Patents

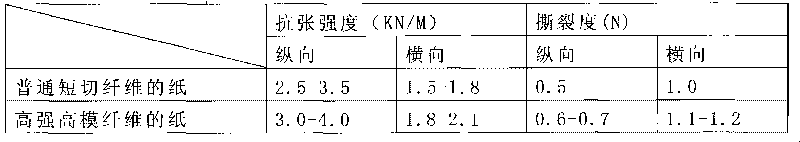

Literature

109 results about "Meta-phenylenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meta Phenylene Diamine, m-Phenylenediamine. Meta Phenylene Diamine,m-Phenylenediamine. Uses: MPD is a chemical intermediate widely used in the synthesis of various engineering polymers, aramid fibers, and thermoplastics, and in the production of dyes for textiles, leather and other materials.

Production method of high-strength high-modulus PMIA super-short fiber

ActiveCN101736431AHigh strengthHigh modulusWet spinning methodsMonocomponent polyamides artificial filamentFiberConductor Coil

The invention discloses a preparation method of high-strength high-modulus PMIA super-short fiber, comprising: m-phthaloyl chloride and metaphenylene diamine are adopted in a system of which the sulphonamide compound is an organic solvent to polymerize solution to obtain m-phenyleneisophthalamide (PMIA) solution comprising polymetaphenylene isophthamide as a repeating unit; performing neutralization reaction by calcium oxide or calcium hydroxide to generate hydrochloric acid so as to obtain spinning solution, wherein the logarithmic viscosity number of the spinning solution is 3-6; high-strength high-modulus PMIA super-short fiber of which the length is 0.5-20 mm is prepared by wet spinning, cleaning, heat treatment, winding, cutting off and packaging. The strength and the modulus of the PMIA super-short fiber are greatly improved compared with the existing like products.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Method for increasing fire resistance of meta-aromatic polyamide polymer

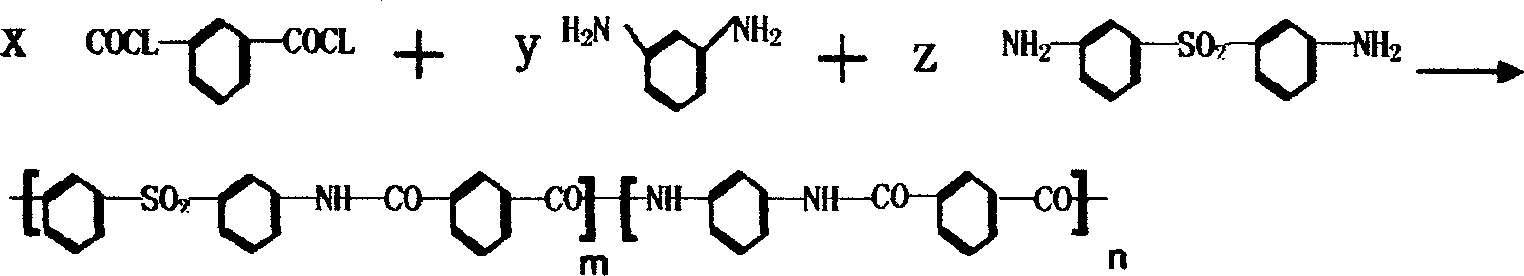

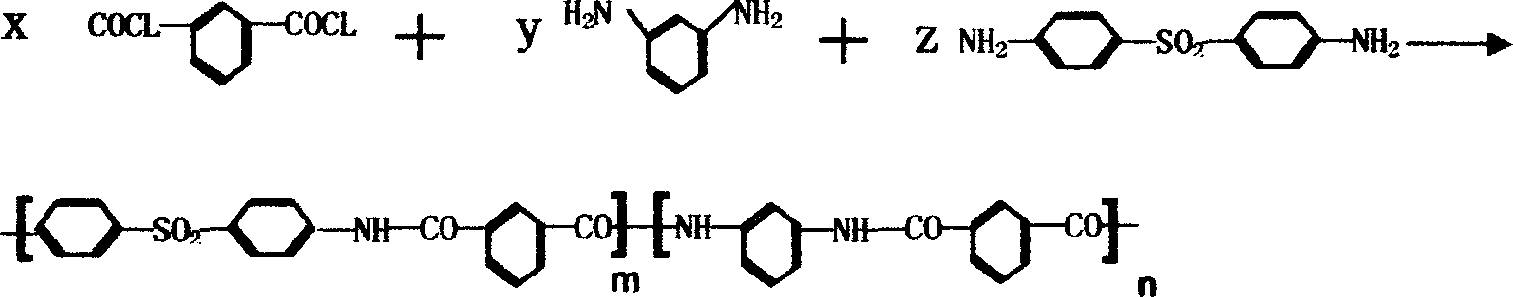

InactiveCN1683431AImprove solubilityRaise the glass transition temperatureVitrificationApparent viscosity

The preparation process of aromatic mata-polyamide with raised fire resistance includes mixing m-phenylene-diamine and R, R'-dismino diphenylsulfone and dissolveing in solvent to compound solution in certain concentration, cooling to -10 deg.c to 0 deg.c, adding m-phenyldimethyl acyl chloride to produce condensation while controlling the reaction temperature in 0-40 deg.c until the solution reaches the target apparent viscosity to obtain aromatic mata-polyamide with raised fire resistance. The present invention has raised production efficiency, lowered production cost, raised vitrification point and raised strength and module of subsequent product.

Owner:邢哲

Surface modification method for lossless environment-friendly convenient aramid fiber material

The invention relates to a surface modification method for a lossless environment-friendly convenient aramid fiber material. The surface modification method comprises the following steps of: taking and placing a Tris-HCl buffer solution with the Ph of 0.7-10.8 in a flask, adding the aramid fiber material into the buffer solution for fully steeping, adding a dopamine hydrochloride modifying agent to the flask, reacting in an open environment under the magnetic stirring condition, and enabling the self-polymerization of the modifying agent to occur; washing and drying the reacted aramid fiber material to obtain the aramid fiber material with modified surface; and continuously steeping the modified aramid fiber material in the dopamine hydrochloride modifying agent solution to enable the self-polymerization of the aramid fiber material to occur, thereby obtaining the modified aramid fiber material with the activated surface and adjustable thickness. The aramid fiber material is a poly-p-phenylene terephthamide or polyisophthaloyl metaphenylene diamine long fiber, chopped fiber or powder. The concentration of the dopamine hydrochloride in the buffer solution is 0.05-2.0mg / ml. A poly-dopamine layer rich in catechol groups is formed on the surface of the modified aramid fiber material obtained by the method; and the modified aramid fiber material has excellent reaction activity and is adjustable in thickness.

Owner:WUHAN UNIV OF TECH

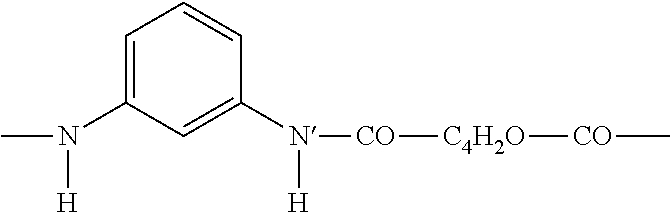

Cross-linked sulfonated polysulfone/polyether sulfone-sulfonated polysulfone composite membrane and manufacturing method thereof

InactiveCN104524993AImprove hydrophilicityImprove performanceSemi-permeable membranesCross-linkFiltration

The invention relates to a cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane and a manufacturing method of the cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane. Polyhydroxyl or multi-amino or hyperbranched substances are selected, a polyether sulfone / sulfonated polysulfone blended ultra-filtration base membrane is coated with a cross-linked sulfonated polysulfone solution to manufacture the composite membrane, a composite membrane separation layer of which the thickness is 1 micrometer-10 micrometers is formed on the surface of the base membrane, the water contact angle of the surface of the composite membrane separation layer ranges from 40 degrees to 90 degrees, and the composite membrane separation layer has good osmosis and separation properties. The manufacturing method includes the steps that sulfonated polysulfone of different concentrations and sulfonation degrees, m-phenylenediamine, polyethylene glycol, dopamine, H30 and other cross-linking agents are dissolved in solvent to manufacture the coating solution, with the polyether sulfone / sulfonated polysulfone blended ultra-filtration being the base membrane, the composite membrane separation layer is manufactured under vacuum conditions, and finally the cross-linked sulfonated polysulfone / polyether sulfone-sulfonated polysulfone composite membrane which is hydrophilic is obtained. The manufactured composite membrane has the good osmosis and separation properties, and can be used for nanofiltration and forward osmosis processes and membrane separation processes including seawater desalting, waste water treatment, domestic water treatment and bio-separation.

Owner:张一琛

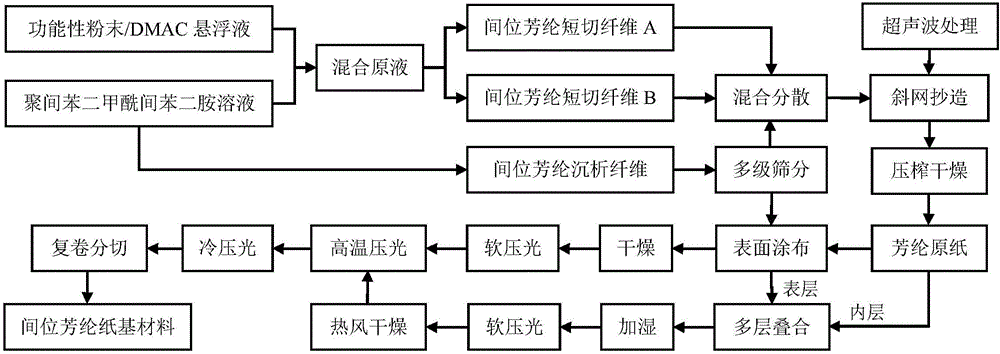

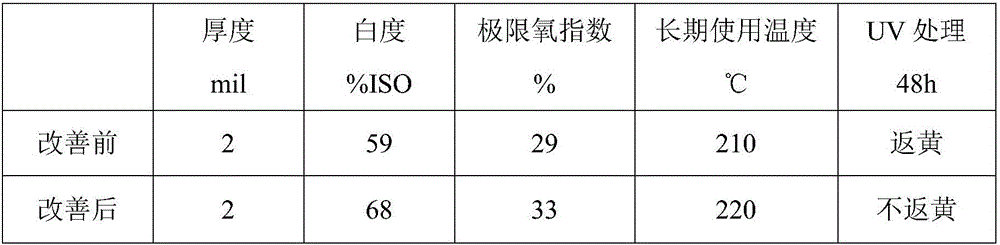

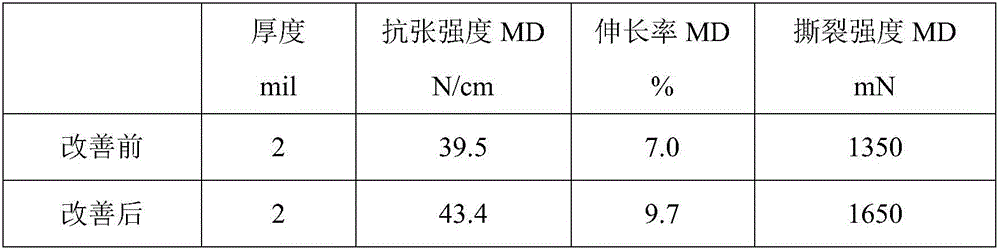

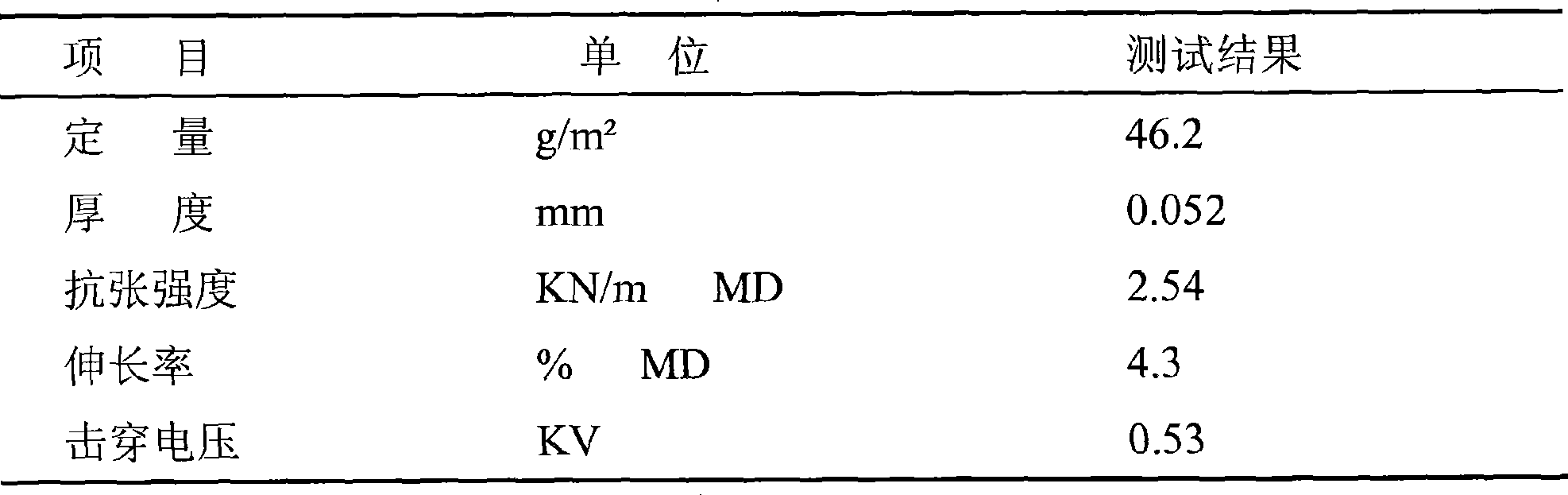

Production method of meta-aramid fiber paper-based material

ActiveCN106245411AHigh whitenessImprove aging resistanceSpecial paperSynthetic cellulose/non-cellulose material pulp/paperAging resistancePapermaking

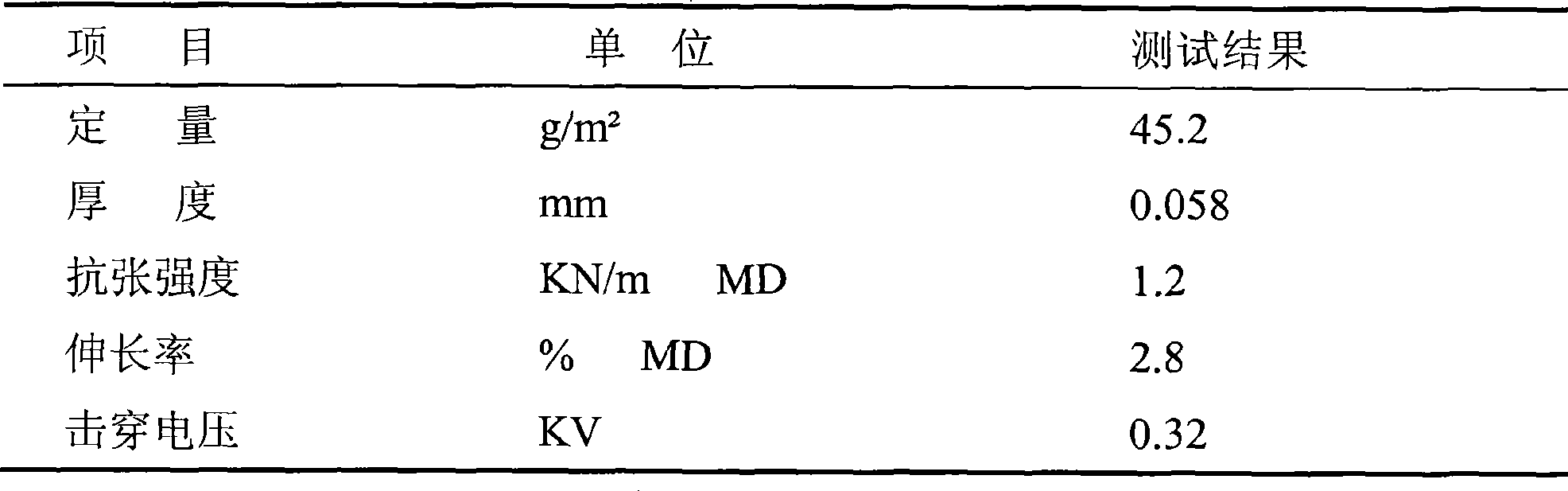

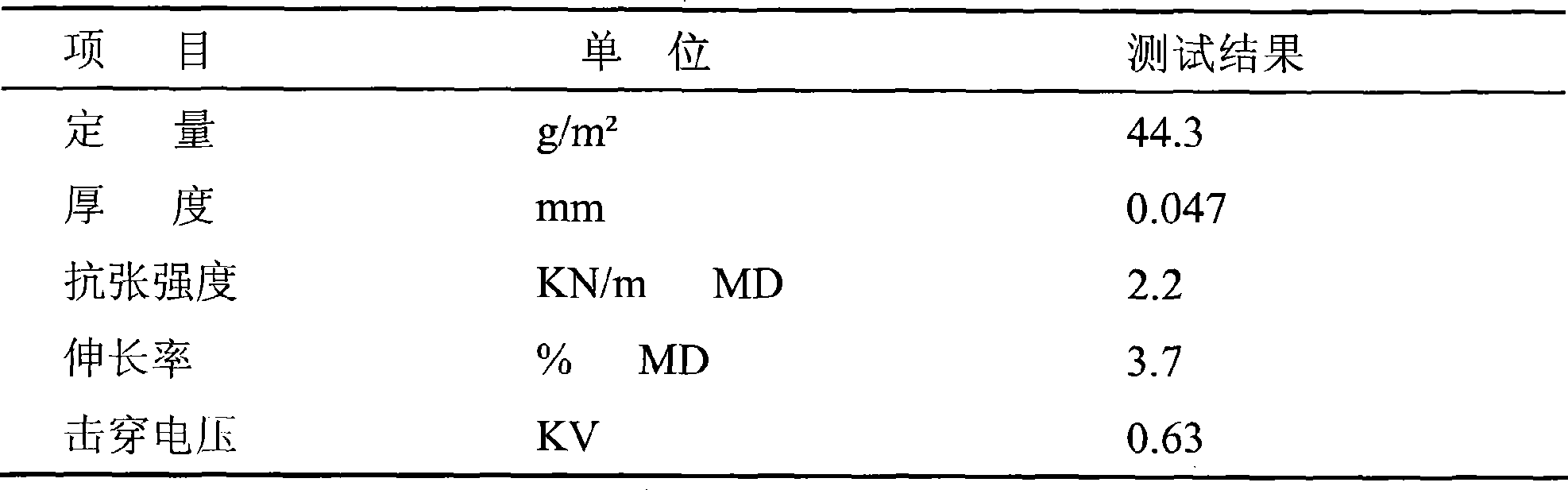

The invention discloses a production method of a meta-aramid fiber paper-based material. The production method includes the following steps that functional powder is added into a polyisophthaloyl metaphenylene diamine solution to obtain a uniform mixed stock solution, and meta-aramid chopped fiber is prepared through a dry spinning method; meta-aramid fibrid is prepared from the polyisophthaloyl metaphenylene diamine solution; the meta-aramid fibrid is screened in a multi-level mode, and fiber with suitable mesh numbers are selected and combined by the ratio; aramid fiber is mixed and defibered uniformly and is formed by adopting an ultralow-concentration inclined wire forming machine through ultrasonic wave treatment in a wet process papermaking mode, aramid raw paper is obtained through squeezing and drying, and surface coating is carried out on the raw paper; multi-section calendaring and rewinding cutting are carried out to prepare the high-performance aramid paper-based material. The meta-aramid paper-based material with the thickness of 1.5-30 mil can be prepared and is high in whiteness, excellent in mechanical strength, dielectric property, ageing resistance and flame retardance and high in performance stability, and the surface is smooth and even.

Owner:YANTAI METASTAR SPECIAL PAPER

Polyamide reverse osmose membrane and production thereof

ActiveCN1817422AExcellent and stable performanceWide variety of sourcesSemi-permeable membranesLiquid layerReverse osmosis

A reverse-osmosis polyamide member is prepared through providing the aqueous solution of lentine and 2.4-diamino phenylsulfonic acid, immersing the porous carrier in it to have a liquid layer on it, and single-surface contacting with the organic solution of isophthalic dichlorid and symphenyl triformyl chloride for interface polymerizing reaction. Said reverse osmosis membrane can be used to treat the saline for removing either impurity (SO4 ions) or NaCl in different condition, having high selectivity.

Owner:凯膜特种分离技术(上海)有限公司

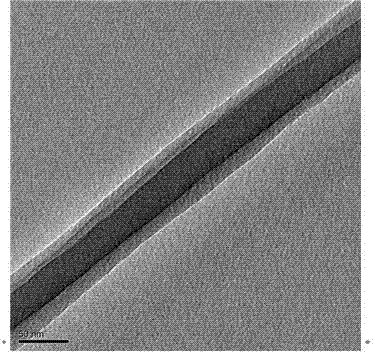

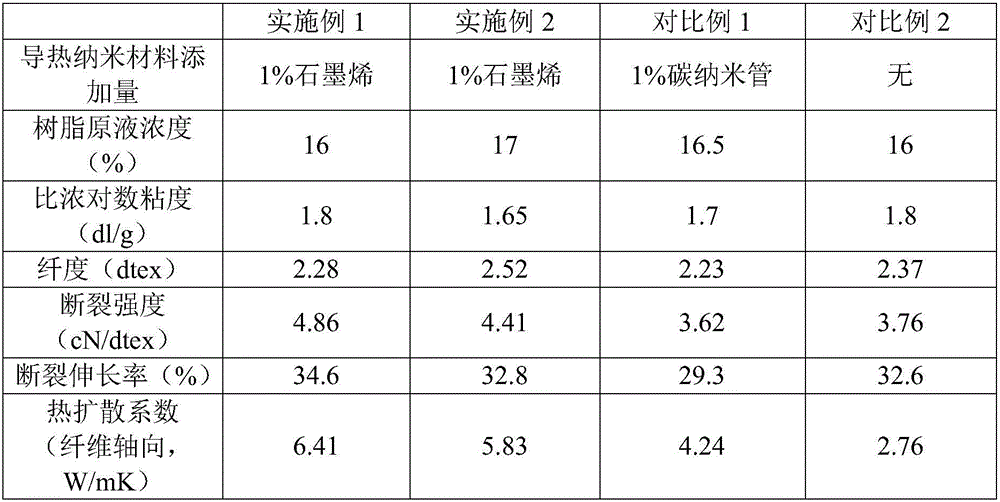

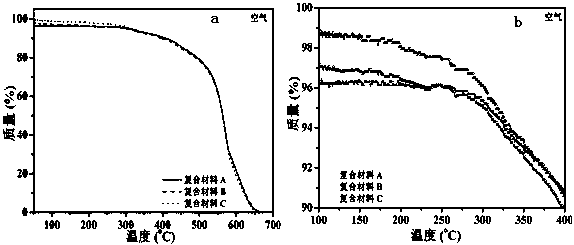

Preparation method and application of high-thermal-conductivity aromatic polyamide fibers

ActiveCN106498538AFast heat conductionReduced Diffusion Path ResistanceArtifical filament manufactureMonocomponent polyamides artificial filamentSolventAramid

A preparation method of high-thermal-conductivity aromatic polyamide fibers includes dispersing oxidized graphene in an organic solvent to obtain dispersion liquid; adding m-phenylenediamine monomers into the dispersion liquid under the protection of inert gas, and cooling a system to a temperature as required by the system; slowly adding part of isophthaloyl dichloride while stirring to allow a polycondensation reaction of the solvent, adding alkaline substances for neutralization, adding the rest isophthaloyl dichloride, and continuing to stir until complete reaction to obtain a meta-position aromatic polyamide resin solution; taking the meta-position aromatic polyamide resin solution as a spinning solution, adopting a dry-spraying and wet-spinning process to spin, and finally preparing the high-thermal-conductivity aromatic polyamide fibers. The high-thermal-conductivity aromatic polyamide fibers have high thermal diffusion coefficients; added carbon nano-materials, graphite nano-materials and the like have antifriction effect, and serve as structure reinforcing materials which obviously improve mechanical properties of aramid fibers.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Polyisophthaloyl metaphenylene diamine fiber and preparation method thereof

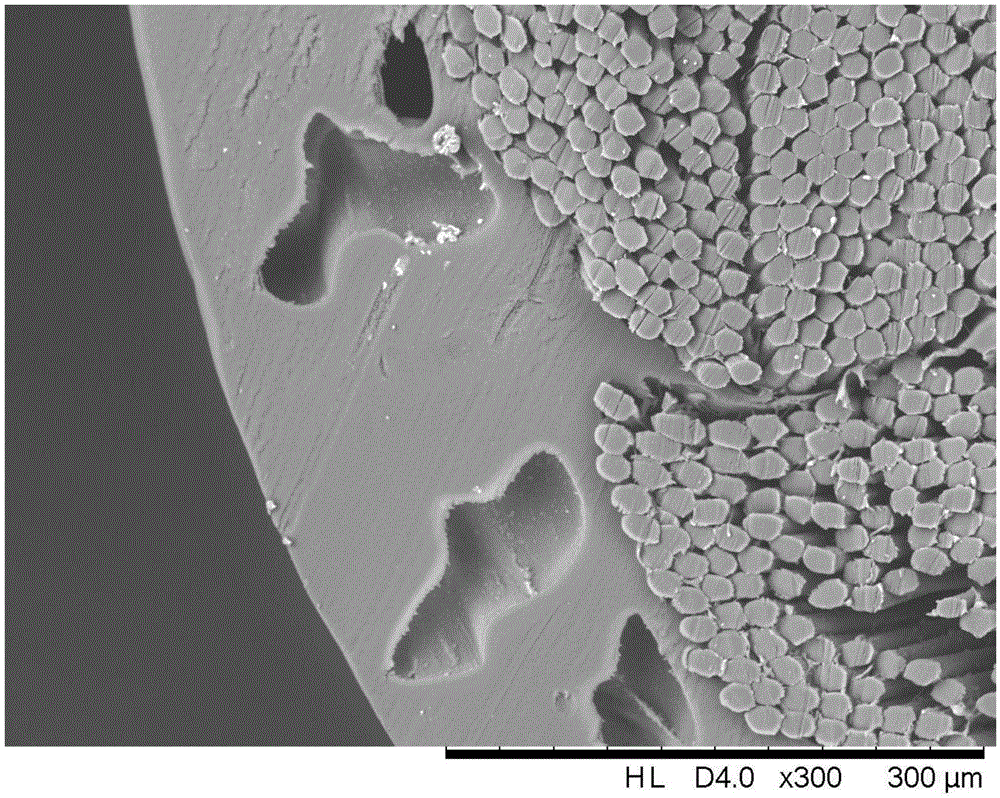

ActiveCN103668533AFully contactedEasy to dyeArtificial filament physical treatmentFilament/thread formingPolymer scienceSpinning

The inventioin discloses a polyisophthaloyl metaphenylene diamine fiber with the strength of 5.2-10.8 cN / dtex and the elongation at break of 2.0-5.0. The invention simultaneously discloses a preparation method of the polyisophthaloyl metaphenylene diamine fiber. The preparation method comprises steps as follows: firstly, metaphenylene diamine and isophthaloyl dichloride are subjected to polymerization reaction, and then, spinning operation is performed. According to the preparation method, gaseous hydrogen chloride produced in the dry spray stage and ammonia gas in a gas storage box react, the amount of hydrogen chloride discharged to the environment is reduced, ammonia gas and dry spray trickle are fully contacted, and forming of a macroscopic void structure during fiber solidification can be inhibited; the polyisophthaloyl metaphenylene diamine fiber prepared and obtained with the method has the advantages of compact structure, high strength and toughness, large specific surface area and convenience for fiber dyeing; and by means of the preparation method, the production efficiency of aramid fiber is improved greatly, and industrial mass production requirements of aramid fiber are met.

Owner:X FIPER NEW MATERIAL CO LTD

Preparation method of high-speed working condition self-lubricating fabric gasket composite material

The invention discloses a preparation method of a high-speed working condition self-lubricating fabric gasket composite material, and the method comprises the following steps: dispersing phenolic resin in an organic solvent, and ultrasonically dispersing graphite fluoride and lamellar basalt flakes in the organic solvent to obtain a self-lubricating fabric impregnating solution; repeatedly impregnating a blend fiber fabric subjected to plasma pretreatment in the self-lubricating fabric impregnation liquid, and drying; and finally, adhering the fabric to the surface of a metal base material byusing the phenolic resin, preserving heat, curing and forming to obtain the self-lubricating gasket composite material. The phenolic resin is used as matrix resin, the polytetrafluoroethylene-polyisophthaloyl metaphenylene diamine blended fabric is used as a reinforcing phase, the bearing capacity of a self-lubricating gasket under the high-speed working condition is greatly improved based on thesynergistic interface physical-chemical effect of the graphite fluoride and the lamellar basalt flakes, the friction coefficient between the self-lubricating gasket and a friction pair is reduced, andthe friction coefficient of the self-lubricating gasket is improved. And the wear resistance and the lubricating property of the self-lubricating gasket are obviously improved, so that the service life of a corresponding self-lubricating knuckle bearing is greatly prolonged.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing synthetic paper containing polysulfone amide precipitation fibers

ActiveCN101392475AImprove initial strengthImprove heat resistanceSynthetic cellulose/non-cellulose material pulp/paperPhysical paper treatmentSynthetic fiberHigh intensity

The invention provides a synthetic fiber paper, which contains the following ingredients in parts of weight: 5-95 parts of structural fiber and 5-95 parts of splicing fibers, wherein, the structural fiber is polyisophthaloyl metaphenylene diamide fiber and the splicing fiber is polysulfonamide precipitated fiber. The synthetic fiber paper is produced by the following steps: the structural fiber and the splicing fiber are made into be formed by a wet method and hot-rolled to obtain the paper. The synthetic fiber paper provided by the invention has high intensity conservation rate under the high temperature, excellent paper-making overall properties compared with the insulation paper made of full para-fiber, meta-fiber and full polysulfonamide material, and is more suitable for the insulation requirement under high-temperature environment.

Owner:LONGPONT

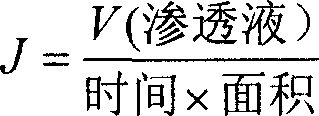

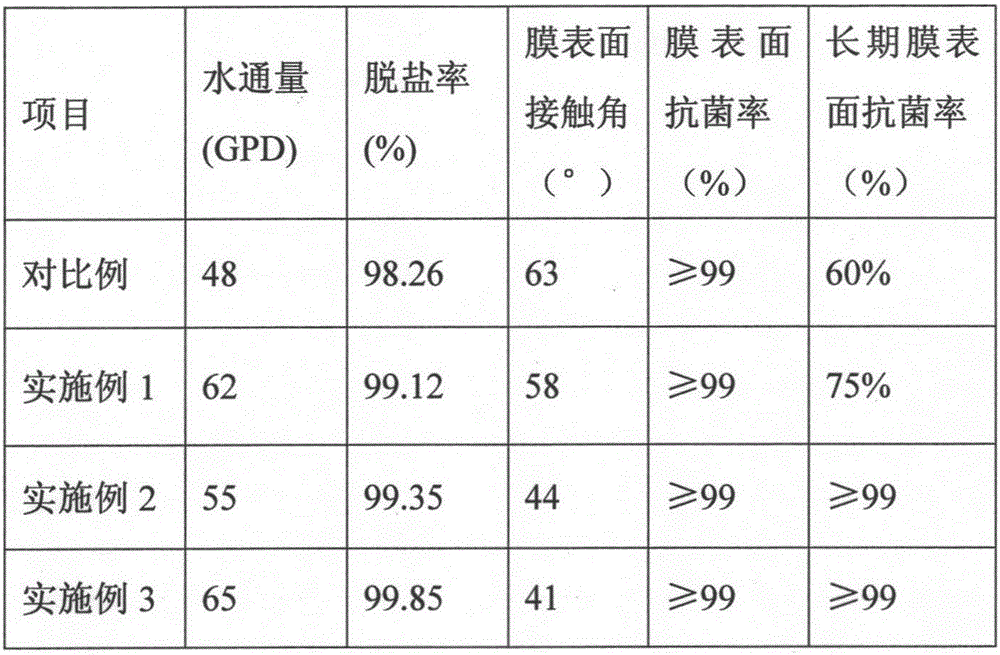

Preparation method for polyisophthaloyl metaphenylene diamine nanofiltration membrane

InactiveCN105413500AAvoid the disadvantage of uneven dispersionIncreased pure water fluxReverse osmosisSilica gelGraphene

The invention provides a preparation method for a polyisophthaloyl metaphenylene diamine nanofiltration membrane and belongs to the field of membrane pollution resistance. The method includes the steps that a fully-dried polyisophthaloyl metaphenylene diamine nanofiltration membrane is flatly laid on a glass plate, the glass plate is placed in a plate frame to be tightened, a prepared solution containing an acid binding agent is poured to the surface of the membrane for impregnation, the remaining solution is poured out, and the membrane is placed in a fume cupboard to be dried in shade; then a prepared crosslinking solution is poured to the surface of the membrane for impregnation, and the surplus solution is removed through a silica gel wheel; then an oxidized graphene solution is poured to the surface of the membrane for impregnation, the remaining solution is poured out, and the membrane is dried in shade; finally the treated membrane is placed within the temperature interval of 40-80 DEG C for heat treatment for 60-180 s, and the modified nanofiltration membrane is obtained. The technological operation is easy, the original excellent characteristics of the polyisophthaloyl metaphenylene diamine nanofiltration membrane are kept, the hydrophilia of the surface of the membrane is also well enhanced, the pollution resistance of the membrane is improved, and wide application prospects are achieved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

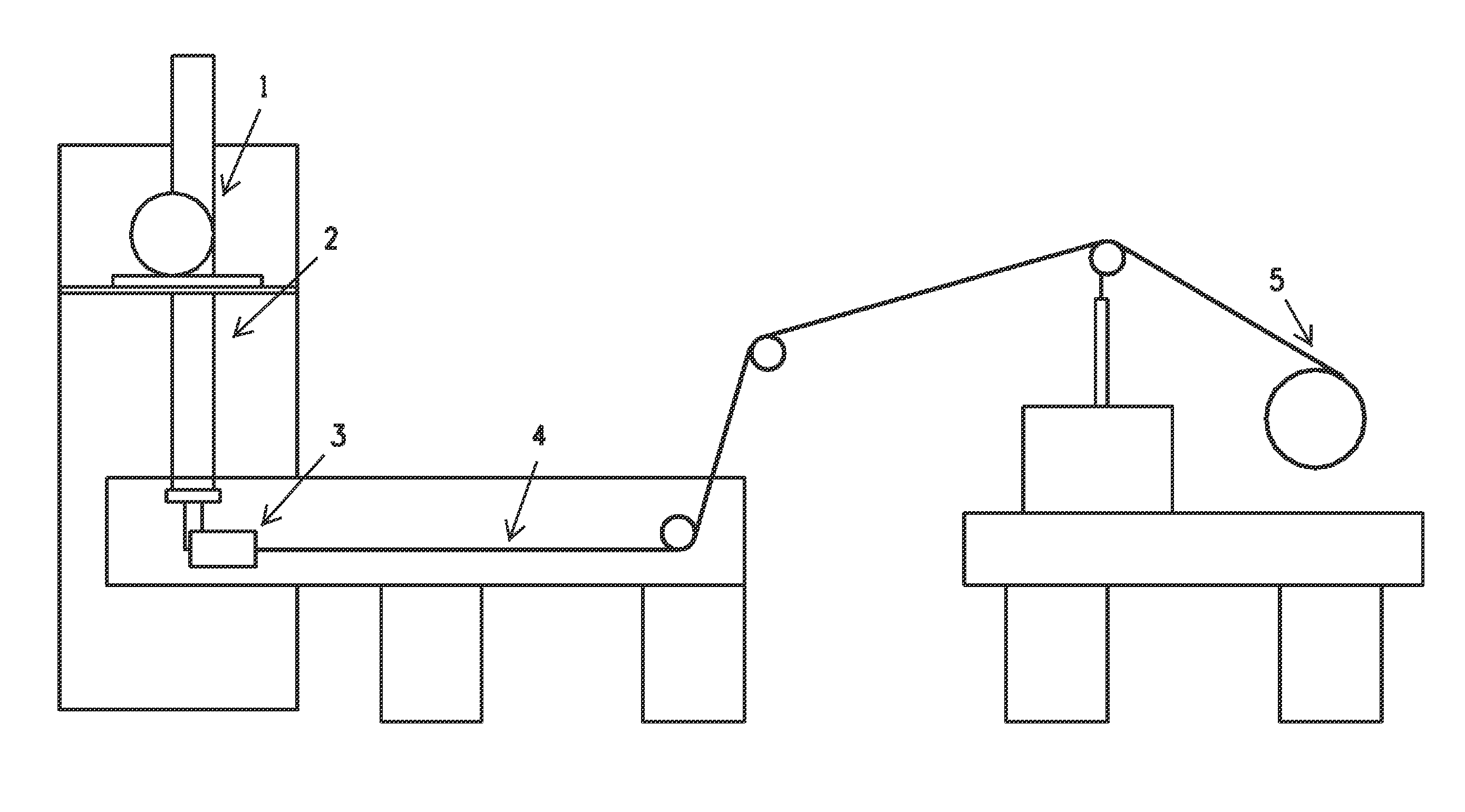

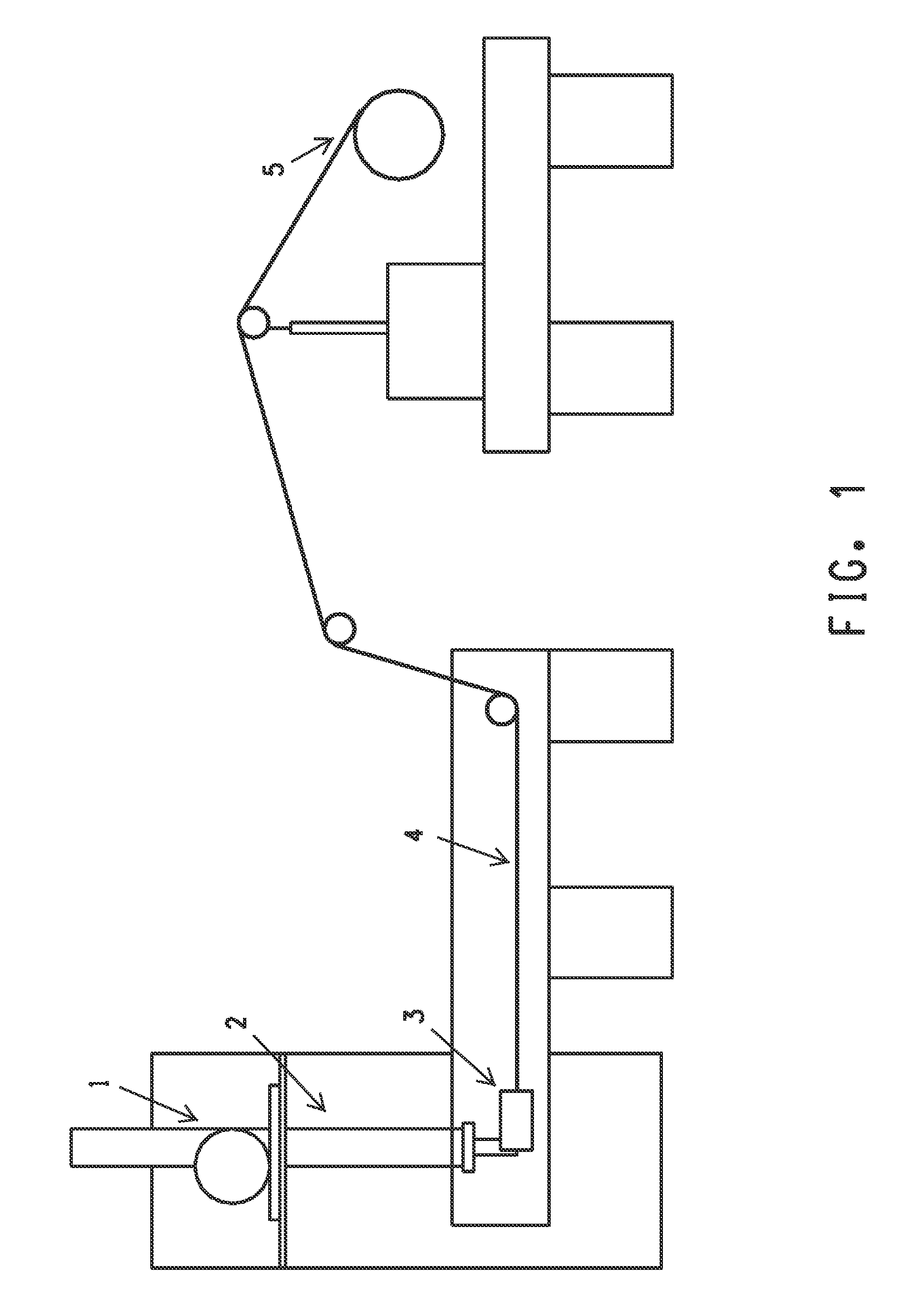

Preparation method of enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane

ActiveCN105597569AImprove solubilityBreaking hydrogen bondsSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a preparation method of an enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane. The preparation method includes the following processing steps of (1) preparation of a hollow braided hose: adopting a well-known two-dimensional braiding technique to braid fibers into the hollow braided hose, and taking the hollow braided hose as an enhancing body of the enhanced hollow fiber membrane; (2) preparation of PMIA membrane casting dissolving fully dried PMIA resin, additives and a pore-forming agent in an organic solvent at the temperature of 60-70 DEG C, stirring for 4-6h to obtain homogeneous solution, and performing vacuum defoaming to obtain the PMIA membrane casting (3) preparation of the enhanced PMIA hollow fiber membrane: adopting a coextrusion composite spinning process to subject the hollow braided hose obtained in the step (1) and PMIA membrane casting solution obtained in the step (2) to coextrusion through an annular spinning jet, uniformly coating the surface of the hollow braided hose with the membrane casting solution, and fully curing to obtain the enhanced PMIA hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

Method for preparing high-throughput and anti-pollution polyisophthaloyl metaphenylene diamine nano-filtration membranes

InactiveCN107158960AImprove throughputImprove hydrophilicityMembranesReverse osmosisFiltration membranePolyether ether ketone

The invention discloses a method for preparing high-throughput and anti-pollution polyisophthaloyl metaphenylene diamine nano-filtration membranes, and belongs to the field of technologies for preparing membranes. The method includes sulfonating polyether ether ketone concentrated sulfuric acid, cleaning the polyether ether ketone concentrated sulfuric acid until the polyether ether ketone concentrated sulfuric acid is neutral and drying the polyether ether ketone concentrated sulfuric acid to obtain sulfonated polyether ether ketone; adding 0.01-1 wt% of treated graphene oxide and 0.01-10 wt% of sulfonated polyether ether ketone into N, N-dimethylacetamide (DMAC) to obtain mixtures, placing the mixtures in a cell grinder and treating the mixtures to obtain dispersion liquid; adding additives into the dispersion liquid with the graphene oxide and the sulfonated polyether ether ketone, stirring the additives and the dispersion liquid to obtain first mixtures, then adding dried PMIA [poly(m-phenylene isophthalamide)] into the first mixtures, dissolving the dried PMIA and the first mixtures at the temperature of 80 DEG C to obtain second mixtures, mechanically stirring the second mixtures, carrying out vacuum defoaming on the second mixtures, preserving the second mixtures for standby application and forming the high-throughput and anti-pollution polyisophthaloyl metaphenylene diamine nano-filtration membranes by means of scraping. The method has the advantages that the method is easy to implement, contact angles of the high-throughput and anti-pollution polyisophthaloyl metaphenylene diamine nano-filtration membranes prepared by the aid of the method can be reduced and reach approximately 45 degrees from the original approximately 78 degrees under the condition that the retention rates keep rising, and the hydrophilicity and the anti-pollution performance of the high-throughput and anti-pollution polyisophthaloyl metaphenylene diamine nano-filtration membranes can be greatly improved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Polyester amide reverse osmosis compound film and its preparation method

InactiveCN1954901AHigh desalination rateImprove throughputSemi-permeable membranesPolyesterPolymer science

A composite reverse osmosis polyester-amide membrane is composed of a porous supporting layer, and a compact polyester-amide surface layer prepared by interface polymerization between aminoglucose or aminobiglucose or the mixture of aminoglucose and metaphenyldiamine and the polyatomic acyl chloride. Its preparing process includes such steps as immersing the one surface of polysulfone film in the aqueous solution of amino monomer, dripdrying, interface polymerization reaction on the solution of polyatomic acyl chloride, drying, heat treating and rinsing in deionized water. It has high water throughput.

Owner:OCEAN UNIV OF CHINA

Furan based polyamides

InactiveUS20150044927A1Filament/thread formingMonocomponent synthetic polymer artificial filamentFuranPolymer science

Disclosed herein are compositions and article made therefrom and processes of making them. The composition comprises a polymer, the polymer comprising a repeat unit of formula shown below:wherein the polymer is derived from an aromatic diamine comprising m-phenylene diamine, and an aromatic diacid or a derivative thereof comprising furan dicarboxylic acid or derivative thereof.

Owner:EI DU PONT DE NEMOURS & CO

Nickel catalyst, process for the preparation thereof, process for hydrogenation of m-dinitro benzene to m-phenylene diamine

InactiveUS20050070740A1Speed up the processLong catalyst lifeMolecular sieve catalystsOrganic compound preparationSolventSilicon dioxide

Owner:COUNCIL OF SCI & IND RES

Base paper of aramid fiber honeycomb core and manufacturing method thereof

ActiveUS20110174452A1Improve flatnessImprove glossinessNon-fibrous pulp additionNatural cellulose pulp/paperPolyesterHoneycomb

A base paper of aramid fiber honeycomb core and its manufacturing method are provided. The base paper comprises 11-90 parts by weight of structural fiber, 10-70 parts by weight of crosslinking fiber, and 0-19 parts by weight of additive fiber, wherein the structural fiber is poly(p-phenylene terephthal amide) fiber, the crosslinking fiber is poly(m-phenylene isophthal amide) fibrid, and the additive is polyester fiber.

Owner:GANZHOU LONGPONT MATERIAL TECH CO LTD

Method for improving water flux and anti-pollution capacity of polyamide reverse osmosis membrane

InactiveCN105664742AStrong anti-pollutionIncrease water fluxSemi-permeable membranesMembranesLiquid layerPolyamide

The invention discloses a method for improving the water flux and anti-pollution ability of a polyamide reverse osmosis membrane, specifically: dissolving polysulfone in N-N, dimethylacetamide solution, adding sodium dodecylsulfonate, Mix well, apply and scrape on the surface of non-woven fabric, immerse in water, remove the solvent to obtain a polysulfone support layer, and then treat the polysulfone support layer with ultraviolet light; rinse the surface of the polysulfone support layer with deionized water repeatedly, and after air-drying, Immerse it in an aqueous solution of m-phenylenediamine, form an aqueous liquid layer on the surface of the polysulfone support layer, and prepare a wet film; immerse the wet film in a naphtha organic solution of trimellitic acid chloride, and interfacially polymerize with it Reaction; immersing the polyamide composite reverse osmosis membrane in an aqueous solution of sodium sulfate; then immersing it in an aqueous solution containing hydroxyethyl acrylate, and performing a contact reaction to obtain a high-flux anti-pollution polyamide composite reverse osmosis membrane. The invention has strong anti-pollution ability, and the water flux is improved compared with the traditional reverse osmosis membrane under the same pressure.

Owner:SHANGHAI EMATE INDAL

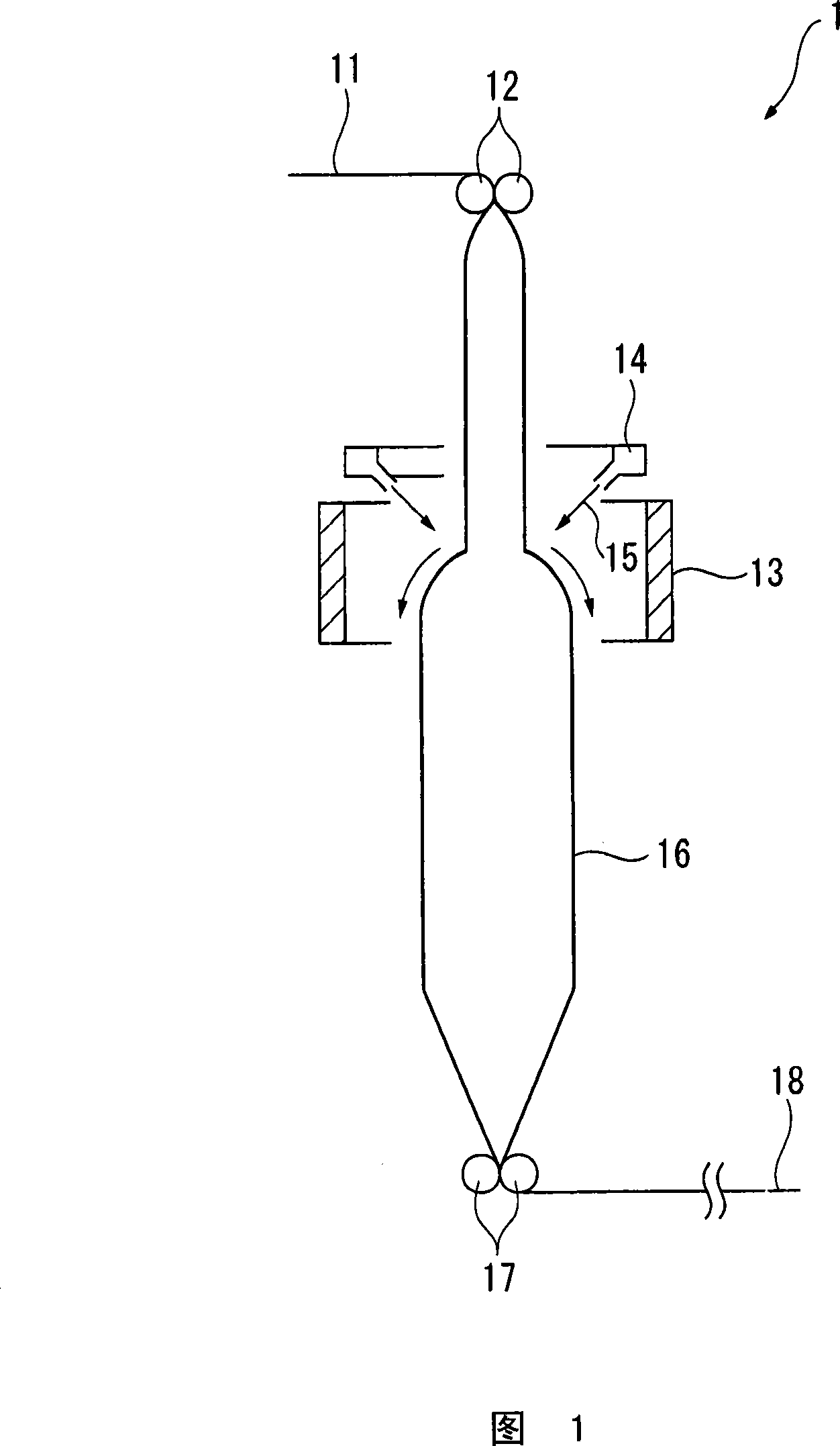

Process for production of poly(m-phenyleneisophthal-amide) porous hollow fiber membrane

InactiveUS20050170176A1High molecular weightIncrease ratingsSemi-permeable membranesMembranesMoistureHeat treated

A polymetaphenylene isophthalamide porous hollow fiber membrane is produced by extruding a film-forming solution comprising polymetaphenylene isophthalamide, polyvinylpyrrolidone and an inorganic salt through a concentric double annular spinning nozzle while keeping the film-forming solution at 70° C. or higher, thereby conducting dry-and-wet spinning, followed by moisture retention treatment, where it is preferable to subject the resulting porous hollow fiber membrane obtained by dry-and-wet spinning to heat treatment in water at 80° C. or higher before the moisture retention treatment. The polymetaphenylene isophthalamide porous hollow fiber membrane resulting from wet heat treatment under wet heat conditions at the temperature of 100° C. and the humidity of 80% for 1,000 hours or more has a strength at break of 10 MPa or more and a elongation at break of 80% or more, where the elongation at break can keep at least 80% as high as that before the wet heat treatment, and also has distinguished resistance to moisture and heat and humidifying performance, so that the membrane can be used as an effective humidifying membrane for polymer electrolyte fuel cells, etc.

Owner:NOK CORP

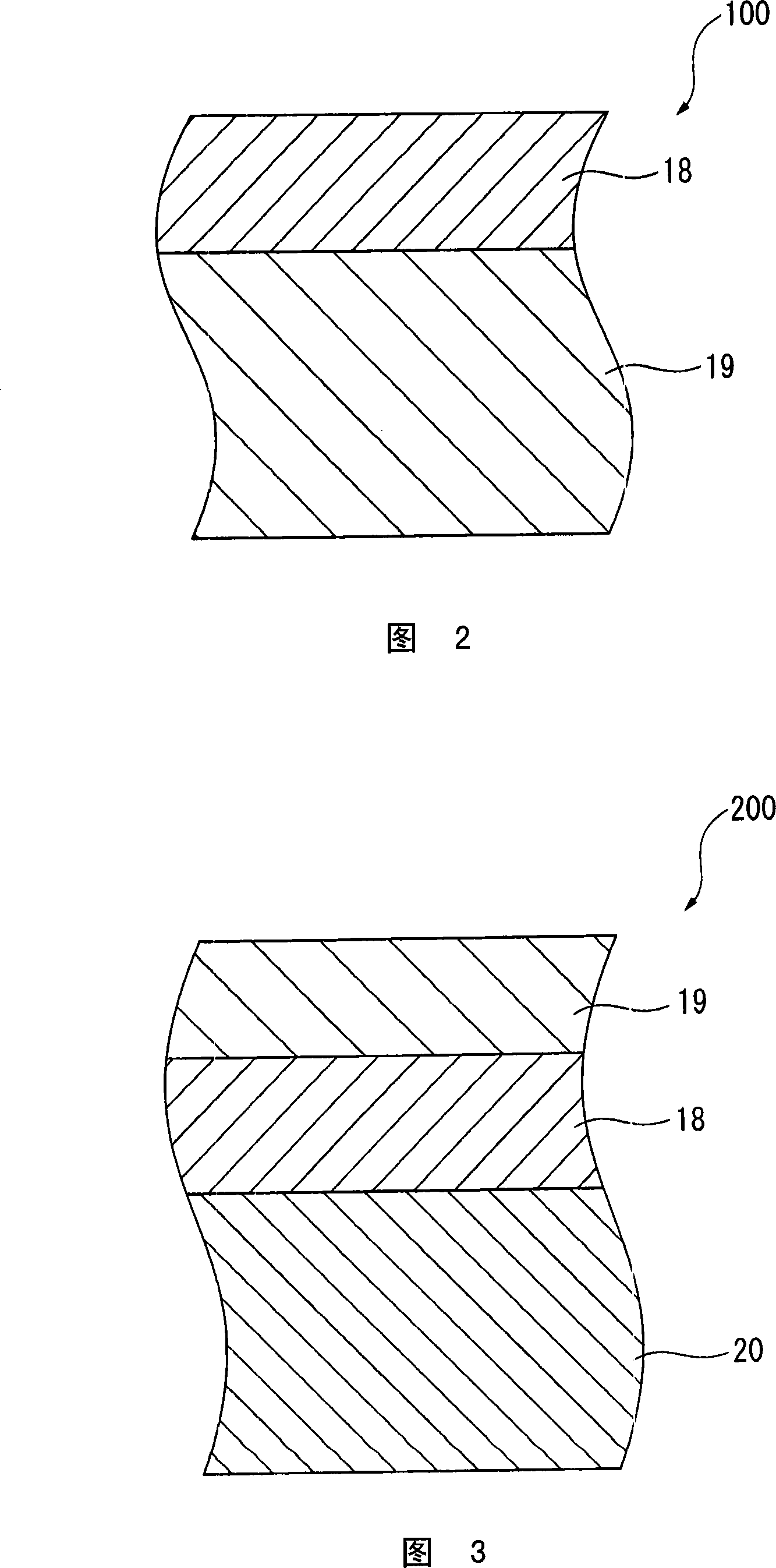

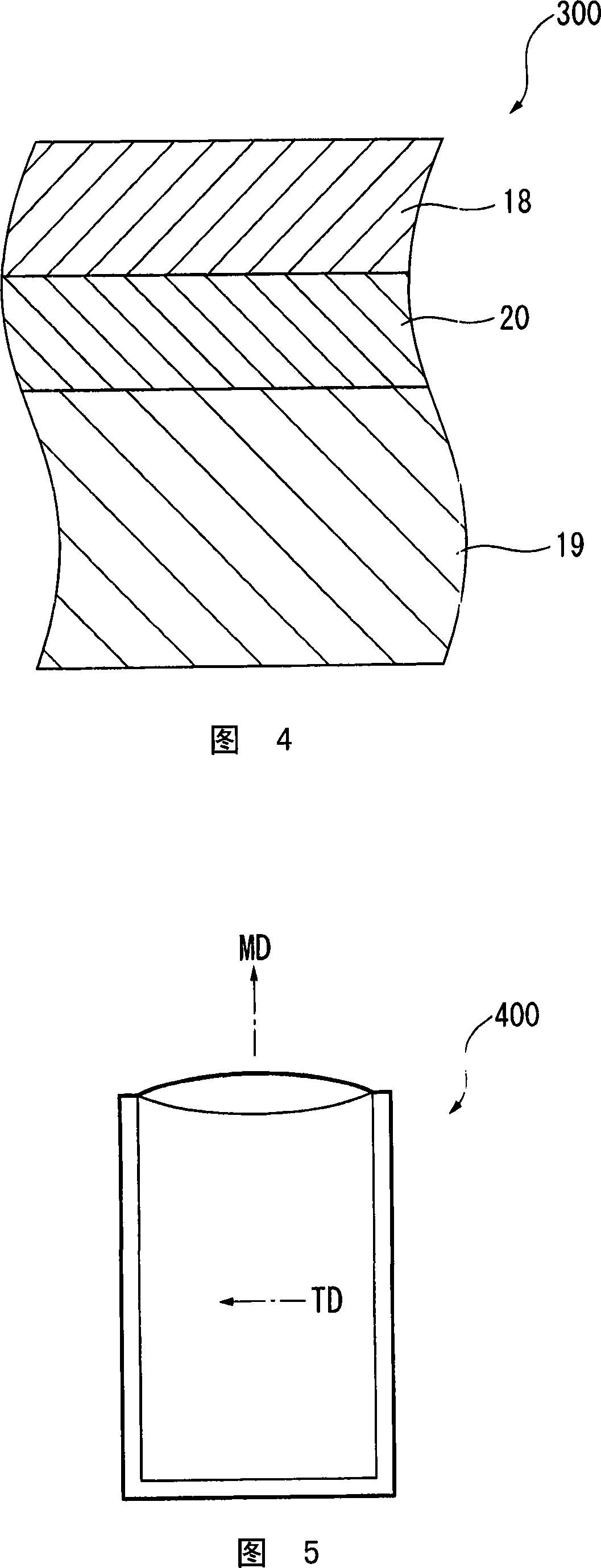

Easy-split contracted film, easy-split laminated film, easy-split bag, and manufacturing method for easy-split contracted film

ActiveCN101108898AExcellent linear cut-offImprove impact resistanceSynthetic resin layered productsPackagingXylyleneNylon 6

The invention relates to a fissility shrinkable film, containing 60-85 mass portion of nylon 6 (Ny6) and 15-40 mass portion of m(p-xylylene adipamide) (MXD6) (total is 100 mass portion) as materials. The material comprises original materials containing 60-85 mass portion of Ny and 15-40 mass portion portion of MXD, and a heat processing matter for melting refining the Ny6 and MXD6 to make the MXD6 melting point be 233-238 DEG C. The content of the heat processing matter is 5-40 mass%. The shrinkage of the fissility shrinkable film is 3-20% when keeping in the hot water at 95 DEG C for 30 mins.

Owner:IDEMITSU UNITECH CO LTD

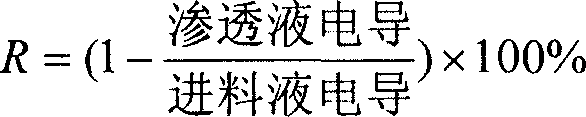

Method for improving polyisophthaloyl metaphenylene diamine hollow fiber nanofiltration membrane hydrophilism and pollution resistant performance

The invention relates to a method for improving polyisophthaloyl metaphenylene diamine hollow fiber nanofiltration membrane hydrophilism and pollution resistant performance. Polyisophthaloyl metaphenylene diamine is used as raw materials, after fully mixing and dissolving with organic dissolvant and pore-foaming agent, nanometer titania particles are increased, fully blended and uniformly distributed, after standing vacuum defoaming, and the hollow fiber nanofiltration membrane is manufactured by adopting an immersion sediment phase inversion method in a pulling mode. The content of the polyisophthaloyl metaphenylene diamine in membrane-manufacturing original liquid is 10%-25wt.%, the content of the organic dissolvant is 50%-70wt.%, the content of the pore-foaming agent is 5%- 25wt.%, and the content of nanometer titania particles is 0.5%- 4wt.%. The prepared hollow fiber nanofiltration membrane contact angle is lowered from 70 degrees to 40 degrees, in the meantime possesses good mechanical property. Tensile strength can meet 10.0 Mpa-18.0 Mpa, and an elongation at break is in the range of 80%-150%. The method for improving polyisophthaloyl metaphenylene diamine hollow fiber nanofiltration membrane hydrophilism and pollution resistant performance has the advantages of being simple in operation, capable of reserving the original good features of the polyisophthaloyl metaphenylene diamine hollow fiber nanofiltration membrane, and further enhancing the hydrophilism of surfaces of membranes, improving the anti-pollution performance of the membranes and wide in application prospect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

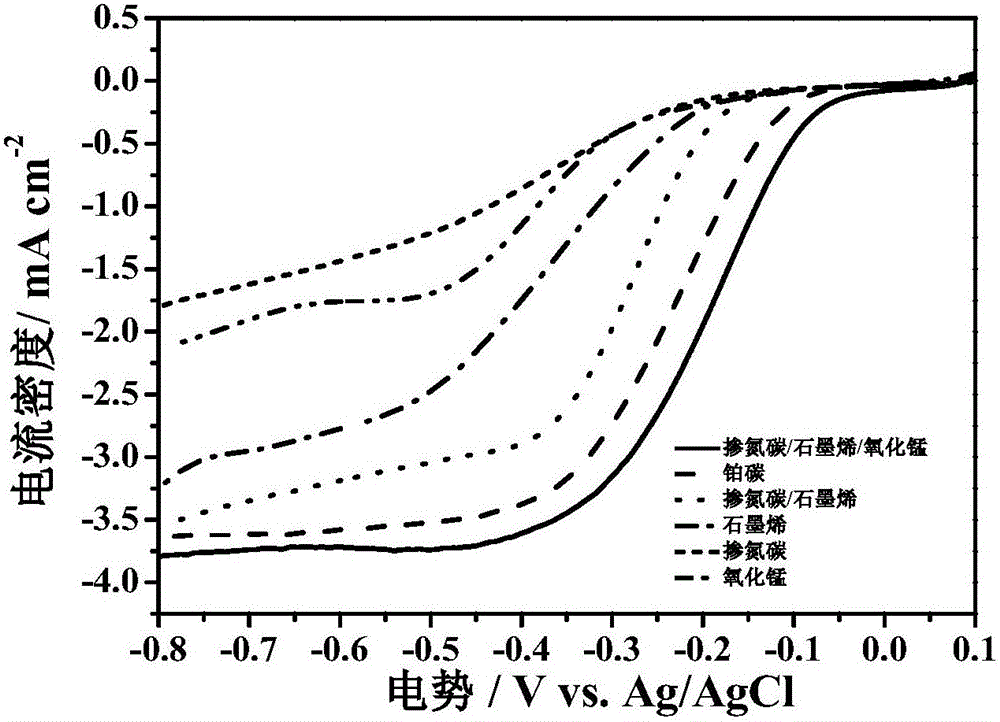

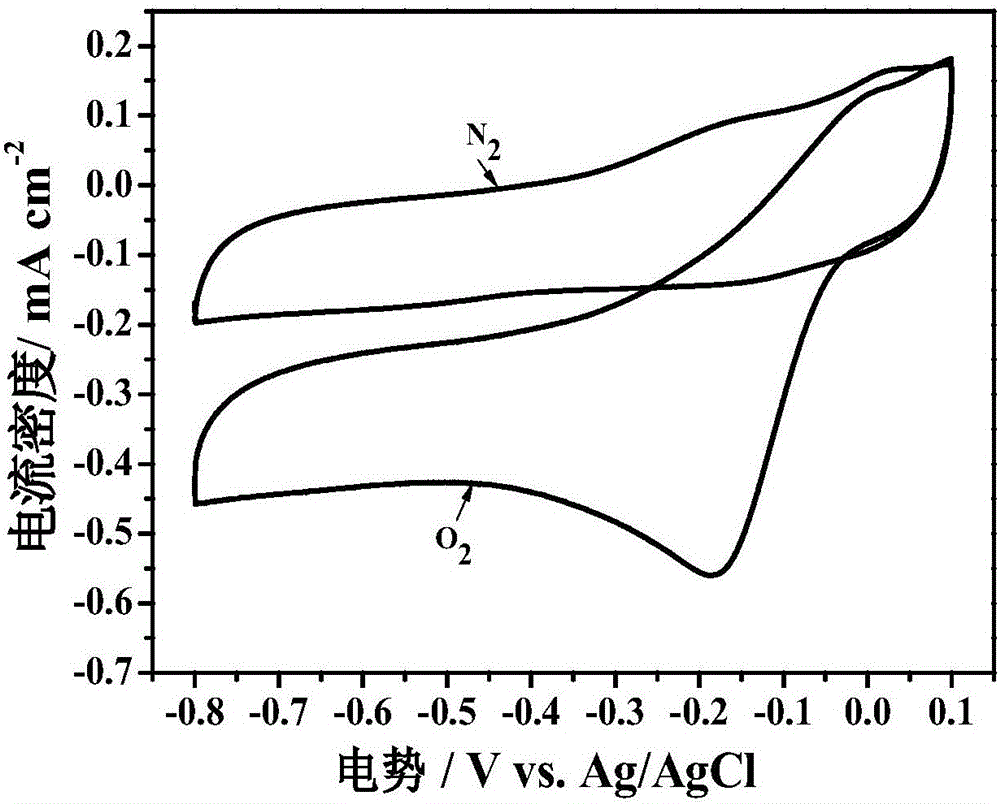

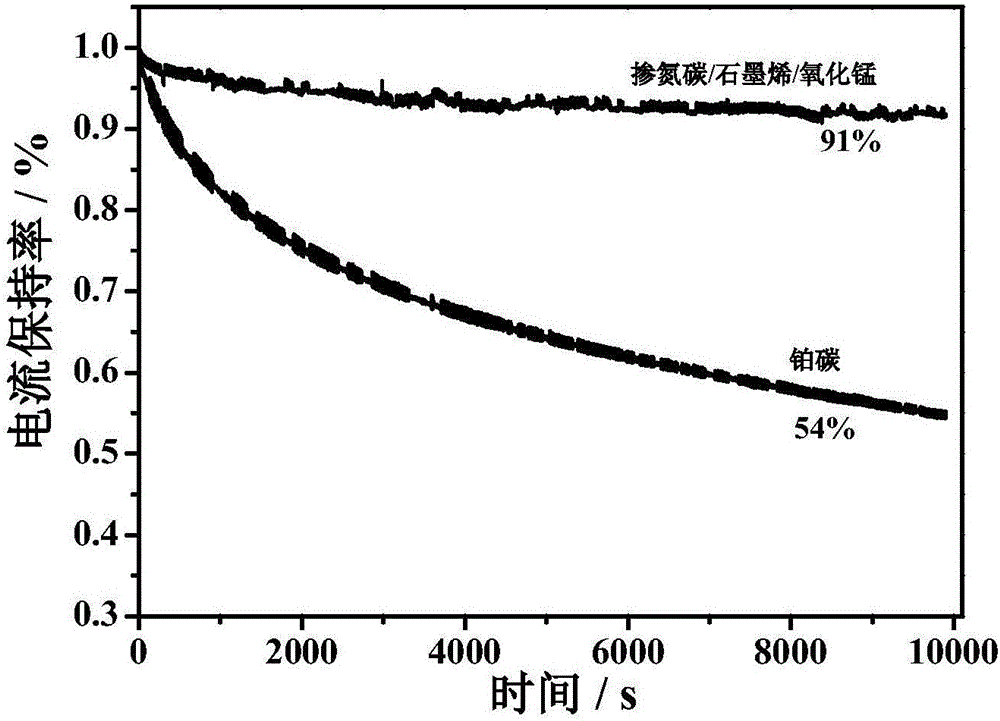

Preparation method of nitrogen-doped carbon/graphene/manganese oxide composite material and application of nitrogen-doped carbon/ graphene/manganese oxide composite material in electrocatalytic reduction of oxygen

The invention relates to a preparation method of a nitrogen-doped carbon / graphene / manganese oxide composite material and an application of the nitrogen-doped carbon / graphene / manganese oxide composite material in electrocatalytic reduction of oxygen. The method comprises the following steps of preparing the nitrogen-doped carbon / graphene / manganese oxide composite material; and modifying the nitrogen-doped carbon / graphene / manganese oxide composite material on an electrode to test the electrocatalytic activity of the material on oxygen reduction. The preparation method has the beneficial effects that the nitrogen-doped carbon / graphene / manganese oxide composite material is prepared by a simple and feasible method; in the overall preparation process, poly-metaphenylene diamine plays an important role; graphene reserves a large specific surface area, and poly-metaphenylene diamine is a nitrogen source of nitrogen-doped carbon; and finally the nitrogen-doped carbon / graphene / manganese oxide composite material has excellent oxygen reduction electrocatalytic properties.

Owner:CHANGZHOU UNIV

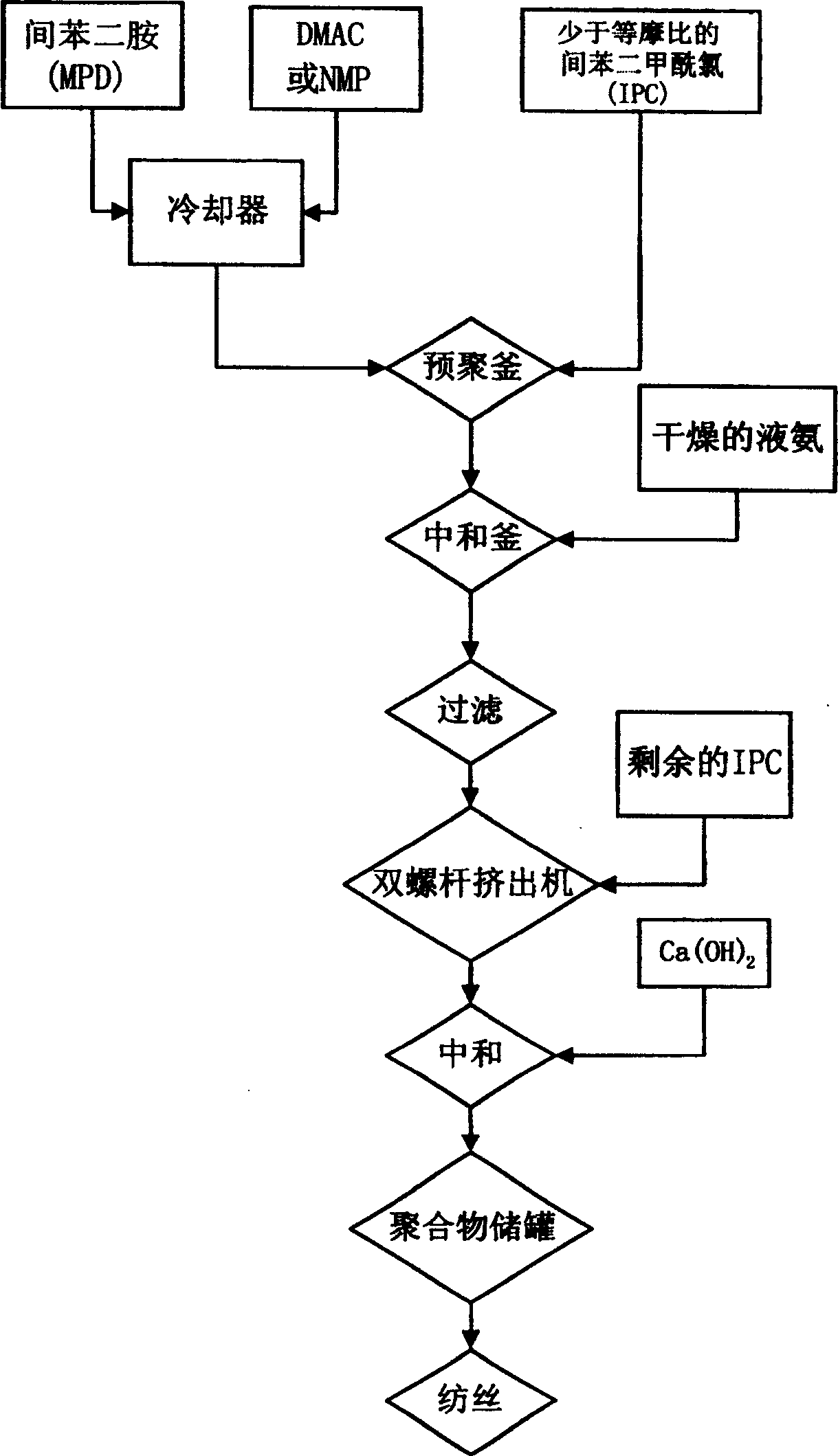

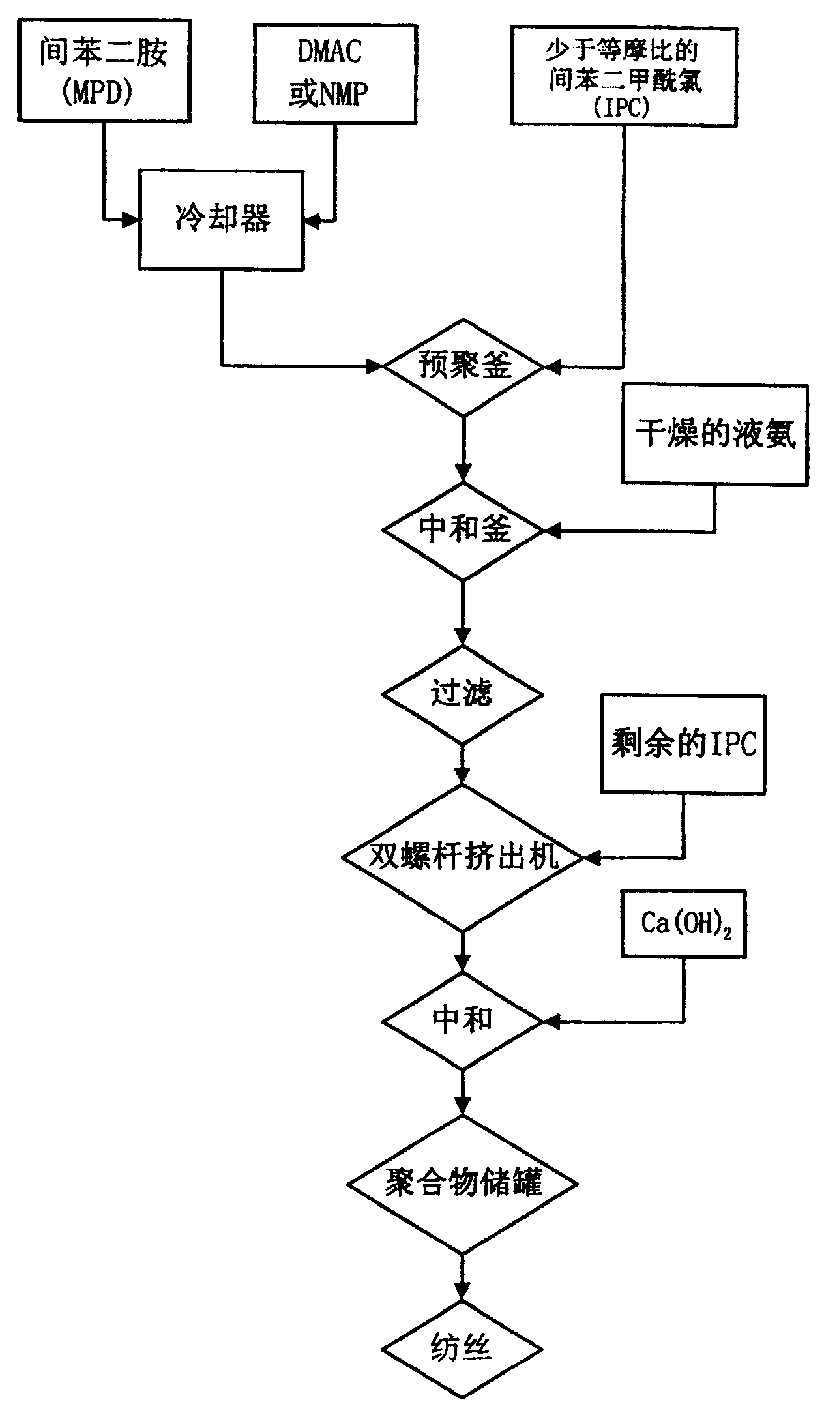

Preparation of polyisophthaloyl m-phenylene diamide spinning solution by using semi-continuous twin screw extruder

InactiveCN1265034CAvoid the problem of non-uniform molecular weightImprove cooling effectSpinning solutions preparationMonocomponent polyamides artificial filamentFiltrationDiameter ratio

The semi-continuous twin screw preparation method of polyisophthaloyl m-phenylene diamide spinning solution uses twin screw extruder as main reactor and adopts the isophthaloyl dichloride double-charged and dried liquid ammonia as preveutralizing agent. The application of twin-screw extruder is favorable for system radiation problem, and prevents non-uniformity of polymer molecular weight distribution, and also id favorable for partially removing small molecular by-product in the polymerization system-hydrogen chloride gas. The length-to-diameter ratio of the twin-screw extruder is greater than 1:30. Said preparation method includes prepolymerization, preneutralization, filtration, polymerization and neutralization.

Owner:DONGHUA UNIV +1

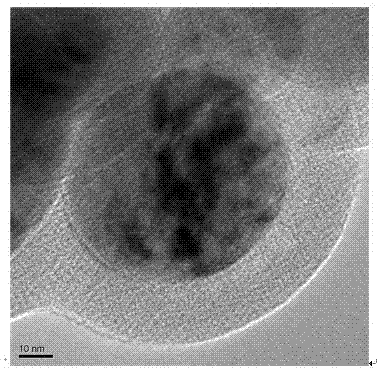

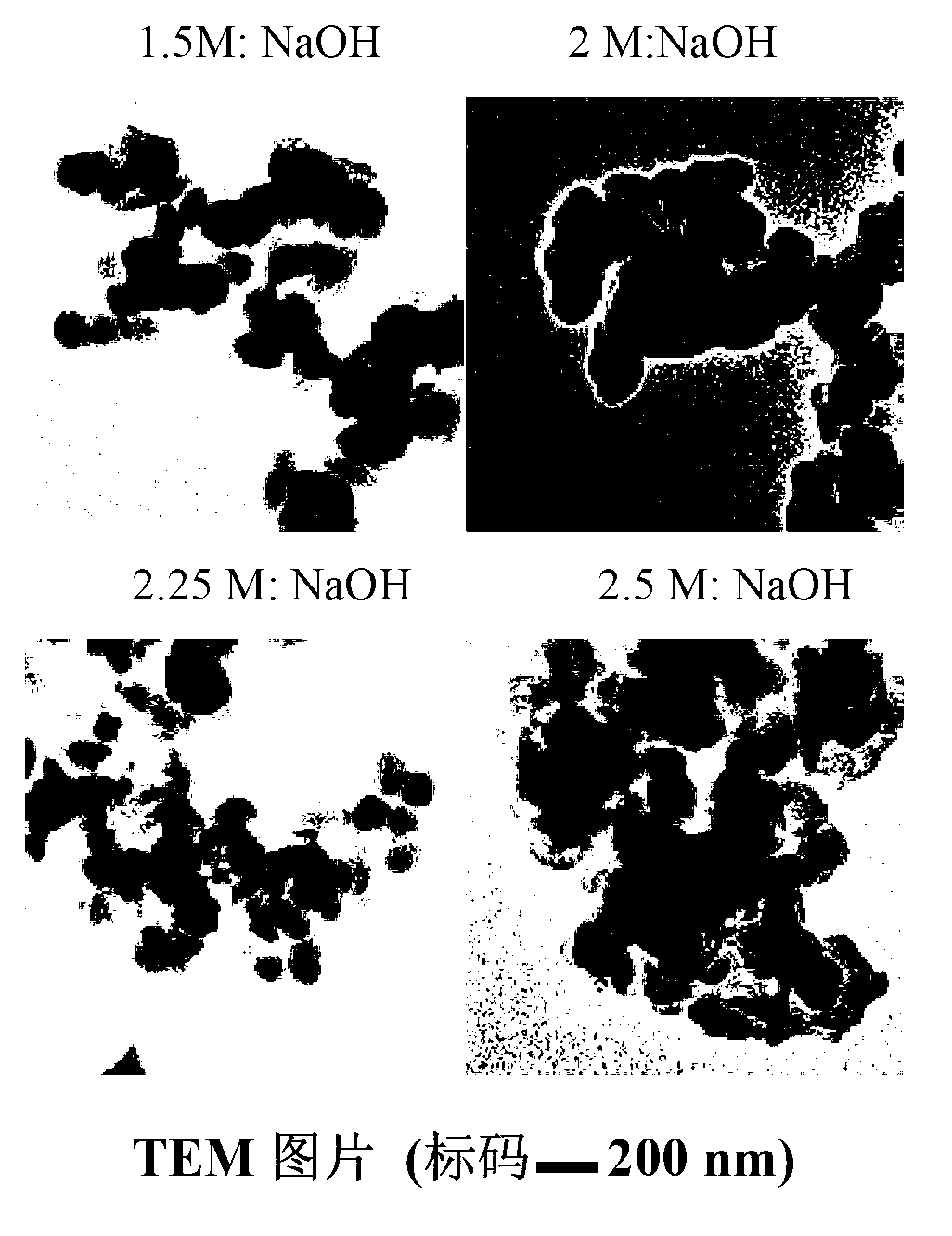

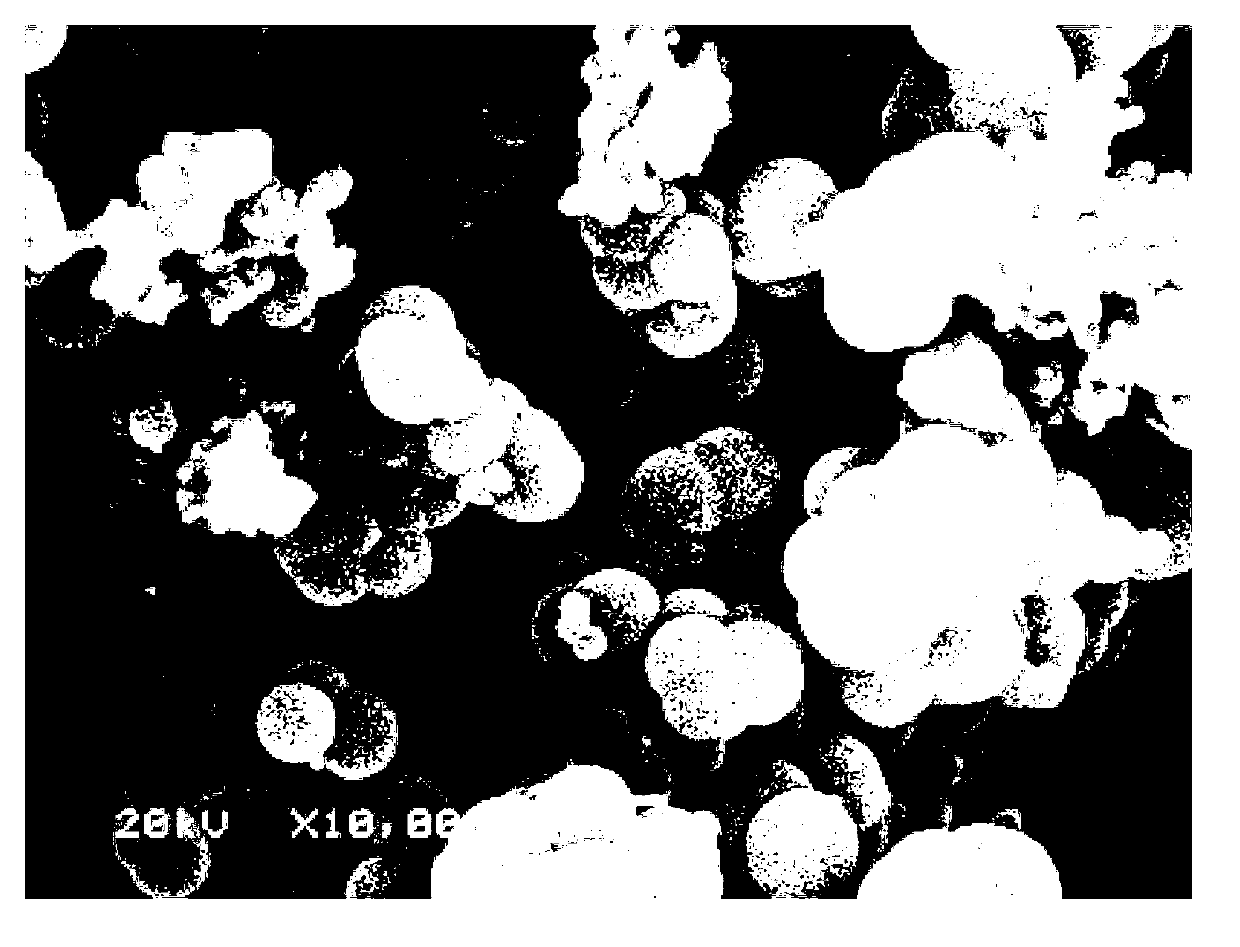

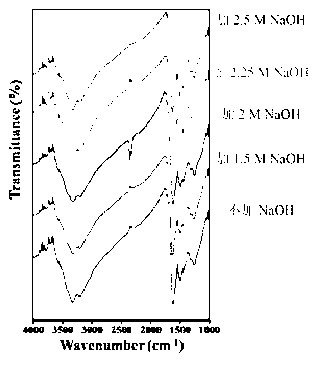

Synthetic method of polymetaphenylene diamine nanoparticle

The invention discloses a synthetic method of polymetaphenylene diamine nanoparticles, and the method is divided into two stages of prepolymerization and oxidation polymerization. The method comprises the following steps: firstly adding a divalent copper ion solution into an aqueous solution of metaphenylene diamine, stirring and reacting for 10-30 min to perform a prepolymerization reaction; then, gradually adding a persulfate aqueous solution and alkali liquor simultaneously within 30-60 min, initiating oxidation polymerization, and continuing stirring and reacting for 5-8 hours; filtering, and washing to obtain the polymetaphenylene diamine nanoparticles. The conversion rate of metaphenylene diamine monomer is up to 90%-98%, and the generation amounts of metaphenylene diamine monomer and its oligomer are effectively reduced. The method of the invention can prepare nanoscale polymetaphenylene diamine with high efficiency, is economical, effective, and simple in operation, and has a greatly improved monomer conversion rate.

Owner:CENT SOUTH UNIV

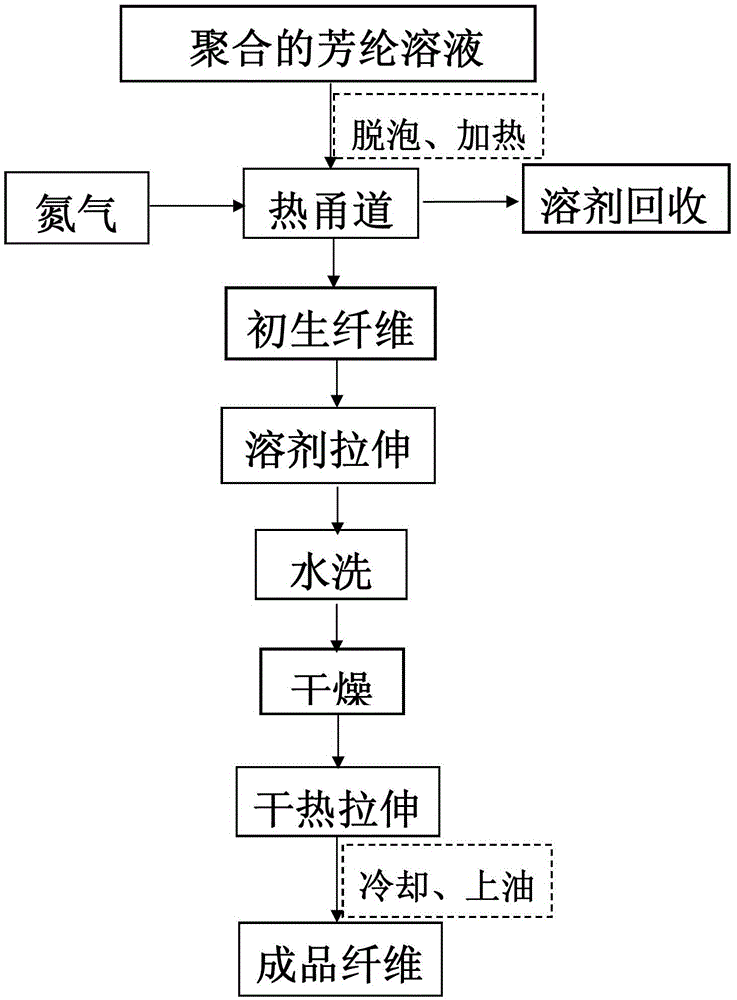

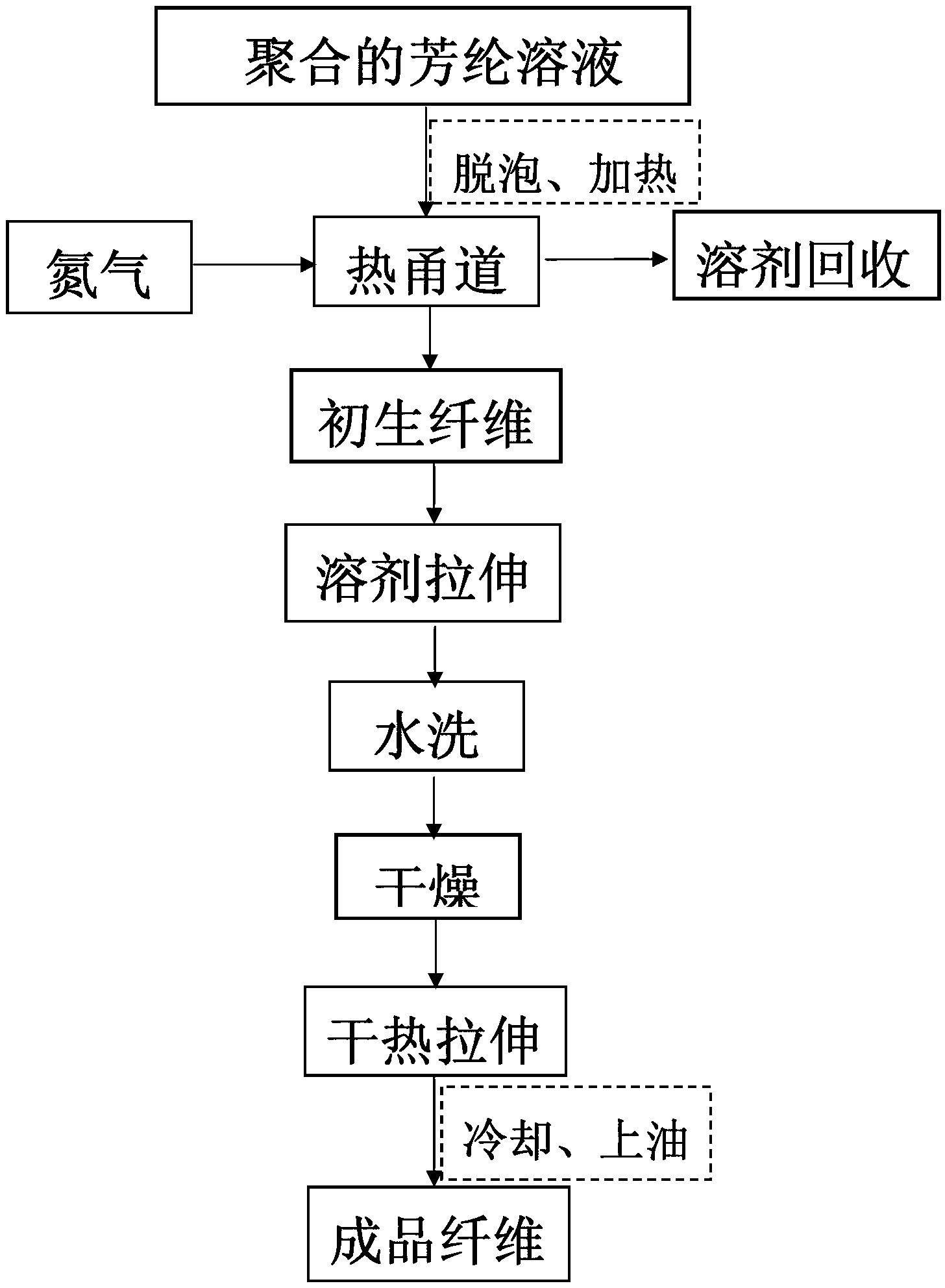

A kind of preparation method of meta-aramid fiber

ActiveCN103233292BLow ion contentSimplify recycling stepsArtificial filament recoveryTextile/flexible product manufactureIon contentHydrogen chloride

The invention relates to a method for preparing meta-position aramid fibers. The method is characterized by comprising the following steps: specially preparing a spinning solution of three components such as poly(m-phenyleneisophthalamide), hydrogen chloride and N, N-dimethylacetamide through adopting polymerization; deaerating the solution, then heating the solution, extruding the solution through a spinneret plate to enter a spinning hot channel, and removing solvents such as the N, N-dimethylacetamide and the hydrogen chloride through the hot channel so as to obtain nascent fibers; and stretching the nascent fibers through the solvent, washing to further removing the hydrogen chloride and the solvent in the nascent fibers, then drying, dry heating and stretching, cooling and oiling to obtain the finished fibers. The poly(m-phenyleneisophthalamide) spinning solution does not contain salt, and the deionized water and the solvent instead of salt are used in a whole fiber production process, so that the finally prepared meta-position aramid fiber products are low in ion content and fiber ash content; and solvent recovery steps are simplified, and energy sources are greatly saved.

Owner:X FIPER NEW MATERIAL CO LTD

Base paper of aramid fiber honeycomb core and manufacturing method thereof

ActiveUS8764941B2Improve insulation performanceImprove performanceNon-fibrous pulp additionNatural cellulose pulp/paperPolyesterHoneycomb

A base paper of aramid fiber honeycomb core and its manufacturing method are provided. The base paper comprises 11-90 parts by weight of structural fiber, 10-70 parts by weight of crosslinking fiber, and 0-19 parts by weight of additive fiber, wherein the structural fiber is poly(p-phenylene terephthal amide) fiber, the crosslinking fiber is poly(m-phenylene isophthal amide) fibrid, and the additive is polyester fiber.

Owner:GANZHOU LONGPONT MATERIAL TECH CO LTD

Modified meta-aramid, preparation method thereof and hollow fiber membrane

ActiveCN109456477AImprove stabilitySimple preparation processSemi-permeable membranesMembranesHollow fibre membranePolymer science

The invention discloses a modified meta-aramid polymer and a preparation method thereof. Metaphenylene diamine, alkyl diamine H2N-M-NH2 and various diamine monomers such as halogenated diamine monomers are poly-condensed with isophthalic chloride by a low-temperature solution polycondensation method to form the modified meta-aramid polymer, wherein the isophthalic chloride is repeatedly added intoreaction solution. The invention further discloses a preparation method for preparing a hollow fiber membrane by the prepared meta-aramid polymer. The prepared modified meta-aramid polymer keeps original excellent performances, further has low intrinsic viscosity and good chlorine resistance and is more applicable to spinning of the hollow fiber membrane, the prepared membrane is more easily preserved in a dry state, and the preparation method is simple, easy to operate and suitable for industrial production and has an excellent market application prospect.

Owner:OCHEMATE MATERIAL TECH CO LTD

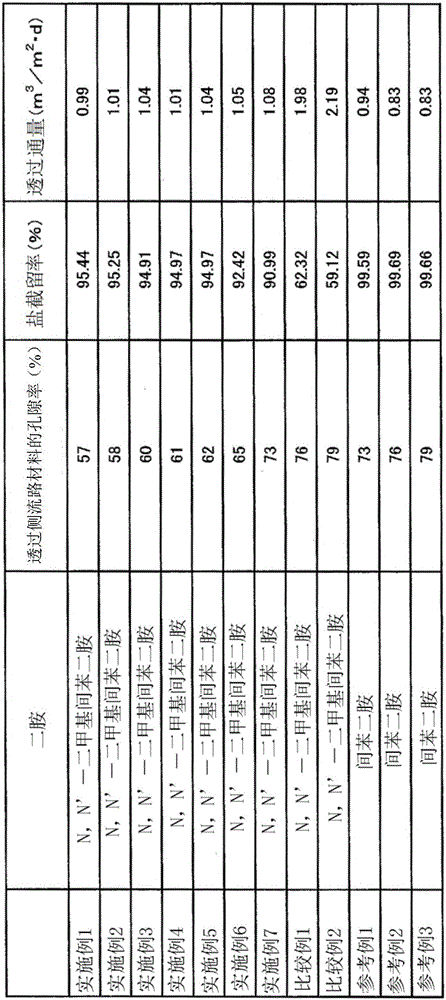

Spiral-type separation membrane element

InactiveCN105939777APreprocessing omitted or simplifiedSemi-permeable membranesMembranesPorosityHalogen

The objective of the present invention is to provide a spiral-type separation membrane element having superior oxidant resistance relative to the prior art, and a salt rejection rate that tends not to decrease. This spiral-type separation membrane element is characterized in including: a supply-side flow-path material; a composite semipermeable membrane in which a skin layer is formed on the surface of a porous support body, the skin layer containing a polyamide resin obtained by interfacial polymerization of a polyfunctional amine component and a polyfunctional acid halogen component; and a permeation-side flow-path material; the polyfunctional amine component containing N,N'-dimethyl meta-phenylenediamine; and the permeation-side flow-path material having a porosity of 40-75%.

Owner:NITTO DENKO CORP

Method for preparing meta-position aramid fibers

ActiveCN103233292ALow ion contentSimplify recycling stepsArtificial filament recoveryTextile/flexible product manufacturePhysical chemistryDry heating

The invention relates to a method for preparing meta-position aramid fibers. The method is characterized by comprising the following steps: specially preparing a spinning solution of three components such as poly(m-phenyleneisophthalamide), hydrogen chloride and N, N-dimethylacetamide through adopting polymerization; deaerating the solution, then heating the solution, extruding the solution through a spinneret plate to enter a spinning hot channel, and removing solvents such as the N, N-dimethylacetamide and the hydrogen chloride through the hot channel so as to obtain nascent fibers; and stretching the nascent fibers through the solvent, washing to further removing the hydrogen chloride and the solvent in the nascent fibers, then drying, dry heating and stretching, cooling and oiling to obtain the finished fibers. The poly(m-phenyleneisophthalamide) spinning solution does not contain salt, and the deionized water and the solvent instead of salt are used in a whole fiber production process, so that the finally prepared meta-position aramid fiber products are low in ion content and fiber ash content; and solvent recovery steps are simplified, and energy sources are greatly saved.

Owner:X FIPER NEW MATERIAL CO LTD

A kind of preparation method of polym-phenylene isophthalamide nanofiltration membrane

InactiveCN105413500BAvoid the disadvantage of uneven dispersionIncreased pure water fluxReverse osmosisMembrane methodSilica gel

The invention provides a preparation method for a polyisophthaloyl metaphenylene diamine nanofiltration membrane and belongs to the field of membrane pollution resistance. The method includes the steps that a fully-dried polyisophthaloyl metaphenylene diamine nanofiltration membrane is flatly laid on a glass plate, the glass plate is placed in a plate frame to be tightened, a prepared solution containing an acid binding agent is poured to the surface of the membrane for impregnation, the remaining solution is poured out, and the membrane is placed in a fume cupboard to be dried in shade; then a prepared crosslinking solution is poured to the surface of the membrane for impregnation, and the surplus solution is removed through a silica gel wheel; then an oxidized graphene solution is poured to the surface of the membrane for impregnation, the remaining solution is poured out, and the membrane is dried in shade; finally the treated membrane is placed within the temperature interval of 40-80 DEG C for heat treatment for 60-180 s, and the modified nanofiltration membrane is obtained. The technological operation is easy, the original excellent characteristics of the polyisophthaloyl metaphenylene diamine nanofiltration membrane are kept, the hydrophilia of the surface of the membrane is also well enhanced, the pollution resistance of the membrane is improved, and wide application prospects are achieved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com