Patents

Literature

179results about How to "Improve spoiler effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

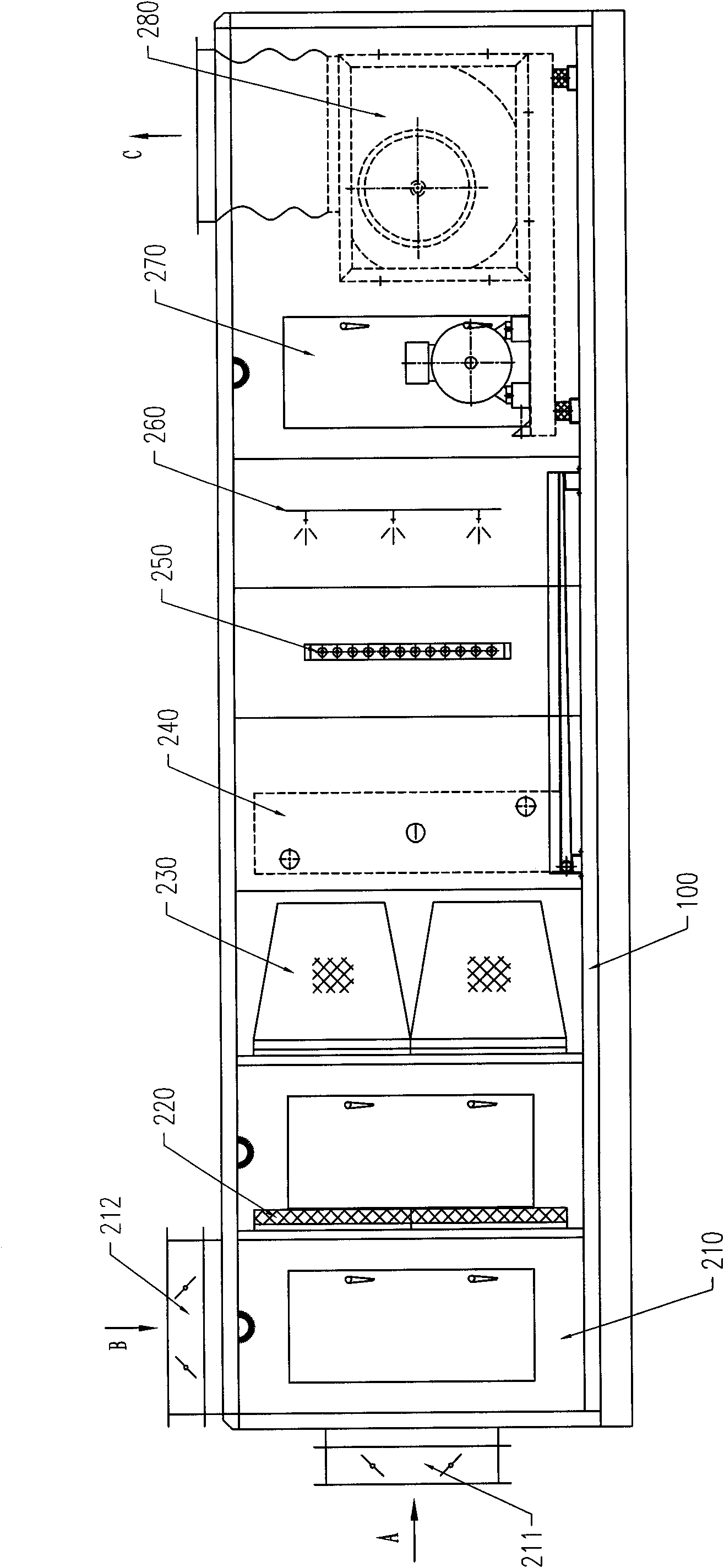

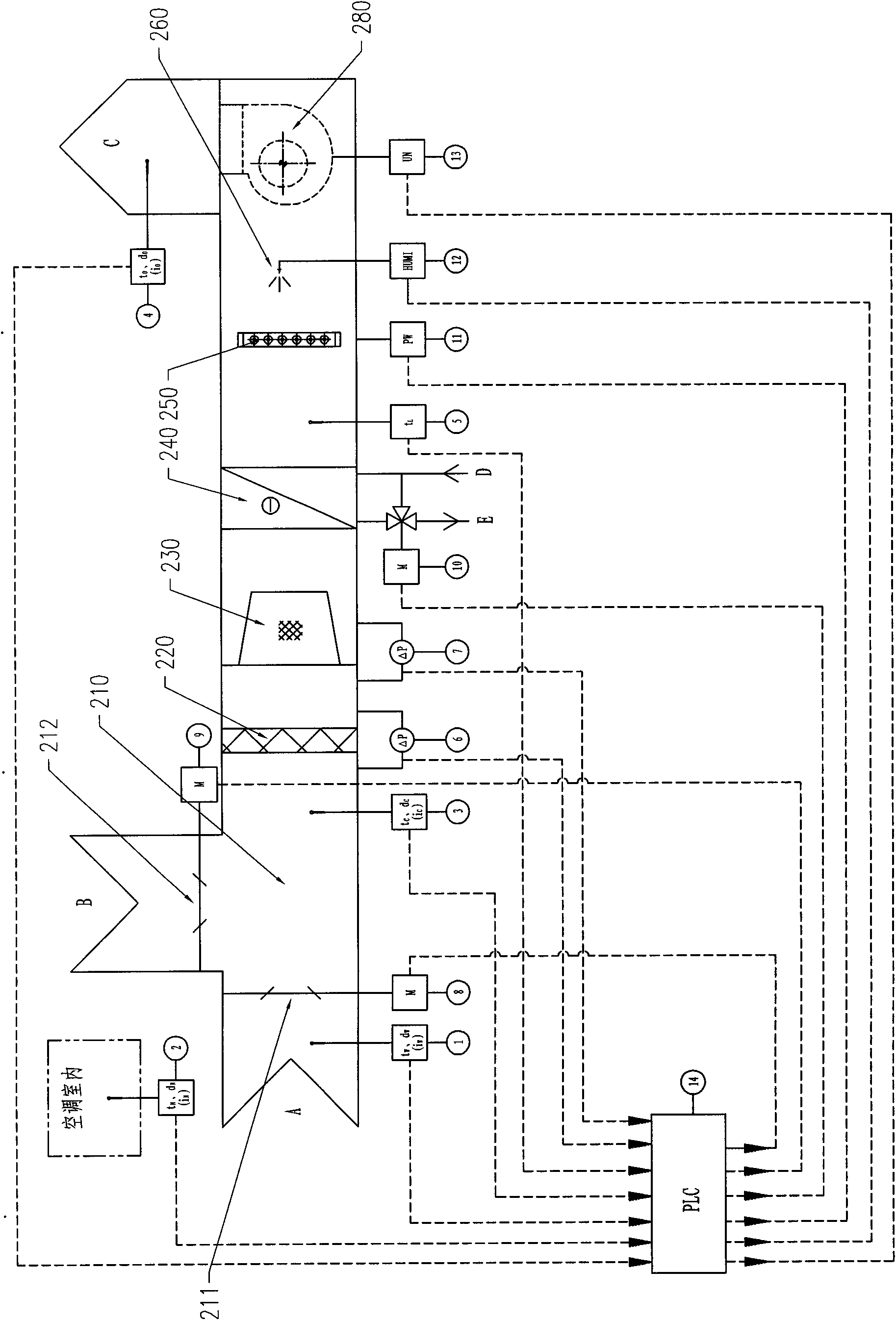

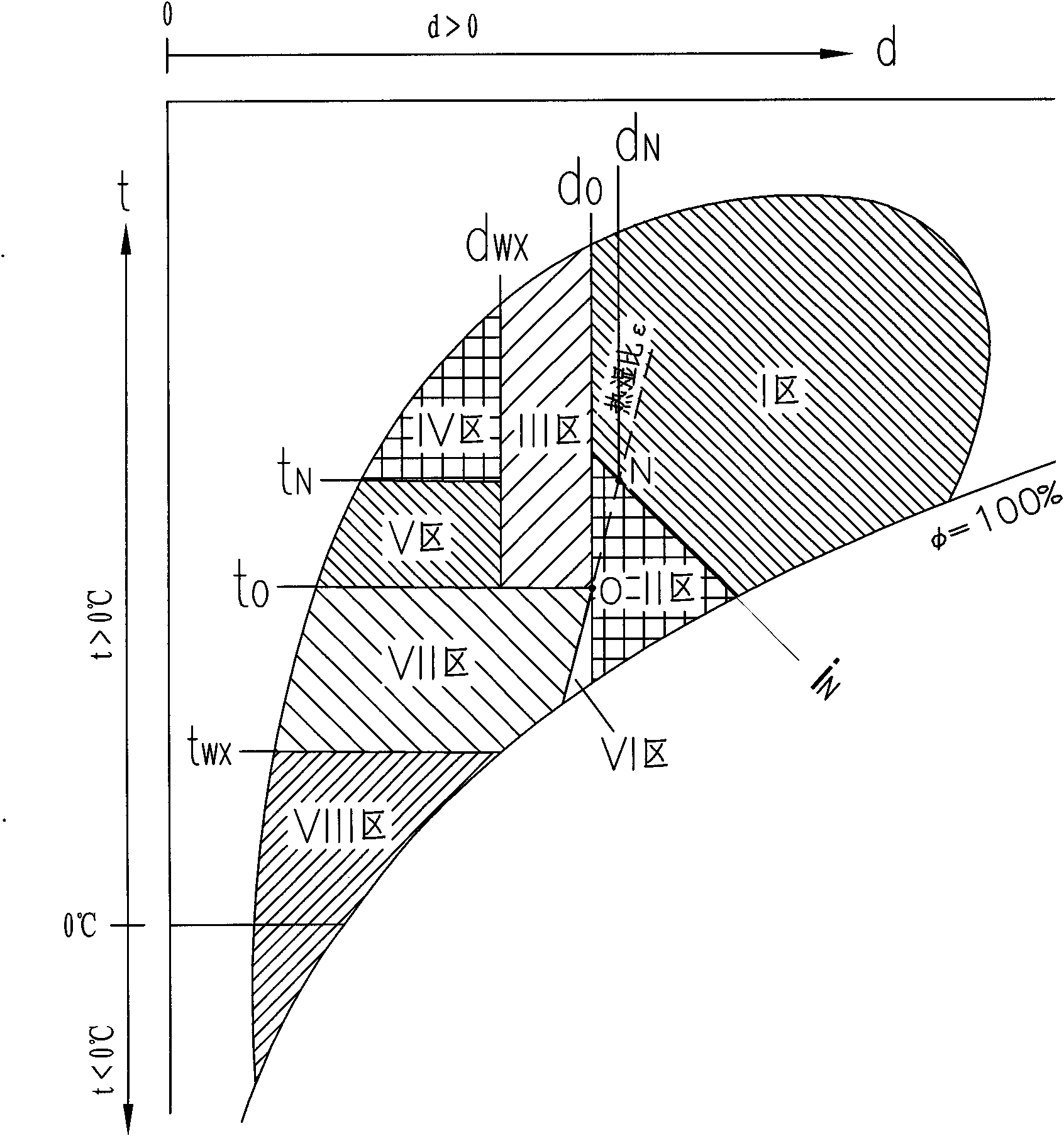

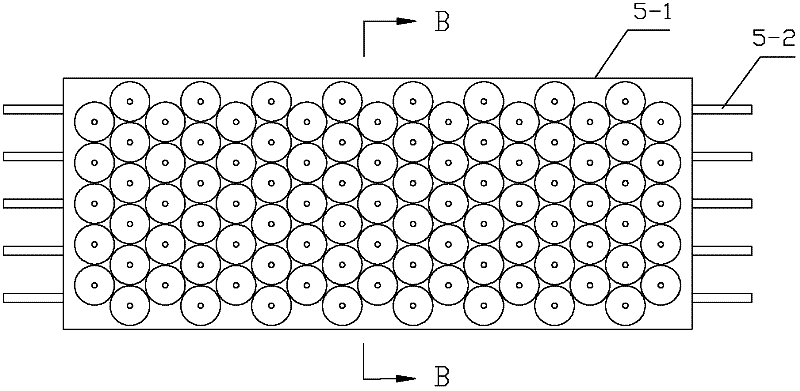

Multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with thermometal compound box body structure

ActiveCN101782263AReduce resistanceFully contactedSpace heating and ventilation safety systemsLighting and heating apparatusControl systemNuclear power

The invention relates to a multi-operating mode energy-saving controlled combined type thermostatic and humidistatic air conditioning unit with a thermometal compound box body structure special for nuclear power stations. The air conditioning unit comprises a control system and a box body structure, wherein a primary-efficiency filter, a medium-efficiency filter, a surface cooler, a heater, a humidifier and a blow-off device are sequentially arranged in the box body; the front side of the primary-efficiency filter is provided with a fresh air and return air mixing section, and inlets of fresh air and return air are respectively provided with a fresh air proportioning valve and a return air proportioning valve; the control system adopts a programmable logic controller (PLC) and adopts air conditioning multi-operating mode zone control to realize the energy-saving operation of the unit; the surface cooler adopts a large temperature difference cold water heat exchanging technology and can save the investment and operation expenses of a water system; and the box body adopts a double-layer compound structure and an anti-shock device to meet the special requirements on the nuclear power stations. The invention has the characteristics of high efficiency, energy saving, good tightness, strong anti-shock capacity, safety, reliability, long service life, and the like.

Owner:广东吉荣核电设备暖通技术有限公司

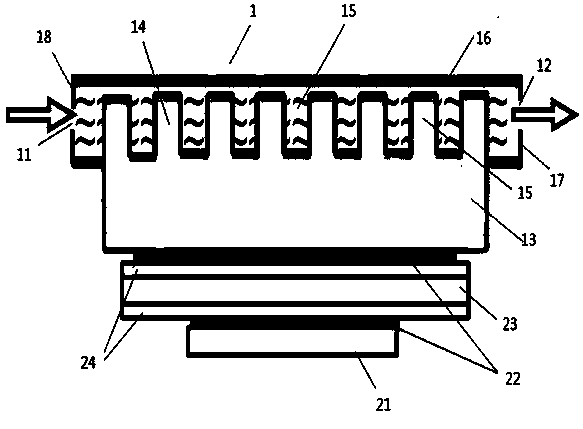

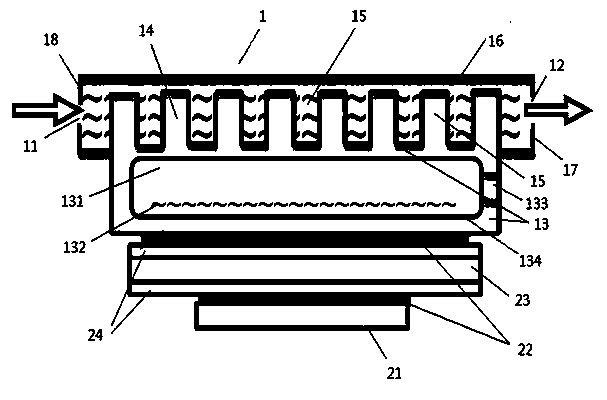

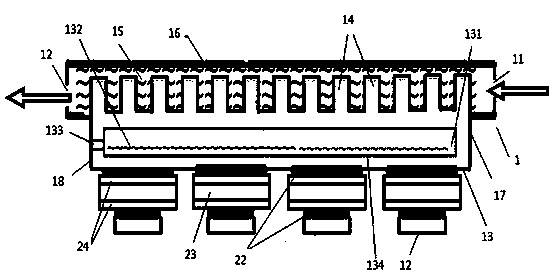

Radiating packaging structure of semiconductor power device

InactiveCN103413794AImprove cooling effectCompact structureSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceSilica gel

The invention provides a radiating packaging structure of a semiconductor power device. The radiating packaging structure of the semiconductor power device is provided with a radiating shell body containing cooling liquid, wherein the inner side of a cover plate of the radiating shell body is provided with radiating assemblies and further forms a fluid flow passage, and meanwhile the other side of the cover plate serves as a substrate of the semiconductor power device, namely, the radiating packaging structure and the semiconductor power devices are integrally formed, so the structure is very compact. The radiating packaging structure is characterized in that due to the integrated packaging structure, heat resistance produced by silica gel with a low heat conductivity coefficient is avoided, the radiating assemblies are located on the other side (namely the substrate) of the cover plate, heat from the power device can be directly dissipated, and meanwhile, the radiating effect of the semiconductor power device is greatly improved under the action of turbulent flow of the radiating assemblies.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

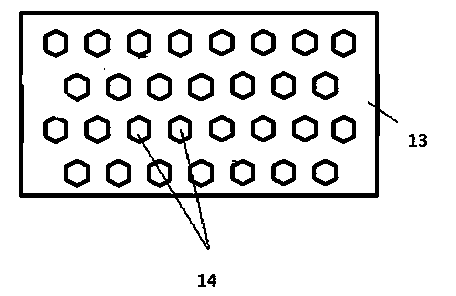

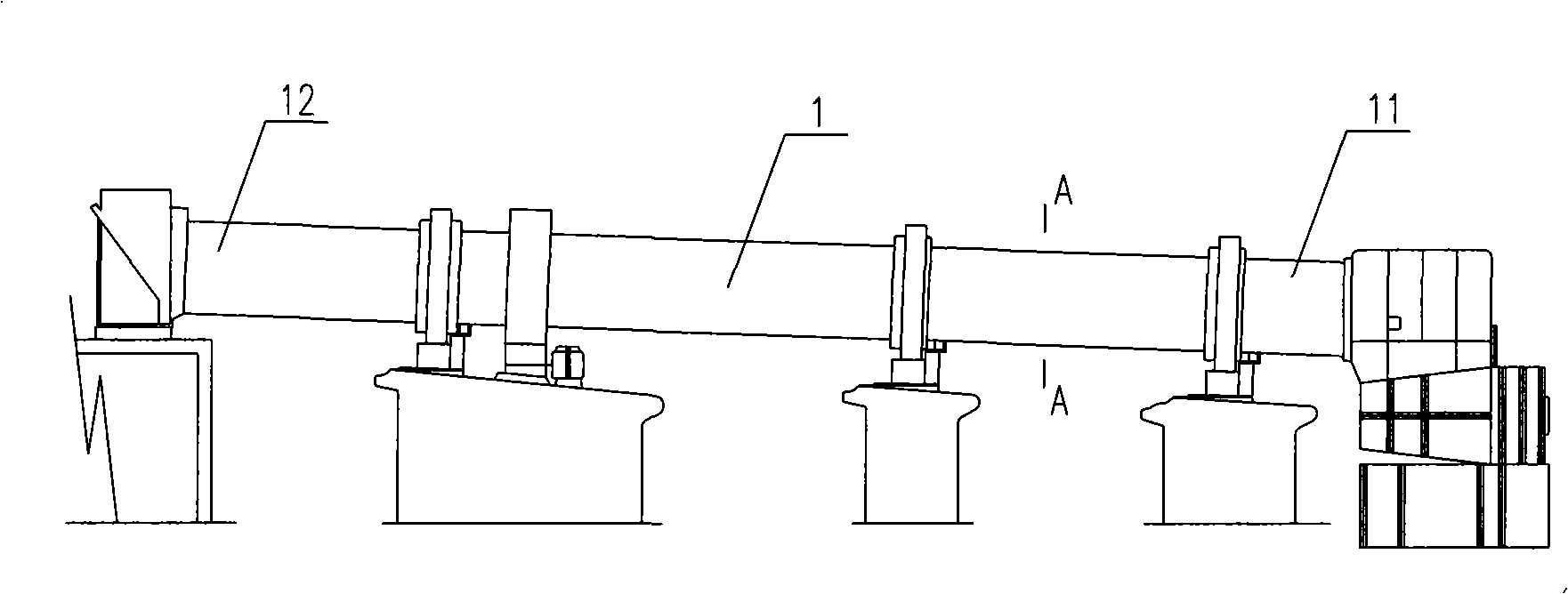

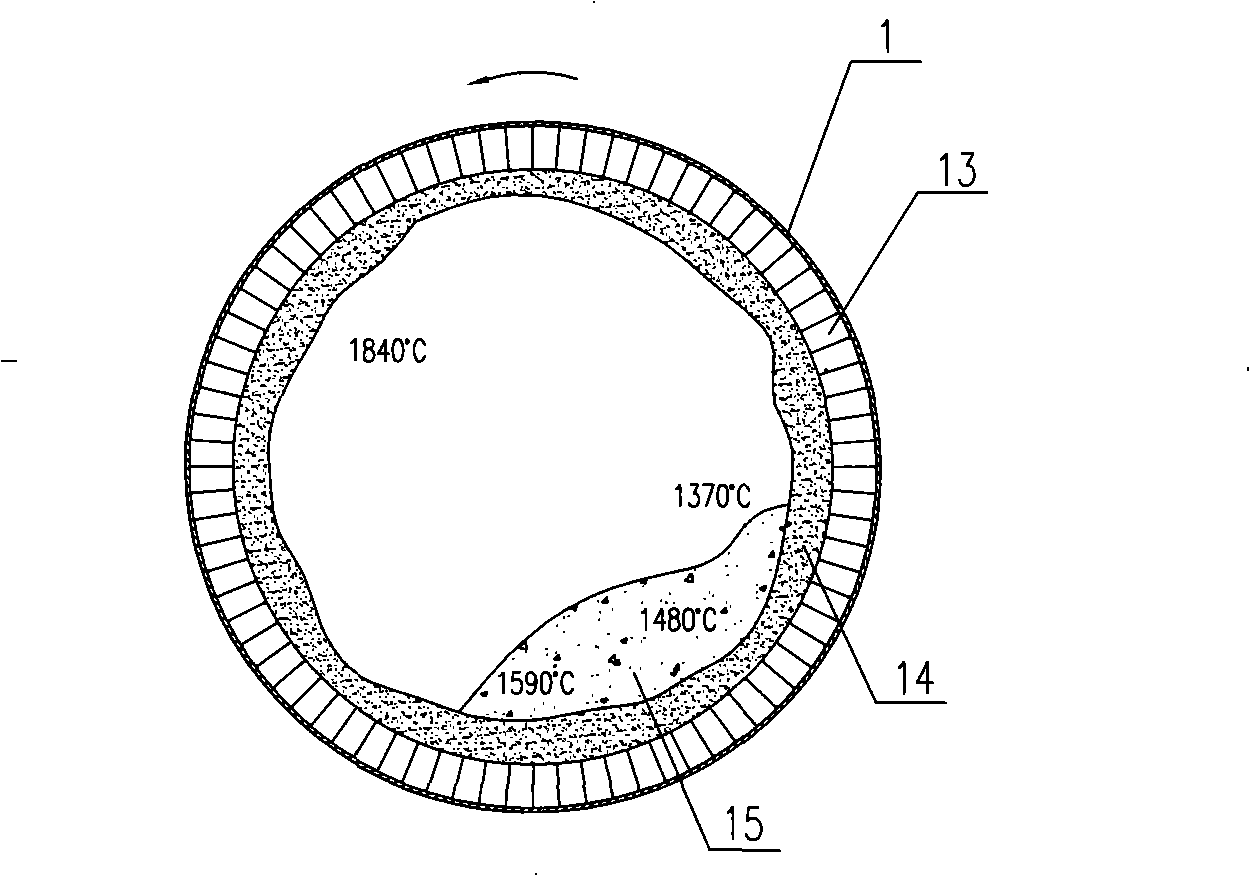

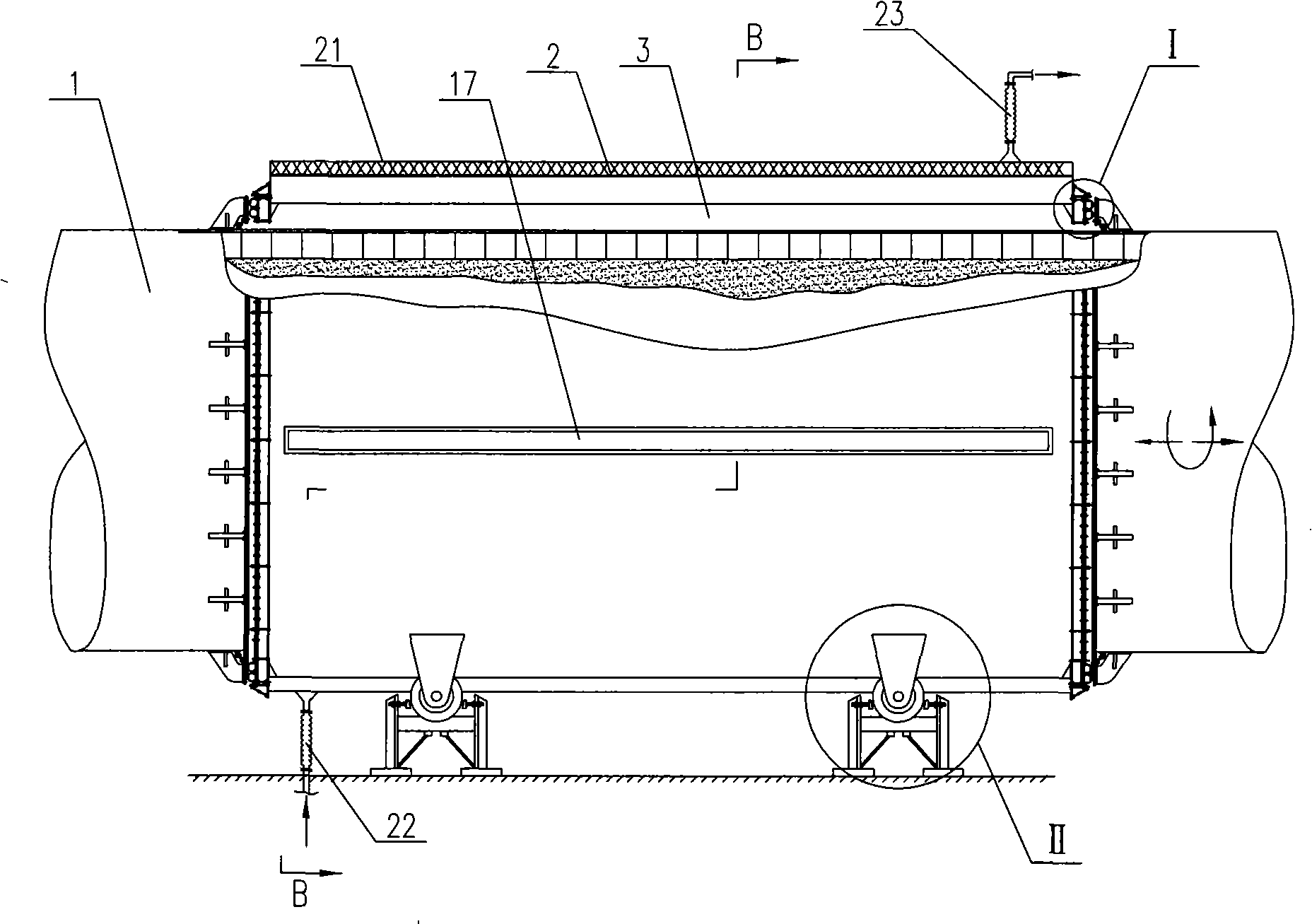

Cement rotary kiln barrel radiation, reclaiming and utilizing device

ActiveCN101290190APracticalSignificant energy saving and economic benefitsRotary drum furnacesIncreasing energy efficiencyCement kilnEngineering

The invention discloses a device for recycling heat radiated from a rotary cement kiln shell body, comprising a plurality of heat transfer covers arranged on the upper section of the rotary cement kiln shell body. Each of the external surfaces of the heat transfer covers is provided with an insulating layer, sealing equipment is arranged between the two ends of the heat transfer covers and the rotary cement kiln shell body, a sealing heat transfer cavity is formed by the inner surfaces of the heat transfer covers and the external surface of the rotary kiln shell body via the sealing equipment, the bottom of the heat transfer covers is provided with an inlet which is communicated with the heat transfer cavity, the top of the heat transfer covers is provided with an outlet which is communicated with the heat transfer cavity, the bottom of the heat transfer covers is connected to a slip fitting so as to realize the axial displacement. The sealing equipment comprises a permanent seat on the external surface of the rotary cement kiln shell body, and one side of the permanent seat is provided with a dynamic sealing ring; the bottom of the dynamic seal ring is hermetically connected to the rotary cement kiln shell body by a temperature resistant rubber I, and a self-propelling stationary seal ring is arranged between the dynamic seal ring and the head face of the heat transfer cover; the top of the self-propelling stationary seal ring is hermetically connected to the head face of the heat transfer cover by a temperature resistant rubber II, the self-propelling stationary seal ring is connected to an elastic stationary seal ring, and a sealing gland is arranged between the elastic stationary seal ring and the dynamic seal ring.

Owner:天津健威泽节能环保科技股份有限公司

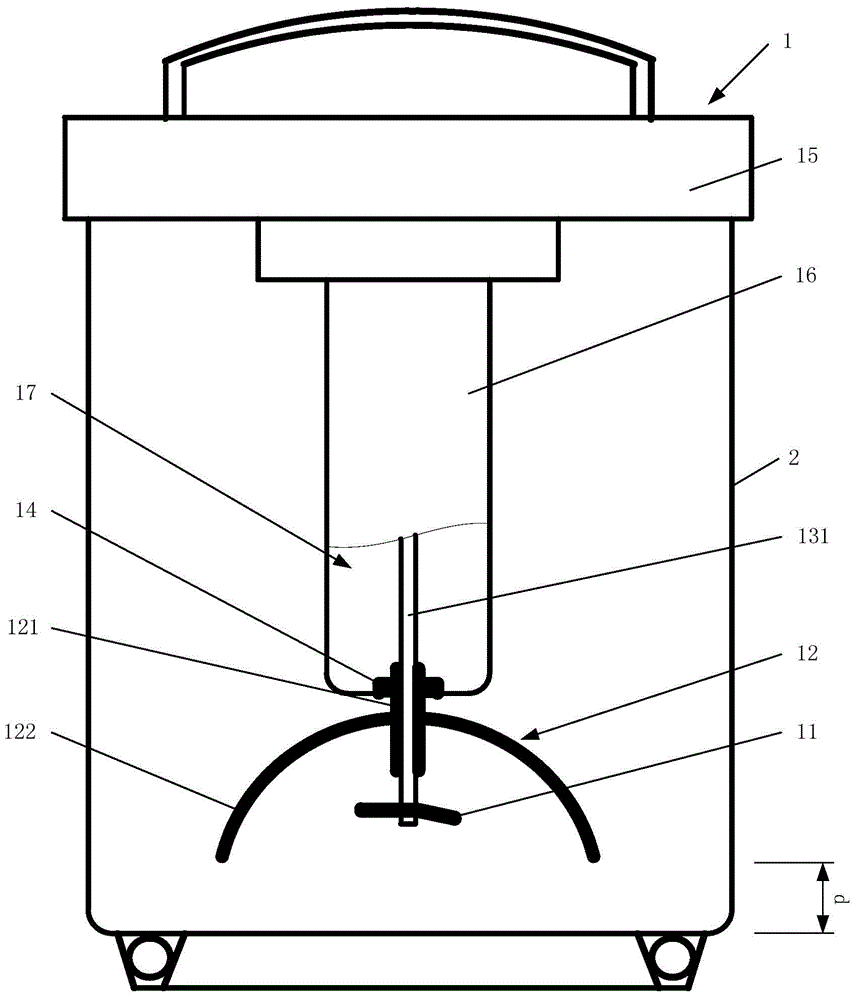

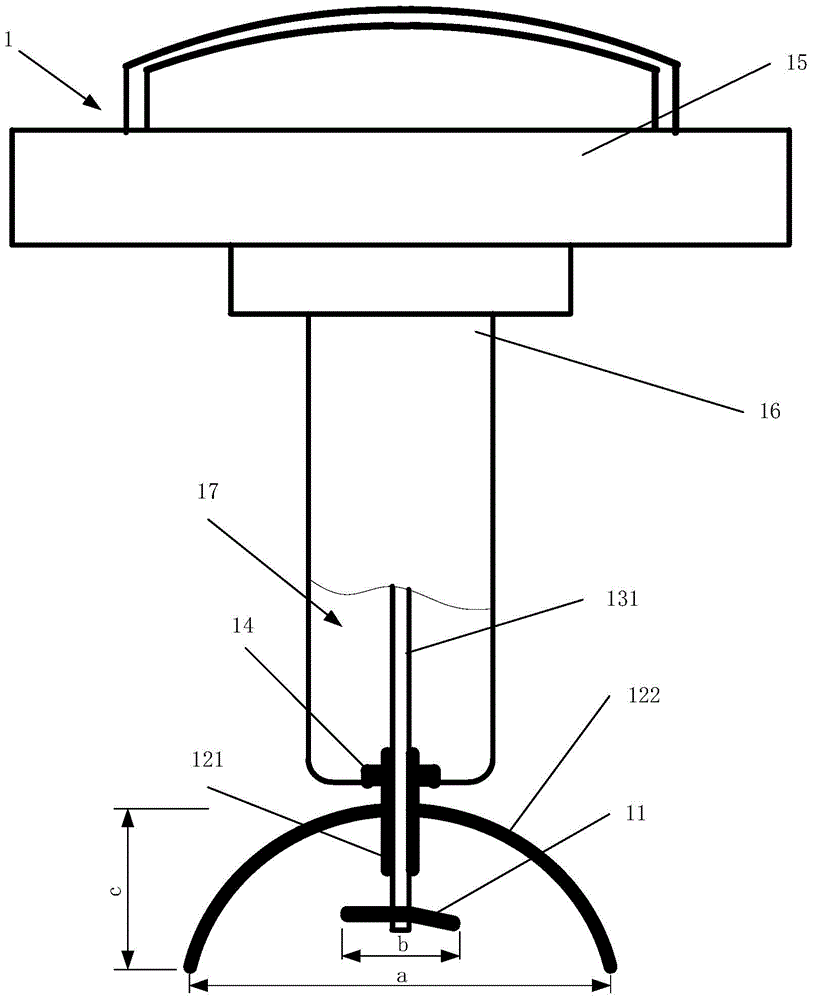

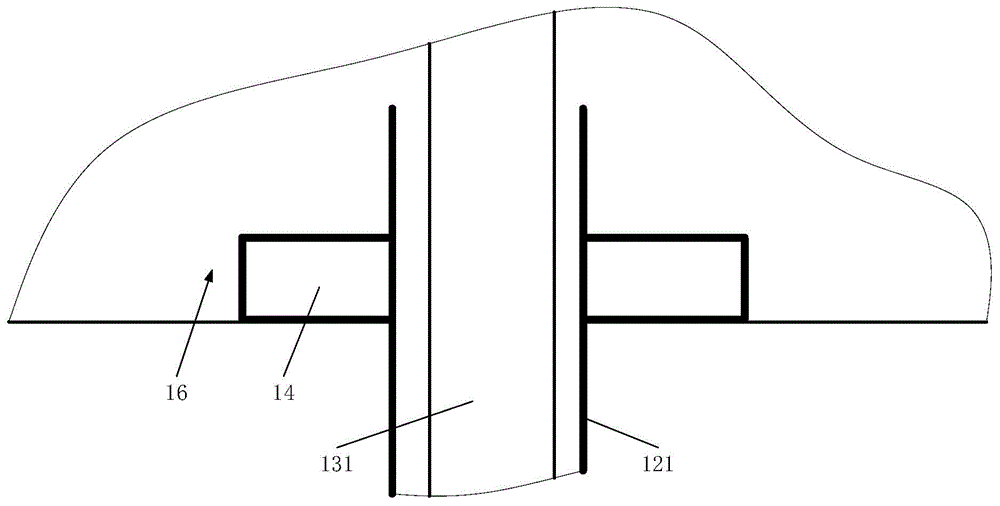

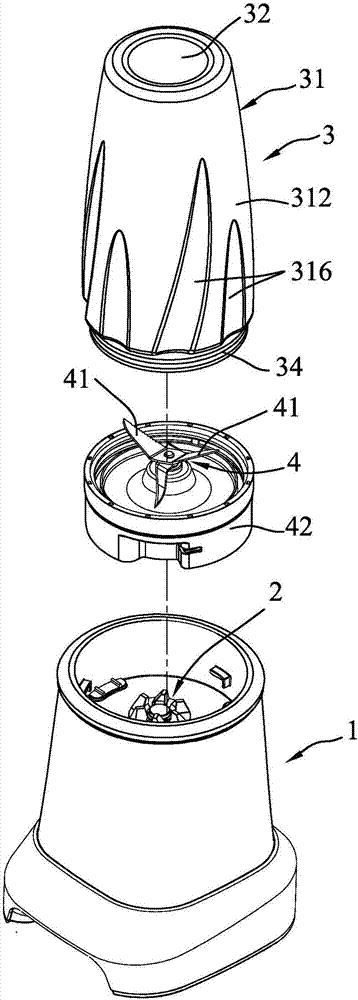

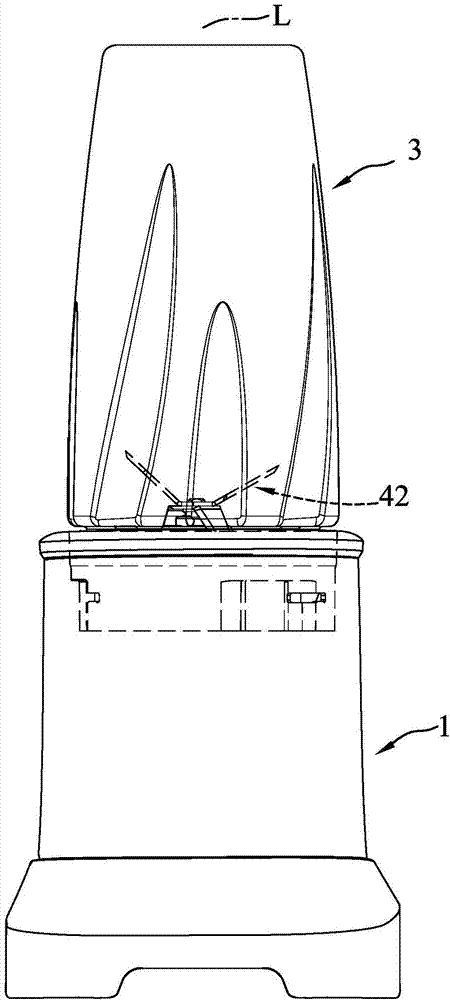

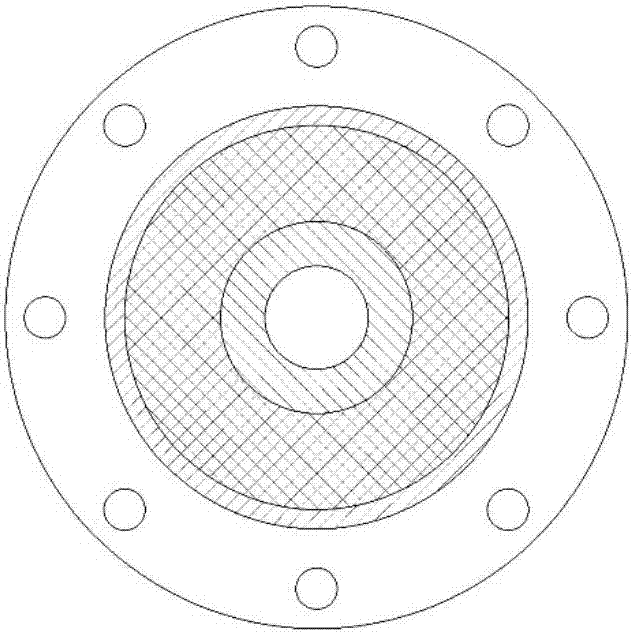

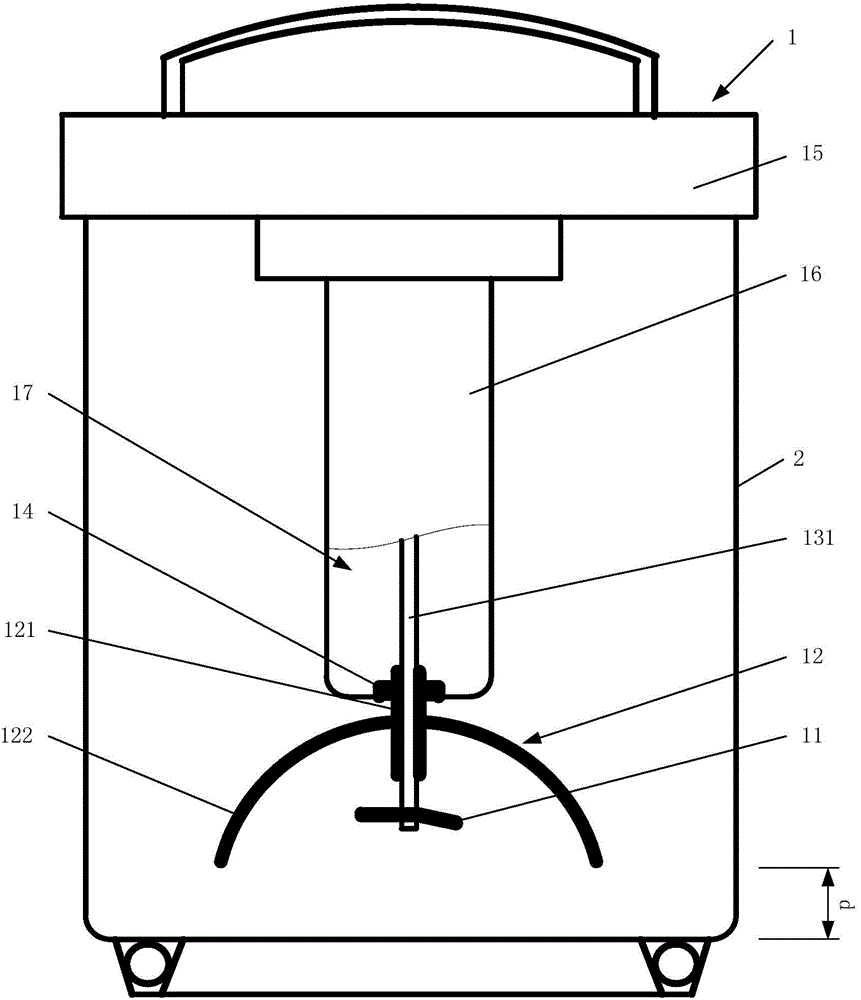

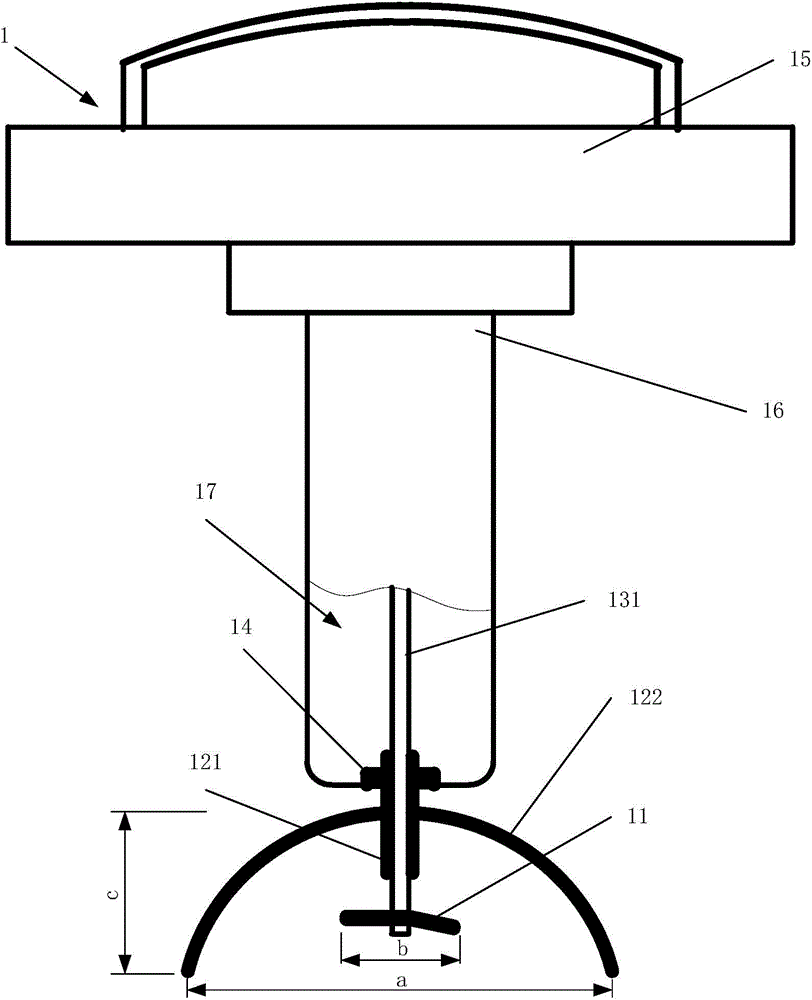

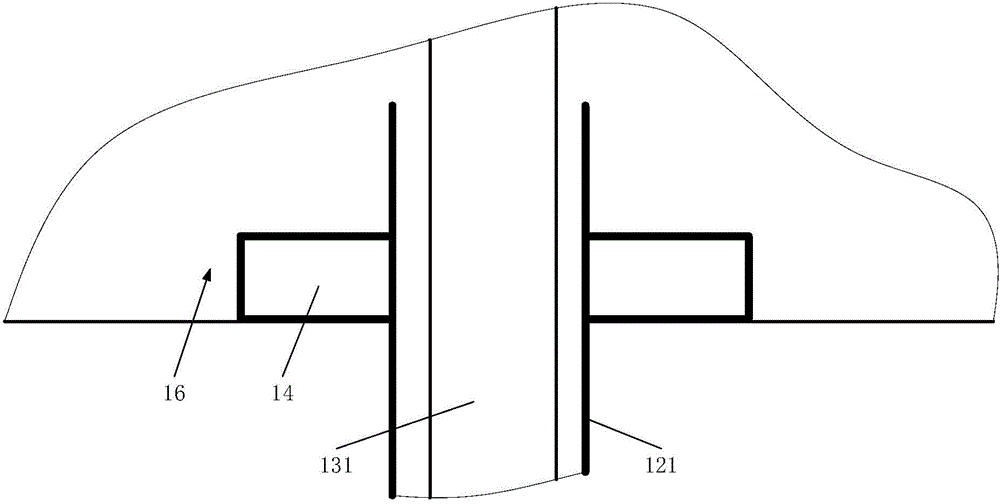

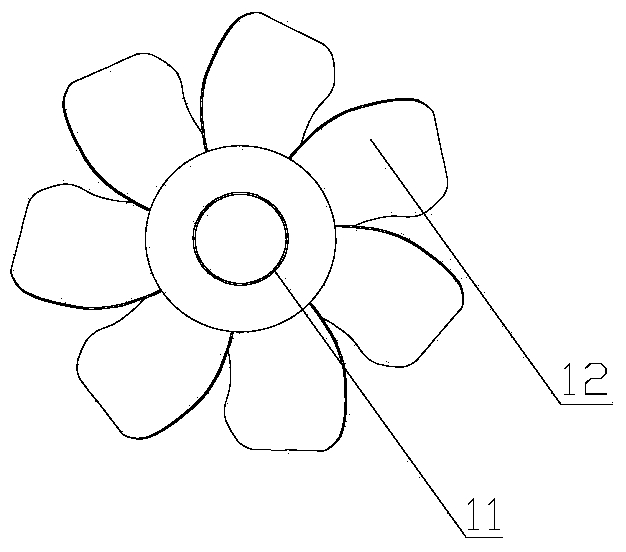

Soymilk machine head

InactiveCN104055423ATo achieve the purpose of noise reductionSmooth rotationBeverage vesselsFood materialEngineering

The invention provides a soymilk machine head, which is arranged on a barrel body of a soymilk machine. A crushing blade and a spoiler are arranged on a rotating shaft of the machine head, wherein the spoiler sleeves on the rotating shaft, and can rotate relative to the rotating shaft, and the crushing blade drives a food material in the barrel body to rotate; the food material drives the spoiler to rotate. According to the soymilk machine head provided by the invention, the rotating shaft drives the crushing blade to rotate at high speed, and the crushing blade which rotates at high speed drives the food material to rotate in the barrel body, accordingly, under the rotation of the food material, the spoiler absorbs the kinetic energy of part of food material to rotate along with the food material in the same direction, and the rotating speed difference between the spoiler and the food material becomes small; meanwhile, by matching of the rotation of the spoiler, the food material can be stably stirred by the spoiler, accordingly, the food material is more uniformly distributed in the barrel body, the rotation of the food material is more stable, and the disturbing effect of the spoiler is more obvious; meanwhile, the noise generated by the larger rotating speed difference between the food material and the spoiler is also reduced to better achieve the purpose of noise reduction in the soymilk machine.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

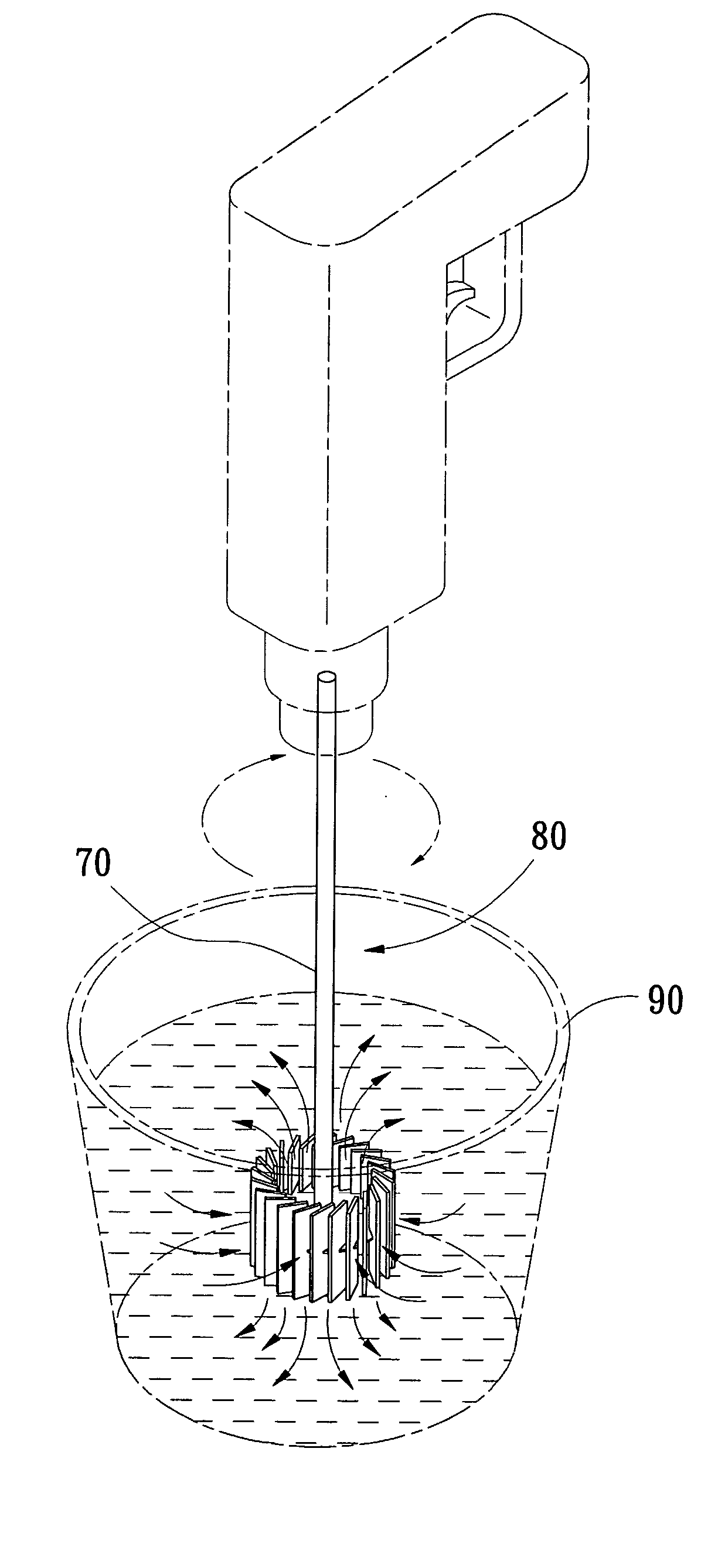

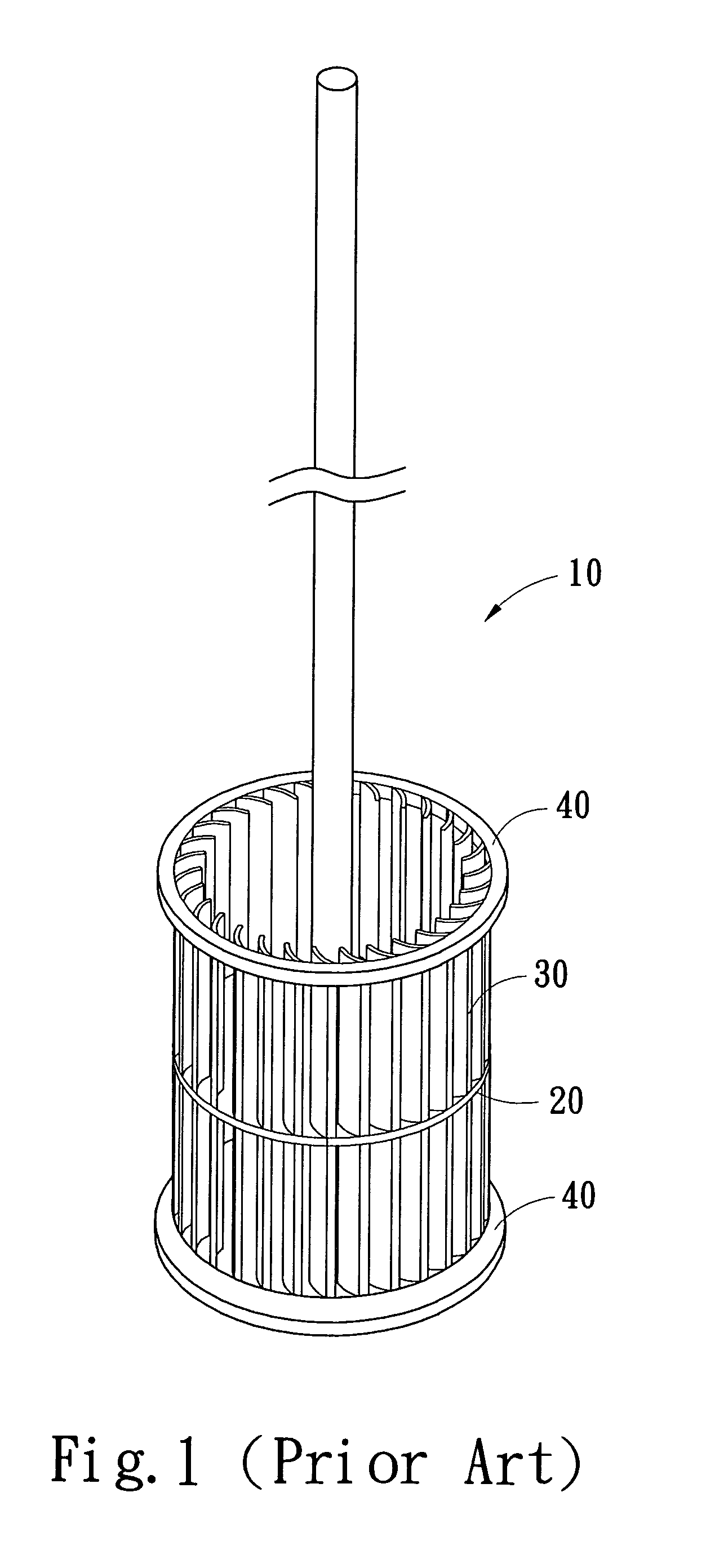

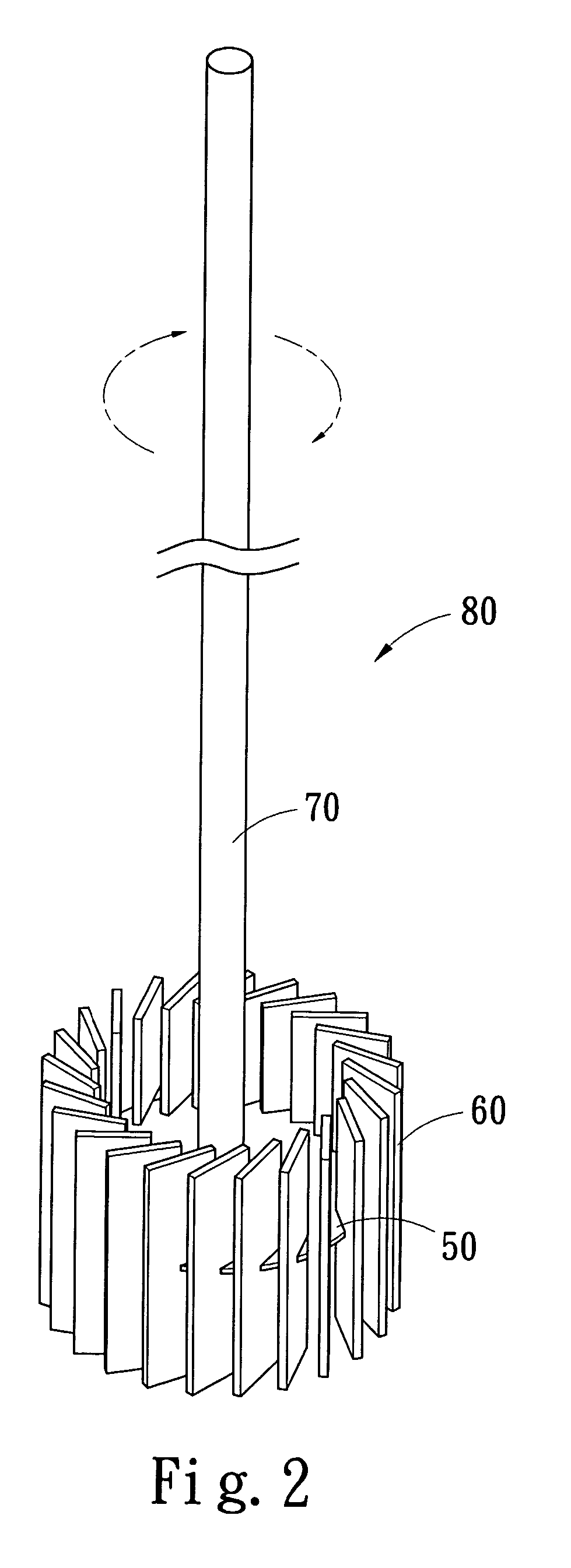

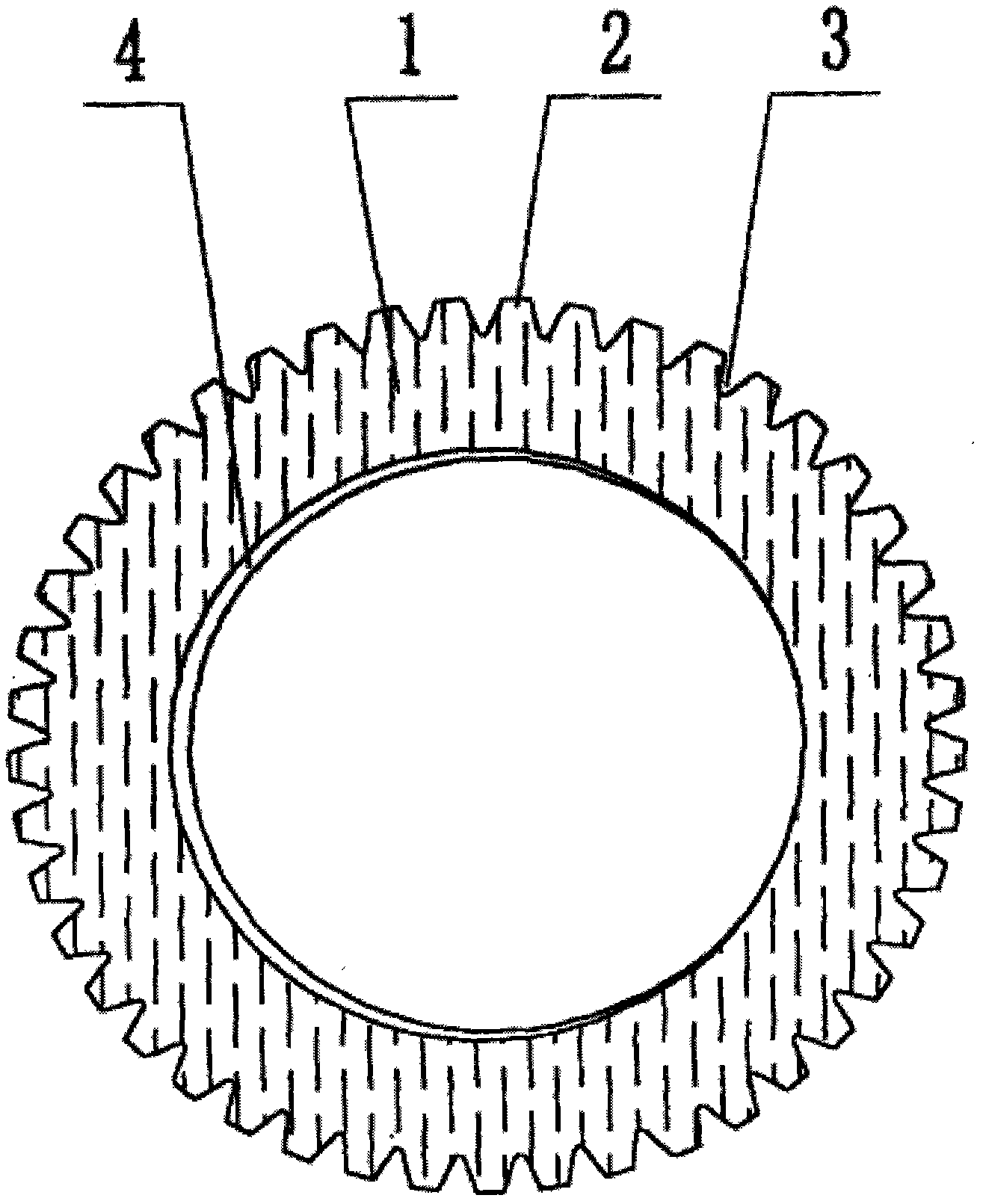

Stirrer

InactiveUS20050047268A1Improve structureGood flow disturb effectRotary stirring mixersTransportation and packagingCircular discEngineering

An improved structure of stirrer is applicable to mixing up liquid, it is provided with a circular disc having peripherally thereof with a plurality of blades inserted therein in a mutually spaced and inclined way, and a shank of which one end is combined with the center of a surface of the circular disc; thereby, when the stirrer is using, liquid can enter from gaps between every two blades around the circular disc and discharge from an upper and a lower opening in order that liquid can be agitated and blended adequately.

Owner:NIEH CHUANG INDAL

Novel bridge vortex-induced resonance control system and control method thereof

InactiveCN107034780AChange forceChange the characteristics of the surrounding flow fieldBridge structural detailsAir velocityControl system

The invention discloses a novel bridge vortex-induced resonance control system and a control method thereof. A main beam of a bridge is provided with a plurality of sets of turbulent flow devices and fans. The wind field information around the main beam is transmitted through sensors, and the fans are controlled, so that the wind field flowing directions and air speed around the main beam are changed, acting force of wind to the main beam section is relieved, the wind field air speed around the main beam is controlled, the vortex drifting speed in wind fields is increased, the vortex falling-off frequency is changed to be away from the inherent frequency of the bridge, and vortex-induced resonance of the main beam is prevented. The turbulent flow devices are simple in structure, convenient to mount, capable of being mounted on the side edges of the main beam in a large number, low in weight, free of burden to the bridge, good in turbulent flow effect and capable of effectively controlling vortex-induced vibration of the bridge and improving stability and safety of wind-induced vibration of the bridge.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

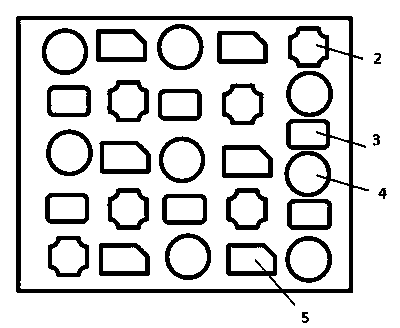

Packaging structure of integrated power control unit

ActiveCN103413790AImprove the stability of useExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesProcess engineeringPower control

The invention provides a packaging structure of an integrated power control unit. Heating elements are not distributed according to a traditional functional module. All the heating elements are distributed in a scattered mode. The problems of the use conditions, power and the like of the heating elements achieving the same function and different functions are comprehensively considered, the heating elements achieving the same function are distributed on a main substrate at intervals, the heating elements achieving the different functions are also distributed on the main substrate at the same time, and therefore under the different use conditions, the heating quantities of different areas on the whole main substrate are even to the great extent. On the one hand, even heating provides the powerful guarantee for even heat dissipation, on the other hand, the simplification of the integrated heat dissipation structure is facilitated, and then the packaging structure is beneficial to meeting the small-size requirement of the control unit. Meanwhile, the even heating is also beneficial to improving the use stability of the main substrate and prolonging the service life of the main substrate.

Owner:SHANDONG INST OF ADVANCED TECH CHINESE ACAD OF SCI CO LTD

Axial stretchable stepped combined type Venturi mixer

ActiveCN105289349AImprove mixing efficiencyReduce the cross-sectional areaFlow mixersEngineeringFlow ratio

The invention relates to an axial stretchable stepped combined type Venturi mixer. The axial stretchable stepped combined type Venturi mixer comprises a main fluid inflow circular pipe, a main fluid gradual contracting section first-level circuit pipe, a main fluid gradual contracting section second-level circuit pipe, a main fluid gradual contracting section third-level circuit pipe, connecting pipes, a sleeve, a main fluid gradual expanding section first-level circuit pipe, a main fluid gradual expanding section second-level circuit pipe, a main fluid gradual expanding section third-level circuit pipe, a main fluid outflow circular pipe, and an introduction pipeline for introducing fluid inflow and arranged on the connecting pipes which are communicated with one another in turn, wherein multi-level circular pipes for the gradual contracting section and the gradual expanding section are nested with one another; contracting sections and expanding sections, which are stretchable, of Venturi pipes are formed on the two sides of the multi-level circular pipes; the circular pipes at the two ends on the outer side of the gradual contracting section and the gradual expanding section can be served as the stretchable main fluid inflow pipelines and the stretchable main fluid outflow pipelines; the connecting pipes on the two sides are connected with each other through the sleeve, so that a stretchable throat of the Venturi mixer is formed. The axial stretchable stepped combined type Venturi mixer can select optimal structure parameters of the Venturi mixer according to the flow ratio of the introduced fluid and the main fluid, is capable of increasing the mixing efficiency and is applicable to relatively wide working conditions.

Owner:度测(上海)科技服务中心

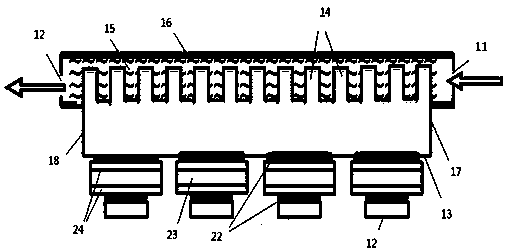

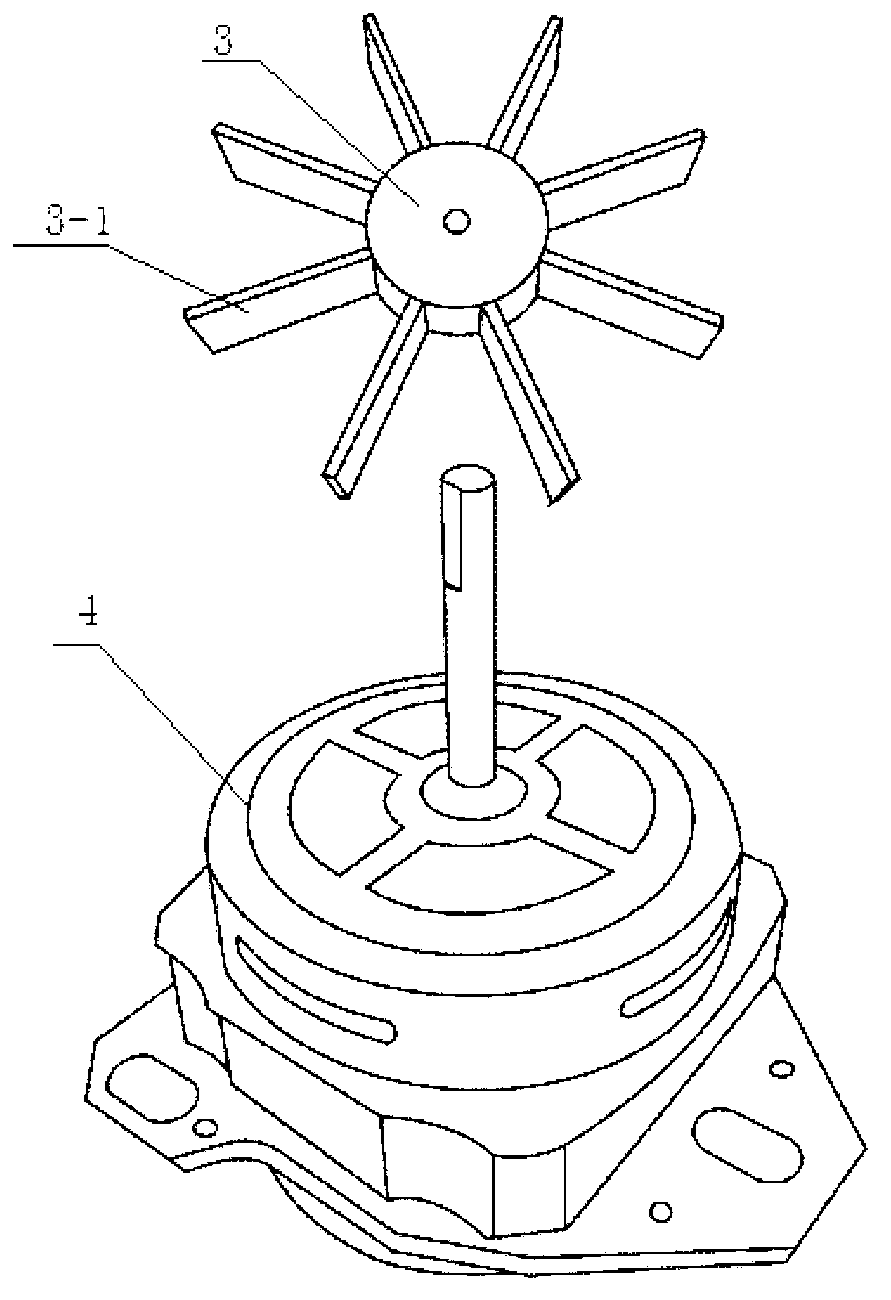

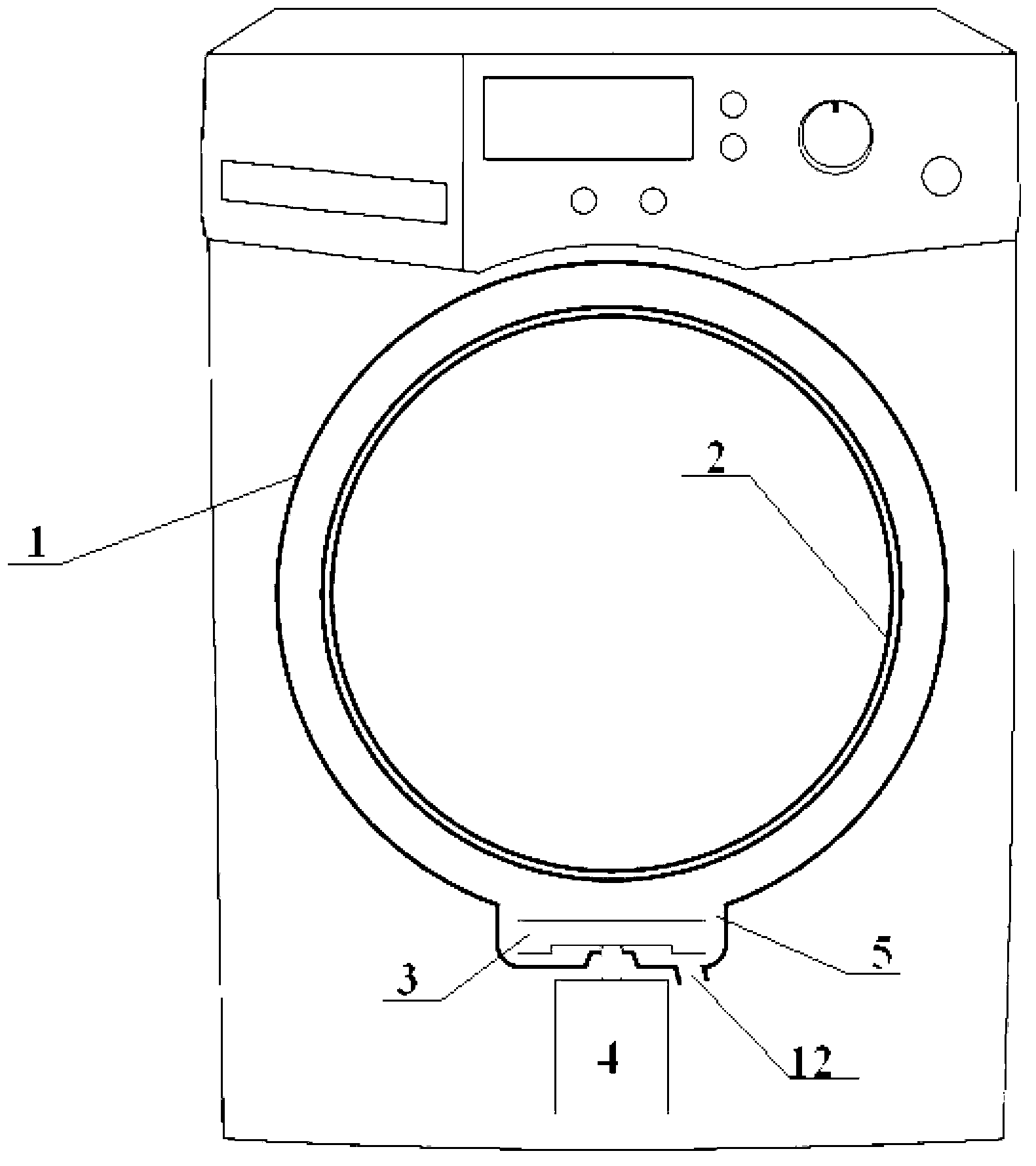

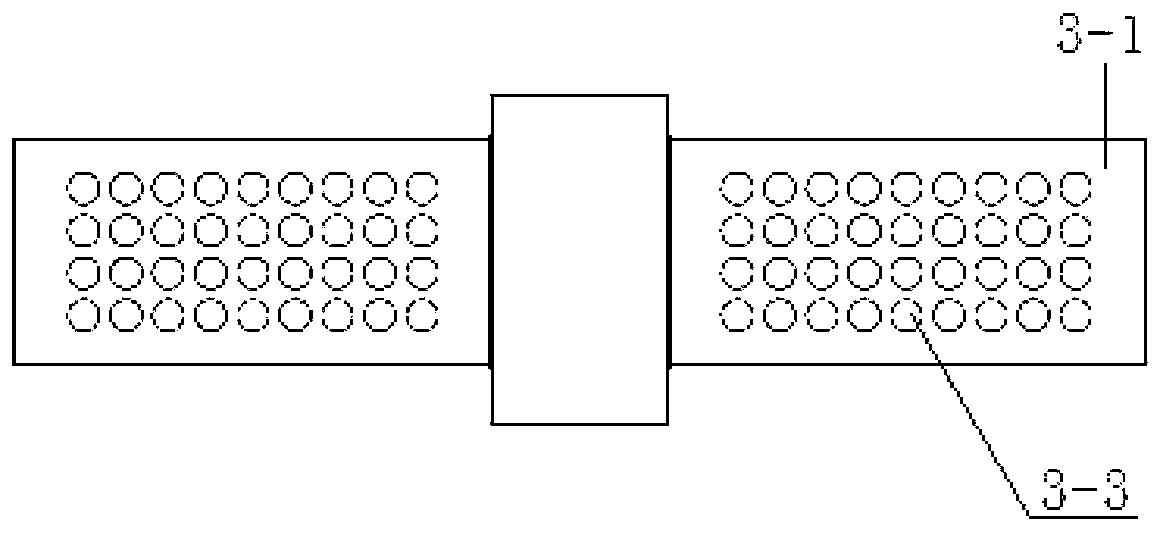

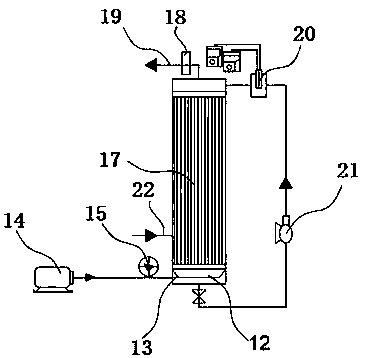

Water circulating device for low temperature fast dissolving of detergent and efficient washing of roller washing machine and working method thereof

ActiveCN103276561AImprove cleaning ratioLower turn-to-stop ratioOther washing machinesControl devices for washing apparatusWater flowWater cycling

The invention relates to a water circulating device for low temperature fast dissolving of detergent and efficient washing of a roller washing machine. The water circulating device comprises a water rotating wheel arranged at the bottom of the roller washing machine and between an outer barrel and an inner barrel, wherein the water rotating wheel comprises a middle shaft and paddle blades fixedly arranged on the middle shaft, and a motor which drives the water rotating wheel to rotate is arranged at the bottom of the outer barrel. The water circulating device achieves strong rotation and spewing for water currents at the bottom of the roller washing machine, then accelerates fast high dissolving of the detergent, and avoids the problem that the detergent is difficult to dissolve due to the facts that the detergent precipitates and stacks at dead angles below the inner barrel formerly. The water circulating device for the low temperature fast dissolving of the detergent and the efficient washing of the roller washing machine achieves double power washing for clothes simultaneously through rotation of a roller and rotating water currents, and achieves a good effect of reducing wear rate of the clothes by reducing the rotation stop rate and the rotation speed of the roller on the basis of improving the cleanly washing rate of the clothes. The water circulating device for the low temperature fast dissolving of the detergent and the efficient washing of the roller washing machine can use a low power motor to drive the water rotating wheel, achieves a good cleanly washing effect of low temperature fast dissolving detergent, and achieves energy conservation and emission reduction really.

Owner:李守林

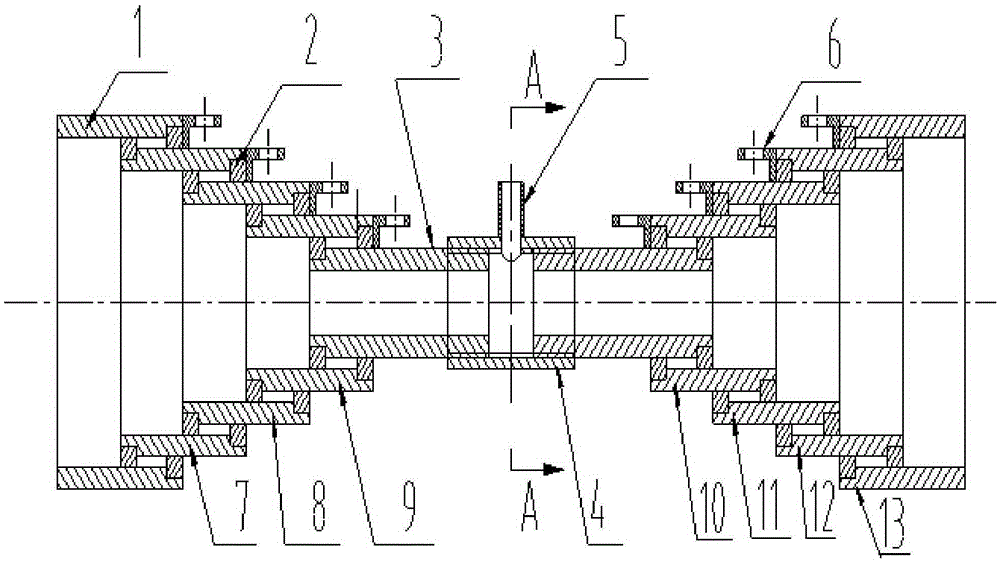

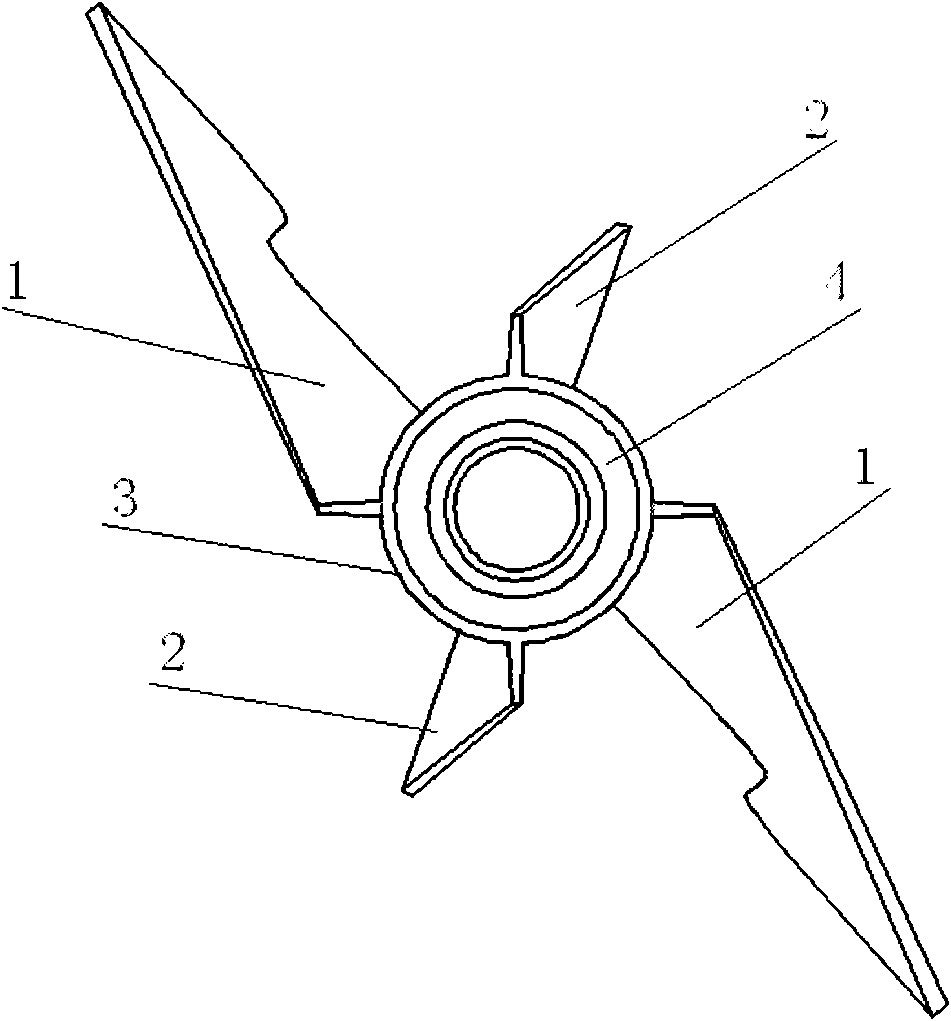

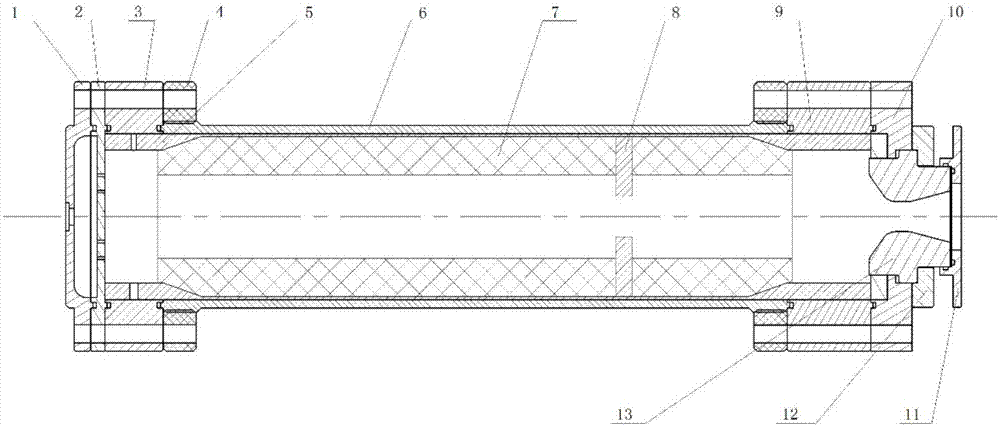

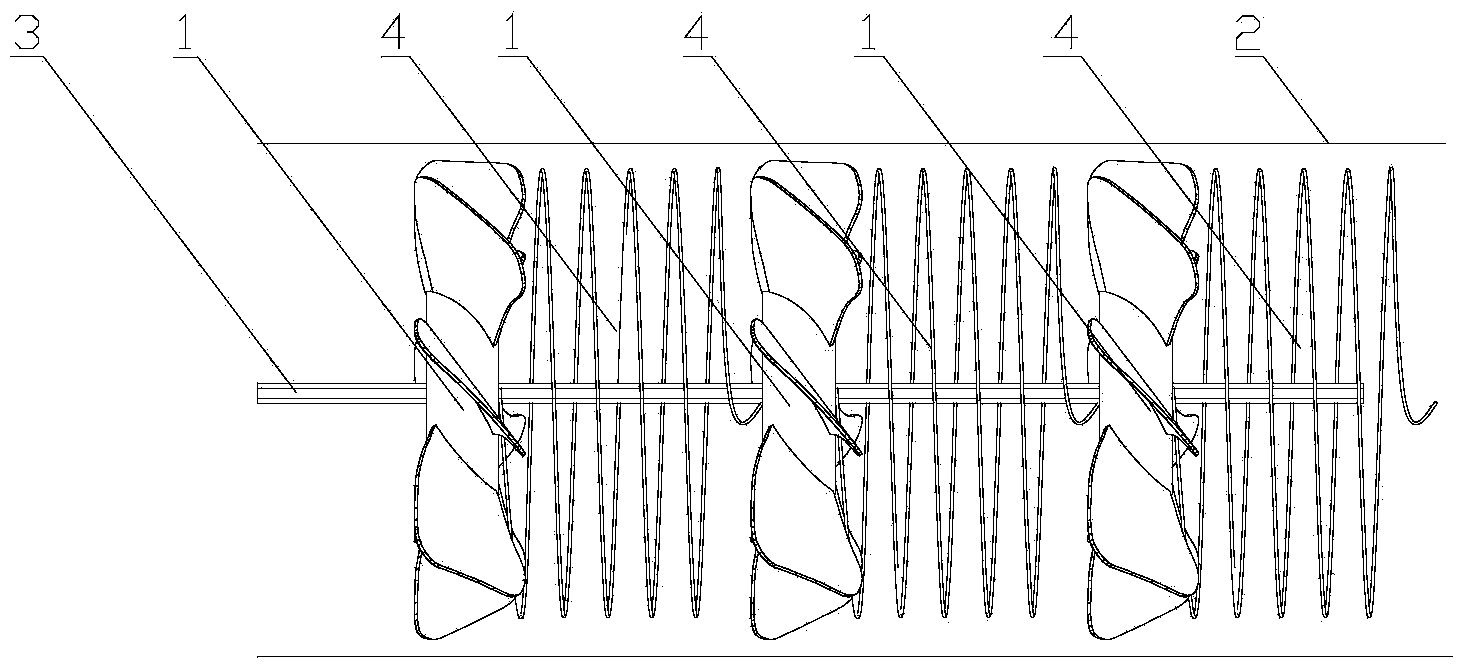

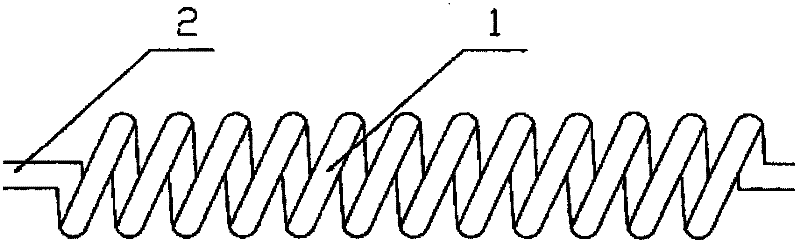

Semi-open-type rotor

ActiveCN101915514AReduce resistanceImprove spoiler effectCorrosion preventionHeat transfer modificationSemi openEngineering

The invention provides a semi-open-type rotor which comprises a hollow shaft, a main blade and an auxiliary blade. The main blade and the auxiliary blade are arranged on the outer surface of the hollow shaft, the main blade has a longer axial length, the main blade at the rear end of the rotor is suspended to form a semi-open-type structure which is axially overlapped with the front end of an adjacent rotor in use, radially forms a gap or is radially matched with the front end of an adjacent rotor, the radial width of the front part of the main blade on the hollow shaft is smaller than the radial width of the rear part, the front part of the main blade has a small rotary diameter, the rear end part of the main blade has a larger rotary external diameter, and the auxiliary blade is arranged at the front end of the rotor and has a shorter axial length. The front part of the main blade of the rotor has the small rotary diameter to take the effect of spoiling central fluid of a heat exchange pipe and scattering the central fluid around, the rear part of the main blade, which has the larger rotary external diameter, has good flow spoiling effect on the boundary layer fluid of an inner laminar flow of the heat exchange pipe and can adjust the rotor-driving torque of the fluid by adjusting the axial length of the auxiliary blade so as to enhance the fluid-adapting performance of the rotor.

Owner:BEIJING UNIV OF CHEM TECH

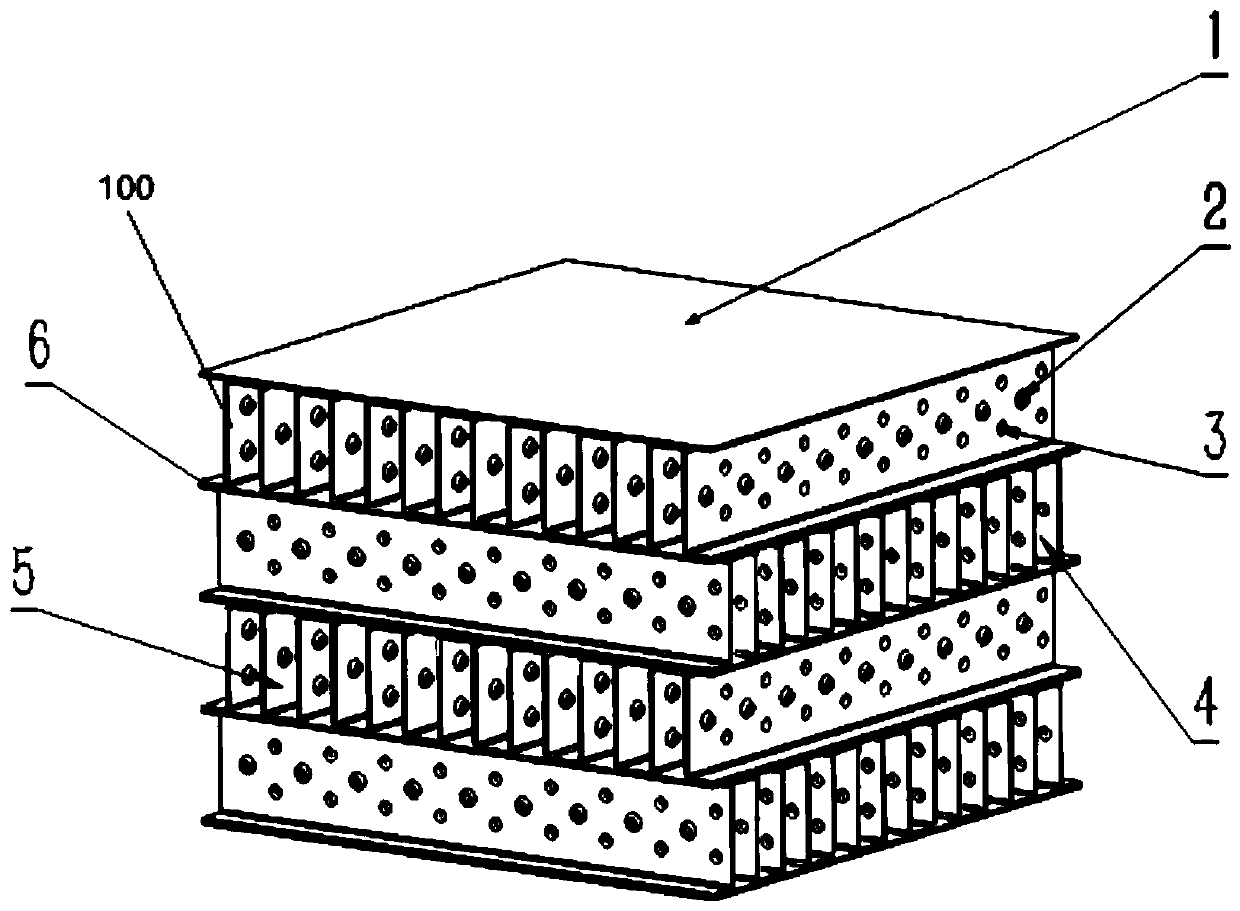

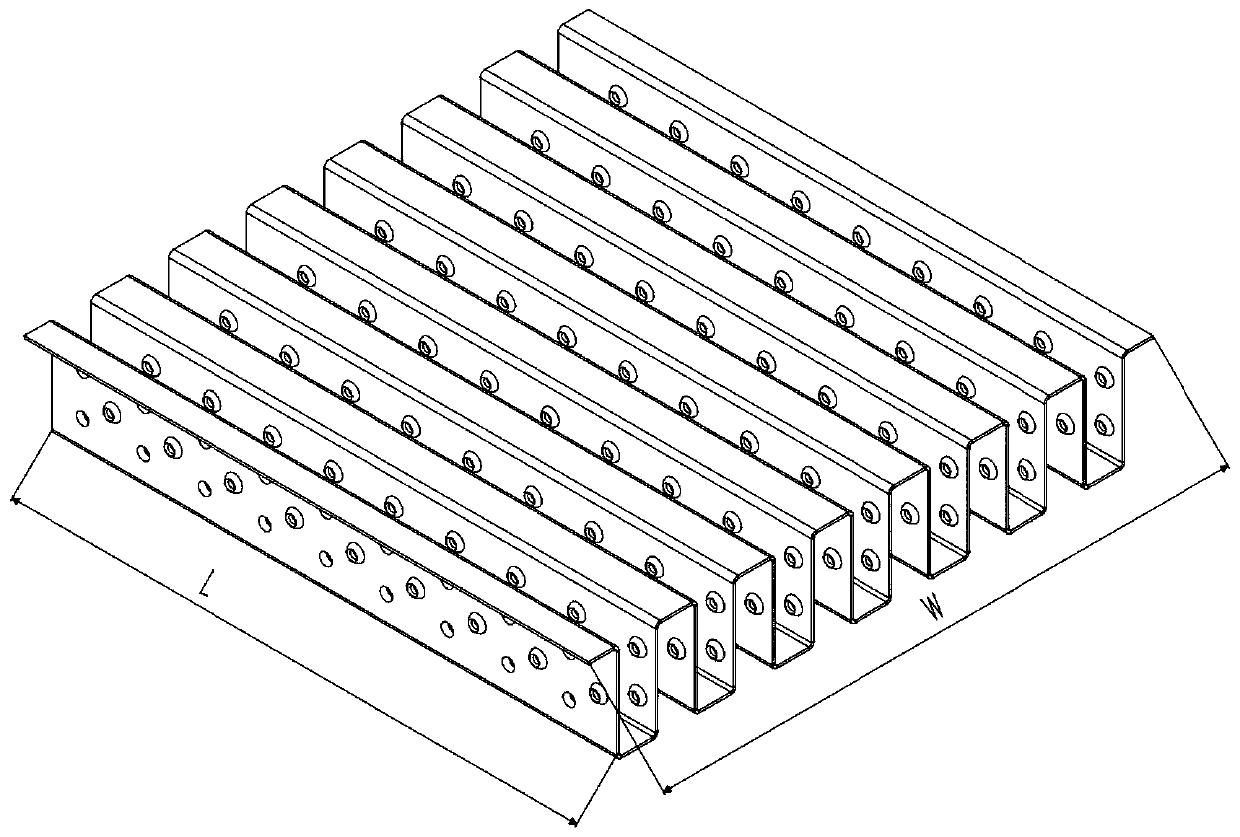

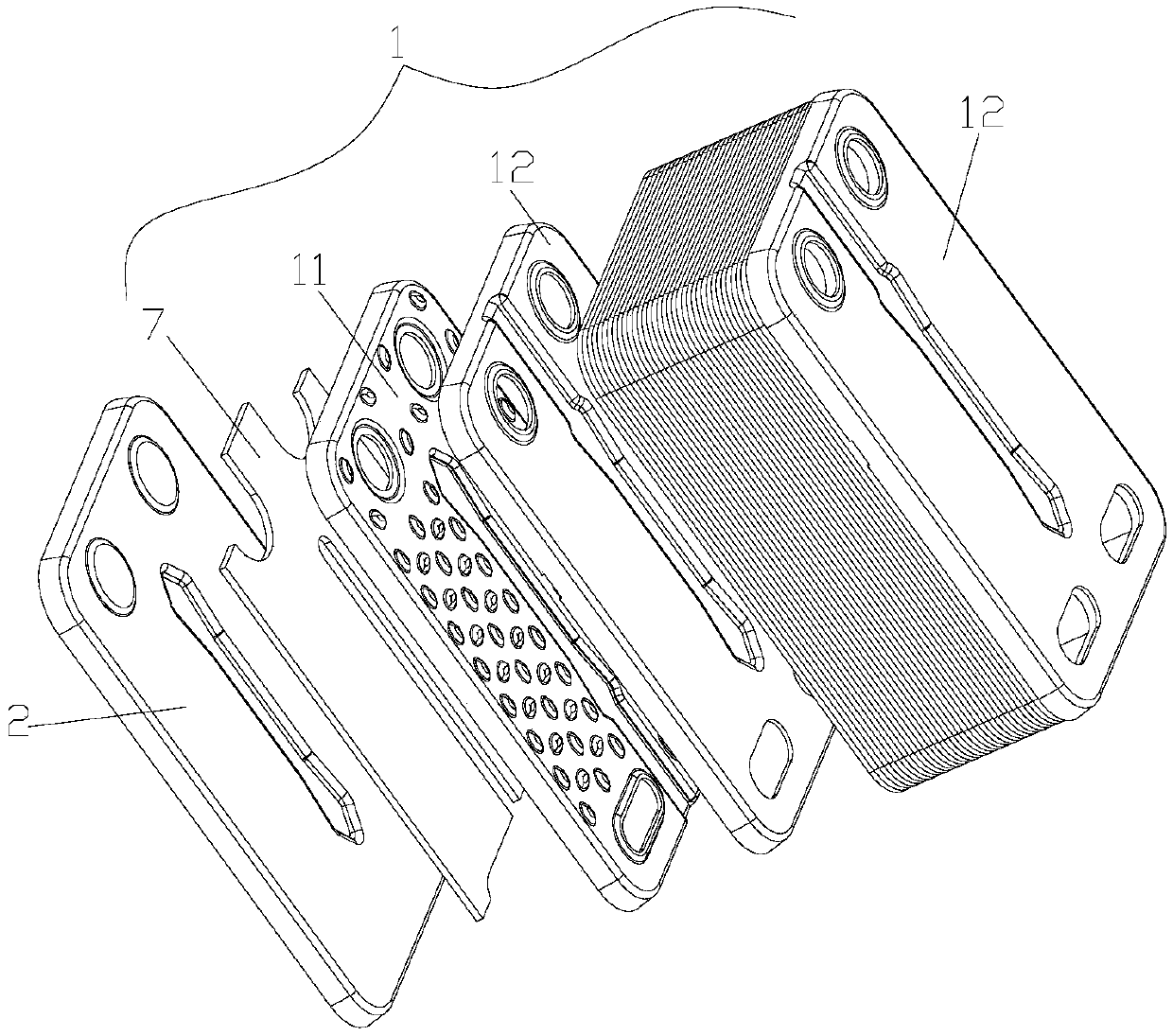

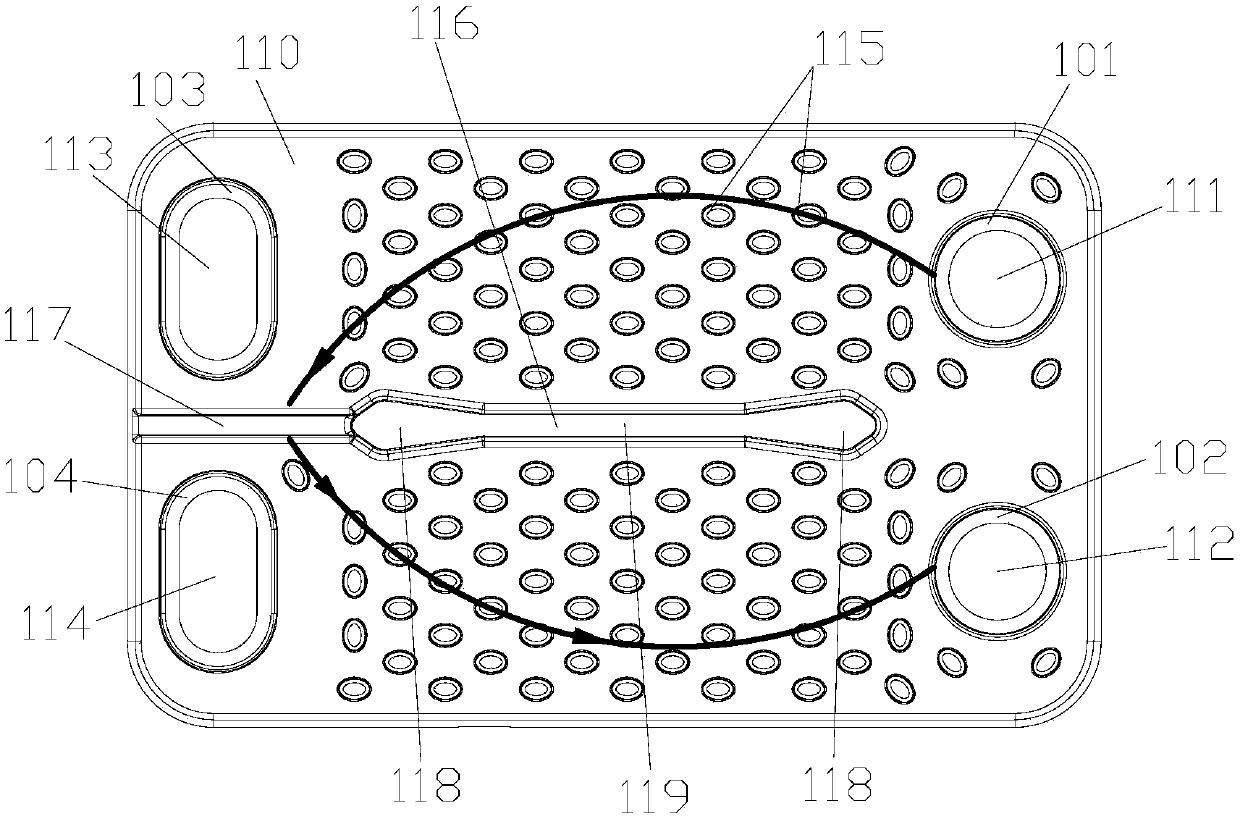

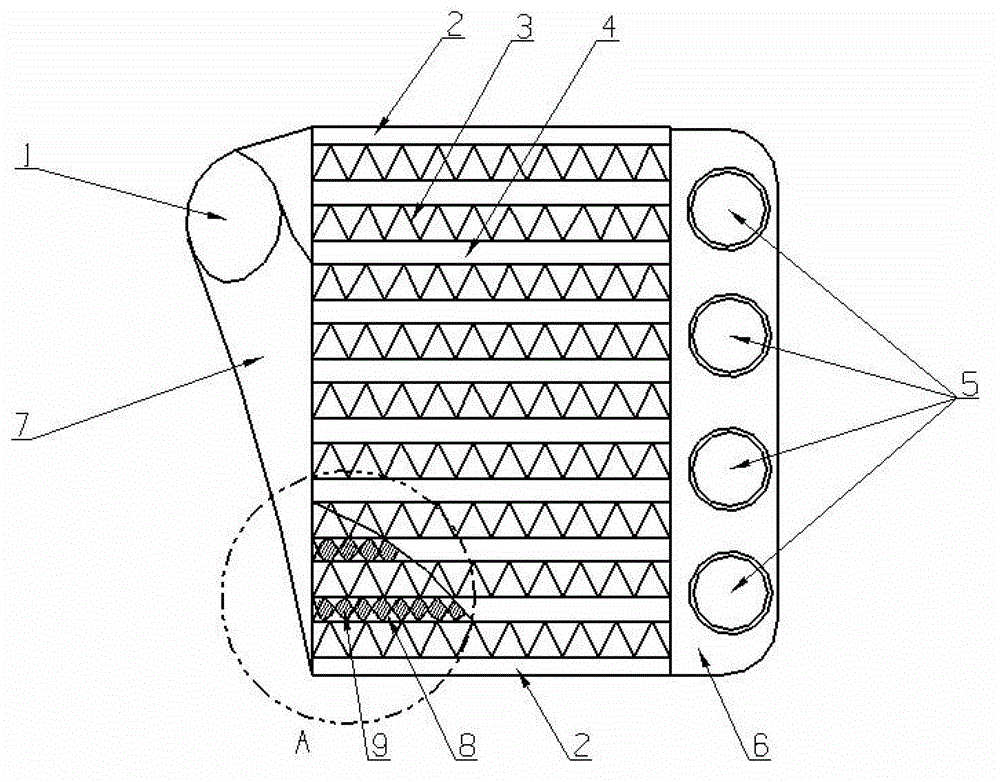

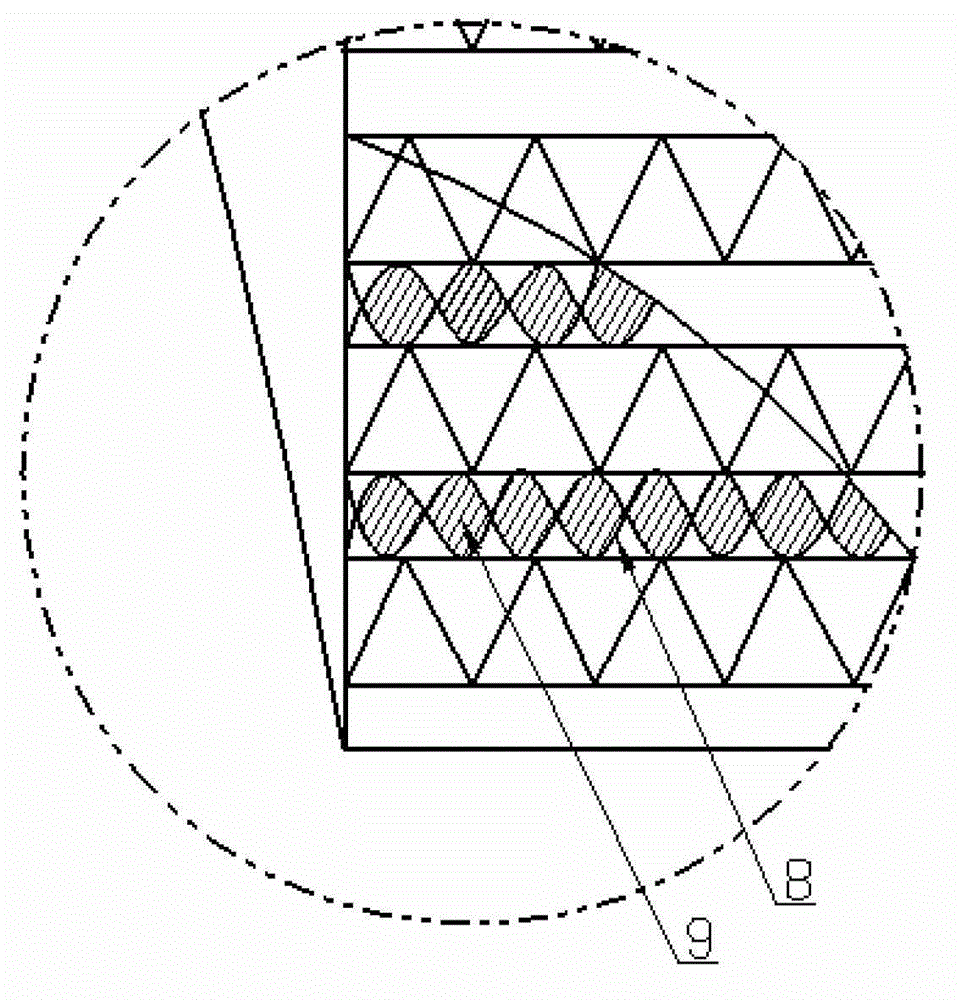

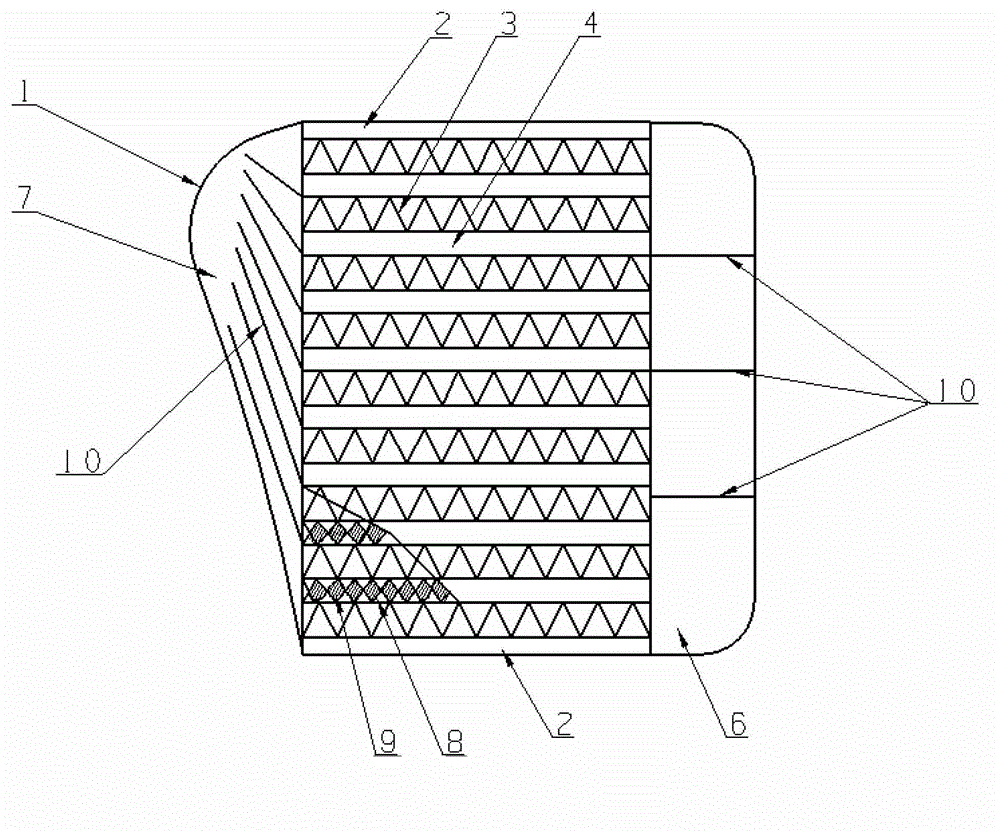

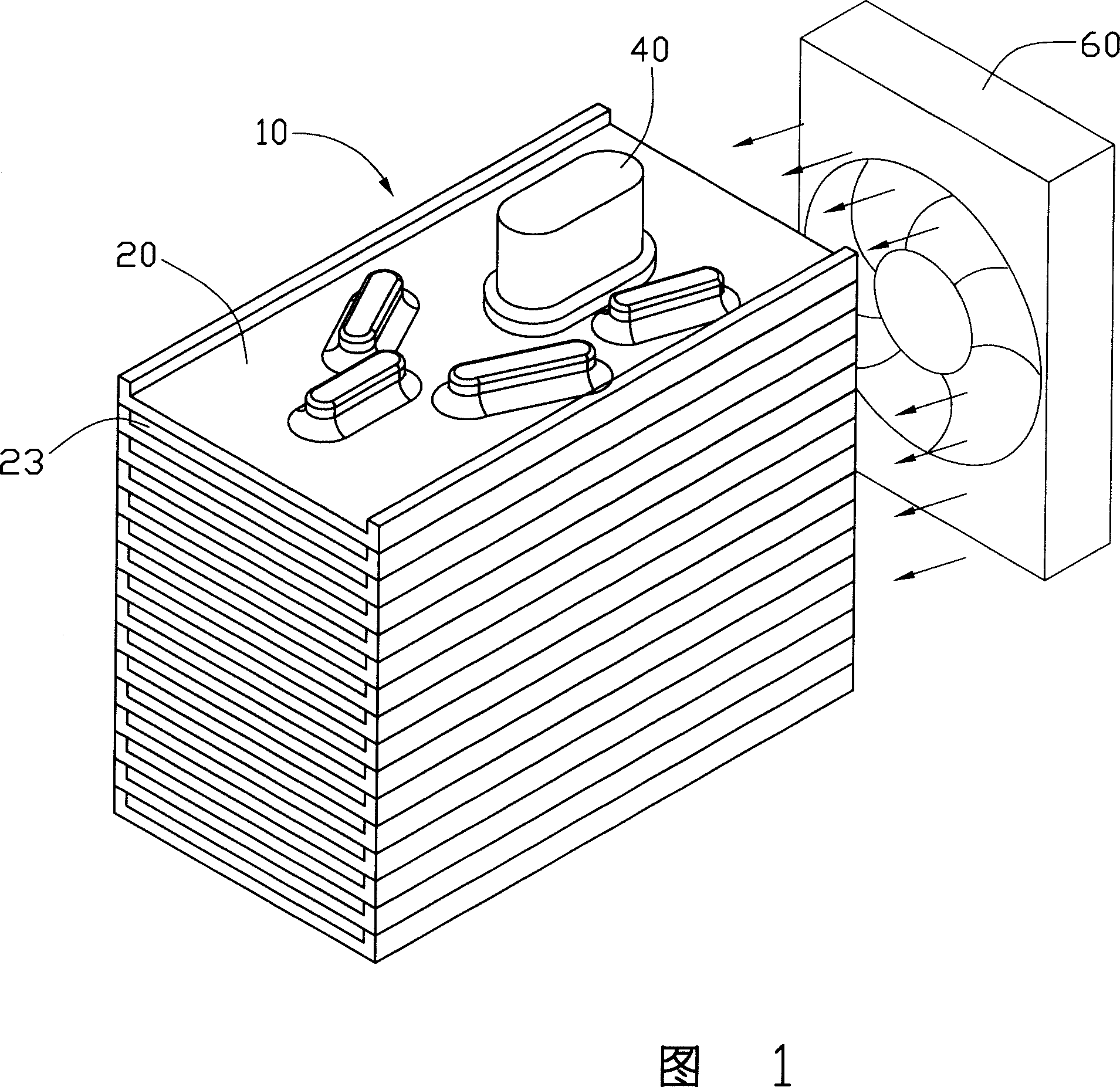

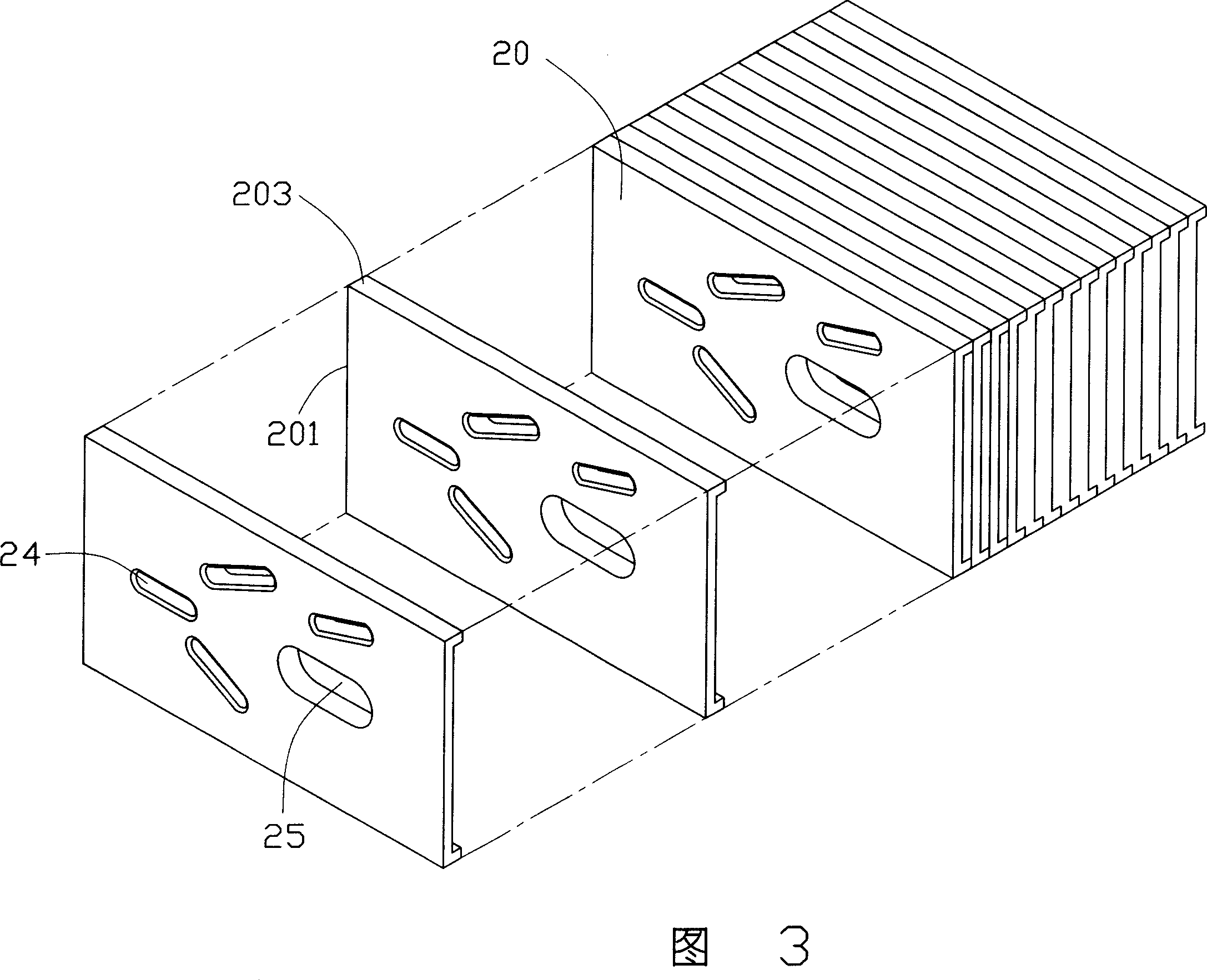

Plate-fin type heat exchanger core and fin structure thereof

PendingCN109883238AIncrease the heat exchange areaIncreased turbulenceHeat exhanger finsLaminated elementsJet flowEngineering

The invention discloses a plate-fin type heat exchanger core and a fin structure thereof. The plate-fin type heat exchanger core comprises a plurality of partition plates and fins; each fin is supported and fixed between the two adjacent partition plates; the part between the adjacent partition plates is sealed to form a flow channel unit; the flow channel unit forms a plurality of medium flowingheat exchange channels between the adjacent partition plates; a plurality of ball convex parts / ball concave parts are arranged on the fins; and the ball convex parts / ball concave parts are provided with punched holes to form punched ball convex parts / punched ball concave parts. The core combines various advantages of the ball convex / ball concave structures and the punched structures; the fins increase the heat exchange area; the ball convex / ball concave structures improve the loading capacity of the plate-fin structure and enhance fluid turbulence, so that a flow boundary layer and a hot boundary layer are thinned; and the punched structure forms local jet flow, so that fluid mixing convection in the fin adjacent flow channels is promoted, the vortex dead zone of the ball convex / ball concave structure is reduced, and the effects of enhancing heat transfer and reducing flowing resistance are achieved.

Owner:XI AN JIAOTONG UNIV

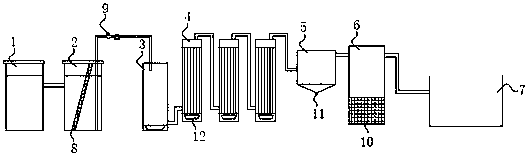

Bacteria and algae collaborated method for efficient treatment of aquaculture sewage

ActiveCN110156242AReduce volumeReduce impactSpecific water treatment objectivesWater aerationAmmonia-oxidizing bacteriaLivestock

The invention discloses a bacteria and algae collaborated method for efficient treatment of aquaculture sewage. Bacteria and algae are compounded for use in combination to treat livestock and poultrysewage. The method specifically includes: adopting autotrophic ammonia oxidizing bacteria, autotrophic nitrification bacteria and heterotrophic nitrification bacteria to convert ammonia nitrogen in livestock and poultry sewage into nitrate nitrogen, then introducing the treated sewage into an airlift columnar photobioreactor, and utilizing the microalgae with a preservation number of CCTCC NO:M 2017461 to remove nitrogen and phosphorus and perform biomass accumulation. The method has the beneficial effects that: through the synergistic action of microbial functional bacteria and microalgae, the method rapidly reduces the nitrogen, phosphorus and other pollutants in livestock and poultry sewage, shortens the hydraulic retention time, improves the microalgae biomass accumulation speed, and can acquire a large number of renewable energy sources while treating livestock and poultry sewage.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

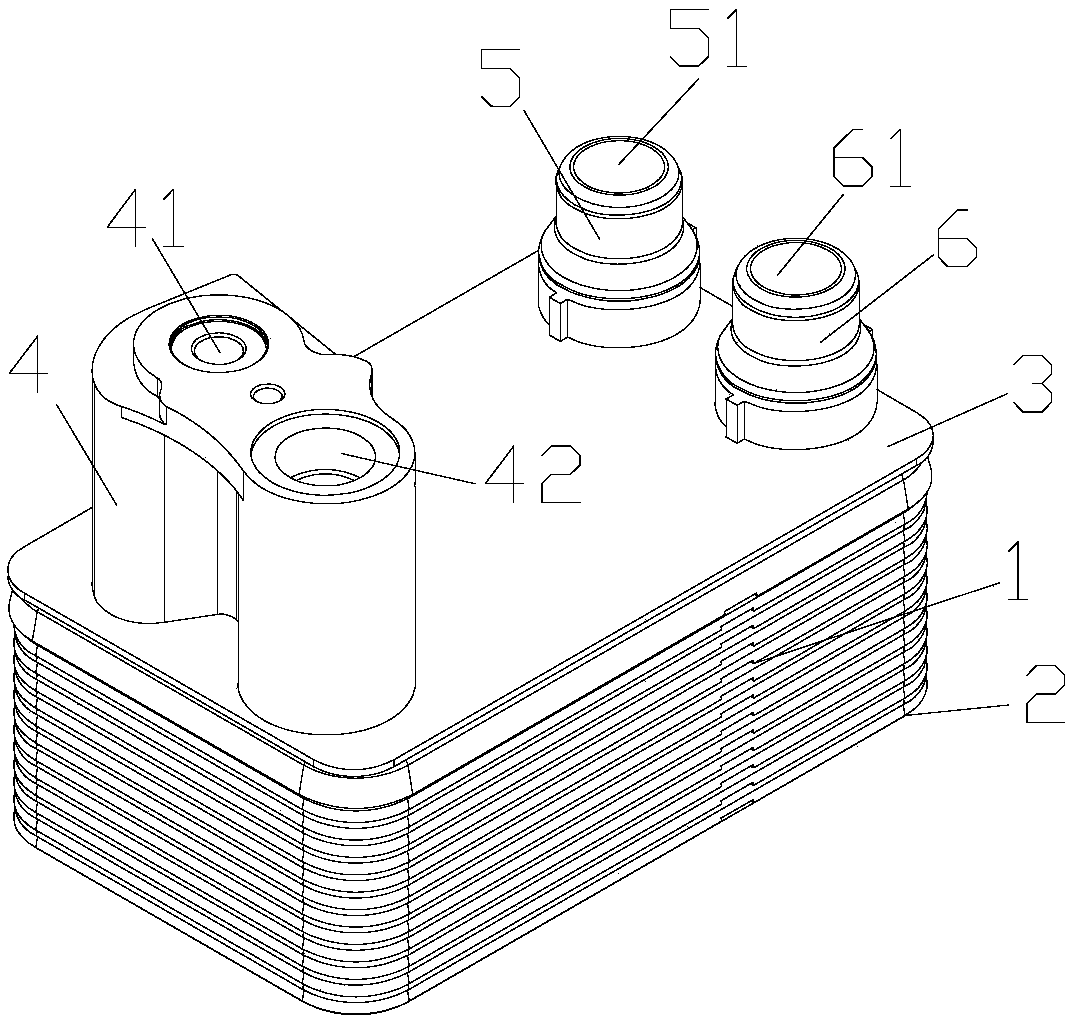

Heat exchanger

ActiveCN110657692AImprove spoiler effectHeat exhanger finsHeat exchanger casingsMechanical engineeringMechanics

The invention discloses a heat exchanger. The heat exchanger comprises first sheet bars and second sheet bars, wherein a plurality of convex parts are arranged on the side of a first sheet face of each first sheet bar, fins are arranged between a second sheet face of each first sheet bar and a first sheet face of the second sheet bar adjacent to the first sheet bar, while no fins are arranged between the side, provided with the convex parts, of each first sheet bar and a second sheet face of the second sheet bar adjacent to the first sheet bar, and the height of the convex parts is smaller than that of the fins. According to the heat exchanger, the flow turbulent performance in a first fluid channel is improved through the fins, the flow turbulent performance in a second fluid channel is improved through the structure of the convex parts, thus low-pressure fluid can flow in the first fluid channel, and high-pressure fluid can flow in the second fluid channel.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

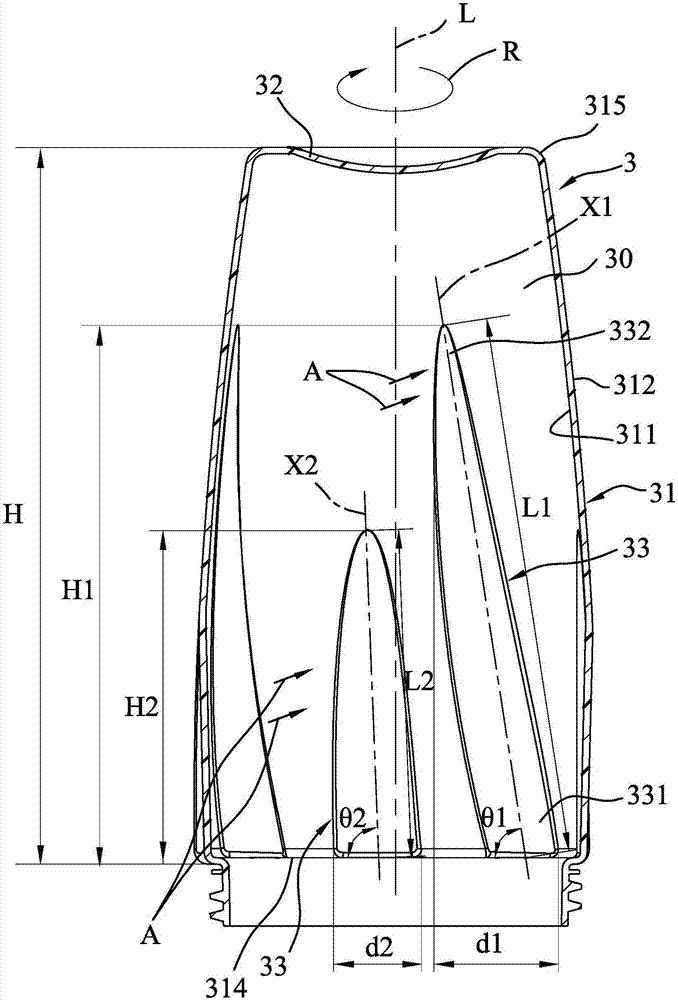

Juice making machine container and juice making machine

The invention discloses a juice making machine container and a juice making machine. The juice making machine container comprises a surrounding wall which surrounds an axis and defines an accommodating space, wherein the surrounding wall is provided with an inner circumference facing the accommodating space; and the inner circumference is provided with a bottom edge and a top edge which is spaced from the bottom edge. The juice making machine further comprises a plurality of turbulence ribs which are located on the surrounding wall and protrude towards the accommodating space; and each turbulence rib is connected to the bottom edge and extends towards a direction which is oblique with the direction of the top edge. A good turbulence effect is guaranteed since the turbulence ribs extend upwards from the bottom edge of the juice making machine container in an oblique mode, and the turbulence ribs can take a retaining effect at the upper side of food so as to prevent overflow. In addition, the juice making machine container is beneficial for the food to flow downwards along the oblique direction of the turbulence ribs and to rapidly concentrate in a working area of a cutting tool, so that an effect of rapidly and uniformly smashing the food is achieved.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Particle dissolving and stirring part

PendingCN111530314AChange lengthImprove spoiler effectTransportation and packagingMixersElectric machineSolid particle

The invention discloses a particle dissolving and stirring part. The particle dissolving and stirring part comprises a variable frequency motor, an output end of the variable frequency motor is fixedly connected with a stirring shaft, an electromagnetic block is embedded in a stirring shaft, two permanent magnet rings are symmetrically arranged on the stirring shaft relative to the electromagneticblock in a sleeving manner, the electromagnetic block and the two permanent magnet rings are arranged in a repulsion manner, the two permanent magnet rings are arranged in an attracting manner, limiting mechanisms are symmetrically arranged on the inner sides of the permanent magnet rings, the stirring shaft is sleeved with a second spring, the two ends of the second spring are fixedly connectedwith the two permanent magnet rings correspondingly, a plurality of main stirring rods are fixedly connected to the outer circumferential faces of the permanent magnet rings in the circumferential direction, and square telescopic grooves are formed in the ends, away from the permanent magnet rings, of the main stirring rods. The main stirring rods and the auxiliary stirring rods form a whole stirring body, the length of the whole stirring body and the position of the whole stirring body relative to the stirring shaft are changed, the dissolving efficiency is greatly improved, solid particles are crushed through the telescopic springs, and the stirring efficiency is improved.

Owner:万强

Solid-liquid rocket engine combustion chamber intermediate flow disturbing device

InactiveCN106870204ASimple structureSimple and clear structureRocket engine plantsSingle holeSilicon oxygen

The invention discloses a solid-liquid rocket engine combustion chamber intermediate flow disturbing device. The solid-liquid rocket engine combustion chamber intermediate flow disturbing device is suitable for solid-liquid rocket engine ground hot firing test, is applied to a center single channel and adopts a single round hole powder charging solid-liquid rocket engine. A flow disturbing plate is a single-hole round ring, the thickness of the flow disturbing plate is 10-15 mm, the ratio of the hole diameter of the flow disturbing plate to the diameter of a grain channel is 0.5-0.6, and the flow disturbing plate is arranged in the position of the 70%-80% length of a combustion chamber, divides a grain into a front section of grain body and a back section of grain body, and is placed on the wall surface of a heat insulating layer of the combustion chamber and the end surface of the grain in a closely attached mode. The flow disturbing plate device is the round hole ring with the axis of the engine as the axis and is made of high-temperature-resistant high-silicon oxygen. According to the solid-liquid rocket engine combustion chamber intermediate flow disturbing device, the specific structure size and the position in the overall structure are given, the flow disturbing effect on fuel gas is achieved, and the requirements for the structural strength and heat protection of the flow disturbing device of the engine in the working process are met.

Owner:BEIHANG UNIV

Soymilk machine head

The invention provides a soymilk machine head, which is arranged on a barrel body of a soymilk machine. A crushing blade and a spoiler are arranged on a rotating shaft of the machine head, wherein the spoiler sleeves on the rotating shaft, and can rotate relative to the rotating shaft, and the crushing blade drives a food material in the barrel body to rotate; the food material drives the spoiler to rotate. According to the soymilk machine head provided by the invention, the rotating shaft drives the crushing blade to rotate at a high speed, and the crushing blade which rotates at a high speed drives the food material to rotate in the barrel body, accordingly, under the rotation of the food material, the spoiler absorbs the kinetic energy of part of food material to rotate along with the food material in the same direction, and the rotating speed difference between the spoiler and the food material becomes small; meanwhile, by matching of the rotation of the spoiler, the food material can be stably stirred by the spoiler, accordingly, the food material is more uniformly distributed in the barrel body, the rotation of the food material is more stable, and the disturbing effect of the spoiler is more obvious; meanwhile, the noise generated by the larger rotating speed difference between the food material and the spoiler is also reduced to better achieve the purpose of noise reduction in the soymilk machine.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Air-cooled intercooler

InactiveCN103061866AImprove stabilityExtended service lifeInternal combustion piston enginesEngineeringIntercooler

The invention discloses an air-cooled intercooler which comprises a core. The core comprises an air inlet chamber, an air outlet chamber, a radiating tube and a radiating fin, two ends of the radiating tube are respectively communicated with the air inlet chamber and the air outlet chamber, and a spoiler is arranged in the radiating tube. An air inlet and an air outlet are respectively connected onto the air inlet chamber and the air outlet chamber, the spoiler is of deoxyribose nucleic acid (DNA) duplex structure, and the spoiler is formed by two frameworks of the duplex structure and a bond-shaped fin connected between the two frameworks. The air-cooled intercooler is provided with the spoiler of the DNA duplex structure and has the advantages of good heat transfer effects and small flow resistance.

Owner:SOUTH CHINA UNIV OF TECH

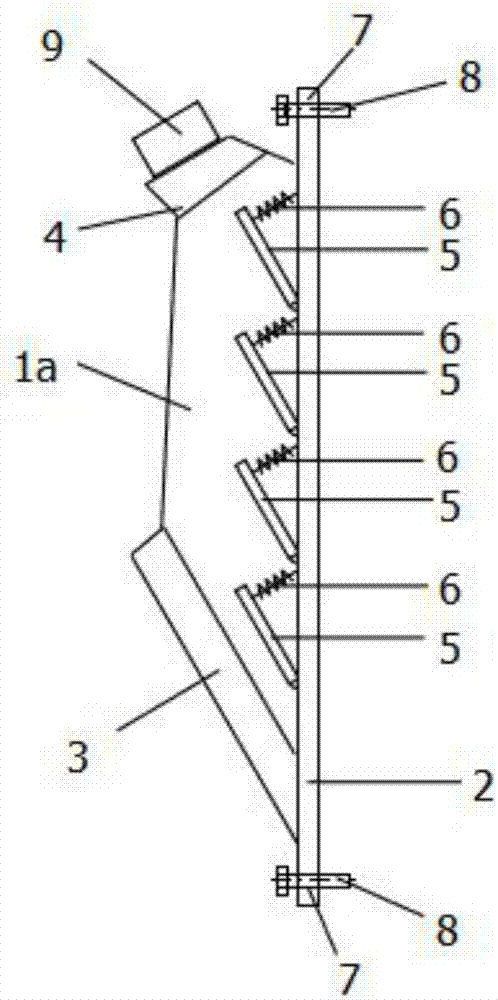

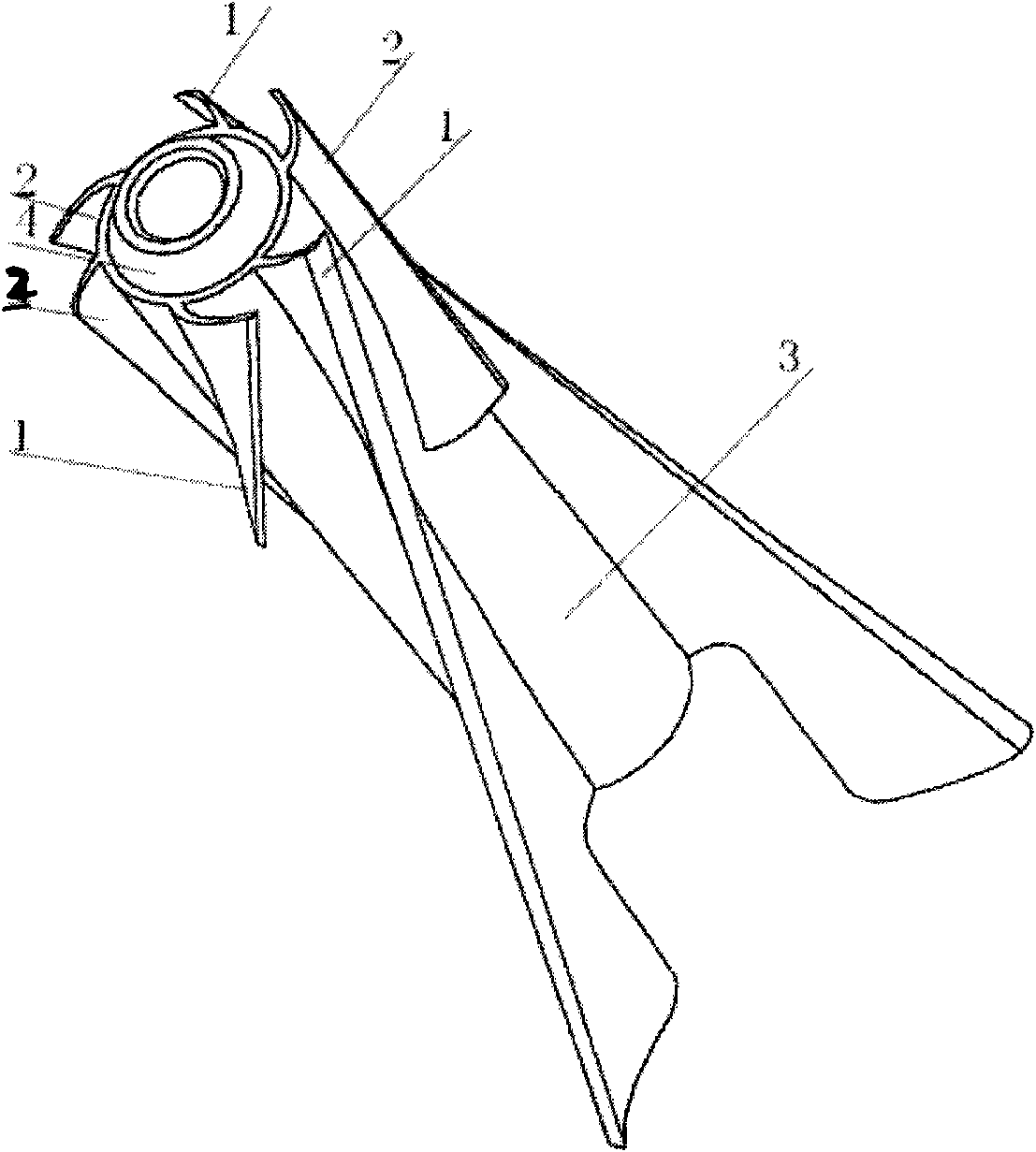

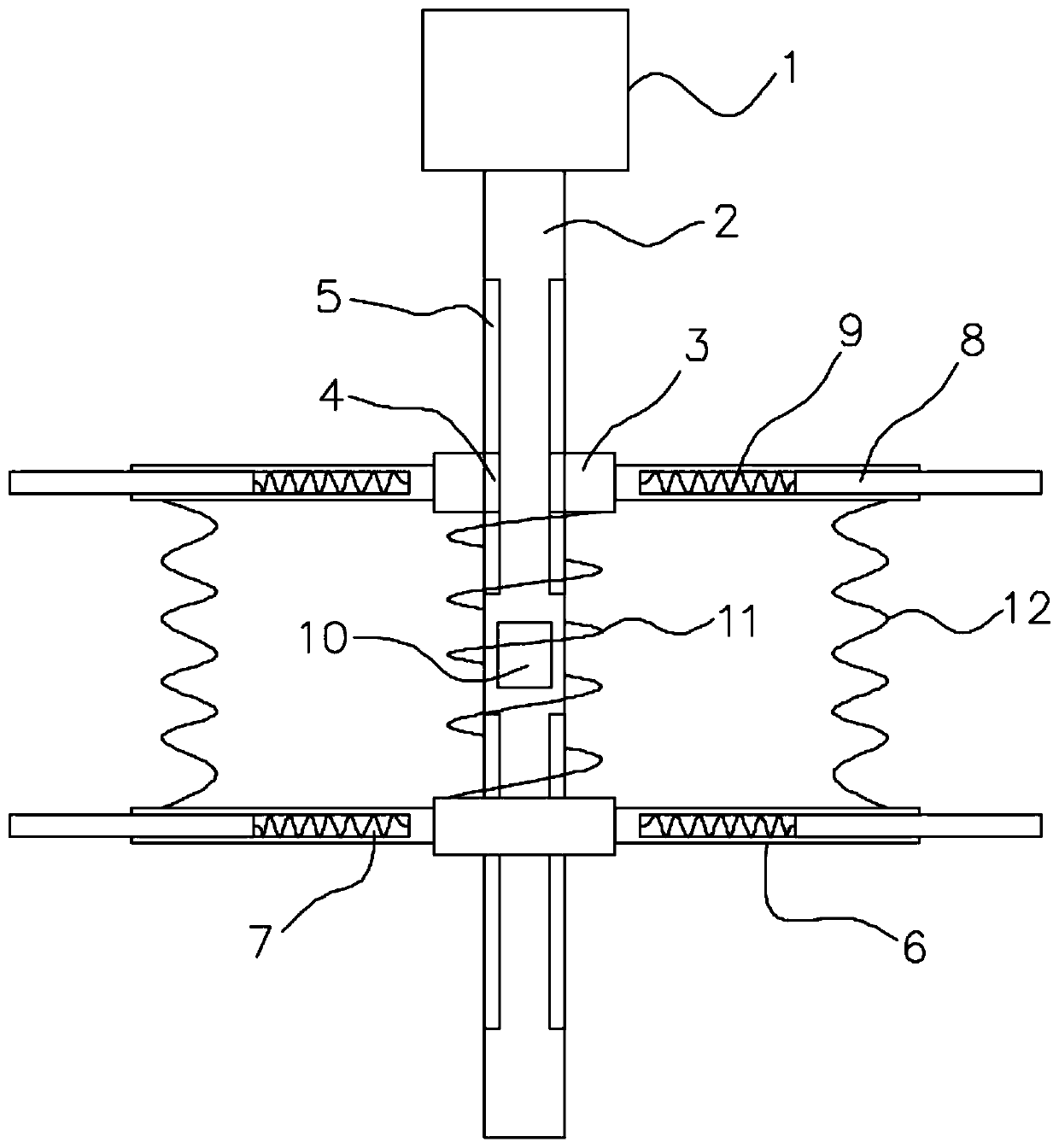

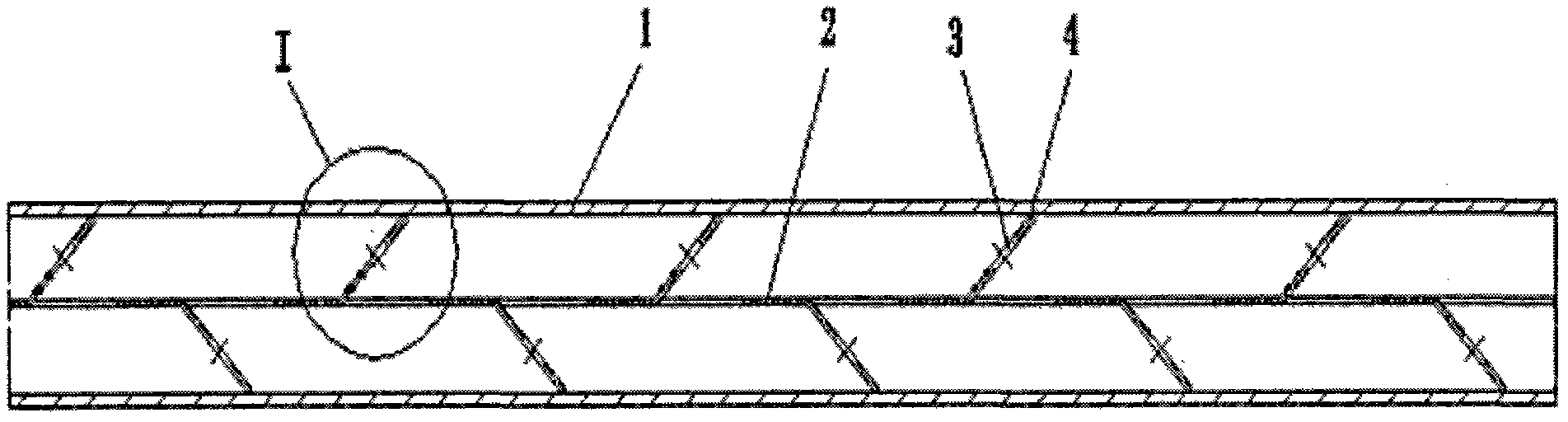

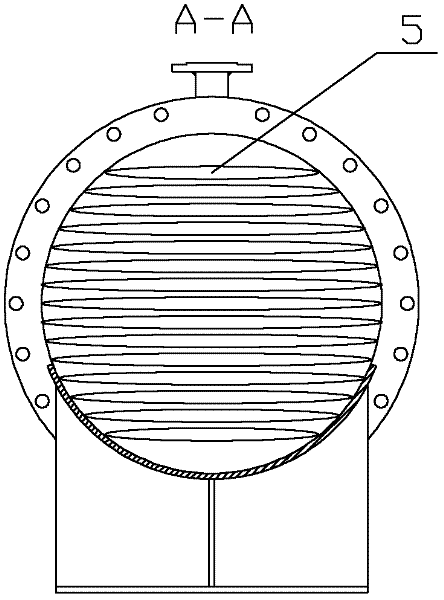

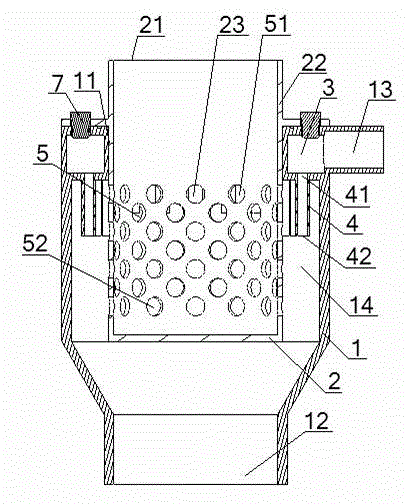

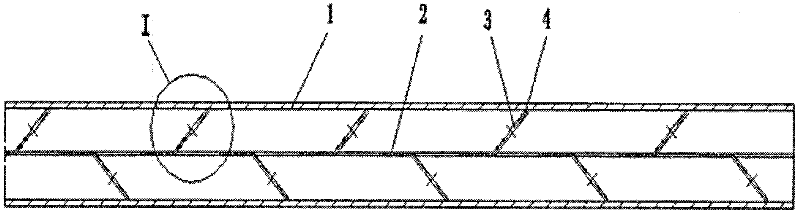

Tubular heat exchanger and turbulence device thereof

ActiveCN103808197AImprove spoiler effectHeat transfer modificationElastic componentPlate heat exchanger

The invention discloses a turbulence device used in a tubular heat exchanger. The turbulence device comprises at least two vertex generators and a fixed shaft which is arranged in a heat exchange tube of the tubular heat exchanger. The fixed shaft extends in the axial direction of the heat exchange tube. The fixed shaft is sleeved with each vertex generator in a clearance fit mode so that the vertex generators can move in the axial direction of the fixed shaft under the action of medium flow. An elastic component is installed between every two adjacent vertex generators. The deformation direction of each elastic component is the axial direction of the fixed shaft, so that axial locating of the vertex generators is realized through the elastic components. In this way, by means of selecting material parameters of the elastic components, namely when the flow velocity of the medium flow can be changed, the axial positions of every two adjacent vertex generators are adjusted in time, so that the turbulence device always has a good turbulence effect at different medium flow velocities, and therefore the turbulence performance of the turbulence device is improved. The invention further discloses the tubular heat exchanger comprising the turbulence device.

Owner:WEICHAI POWER CO LTD

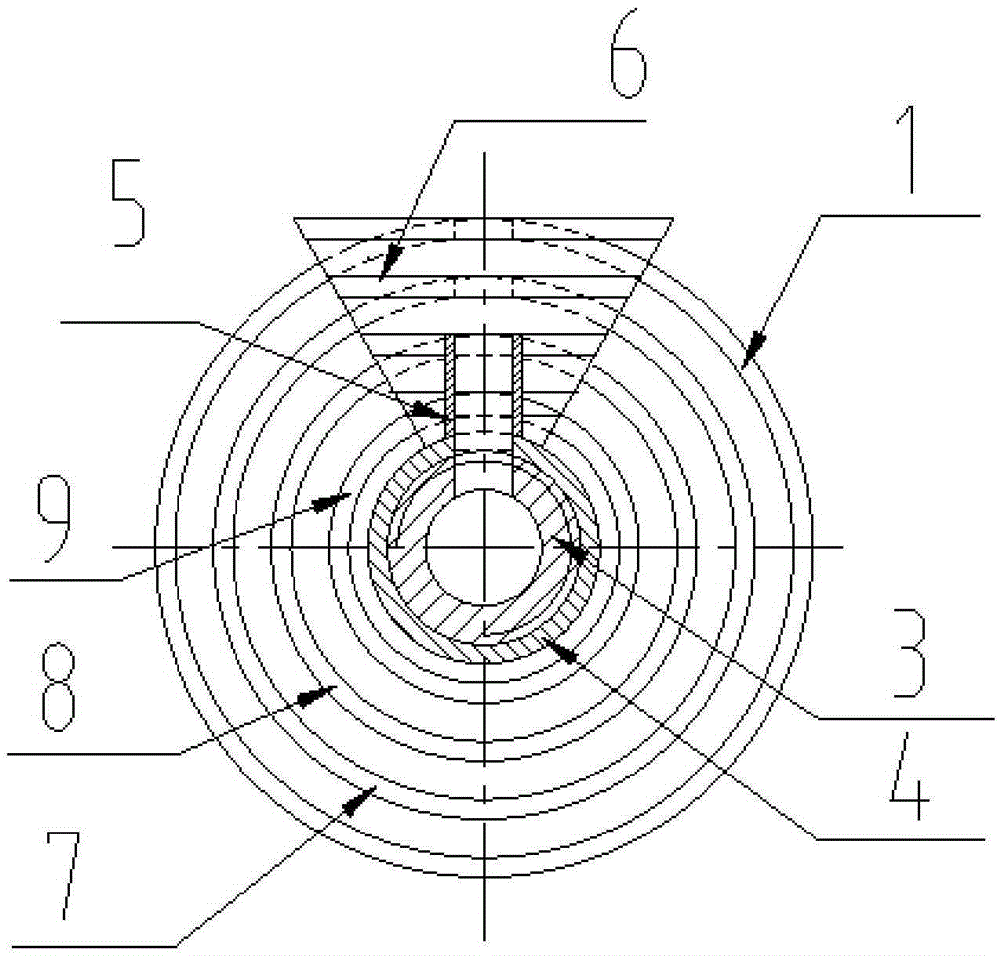

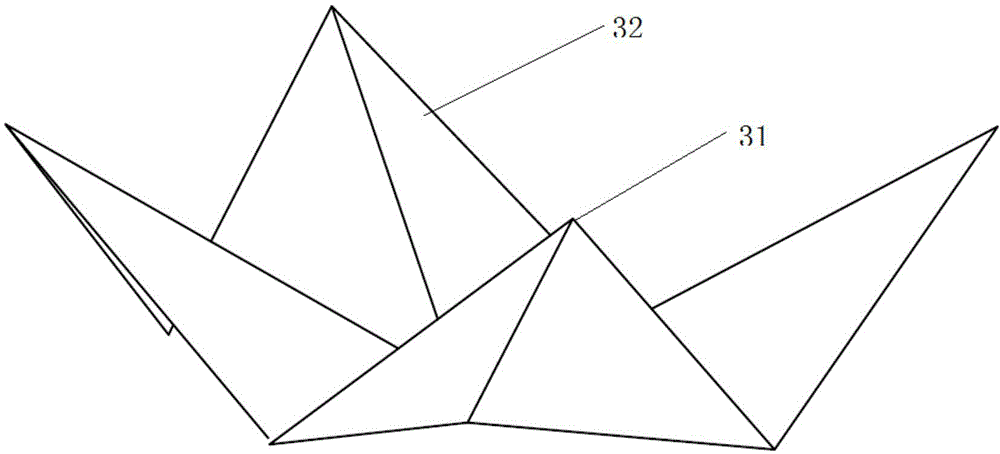

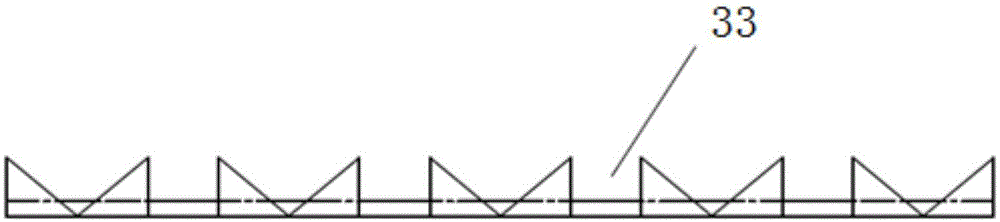

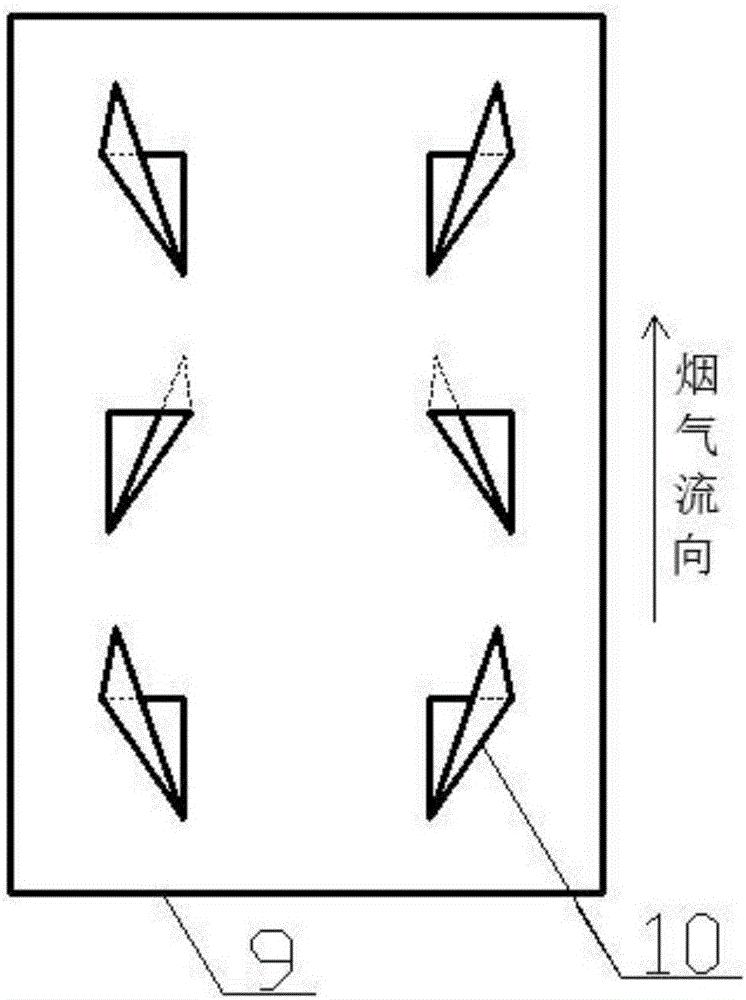

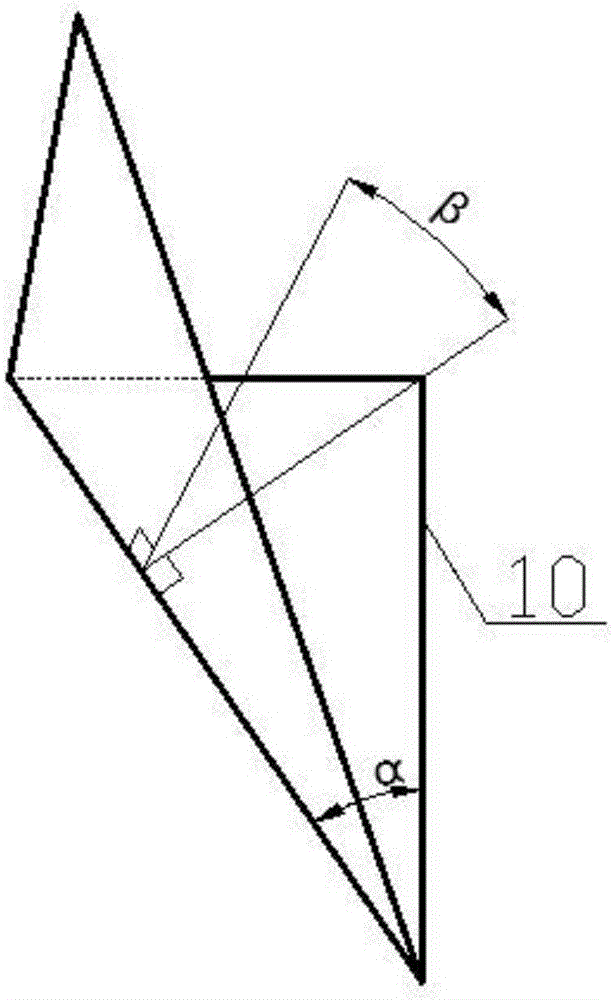

Static mixer for selective catalytic reduction flue gas denitration system

ActiveCN104096477AQuick mixWell mixedFlow mixersDispersed particle separationSet squareRight triangle

The invention discloses a static mixer for a selective catalytic reduction flue gas denitration system. The static mixer is mounted in a flue of the denitration system, and comprises a plurality of mixing units in the same structure, wherein each mixing unit is formed by jointly splicing eight identical right-angle set square structures around the same central point; the eight identical right-angle set square structures are divided into four groups; each group comprises two right-angle triangle structures connected via right-angle sides; the adjacent groups are completely connected via bevel sides of the right-angle set square structures respectively; and central points of the mixing units are correspondingly located right above circle centers of nozzles of an ammonia spray grid of the flue respectively. According to the static mixer, the mixing degree of ammonia and flue gas can be improved significantly; the uniformity of a mole ratio of ammonia to nitrogen is improved; smaller pressure loss of the system is generated; short-distance mixing is achieved; and the static mixer has the characteristics of obvious burbling effect, compact overall structure, convenience in processing and mounting and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

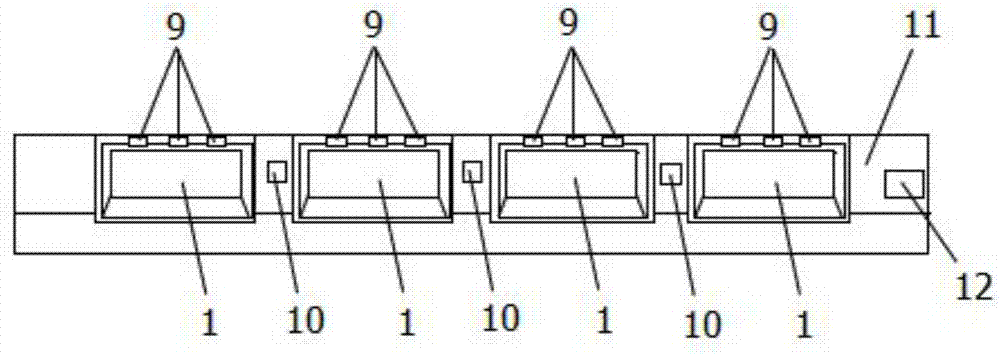

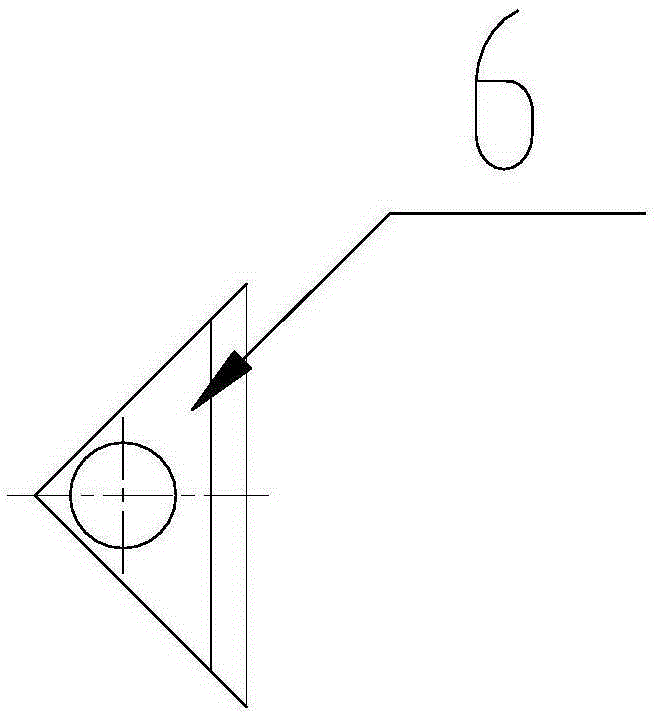

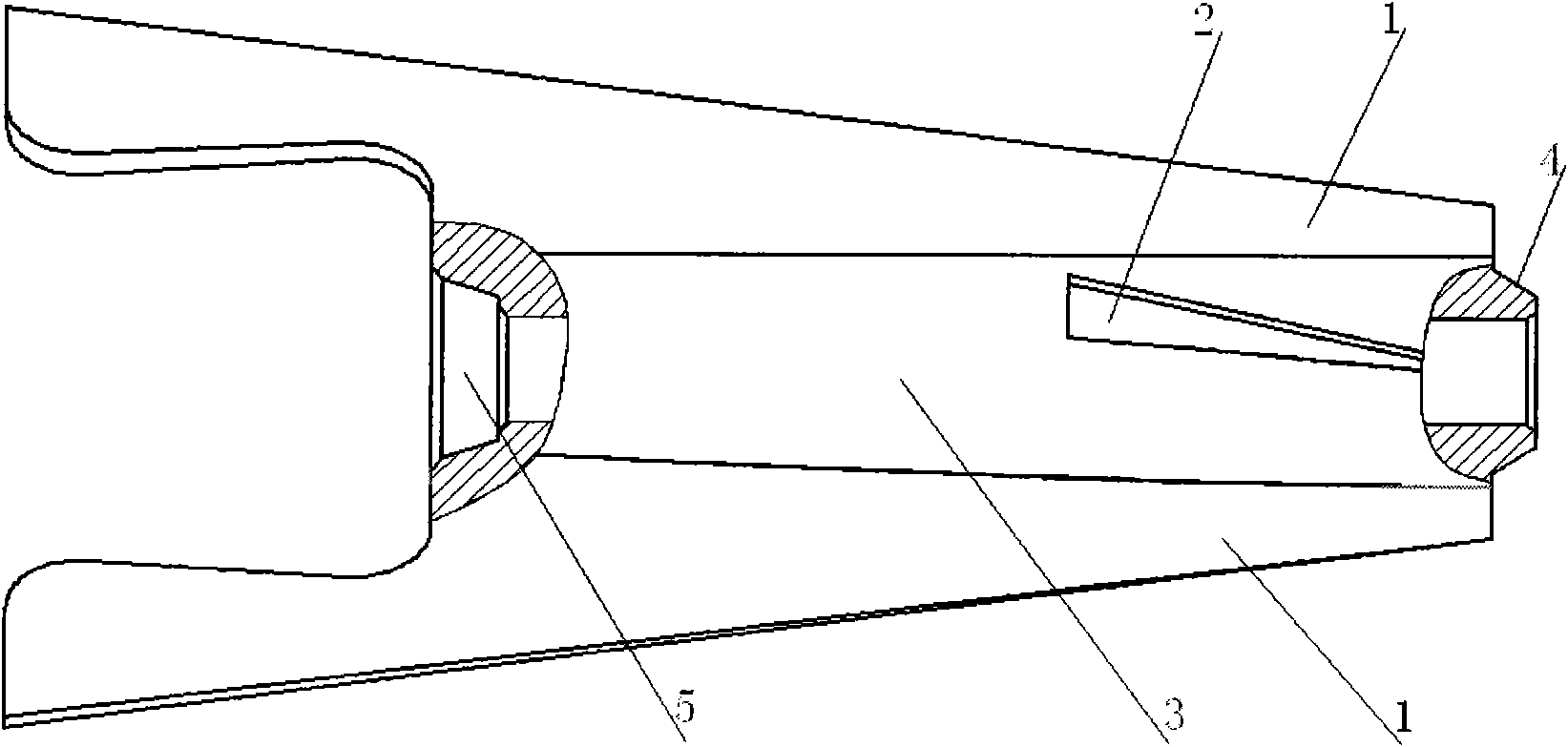

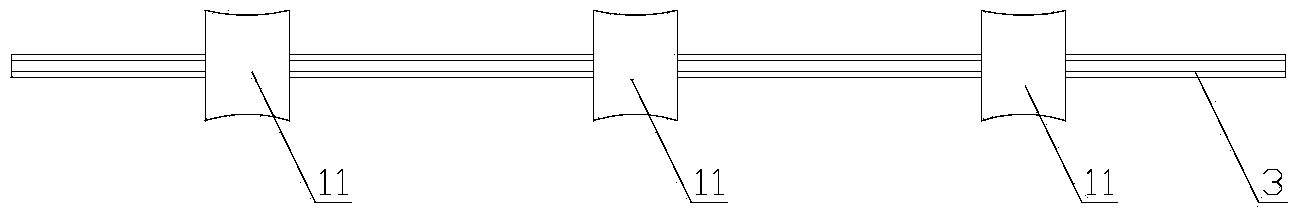

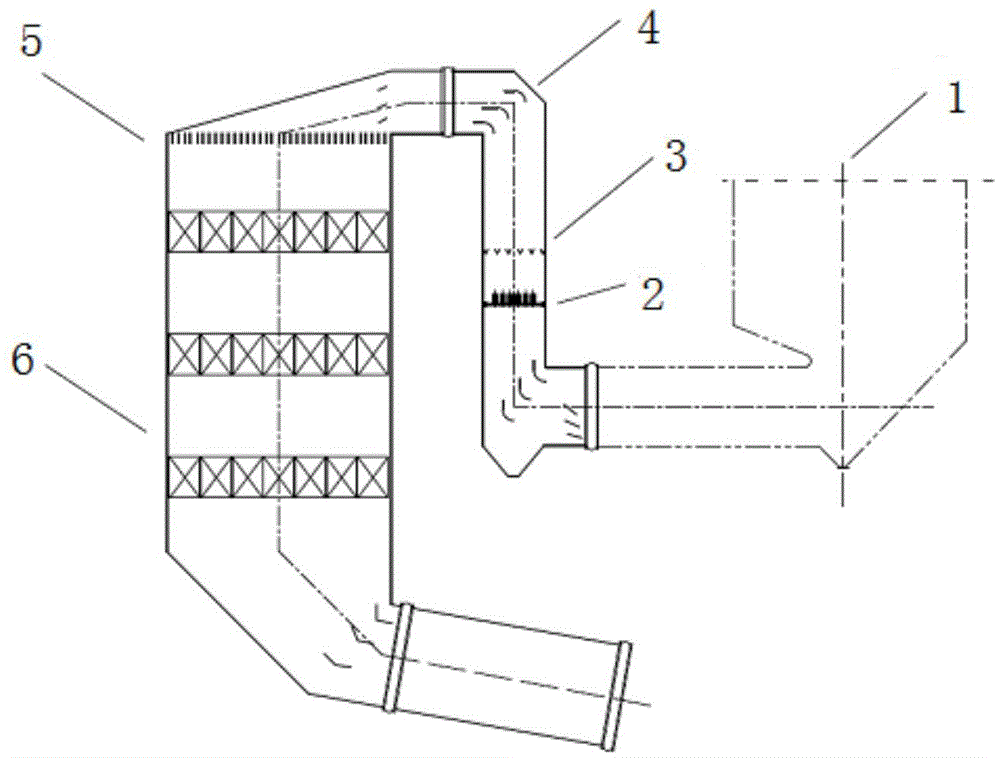

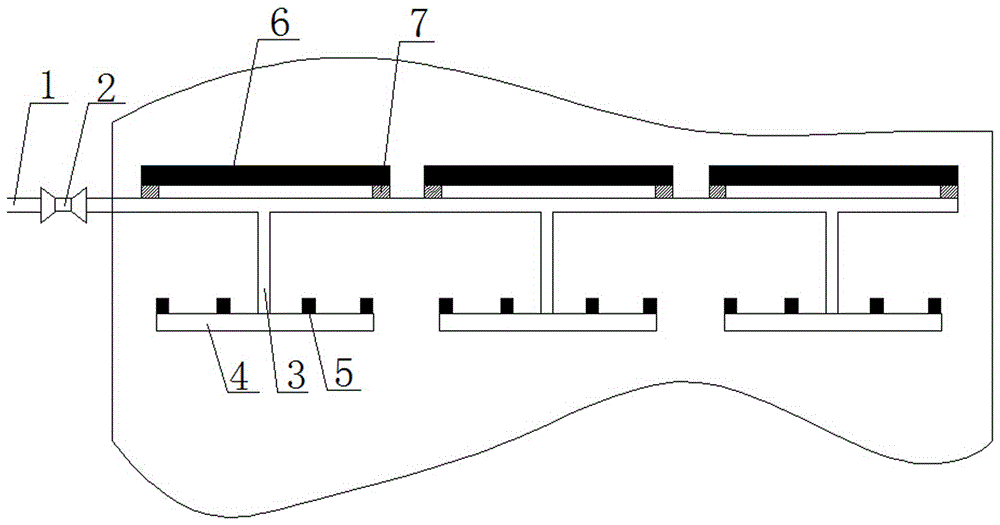

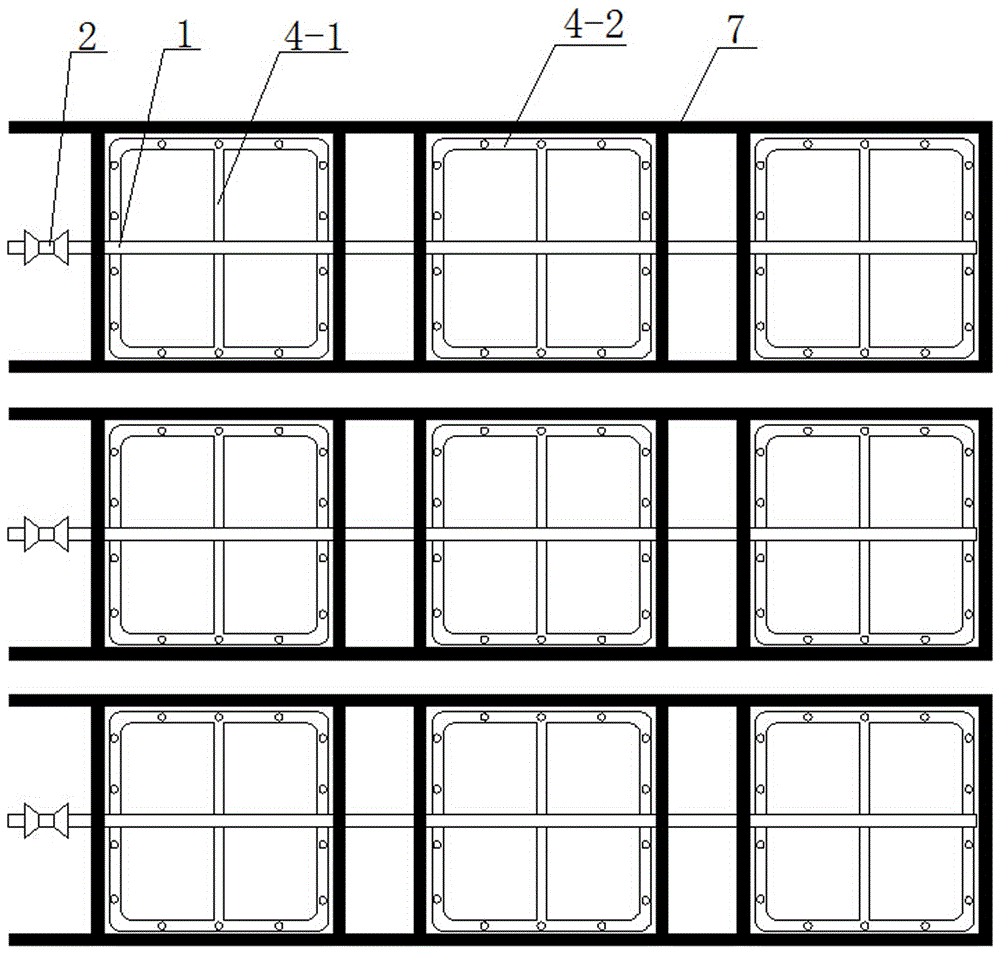

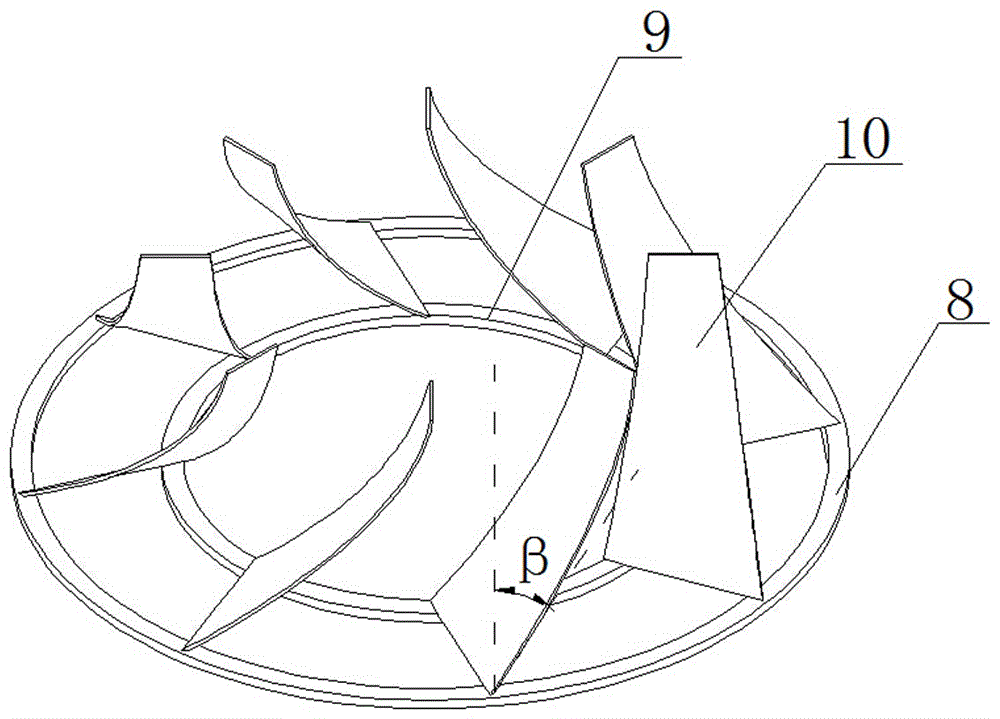

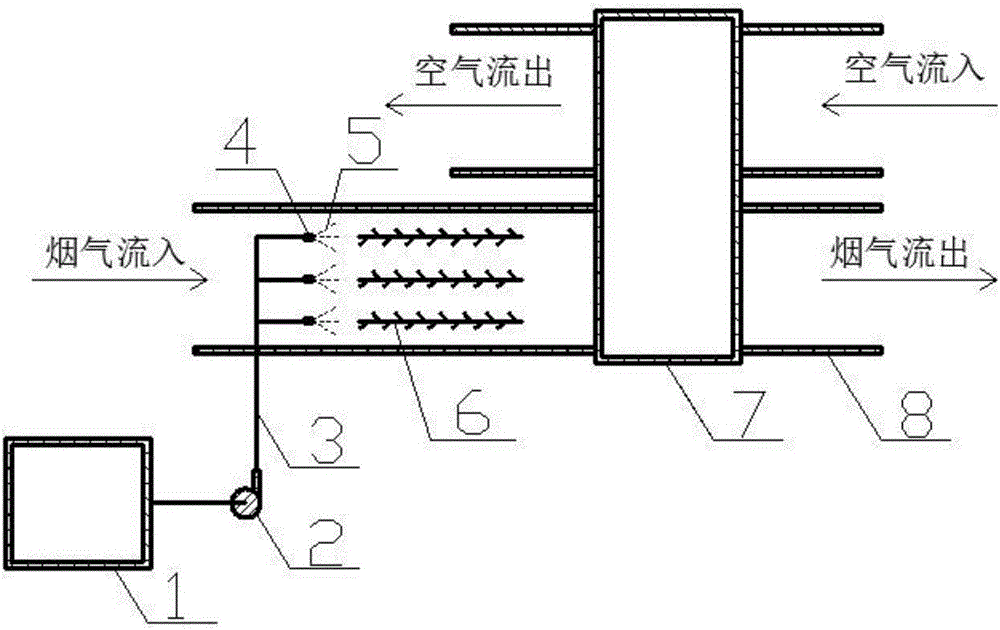

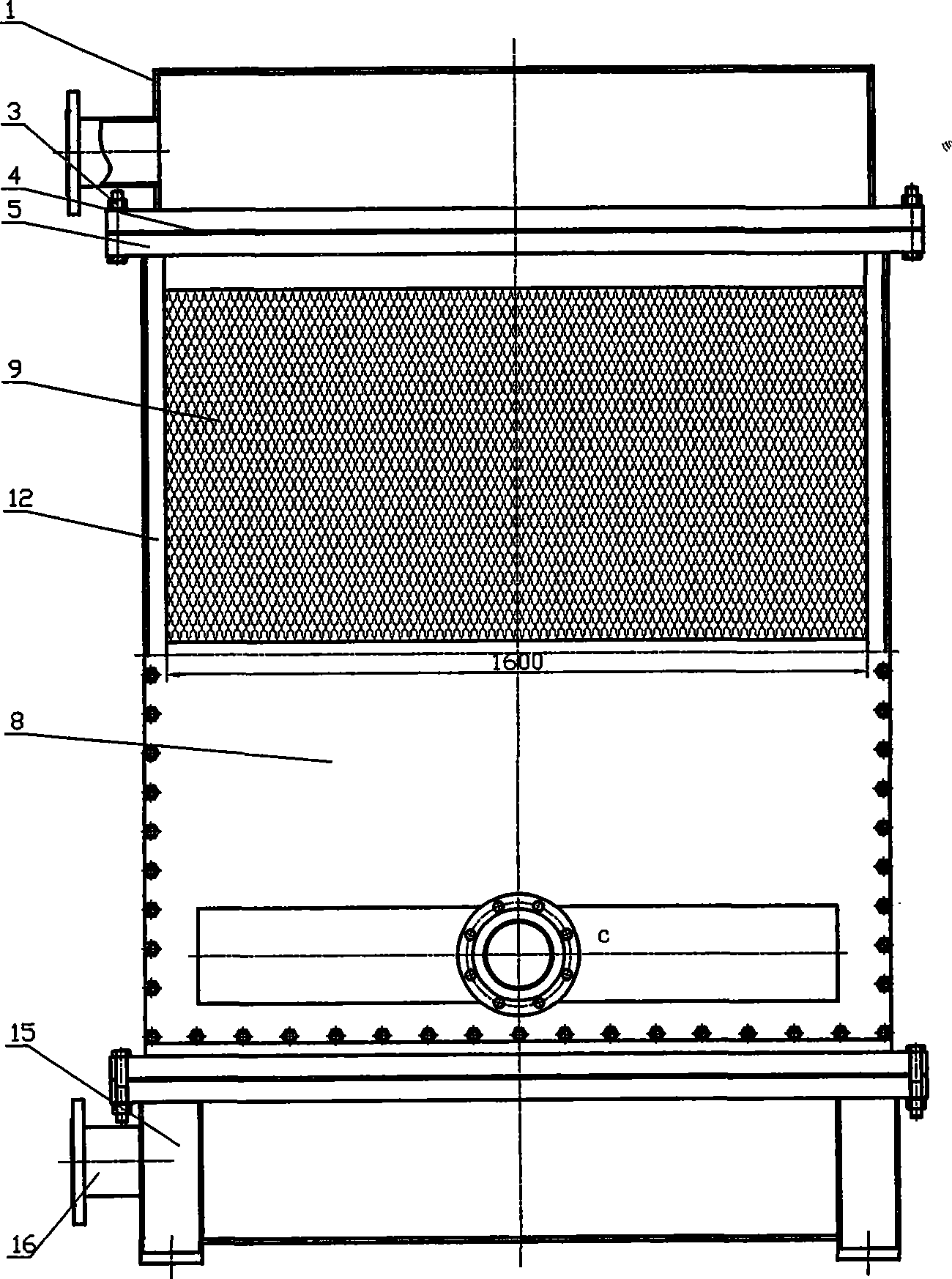

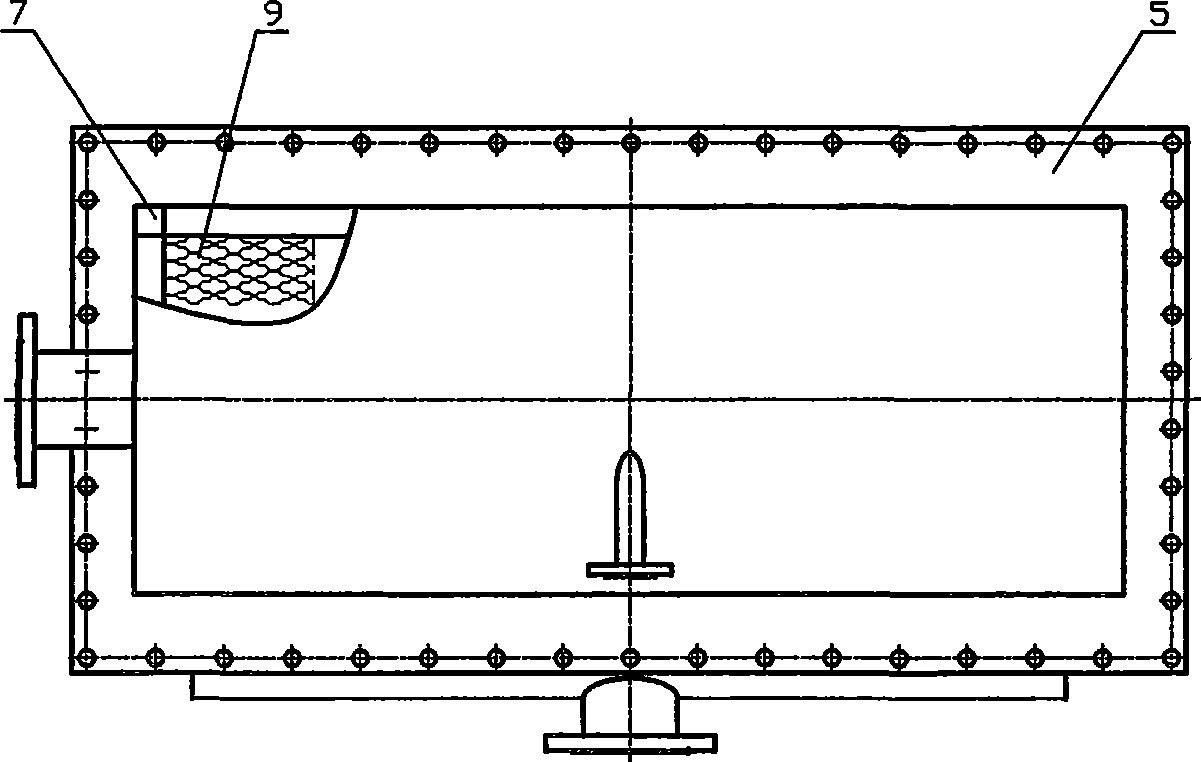

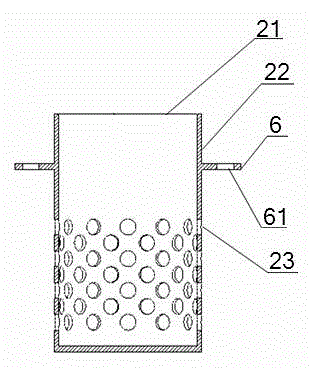

Ammonia spraying device of SCR (selective catalyst reduction) flue gas denitration system

ActiveCN106731811AEject evenlyConsistent pressureGas treatmentDispersed particle separationShortest distanceFlue gas

The invention discloses an ammonia spraying device of an SCR (selective catalyst reduction) flue gas denitration system. The ammonia spraying device comprises a plurality of input pipes (1) and a plurality of groups of uniformly distributed ammonia spraying units, wherein the input pipes (1) are uniformly arranged in a flue; the ammonia spraying units are connected with the input pipes (1) and are uniformly distributed; a spoiler (6) is arranged above each ammonia spraying unit; each ammonia spraying unit comprises a closing type spray pipe (4) and a branch pipe (3), and each branch pipe (3) is used for connecting the corresponding input pipe (1) and the corresponding closing type spray pipe (4); a spray nozzle (5) is arranged on each closing type spray pipe (4); each spoiler (6) comprises a casing and a plurality of blades arranged on the casing, and each blade (10) is of an arc-shaped trapezoidal structure. The ammonia spraying device has the advantages that by arranging the spoilers in the ammonia spraying device, flue gas can be fully and comprehensively mixed with ammonia gas in short distance, so that the additional arrangement of a static mixer is not needed, and the cost is low; by arranging the ammonia spraying device, the reverse flowing of the flue gas into an ammonia spraying pipeline is prevented.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

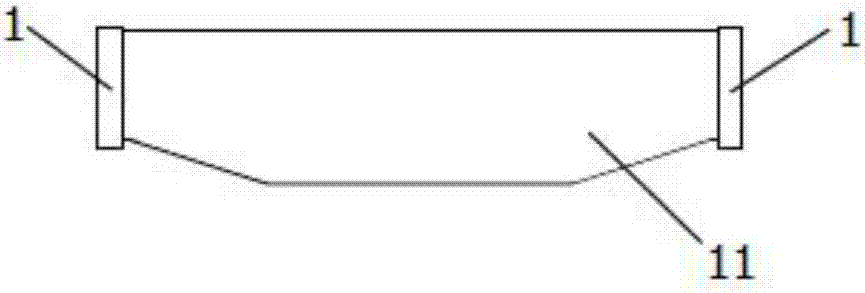

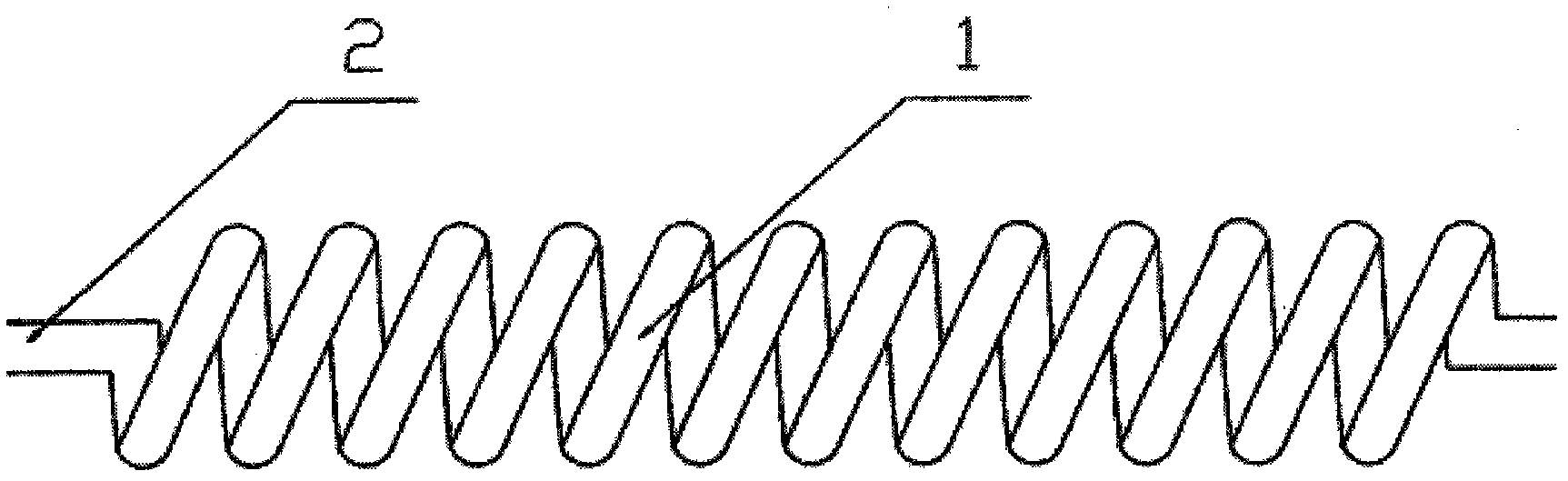

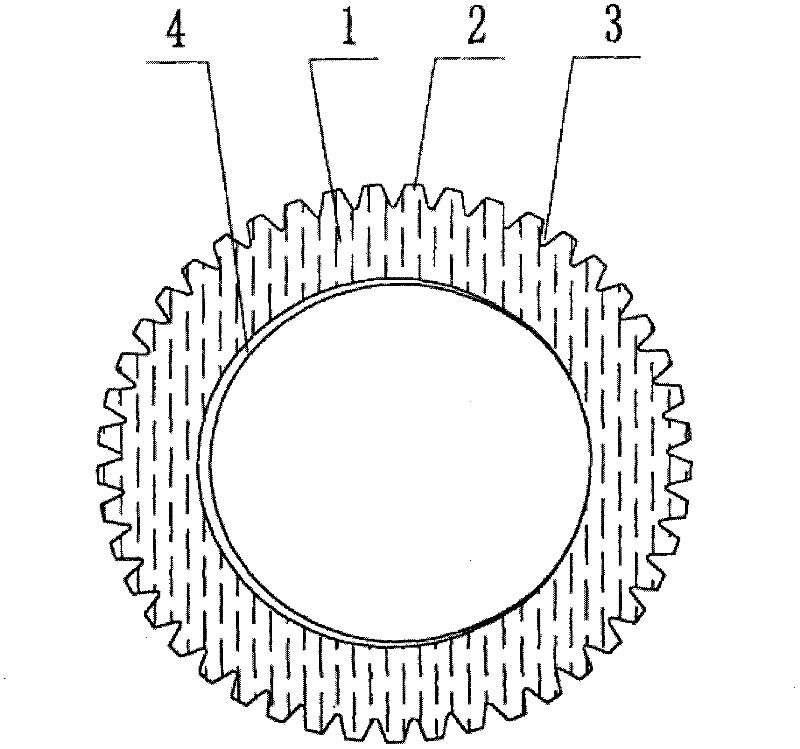

Elliptical and flat spiral heat exchange tube and processing technology thereof

InactiveCN102368028AImprove spoiler effectThe effect of heat exchange is sufficientTubular elementsStraight tubeEllipse

The invention discloses an elliptical and flat spiral heat exchange tube, which at least comprises a tube body, wherein the tube body encircles a medium channel; the tube body is integrally formed by a special tube section in the middle as well as a first straight tube section and a second straight tube section at the two ends of the special tube section; the special tube section is provided with an elliptical and flat cross section; and the long axis and short axis of the ellipse form a rotation angle to the axis of the tube body. The invention also discloses a processing technology of the elliptical and flat spiral heat exchange tube. Due to the adopted special tube section, the elliptical and flat spiral heat exchange tube is simple in structure, easy to process, is utilized to improve the heat exchange efficiency of the tube body, has the beneficial effects of fewer dirts and easiness in cleaning, and can be widely applied to various heat exchange devices.

Owner:SHANGHAI KEMI STEEL TUBE

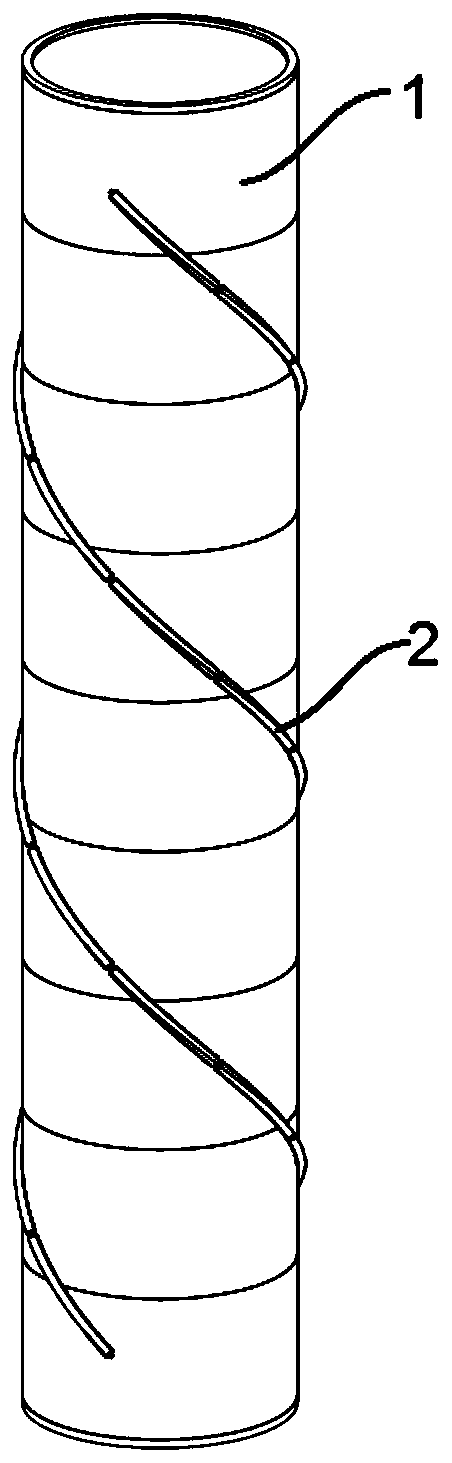

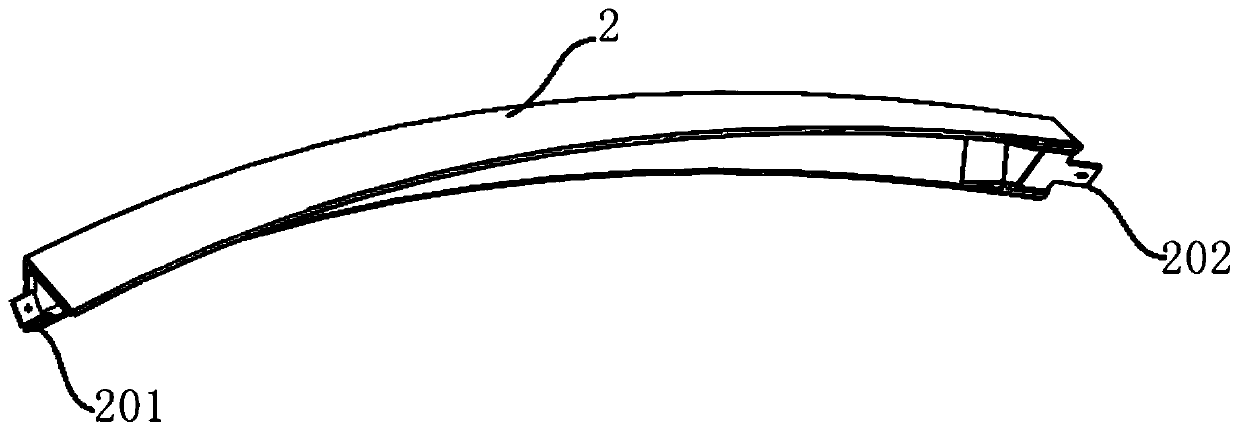

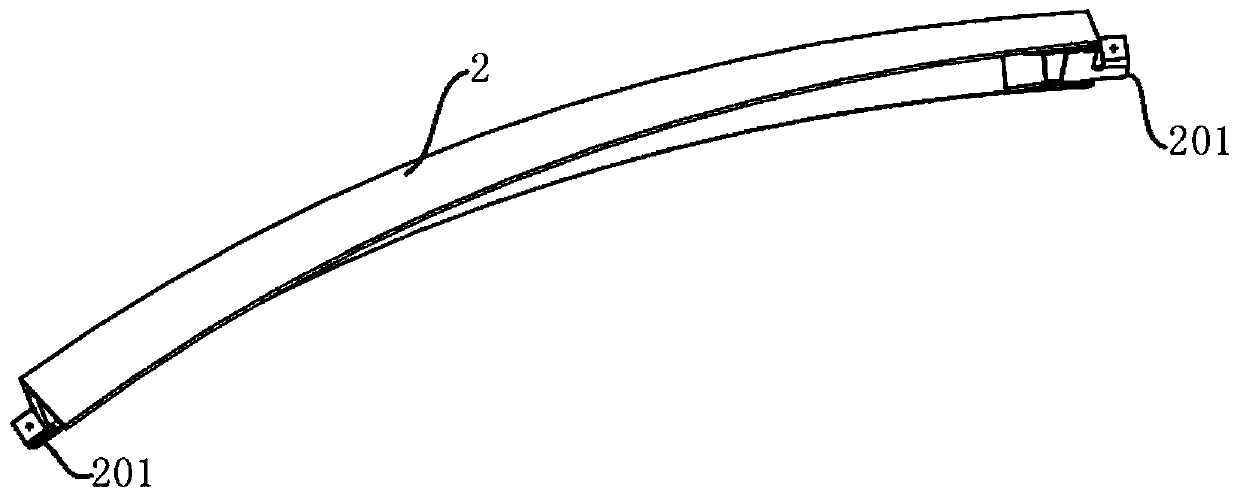

Wind electricity tower spoiler

PendingCN110925148APrevention of first-order vortex resonancePrevention of second-order vortex resonanceWind motor controlWind motor supports/mountsEngineeringTower

The invention discloses a wind electricity tower spoiler, which consists of a plurality of spoiler units, wherein the section of each spoiler unit is of a sealed three-edge solid structure or a three-edge thin-wall structure with an opening end; the plurality of spoiler units are connected in sequence to form one strand of continuous spiral line; in addition, the spiral line is fixed on the outerwall of the tower through the spoiler units positioned on the end parts; the bottom surface of each spoiler unit is fit to the outer wall of the tower; or the plurality of spoiler units form one strand of continuous spiral line, the continuous spiral line is arranged on the outer wall of the tower, i.e., each spoiler unit is fixed on the outer wall of the tower, and in addition, the bottom surfaceof each spoiler unit is fit to the outer wall of the tower; and two adjacent spoiler units are arranged at an interval. The spoiler can adapt to the shape follow-up technology of different external diameters of the whole tower, has a good spoiling effect and has a long service life.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

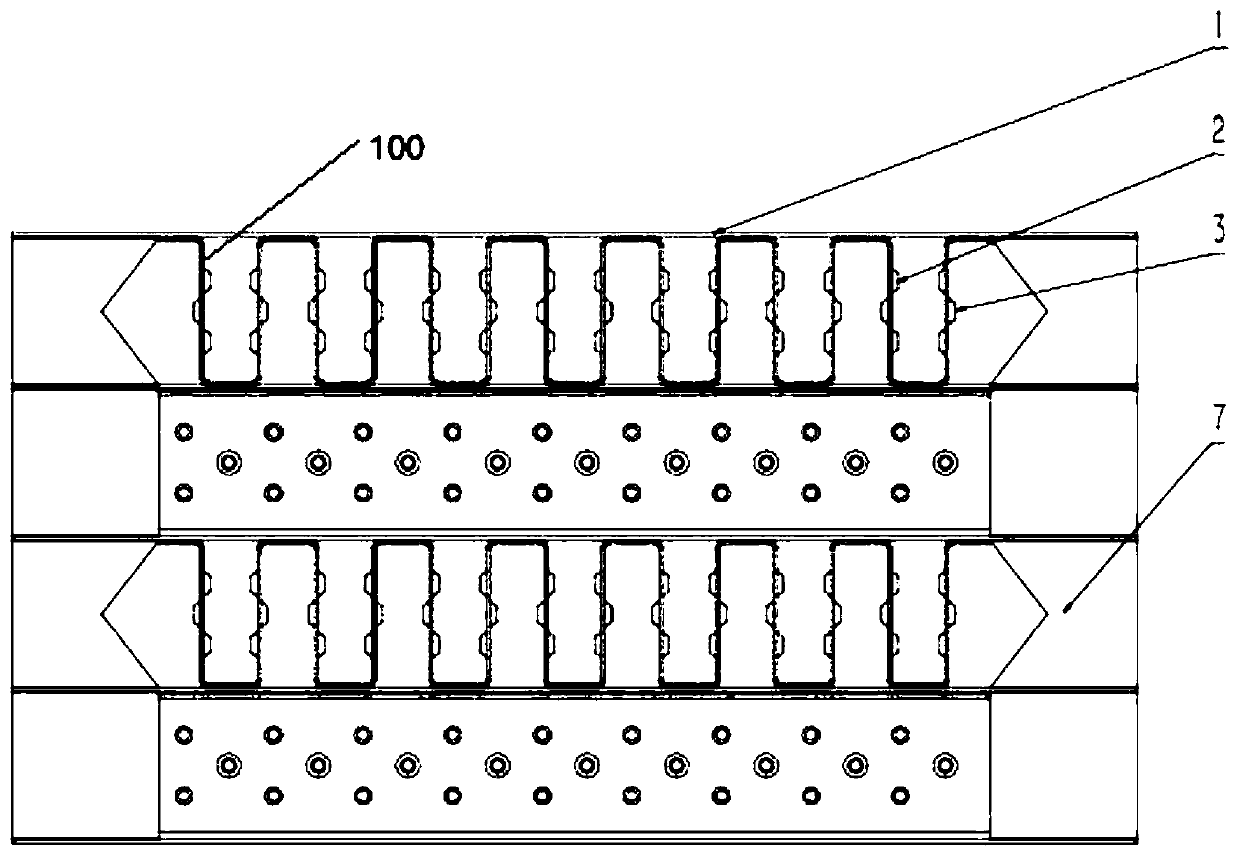

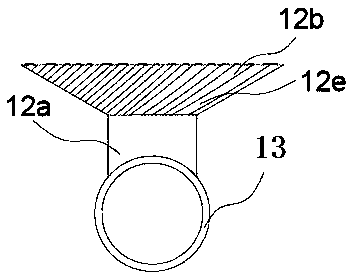

Device for desorbing sulfur trioxide in the front of air preheater

ActiveCN106492603AShorten the lengthReduce corrosionDispersed particle separationAir preheaterFlue gas

The invention discloses a device for desorbing sulfur trioxide in the front of an air preheater. The device comprises a plurality of groups of alkali injection units and flue gas mixing units which are arranged in a one-to-one correspondence manner; each alkali injection unit comprises an alkali pool, a pump and an atomizing spray nozzle which are sequentially connected; an alkali absorbing agent is stored in each alkali pool; the atomizing spray nozzles are arranged in a front flue of the air preheater; each flue gas mixing unit comprises a substrate flat plate and fins; each substrate flat plate is arranged on the downstream of the corresponding atomizing spray nozzle in the front flue and is arranged along the direction of mainstream flue gas; the fins are arranged on two sides of the substrate flat plate at intervals. According to the device disclosed by the invention, the alkali injection units are arranged in the front flue of the air preheater and spray the alkali absorbing agents in flue gas; turbulence mixing is performed by using the flue gas mixing units; the sulfur trioxide is desorbed by using the strong alkali characteristic of the alkali absorbing agents, and the desorption rate can reach 80 percent or above; by adjusting the atomizing spray nozzles and the flue gas mixing units, the mixing uniformity of the flue gas and the absorbing agent is guaranteed, the length of a reaction zone is shortened, and the service life of a heat storage element of the air preheater is prolonged.

Owner:XI AN JIAOTONG UNIV

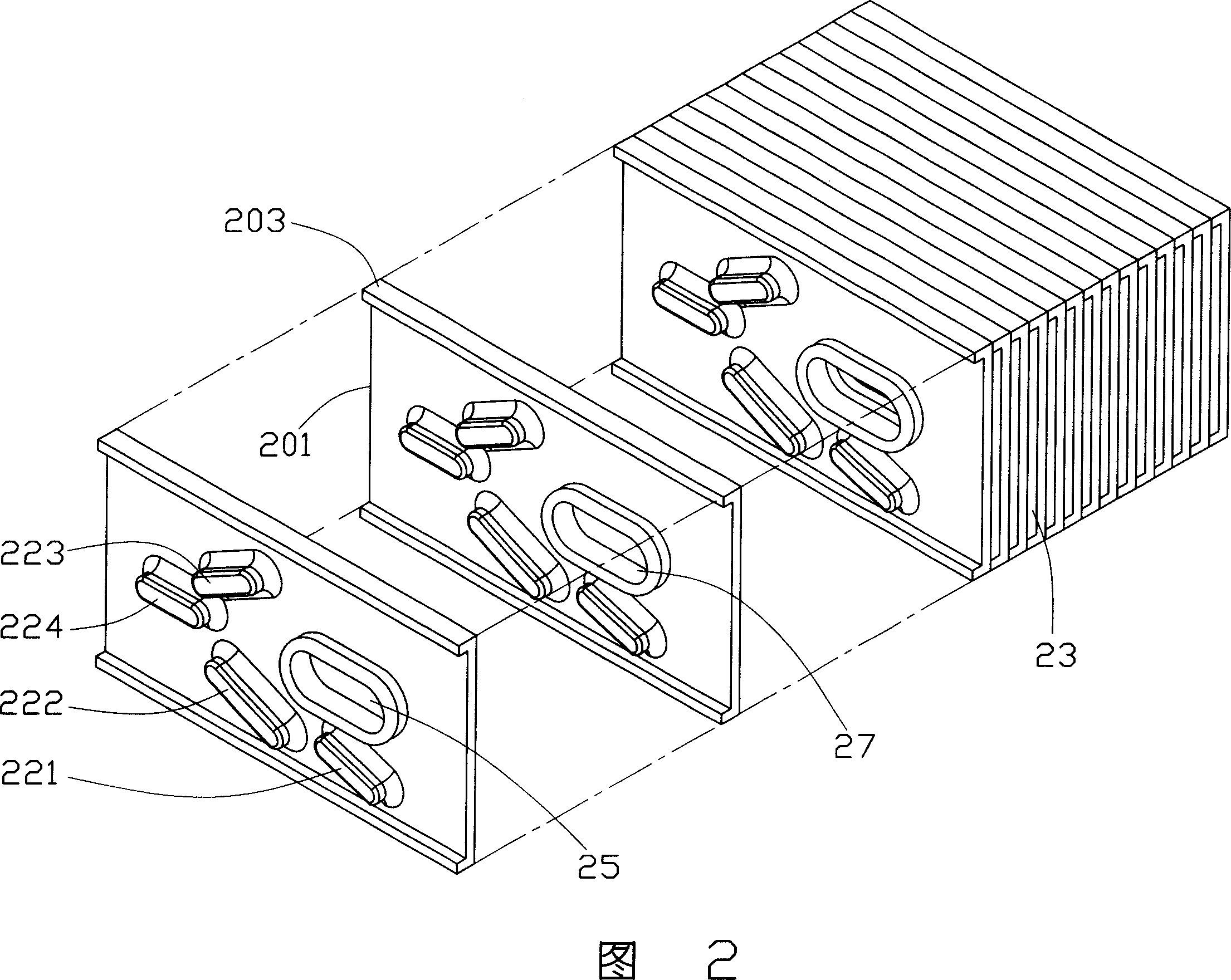

Welded plate type heat exchanger

ActiveCN101392994AImprove antioxidant capacityImprove corrosion resistanceStationary plate conduit assembliesCarbon steelAluminium

The invention discloses a welded plate type heat exchanger, which comprises a frame and support legs, wherein the upper part and the lower part of the frame are provided with an end closure respectively provided with a medium II inlet or outlet and an air exhaust port or a drain, the middle part of the frame is provided with a movable plate and a fixing plate, the upper part and the lower part of the movable plate are provided with a collection box respectively, and the collection box is welded with a medium I inlet or outlet; an upper end closure, a lower end enclosure, the movable plate and the fixing plate are in sealing connection with the frame by connecting square flanges, gasket seals and bolts so as to form a heat exchanger box body, the inner part of the heat exchanger box body is provided with a heat exchange plate bundle, the heat exchange plate bundle is formed by the stacking of plate groups formed by the welding of the heat exchange plates, medium I flow passages are formed in the plate groups, and medium II flow passages are formed between the adjacent plate groups; the heat exchange plates are made by the punching of carbon steel or stainless steel; and the both surfaces of the heat exchange plates are provided with aluminizing diffusion layers. The heat exchanger has the advantages of higher bearing operation temperature and better corrosion resistance.

Owner:辽宁远大换热装备(集团)有限公司

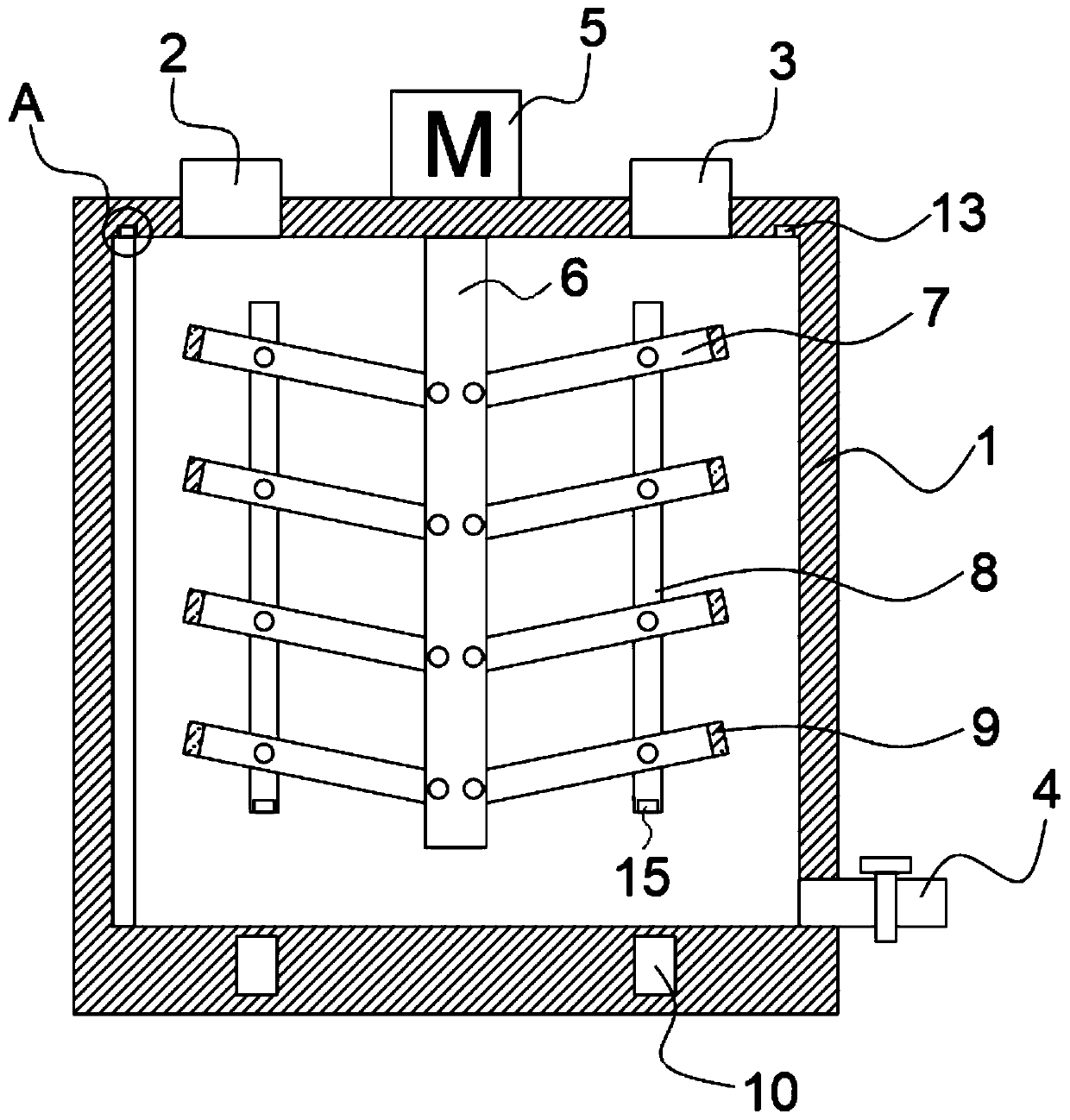

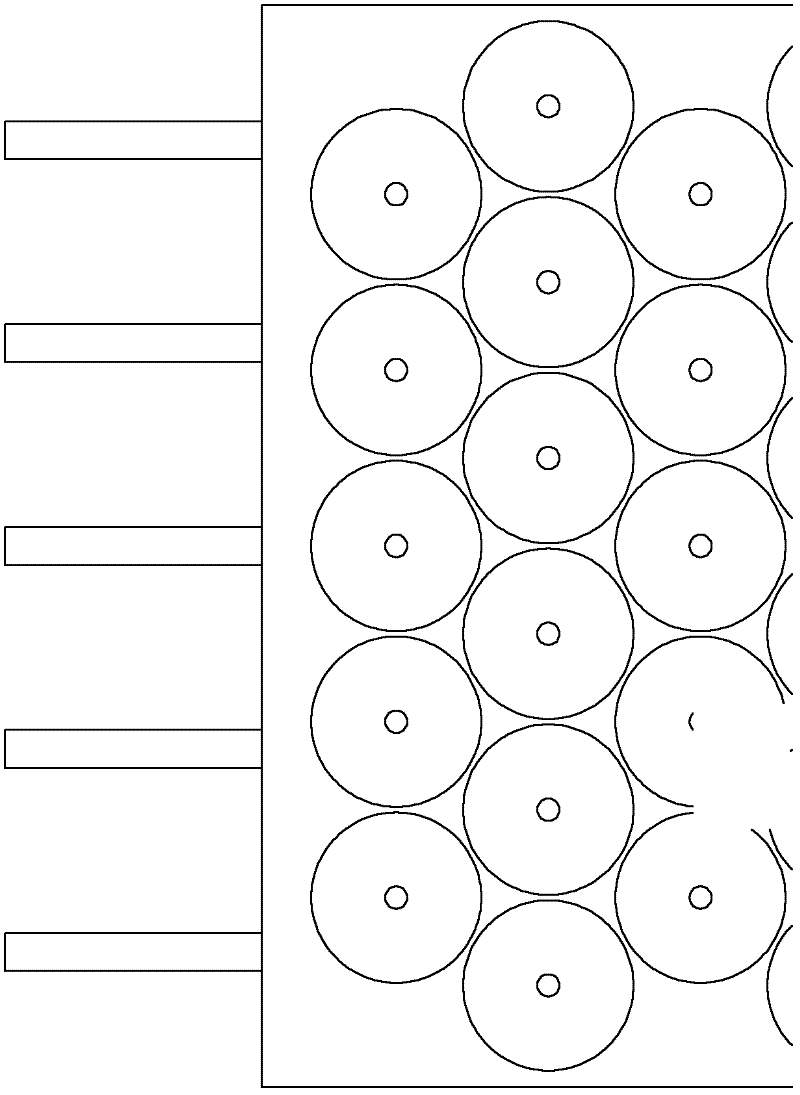

Electromagnetic mixing device with changeable stirring forms

InactiveCN110624454AImprove spoiler effectShorten mixing cycleShaking/oscillating/vibrating mixersTransportation and packagingVisual observationEngineering

The invention discloses an electromagnetic mixing device with changeable stirring forms. The mixing device includes a cylindrical mixing tank, a rotating electrical machine is fixedly installed at themiddle of the upper end of the mixing tank, the output end of the rotating electrical machine is fixedly connected with a vertically arranged stirring shaft, the lower end of the stirring shaft passes through the mixing tank and extends to the inner bottom of the mixing tank, and the left and right sides of the stirring shaft are symmetrically provided with stirring components; and each stirringcomponent includes a plurality of rotating grooves arranged in one side of the stirring shaft at equal intervals, the interior of each rotating groove is rotatably connected with a stirring blade through a pin shaft, a plurality of stirring blades are rotationally connected with synchronization rods in a vertical direction, and a permanent magnet is embedded into the bottom end of each synchronization rod. The device has the following advantages: from the visual observation, in the process of performing stirring as the whole stirring components rotate, the plurality of stirring blades on the left and right sides of the stirring shaft are rotated in a rotation angle range, so that the turbulence effect during stirring is greatly enhanced, the mixing stirring cycle is shortened, and the mixing efficiency is improved.

Owner:郑中光

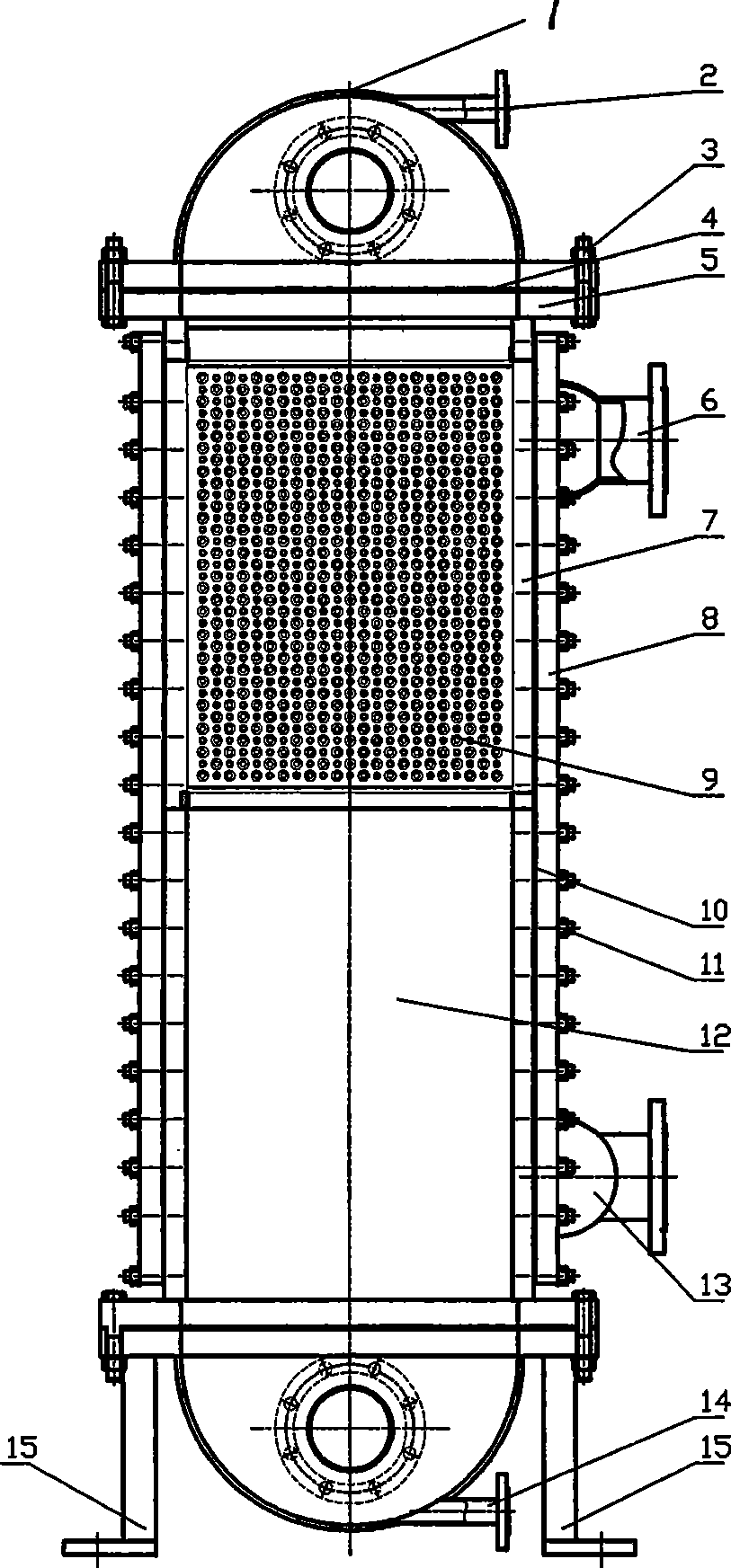

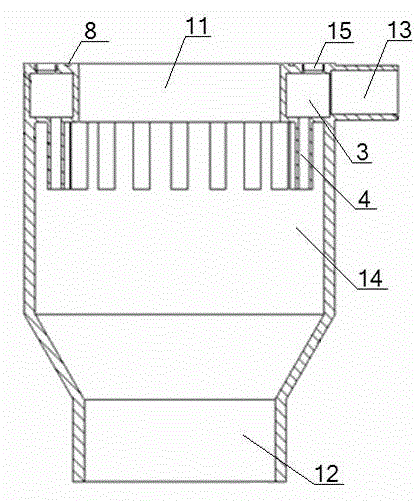

Detachable plate shell type heat exchanger

InactiveCN102353285AImprove spoiler effectImprove heat transfer performanceHeat transfer modificationLaminated elementsParallel plateEngineering

The invention discloses a detachable plate shell type heat exchanger. Pipe boxes are arranged at the two ends of a shell, two pipe plates are arranged between the pipe boxes and the shell and fixed together by flanges, a plate bundle consisting of parallel plate sheets is arranged between the pipe plates on the two sides, the two ends of each plate sheet are fixed on the two pipe plates on the two sides by plate pipes and communicated with the pipe boxes, a shell pass inlet and a shell pass outlet are formed on the shell, plate pass inlets and plate pass outlets are formed on the pipe boxes, the plate sheets comprise flow passage cavities and the plate pipes, the sections of the flow passage cavities are oblate, honeycomb structures are formed in the flow passage cavities, the two ends ofeach flow passage cavity are welded with the plate pipes which are communicated with the flow passage cavity, the plate pipes are inserted into the pipe holes of the pipe plates, and the outer surfaces of the plate pipes and the pipe holes are sealed by internal pipe plate compacting sealing rings and external pipe plate compacting sealing rings; the plate sheets comprise long plate sheets and short plate sheets, so that a shell pass has a multi-shell pass structure; and flow passages among the plate sheets are separated and supported by pull rods. The detachable plate shell type heat exchanger has high heat exchanging performance and is convenient to disassemble, wash, replace and assemble.

Owner:SOUTH CHINA UNIV OF TECH

Radiator

InactiveCN101087508AIncrease cooling areaChange flow fieldDigital data processing detailsSemiconductor/solid-state device detailsHeat spreaderPhysics

A kind of radiator includes several radiating fins which are set parallel with each other and hot pipe which is set through the radiating fins, flow channel for air flow is formed between adjacent radiating fins, a through hole for the hot pipe is set on every radiating fin, several heaves are set around the through hole on the radiating fin, said several heaves are arranged to shrinkage type. Said heaves can increase radiating area of radiating fin, at the same time it can guide flow and change flow field of air flow, increase burbling effect of radiating fin, radiating efficiency can be increased.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Engine mixer

ActiveCN104314713AShorten the lengthFast control responseInternal combustion piston enginesFuel supply apparatusMomentumEngineering

The invention discloses an engine mixer which comprises a mixer body and a mixer tube core, wherein the mixer body adopts a hollow structure of which two ends are opened and comprises an air inlet end, a mixed gas outlet end and an inner cavity; the inner wall of the air inlet end and the outer wall of the mixer tube core are matched in an inserting manner; a natural gas inlet pipe is connected onto the outer wall of the air inlet end and is communicated with the mixed gas outlet end through the inner cavity; the mixed tube core adopts a hollow structure of which one end is opened; an opening end of the mixed tube core is an air inlet; the air inlet is communicated with the inner cavity through a plurality of through holes formed in the tube wall of the mixer tube core. According to the engine mixer, natural gas flow beams are dispersed by using greater momentum of air flow beams, so that the mixing uniformity of natural gas and air is improved, and the flowing resistance is reduced.

Owner:DONGFENG COMML VEHICLE CO LTD

Spiral arc-shaped heat exchange pipe and machining processes thereof

InactiveCN102331207AThe effect of heat exchange is sufficientImprove heat exchange efficiencyTubular elementsEngineeringMachining process

The invention discloses a spiral arc-shaped heat exchange pipe, which at least comprises a pipe body, wherein the pipe body encircles to form a medium channel and is a special pipe section; a groove which extends in an arc shape is formed on the pipe wall of the special pipe section, and forms a rotary included angle with an axis of the pipe body; and the groove is provided with convex arc-shaped grains on the inner wall of the pipe body correspondingly. The invention also discloses several machining processes for the spiral arc-shaped heat exchange pipe. In the spiral arc-shaped heat exchange pipe, due to the adoption of the special pipe section with the structural design, arc-shaped ripples are formed on the inner wall of the heat exchange medium channel; when a heat exchange medium flows in the medium channel, the heat exchange medium is subjected to turbulent influence of the arc-shaped ripples while rotating, and a turbulence effect is obvious, so a heat exchange effect of the heat exchange medium inside the pipe and outside the pipe is full, and the heat exchange efficiency of the pipe body is improved; and the spiral arc-shaped heat exchange pipe has the advantages that a few scales are formed, the spiral arc-shaped heat exchange pipe is easy to clean and the like, and can be widely applied to various heat exchange devices in fields of industry, household appliances, automobiles and the like.

Owner:SHANGHAI KEMI STEEL TUBE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com