Method and device for refining crude products of m-phthaloyl chloride

A crude isophthaloyl chloride, isophthaloyl chloride technology, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds and other directions, can solve the problem of unqualified product indicators, environmental pollution, isophthalic Problems such as small processing capacity of acid chloride refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

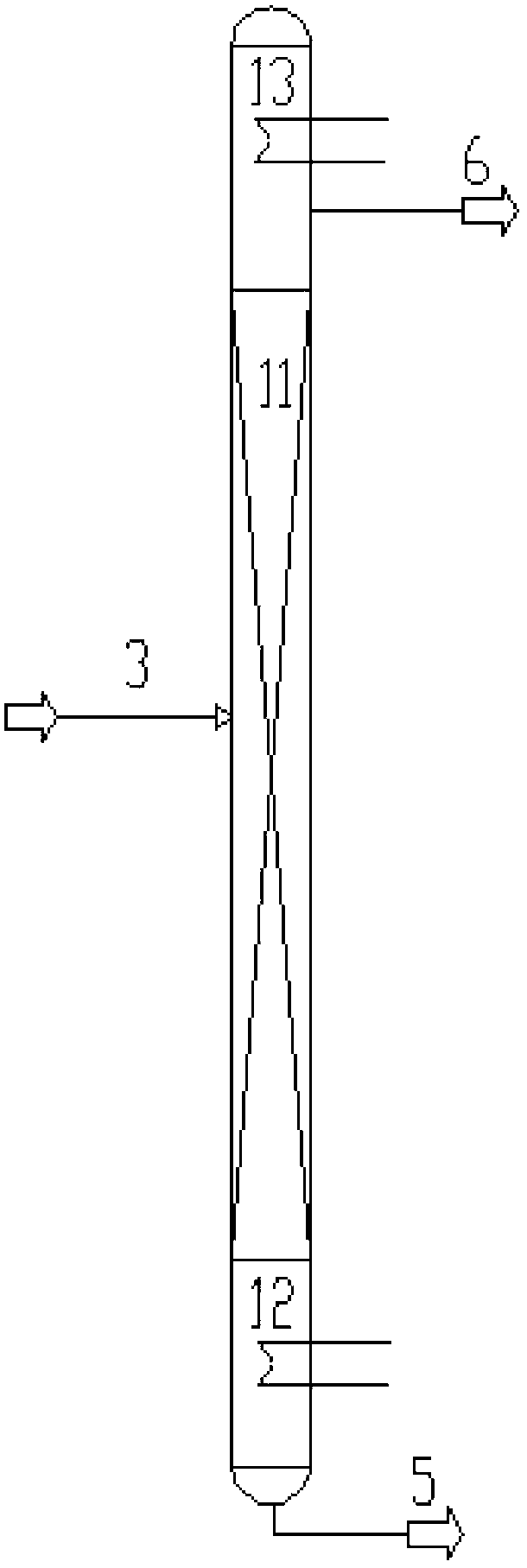

[0024] Equipment Description: The top condensing device (17) of the light fraction rectification tower and the bottom heating device (16) of the light fraction rectification tower adopt the following figure 1 The external structure shown. The isophthaloyl dichloride product rectifying tower top condensing device (13) and the isophthaloyl dichloride product rectifying tower bottom heating device (12) also adopt such as figure 1 The external structure shown.

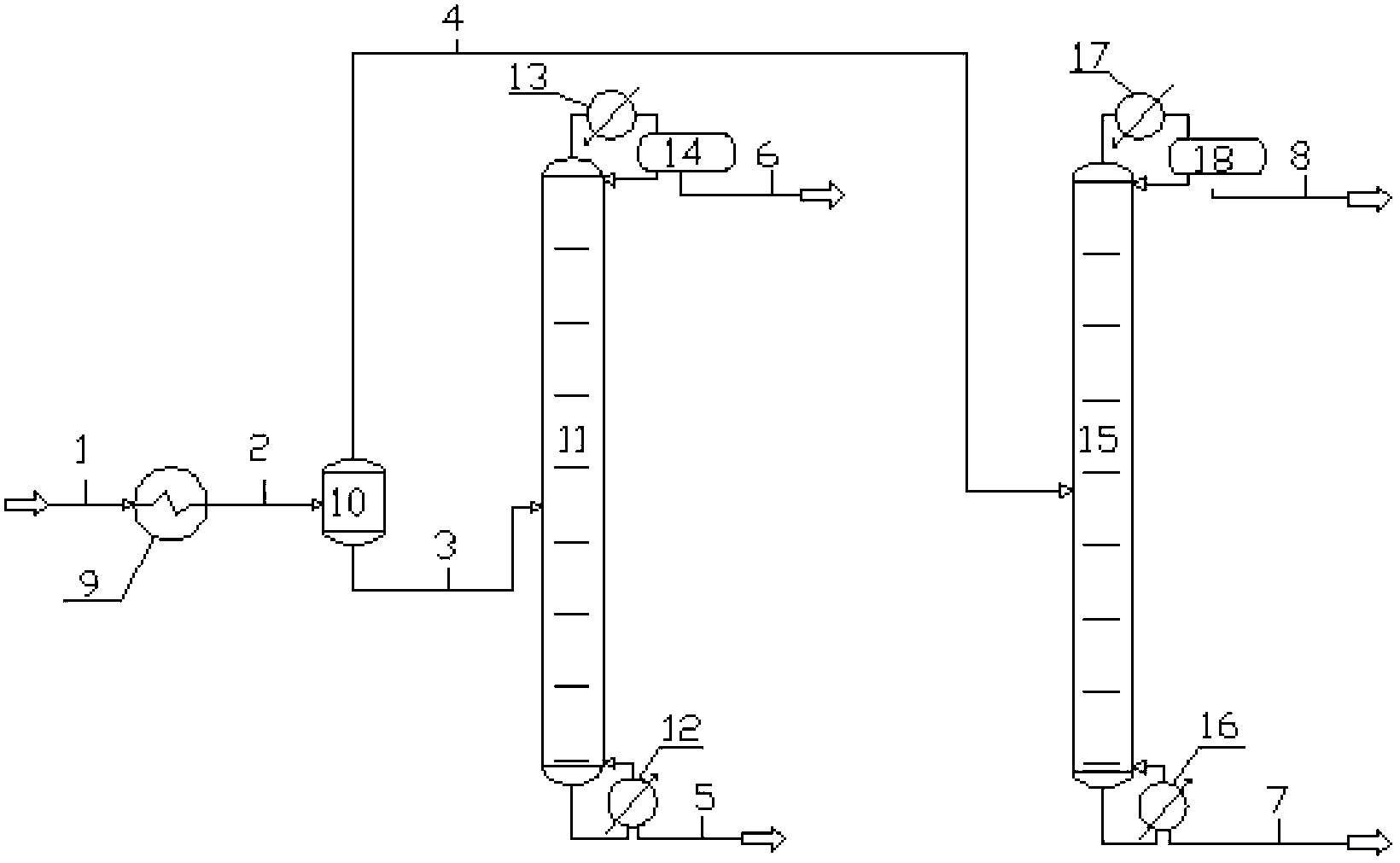

[0025] The crude material of isophthaloyl chloride (1) is composed as follows: 70% of isophthaloyl chloride, 26% of thionyl chloride, 1% of DMF, 0.5% of other light components (boiling point lower than isophthaloyl chloride), 0.5% of heavy components (boiling point higher than isophthaloyl chloride) 2.5%. Such as figure 1 As shown, the crude isophthaloyl chloride raw material (1) is sent to the evaporation device (10) via the heating device (9) to evaporate the light component raw material or catalyst, mainly thionyl ch...

Embodiment 2

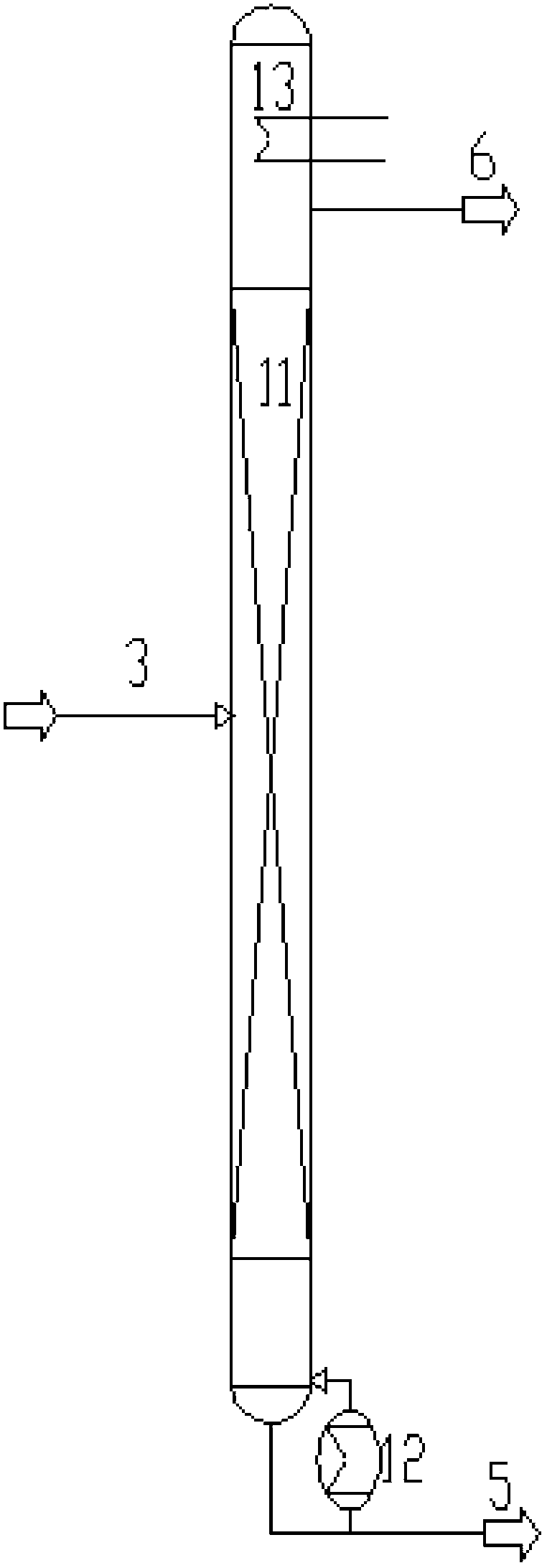

[0027] Equipment Description: The top condensing device (17) of the light fraction rectification tower and the bottom heating device (16) of the light fraction rectification tower adopt the following figure 2 The built-in structure shown. The isophthaloyl dichloride product rectification tower top condensing unit (13) and the isophthaloyl dichloride product rectification tower bottom heating device (12) adopt such as Figure 5 The built-in structure shown.

[0028]The crude material of isophthaloyl chloride (1) is composed as follows: 65% of isophthaloyl chloride, 28% of thionyl chloride, 3% of pyridine, 1.5% of other light components (boiling point lower than isophthaloyl chloride), recombined points (boiling point higher than isophthaloyl chloride) 2.5%. Such as figure 1 As shown, the crude isophthaloyl chloride raw material (1) is sent to the evaporating device (10) via the heating device (9) to evaporate the light component raw material or catalyst, mainly thionyl chlo...

Embodiment 3

[0030] Device Description:

[0031] The top condensing device (17) of the light fraction distillation column adopts a built-in structure and the bottom heating device (16) of the light fraction distillation column adopts an external structure, such as image 3 shown. The top condensing device (13) of the isophthaloyl chloride product rectification tower adopts a built-in structure and the isophthaloyl dichloride product rectification tower bottom heating device (12) adopts an external structure such as Figure 6 shown.

[0032] The crude material of isophthaloyl chloride (1) is composed as follows: 72% of isophthaloyl chloride, 26% of triphosgene, 1% of DMF, 0.5% of other light components (boiling point lower than isophthaloyl chloride), 0.5% of heavy components (boiling point higher than isophthaloyl chloride) 0.5%. Such as figure 1 As shown, the raw material (1) of isophthaloyl chloride crude product is sent to the evaporation device (10) via the heating device (9) to ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com