Patents

Literature

9233 results about "Milling cutter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter's shape (e.g., a form tool such as a hobbing cutter).

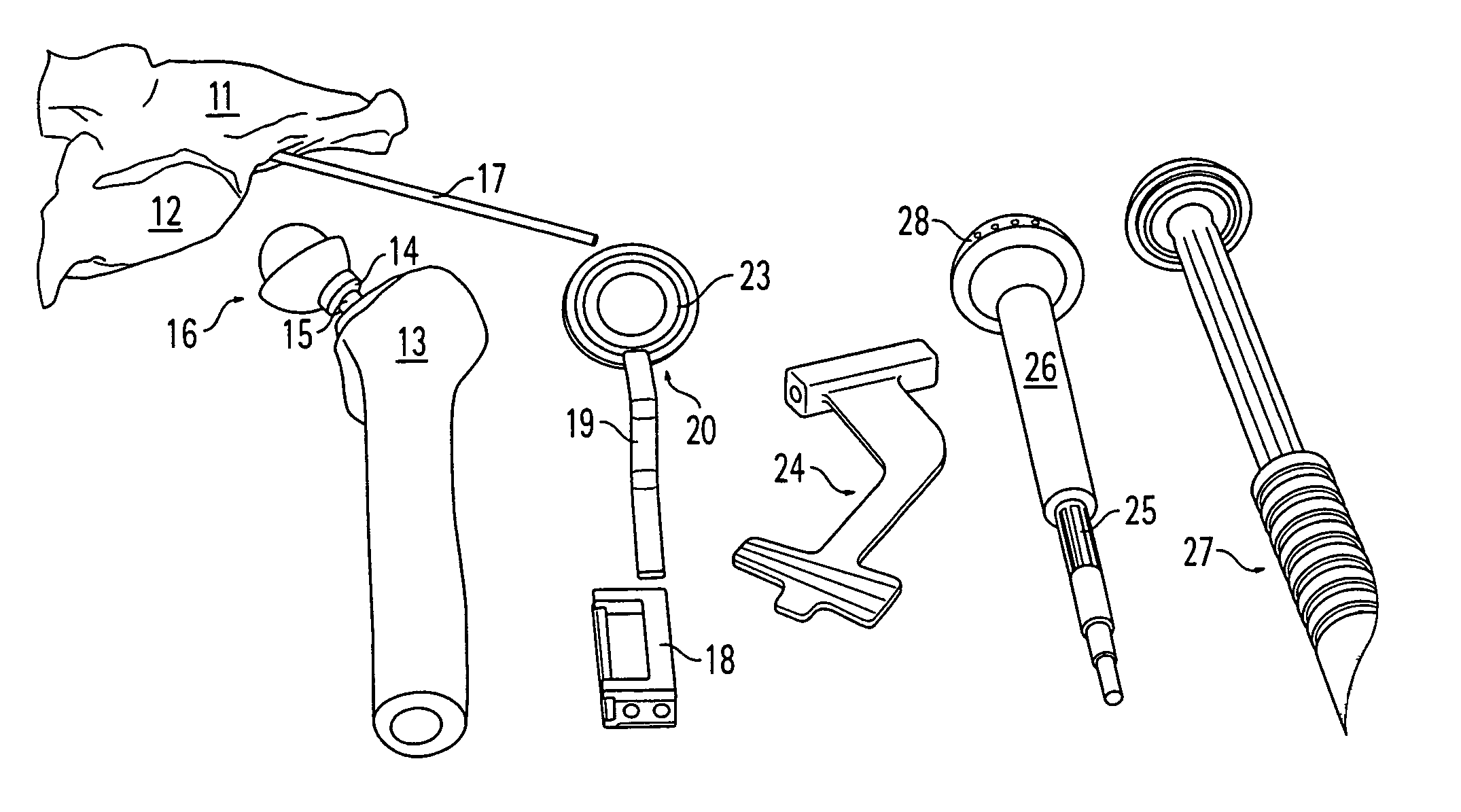

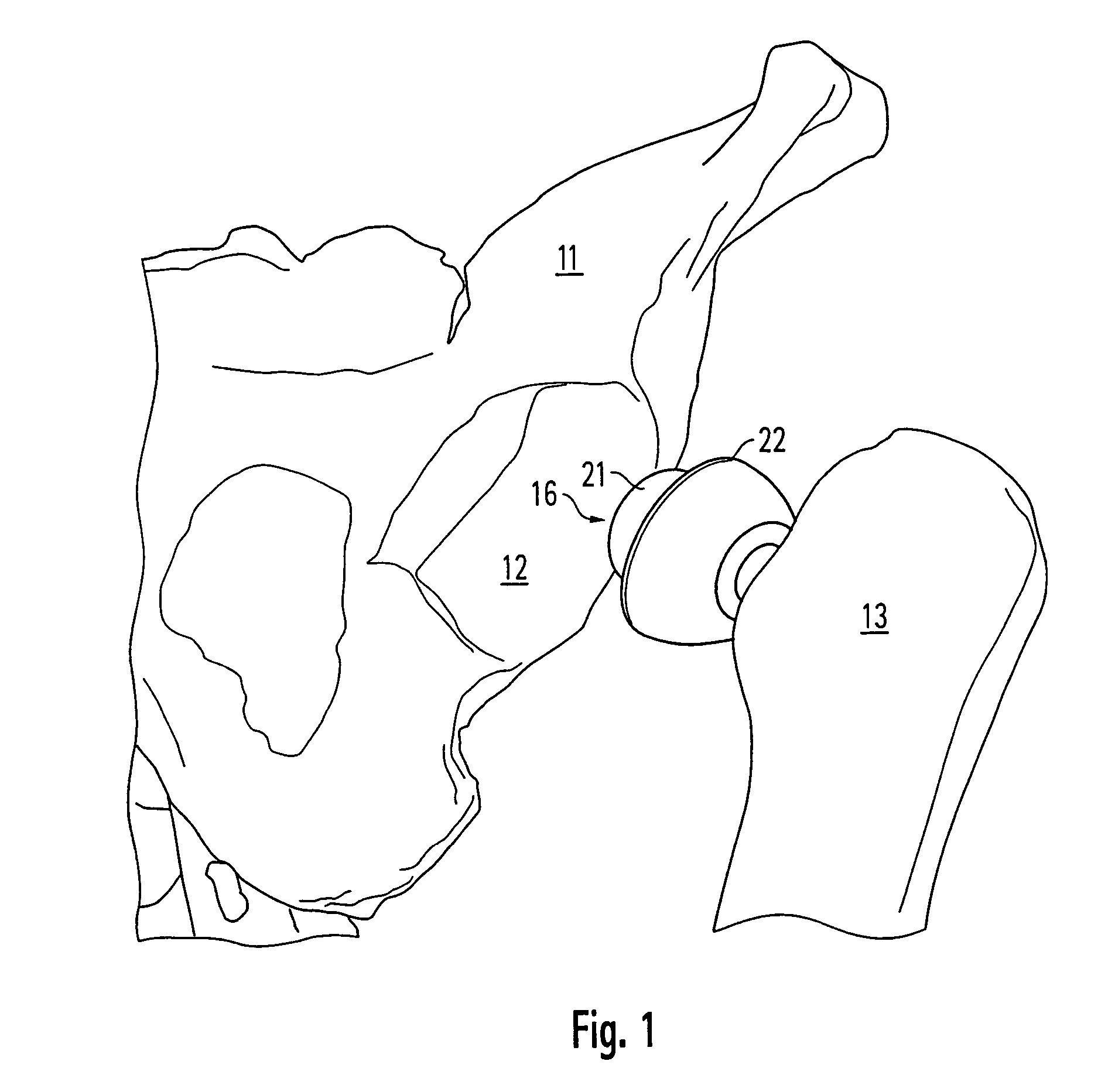

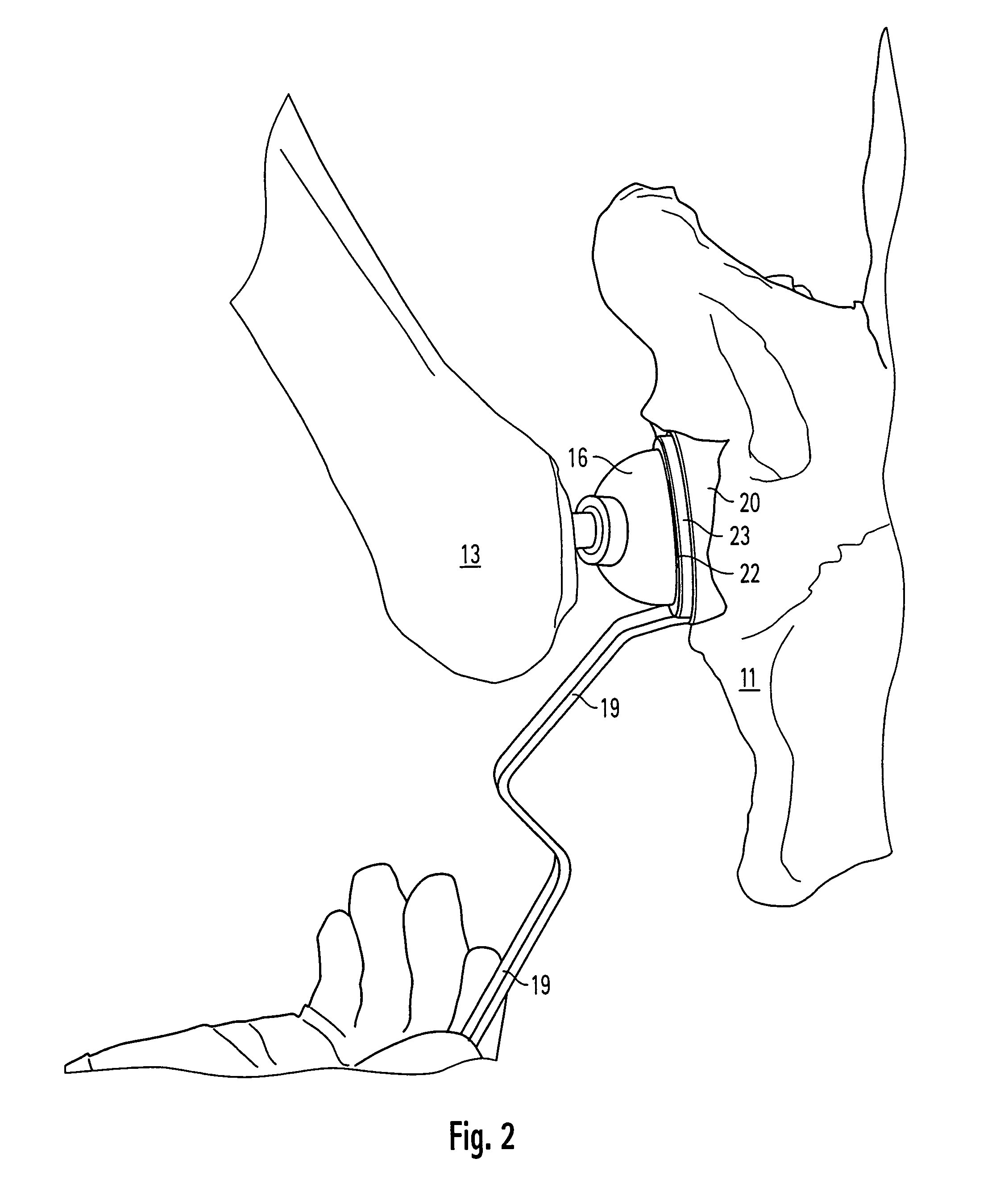

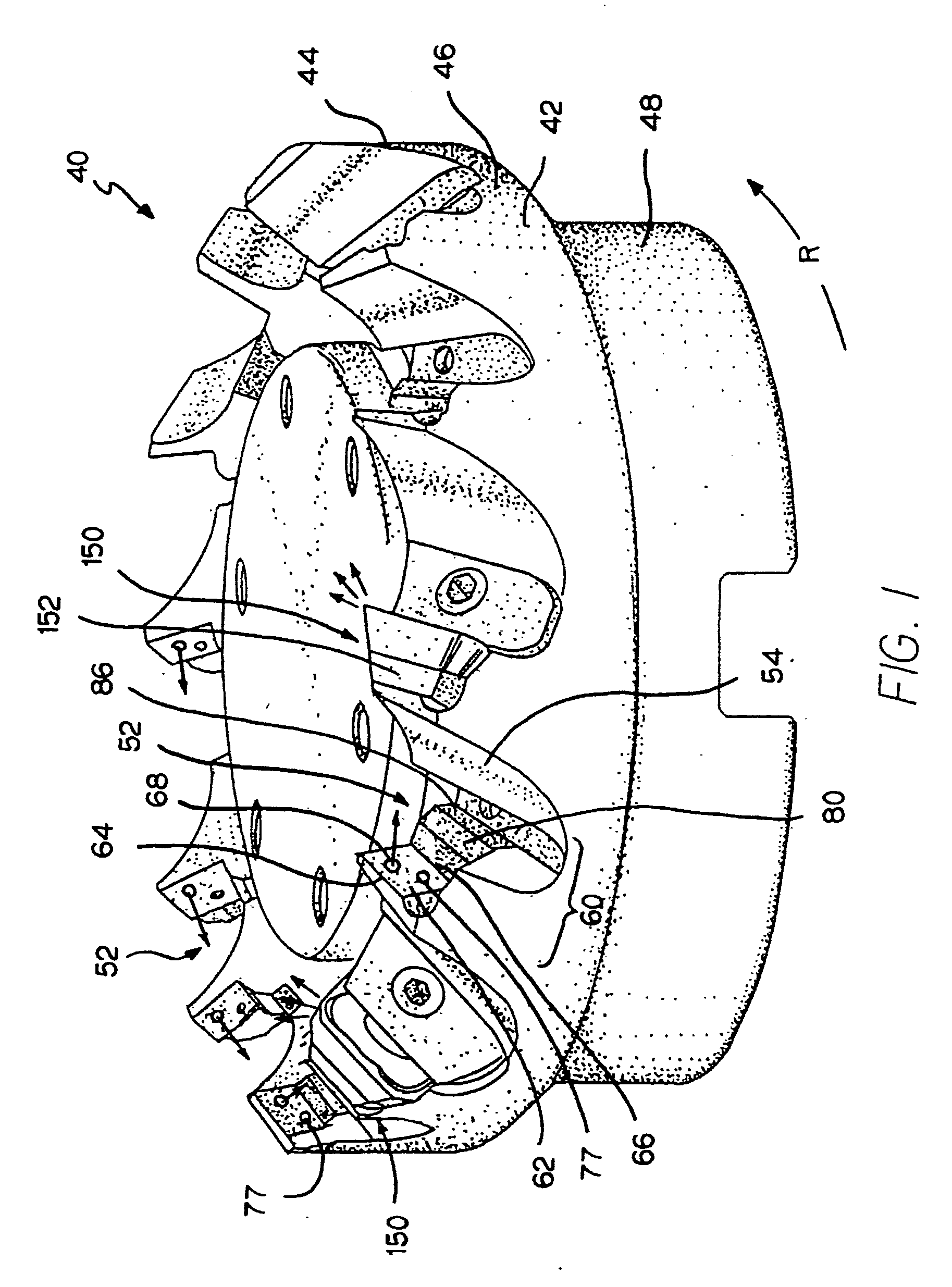

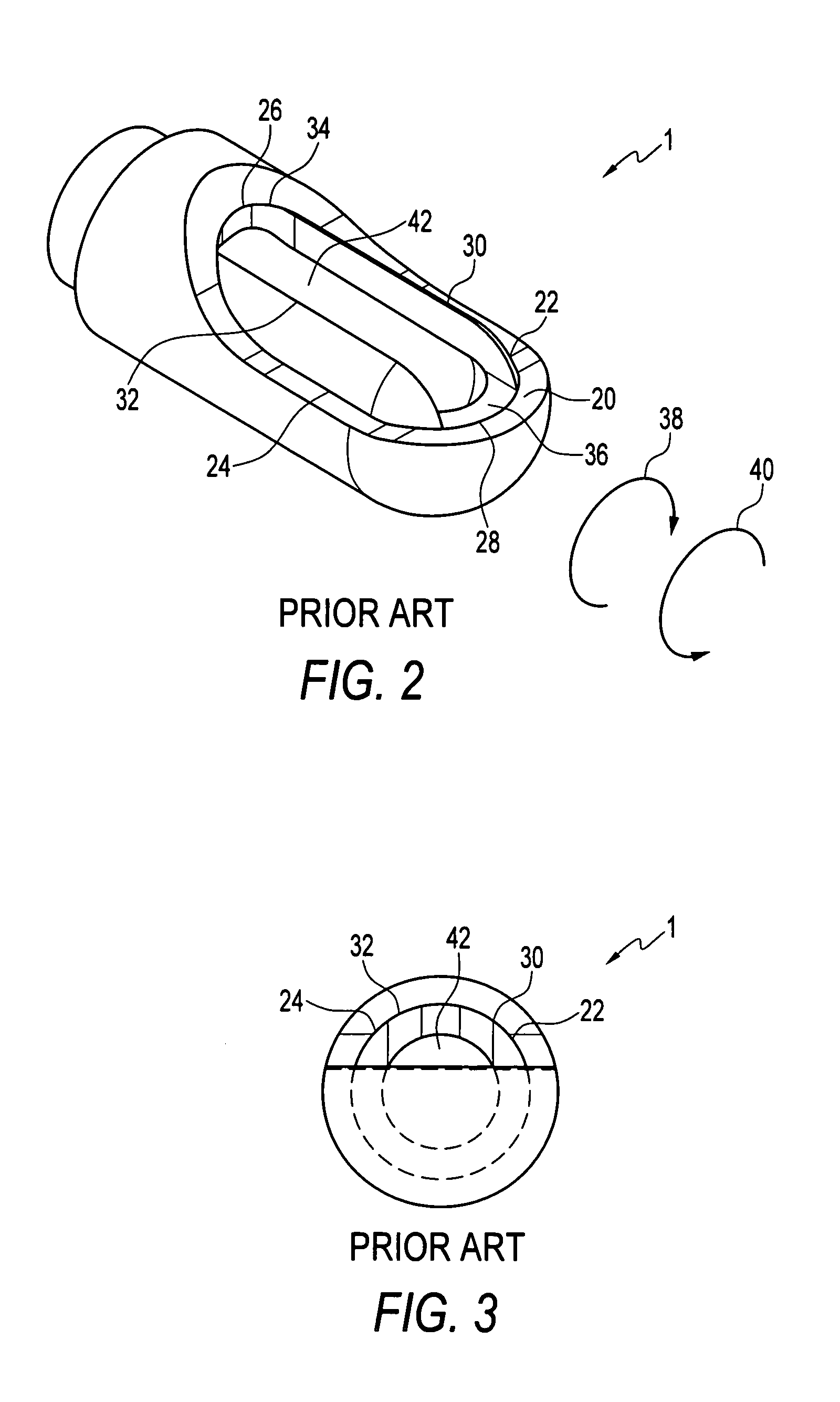

Accessory for implanting a hip endoprosthesis, and method for manipulating the same

Accessory for implantation of a hip joint endoprosthesis, with a manipulation cup, a manipulation joint head with means for orienting the manipulation cup in the acetabulum, and with a device to represent the correctly oriented position of the manipulation cup such that by means of this device a bone-milling cutter and an impact instrument can then oriented appropriately for placement of the prosthesis cup.

Owner:SMITH & NEPHEW ORTHOPAEDICS

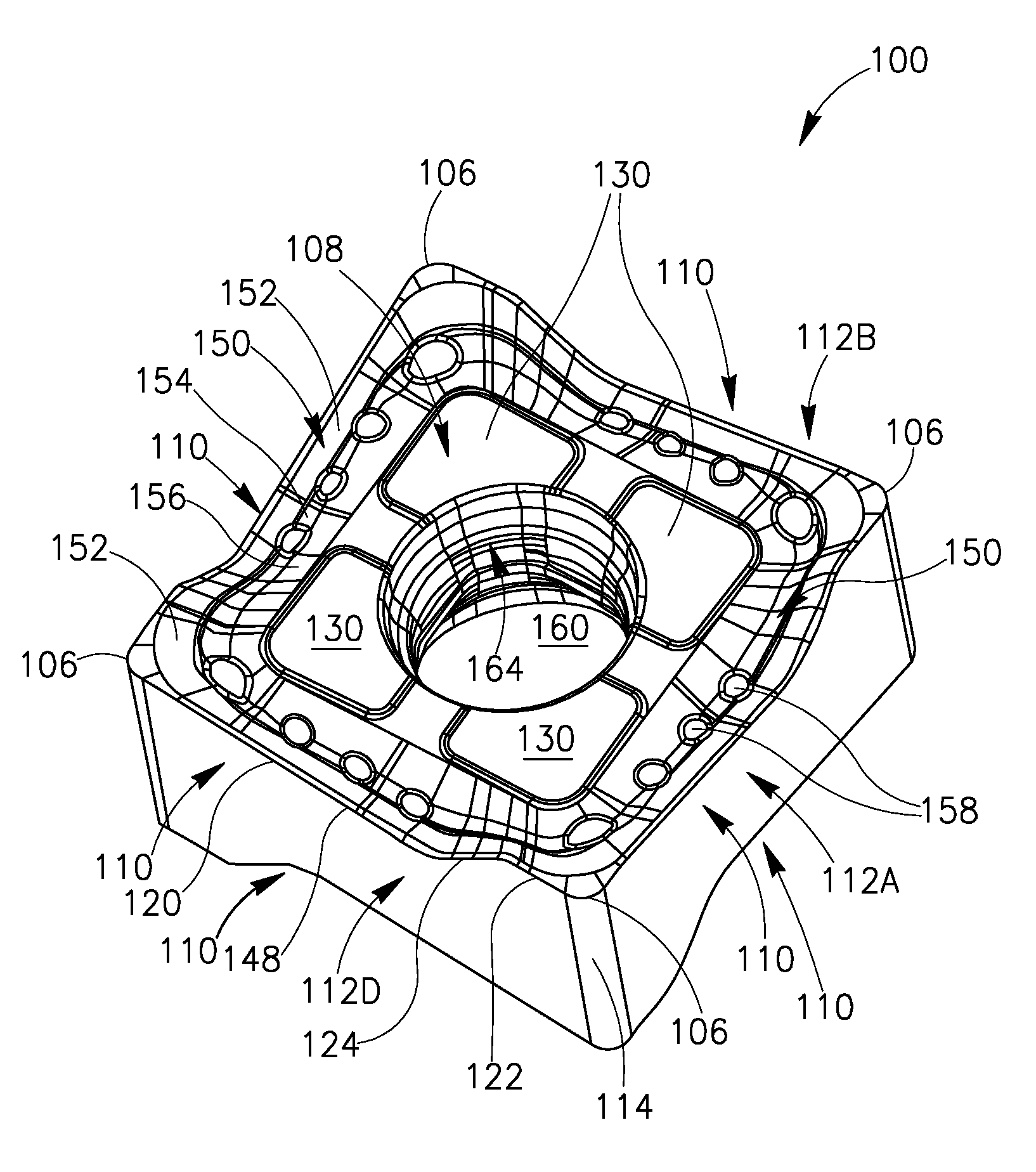

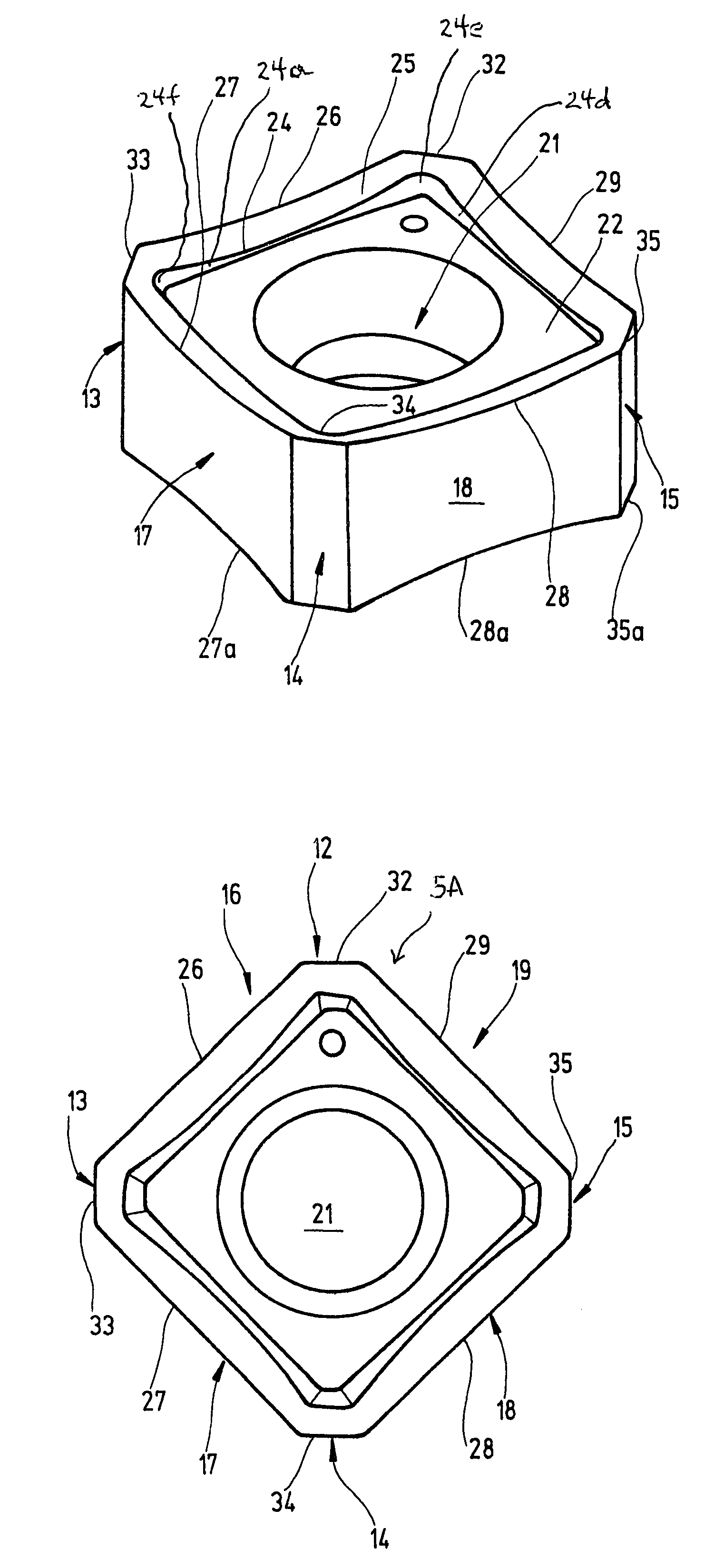

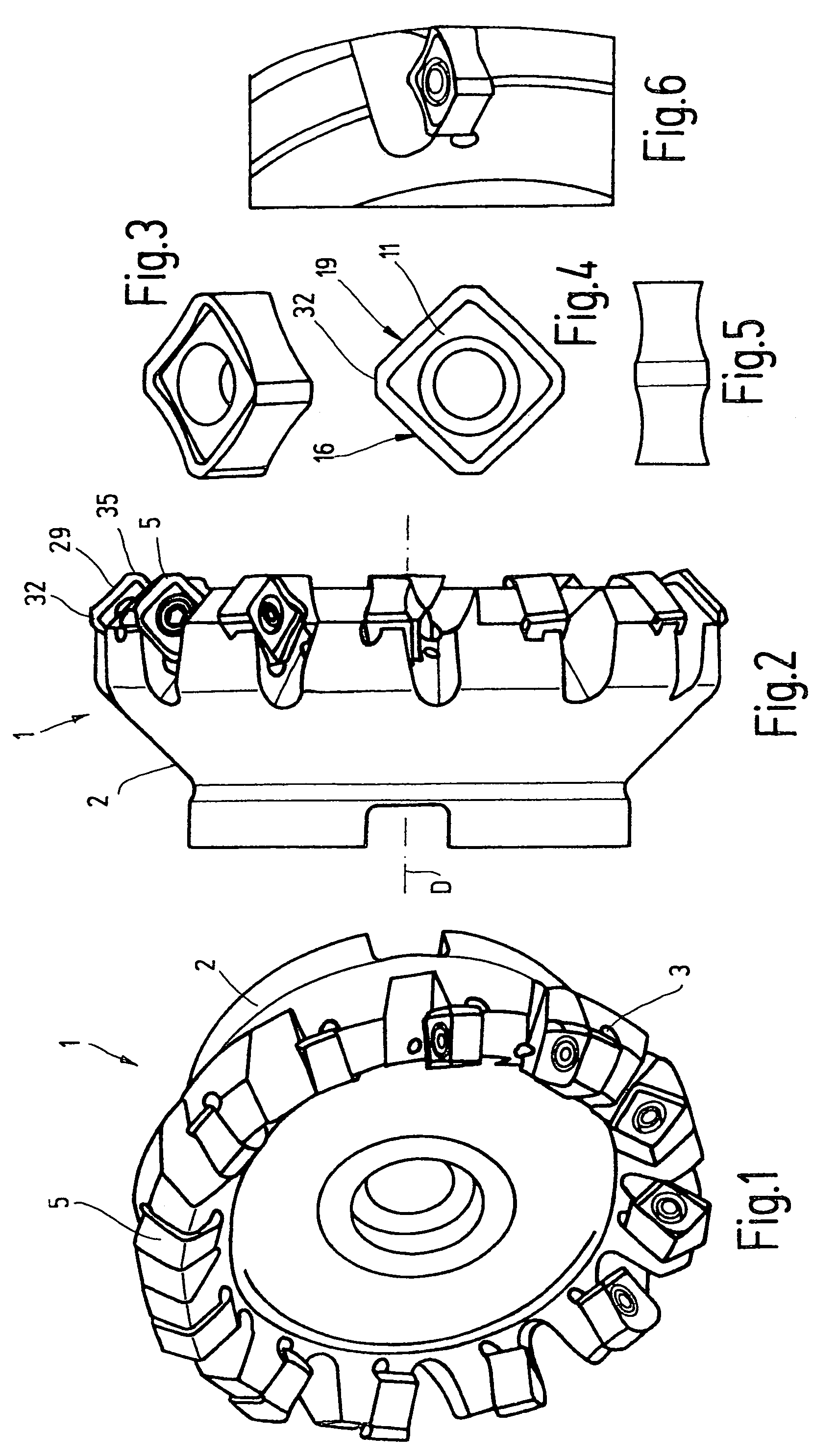

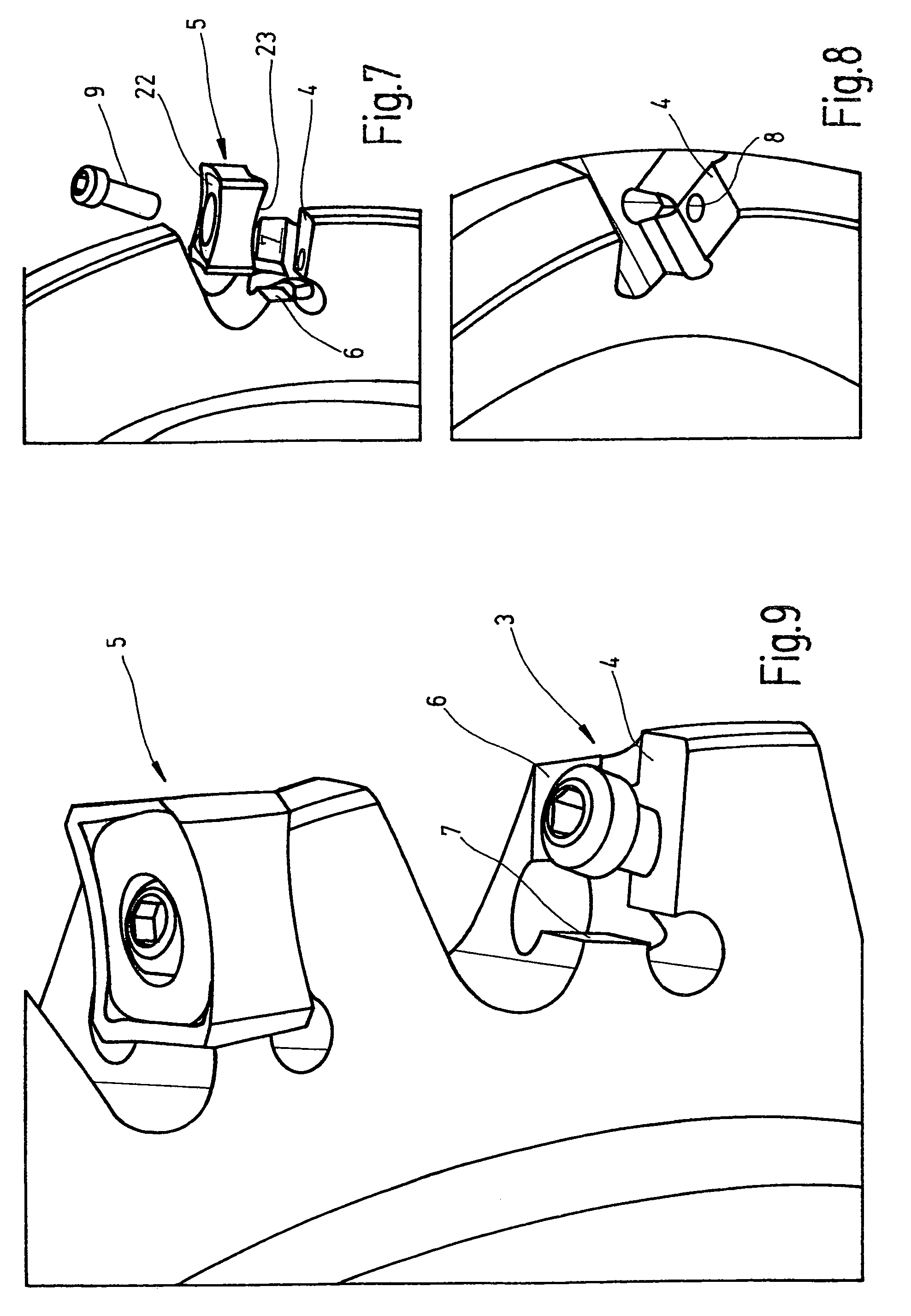

Cutting Insert for a Milling Cutter

ActiveUS20080232912A1Clearance can be providedMilling cuttersShaping cuttersMilling cutterEngineering

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

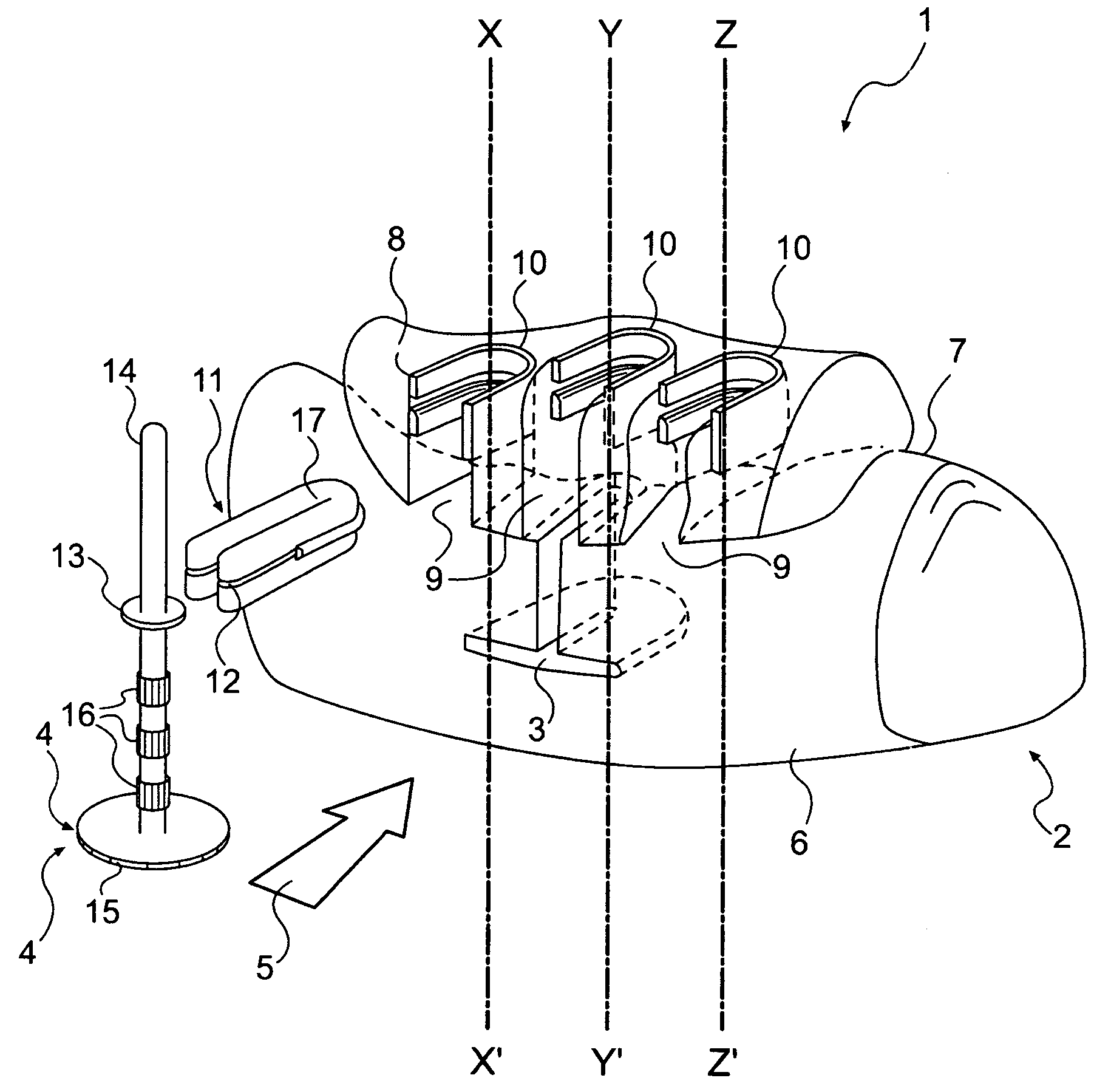

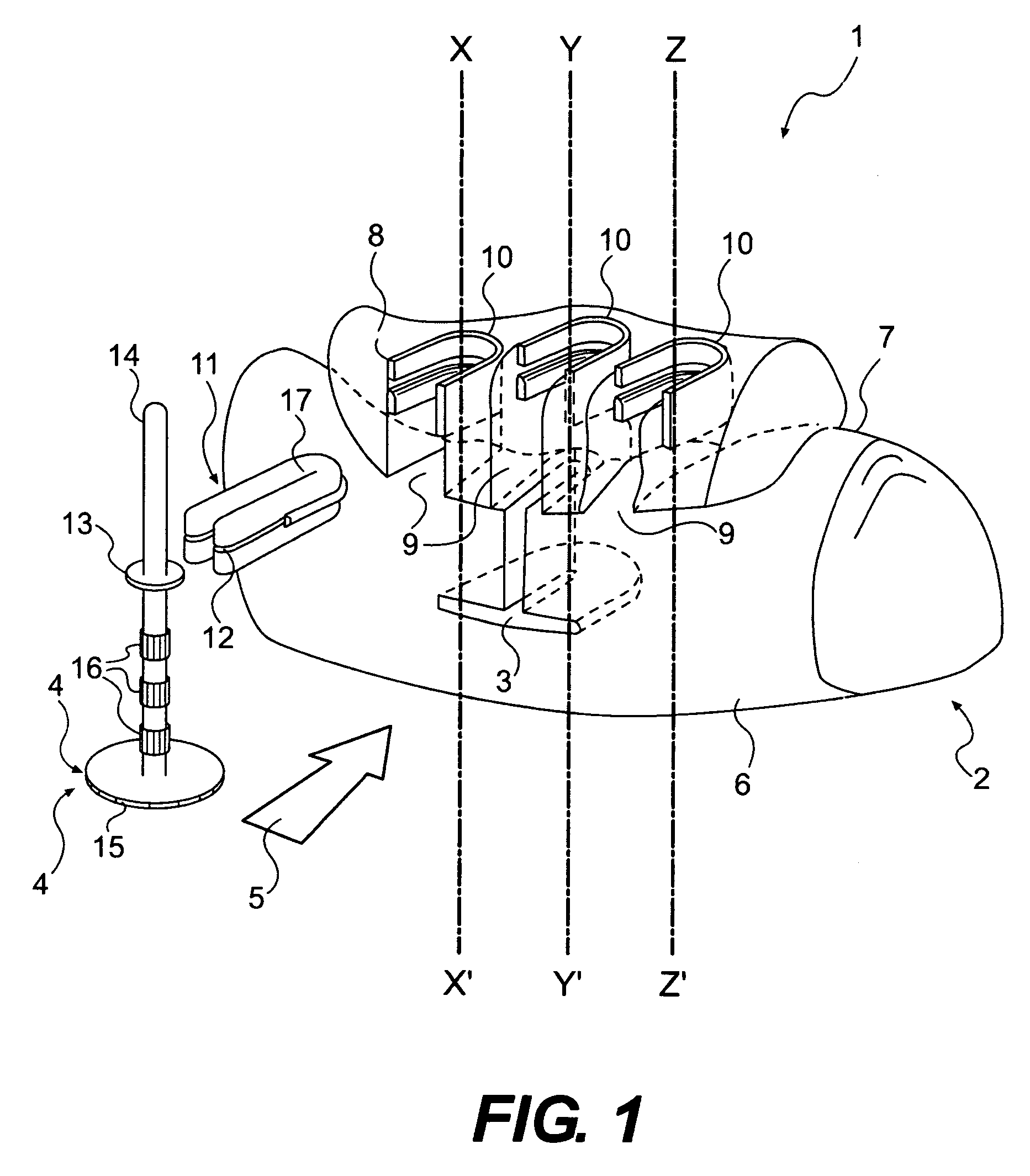

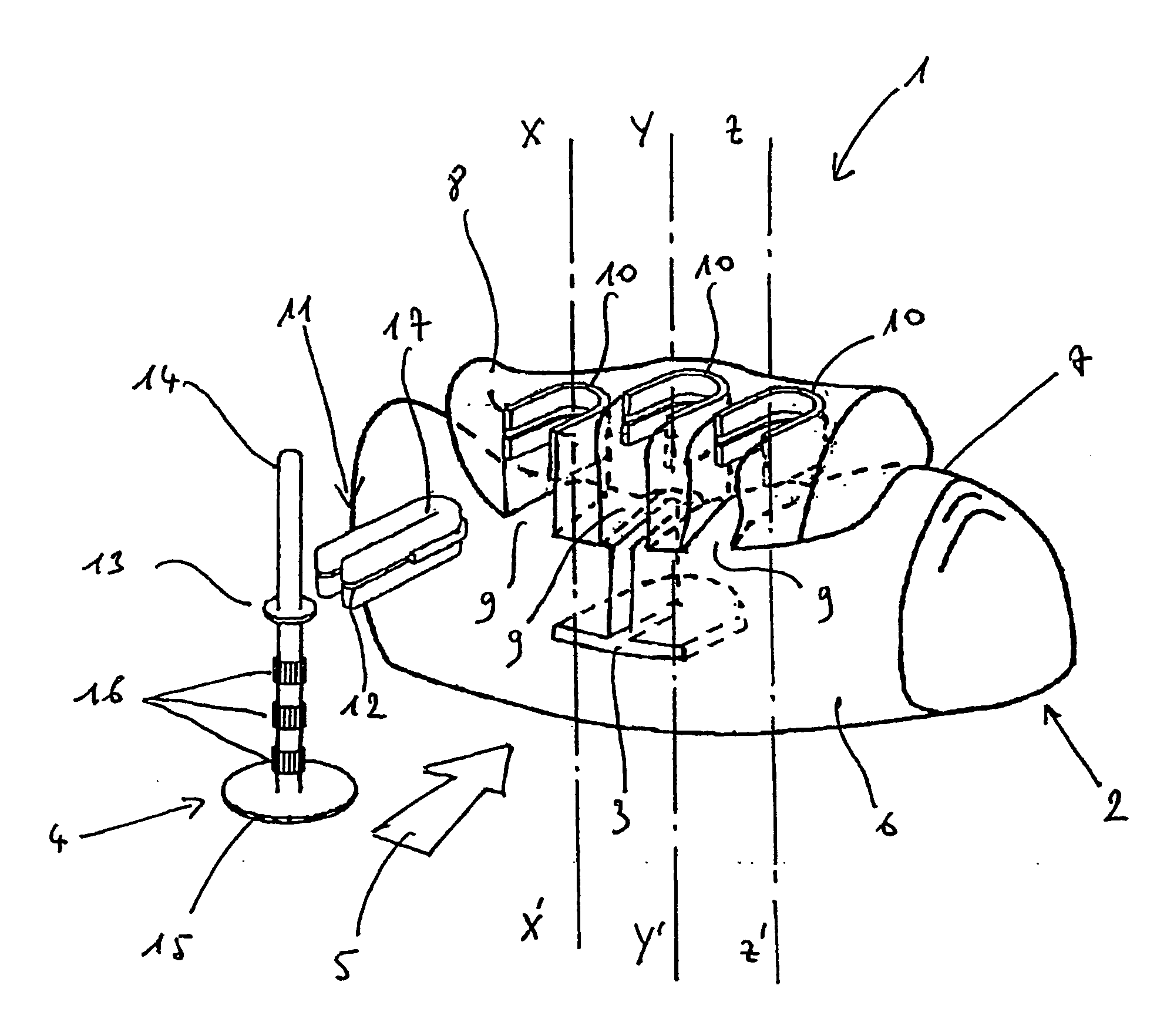

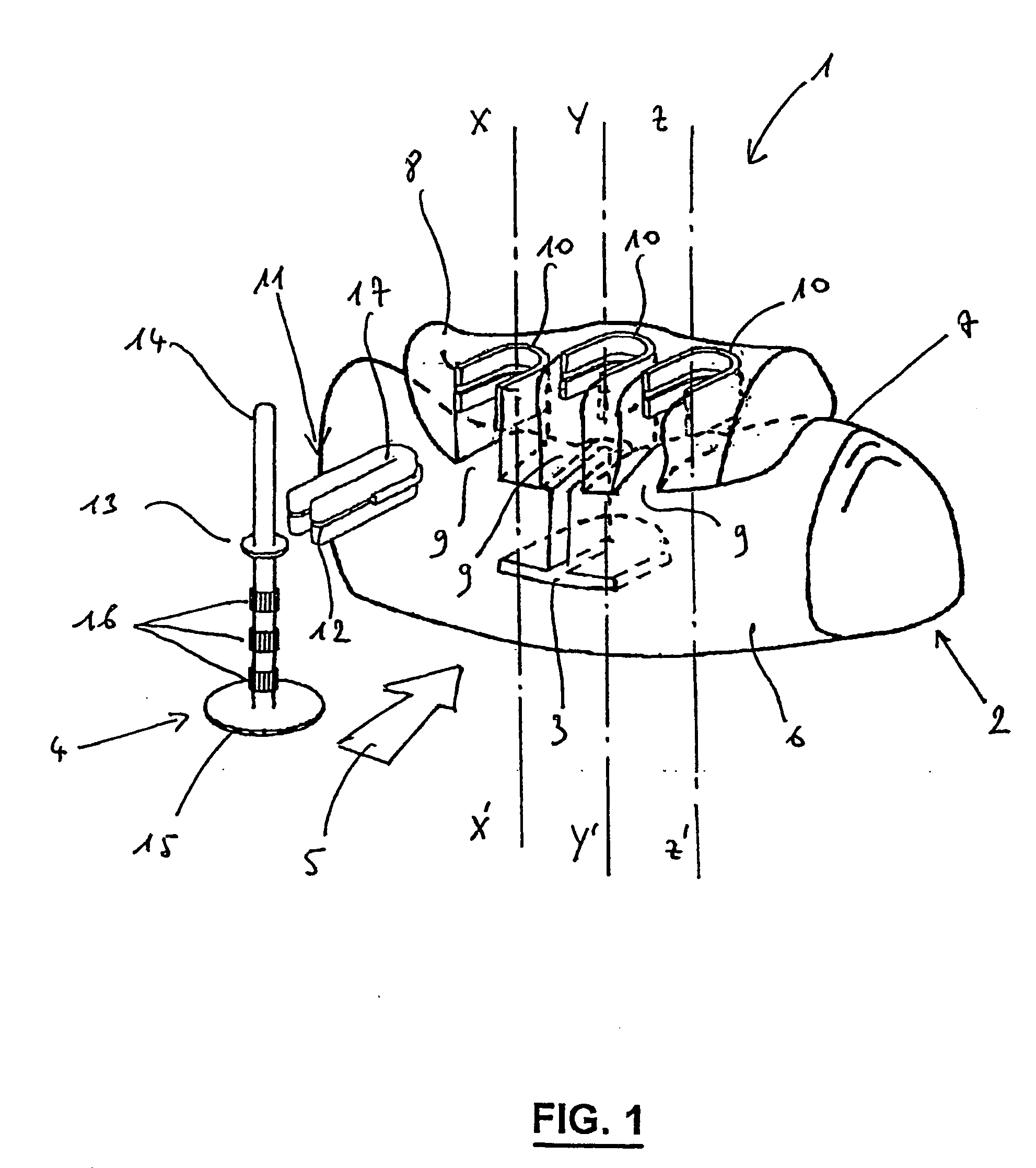

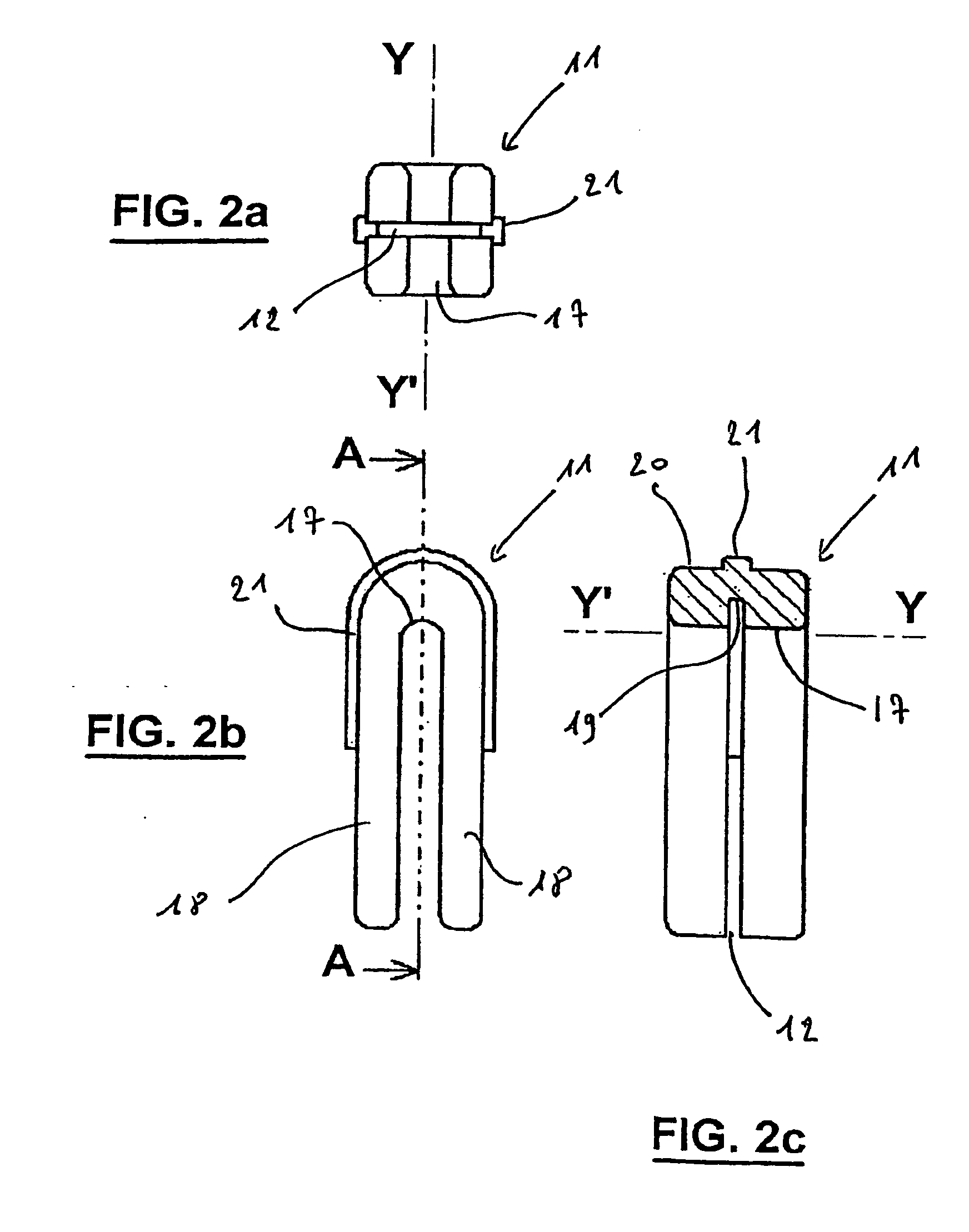

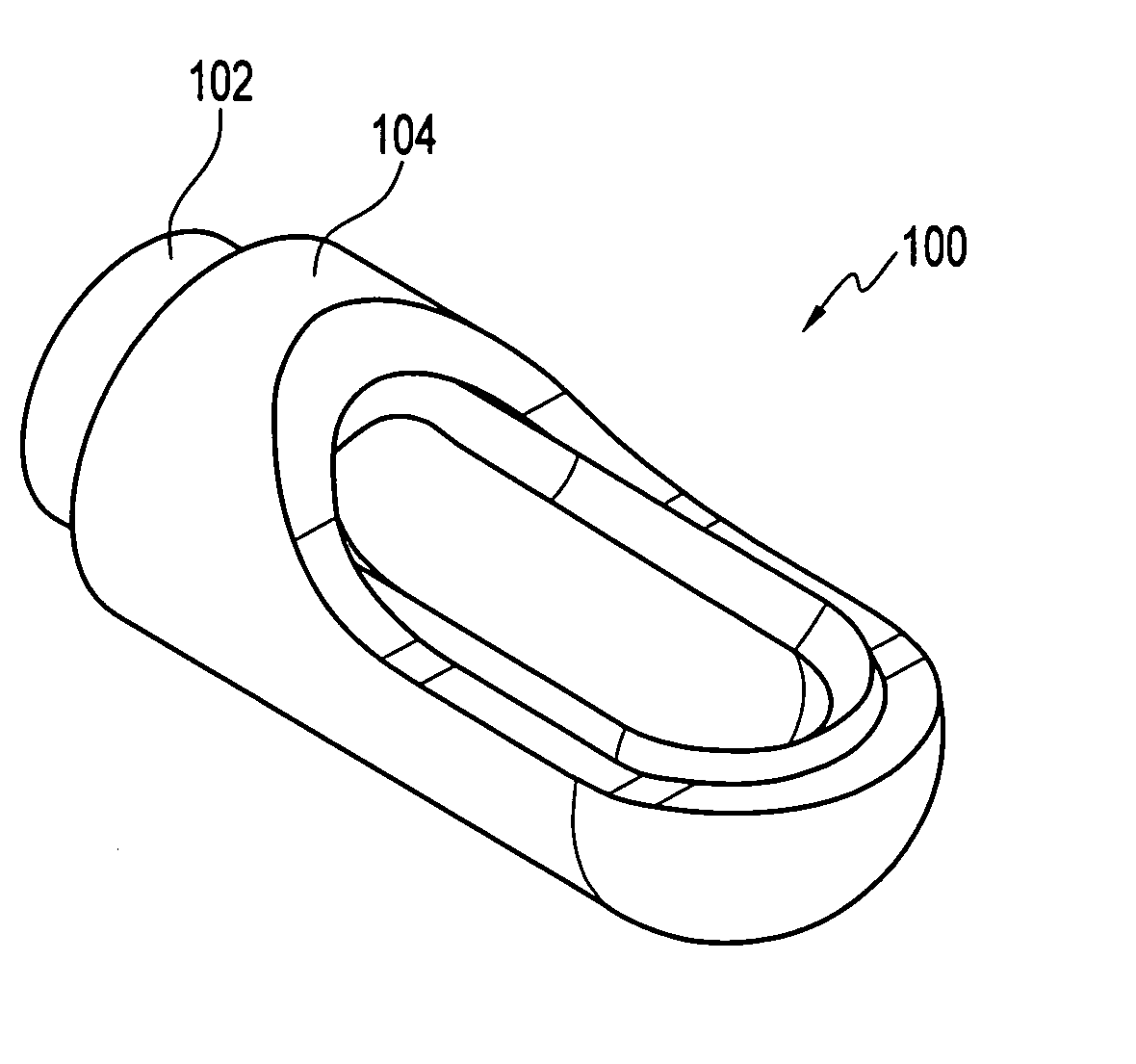

Custom-fit implant surgery guide and associated milling cutter, method for their production, and their use

InactiveUS7824181B2Ensure total axial stabilityEnsure stabilityDental implantsAdditive manufacturing apparatusMilling cutterEngineering

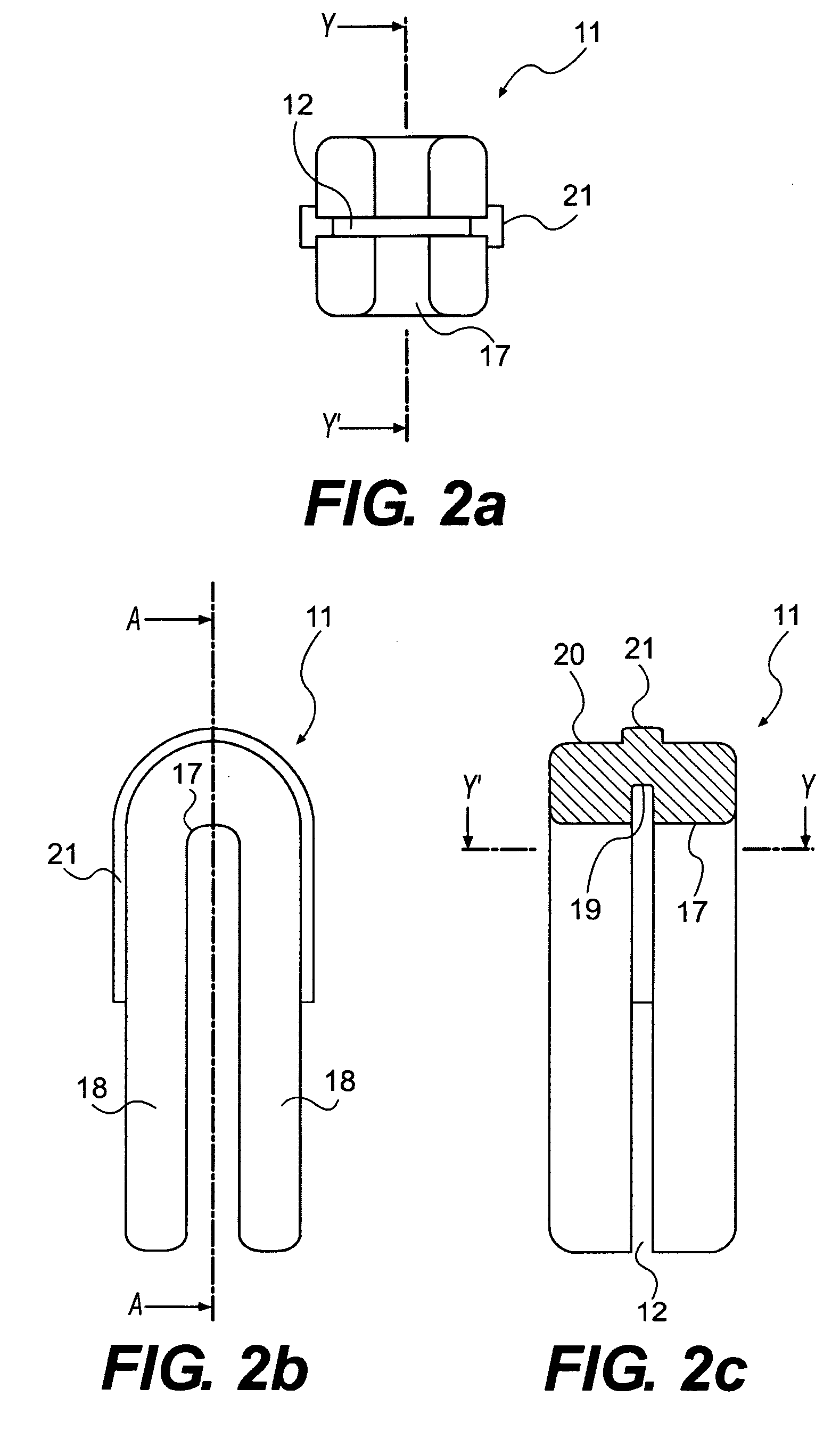

The invention relates to a custom-fit implantable surgical guide (1) and an associated milling tool (4), which is positioned in straddling on the alveolar ridge (7) of a maxillary or mandible arch (2) and comprises at least one drilling barrel (11) for axially guiding said milling tool (4), wherein said barrel (11) is laterally open and at least one part of the internal surface thereof (17) and at least one part of the external surface of the milling tool (4) interact and axially maintain the entire milling tool (4) with respect to the barrel (11). Said invention makes it possible to carry out high precision osteotomies for lateral insertion dental implants.

Owner:MATERIALISE DENTAL NV

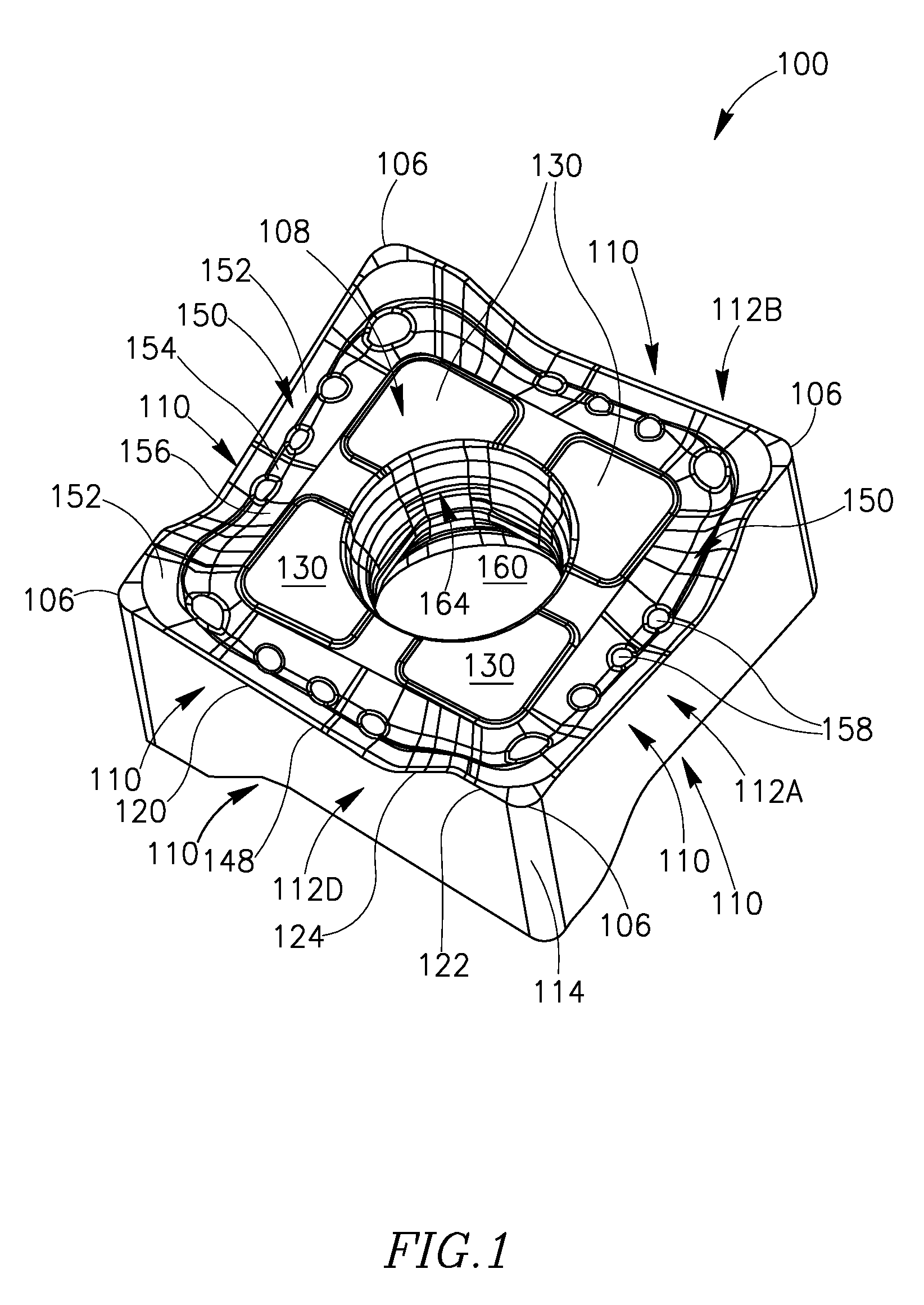

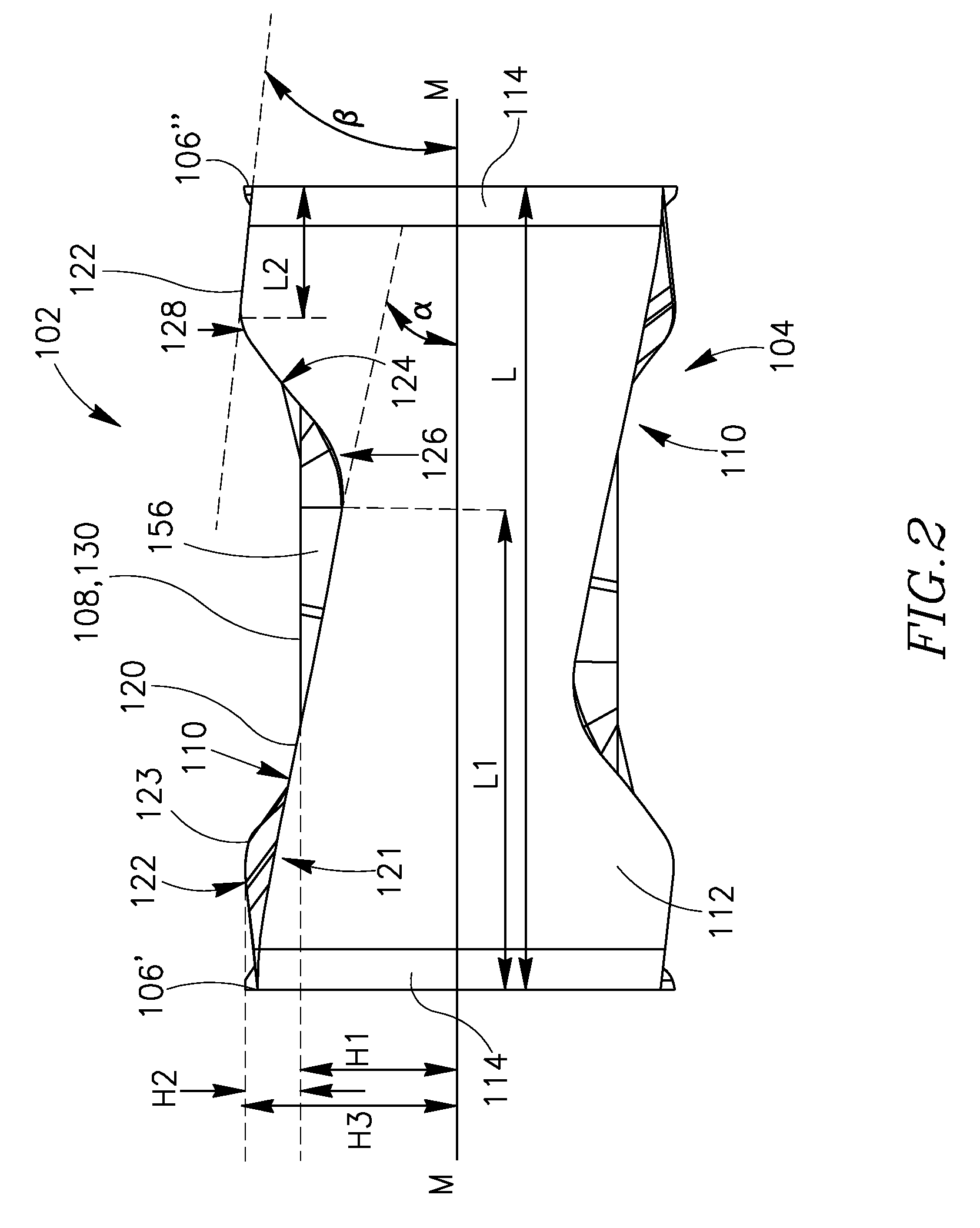

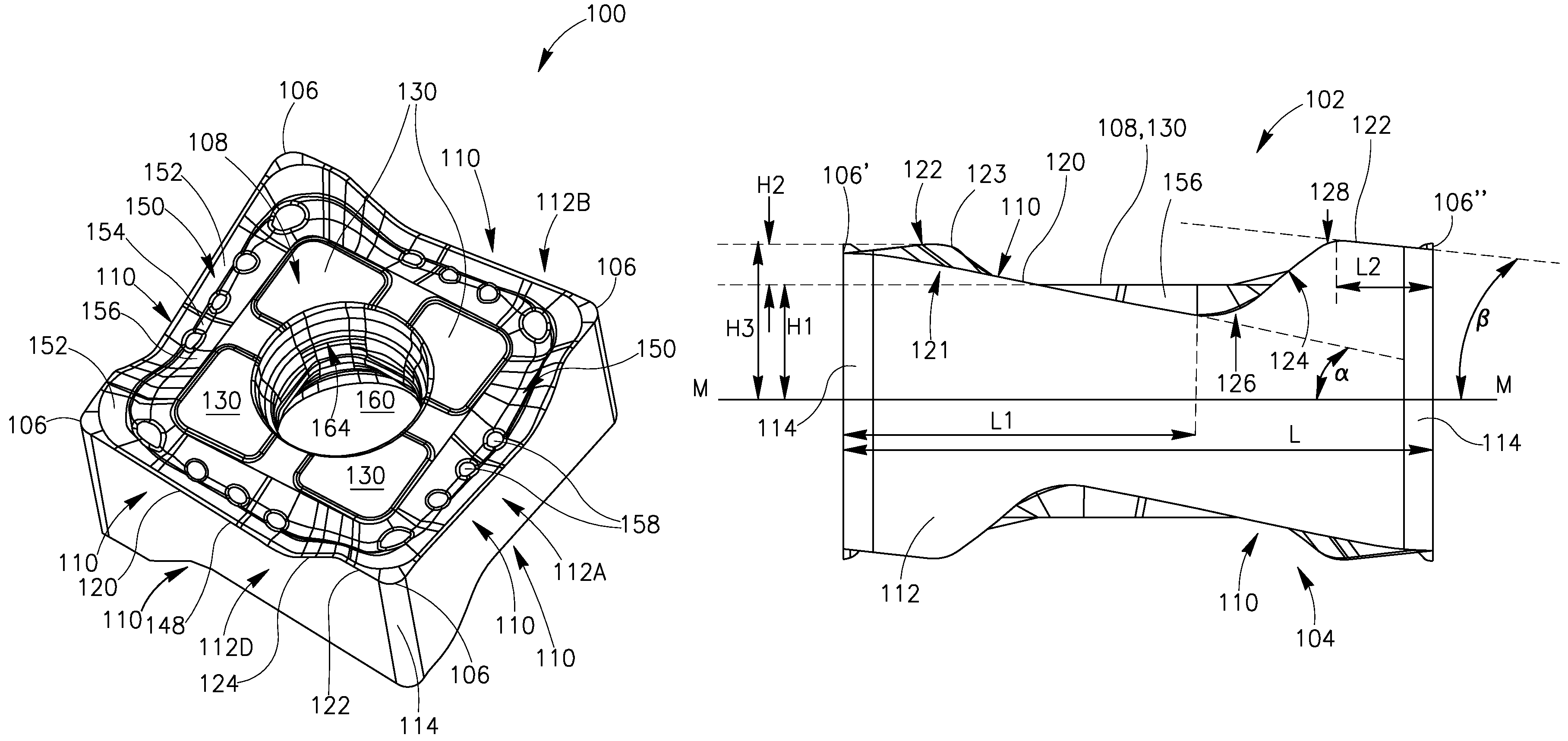

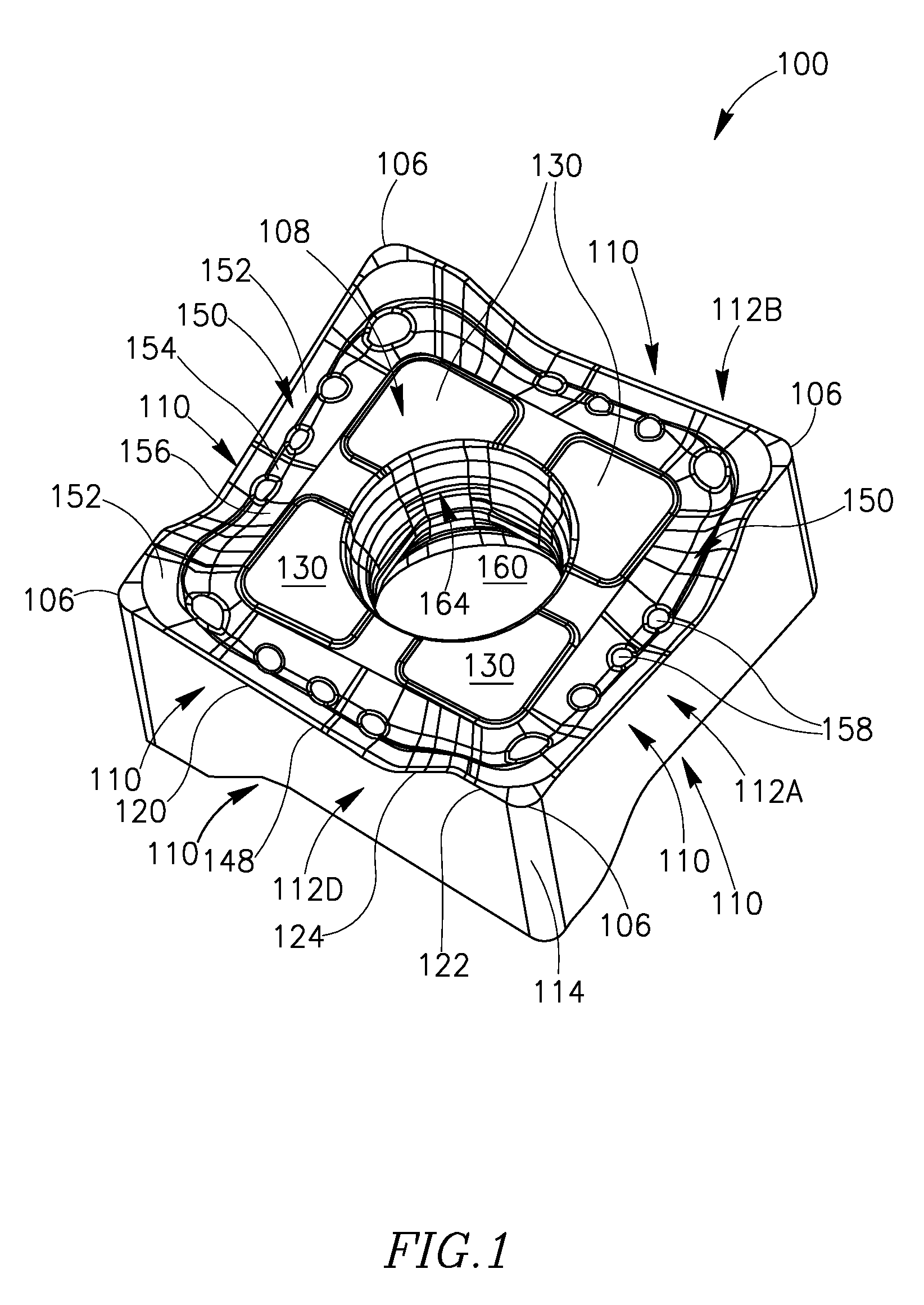

Double-sided cutting insert and milling cutter

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

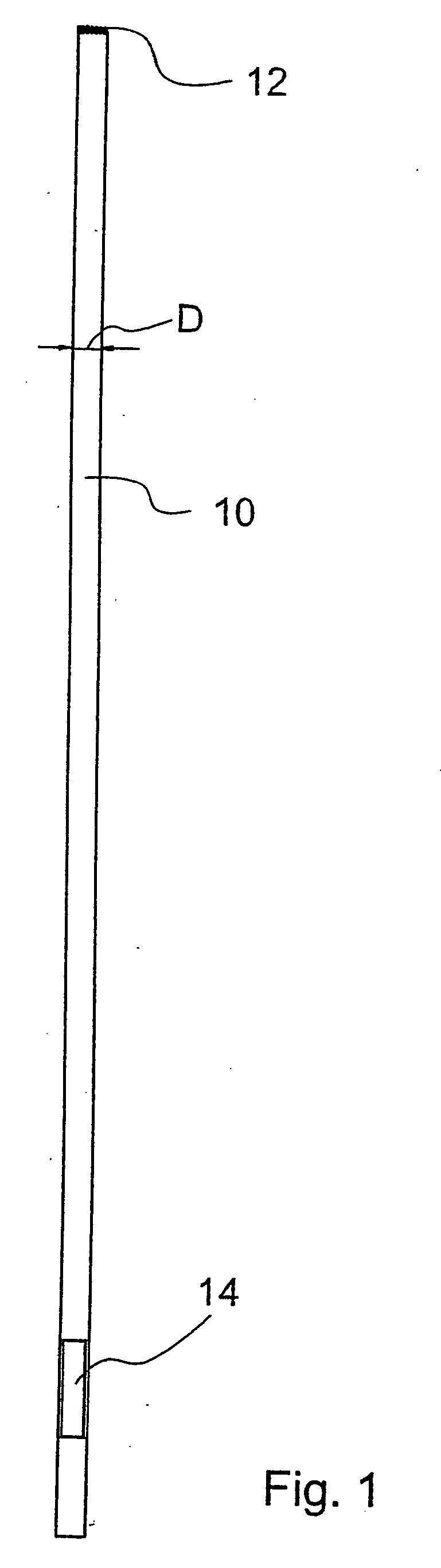

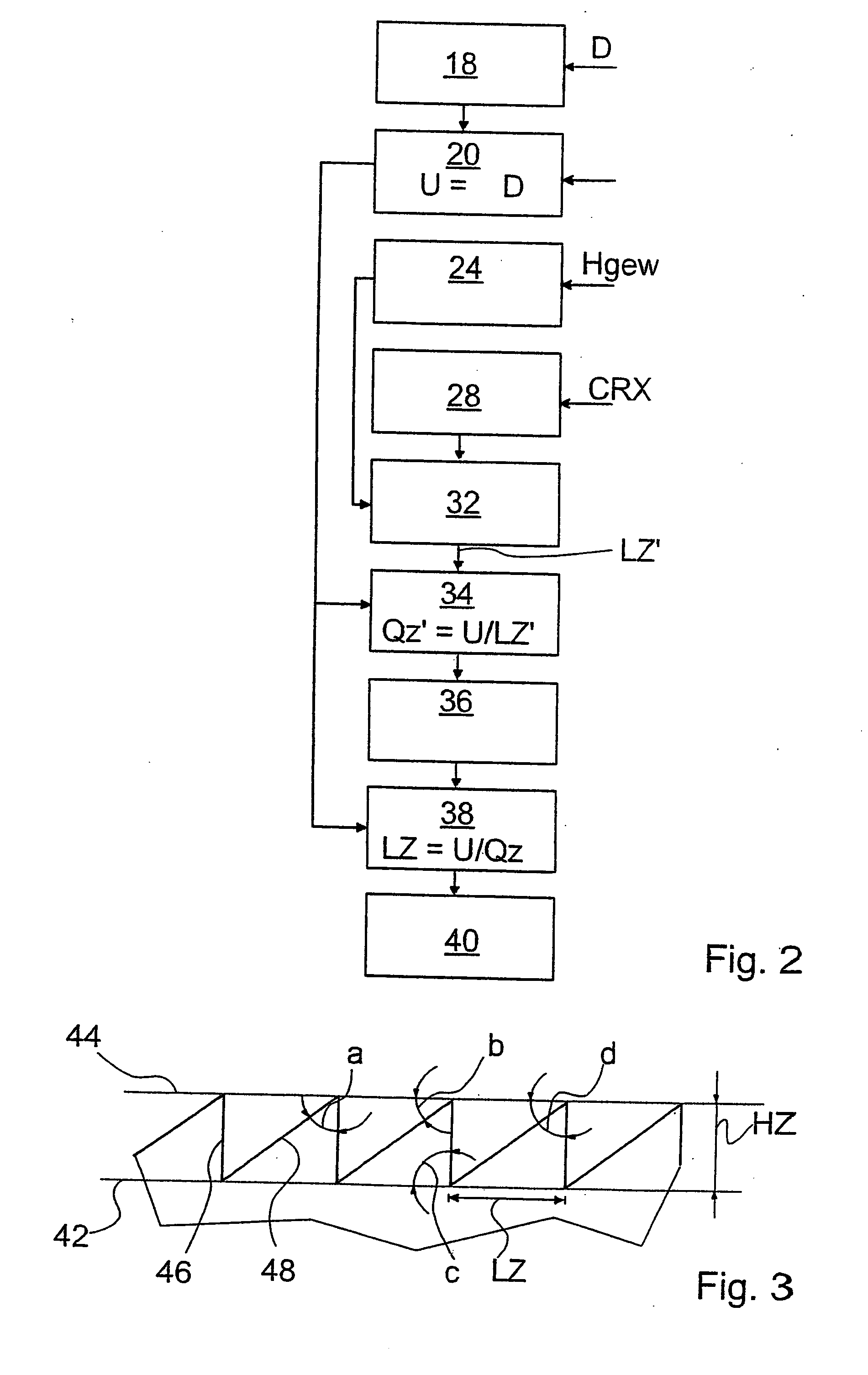

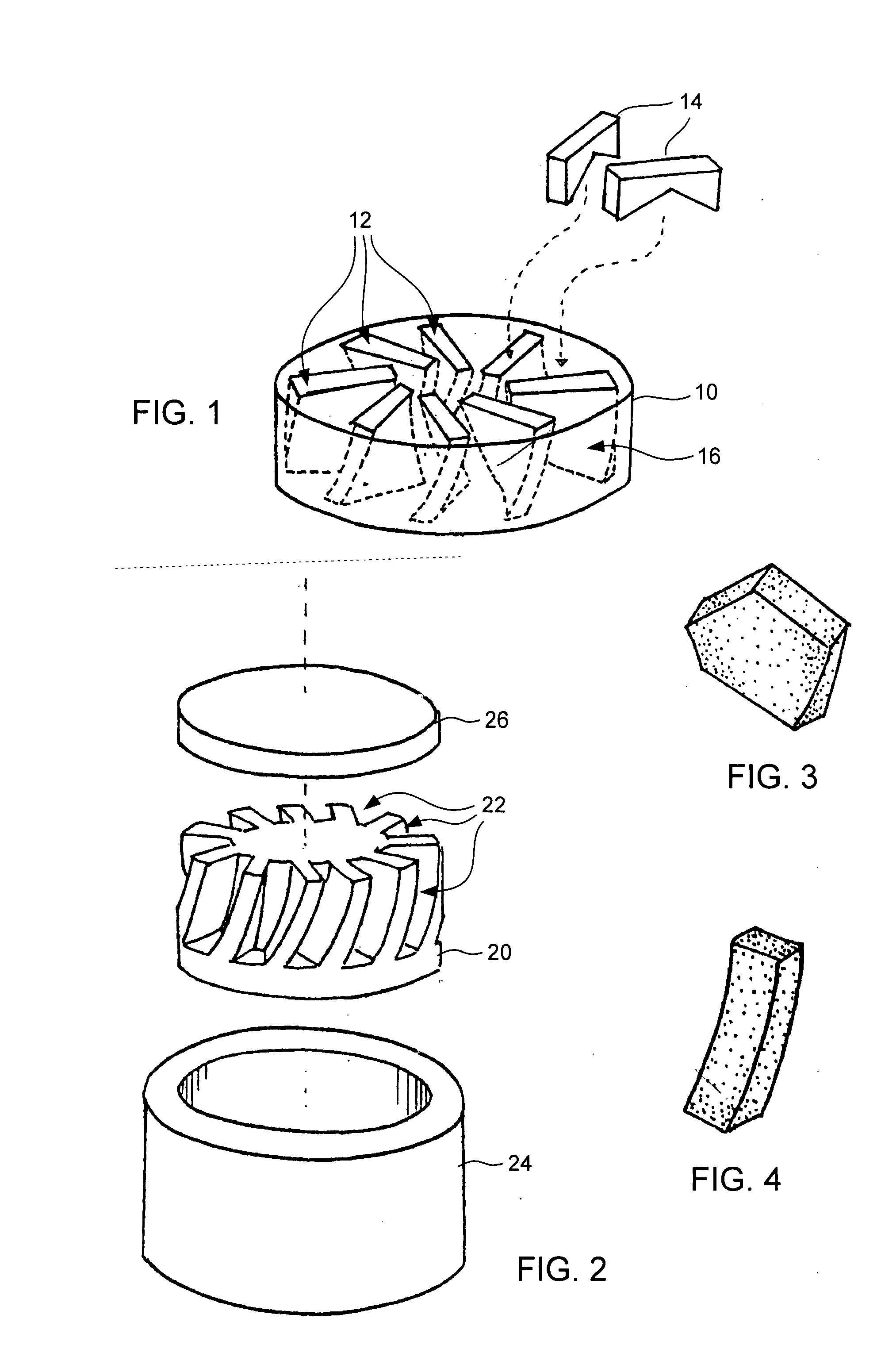

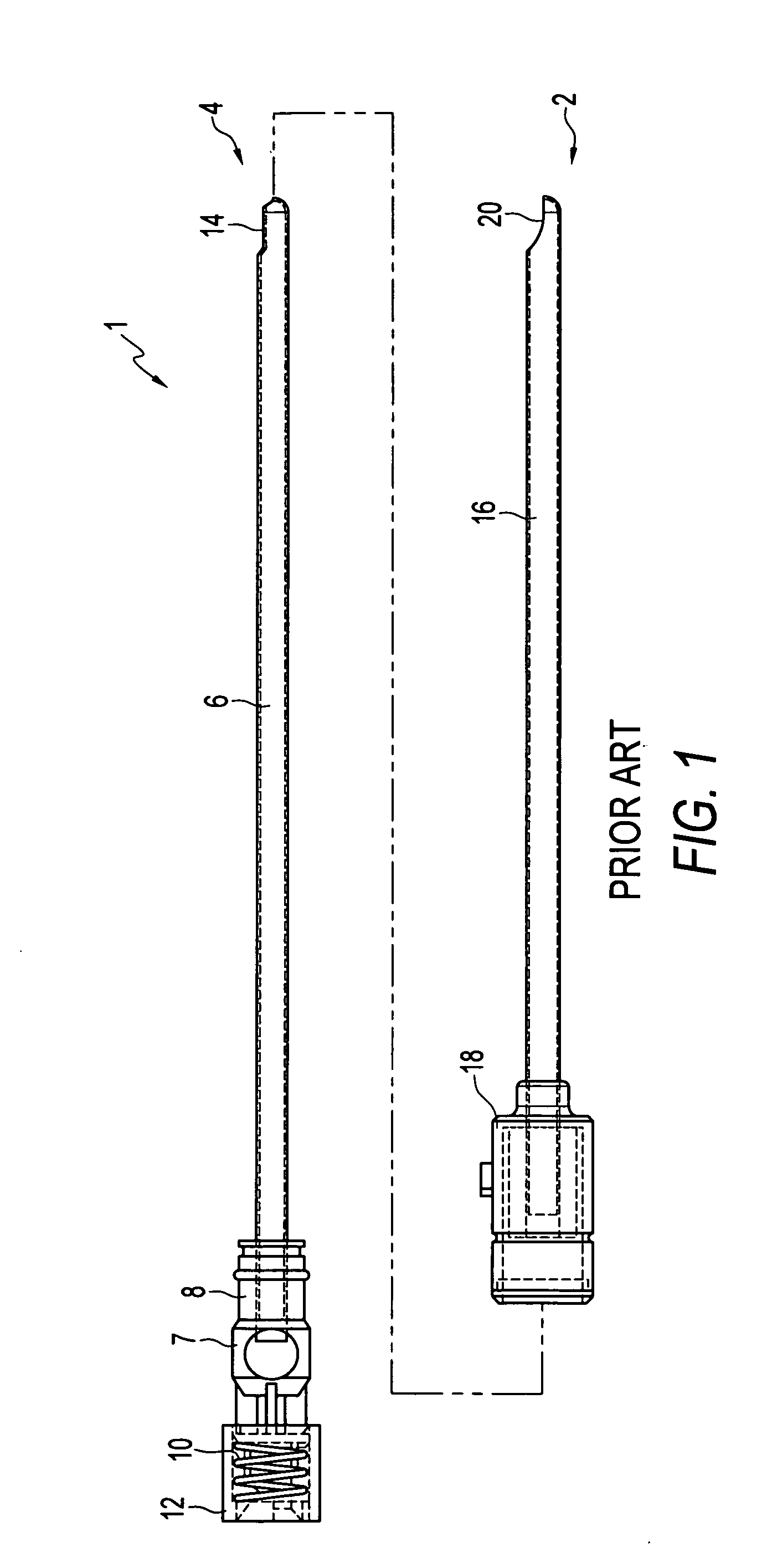

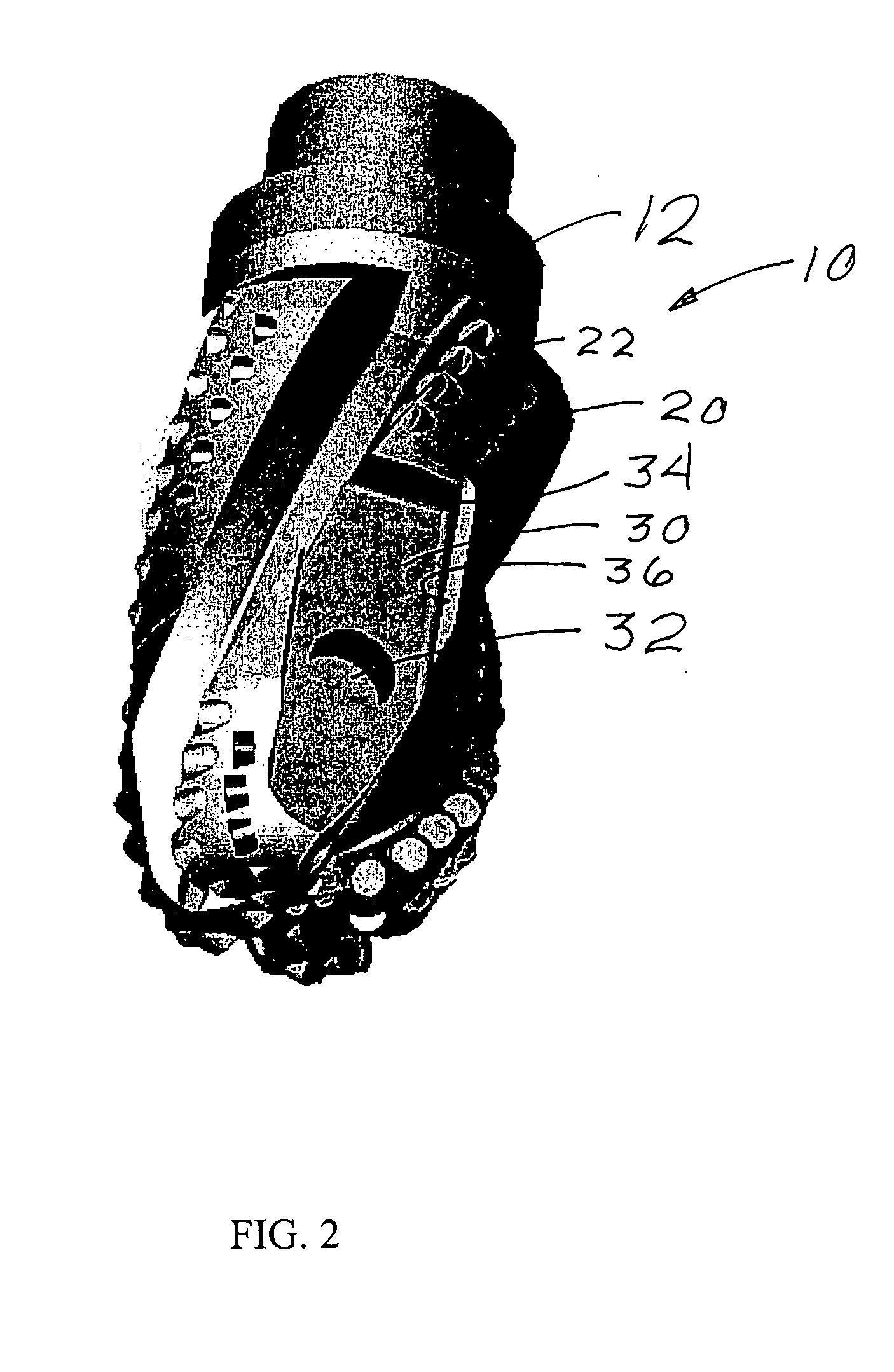

Method for determining a tooth period length of a bone milling cutter

ActiveUS20080077148A1Great dimensionImprove stabilityDiagnosticsSurgical needlesMilling cutterEngineering

A method for manufacturing bone milling cutters, wherein a milling cutter toothing (12) is created at a distal face of a tubular milling cutter shaft (10) of a bone milling cutter at a given outer diameter (D) of the milling cutter shaft (10). The following steps are carried out: determining the tube circumference (U) of the milling cutter shaft (10); ascertaining an average desired tooth height (Hgew) of the milling cutter toothing (12); ascertaining the desired tooth period length (LZ′) of the milling cutter toothing from the desired tooth height (Hgew) at given parameters of a tooth period pattern; dividing the tube circumference (U) by the desired tooth period length (LZ); rounding the results to an even number value (Qz); and dividing the tube circumference (U) by the value (Qz) in order to obtain the tooth period length (LZ).

Owner:JOIMAX GMBH

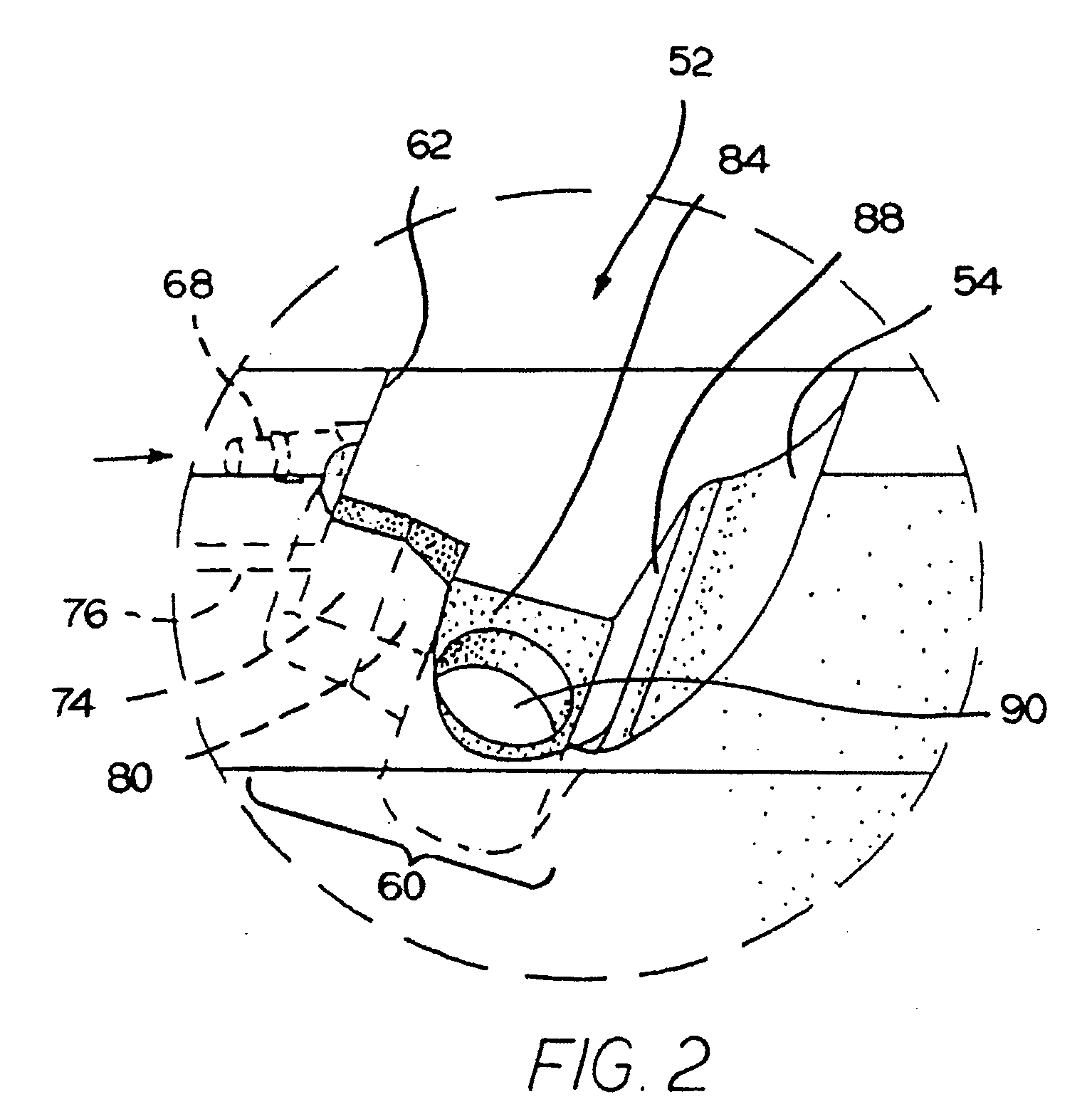

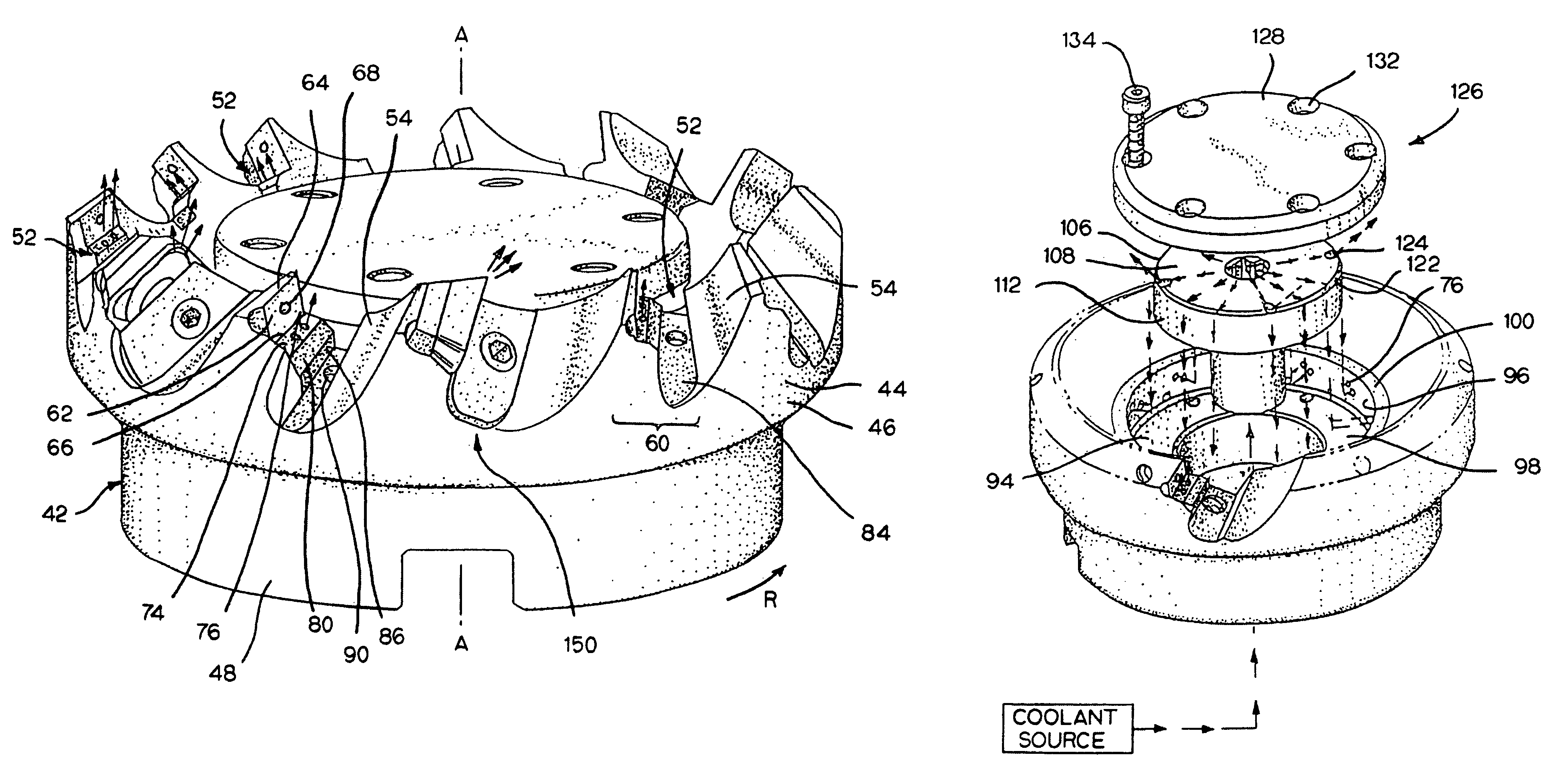

Milling cutter and milling insert with coolant delivery

A cutting insert for use in chipforming and material removal from a workpiece wherein coolant is supplied to the cutting insert from a coolant source. The cutting insert includes at least one discrete cutting location and at least one distinct internal channel that corresponds to the cutting location. The internal channel has an inlet to receive coolant and an outlet to exit coolant. The outlet is proximate to the cutting location, and the inlet is radial inward of the outlet.

Owner:KENNAMETAL INC

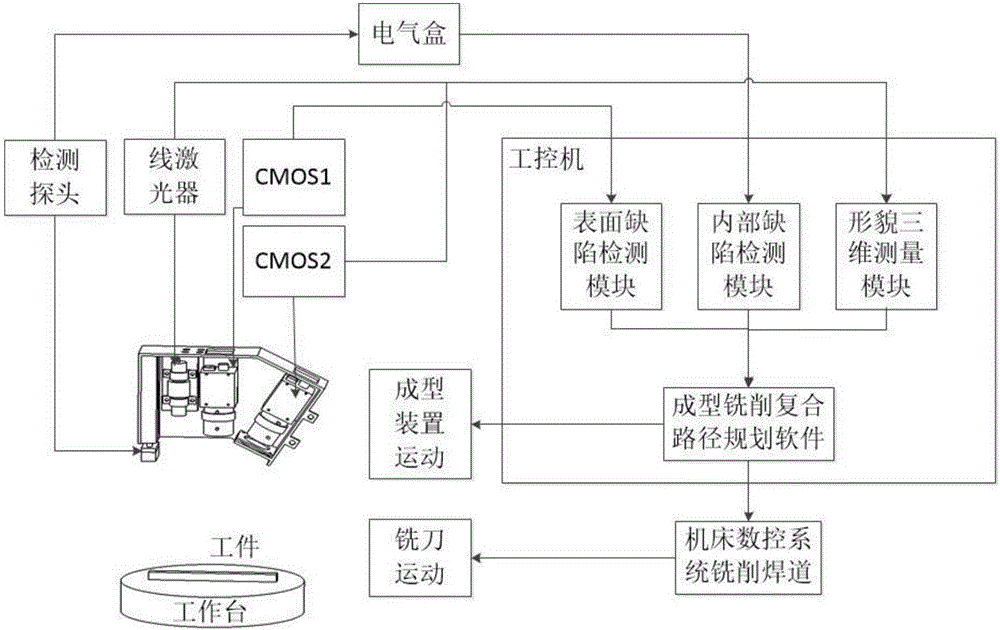

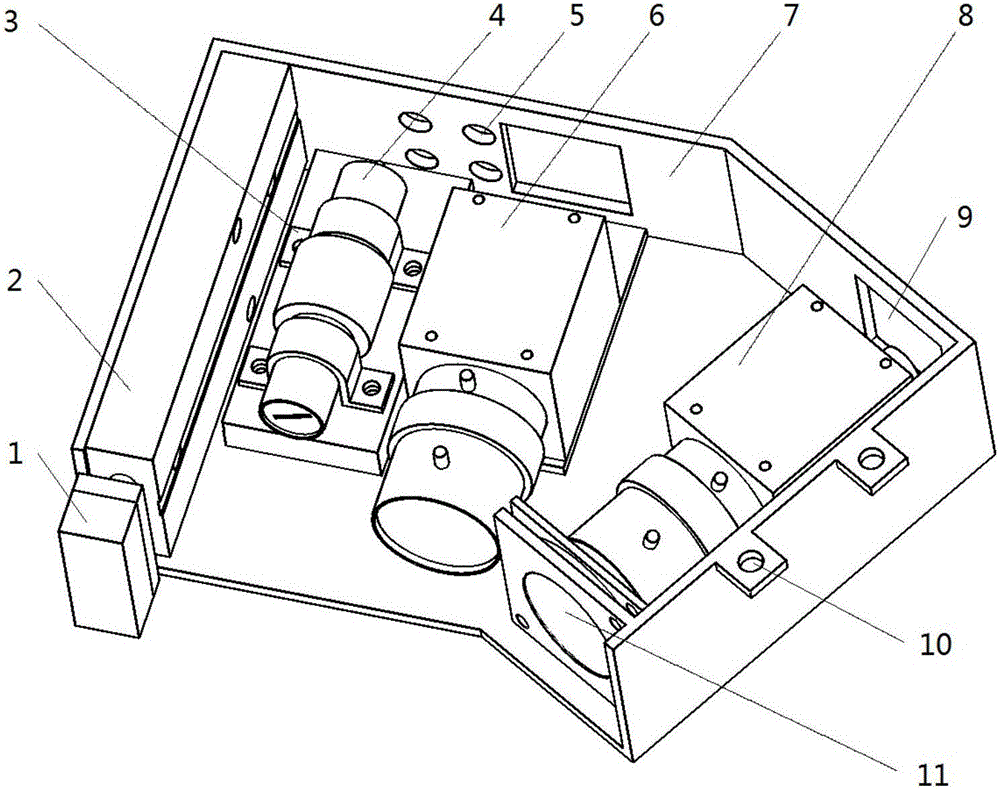

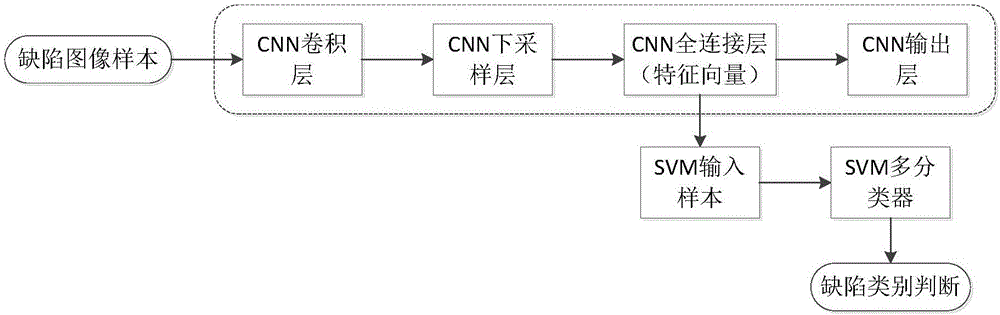

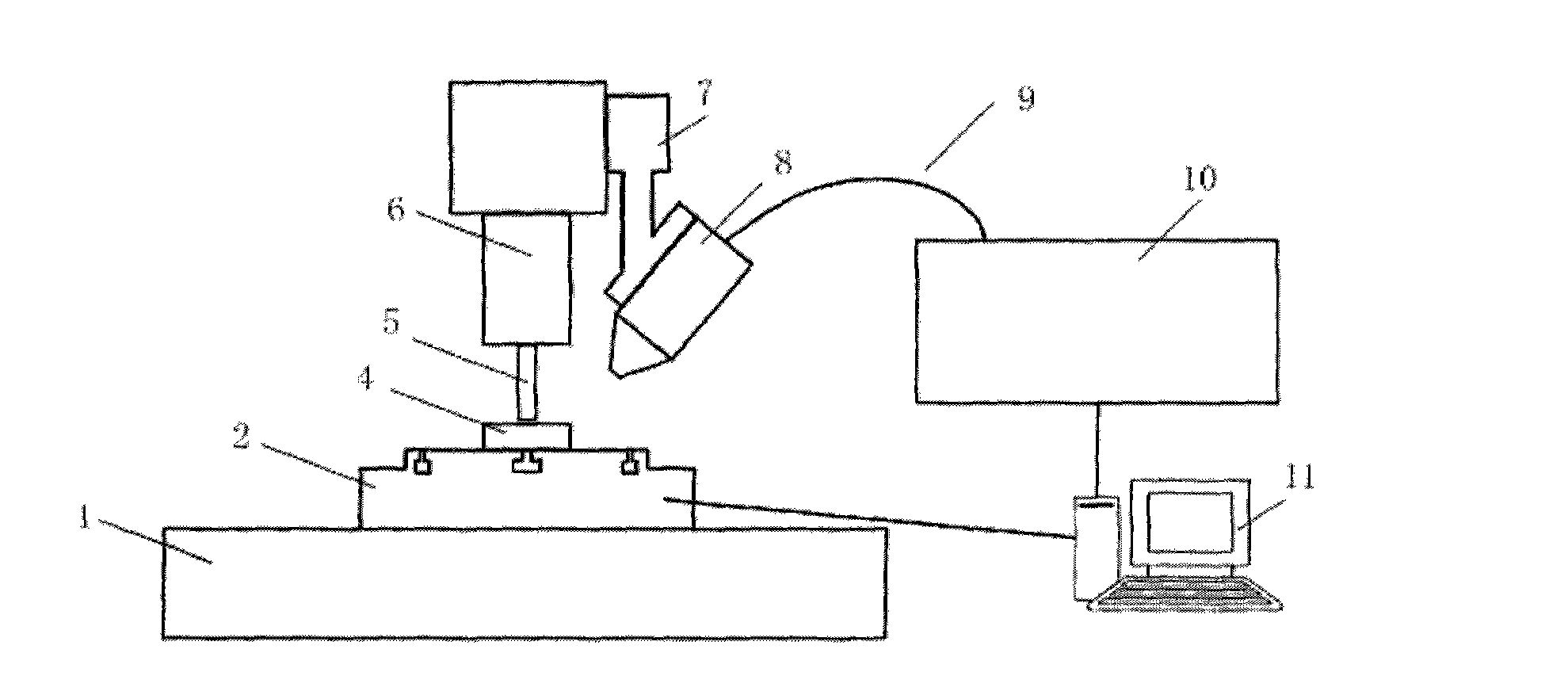

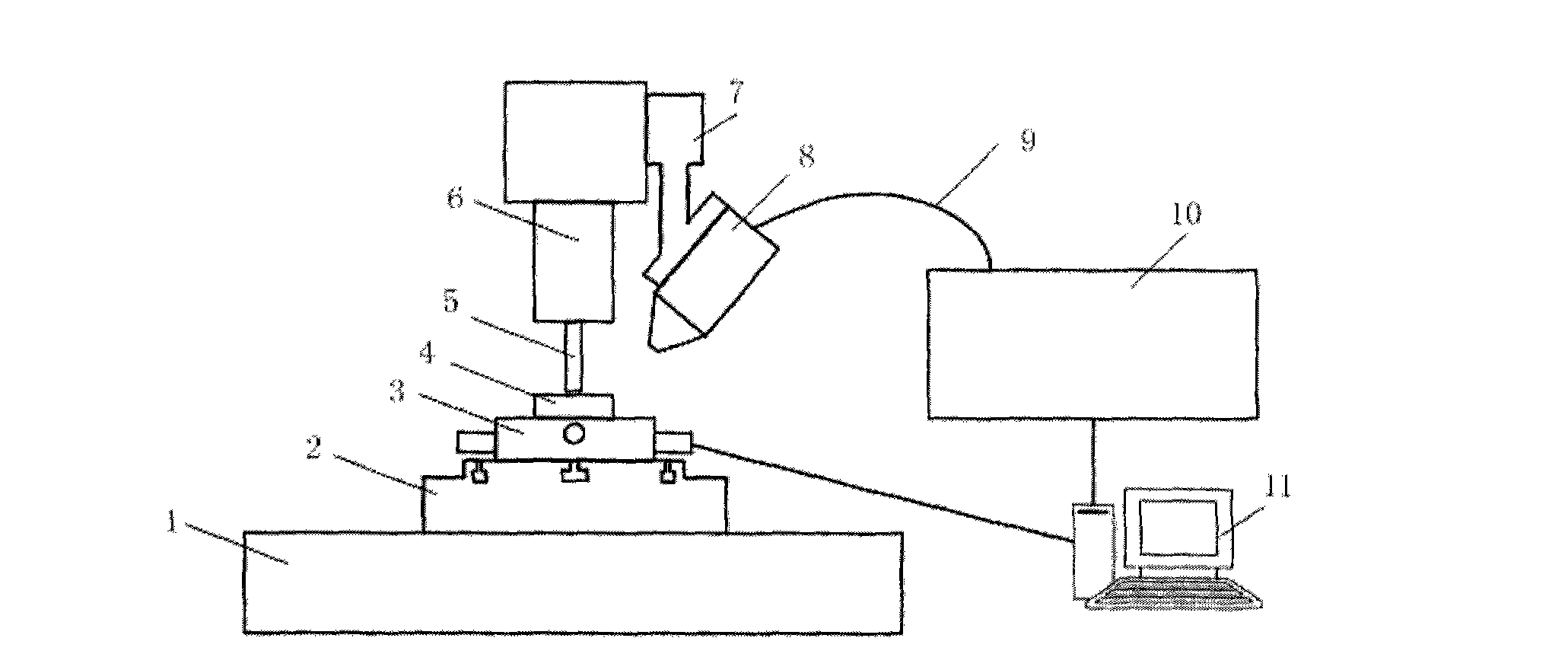

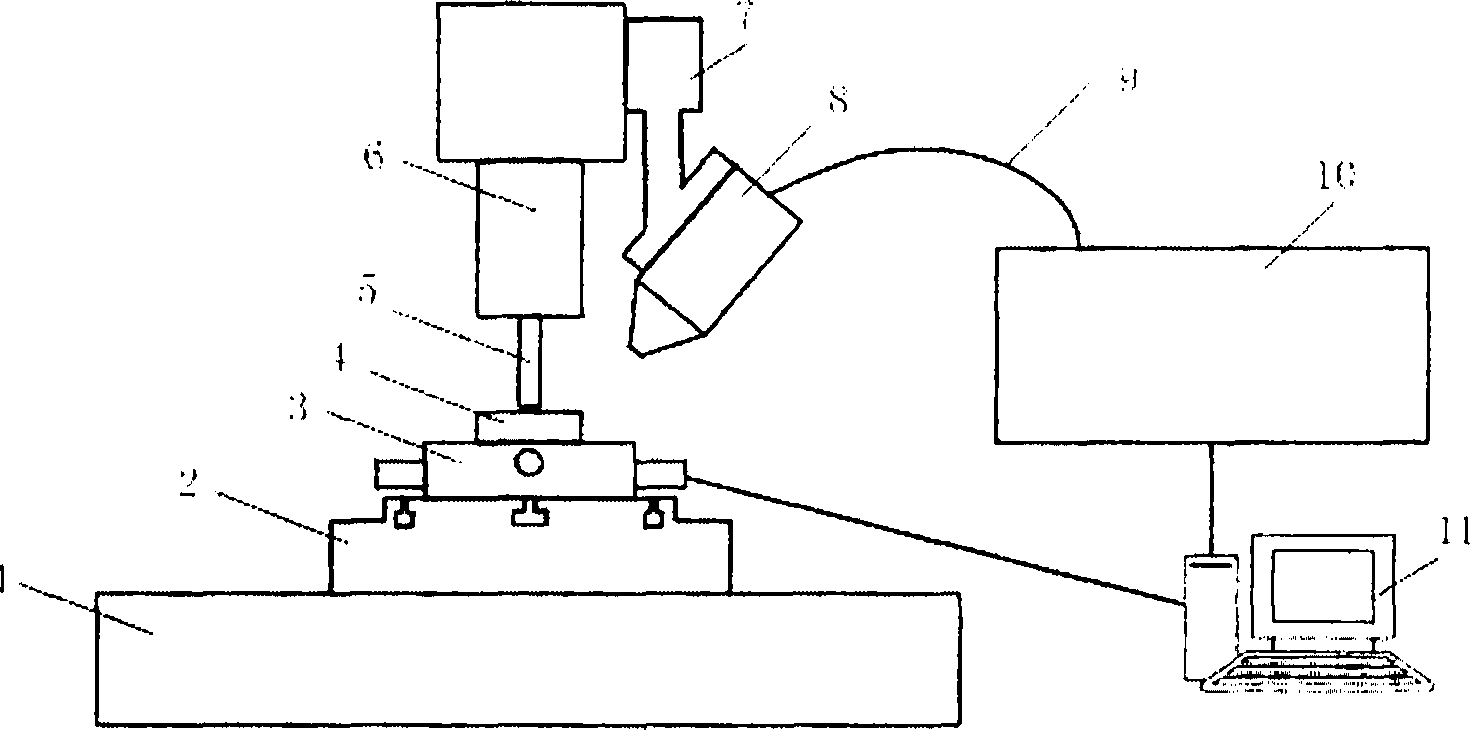

Additive manufacturing surface defect, internal defect and shape composite detection method and device

ActiveCN106338521AReal-time detectionOptically investigating flaws/contaminationUsing optical meansCMOSMagnetic disturbance

The invention discloses an additive manufacturing surface defect, internal defect and shape composite detection device which comprises a surface defect detection system, an internal defect detection system, a shape three-dimensional measurement system and a clamping device, wherein the surface defect detection system comprises a first CMOS industrial camera; the internal defect detection system comprises an air cylinder and a detection probe; the detection probe is used for generating a magnetic field to be close to the detected surface and establish magnetic mutual action with a workpiece to form a magnetic disturbance environment; the shape three-dimensional measurement system comprises a line laser, a light filter and a second CMOS industrial camera. The device can perform real-time and comprehensive detection on the surface defect, the internal defect and the shape three-dimensional size in additive manufacturing, transmits data to an industrial personal computer for analysis, interacts with forming milling composite route planning software, and can control a shaping device in real time to perform formation and generate a milling code and control a milling cutter to perform milling on the additive manufacturing surface.

Owner:HUAZHONG UNIV OF SCI & TECH

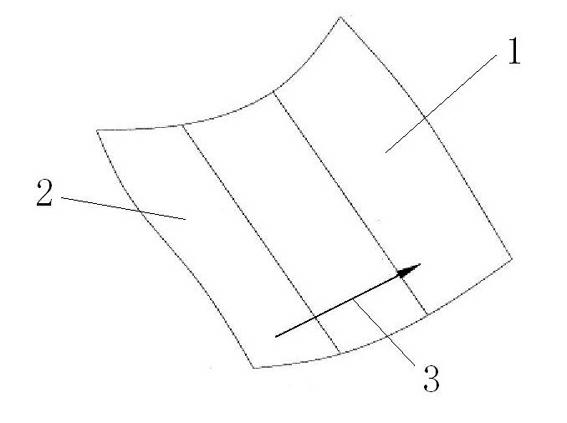

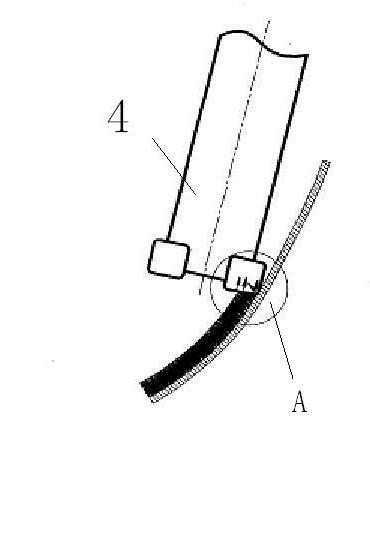

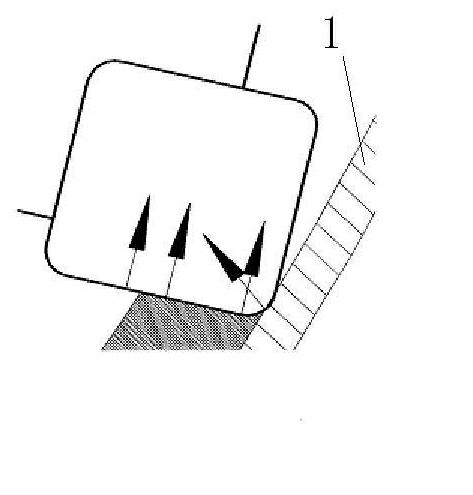

Custom-Fit Implantable Surgical Guide and Associated Milling Tool, Method for the Production and Use Thereof

InactiveUS20080287953A1Ensure total axial stabilityEnsure stabilityDental implantsAdditive manufacturing apparatusMilling cutterOsteotomy

The invention relates to a custom-fit implantable surgical guide (1) and an associated milling tool (4), which is positioned in straddling on the alveolar ridge (7) of a maxillary or mandible arch (2) and comprises at least one drilling barrel (11) for axially guiding said milling tool (4), wherein said barrel (11) is laterally open and at least one part of the internal surface thereof (17)and at least one part of the external surface of the milling tool (4) interact and axially maintain the entire milling tool (4) with respect to the barrel (11). Said invention makes it possible to carry out high precision osteotomies for lateral insertion dental implants.

Owner:MATERIALISE DENTAL NV

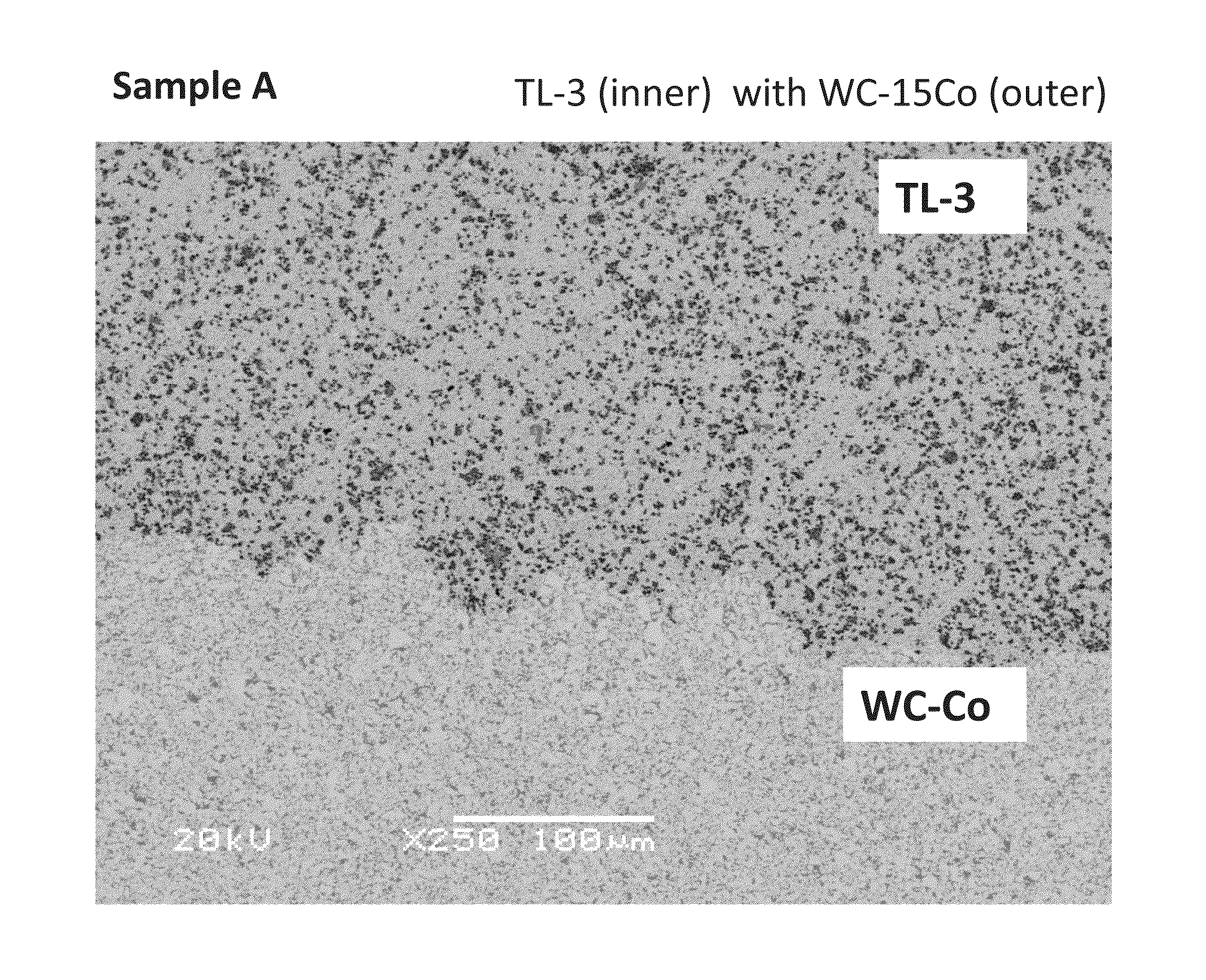

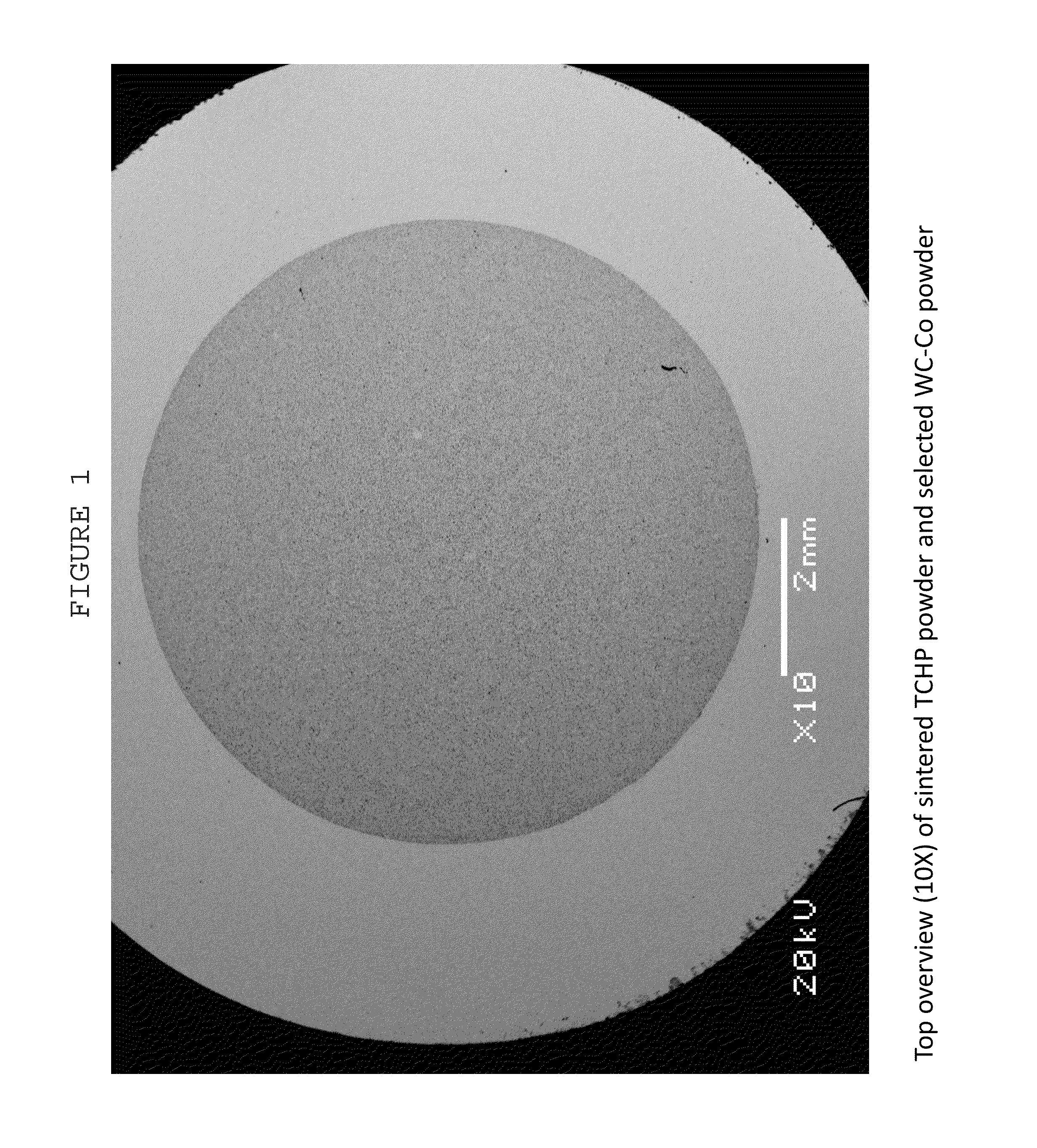

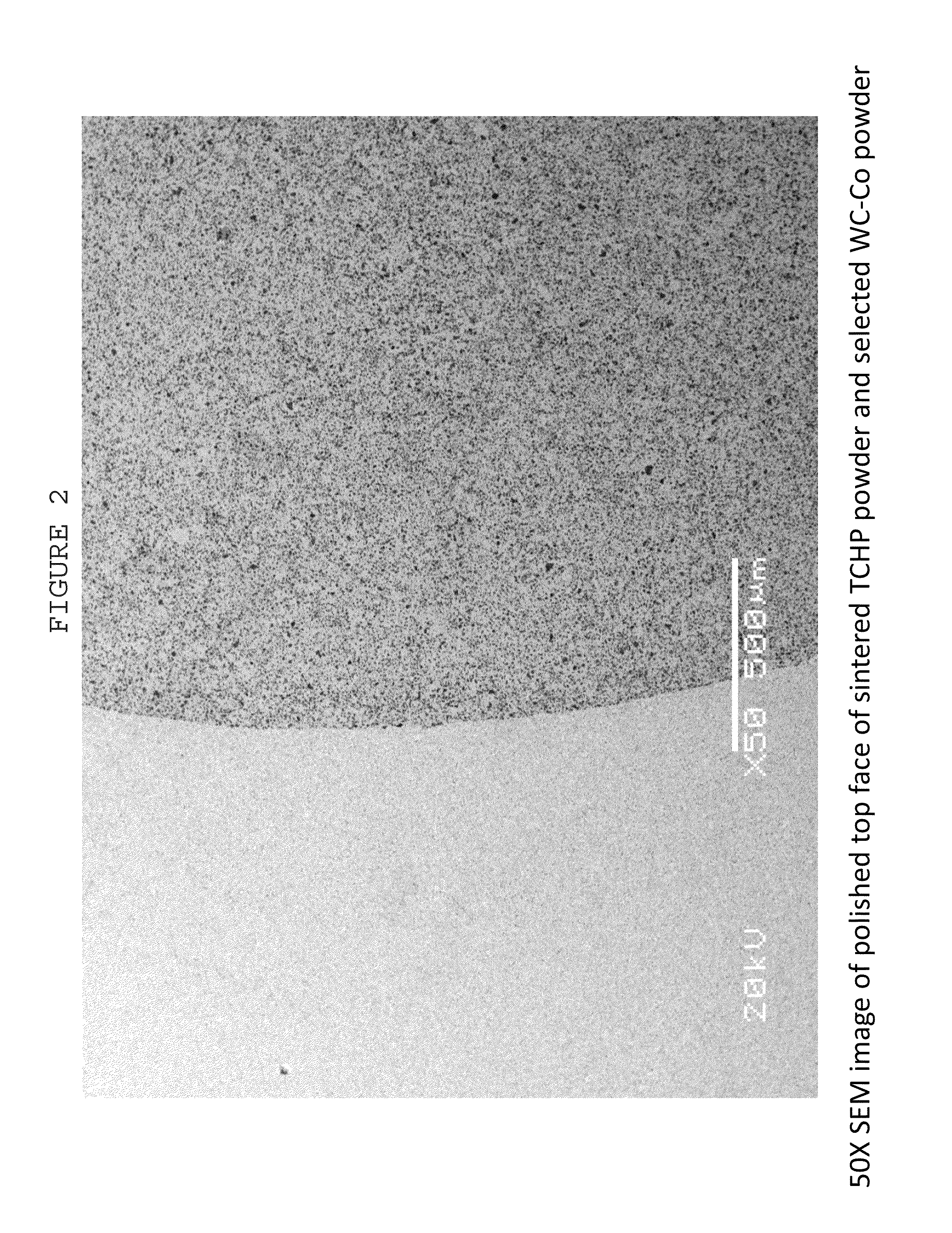

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS20140087210A1Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsCarbideFunctionally graded material

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

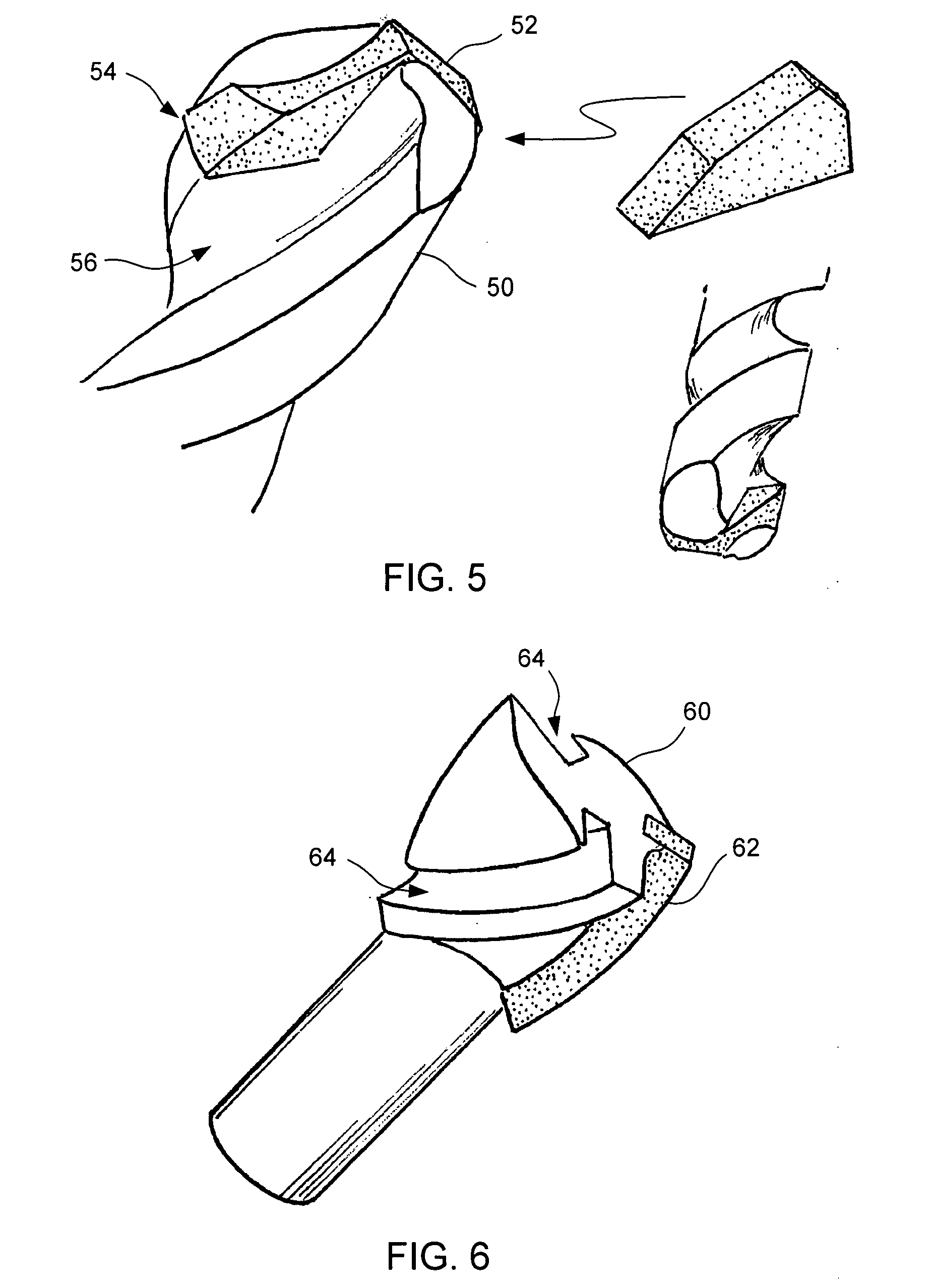

Contoured PCD and PCBN for twist drill tips and end mills and methods of forming the same

ActiveUS20080247899A1Easy to provideLess grinding timePigmenting treatmentAdditive manufacturing apparatusMilling cutterMaterials science

Contoured solid polycrystalline superabrasive material such as twist drill tips and endmill flank segments can be formed by preparing a precursor mold having a plurality of shaped openings each corresponding to a predetermined shape. A specially prepared charge feed can be placed into the shaped openings to form a charged precursor. The charge feed can include a substantially homogeneous mixture of superabrasive source particulates, sintering binder, and optional inorganic bonding medium. A loaded reaction cup-assembly including the charged precursor can be subjected to a pressure, temperature and time sufficient for sintering and formation of the contoured polycrystalline superabrasive material. Reduced finishing steps and increased tailorability of grade and quality of final polycrystalline products can be readily achieved.

Owner:CHO H SAM +4

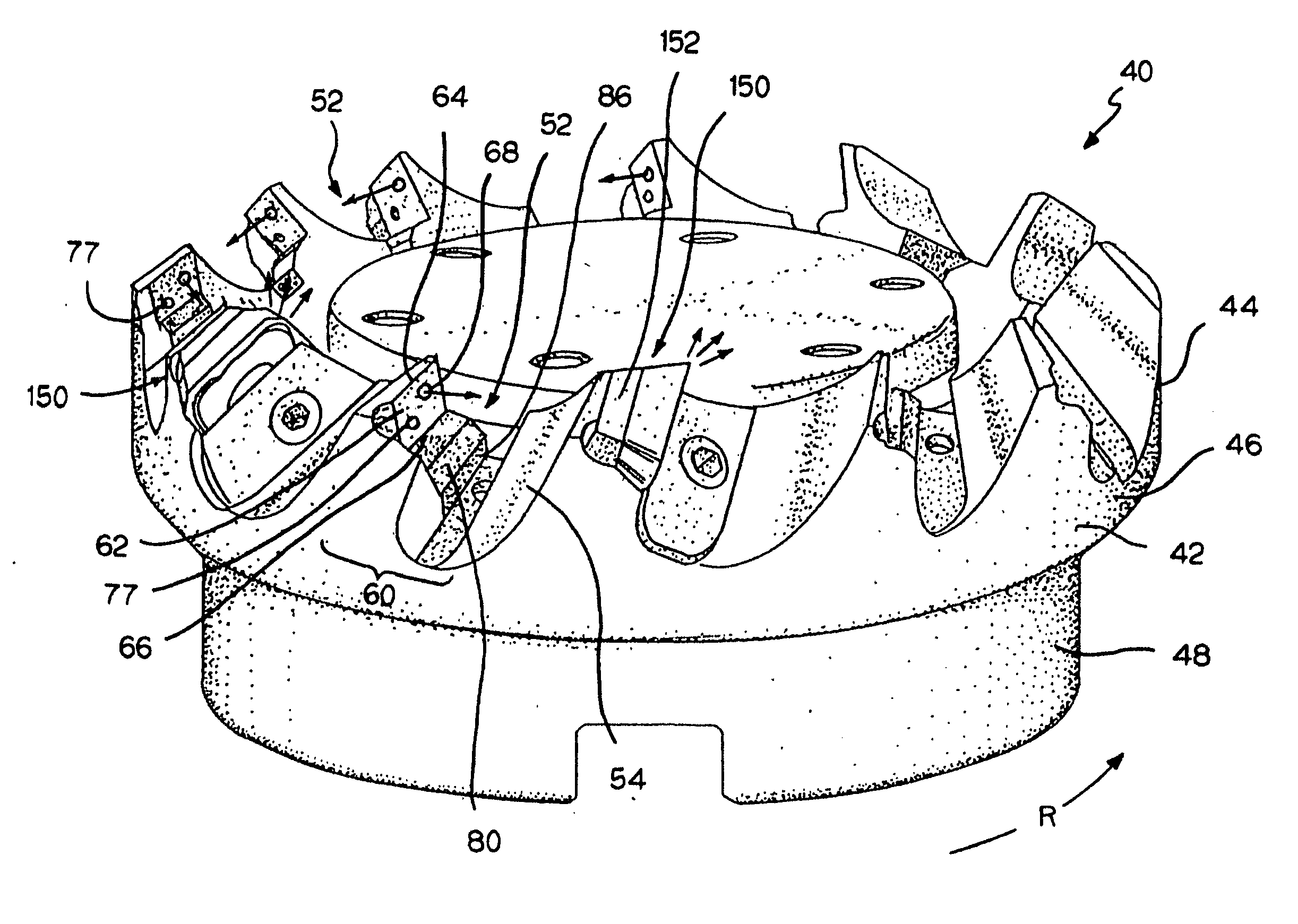

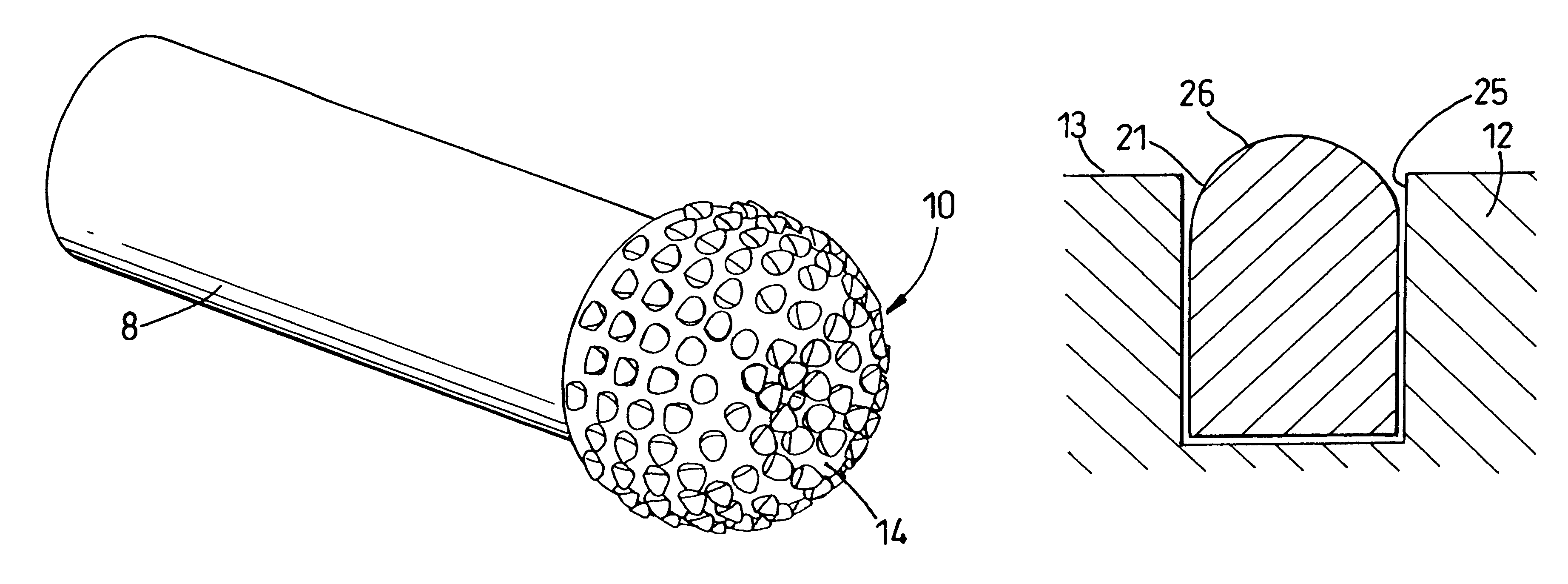

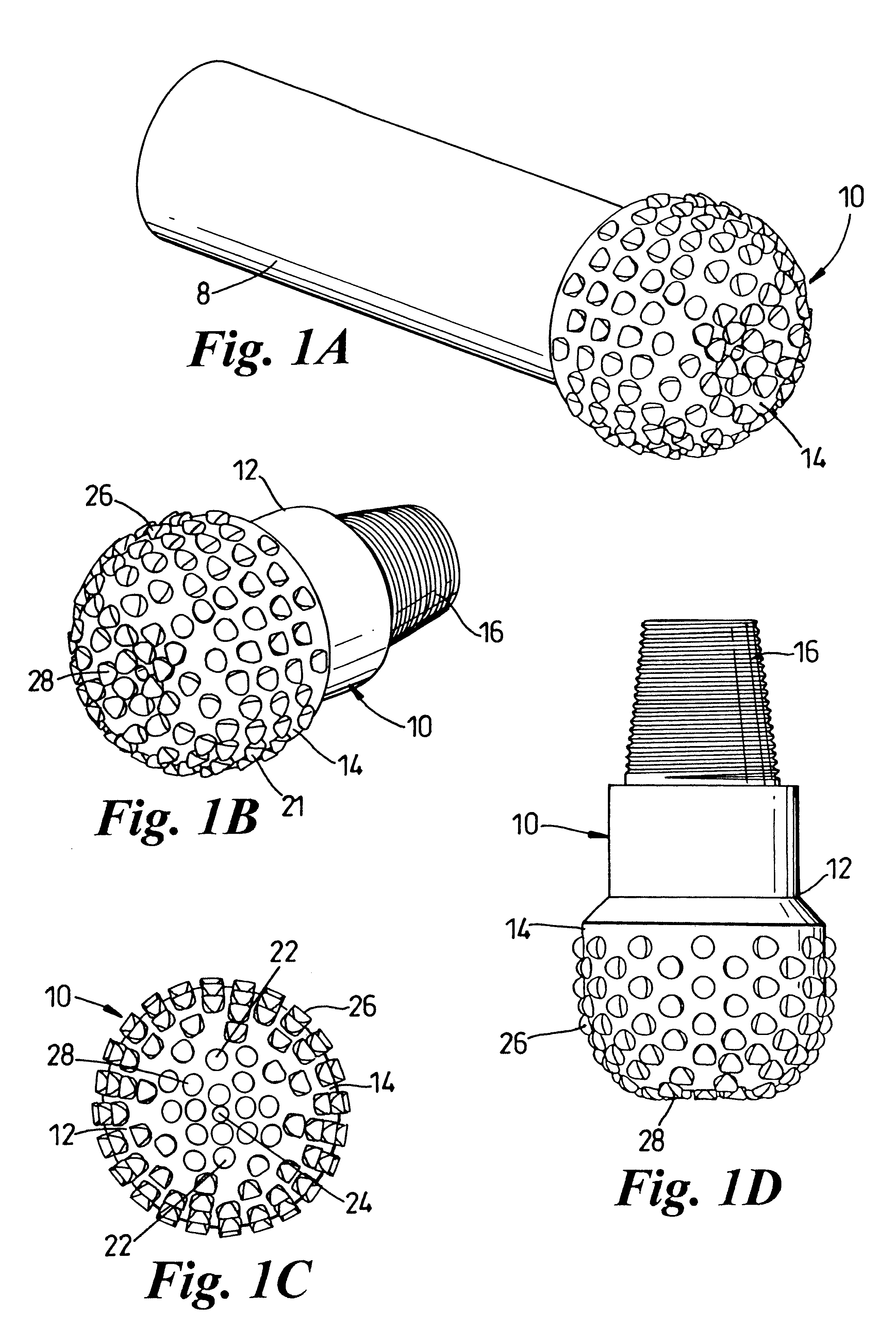

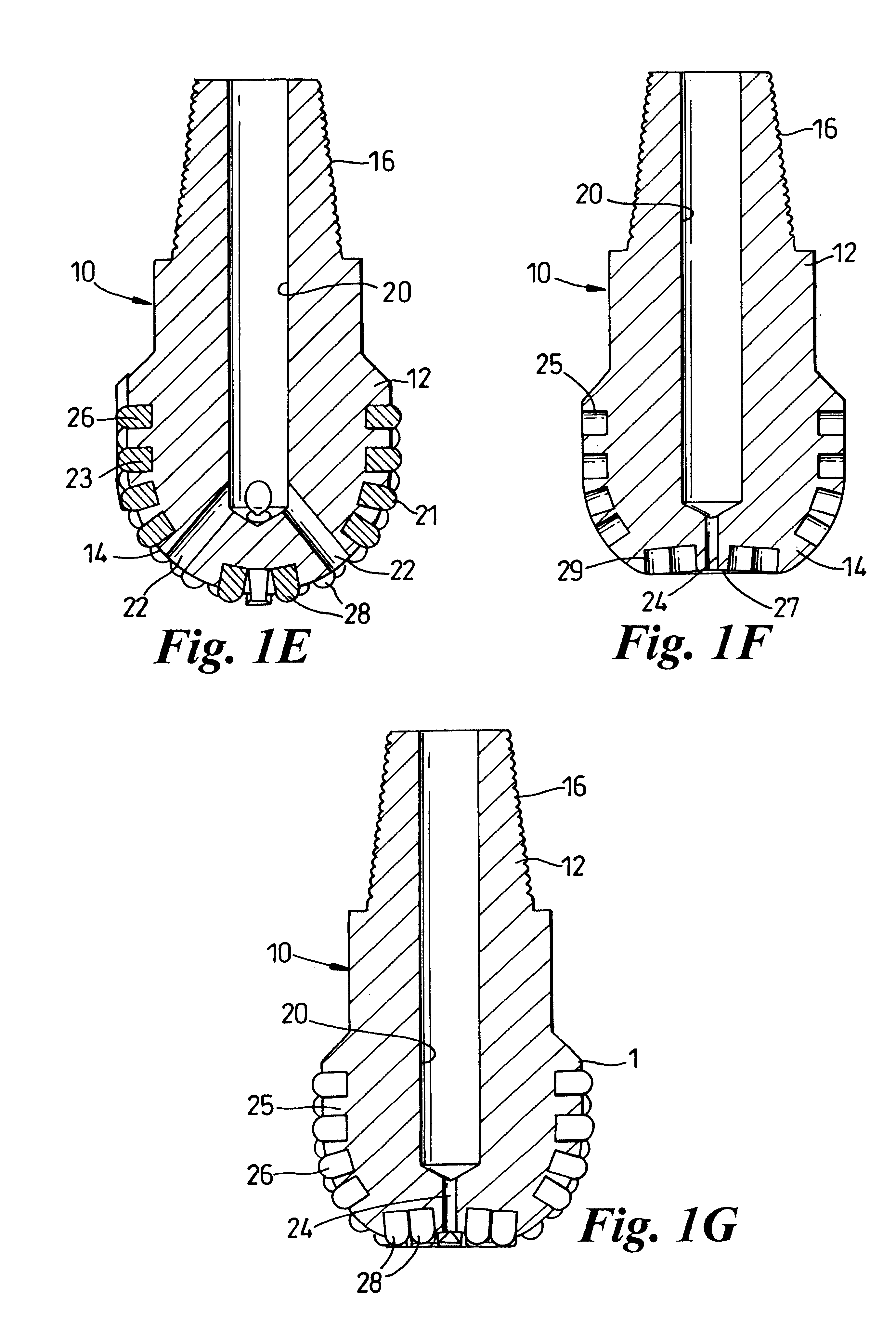

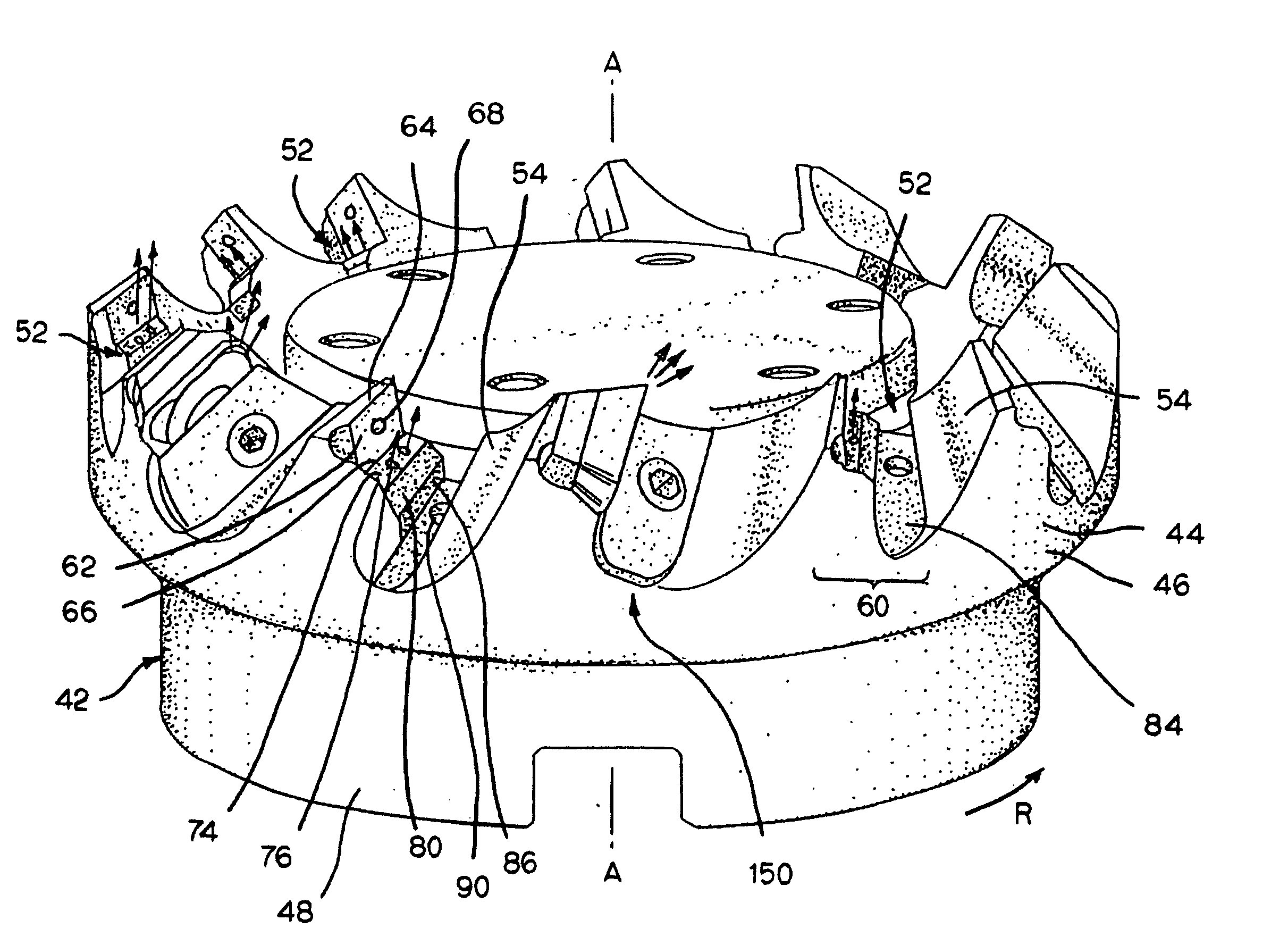

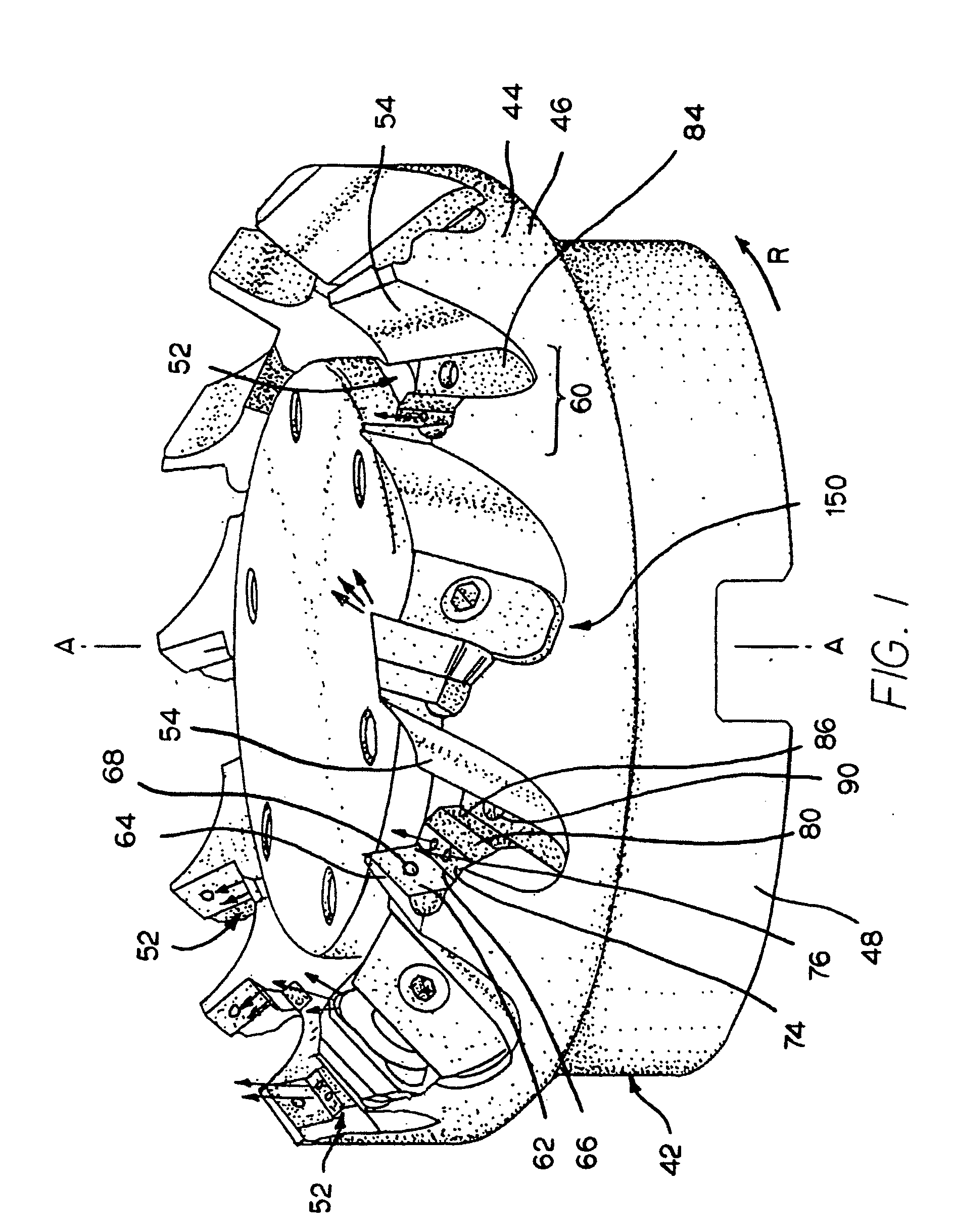

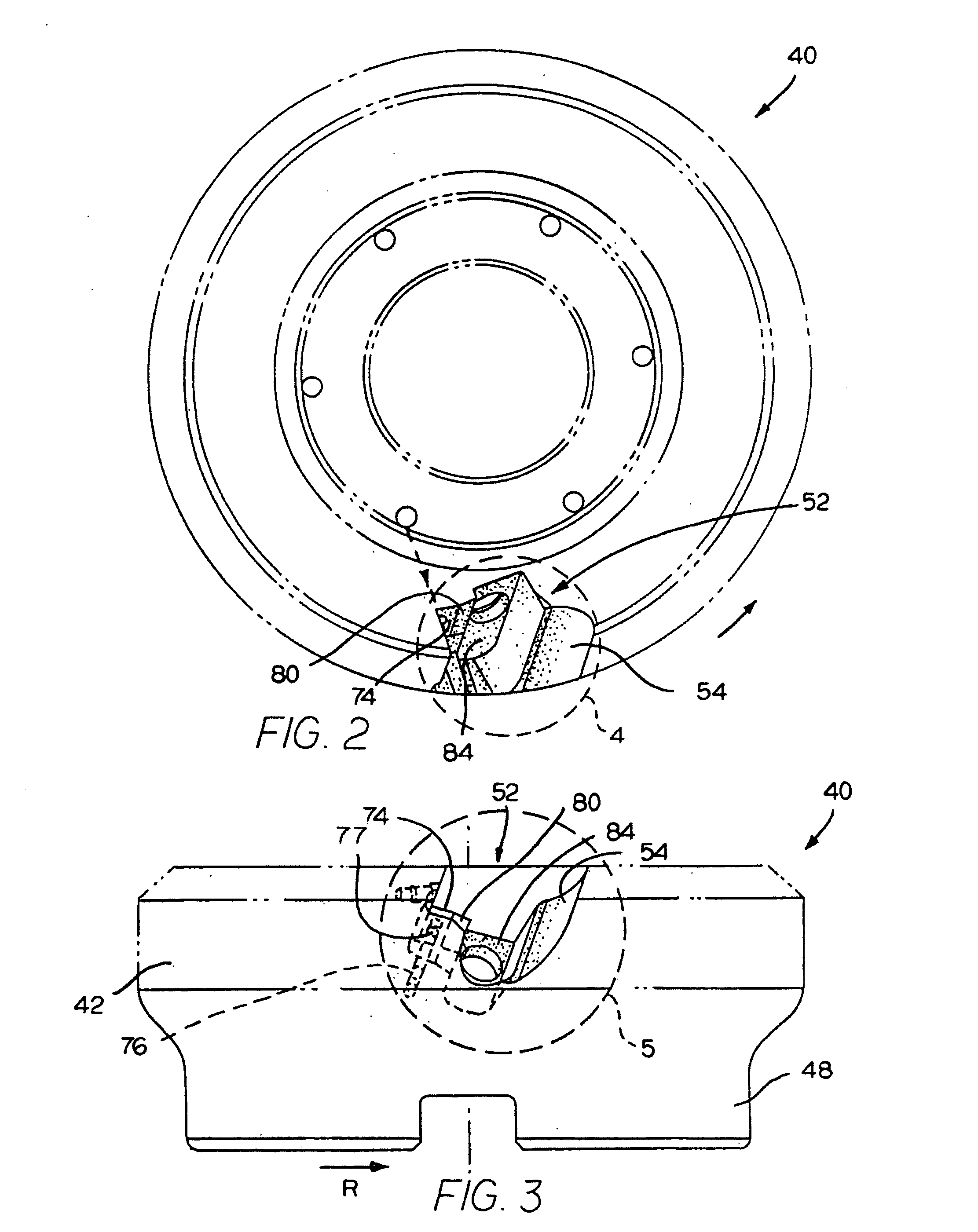

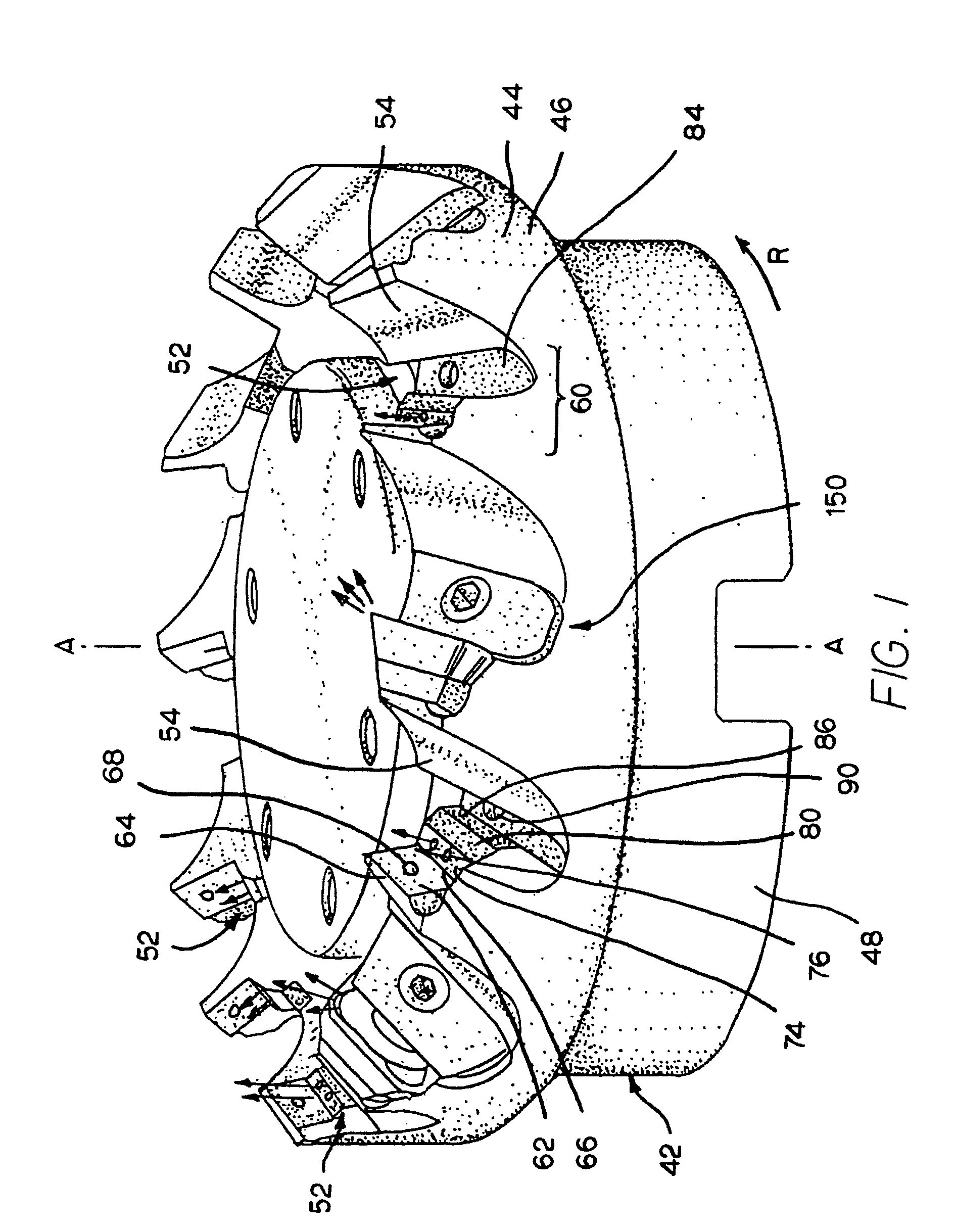

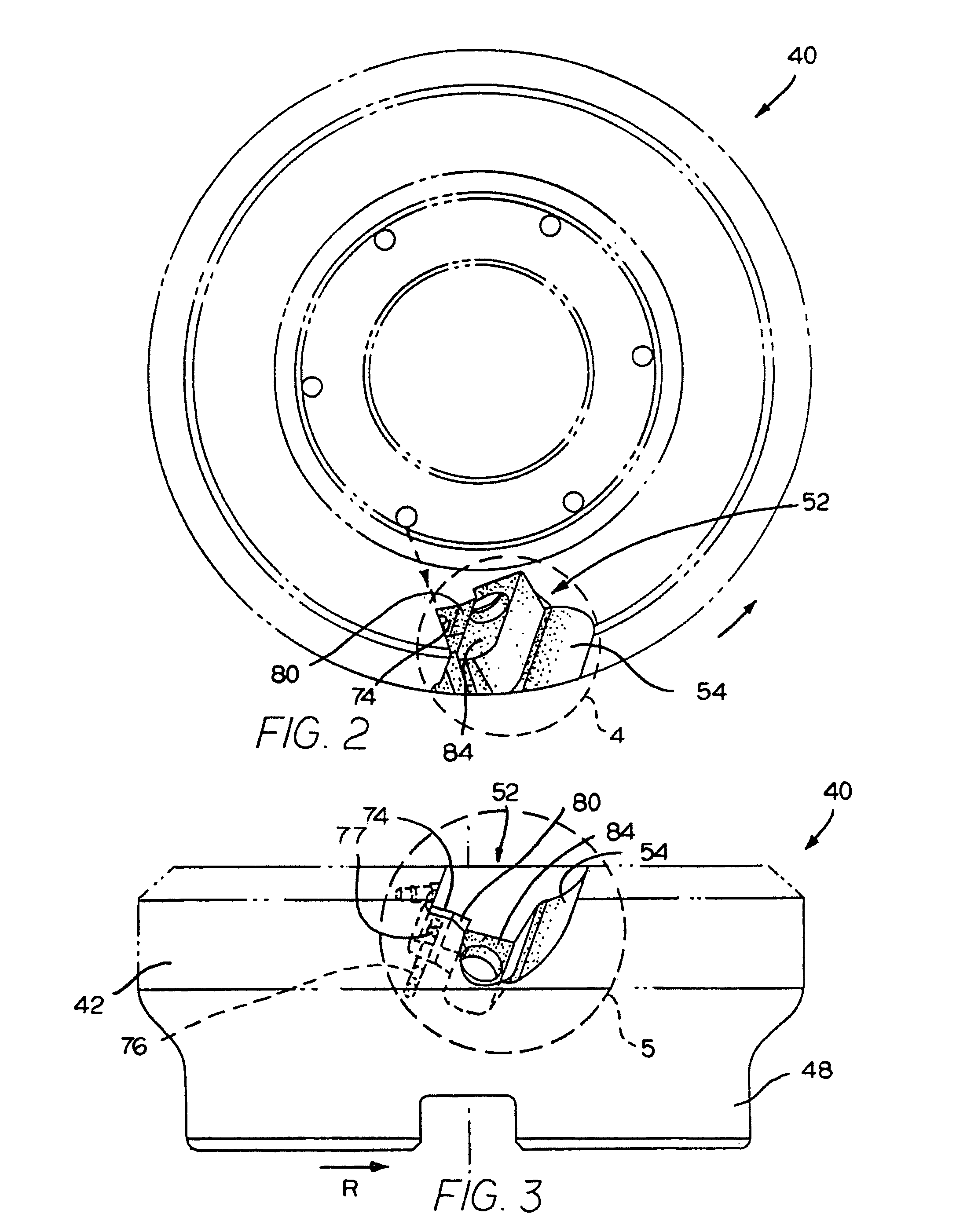

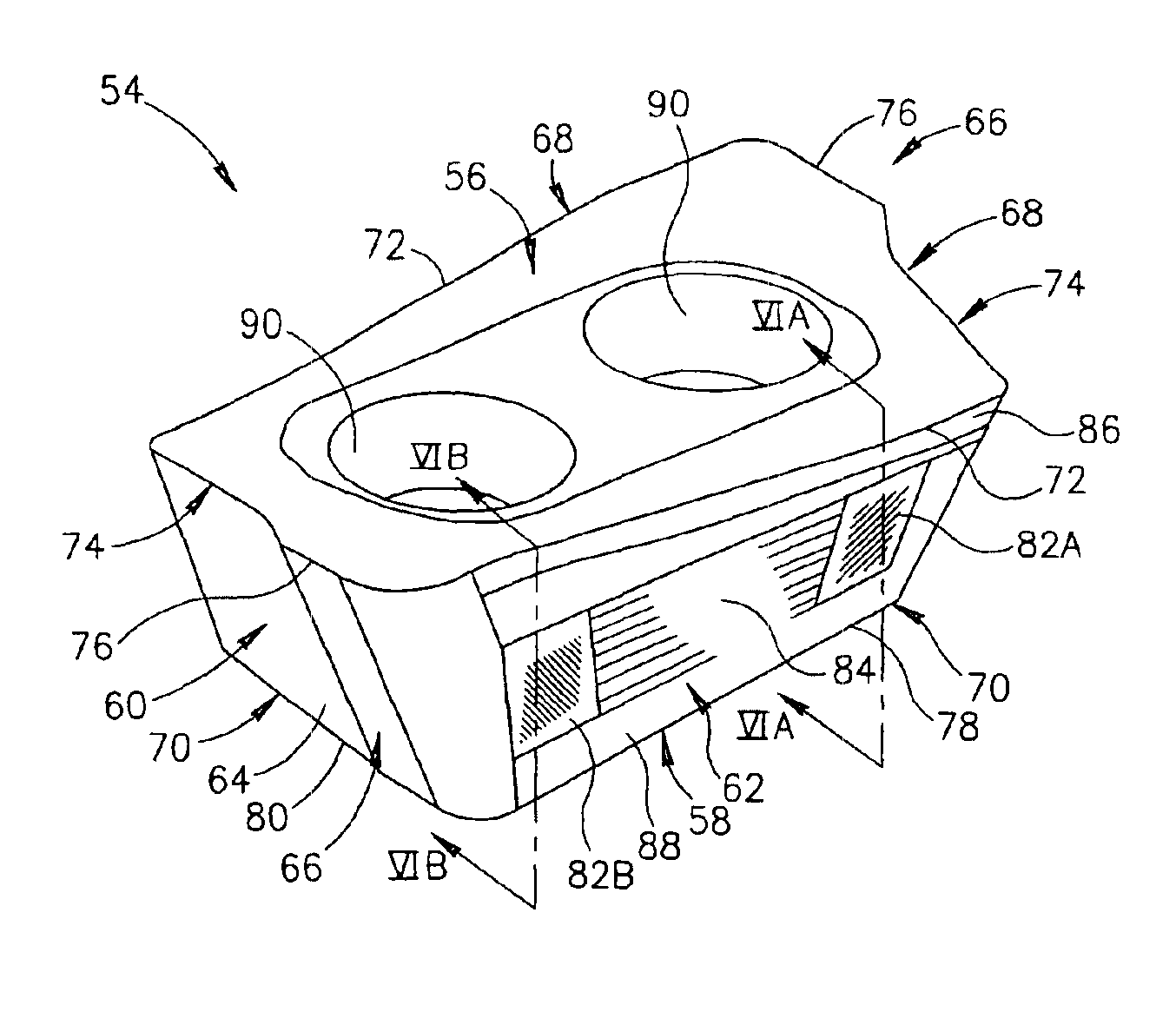

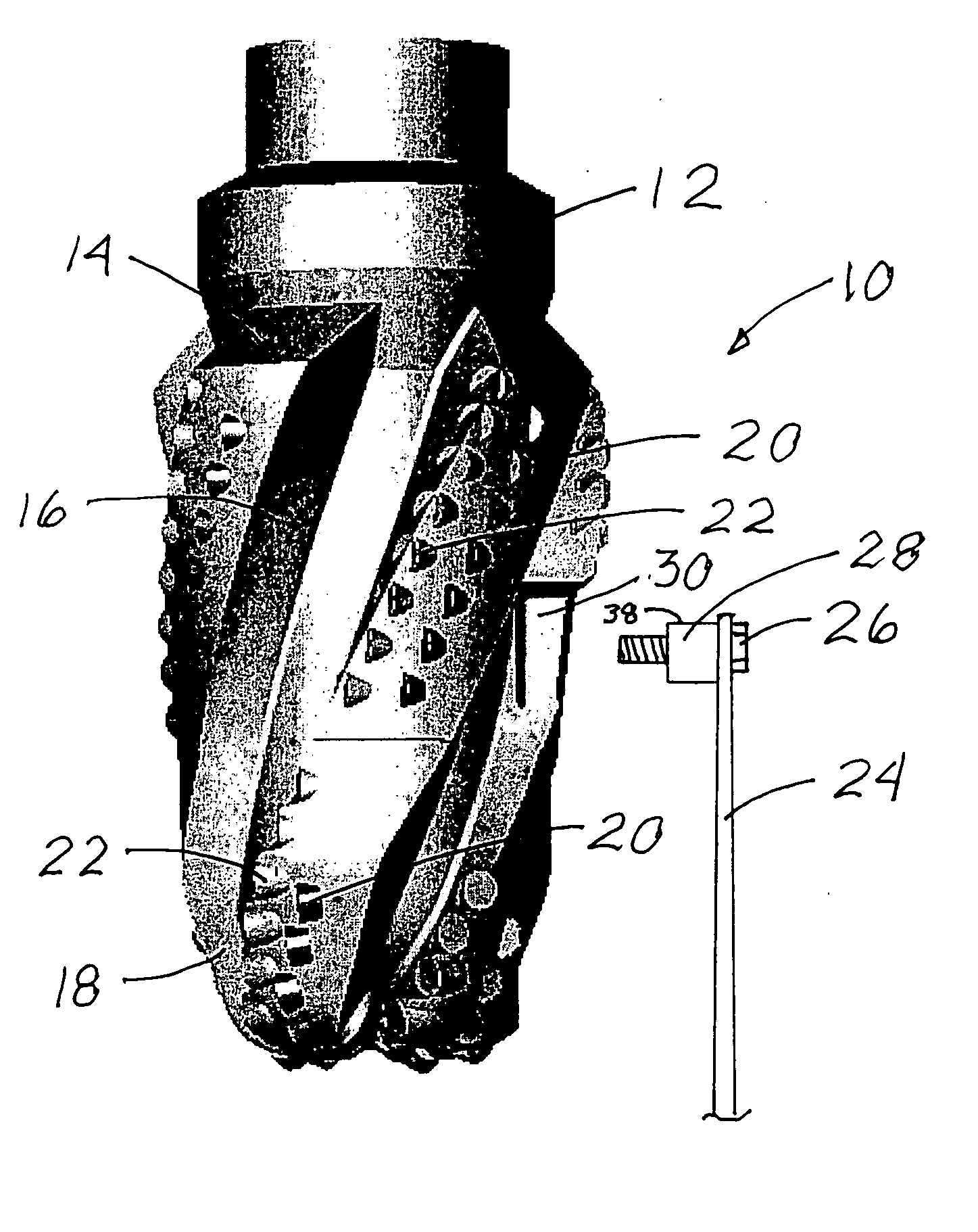

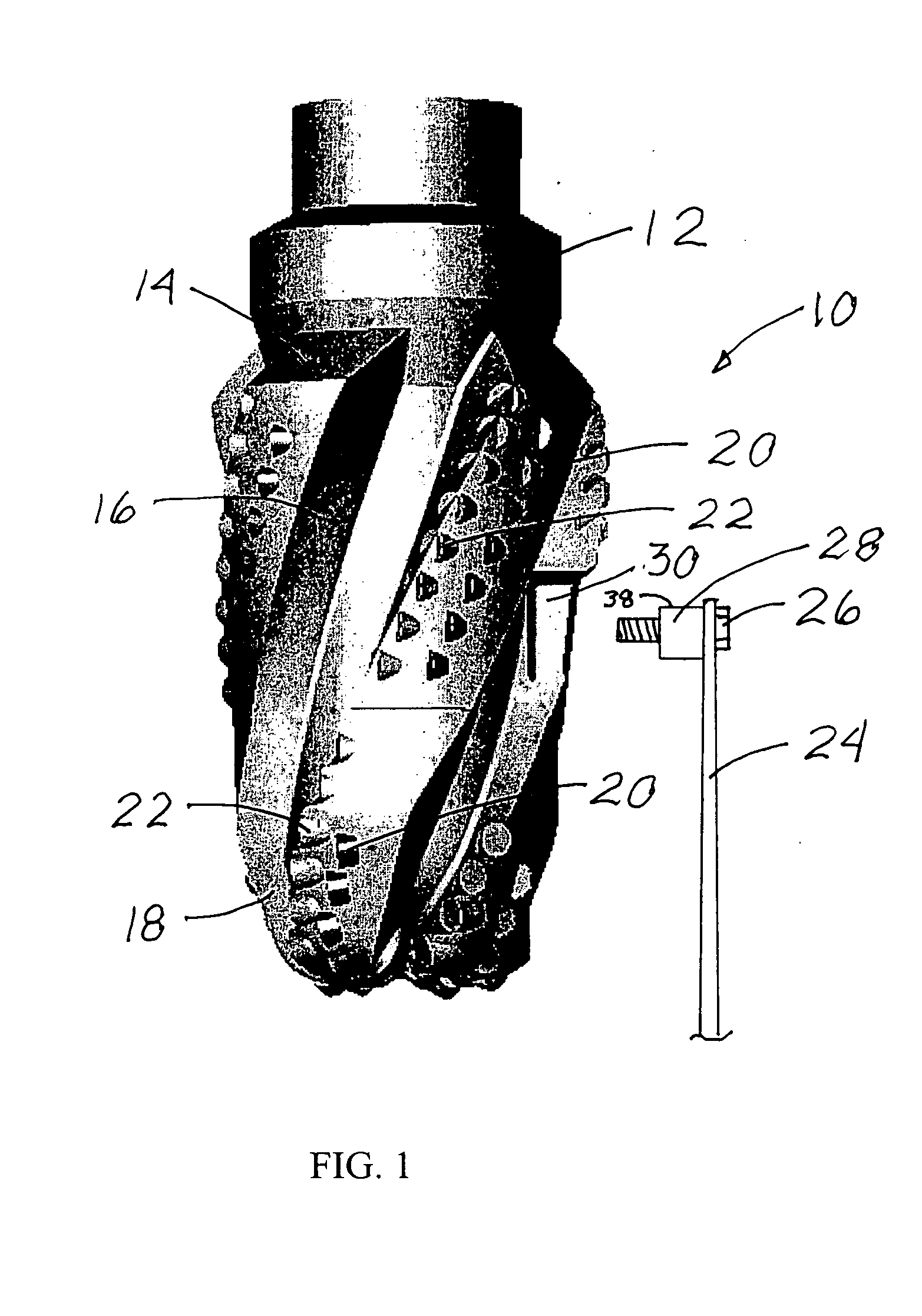

Mills for wellbore operations

A wellbore mill has been invented that, in certain aspects, has a body having a top and a bottom and, optionally, a fluid flow channel extending therethrough from top to bottom with, optionally, one or more fluid jetting ports in fluid communication with the fluid flow channel, milling apparatus on the body including a plurality of milling inserts, each insert mechanically secured in a corresponding recess in the body, said mechanical securement sufficient for effective milling in a wellbore. A wellbore milling method for milling an opening in a selected tubular of a tubular string in a wellbore has been invented that includes installing and using such a mill.

Owner:WEATHERFORD TECH HLDG LLC

Tangential cutting insert and milling cutter

A tangential cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces and two identical opposing minor side surfaces extending between them. Each end surface has a peripheral edge containing cutting edges and four corners of which two are lowered and two are raised. Each end surface is provided with at least one projecting abutment member having a projecting abutment surface, wherein in a side view of either major side surface, the at least one projecting abutment surface is concave.

Owner:ISCAR LTD

Milling cutter and milling insert with coolant delivery

A cutting insert assembly for use in chipforming and material removal wherein the cutting insert assembly is received in a pocket of a cutter body wherein coolant can flow out of a pocket opening contained in the pocket. The cutting insert assembly includes a cutting insert body that presents at least two discrete cutting locations. The cutting insert body contains a coolant entry passage aligned with the pocket opening for coolant to flow through the coolant entry passage. The cutting insert body has a rake surface that contains at least two of the discrete depressions wherein each one of the discrete depressions corresponds to one of the cutting locations. Each one of the discrete depressions extends toward its corresponding cutting location. The assembly includes a diverter that is positioned adjacent to the cutting insert body wherein the diverter has a receiving opening aligned with the coolant entry passage to receive coolant through the coolant entry passage. The diverter includes a coolant trough in communication with the receiving opening wherein the coolant trough is aligned toward a selected one of the cutting locations whereby the coolant trough and the discrete depression corresponding to the selected cutting location define a conduit for the flow of coolant toward the selected cutting location.

Owner:KENNAMETAL INC

Cutting insert having a rake surface and a plateau surface separated by a step

ActiveUS7306409B2Convenient heightImprove protectionTransportation and packagingMilling cuttersMilling cutterPlateau

A cutting insert intended exemplarily for use in a face-milling cutter, has an all-around extending rake surface which changes into a plateau surface by an uninterrupted step. The step reaches its greatest height in the corner regions of the cutting insert. The rake surface defines a positive rake angle. The step prevents the produced chips from running onto the plateau surface. As a result of such a measure, a smear-on of material onto the plateau surface from a chip is prevented.

Owner:WALTER AG

Cutting insert for a milling cutter

A fully indexable square cutting insert has four side surfaces connecting to two end surfaces. At the intersection of each side surface with an end surface is a primary cutting edge which extends from an insert corner and along a first side surface, in a downward direction towards a median plane. A wiper extends from the same insert corner and along an adjacent side surface, in an upward direction away from the median plane, to rise above an abutment surface of an associated end surface. The geometry of the cutting insert and of the insert pocket in which the insert is seated are such that the primary cutting edge has a positive axial angle (helix), while the insert has an overall negative axial angle for providing axial clearance and an overall negative radial angle for providing radial clearance.

Owner:TAEGUTEC INDIA P

Milling cutter and milling insert with coolant delivery

Owner:KENNAMETAL INC

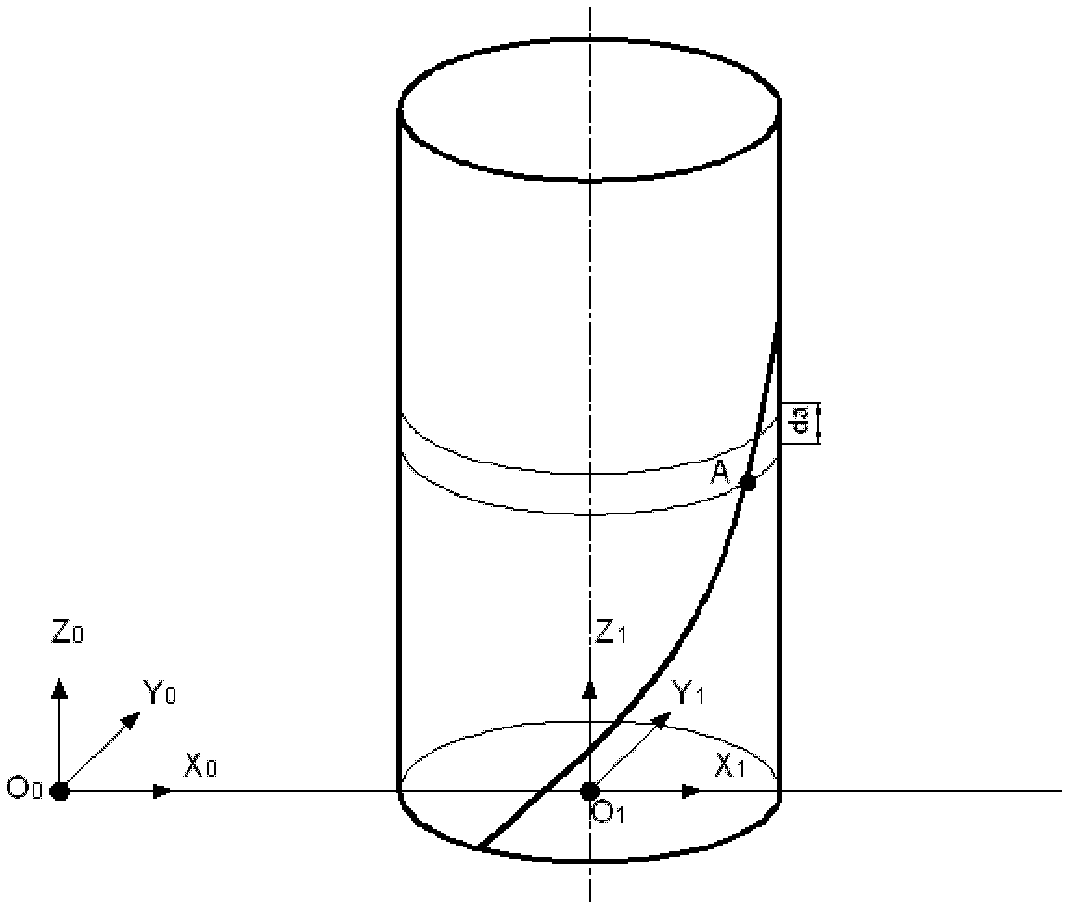

Method for predicating surface roughness and surface topography simulation of car milling compound machining

A method for predicating surface roughness and surface topography simulation of a car milling compound machining comprises the following six steps: step one, a modeling of a unified cutter position coordinate model of a whole cutter and an inserted blade cutter; step two, a modeling of the geometrical movement trace of a milling cutter cutting edge; step three, a consideration of influences of the vibration of the cutters to a workpiece surface morphology; step four, a microscopic surface morphology representation method; step five, a car milling compound machining basic structure function; step six, a simulation algorithm example and an orthogonal test method. The method combines the geometrical simulation and the physical simulation together, static and dynamic deformations which are produced when cutters cut under stress are fully considered, models for general car milling compound machining method of any angle are theoretically built, and a surface method of the roughness calculation of the car milling compound machining is deduced. The method for predicating surface roughness and surface topography simulation of the car milling compound machining has good practical values and broad application prospects in the technical field of machinery manufacturing processing.

Owner:BEIHANG UNIV

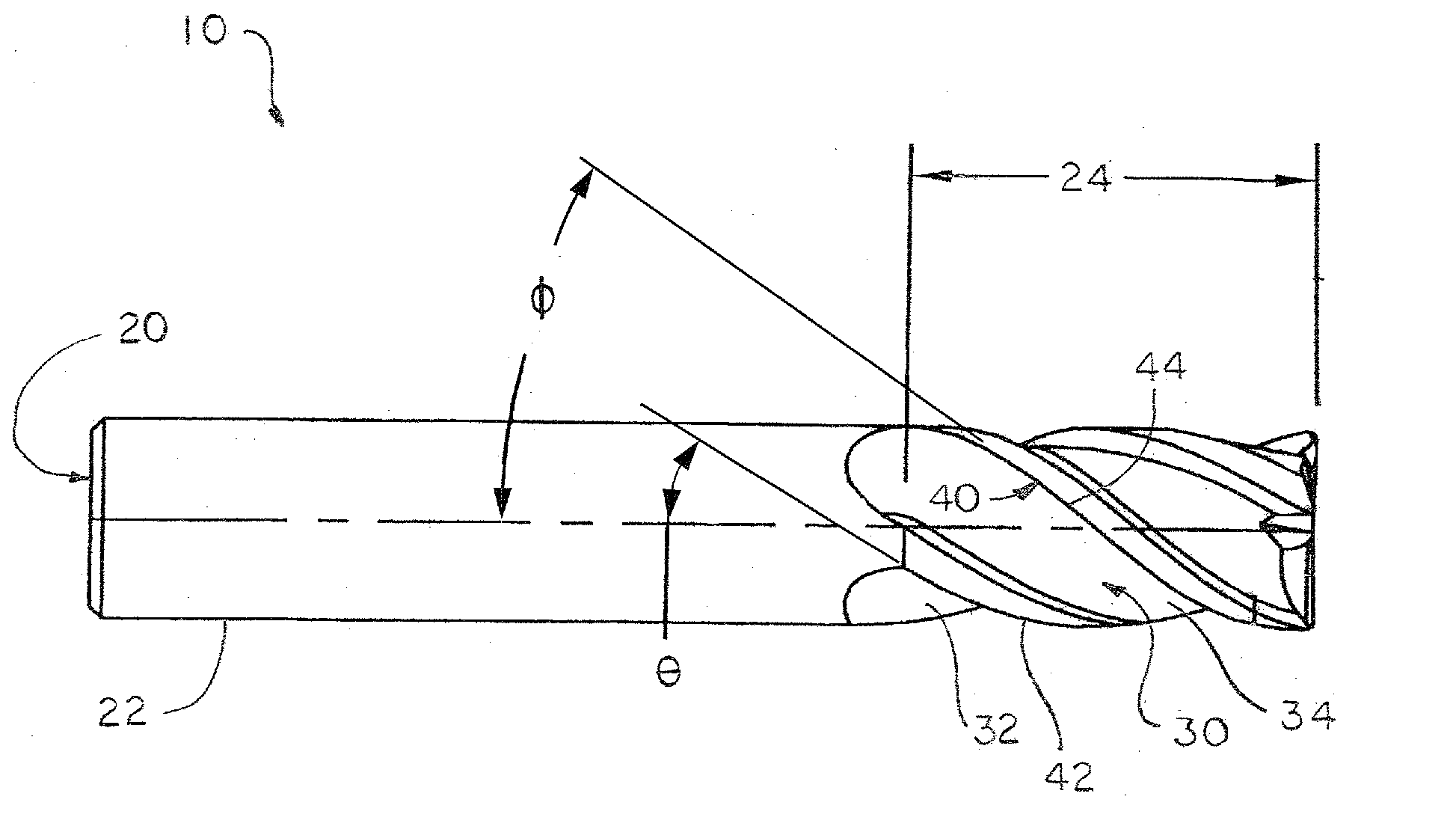

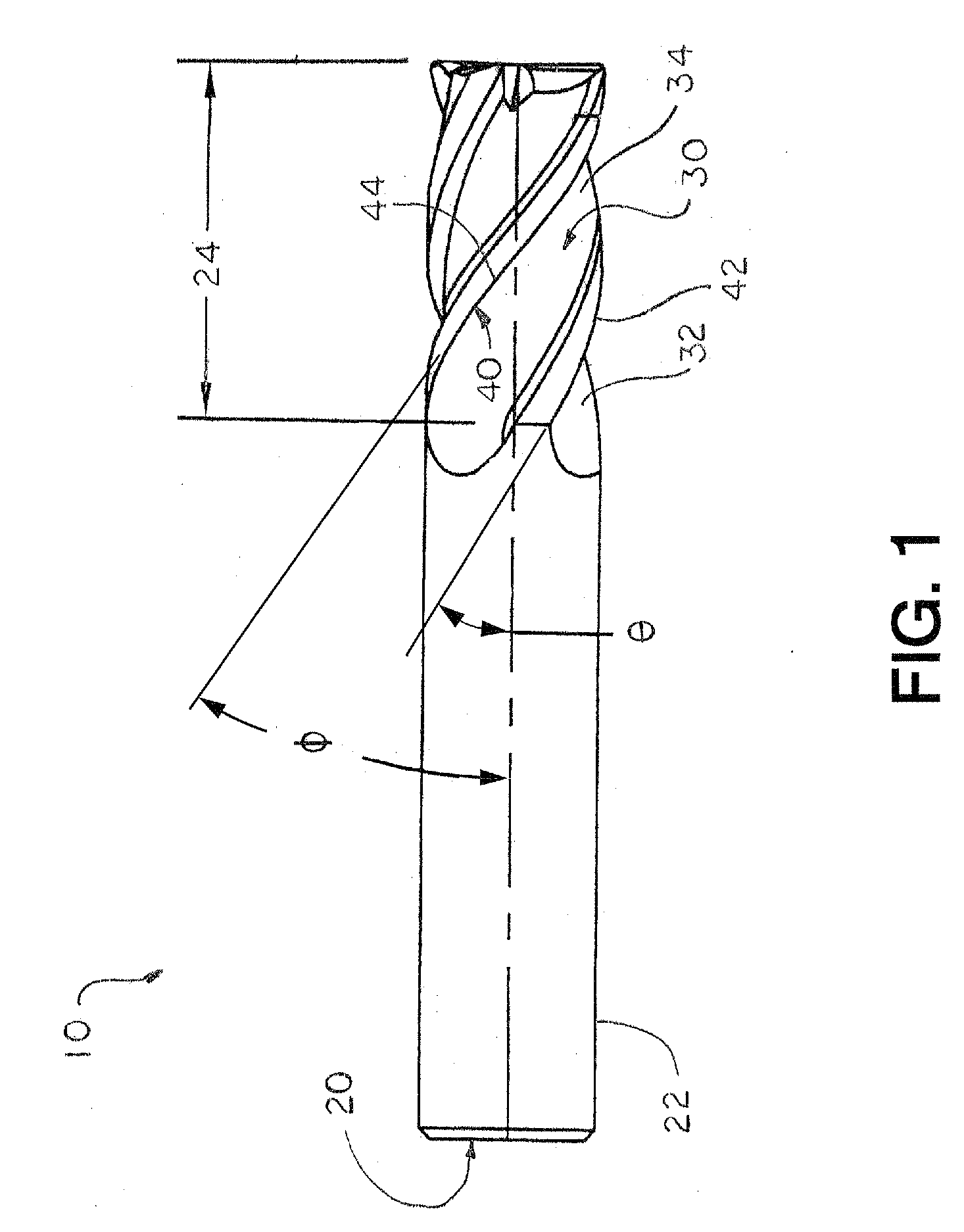

Rotary cutting tool

ActiveUS20070154272A1Overcome disadvantagesMilling cuttersAdverse effect compensationFluteRadial plane

A rotary cutting tool or end mill is provided, the tool comprising a plurality of pairs of diametrically-opposed, symmetrical, helical flutes formed in a cutting portion of the tool body, wherein the pitch between at least one pair of adjacent helical flutes is less than or greater than the pitch of at least one other pair of adjacent helical flutes in at least one radial plane along the axial length of the flutes, a plurality of peripheral cutting edges, wherein at least one of the peripheral cutting edges has a radial rake angle different from radial rake angle of a peripheral cutting edge of a different helical flute.

Owner:KYOCERA SGS PRECISION TOOLS INC

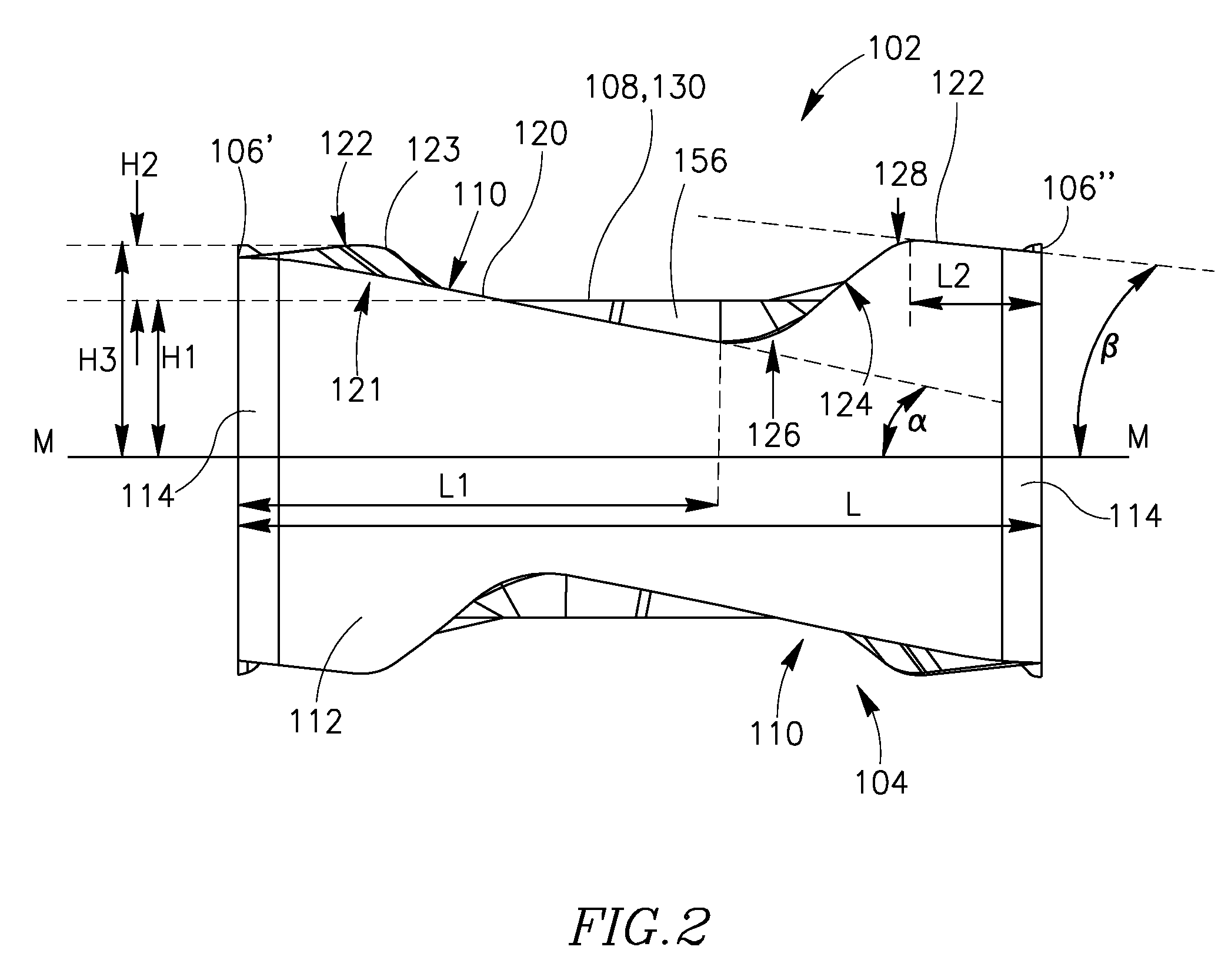

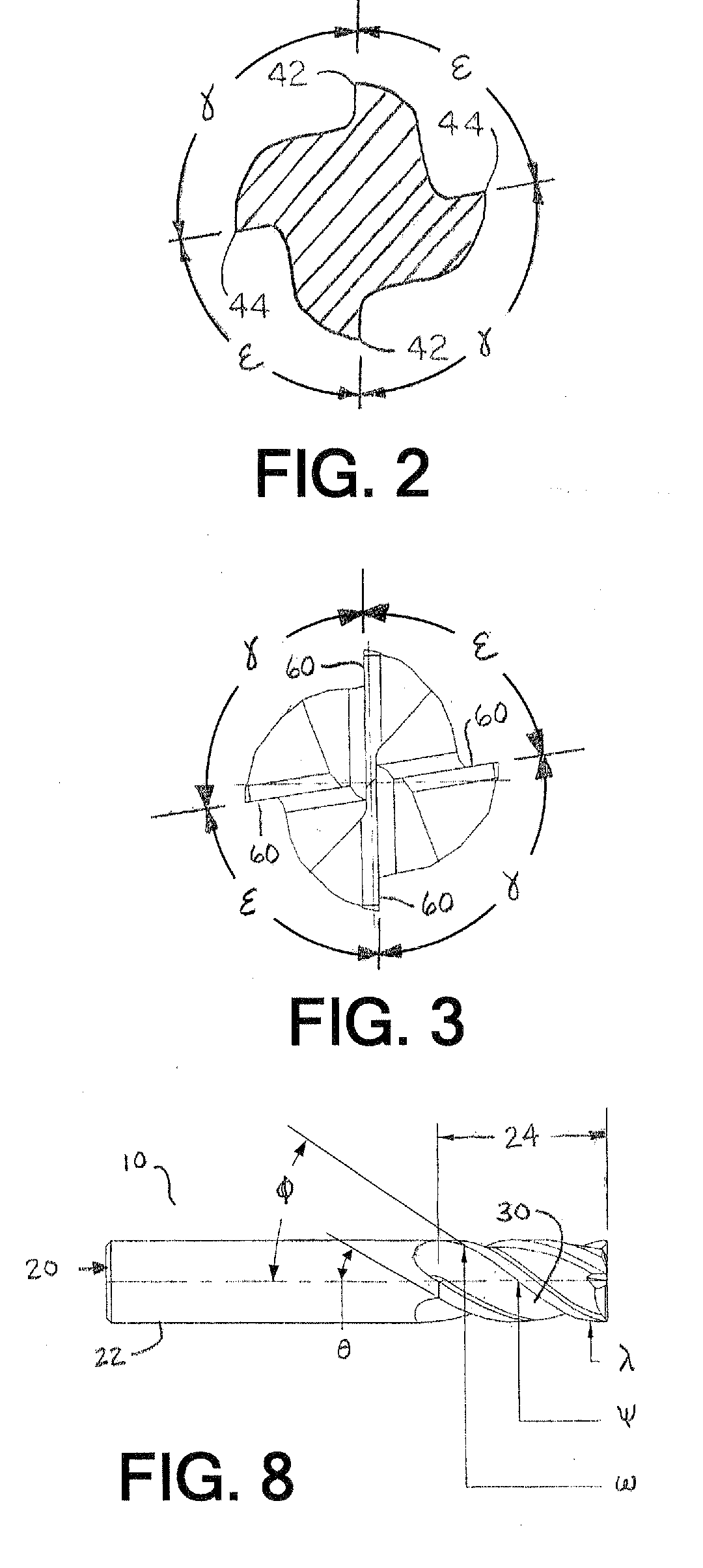

Arthroscopic shaver and method of manufacturing same

InactiveUS20060212060A1Improve efficiencyCuts bone efficientlyOther manufacturing equipments/toolsEndoscopic cutting instrumentsMilling cutterArthroscopy

An arthroscopic shaver with an inner cutting window having a plurality of teeth positioned along the lateral cutting edges, the teeth being configured for easy penetration into tissue to prevent ejection of tissue from the cutting window during closure. The inner cutting edges are formed in a milling operation using a milling cutter having an end radius equal to that of the surfaces forming the inner surfaces of the cutting edges. The teeth may be symmetrically or asymmetrically placed about the tube axis when viewed in a plan view.

Owner:ARTHREX

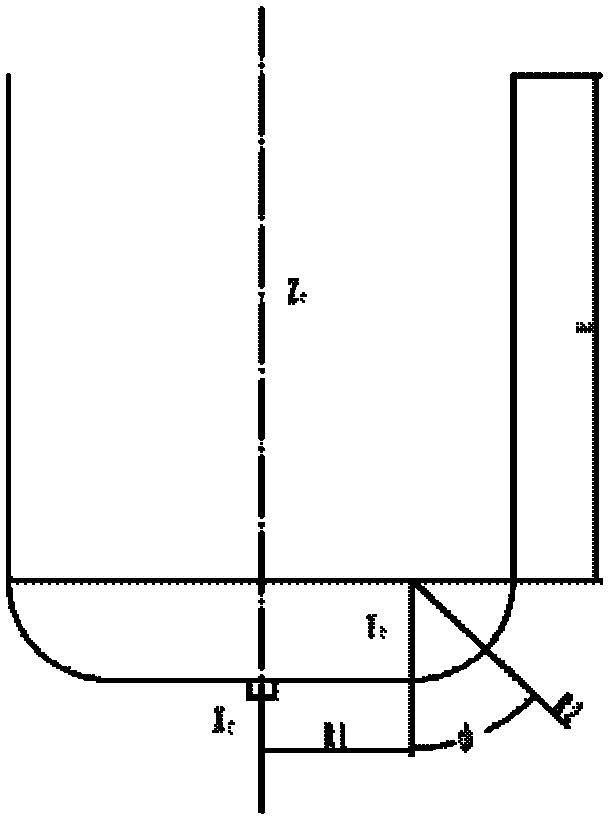

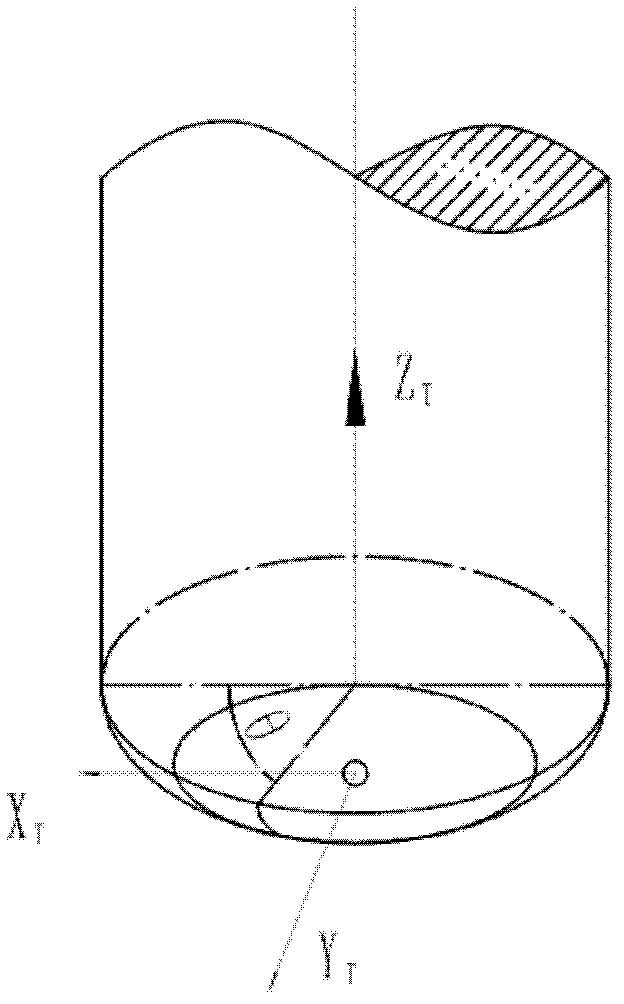

Five-axis linkage variable-axis plunge milling numerically controlled processing method for blade part of integral impeller

InactiveCN102085576ASolve the technical problems of low removal efficiencyImprove processing efficiencyAutomatic control devicesFeeding apparatusImpellerStress conditions

The invention discloses a five-axis linkage variable-axis plunge milling numerically controlled processing method for a blade part of an integral impeller. The method comprises the following steps: 1) dividing a spatial free-form surface to be processed of a part into multiple areas to be processed; 2) analyzing the stress conditions in a tooling process; 3) selecting a proper plunge milling cutter; 4) planning a processing route; 5) generating a track of a numerically controlled cutter; 6) simulating by utilizing a numerically controlled program; 7) editing the numerically controlled program; and 8) processing the part. The method is characterized in that by adopting a five-axis linkage variable-axis plunge milling manner, the processing efficiency of removing large margin by virtue of rough grooving of the integral impeller is improved, and the processing problem that finishing process with a ball cutter is required as the residual margin on a blade surface is not uniform after the plunge milling of a fixed axle of the free-form surface is solved; and the method disclosed by the invention can be applied to the five-axis numerically controlled milling processing needing to remove large-margin parts of the complicated free-form surface structures such as axial-flow type integral impellers, integral blade rings and the like as well as to the multi-axis numerically controlled milling processing of the parts of simple free-form surface structures such as centrifugal type integral impellers, mould processing and the like.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

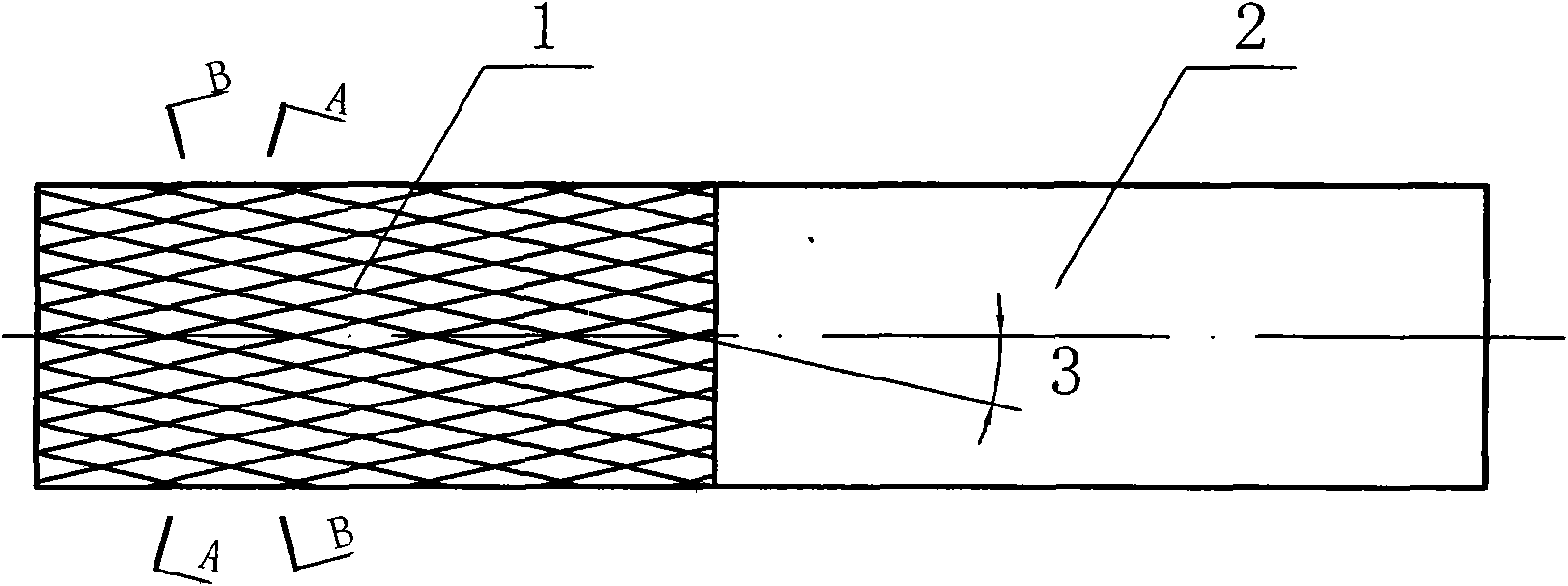

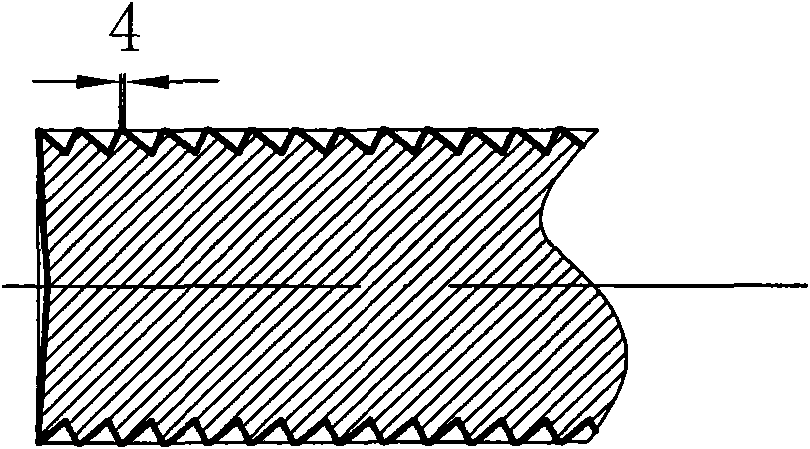

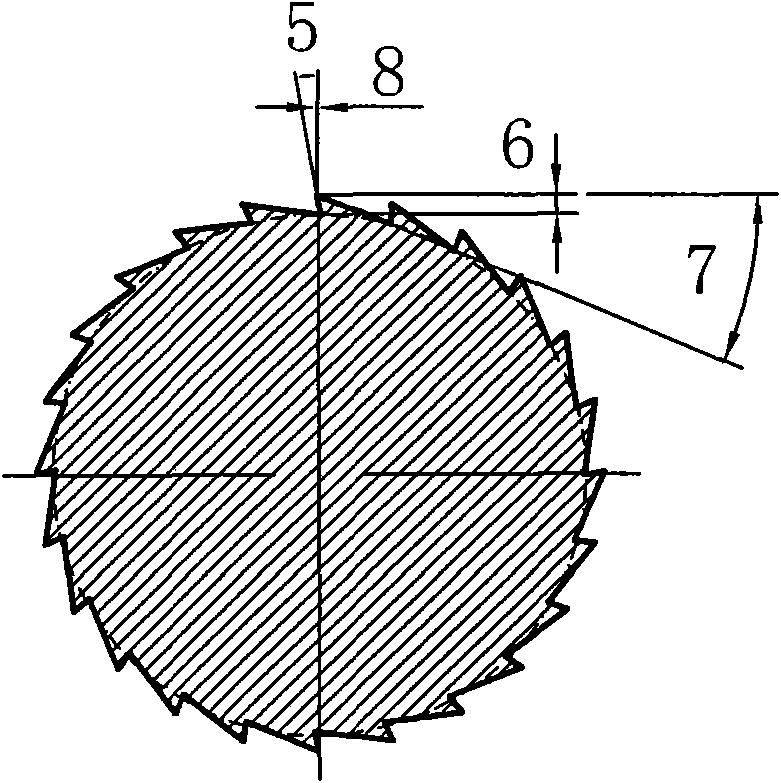

Integral carbide goldfish scale milling cutter

InactiveCN101623778AExtended service lifeImprove processing efficiencyMilling cuttersWorkpiecesGlass fiberFiber

The invention discloses an integral carbide goldfish scale milling cutter used for milling and processing composite materials such as carbon fiber, glass fiber and the like. The milling cutter of the invention comprises a milling cutter blade and a milling handle, wherein the cutting blade on the milling cutter blade is a cutting unit formed by left and right-handed rotation symmetrical staggered spiral grooves, and the number of the left spiral groove is two more than that of the right spiral groove; the length of the cutting blade of each cutting unit is 0.05-0.1mm, and the width of the rear cutter surface of the cutting blade along the cylinder surface is 0-0.01mm; the anterior angle of the cutting blade is 10-15 degrees, the front cutter surface is a straight line on a normal plane; the relief angle of the cutting blade is 20-25 degrees; the depth of the spiral cutter groove is 7-8% of the diameter of the cutter. The invention has the advantages that the cutting blade of the integral carbide goldfish scale milling cutter is composed of a plurality of cutting units and is sharp, which greatly lowers cutting resistance and realizes high speed cutting so as to obtain the effect of using milling for replacing abrading, so that the processing efficiency and the surface quality of the composite materials can be improved, and the service life of the milling cutter can be prolonged.

Owner:SHENYANG AIRCRAFT CORP

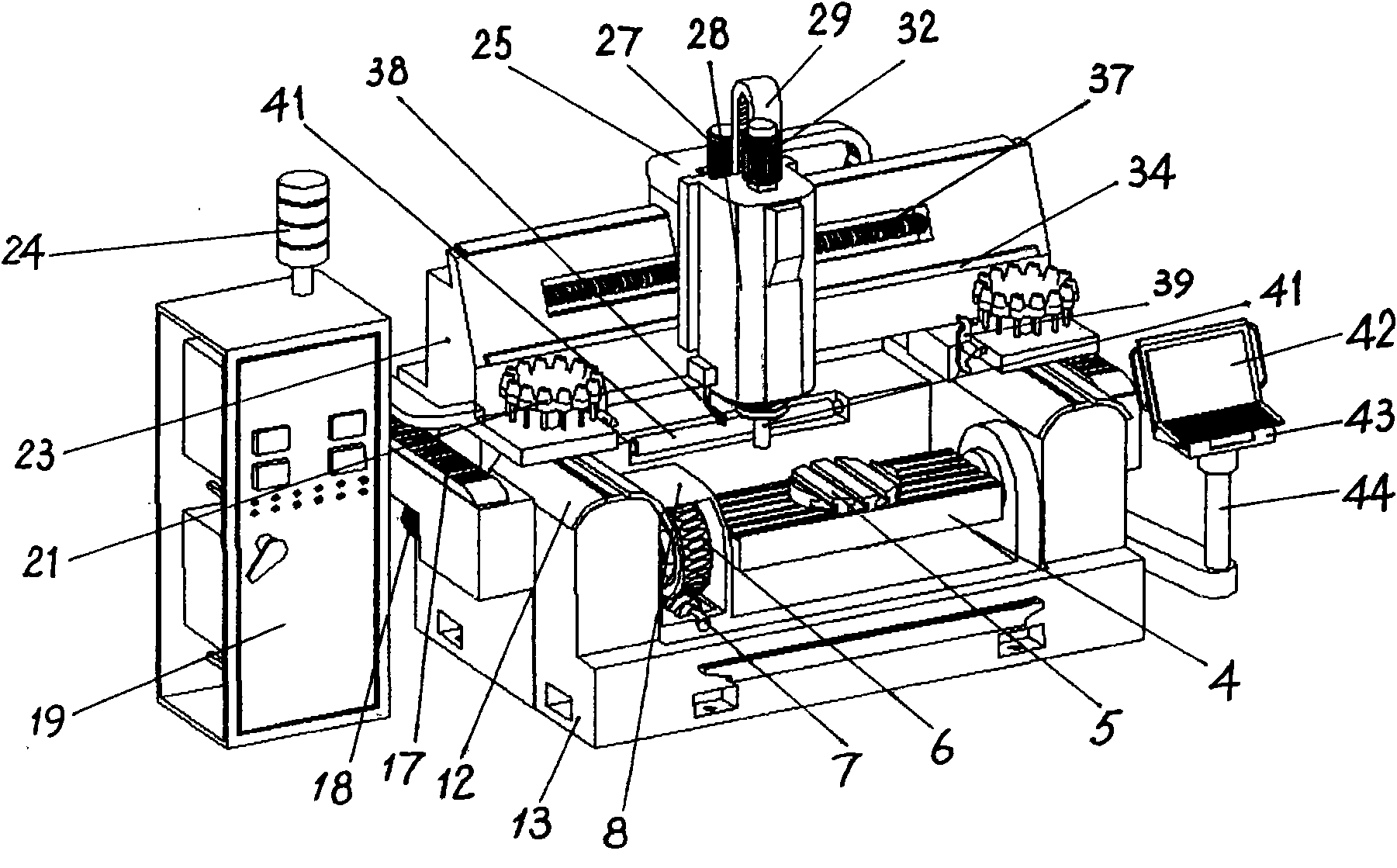

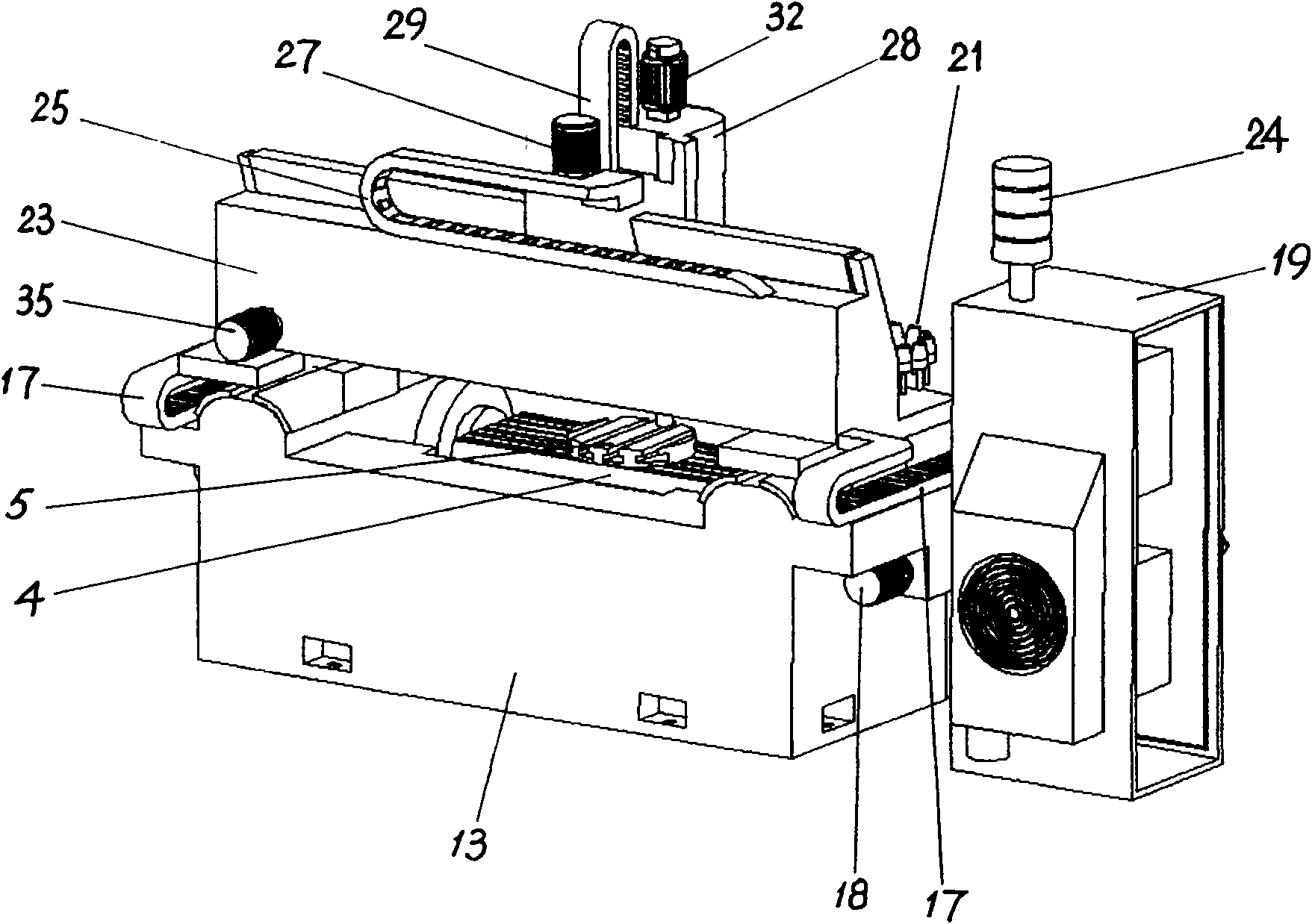

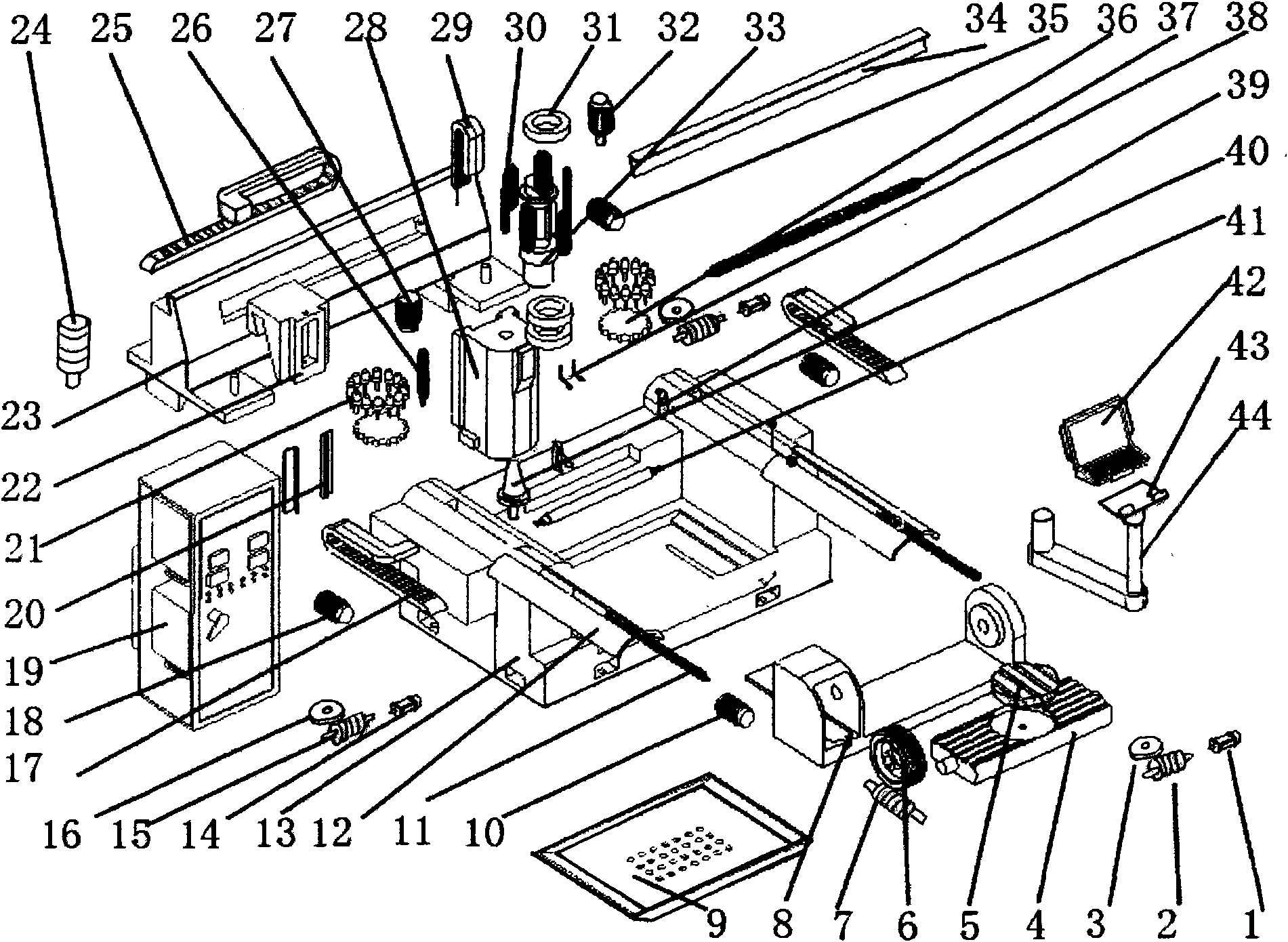

Vertical five axle interlocked gantry digital control milling machining center

ActiveCN101870063AReduce the number of clampingReduce machining errorsOther manufacturing equipments/toolsMilling cutterEngineering

The invention provides a vertical five axle interlocked gantry digital control milling machining center, comprising a planer body, a portal frame, a rotary workbench stand, an electrical appliance control cabinet, a cutter, a main spindle box, an operation panel, a rotary workbench, X, Y and Z shaft driving screws and rotary tool changers, wherein the rotary workbench is formed by a large rotary workbench and a small rotary workbench which respectively rotate around an A shaft and a B shaft; the portal frame is arranged on the planer boxy and can move back and forth via the X shaft driving screws arranged at the two sides of the planer body, a Y-Z shaft connection block moves left and right via the Y shaft driving screw in the portal frame, and a main spindle in the main spindle box moves up and down via the Z shaft driving screw on the Y-Z connection block so as to form five axle interlocking; and the rotary tool changers arranged at the two sides of the portal frame are internally provided with 32 grinding cutters and milling cutters, and tool changing is realized by a tool changing manipulator. The invention has the positive effects of realizing multiply functions of one machine, and can process as many as five interfaces by primary clamping, thus reducing clamping times, saving labor, time and space, and having convenient equipment maintenance.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

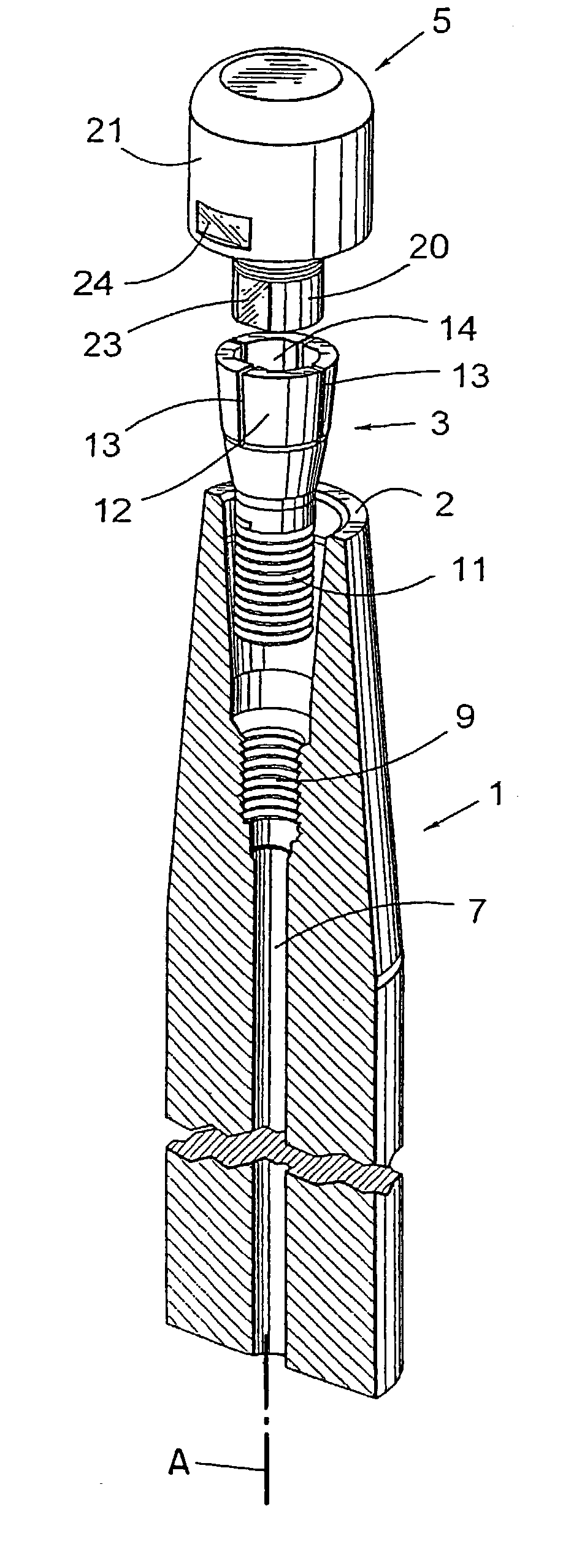

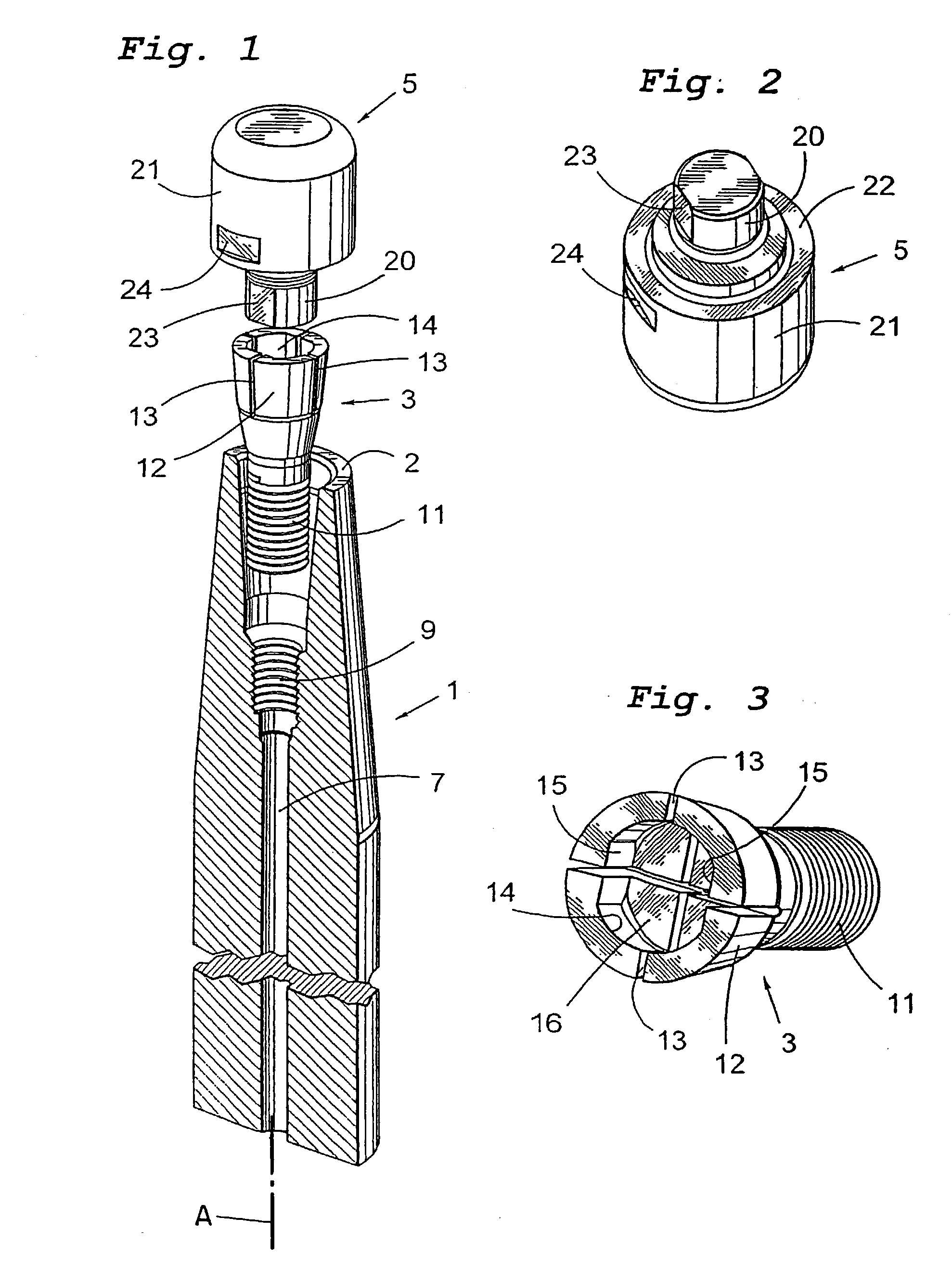

Rotary tool and cutting part comprised in the tool

InactiveUS20030210963A1Acceptable toleranceTransportation and packagingMilling cuttersInterference fitMilling cutter

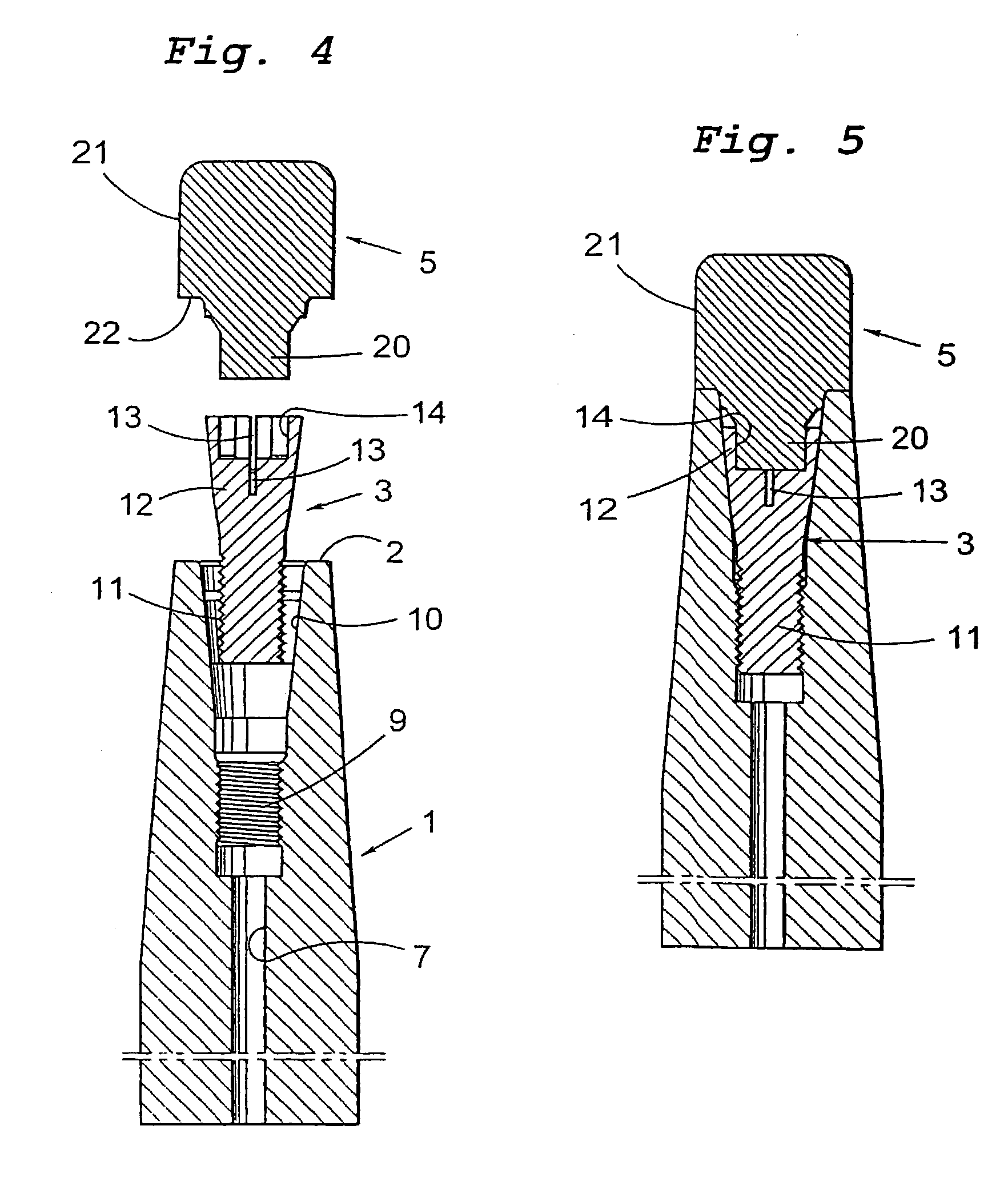

A rotary tool for chip removing machining, for example a milling cutter or a drill, includes a shaft, a holder, and a cutting part. The shaft has a conical seating arranged in its front end. The holder has a slightly conical recess, whose cross-sectional dimension decreases toward the open end of the recess. The cutting part has a slightly conical pin designed to be received in the recess and has a cross-sectional dimension which increases in the direction of the free end of the pin. The recess is formed by a wall which is elastically flexible in a radial direction. When the holder is drawn axially into the seating, the wall is flexed radially inwardly, causing the conical surface of the recess to tightly grip the conical surface of the pin and create an interference fit of the pin in the recess.

Owner:SANDVIK AB

Tangential cutting insert and milling cutter

A tangential milling cutting insert having two identical opposing end surfaces with two identical opposing major side surfaces of a generally isosceles trapezoidal shape and two identical opposing minor side surfaces extending between them is disclosed. Each end surface has a peripheral edge containing cutting edges and four corners of which two diagonally opposed corners are lowered and the other two are raised. Each end surface is provided with an abutment member having an abutment surface. In each cross section of the cutting insert taken in a plane parallel to a minor plane of the cutting insert, the abutment surface is closer to a median plane than a respective leading section of a major cutting edge.

Owner:ISCAR LTD

Cutting insert and milling cutter

A milling cutter has a cutter body having insert pockets, with cutting inserts seated in the insert pockets. Each insert pocket has adjacent side and rear walls generally transverse to a base, the side wall being provided with two spaced apart generally flat and non-coplanar side support surfaces. Each cutting insert has a pair of opposing major side surfaces including two spaced apart generally flat and non-coplanar abutment surfaces. Upper edges of the side support surfaces abut the abutment surfaces.

Owner:ISCAR LTD

Double-sided cutting insert and milling cutter

A double-sided cutting insert, for use in a milling cutter, having two identical opposing end surfaces and two opposing identical major side surfaces with a through bore extending between, and opening out to, the major side surfaces. Major cutting edges are formed at the intersection of each major side surface with each end surface. Adjacent each major cutting edge, in each major side surface, is a primary relief surface. In each cross section of the cutting insert taken in a plane generally perpendicular to the major side surfaces, a line tangent to the primary relief surface at the major cutting edge is inclined to a median plane of the cutting insert at an acute interior angle.

Owner:ISCAR LTD

Window mill and drill bit

A method and apparatus for running a whipstock into a well bore attached to a combination mill and drill bit, releasing the mill / bit from the whipstock, milling a window in the casing, and drilling a lateral well bore, all in one trip. The mill / bit is provided with a primary cutting structure better suited for milling through the casing, and a secondary cutting structure, better suited for drilling through the earth formation. The secondary cutting structure is initially smaller in diameter than the primary cutting structure. The whipstock can be attached to the mill / bit with a shear bolt supported by a boss on the whipstock, with the boss designed to arrest axial motion of the mill / bit after shearing of the bolt.

Owner:BAKER HUGHES INC

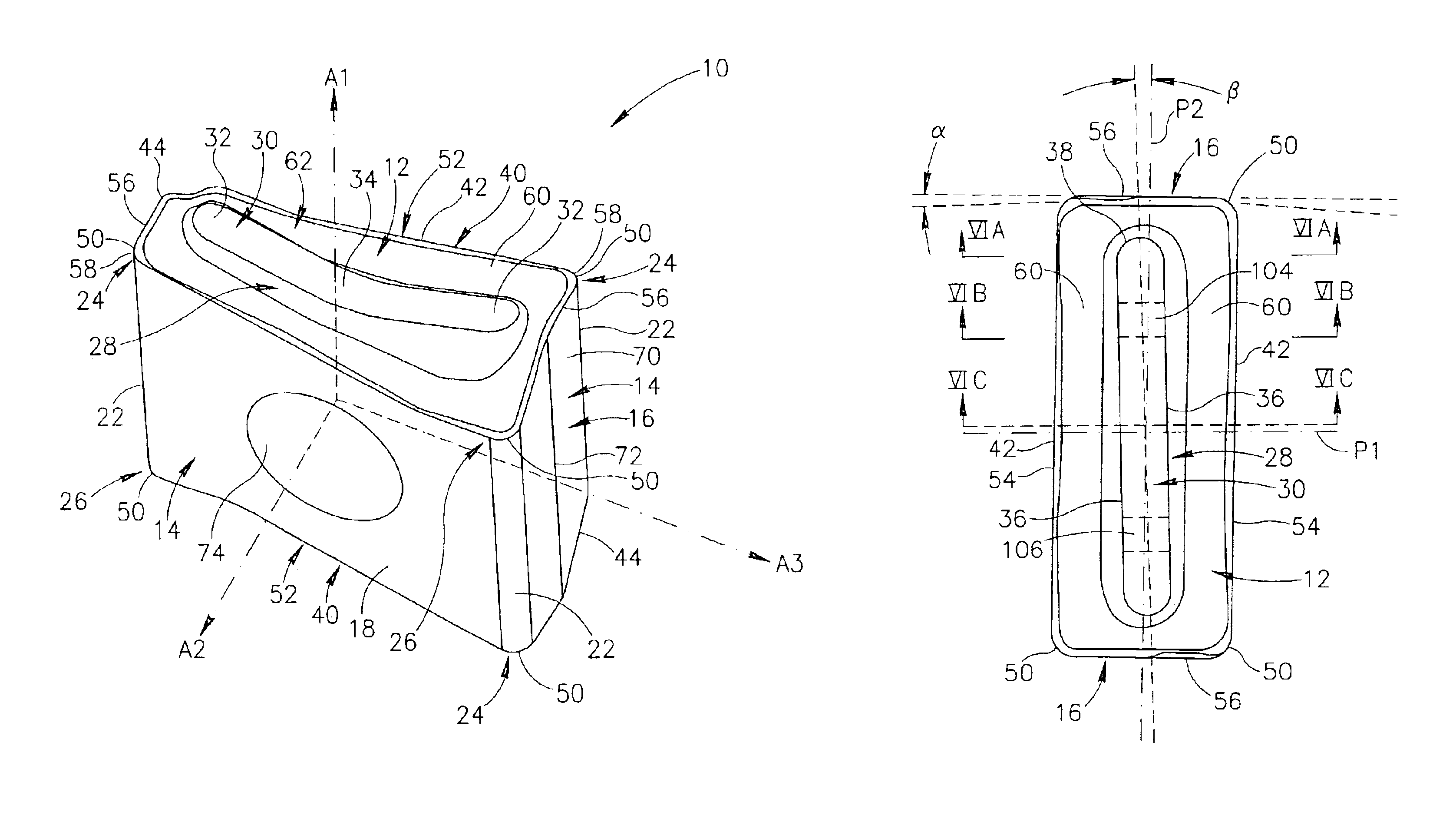

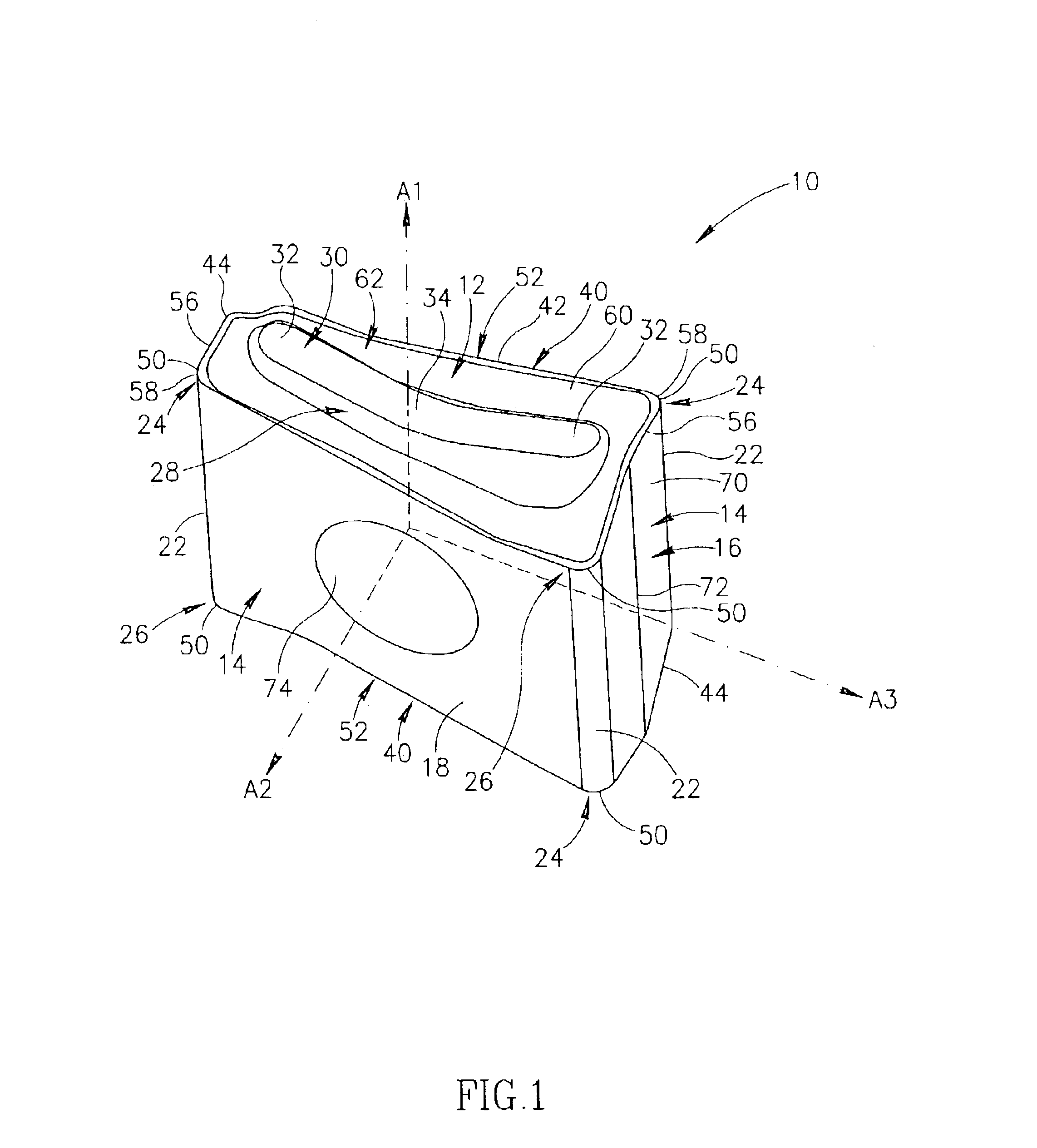

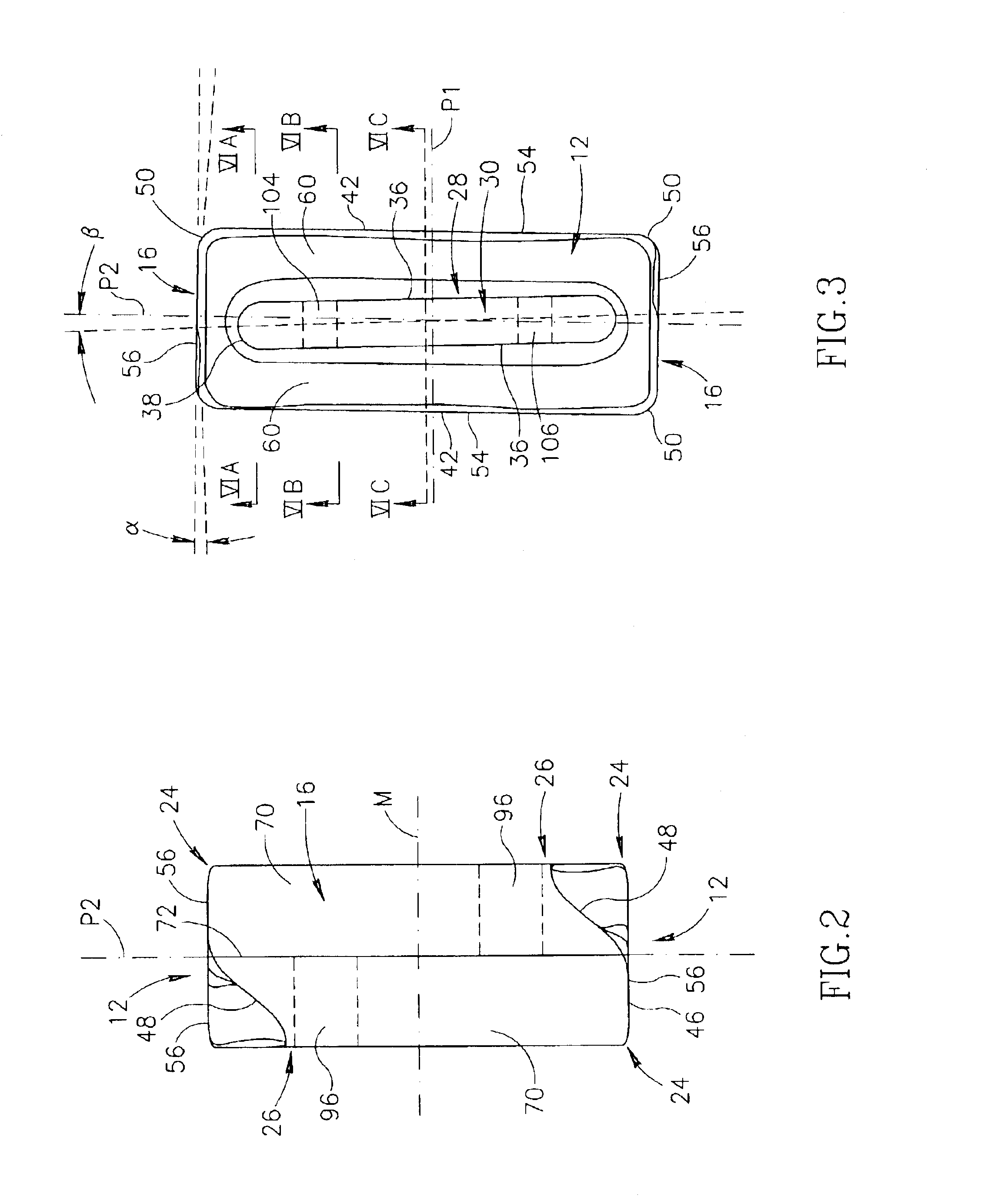

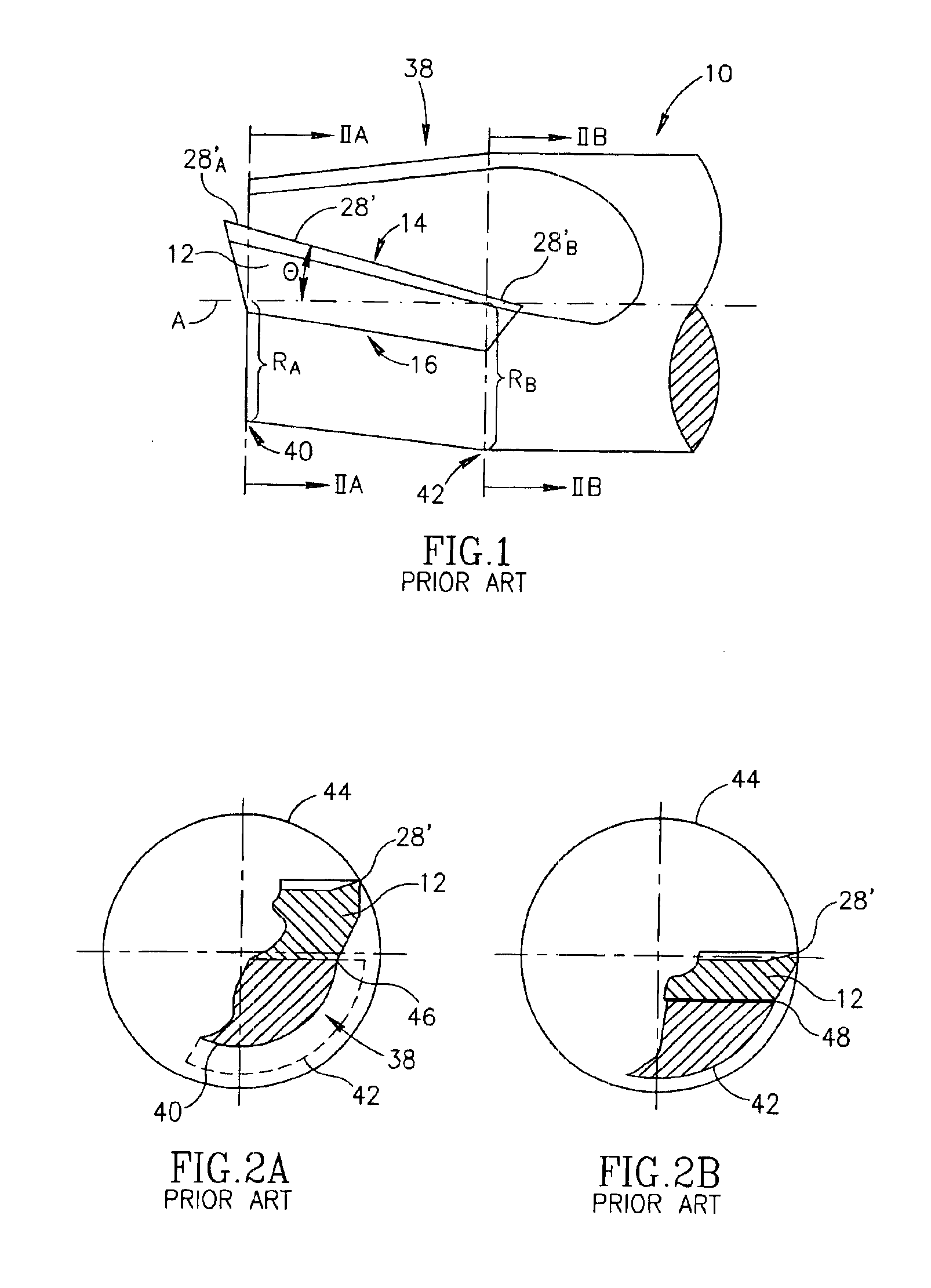

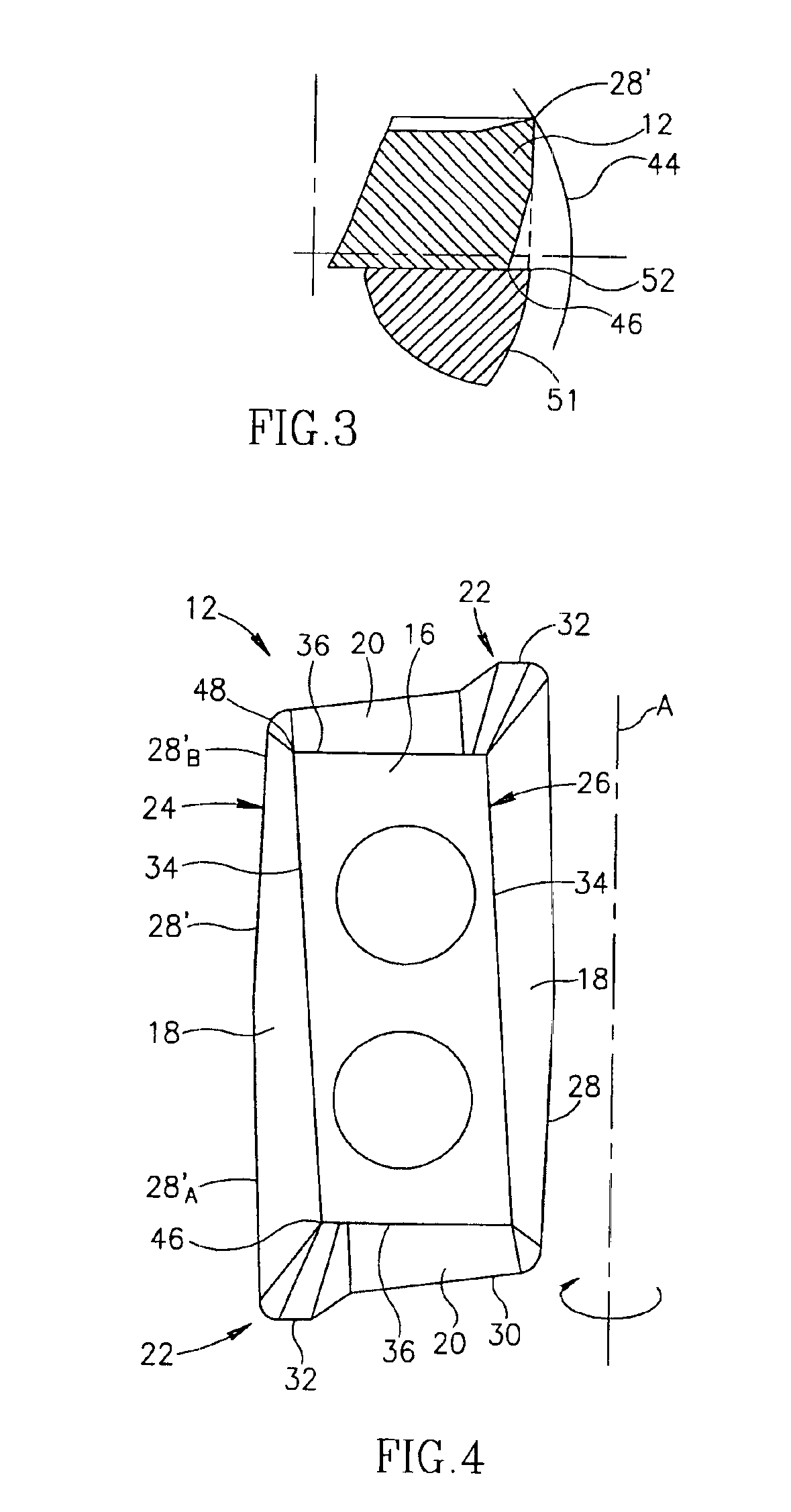

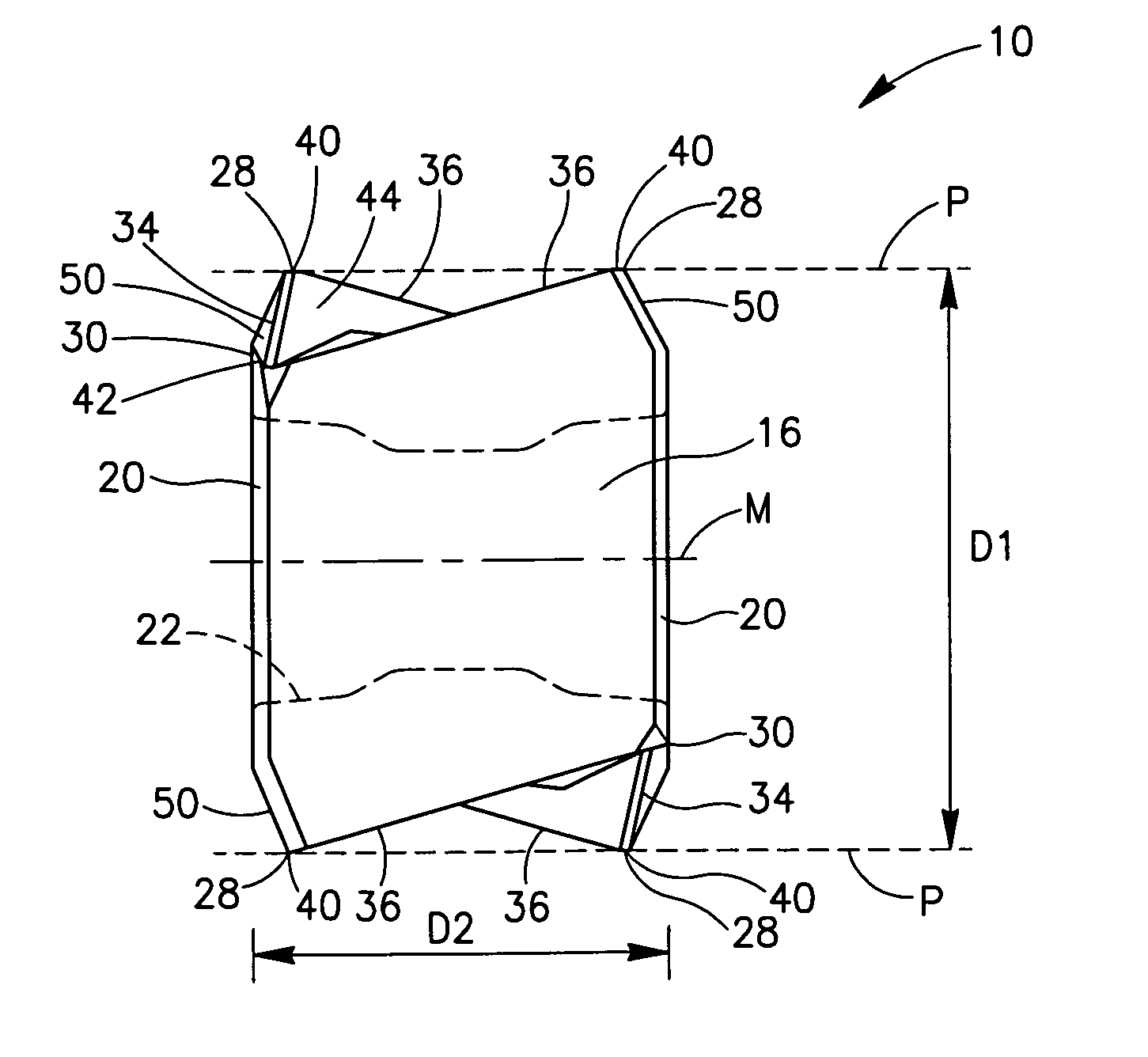

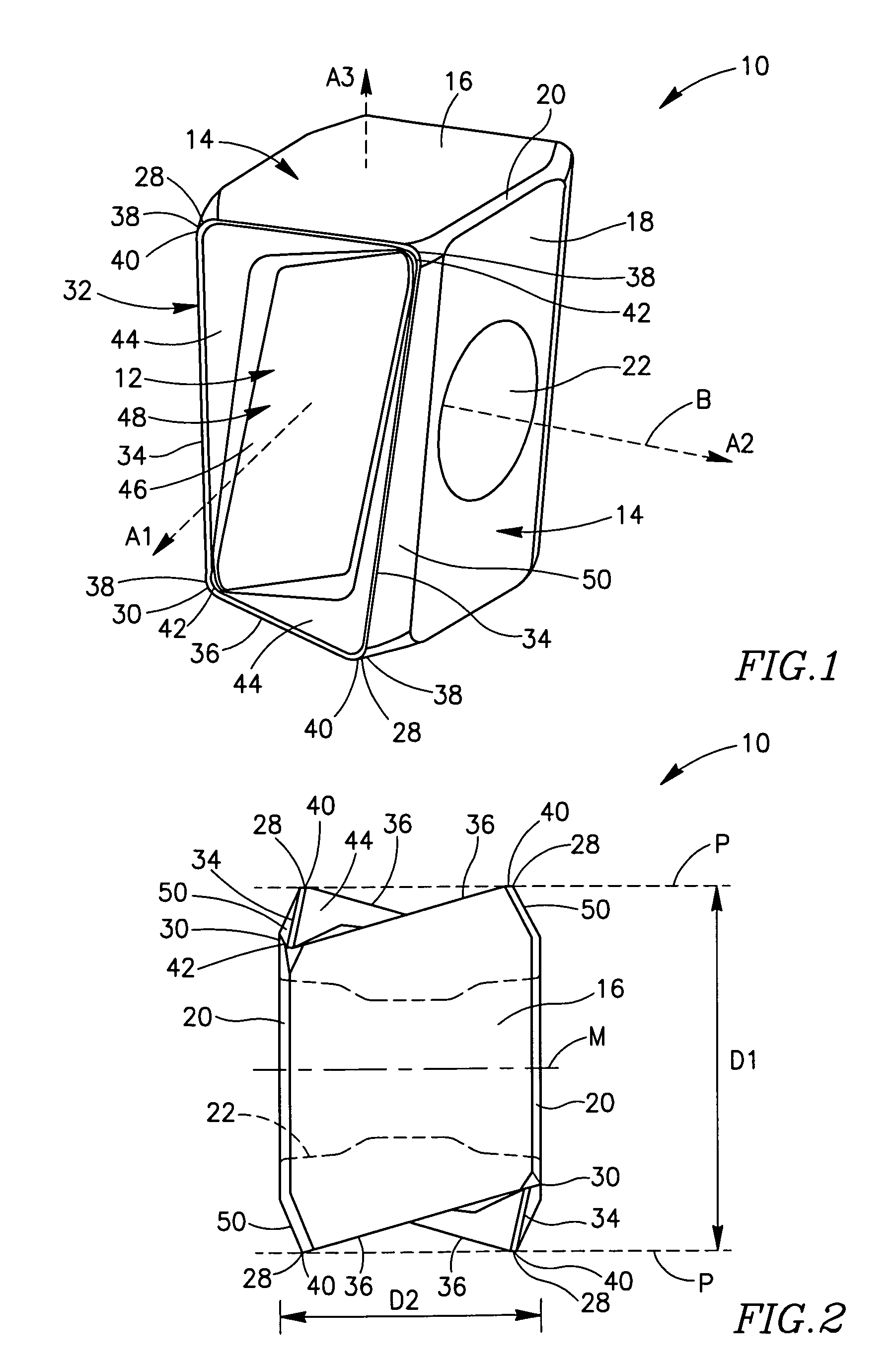

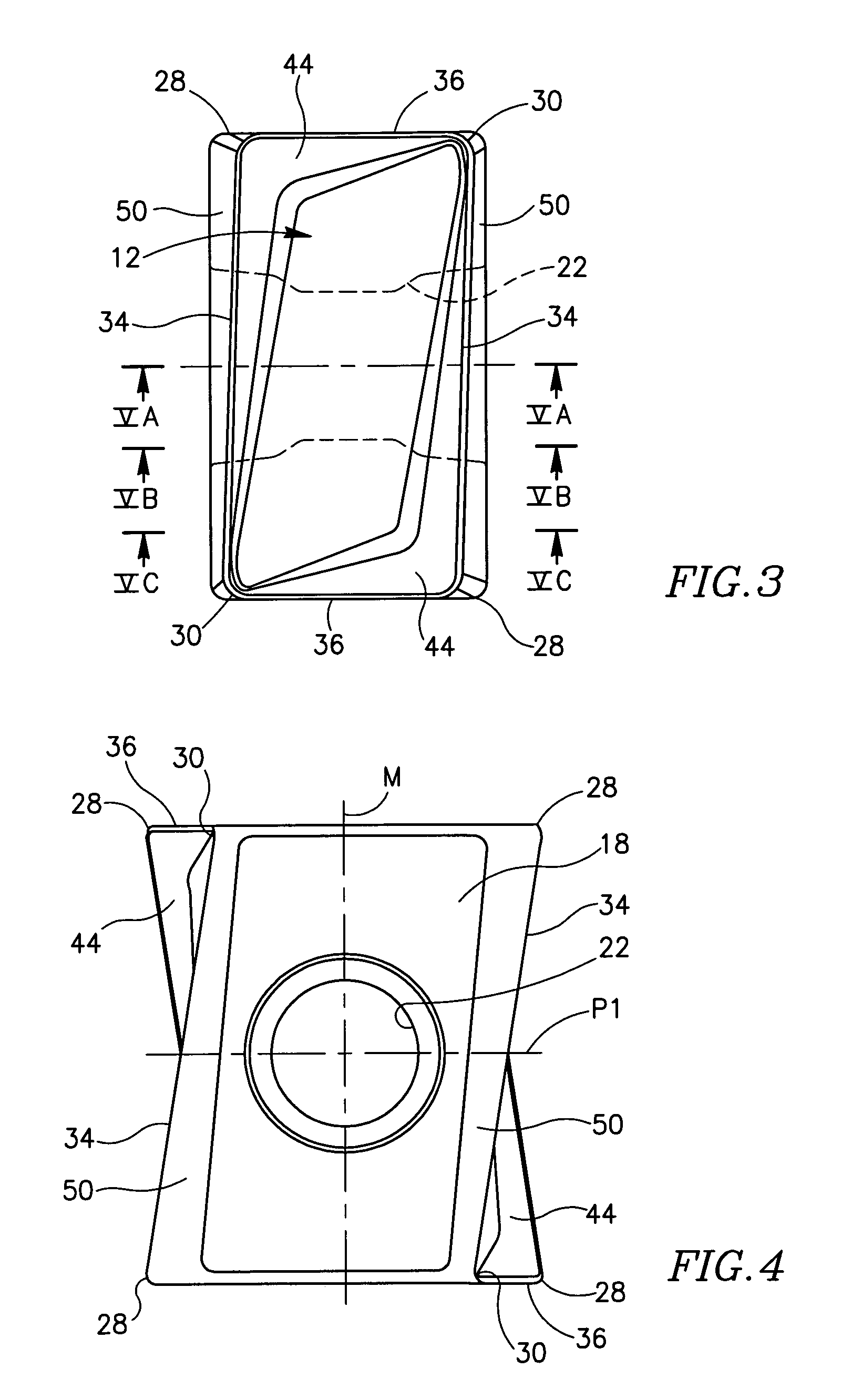

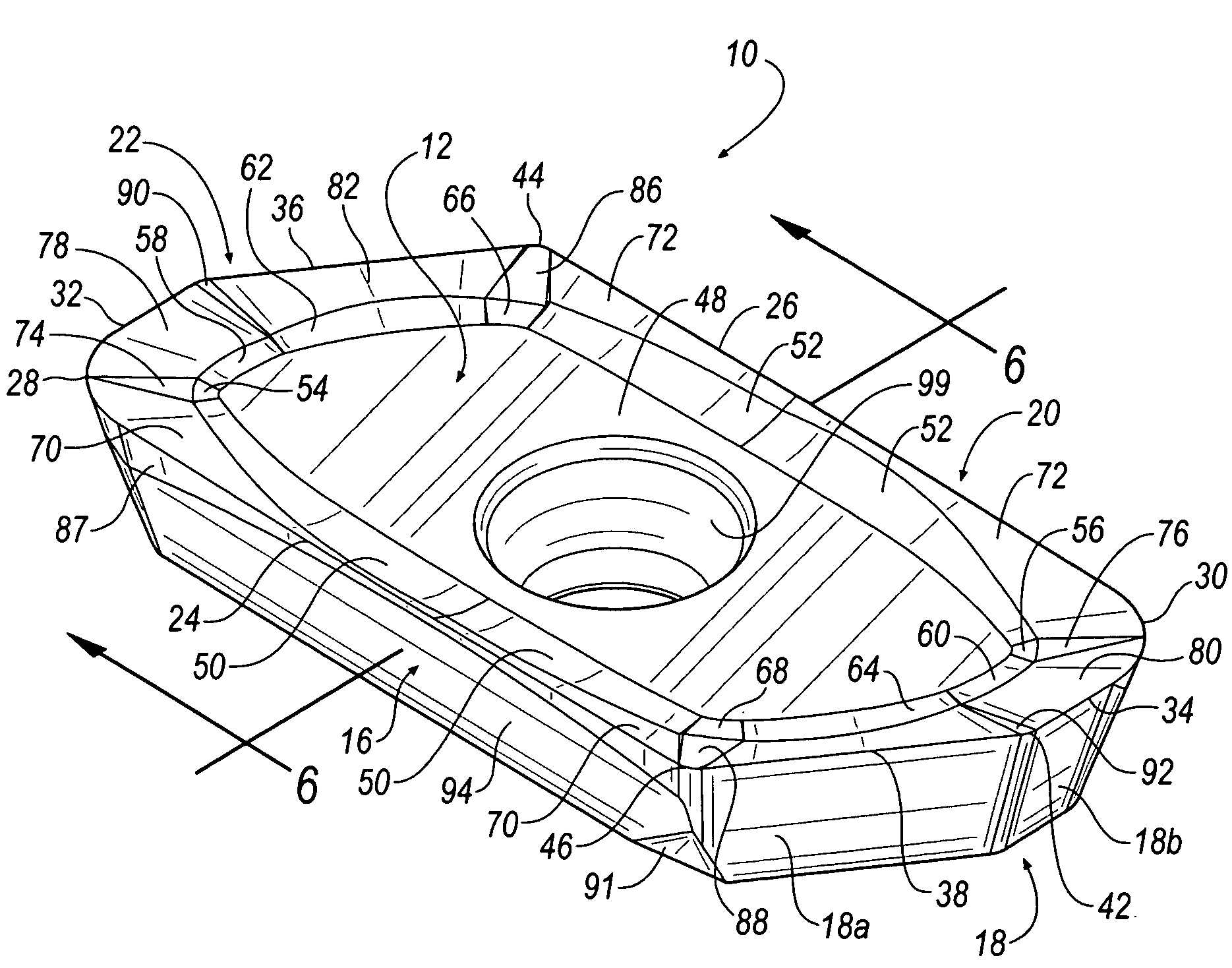

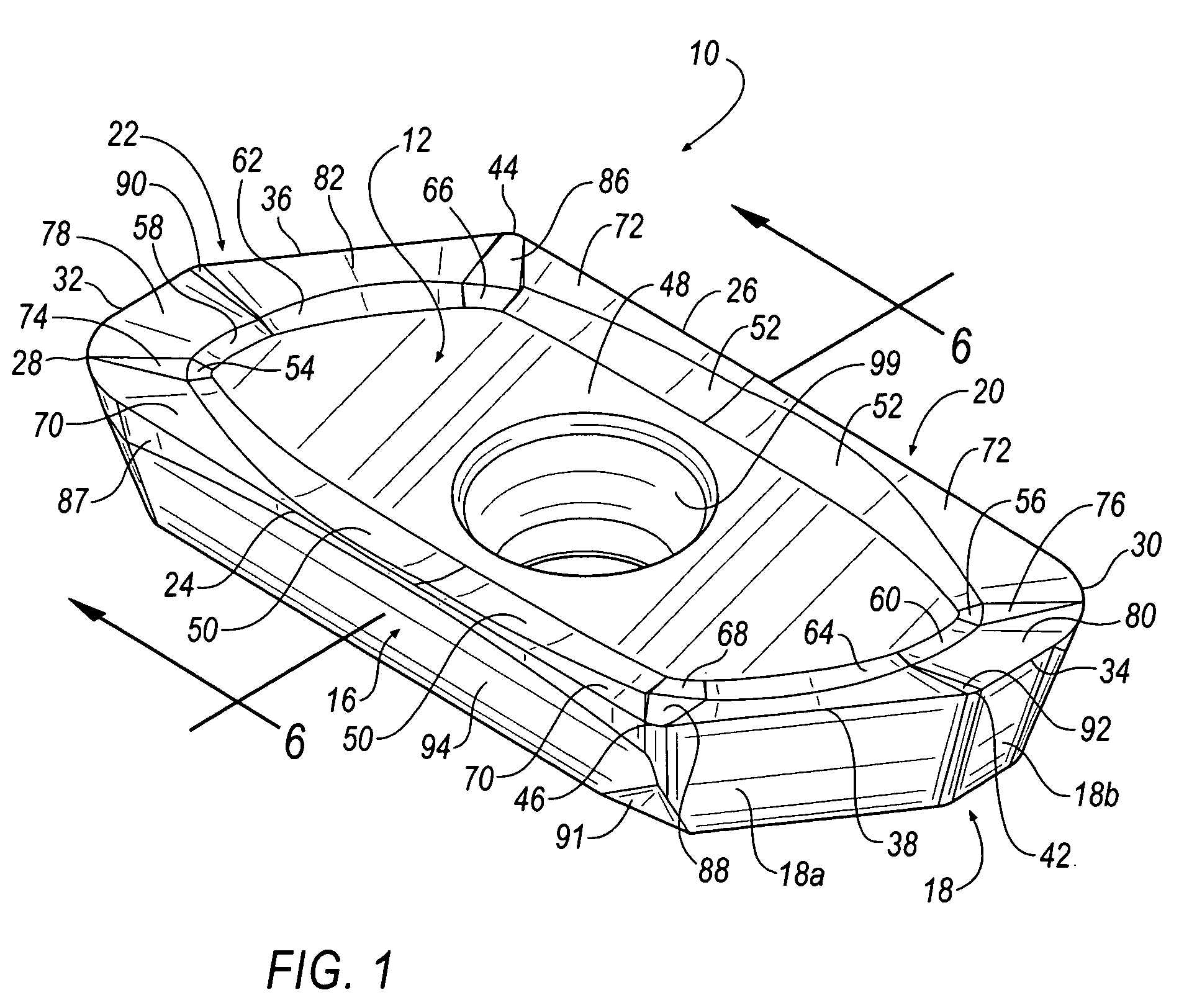

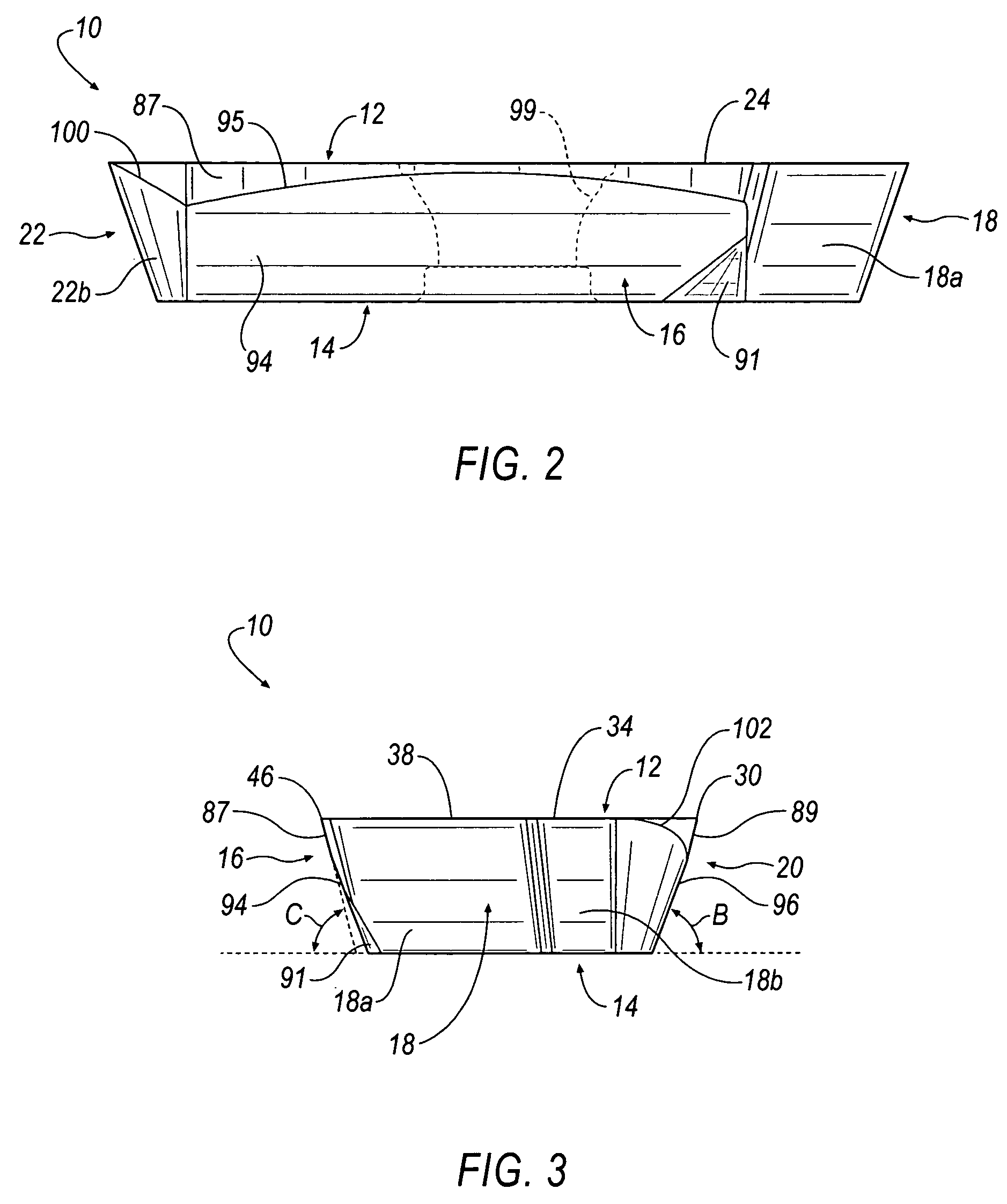

Cutting insert for high-speed milling cutter

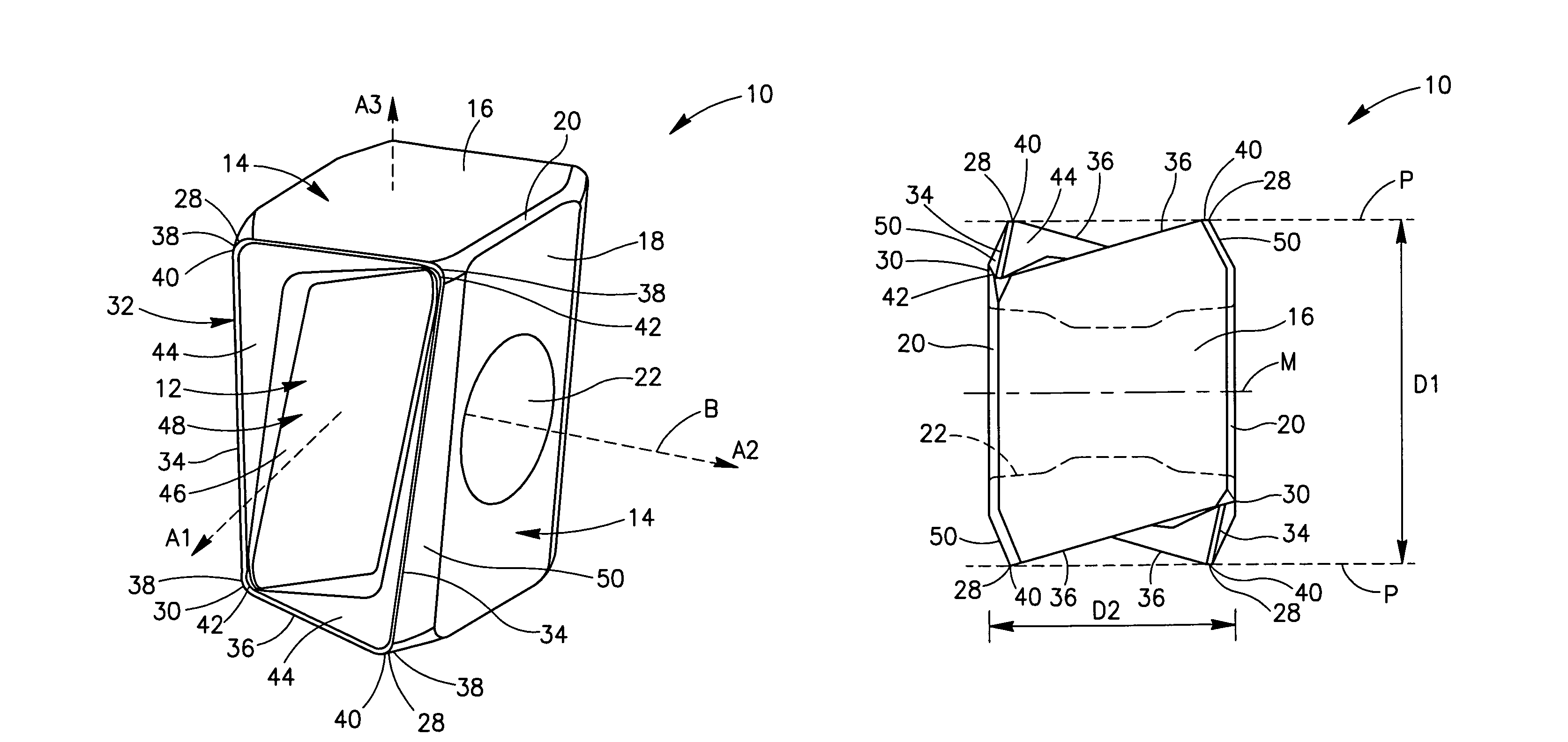

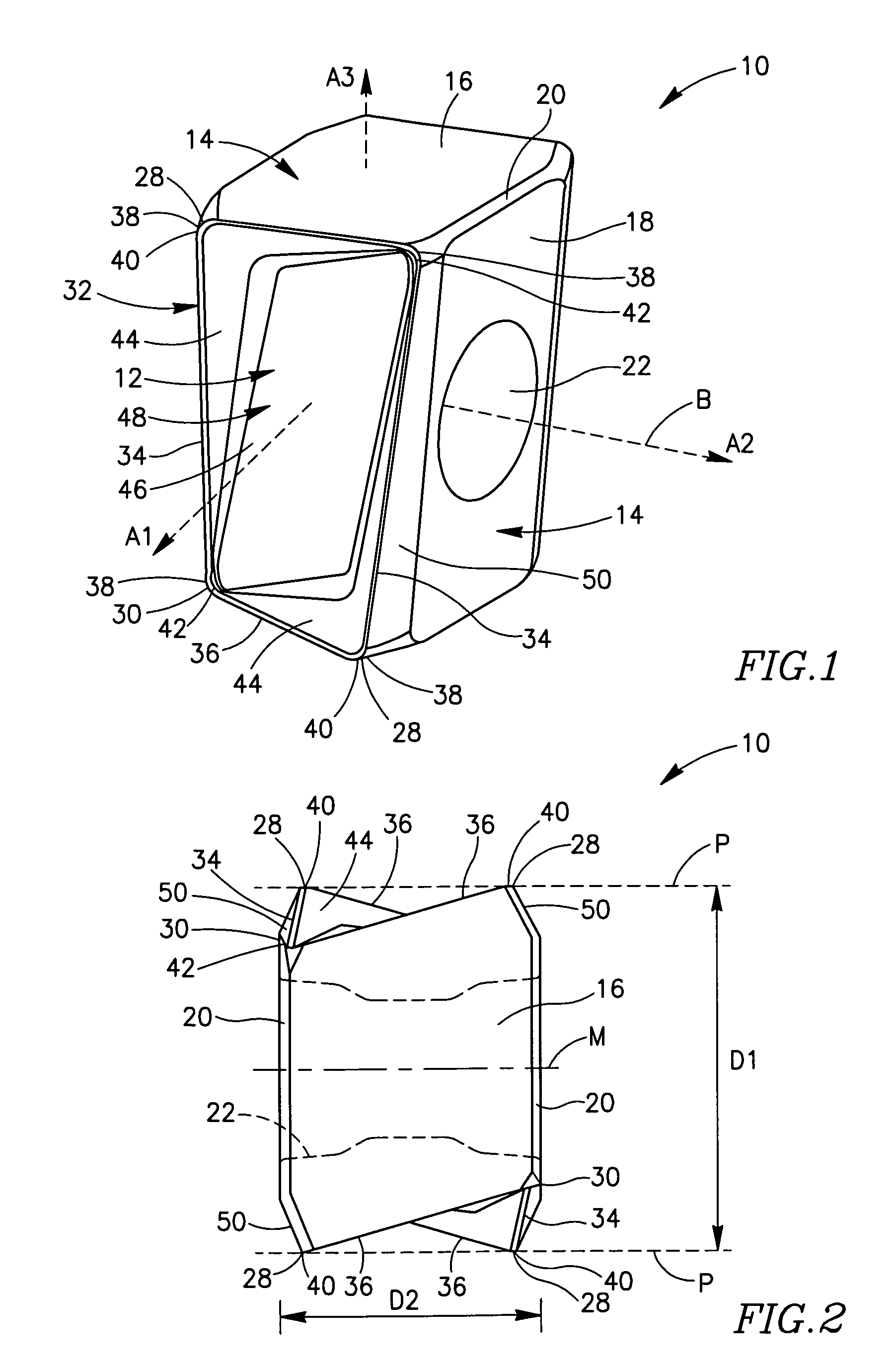

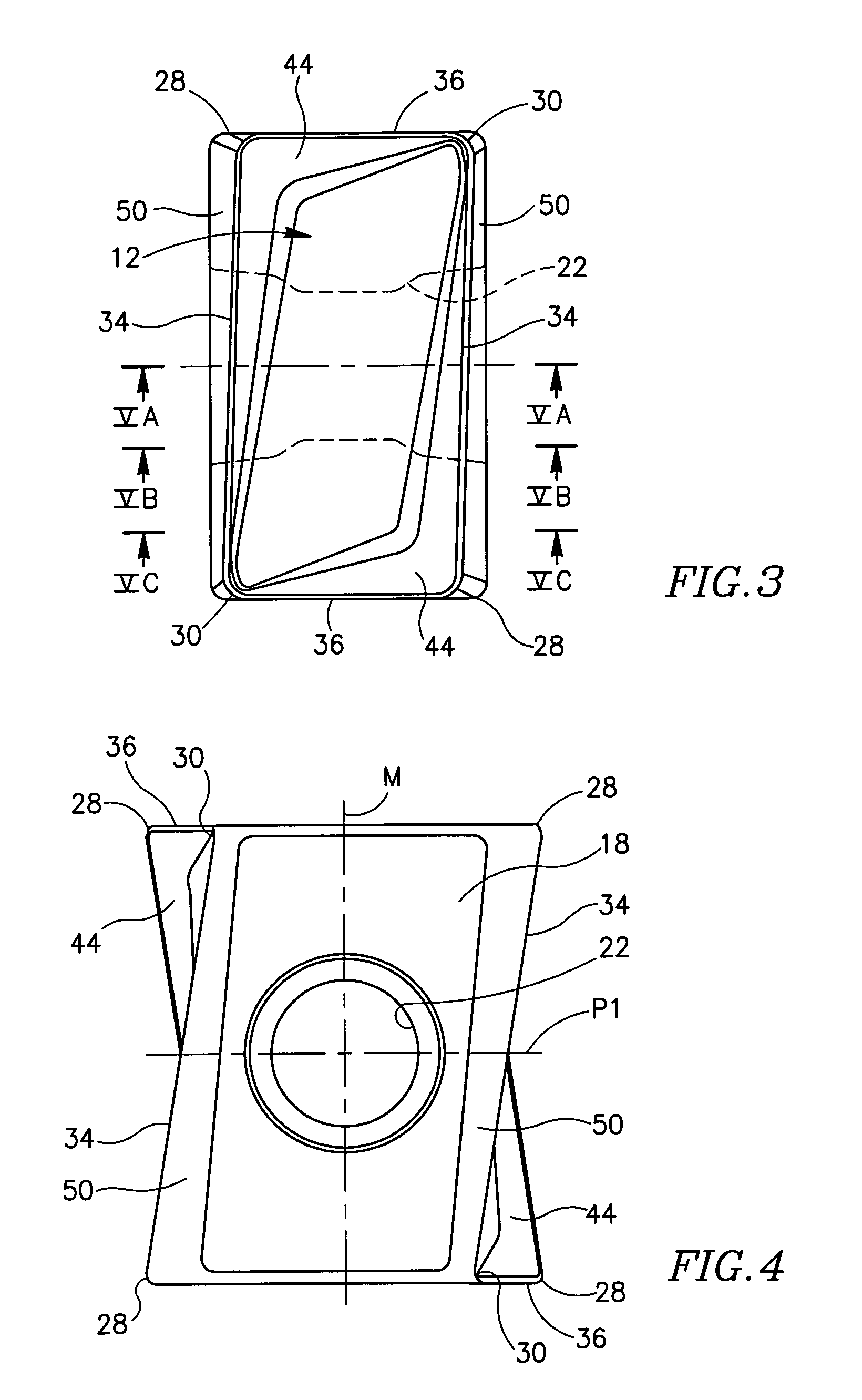

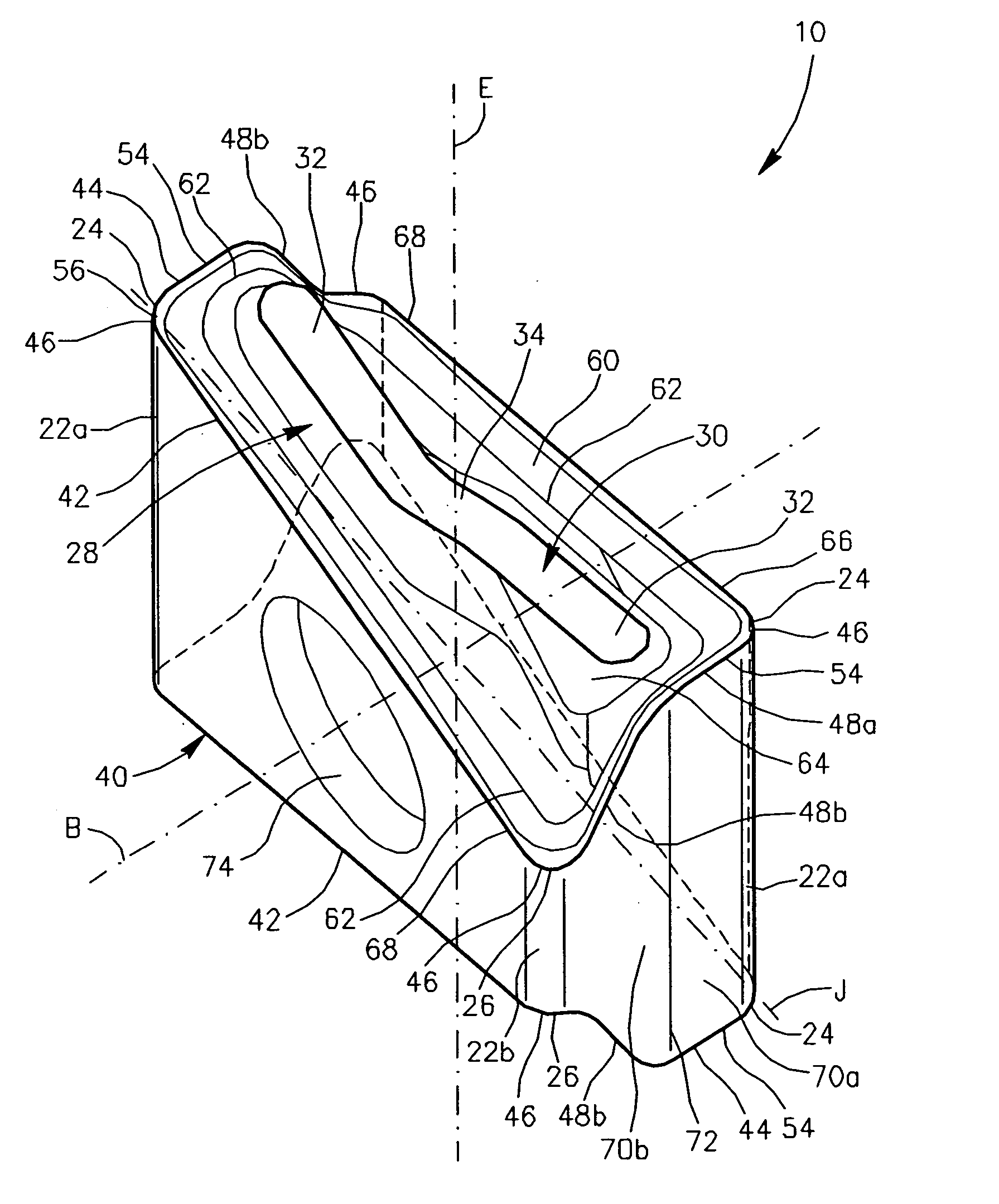

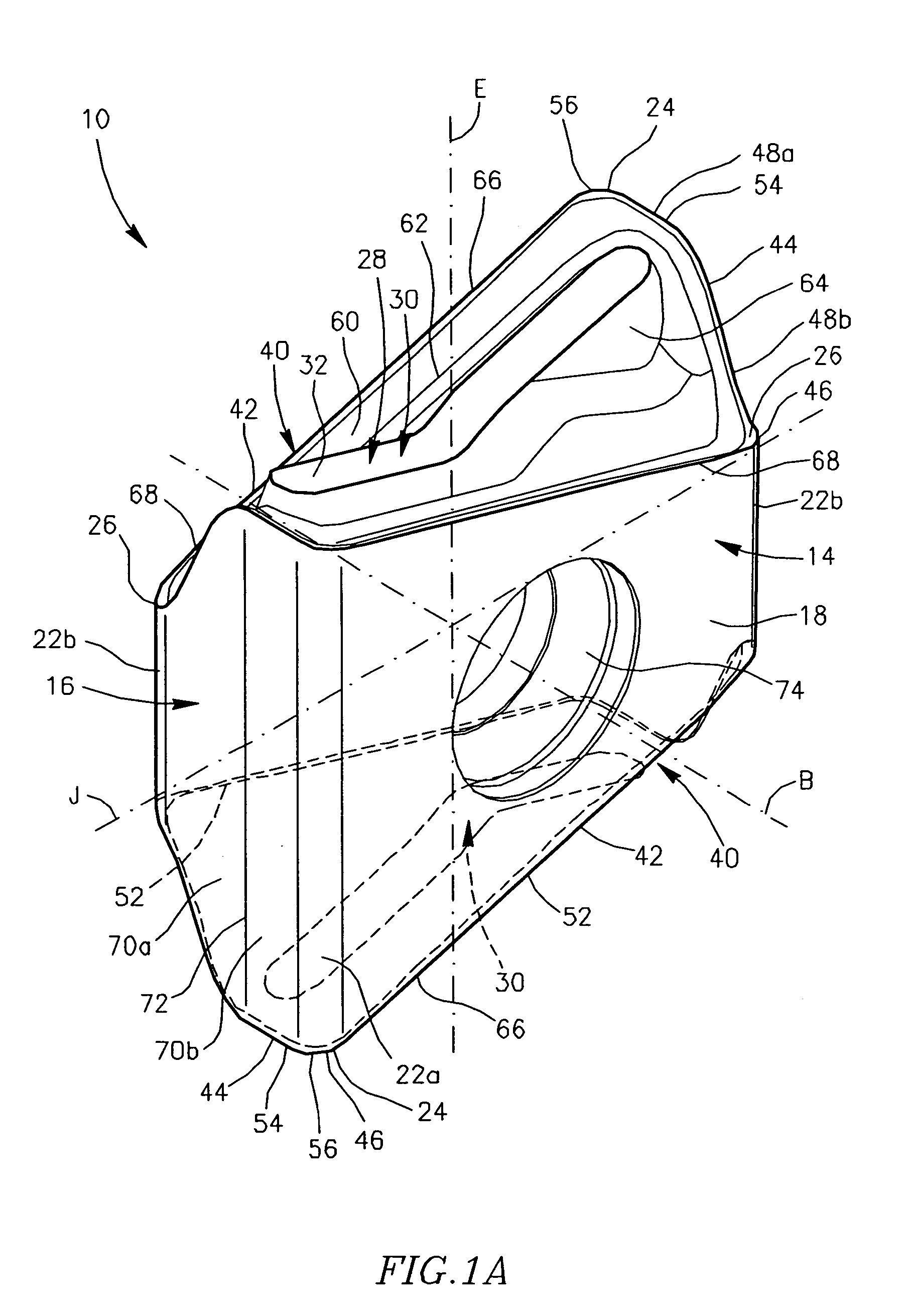

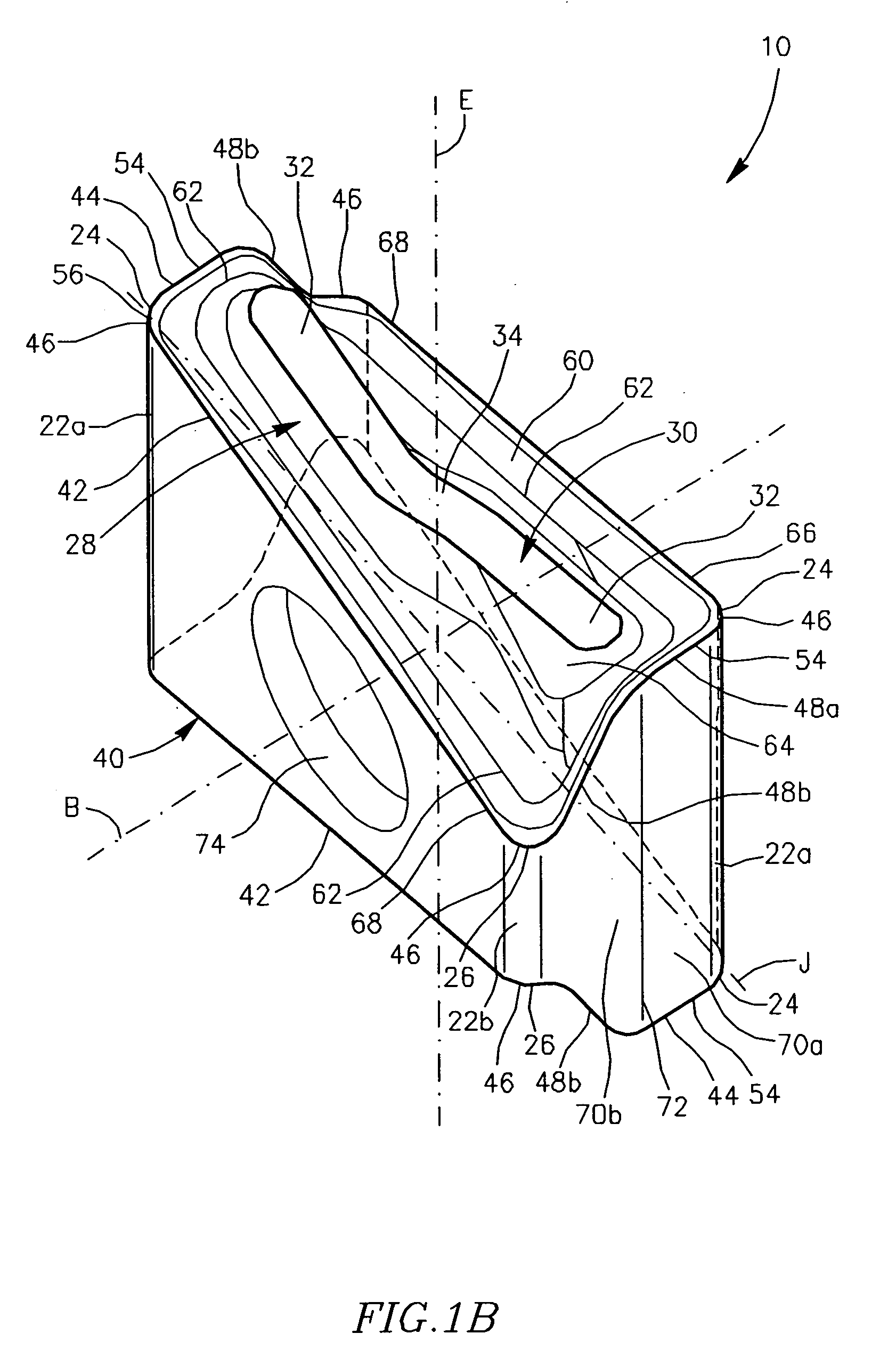

An indexable cutting insert (10) having a top surface (12) including a substantially planar central portion (48), a substantially planar bottom surface (14), and a plurality of side surfaces (16, 18, 20, 22). A long cutting edge (24, 26), a corner radius cutting edge (28, 30), a facet radius cutting edge (32, 34), and ramping cutting edge (36, 38) are defined at an intersection between the top surface (12) and one of the side surfaces (16, 18, 20, 22). A margin (87, 89) extends around a nose radius of the cutting insert (10) and blends into a flat surface (94, 96). A margin angle, C, formed by the margins (87, 89) is less than a seating angle, B, formed by the flat surfaces (94, 96). The top surface (12) includes a plurality of upward sloping radius blends (50, 52, 54, 56, 58, 60, 62, 64) extending between the substantially planar central portion (48) and a plurality of upward sloping rake faces (70, 72, 74, 76, 78, 80, 82, 84, 86, 88, 90, 92) extending between a respective radius blend and its respective cutting edge such that the rake face forms an angle, A, of between five and twenty-five degrees with respect to the central portion (48) of the top surface (12).

Owner:KENNAMETAL INC

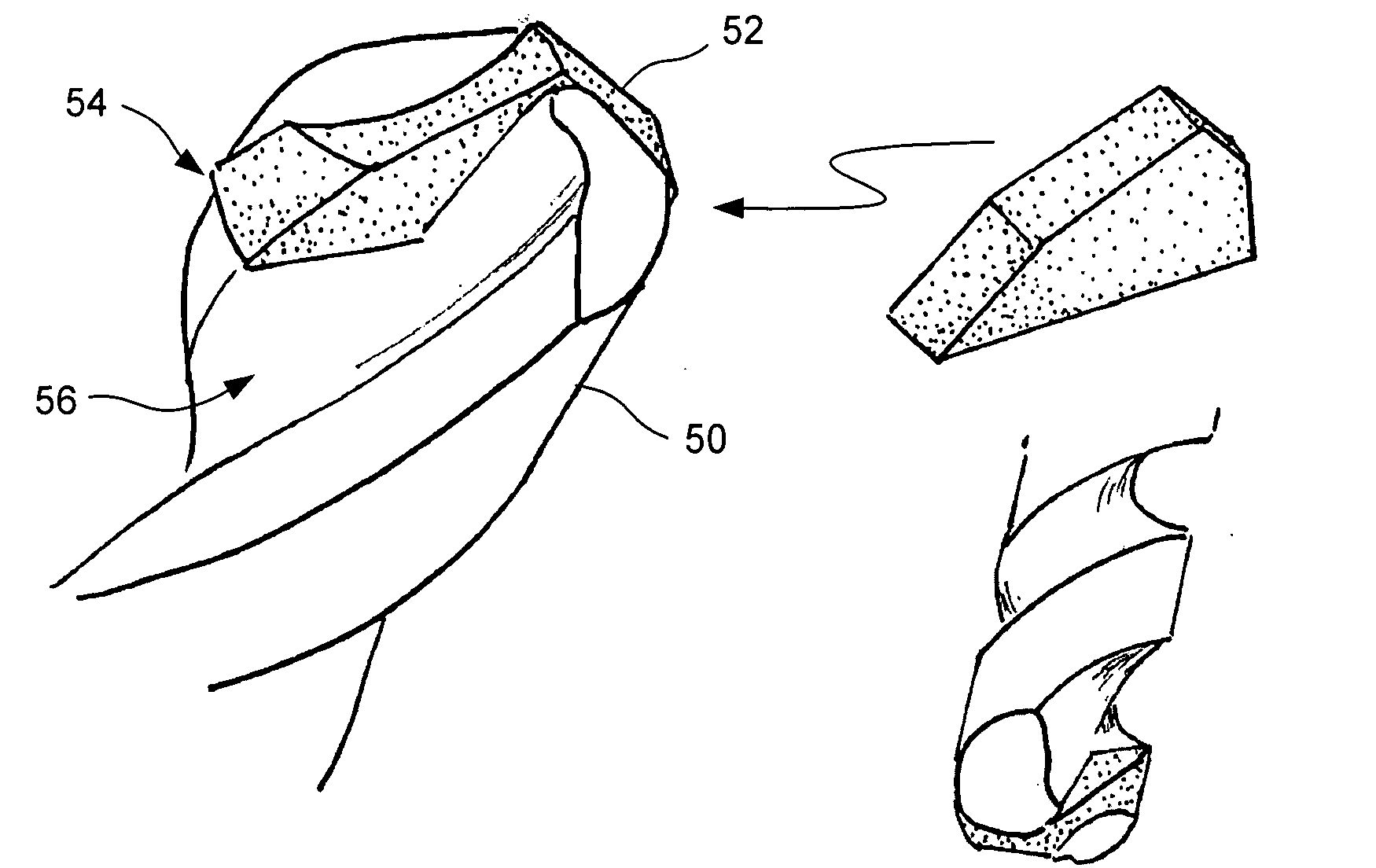

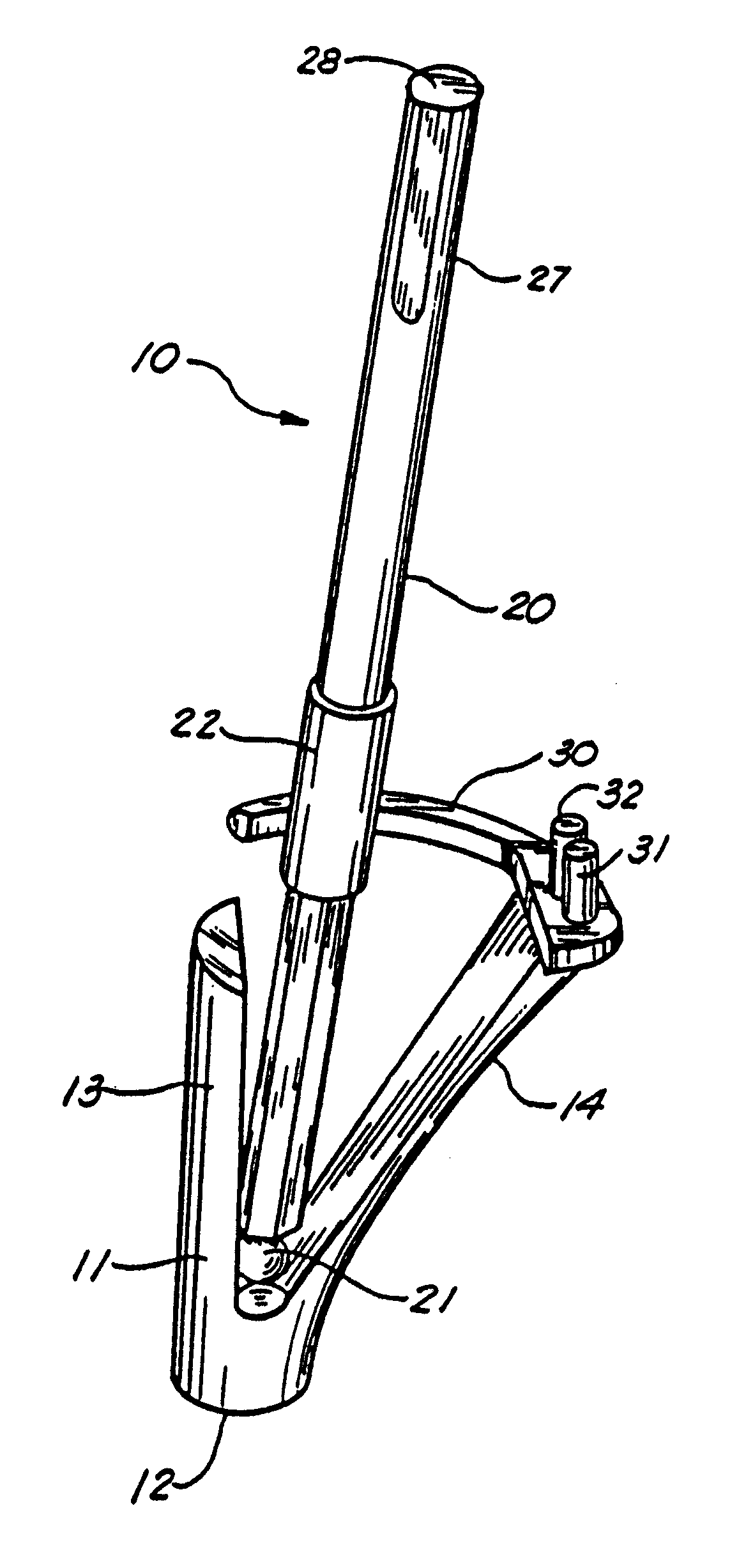

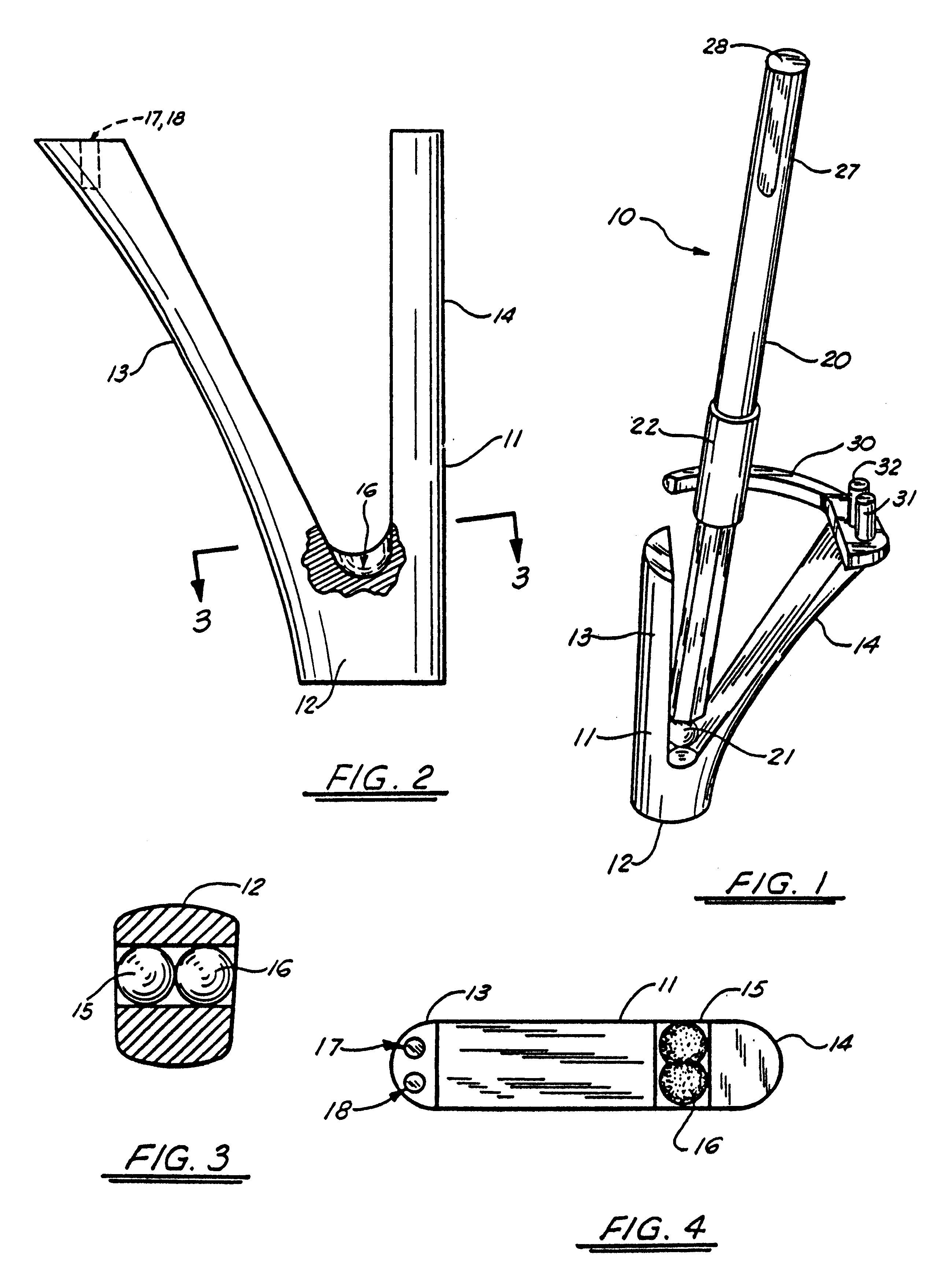

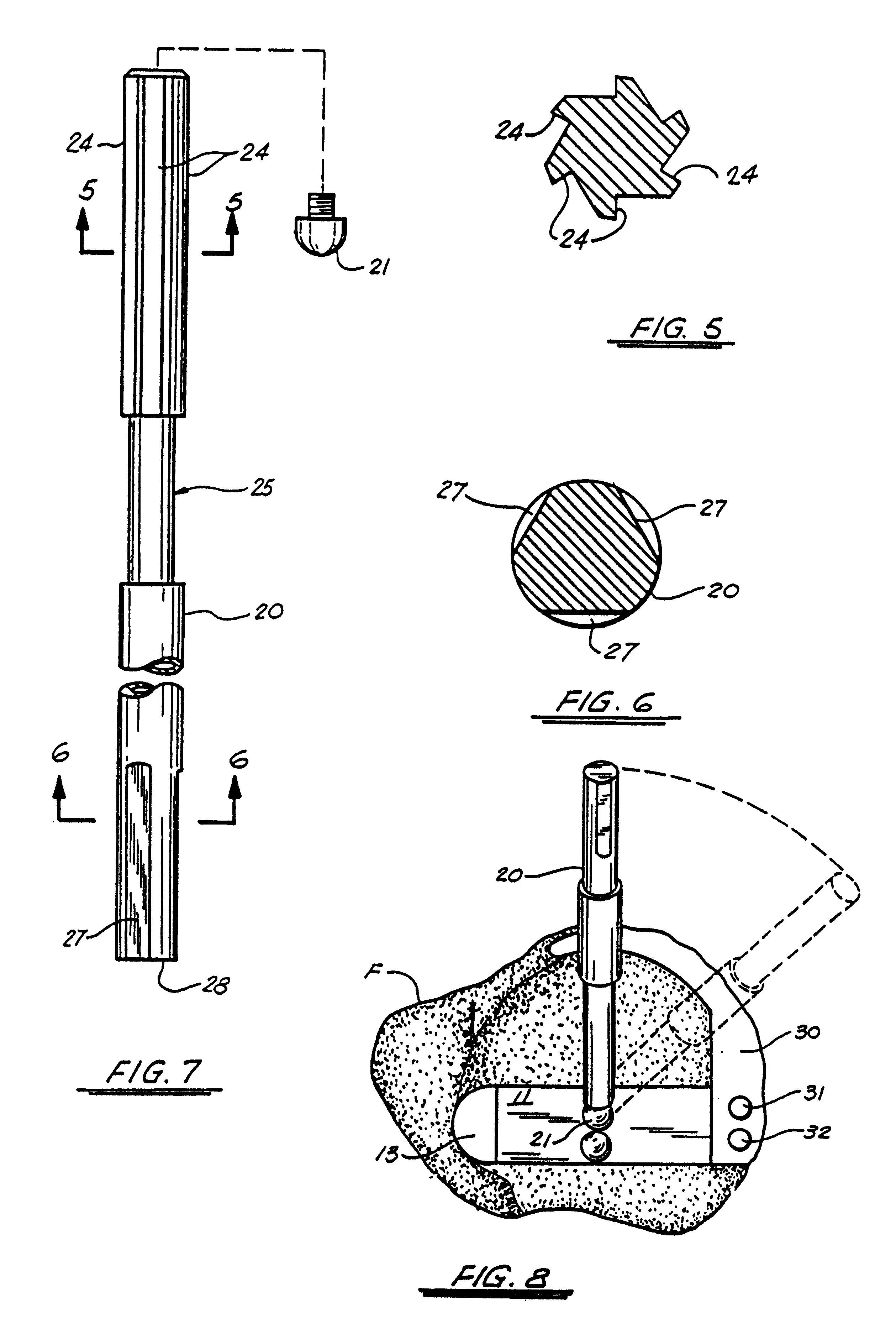

Mill and guide apparatus for preparation of a hip prosthesis

A guide apparatus for preparing the femur of a patient with a rotary mill to receive a femoral hip prosthesis includes a V-shaped guide body having a lower end base portion adapted to extend into the intermedullary canal of the femur and an upper end portion comprised of at least two spaced apart struts so that the overall guide body had a configuration substantially the same as the prosthesis body sought to be implanted in the patient. The lower end of the guide body base provides one or more hemispherical receptacles for holding the hemispherical end portion of a spinning mill bit. A preferably removable transverse guide rail has connection pins at one end portion thereof for forming a connection with the upper end of the guide body at one of the struts, the arm having a curved surface that is adapted to guide the mill bit during preparation of the intermedullary canal of the patient's femur for receiving a hip prosthesis thereafter.

Owner:SMITH & NEPHEW INC

Auxiliary laser heating milling device and method

InactiveCN102430904AEasy to set upEasy to operateMilling equipment detailsNumerical controlMilling cutter

The invention discloses an auxiliary laser heating milling device and method. A laser focusing head is arranged on the traditional numerical control milling machine, and laser is introduced in through optical fiber to increase the local workpiece temperature so as to achieve the purpose of improving the material processability. A rotating workbench is additionally arranged on the condition that the laser focusing head and a milling cutter are fixed relatively, and the method of rotating a workpiece is adopted so that the workpiece direction relative to the laser incidence direction is changed and the auxiliary laser heating milling of the complex workpiece is hereby realized. The invention overcomes the defect that the auxiliary heating milling direction can not be changed and provides a new method for processing the complex workpiece made of the material which is difficult to process.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com