Patents

Literature

109results about How to "Excellent thermal diffusivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

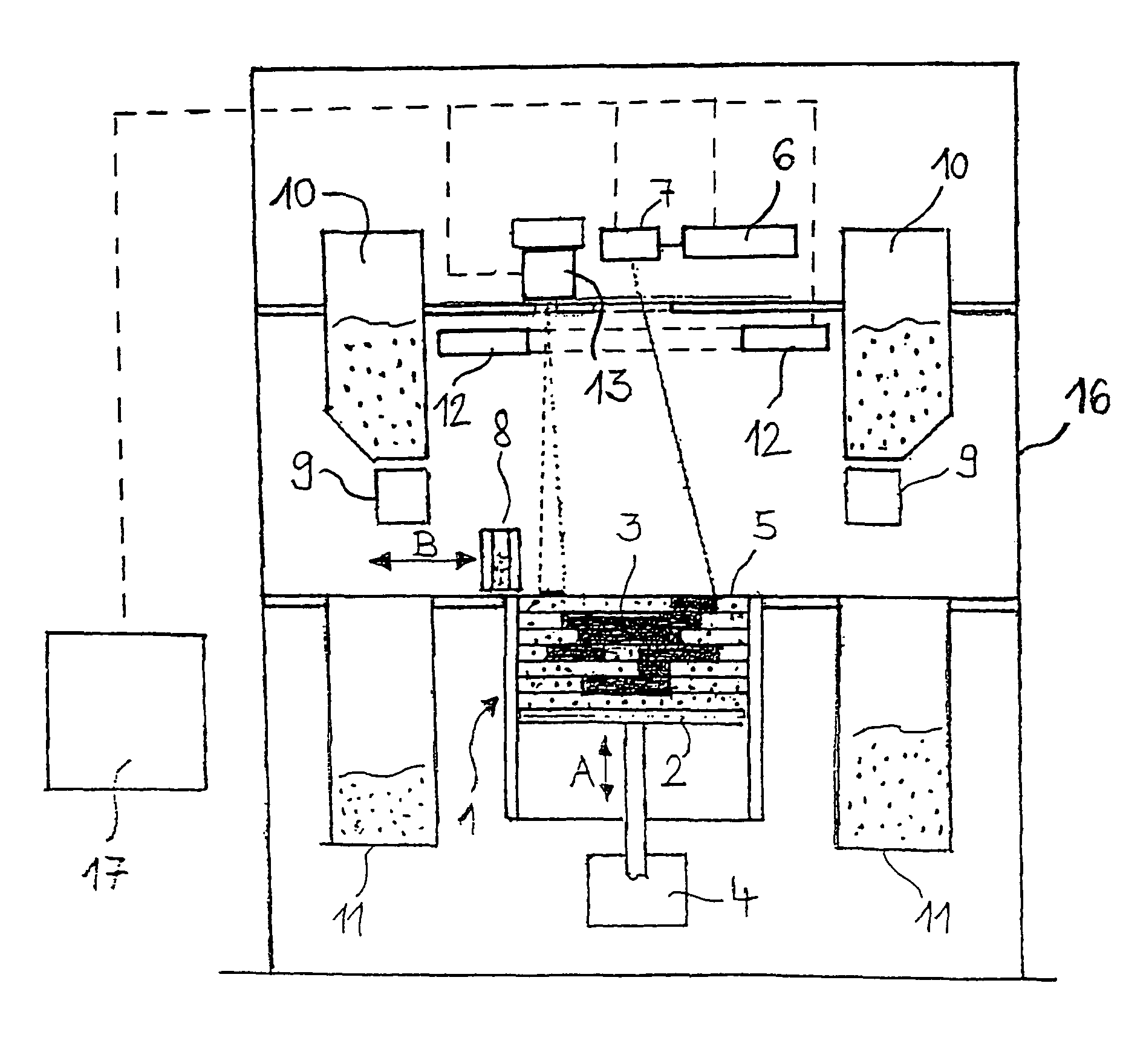

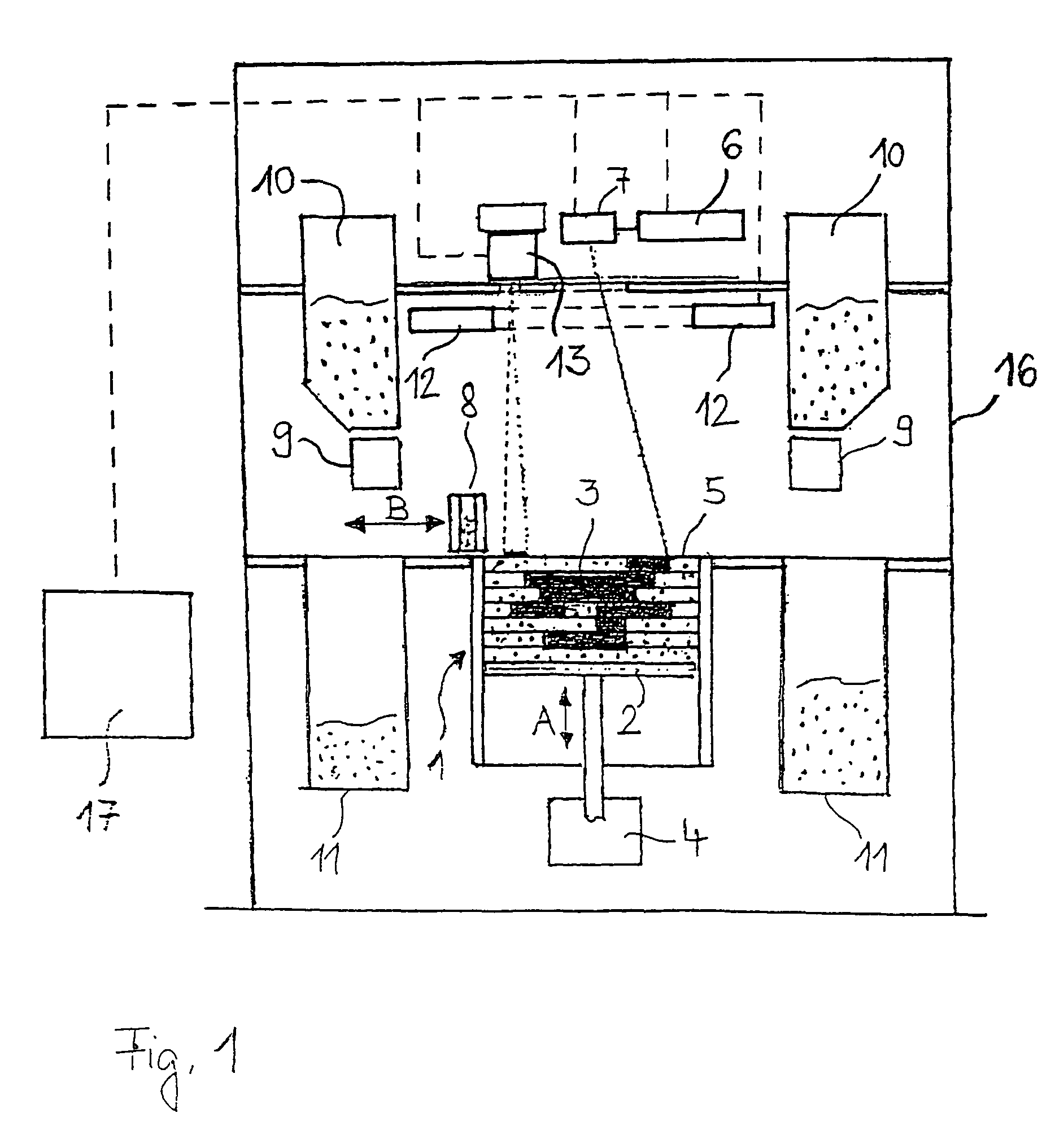

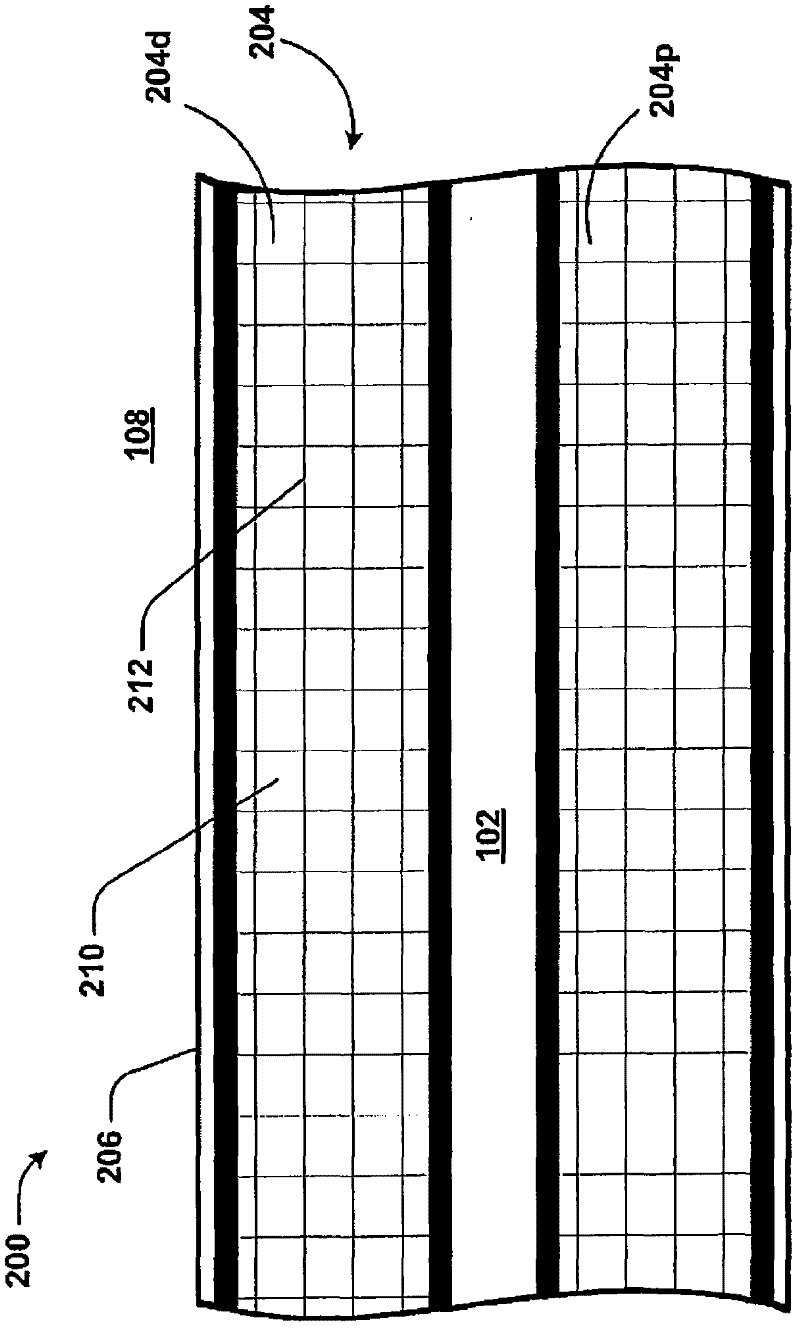

Radiant heater for heating the building material in a laser sintering device

InactiveUS8073315B2Reduce the temperatureThermal inertiaDomestic stoves or rangesDrying solid materials with heatRadiant heaterMetallurgy

A radiant heating for heating the building material in a laser sintering device and a laser sintering device having such a radiant heating are described. The radiant heating has a sheet-like heat radiating element (113, 213, 313), which is characterized in that it is made of a material, that has a low thermal inertia with a thermal diffusivity of preferably more than 1.5·10−4 m2 / s and preferably has a thickness of 2 mm or less.

Owner:EOS ELECTRO OPTICAL SYST

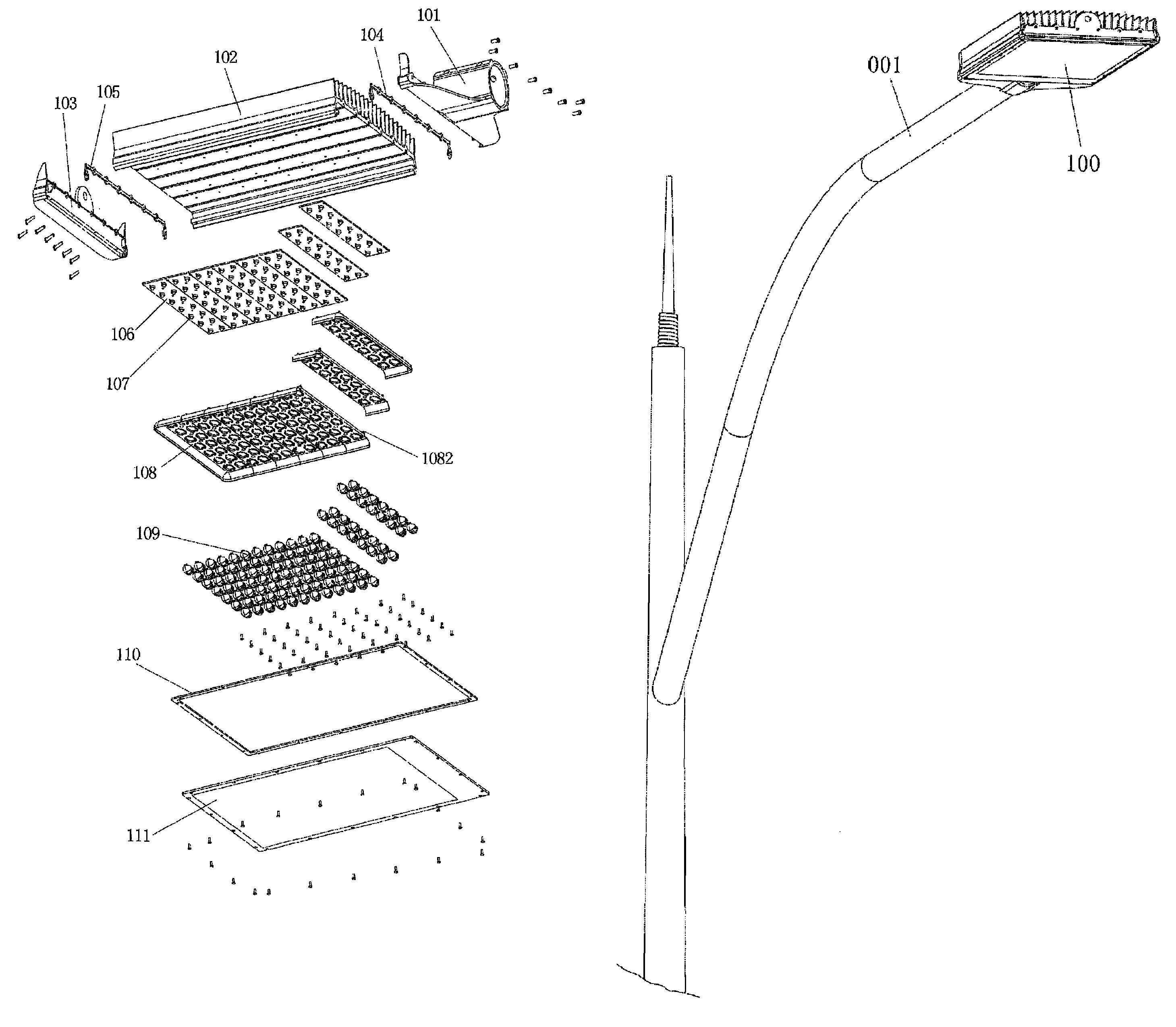

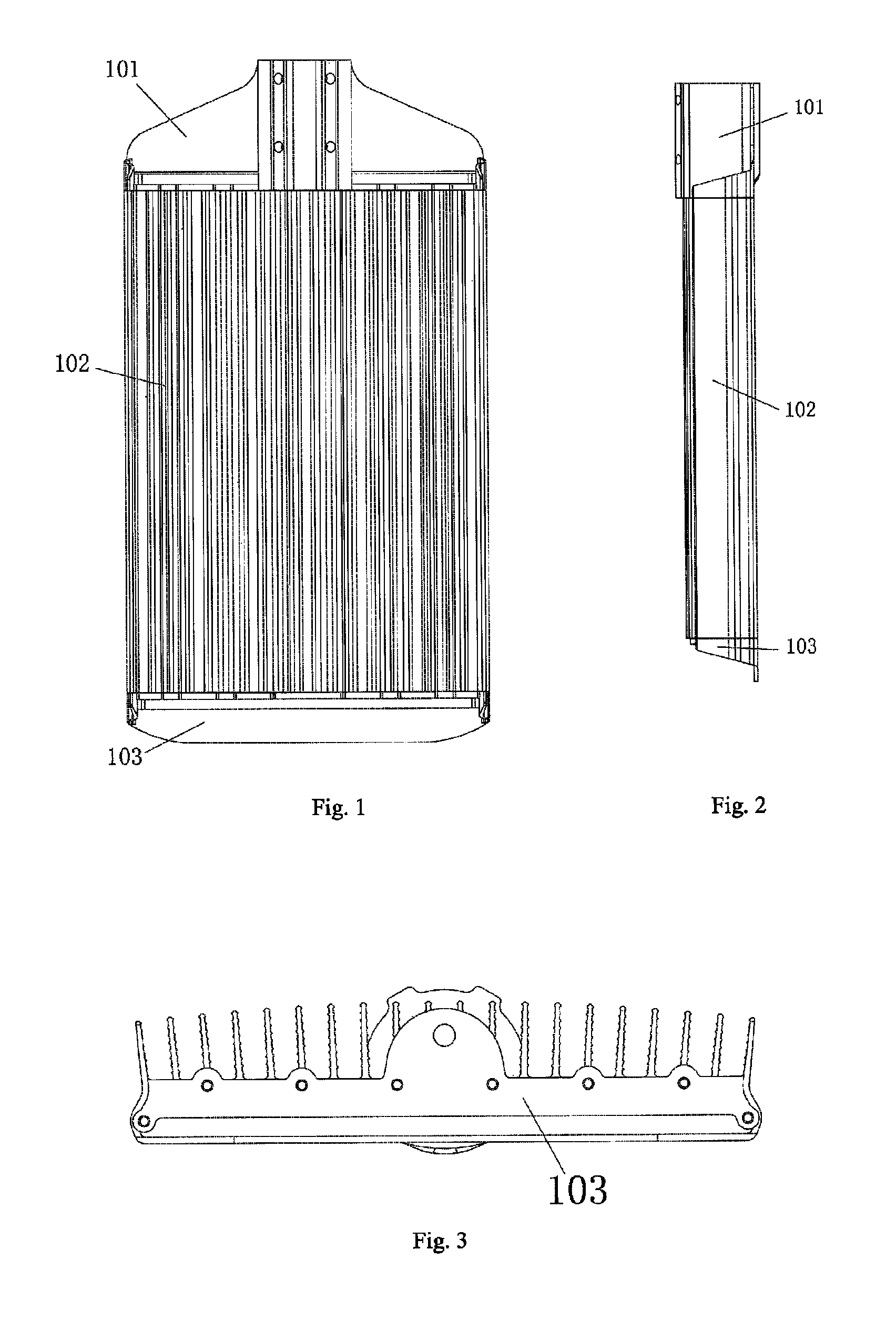

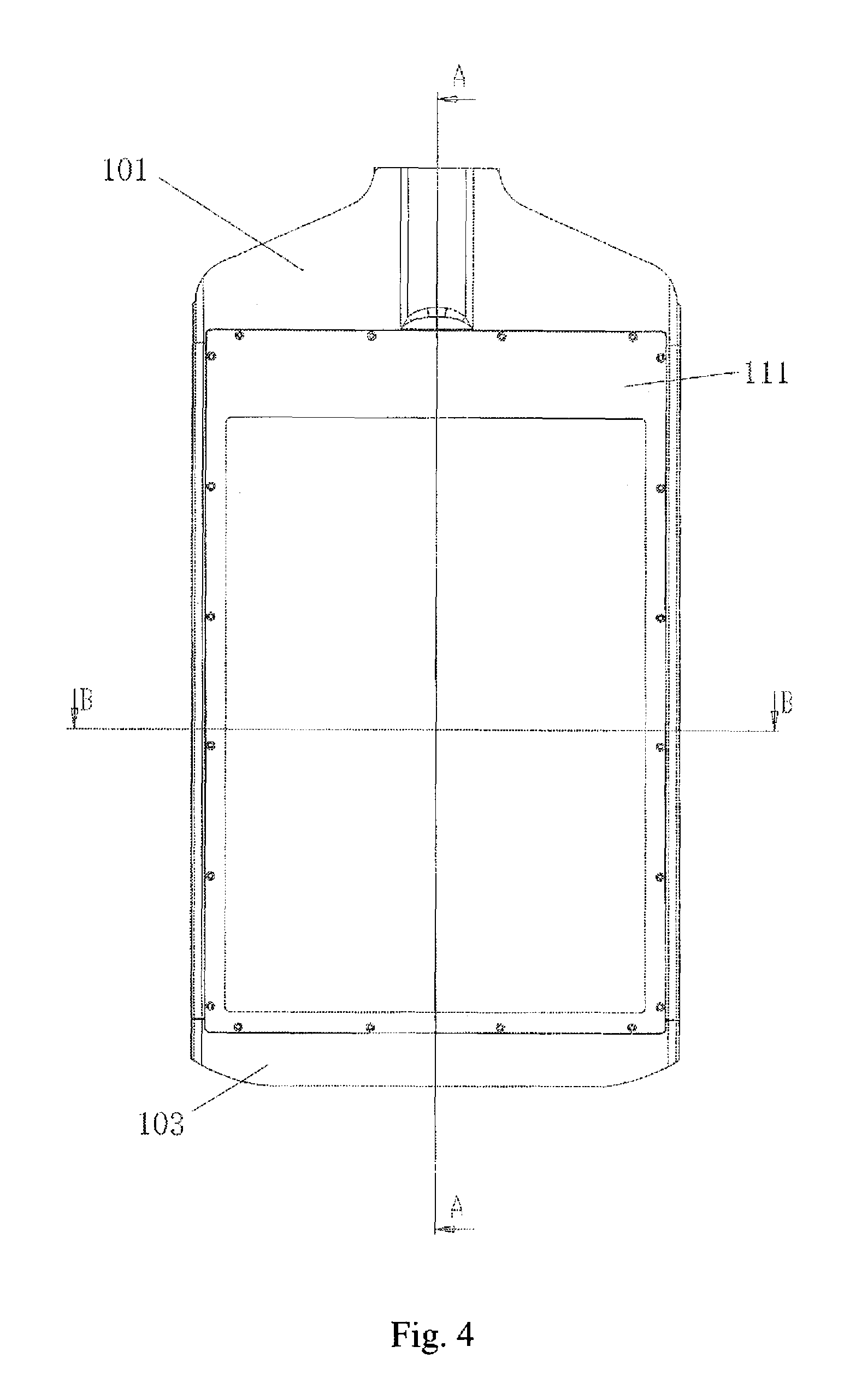

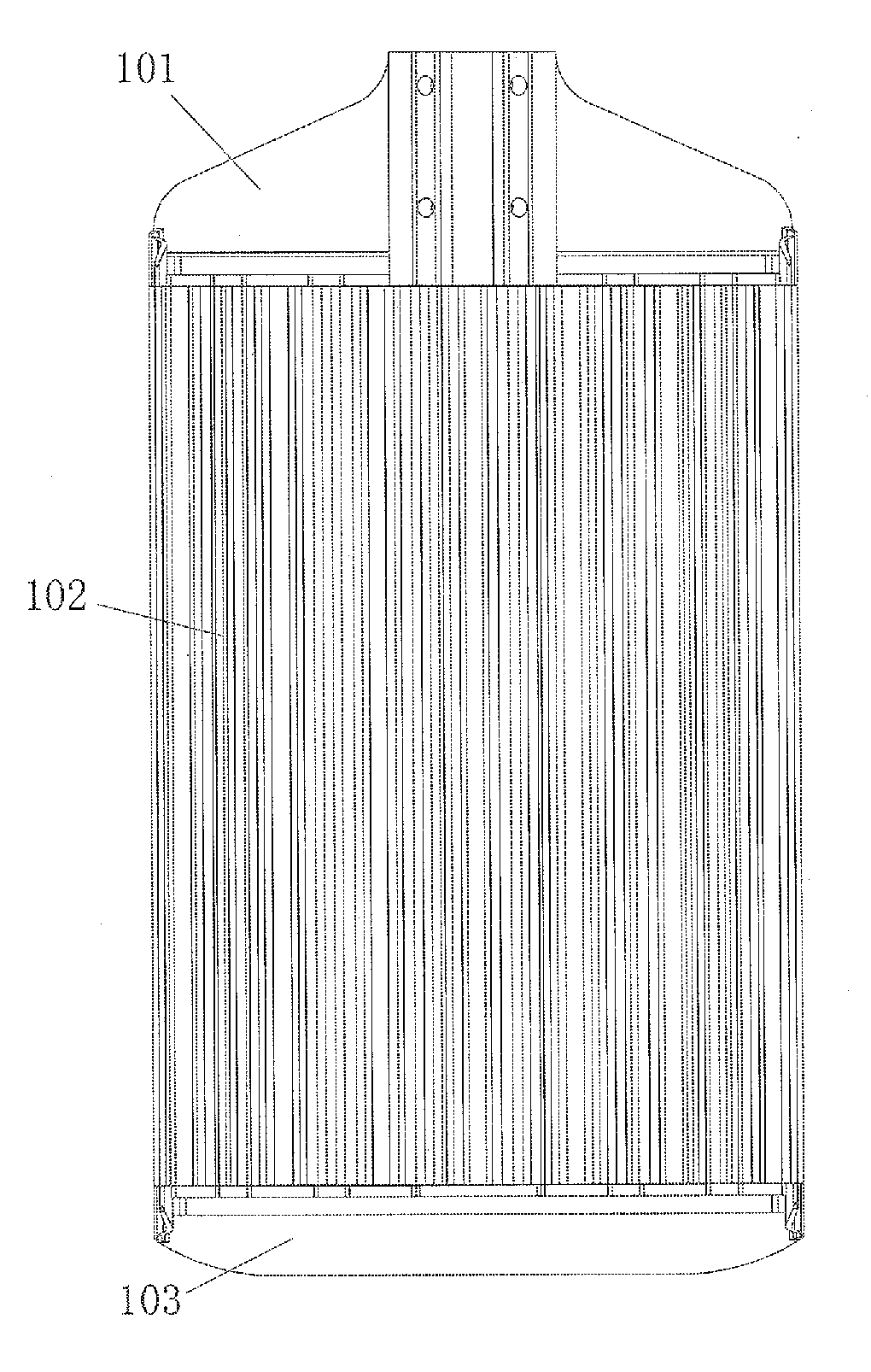

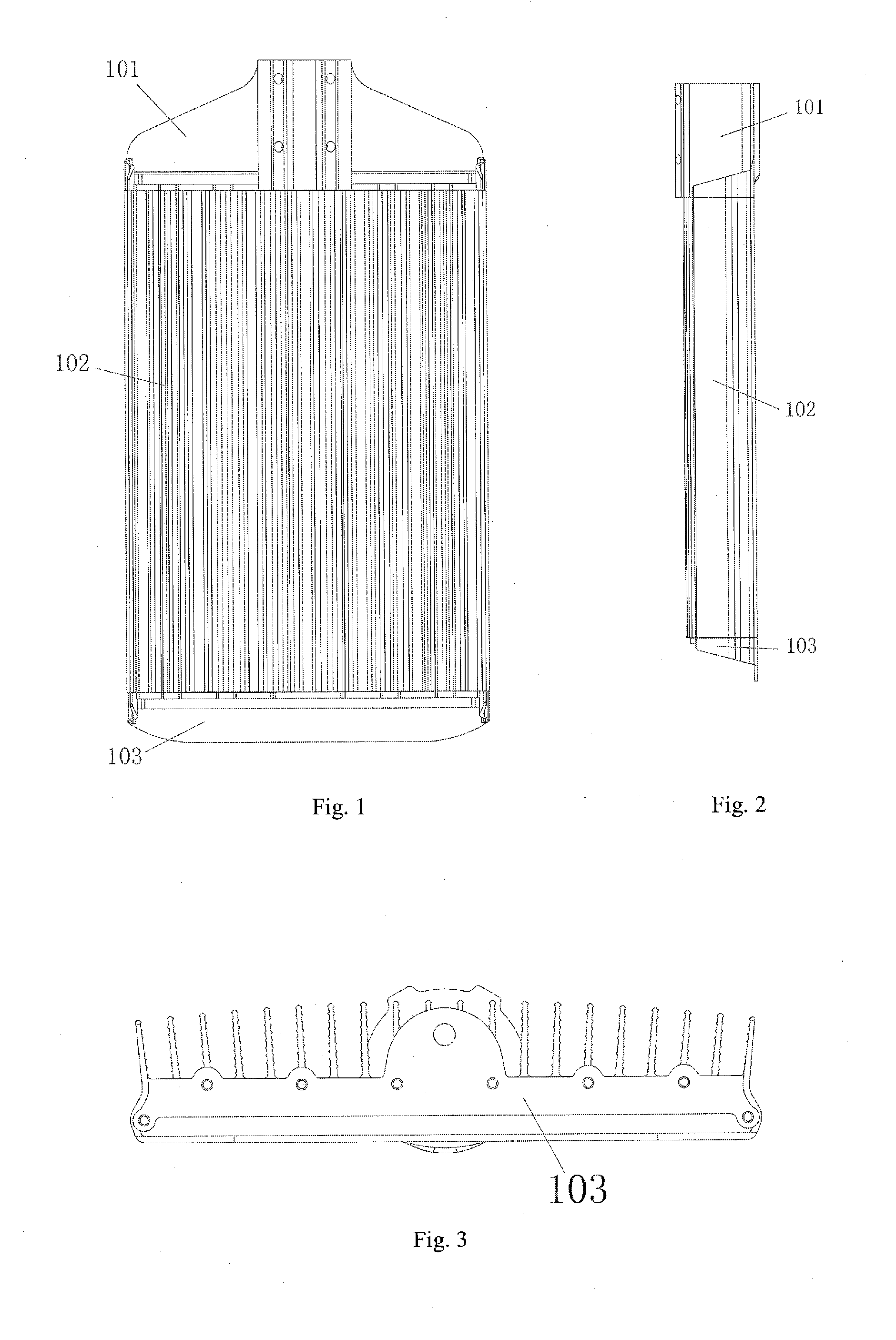

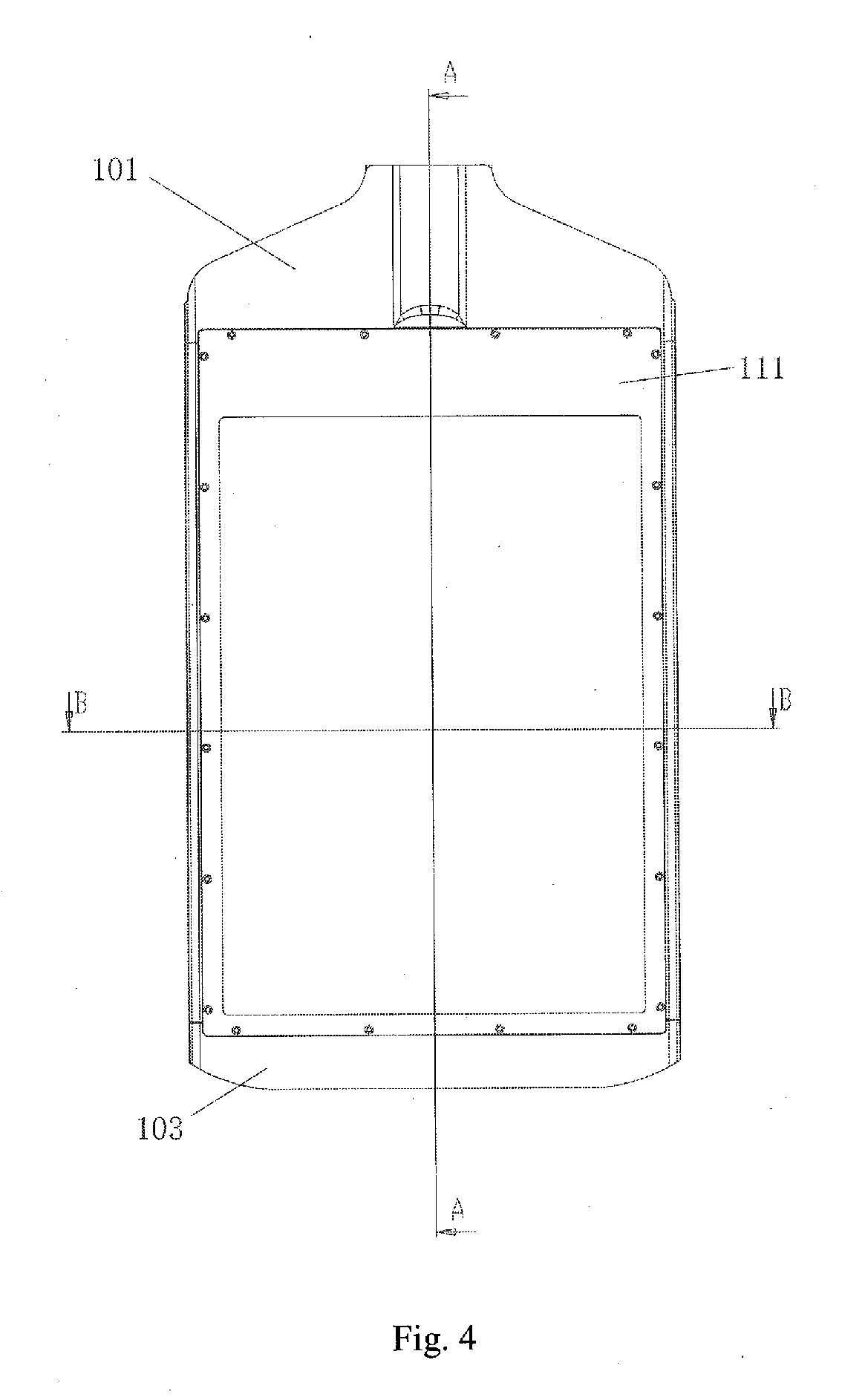

LED street lamp

InactiveUS7922372B2Excellent thermal diffusivityReduce chancePlanar light sourcesMechanical apparatusEngineeringLED lamp

A combined LED street lamp (100), comprises a lamp body and a LED bulb (107); the lamp body comprises a head portion (101), a middle portion (102), and a tail portion (103); a first gasket (104) is set between the head portion (101) and the middle portion (102), a second gasket (105) is set between the tail portion (103) and the middle portion (102); the head portion (101) and the tail portion (103) connect to the middle portion (102) with fasteners; the middle portion (102) is a profile which has the same cross section in different position along its length direction. Products with different size can be made by the same group of moulds.

Owner:DONGGUAN KINGSUN OPTOELECTRONIC CO LTD

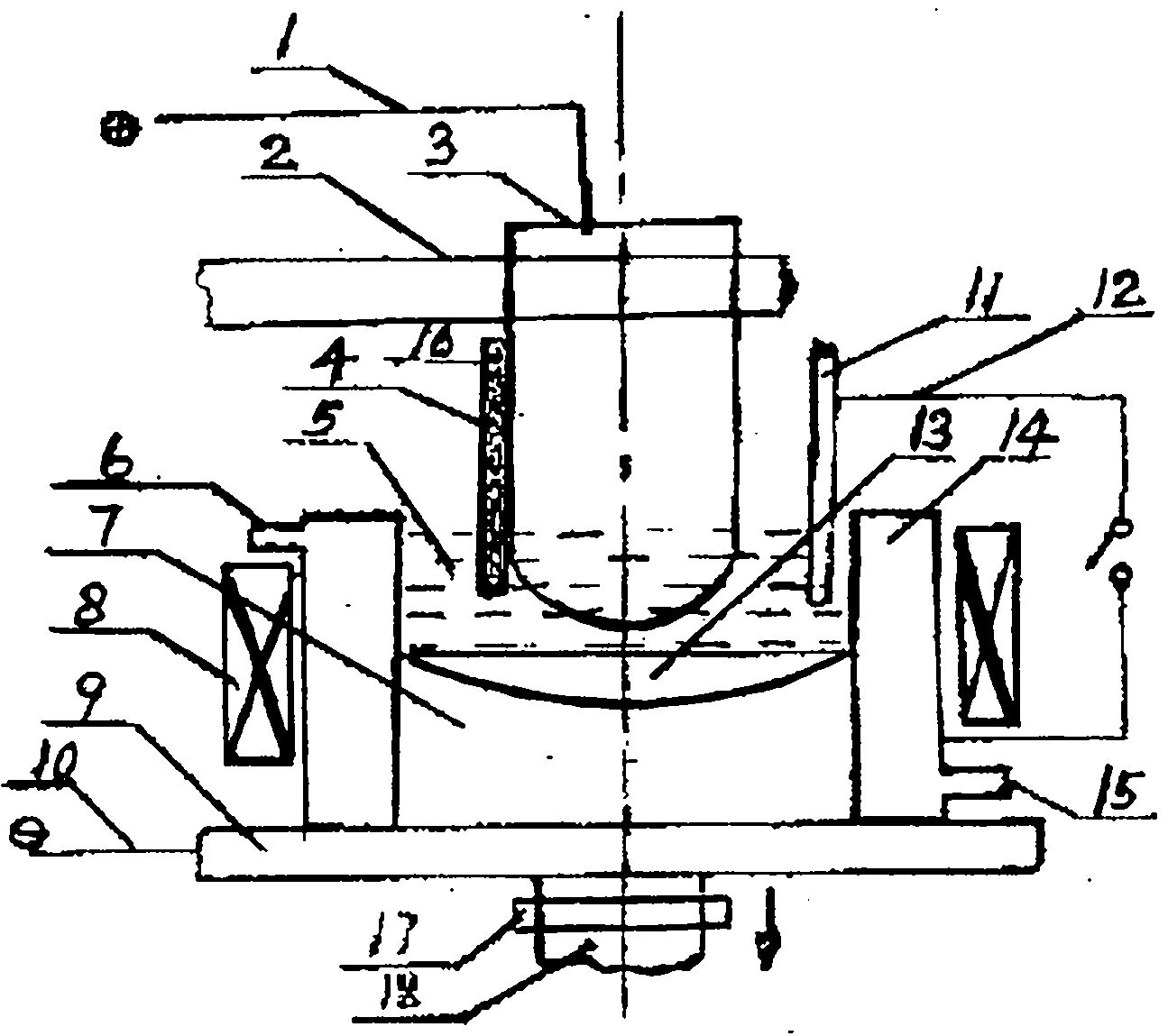

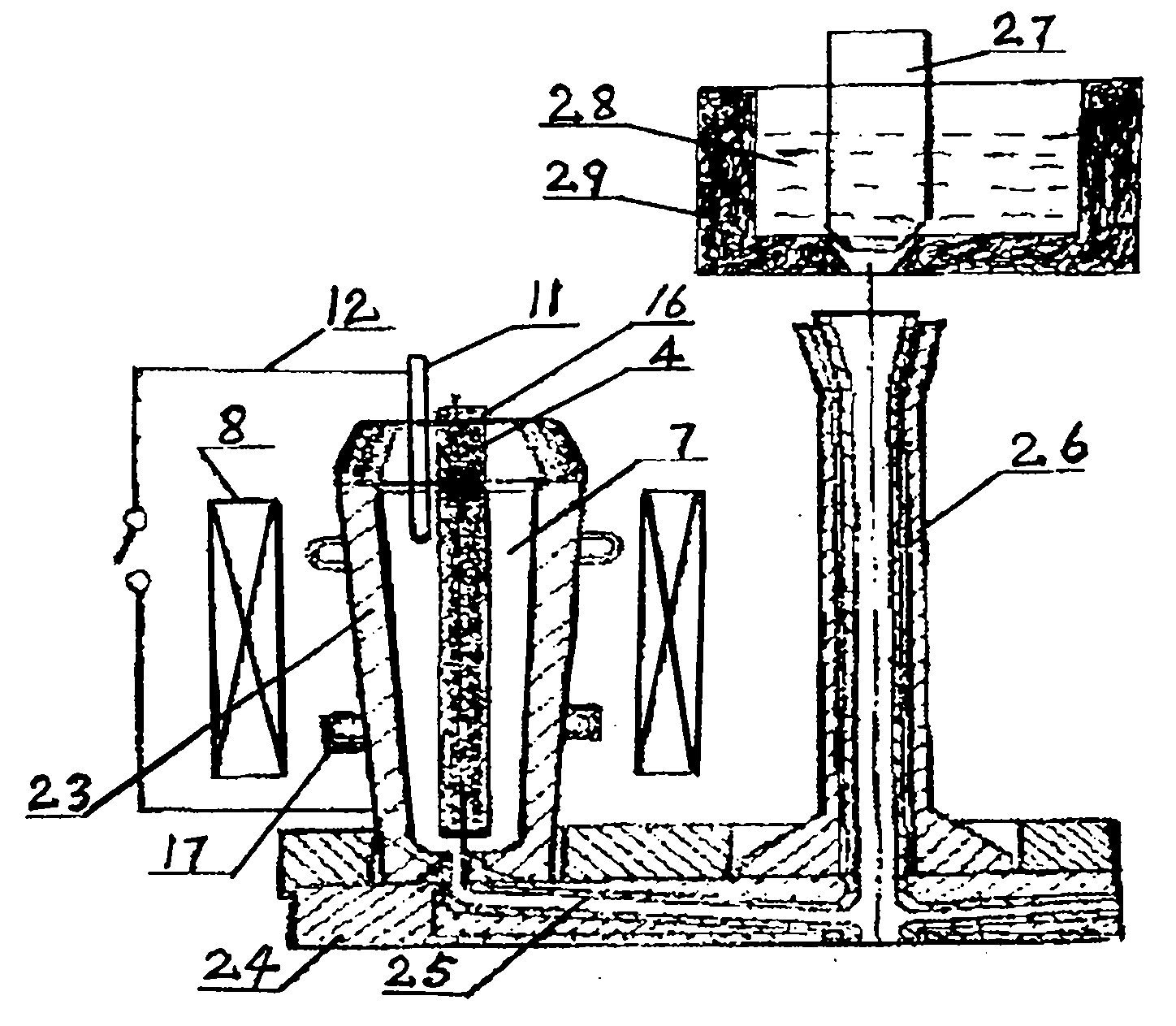

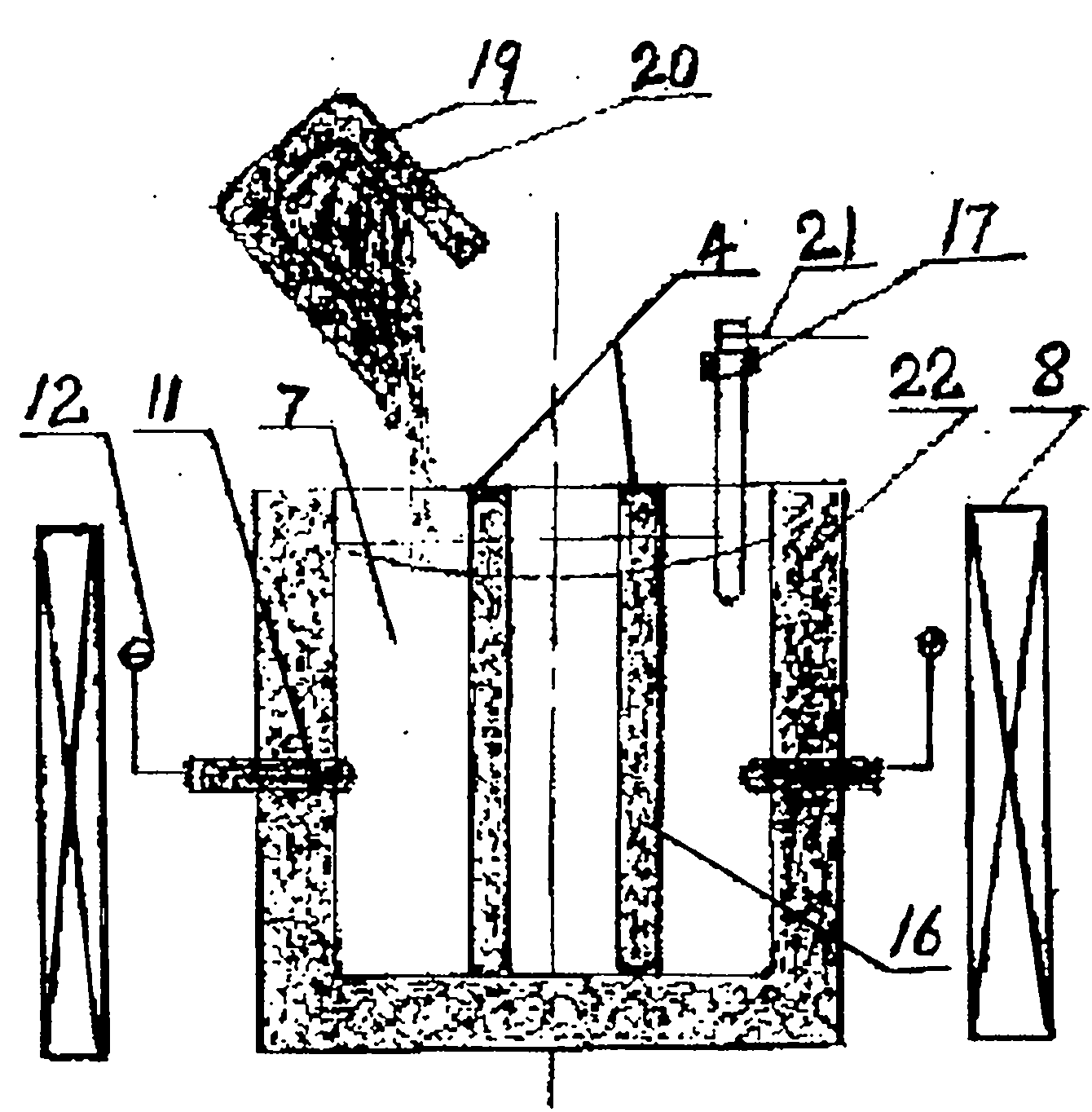

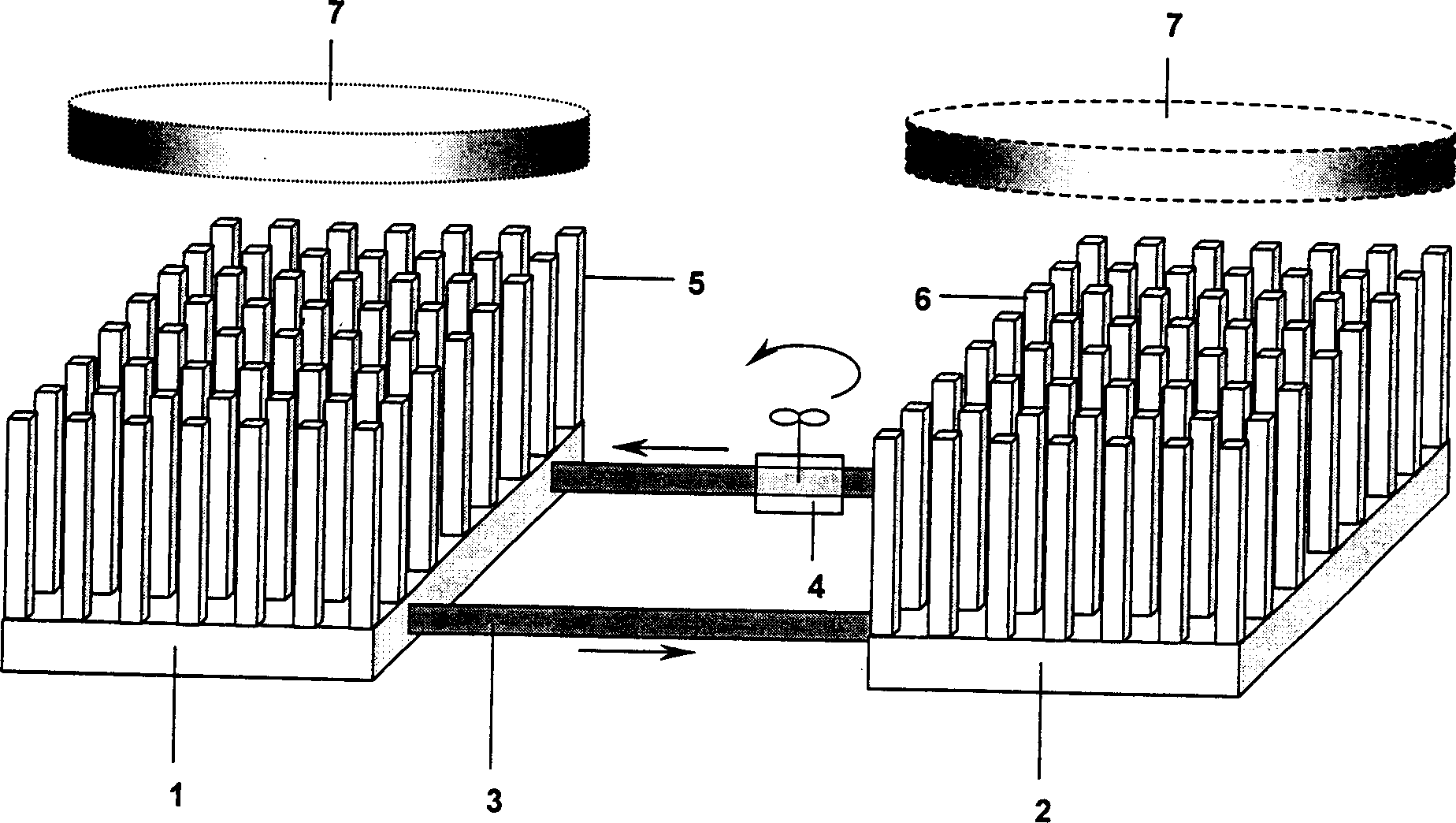

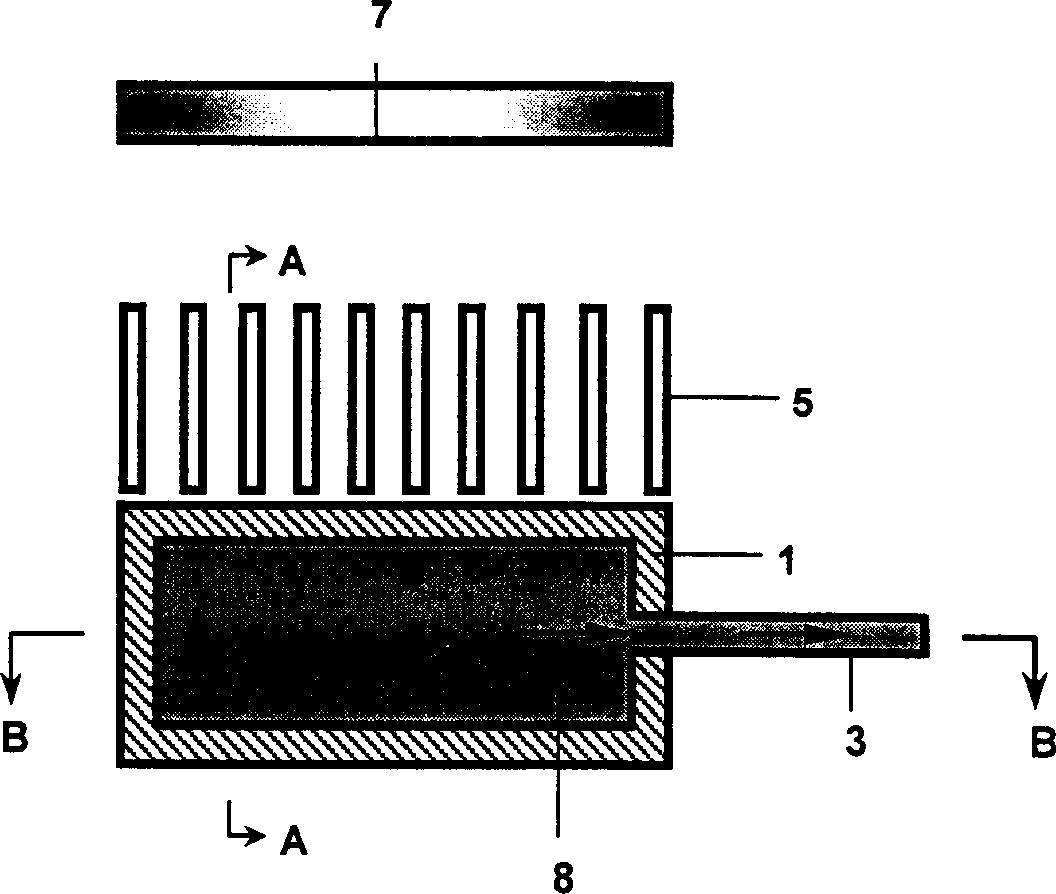

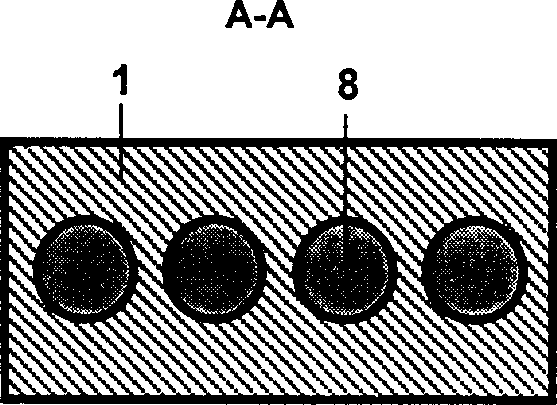

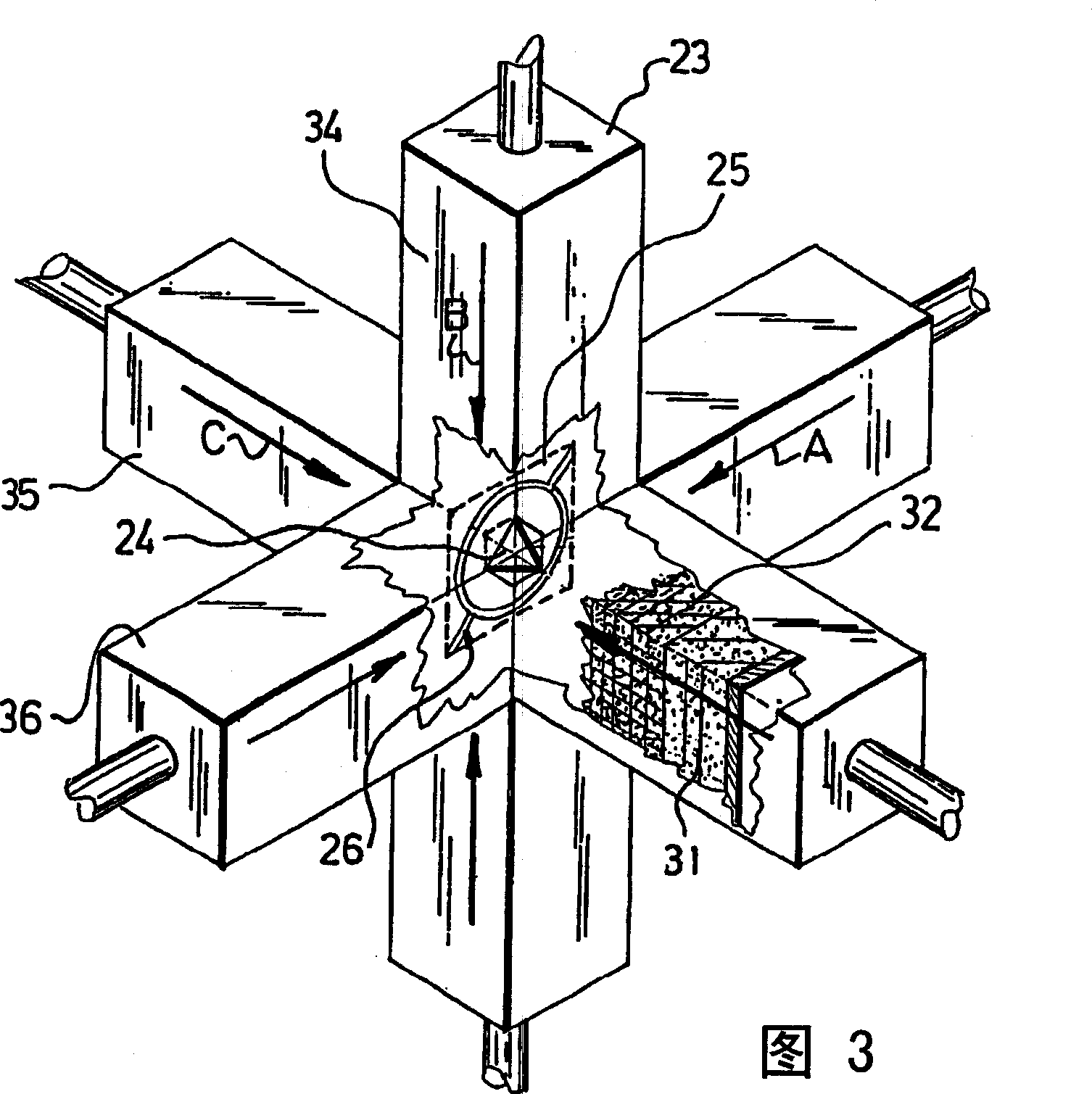

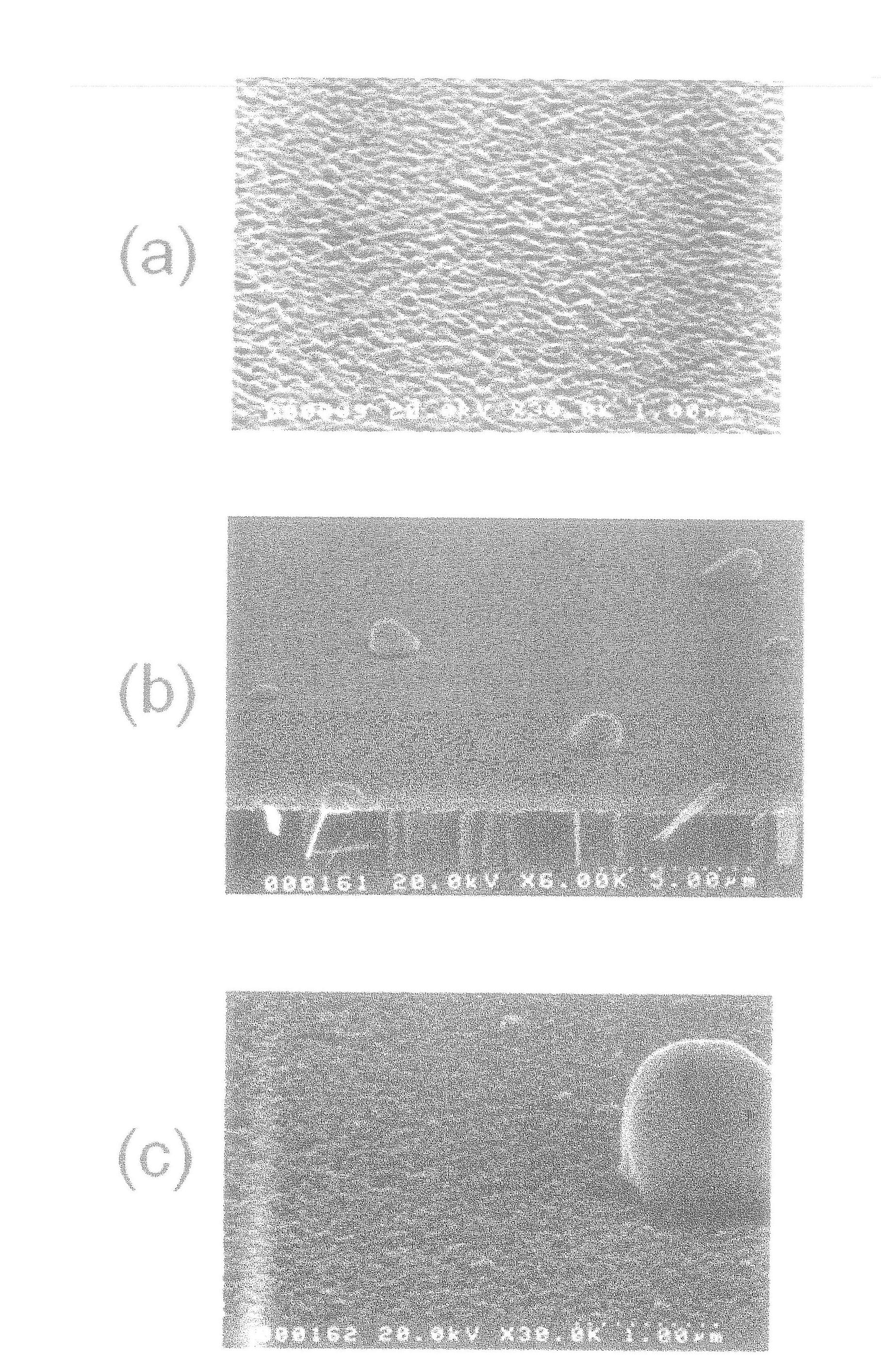

Process and equipment for preparing nanoparticle-reinforced metal matrix composite material

The invention discloses a process and equipment for preparing a nanoparticle-reinforced metal matrix composite material. The process comprises the following steps of: mixing reinforcing nanoparticles with matrix metals and a grain growth inhibitor in a stirring ball mill together, and then loading the mixture into a steel pipe; casting the mixture together with the matrix metals in a water cooling crystallizer or casting and forming the mixture together with a molten metal in a casting mould; and performing quick solidification and crystallization after electromagnetic stirring and ultrasonic vibration to ensure that the two phase materials achieve complete metallurgical bonding, wherein because of the electromagnetic stirring and the ultrasonic vibration, the two phase materials are mixed more uniformly, and all properties of the composite material can be further improved. by using the process and the equipment, a production process is simple, the cost is low, the efficiency is high, the product performance is high, the process is easy to control, the external dimensions of products are not limited by the process, and large-sized nanoparticle-reinforced metal matrix composite materials can be manufactured.

Owner:丁家伟

LED street lamp

InactiveUS20090237930A1Reduce chanceGood dispersionPlanar light sourcesMechanical apparatusEngineeringLED lamp

A combined LED street lamp (100), comprises a lamp body and a LED bulb (107); the lamp body comprises a head portion (101), a middle portion (102), and a tail portion (103); a first gasket (104) is set between the head portion (101) and the middle portion (102), a second gasket (105) is set between the tail portion (103) and the middle portion (102); the head portion (101) and the tail portion (103) connect to the middle portion (102) with fasteners; the middle portion (102) is a profile which has the same cross section in different position along its length direction. Products with different size can be made by the same group of moulds.

Owner:DONGGUAN KINGSUN OPTOELECTRONIC CO LTD

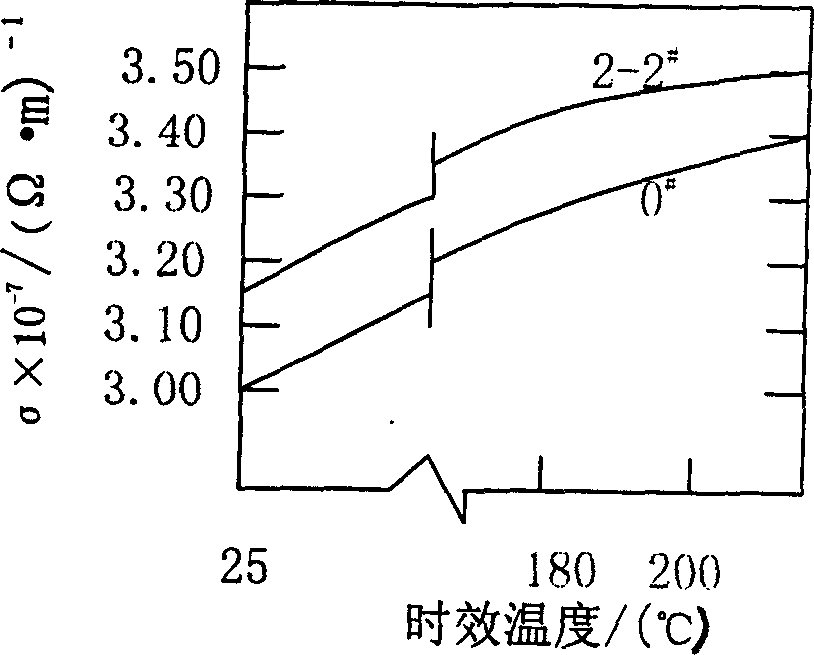

Improved 6063 aluminium alloy materials

ActiveCN1456697AImprove mechanical propertiesImprove thermal conductivityRare-earth elementAluminium alloy

Owner:广东广铝铝型材有限公司

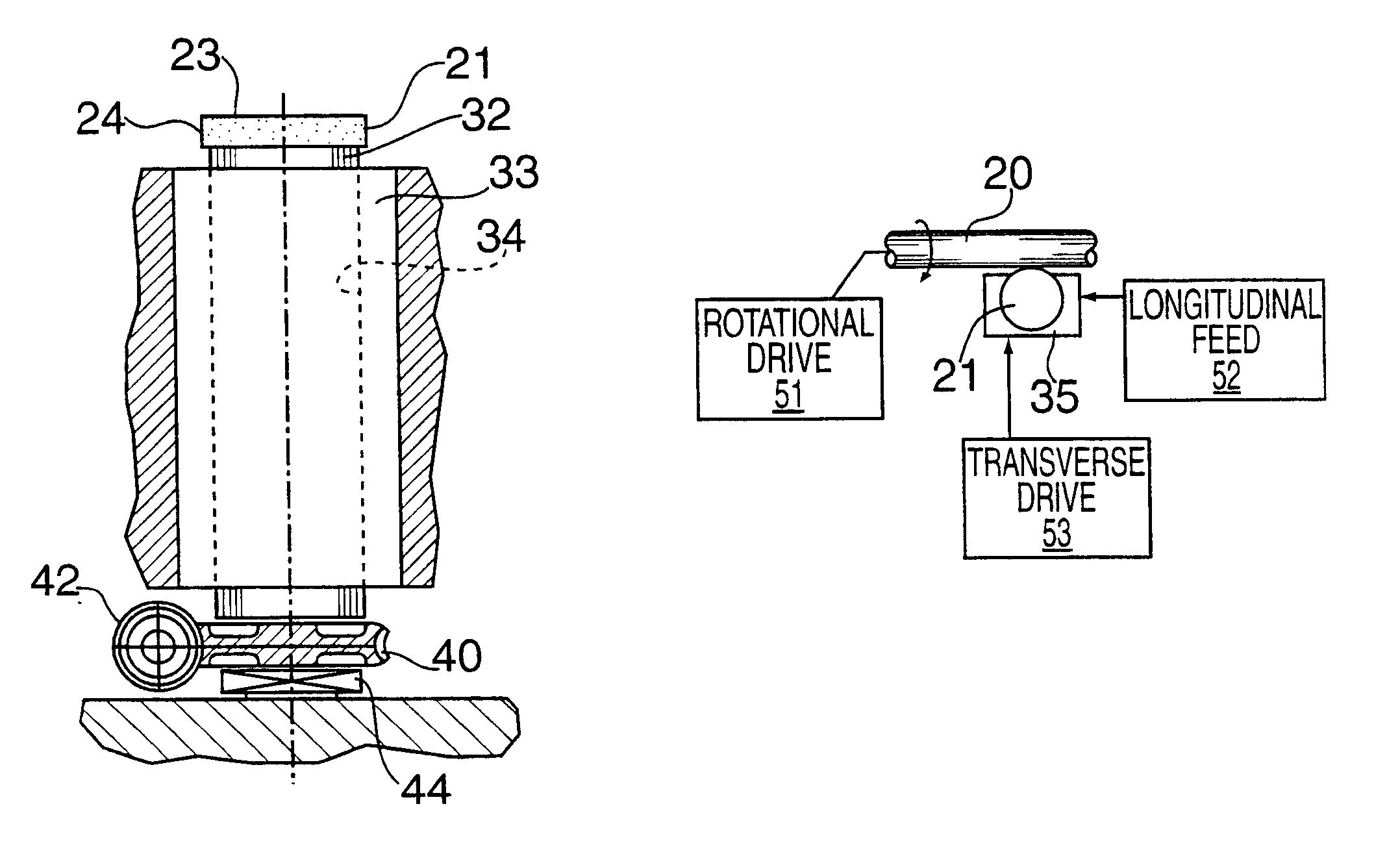

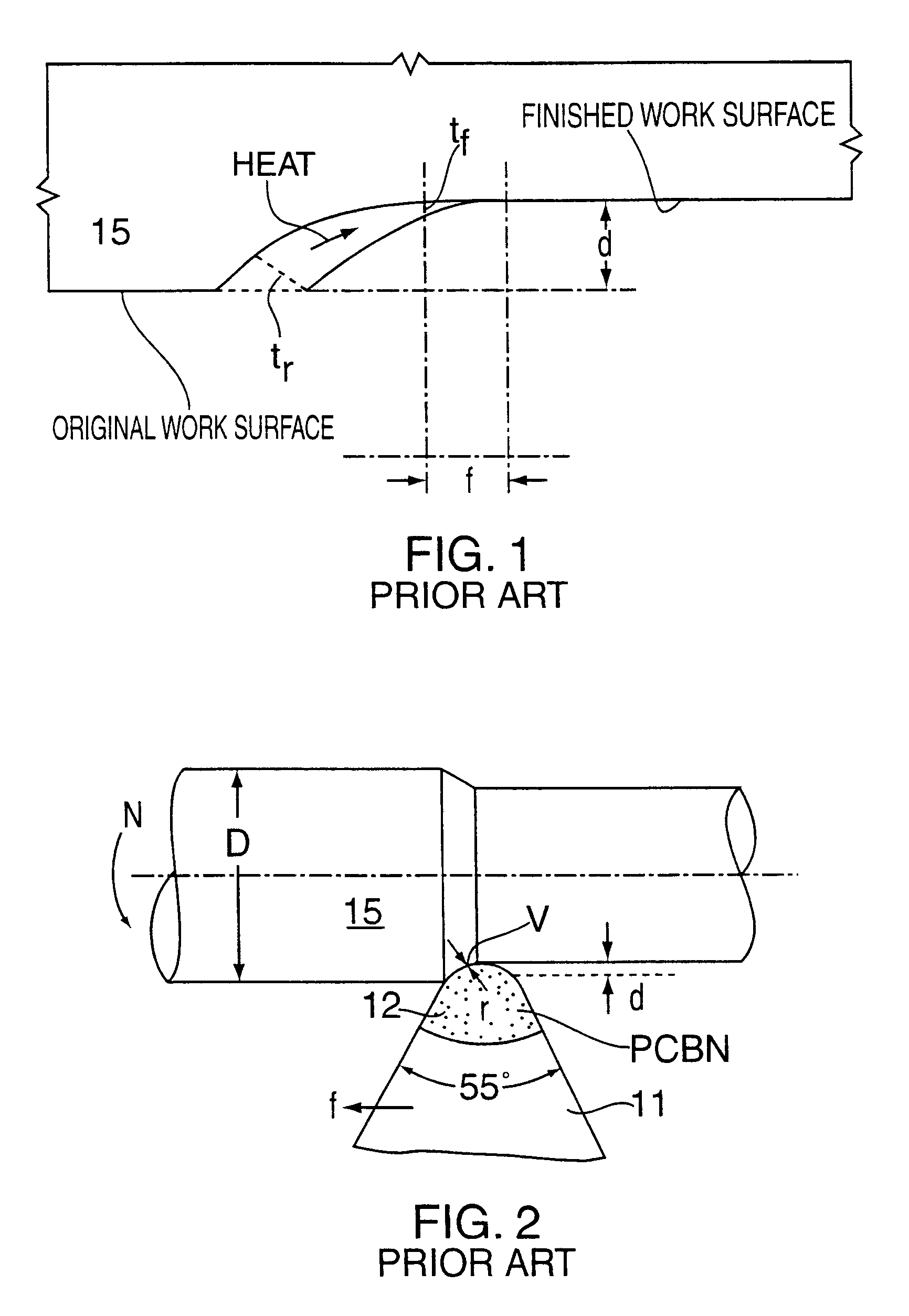

Method and apparatus for hard machining

InactiveUS6733365B1Offsetting tool lifeLow costEdge grinding machinesRevolution surface grinding machinesSwarfEngineering

A hard machining process uses a cylindrical tool (21) of ceramic or other hard machining material of comparatively low cost that provides a circular cutting edge to be engaged in cutting relation with hardened workpiece (20) to be machined. As tool cutting edge wear occurs, the tool (21) is rotated through a small angle to bring into contact with the workpiece (20) a fresh portion of the cutting edge. It is not necessary to rotate that tool (21) sufficiently to effect replacement of the entire cutting edge portion in engagement with the tool. Sufficient angular movement of the tool is made to replace that of the cutting edge that has the greatest effect on the finish of the machined workpiece (20), which is the cutting location where the removed chip is thinnest.

Owner:ARIZONA STATE UNIVERSITY

Radiating device of chip radiation using low-melting-point metal or its alloy as flow working medium

InactiveCN1489020ASmall sizeIncrease heat dissipation surfaceDigital data processing detailsSemiconductor/solid-state device detailsCyclic processLiquid metal

The heat abstractor comprises a main radiator, an auxiliary radiator, a connecting pipe and a minipump. The main radiator possesses flow passages, where molten metal with low melting point or alloy flow working medium are contained. Cooling fins are setup at surface of the main radiator contacted to surface of the chip to be cooled. Cooling fins are also setup at surface of the auxiliary radiator possessing flow passages, where liquid metal with low melting point or alloying flow working medium are contained. The connecting pipe connects between the main and auxiliary radiators. The minipump is installed on the connecting pipe for driving liquid metal and working medium. The said working medium is metal gallium or its alloy, which are meltable near room temperature. The invention integrates fin cooling and convective cooling, providing advantages of small size, large cooling area, high heat transfer efficiency, close cyclic process without influence on environment.

Owner:北京中科高意引擎技术有限公司

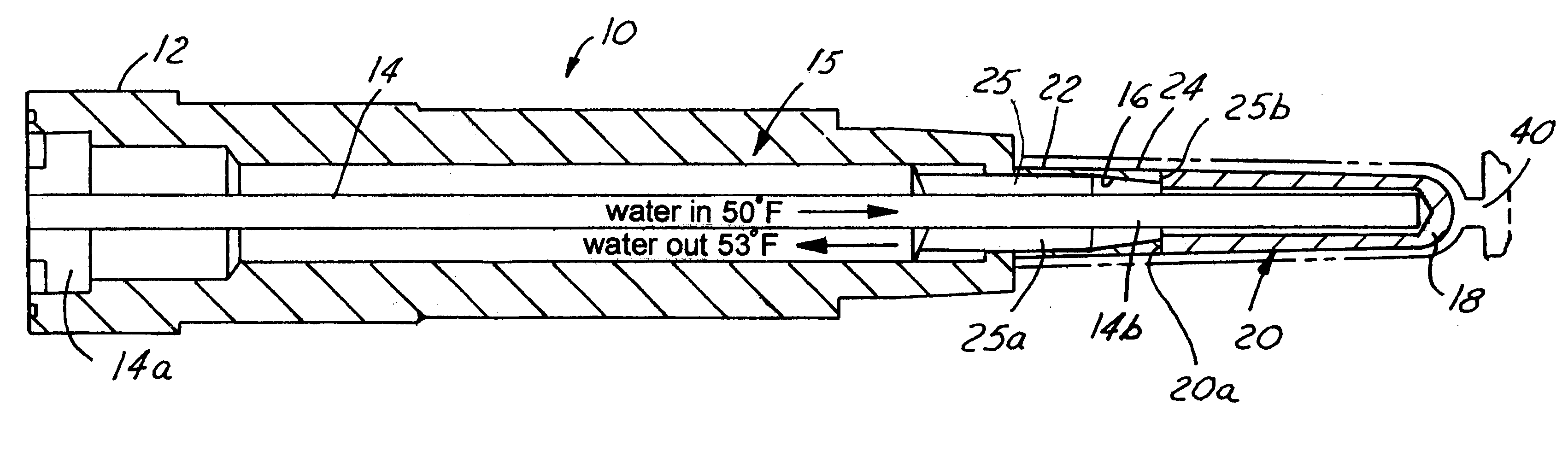

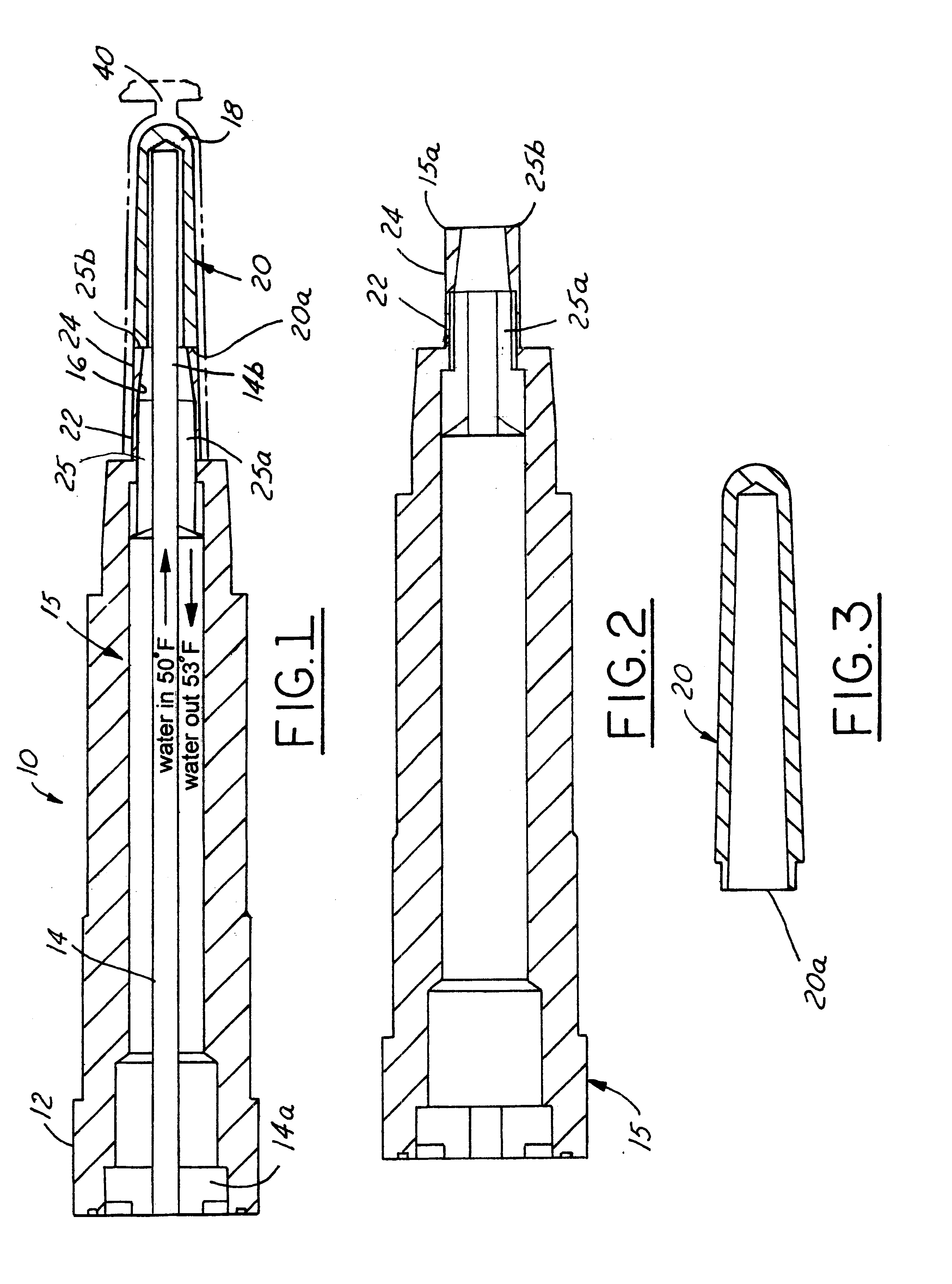

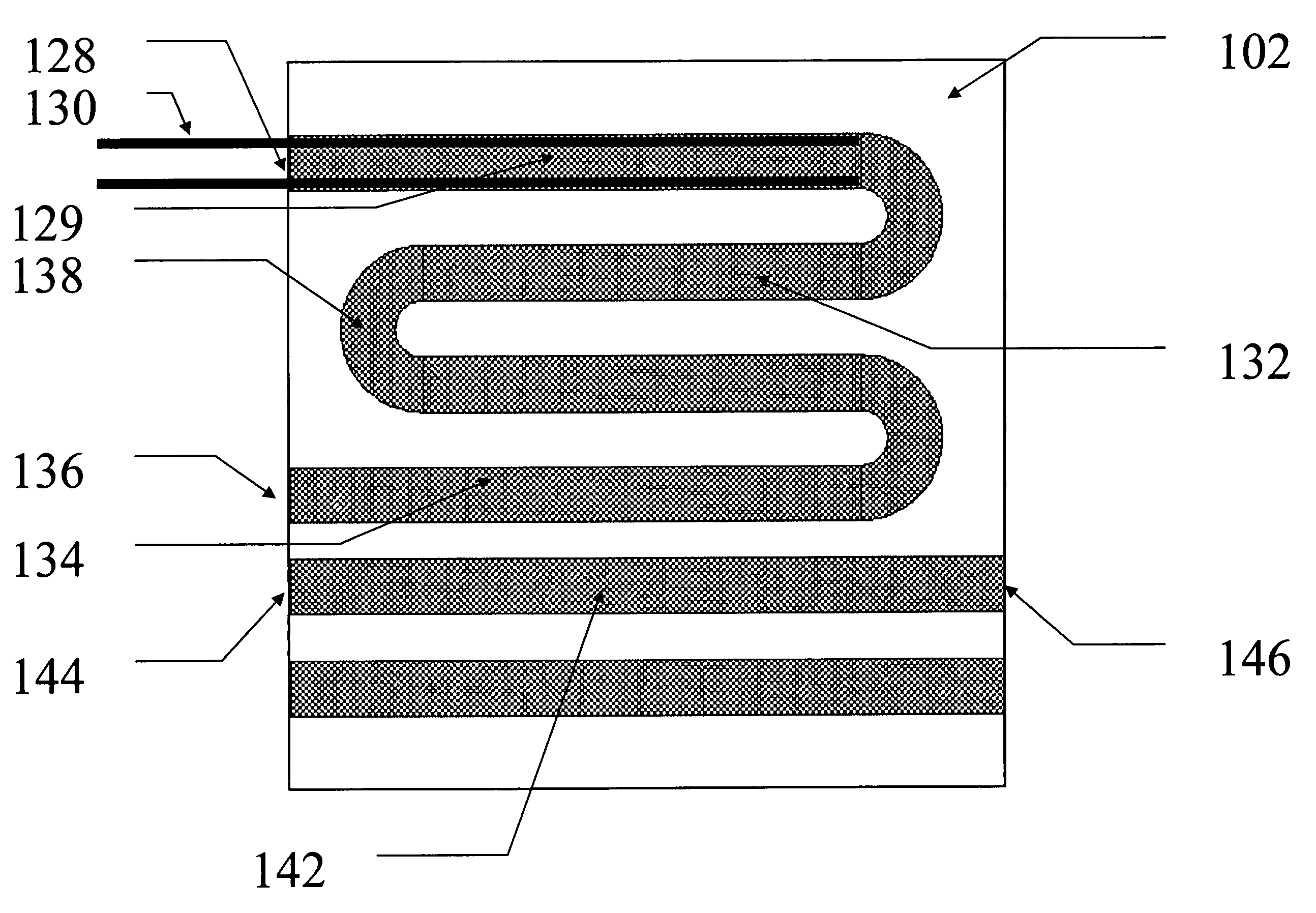

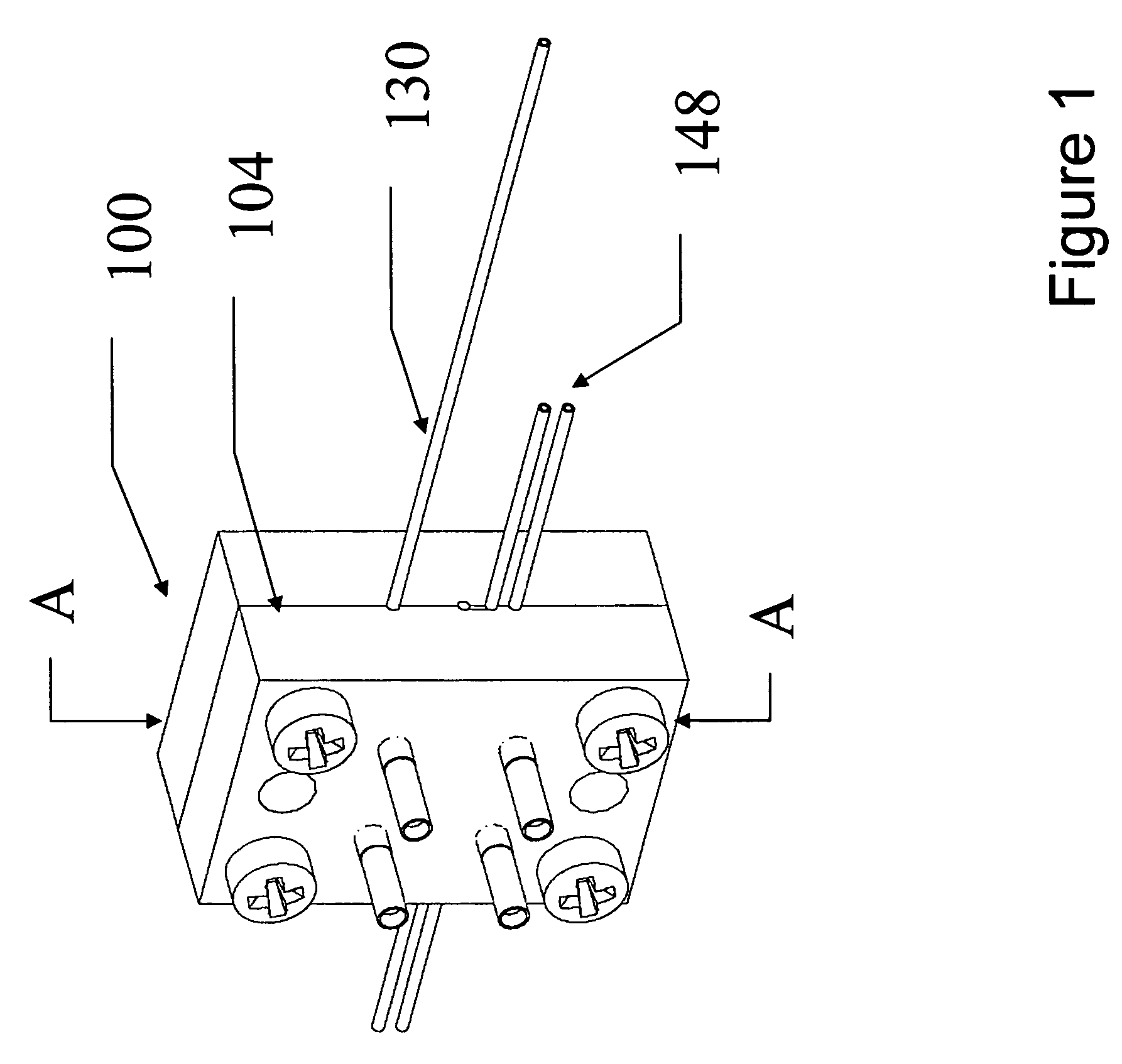

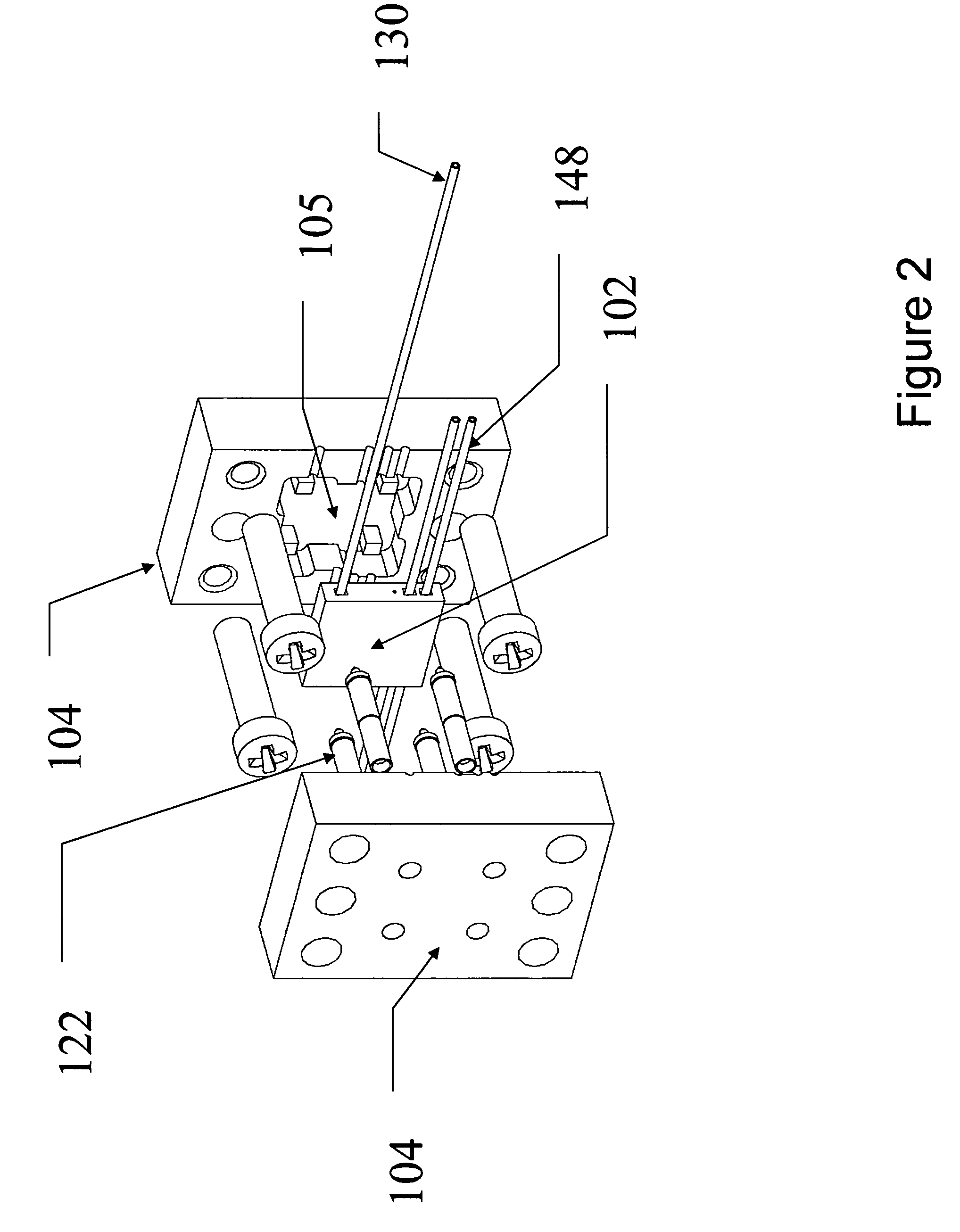

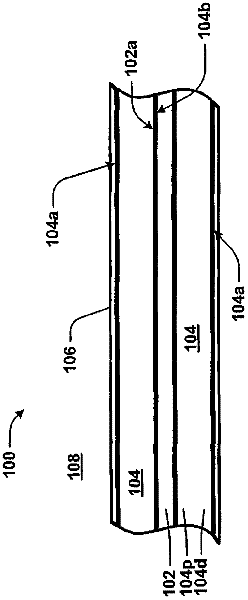

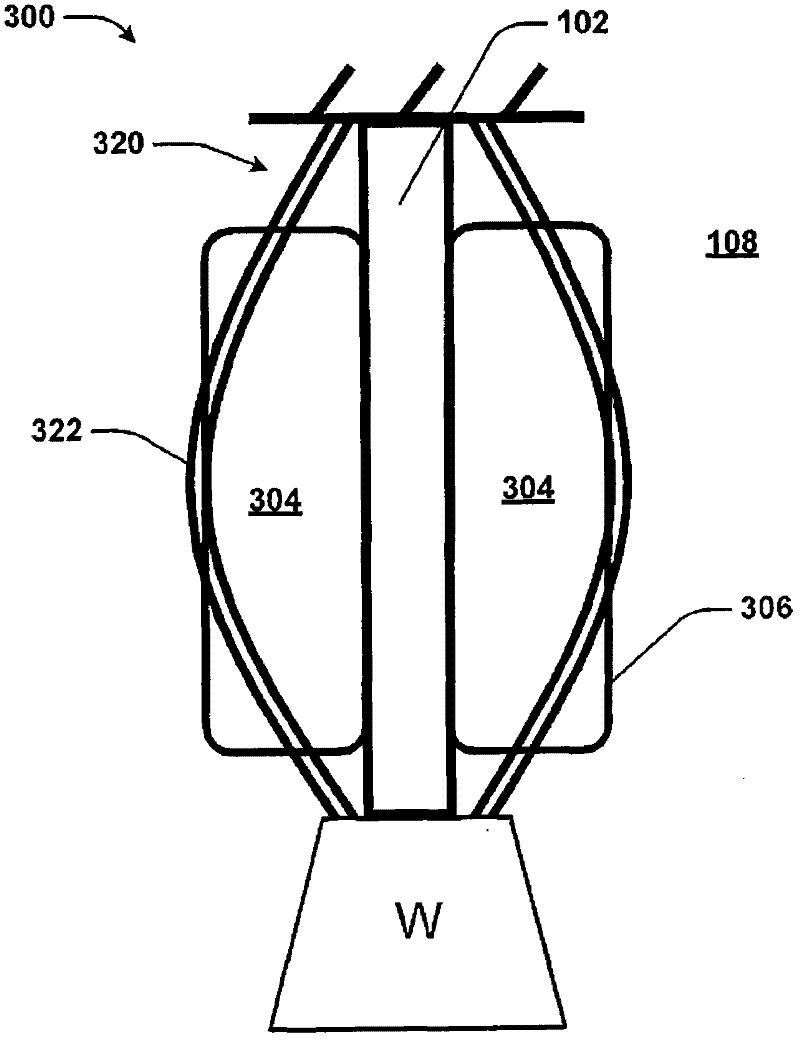

Bubbler tube with integral inlet pipe and bimetal core for injection molding tools and method of making the bubbler tube

InactiveUS6425752B1Excellent thermal diffusivityHigh strengthFoundry mouldsFood shapingThermal diffusivityHigh intensity

A mold assembly including moveable mold parts, one of which includes a plurality of hollow cavities. Each hollow cavity forms an outer wall of an elongated, generally annular portion of a molded part and the other mold part includes a corresponding plurality of core elements, which form an inner wall of the same portion of the molded part. Each core is disposed within a corresponding cavity to define a generally annular mold chamber portion for receiving molten material to be molded to form the shape of the portion of the molded part. Each core element includes a cooling apparatus and each cavity includes an outside cavity-cooling device. Each core element includes a first portion made of high strength material and a tip portion made of material having a greater heat diffusivity and heat transfer coefficient than said first portion.

Owner:CHECK JOHN M

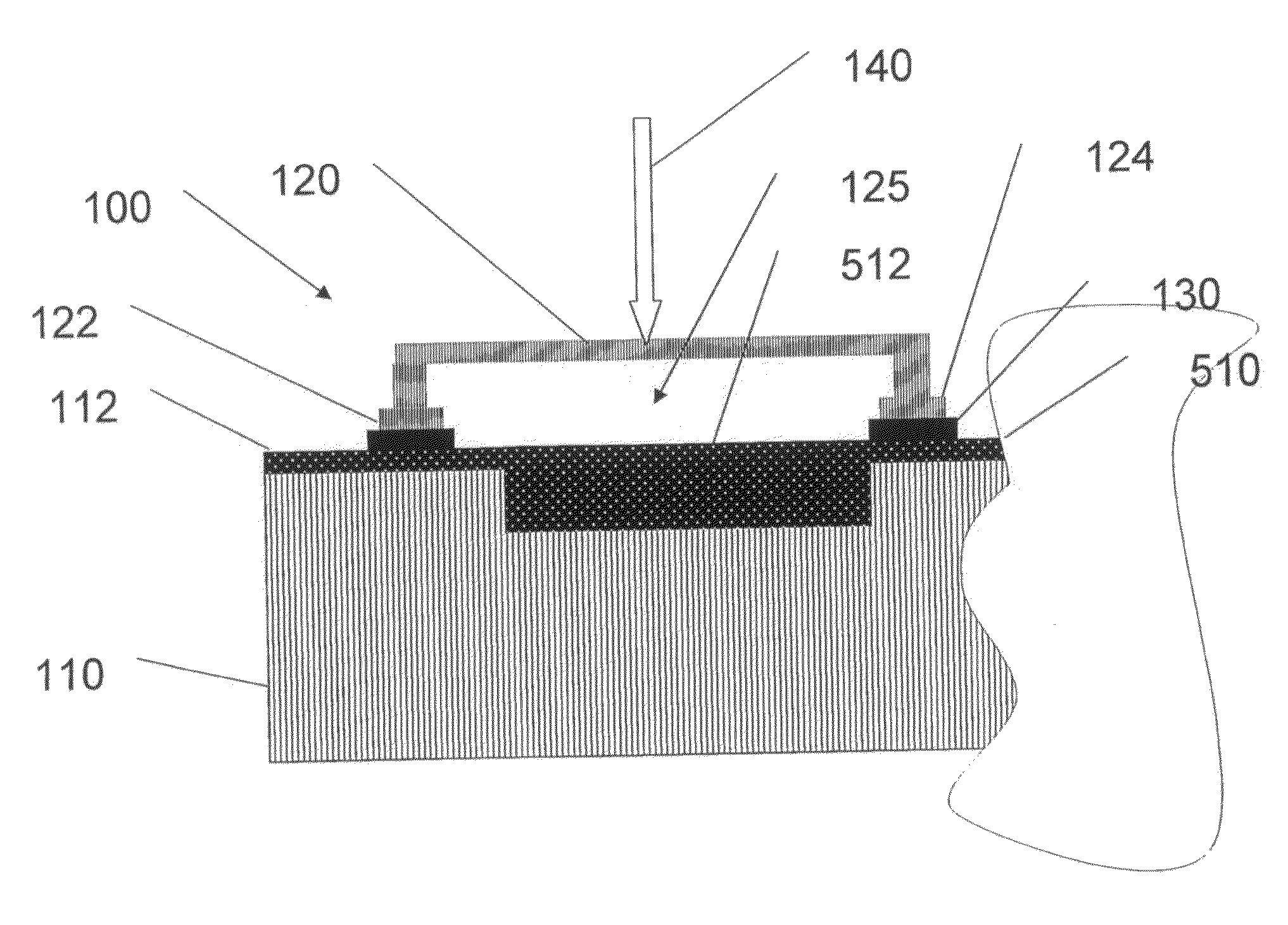

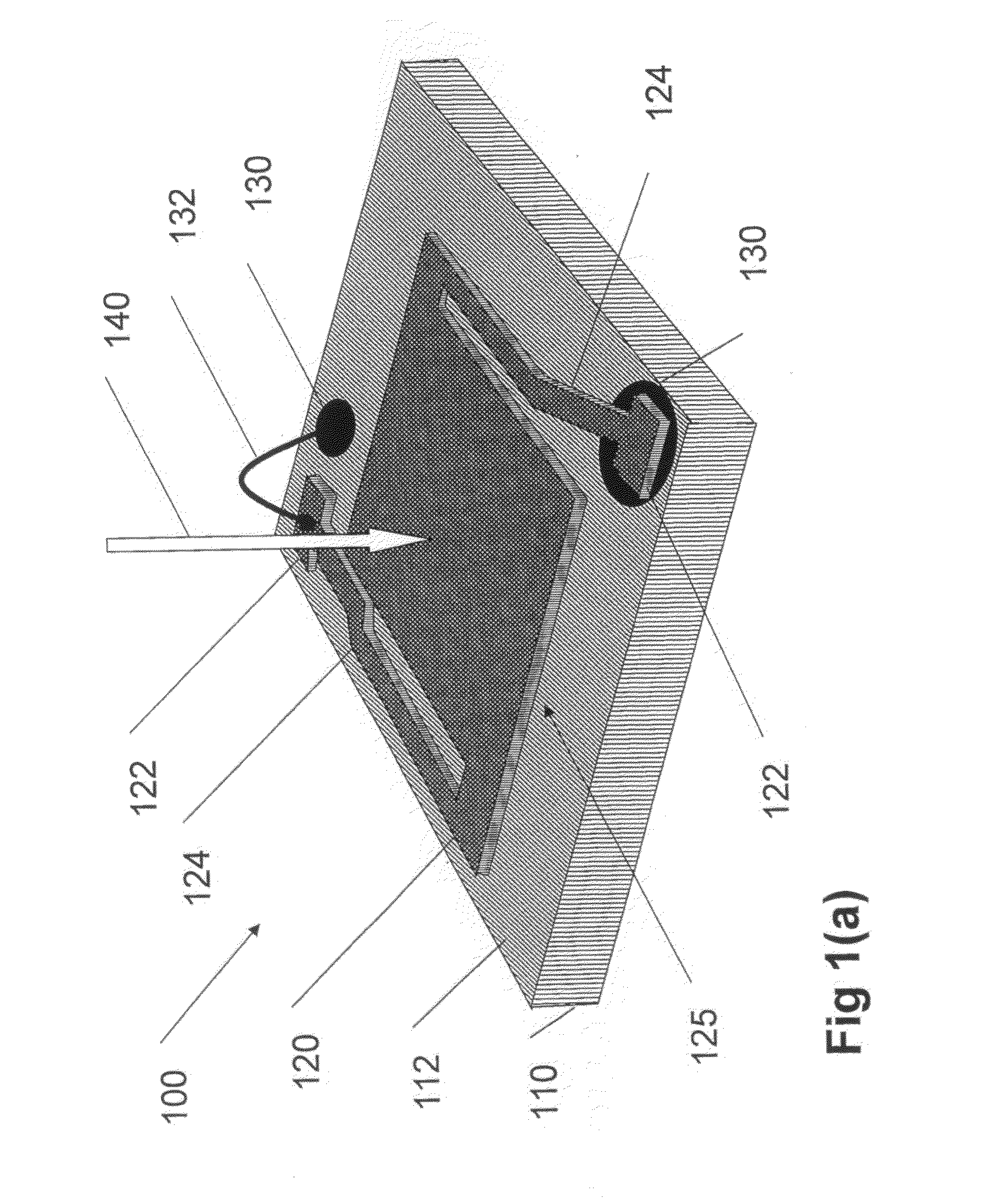

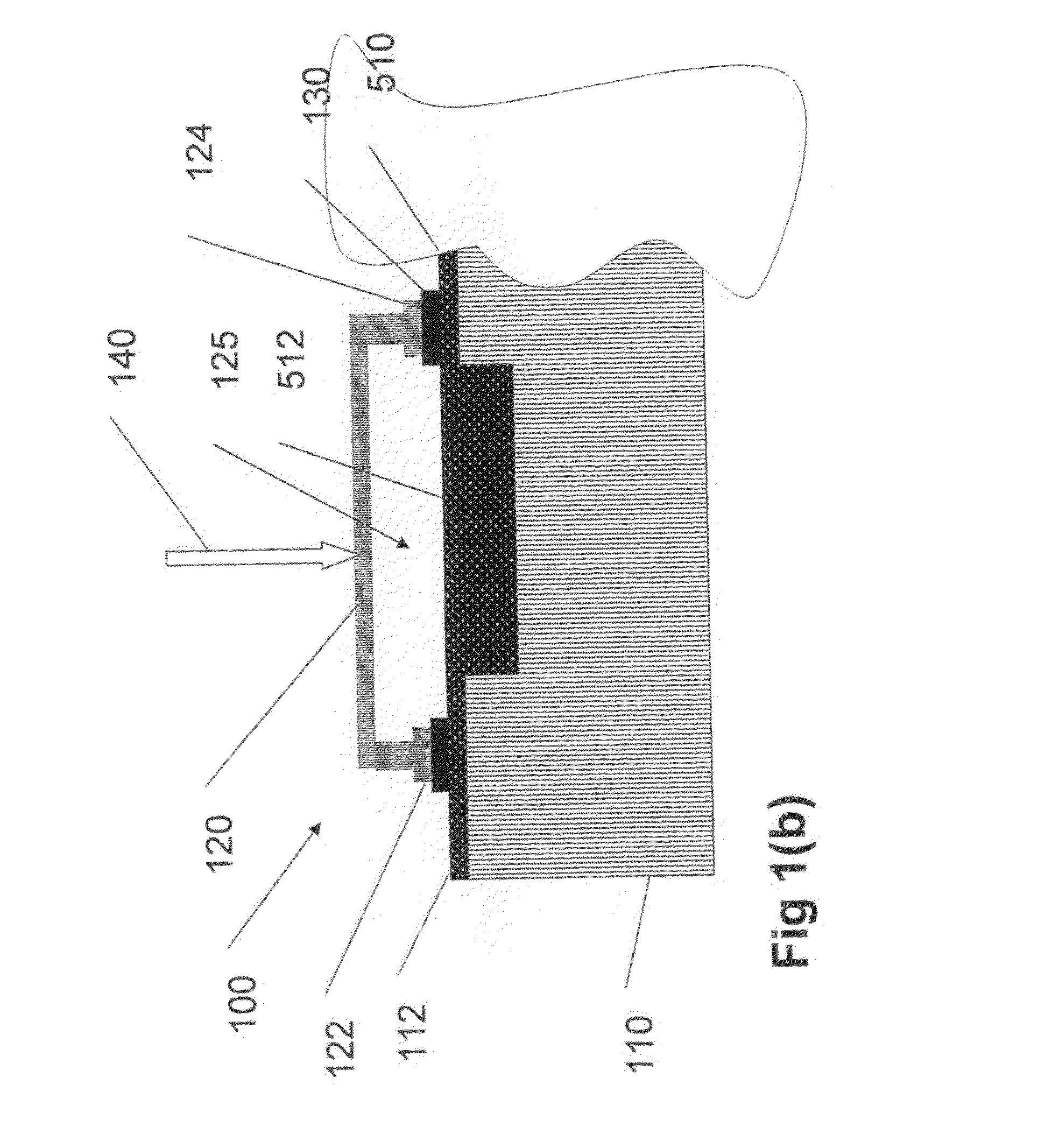

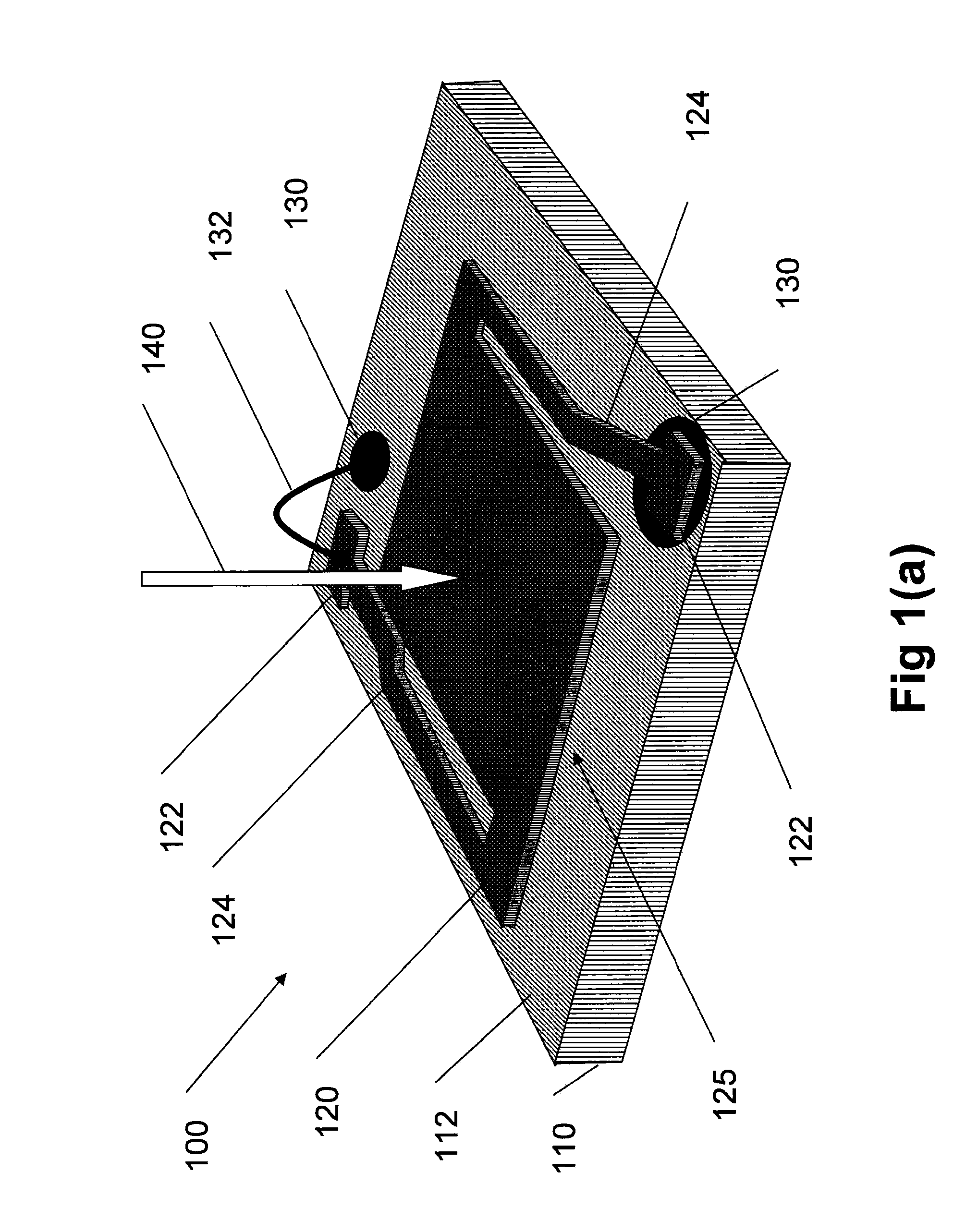

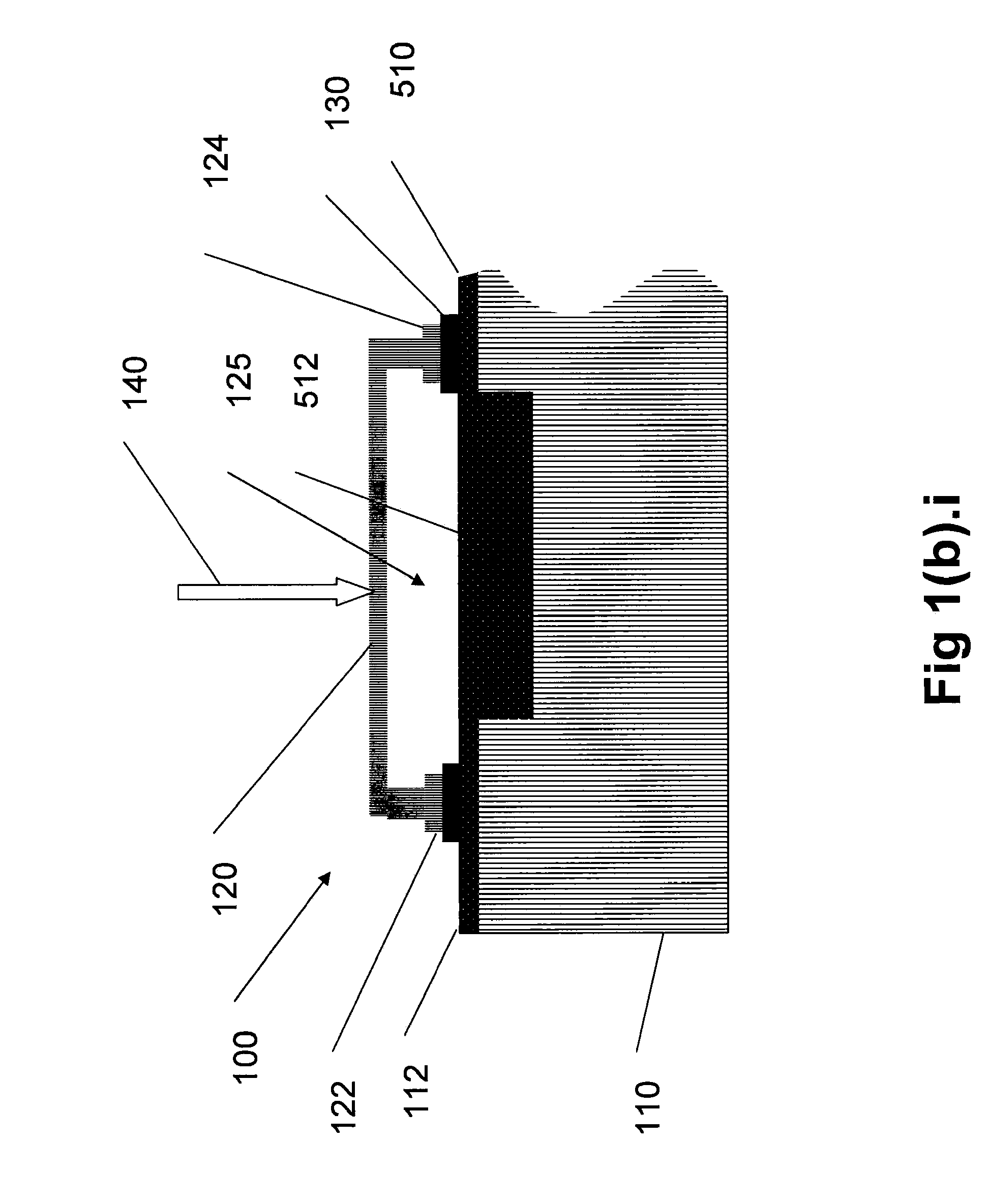

Thermal detection and imaging of electromagnetic radiation

InactiveUS20110204231A1High sensitivityImprove performanceMaterial analysis by optical meansPhotovoltaicsEnergy absorptionParticle physics

The current invention provides a method for improving the sensitivity of bolometric detection by providing improved electromagnetic power / energy absorption. In addition to its role in significantly improving the performance of conventional conducting-film bolometric detection elements, the method suggests application of plasmon resonance absorption for efficient thermal detection and imaging of far-field radiation using the Surface Plasmon Resonance (SPR) and the herein introduced Cavity Plasmone Resonance (CPR) phenomena. The latter offers detection characteristics, including good frequency sensitivity, intrinsic spatial (angular) selectivity without focusing lenses, wide tunability over both infrared and visible light domains, high responsivity and miniaturization capabilities. As compared to SPR, the CPR-type devices offer an increased flexibility over wide ranges of wavelengths, bandwidths, and device dimensions. Both CPR and SPR occur in metallic films, which are characterized by high thermal diffusivity essential for fast bolometric response.

Owner:TECHNION RES & DEV FOUND LTD

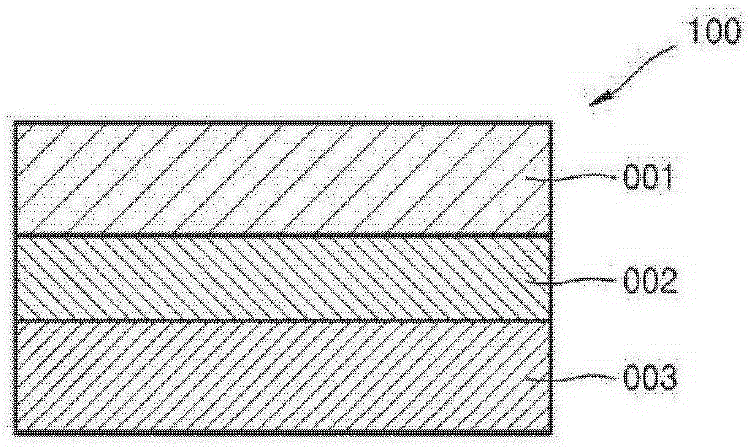

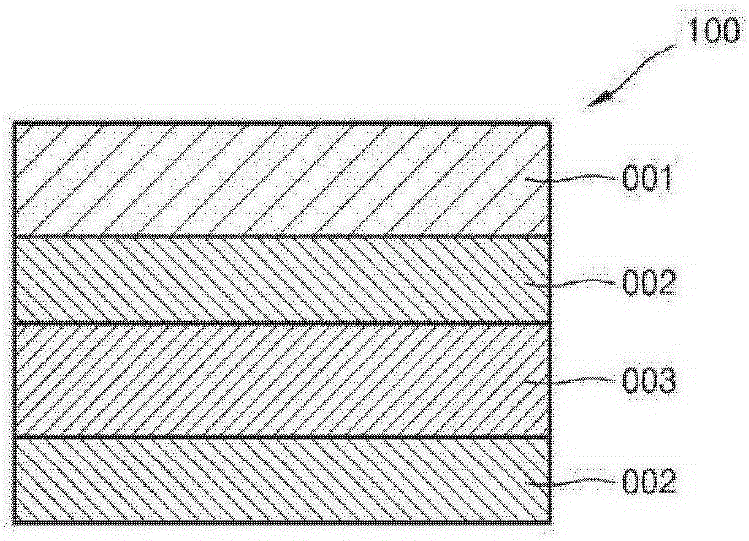

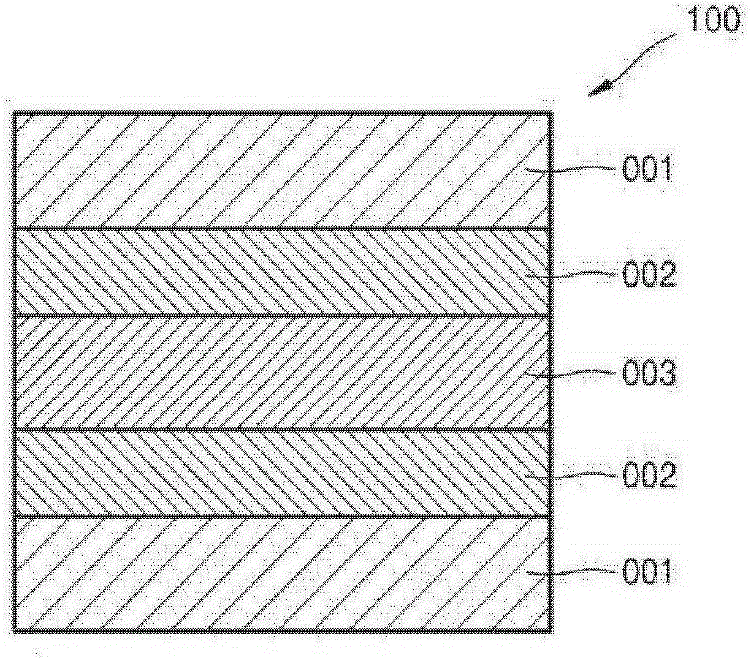

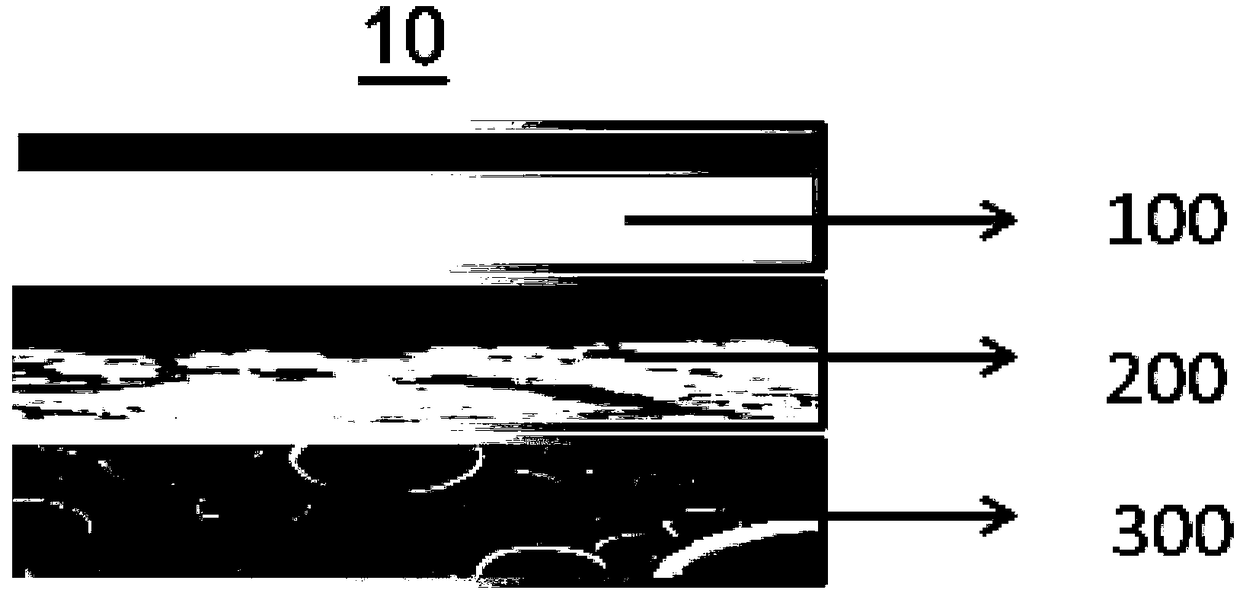

Conductive heat-dissipating sheet, and electrical parts and electronic devices comprising same

InactiveCN105325067AExcellent thermal diffusion performanceExcellent electromagnetic wave shielding performanceMagnetic/electric field screeningSemiconductor/solid-state device detailsHeat sinkMetallic materials

Disclosed herein are a conductive heat-dissipating sheet comprising a heat diffusion layer formed using metal materials; a heat conduction layer which is disposed on one surface or both surfaces of the heat diffusion layer and which is formed using inorganic materials including at least one material from the group consisting of metal oxides and alloys; and an adhesive layer disposed on one surface or both surfaces of the heat conduction layer; and an electrical part and an electronic device comprising the conductive heat-dissipating sheet.

Owner:ILJIN MATERIALS CO LTD

Cavity Plasmon Resonance Biosensing Device, Method And System

InactiveUS20110001975A1Promise detection capabilityPromising detection capabilityScattering properties measurementsPyrometry using electric radation detectorsLayered structurePneumatic pressure

The current invention provides a devices methods and systems for efficient biosensing using the Surface Plasmon Resonance (SPR) and Cavity Plasmon Resonance (CPR) phenomena. The miniature biosensor comprises a stratified structure having a channel for analyte form between a substrate and thin metallic absorber layer in which plasmon are resonantly excited. Presence of analyte in the channel, changes the resonance conditions, thus changing the energy absorbed by the biosensor. Bolometric signal from the absorber; layer or detection of the radiation not absorbed by the biosensor is used to detect, measure the concentration of, or monitor the analyte.

Owner:TECHNION RES & DEV FOUND LTD

Composite ceramic material and inner container of electric cooker prepared from composite ceramic material

ActiveCN105084905AExcellent thermal diffusivityImprove heat transfer efficiencyCooking-vessel materialsPtru catalystComposite ceramic

The invention discloses a composite ceramic material and an inner container of an electric cooker prepared from the composite ceramic material. The composite ceramic material is prepared from the following components in parts by weight: 3-8 parts of barium carbonate, 20-35 parts of calcite, 5-10 parts of kaolin, 35-55 parts of silica powder, 3-8 parts of potassium nitrate, 10-15 parts of paraffin, 3-8 parts of sodium carbonate, 7-8 parts of boric acid, 11-15 parts of quartz, 50-75 parts of aluminum nitride powder, 2-3 parts of yttrium oxide and 3-5 parts of lanthanum oxide, wherein the aluminum nitride powder is generated by reacting aluminum oxide powder serving as an aluminum source and carbon black powder in the flowing nitrogen atmosphere at the temperature of 1500-1700 DEG C; calcium oxide is added as a catalyst in the reaction process, and decarbonization is carried out in dry air with the temperature of 700-800 DEG C after the reaction is finished; the mass content of cation impurities in the aluminum oxide powder is lower than or equal to 0.02%, and the mass contents of silicon and iron impurities are respectively lower than 0.001%; and the average particle size of the carbon black powder is 35-40nm, and the specific surface area is smaller than or equal to 90m<2> / g.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

A heat dissipation magnetic insulation tape and a wireless charging power receiver

ActiveCN109245325AGood adhesionGood electromagnetic shielding functionBatteries circuit arrangementsModifications for power electronicsThin metalAdhesive

A heat dissipation magnetic insulation tape includes an insulating protective adhesive layer, a composite heat dissipation adhesive layer, and a magnetic insulation adhesive layer which are stacked. the composite heat dissipation adhesive layer is made of thin metal foil coated with heat dissipation graphene, which has good thermal diffusion performance. At the same time, compared with the traditional graphite sheet, the metal foil is not fragile, and no fragments will enter the equipment body. In addition, the metal foil also has excellent electromagnetic shielding function. The heat dissipation and magnetic insulation tape has the characteristics of excellent magnetic insulation effect, good heat dissipation performance and stable adhesion. A wireless charging power receiver includes theheat dissipation magnetic isolation tape, which is thin in thickness, excellent in heat dissipation magnetic isolation performance, stable in adhesion performance, and has high charging efficiency.

Owner:SHENZHEN MEIXIN ELECTRONICS +1

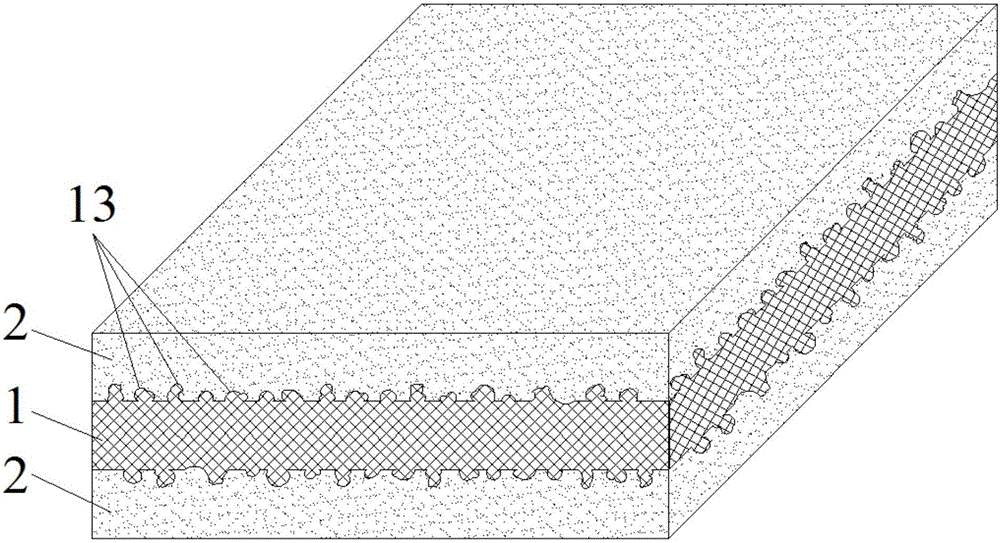

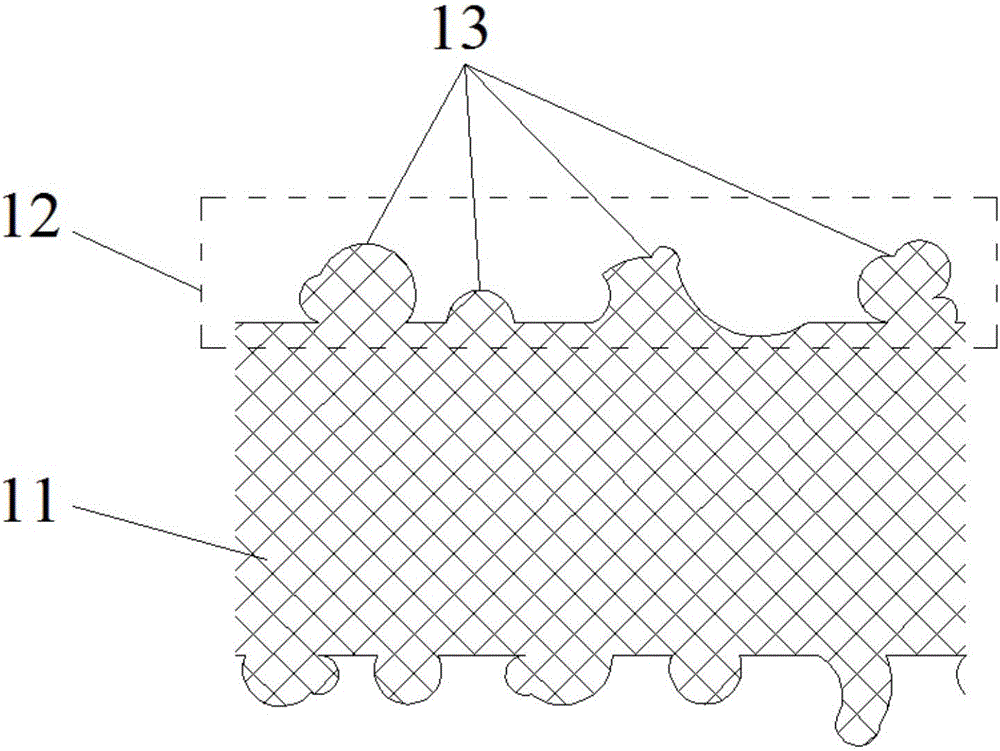

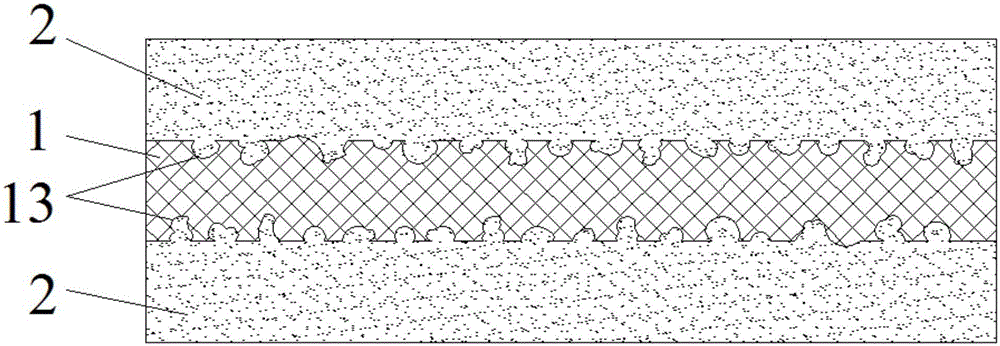

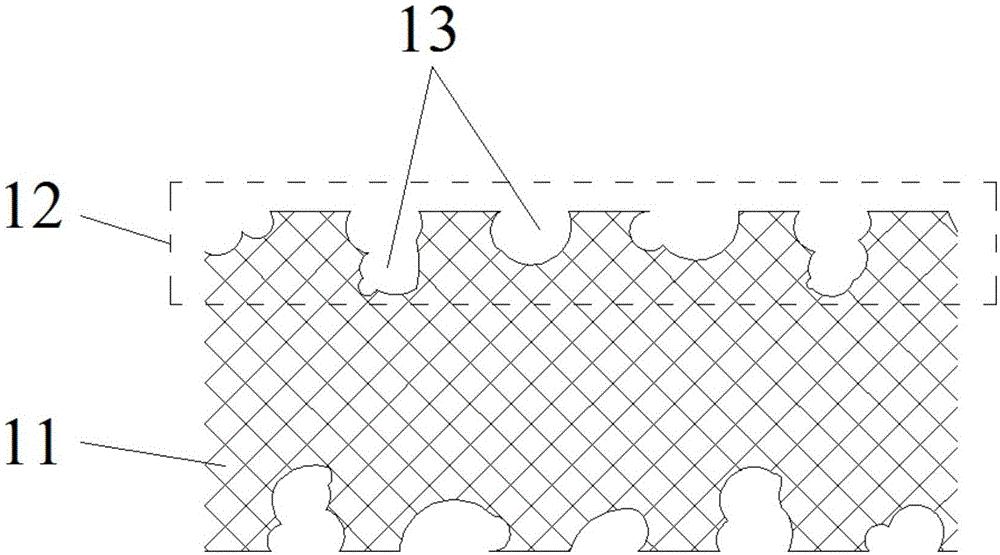

Natural graphite/copper composite heat sink and fabrication method thereof

InactiveCN105101758AImprove thermal conductivityImprove mechanical propertiesMagnetic/electric field screeningCooling/ventilation/heating modificationsCopper foilElectromagnetic shielding

The invention discloses a natural graphite / copper composite heat sink and a fabrication method thereof, relating to the field of cooling and electromagnetic shielding of a heating component of an electronic product. The natural graphite / copper composite heat sink comprises a copper foil layer and graphite layers, wherein the graphite layers are arranged on the upper surface and the lower surface of the copper foil layer; the copper foil layer comprises a copper substrate and armoring layers arranged on the upper surface and the lower surface of the copper substrate; warty copper particle structures are uniformly distributed on the surfaces of the armoring layers; and the armoring layers are engaged with the graphite layers through the warty copper particle structures. The fabrication method of the natural graphite / copper composite heat sink comprises the following steps of: pre-processing the surface of a copper foil; roughening and curing the copper foil; uniformly stacking puffed worm graphite and laying on the copper foil; and calendering step by step to obtain the natural graphite / copper composite heat sink. The heat sink disclosed by the invention has favorable heat conduction performance and a favorable electromagnetic shielding effect, is resistant to stretch, and can be bent for 180 degrees, the interface resistance between the copper foil and the graphite is lower, and the heat conduction performance is improved.

Owner:QIHUA OPTRONICSKUNSHAN CO LTD

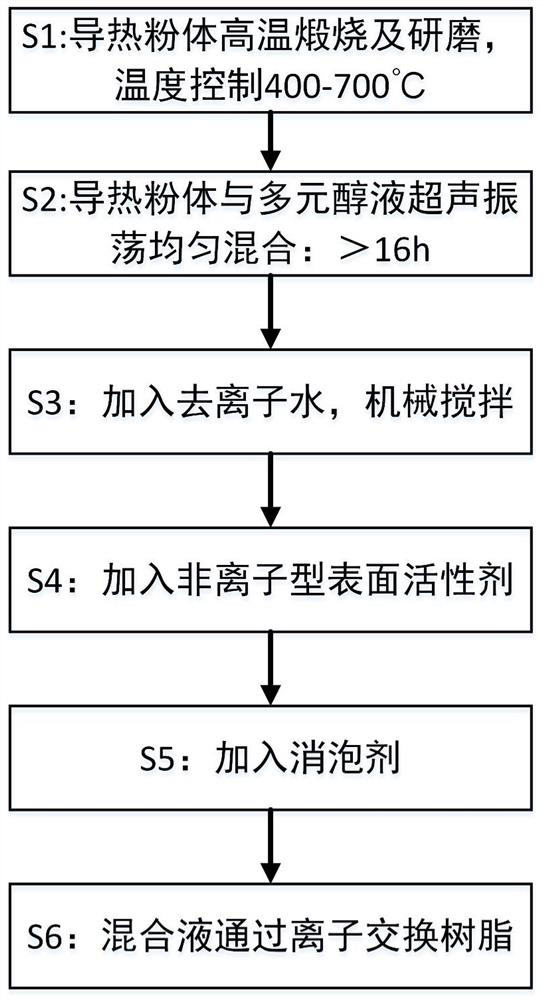

Fuel cell cooling liquid and preparation method thereof

PendingCN112457822AImprove heat transfer performanceSmall sizeFinal product manufactureHeat-exchange elementsActive agentIon exchange

The invention discloses a fuel cell cooling liquid and a preparation method thereof, wherein the fuel cell cooling liquid comprises, by mass, 2-97% of an ethylene glycol organic liquid, 2-97% of deionized water, 0.1-13% of heat conduction powder, 0.1-5% of a surfactant and 0.2-1% of an antifoaming agent. The method comprises: carrying out high frequency ultrasonic oscillation and mechanical stirring treatment on the raw materials, so that the periphery of heat conduction powder particles is compactly coated with the surfactant so as to form a stable suspended mixed liquid; and removing conductive ions in the liquid through anion-cation exchange resin treatment to obtain the cooling liquid for the fuel cell. The fuel cell cooling liquid prepared by the method has good thermal conductivity and excellent insulativity, can meet the use requirements of the fuel cell cooling liquid, is simple in preparation process, easy in parameter control and low in cost, and is suitable for batch production and commercial popularization.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Natural graphite/aluminium composite radiating fin and preparation method thereof

InactiveCN105142380AHigh thermal conductivityImprove thermal conductivityCooling/ventilation/heating modificationsMetal layered productsElectromagnetic shieldingInterfacial thermal resistance

The present invention provides a natural graphite / aluminium composite radiating fin and a preparation method thereof, relating to the field of heat radiation of heating elements of electronic products and the field of electromagnetic shielding of electronic products. The natural graphite / aluminium composite radiating fin includes an aluminum foil layer and graphite layers located on two faces of the aluminum foil layer. The aluminum foil layer includes an aluminium base material and coarsening layers located on two faces of the aluminium base material. Holes are distributed on the surface of the coarsening layer. The coarsening layer connects the graphite layer in an occlusion manner. The preparation method includes the steps as follows: pre-processing the surface of the aluminium foil; performing a coarsening process for the aluminium foil; stacking expanded worm-like graphite evenly and tiling the expanded work-like graphite on the aluminium foil; and performing staged rolling to obtain the natural graphite / aluminium composite radiating fin. The graphite layer connects the aluminium foil layer in an occlusion manner through holes so that the interface resistance of the aluminium foil and the graphite is lesser and the thermal conductivity in the Z-axis direction is increased greatly, the radiating fin has the excellent thermal conducting property and the excellent electromagnetic shielding effect, the radiating fin has the anti-stretching property, and the radiating fin can be bended for 180 degrees.

Owner:QIHUA OPTRONICSKUNSHAN CO LTD

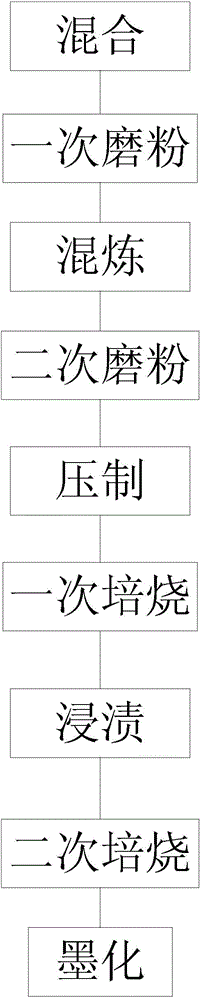

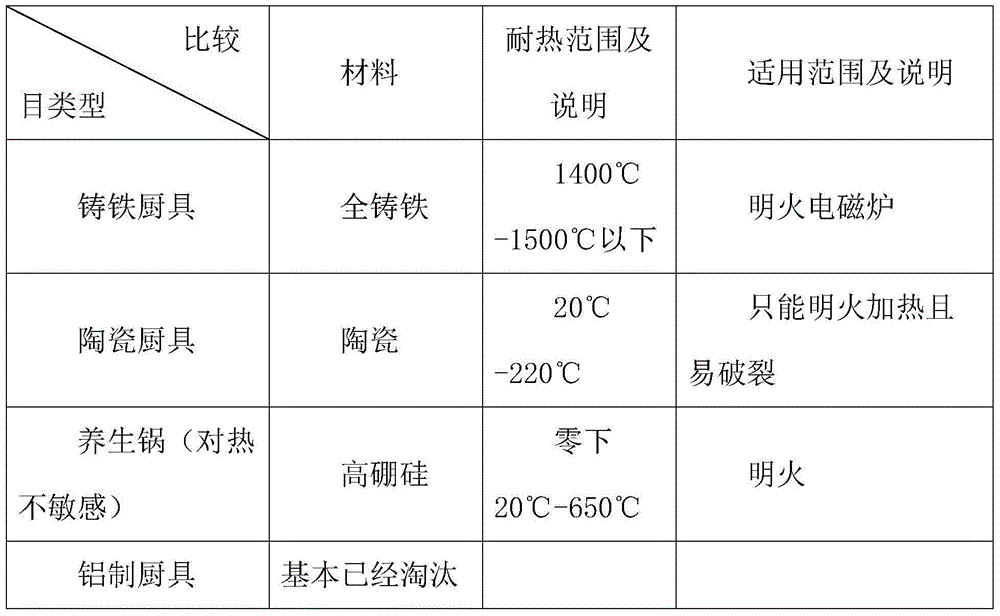

Graphite material and preparation and application thereof

InactiveCN104609412ALow densityReduce weightCooking vesselsRoasters/grillsHeat resistanceKitchen utensils

The invention provides a graphite material prepared by a special process; the graphite material has the characteristics of low density, light weight, low ash content, high quality and good compression resistance and bending resistance; kitchen utensils made of the graphite material have the advantages of light weight, wide heat resistance range, small coefficient of thermal expansion, high thermal diffusivity and high heat conductivity, fast heat transfer and even heating; and the graphite material has high market promotion value.

Owner:PINGDINGSHAN XINRUIDA NEW MATERIAL TECH CO LTD

Polyimide foam, and preparation method and application thereof

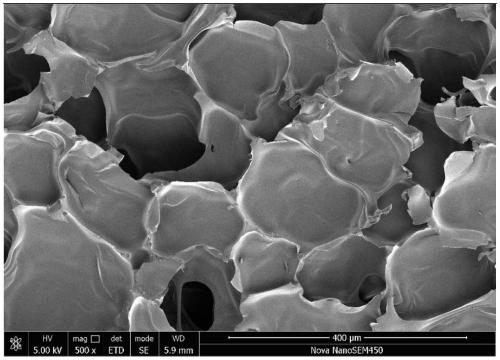

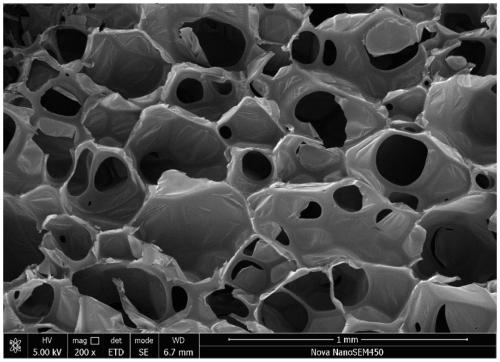

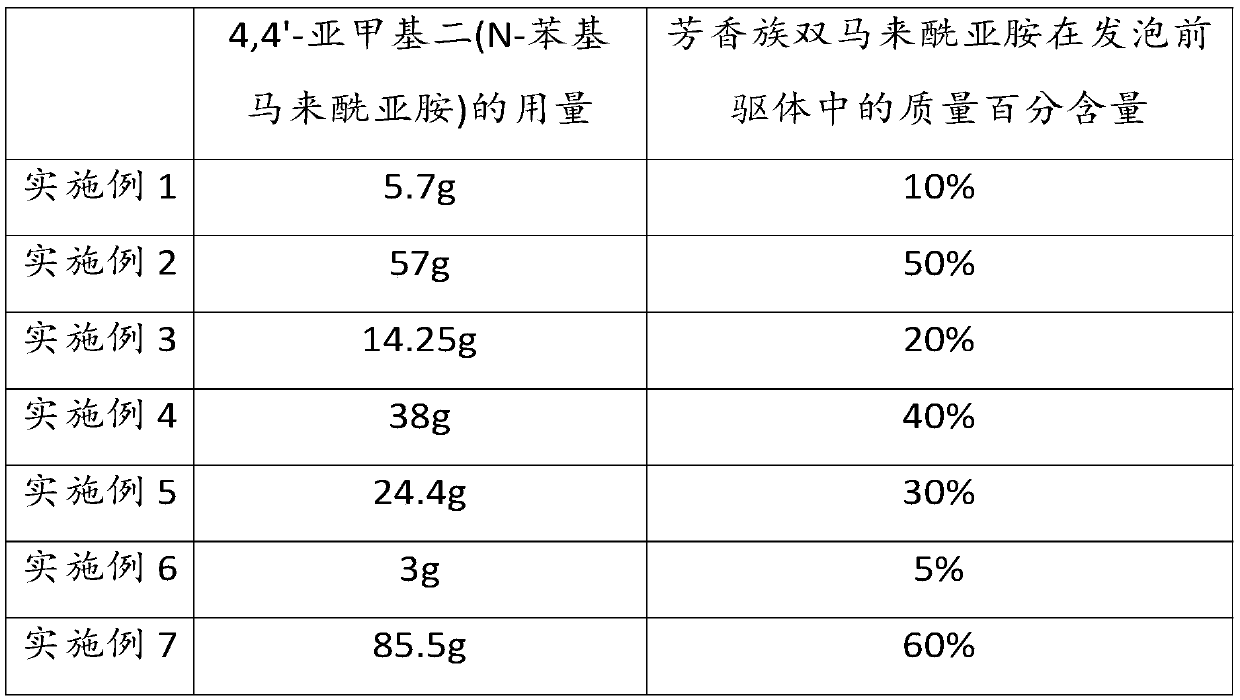

The invention provides a polyimide foam, and a preparation method and an application thereof, and belongs to the technical field of polymer materials. The preparation method of the polyimide foam comprises the following steps: uniformly mixing a glue solution containing a poly(ester-amine salt) oligomer with aromatic bismaleimide, and removing a solvent to obtain a foam precursor; and performing foaming, curing and heat treatment to obtain the polyimide foam. The crosslinking curing reaction of the aromatic bismaleimide and the imidation process of the polyimide in the method are carried out simultaneously, so the hybridization enhancement at the molecular scale is realized, an intertwined thermoplastic-thermosetting polymer chain network is formed, and the foam has good strength and toughness; the aromatic bismaleimide makes the cells of the obtained polyimide foam small and uniform, so mechanical properties of the polyimide foam are improved, and the heat resistance is kept; and theobtained polyimide foam has both good mechanical properties and good heat resistance.

Owner:SICHUAN UNIV

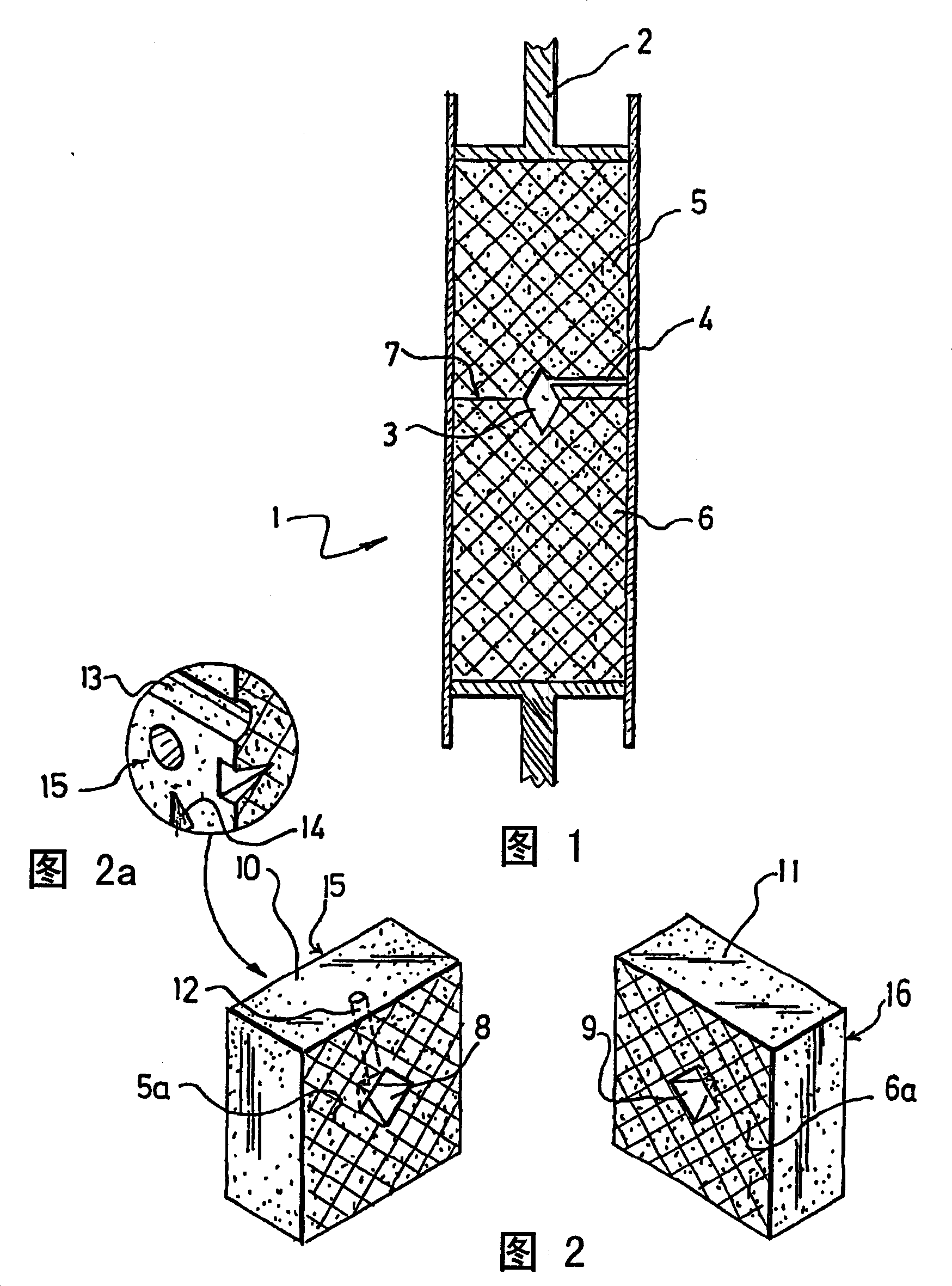

Procede de fabrication d'un moule et moule obtenu.

InactiveCN1863622ASimple methodSimple Execution SpeedFoundry mouldsFoundry coresVolumetric Mass DensityGraphite

The invention relates to a method for producing a mould for moulding objects in a mouldable material consisting in using a pattern for objects to be moulded and in coating said pattern with a moulding material. The inventive method is characterised in that it also consists in using expanded graphite in the form of a moulding material, coating the pattern (3) with said expanded graphite, thereby forming a continuous expanded graphite layer or several separated expanded graphite layers (5, 6) distributed along the pattern, in pressing the expanded graphite layer(s) against the pattern in such a way that a consolidated graphite block impermeable for the mouldable material is formed for each layer. In another variant, the inventive method consists in using at least one pre-consolidated layer made of the expanded graphite which is re-compressed at least in one direction in such a way that the density thereof ranges from 30 to 50 kg / m3.

Owner:6T MIC INGIES

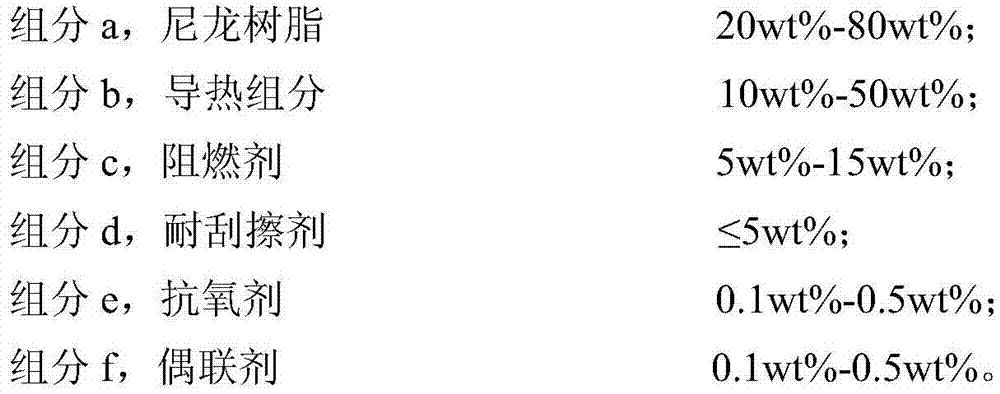

Impact-resistant scratch-resistant thermal-conduction nylon composite material and preparation method thereof

The present invention relates to an impact-resistant scratch-resistant thermal-conduction nylon composite material and a preparation method thereof, wherein a nylon composition containing copolymerized nylon is adopted as a resin matrix, and the impact-resistant scratch-resistant thermal-conduction nylon composite material is prepared from the nylon composition, a thermal conduction component, a flame retardant agent, an antioxidant, a coupling agent and an optional scratch-resistant agent through a two-step melt blending method. According to the present invention, the impact-resistant scratch-resistant thermal-conduction nylon composite material has advantages of good toughness, good low temperature impact resistance, low surface hardness, excellent scratch resistance, good thermal conduction performance, good mechanical property and good flame-retardant property, and can be widely used in electric tool shells, battery pack shells, LED heat dissipators, vehicle LED brackets, and other plastic part fields having high heat dissipating requirements.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

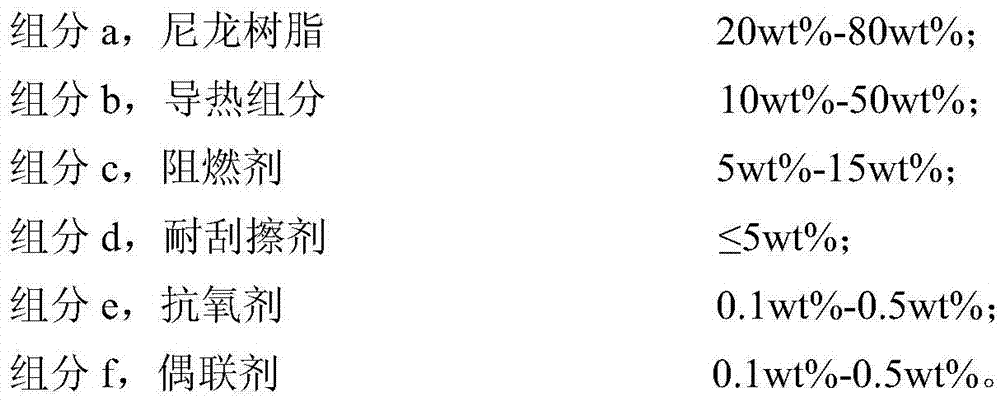

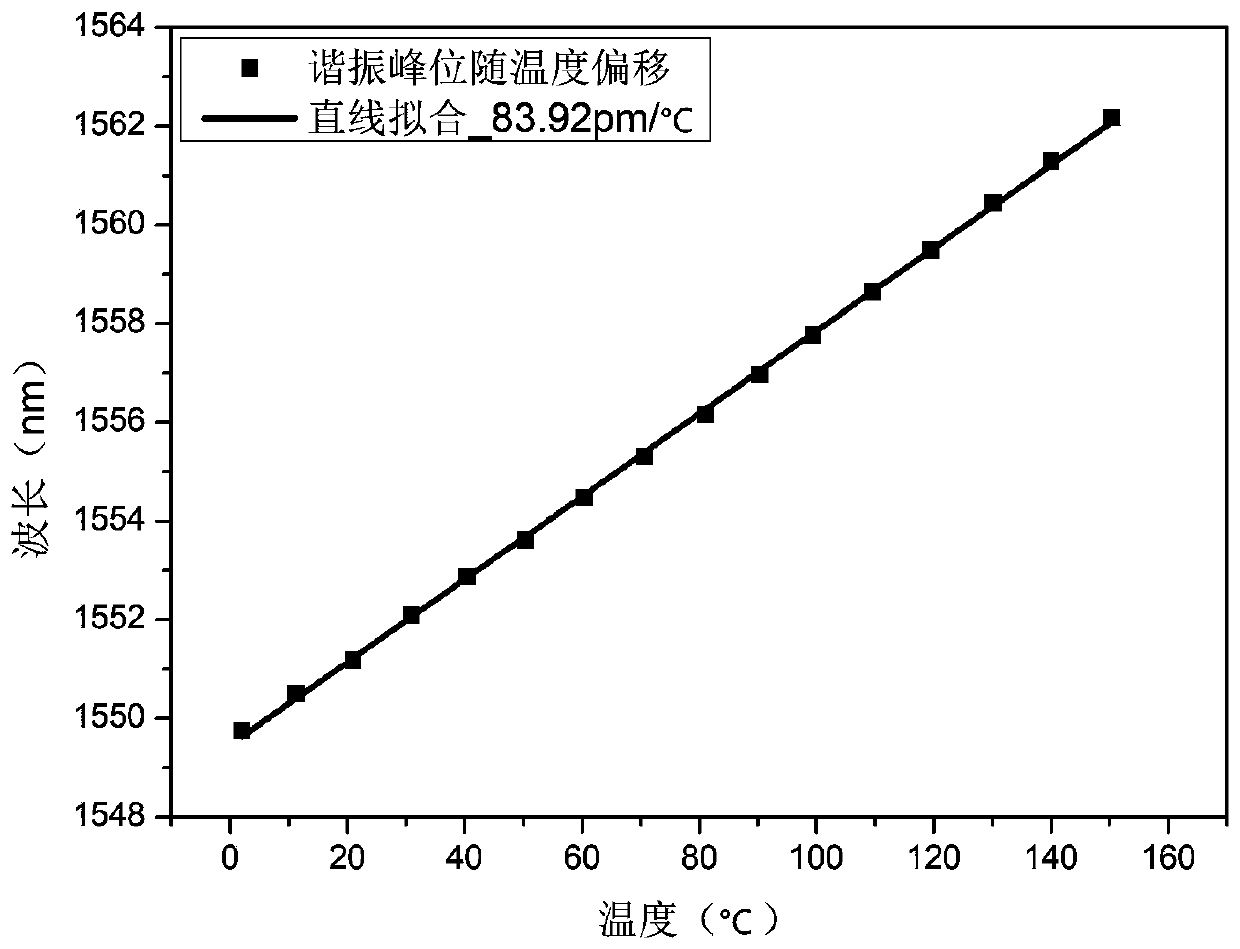

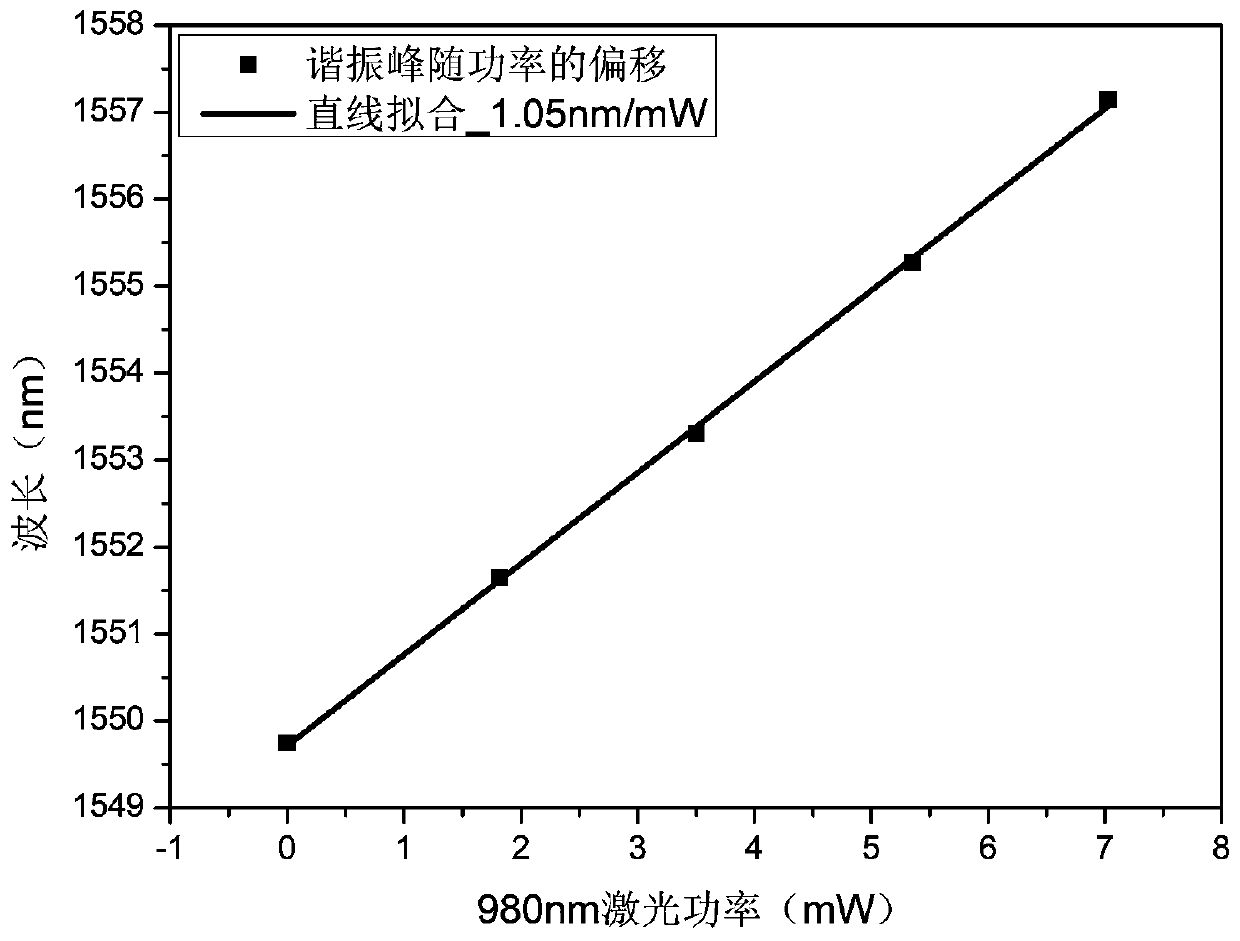

Fabry-Perot sensor based on silicon core optical fiber and preparation and application thereof

ActiveCN110160571AIncrease contrastLarge free spectral rangePhotometryThermometers using physical/chemical changesRepeatabilitySilicon

The invention relates to the technical field of optical fiber sensing, in particular to a Fabry-Perot sensor based on a silicon core optical fiber and a preparation method thereof. The Fabry-Perot sensor based on the silicon core optical fiber comprises a common single mode optical fiber, an optical fiber fusion end face, the silicon core optical fiber and a polished end face, wherein an input optical fiber and the silicon core optical fiber are fused to form a fusion end face, the silicon core optical fiber consists of a silicon core optical fiber cladding and a silicon core optical fiber core, the polished end face is formed by grinding and polishing the end face of the silicon core optical fiber, and the fusion end face and the polished end face form two mirror faces of a silicon core optical fiber Fabry-Perot cavity. The Fabry-Perot sensor based on the silicon core optical fiber prepared by the invention has high temperature sensitivity, laser power sensitivity and response speed,and the Fabry-Perot sensor based on the silicon core optical fiber also has the advantages of simple structure, easiness in manufacturing, good repeatability and the like.

Owner:SHANGHAI UNIV

High pressure capillary micro-fluidic valve device and a method of fabricating same

ActiveUS7204264B2Reduce impactIncrease consumptionDomestic cooling apparatusLighting and heating apparatusFreeze thawingCapillary Tubing

Owner:SANDIA NAT LAB +1

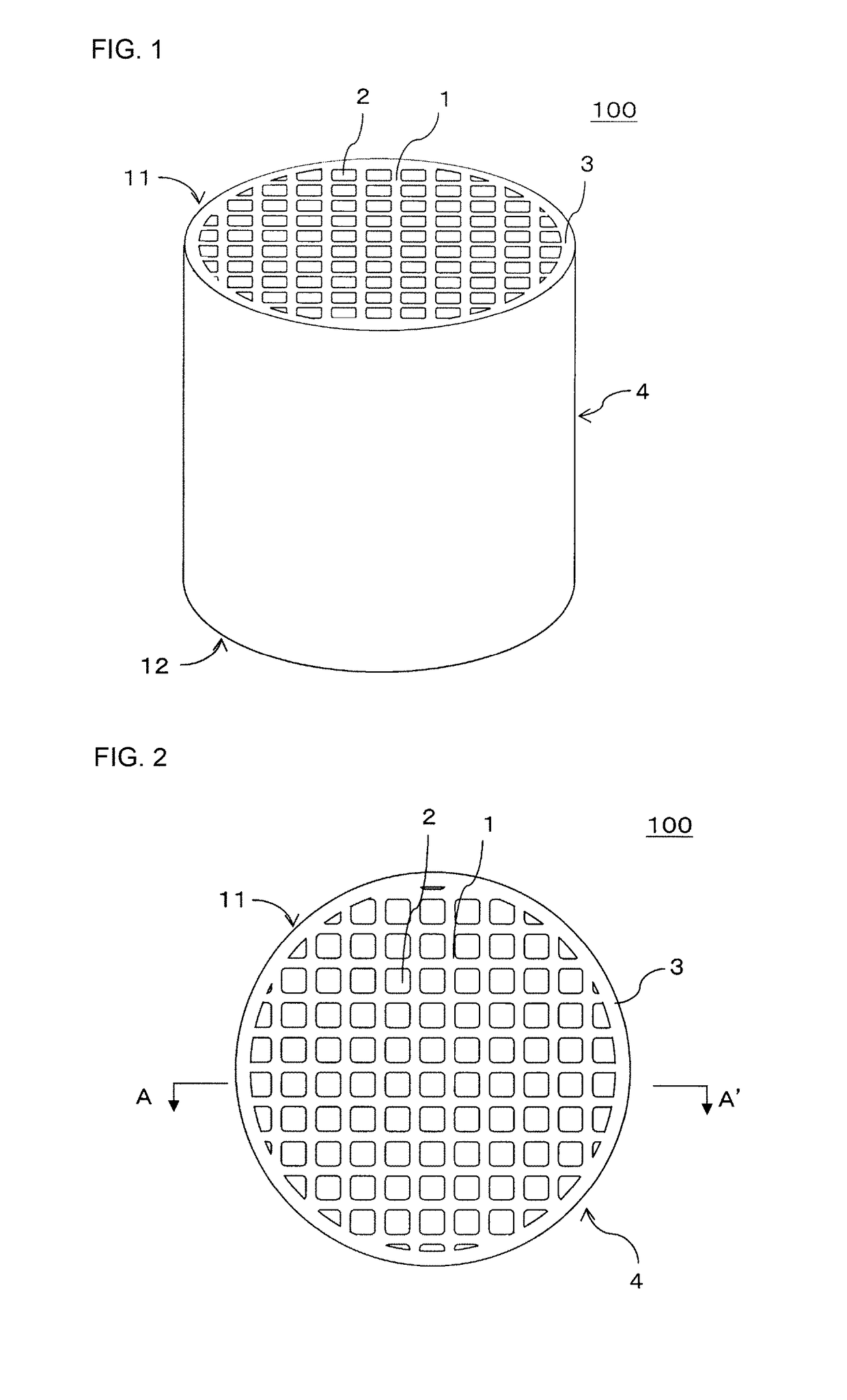

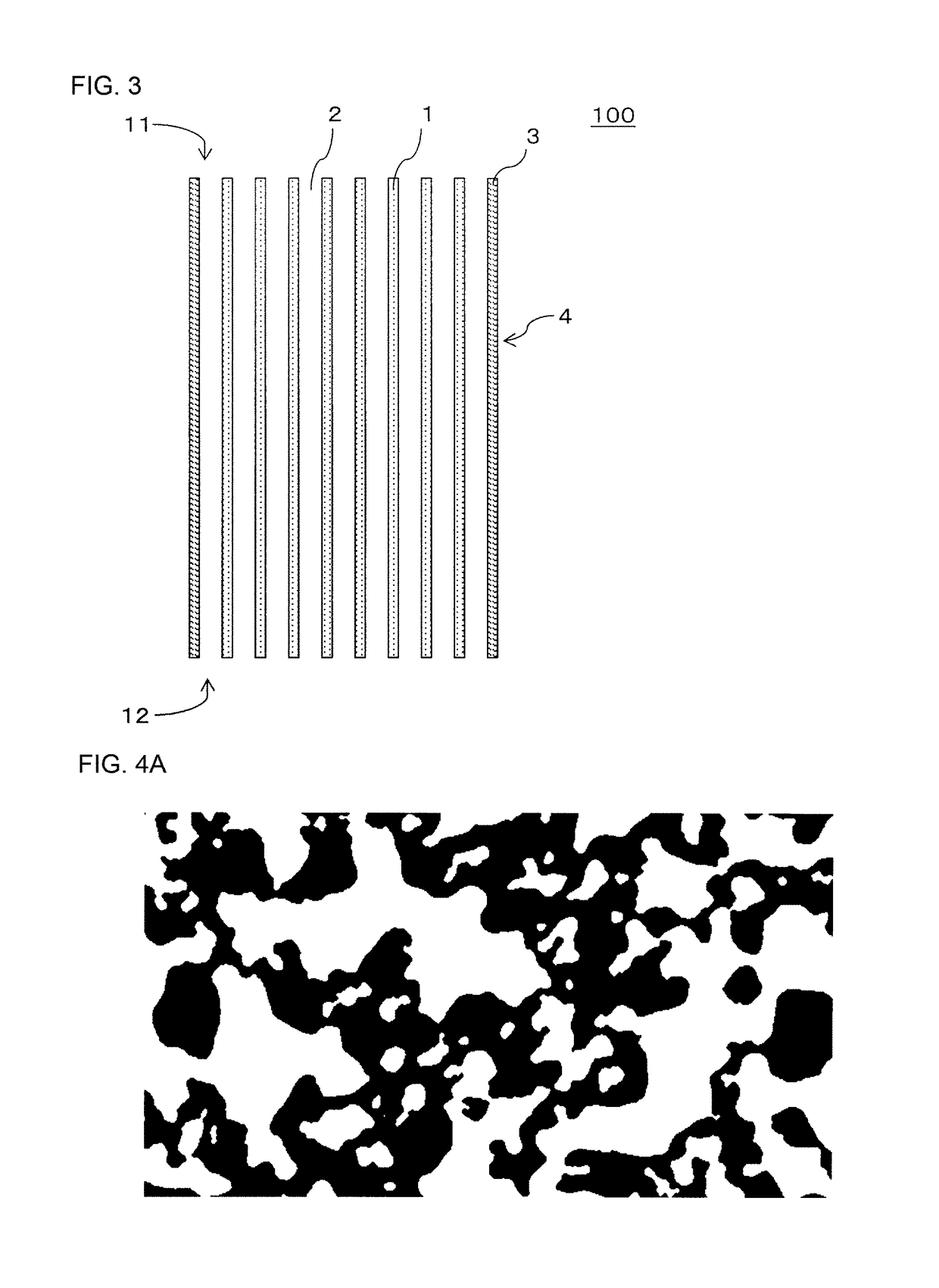

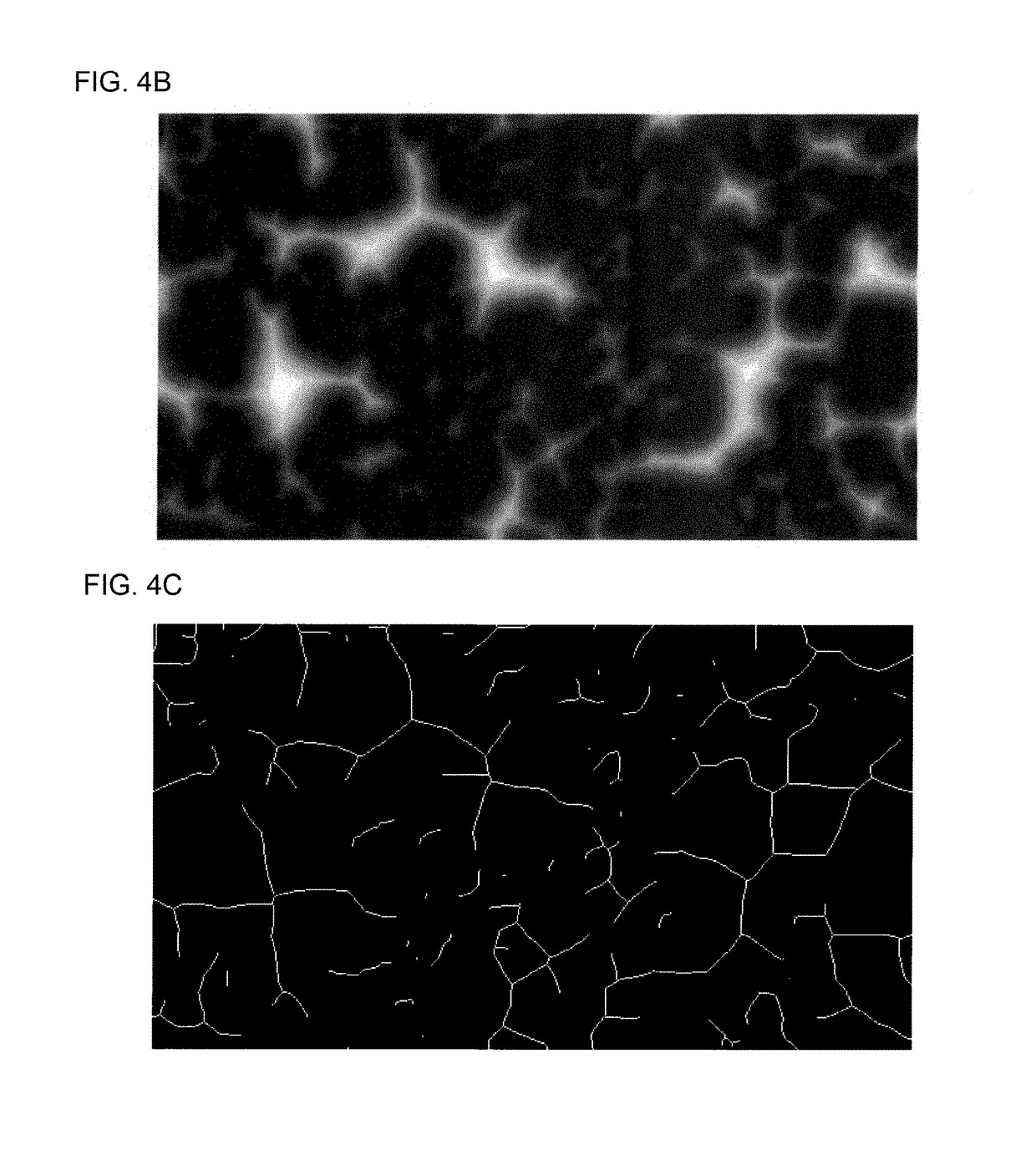

Honeycomb structure

ActiveUS10232298B2Reduced diffusivityReduced strengthPhysical/chemical process catalystsDispersed particle filtrationHoneycomb structureMaterials science

A honeycomb structure includes a pillar-shaped honeycomb structure body having a porous partition wall. The honeycomb structure body includes a plurality of cells defined by the partition wall so as to extend from a first end face to a second end face of the honeycomb structure body, the partition wall is formed by a porous body including a silicon phase as a main phase, and the silicon phase as the main phase has content of each of metals other than silicon and metals making up silicide that is 0.3 part by mass or less with respect to 100 parts by mass of silicon.

Owner:NGK INSULATORS LTD

Thermally-activated material assembly containing phase-change material and method for using same

ActiveCN102661260AMake sure to spread the wordIncrease heat transfer areaMachines/enginesMechanical power devicesEngineeringActuator

The present invention relates to a thermally-activated material assembly converting between a actuation condition and a non-actuation condition. The assembly comprises an actuator material for enabling an actuator component to actuate from a non-actuation shape to an actuation shape responding to being heated or cooled to be higher or lower than an actuation temperature, and vice versa. The assembly has a phase-change material (PCM) connected with the drive mechanism of the actuator component and connected with the drive mechanism. The drive mechanism enables the PCM to be directly jointed with the actuator component when the actuator assembly is in the non-actuation condition and to be separated from the actuator component when the actuator assembly is in the actuation assembly (i), or enables the PCM to be directly jointed with the actuator component when the actuator assembly is in the actuation condition and to be separated from the actuator component when the actuator assembly is in the non-actuation assembly element (ii).

Owner:GM GLOBAL TECH OPERATIONS LLC

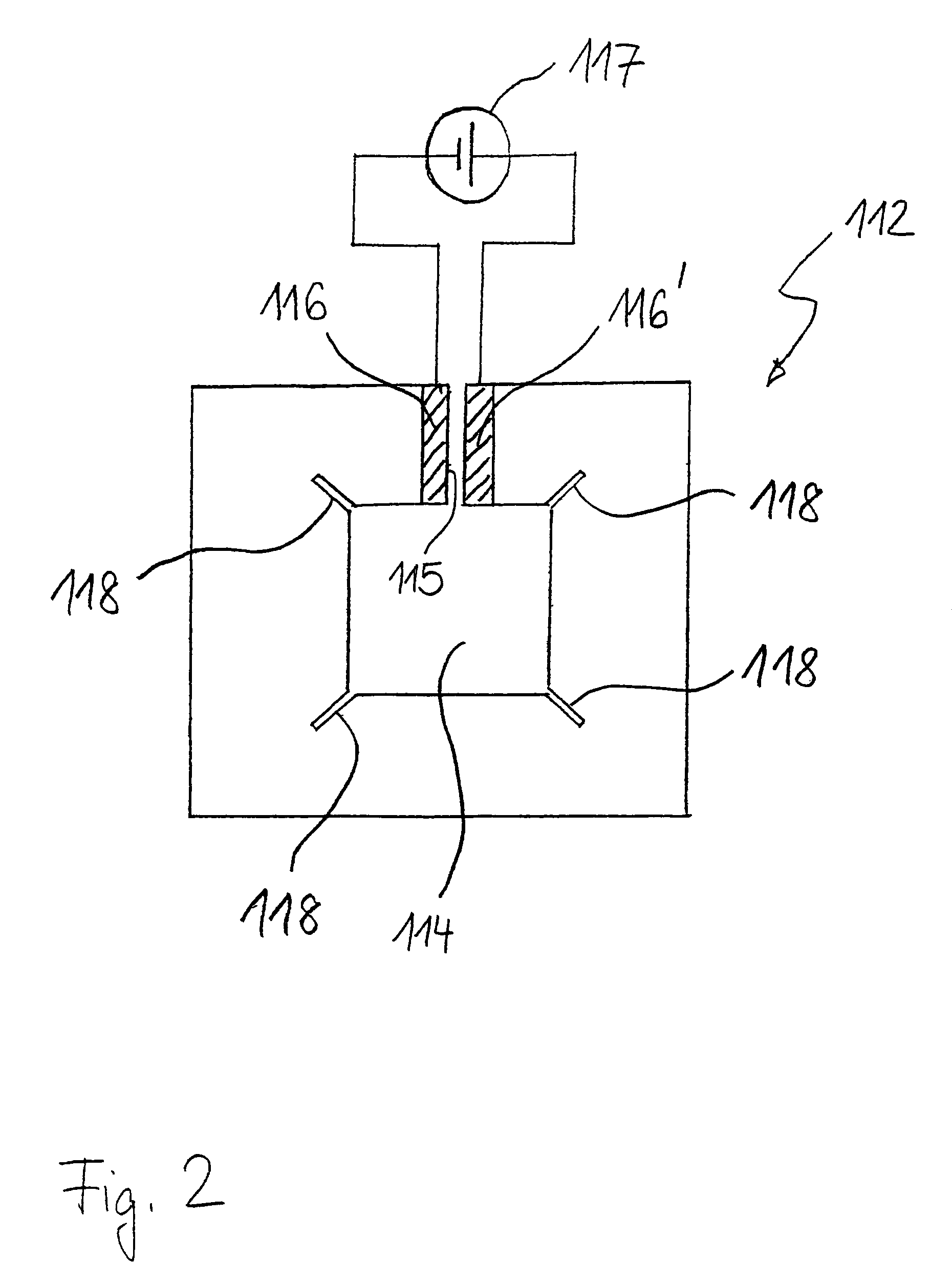

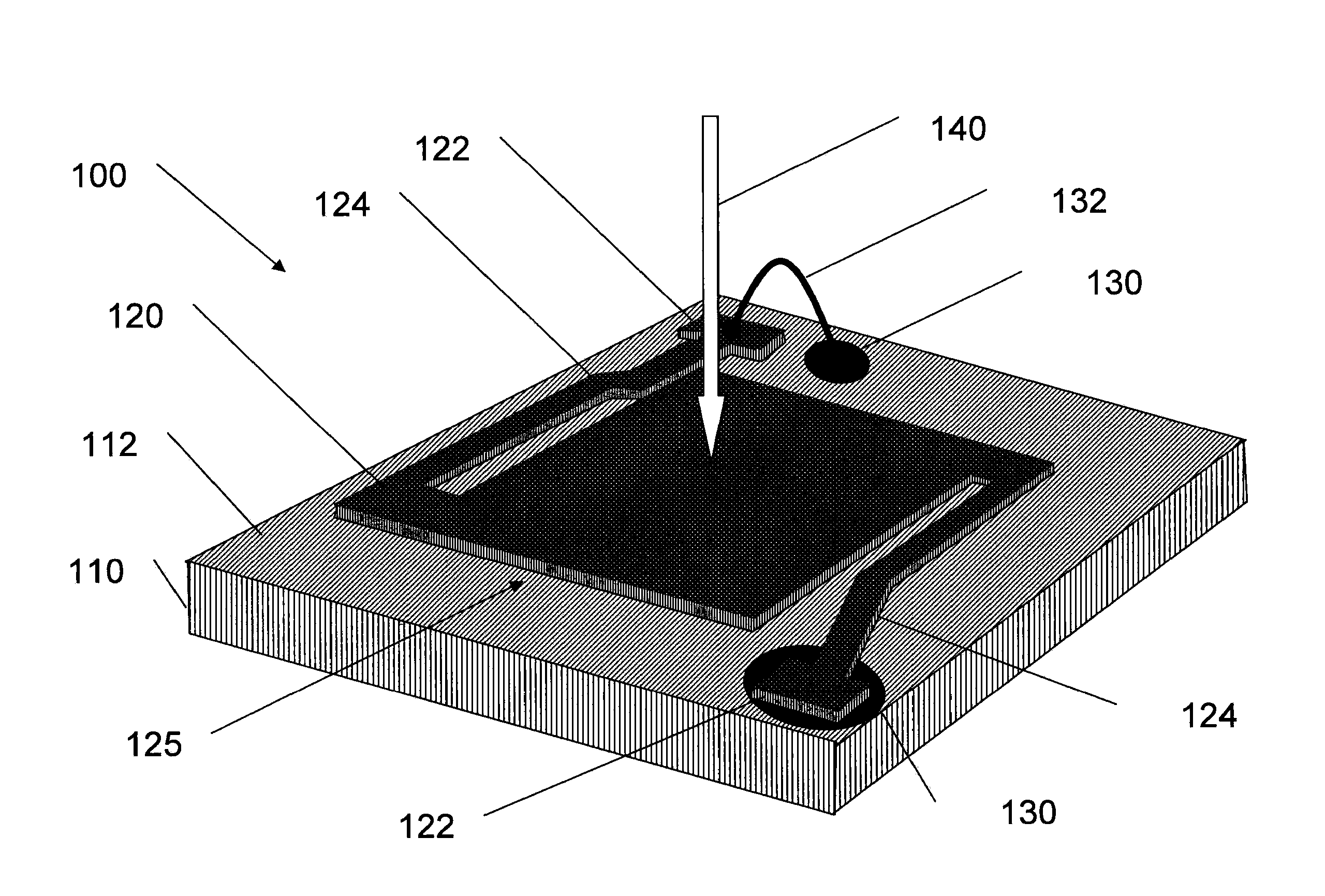

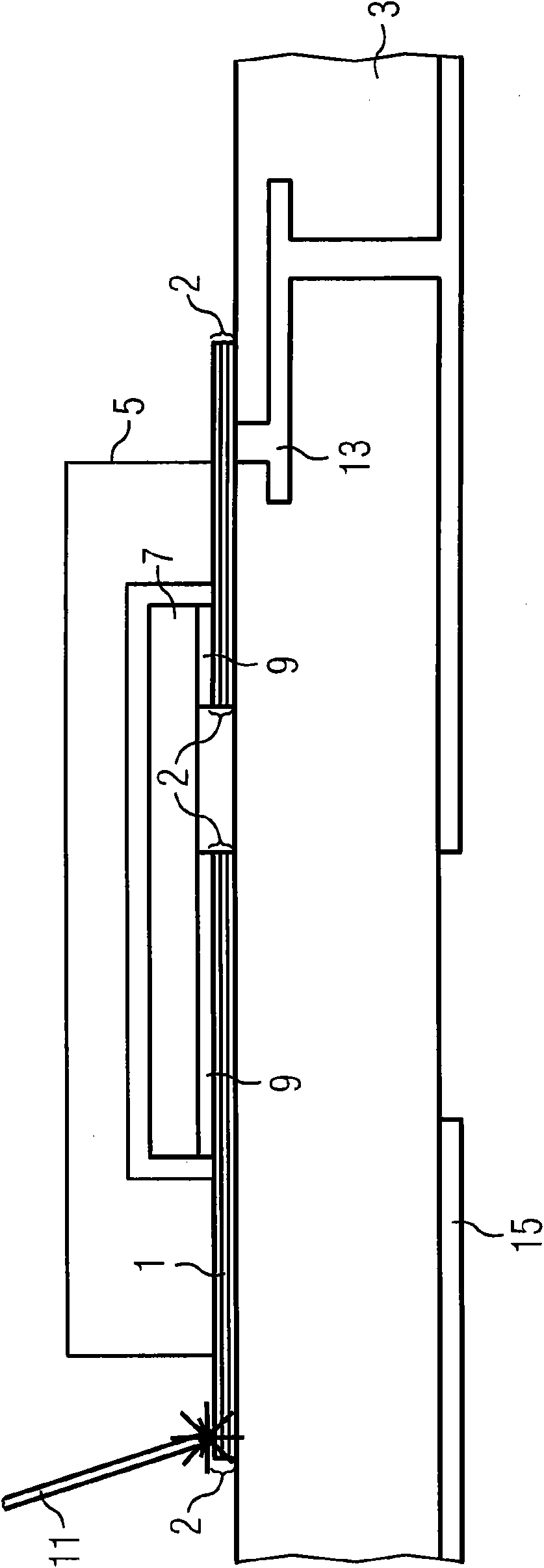

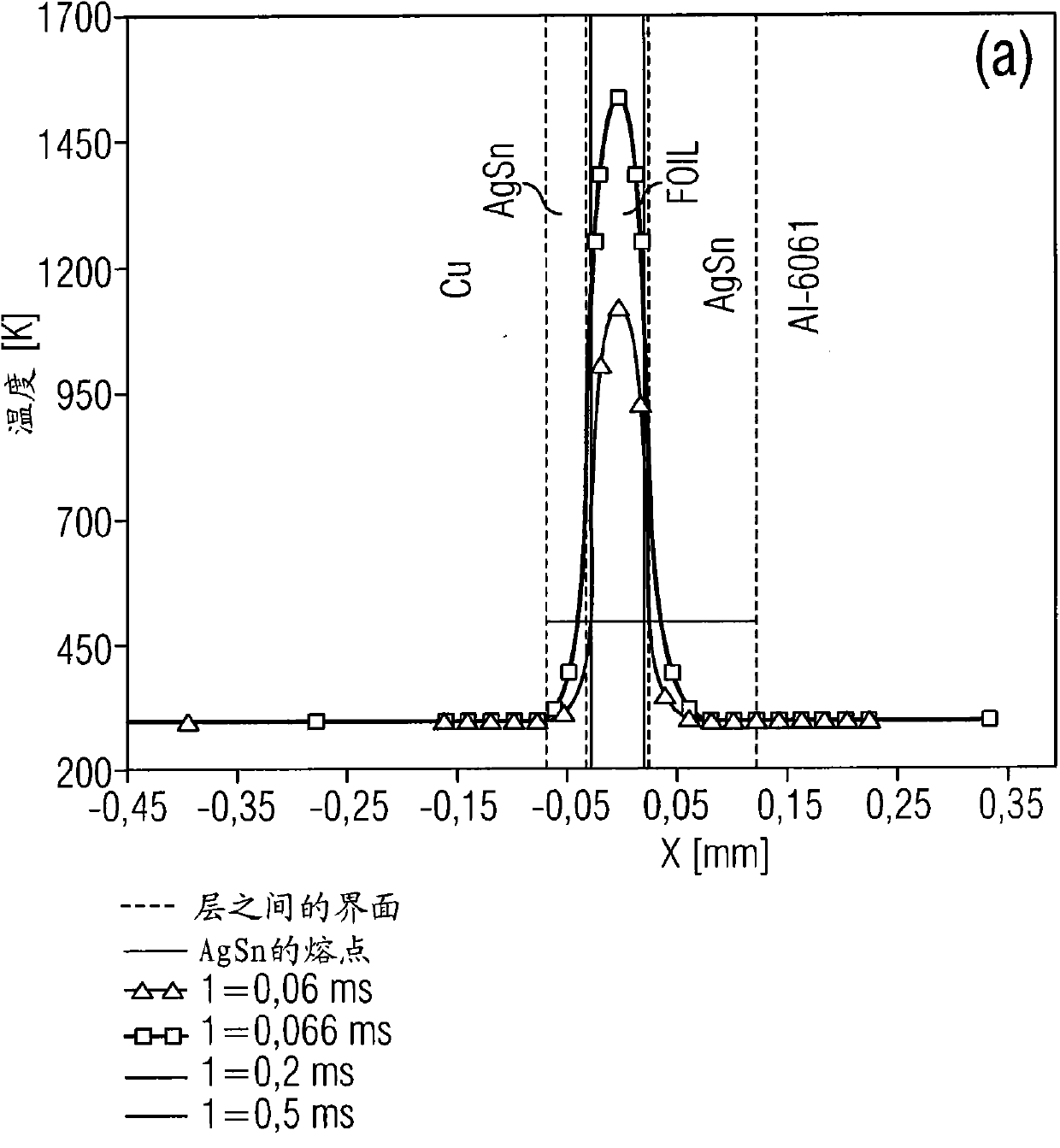

Method for producing a hermetically sealed, electrical feedthrough using exothermic nanofilm

InactiveCN102017110AImprove thermal conductivityExcellent thermal diffusivitySemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical connection

The present invention relates to a method for generating at least one electrical connection (1) from at least one electronic component (7), which is positioned on a substrate (3) inside an encapsulation (5), to outside the encapsulation (5). The functional capability of the electrical connection (1) is to be provided at ambient temperatures greater than 140 DEG C and in the event of large power losses and extreme environmental influences. The invention is characterized in that a reactive nanofilm (2), having targeted reaction, which can be triggered exothermically by laser, is used to produce hermetically sealed electrical connections (1). Using the nanofilm (2), an output of an electrical connection (1) and a contact of the electrical connection (1) to at least one further electrical contact can be provided.

Owner:SIEMENS AG

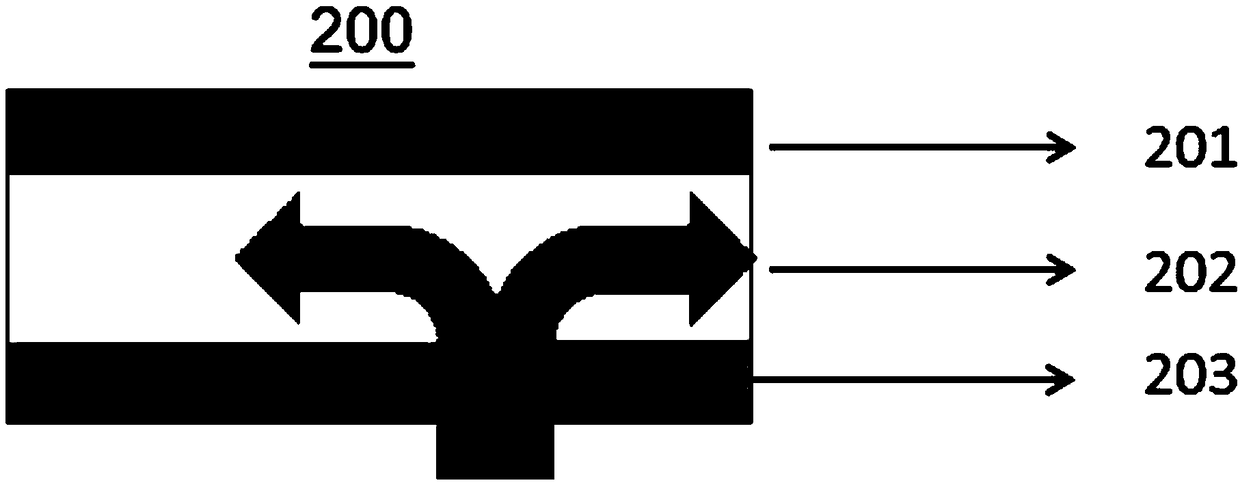

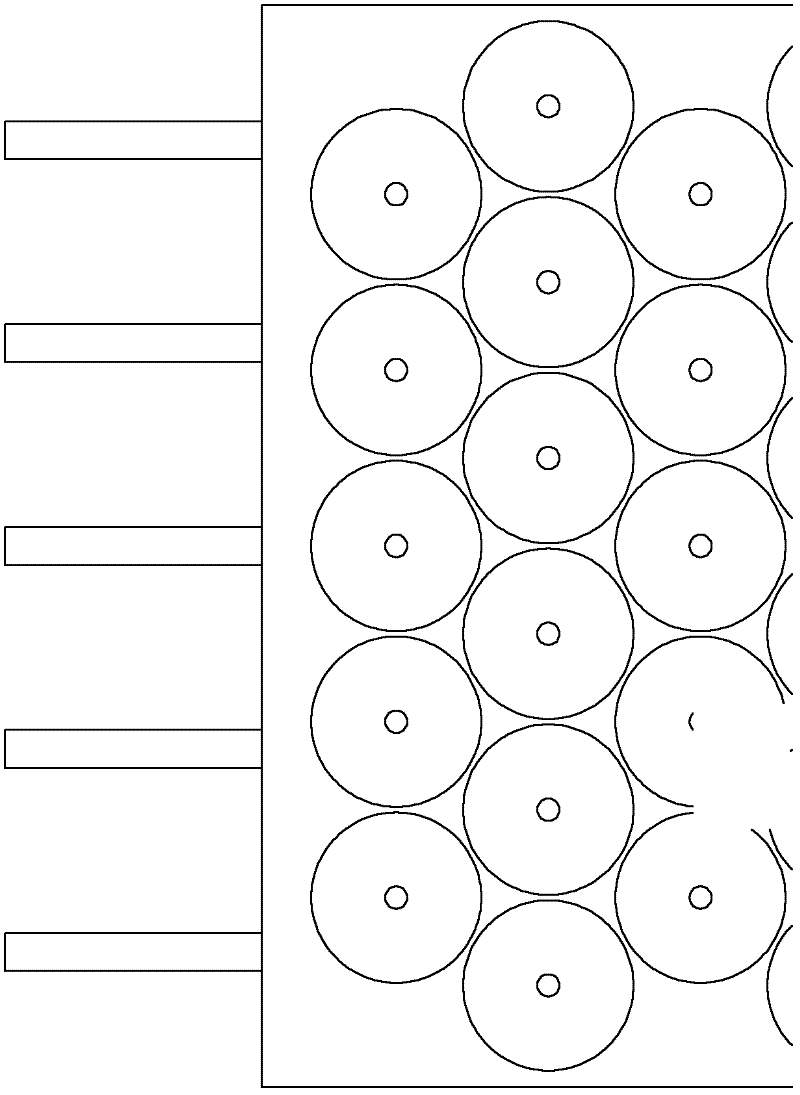

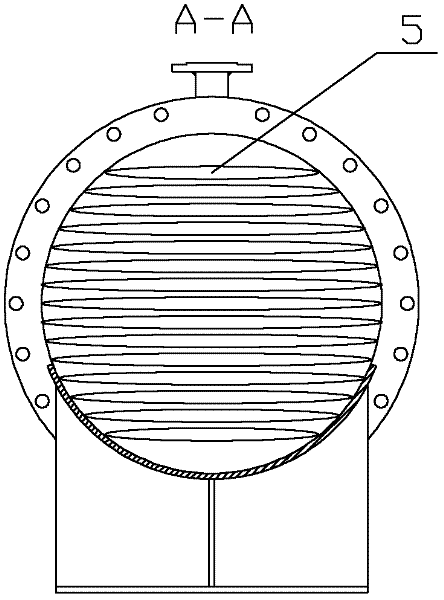

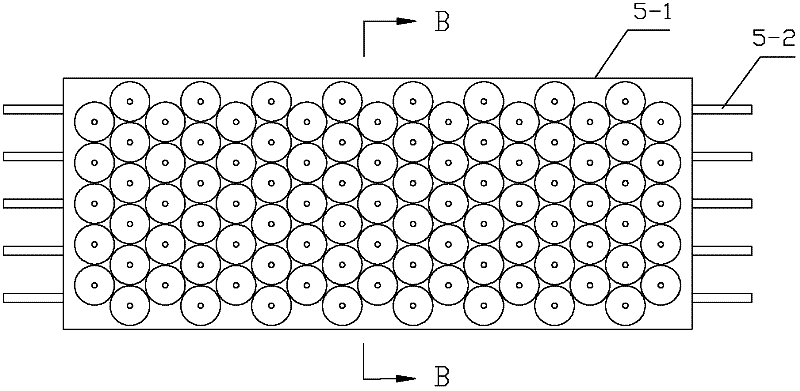

Detachable plate shell type heat exchanger

InactiveCN102353285AImprove spoiler effectImprove heat transfer performanceHeat transfer modificationLaminated elementsParallel plateEngineering

The invention discloses a detachable plate shell type heat exchanger. Pipe boxes are arranged at the two ends of a shell, two pipe plates are arranged between the pipe boxes and the shell and fixed together by flanges, a plate bundle consisting of parallel plate sheets is arranged between the pipe plates on the two sides, the two ends of each plate sheet are fixed on the two pipe plates on the two sides by plate pipes and communicated with the pipe boxes, a shell pass inlet and a shell pass outlet are formed on the shell, plate pass inlets and plate pass outlets are formed on the pipe boxes, the plate sheets comprise flow passage cavities and the plate pipes, the sections of the flow passage cavities are oblate, honeycomb structures are formed in the flow passage cavities, the two ends ofeach flow passage cavity are welded with the plate pipes which are communicated with the flow passage cavity, the plate pipes are inserted into the pipe holes of the pipe plates, and the outer surfaces of the plate pipes and the pipe holes are sealed by internal pipe plate compacting sealing rings and external pipe plate compacting sealing rings; the plate sheets comprise long plate sheets and short plate sheets, so that a shell pass has a multi-shell pass structure; and flow passages among the plate sheets are separated and supported by pull rods. The detachable plate shell type heat exchanger has high heat exchanging performance and is convenient to disassemble, wash, replace and assemble.

Owner:SOUTH CHINA UNIV OF TECH

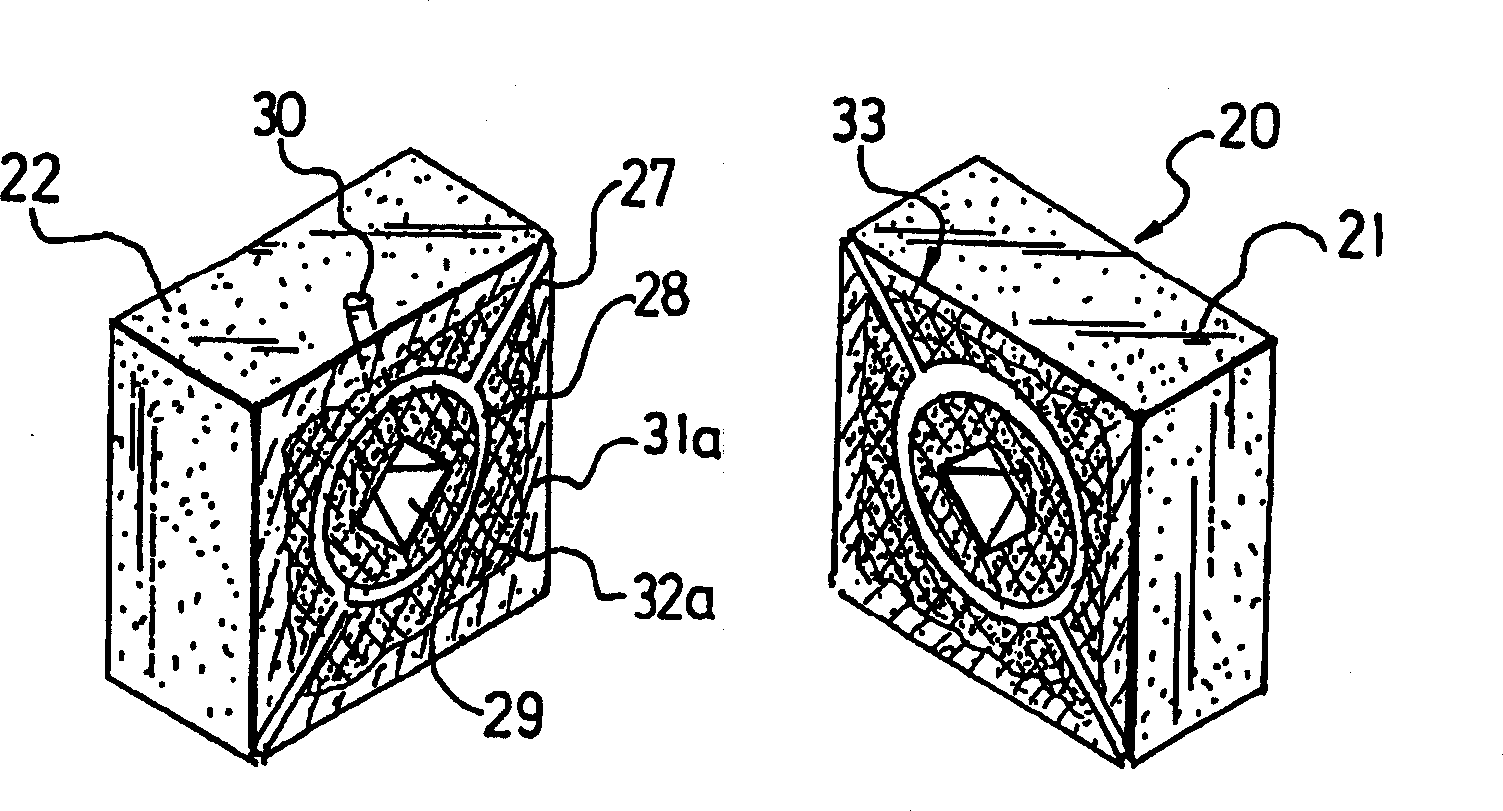

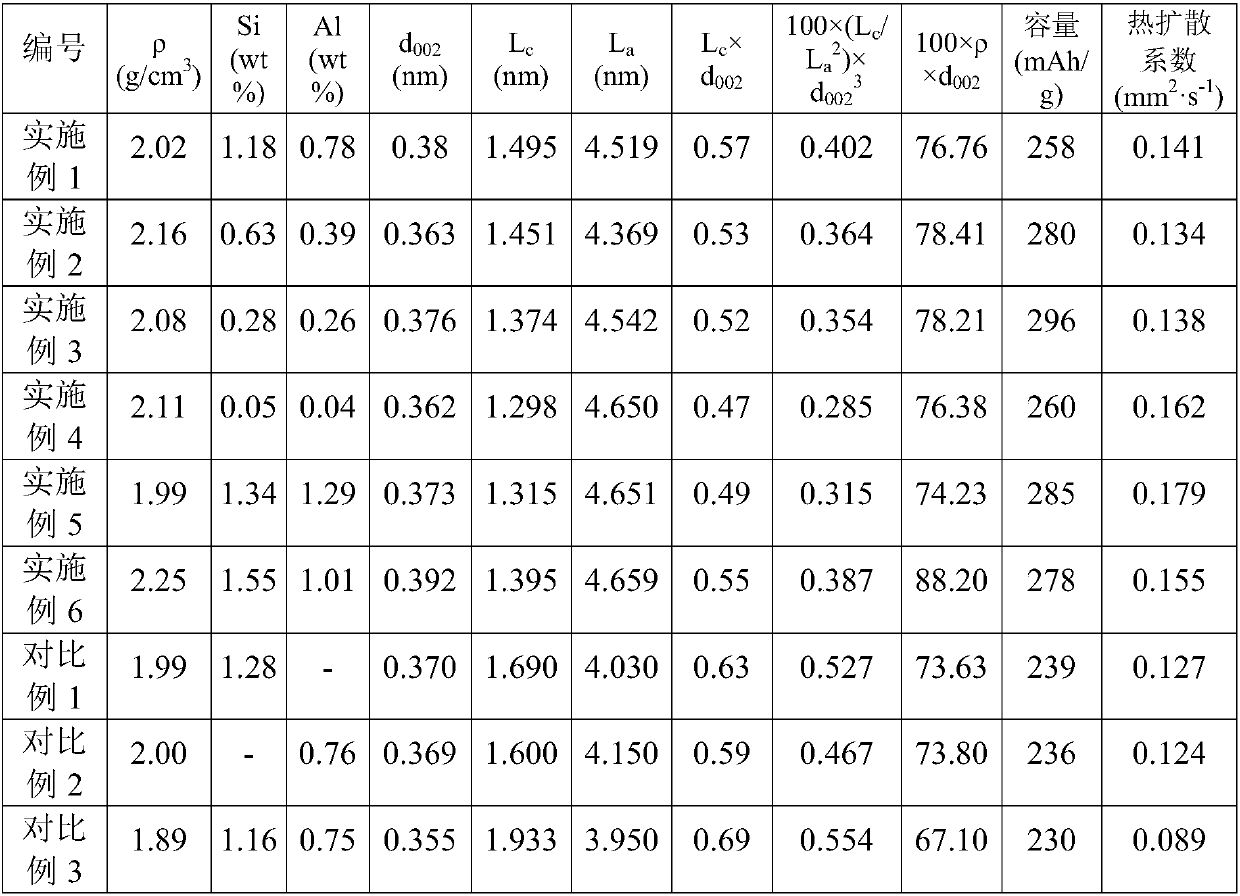

Amorphous carbon material and preparing method and application

ActiveCN108565401AHigh thermal diffusivityGood heat transfer performanceCarbon compoundsElectrode thermal treatmentPowder xrdSpectral analysis

The invention relates to the field of carbon materials, in particular to an amorphous carbon material and a preparing method and application. The amorphous carbon material is characterized in that thereal density rho of the amorphous carbon material and the interlayer spacing d002 obtained through powder XRD spectral analysis meet the relation: 100*rho*d002> / =70; the interlayer spacing d002, La and Lc meet the relation: Lc*d002 < / =0.58 and 100*(Lc / La2)*d0023< / =0.425; on the basis of the total mass of the amorphous carbon material, the amorphous carbon material contains 0.001-2% of silicon component and 0.001-2% of aluminum component. The prepared amorphous carbon material has good heat conductivity and can provide high battery capacity.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Stockpot

The present invention relates to a stockpot, and belongs to the technical field of pots. According to the stockpot, a pot body is prepared by a graphite composite material, and a non-stick layer is coated to an internal surface of the pot. The graphite composite material comprises 1-3% of glass fibre, 5-10% of talcum powder, 0.3-2% of aluminum powder, 0.1-0.5% of titanium powder, 0.5-2% of magnesium oxide, 0.5-2% of silicon nitride, 0.5-3% of calcium carbonate and 30-50% of ceramic clay, the balance being graphite. The stockpot is prepared by the graphite composite material with reasonable compatibility. The prepared stockpot has light weight, a large heat-resisting range, a small thermal expansion coefficient, high thermal diffusivity and thermal conductivity and rapid heat transfer, andis heated uniformly. Furthermore, acrylic acid is added to the coating of the non-stick layer, so that the gap of molten resin particles can be tensioned by the capillary effect generated due to the fact that the surface coating is volatilized away when sintered to form a film, high-temperature degradation of a little PTFE is suppressed, and therefore yellow stain of the surface coating is reduced.

Owner:NINGBO BEEFIT KITCHENWARE

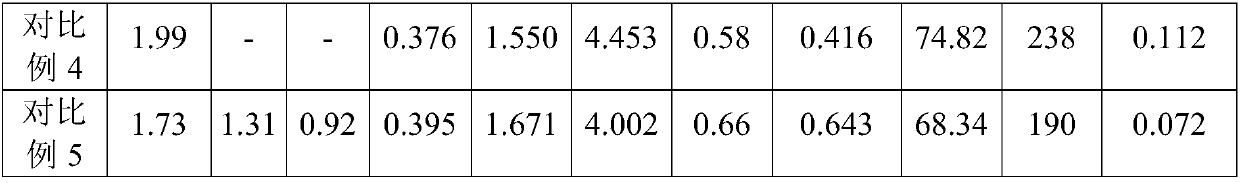

Ag alloy thermal diffusion control film used in magnetic recording medium for thermally assisted recording, magnetic recording medium for thermally assisted recording, and sputtering target

InactiveCN102612713AFast heat conductionExcellent thermal diffusivityVacuum evaporation coatingSputtering coatingHeat resistanceMagnetic media

Disclosed is an Ag alloy thermal diffusion control film to be used in a magnetic medium for thermally assisted recording, said thermal diffusion control film maintaining a high heat conductivity, and at the same time, having all of a high thermal diffusivity, a smooth surface roughness, and a high heat resistance. The Ag alloy thermal diffusion control film, is composed of an Ag alloy having Ag as a main component, and satisfies a surface roughness (Ra) of 1.0 nm or less, a heat conductivity of 100W / (mK) or more, and a thermal diffusivity of 4.010-5m2 / sec or more.

Owner:KOBE STEEL LTD

PA6-based thermal conductive composite material and preparation method thereof

InactiveCN109456593AExcellent mechanical properties and thermal conductivityHigh thermal conductivityHeat-exchange elementsMaleic anhydrideInjection molding process

The invention provides a PA6-based thermal conductive composite material and a preparation method thereof. High-flowability PA6, HDPE (high-density polyethylene), surface treated thermal conductive fillers and maleic anhydride bulking agents are uniformly premixed and added from a main feeding port of a double-screw extruder, carbon fibers are added from a glass fiber port, extruded and granulatedto obtain the PA6-based thermal conductive composite material. The composite material prepared by the preparation method has high thermal conductivity, high thermal diffusion coefficient, good mechanical performances and excellent comprehensive performances, is easy to form and can be widely applied to the field of thermal conductive materials such as thermal conductive plastic pipelines, automobile parts, LED (light-emitting diode) lamp cooling devices and the like, and the parts can be prepared by an injection molding process.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com