Patents

Literature

3686results about "Stripping-off devices" patented technology

Efficacy Topic

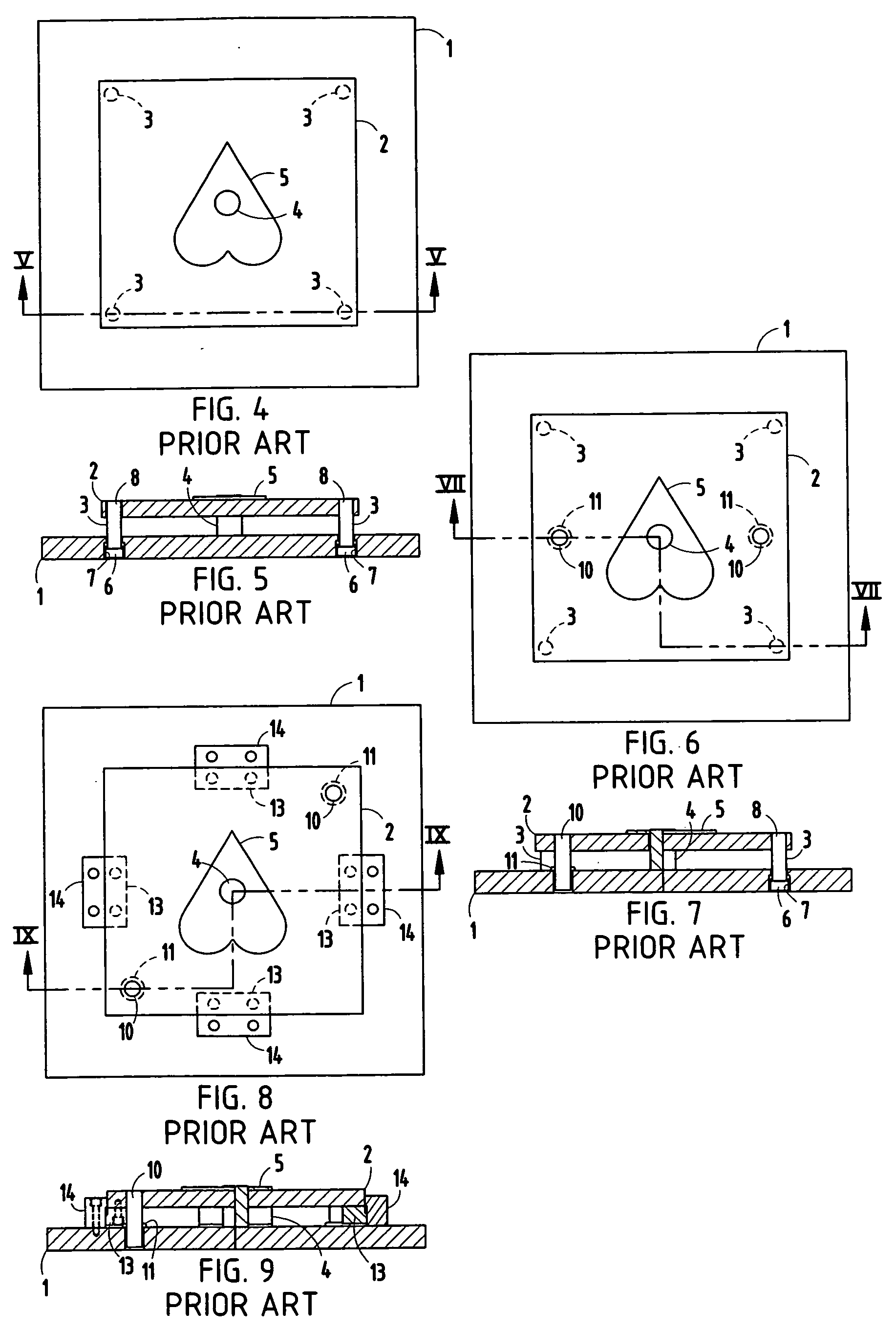

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

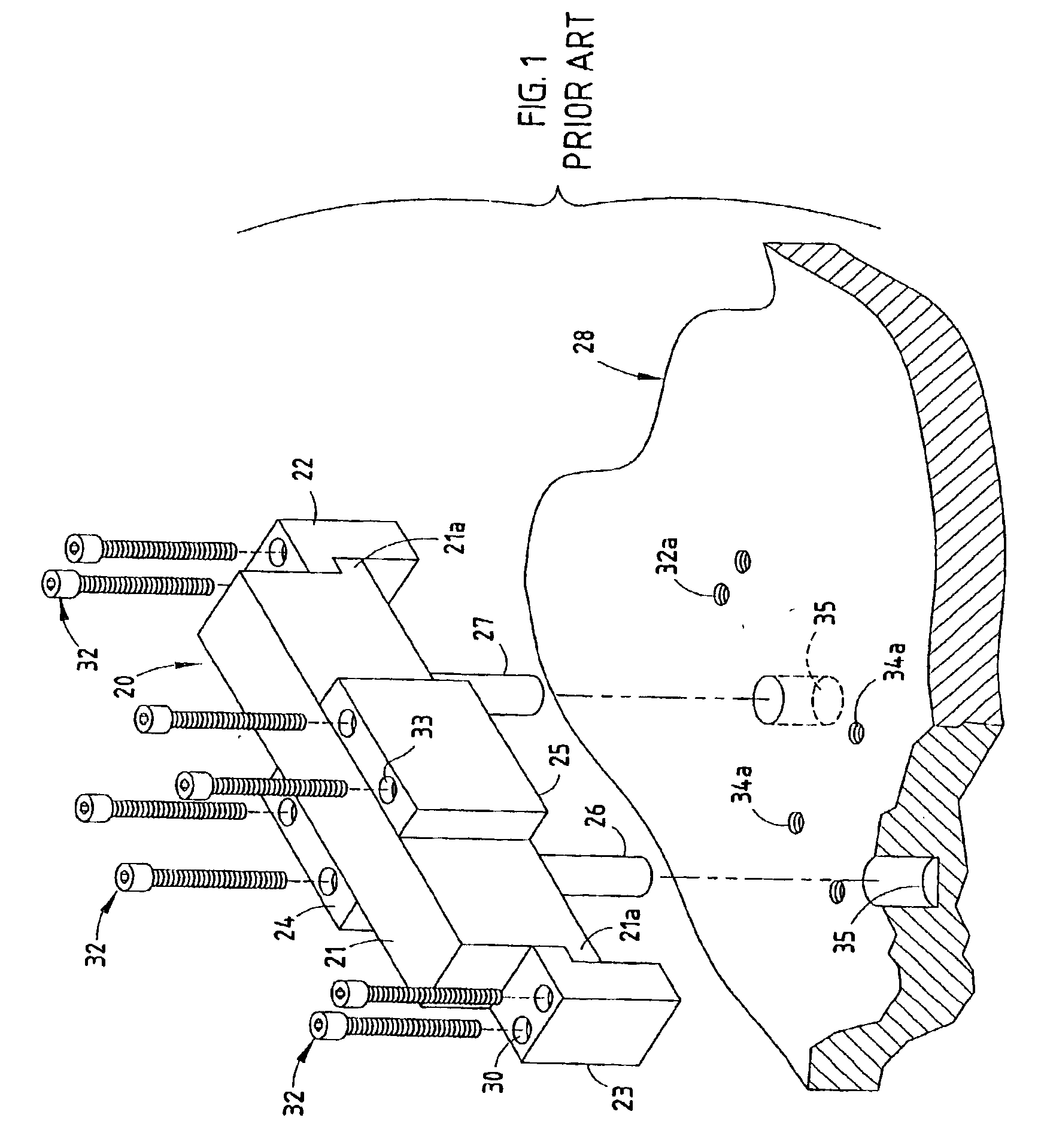

Stock lifter for metal forming dies and method for making the same

InactiveUS6848290B2Reduce design costReduce manufacturing costShaping toolsMetal-working feeding devicesMetal formingReciprocating motion

A self-contained stock lifter is particularly adapted for use in multiple station, progressive metal forming dies and the like, and includes a base plate with two vertical through holes adjacent opposite sides, and a vertical spring unit aperture located between the through holes. The stock lifter also includes a lifter bar having two vertical through holes in vertical registry with the base plate through holes. Two rigid guide shafts are mounted in the base plate through holes to permit the lifter bar to reciprocate in a manner which selectively lifts stock in the die to permit longitudinal shifting of the stock along the multiple die stations. A spring unit has a base retained in the spring unit aperture, and a reciprocating rod biased outwardly, with a free end abutting a central portion of the lifter bar to shift the lifter bar to an extended position, thereby defining a fully self-contained unit that can be readily mounted in and removed from the die to reduce manufacturing and repair costs.

Owner:PYPER TOOL & ENG

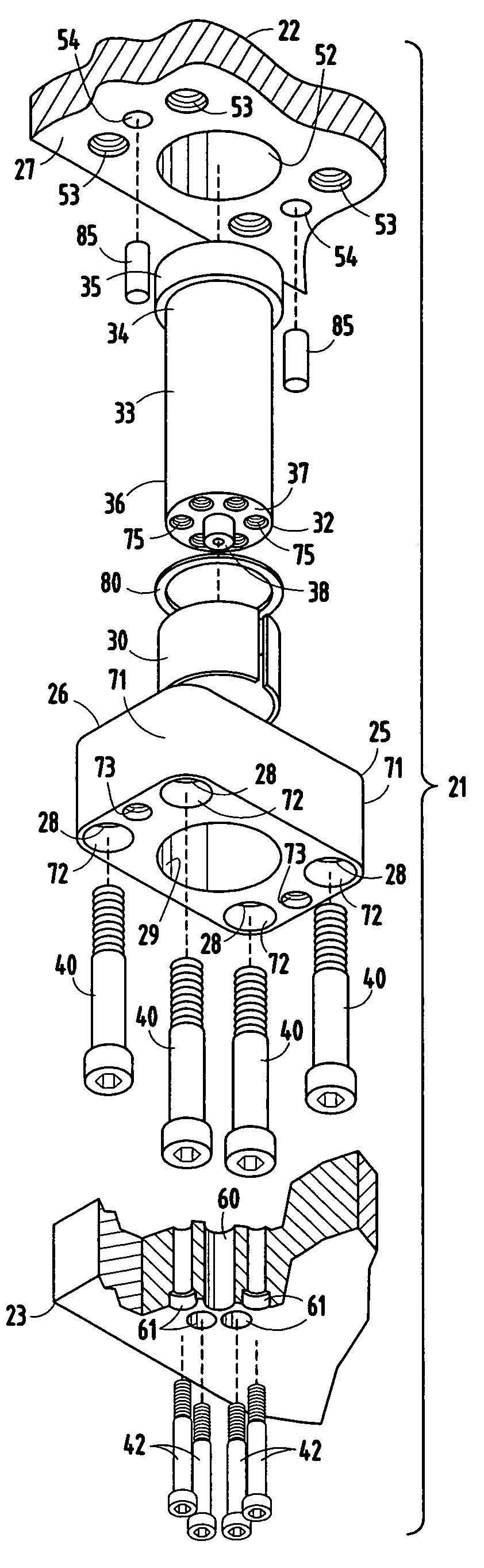

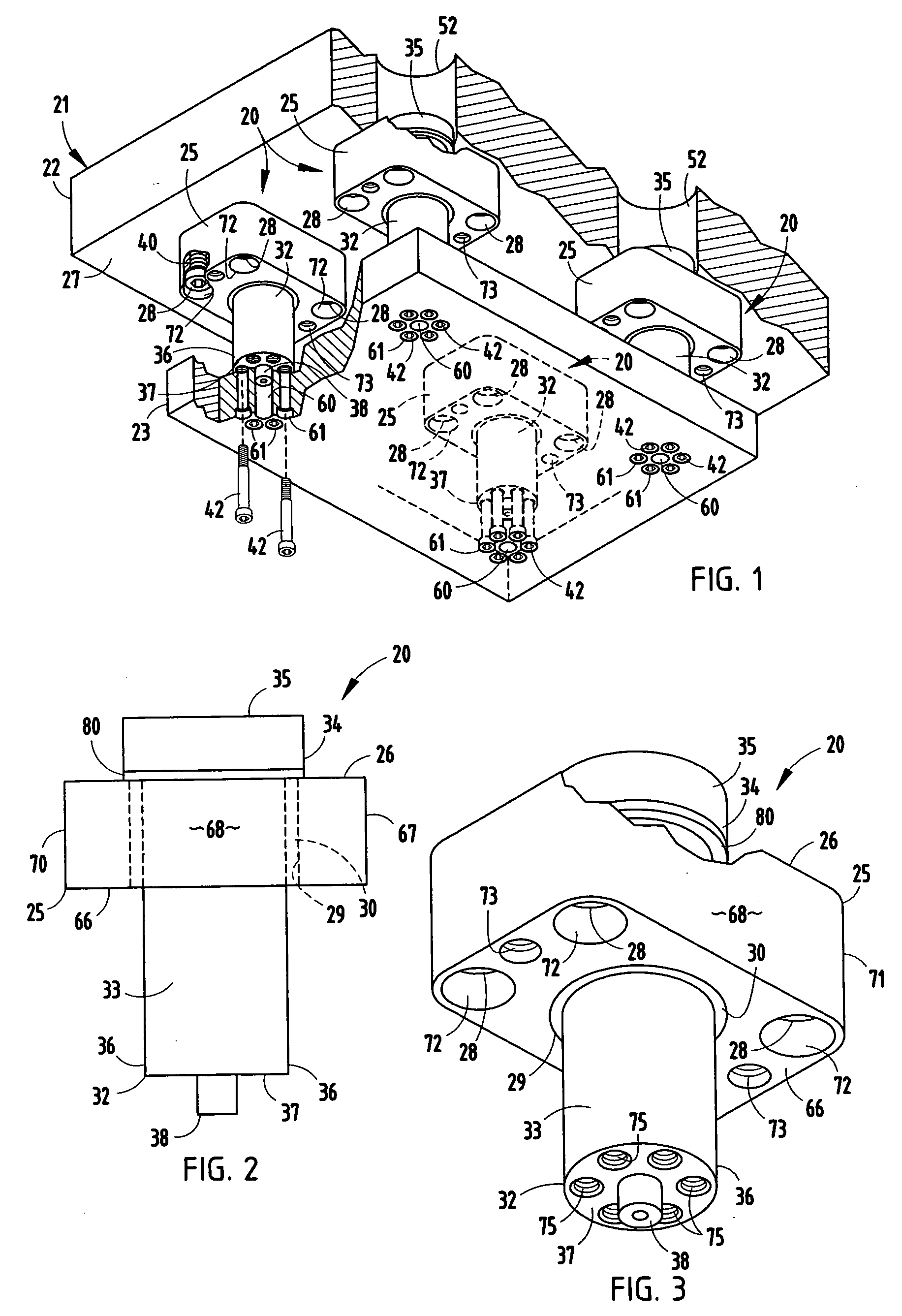

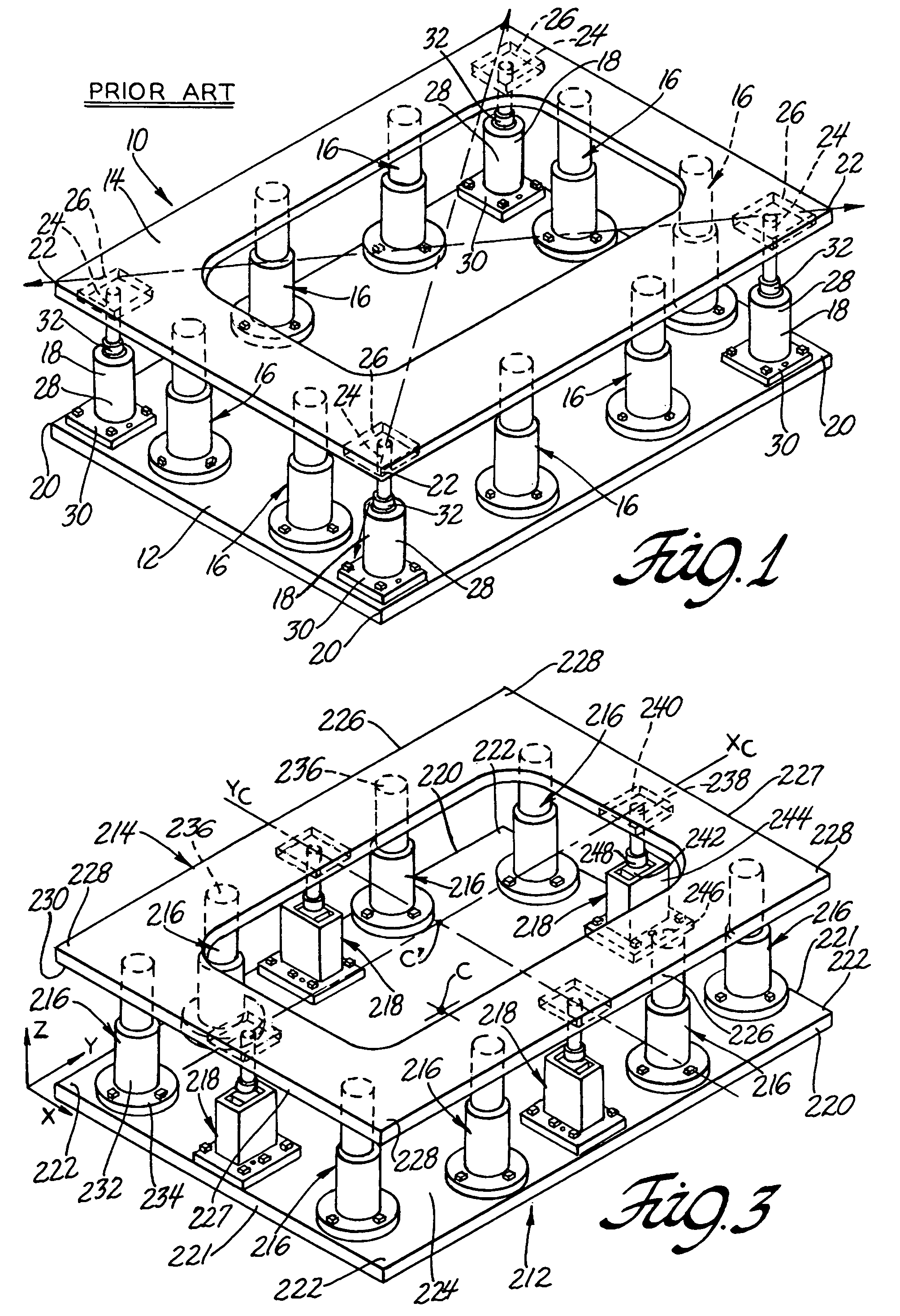

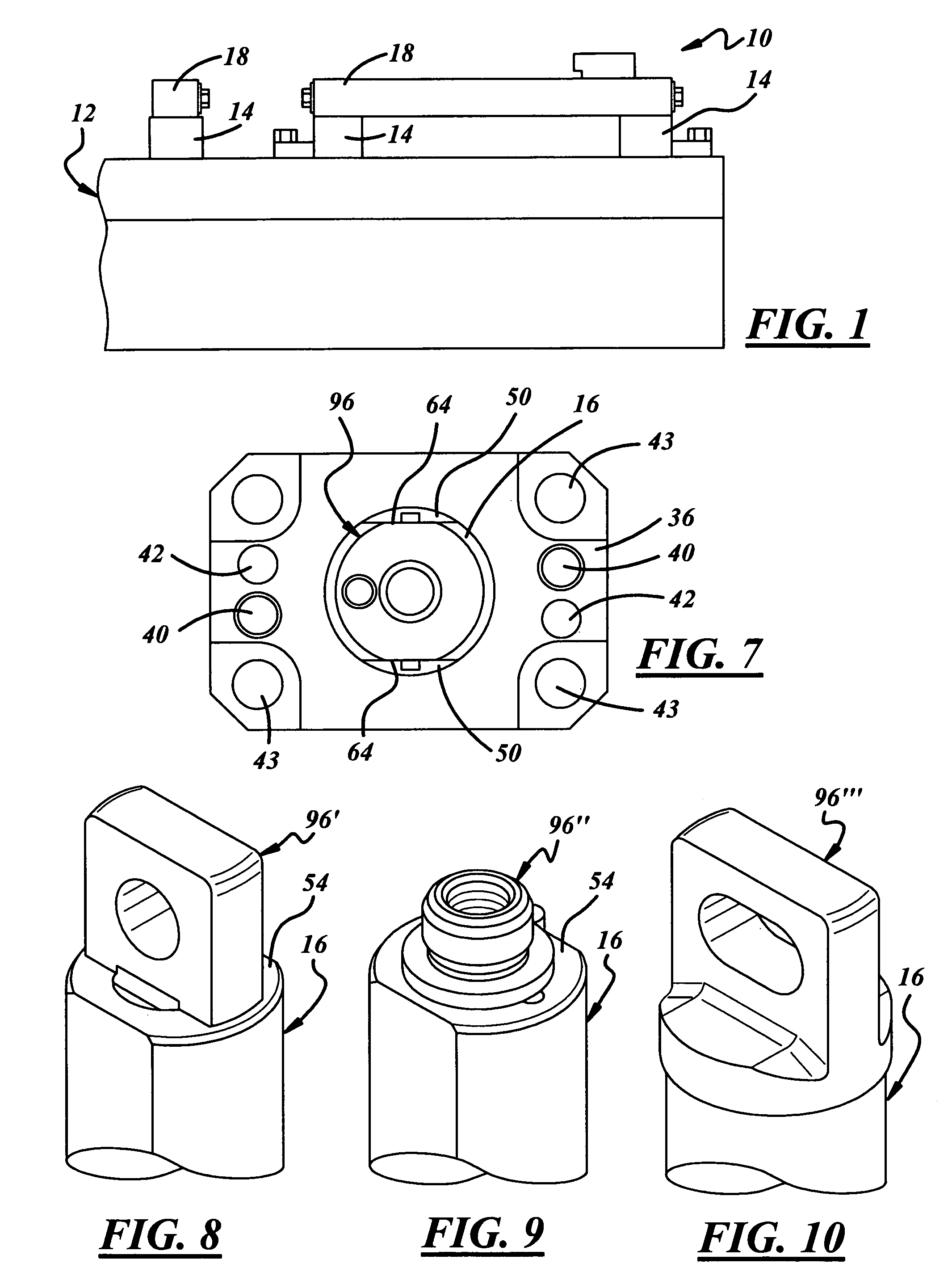

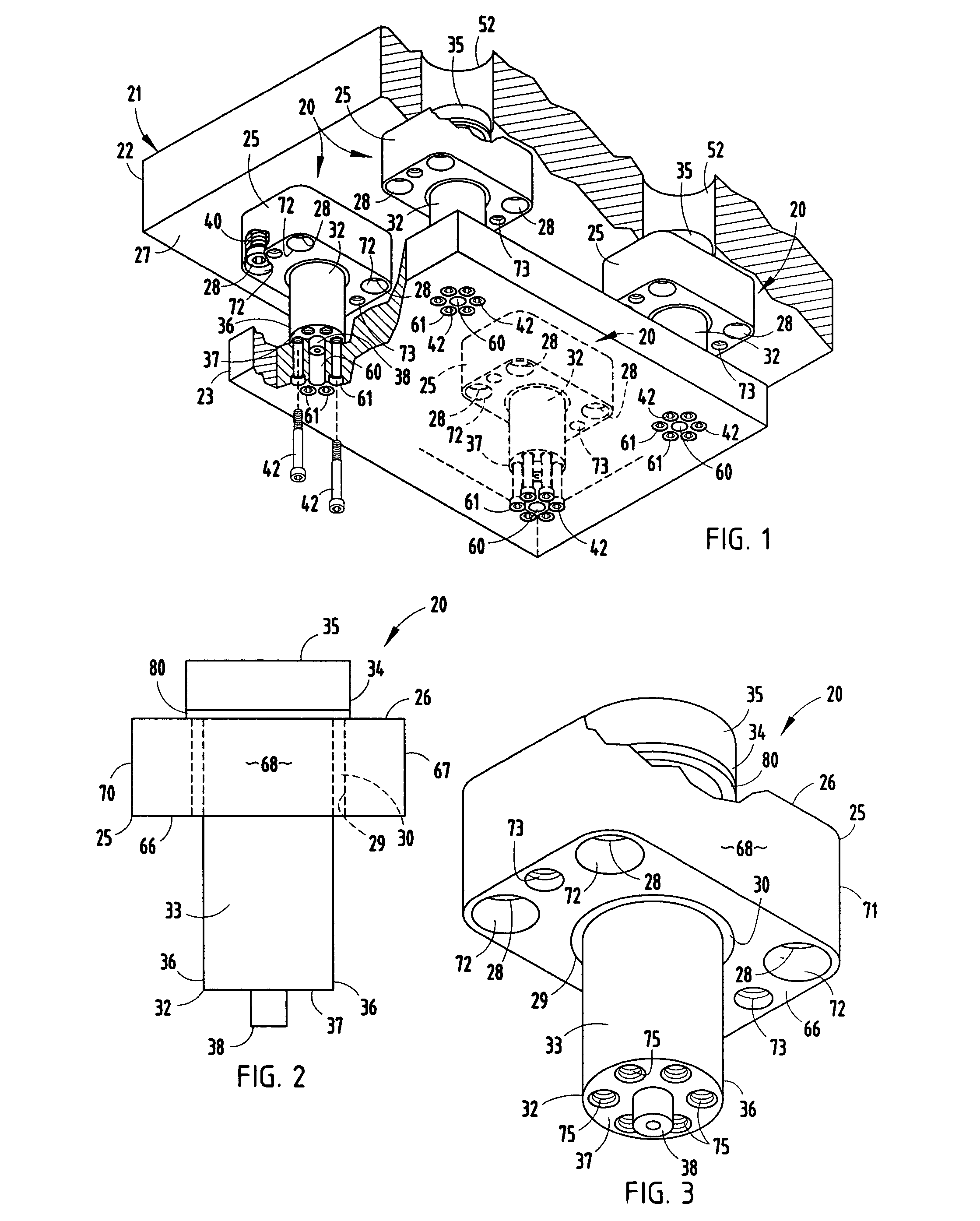

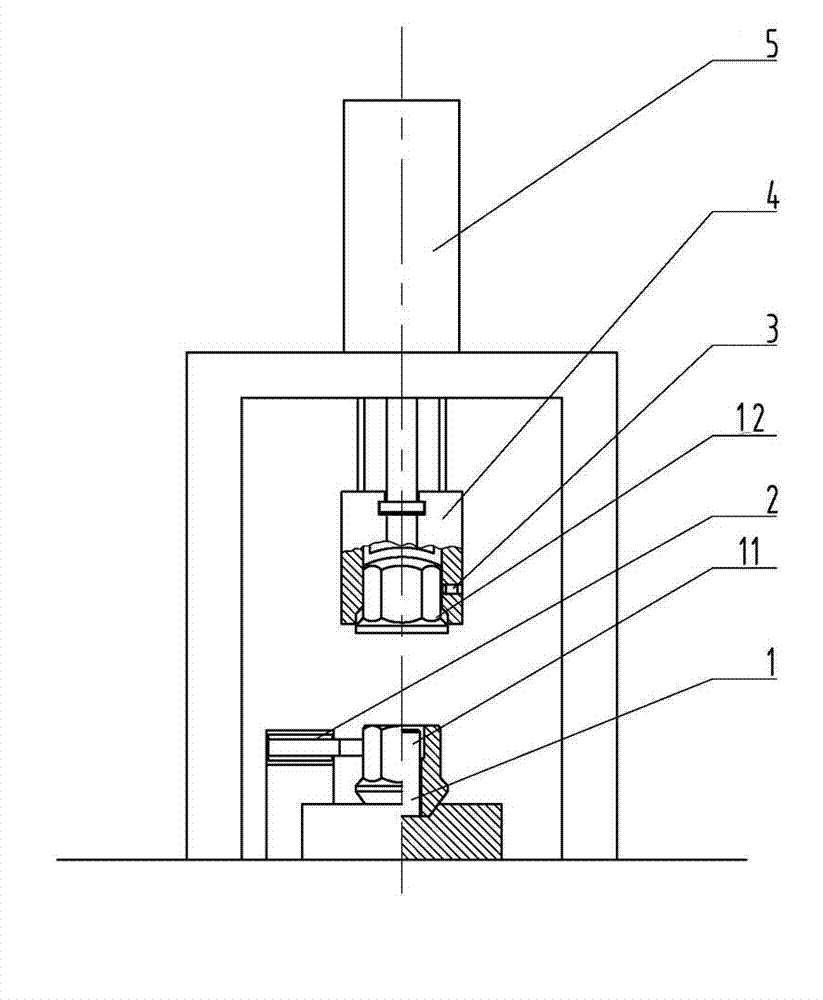

Guided keeper assembly and method for metal forming dies

ActiveUS20090193865A1Facilitate transport and mountingEasy to installShaping toolsStripping-off devicesMetal formingReciprocating motion

A guided keeper assembly and method for metal forming dies includes a base having a mounting face, a connector portion and a central aperture. A guide pin has a cylindrical center portion closely received in the central aperture of the base for reciprocation, an enlarged first end with an alignment member, and an outwardly opening circumferential groove. A retainer ring is removably mounted in and protrudes radially outwardly of the groove to securely, yet detachably, retain the base on the guide pin between the enlarged head and the retainer ring in an assembled condition to facilitate transport and mounting of the guided keeper assembly.

Owner:STANDARD LIFTERS INC

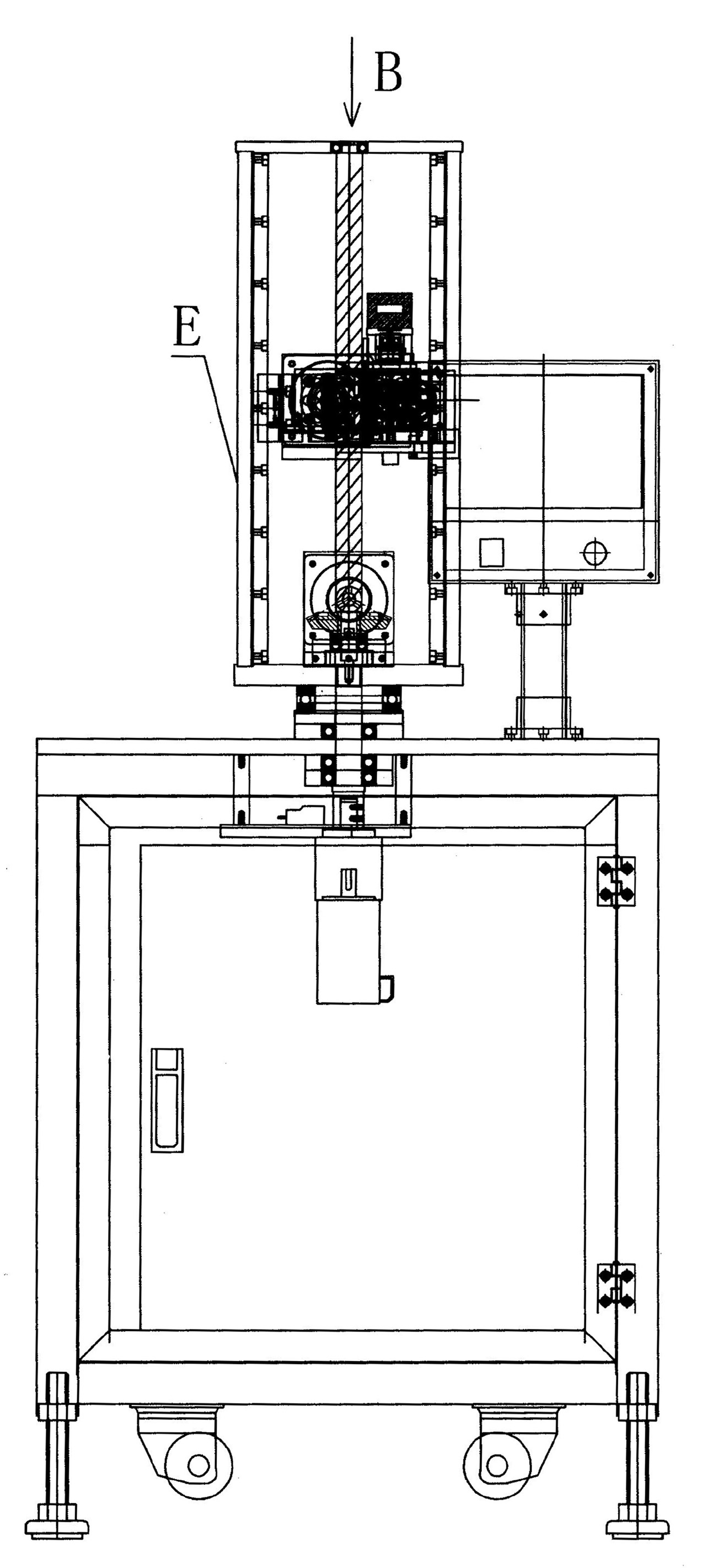

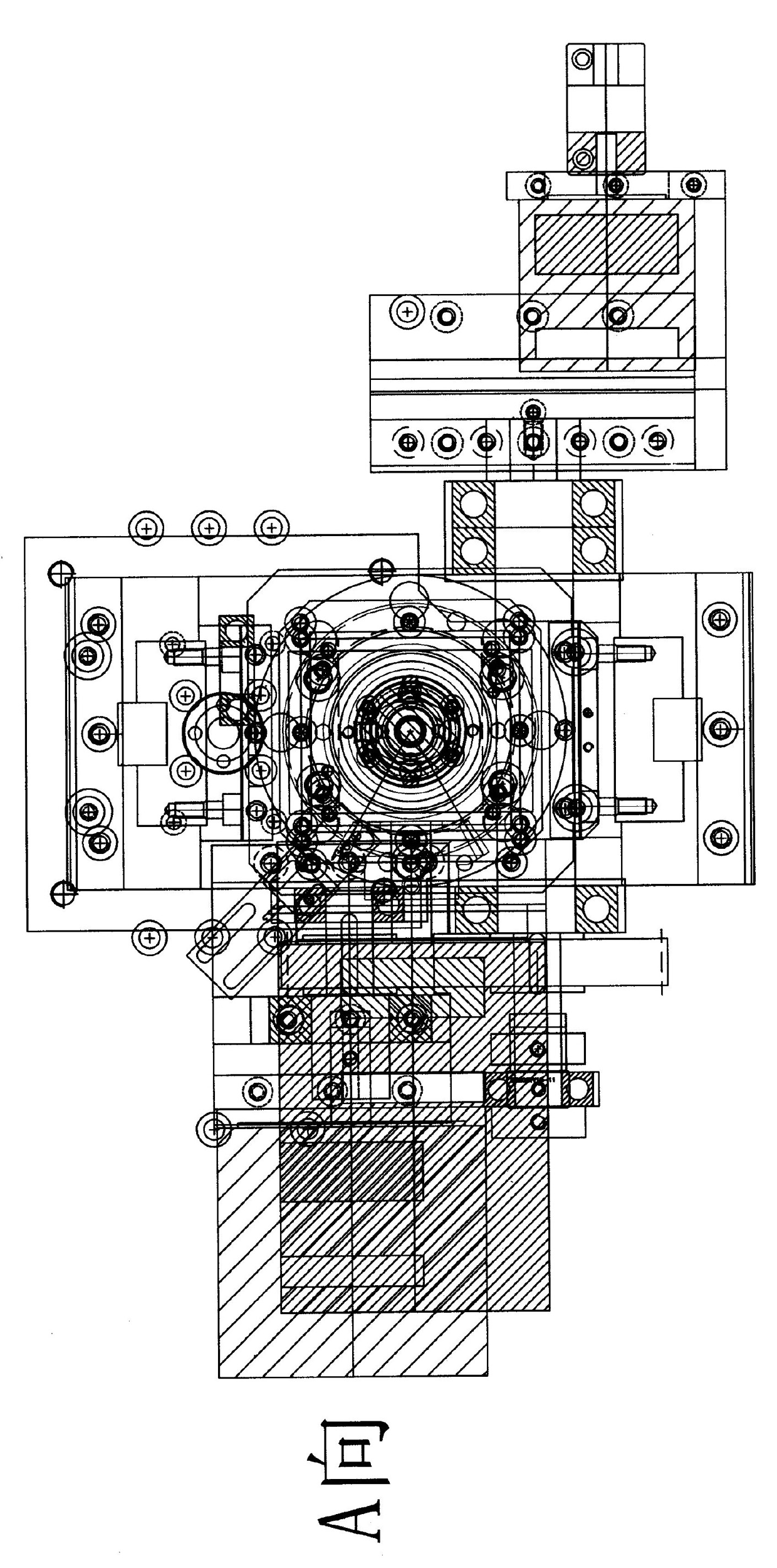

Intelligent mechanical arm of punch press

InactiveCN101947607AWork fasterOperating speed and power savingProgramme-controlled manipulatorMetal-working feeding devicesPunch pressGear wheel

The invention relates to an intelligent mechanical arm of a punch press. In the invention, a horizontal movement mechanism of the mechanical arm is transmitted by adopting a stepper motor and a linear ball screw; a mechanical arm rolling-over mechanism is transmitted by adopting a stepper motor and a gear, connected by a rolling-over spindle and rolled over by a driving arm, and the driving arm is provided with the mechanical horizontal movement mechanism which rolls over together; the mechanical horizontal movement mechanism is transmitted by adopting a servo motor and a planetary reducer; an executing end rotating movement mechanism is transmitted by a stepper motor and a synchronizing wheel, an executing part is a vacuum sucking disc, and the executing end rotating movement mechanism is arranged on the arm of the horizontal movement mechanism; a vertical movement mechanism is transmitted by adopting a stepper motor, a pair of bevel gears, a ball screw and a screw nut sleeve; and the horizontal movement mechanism, the rolling movement mechanism and the executing end rotating movement mechanism are all arranged on the screw nut sleeve of the vertical movement mechanism. The invention adopts a servo system in the aspect of electrical control to ensure that the running speed of the machine is improved, electricity is saved, and the effects of energy saving and environmental protection are achieved.

Owner:FOSHAN DINGFENG ROBOT

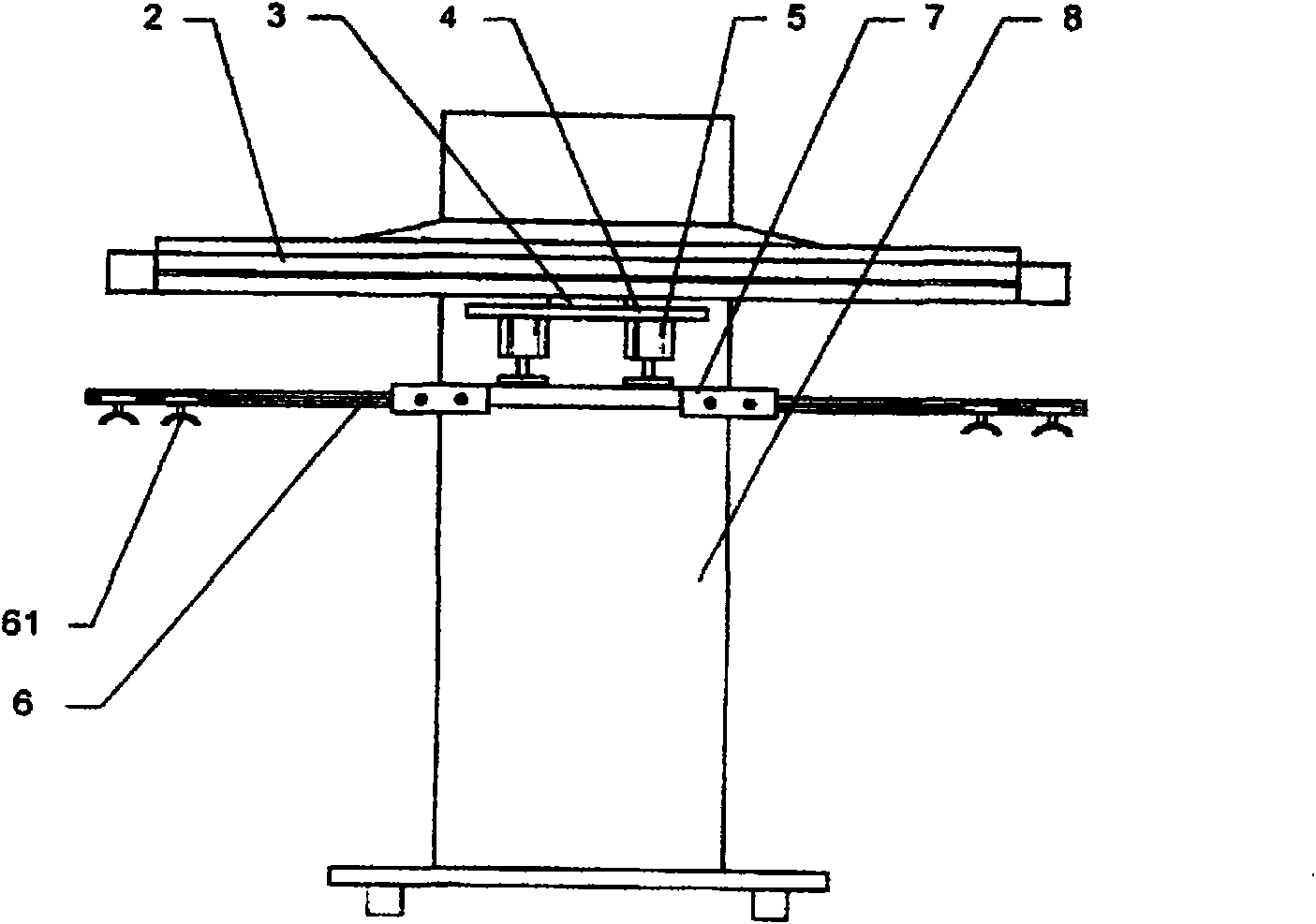

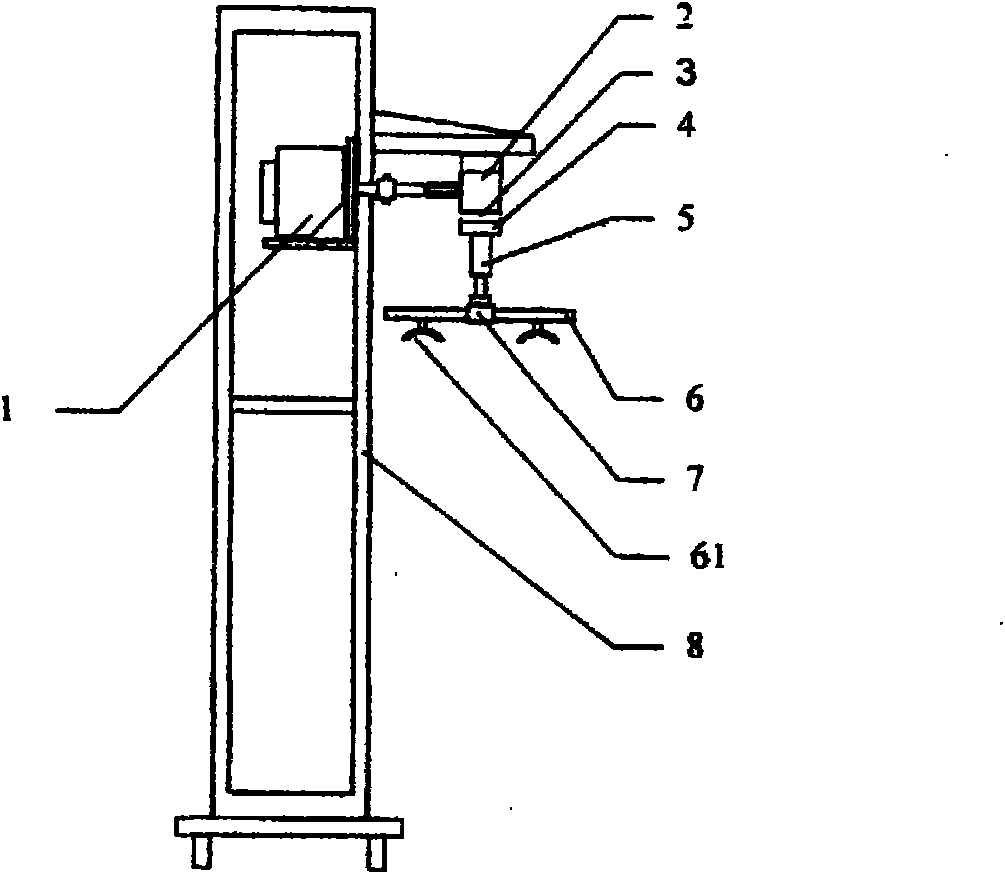

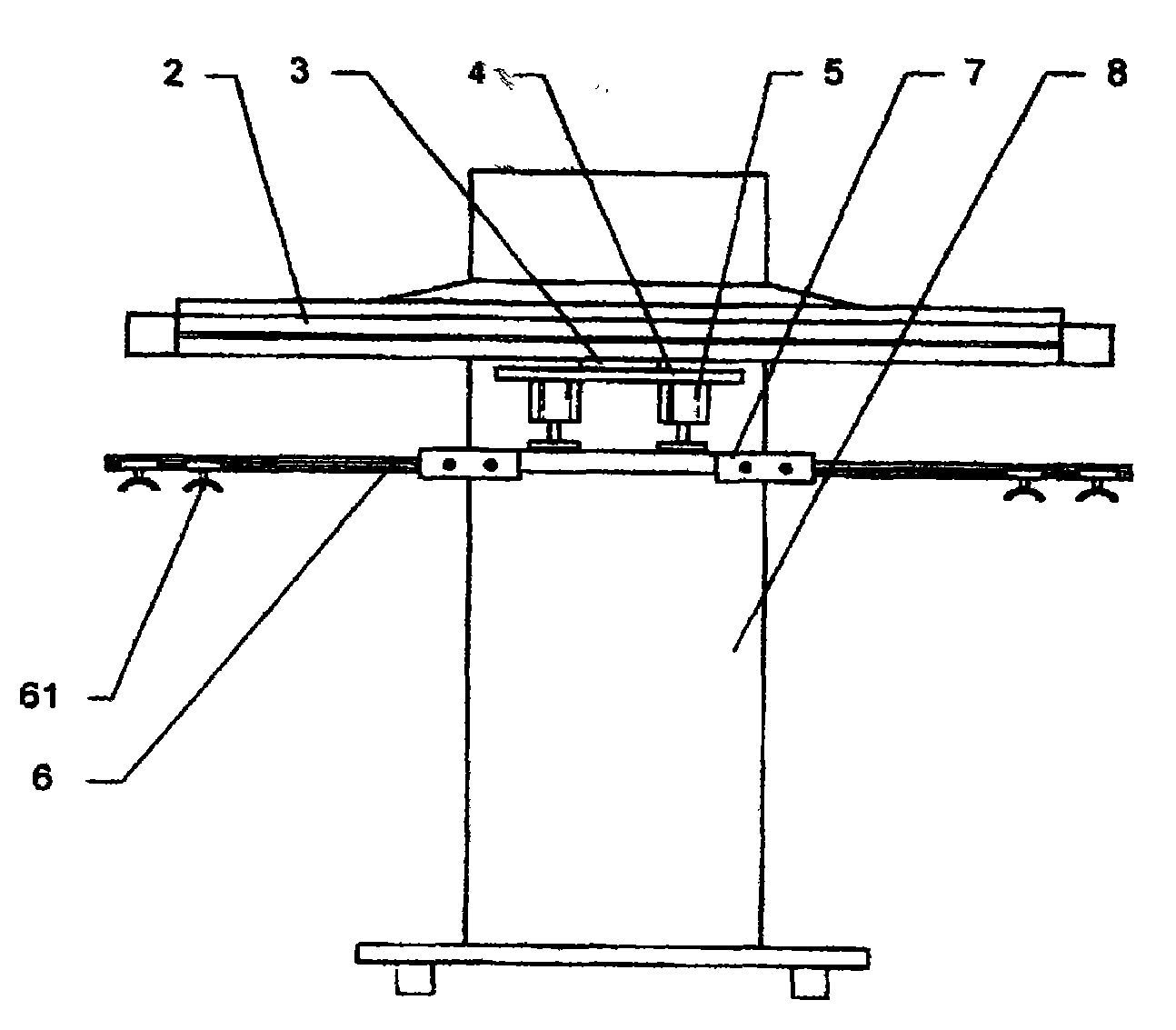

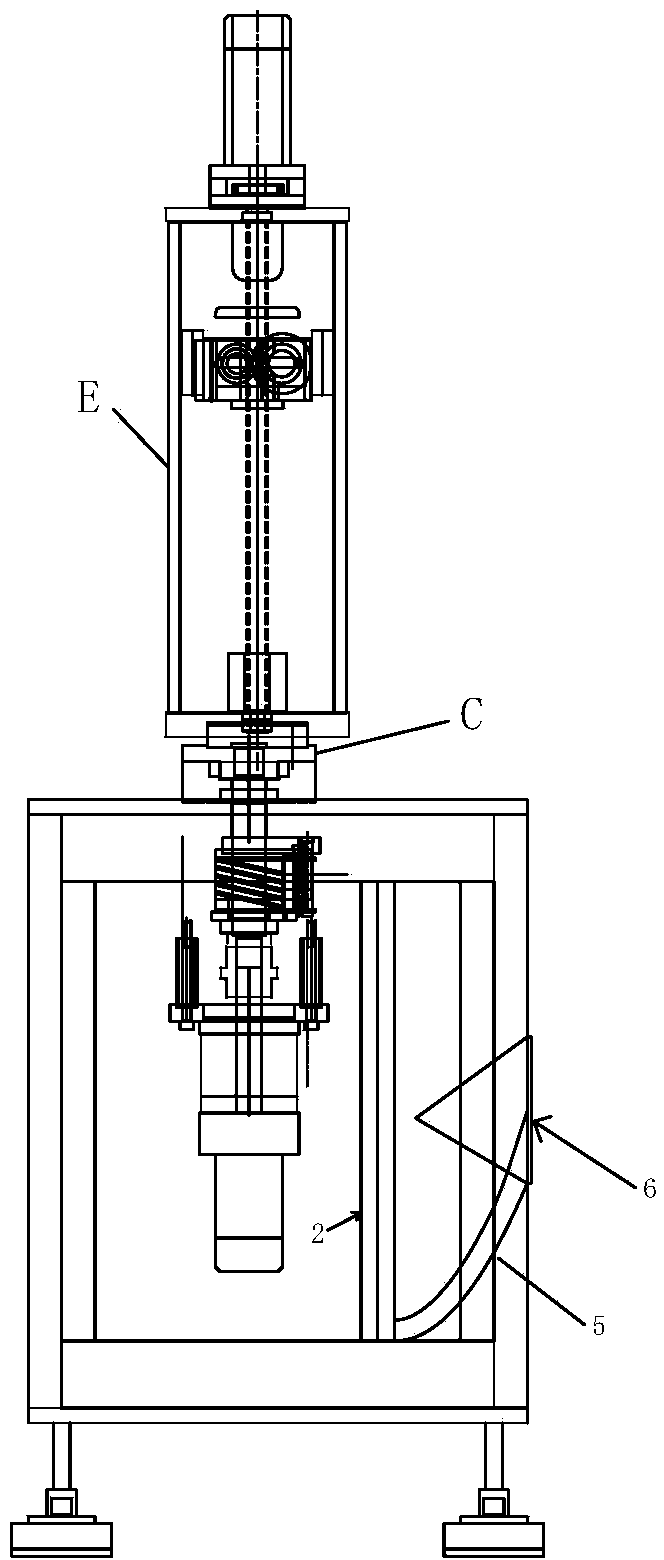

Mechanical hand for stamping and automatic loading and unloading

InactiveCN101987339AMeet stamping productionFlexibleProgramme-controlled manipulatorStripping-off devicesTime controlManipulator

The invention discloses a mechanical hand for stamping and automatic loading and unloading, which is independently placed beside a press machine and comprises a servo motor (1), a linear guide rail (2), a sliding block (3), an air cylinder (5), end pickers (6) and a stand (8), wherein the servo motor (1) controlled by a controller is installed on the stand (8), and on one side of the stand (8), the servo motor (11) is engaged with a belt pulley of the linear guide rail (2) through a belt pulley of a synchronous belt; the sliding block (3) is fixedly installed on the synchronous belt of the linear guide rail (2), and the lower part of the sliding block (3) is fixedly connected with the air cylinder (5) through a support plate (4); a support seat (7) is located below the air cylinder (5), and the end pickers (6) are arranged on both sides of the support seat (7). Because the end pickers in the invention are removable, the position of a vacuum chuck is adjustable and the controller is in real-time control, the stamping production of different products and different press machines can be met, and the mechanical hand has flexibility.

Owner:孟津县平乐新兴铸造厂

Die cushion apparatus for hot stretch-forming

ActiveUS7004007B2Accurate locationInhibit bindingShaping toolsPlywood pressesRelative displacementThermal expansion

A self-contained die cushion assembly for use in a stretch-forming process involving heated tooling. A lower plate is mounted below an upper plate that undergoes different thermal expansion than the lower plate. Guidance devices are mounted between the upper and lower plates and include a guide post, a bearing sleeve circumscribing the guide post, and a cylinder circumscribing the bearing sleeve. The guide post is mounted in fixed relation to the upper plate, and the cylinder is mounted in laterally translatable relation to the lower plate to accommodate lateral relative displacement between the upper and lower plates due to different thermal expansion thereof, thereby preventing binding of the guidance devices.

Owner:GM GLOBAL TECH OPERATIONS LLC

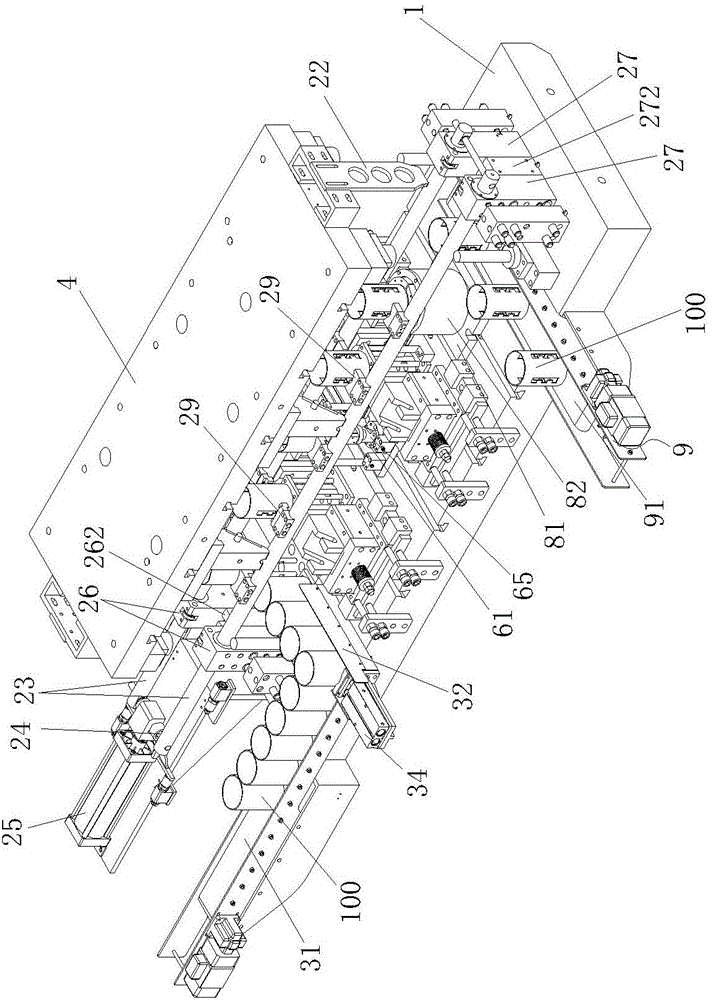

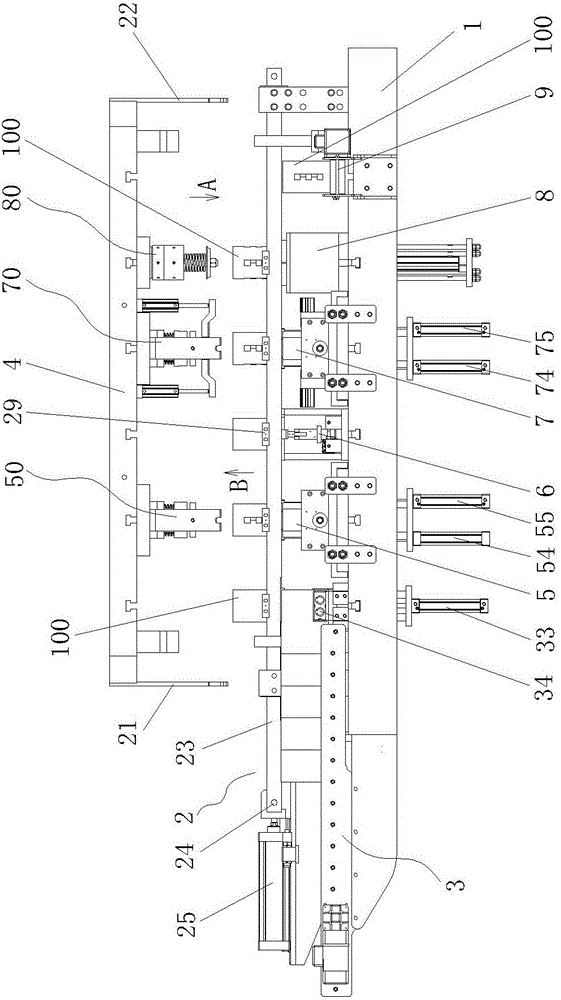

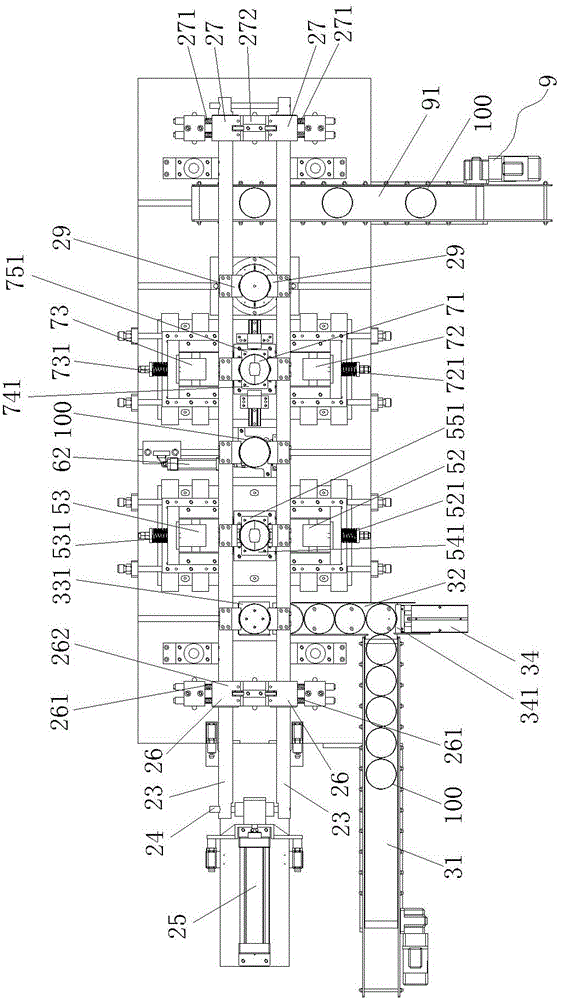

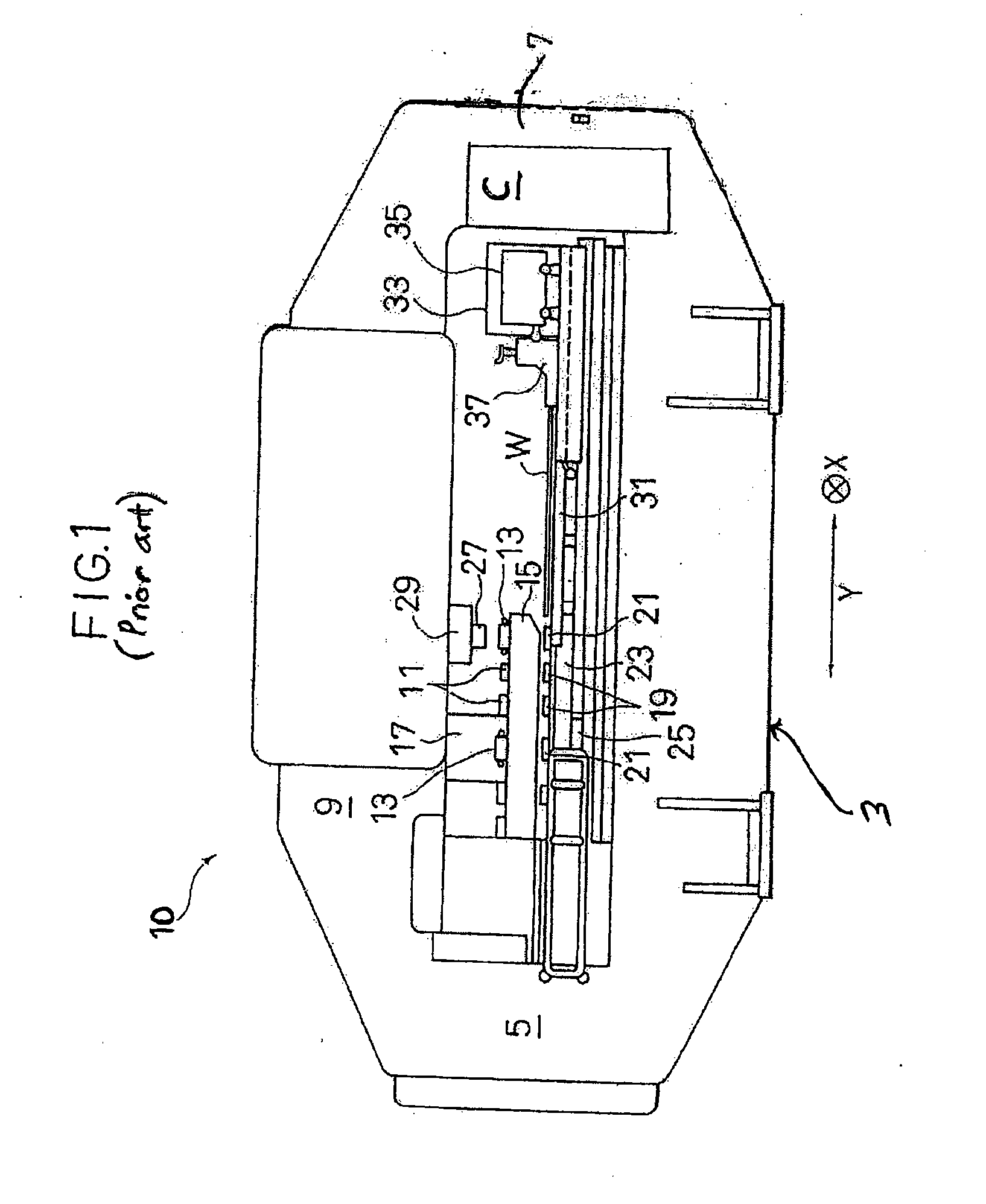

Punching production line for punching circular tube type workpiece

InactiveCN102873159AReduce labor intensityReduce operational riskMetal-working feeding devicesStripping-off devicesProduction linePunching

The invention discloses a punching production line for punching a circular tube type workpiece. The punching production line comprises a press machine, wherein a moving mechanism and a feeding mechanism are assembled on an operating platform of the press machine, the moving mechanism sequentially clamps the circular tube type workpiece from one station to another station, and the feeding mechanism conveys the circular tube type workpiece from the outside to an initiation position from where the moving mechanism clamps; a first side punching lower die, a first circular tube type workpiece rotating mechanism, a second side punching lower die, a circular tube type workpiece shaping lower die and a discharging mechanism which discharges a circular tube type workpiece out of the operating platform of the press machine are at least assembled on the operating platform of the press machine below the moving mechanism; a first drive and a pressing component which are matched with the first side punching lower die and a second drive and the pressing component which are matched with the second side punching lower die are assembled on a sliding block of the press machine; and a press-in component which is matched with the shaping lower die is arranged. According to the punching production line, one press machine can be used for simultaneously carrying out multiple processing on the circular tube type workpiece, the production efficiency and automation degree are high, and the labor intensity and operation risk of operators are effectively reduced.

Owner:厦门锻压机床有限公司

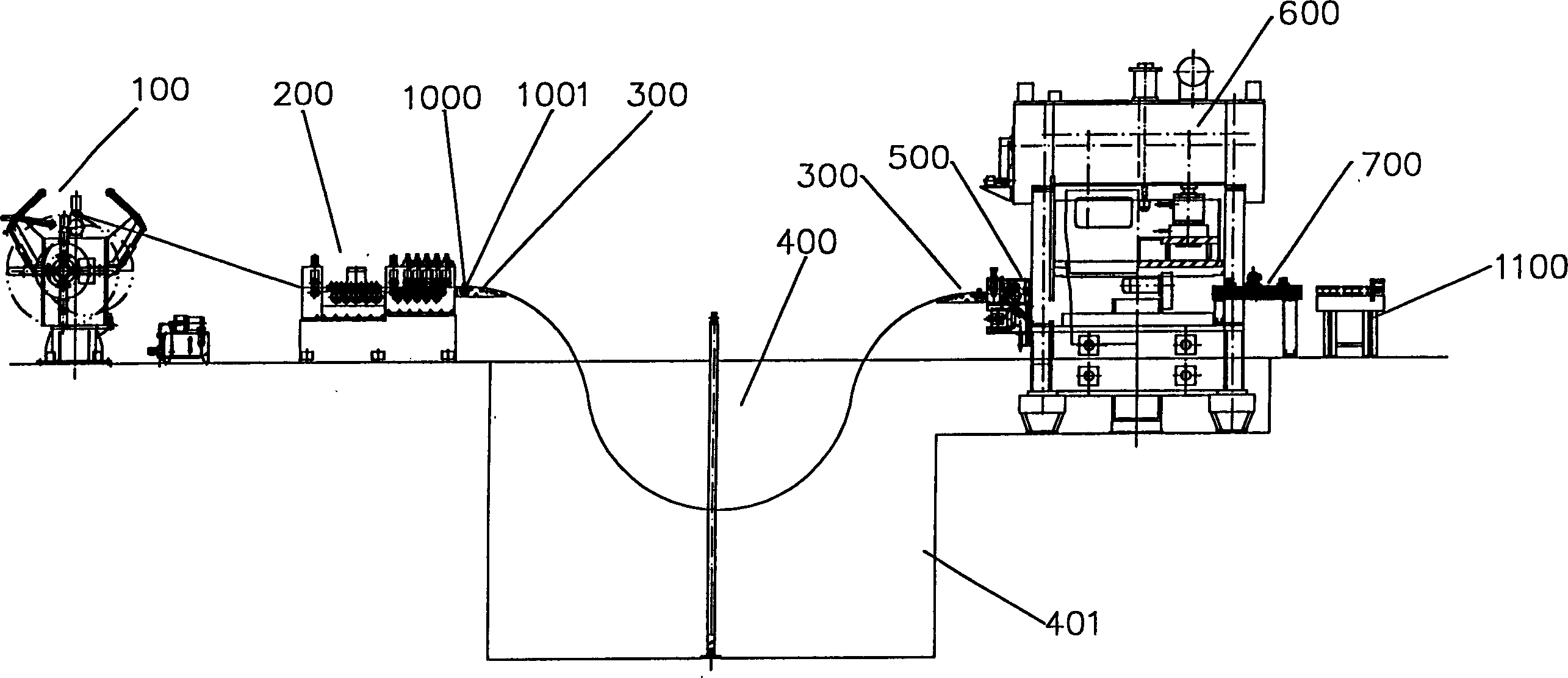

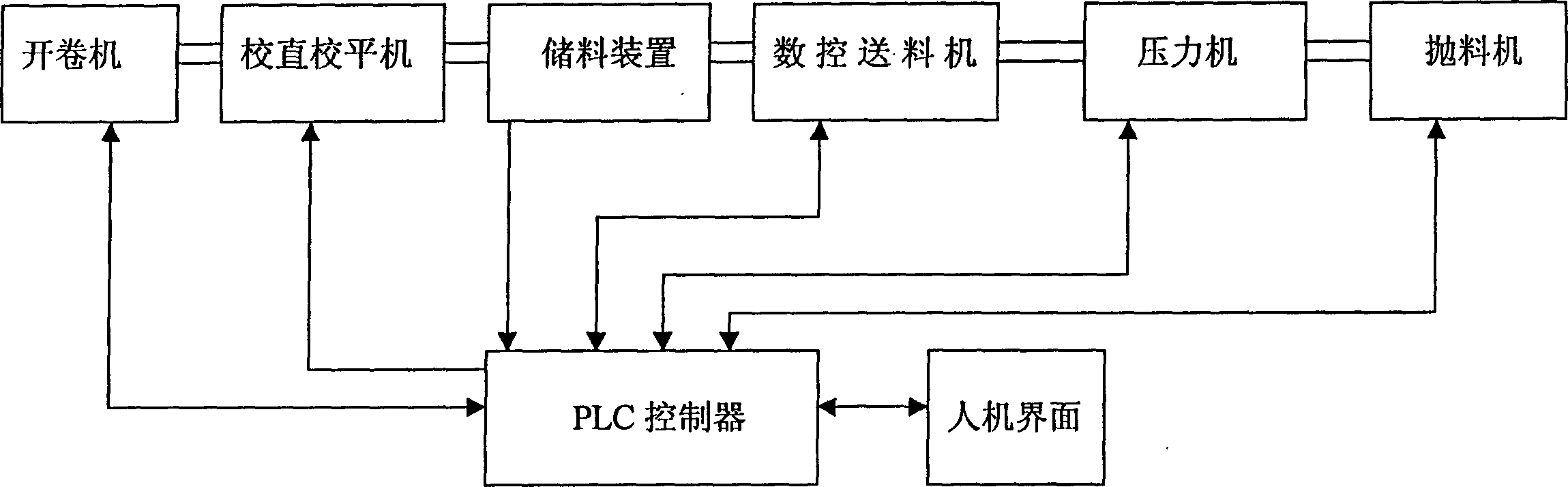

Continuous steel belt punching production line

InactiveCN1416974AImprove machining accuracyIncrease productivityMetal-working feeding devicesShaping safety devicesProduction linePunching

The continuous steel belt punching production line incldues steel belt unwinding machine, straightening machine, material storage in the back of the straightening machine, numerically controlled feeding mechanism connected to the material storage, pressing machine, material thrower, laser ranger, two regulating trays in the tail and the feeding end of the numerically controlled feeding mechanism separately and electric controller unit. By means of the PLC program controller in the electric controller unit, the production line can punch continuously and automatically in high production efficiency and high product precision.

Owner:BEI JING NEW BUILDING MATERIALGRP

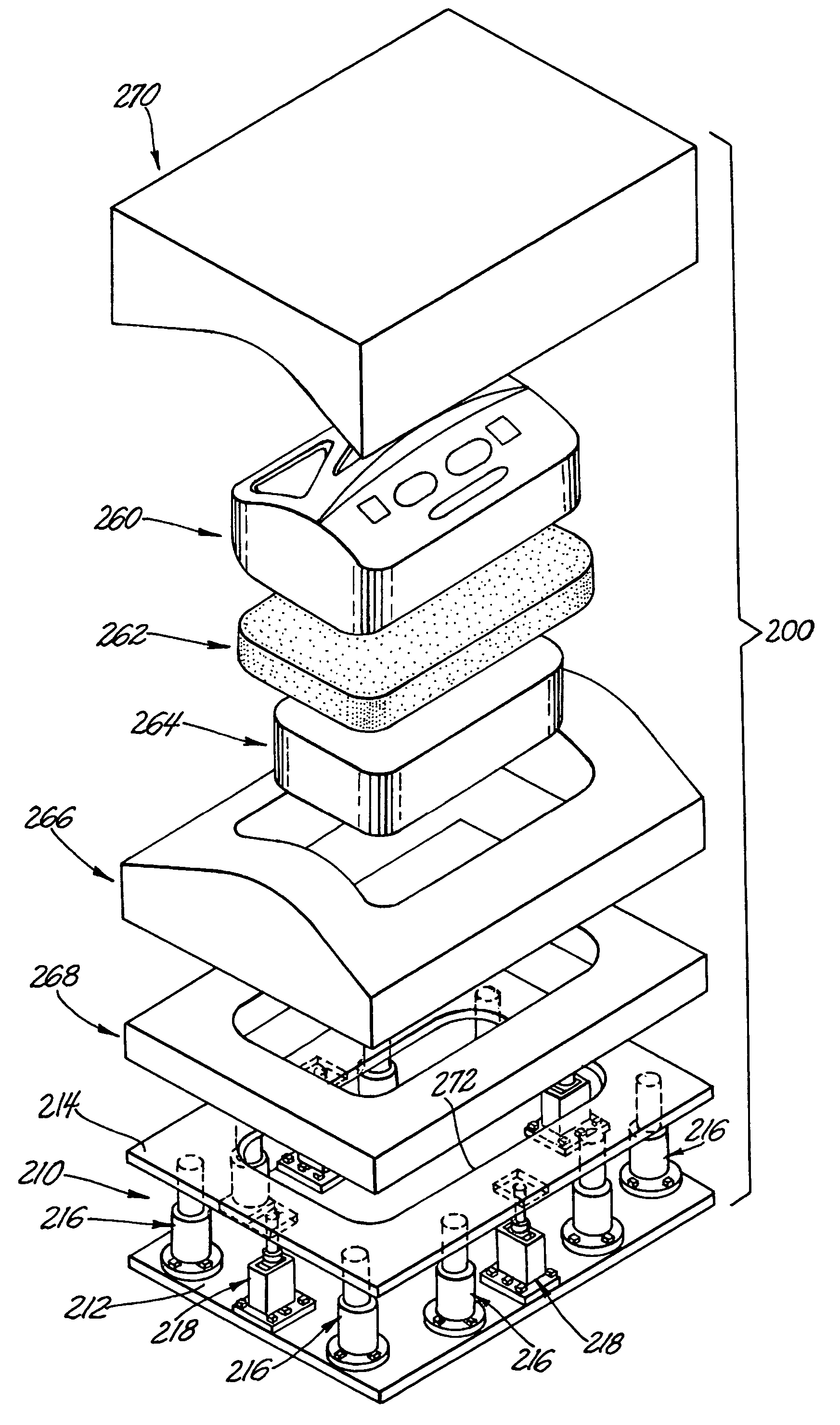

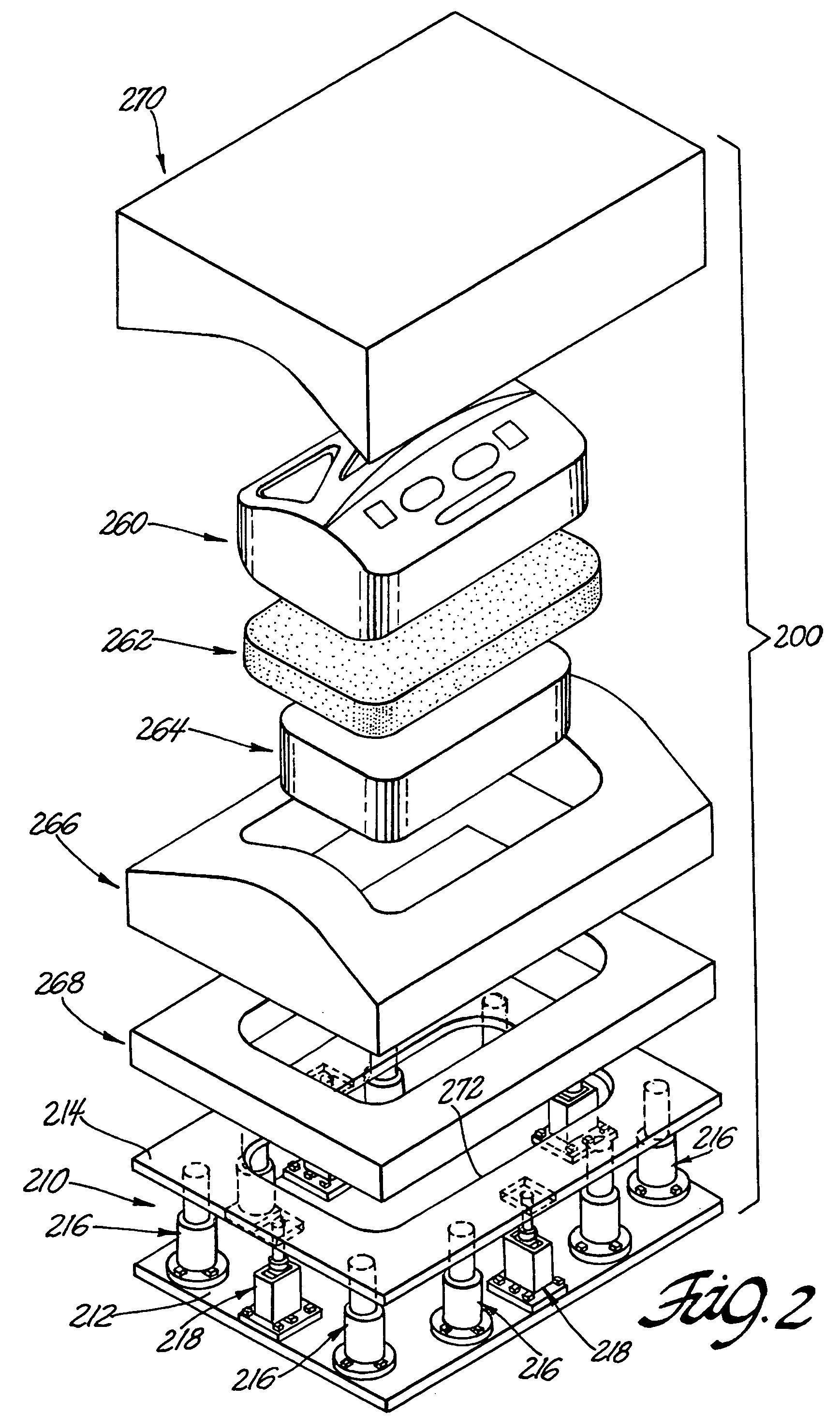

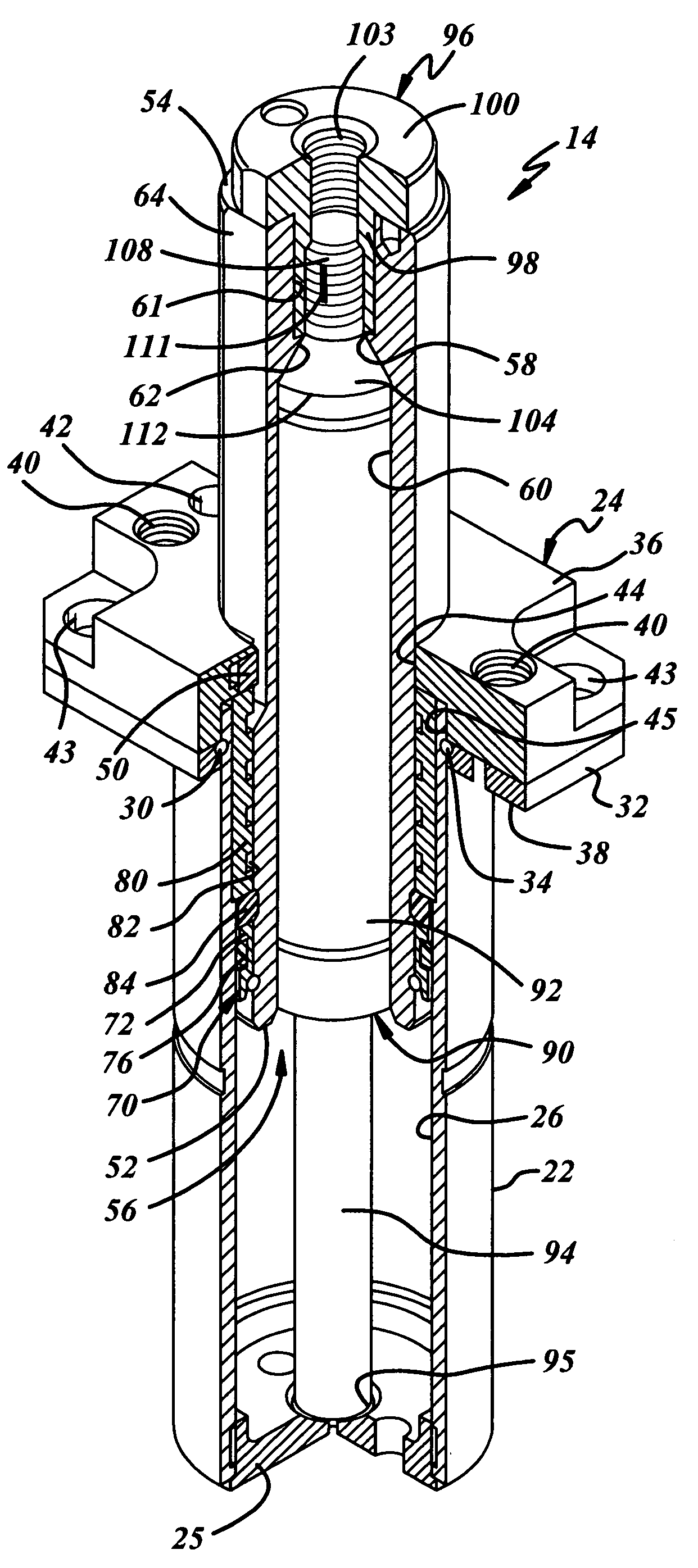

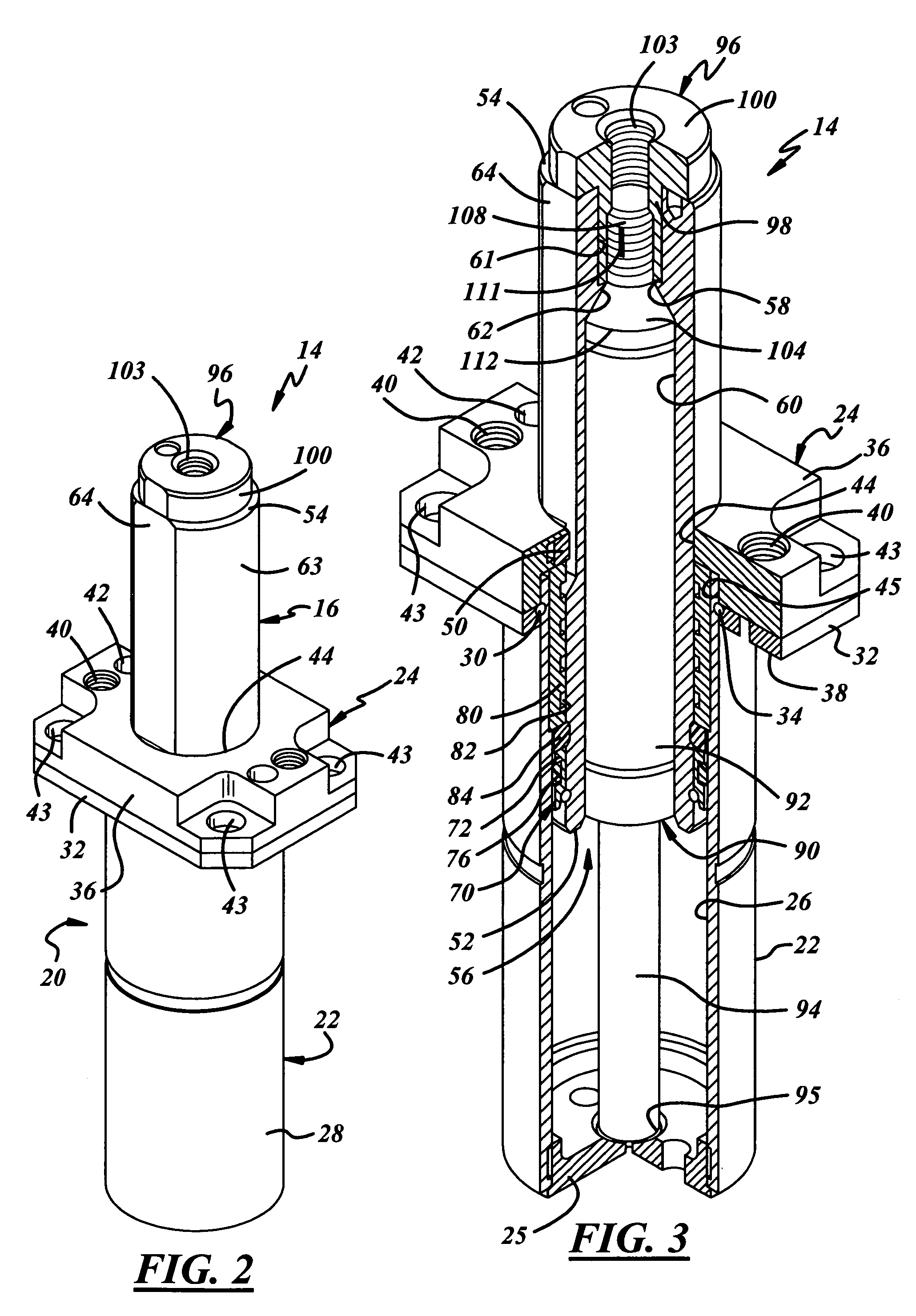

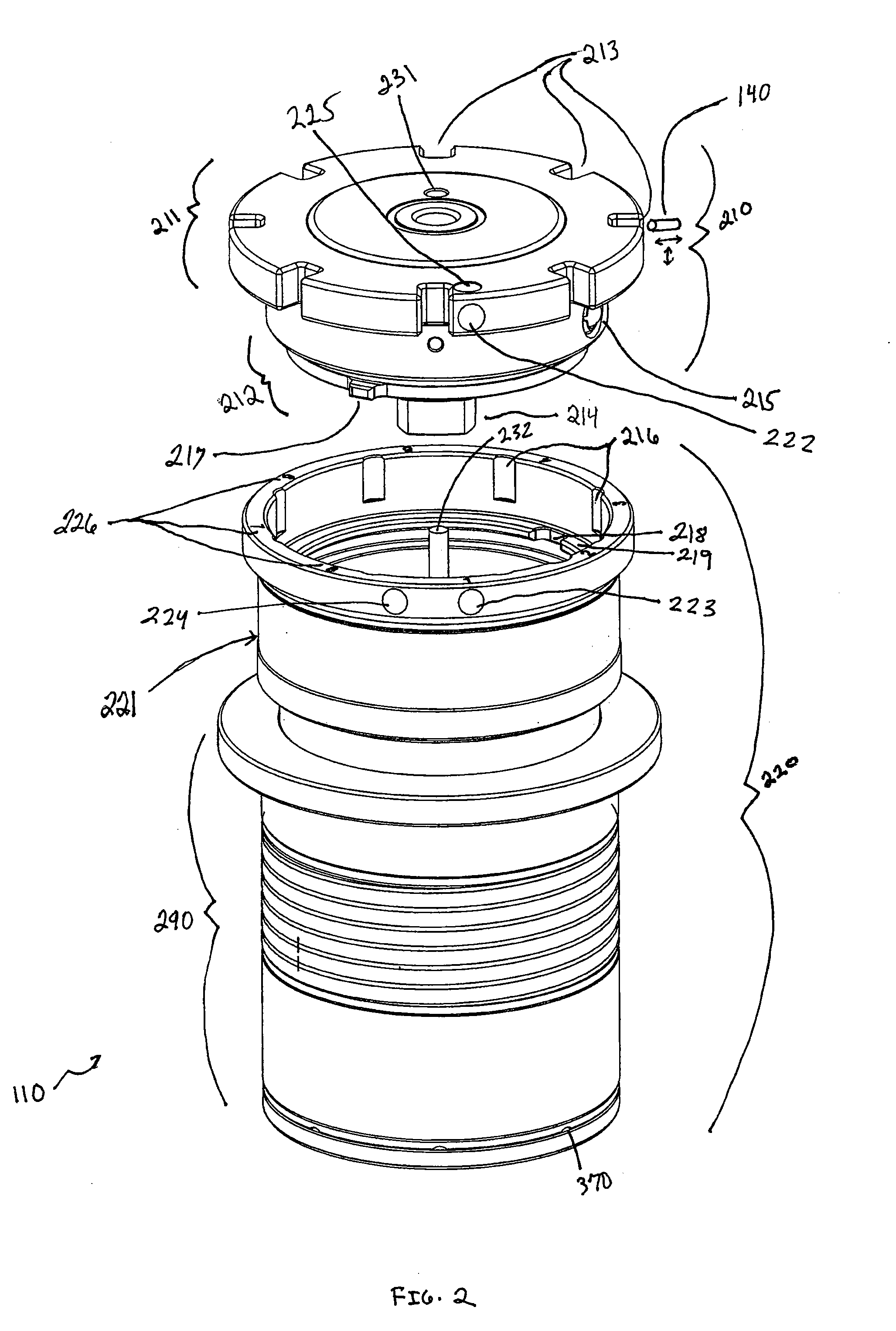

Reaction device for forming equipment

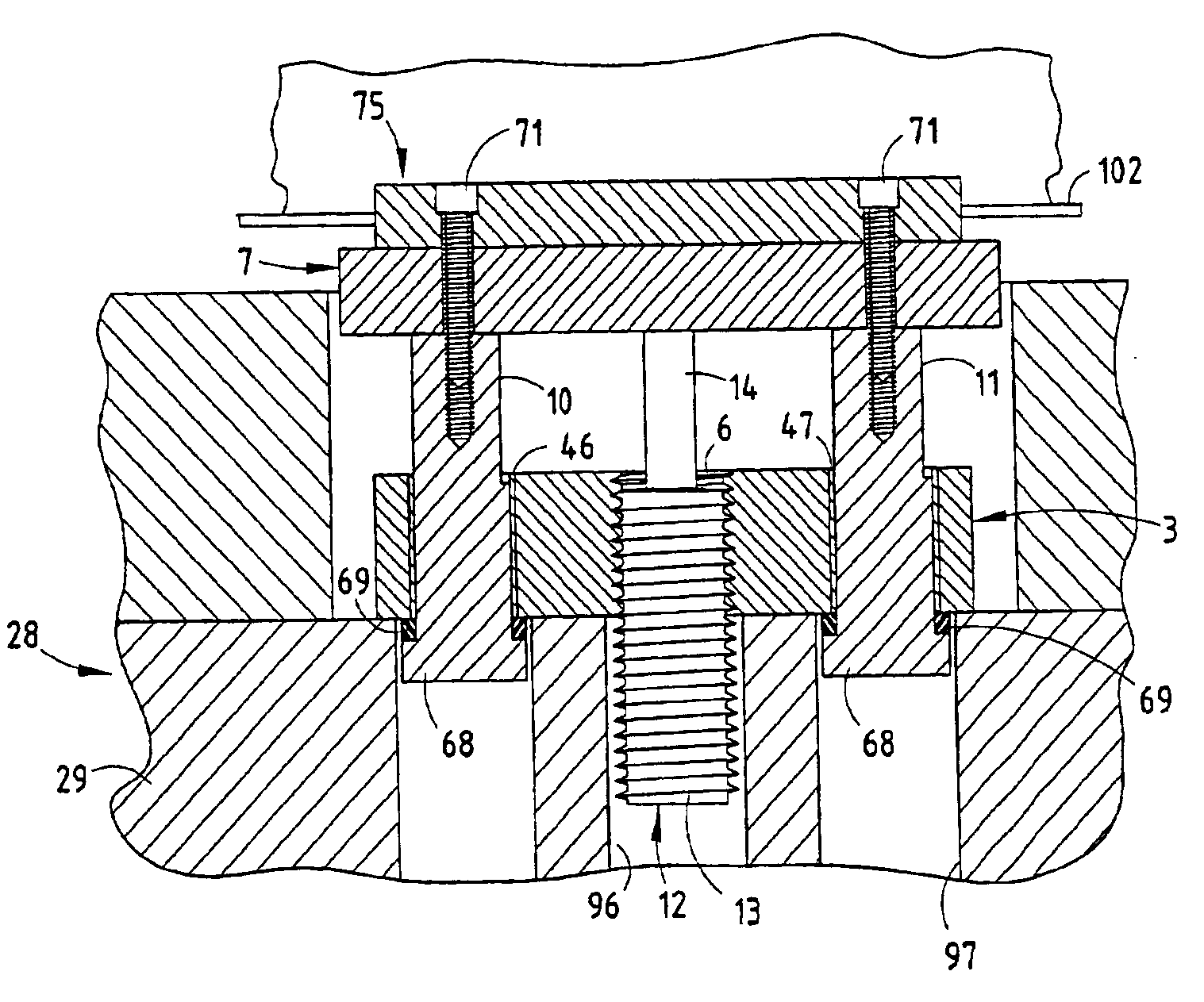

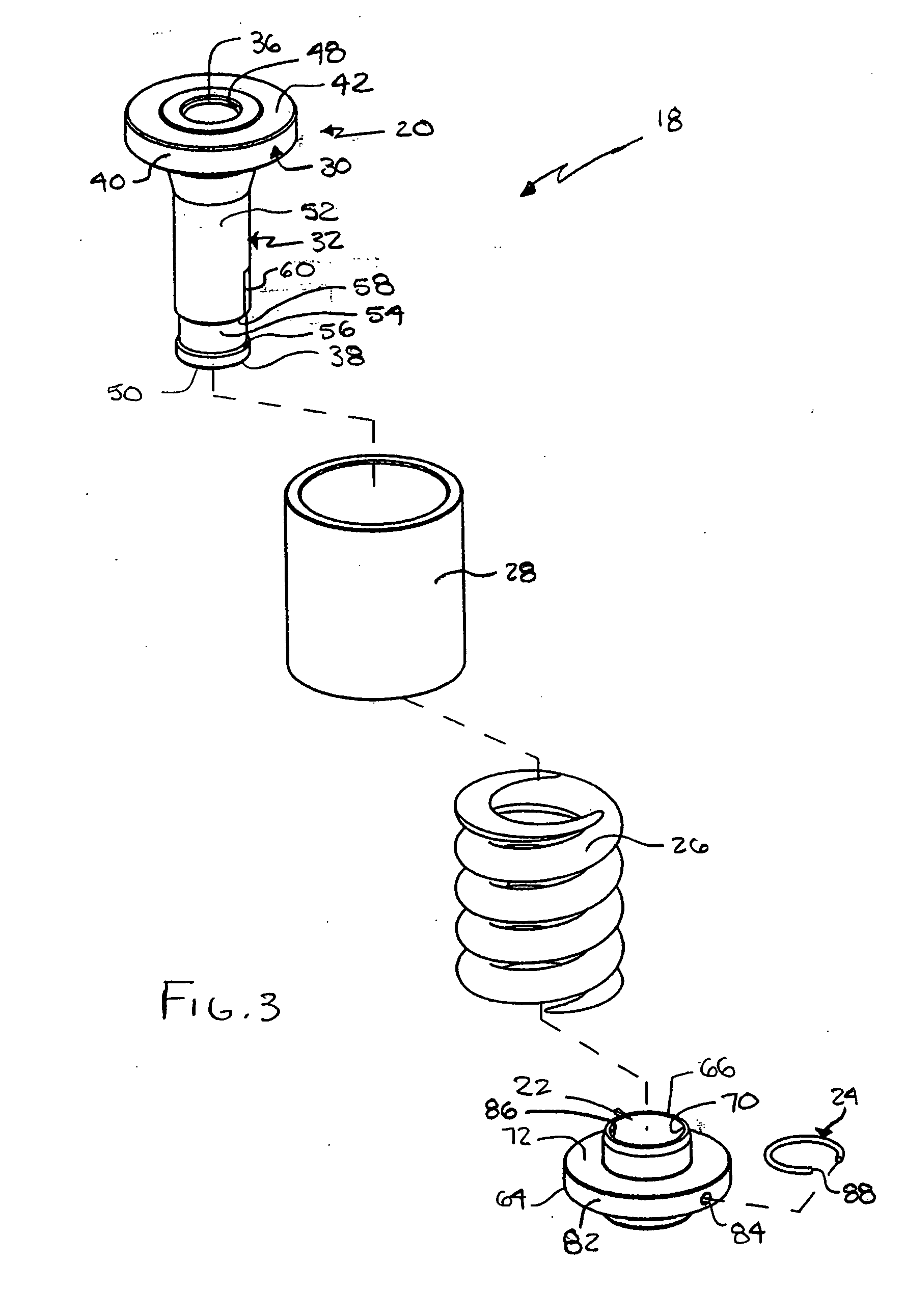

ActiveUS7152451B1Easy to useEasy maintenanceSpringsStripping-off devicesEngineeringMechanical engineering

A reaction device for forming equipment includes a housing having a mount adapted to be connected to a forming die and a casing carried by the mount. A lift rod is disposed at least partially on the housing for movement relative to the house between extended and retracted positions. The lift rod has a first end disposed in the housing, a second end and a passage extending through the lift rod between its ends. An adapter is connected to the lift rod within the passage and is adapted to be coupled to a lift bar of the forming equipment. A biasing member is disposed between the lift rod and the housing to yieldably bias the lift rod to its extended position.

Owner:DIEBOLT INT

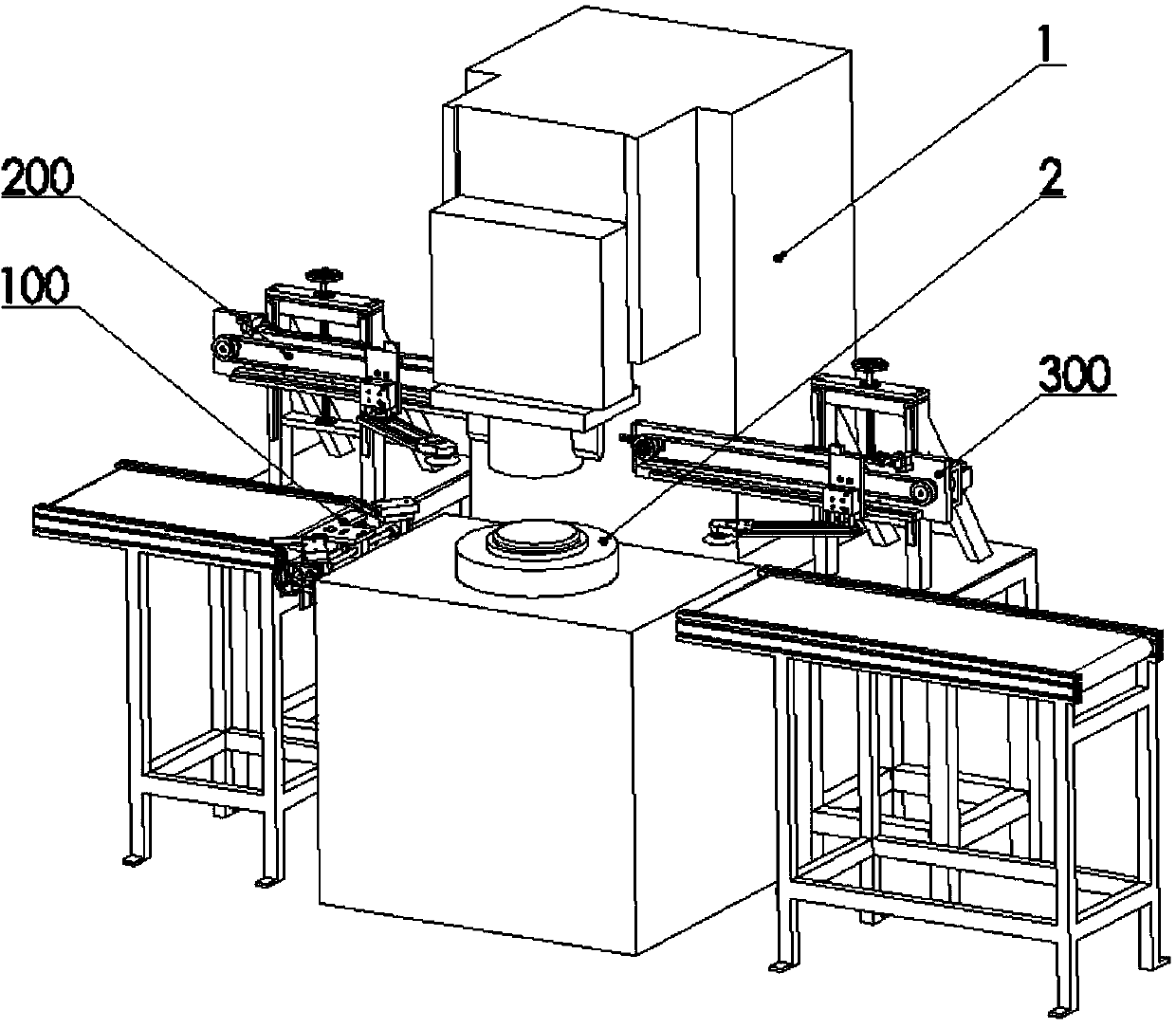

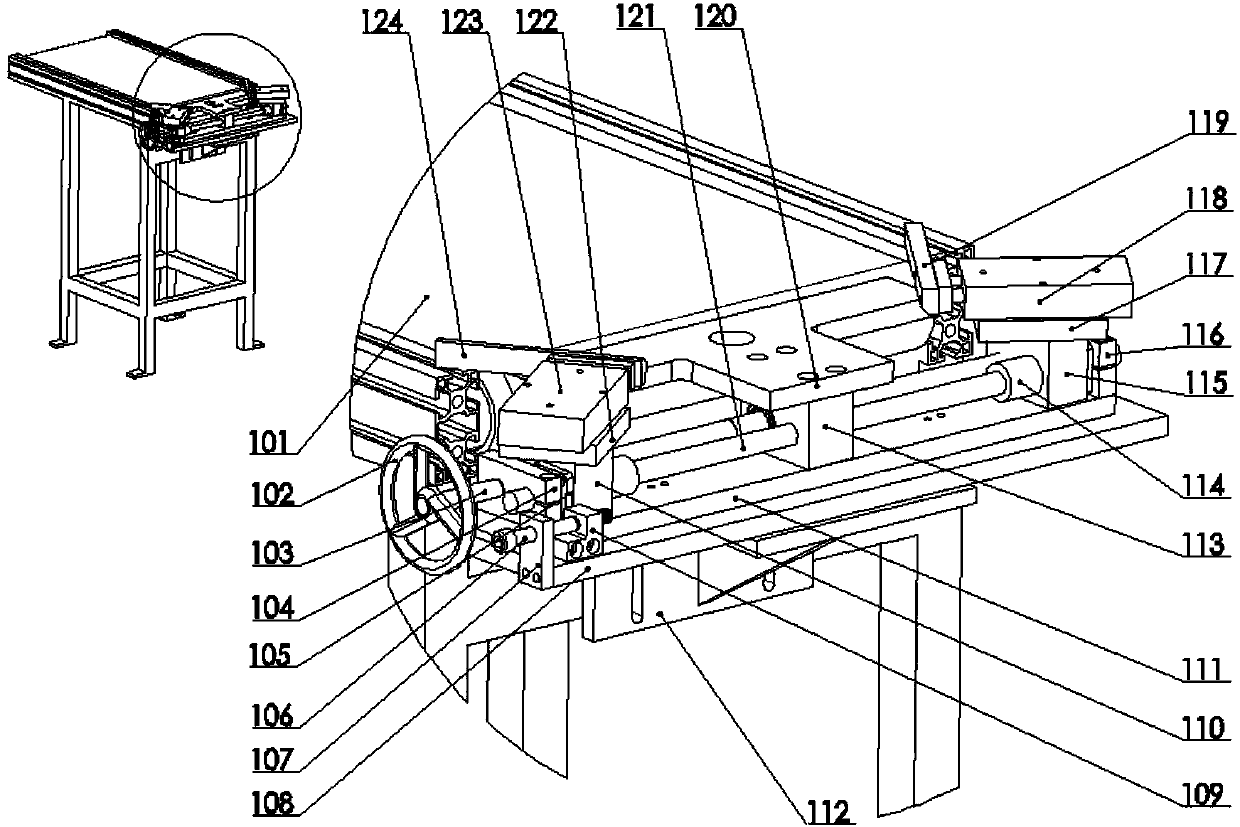

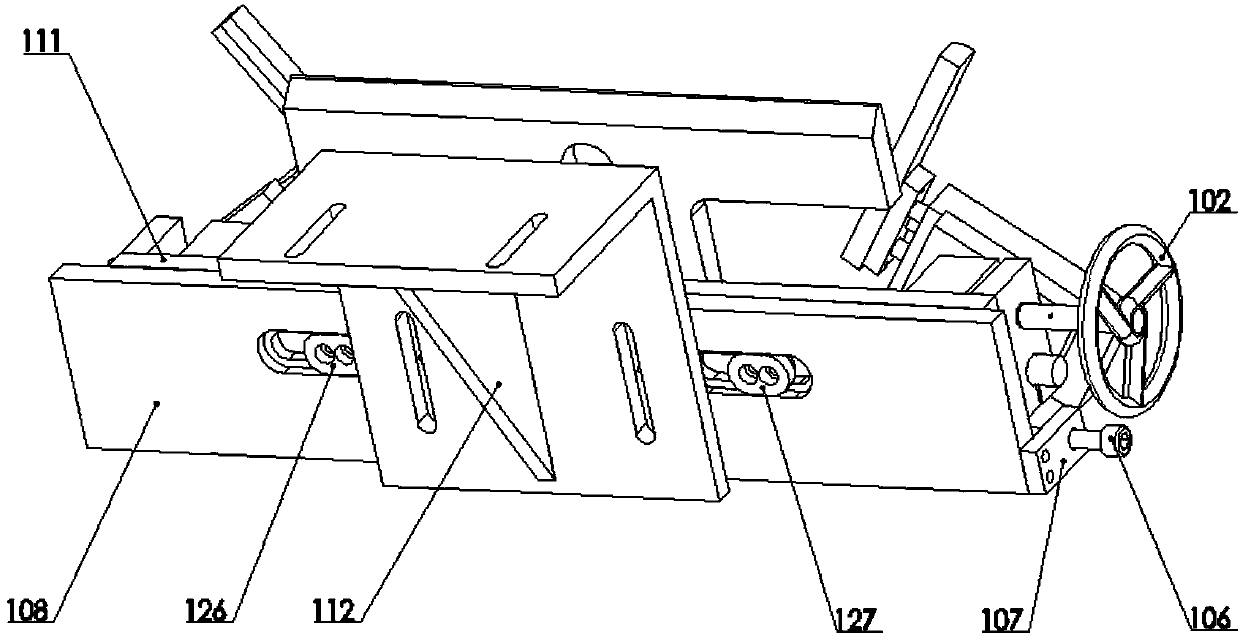

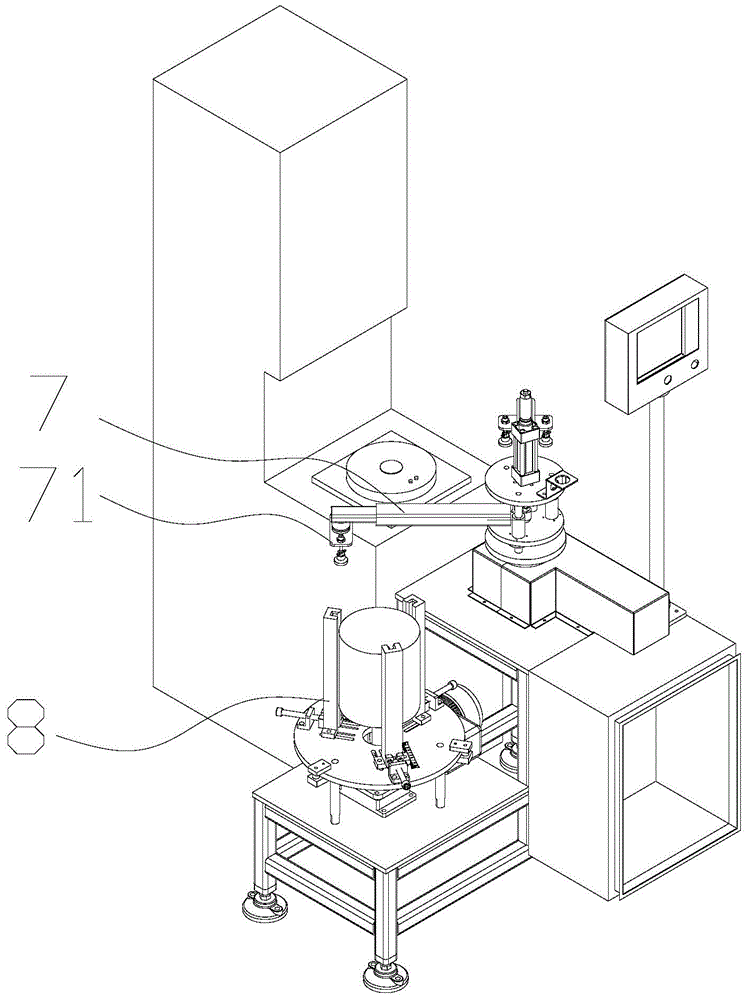

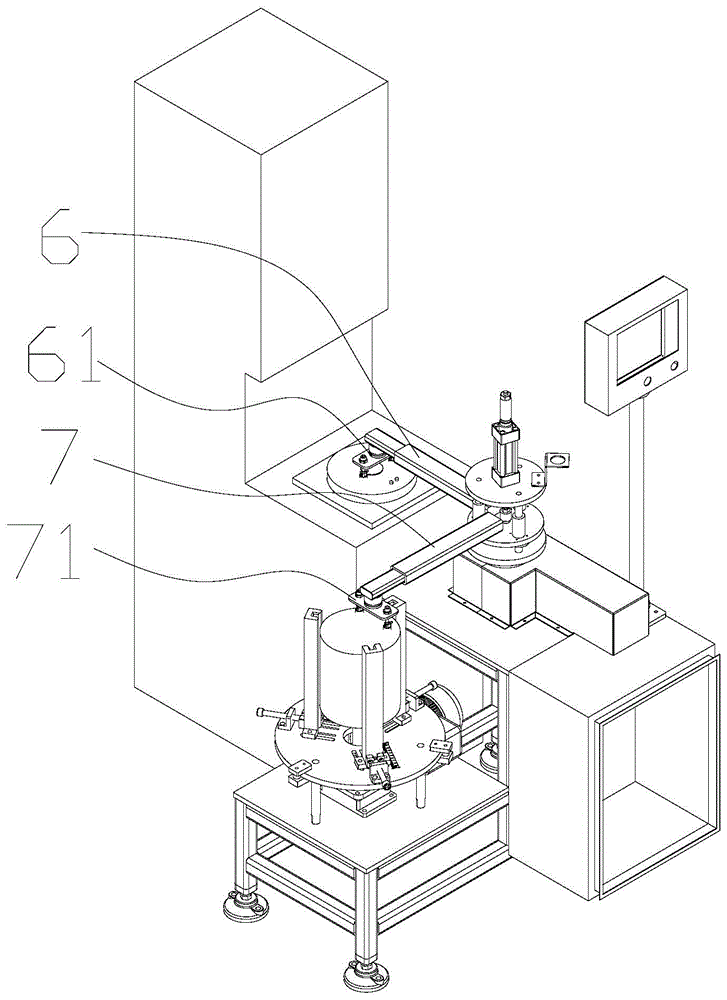

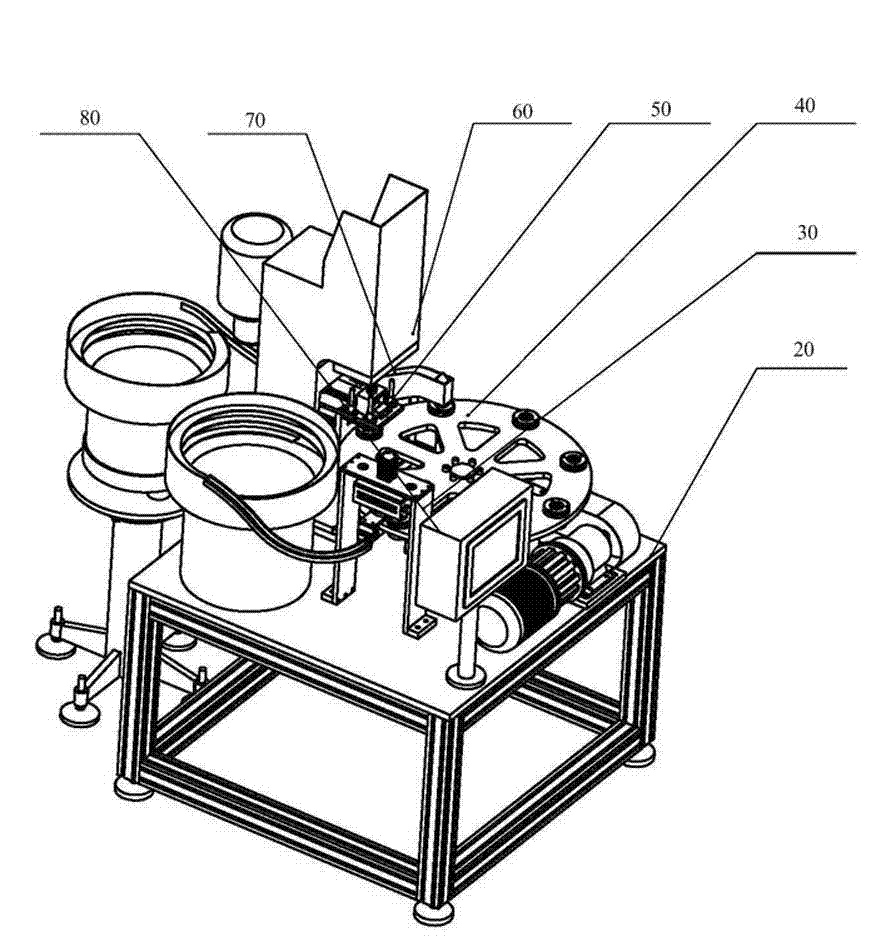

Automatic trimming feed and take-out device for round metal pots

ActiveCN103611837AEnsure safetyQuality assuranceMetal-working feeding devicesStripping-off devicesEngineeringUltimate tensile strength

The invention relates to the technical field related to automatic trimming of metal pots, in particular to an automatic trimming feed and take-out device for round metal pots. The device comprises a positioning unit, a feed unit and a take-out unit, wherein the feed unit and the take-out unit are sequentially arranged above the positioning unit. The positioning unit is used for positioning the metal ports with various standards and enabling the circle centers of the round metal pots conveyed by a conveyer belt to coincide with a designated position point. The feed unit is used for taking the round metal pots out of the positioning unit by the adoption of a feed vacuum suction disc, and conveying the round metal pots to a trimming die of an oil press. The take-out device is used for taking workpieces trimmed on the die of the oil press out of the die of the oil press, and placing the workpieces to the conveying belt. The automatic trimming feed and take-out device for the round metal pots effectively reduces labor intensity of workers, improves working efficiency and ensures trimming quality.

Owner:XINXING XIANFENG STAINLESS STEEL PROD MFGR CO LTD

Feeding and discharging mechanical arm and device for stamping process

InactiveCN104785655AAutomatic and flexible reclaimingAutomatic and flexible feedingProgramme-controlled manipulatorMetal-working feeding devicesElectricitySingle process

The invention discloses a feeding and discharging mechanical arm and device for the stamping process. The feeding and discharging mechanical arm structurally comprises an electric control cabinet, a rack, a main rotating shaft, a fixing base, a vertical shaft, a first mechanical arm body, a second mechanical arm body, a first mechanical claw and a second mechanical claw. The included angle between the first mechanical arm body and the second mechanical arm body ranges from 90 degrees to 120 degrees, and the first mechanical arm body and the second mechanical arm body can move vertically along with the vertical shaft. The vertical shaft and the fixing base can rotate horizontally along with the main rotating shaft. The main rotating shaft, the vertical shaft, the first mechanical arm body and the second mechanical arm body are driven by different motors, and all the motors are electrically connected with the electric control cabinet. The feeding and discharging mechanical arm has the functions of taking and placing materials automatically and flexibly, is suitable for single-process stamping as well as whole-line multi-station stamping, solves the technical problems that existing equipment is low in applicability, low in working efficiency and likely to cause industrial accidents, and improves working efficiency, flexibility and safety.

Owner:FOSHAN IROBOT AUTOMATIC

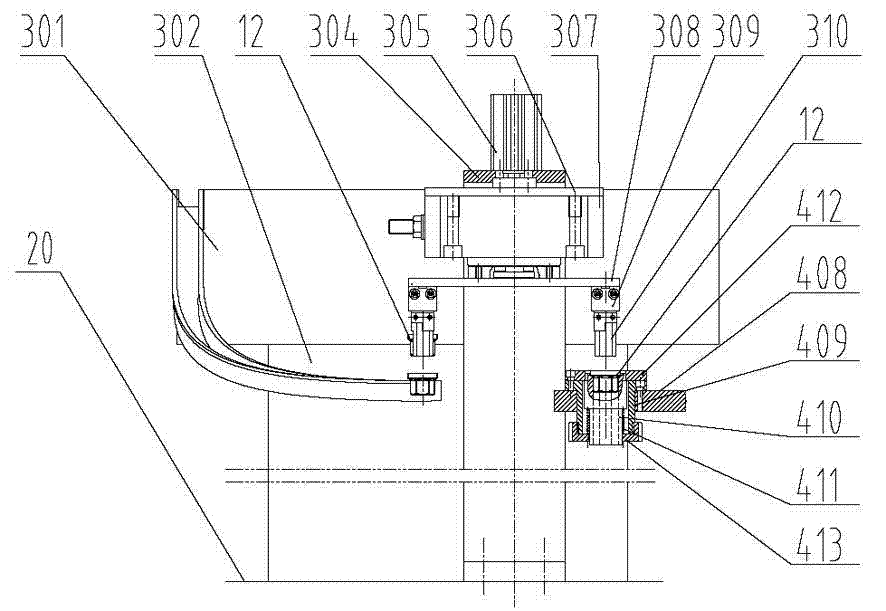

Automatic machining equipment for three-way pipe

ActiveCN104646559ARealize fully automatic processingIncrease productivityMetal-working feeding devicesStripping-off devicesEngineeringManipulator

The invention discloses automatic machining equipment for a three-way pipe. The invention discloses a machine frame, a flaring mechanism and a flattening forming mechanism which are arranged on the machine frame, a feeding device which is arranged at a feeding opening, a discharging device which is arranged at a discharging opening, and a manipulator mechanism which is arranged above the flaring mechanism and the flattening forming mechanism; the manipulator mechanism conveys a workpiece to the flaring mechanism from the feeding opening of the feeding device for the flaring mechanism to perform flaring on the workpiece, and conveys the workpiece to the flattening forming mechanism from the flaring mechanism for the flattening forming mechanism to form the workpiece; the formed workpiece is discharged by put into the discharging device through the manipulator mechanism. The invention provides the automatic machining equipment for the three-way pipe, the automatic machining of the flaring and the flattening forming of the three-way pipe is realized; the production efficiency is high; the automatic machining equipment is suitable for batch production.

Owner:浙江长兴和良智能装备有限公司

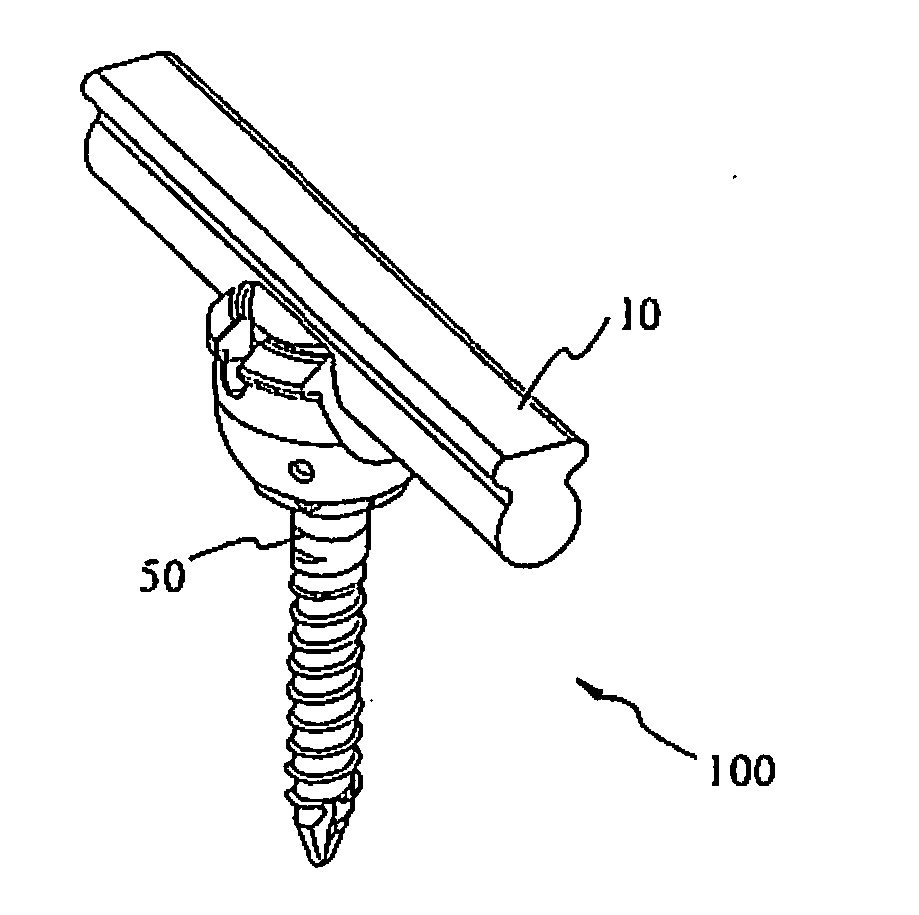

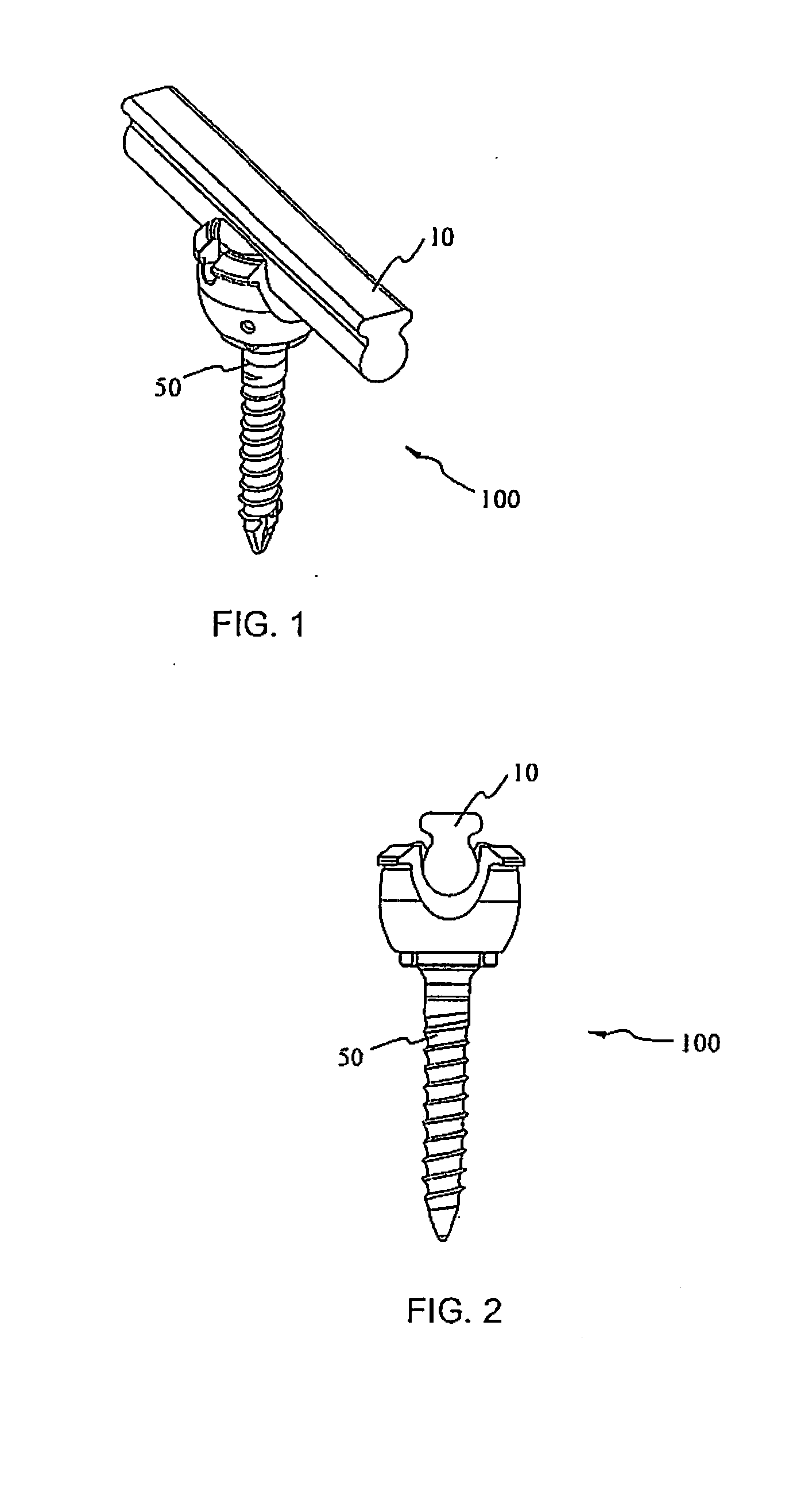

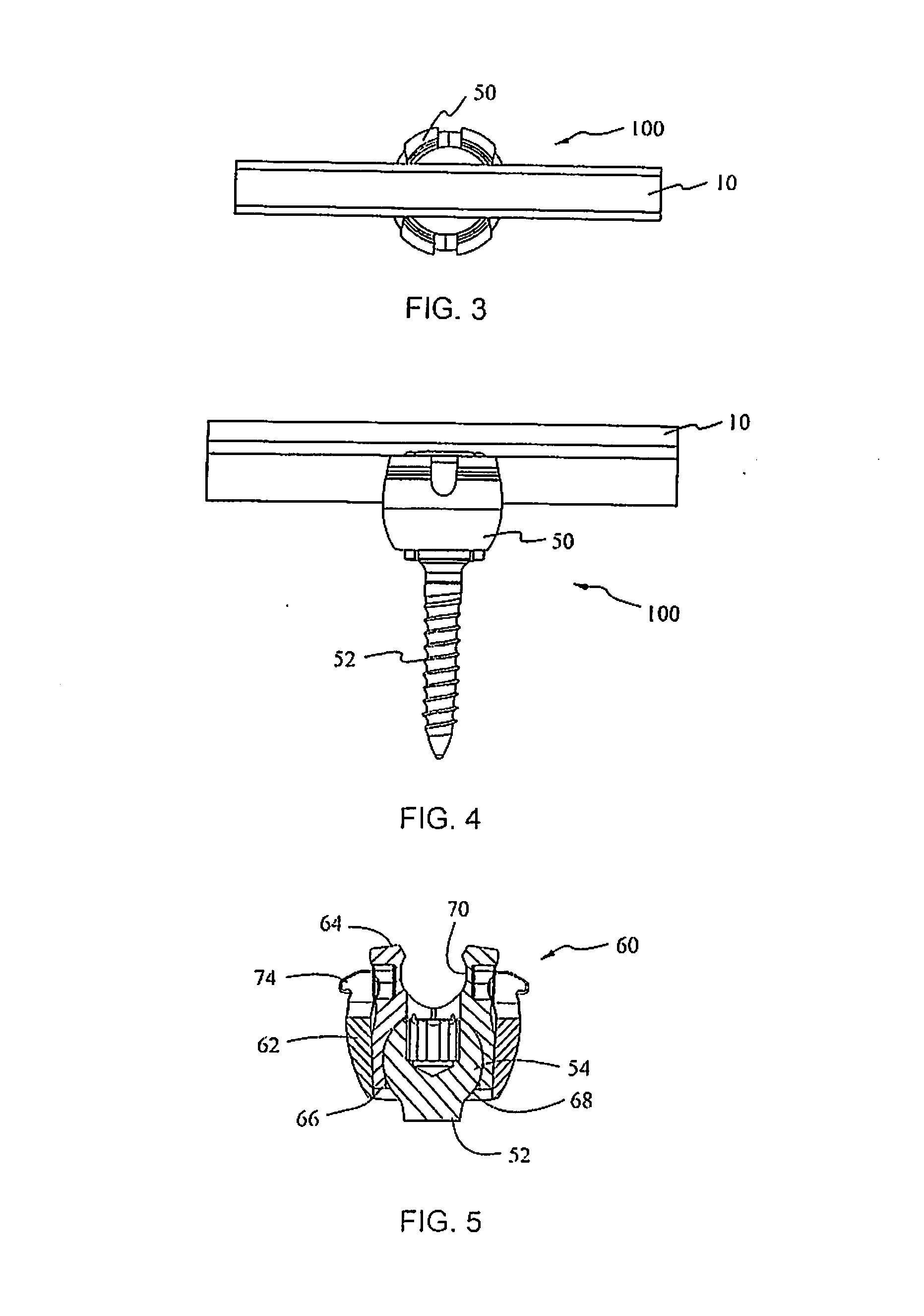

Spine stabilization system

ActiveUS20130144342A1Easy to bendInternal osteosythesisStripping-off devicesBiomedical engineeringBone screws

A spinal stabilization system includes a connecting rod, a rod bending device, and a plurality of bone screws. The connecting rod includes an elongate round portion, an elongate head portion and a neck portion connecting the elongate round portion with the elongate head portion. The rod bending device includes an elongate body defining an aperture configured and dimensioned to receive the connecting rod therethrough in a single orientation. The bone screws include a housing portion and a screw shaft distally extending from the housing portion. The housing portion includes an inner housing and an outer housing slidably surrounding at least a portion of the inner housing. The inner housing defines a slot configured and dimensioned to releasably secure the elongate round portion of the connecting rod therein. The outer housing is movable relative to the inner housing between an unlocked state and a locked state.

Owner:K2M

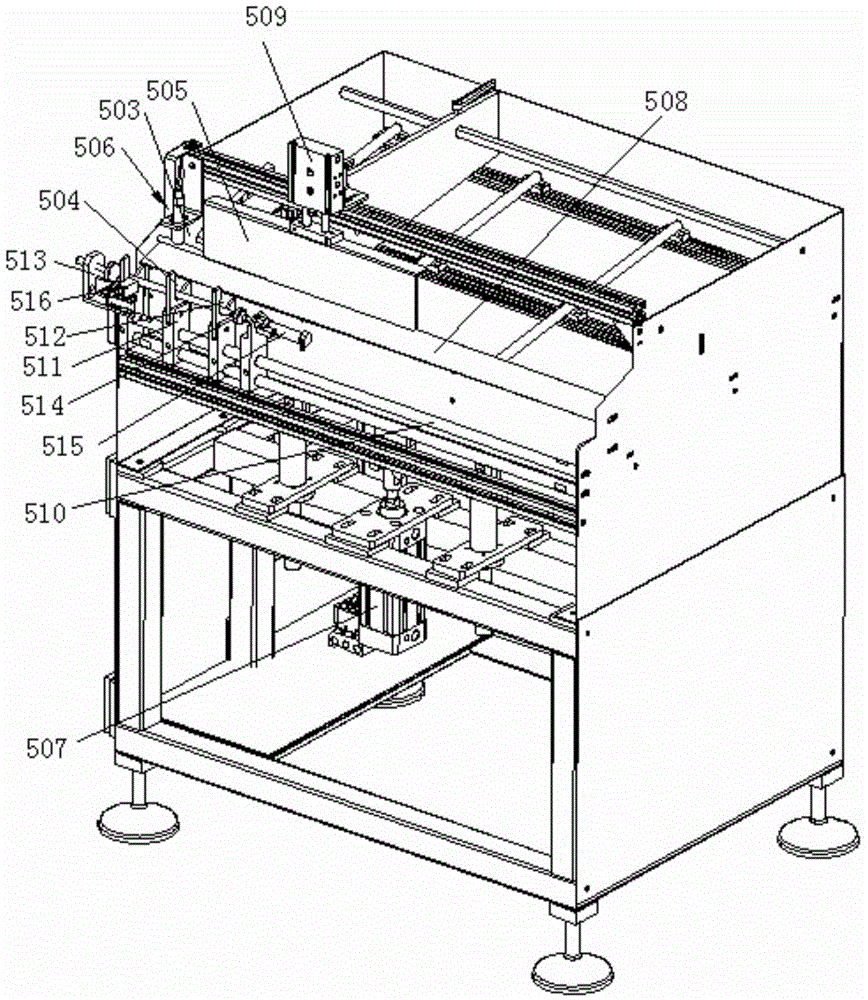

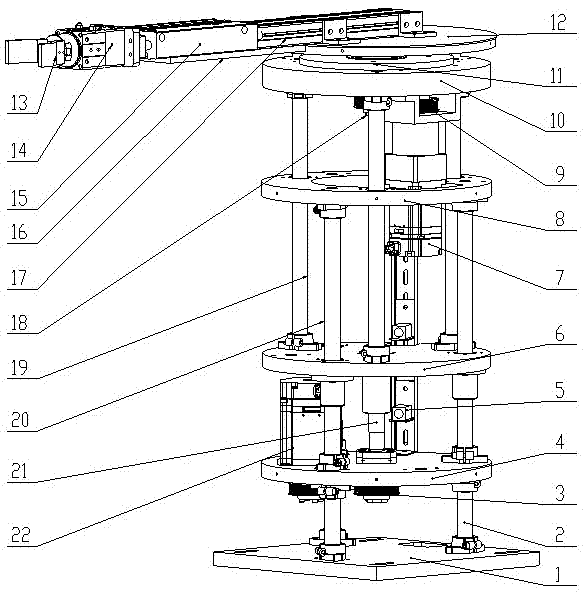

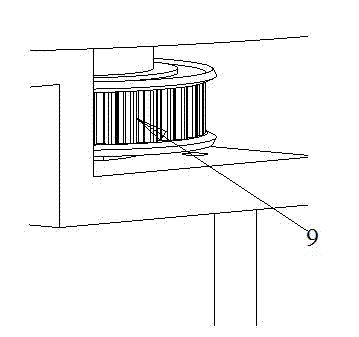

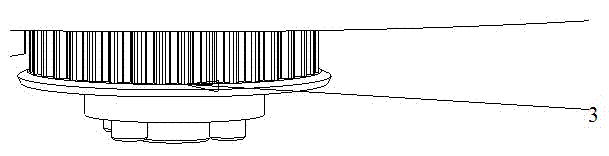

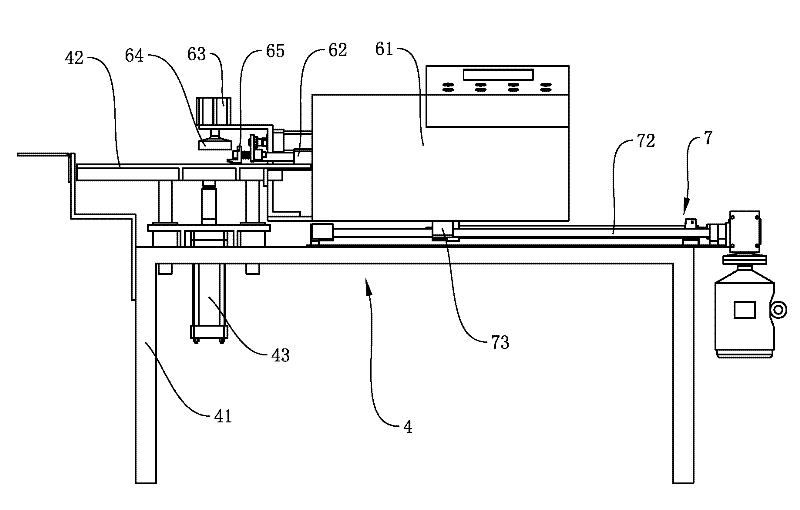

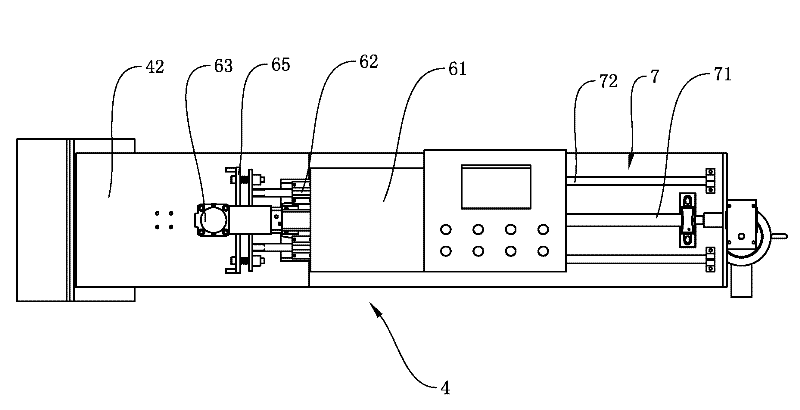

Automatic manipulator of caster support press line

InactiveCN102848379ARealize lifting movementRealize pickup and deliveryProgramme-controlled manipulatorMetal-working feeding devicesRotary stagePunch press

The invention relates to an automatic manipulator of a caster support press line. The automatic manipulator comprises a shell, a structural support, an electric manipulator, a driving device and a control device. The structural frame comprises a fixing plate, guide columns, an upper base, a lower base, an upper lifting table, a lower lifting table and a rotating table, and the upper base, the lower base, the upper lifting table and the lower lifting table are supported by the guide columns in a crossing manner; the electric manipulator is mounted on the rotating table; the driving device comprises two stepper motors, one stepper motor is mounted on the upper lifting table, is connected with a rotary shaft of the rotating table by a synchronous belt pulley and drives the manipulator to rotate, and the other stepper motor is mounted on the lower base, is connected with the lifting tables by a synchronous belt pulley and a lead screw and enables the manipulator to ascend and descend; and the control device comprises sensors and a programmable controller. The automatic manipulator is low in cost and easy to operate, is simple, convenient and stable, can move in various manners, has dust and chip prevention functions, can accurately extend onto a cavity of a punch press according to different characteristics of dies at different stations of the press line, picks up and delivers workpieces and replaces workers to carry out tasks such as carrying, feeding and discharging.

Owner:SOUTH CHINA UNIV OF TECH

Full-automatic four-roller plate rolling machine

InactiveCN102527785AFeed realizationIncrease productivityMetal-working feeding devicesStripping-off devicesHydraulic cylinderEngineering

The invention relates to the technical field of plate rolling machines, in particular to a full-automatic four-roller plate rolling machine. The full-automatic four-roller plate rolling machine comprises a body and a rolling and pressing device assembled on the body, wherein the rolling and pressing device comprises an upper roller, a lower roller, and a front roller and a rear roller which are positioned on two sides of the lower roller respectively; the upper roller comprises a movable end and a fixed end which is in drive connection with a motor; the fixed end is fixed on the body through a bearing; the movable end is provided with a movable shaft seat with opening and closing actions; the movable shaft seat is connected with a shaft seat hydraulic cylinder; two ends of the lower roller, the front roller and the rear roller are connected with a lifting hydraulic cylinder respectively; an automatic feeding device is arranged besides the radial direction of the rolling and pressing device; and an automatic discharging device is arranged besides the axial direction of the rolling and pressing device. The full-automatic four-roller plate rolling machine is provided with a plate rolling control device corresponding to the rolling and pressing device, the automatic feeding device and the automatic discharging device. The plate rolling machine can realize automatic feeding, automatic rolling and automatic discharging and has high production efficiency.

Owner:DONGGUAN YUNDONG PRINTING PLATEMAKING EQUIP

Biasing assembly for a punching device

ActiveUS20060060046A1Easy to adjustMinimal numberPerforating toolsStripping-off devicesPunchingEngineering

A biasing assembly for a punching device that includes a punch support member adapted to support a punch and including a head portion and a main portion extending from the head portion. The main portion has a recessed surface. A retaining member is coupled to the punch support member with the punch support member being slidable with respect to the retaining member. A coupling member is disposed between the main portion of the punch support member and the retaining member. A portion of the coupling member engages the recessed surface. A biasing member is supported between the head portion of the punch support member and the retaining member. The punch support member is movable between at least first and second positions with respect to the coupling member.

Owner:AMADA TOOL AMERICA

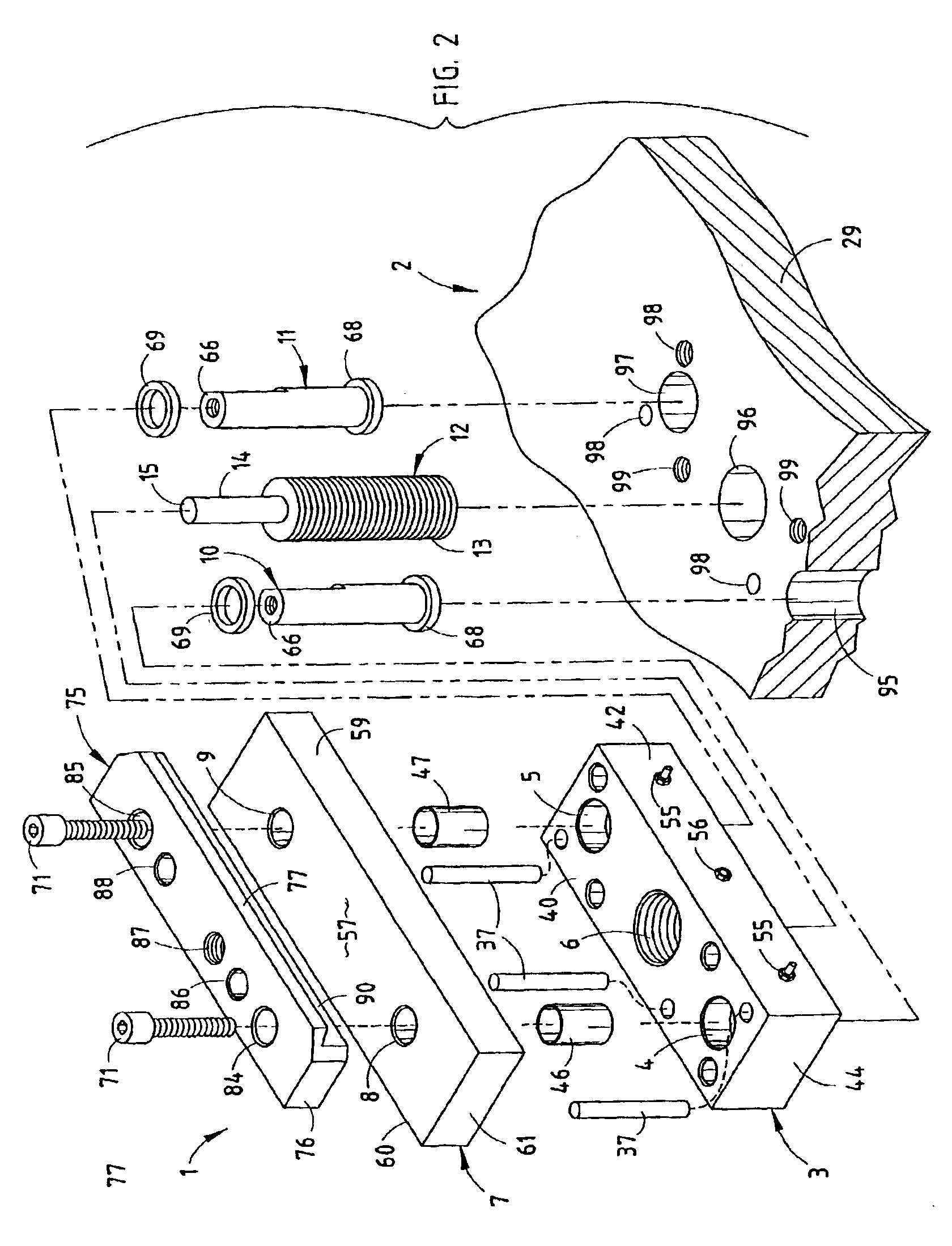

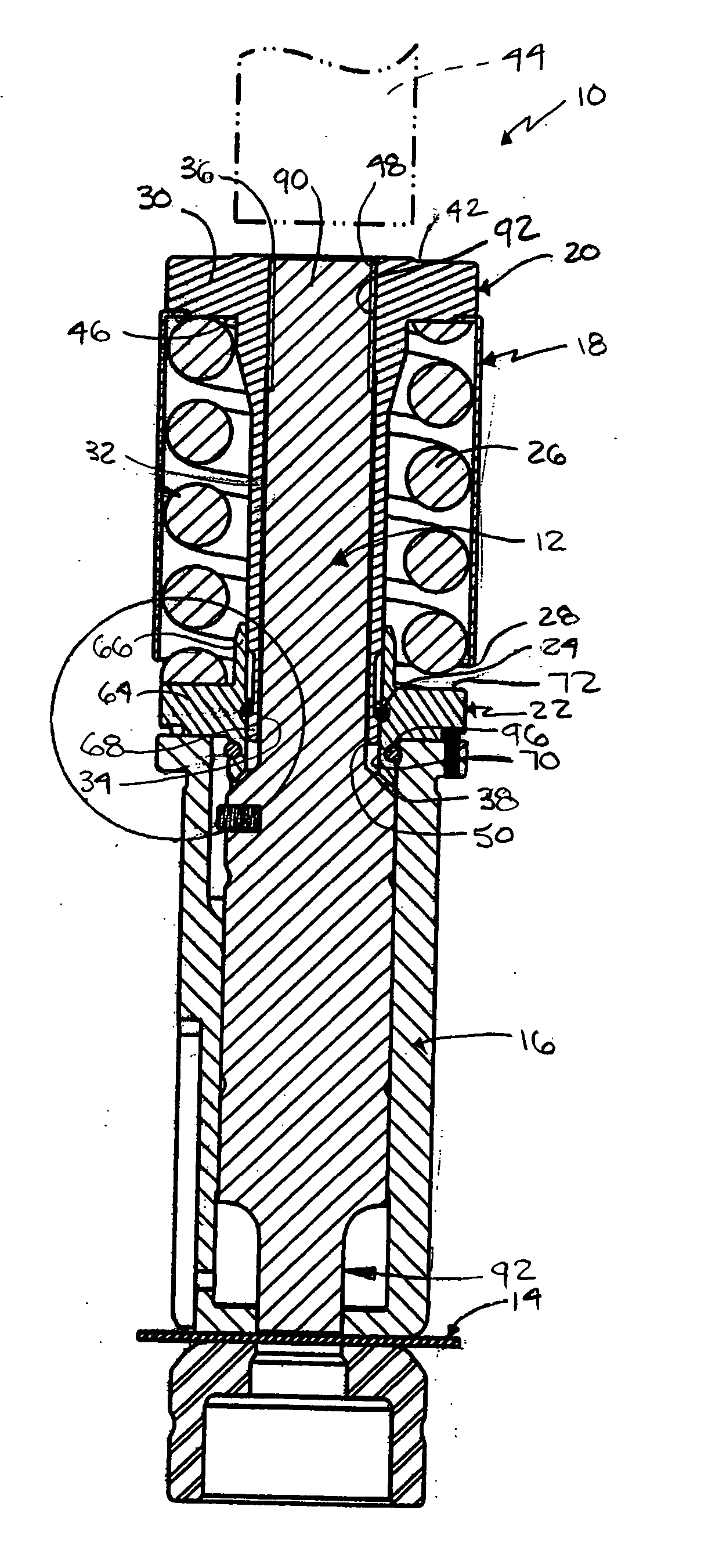

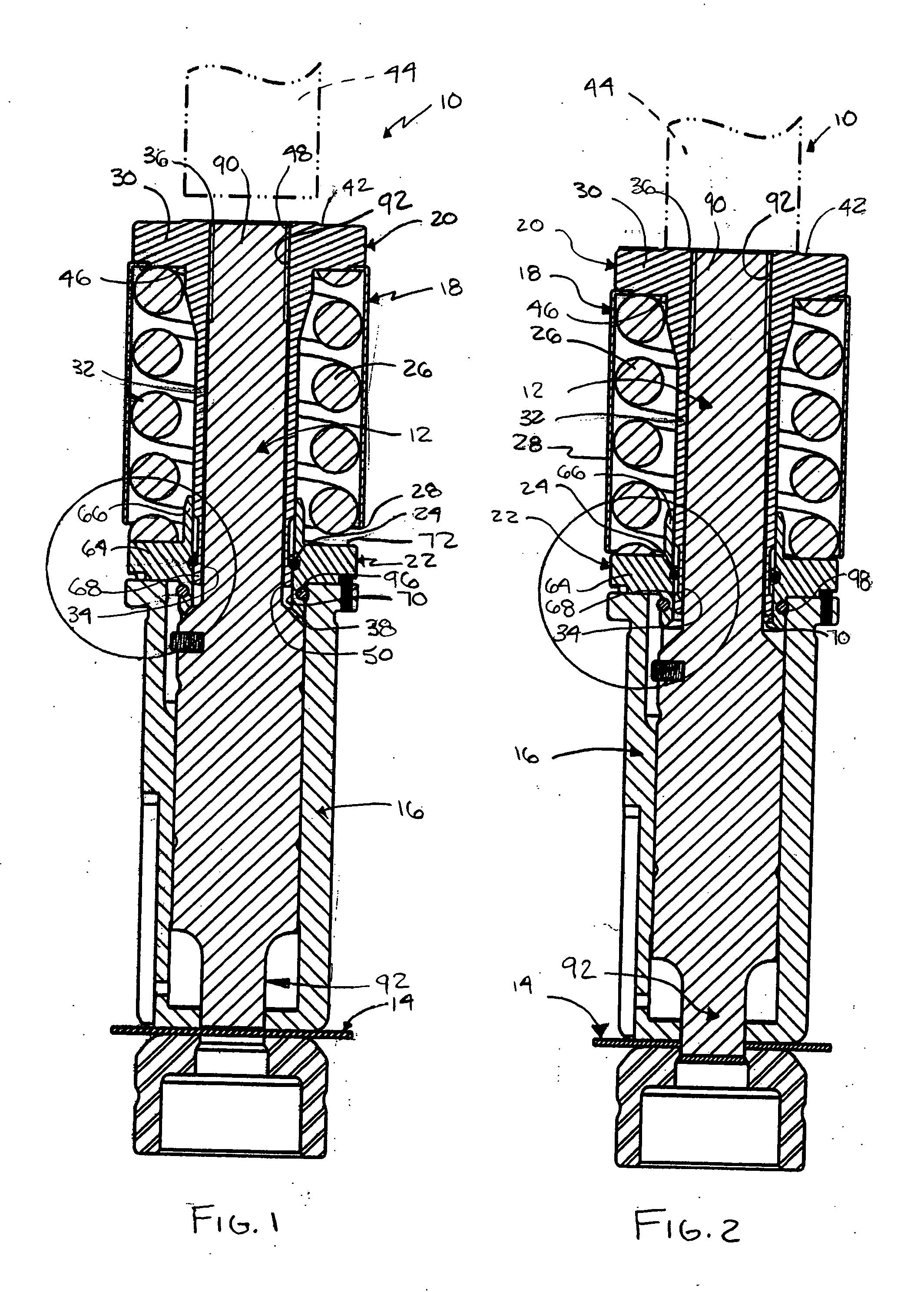

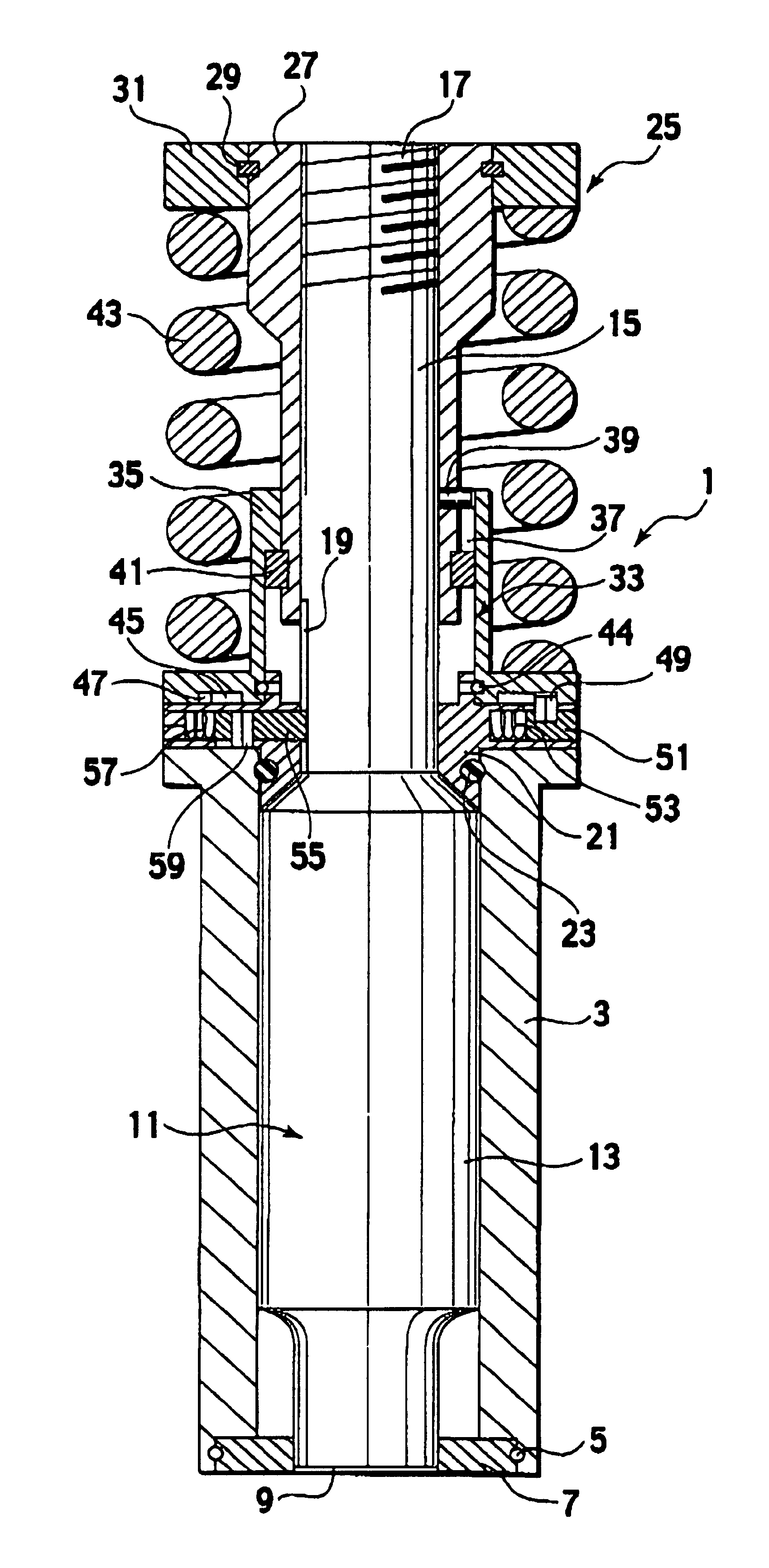

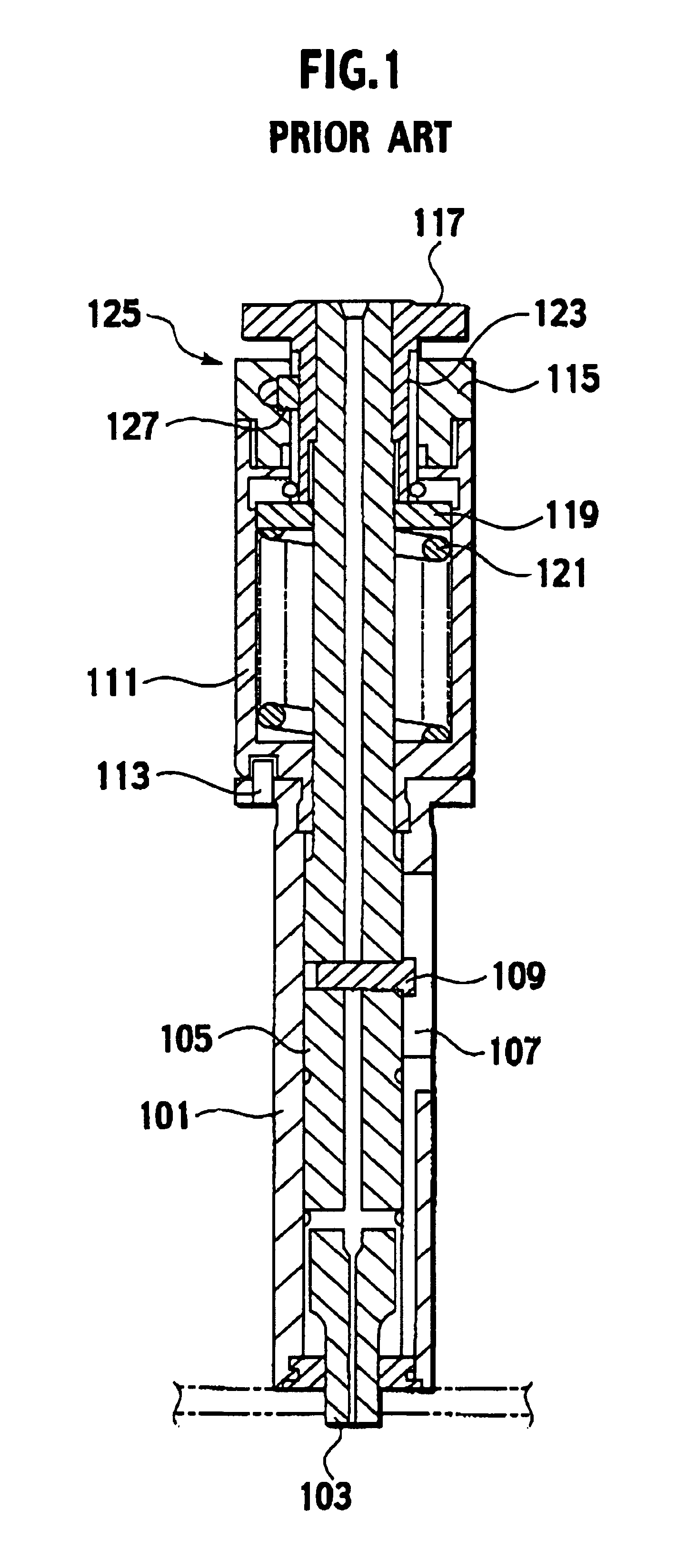

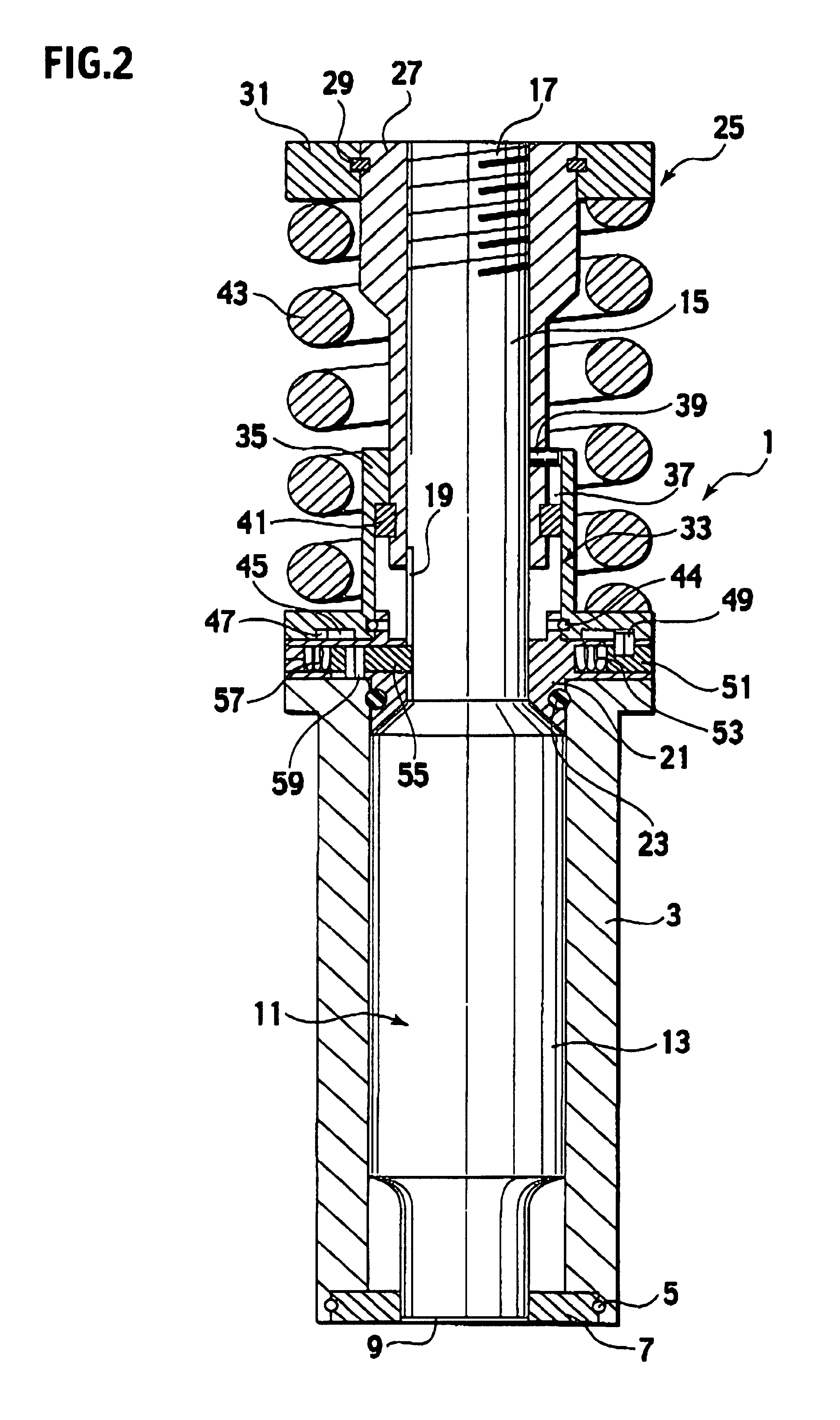

Guided keeper assembly and method for metal forming dies

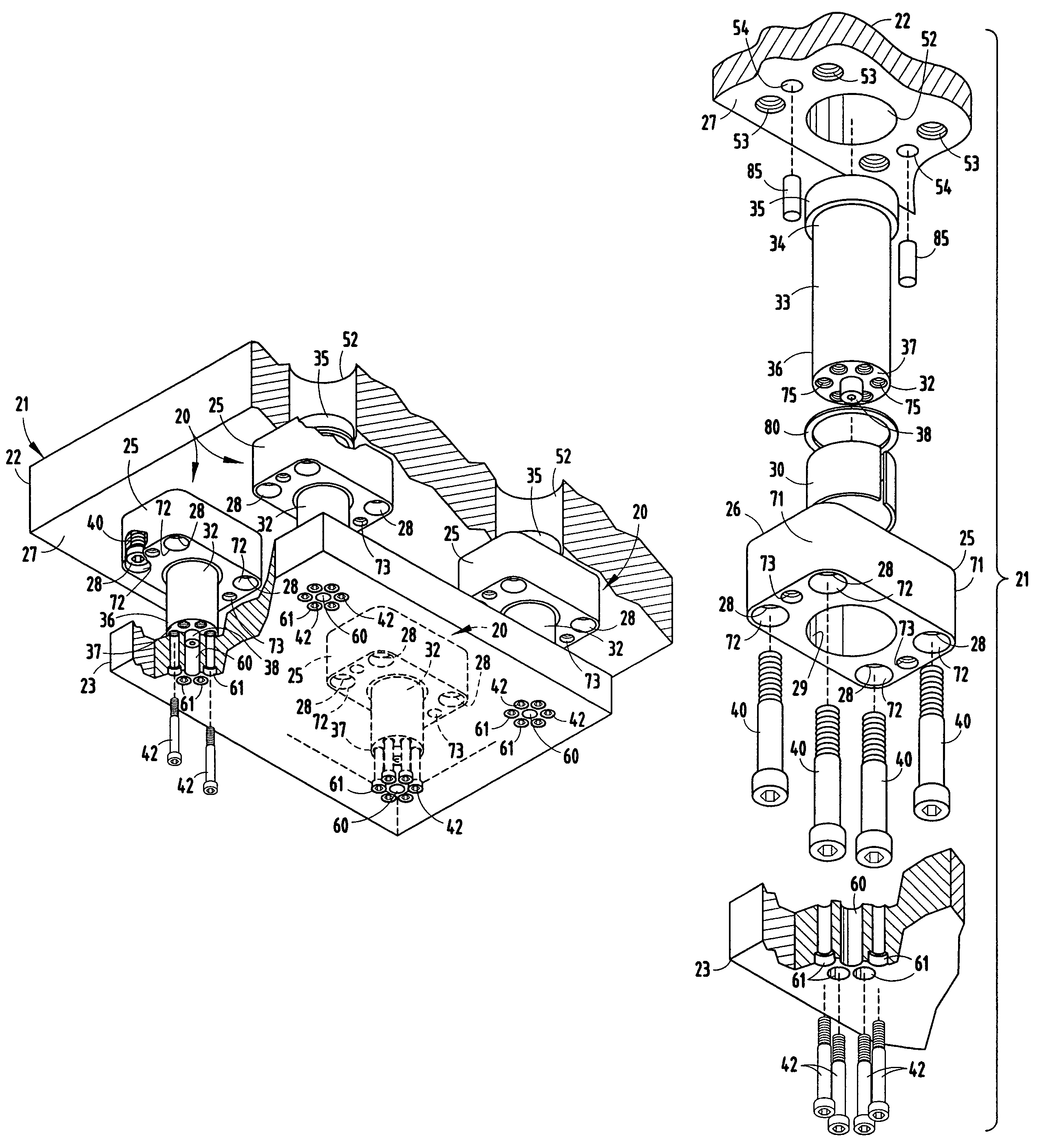

ActiveUS7730757B2Accurate locationSmall and compact footprintShaping toolsStripping-off devicesMetal formingReciprocating motion

A guided keeper assembly and method for metal forming dies includes a base having a flat mounting face and at least one marginal fastener aperture to detachably mount the base to an associated die shoe, as well as a central guide aperture. The assembly also includes a guide pin having a central portion closely received in the central guide aperture of the base for precisely guiding reciprocal motion between the die pad and an associated die shoe. The guide pin has an enlarged head at a first end thereof which abuts the mounting face of the base to positively limit travel between the die shoe and the die pad, and a shoulder at the opposite or second end thereof with an alignment mechanism that precisely locates the second end of the guide pin on the die pad. A first fastener extends through the marginal fastener aperture in the base to securely, yet detachably, connect the same with the die shoe. A second fastener securely, yet detachably, connects the second end of the guide pin with the die pad.

Owner:STANDARD LIFTERS INC

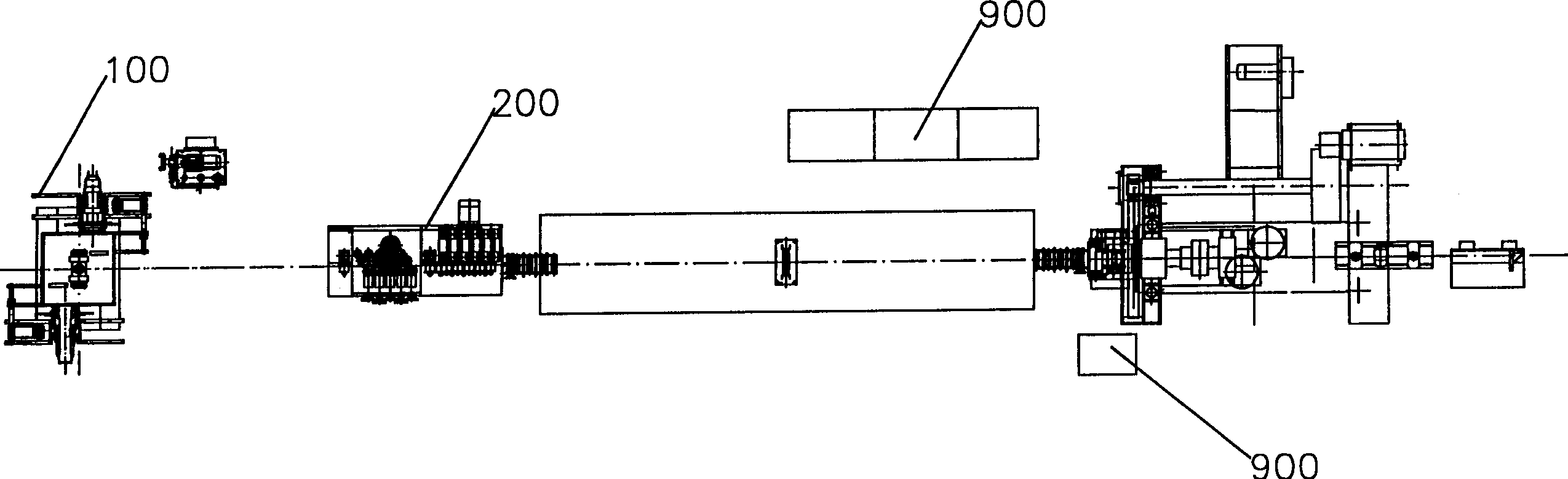

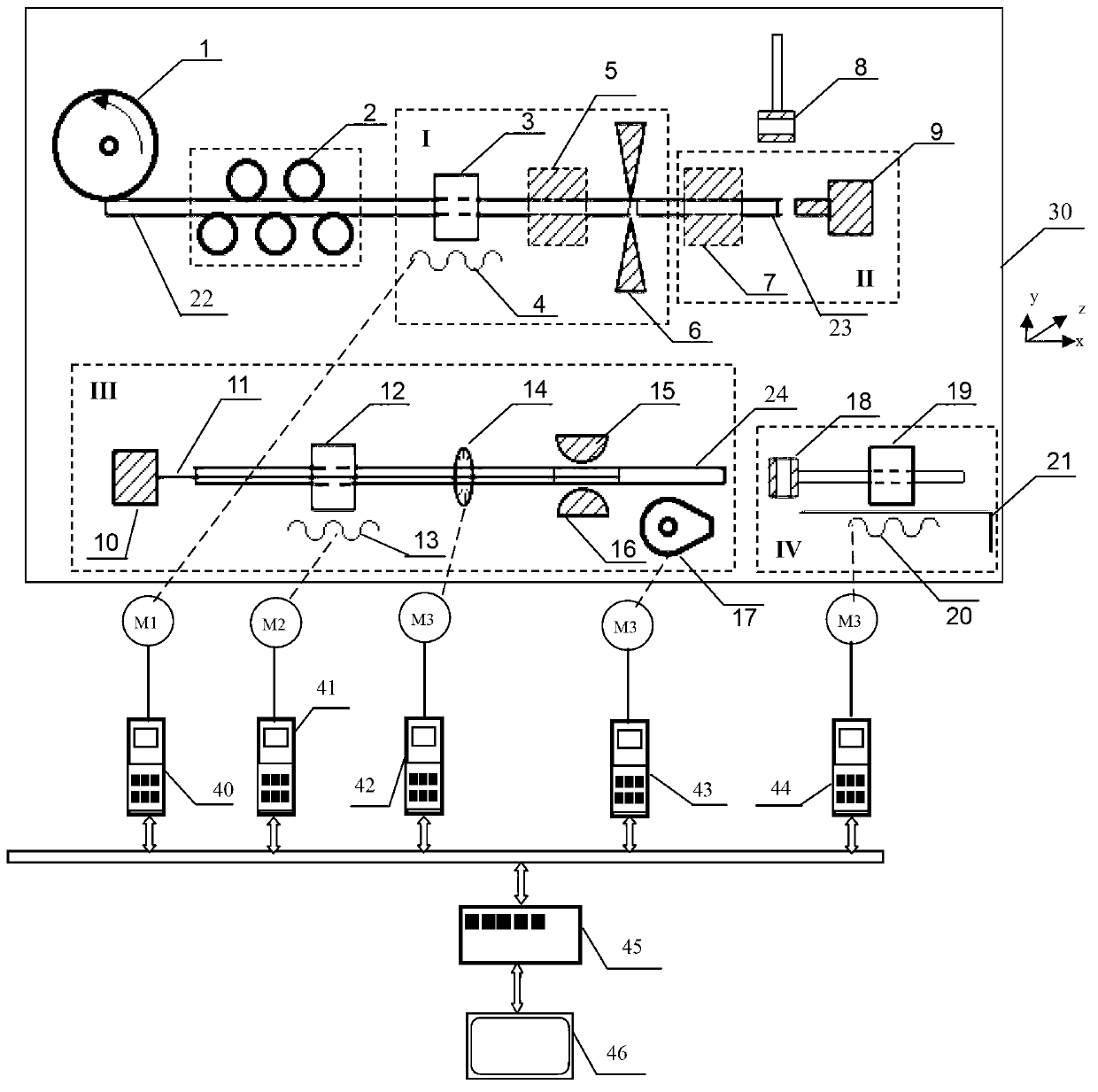

Method for optimization of pipe integrated numerical control machining process

InactiveCN103341521AImprove production efficiencyImprove processing qualityMetal-working feeding devicesStripping-off devicesNumerical controlMotor drive

The invention provides a method for optimization of a pipe integrated numerical control machining process. The method comprises the following steps of rough shape cutting, pipe end molding, bend pipe molding, and split charging and discharging. A controller transmits control signals to servo drivers ((40)-(44)). The servo drivers drive motors (M1-M5) on processing devices and the motors drive the corresponding processing devices to work so that high-precision processing is finished. The method can automatically realize integrated numerical control machining or any combined machining such as pipe rough shape cutting and feeding, chipless rough shape cutting, spinning pipe end molding, bend pipe and manipulator automatic-feeding, three-dimensional bend pipe and manipulator automatic-discharging according to drawing information only by manual introduction of a pipe to a material picking opening of a machine tool, can avoid complex processing adopting multiple machine tools and multiple processing steps, can realize continuous automatic production, can improve production benefits and processing quality of pipe production, and can be used for bending molding processing of pipes used in the industries of air conditioners, water heaters, refrigerators or automobiles.

Owner:WUHAN UNIV OF TECH

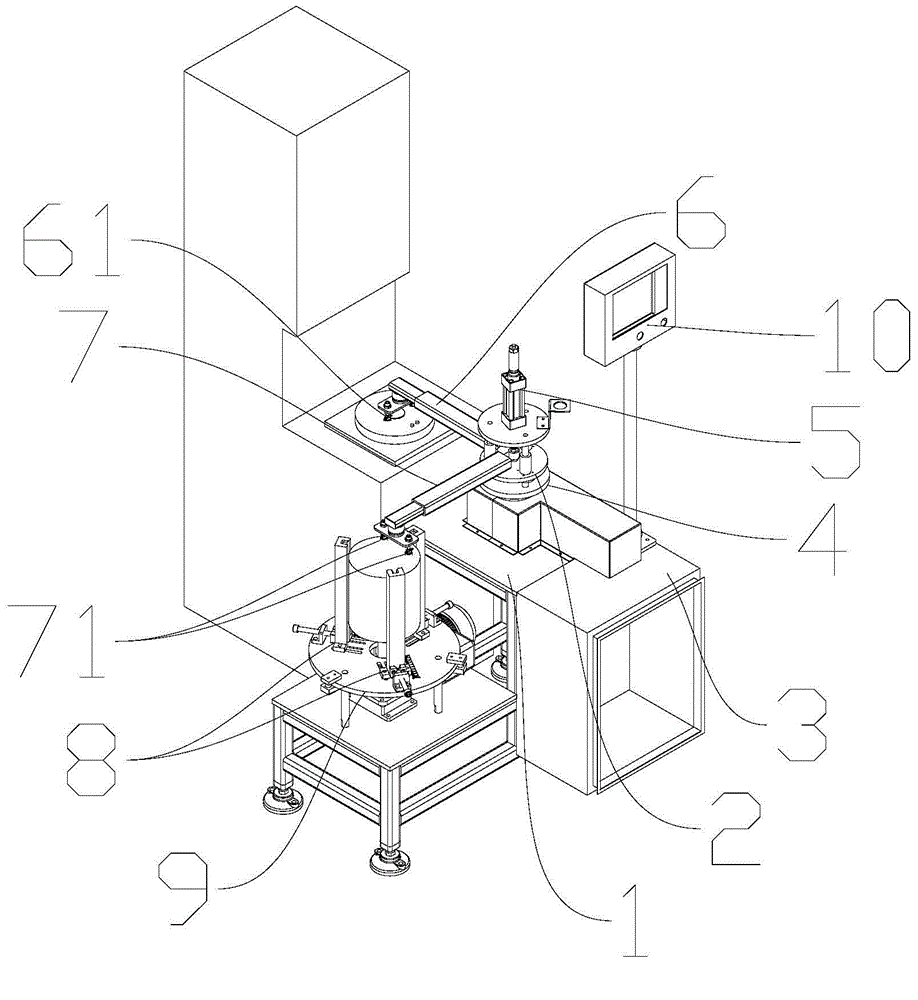

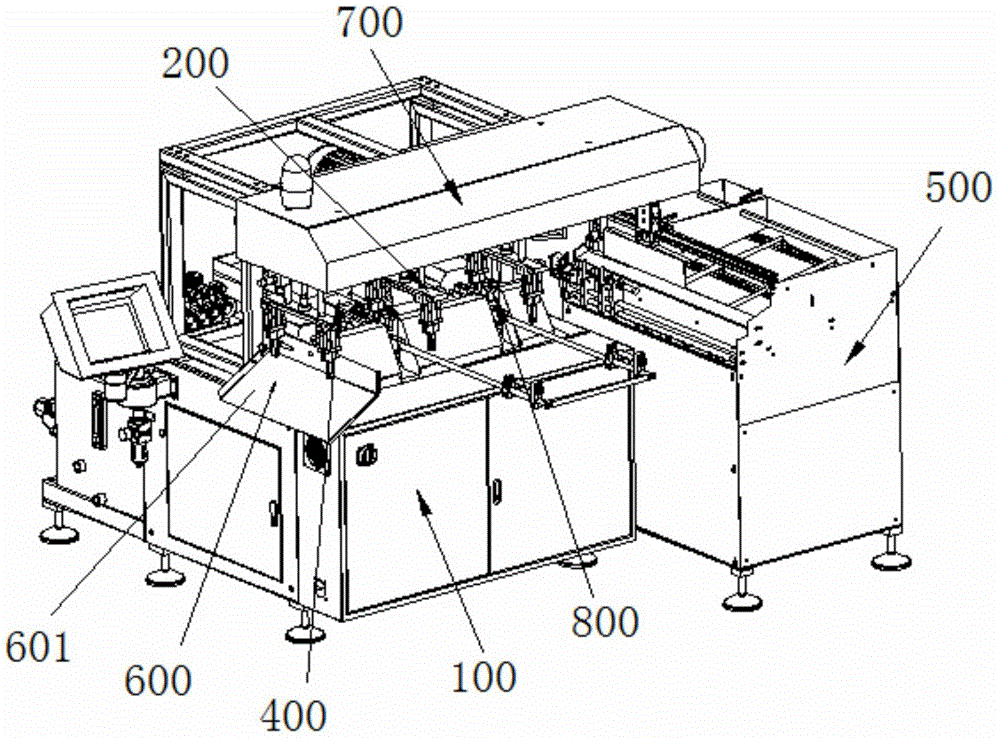

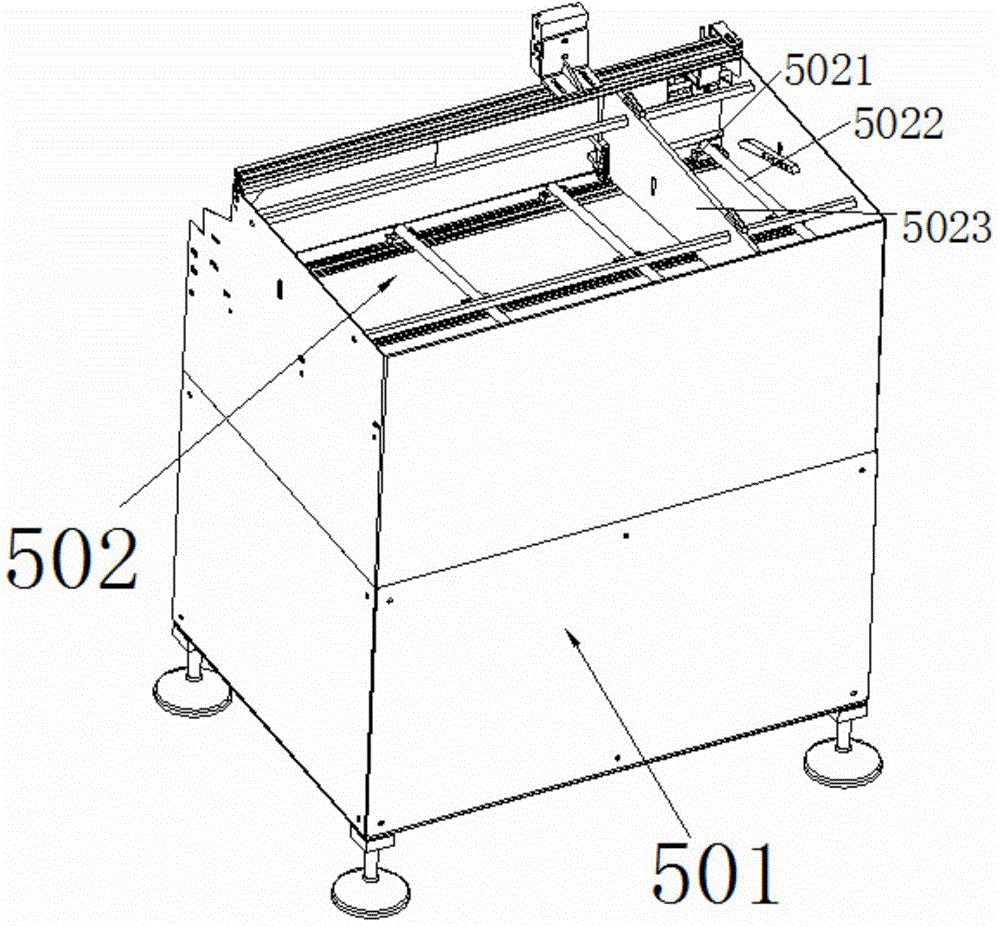

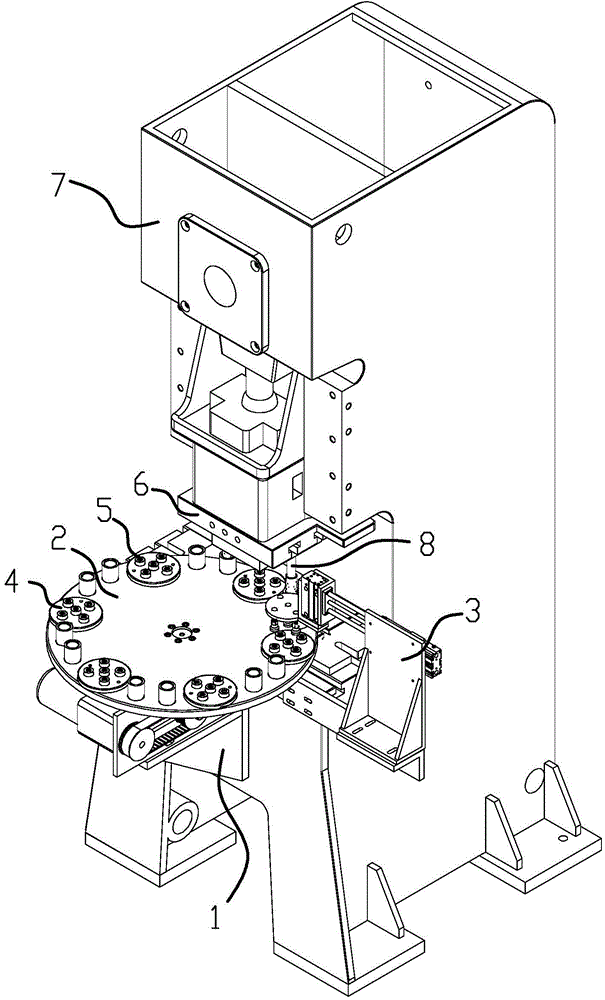

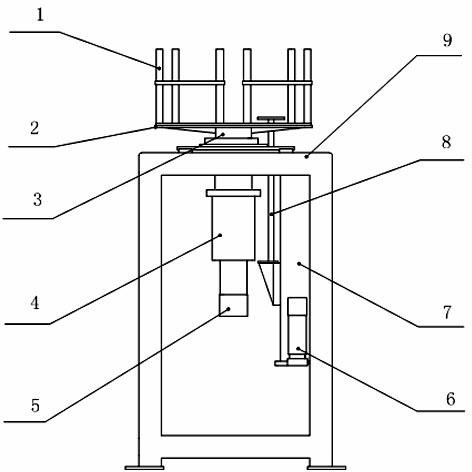

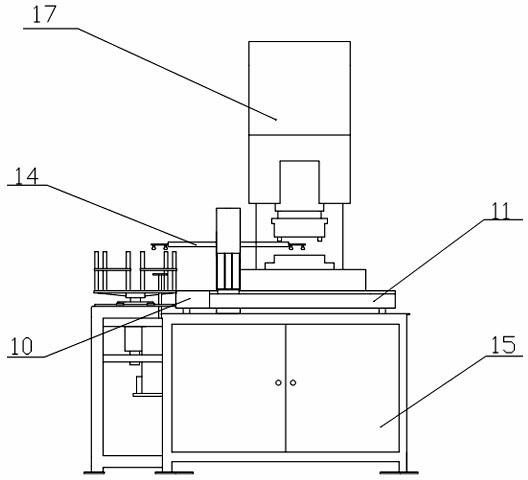

Fully-automatic multi-station nut riveting press

ActiveCN102921819ARealize riveting automationIncrease productivityMetal-working feeding devicesStripping-off devicesHydraulic cylinderAutomatic control

The invention provides a fully-automatic multi-station nut riveting press, comprising a rack for supporting, as well as a hexagonal nut cap loading device, a multi-station hexagonal nut cap indexing positioning device, a hexagonal nut loading positioning device, a riveting device, an unloading device and a PLC (programmable logic controller) frequency converter touch screen automatic control system which are installed on the rack, wherein the riveting device comprises a riveting hydraulic cylinder, a press rod, a clamping-releasing slide block, a buffering spring, a bearing base and a hydraulic system; and the multi-station hexagonal nut cap indexing positioning device comprises a turntable and a plurality of hexagonal nut cap positioning dies. According to the invention, riveting automation for the nuts of a tire is realized, production efficiency is increased to a large extent, the occurrence of safety accidents is avoided, labour intensity is lightened, manpower input is reduced, cost is decreased, and enterprise competitiveness is enhanced.

Owner:ZHEJIANG CHANGHUA AUTO PARTS

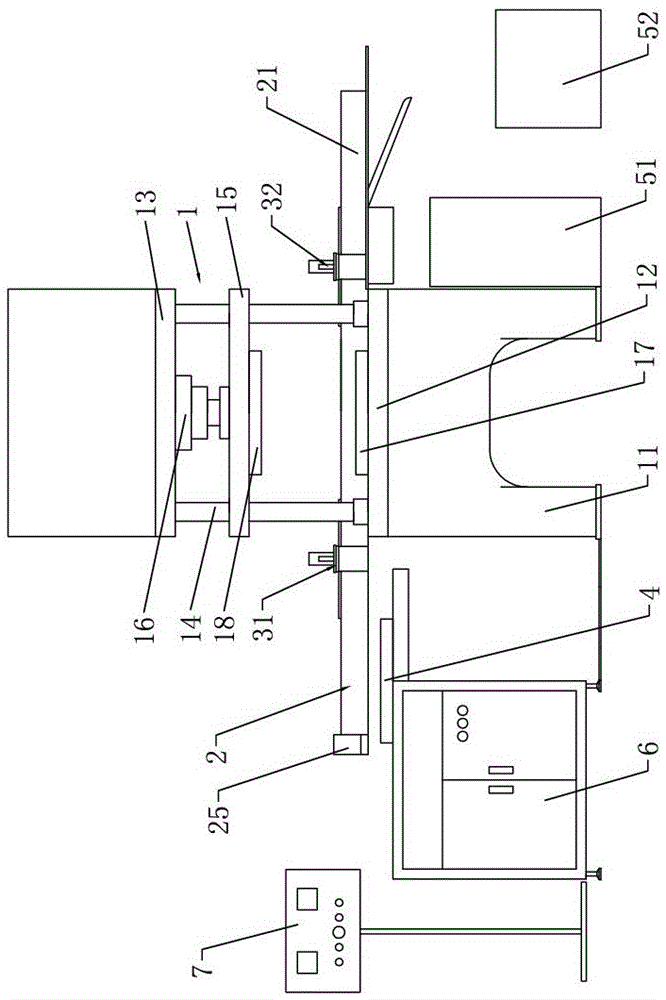

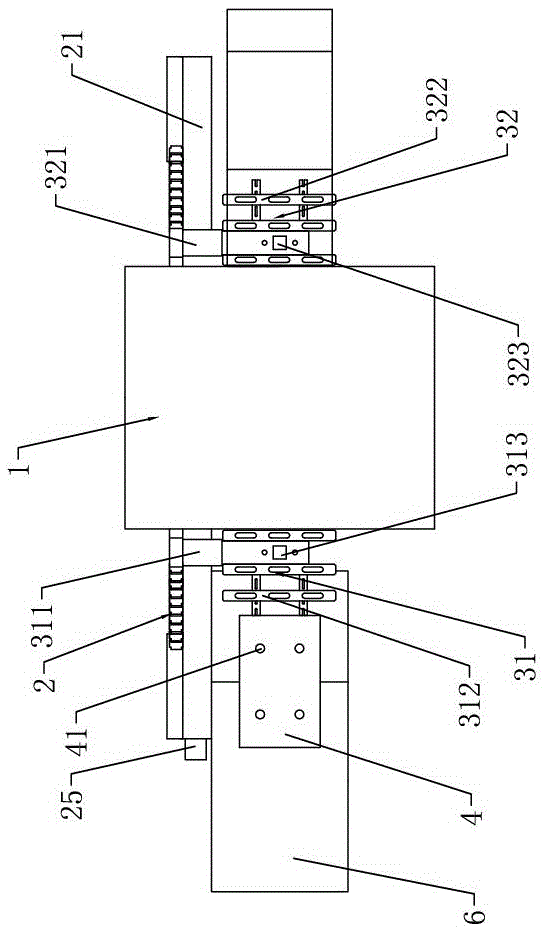

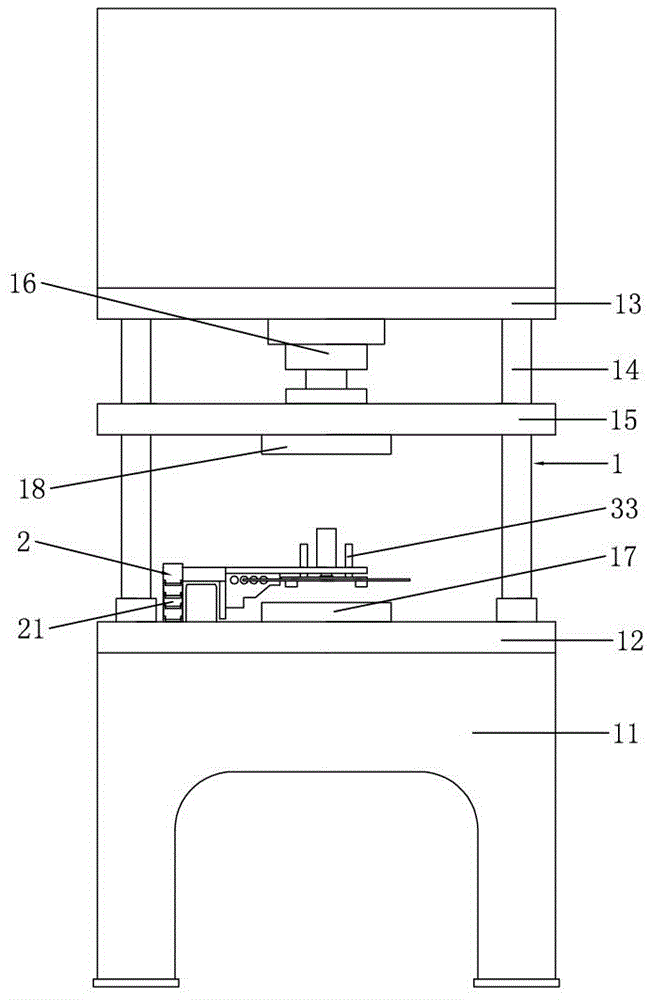

Full-automatic oil press production line capable of automatic material feeding and discharging

InactiveCN105665503AAchieve separationRealize the collectionMetal-working feeding devicesStripping-off devicesProduction lineEngineering

The invention discloses a full-automatic oil press production line capable of automatic material feeding and discharging. The full-automatic oil press production line comprises an automatic oil press, a control cabinet, a horizontal diving linear module, a material feeding manipulator, a material discharging manipulator, a material feeding module table, a finished product containing box and a scrap containing box; the automatic oil press comprises an oil press machine table, a lower end fixing assembly plate, an upper end fixing assembly plate, a movable assembly plate, a driving oil cylinder, a compression moulding lower mould and a compression moulding upper mould; the horizontal driving linear module comprises a linear module shell, a driving synchronous belt pulley, a driven synchronous belt pulley, a transmission synchronous belt and a servo driving motor; the material feeding manipulator comprises a material feeding assembly rack, a material feeding suction disc assembly rack, a material feeding suction disc and a material feeding side driving cylinder; and the material discharging manipulator comprises a material discharging assembly rack, a material discharging suction disc assembly rack, a material discharging suction disc and a material discharging side driving cylinder. The full-automatic oil press production line disclosed by the invention has the advantages that the design is novel; the automation degree is high; the production efficiency is high; the safety is high; manual cost can be effectively reduced; and finished products and scraps can be automatically separated and collected.

Owner:DONGGUAN YINTONG MACHINERY TECH

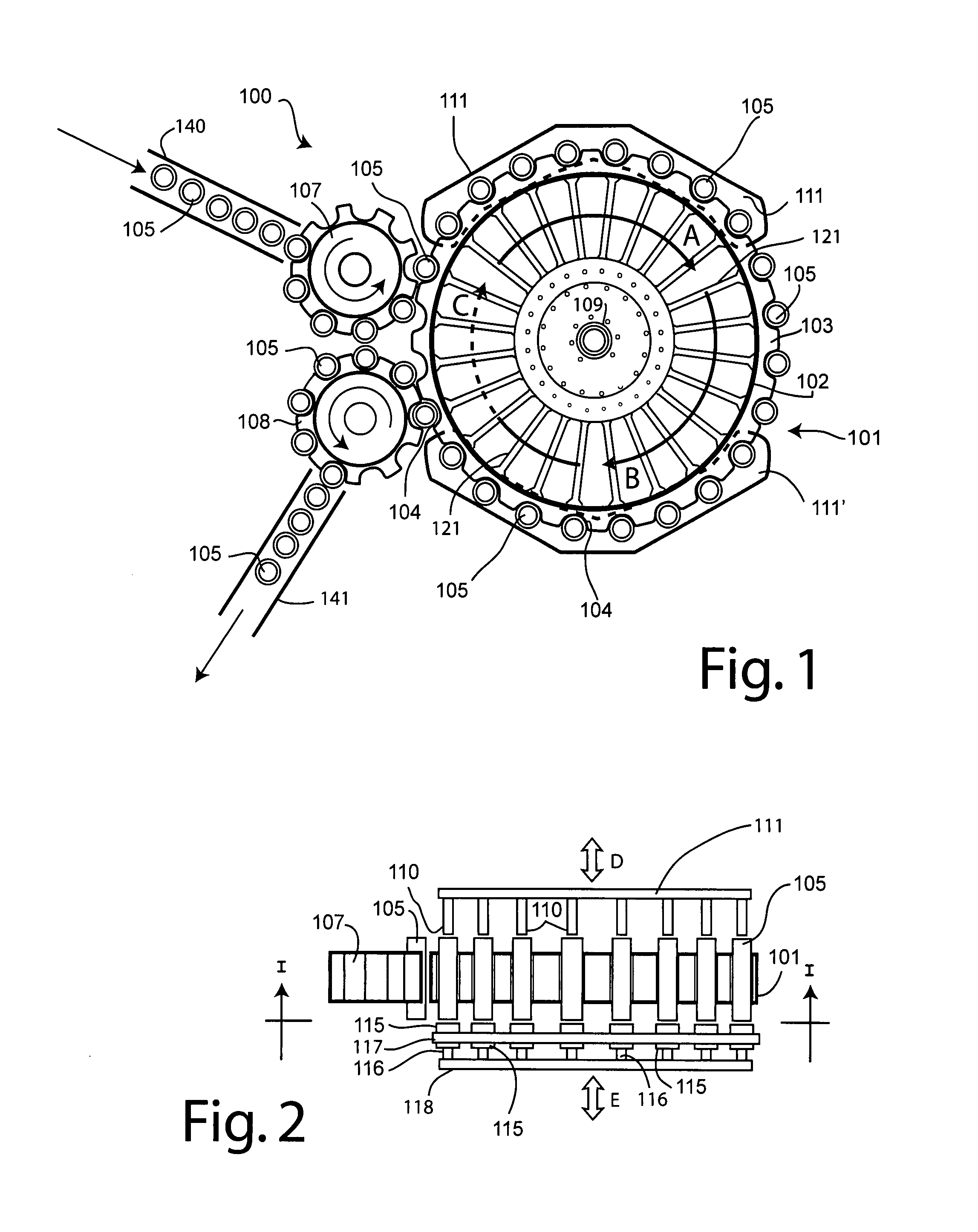

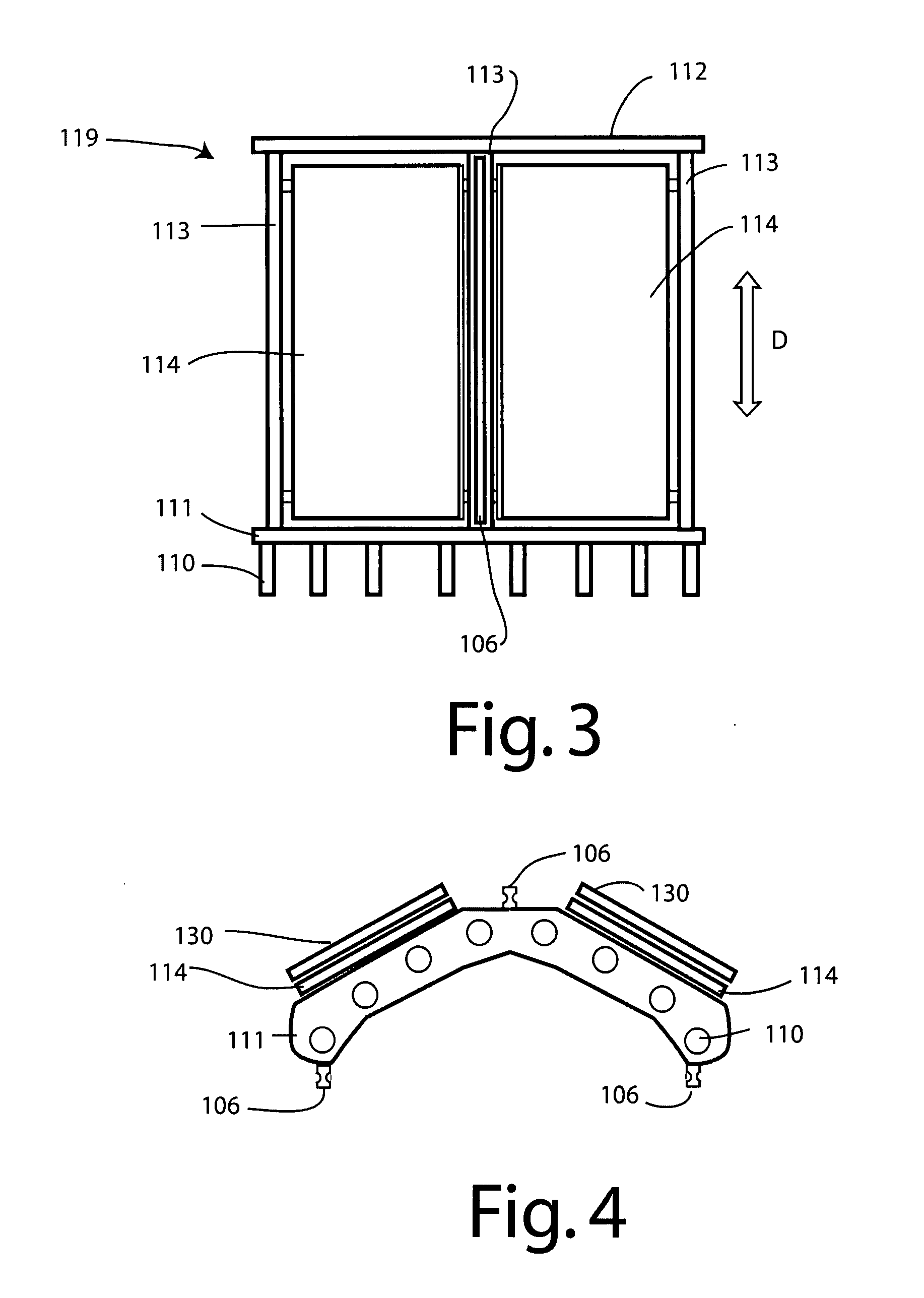

Forming of metal container bodies

ActiveUS20080148801A1Improve throughputMetal-working feeding devicesForging hammersMetalElectric motor

Apparatus and method for forming (e.g. die necking) open ends of open-ended metal container bodies. An exemplary embodiment provides a number of movable holders for container bodies that move the container bodies along a path extending through the apparatus. A motor advances the holders and container bodies along the path in steps with pauses between each step. Each step advances one or more container bodies (and preferably two or more). One or more groups of work stations positioned adjacent to the path provides tool sets for carrying out a forming operation on one (and preferably two or more) container bodies simultaneously. Individual container bodies, or more preferably groups of two or more, are subjected to one or more forming operations during passage along the path (preferably the periphery of one or more star wheels).

Owner:CROWN PACKAGING TECH

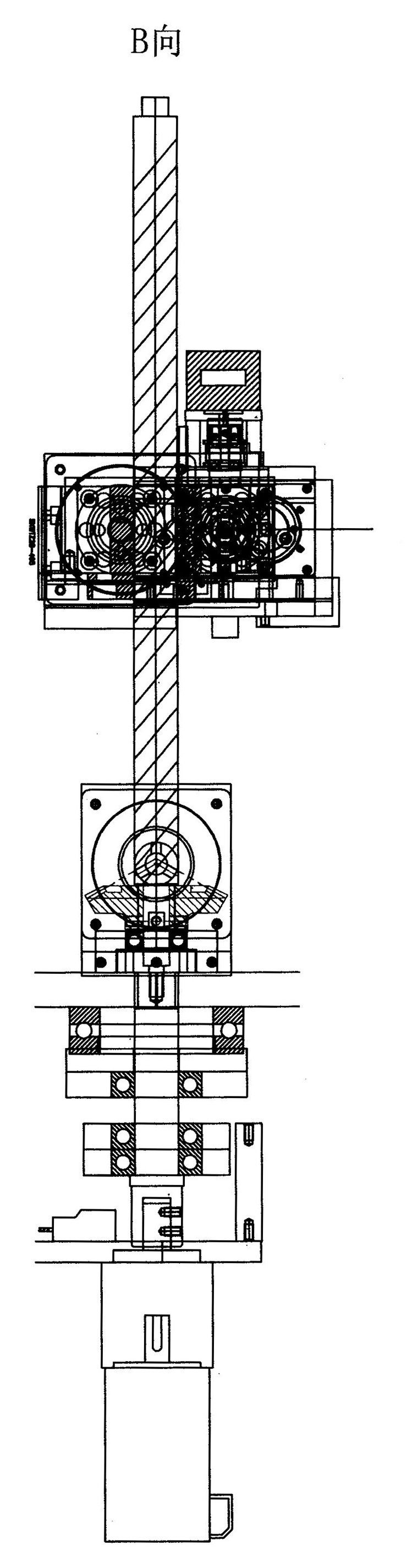

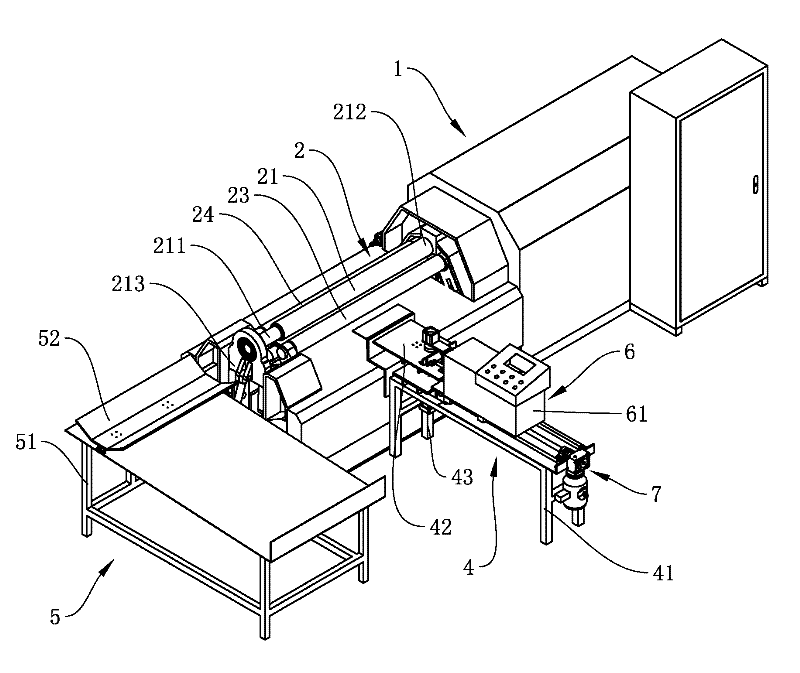

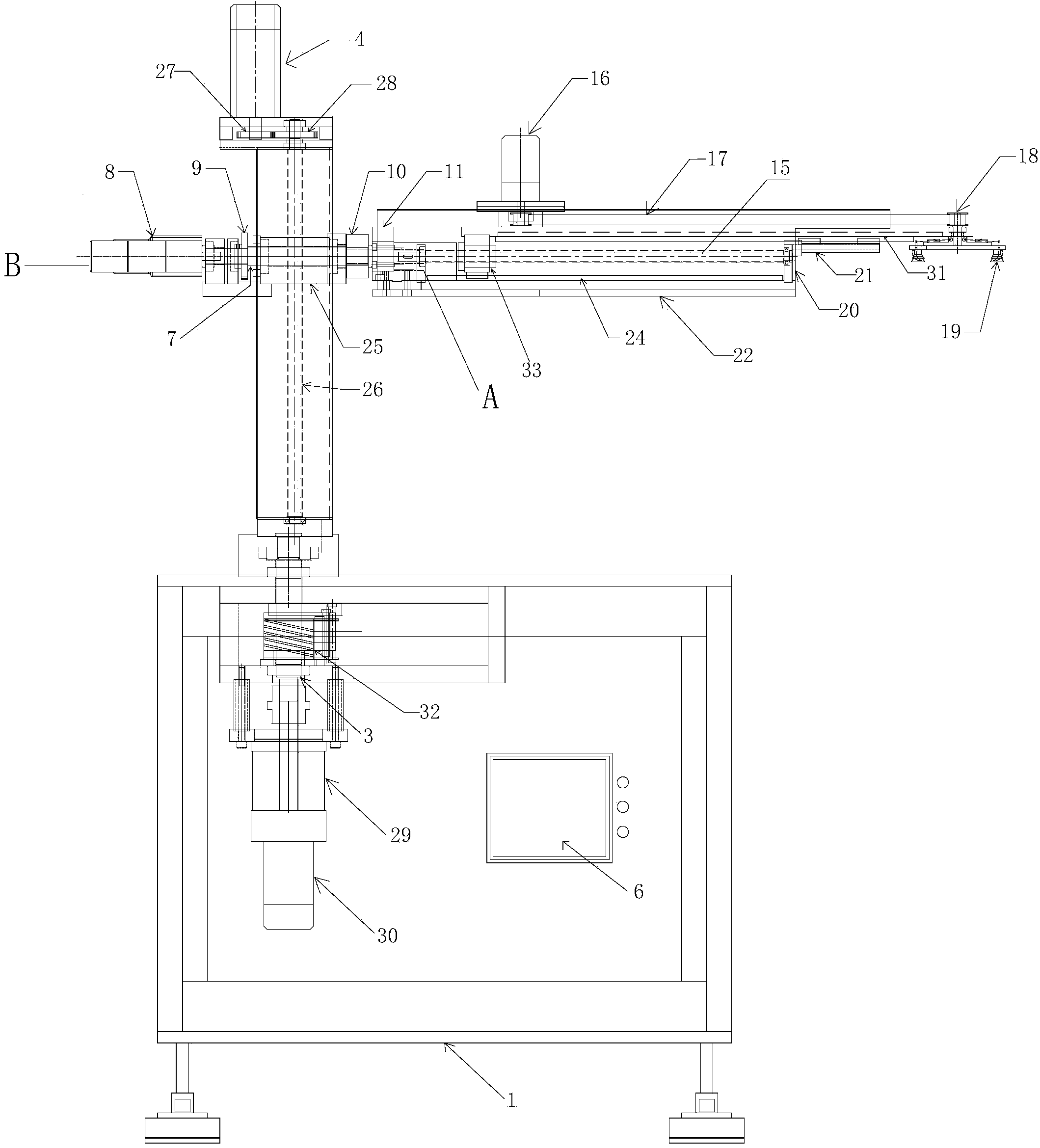

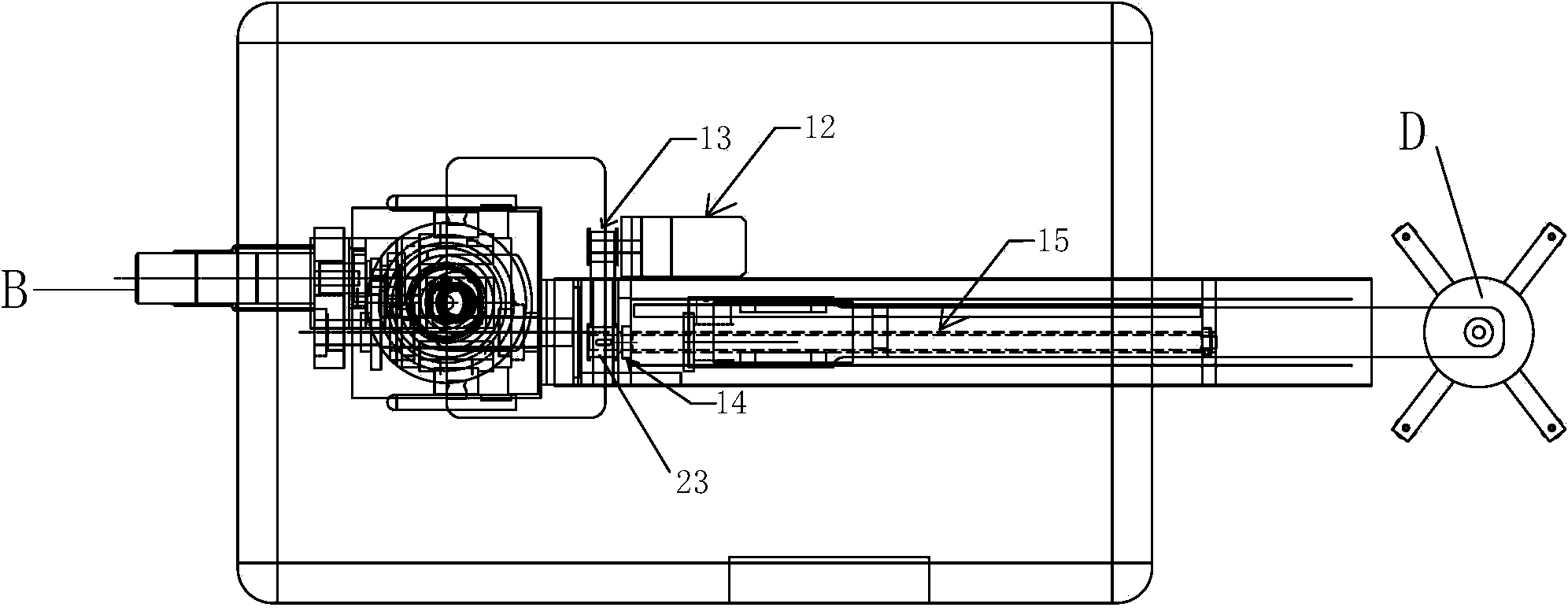

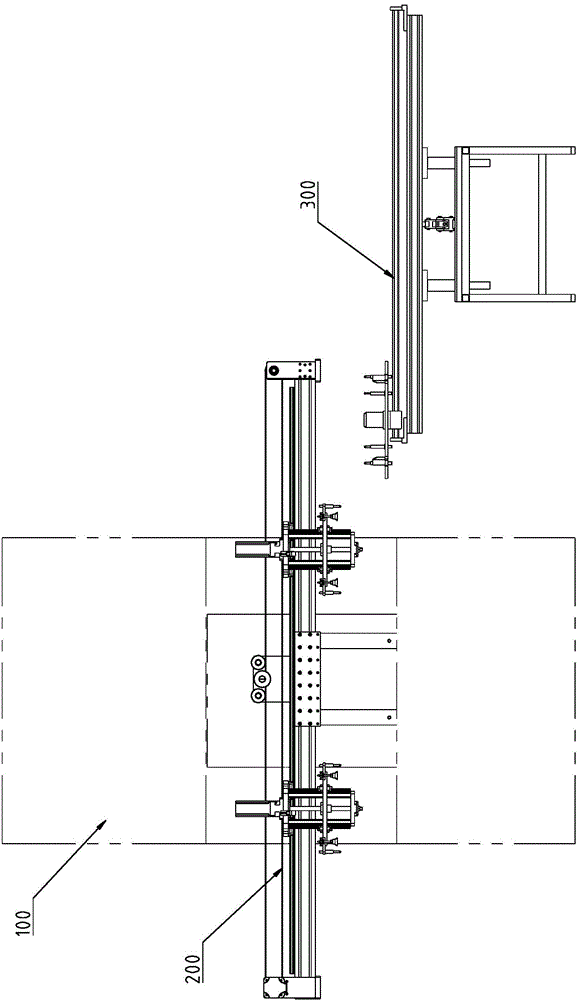

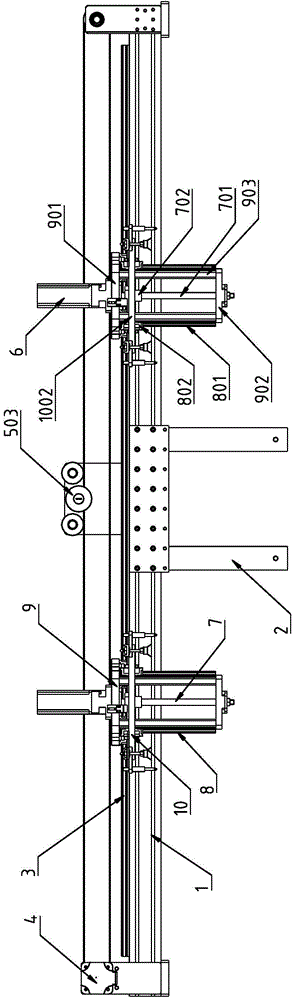

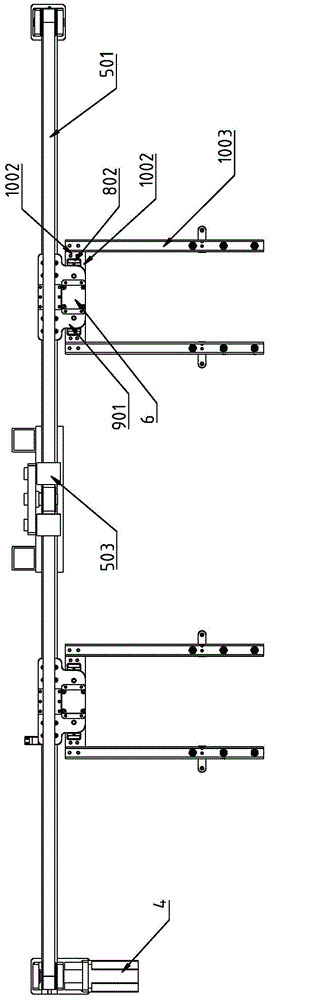

Flexible stamping mechanical arm

InactiveCN104015187AEffective protectionAvoid bruisesProgramme-controlled manipulatorMetal-working feeding devicesMan machineManipulator

The invention provides a flexible stamping mechanical arm which comprises a machine frame. A mechanical arm swinging moving mechanism, a vertical moving mechanism, a horizontal moving mechanism, a mechanical arm turning moving mechanism and an executing end rotating moving mechanism are arranged on the machine frame. By matching of the five moving mechanisms, rotating and moving of a workpiece at a three-dimensional direction can be achieved. The flexible stamping mechanical arm is high in operation accuracy, and product taking and placing are convenient, quick, accurate and easy. Cone tooth meshing is changed into straight tooth meshing, the bearing capacity and the constant operation speed of equipment are improved, a foundation is laid for future expanding, response time is shortened, efficiency is improved, the structure is simplified, the modes for grabbing products are increased, and grabbing of various products in various shapes can be well achieved. An embedded type man-machine screen control box is added, a control man-machine screen is effectively protected, and hard object hitting damage is avoided. The flexible stamping mechanical arm reinforces an equipment structure, the equipment structure is reasonable, and the moving principle is optimized.

Owner:SUZHOU XIDIAN METALWORKING PRECISION MACHINERY

Upper tool device and punch therefor

InactiveUS20070034069A1Easy to adjustEasy to assembleStripping-off devicesMetal working apparatusKnife blades

An upper tool device includes: a punch body having a punch blade at a lower end of the punch body; a punch guide into which the punch body is fitted so as to be movable in vertical direction; an adjustment screw member provided above the punch guide, the adjustment screw member screwed with a screw formed on the punch body; a stripper unit including an urging unit urging the punch body in an upward direction; and a retainer collar including a stopper piece having a tip end disengageably engaged with a stopper formed on the punch body. In the device, the stripper unit is detachably provided in the upper tool device, and the retainer collar is provided between the punch guide and the stripper unit in a manner such that the retainer collar can be relatively rotated against the stripper unit.

Owner:AMADA TOOL TECHNICA +1

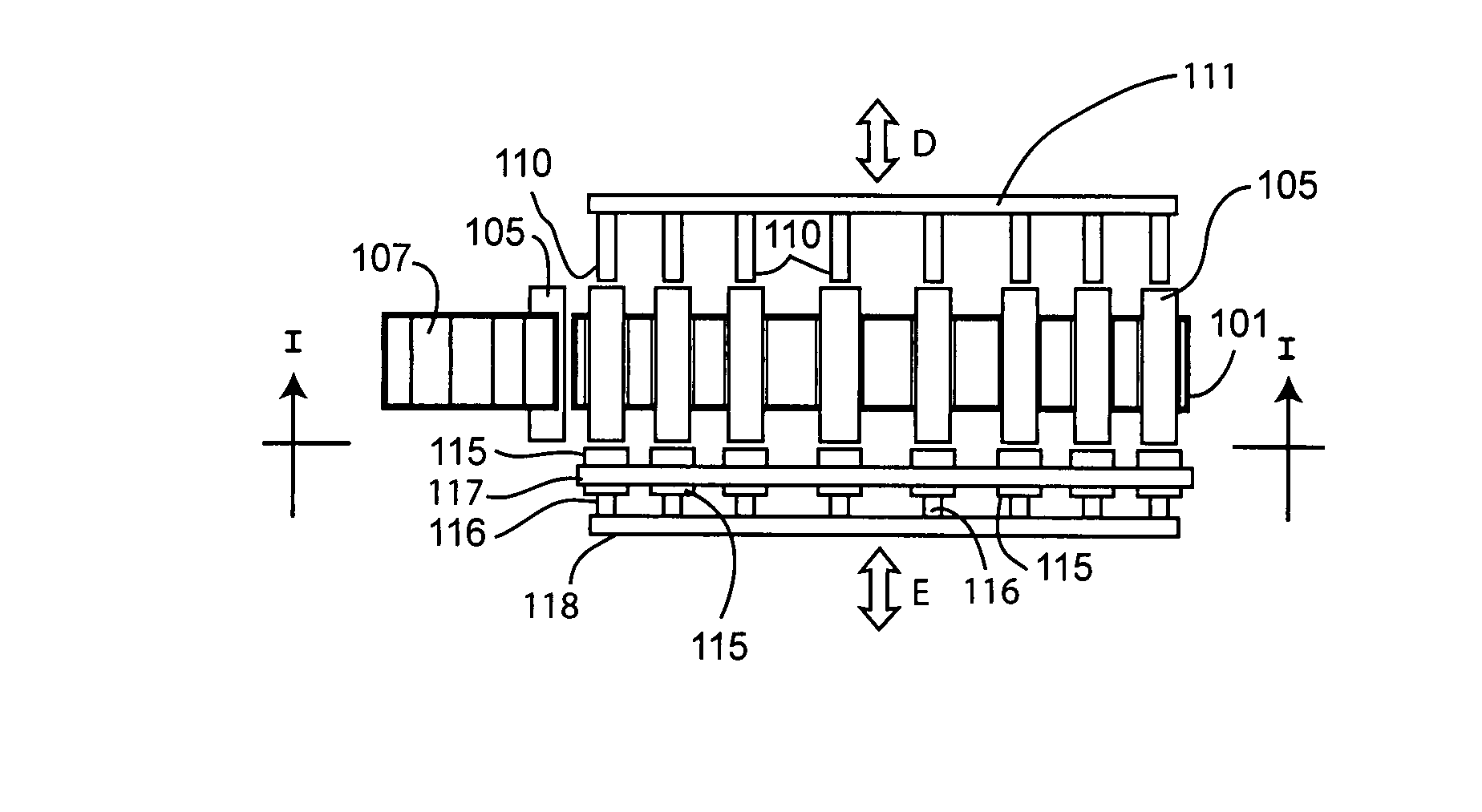

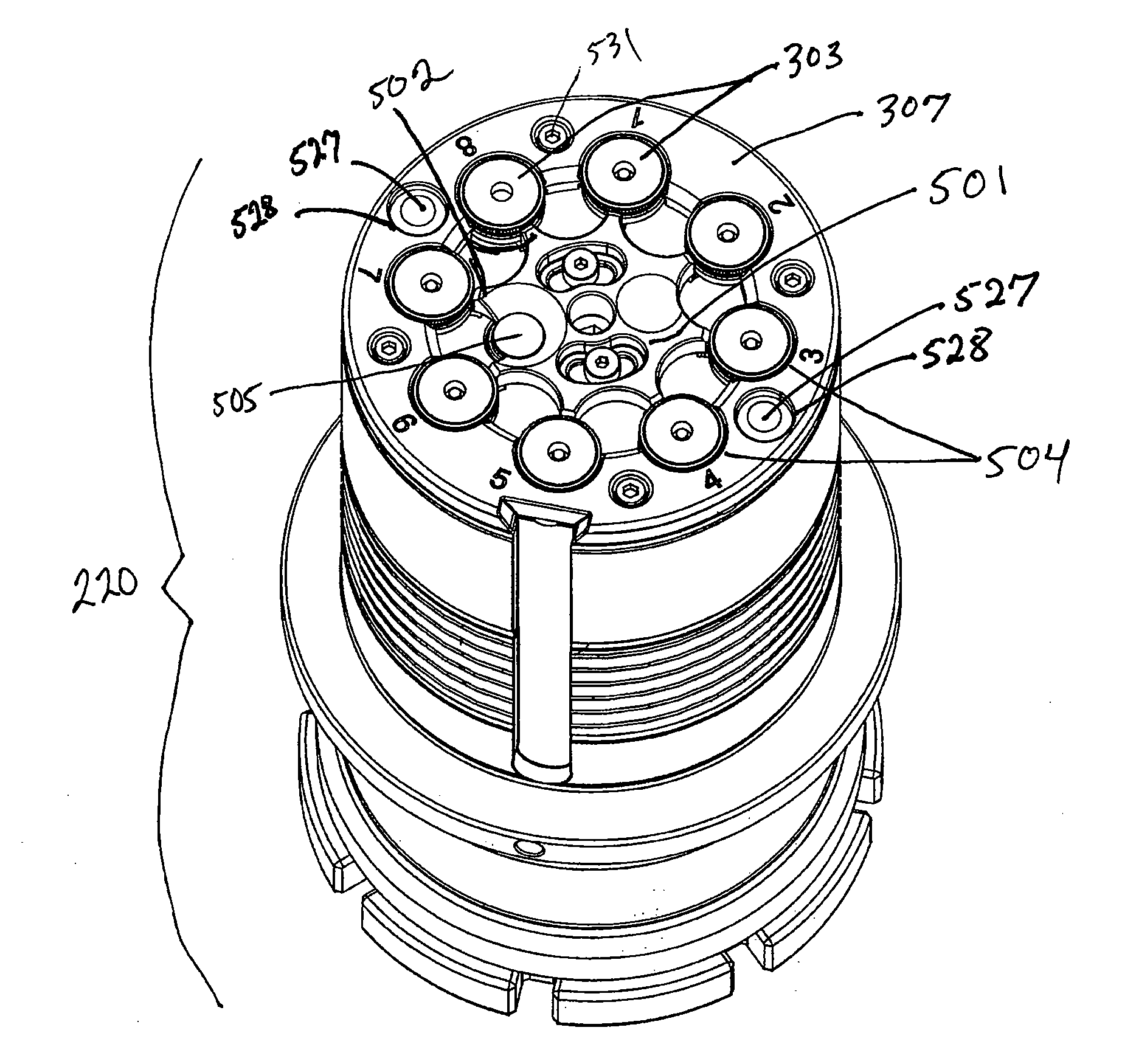

Multiple Punch and Die Assembly

ActiveUS20110107888A1Prevent movementAutomatic/semiautomatic turning machinesShaping toolsIndependent motionPunch press

A multiple punch and die assembly adapted to be placed in a punch press having a punch ram for imparting movement to a selected punch assembly for carrying out a punching or forming operation comprises a punch assembly for holding a plurality of selectively operable punches mounted for independent movement in the punch assembly so as to selectively engage a workpiece. The punch assembly has a punch carrier for reciprocal motion within a punch guide and a striker body engaging the punch carrier, said striker body being selectively, toollessly connectable to the punch carrier by a pair of tabs located on a lower circumference of the striker body, said pair of tabs located on a lower circumference of the striker body with a radial separation other than 180 degrees. A circumferential lip in the punch carrier receives the pair of tabs and has corresponding radially separated reliefs for allowing the pair of tabs to pass the circumferential lip, the engagement of the pair of tabs by the circumferential lip thereby locking the striker body to the punch carrier while permitting relative rotation of the striker body and punch carrier to select a punch for engagement by the striker. A detent means releasably positions the striker body in one of a plurality of operating positions, at which a punch is positioned for being struck selectively by the ram via the striker body such that one punch is driven to an operating position when at least one other punch is in inactive. In another embodiment the assembly has a stripper retainer that has precision pockets for holding strippers corresponding to the selectively operable punches.

Owner:MATE PRECISION TECH INC

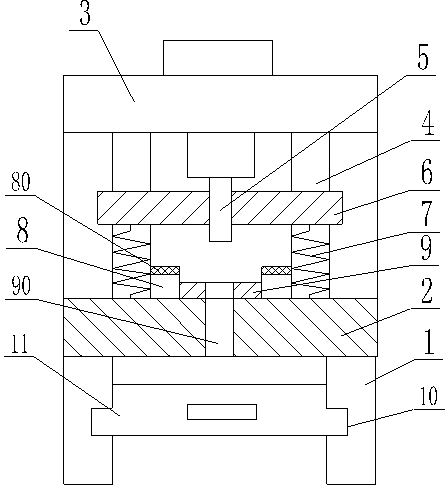

Punching machine

InactiveCN103736805AReduce shockQuick collectionShaping toolsStripping-off devicesPunchingEngineering

The invention relates to a punching machine which comprises a supporting leg, wherein a lower die seat is arranged at the upper end of the supporting leg, guide rods are arranged between the lower die seat and an upper die seat, a guide plate is arranged between the guide rods, a punching head is arranged in the middle of the guide plate, stoppage blocks are arranged on the inner sides of the guide rods, a concave die is arranged between the two stoppage blocks, a discharging hole is formed in the concave die and the lower die seat, grooves are formed in the inner side of a supporting seat, a containing box is arranged between the grooves, return springs are arranged in the guide rods and positioned between the guide plate and the lower die seat, and damping layers are arranged at upper ends of the stoppage blocks. The punching machine is simple in structure and reasonable in design. The return springs are arranged between the guide plate and the lower die seat, so that the guide plate can return to the original place automatically after the punching machine punches plates, and electric energy is saved. Furthermore, due to the fact that the damping layers are arranged on the stoppage blocks, impact force to the guide plate and the stoppage blocks is effectively retarded, and the guide plate is protected.

Owner:KUNSHAN HUAKUI MACHINERY ELECTRONICS

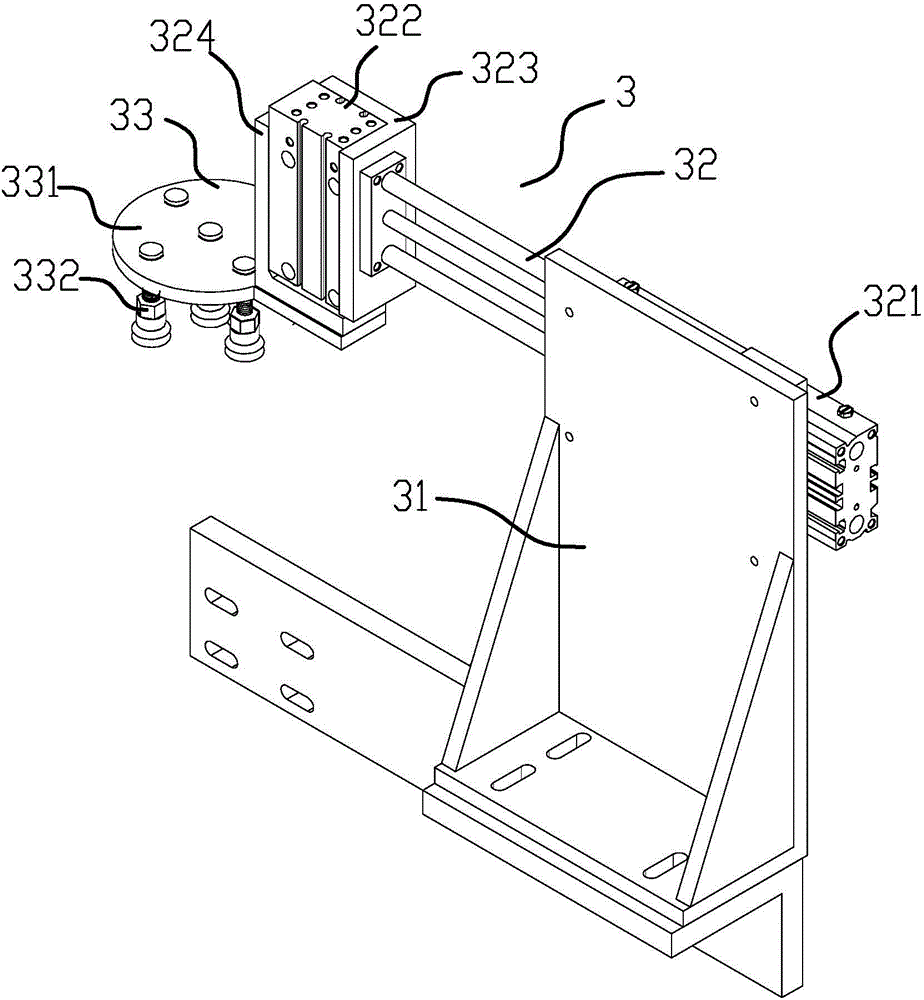

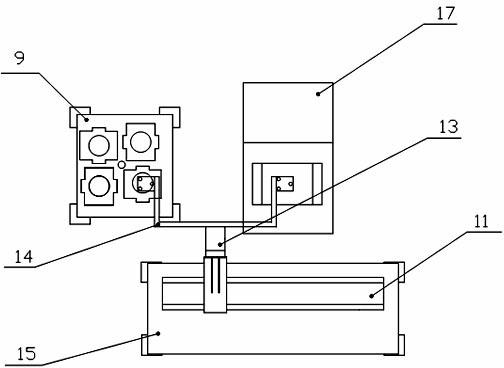

Multi-station die and machining punch

InactiveCN104959470AIncrease productivityReduce labor intensityShaping toolsMetal-working feeding devicesPunch pressEngineering

The invention provides a multi-station die and a machining punch, and belongs to the technical field of punching. The multi-station die and the machining punch solve the problems that an existing punch is high in labor intensity and low in working efficiency. The multi-station die comprises a base and a rotary table mechanism installed on the base and further comprises a mechanical arm assembly arranged on one side of the rotary table mechanism. The rotary table mechanism comprises a rotary table and a plurality of positioning plates which are evenly distributed on the rotary table and can rotate along with the rotary table. Workpieces are installed on the positioning plates. The mechanical arm assembly comprises a feeding mechanism and a grabbing mechanism installed on the feeding mechanism. The feeding mechanism can push the grabbing mechanism to move and the grabbing mechanism can grab the workpieces on the positioning plates. A punching sheet material lift tool has the advantages of being small in occupied space, high in machining efficiency and good in safety.

Owner:NINGBO XINYONGCHENG NUMERICAL CONTROL AUTOMATION EQUIP

Car audio hardware stamping automatic feeding and unloading manipulator

InactiveCN102601255AHigh-speed loading and unloading workEfficient loading and unloading workMetal-working feeding devicesStripping-off devicesReducerManipulator

The invention discloses a car audio hardware stamping automatic feeding and unloading manipulator comprising a fixing support, a rotating disc, a shaft, a reducer, a first servo motor, a second servo motor, a first linear guide rail, a push rod, a rack, a third servo motor, a second linear guide rail, a fourth servo motor, a third linear guide rail, a manipulator, a control cabinet, a touch screen, a press and a sucker. The lower end of the reducer is set with the first servo motor and the upper end of the reducer is penetrated through a flange to be fixedly connected with the shaft. The upper end of the shaft is fixedly connected with the rotating disc set with the fixing support. One side of the reducer is set with the push rod fixed on a slide block of the first linear guide rail which is set at the inner side of the rack. The car audio hardware stamping automatic feeding and unloading manipulator is reasonable in structure and convenient in operation, capable of fast and effectively finishing the feeding and unloading of the press and suitable for stamping production of presses of different models and different products by changing program conveniently and flexibly.

Owner:丰顺县培英电声有限公司

Punching machine mechanical arm device

InactiveCN104907443AEasy loading and unloadingEasy maintenanceMetal-working feeding devicesStripping-off devicesPunch pressEngineering

The invention discloses a punching machine mechanical arm device. The punching machine mechanical arm device comprises a rack, two mechanical arms and a transverse driving mechanism, wherein the rack comprises a cross beam, the transverse driving mechanism is installed on the cross beam, each mechanical arm comprises a trolley, a sucking disk and a sucking disk lifting mechanism; the trolleys of the two mechanical arms are installed on the cross beam and arranged in a separating mode, the trolleys are driven by the transverse driving mechanism to conduct movement in the same direction; the travel distance of the movement the trolleys is the spacing distance between the two trolleys. The two mechanical arms of the punching machine mechanical arm device are provided with the two independent sucking disk lifting mechanisms, the cross beam of the mechanical arm device can be installed behind a punch of a punching machine, the front side of a punching machine die is provided with an air cylinder for shielding, the operation and the observation of operators can not be influenced, and the assembly and the disassembly and the maintenance of the punching machine die are also facilitated.

Owner:SHENZHEN UNIV

Punching machine

ActiveCN103341541AIngenious design structureRealize continuous processingMetal-working feeding devicesStripping-off devicesPunchingEngineering

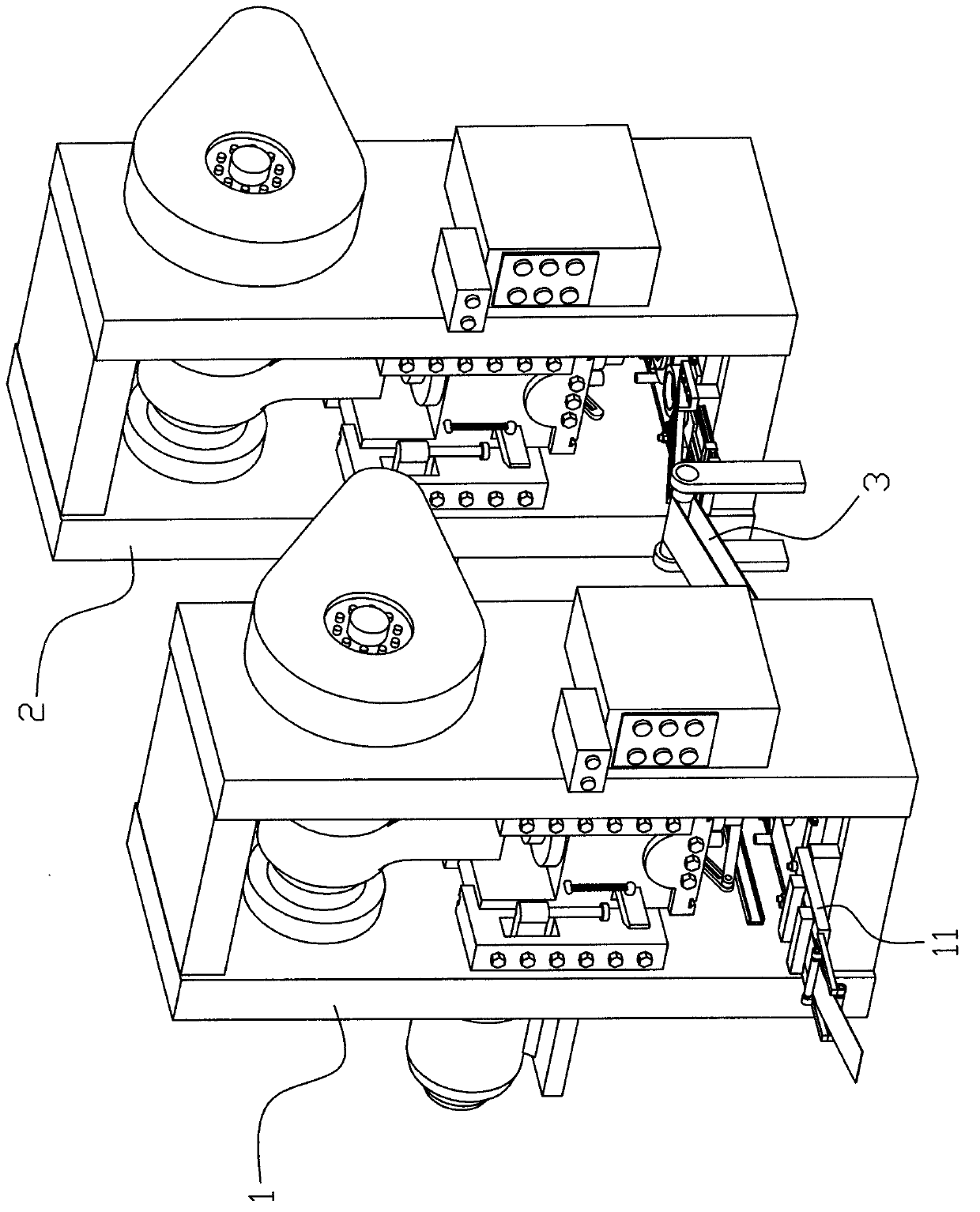

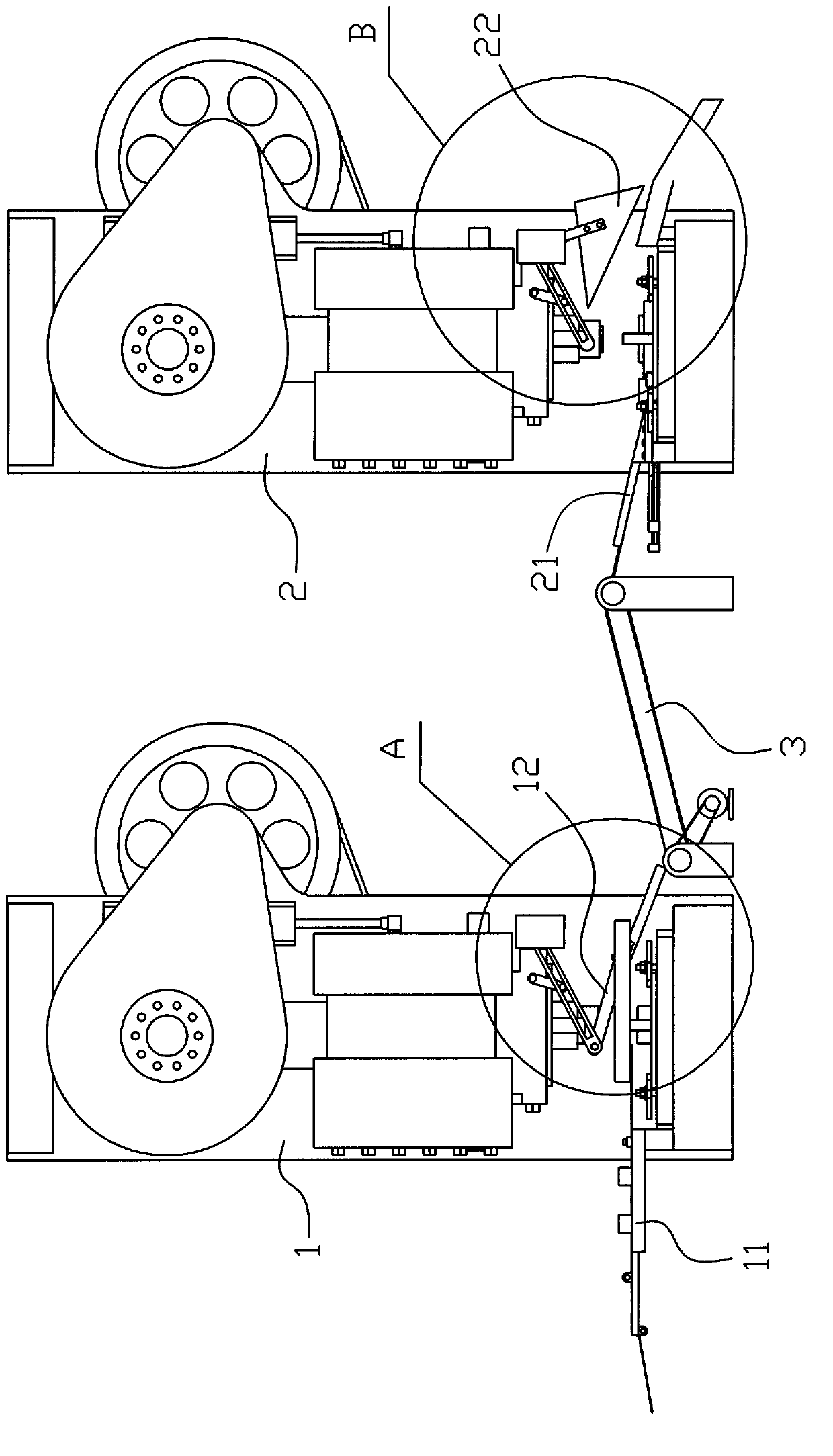

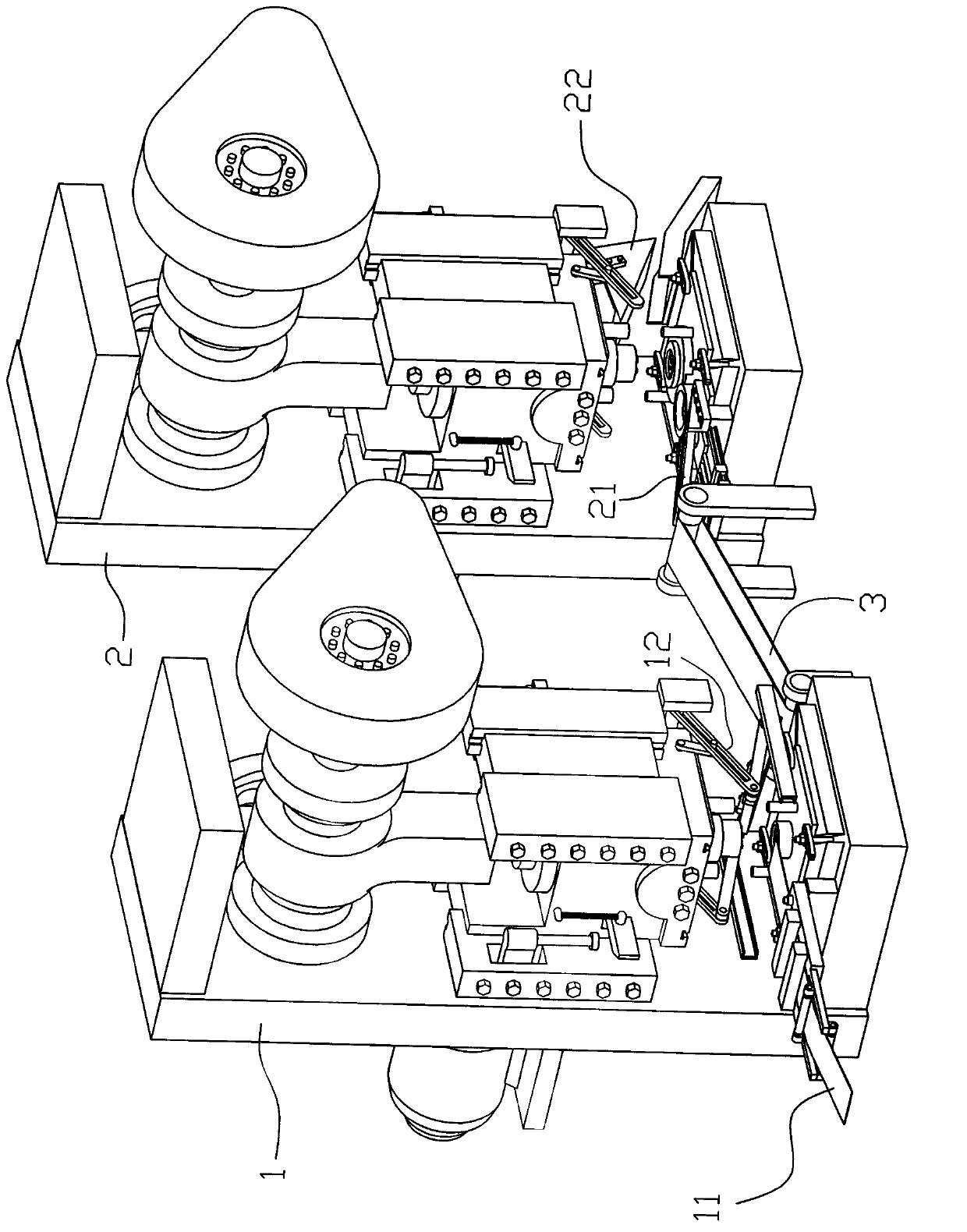

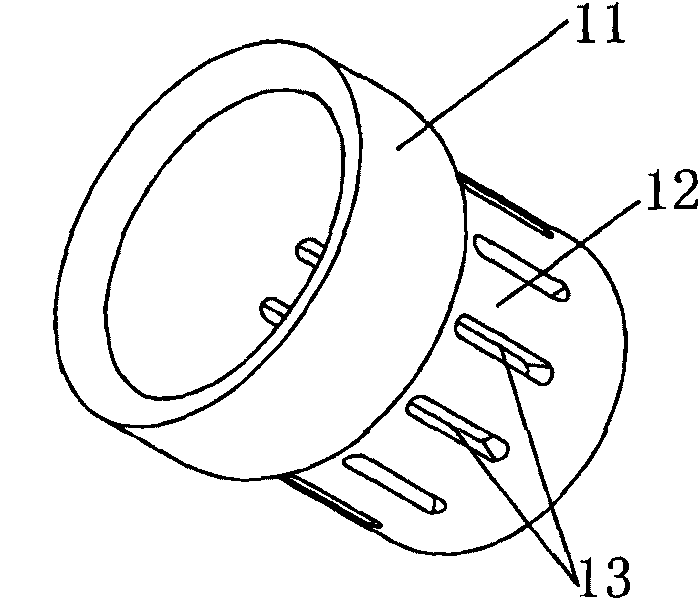

Disclosed is a punching machine. The punching machine comprises a first punching machine (1) and a second punching machine (2), and further comprises a steel strip feeding device (11), a first discharging device (12), a workpiece feeding device (21), a second discharging device (22) and a conveying device (3). The steel strip feeding device and the first discharging device are horizontally installed on the first punching machine and synchronously work with the first punching machine in a coordinated mode; the workpiece feeding device (21) and the second discharging device (22) are horizontally installed on the second punching machine (2) and synchronously work with the second punching machine (2) in a coordinated mode; the conveying device (3) is arranged between the steel strip feeding device (11) arranged on the first punching machine (1) and the workpiece feeding device (21) arranged on the second punching machine (2). The punching machine has the advantages of being ingenious in structural design because two punching machines are integrated through an automatic conveying device, and therefore the purpose of continuously machining workpieces is achieved, reducing labor intensity, substantially improving production efficiency of product machining, and effectively reducing production cost of labor force.

Owner:舟山神鹰滤清器制造有限公司

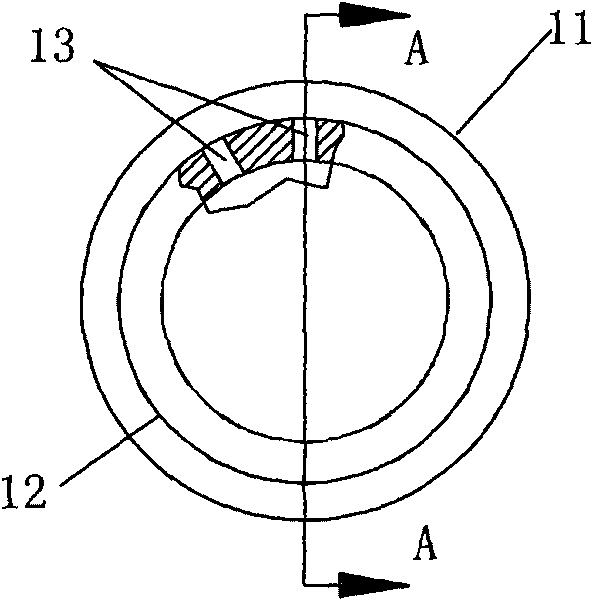

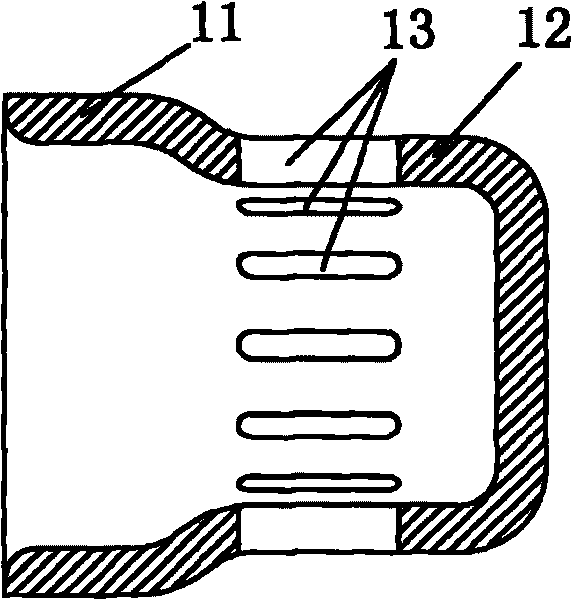

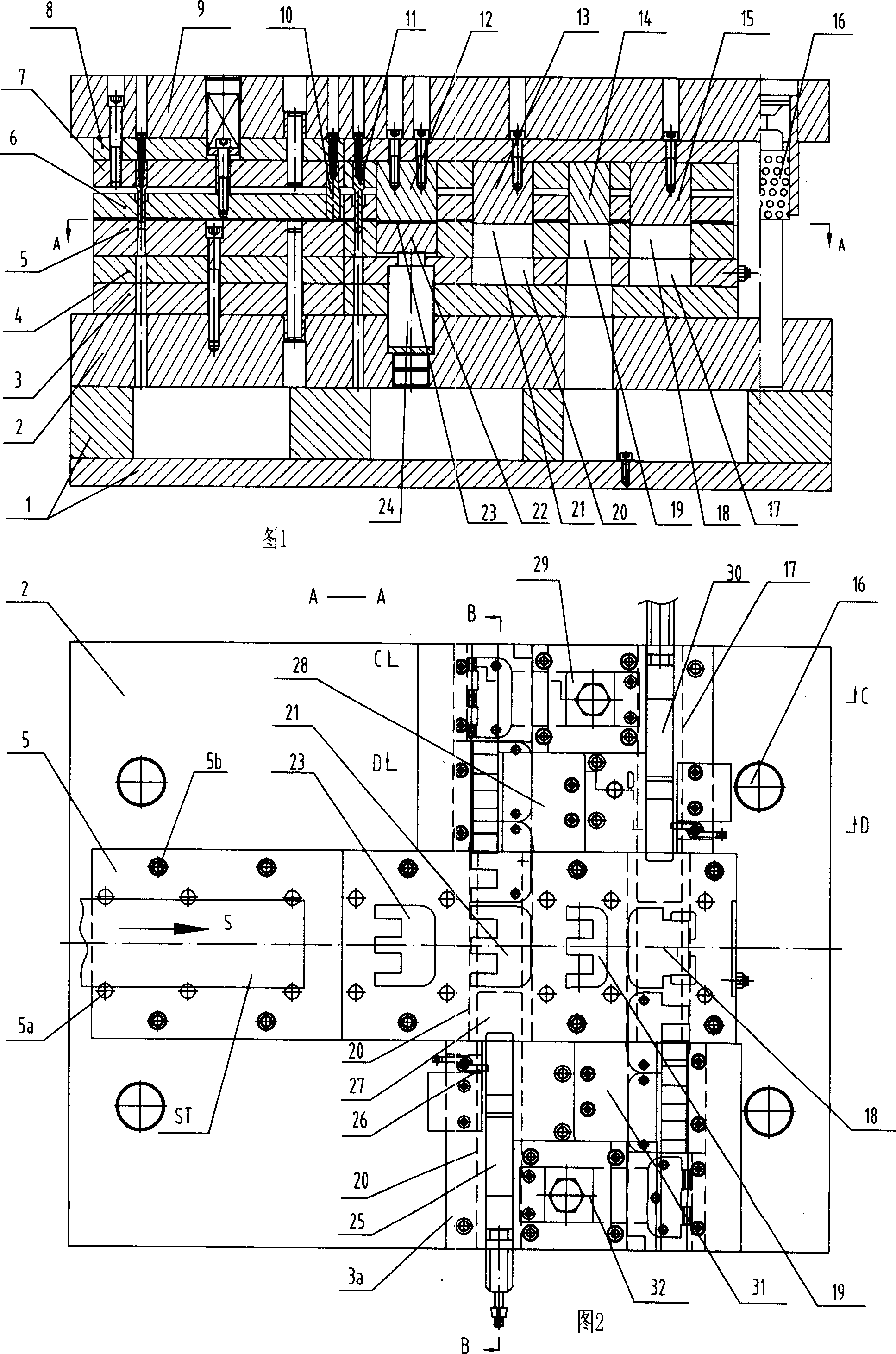

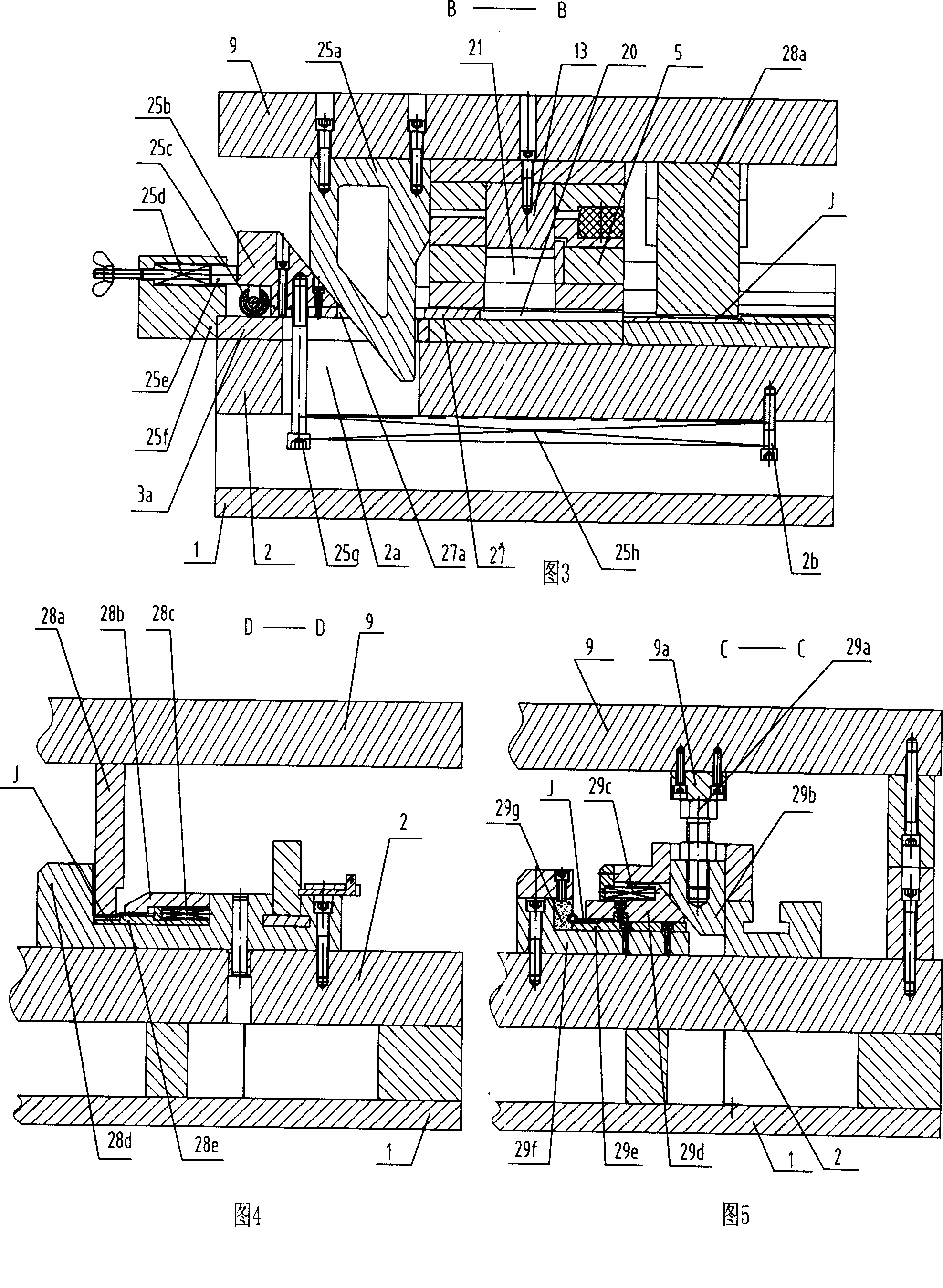

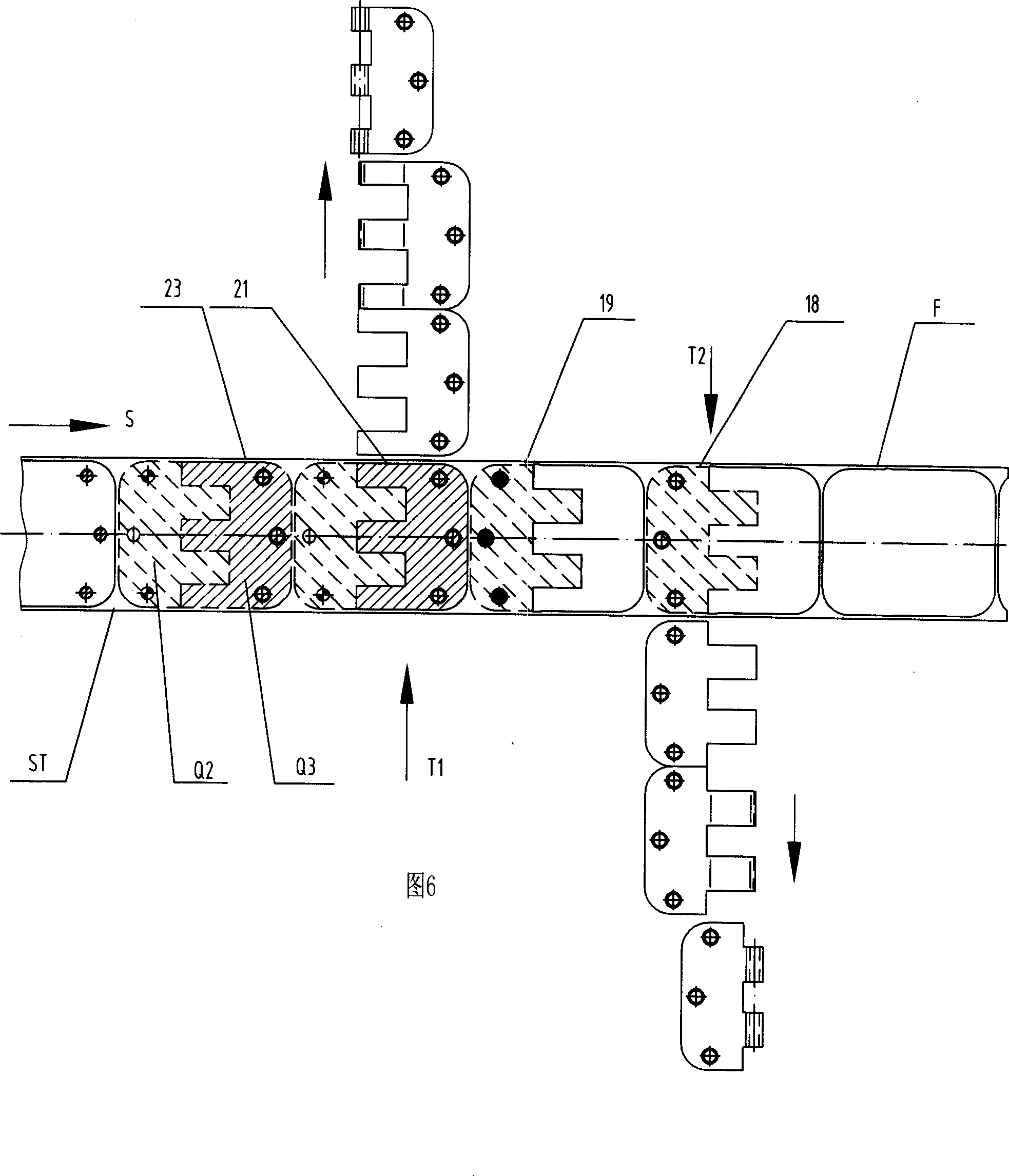

Side hole cover progressive die

ActiveCN101733327AAvoid precision errorsImprove processing efficiencyShaping toolsStripping-off devicesPunchingHigh volume manufacturing

The invention discloses a side hole cover progressive die comprising more than two sets of deep drawing devices which are arranged at a deep drawing working position for drawing material strips deep. The side hole cover progressive die further comprises a side punching device; the deep drawing devices draw deep in two steps or more than two steps; the side punching device is arranged on a side punching working position behind the deep drawing device for side punching of side holes on the side wall of a cover part blank drawn deep out by the material strip. With the adoption of the technical scheme, the side hole progressive die can greatly improve the processing efficiency and make rapid large-batch production to ensure timely supply compared with the traditional processing mode of adopting multidie single procedure as the deep drawing die and the side punching die are combined together; and meanwhile, the labor cost is greatly reduced, and the labor of operators is lightened. In addition, the side hole progressive die avoids the precision error brought by the moving of a workpiece blank between different working positions, thereby having higher processing precision and better quality stability.

Owner:上海晨昌精密模具有限公司

Complete cutting type belt coil pipe stepped mould for hinger

InactiveCN101011716AGuaranteed utilizationRealize one-time moldingShaping toolsMetal-working feeding devicesPunch pressStirrup

A hinge blade nest cutting winding progressive die comprises up die and bottom die and the connecting guide post, with the up die having stirrup punch head, three claw punch head and two claw punch head, with the bottom die having stirrup, three claw die and two claw die, with the later tow having a horizontal slide path, one side of which having a discharge device linked with the up die, bending die linked with the up die on the other side, and the winding die. It realizes the one time forming with the stirrup, shear cutting, bending and winding, with precision and improved production efficiency and reduced cost. One set of die, a punch machine and an operator will get everything done.

Owner:伟业重工(安徽)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com