Ammonia spraying device of SCR (selective catalyst reduction) flue gas denitration system

A technology for denitration and flue gas, which is applied in the field of denitration devices, can solve the problems of difficult and uniform mixing, insufficient mixing effect, etc., and achieves the effects of convenient installation and uniform ammonia ejection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

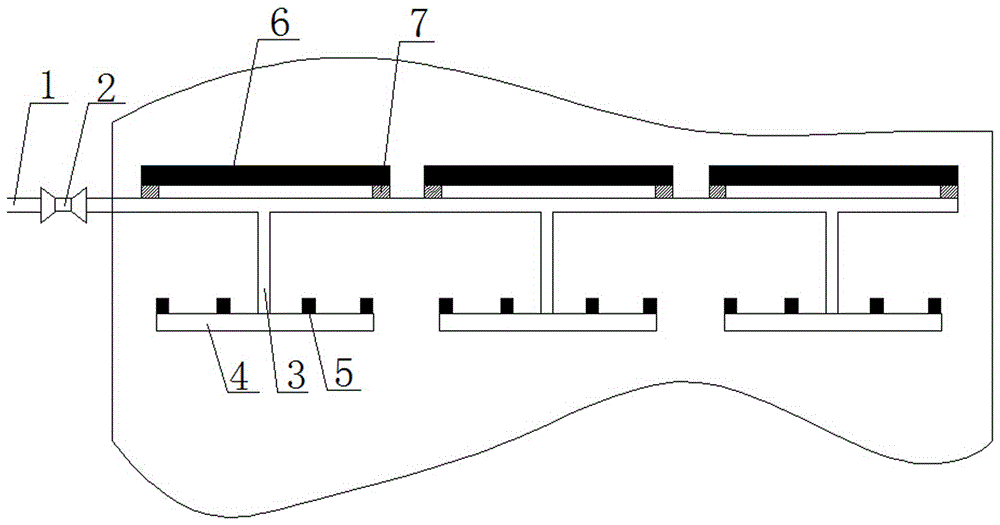

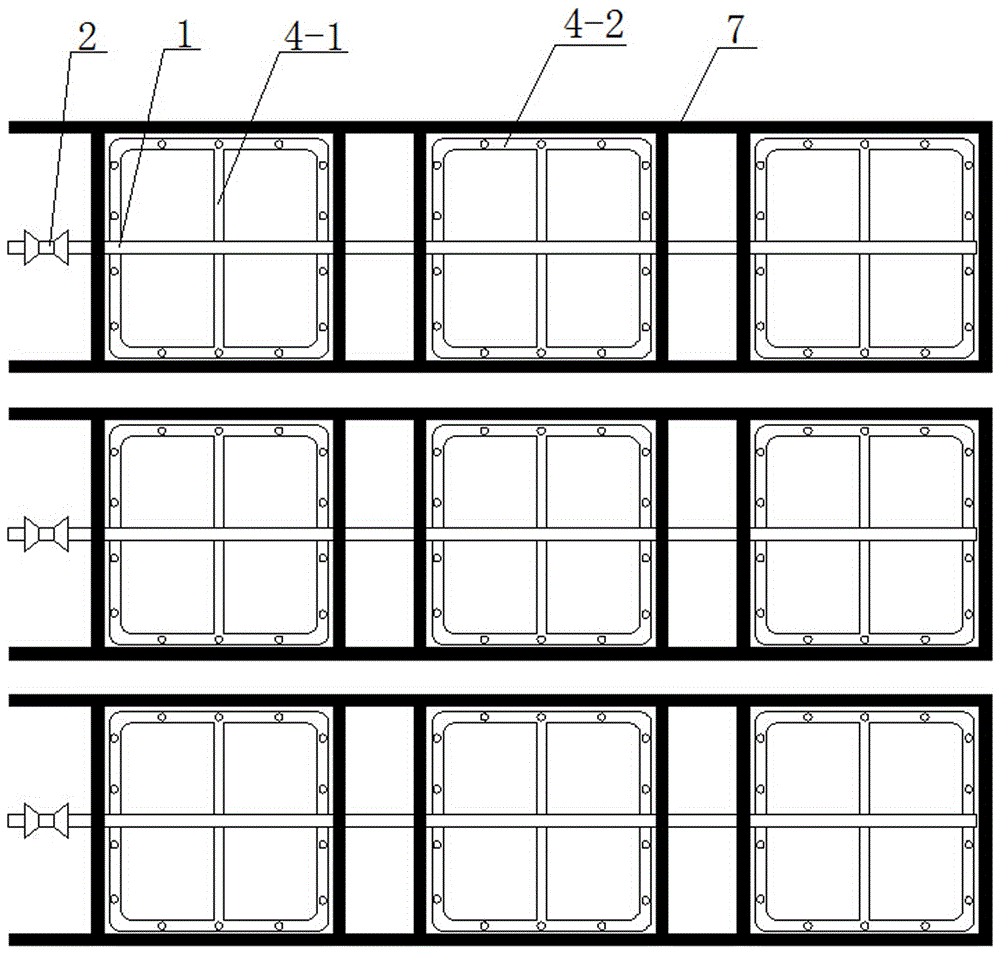

[0036] Such as Figure 1-3 As shown, an ammonia injection device for an SCR flue gas denitrification system includes a plurality of input pipes 1 uniformly arranged in the flue and a plurality of uniformly distributed ammonia injection units connected to the input pipes 1, wherein each input pipe 1 is provided with Valve 2; a spoiler 6 is arranged above each ammonia injection unit, and the spoiler 6 is fixed on the input pipe 1 through a support structure 7 .

[0037] The ammonia injection unit includes a closed nozzle 4 and a branch pipe 3 connecting the input pipe 1 and the closed nozzle 4. The closed nozzle 4 includes an annular pipe 4-2 connected end to end and a central pipe 4-1, wherein the central pipe 4 -1 The two ends of the head and the tail are respectively communicated with the annular pipe 4-2, and the input pipe 1 and the central pipe 4-1 on the closed nozzle 4 are communicated through the branch pipe 3; wherein the annular pipe 4-2 can be a regular circle Ring ...

Embodiment 2

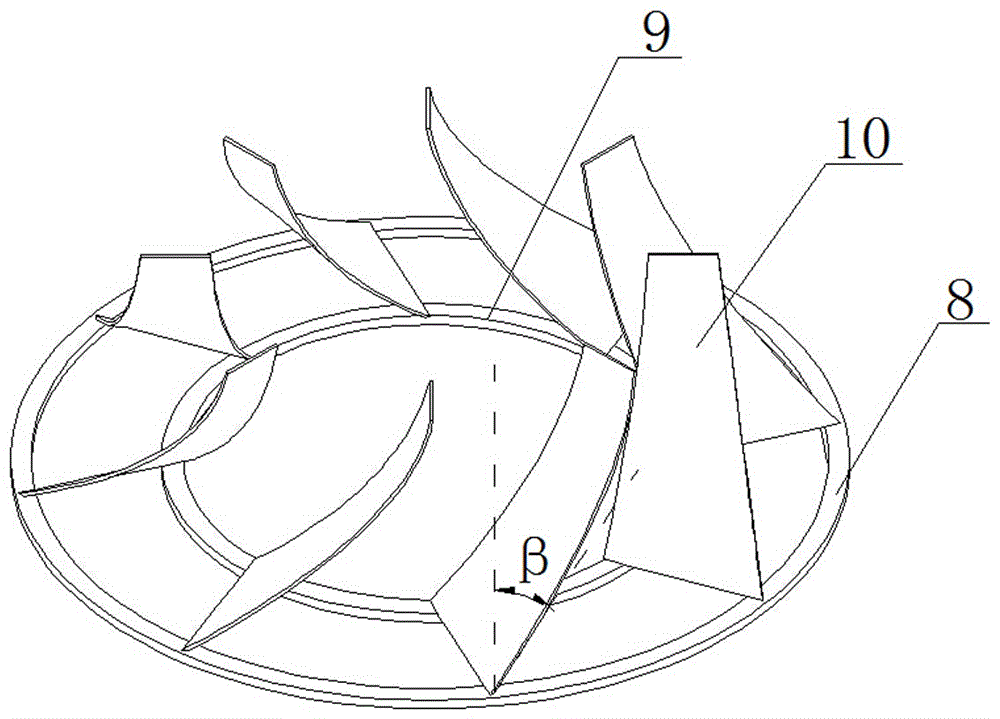

[0042] Embodiment 2 is basically the same structure as Embodiment 1, except that the structure of the nozzle is different, such as Figure 8 As shown, the nozzle 5 is provided with a plurality of spouts 5-1 evenly distributed along the axis of the nozzle 5. In this embodiment, the number of spouts is 4, and the automatic control shrapnel 5-2 is set in the spout 5-1, and the automatic control shrapnel 5-1 2 One end is hinged with the inner wall of the spout 5-1, and the other end is in contact with the stopper 5-3 arranged on the inner wall of the spout 5-1. Since the direction of injecting ammonia gas from the spout is horizontal and perpendicular to the direction of the smoke, it can enhance The mixing intensity of ammonia gas and flue gas; In addition, the setting of the shrapnel is automatically controlled. When the valve 2 is opened and ammonia gas is sprayed, the internal pressure of the nozzle 5 is stronger than the internal pressure of the flue, and the opening of the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com