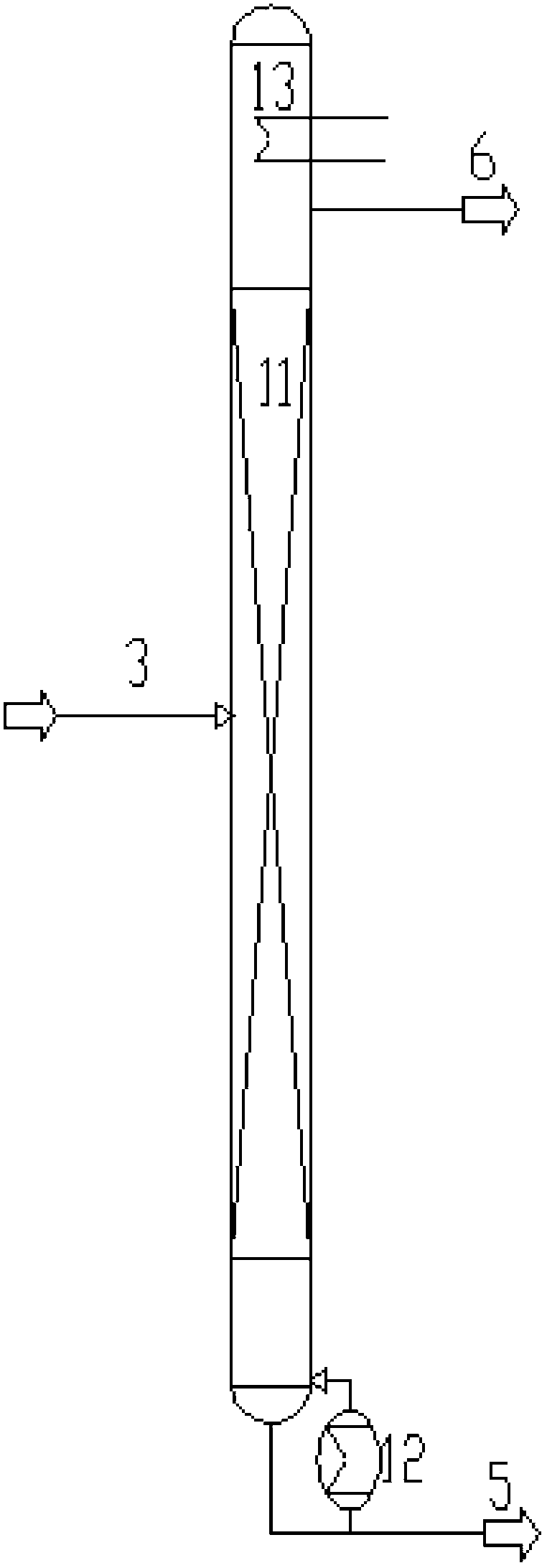

Multilayer fluidized solid continuous distillation column

ActiveCN102335520ALow in ethanolIncreased heat and mass transfer intensitySteam distillationDistillationSlag

The invention relates to a multilayer fluidized solid continuous distillation column which comprises a column body, a mixed steam outlet at the top of the column body, a feed inlet at a sidewall of the upper part of the column body, a superheated steam inlet at a sidewall of the lower part of the column body, and a slag outlet and a cleaning liquid outlet at the bottom of the column body. A set of gas distribution plates are staggerly installed at intervals on the internal wall of the column body between the feed inlet and the slag outlet, and included angles between the set of gas distribution plates and a horizontal plane are adjustable; each gas distribution plate is provided with steam pores; places of the column body corresponding to side edges of bottom ends of gas distribution plates are all provided with a material blanking control unit. The distillation column provided in the invention has the advantages of simple construction, convenient operation, great treatment capacity and a high degree of automation; multilayer gas distribution plates arranged in the distillation column allow a ferment material to be fluidized or periodically fluidized in the process of distillation, which enables rapid and high efficiency continuous distillation technology to be realized, and therefore, the multilayer fluidized solid continuous distillation column provided in the invention is update equipment for existing solid distillation columns.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for preparing pure triethanolamine (TEOA)

ActiveUS8466323B2Improve color qualityImprove the quality of purityAmino compound purification/separationOrganic compound preparationDistillationResidence time

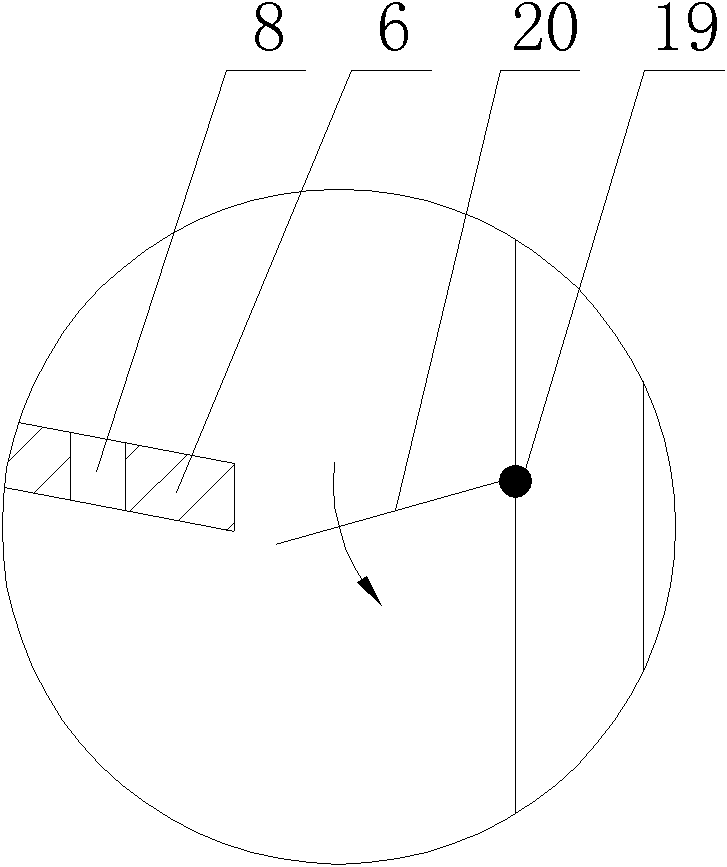

A process for preparing pure triethanolamine (TEOA) by continuously distillatively separating an ethanolamine mixture comprising TEOA and diethanolamine (DEOA), by distilling off DEOA in a distillation column (DEOA column) and supplying the resulting bottom stream comprising TEOA to a downstream column (TEOA column) in which the pure TEOA is withdrawn as a side draw stream, wherein the residence time of the ethanolamine mixture in the bottom of the DEOA column is <20 minutes.

Owner:BASF AG

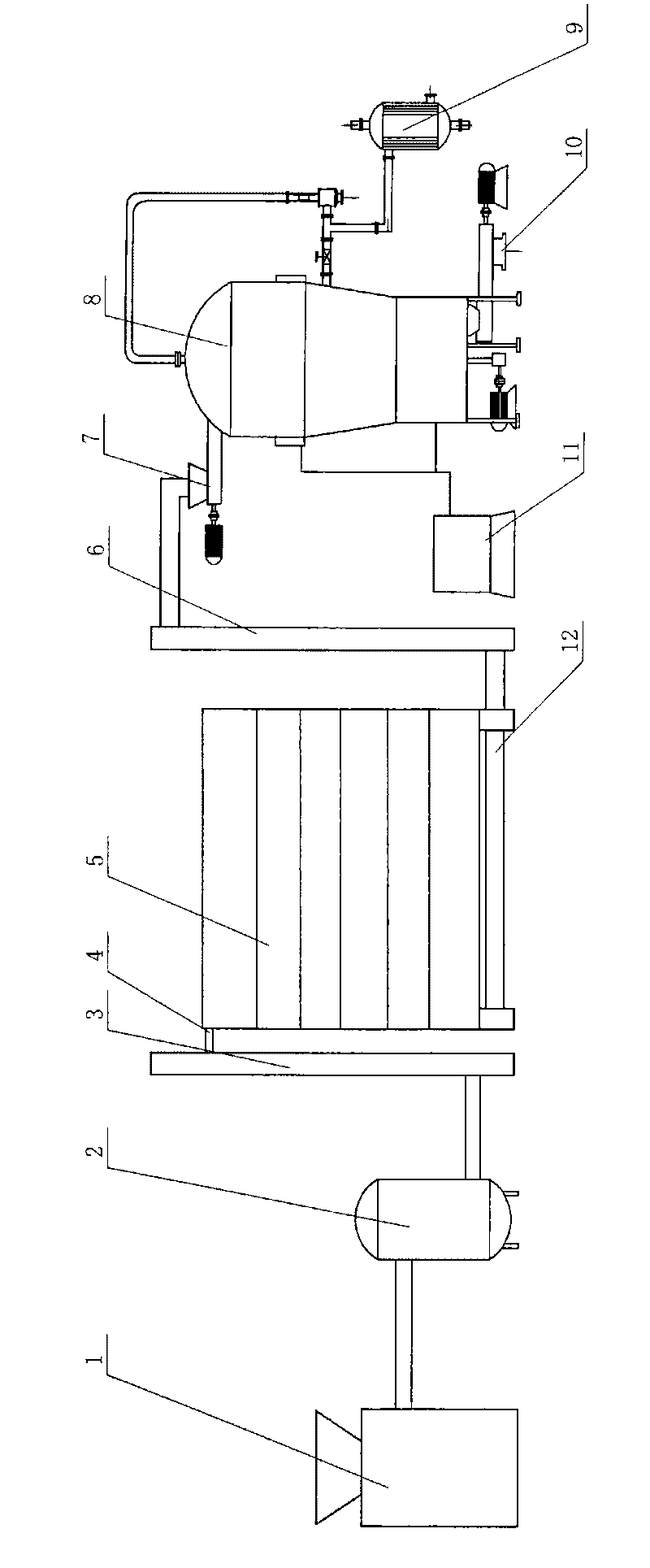

Testing device for simulating equipment corrosion of continuous distillation industrial device

ActiveCN102445411AAvoid revaporizationEnable accurate simulationWeather/light/corrosion resistanceBoiling pointControl system

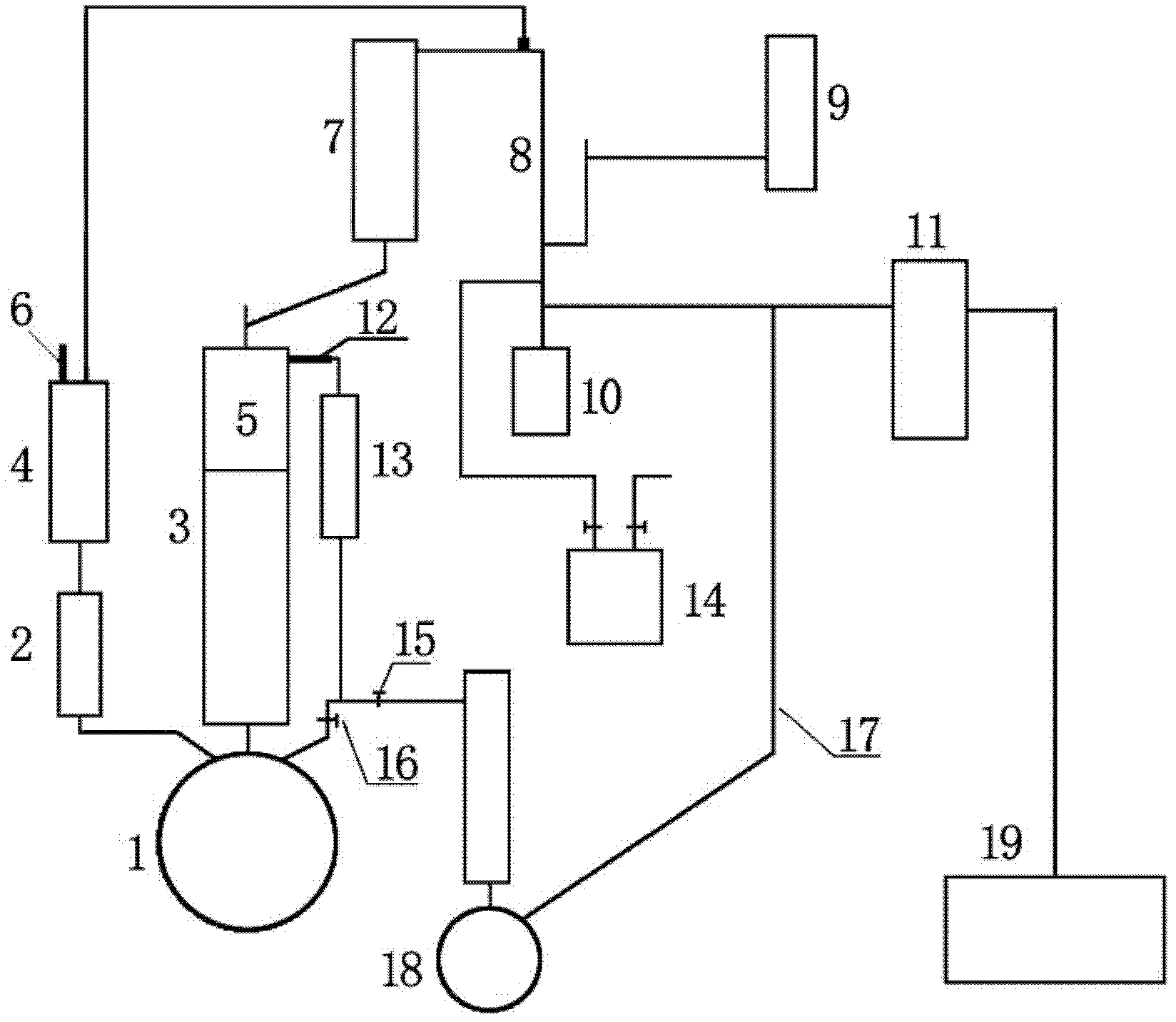

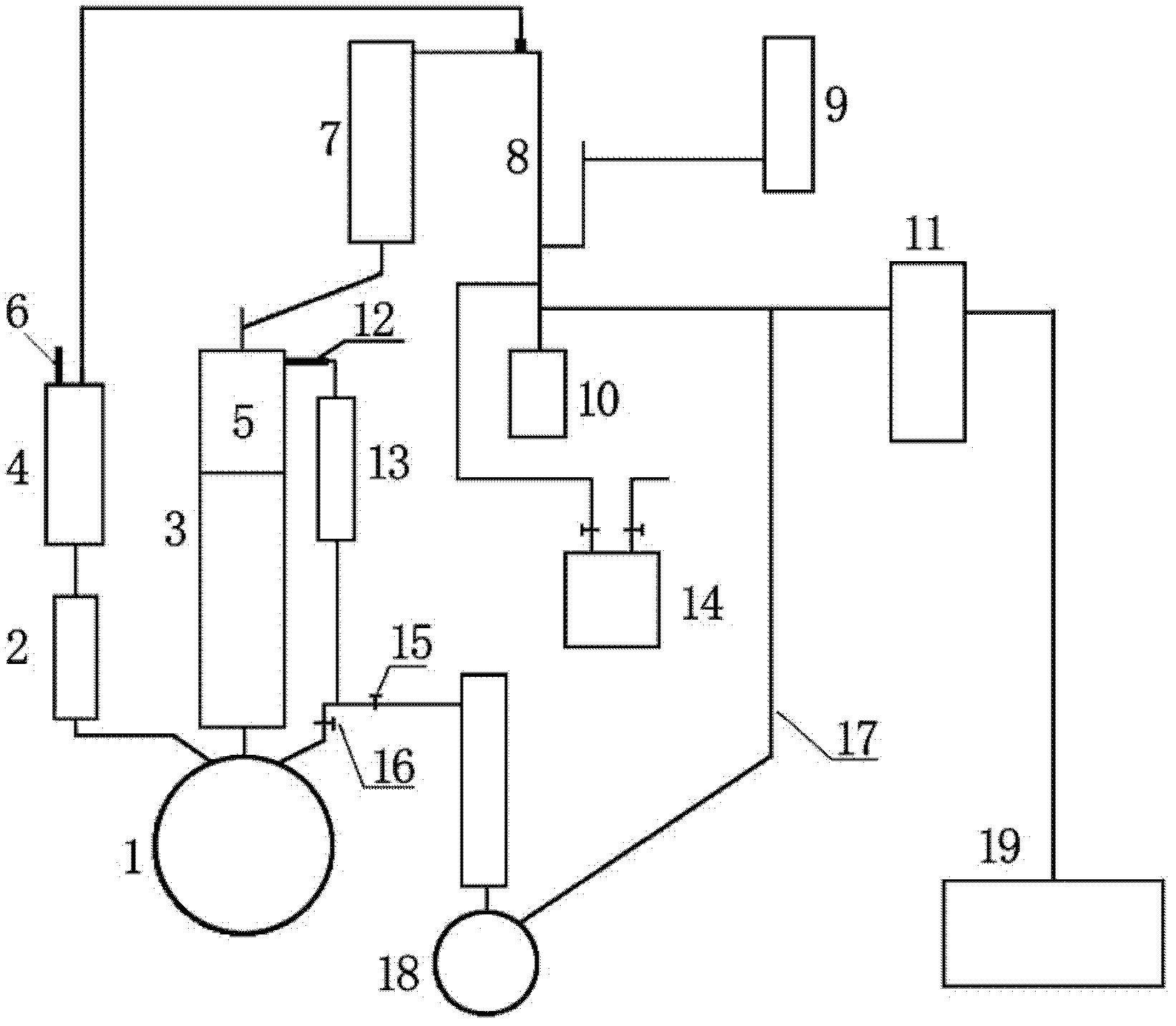

The invention relates to a testing device for simulating the equipment corrosion of a continuous distillation industrial device. The testing device comprises a continuous distillation system, a pressure control system and a corrosion sample system, wherein the top interface of a multi-mouth flask is connected with the bottom of a main reactor; the top interface of the main reactor is connected with the bottom of a main condenser; the top of the main condenser is connected with a non-condensable gas receiving tank, a cold trap, a gas buffering tank and an exhaust system through connecting pipes respectively, and is connected to a vacuum pump through the cold trap; and the corrosion sample system comprises a sample hanging device for placing samples into a steam phase and a liquid phase. A skillful reflow design is adopted in the invention, so that a condensed low-boiling-point liquid does not flow through the high-temperature main reactor, so that re-vaporization before reflowing to the bottom of the multi-mouth flask is avoided. Under the action of a reflow bypass, condensed low-boiling-point components and high-boiling-point components left at the bottom of the multi-mouth flask are fully mixed forcedly, and the distillation process is started once again, so that accurate simulation of continuous distillation is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tester for simulating high-temperature corrosion in continuous distillation apparatus

ActiveCN102507422ASolving Realistic Simulations of CorrosionWeather/light/corrosion resistanceDistillationEngineering

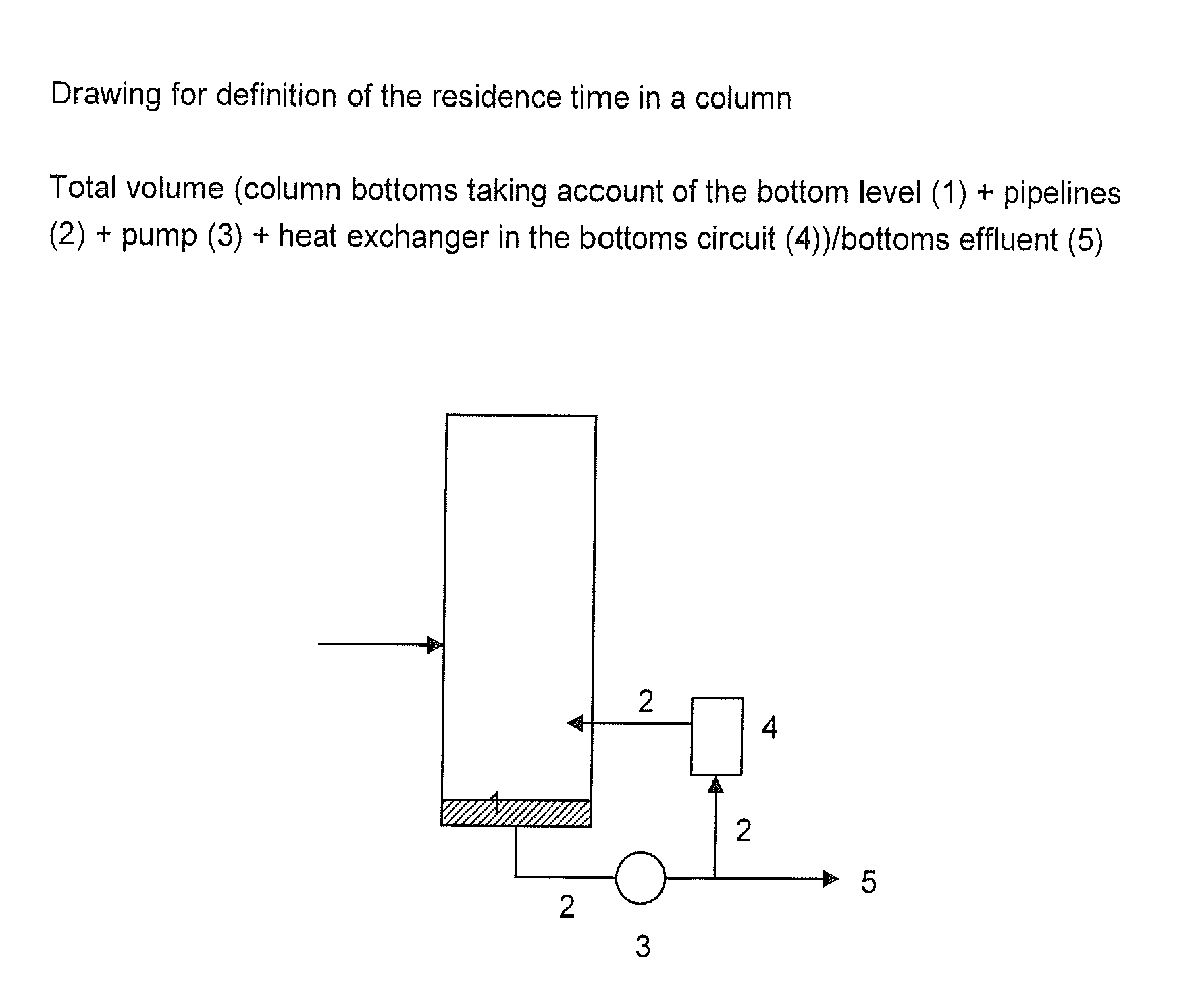

The invention provides a tester for simulating high-temperature corrosion in a continuous distillation apparatus, comprising a feeding module, a kettle corrosion detection module, a vacuumizing module, a control module of the vacuumizing module and a temperature and pressure control module, wherein the feeding module comprises a filter 2, an experiment oil material tank 4 and a plunger-type feeding pump 5; the kettle corrosion detection module comprises a reaction kettle 19 with condensers 14 and 15; a nitrogen inlet 8, the first condenser 14 and the second condenser 15 are arranged on a cover of the reaction kettle 19; the first condenser 14 is connected with a discharge tank 20, and the second condenser 15 is orderly connected with a vacuum cold trap 10, a vacuum buffer tank 12 and a vacuum pump 11 of the vacuumizing module. According to the invention, accurate simulation of a corrosion problem in a continuous industrial process can be realized by continuously updating experiment medium of the corrosion test part, and real simulation problems of gas-liquid phase corrosion in petroleum refining and chemical processes, such as continuous normal pressure distillation, reduced pressure distillation and the like, are solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

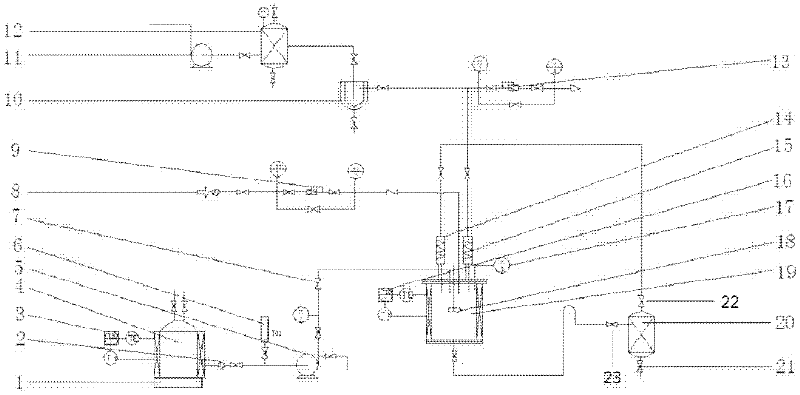

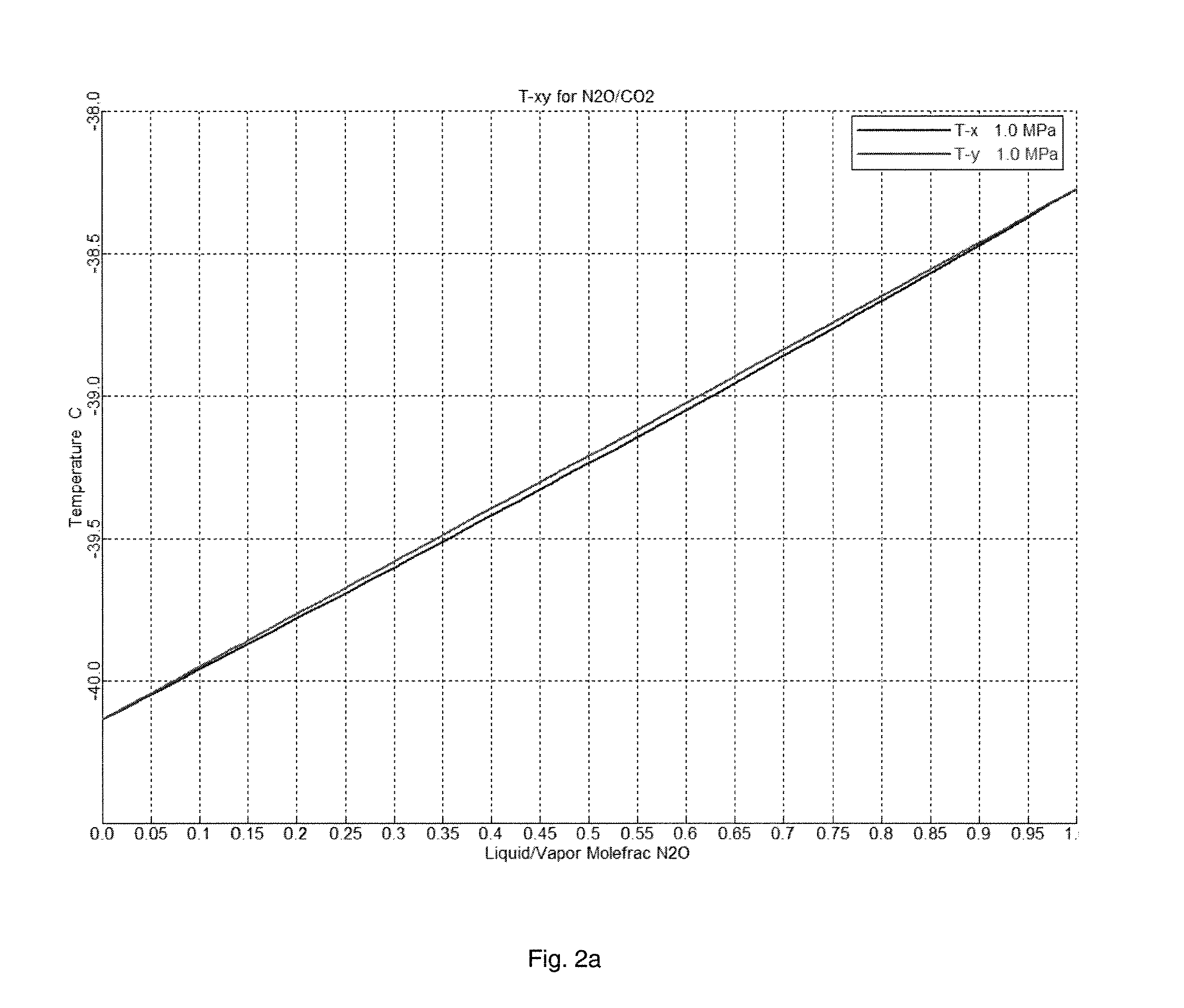

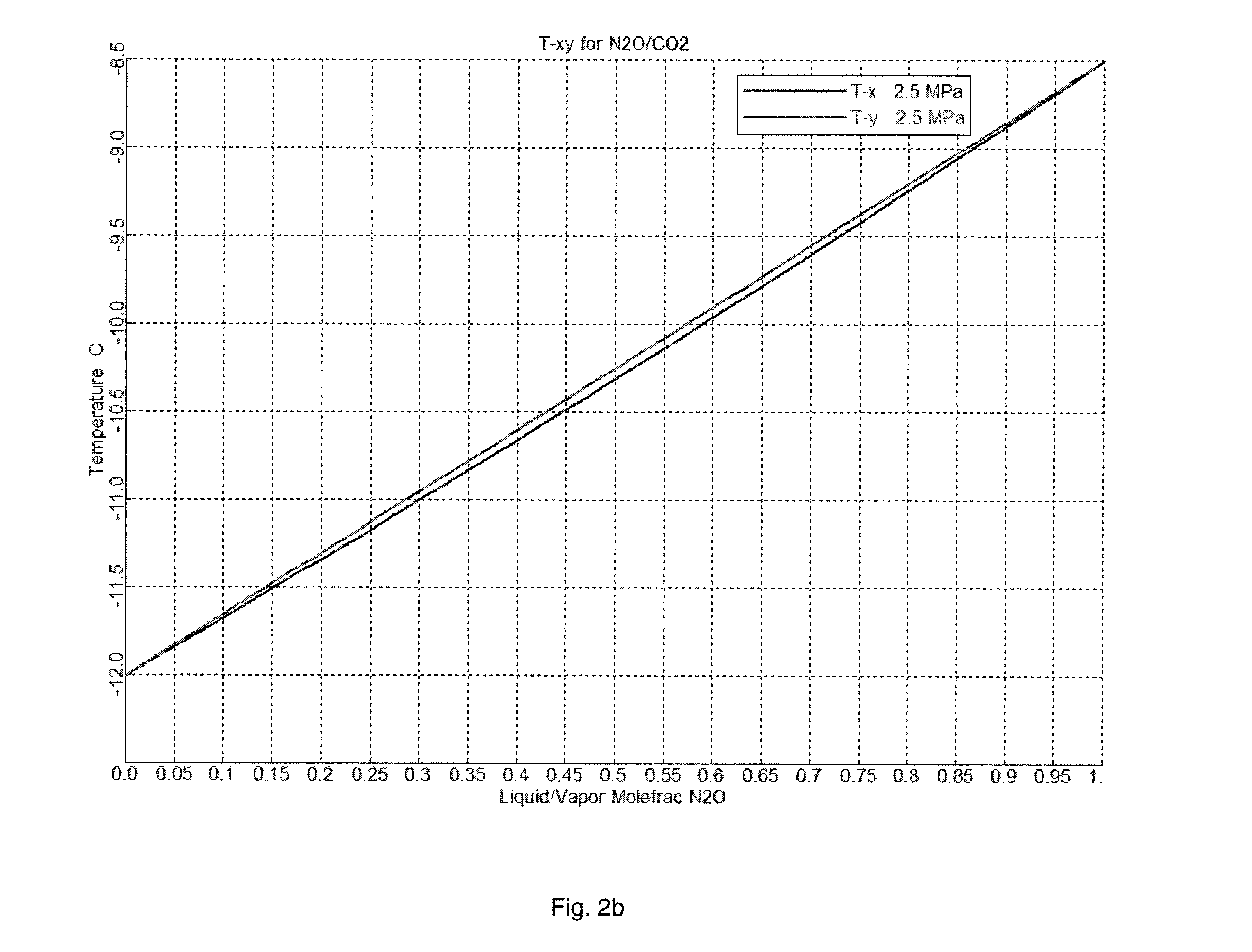

Process for Recovery and Purification of Nitrous Oxide

This invention is aimed at recovering and purifying nitrous oxide from the gas stream containing N2O to produce different grade of nitrous oxide by combination of unit operation including, but not limited to, wet scrubbing, adsorption, liquefaction, flash distillation or continuous distillation with reflux.

Owner:VERSUM MATERIALS US LLC

Technical process of preparing high-purity L-lactic acid

ActiveCN101007756AEasy to recycleHigh purityCarboxylic compound separation/purificationIon exchangeContinuous distillation

The invention discloses a making method of high-purity L-lactic acid, which comprises the following steps: a) extracting; crystallizing; decoloring; proceeding ion exchange or film separation; transmitting predisposed L-lactic acid into condenser under 0.5-0.95Mpa at 50-90 deg.c to condensate; b) transmitting L-lactic acid into at least two-grade cascading short-path distill devices to distill; setting one-grade short-path under 50-500Pa at 50-130 deg.c to distill; transmitting the heavy component into two-grade short-path distill device; collecting light component to obtain high-purity L-lactic acid; distilling heavy component from two-grade short-path distill device under 10-500Pa at 100-120 deg.c to distill; collecting light component as high-purity product.

Owner:马鞍山同杰良生物材料有限公司

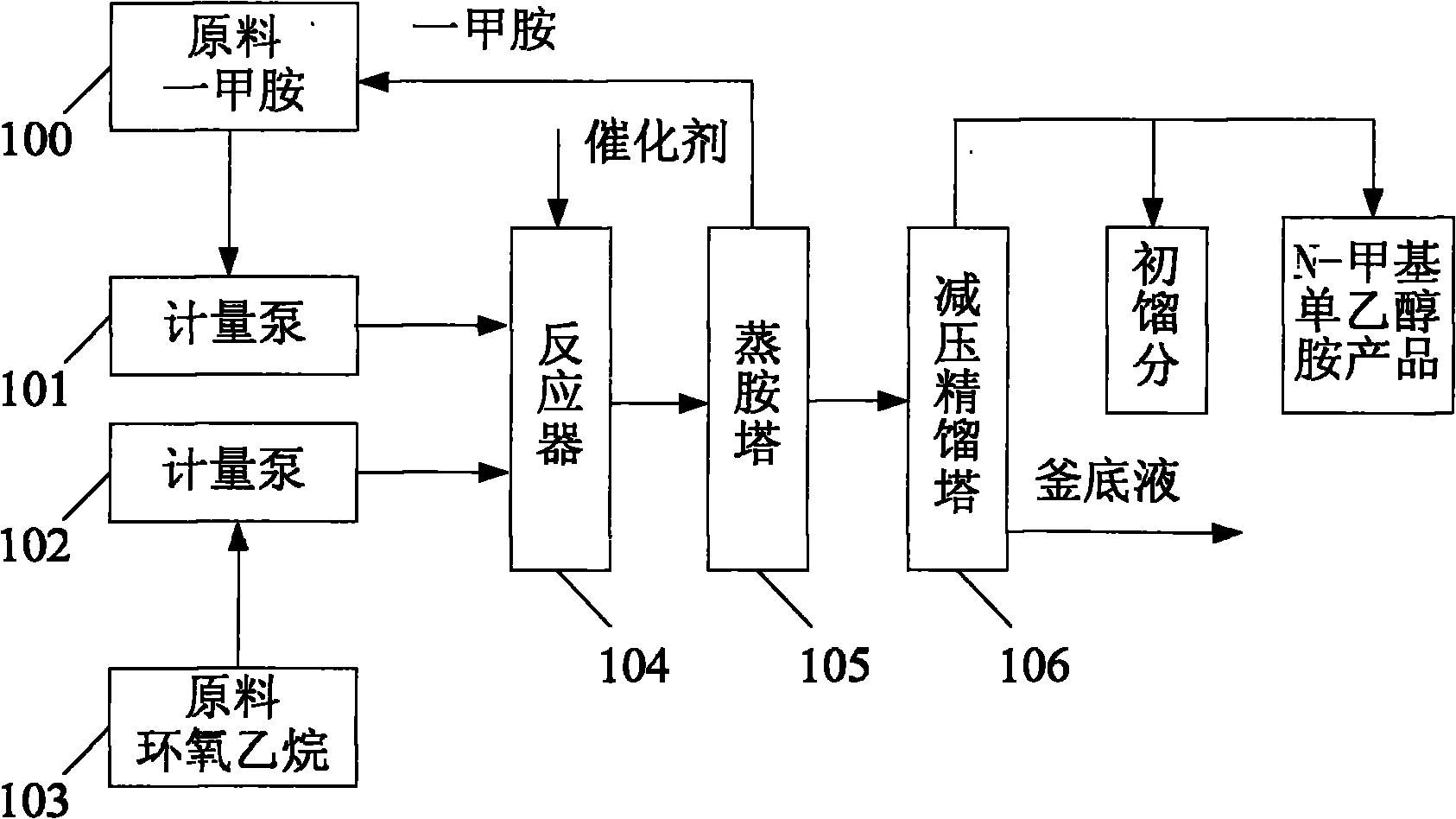

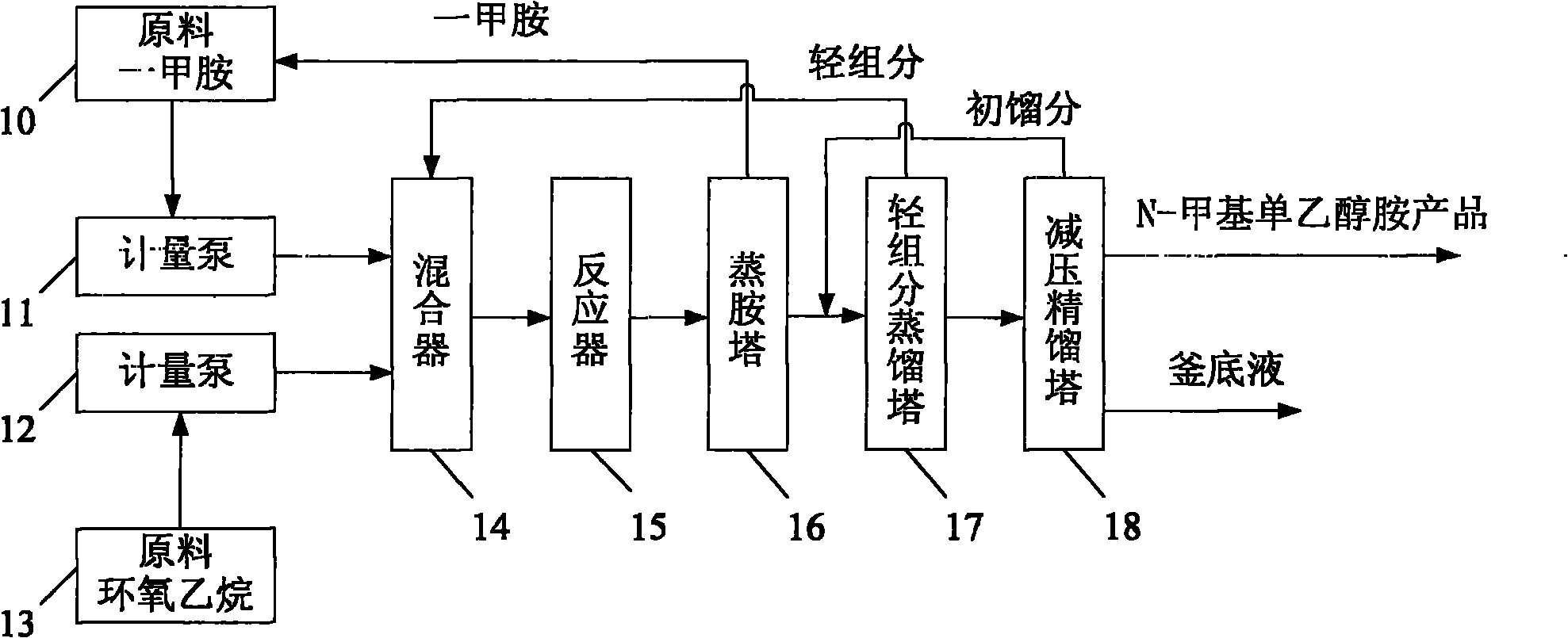

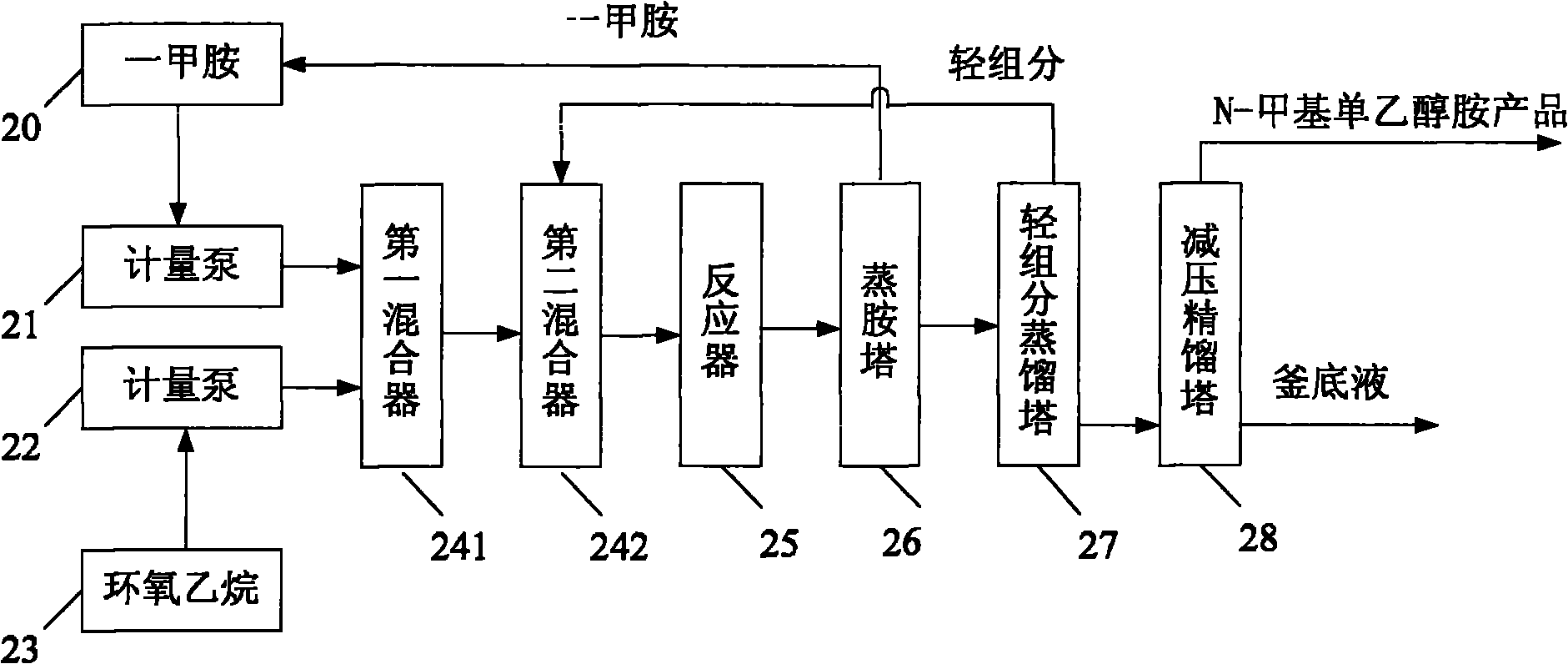

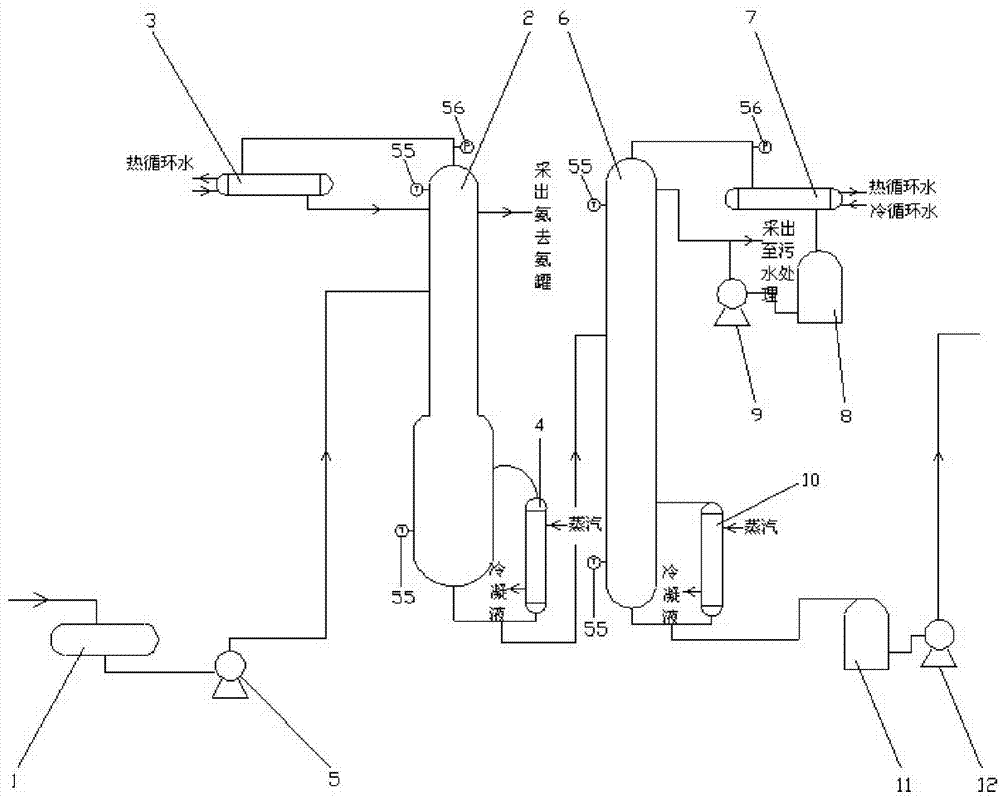

Process for continuously producing N-monomethylethanolamine

ActiveCN101830812AReduce labor intensityLower working temperatureOrganic compound preparationAmino-hyroxy compound preparationEthylene oxideDistillation

The invention discloses a process for continuously producing N-monomethylethanolamine, which comprises the following steps of: (1) pumping an ethylene oxide raw material and a monomethylamine raw material into a mixer or a two-stage mixer through a metering pump respectively, mixing the raw materials, and then reacting the mixed materials in a reactor to generate a mixture containing the N-monomethylethanolamine, wherein the mass ratio of the ethylene oxide raw material to the monomethylamine raw material is 1: 2-3; (2) delivering the mixture containing the N-monomethylethanolamine to an amine distillation tower, separating monomethylamine and an N-monomethylethanolamine coarse product by distillation, and conveying the distilled monomethylamine to a monomethylamine raw material container; and (3) conveying the N-monomethylethanolamine coarse product to a light component distillation tower and a reduced pressure rectifying tower in which efficient pore plate ripple fillers are filled and which are connected in series, separating an N-monomethylethanolamine product by continuous distillation, and continuously discharging the N-monomethylethanolamine product from the side or the topof the reduced pressure rectifying tower. The process is characterized in that the production process is continuous, the produced product has stable quality and high yield, and meanwhile, the processcan improve the yield and reduce the energy consumption and the material consumption, and is suitable for industrialized popularization and application.

Owner:MAOMING YUNLONG IND DEV

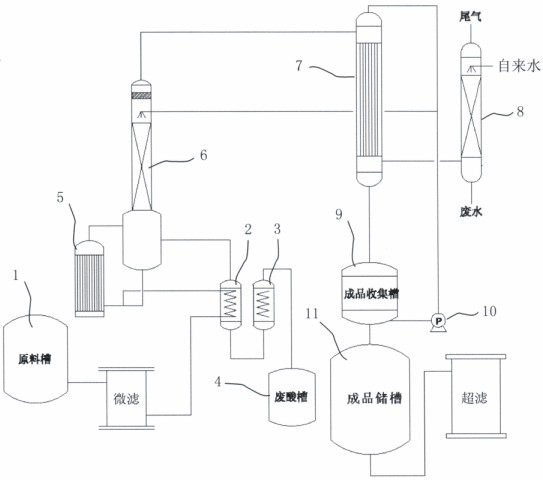

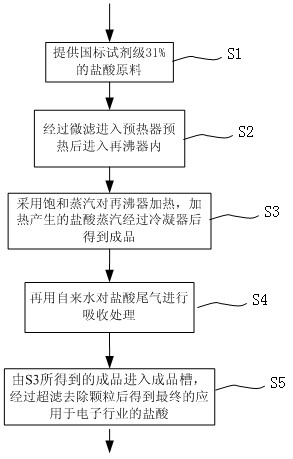

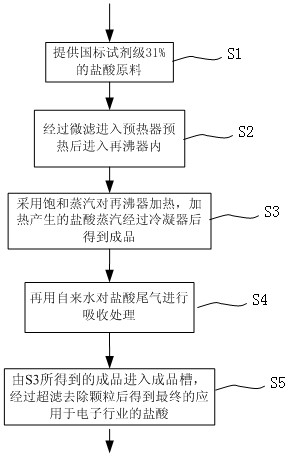

Method for producing electronic grade hydrochloric acid

ActiveCN102060271AContinuous productionLarge output and energy consumption ratioChlorine/hydrogen-chloride purificationProcess engineeringMicrofiltration

The invention discloses a method for producing electronic grade hydrochloric acid, sequentially comprising the following steps of: (a) providing a 31% hydrochloric acid raw material with a national standard reagent grade; (b) carrying out microfiltration on the hydrochloric acid raw material, preheating in a preheater and putting into a reboiler; (c) heating the reboiler by utilizing saturated steam and obtaining an end product after hydrochloric acid steam generated through the heating passes through a condenser; (d) absorbing hydrochloric acid tail gas by utilizing running water; and (e) putting the end product obtained in the step (c) into an end product storage tank, carrying out ultrafiltration to remove grains and obtaining final hydrochloric acid which is applied to electronic industry. The method for producing the electronic grade hydrochloric acid, which is provided by the invention, is used for obtaining 37% electronic grade hydrochloric acid by adopting the method of carrying out direct and continuous distillation and purification on the 31% hydrochloric acid with the national standard reagent grade, has the characteristics of large ratio of yield to energy consumption,production continuity, simple process and equipment and good stability; furthermore, the concentration of the hydrochloric acid raw material has no specific requirement and the concentration of the end product can be adjusted at will.

Owner:SHANGHAI ZHENGFAN TECH

Method and device for refining crude products of m-phthaloyl chloride

InactiveCN102701960AEasy to handleQuality improvementOrganic compound preparationCarboxylic compound preparationBoiling pointEvaporation

The invention relates to a method and a device for refining crude products of m-phthaloyl chloride. The crude products are heated to evaporate light components. The light components with boiling points lower than that of m-phthaloyl chloride are separated from bulk solution through a gasification and transferred into a light components continuous distillation system from an evaporation unit to be refined to obtain a small amount of light components and m-phthaloyl chloride in the tower and the light component products at tower top, which meet the requirements of national standards. The liquid of m-phthaloyl chloride crude products without the light components is transferred into an m-phthaloyl chloride continuous distillation system from the evaporation unit to be refined to obtain m-phthaloyl chloride product with a purity of 99.96% and a yield of over 90% at tower top. With the adoption of the device, a continuous treatment process is realized and the problems of low productivities of a single set of batch or semi-batch refining device and serious environmental pollutions caused by unqualified products are solved.

Owner:TIANJIN UNIV

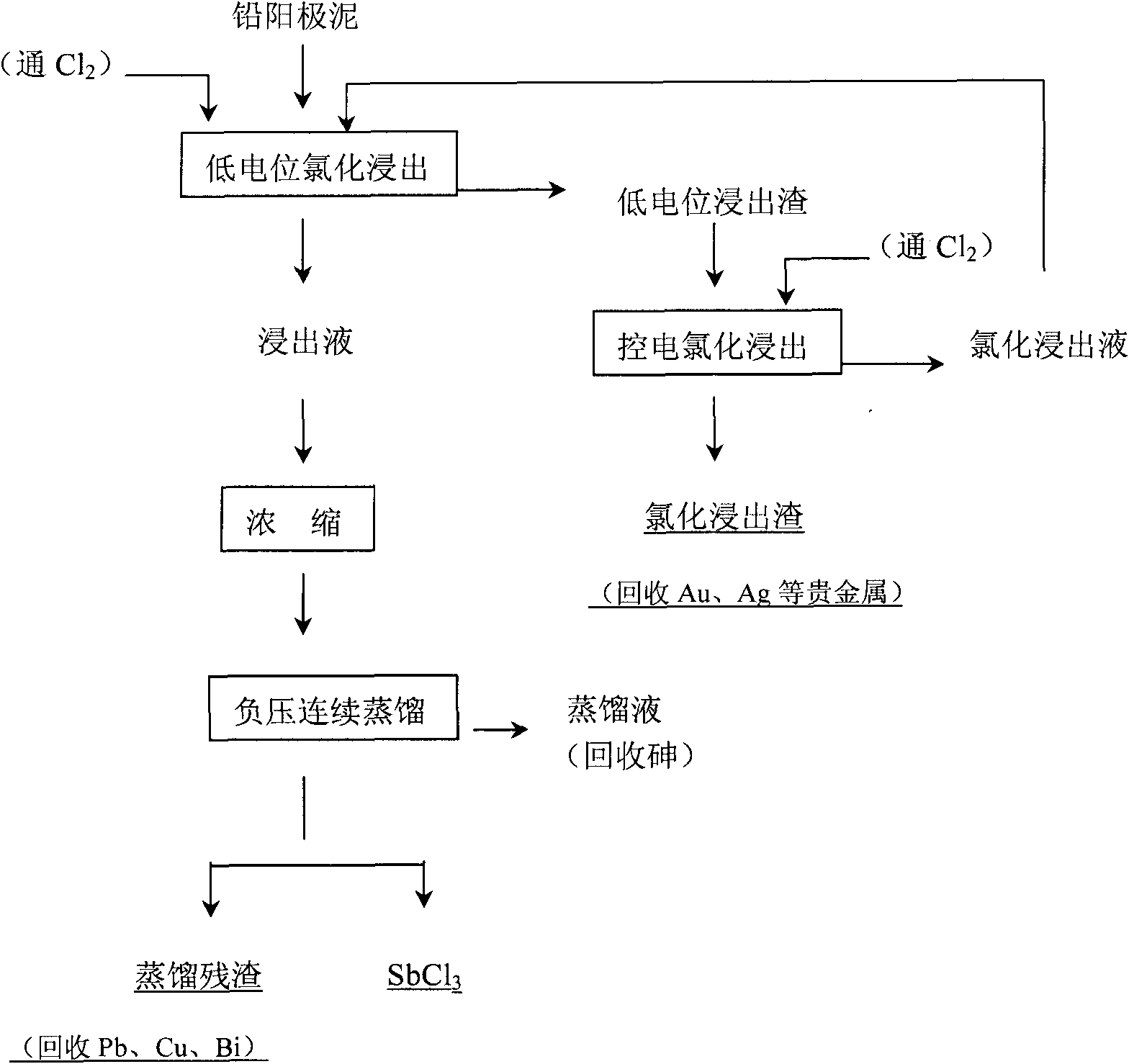

Method for wet processing of high antimony-lead anode mud

InactiveCN101787440AIncrease concentrationImprove leaching rateAntimony compoundsProcess efficiency improvementElectrolysisDistillation

The invention discloses a method for wet processing of high antimony-lead anode mud, which comprises the following steps: putting high antimony-lead anode mud of which the content of antimony generated during the lead electrolysis is between 40% and 75% in hydrochloric aid medium, adopting two-section electric potential control of chlorination leaching, wherein oxidation-reduction potential of the end point of the first section chlorination leaching is controlled to be between 200-300mv, while oxidation-reduction potential of the end point of the second chlorination leaching is controlled to be 400-450mv, and 99.5% of golden and 99% of silver are enriched in the slag of the second chlorination leaching and can be subjected to further process. The silicofluoric acid in the first section chloridizing leachate is evaporated by concentration and distillation, the high-purity antimony butter is prepared from distilled and concentrated mother liquor by a continuous distillation method, and the yield of antimony metal is 95%.

Owner:广西华锡集团股份有限公司 +1

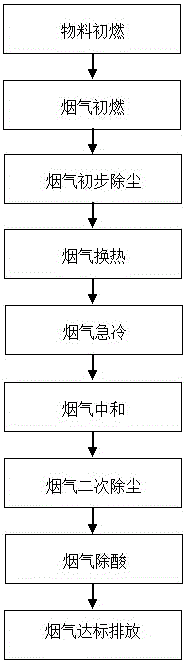

Preparation method based on rotary kiln-type continuous distillation pyrolysis and gasification incinerator

ActiveCN105114955AEfficient removalSolve temperature problemsIncinerator apparatusCombustion chamberCooling tower

Owner:江苏鼎新环保科技有限公司

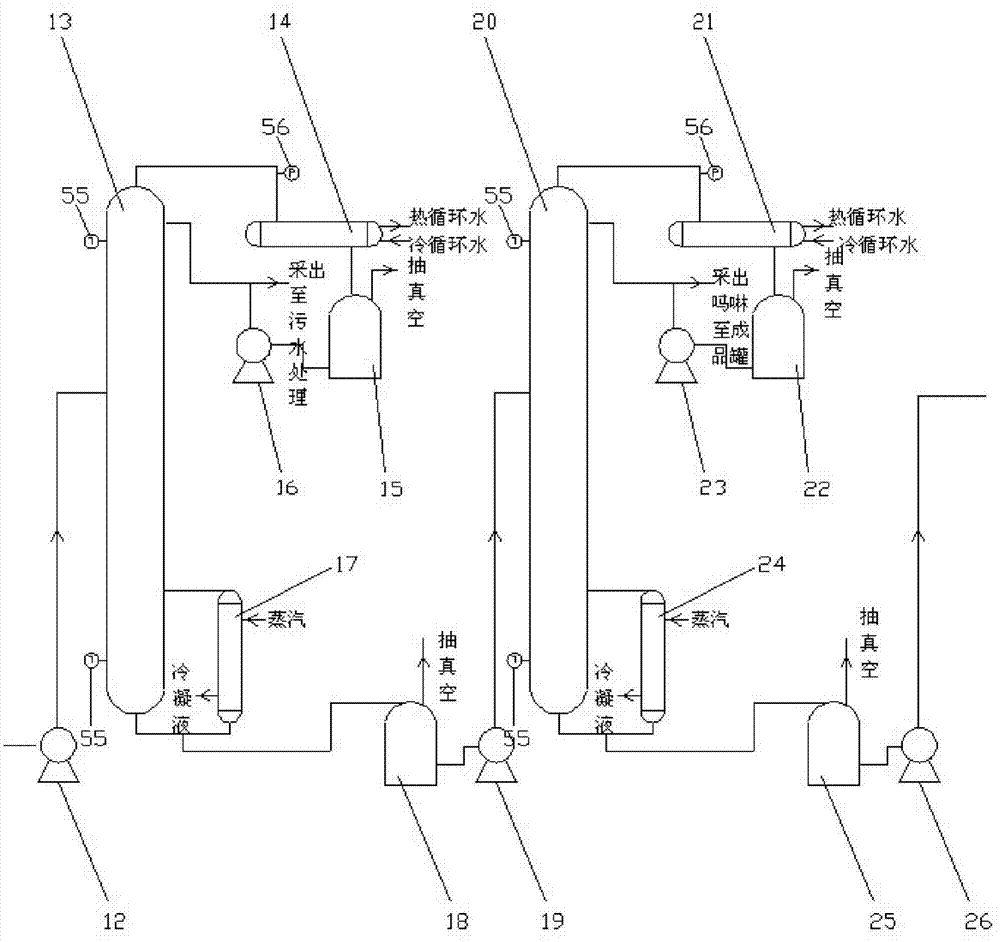

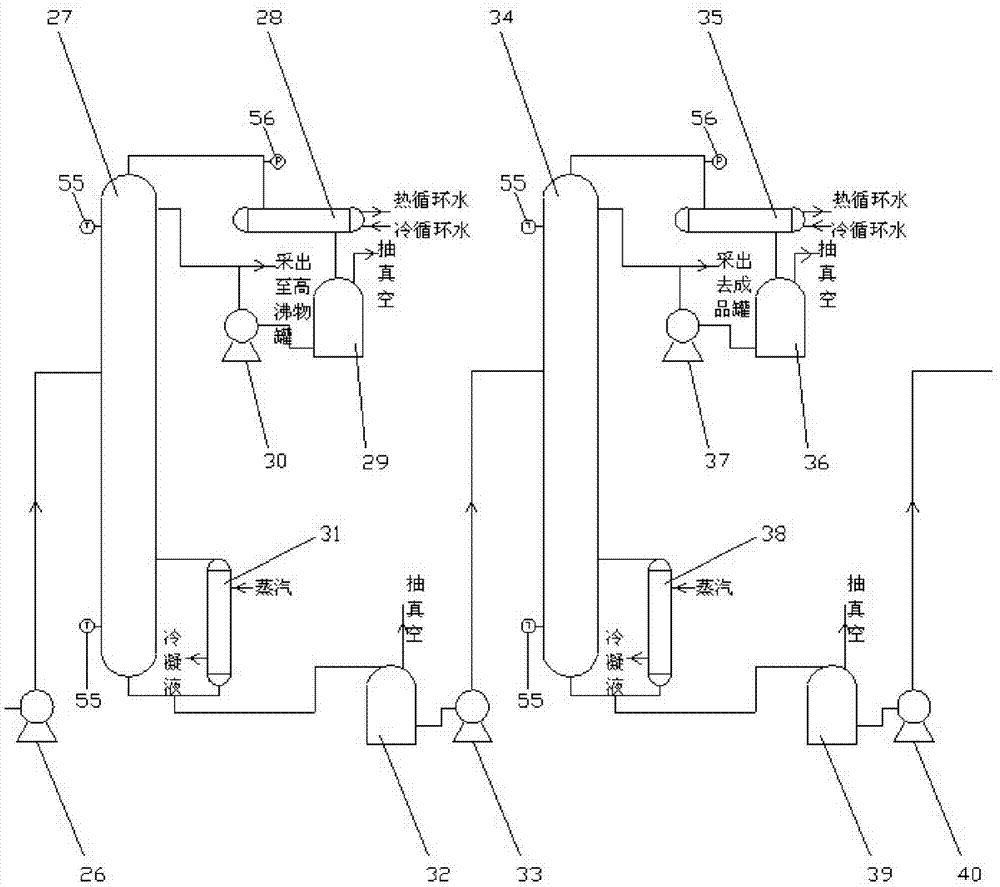

Separation and purification method of coarse diglycolamine

ActiveCN104262177AReduce energy consumptionSimple processEther separation/purificationOrganic compound preparationPurification methodsMorpholine

The invention discloses a separation and purification method of coarse diglycolamine. The method comprises the following steps: sequentially carrying out continuous distillation on coarse diglycolamine which is prepared from diglycol in a manner of catalytic ammoniation through eight towers under the pressurized or atmospheric condition; separating out diglycolamine, morpholine and diglycol from un-reacted raw materials and impurities to obtain a diglycolamine product with the purity being over 99%; and simultaneously generating a byproduct morpholine and recovering un-reacted diglycol, wherein the eight towers are sequentially a deamination tower, an atmospheric azeotropic tower, a vacuum dehydrating tower, a vacuum morpholine recovery tower, a vacuum diglycolamine refining tower, a vacuum diglycolamine tower, a vacuum diglycol refining tower and a vacuum diglycol recovery tower. The separating and refining processes of the method are low in energy consumption, simple in flow, and easy to operate; the diglycolamine product with the purity being over 99% and the morpholine byproduct with the purity being over 99.5% are obtained; and the yield reaches 99.5%.

Owner:ANHUI HAOYUAN CHEM IND GRP

Process for recovering N-vinyl-2-pyrrolidone

InactiveUS6436243B1Recovered continuously, efficiently and steadilyHigh purityOrganic compound preparationDistillation regulation/controlBoiling point2-Pyrrolidone

A process for recovering N-vinyl-2-pyrrolidone is provided which allows to recover N-vinyl-2-pyrrolidone efficiently and steadily and in high purity by continuous distillation from a mixed liquid containing N-vinyl-2-pyrrolidone, N-(2-hydroxyethyl)-2-pyrrolidone, compounds having a higher boiling point than N-vinyl-2-pyrrolidone and water. The process includes continuously distilling the mixed liquid using a distilling column, controlling the temperature of the bottom liquid of the distilling column at 180° C. or less.

Owner:NIPPON SHOKUBAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com