Patents

Literature

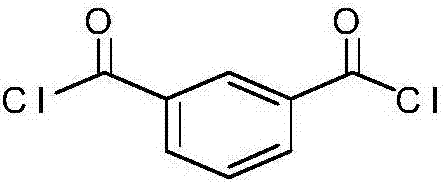

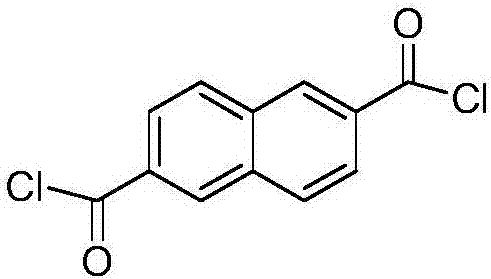

71 results about "Isophthaloyl dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyisophthaloyl metaphenylene diamine fiber and preparation method thereof

ActiveCN103668533AFully contactedEasy to dyeArtificial filament physical treatmentFilament/thread formingPolymer scienceSpinning

The inventioin discloses a polyisophthaloyl metaphenylene diamine fiber with the strength of 5.2-10.8 cN / dtex and the elongation at break of 2.0-5.0. The invention simultaneously discloses a preparation method of the polyisophthaloyl metaphenylene diamine fiber. The preparation method comprises steps as follows: firstly, metaphenylene diamine and isophthaloyl dichloride are subjected to polymerization reaction, and then, spinning operation is performed. According to the preparation method, gaseous hydrogen chloride produced in the dry spray stage and ammonia gas in a gas storage box react, the amount of hydrogen chloride discharged to the environment is reduced, ammonia gas and dry spray trickle are fully contacted, and forming of a macroscopic void structure during fiber solidification can be inhibited; the polyisophthaloyl metaphenylene diamine fiber prepared and obtained with the method has the advantages of compact structure, high strength and toughness, large specific surface area and convenience for fiber dyeing; and by means of the preparation method, the production efficiency of aramid fiber is improved greatly, and industrial mass production requirements of aramid fiber are met.

Owner:X FIPER NEW MATERIAL CO LTD

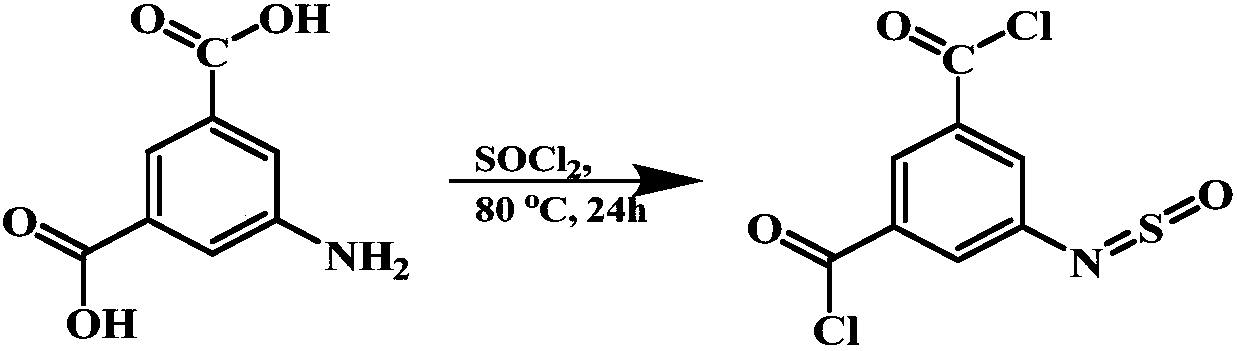

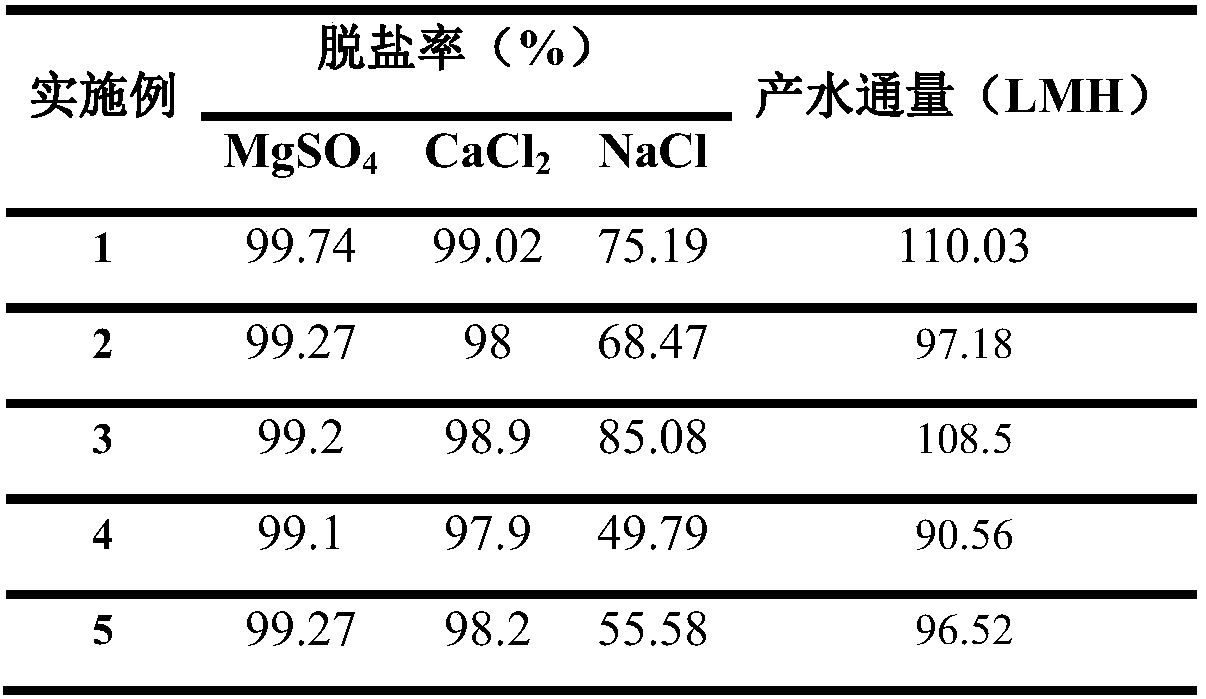

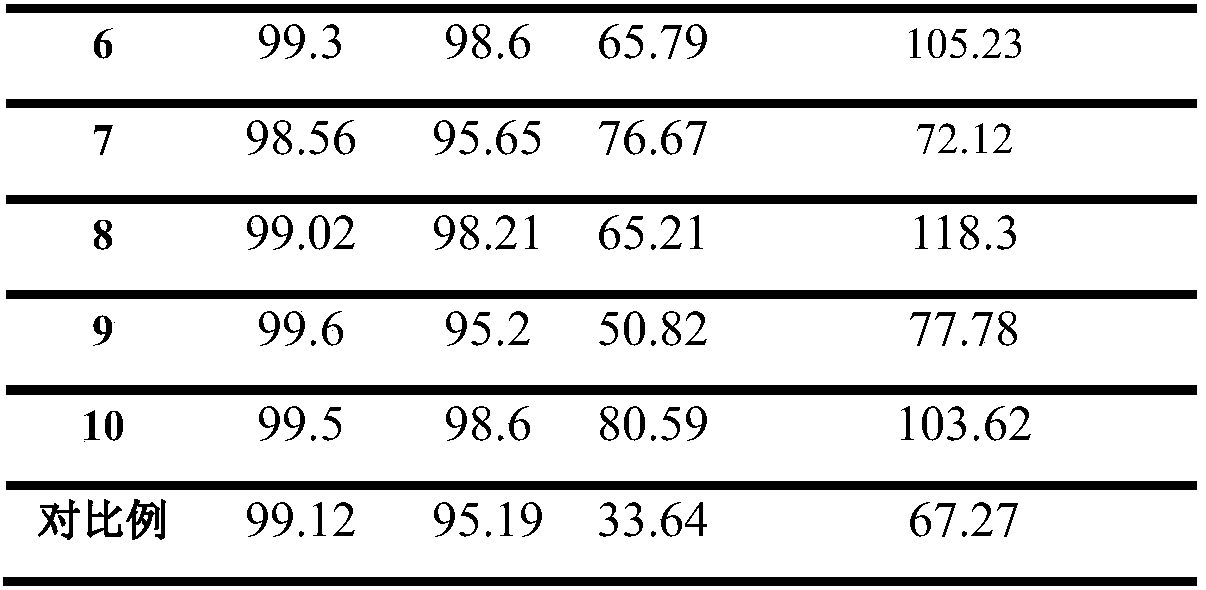

High-throughput polyamide nanofiltration composite membrane and preparation method thereof

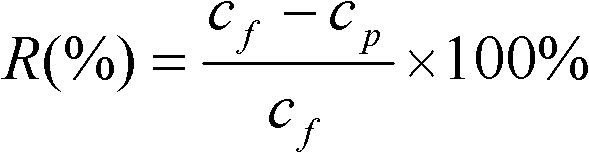

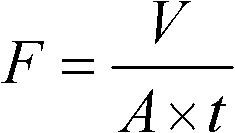

InactiveCN108187512ALow operating pressureImprove throughputSemi-permeable membranesWater desalinationChemical oxygen demand

The invention discloses a high-throughput polyamide nanofiltration composite membrane and a preparation method thereof, which belong to the field of polymeric membrane materials. The composite membrane is prepared by the interfacial polymerization reaction between 5-(N-sulfonamido)isophthaloyl dichloride or a mixture of 5-(N-sulfonamido)isophthaloyl dichloride and 1,3,5-trimesoyl chloride and piperazine monomer, and can be widely used in a water softening process for removing bivalent cations such as Ca<2+> and Mg<2+>. The high-throughput polyamide nanofiltration composite membrane is structurally provided with an ultrathin (10nm) release layer, surface charge are low in electronegativity, the membrane surface property is smooth and hydrophilic, high throughput is shown in terms of properties, the high-throughput polyamide nanofiltration composite membrane has an excellent trapping effect on bivalent and polyvalent cations and good pollution resistance, and the high-throughput polyamide nanofiltration composite membrane can be widely applied in high-throughput domestic water purifiers, sea water desalination, brackish water pretreatment, removal of COD (chemical oxygen demand) suchas dye molecules and phenol molecules in wastewater, separation of dye / salt and material separation and concentration processes in pharmaceutical and food industries.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

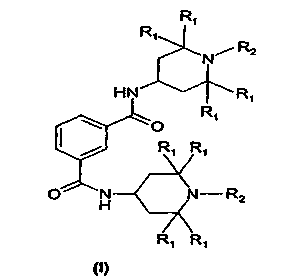

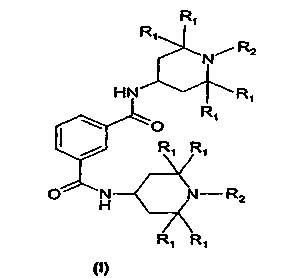

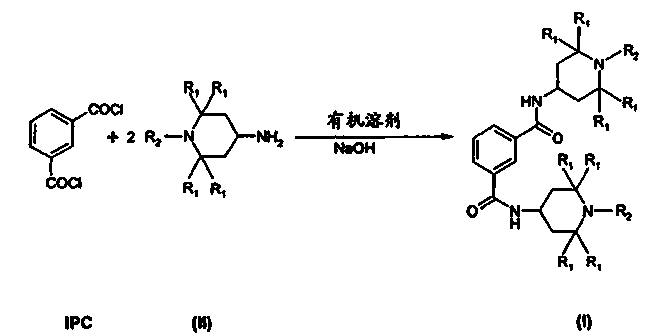

Preparation method for multifunctional nylon stabilizer

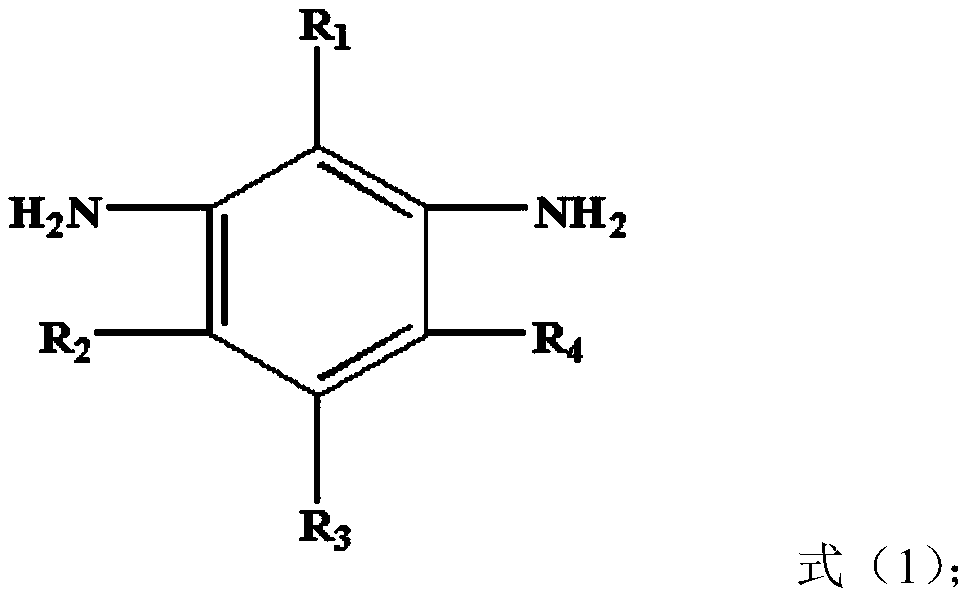

ActiveCN103554009AReduce consumptionReduce loadOrganic chemistryOrganic solventHindered amine light stabilizers

The invention discloses a preparation method for a multifunctional nylon stabilizer which is shown as a preparation formula (I). The preparation method comprises the steps: condensing isophthaloyl dichloride and stereo-hindered amine of tetraalkylpiperidine, selecting a proper organic solvent, reacting at 20-40DEG C in a stirring condition in the presence of an NaOH solution, distilling and recovering the solvent, and separating to obtain the multifunctional nylon stabilizer compound in the formula (1). The preparation method has the beneficial effects that through using the method, the reaction yield can be increased to 94%, and the waste water consumption and load can be obviously reduced.

Owner:SHANXI CHEM RES INST

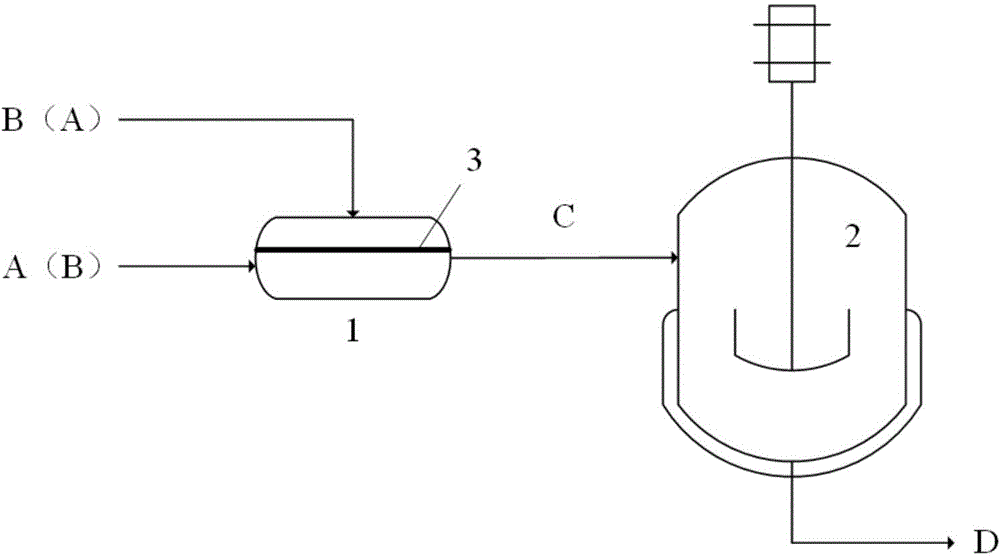

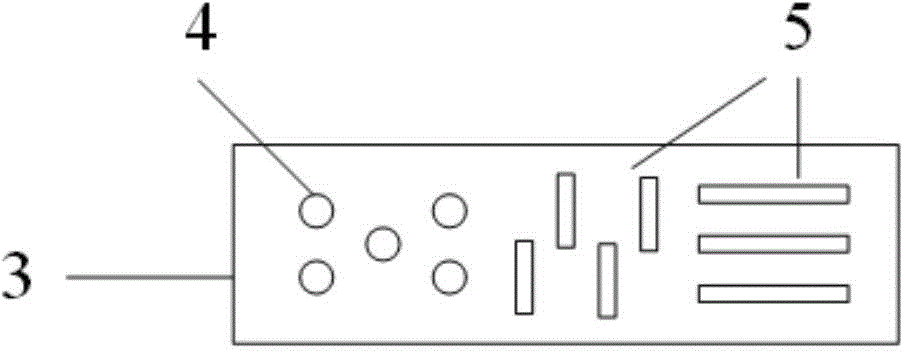

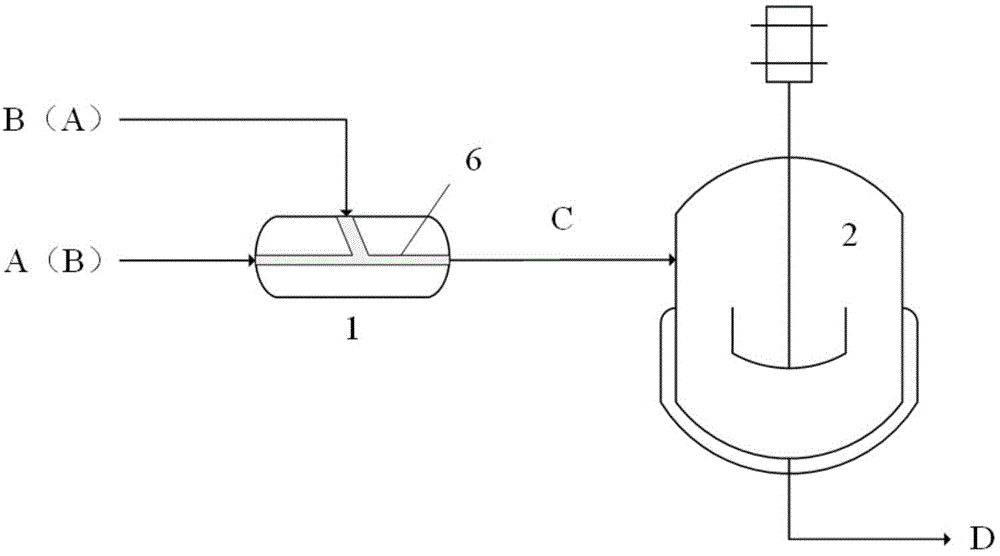

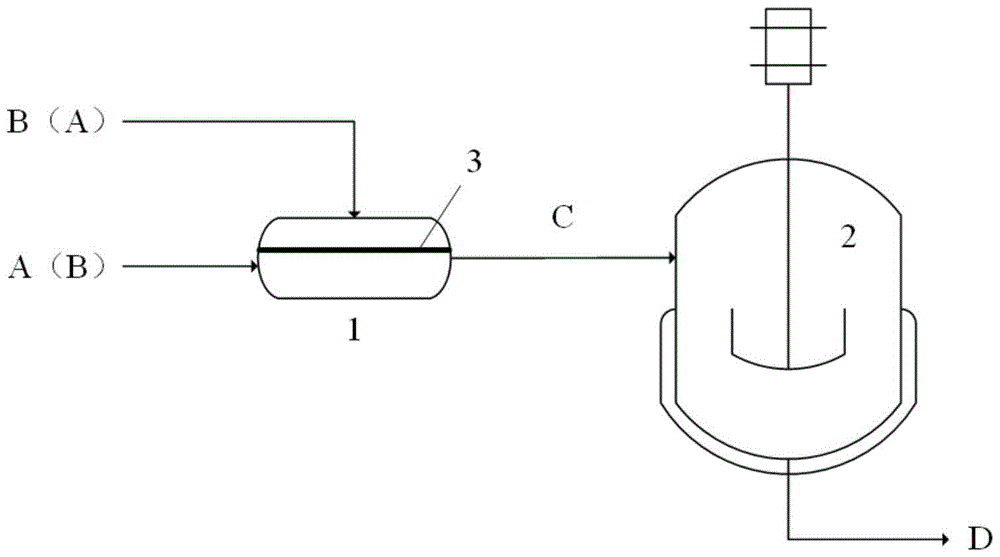

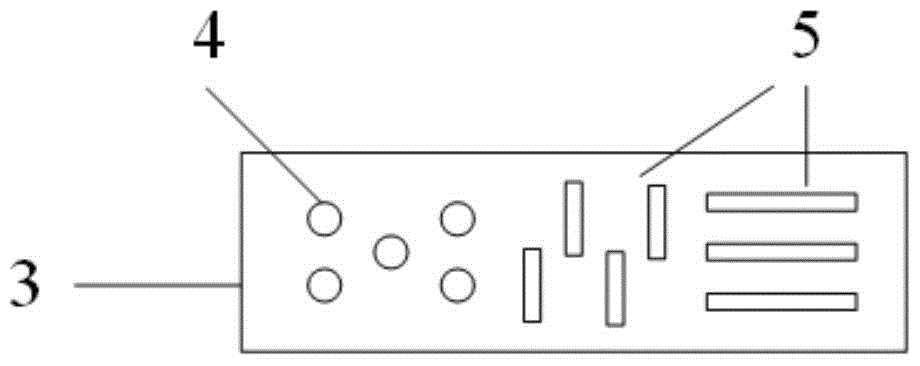

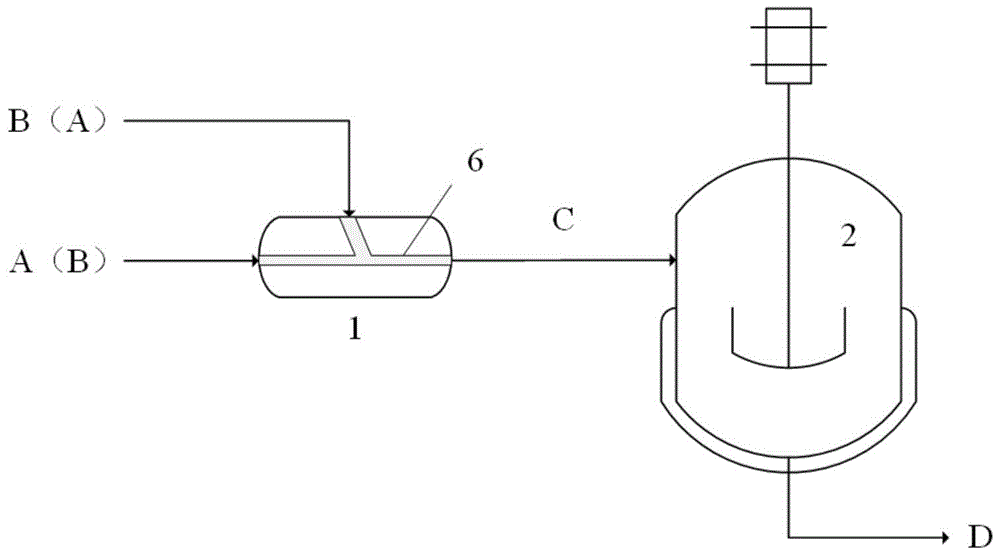

Micro-reaction system and micro-reaction method for preparing para/meta-aramid

ActiveCN104667846AEfficient removalRemove suppressionChemical/physical/physico-chemical stationary reactorsChloridePyridine

The invention relates to a micro-reaction system and a micro-reaction method for preparing para / meta-aramid. The micro-reaction system is composed of a micro-reactor and a stirring kettle, wherein the micro-reactor is internally provided with a microstructure distribution plate or a micro-channel; and sieve pores or through grooves are formed in the microstructure distribution plate. The method comprises the steps of dissolving p / m-phenylenediamine into a calcium chloride solution, and adding pyridine to obtain a reaction solution A; dissolving isophthaloyl dichloride / paraphthaloyl chloride into the calcium chloride solution to obtain a reaction solution B; mixing the reaction solutions A and B in the micro-reactor, and triggering condensation polymerization reaction to obtain a reaction solution C; enabling the reaction solution C to enter the stirring kettle, and reacting under stirring to produce a product D; and washing the product D to obtain para / meta-aramid. The material mixing effect is enhanced through the micro-reactor, so that reaction heat can be rapidly removed, and the process stability is improved; and due to the further reaction in the stirring kettle, the polymerization degree is further increased, the pressure drop in the reaction process is reduced, and the safety is improved.

Owner:TSINGHUA UNIV

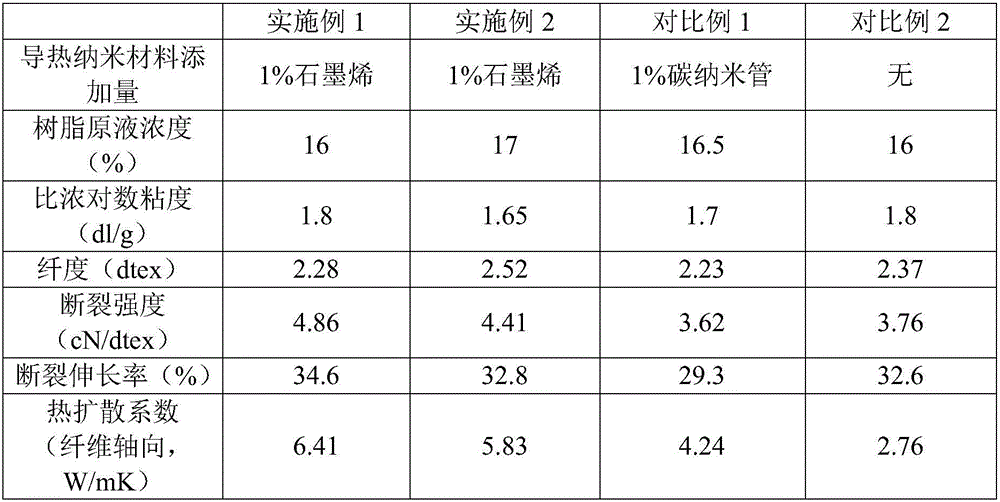

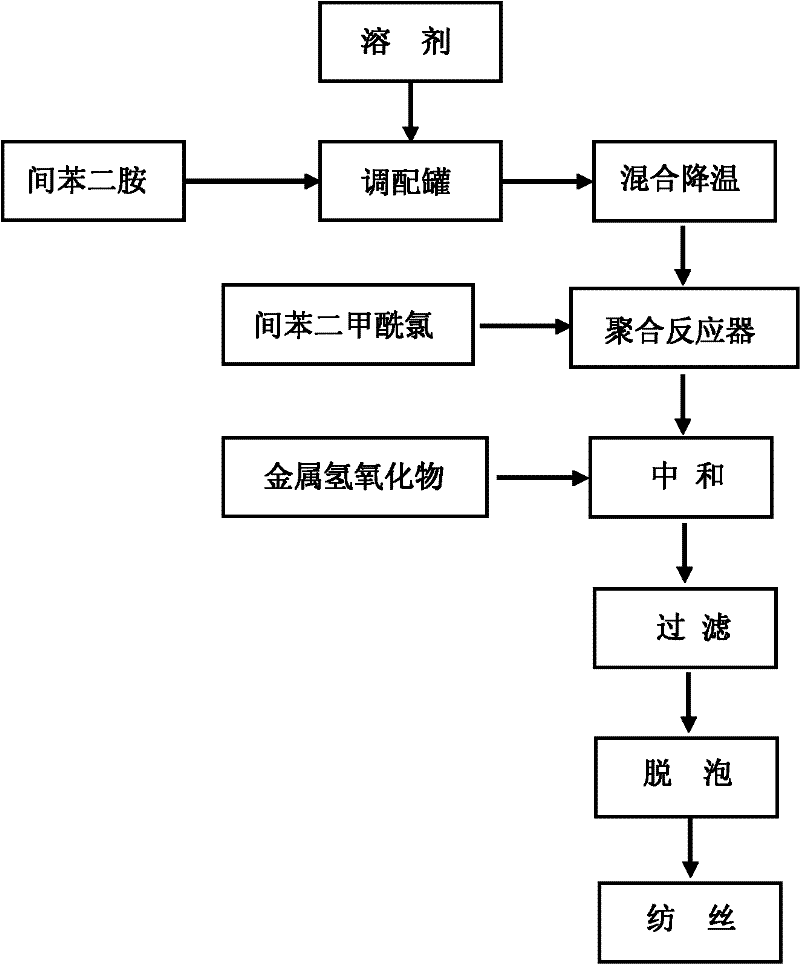

Preparation method and application of high-thermal-conductivity aromatic polyamide fibers

ActiveCN106498538AFast heat conductionReduced Diffusion Path ResistanceArtifical filament manufactureMonocomponent polyamides artificial filamentSolventAramid

A preparation method of high-thermal-conductivity aromatic polyamide fibers includes dispersing oxidized graphene in an organic solvent to obtain dispersion liquid; adding m-phenylenediamine monomers into the dispersion liquid under the protection of inert gas, and cooling a system to a temperature as required by the system; slowly adding part of isophthaloyl dichloride while stirring to allow a polycondensation reaction of the solvent, adding alkaline substances for neutralization, adding the rest isophthaloyl dichloride, and continuing to stir until complete reaction to obtain a meta-position aromatic polyamide resin solution; taking the meta-position aromatic polyamide resin solution as a spinning solution, adopting a dry-spraying and wet-spinning process to spin, and finally preparing the high-thermal-conductivity aromatic polyamide fibers. The high-thermal-conductivity aromatic polyamide fibers have high thermal diffusion coefficients; added carbon nano-materials, graphite nano-materials and the like have antifriction effect, and serve as structure reinforcing materials which obviously improve mechanical properties of aramid fibers.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

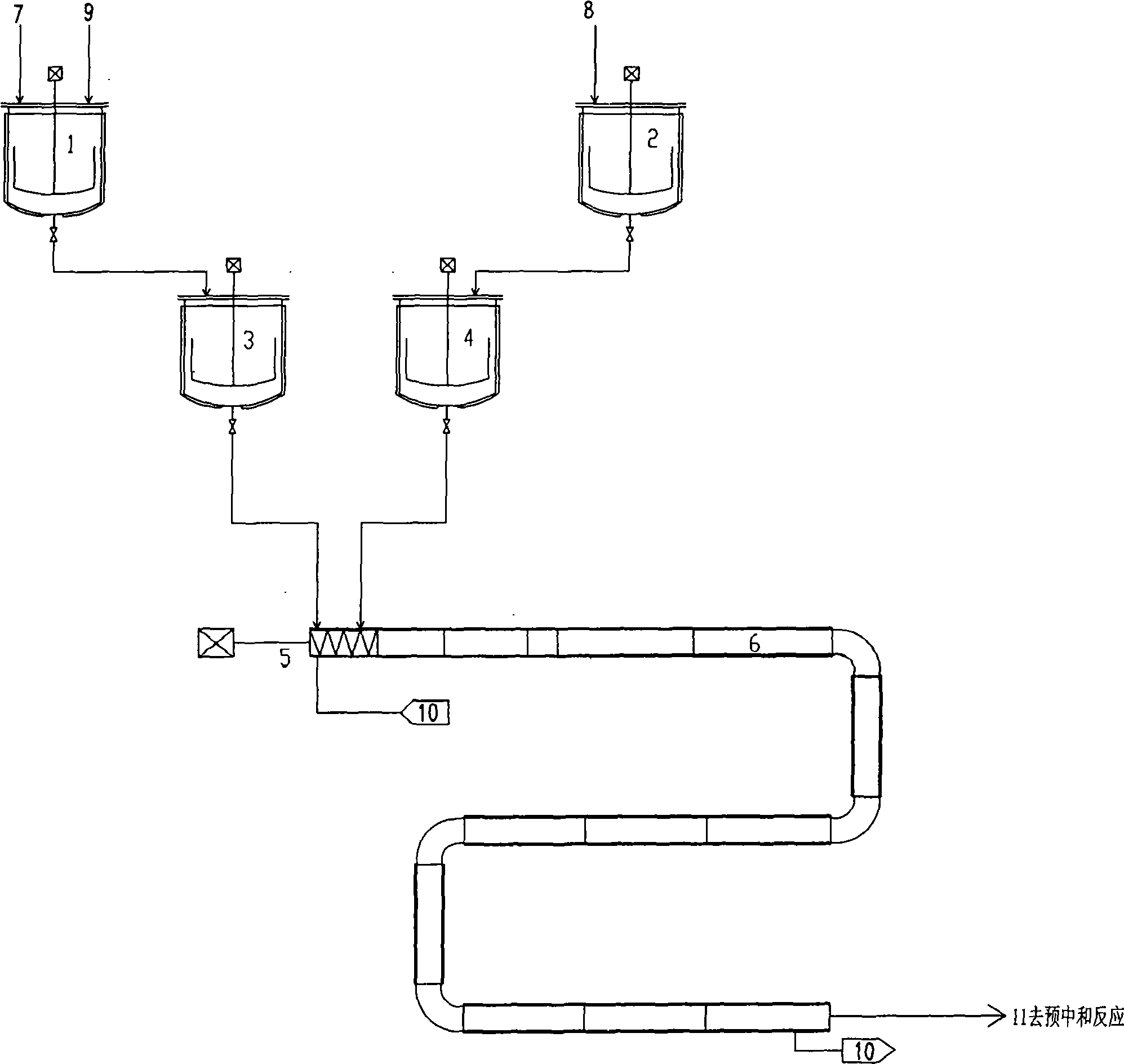

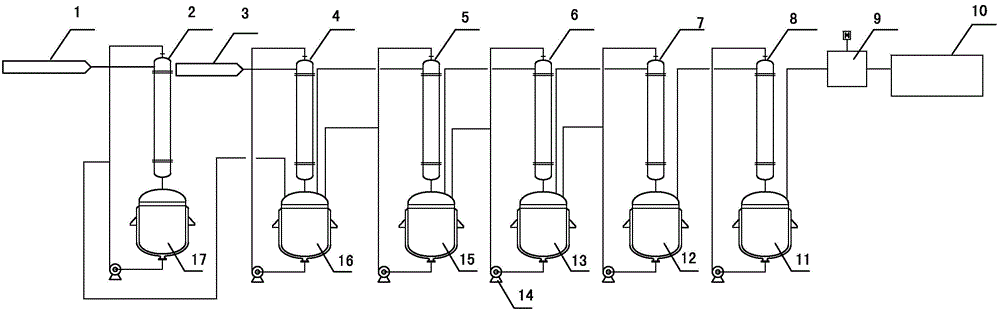

Method for polymerizing polymerized continuous solution of aromatic polyamide

The invention provides a method for polymerizing polymerized continuous solution of aromatic polyamide, belonging to the technical field of methods for preparing aromatic polyamide. The method mainly comprises the following steps: diamine is dissolved by organic solvent into solution of a certain concentration; acyl chloride is added to a melting pot to be melted into solution; the two solutions, after being mixed according to a certain proportion for a certain time by a static mixer, react at a certain temperature at a certain speed to generate prepolymer solution; and after the prepolymer solution is preneutralized and filtered for the first time, isophthaloyl dichloride is added to the prepolymer solution, and the new solution generated is preneutralized and filtered for the second time, polymer solution, i.e., spinning solution is prepared, wherein the spinning solution can be used for spinning to produce aromatic polyamide fiber through spinning and pulping to produce pulp. The invention provides the method for preparing prepolymer of the aromatic polyamide polymer with continuous solution polymerization process. The continuous prepolymerization of aromatic polyamide can eliminate the batch difference from the discontinuous prepolymerization of the aromatic polyamide and improves the uniformity of prepolymer solution and the spinning solution; the prepolymer has moderate viscosity and is convenient to cool, convey and filter; and the wall of a reactor is not easy to crust. The invention consumes less energy, simplifies production and control processes and has low cost.

Owner:张瑞业

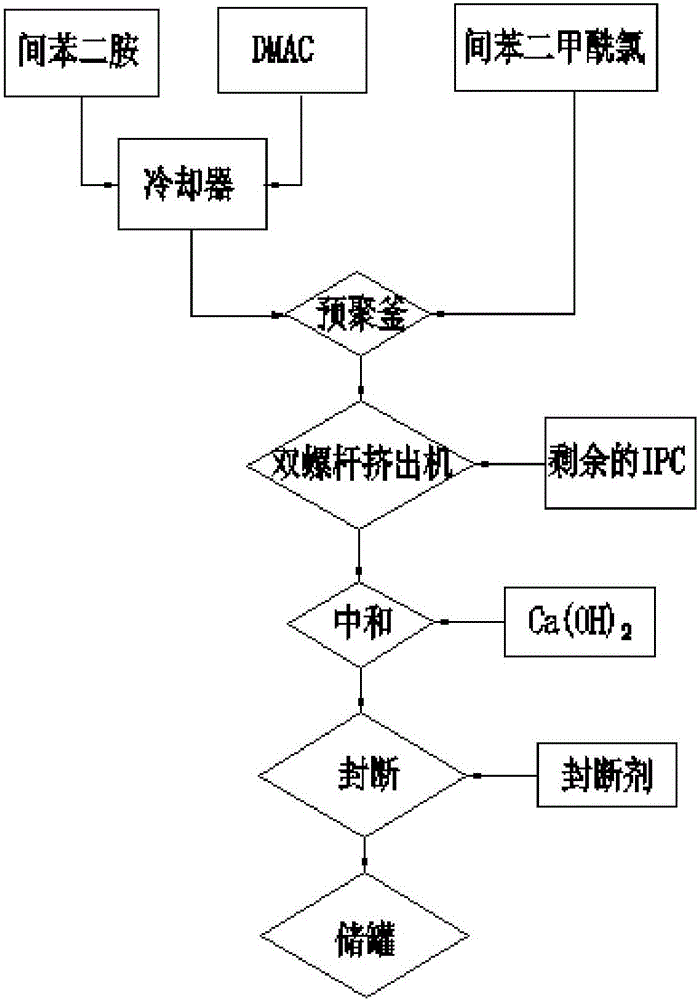

Method for continuous production of polyisophthaloyl metaphenylene diamine spinning stock solution

InactiveCN102517677AQuality improvementImprove uniformityWet spinning methodsDry spinning methodsFiberPolymer science

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

High-flux composite reverse osmosis membrane

The invention relates to a polymeric membrane for water treatment, in particular to a high-flux composite reverse osmosis membrane. An ultrathin desalination separation layer is compounded on a porous supporting membrane through interfacial polycondensation between a polyamine-containing aqueous solution and an organic solution containing aromatic polyacyl chloride; the polyamine is a mixture of metaphenylene diamine and sericin; and the aromatic polyacyl chloride is benzenetricarbonyl trichloride, 5-isocyanate- isophthaloyl chloride, 5-oxoformyl chloride-isophthaloyl chloride, isophthaloyl dichloride, paraphthaloyl chloride or 2,4-toluene diisocyanate. The high-flux composite reverse osmosis membrane has the advantages of readily available raw materials, low price and excellent selective separation property. The water flux of the high-flux composite reverse osmosis membrane is higher than that of the conventional polyamide composite reverse osmosis membrane. The high-flux composite reverse osmosis membrane has high membrane surface hydrophilicity and high pollution resistance. The high-flux composite reverse osmosis membrane has wide application.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

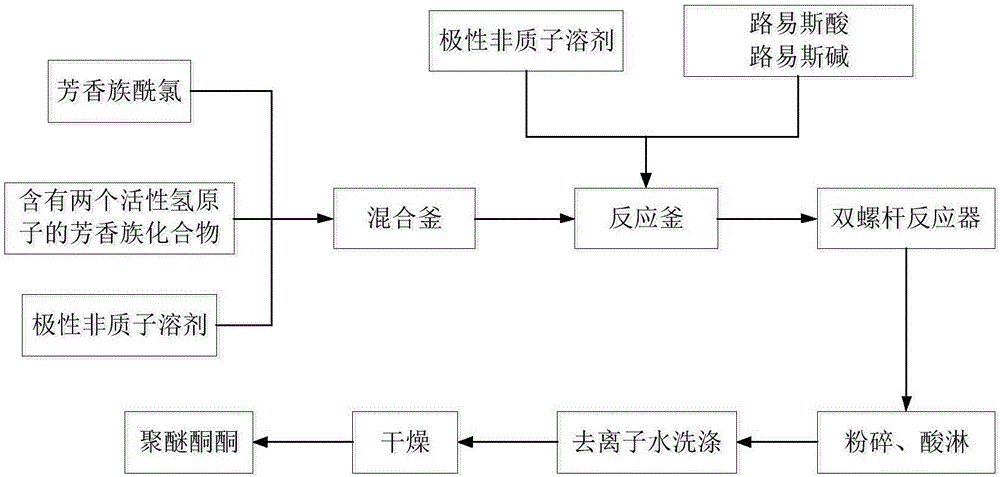

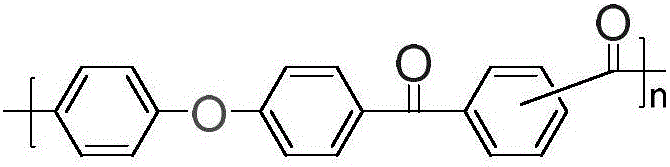

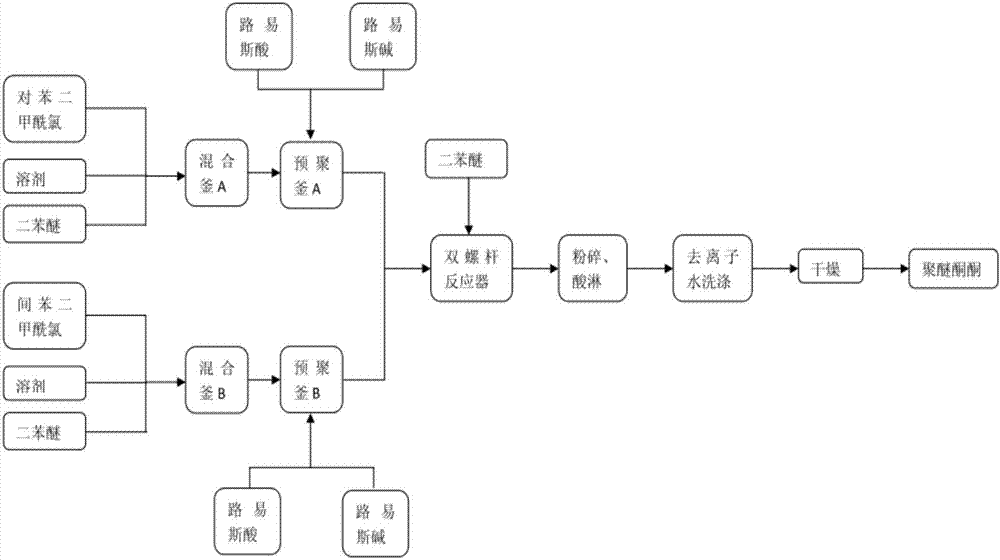

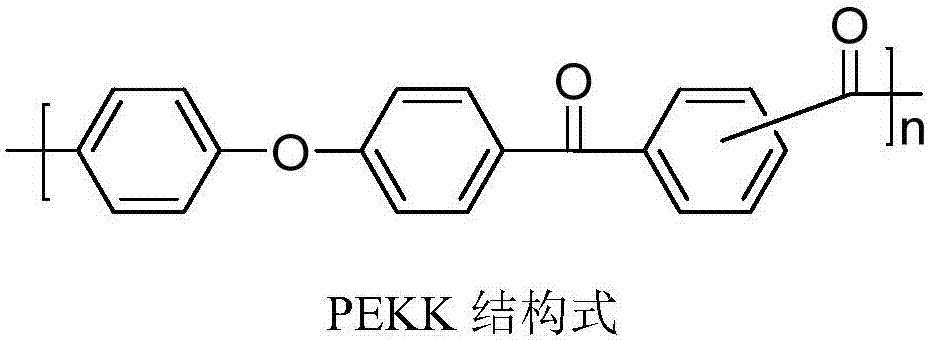

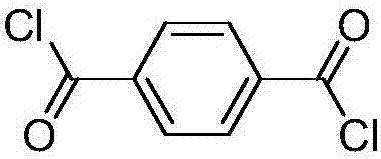

Polyether ketone ketone continuous production technology

ActiveCN106800649AImprove utilization efficiencyShorten the production cycleEngineering plasticSolvent

The invention relates to a polyether ketone ketone continuous production technology and belongs to the technical field of macromolecule special engineering plastics. The technology comprises the steps of adding paraphthaloyl chloride, isophthaloyl dichloride and diphenyl ether into a mixing kettle; adding a polar aprotic solvent to dissolve; adding the polar aprotic organic solvent into the mixing kettle at the same time; then adding lewis acid and lewis base to react after cooling to obtain a reaction solution; adding a mixed solution into the reaction solution to react to obtain a prepolymer; adding the prepolymer into a double-screw reactor to be extruded out to obtain a polymer; smashing the polymer at a machine head of the double-screw reactor; spraying a hydrochloric acid solution at the same time; filtering, washing with deionized water and drying to obtain the polyether ketone ketone. A strong shearing effect of the double-screw reactor is utilized to process high-viscosity materials, so that reaction time is reduced. The production technology disclosed by the invention can achieve continuous production, has a short production period and greatly improves utilization rate of the reaction kettle.

Owner:SHANDONG KAISHENG NEW MATERIALS

Weatherable block copolyestercarbonates and blends containing them

A process for preparation of block copolyestercarbonates which is implemented as follow: first conducting a reaction between at least one of resorcinol or an alkyl- or haloresorcinol and at least one aromatic dicarboxylic acid dichloride, preferably isophthaloyl dichloride, terephthaloyl dichloride or a mixture thereof, to produce a hydroxy-terminated polyester intermediate, and then conducting a reaction of the intermediate with a carbonate precursor, preferably in the presence of a dihydroxy compound such as bisphenol A. The products have excellent physical properties, including a high degree of weatherability. They may be blended with other polymers such as polycarbonates, poly(alkylene carboxylates), polyarylates, polyetherimides, and addition polymers to improve the weatherability thereof.

Owner:SABIC GLOBAL TECH BV

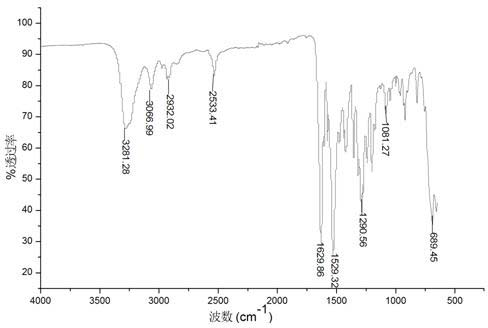

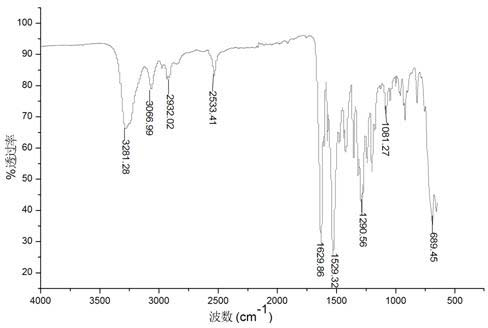

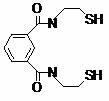

Sulfide heavy metal trapping agent and preparation method thereof

InactiveCN102531138APrecipitation particles are largeDense flocThiol preparationWater/sewage treatmentTreatment effectWater insoluble

The invention discloses a sulfide heavy metal trapping agent N,N-bis(2-mercaptoethyl))-1,3-benzenedicarboxamide and a preparation method thereof. The preparation method of the trapping agent comprises the steps of: under the protection of nitrogen, at a certain temperature, dissolving thioethanolamine hydrochloride and isophthaloyl dichloride into trichloromethane, adding an acid binding agent, and stirring for reacting to obtain the N,N-bis(2-mercaptoethyl))-1,3-benzenedicarboxamide. The sulfide heavy metal trapping agent provided by the invention is used for treating industrial wastewater containing heavy metal ions, can effectively avoid generating hydrogen sulfide, and reacts with various heavy metal ions in the wastewater for rapidly reacting at normal temperature to generate a water insoluble sulfide precipitate which has large particle size and compact flocculating constituent; and sedimentation time is shortened, heavy metals can be recycled from residuals, and secondary pollution can not be easily caused. The preparation method has the advantages of simple process, convenience for use and good treatment effect.

Owner:NANJING NORMAL UNIVERSITY

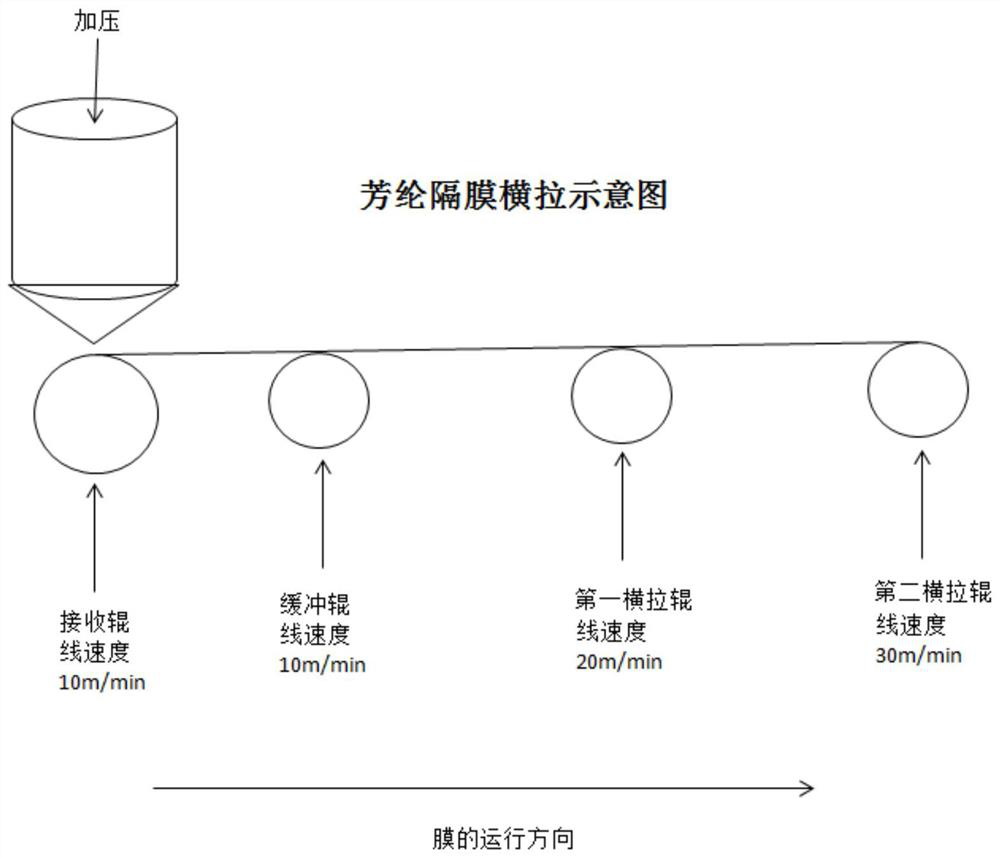

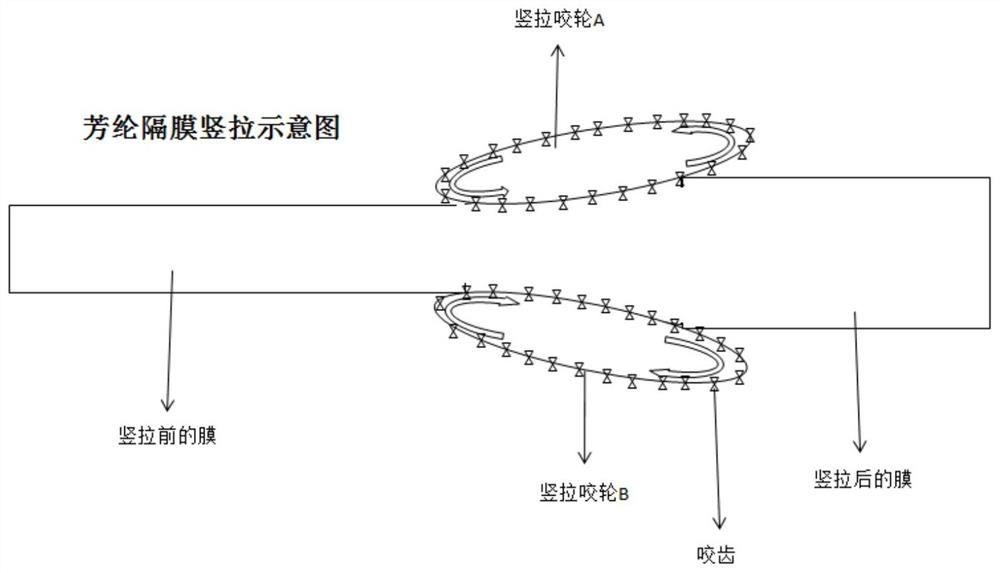

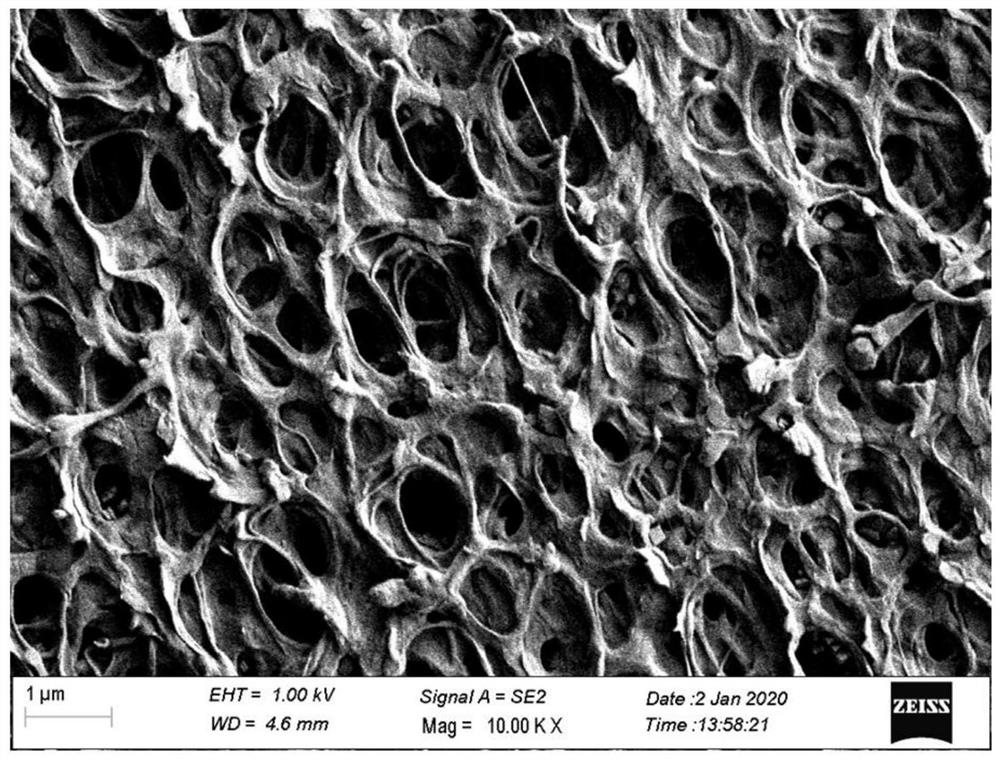

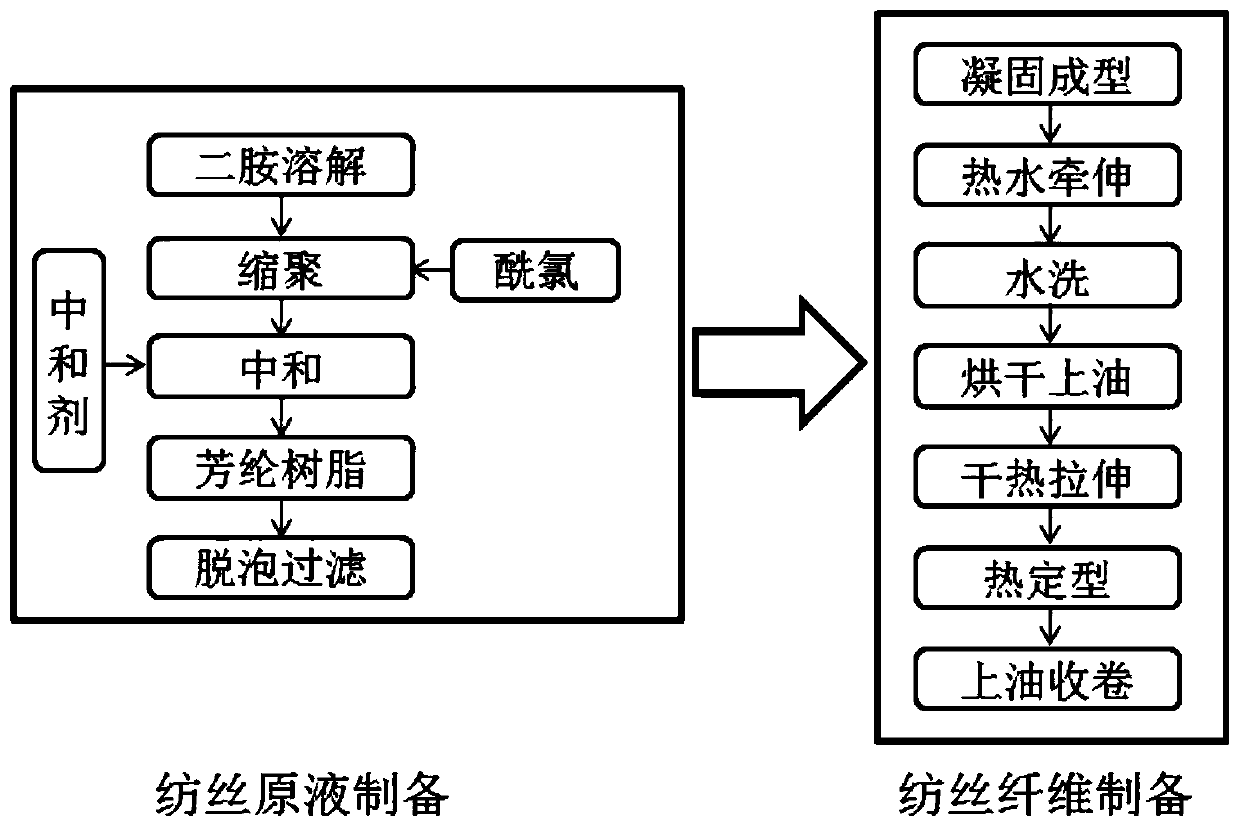

Meta-aramid diaphragm and preparation method thereof

InactiveCN111668425AHigh molecular weightReduce internal stressCell component detailsArtifical filament manufactureCalcium hydroxidePolymer science

The invention discloses a preparation method of a meta-aramid diaphragm. The method comprises the following steps: reacting m-phenylenediamine, isophthaloyl dichloride and calcium hydroxide in dimethylacetamide to obtain a meta-aramid solution; uniformly mixing the meta-aramid solution with dimethyl carbonate, and adjusting the viscosity to 25000-30000 mpa.s to obtain meta-aramid slurry; extrudingthe meta-aramid slurry to obtain a cast sheet, and transversely stretching the cast sheet to obtain a diaphragm precursor; vertically stretching the diaphragm precursor to obtain a diaphragm semi-finished product; and carrying out extraction curing on the semi-finished diaphragm product, drying, and rolling to obtain the meta-aramid diaphragm. According to the invention, a considerable amount ofcalcium hydroxide is added in a synthesis process of meta-aramid to form a calcium salt system in a meta-aramid solution, so that the molecular weight of the meta-aramid is improved, and the viscosityand toughness of the slurry of the meta-aramid are improved; and transverse and vertical stretching is carried out in the membrane preparation process, so that the slurry forms a membrane uniformly,the internal stress during extraction and curing is reduced, pores are formed in the membrane uniformly, and the high-temperature resistance of the membrane is remarkably improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

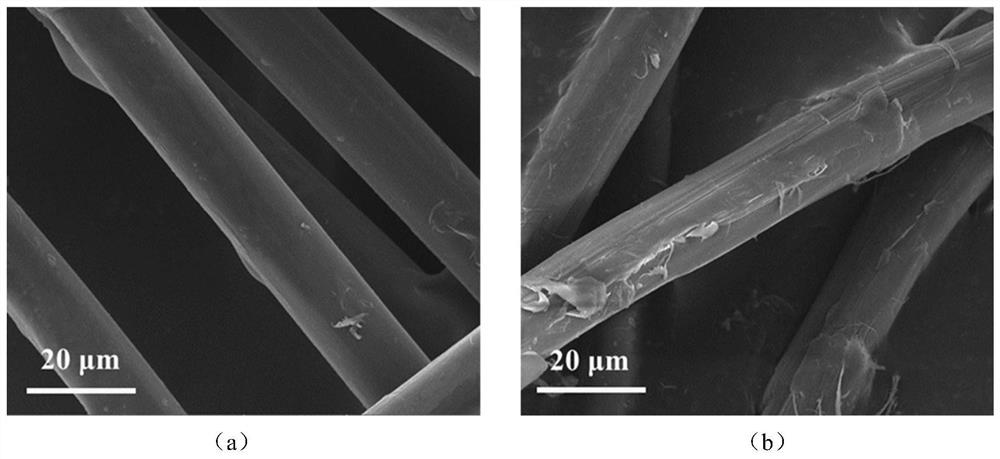

Preparation method for copolymerization modification aramid 1313 fiber

PendingCN110592707AIncrease surface polarityHigh tensile strengthMonocomponent copolyamides artificial filamentArtificial filament heat treatmentDry heatAramid

The invention provides a preparation method for a copolymerization modification aramid 1313 fiber. The preparation method includes the following steps that m-phenylenediamine and aromatic diamine withpolar groups are dissolved in a amide solvent, and a mixed solution is frozen and cooled and then subjected to a mixed reaction with a fused isophthaloyl dichloride in a low-temperature environment,so that a copolymerization modification aramid solution is obtained; a neutralizing agent is adopted for neutralizing and conducting impurity removal on the copolymerization modification aramid solution, so that a spinning stock solution is obtained; the spinning stock solution is subjected to vacuum defoaming and filtering and then enters a first-stage coagulating bath through a spinneret plate,and then through a second-stage coagulating bath, hot water drafting, washing, drying, oil applying, dry heat stretching, heat setting, cooling oil applying and rolling, the copolymerization modification aramid 1313 fiber is obtained. Through the method, the surface polarity of the fiber is optimized basically, a complex technological process that after the fiber is made, the surface of the fiberis modified is avoided, and production efficiency is improved; meanwhile, technological costs are low, operation is easy, safe and environmentally friendly, and the fiber is suitable for large-scale production.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Waste gas treatment process and device in isophthaloyl dichloride/paraphthaloyl chloride production

ActiveCN104138703AEmission reductionAchieve recyclingDispersed particle separationSulfur compoundsExhaust fumesProduct gas

The invention relates to a waste gas treatment process and device in isophthaloyl dichloride / paraphthaloyl chloride production, and belongs to the technical field of waste gas treatment. The process includes the steps that sulfur dioxide waste gas and hydrogen chloride waste gas which are generated in the reaction process of preparing isophthaloyl dichloride / paraphthaloyl chloride through thionyl chloride are absorbed through an absorption tower and are then recycled through a drying tower and a pressurization device; waste gas generated at the feed stage and the thionyl chloride recycling and rectifying stage enters an alkali absorption tower, and then the solution obtained after absorption is conducted is sent to an absorption device to release sulfur dioxide gas for recycle. By means of the process, emission of waste gas is reduced, recycling of sulfur dioxide is achieved, and the utilization rate of sulfur dioxide is further increased; the invention further provides the waste gas treatment device which is easy and convenient to operate in isophthaloyl dichloride / paraphthaloyl chloride production.

Owner:SHANDONG KAISHENG NEW MATERIALS

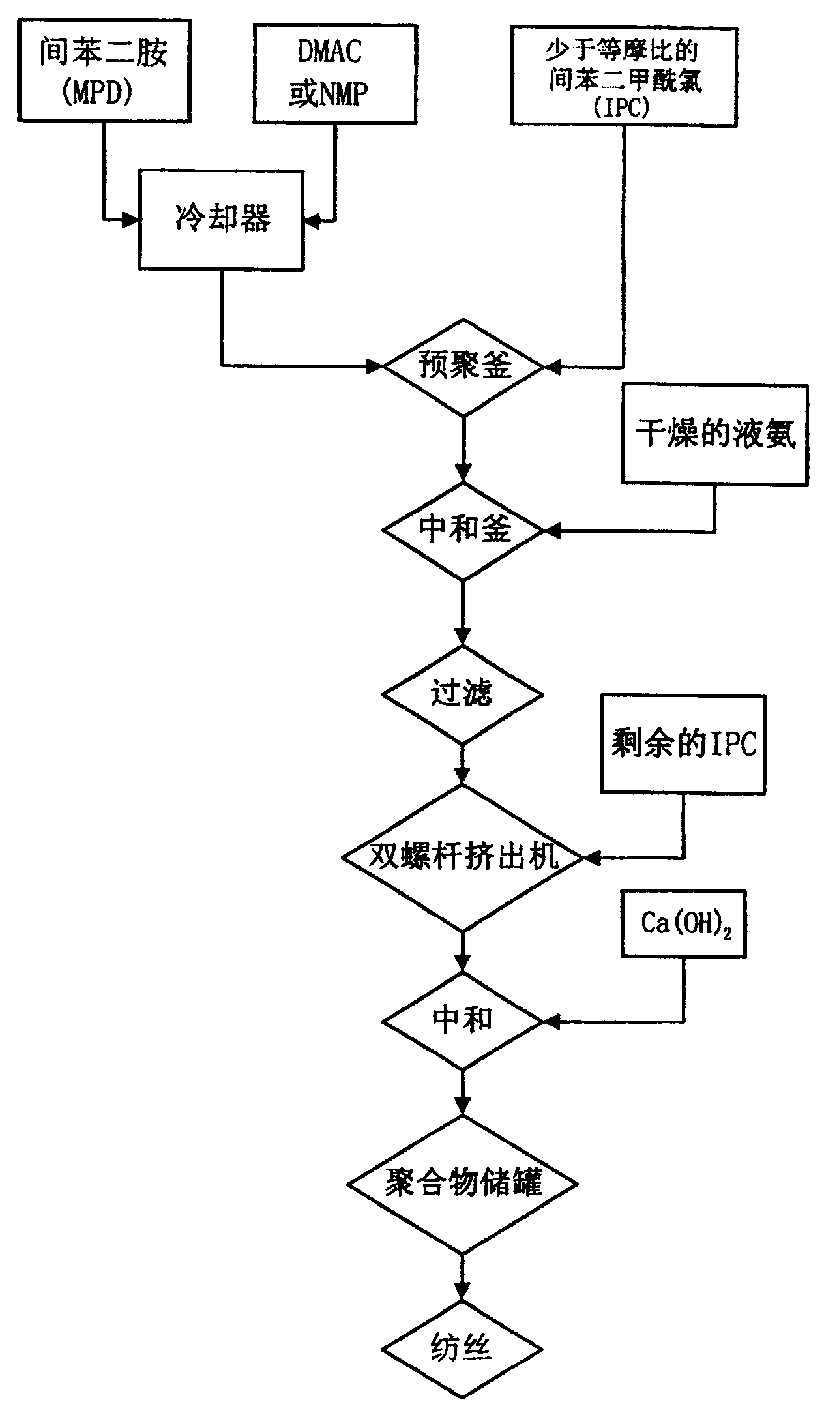

Method for preparing polyisophthaloyl metaphenylene diamine solution without metal ions

InactiveCN103806121AReduce thermal processReduce degradationSpinning solutions preparationMonocomponent polyamides artificial filamentFiltrationAramid

The invention relates to a method for preparing a polyisophthaloyl metaphenylene diamine solution without metal ions. The method is characterized by comprising the following steps: (1) dissolving certain moles of m-phenylenediamine into an amide polar organic solution, and reducing the temperature of the system to be minus 10-20 DEG C; (2) adding isophthaloyl dichloride (80-95% of the equal mole ratio) which is less than the mole ratio into the system, performing condensation polymerization for 10-30 minutes, subsequently adding the rest isophthaloyl dichloride to stir and reacting for 0.5-1 hour to accomplish the condensation polymerization reaction; and (3) adding ammonia water into a polymerized solution after the ammonium hydroxide reaction, neutralizing hydrogen chloride generated in the reaction, and filtering to remove ammonium chloride so as to prepare a polyisophthaloyl metaphenylene diamine spinning solution. As isophthaloyl dichloride is added twice, the reaction heat released from polymerization is reduced, the acidity is reduced through filtration, the degradation function of a polymer is alleviated, the energy consumption is reduced, and no metal ions are introduced in the neutralization reaction, so that the prepared spinning solution is free of the metal ions, and the requirements of industrial large-scale production of aramid fiber insulting paper are met.

Owner:X FIPER NEW MATERIAL CO LTD

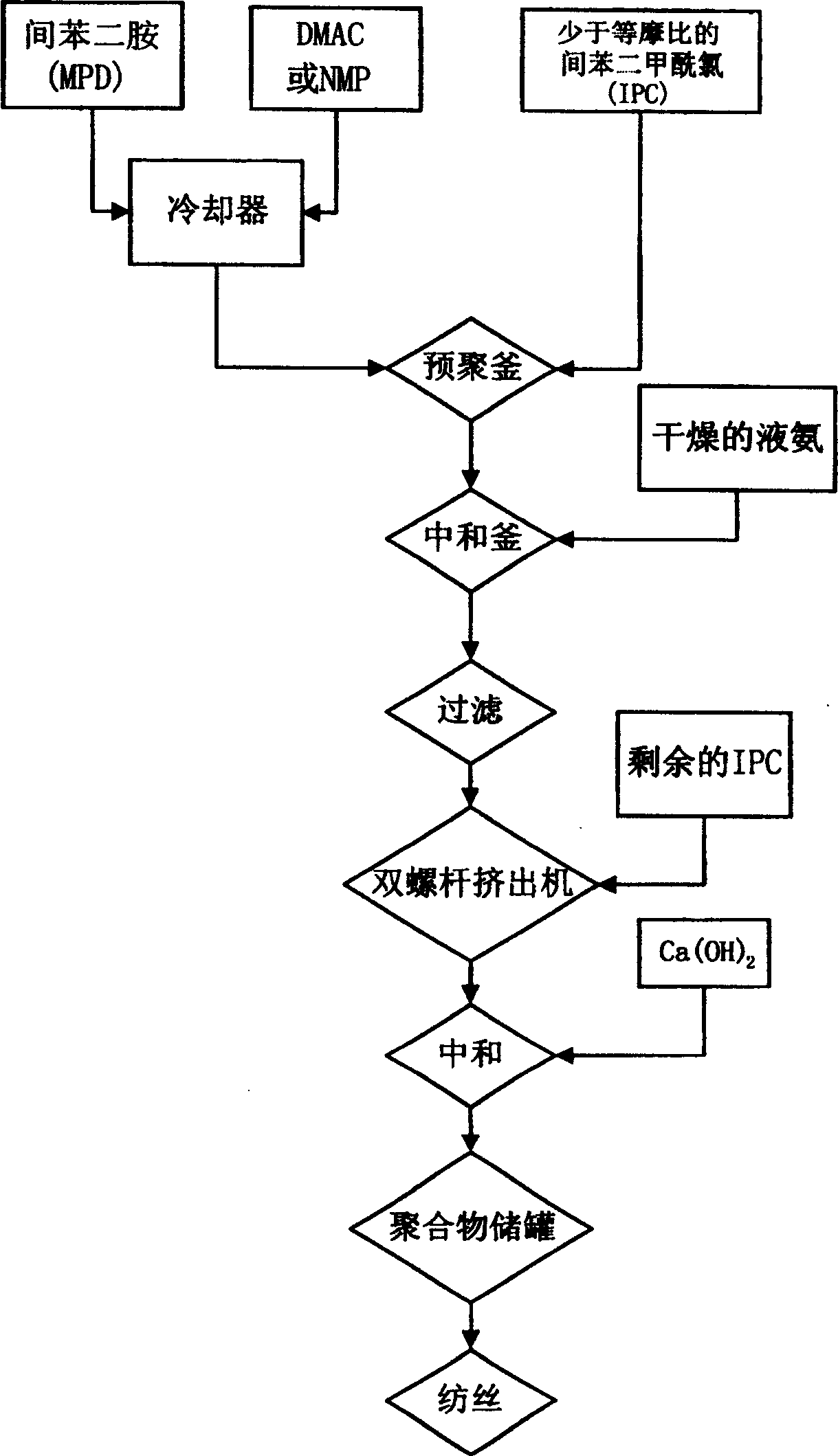

Preparation of polyisophthaloyl m-phenylene diamide spinning solution by using semi-continuous twin screw extruder

InactiveCN1265034CAvoid the problem of non-uniform molecular weightImprove cooling effectSpinning solutions preparationMonocomponent polyamides artificial filamentFiltrationDiameter ratio

The semi-continuous twin screw preparation method of polyisophthaloyl m-phenylene diamide spinning solution uses twin screw extruder as main reactor and adopts the isophthaloyl dichloride double-charged and dried liquid ammonia as preveutralizing agent. The application of twin-screw extruder is favorable for system radiation problem, and prevents non-uniformity of polymer molecular weight distribution, and also id favorable for partially removing small molecular by-product in the polymerization system-hydrogen chloride gas. The length-to-diameter ratio of the twin-screw extruder is greater than 1:30. Said preparation method includes prepolymerization, preneutralization, filtration, polymerization and neutralization.

Owner:DONGHUA UNIV +1

Synthesis method of light stabilizer N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide

ActiveCN105481759AReduce pollutionEasy to separate and purifyOrganic chemistryPtru catalystMethyl palmoxirate

The invention discloses a synthesis method of light stabilizer N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide. Isophthaloyl dichloride and 2,2,6,6-tetramethyl-4-piperidyl are taken as raw materials and react in the presence of a catalyst and a solvent, and N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide is prepared. According to the synthesis method of the N,N-bis-(2,2,6,6-tetramethyl-4-piperidyl) isophthalamide, the separation and purification process is simple, the reaction time is short, the product yield can be higher than 96%, the product purity is higher, the energy consumption is low, the environmental pollution is small, the cost is low, and the method is a more ideal process for industrial production.

Owner:RUDONG JINKANGTAI CHEM CO LTD

Preparation method of poly(m-phenylene isophthalamide) fibrid colloid polymer

The invention discloses a preparation method of poly(m-phenylene isophthalamide) fibrid colloid polymer. The preparation method comprises following steps: an amide-based polar organic solvent is added into a polyreactor, m-phenylenediamine is added for dissolving at a temperature of 20 to 60 DEG C; isophthaloyl dichloride is added when m-phenylenediamine is dissolved fully, and the mixture is subjected to polymerization, wherein the reaction is an exothermic reaction, so that the temperature of the reaction system is kept at 20 to 40 DEG C by using a refrigerant; after the reaction, the colloid is neutralized with an alkaline earth oxide or a hydroxide so as to obtain the poly(m-phenylene isophthalamide) fibrid colloid polymer. A low temperature (-20 to 10 DEG C) is not needed by the preparation method; investment on production equipment is less; production processes are stable; technology points and control points are few; performances of the colloid polymer are stable; and quality is excellent.

Owner:东莞市灿森新材料有限公司

Semi-continuous preparation process for block PEKK (polyetherketoneketone)

InactiveCN107880262AIncreased chance of collisionHigh intrinsic viscosityDiphenyl etherPolymer science

The invention belongs to the technical field of polymer synthesis and particularly relates to a semi-continuous preparation process for block PEKK (polyetherketoneketone). A solvent, a Lewis acid anda Lewis base are added to two prepolymerization reactors respectively; diphenyl ether and isophthaloyl dichloride or terephthaloyl chloride are added in equal molar ratio for reactions, and a prepolymer A and a prepolymer B which have better flowability are formed; then the prepolymer A and the prepolymer B which have better flowability as well as residual diphenyl ether are quantitatively added to a twin-screw reactor by a feeder, the materials are mixed under the strong shear action of the twin-screw reactor, the probability of collision of active end groups is increased, the polymerizationreaction rate is increased, and PEKK with high intrinsic viscosity is prepared within short time.

Owner:SHANDONG KAISHENG NEW MATERIALS

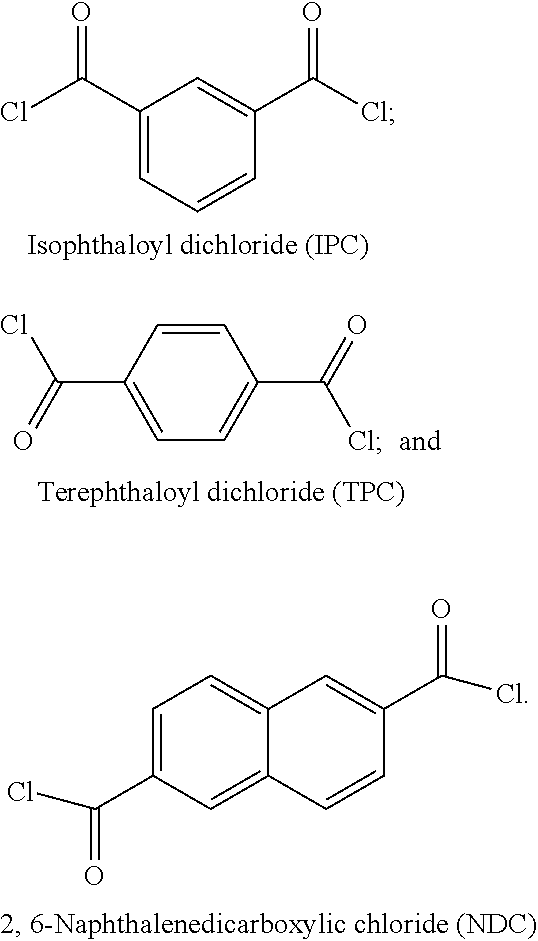

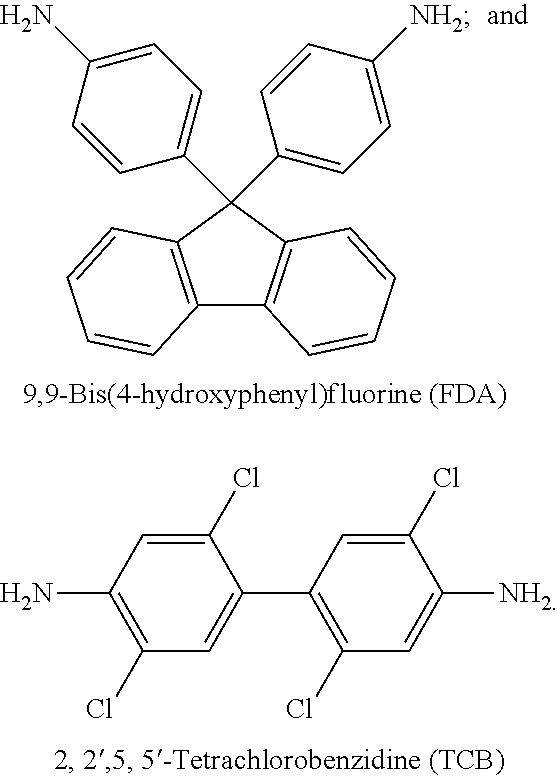

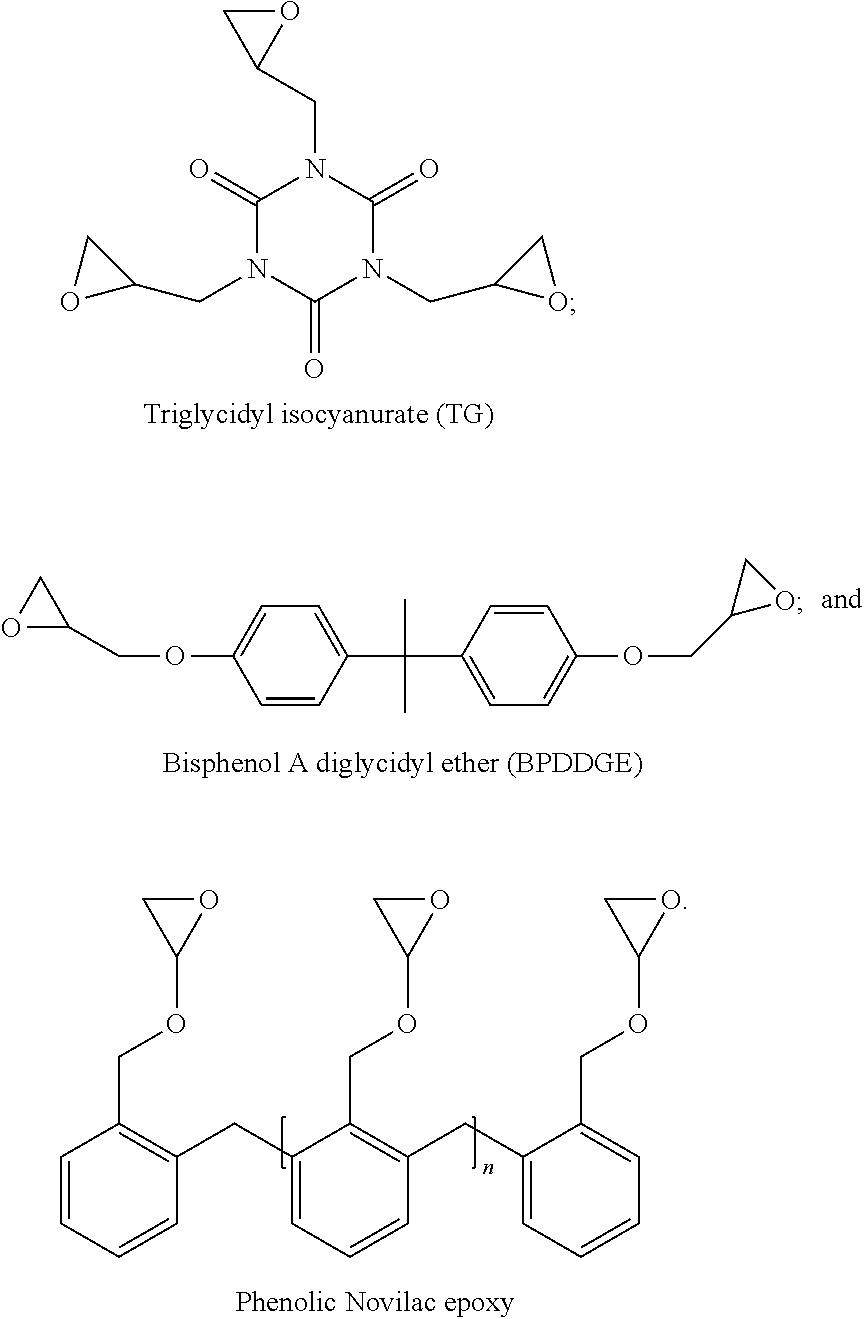

Solvent resistant, transparent aromatic polyamide films with high refractive indices

A solvent resistant, transparent aromatic polyamide film with a high refractive index may be made by reacting at least one aromatic diacid chloride, a first aromatic diamine, and at least one crosslinking agent or a second aromatic diamine in an organic solvent to form an aromatic polyamide polymer in solution. In one embodiment, the at least one aromatic diacid chloride is selected from the group consisting of isophthaloyl dichloride, terephthaloyl dichloride, 2, 6- naphthalene-dicarboxylic chloride, or combinations thereof and the first aromatic diamine is selected from the group consisting of 9, 9-Bis(4-hydroxyphenyl)fluorine, 2, 2 ',5,5'- Tetrachlorobenzidine, or combinations thereof. The organic solvent is then evaporated from the aromatic polyamide polymer in solution to form a transparent aromatic polyamide precursor film. The precursor film is then heated at a temperature close to the glass transition temperature of the transparent aromatic polyamide precursor film to form the solvent resistant, transparent aromatic polyamide film.

Owner:AKRON POLYMER SYST +4

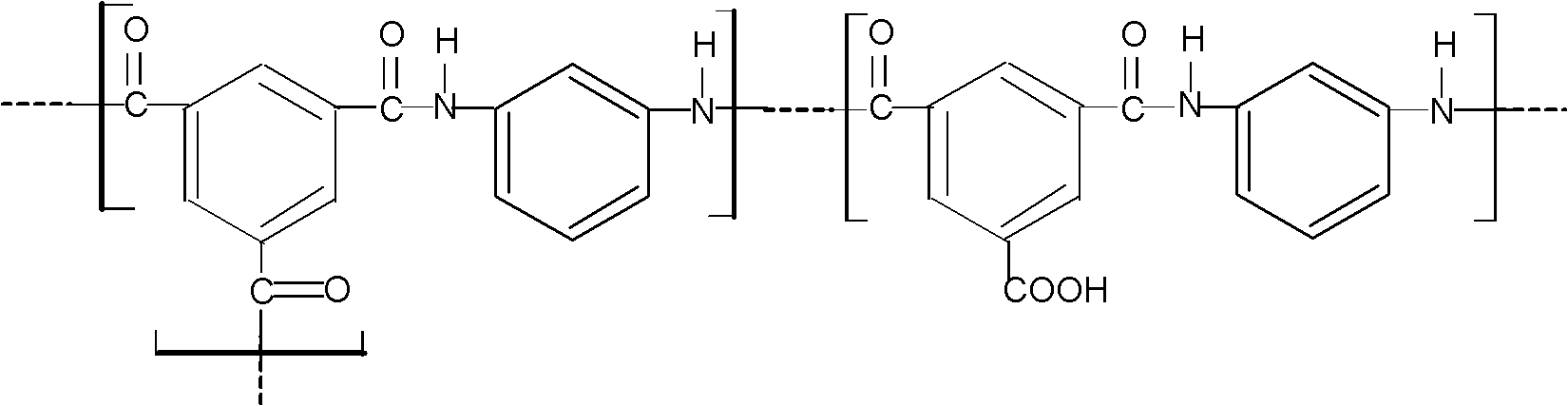

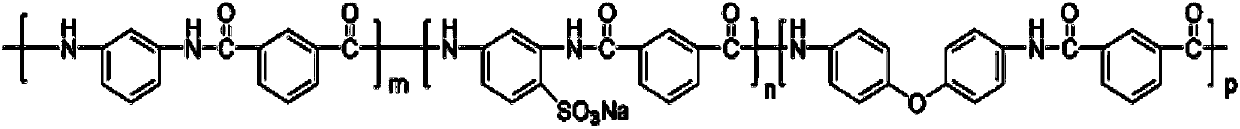

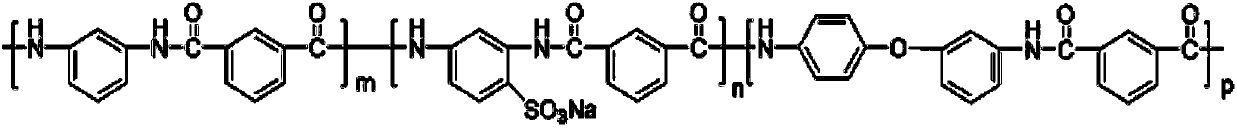

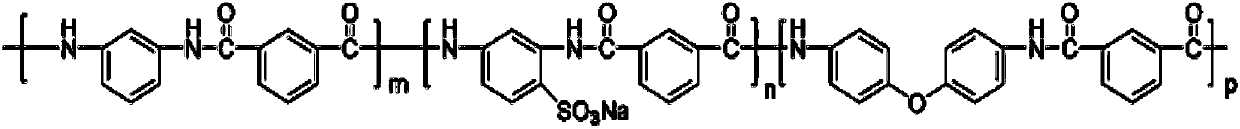

Modified poly(isophthaloyl metaphenylene diamine) for realizing easy dyeing effect of cationic dyes, and preparation method and application thereof

ActiveCN107814928AImprove solubilityImprove spin performanceMonocomponent copolyamides artificial filamentOrganic solventAramid

The invention relates to a modified poly(isophthaloyl metaphenylene diamine) for realizing easy dyeing effect of cationic dyes, and a preparation method and application thereof. The modified poly(isophthaloyl metaphenylene diamine) is prepared from the following components of MPD (m-phenylenediamine), IPC (isophthaloyl dichloride), 2,4-diaminobenzenesulfonic acid sodium salt, and ether-containingaromatic diamine, and is prepared by performing co-condensation on the four types of monomers in an organic solvent at low temperature. The prepared modified poly(isophthaloyl metaphenylene diamine) has the advantages that the logarithmic viscosity number can reach 1.5 to 2.1dL / g, the good dissolving property is realized in the organic solvent, the spinnability is better, and the modified poly(isophthaloyl metaphenylene diamine) can be further prepared into fiber or resin. The prepared fiber has the advantages that the easy dyeing effect of the cationic dye in common-pressure boiled water dyeing bath can be realized, the high temperature-resistant property is excellent, the mechanical property is better, and the problem of difficulty in dyeing by the conventional method due to no dyeing affinity groups because of tight arrangement of meta-aramid molecules is solved.

Owner:DONGHUA UNIV

Production process for preventing discoloration of aramid polymerized size

InactiveCN106046366APrevent discolorationSolve processabilityMonocomponent polyamides artificial filamentFiltrationSlurry

The invention relates to a production process for preventing discoloration of aramid polymerized size. The production process comprises the following steps: dissolving m-phenylene diamine in a dimethylacetamide solvent; adding isophthaloyl dichloride for polymerization; adding a chain extender for chain extending after polymerization; adding a neutralizer for neutralization to obtain an acidic size; then adding a sealing off agent in the acidic size to seal off residual amino groups in the acidic size; finally, carrying out filtration and defoaming, so as to obtain the aramid polymerized size which can be applied to spinning and pulping. According to the production process, the problem that as size discolors in a short term, and a product made of the size discolors in a long term, subsequent process and storage are difficult is solved. Therefore, the influence on the expansion of the application field of aramid is great.

Owner:SRO ARAMID HUAIAN CO LTD

Synthetic method of diphenyl iso-phthalate

ActiveCN102675112AOvercome the color problemAvoid incomplete responsePreparation from carboxylic acid halidesDistillationWastewater

The invention belongs to the field of fine chemical engineering and relates to a synthetic method of diphenyl iso-phthalate. Under the catalytic effect of double catalysts, isophthaloyl dichloride and phenol are subjected to reaction, the reduced pressure distillation is carried out, and high-purity diphenyl iso-phthalate is obtained. Under the catalytic effect of the double catalysts, the isophthaloyl dichloride and the phenol take reaction, the reduced pressure distillation is carried out, and the high-purity diphenyl iso-phthalate is obtained. The synthetic method has the advantages that the adverse influence on the next step polymerization reaction caused by free acid groups because of reaction incompletion in the direct esterification method is avoided; the problem of product coloring in an ester exchange method is also solved; and meanwhile, the problem of treatment difficulty of phenol-containing wastewater generated in the traditional phase transfer catalysis method is also solved. The synthetic method is safe and environment-friendly and is suitable for industrial production. The diphenyl iso-phthalate prepared by the synthetic method has the advantages that the chromatographic content is higher than 99.5 percent, and the average yield is higher than 98 percent.

Owner:SHANDONG KAISHENG NEW MATERIALS

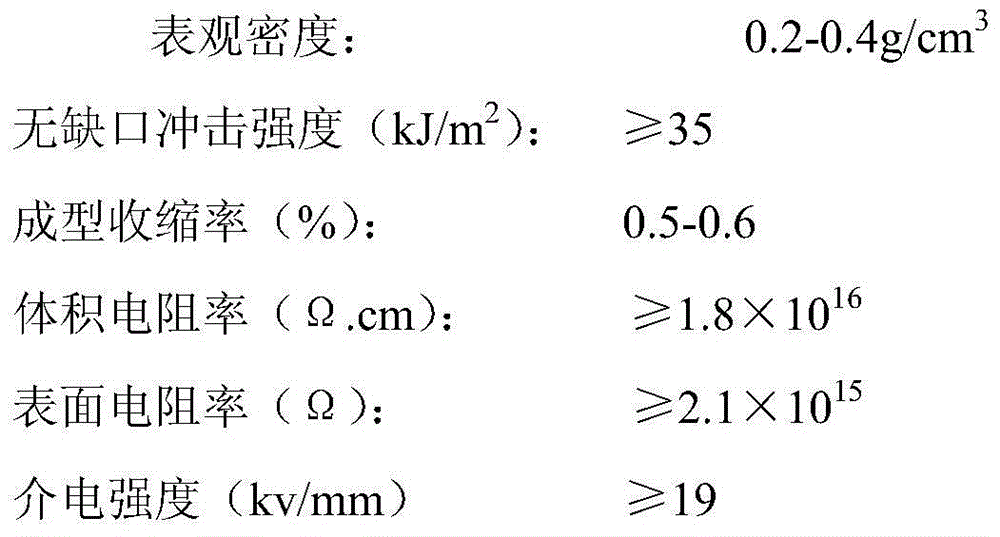

Method for preparing aromatic polyamide

The invention relates to a method for preparing aromatic polyamide. The method comprises the following steps: carrying out a solution polymerization reaction on m-phenylenediamine, paraphthaloyl chloride and isophthaloyl dichloride in an aprotic polar solvent at 0-10 DEG C for 5-8 hours, wherein the usage of the aprotic polar solvent is 10-12 times of the mass of m-phenylenediamine, and the molar ratio of paraphthaloyl chloride to isophthaloyl dichloride is (70-50):(30-50); adding a combined antioxidant into the reaction liquid, uniformly stirring the reaction liquid, and adding into stirring water to precipitate a copolymer; and filtering, washing and drying the copolymer to obtain an aromatic polyamide copolymer which has a specific viscosity of 0.8-1.6, wherein the addition amount of the antioxidant is 0.5-1.0 percent of the weight of copolyamide. The product processing sample performance indexes include more than or equal to 35kJ / m<2> of unnotched impact strength, 0.5-0.6 percent of molding shrinkage, more than or equal to 1.8*10<16> omega.cm of volume resistivity and more than or equal to 19kV / mm of dielectric strength.

Owner:SHANGHAI PLASTICS RES INST CO LTD

A micro-reaction system and method for preparing p-/meta-aramid fibers

ActiveCN104667846BEfficient removalRemove suppressionChemical/physical/physico-chemical stationary reactorsMicroreactorChloride

The invention relates to a micro-reaction system and a micro-reaction method for preparing para / meta-aramid. The micro-reaction system is composed of a micro-reactor and a stirring kettle, wherein the micro-reactor is internally provided with a microstructure distribution plate or a micro-channel; and sieve pores or through grooves are formed in the microstructure distribution plate. The method comprises the steps of dissolving p / m-phenylenediamine into a calcium chloride solution, and adding pyridine to obtain a reaction solution A; dissolving isophthaloyl dichloride / paraphthaloyl chloride into the calcium chloride solution to obtain a reaction solution B; mixing the reaction solutions A and B in the micro-reactor, and triggering condensation polymerization reaction to obtain a reaction solution C; enabling the reaction solution C to enter the stirring kettle, and reacting under stirring to produce a product D; and washing the product D to obtain para / meta-aramid. The material mixing effect is enhanced through the micro-reactor, so that reaction heat can be rapidly removed, and the process stability is improved; and due to the further reaction in the stirring kettle, the polymerization degree is further increased, the pressure drop in the reaction process is reduced, and the safety is improved.

Owner:TSINGHUA UNIV

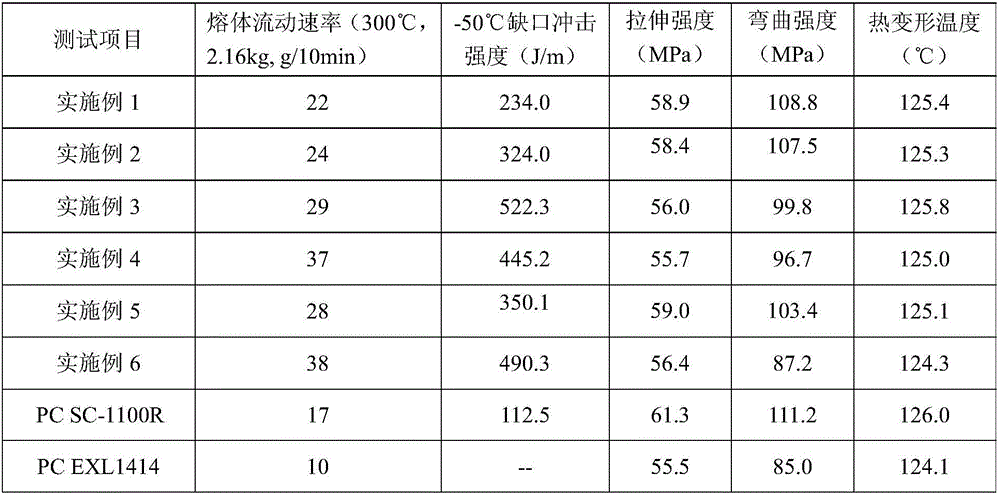

Polyarylester-polydimethylsiloxane block copolymer modified polycarbonate and preparation method thereof

ActiveCN105802175ALower glass transition temperatureImprove the lubrication effectAntioxidantPolycarbonate

The invention discloses polyarylester-polydimethylsiloxane block copolymer modified polycarbonate and a preparation method thereof. A raw material formula of polycarbonate comprises components in percentage by mass as follows: 91.6%-97.8% of bisphenol A type polycarbonate, 2%-8% of a polyarylester-polydimethylsiloxane block copolymer and 0.2%-0.4% of an antioxidant. The preparation method of the polyarylester-polydimethylsiloxane block copolymer comprises steps as follows: bisphenol A, sodium hydroxide and deionized water are mixed and dissolved, benzyl triethyl ammonium chloride is added, and an aqueous phase is formed; isophthaloyl dichloride is dissolved in dried dichloromethane, and an organic phase is formed; the organic phase is dropwise added to the aqueous phase, the temperature is reduced to 5-10 DEG C, the stirring reaction is performed, sodium hydroxide and amino-terminated polydimethylsiloxane are added, the normal-temperature reaction is performed, and a polyarylester-polydimethylsiloxane block copolymer emulsion is obtained. The prepared polycarbonate is good in low-temperature toughness and high in melt fluidity.

Owner:铨盛聚碳科技股份有限公司

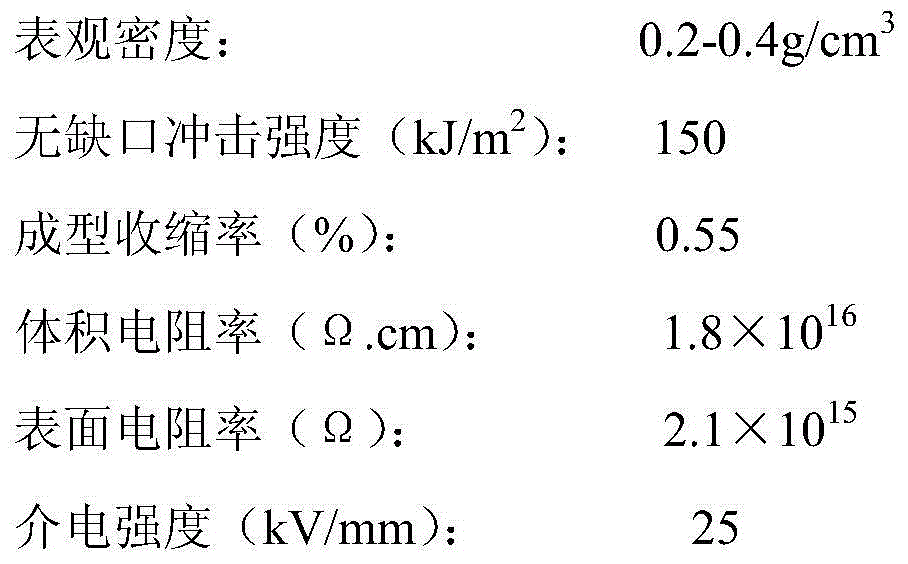

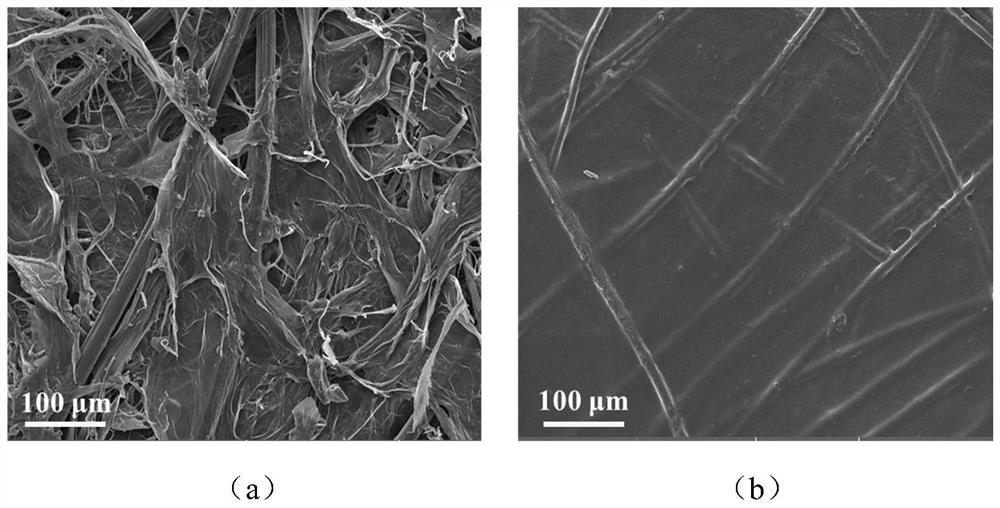

Preparation method of aramid fiber paper coated with aramid fiber spinning solution

ActiveCN113737569ACompact structureHigh dielectric strengthSpecial paperPaper/cardboardPolymer scienceAramid

The invention discloses a preparation method of aramid fiber paper coated with an aramid fiber spinning solution, which comprises the following steps: respectively defibering and dispersing meta-aramid chopped fibers and meta-aramid fibrids, defibering and mixing the components to obtain a slurry dispersion liquid, homogenizing the slurry dispersion liquid, and filtering, dehydrating, forming, squeezing and drying the liquid to obtain meta-aramid fiber base paper; then dissolving m-phenylenediamine in an N,N-dimethylacetamide solvent, adding isophthaloyl dichloride under stirring, and carrying out condensation polymerization under a low-temperature condition; and then adding oxychloride generated by an alkali neutralization reaction, and carrying out concentration adjustment and uniform stirring so as to obtain a meta-aramid spinning coating solution; finally, uniformly coating two surfaces of meta-aramid base paper with the prepared meta-aramid spinning coating liquid, and drying the base paper at high temperature to obtain the coated aramid paper.

Owner:SHAANXI UNIV OF SCI & TECH

Method used for preparing isophthaloyl dichloride and paraphthaloyl chloride

InactiveCN105367407AWell mixedEasy to removeOrganic compound preparationCarboxylic compound preparationChemical synthesisReaction rate

The invention belongs to the technical field of chemical synthesis, and more specifically relates to a method used for preparing isophthaloyl dichloride and paraphthaloyl chloride. The method comprises following steps: m-phthalic acid, terephthalic acid, a catalyst, and thionyl chloride are delivered into a reaction vessel, and nitrogen is delivered into the reaction vessel in a bubbling manner; and after reaction, nitrogen is added continuously, solvents are removed, and an obtained product is subjected to refining so as to obtain a finished product. The method is beneficial for mixing of reaction materials, and rapid discharging of tail gas generated in reaction, so that reaction rate is increased, and it is beneficial for removing of excess solvent.

Owner:SHANDONG KAISHENG NEW MATERIALS

Solvent Resistant, Transparent Aromatic Polyamide Films with High Refractive Indices

A solvent resistant, transparent aromatic polyamide film with a high refractive index may be made by reacting at least one aromatic diacid chloride, a first aromatic diamine, and at least one crosslinking agent or a second aromatic diamine in an organic solvent to form an aromatic polyamide polymer in solution. In one embodiment, the at least one aromatic diacid chloride is selected from the group consisting of isophthaloyl dichloride, terephthaloyl dichloride, 2,6-naphthalene-dicarboxylic chloride, or combinations thereof and the first aromatic diamine is selected from the group consisting of 9,9-Bis(4-hydroxyphenyl)fluorine, 2,2′,5,5′-Tetrachlorobenzidine, or combinations thereof. The organic solvent is then evaporated from the aromatic polyamide polymer in solution to form a transparent aromatic polyamide precursor film. The precursor film is then heated at a temperature close to the glass transition temperature of the transparent aromatic polyamide precursor film to form the solvent resistant, transparent aromatic polyamide film.

Owner:AKRON POLYMER SYST

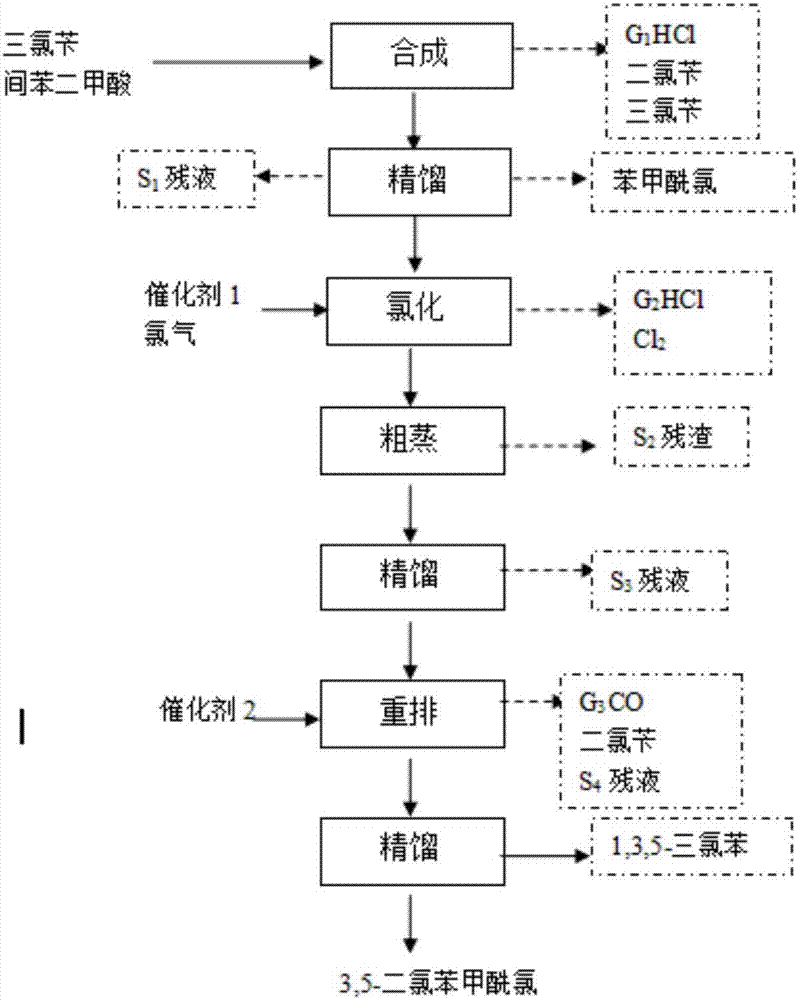

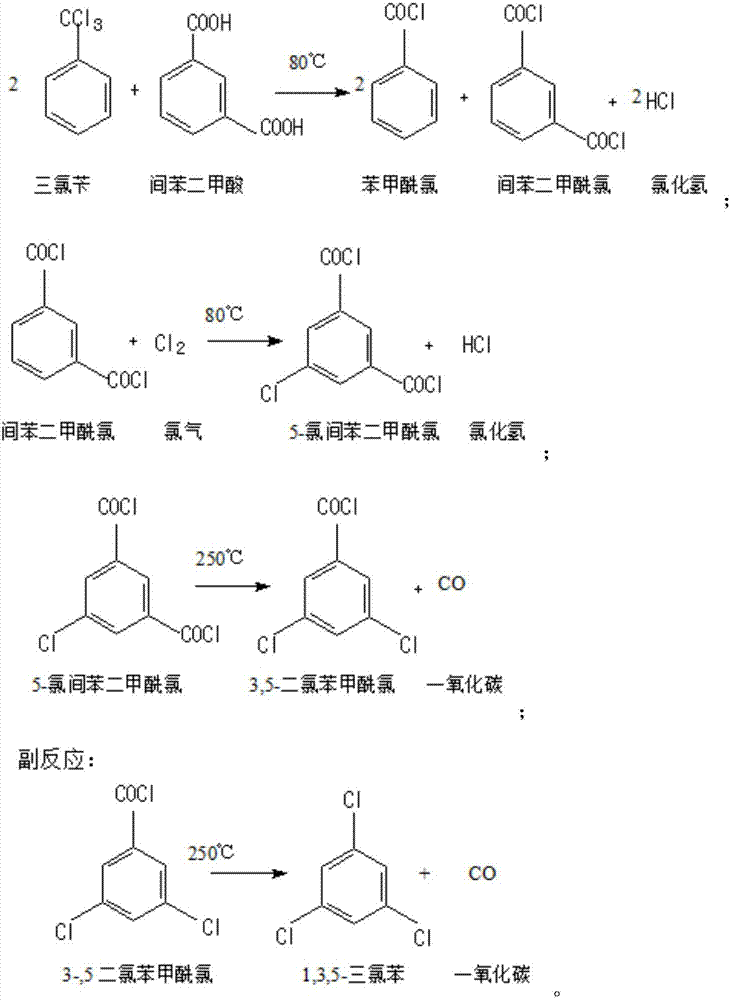

Production method for co-producing benzoyl chloride and trichlorobenzene from dichlorobenzoyl chloride

InactiveCN107501087AHigh yieldHigh purityOrganic compound preparationHalogenated hydrocarbon preparationBenzeneBenzoyl chloride

The invention provides a production method for co-producing benzoyl chloride and trichlorobenzene from dichlorobenzoyl chloride. The method comprises the following steps: enabling trichlorobenzene and m-phthalic acid to react at the temperature of 80 DEG C so as to obtain benzoyl chloride and m-phthaloyl chloride; enabling m-phthaloyl chloride and chlorine to react at the temperature of 80 DEG C so as to obtain 5-chloro isophthaloyl dichloride; and carrying out a rearrangement reaction on the 5-chloro isophthaloyl dichloride at the temperature of 250 DEG C, thereby obtaining 3,5-dichlorobenzoyl chloride and the by-product, 1,3,5-trichloro-benzene. Compared with the prior art, the production method disclosed by the invention has the beneficial effects of high product yield, high purity and high production efficiency.

Owner:南通利奥化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com