Patents

Literature

11288results about How to "Improve processing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

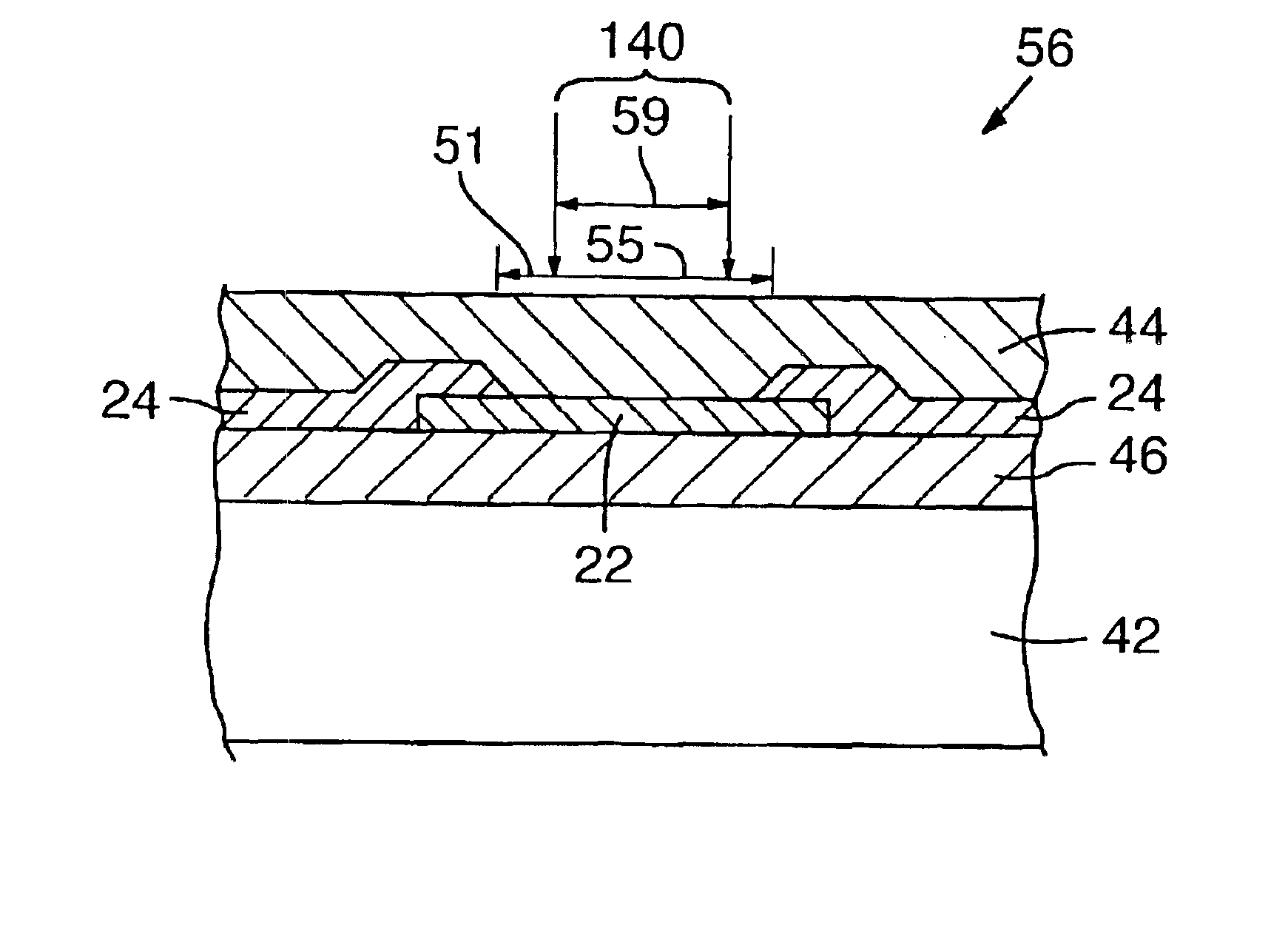

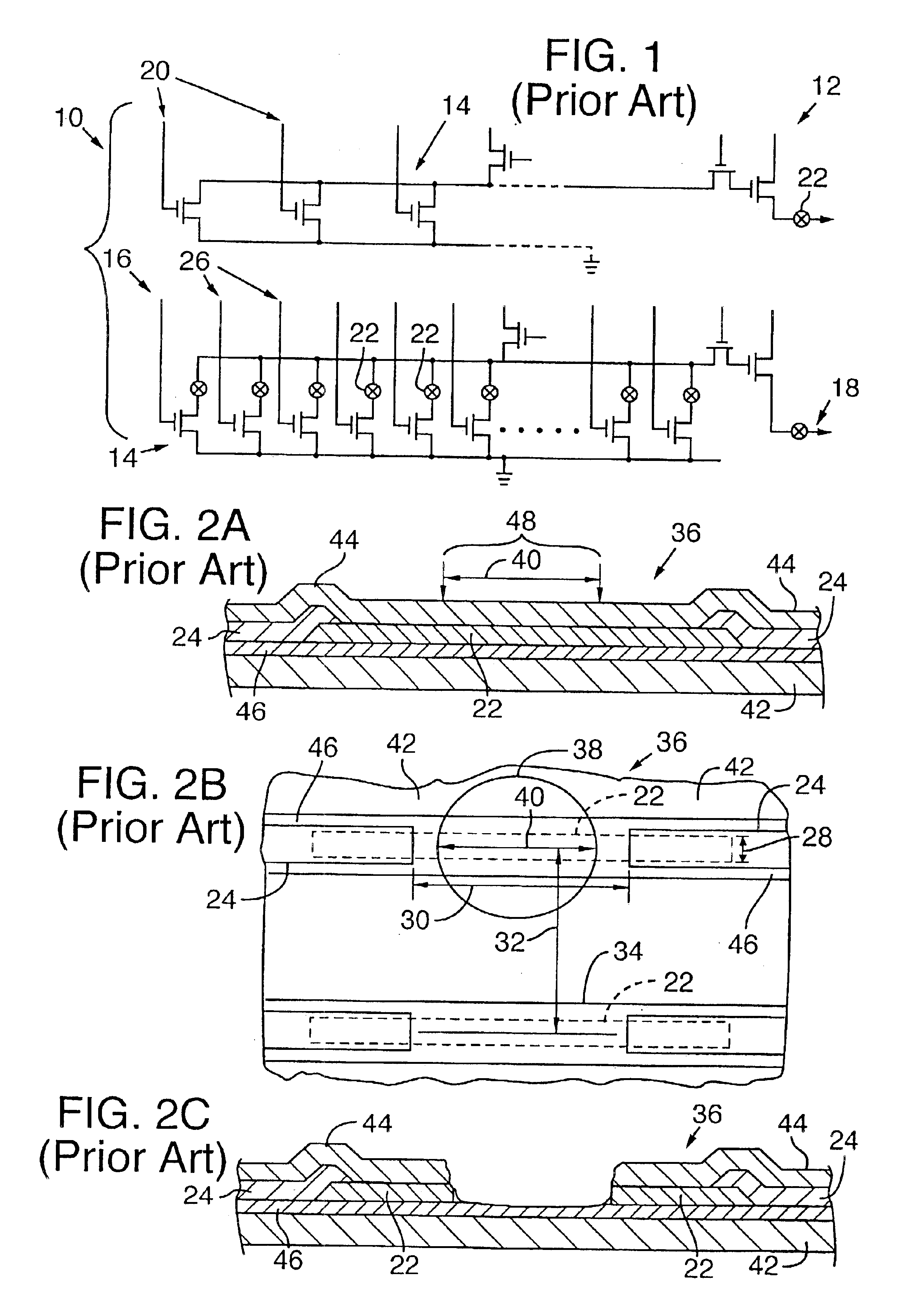

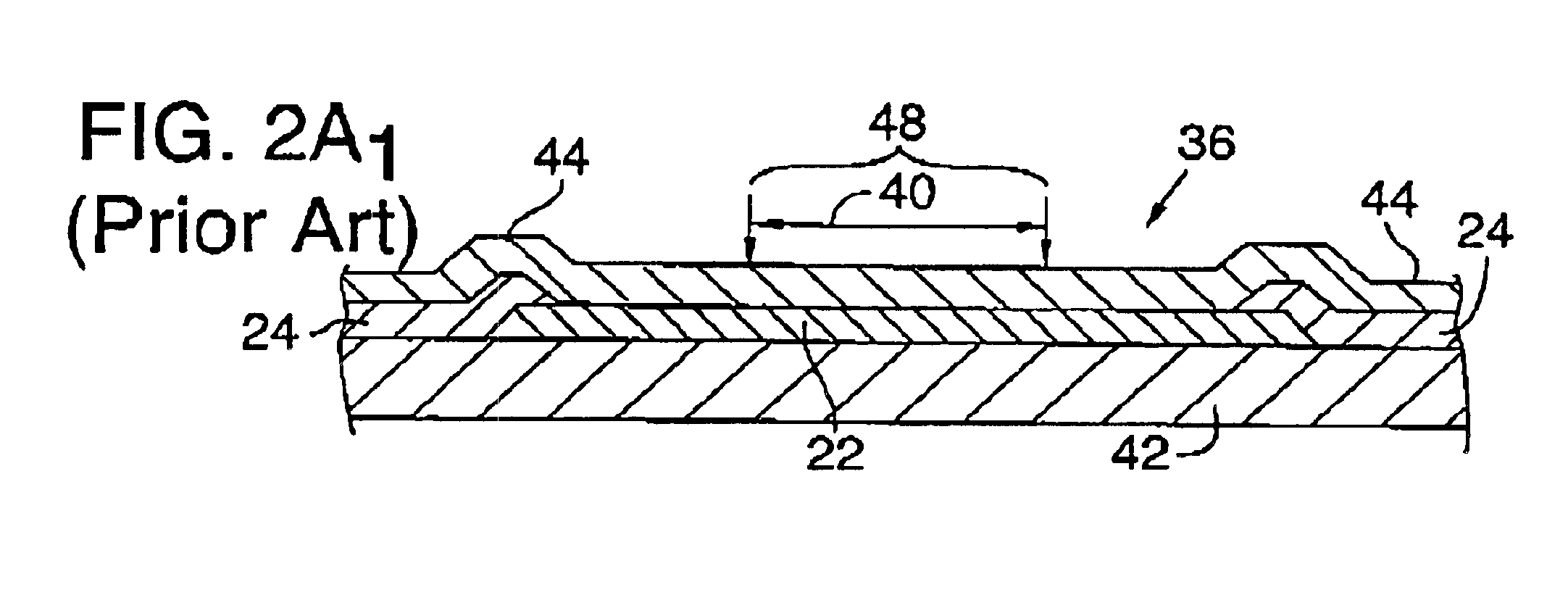

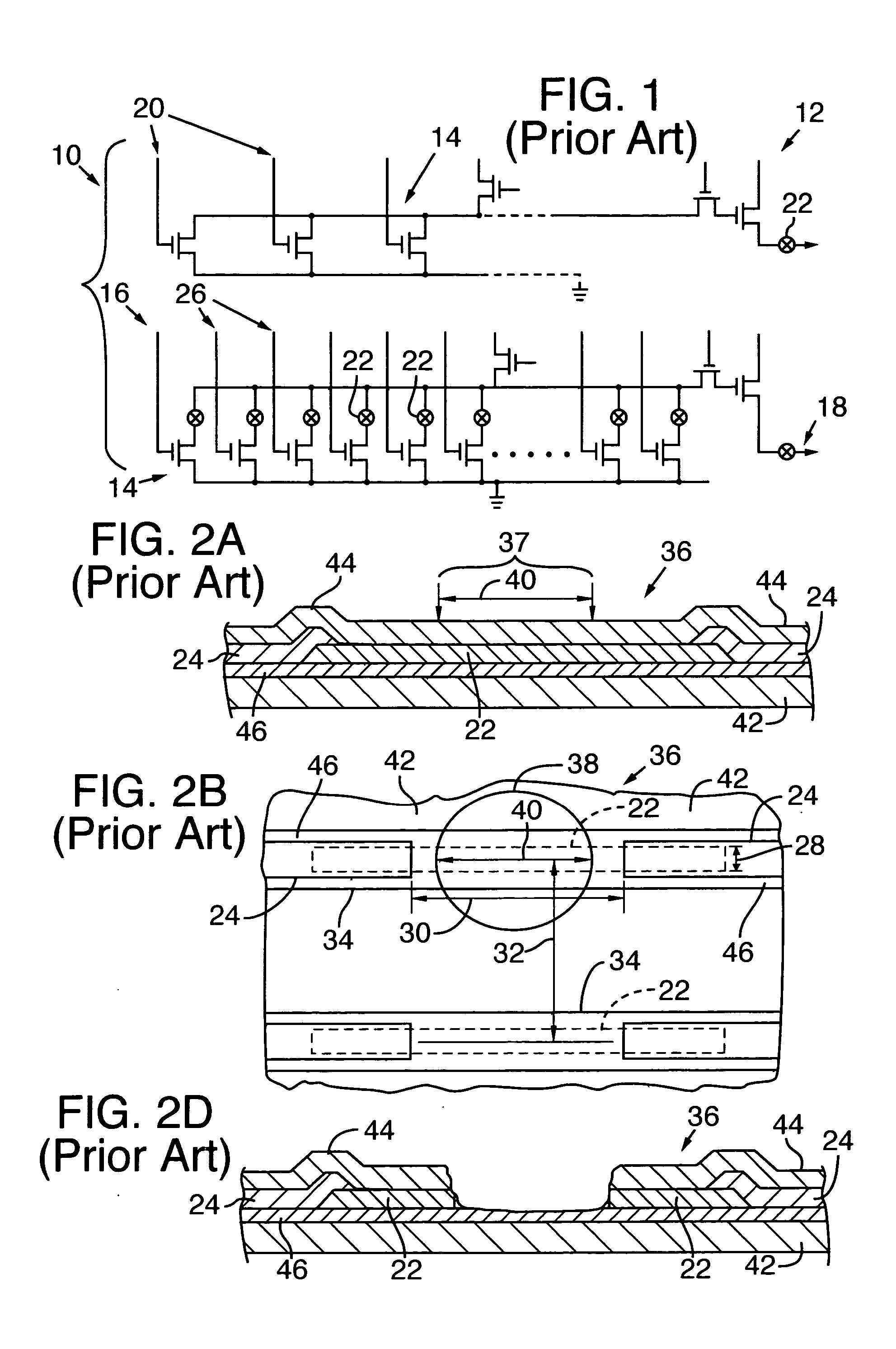

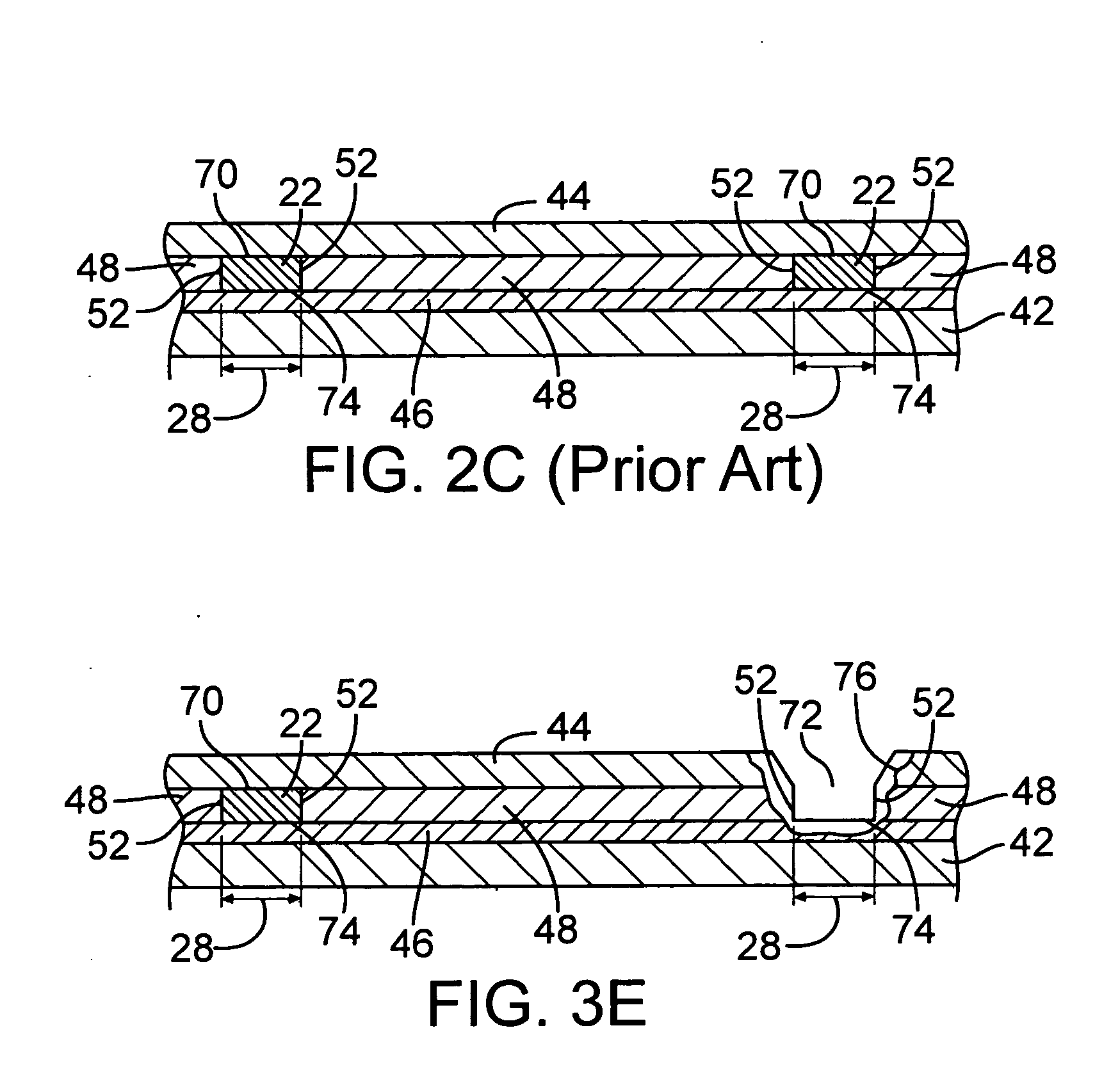

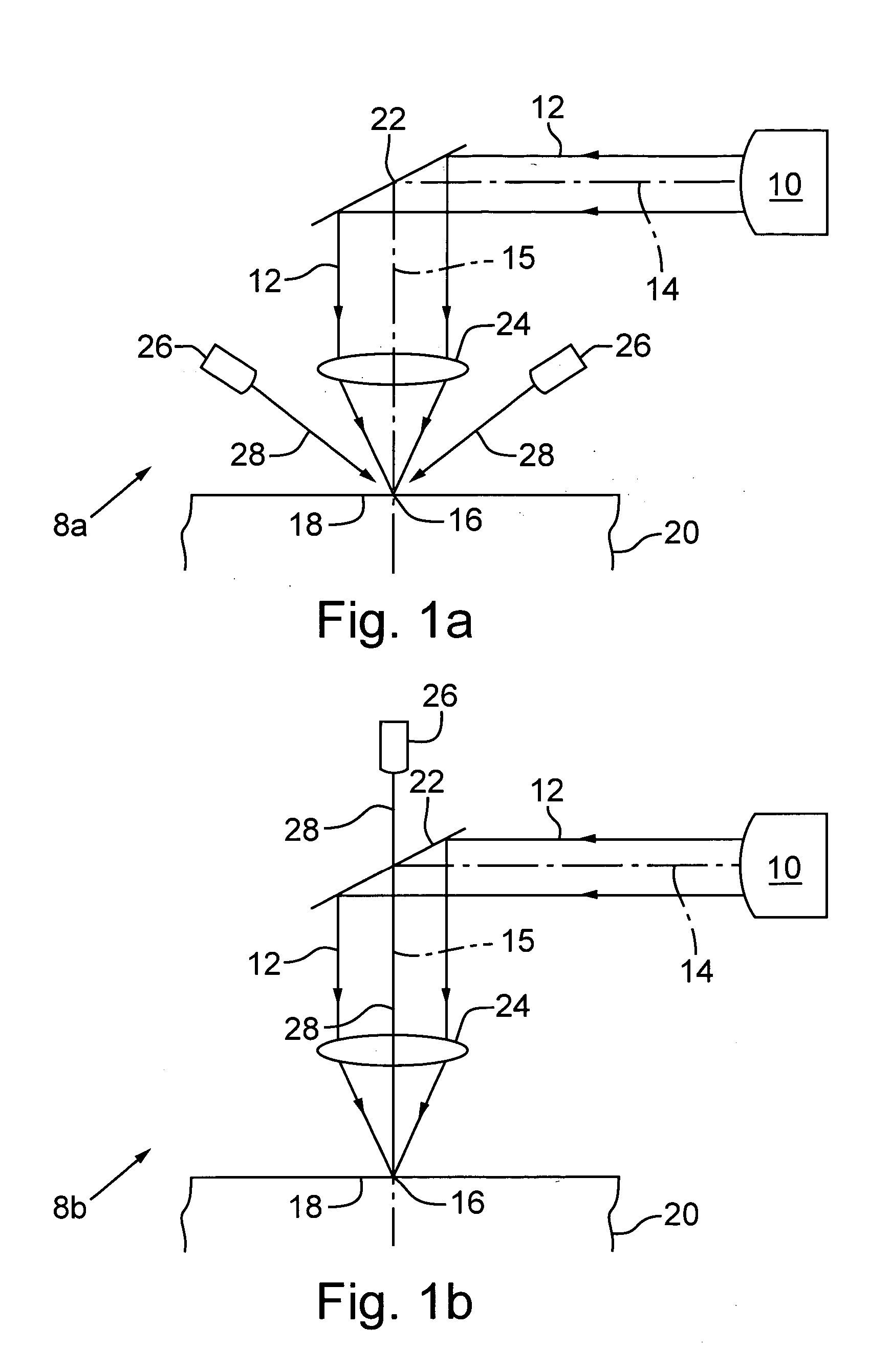

Passivation processing over a memory link

InactiveUS6887804B2Improve processing qualityAvoid and minimize substrate damage and undesirable damageSemiconductor/solid-state device detailsSolid-state devicesEtchingHarmonic

A set (50) of one or more laser pulses (52) is employed to remove passivation layer (44) over a conductive link (22). The link (22) can subsequently be removed by a different process such as chemical etching. The duration of the set (50) is preferably shorter than 1,000 ns; and the pulse width of each laser pulse (52) within the set (50) is preferably within a range of about 0.05 ps to 30 ns. The set (50) can be treated as a single “pulse” by conventional laser positioning systems (62) to perform on-the-fly material removal without stopping whenever the laser system (60) fires a set (50) of laser pulses (52) at each target area (51). Conventional wavelengths in the IR range or their harmonics in the green or UV range can be employed.

Owner:ELECTRO SCI IND INC

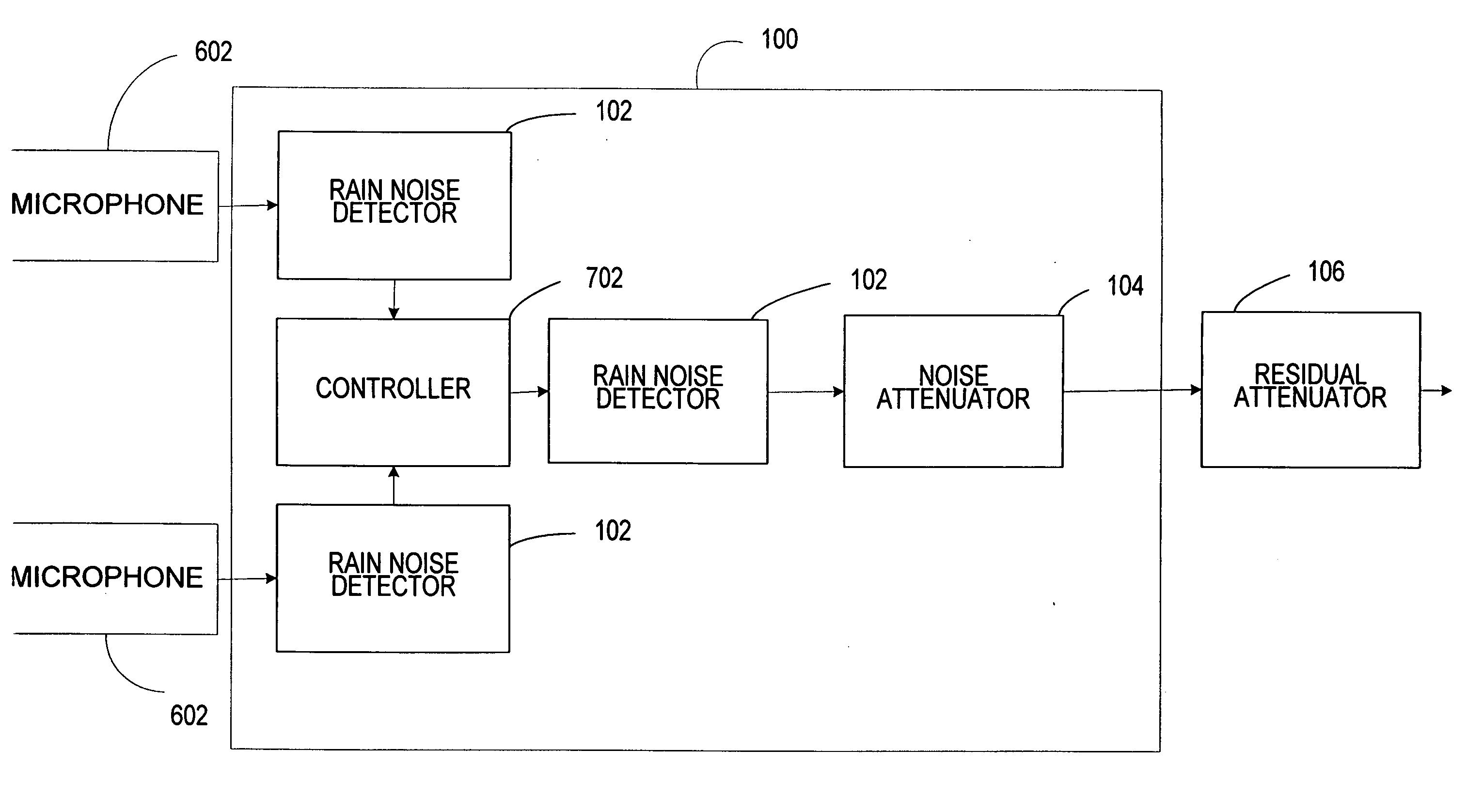

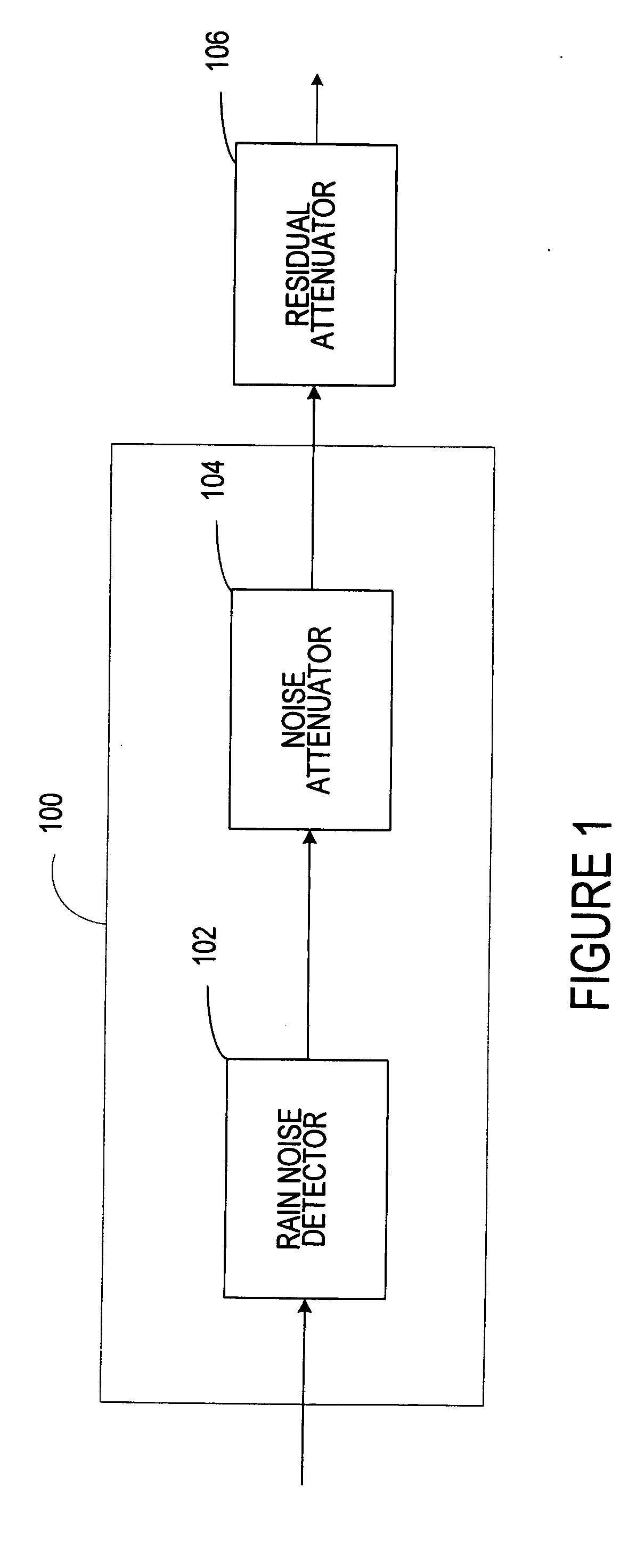

System for suppressing rain noise

ActiveUS20050114128A1Improve processing qualityReduce and dampen noiseTransducer acoustic reaction preventionSpeech recognitionComputer scienceSpeech sound

A voice enhancement logic improves the perceptual quality of a processed signal. The voice enhancement system includes a noise detector and a noise attenuator. The noise detector detects and models the noise associated with rain. The noise attenuator dampens or reduces the rain noise from a signal to improve the intelligibility of an unvoiced, a fully voiced, or a mixed voice segment.

Owner:MALIKIE INNOVATIONS LTD

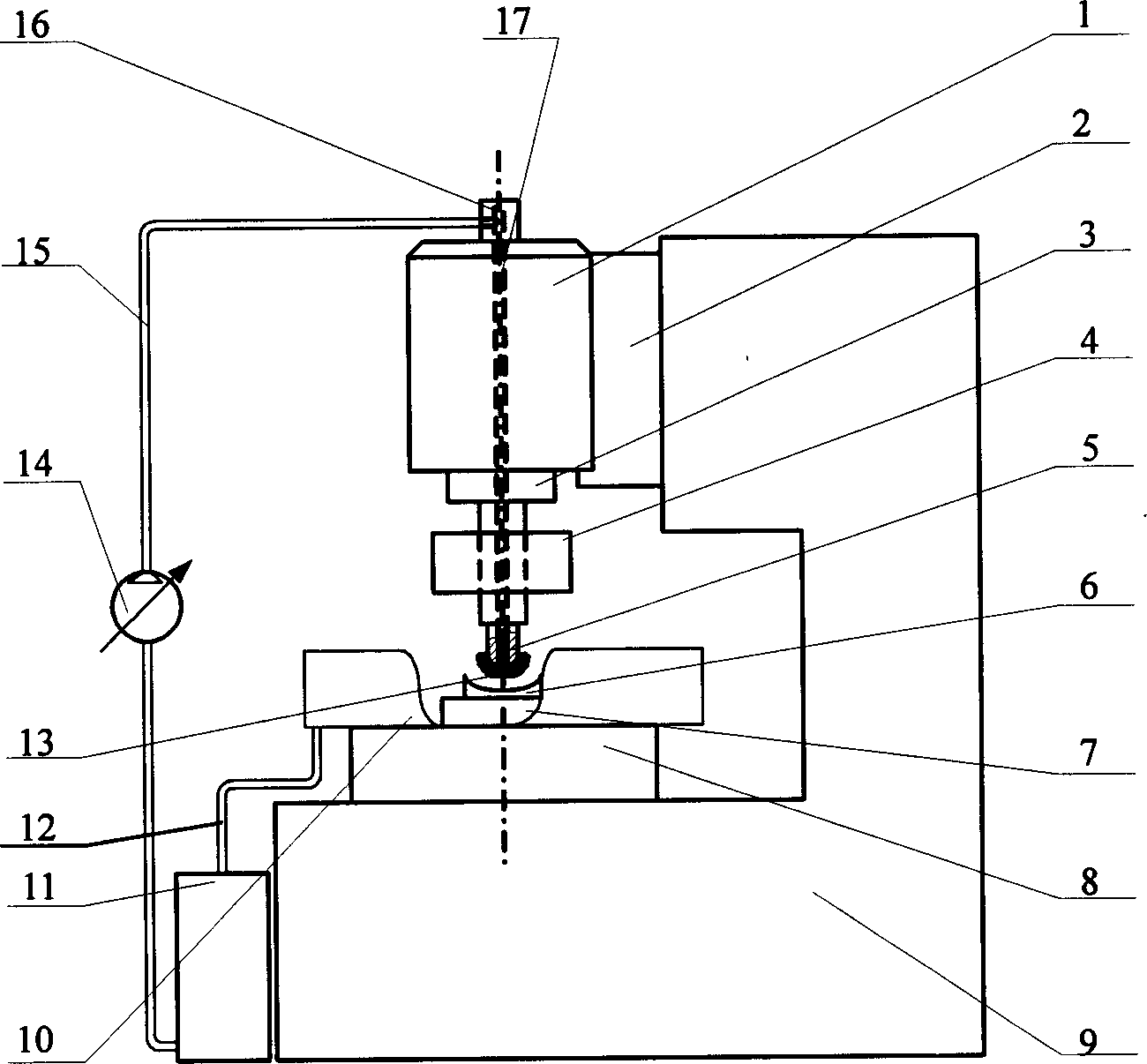

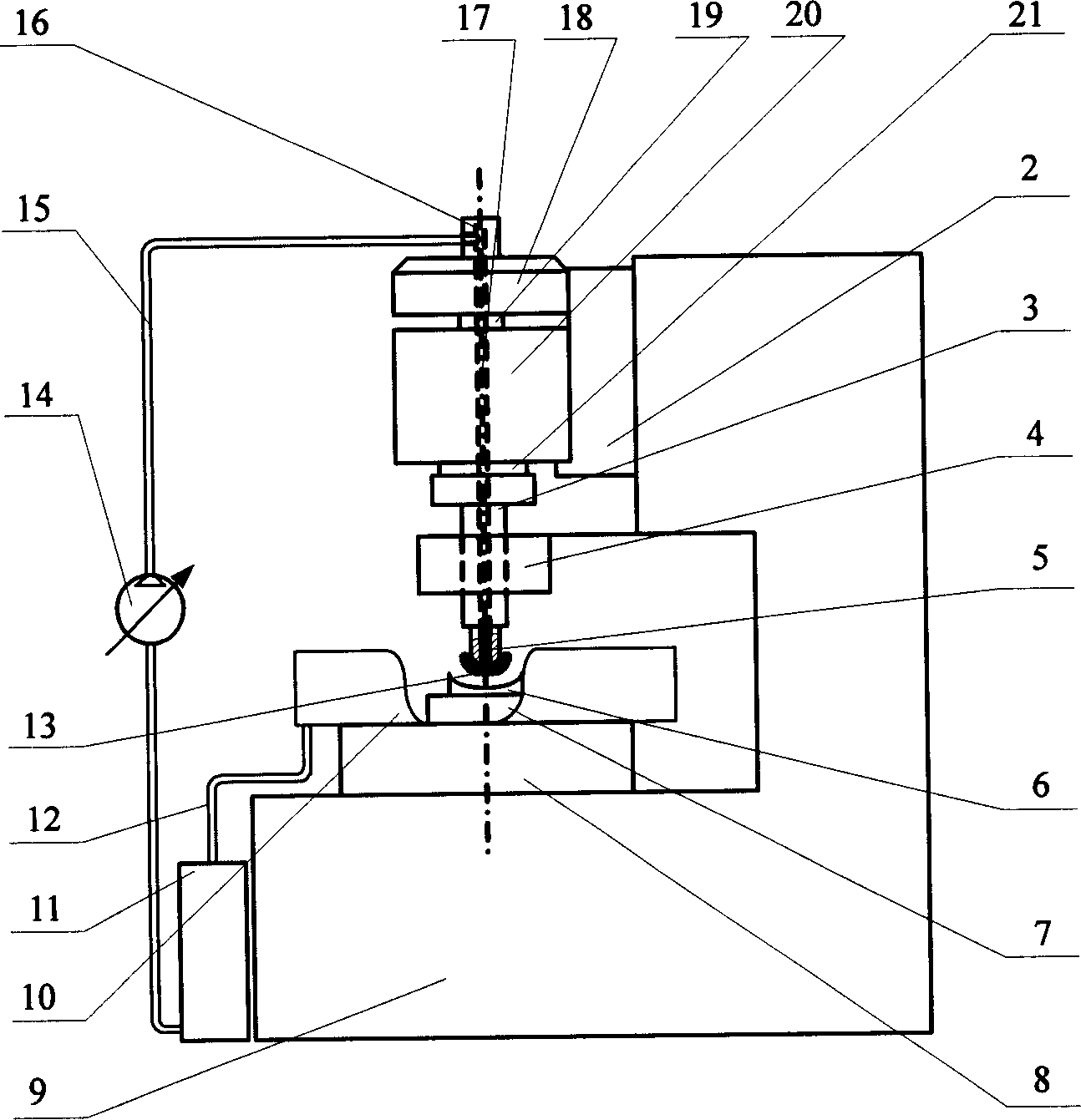

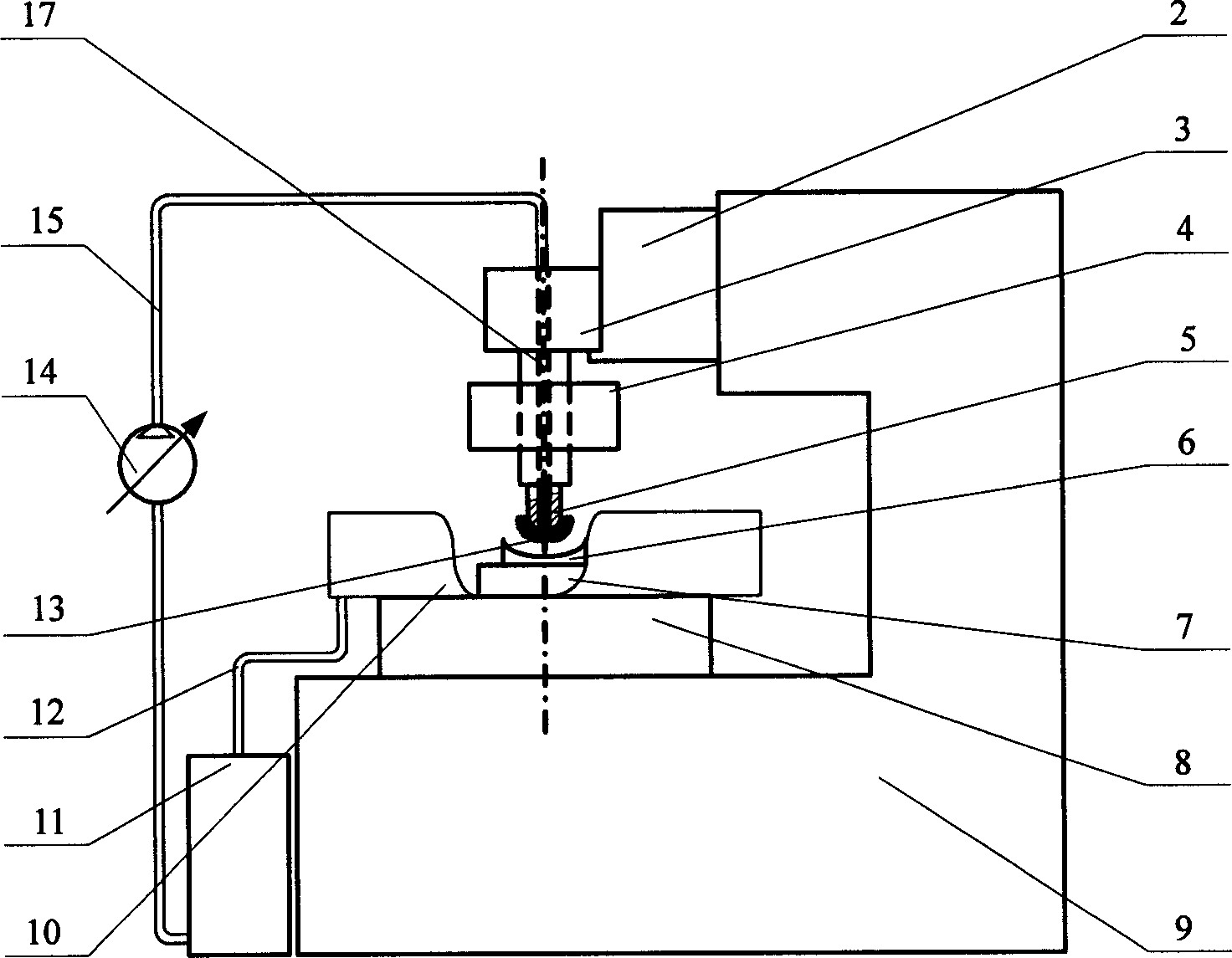

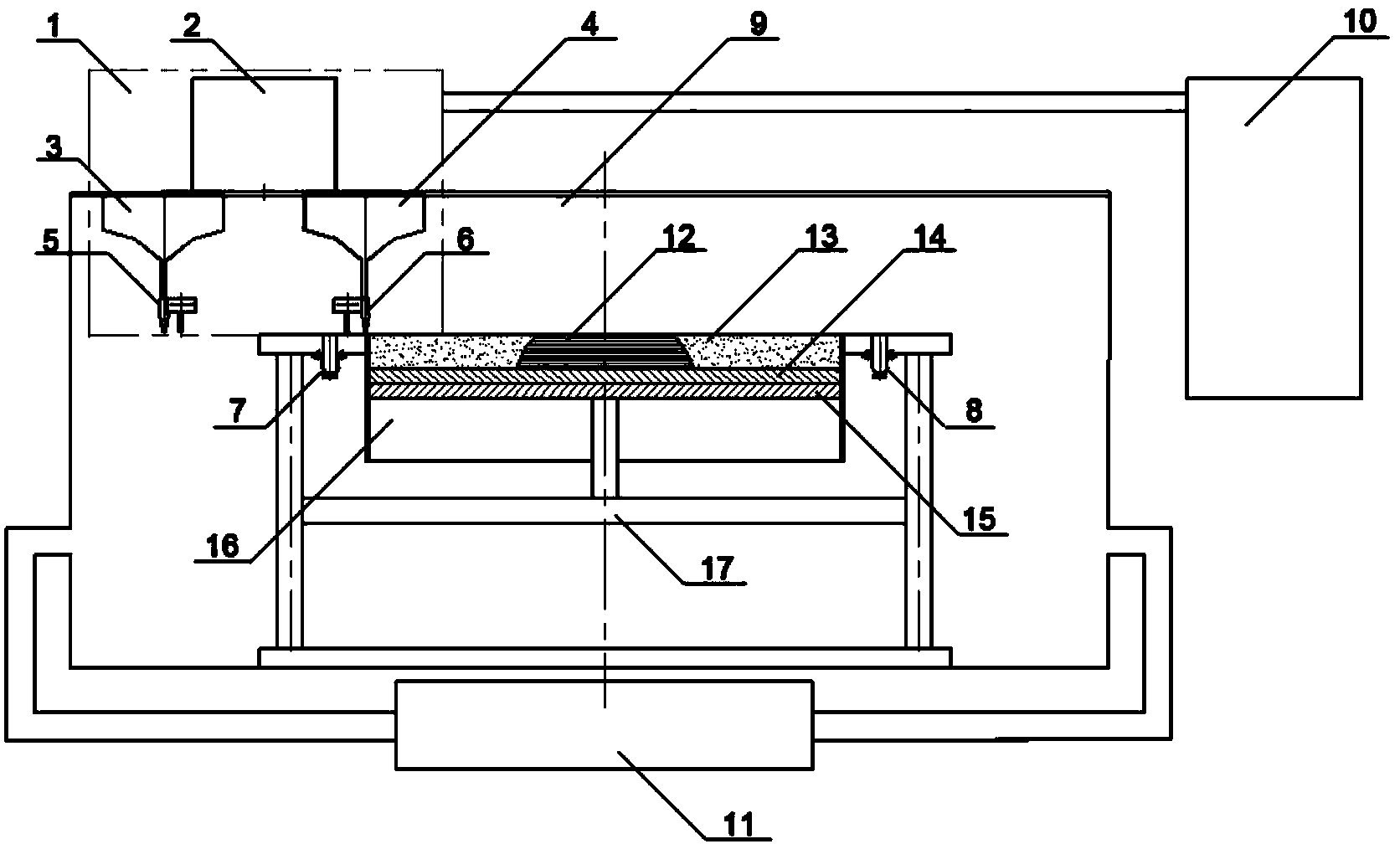

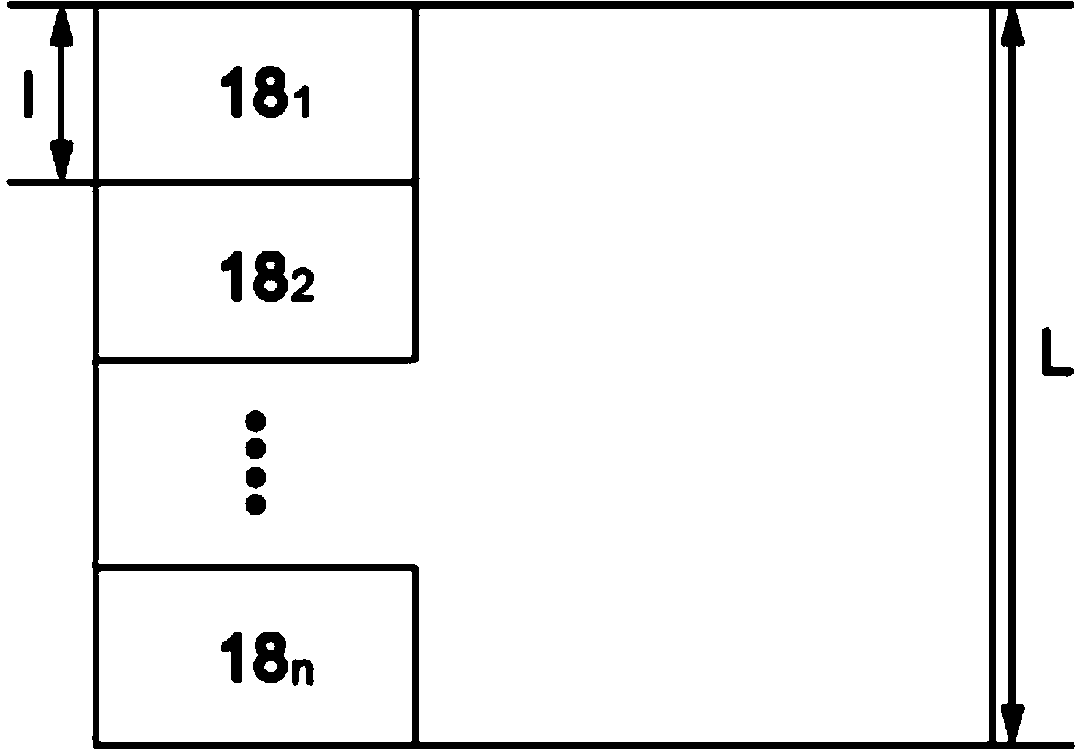

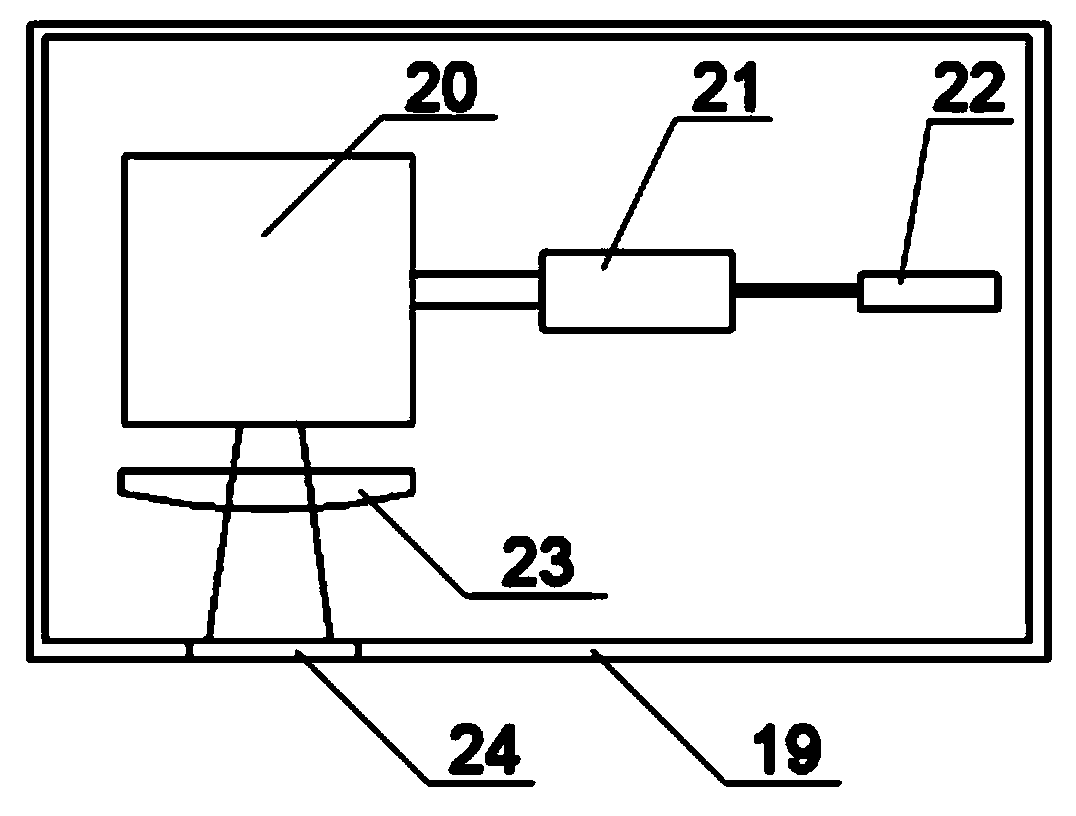

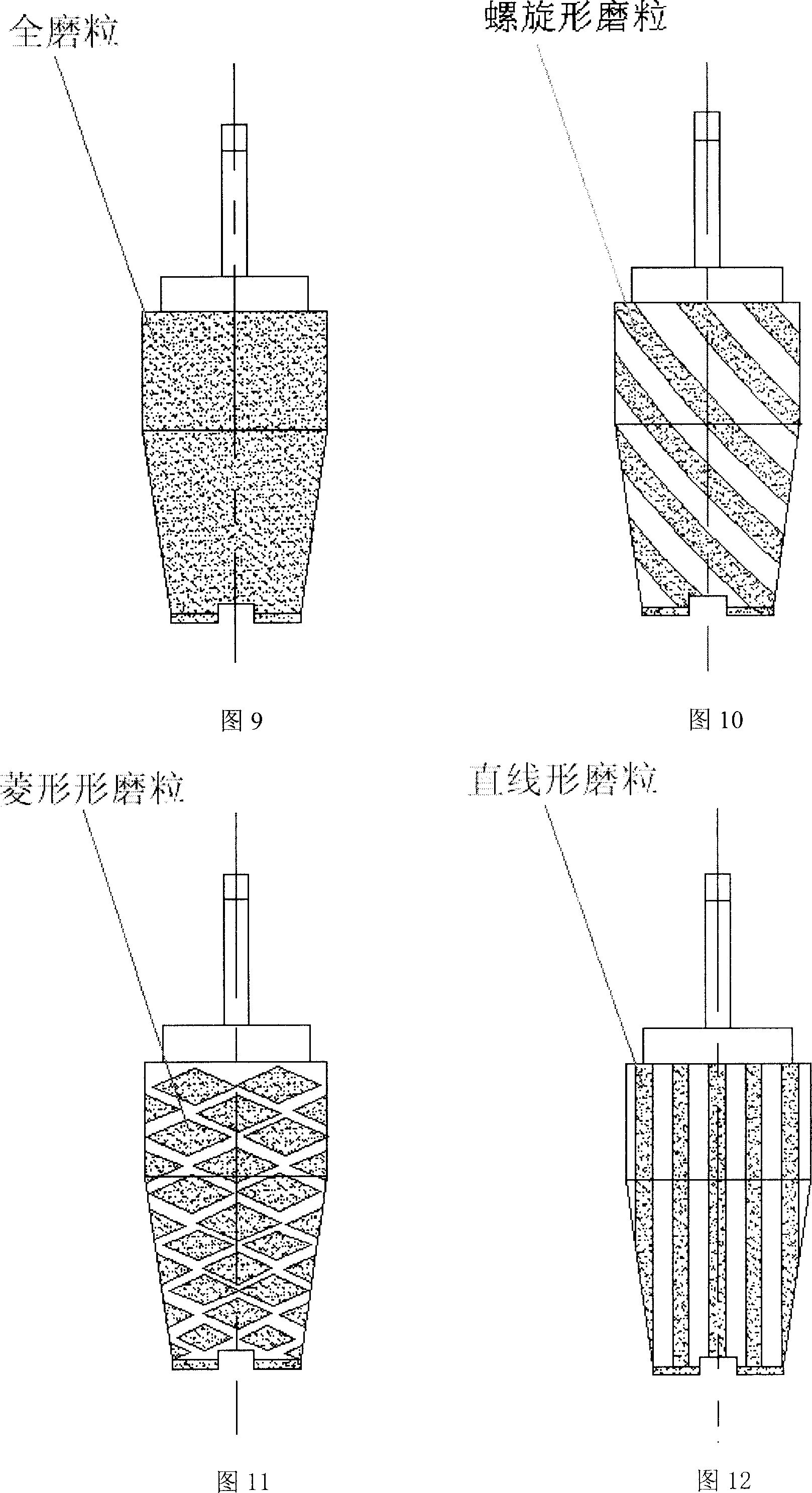

Ultrasonic magnetic rheological composite polishing method and polisher thereof

InactiveCN1613605AAchieve recyclingStable Polishing PropertiesOptical surface grinding machinesUltrasonic vibrationEngineering

An ultrasonic-magnetorheologic polishing method features that the mixture of abrasive material and magnetorheologic liquid is filled in a small-diameter rotary hollow polishing head and a magnetic field is applied to it to make the magnetorheologic liquid become flexible polishing liquid on the polishing head while the ultrasonic vibration is applied to it for higher polishing effect. Its apparatus is composed of polishing head, ultrasonic generator, and electromagnet.

Owner:HARBIN INST OF TECH

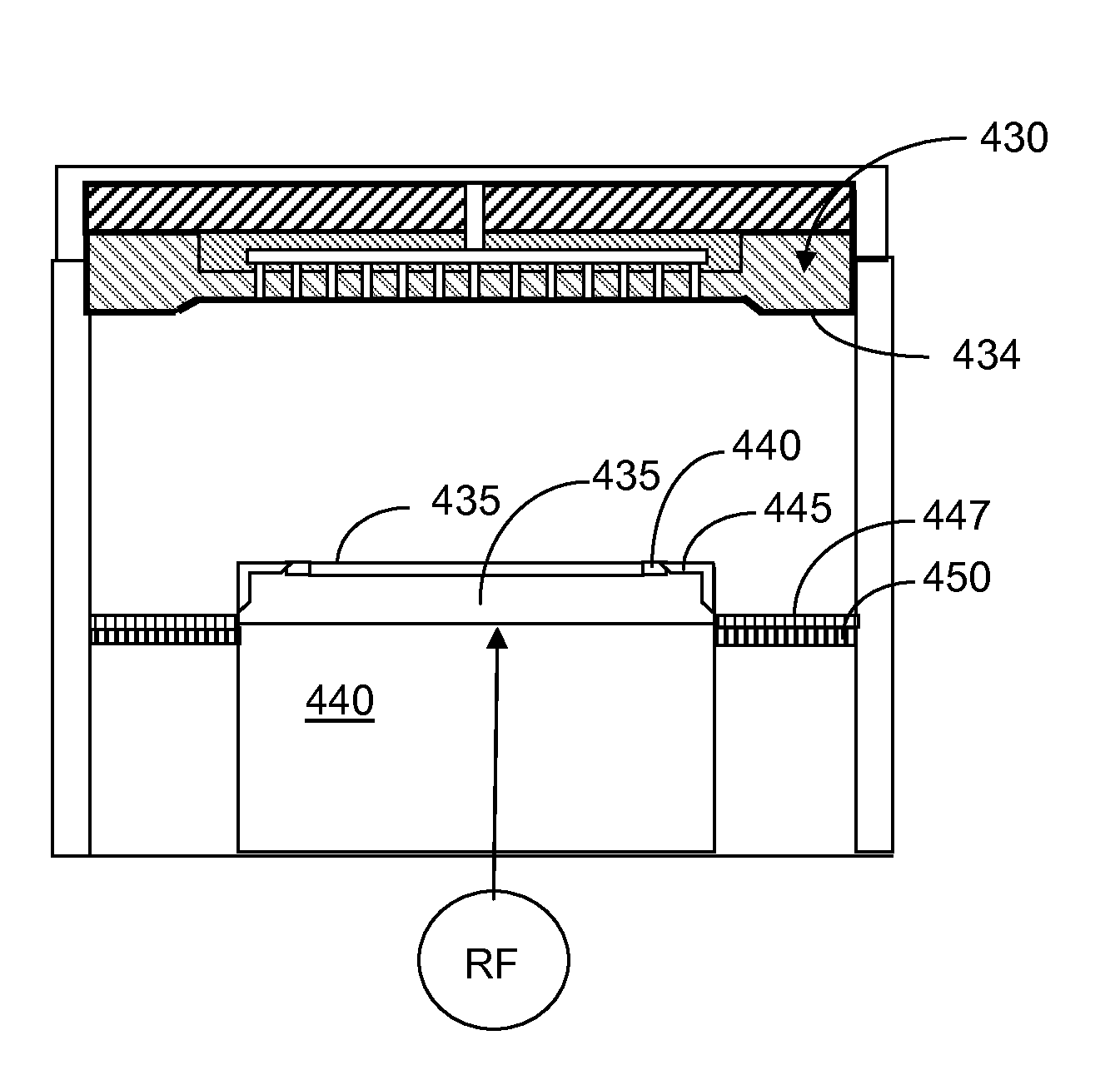

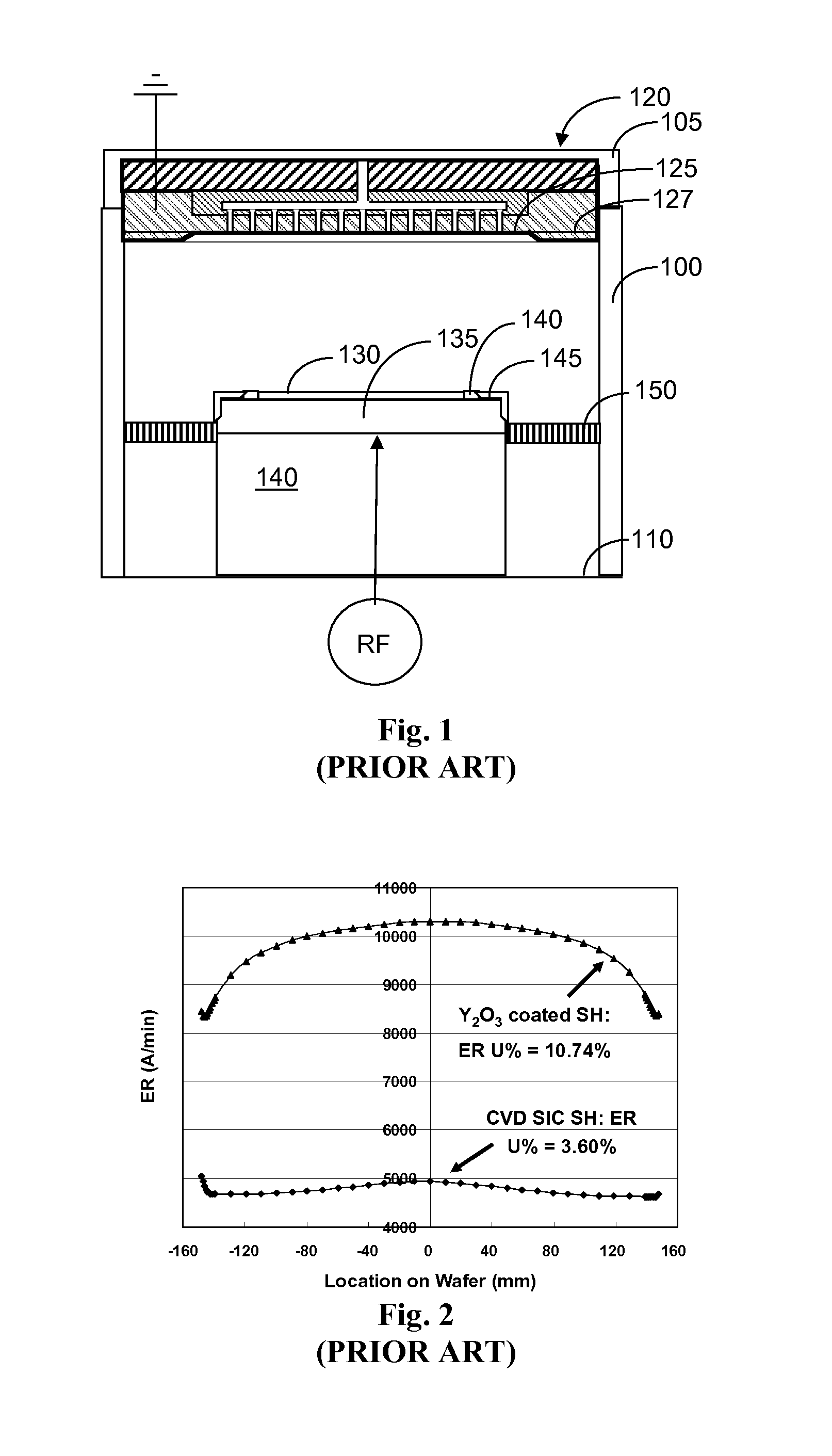

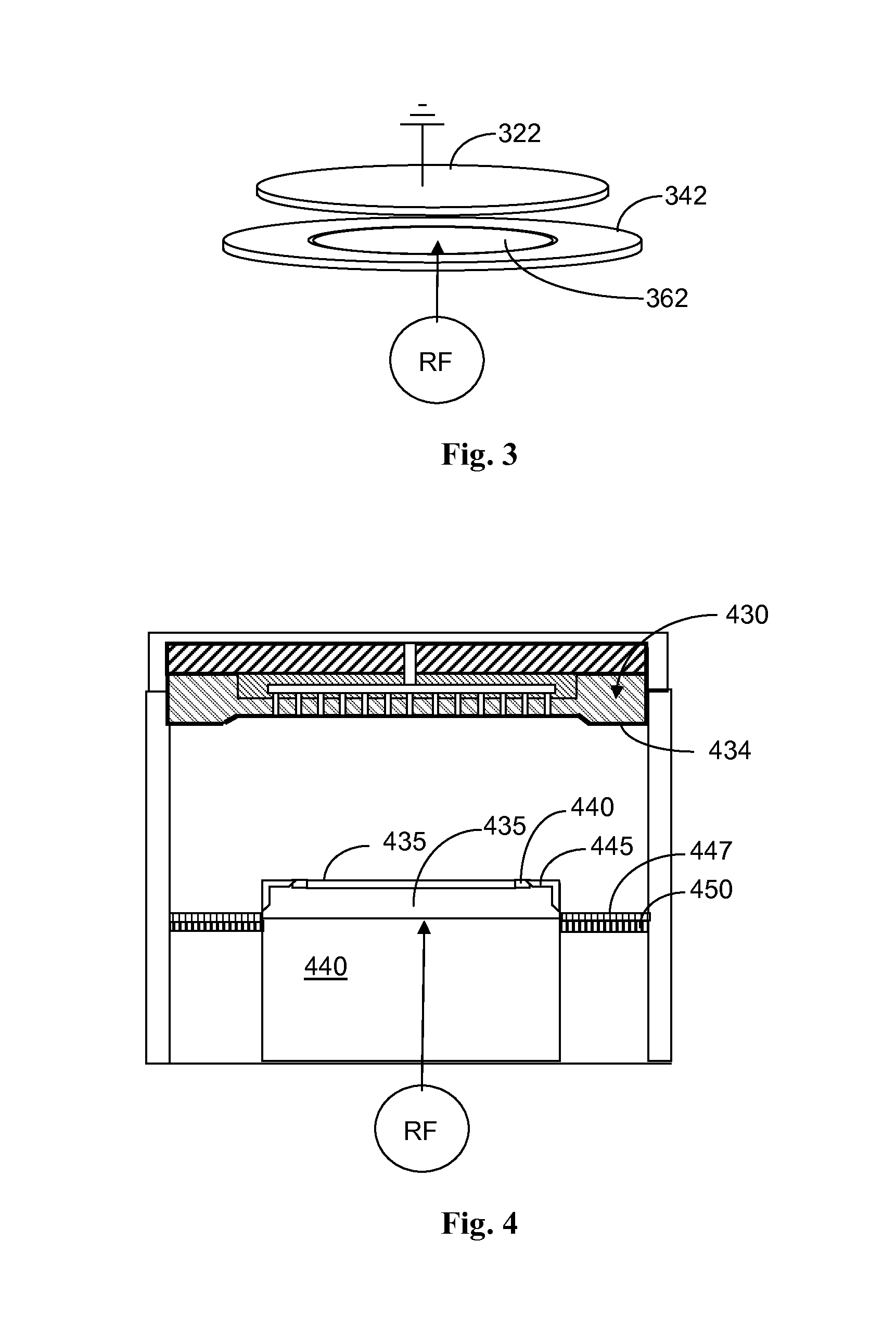

Coating for performance enhancement of semiconductor apparatus

InactiveUS20140116338A1Improve performanceImprove stabilityElectric discharge tubesVacuum evaporation coatingPerformance enhancementPlasma coating

A plasma processing chamber having advanced coating for the showerhead and for an extended bottom electrode. The extended bottom electrode can be formed by one or more of the focus ring, cover ring, and plasma confinement ring. The extended electrode can be formed using a one-piece composite cover ring. The composite cover ring may be made of Al2O3 and include a Y2O3 plasma resistant coating. The plasma confinement ring may include a flow equalization ion shield that may also be provided with the plasma resistant coating. The plasma resistant coating of the extended electrode may have elements matching that of the showerhead.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

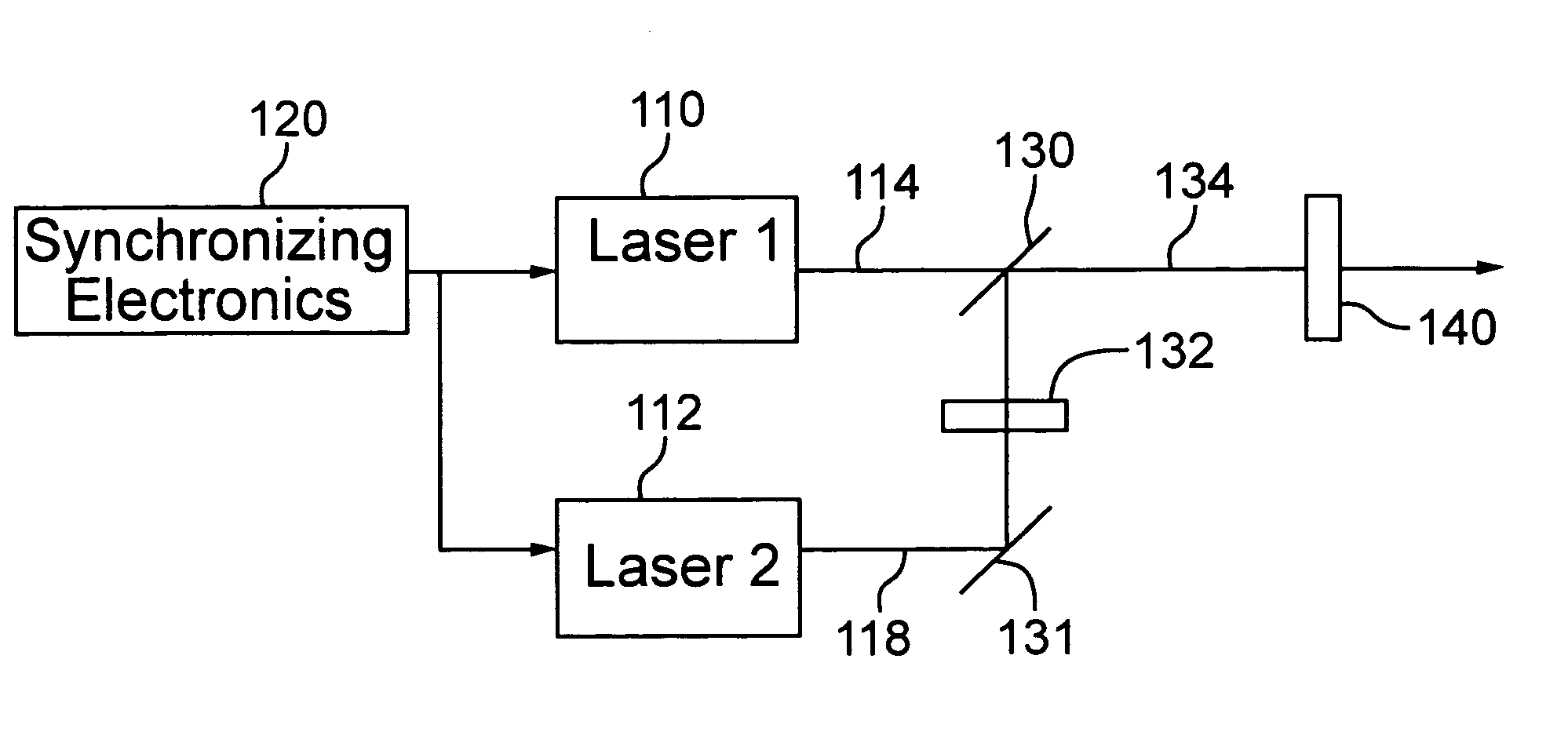

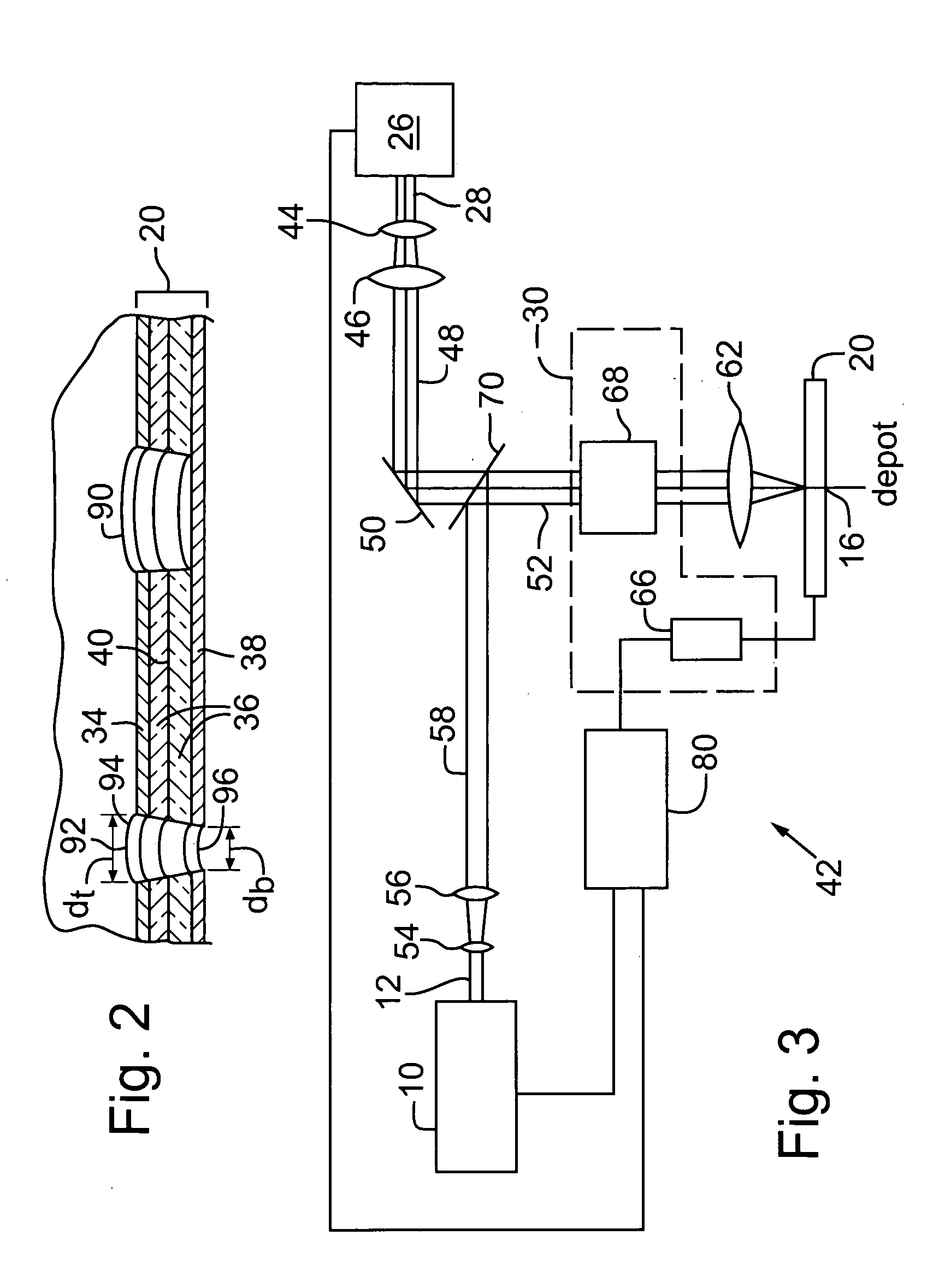

Methods of and laser systems for link processing using laser pulses with specially tailored power profiles

ActiveUS20050067388A1Improve removal qualityImprove processing qualityLaser detailsSemiconductor/solid-state device detailsPulse energyUltraviolet

Owner:ELECTRO SCI IND INC

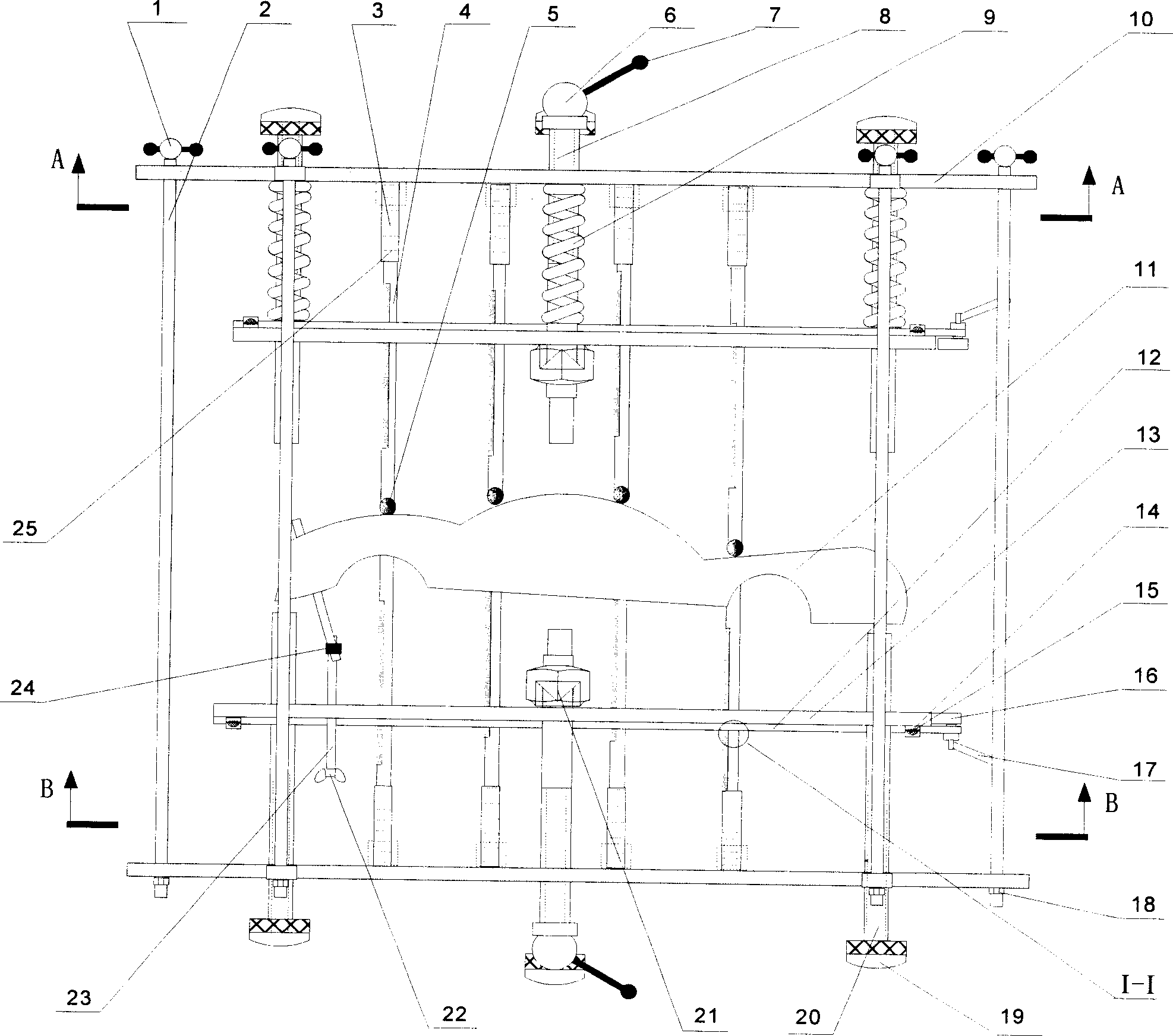

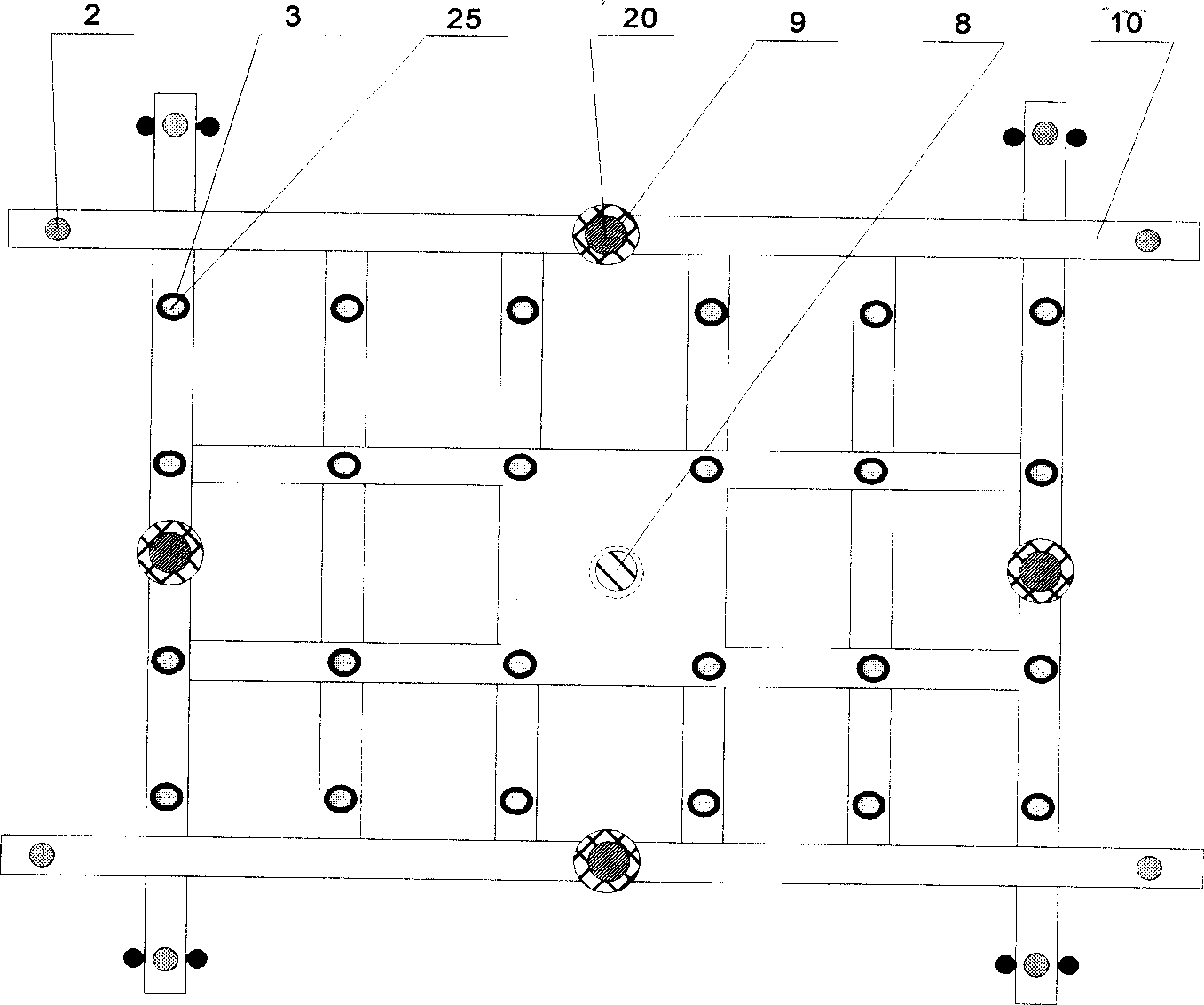

Flexible device for multipoint clamping and positioning spatial 3D thin wall part

InactiveCN1695896APrecise liftingConvenient location changeWelding/cutting auxillary devicesWork holdersCircular discMultiple point

Owner:SHANGHAI JIAO TONG UNIV

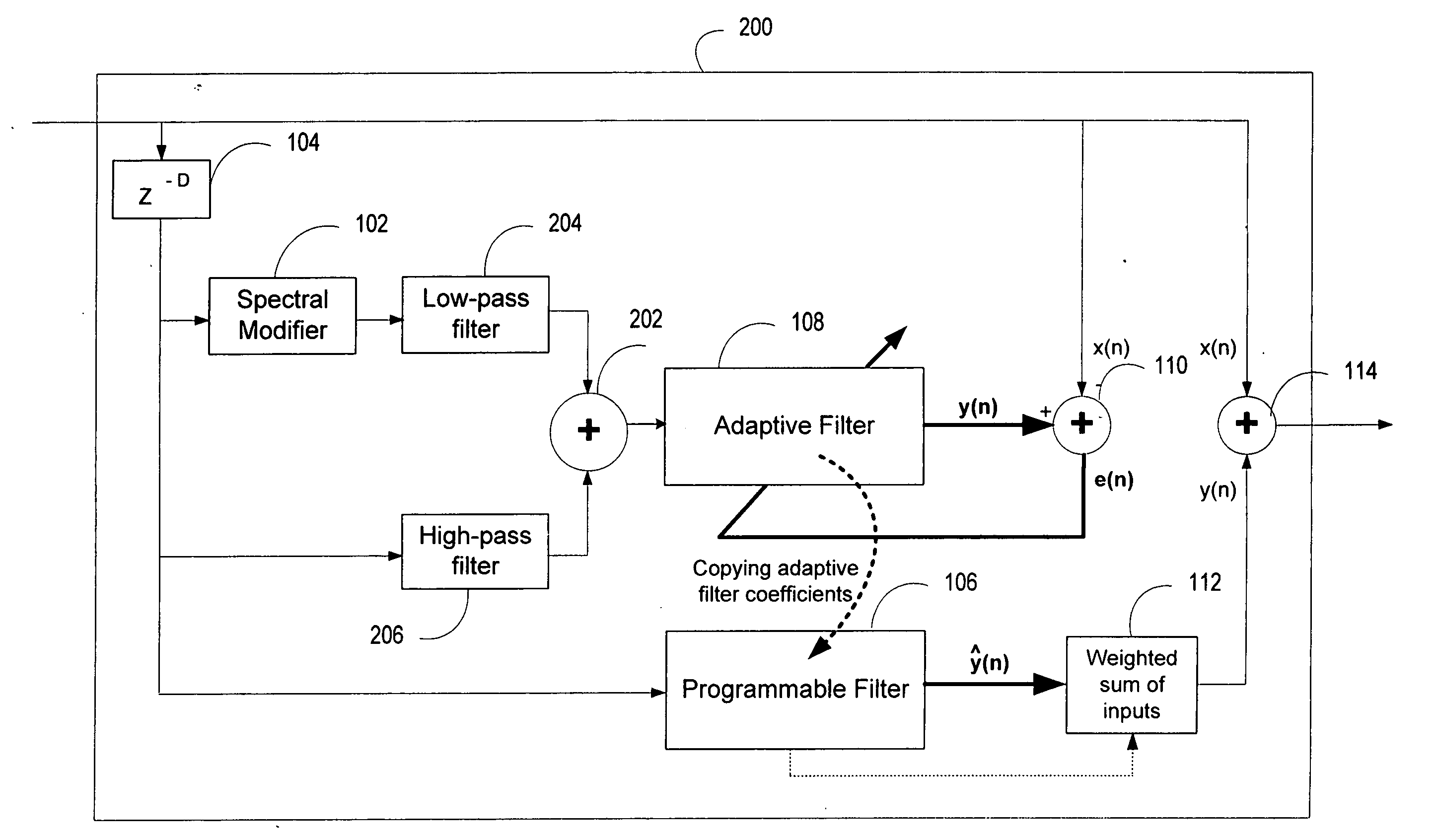

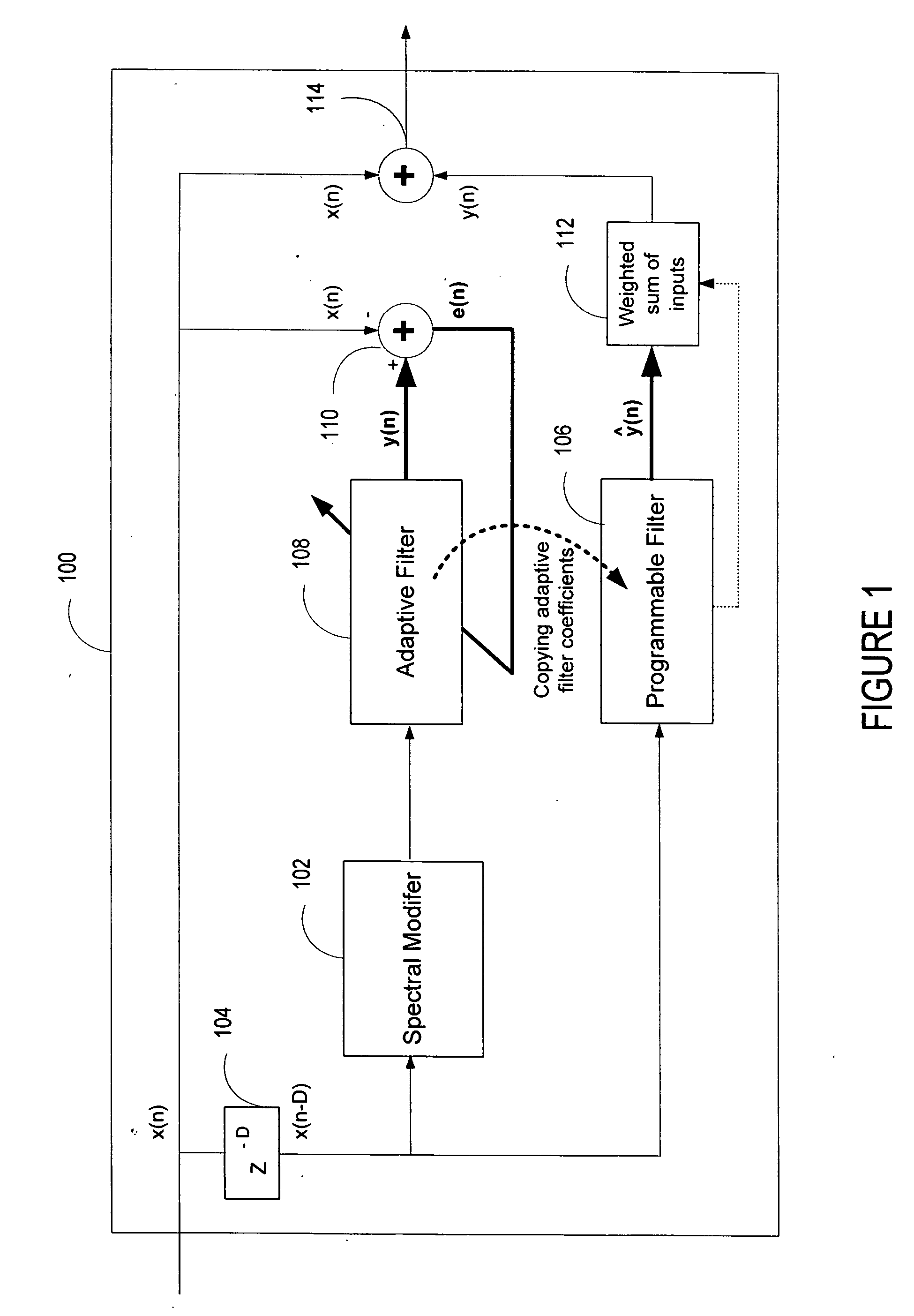

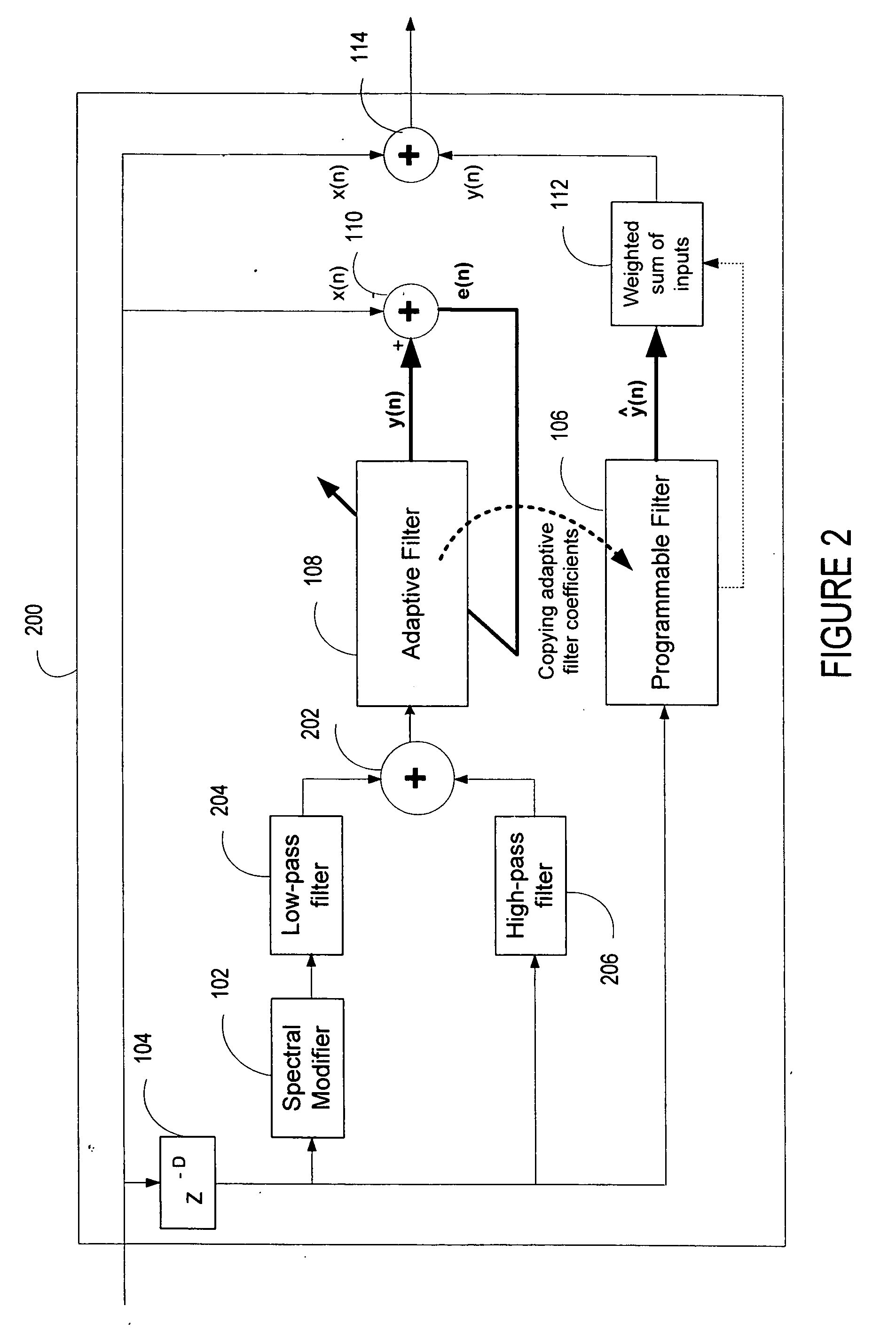

Advanced periodic signal enhancement

ActiveUS20060136199A1Improve processing qualityFlatten spectral character of background noiseAdaptive networkSpeech analysisFrequency spectrumProgrammable filters

An enhancement system improves the perceptual quality of a processed speech. The system includes a delay unit that delays a signal received through a discrete input. A spectral modifier linked to the delay unit is programmed to substantially flatten the spectral character of a background noise. An adaptive filter linked to the spectral modifier adapts filter characteristics to match a response of a non-delayed signal. A programmable filter is linked to the delay unit. The programmable filter has a transfer function functionally related to a transfer function of the adaptive filter.

Owner:BLACKBERRY LTD

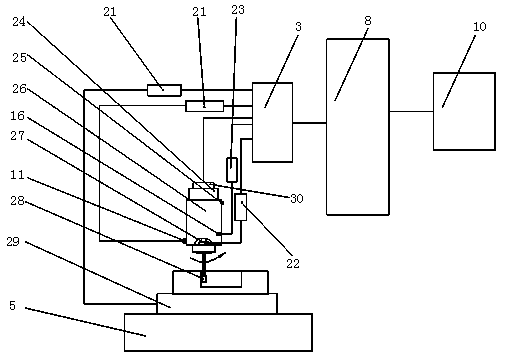

Equipment for manufacturing large-size metal part in high energy beam additive manufacturing mode and control method of equipment

ActiveCN104001915AImprove forming efficiencyShorten the "waiting time"Increasing energy efficiencyControl systemEngineering

The invention discloses equipment for manufacturing a large-size metal part in a high energy beam additive manufacturing mode and a control method of the equipment. The equipment comprises a work cavity, a worktable, a control system, a high energy beam scanning generator, a powder storage hopper, a powder laying device and a gas purification module, wherein the worktable is composed of a forming cylinder and a powder recycling cylinder, and the upper surface of the forming cylinder and the upper surface of the powder recycling cylinder are coplanar and form a work plane. The control system controls the high energy beam scanning generator and the powder laying device to move opposite to the worktable in the powder laying direction. The equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment largely shorten the waiting time caused by pre-installation of a powder bed when a common laser / electron beam selective melting technology is used for processing a part, thereby obviously improving the forming efficiency of high energy beam additive manufacturing. Through the application of the equipment for manufacturing the large-size metal part in the high energy beam additive manufacturing mode and the control method of the equipment, a metal part with a meter-grade size, high performance, high accuracy and a complex structure can be manufactured efficiently and rapidly.

Owner:TECH LASER TECH SHANGHAI CO LTD

Integral impeller processing method

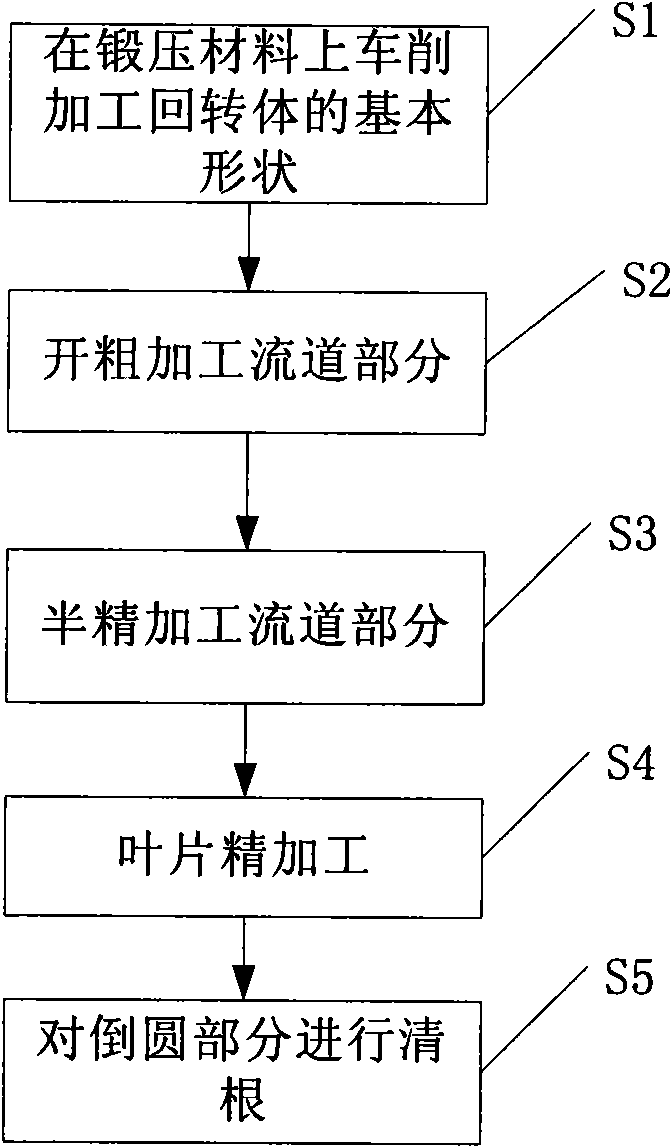

InactiveCN101590587AHigh roughing efficiencyProcessing quality is stableMilling equipment detailsImpellerEngineering

The invention discloses an integral impeller processing method for processing an integral impeller through a five-axle number control machine tool. The method comprises the following steps: S1. turning the basic shape of a revolving body on a forging material; S2. performing rough milling to a flow channel part; S3. performing semi finishing to the flow channel part; S4. performing fine finishing to blades; and S5. performing back chipping to the rounding part. The invention ensures that the processing path on the surfaces of the blades can meet the requirement of geometric accuracy, also ensures the processing quality and has high processing efficiency and stable quality.

Owner:SHANGHAI ELECTRICGROUP CORP

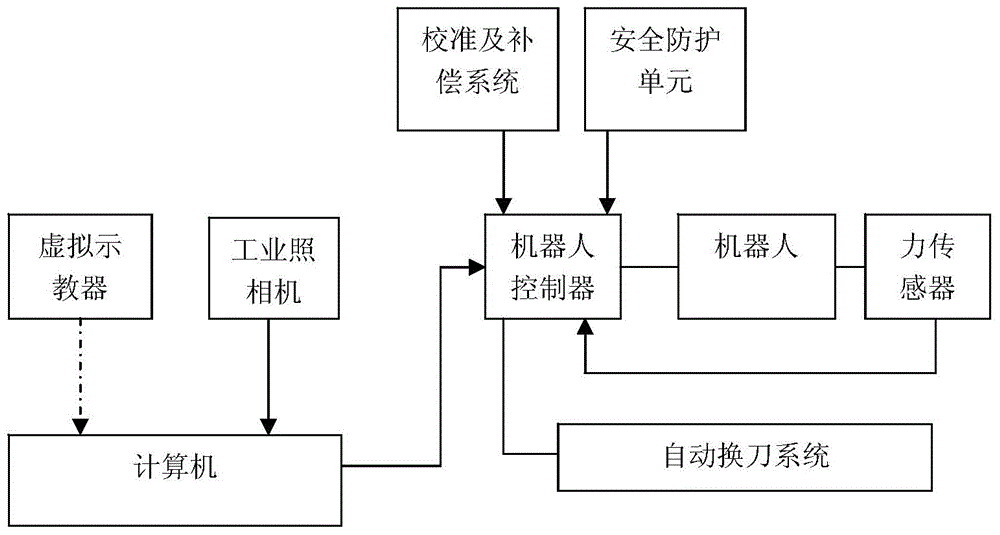

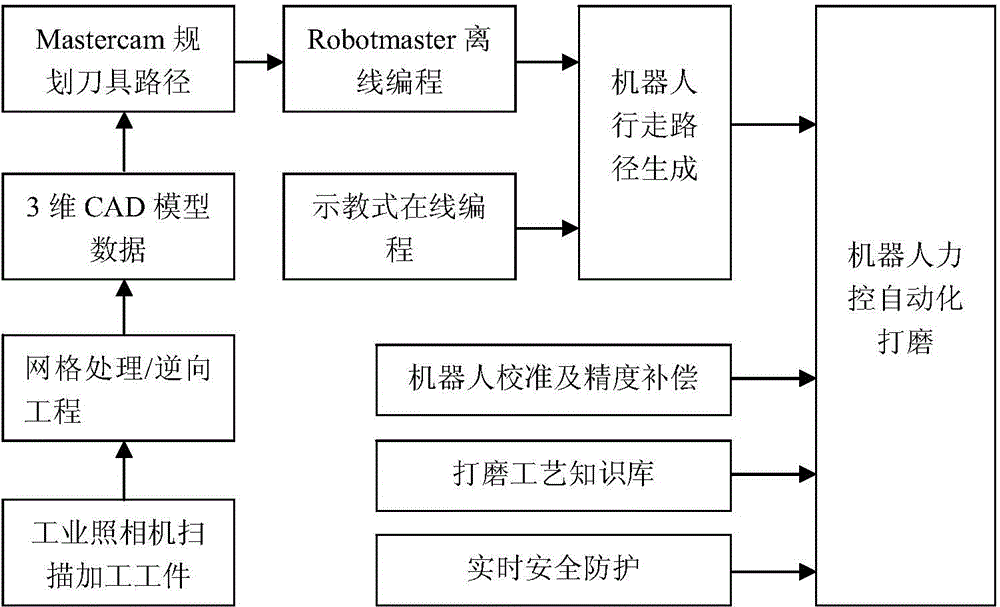

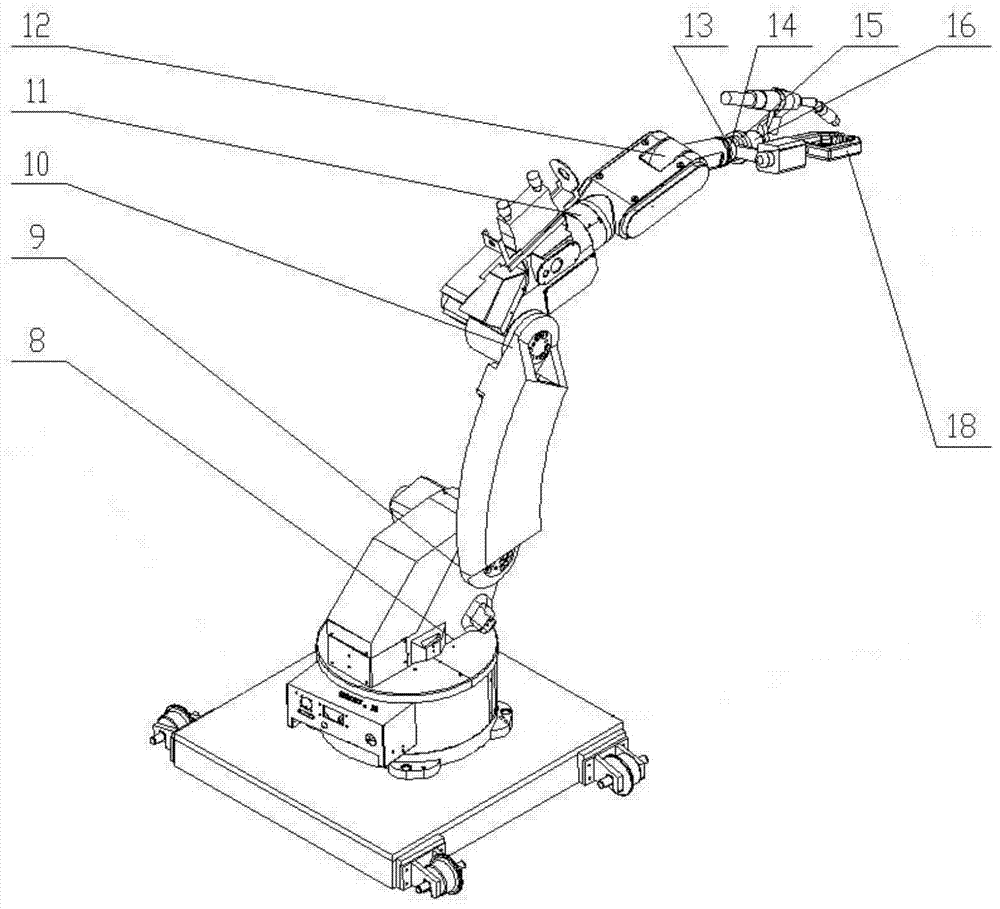

Intelligent force control robot grinding system and method

ActiveCN104972362ARealize automatic processingImprove machining accuracyAutomatic grinding controlSurface finishControl theory

The invention relates to an intelligent force control robot grinding system. The intelligent force control robot grinding system comprises a computer, an industrial camera, a robot, a robot controller, a calibration and compensation system, a safety protection unit, a force sensor and an automatic knife changing system. The computer is connected with the industrial camera. The robot controller is connected with the computer, the robot, the calibration and compensation system, the safety protection unit, the force sensor and the automatic knife changing system. A method comprises the steps that the computer receives workpiece scanning data collected by the industrial camera, generates a knife path and converts the knife path into the robot posture and the tail end path; calibration and compensation are carried out; the robot controller controls all joints to move while the robot posture and the tail end path are adjusted. Hardware of a high-precision force control grinding system is achieved, the path self-calibration and online compensation technology is adopted, and the machining of a complex hook face with the high requirements for machining precision and surface smoothness can be finished.

Owner:宏阔(南通)智能装备有限公司

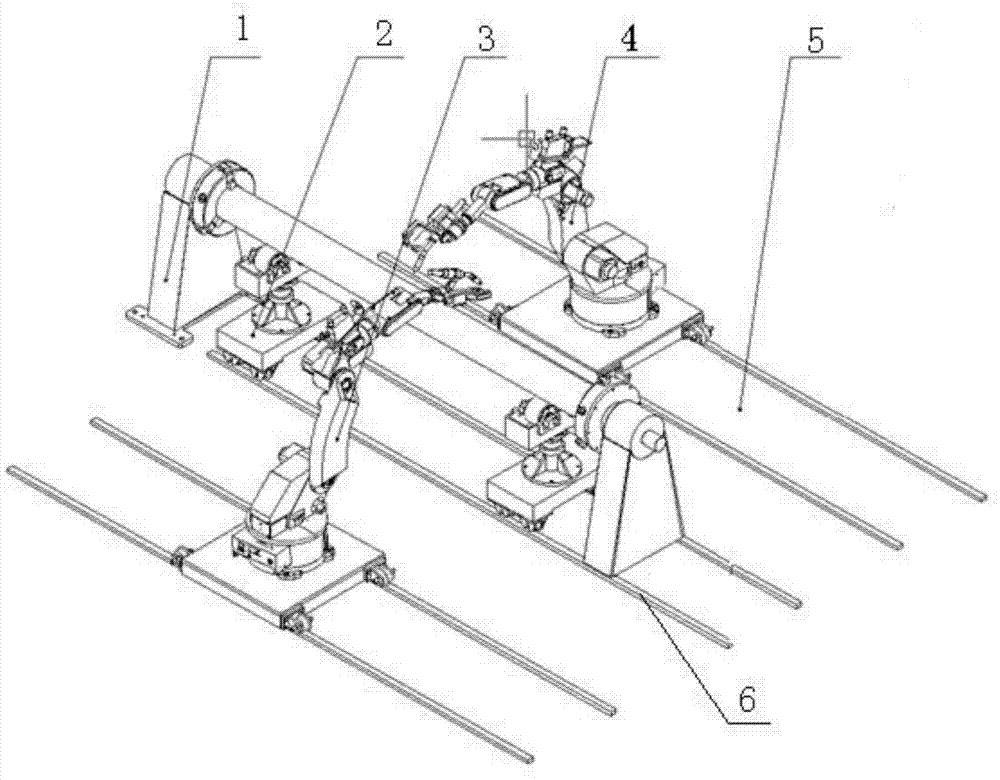

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677AImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

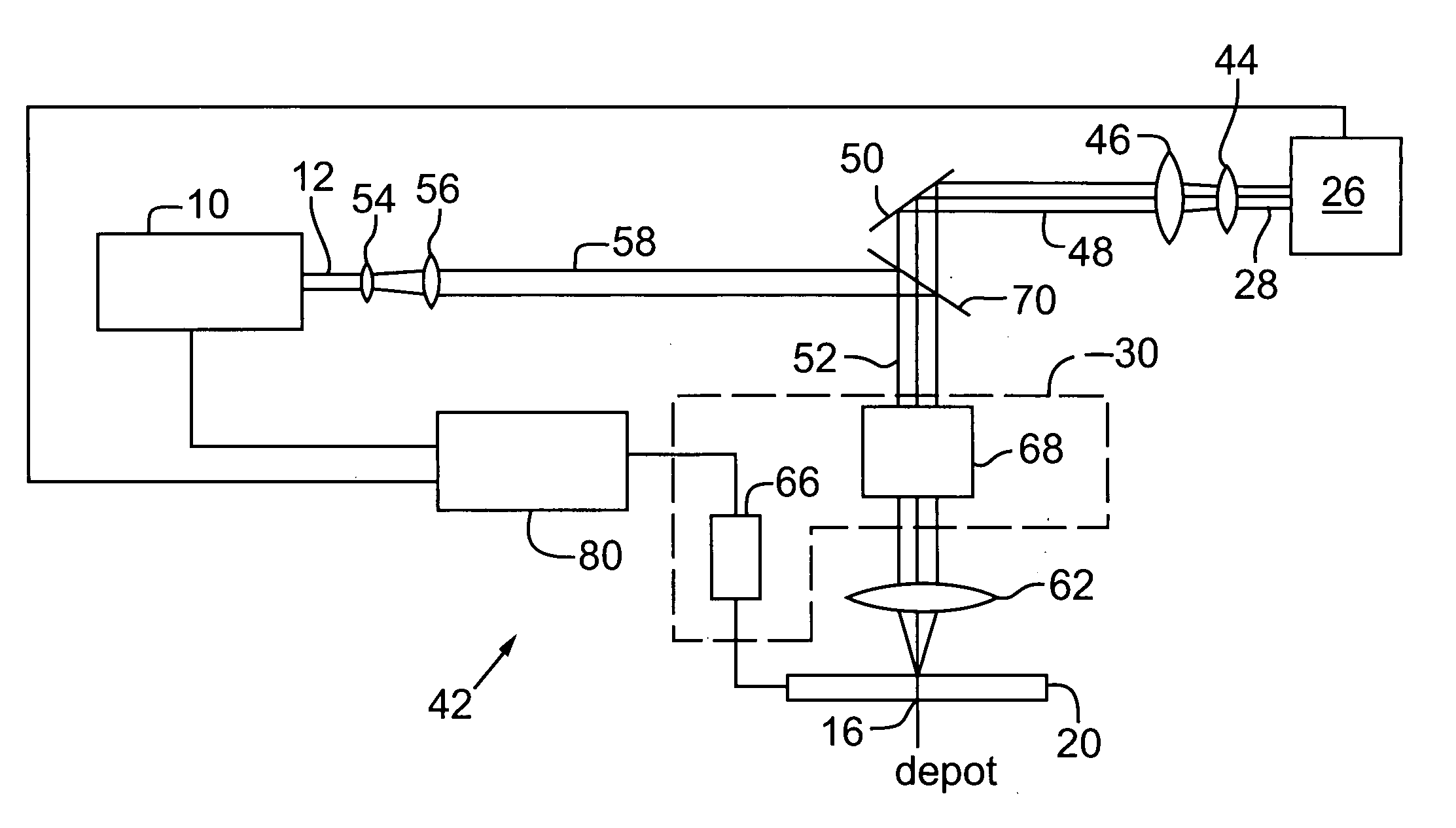

Laser processing of a locally heated target material

InactiveUS20050087522A1Improve efficiencyIncrease speedPrinted circuit manufactureWelding/soldering/cutting articlesThermal energyLaser processing

A method and laser system effect rapid removal of material from a workpiece by applying heating energy in the form of a light beam to a target location on the workpiece to elevate its temperature while maintaining its dimensional stability. When the target portion of the workpiece is heated, a laser beam is directed for incidence on the heated target location. The laser beam preferably has a processing laser output that is appropriate to effect removal of the target material from the workpiece. The combined incidence of the processing laser output and the heating energy on the target location enables the processing laser output to remove a portion of the target material at a material removal rate that is higher than the material removal rate achievable when the target material is not heated.

Owner:ELECTRO SCI IND INC

Water-soluble total-synthesis metal working fluid and application thereof

The invention discloses a water-soluble total-synthesis metal working fluid and application thereof. The working fluid is prepared from the following raw materials in percentage by weight: 1wt%-30wt% of a lubricant, 1wt%-40wt% of a corrosion inhibitor, 1wt%-40wt% of organic amine, 1wt%-20wt% of a cleaning agent, 1wt%-20wt% of a coupling agent, 0.5wt%-5wt% of an antifoaming agent and the balance of water. The working fluid can form water-based steam with anti-rust property in an induction manner in the use procedure, so that the problem of rusting caused by steam which is easily generated by a closed machine tool is solved, and therefore, the working fluid is suitable for a high-precision machine tool, especially a numerical control machine tool with a closed structure.

Owner:TSINGHUA UNIV

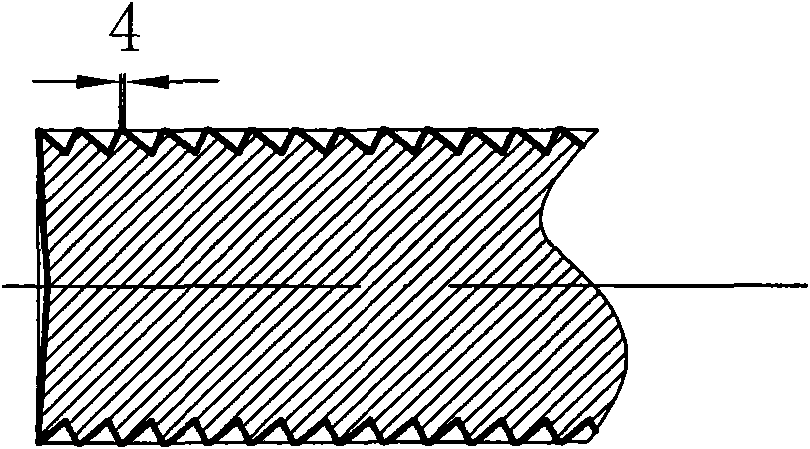

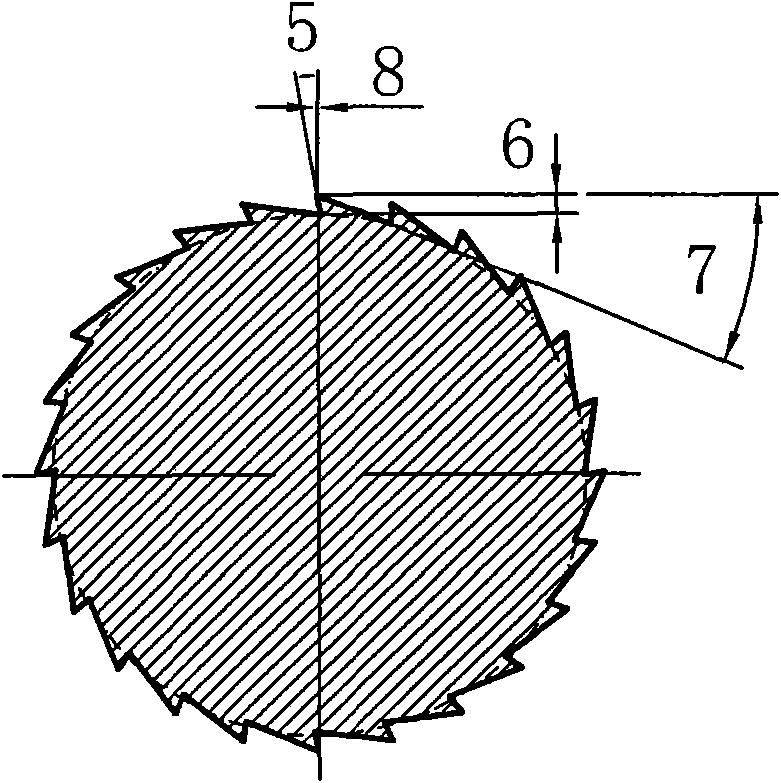

Integral carbide goldfish scale milling cutter

InactiveCN101623778AExtended service lifeImprove processing efficiencyMilling cuttersWorkpiecesGlass fiberFiber

The invention discloses an integral carbide goldfish scale milling cutter used for milling and processing composite materials such as carbon fiber, glass fiber and the like. The milling cutter of the invention comprises a milling cutter blade and a milling handle, wherein the cutting blade on the milling cutter blade is a cutting unit formed by left and right-handed rotation symmetrical staggered spiral grooves, and the number of the left spiral groove is two more than that of the right spiral groove; the length of the cutting blade of each cutting unit is 0.05-0.1mm, and the width of the rear cutter surface of the cutting blade along the cylinder surface is 0-0.01mm; the anterior angle of the cutting blade is 10-15 degrees, the front cutter surface is a straight line on a normal plane; the relief angle of the cutting blade is 20-25 degrees; the depth of the spiral cutter groove is 7-8% of the diameter of the cutter. The invention has the advantages that the cutting blade of the integral carbide goldfish scale milling cutter is composed of a plurality of cutting units and is sharp, which greatly lowers cutting resistance and realizes high speed cutting so as to obtain the effect of using milling for replacing abrading, so that the processing efficiency and the surface quality of the composite materials can be improved, and the service life of the milling cutter can be prolonged.

Owner:SHENYANG AIRCRAFT CORP

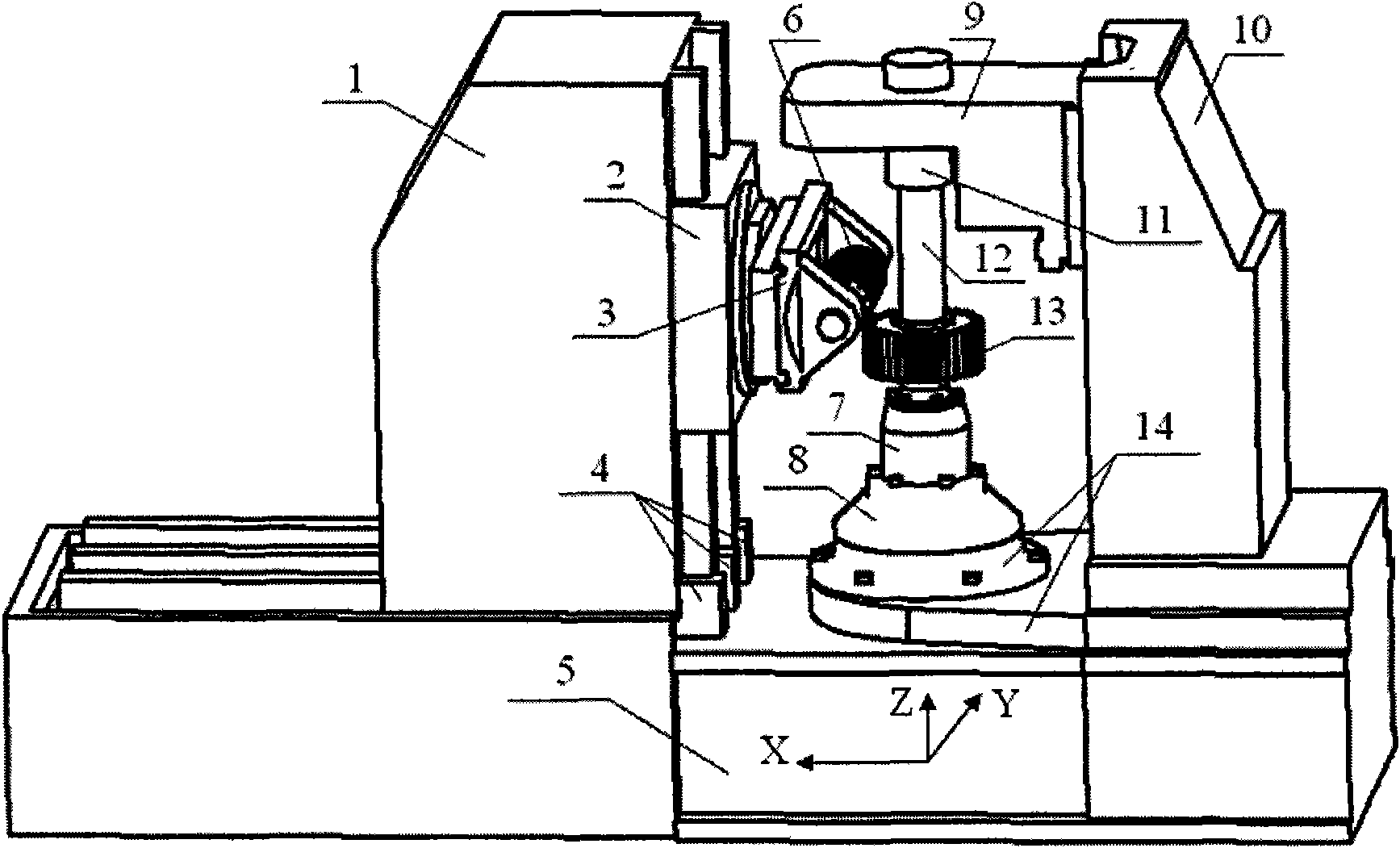

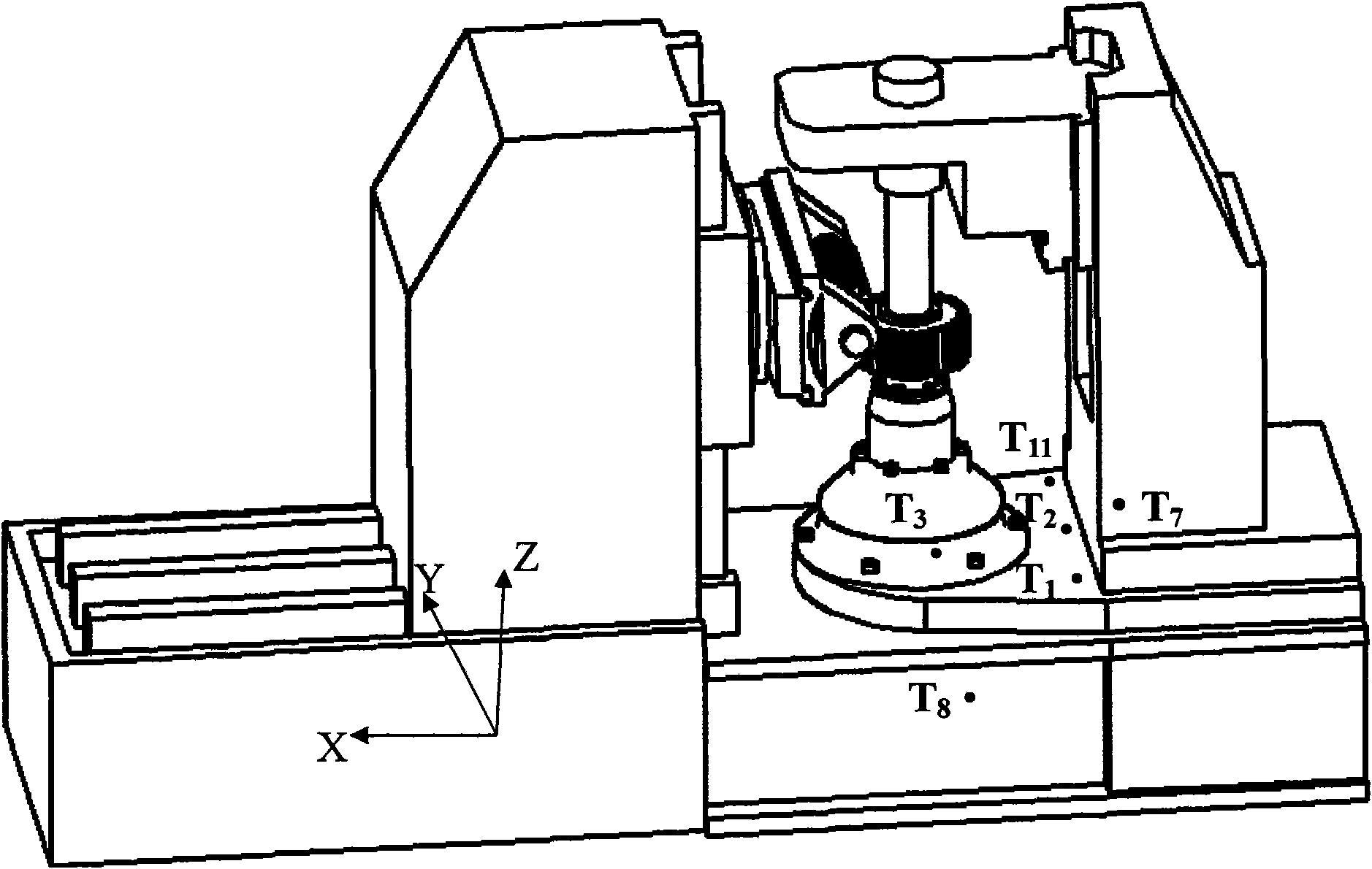

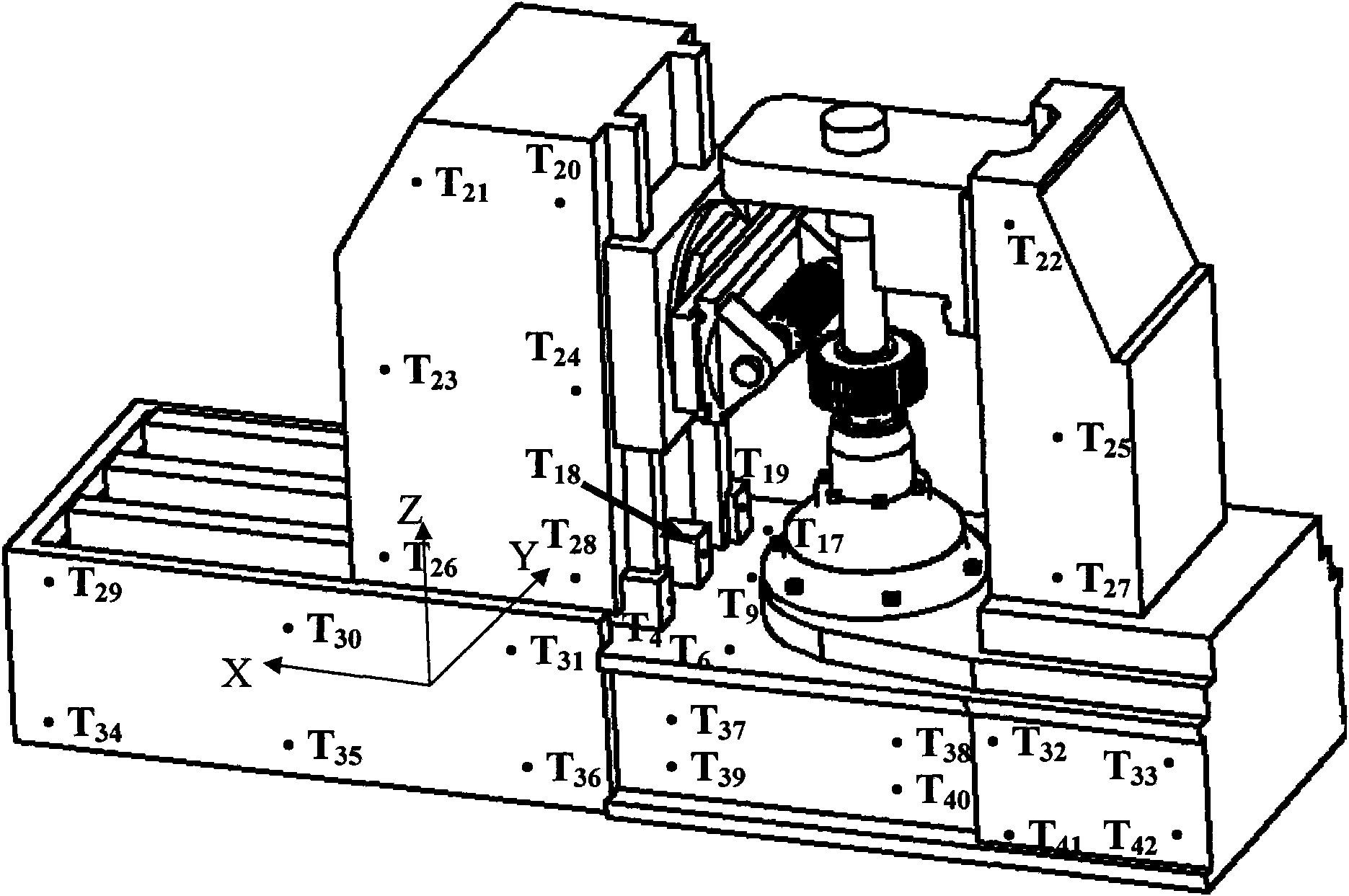

Method for thermal deformation error compensation of digital control gear hobbing machine

ActiveCN101797704APracticalImprove stabilityOther manufacturing equipments/toolsLeast squaresMachining process

The invention discloses a method for thermal deformation error compensation of a digital control gear hobbing machine, which comprises the following steps of: 1, adopting temperature and displacement sensors to detect variable values of a temperature and a thermal deformation displacement on line when the digital control gear hobbing machine is in the course of working; 2, using a fuzzy clustering analytic method to calculate linearly dependent coefficients of variables of the temperature and the displacement, performing classification and optimization on the variable of the temperature, and determining the displacement variable Xi for model building and optimized p temperature independent variables T1, T2, T3, ..., and Tp; 3, adopting a multiple linear regression-least square method to establish a mathematic model of thermal errors and temperature variables; and 4, realizing online real-time compensation of thermal deformation errors of the digital control gear hobbing machine by using a zero programming system. The method solves thermal deformation error problems of a processing gear of the digital control gear hobbing machine, and by performing the online real-time error compensation on the digital control gear hobbing machine, the method improves the gear processing quality, the accuracy and the efficiency, reduces the rejection rate, saves the cost and shortens the processing cycle.

Owner:CHONGQING MACHINE TOOL GROUP +1

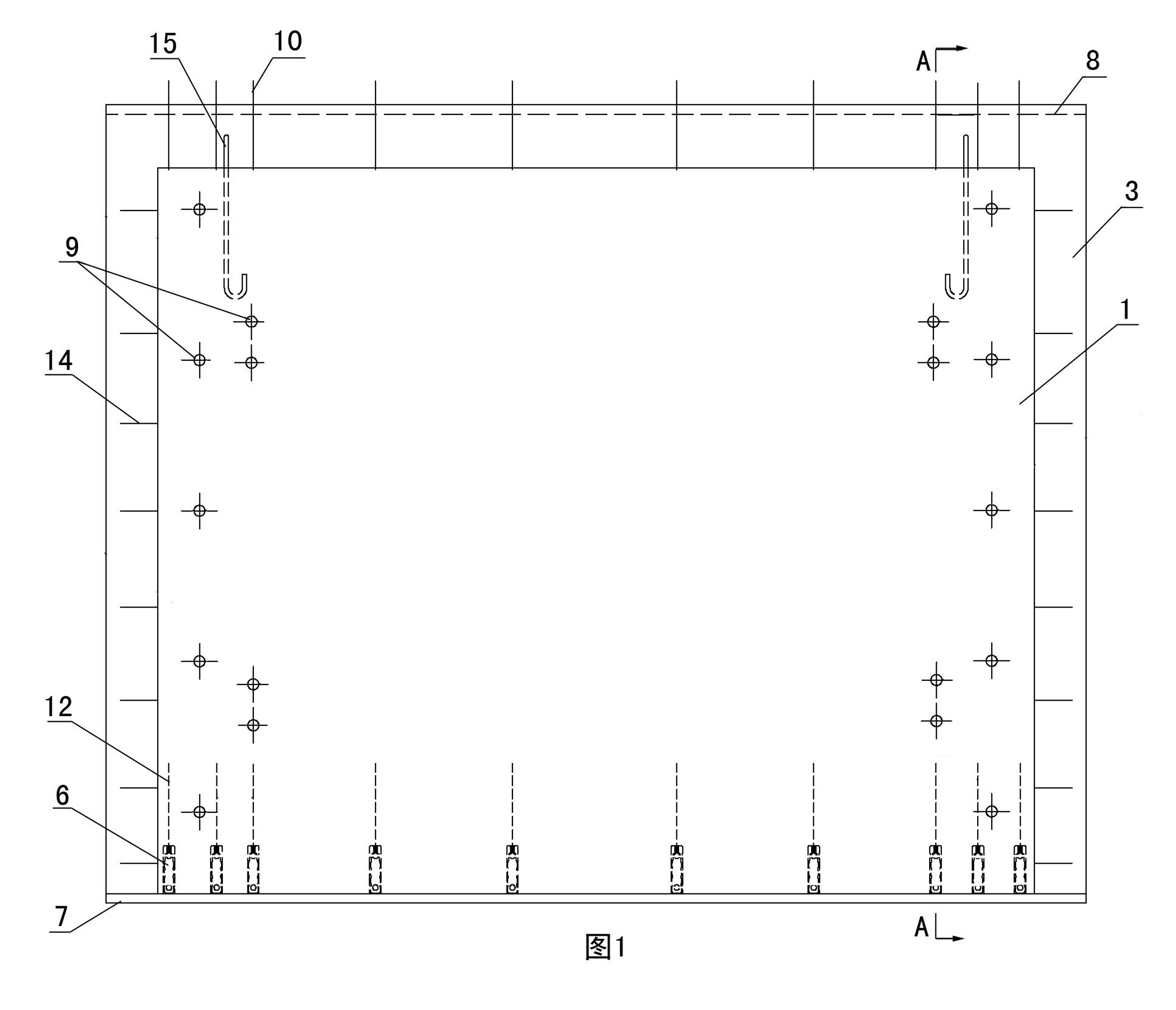

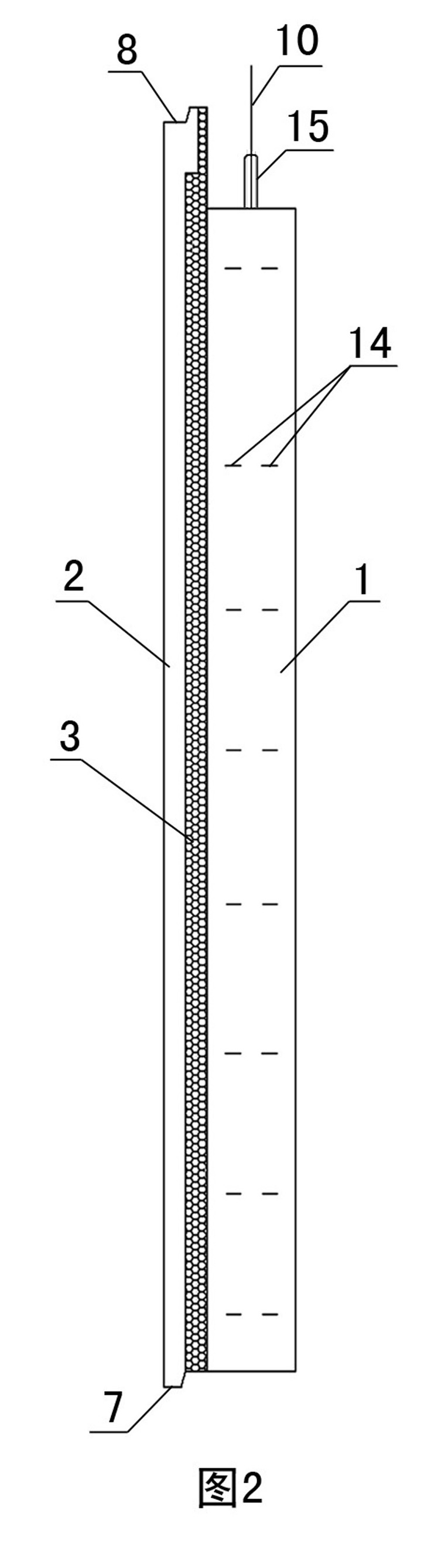

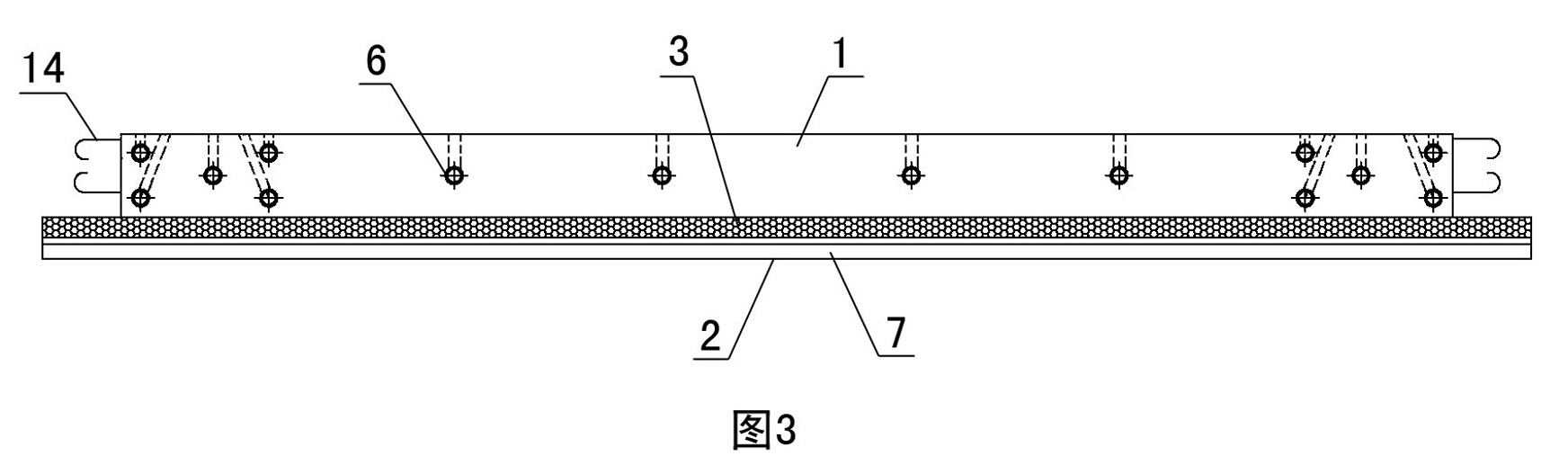

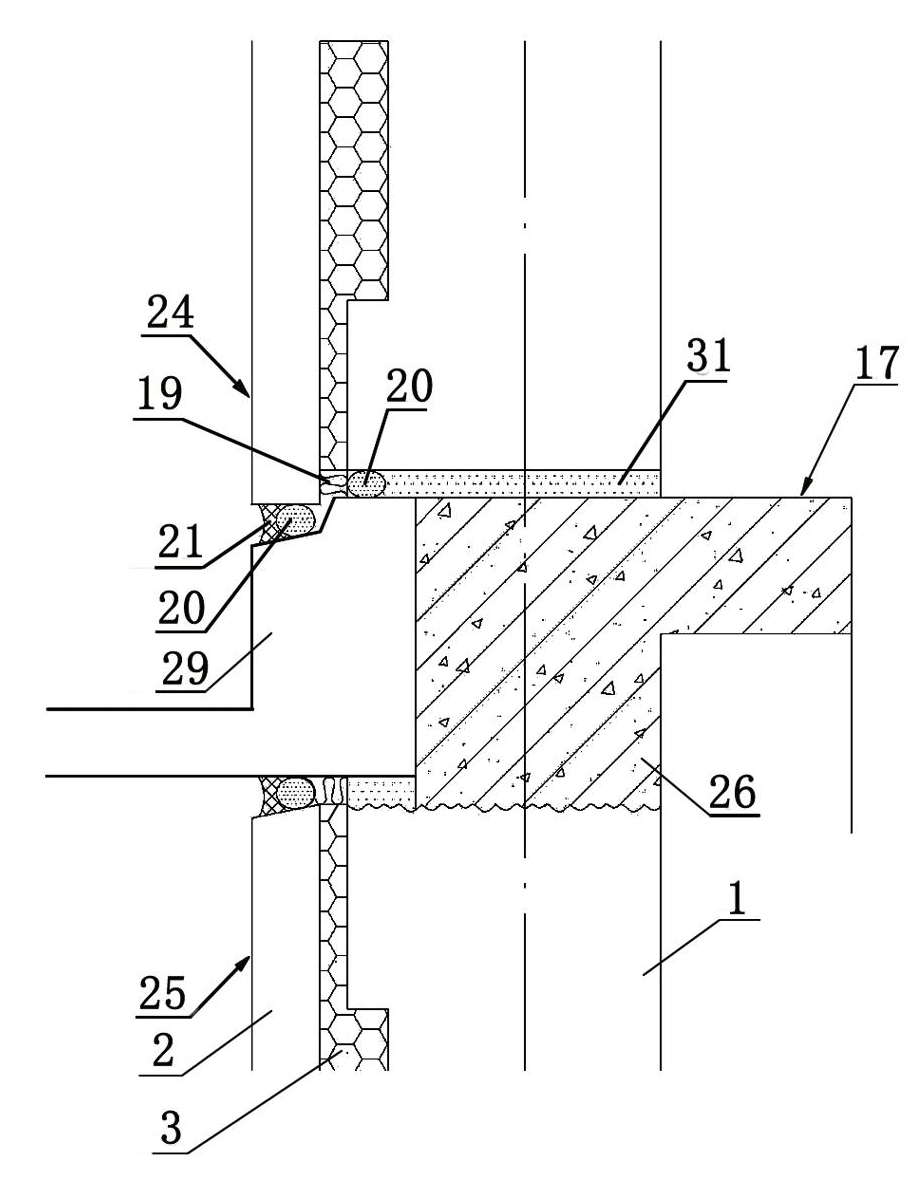

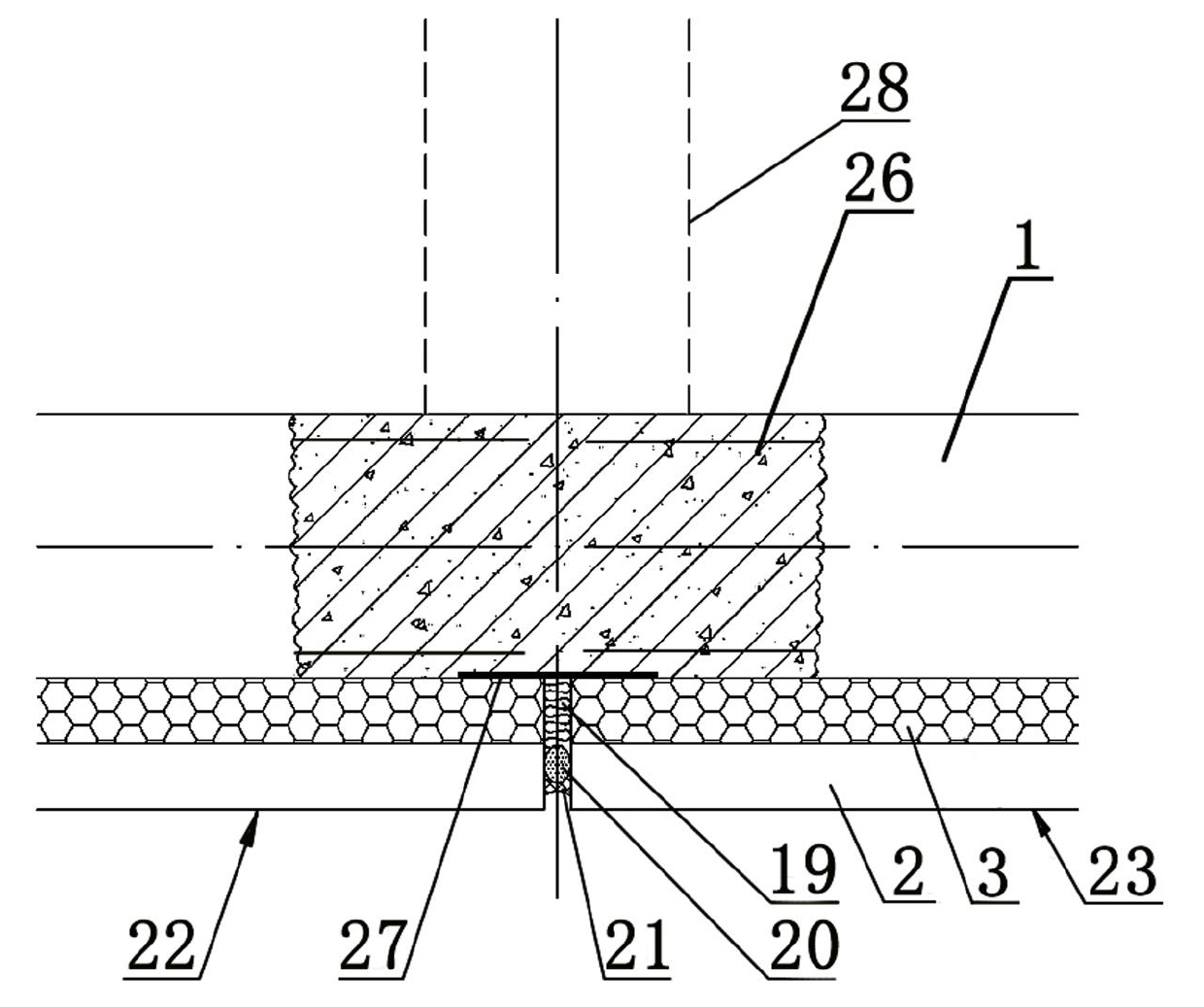

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

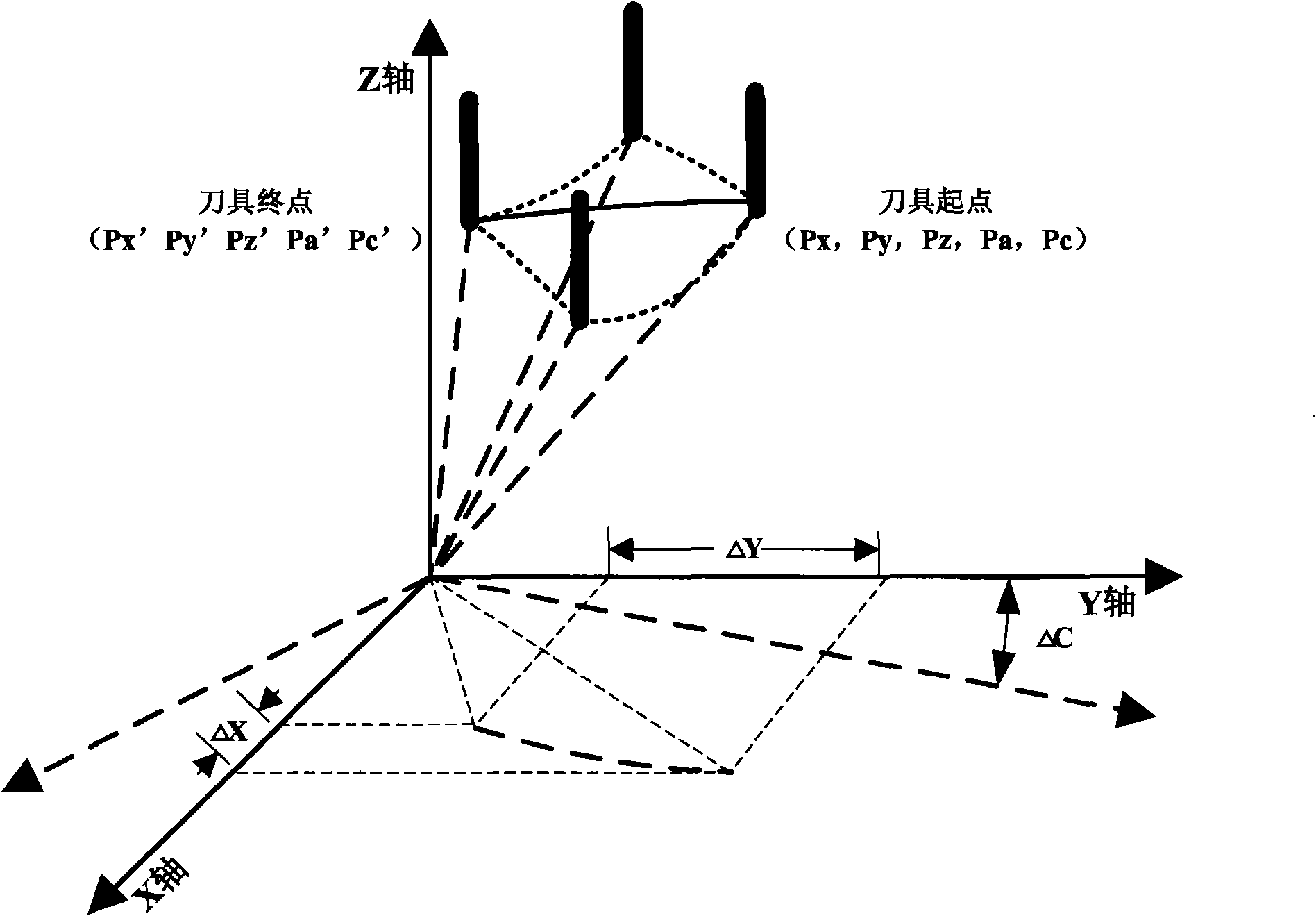

Five-axis linkage numerical control (NC) machining post processor and processing method thereof

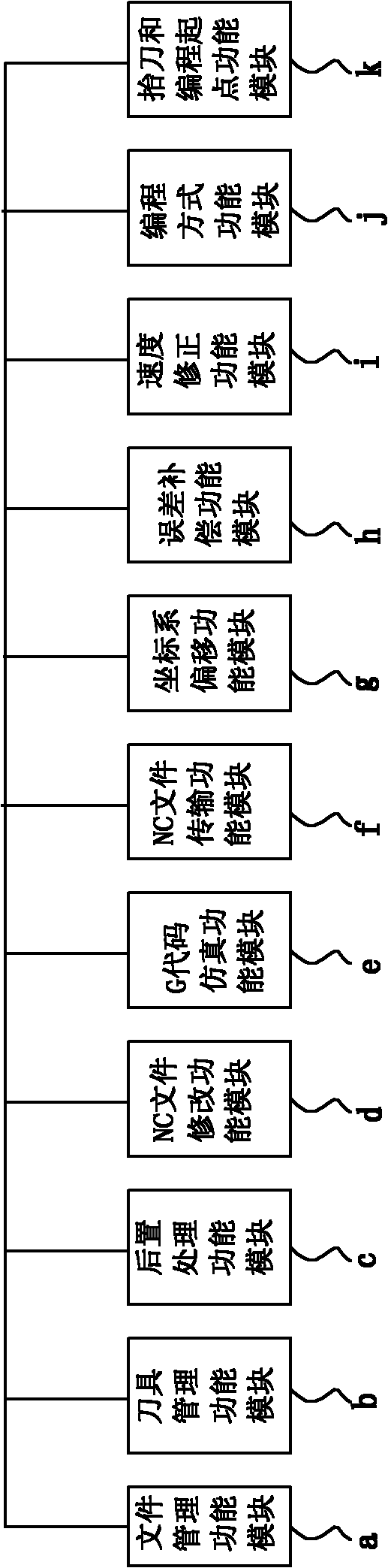

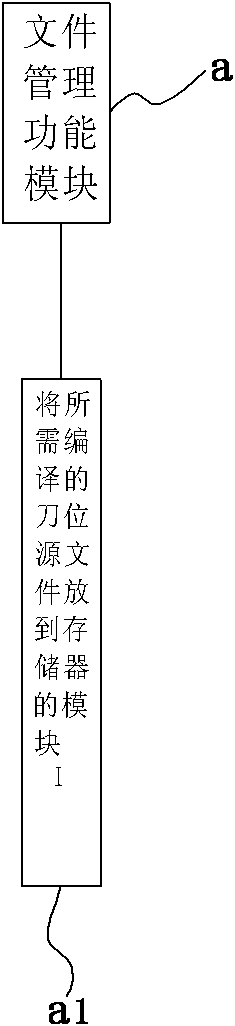

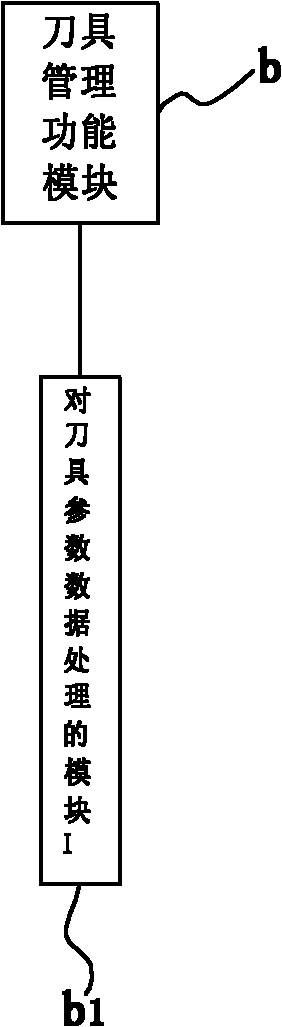

InactiveCN102023613ARealize simulationRealize serial communicationProgramme controlComputer controlPost processorManagement functions

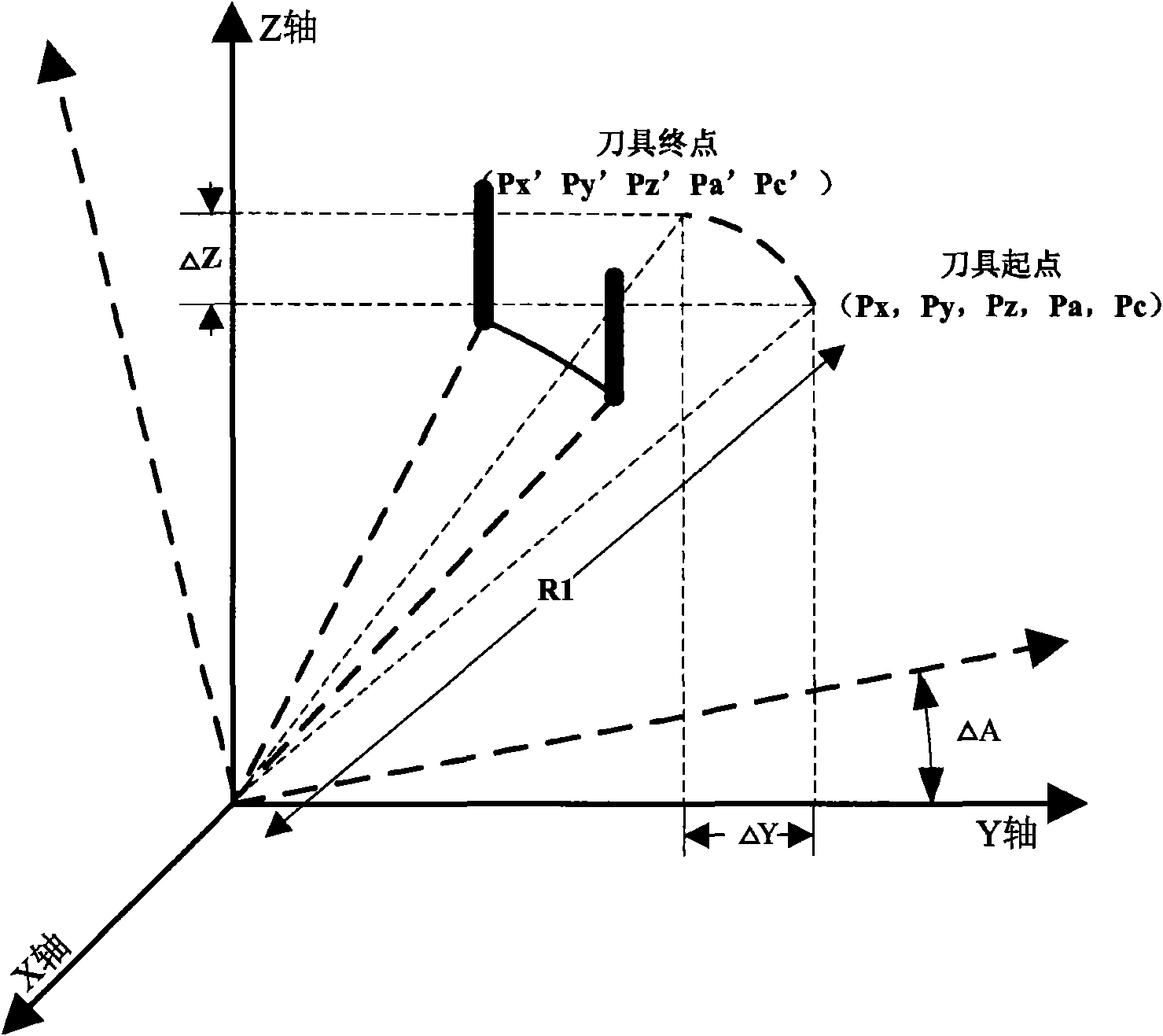

The invention discloses a five-axis linkage numerical control (NC) machining post processor and a processing method thereof, and relates to a post processor for an NC machining program and a processing method. The processor comprises computer program software which is used for processing a cutter location source file generated by a workpiece shape characteristic and a machining process, wherein the computer program software comprises a file management function module, a cutter management function module, a postprocessing function module, an NC file modification function module, a G code simulation function module, an NC file transmission function module, a coordinate system offset function module, an error compensation function module, a speed modification function module, a programming mode function module and a cutter-lifting and programming staring point function module. The processing method comprises the steps of setting a file, arranging a cutter, processing a programming mode, processing data of machine tool motion parameters, processing data of cutter dynamic cutting speed, outputting a G code file and the like. By the processor and the processing method, machining dynamic speed, speed compensation, non-linear error compensation and analog simulation of G code five-axis linkage can be realized.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY +1

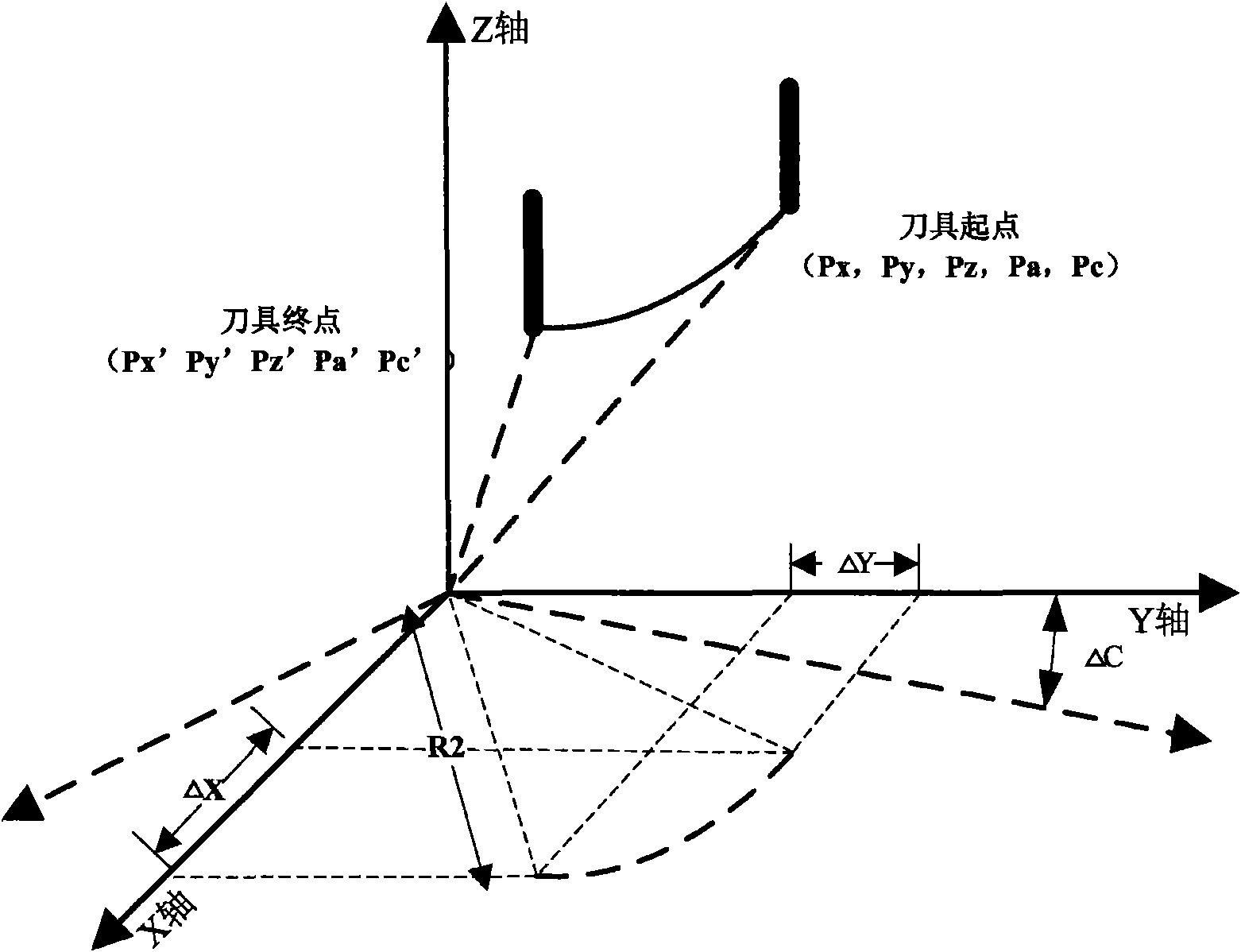

Method for compensating central point of double-turntable five-axis linked numerical control machining rotary tool

InactiveCN101980091ASolve the problem of nonlinear motion errorImprove performanceProgramme controlComputer controlLinear motionNonlinear motion

The invention discloses a method for compensating a central point of a double-turntable five-axis linked numerical control machining rotary tool. The method is characterized by comprising the following steps of: when a tool trace of a double-turntable five-axis linked numerical control system which machines a spatial complex curved surface is a straight line, discretely approximating the movement trace of the central point of the tool through line interpolation, starting a real time control protocol (RTCP) module, obtaining a normal plane compensation vector and performing projection to obtain a central point compensation vector and output displacement by using the RTCP module, and inputting a number axis center distance parameter to realize the compensation of a nonlinear movement error during the machining of the double-turntable five-axis linked numerical control system. The method can well inhibit the nonlinear movement error, so that the running efficiency of the numerical control machining equipment is improved, the numerical control equipment can perform high-precision and high-efficiency machining, the machining quality of parts can be remarkably improved, and the method has excellent application prospect in the field of mechanical engineering.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

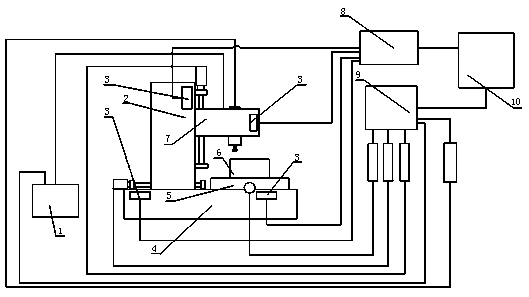

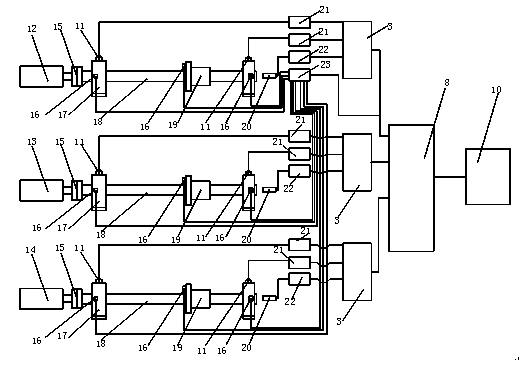

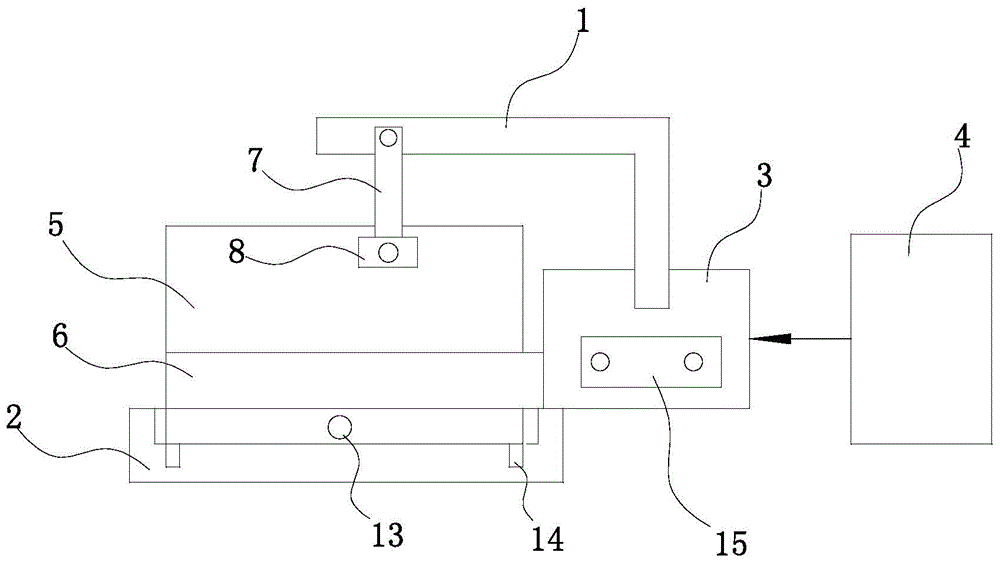

Numerical machine tool machining state multi-parameter online active monitoring system and implement method thereof

ActiveCN103823409AImprove processing qualityImprove processing efficiencyProgramme controlComputer controlActive monitoringState parameter

The invention discloses a numerical machine tool machining state multi-parameter online active monitoring system and an implement method thereof. The system and the method mainly solve the problems that state detection performance indexes of an existing numerical control machine tool are not comprehensive, and closed-loop control during the machining process can not be achieved. The numerical machine tool machining state multi-parameter online active monitoring system comprises a first sensor assembly arranged on a numerical control machine tool servo feeding unit, a second sensor assembly arranged on a main shaft unit, a third sensor assembly disposed on a cooling liquid circulating unit and a multi-channel synchronous data collecting PXI box used for receiving information of collected data. The multi-channel synchronous data collecting PXI box sends related collected state signals to a monitoring computer in real time for analysis, calculation, display and storage, the monitoring computer generates related control instructions according to abnormal or optimized machining state parameters, transmits the related control instructions to a numerical control system of the numerical control machine tool through an Ethernet bus and executes related active control instruments, and accordingly real-time adjustment and control of numerical control machining process states are finished.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

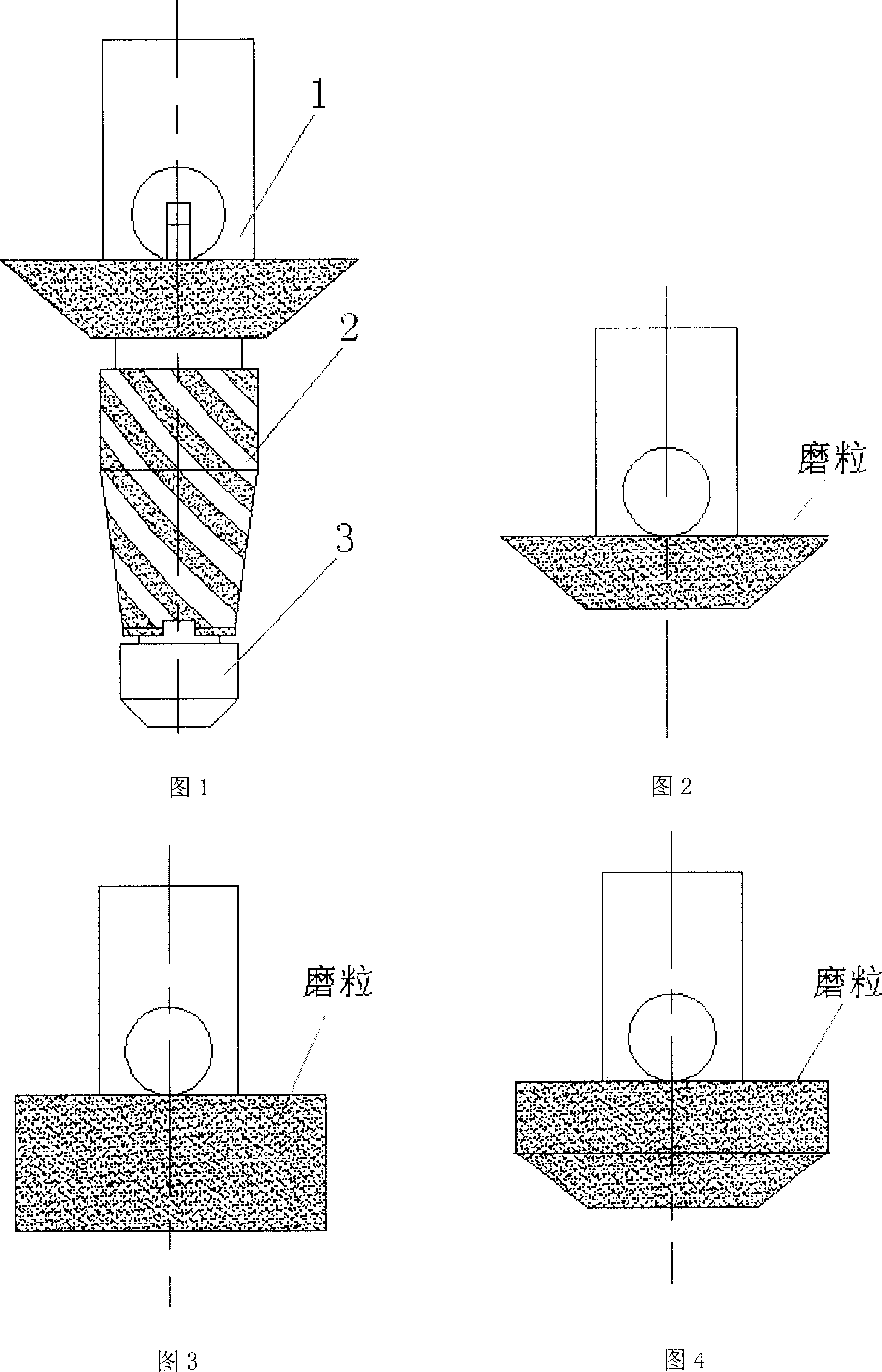

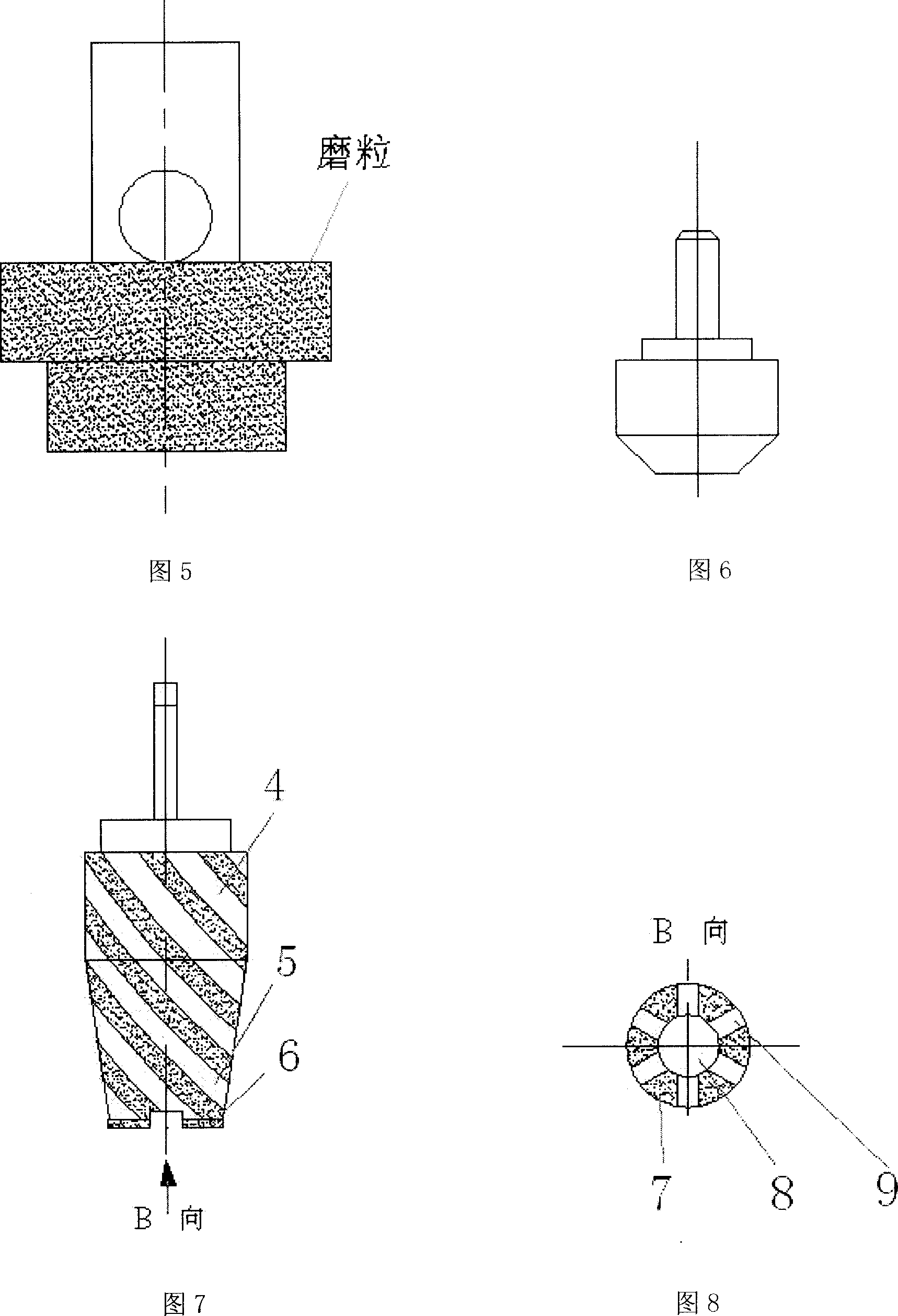

Drilling/grinding integrated combined tool

InactiveCN1935430AImprove processing qualityExtend your lifeTransportation and packagingAbrasion apparatusStructural engineeringConoid

The present invention relates to an integral combined cutting-tool with hole-drilling and hole-grinding functions. Said cutting-tool is formed from three portions of counter-boring hole-grinding and hole-sinking section, hole-expanding and hole-grinding section and guide head. Said invention also provides the concrete structure of the above-mentioned every portion and its production method.

Owner:DALIAN UNIV OF TECH

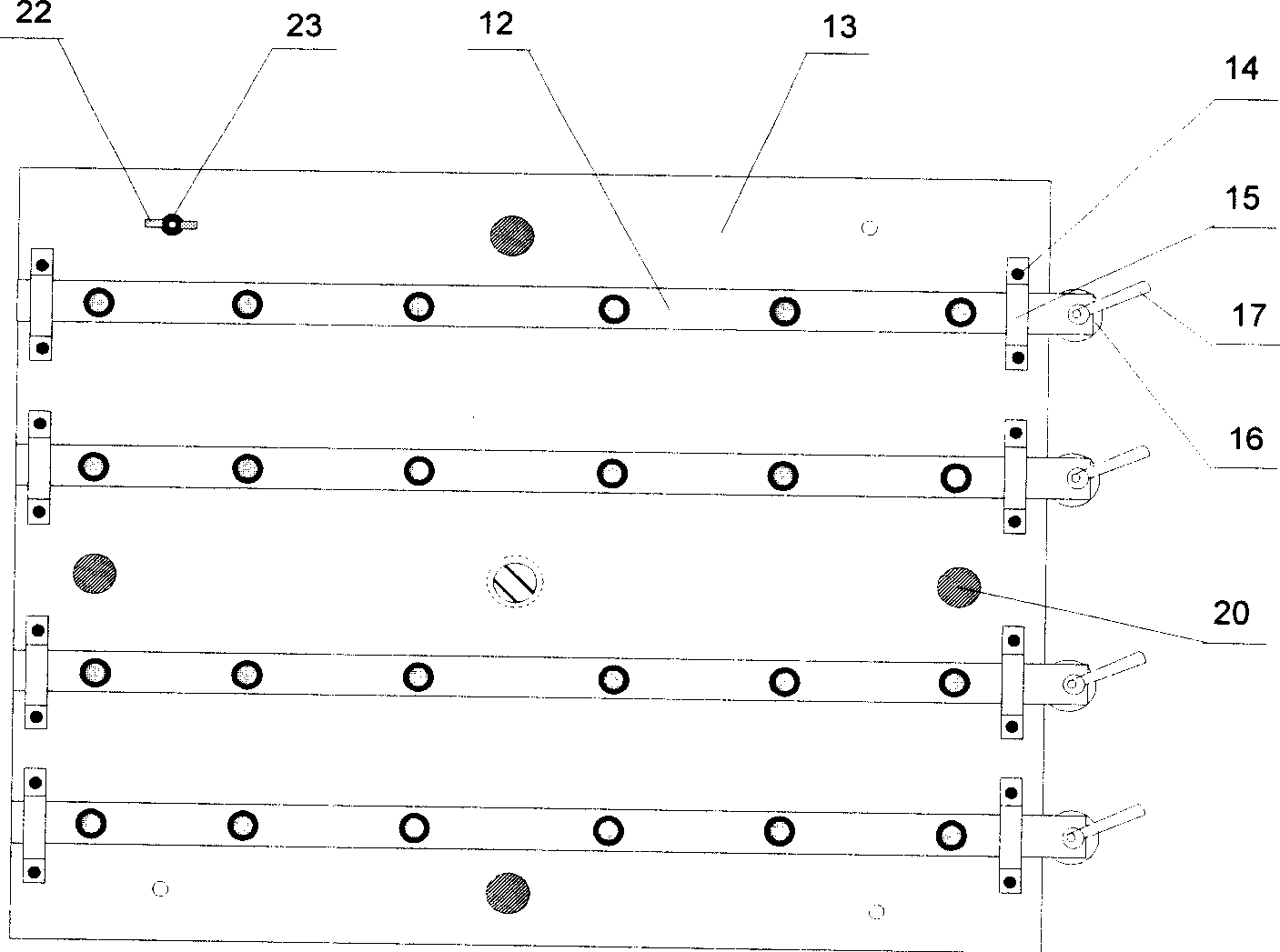

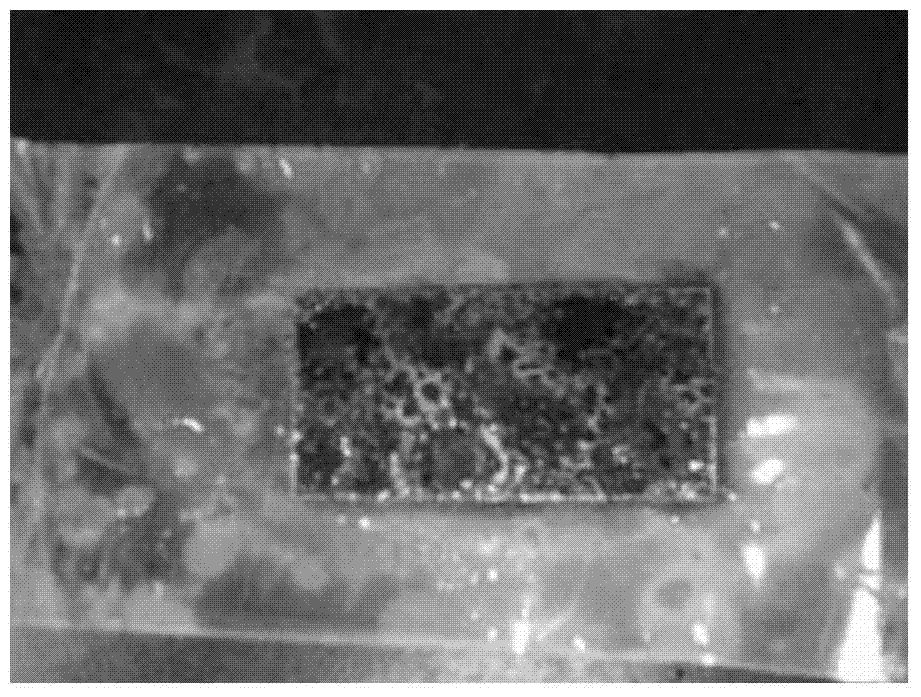

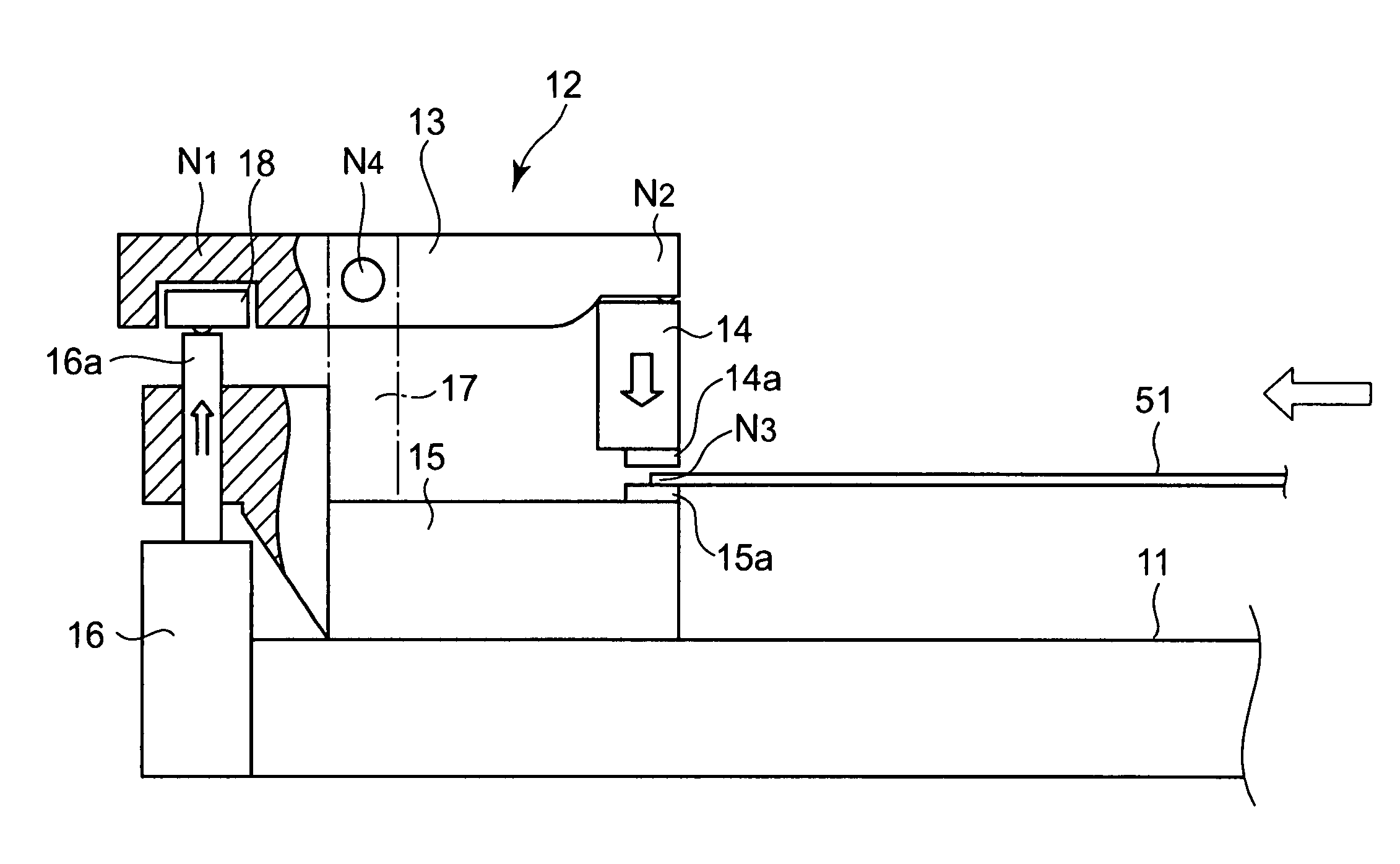

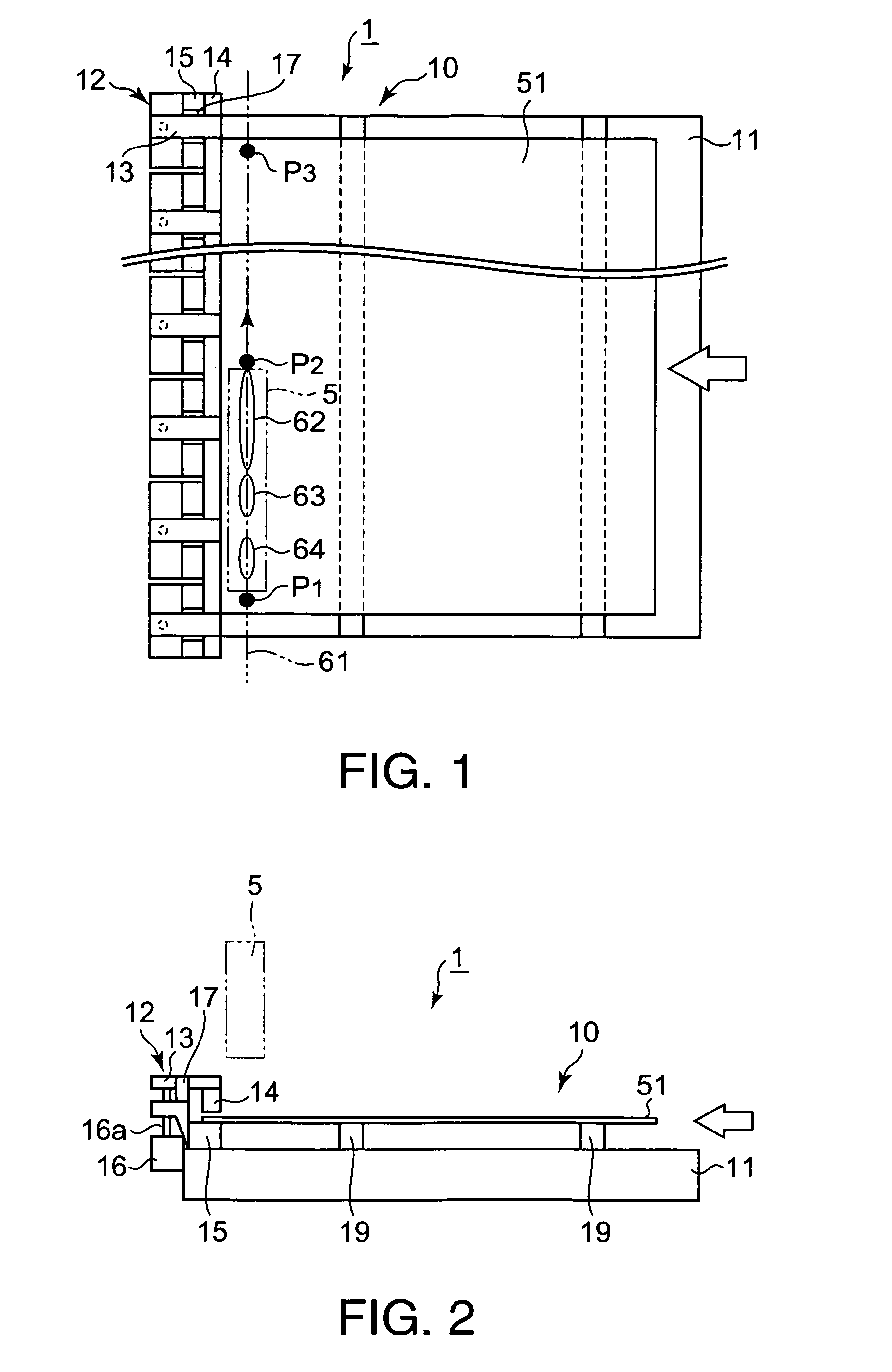

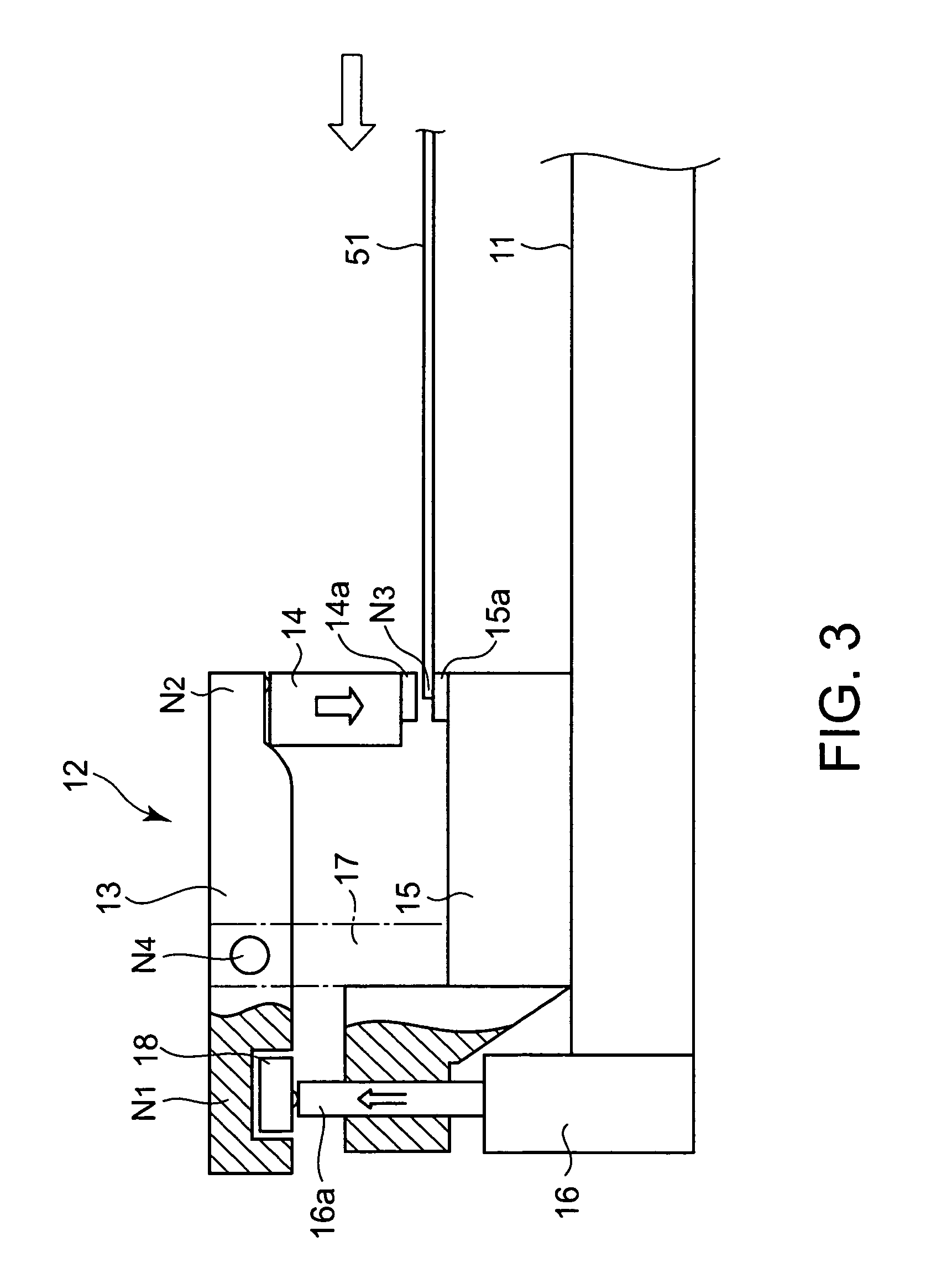

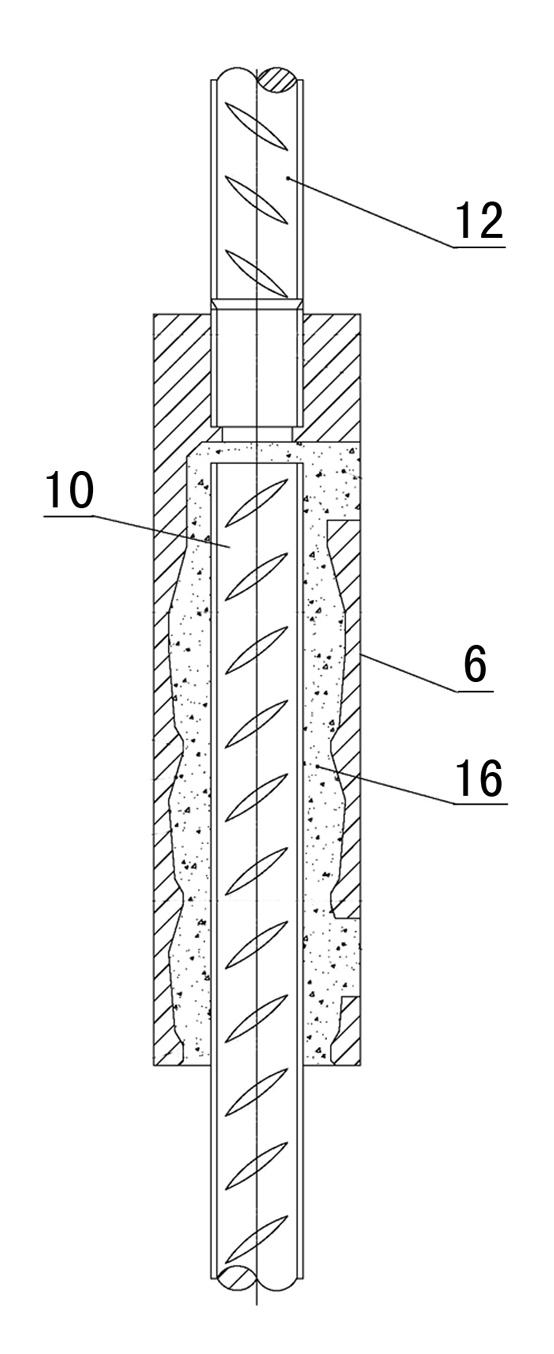

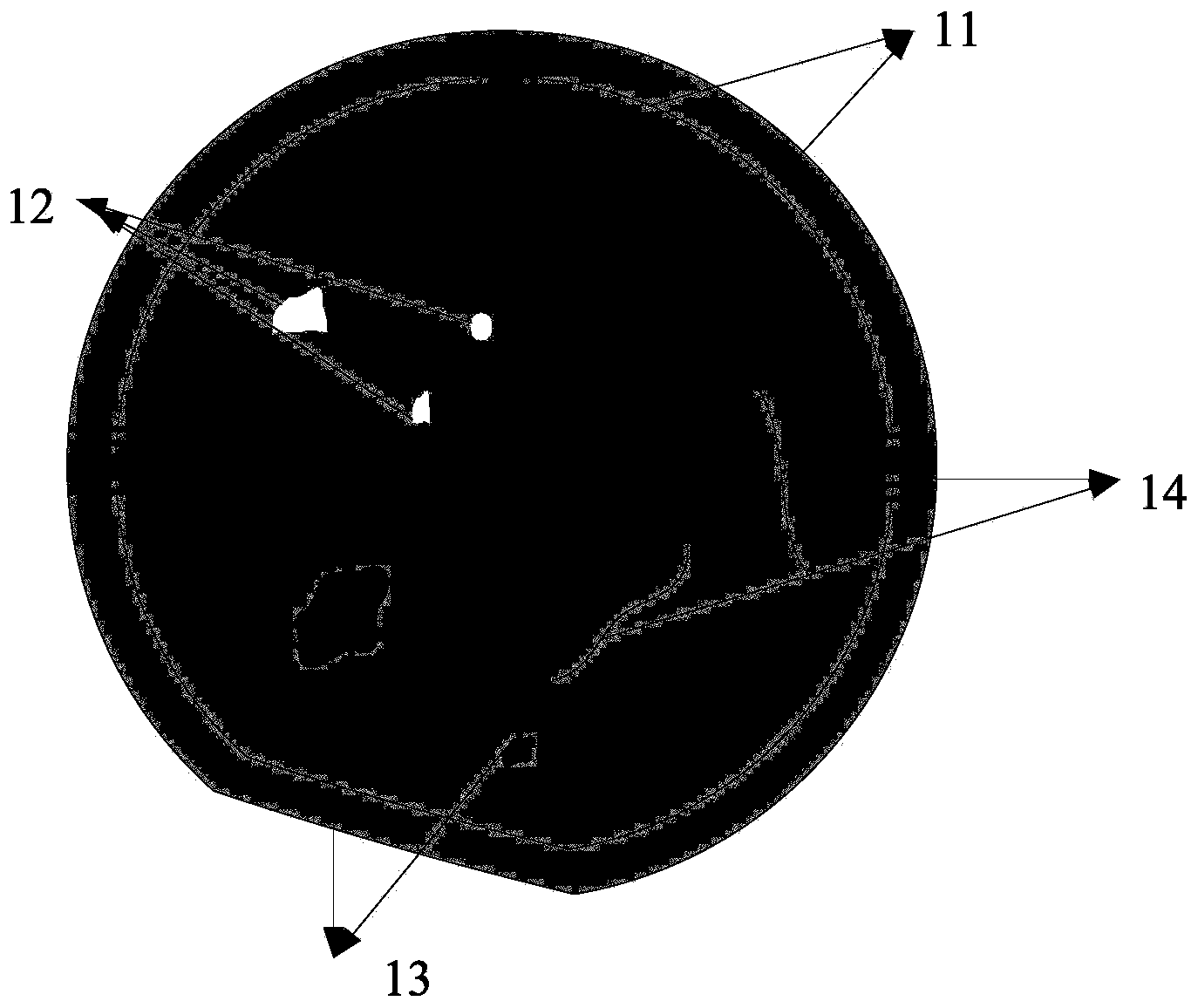

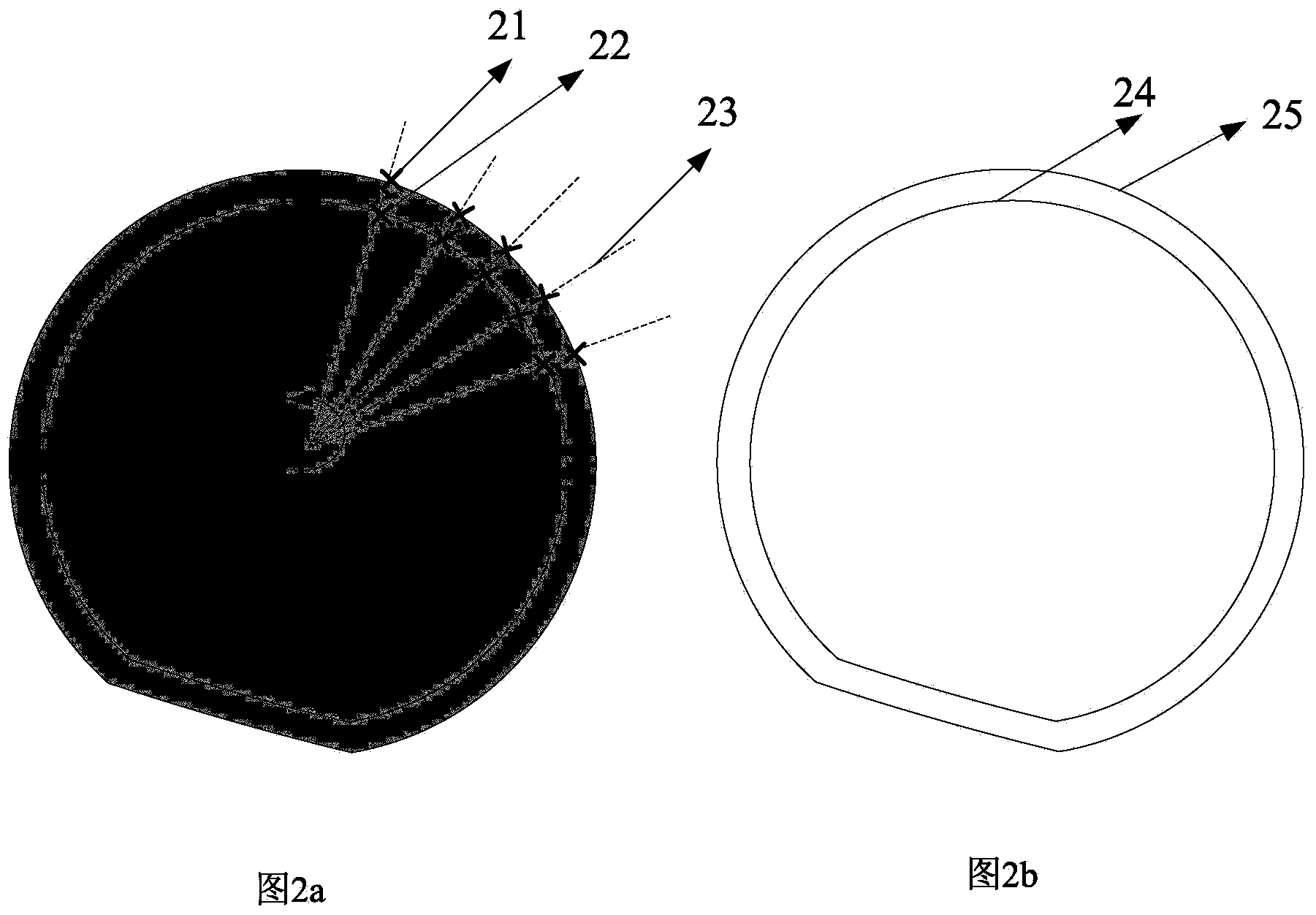

Brittle workpiece splitting system and brittle workpiece splitting method

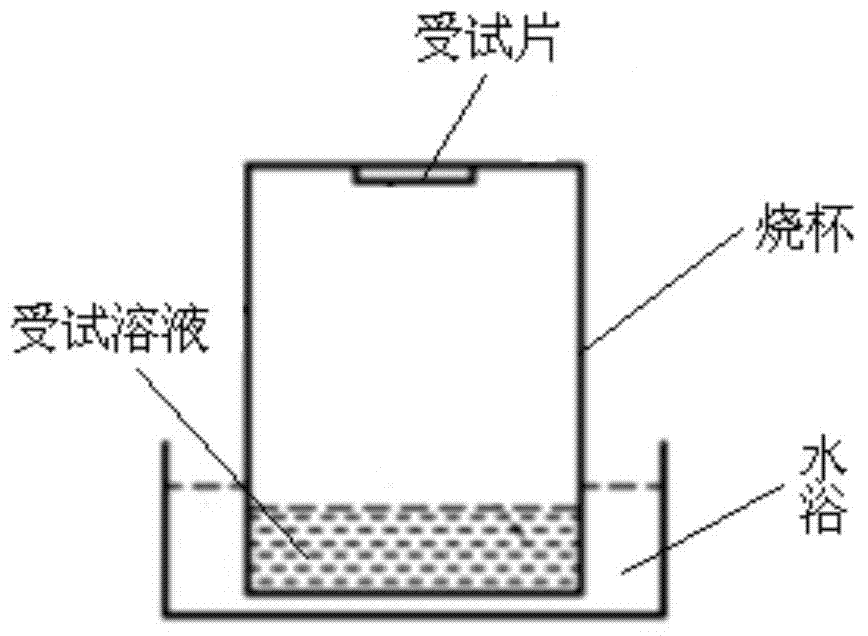

InactiveUS8104385B2Improve processing qualityAchieving splitting processGlass blowing apparatusGlass reforming apparatusSplit linesMechanical engineering

The brittle workpiece splitting system 1 includes a substrate holding mechanism 10 for holding a substrate 51, and a processing unit 5 for splitting the substrate 51 held by the substrate holding mechanism 10 by a splitting process. The substrate holding mechanism 10 has an edge damper 12 adapted to clamp an edge part of the substrate 51 from the sides of the opposite surfaces of the edge part, and support members 19 for supporting the substrate 51 thereon at a predetermined height. The support members 19 are disposed on the side opposite the side of the edge damper 12 with respect to the intended split line 61 parallel to the edge part of the substrate 51. The edge damper 12 has an edge holder 15 on which the substrate 51 is seated, and a pressure bar 14 for pressing the substrate 51 against the edge holder 15 to hold the substrate 51 between the edge holder 15 and the pressure bar 14. Resin members 14a and 15a made of an elastic material having comparatively high rigidity are attached to parts, to be brought into contact with the substrate 51, of the pressure bar 14 and the edge holder 15, respectively. The support members 19 are made of a low-friction material to permit the horizontal movement of the substrate 51 during the splitting process.

Owner:SHIBAURA MECHATRONICS CORP +1

Assembled integral shear wall structure system and construction method thereof

ActiveCN101818527ALow costGuarantee the construction qualityWallsBuilding material handlingReinforced concretePolystyrene

The invention discloses an assembled integral shear wall structure system and a construction method thereof. Prefabricated composite wallboards are hoisted and assembled integrally at a construction site; a board body of the prefabricated composite wallboards comprises a structural layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; the insulating layer is an extruded polystyrene foam plastic board; steel meshes are arranged in the concrete of the protective layer; and anchor bolts in a dotted distribution are connected among the structural layer, the insulating layer and the protective layer. Vertical seams and horizontal seams of prefabricated composite walls adopt structural self-waterproofing, so that common quality problems such as leakage and cracks and the like in a traditional process are solved. The prefabricated composite walls simplify construction processes, speed up the construction, and lower the construction cost. Furthermore, products prefabricated in a factory have uniform specifications and unified quality, so that the construction quality of a building construction can be sufficiently guaranteed; the industrialization, standardization, and generalization of the building walls are realized; and the products can be widely applicable to the construction of reinforced concrete buildings in the construction industry.

Owner:华筑(辽宁)建筑工程设计有限公司

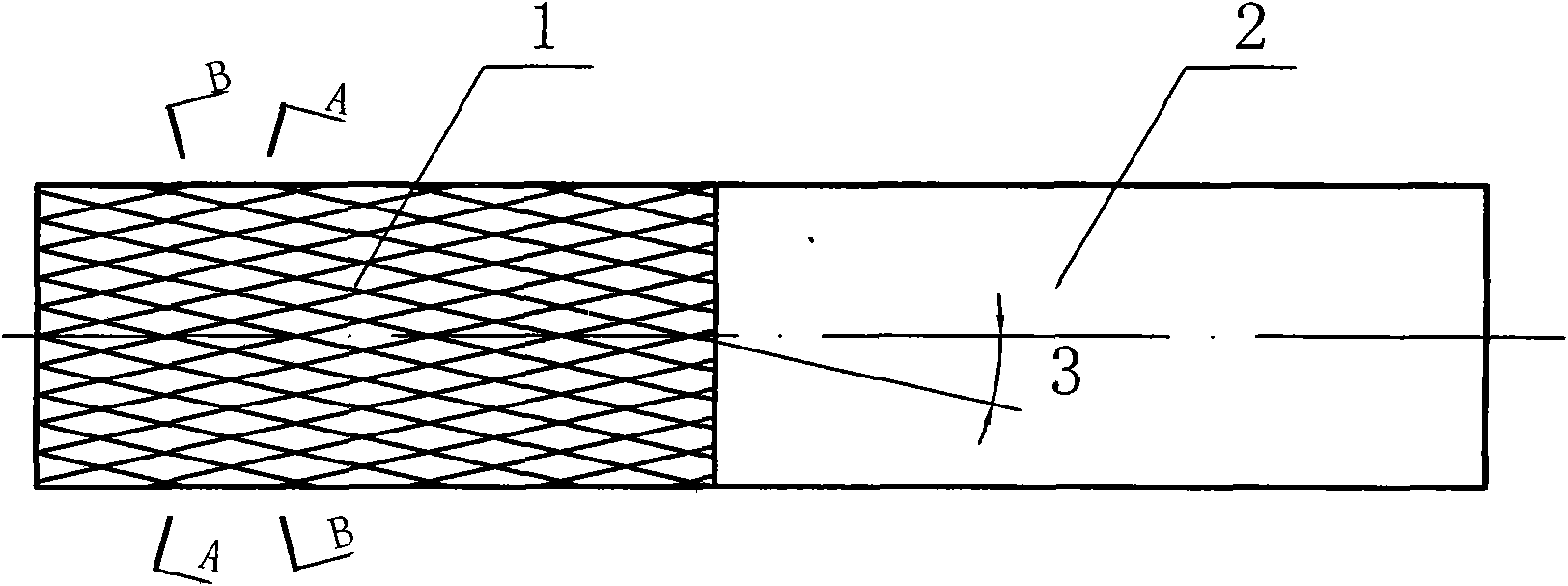

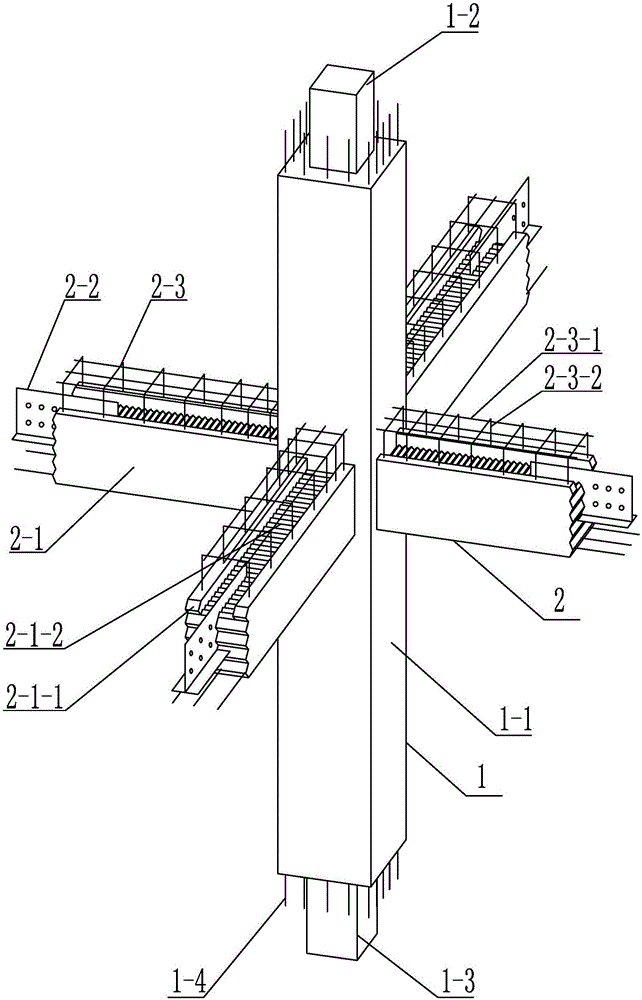

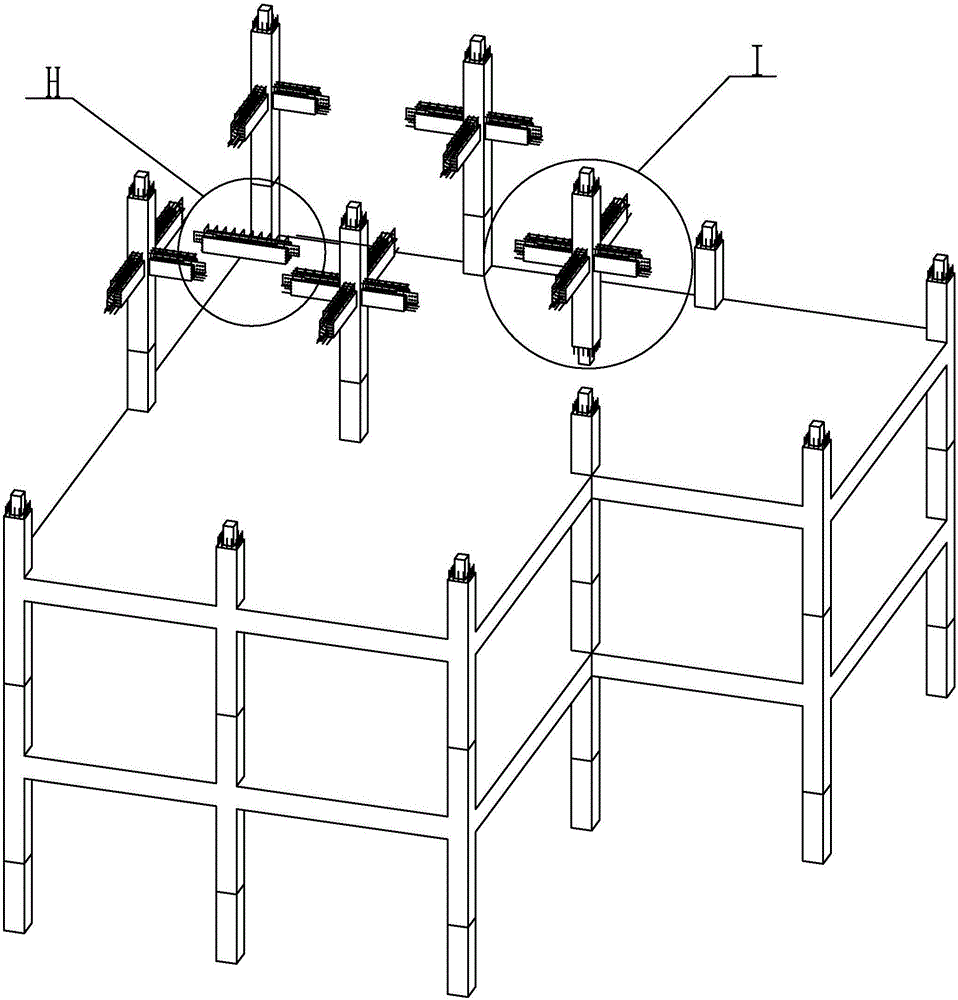

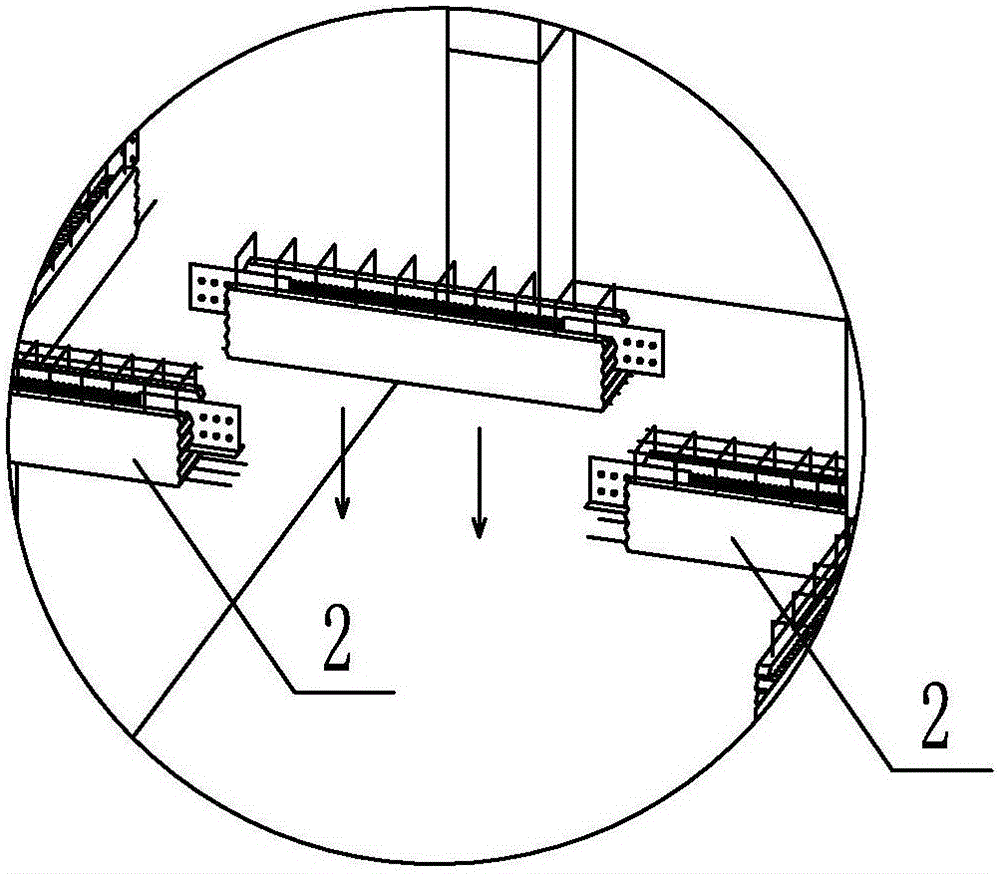

Single-layer prefabricated assembly type reinforced concrete beam-column joint

The invention relates to a prefabricated reinforced concrete beam-column joint, in particular to a single-layer prefabricated assembly type reinforced concrete beam-column joint. In order to solve the problem that the connection integrity of existing prefabricated beams and prefabricated columns is hard to guarantee, the prefabricated joint for one-piece casting manufacturing of a column section and part of beam sections is provided according to the concept of the point of inflection. The single-layer prefabricated assembly type reinforced concrete beam-column joint is formed by overall manufacturing of a vertical column section (1) and joint superposed beam sections (2) in a factory for prefabrication. A manufacturing method comprises the steps of beam-column longitudinal bar and stirrup binding, connector pre-burying, formwork erecting and concrete pouring and curing. The height of the vertical column section (1) of the joint is 1 / 2 of the storey height, and the length of each joint superposed beam section (2) is 1 / 3 of the span of adjacent columns. The vertical column section (1) comprises a pouring section (1-1), a concrete filled steel tube connector (1-2), a steel tube connector (1-3) and column section longitudinal bars (1-4). Each joint superposed beam section (2) comprises a groove-shaped pouring section (2-1), inverted-T-shaped structural steel connectors (2-2) and a reinforcement cage framework (2-3). The single-layer prefabricated assembly type reinforced concrete beam-column joint is applied to the construction industry.

Owner:HARBIN INST OF TECH

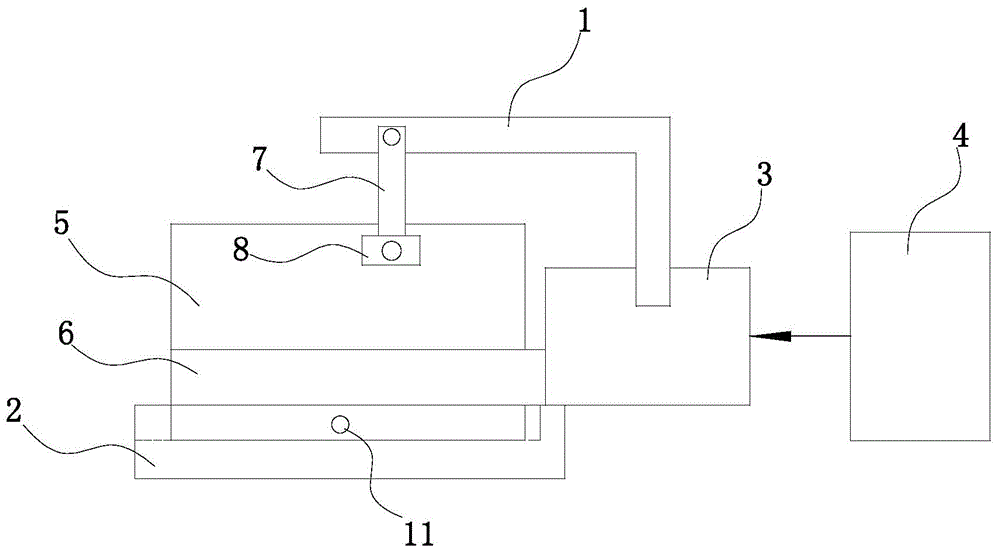

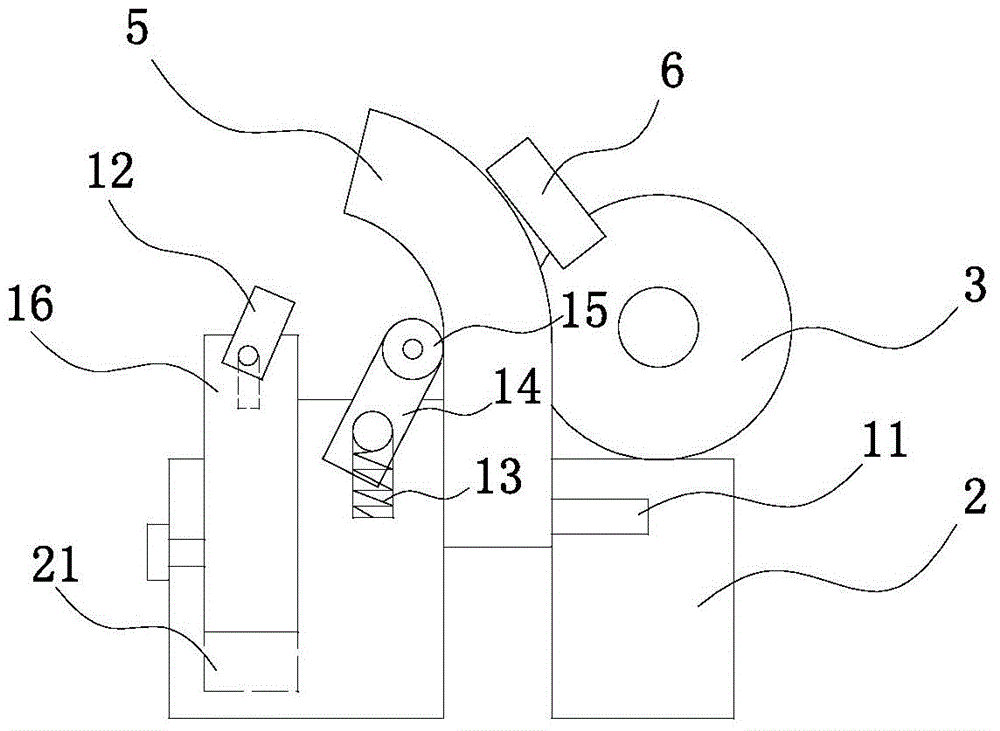

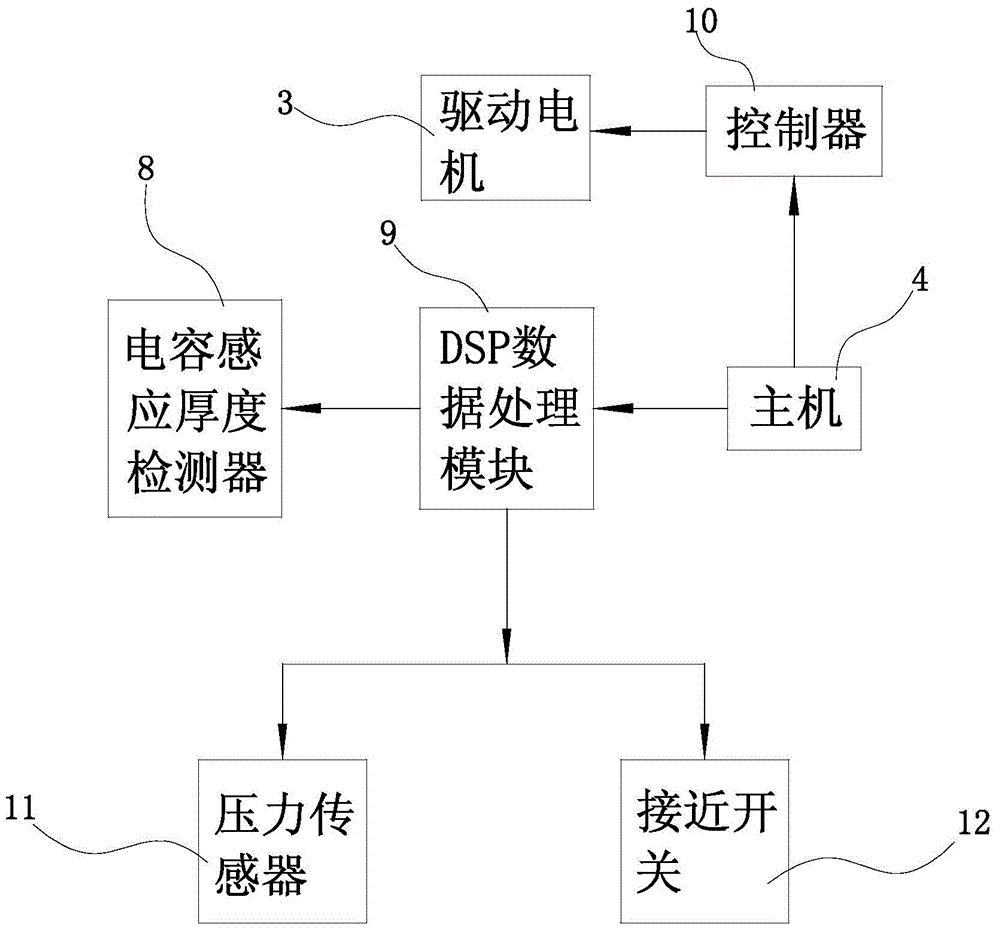

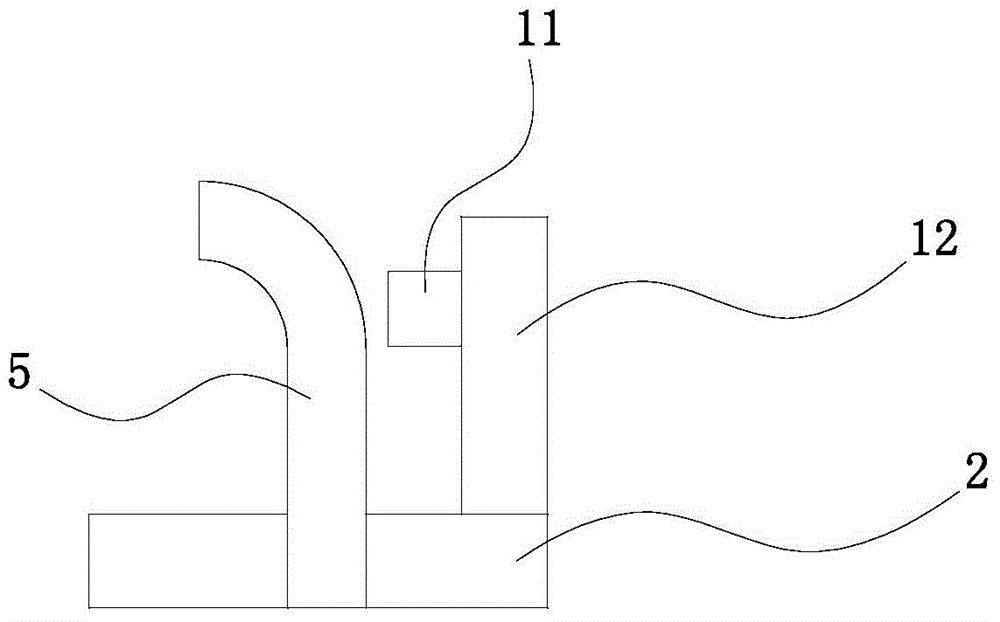

Bending machine controlling torque adjustment and roll bending through PLC and method

InactiveCN104624737APrevent looseningPrevent excessive deformationMetal-working feeding devicesMetal working apparatusCapacitanceAutomatic control

The invention relates to a bending machine controlling torque adjustment and roll bending through a PLC and a method. The bending machine comprises a driving motor, a clamping-fixing seat and a PLC mainframe, wherein the driving motor, the clamping-fixing seat and the PLC mainframe are arranged on a machine frame, a bending shaft is installed on the driving motor, and a machined part is arranged on the clamping-fixing seat. The bending machine further comprises a capacitive sensing thickness detector installed on the machine frame through a support, a proximity switch installed on the clamping-fixing seat, a pressure sensor and a rolling shaft, wherein the rolling shaft is connected to the upper end face of an adjusting plate, and the lower end face of the adjusting plate is installed in an installing groove formed in the clamping-fixing seat by means of a rotary shaft and a spring. The bending machine adopts the pressure sensor to control clamping force, and excessive deformation and looseness of boards are avoided. Bending is performed by utilizing most suitable torque, and machining quality is improved. The bending machine automatically controls a bending angle through the arranged proximity switch and prevents excessive bending. The inner concave face of the machined part is rolled through the rolling shaft, and cracks and burrs at the position of the concave face are decreased.

Owner:DONGGUAN ZHENGQIANG HARDWARE ELECTRONICS

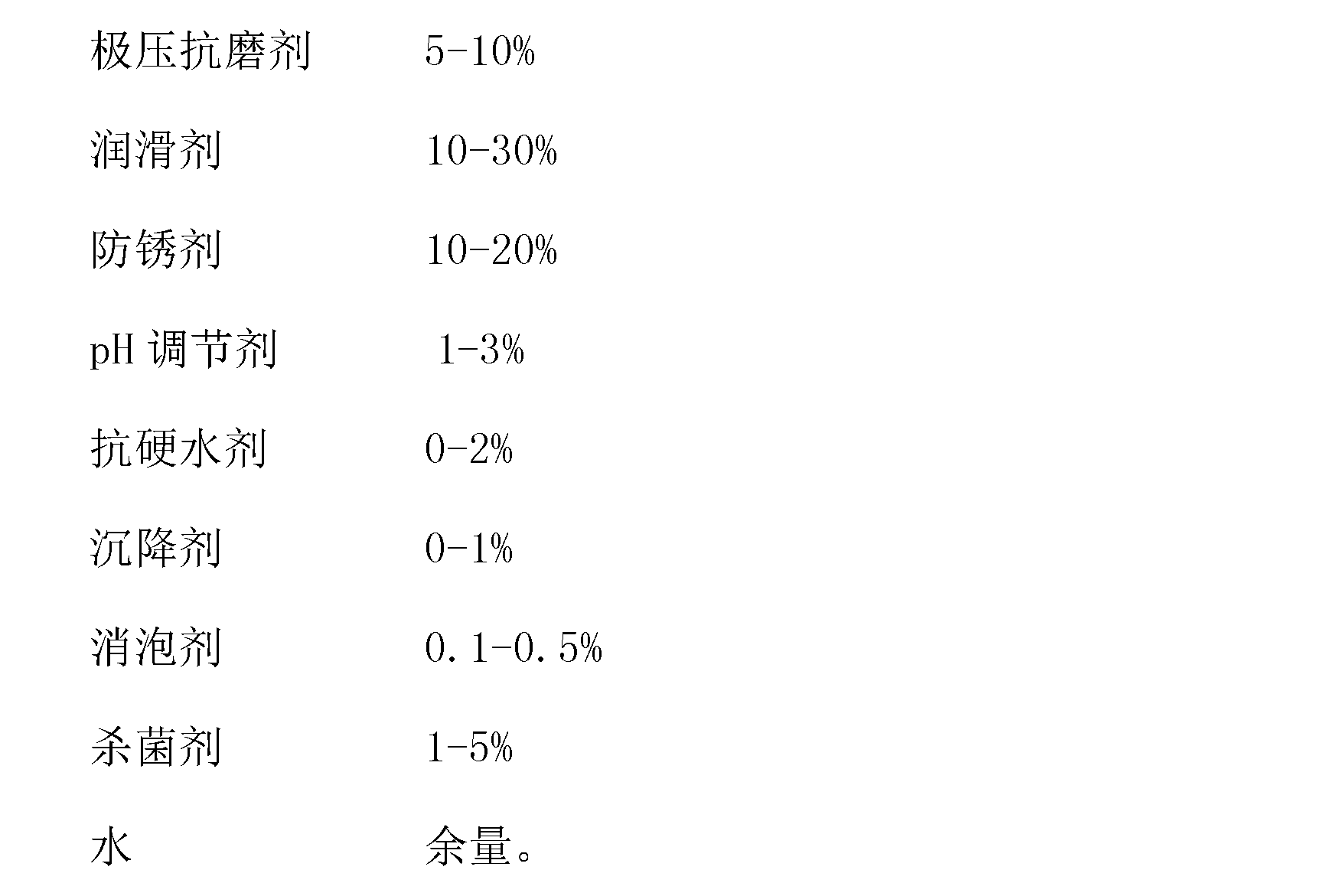

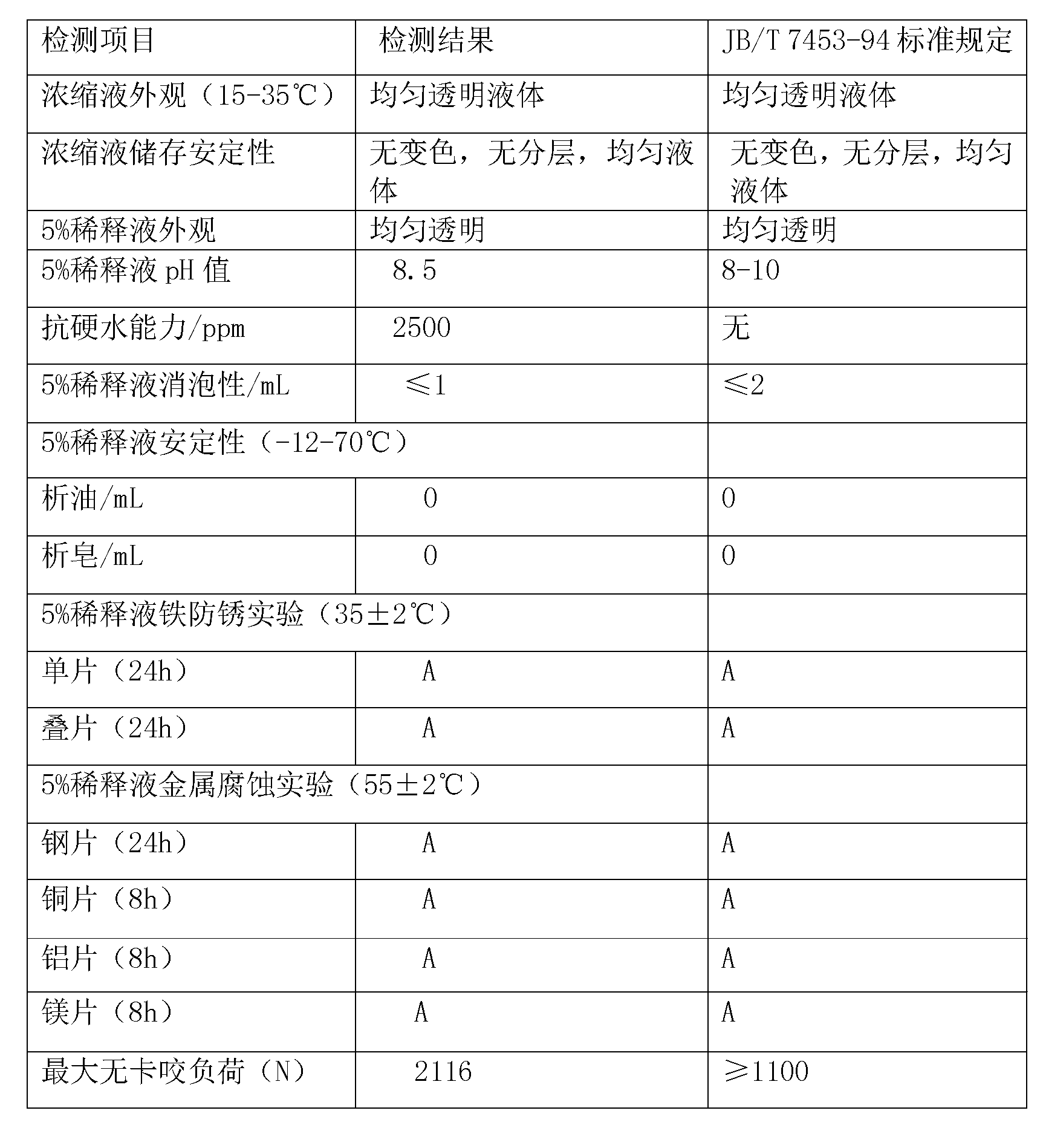

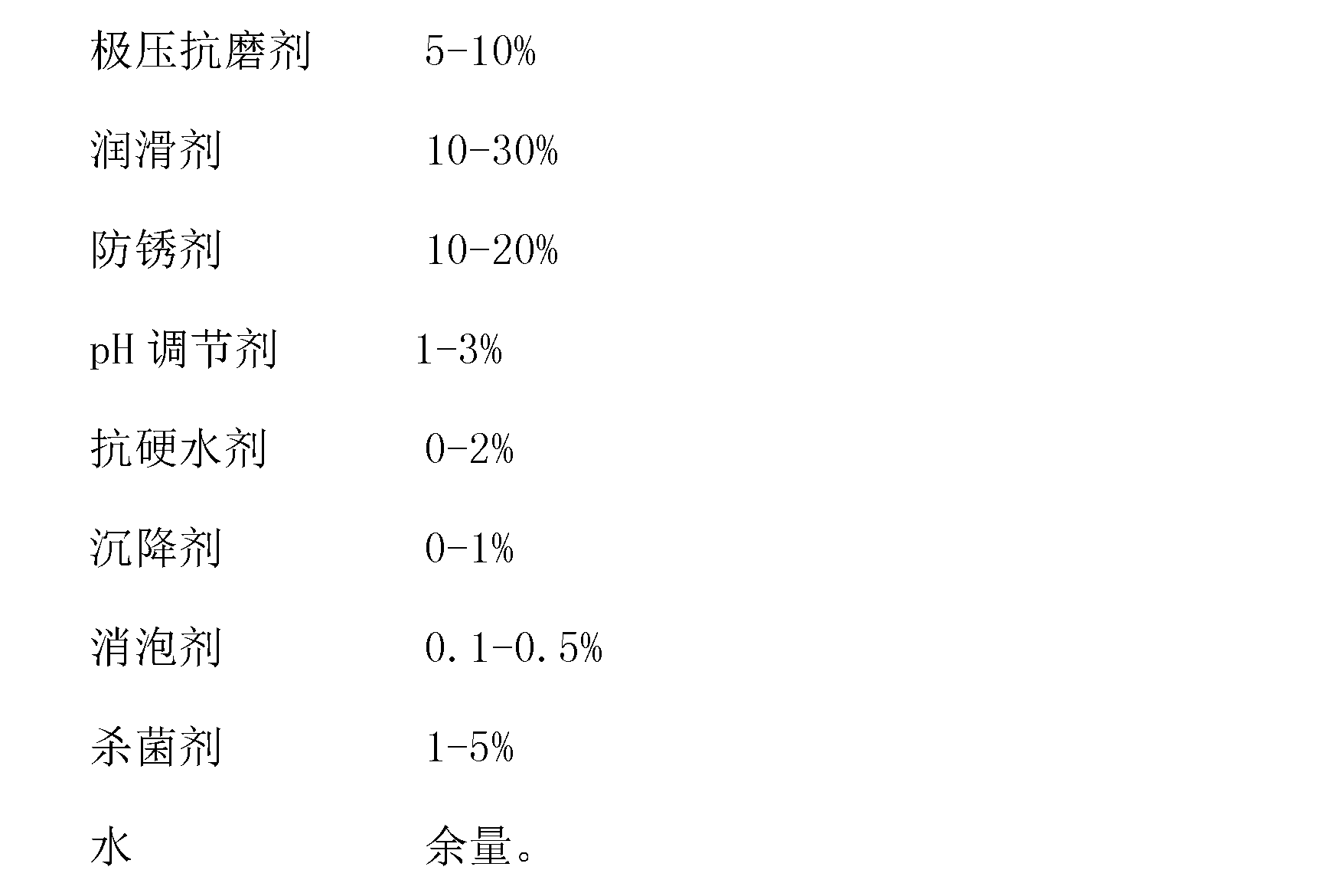

Aluminum-magnesium alloy cutting fluid

ActiveCN102703194AExcellent lubricating and anti-wear propertiesImprove cooling effectLubricant compositionRust converterDefoaming Agents

The invention discloses an aluminum-magnesium alloy cutting fluid which consists of the following components in percentage by weight: 5-10 percent of extreme pressure anti-wear additive, 10-30 percent of lubricating agent, 10-20 percent of anti-rusting agent, 1-3 percent of pH regulator, 0-2 percent of hard water resisting agent, 0-1 percent of settling agent, 0.1-0.5 percent of defoaming agent, 1-5 percent of sterilizing agent and the balance of water. According to the aluminum-magnesium alloy cutting fluid, excellent lubricating and wear resisting performances, cleaning and cooling performance and rust and corrosion resisting performances are obtained, thus cutting bumps can be avoided, a cutter is effectively protected and the processing quality is improved; more heat generated in the processing process is taken away, so that the temperature of the processing surface is reduced and the defects of the curling and the deformation of workpieces caused by high temperature, flammabilityof scrap magnesium at high temperature and the like are effectively overcome; and a processing technique is simplified, and thus the processing period is shortened and the production efficiency is increased.

Owner:上海福岛新材料科技有限公司

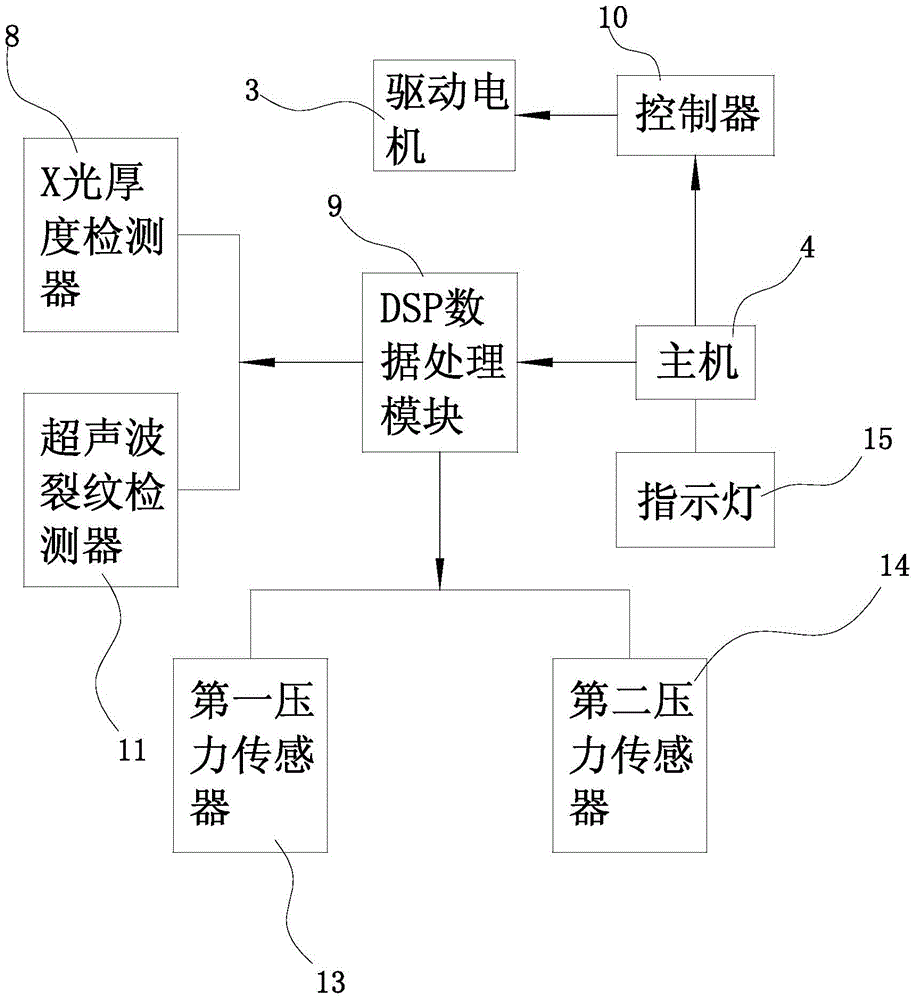

X-ray thickness detection and bending speed adjusting bending machine based on PLC

ActiveCN104624726AAvoid bendingAvoid empty foldsMetal-working feeding devicesShaping safety devicesX-rayDrive motor

The invention relates to an X-ray thickness detection and bending speed adjusting bending machine based on a PLC. The X-ray thickness detection and bending speed adjusting bending machine comprises a driving motor, a clamping fixing base, a main machine as well as an X-ray thickness detector, a first pressure sensor, a second pressure sensor and a detection feedback device, wherein the driving motor is arranged on a rack; the main machine is used for controlling the driving motor; a bending shaft is mounted on a motor shaft of the driving motor; a processed workpiece is arranged on the clamping fixing base; the X-ray thickness detector is mounted on the rack through a first bracket; the first pressure sensor and the second pressure sensor are arranged on the clamping fixing base; the detection feedback device comprises an ultrasonic crack detector which is arranged on the clamping fixing base through a second bracket. The invention further provides a bending processing method adopting the bending machine. Due to PLC controlled sectional processing and positioning detection, the phenomenon of bending deviation or bending omission can be avoided, and the processing reliability can be improved; the processed workpiece can be bent according to most appropriate torque, so that the processed workpiece is prevented from being affected by too large or too small torque, bending cracks can be reduced, and the processing quality can be improved.

Owner:南京比泰数控机械设备有限公司

Classification and detection method of wafer appearance defects

ActiveCN103674965AImprove processing efficiencyImprove processing qualityOptically investigating flaws/contaminationRegion of interestSemiconductor

The invention relates to the field of semiconductor device manufacture equipment, and especially relates to a classification and detection method of wafer appearance defects. The method comprises the following steps: S1, screening to obtain a wafer image; S2, performing edge extraction on the wafer image to calculate the edge width; S3, segmenting out wafer region of interest; S4, performing appearance defect detection on the wafer region of interest; and S5, performing classification on wafer appearance defects. The method provided by the invention helps to improve the processing efficiency and quality of wafers.

Owner:HANS LASER TECH IND GRP CO LTD +1

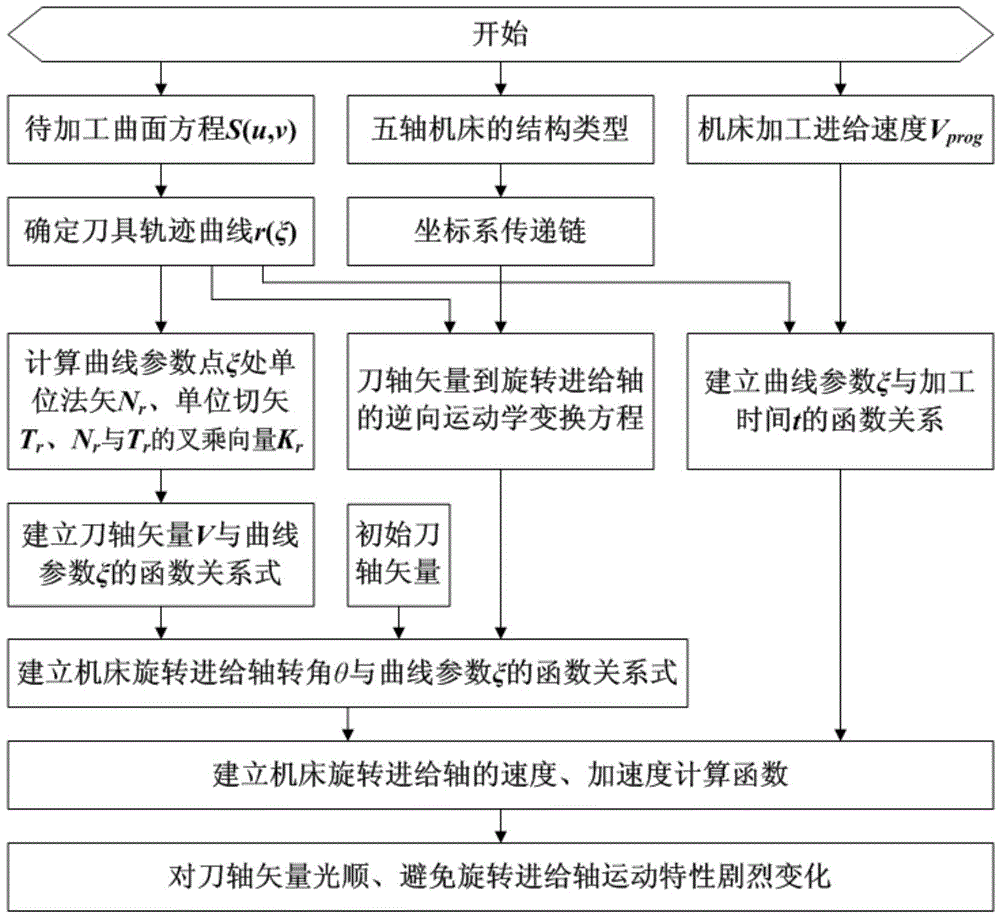

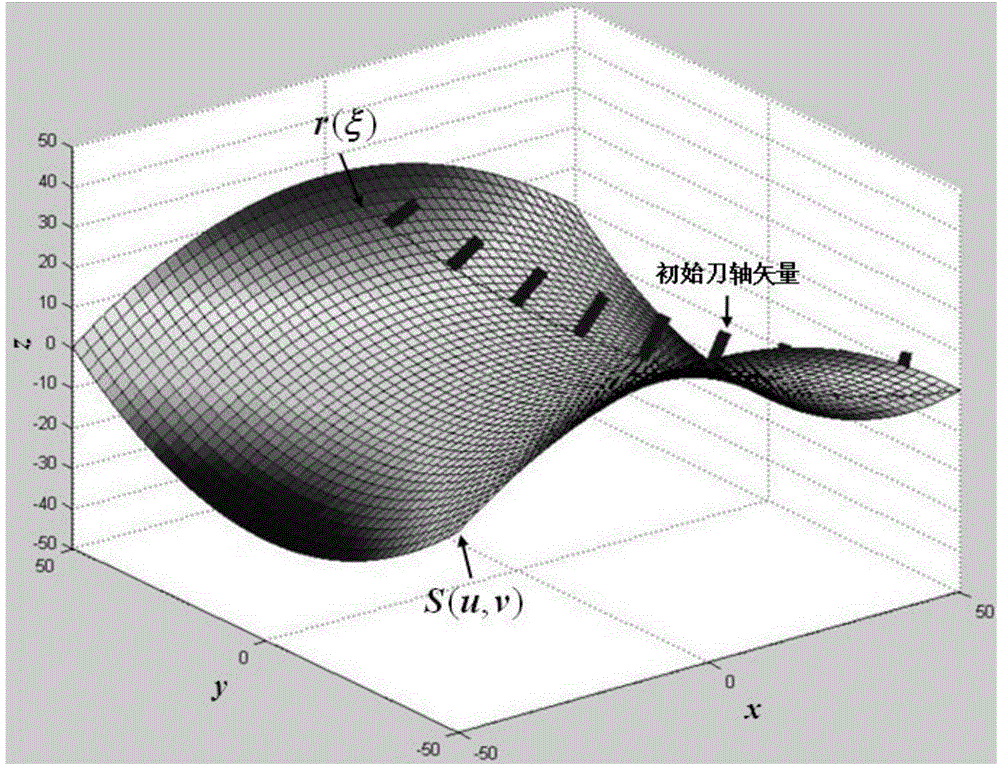

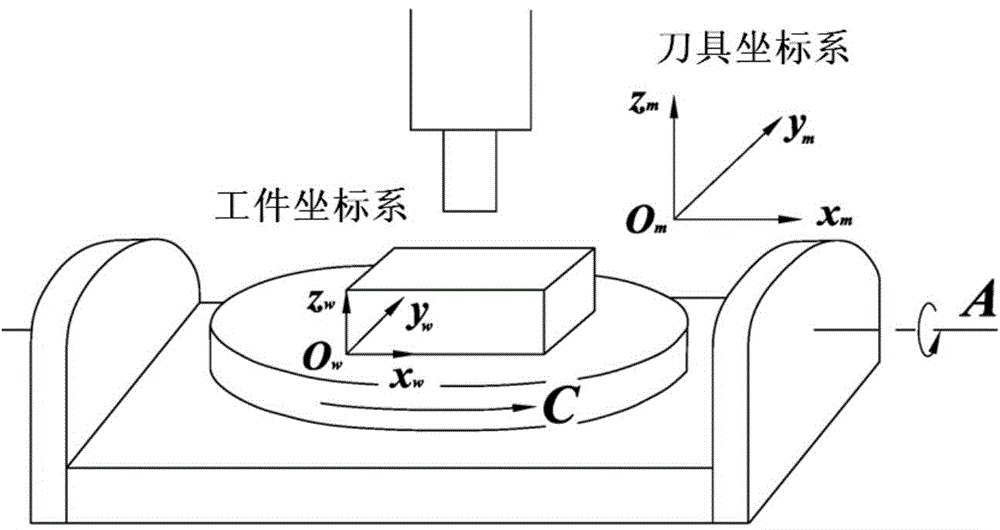

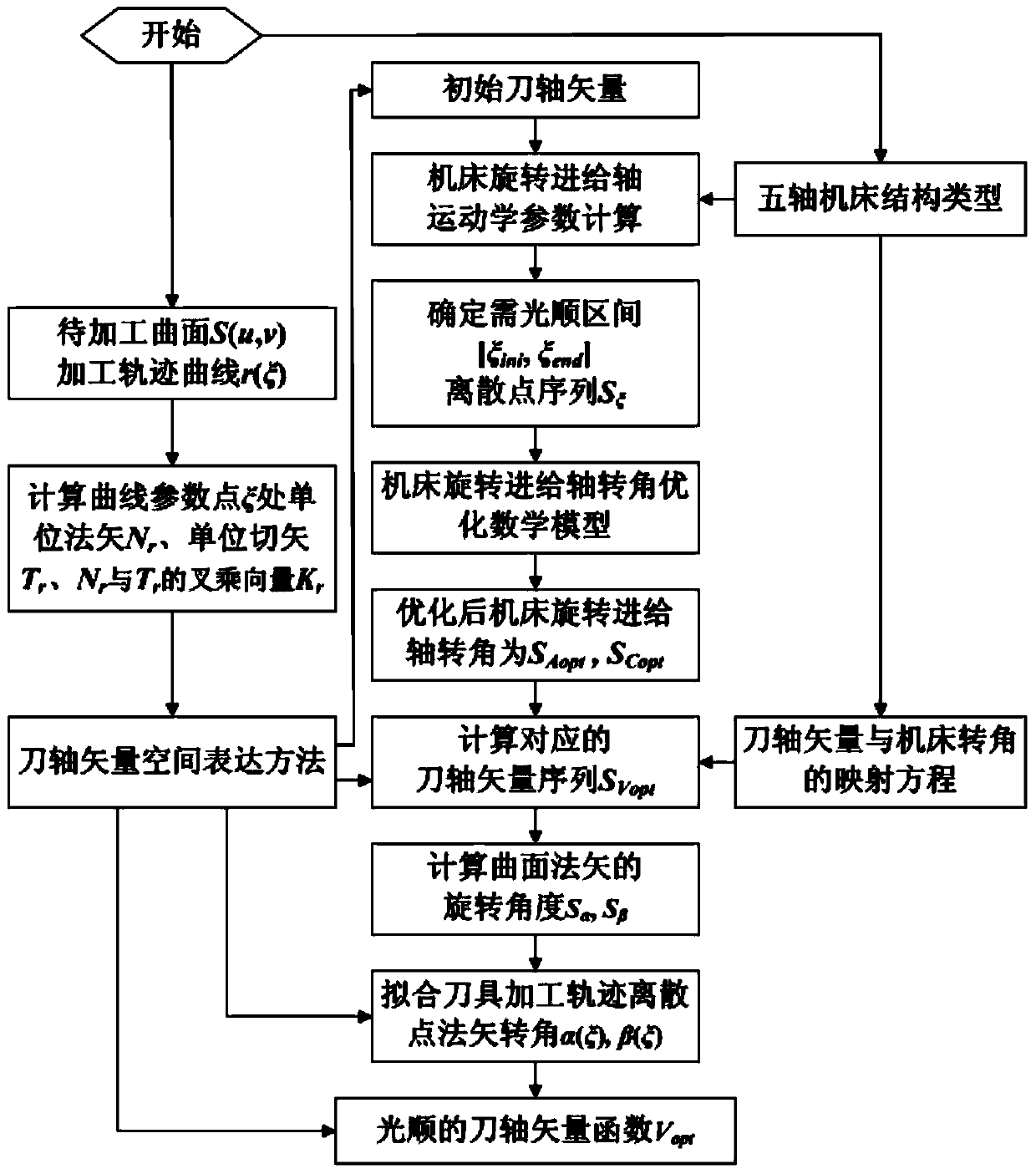

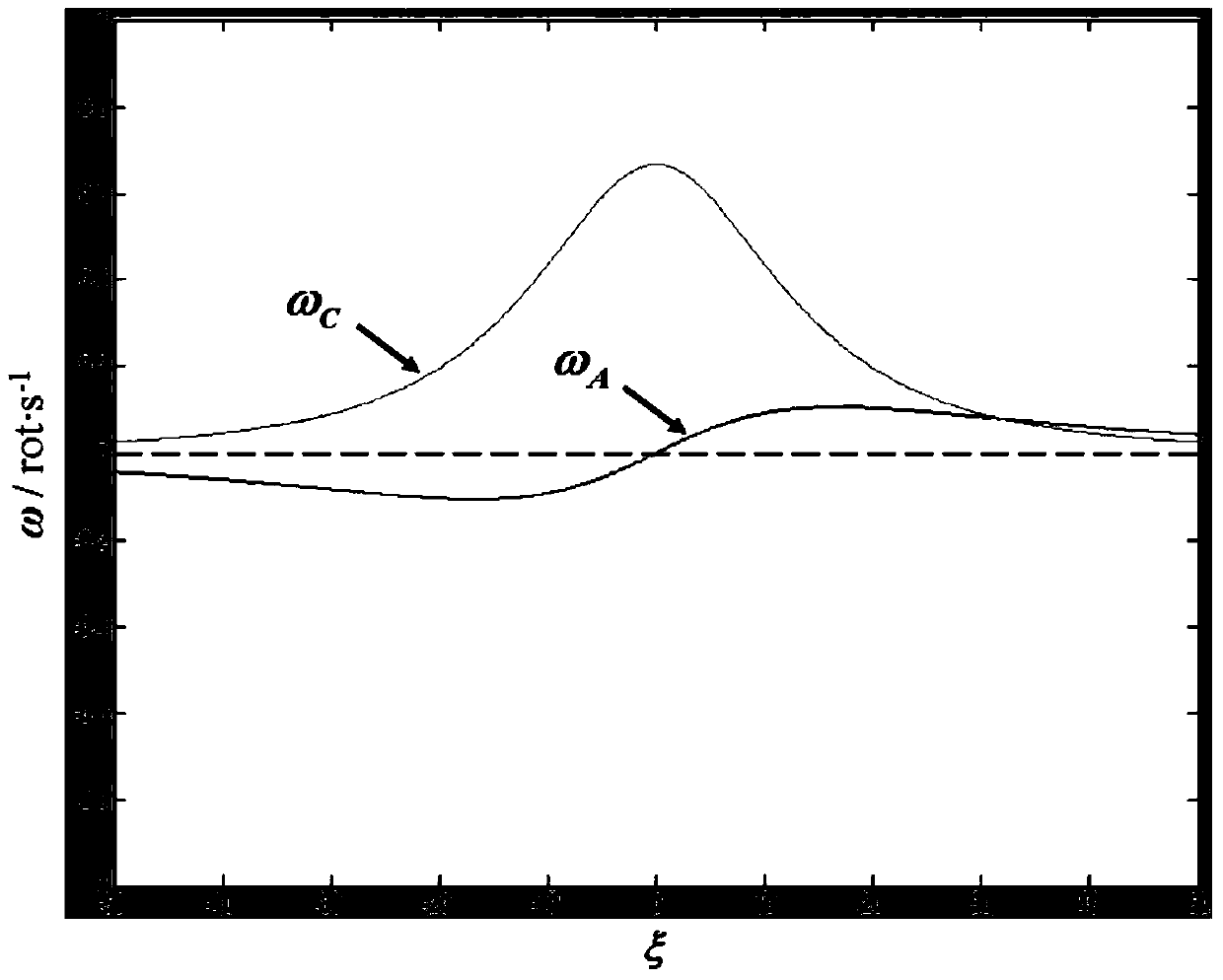

Kinematics control method for complex-curved-surface five-axis numerical control machining cutter vectors

ActiveCN103558808AAvoid vibrationImprove processing qualityNumerical controlNumerical controlKinematics

The invention provides a kinematics control method for complex-curved-surface five-axis numerical control machining cutter vectors, belongs to the field of complex-curved-surface five-axis numerical control machine took precise and efficient machining, and particularly relates to a kinematics control method of cutter shaft vectors in the complex-curved-surface five-axis numerical control machining process. According to the kinematics control method of the cutter vectors, on the basis that a complex-curved-surface parametric equation is determined, the function relationship between the cutter shaft vectors and machining track curved line parameters can be established. Then, a motion parameter calculation method for a five-axis numerical control machine tool rotating feed shaft is established, so an angular velocity calculation result and an angular acceleration calculation result of the rotating feed shaft can be obtained. Finally, smoothing is carried out on the cutter shaft vectors to ensure that the rotating feed shaft of the machine tool moves smoothly and achieve the kinematics control over the cutter shaft vectors. The kinematics control method for the complex-curved-surface five-axis numerical control machining cutter vectors is wide in application scope, effectively improves machining quality of a complex curved surface, and gives better play to the performance of the machine tool.

Owner:DALIAN UNIV OF TECH

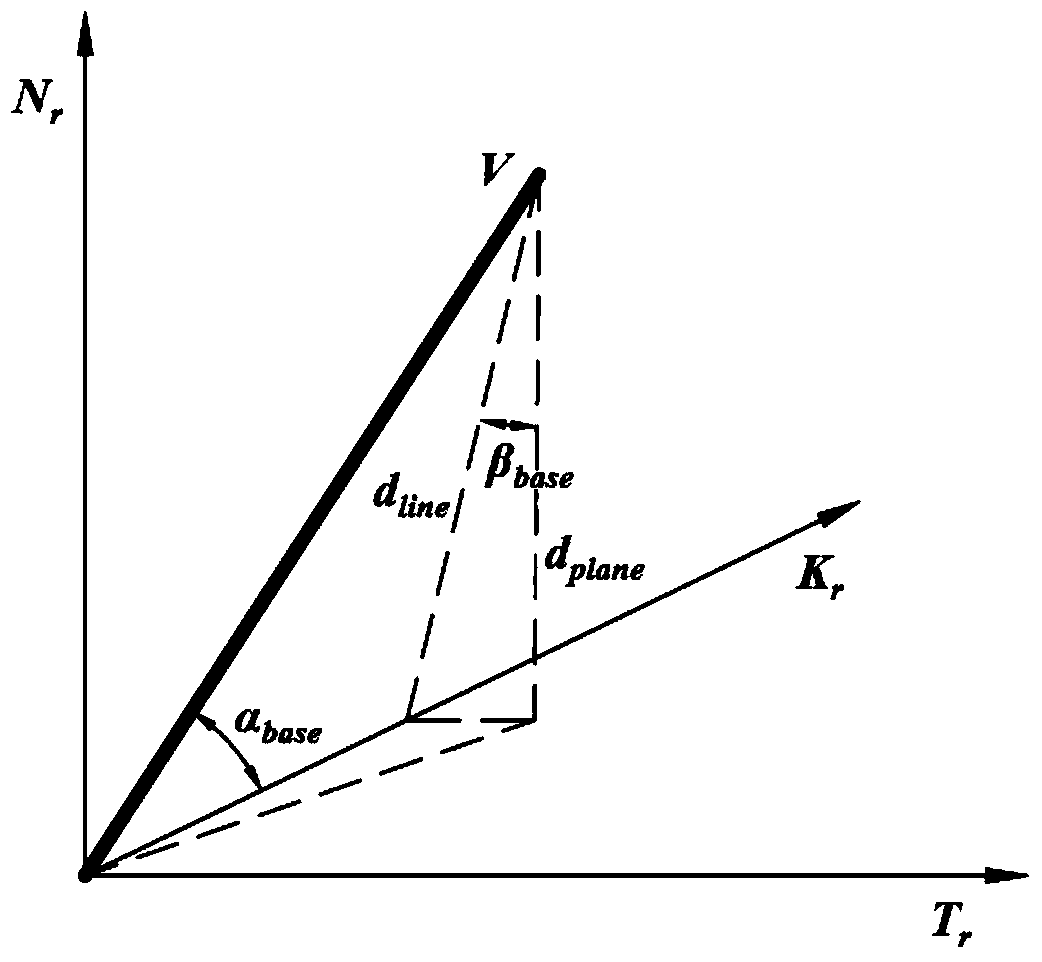

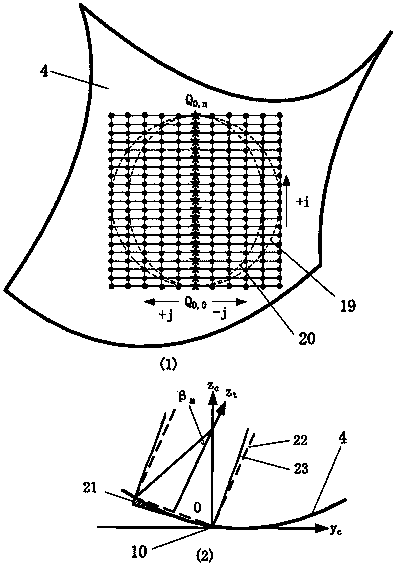

Method for cutter-axis vector fairing of complex curved surface five-axis numerical control machining based on kinematical constraints

ActiveCN103592891AImprove processing qualityImprove processing efficiencyNumerical controlNumerical controlKinematics

The invention relates to a method for cutter-axis vector fairing of complex curved surface five-axis numerical control machining based on kinematical constraints, which belongs to the field of precise and efficient processing of complex curved surface five-axis numerical control machining, and particularly relates to a method for cutter-axis vector fairing based on machine tool kinematical constraints in the process of complex curved surface five-axis numerical control machining. The method is characterized by establishing a machining tool swivel feeding shaft angle optimized mathematical model on the basis of determining a cutter-axis fairing adjustment interval on a processing track curve and determining a discrete point according to the cutter step length, carrying out optimization on the corresponding machining tool swivel feeding shaft angle of the discrete point, and determining a corresponding coordination calculation method of a cutter-axis vector; then calculating the rotation angle of the cutter-axis vector opposite to the curved surface normal vector corresponding to the discrete point; and finally, carrying out fitting on the acquired discrete processing track normal vector angle, thereby acquiring a cutter-axis vector function for fairing, and ensuring a rotation axis of a machine tool to be smooth in motion. The method provided by the invention realizes smooth motion of the rotation axis of a five-axis numerical control machine tool, is wide in application range, and effectively improves the processing quality of the complex curved surface.

Owner:DALIAN UNIV OF TECH

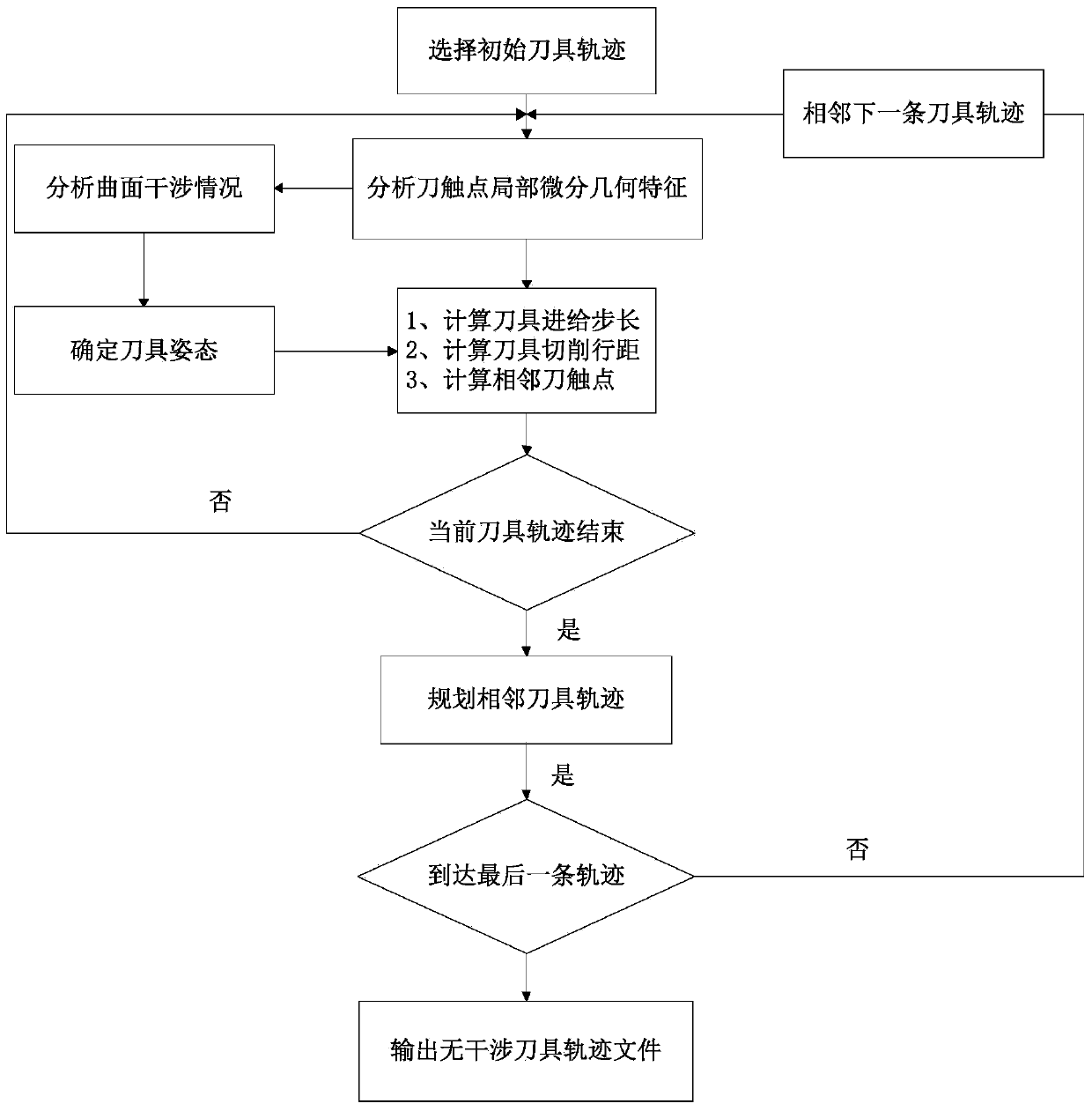

Interference-free tool path generation method in machining of transitional surfaces by flat-end milling cutter

InactiveCN103744349AImprove processing efficiencyReduce surface roughnessNumerical controlMilling cutterPath generation

The invention discloses a method for generating interference-free flat-end milling cutter process path along the ridge direction of transitional surfaces. The method comprises the following steps: (1) initial machining tool path is set, a tool is processing along the ridges of transitional surfaces, a current tool contact is calculated to obtain effective curvature of the machining tool at the tool contact; (2) curvature interference analysis of transitional surface machining is carried out according to the effective curvature of the machining tool at the tool contact, tool bottom interference is analyzed, and the angle of the tool is deflected at the tool contact to obtain interference-free tool posture; (3) parameter calculation is carried out on the adjusted tool path so as to obtain step-length and cut row distance; and (4) adjacent tool path lines are calculated, including calculation of adjacent tool contacts and calculation of tool location data, and interference-free tool path is finally obtained. By the method, automatic planning of interference-free tool path can be realized; large cut row distance is obtained; cutting efficiency is high; machining surface roughness is low; surface fairness is good; and problems of low cutting efficiency, poor machining surface quality and the like by machining of a ball-end milling cutter are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com