Preparation method and application of high-thermal-conductivity aromatic polyamide fibers

An aromatic polyamide, high thermal conductivity technology, applied in the direction of single-component polyamide rayon, fiber chemical characteristics, rayon manufacturing, etc., to achieve the effect of improving thermal conductivity and reducing diffusion path resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

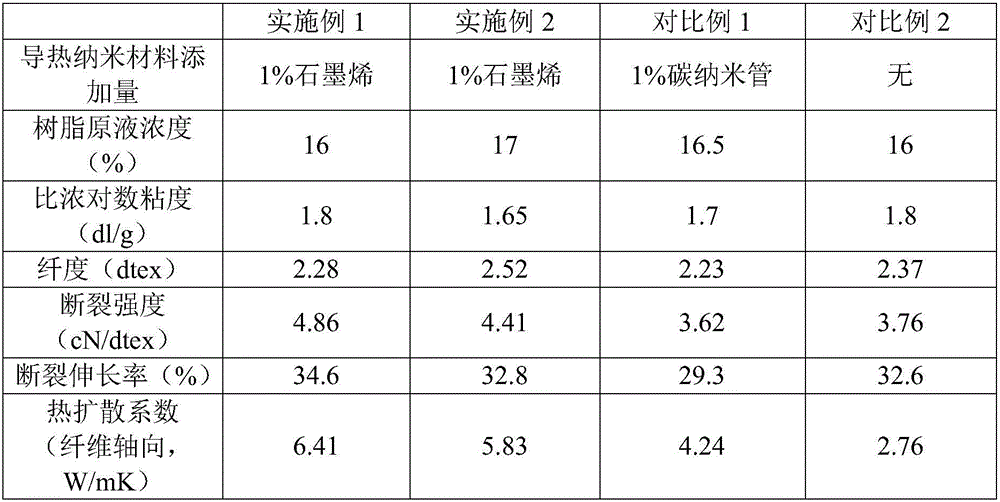

Examples

Embodiment 1

[0029] A preparation method of the high thermal conductivity aromatic polyamide fiber of the present invention, comprises the following steps:

[0030] (1) Dissolve 2g of graphene oxide in 1000mL of DMAc by ultrasonic and mechanical stirring at room temperature for 1h, then add 3000mL of 1,6-hexanediamine, continue ultrasonic dispersion for 1h; then add 0.1g of aminated coupling agent HATU, and transferred to a 60°C water bath and refluxed for 6 hours; after the reaction was completed, the product was diluted with ethanol, filtered, and the excess 1,6-hexamethylenediamine was washed with ethanol, and finally the product was dried; after the above pretreatment The graphene oxide powder was ultrasonically dispersed in DMAc, and a 1% dispersion was finally prepared.

[0031] (2) Under the protection of nitrogen, add the m-phenylenediamine (MPD) monomer purified by vacuum distillation into the above dispersion liquid to dissolve, then cool the system to -10°C, and then slowly add ...

Embodiment 2

[0036] A preparation method of the high thermal conductivity aromatic polyamide fiber of the present invention, comprises the following steps:

[0037] (1) Dissolve 2g of graphene oxide in 1000mL of DMAc by ultrasonic and mechanical stirring at room temperature for 1h, then add 3000mL of 1,6-hexanediamine, continue ultrasonic dispersion for 1h; then add 0.1g of aminated coupling agent HATU, and transferred to a water bath at 60°C and refluxed for 6 hours; after the reaction was completed, the product was diluted with ethanol, filtered, and the excess 1,6-hexamethylenediamine was rinsed with ethanol, and finally the product was dried; the above pretreated The graphene oxide powder was dispersed in DMAc by ultrasonic, and a 1% dispersion was finally prepared.

[0038] (2) Under the protection of nitrogen, add the m-phenylenediamine (MPD) monomer refined by vacuum distillation into the above dispersion liquid to dissolve, then cool the system to -10°C, and slowly add the compound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inherent viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com